Patents

Literature

183results about How to "Shorten the annealing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

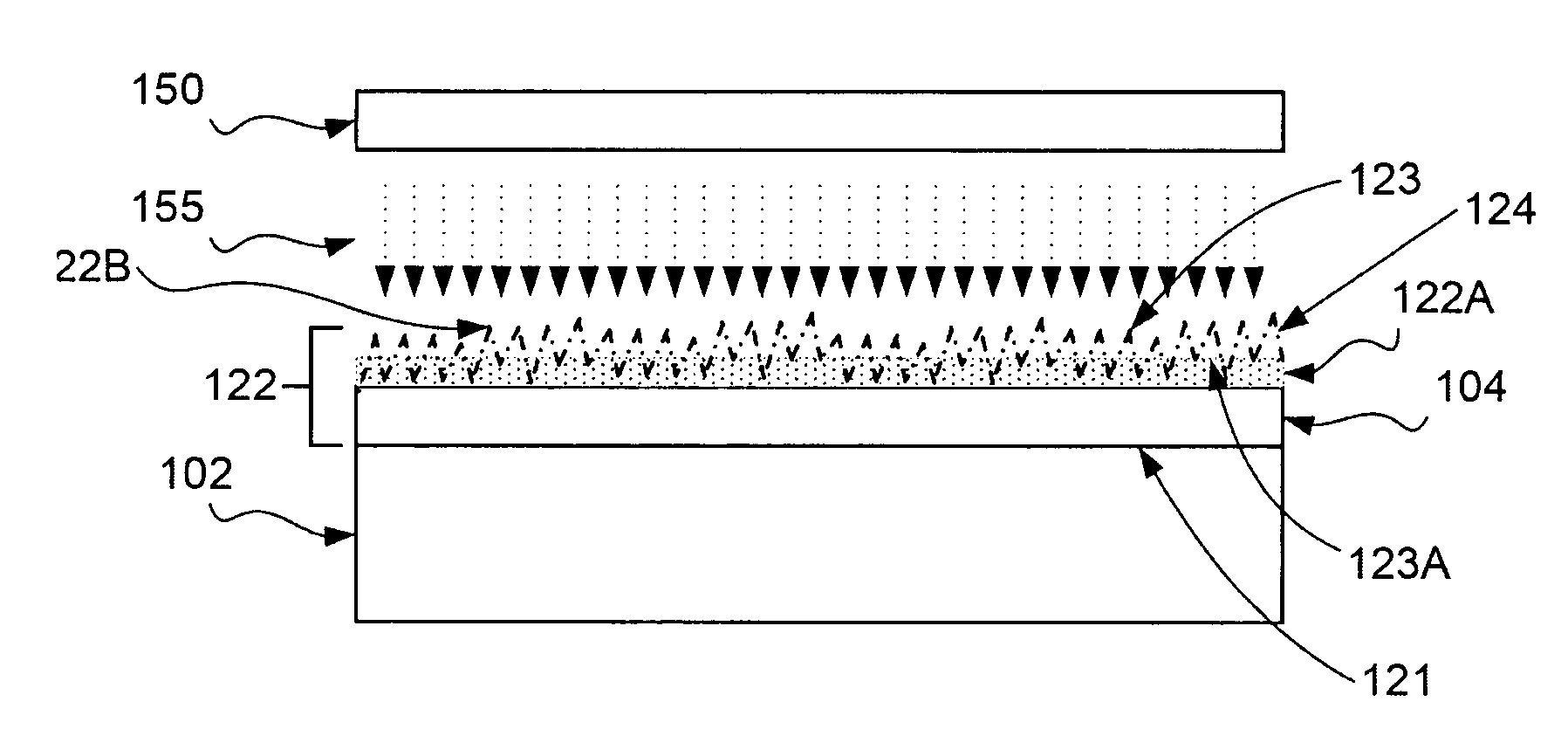

Semiconductor on insulator structure made using radiation annealing

InactiveUS20070281172A1Healing damageReduce roughnessElectric discharge tubesSolid-state devicesWaferingIon implantation

Systems and methods for and products of a semiconductor-on-insulator (SOI) structure including subjecting at least one unfinished surface to a laser annealing process. Production of the SOI structure further may include subjecting an implantation surface of a donor semiconductor wafer to an ion implantation process to create an exfoliation layer in the donor semiconductor wafer; bonding the implantation surface of the exfoliation layer to an insulator substrate; separating the exfoliation layer from the donor semiconductor wafer, thereby exposing at least one cleaved surface; and subjecting the at least one cleaved surface to the laser annealing process.

Owner:CORNING INC

Semiconductor on insulator structure made using radiation annealing

InactiveUS7579654B2Healing damageReduce roughnessElectric discharge tubesSolid-state devicesIon implantationSemiconductor

Owner:CORNING INC

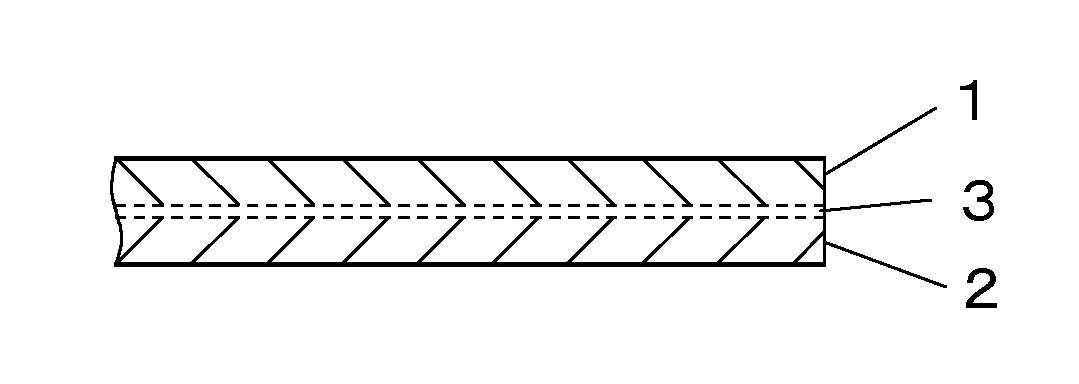

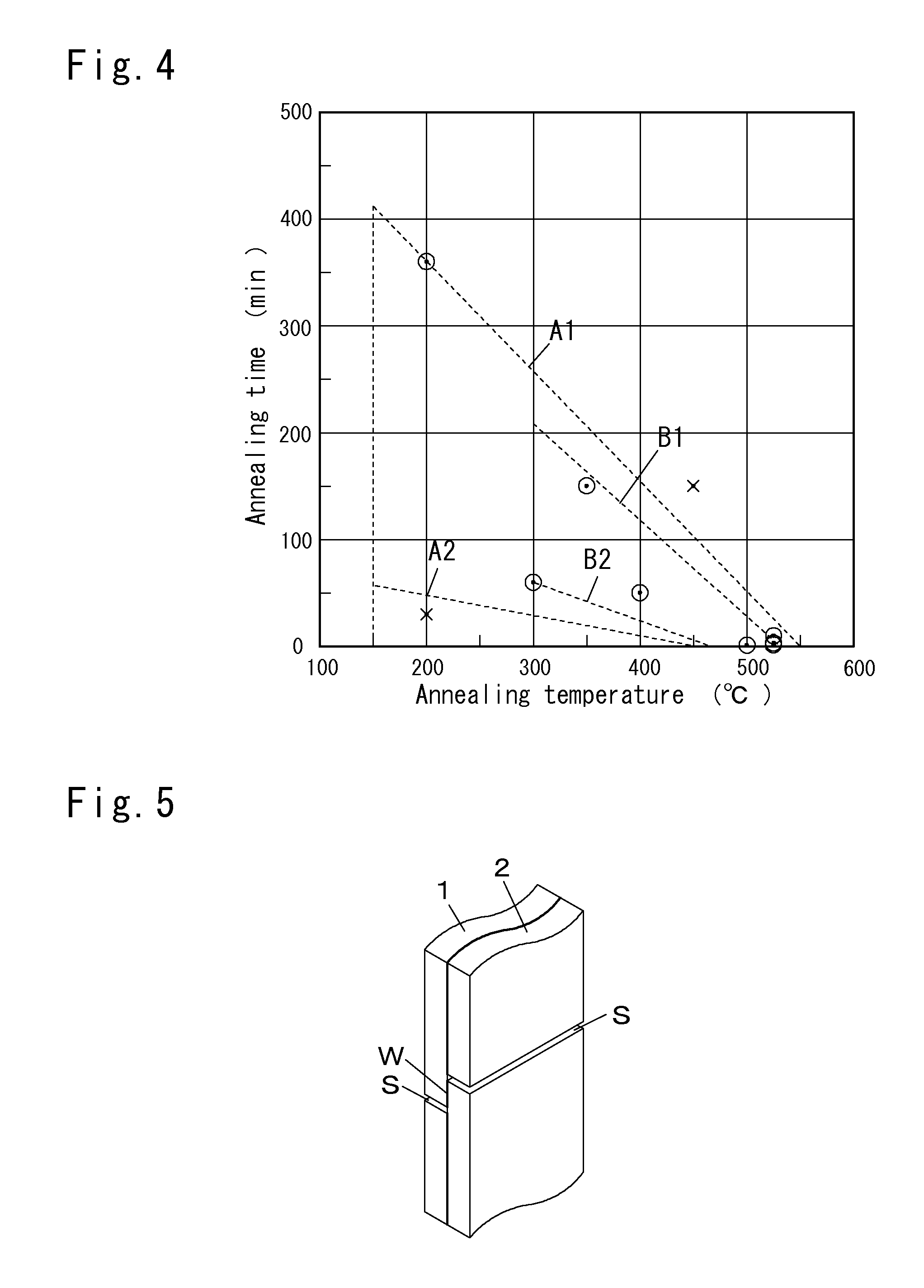

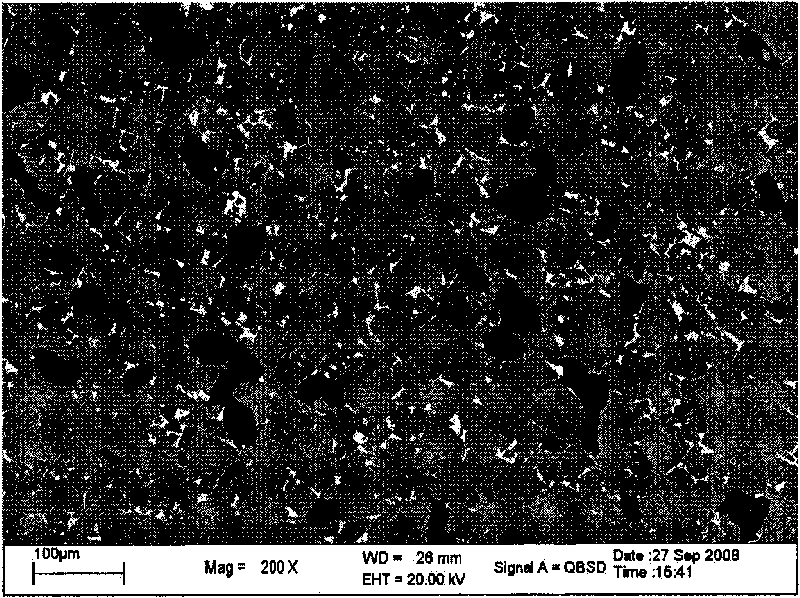

Aluminum copper clad material

InactiveUS20130071686A1Shorten the annealing timeImprove productivityFurnace typesHeat treatment process controlCopperBond strength

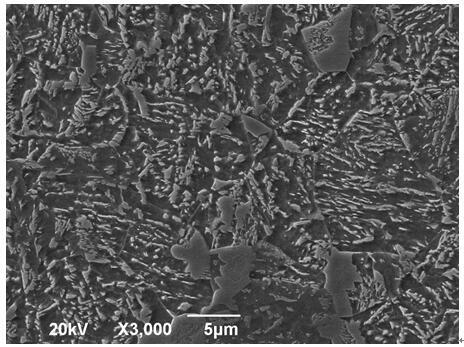

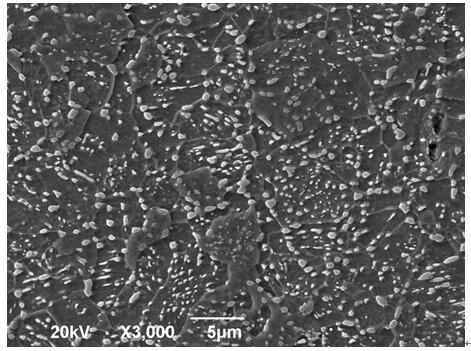

An aluminum copper clad material has excellent bonding strength and includes an aluminum layer and a copper layer that are bonded without a nickel layer interposed therebetween.The aluminum layer and the copper layer that are diffusion-bonded via an Al—Cu intermetallic compound layer. The copper layer satisfies Dcs≦0.5×Dcc, where Dcc represents the average crystal grain size of crystal grains in a central portion in the thickness direction of the copper layer, and Dcs represents the average crystal grain size of an interface adjacent portion C2 in the copper layer that is about 0.5 μm apart from the interface between the copper layer and the intermetallic compound layer. The intermetallic compound layer has an average thickness of about 0.5 μm to about 10 μm.

Owner:NEOMAX MATERIALS

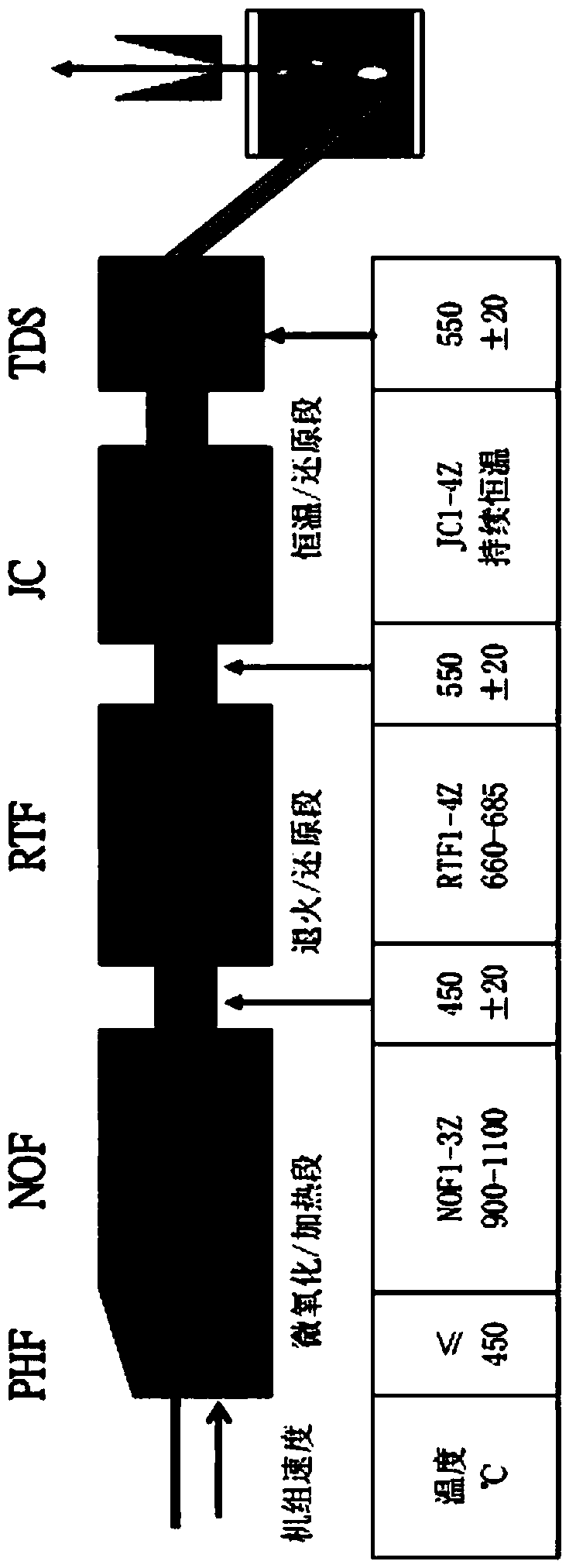

Production method for continuous annealing process high strength and plasticity product automobile steel plate

ActiveCN102021472AMeet continuous annealing production requirementsIncreased strength and plasticityFurnace typesHeat treatment furnacesSheet steelContinuous annealing

The invention discloses a production method for a continuous annealing process high strength and plasticity product automobile steel plate, which belongs to the technical field of automobile steel. By increasing the deformation energy storage of a cold-rolled steel plate and acquiring nonequilibrium structure, the time for reverting austenite is reduced greatly, a condition for obtaining better strength and plasticity product in an annealing and heat preservation time period of 1 to 10 minutes is created, and the process conditions of the conventional automobile steel cold-rolled plate continuous annealing and continuous galvanizing production equipment are met. In addition, through structural heredity, the strength and plasticity product of a cold-rolled reversed austenite annealing steel plate is improved by over 10 percent compared with that of reversed austenite annealing hot-rolled steel plate.

Owner:CENT IRON & STEEL RES INST

Annealing method applied to sapphire processing

ActiveCN103643300AStress reliefConducive to post-process processingPolycrystalline material growthAfter-treatment detailsMetallurgySapphire wafer

During sapphire processing, grinding causes relatively large stress, and consequently the angularity of a product is increased and the polishing difficulty is substantially increased. The invention aims at the above disadvantages in the prior art and provides a convenient practical annealing method applied to sapphire processing, and the method is mainly used for sapphire wafers subjected to cutting and grinding. By performing the annealing treatment on the sapphire wafers, the processing stress during cutting and grinding can be effectively removed; and the processing stress of the wafers employing the method for annealing is basically eliminated, the annealing of the wafers is uniform, the angularity of the wafers subjected to annealing is small, and the later-period polishing processing is facilitated.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

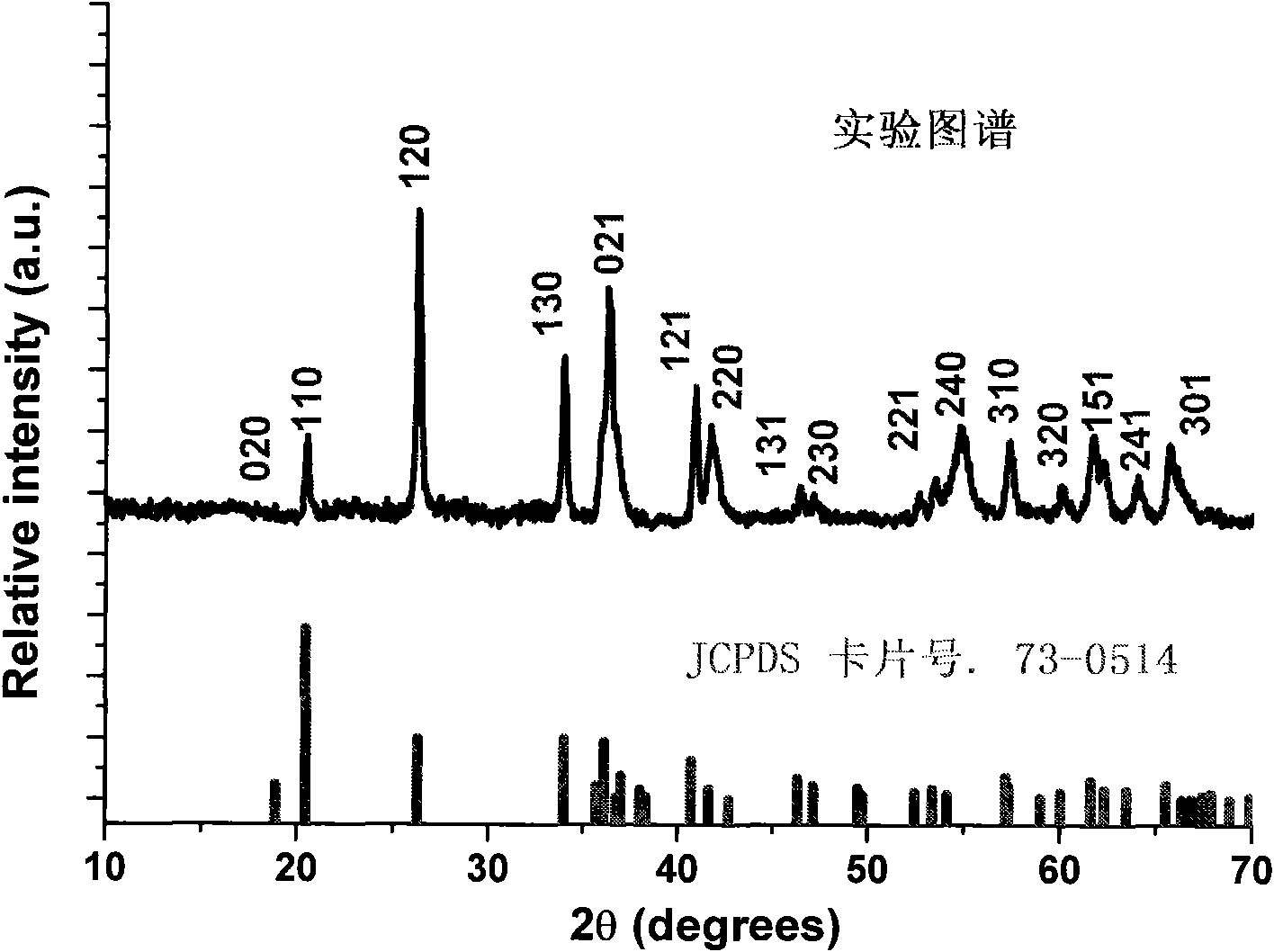

Method for quickly preparing monoclinic phase VO2

The invention discloses a method for quickly preparing monoclinic phase VO2. In the method, metastable phase reactant containing vanadium or VOOH reactant reacts for 1 minute to 12 hours at the temperature of 200-500 DEG C in the atmosphere of inert gases or inert gases doped with oxygen, and the monoclinic phase VO2 is obtained after cooling. The method can quickly convert the metastable phase reactant containing vanadium or VOOH into the monoclinic phase VO2 under the protection of normal-pressure inert atmosphere. The method has simple technology, low cost, high yield and favorable purity and can quickly prepare the intelligent energy-saving monoclinic phase VO2 powder on a large scale.

Owner:UNIV OF SCI & TECH OF CHINA

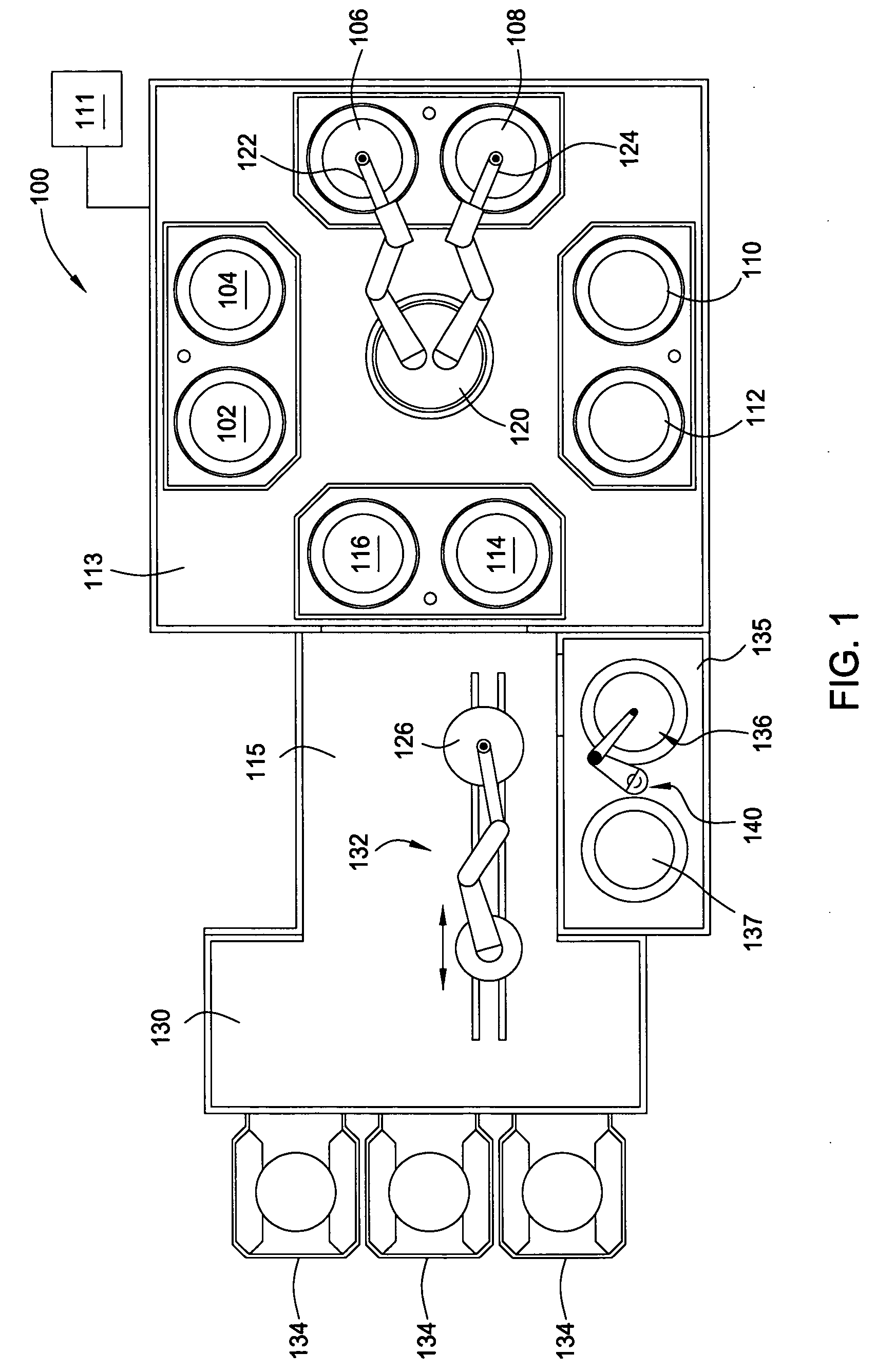

Method and apparatus for infilm defect reduction for electrochemical copper deposition

InactiveUS20050173253A1Minimize crackingShorten annealing timeCellsLiquid/solution decomposition chemical coatingElectrochemistryElectroplating

Embodiments of the invention provide a method and apparatus for processing a substrate. The apparatus includes a substrate rinse cell configured to dispense a heated processing fluid onto the substrate prior to an annealing process. The method includes plating a conductive layer onto a substrate, heating the substrate in a cleaning cell via application of a heated cleaning fluid to the substrate, drying the substrate in the cleaning cell, and annealing the substrate at an annealing station at a temperature of between about 150° C. and about 450° C.

Owner:APPLIED MATERIALS INC

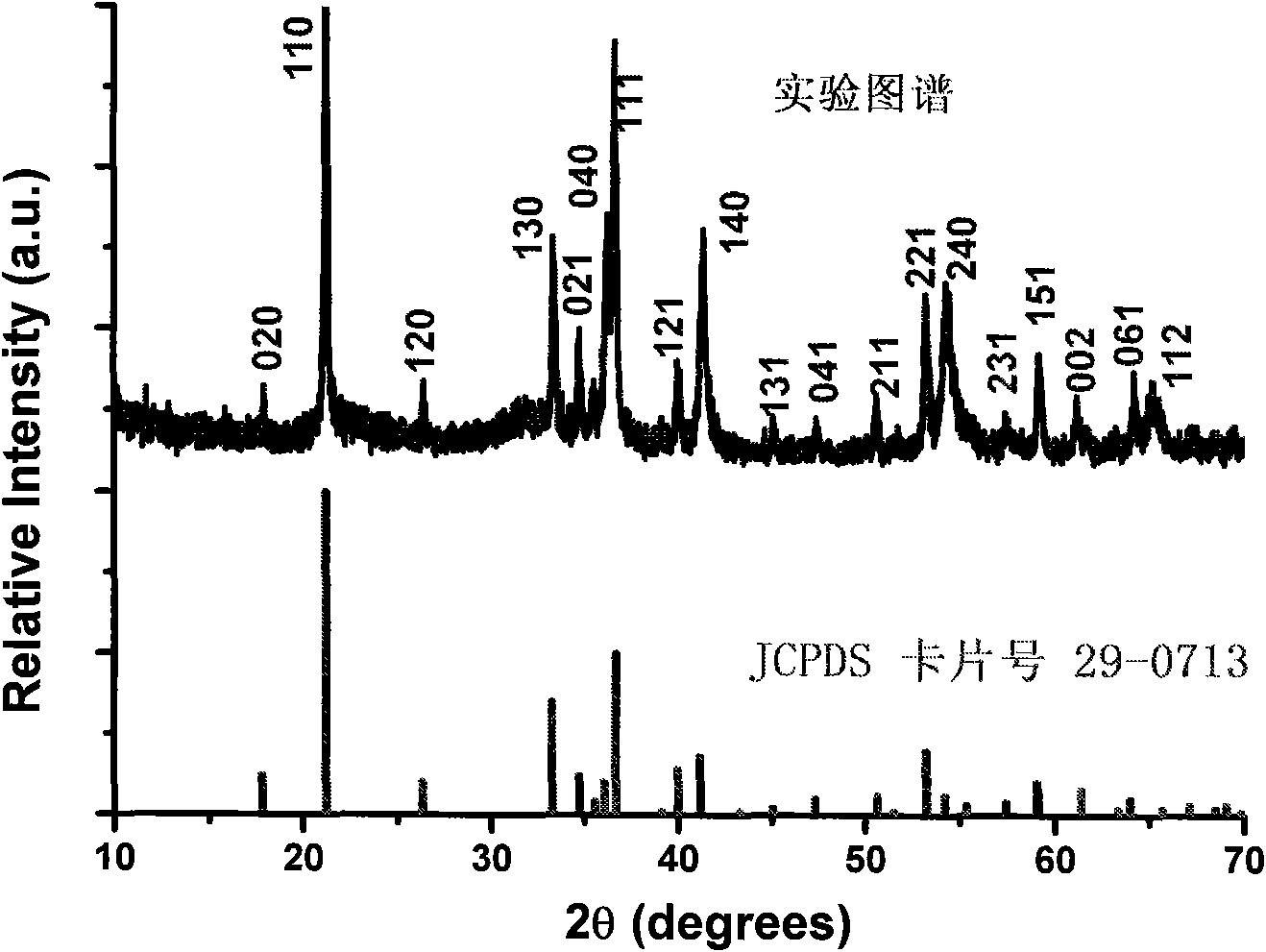

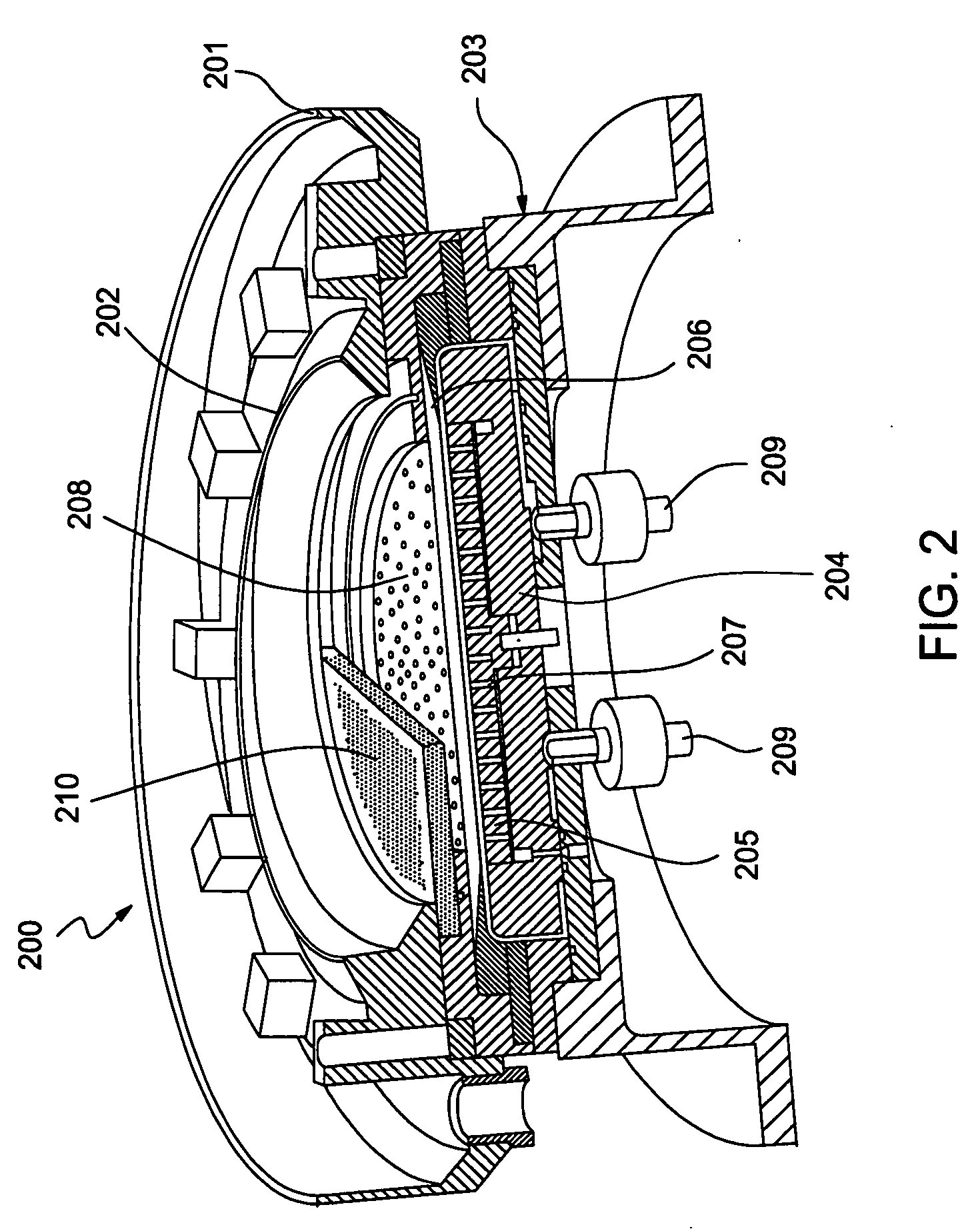

Preparation method of carbonic rare earth-ferrum, cobalt and silicon compound with NaZn1 structure

InactiveCN101748326AShorten the annealing timeReliable performanceEnergy efficient heating/coolingMagnetic materialsPhase transitionCurie temperature

The invention provides a preparation method of carbonic rare earth-ferrum, cobalt and silicon compound with NaZn1 structure, belonging to the technical field of magnetic refrigeration material; in the invention, a vacuum induction furnace is adopted for smelting, vacuumizing is carried out to above 2*10-1Pa, the pressure of common argon is from -0.05MPa to -0.02MPa, the smelting temperature is more than from 50 DEG C to 200 DEG C than the melting point, the smelting time is from 3-20min; the material is poured into a casting mould with red copper material to obtain mother alloy after being smelted, annealing treatment is carried out to the smelted mother alloy, so as to prepare the carbonic rare earth-ferrum, cobalt and silicon compound with 0.1-0.4 of C atom content alpha. The method can prepare the carbonic rare earth-ferrum, cobalt and silicon compound with more than 3mm of bulk mass, the annealing time is greatly shortened, and the obtained carbonic rare earth-ferrum, cobalt and silicon compound belongs to second-order phase transition without heat stagnation and magnetism stagnation, the performance is stable and reliable, Curie temperature can be regulated to more than room temperature, and the carbonic rare earth-ferrum, cobalt and silicon compound is applied to the magnetic cooling air-conditioning technology and wide magnetic refrigeration technology.

Owner:UNIV OF SCI & TECH BEIJING

METHOD OF PERSISTENT CURRENT MODE SPLICING OF 2G ReBCO HIGH TEMPERATURE SUPERCONDUCTORS USING SOLID STATE PRESSURIZED ATOMS DIFFUSION BY DIRECT FACE-TO-FACE CONTACT OF HIGH TEMPERATURE SUPERCONDUCTING LAYERS AND RECOVERING SUPERCONDUCTIVITY BY OXYGENATION ANNEALING

InactiveUS20150357089A1Shorten the annealing timeImprove superconductivityContact member manufacturingSuperconductors/hyperconductorsElectrical conductorReaction temperature

Disclosed is a method of splicing ReBCO high temperature superconductors (HTSs), which ensures excellent superconductivity after splicing. The method of splicing 2G ReBCO HTSs allows a superconductors-spliced assembly to exhibit excellent superconductivity by direct contact of high temperature superconducting layers of two strands of 2G ReBCO HTSs and solid state atoms diffusion pressurized splicing there between at a ReBCO below peritectic reaction temperature in a vacuum, and enables loss of superconductivity caused by loss of oxygen due to transport and out-diffusion of oxygen to atoms during splicing to be recovered through oxygenation annealing.

Owner:K JOINS

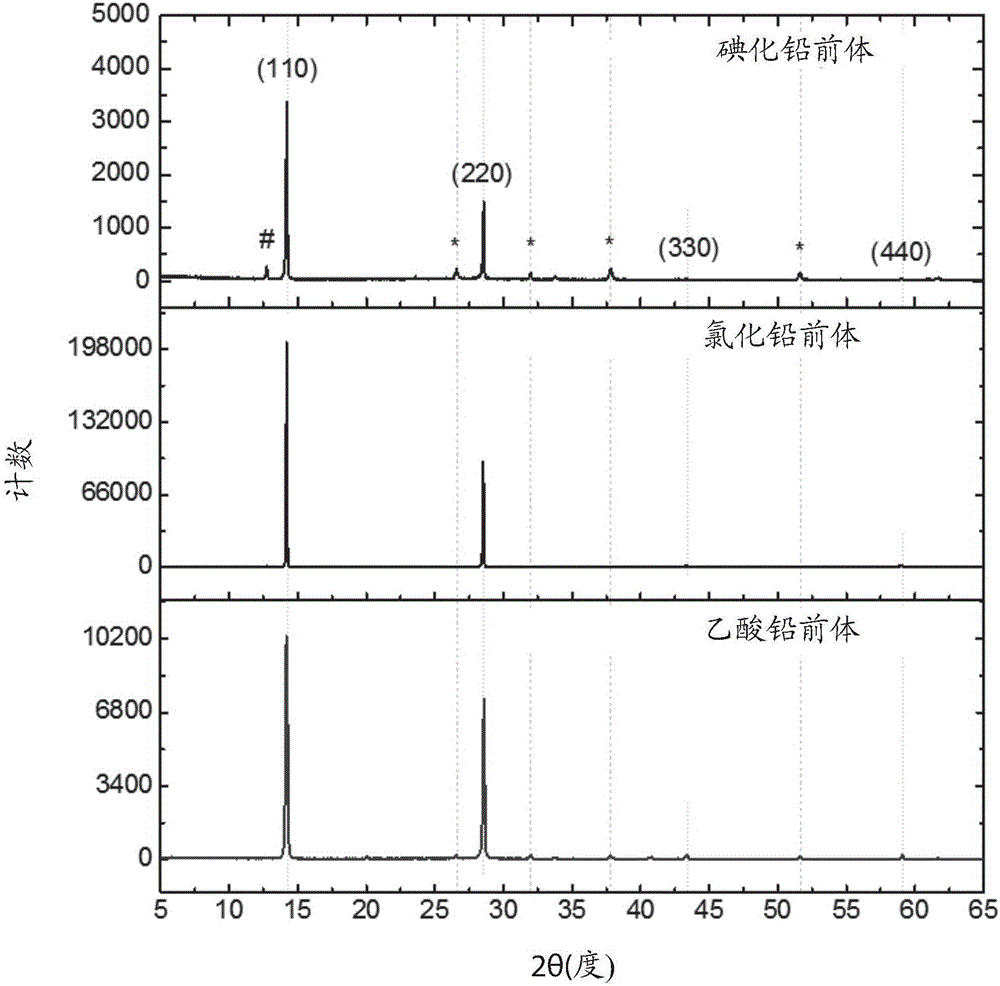

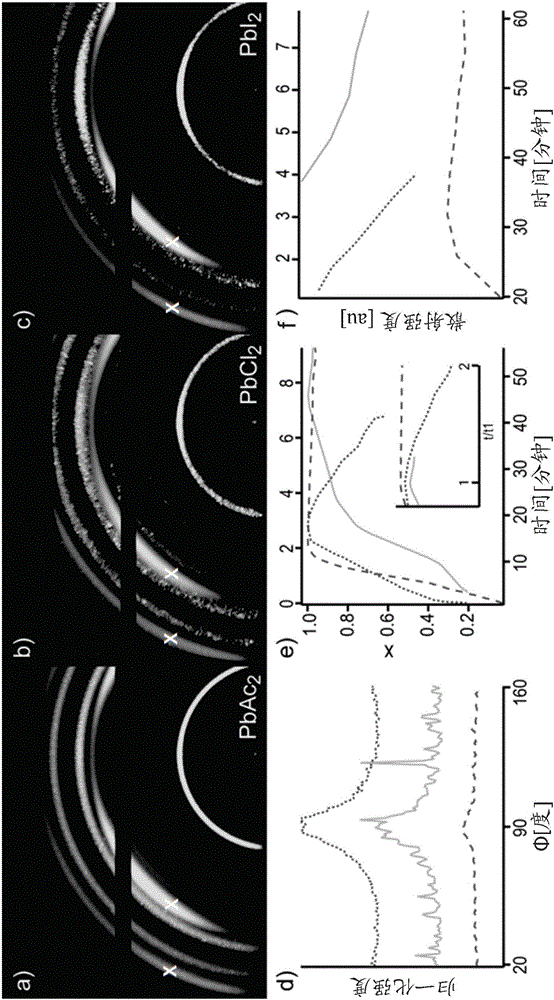

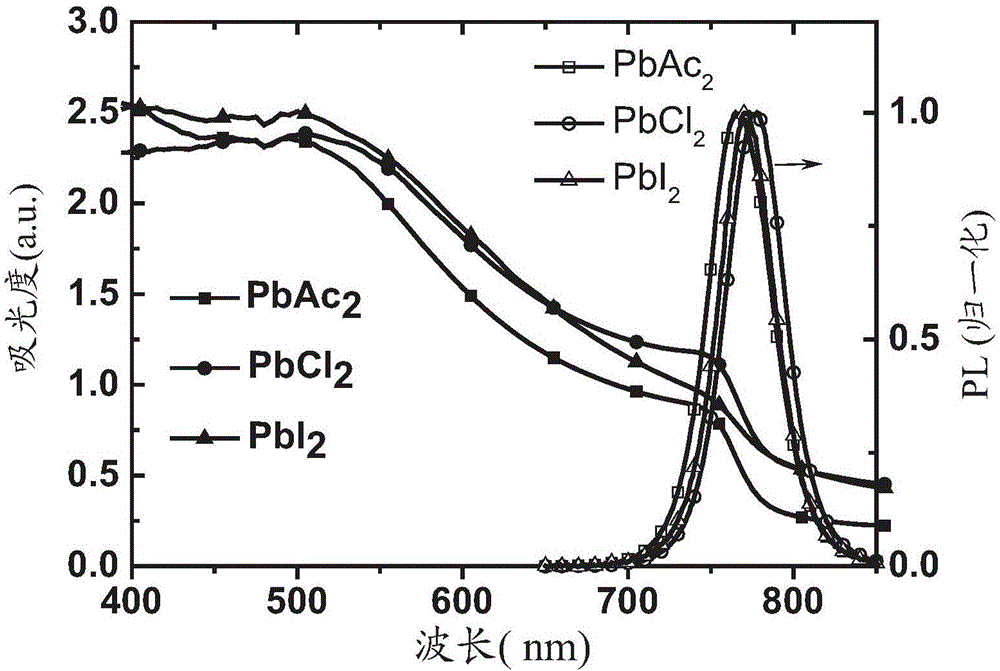

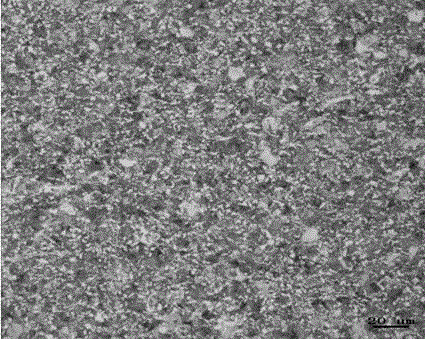

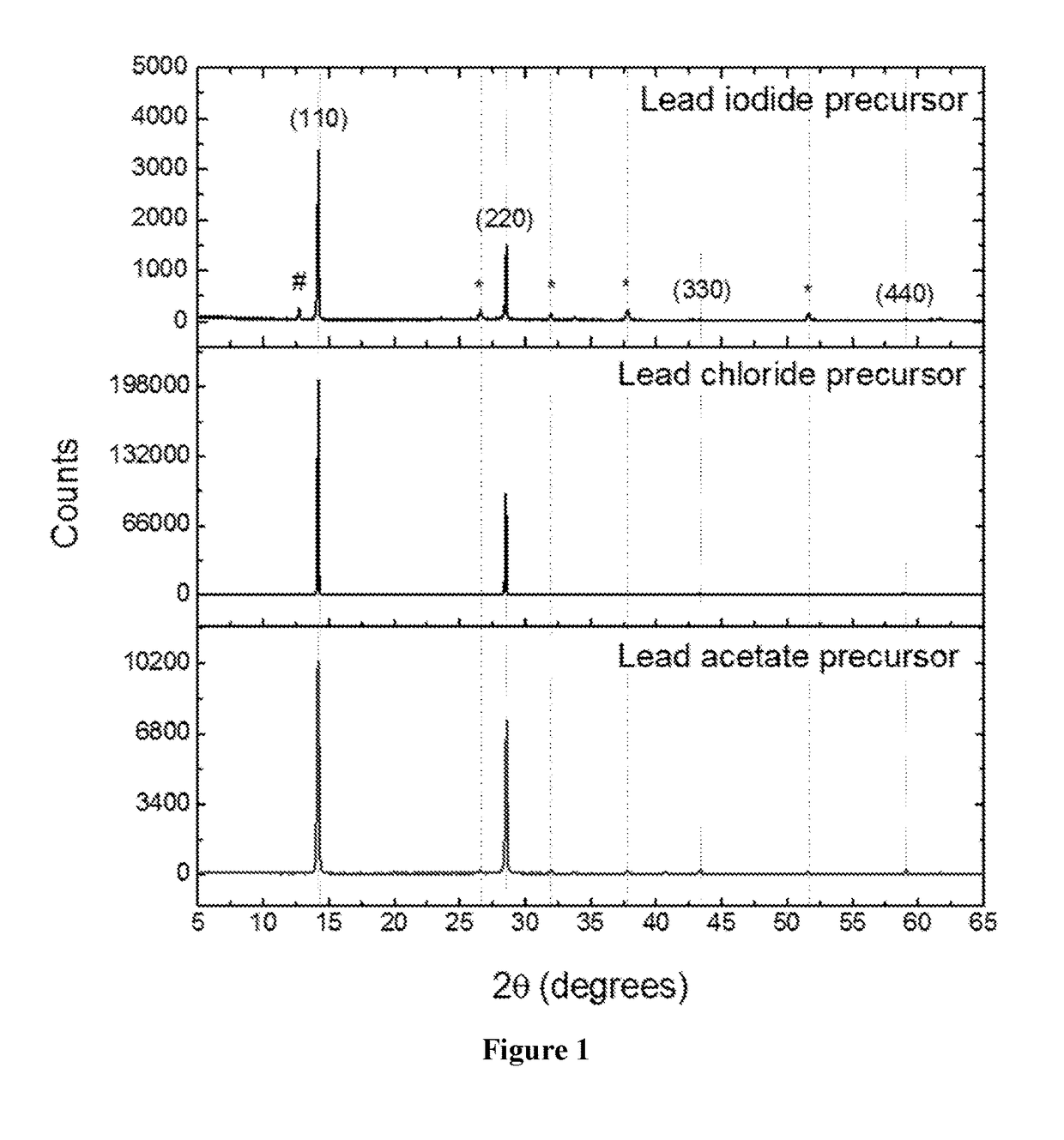

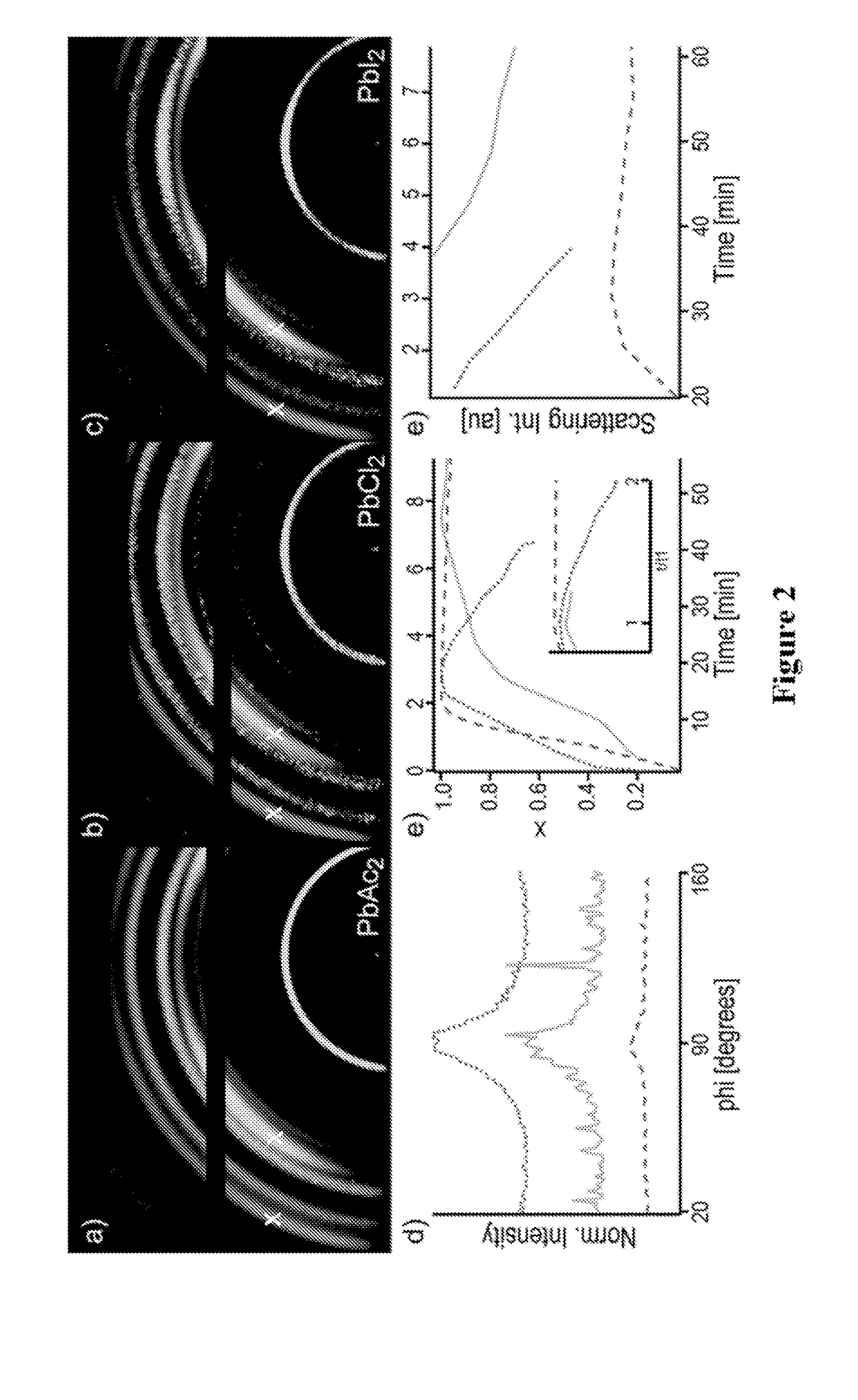

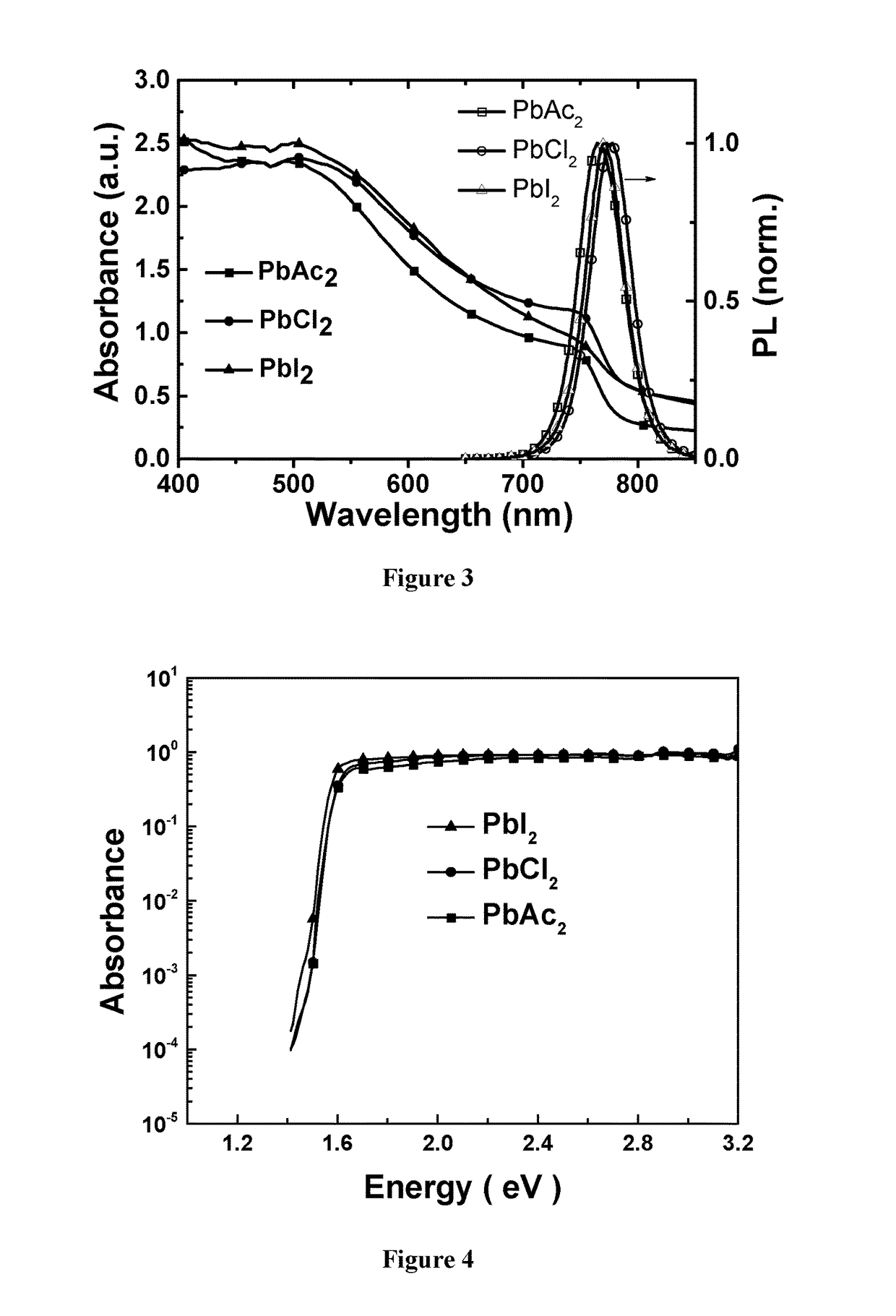

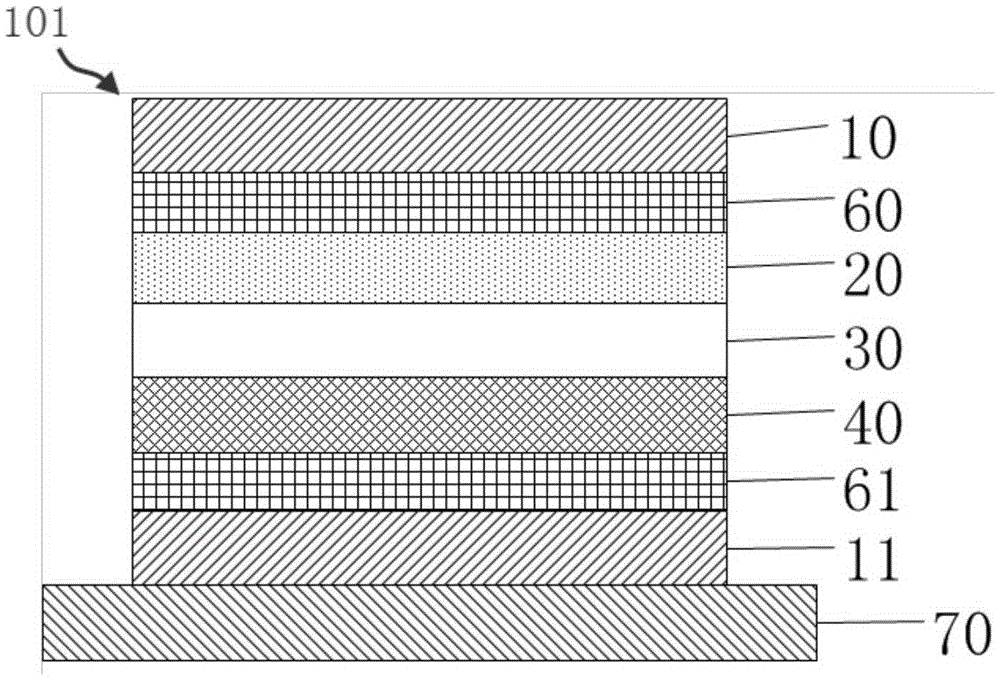

Process for producing layer of organic perovskite material with improved crystallinity

ActiveCN106796988AImprove smoothnessShorten the annealing timeTin organic compoundsElectrolytic capacitorsCrystalline materialsCombinatorial chemistry

The present invention relates to a process for producing a layer of a crystalline material, which process comprises disposing on a substrate: a first precursor compound comprising a first cation and a sacrificial anion, which first cation is a metal or metalloid cation and which sacrificial anion comprises two or more atoms; and a second precursor compound comprising a second anion and a second cation, which second cation can together with the sacrificial anion form a first volatile compound. The invention also relates to a layer of a crystalline material obtainable by a process according to the invention. The invention also provides a process for producing a semiconductor device comprising a process for producing a layer of a crystalline material according to the invention. The invention also provides a composition comprising: (a) a solvent; (b) NH4X; (c) AX; and (d) BY2 or MY4; wherein X, A, M and Y are as defined herein.

Owner:OXFORD UNIV INNOVATION LTD

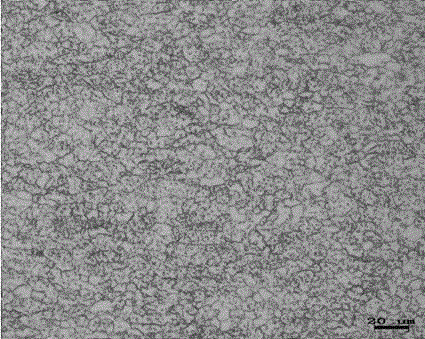

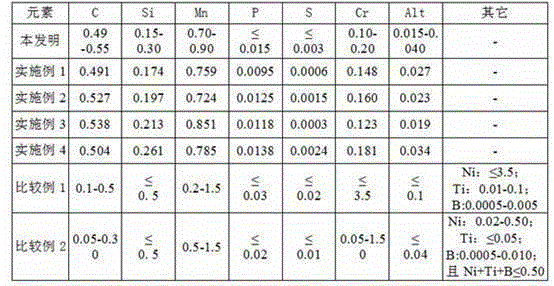

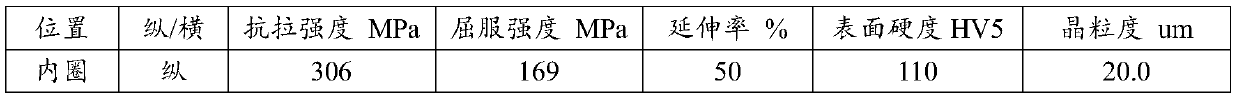

Cold-rolling strip steel used for automobile flywheel processed by precision stamping and manufacture method thereof

ActiveCN106256918ASmall range of performance fluctuationsHigh strengthCompound (substance)Strip steel

The invention relates to a cold-rolling strip steel used for an automobile flywheel processed by precision stamping and a manufacture method thereof, which solves the technical problems that the manufacture cost of the cold-rolling strip steel used for precision stamping is high, the high strength and toughness of the cold-rolling strip steel are not matched, and the precision stamping moulding cannot be satisfied. The cold-rolling strip steel comprises the following chemical components by mass percentage: 0.49-0.54% of C, 0.15-0.30% of Si, 0.70-0.90% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, 0.10-0.20% of Cr, 0.015-0.040% of Alt, and the balance of iron and unavoidable impurity. The structure is composed of block ferrite, granular pearlite and a few of sheet-shaped pearlite, the yield strength of the cold-rolling strip steel is 410-460 MPa, and the percentage elongation after fracture A50 is 25-33%. The cold-rolling strip steel is used for fine blanking of the automobile flywheels.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

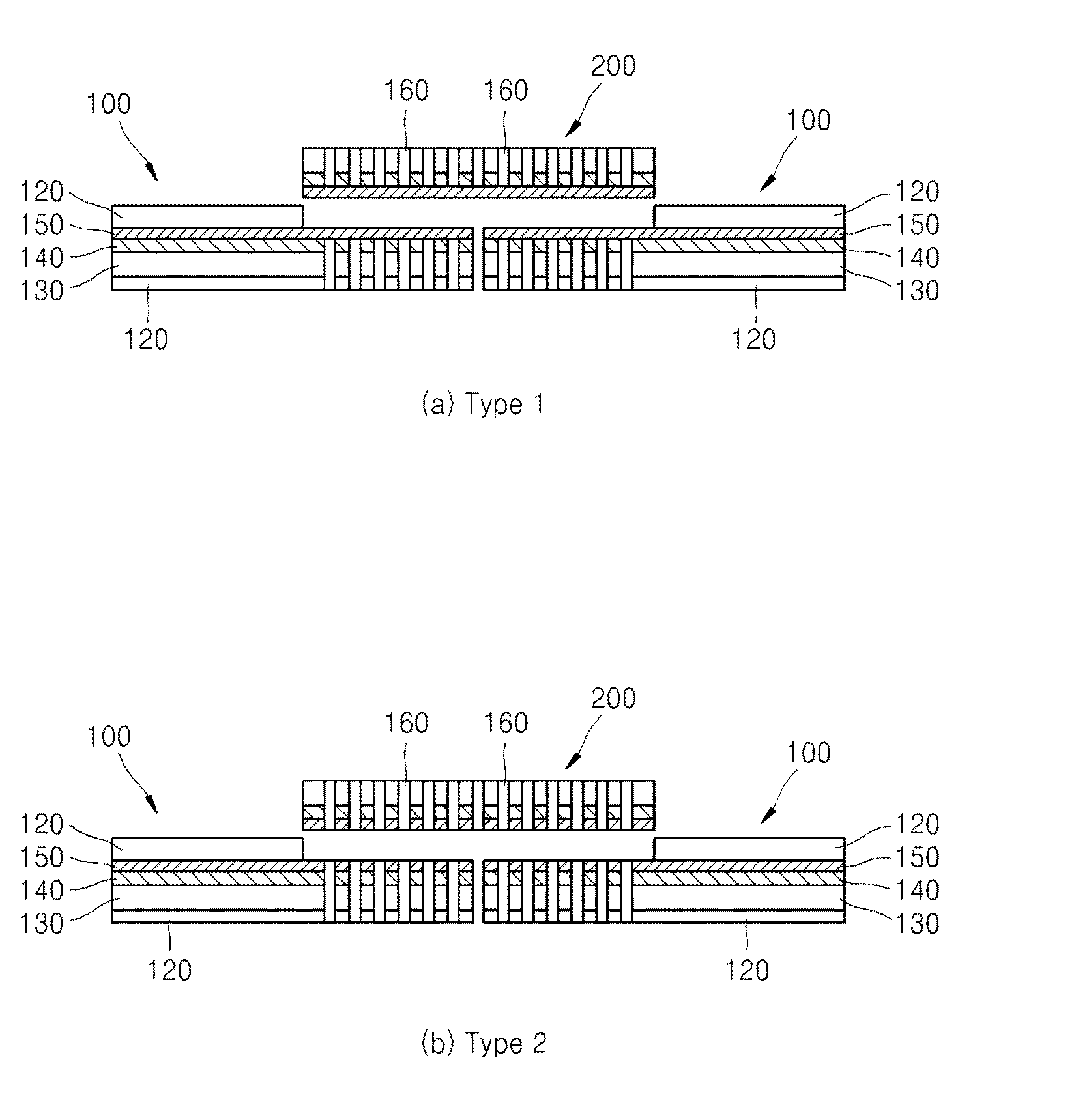

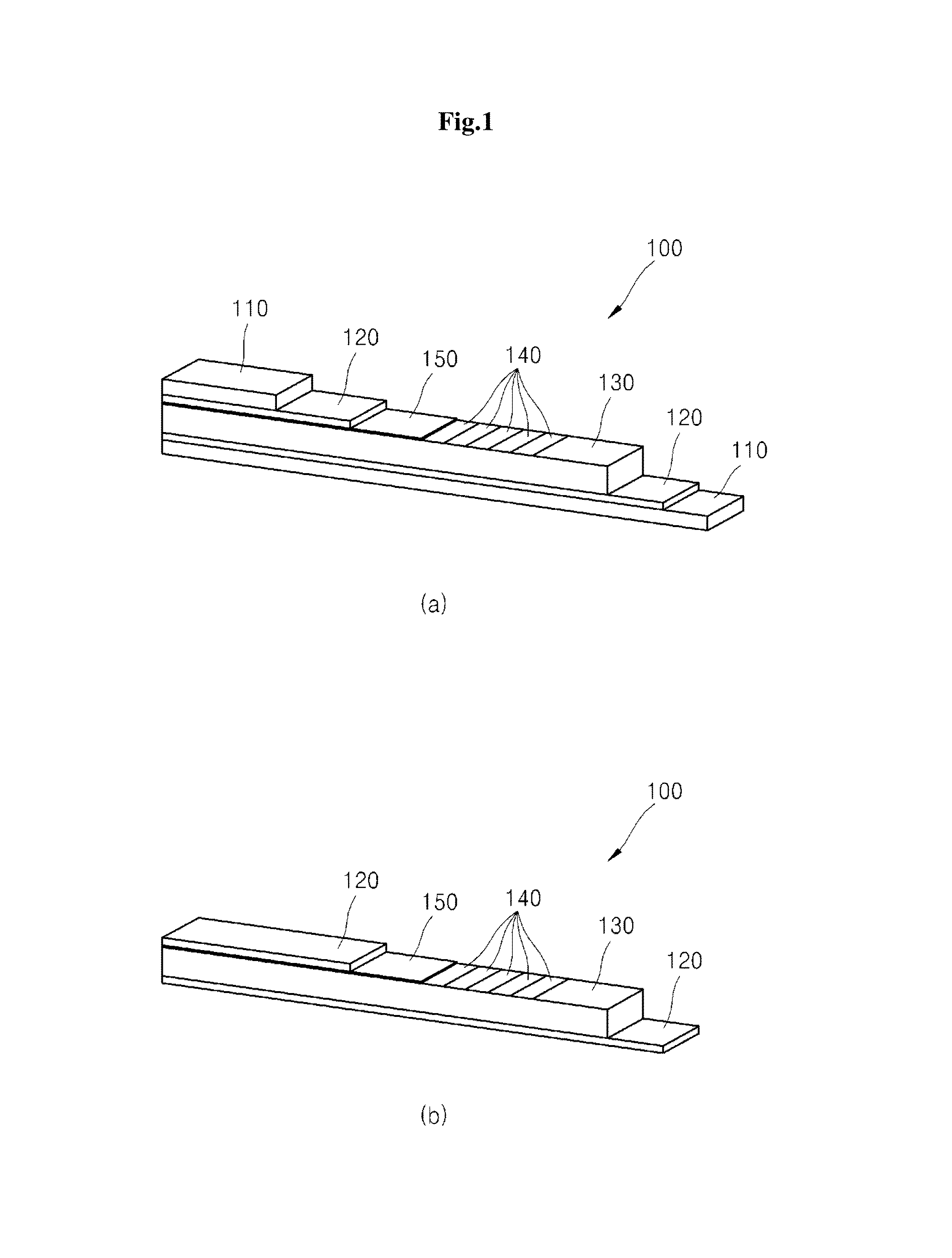

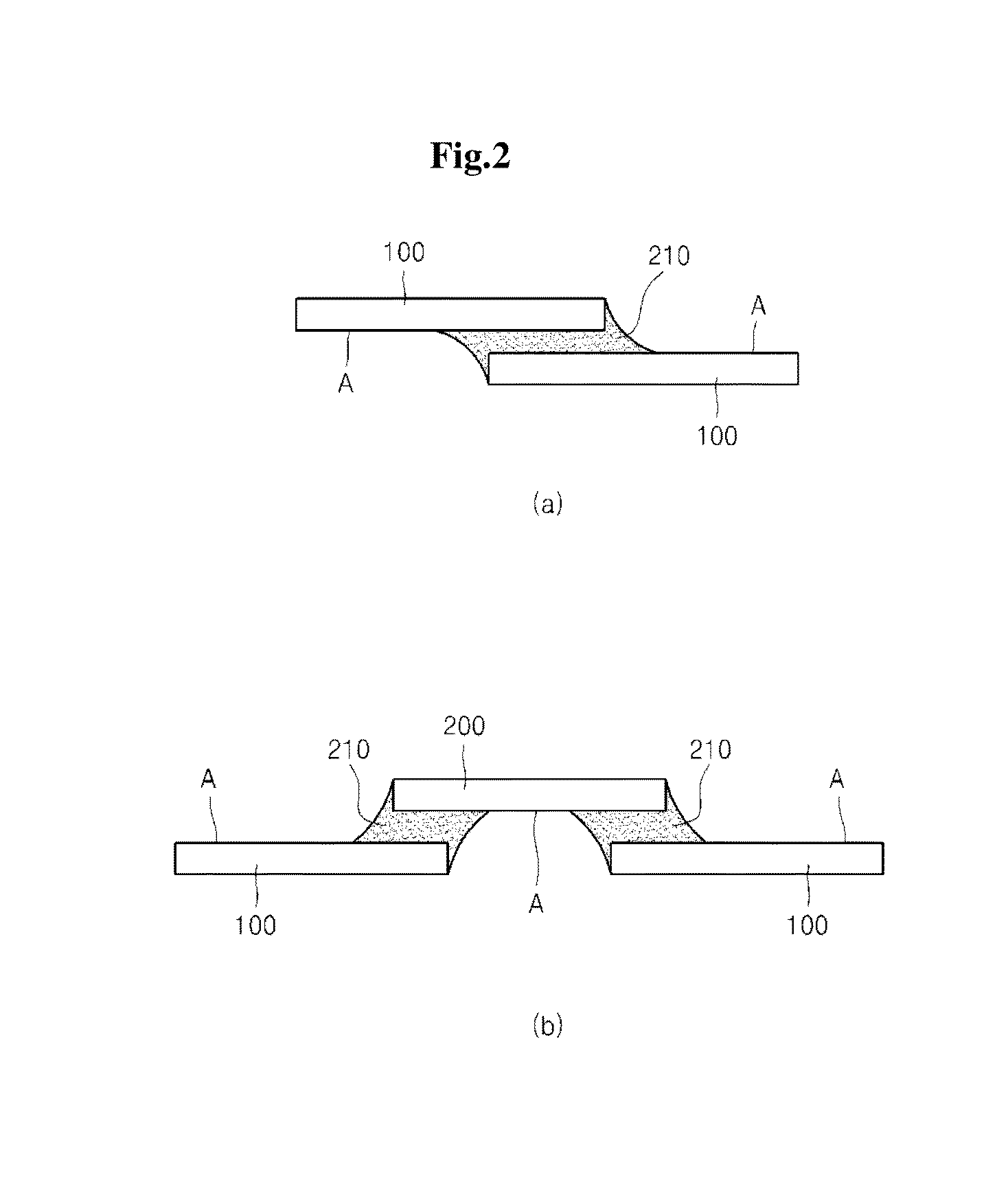

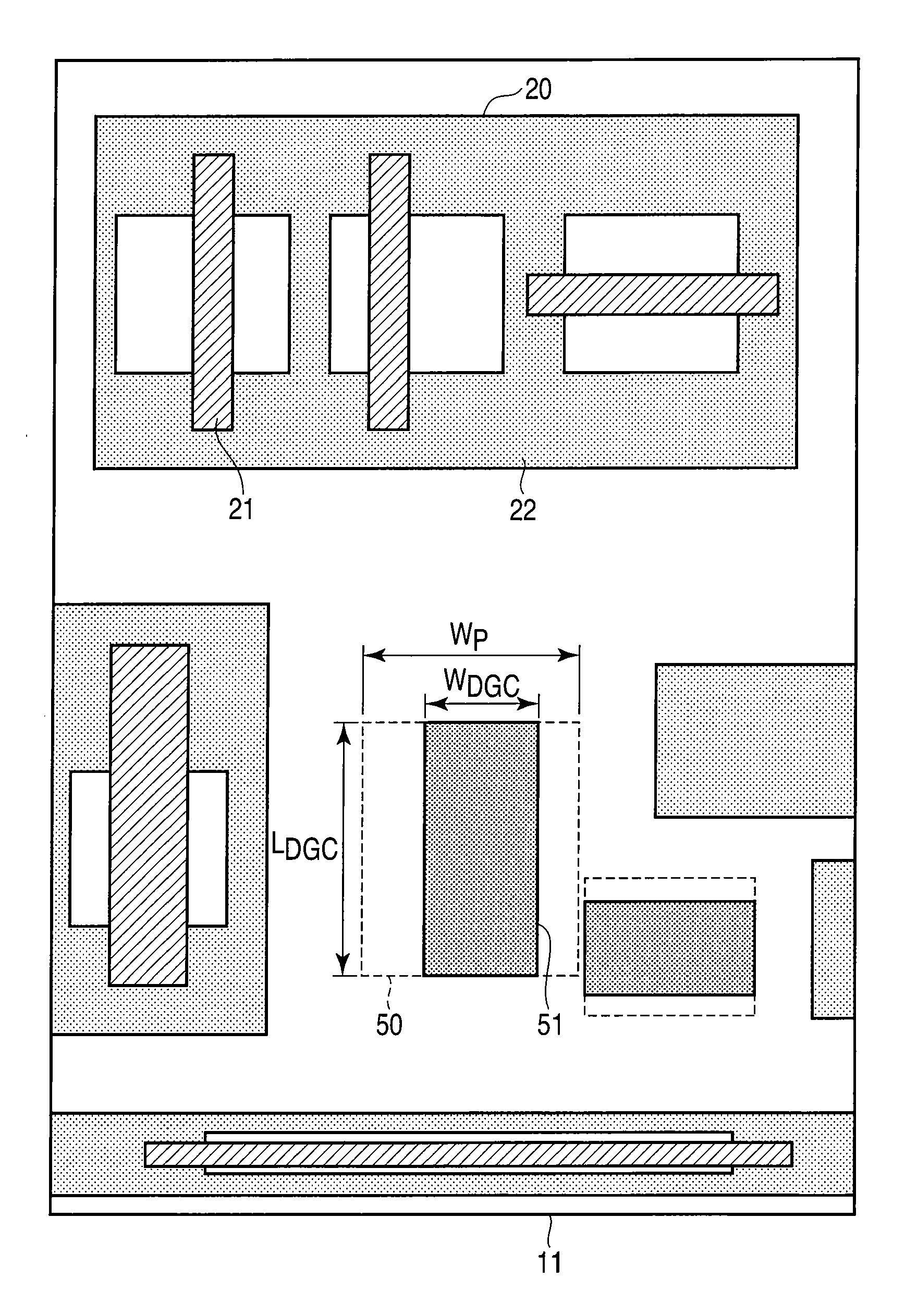

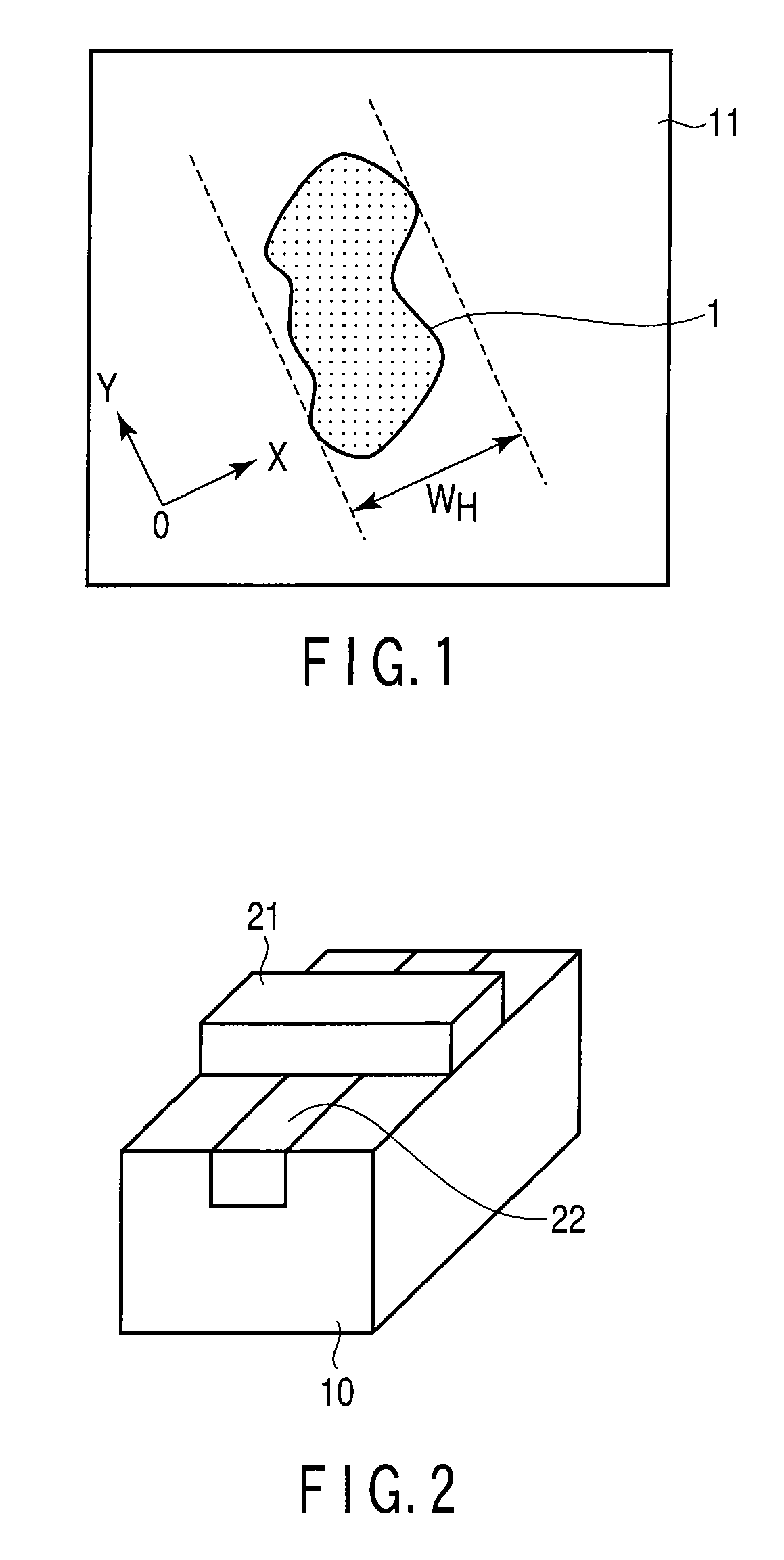

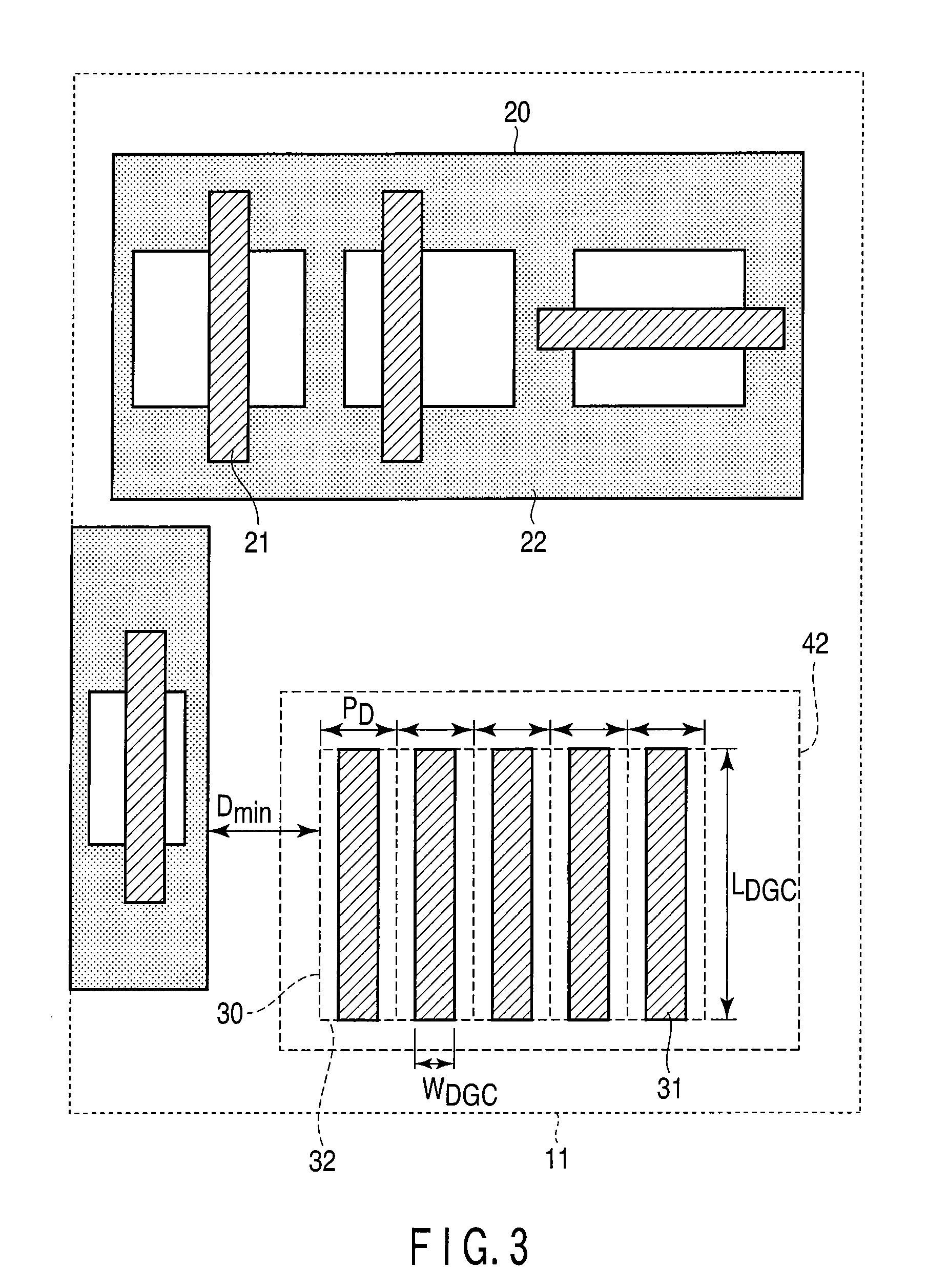

Semiconductor device and manufacturing method thereof

InactiveUS20090146310A1Shorten the annealing timeTransistorSemiconductor/solid-state device detailsDevice materialLength wave

A semiconductor device subjected to an optical annealing process by radiation light whose principal wavelength is 1.5 μm or less includes a circuit pattern region formed on a semiconductor substrate, and a dummy pattern region formed separately from the circuit pattern region on the semiconductor substrate. The circuit pattern region has an integrated circuit pattern containing a gate pattern related to a circuit operation. The dummy pattern region has dummy gate patterns that have the same structure as that of a gate pattern used in the integrated circuit pattern and the dummy gate patterns are repeatedly arranged with a pitch 0.4 times or less the principal wavelength.

Owner:TOSHIBA MEMORY CORP

Grain-oriented pure iron manufactured through adopting single cold rolling method and method

The invention relates to grain-oriented pure iron manufactured through adopting a single cold rolling method and a method. The method comprises the steps of converter smelting, liquid steel refining through a vacuum cycle degassing process, continuous casting, slab heating, hot rolling, normalizing, cold rolling and annealing, wherein after the continuous casting step, an obtained continuous cast slab comprises the following components by mass percent: 0.01 to 0.08% of C, 0.01 to 1.0% of Si, 0.05 to 0.5% of Mn, 0.01 to 0.1% of P, 0.003 to 0.01% of S, 0.005 to 0.05% of Als, 0.005 to 0.02% of N and 0.05 to 0.8% of Cu, and the balance being Fe; in the hot rolling process, the content of gamma phases obtained during finish rolling is controlled to be 10 to 30% by mass percent; in the normalizing step, the temperature of 650 to 800 DEG C is maintained for 30 to 600 s; and the annealing step comprises decarburizing annealing and high temperature annealing. According to the method, the grain-oriented pure iron which has high saturation magnetic induction intension and sharp {110}<001> preferred orientation can be obtained through utilizing conventional production devices of conventional iron and steel enterprises, through utilizing means such as component design, reasonable cooperation of inhibitor composition and appropriate setting of rolling and thermal treatment technologies, and through utilizing a traditional thick slab production technology.

Owner:CENT IRON & STEEL RES INST +1

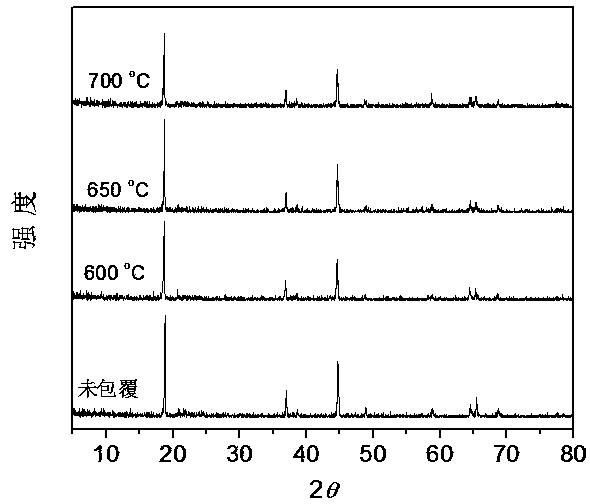

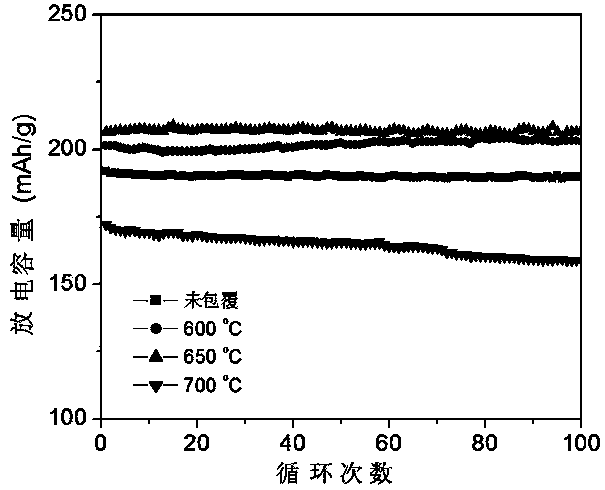

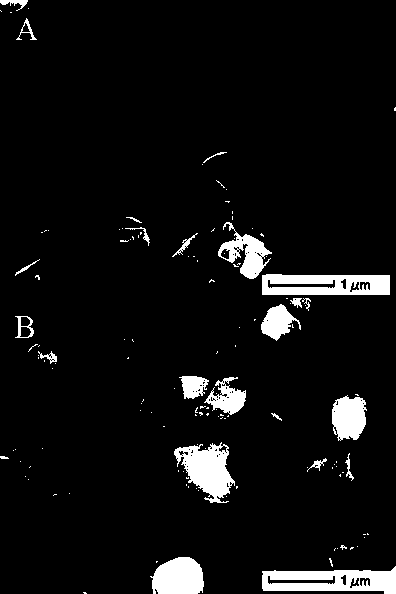

Clad modified layered cathode material of lithium-ion battery and preparation method of layered cathode material

InactiveCN104022276AIncreased diffusion rateShorten the annealing timeCell electrodesSecondary cellsPhysical chemistryLithium-ion battery

The invention discloses a clad modified layered cathode material of a lithium-ion battery and a preparation method of the layered cathode material. The material is obtained by evenly covering the layered cathode material of the lithium-ion battery by a Li2TiO3 thin film. The preparation method comprises the following steps: (1) dissolving a titanium source in an ethanol solution, and dropwise adding glycol to form a solution A; dissolving a lithium salt and a complexing agent in deionized water to form a solution B; (2) mixing the two solutions and regulating the pH value of the mixed solution to the range of 5-7 by use of a weakly alkaline liquor or a weakly acidic liquor; (3) adding the layered cathode material of the lithium-ion battery to a suspension, and heating and stirring to obtain a sol; drying the sol to obtain a precursor; grinding and annealing the precursor to obtain the target product. The method is used for modifying the layered cathode material of the lithium-ion battery by covering the layered cathode material with the Li2TiO3 thin film; the surface thin film covering the cathode material by use of the method is clad evenly, and the method is mature and reliable.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

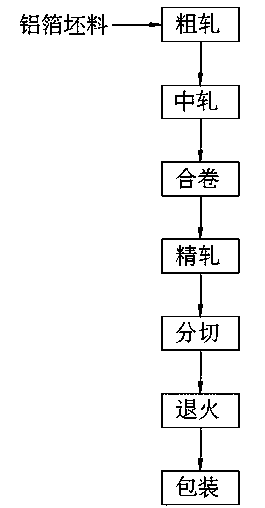

Aluminium foil rolling technology

InactiveCN103464479AQuality assuranceShorten the annealing timeWork treatment devicesMetal rolling arrangementsAluminium foilDistillation

The invention relates to an aluminium foil rolling technology including rough rolling, intermediate rolling, coiling, finish rolling, slitting, annealing and packaging. Conventional rolling oil is sprayed during rough rolling, intermediate rolling and finish rolling, and low-flash double-mixing oil is sprayed during coiling. In the coiling process of aluminium foil production, the low-flash double-mixing oil is adopted, so that interlayer friction coefficient generated by metal deformation during rolling can be reduced effectively, and pinholes of aluminium foil are decreased; more importantly, during the annealing technology, due to the characteristics of small distillation range and low predistillation and final distillation temperatures of the low-flash double-mixing oil, annealing and oil removal are facilitated, further annealing time is shortened, equipment utilization rate is increased greatly, and production cost is reduced.

Owner:JIANGSU ZHONGJI LAMINATION MATERIALS

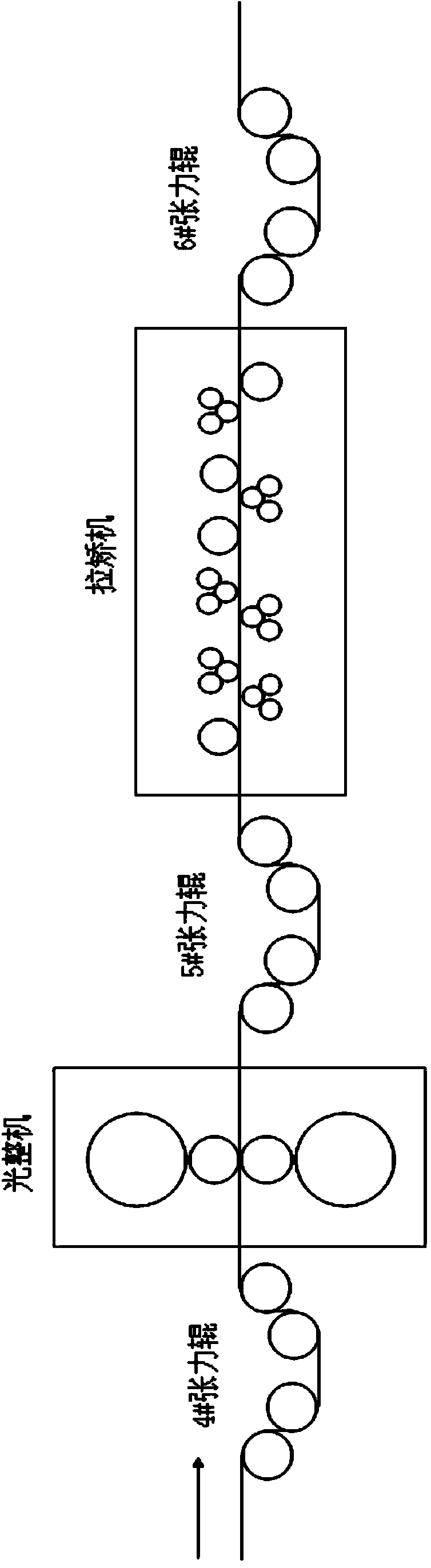

Cold-rolled high-strength steel used for automobile structural member and manufacture method of cold-rolled high-strength steel

The invention discloses a cold-rolled steel plate used for manufacturing automobile structural components and a manufacture method of the steel plate. The steel plate comprises, by weight percentage,0.06-0.08% of C, 0.65-0.95% of Mn, no more than 0.05% of Si, no more than 0.015% of P, no more than 0.015% of S, 0.030-0.055% of Als, 0.025-0.040% of Nb, and 0.010-0.030% of Ti, with the balance beingFe and inevitable impurities. A continuous casting slab containing the chemical components above undergoes hot rolling, acid-pickling cold continuous rolling, continuous annealing, flattening, and tension leveling to obtain a high-strength steel plate having the yield strength of 330-400 MPa, the tensile strength of 410-500 MPa, and the elongation at break no less than 25.0%. The method is low inproduction cost, and the obtained steel plate is stable in mechanical property, excellent in stamping performance, and superior in surface quality.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

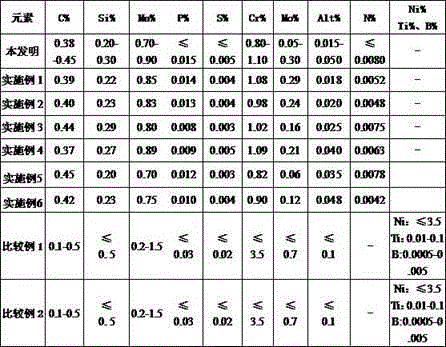

Cold-rolled steel sheet for automobile-seat-adjusting toothed plate produced through precision stamping and manufacturing method of cold-rolled steel sheet

The invention relates to a cold-rolled steel sheet for an automobile-seat-adjusting toothed plate produced through precision stamping and a manufacturing method of the cold-rolled steel sheet, and solves the technical problem that a cold-rolled steel sheet for an automobile-seat-adjusting toothed plate prepared through precision stamping in the prior art is low in size precision and relatively low in spheroidization rate, and is not suitable for high-speed precision stamping. The cold-rolled steel sheet comprises chemical components, by weight: 0.38-0.45% of C, 0.20-0.30% of Si, 0.70-0.90% of Mn, no more than 0.015% of P, no more than 0.005% of S, 0.80-1.10% of Cr, 0.05-0.30% of Mo, 0.015-0.050% of Alt, and no more than 0.0080% of N, with the balance being iron and inevitable impurities. The cold-rolled steel sheet is used for high-speed precision stamping to produce components, such as an automobile-seat-adjusting toothed plate.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Production process of hot-dip aluminum-zinc steel plate

ActiveCN103993150AShorten the annealing timeHigh strengthHot-dipping/immersion processesHigh intensityContinuous annealing

The invention discloses a production process of a hot-dip aluminum-zinc steel plate. The production process is characterized by comprising the steps of 1) using a low-carbon steel cold-hard roll as a cold-rolled steel plate; 2) performing continuous annealing treatment; 3) performing optical finishing treatment; 4) performing withdrawal and straightening treatment. The production process adopts the low-carbon steel cold-hard roll as a base plate, shortens the annealing time by reducing the annealing plate temperature of continuous annealing steel plates, and controls a withdrawal and straightening machine to obtain a high-strength aluminum-zinc plated steel plate with relatively good plate shapes by regulating the rolling force of an optical finisher; the high-strength aluminum-zinc plated steel plate can be applied to high-strength and high-tensile building materials.

Owner:华冠新型材料股份有限公司

Annealing method for aluminum used for cable and aluminum alloy belt and foil

ActiveCN102899593AImprove toughnessHigh elongationSingle bars/rods/wires/strips conductorsMetal/alloy conductorsFurnace temperatureElectric cables

The invention relates to an annealing method for aluminum used for a cable and an aluminum alloy belt and foil. The annealing method comprises the following four steps: step one, heating the furnace temperature of a box-type annealing furnace to 190-250 DEG C, with the temperature rise gradient of 2-3 DEG C per hour, and the heat preservation time of 60-250 minutes; step two, heating the furnace temperature of the box-type annealing furnace to 380-435 DEG C, with the temperature rise gradient of 2-3 DEG C per hour, and the heat preservation time of 10-20 hours; step three, reducing the furnace temperature of the box-type annealing furnace to 340-370 DEG C, with the temperature fall gradient of 5-6 DEG C per hour, and the heat preservation time of 4-15 hours; and step four, reducing the furnace temperature of the box-type annealing furnace to 190-220 DEG C, with the temperature fall gradient of 5-6 DEG C per hour, and the heat preservation time of 1-4 hours; and adopting air cooling outside the furnace as a cooling mode. The annealing method can effectively prevent oil stain on material surface and improve the elongation, and is short in production cycle and low in production cost.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

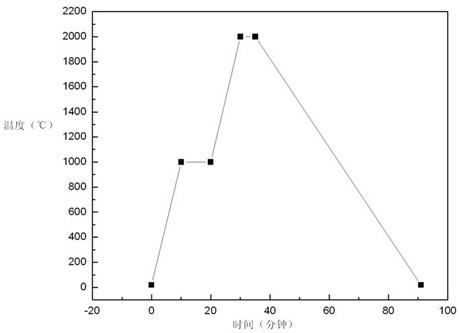

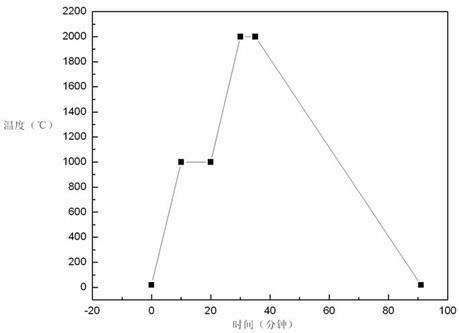

High-temperature annealing method for manufacturing silicon carbide device

ActiveCN102664151AImprove reliabilityImprove yieldSemiconductor/solid-state device manufacturingShielding gasProtection layer

The invention discloses a high-temperature annealing method for manufacturing a silicon carbide device. The high-temperature annealing method includes 1), cleaning an SiC chip injected with ions by acid solution; 2), coating a layer of organic compounds to be used as a protective layer on the SiC chip; 3), placing the SiC chip into a high-temperature annealing furnace and filling argon into the high-temperature annealing furnace to be used as protective gas; 4), heating the SiC chip to reach first temperature and carbonizing the protective layer; 5), heating the SiC chip to reach second temperature and carrying out high-temperature annealing; and 6), cooling. The high-temperature annealing method has the advantages that carbonized photoresist is used as the protective layer when in high-temperature annealing, extra equipment for preparing the protective layer is omitted, the protective layer can be prepared in the high-temperature furnace, a process is simple, and cost is low; the protective gas is the argon, and a tail gas treatment system for equipment is omitted; the process time can be greatly shortened owing to improved annealing conditions; and the surface of the SiC chip can be protected completely and cannot be affected in a high-temperature annealing procedure, and reliability and yield of the device are finally improved.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Thin film production

ActiveUS20170229249A1Good film formingFormation of improvedTin organic compoundsLight-sensitive devicesCrystalline materialsCombinatorial chemistry

The present invention relates to a process for producing a layer of a crystalline material, which process comprises disposing on a substrate: a first precursor compound comprising a first cation and a sacrificial anion, which first cation is a metal or metalloid cation and which sacrificial anion comprises two or more atoms; and a second precursor compound comprising a second anion and a second cation, which second cation can together with the sacrificial anion form a first volatile compound. The invention also relates to a layer of a crystalline material obtainable by a process according to the invention. The invention also provides a process for producing a semiconductor device comprising a process for producing a layer of a crystalline material according to the invention. The invention also provides a composition comprising: (a) a solvent; (b) NH4X; (c) AX; and (d) BY2 or MY4; wherein X, A, M and Y are as defined herein.

Owner:OXFORD UNIV INNOVATION LTD

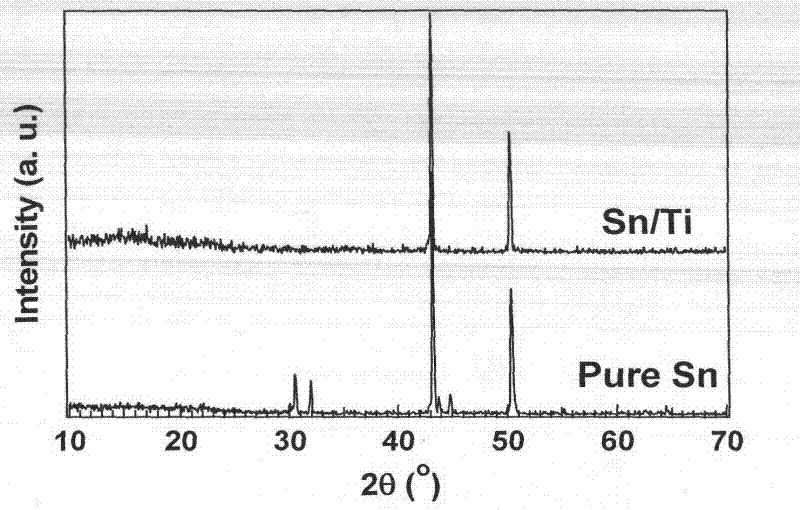

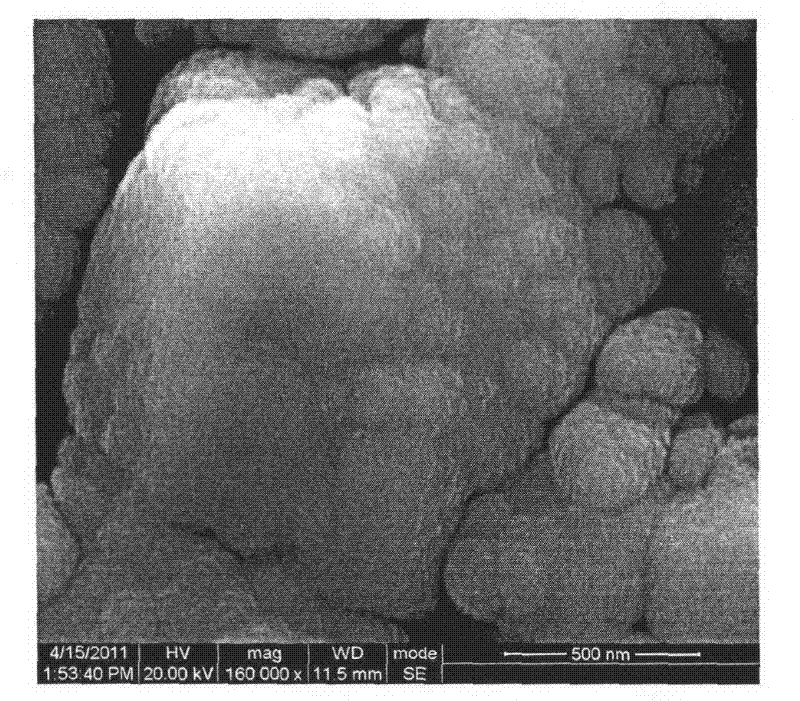

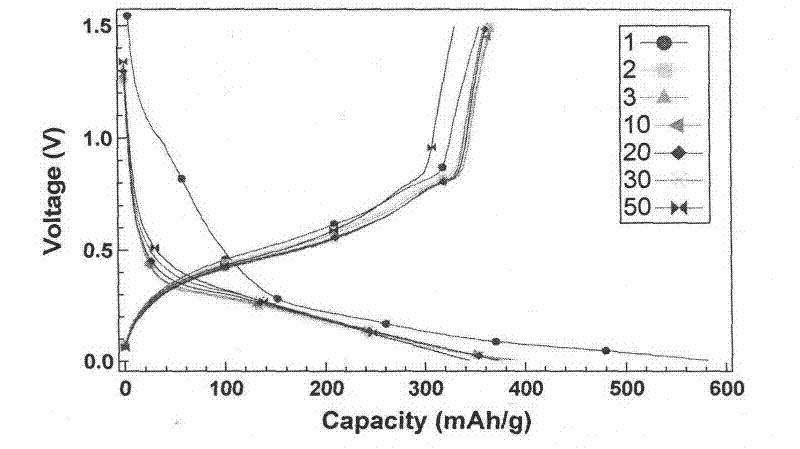

Magnetron sputtering preparation method of tin titanium film cathode of lithium ion battery

InactiveCN102212789AGood repeatabilityAvoid complex controlsCell electrodesVacuum evaporation coatingRoom temperatureTitanium

The invention belongs to the field of a chemical power source, and particularly relates to a magnetron sputtering preparation method of a tin titanium film cathode of a lithium ion battery. The method is characterized by comprising the following steps: alternately sputtering or cosputtering pure tin and pure titanium targets to prepare a tin titanium film, and then maintaining annealing treatment at a temperature ranging from room temperature to 300 DEG C for 0-6 hours. In the two-target alternate sputtering method, an Sn / Ti or Ti / Sn laminated film can be formed, when the number of times of alternation is more than one, on the basis of the material which is sputtered firstly. The method disclosed by the invention has the advantages of simple process and low cost, and is beneficial to environment protection; and the prepared film is used as a cathode of a lithium ion battery, and has high specific capacity and excellent cycle performance.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

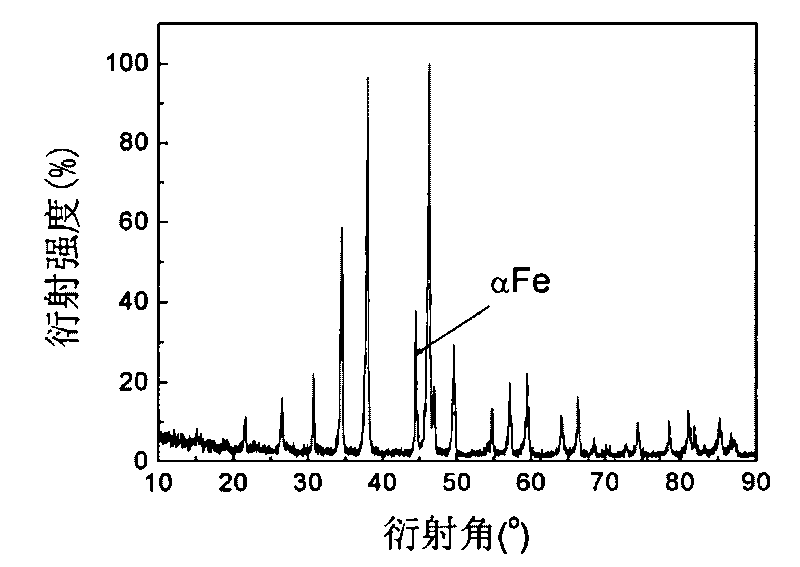

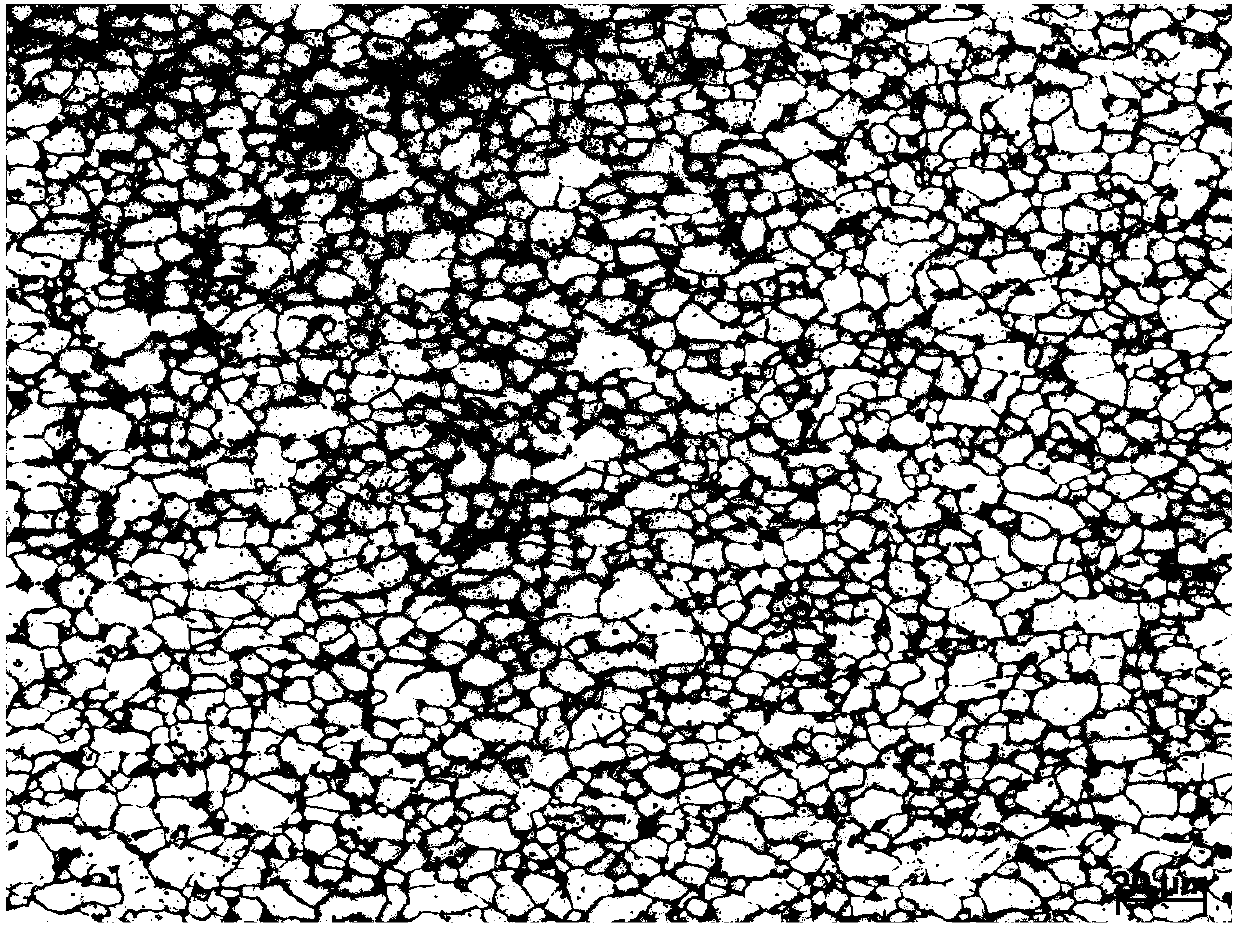

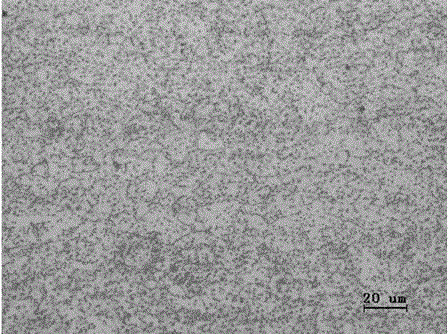

Production method of bainite cold forging steel wire rod

The invention discloses a production method of a bainite cold forging steel wire rod. The production method comprises the following production process flows of molten iron pretreatment, converter smelting, CAS (composition adjustments by sealed argon) refining, LF (ladle furnace) refining, continuous casting, casting blank grinding, controlled rolling and controlled cooling, finished product inspection and warehousing. The steel comprises the following chemical components in weight percentage: 0.33 to 0.38 percent of C, 0.15 to 0.35 percent of Si, 0.60 to 0.90 percent of Mn, not greater than 0.030 percent of P, not greater than 0.030 percent of S, 0.90 to 1.20 percent of Cr, not greater than 0.25 percent of Ni, 0.15 to 0.30 percent of Mo and the balance Fe and few impurities. The bainite cold forging steel wire rod produced by the production method disclosed by the invention is a Cr-Mo series alloy cold forging steel wire rod which can be shortened in annealing time, and the Cr-Mo series alloy cold forging steel wire rod mainly includes an SCM435 wire rod. Through thermal simulation and laboratory investigation, the phase change law of Cr-Mo series alloy cold forging steel is mastered; through controlled rolling and controlled cooling, a hot rolled wire rod forms massive bainite, little ferrite and few martensitic structures, so that structural preparation is provided for shortening the annealing time of the wire rod.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Heat treating process for eliminating mixed crystal of low-alloy quick-cutting steel

The invention discloses a low alloy high speed steel mischcrystal elimination heat treatment process. The process comprises an annealing procedure and a quenching procedure. The annealing procedure comprises the following steps: heating up a low alloy high speed steel ingot to 890 to 910 DEG C at the speed of 300 DEG C per hour; controlling an annealing cooling rate at 25 to 30 DEG C per hour when the temperature of the ingot is above 600 DEG C; and cooling the ingot in the furnace when the temperature of the ingot is less than or equal to 600 DEG C. The quenching procedure comprises the following steps: preheating the annealed steel ingot to 800 to 850 DEG C, and controlling the heating time to be 5 to 15 minutes; continuing to heat up the ingot and increase the temperature to 1,170 to 1,190 DEG C, and controlling the holding time to be 2 to 6 minutes; and cooling the ingot through interrupted quenching. The process improves the annealing temperature rising rate and the annealing heating temperature, thereby enabling an annealed structure to be closer to an equilibrium structure, effectively avoiding the uneven growth of quenching austenite grains in a subsequent temperature span easily producing mischcrystal, improving the quenching temperature of the low alloy high speed steel, and reaching the aim of improving the red hardness of the high speed steel while simultaneously obtaining high tenacity.

Owner:江苏华久特钢工具有限公司

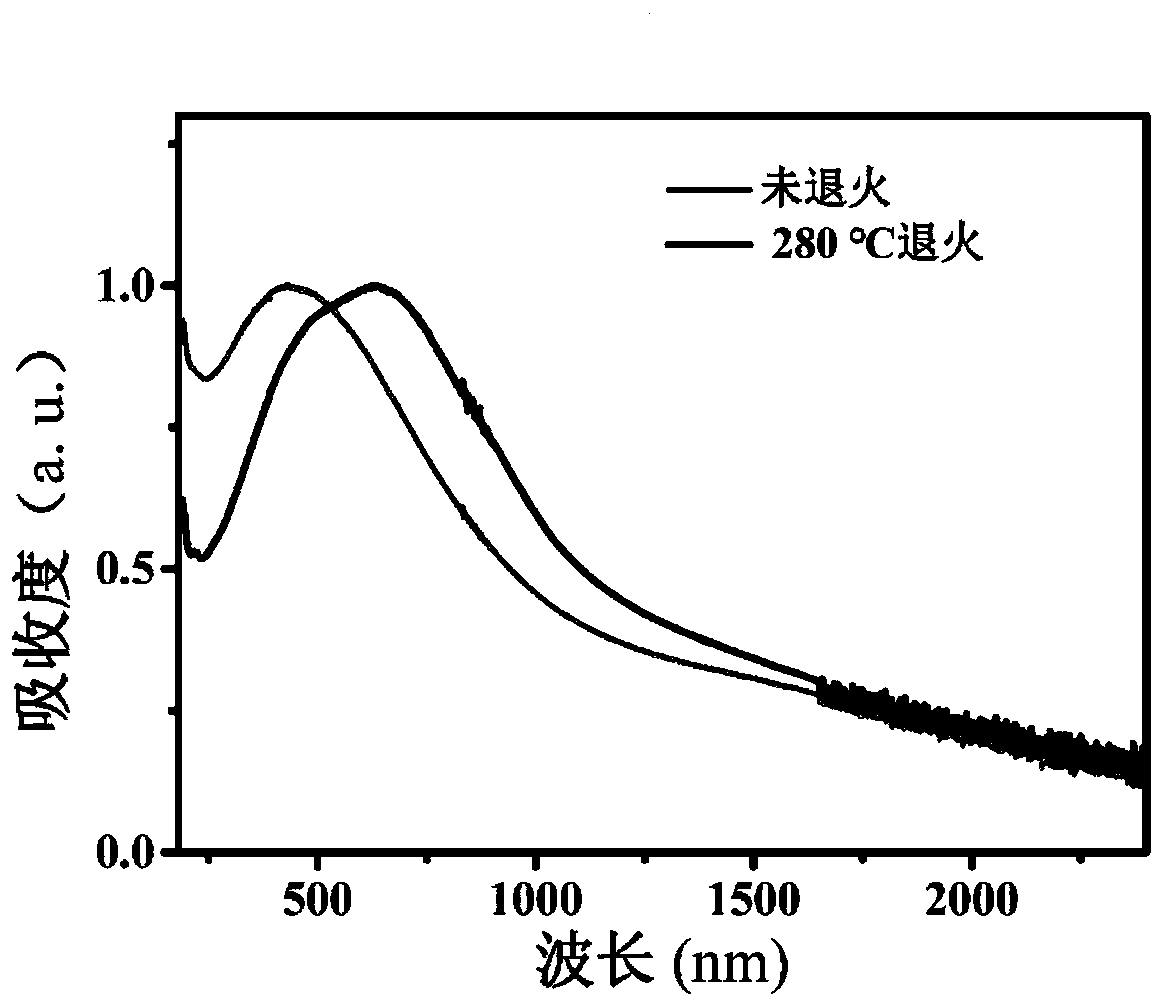

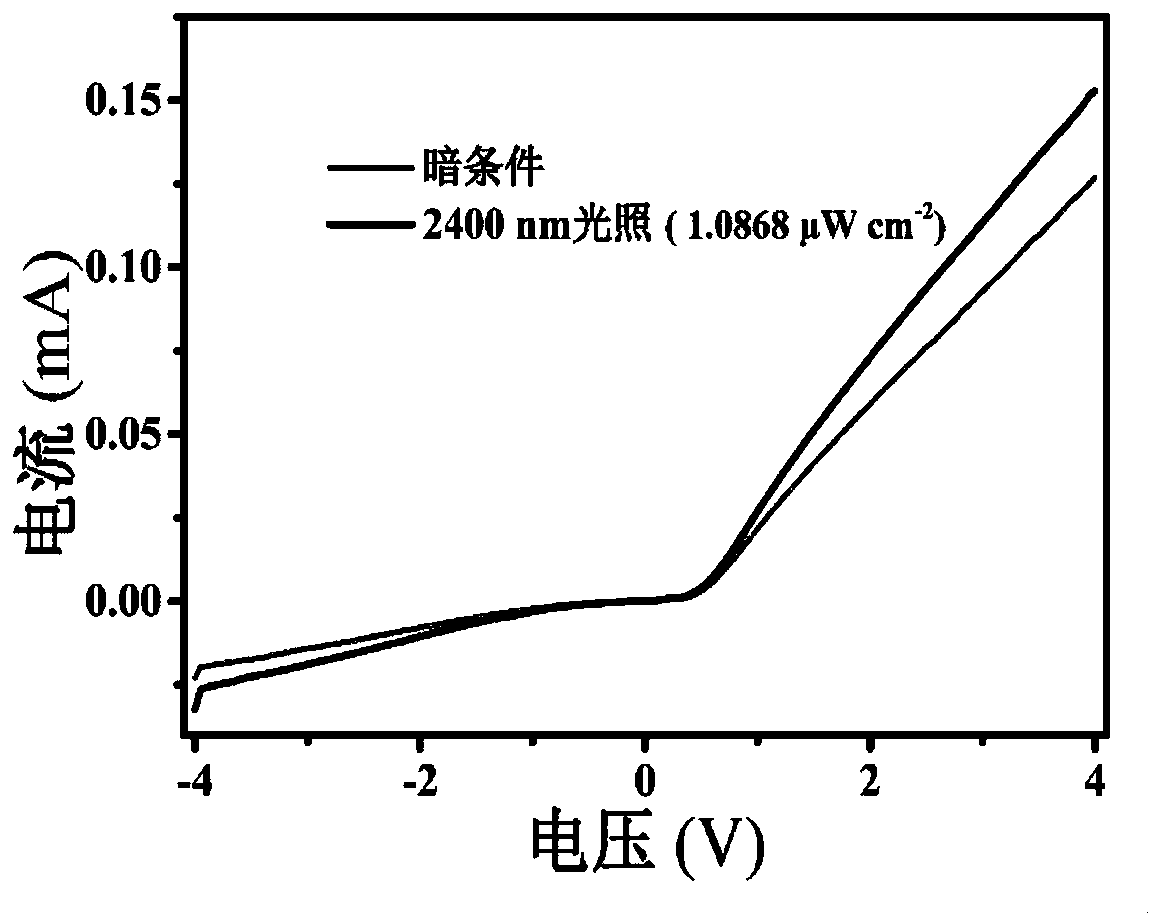

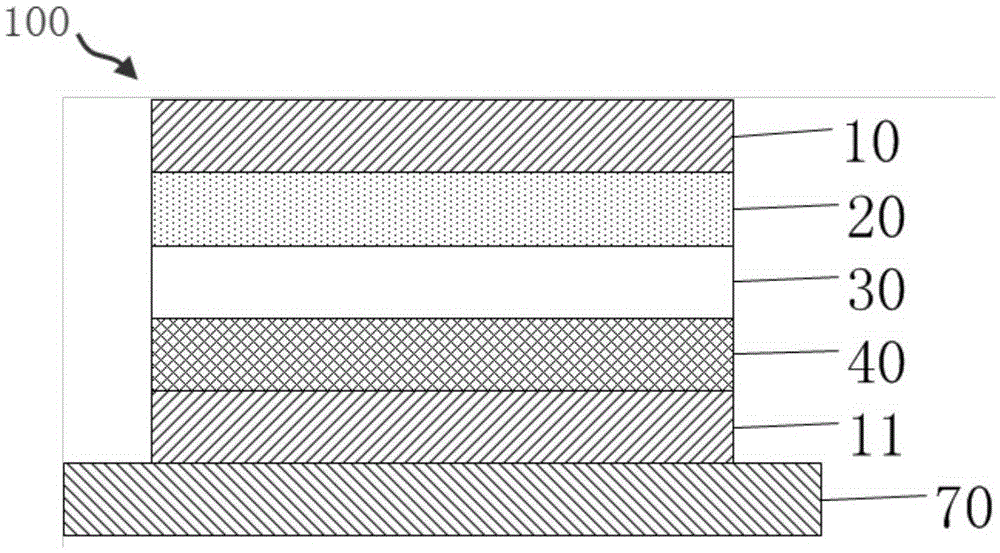

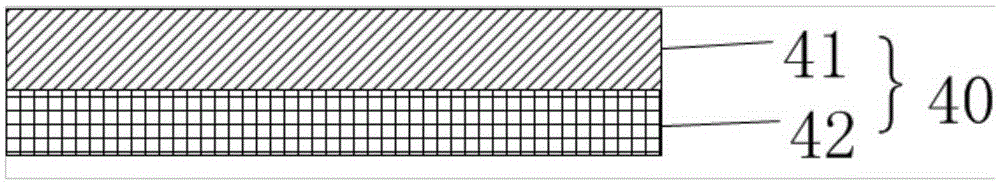

Wide-response spectrum detector based on antimony telluride material and preparation method thereof

InactiveCN110729365ALow cost of preparationShorten the annealing timeFinal product manufactureSemiconductor devicesPhysicsThin membrane

Provided are a wide-response spectrum detector based on an antimony telluride material and a preparation method thereof. The invention relates to the technical field of photoelectric, and particularlyrelates to a photoelectric detector with high detection rate, high response rate and wide response spectrum based on a topological insulator material Sb2Te3 and n-Si and a preparation method thereof.According to the wide-response spectrum detector based on an antimony telluride material, a spectrum response layer is a topological insulator material Sb2Te3 film, and a substrate is an n-Si heterojunction substrate. The preparation process comprises the steps of substrate cleaning, Sb2Te3 film sputtering, annealing and Al electrode plating. Compared with the prior art, the preparation of a high-performance wide-spectrum prototype photoelectric detector with a response range of 250-2400nm is realized, and the detector can respond to 250nm in the ultraviolet band and respond to 2400nm in theinfrared band. The preparation period is short, and the device performance is good.

Owner:KUNMING INST OF PHYSICS

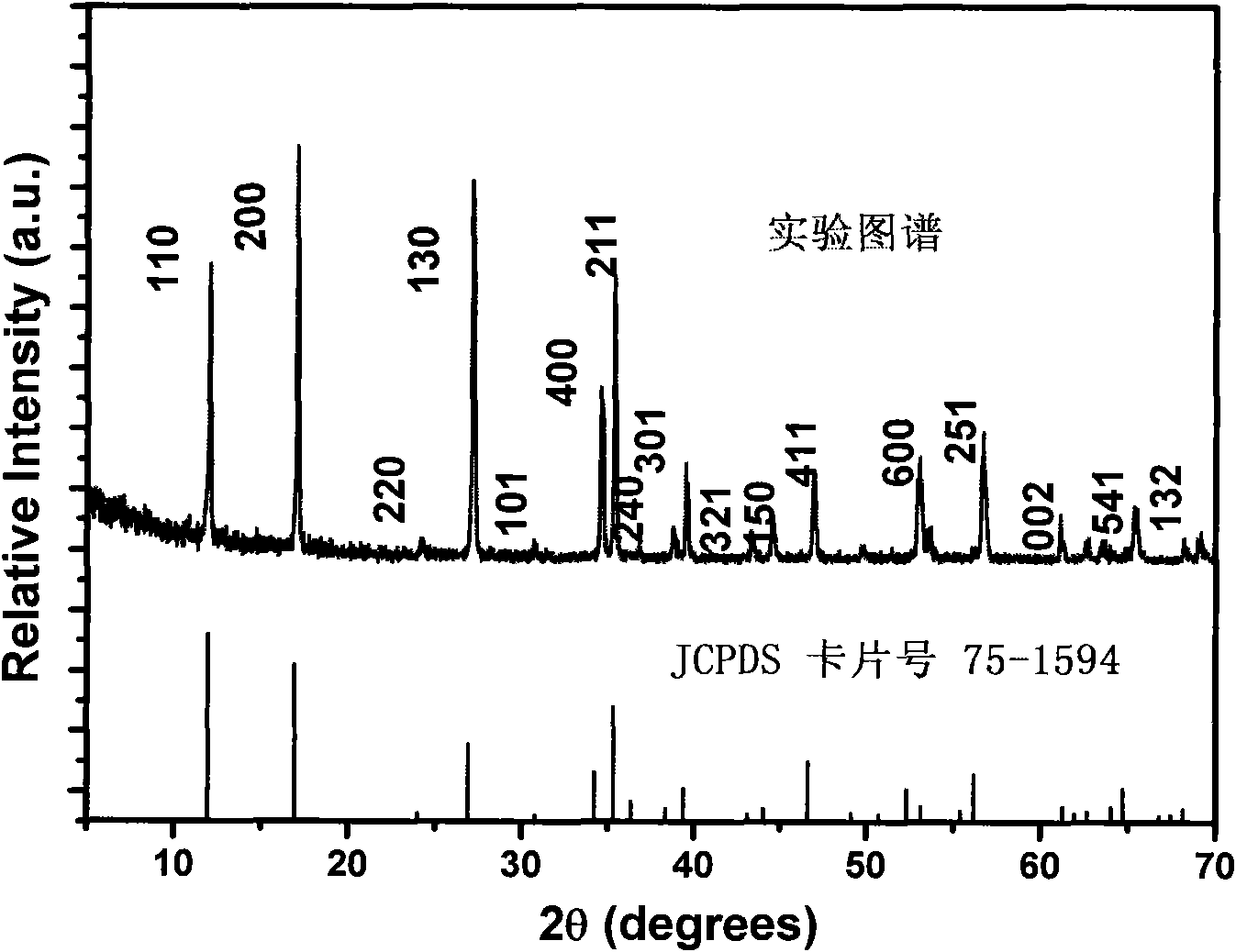

Magnetic tunnel junction and preparation method thereof

ActiveCN105280809ALow annealing temperatureShorten the annealing timeGalvano-magnetic material selectionGalvano-magnetic device manufacture/treatmentThermal stabilityTunnel junction

The invention discloses a magnetic tunnel junction and a preparation method thereof. The magnetic tunnel junction includes a first electrode layer, and a first magnetic layer, an insulation tunneling layer, a second magnetic layer, and a second electrode layer that are successively arranged on the first electrode layer, at least one of the first magnetic layer and the second magnetic layer is in a CoFe(R) / FePt structure, the CoFe(R) / FePt structure is formed by the overlapping of a CoFe(R) layer and a FePt layer, the CoFe(R) layer is closer to the insulation tunneling layer than the FePt layer, and the CoFe(R) layer is made of CoFe doped with R, and R is at least one of B, Al, and Ni. The magnetic tunnel junction concerns the compatibility of the small size of a device, the high thermal stability, and a CMOS process, so that the magnetic tunnel junction can be widely applied to a sensor, a storage device, and a logic calculating apparatus.

Owner:HUAZHONG UNIV OF SCI & TECH

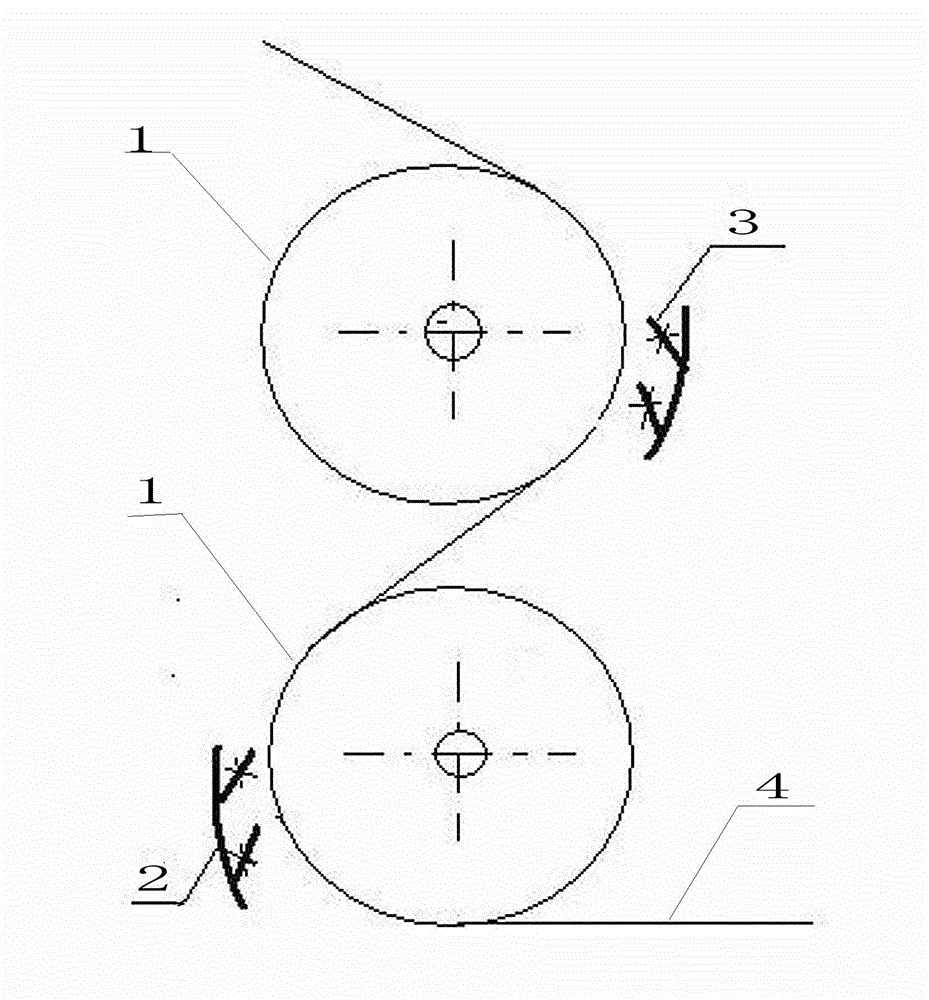

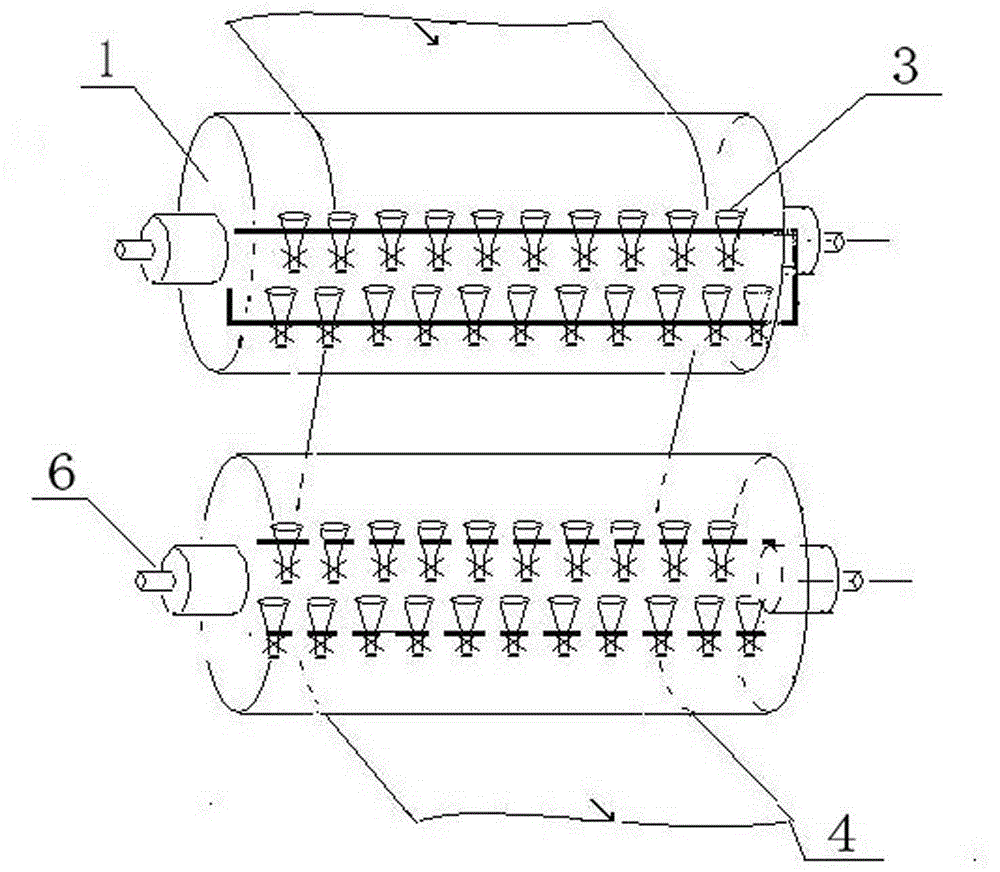

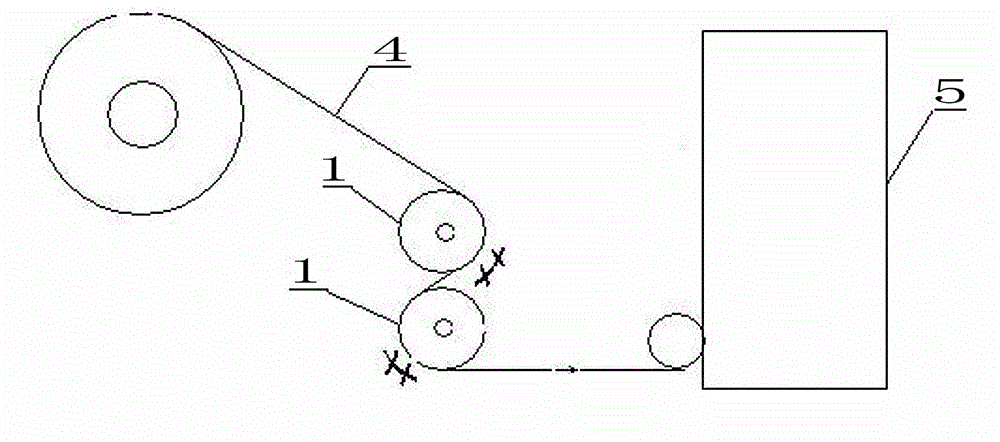

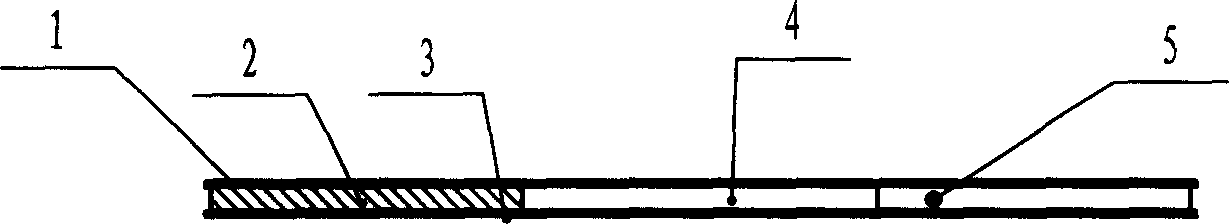

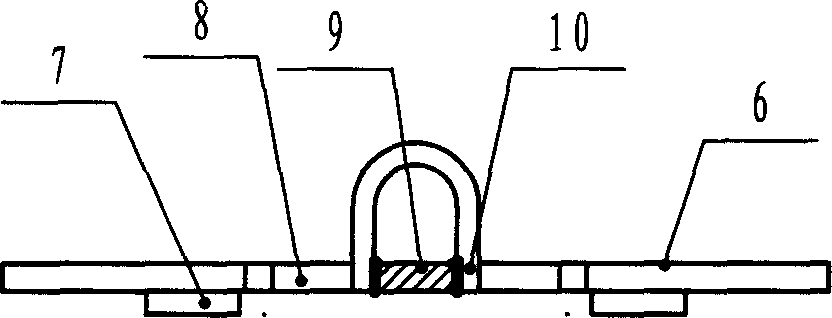

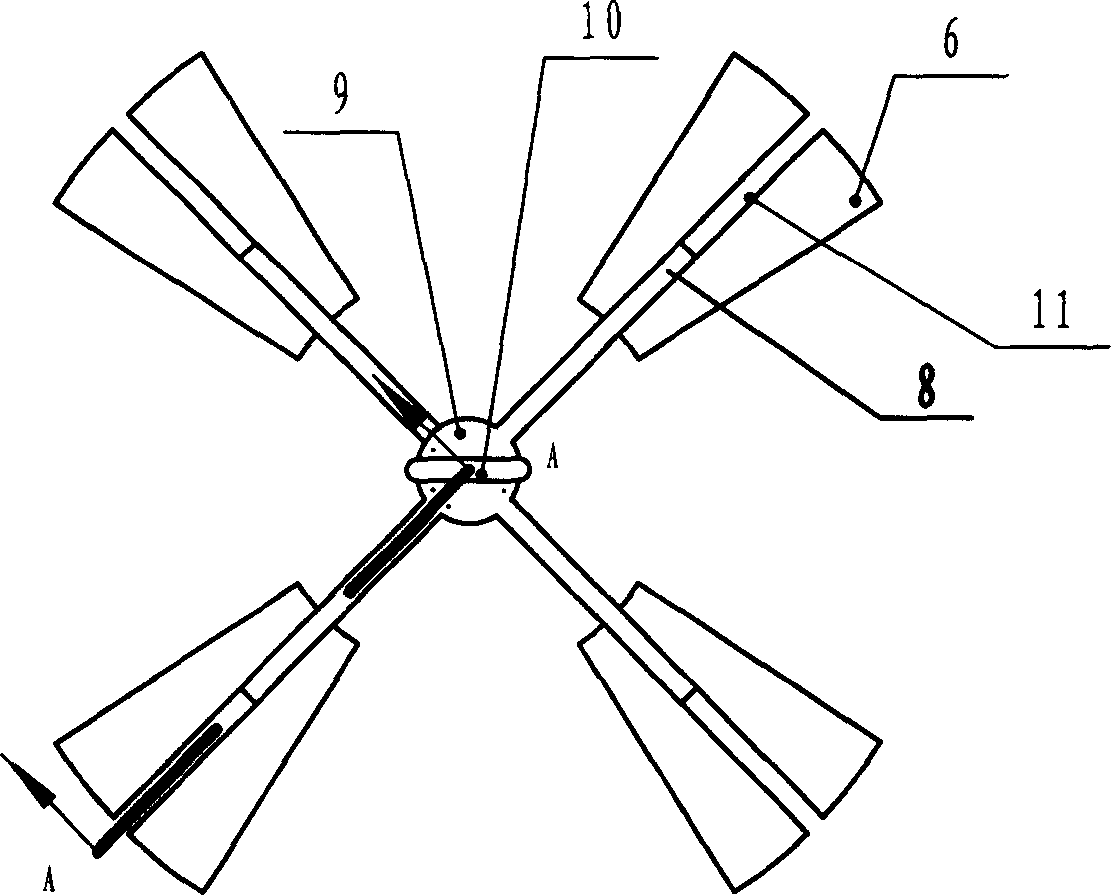

Aluminum foil surface residual oil pretreatment temperature control purging device and use method and application thereof

ActiveCN102909226AQuality improvementShorten the annealing timeWork treatment devicesMetal rolling arrangementsTemperature controlAluminum foil

The invention belongs to the technical field of nonferrous metallurgy processing and relates to an aluminum foil surface residual oil pretreatment device used in the aluminum foil slitting or finishing process, in particular to an aluminum foil surface residual oil pretreatment temperature control purging device and a use method and application thereof. The aluminum foil surface residual oil pretreatment temperature control purging device is composed of an electric heating guide roller (1), a cross beam (2), a tuyere (3), an intelligent temperature controller and a compressed air source. The electric heating guide roller (1) and the cross beam (2) are parallel in the axial direction and are fixed by a support, the tuyere (3) is fixed on the cross beam (2), the intelligent temperature controller is used for controlling temperature of the electric heating guide roller (1), compressed air in the compressed air source is guided into the electric heating guide roller (1) to be heated, and the heated compressed air serves as working media of the tuyere (3). The use method and application of the aluminum foil surface residual oil pretreatment temperature control purging device are further disclosed. The aluminum foil surface residual oil pretreatment temperature control purging device and the use method and application thereof have obvious effects in shortening aluminum foil annealing cycle and reducing oxidization and annealing soft bar happening.

Owner:JIANGSU DAYA ALUMINUM

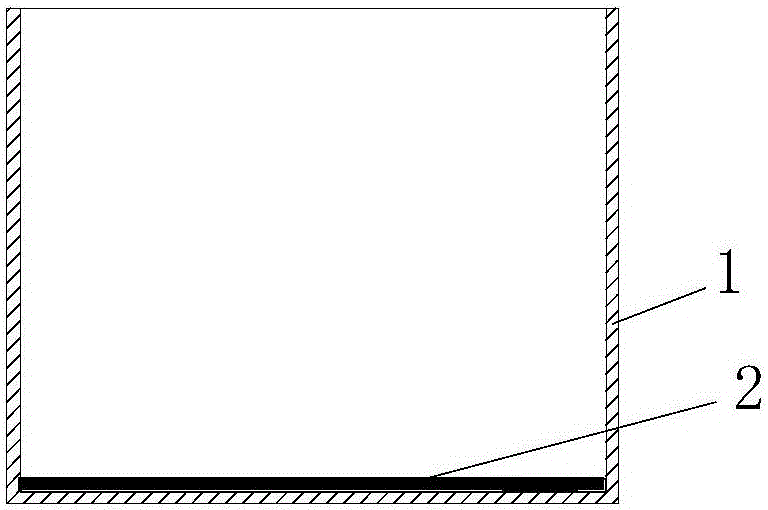

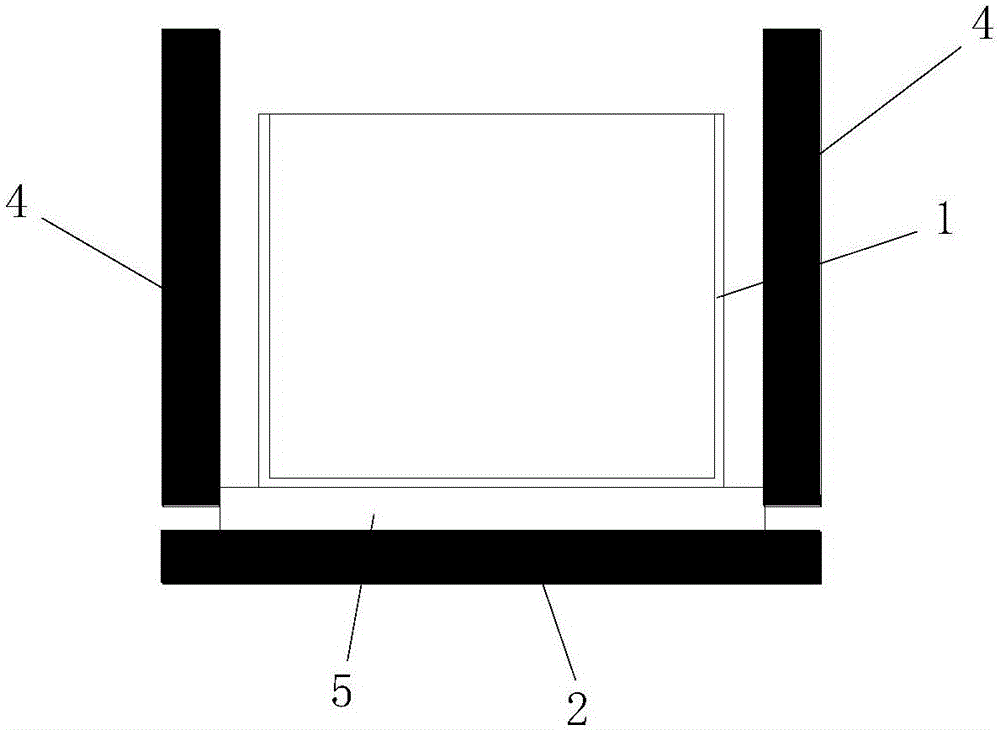

Cage type furnace convection plate

InactiveCN1718776AReduce temperature differenceReduce uniformityFurnace typesHeat treatment furnacesEngineeringHeat treated

A convection plate of hood-type furnace for tempering the coiled steel band with smooth airflow and high effect is composed of isolating plates, connecting part which is a number of radial connecting rods surrounding a connecting plate, and a reverse U-shaped hanging ring being welded to upper and lower connecting plates. Said isolating plates are the sectorial plates welded to both sides of each connecting rod and with the strip pads on its bottom surface.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Preparing process of titanium strip coil used for high-end anode

InactiveCN110814079AUniform temperatureImprove performance uniformityMetal rolling arrangementsEtchingSurface oxidation

The embodiment of the invention provides a preparing process of a titanium strip coil used for a high-end anode. The preparing process comprises two rolling processes, the size and the uniformity of grains of a finished product are controlled conveniently, surface defects of the produced titanium coil are less, compared with first rolling process rolling, namely a hot rolling coil is directly rolled to the thickness of a second-thickness cold rolling coil, the pausing does not occur in the middle, and if continuous annealing and surface treatment are carried out firstly, and then second rolling process rolling is carried out, the surface defects of the finally obtained finished product are more. After the finished product is annealed, then flatten treatment is conducted, and then an oxidelayer on the surface of the titanium coil is uniformly crushed, so that a more consistent condition is provided for the etching of the subsequent titanium coil, the etching effect can be improved, thesurface color of an etched titanium plate is consistent, and finally, the titanium plate coating is better facilitated.

Owner:湖南湘投金天钛金属股份有限公司

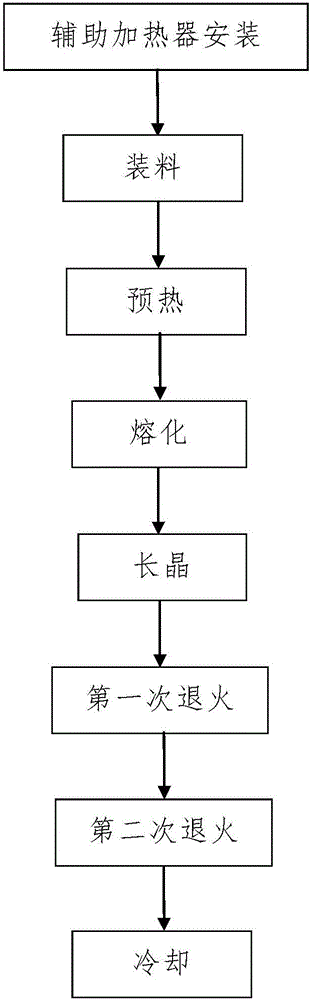

Method for polycrystalline silicon ingot casting

InactiveCN106087053AThe method steps are simpleReasonable designPolycrystalline material growthAfter-treatment detailsCrucibleIngot casting

The invention discloses a method for polycrystalline silicon ingot casting. The method comprises a first step of installation of an auxiliary heater, wherein the auxiliary heater is installed in a polycrystalline silicon ingot furnace, the auxiliary heater is a bottom heater below a crucible, and the auxiliary heater forms a six-side heating device together with a top heater and four side heaters; a second step of charging; a third step of preheating; a fourth step of melting: six-side heating melting, fifth-side heating melting and follow-up melting; a fifth step of crystal growth; a sixth step of annealing and cooling which comprise primary annealing, secondary annealing and cooling, wherein during the primary annealing, the heating temperature of the polycrystalline silicon ingot furnace is reduced to T4 and heat insulation is performed for 2-3 h, and T4=1250-1280 DEG C; during the secondary annealing, the heating temperature of the polycrystalline silicon ingot furnace is reduced to T5 and heat insulation is performed for 2-3 h, and T5=900-950 DEG C. The method is simple in steps, reasonable in design, convenient to implement and good in using effect. The six-side heating device is adopted for heating, the oxygen content of the bottom of the crucible can be effectively reduced; the annealing process is adjusted, and the quality of a finished ingot can be effectively improved.

Owner:XIAN HUAJING ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com