Patents

Literature

218results about How to "Reduce productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

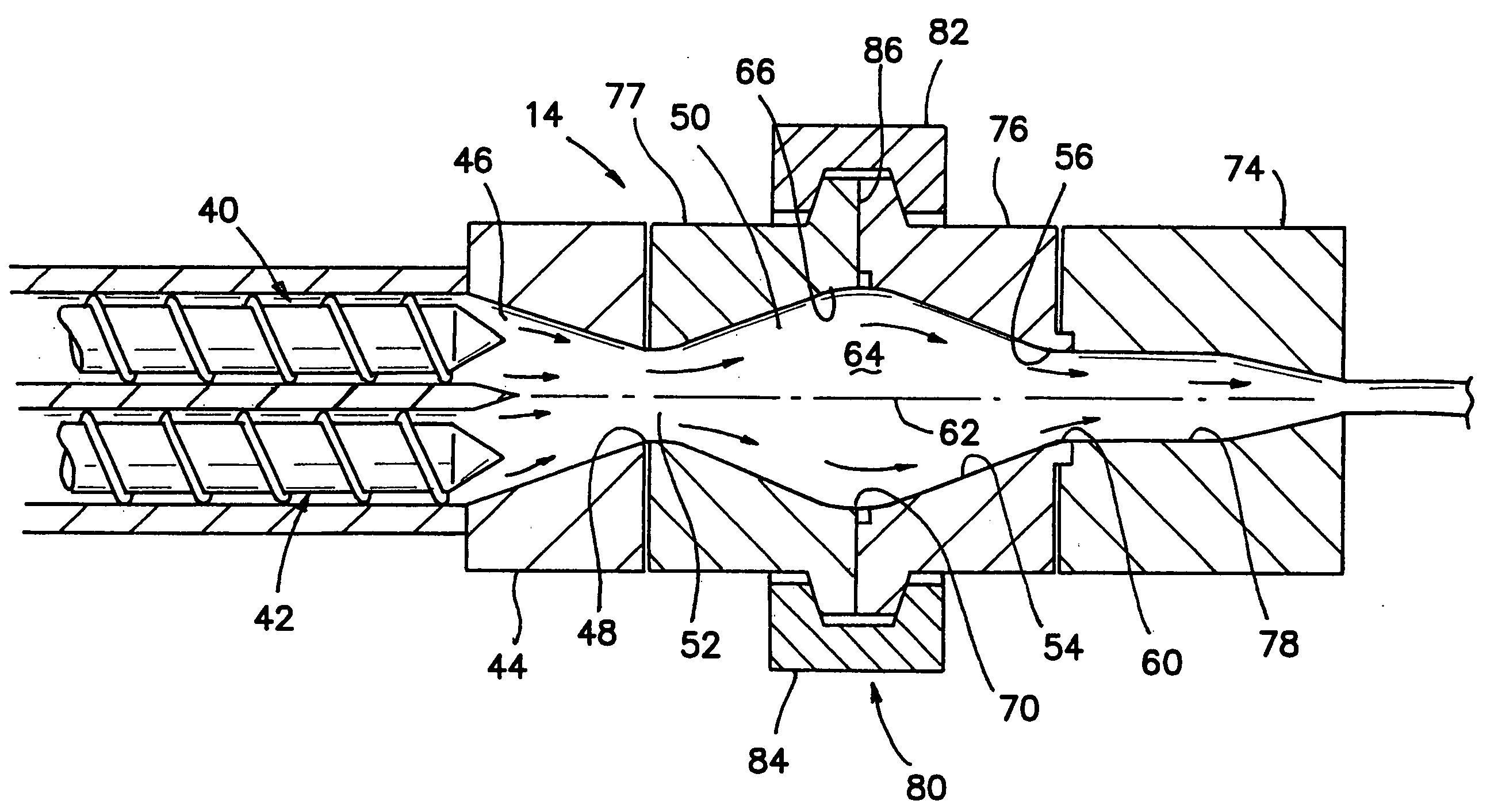

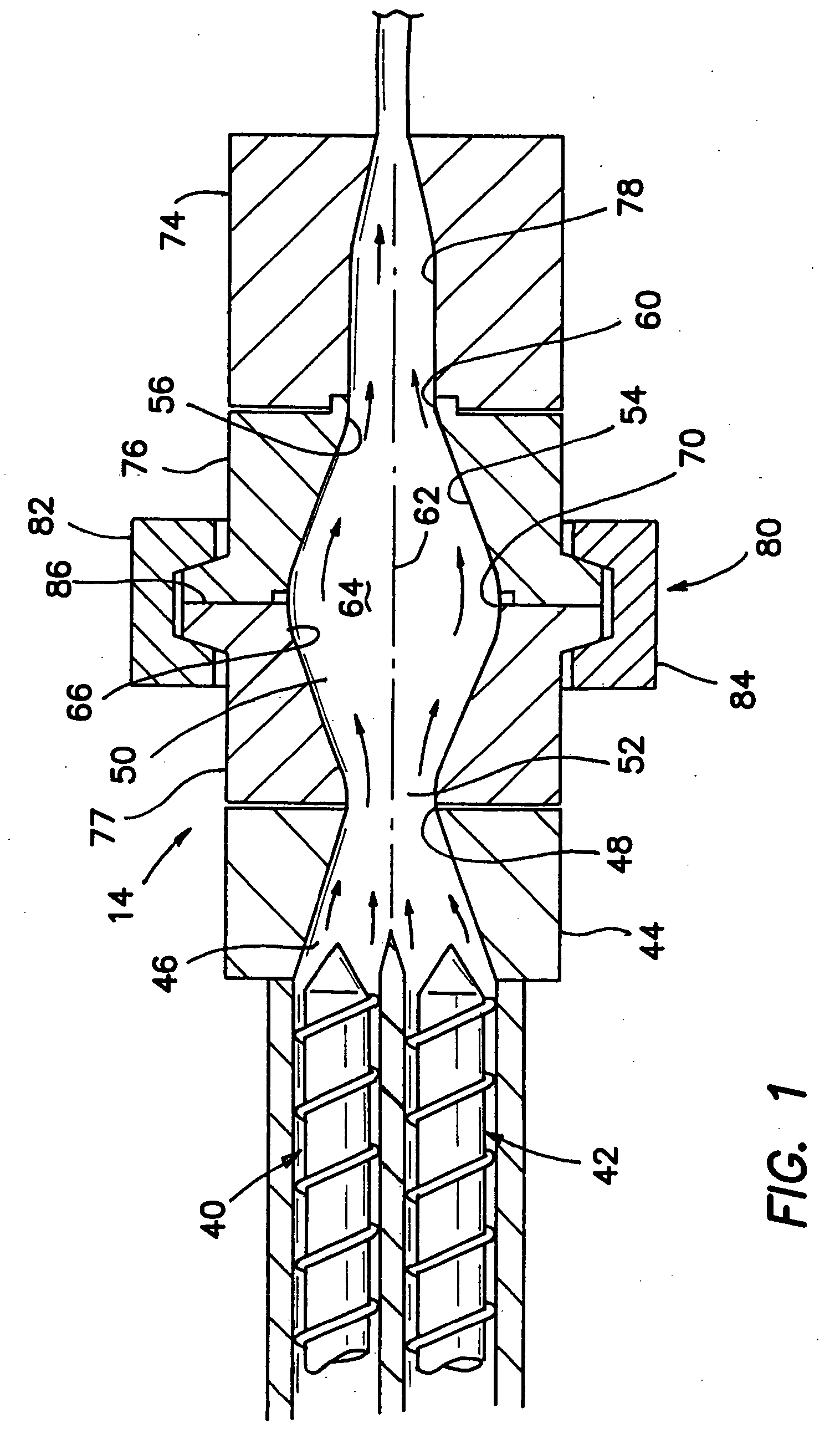

Polymer processing system including compression chamber and method for using same

InactiveUS20060105072A1Efficient extrusionReduce productivityConfectionerySweetmeatsDecompression chamberEngineering

Polymer processing systems are provided including an extrusion assembly, a specially configured decompression chamber assembly, and a die assembly. Such systems are effective to provide shaped polymer products having reduced extrusion markings. Methods of using such systems are also provided.

Owner:EXTRUTECH INT

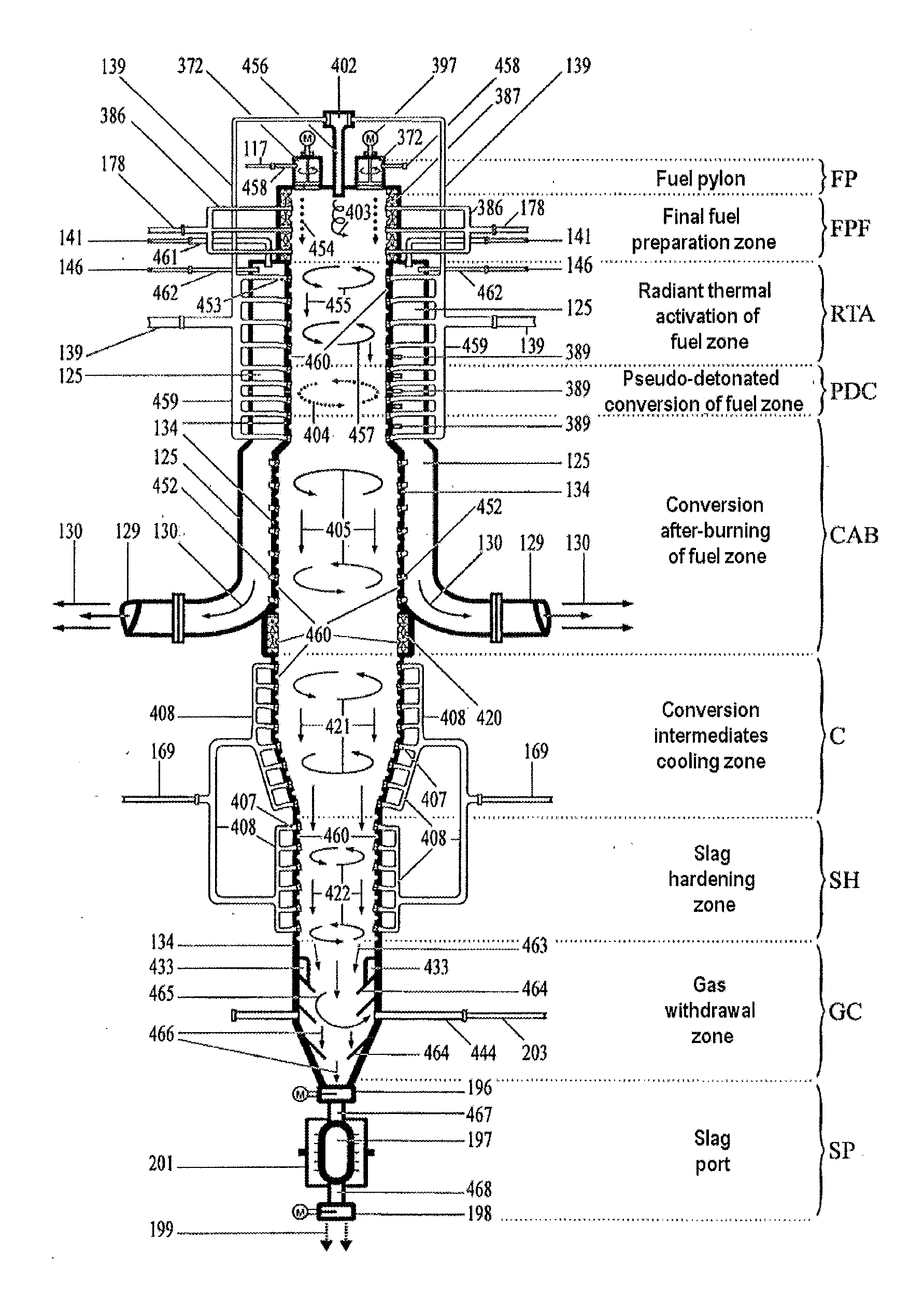

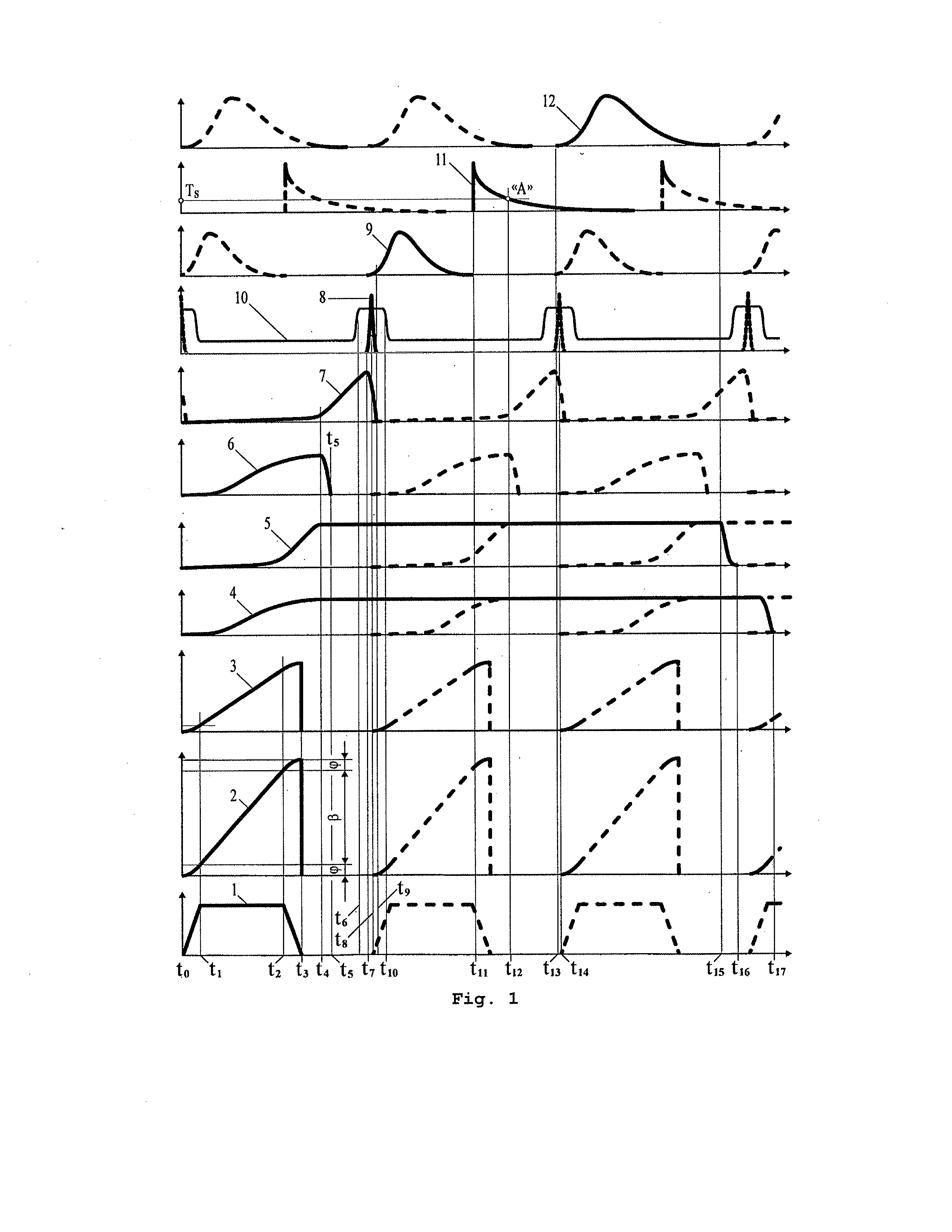

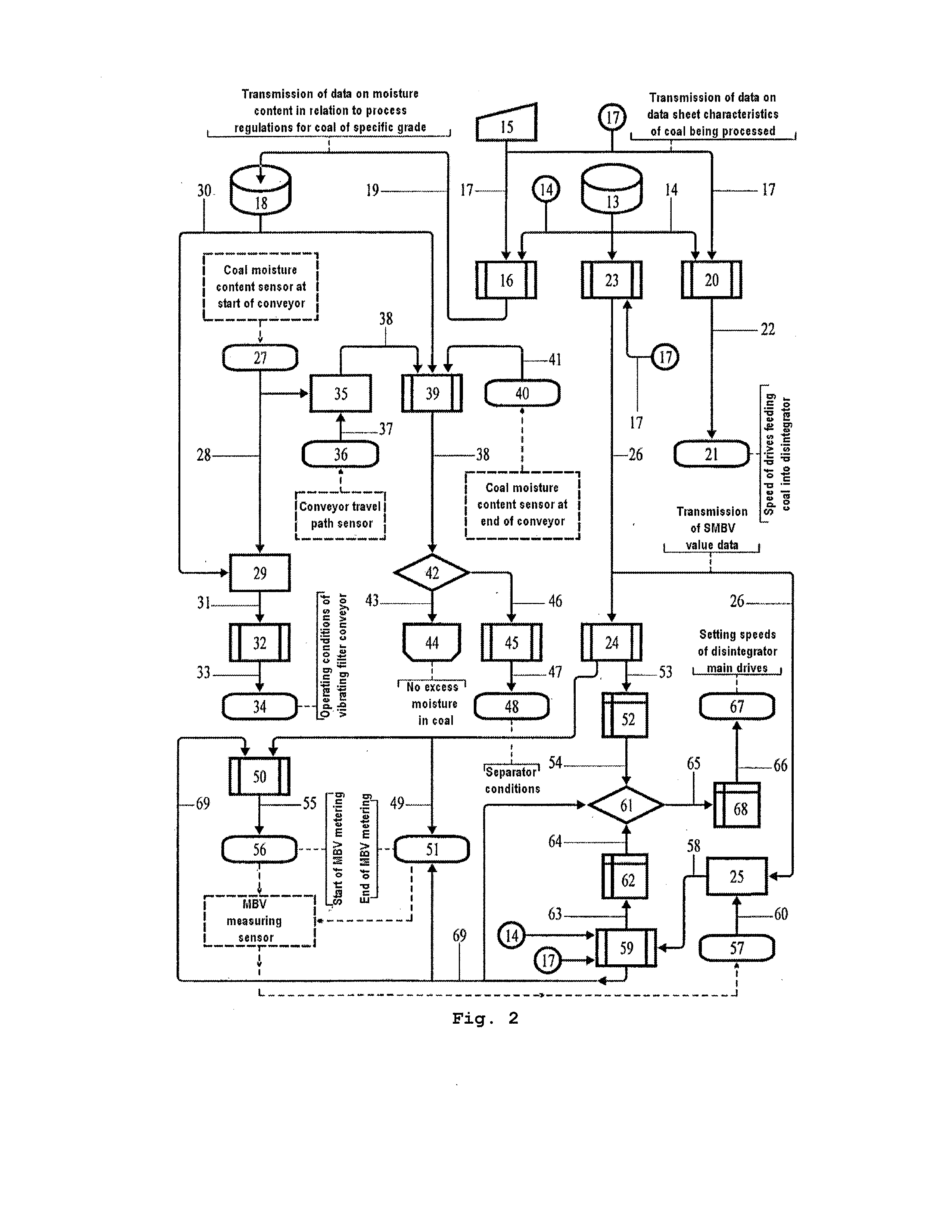

Method for the pseudo-detonated gasification of coal slurry in a combined cycle

InactiveUS20130167441A1High radiation transparencyImprove productivityGasification processes detailsLiquid carbonaceous fuelsThermal energyPower engineering

The invention relates to the field of power engineering and, more specifically, to systems for generating electricity based on the use of solid fuel, primarily brown and black coal. In the coal gasification method, a gasifier is fed with a uniform activated coal water fuel, the droplets of which are of equal size and the coal particles in said droplets having a similar granulometric composition. The fuel droplets are introduced intermittently in separate doses of fuel with a certain amount of motion being imparted thereto. The milling of the coal for the activated coal water fuel preparation method is adjusted adaptively according to the criterion of the actual amount of volatile substances given off by the coal, and the coal is thoroughly classified according to its granulometric composition. The invention provides for more extensive recovery of thermal energy from coal and more efficient electricity generation.

Owner:ASTRA INTERECOTECH

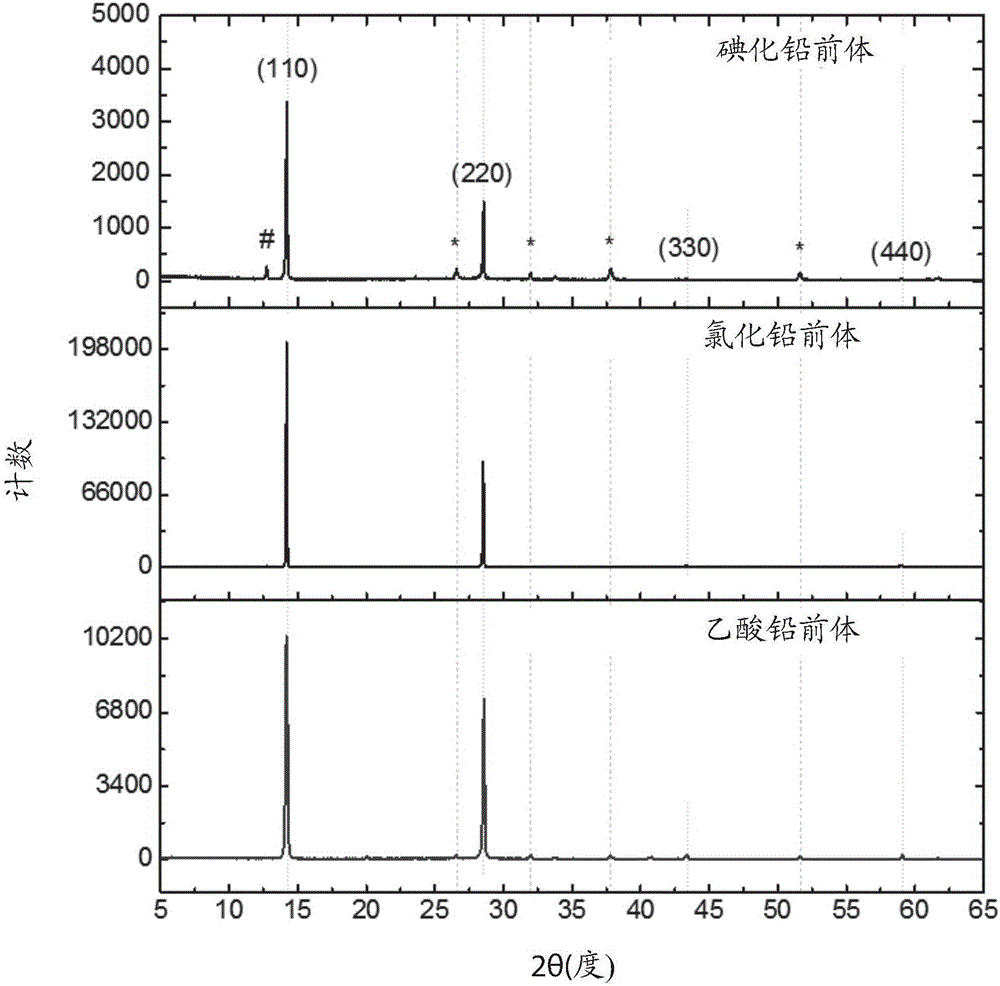

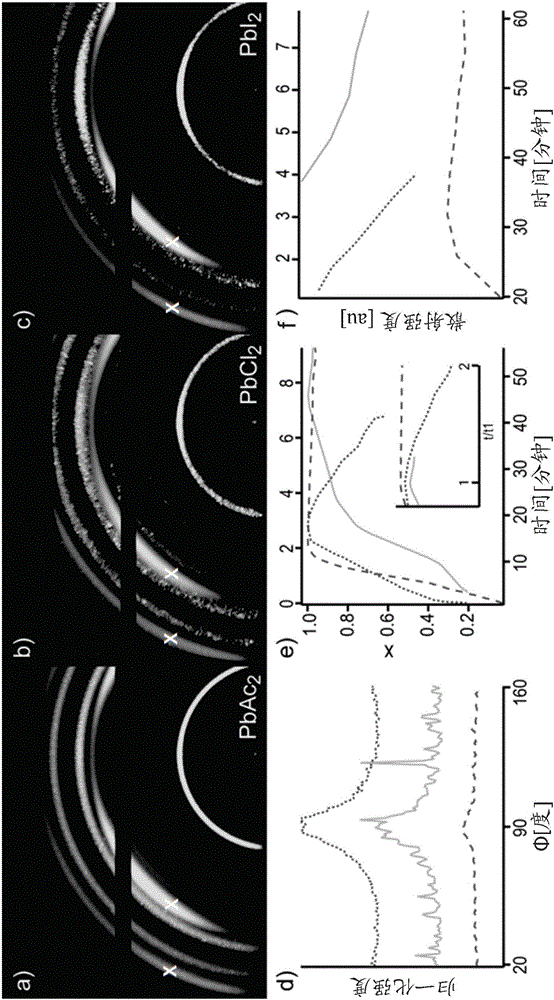

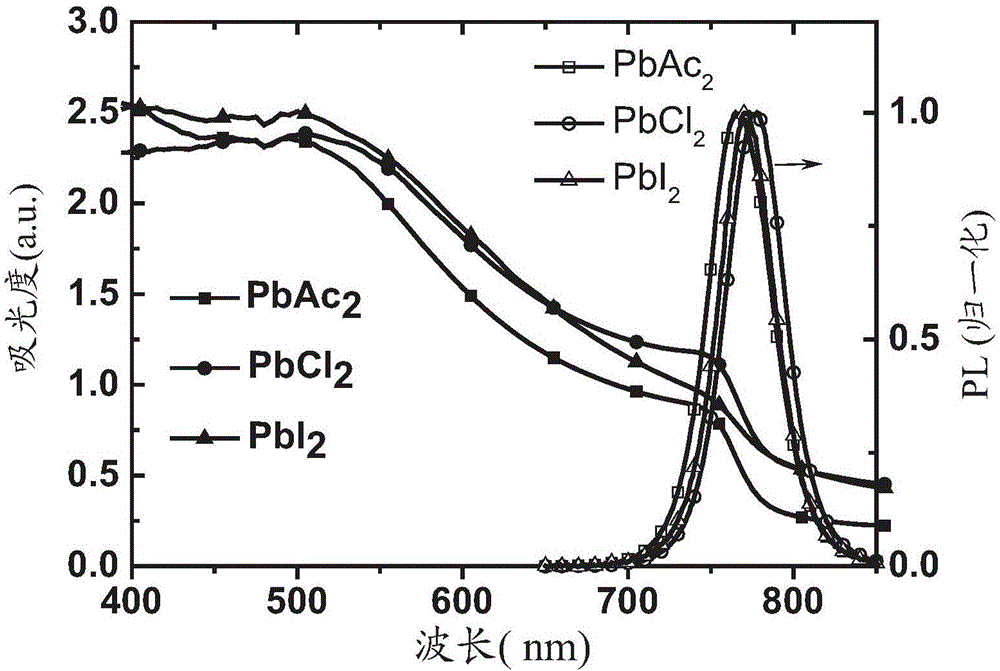

Process for producing layer of organic perovskite material with improved crystallinity

ActiveCN106796988AImprove smoothnessShorten the annealing timeTin organic compoundsElectrolytic capacitorsCrystalline materialsCombinatorial chemistry

The present invention relates to a process for producing a layer of a crystalline material, which process comprises disposing on a substrate: a first precursor compound comprising a first cation and a sacrificial anion, which first cation is a metal or metalloid cation and which sacrificial anion comprises two or more atoms; and a second precursor compound comprising a second anion and a second cation, which second cation can together with the sacrificial anion form a first volatile compound. The invention also relates to a layer of a crystalline material obtainable by a process according to the invention. The invention also provides a process for producing a semiconductor device comprising a process for producing a layer of a crystalline material according to the invention. The invention also provides a composition comprising: (a) a solvent; (b) NH4X; (c) AX; and (d) BY2 or MY4; wherein X, A, M and Y are as defined herein.

Owner:OXFORD UNIV INNOVATION LTD

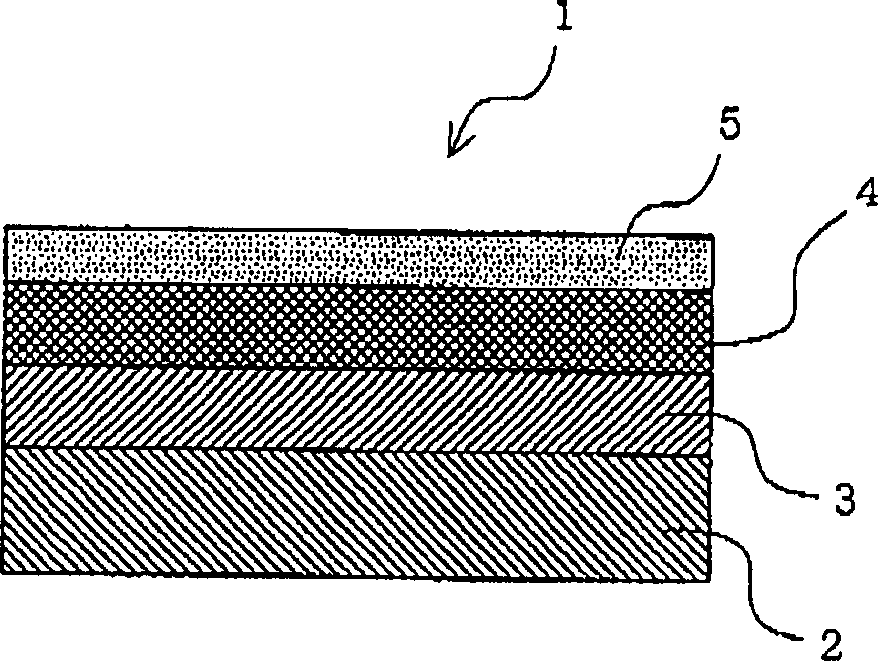

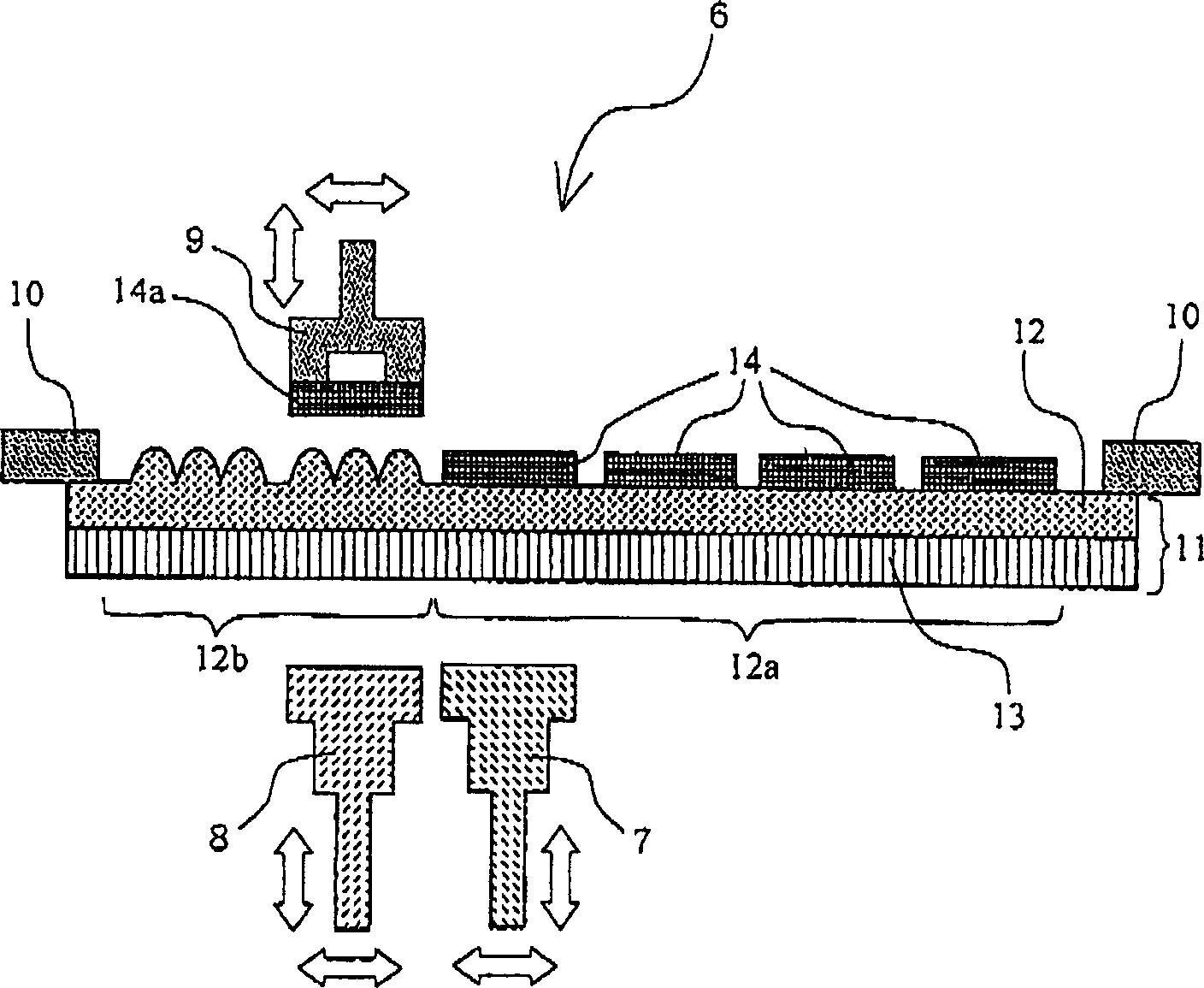

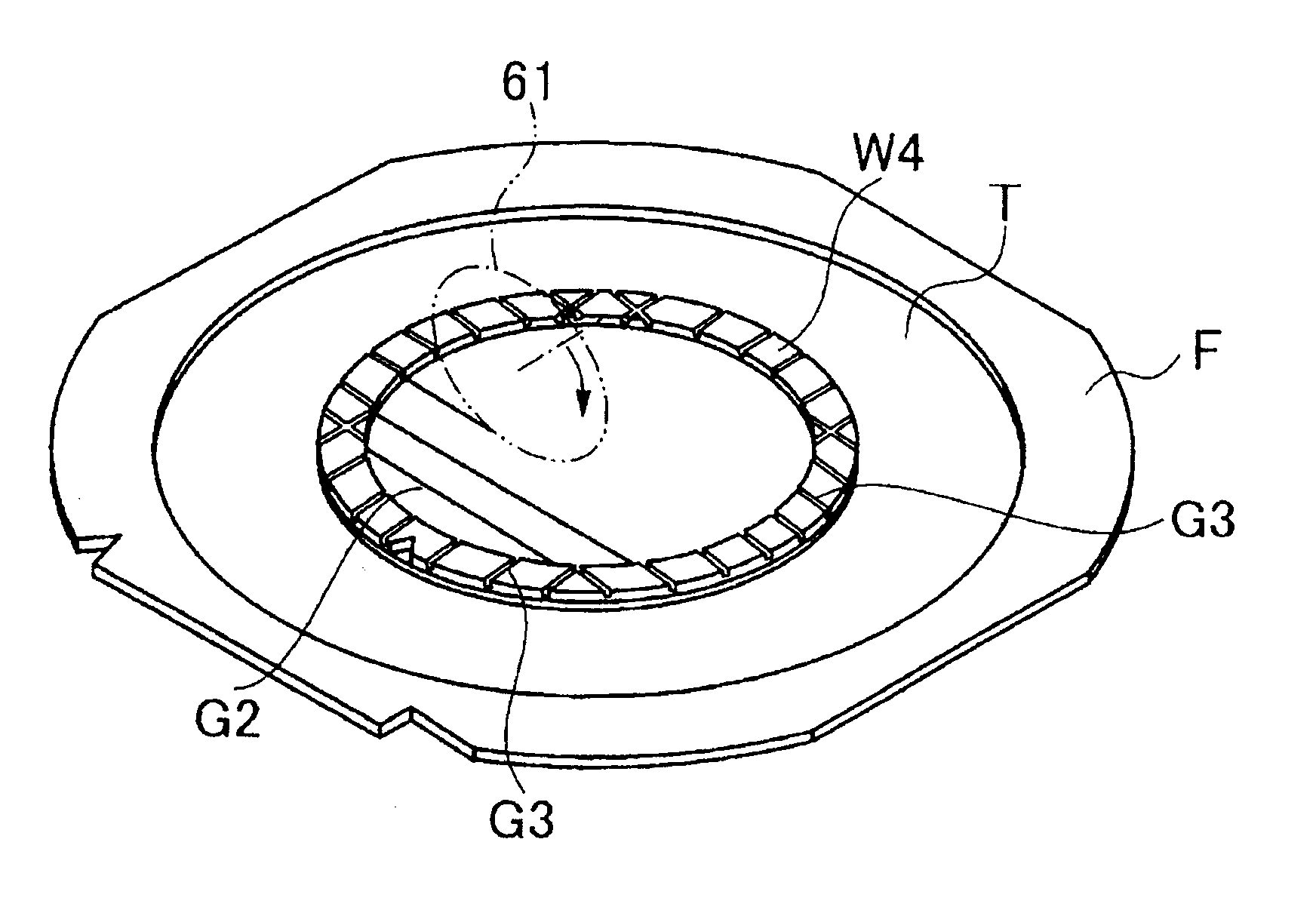

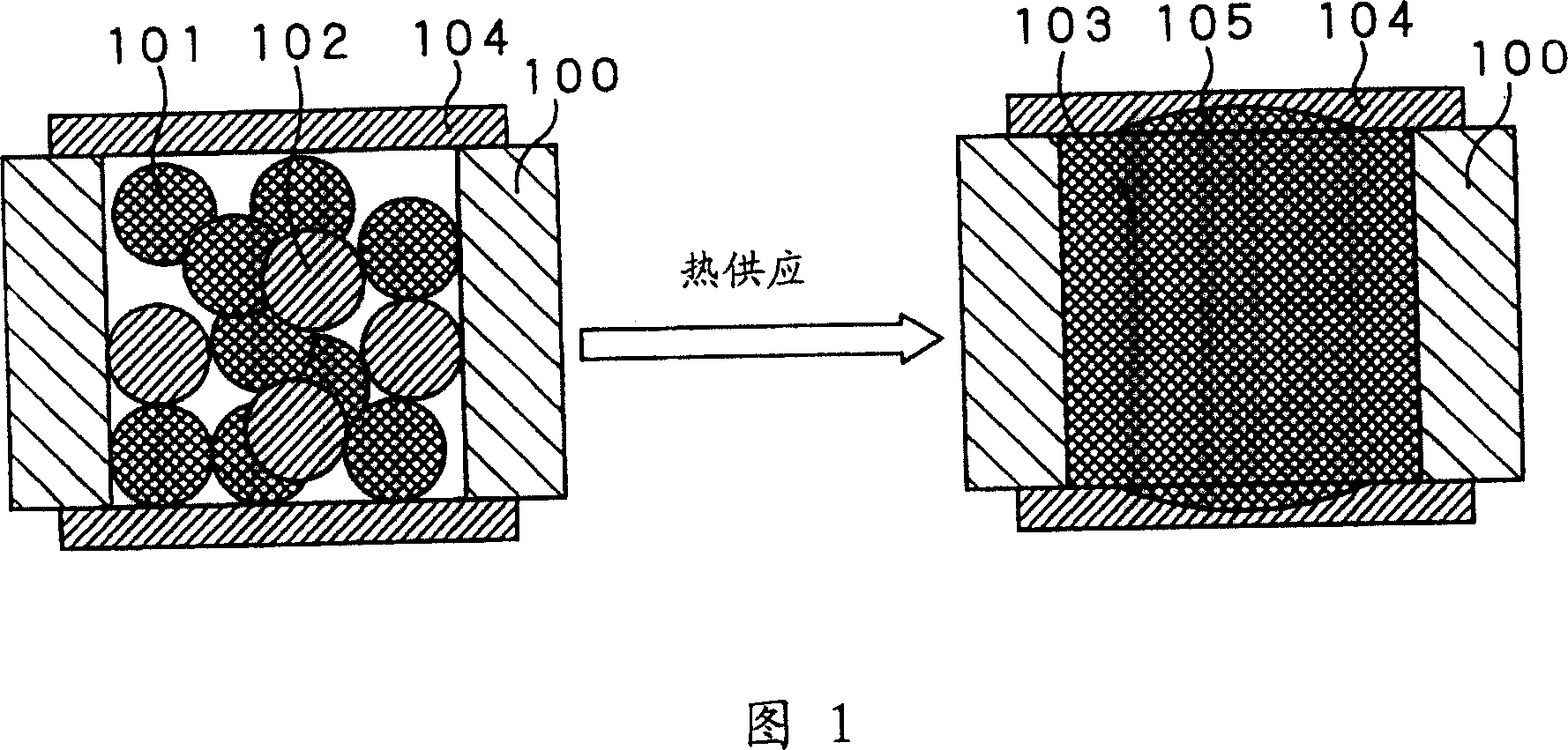

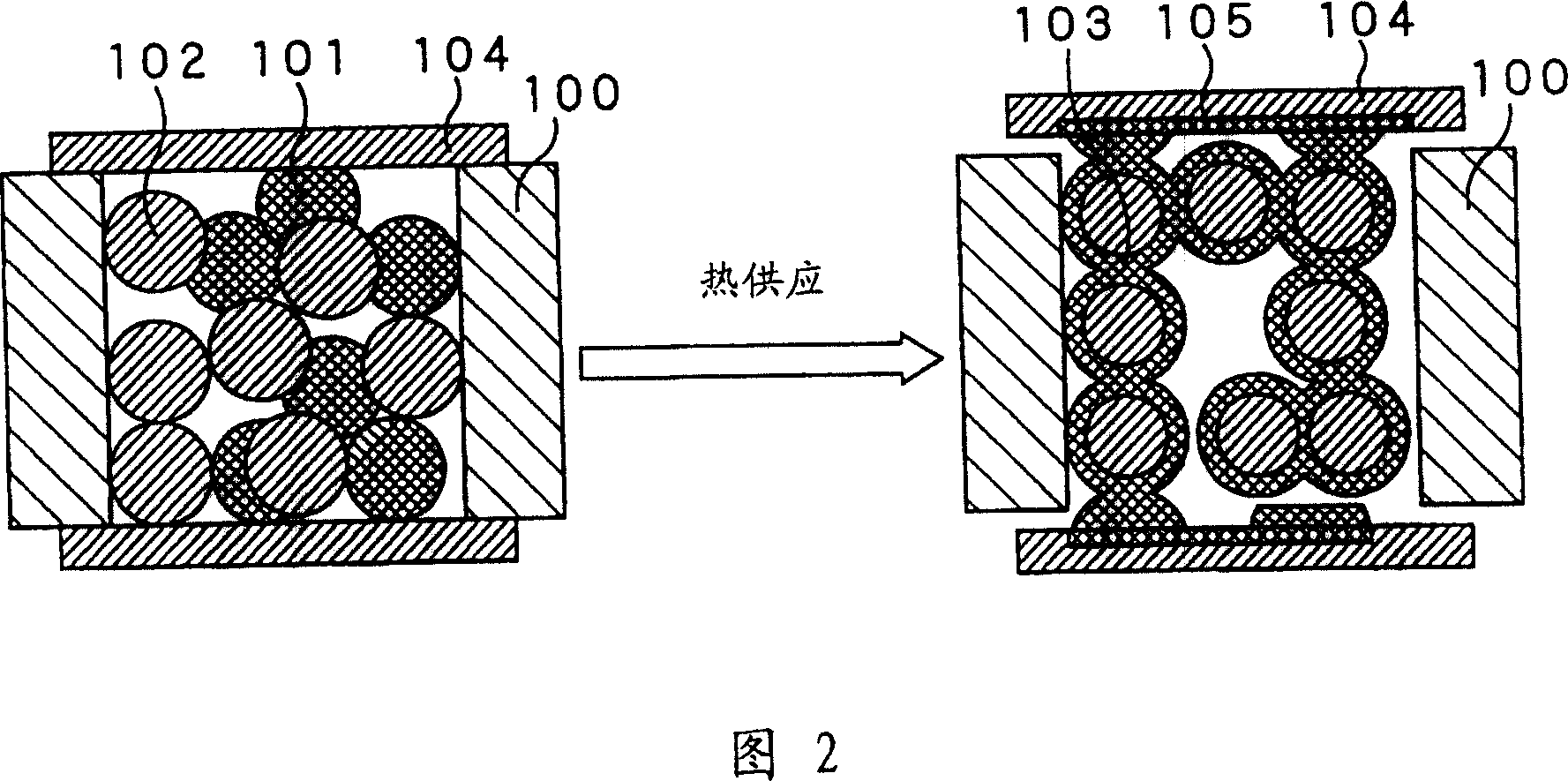

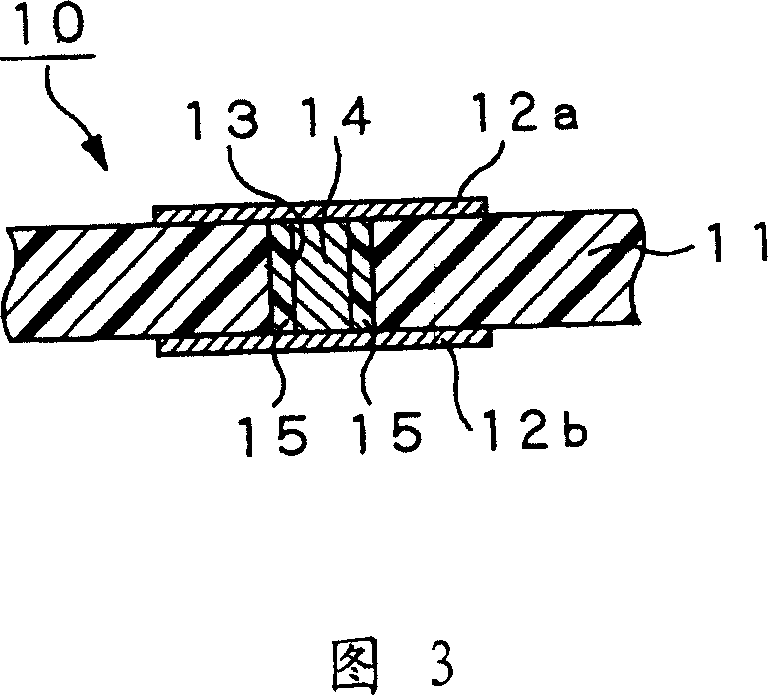

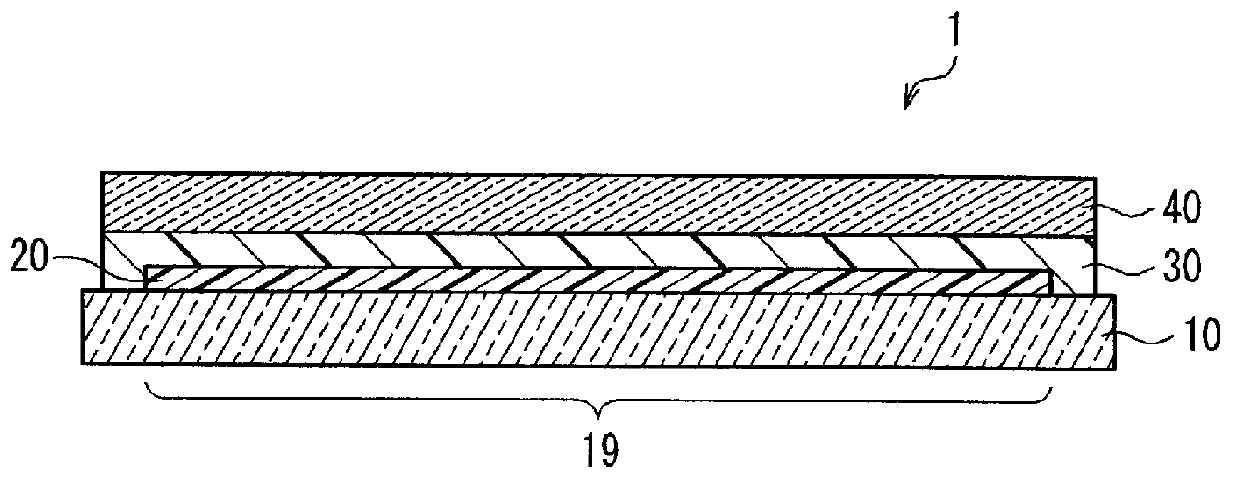

Method of thermal adherend release and apparatus for thermal adherend release

InactiveCN1787169AWill not cause sheddingStripping does not causeSolid-state devicesSemiconductor/solid-state device manufacturingFoaming agentSwelling pressure

A heat-adherent peeling method, wherein a part of an adherend adhered to a heat-peelable pressure-sensitive adhesive sheet having a heat-expandable layer containing a foaming agent is partially heated by partially heating the heat-peelable pressure-sensitive adhesive The adhesive sheet is selectively peeled from the pressure-sensitive adhesive sheet, wherein the method comprises preheating the adherend to be peeled off at a temperature at which the heat-expandable layer of the heat-peelable pressure-sensitive adhesive sheet does not expand. The adherend is then heated at the temperature at which the heat-expandable layer expands, thereby selectively peeling the adherend.

Owner:NITTO DENKO CORP

Method for mfg. optical elements

An optical element comprising at least a plurality of pixels formed on a substrate and partition walls arranged respectively between adjacent pixels is manufactured by a method comprising steps of forming partition walls of a resin composition on a substrate, performing a dry etching process of irradiating the substrate carrying the partition walls formed thereon with plasma in an atmosphere containing gas selected at least from oxygen, argon and helium, performing a plasma treatment process of irradiating the substrate subjected to the dry etching process with plasma in an atmosphere containing at least fluorine atoms, and forming pixels by applying ink to the areas surrounding by the partition walls by means of an ink-jet system.

Owner:CANON KK

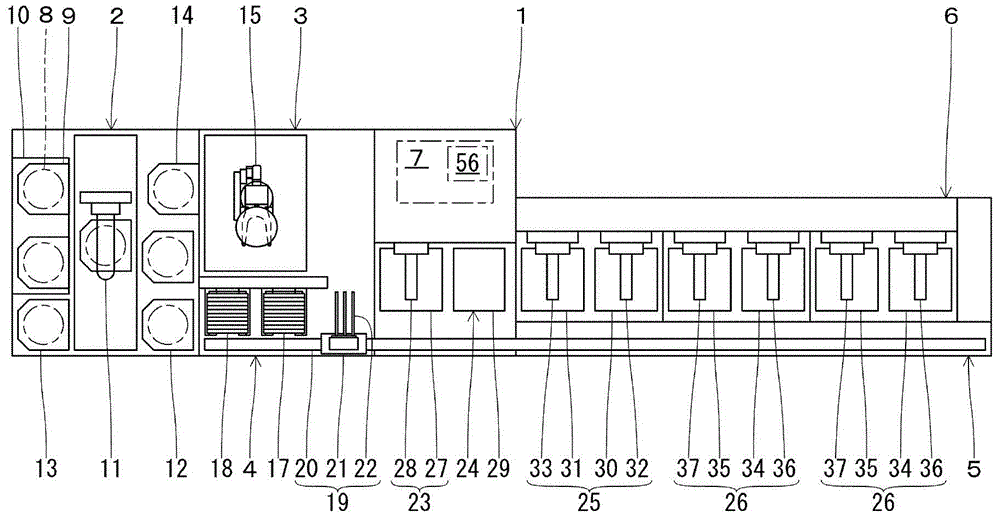

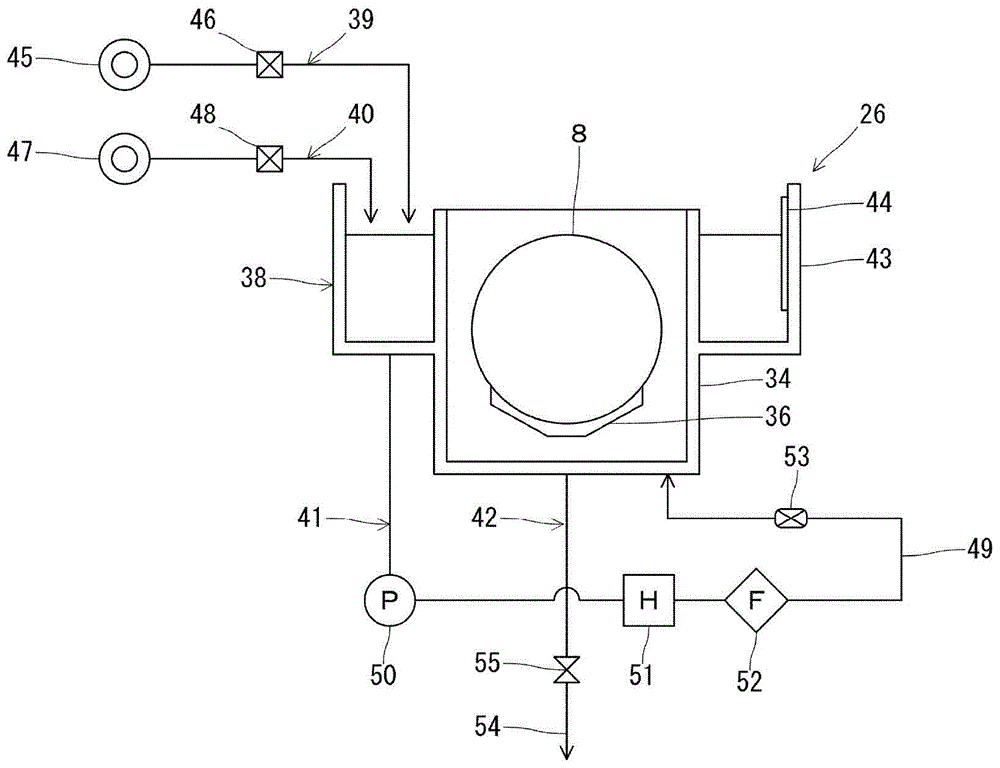

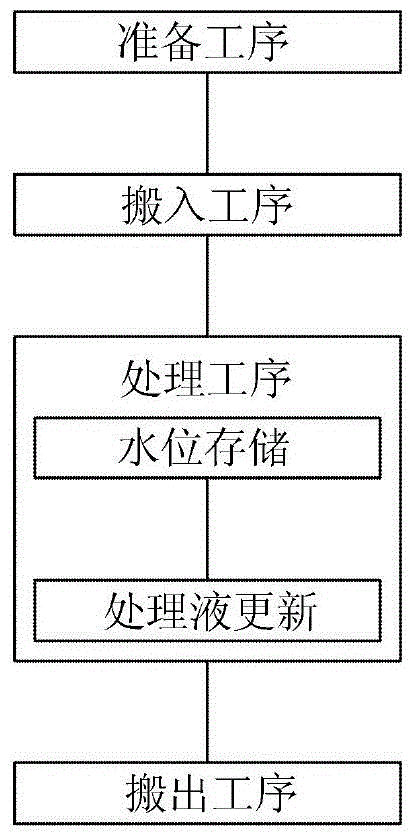

Substrate liquid processing apparatus and substrate liquid processing method

ActiveCN104821285AReduce productivityGood liquid handlingSemiconductor/solid-state device manufacturingCleaning using liquidsAqueous solutionChemical agent

Disclosed is a method for performing a liquid processing on a substrate using an aqueous solution of a chemical agent at a predetermined concentration as a processing liquid. The method includes: storing the processing liquid in a processing liquid storage unit; and supplying an aqueous solution of the chemical agent at a different concentration from the concentration of the processing liquid to the processing liquid storage unit, discharging the processing liquid from the processing liquid storage unit so as to update the processing liquid stored in the processing liquid storage unit. The aqueous solution in a predetermined amount is supplied to the processing liquid storage unit, and the processing liquid is discharged from the processing liquid storage unit, the processing liquid containing the chemical agent in the same amount as the amount of the chemical agent contained in the aqueous solution supplied to the processing liquid storage unit.

Owner:TOKYO ELECTRON LTD

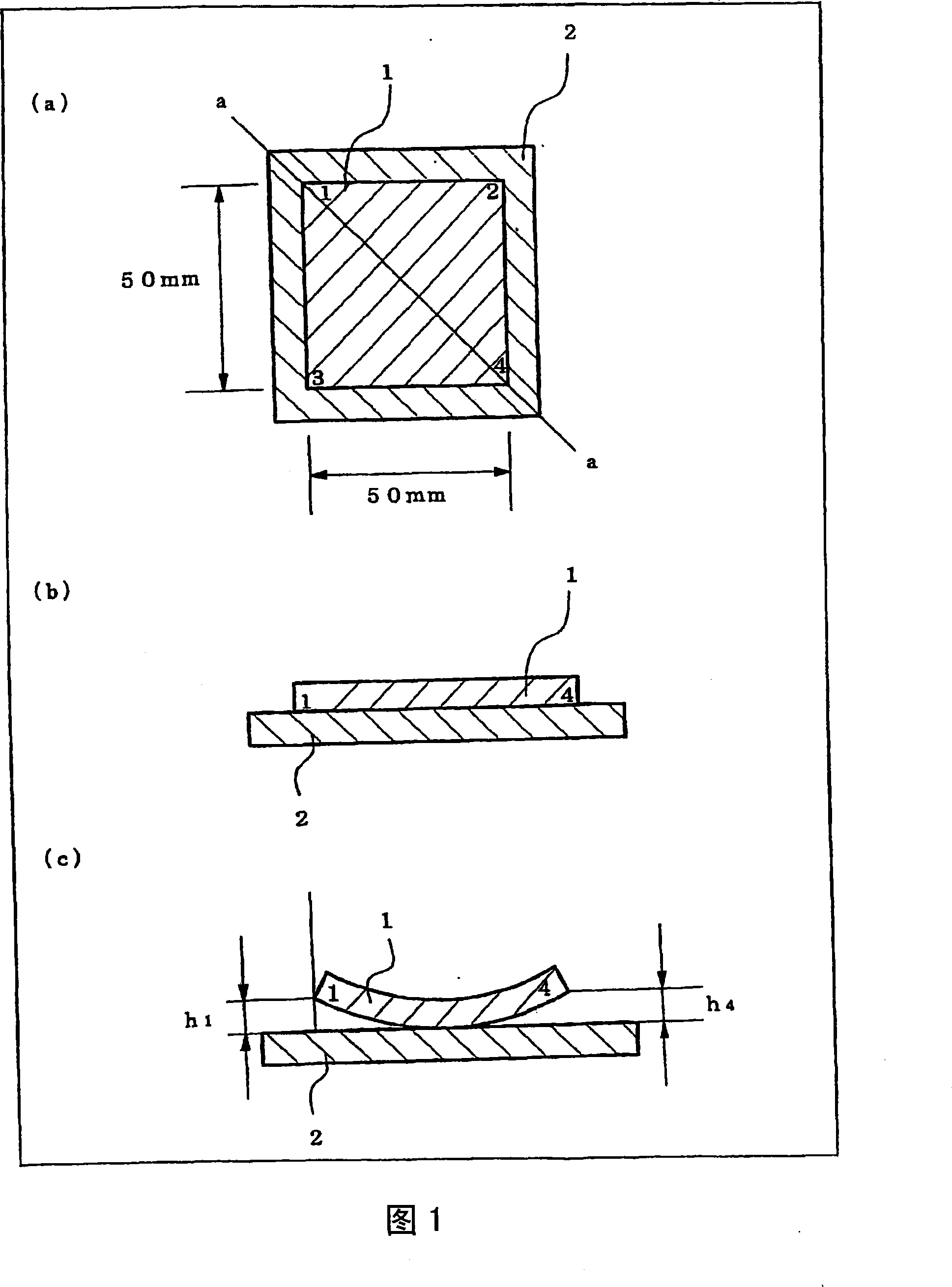

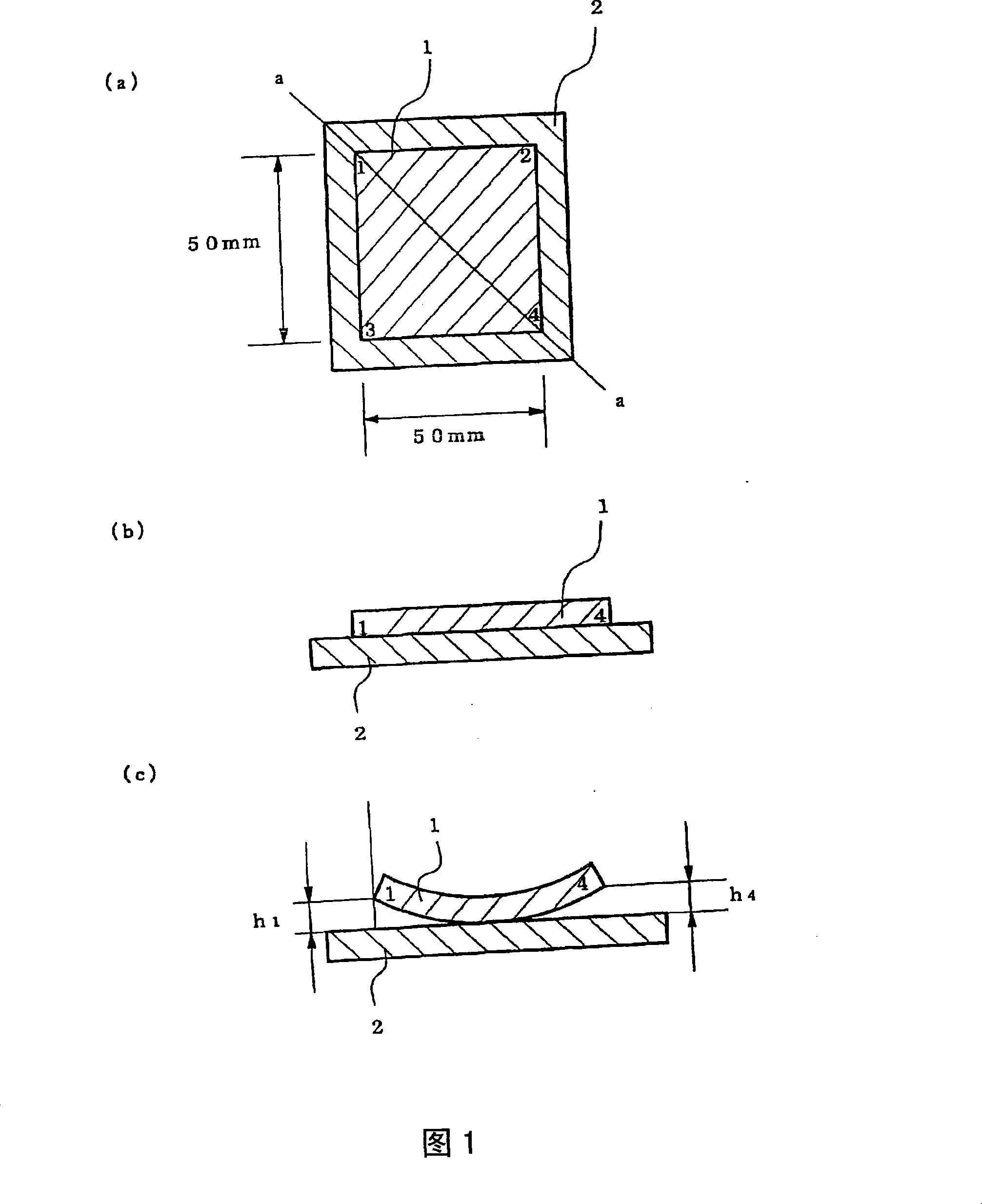

Thin film-laminated polyimide film and flexible printed wiring board

ActiveCN101193750AReduce productivitySynthetic resin layered productsPrinted circuit aspectsEngineeringFlexible electronics

The thin film-laminated polyimide film contains a substrate film and a thin film layer formed at least on one surface of the substrate film. The substrate film is made of a polyimide film showing a degree of curl after a heat treatment at 300°C of not more than 10%. Use of this thin film-laminated polyimide film as a substrate of electronic parts such as solar battery, capacitor and the like exposed to high temperatures prevents easy development of warpage and distortion during production, and can improve quality and yield of electronic parts.

Owner:TOYOBO CO LTD

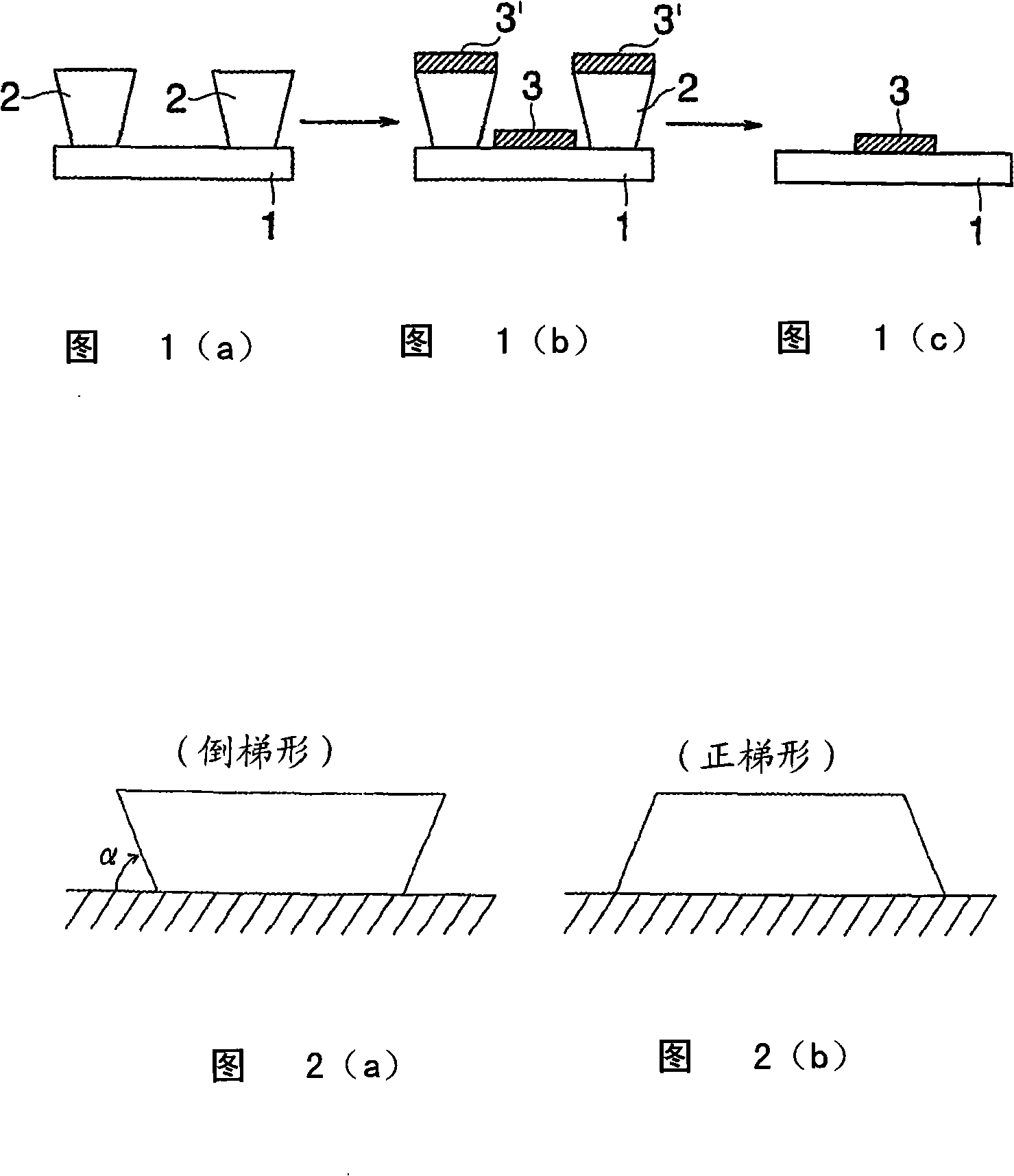

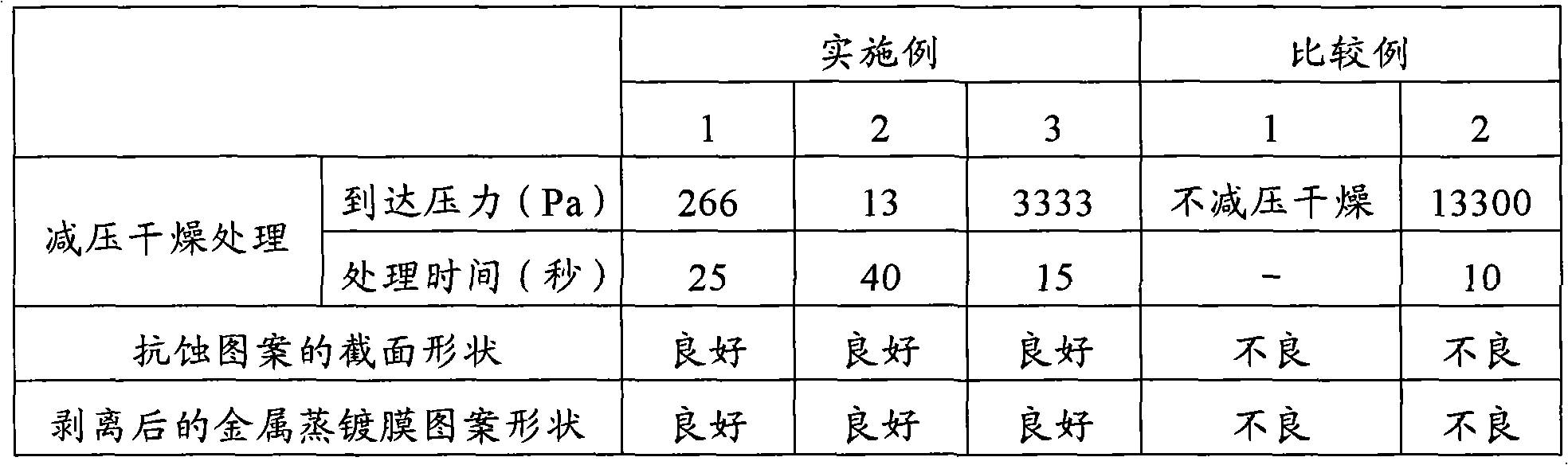

Process for producing substrate with metal wiring

InactiveCN101278239AReduce productivityCheap manufacturingSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusSolventChemistry

The invention provides a process for producing a substrate bearing a metal wiring, which comprises (a) a step in which a positive photosensitive resin composition comprising (A) an alkali-soluble resin, (B) a compound having a quinonediazide group, and (C) a solvent is applied to a substrate to form a coating film, (b) a step in which the coating film is dried under vacuum to form a photosensitive layer, (c) a step in which the photosensitive layer is pattern-wise exposed to light and then developed to form a resist pattern in a reversed taper form, (d) a step in which a metal is vapor-deposited on the substrate having the resist pattern in a reversed taper form obtained in the step (c), and (e) a step in which both of the resist pattern in a reversed taper form and the vapor-deposited metal film formed thereon are removed by a lifting-off operation from the substrate which has undergone metal vapor deposition in the step (d). The target substrate can be inexpensively produced with satisfactory productivity from a substrate having a reversed-taper-form resist pattern obtained from a common positive photoresist.

Owner:ZEON CORP

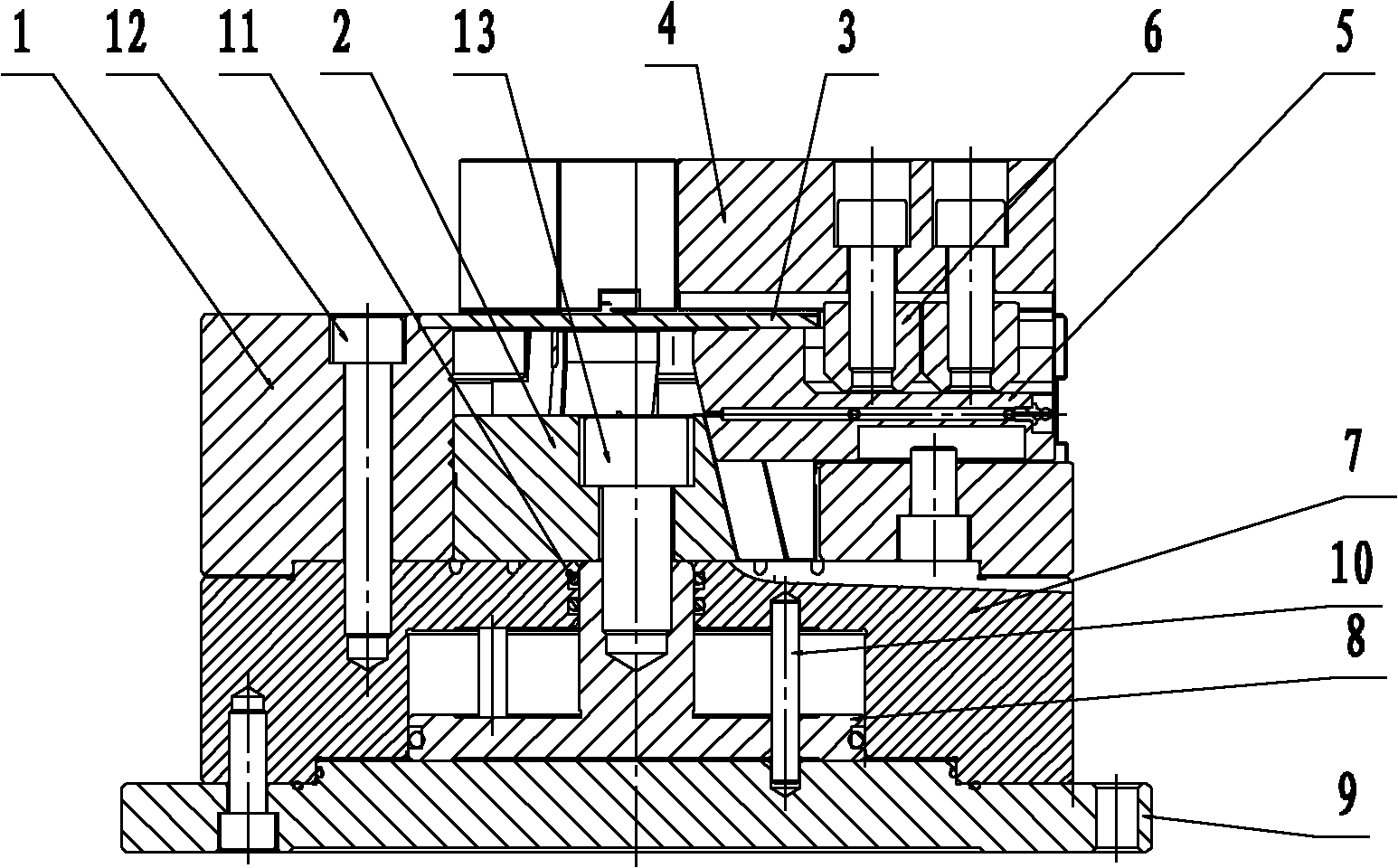

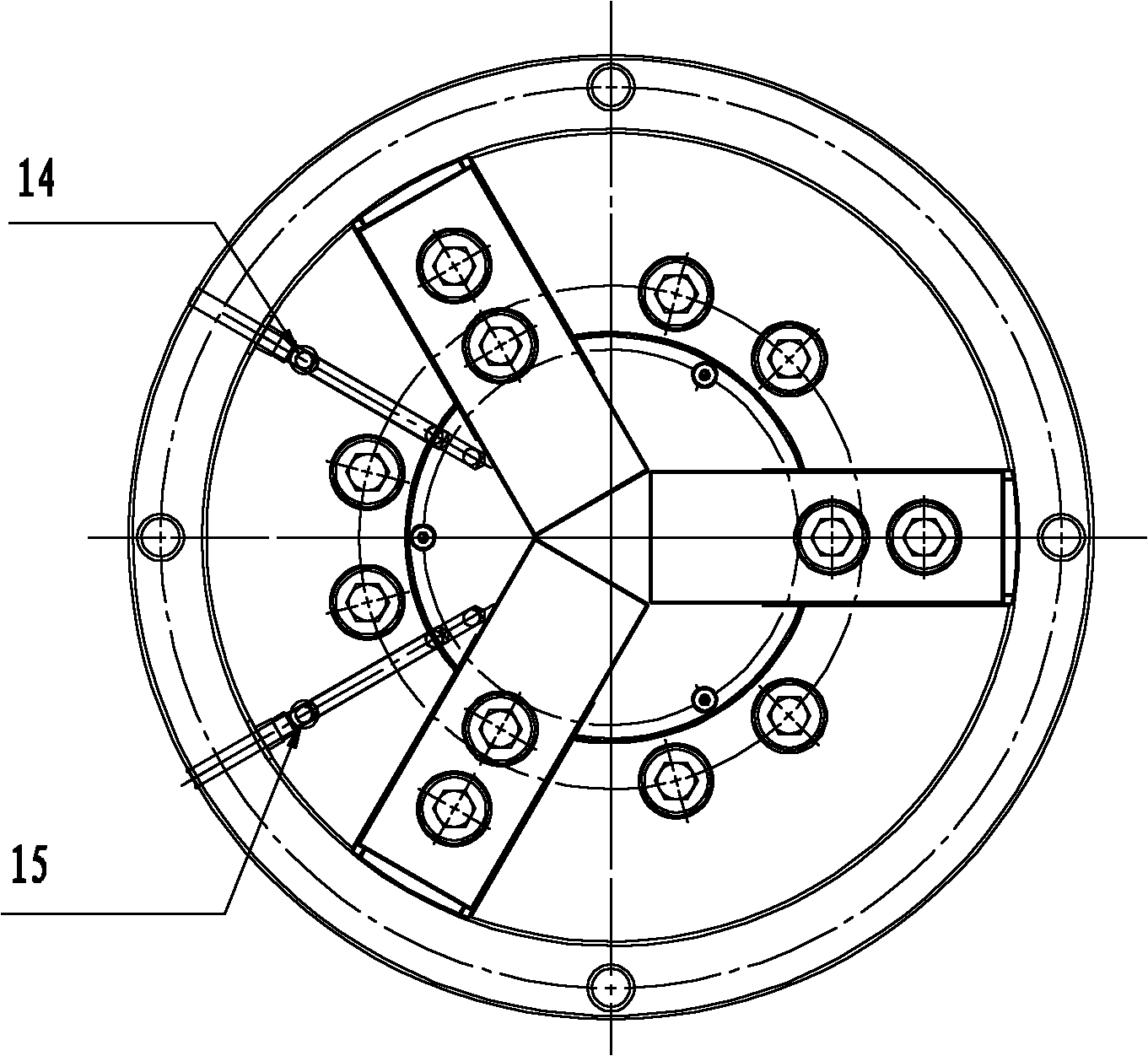

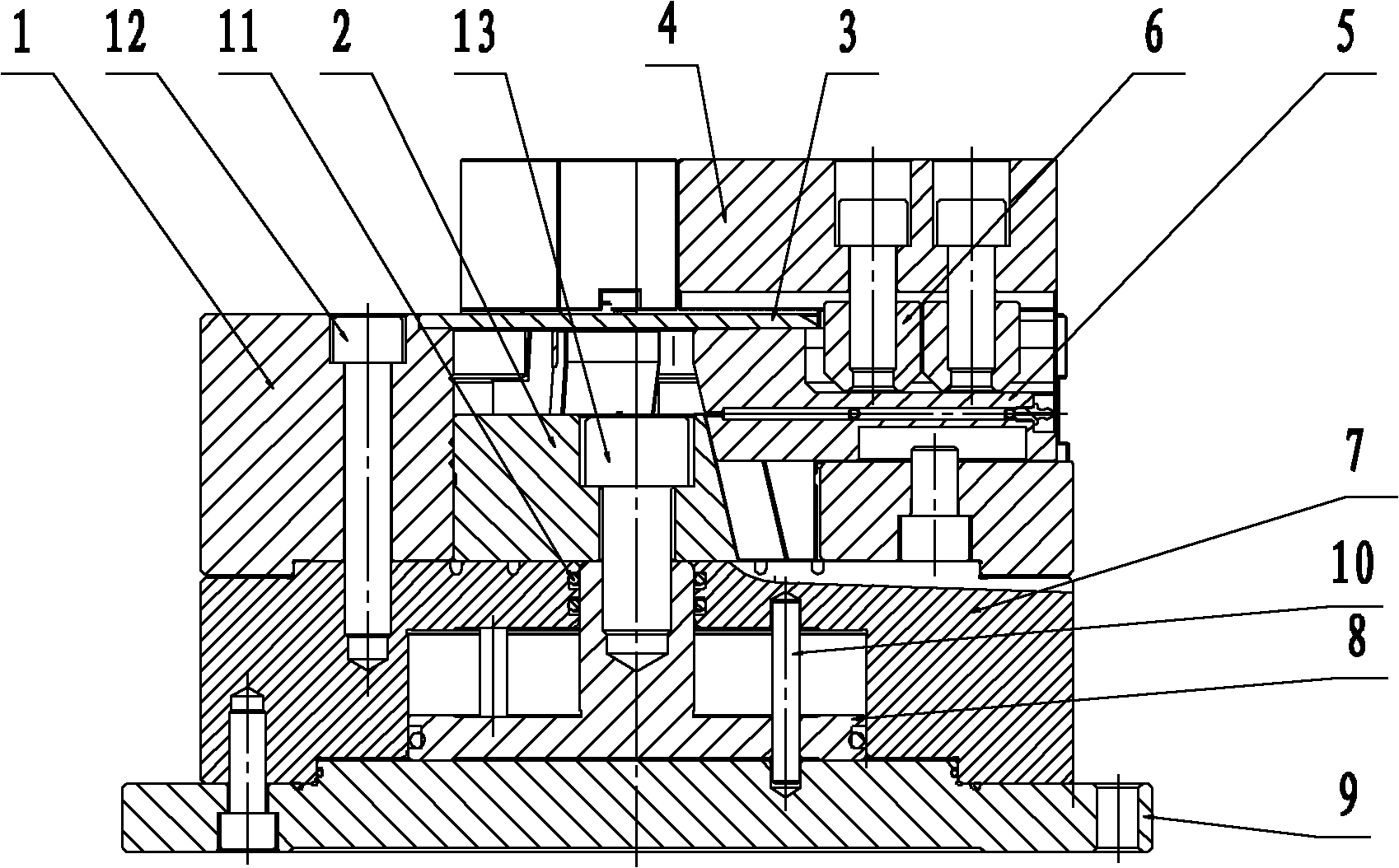

Vertical type fixed hydraulic power chuck

The invention relates to a vertical type fixed hydraulic power chuck which comprises a chuck body, a wedge catch system, a blocking cover, three claws, three slide carriages and six T-shaped blocks, and is characterized in that an oil cylinder body and a base form an oil cylinder main body; a piston is installed in the oil cylinder body and slides in the oil cylinder body along the direction of a guiding shaft; an upper oil chamber and a lower oil chamber are formed above and below the piston; the control hydraulic oil of the upper oil chamber and the lower oil chamber is controlled by a left oil inlet and outlet hole or a right oil inlet and outlet hole; the piston is connected with the wedge catch system by a driving connecting screw; under the driving of the piston, the wedge catch system slides up and down in the chuck body; and the chuck body is connected seamlessly and fixedly with the oil cylinder body by a connecting bolt. The structure of the invention is simple, compact and reasonable, the vertical type fixed hydraulic power chuck connects the cylinder body and the chuck integrally and is loaded on a work bench, a workpiece can be loaded and clamped conveniently, and quick die changing can be realized, thereby greatly lightening the labor intensity, shortening the clamping time, improving the productivity, having adjustable clamping force, and being suitable for matching with a numerical control machining center.

Owner:江苏无锡建华机床附件集团有限公司

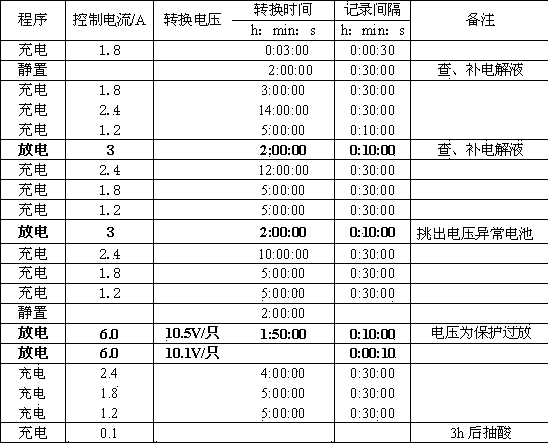

Five-charge three-discharge storage battery container formation method

InactiveCN103647114AQuality improvementReduce wasteSecondary cells charging/dischargingEconomic benefitsEngineering

The invention relates to a five-charge three-discharge storage battery container formation method. The method is characterized by adopting a five charging steps and three discharging steps to complete the container formation and comprising the following steps of first-time charging: charging the storage battery for 3min through the current of 1.8A, and standing for 2h; second-time charging: charging the storage battery for 3h through the current of 1.8A, then charging the storage battery for 14h through the current of 2.4A, and charging the storage battery for 5h through the current of 1.2A; first-time discharging: discharging the storage battery for 2h through the current of 3A; third-time charging: charging the storage battery for 12h through the current of 2.4A, and then charging the storage battery for 5h respectively through the currents of 1.8A and 1.2A; second-time discharging: discharging the storage battery for 2h through the current of 3A; fourth-time charging: charging the storage battery for 10h through the current of 2.4A, then charging the storage battery for 5h respectively through the currents of 1.8A and 1.2A, and standing for 2h; third-time discharging: discharging the storage battery to 10.5V through the current of 6A; and fifth-time charging: charging the storage battery for 4h through the current of 2.4A, charging the storage battery for 5h through the current of 1.8A, charging the storage battery for 5h through the current of 1.2A, charging the storage battery for 3h through the current of 0.1A, and finally extracting the acid. The method is simple in process, a great amount of working hours and energy can be saved, and the economic benefit of enterprises can be improved.

Owner:TIANNENG BATTERY WUHU

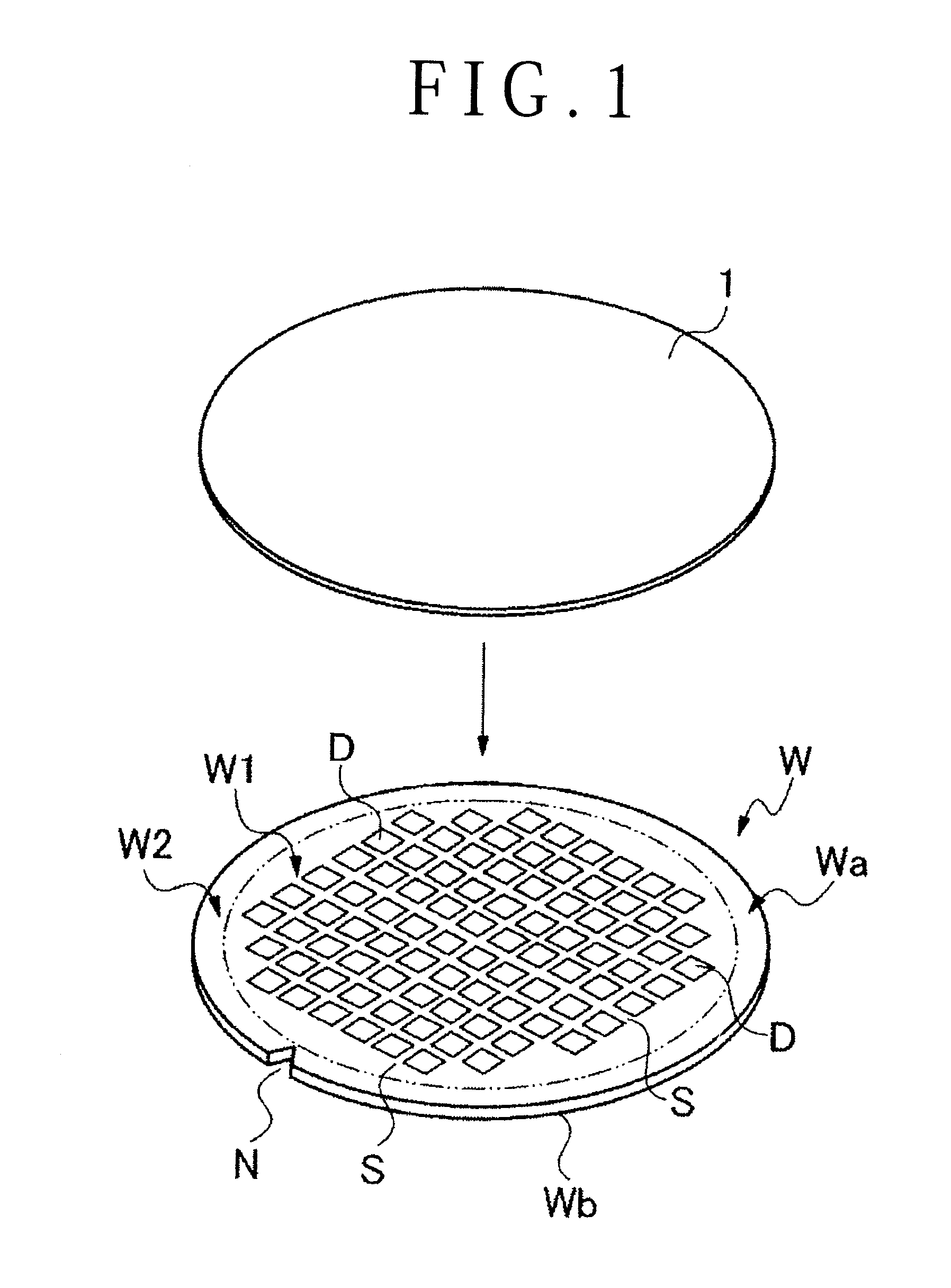

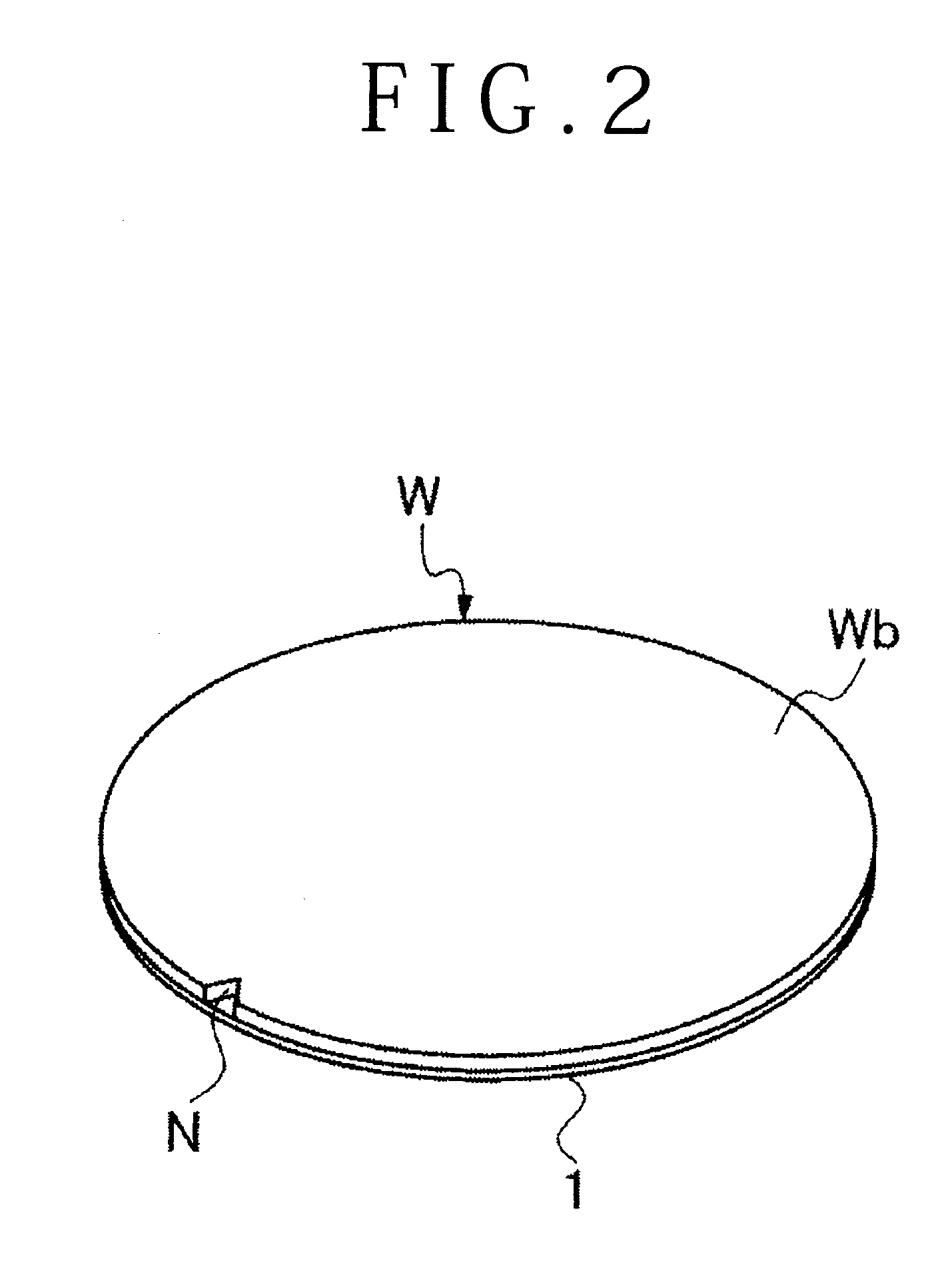

Wafer processing method

ActiveUS20100255657A1Reduce productivityDecrease productivitySemiconductor/solid-state device manufacturingEngineeringFilm coating

A wafer processing method of dividing a wafer into individual devices, the wafer having on a front surface a device area and an external circumferential redundant area surrounding the device area, the method including: a wafer grinding step in which, in the state where the wafer is held on the side of a protection tape stuck to the front surface of the wafer, a rear side of the device area in a rear surface of the wafer is ground to form a recessed portion to form a ringlike reinforcing portion on an outer circumferential side of the recessed portion; a metal film coating step for coating, with a metal film, a rear surface of the wafer stuck with the protection tape on the front surface; and a wafer dividing step for cutting the predetermined dividing lines from a rear surface side of the wafer stuck with the protection tape on the front surface, thereby dividing the wafer into the individual devices.

Owner:DISCO CORP

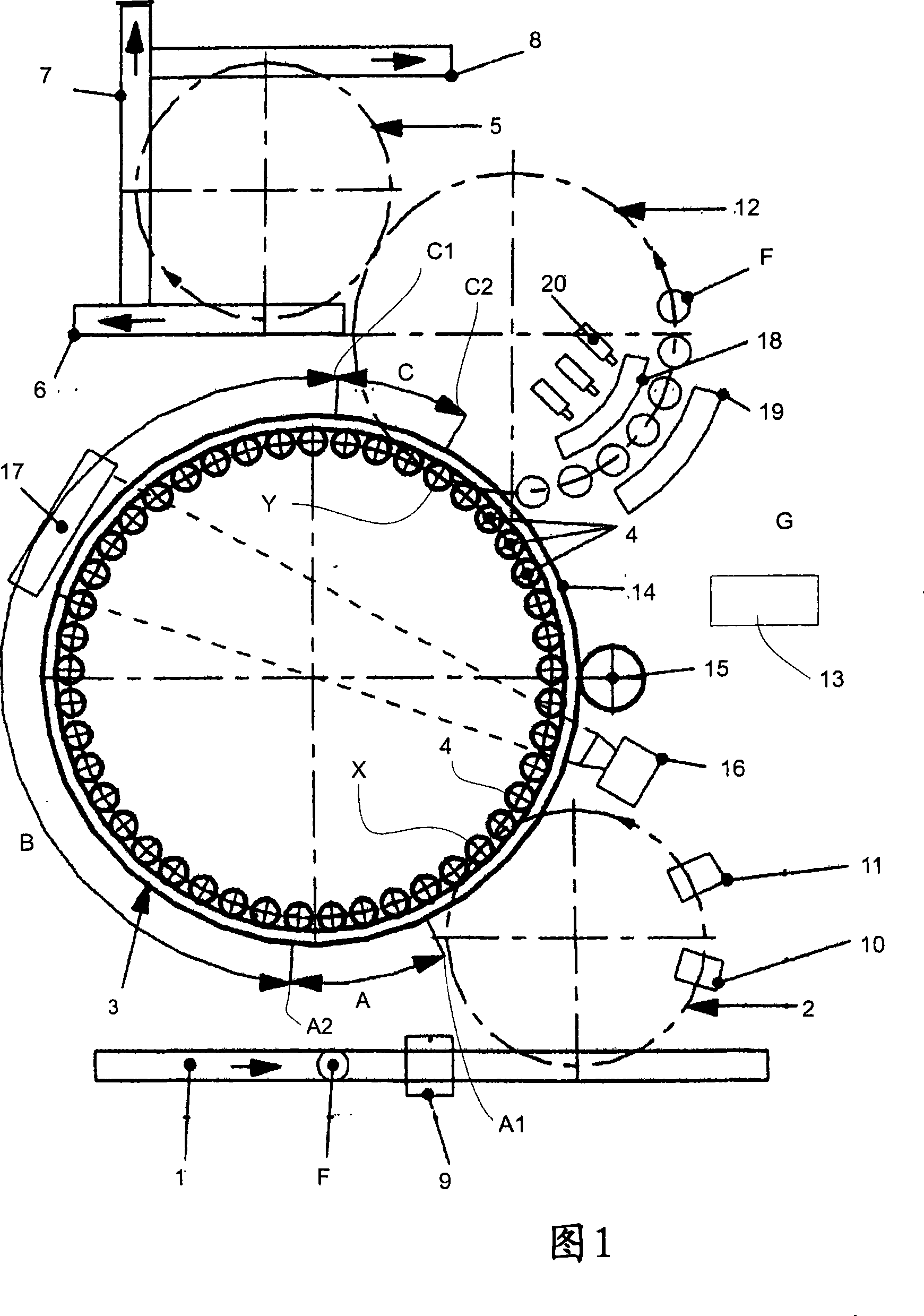

Method and device for inspecting containers

InactiveCN101210885AReduce productivitySimple designOptically investigating flaws/contaminationStructural engineeringMechanical engineering

Owner:KRONES AG

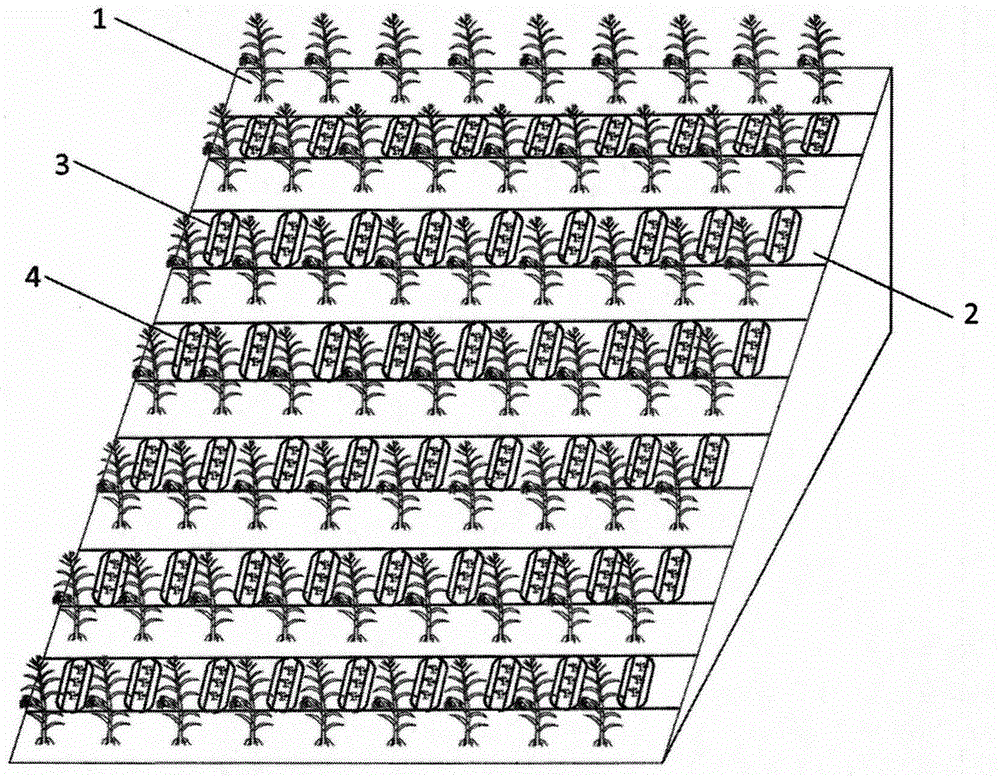

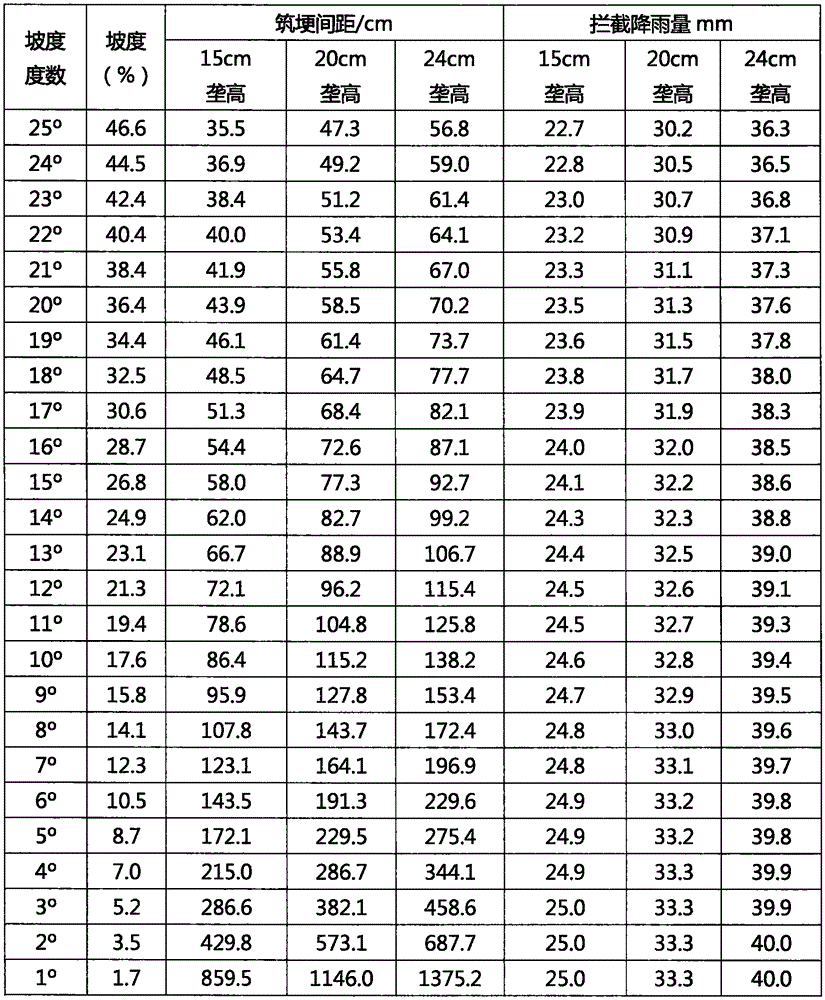

Hedge earth bank ridge-direction pitting field having functions of conserving water, soil, nitrogen and phosphorus and cultivation method

InactiveCN105145068AImprove retentionIncrease moisture contentHorticultureSoil-working methodsEconomic benefitsNitrogen

The invention relates to a hedge earth bank ridge-direction pitting field having functions of conserving water, soil, nitrogen and phosphorus. The field comprises ridges and multiple earth banks, and the ridges comprise ridge bodies and furrows; the multiple ridge bodies and the multiple furrows are arranged in parallel and at intervals; multiple earth banks are arranged in each furrow in the extending direction of the corresponding furrow, and each earth bank is provided with a hedge. The invention further relates to a cultivation method of the ridge-direction pitting field. The cultivation method comprises the steps of measuring the slope and length of the field; making selection between downslope ridge culture or cross-slope ridge culture according to the measured slope and length, and arranging the multiple furrows and ridge bodies, wherein the furrows and the ridge bodies are arranged in parallel and at intervals; arranging the multiple earth banks in each furrow in the extending direction of the corresponding furrow; planting plants on each earth bank for forming the corresponding hedge. According to the hedge earth bank ridge-direction pitting field and the cultivation method, the hedges are reasonably arranged, the stability and firmness of the earth banks are improved, meanwhile, the water, soil, nitrogen and phosphorus conservation effects are greatly improved, the water and soil conservation effect is made to be more ideal, environmental benefits are achieved, and meanwhile economic benefits are combined.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

Overmoulding of receptacles with a thermoplastic material at a high rate of production

InactiveUS7569171B2Reduce productivityReduce breakagePackaging toiletriesFood shapingProduction rateHigh rate

An overmolding process for a hollow receptacle provided with a neck, and an axial body with a shoulder a sidewall and a bottom, the hollow receptacle, having axial height H and larger cross-section S. When the mould is open, the neck bears in contact with an axial support so as to mask the neck during the overmolding process. Before closing the mold, the sidewall is placed in a lateral positioning device that can be moved along an axial direction of the mold. After the mold has been closed, the lateral positioning device is displaced in the axial direction as the material flow injected into the axial cavity and forming an annular flow.

Owner:ALCAN PACKAGING BEAUTY SERVICES

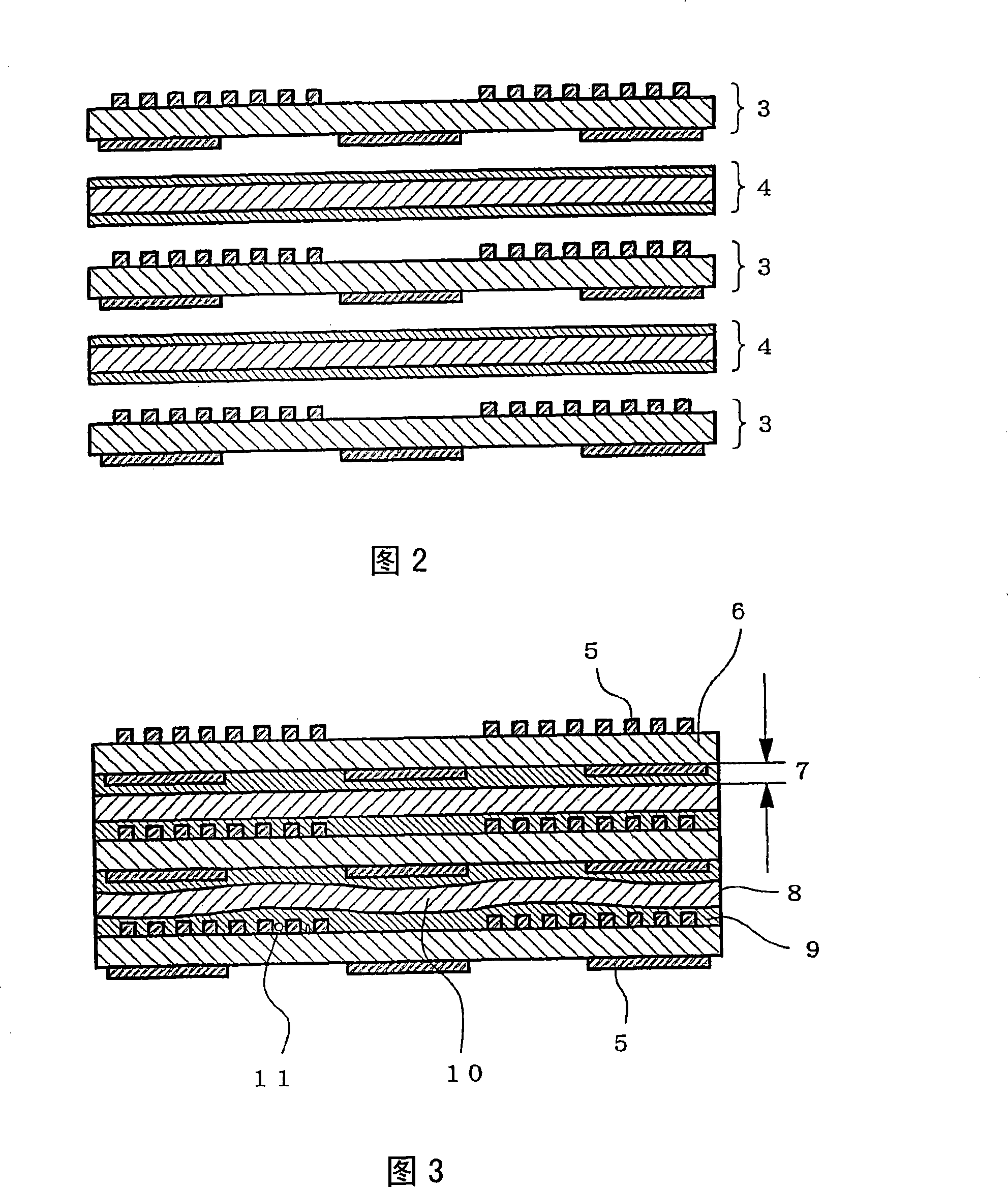

Multilayer wiring board and fabricating method of the same

InactiveCN1933696AUniform structureImprove connection stabilityElectrical connection printed elementsMultilayer circuit manufactureElectrical conductorTextile

The invention improves reliability of interlayer connection of a multilayer wiring board. Plural metal conductor pattern layers are formed on a base material made of thermoplastic resin. Then, high melting metal containing copper, low melting metal containing tin, and binder resin are packed into a via hole. Subsequently, predetermined heat and pressure are applied. Then, while half-melted metal mixture droplets of the low and high melting metals and melted binder resin are phase separated from each other, the surfaces of the conductor patterns that face the openings of the via and the low melting metal are alloyed with each other to form an alloy layer as well as the high and low meting metals are alloyed with each other to form a columnar-shaped interlayer connection part. As a result, an intermediate layer is formed between the outer surface of the columnar-shaped interlayer connection part and inner surface of the via hole.

Owner:SONY CORP

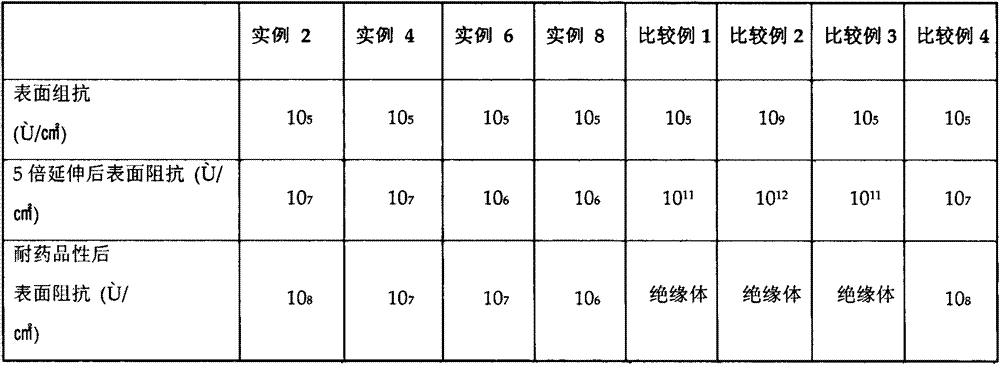

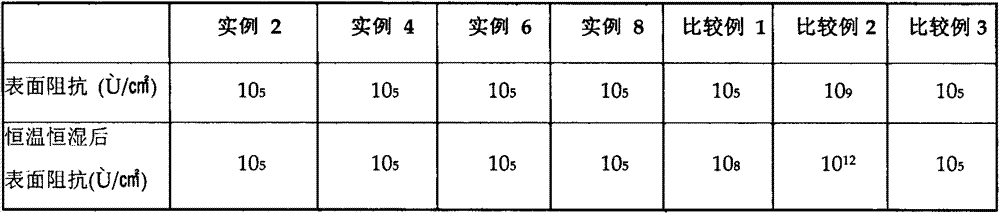

Processing method for producing anti-static sheet through continuous process

The invention relates to a processing method for producing an anti-static sheet through a continuous process. According to the processing method, in the process of extruding thermoplastic polymer resin of an insulator into the sheet through an extruder, an anti-static liquid is coated on at least one side of the sheet online to form an anti-static layer, wherein the anti-static liquid is kiss roll coating liquid which contains thermocuring resin and carbon nanotubes with the weight ratio of 100: (0.1-500), as well as the thermocuring resin and water or an organic solvent with the weight ratio of 100: (10-2000). The process of online kiss roll coating on at least one side simultaneously when the sheet is extruded refers to the continuous process [one-step (in-line)]. Compared with an off-line coating mode, the sheet extrusion mode through in-line kiss roll coating has the characteristics of relative corrosion resistance, strong extensibility, excellent anti-static performance of the sheet and the like.

Owner:恩斯盟防静电材料(镇江)有限公司

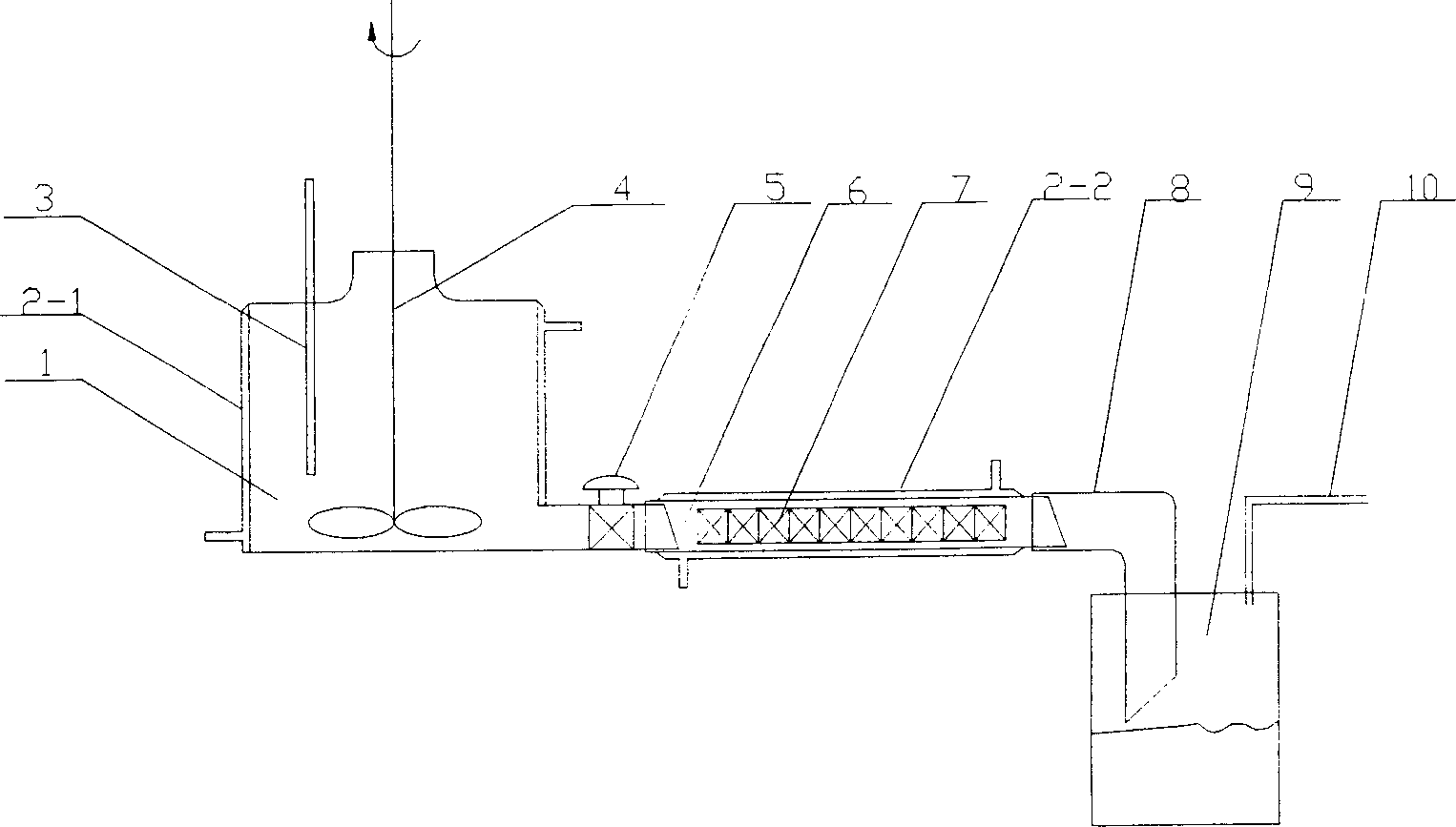

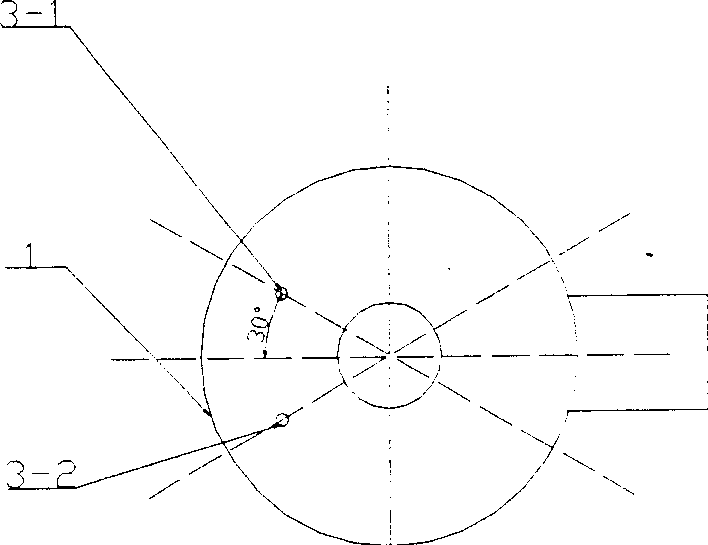

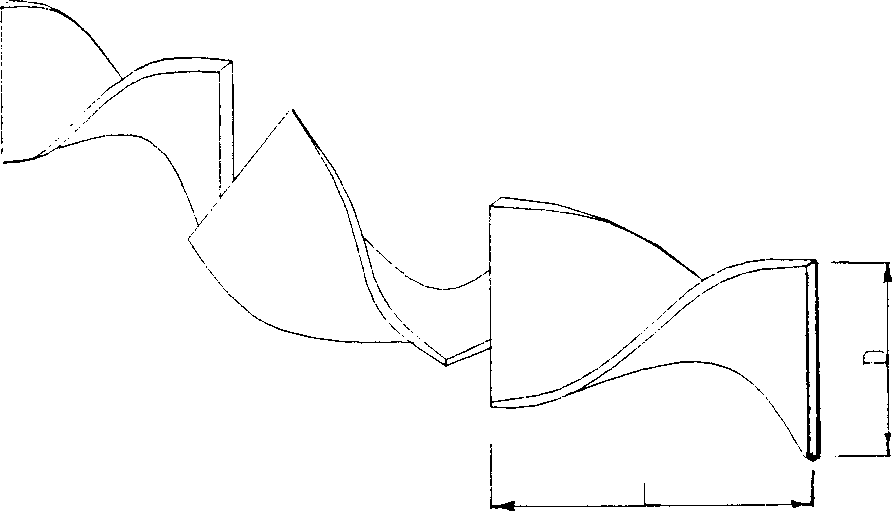

Technique for continuously preparing super fine nano powder by using precipitation method and its specialized equipment

ActiveCN1446654ASame sizeUniform particle sizeCalcium/strontium/barium oxides/hydroxidesCrystalliteNanometre

A process for continuously preparing nano powder by deposition method includes quantiatively and proportionally feeding raw materials in reactor at a certain speed, stirring while nucleating reaction, quickly coming in crystal nuclear growing tube, moving forward under the action of mixer, collecting suspension at tube end, and drying. Its advantages are controllable granularity, high dispersity and uniformity, and high productivity.

Owner:NANJING UNIV OF TECH

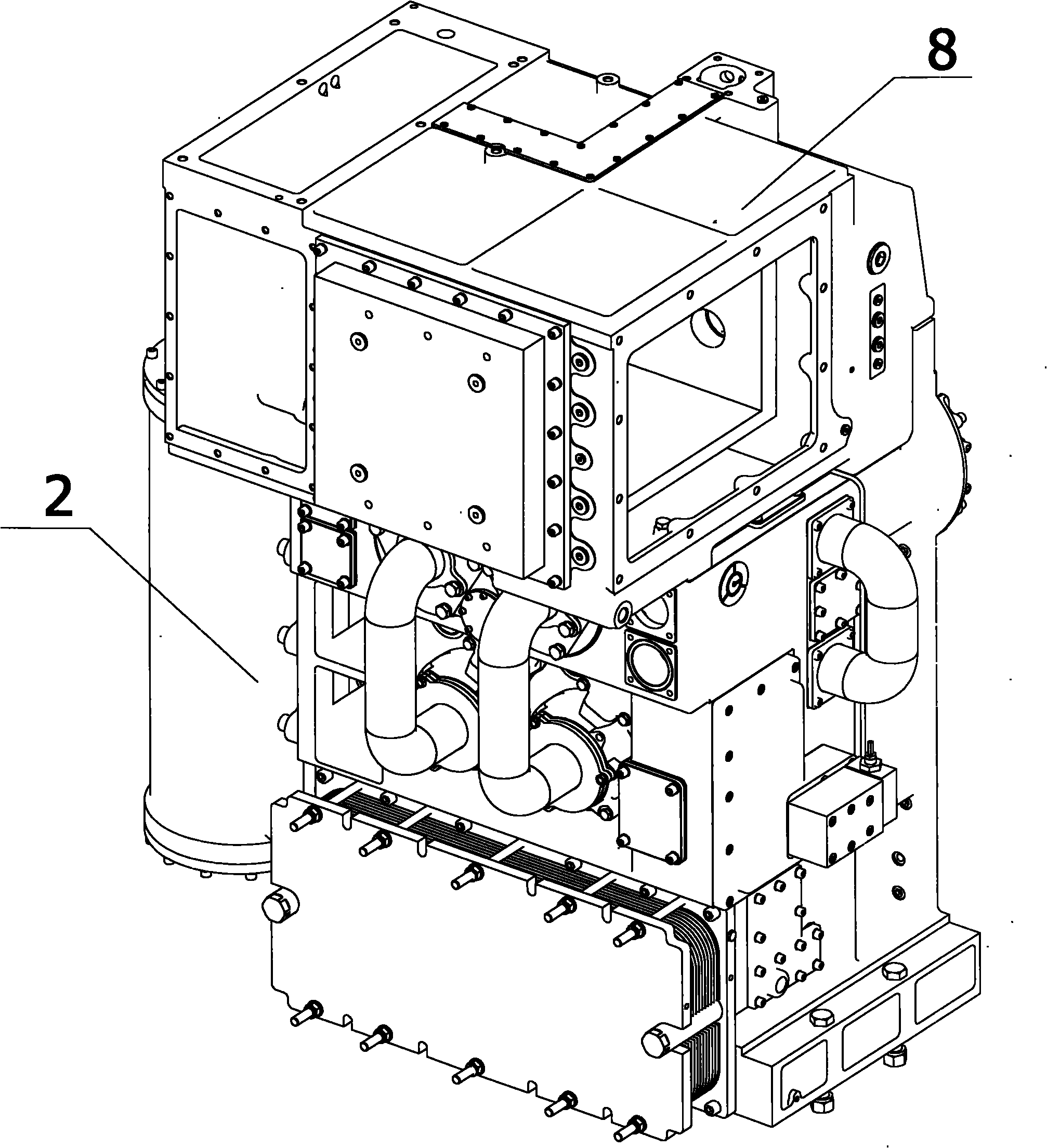

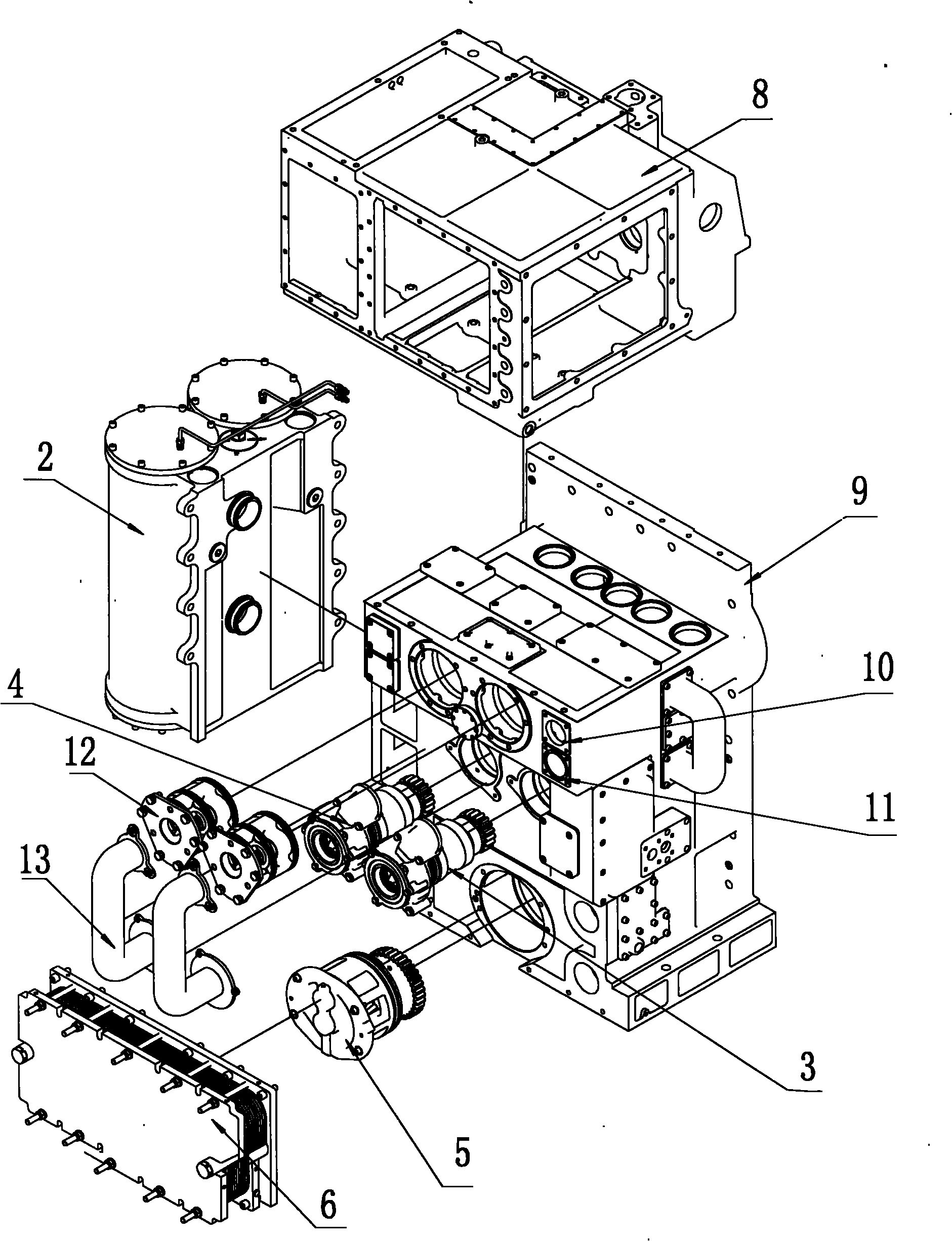

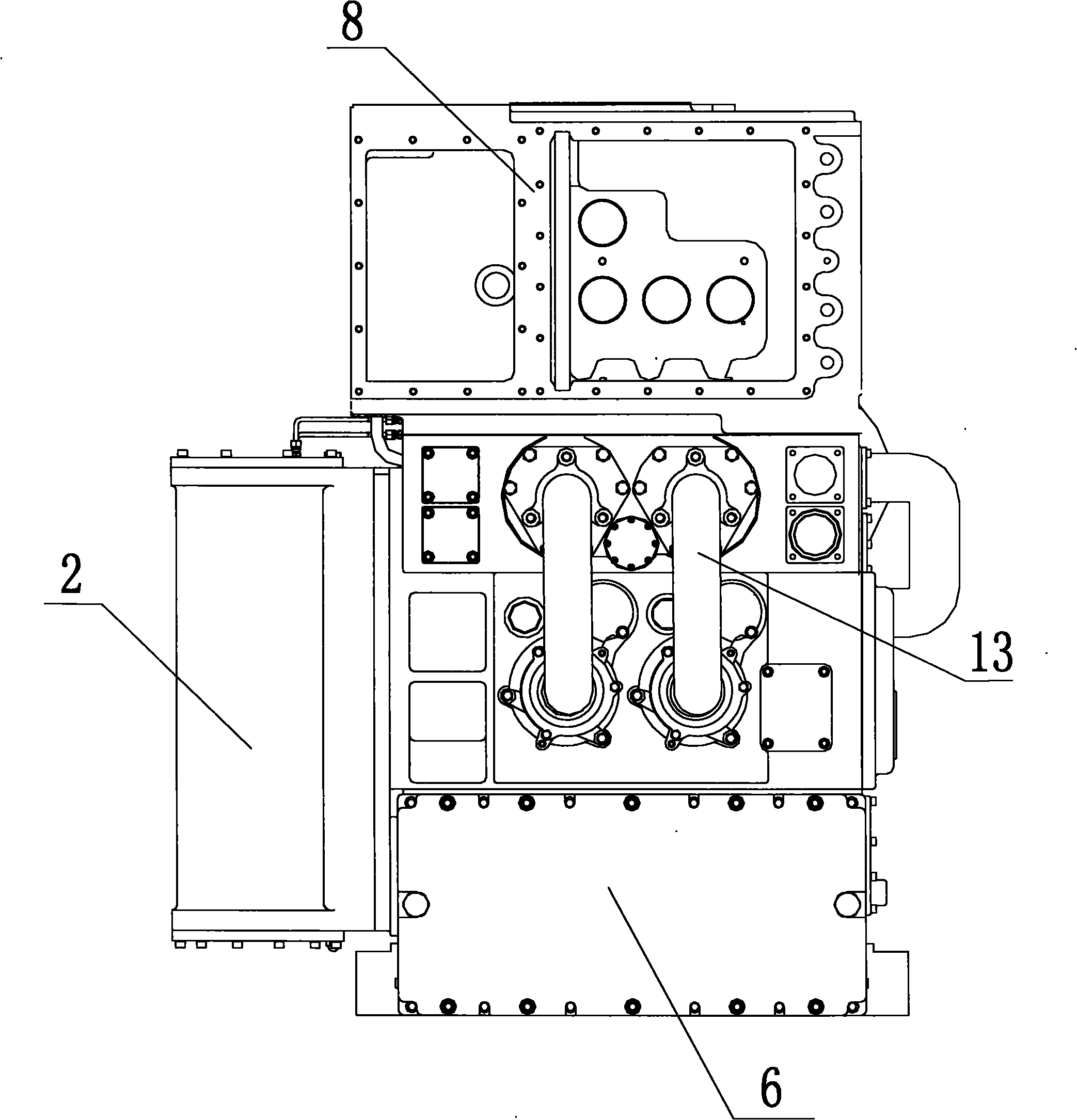

Auxiliary system for diesel engine

ActiveCN101922344AHighly integratedAuxiliary pipeline lessCoolant flow controlInternal combustion piston enginesProduction rateIntercooler

The invention discloses an auxiliary system for a diesel engine, which comprises a lubricating oil filter, a low-temperature cooling water pump, a high-temperature cooling water pump, a main engine oil pump, a lubricating oil cooler, a cooling circulating water temperature controlling device, an intercooler installing box and an auxiliary supporting box body, wherein an external cooling water inlet and an external cooling water outlet are arranged at the upper part of the front surface of the auxiliary supporting box body; the low-temperature cooling water pump, the high-temperature cooling water pump and the cooling circulating water temperature controlling device are integrated at the upper part of the front surface of the auxiliary supporting box body; the main engine oil pump and the lubricating oil cooler are integrated at the lower part of the front surface of the auxiliary supporting box body; the intercooler installing box is integrated on the top surface of the auxiliary supporting box body; a filter connecting outlet is arranged on the lubricating oil filter; and the lubricating oil filter is integrated on the lateral surface of the auxiliary supporting box body through the filter connecting outlet. The invention has higher integration level and less auxiliary pipelines, simplifies the assembly process, is convenient for maintenance, reduces the casting difficulty, and lowers the production efficiency of waste products.

Owner:CHONGQING PUSH MECHANISM

Heat-curable resin composition including silicone powder

InactiveUS20090133905A1Reduce productivityDecrease in electrical propertySemiconductor/solid-state device detailsPrinted circuit aspectsIsocyanateSpecific gravity

A heat-curable resin composition has excellent printability, non-tackiness, matte and electrical properties. The heat-curable resin composition includes a heat-curable resin (A) and silicone powder (B). Preferably, the silicone powder (B) is spherical or substantially spherical, and has a specific gravity of 0.95 to 1.5 and a particle diameter of 0.01 to 10 μm. The heat-curable resin (A) preferably includes a carboxyl group-containing polyurethane and a heat-curable component. The carboxyl group-containing polyurethane is obtained by reacting a polyisocyanate compound (a), a polyol compound (b) (other than compound (c)), and a carboxyl group-containing dihydroxy compound (c).

Owner:SHOWA DENKO KK

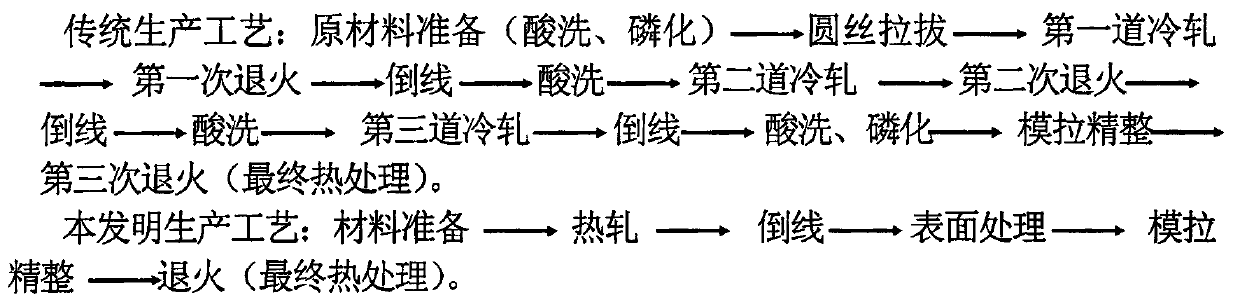

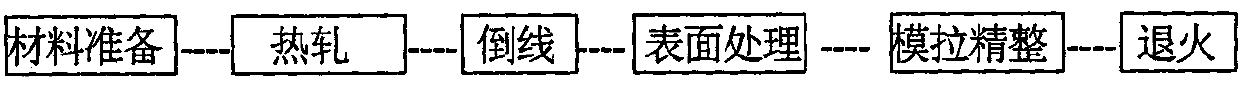

Processing method for flat wire used for tensioning wheel of engine

InactiveCN103357695AImprove productivityHigh scrap rateFurnace typesMetal rolling arrangementsWire rodEngineering

The invention discloses a processing method for a flat wire used for a tensioning wheel of an engine. The processing method comprises the following steps of drawing a carbon steel wire rod or an alloy steel wire rod with the diameter of 11.0-12.0 mm into roulette wounded wire with the diameter of 10.0-10.8 mm; heating the steel wire to a temperature of 900-1,100 DEG C at a heating speed of 6.0-12.0 m / s by power-on heating; rolling the roulette wounded wire to the thickness of 3.4-4.5 mm and the width of 16.5-17.0 mm through a rolling mill once; performing pickling and phosphating surface treatment on the hot-roll flat wire; drawing the wire into the size of a product; winding the wire by a detachable roulette; removing the roulette; and carrying out annealing treatment at a temperature of 650-720 DEG C and keeping the temperature for 2-5 h. The production process can roll the wire into required size once, is high in production efficiency and stable in product quality, can save energy consumption, overcomes the disadvantages of a conventional production process, and omits tedious backwinding and pickling processes.

Owner:SINOSTEEL ZHENGZHOU AOWEI STEEL WIRE TECH

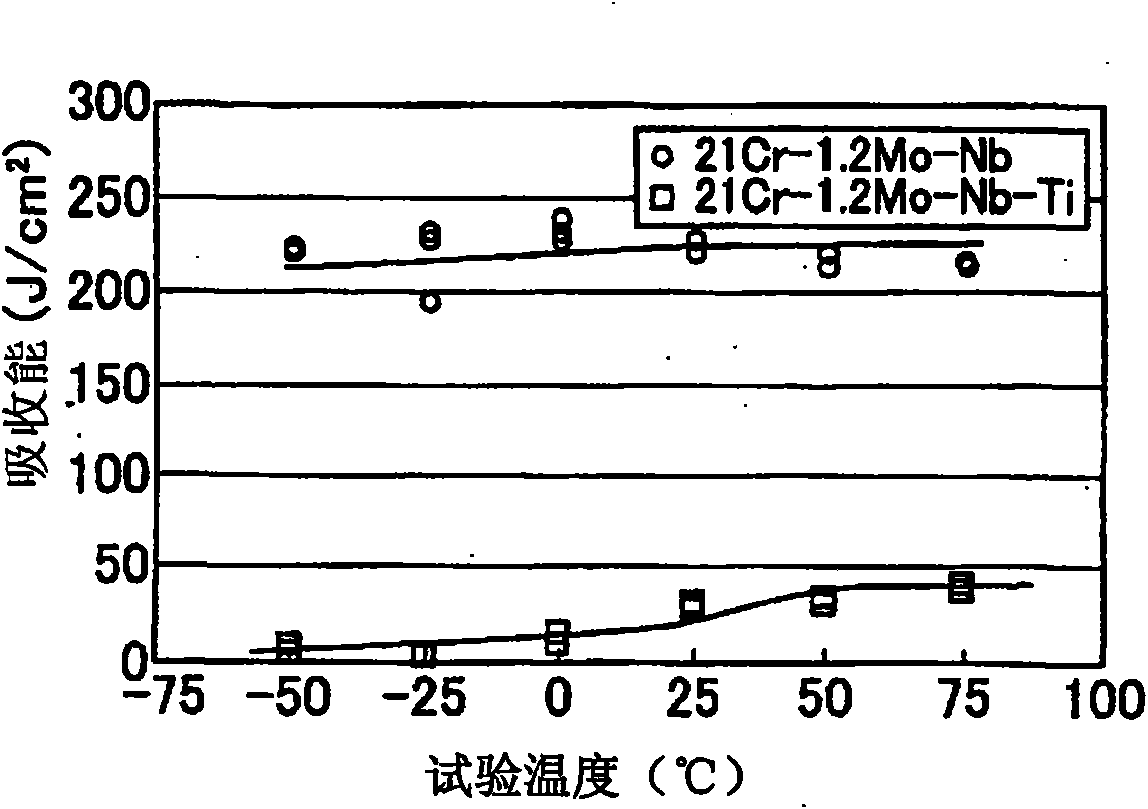

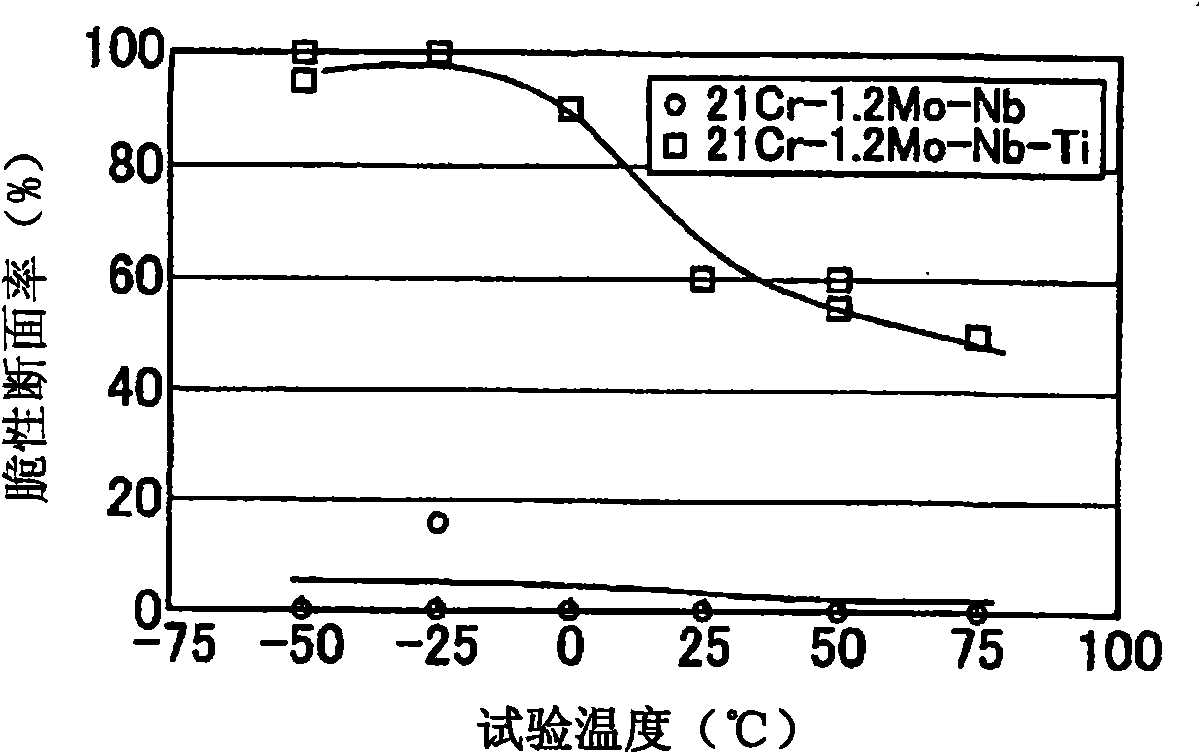

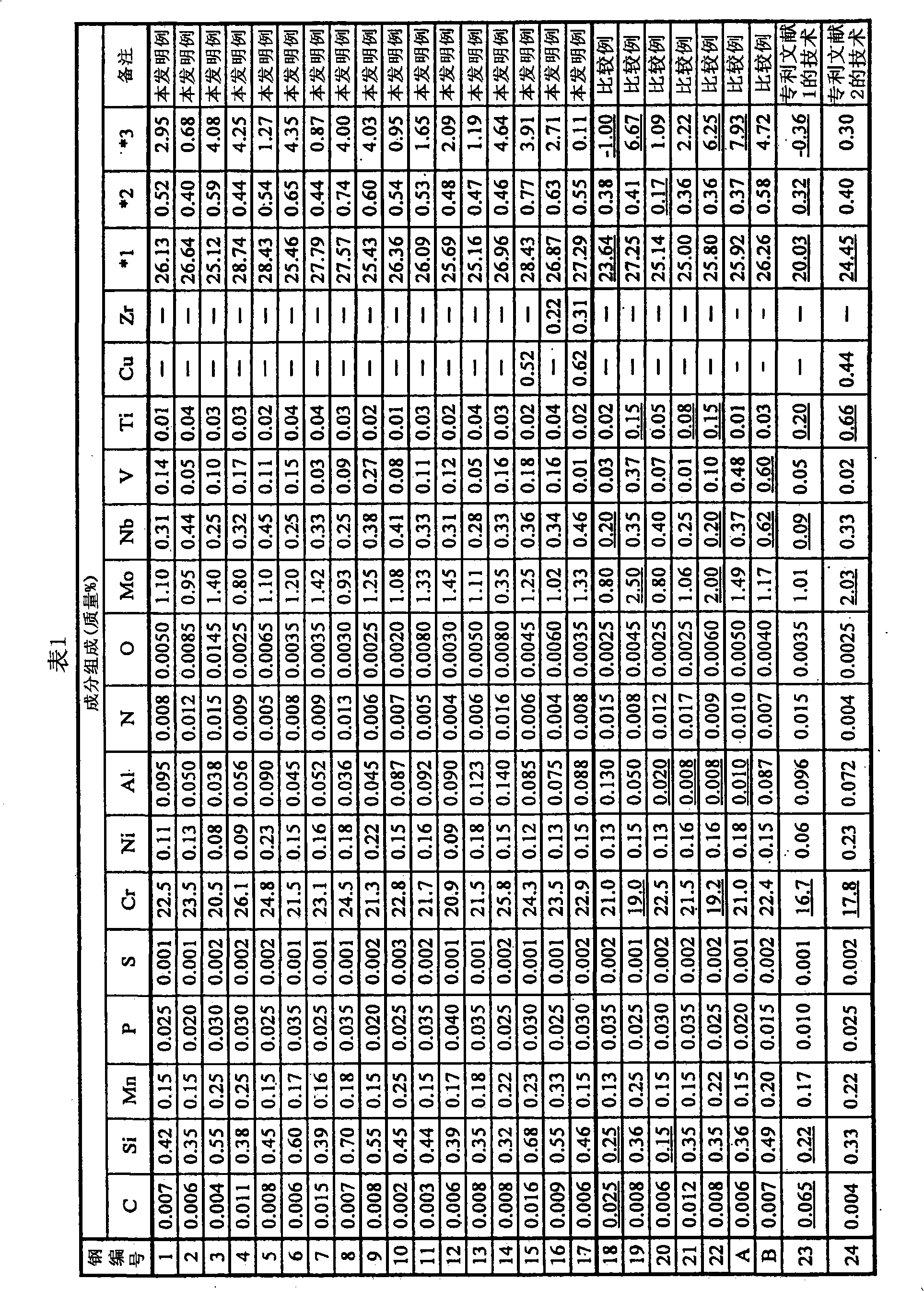

Ferritic stainless steel sheet for water heater excellent in corrosion resistance at welded part and steel sheet toughness

ActiveCN101578385AImprove corrosion resistanceReduce productivityFurnace typesHeat treatment furnacesSheet steelCorrosion

Disclosed is a ferritic stainless steel sheet for a water heater, which shows excellent corrosion resistance at a welded part and has an excellent steel sheet toughness. Specifically disclosed is a ferritic stainless steel sheet for a water heater, which comprises the following components (by mass): C: 0.020% or less, Si: 0.30-1.00%, Mn: 1.00% or less, P: 0.040% or less, S: 0.010% or less, Cr: 20.0-28.0%, Ni: 0.6% or less, Al: 0.03-0.15%, N: 0.020% or less, O: 0.0020-0.0150%, Mo: 0.3-1.5%, Nb: 0.25-0.60%, and Ti: 0.05% or less, with the remainder being Fe and unavoidable impurities, and which satisfies the requirements expressed by the following formulae (1) and (2). 25 <= Cr+3.3Mo <= 30 (1) 0.35 <= Si+Al <= 0.85 (2), wherein 'Cr', 'Mo', 'Si' and 'Al' represent the contents (expressed by mass%) of Cr, Mo, Si and Al, respectively.

Owner:JFE STEEL CORP

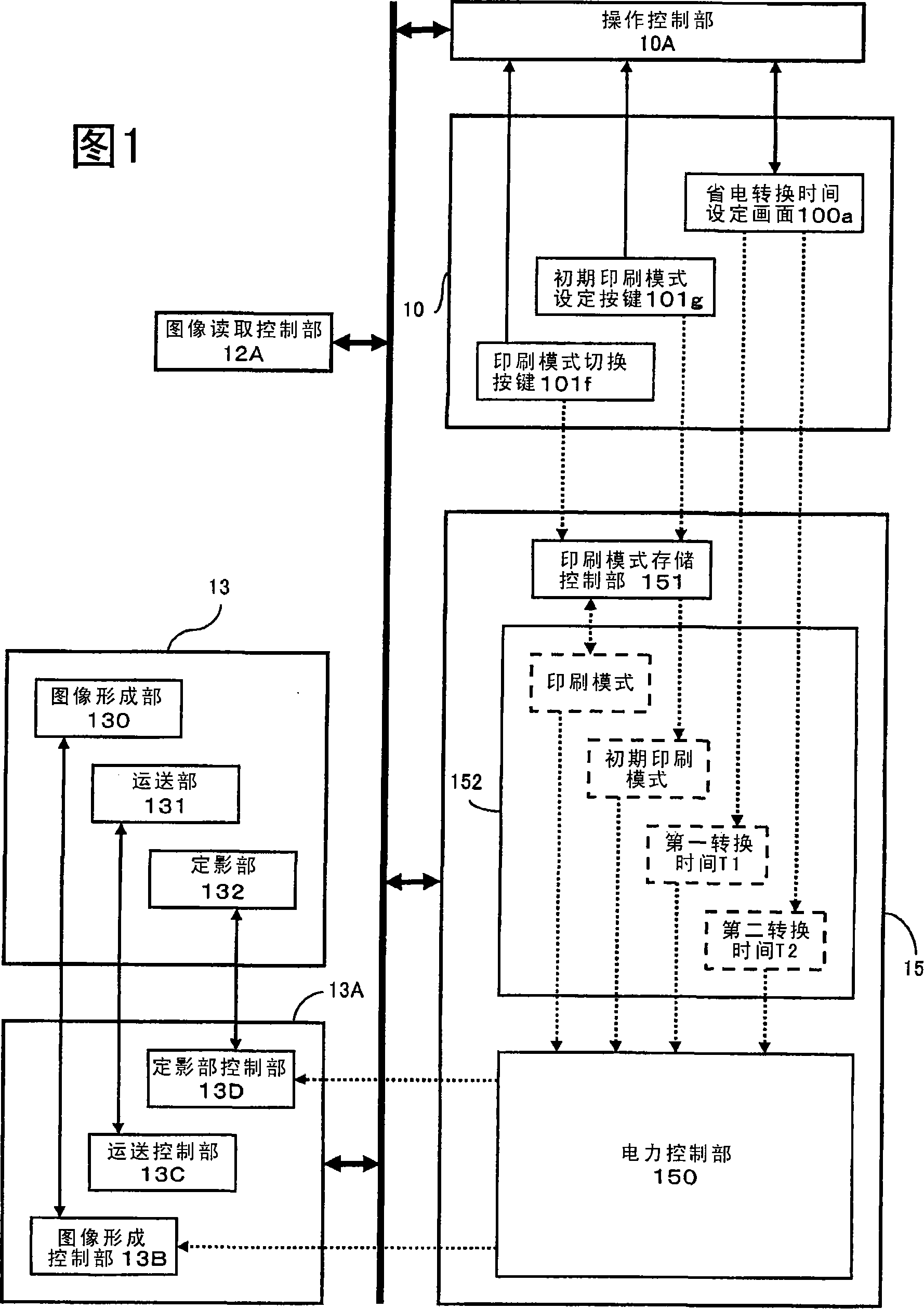

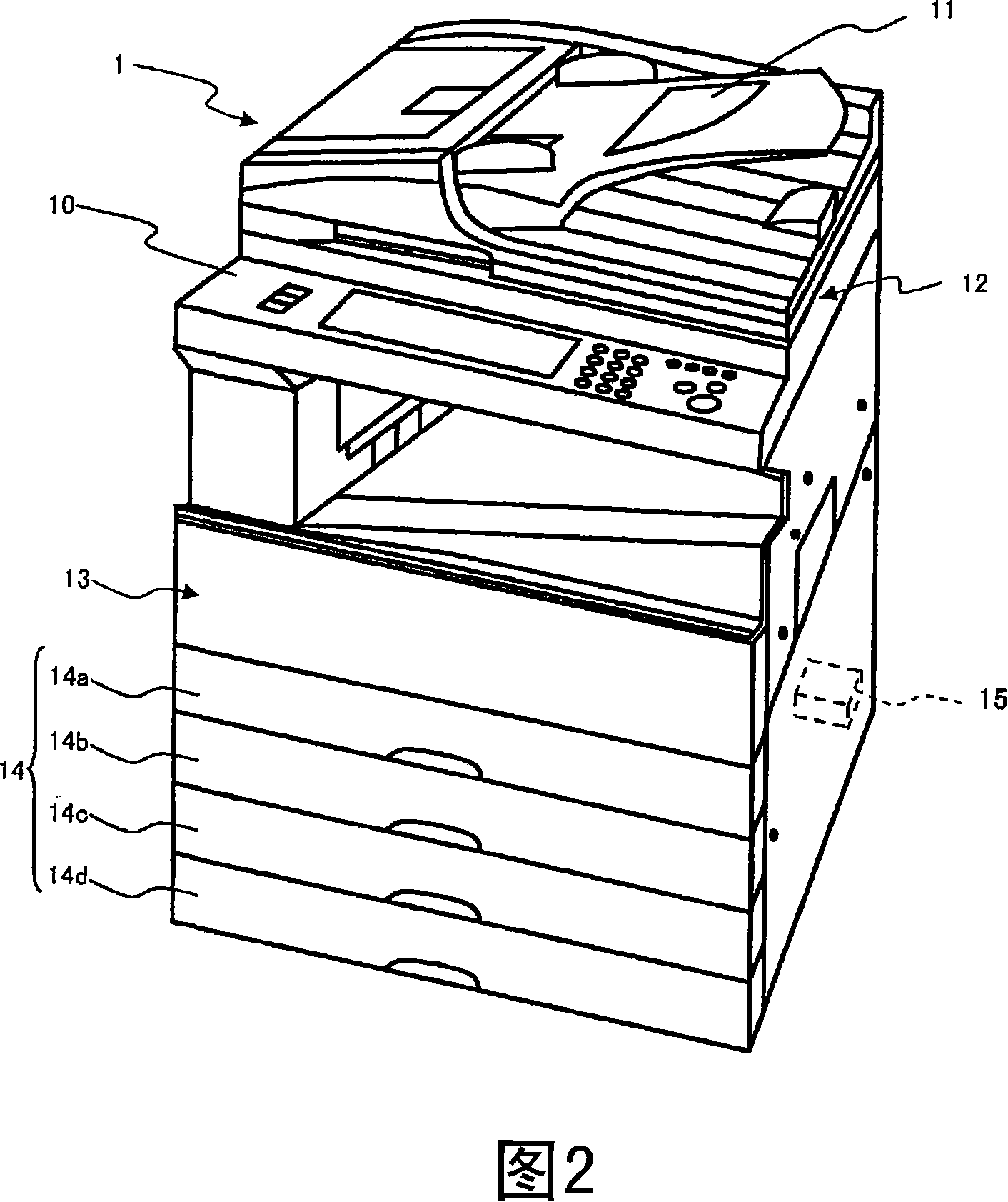

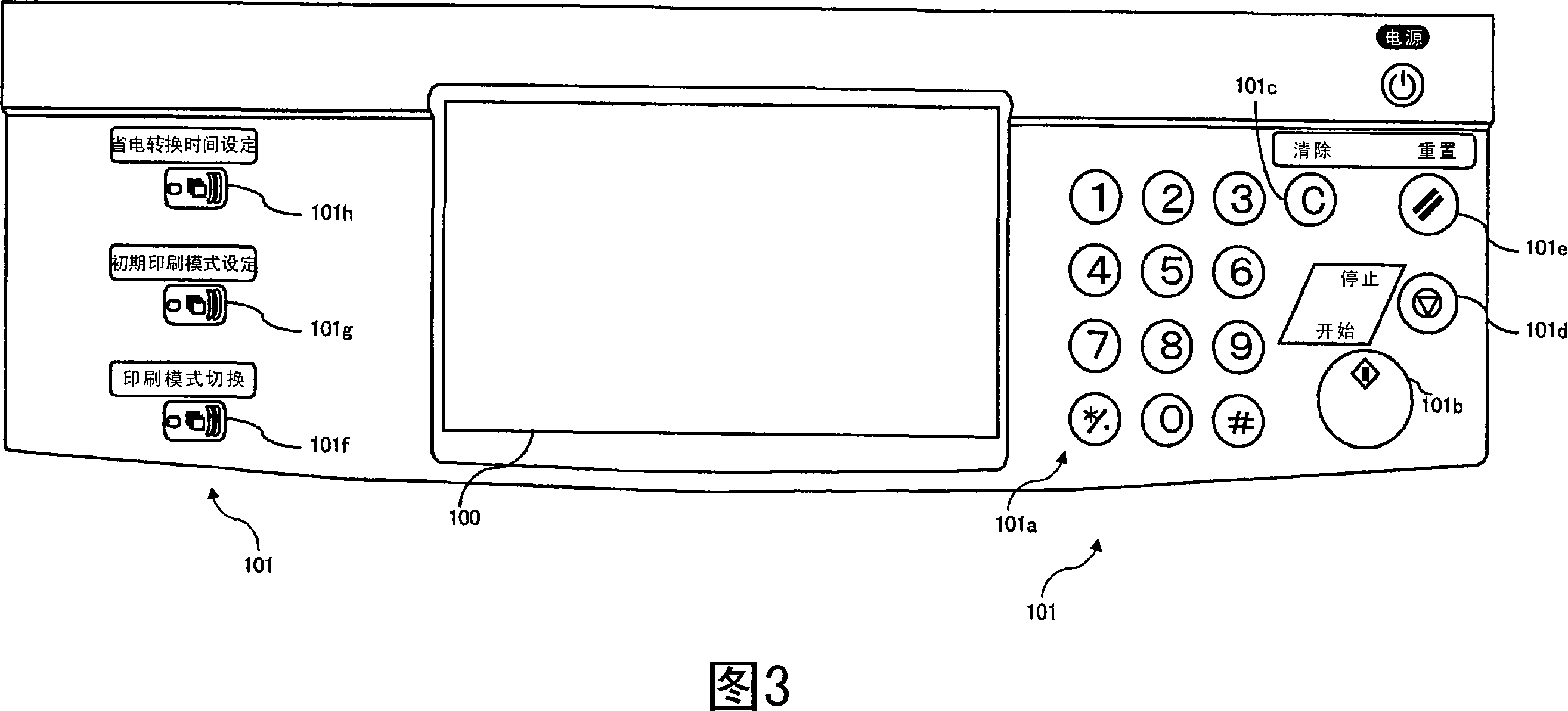

Color image forming device

InactiveCN101154066AReduce productivityReduce power consumptionElectrographic process apparatusColor imageProduction rate

To provide a color image forming device that is capable of reducing the power consumption and unnecessary consumption of toners without deteriorating the productivity of a printing job. Provided is a color image forming device which includes a power control part 150 which controls switching of a mode from a normal power supply mode to a power saving mode when a power-saving shift time T 1 or T 2 has passed during a standby state; a printing mode switching part 101 f for switching a single-color printing mode and a full-color printing mode; and an initial printing mode setting part 101 g for setting an initial printing mode at the time of supplying a power source to one of the printing modes, wherein a different power-saving shift time T 1 or T 2 is set depending on the printing mode that is initially set by the initial printing mode setting part 101 g.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

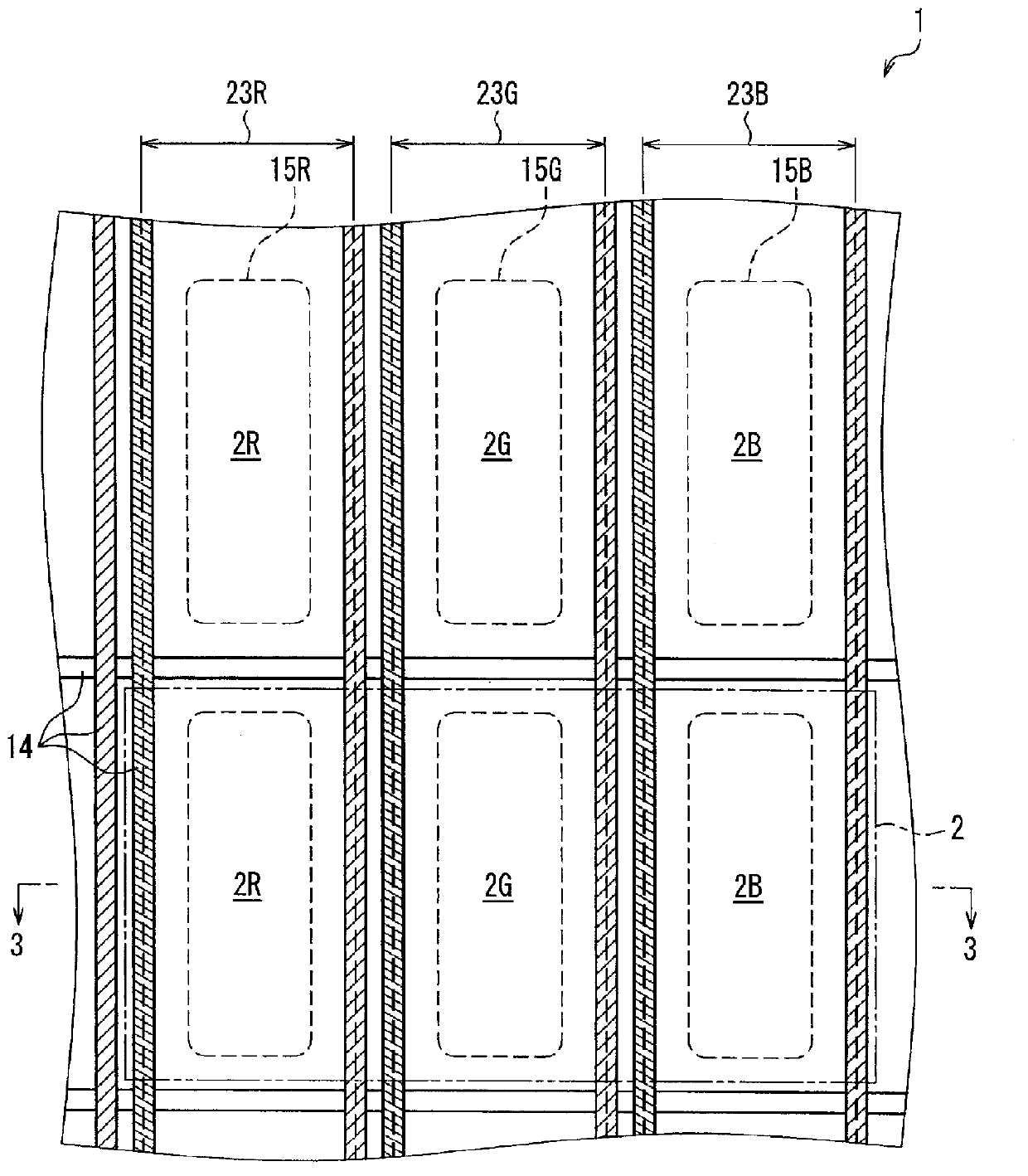

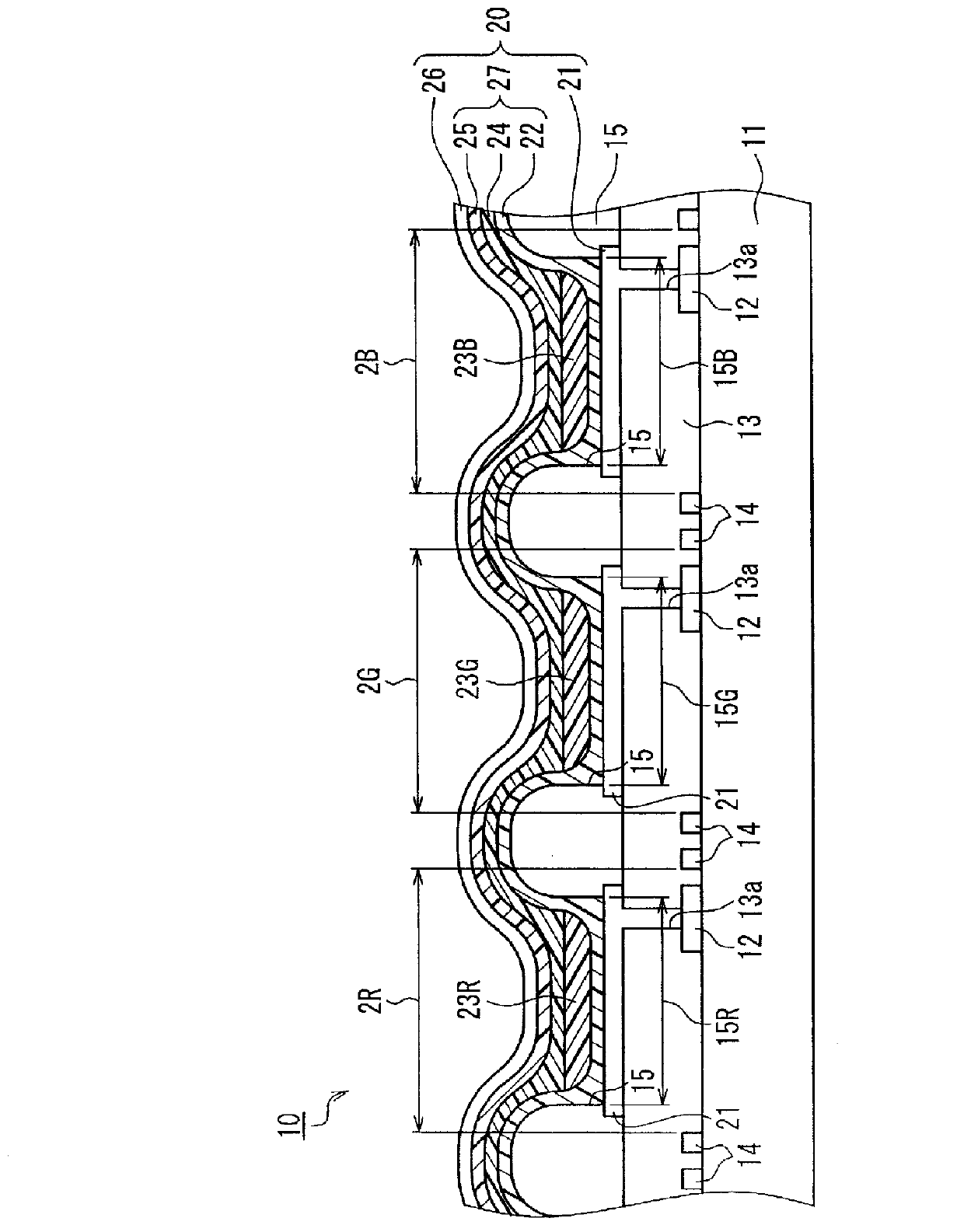

Vapor deposition device, vapor deposition method, and organic EL display device

InactiveCN103282543ASuppress blurLow costVacuum evaporation coatingElectroluminescent light sourcesDisplay deviceEngineering

Vapor deposition particles (91) released from at least one vapor deposition source opening (61) pass through a plurality of restriction openings (82) in a restriction unit (80) and a plurality of mask openings (71) in a vapor deposition mask (70), and adhere to and thereby form a coating on a substrate (10) which moves in a relative manner in a second direction (10a). The restriction unit includes a plurality of stacked plate materials. It is therefore possible to form a vapor-deposited coating having minimal blurring at the edges on a large substrate with good efficiency and at low cost.

Owner:SHARP KK

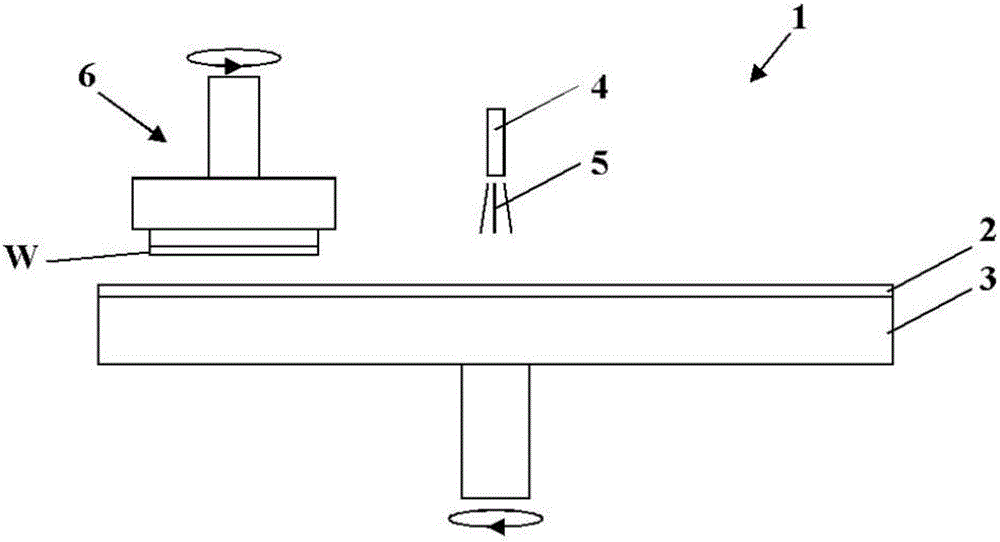

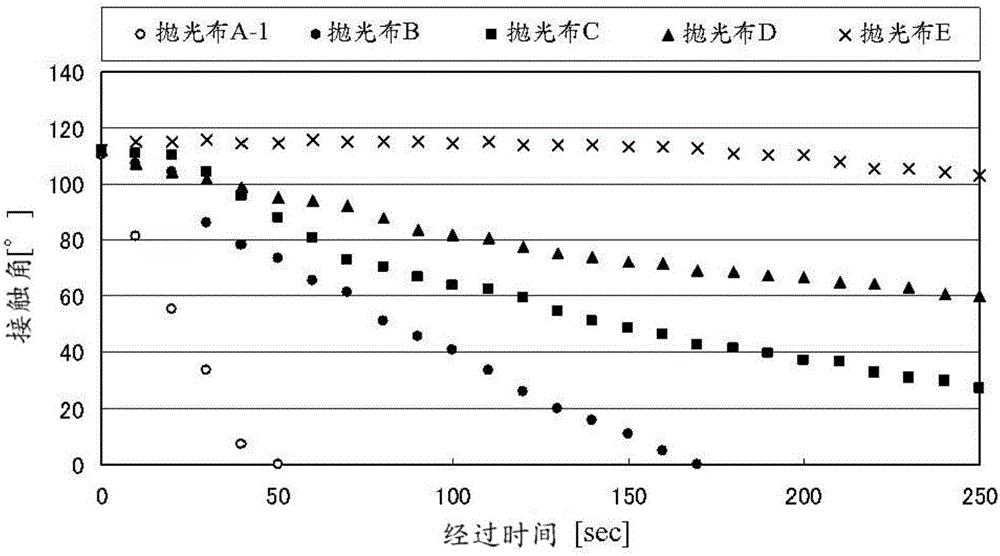

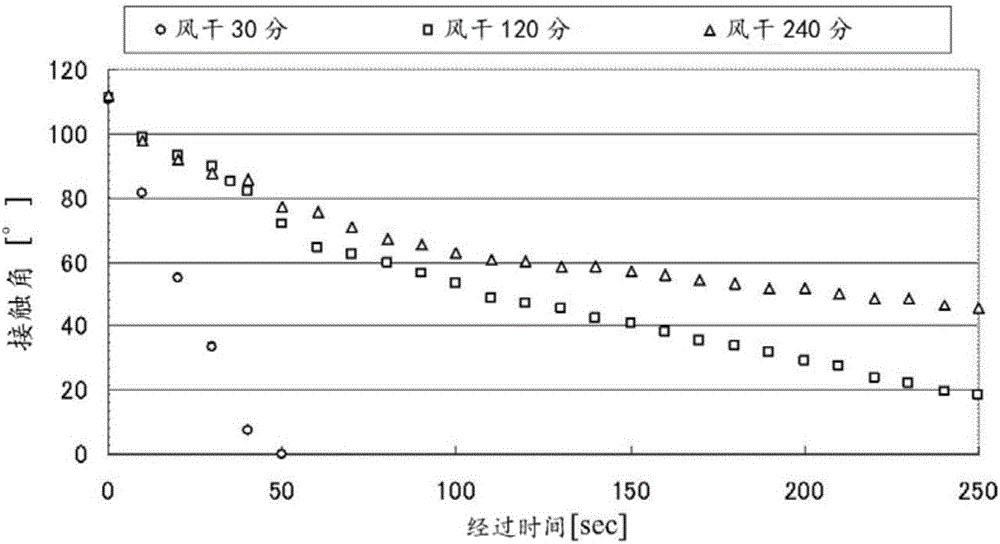

Method for final polishing of silicon wafer, and silicon wafer polished by method

ActiveCN106663621AShort lifeReduce production capacityOther chemical processesSemiconductor/solid-state device manufacturingColloidal silicaAmmonia

A final polishing method comprising using: a polishing agent which contains colloidal silica, ammonia and hydroxyethyl cellulose, and in which the primary particle diameter of the colloidal silica is 20 nm or more and less than 30 nm, the weight-average molecular weight of hydroxyethyl cellulose is 400,000 or more and not more than 700,000, and the ratio D1 / D2 [wherein D1 represents a particle diameter corresponding to a cumulative volume ratio of 95% of particles present in the polishing agent, and D2 represents a particle diameter corresponding to a cumulative volume ratio of 95% of the colloidal silica in the case of dispersing the colloidal silica in water so as to give the same concentration as the colloidal silica concentration of the polishing agent] is 1.5 or more and not more than 2.5; and a piece of polishing cloth which shows a contact angle of 60 degrees or more, said contact angle being measured 100 seconds after dropping purified water on the polishing cloth that has been seasoned and dried. Thus, provided is a method for final polishing of a silicon wafer whereby a silicon wafer having an excellent haze level as a whole, little haze irregularity in an outer circumferential part and few minute defects can be obtained.

Owner:SHIN-ETSU HANDOTAI CO LTD

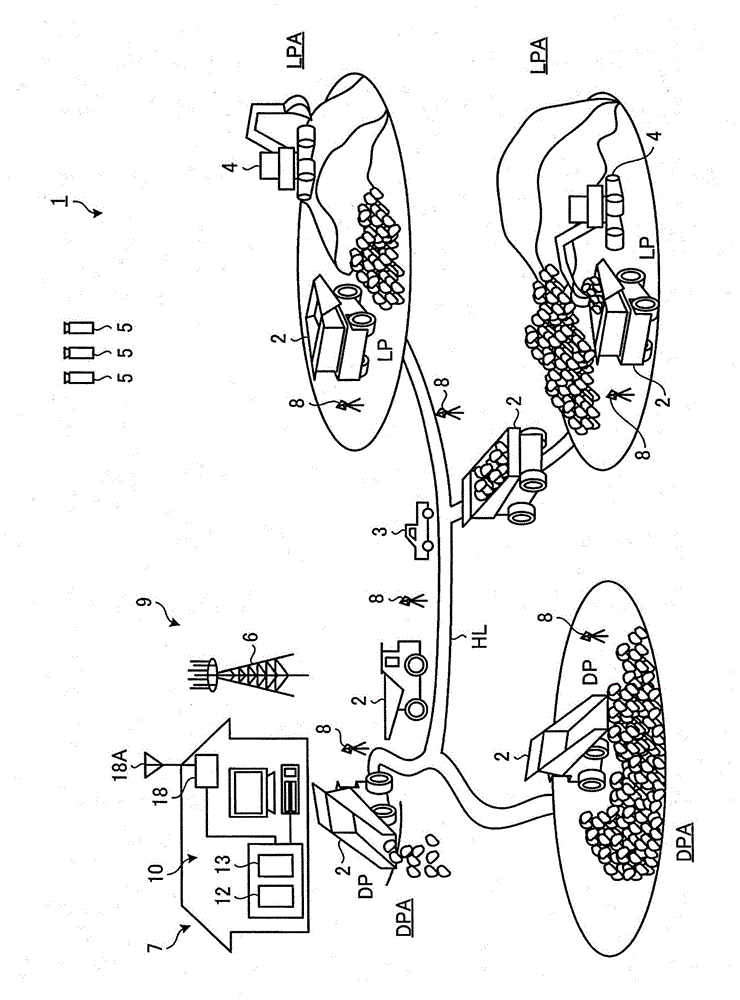

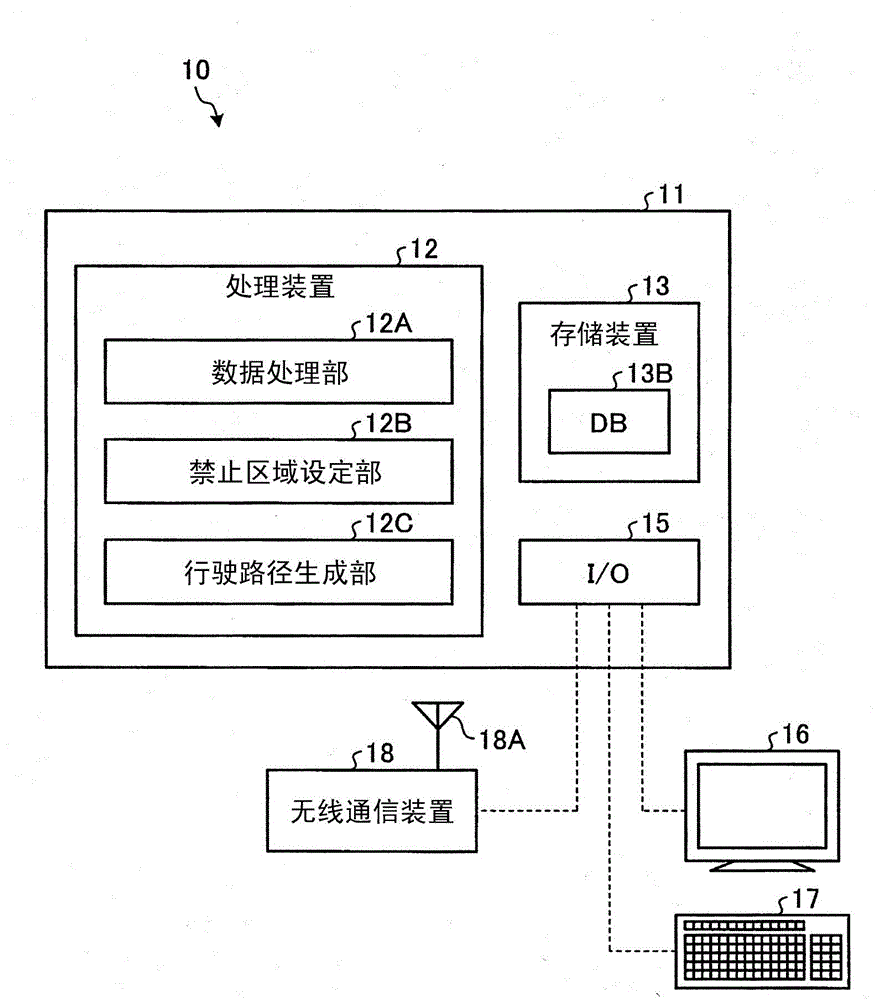

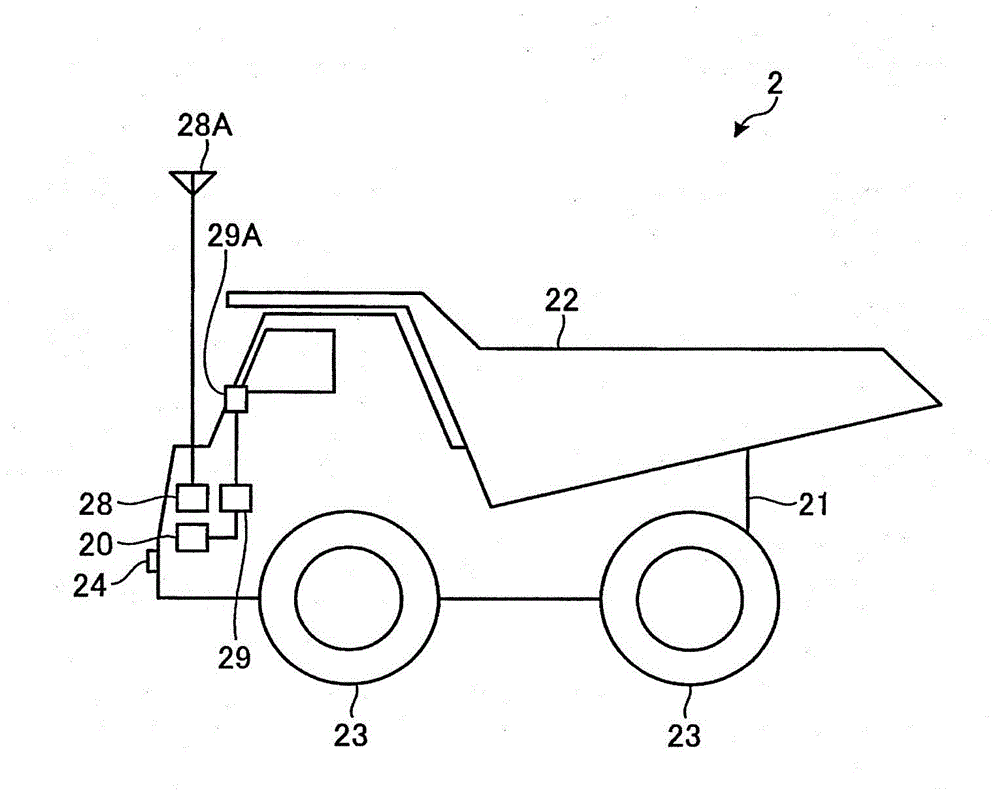

Management system and management method for mining machine

ActiveCN104541217AReduce productivityPosition/course control in two dimensionsVehiclesEngineeringManagement system

This mining-machine management system is equipped with: a landmark which makes it possible to detect the relative position therefrom of a mining machine by using a contactless sensor disposed on the mining machine which is located in a mining site and capable of travel in the mining site; a storage device for recording the landmark position detected by using an omnidirectional measurement system; and a processing device for, when recording, setting a prohibited region for prohibiting an intrusion of the mining machine so as to include the position of the landmark.

Owner:KOMATSU LTD

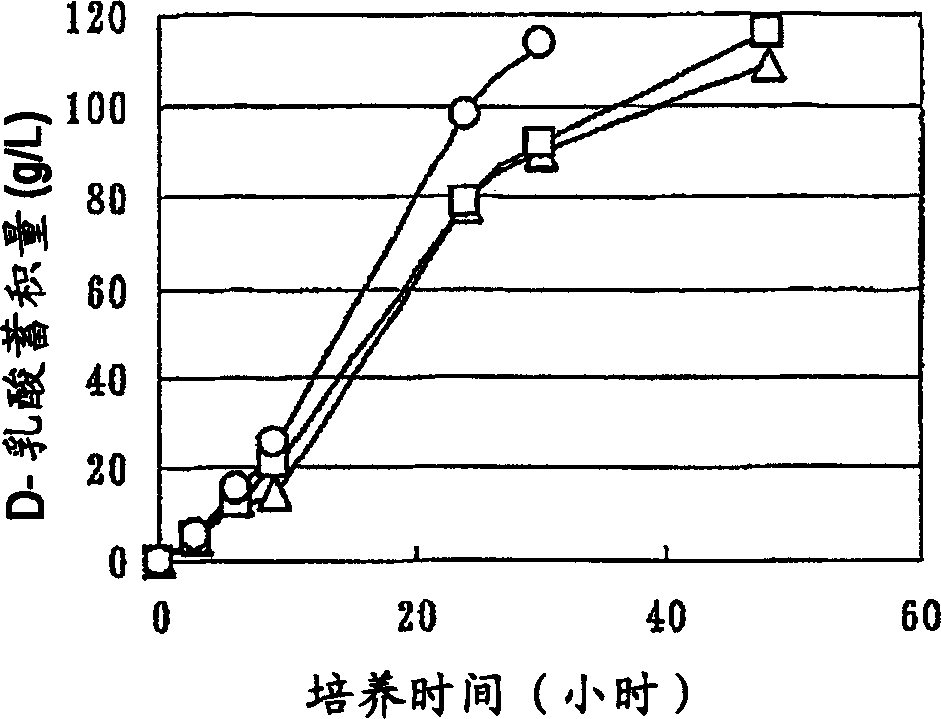

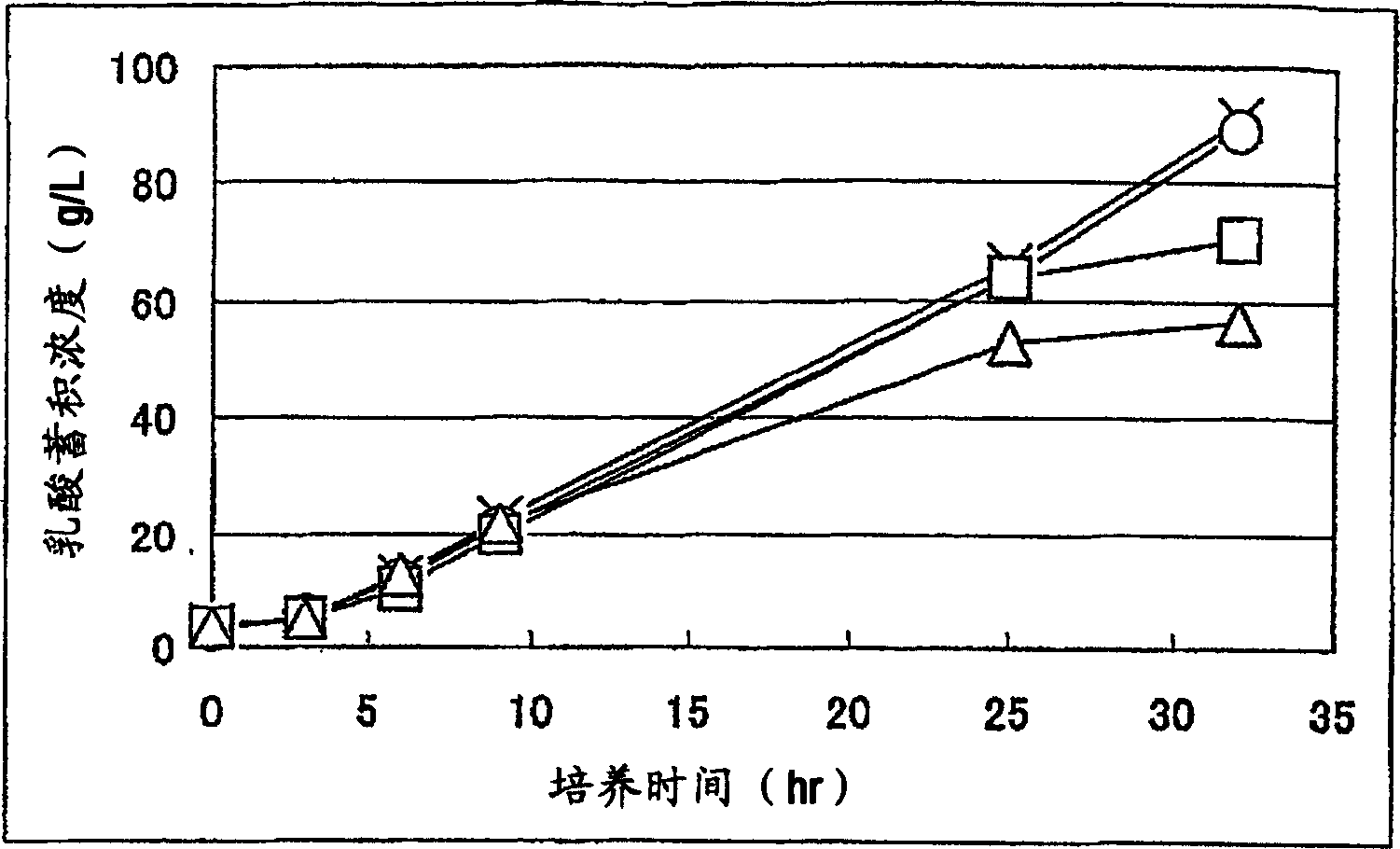

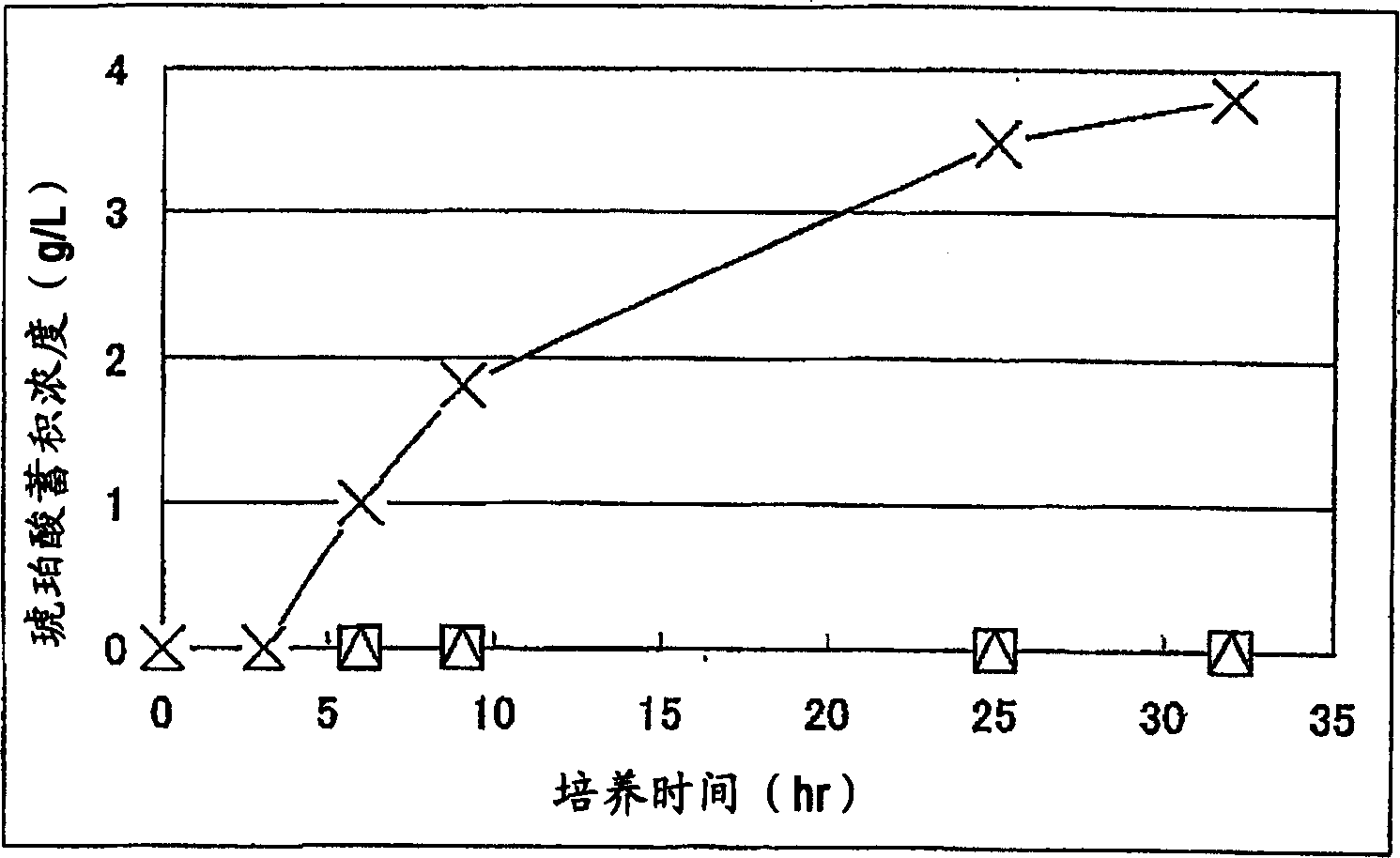

Biocatalyst for producing d-lactic acid

ActiveCN1856577AImprove productivityHigh purityBacteriaRecombinant DNA-technologyD-lactic acid dehydrogenase activityEscherichia coli

It is intended to provide a process for highly producing D-lactic acid. It is also intended to provide a process for highly selectively producing D-lactic acid having a high optical purity with the formation of little organic acids as by-products. D-Lactic acid is produced by culturing a microorganism having inactivated or lowered pyruvate formate-lyase activity and elevated Escherichia coli-origin NADH-dependent D-lactic acid dehydrogenase (ldhA) activity, a microorganism having inactivated or lowered FAD-dependent D-lactic acid dehydrogenase activity, or a microorganism as described above having a TCA cycle, inactivated or lowered malic acid dehydrogenase activity and inactivated or lowered aspartic acid ammonia-lyase activity. The ldhA activity is elevated by ligating a gene encoding ldhA to a promoter of a gene controlling the expression of a protein, which participates in a glycolysis system, a nucleic acid biosynthesis system or an amino acid biosynthesis system, on genome.

Owner:MITSUI CHEM INC

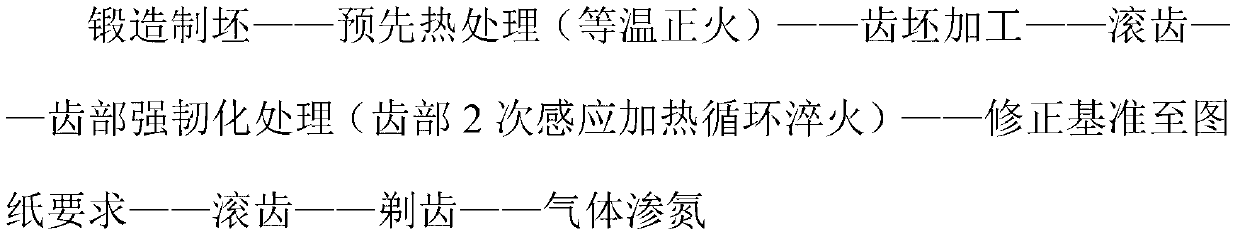

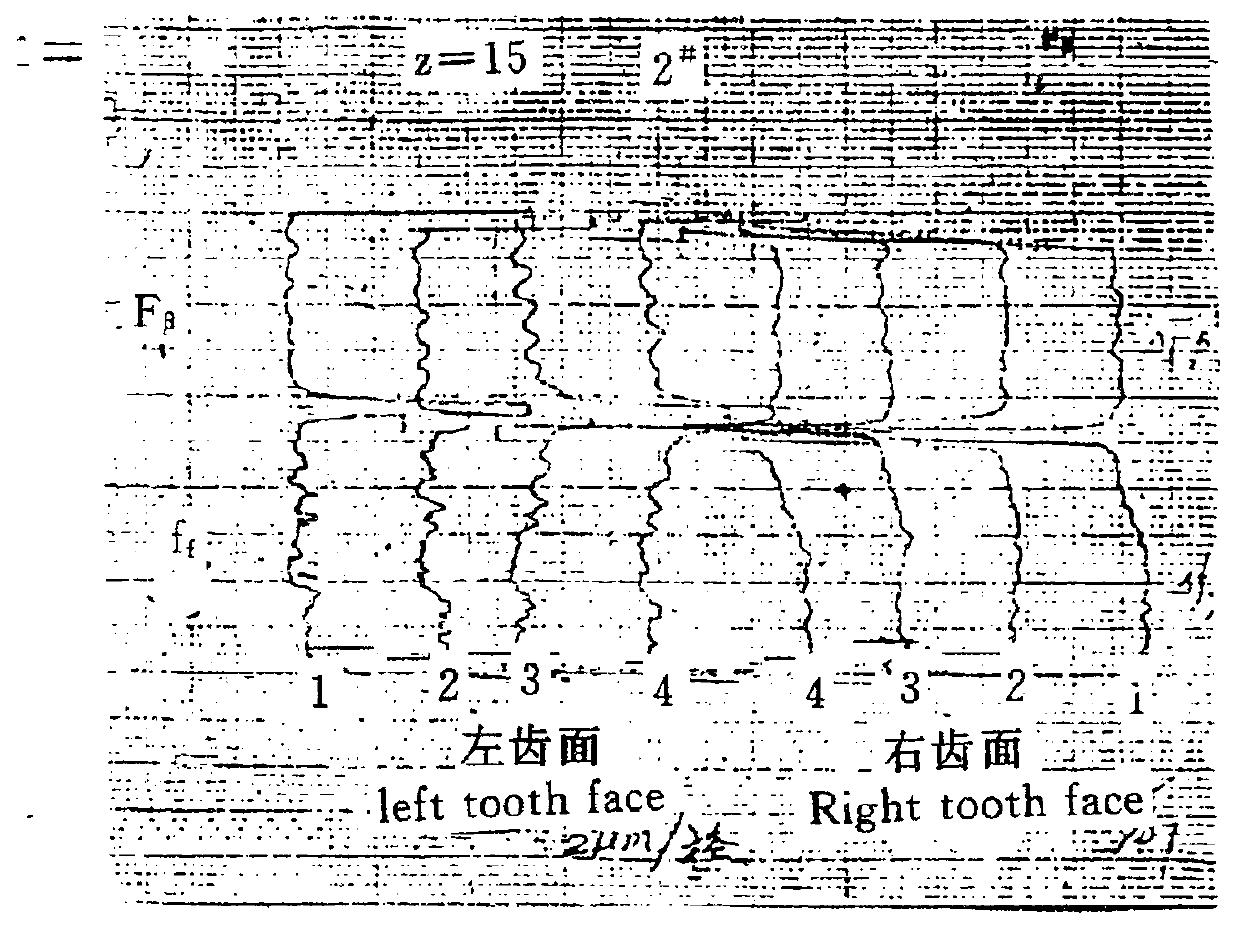

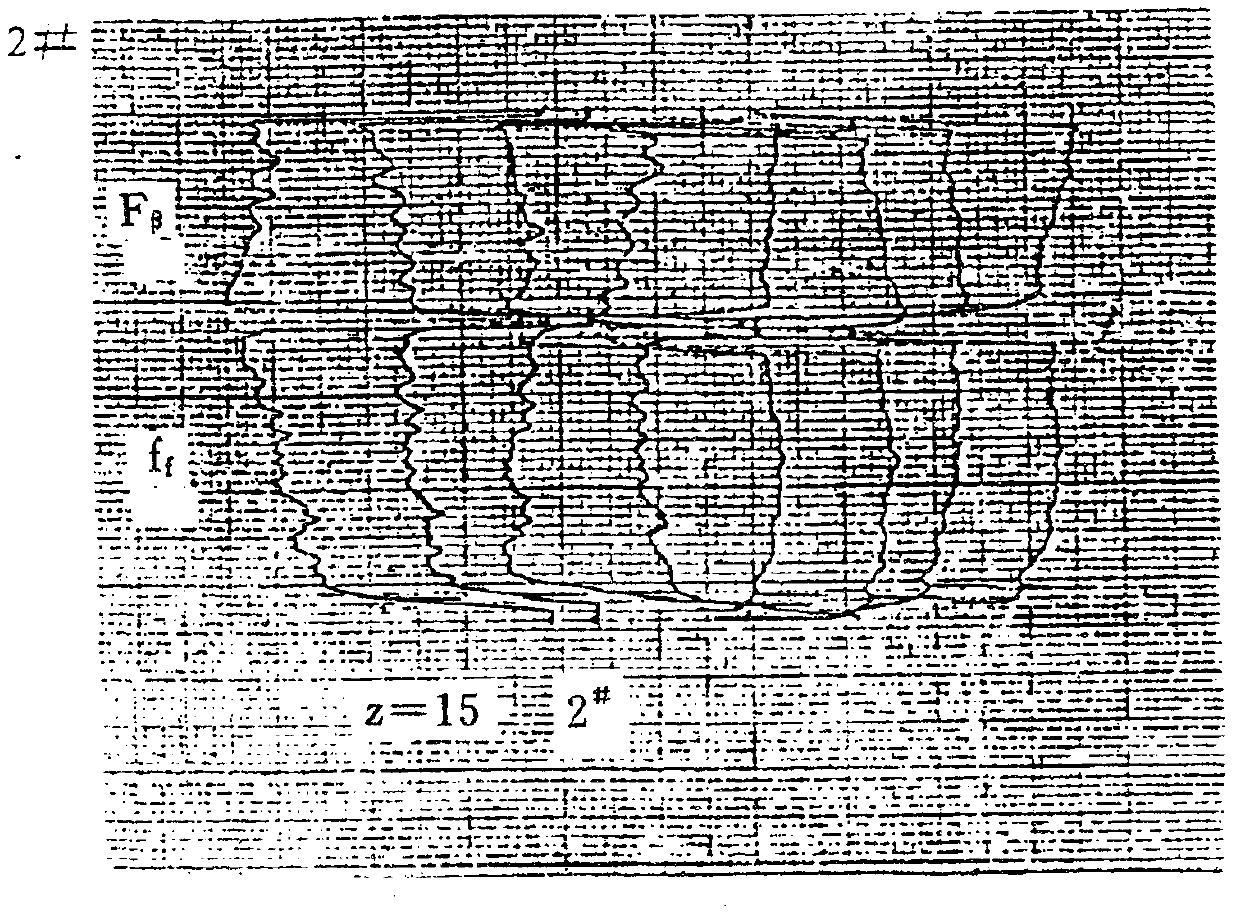

Anti-fatigue manufacturing method of car transmission gear

ActiveCN103302464AEasy to adjustImprove fatigue lifeSolid state diffusion coatingFurnace typesCarrying capacityHobbing

An anti-fatigue manufacturing method of a car transmission gear comprises the steps that forging blanking, heat pretreatment (isothermal normal fire), gear blank processing, gear hobbing, gear strengthening and toughening treatment (the gear part is subject to two times of induction heating and circulatory quenching), modification of criteria to the drawing demand, gear hobbing, gear shaving and gas nitrizing process are carried out in sequence. By adopting the method, 6-grade or more than 6-grade precise car gears can be efficiently produced in batch at low price, and the produced car gears has the bearing / carrying capacity almost as well as that of alloy cemented steel. The car transmission gear manufactured by adopting the method can replace the carburized and quenched gear in the prior art.

Owner:天津市天瑞硬化工程有限公司

Adhesive sheet, metal laminate sheet and printed wiring board

ActiveCN101193751AEliminate warpingEliminate deformationSynthetic resin layered productsPrinted circuit aspectsEngineeringPolyimide membrane

Disclosed is an adhesive sheet comprising a base film and an adhesive layer formed on at least one side of the base film. The base film is composed of a polyimide film whose degree of curling is not more than 10% after a heat treatment at 300 DEG C. Since this adhesive sheet is suppressed in warping or strain caused by high-temperature treatments, it can be used for electronic devices and the like which are exposed to high temperatures and enables to improve the qualities and yields of the electronic devices and the like.

Owner:TOYOBO CO LTD

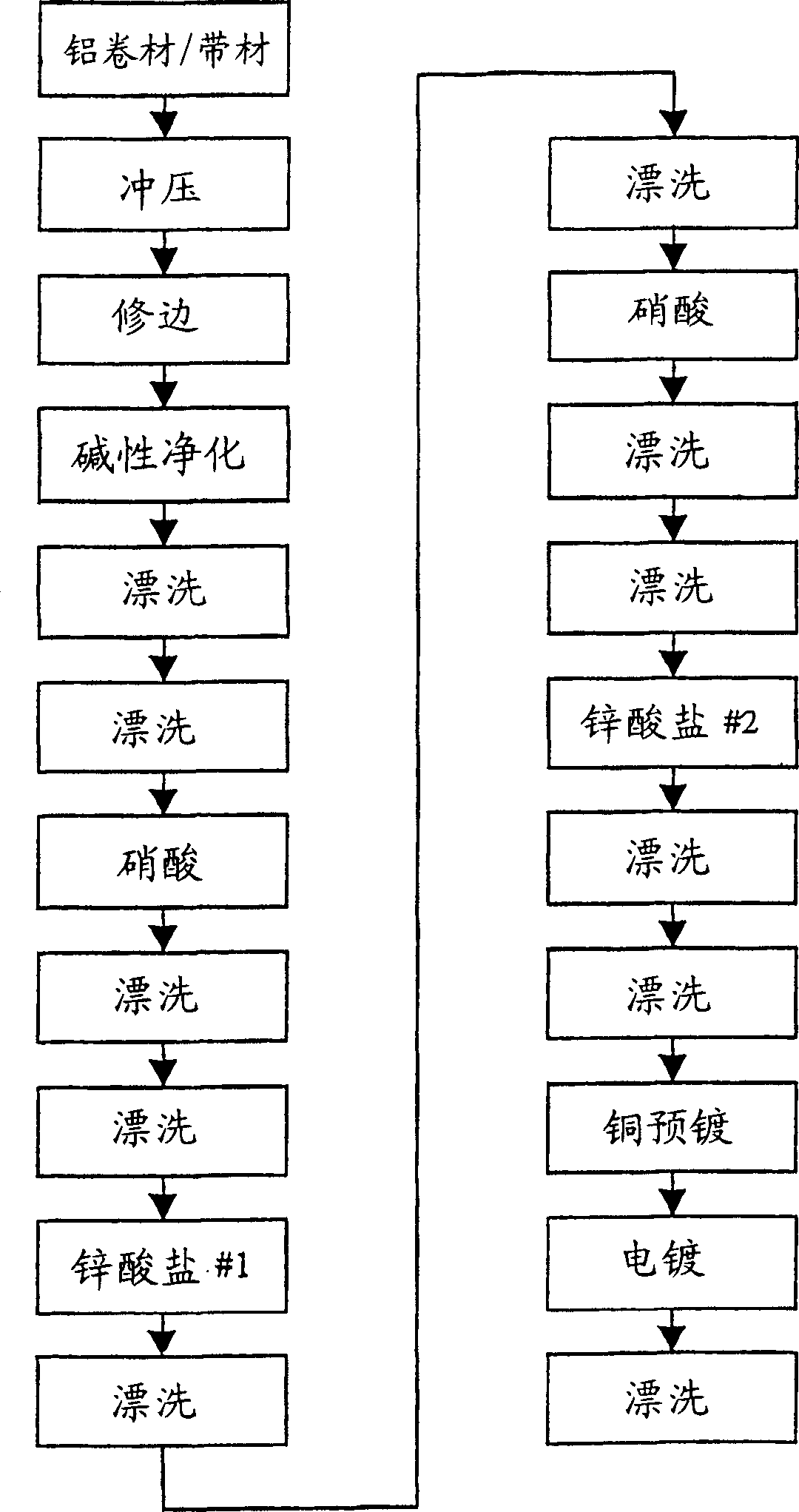

ELectroplated aluminium parts and process of production thereof

InactiveCN1498288AReduce productivityReduce areaDomestic articlesThin material handlingPre treatmentZincate

The invention provides a pretreatment process for electroplating aluminum parts or strip, in which the zincating solution is modified to improve the adhesion of the subsequent electroplate to the substrate. The aluminum part or strip, such as an aluminum coin blank or strip for coin blanks, is pretreated with an improved zincate solution which provides hydroxide ions in an amount in the range of 75-175 gpl, zinc ions in an amount in the range of 15-40 gpl, nickel ions in an amount in the range of 2-10 gpl and copper ions in an amount in the range of 1.5-5 gpl. The pretreatment process preferably includes a copper strike applied from a copper cyanide strike bath at a pH in the range of 8.5-11.0, using a current density in the range of 0.1-10 A / dm2. The pretreatment and electroplating steps arc preferably conducted by barrel plating, in accordance with another aspect of the invention. The invention also provides electroplated aluminum parts or strip, such as electroplated coin blanks, including a substrate formed from aluminum or an aluminum alloy and having multiple surfaces, a layer of zincate on at least one of the surfaces of the substrate and preferably completely encasing the substrate, a strike layer of a strike metal covering the layer of zincate, and one or more electroplated layers of one or more metals covering the strike layer, said one or more electroplated layers adhering to the substrate to withstand a deformation process without delamination from the substrate.

Owner:THE WESTAIM CORP

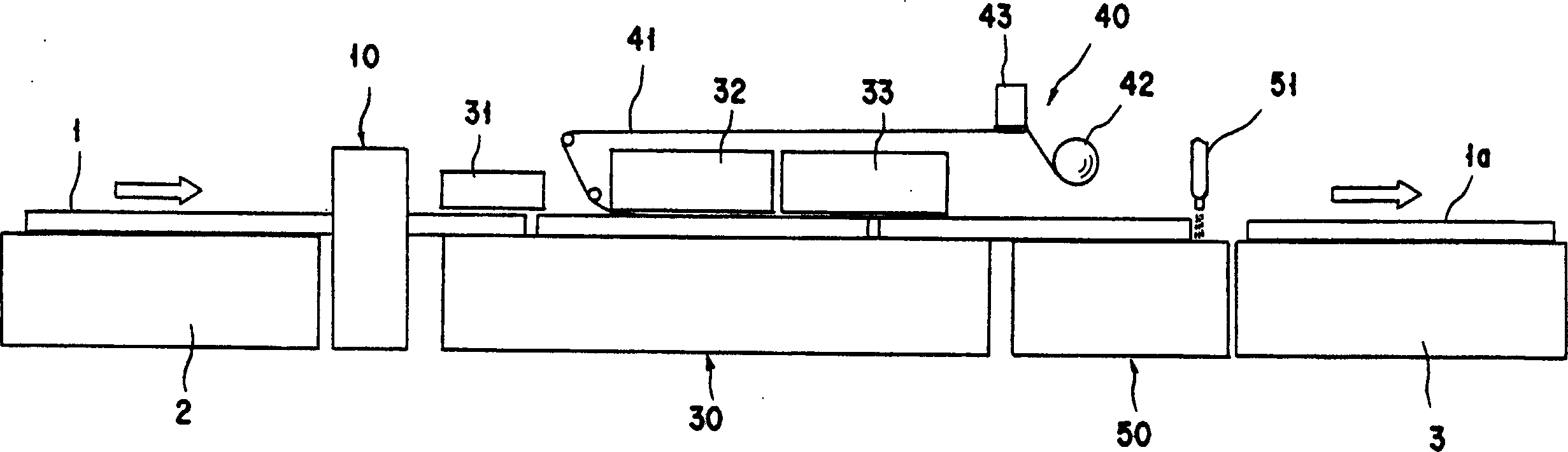

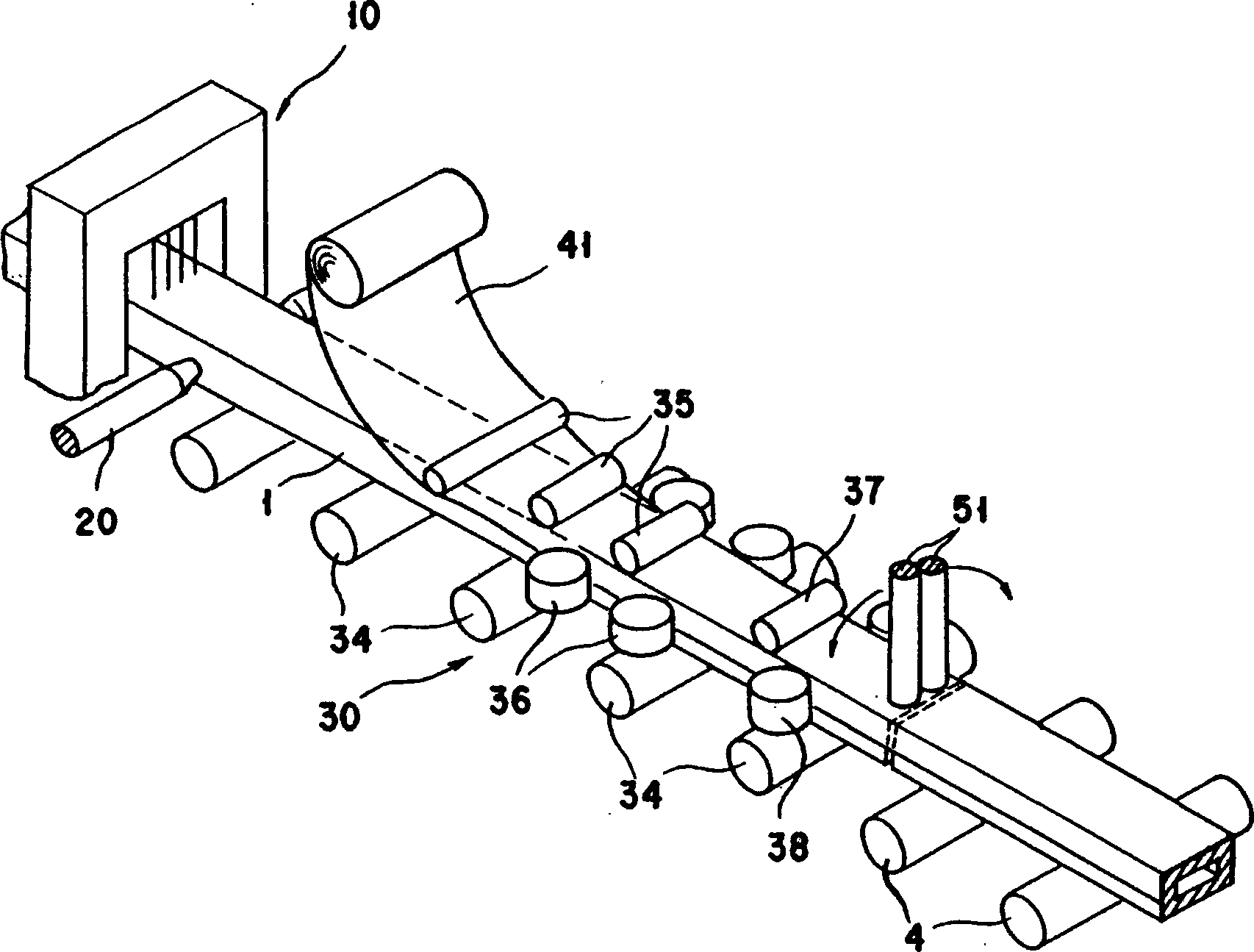

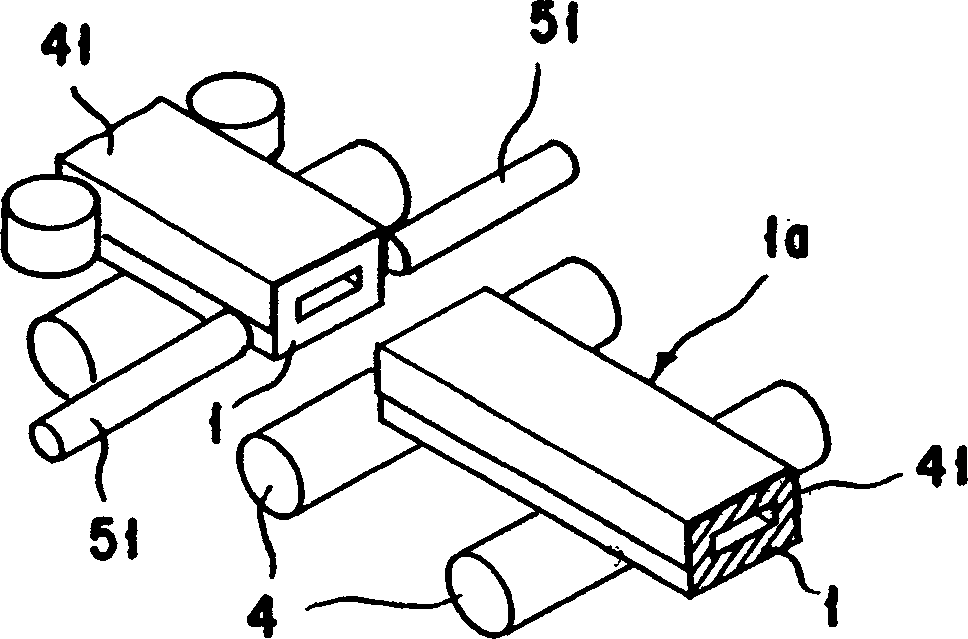

Manufacturing metod and equipment of sheet laminated aluminium section bar

InactiveCN1496783AIncrease stickinessLow costLamination ancillary operationsLaminationElectric dischargeCorona discharge

A method for the manufacture of an aluminum profile having a resin sheet material integrally laminated thereon and an apparatus to be used therefor are provided. A coated aluminum profile (1) is subjected to the surface modification by means of a corona discharge treatment unit (10). Preferably, a surface portion of the aluminum profile on which an edge portion of the sheet material is to be laminated is further subjected to a local electric discharge treatment by means of a local electric discharge treatment unit (20). Then, a sheet material (41) is continuously laminated on a plurality of aluminum profiles being conveyed, and thereafter the sheet material is cut at a position between the aluminum profiles by means of an electric discharge cutting device (51) to form the sheet-laminated aluminum profile (1a).

Owner:YKK AP INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com