Patents

Literature

58611results about "Cleaning using liquids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

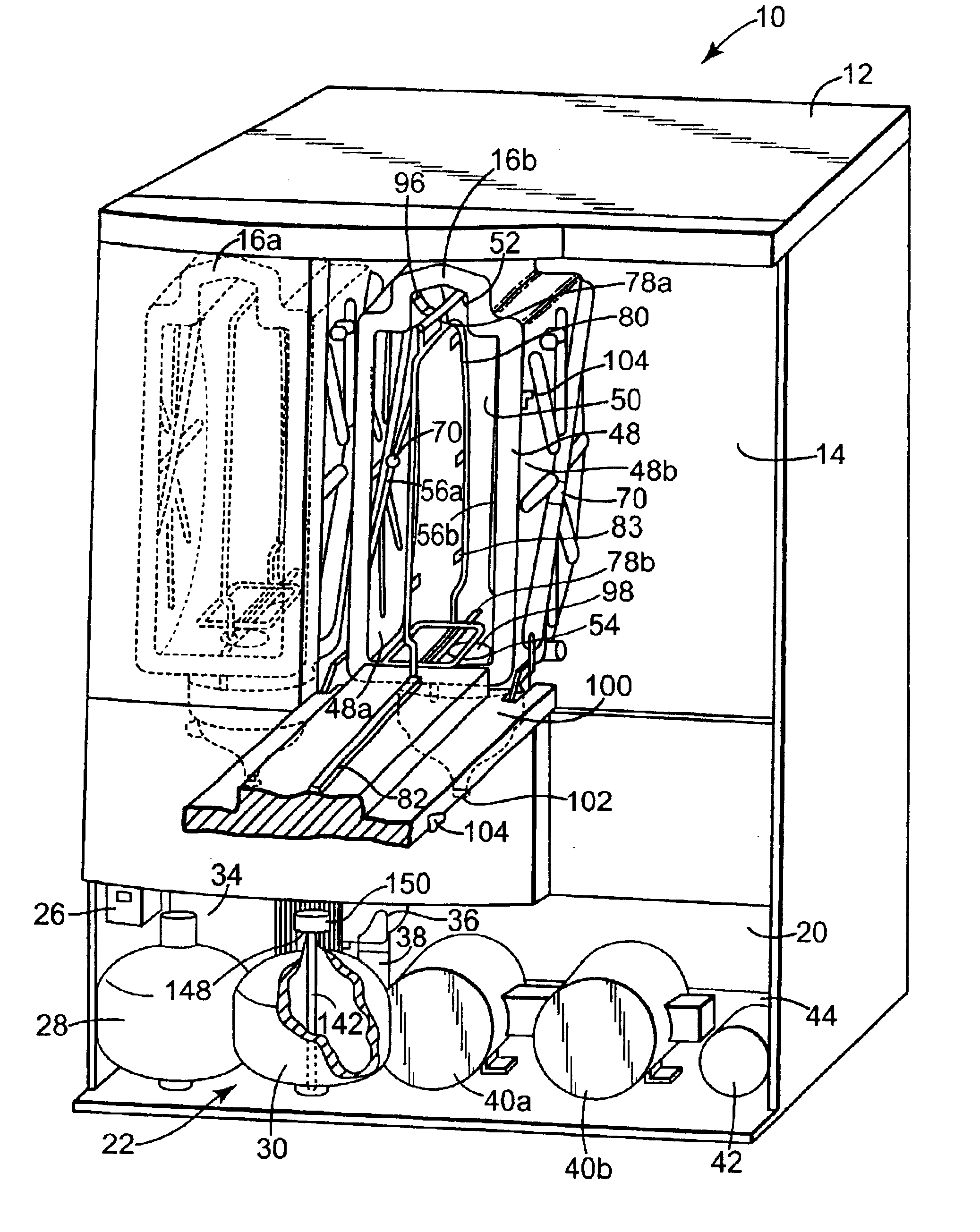

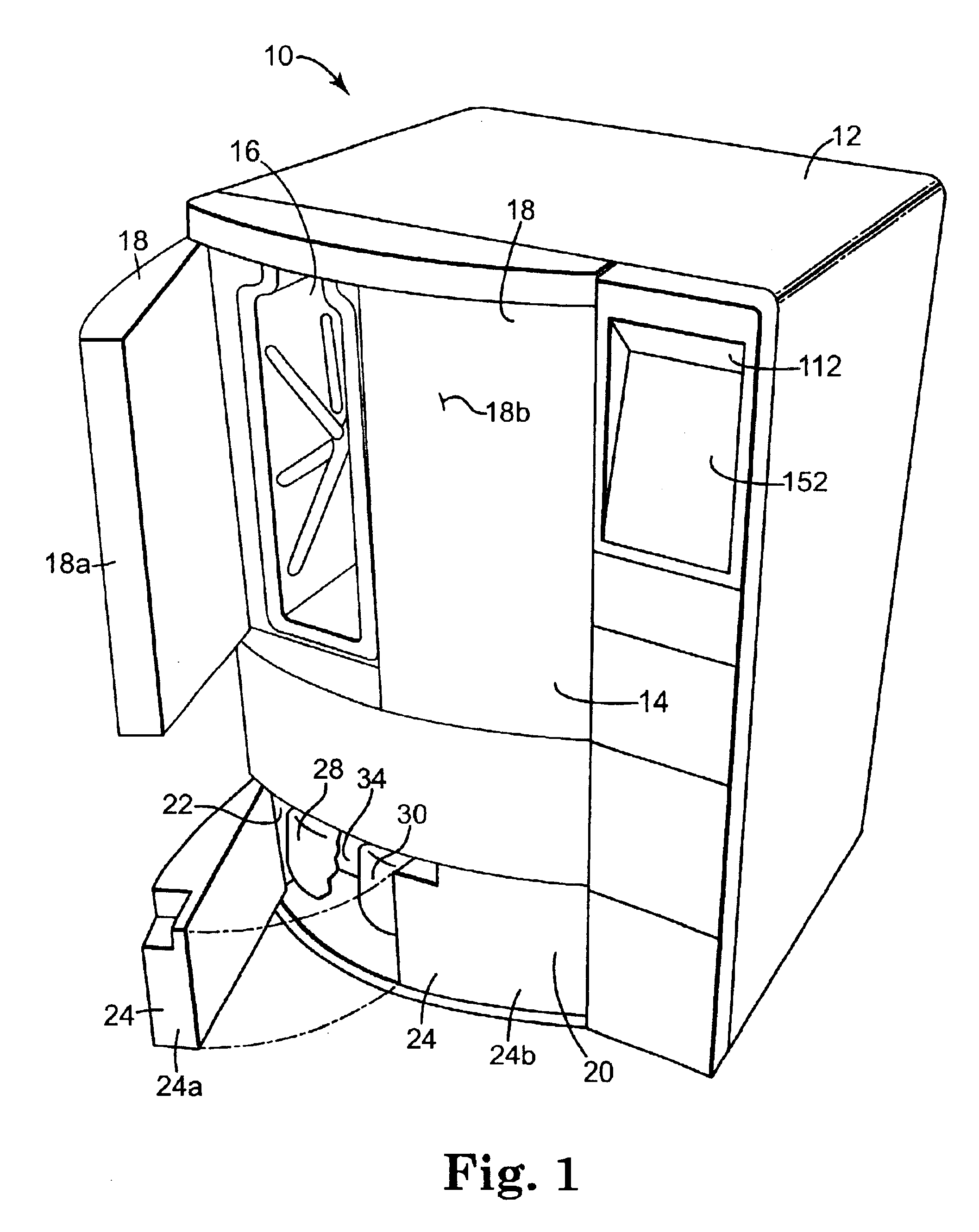

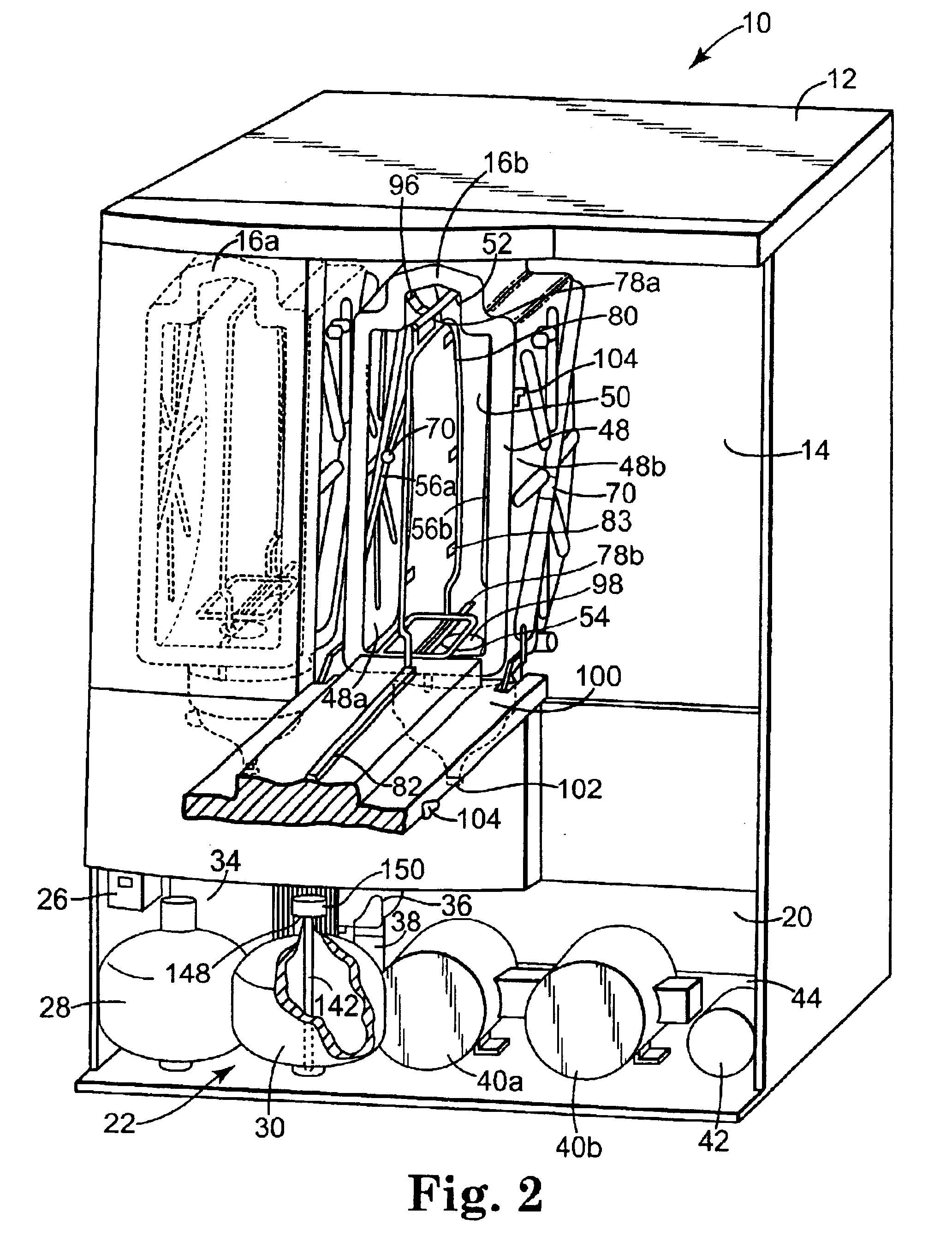

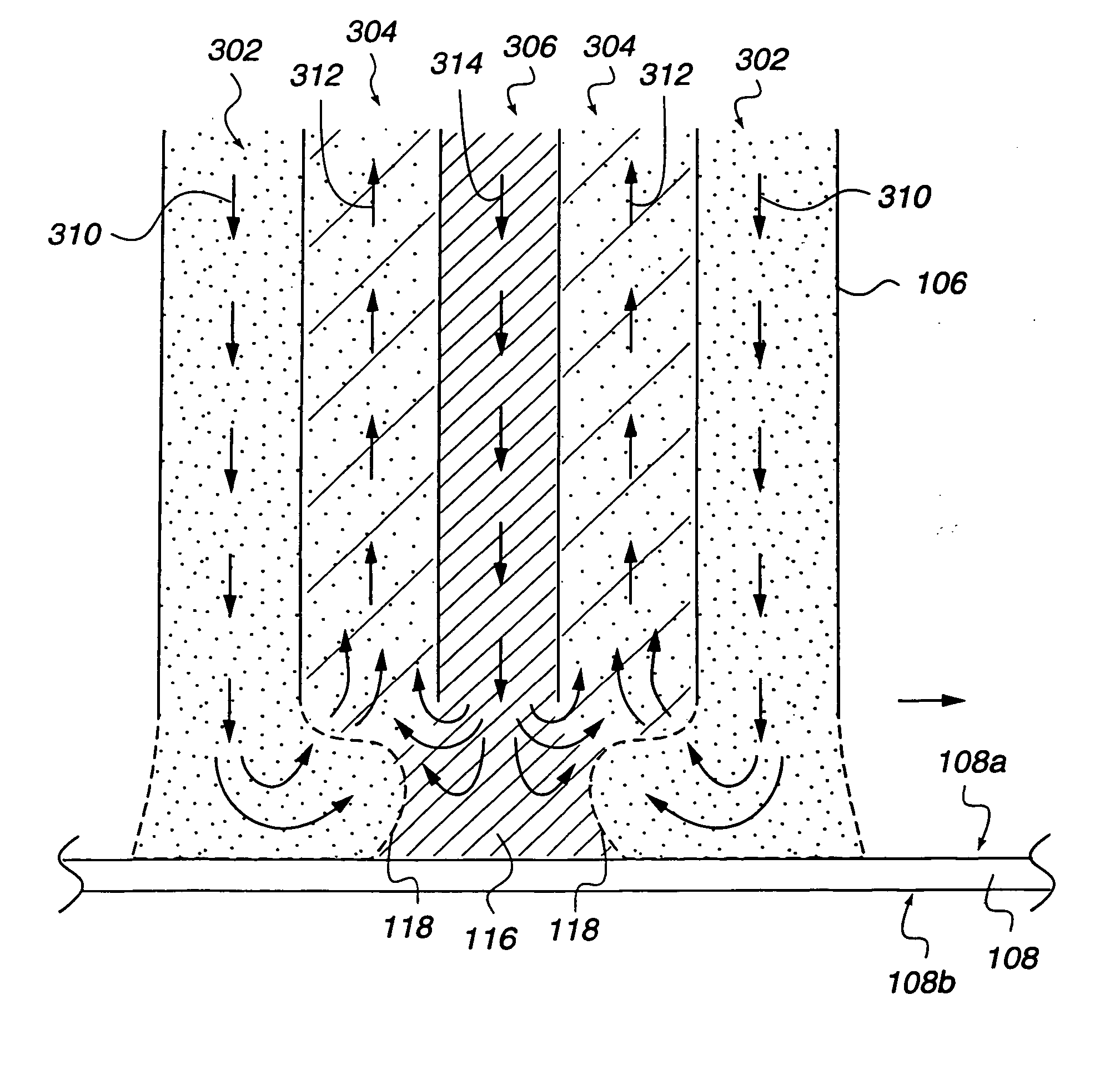

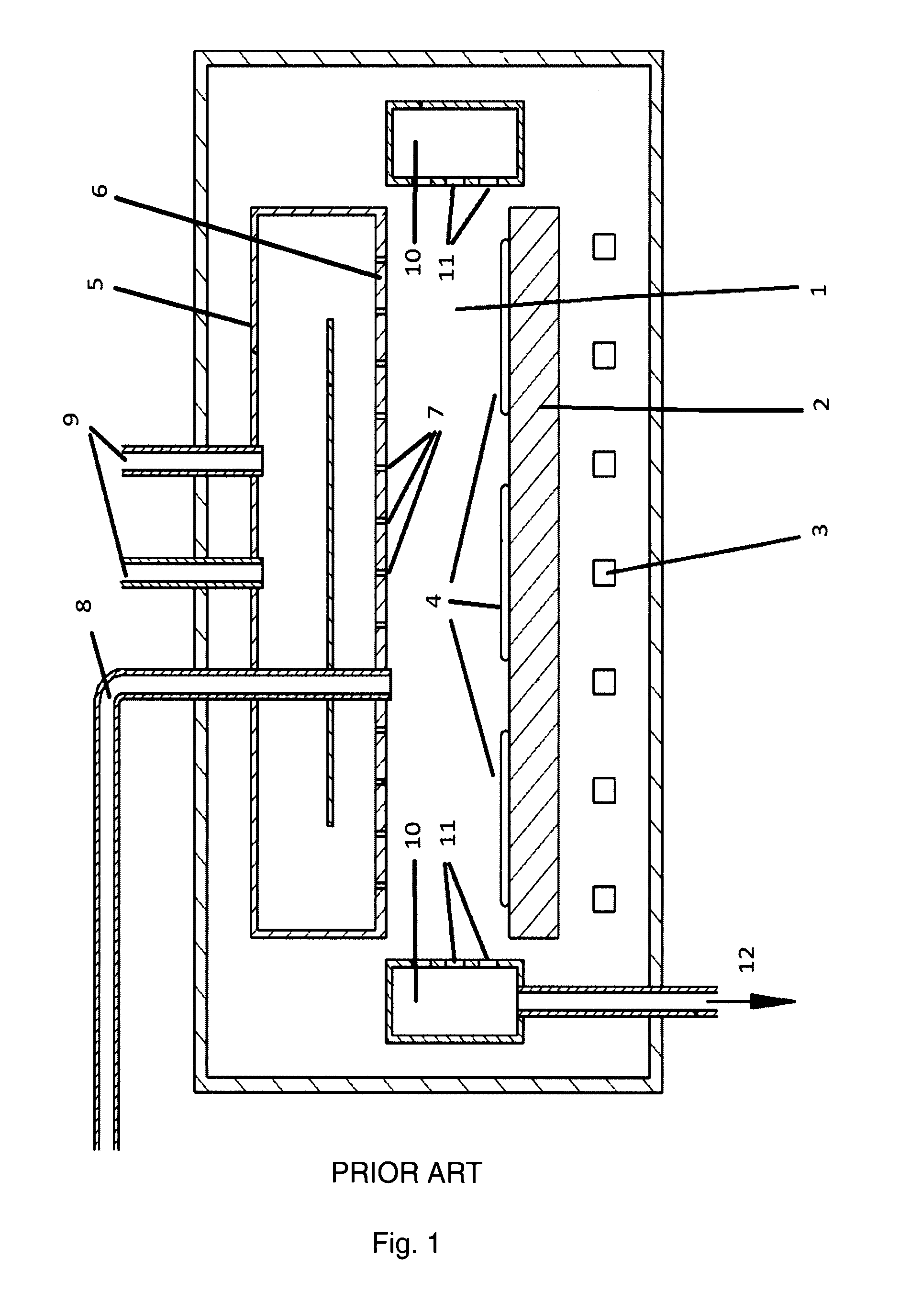

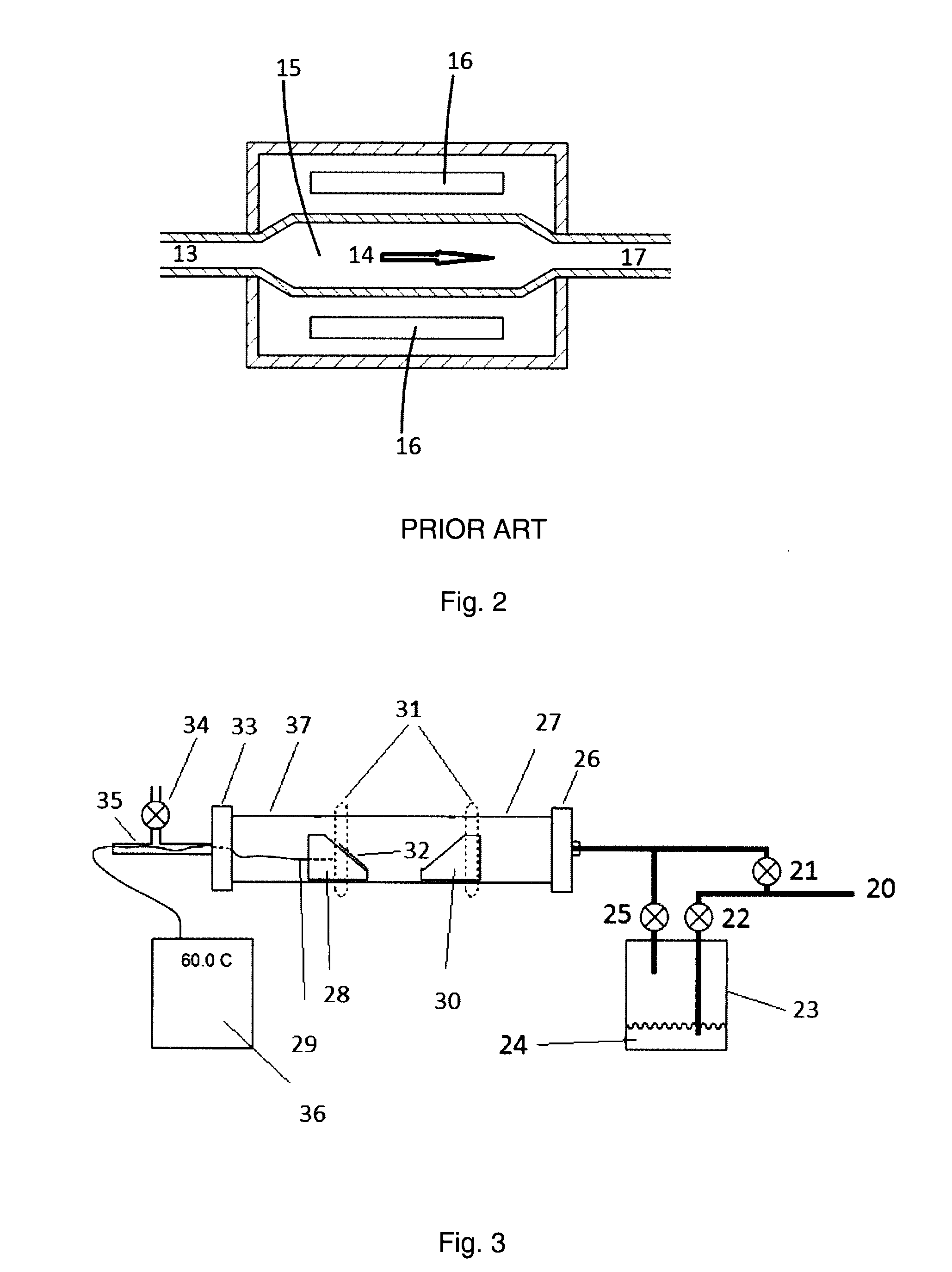

Apparatus and method for steam reprocessing flexible endoscopes

A system for reprocessing flexible endoscopes having lumen therein. The reprocessing system deploys steam to disinfect and / or sterilize the endoscopes, and designs, components, and methods for reducing or balancing the reprocessing cycle time and the effects of thermal expansion and contraction on the endoscopes.

Owner:MEDIVATORS INC

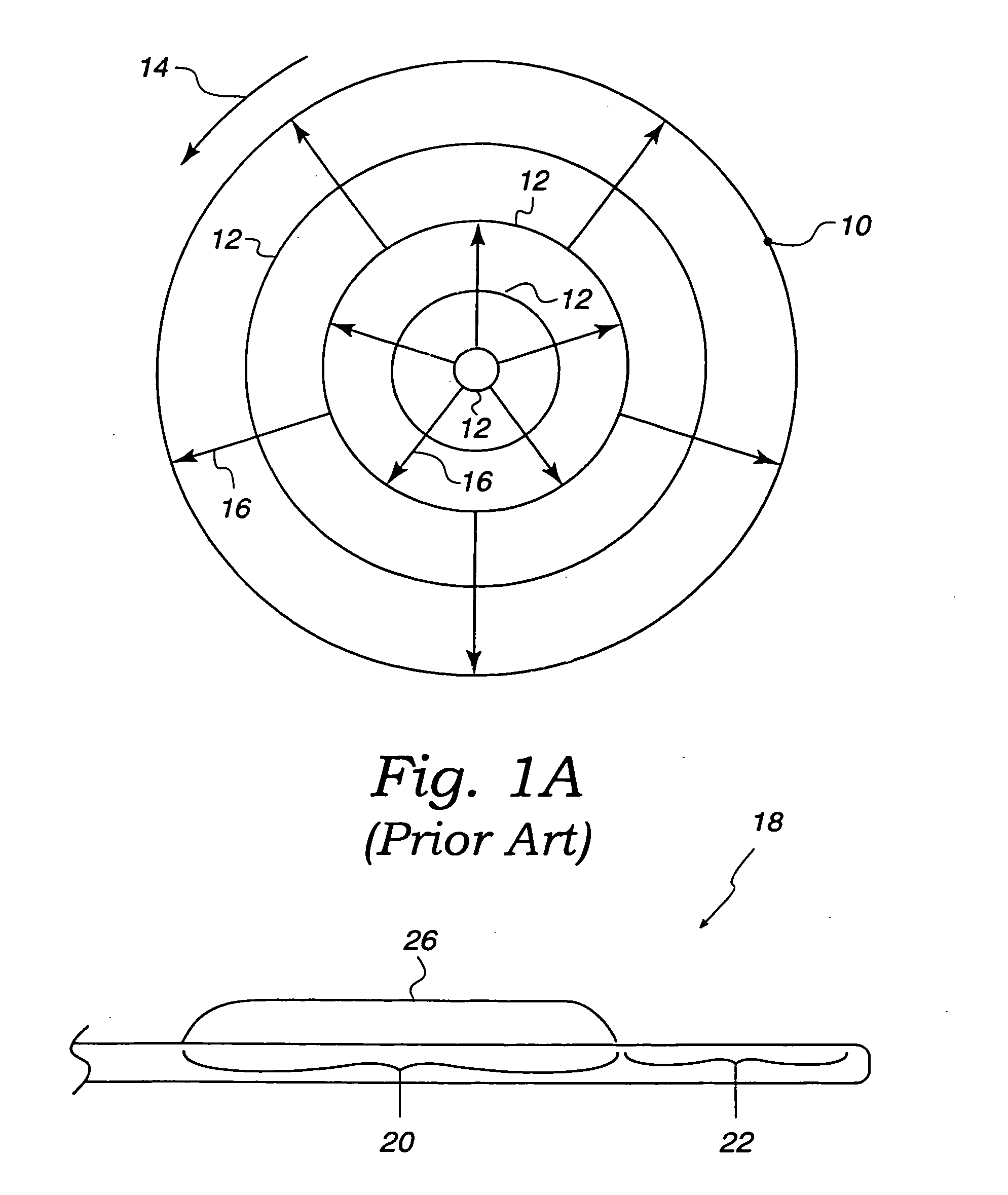

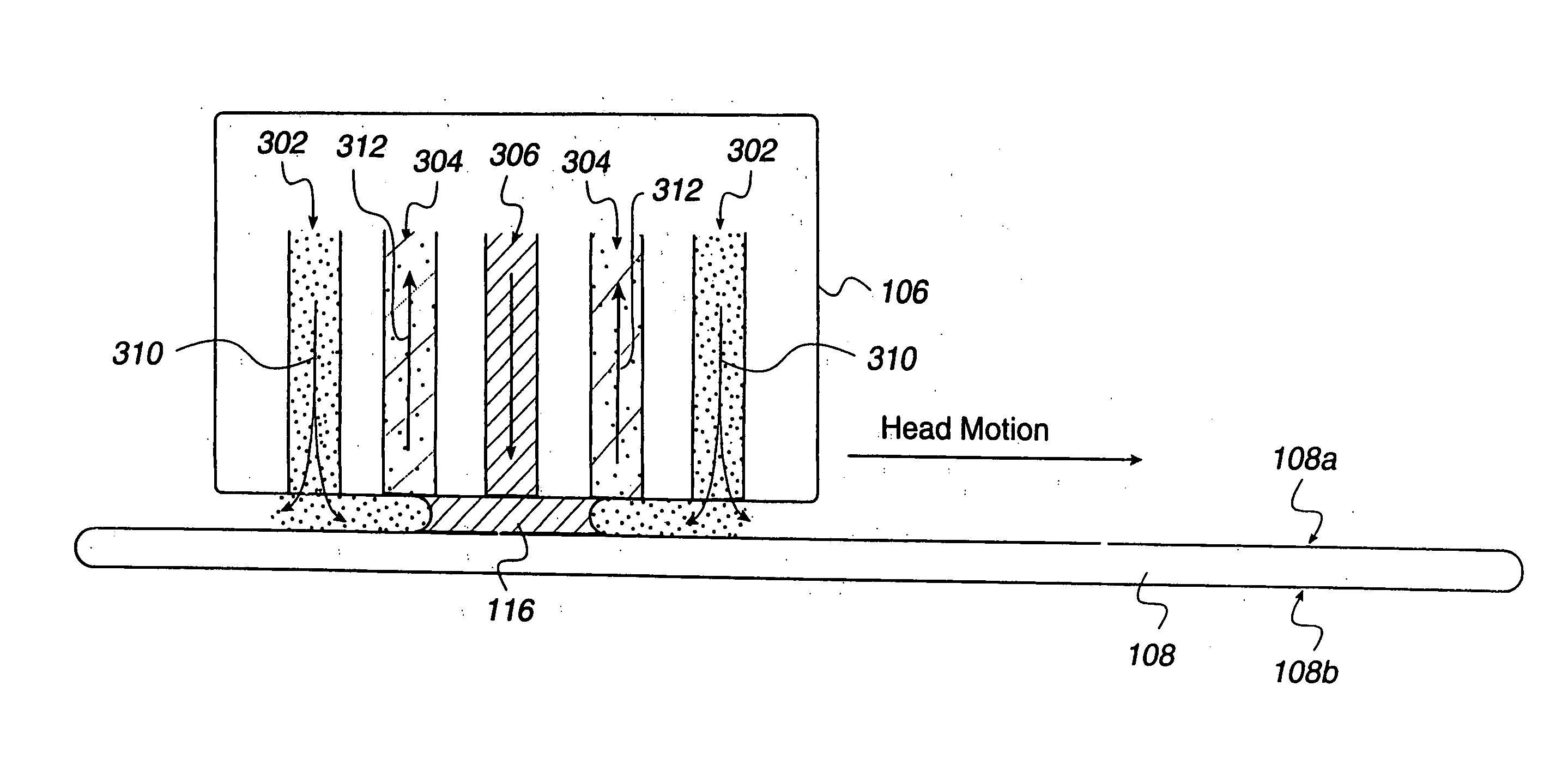

Apparatus and method for utilizing a meniscus in substrate processing

InactiveUS20050217703A1Process environment can be powerfully controlled and managedMore processedLiquid surface applicatorsSemiconductor/solid-state device manufacturingActive agentEngineering

An apparatus for processing a substrate is provided which includes a proximity head proximate to a surface of the substrate when in operation. The apparatus also includes an opening on a surface of the proximity head to a cavity defined in the proximity head where the cavity delivers an active agent to the surface of the substrate through the opening. The apparatus further includes a plurality of conduits on the surface of the proximity head that generates a fluid meniscus on the surface of the substrate surrounding the opening.

Owner:LAM RES CORP

Method of cleaning etching apparatus

ActiveUS20060191555A1Clean interiorMaintain repeatabilityHollow article cleaningElectrostatic cleaningBoron trichlorideOxygen

To provide a cleaning method for an etching apparatus for a metal film that efficiently removes an etching residue deposited in an etching process chamber, assures the reproducibility of the etching performance, and keeps the etching process chamber in a low-dust-emission condition. Each time one workpiece with a metal film is etched (S1), the interior of the vacuum chamber is cleaned by replacing the workpiece with a dummy substrate (S2), performing a first step of plasma processing using oxygen (O2) and carbon tetrafluoride (CF4) to remove a carbon-based deposit pile (S3), and performing a second step of plasma processing using boron trichloride (BCl3) and chlorine (Cl2) to remove a residue that could not be removed by the first step and an etching residue of the metal film (S4).

Owner:HITACHI HIGH-TECH CORP

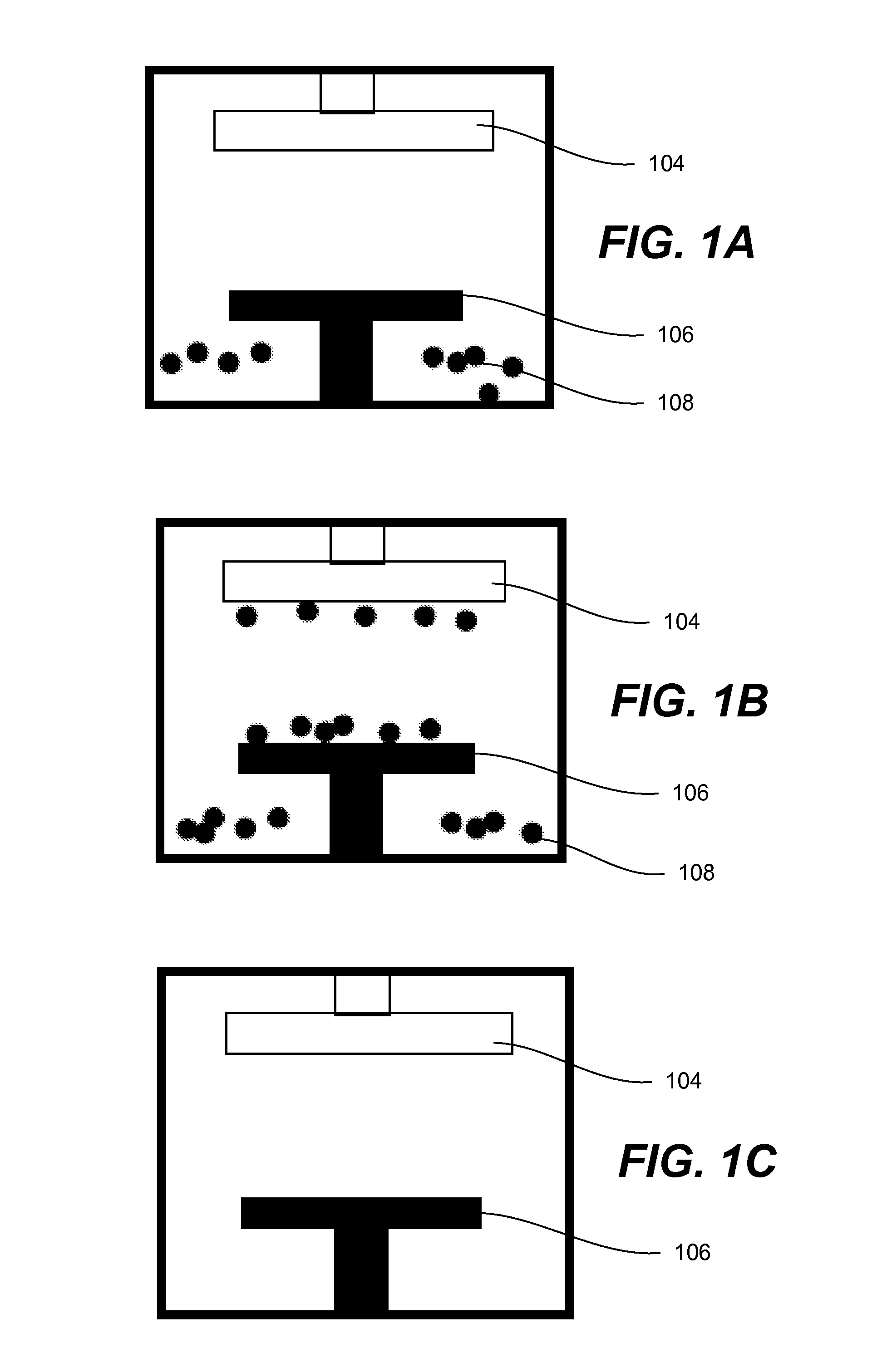

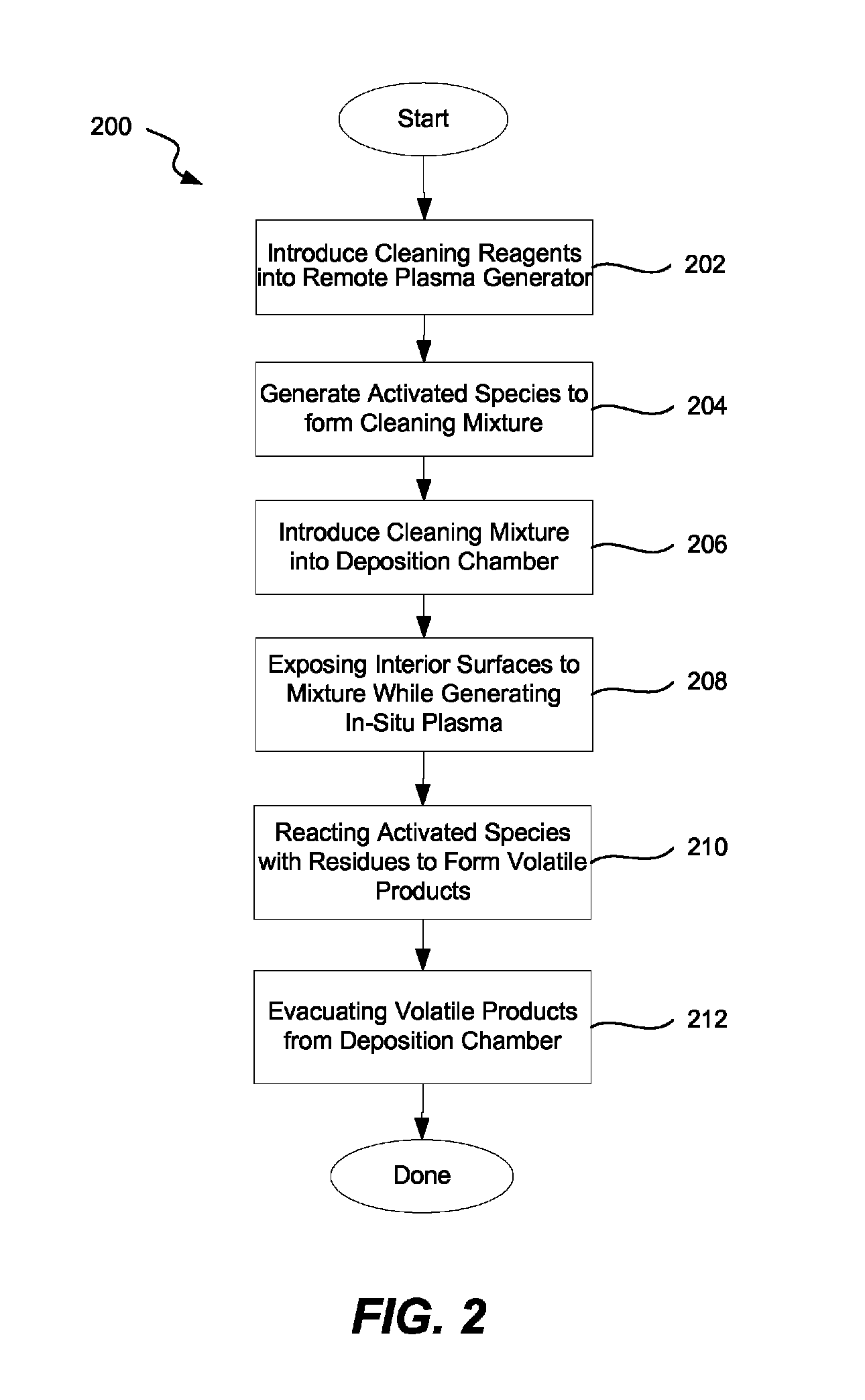

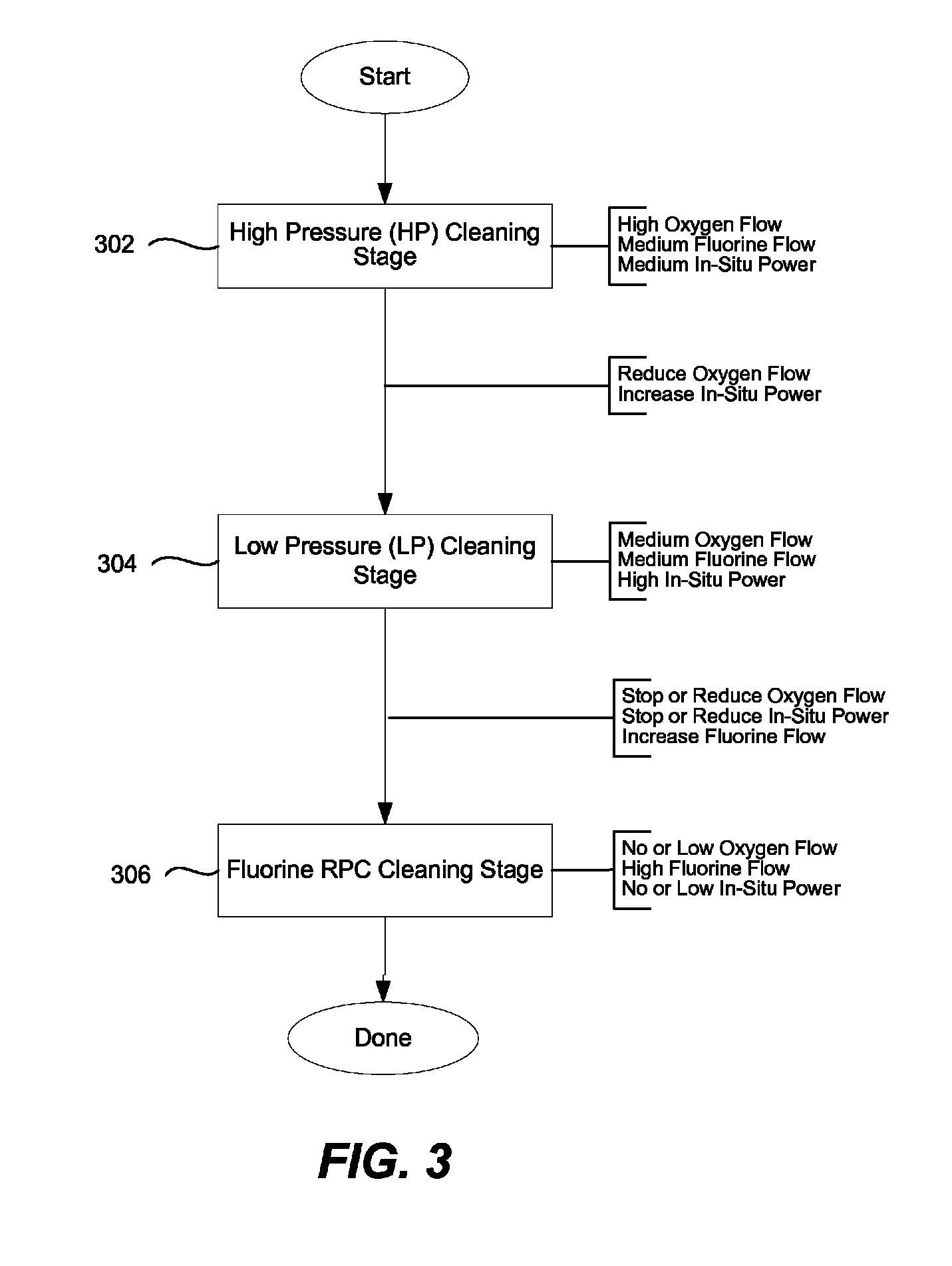

Plasma clean method for deposition chamber

ActiveUS8591659B1Improve cleaning efficiencyEasy to cleanElectric discharge tubesDecorative surface effectsRemote plasmaImproved method

Improved methods and apparatuses for removing residue from the interior surfaces of the deposition reactor are provided. The methods involve increasing availability of cleaning reagent radicals inside the deposition chamber by generating cleaning reagent radicals in a remote plasma generator and then further delivering in-situ plasma energy while the cleaning reagent mixture is introduced into the deposition chamber. Certain embodiments involve a multi-stage process including a stage in which the cleaning reagent mixture is introduced at a high pressure (e.g., about 0.6 Torr or more) and a stage the cleaning reagent mixture is introduced at a low pressure (e.g., about 0.6 Torr or less).

Owner:NOVELLUS SYSTEMS

Method of cleaning UV irradiation chamber

ActiveUS7789965B2Improve efficiencyKeep for a long timeLighting and heating apparatusHollow article cleaningIrradiationPhotochemistry

A method of cleaning a UV irradiation chamber includes steps of: (i) after completion of irradiating a substrate with UV light transmitted through an optical transmitted window provided in the UV irradiation chamber, generating radical species of a cleaning gas outside the UV irradiation chamber; and (ii) introducing the radical species from the outside of the UV irradiation chamber into the UV irradiation chamber, thereby cleaning the optical transmitted window.

Owner:ASM JAPAN

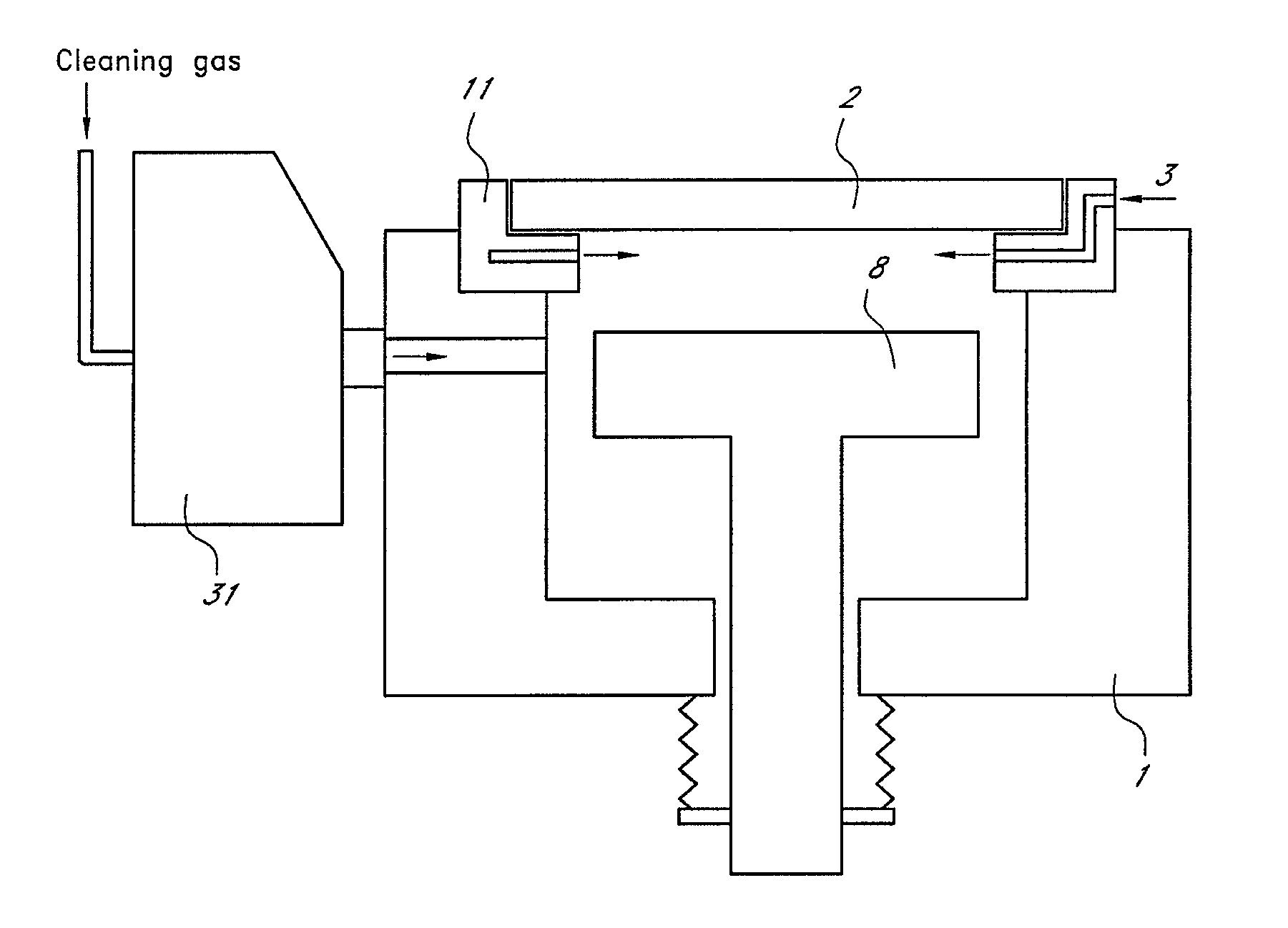

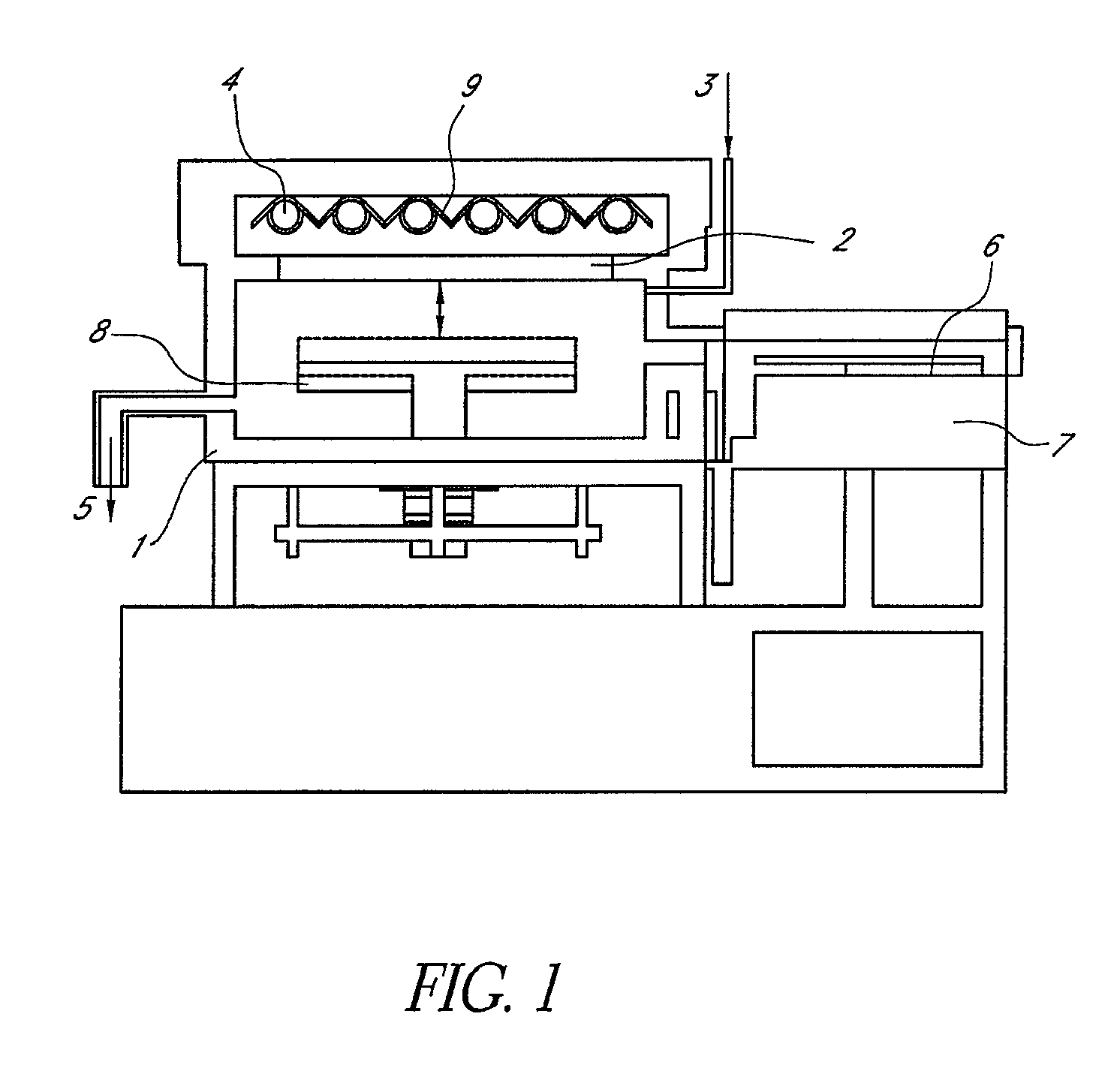

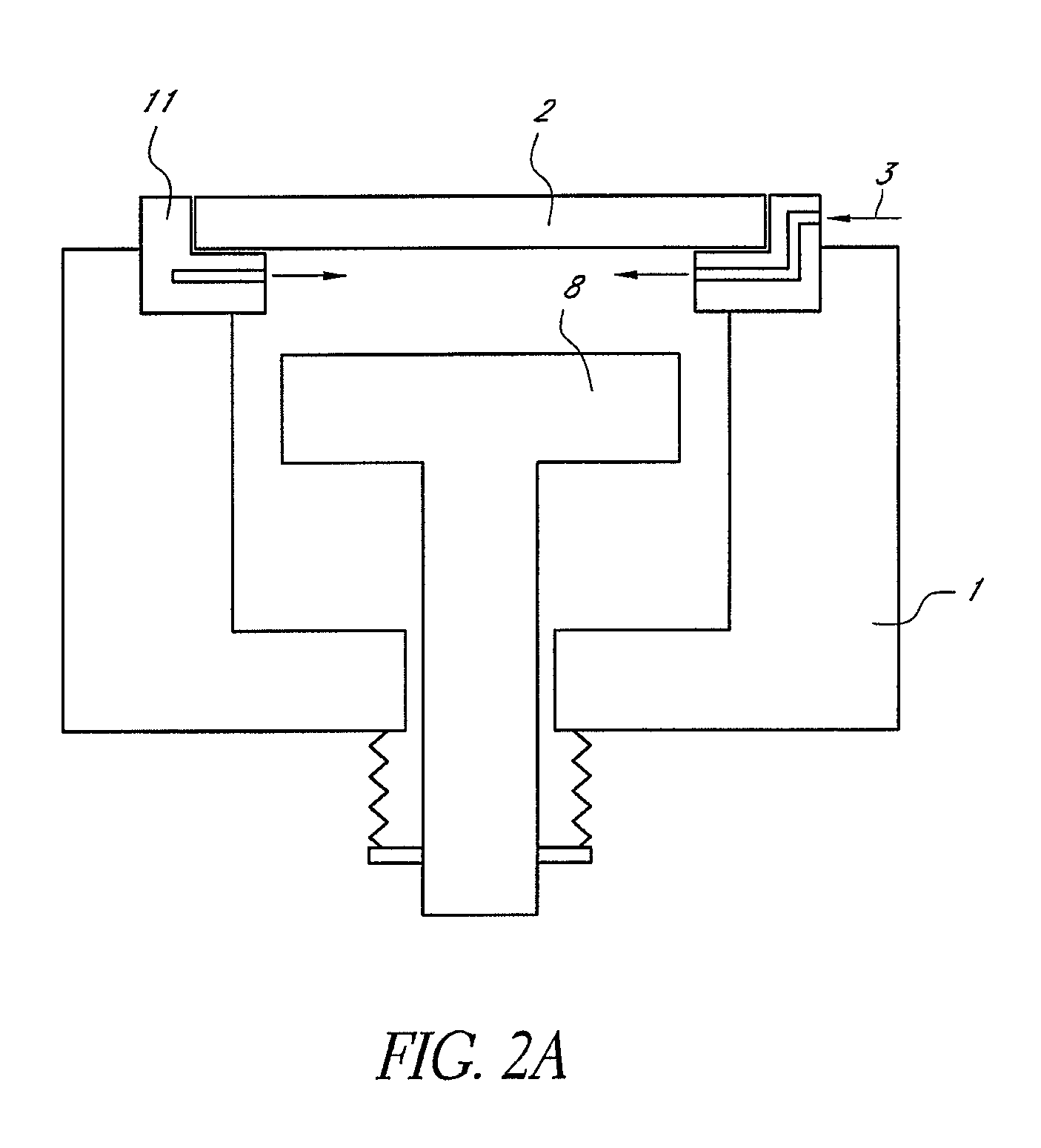

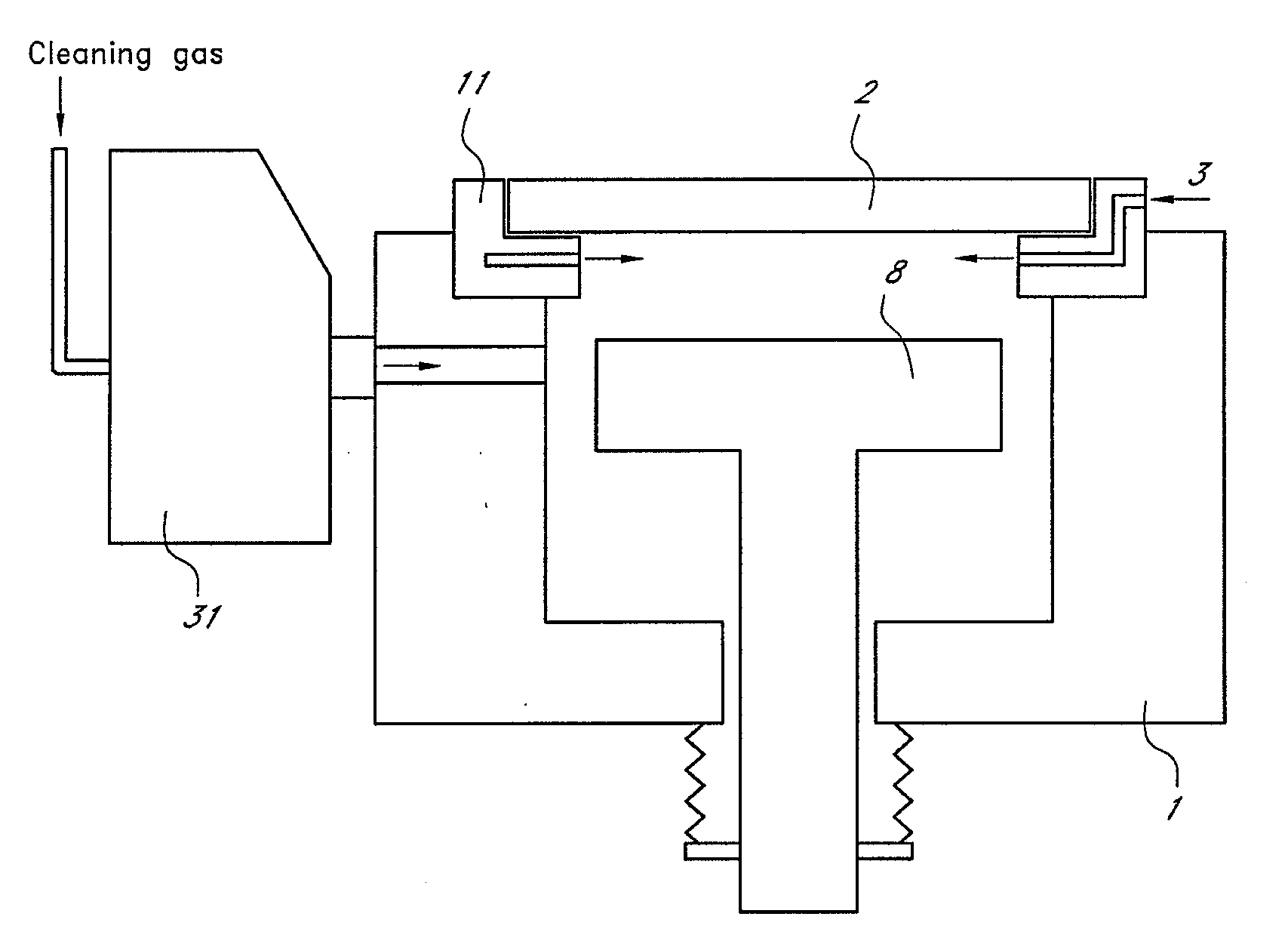

Method of cleaning UV irradiation chamber

ActiveUS20080066778A1Improve efficiencyLong cleaning timeLighting and heating apparatusHollow article cleaningIrradiationPhotochemistry

A method of cleaning a UV irradiation chamber includes steps of: (i) after completion of irradiating a substrate with UV light transmitted through an optical transmitted window provided in the UV irradiation chamber, generating radical species of a cleaning gas outside the UV irradiation chamber; and (ii) introducing the radical species from the outside of the UV irradiation chamber into the UV irradiation chamber, thereby cleaning the optical transmitted window.

Owner:ASM JAPAN

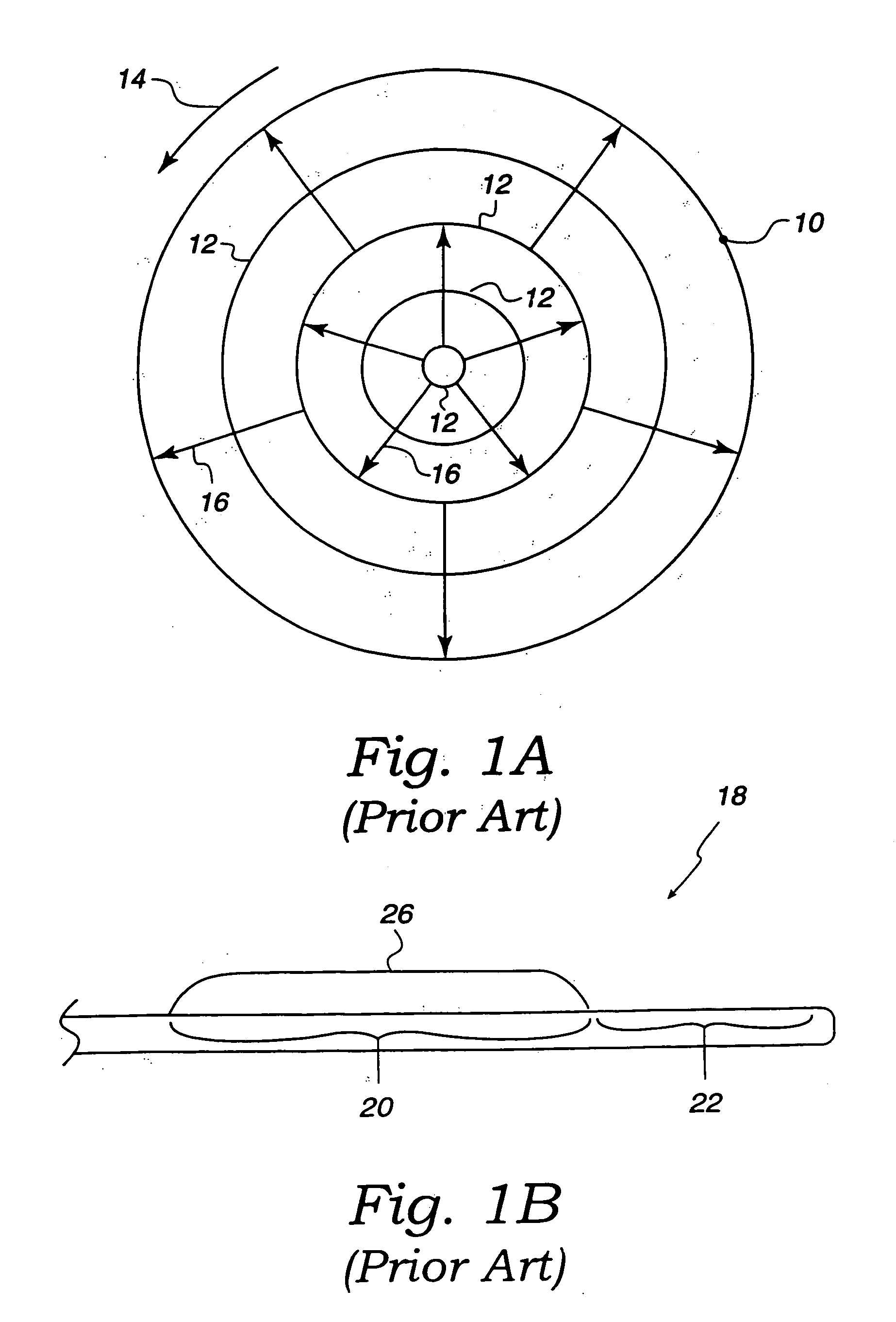

Method and apparatus for processing wafer surfaces using thin, high velocity fluid layer

InactiveUS20050145265A1Efficient processingReducing unwanted fluidElectrolysis componentsDrying solid materials without heatHigh velocityBiomedical engineering

Among the many embodiment, in one embodiment, a method for processing a substrate is disclosed which includes generating a fluid layer on a surface of the substrate, the fluid layer defining a fluid meniscus. The generating includes moving a head in proximity to the surface, applying a fluid from the head to the surface while the head is in proximity to the surface of the substrate to define the fluid layer, and removing the fluid from the surface through the proximity head by a vacuum. The fluid travels along the fluid layer between the head and the substrate at a velocity that increases as the head is in closer proximity to the surface.

Owner:LAM RES CORP

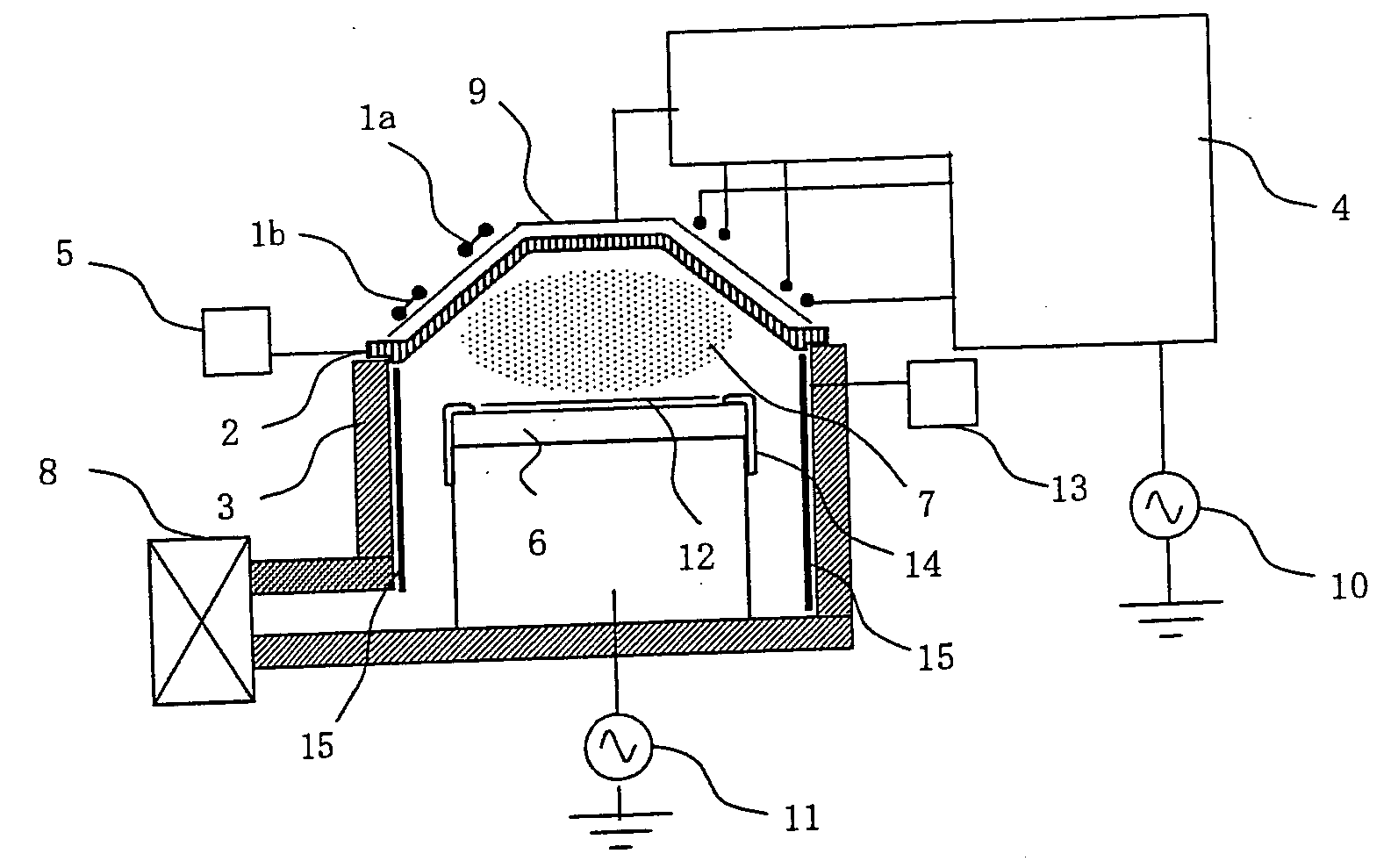

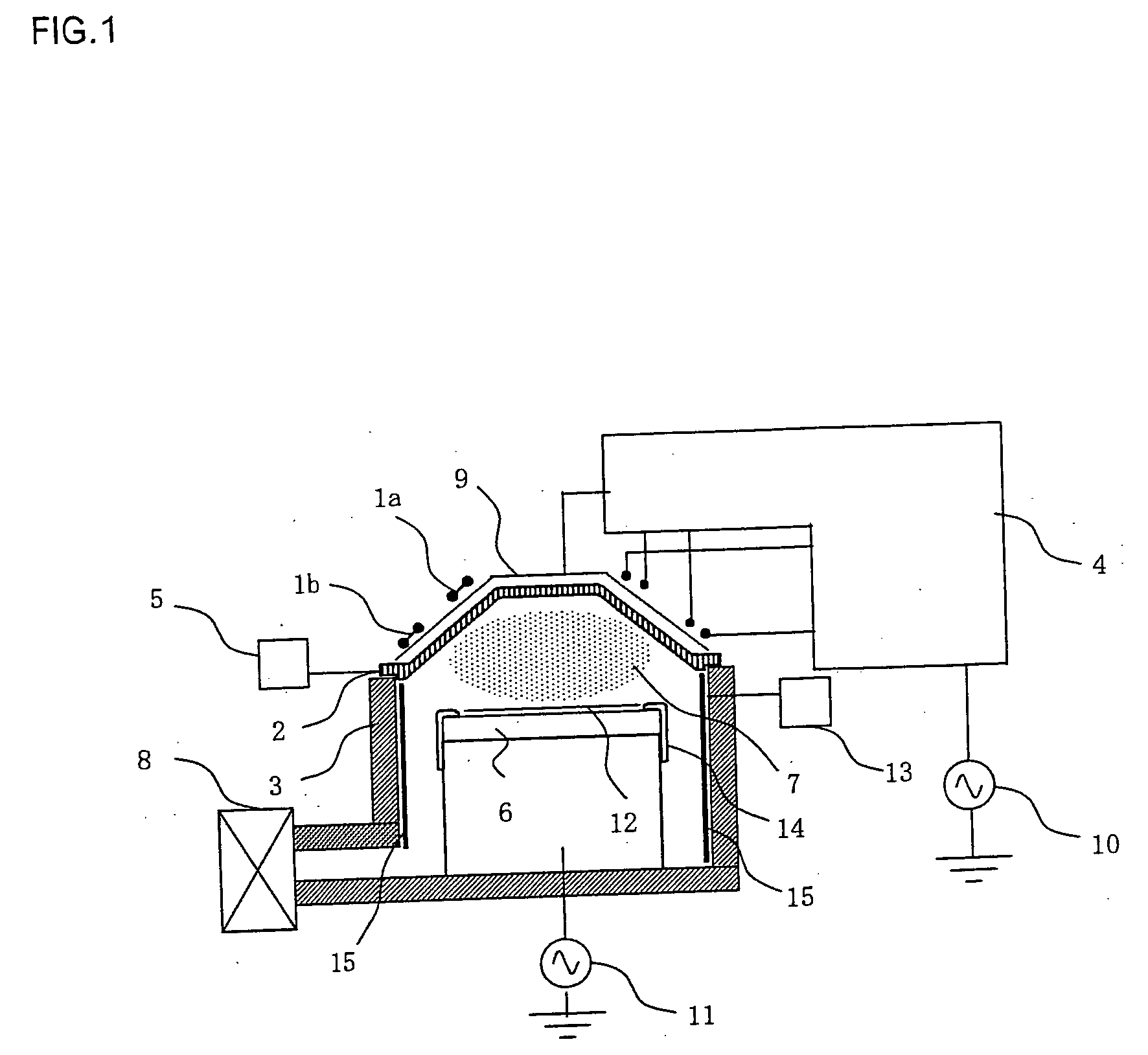

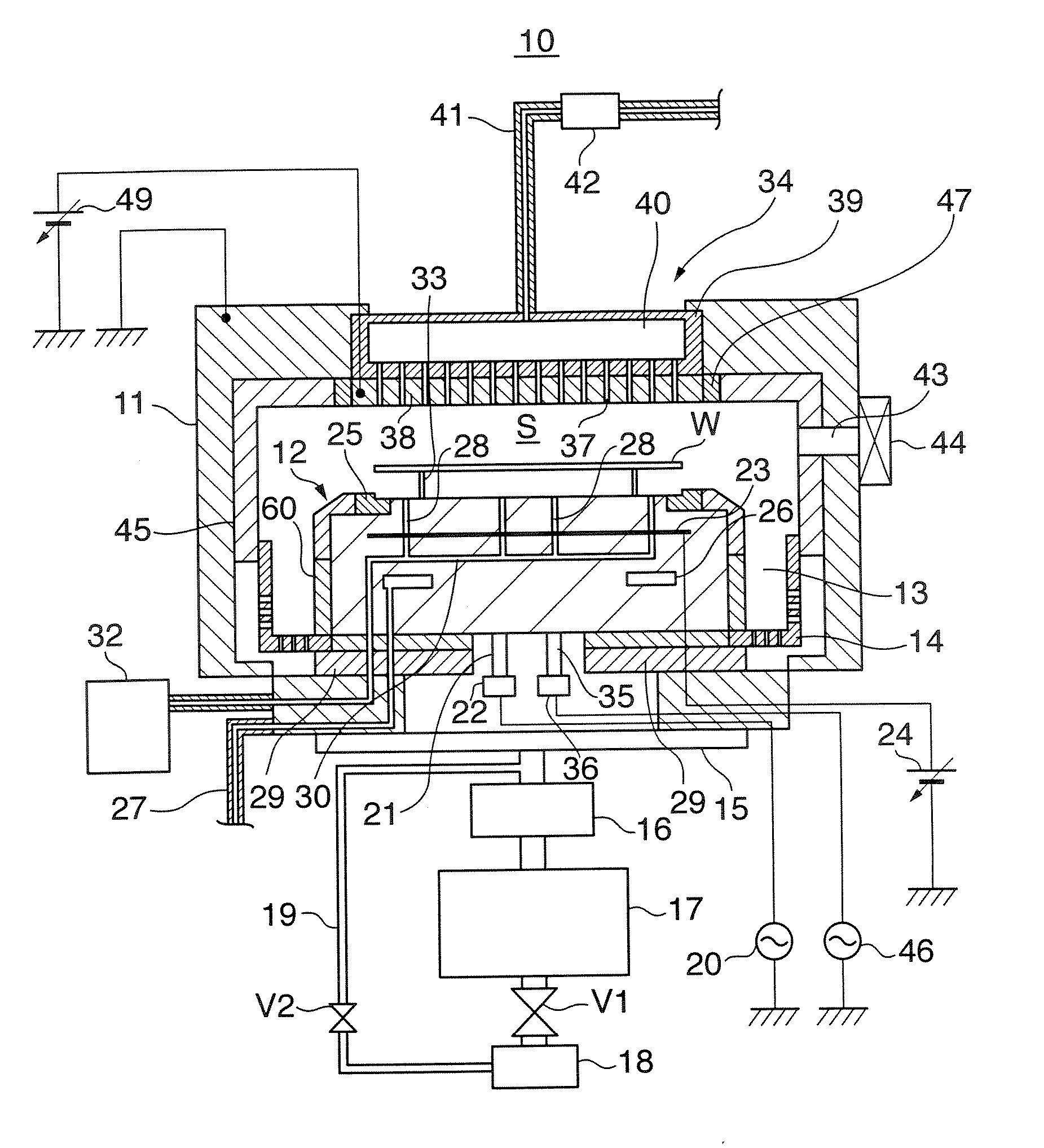

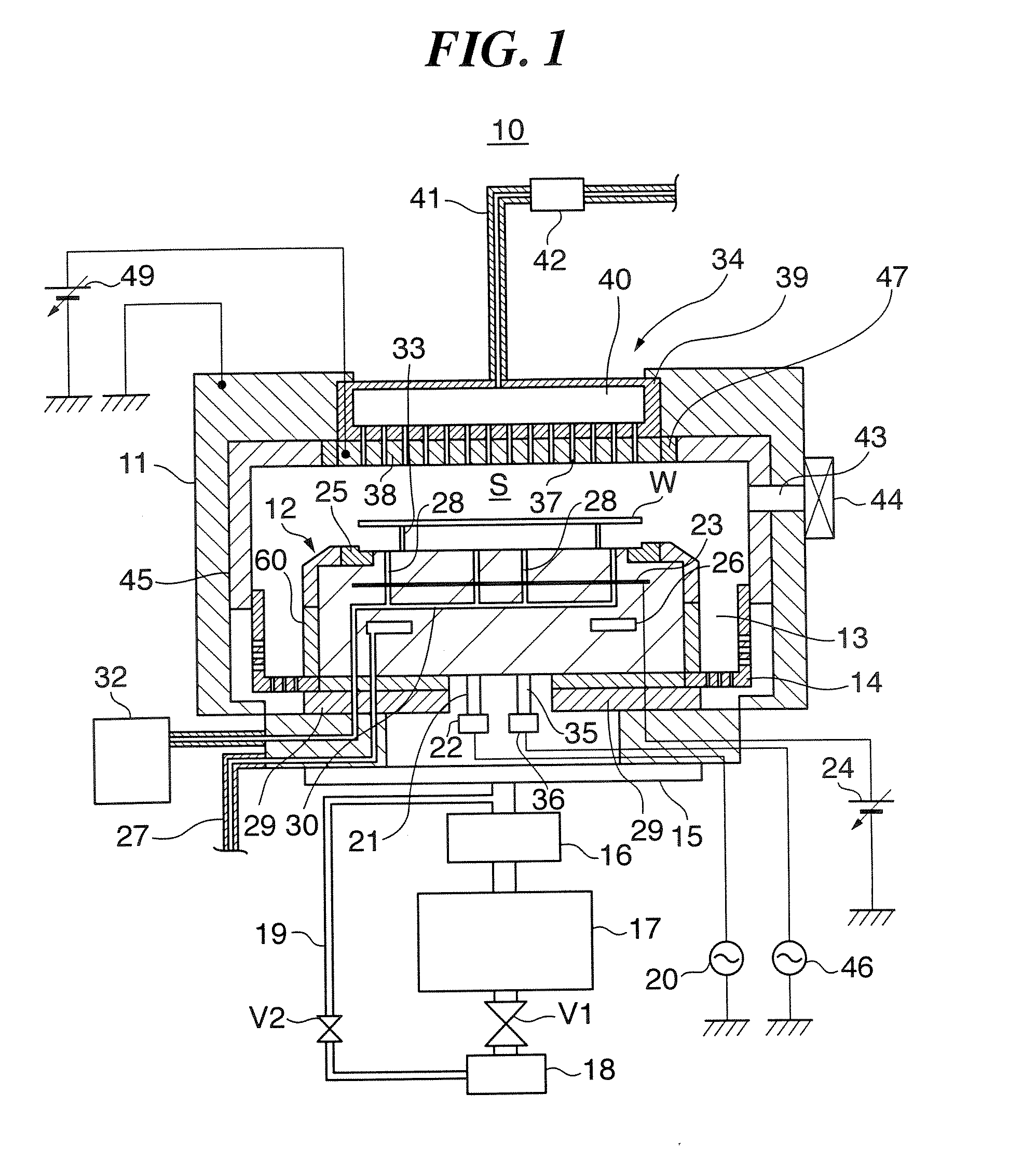

Method of cleaning substrate processing chamber, storage medium, and substrate processing chamber

ActiveUS20070186952A1Inhibition formationElectric discharge tubesHollow article cleaningElectricityReactive-ion etching

A method of cleaning a substrate processing chamber that enables formation of an oxide film on a surface of a processing chamber inside component to be prevented. A substrate processing chamber 11 has therein a processing space S into which a wafer W is transferred and carries out reactive ion etching on the wafer W in the processing space S. The substrate processing chamber 11 has an upper electrode plate 38 that comprises silicon and a lower surface of which is exposed to the processing space S. A dry cleaning is carried out on the upper electrode plate 38 using oxygen radicals produced from oxygen gas introduced into the processing space S. An oxide removal processing is carried out on the upper electrode plate 38 using fluorine ions and fluorine radicals produced from carbon tetrafluoride gas introduced into the processing space S.

Owner:TOKYO ELECTRON LTD

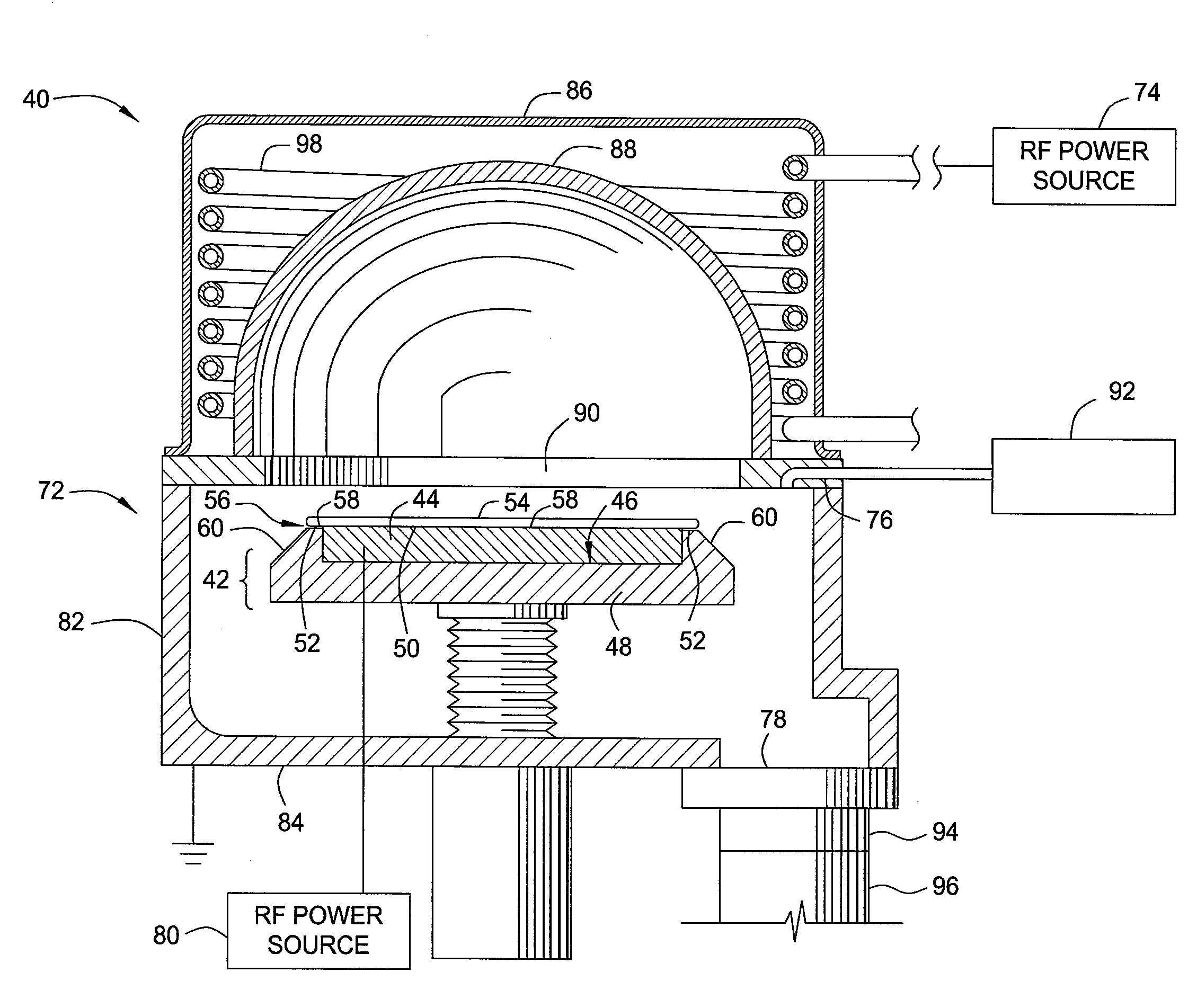

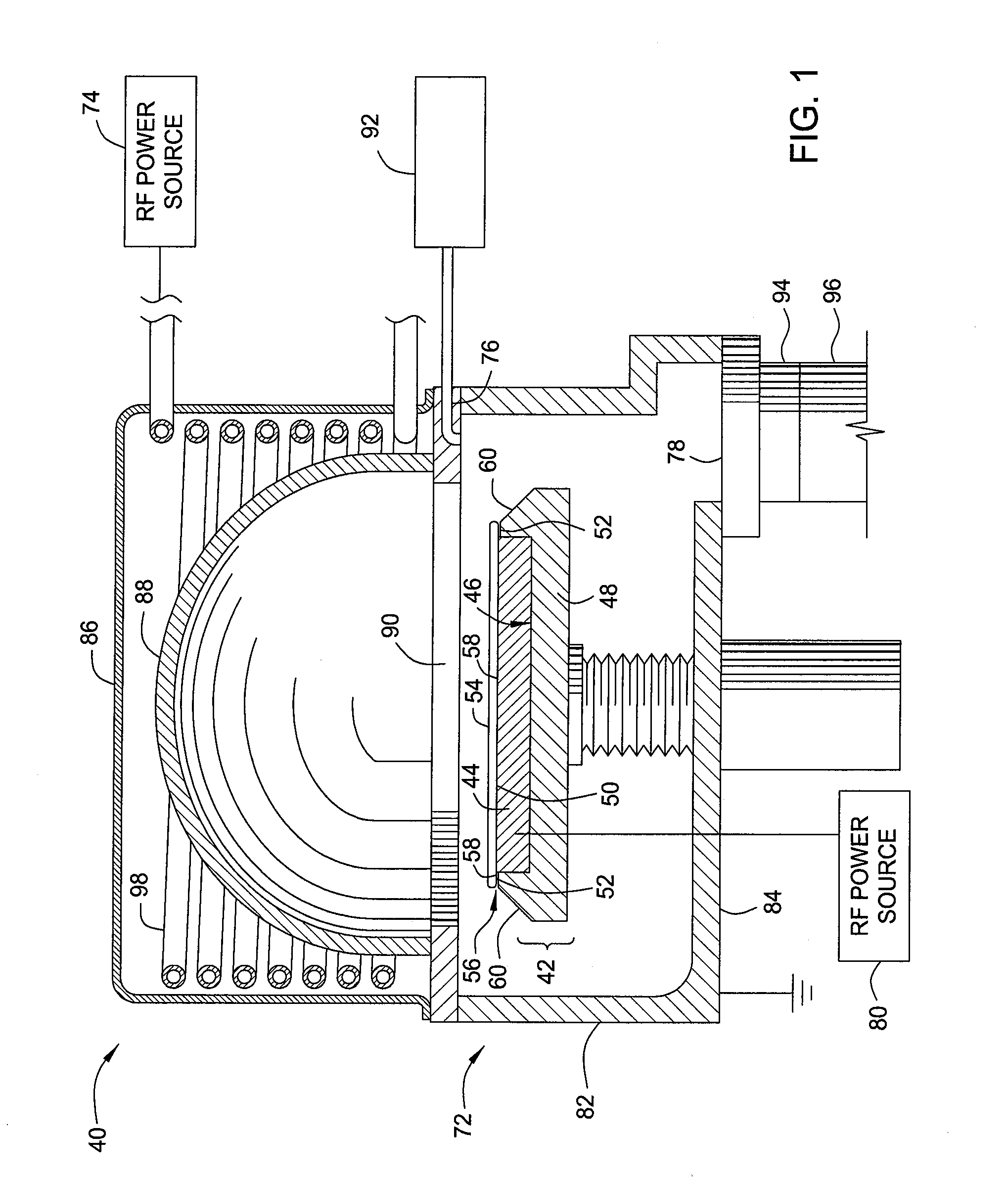

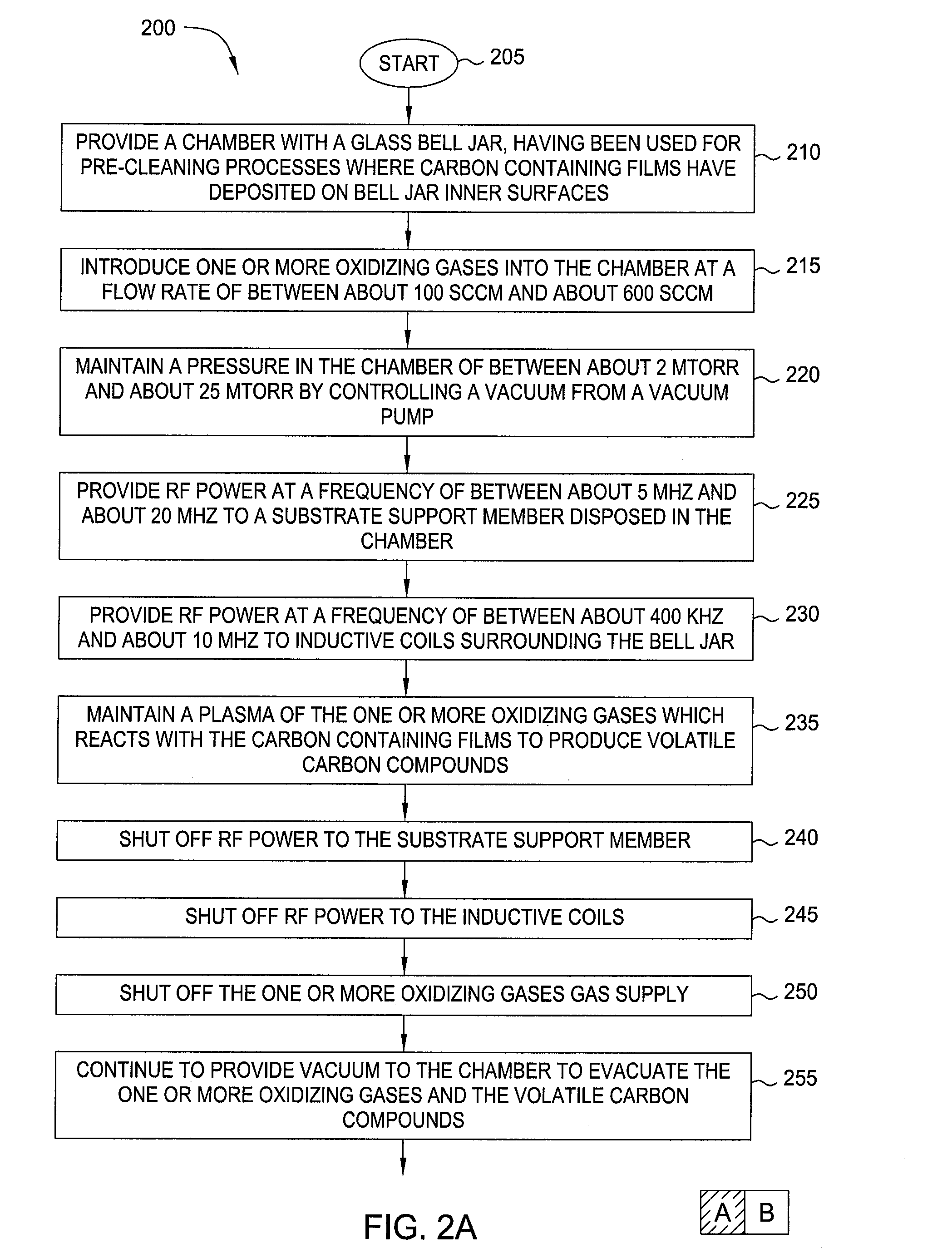

Oxygen plasma clean to remove carbon species deposited on a glass dome surface

InactiveUS20080173326A1Decorative surface effectsHollow article cleaningChemical compoundOxygen plasma

A method for in-situ cleaning of a dielectric dome surface having been used in pre-clean processes is provided. Carbon containing deposits are removed by providing a plasma of one or more oxidizing gases which react with the carbon containing films to form volatile carbon containing compounds.

Owner:APPLIED MATERIALS INC

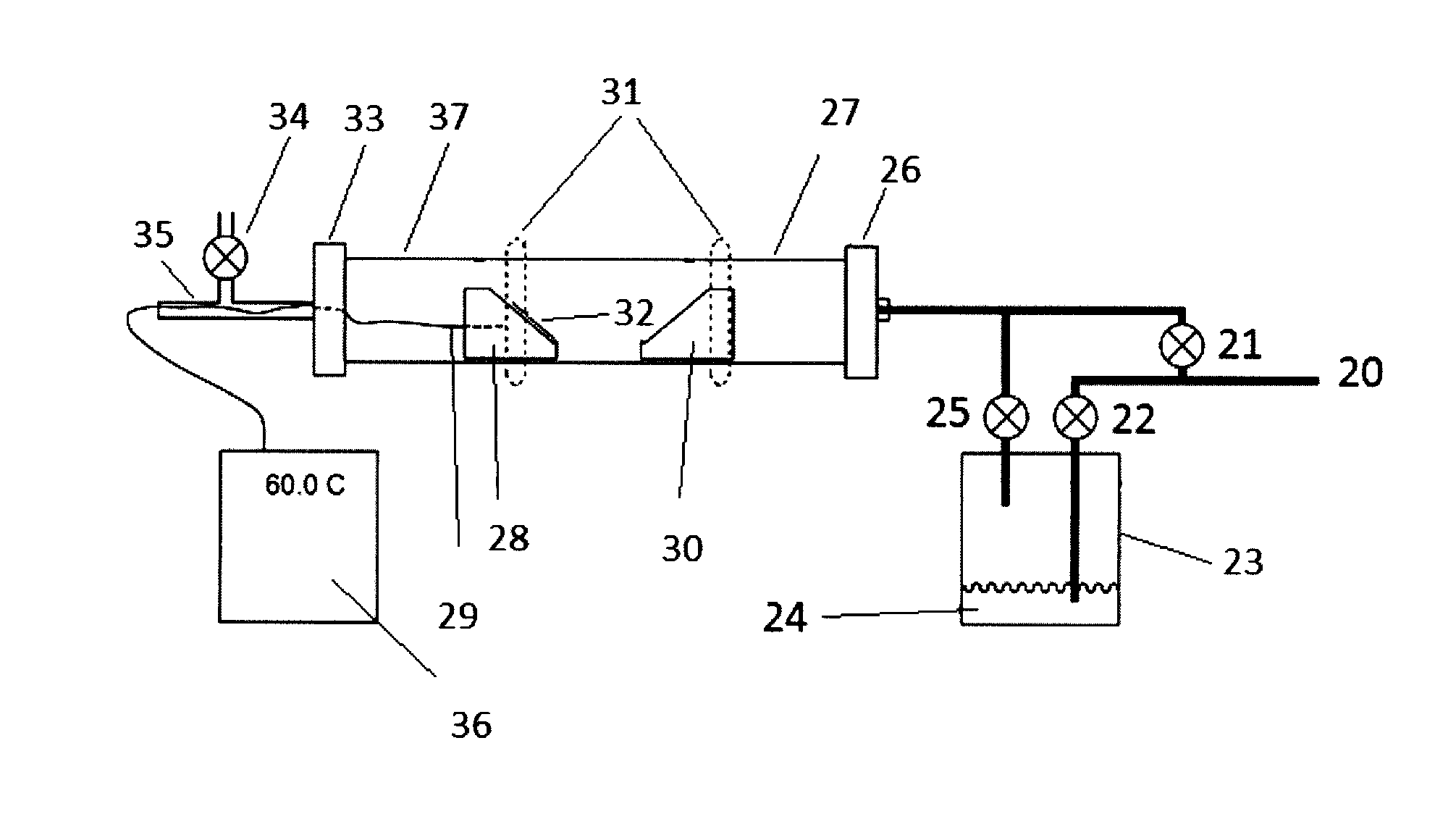

Method and apparatus for cleaning of a CVD reactor

InactiveUS20090269506A1Efficient and uniform remote plasma cleaningImprove efficiencyVacuum evaporation coatingElectrostatic cleaningRemote plasmaOxygen

The present invention provides a process and an apparatus for remote plasma cleaning of a process chamber of a chemical vapor deposition (CVD) reactor. The reactive species are generated in a remote plasma unit and are introduced into the process chamber through a plurality of inlet holes. The reactive species are free radicals such as oxygen radicals, fluorine radicals, and the like. These reactive species react with the unwanted residues in the process chamber and generate volatile products. The invention also provides a method for controlling the flow rate of the reactive species.

Owner:ASM JAPAN

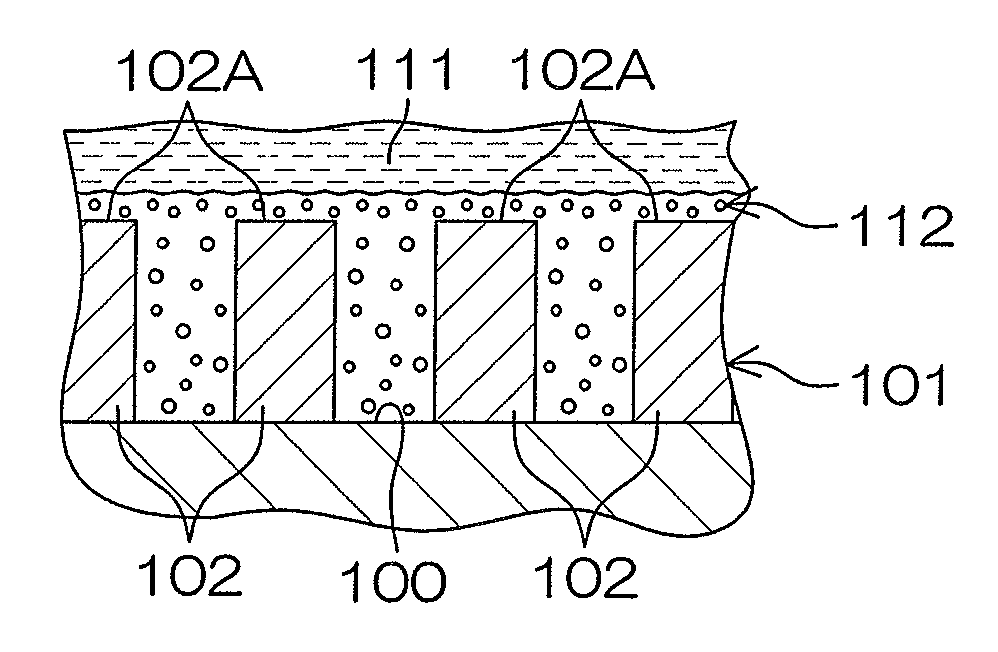

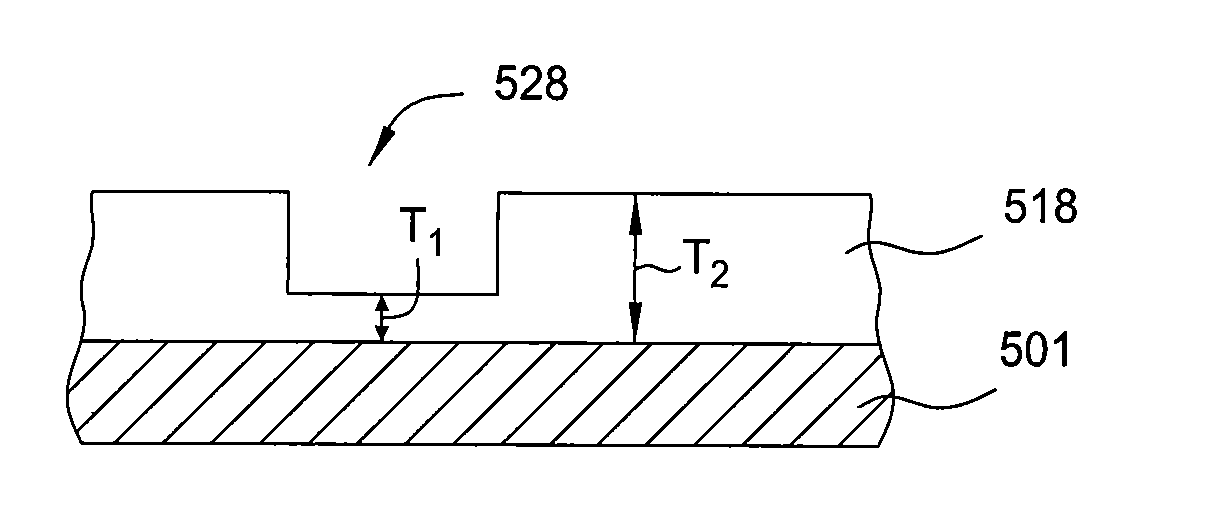

Substrate treatment method and substrate treatment apparatus

ActiveUS20150279708A1Reduce surface tensionLess attractiveSemiconductor/solid-state device manufacturingCleaning using liquidsOrganic solventBoiling point

A substrate treatment method is provided, which includes: an organic solvent replacing step of supplying an organic solvent, whereby a liquid film of the organic solvent is formed on the substrate as covering the upper surface of the substrate to replace a rinse liquid with the organic solvent; a substrate temperature increasing step of allowing the temperature of the upper surface of the substrate to reach a first temperature level higher than the boiling point of the organic solvent after the formation of the organic solvent liquid film, whereby a vapor film of the organic solvent is formed below the entire organic solvent liquid film between the organic solvent liquid film and the substrate to levitate the organic solvent liquid film above the organic solvent vapor film; and an organic solvent removing step of removing the levitated organic solvent liquid film from above the upper surface of the substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

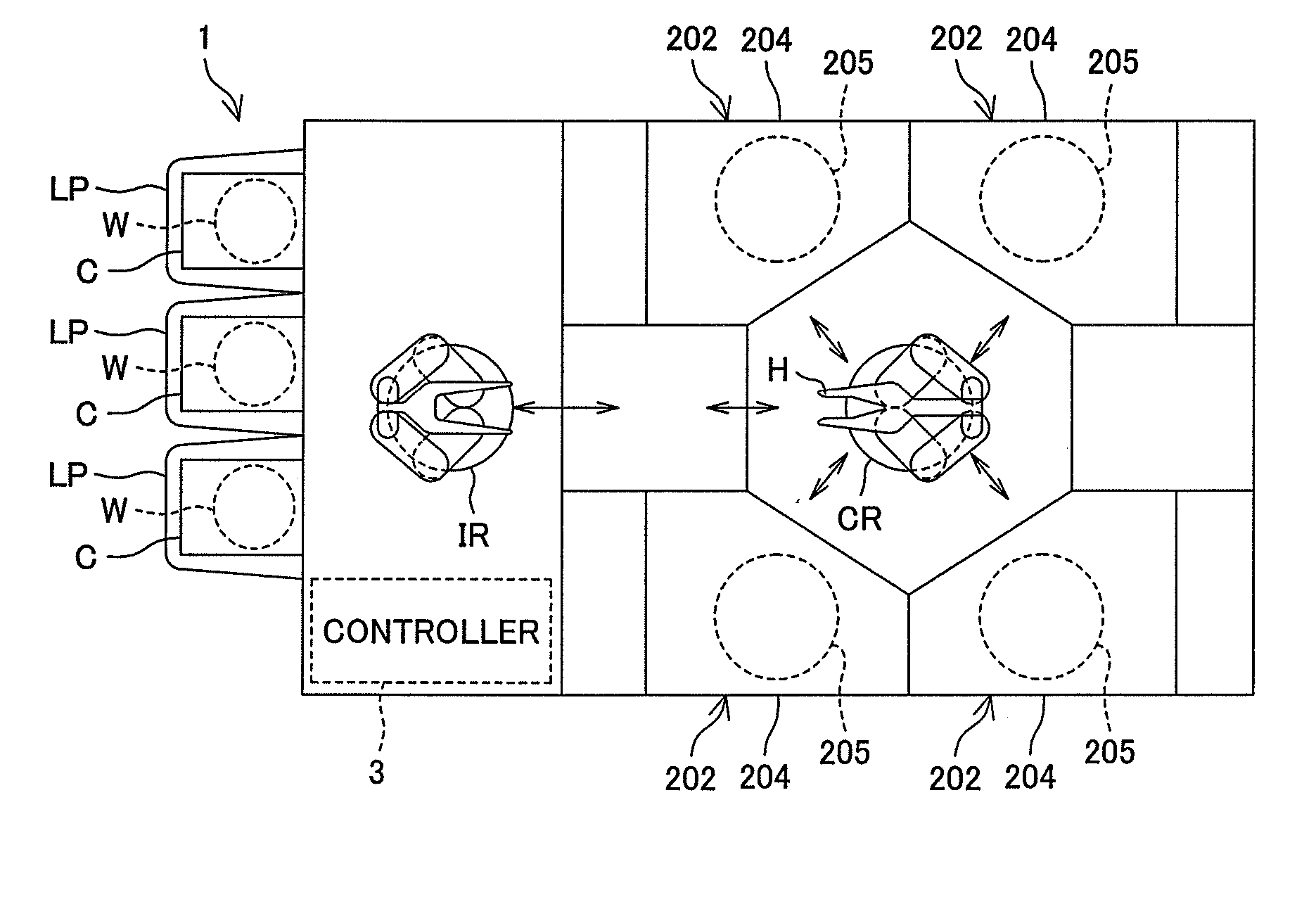

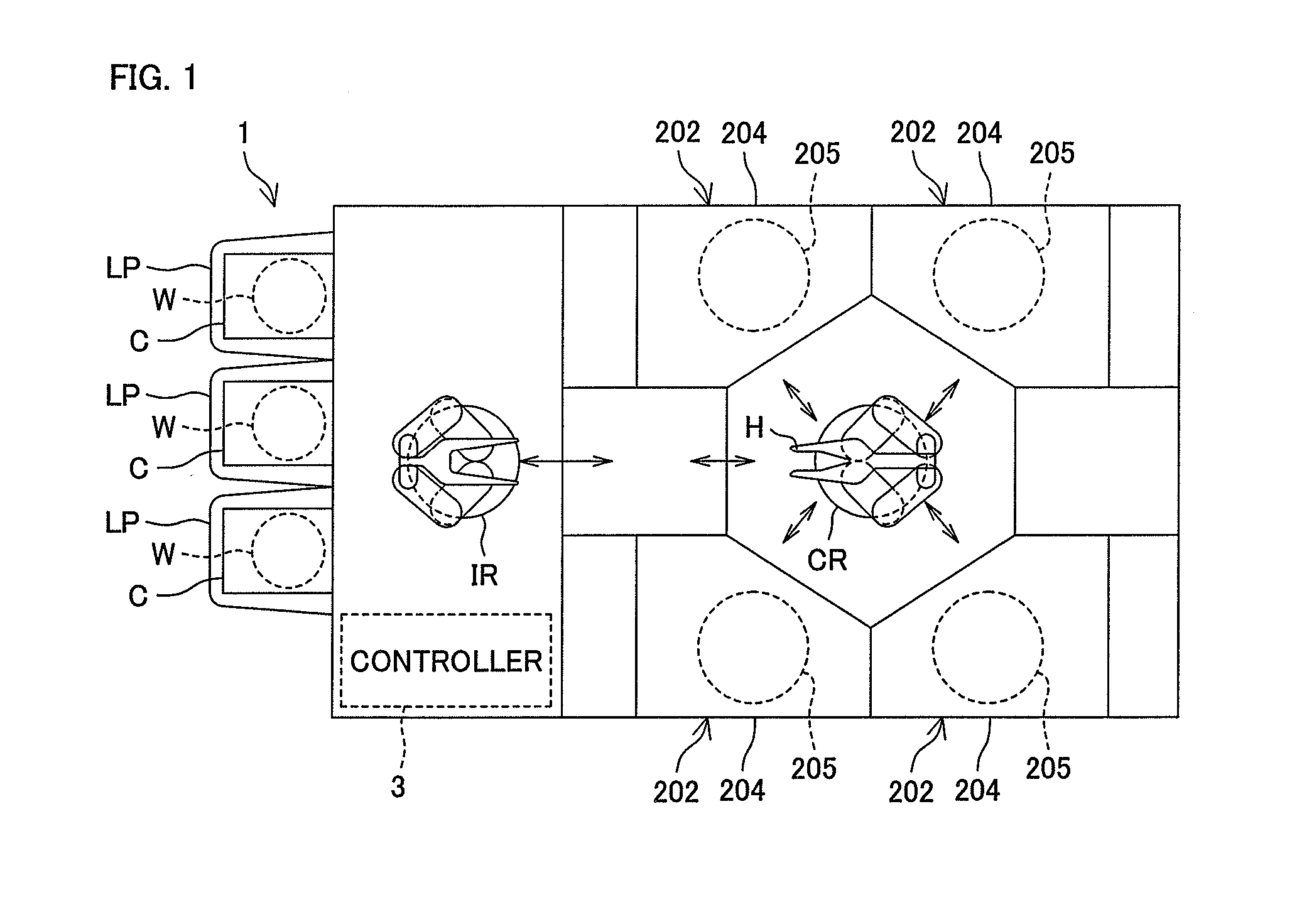

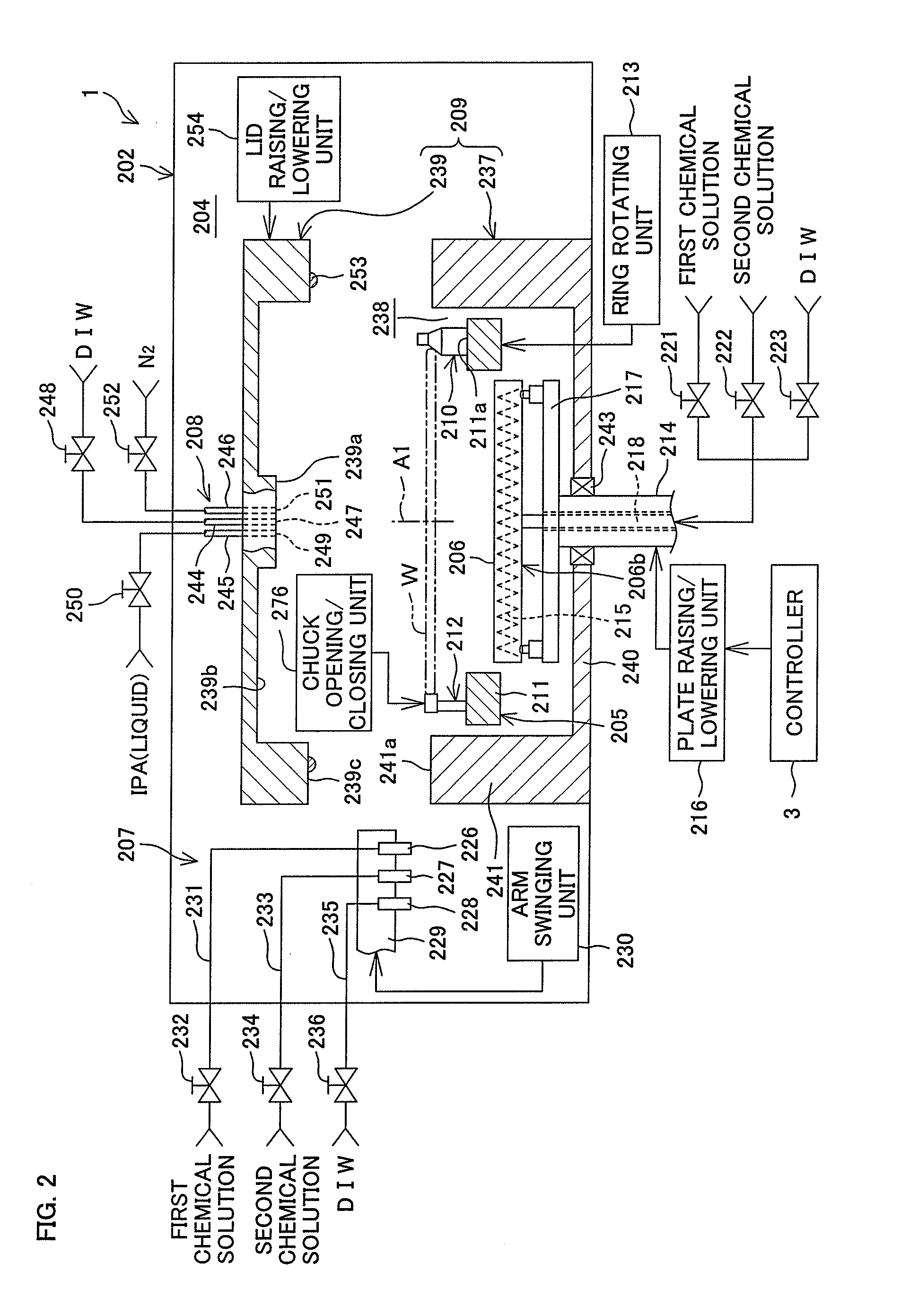

Substrate processing apparatus and substrate processing method

InactiveUS20150270146A1Supply is stoppedDry surfaceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingOrganic solventEngineering

In parallel with a substrate heating step, a liquid surface sensor is used to monitor the raising of an IPA liquid film. An organic solvent removing step is started in response to the raising of the IPA liquid film over the upper surface of the substrate. At the end of the organic solvent removing step, a visual sensor is used to determine whether or not IPA droplets remain on the upper surface of the substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

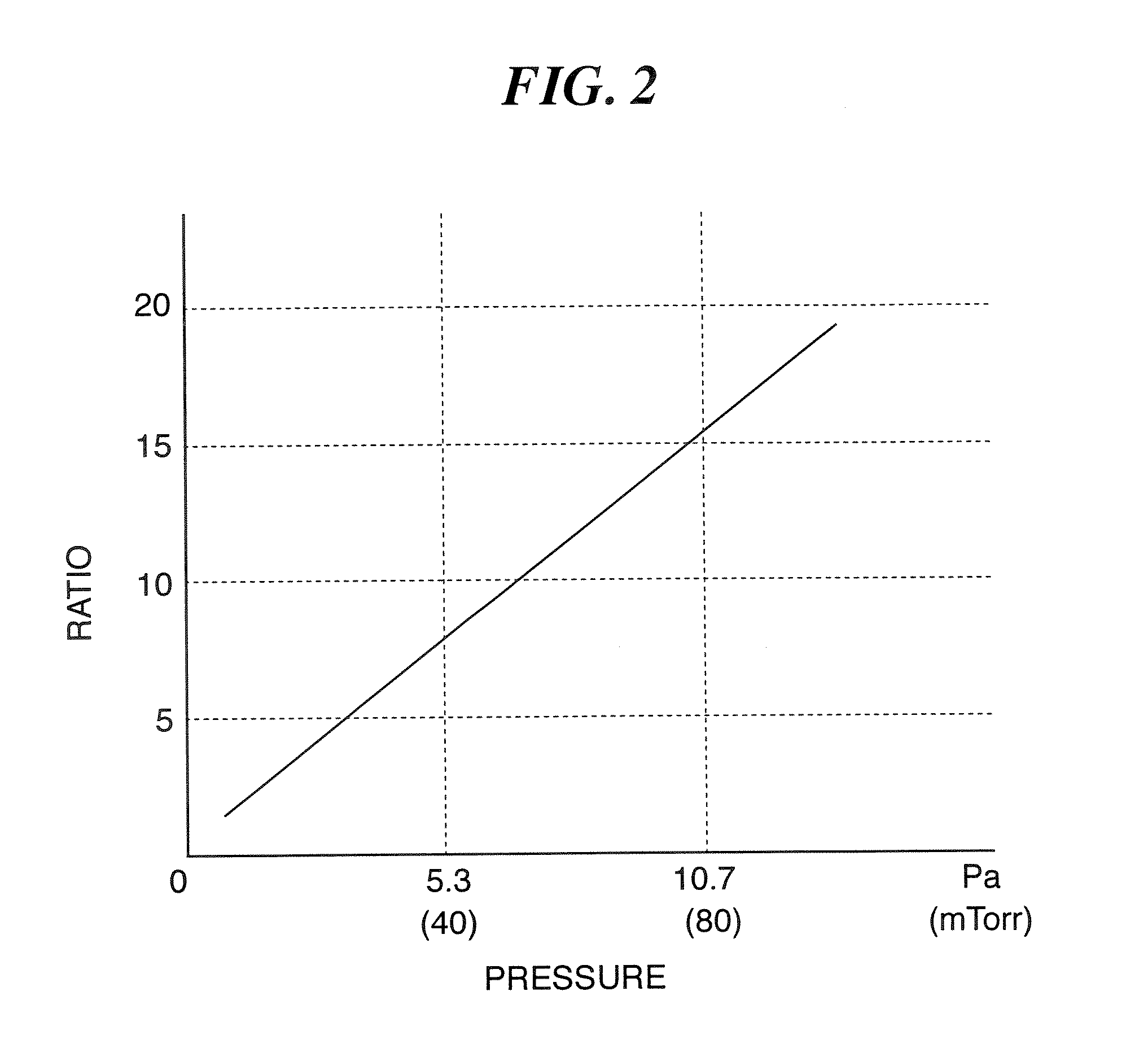

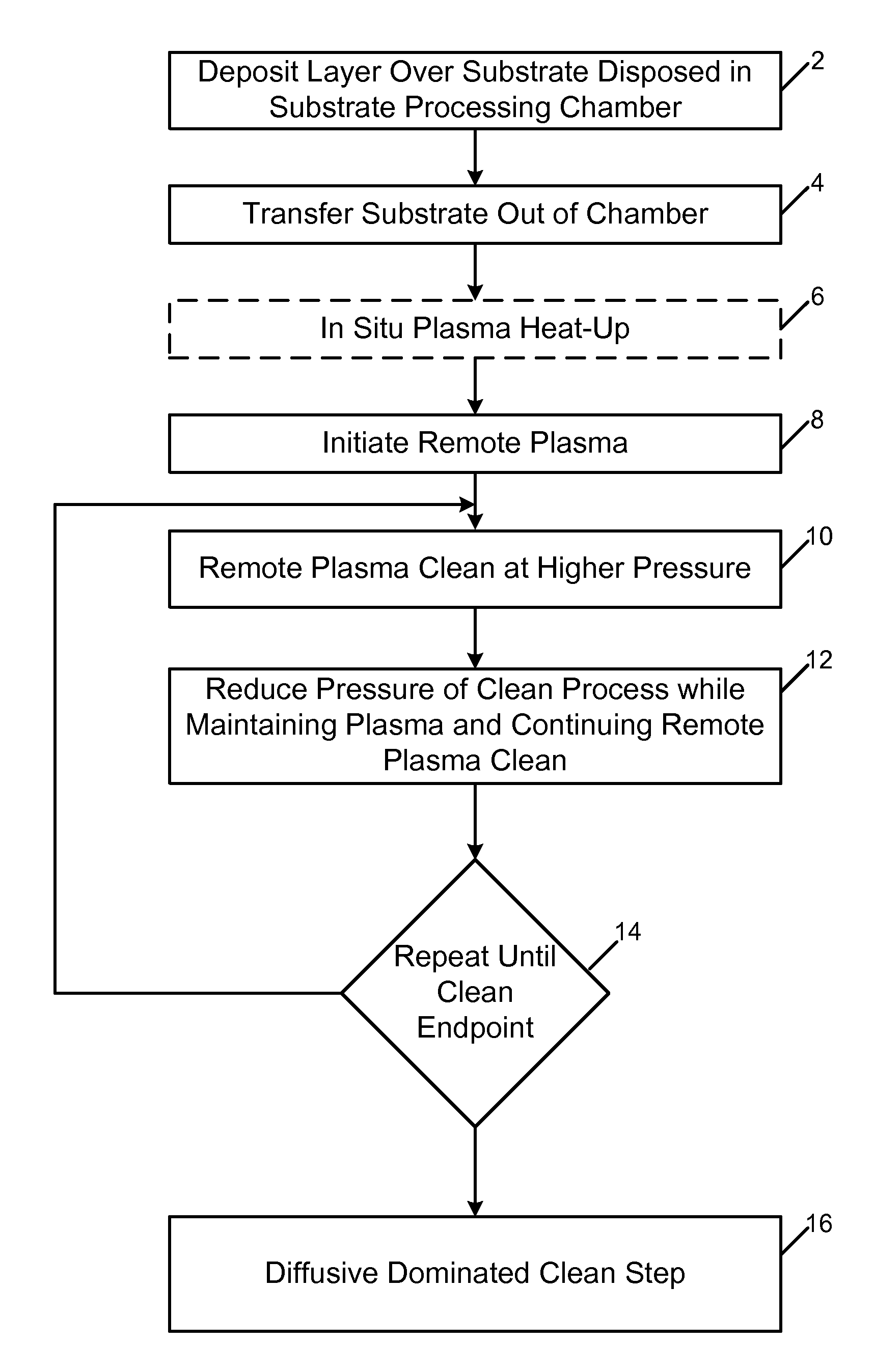

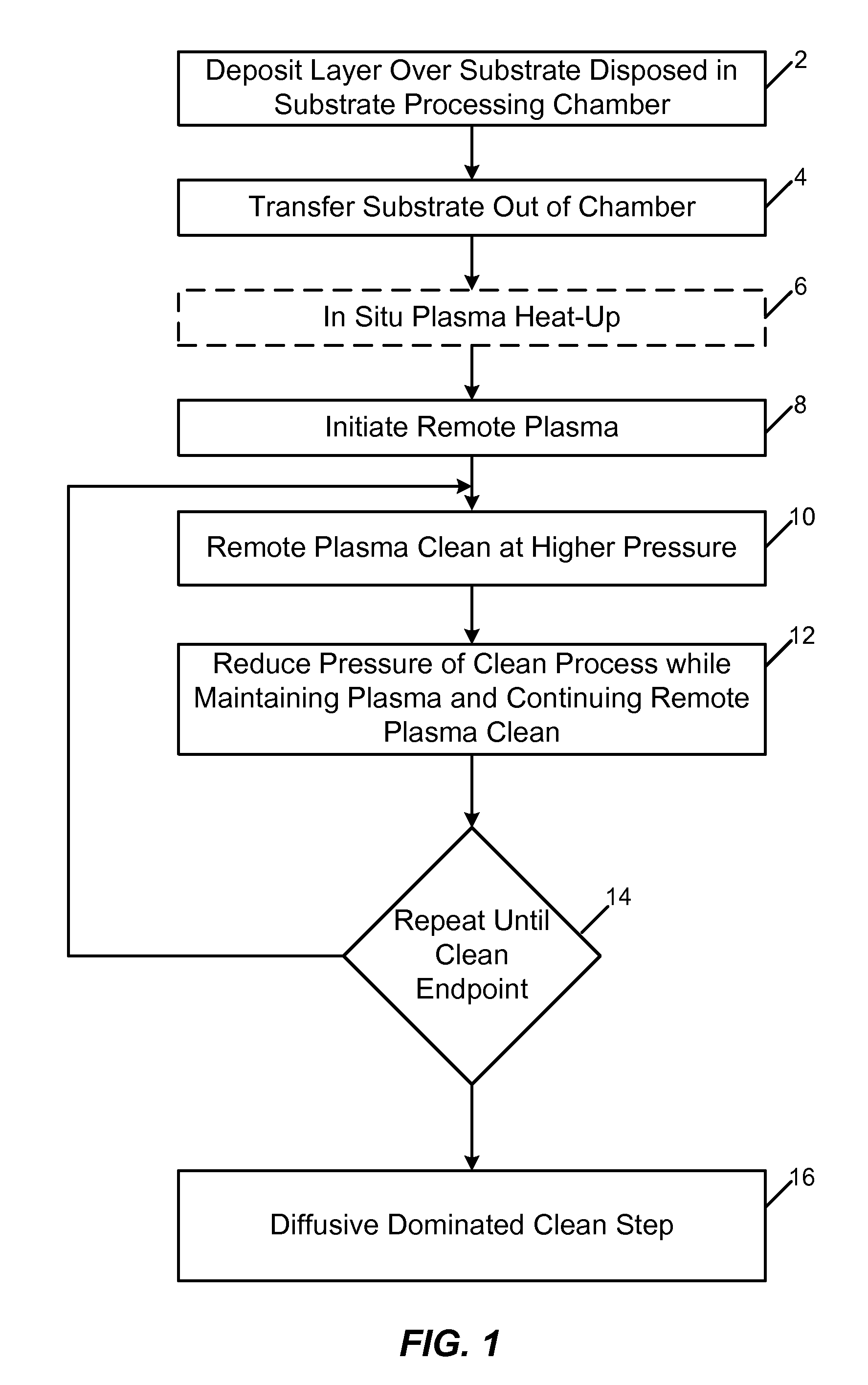

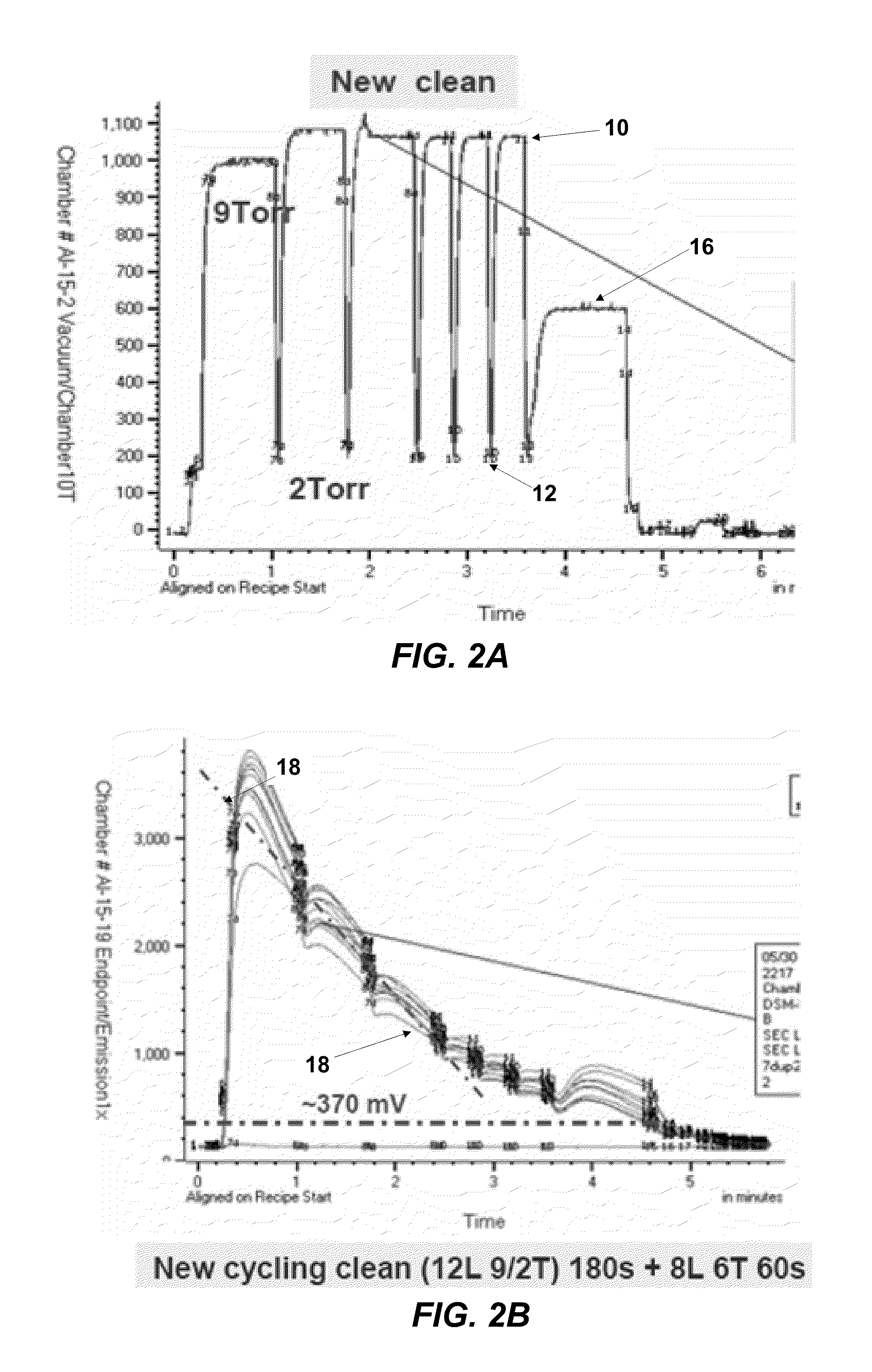

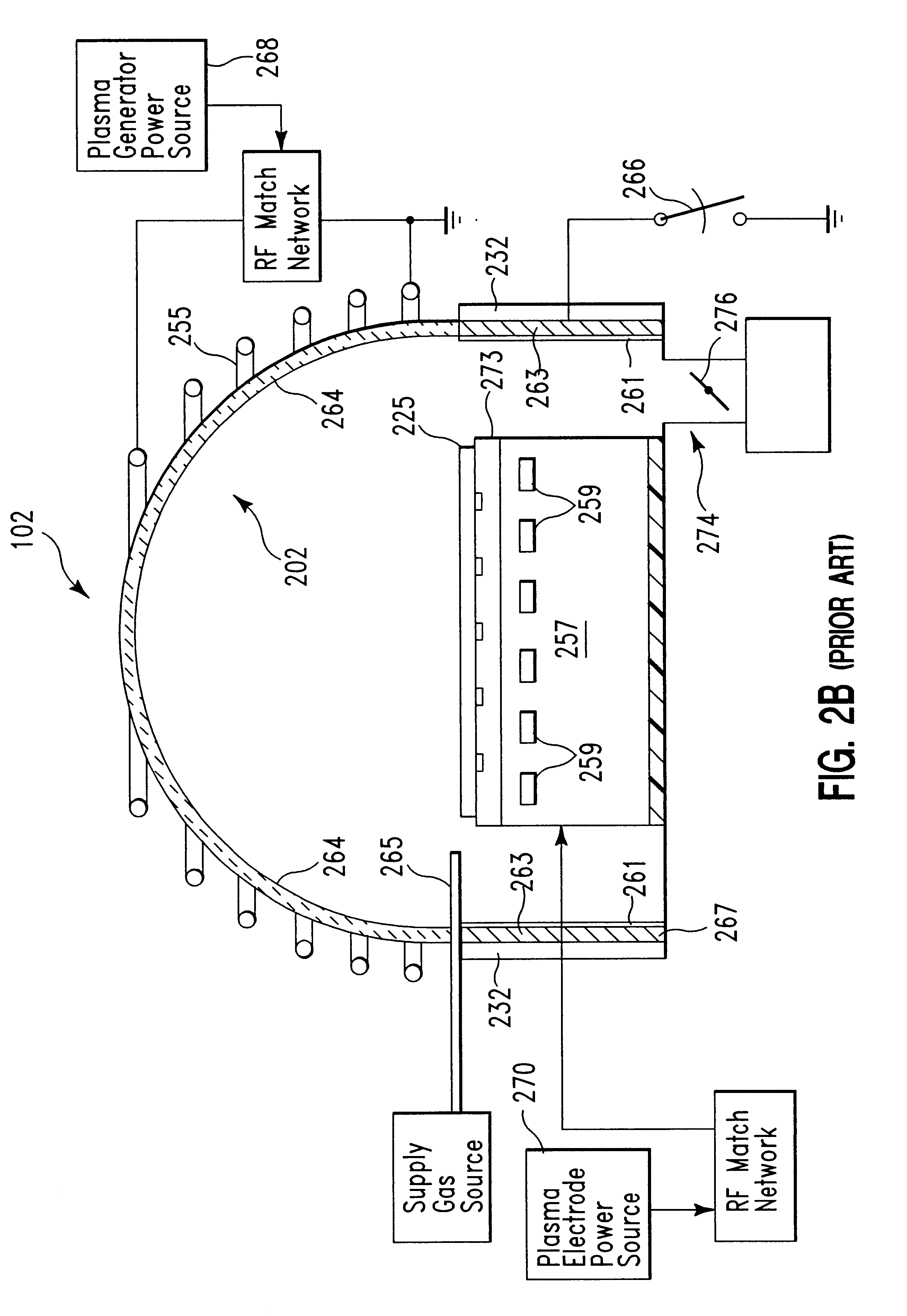

Remote plasma clean process with cycled high and low pressure clean steps

InactiveUS7967913B2Hollow article cleaningSemiconductor/solid-state device manufacturingRemote plasmaContinuous flow

A remote plasma process for removing unwanted deposition build-up from one or more interior surfaces of a substrate processing chamber after processing a substrate disposed in the substrate processing chamber. In one embodiment, the substrate is transferred out of the substrate processing chamber and a flow of a fluorine-containing etchant gas is introduced into a remote plasma source where reactive species are formed. A continuous flow of the reactive species from the remote plasmas source to the substrate processing chamber is generated while a cycle of high and low pressure clean steps is repeated. During the high pressure clean step, reactive species are flown into the substrate processing chamber while pressure within the substrate processing chamber is maintained between 4-15 Torr. During the low pressure clean step, reactive species are flown into the substrate processing chamber while reducing the pressure of the substrate processing chamber by at least 50 percent of a high pressure reached in the high pressure clean step.

Owner:APPLIED MATERIALS INC

Process and method for in-situ dry cleaning of thin film deposition reactors and thin film layers

ActiveUS20150218695A1Efficient dry etching.Easy to useLighting and heating apparatusVacuum evaporation coatingHalogenChemical vapor deposition

The invention relates to the use of thionyl chloride and related materials for dry etching of internal surfaces of metalorganic vapour phase epitaxy (MOVPE) reactors to remove deposits. The method is also useful for the dry etching of process substrates within such reactors for cleaning and processing of those substrates. The invention may be particularly adaptable to chemical vapor deposition reactors used in the manufacture of high brightness LED's based on III-V semiconductors such as GaN and related materials. Features of the process include thermal, UV, and plasma activated dry cleaning, and the use of etchant gases such as COCl2, COBr2, COl2, SOl2, SOCl2, SOBr2, SO2Cl2, SO2Br2, NOCI, NOBr, NOl, S2Cl2, S2Br2, SCI2, SBr2, SOClBr, SOClF and SOFBr, either formed from neat materials or combinations of constituent gases such as CO, SO, SO2 or NO with halogens, to achieve the desired effect.

Owner:SEASTAR CHEM

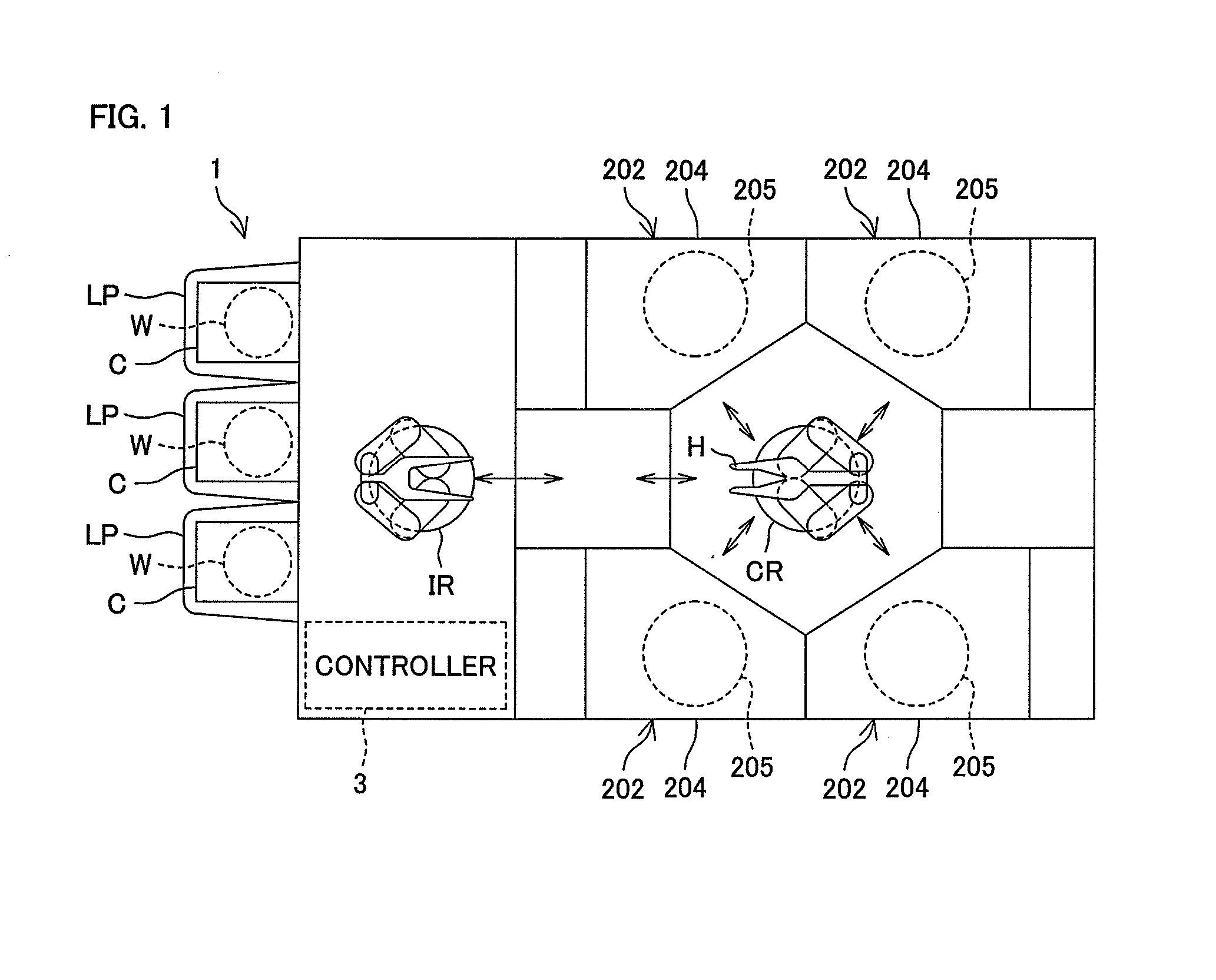

Substrate treatment method and substrate treatment apparatus

ActiveUS9698031B2Reduce surface tensionCollapse of the pattern is preventedSemiconductor/solid-state device manufacturingCleaning using liquidsOrganic solventOrganic chemistry

A substrate treatment method is provided, which includes: an organic solvent replacing step of supplying an organic solvent, whereby a liquid film of the organic solvent is formed on the substrate as covering the upper surface of the substrate to replace a rinse liquid with the organic solvent; a substrate temperature increasing step of allowing the temperature of the upper surface of the substrate to reach a first temperature level higher than the boiling point of the organic solvent after the formation of the organic solvent liquid film, whereby a vapor film of the organic solvent is formed below the entire organic solvent liquid film between the organic solvent liquid film and the substrate to levitate the organic solvent liquid film above the organic solvent vapor film; and an organic solvent removing step of removing the levitated organic solvent liquid film from above the upper surface of the substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

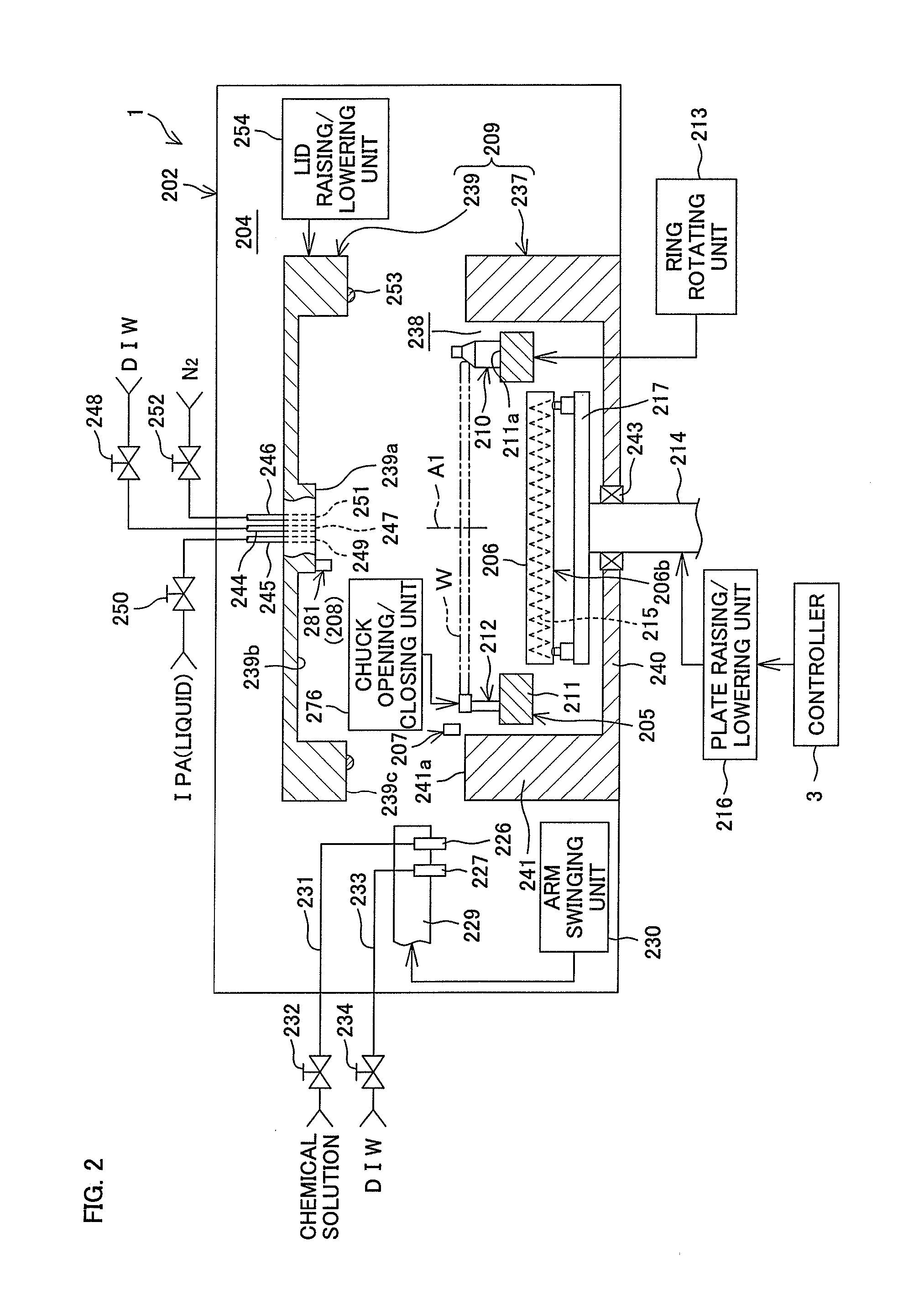

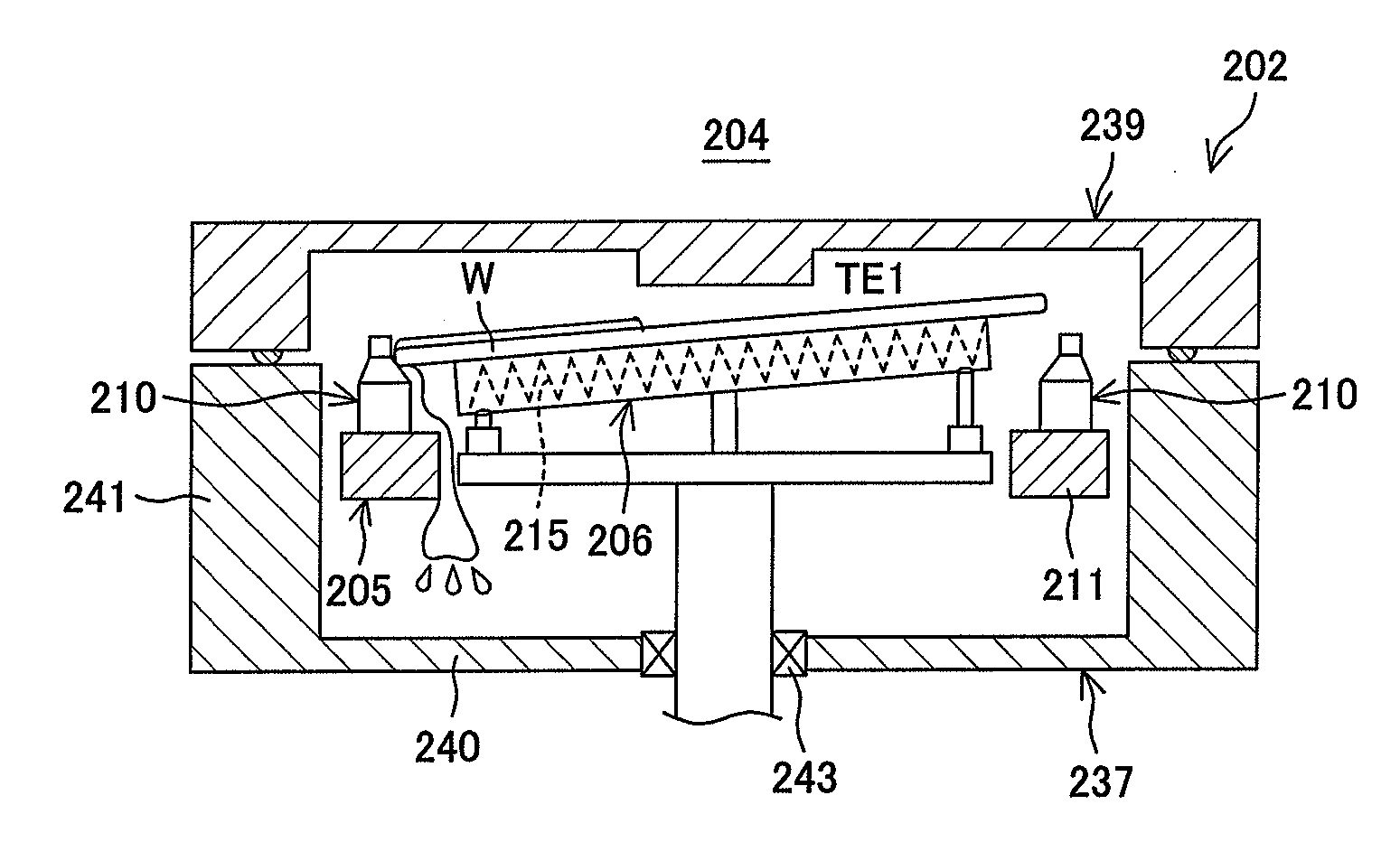

Substrate processing apparatus and substrate processing method

ActiveUS20150243542A1Short timeEasy to removeLiquid surface applicatorsLighting and heating apparatusOrganic solventEngineering

A substrate processing apparatus includes a substrate heating unit arranged to heat the underside of a substrate while supporting the substrate thereon and an attitude changing unit arranged to cause the substrate heating unit to undergo an attitude change between a horizontal attitude and a tilted attitude. In an organic solvent removing step to be performed following a substrate heating step of heating the substrate, the substrate heating unit undergoes an attitude change to the tilted attitude so that the upper surface of the substrate becomes tilted with respect to the horizontal surface.

Owner:DAINIPPON SCREEN MTG CO LTD

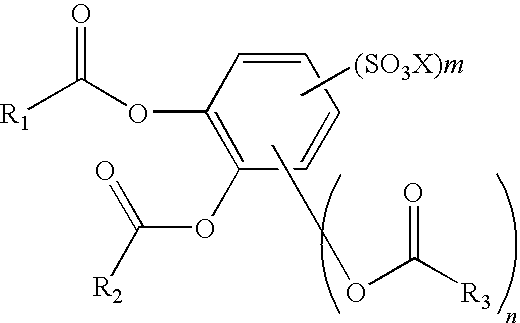

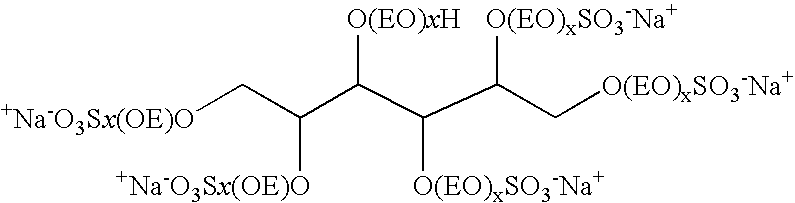

Composition containing an esterified substituted benzene sulfonate

InactiveUS7585376B2Non-ionic surface-active compoundsOrganic detergent compounding agentsBenzenesulfonatesChemistry

Owner:PROCTER & GAMBLE CO

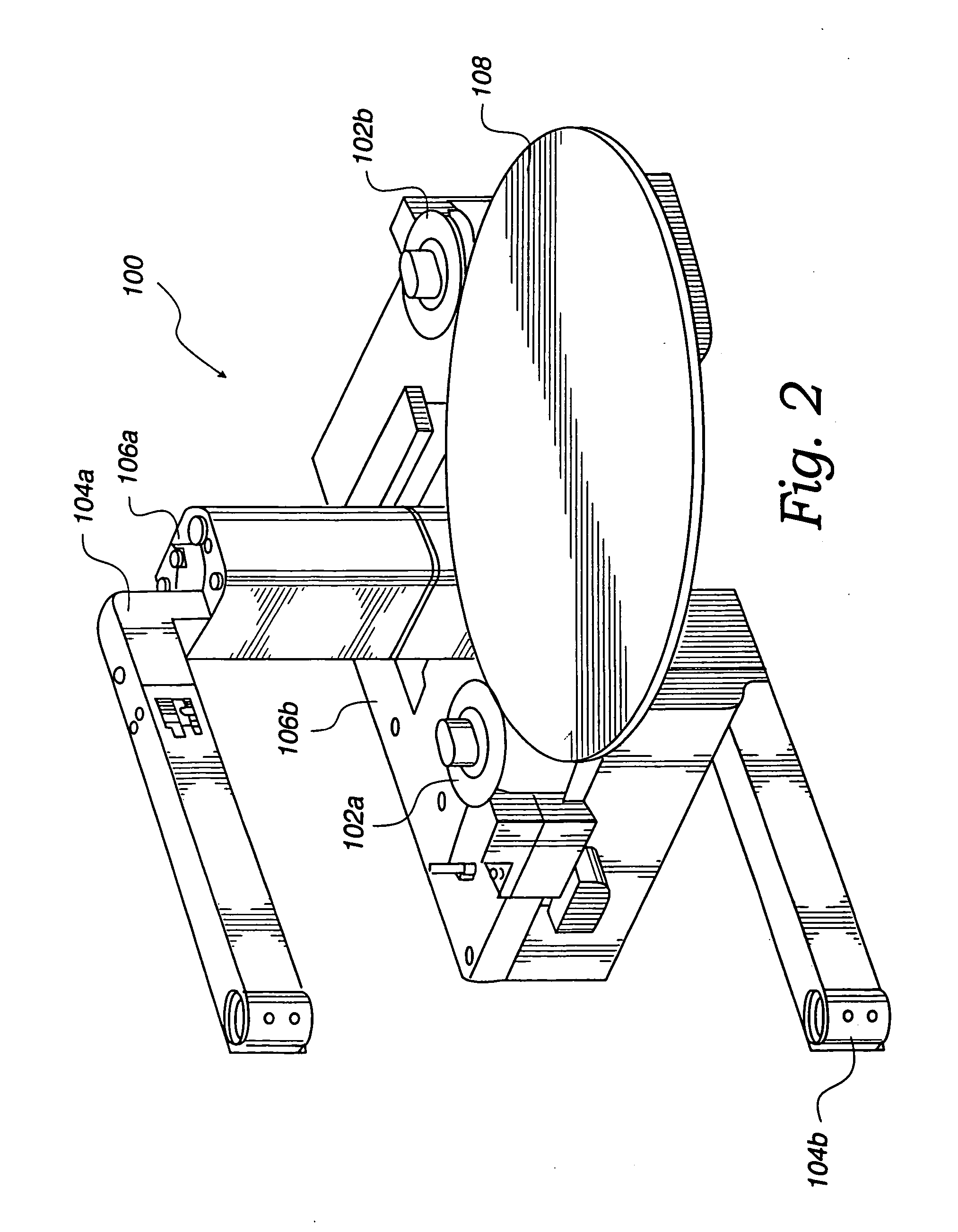

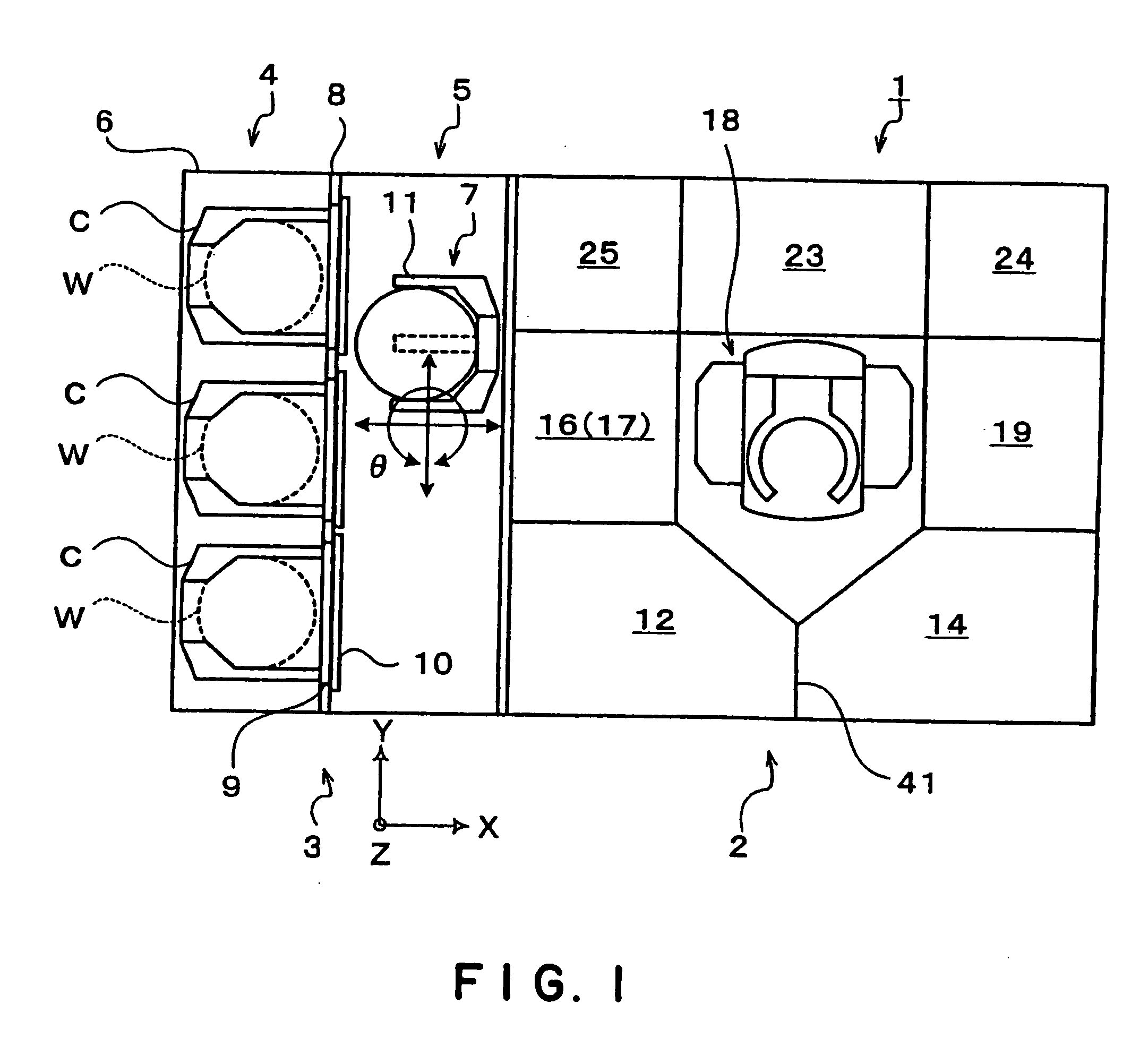

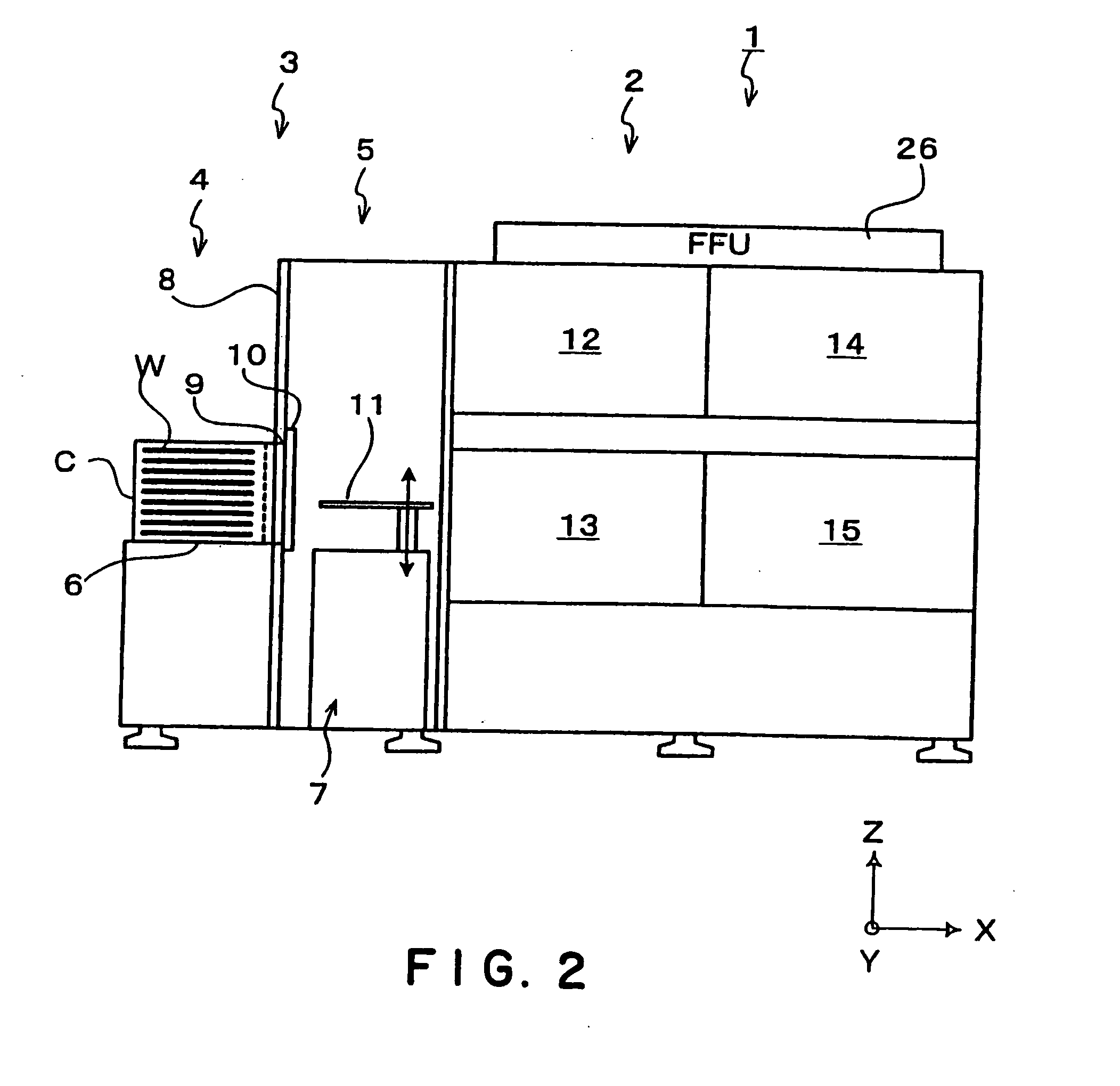

Substrate processing apparatus

InactiveUS20080210278A1Stable processingImprove throughputPretreated surfacesSemiconductor/solid-state device manufacturingResistLow speed

A substrate processing apparatus is provided. The apparatus includes a plurality of fluid suppliers 61, 61, 63 for supplying different processing fluids. In processing a wafer W, the substrate processing apparatus moves the fluid suppliers 61, 62, 63 along the peripheral part of the wafer W relatively. The fluid suppliers 61, 62, 63 are arranged in a direction extending from the circumference of the wafer W to its inside. With the arrangement, the apparatus is capable of stable processing of the wafer W in spite of rotating the wafer W at a low speed. Further, it is possible to improve a throughput of the apparatus in resist processing.

Owner:TOKYO ELECTRON LTD

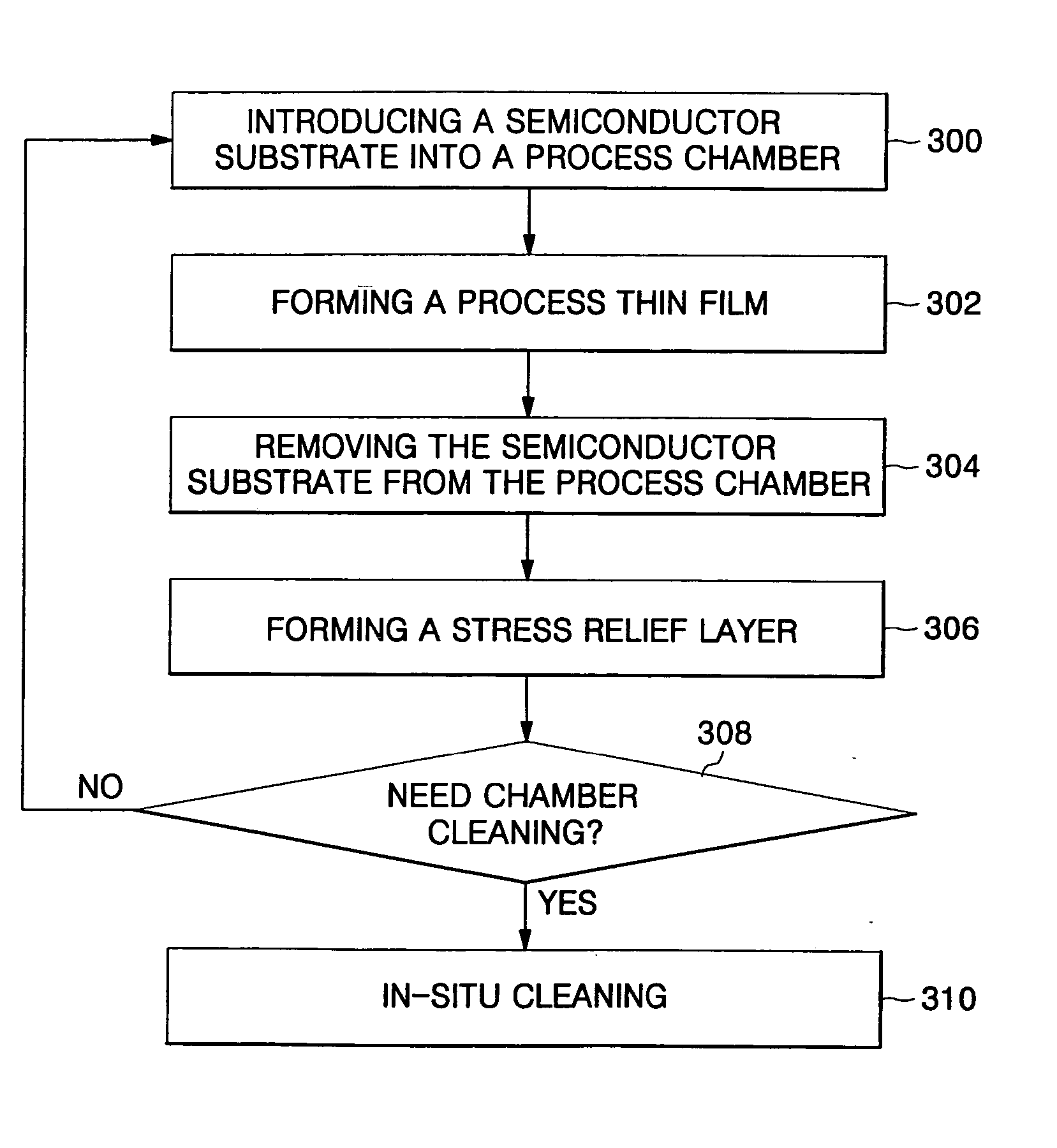

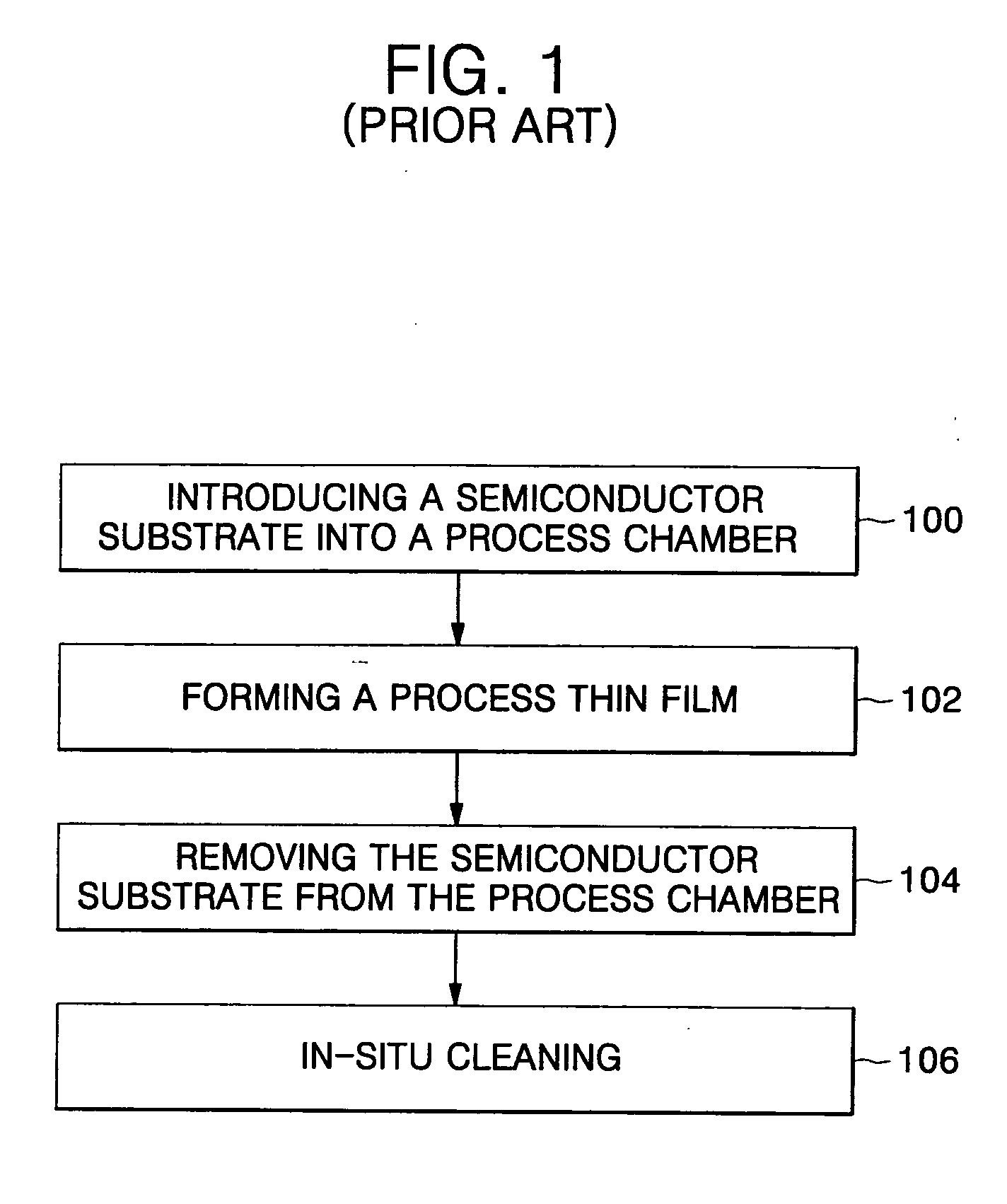

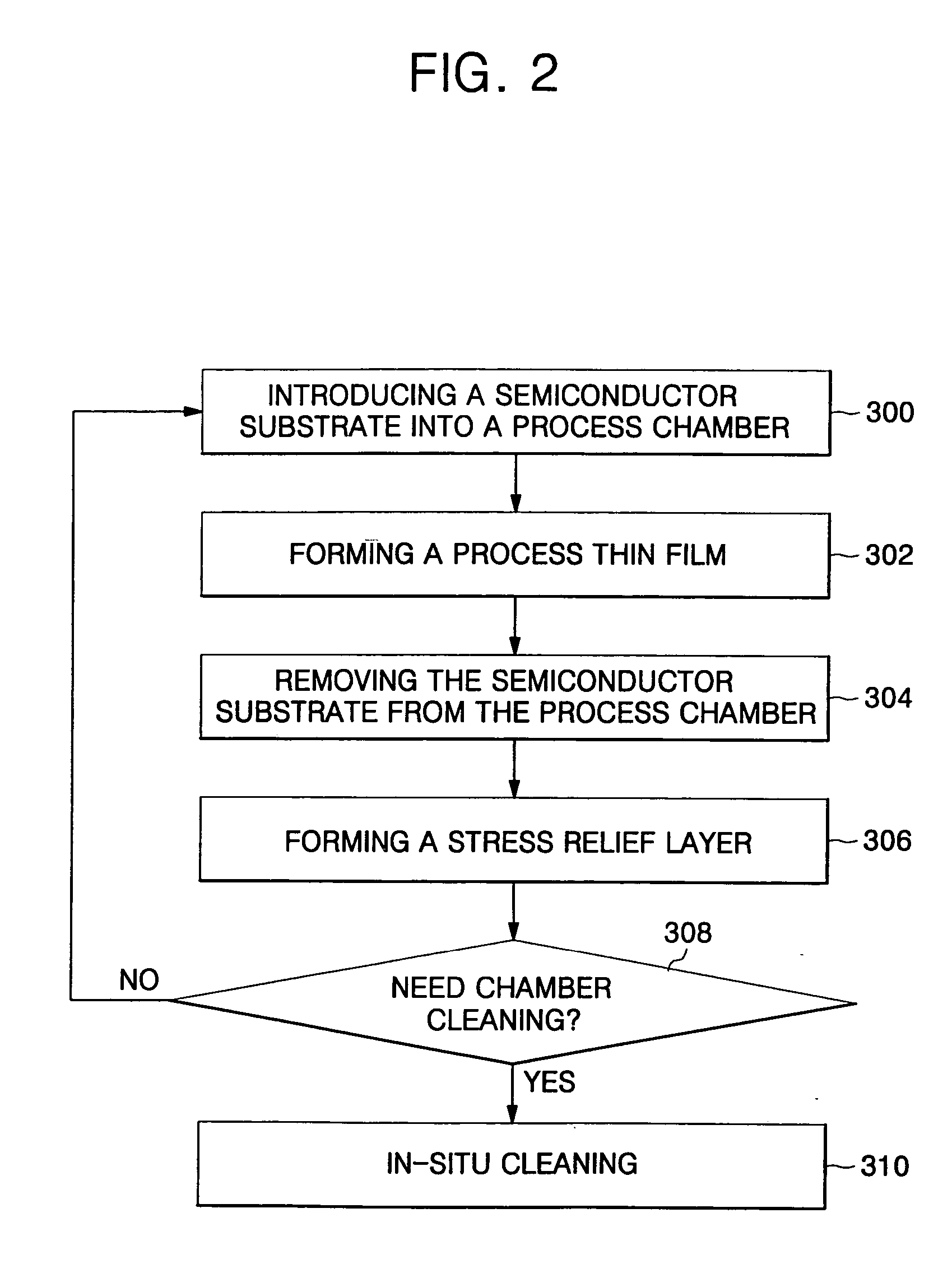

Method of forming thin film for improved productivity

ActiveUS20050130427A1Extended maintenance periodReduce processing timeElectrostatic cleaningSemiconductor/solid-state device manufacturingProduction rateStress relief

There is provided a method of forming a thin film for providing improved fabrication productivity. The method includes introducing a semiconductor substrate into a process chamber. A process thin film is formed on the semiconductor substrate, in which a chamber coating layer is formed on inner walls of the process chamber while the process thin film is formed. The semiconductor substrate is removed from the process chamber. A stress relief layer is formed on the chamber coating layer. After all of the above operations are repeatedly performed at least one time, an in-situ cleaning is performed on the chamber coating layer and the stress relief layer, which are alternately formed in stack on the inner walls of the process chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

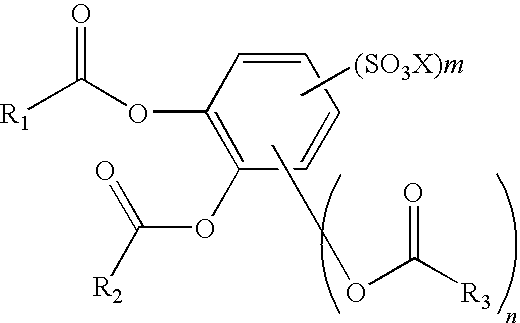

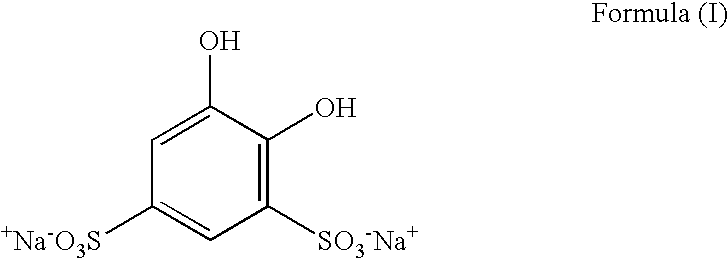

Compositions containing anionically modified catechol and soil suspending polymers

InactiveUS7445644B2Organic detergent compounding agentsNon-ionic surface-active compoundsPolyphenolCatechol

Owner:THE PROCTER & GAMBLE COMPANY

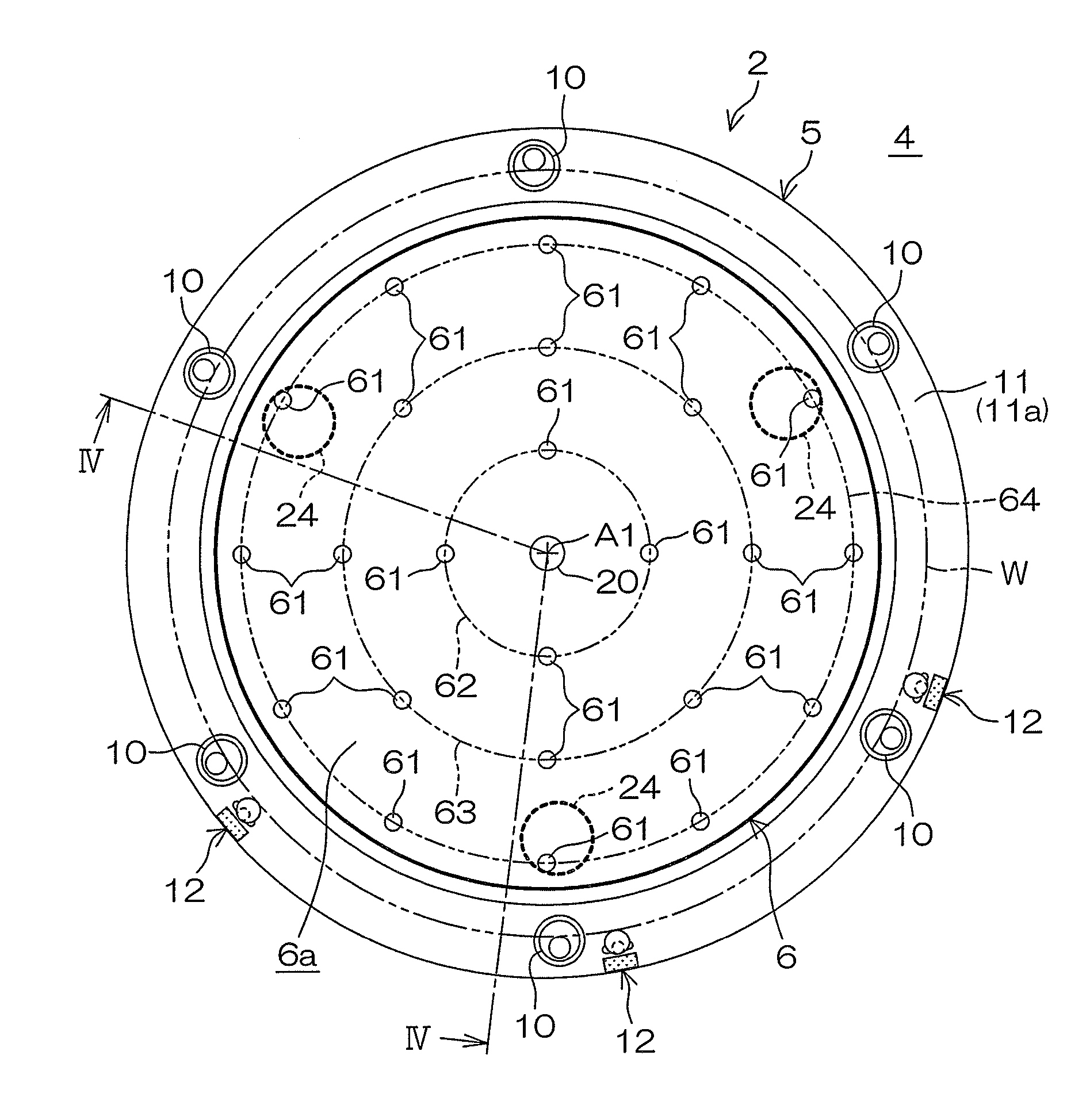

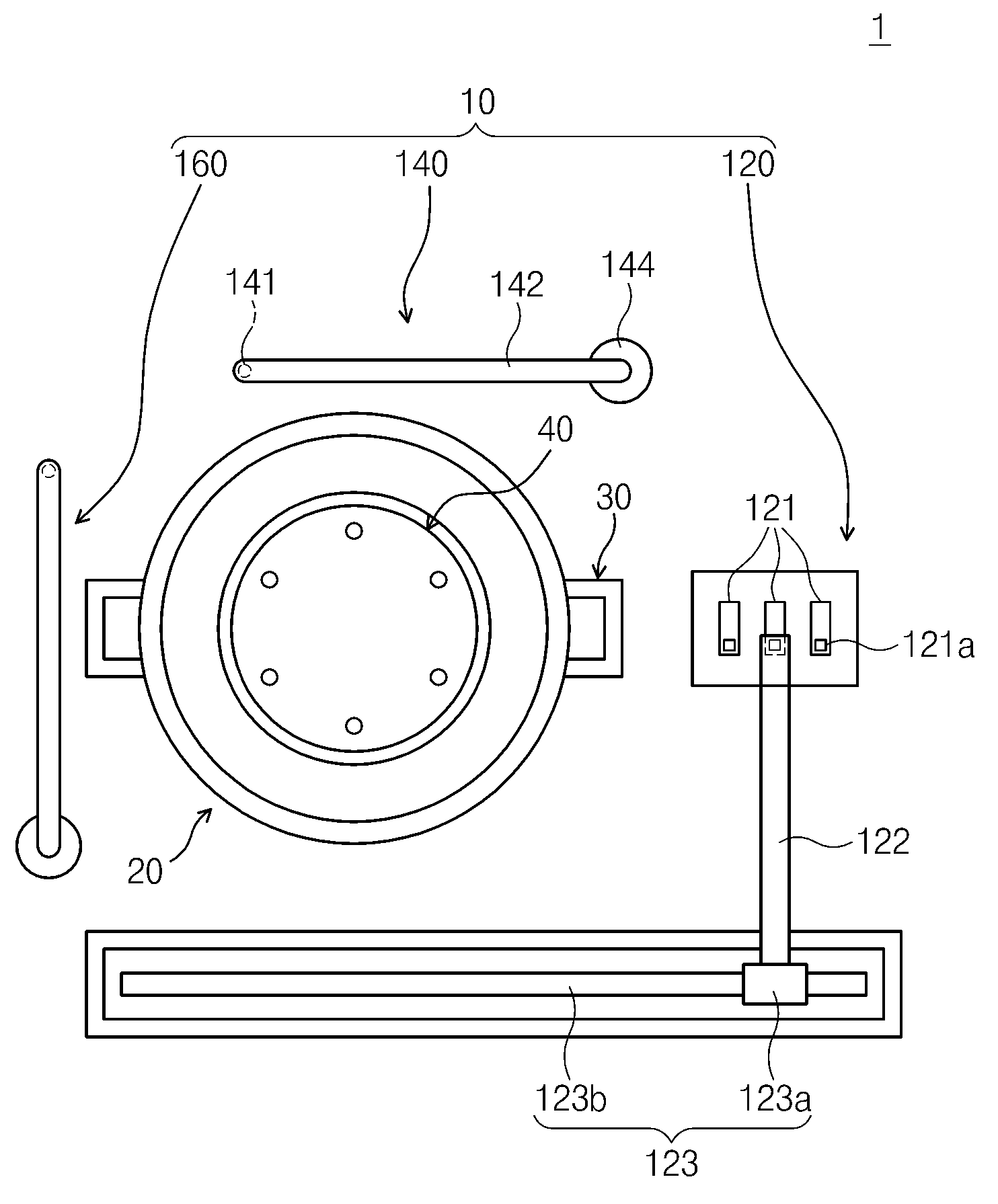

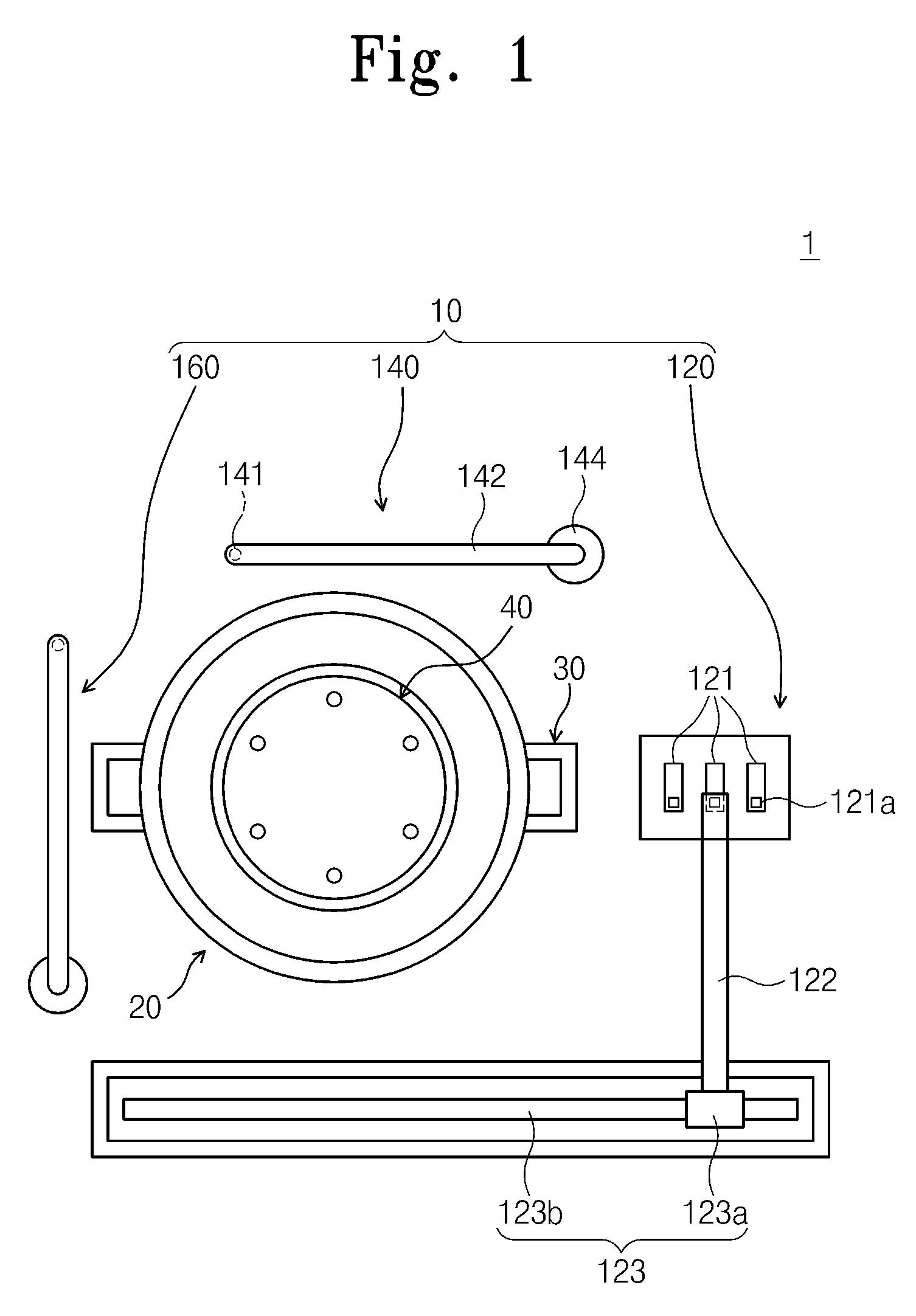

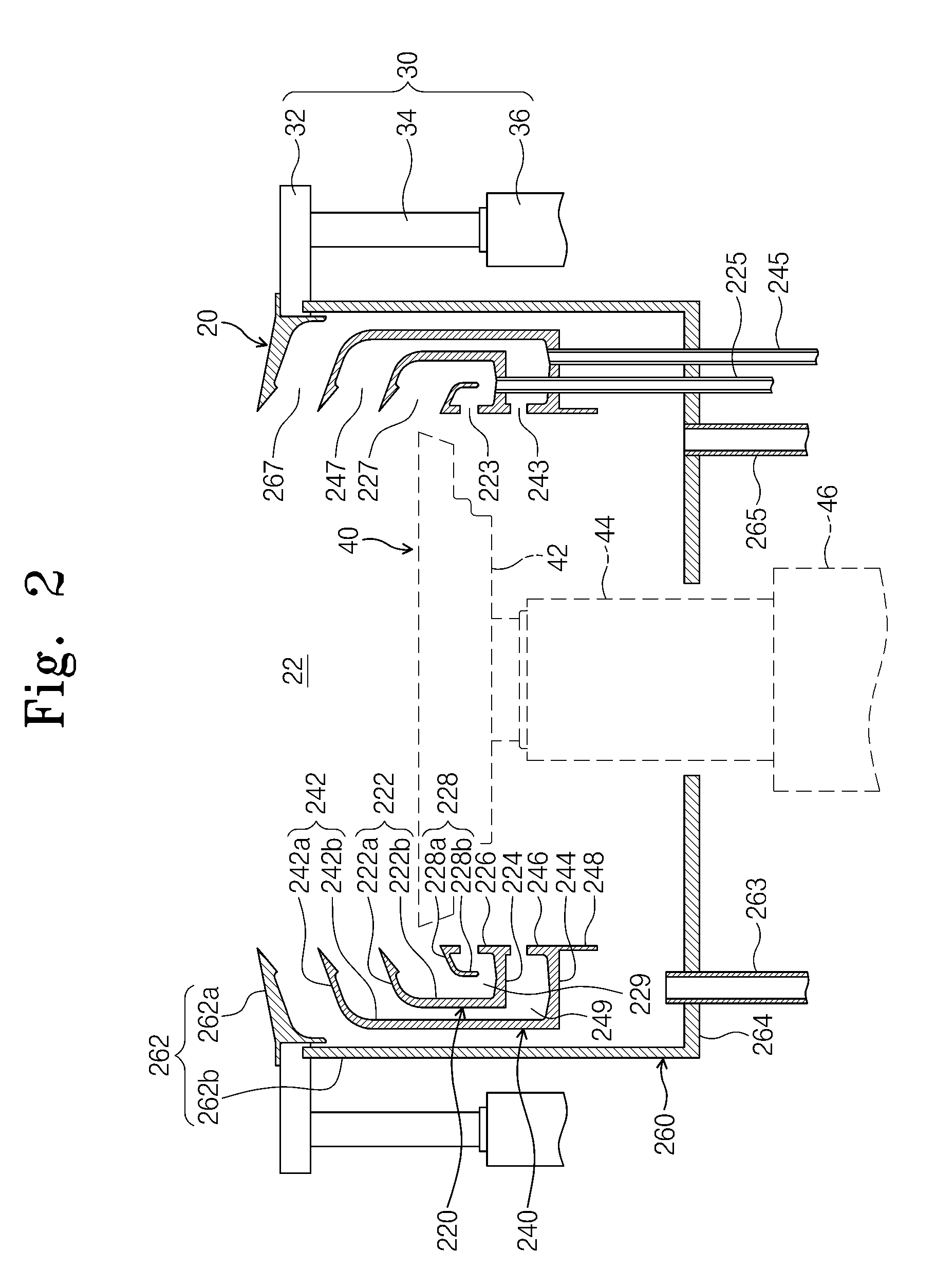

Spin head, apparatus for treating substrate, and method for treating substrate

ActiveUS20100126539A1Prevent excessive speedSemiconductor/solid-state device manufacturingCleaning using liquidsRotational axisCentrifugal force

Provided is a spin head supporting a substrate and rotating the substrate. The spin head includes a body, chuck pins installed on the body and moving between supporting positions where a substrate is supported and waiting positions providing space for loading / unloading of the substrate, and a chuck pin moving unit configured to move the chuck pins. The chuck pin moving unit includes a rotation rod coupled with each of the chuck pins, a pivot pin fixing the rotation rod to the body, and a driving member rotating the rotation rod about the pivot pin as a rotation shaft to move the chuck pin from the supporting position to the waiting position. When the body rotates, the rotation rod uses reverse centrifugal force to apply force to the chuck pin from the waiting position to the supporting position. The chuck pins include first pins and second pins that alternately chuck a substrate during a process.

Owner:SEMES CO LTD

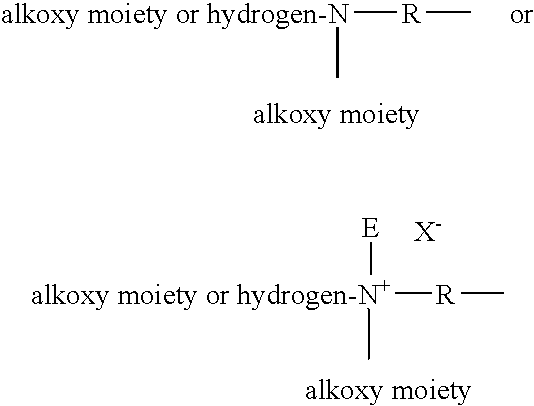

Method for forming a photoresist pattern

InactiveUS20070163625A1Inhibition formationSurface-active detergent compositionsNon-surface-active detergent compositionsResistPhotoresist

A photoresist cleaning solution and method for forming photoresist patterns using the same. More specifically, disclosed are a photoresist cleaning solution comprising H2o and an ionic surfactant represented by Formula 1, and a method for forming a photoresist pattern using the same. By spraying the cleaning solution of the present invention over photoresist film before and / or after exposing step, pattern formation in an undesired region caused by ghost images can be removed.

Owner:SK HYNIX INC

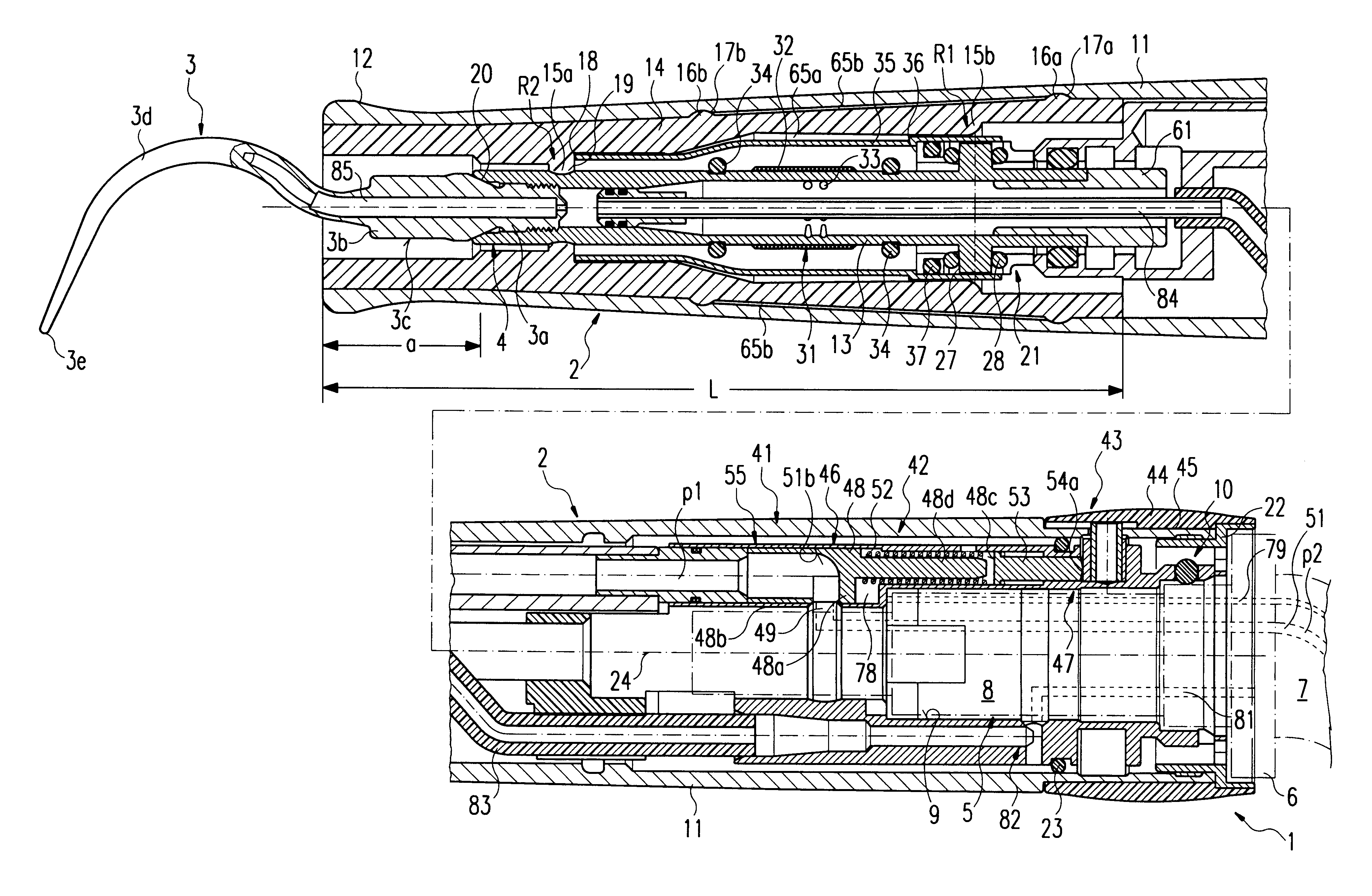

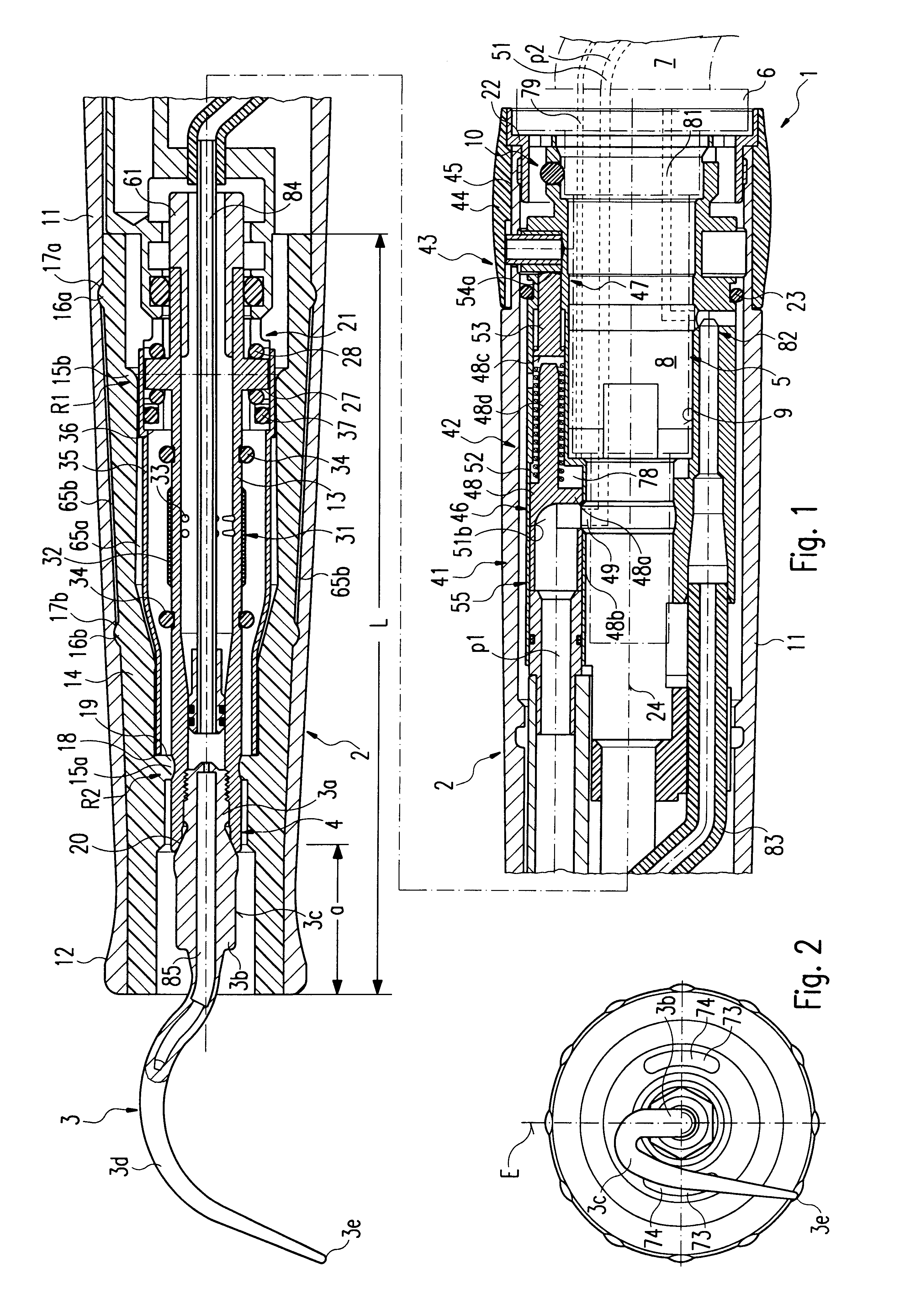

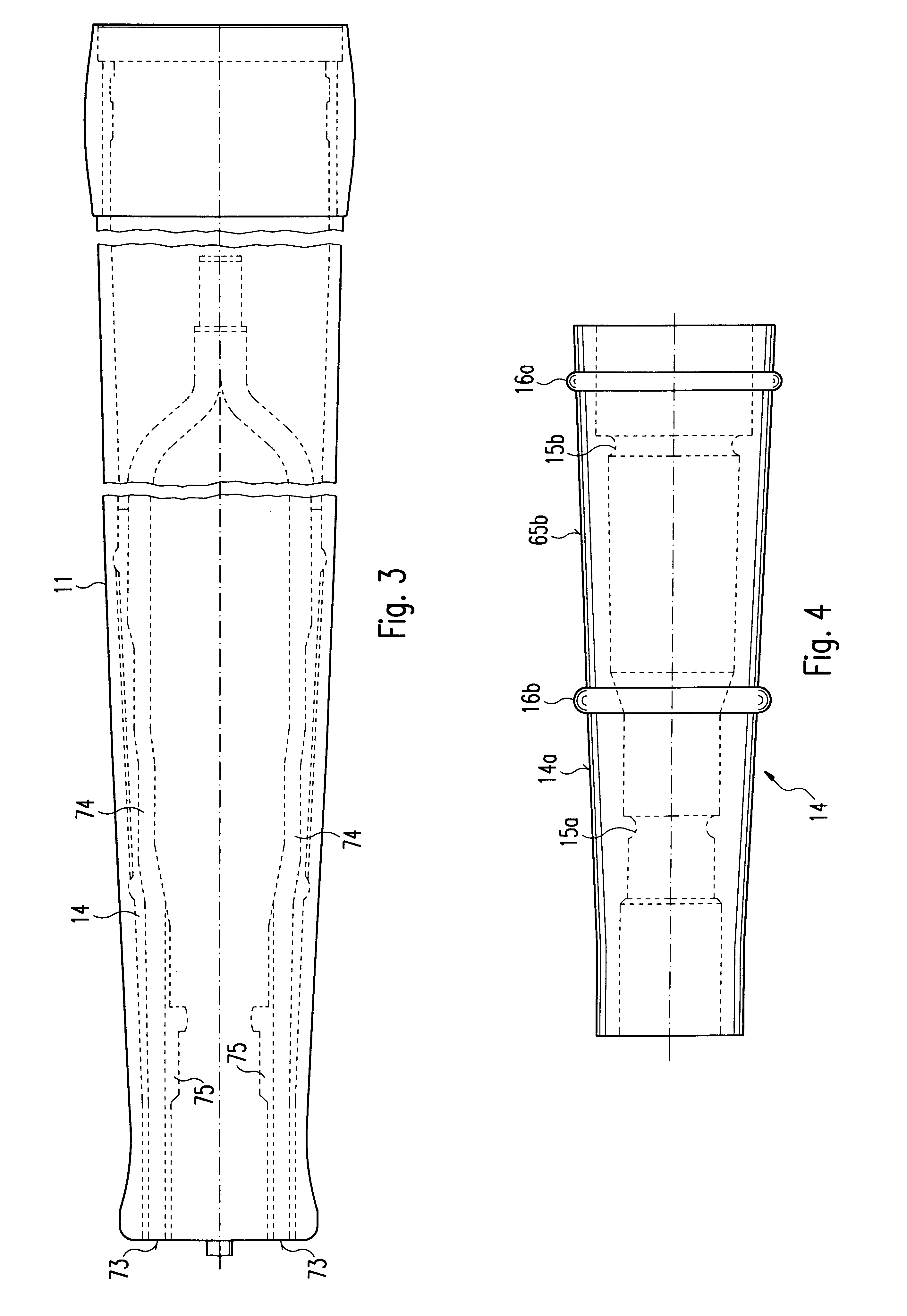

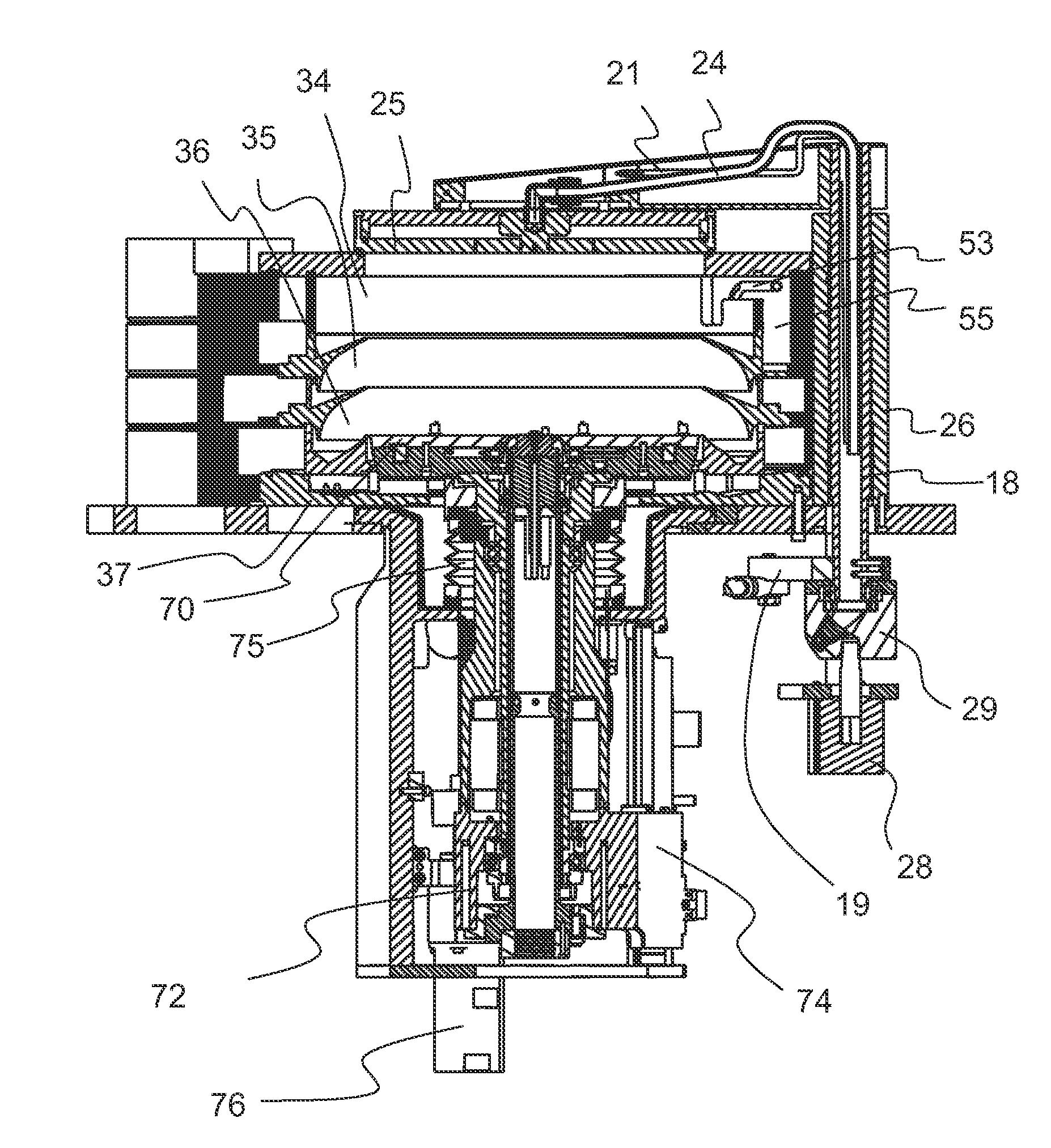

Medical and/or dental instrument with oscillatory rod

InactiveUS6616450B2Compact structureLittle effortTooth pluggers/hammersPiezoelectric/electrostriction/magnetostriction machinesDental instrumentsEngineering

The invention relates to a medical or dental-medical treatment instrument (1) having a grip sleeve (11), an oscillatory rod (13) which extends longitudinally in the grip sleeve (11) and is mounted therein in a radially or also axially elastically yielding manner, and an oscillation generator (31) for transmitting oscillations to the oscillatory rod (13). In order to attain a compact construction, the oscillatory rod (13) is of a base part and an attachment part which is fixed on the base part.

Owner:KALTENBACH & VOIGT GMBH & CO

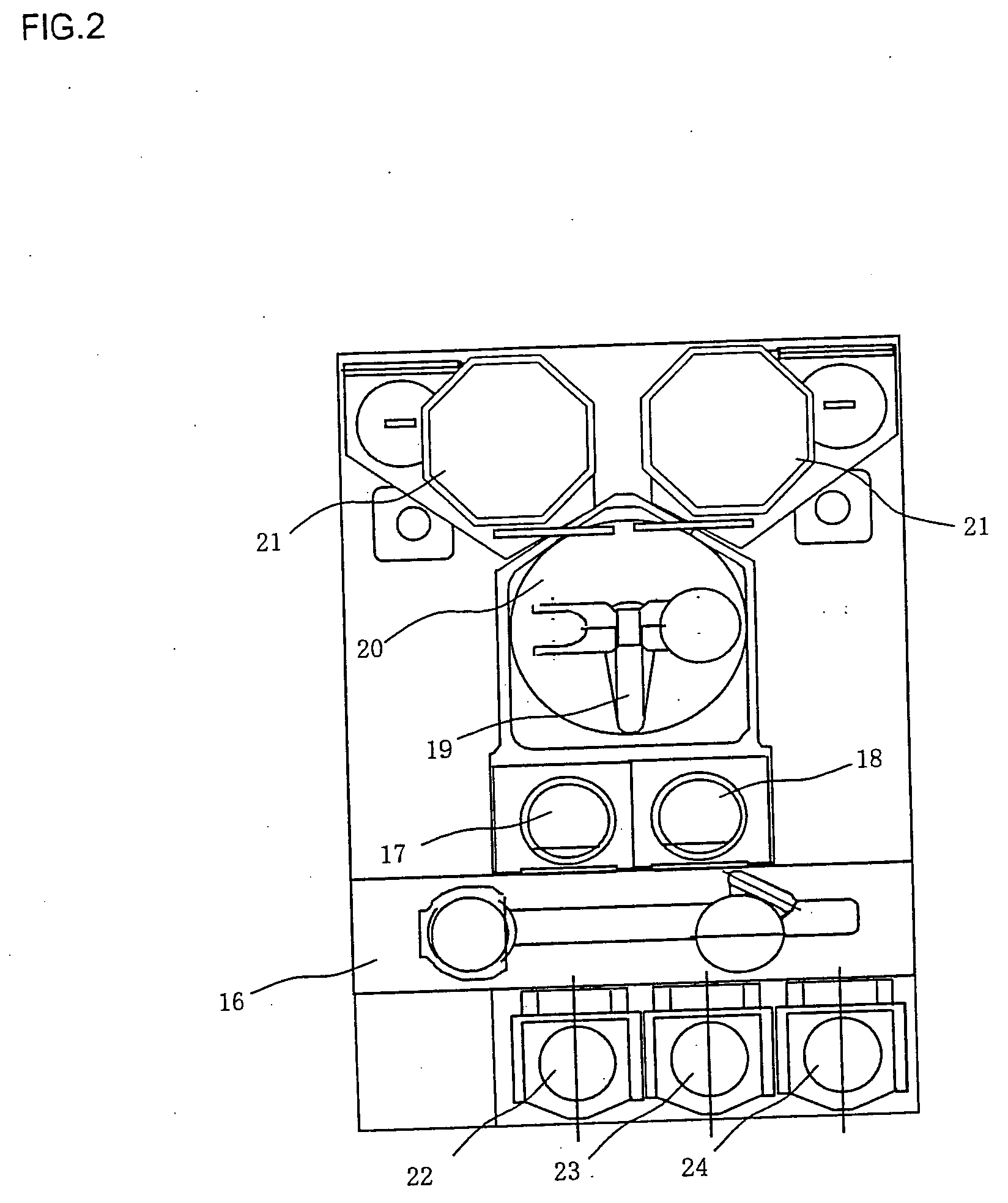

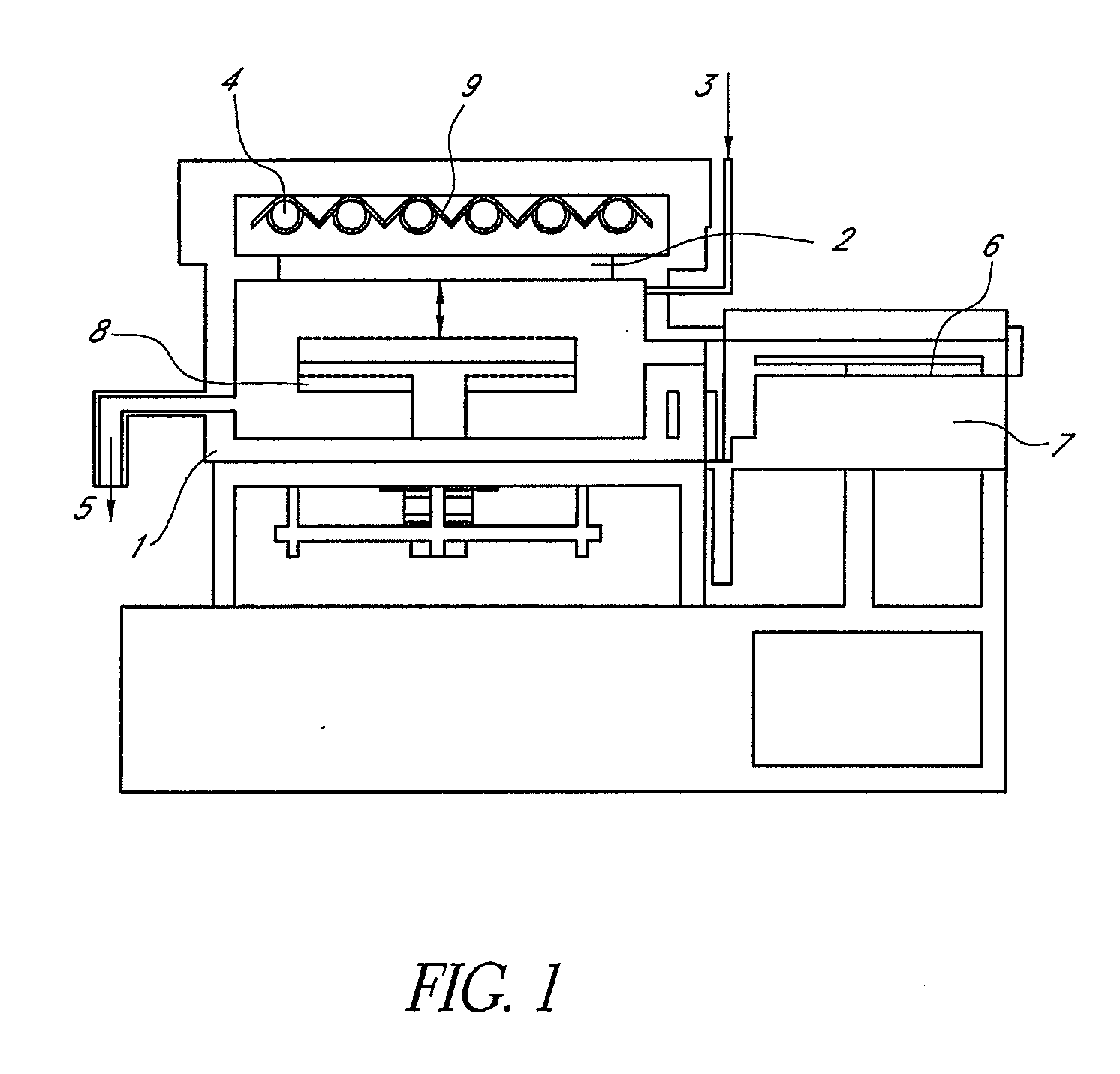

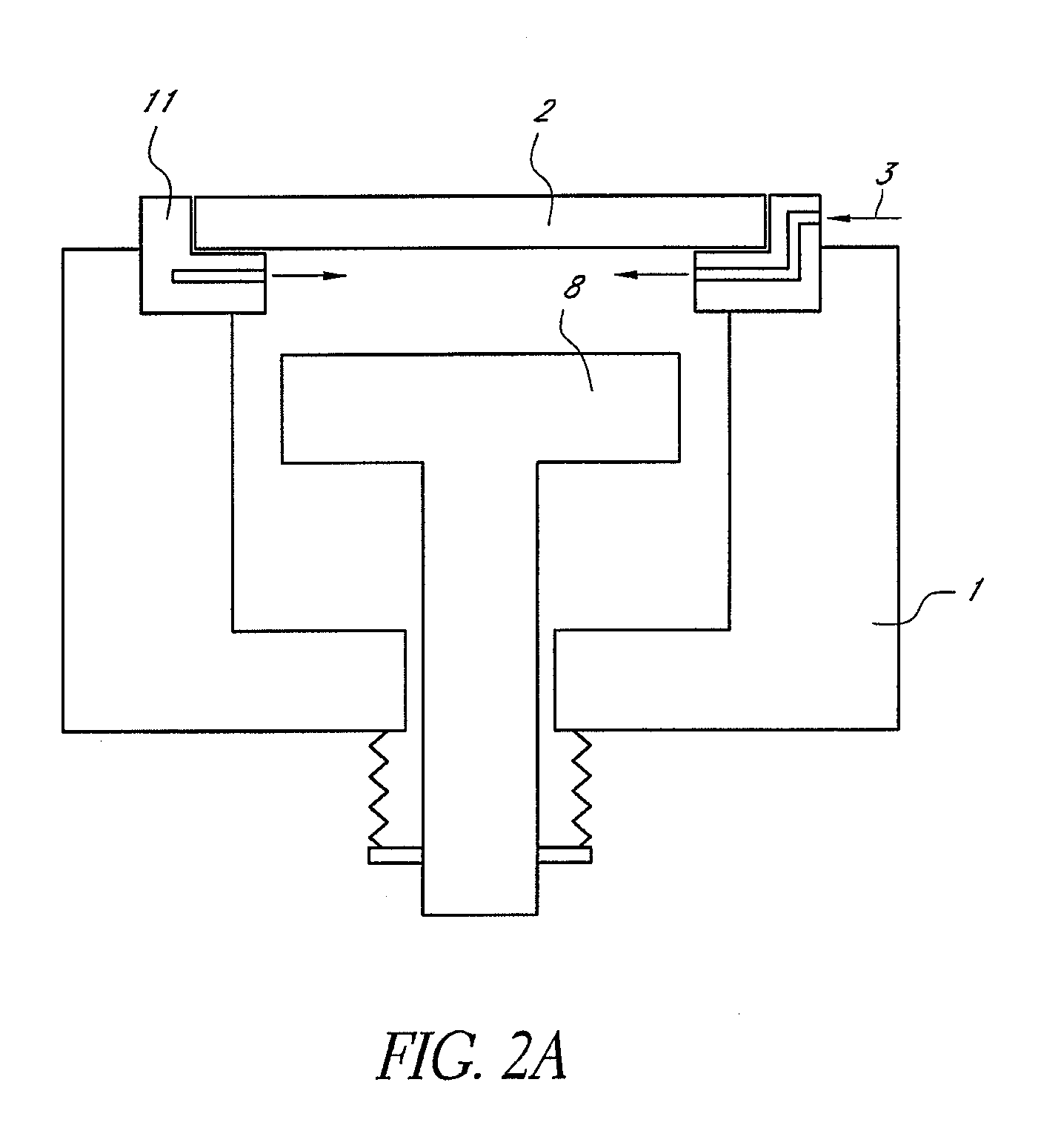

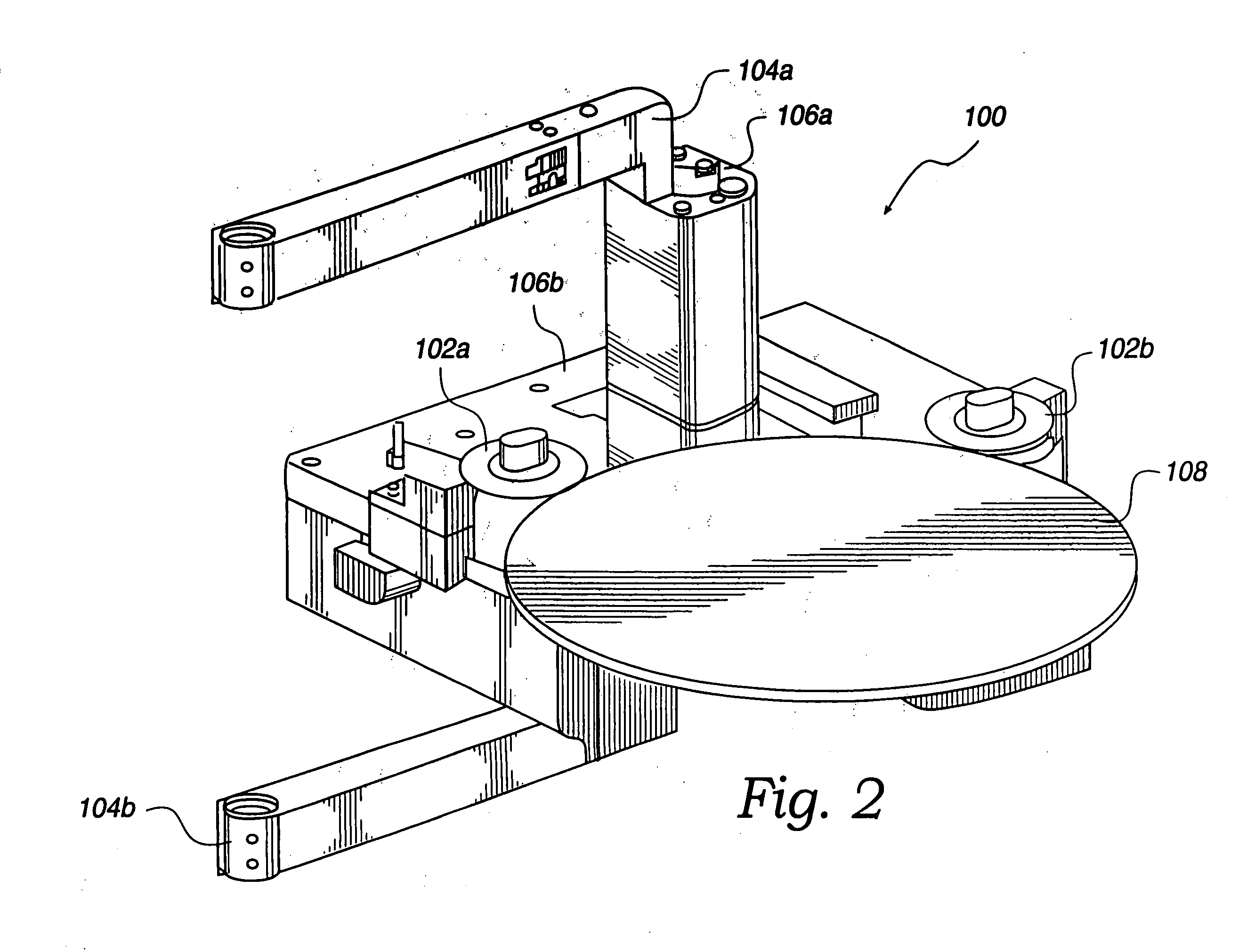

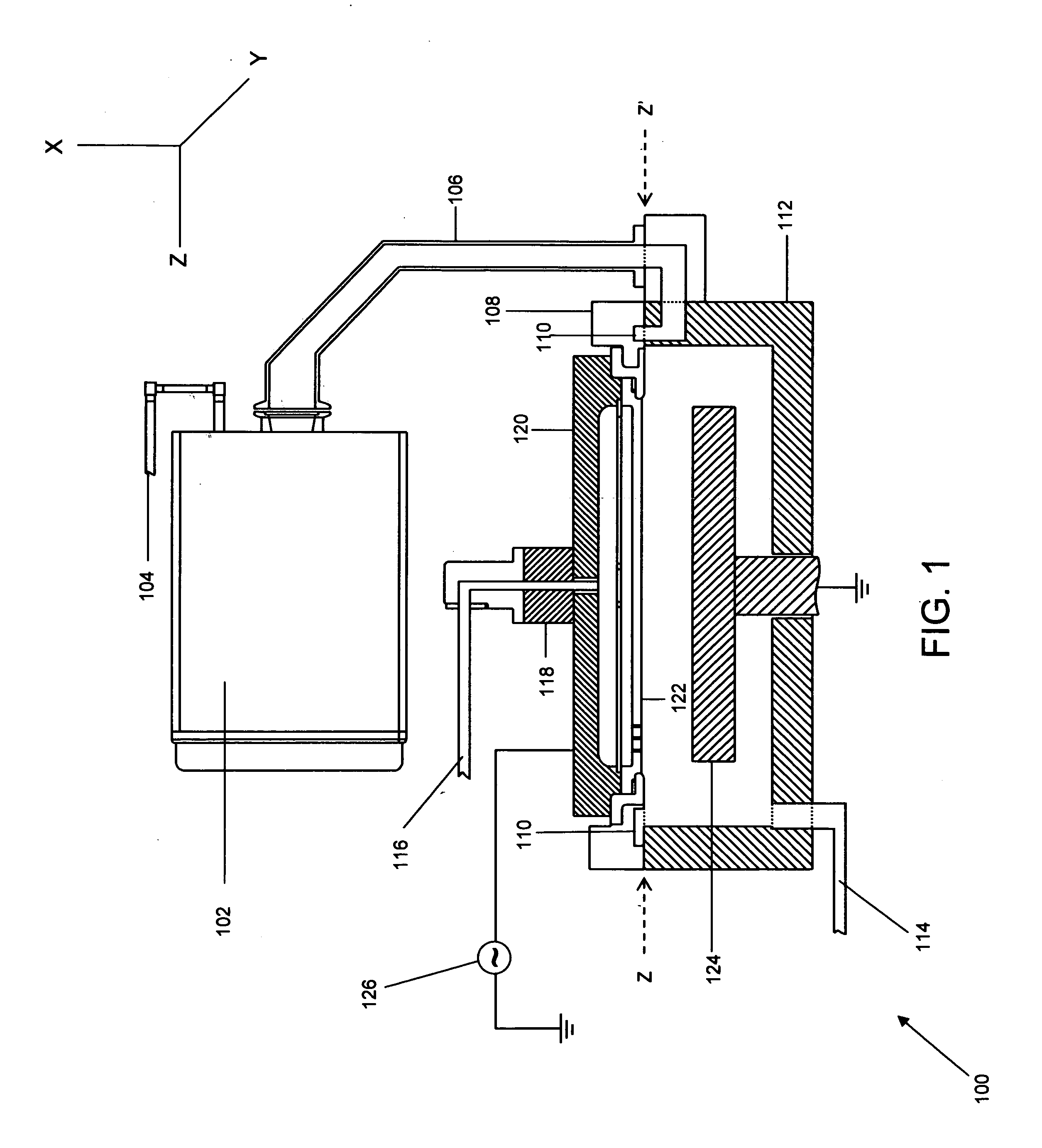

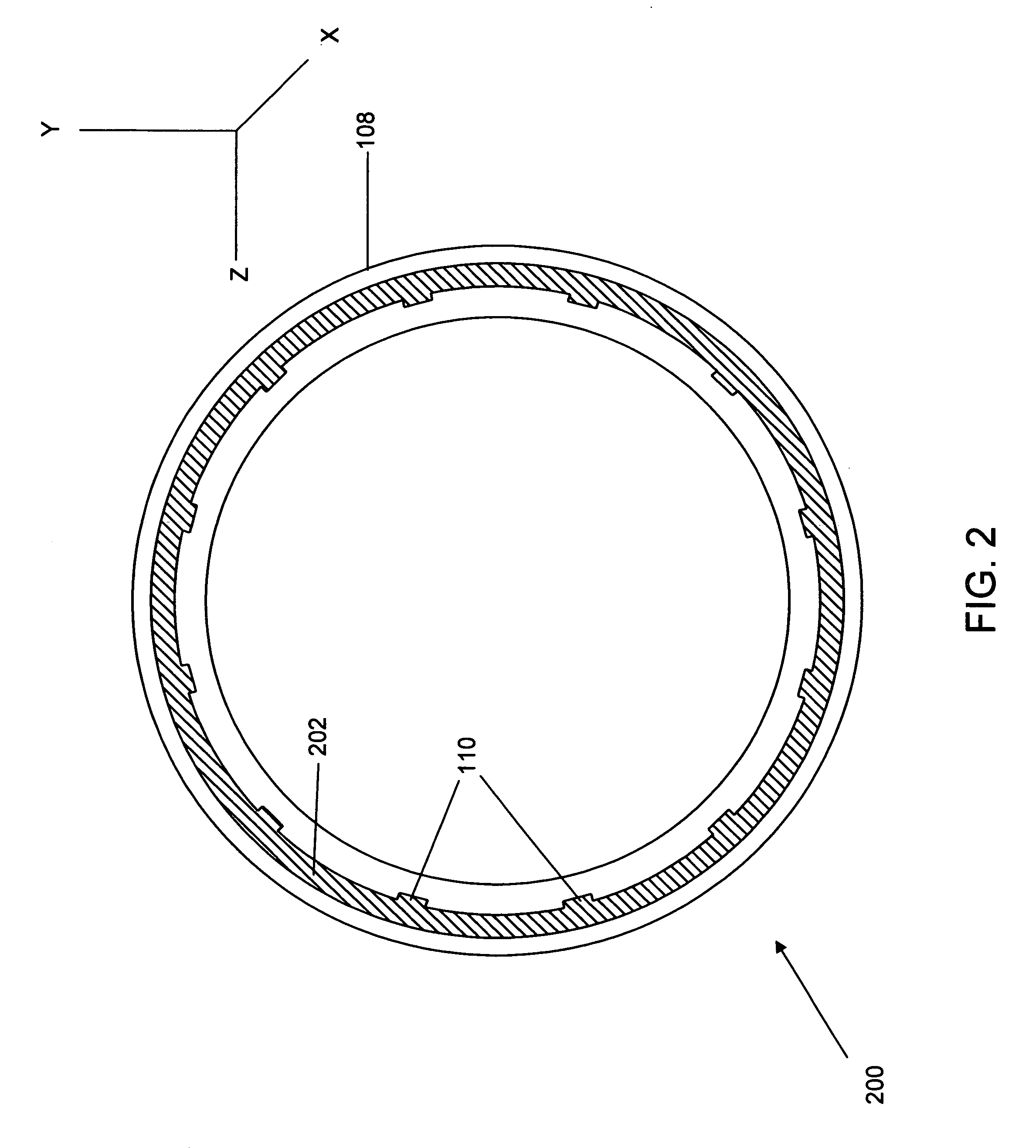

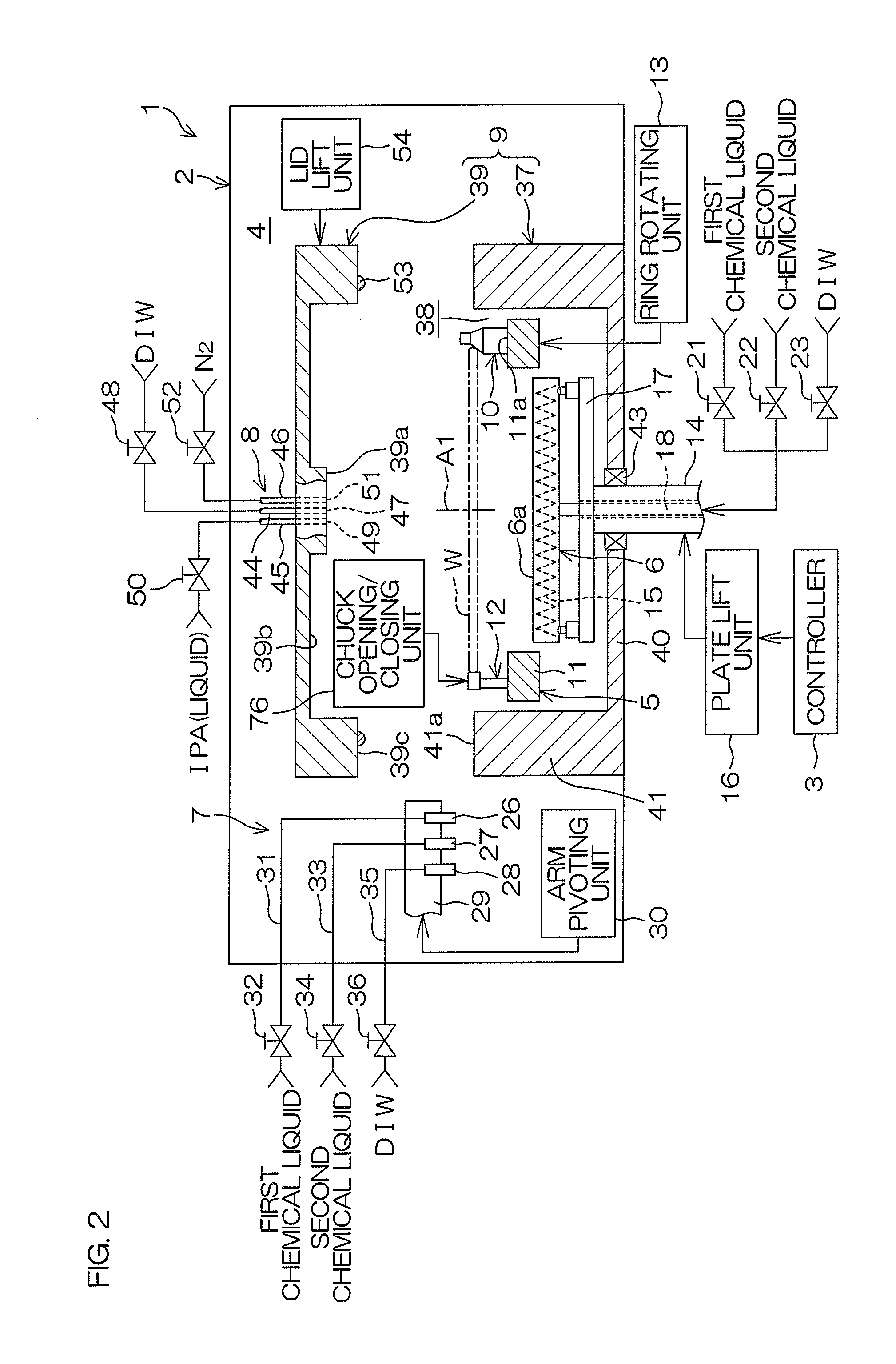

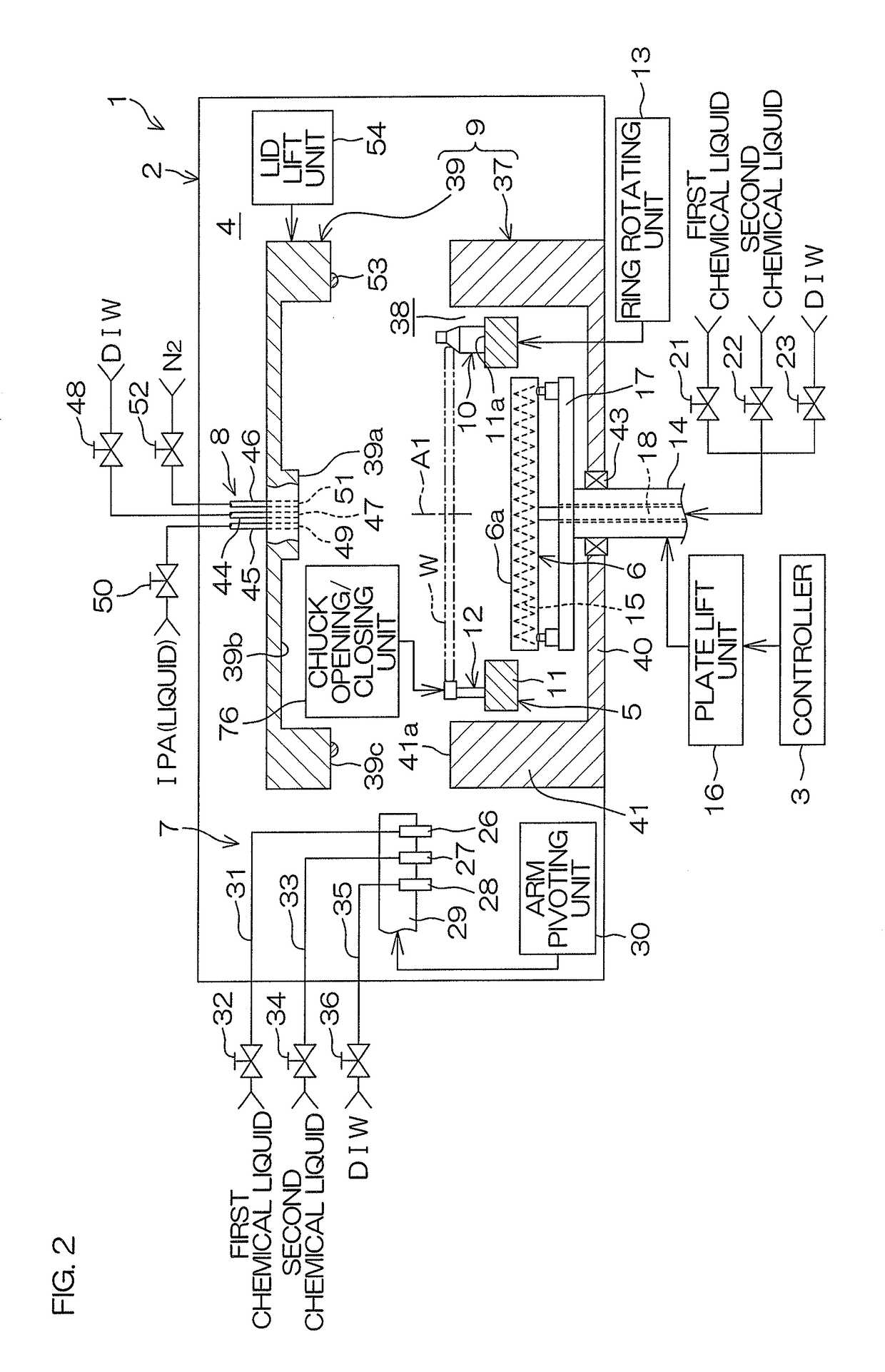

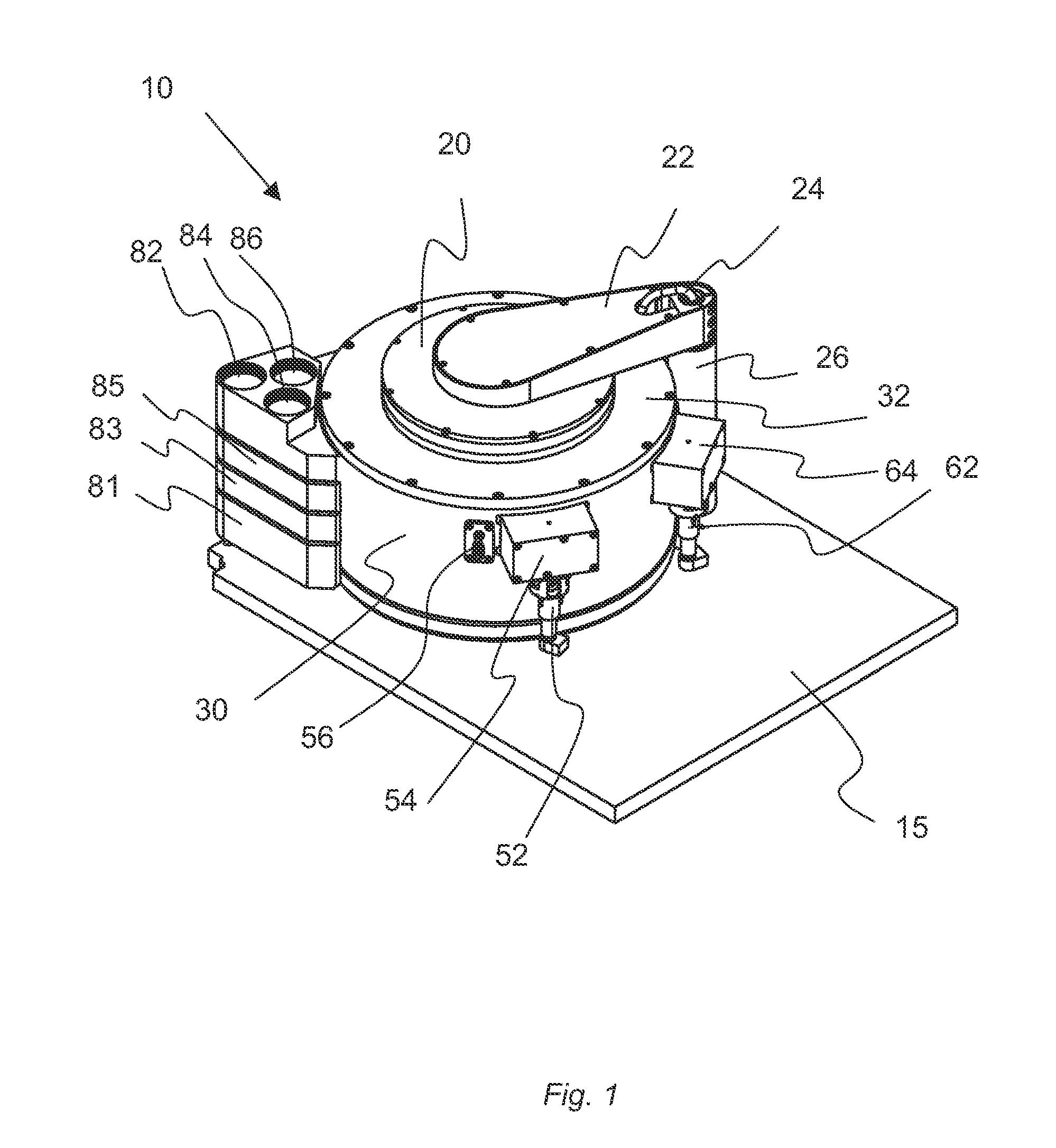

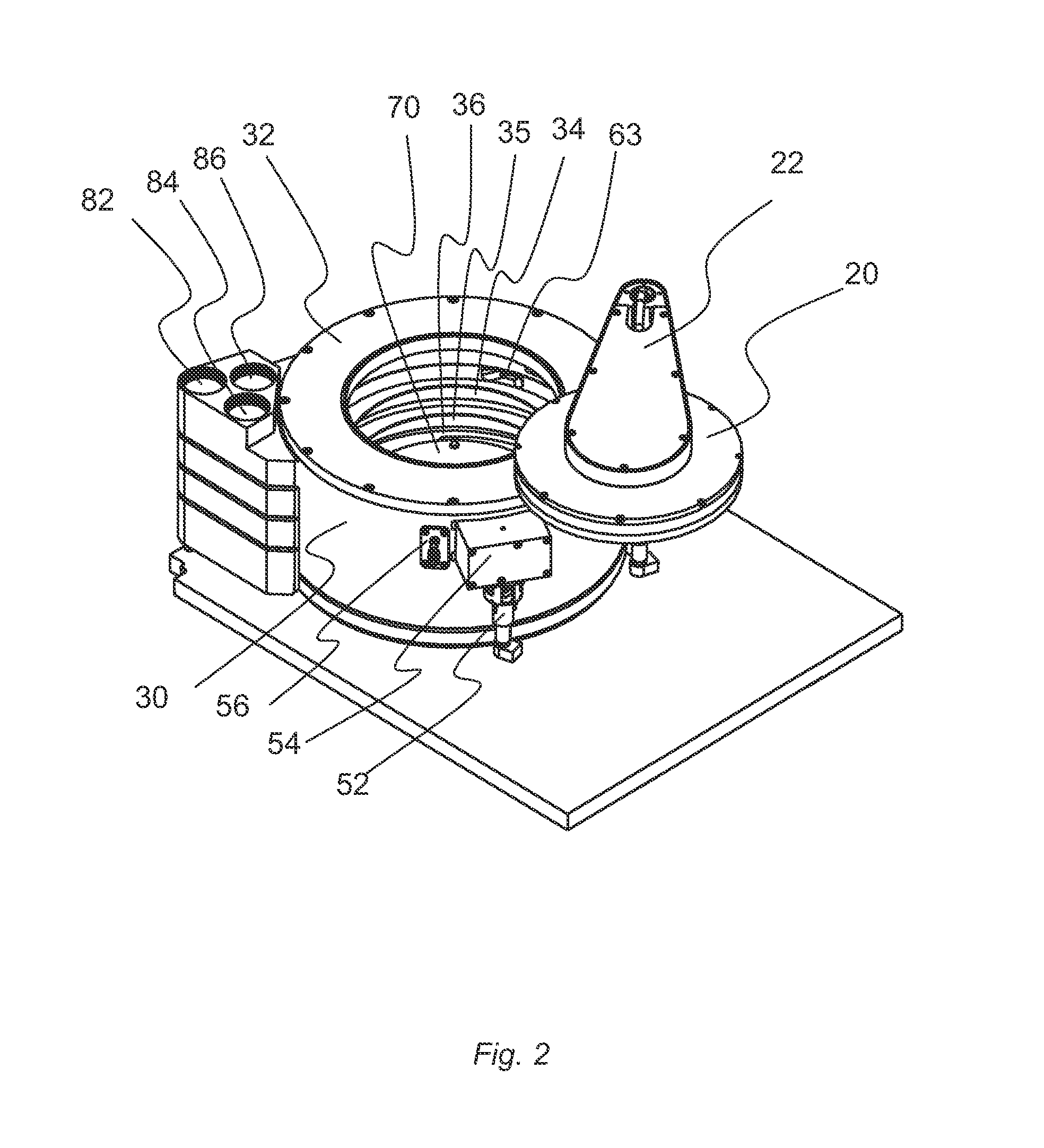

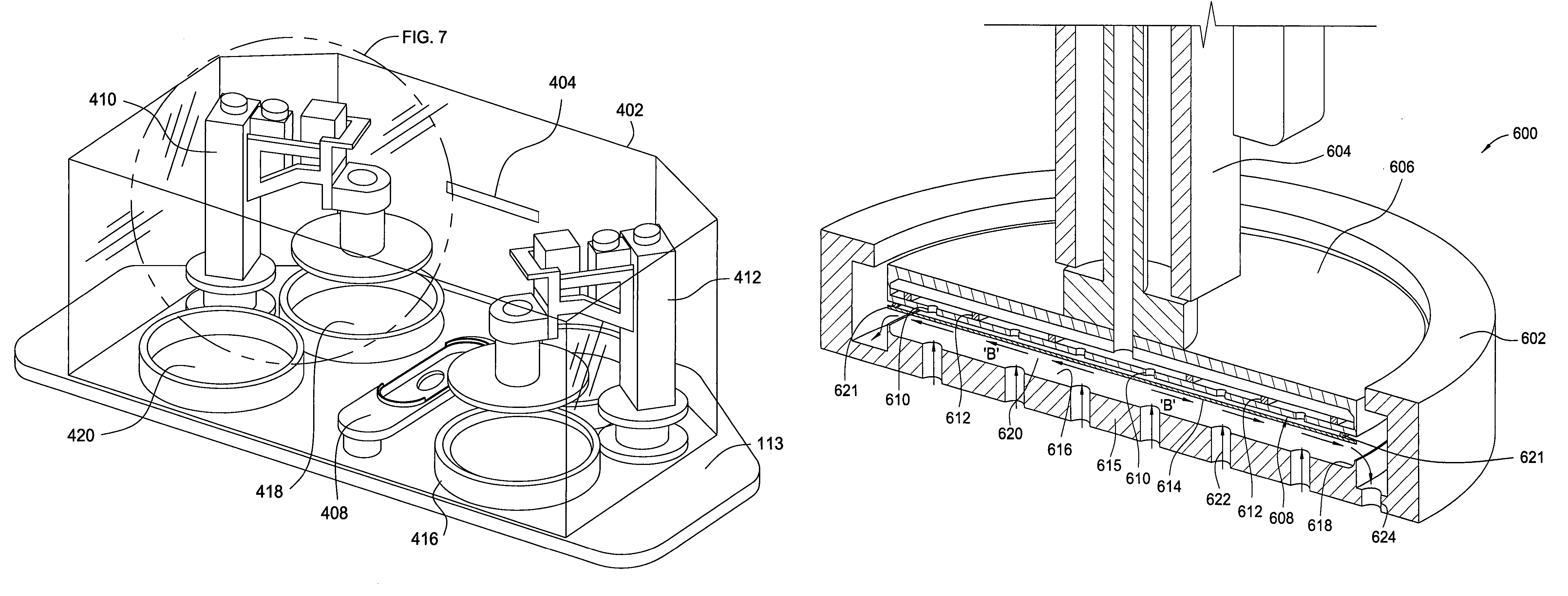

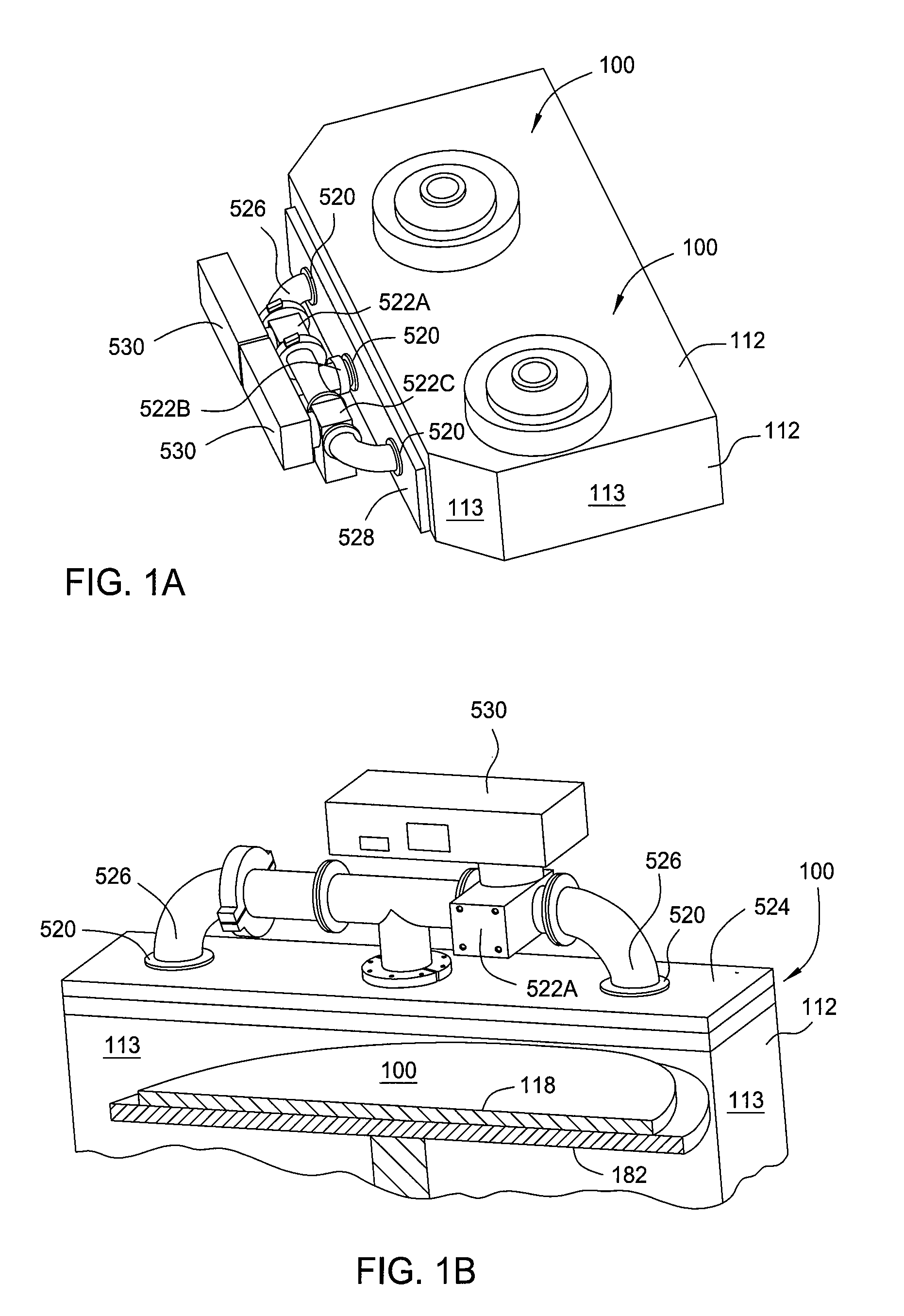

Closed chamber for wafer wet processing

ActiveUS20120103522A1Semiconductor/solid-state device manufacturingCleaning using liquidsProcess moduleClosed chamber

An improved design for a closed chamber process module for single wafer wet processing utilizes a combination lid and gas showerhead for sealing the chamber from above. One or more media arms dispense liquid onto a wafer in the chamber. The media arms are mounted inside the chamber but are connected by a linkage that passes through the chamber wall to a drive unit mounted outside the chamber.

Owner:LAM RES AG

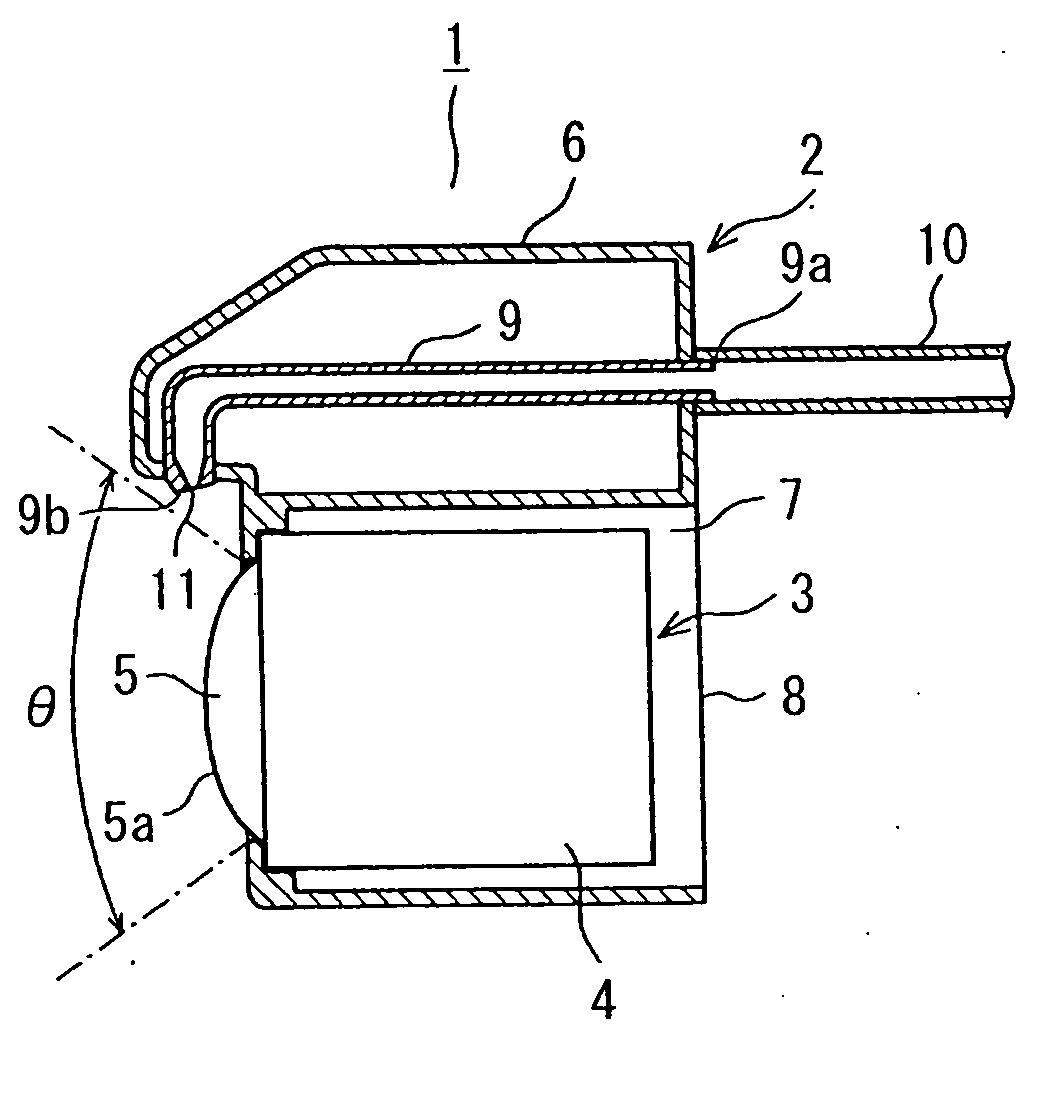

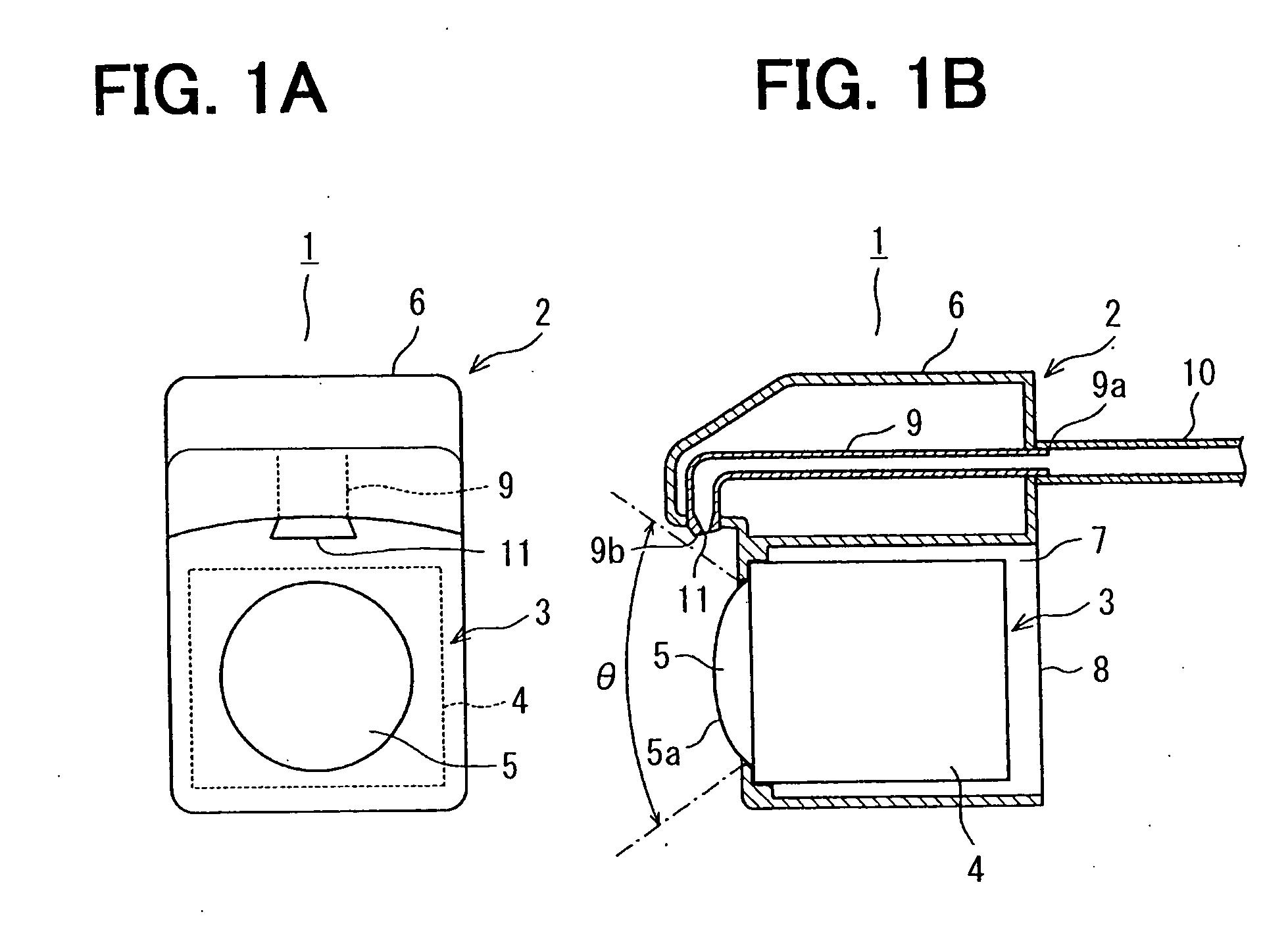

On-board optical sensor cover and on-board optical apparatus

An on-board optical sensor apparatus includes an optical sensor, an optical sensor cover, and a controller. The optical sensor has a lens. The optical sensor cover includes a holder and a washer nozzle. The holder holds the optical sensor. The washer nozzle performs a washing operation to wash a lens surface of the lens of the optical sensor or a glass surface of a cover glass located facing the lens by spraying a washer fluid, supplied from a washer fluid tank, onto the lens surface or the glass surface. The controller controls the washing operation of the washer nozzle.

Owner:DENSO CORP

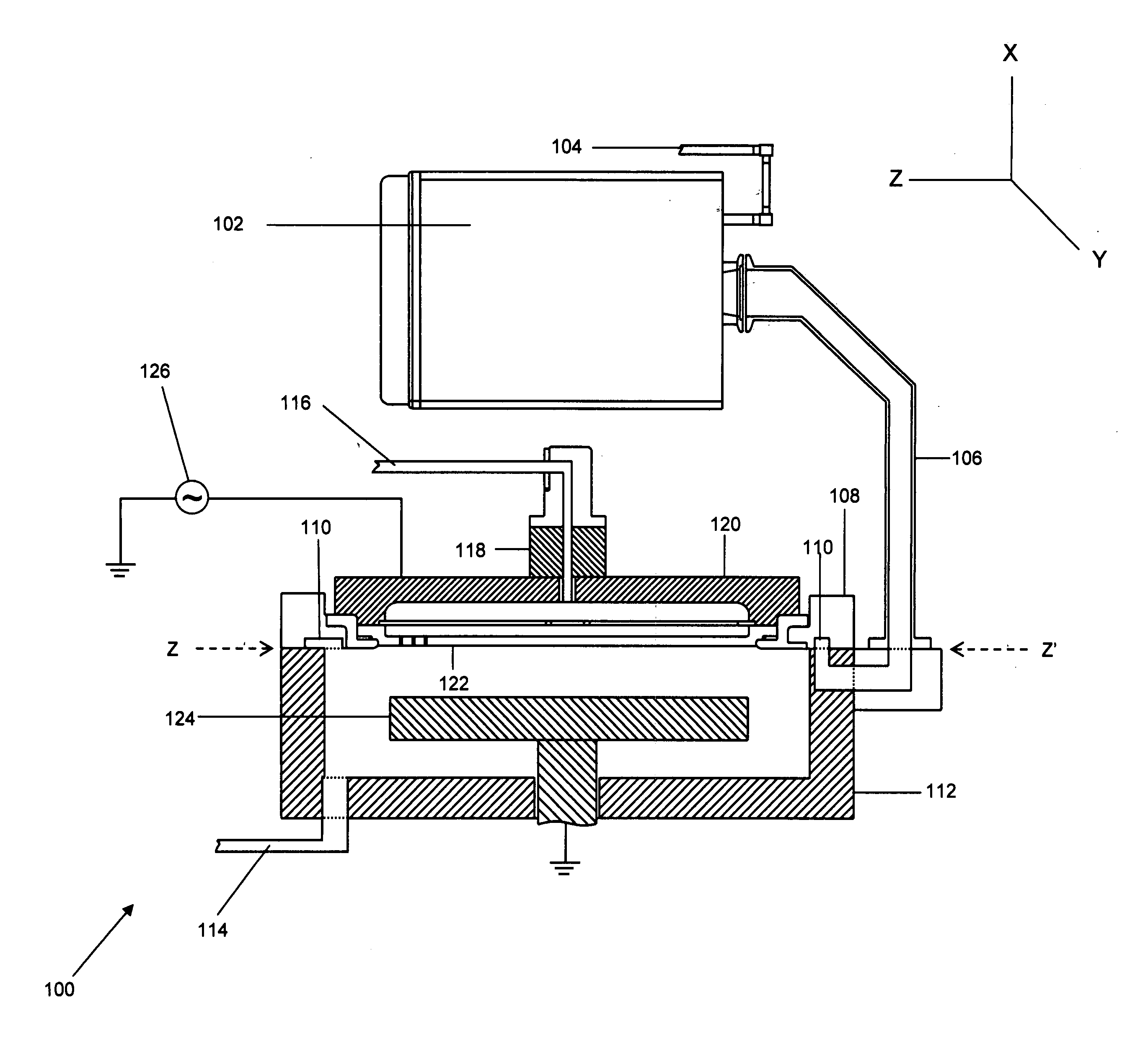

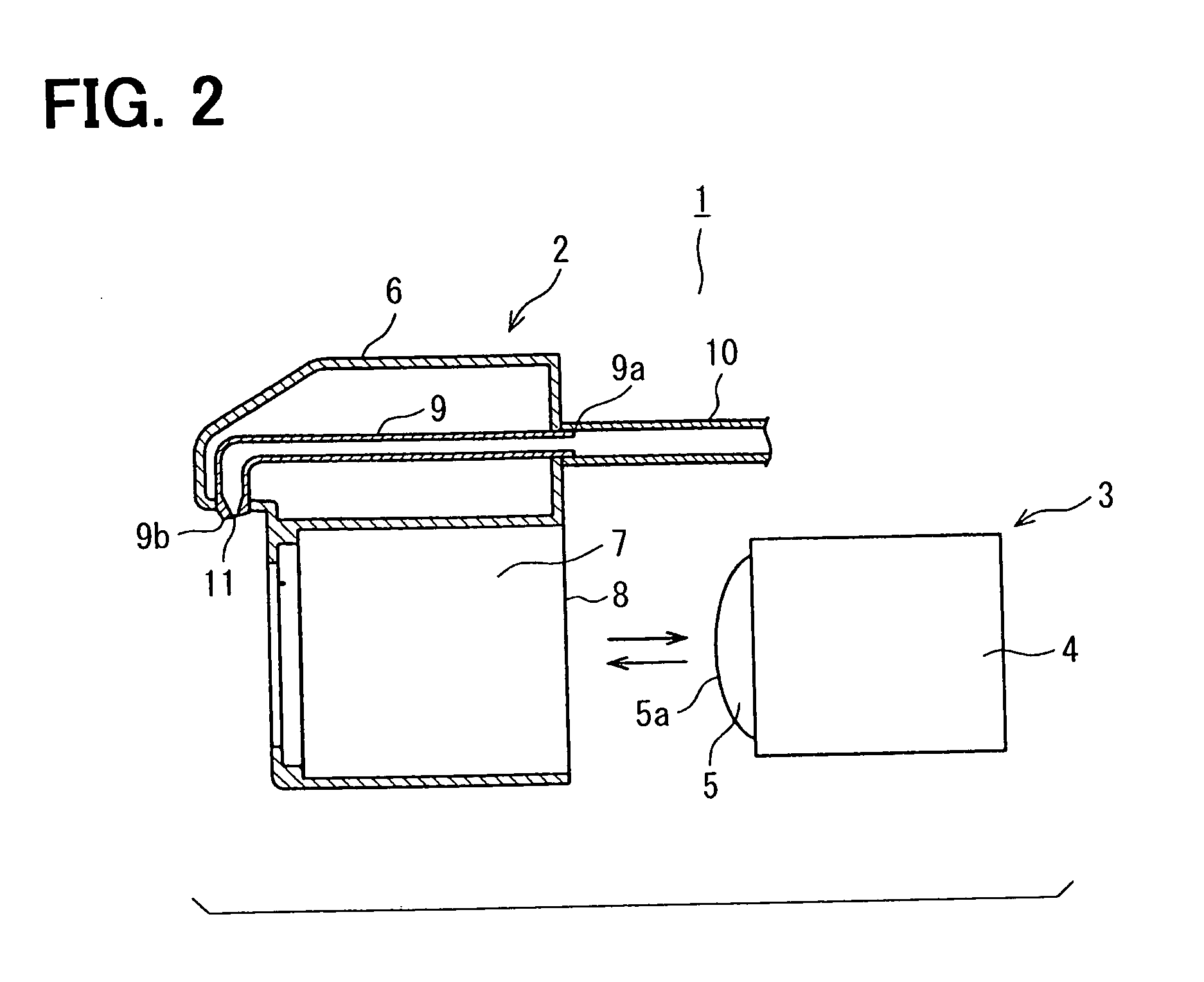

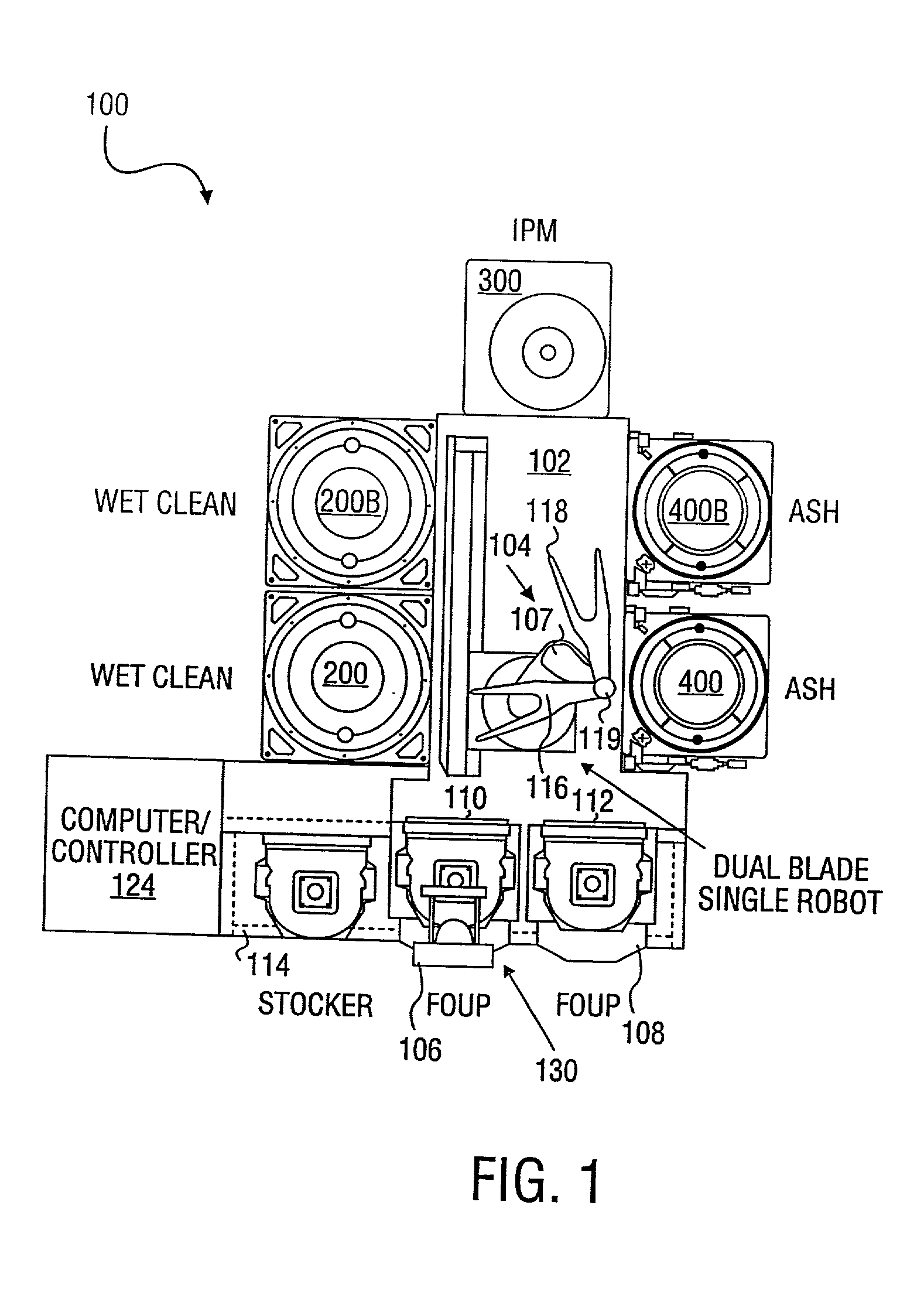

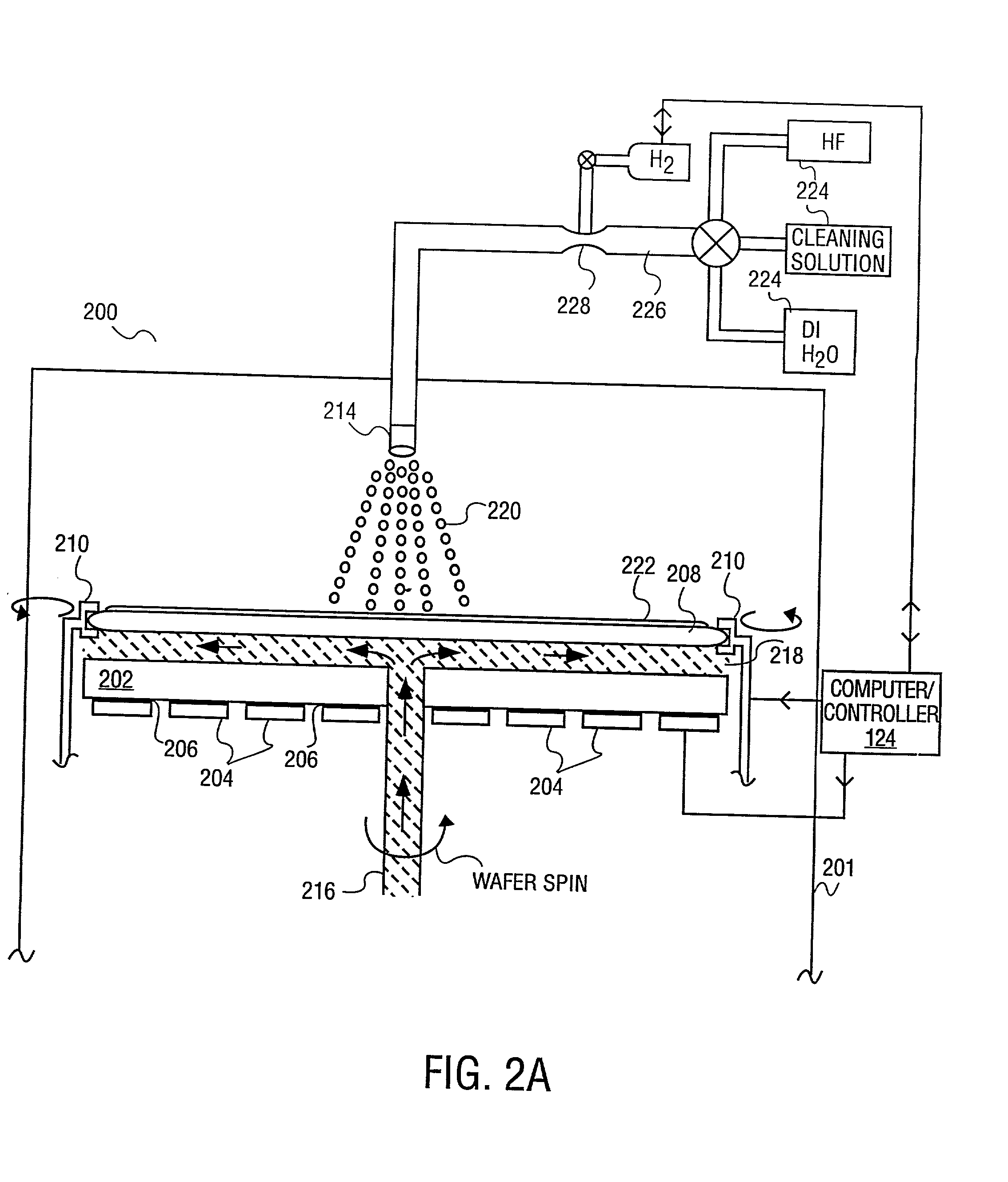

Method and apparatus for processing a wafer

InactiveUS20030045098A1Vacuum evaporation coatingPhotomechanical apparatusEngineeringMechanical engineering

A method of a single wafer wet / dry cleaning apparatus comprising: a transfer chamber having a wafer handler contained therein; a first single wafer wet cleaning chamber directly coupled to the transfer chamber; and a first single wafer ashing chamber directly coupled to the transfer chamber.

Owner:APPLIED MATERIALS INC

Method of cleaning a semiconductor device processing chamber after a copper etch process

The present invention is a method for removing deposited etch byproducts from surfaces of a semiconductor processing chamber after a copper etch process. The method of the invention comprises the following general steps: (a) an oxidation step, in which interior surfaces of the processing chamber are contacted with an oxidizing plasma; (b) a first non-plasma cleaning step, in which interior surfaces of the processing chamber are contacted with an H+hfac-comprising gas; and (c) a second cleaning step, in which interior surfaces of the processing chamber are contacted with a plasma containing reactive fluorine species, whereby at least a portion of the copper etch byproducts remaining after step (b) are volatilized into gaseous species, which are removed from the processing chamber. The method of the invention is preferably performed at a chamber wall temperature of at least 150° C. in order to achieve optimum cleaning of the chamber at the chamber operating pressures typically used during the cleaning process. The dry cleaning method of the invention can be performed between wafer processing runs without opening the processing chamber, thereby minimizing potential contamination to the chamber as well as chamber downtime.

Owner:APPLIED MATERIALS INC

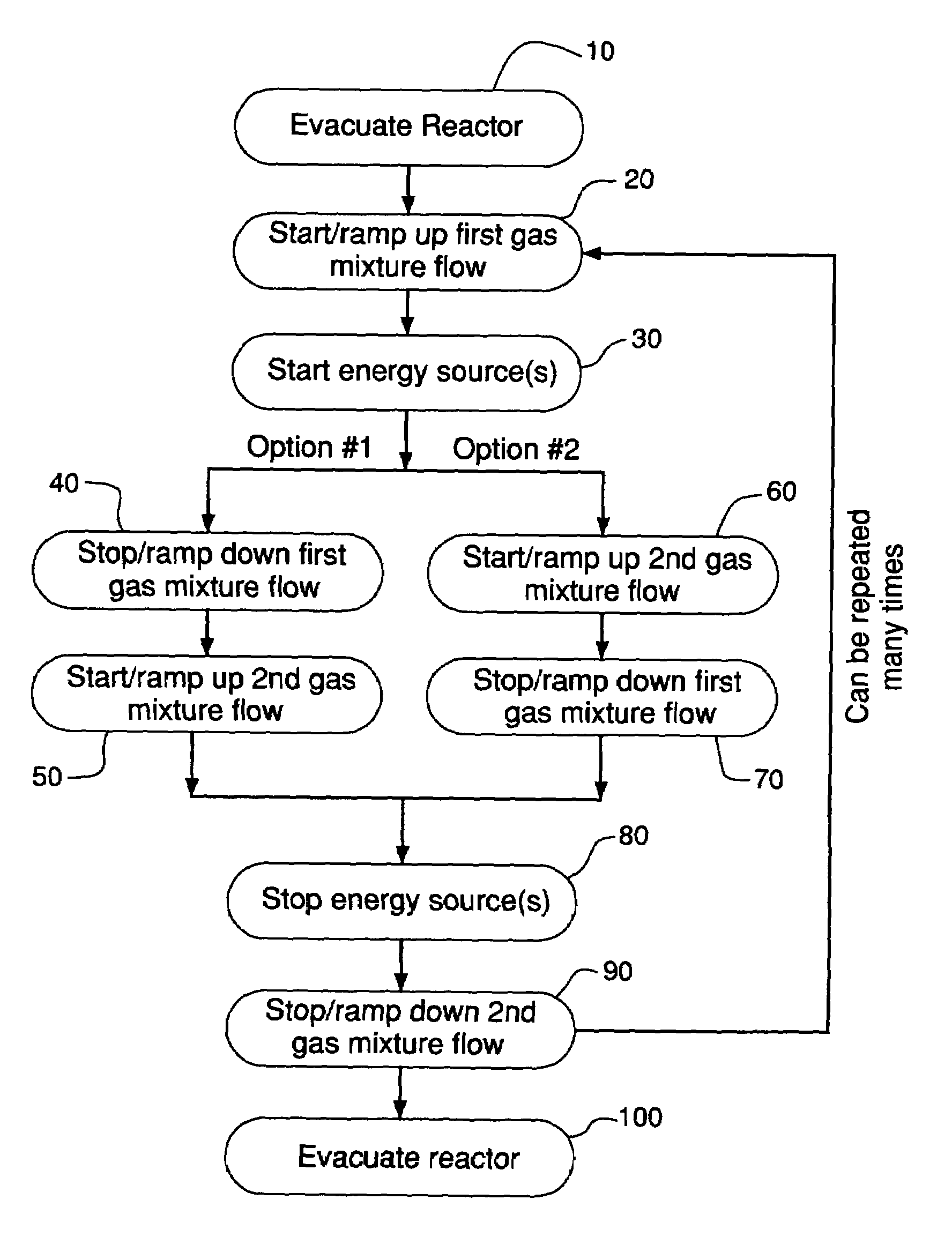

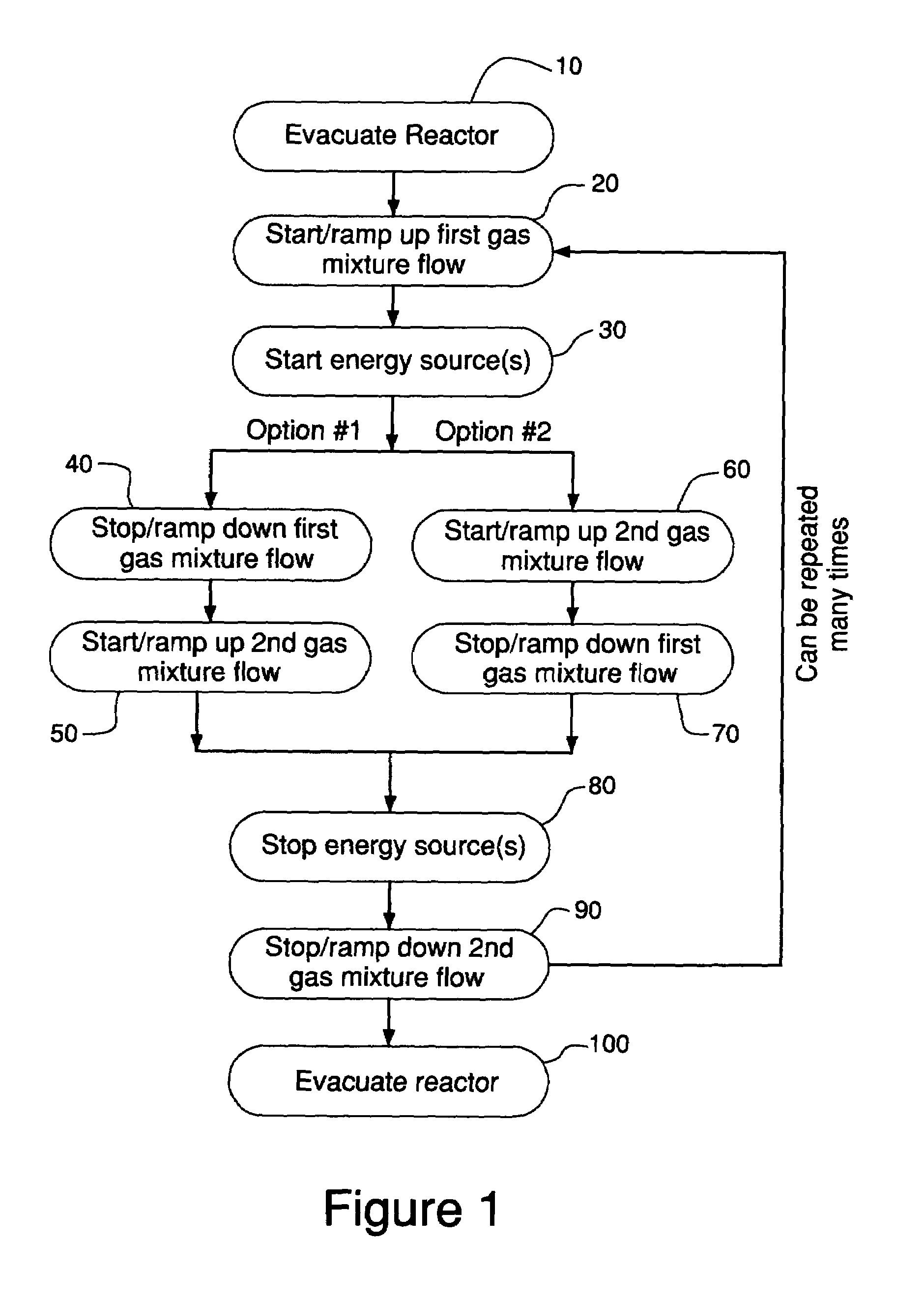

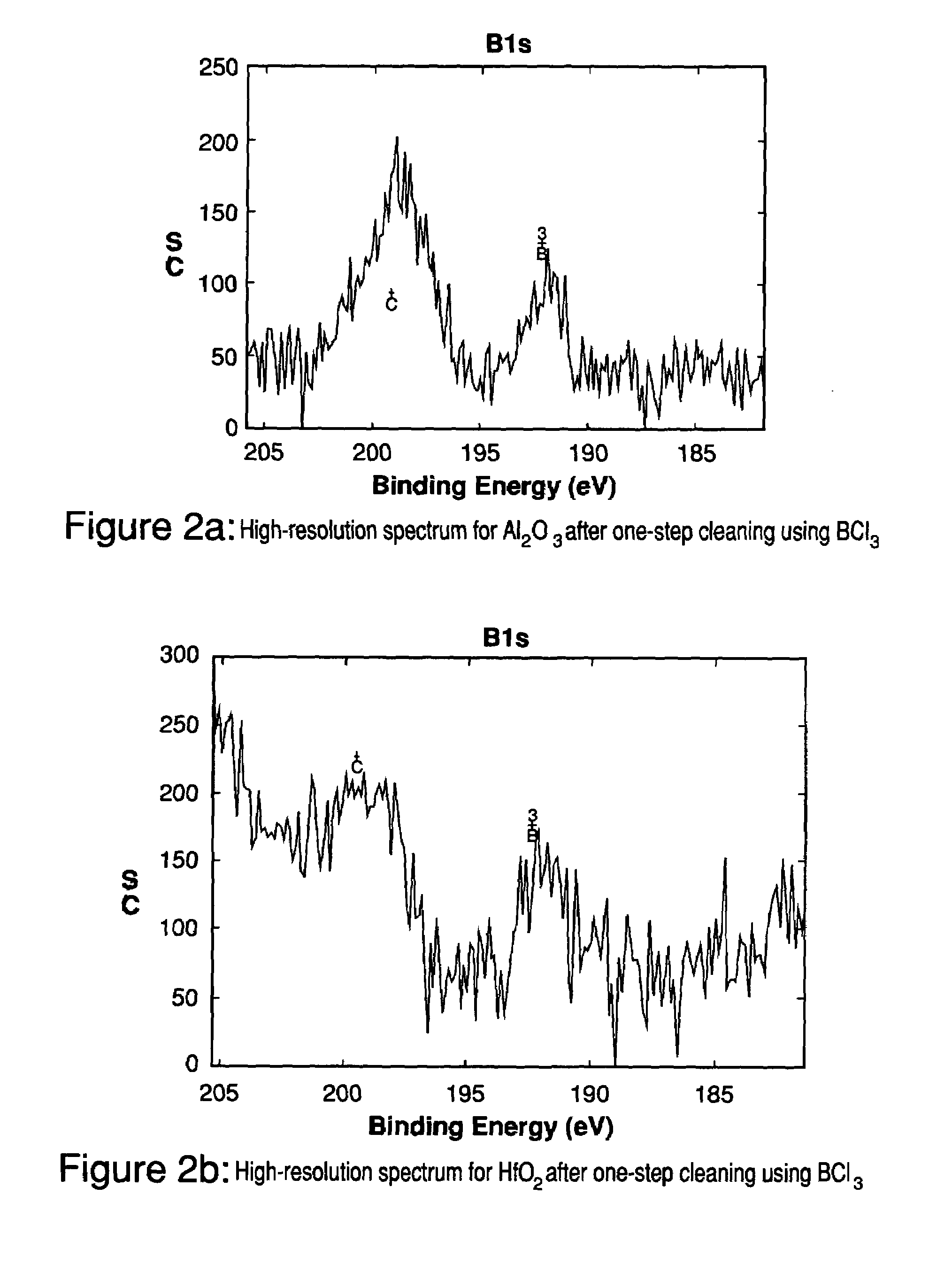

Method for cleaning deposition chambers for high dielectric constant materials

A method for dry etching and chamber cleaning high dielectric constant materials is disclosed herein. In one aspect of the present invention, there is provided a process for cleaning a substance comprising a dielectric constant greater than the dielectric constant of silicon dioxide from at least a portion of a surface of a reactor comprising: introducing a first gas mixture comprising a boron-containing reactive agent into the reactor wherein the first gas mixture reacts with the substance contained therein to provide a volatile product and a boron-containing by-product; introducing a second gas mixture comprising a fluorine-containing reactive agent into the reactor wherein the second gas mixture reacts with the boron-containing by-product contained therein to form the volatile product; and removing the volatile product from the reactor.

Owner:AIR PROD & CHEM INC

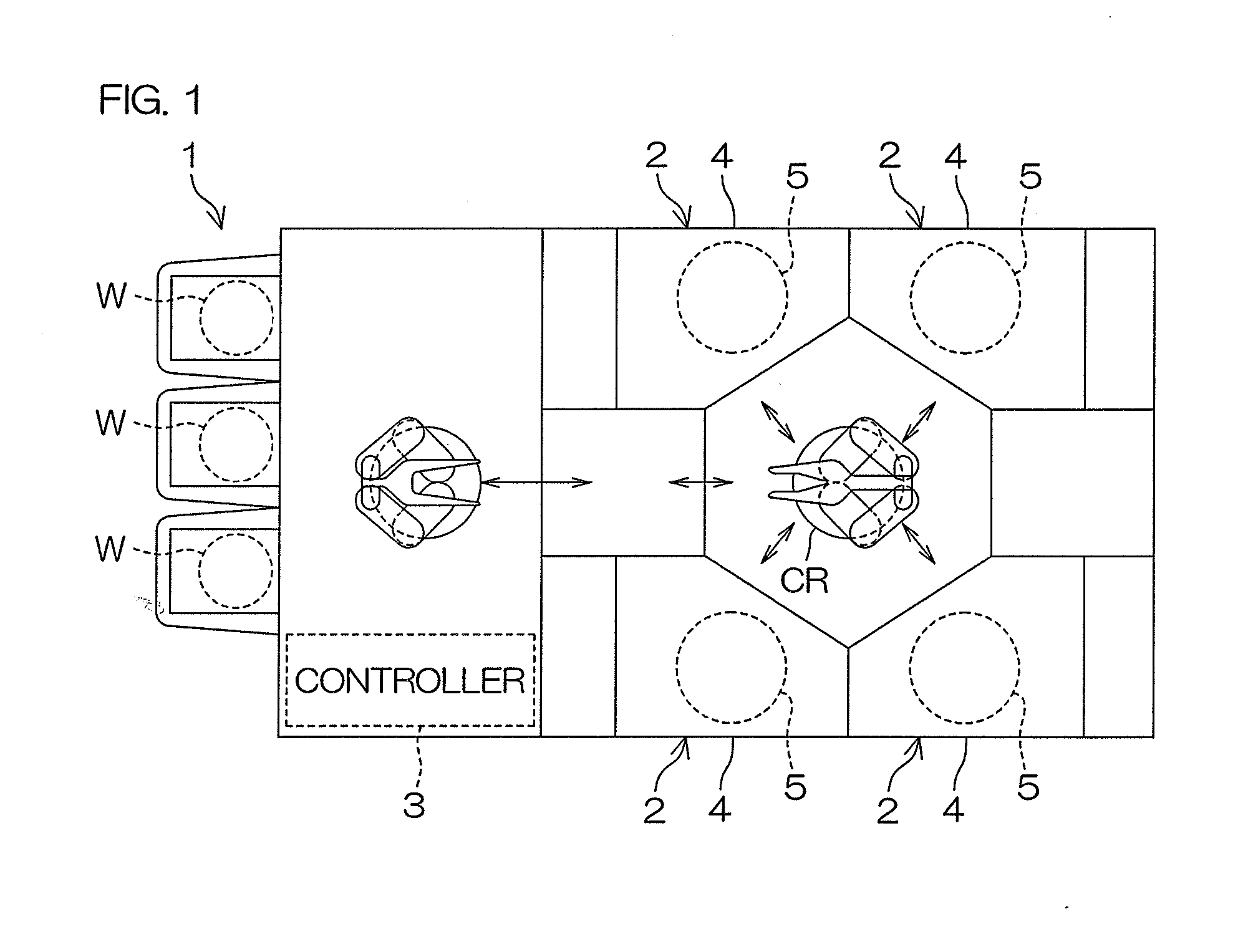

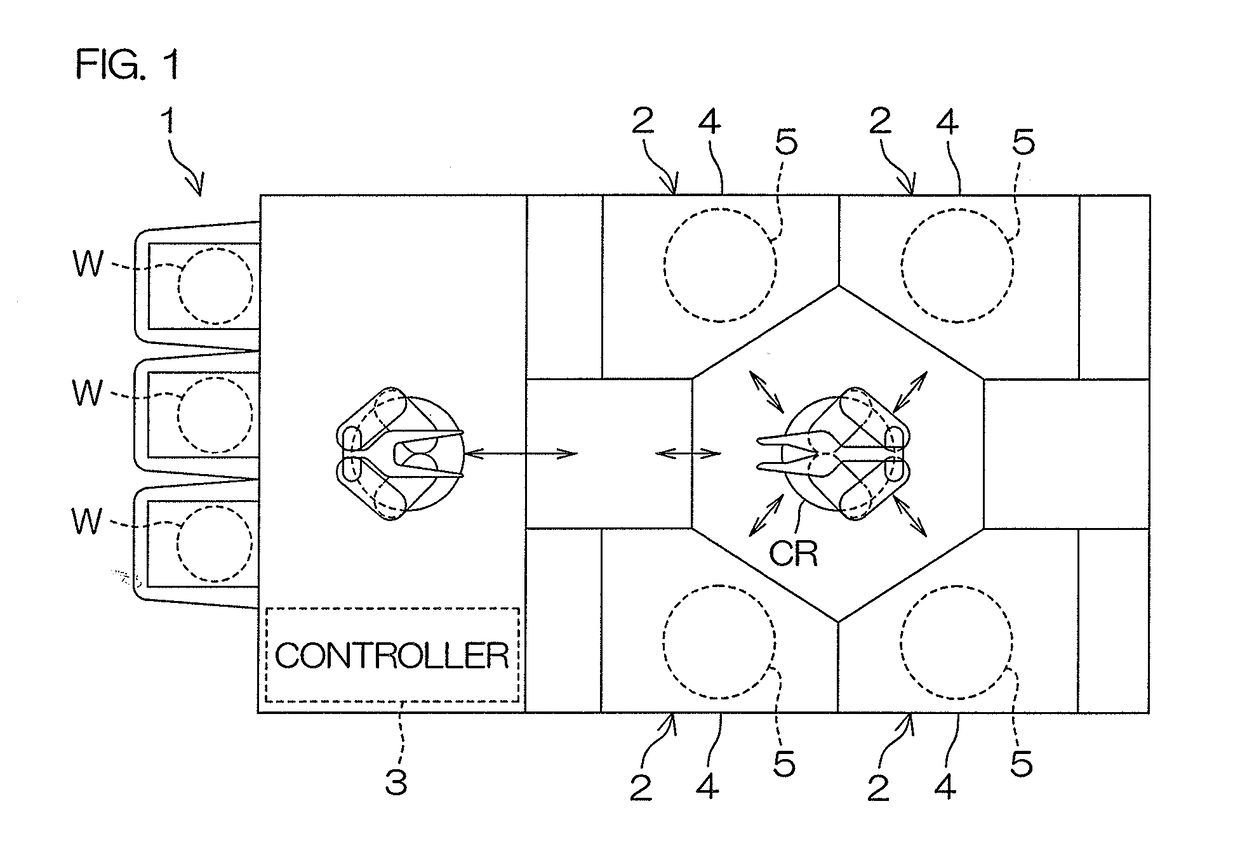

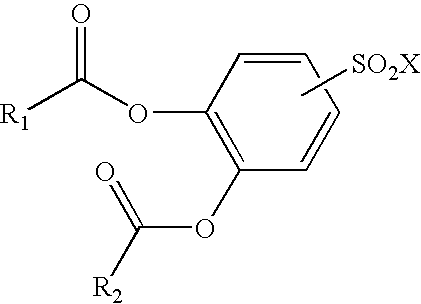

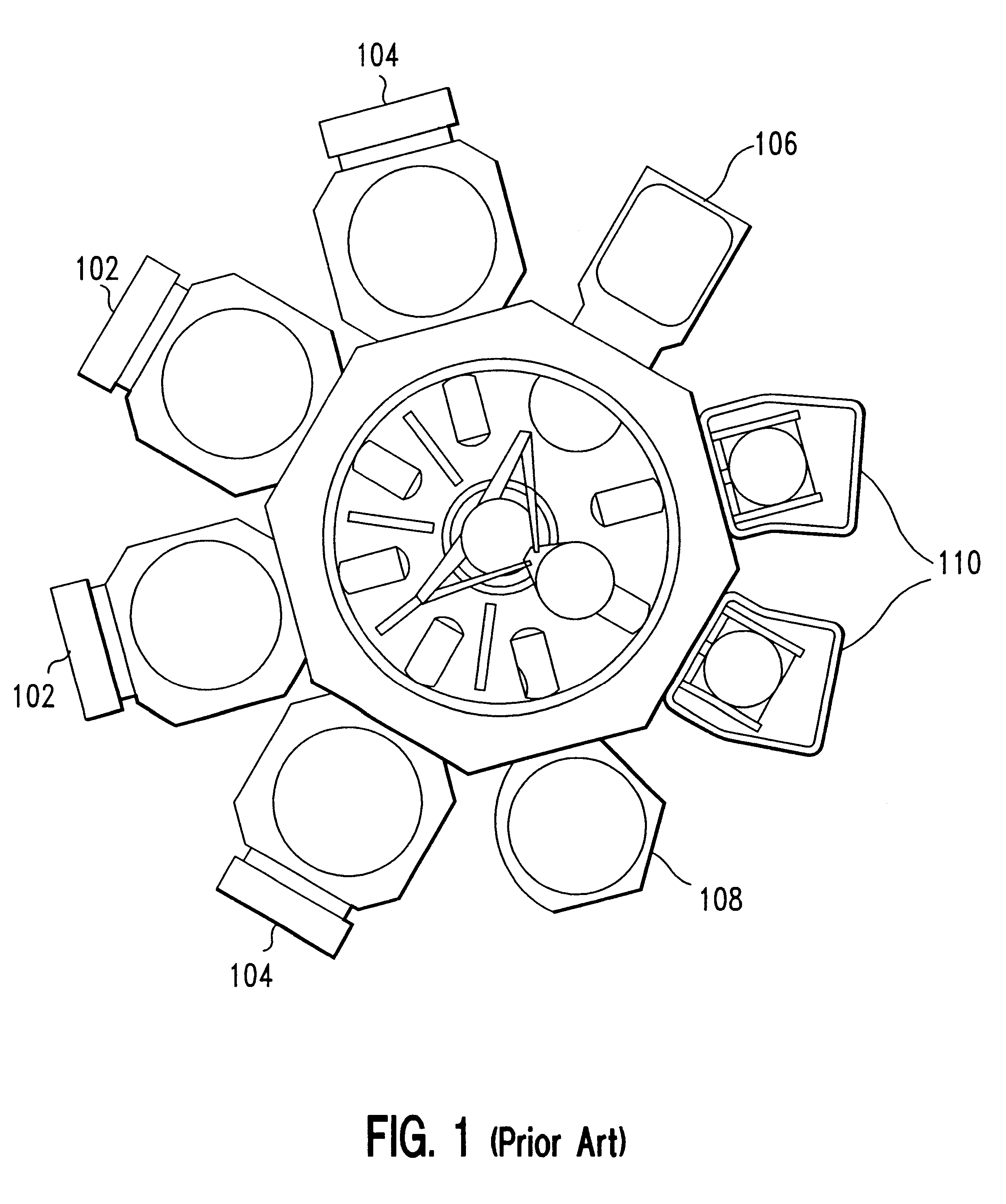

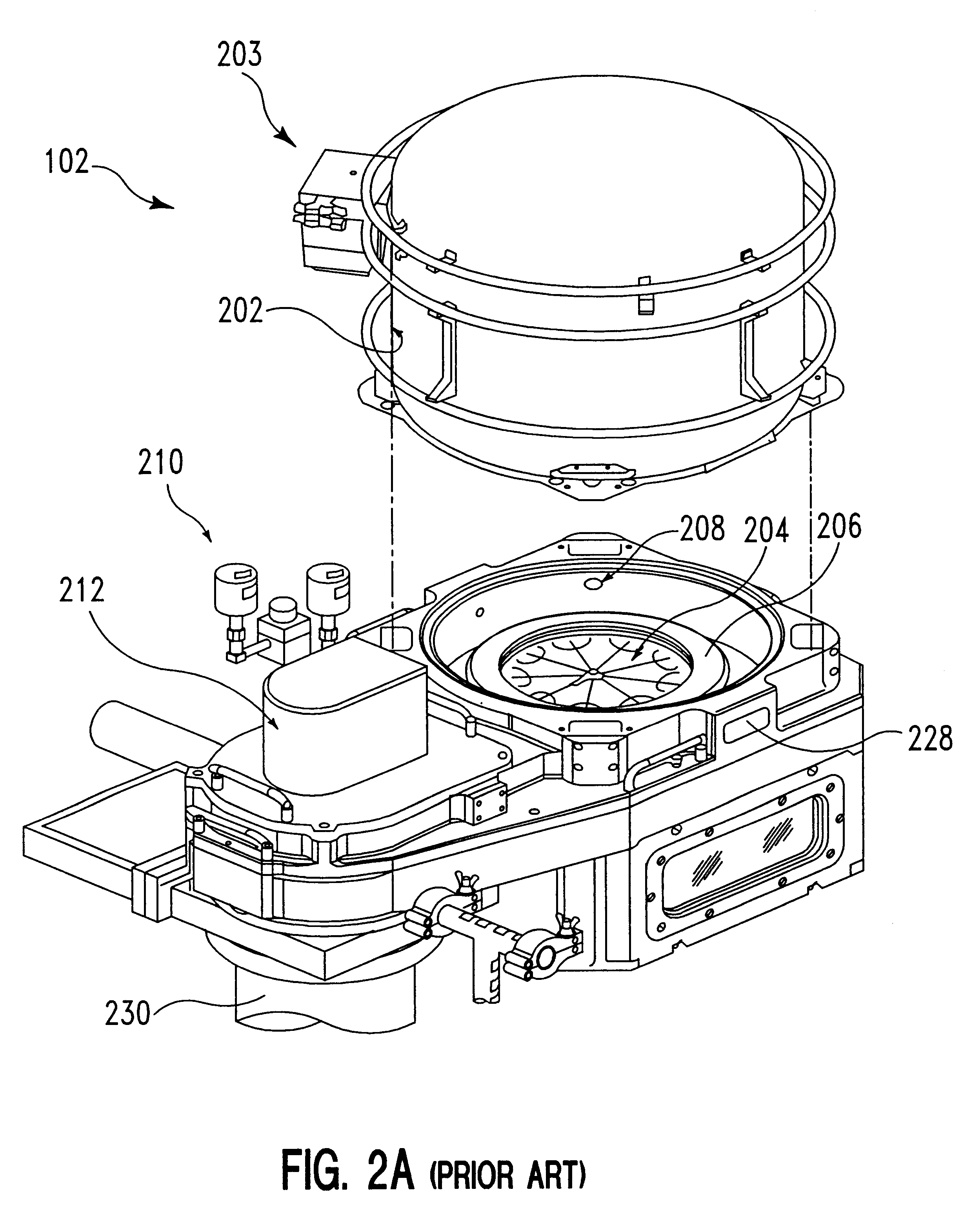

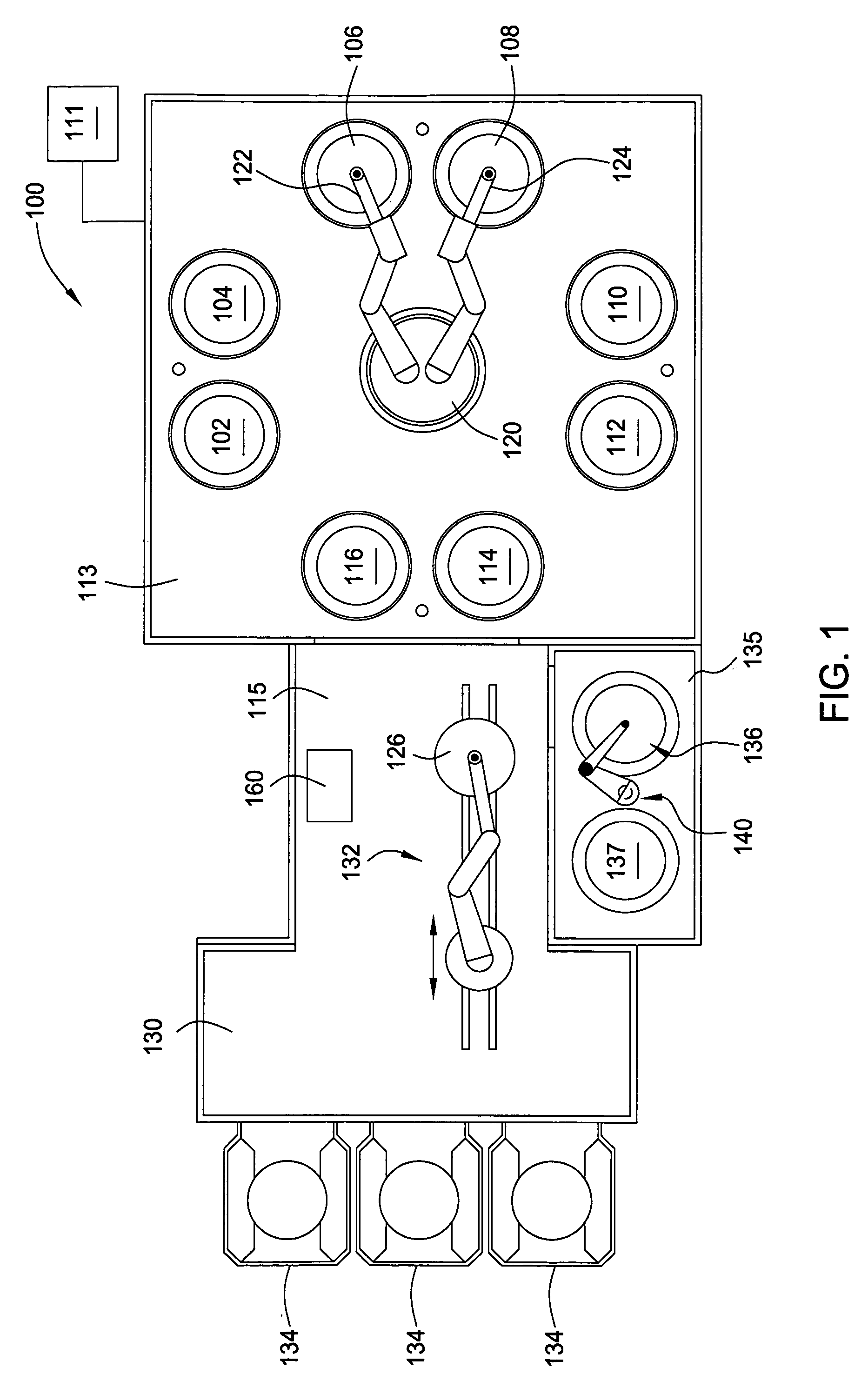

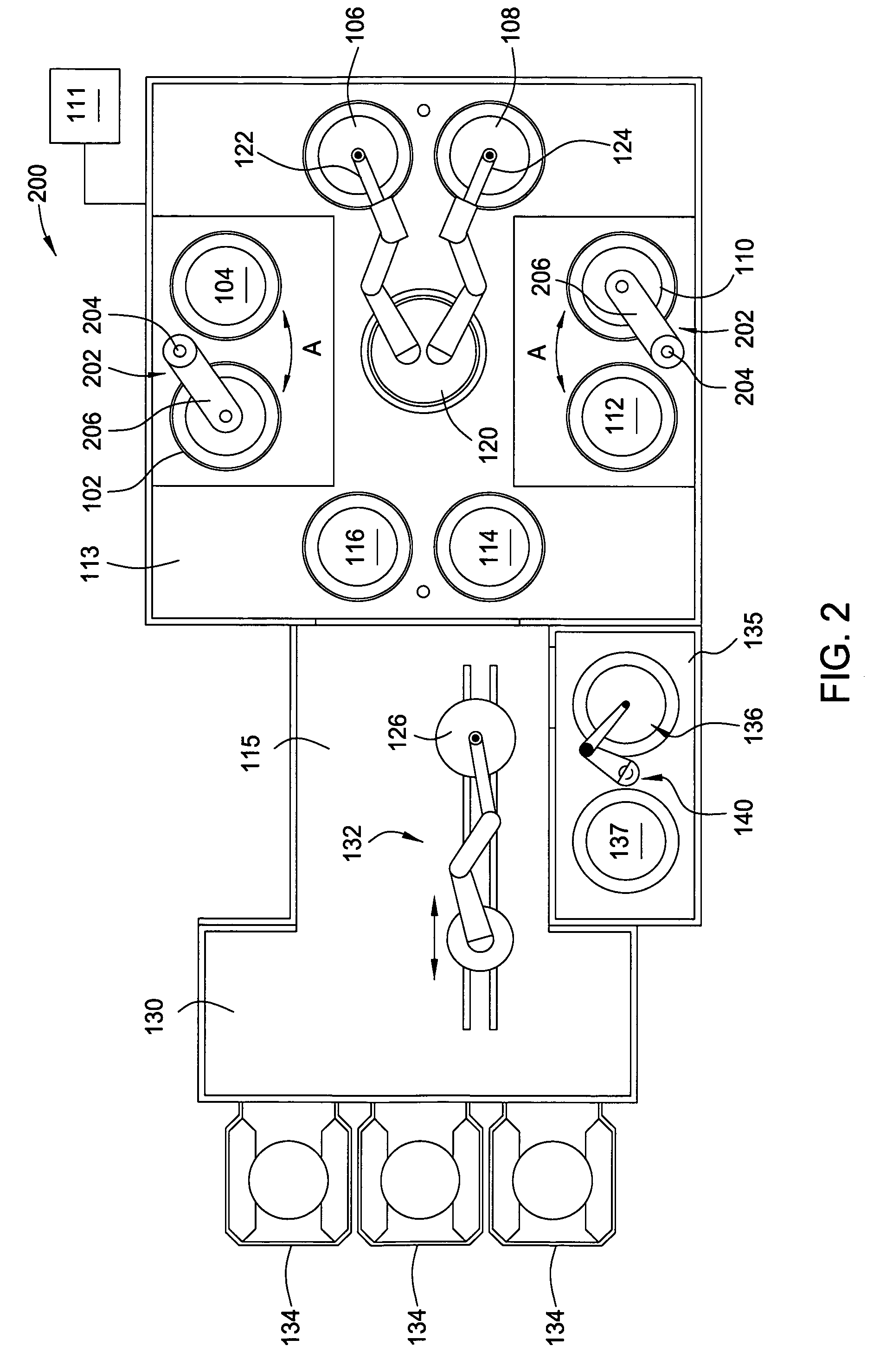

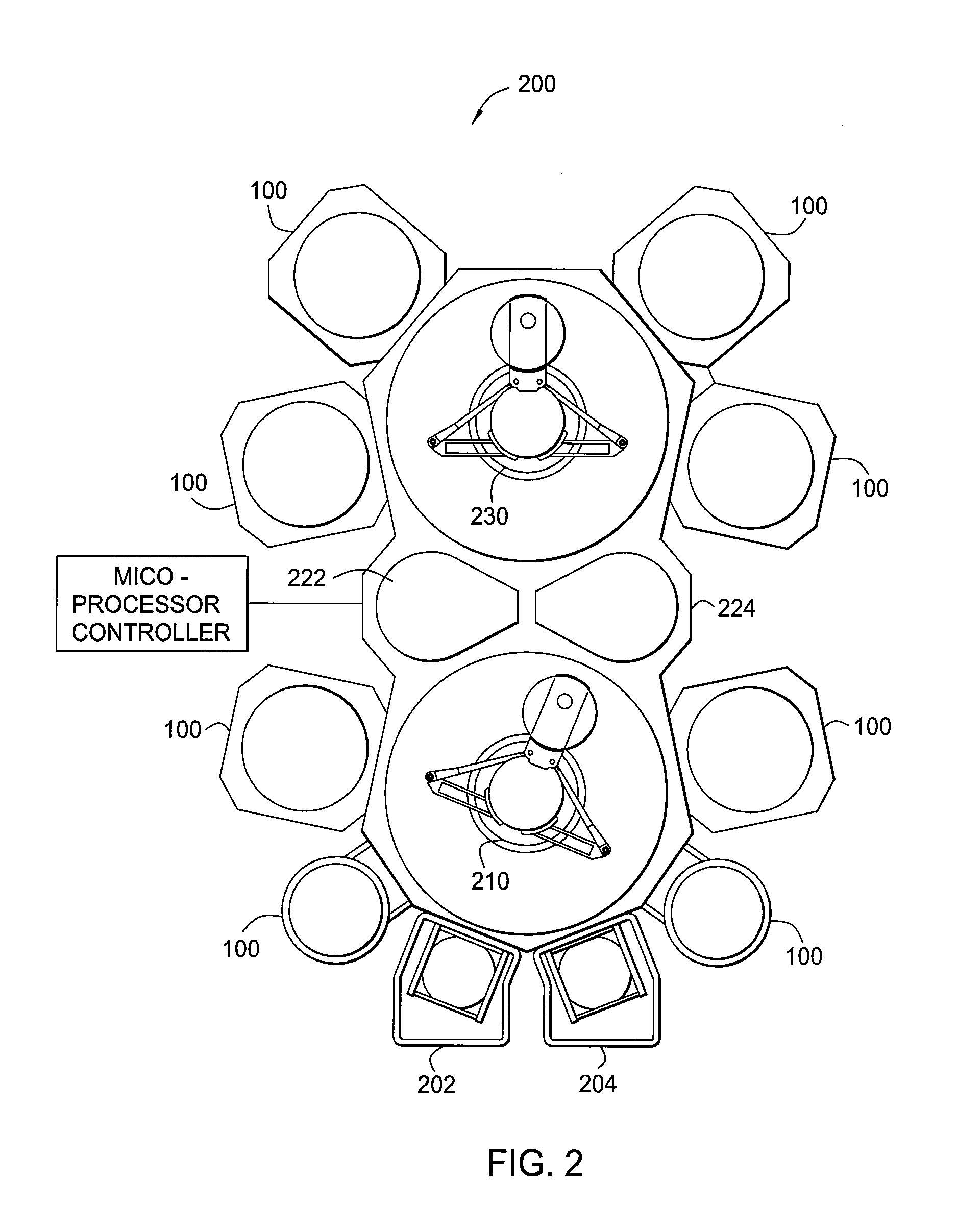

Apparatus for electroless deposition

ActiveUS7341633B2Liquid surface applicatorsVacuum evaporation coatingElectroless depositionEngineering

Embodiments of the invention generally provide a fluid processing platform. The platform includes a mainframe having a substrate transfer robot, at least one substrate cleaning cell on the mainframe, and at least one processing enclosure. The processing enclosure includes a gas supply positioned in fluid communication with an interior of the processing enclosure, a first fluid processing cell positioned in the enclosure, a first substrate head assembly positioned to support a substrate for processing in the first fluid processing cell, a second fluid processing cell positioned in the enclosure, a second head assembly positioned to support a substrate for processing in the second fluid processing cell, and a substrate shuttle positioned between the first and second fluid processing cells and being configured to transfer substrates between the fluid processing cells and the mainframe robot.

Owner:APPLIED MATERIALS INC

Methods of end point detection for substrate fabrication processes

InactiveUS20130193108A1Liquid surface applicatorsVacuum gauge using ionisation effectsEngineeringThroughput

Methods and substrate processing systems for analyzing an end point of a process are provided. By-products of the process are detected and monitored to determine the completion of various types of reaction processes within a substrate processing chamber. The methods provide real time process monitoring, thereby reducing the need to rigidly constrain other substrate processing parameters, increasing chamber cleaning efficiency, and / or increasing substrate processing throughput.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com