Patents

Literature

214results about How to "Shorten process time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

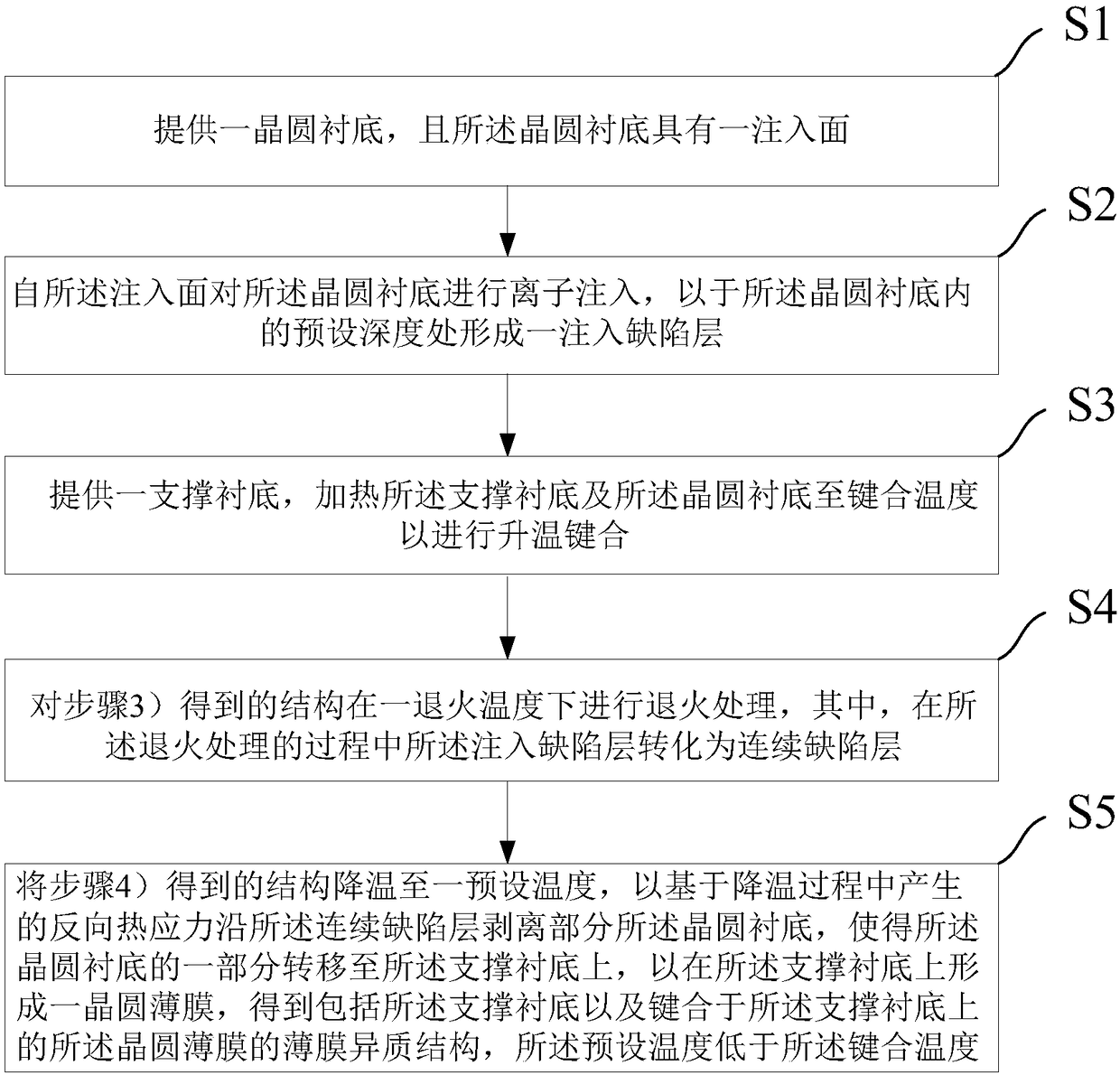

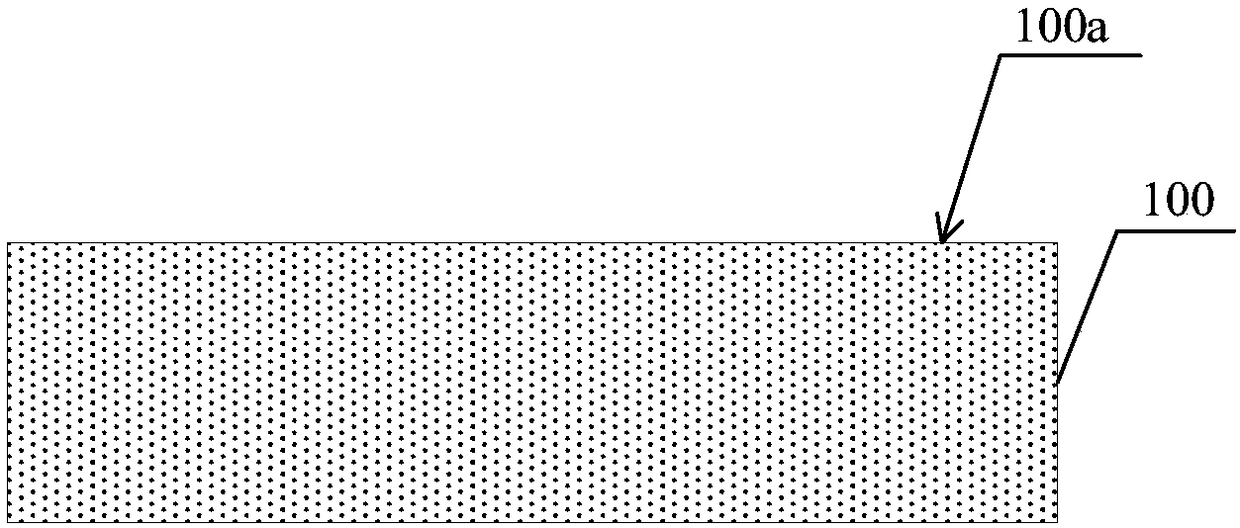

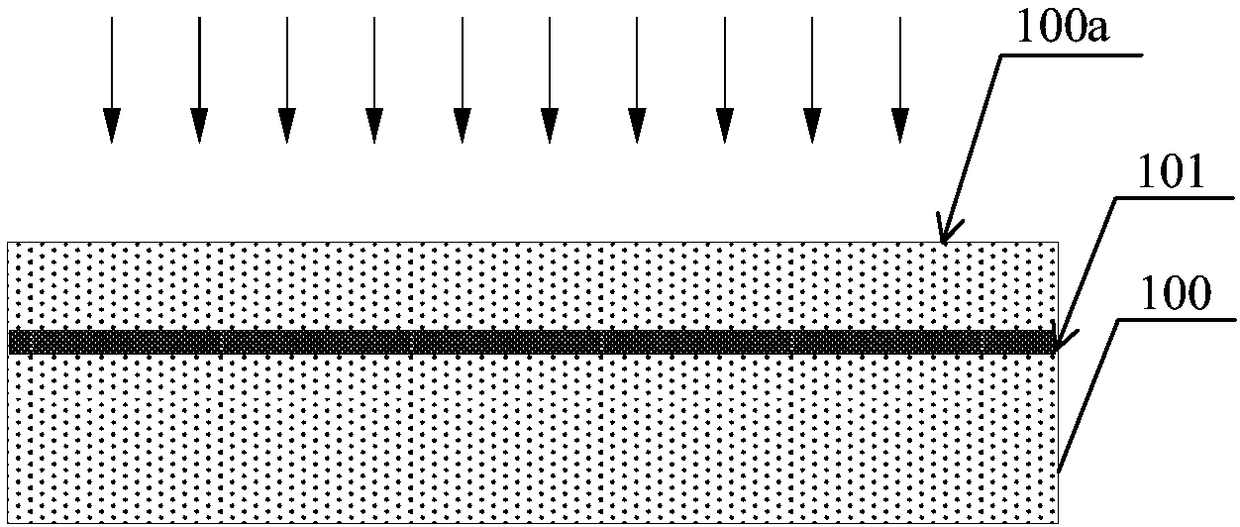

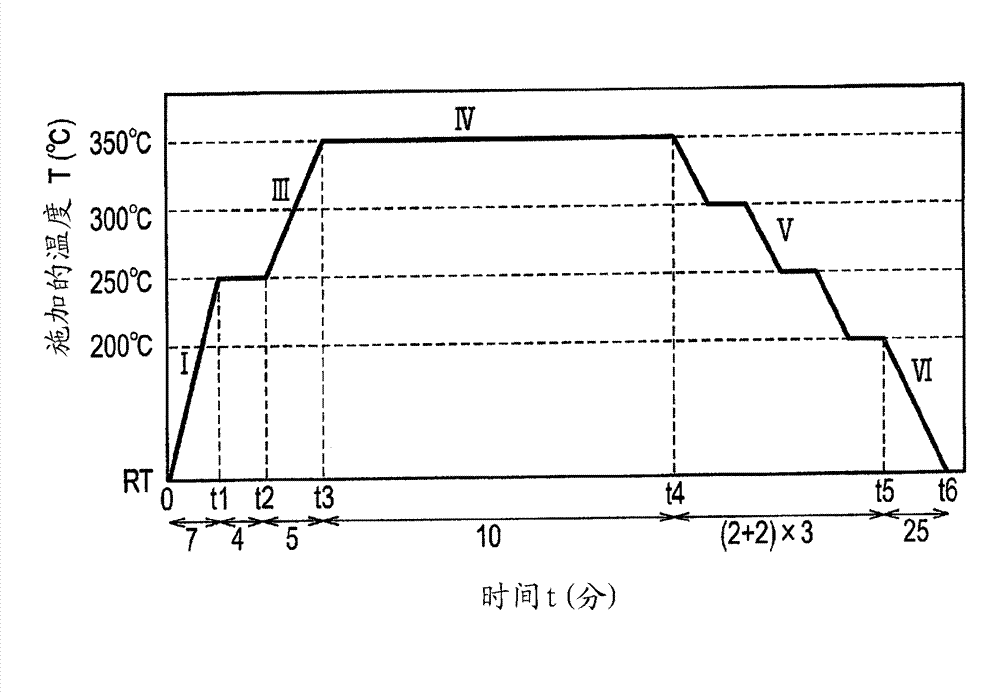

Thin film heterostructure preparation method

ActiveCN108493334ALow annealing temperatureShorten process timePiezoelectric/electrostrictive/magnetostrictive devicesOptoelectronicsHigh-temperature corrosion

The invention provides a thin film heterostructure preparation method. The method comprises steps: a wafer substrate with an injection surface is provided; ion implantation is carried out on the wafersubstrate from the injection surface, and an injection defect layer is formed at a preset depth in the wafer substrate; a support substrate is provided, and the support substrate and the wafer substrate are subjected to temperature rise bonding; the obtained structure is subjected to annealing treatment to form a continuous defect layer; the temperature of the obtained structure is reduced to a preset temperature, reverse thermal stress generated based on temperature reduction strips part of the wafer substrate along the continuous defect layer, and a thin film heterostructure comprising thesupport substrate and the wafer thin film is obtained, wherein the preset temperature is lower than the bonding temperature. In the temperature rise bonding mode, the thermal stress of the bonding structure can be reduced, the bonding structure can keep stable and complete in a high temperature process, the problem of wafer crack generated by thermal mismatch in the stripping process can be effectively solved, and through the reverse thermal stress assisting method, the bonding structure is separated at the continuous defect layer and a bonding interface is not influenced.

Owner:上海新硅聚合半导体有限公司

Technology for processing formaldehyde-free and benzo(alpha)pyrene-free smoked meat product

ActiveCN102742857AOptimizing the smoking processShorten process timeMeat/fish preservationFood preparationPyreneBenzene

The invention belongs to the field of food processing and discloses a technology for processing a formaldehyde-free and benzo(alpha)pyrene-free smoked meat product. The technology comprises the following steps of 1, raw material selection and pretreatment, 2, pickling liquid preparation and pickling, 3, washing and drying in air, 4, pre-heating, drying and smoking, and 5, heat dissipation, vacuum packaging, labeling and warehousing. The technology adopts a sectional-type baking technology, improves product quality and solves the problems of meat product surface scabbing, drying and hardening caused by the traditional technology. The technology simplifies and optimizes the traditional smoking technology, shortens processing time, reduces a production cost, obviously improves product quality, and well solves the problems of meat product surface scabbing, drying and hardening caused by the traditional technology. Through the combination of the processes and use of a smoking solution which has effects of coloring and improving a taste and is safe, the formaldehyde-free and benzo(alpha)pyrene-free smoked meat product is obtained.

Owner:NANJING AGRICULTURAL UNIVERSITY

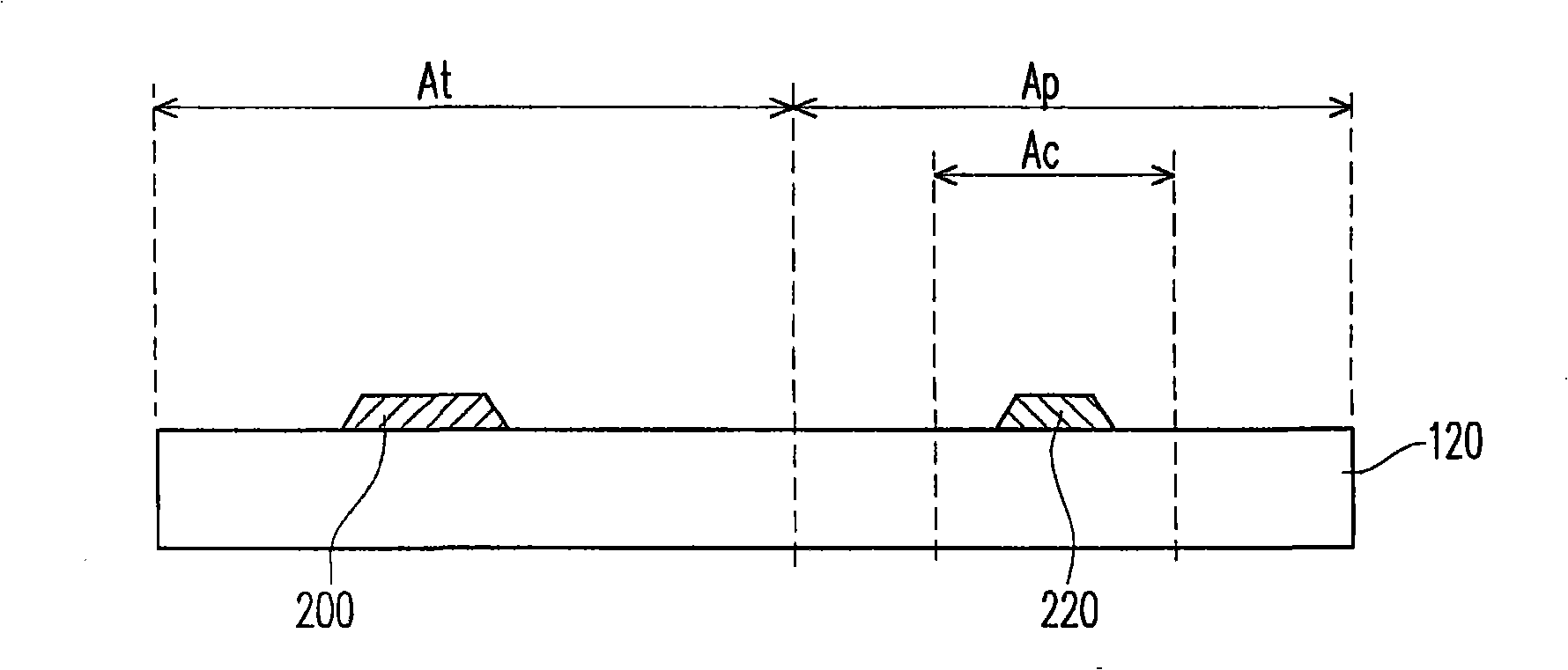

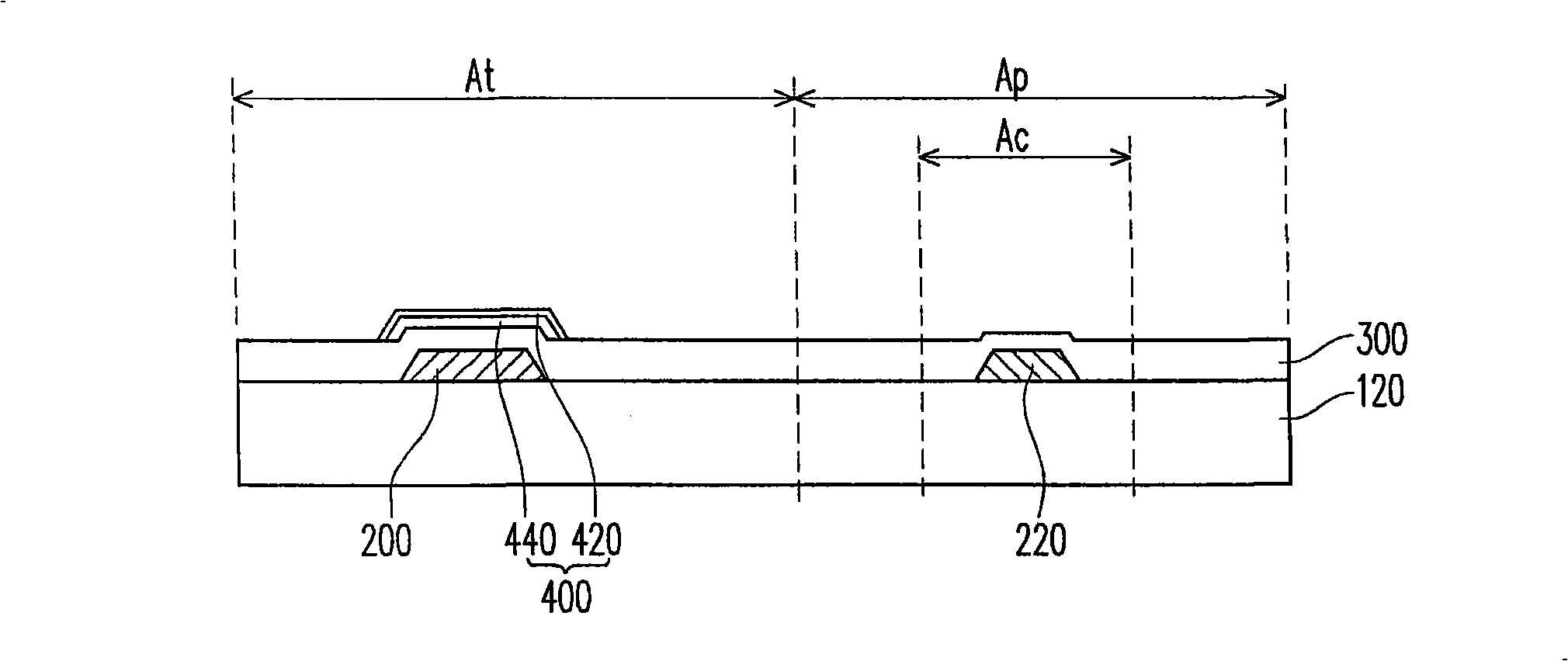

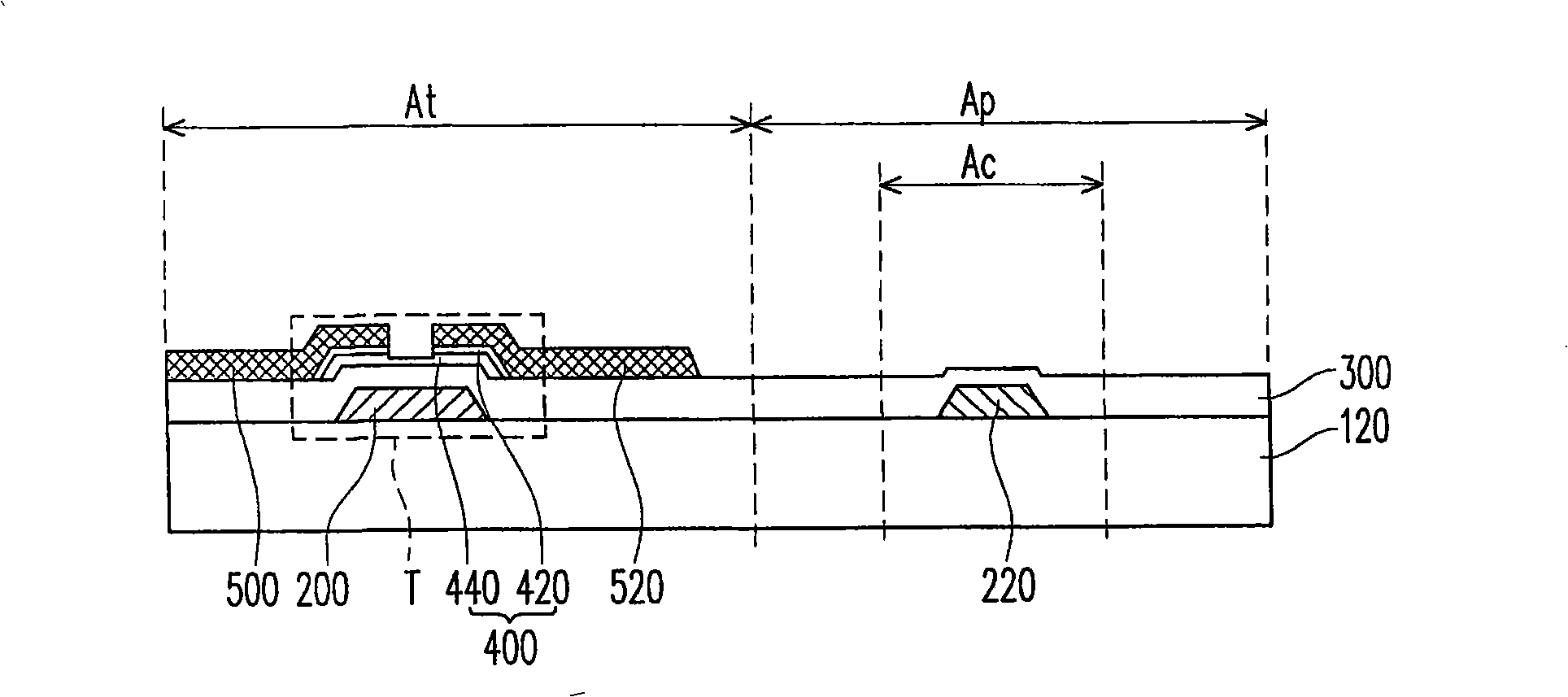

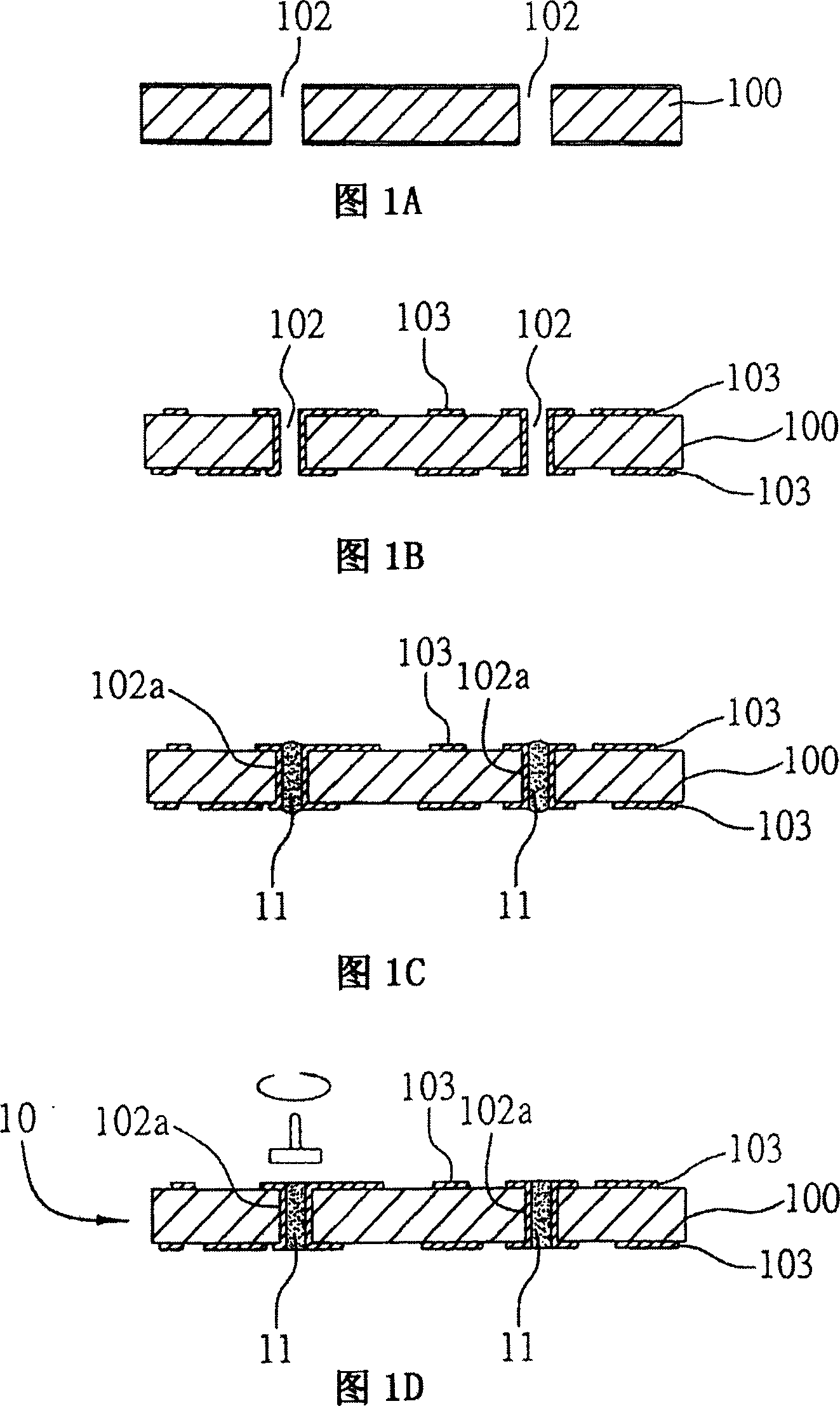

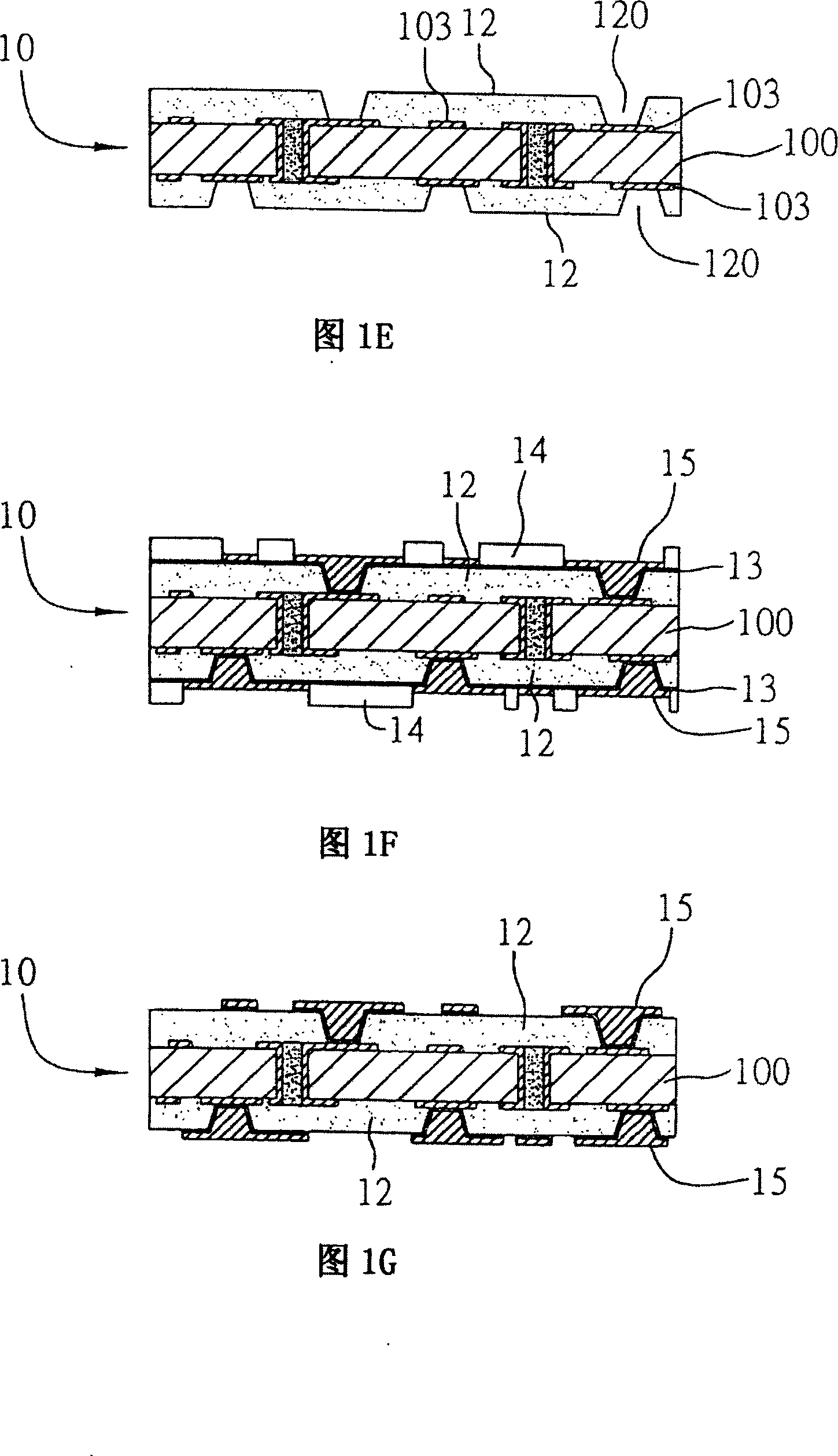

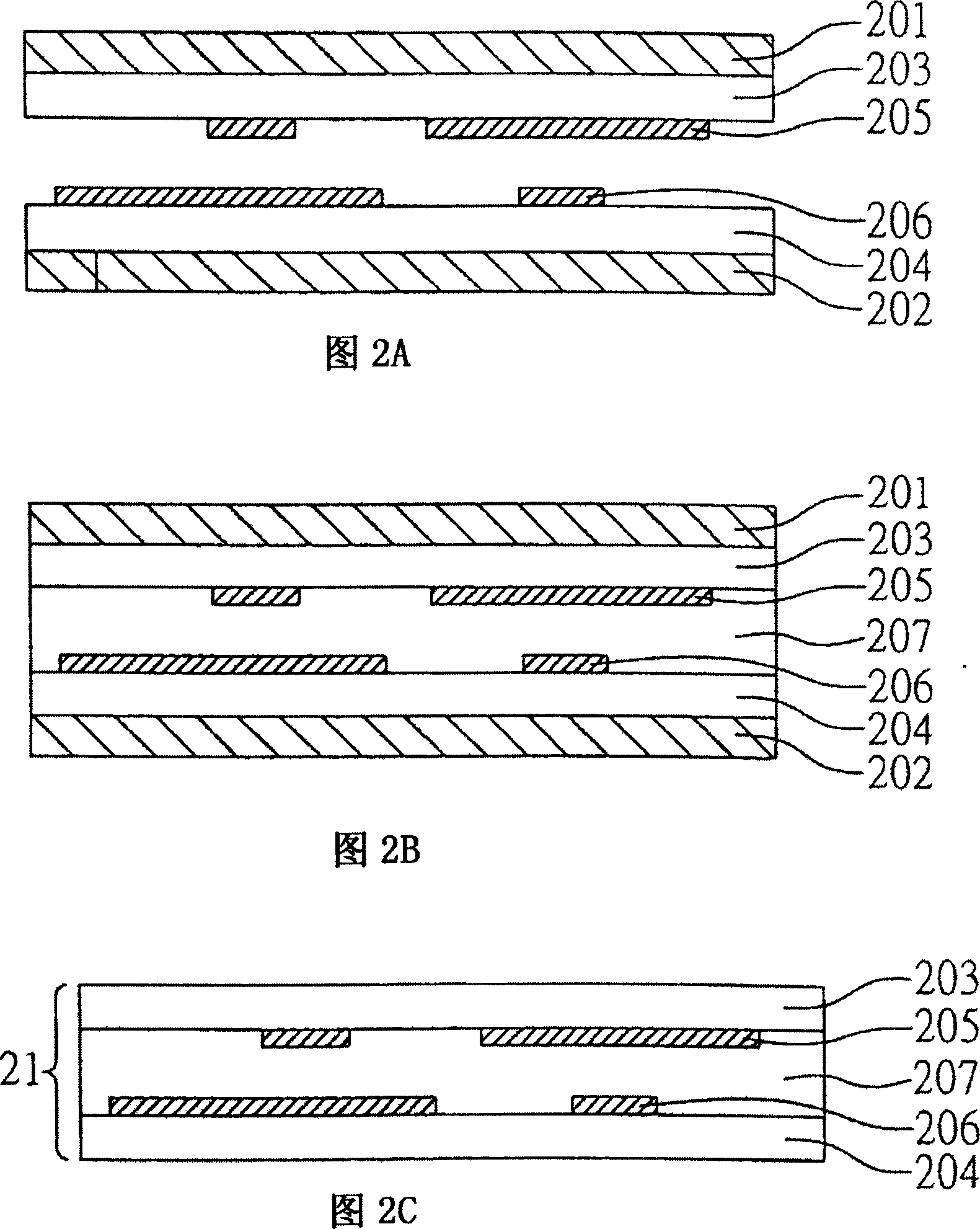

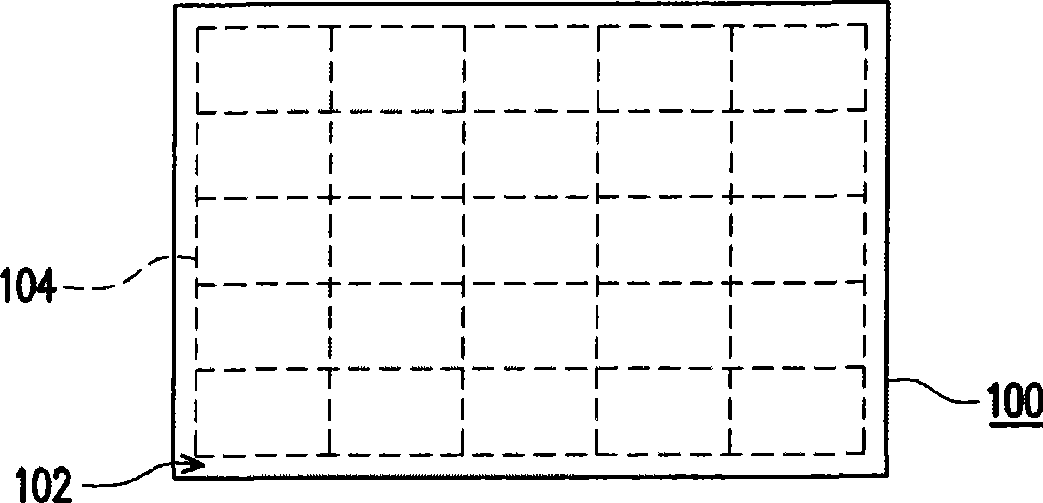

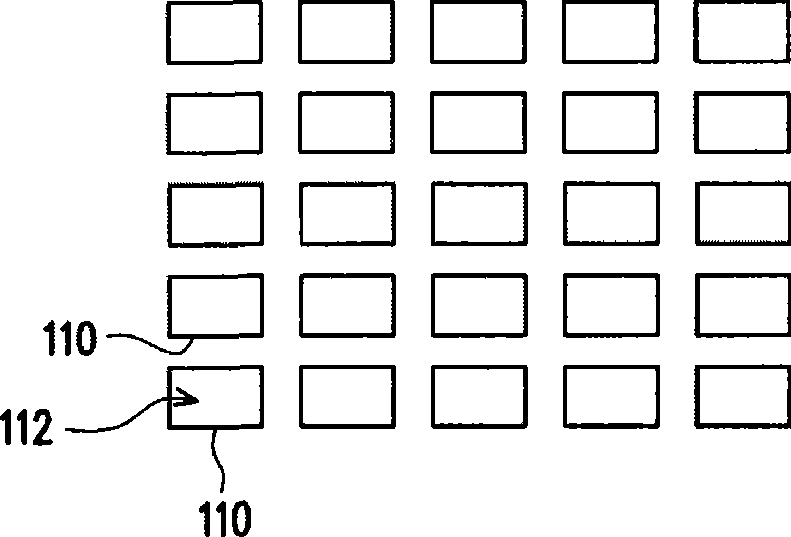

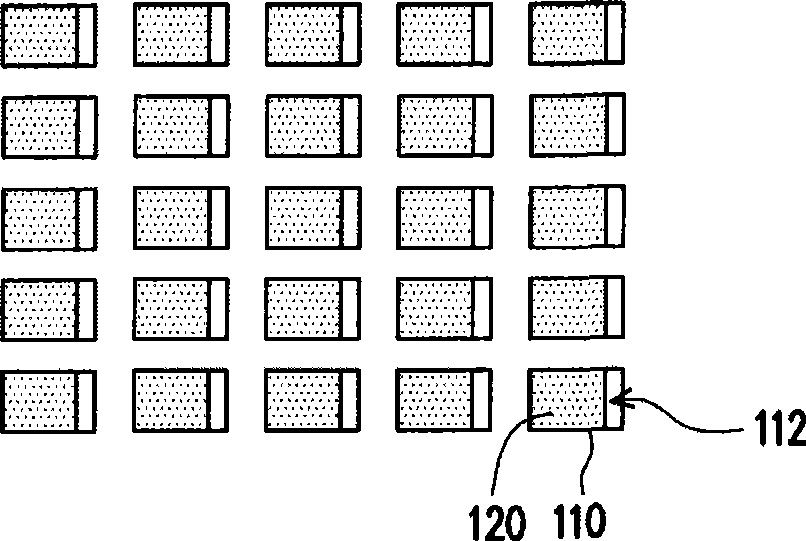

Pixel structure, display panel and method for manufacturing optoelectronic device

ActiveCN101409263AShorten process timeIncrease production capacitySemiconductor/solid-state device manufacturingNon-linear opticsPhotoresistCapacitance

The invention provides methods for manufacturing a pixel structure, a display panel and a photoelectrical device. The method for manufacturing the pixel structure comprises the steps as follows: firstly, a baseplate is provided and is provided with a transistor area, a capacitor area and a pixel area; subsequently, a film transistor and a capacitor electrode are formed on the baseplate, wherein, the capacitor electrode is covered by a dielectric layer; then, a color filter layer is formed on the film transistor and the capacitor electrode, and a protection layer is formed on the color filter layer; patterned photoresist layers with different thicknesses are formed on the protection layer, and partial protection layer and partial patterned photoresist layers are removed sequentially to expose partial source / drain electrode of the film transistor and partial protection layer; then, the protection layer is covered by a conductive layer in a conformal way, and partial patterned photoresist layer is removed to define a pixel electrode. The invention can reduce the manufacturing cost, shorten technical time and increase the productivity, and the capacitance value of the capacitance stored in the pixel structure is improved effectively.

Owner:AU OPTRONICS CORP

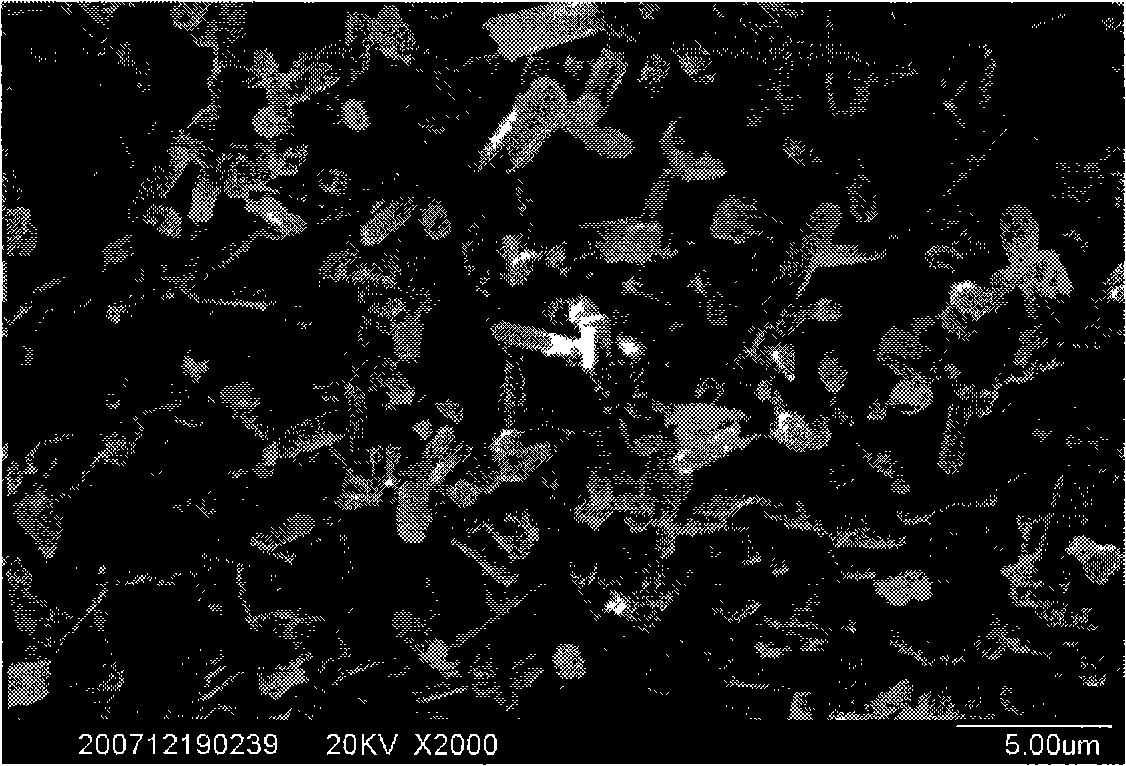

Silicon nitride porous ceramic composition and preparation method thereof

The invention discloses a porous silicon nitride ceramics composing prescription and a method for the products thereof, containing the following components by weight: 50-70 per centsilicon nitride powder, 5-30 per cent bentonite, 0-10 per cent sintering additives and 20-30 per cent water. The sintering additives, contain at least one of Y2O3, Al2O3 and MgO and the method includes: weighing the components except water before placing into a ball mill for dry mixing-grinding to make a mixed powder which is then put into a wheel roller for wheel grinding and kneading to obtain a pug; putting the pug into an extruder for extrusion forming to obtain a shaped body; then drying the shaped body before putting into an atmosphere oven where the shaped body is heated to a temperature of 1700-1850 DEG C in the nitrogen at a heating rate of 10 DEG C / min and then insulation sintered for 1 to 3 hours at a nitrogen pressure of 1-6 atmospheric pressure to obtain a sintered body . The porous silicon nitride ceramics of the invention can be widely used as matrix of filters for gas separation at high temperature and in corrosive atmosphere and as heat-resistant or enhanced materials for power generation gas turbines, engines and space shuttles.

Owner:XI AN JIAOTONG UNIV

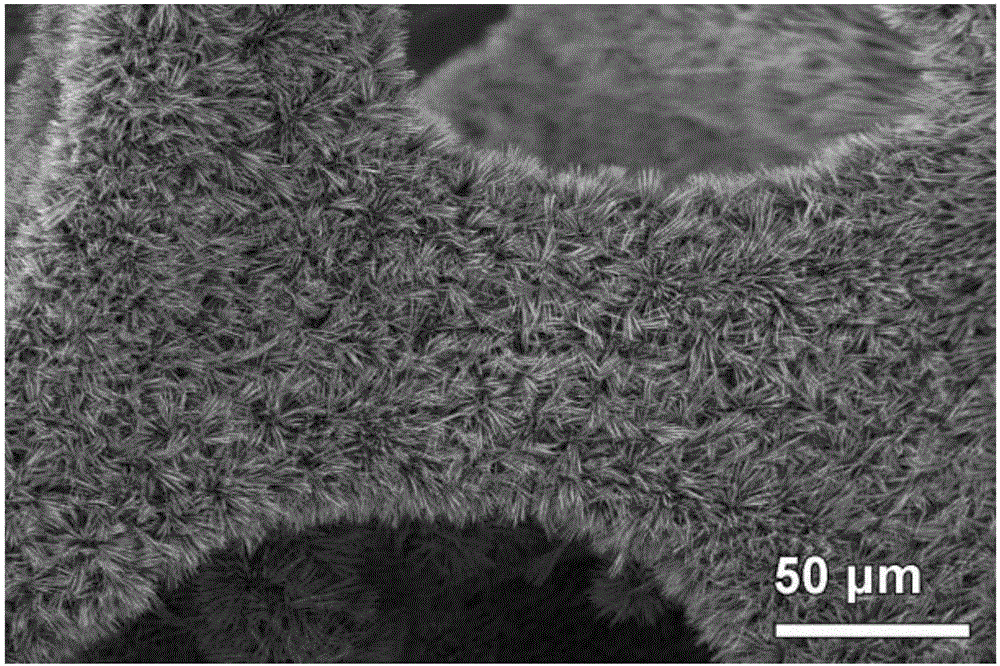

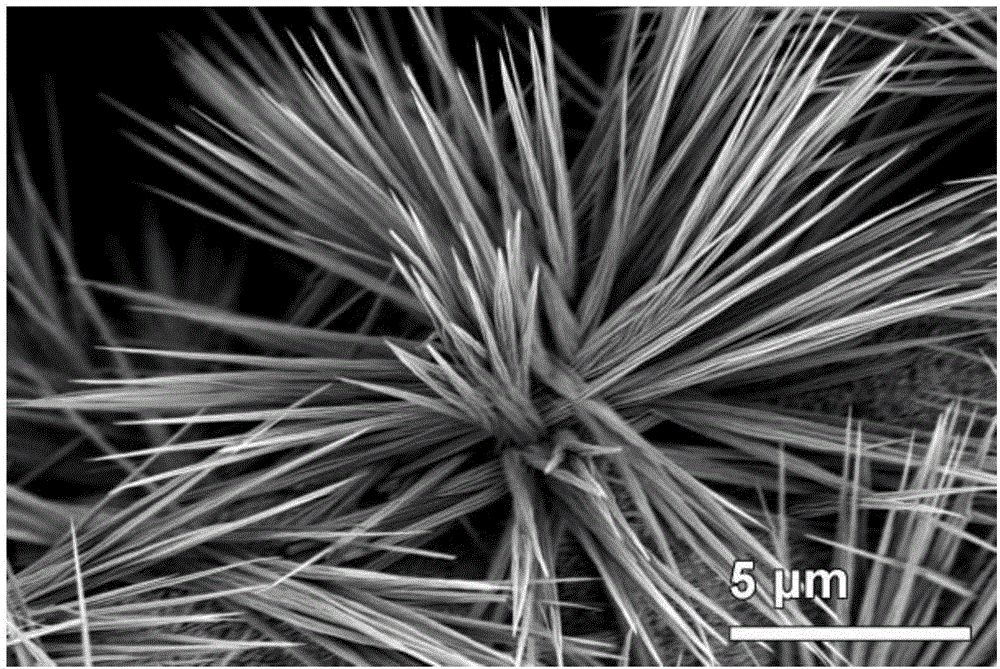

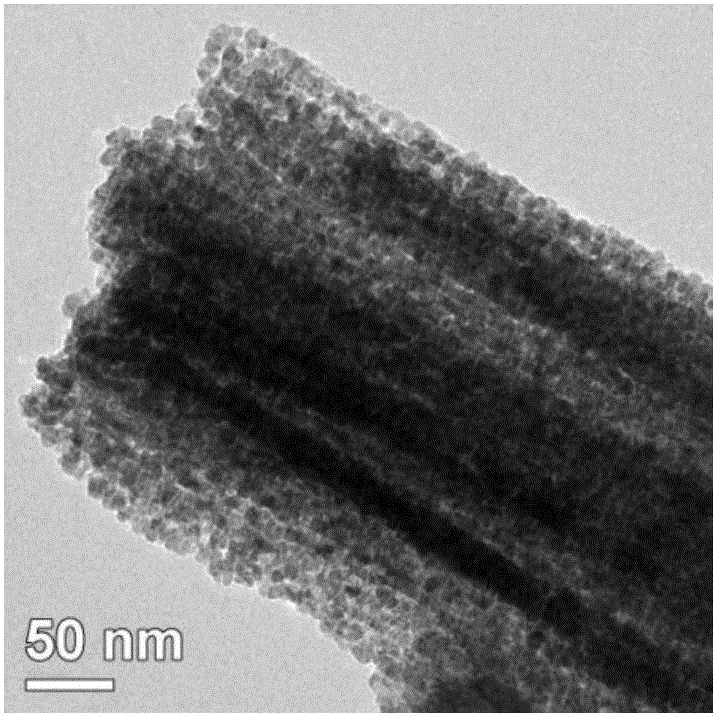

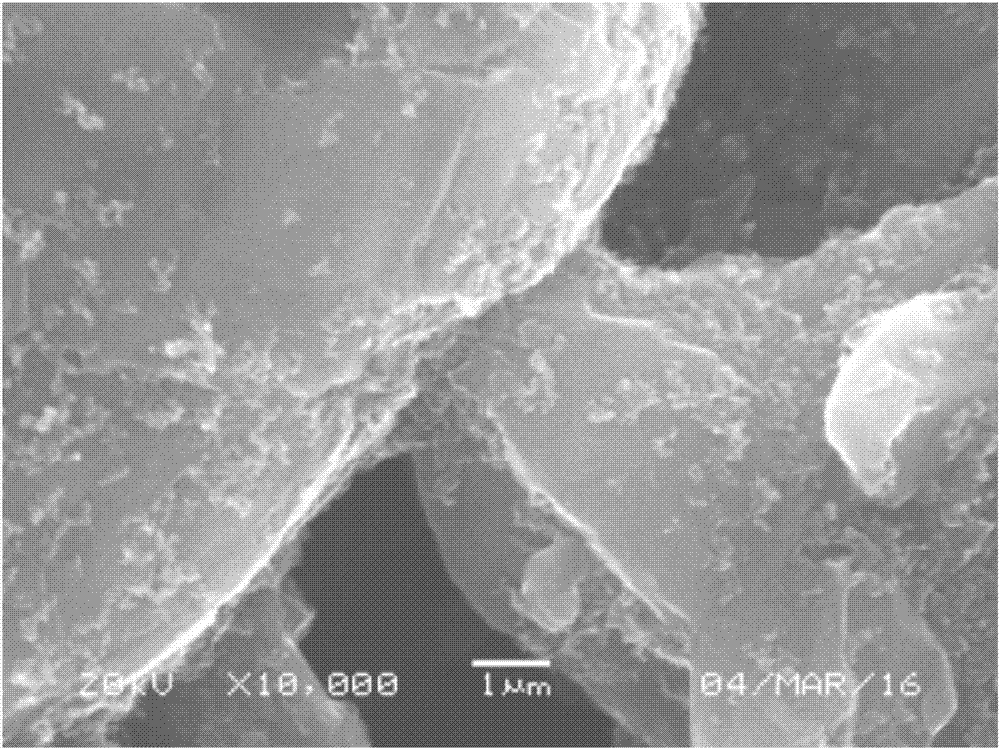

Foam copper-supported porous copper oxide nanowire composite material and preparation method and application thereof

The invention discloses a foam copper-supported porous copper oxide nanowire composite material. The material comprises a foam copper substrate and a copper oxide nanowire supported on the surface, wherein the copper oxide nanowires are 8 to 12 mum in lengths, and are 150 to 250 nanometers in widths; the nanowires do not crack or fall easily; microscopically, the nanowires have porous structures, and pore diameters are 2 to 4 nanometers; macroscopically, the nanowires are distributed radially, and every 60 to 150 nanowires constitute a copper oxide micro-flower. The obtained composite material has a multi-grade and porous structure, and the whole three-dimensional structure is rich in apertures which are suitable for the permission of light rays and ion transport. When the composite material is taken as a photocatalytic degradation organic dye, the degradation efficiency can be increased by over 10 times; when the composite material is taken as a negative electrode material of a lithium ion battery, the capacity retention ratio can be increased by over 30 percent.

Owner:HEBEI UNIV OF TECH

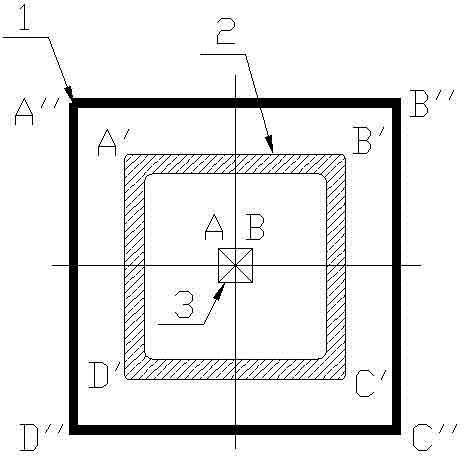

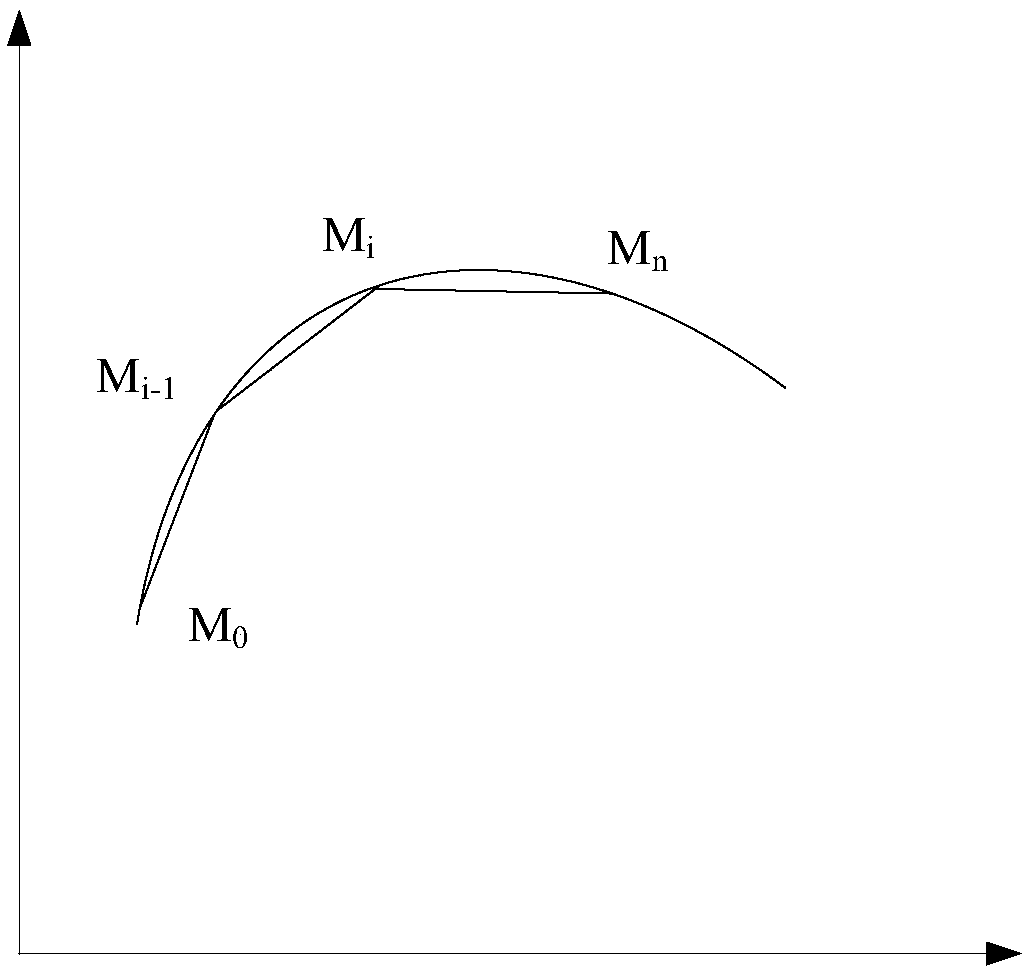

Growth method for preparing square sapphire crystal by Kyropoulos process

ActiveCN104911708ASingle crystal stress is smallReduce internal defectsPolycrystalline material growthUsing seed in meltHigh rateCrucible

The invention provides a growth method for preparing a square sapphire crystal by a Kyropoulos process. The sapphire monocrystal growth technique mainly comprises the following steps: crystal seeding, shouldering, isometric growing, end pulling, and cooling and annealing. The square crucible and square heating body must be concentric during furnace loading, the side wall is parallel to the side surface of the square heating body, and the seed crystal is the square seed crystal of which both the end surface and side surface are finely oriented. In the isometric growth step, the cooling rate is increased, and the pull rate is decreased. In the end pulling step, proper heating is performed to bake the edges of the crystal end part, and the pull rate is increased, so that the crystal is automatically separated from the crucible. Cooling is performed at higher rate in the early and later periods of the cooling and annealing step; and in the intermediate period, the cooling is stopped, and the temperature is kept for some time. The growth technique is beneficial to growing the large-size high-grade square sapphire monocrystal. The technique for growing the square sapphire monocrystal has the advantage of high crystal quality, and can greatly enhance the working efficiency and the yield of the square lump material.

Owner:HARBIN AURORA OPTOELECTRONICS TECH

Process for dyeing silk interwoven jacquard fabric

ActiveCN104018369AShorten process timeIncrease productivityDyeing processColour fastnessPolymer science

The invention discloses a process for dyeing a silk interwoven jacquard fabric, belonging to the field of silk interwoven jacquard fabric dyeing technology. The process comprises the steps of dye fixing, primary washing, soaping, secondary washing and cylinder discharge and drying, wherein in the dye fixing step, the pretreated silk interwoven jacquard fabric is put into an active dye solution and dyed by adopting a jig dyeing method at 80-85 DEG C for 60-200 minutes; the active dye solution is obtained by mixing 1-5% owf of lanasol dye, 1-5% owf of HE type dye, 20-50g / L of anhydrous sodium sulphate, 5-20g / L of sodium carbonate and water. The process disclosed by the invention can be used for realizing bath dyeing when silk fibers and cellulose fibers in the silk interwoven jacquard fabric are dyed with different colors respectively, the color fastness of the obtained silk interwoven jacquard fabric with the double-color effect can reach the two-bath dyeing fastness, meanwhile, energy is saved, emission is reduced, and the process time is obviously shortened.

Owner:ZIBO DARANFANG SILK GRP

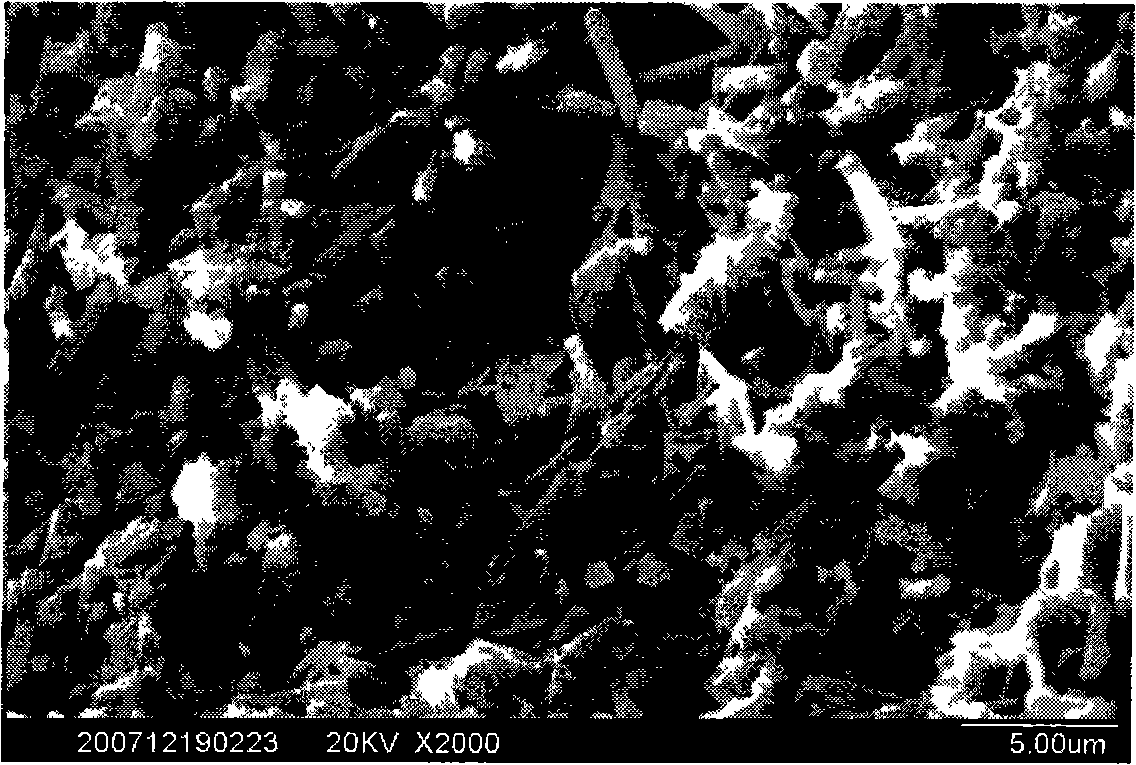

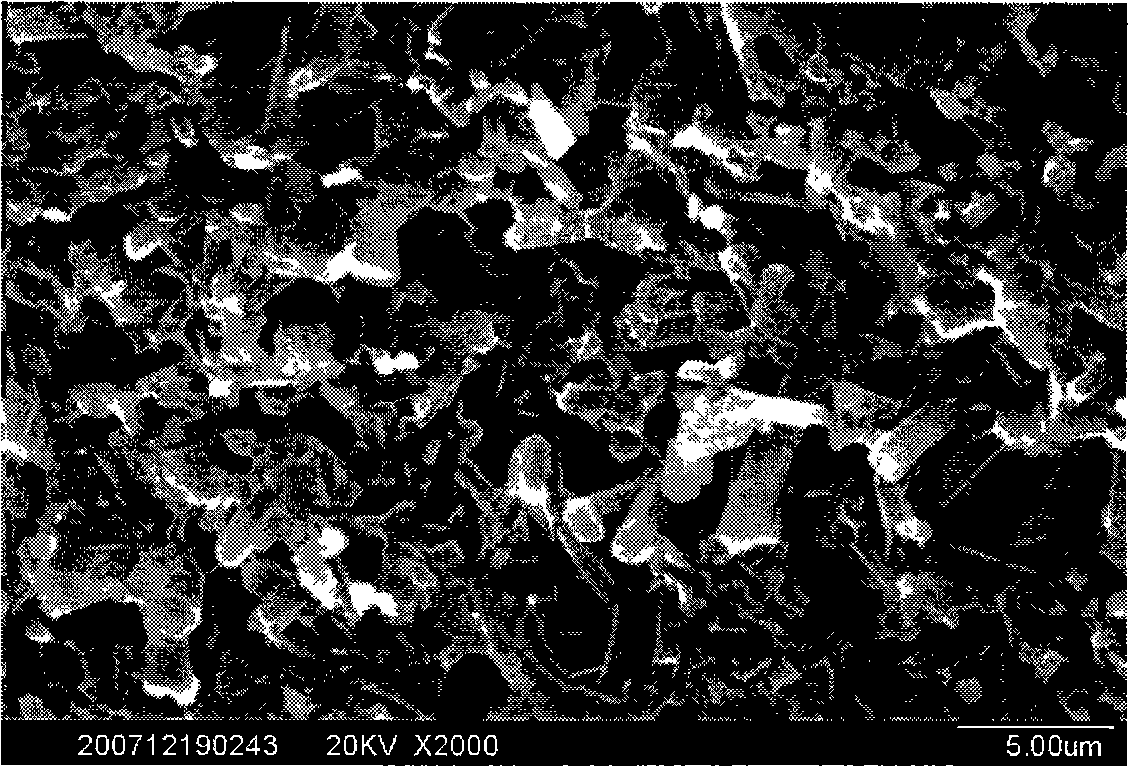

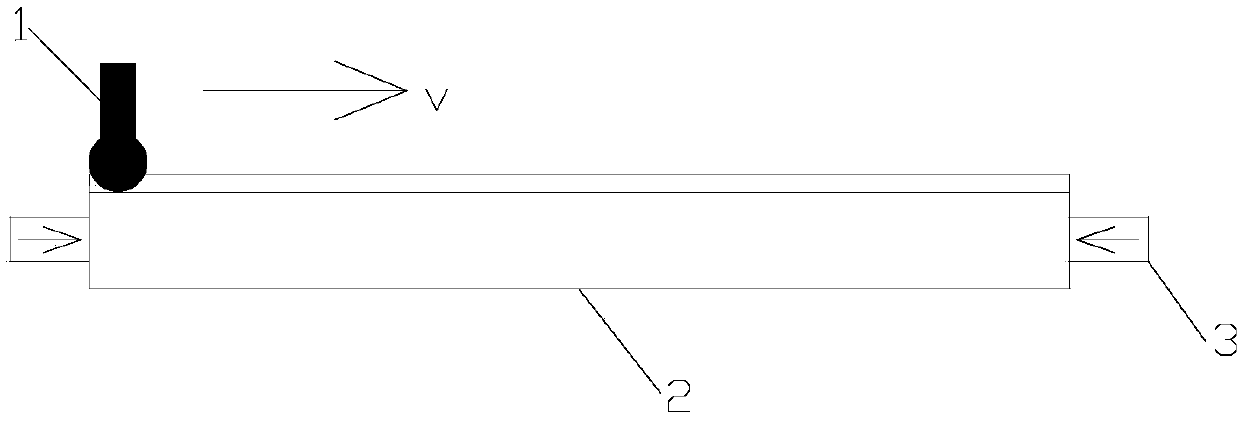

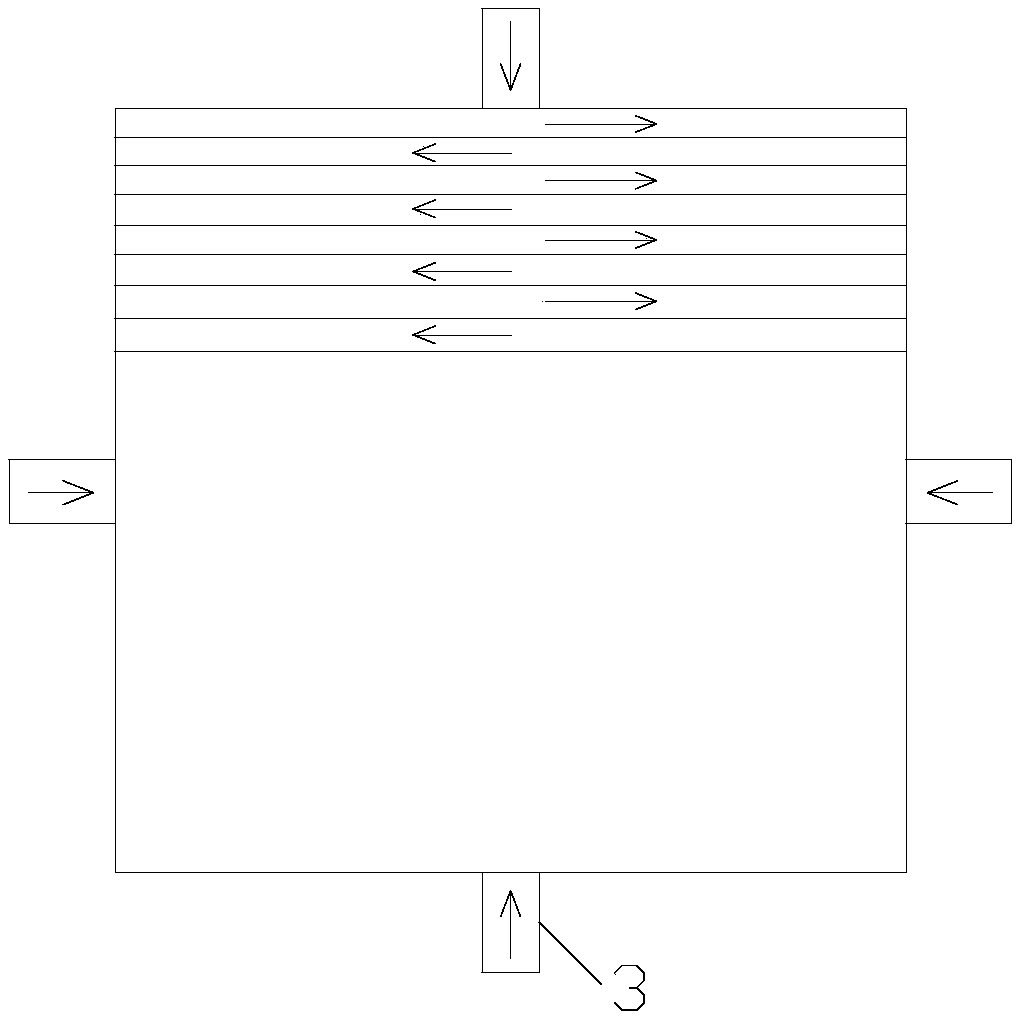

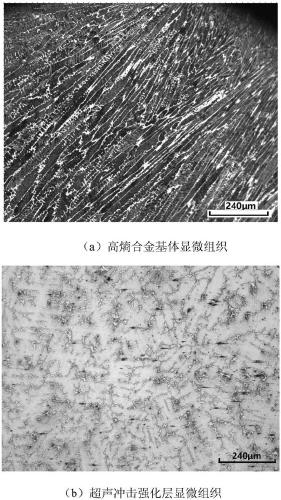

Method for improving surface performance of single-phase high-entropy alloy

The invention discloses a method for improving surface performance of a single-phase high-entropy alloy, and belongs to the technical field of high-entropy alloy surface strengthening. The single-phase high-entropy alloy is an Al<x>CrCoFeMnNi alloy, wherein x represents the mole number, and is equal to 0-0.5; after the single-phase high-entropy alloy is subjected to solution treatment and surfacepretreatment, the surface of the high-entropy alloy is strengthened through ultrasonic impact equipment; and the high-entropy alloy is of a single-phase face-centered cubic structure, a certain depthof plastic deformation layer is formed on the surface of the high-entropy alloy after ultrasonic impact, grains are obviously refined, a gradient structure is formed from the surface to the core, andhardness and abrasion resistance are significantly improved. According to the method, a fine structure and a large number of microscopic defects can be obtained on the surface of the high-entropy alloy while the chemical composition of the surface of the high-entropy alloy is ensured to be unchanged and the toughness of the core is ensured, thus the hardness of the surface of the high-entropy alloy is increased by 1.8-2.5 times, the abrasion resistance is increased by 1.3-2.5 times, the method is simple, easy to operate, safe, reliable, small in energy consumption, economical and practical.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method of PERC solar cell

ActiveCN105810779AShorten process timeReduce manufacturing costFinal product manufacturePhotovoltaic energy generationSilicon nitrideSolar cell

The invention discloses a preparation method of a PERC solar cell. The preparation method comprises the following steps of texturing, diffusing, back polishing, etching, impurity glass removal, passivation lamination film deposition on a back surface, a silicon nitride anti-reflection layer deposition on a front surface, local opening in the back surface, metal paste silk-screen printing on the front surface and the back surface and sintering, wherein the step of passivation lamination film deposition on the back surface comprises the following steps of (1) depositing an Al2O3 thin film on the back surface of a silicon wafer battery by an atomic layer deposition method; and (2) placing the battery in the step (1) in a tubular furnace for pre-annealing, depositing a SiO2 thin film on the battery, and depositing a SiNx thin film on the above SiO2 thin film. The steps of annealing and SiO2 / SiNx thin film deposition are integratedly carried out in the same tube, thus, the step of separate annealing of the Al2O3 passivation film and an annealing tube are omitted, the process time is saved, the production cost is reduced, and the preparation method is applicable to industrial production.

Owner:CSI CELLS CO LTD +1

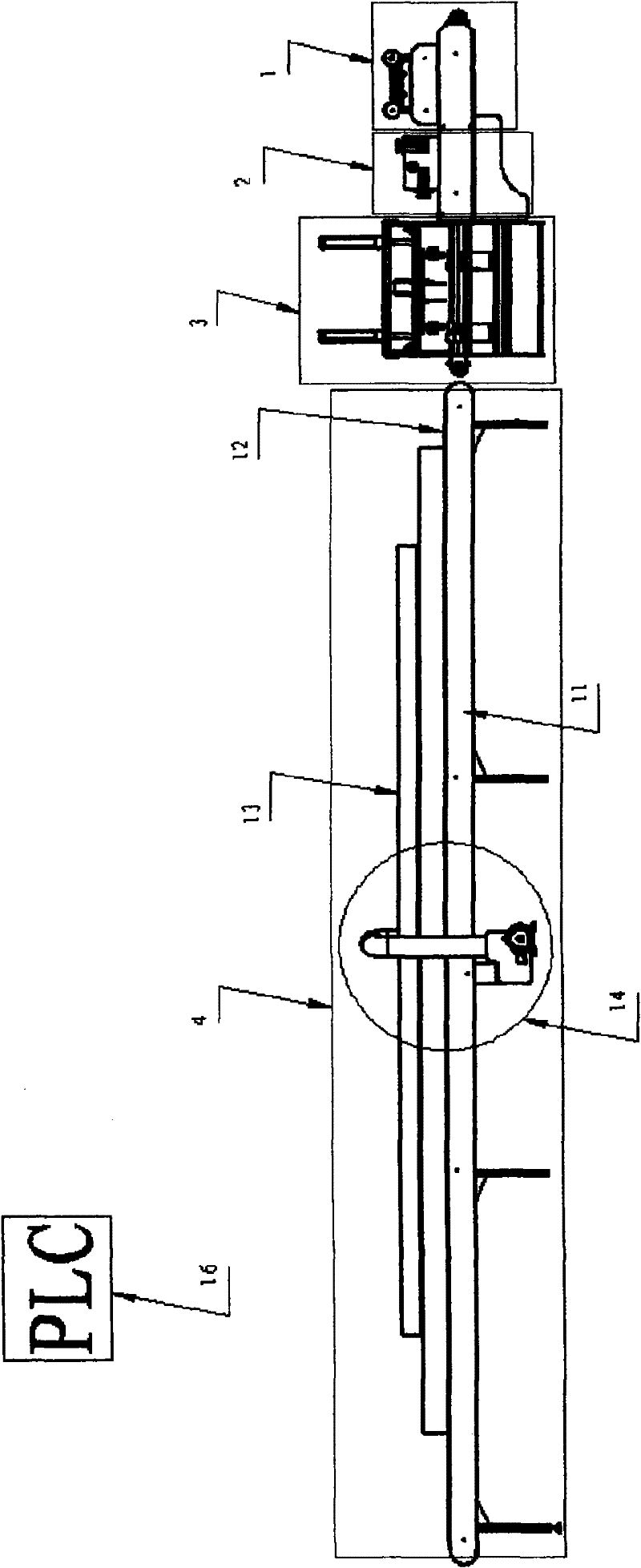

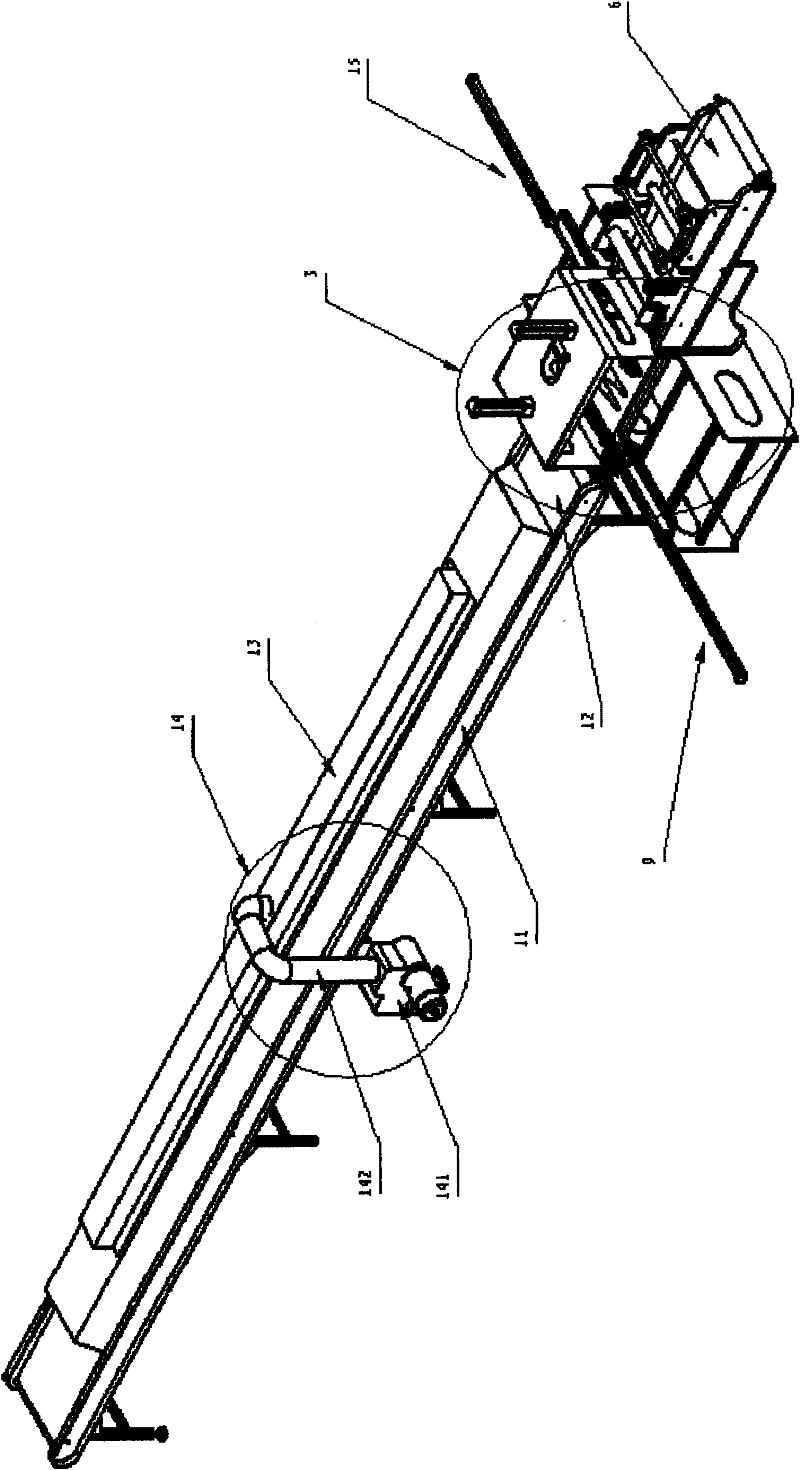

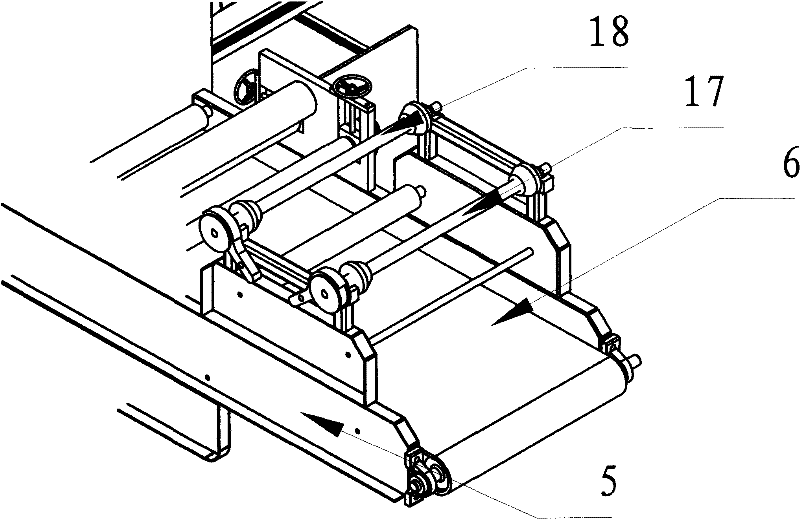

Fully-automatic line production cloth sticking machine

InactiveCN102218888AFully automatedReduce in quantityLaminationLamination apparatusControl systemEngineering

The invention relates to a fully-automatic line production cloth sticking machine. The cloth sticking machine is characterized in that: a feeder, a gluing device, a cloth sticking device and a dryer which are connected in sequence to form the cloth sticking machine are respectively connected with a fully-automatic control system; the feeder comprises a frame, an automatic feeding belt mechanism which is arranged under the emptying rack, and a batch emptying rack which is arranged on the frame; the gluing device comprises a frame, and a supporting roller, a rolling turning roller, a glue spreader and an adhesive groove which are respectively placed on the frame; and the cloth sticking device comprises a frame, and a left cloth clamping and cutting device, a right cloth clamping and cutting device and a cloth shearing mechanism which are placed on the frame; and the dryer comprises a frame, and an automatic feeding belt mechanism, an oven heating mechanism and a hot gas cycling mechanism which are respectively placed on the frame. In the invention, each component is coordinated by a program of the control system, a laminated product is obtained through sticking the cloth with glue to a substrate and passing through a pressure roller. The fully-automatic line production cloth sticking machine allows the product quality and the production efficiency to be improved, the production cost to be reduced, and the labor force to be released.

Owner:蒋均利

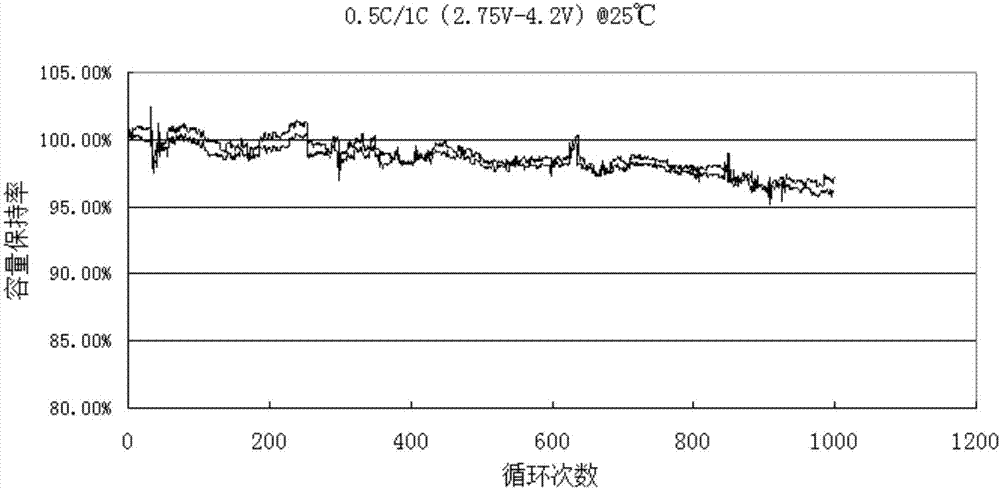

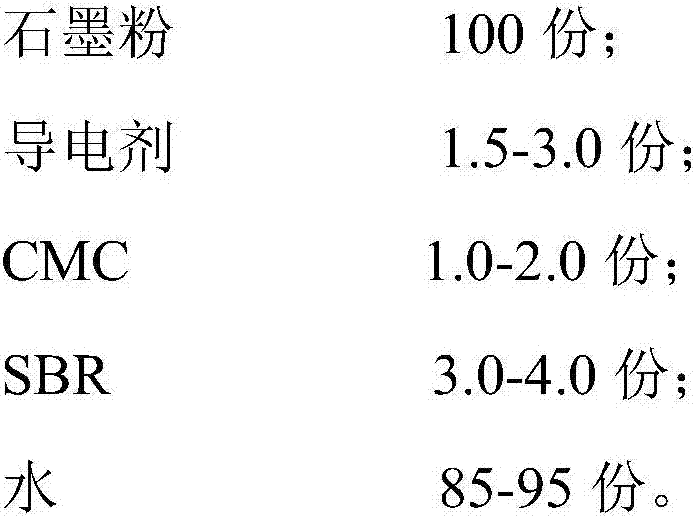

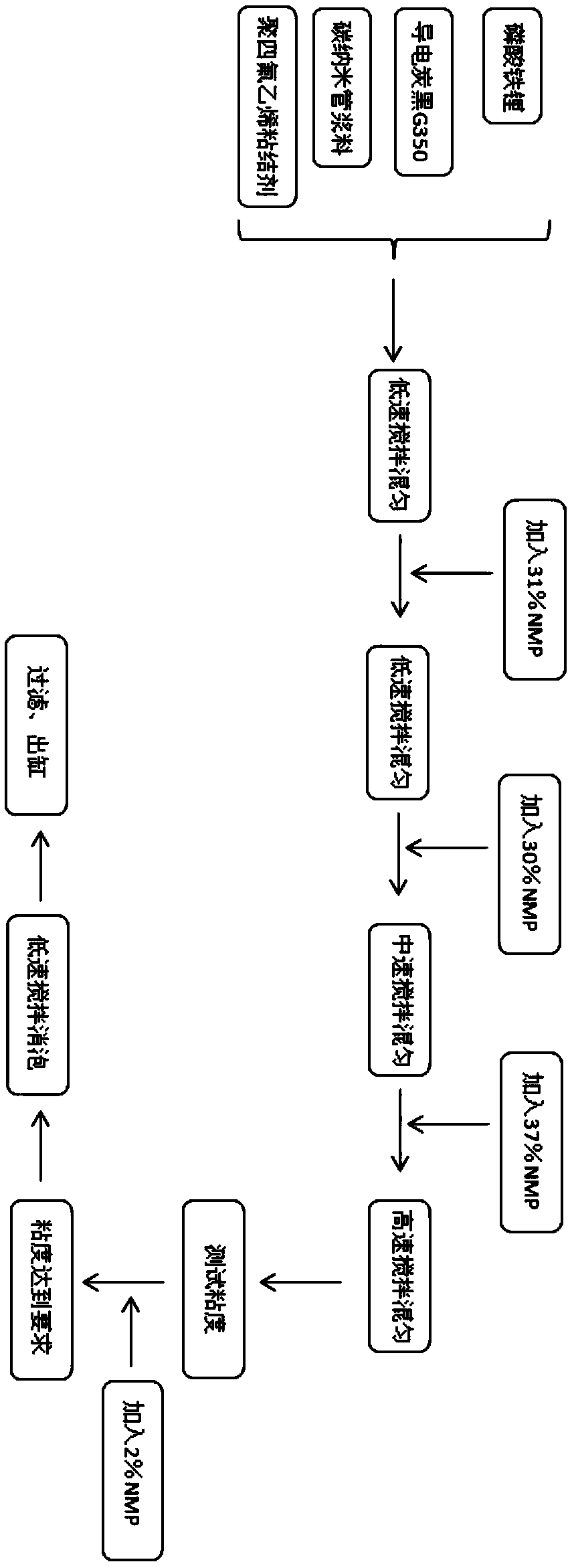

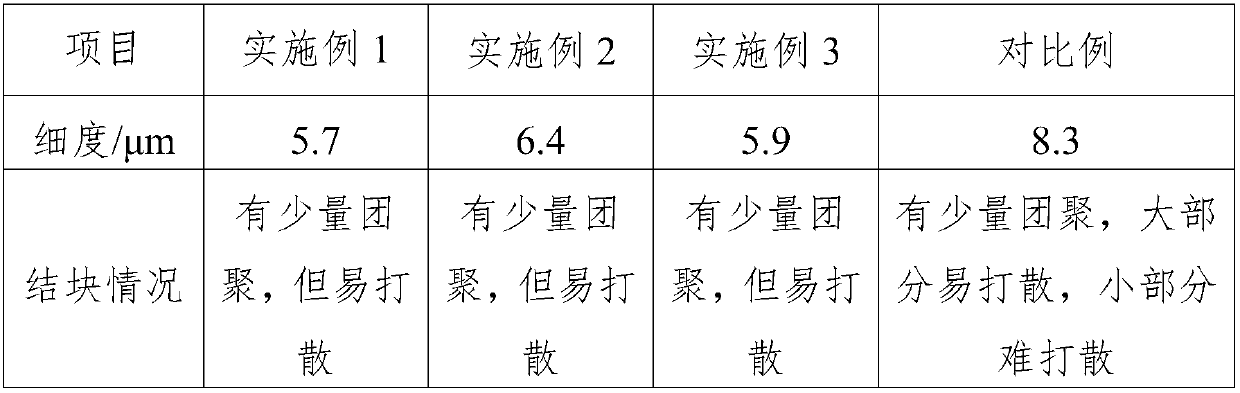

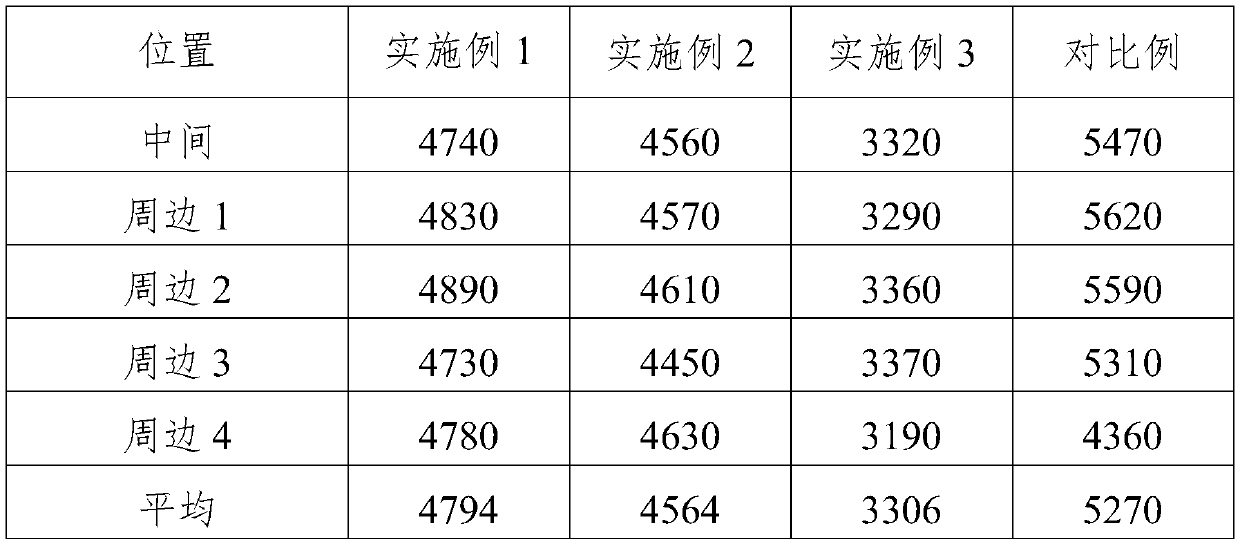

Paste homogenizing and stirring process for lithium ion battery negative electrode

PendingCN107492628AImprove cycle lifeShorten completion timeElectrode manufacturing processesSecondary cellsMaterials scienceLithium electrode

The invention provides a preparation method for lithium ion battery negative paste. The preparation method at least comprises the following steps of providing a raw material constituent of a lithium ion battery negative electrode, pre-dispersing the raw material constituent by an agitator to obtain pre-dispersion paste; and performing high-speed dispersing on the pre-dispersion paste by employing high-speed dispersing equipment at a speed larger than or equal to 2,500rpm to obtain the negative paste.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

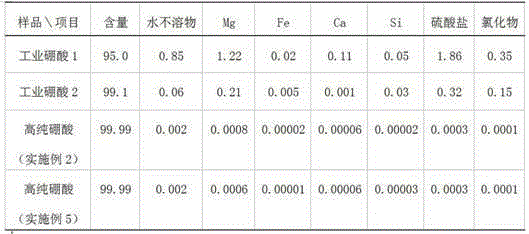

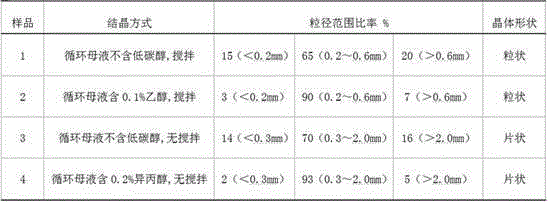

Preparation method of high-purity boric acid

ActiveCN105347353ANo pollution in the processSimple processBoron oxyacidsLamellar crystalsPhysical chemistry

The invention provides a preparation method of high-purity boric acid. The preparation method comprises the following steps: putting industrial boric acid into a mixed solution of circulating mother liquor and trace inorganic acid, stirring, and heating for dissolution; performing thermal reaction for 1-2 hours in a temperature range of 80-95 DEG C; cooling to obtain wet boric acid crystals; respectively washing the crystals by virtue of mother liquor alternately purified by a cation exchange resin column and an anion exchange resin column; and drying to prepare high-purity boric acid. Compared with the prior art, the technical scheme provided by the invention has the technical advantages of being simple in process flow, having no environmental pollution, being high in crystal purity and low in manufacturing cost, selecting between granular or lamellar crystals, and the like; moreover, the crystal particle size distribution can be greatly improved.

Owner:DANDONG CHEM REAGENT FACTORY

Government service system based on Internet

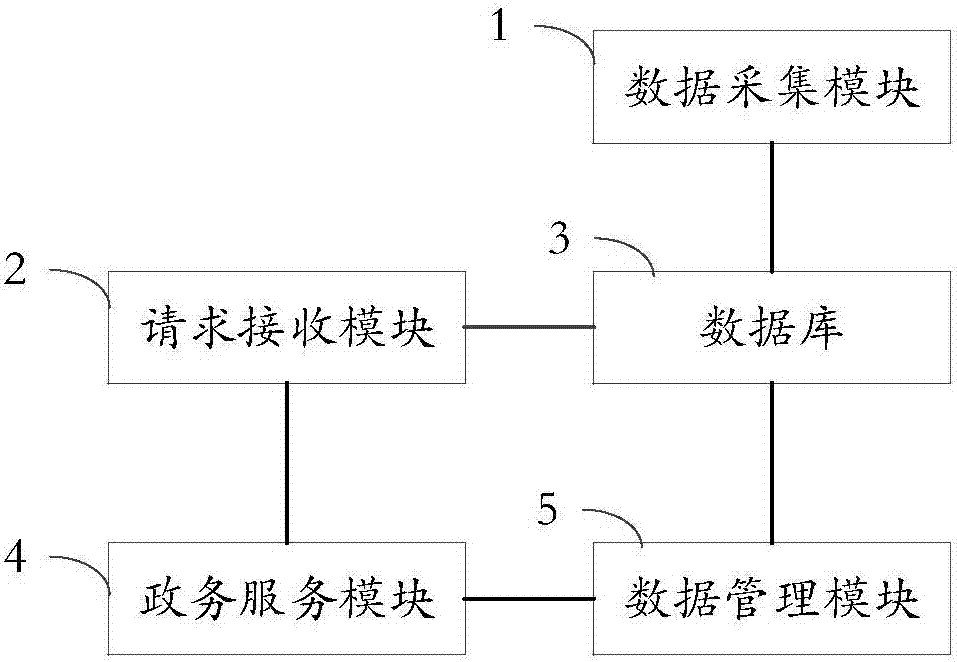

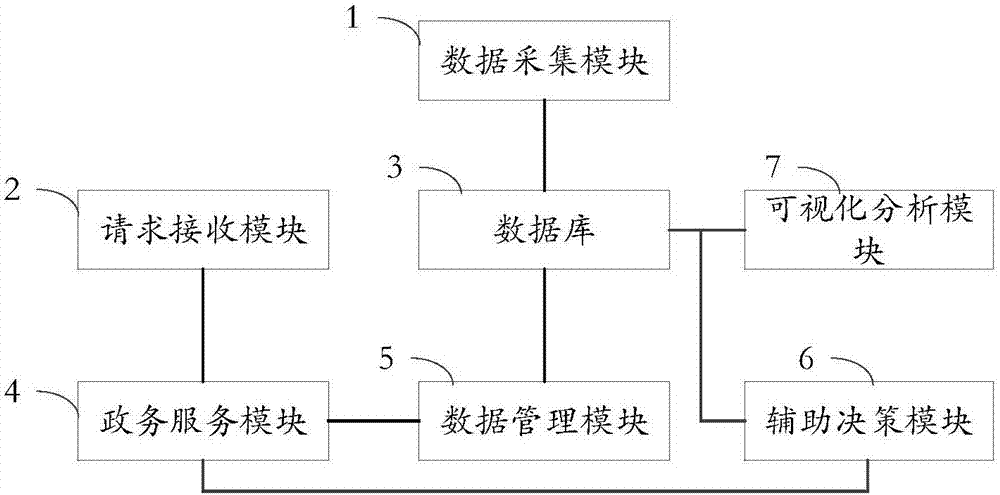

InactiveCN107067355ALower service costsShorten process timeOffice automationResourcesComputer moduleData acquisition

The invention discloses a government service system based on the Internet, comprising a data acquisition module, a request receiving module, a database, a government service module, and a data management module. The data acquisition module is used for acquiring information of an area under administration and storing the information in the database. The request receiving module is used for receiving a request input by a user side and sending the request to the government service module. The government service module is used for pushing policy information to the user side, making the data management module process data according to the request input by the user side, returning the processing result to the user side, and storing the processing processes of all events in a log. The beneficial effects are as follows: grass-roots government service matters are processized and electronized online, online application, acceptance, examination, decision and delivery are realized, the handling time is shortened, and the cost of service is saved for enterprises and the masses; and a public participation mechanism is established, satisfaction evaluation is carried out, and convenient comprehensive service is provided for the masses.

Owner:重庆指讯科技股份有限公司

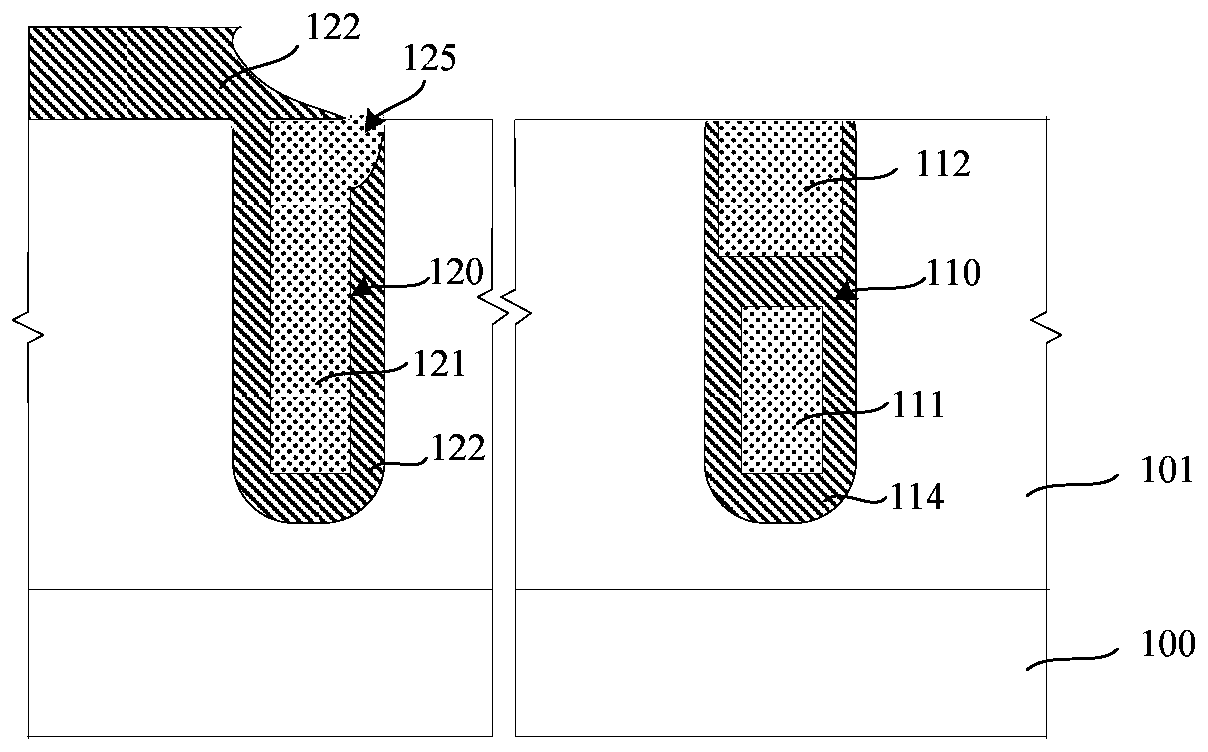

Manufacturing method of shield gate trench power device

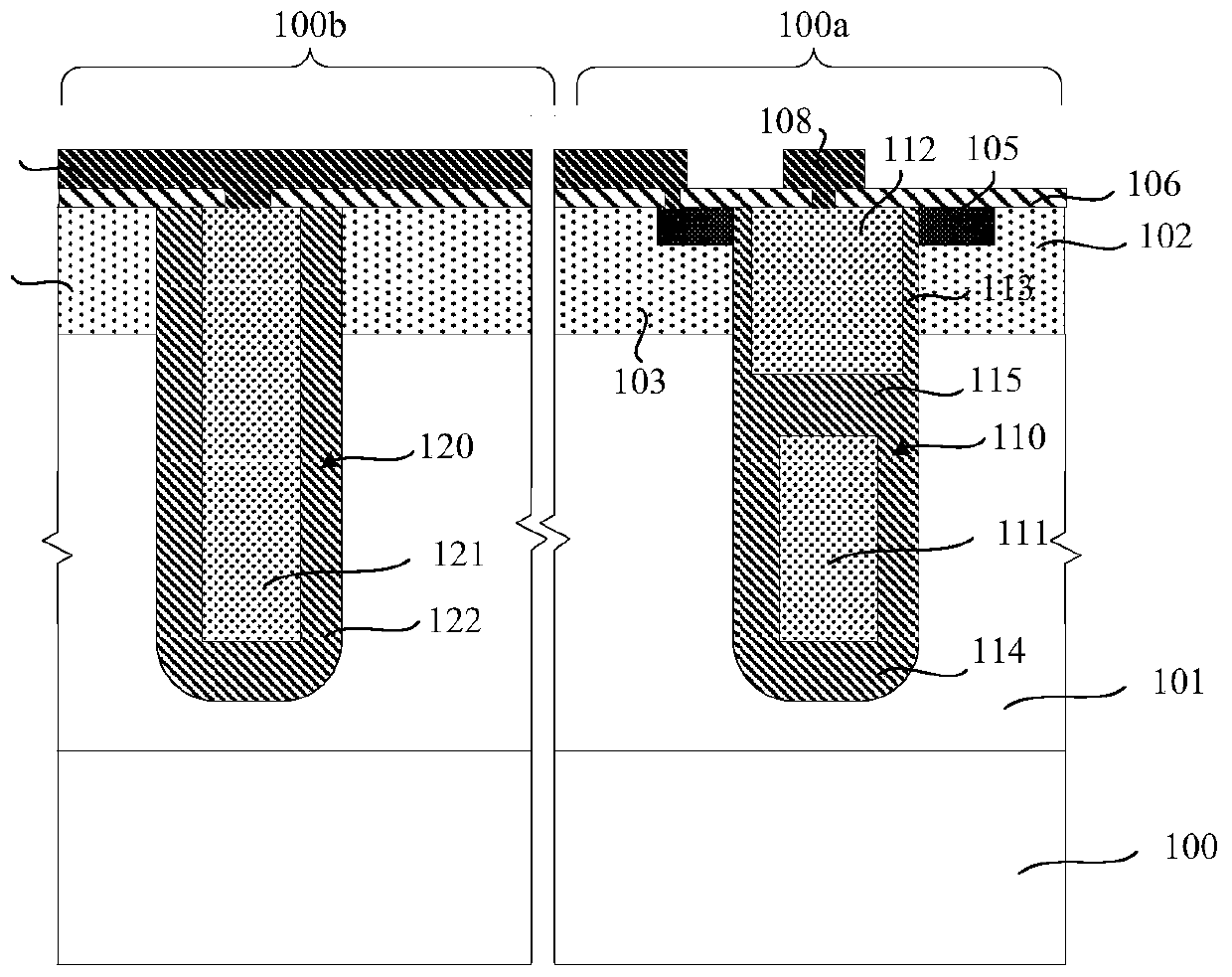

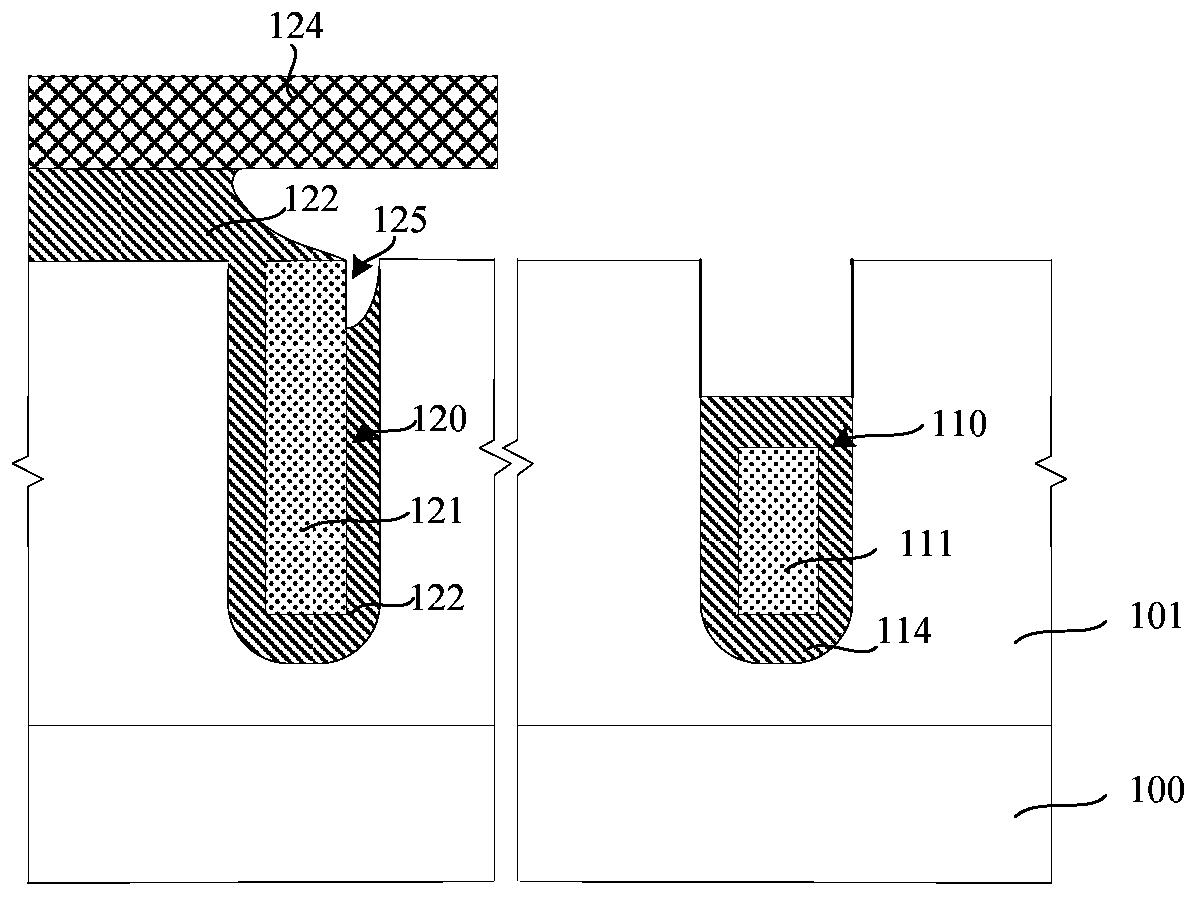

PendingCN111081540AShorten process timeAvoid undercutting problemsSemiconductor/solid-state device manufacturingSemiconductor devicesPhysicsElectrically conductive

The invention provides a manufacturing method of a shield gate trench power device. The method comprises the following steps of: providing a substrate, forming at least one first trench in a device unit region of the substrate, forming at least one second trench in an electrode connection region of the substrate, and forming first dielectric layers on the side walls and the bottoms of the first trench and the second trench; forming a shielding gate in the first trench, partially filling the first trench with the shielding gate, and filling the second trench with a conductive material; forminga second dielectric layer which fills the first trench and covers the surface of the substrate and the conductive material; removing the second dielectric layer on the device unit region by adopting adry isotropic etching process, and exposing a part of the first trench; forming a gate in the first trench. According to the invention, before the gate is formed, the second dielectric layer on the device unit region is removed through dry isotropic etching, and part of the first trench is exposed, so that compared with the traditional wet etching removal, the process time is shortened, and the undercutting problem is effectively reduced and even avoided.

Owner:GUANGZHOU CANSEMI TECH INC

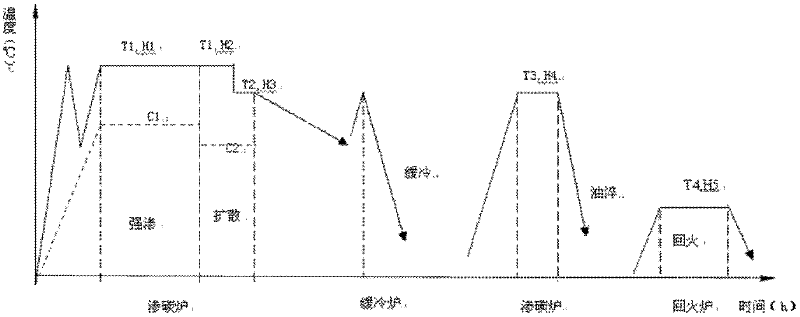

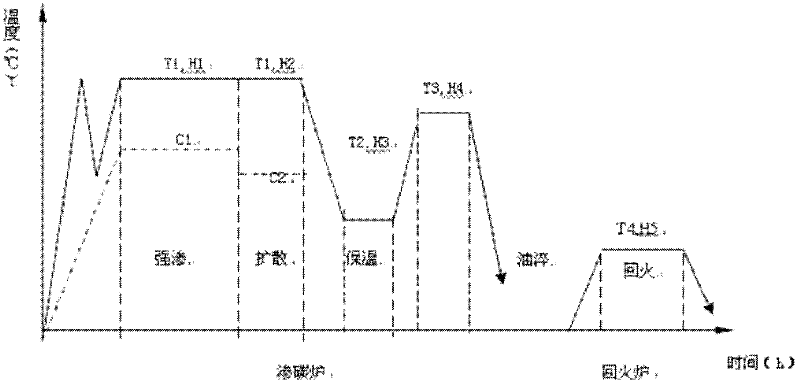

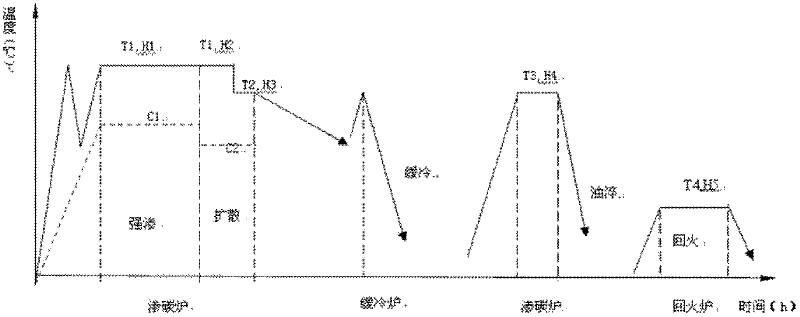

Carburizing direct quenching process for large-scale wind power gear/gear shaft

InactiveCN102392260AShorten process timeLow costSolid state diffusion coatingFurnace typesCarburizingAustenite

The invention relates to a carburizing direct quenching process for a large-scale wind power gear / gear shaft. The process comprises the following steps of: (1) carburizing at the temperature of between 910 and 970 DEG C for 8 to 72 hours, wherein C1 is 0.9 to 1.2 percent C; (2) diffusing at the temperature of between 910 and 970 DEG C for 2 to 8 hours, wherein C2 is 0.65 to 0.9 percent C; (3) keeping temperature at low temperature of between 620 and 700 DEG C for 2 to 8 hours; (4) keeping the temperature at the temperature of between 810 and 850 DEG C for 2 to 8 hours before oil extraction; (5) performing the oil extraction, namely moving workpieces from a carburizing furnace to a quenching furnace for quenching; and (6) tempering in a tempering furnace at the temperature of between 150 and 200 DEG C for 4 to 48 hours. In the carburizing direct quenching process for the large-scale wind power gear / gear shaft, a process of direct tapping and quenching after carburizing is adopted, the intermediate temperature heat-preserving phase after the carburizing is added, the time of the process is reduced by about one third, the cost is reduced by about one half, the length of martensite of the workpieces can be reduced, and the number of residual austenite can be reduced obviously.

Owner:天津市祥威传动设备有限公司

Preparation method of lithium ion battery sizing agent

InactiveCN109560264ASimplify process stepsShorten process timeCell electrodesSecondary cellsSizingLithium electrode

The invention relates to the field of lithium ion batteries, and specifically relates to a preparation method of a lithium ion battery sizing agent. The preparation method of the lithium ion battery sizing agent disclosed by the invention comprises the following five steps: dry material blending, low-speed high-viscidity stirring, medium-speed medium-viscidity stirring, high-speed low-viscidity stirring, viscidity modification and sizing agent discharge. The preparation method can be used for preparing an oily positive electrode sizing agent, an oily negative electrode sizing agent and an aqueous negative electrode sizing agent, the special working procedure of prefabricating a glue solution can be saved, the technological operating steps of the blending working procedure are simplified, the technological time is shortened, the utilization rate and capacity of the equipment are improved, gluing equipment, glue solution storage equipment or transfer equipment does not need to be purchased, the automation degree of blending is improved, and the uniformity and stability of the sizing agent are improved.

Owner:福建冠城瑞闽新能源科技有限公司

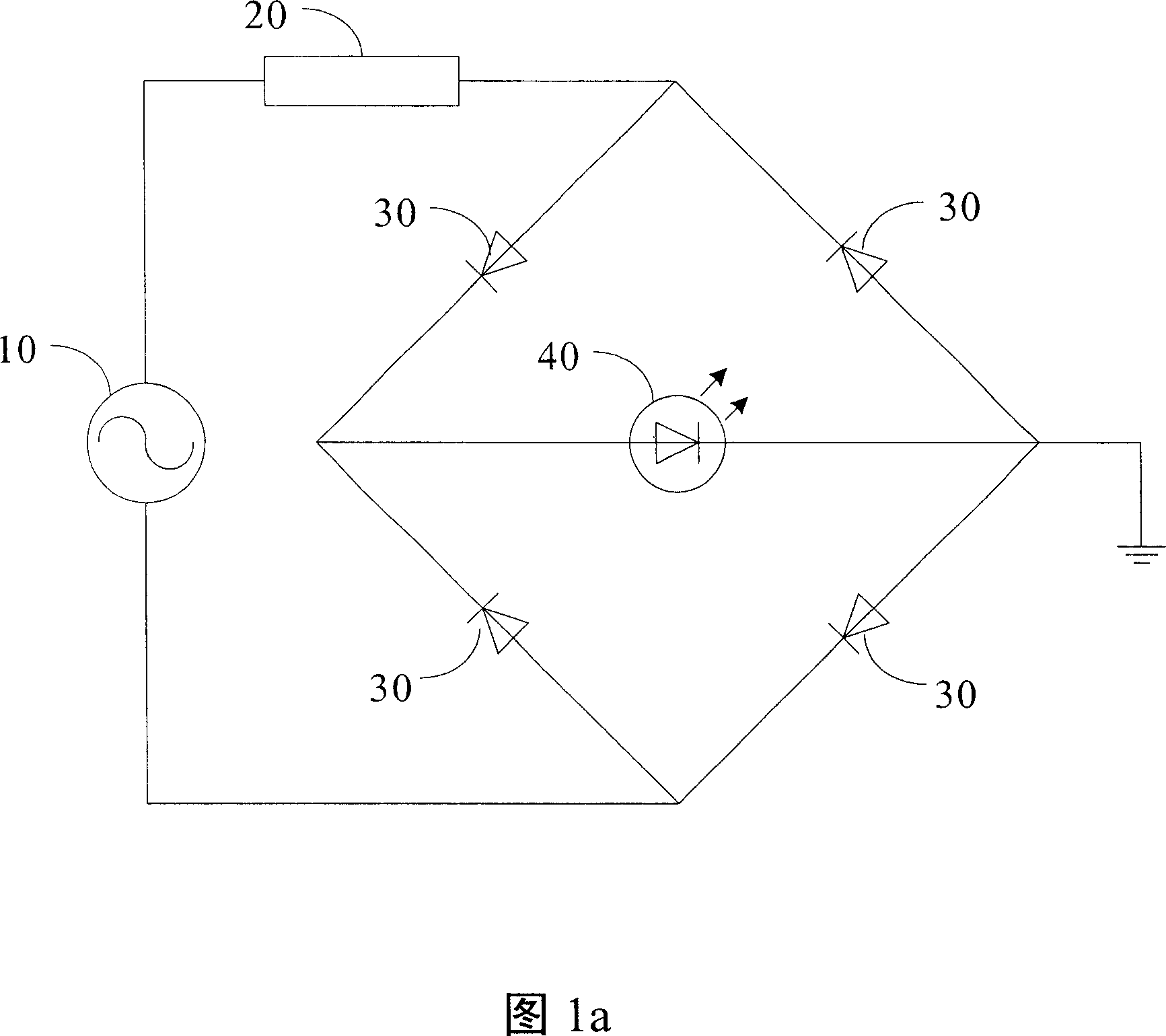

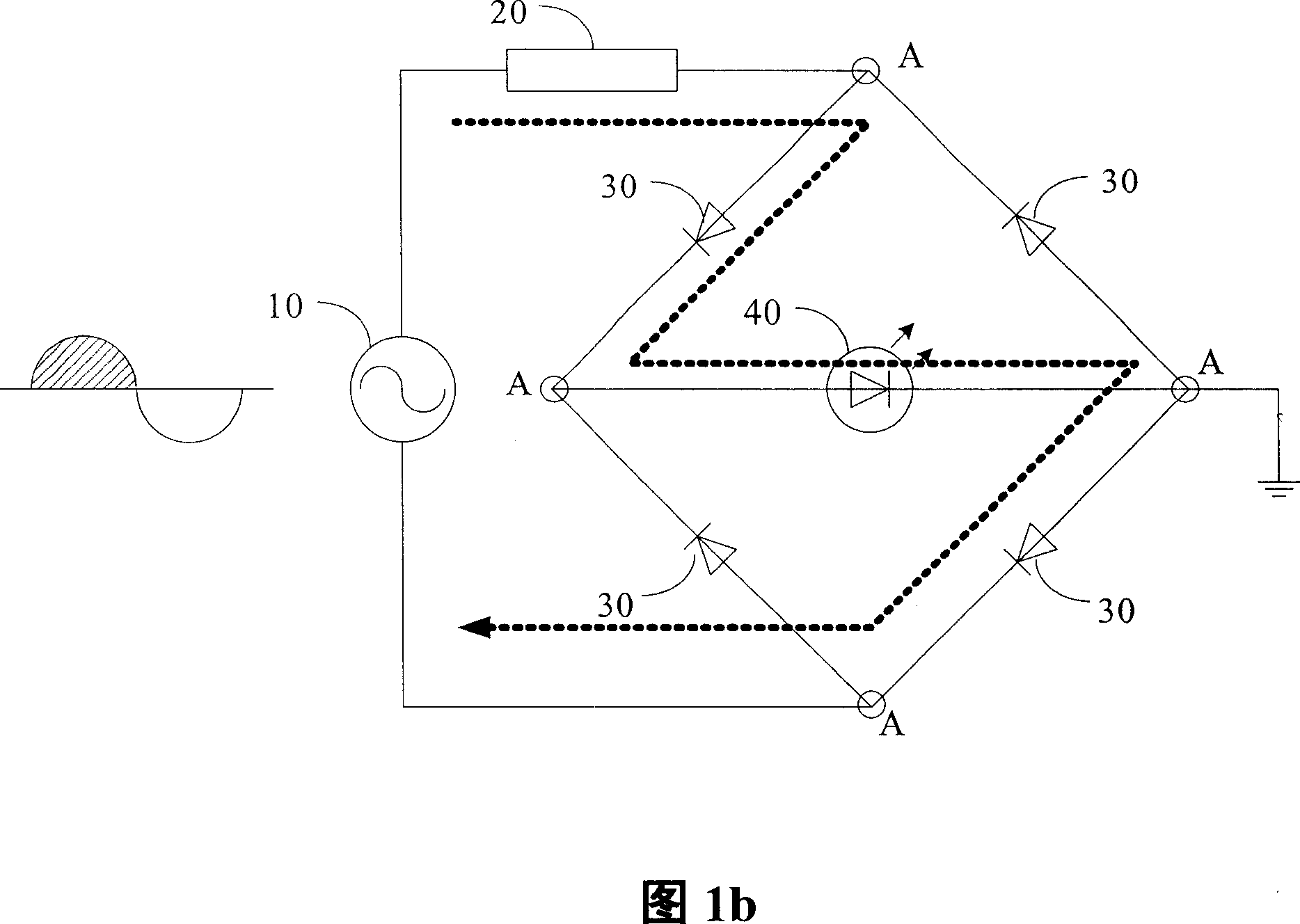

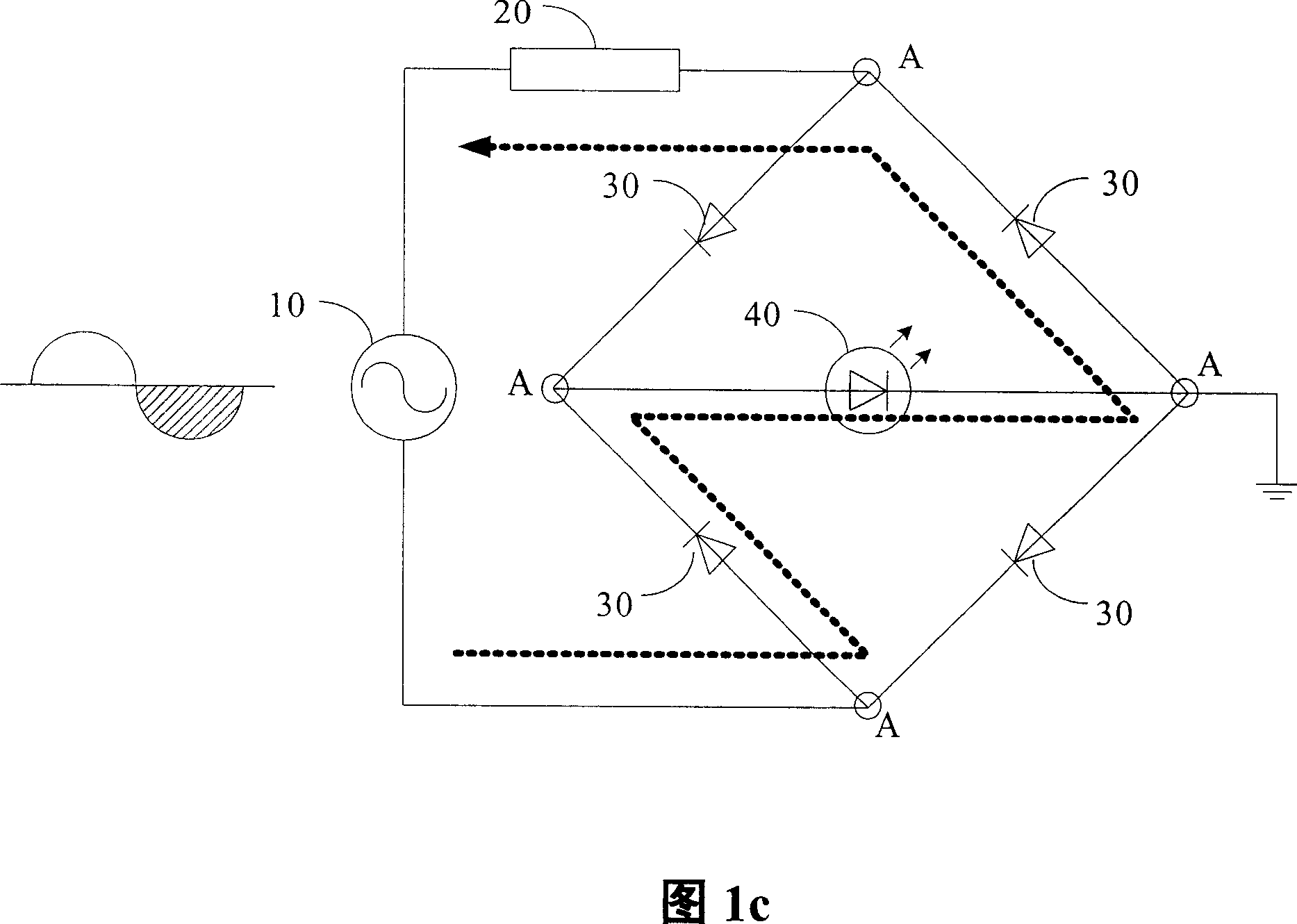

LED luminescent device combined with rectifying circuit on secondary carrier and its production

ActiveCN1983594AShorten process timeReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitMetal

The invention is concerned with the illumination equipment and the corresponding method for the alternating current direct drive, the conformity commutating circuit and the light-emitting diode (LED). The LED illumination equipment includes the base-board, the top base-board, and the bottom base-board. The bottom base-board uses the manufacture of the integrate circuit to implement the commutating circuit, and sets the fit electric point on the surface. The top base-board uses the manufacture of the integrate circuit to implement the several LED in it by the arrangement mode of insulating independent N*M matrix. Between the N*M of LED forms the fit circuit by the connection of the lead. The top base-board and the bottom base-board are opposite, and finish the electric connection between the commutating circuit and the LED by the metal protruding block.

Owner:TYNTEK

Circuit board structure and making method

InactiveCN1980540AShorten process timeReduce process costPrinted electric component incorporationMultilayer circuit manufactureElectric propertiesEngineering

Owner:PHOENIX PRECISION TECH CORP

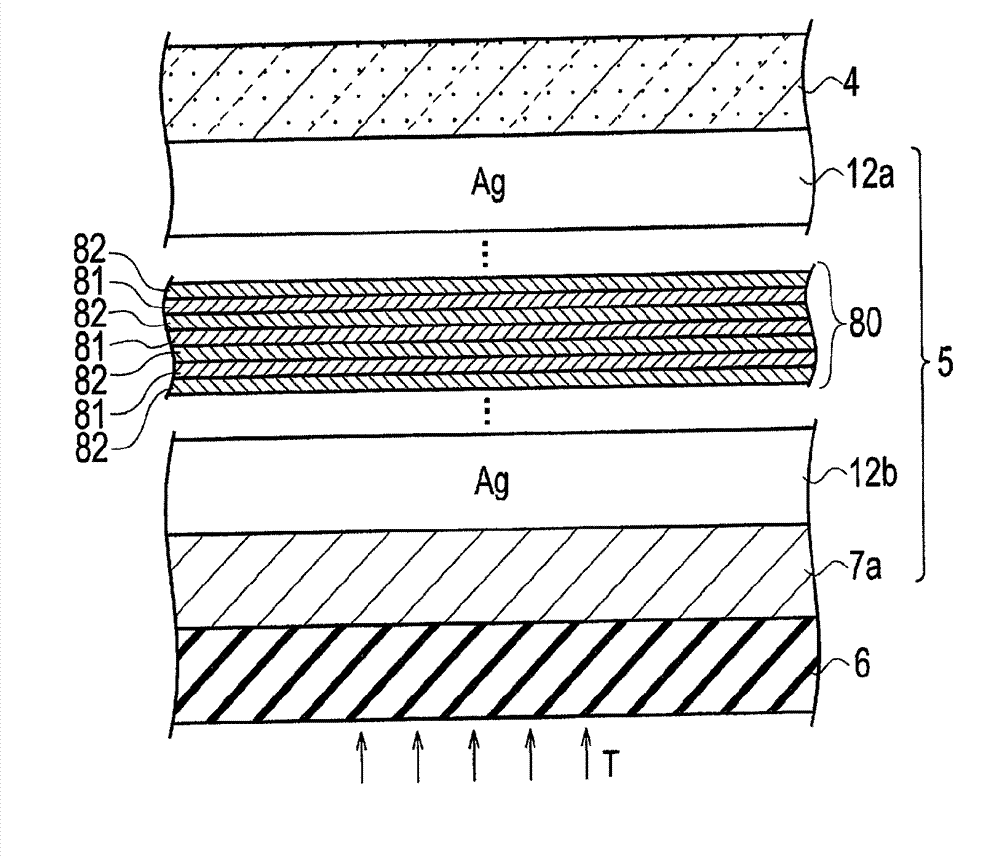

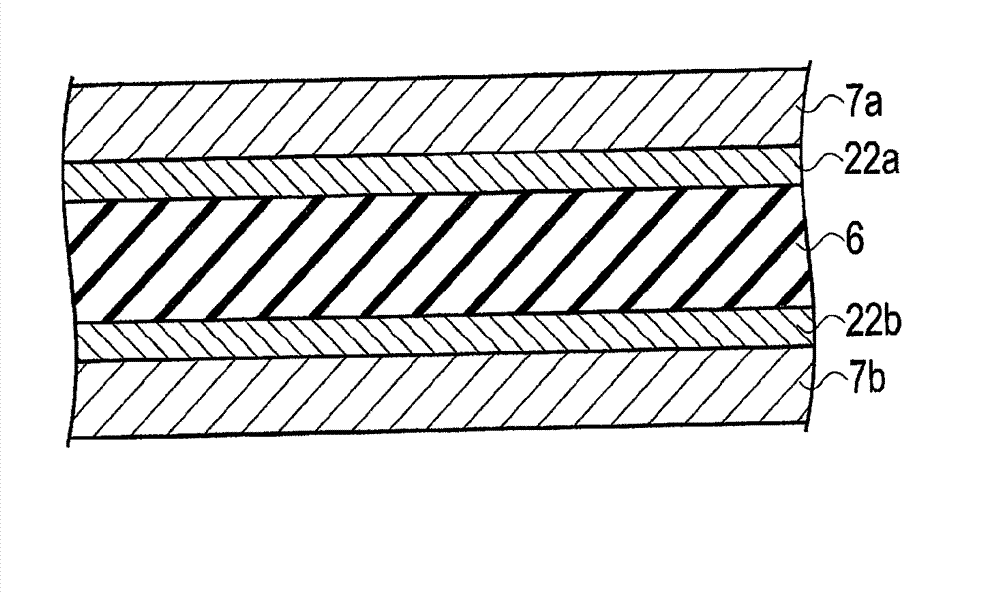

Laminated high melting point soldering layer and fabrication method for the same, and semiconductor device

InactiveCN102856282AShorten process timeIncreased mass production efficiencySemiconductor/solid-state device detailsSolid-state devicesLayered structureSoldering

The laminated high melting point soldering layer includes: a laminated structure which laminated a plurality of three-layered structures, the respective three-layered structures including a low melting point metal thin film layer and a high melting point metal thin film layers disposed on a surface and a back side surface of the low melting point metal thin film layer; a first high melting point metal layer disposed on the surface of the laminated structure; and a second high melting point metal layer disposed on the back side surface of the laminated structure. The low melting point metal thin film layer and the high melting point metal thin film layer are mutually alloyed by TLP, and the laminated structure, and the first high melting point metal layer and the second high melting point metal layer are mutually alloyed by the TLP bonding.

Owner:ROHM CO LTD

Novel technique for dewatering and rinsing medical dressing by one-bath method

InactiveCN101411885AShorten process timeSave on electricity billsBleaching apparatusAbsorbent padsChemistryNovel technique

The invention discloses a new bath bleaching technique for medical dressing, which comprises two steps, namely prewashing and bleaching, wherein the prewashing step is as follows: adding 0.5 to 1 weight percent of cleaning bleacher and 0.1 to 0.5 weight percent of refining agent of the dressing, prewashing the dressing from 10 to 40 minutes in a reaction kettle at a temperature range of between 30 and 90 DEG C, discharging liquid, then pressurizing and rinsing or rinsing the dressing by liquid flow in the reaction kettle for 10 to 25 minutes, and discharging liquid; and after prewashing the dressing, adding bleacher containing sodium hydroxide and oxydol in the reaction kettle, and bleaching the dressing. The technique effectively solves the problems that the prior bleaching technique consumes much time and much energy and produces much sewage, the product becomes yellow and crisp easily, and the like. By adopting the technique, the total cost reduces greatly; and the technique has favorable economic benefit and social benefit.

Owner:宁波米杰纺织材料有限公司 +2

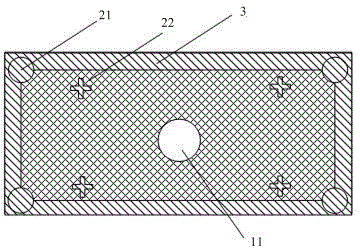

Cutting technique

ActiveCN101445319AShorten process timeSmall toleranceGlass severing apparatusBiomedical engineeringMachine tool

The invention provides a cutting technique suitable for cutting a workpiece. The cutting technique comprises the following steps: at first, an optics membrane is stuck on the surface of the workpiece; then, the surface of the workpiece is cut by a machining tool, so as to form an initial crack on the edge of the workpiece; finally, a cutting beam is supplied by which the workpiece and the optics membrane are cut simultaneously starting from the initial crack. Employing the cutting technique of the invention can not only save the technique time, and reduce the technique cost, but also have a better rate of finished products.

Owner:AU OPTRONICS CORP

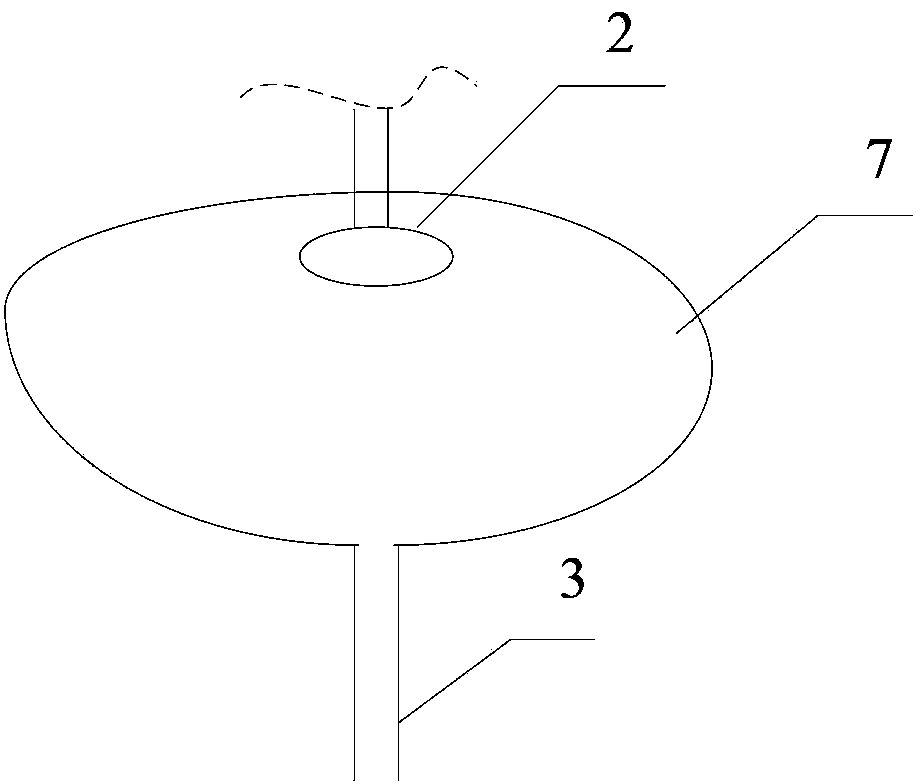

Sealing agent curing device

The invention discloses a sealing agent curing device, and aims to solve the problems that the product yield is reduced and the curing time is long when a curing device in the prior art is used for performing sealing agent curing. The seal material curing device comprises a seal box, an ultraviolet source arranged in the seal box and optical fibers arranged in the seal box and connected with the ultraviolet source, wherein ultraviolet light of the ultraviolet source is transmitted onto the position of a to-be cured sealing agent on a package substrate in the seal box, and is exposed in the position, so that the light emitted from the ultraviolet source cannot be scattered to other positions, and a mask plate is not required to be independently arranged for shielding.

Owner:BOE TECH GRP CO LTD

Dyeing technology for carrying out one-bath scouring and dyeing on lycra-containing cotton knitted fabric by active turquoise blue

ActiveCN104179041AReduce process stepsReduce water consumptionBiochemical fibre treatmentBleaching apparatusElectricityEngineering

The invention discloses a dyeing technology for carrying out one-bath scouring and dyeing on a lycra-containing cotton knitted fabric by active turquoise blue, mainly aims at solving the problems that a traditional technology is relatively large in water consumption and coal consumption, long in technology duration and high in power consumption. The dyeing technology comprises the working procedures of preshaping, stitching the edge, carrying out one-bath scouring and dyeing, and carrying out aftertreatment and afterfinish in sequence, wherein in the working procedure of the preshaping, a chelating agent, a deoiling agent, tea saponin, a tea saponin dispersion dispersion liquid and a scouring agent are fed; in the working procedure of the one-bath scouring and dyeing, the deoiling agent, a defoaming agent and refined enzyme are fed into a dye vat after being diluted by clear water, a leveling agent, anhydrous sodium sulphate and sodium carbonate are fed into the dye vat in a way of circulating material injection, the active turquoise blue and urea are fed in a way of dissolving the materials by the clear water, and the heat preservation is carried out at the temperature of 80 DEG C. After the dyeing technology is adopted, the lycra-containing cotton knitted fabric can be bleached, dyed and scoured by the working procedure of the one-bath scouring and dyeing, so that a plurality of tasks can be completed in one working procedure, the technological process is shortened, the processing steps are reduced, and the water consumption, the electricity consumption and the coal consumption in the processing steps can be omitted.

Owner:JIHUA 3543 KNITTING CLOTHING

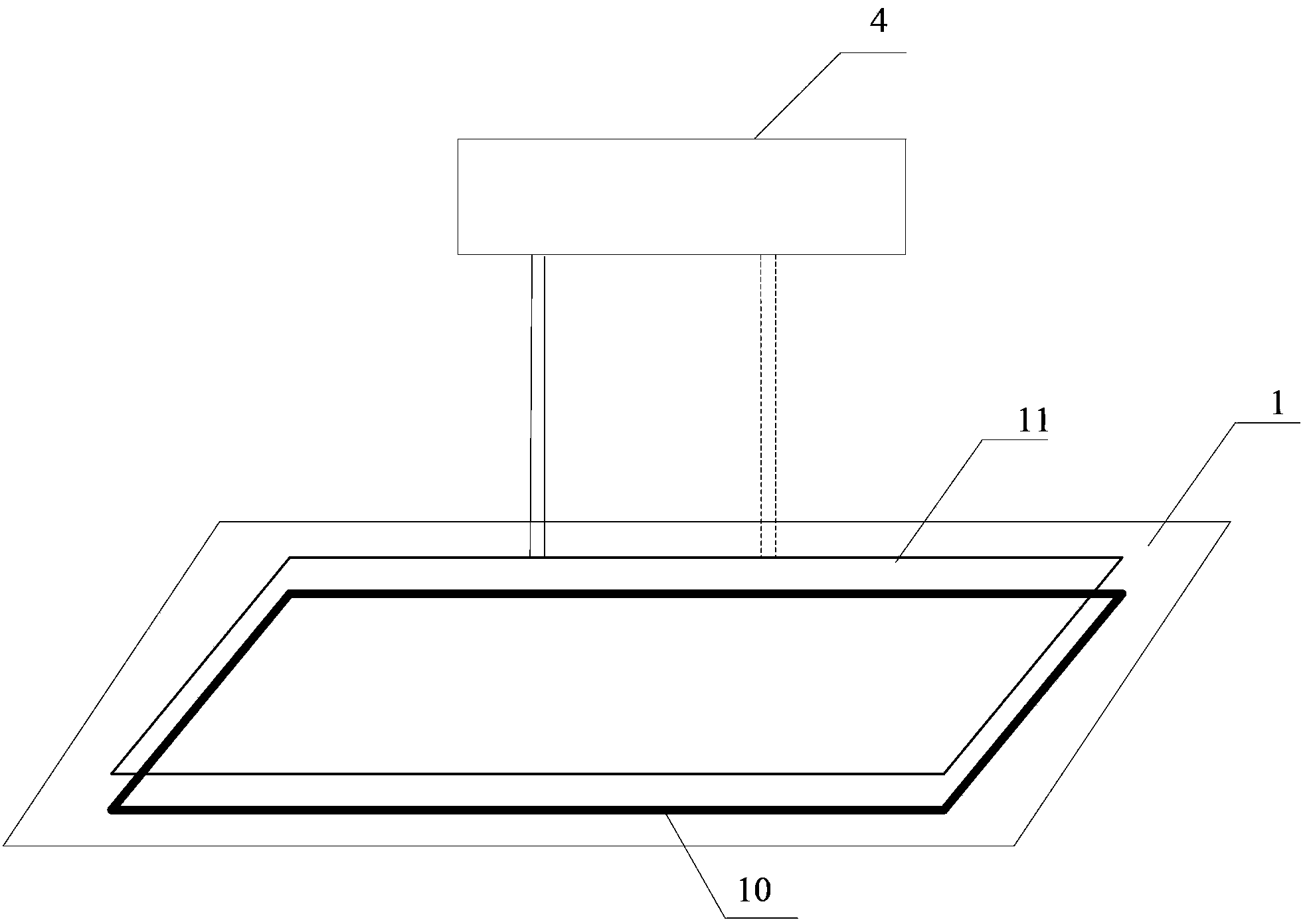

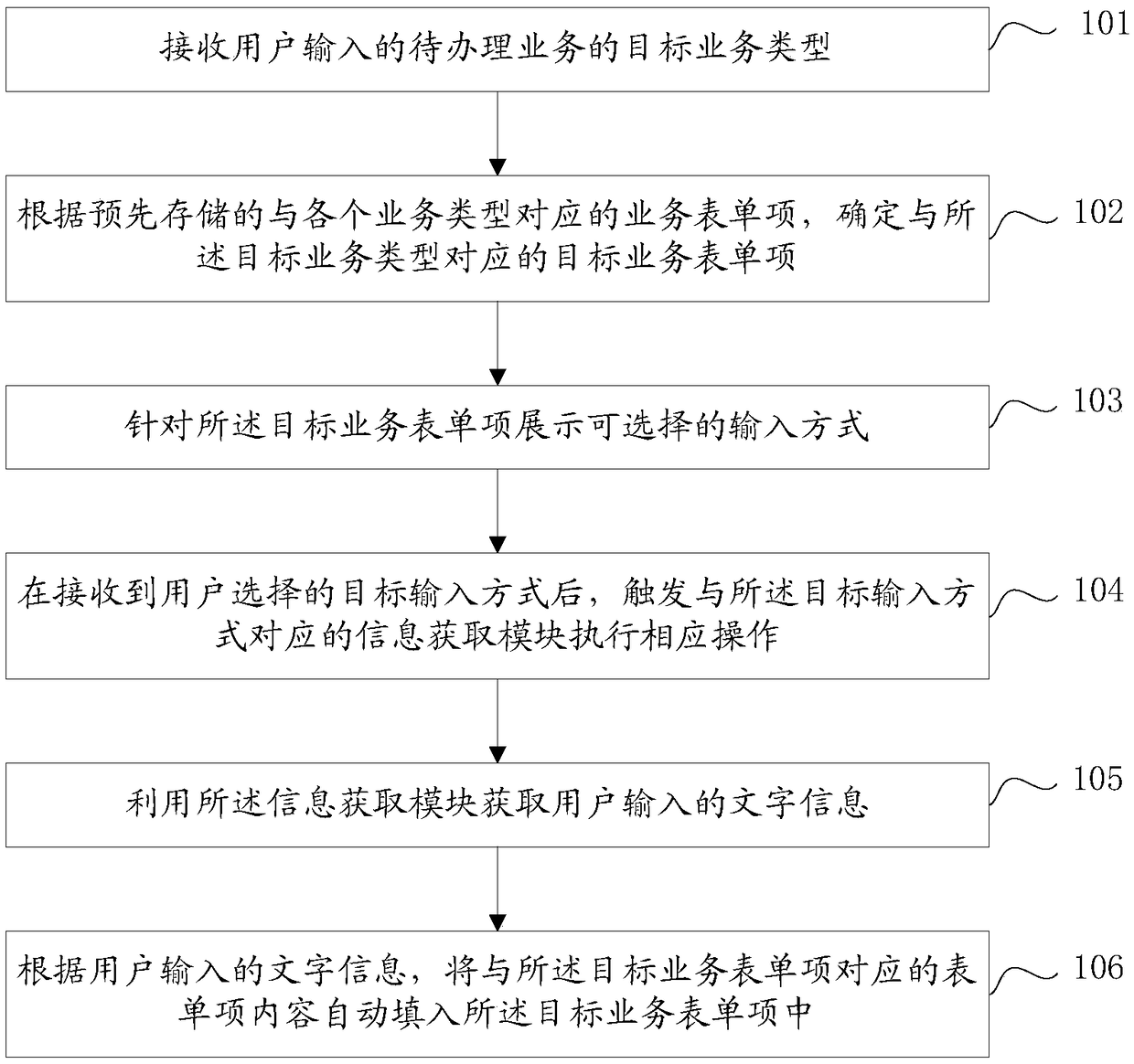

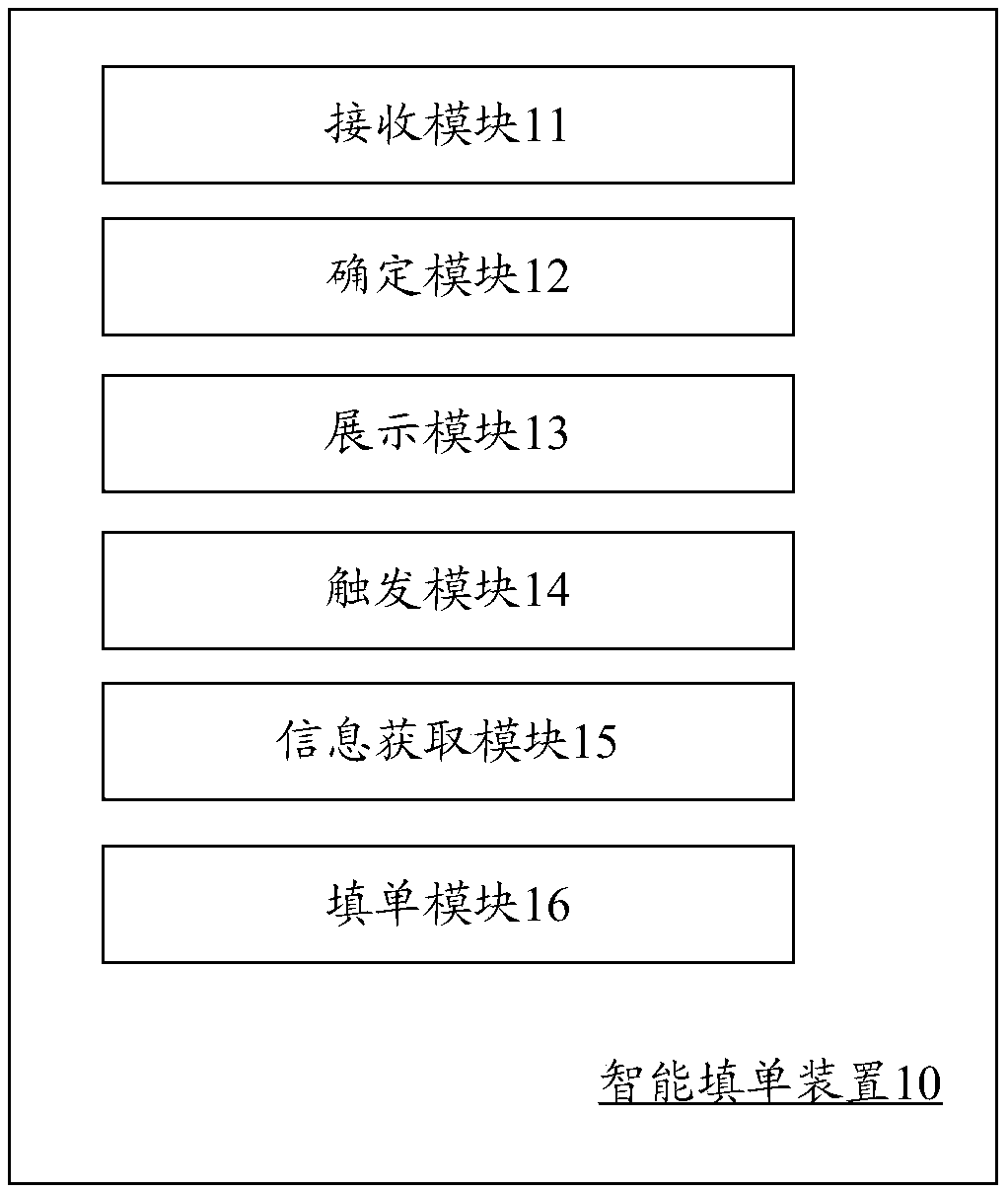

Intelligent sheet filling method, device, computer device and storage medium

InactiveCN109145760AShorten process timeImprove form filling efficiencyCharacter and pattern recognitionNatural language data processingDatabaseBusiness forms

The invention provides a method for intelligently filling sheets a DEVICE, a COMPUTER DEVICE AND a STORAGE MEDIUM. By receiving the target service type of the agent service input by the user, the target business form item corresponding to the target business type is determined, and after the user has determined the target input mode, the information obtaining module corresponding to the target input mode is triggered to obtain the text information inputted by the user, and according to the text information inputted by the user, the form item content corresponding to the target service form item is automatically filled into the target service form item, so that the filling efficiency can be improved and the service processing time can be shortened.

Owner:SUZHOU LANGCHAO INTELLIGENT SOFTWARE CO LTD

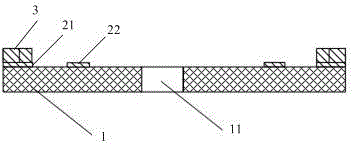

Chip positioning clamp of vacuum eutectic soldering, manufacturing method and chip transferring method

ActiveCN104900575AShorten process timeReduce positional deviationSemiconductor/solid-state device manufacturingProcess engineeringElectrical and Electronics engineering

The invention discloses a position clamp of vacuum eutectic soldering, a manufacturing method and a chip transferring method. The positioning clamp comprises a substrate, a supporting step and a limiting step. The substrate is provided with an adsorbing hole. The supporting step is used for supporting a chip. The limiting step is used for limiting the chip. The manufacturing method comprises the steps of: forming the supporting step on the surface of substrate; forming the limiting step on the surface of the supporting step; and manufacturing the adsorbing hole on the center position of the substrate. The chip transferring method comprises the steps that an adsorbing head adsorbs the chip positioning clamp; the adsorbing head adsorbs the chip into the limiting step of the chip positioning clamp through the absorbing hole; the chip is moved to a suitable position in a packaging box; and the adsorbing head is dismounted, and a pressure rod is installed. By adopting the positioning clamp, the manufacturing method and the chip transferring method, the chip transferring process is simplified, the processing time is saved, the position tolerance in the chip transferring process is reduced, and the position precision is improved.

Owner:SHANGHAI SPACEFLIGHT ELECTRONICS & COMM EQUIP RES INST

Instant spicy fish and method for making same

The invention discloses instant spicy fish and a method for making the same. The method includes steps of (1), carrying out preprocessing, to be more specific, removing the fish heads and the internal organs of fish, thoroughly washing the fish by the aid of water, draining the fish and weighing the fish; (2), removing the fishiness of the fish; (3), steaming the fish; (4), primarily drying the fish; (5), frying the fish in oil; (6), seasoning the fish, and to be more specific, soaking fried fish sections in flavoring liquid with chili oil under vacuum conditions; (7), secondarily drying the fish sections; (8), sterilizing the fish sections. The instant spicy fish and the method have the advantages that a vacuum soaking process is combined with the method in the aspect of fishiness removing and seasoning operation, accordingly, the fishiness of the fish can be quickly removed, the fish can be quickly seasoned, and the technological duration can be shortened; ultrahigh-pressure sterilization techniques are implemented in the aspect of product sterilization, and accordingly flavor, textures and the nutritional quality of products can be effectively kept; the instant spicy fish is crispy, tasty, sweet, sour and pungent without loss of aroma of the fish, is easily accepted by testers and can be eaten conveniently and safely, and requirements of consumers on the safety, the deliciousness and the convenience of modern food can be met.

Owner:TIANJIN AGRICULTURE COLLEGE

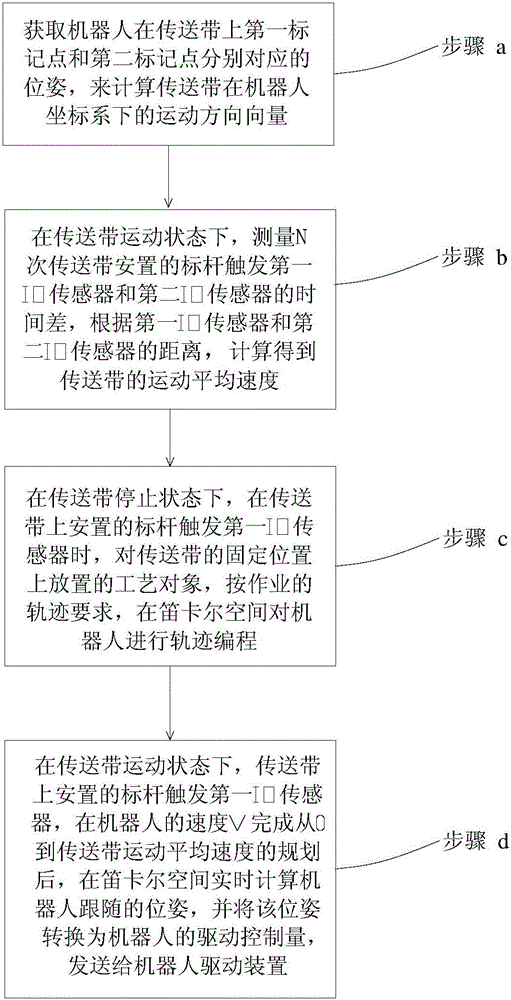

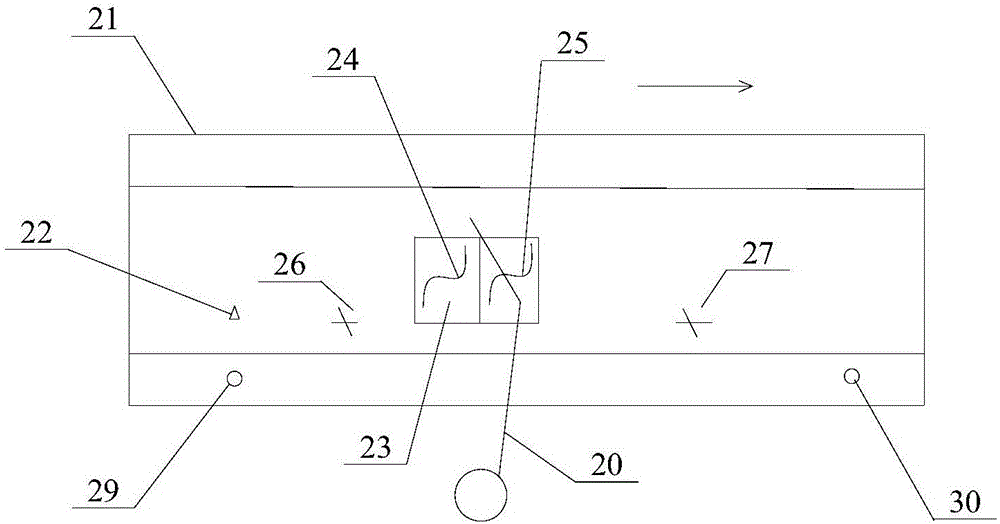

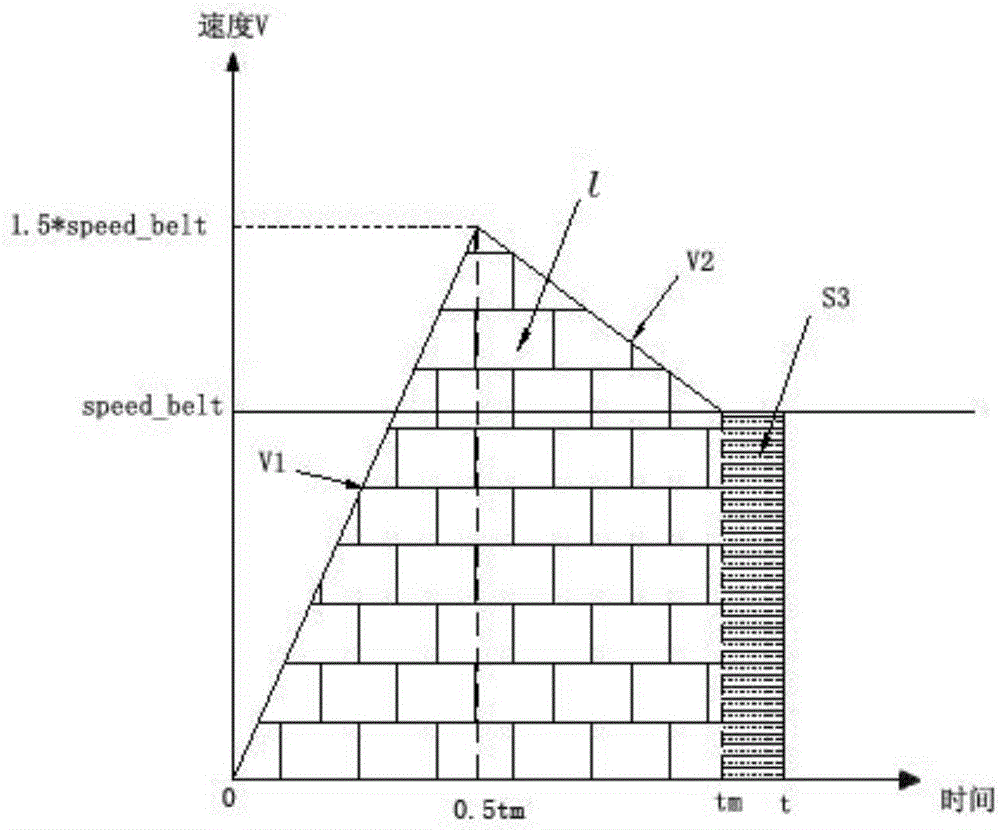

Method and device for controlling robot to move with conveyor belt

ActiveCN106483984AImprove how stagger worksLimited rangeControl using feedbackEngineeringOperation mode

The invention discloses a method and device for controlling robot to move with conveyor belt, wherein the device comprises a conveyor belt direction calculating unit, a conveyor belt speed calculating unit, a track programming unit and a following control unit. According to the invention, in conveyor belt motion state, the average movement velocity of the conveyor belt can be obtained based on time difference calculation, there are no direction requirement for the conveyor belt relative to a robot, in the stop state of the conveyor belt, the robot can perform track programming on a component of technical operation, an operation mode that the conveyor belt and the robot are completely staggered is improved, a plurality of points of the component of the technical operation can follow the conveyor belt to move and work, the limitation of work application range is small, the device is simple and easy to use, the device is suitable for flow line production of robot and conveyor belt, the technical operation time is helped to shorten, and the work efficiency is improved.

Owner:广州智能装备研究院有限公司

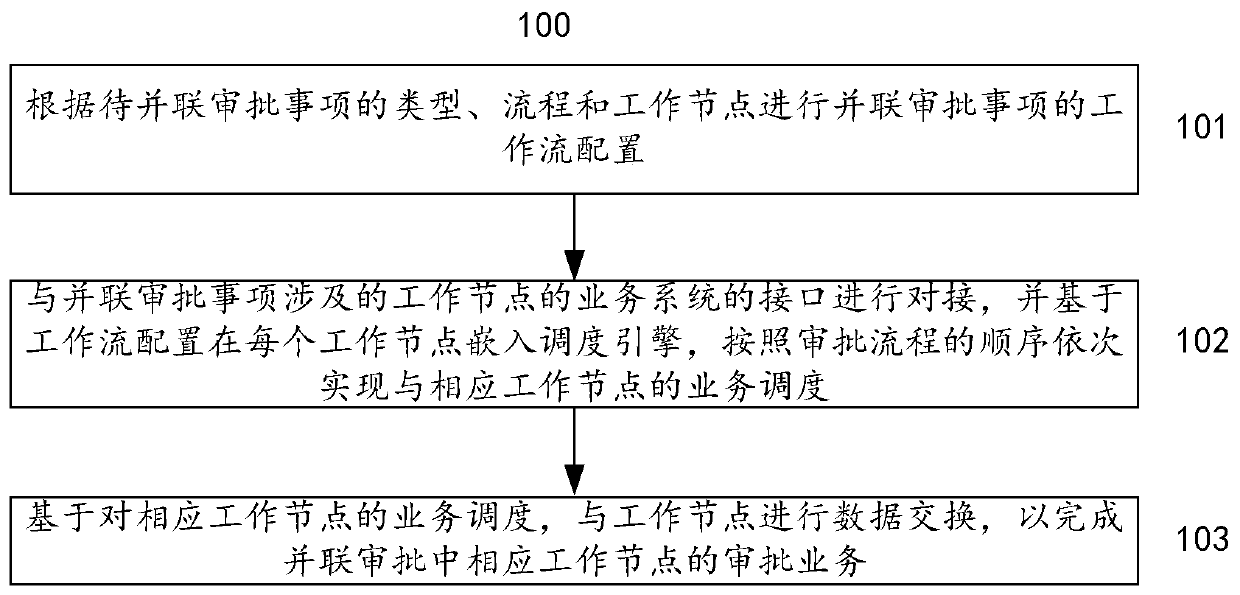

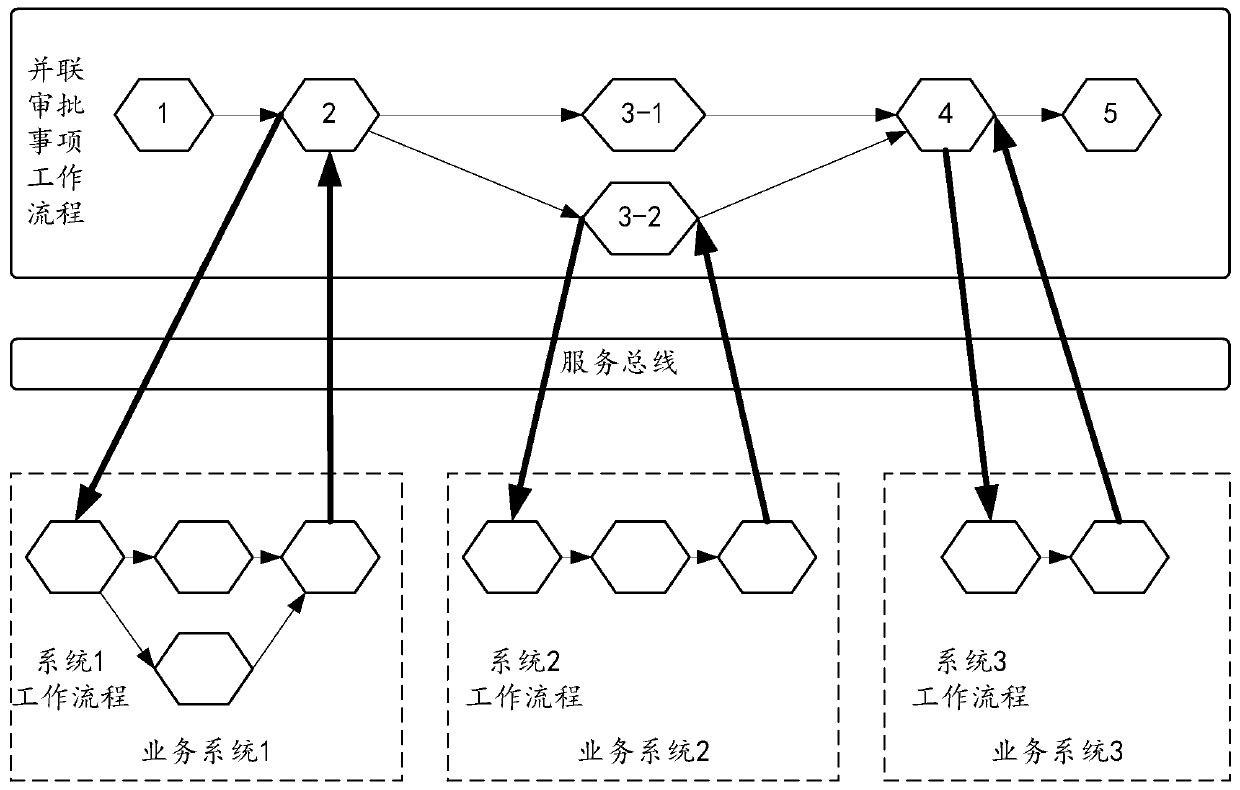

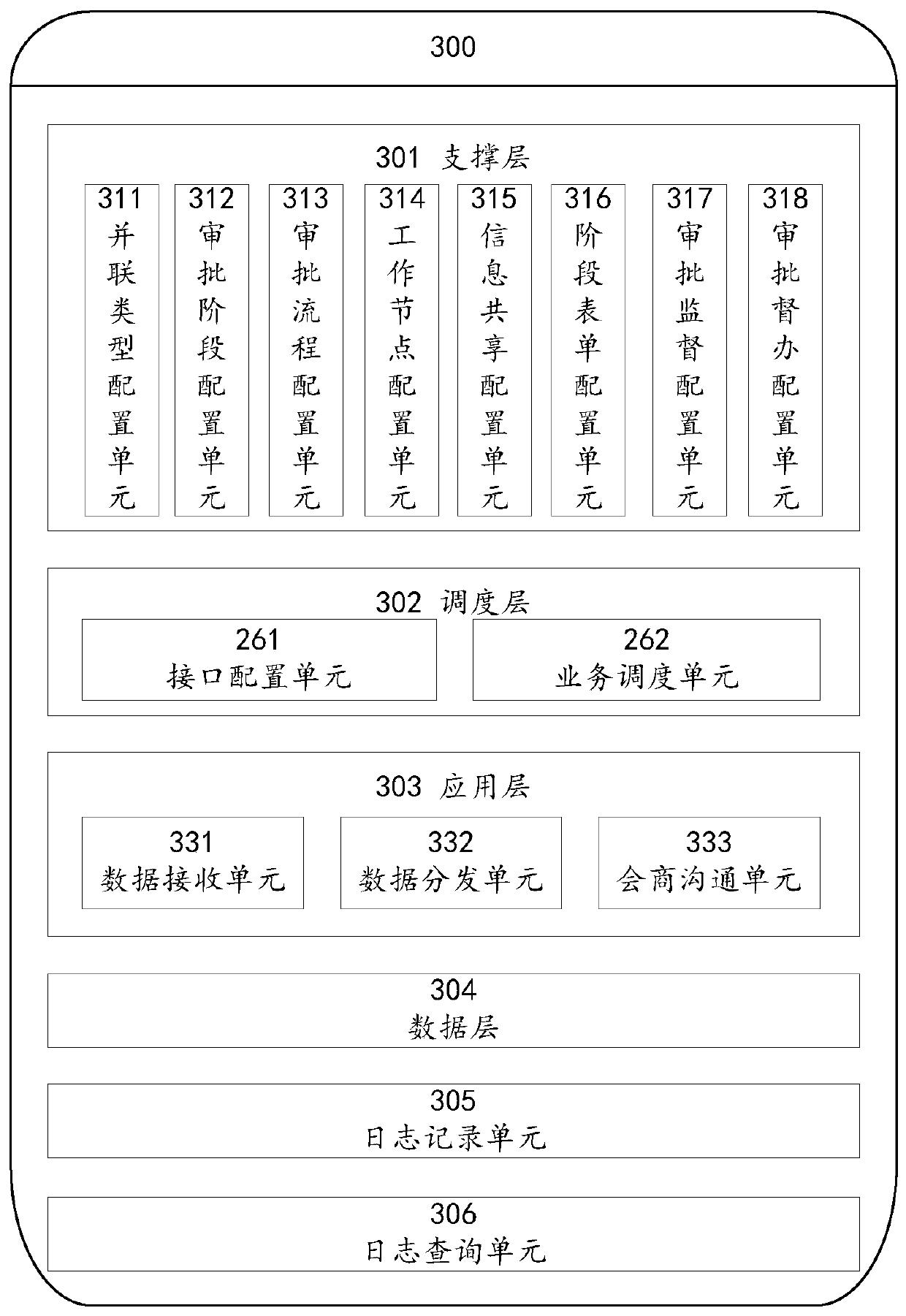

A parallel approval method and system based on a scheduling workflow

PendingCN109829683AImprove the efficiency of collaborative workShorten process timeOffice automationProcess configurationWorkflow

The invention provides a parallel approval method and system based on a scheduling workflow. According to the method and the system, a scheduling engine is embedded into a working node corresponding to a workflow; different approval processes are sequentially activated according to an approval process configuration sequence; the business scheduling of the approval platform of the items involved incooperation in the cross-business system is realized, the variable and variable approval items are subjected to business handling in the cross-department approval system through the scheduling workflow, the handling time limit of the parallel approval items is greatly shortened, and thus the cross-department collaborative handling efficiency is improved.

Owner:AEROSPACE INFORMATION

Frame sealing glue coating device

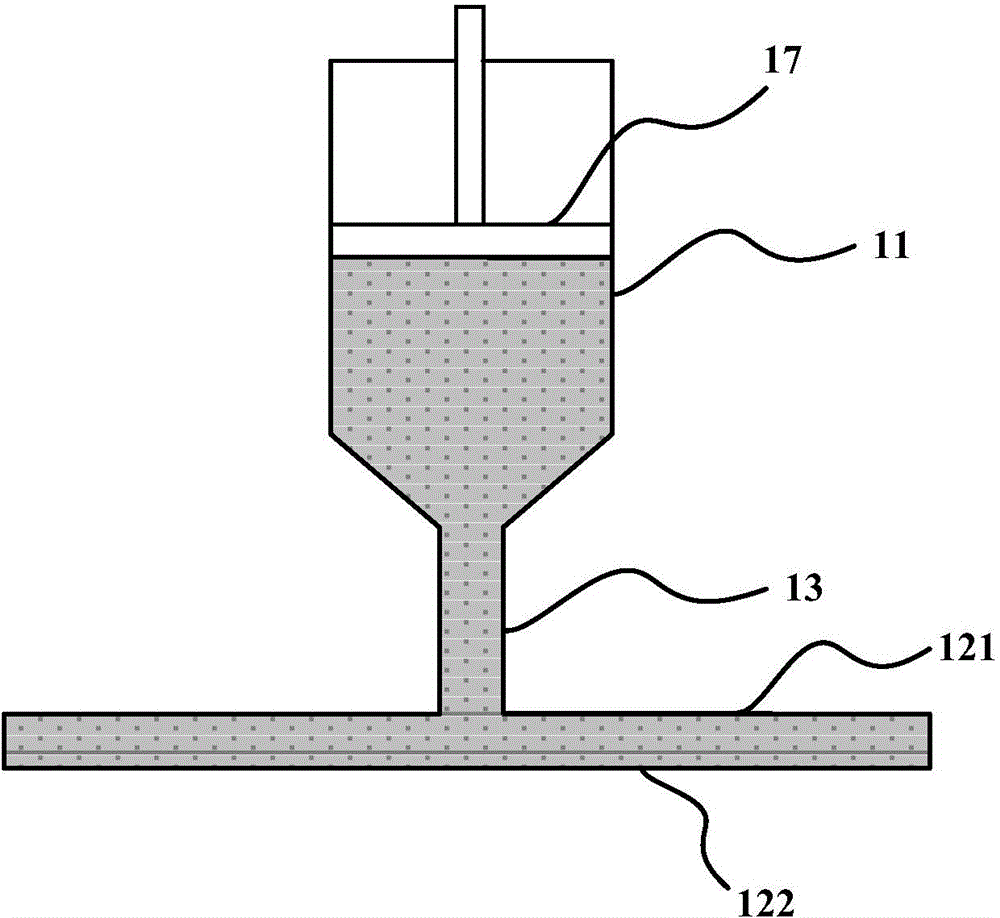

InactiveCN104678659AShorten process timeImprove coating efficiencyLiquid surface applicatorsLiquid spraying apparatusEngineeringNozzle

The invention discloses a frame sealing glue coating device for shortening the process time of coating frame sealing glue, improving the coating efficiency and improving the thickness uniformity of coating the frame sealing glue. The frame sealing glue coating device comprises a storage cavity, a nozzle, a connecting guide pipe and a power driving component, wherein the nozzle comprises a nozzle cavity and a nozzle opening; the nozzle opening is positioned below the nozzle cavity and is matched with the shape of a frame sealing glue coating zone of a baseplate; the connecting guide pipe is used for communicating a storage cavity and the nozzle cavity; the power driving component is used for squeezing frame sealing glue in the storage cavity to the nozzle cavity through the connecting guide pipe and is squeezed out through the nozzle opening. When the power driving component drives the frame sealing glue to be squeezed out from the nozzle opening, the frame sealing glue can be integrally coated to the frame sealing glue coating zone of the baseplate, so that the process time of coating the frame sealing glue is greatly shortened and the coating efficiency is improved by the adoption of the solution. Furthermore, owing to integrated coating of the frame sealing glue, a coating start end and a coating stop end are cancelled, so that coating overlap can be avoided, and thus the thickness uniformity of coating the frame sealing glue is improved.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

Efficient sewage denitrification process

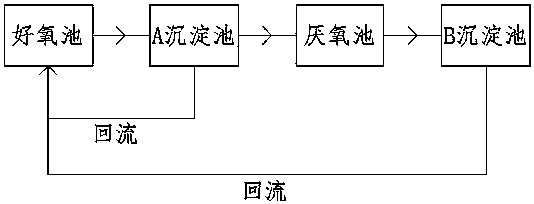

InactiveCN108249569AReduce constructionLow costWater contaminantsTreatment with aerobic and anaerobic processesNitrifying bacteriaSewage

The invention discloses an efficient sewage denitrification process which comprises the following steps: converting a part of ammonia in ammonia-containing sewage into nitrite by aerobic nitrifying bacteria in an aerobic tank; introducing sewage treated in the aerobic tank into an anaerobic tank; and converting ammonia and nitrite into nitrogen by anaerobic ammonium oxidizing bacteria in an anaerobic tank. The invention has the beneficial effects that the solution converts a part of ammonia into nitrite by aerobic nitrifying bacteria and then converts the remaining ammonia and nitrite into nitrogen by the anaerobic ammonium oxidizing bacteria, compared with a traditional treatment method, when treating the same amount of sewage, the solution takes less time for nitrification in the aerobictank, consumes less oxygen, and can reduce energy consumption of aeration, shorten process time and reduce construction and use costs of the aerobic tank; the anaerobic ammonium oxidizing bacteria can be used for simultaneously treating ammonia and nitrite so as to improve denitrification efficiency at an anaerobic stage, thereby shortening the time for the entire denitrification process.

Owner:简阳海天水务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com