Magnetron sputtering preparation method of tin titanium film cathode of lithium ion battery

A lithium-ion battery, magnetron sputtering technology, applied in battery electrodes, sputtering plating, ion implantation plating, etc., to achieve the effects of reducing production costs, simplifying the preparation process, and shortening the annealing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0035] Adopt sequential sputtering method to prepare the tin-titanium thin film negative electrode of lithium ion battery, its preparation method and steps are as follows:

[0036] 1. Install the cleaned Cu foil at the sample position in the magnetron sputtering chamber, and then install the pure Sn target and pure Ti target. The purity of the two targets is 99.99%. Move the sample to the sample position facing the Sn target by revolution. The sample rotation speed was 20 rpm.

[0037] 2. Then vacuum the cavity to 1.0×10 -3 Below Pa, 99.999% Ar gas is introduced to keep the pressure in the sputtering chamber at 0.5Pa.

[0038] 3. Close the baffle on the metal Sn target, apply a DC voltage of 1050V to the target with a DC sputtering power supply, control the current at 0.22A, and clean the surface of the target by self-sputtering after ignition.

[0039] 4. After the self-sputtering time of the Sn target reaches 5 minutes, open the baffle of the target.

[0040] 5. After th...

Embodiment example 2

[0050] Adopt sequential sputtering method to prepare the titanium-tin laminated film negative electrode of lithium-ion battery, its preparation method and steps are as follows:

[0051] 1. Install the cleaned Cu foil at the sample position in the magnetron sputtering chamber, and then install the pure Sn target and pure Ti target. The purity of the two targets is 99.99%. Move the sample to the sample position facing the Ti target by revolution. The sample rotation speed is 20 rpm.

[0052] 2. Then vacuum the cavity to 1.0×10 -3 Below Pa, 99.999% Ar gas is introduced to keep the pressure in the sputtering chamber at 0.5Pa.

[0053] 3. Close the baffle on the metal Ti target, apply a 420V DC voltage on the target with a DC sputtering power supply, control the current at 0.18A, and clean the surface of the target by self-sputtering after ignition.

[0054] 4. After the self-sputtering time of the Ti target reaches 5 minutes, open the baffle of the target.

[0055] 5. After th...

Embodiment example 3

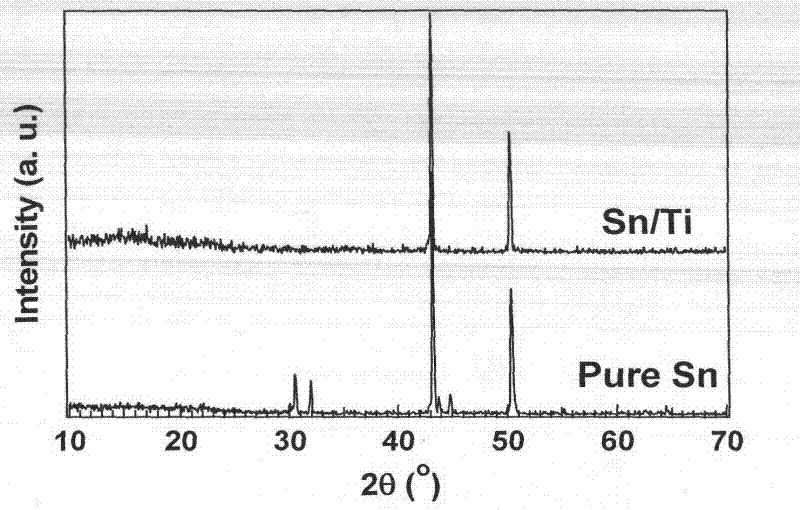

[0065] The sequential sputtering method is used to prepare the four-layer titanium-tin film electrode, and it is subjected to thermal annealing treatment. The preparation method and steps are as follows:

[0066] 1. Install the cleaned stainless steel sheet at the sample position in the magnetron sputtering chamber, and then install the pure Sn target and the pure Ti target. The purity of the two targets is 99.99%. Move the sample to the sample position facing the Ti target by revolution. The sample rotation speed is 20 rpm.

[0067] 2. Then vacuum the cavity to 1.0×10 -3 Below Pa, 99.999% Ar gas is introduced to keep the pressure in the sputtering chamber at 0.5Pa.

[0068] 3. Close the baffle plate on the metal Ti target, apply a voltage of 510V to the target with a radio frequency sputtering power supply, control the current at 0.23A, and use self-sputtering to clean the surface of the target after ignition.

[0069] 4. After the self-sputtering time of the Ti target rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com