Patents

Literature

20305results about How to "Improve cleaning efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cleaning robot and cleaning method thereby

ActiveCN102138769AImprove cleaning efficiencyFloor sweeping machinesCleaning methodsComputer science

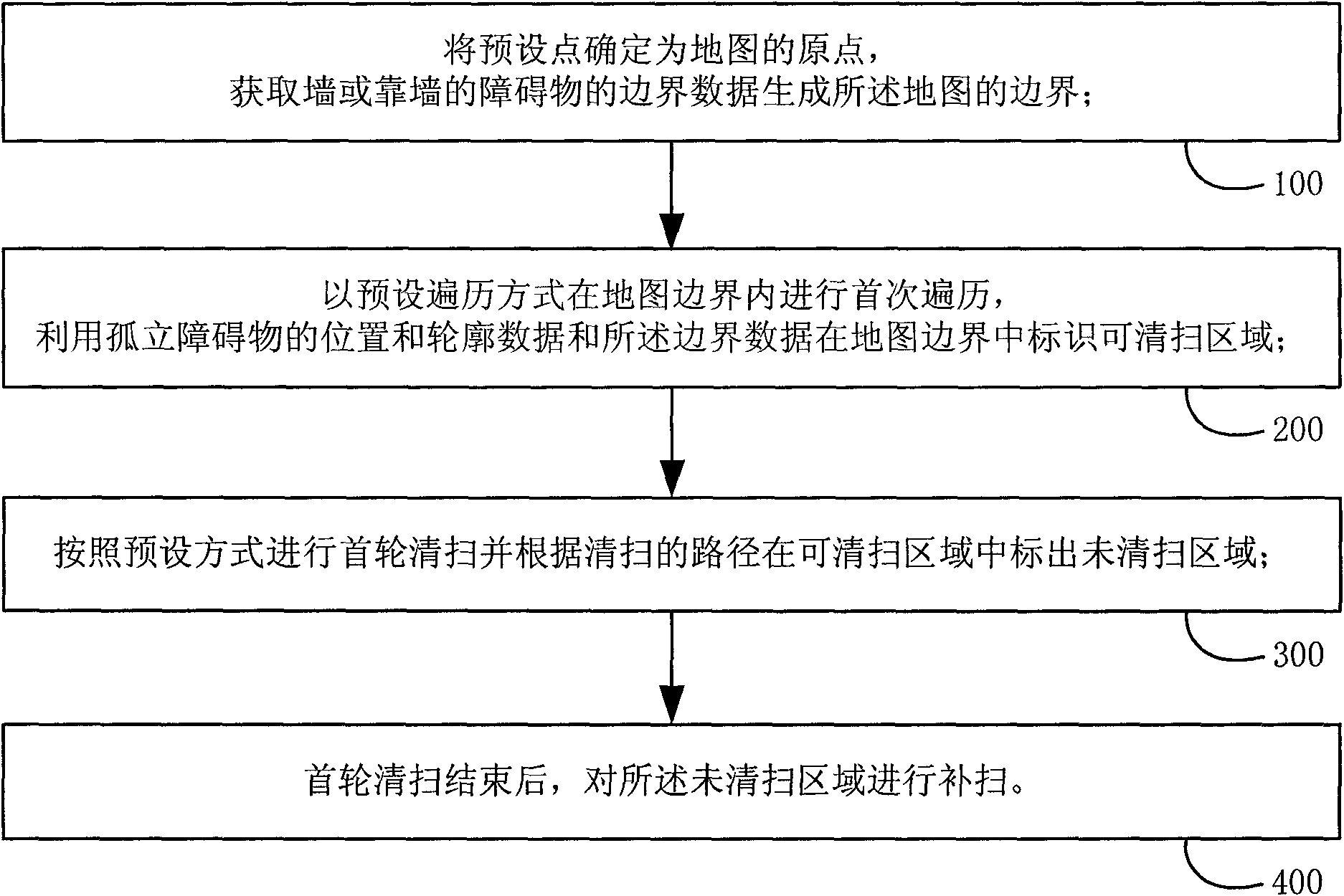

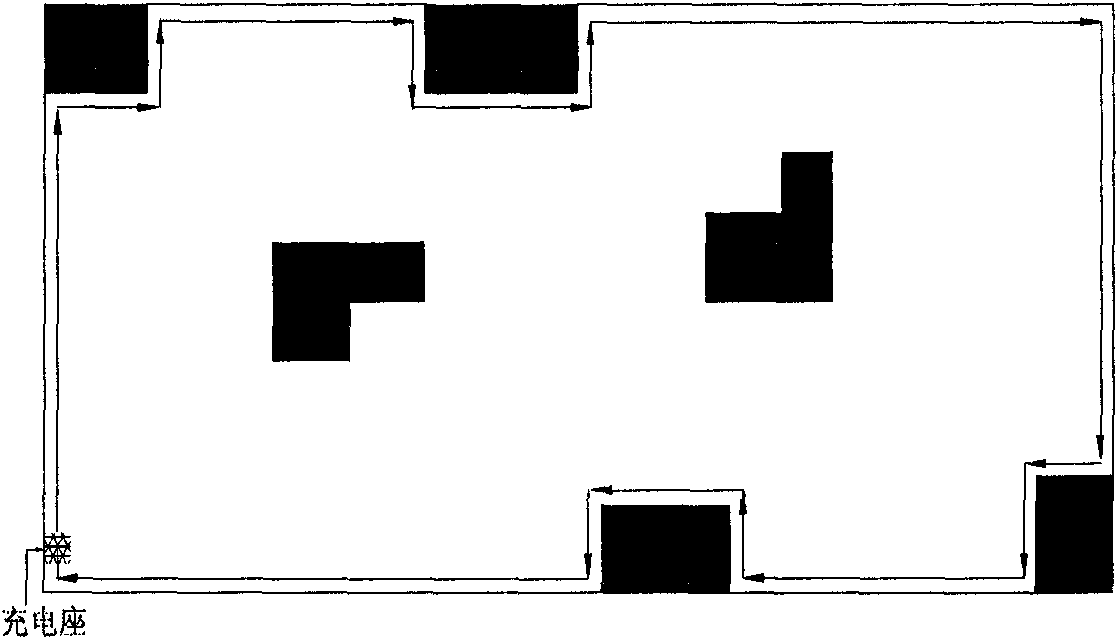

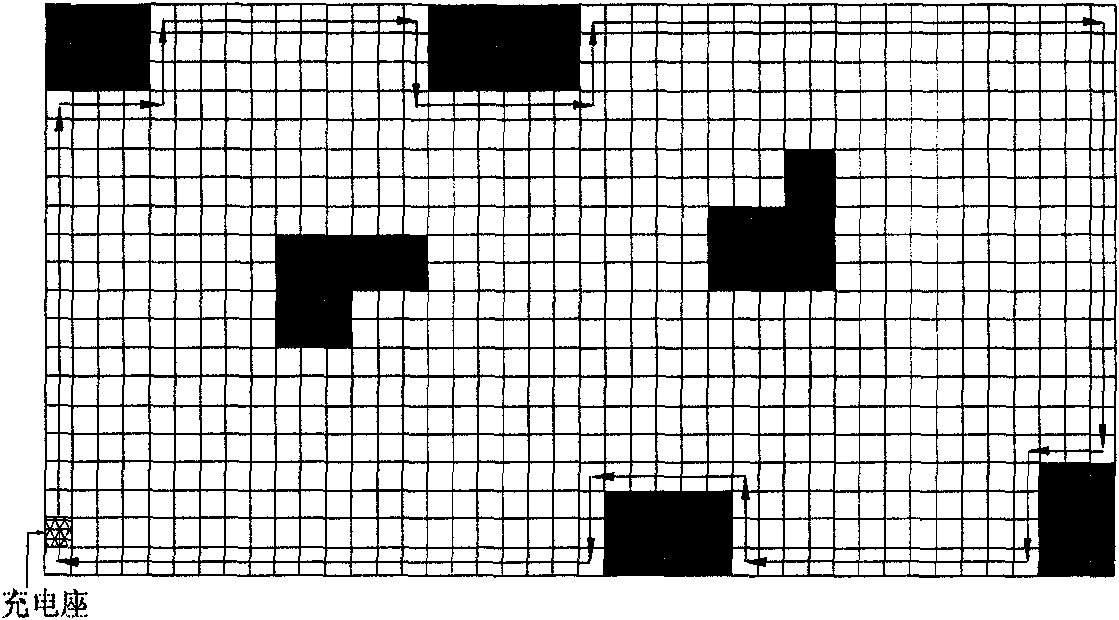

The invention provides a cleaning robot and a cleaning method thereby. On the basis of acquired detection data and the current position and gesture data, the method comprises the following steps of: determining a preset point as the original point of a map; acquiring boundary data of a wall or an obstacle near the wall to generate the boundary of the map; performing first ergodic operation in the boundary of the map in a preset ergodic mode; if encountering an isolated obstacle, acquiring position and outline data by surrounding the isolated obstacle; identifying regions which can be cleaned in the map boundary according to the position and outline data and the boundary data; at the same time of or after the first ergodic operation, cleaning according to the preset cleaning mode; identifying the non-cleaning regions in the cleaning regions according to the cleaning route; and then cleaning the non-cleaning regions. Compared with the conventional blind cleaning methods, the cleaning method has the advantage of greatly improving cleaning efficiency.

Owner:SHENZHEN INST OF ADVANCED TECH +1

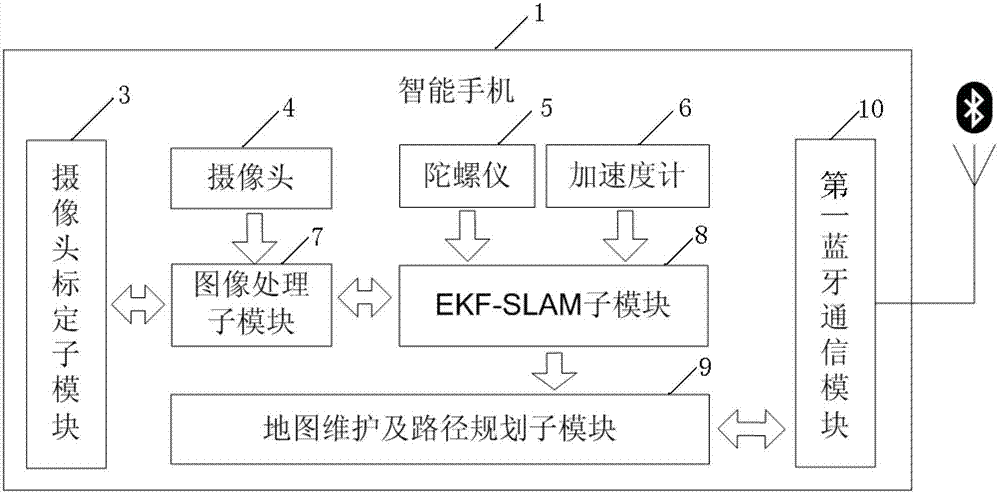

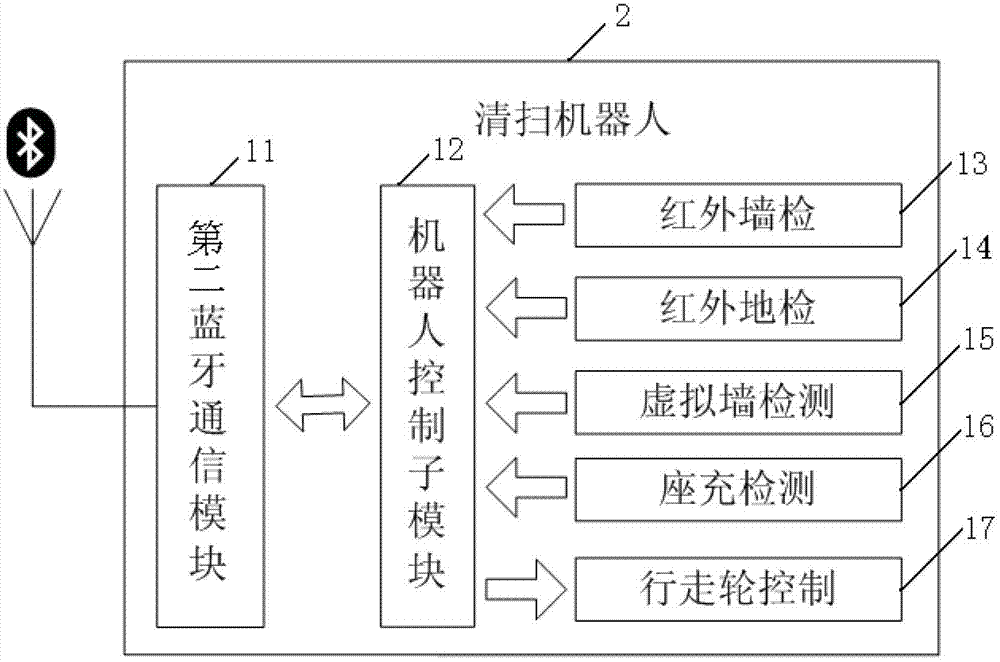

Sweeping robot navigated by smart phone and navigation sweeping method of sweeping robot

ActiveCN102866706AMinor changesEasy to implementPosition/course control in two dimensionsMarine navigationSmart phone

A sweeping robot navigated by a smart phone comprises a sweeping robot module and further comprises a smart phone module which comprises a smart phone camera, an image processing submodule, a camera calibrating submodule, an EKF-SLAM (Extended Kalman Filter for Simultaneous Localization And Mapping) submodule, a map maintenance and routine planning submodule, a sensor submodule and a sensor data acquisition submodule. A navigation sweeping method sequentially comprises the following steps of: 1, calibrating parameters in the smart phone camera with a calibrating template; 2, establishing bluetooth communication connection; 3, activating the EKF-SLAM submodule for accurate localization and creating a three-dimensional environment map; 4, establishing an obstacle covering map of an indoor environment; 5, automatically planning a sweeping routine of the sweeping robot; and 6, controlling the next motion of walling wheels of the sweeping robot. Sensors and hardware equipment of navigation localization and the like do not need to be directly arranged on the sweeping robot. The sweeping robot has the advantages of simplicity in realization, small modification on hardware, accurate localization, large sweeping covering area and high sweeping efficiency.

Owner:SHENZHEN SILVER STAR INTELLIGENT TECH CO LTD

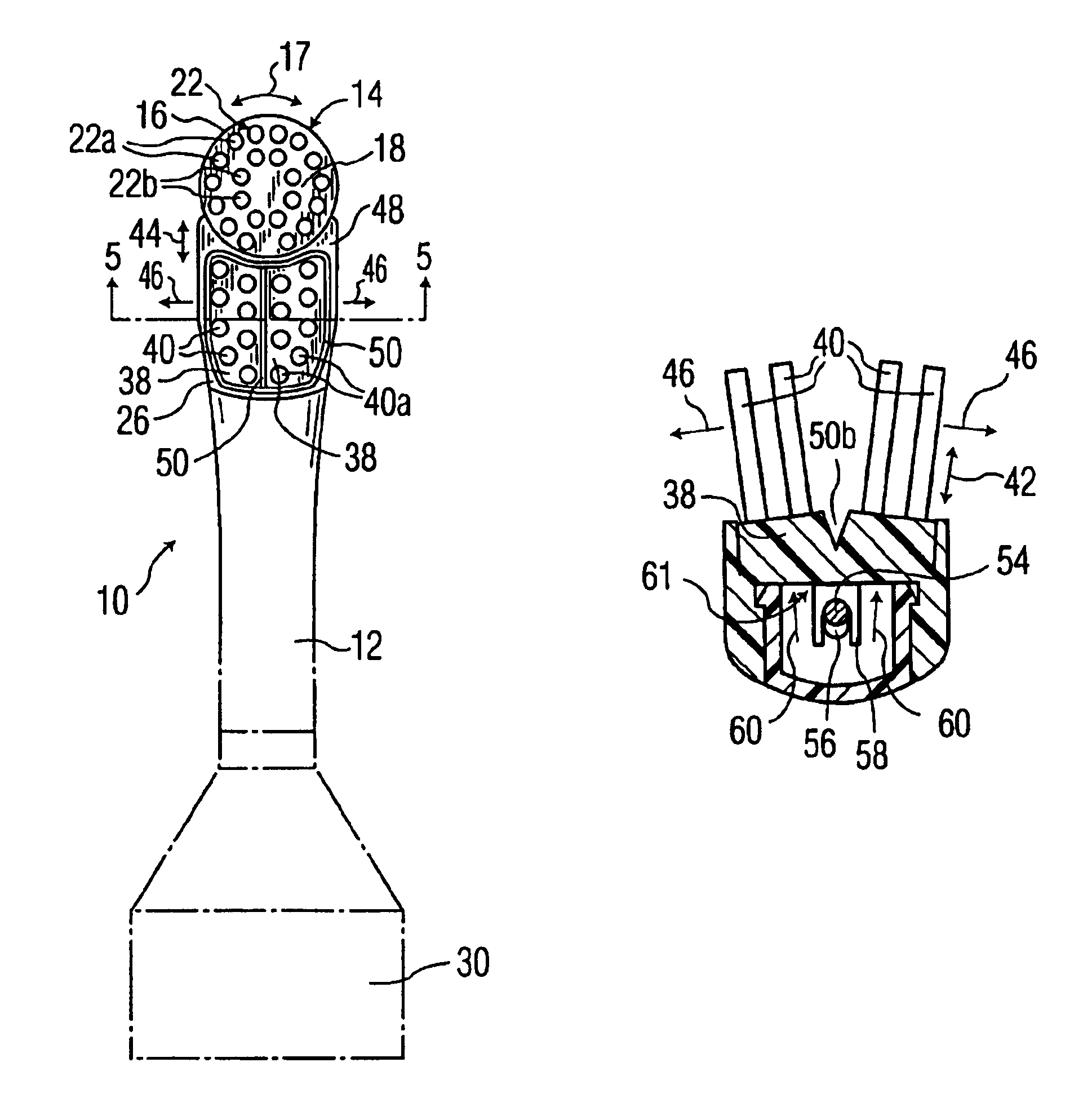

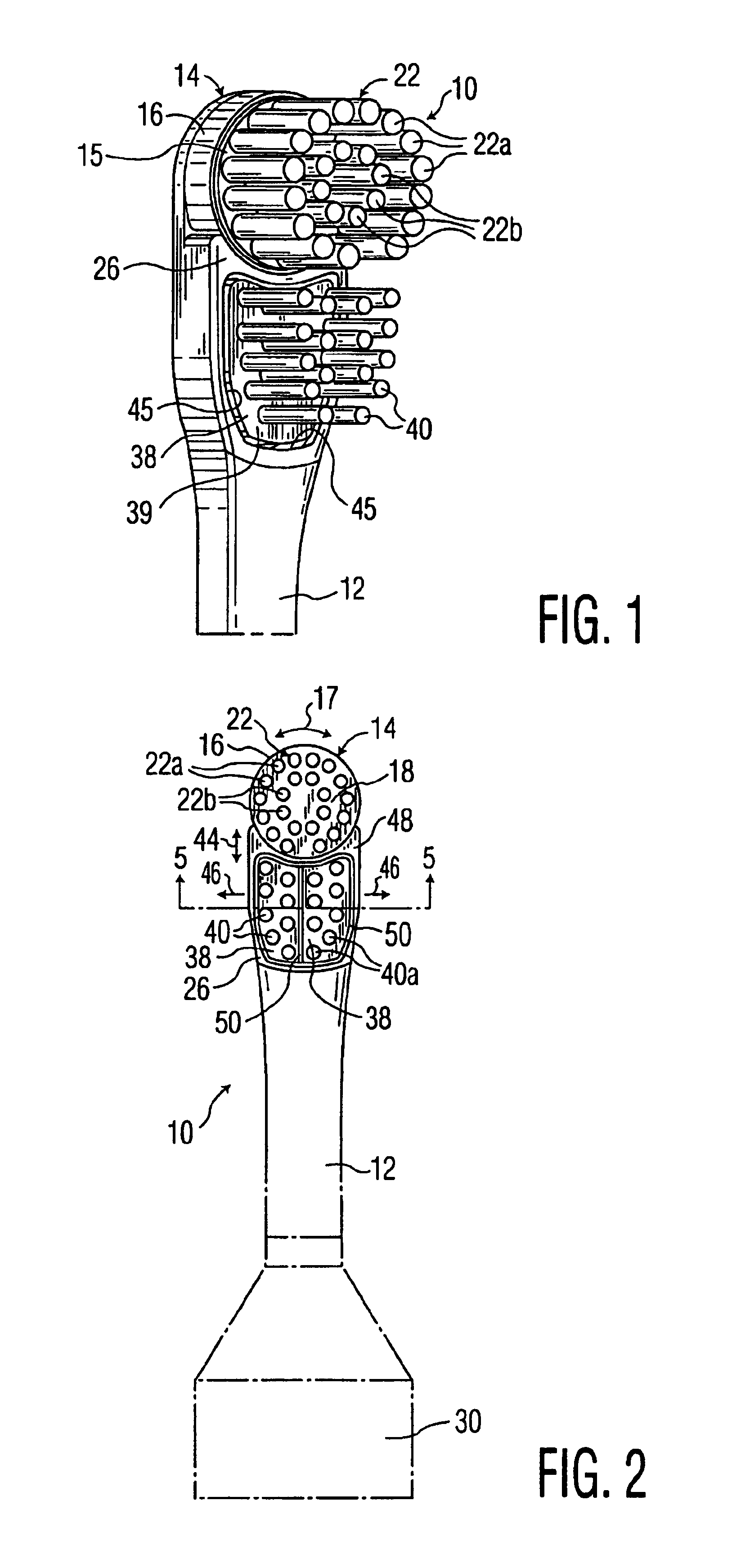

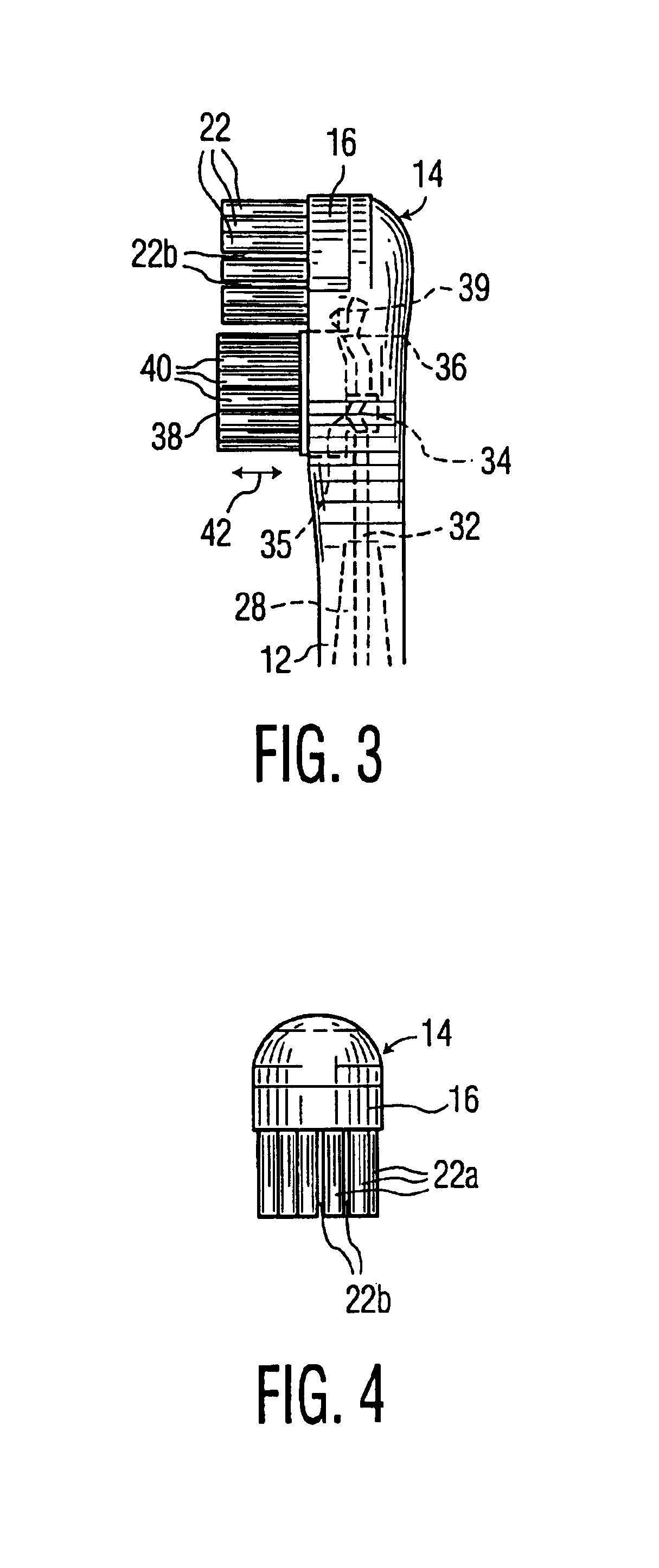

Powered toothbrush

InactiveUS6892412B2Improve cleaning efficiencyEasy to cleanCarpet cleanersKitchenware cleanersBristleMechanical engineering

The head of a powered toothbrush includes a first tuft block mounted for rotational oscillation about an axis generally perpendicular to the outer surface of the head, and a second tuft block having fixed bristles or bristles independently movable by being mounted on an elastomeric base. The second tuft block oscillates perpendicular to a longitudinal axis of the head and in an in and out direction perpendicular to the outer surface of the head. A third stationary block may also be mounted on the head of the powered toothbrush. The bristles on the first, second, and third tuft blocks may be of various lengths, colors and stiffness, and may be mounted perpendicularly to or at an angle to the outer surface of the head.

Owner:COLGATE PALMOLIVE CO

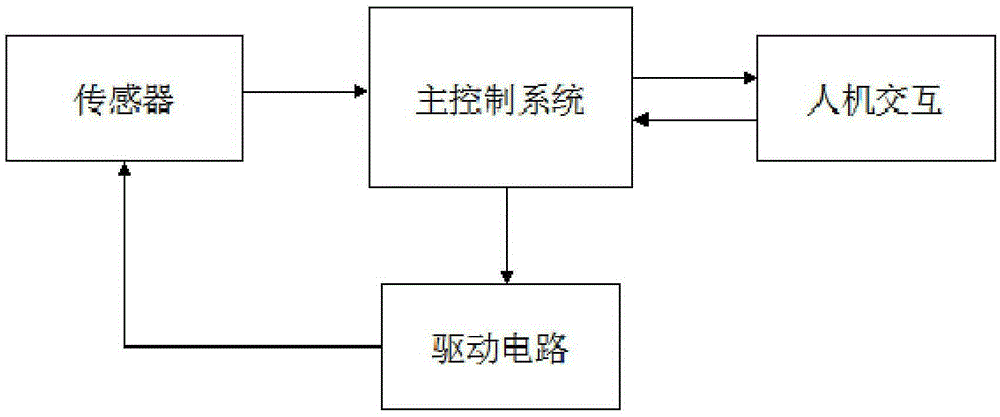

Intelligent cleaning robot based on advanced path programming technology and cleaning method thereof

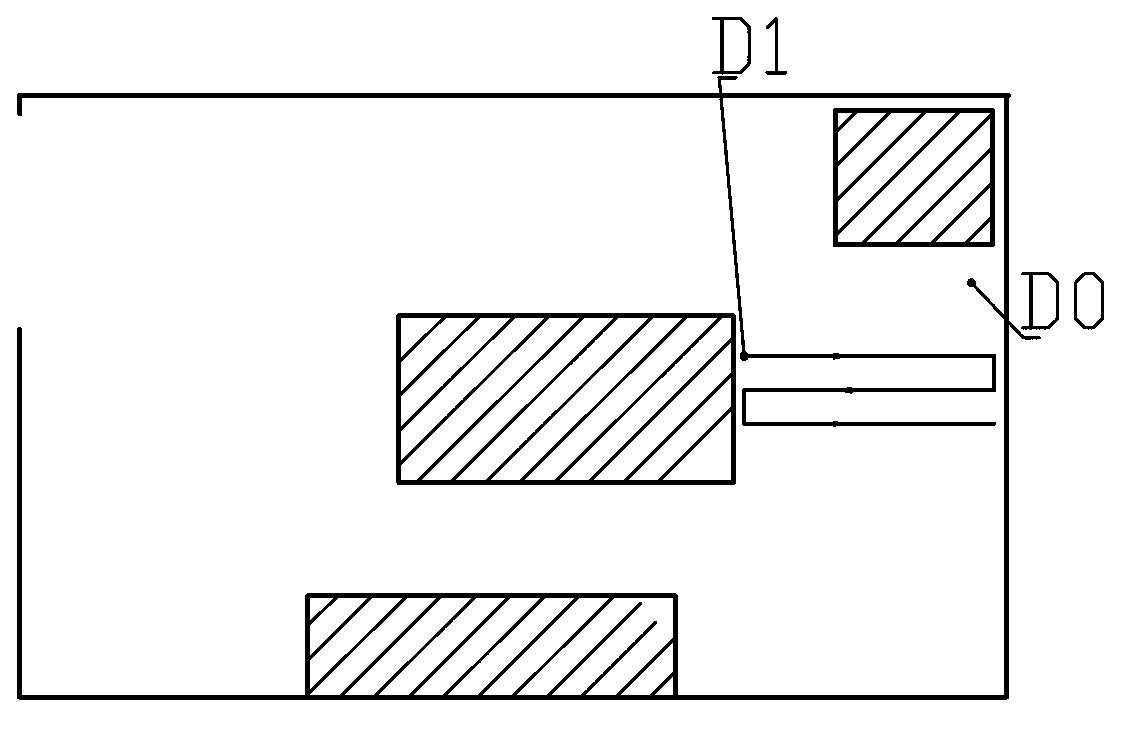

InactiveCN105425801ASave cleaning timeAchieve maximum coveragePosition/course control in two dimensionsMotor driveControl system

The invention relates to an intelligent cleaning robot based on an advanced path programming technology and a cleaning method thereof. An external environment information detection system installed on a robot body, a real-time positioning system, a main control system, a motor driving module and a power supply are included. The external environment information detection system is used for detecting external environment information. The real-time positioning system is used for acquiring a real-time position where the robot is located. The main control system is used for acquiring external environment information and establishing a grid map. Through combining the grid map and the real-time position, a cleaning path is programmed. The motor driving module is used for driving the robot to operate according to the programmed cleaning path and clean. The power supply is used for providing power for the main control system and the motor driving module. A path programming technology of boundary cleaning, rectangular manufacturing, parallel paving and cleaning and obstacle consideration is used to design the cleaning path, a current position is determined in real time, cleaning time is saved and simultaneously a largest coverage rate to an cleaning environment is realized.

Owner:CHANGAN UNIV

Robot cleaner and cleaning path planning method thereof

ActiveCN105320140ALow costPracticalPosition/course control in two dimensionsVehiclesPlanning methodTransport engineering

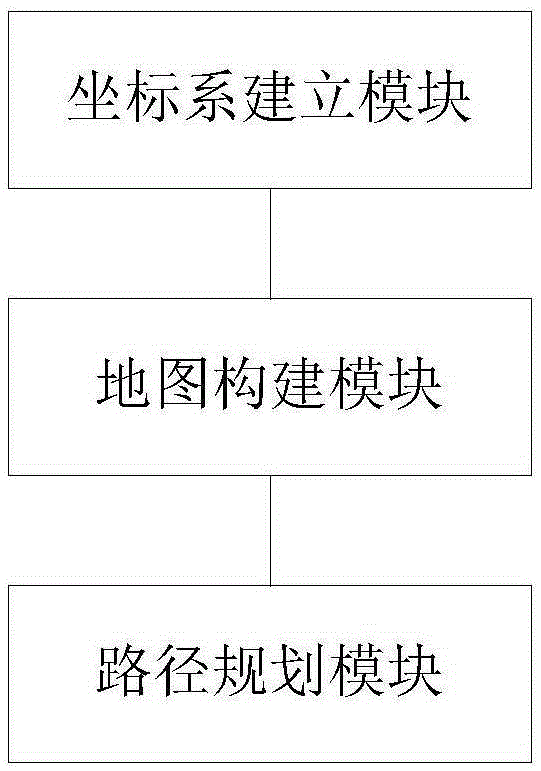

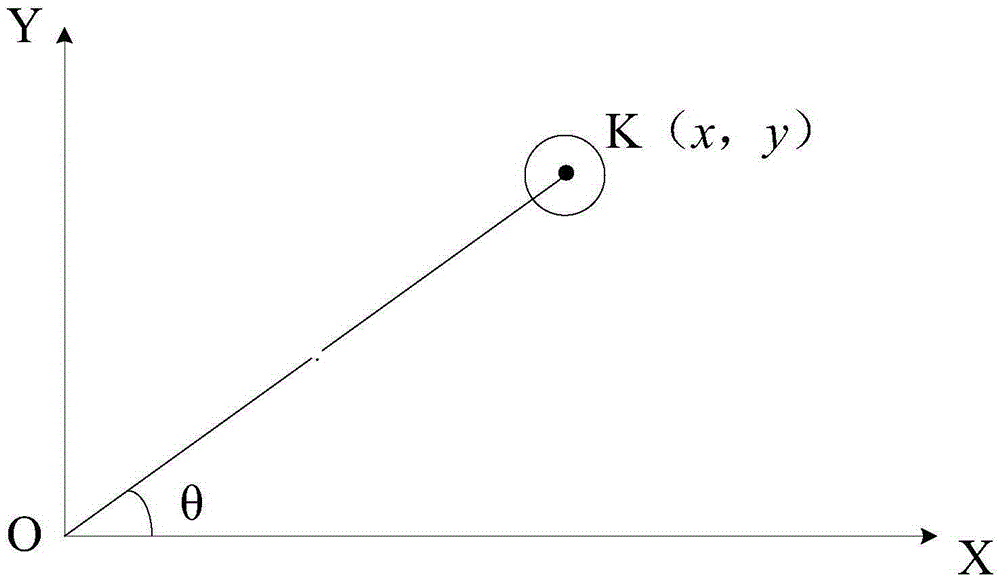

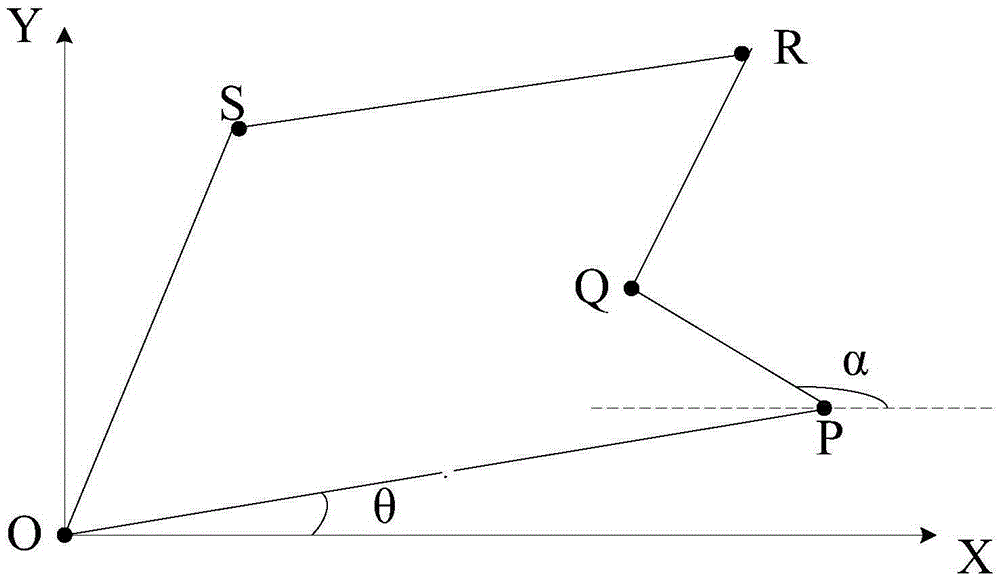

The invention discloses a robot cleaner and a cleaning path planning method thereof. The robot cleaner comprises a coordinate system establishing module, a map building module and a path planning module. The method comprises the steps of establishing a coordinate system by taking the corner point of a to-be-cleaned room found by the robot cleaner firstly as a reference system; building a map of the to-be-cleaned room according to the cleaning path of the robot cleaner, and recording the collision point, the corner point of the room and the peaks of barriers in the building process; and finally, planning the cleaning path according to the recorded collision point, the corner point of the room and the peaks of the barriers. The robot cleaner and the cleaning path planning method can well adapt to the unknown environment, the cleaning efficiency is improved, the cleaning area is increased, the cost is low, and the practicability is strong.

Owner:ZHEJIANG UNIVIEW TECH CO LTD

Stainless steel cleaning agent

InactiveCN101135056AImprove cleaning efficiencySimple cleaning processPhosphoric acidCleansing Agents

The stainless steel detergent for washing stainless steel product is prepared with acids, basic salts, surfactant, assistant, stabilizer and water, and through stirring and reaction at normal temperature. Specifically, it consists of sodium carbonate, sodium tripolyphosphate, tartaric acid, citric acid, hydrofluoric acid, nitric acid, phosphoric aicd, JFC, OP-10, triethanolamine, urotropin, trisodium phosphate, acetic acid, alcohol and water in certain weight proportion. It has the features of simple preparation process, environment friendship, high cleaning efficiency, low cleaning cost, etc.

Owner:吴铭鑫

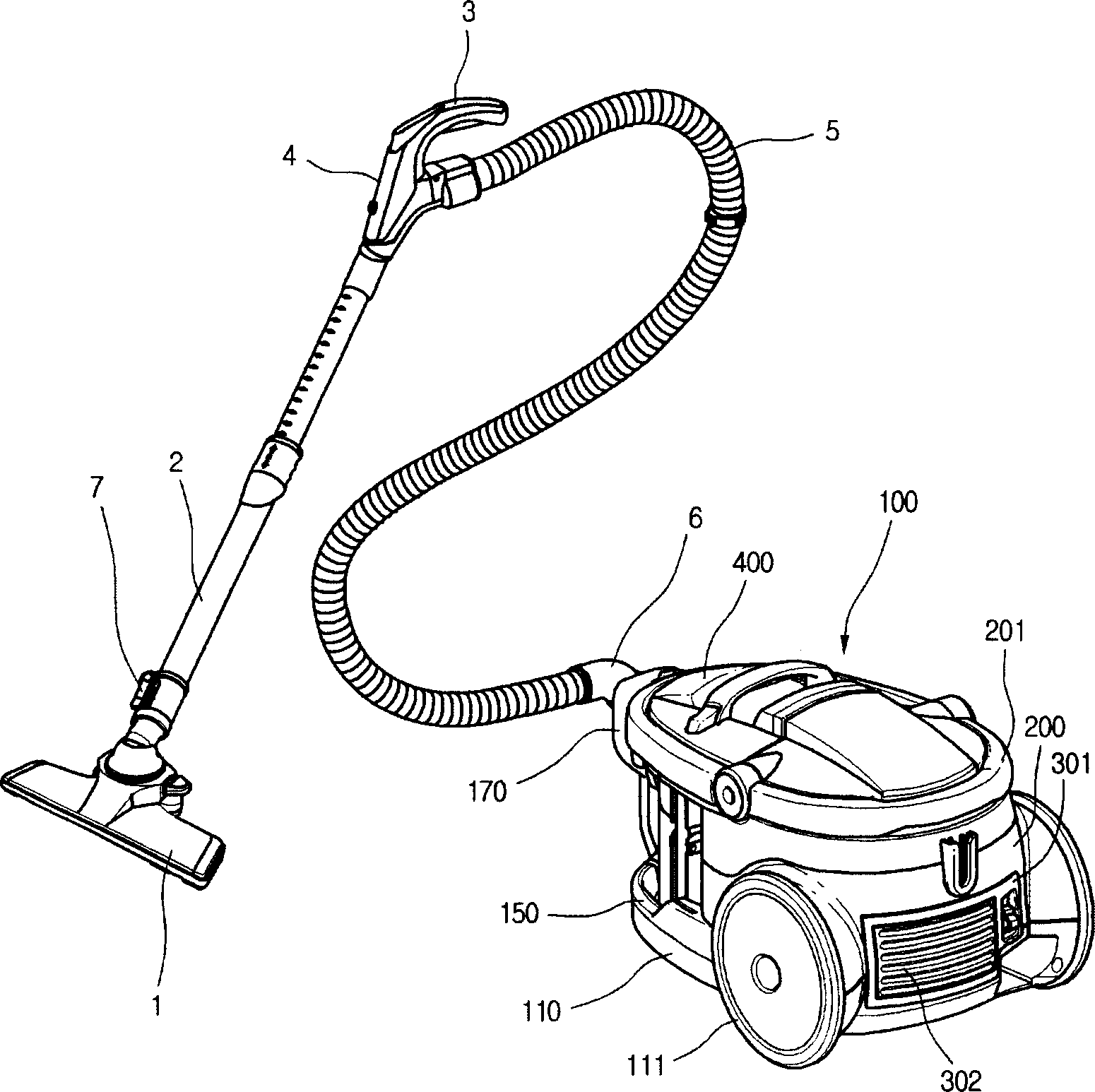

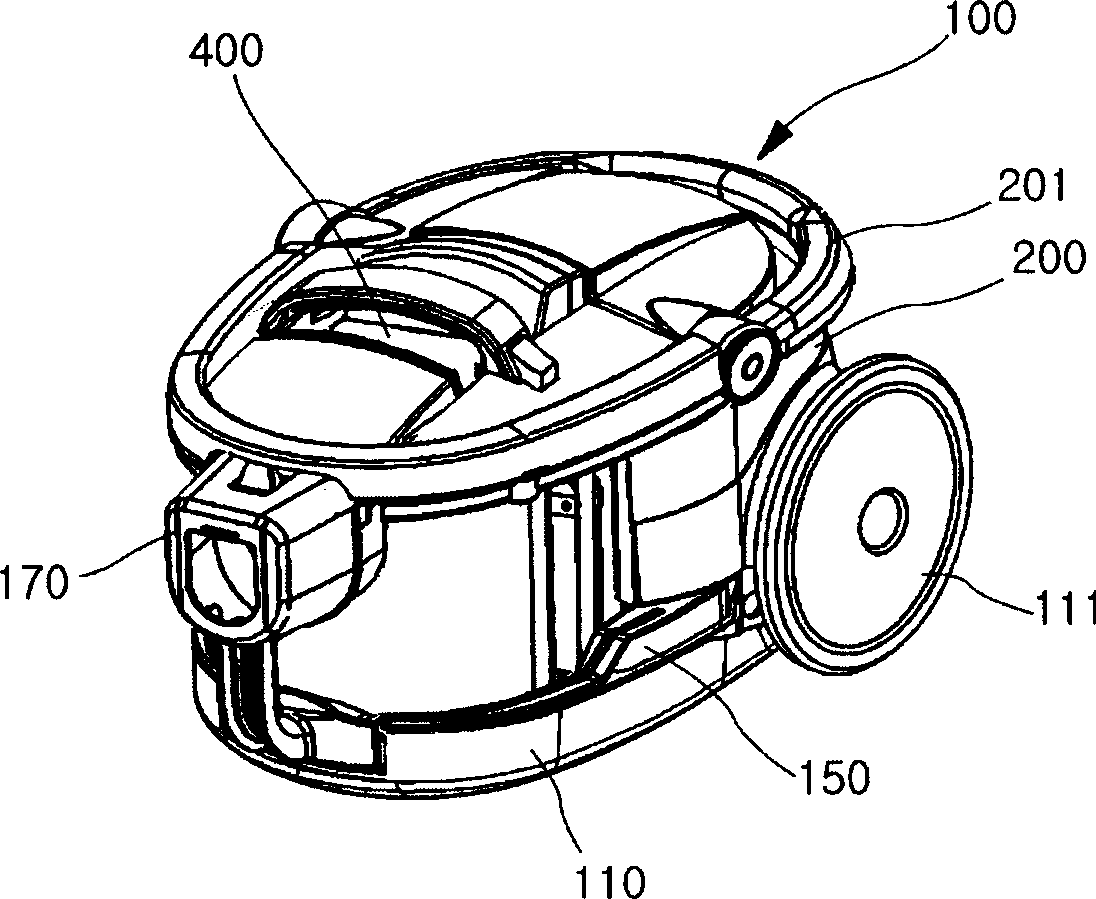

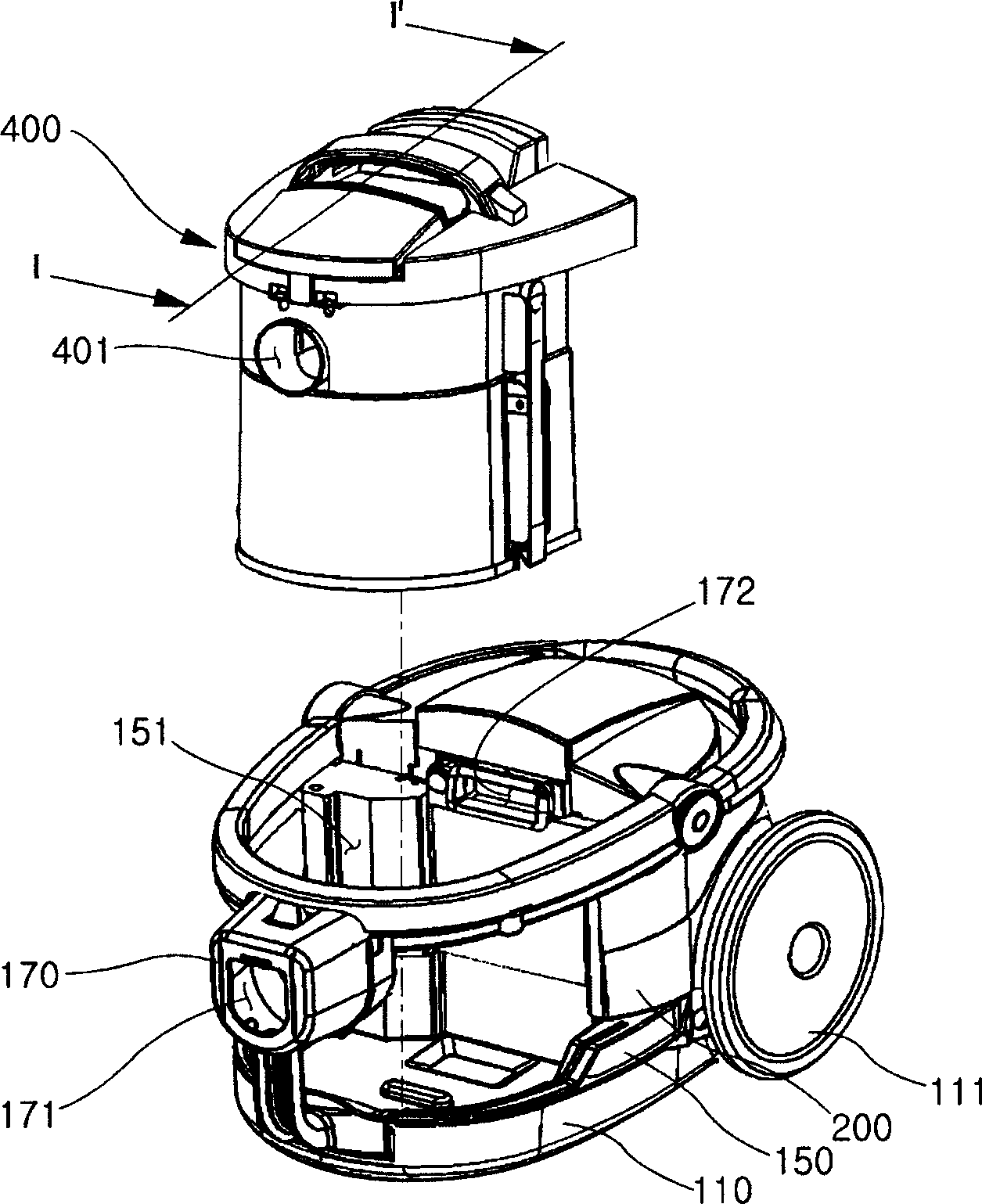

Channel structure of vacuum cleaner

InactiveCN1875855ADoes not affect operating efficiencyImprove cleaning efficiencySuction filtersEngineeringVacuum cleaner

The invention discloses a channel structure of vacuum cleaner, which comprises the following parts: dust collecting device of filtered air, motor rack to lead air of dust collecting device under motor exposing condition, bulk vent on the back of vacuum cleaner to discharge the air through motor. The invention improves the utility rate of vacuum cleaner, which reduces channel resistance.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

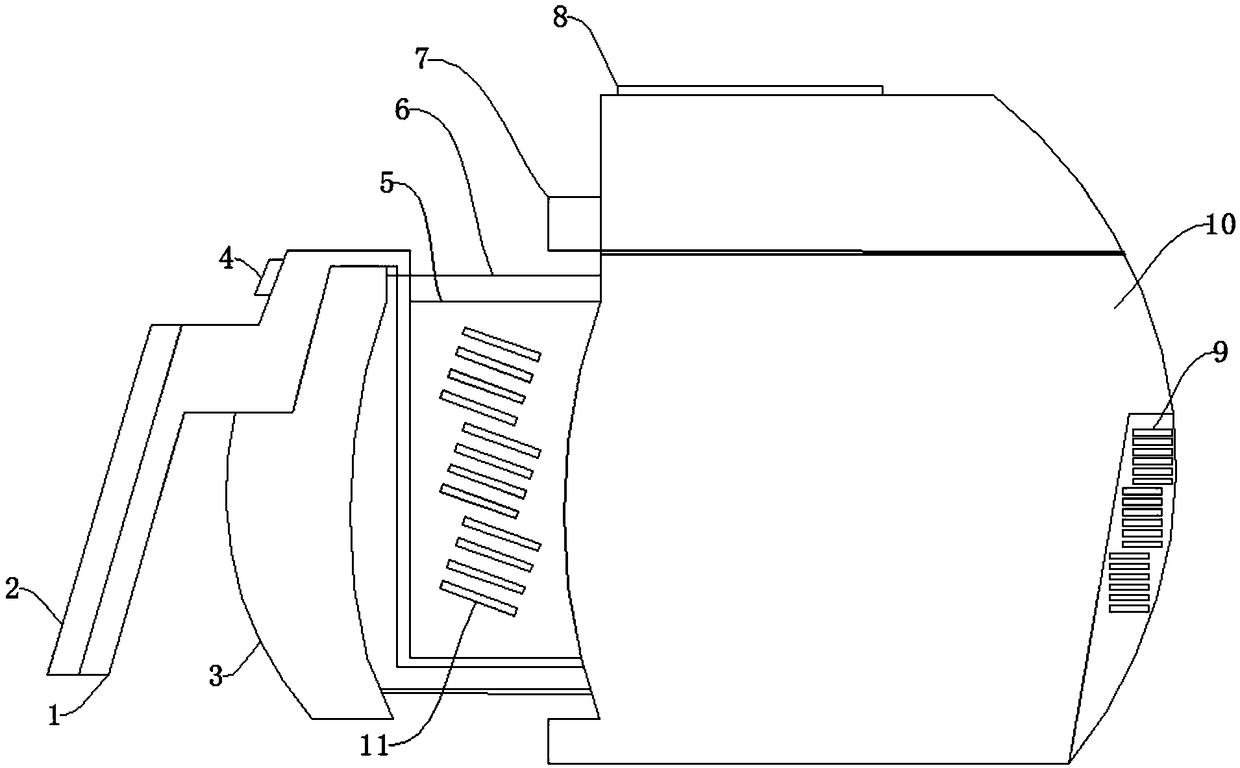

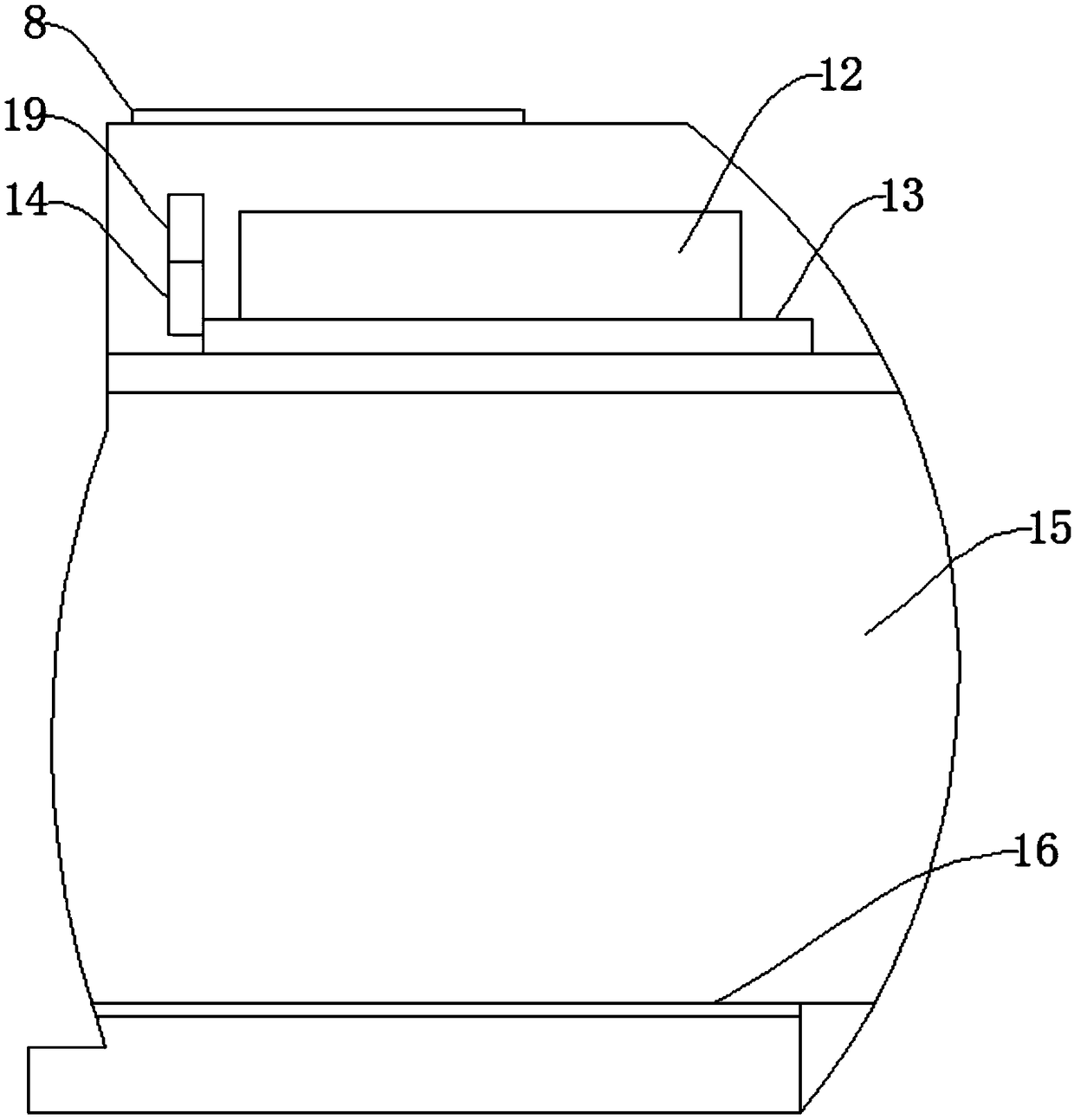

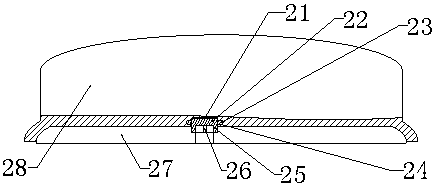

Air fryer with transparent visual window

InactiveCN108618651AObserve the frying situationGuaranteed frying qualityRoasters/grillsRemote controlEngineering

The invention discloses an air fryer with a transparent visual window. The air fryer comprises a fryer body, a handle and a transparent fryer shell, wherein the side, away from the transparent fryer shell, of the handle is provided with an anti-skid pad; a release key is arranged on the upper side of the handle. The air dryer has the advantages that through the arrangement of a transparent fryer body and the transparent fryer shell, the frying condition of food in a frying basket can be visually observed by an operator, and the frying quality of the food is guaranteed; due to the arrangement of a wireless connector, the operator can control the air fryer by being connected to a wireless network and a remote control terminal when away from the fryer body, and application is greatly facilitated; due to the arrangement of the release key, the separation step of the frying basket and the fryer is simplified, the operation is easy and convenient, and the cleaning efficiency of the frying basket is greatly improved.

Owner:郭鑫

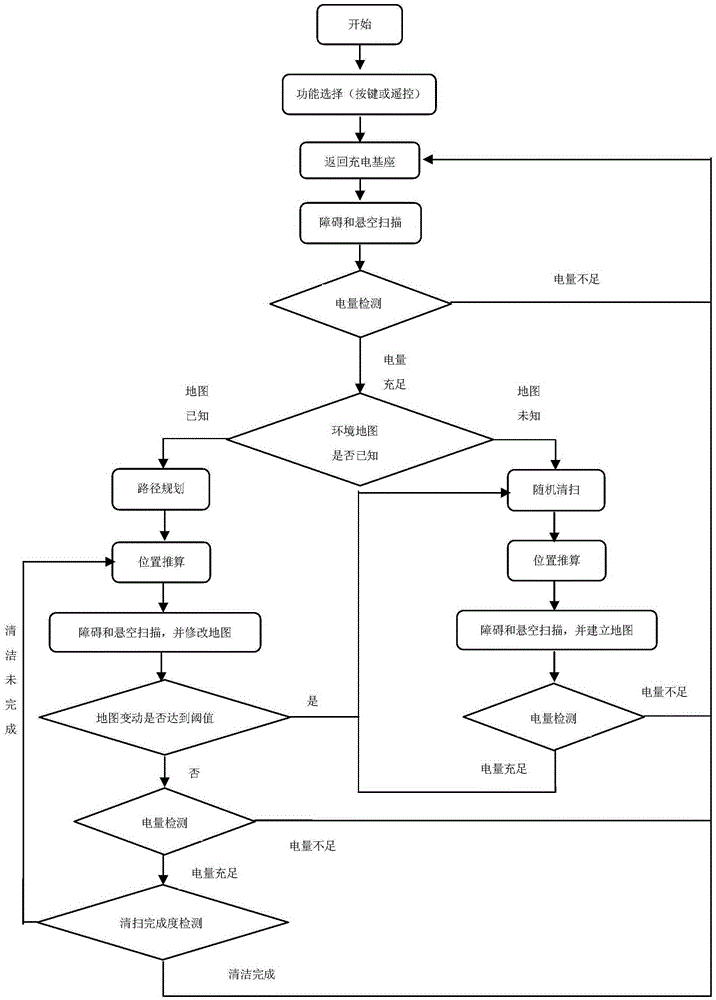

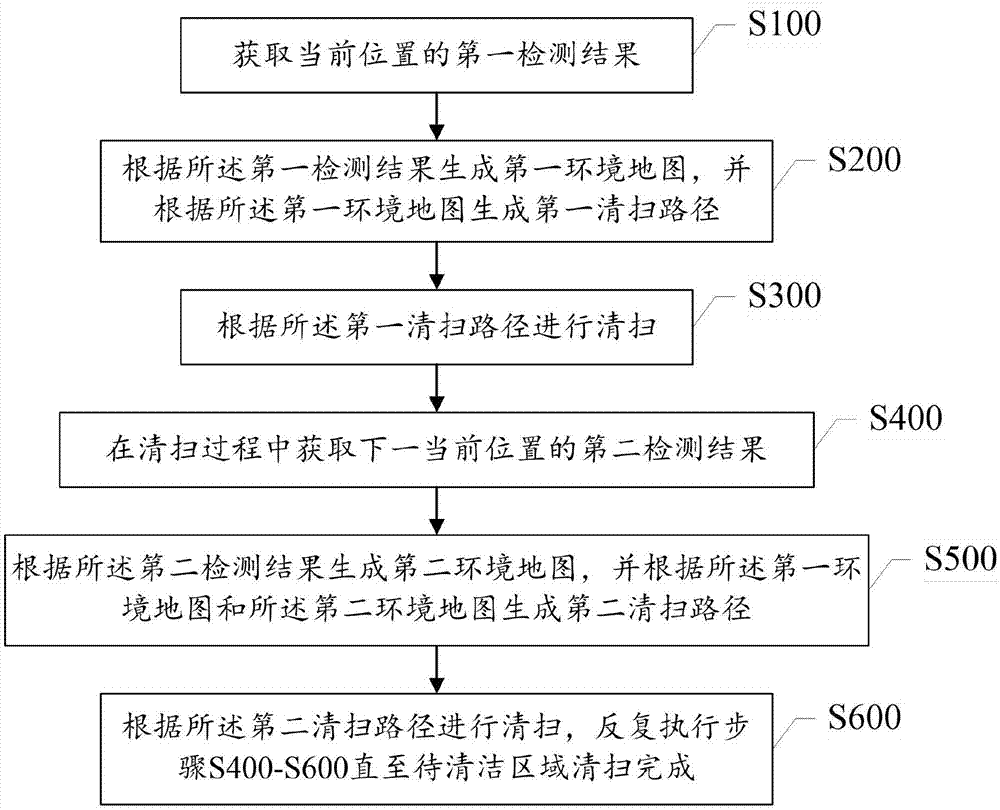

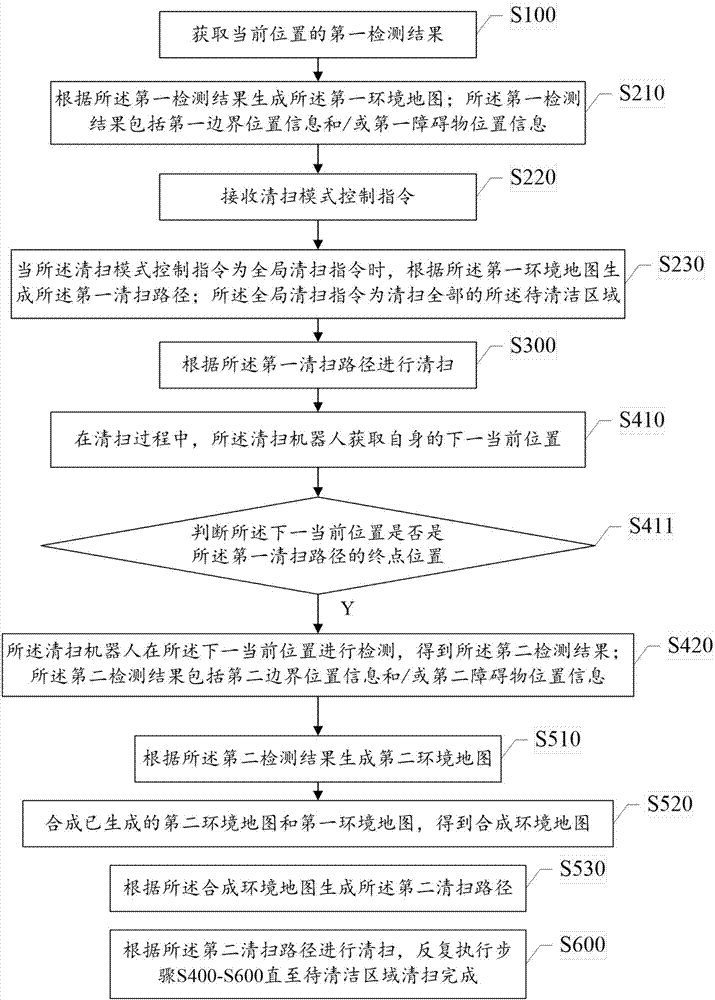

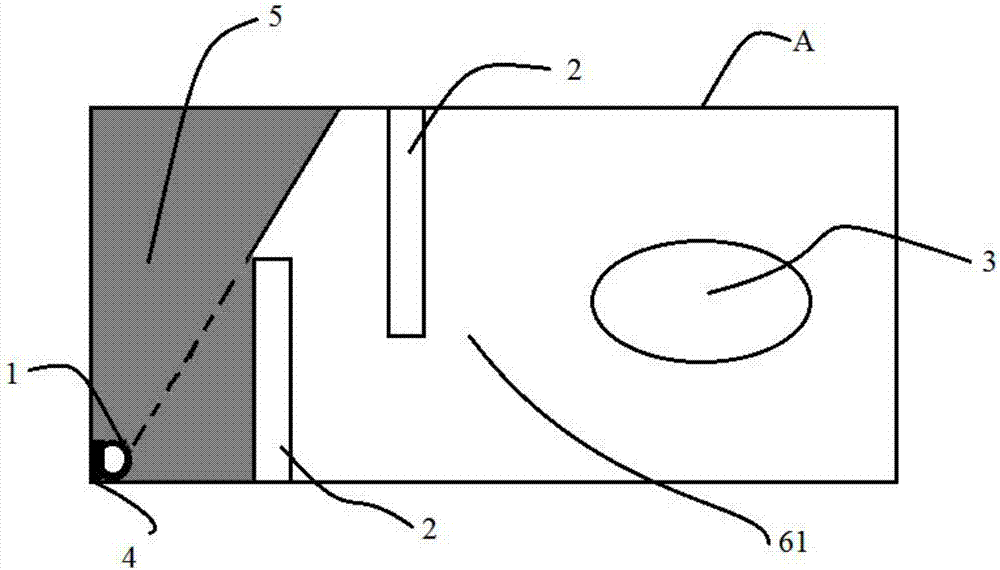

Planning method of cleaning robot cleaning route and cleaning robot

InactiveCN107328419AImprove cleanlinessShorten movement timeNavigational calculation instrumentsFloor sweeping machinesEngineeringPlanning method

The invention provides a planning method of a cleaning robot cleaning route and a cleaning robot. The planning method comprises the steps as follows: S100, a first detection result of a current location is acquired; S200, a first environment map is generated according to the first detection result, and a first cleaning route is generated according to the first environment map; S300, the cleaning robot performs cleaning according to the first cleaning route; S400, a second detection result of a next current position is acquired in a cleaning process; S500, a second environment map is generated according to the second detection result, and a second cleaning route is generated according to the first environment map and the second environment map; S600, cleaning is performed according to the second cleaning route, and the steps S400-S600 are executed repeatedly until cleaning of a to-be-cleaned area is completed. According to the planning method and the cleaning robot, cleaning and detecting are executed simultaneously by the cleaning robot, the cleaning route is updated in real time, cleaning efficiency is improved, and resources are saved.

Owner:台州市吉吉知识产权运营有限公司

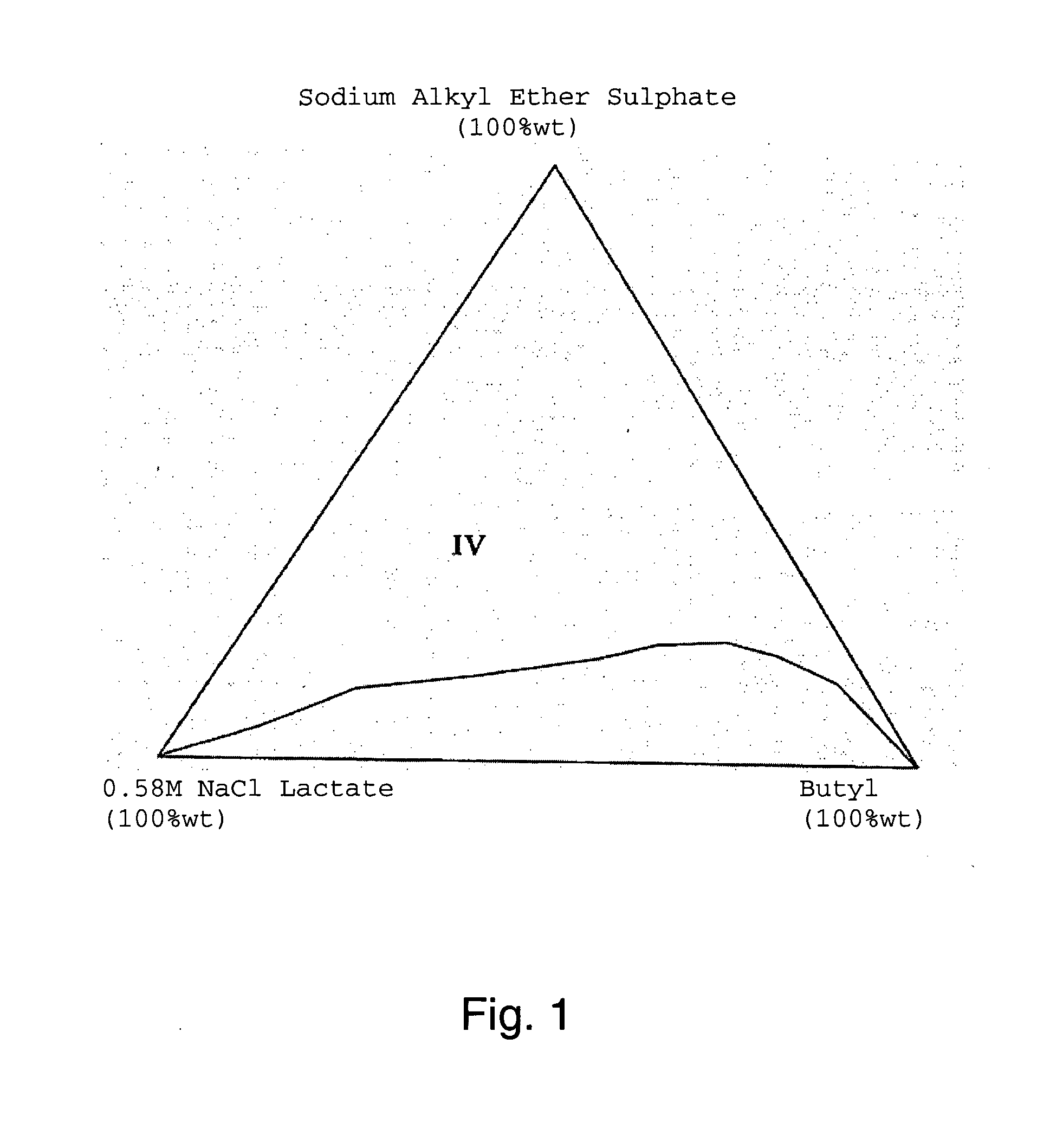

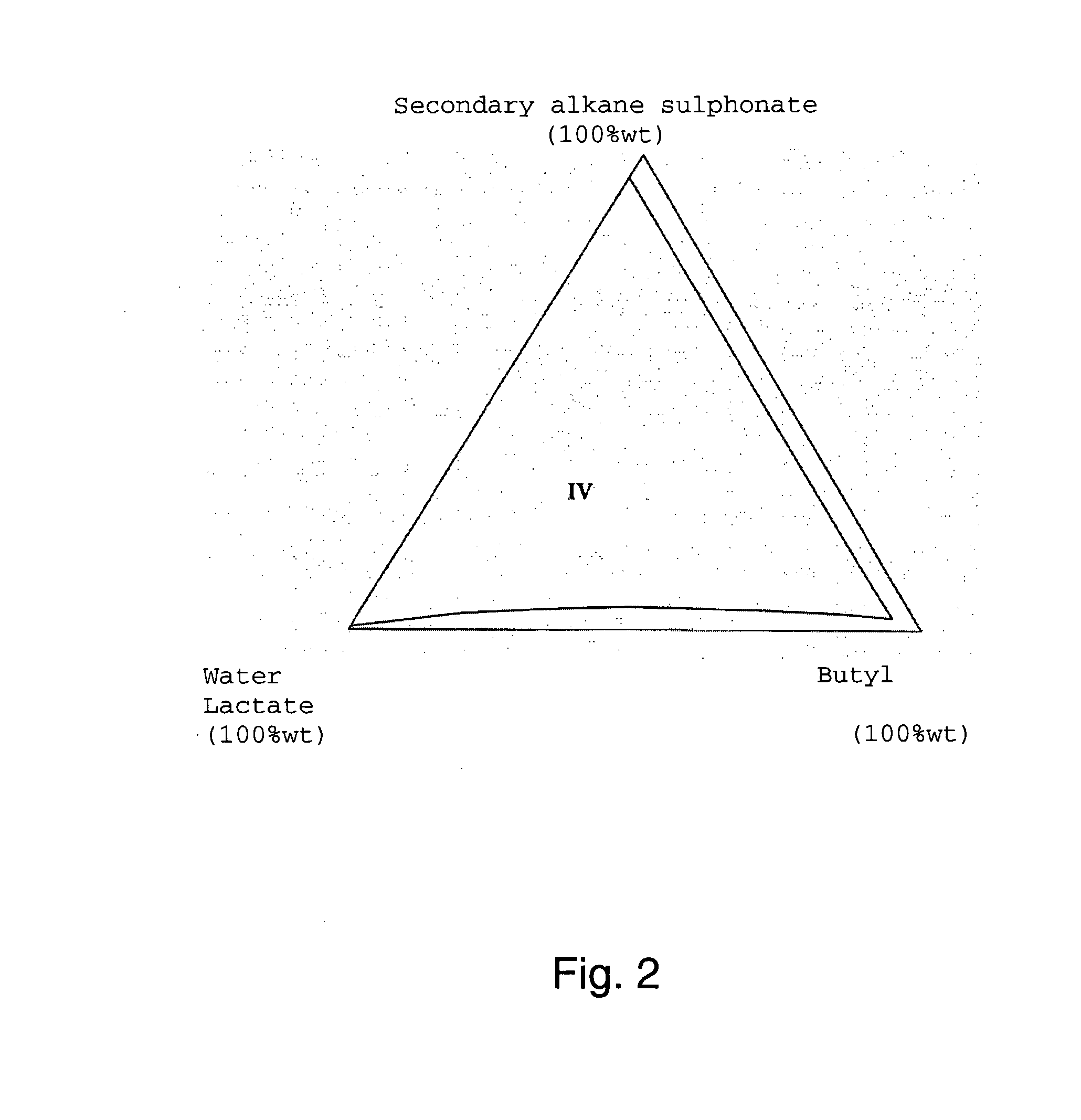

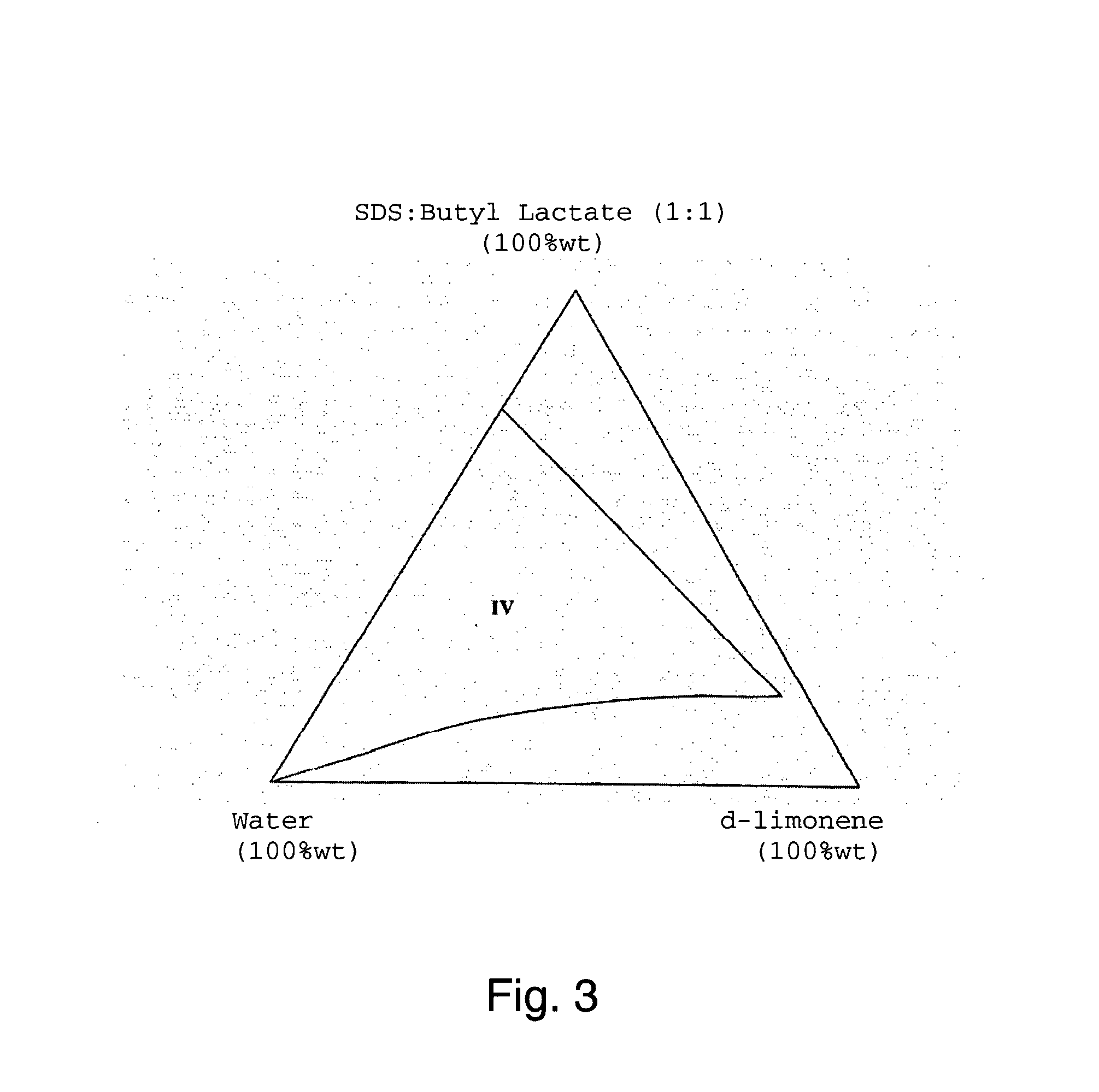

Surfactant System Method

InactiveUS20070295368A1Improve cleaning efficiencyAvoid damageInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater basedSurface cleaning

The invention relates to the formulation and application of water based predominantly pH neutral microemulsions and microemulsion forming surfactant systems essentially comprising a surfactant or surfactant˜end, lactates)—esters) of lactic acid—and water / brine and optionally solvent. Uniquely the formulations are acid and caustic free and also do not make use of alcohol, glycol and glycol ether components in the systems as co surfactant, co-solvent or mutual solvent. In particular the invention relates to the methods and the application of this microemulsion technology for use in industrial hard surface cleaning applications especially the inks and printing industries and the oil and gas industry. In addition the formulations can be used in the production of microemulsion based drilling muds (which may or may not be Oil Based Muds—OBMs) and they may be used to enhance the drill cuttings slurrification processes for re-injection purposes or for facilitated cuttings transport.

Owner:SURFACTANT TECH +1

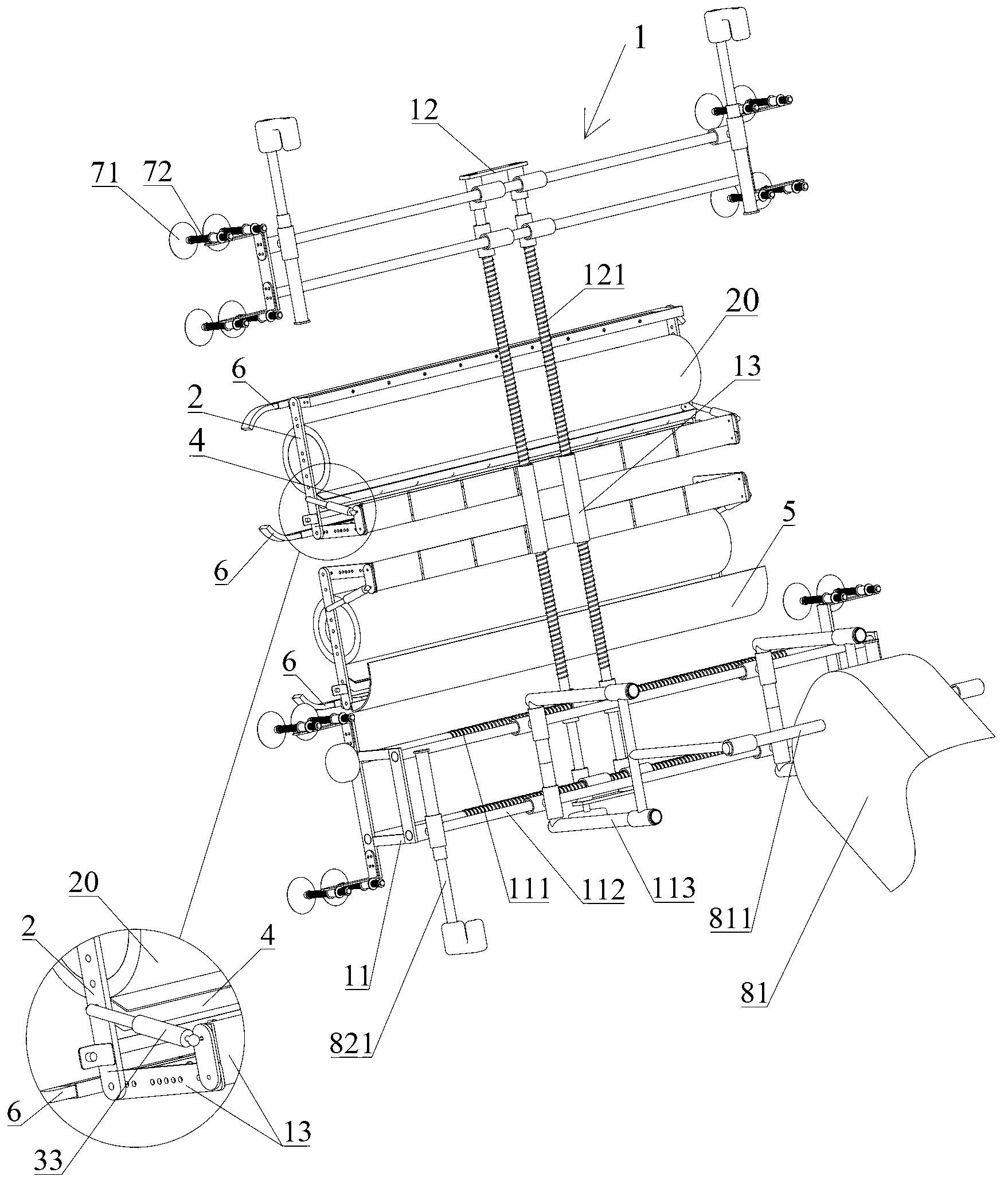

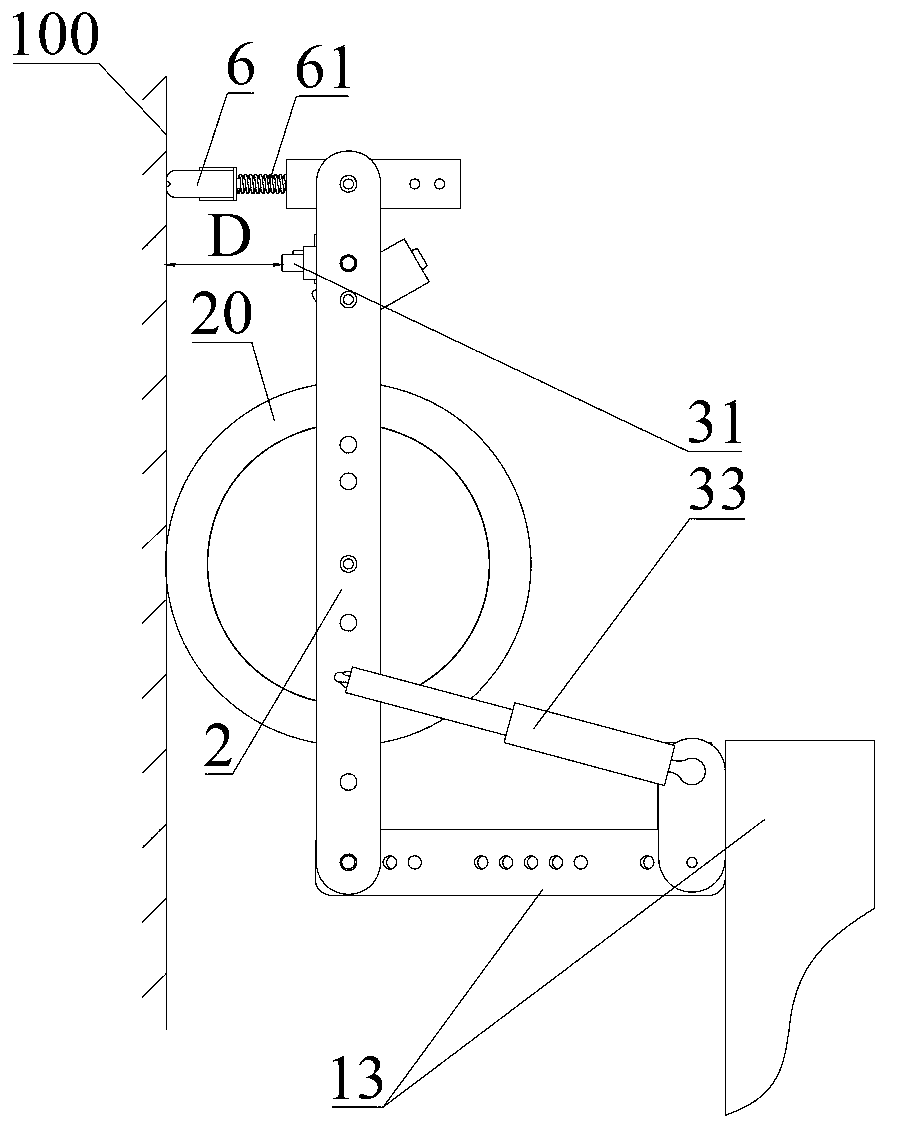

Outer wall cleaning machine

The invention provides an outer wall cleaning machine which comprises a rack and a cleaning brush device arranged on the rack. The cleaning brush device comprises a first support with a cleaning brush, a first distance detecting unit, a first control unit and a first driving mechanism, wherein the first support is movably connected with the rack, the first distance detecting unit is used for measuring the first distance between the first distance detecting unit and a cleaning face, the first control unit is used for controlling the first driving mechanism according to the first distance, and the first driving mechanism is used for driving the first support to carrying out motion. The outer wall cleaning machine can clean a flat cleaning face and a flat cleaning face with protrusions safely and efficiently.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

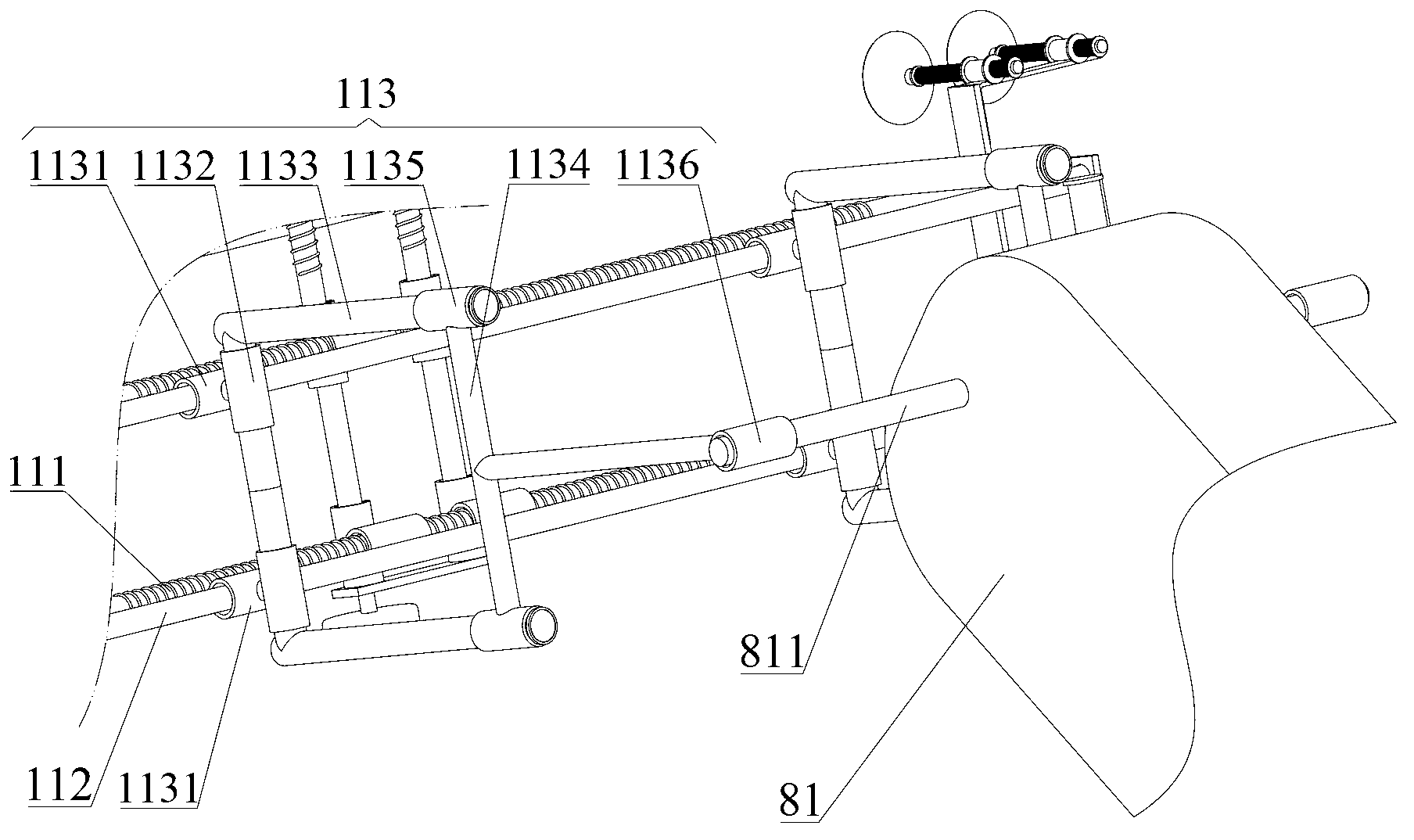

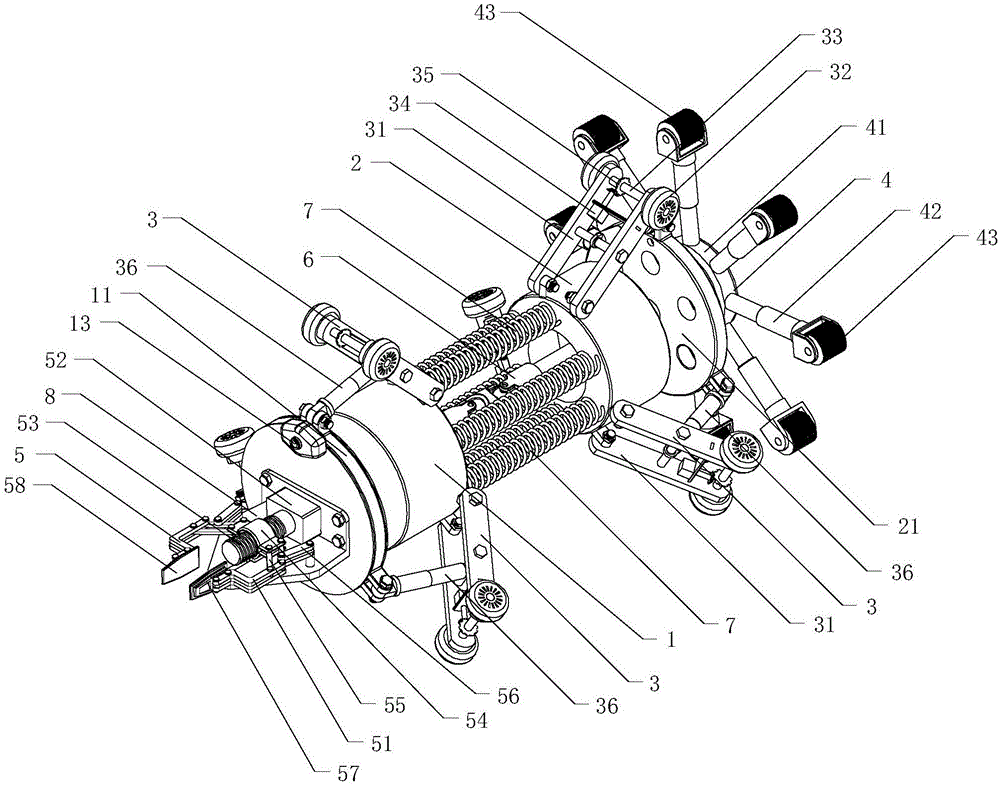

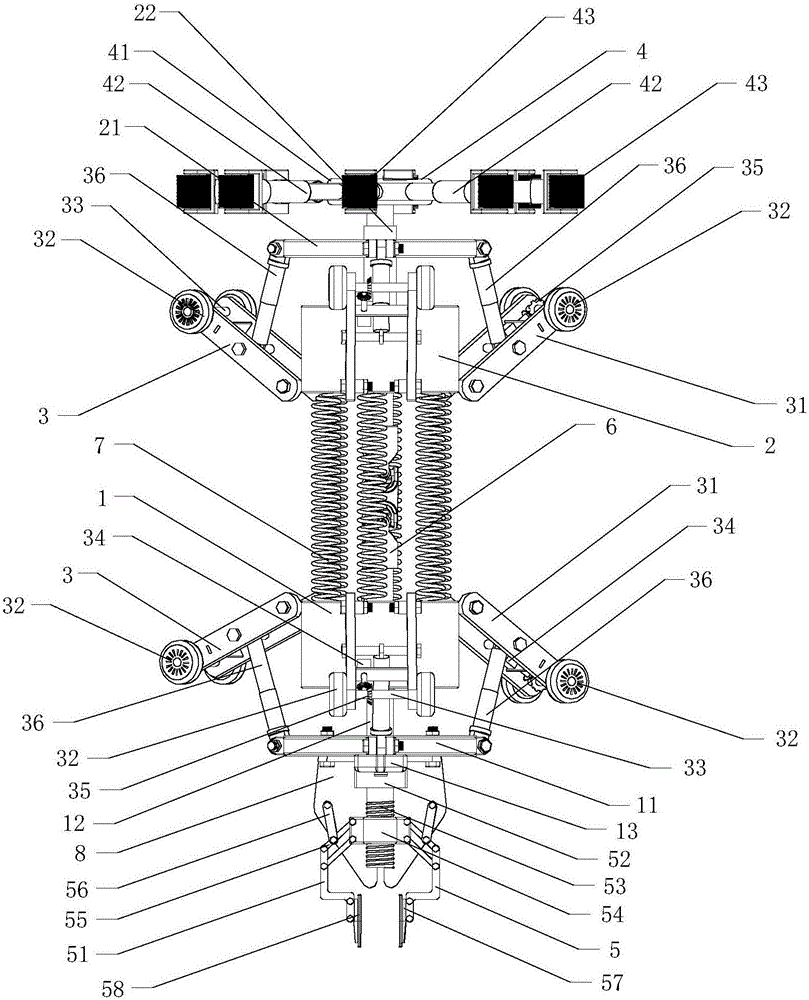

Novel telescopic pipeline cleaning robot

ActiveCN106623296AImprove working environmentEliminate sanitary cornersHollow article cleaningCouplingEngineering

The invention discloses a novel telescopic pipeline cleaning robot which comprises a first body, a second body, two traveling mechanisms, a cleaning device and a mechanical arm. The first body and the second body are arranged in the front-back direction and connected through a double-joint universal coupler. The traveling mechanisms are arranged on the outer side of the first body and the outer side of the second body correspondingly. The cleaning device is arranged on the rear side of the second body and comprises a cleaning disc and a plurality of telescopic rods. The cleaning disc is connected with a first motor arranged inside the second body. The multiple telescopic rods are evenly arranged on the edge of the cleaning disc in an annular mode. One end of each telescopic rod is fixedly connected with the cleaning disc, and a cleaning wheel is arranged at the other end of each telescopic rod. A bracket is arranged on the front side of the first body, and the mechanical arm is installed on the bracket. When the novel telescopic pipeline cleaning robot is used for cleaning different pipelines, the inner walls of the pipelines with different diameters and curvature degrees can be cleaned by adjusting the lengths of the telescopic rods, the novel telescopic pipeline cleaning robot is suitable for variable-diameter pipelines of complex structures, the adaptability is high, and the cleaning efficiency is high.

Owner:SHANDONG UNIV OF SCI & TECH

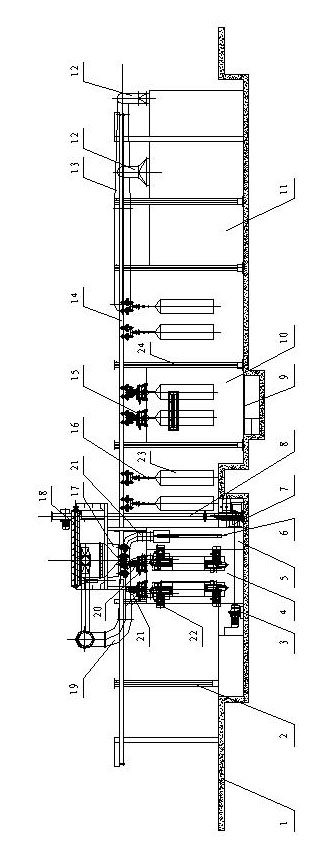

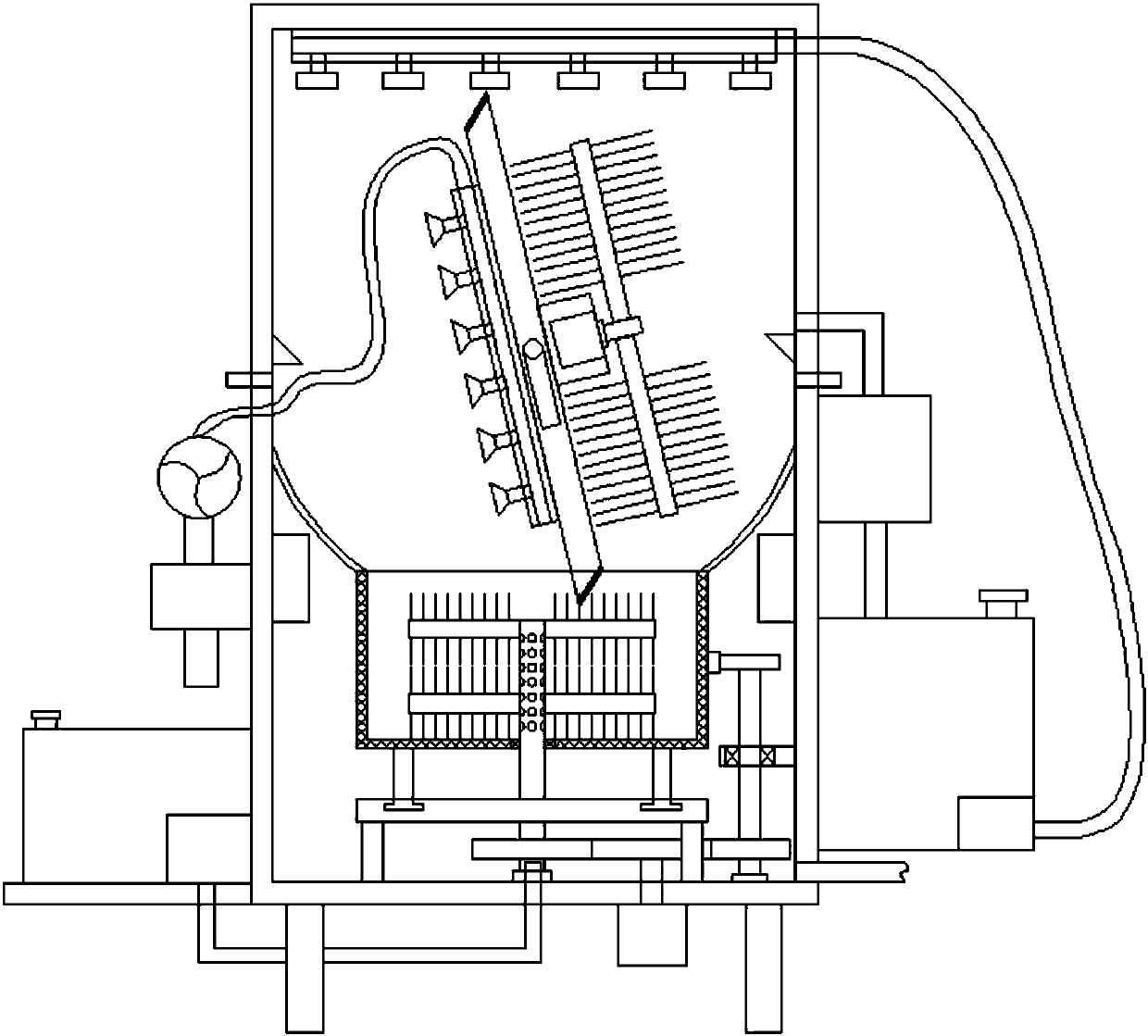

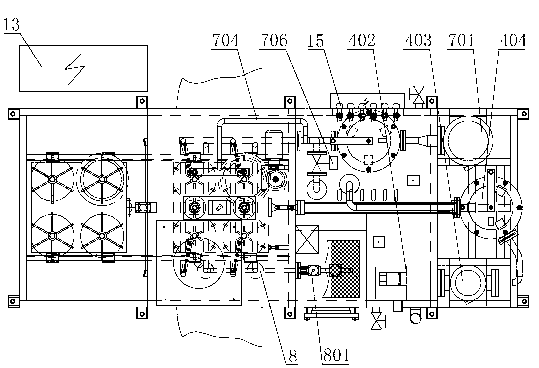

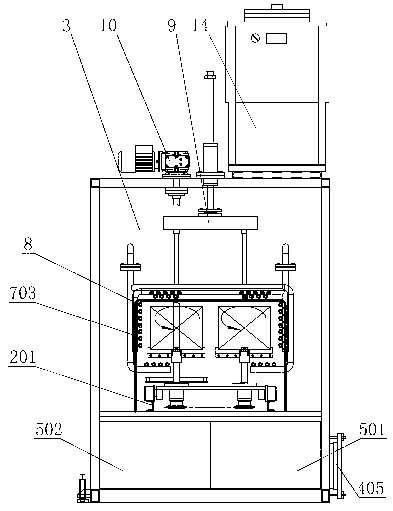

Hydraulic cylinder surface shot blasting, paint spraying and drying system and shot blasting, paint spraying and drying process thereof

InactiveCN101972726AIncrease productivityImprove cleanlinessSpraying apparatusPretreated surfacesHydraulic cylinderLacquer

The invention relates to a hydraulic cylinder surface shot blasting, paint spraying and drying system and a shot blasting, paint spraying and drying process thereof, and the hydraulic cylinder surface shot blasting, paint spraying and drying system consists of a hanging chain conveying system, a shot blasting working position, a paint spraying working position, a drying working position, an overhauling working position, an unloading working position, a loading working position, a paint mixing room, an air compressor and an operating room. The shot blasting, paint spraying and drying process comprises the following process steps: loading of a piece, shot blasting, derusting and cleaning (10-15min), automatic paint spraying (3-5min), paint refinishing, leveling (5min), drying at 60-80 DEG C (30min), natural cooling and unloading of the piece. The hydraulic cylinder surface shot blasting, paint spraying and drying system has the advantages of high degree of mechanical and electrical automation, small occupied area, good safety performance, and high production efficiency, is not affected by weather and can ensure the cleanliness, the temperature, the illumination and the safety and sanitation standard required by the paint spraying environment; and the shot blasting, paint spraying and drying process is simple, safe, time-saving, environment-friendly and high in working efficiency and can obtain the good appearance quality of a paint film.

Owner:中煤邯郸煤矿机械有限责任公司

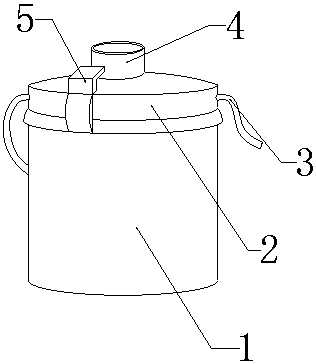

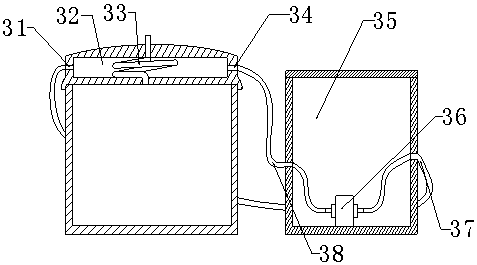

Cooker cover and electric pressure cooker

InactiveCN107550258AImprove cleaning efficiencyReduce labor intensityPressure-cookersCookerEngineering

The invention provides a pot cover and an electric pressure cooker, including a rotating shaft, a limit groove, a cross groove, a cross connecting column, a cleaning brush, a pot cover body, a cavity, a coil tube, a box body, a column and a liquid return frame. The cross groove is provided with On the lower end face of the rotating shaft, the upper end of the cross connecting column is assembled inside the cross groove, the cleaning brush is fixed on the annular side surface of the cross connecting column, and the cleaning brush is assembled inside the pot cover. This design is convenient for the cleaning of the pot cover in the present invention. The upper end of the inner wall of the lid, the coil is arranged inside the cavity, and the upper end of the coil passes through the lid and extends to the upper side of the lid. This design is convenient for the utilization of high-temperature steam. The box body is assembled on the annular side of the upper end of the coil. The upright column is fixed on the lower end face of the box body, the liquid return frame is fixed on the upper end face of the upright column, and the liquid return frame is arranged on the upper side of the coil. high.

Owner:柴永朋

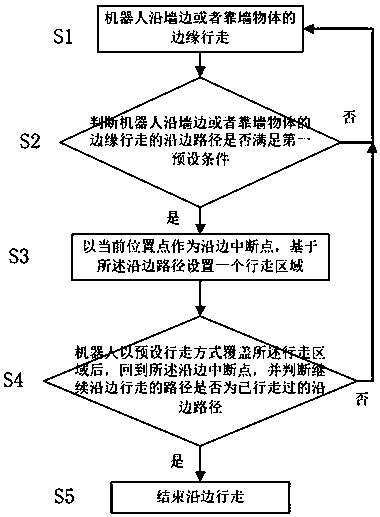

Control method for autonomous mobile robot walking along edge

ActiveCN108196555AClean thoroughlyAvoid cleaningAutomatic obstacle detectionAutonomous decision making processEngineeringAlong edge

The invention relates to a control method for an autonomous mobile robot walking along an edge. The robot walks along the edge of a wall or an object against the wall, plans a corresponding walking area according to a path for walking along the edge, and walks over the walking area. Through the method of walking along the edge, the walking area is planned and covered. The problem of loss sweepingor repeated cleaning is effectively avoided. The cleaning efficiency in an open environment is improved. The cleaning robot can easily find the entrance and exit of a room. Each room is completely cleaned. The cleaning efficient is high.

Owner:ZHUHAI AMICRO ROBOTICS CO LTD +1

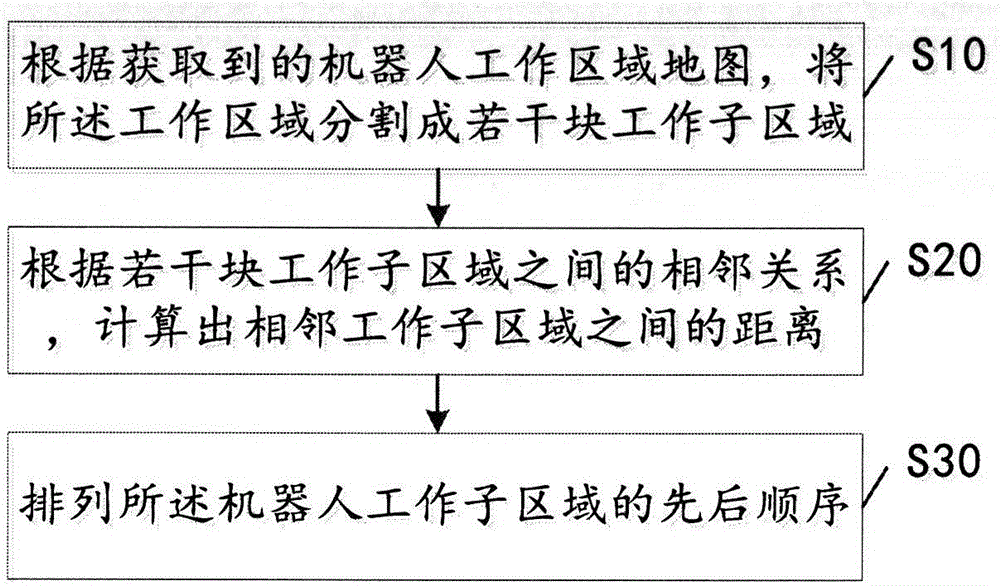

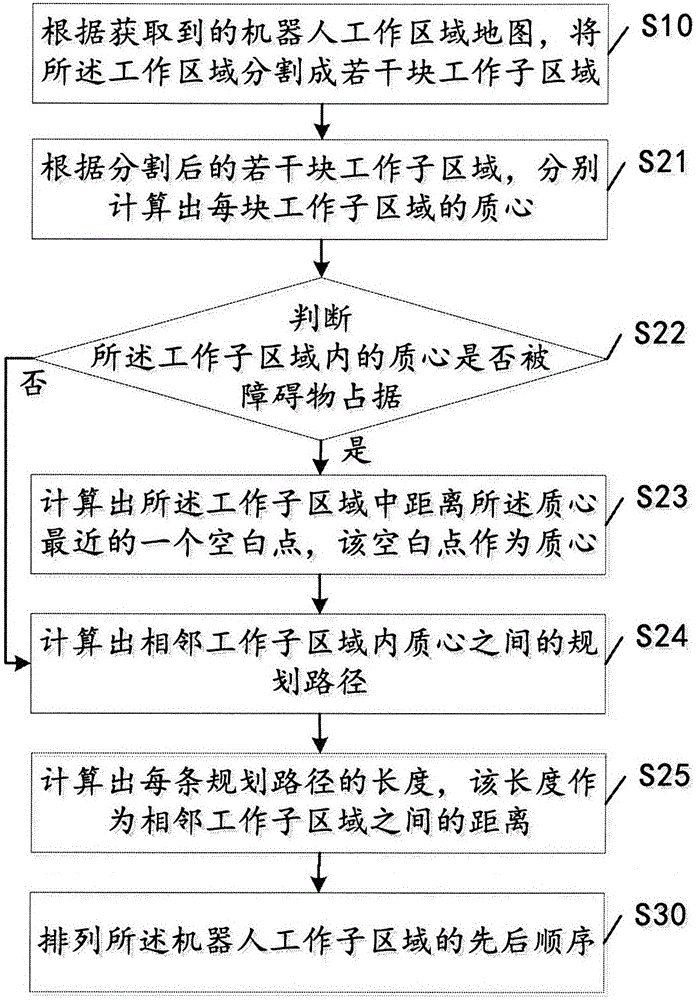

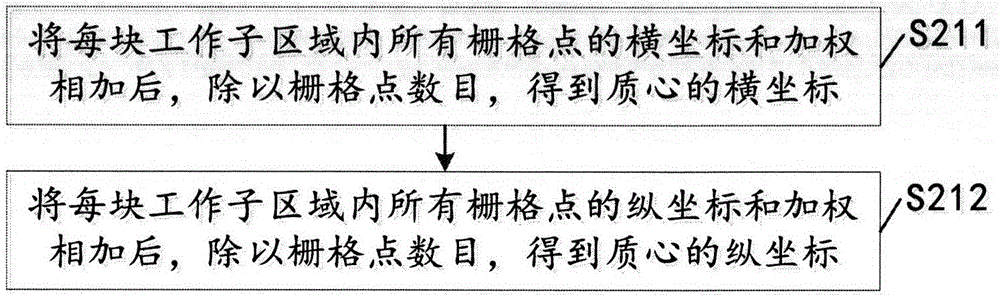

Working area ranking method and ranking system for robot

ActiveCN105739504AImprove cleaning efficiencyStrong stabilityPosition/course control in two dimensionsVehiclesComputer scienceRobot workspace

The invention provides a working area ranking method and ranking system for a robot. The method includes the steps of S10 dividing the working area into a plurality of working sub-areas according to a working area map of the robot, S20 calculating distances between adjacent working areas according to the adjacent relationship among the working sub-areas, and S30 ranking the working sub-areas according to the current working sub-area of the robot, the adjacent relationship among the working sub-areas and the distance between the adjacent working areas. The working area is segmented before cleaning to obtain a plurality of working sub-areas, each of which is regularly shaped. Ranking of the working sub-areas is facilitated, and planning a cleaning path for each working sub-area is more convenient, so that total path of the robot travels in the working sub-areas is the shortest. The cleaning efficiency of a sweep robot is improved.

Owner:平邑经济开发区投资发展有限公司

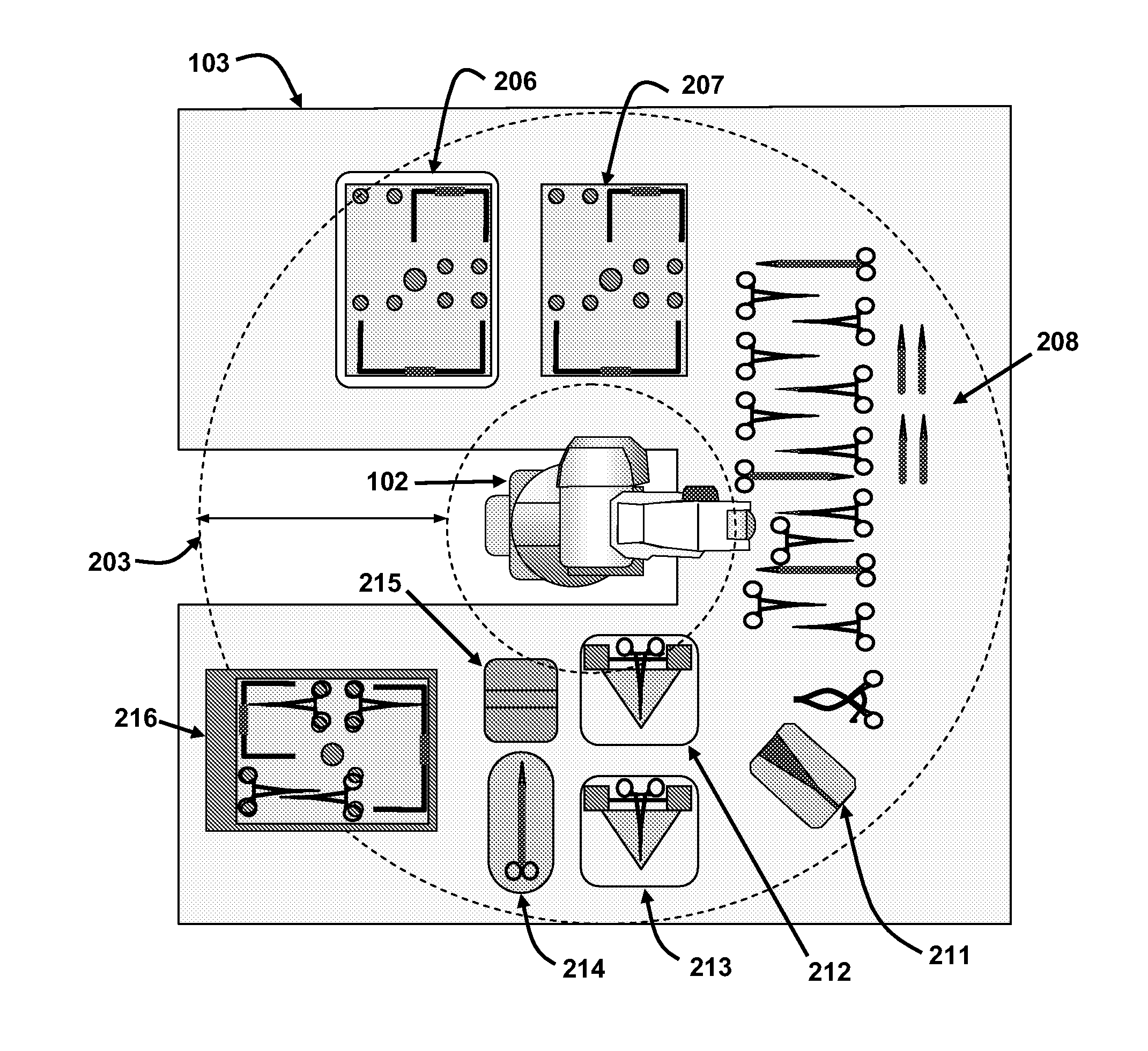

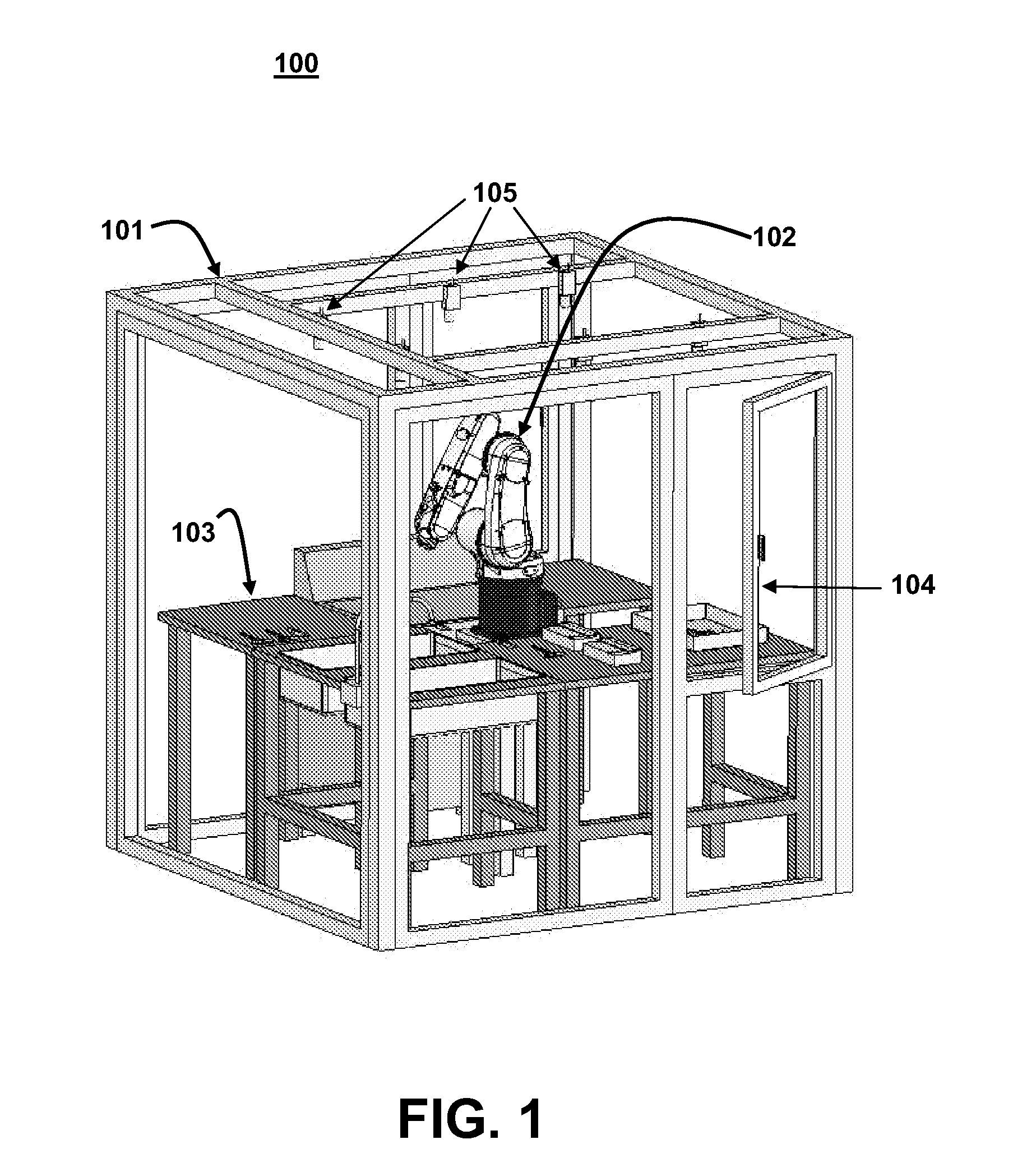

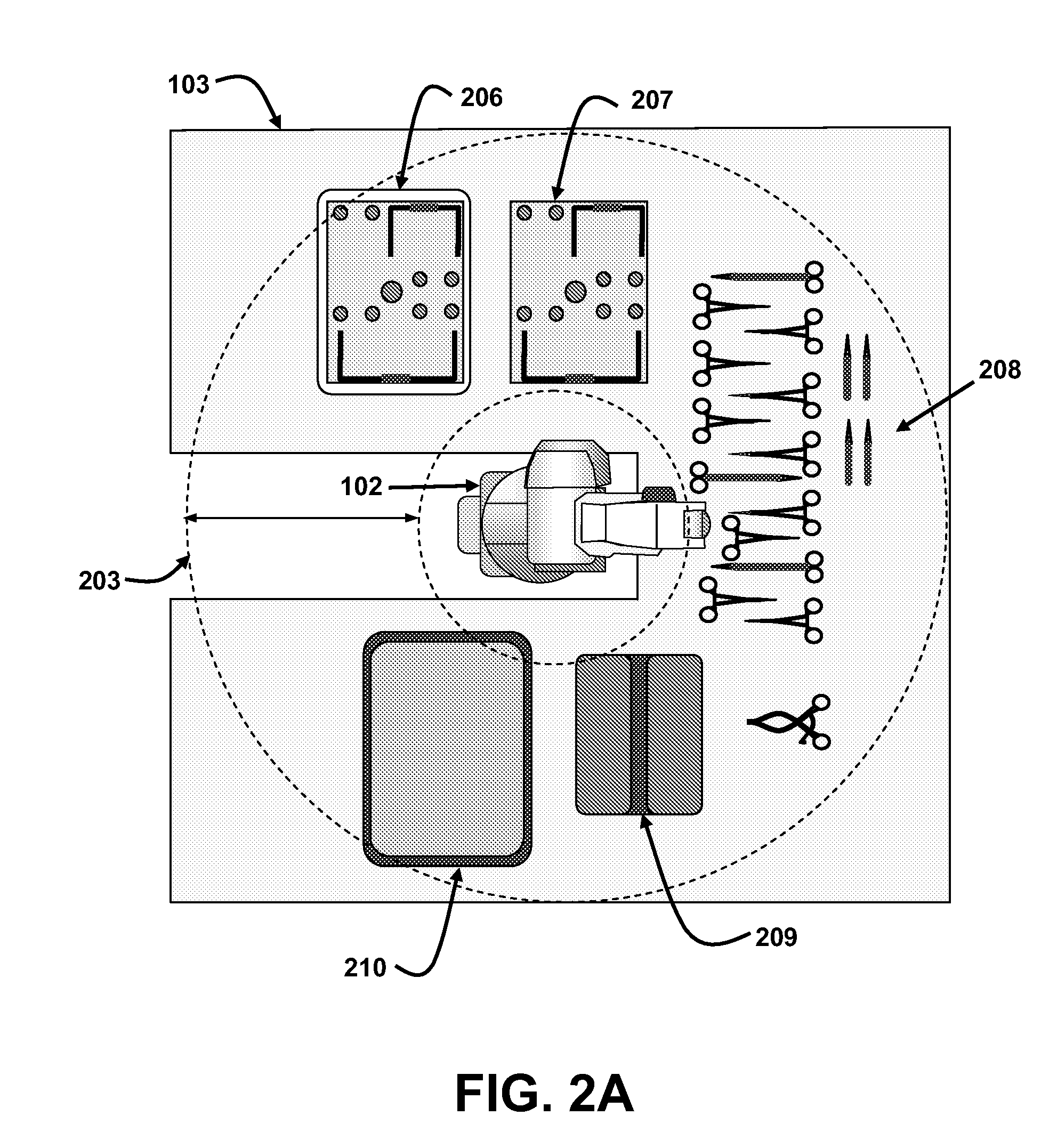

Automated robotic system for handling surgical instruments

InactiveUS20110005342A1Improve cleaning efficiencyReduce in quantityProgramme-controlled manipulatorSurgical furnitureRobotic systemsEngineering

Systems and methods that process a plurality of surgical instruments for cleaning and / or packaging. A device identifies a robot-ready insert having a predetermined configuration for accepting at least one type of surgical instrument. The surgical instruments are identified and oriented according to type using an automated apparatus. Specialized tools are also provided for automatically opening and closing surgical instruments, flipping instruments and assisting in the processing and maintenance of surgical instruments. The automated apparatus then places each of the surgical instrument types in one or more predetermined areas of the insert, configured to accept a predetermined set of surgical instrument types.

Owner:RST AUTOMATION LLC

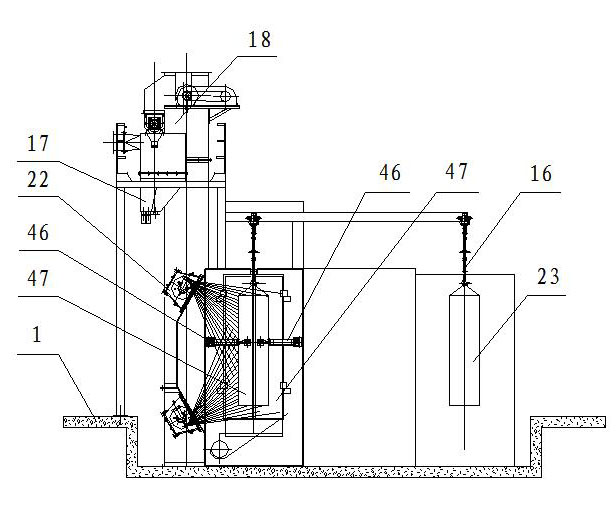

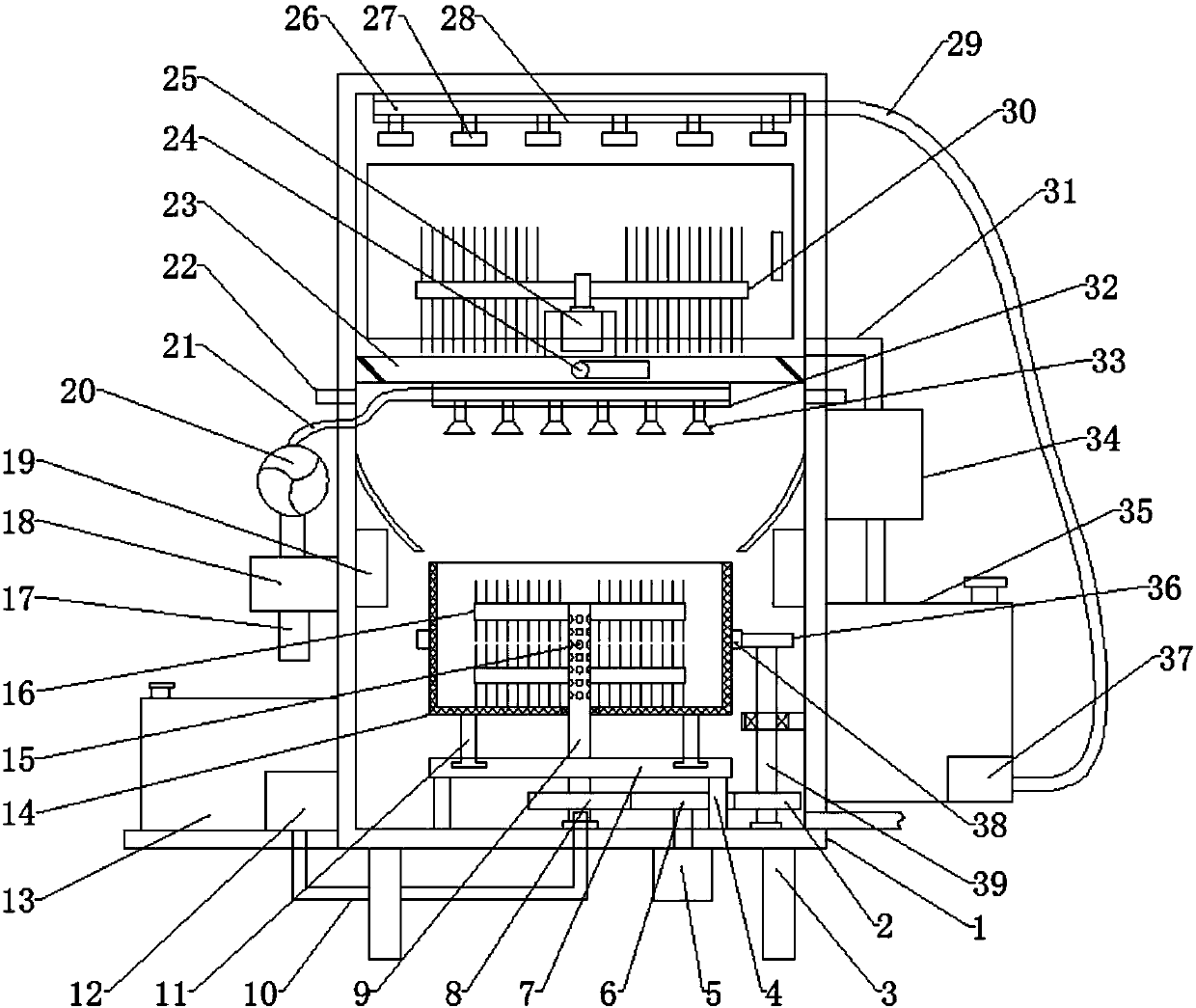

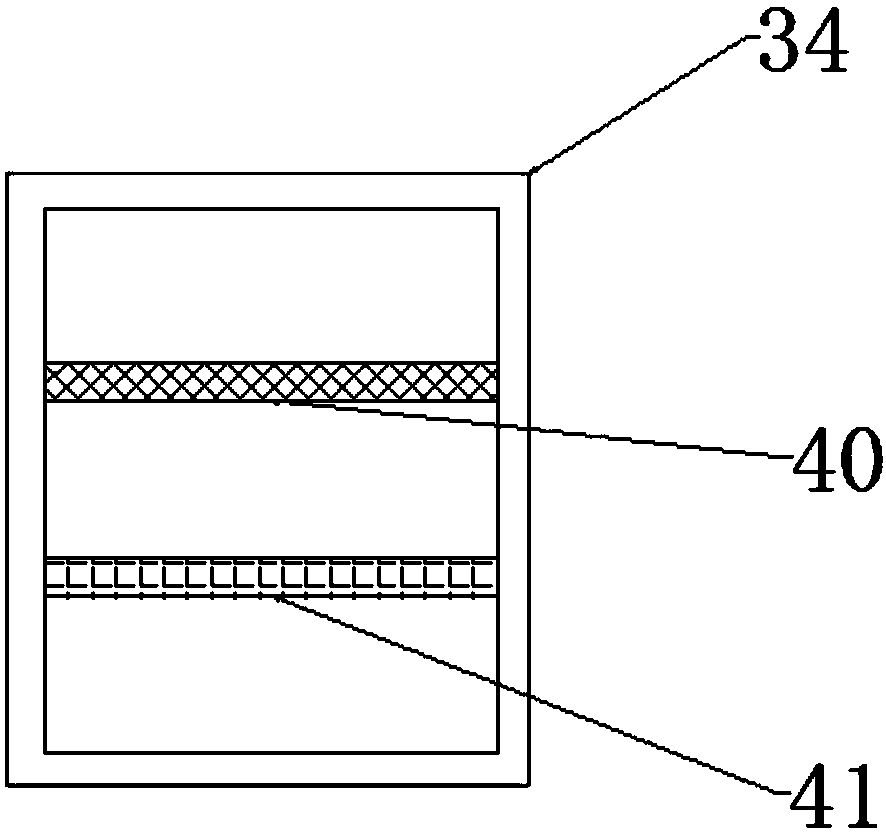

Medical device disinfection, washing and drying integrated equipment

InactiveCN107552429AAvoid wastingSimple structureDrying gas arrangementsCleaning using toolsDisinfectantSpray nozzle

The invention discloses an integrated equipment for disinfection, cleaning and drying of medical instruments, which includes a box body, a disinfection chamber, a cleaning and drying chamber, a rotating plate, a first motor, a pole, a brush, a hard water pipe, a nozzle, a filter device, a trachea, Nozzle, hot air blower, cleaning frame, electric heating element, hollow pipe, third water pipe, second water pump, water tank, first gear, second gear, third gear, rotating shaft, fourth gear and ring gear, the present invention has The disinfection chamber is equipped with a first motor, a pole and a brush, which can fully sterilize medical instruments. It is equipped with a filter device, which can recycle the disinfectant and avoid wasting the disinfectant. It is equipped with a rotating plate. It can quickly transfer medical instruments from the disinfection chamber to the cleaning and drying chamber. It has a simple structure and is easy to operate. It is equipped with a cleaning frame and a hollow tube, which can efficiently scrub medical instruments. It is equipped with a hot air blower, nozzles and electric heating elements. Medical equipment is dried, which is convenient and practical.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

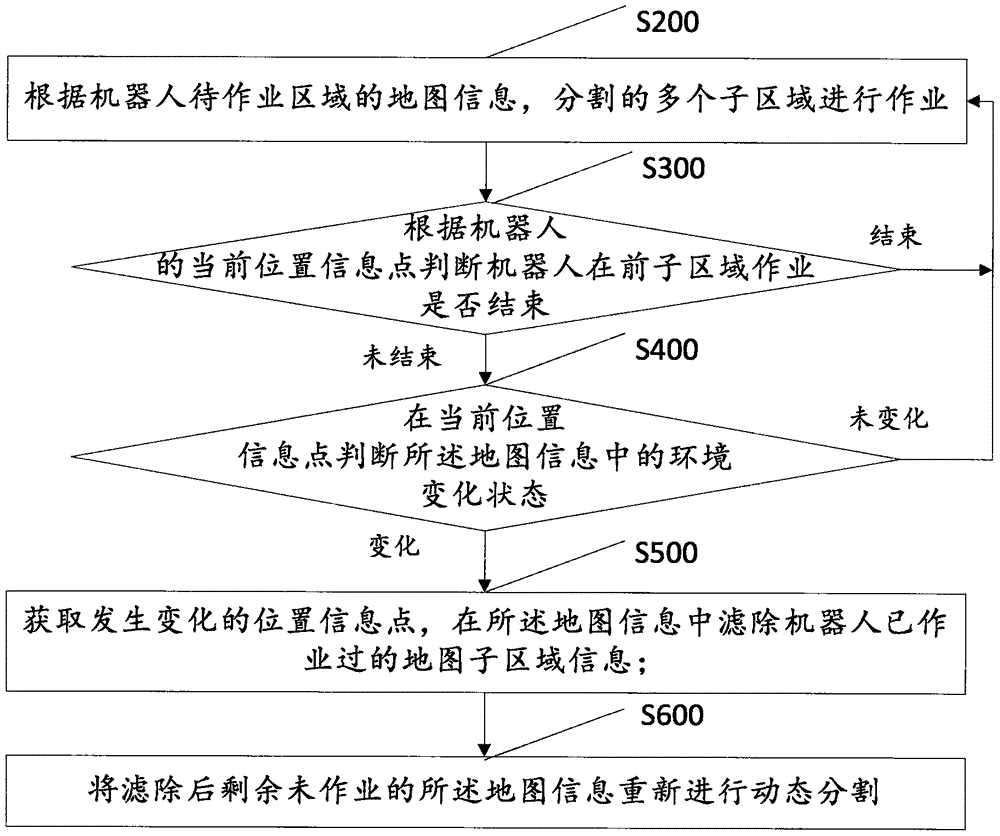

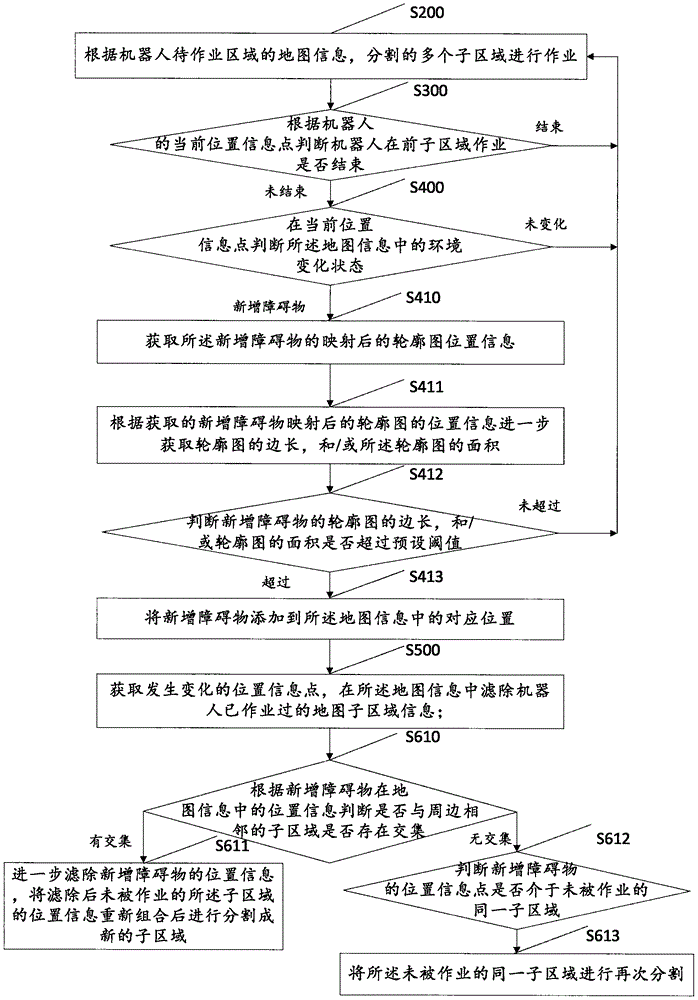

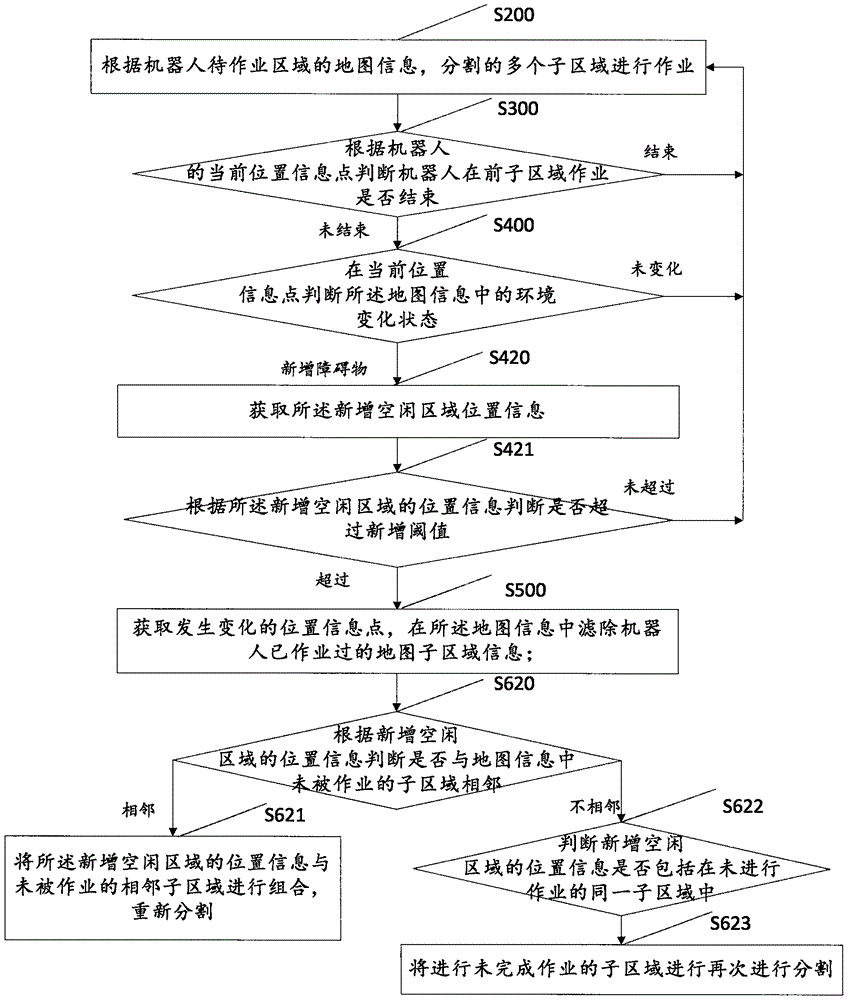

Dynamic dividing method and system of robot operation area

ActiveCN106564054AImprove work efficiencyEasy to operateProgramme-controlled manipulatorPosition/course control in two dimensionsComputer scienceRobot

The invention discloses a dynamic dividing method and system of a robot operation area. The dynamic dividing method comprises the steps that according to obtained cartographic information of the area, to be operated, of a robot, and the area is divided into a plurality of subareas for operation; according to the current position information point, whether operation of the robot in the current subarea is finished or not is judged; the environment change state in the cartographic information is judged at the current position information point; when it is judged that the environment change state in the cartographic information is changed at the current position information position, the position information point of the change is obtained, and cartographic subarea information of the subareas which are operated by the robot is filtered out from the cartographic information; and after filtering is conducted, the cartographic information of the residual un-operated subareas is subjected to dynamic dividing again. The dynamic dividing method and system aim to monitor the operation cartographic information state in real time and conduct dynamic dividing on the operation areas simultaneously during operation of the robot, and thus the operation efficiency of the robot is greatly improved.

Owner:山东越浩自动化设备有限公司

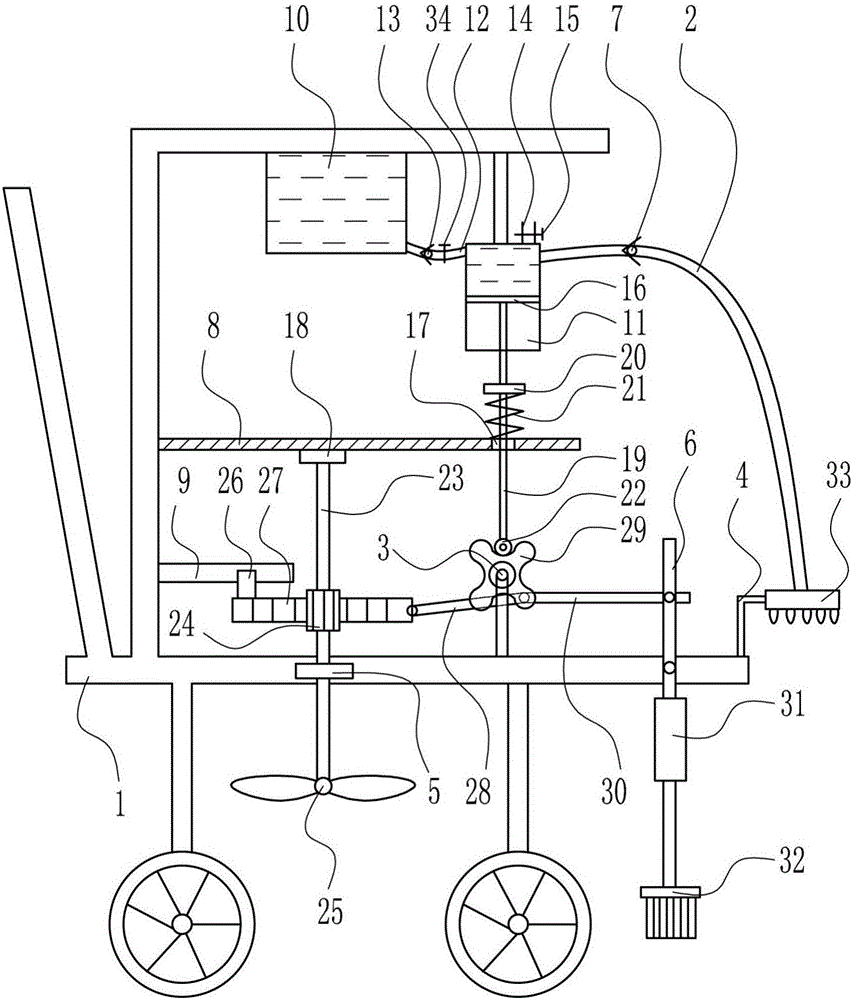

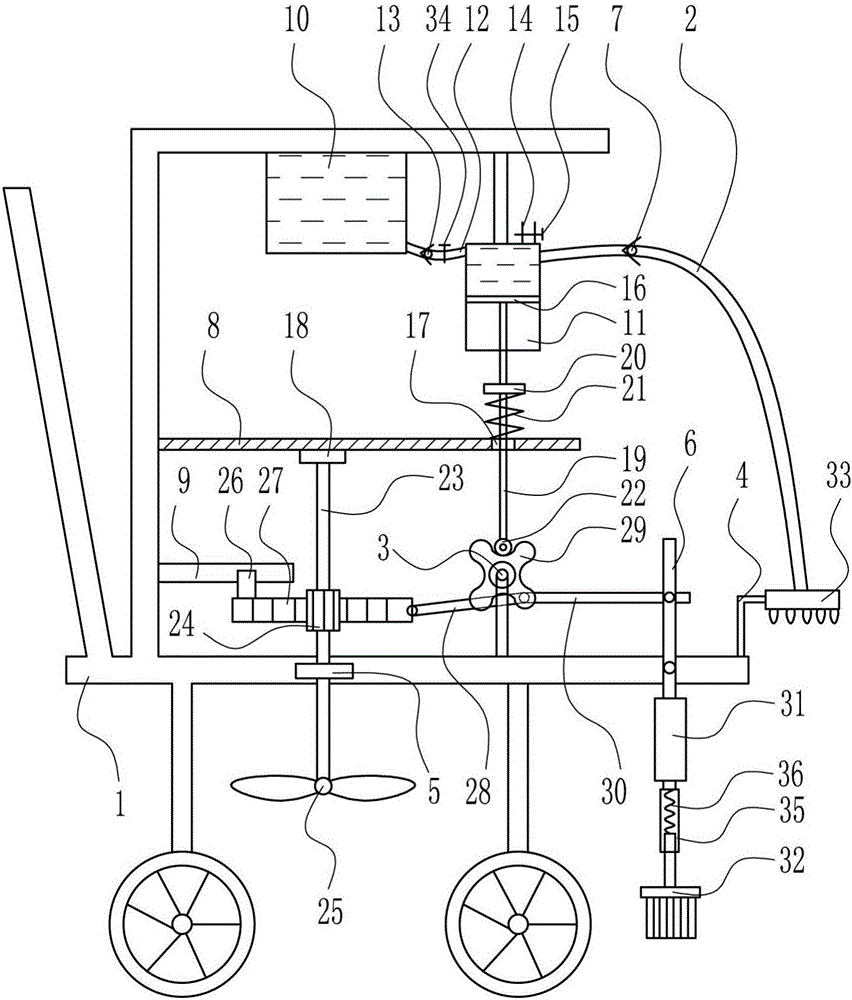

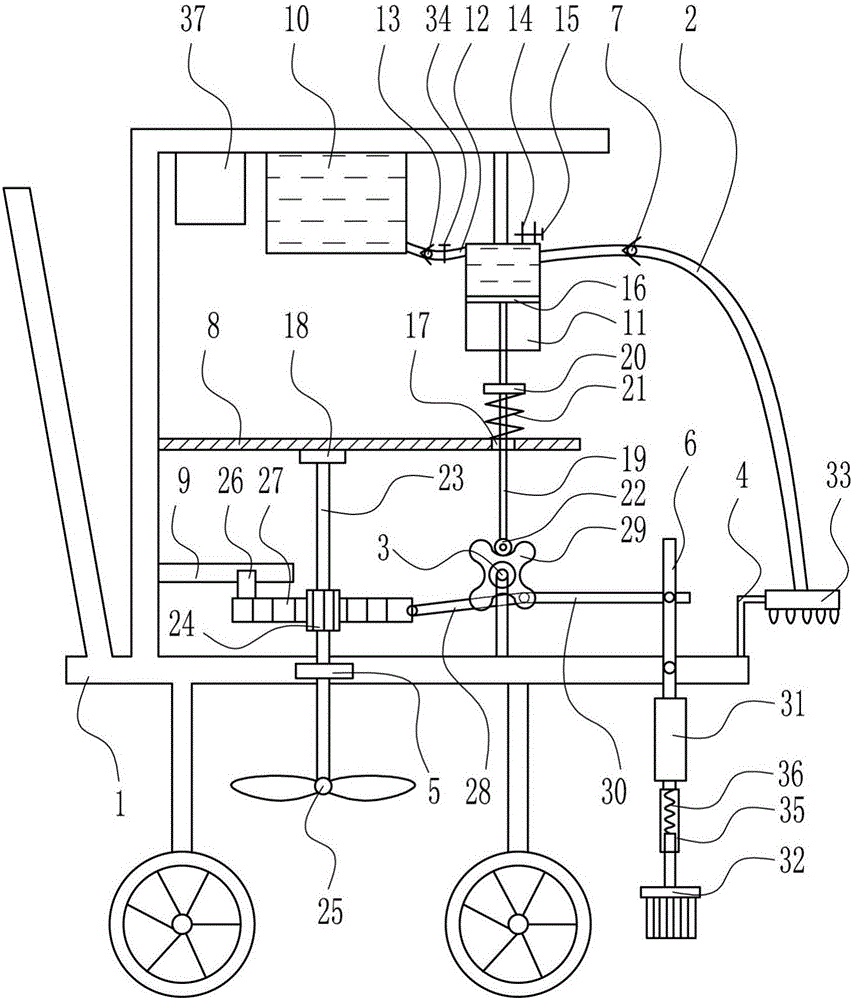

Efficient hog house cleaning device for livestock raising

The invention relates to a hog house cleaning device, in particular to an efficient hog house cleaning device for livestock raising. According to the technical aim to be achieved, the efficient hog house cleaning device for livestock raising is high in cleaning efficiency, good in cleaning effect and easy to operate. In order to achieve the technical aim, the efficient hog house cleaning device for livestock raising is provided comprises a cart, a water outlet pipe, a motor, an L-shaped rod, a first bearing pedestal, a strut, a second one-way valve, a guide plate, a sliding rail, a water tank, a cylinder, a water inlet pipe, a first one-way valve, a first electronic control valve, a piston, a second bearing pedestal, a lifting rod, a fixed check block, an elastic part, a contact wheel, a rotary shaft, a gear, a blade, a sliding block, a gear rack, a first connecting rod, a disc cam, a second connecting rod, an air cylinder, a brush, a spray head and a second electronic control valve. Motor driving is adopted, the brush, the spray head and the blade can be driven to operate at the same time through one rotating action of the motor, and the number of the operation steps is small.

Owner:季虎

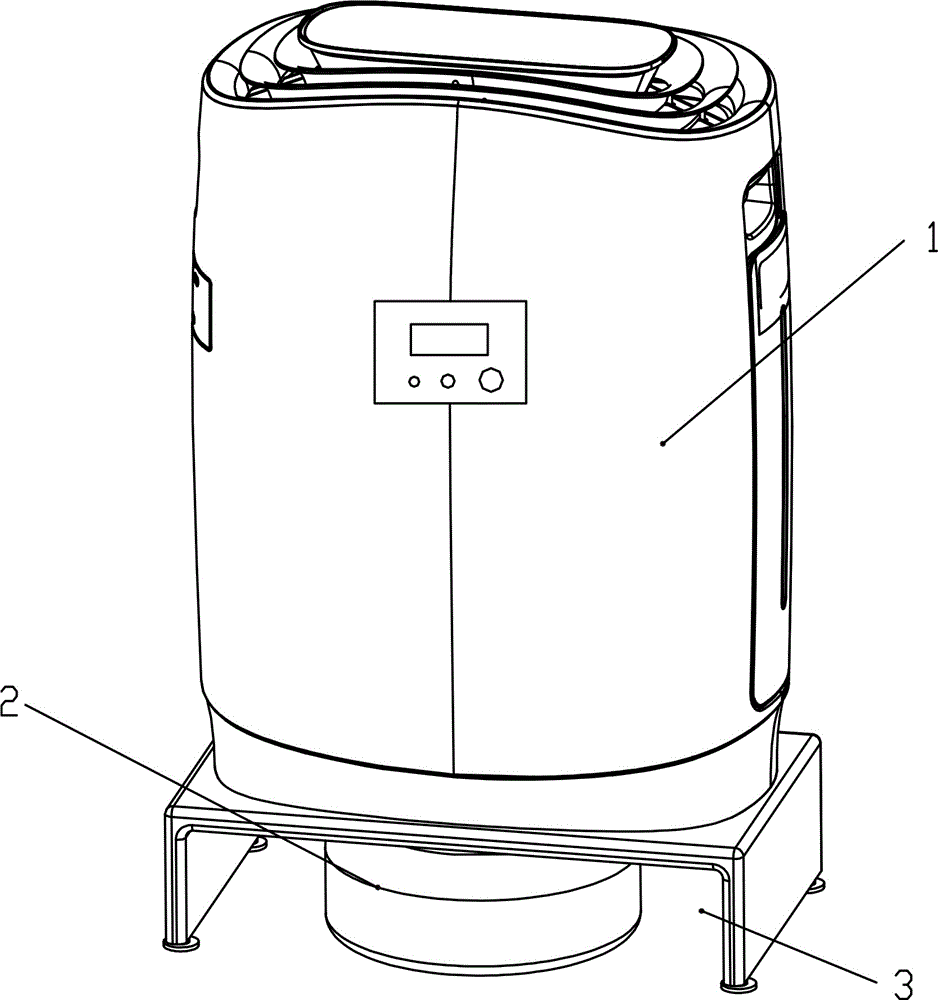

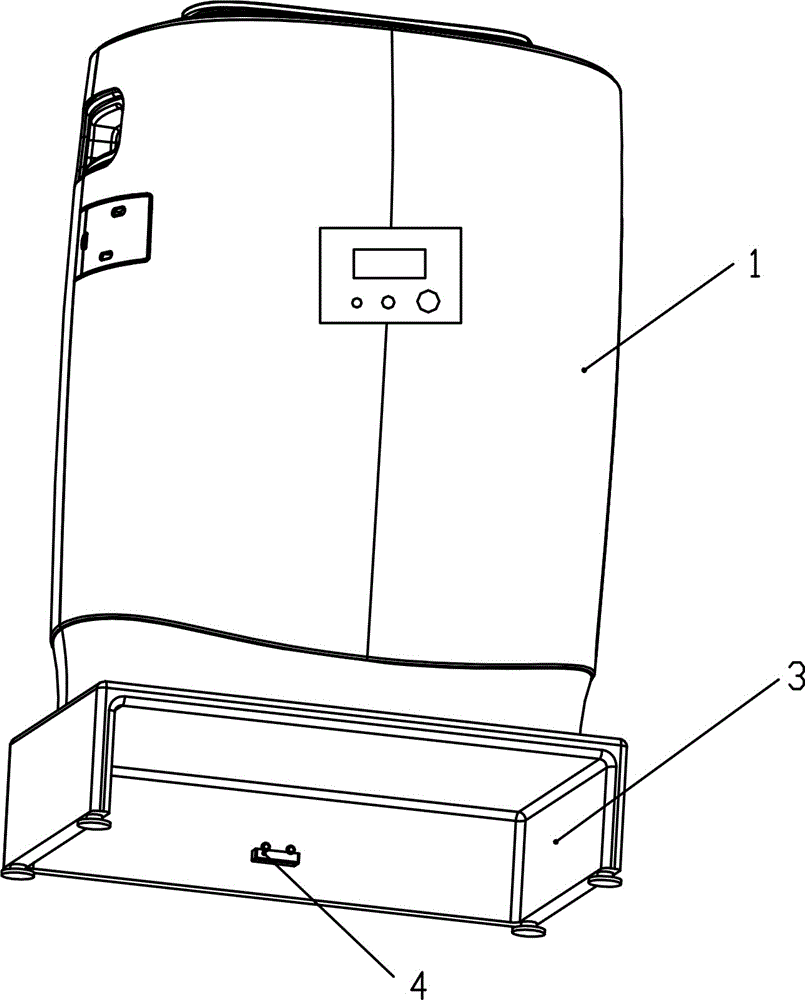

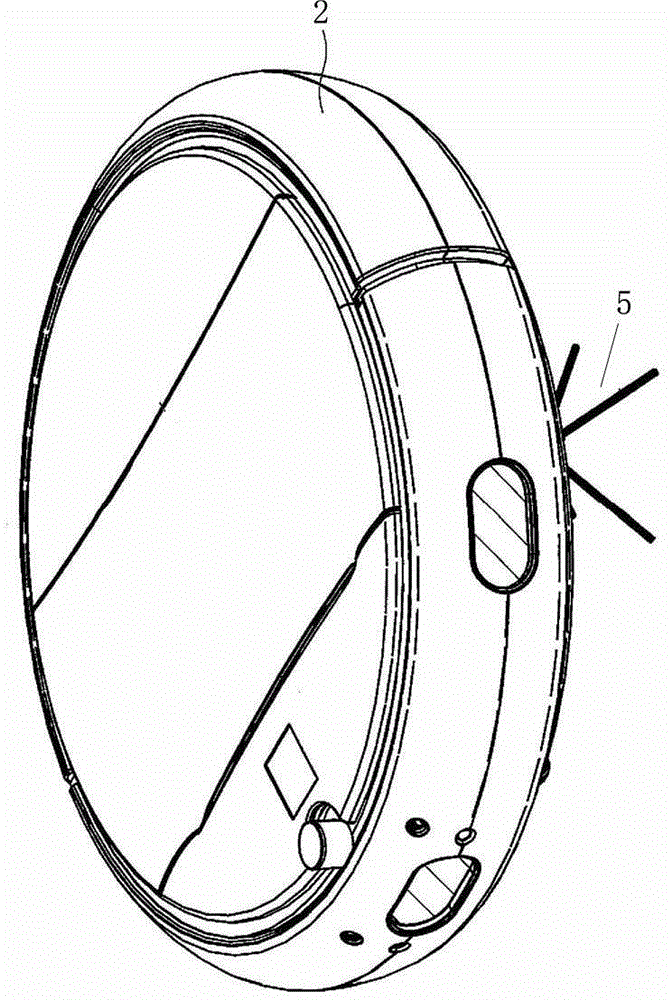

Novel air purification and automatic sweeping integrated machine

ActiveCN104132412ASo neatSave interior spaceCarpet cleanersLighting and heating apparatusEmbedded systemElectricity

The invention relates to a novel air purification and automatic sweeping integrated machine. The integrated machine comprises an air purifier. The air purifier comprises a shell and an electric control device. The integrated machine further comprises an automatic walking sweeping robot used in combination with the air purifier. A containing chamber for containing the automatic walking sweeping robot is formed in the bottom of the shell. A storage battery is arranged on the sweeping robot. A charging socket allowing the sweeping robot to be charged is arranged on the shell. The sweeping robot and the charging socket are connected through a separable electric connector. The electric control device comprises a controlled module arranged on the sweeping robot and a master control module arranged on the air purifier. The master control module and the controlled module are in wireless communication. The novel air purification and automatic sweeping integrated machine has the advantages of being convenient to use and capable of saving energy.

Owner:XIAMEN BRI ENVIRONMENTAL IND CO LTD

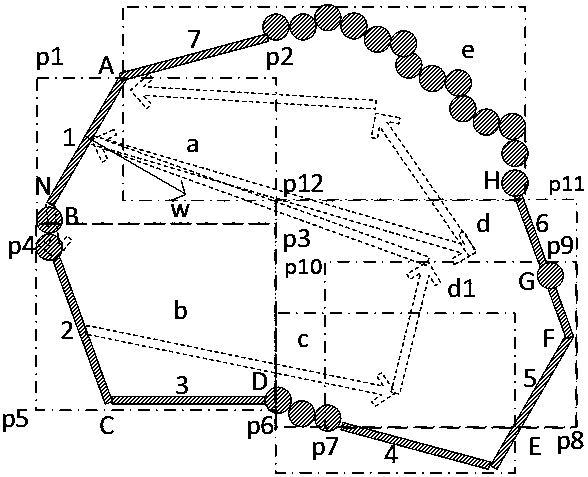

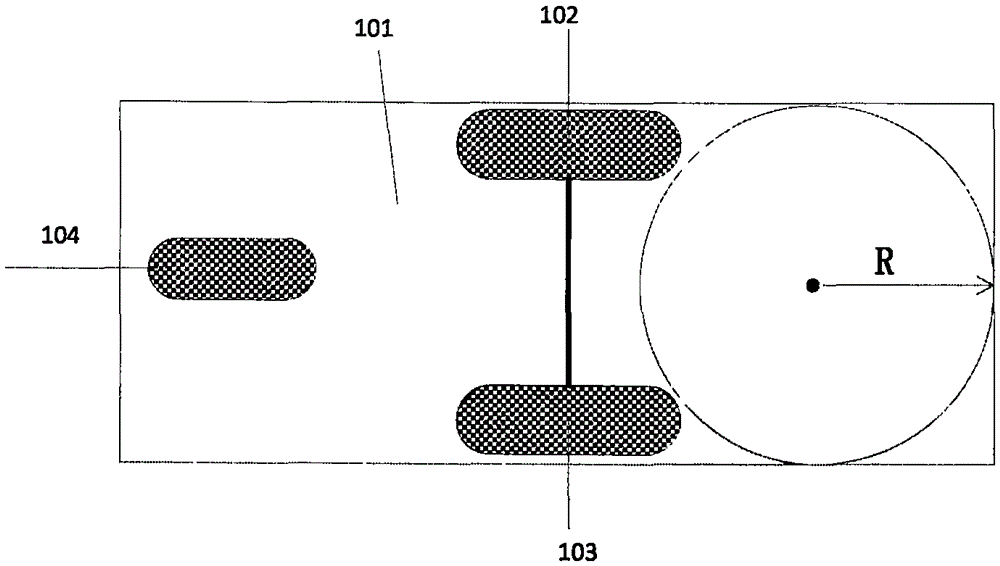

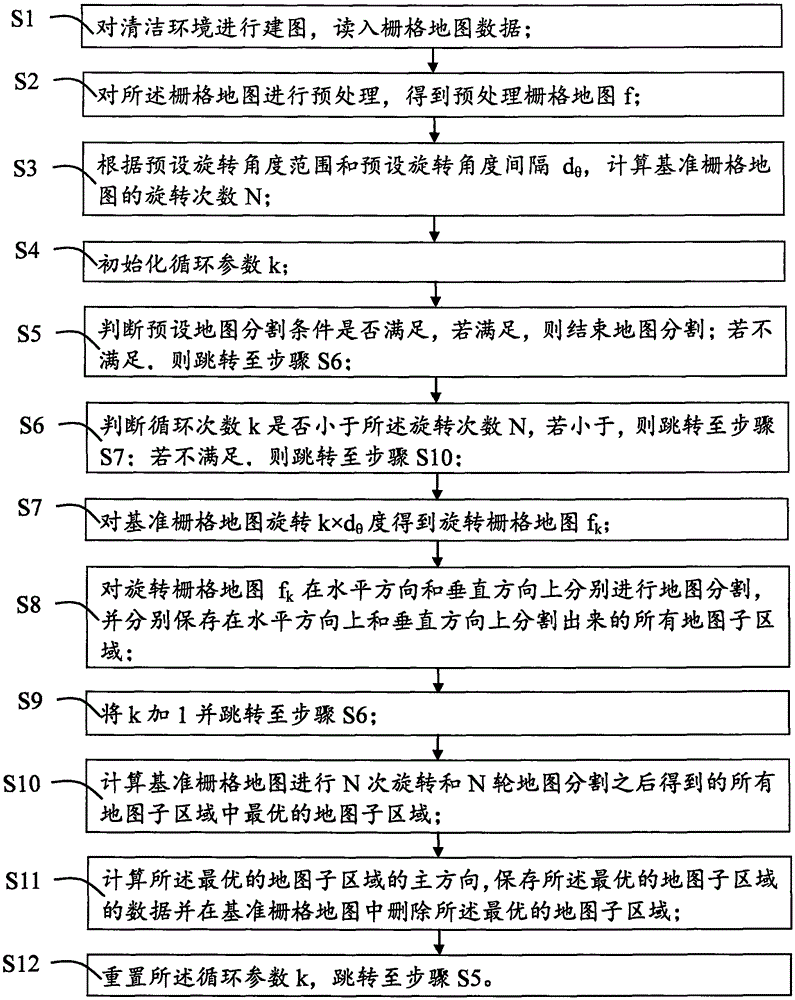

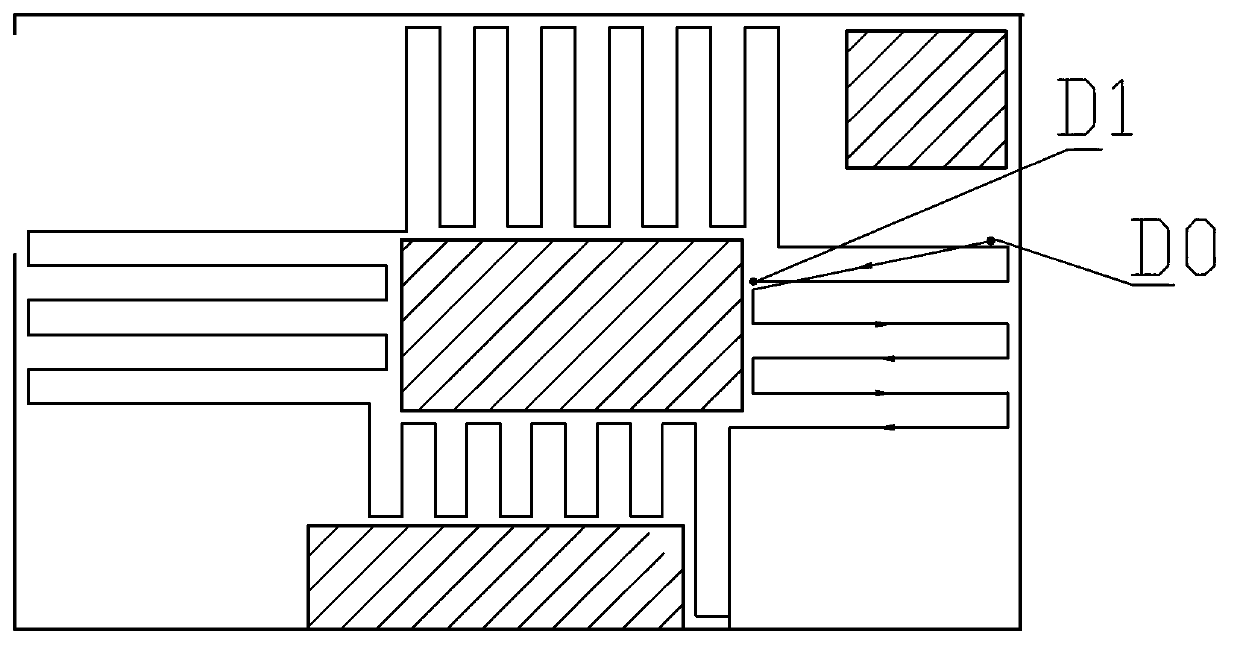

Area segmentation method based on cleaning robot

ActiveCN105302136ASolve the problem that requires multiple mappingImprove cleaning efficiencyPosition/course control in two dimensionsComputer scienceReference grid

The invention provides an area segmentation method based on a cleaning robot. The method comprises steps that, grid map data is read in; pre-processing on a grid map is carried out; a rotation number N of a reference grid map is calculated; a cycle parameter k is initialized; whether a preset map segmentation condition is satisfied is determined; whether the cycle parameter k is smaller than the rotation number N is determined; a rotation grid map fk is acquired through k*dtheta-DEG rotation of the reference grid map; map segmentation on the rotation grid map fk is carried out; an optimal map sub area in all map sub areas acquired after rotation of the reference grid map is calculated; a main direction of the optimal map sub area is calculated, and the optimal map sub area is deleted from the reference grid map; the cycle parameter k is re-set, whether the preset map segmentation condition is satisfied is re-determined, and a cycle mode is carried out. Through the area segmentation method, a problem of multi-time map establishment existing in cleaning robots in the prior art is solved, and cleaning efficiency of the cleaning robot is greatly improved.

Owner:SHANDONG ZHONGHAO PLASTIC IND CO LTD

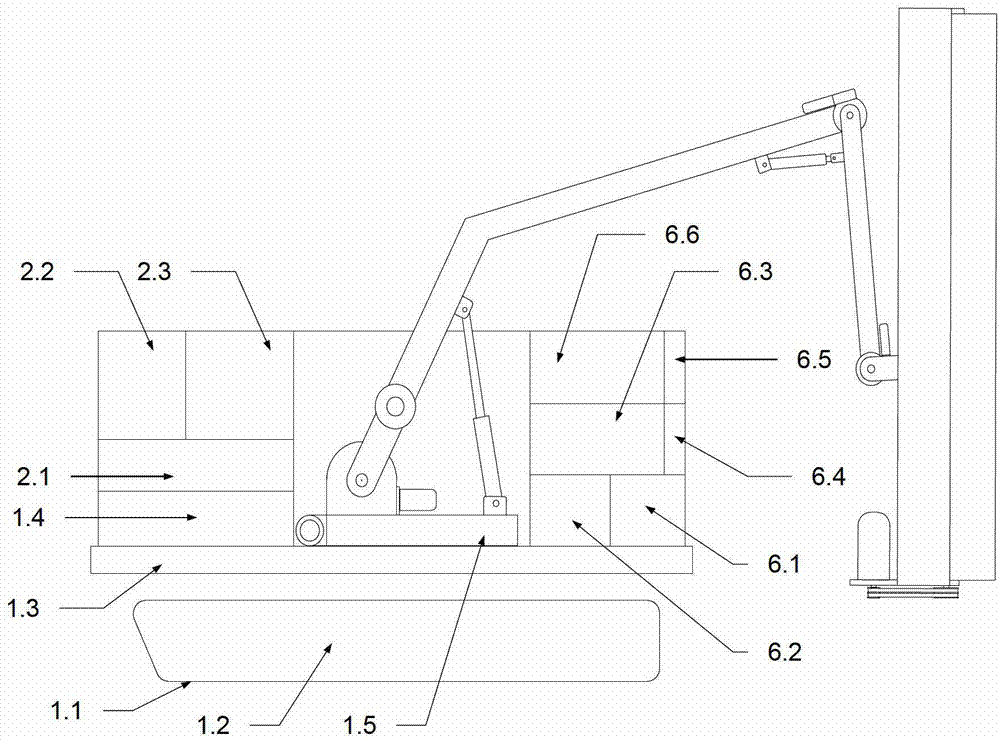

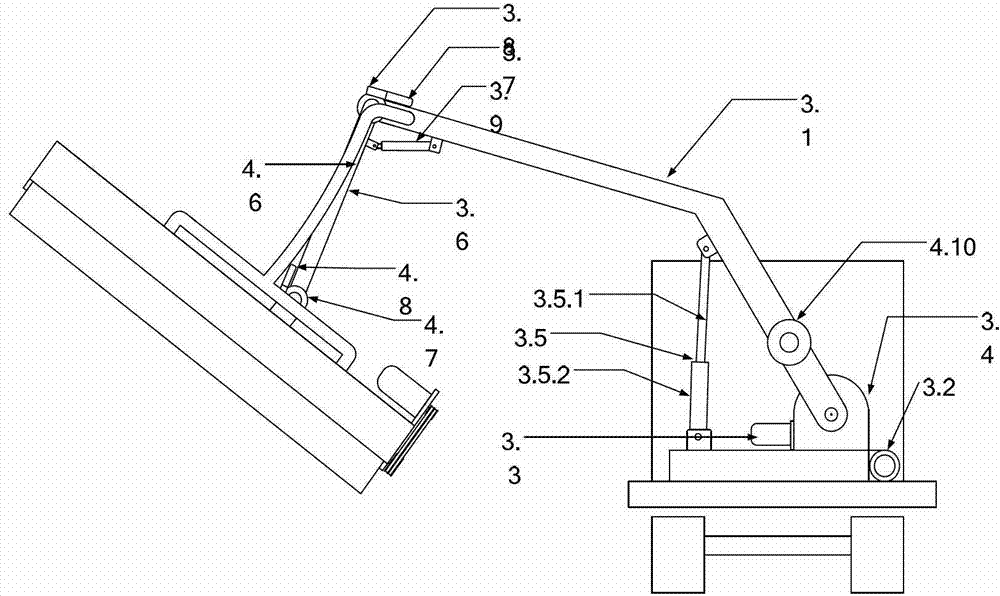

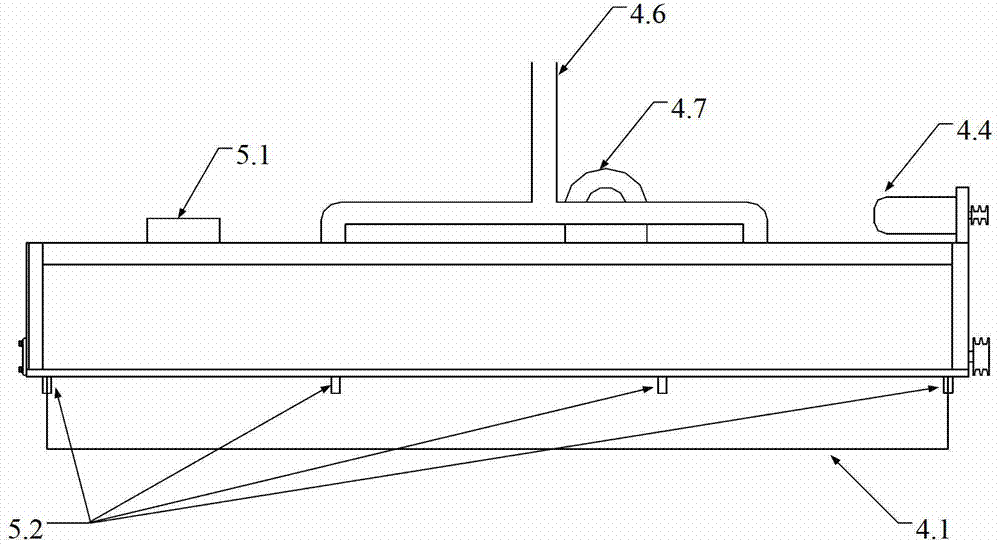

Full-automatic intelligent cleaning device of photovoltaic power station modules

The invention relates to a full-automatic intelligent cleaning device of photovoltaic power station modules, in particular to a high-efficiency dust-cleaning device for various long or short square photovoltaic modules of a large-scale photovoltaic power station. The full-automatic intelligent cleaning device of the photovoltaic power station modules comprises a cleaning car, an electromechanical braking system and an intelligent control system. The electromechanical braking system comprises a power supply unit, a support arm unit and a cleaning unit. The electromechanical braking system has the functions of cleaning and dust-cleaning with a plurality of degrees of freedom according to the surfaces of the photovoltaic modules. The intelligent control system comprises a perception unit, a processing unit and a remote control unit and can achieve full-automatic, real-time and remote controlled high-accuracy control of the cleaning car and a cleaning mechanism. The full-automatic intelligent cleaning device of the photovoltaic power station modules enables the cleaning device to be intelligentized, can carry out one-time high-accuracy dust-cleaning to the various long or short square under different road conditions, is safe, stable, reliable and full-automatic, and effectively solves the technical problems that cleaning is excessively dependent on manpower to supervise and the cleaning efficiency of the large-scale photovoltaic power station is low in the prior art.

Owner:北京安必信金属制品有限公司

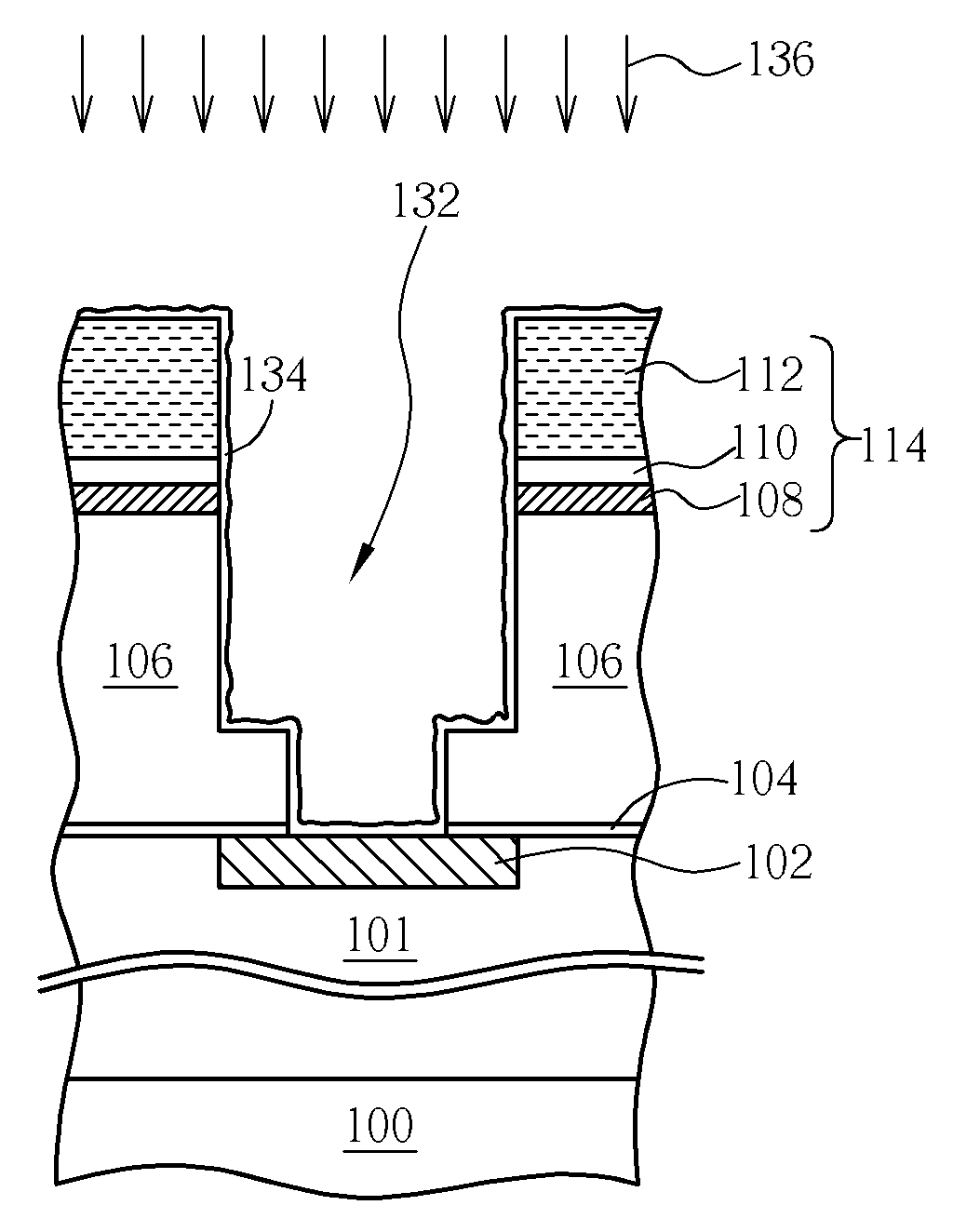

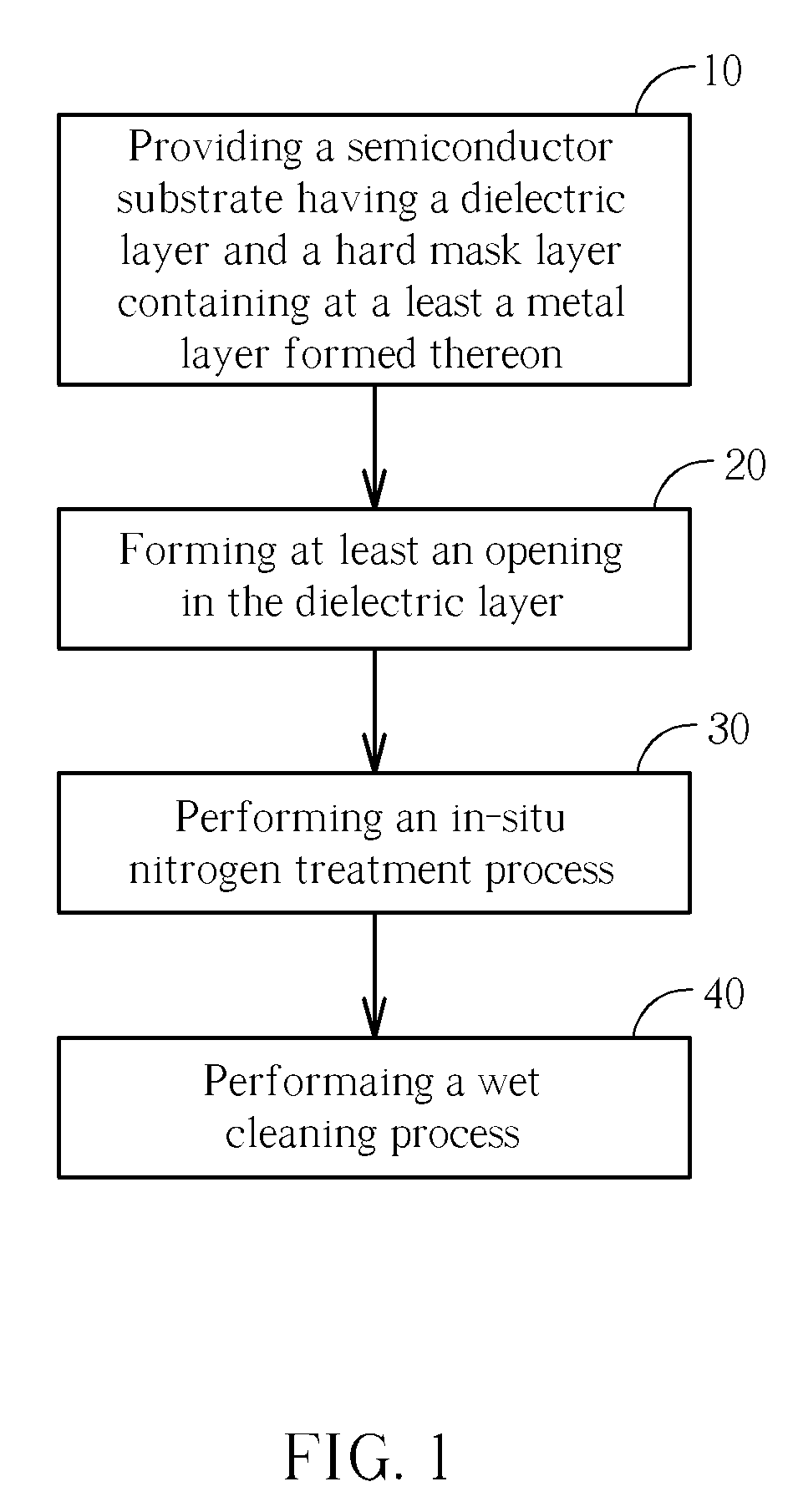

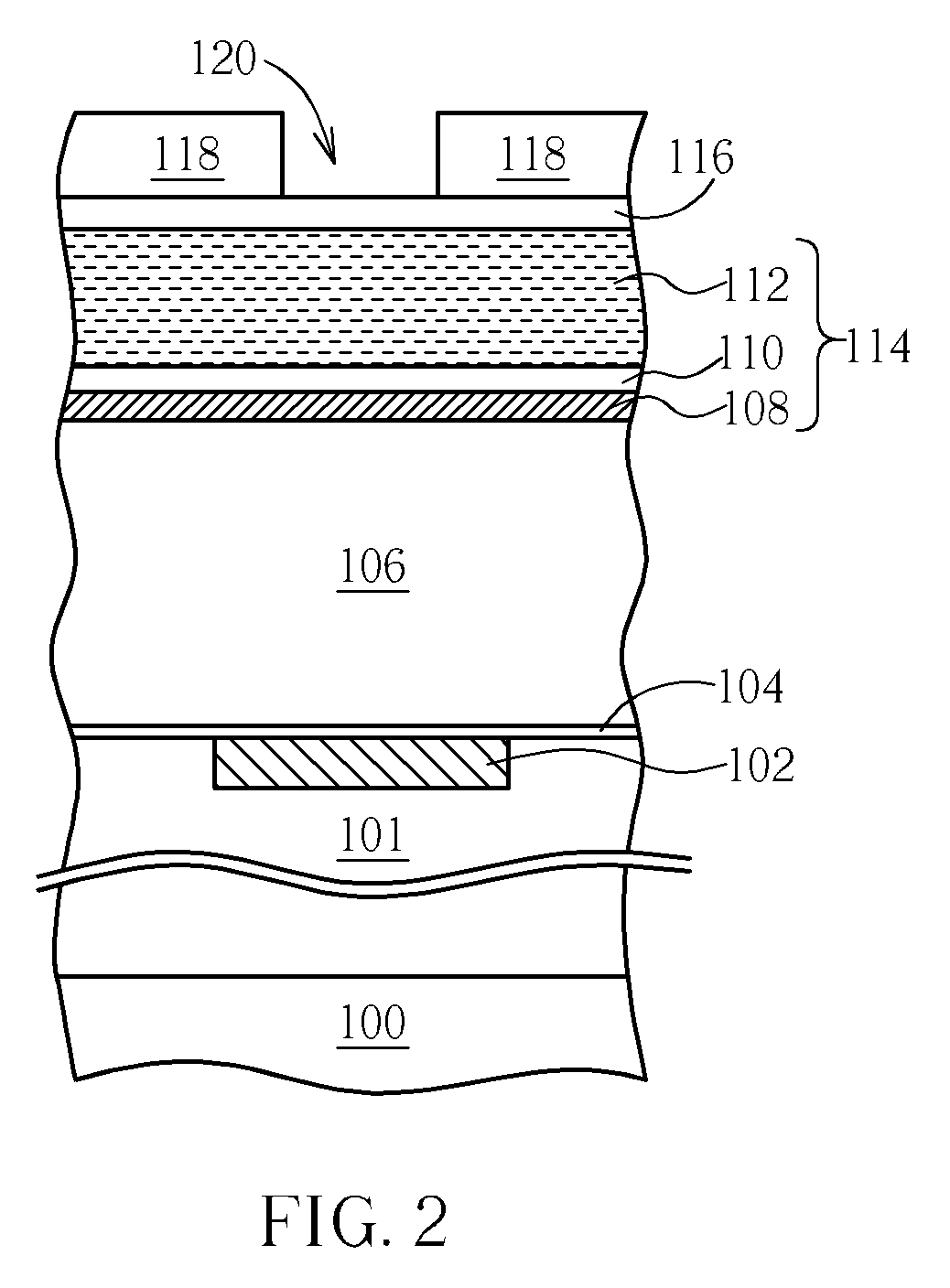

Cleaning method following opening etch

ActiveUS20090142931A1Improve cleaning efficiencyFabrication processDecorative surface effectsSemiconductor/solid-state device manufacturingEtchingNitrogen

A cleaning method following an opening etching is provided. First, a semiconductor substrate having a dielectric layer is provided. The hard mask layer includes at least a metal layer. The opening etch is then carried out to form at least an opening in the dielectric layer. A nitrogen (N2) treatment process is performed to clean polymer residues having carbon-fluorine (C—F) bonds remained in the opening. Finally, a wet cleaning process is performed.

Owner:UNITED MICROELECTRONICS CORP

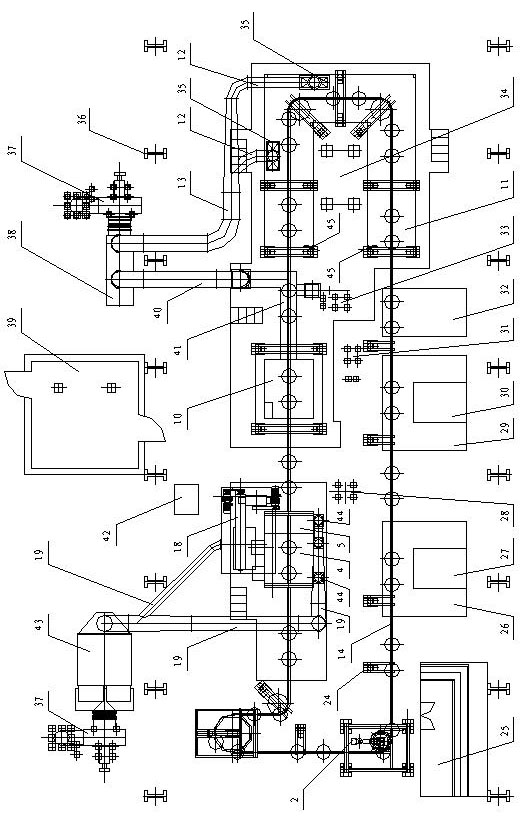

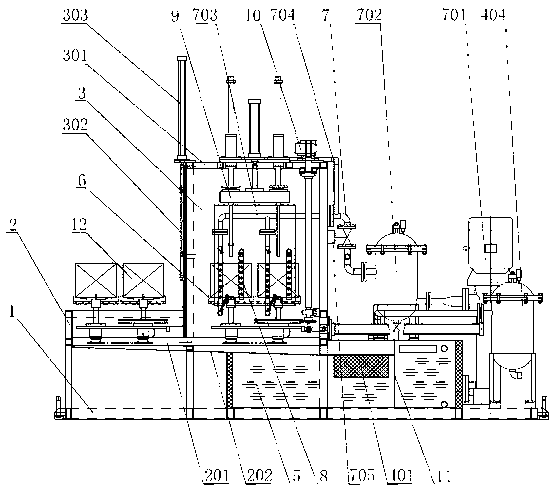

Cylinder part cleaning machine

ActiveCN103008274AImprove cleaning efficiencyRealize automatic feedingDrying gas arrangementsMultistage water/sewage treatmentElectric heatingEngineering

The invention discloses a cylinder part cleaning machine, which comprises a frame and an electric control cabinet, wherein the frame is horizontally provided with a workpiece station, a cleaning chamber and a water treatment system; a water tank is arranged below the cleaning chamber, extends to the water treatment system and comprises a waste water tank and a clear water tank; an electric heating tube is arranged in the clear water tank; the workpiece station is provided with a track which extends to the cleaning chamber to be fixedly connected with the inner wall of the cleaning chamber; and a guide plate is arranged below the track. The cleaning machine further comprises a conveying vehicle assembled on the track, and a cleaning pipeline, a drying pipeline, a lifting probe cleaning device and a driving device which are arranged in the cleaning chamber, wherein the conveying vehicle is provided with a plurality of bearing disks which can rotate 360 degrees; and the cleaning pipeline is divided into two paths, one of which directly leads to the cleaning chamber to clean the outer surface of a cylinder part, and the other of which enters the probe cleaning device through a pipe to clean the inner chamber of the cylinder part. The cylinder part cleaning machine can clean the inner and outer surfaces of a plurality of cylinder parts and is low in labor intensity, high in cleaning efficiency and good in cleaning effect.

Owner:安徽宝辉清洗设备制造有限公司

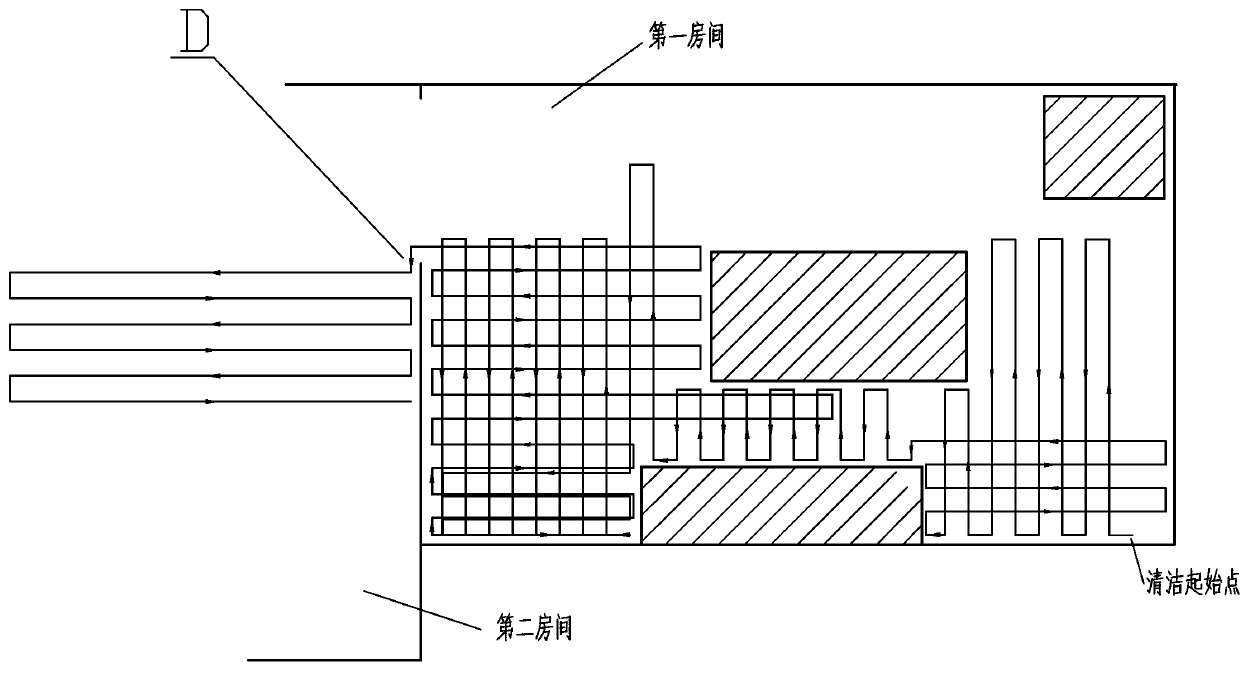

Cleaning method using cleaning robot by means of edgewise navigating and intro-expanding

ActiveCN103099586AAvoid missed or repeated cleaningsImprove cleaning efficiencyAutomatic obstacle detectionTravelling automatic controlStructural engineeringMechanical engineering

The invention aims at providing a cleaning method by using a cleaning robot, which can traverse regions which need to be cleaned in a plurality of rooms, and can reduce a repeated forwarding route, i.e., a cleaning method using the cleaning robot by means of edgewise navigating and intro-expanding. The cleaning robot advances along the outer wall of a wall body of the room, and the cleaning robot leaves away from the outer wall of the wall body for a plurality of times to move to the direction which is far away from the outer wall of the wall body to clean the ground. After the cleaning robot leaves away from the outer wall of the wall body at a certain distance or encounters a barrier every time, the cleaning robot firstly rotates for a preset angle, advances at a section of preset distance, and returns to the outer wall of the wall body, so that the traversing and the cleaning of the region which needs to be cleaned can be realized.

Owner:重庆艾亿佳智能技术有限公司

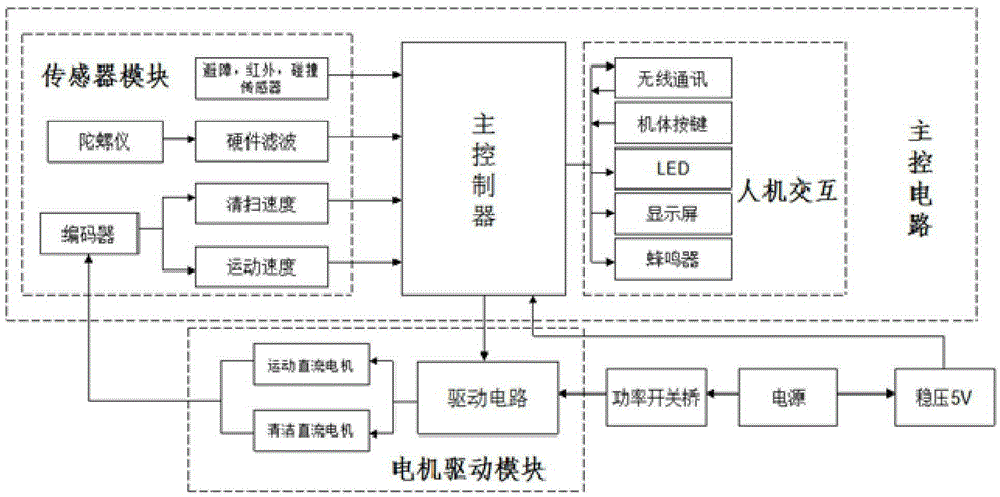

Intelligent cleaning robot and path planning method thereof

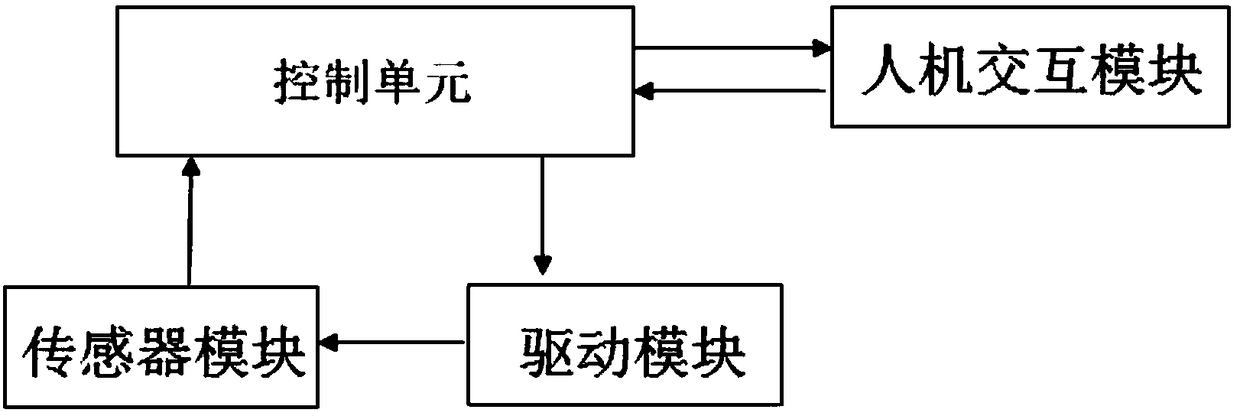

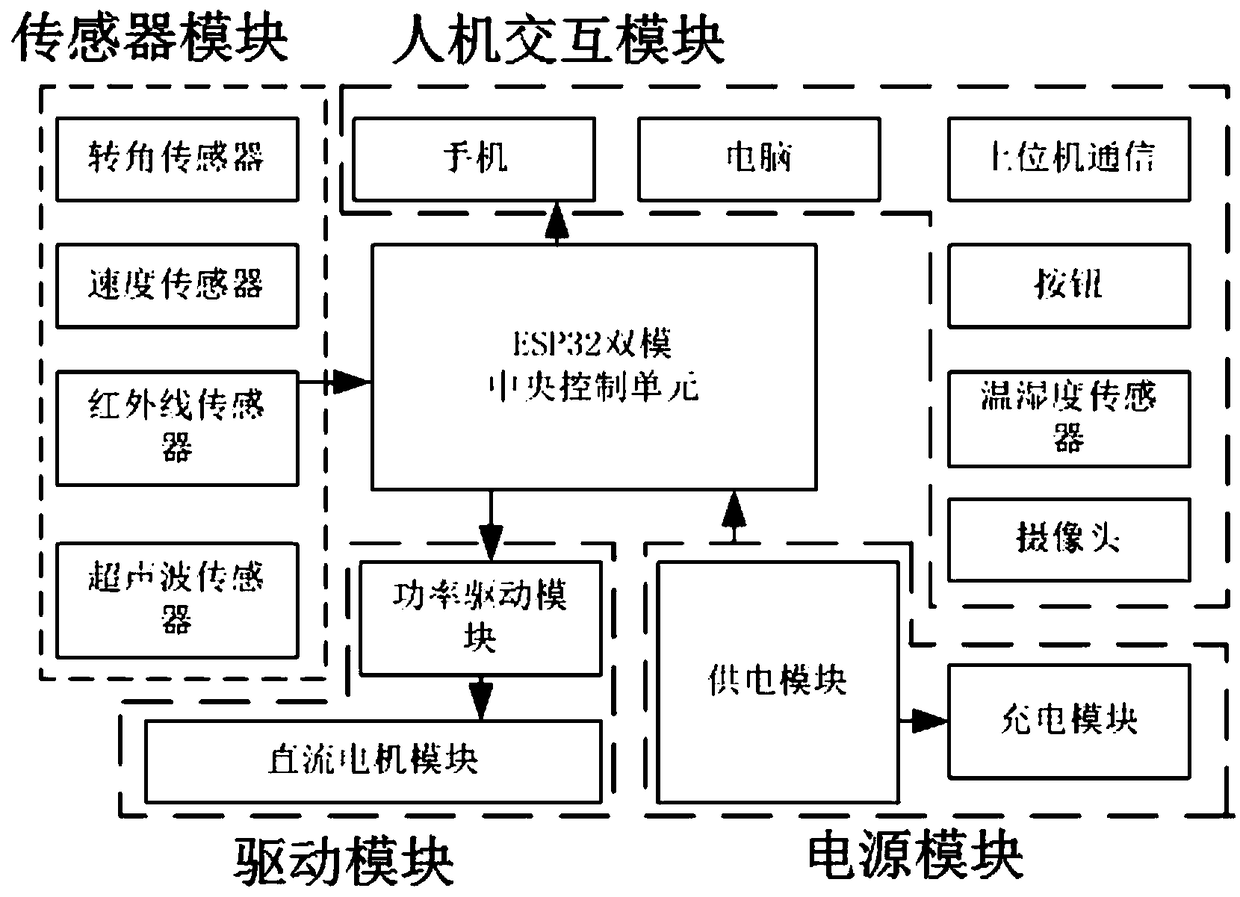

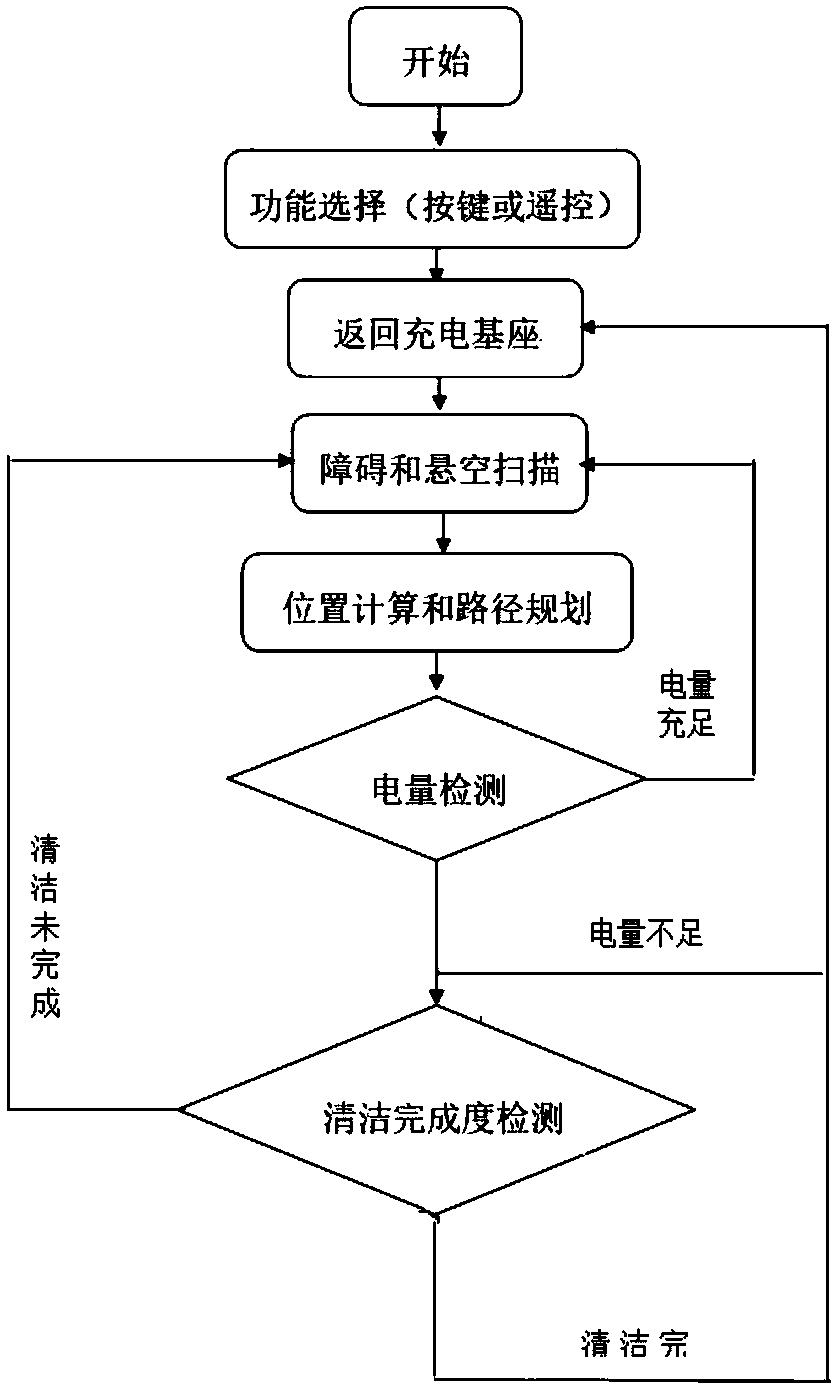

ActiveCN109144067AAchieve maximum coverageAchieving cleanlinessPosition/course control in two dimensionsVehiclesReal time analysisRemote control

The invention discloses an intelligent cleaning robot and a path planning method thereof. A sensor module is used for analyzing and feeding back real-time cleaning environment information; an accuratepositioning module is used for acquiring the position of the current intelligent cleaning robot on the environment map which is established through a geometric-topological hybrid map technology, andthe environment map and the real-time position are combined, the optimal sweeping path is planned by using an advanced path planning algorithm, and the data is uploaded to a cloud platform for realizing the real-time analysis, recording, and control; a driving module is used for driving the intelligent cleaning robot to run according to the planned optimal path and carrying out cleaning operation;a man-machine interaction module can be used for displaying the working state and performance of the intelligent cleaning robot by combining the temperature and humidity sensor with the camera, and the remote control and reservation functions of the intelligent cleaning robot can be completed through wifi / Bluetooth technology. According to the invention, the labor intensity is reduced, the laborefficiency is improved, and the robot is suitable for hotels, libraries, office places and public families.

Owner:CHECC DATA CO LTD +1

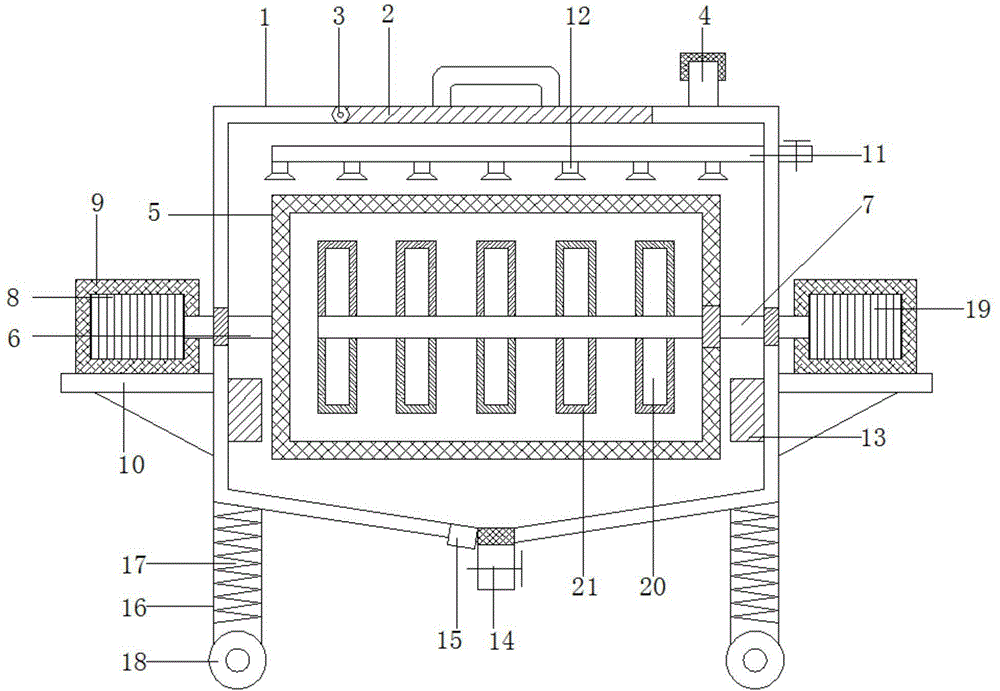

Efficient vegetable cleaning machine

The invention discloses an efficient vegetable cleaning machine. The efficient vegetable cleaning machine comprises a cleaning machine main body, a cleaning barrel and a cleaning brush layer, wherein a cover board is arranged on the upper surface of the cleaning machine main body, the left end of the cover board is fixedly connected with the inner wall of the upper side of the cleaning machine main body through a rotating shaft, a liquid inlet pipe is arranged at the right end of the upper side of the cleaning machine main body, and the cleaning barrel is horizontally arranged in the center in the cleaning machine main body. According to the efficient vegetable cleaning machine disclosed by the invention, motors drive the cleaning barrel horizontally arranged to rotate so as to turn over and clean vegetables, and besides, the rotating shaft drives the cleaning brush layer to rotate backwards to scour the vegetables, so that the cleaning effect and the cleaning efficiency of the cleaning machine are greatly improved; in addition, ultrasonic cleaning and spraying of cleaning liquid are used for cleaning the vegetables, so that the cleaning efficiency is further improved, and sanitation and hygiene of the vegetables are ensured; the cleaning machine can freely and conveniently move, so that the convenience and the practicality are high; springs can effectively reduce the vibration of a machine body, so that the mechanical stability of the machine body is improved; in addition, when the cleaning machine works, the noise is small.

Owner:苏晓玲

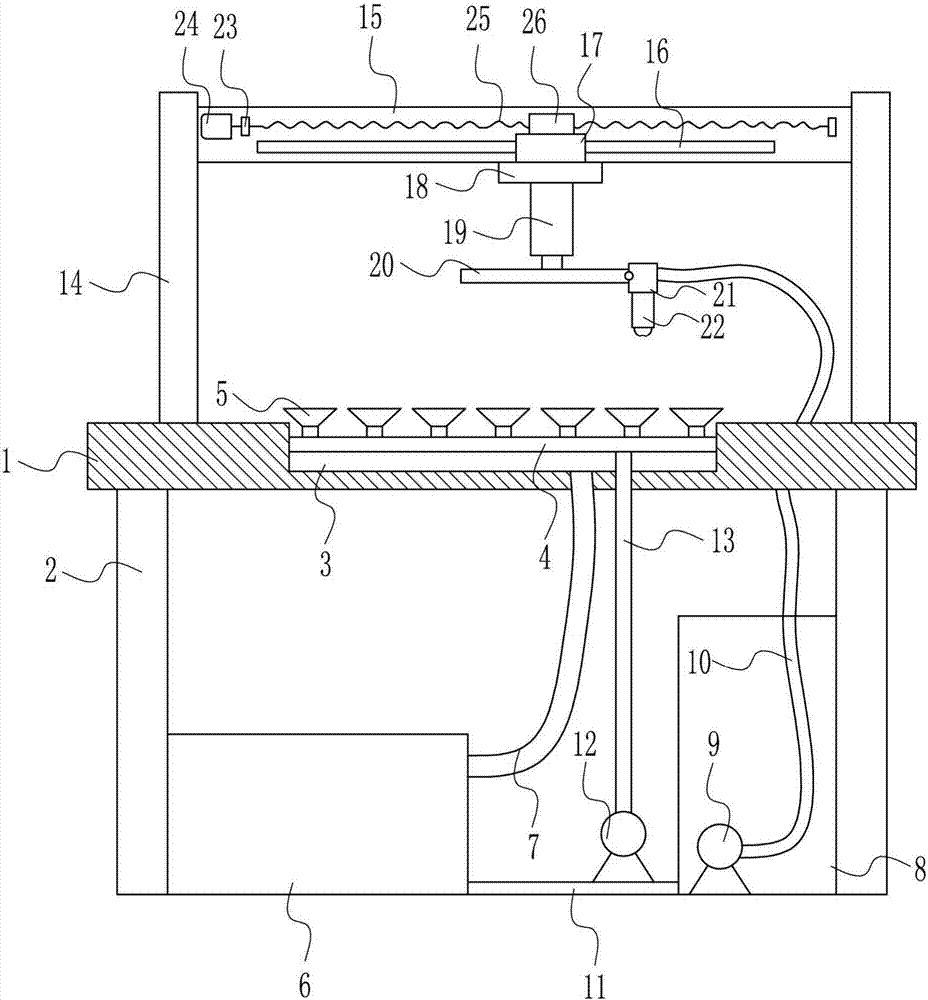

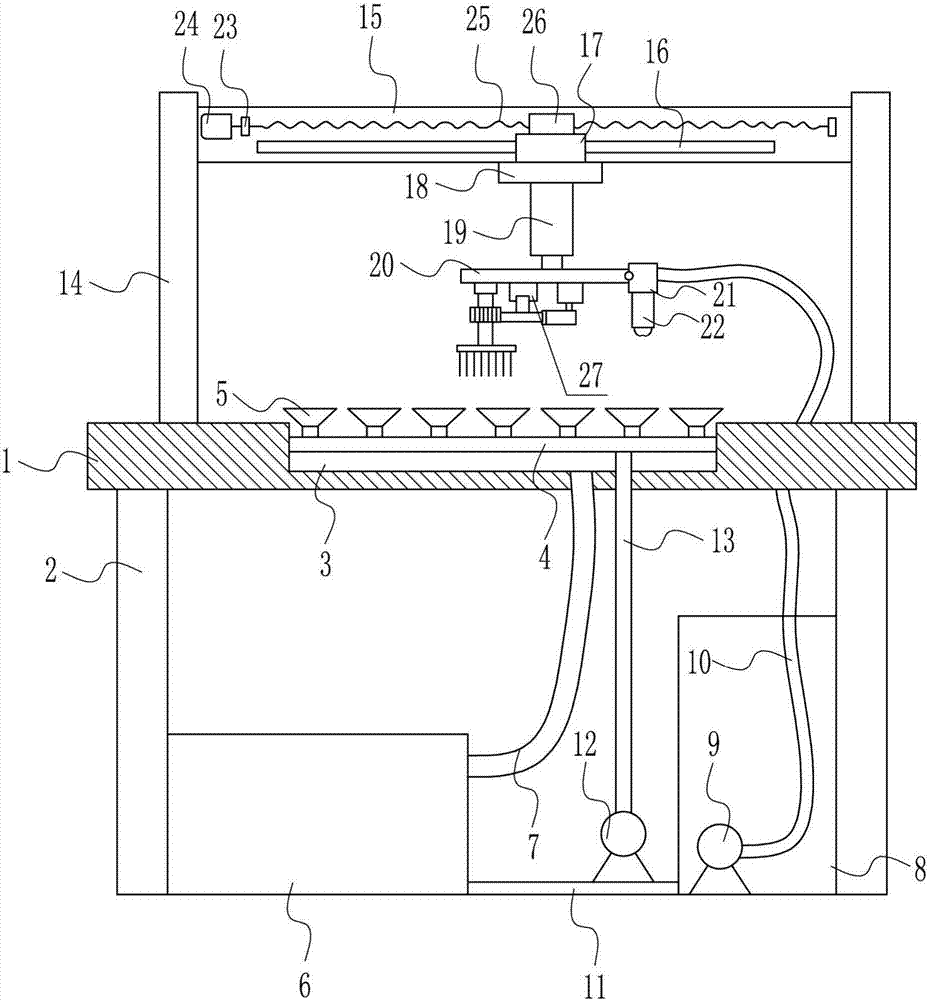

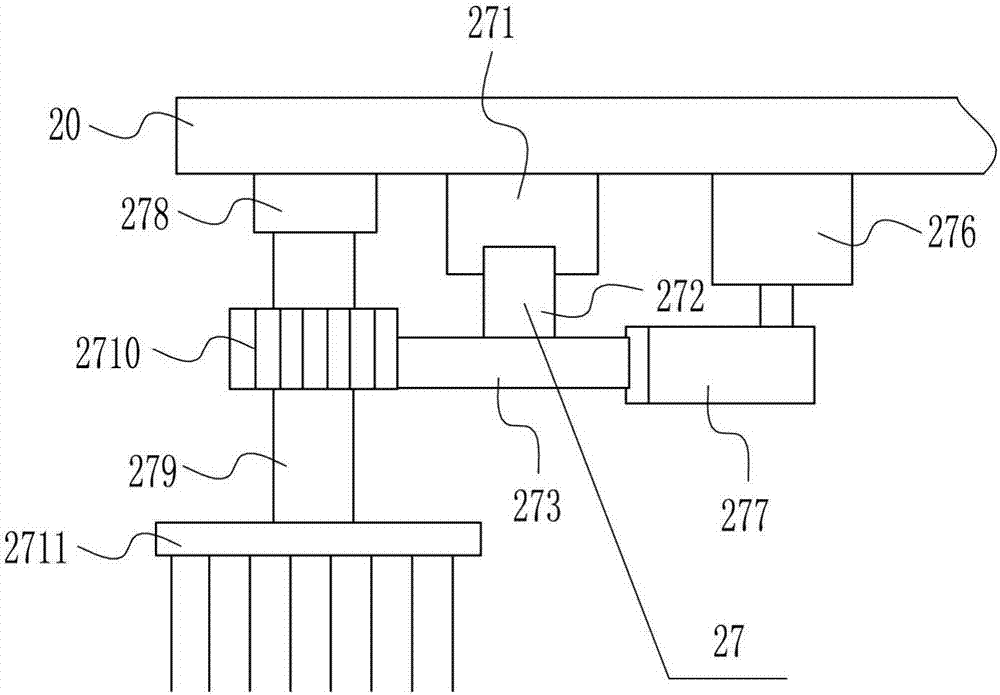

Epitaxial slice cleaning device for LED lamp production

InactiveCN106964588APrevent splashExpand the spraying areaSemiconductor/solid-state device manufacturingCleaning using toolsRefluxEngineering

The invention relates to an LED lamp production device, in particular to an epitaxial slice cleaning device for LED lamp production. The technical problem to be solved by the invention is to provide the epitaxial slice cleaning device for LED lamp production capable of saving both time and labors, improving the cleaning efficiency and protecting the health of workers. In order to solve the technical problem, the invention provides the epitaxial slice cleaning device for LED lamp production. The device comprises a worktable tabletop, support legs, a first air pipe, a vacuum sucker, a recovery water tank, a reflux water pipe, a solution tank, a water pump, a water outlet pipe, a support plate, a vacuum pump and the like; and the support legs are connected to the bottom of the worktable tabletop through a bolt connecting mode. A nozzle sprays out cleaning solution, and moves left and right to once clean more epitaxial slices, so that the effect of saving both time and labors is achieved, and the cleaning efficiency can be improved.

Owner:冯晓栋

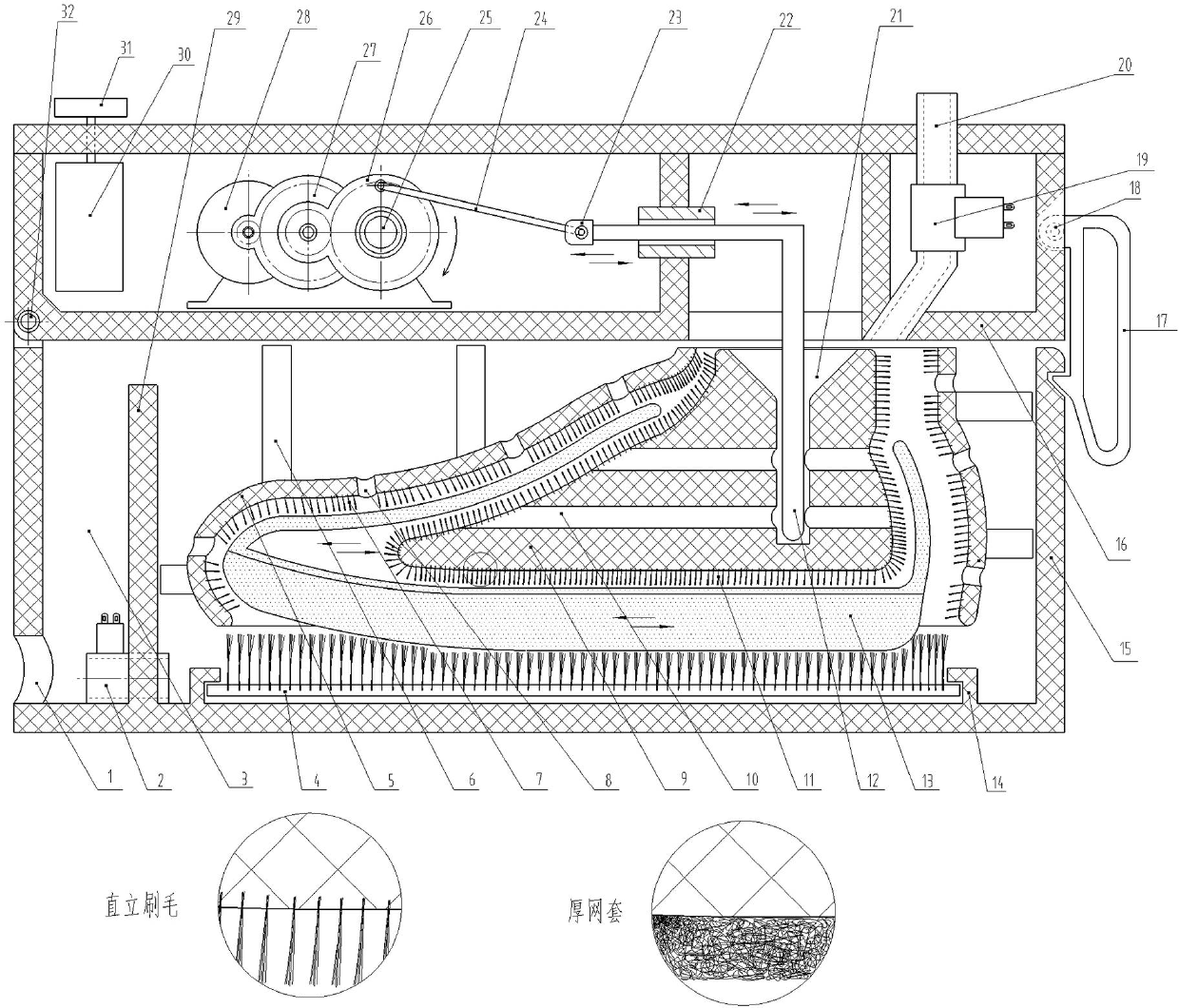

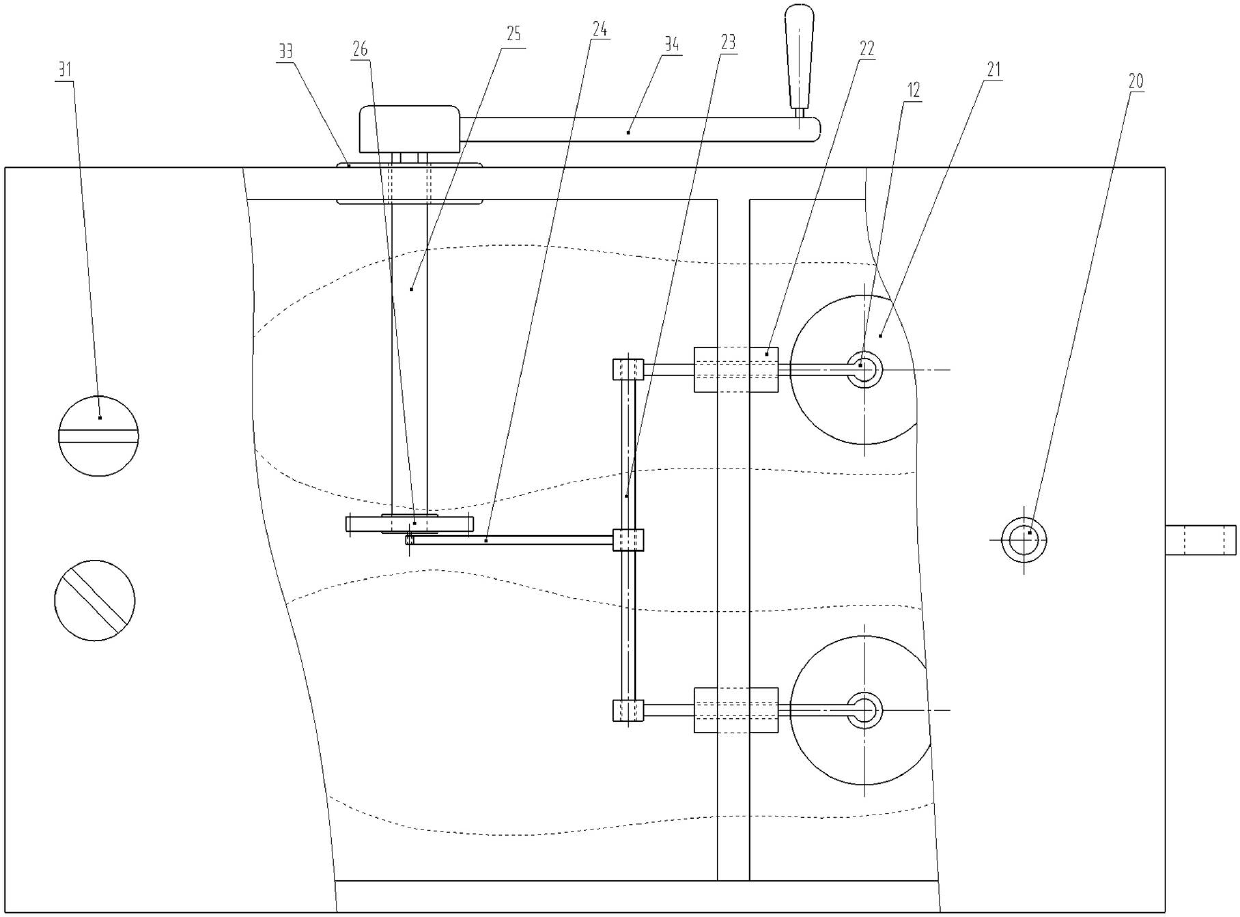

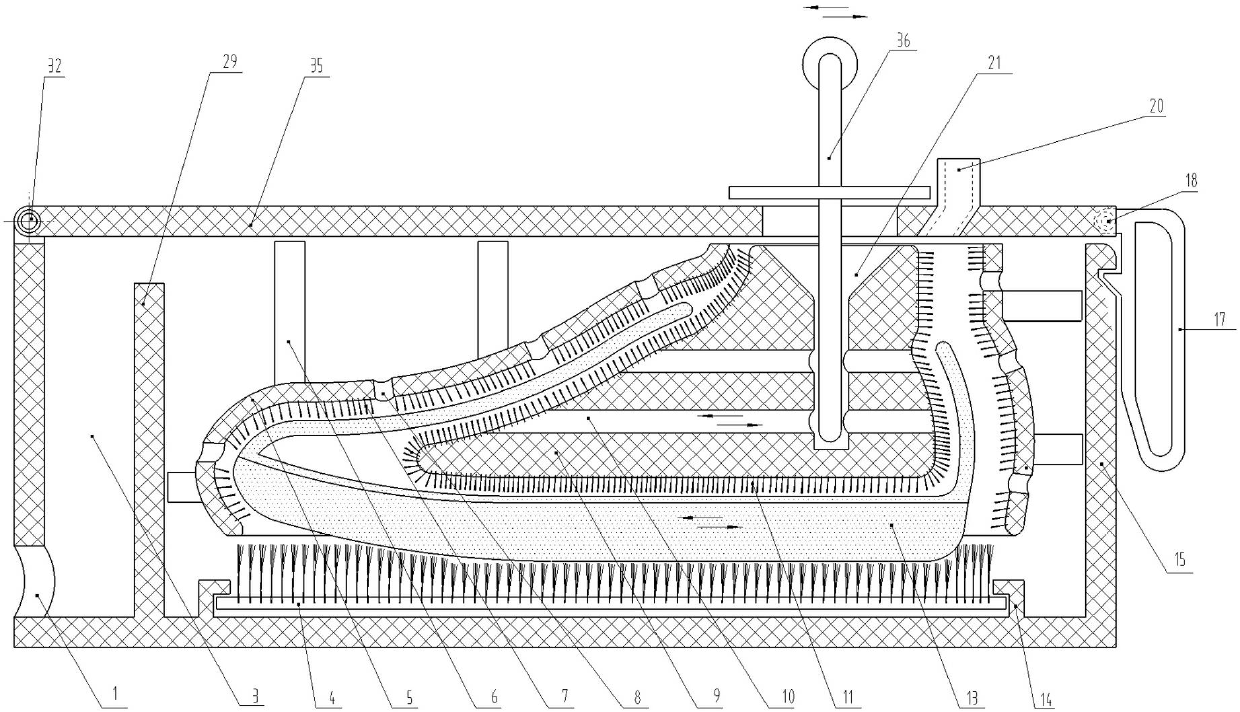

Profiling brush type shoe washing machine

InactiveCN102166115ALow production costReduce usageFootwear cleanersManufacturing cost reductionBristle

The invention relates to a shoe washing machine, in particular to a profiling brush type shoe washing machine. An internal profiling brush, the external surface of which is covered by a brush bristle structure, is placed into the internal space of each shoe; an external profiling brush, the internal surface of which is covered by a brush bristle structure, is sleeved outside the shoe; and then the shoe is immerged into a water washing tank with a washing solution; with brush bristles against a sole of the shoe, sole brushes are fixed in the water washing tank; and the internal profiling brushis driven by a power device to move in a reciprocating way so that the shoe can move relative to each part of brush bristles to achieve a purpose of cleaning; and the profiling brush type shoe washing machine of the invention, which has the advantages of small volume, simple structure and high washing efficiency, can effectively reduce energy consumption in use and reduce the manufacturing cost.

Owner:刘丰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com