Patents

Literature

236results about How to "Low annealing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

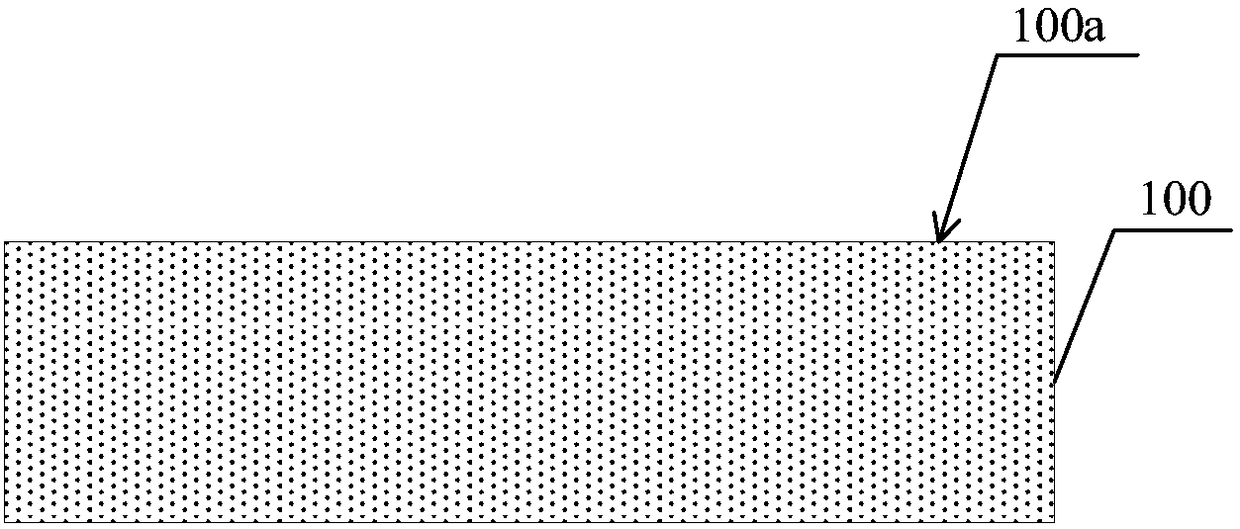

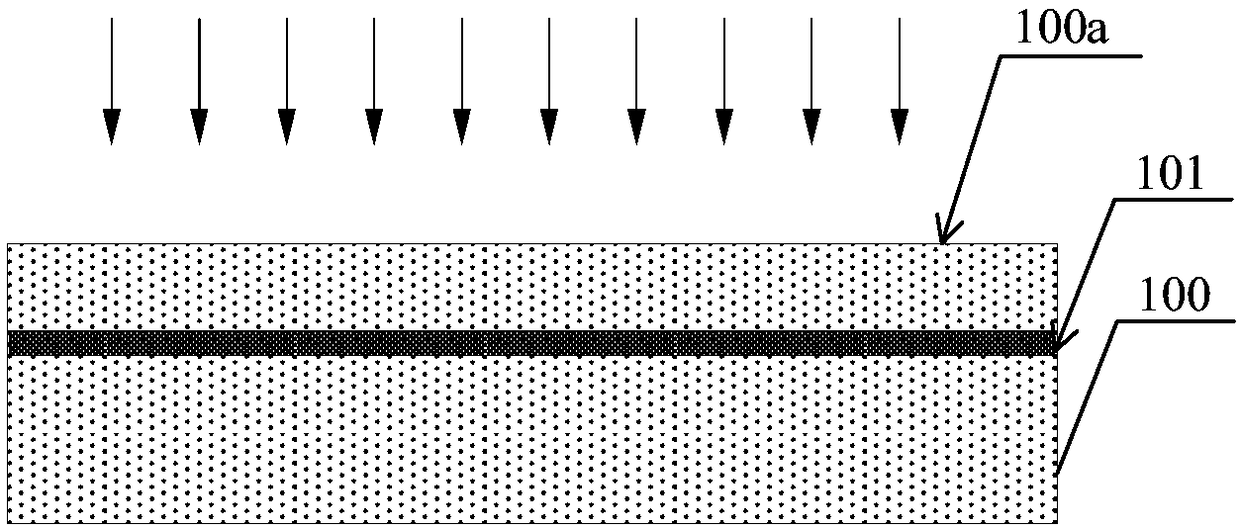

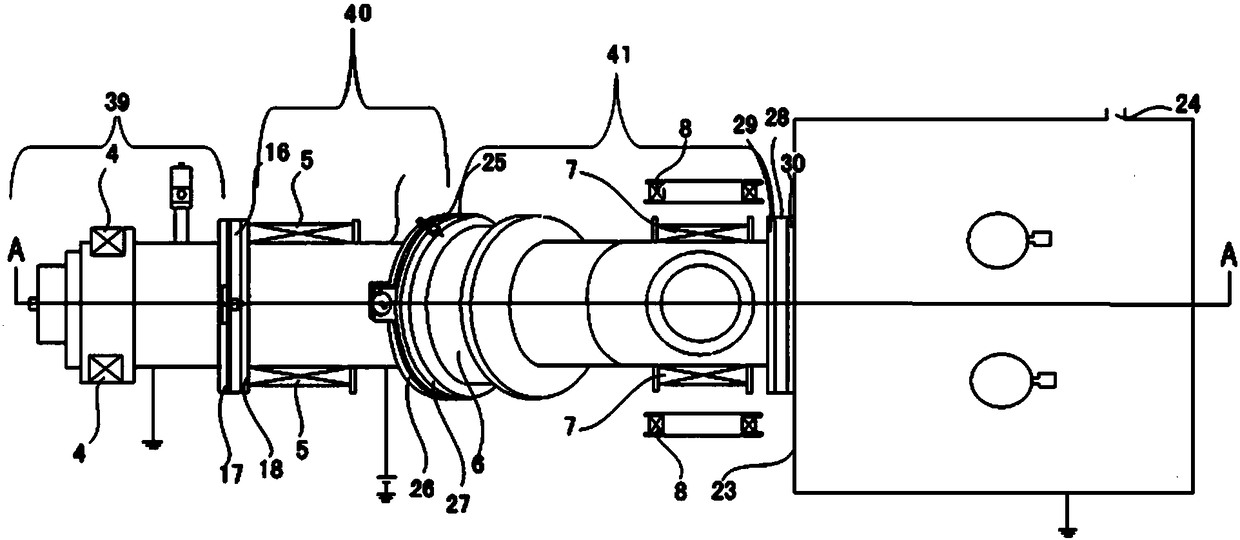

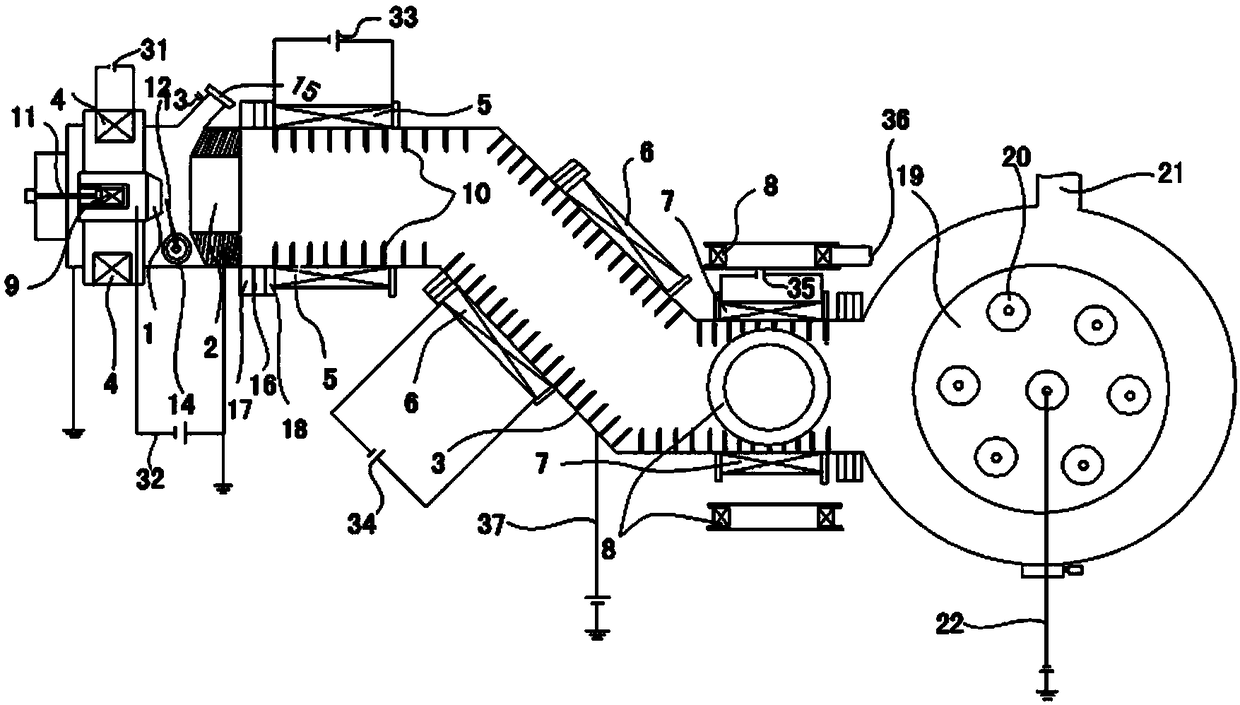

Method for preparing thin film heterostructure

InactiveCN108336219AReduce thermal strainAvoid chippingPiezoelectric/electrostrictive/magnetostrictive devicesOptoelectronicsIon implantation

The invention provides a method for preparing a thin film heterostructure. The method comprises the steps of providing a wafer substrate with an injection surface; conducting ion injection from the injection surface on the wafer substrate to form an injection defect layer at the predetermined depth of the wafer substrate; providing a support substrate, and performing temperature rising bonding onthe support substrate and the wafer substrate; annealing a obtained structure to form a continuous defect layer; stripping part of the wafer substrate through external force assisting, and forming wafer film on the wafer substrate to obtain a thin film heterostructure including the support substrate and the wafer film. The method can reduce the thermal strain of a bonding structure through the temperature rising bonding, so that the bonding structure remains stable and complete in the high-temperature process, and avoid the problem of film cracking caused by thermal mismatch in the stripping process, the bonding structure is separated from the continuous defect layer through the external force assisting method, so that no effect is caused on a bonding interface, and an external force assisting stripping method can reduce stripping temperature and stripping time, thereby reducing the cumulative effect of thermal stress in a piezoelectric crystal.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

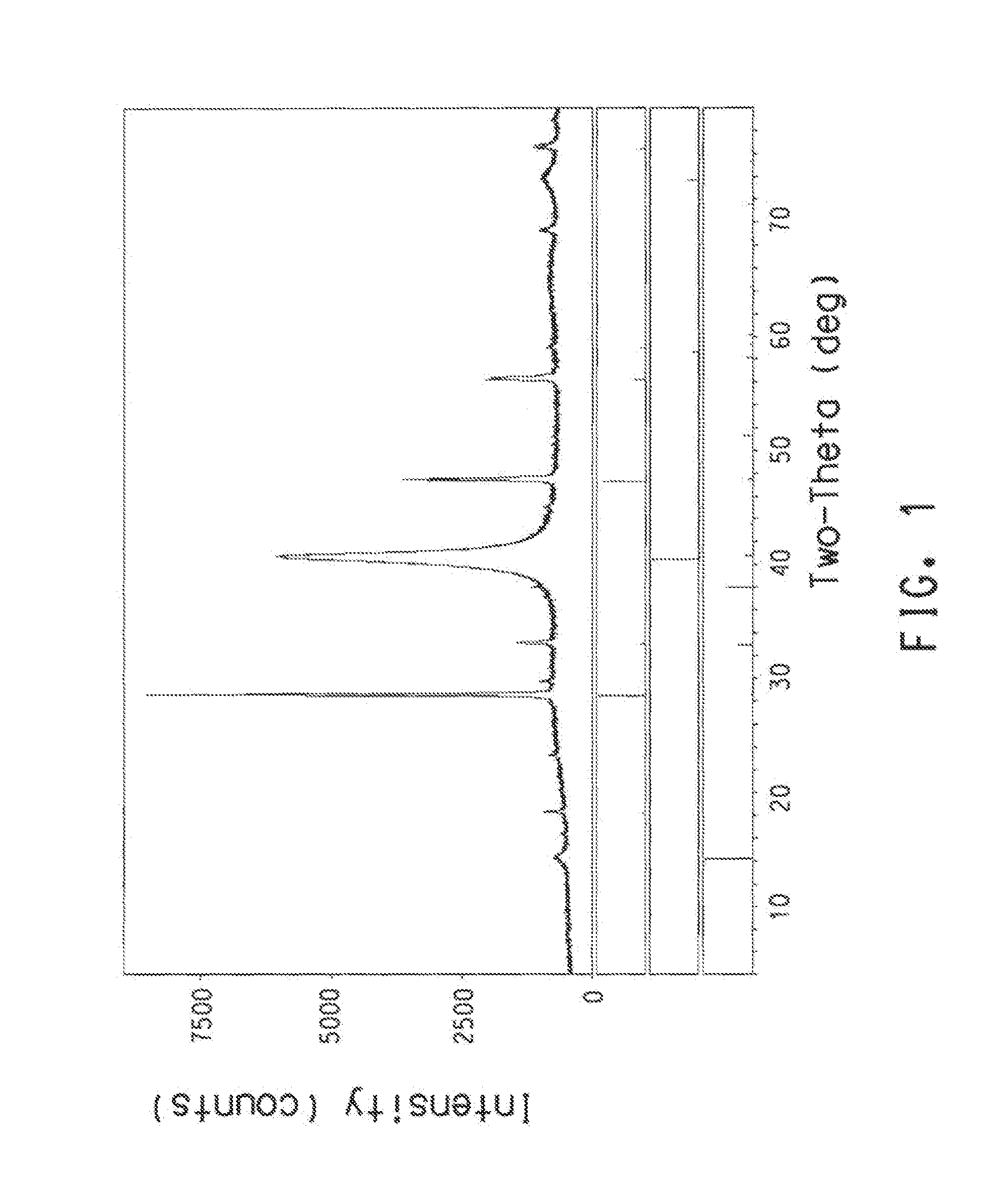

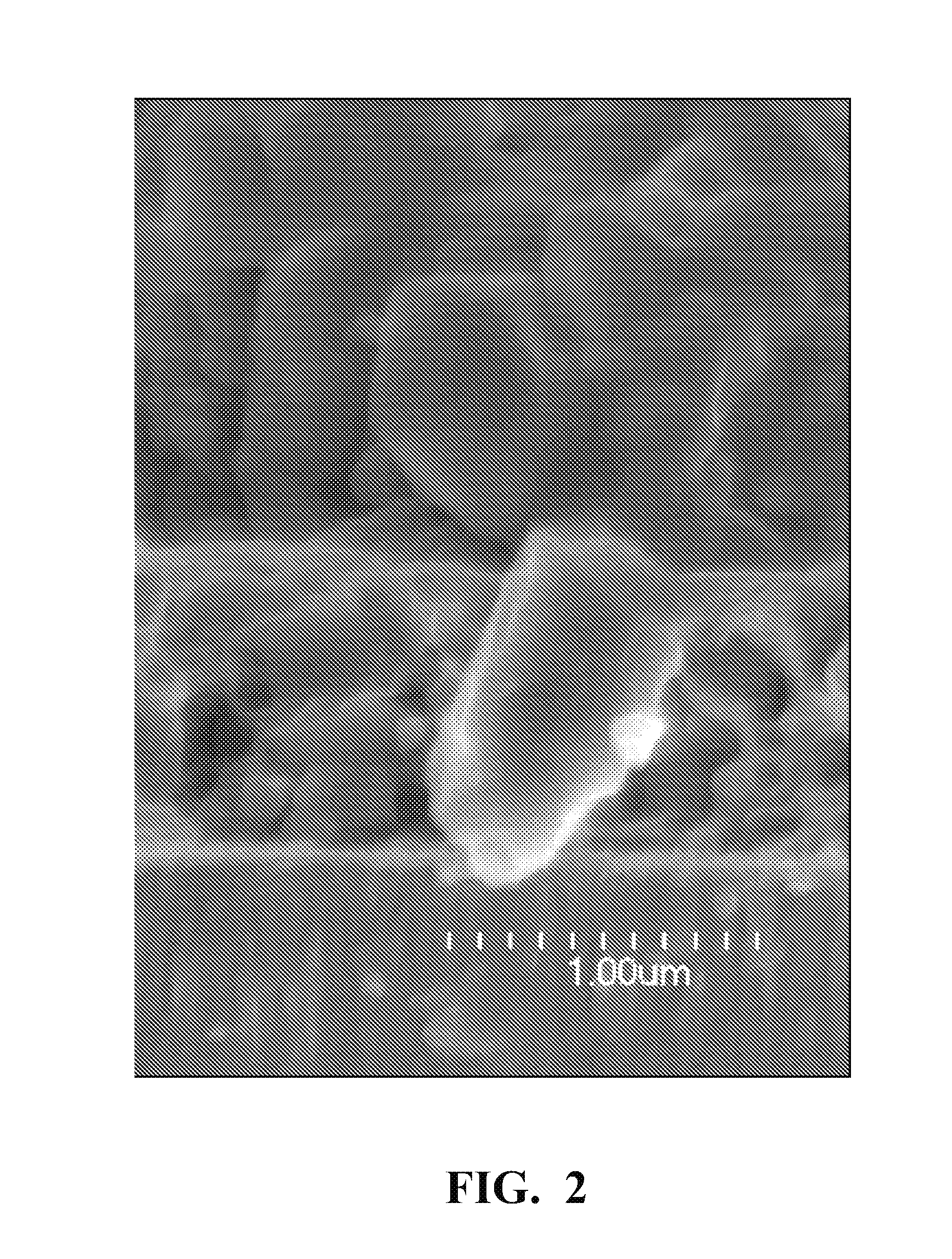

Inks and processes to make a chalcogen-containing semiconductor

InactiveUS20130221489A1Minimize crack and pinholeImprove performanceConductive materialSemiconductor/solid-state device manufacturingZincCopper

Owner:EI DU PONT DE NEMOURS & CO

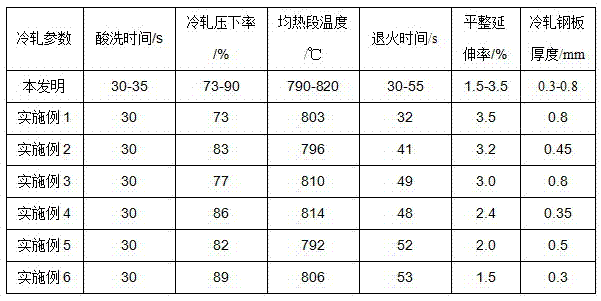

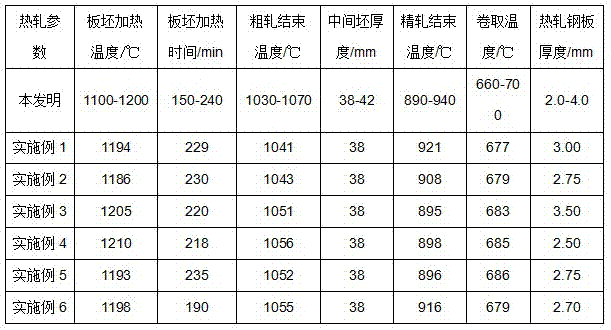

Low-cost high-strength prepainted steel sheet and manufacture method thereof

InactiveCN101880832AHigh strengthGood stamping performanceHot-dipping/immersion processesMetal rolling arrangementsCorrosion preventionHigh intensity

The invention discloses a low-cost high-strength prepainted steel sheet and a manufacture method thereof. The low-cost high-strength prepainted steel sheet comprises the following base materials containing chemical components in percent by weight: 0.06-0.10 percent of C, not more than 0.05 percent of Si, 0.30-0.70 percent of Mn, 0.01-0.03 percent of P, not more than 0.02 percent of S, 0.01-0.07 percent of solAl, not more than 0.005 percent of N, not more than 0.08 percent of Cr, not more than 0.11 percent of Cu, not more than 0.06 percent of Ni and the balance of Fe and unavoidable impurities. The preparation method comprises the steps of: steel-making through molten iron, continuously casting, hot-rolling, acid-washing, hot dipping, alloying, finishing and prepainting. The prepainted steel sheet has the advantages of good stamping property, excellent corrosion prevention property, low production cost and better economic and social benefits, and can be widely applied to the outdoor large building industry.

Owner:WUHAN IRON & STEEL (GROUP) CORP

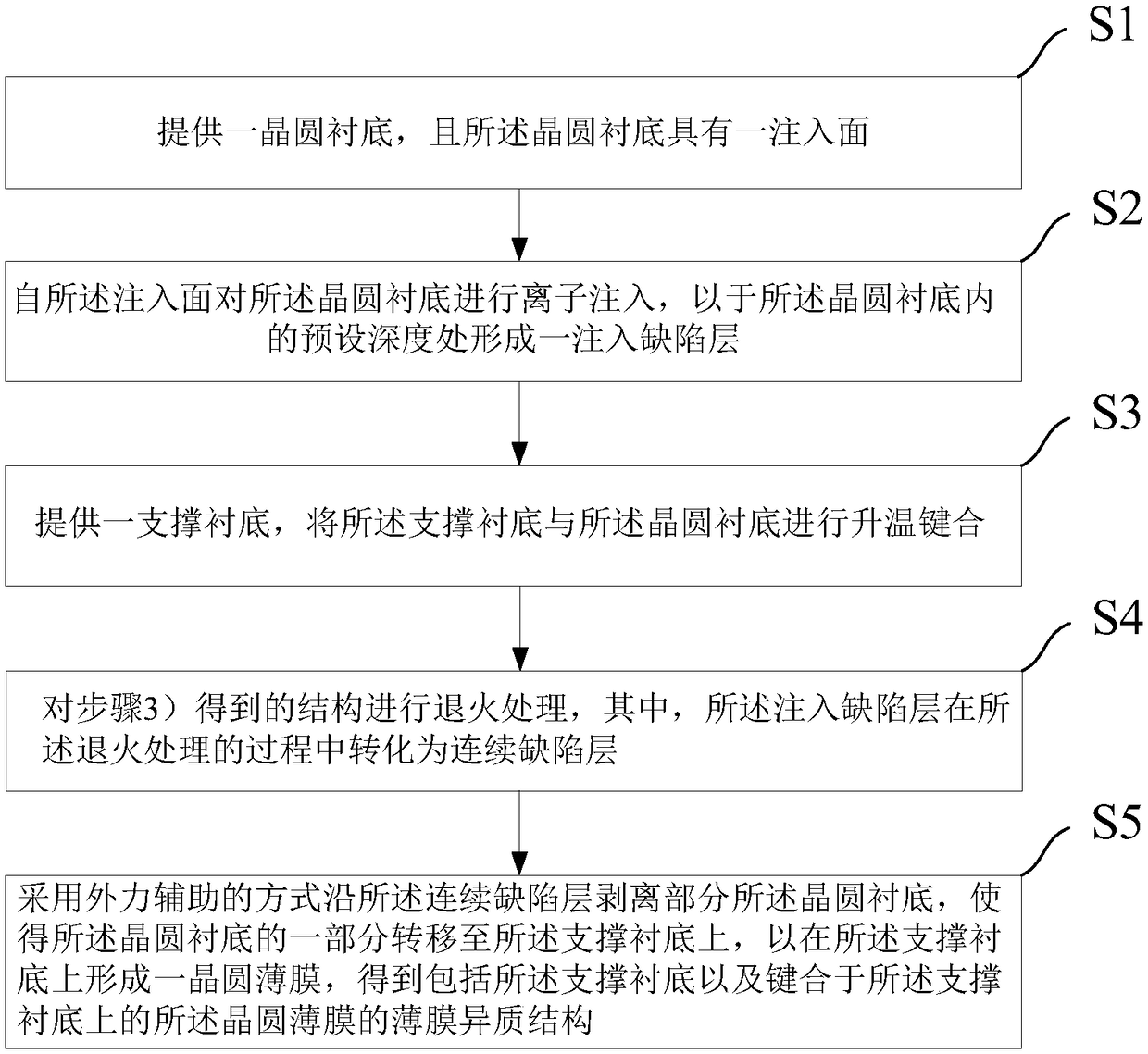

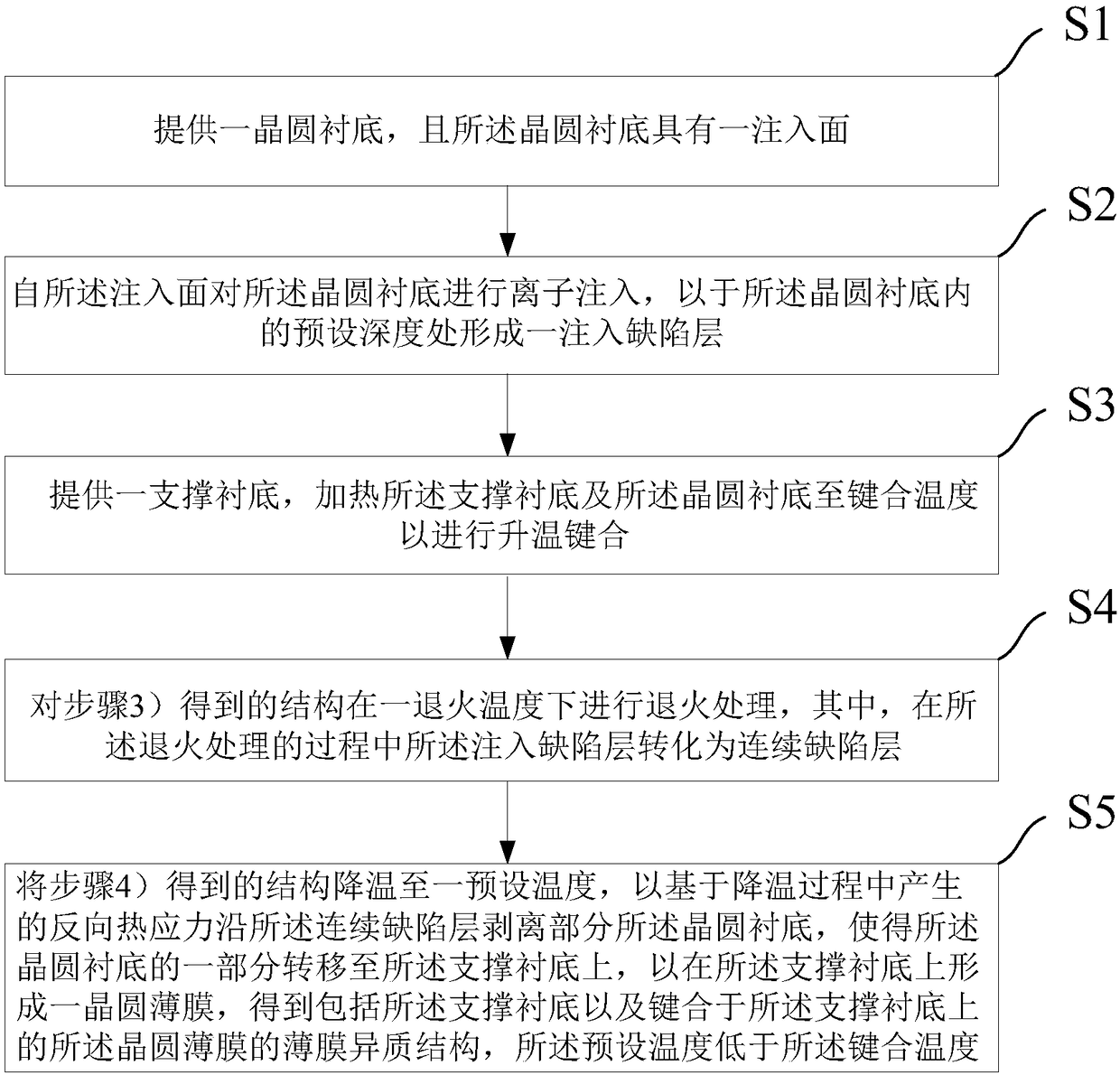

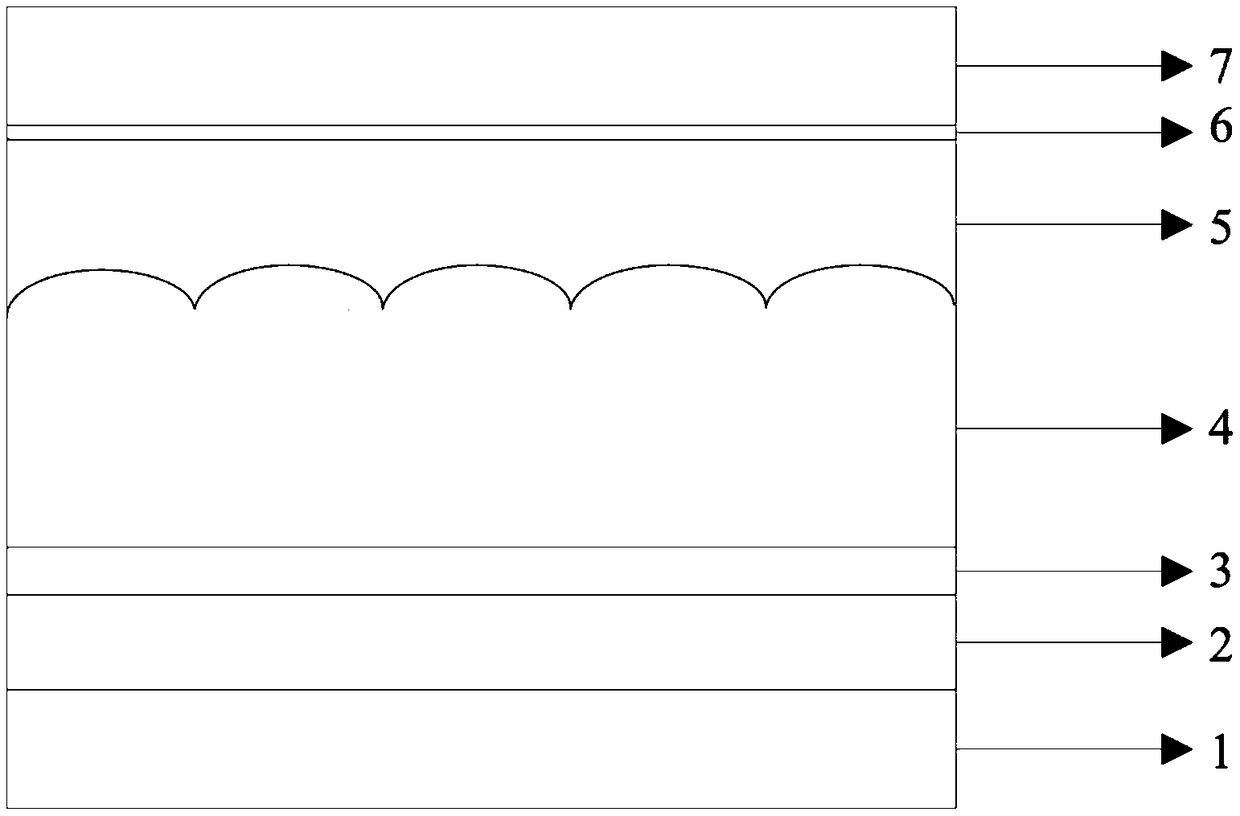

Thin film heterostructure preparation method

ActiveCN108493334ALow annealing temperatureShorten process timePiezoelectric/electrostrictive/magnetostrictive devicesOptoelectronicsHigh-temperature corrosion

The invention provides a thin film heterostructure preparation method. The method comprises steps: a wafer substrate with an injection surface is provided; ion implantation is carried out on the wafersubstrate from the injection surface, and an injection defect layer is formed at a preset depth in the wafer substrate; a support substrate is provided, and the support substrate and the wafer substrate are subjected to temperature rise bonding; the obtained structure is subjected to annealing treatment to form a continuous defect layer; the temperature of the obtained structure is reduced to a preset temperature, reverse thermal stress generated based on temperature reduction strips part of the wafer substrate along the continuous defect layer, and a thin film heterostructure comprising thesupport substrate and the wafer thin film is obtained, wherein the preset temperature is lower than the bonding temperature. In the temperature rise bonding mode, the thermal stress of the bonding structure can be reduced, the bonding structure can keep stable and complete in a high temperature process, the problem of wafer crack generated by thermal mismatch in the stripping process can be effectively solved, and through the reverse thermal stress assisting method, the bonding structure is separated at the continuous defect layer and a bonding interface is not influenced.

Owner:上海新硅聚合半导体有限公司

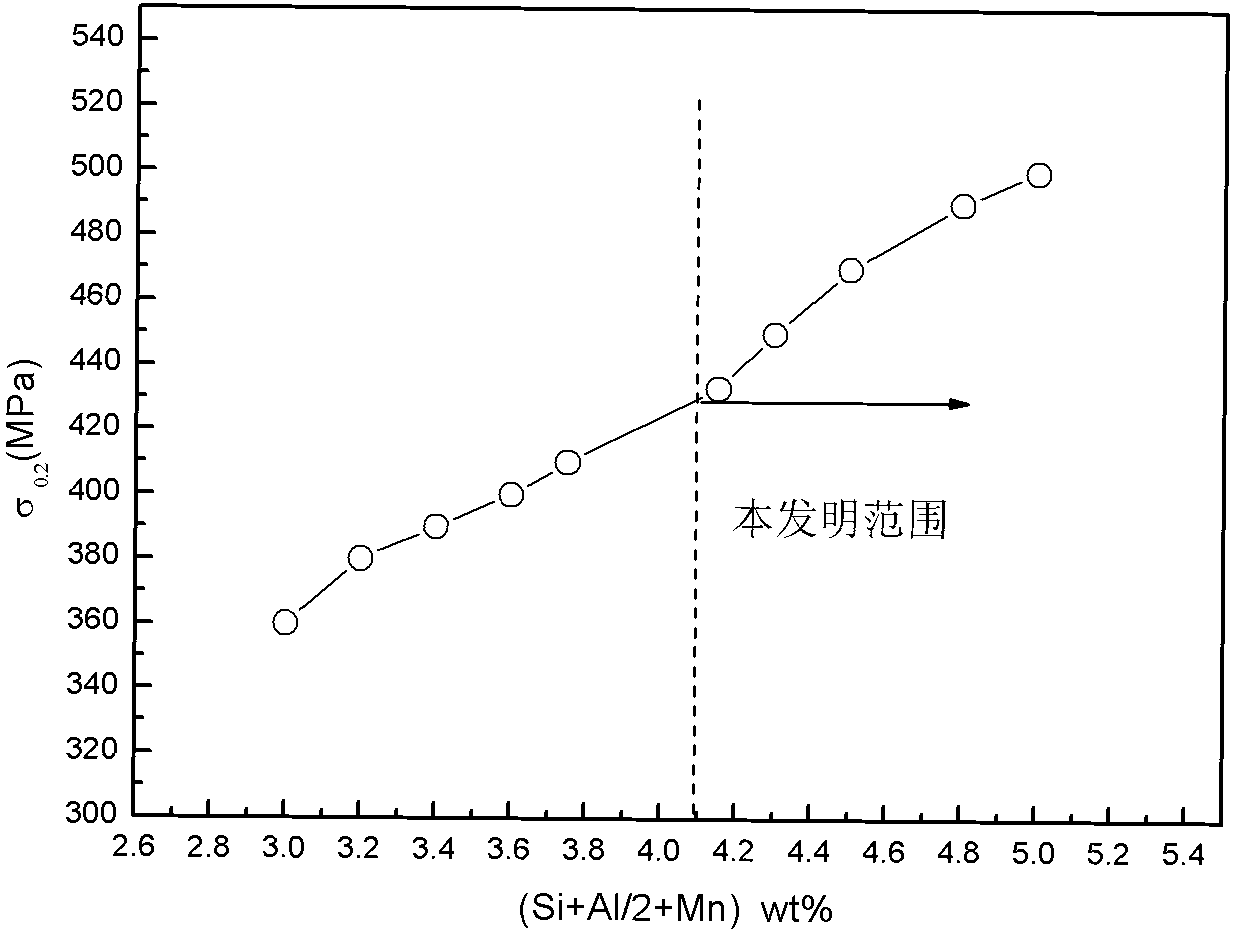

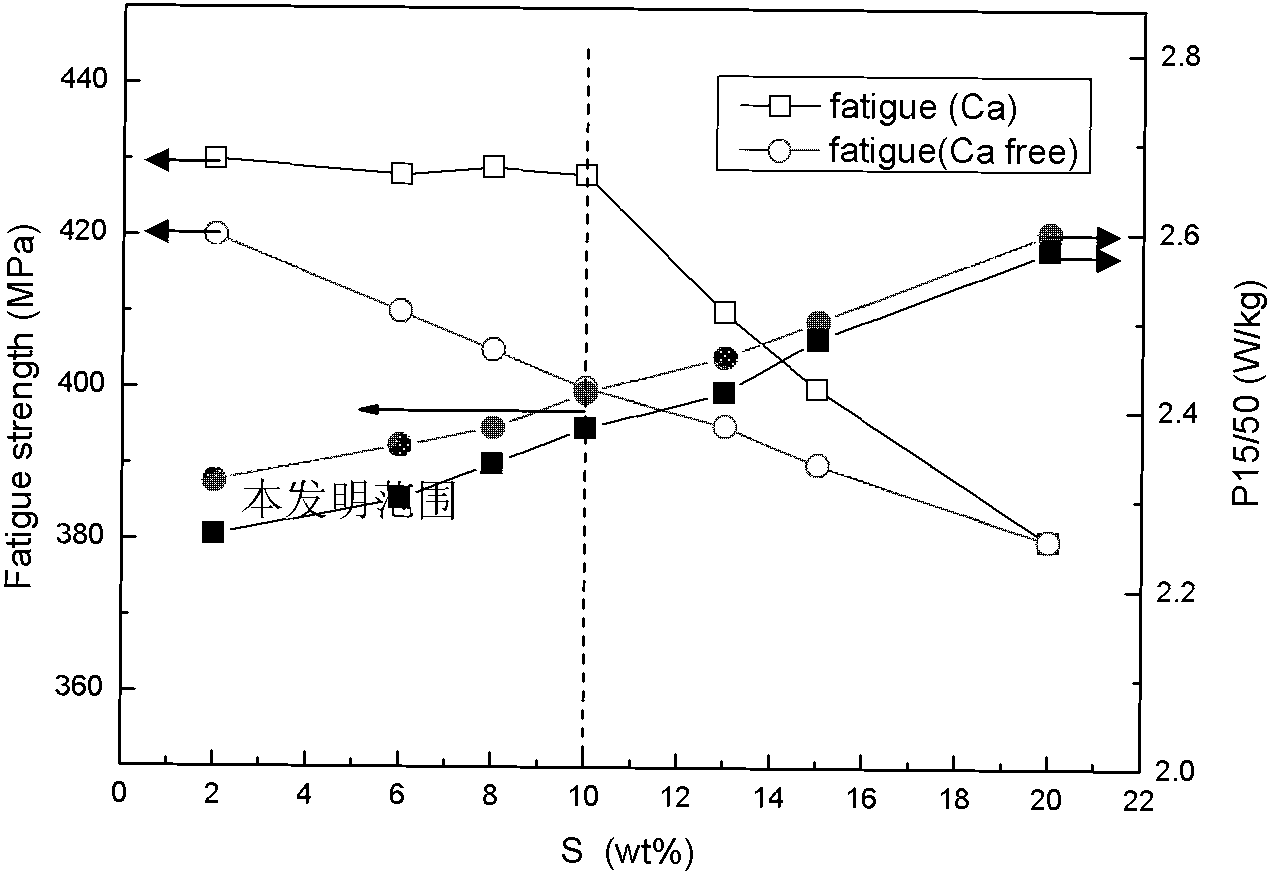

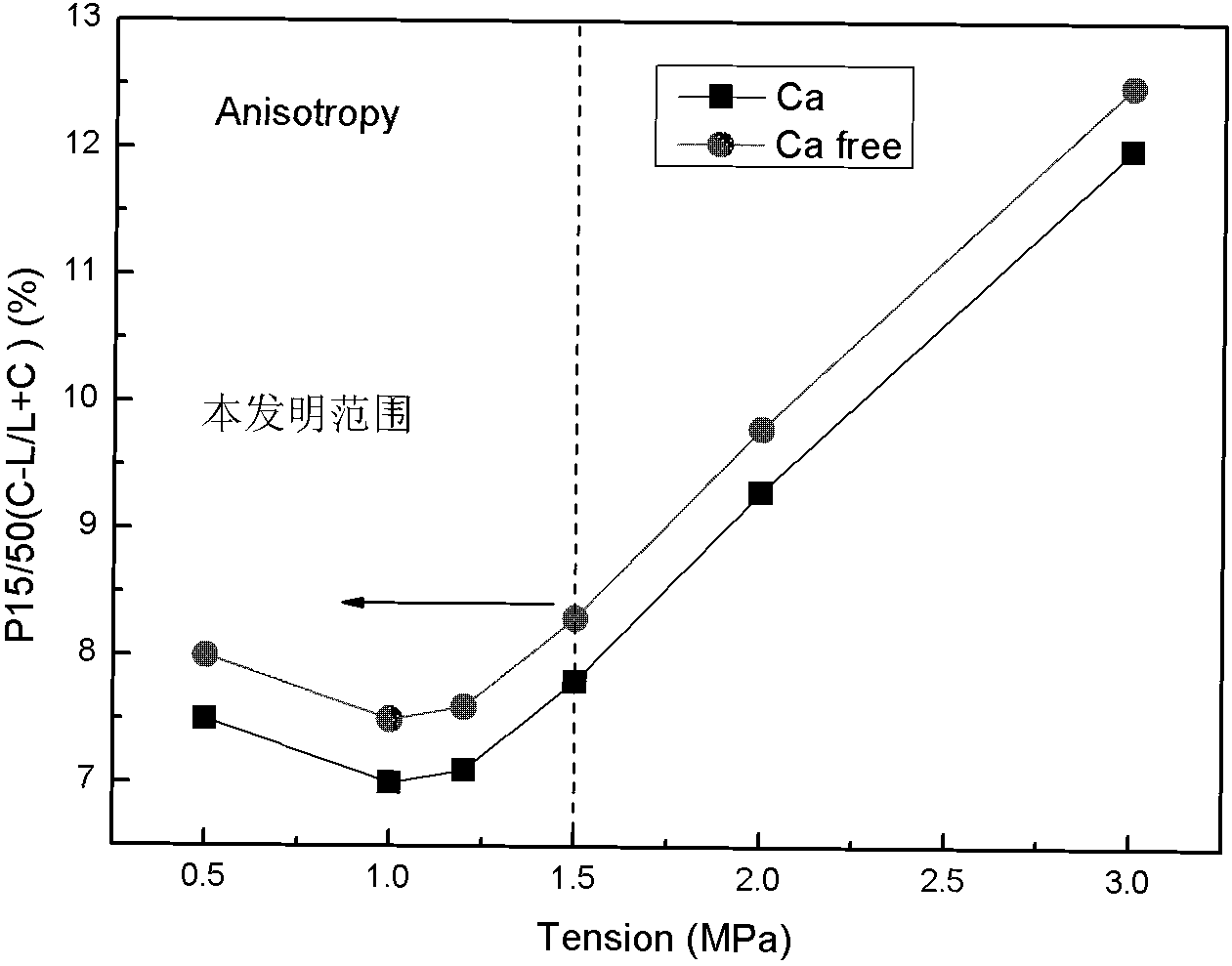

Non-oriented silicon steel for rotor and production method thereof

The invention discloses a non-oriented silicon steel for a rotor and a production method thereof. The steel consists of the following components in percentage by weight: 0.001-0.004% of C, 2.5-4.0% of Si, 0.5-1.5% of Al, 0.10-1.50% of Mn, not more than 0.02% of P, not more than 0.001% of S, not less than 4.1% and not more than 6.0% of Si+Al / 2+Mn, not more than 0.002% of N, not more than 0.005% of B and the balance of Fe and inevitable impurities. The production method mainly comprises the following steps of: refining process, namely sequentially deoxidizing Si and Al, and finally, adding CaSi alloy for Ca treatment; heating a casting blank in a heating furnace to be 1100 DEG C, insulating and then rolling; normalizing, carrying out acid cleaning and cold rolling, wherein the reduction rate is 70-78%; and tensioning and annealing a belt, wherein the temperature is 920-980 DEG C, and the tension is controlled between 0.5MPa and 1.5MPa. By utilizing the method, electrical sheets with excellent electromagnetic property, yield strength and fatigue performance can be obtained, the annealing temperature is reduced, the production energy consumption can be decreased, and furthermore, the production cost is lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

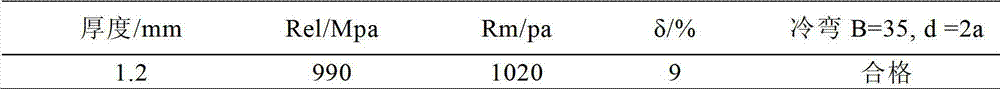

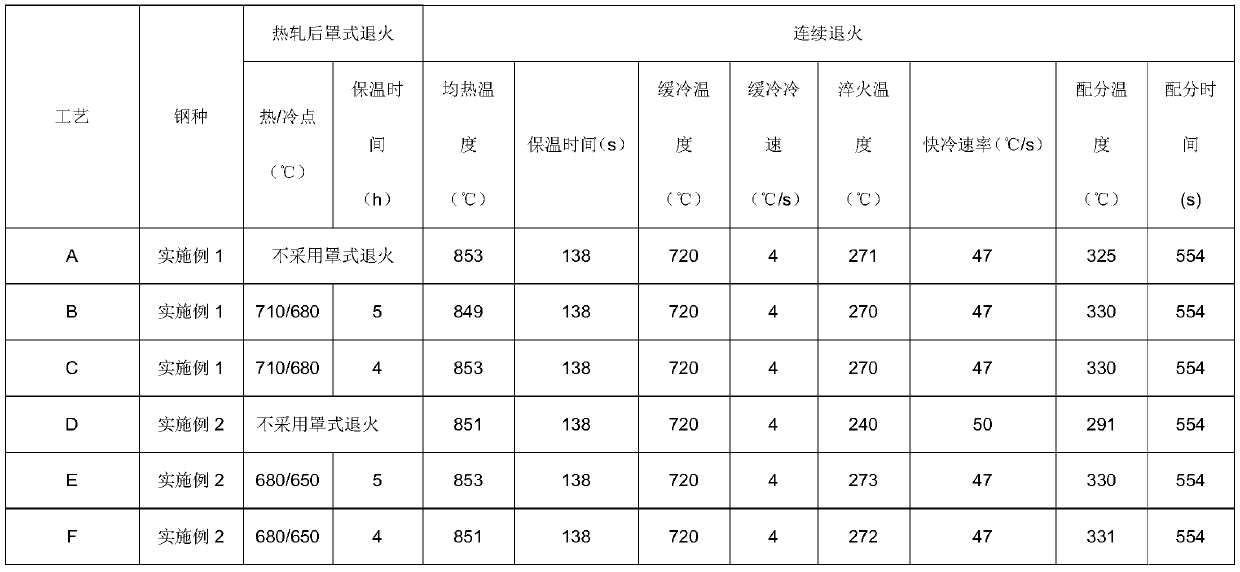

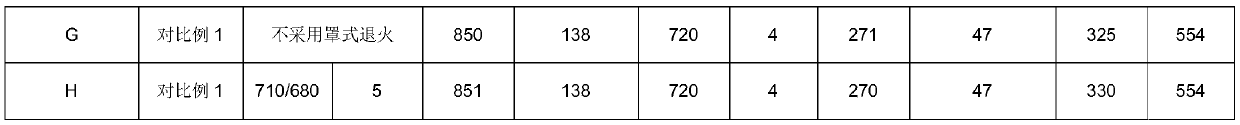

Cold-rolled steel sheet with yield strength of 980 MPa grade and manufacturing method thereof

ActiveCN102925817AHigh yield ratioLow annealing temperatureBell type furnacesRolling millHigh strength steel

The invention discloses a cold-rolled steel sheet with yield strength of 980 MPa grade, and belongs to the technical field of cold-rolled high strength steel. The steel sheet comprises the following chemical components in percentage by weight: 0.08-0.13% of C, 0.05-0.5% of Si, 1.2-2.0% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.6-1.5% of Cr, 0.08-0.20% of Ti, 0.02-0.08% of Nb, 0.04-0.2% of V, one or more of Nb, V and Ti, 0.02-0.1% of Alt, less than or equal to 0.006% of N, less than or equal to 0.004% of O, and the balance of Fe and unavoidable impurities. The tensile strength of the steel sheet is more than 980 MPa, therefore, the steel sheet is excellent in plasticity and forming performance. The manufacturing method of the steel sheet is a low-cost cold-rolled annealed steel sheet manufacturing method, and can be implemented on common reversing cold rolling mills and cover annealing devices.

Owner:LAIWU IRON & STEEL GRP

Short-flow high-efficiency production method for white brass alloy pipes

The invention relates to a short-flow high-efficiency production method for white brass alloy pipes, belonging to the field of metal materials. In the method, a white brass pipe produced by virtue of a hot-cold-combined casting-mould horizontal continuous casting process is used as a blank; in a straight white brass pipe production process, the pipe blank is directly subjected to cold rolling with the total deformation amount of 50-90% and the single-pass deformation amount of not more than 20-25%; in a white brass coiled pipe production process, the pipe blank is subjected to the cold rolling deformation with the total deformation amount of not more than 50-70% and the single-pass deformation amount of not more than 20-25%, low-temperature recovery annealing is carried out at the temperature of 300-550 DEG C for 1-2 hours after the rolling is completed, an annealing protection atmosphere is formed by 2% of H2 and the balance of N2, and the annealed coiled pipe is bound to be subjected to once finishing in a serial continuous drawing way or triple continuous drawing before coil drawing; and in a subsequent coil drawing process, an average pass lengthening coefficient is 1.2-1.5, and the coil drawing speed is 1-1,000m / min. Compared with the traditional casting and rolling drawing method for producing the white brass pipes, the method provided by the invention has the advantages of short process flow, obviously decreased annealing frequency and low annealing temperature, and is beneficial to energy conservation and production efficiency improvement.

Owner:UNIV OF SCI & TECH BEIJING

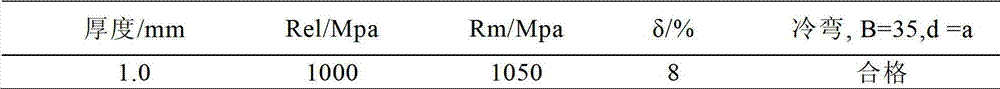

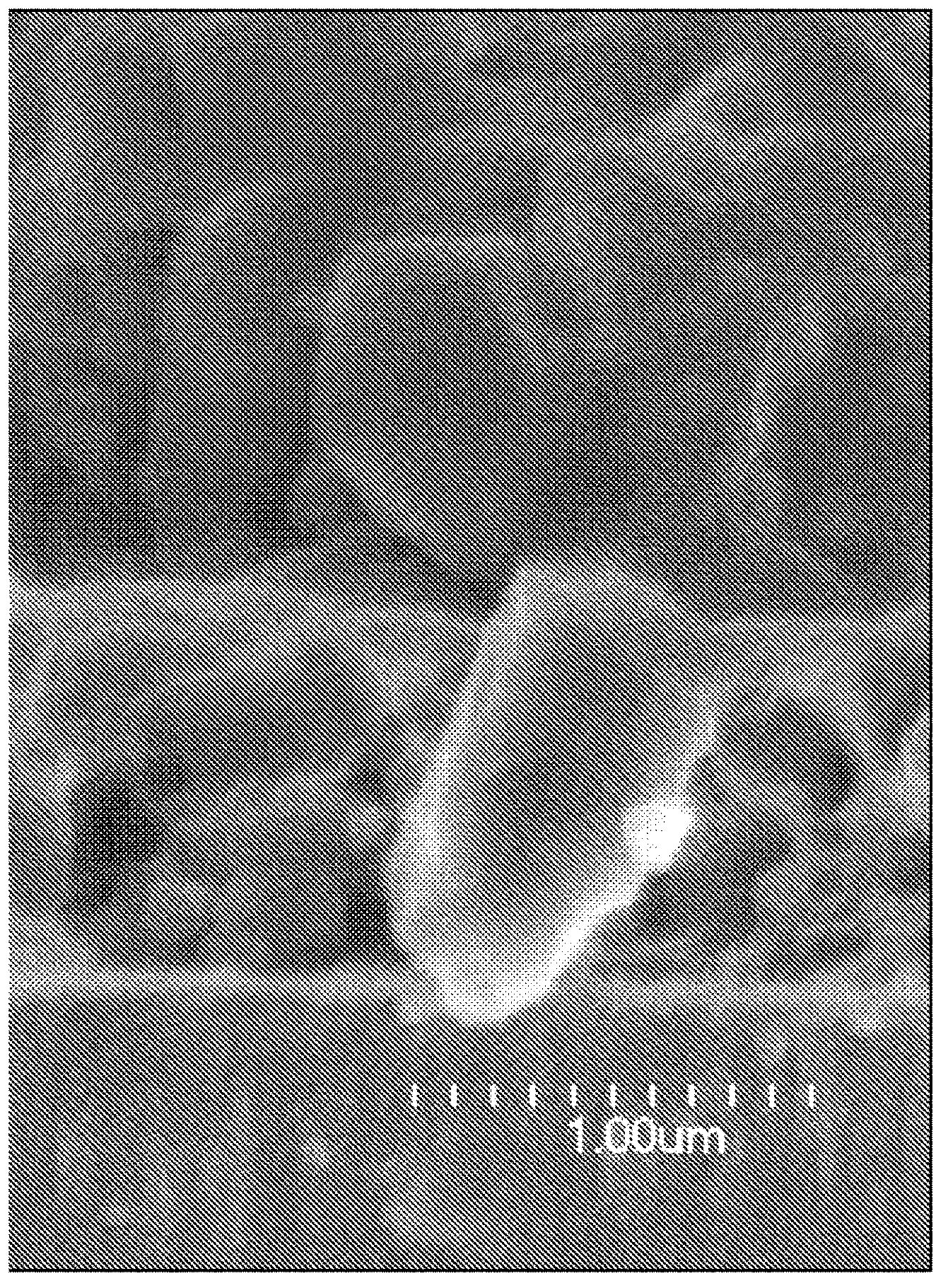

Metal nanoparticles stabilized with a carboxylic acid-organoamine complex

InactiveCN101450387AImprove stabilityExtended storage timeMaterial nanotechnologyMetal-working apparatusCarboxylic saltOrganic group

Metal nanoparticles with a stabilizer complex of a carboxylic acid-amine on a surface thereof are formed by reducing a metal carboxylate in the presence of an organoamine and a reducing agent compound. The metal carboxylate may include a carboxyl group having at least four carbon atoms, and the amine may include an organo group having from 1 to about 20 carbon atoms.

Owner:XEROX CORP

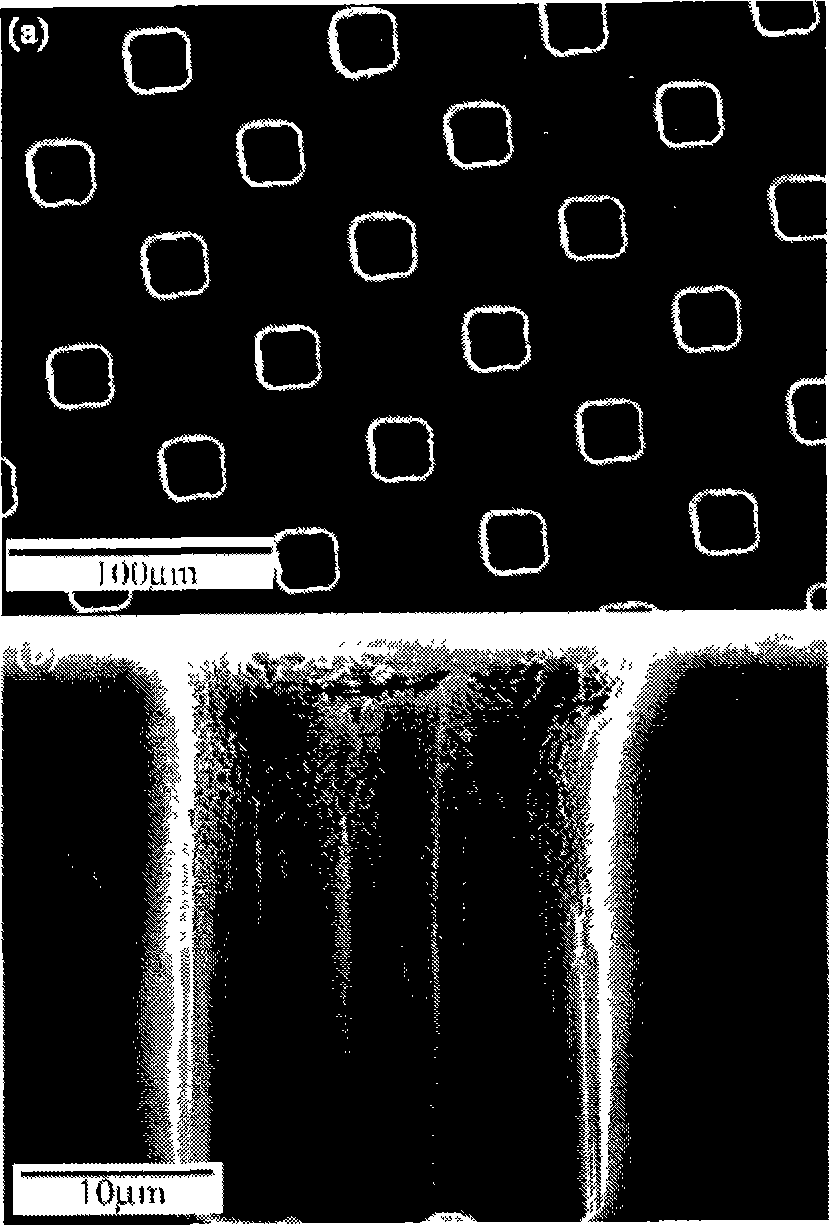

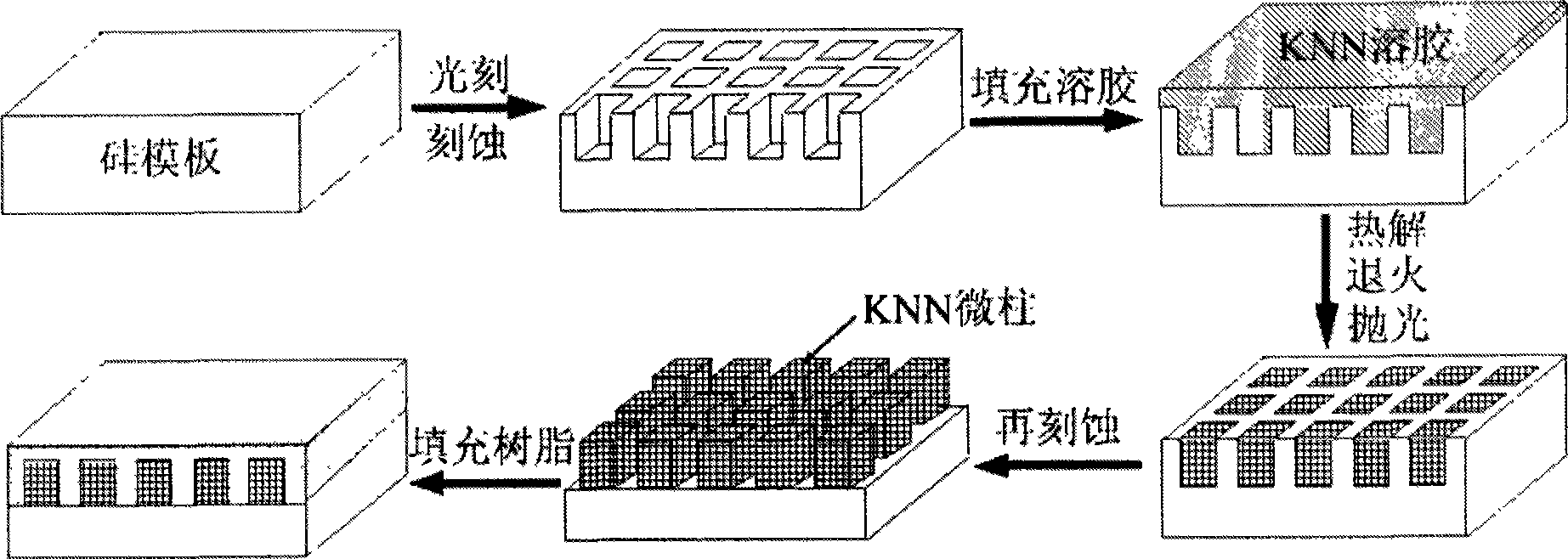

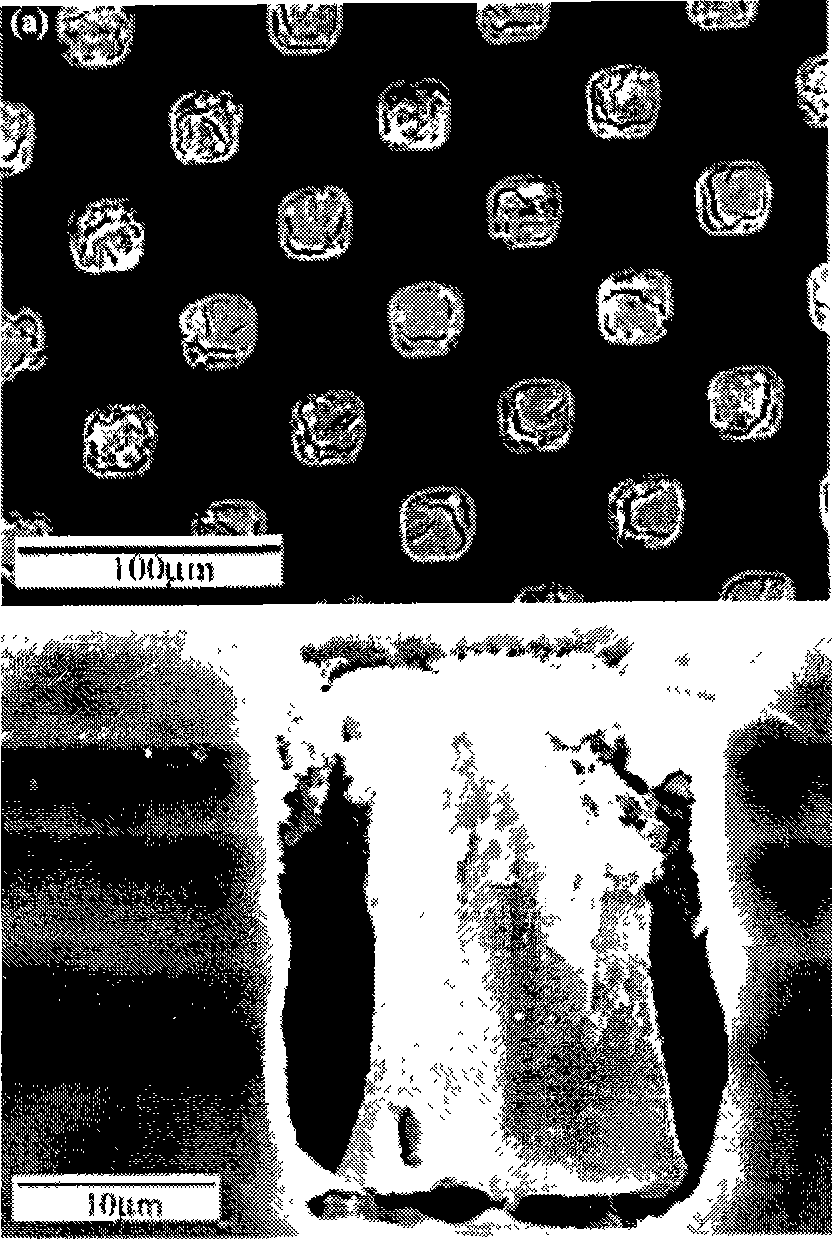

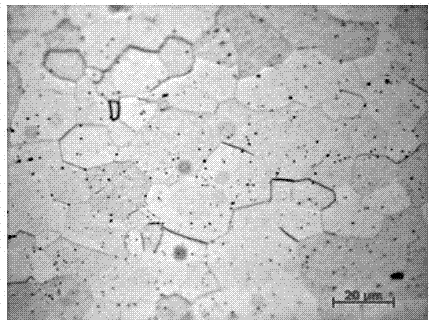

Microfine piezoelectric ceramics array structure composite material and preparation thereof

The invention discloses a hyperfine piezoelectric ceramic array structure composite material and a preparation method, belonging to the field of functional ceramics material and the preparation technology thereof. The preparation technique comprises: a metal alkoxide reflux method is adopted to prepare sol precursor, silicon micromachining technology is used for preparing a silicon template; then, piezoelectric ceramic microcolumn array which has the length and the width being 5-100 microns, the hole height being 1-500 microns and the spacing being 10-200 microns is prepared by sol padding template technique and the subsequent pyrogenation and annealing processing process; finally, the microcolumn array is compounded with polymer to obtain 1-3 type piezoelectric ceramic / polymer composite material. Compared with the traditional mechanical cutting technique, the invention can prepare the ceramic microcolumn with smaller size and better array period, and the minimum column width can reach 7mum, thereby being suitable for a micro electrical / mechanic system (MEMS); compared with the array preparation techniques such as heat pressing, laser cutting and the like, the invention has simple equipment condition and is easy to realize.

Owner:TSINGHUA UNIV

Phosphorus-containing interstitial-free cold-rolled galvanized steel sheet, and manufacturing method thereof

The invention relates to a phosphorus-containing interstitial-free (IF) cold-rolled galvanized steel sheet, and a manufacturing method thereof. The manufacturing method is mainly used for solving technical problems in the prior art that the manufacturability of phosphorus-containing IF steel is poor, and manufacturing cost is high. The phosphorus-containing interstitial-free (IF) cold-rolled galvanized steel sheet comprises, by weight, C<=0.003%, Si<=0.03%, 0.2 to 0.6% of Mn, 0.04 to 0.08% of P, S<=0.02%, N<=0.005%, 0.02 to 0.06% of Alt, 0.004 to 0.089% of Ti, and the balance Fe and inevitable impurities, wherein 0.004%<=Ti-(3.4N+1.5S+4C)<=0.03%. The yield strength of the phosphorus-containing interstitial-free (IF) cold-rolled galvanized steel sheet R<P0.2> is equal to or larger than 260MPa, and the phosphorus-containing interstitial-free (IF) cold-rolled galvanized steel sheet is mainly used for preparing color-coated sheet base plates and household electrical appliance panels.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

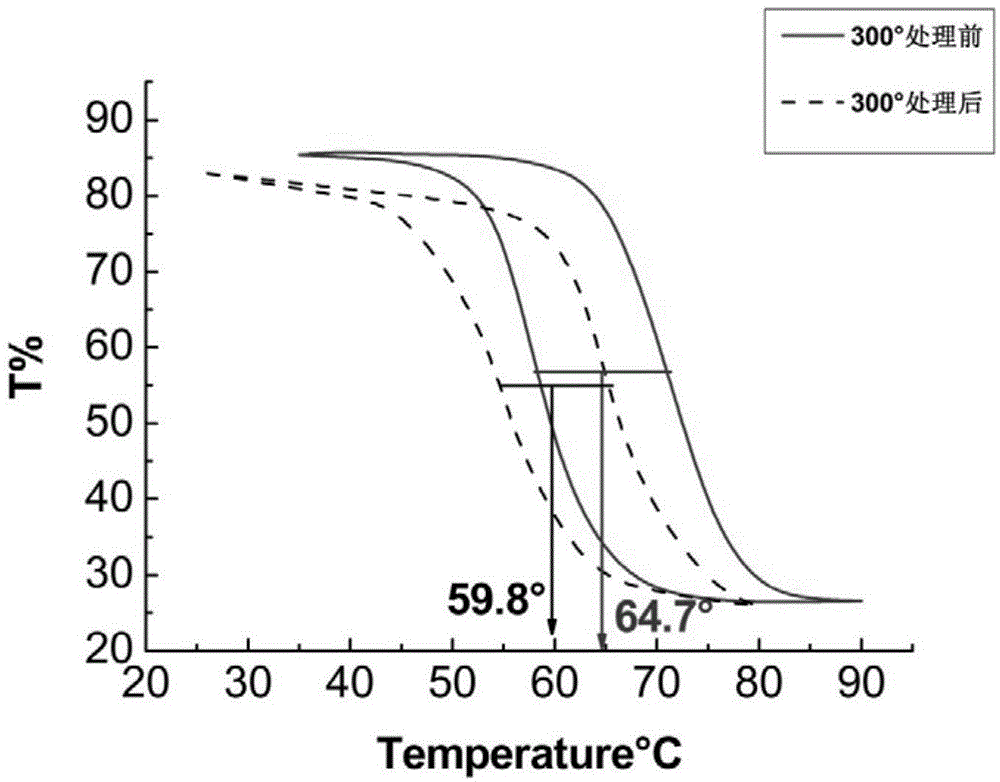

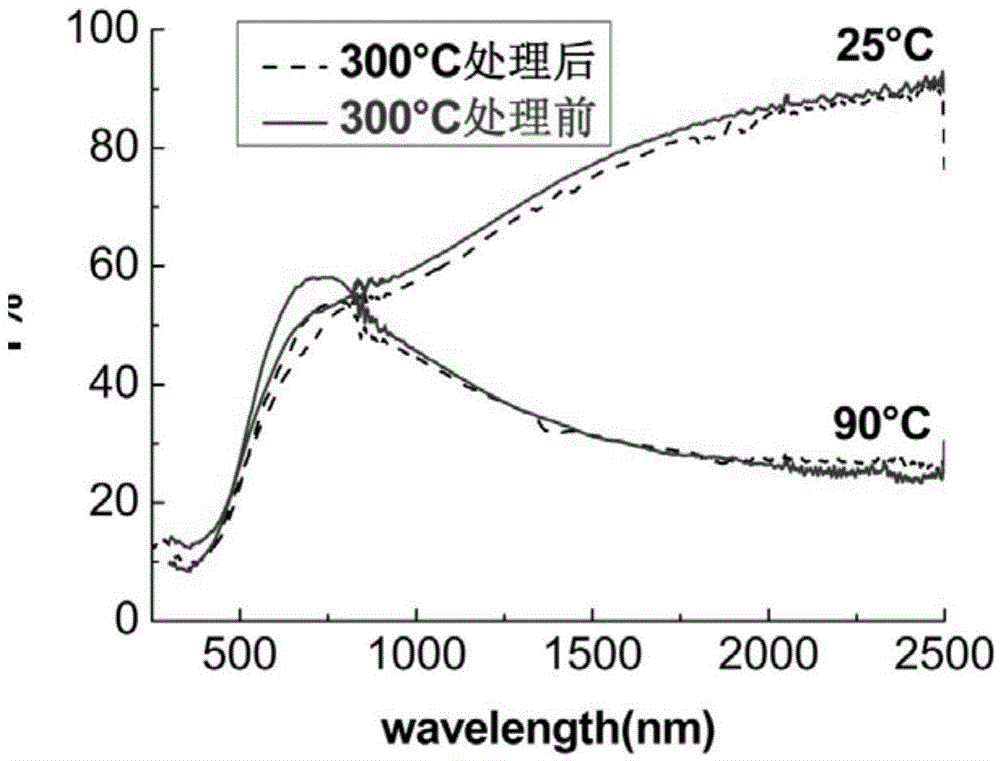

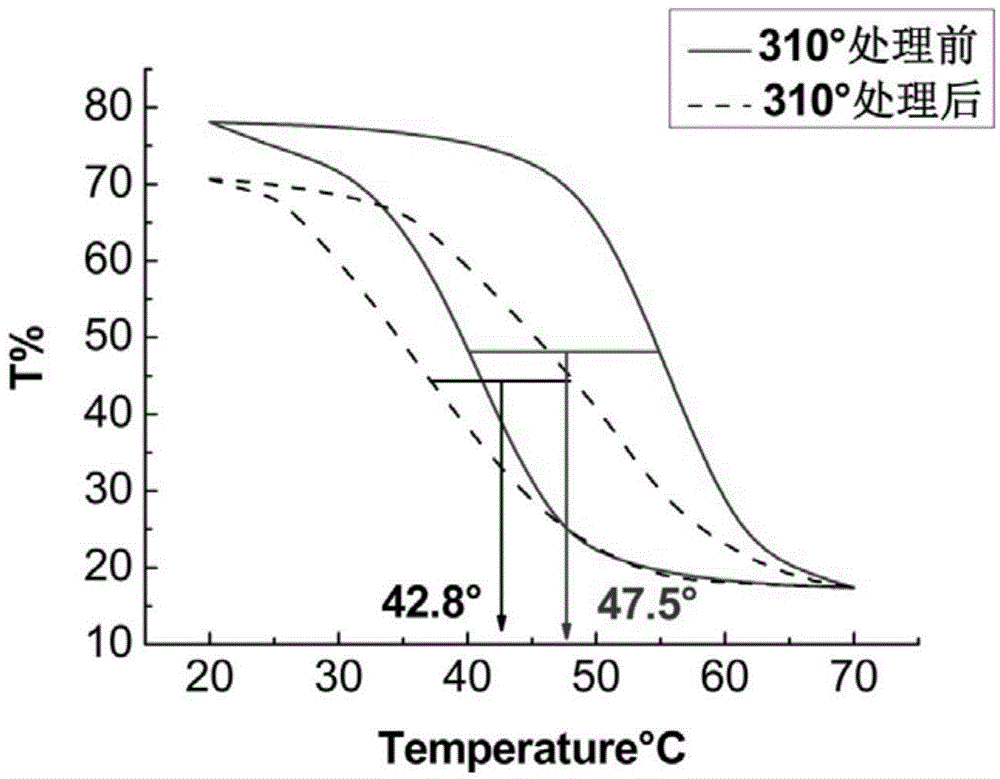

Method for reducing phase change temperature of vanadium dioxide film

InactiveCN104445990ALower phase transition temperatureGood optical performanceHeat-exchange elementsCoatingsVanadium dioxidePhase change temperature

The invention discloses a method for reducing the phase change temperature of a vanadium dioxide film. The method comprises the following steps: 1) preparing an M-phase vanadium dioxide film with a phase change function, wherein the M-phase vanadium dioxide film is formed on a substrate; 2) putting an M-phase vanadium dioxide film sample prepared in the step 1) into an annealing device, vacuumizing the annealing device till the vacuum degree is 200-2000 Pa, keeping the vacuum degree, or vacuumizing till the vacuum degree is 200-2000 Pa, subsequently introducing inert gas to the standard atmospheric pressure, heating to be 280-320 DEG C, keeping the temperature for 0.5-3 hours, and natural cooling to be the room temperature in a furnace, thereby obtaining the vanadium dioxide film with reduced phase change temperature. By adopting the method, the phase change temperature of a pure vanadium dioxide film can be reduced, and the phase change temperature of a doped vanadium dioxide film can also be reduced, so that the method has a very wide application range. In addition, the method is low in treatment temperature, simple in process, good in safety and wide in application prospect in the field of high-end photoelectric functional materials.

Owner:WUHAN UNIV OF TECH

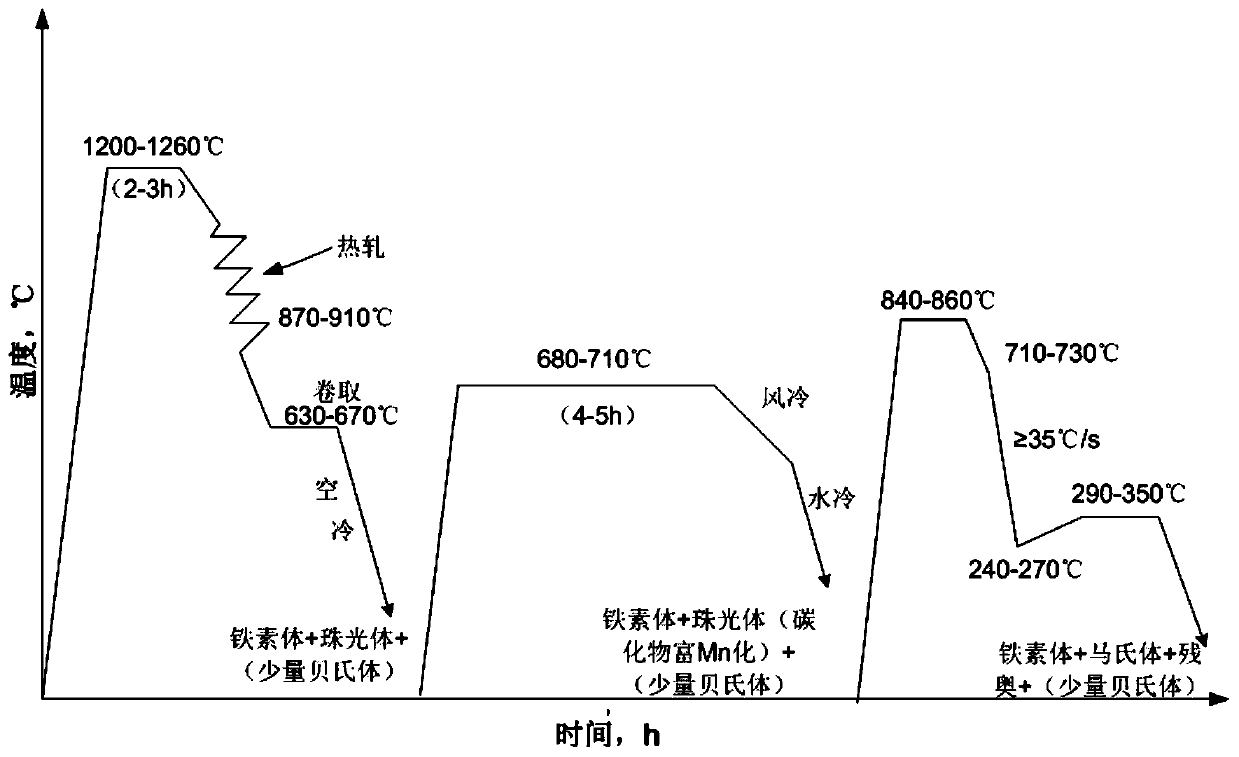

980MPa-grade cold-rolled Q&P steel with excellent plasticity and manufacturing method thereof

The invention provides 980MPa-grade cold-rolled Q&P steel with excellent plasticity and a manufacturing method thereof. The 980MPa-grade cold-rolled Q&P steel comprises the following components of 0.18%-0.21% of C, 1.4%-1.6% of Si, 1.8%-2.1% of Mn, 0.04%-0.06% of Nb, 0.02%-0.05% of Al, less than or equal to 0.01% of P, less than or equal to 0.01% of S and the balance Fe. According to the 980MPa-grade cold-rolled Q&P steel with the excellent plasticity, compared with the prior art, noble metal elements such as Al, Ni and Mo are not added, the content of Mn is relatively low, the Mn element is mainly used for enriching and stabilizing austenite in the austenite, the plasticity of the material is obviously improved, and the product of strength and elongation can reach 25 GPa%; two-phase region annealing is adopted, the annealing temperature is low, and quenching partition treatment can be implemented on an existing continuous annealing production line through adopting an approximate one-step method; and on the other hand, through annealing treatment of the hot-rolled coil, the influence of the alloy element Mn on the material performance is improved, and equipment does not need to betransformed and invested.

Owner:MAANSHAN IRON & STEEL CO LTD

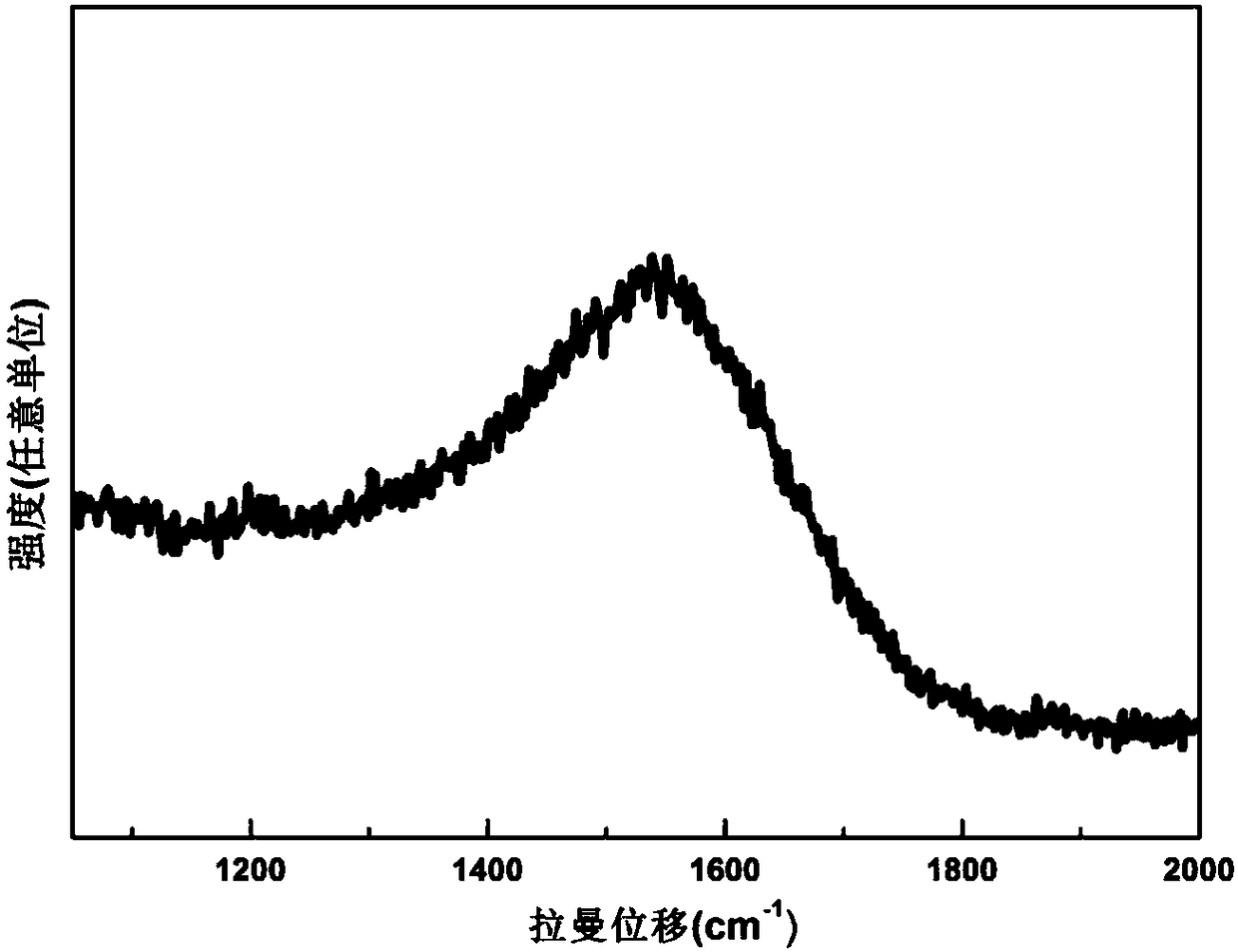

Graphene preparation method

ActiveCN108203090ASimple processLow costVacuum evaporation coatingSputtering coatingEvaporationCvd graphene

The invention provides a graphene preparation method, which combines a cathode vacuum electric arc deposition technology, an electron beam evaporation plating technology and a vacuum annealing process. According to the method, by optimizing process parameters, an amorphous carbon film with high sp3 content is deposited on the surface of a matrix, a catalyst film is subjected to evaporation platingat the surface through an electron beam, and finally annealing is performed at a temperature of 450-500 DEG C to diffuse and precipitate carbon onto the surface of the catalyst film so as to convertthe structure into the graphene structure to form the few-layer or multi-layer graphene. Compared to the existing graphene preparation process, the graphene preparation process of the invention has advantages of simpleness, easy performing, low annealing temperature and reduced cost; and the used carbon source is not the gas but the solid, and the number of the layers of graphene can be controlledby controlling the thickness of the carbon source so as to achieve the controlled preparation of graphene.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for producing lead belt of battery plate

InactiveCN102925834ASimple preparation processLow annealing temperatureLead-acid accumulator electrodesHeat conservationThermal treatment

The invention relates to a method for producing a lead belt of a battery plate. The technical scheme is that lead alloy for manufacturing the lead belt of the storage plate is performed with melting, continuous casting and rolling, and the thickness of a finished product of the lead belt of the battery plate is 0.4-1.2mm; and rolling reduction rate of pre-rolling pass of the finished product of the lead belt of the battery plate and rolling pass of the finished product of the lead belt of the battery plate is 22-44%. Thermal treatment is respectively performed before and after the rolling pass of the finished product of the lead belt of the battery plate, the thermal treatment temperature is 240-290 DEG C, and the heat preservation time is 8-356 seconds. The chemical components of the lead alloy for producing the lead belt of the battery plate contain: 0.04-0.1wt% of Ca, 0.9-1.8wt% of Sn, 0.01-0.03wt% of Al and the balance of Pb. The method for producing the lead belt of the battery plate has the advantages of being simple in production process, and the prepared lead belt of the battery plate is strong in corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

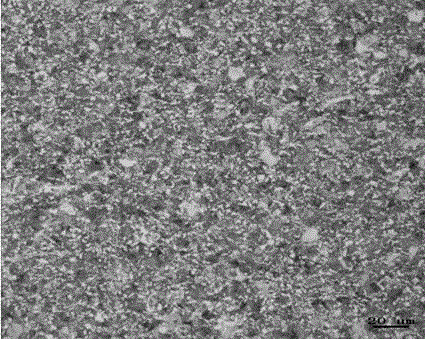

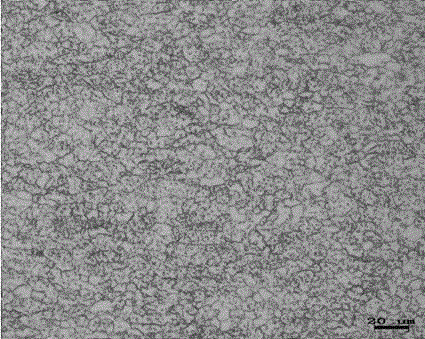

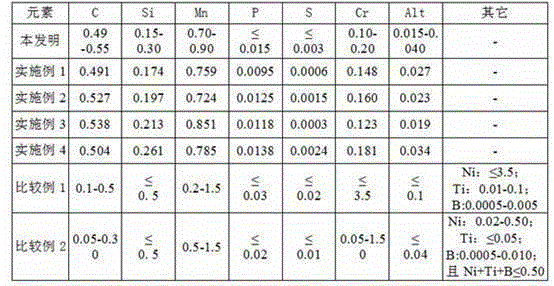

Cold-rolling strip steel used for automobile flywheel processed by precision stamping and manufacture method thereof

ActiveCN106256918ASmall range of performance fluctuationsHigh strengthCompound (substance)Strip steel

The invention relates to a cold-rolling strip steel used for an automobile flywheel processed by precision stamping and a manufacture method thereof, which solves the technical problems that the manufacture cost of the cold-rolling strip steel used for precision stamping is high, the high strength and toughness of the cold-rolling strip steel are not matched, and the precision stamping moulding cannot be satisfied. The cold-rolling strip steel comprises the following chemical components by mass percentage: 0.49-0.54% of C, 0.15-0.30% of Si, 0.70-0.90% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, 0.10-0.20% of Cr, 0.015-0.040% of Alt, and the balance of iron and unavoidable impurity. The structure is composed of block ferrite, granular pearlite and a few of sheet-shaped pearlite, the yield strength of the cold-rolling strip steel is 410-460 MPa, and the percentage elongation after fracture A50 is 25-33%. The cold-rolling strip steel is used for fine blanking of the automobile flywheels.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

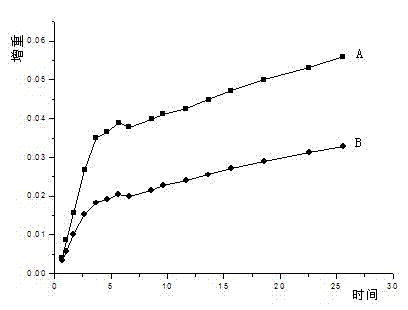

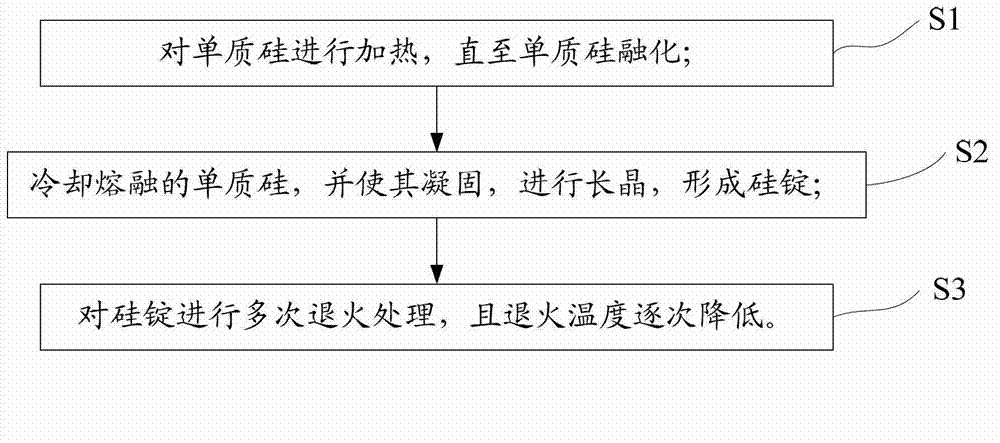

Polycrystalline silicon ingot casting process

ActiveCN103046129AReduce thermal stressLow annealing temperaturePolycrystalline material growthSingle crystal growth detailsIngot castingNucleation

The invention discloses a polycrystalline silicon ingot casting process, comprising the following steps of: 1) heating monatomic silicon until the monatomic silicon is melted; 2) cooling the molten monatomic silicon and solidifying the molten monatomic silicon, and performing nucleation, thereby forming a silicon ingot; and 3) performing multiple times of annealing on the silicon ingot, wherein the annealing temperatures are reduced gradually. In this way, the silicon ingot is subjected to multiple times of annealing, so that thermal stress formed between two adjacent annealing temperatures can be reduced accordingly and the thermal stress in the silicon ingot is eliminated a plurality of times; and compared with once annealing in the prior art, the thermal stress in the silicon ingot can be effectively reduced.

Owner:TIANJIN YINGLI NEW ENERGY RESOURCES

Cold-rolling production process of high-carbon steel

ActiveCN111054746AExtended service lifeSpheroidizing annealing reducesRoll mill control devicesBell type furnacesCarbon steelPickling

The invention discloses a cold-rolling production process of high-carbon steel. The cold-rolling production process comprises the following steps of pickling, first annealing, first calendering, second annealing, second calendering, third annealing, finishing and warehousing of finished products. According to the cold-rolling production process, the first annealing temperature after pickling is reduced, so that production is carried out in a conventional annealing furnace, the production cost is lower, the service life of the production equipment is prolonged, and the produced products have excellent performance.

Owner:佛山市高明基业冷轧钢板有限公司

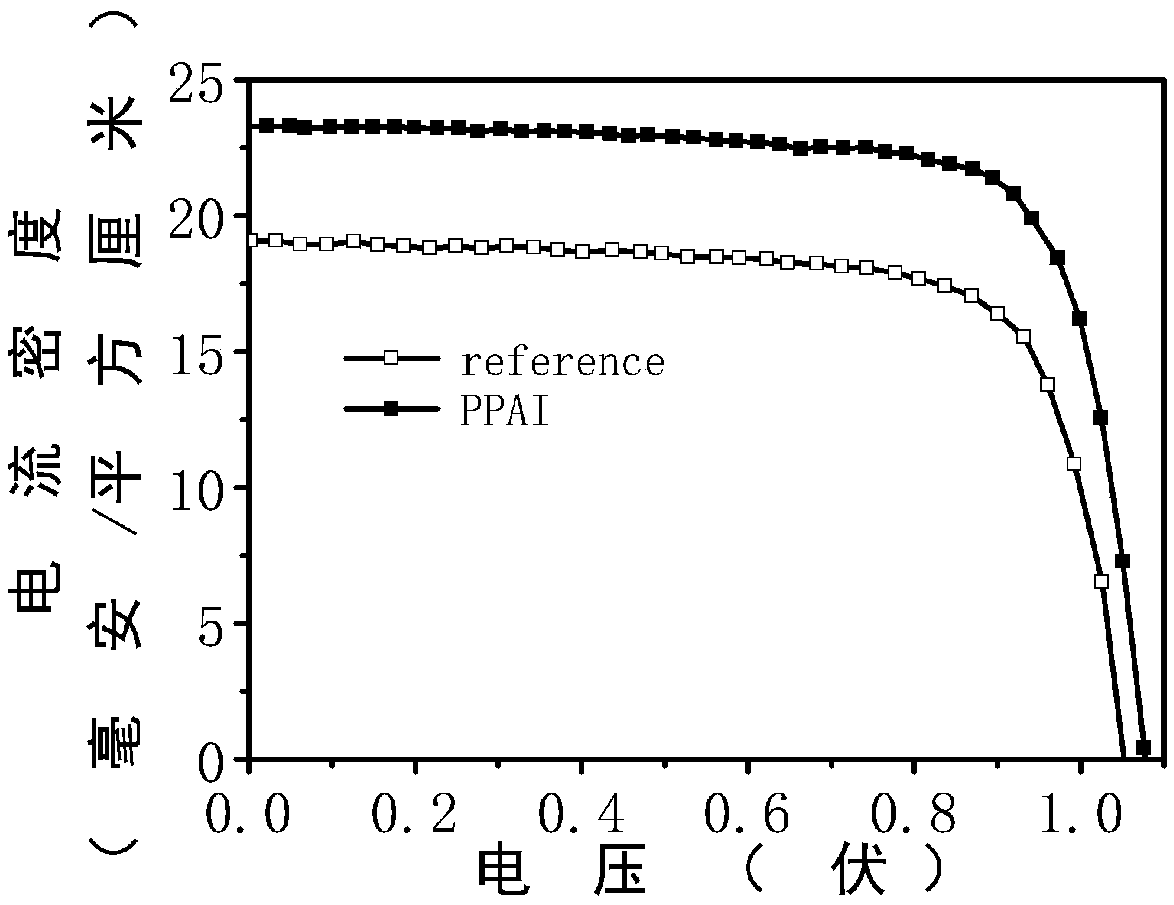

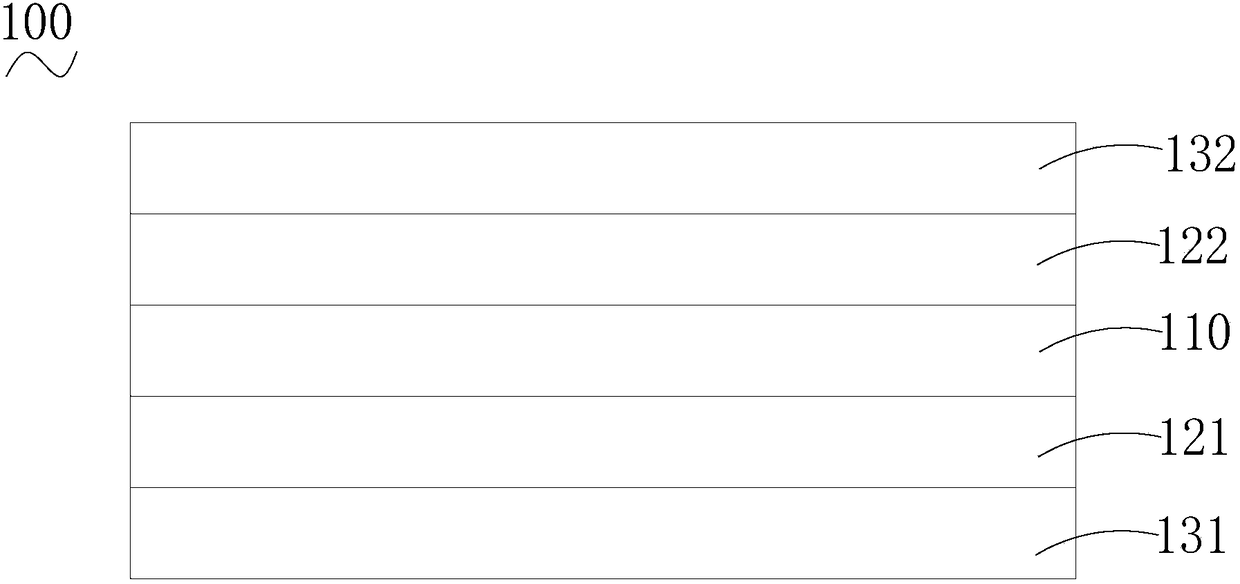

Solar cell and preparation method thereof and method for improving transmission characteristic of perovskite layer

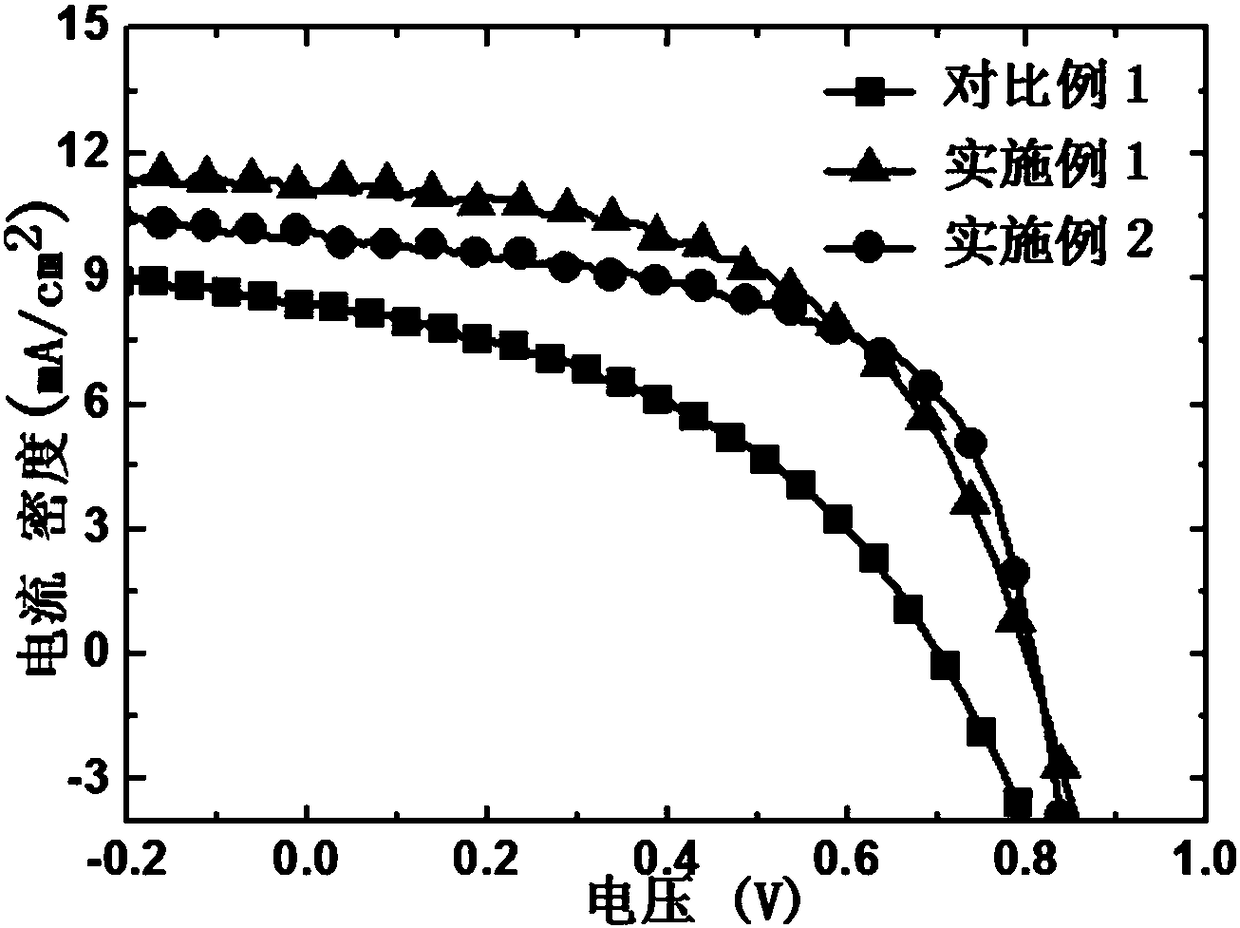

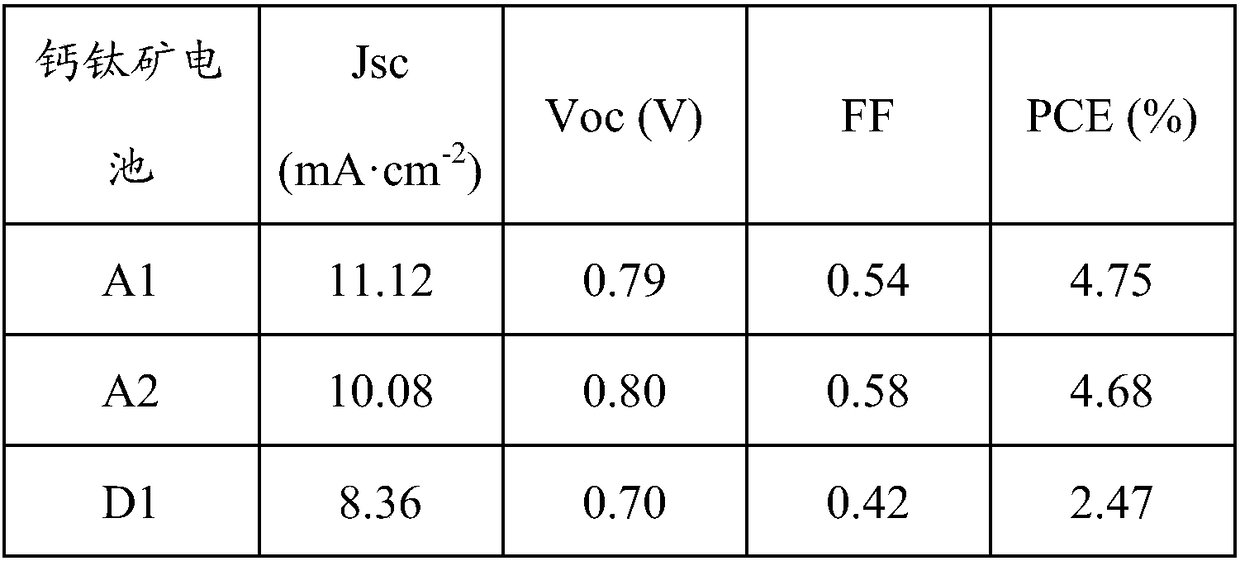

ActiveCN109411607AQuality improvementImprove poor electrical conductivitySolid-state devicesSemiconductor/solid-state device manufacturingCharge carrier mobilitySolar cell

The invention discloses a solar cell and a preparation method thereof and a method for improving transmission characteristic of a perovskite layer. Conjugated organic ammonium salt is added into a DMF / DMSO solution of a perovskite precursor, and annealing and cleaning are carried out to obtain a perovskite layer thin film; and the crystal growth of the perovskite thin film is regulated and controlled by utilizing the organic conjugated ammonium salt, and the charge recombination is inhibited. According to the method, the defect of the crystallized perovskite light absorption layer thin film isobviously reduced, the carrier mobility is improved, the device conversion efficiency is improved by 20% or above, and the requirements of commercial use of devices can be fully met.

Owner:XI AN JIAOTONG UNIV

Spray coating solution, perovskite layer, preparation method of perovskite layer and perovskite cell

ActiveCN108057590AGood film formingImprove continuityFinal product manufactureSolid-state devicesAlcoholSpray coating

The invention relates to the photovoltaic field, in particular to a spray coating solution used for preparing a perovskite layer. The spray coating solution comprises a mixed solvent and a perovskitematerial. The mixed solvent is formed by mixing acetonitrile and an amine solution. The solute of the amine solution is at least one of methylamine, propylamine and butyl amine. The solvent of the amine solution is at least one of methyl alcohol, ethyl alcohol and tetrahydrofuran. According to the spray coating solution, the acetonitrile and the amine solution are used as the mixed solvent to dissolve the perovskite material, after spray coating and annealing, the obtained perovskite layer is good in film-forming property and continuity, the film is provided with few holes and is smooth, uniform and good in quality, and therefore the property improvement of a perovskite cell is facilitated. In addition, by the adoption of the spray coating solution, the annealing temperature is low, the utilization rate of the materials is high, and therefore the production cost of the perovskite layer is lowered. The invention further discloses a preparation method of the perovskite layer, the perovskite layer and the perovskite cell.

Owner:KUNSHAN GCL OPTOELECTRONIC MATERIAL CO LTD

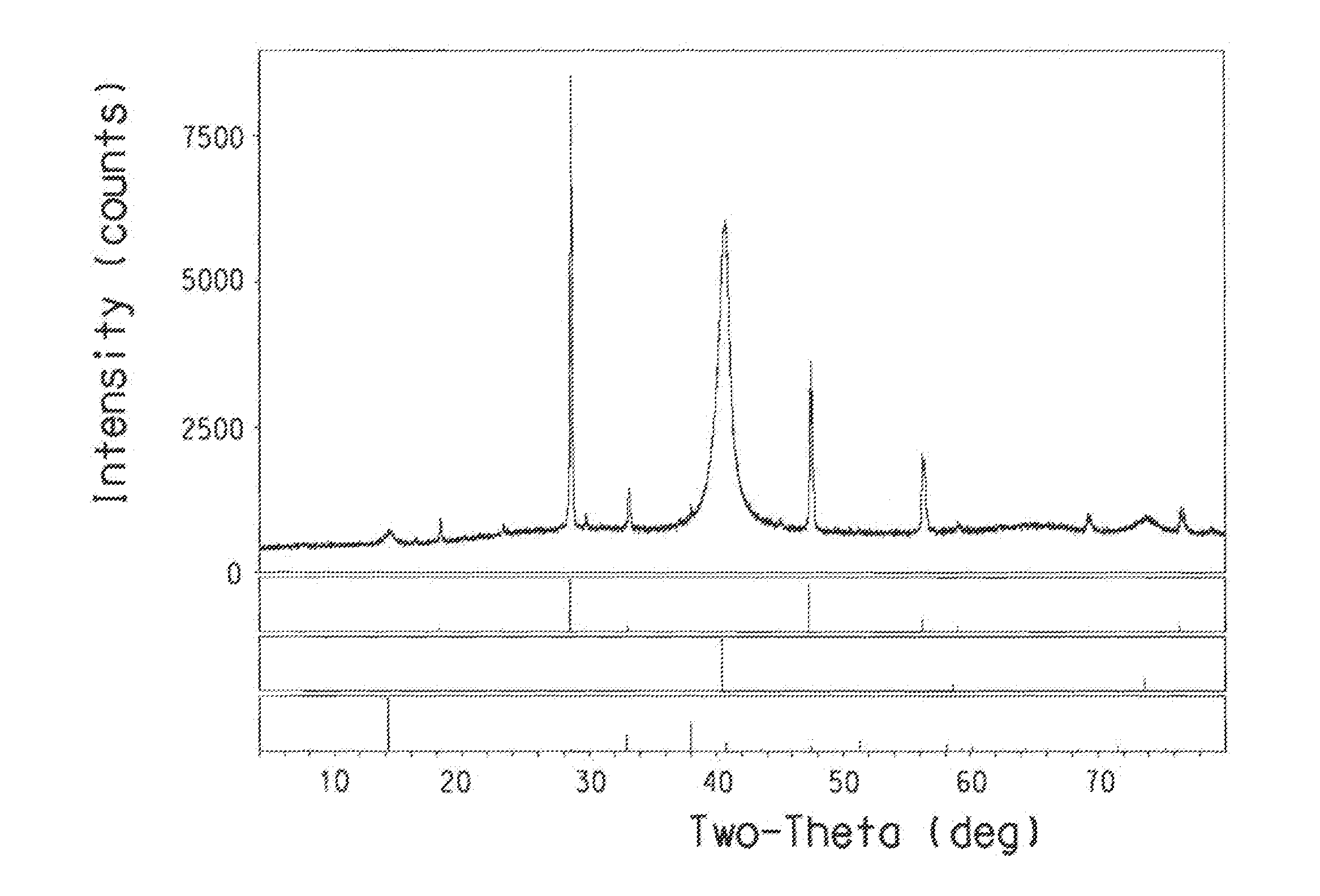

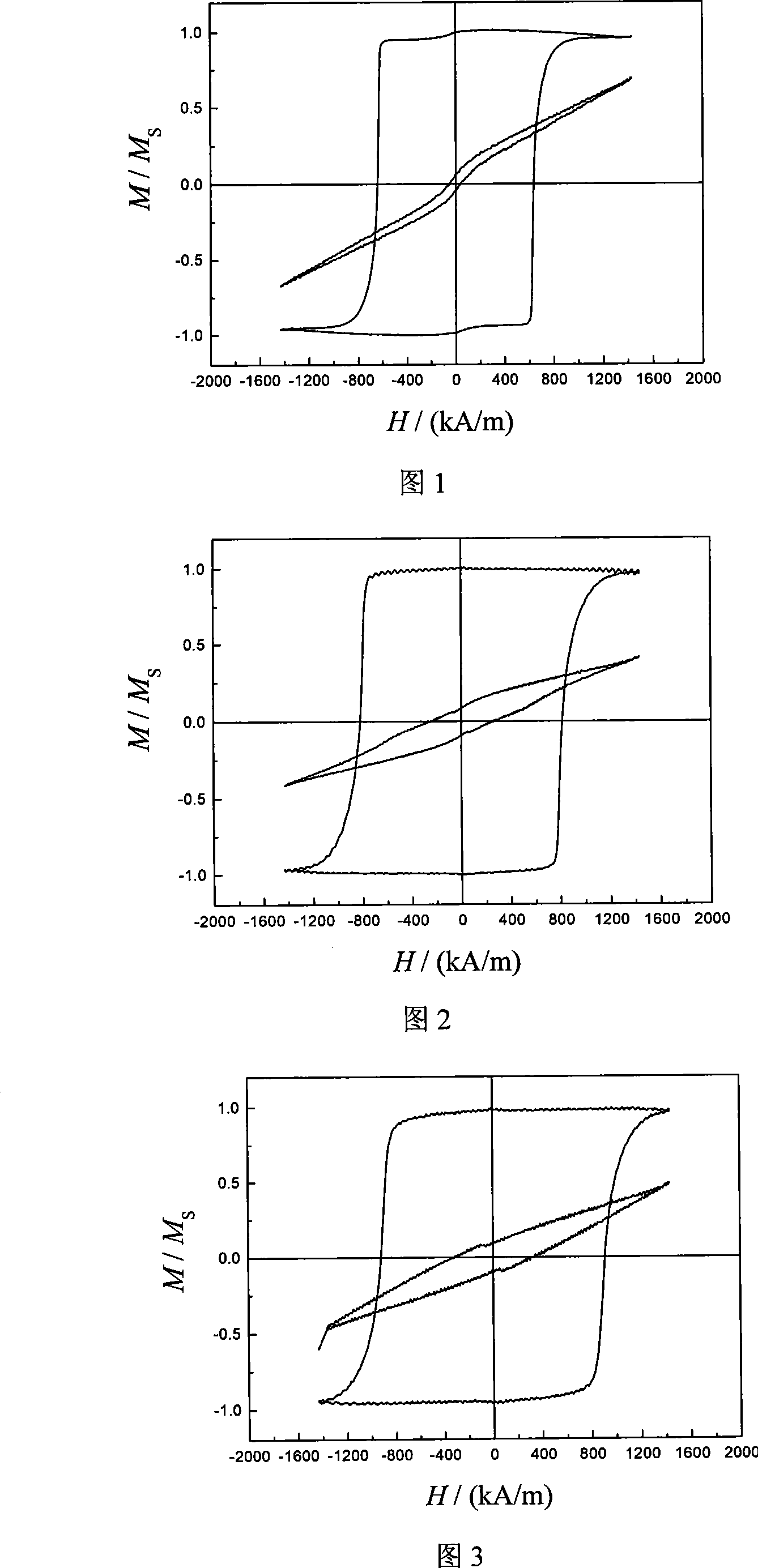

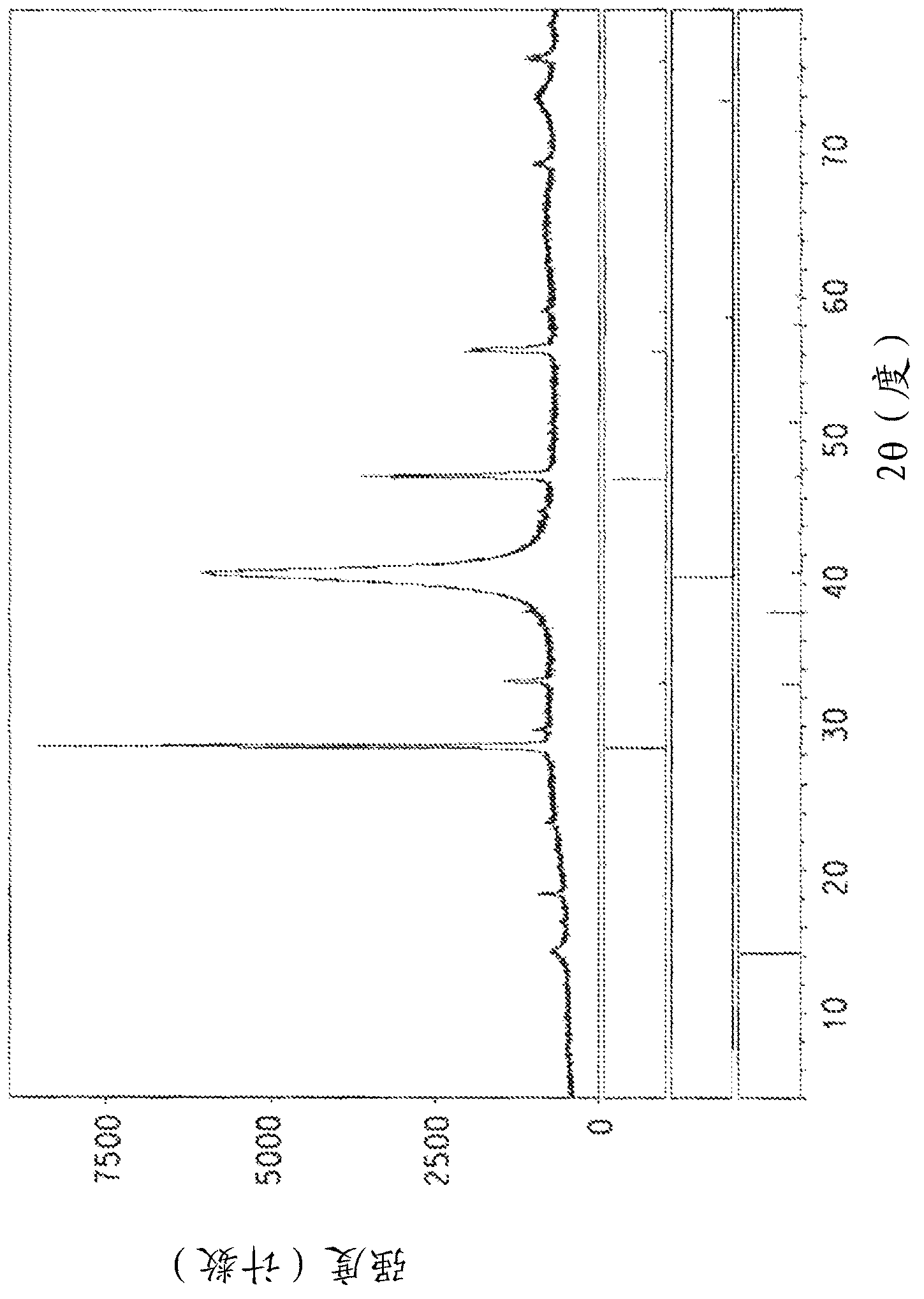

A preparation method for ultra-high density perpendicular magnetic recording medium

InactiveCN101217041AIncreasing the thicknessReduce thicknessCoating by sputteringRoom temperatureSingle crystal substrate

The invention provides a preparation method used for ultra-high density perpendicular magnetic recording medium. A multilayer film [FePt (5-20) / Au (2.5-7)] 5-10 deposits on a heated MgO (001) single crystal substrate by utilizing the Magnetron Sputtering method. The temperature of the substrate is 100-450 DEG C, background pressure in the sputtering chamber is 1*10<-5>-7*10<-5>Pa, and argon pressure is 0.9-1.6 Pa when sputtering. After deposition, the film is cooled to the room temperature and then put into a vacuum annealing furnace for heat treatment with the annealing temperature is 470-700 DEG C, the annealing time is 20m-4 h, and the background pressure in the annealing furnace is 2*10<-5>-7*10<-5>Pa. The prepared L10-FePt film is characterized in vertically alignment, superior magnetic property and particle size smaller than 10nm, and is suitable for ultra-high density perpendicular magnetic recording medium. The method has the advantages of low cost, easy preparation and suitability for industrial application.

Owner:UNIV OF SCI & TECH BEIJING

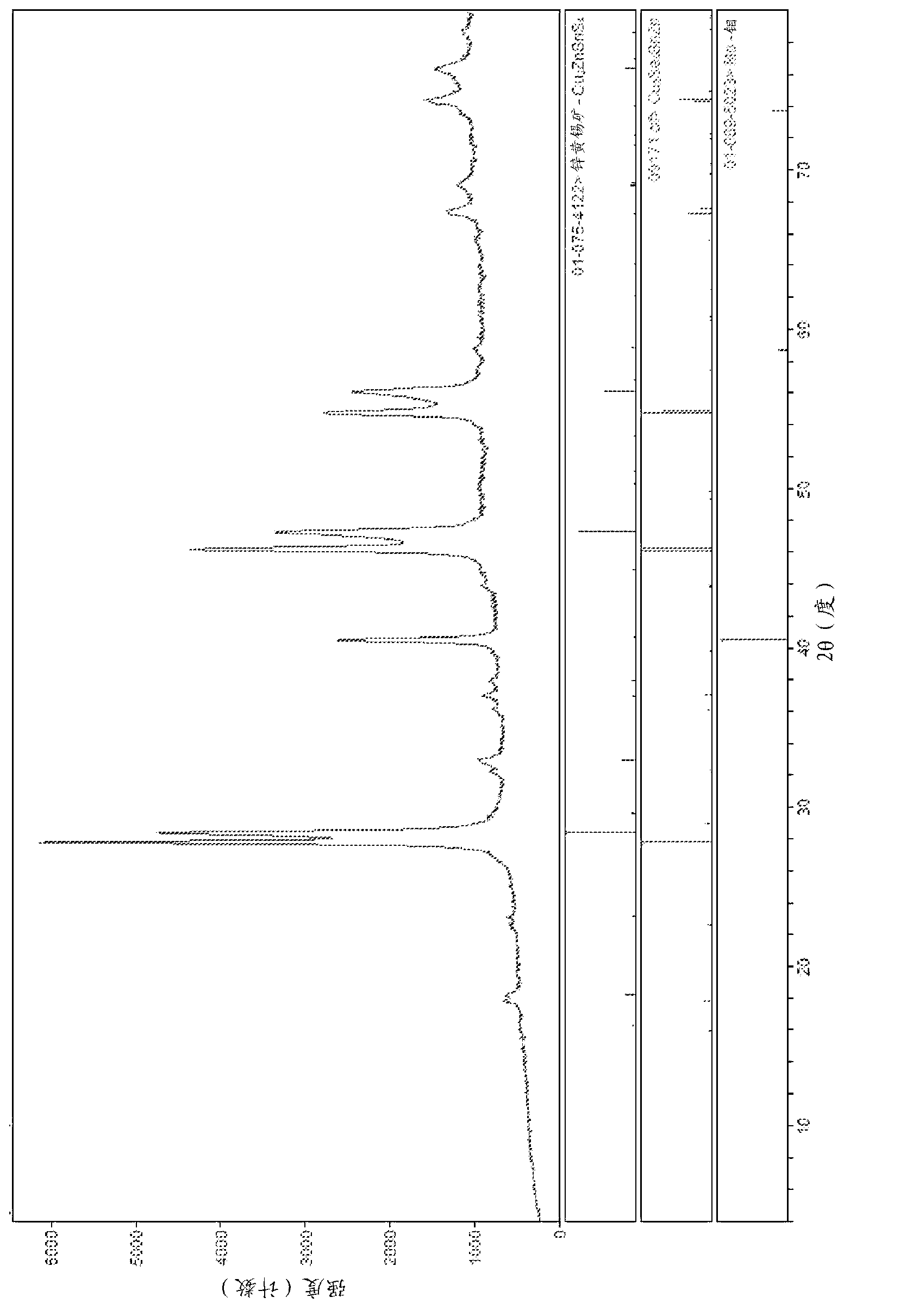

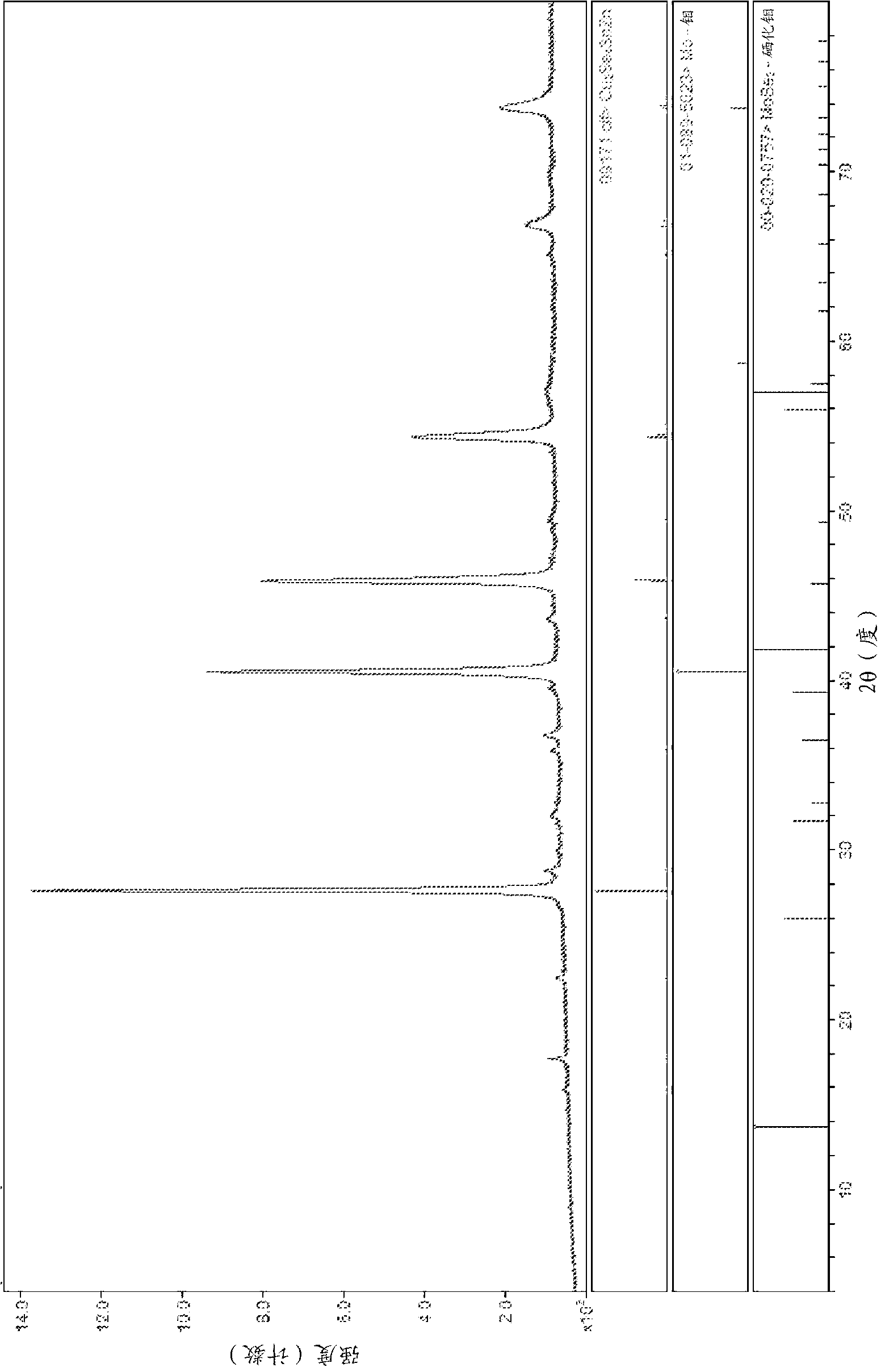

Semiconductor inks, films, coated substrates and methods of preparation

InactiveCN103221471AEasy to manufactureStacked tightlySemiconductor/solid-state device manufacturingInksCZTSMicroparticle

This invention provides compositions useful for preparing films of CZTS and its selenium analogues on a coated substrate. This invention also provides processes for preparing films and coated substrates comprising CZTS / Se microparticles embedded in an inorganic matrix. This invention also provides processes for preparing photovoltaic cells comprising films of CZTS and its selenium analogues.

Owner:EI DU PONT DE NEMOURS & CO

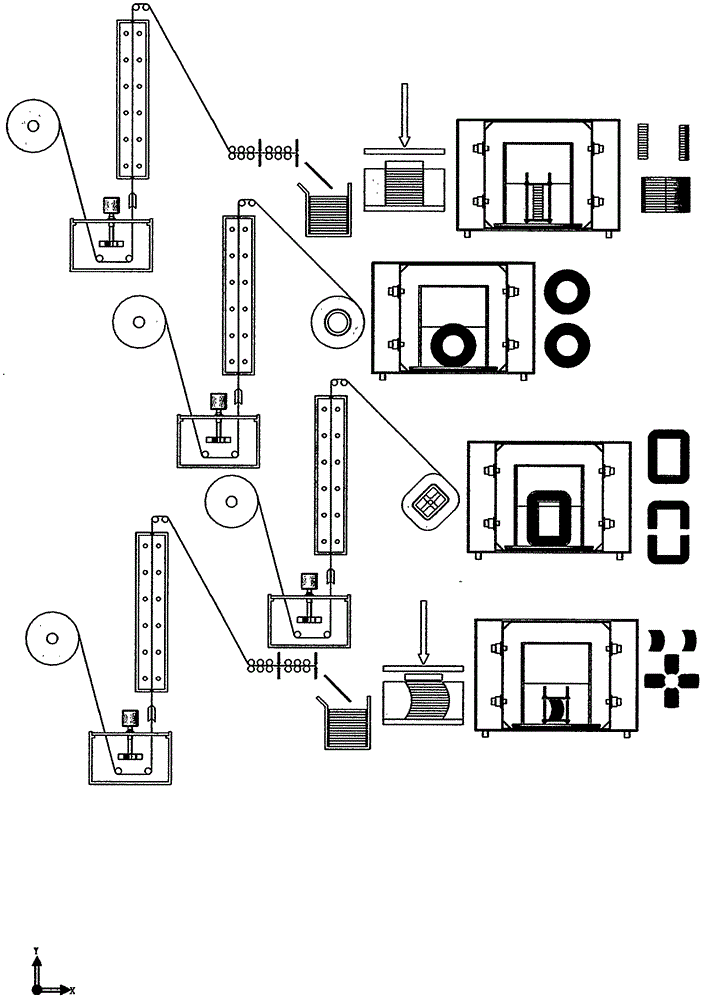

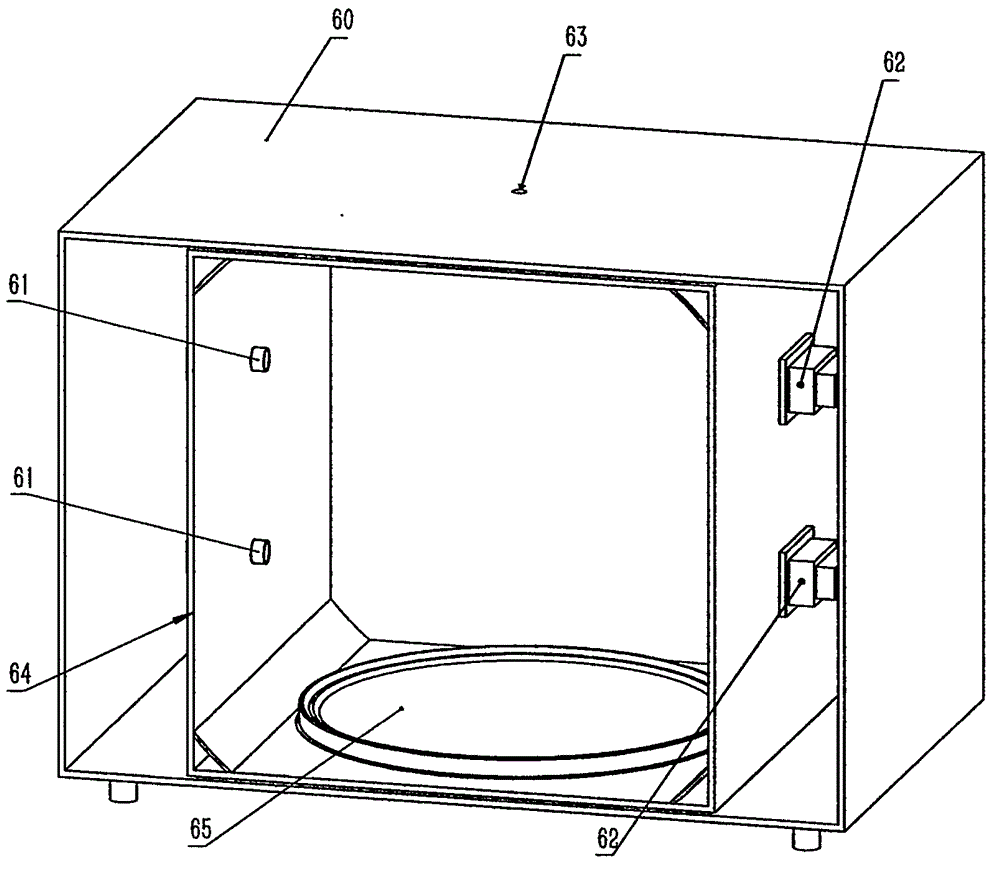

Manufacturing method for amorphous alloy core used for motor and transformer

InactiveCN105118653AAvoid blanking processAvoid the disadvantages of uneven distributionInductances/transformers/magnets manufactureManufacturing stator/rotor bodiesMicrowave ovenTransformer

The invention discloses a manufacturing method for amorphous alloy cores used for motors and transformers. The method comprises the following steps: using an inorganic insulating high-temperature resistant binder to coat double surfaces of an amorphous alloy strip, drying the strip; cutting the strip, overlaying amorphous alloy sheets in the same shape in a die in a linear or arc manner, vertically pressing to form a linear or arc stacked body iron core billet; or tightly winding the amorphous alloy strip to form an annular iron core billet; or tightly winding the amorphous alloy strip to form a track iron core billet; fixing the iron core billets in different kinds in fixtures in different structures and shapes, the fixtures being made of a microwave-transmitting and high-temperature resistant material; heating / annealing / solidifying the iron core billets in a microwave oven; and performing subsequent processing and surface coating processing on the iron core billets, to form iron cores or core components in required shapes and sizes. The method can be used to manufacture radial, transverse, and axial magnetic flux motors and amorphous alloy cores of transformers.

Owner:王新

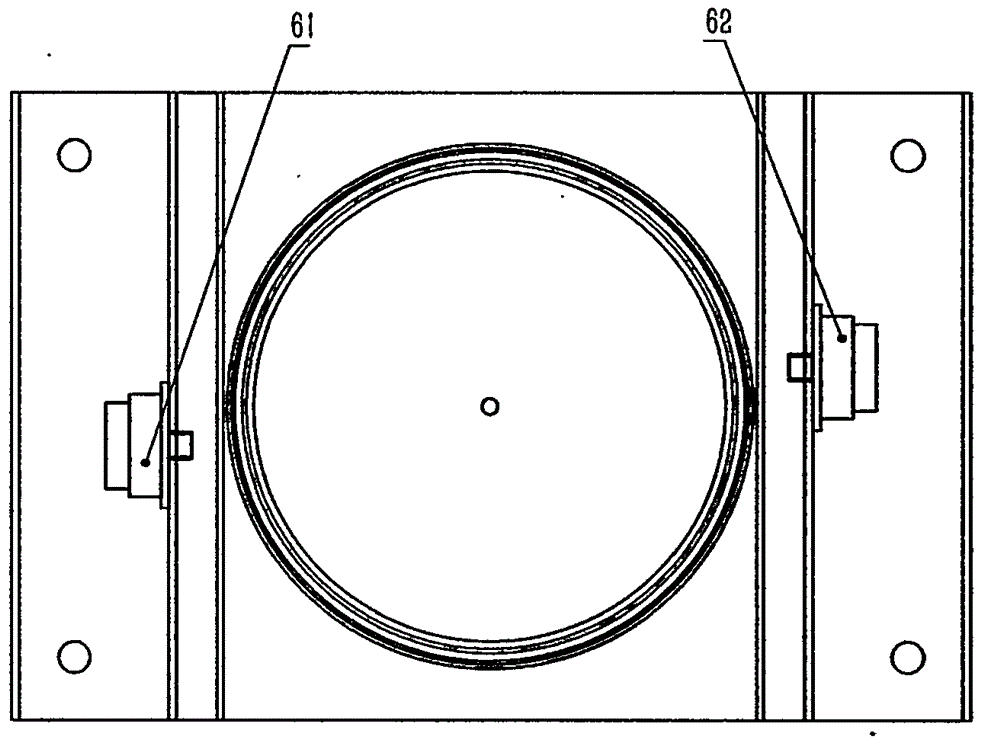

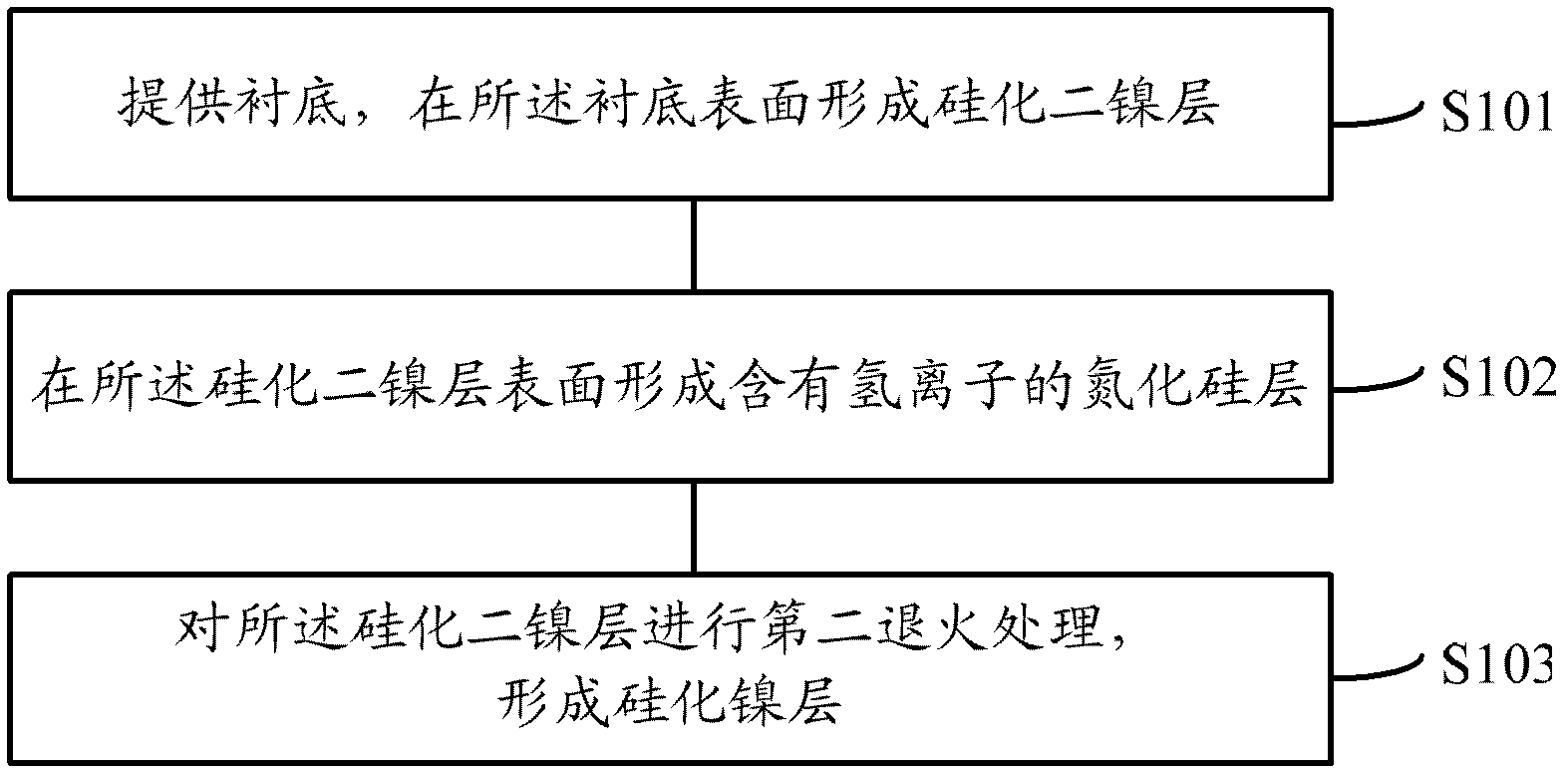

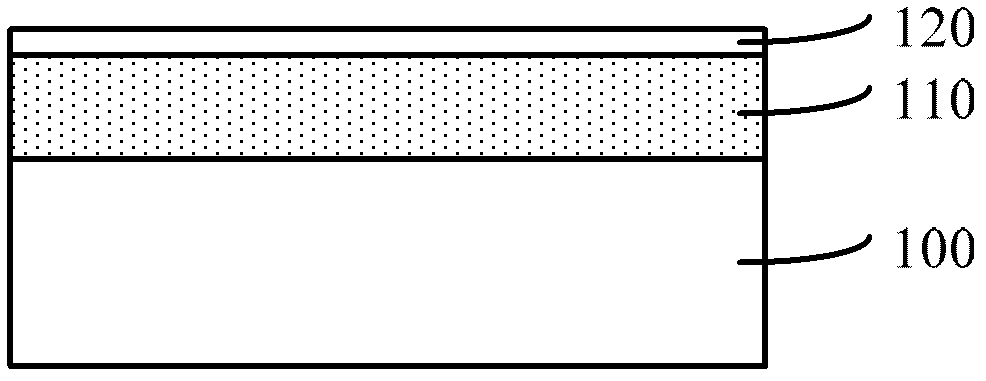

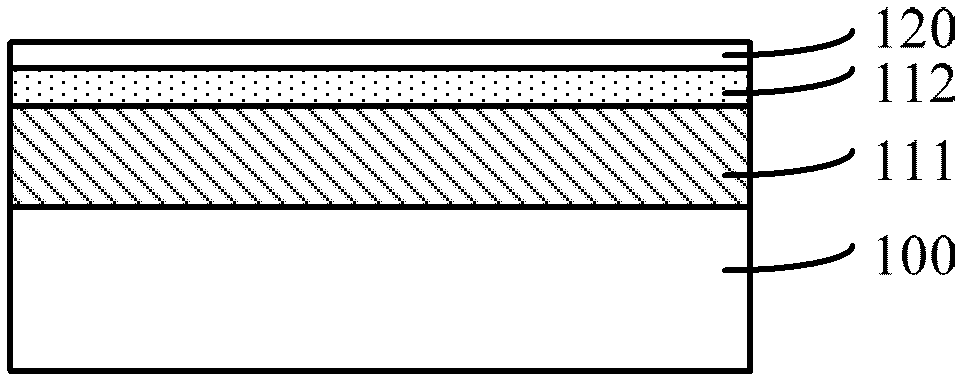

Nickel silicide layer forming method and semiconductor device forming method

ActiveCN103014656ALower resistanceIncrease contentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenSemiconductor

The invention discloses a nickel silicide layer forming method and a semiconductor device forming method, wherein the nickel silicide layer forming method comprises the following steps of: providing a substrate, and forming a dinickel silicide layer on the surface of the substrate; forming a hydrogen ion containing silicon nitride layer on the surface of the dinickel silicide layer; and carrying out secondary annealing treatment on the dinickel silicide layer so as to form a nickel silicide layer. Before the step of carrying out secondary annealing treatment on the dinickel silicide layer so as to form a nickel silicide layer, a hydrogen ion containing silicon nitride layer is formed on the surface of the dinickel silicide layer, and in the process of carrying out secondary annealing treatment, hydrogen ions in the silicon nitride layer are diffused into the dinickel silicide layer, so that the finally formed nickel silicide layer internally contains hydrogen ions, therefore, the resistance of the nickel silicide layer can be effectively decreased, and the RC delay of a circuit can be reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

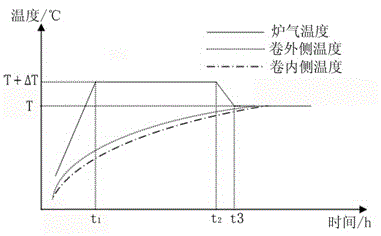

Annealing process of aluminum alloy coiled material

ActiveCN104087879AEffective monitoring of annealing temperatureMonitor annealing temperatureHeating furnaceToughness

The invention provides an annealing process of an aluminum alloy coiled material. According to the annealing process provided by the invention, the annealing time is greatly shortened,the problem of poor finished material coil head-tail structure property difference generated when annealing treatment is carried out on an aluminum-magnesium alloy coiled material is solved by adopting an existing aluminum alloy annealing process, the size of a crystal grain can be effectively controlled and the plasticity and toughness of a finished product state coiled material are improved. The annealing process is characterized by comprising the following steps: placing the aluminum alloy coiled material into an annealing heating furnace; fast heating the aluminum alloy coiled material by setting the furnace gas temperature of the annealing heating furnace as T+delta T, and monitoring the temperature of the aluminum alloy coiled material; when the outer side temperature of the aluminum alloy coiled material, namely the high-point temperature of the aluminum alloy coiled material, reaches T-delta t, reducing the furnace gas temperature of the annealing heating furnace to T, wherein the temperature reduction time is 60-90 minutes; and when the inner side temperature of the aluminum alloy coiled material, namely the low-point temperature of the aluminum alloy coiled material, is monitored to reach T-(5-30 DEG C), preserving heat for 60-120 minutes, and then taking out of the furnace for air-cooling, wherein the temperature T is the predetermined target temperature of the annealing of the aluminum alloy material, the delta T is 20-150 DEG C, and the delta t is 10-70 DEG C.

Owner:YINBANG CLAD MATERIAL

Inks and processes to make a chalcogen-ontaining semiconductor

InactiveCN103222062AEasy to manufactureStacked tightlySemiconductor/solid-state device manufacturingInksCopperChalcogen

The invention relates to an ink composition in admixture. The ink composition in admixture comprises a vehicle; a copper source selected from the group consisting of elemental copper-containing particles, copper-containing chalcogenide particles, and 10 mixtures thereof; a zinc source selected from the group consisting of: elemental zinc-containing particles, zinc-containing chalcogenide particles, and mixtures thereof; and a tin source selected from the group consisting of: elemental tin-containing particles, tin-containing chalcogenide particles, and mixtures thereof; wherein at least one of the copper, zinc or tin sources comprises elemental copper-containing, elemental zinc-containing, or elemental tin-containing particles.

Owner:EI DU PONT DE NEMOURS & CO

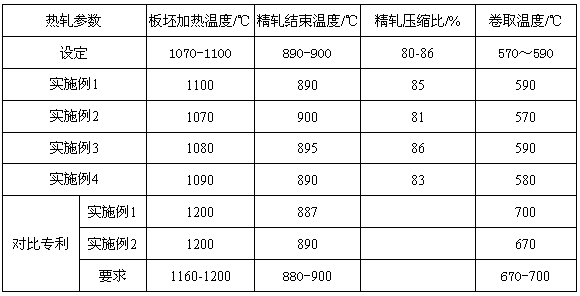

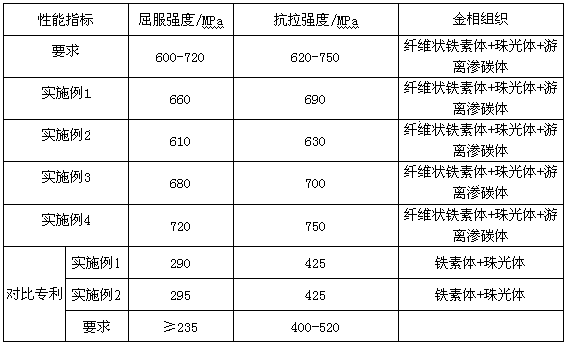

Inboard plate high strength steel and production method thereof

The invention relates to a high strength steel and a production method thereof, and specially relates to an inboard plate high strength steel and a production method thereof. The invention aims to solve the technical problems that the cost of high strength steel is high because of the large using amount of alloy elements and the yield strength of cheap inboard plate cannot meet the requirements. The high strength steel is characterized by being composed of the following elements in percentage by weight: 0.04 to 0.06% of carbon, 0.005 to 0.03% of silicon, 0.15 to 0.25% of manganese, not more than 0.016% of phosphor, not more than 0.015% of sulfur, 0.002 to 0.003% of boron, 0.025 to 0.05% of aluminum, and the balance being Fe and inevitable impurity elements. The steel is used to manufacture inboard plates, the yield strength Rel is 600 to 720 MPa, the tensile strength Rm is 620 to 750 MPa, and the microstructure of the steel is a composite of fibrous ferrite, pearlite, and free cementite.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Cold rolling for 2B surface of 439 ferrite stainless steel

ActiveCN110814032AHigh surface quality requirementsAvoid chromatic aberrationRoll force/gap control deviceFurnace typesNitrogen oxidesElectrolysis

The invention discloses a cold rolling method of a 2B surface of 439 ferrite stainless steel, and belongs to the field of stainless steel surface treatment. The problem that a white strip-shaped titanium stripe defect exists on the surface of a cold rolling 2B surface exists is solved. The cold rolling method comprises the following steps of 1, hot wire annealing acid washing; 2, rolling by a coldrolling mill; 3, cold line annealing acid washing; and 4, online flattening. In the step 1, a neutral salt electrolytic plus nitric acid electrolysis and low-concentration mixed acid pickling technology is adopted by the cold rolling method, the annealed strip steel is treated through a reasonable acid pickling method to obtain the cold rolled 2B surface with high surface quality requirement. The2B surface obtained by the cold rolling method is completely different from the 2B surface obtained by a traditional method, the surface is bright and uniform, white strip-shaped titanium stripe defects are avoided, high corrosion resistance and high surface quality are met, and the use requirements in the field of decorative panels are met. The low-concentration mixed acid pickling technology isadopted by the cold rolling method, so that the emission of nitrogen oxides can be greatly reduced, and the environmental protection burden is reduced.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Copper cladded aluminum composite thin flat wire and its preparation method

ActiveCN101169987AReduce weightIncrease slot fill rateSingle bars/rods/wires/strips conductorsFlat/ribbon cablesFine lineAluminum composites

The invention relates to a copper-clad aluminum composite thin flat wire and a preparation method thereof. The copper-clad aluminum composite thin flat wire is composed of a core aluminum body and a pure copper cladding layer, and the pure copper cladding area ratio is 10% to 30%. , the thickness of the copper layer is evenly distributed, the minimum width of the cross-sectional dimension can reach 0.08mm, and the minimum thickness can reach 0.02mm. It is beneficial to reduce the volume and weight of the coil, and can meet the use requirements of micro-motor enameled wires for various precision micro-electrical appliances. The copper-clad aluminum composite thin flat wire is prepared by cold liquid extrusion to prepare copper-clad aluminum wire billet, combined with subsequent cold deformation strong processing (drawing, rolling) to prepare copper-clad aluminum composite thin flat wire, the prepared copper-clad aluminum composite thin The preparation process of the flat wire greatly reduces the number of annealing times, lowers the annealing temperature, and even does not need annealing according to needs, simplifies the production process, and reduces the production cost.

Owner:UNIV OF SCI & TECH BEIJING

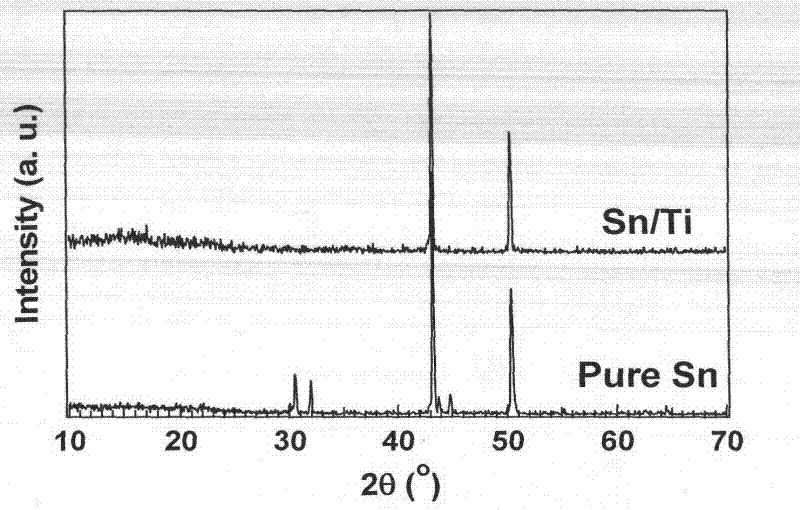

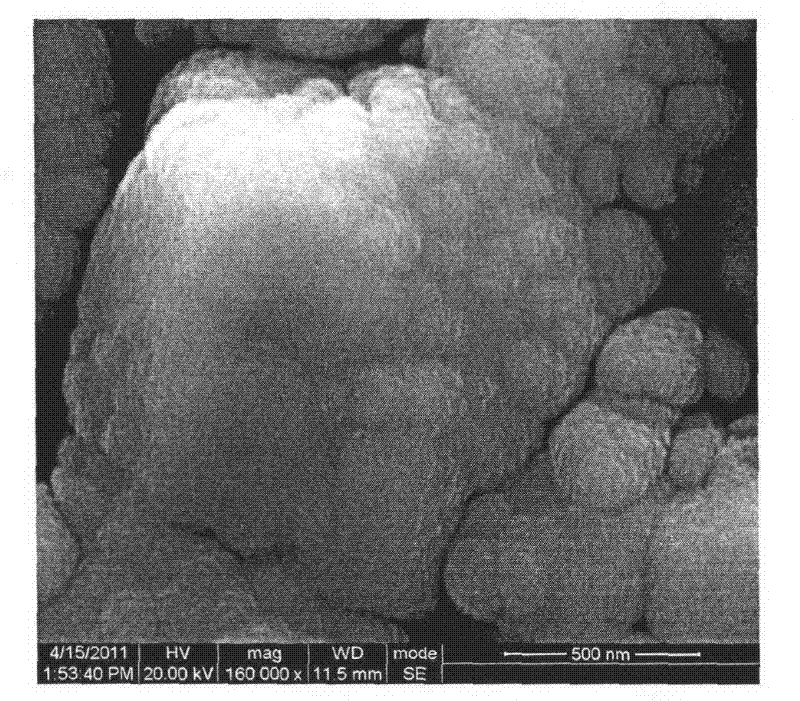

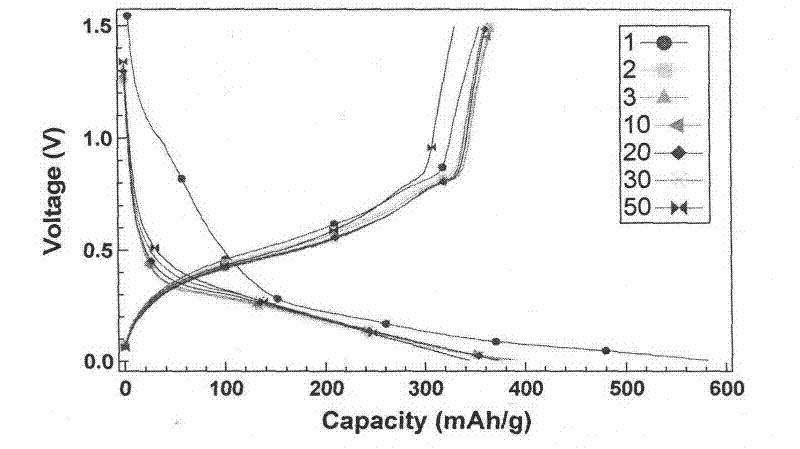

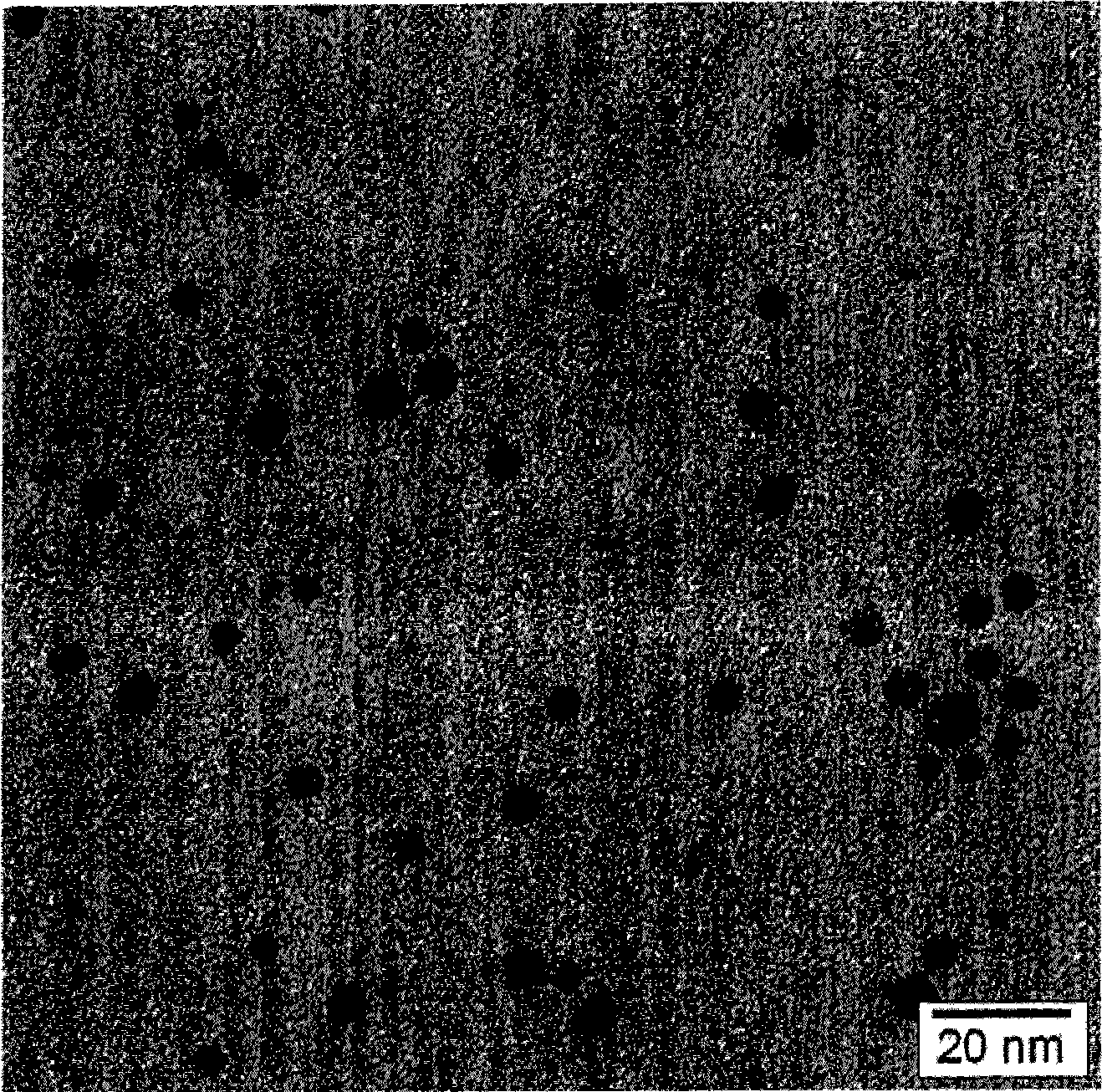

Magnetron sputtering preparation method of tin titanium film cathode of lithium ion battery

InactiveCN102212789AGood repeatabilityAvoid complex controlsCell electrodesVacuum evaporation coatingRoom temperatureTitanium

The invention belongs to the field of a chemical power source, and particularly relates to a magnetron sputtering preparation method of a tin titanium film cathode of a lithium ion battery. The method is characterized by comprising the following steps: alternately sputtering or cosputtering pure tin and pure titanium targets to prepare a tin titanium film, and then maintaining annealing treatment at a temperature ranging from room temperature to 300 DEG C for 0-6 hours. In the two-target alternate sputtering method, an Sn / Ti or Ti / Sn laminated film can be formed, when the number of times of alternation is more than one, on the basis of the material which is sputtered firstly. The method disclosed by the invention has the advantages of simple process and low cost, and is beneficial to environment protection; and the prepared film is used as a cathode of a lithium ion battery, and has high specific capacity and excellent cycle performance.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Nanoparticles, methods of making, and applications using same

InactiveCN101479065AEasy to manufactureLow annealing temperatureMaterial nanotechnologyPigmenting treatmentNanoparticleSolvent

Methods for forming nanoparticles under commercially attractive conditions. The nanoparticles can have very small size and high degree of monodispersity. Low temperature sintering is possible, and highly conductive films can be made. Semiconducting and electroluminescent films can be also made. One embodiment provides a method comprising: (a) providing a first mixture comprising at least one nanoparticle precursor and at least one first solvent for the nanoparticle precursor, wherein the nanoparticle precursor comprises a salt comprising a cation comprising a metal; (b) providing a second mixture comprising at least one reactive moiety reactive for the nanoparticle precursor and at least one second solvent for the reactive moiety, wherein the second solvent phase separates when it is mixed with the first solvent; and (c) combining said first and second mixtures in the presence of a surface stabilizing agent, wherein upon combination the first and second mixtures phase-separate and nanoparticles are formed.

Owner:NANOMAS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com