Process for producing layer of organic perovskite material with improved crystallinity

一种晶体材料、有机阴离子的技术,应用在铜有机化合物、锡有机化合物、铅有机化合物等方向,能够解决没有很好地理解钙钛矿等问题,达到膜光滑度改善的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0324] Example 1: Sacrificial anion

[0325] method

[0326] Preparation of Perovskite Precursors

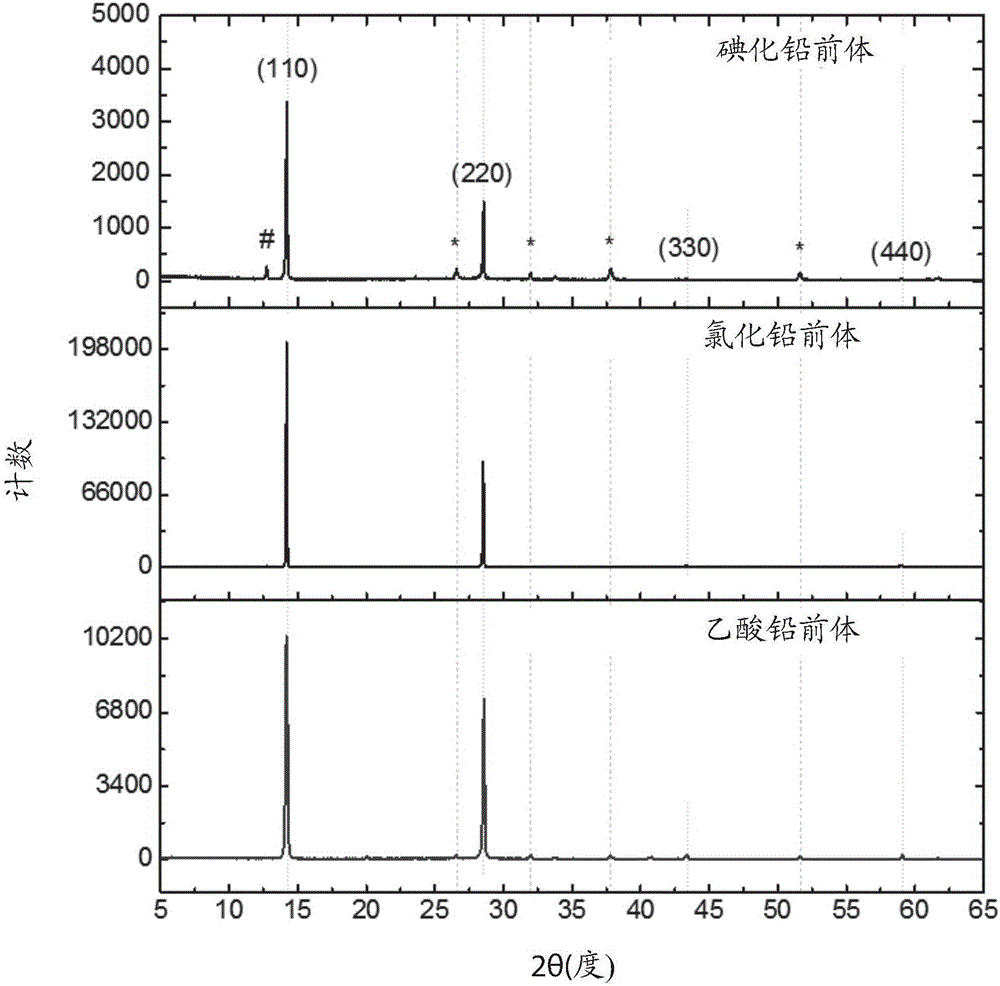

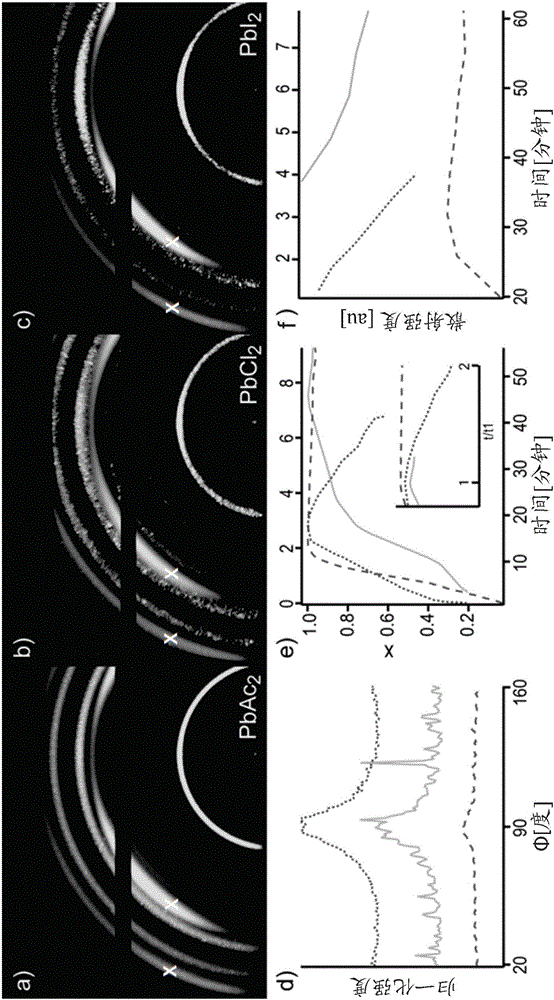

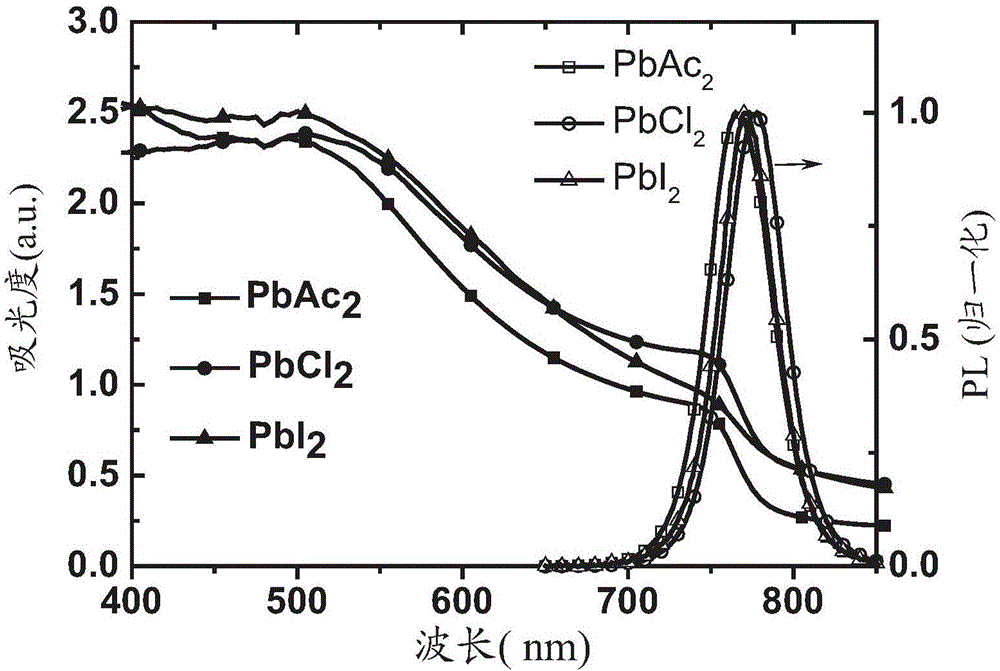

[0327] Methylammonium iodide (MAI) was prepared by reacting 33 wt% methylamine (Sigma-Aldrich) in ethanol with 57 wt% hydroiodic acid (HI) in water (Sigma-Aldrich) at room temperature. HI was added dropwise with stirring. Upon drying at 100 °C, a white powder formed, which was dried in a vacuum oven overnight and purified with ethanol before use. To form a perovskite precursor solution, MAI and PbX 2 (X=Ac, Cl, I, wherein Ac is the acetate ion H 3 CCOO – ) was dissolved in anhydrous N,N-dimethylformamide (DMF) at a molar ratio of 3:1 to a final perovskite precursor concentration of ~40 wt%.

[0328] Substrate preparation

[0329] The glass substrates for photoluminescence (PL) measurement were sequentially cleaned with 2% hallmanex detergent, acetone, 2-propanol and oxygen plasma. Fluorine-doped tin oxide (FTO) coated glass (Pilkington, 7Ω□ -1 ) to fabricate devices. T...

Embodiment 2

[0374] Example 2: Sacrificial anions and sacrificial cations

[0375] In addition to having sacrificial anions in the metal salt component to enable crystallization at lower temperatures, some second cations (typically the methylammonium ion of the methylammonium lead halide perovskite) can also be present in the precursor solution Replaced by components that can be "sacrificed" at higher or lower temperatures to affect crystallization. If smaller or lighter cations are chosen, this can enable even faster crystallization to facilitate processing or film uniformity; or slower crystallization to grow larger, higher quality crystals.

[0376] Among the reactions proposed for perovskite crystallization, the example of a mixed halomethylammonium halide lead perovskite: 3MAI+PbCl 2 →MAPbI 3 +2 MACl. It seems that in MAPbI 3 Upon complete crystallization, MA+Cl will be lost in the form of MACl or its decomposition products. Example 1 has shown that the annealing process can be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com