Patents

Literature

88 results about "Robot workspace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

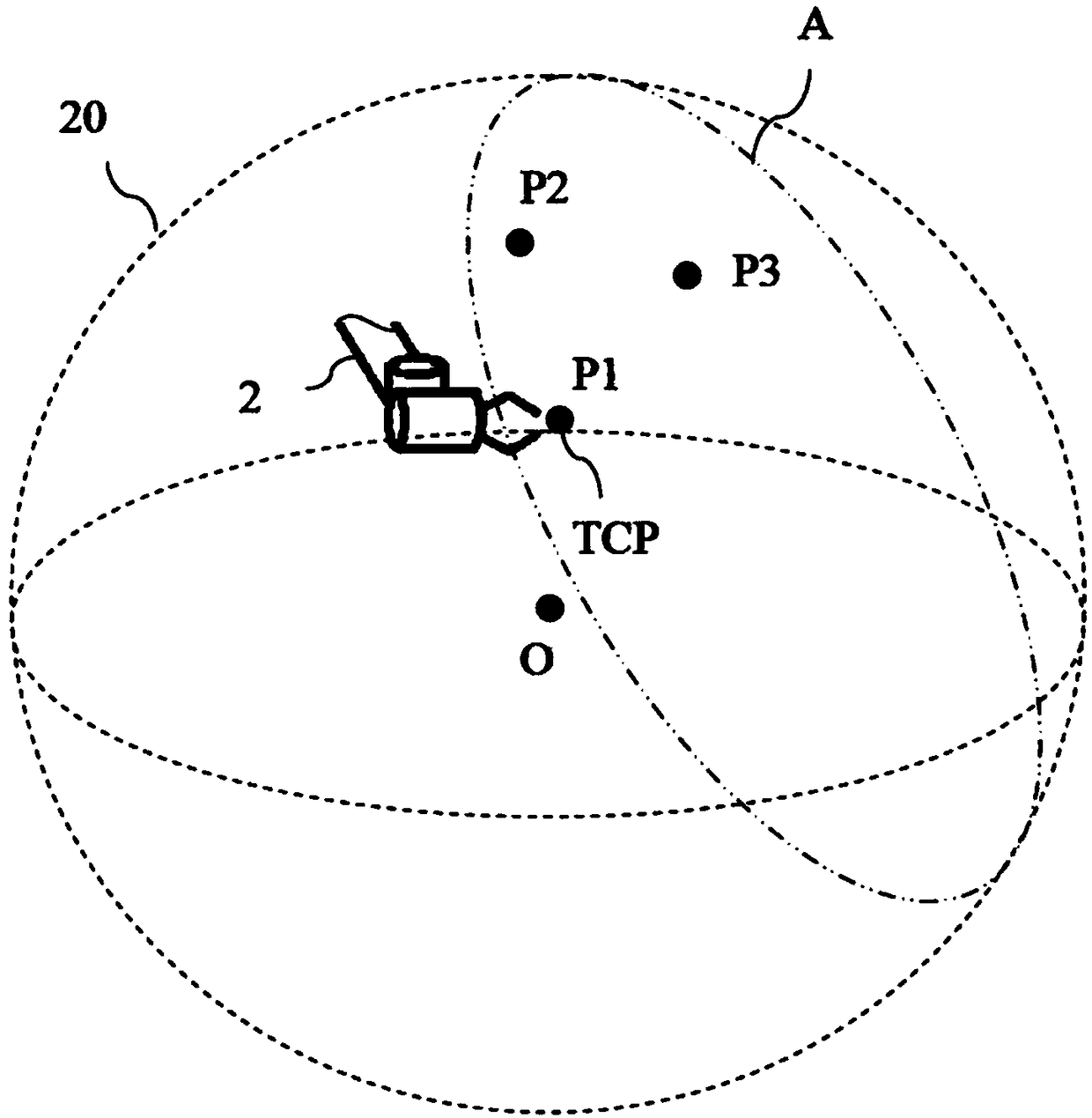

A robot's workspace is the total volume swept out by the end effector as the manipulator executes all possible motions.

Parallel kinematic machine trajectory planning method

InactiveUS20120290131A1Minimize timeMinimizing energyProgramme-controlled manipulatorComputer controlData setParallel kinematics

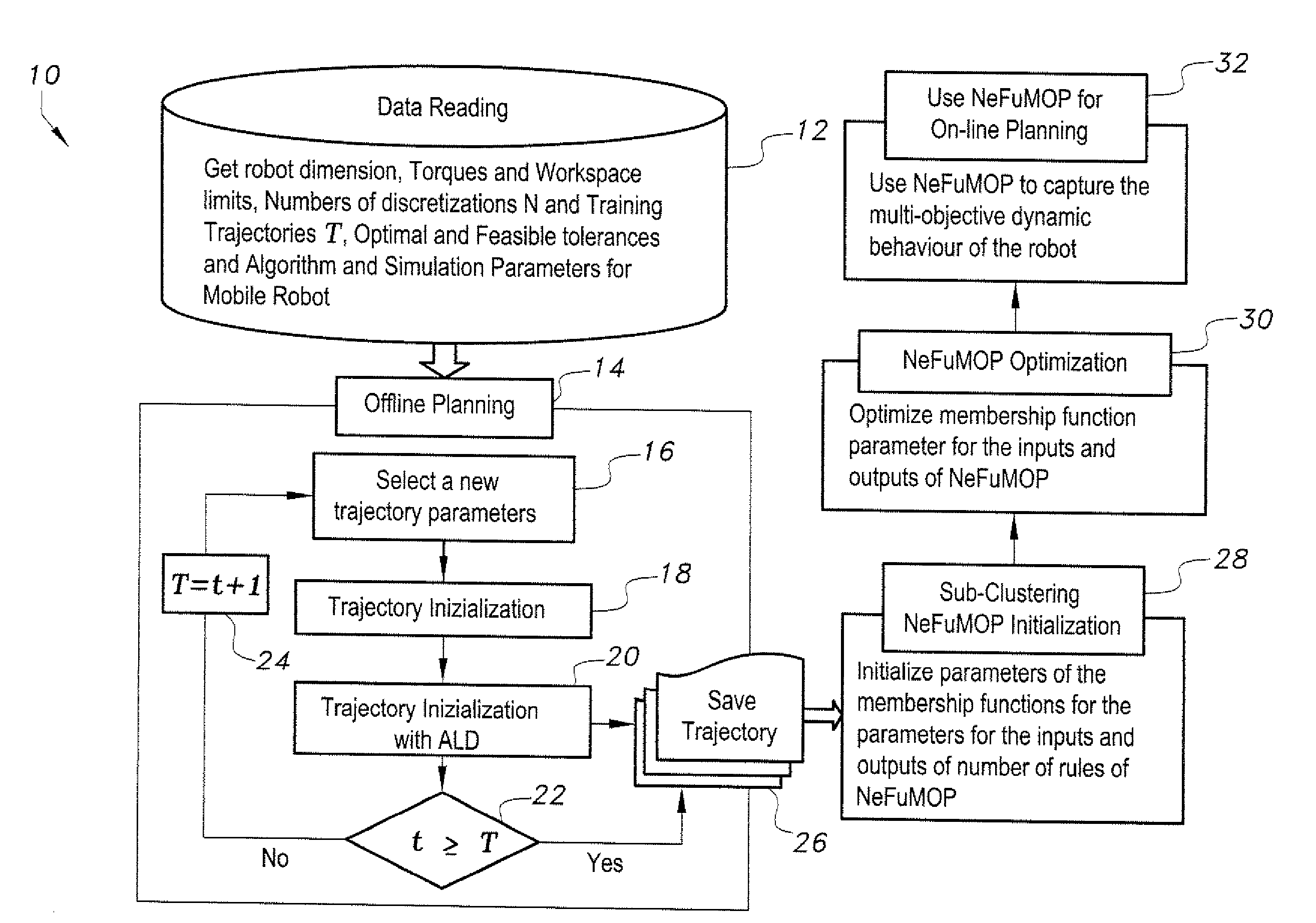

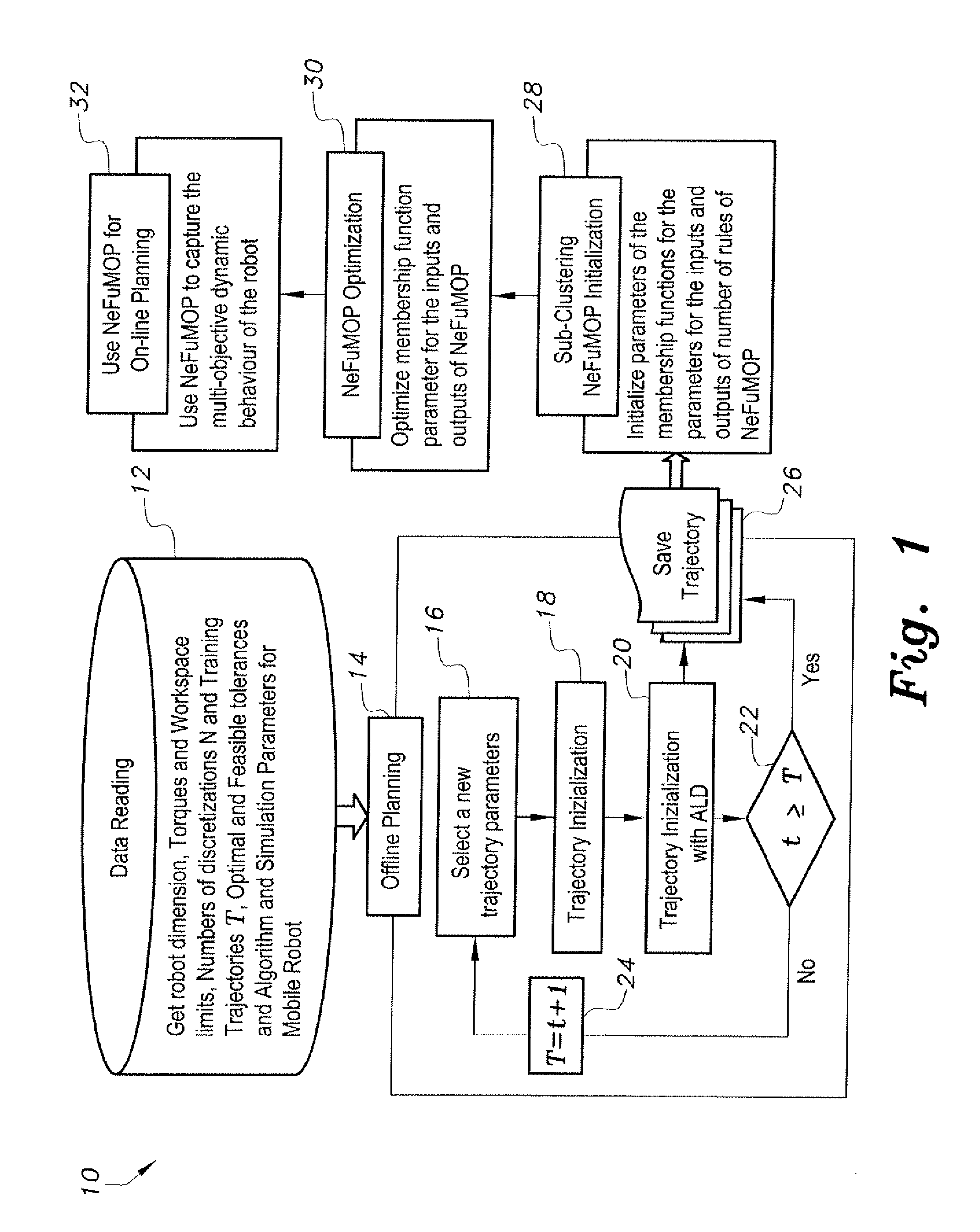

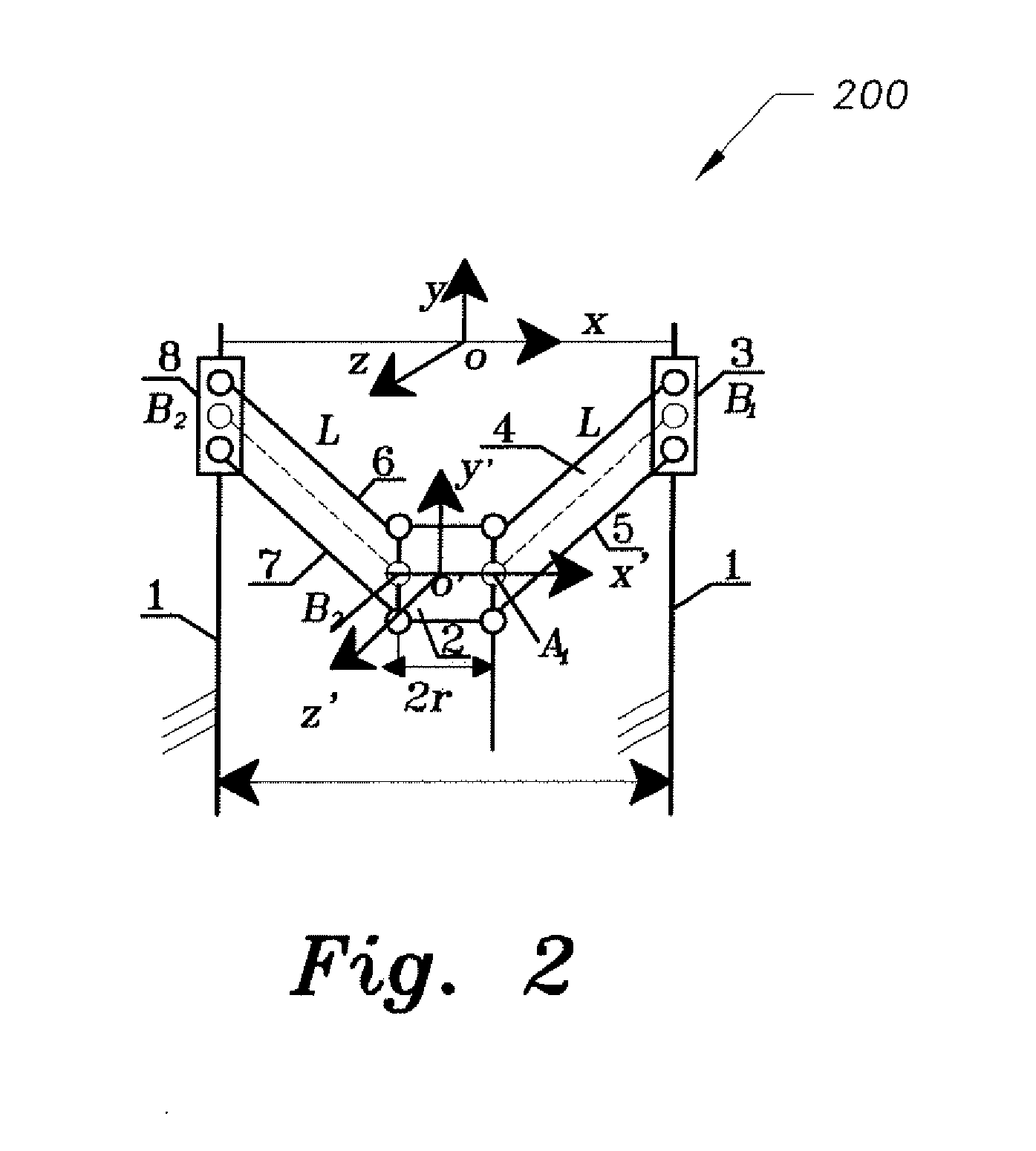

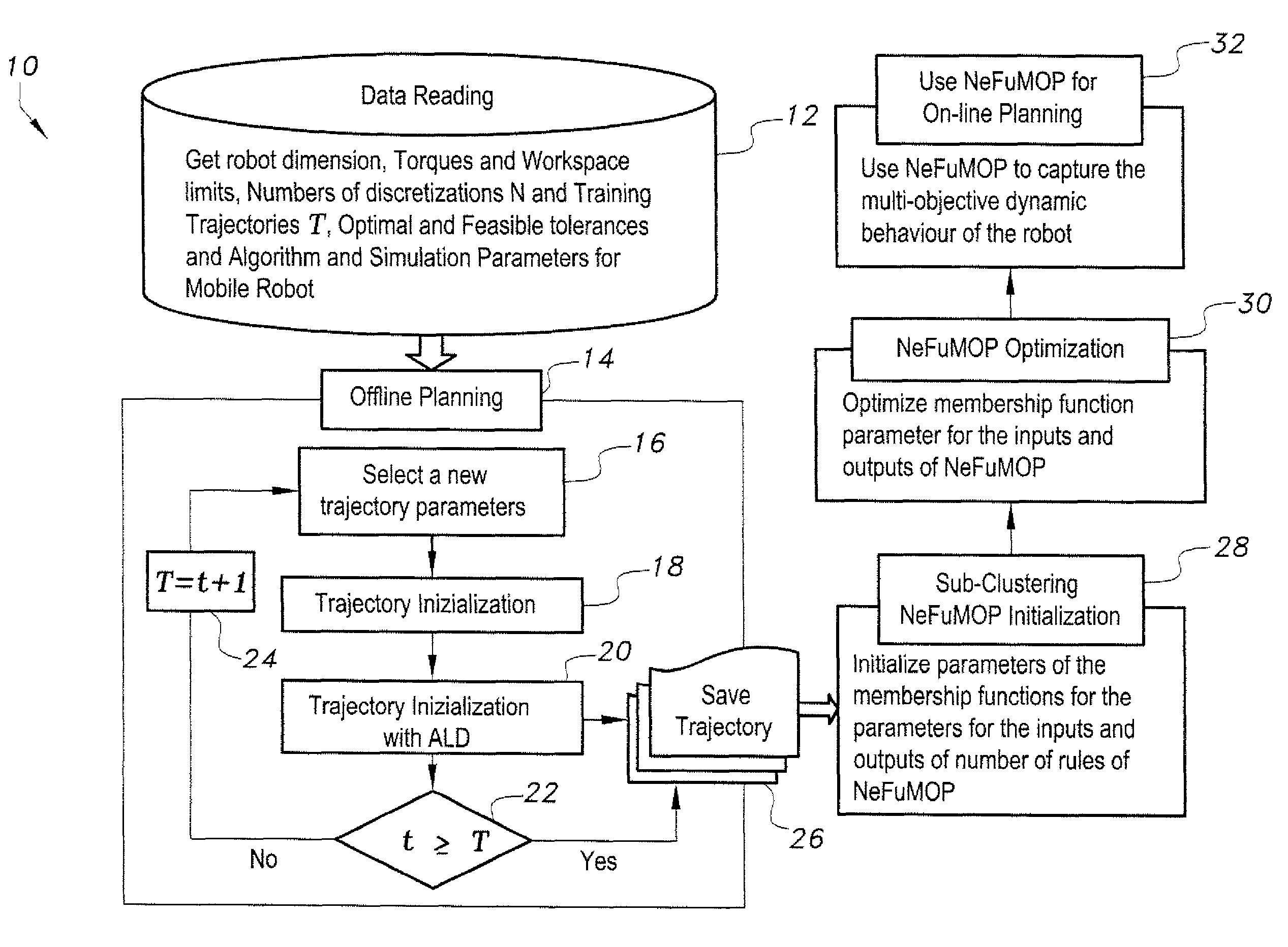

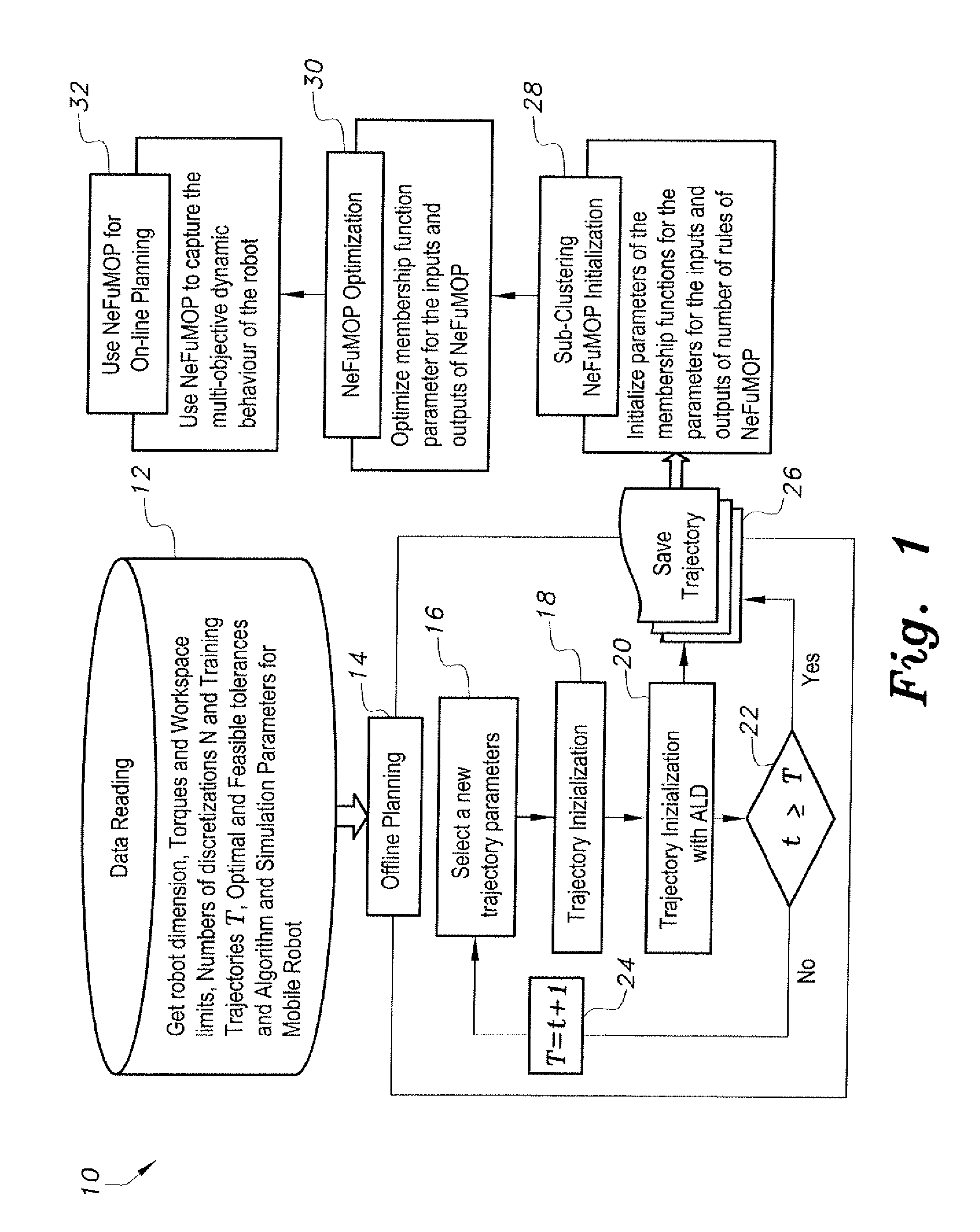

The parallel kinematic machine (PKM) trajectory planning method is operable via a data-driven neuro-fuzzy multistage-based system. Offline planning based on robot kinematic and dynamic models, including actuators, is performed to generate a large dataset of trajectories, covering most of the robot workspace and minimizing time and energy, while avoiding singularities and limits on joint angles, rates, accelerations and torques. The method implements an augmented Lagrangian solver on a decoupled form of the PKM dynamics in order to solve the resulting non-linear constrained optimal control problem. Using outcomes of the offline-planning, the data-driven neuro-fuzzy inference system is built to learn, capture to and optimize the desired dynamic behavior of the PKM. The optimized system is used to achieve near-optimal online planning with a reasonable time complexity. The effectiveness of the method is illustrated through a set of simulation experiments proving the technique on a 2-degrees of freedom planar PKM.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

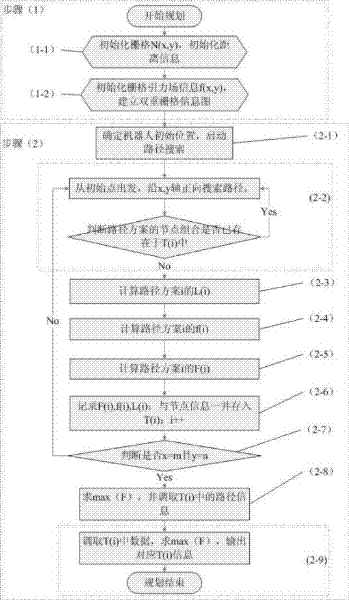

Physical modeling-based robot obstacle avoidance path planning method

InactiveCN102520718AImprove efficiencyOvercome the disadvantage of not considering geometric attributesPosition/course control in two dimensionsObstacle avoidanceControl theory

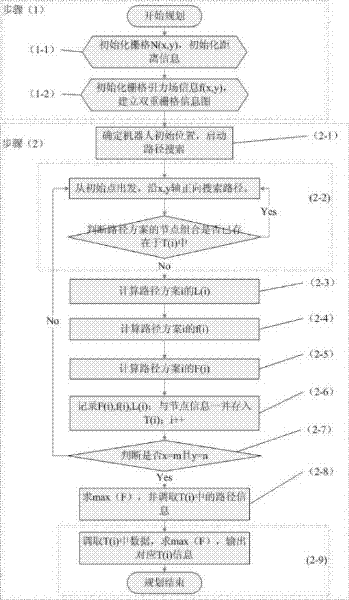

The invention discloses a physical modeling-based robot obstacle avoidance path planning method, which comprises the following steps of: setting a gravitational field grid and a distance information grid of a robot working region to establish a robot double-grid information graph; based on the double-grid information graph, searching all feasible paths by using a directional ergodic method; calculating a comprehensive evaluation value of a gravity value and a distance value; and taking a path scheme corresponding to the maximum value as a robot optimal obstacle avoidance path planning scheme.By using the method, the defect that geometric attributes of moving objects and obstacles in robot path planning are not considered is overcome; during path searching after double grids are established by the method, robot obstacle avoidance path planning is performed according to the value of the double grids; and thus, the problems of the shortest path and moving safety are both taken into consideration, the efficiency of path planning is increased, and damage accidents which probably occur in path optimization are reduced.

Owner:SHANGHAI UNIV

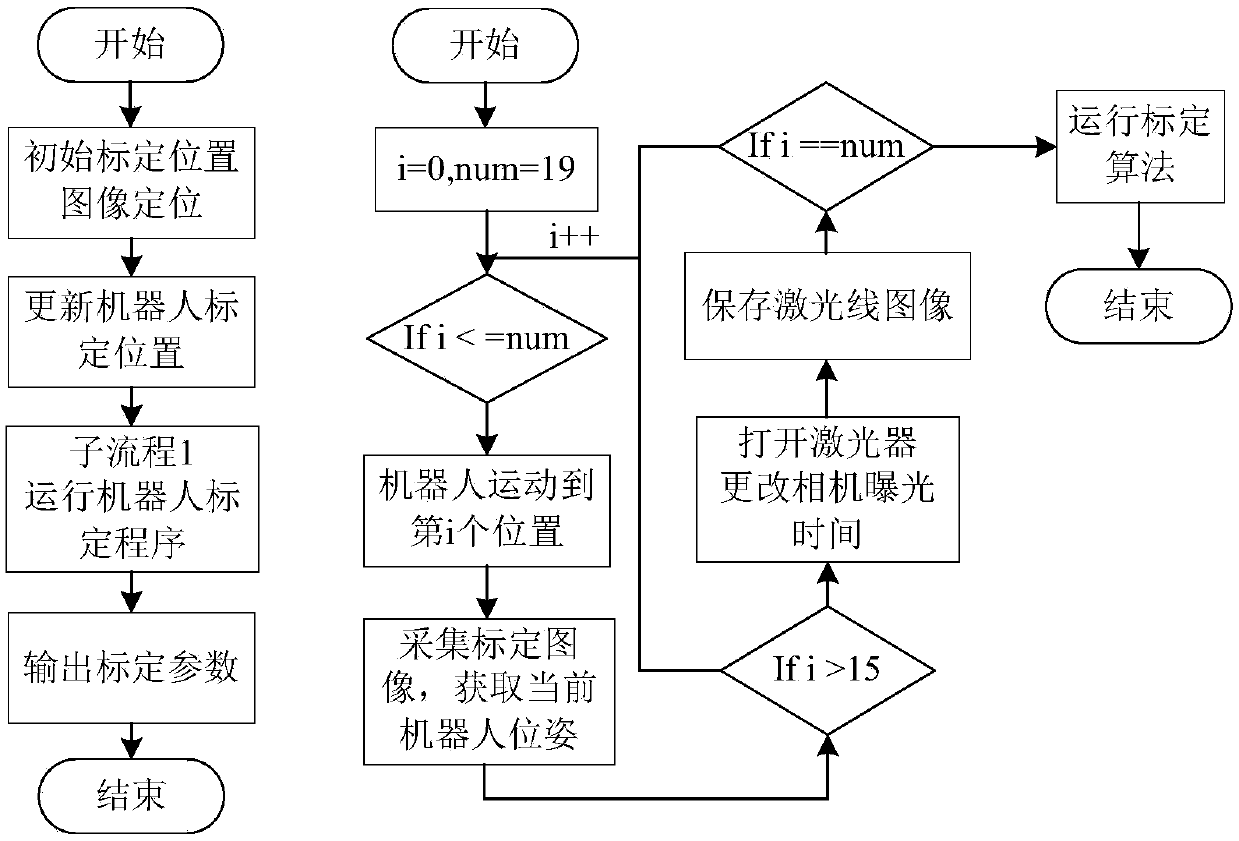

Automatic calibration method for line structured light visual system of arc welding robot

ActiveCN108717715AHigh precisionIncrease flexibilityImage analysisManipulatorEngineeringRobot workspace

The invention discloses an automatic calibration method for a line structured optical visual system of an arc welding robot. The method comprises the steps of: 1, placing a calibration plate at any position in a working area of the robot according to a predetermined constraint limit; 2, manually manipulating the robot to ensure that the position of the calibration plate is in a rectangular frame in the middle of a collected image and updating the position component of each collection point in a robot calibration program on the basis; 3, collecting 15 calibration plate images in 15 positions and calibration plate images in other 4 positions and the corresponding laser stripe images; and 4, calculating internal parameters of a camera and hand-eye relationship parameters through the collectedprevious 15 images and calculating structured light plane parameters through the collected latter four images. The method disclosed by the invention has the advantages that image positioning is onlycarried out on the first collection position of the calibration plate and the subsequent positions are automatically updated through translation transformation with no need for human operation, so that the calibration method is convenient and quick, the flexibility and the rapidity are greatly increased and the method can meet the needs of actual production environments.

Owner:SOUTH CHINA UNIV OF TECH +1

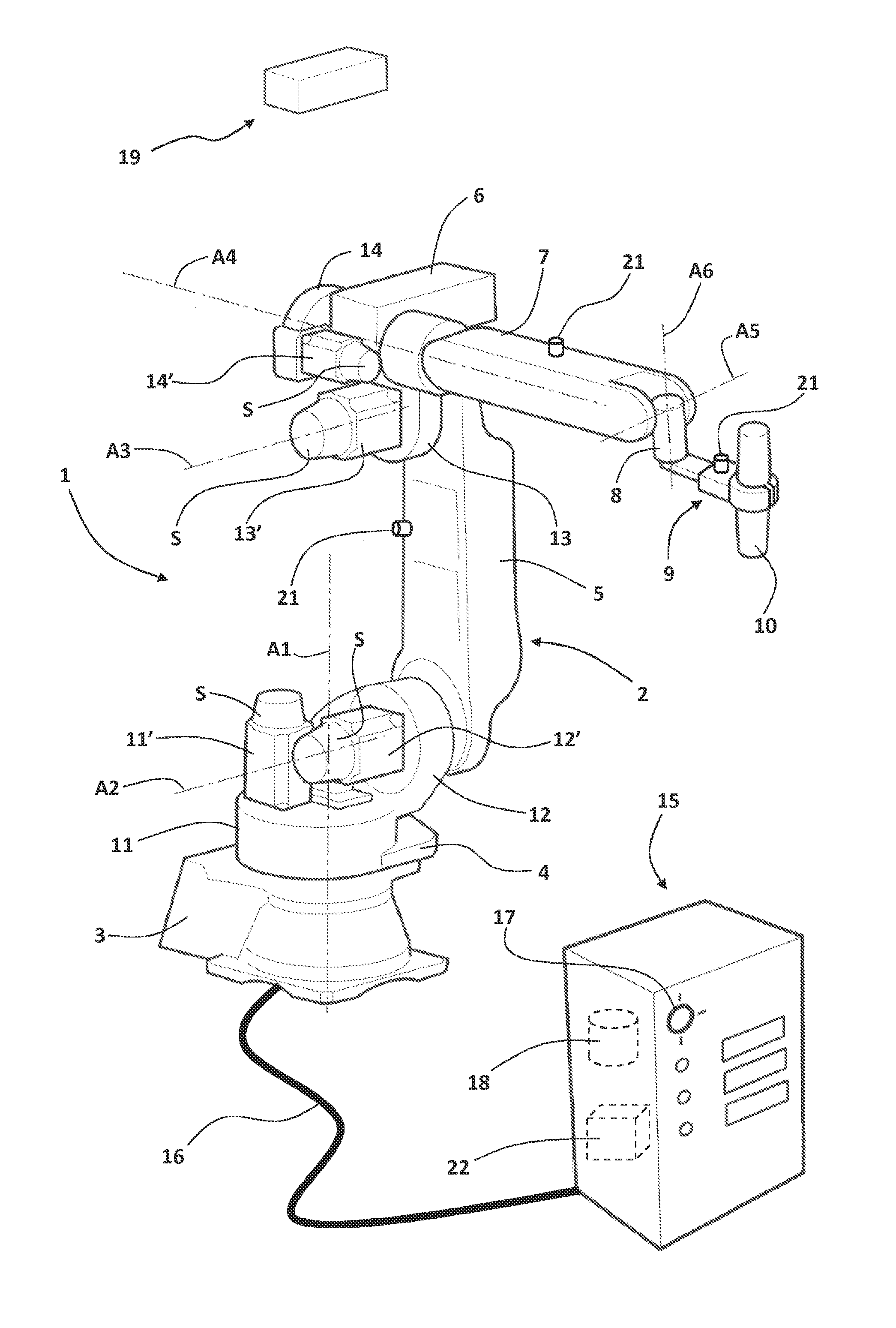

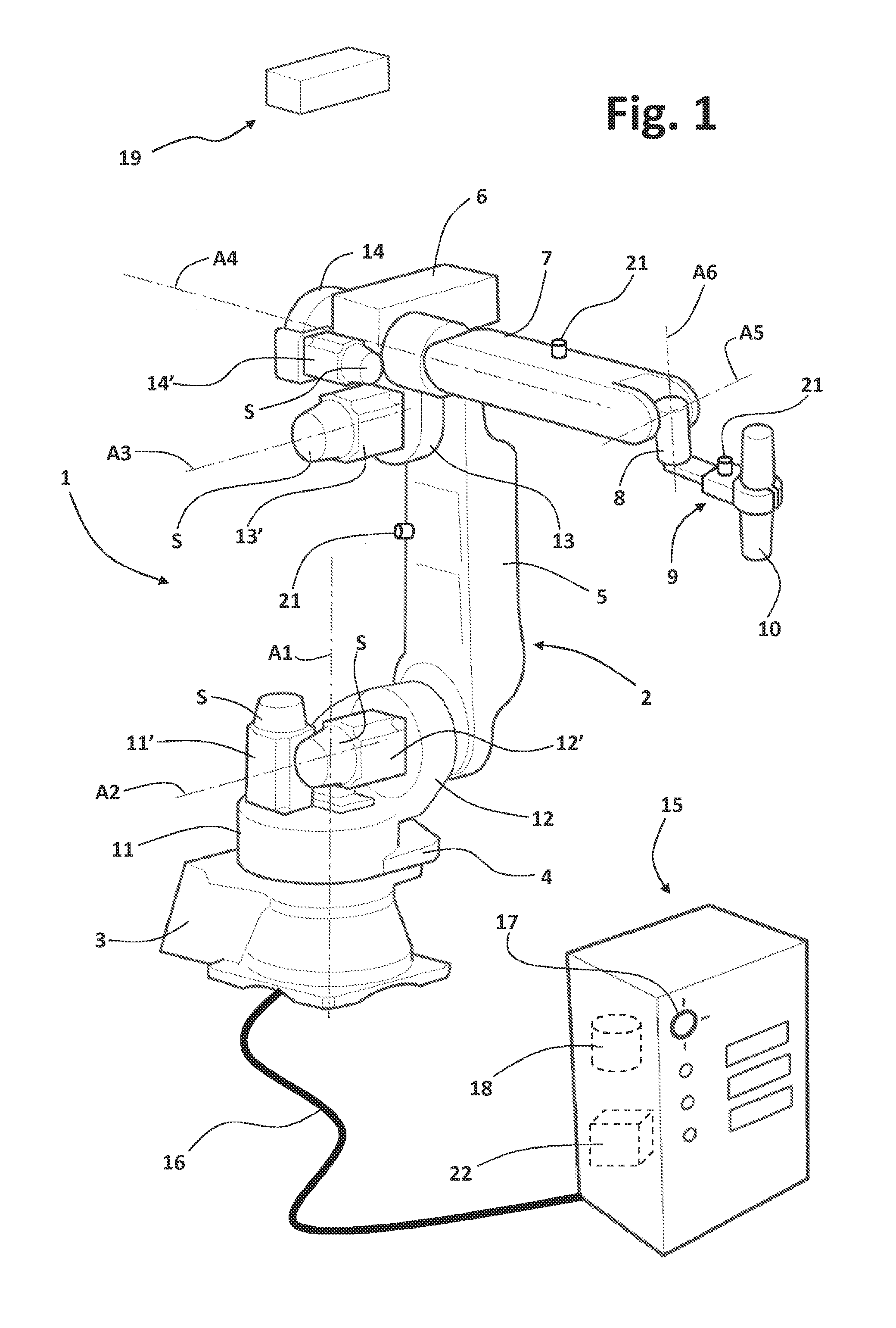

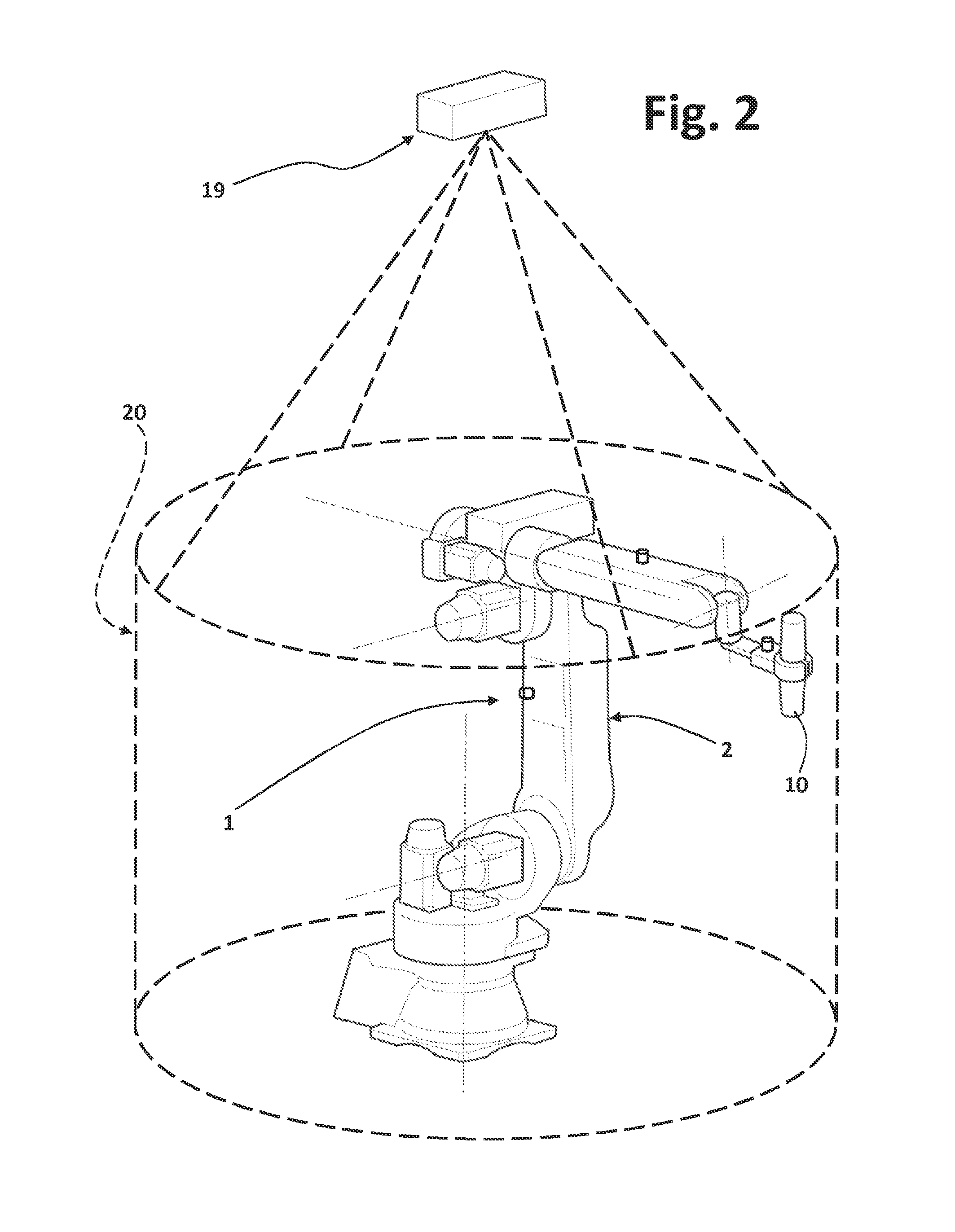

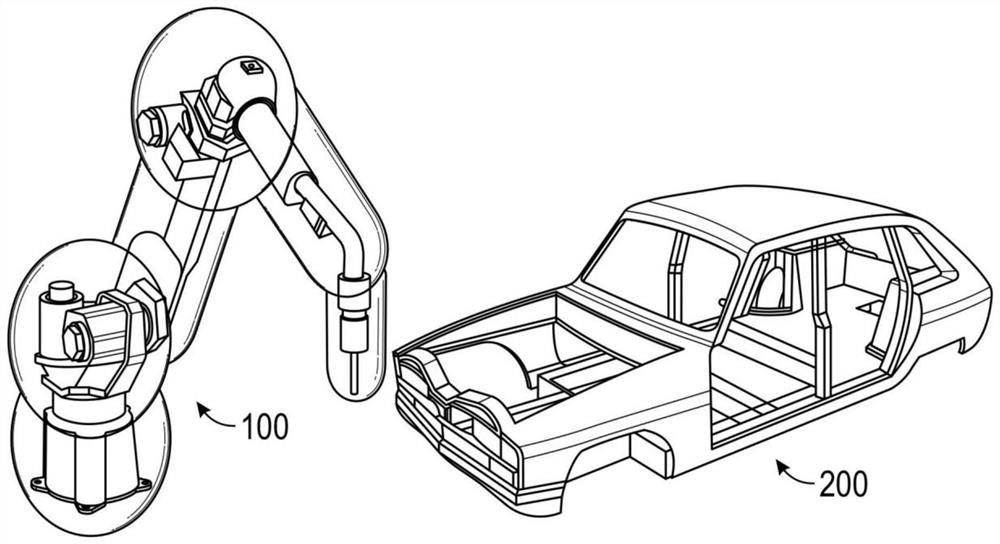

Industrial robot and a method for controlling an industrial robot

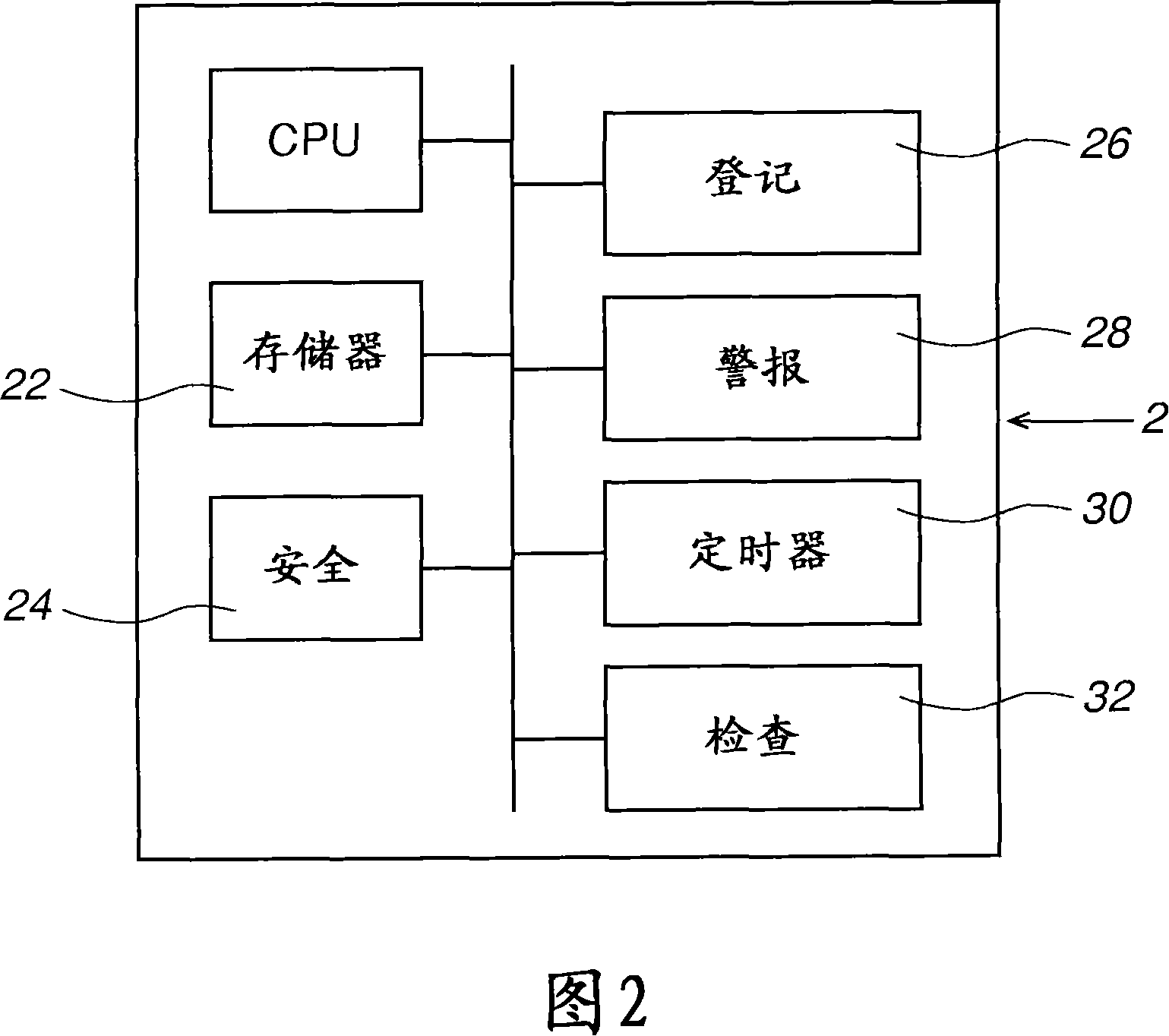

ActiveUS20160129595A1High degreeProgramme-controlled manipulatorComputer controlForeign matterControl system

An industrial robot and control system including a high degree of cooperation between a human operator and the robot for increased safety. In an automatic operation mode, at least a first detection device detects the presence of a foreign body in the robot working area and the control system places the robot in a safe automatic operating mode. A second and third detection devices may be employed to detect possible impacts with the robot.

Owner:COMAU SPA

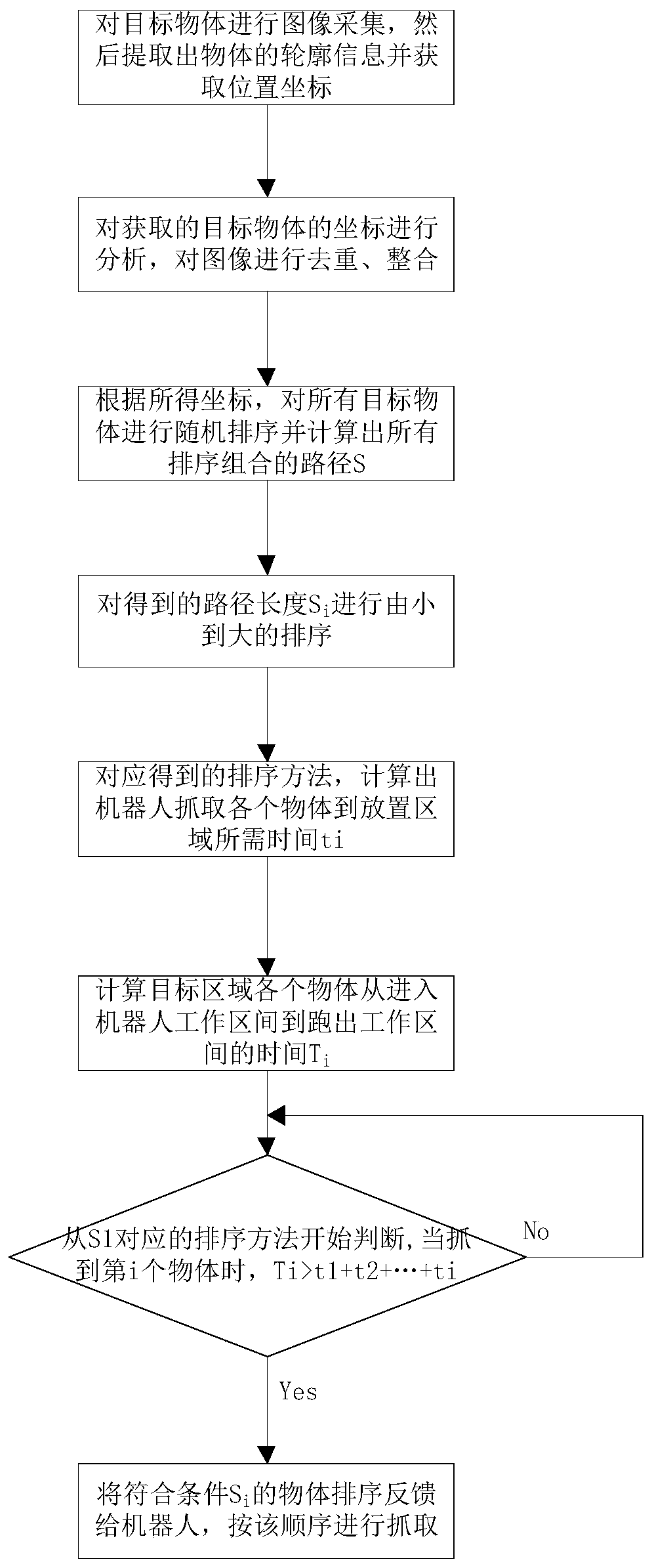

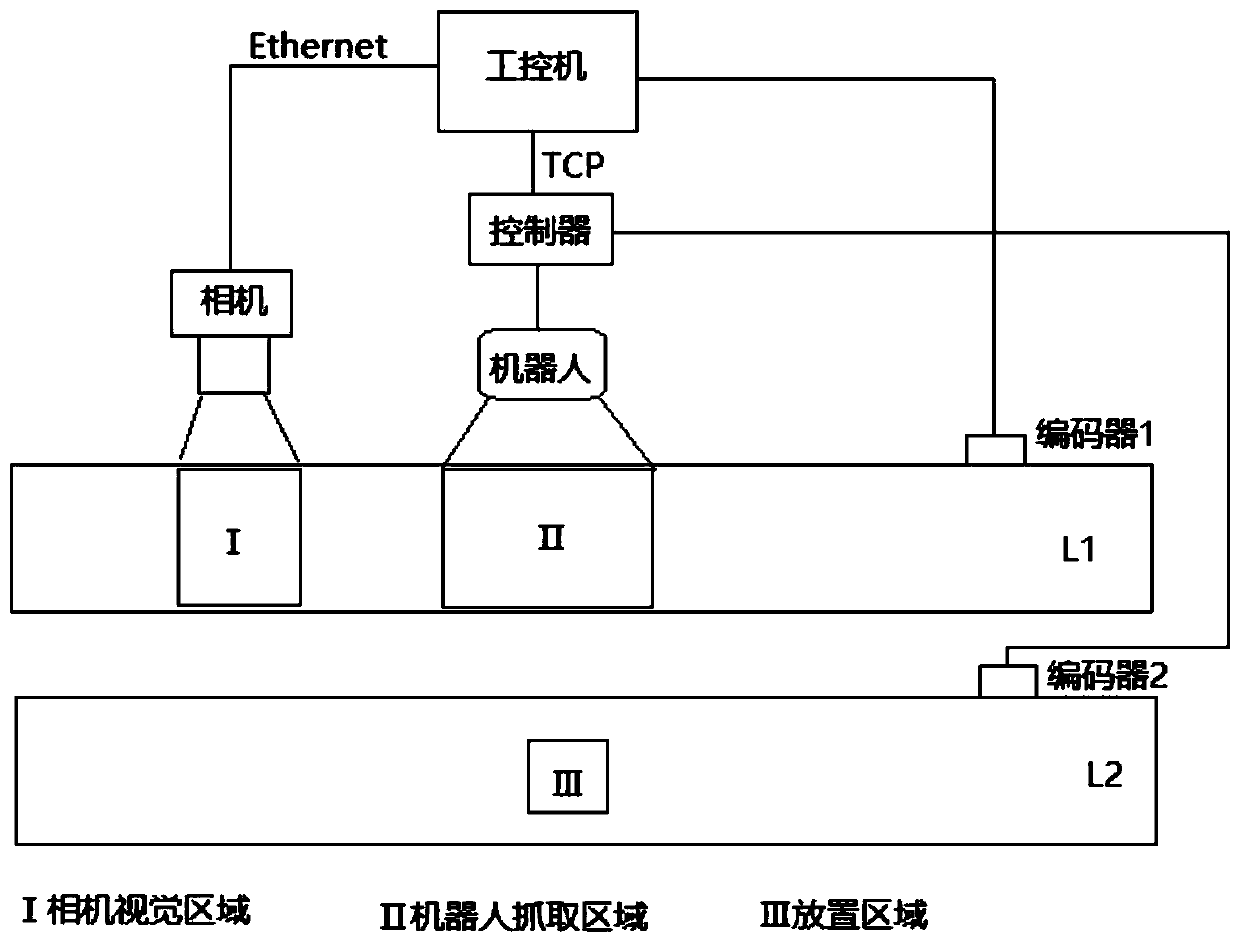

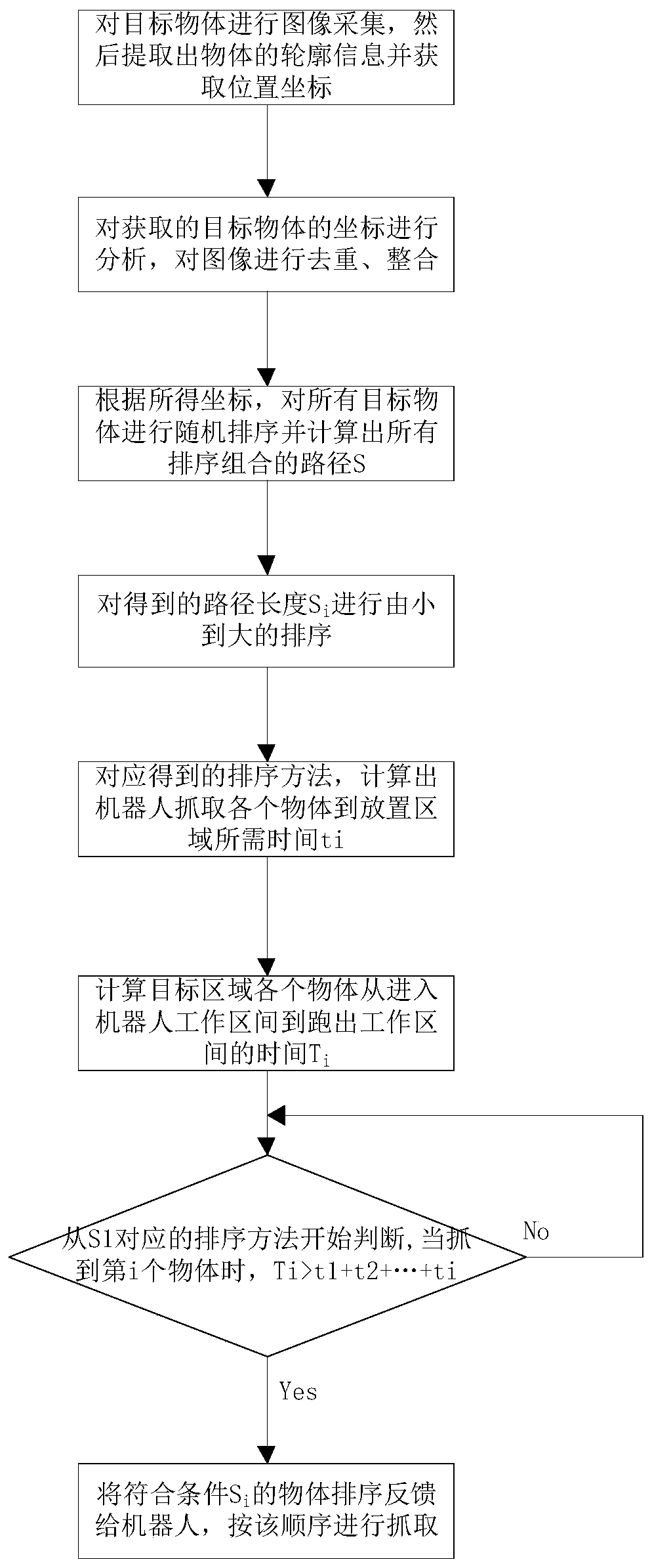

Method for optimizing robot grabbing sequence

InactiveCN109834712AShorten the crawl pathImprove crawling efficiencyProgramme-controlled manipulatorAlgorithmComputer vision

The invention discloses a method for optimizing the robot grabbing sequence. The method comprises the following steps: target objects are subjected to image collecting, then outline information of theobjects is extracted, and position coordinates are obtained; the obtained coordinates of the target objects are analyzed, and images are subjected to repetition removal and integration; according tothe obtained coordinates, all the target objects are sequenced at random, and routes S of all sequenced combinations are calculated; the obtained routes Si are sequenced from small to large; the needed time ti when a robot grabs all the objects to a placement area is calculated corresponding to obtained sequencing methods; the time Ti from entering a robot working interval to running out of the working interval of all the objects in a target area is calculated; and judging is started from the sequencing method corresponding to S1, when the i object is grabbed, if the relation that Ti is larger than t1+t2+...+ti is established, the condition is conformed, the object sequence conforming to the condition Si is fed back to the robot, grabbing is conducted accordingto the sequence, and if the relation is not established, grabbing is conducted according to the grabbing sequence corresponding to the route adopting the next sequencing method.

Owner:GUANGDONG UNIV OF TECH

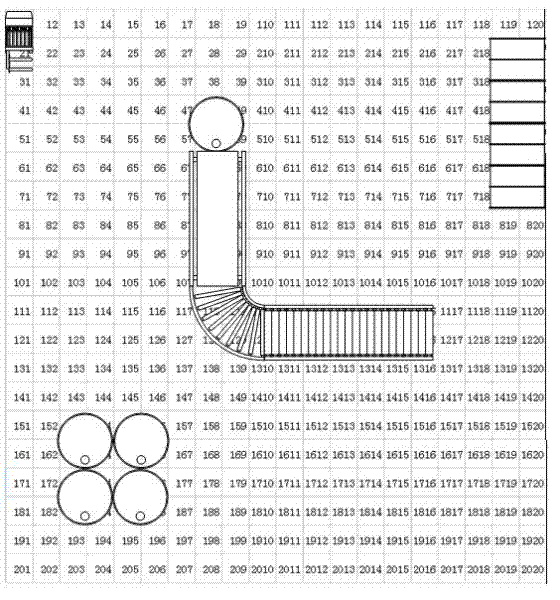

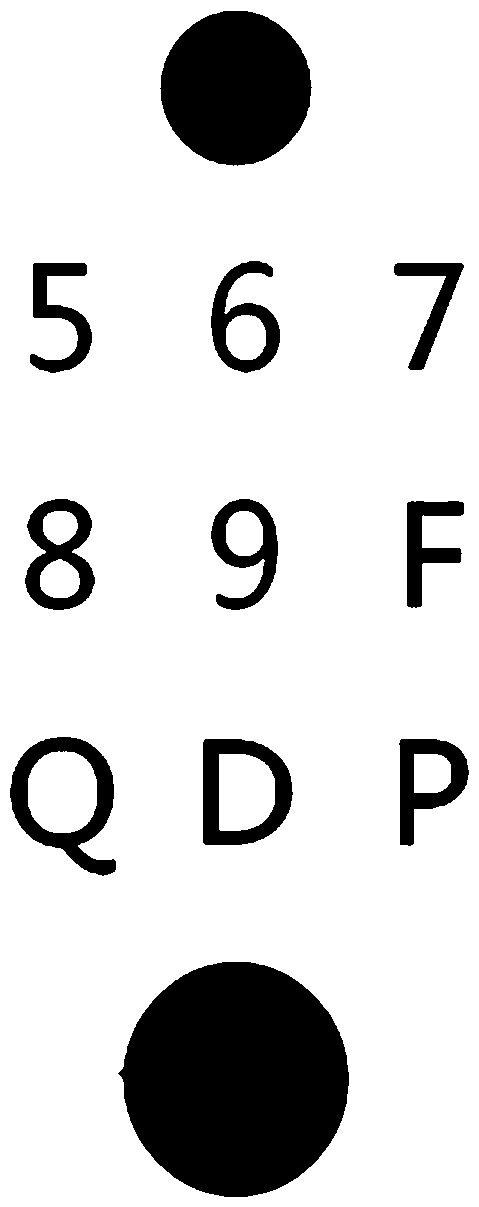

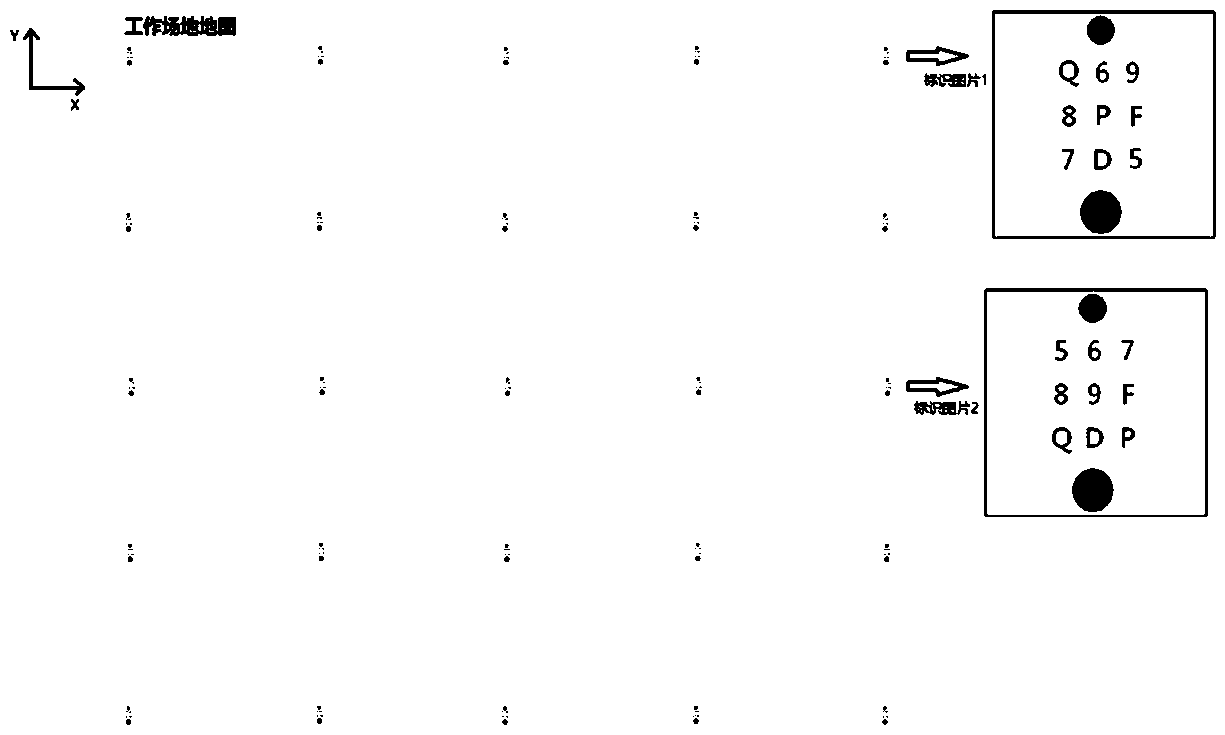

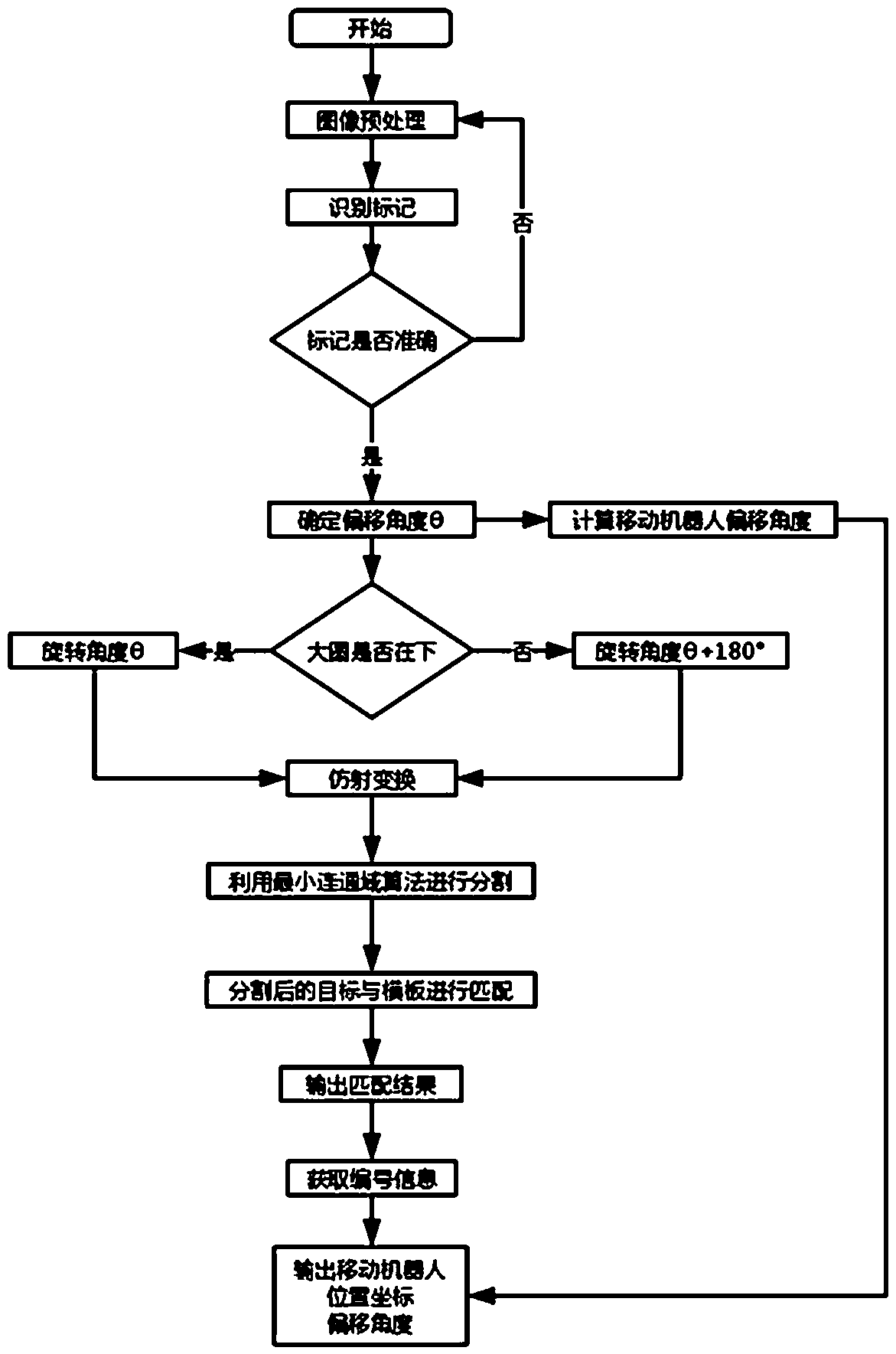

Method for positioning mobile robots on basis of digital letter recognition

ActiveCN107782305AEasy to readFlexible deploymentNavigational calculation instrumentsNavigation by terrestrial meansComputer visionRobot workspace

The invention provides a method for positioning mobile robots on the basis of digital letter recognition. The method includes manufacturing identification pictures and setting number identification for acquiring coordinate information and angle identification for acquiring direction and angle information on the identification pictures; placing working regions of the robots in world coordinate systems, laying a plurality of identification pictures in each working region and creating number identification-coordinate comparison tables; recognizing the number identification when the identificationpictures are photographed in robot advancing procedures, comparing the number identification to the number identification-coordinate comparison tables and acquiring the coordinate information corresponding to the current number identification; recognizing the angle identification and acquiring current advancing directions of the robots and deviation angles relative to the world coordinate systems. The method has the advantages that identification, which contains the coordinate information, in the identification pictures is digital letters, accordingly, sufficient number information can be acquired by the aid of the method and is easy and convenient to read, and information can be corrected read without alignment regardless of scanning at optional angles.

Owner:河南冠晶半导体科技有限公司

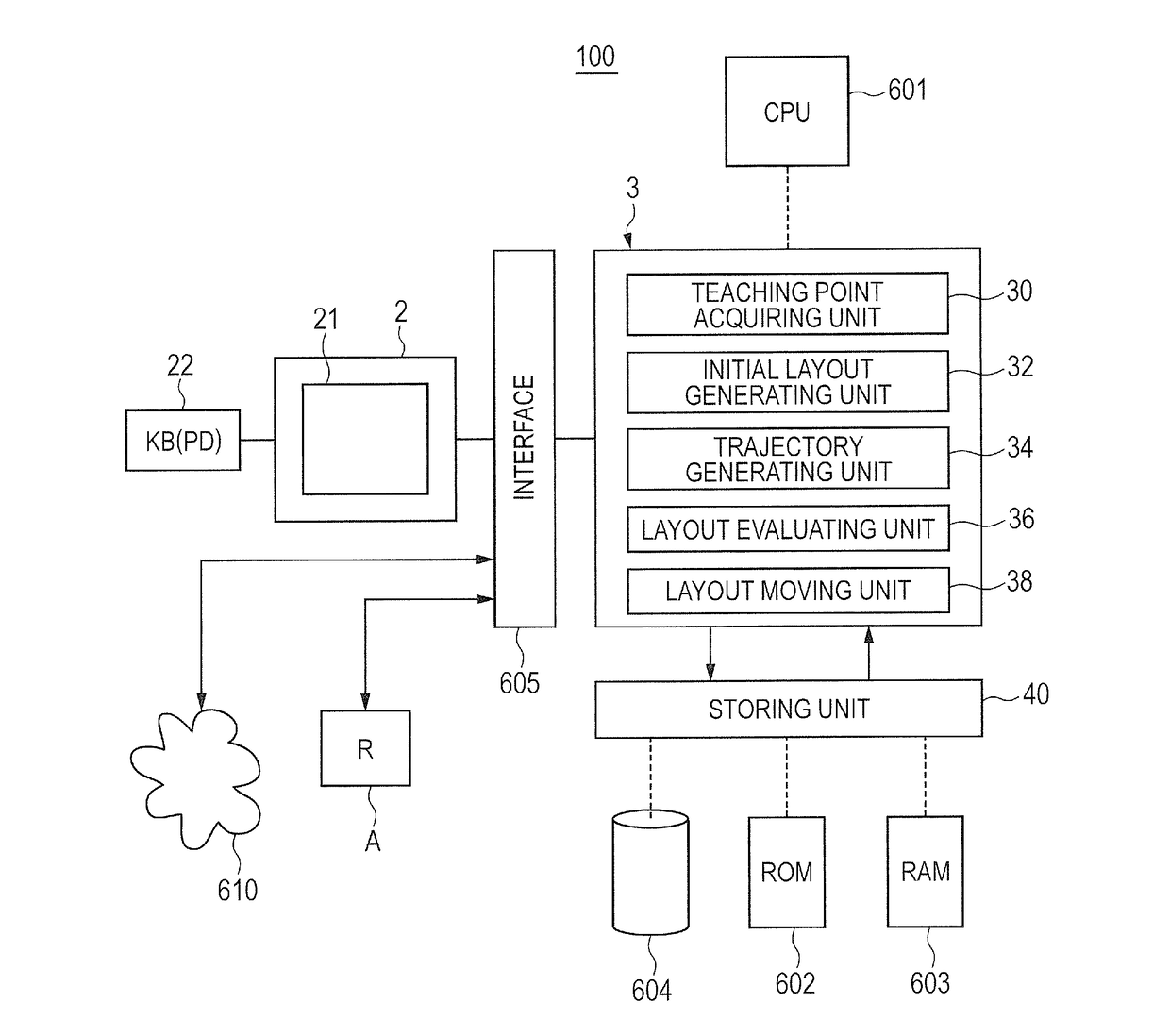

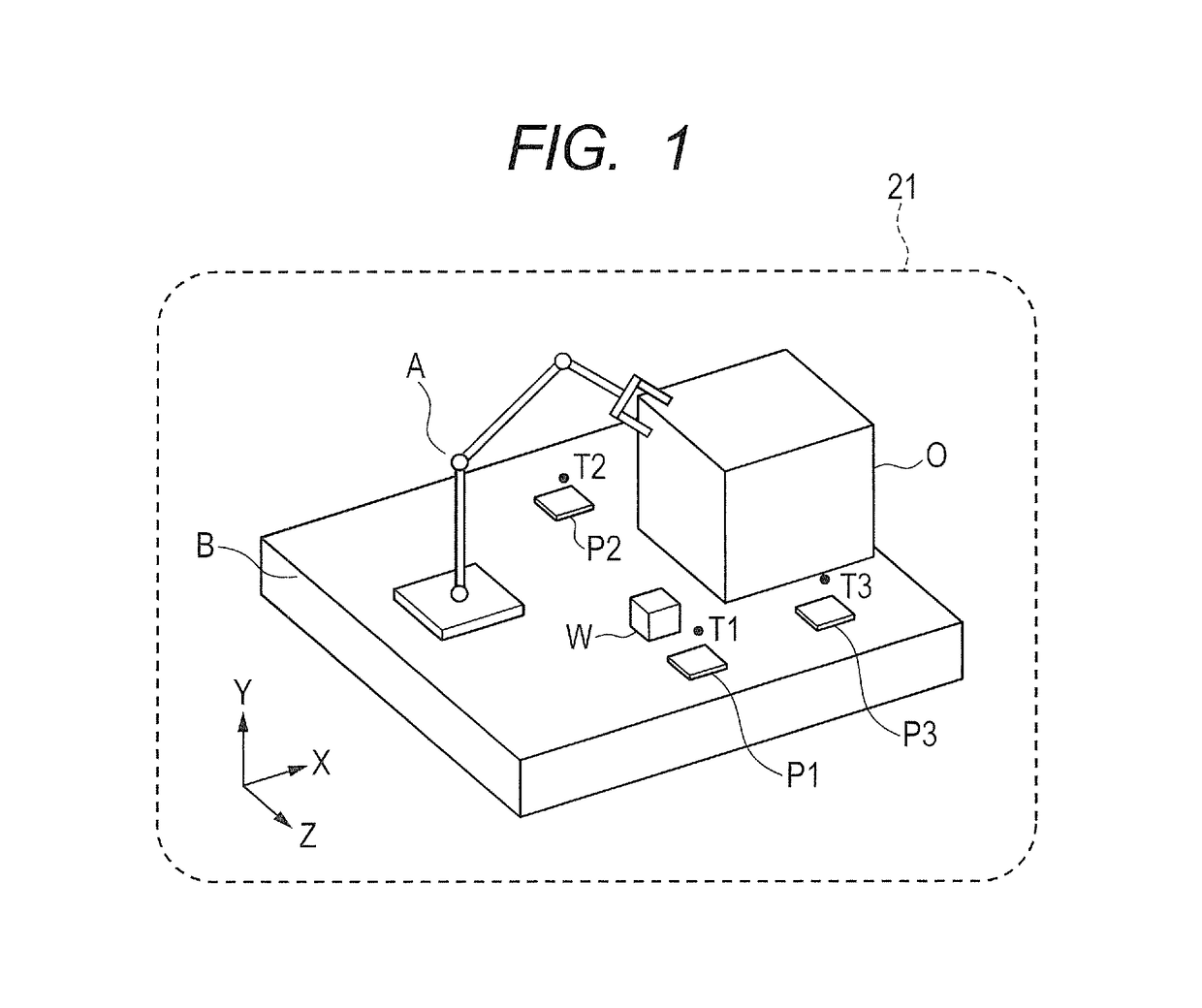

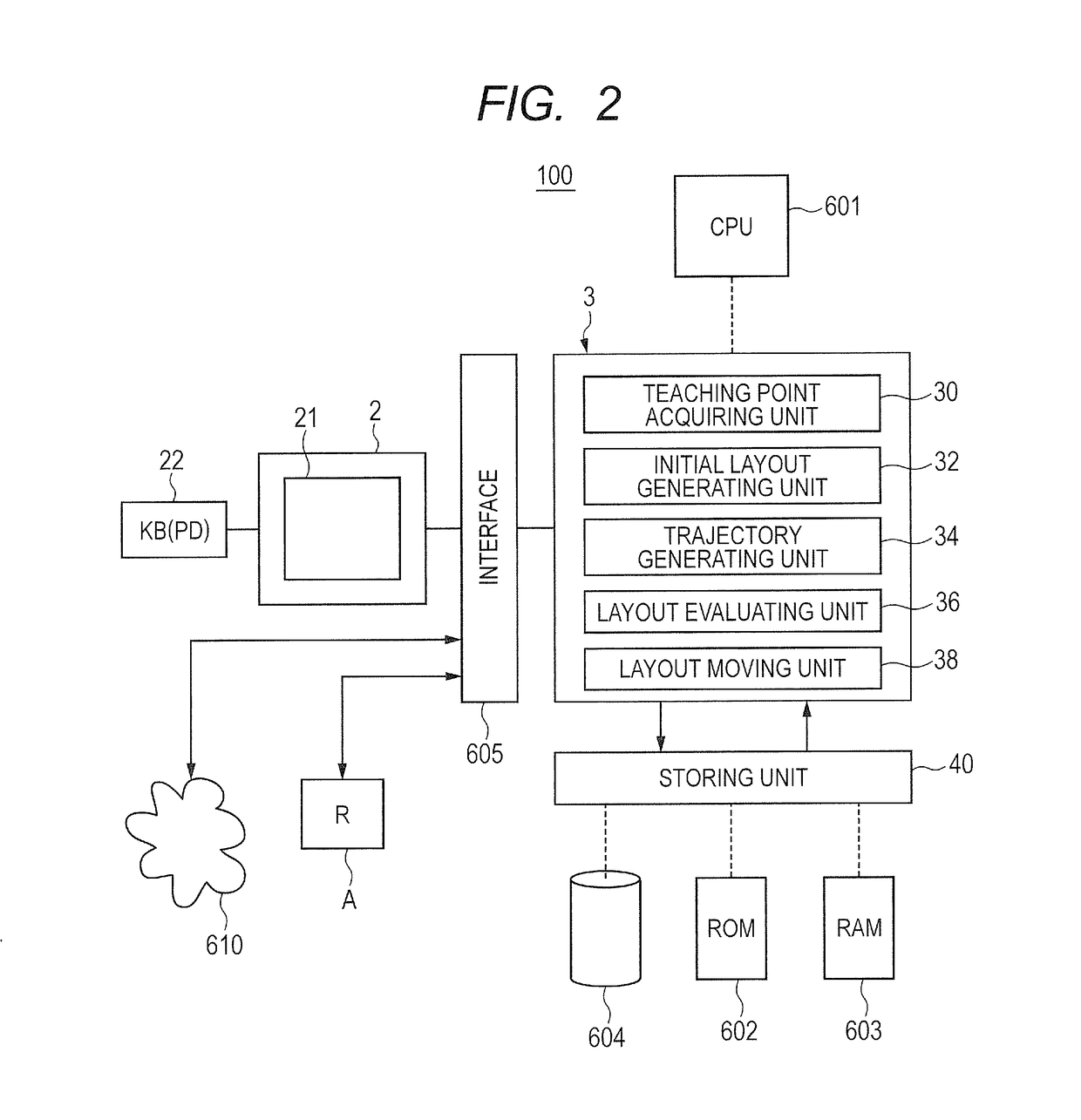

Layout setting method and layout setting apparatus

It becomes possible to optimize setting of a layout of a robot and a peripheral device efficiently and at high speed in a robot workspace. A teaching point acquiring unit acquires a teaching point which corresponds to a specific operation that a robot arm accesses the peripheral device, and through which it allows a reference region of the robot arm to pass. An initial layout generating unit generates an initial layout of the robot arm and the peripheral device. A trajectory generating unit generates a trajectory of the robot arm based on the teaching point. Layout evaluating and layout moving units generate a new layout by changing an arrangement of each device based on the initial layout using a meta-heuristic calculation, set an evaluation value concerning fitness for the specific operation in the initial layout or the new layout, and set the layout based on the set evaluation value.

Owner:CANON KK

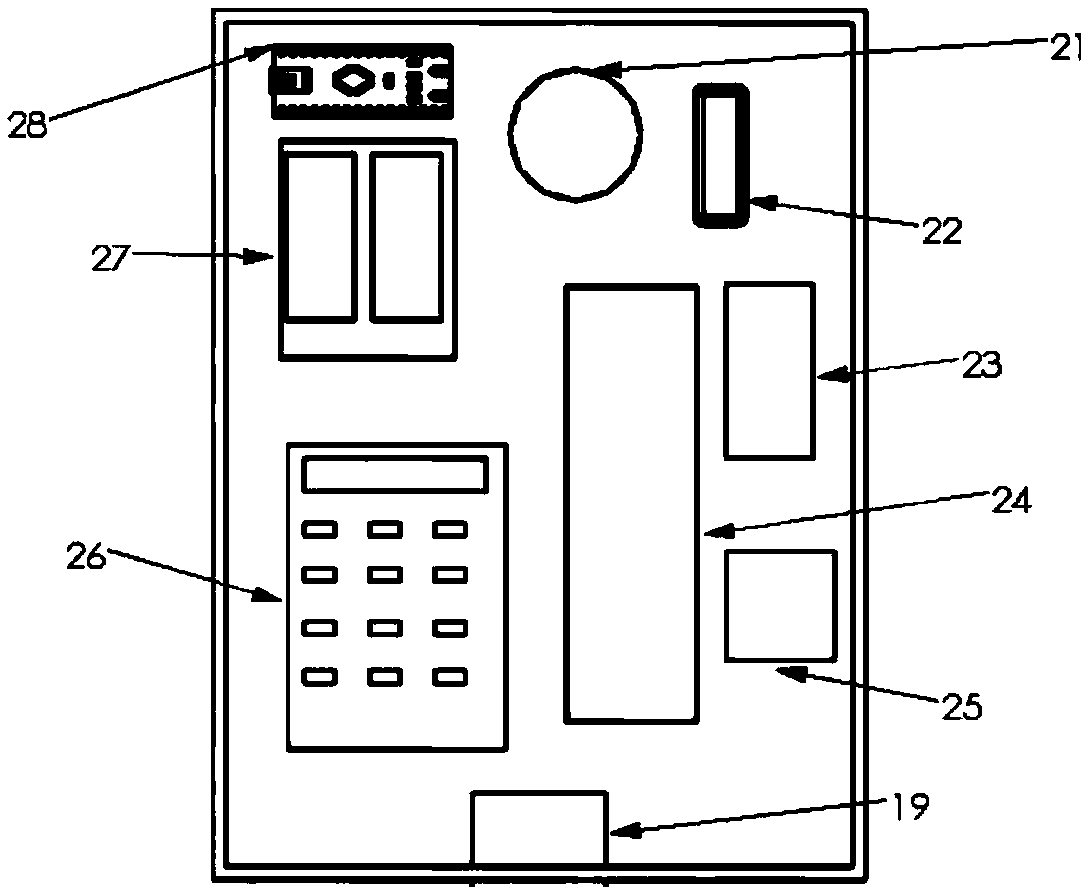

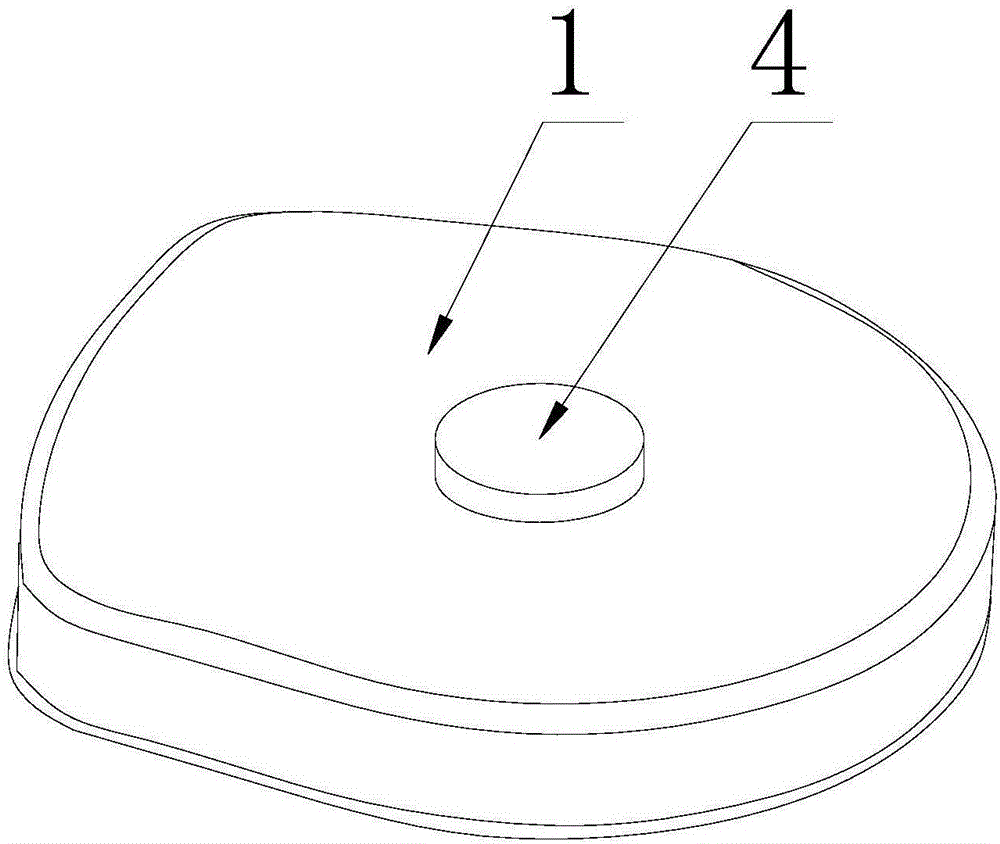

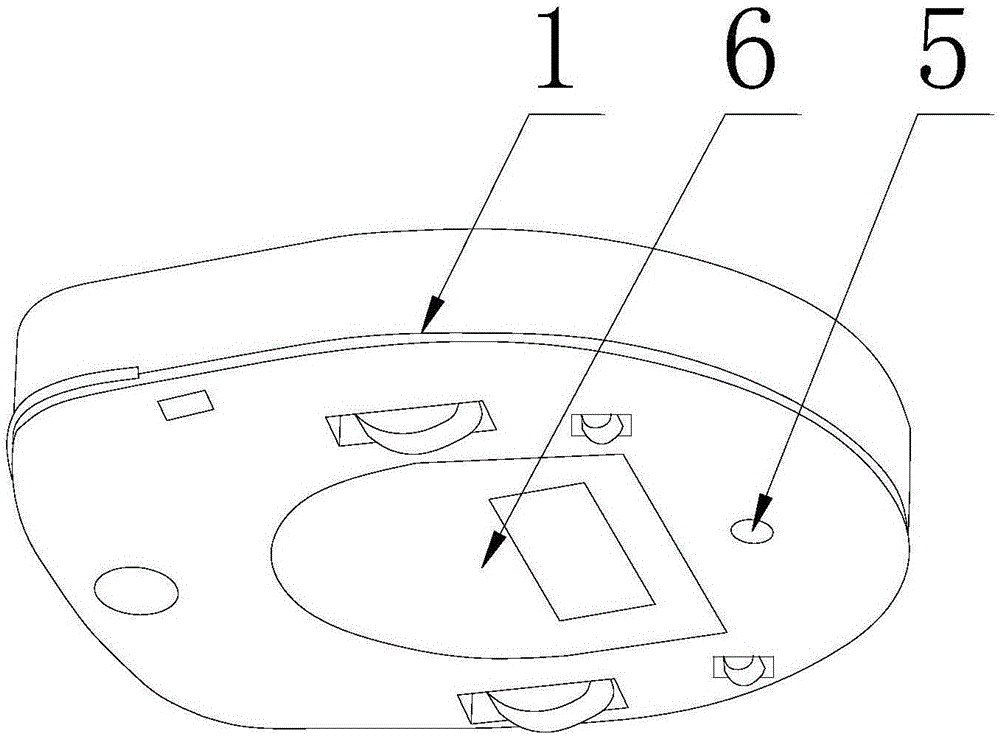

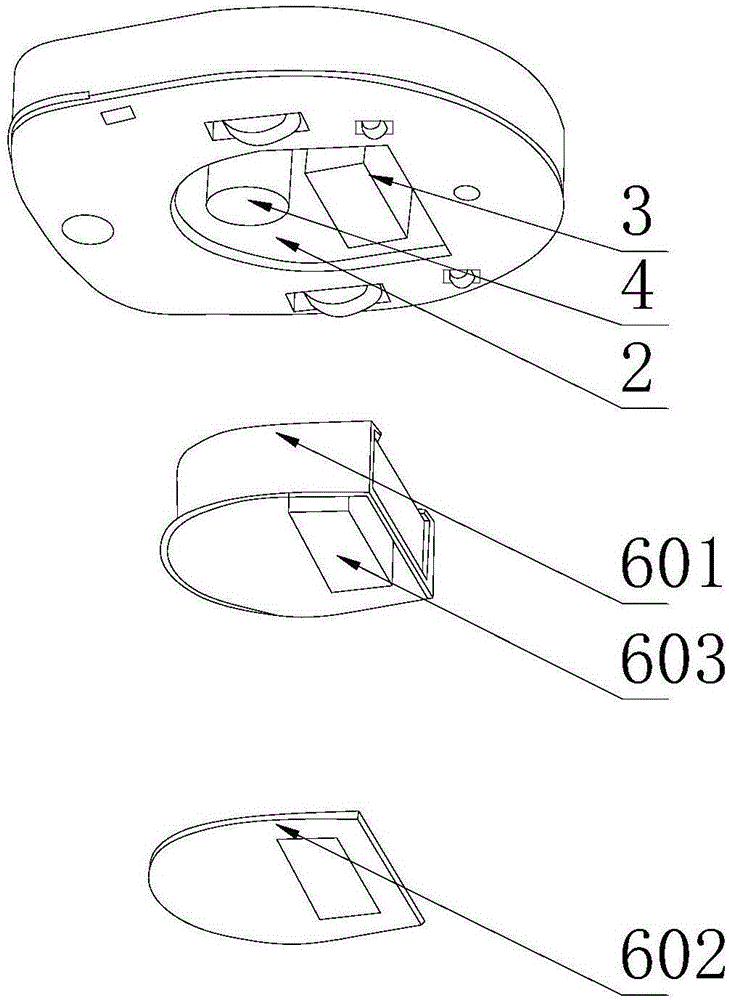

System and method for limiting robot work region

InactiveCN101344790ANear-field transmissionVehicle position/course/altitude controlEngineeringRobot workspace

The invention relates to a system and a method for restricting working areas of robots. The system comprises: a movable robot, which comprises a first signal emitting unit, a second signal receiving unit and a control unit for controlling movement of the robot; and a portable responder, which comprises a first signal receiver mainly used for receiving a first emission signal emitted by the robot in a restricted area which forms a guided virtual disorientation, and the portable responder emits a second emission signal after the first emission signal is received by the first signal receiver. Then, once detecting the second emission signal, the robot detector avoids the virtual disorientation, and the control unit of the robot executes an algorithm which comprises robot turning or backing procedures until the detector cannot receive the first emission signal.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

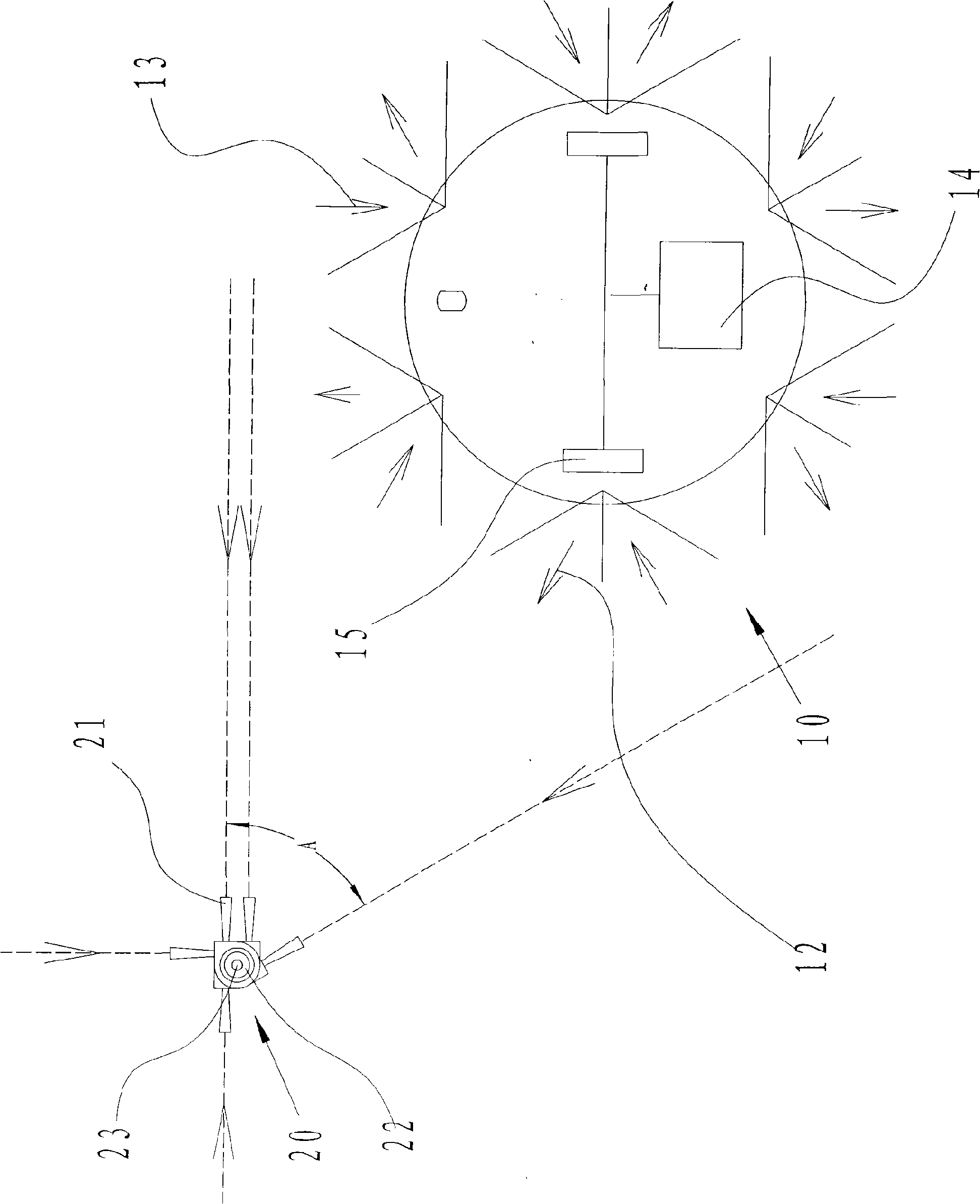

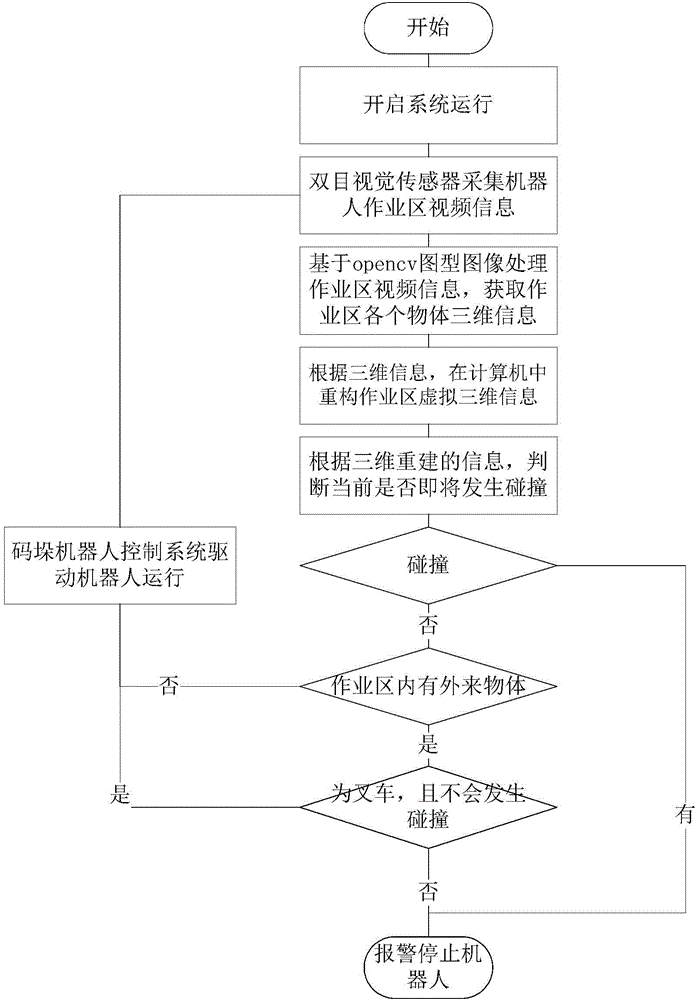

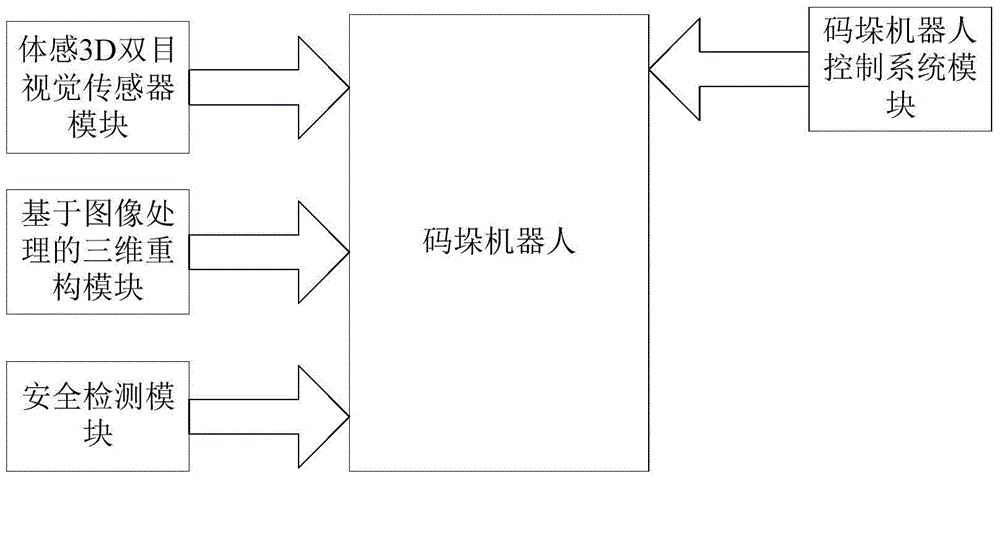

Safe robot palletizer controlling method based on three-dimensional image reconstruction

InactiveCN104944168AEnsure safetyImprove work efficiencyConveyorsStacking articlesSimulationWorking environment

The invention discloses a safe robot palletizer controlling method based on three-dimensional image reconstruction, and relates to a robot controlling method, in particular to a safe and efficient robot controlling method oriented to a robot palletizer. According to the method, a binocular camera is used for collecting visual information of a working environment of a robot, by means of the collected information, a virtual real-time three-dimensional environment graph is reconstructed, by analyzing the three-dimensional environment graph, at first, whether collision occurs in a working area of the robot is judged, if collision occurs, the robot is stopped immediately, and if no collision occurs, then whether an abnormal object enters the working area of the robot and whether collision will occur are judged. The method fully ensures the work safety of the robot palletizer and improves the working efficiency of the robot palletizer.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

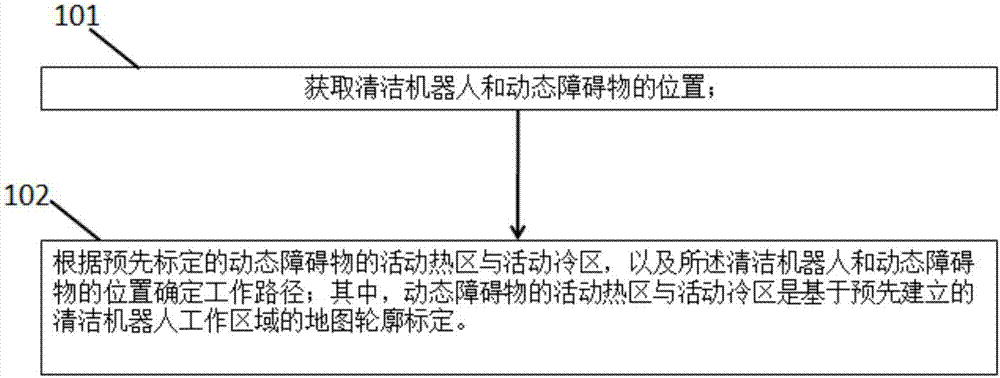

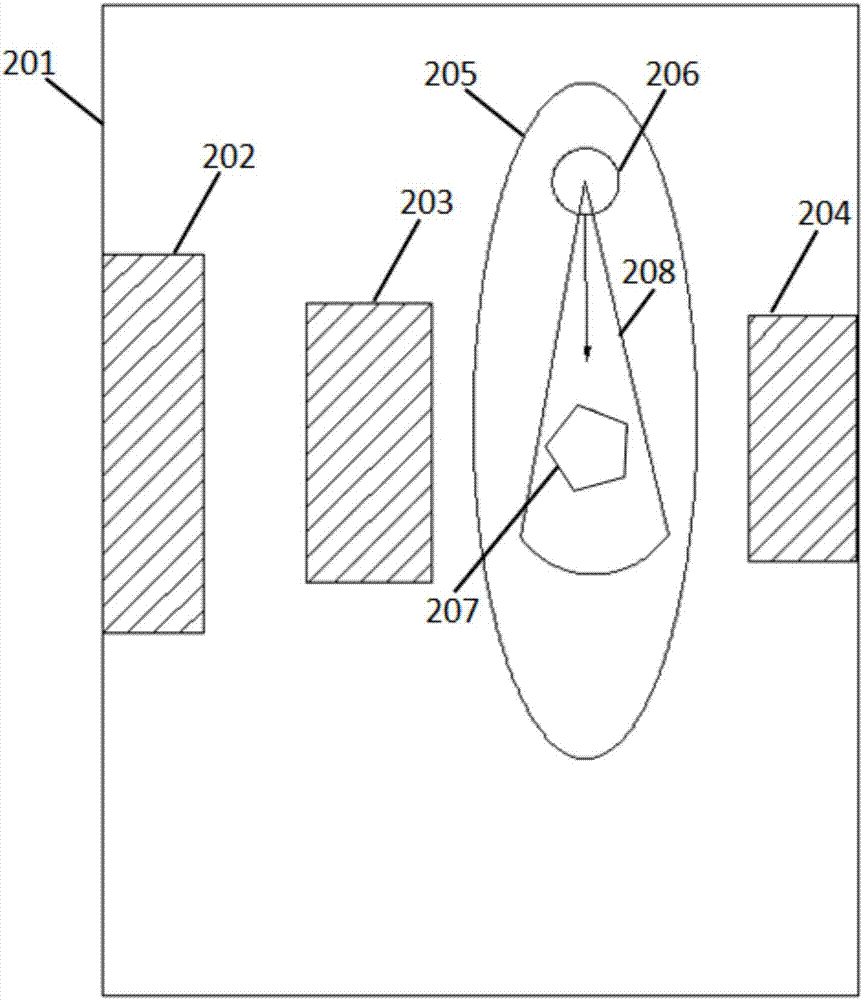

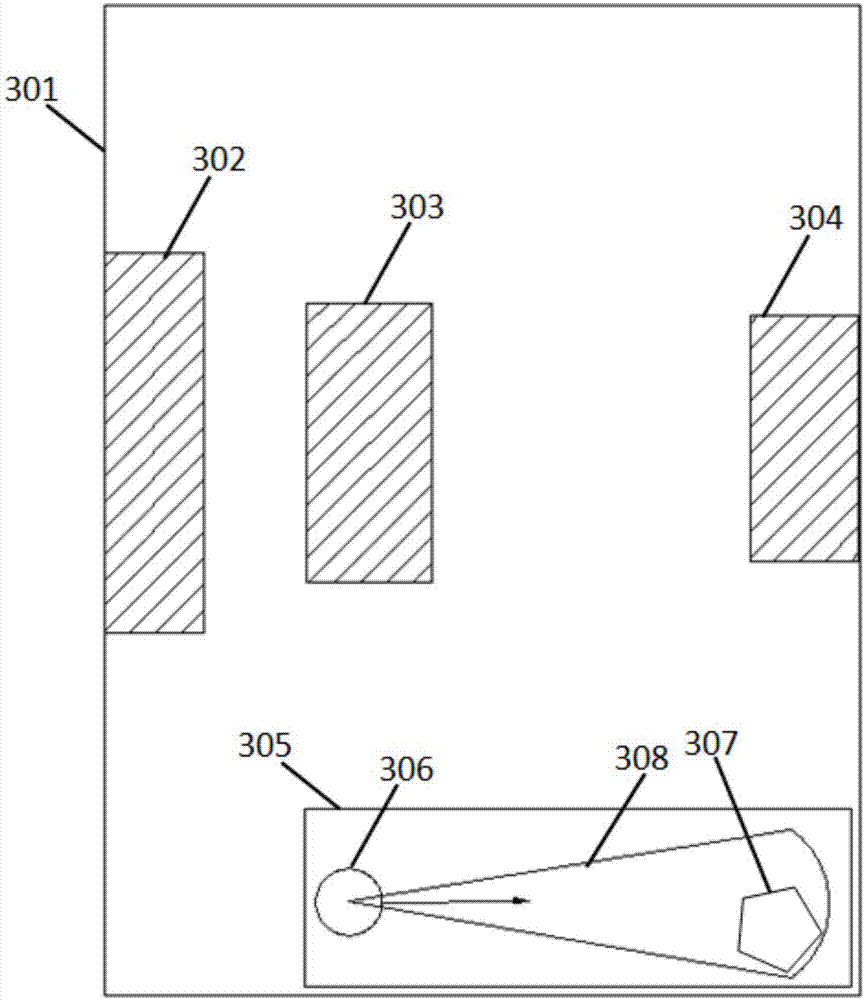

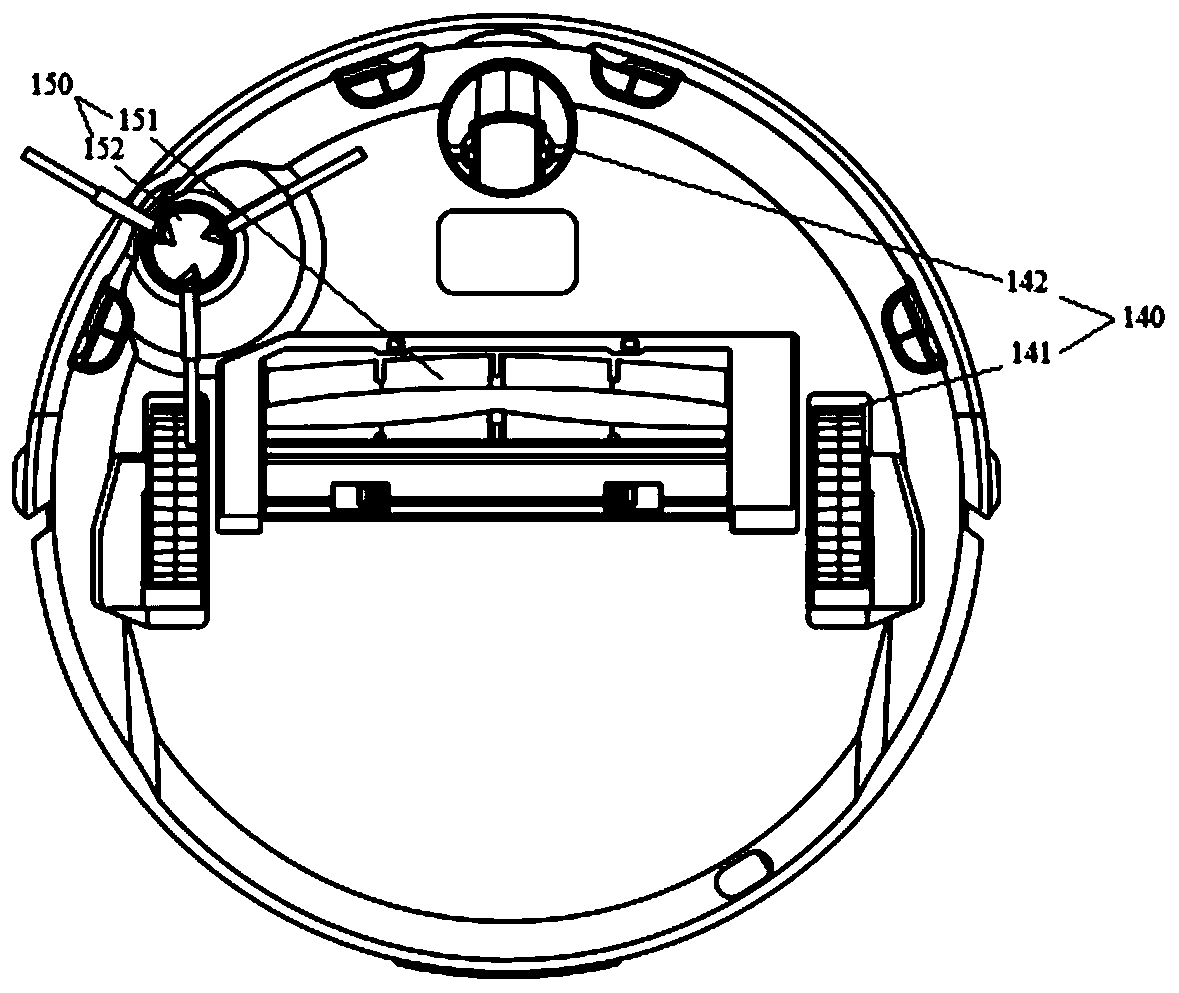

Path planning method for cleaning robot

ActiveCN107256019AMake up for the flaws that are prone to misjudgmentImprove cleaning efficiencyPosition/course control in two dimensionsVehiclesPlanning approachRobot workspace

The invention discloses a path planning method for a cleaning robot. The method comprises: positions of a cleaning robot and a dynamic obstacle are obtained; and according to pre-calibrated active hot region and active cold region of the dynamic obstacle as well as the positions of the cleaning robot and the dynamic obstacle, a working path is determined, wherein the active hot region and active cold region of the dynamic obstacle are calibrated based on a map contour of a predetermined cleaning robot working region. Therefore, the cleaning robot has a self-learning ability; the error rate of the navigation path is reduced; and the navigation frequency is reduced.

Owner:HONGYANG HOME APPLIANCES

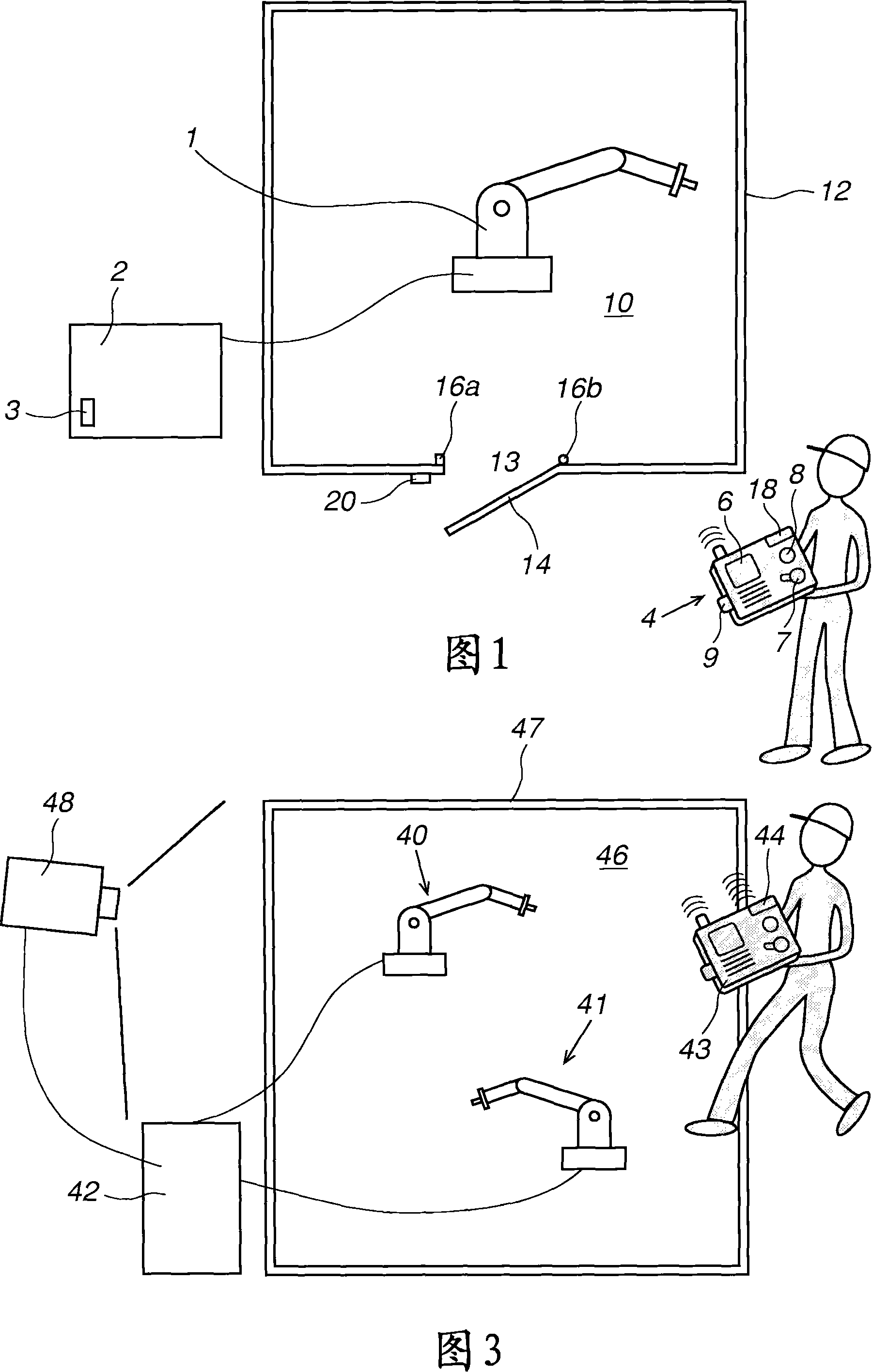

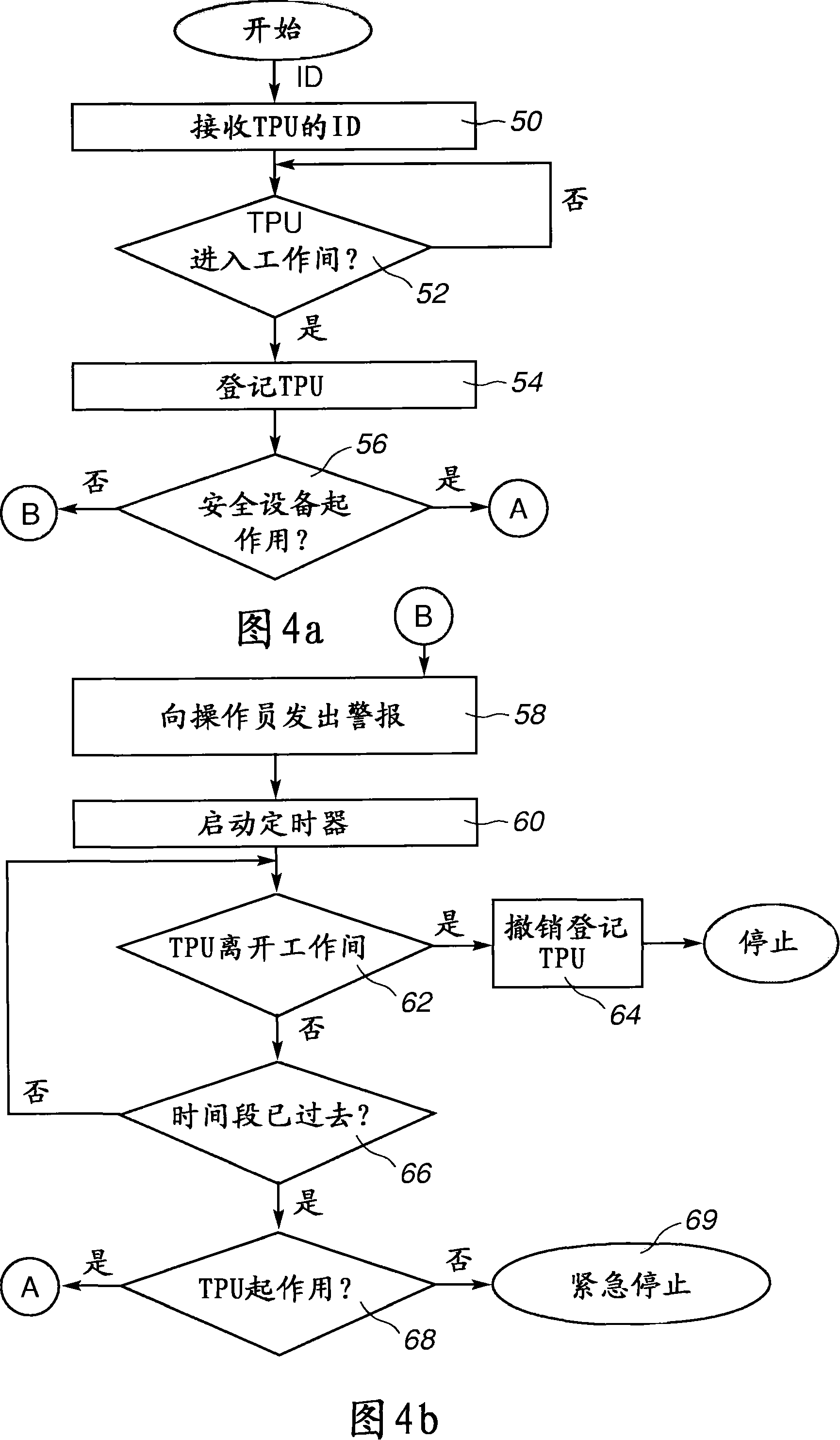

An industrial robot system with a teaching portable unit and a detecting unit for detecting when the tpu leaves the robot cell

An industrial robot system comprising: at least one industrial robot comprising at least one manipulator (1) located in a robot cell (10); a control unit (2) for controlling the manipulator; and a portable operator control device (4 ), which is hereinafter referred to as TPU, is used to teach or manually operate the manipulator. The system also includes: a detection unit (16a, 16b) for detecting when the TPU leaves the robot cell; and an alarm generator for alerting an operator when the TPU is detected to leave the robot cell.

Owner:ABB (SCHWEIZ) AG

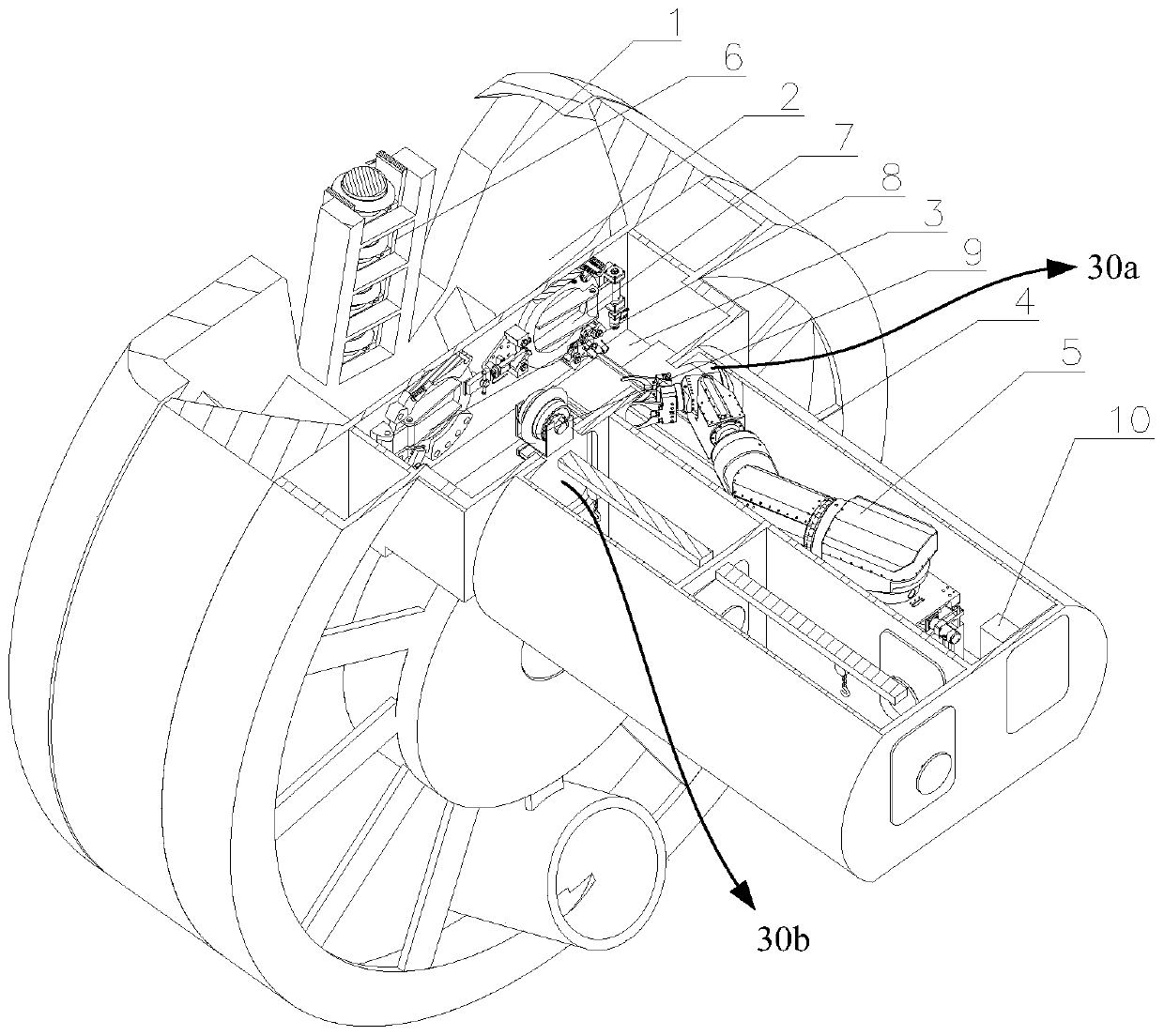

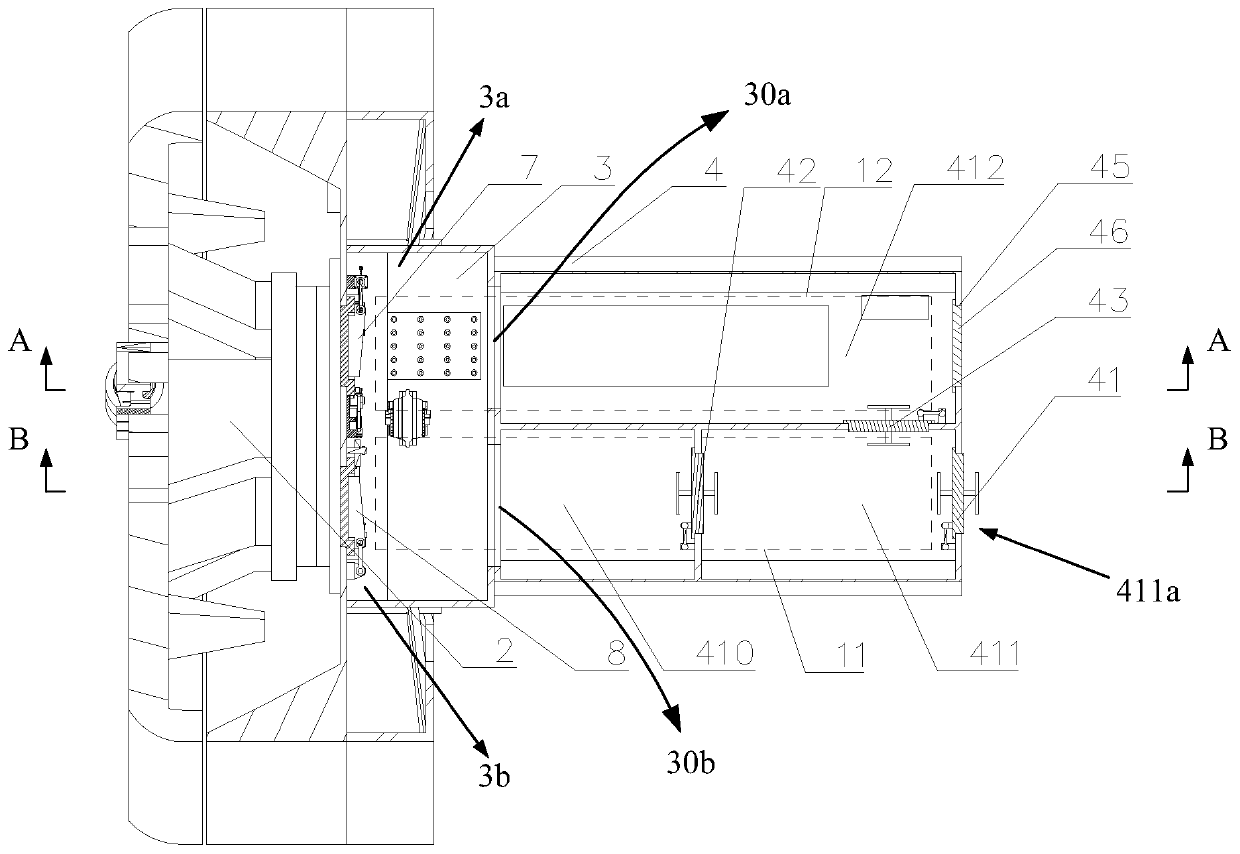

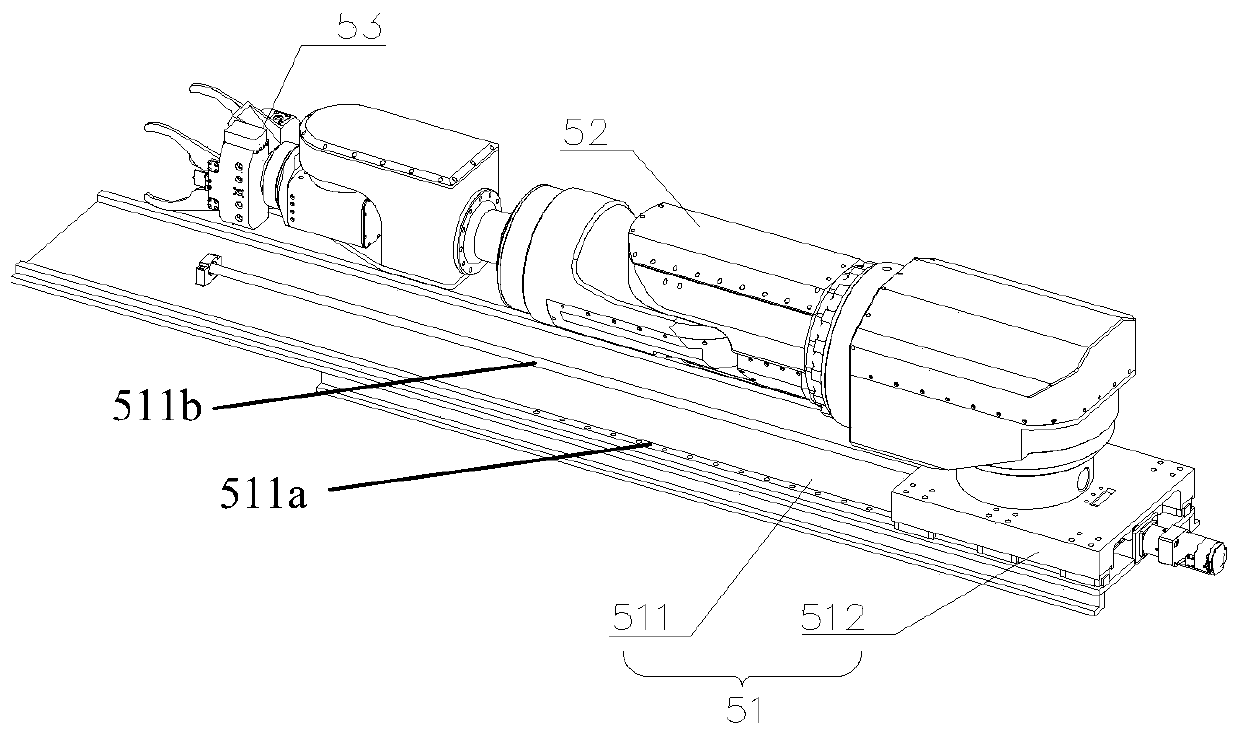

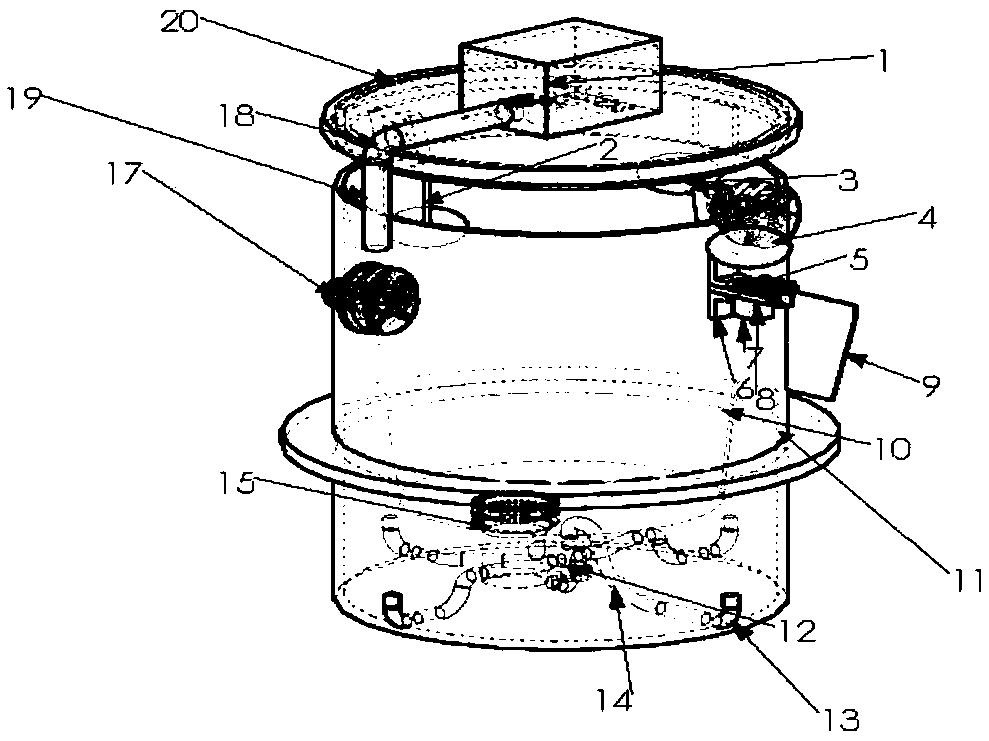

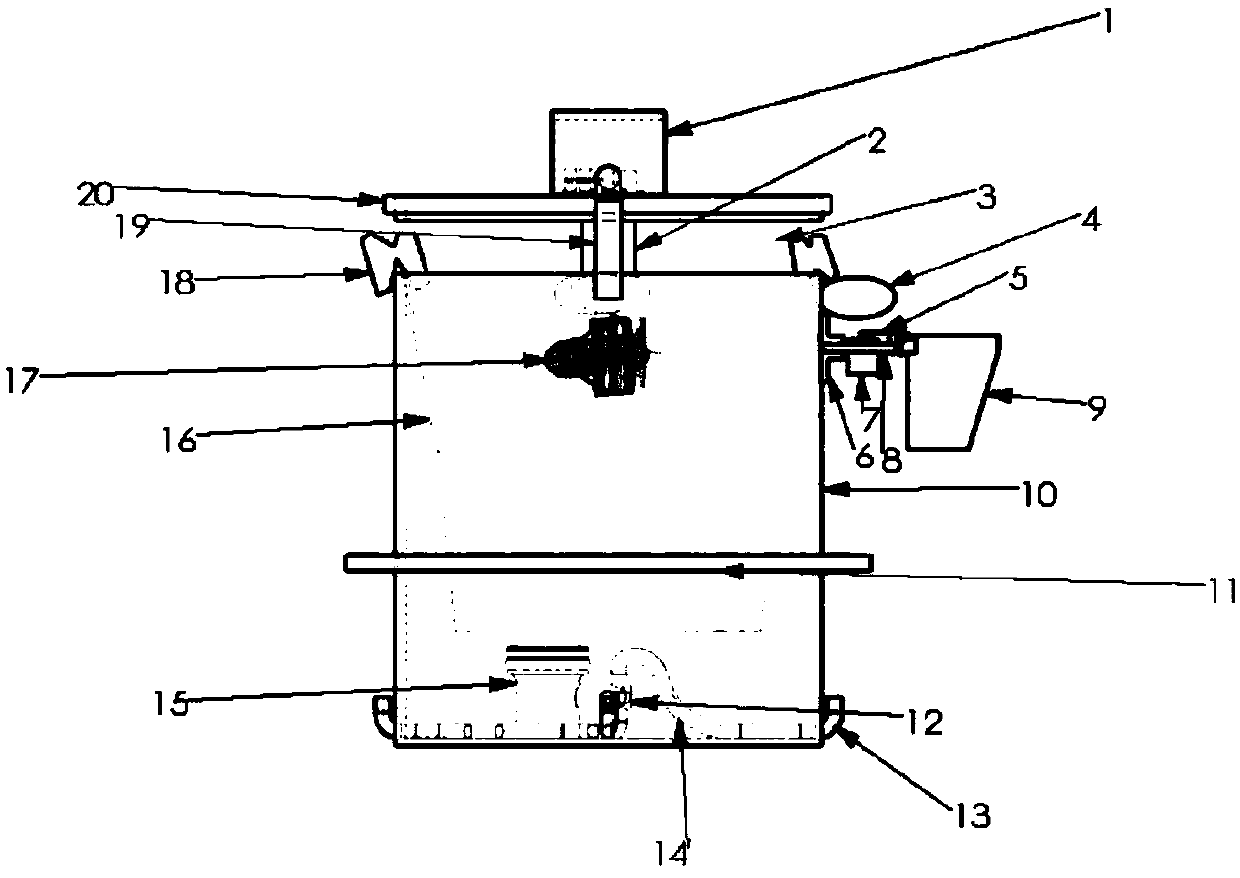

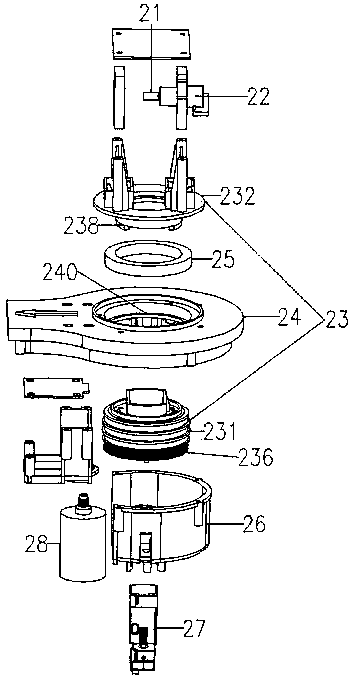

Shield tunneling machine tool disc system and tool changing method thereof

The invention provides a shield tunneling machine tool disc system. Automatic tool changing can be achieved, and the safety of operators can be guaranteed when tools are changed. The invention provides a shield tunneling machine tool disc tool changing method which adopts the shield tunneling machine tool disc system. According to the shield tunneling machine tool disc system, the shield tunneling machine tool disc system comprises a tool disc, and a muddy water bin, an air cushion bin, a manhole bin and an automatic tool changing device which are sequentially arranged behind the tool disc. The automatic tool changing device comprises a sliding rail moving platform, a six-degree-of-freedom mechanical arm, a tail end actuator and an electrical cabinet used for controlling the equipment above, wherein the manhole bin comprises a manpower working area, a robot working area and a tool area which are arranged at intervals, a first cabin door is arranged between the manpower working area and the tool area, a second cabin door is arranged between the robot working area and the tool area, a rear side channel capable of communicating is formed between the tool area and the rear side space of the tool disc system, and the rear side channel is closed by a third cabin door.

Owner:HONGRUN CONSTR GROUP STOCK +1

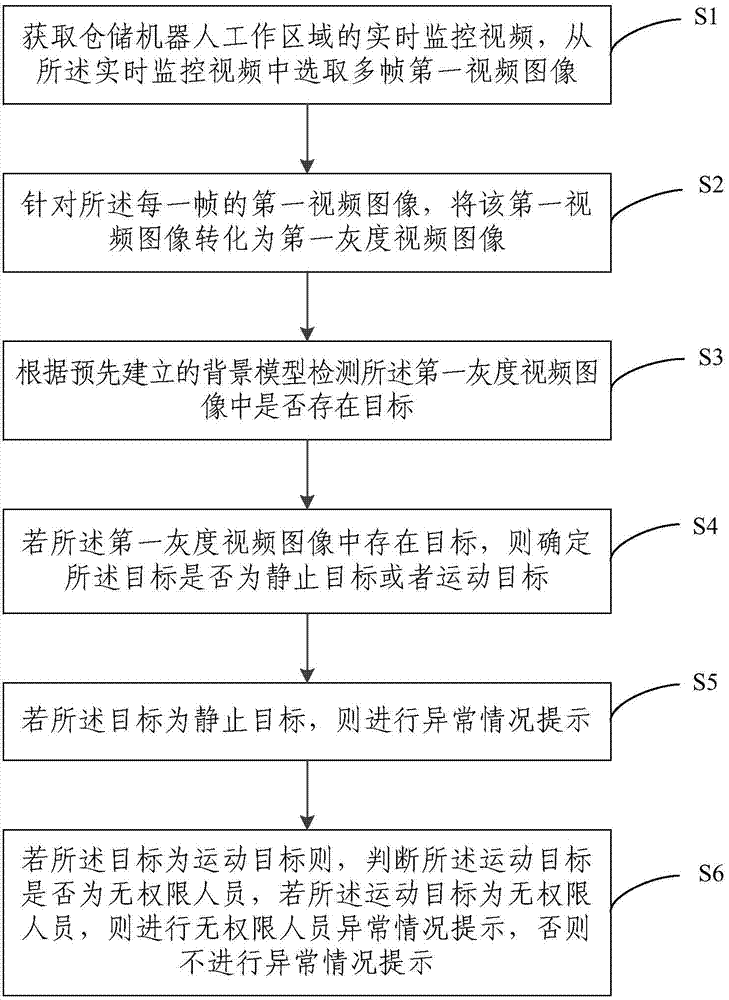

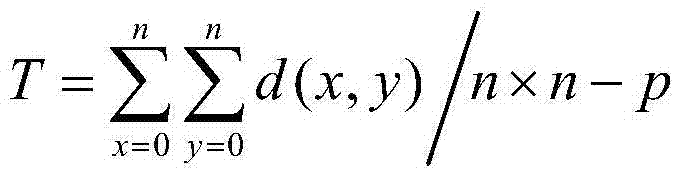

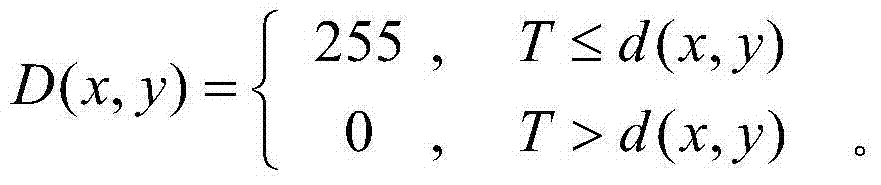

Method for monitoring abnormal conditions of working region of warehouse logistics robot

ActiveCN104751483ARealize real-time monitoringEasy to operateImage analysisClosed circuit television systemsLogistics managementGray level

The invention specifically relates to a method for monitoring the abnormal conditions of a working region of a warehouse logistics robot. The method comprises the steps of selecting a first video image from the real-time monitoring videos of the working region of the warehouse logistics robot, converting the first video image into a first gray level video image and preprocessing the first gray level video image, detecting whether an object is present in the first gray level video image according to a pre-constructed background model, determining whether the object is a static object or a movable object if the object is present in the first gray level video image according, and if the object is the static object or the movable object and the personnel has no authority, providing prompting on the abnormal conditions, otherwise not providing prompting on the abnormal conditions. The method is capable of monitoring the working region of the warehouse logistics robot in real time; when the abnormal conditions of the warehouse robot and the working region are founded, prompting is provided on the abnormal conditions immediately; as a result, normal and efficient operation of the warehouse logistics system is guaranteed.

Owner:北京市农林科学院信息技术研究中心

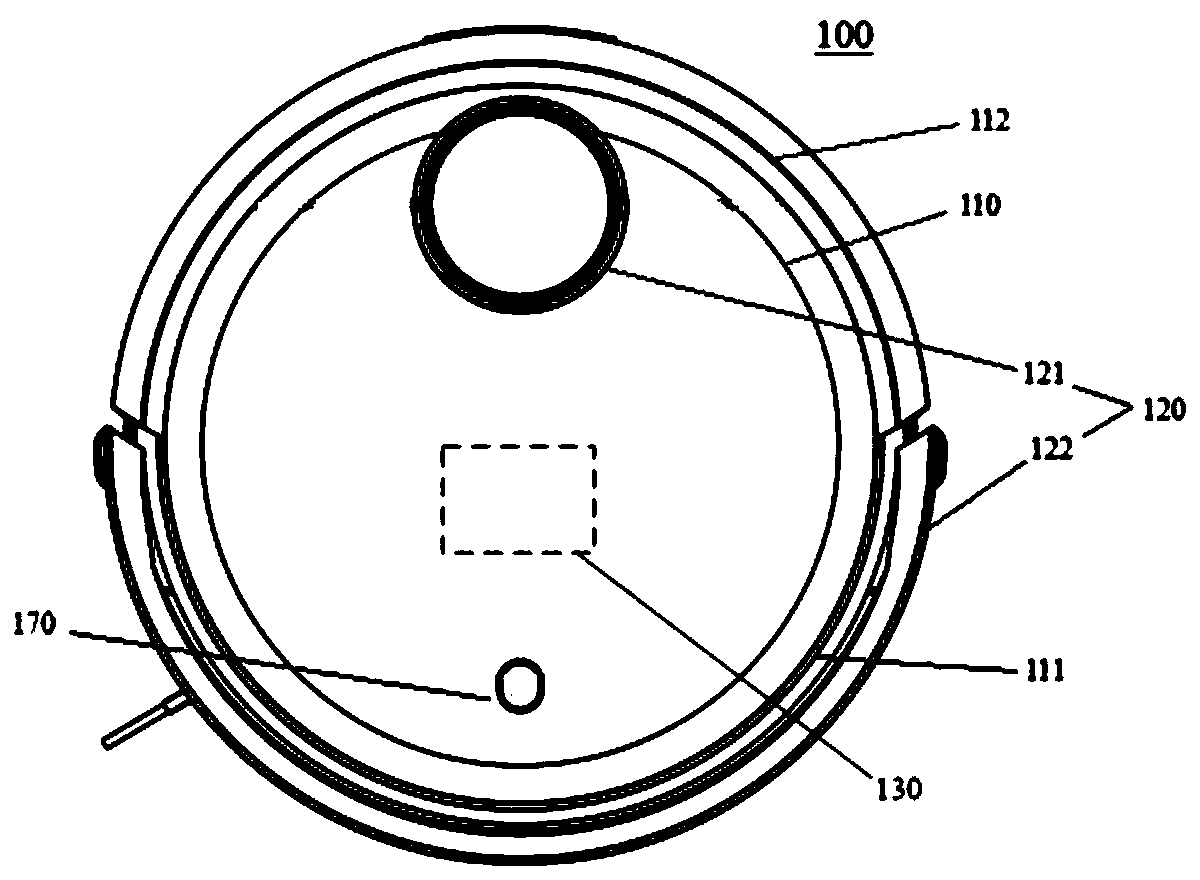

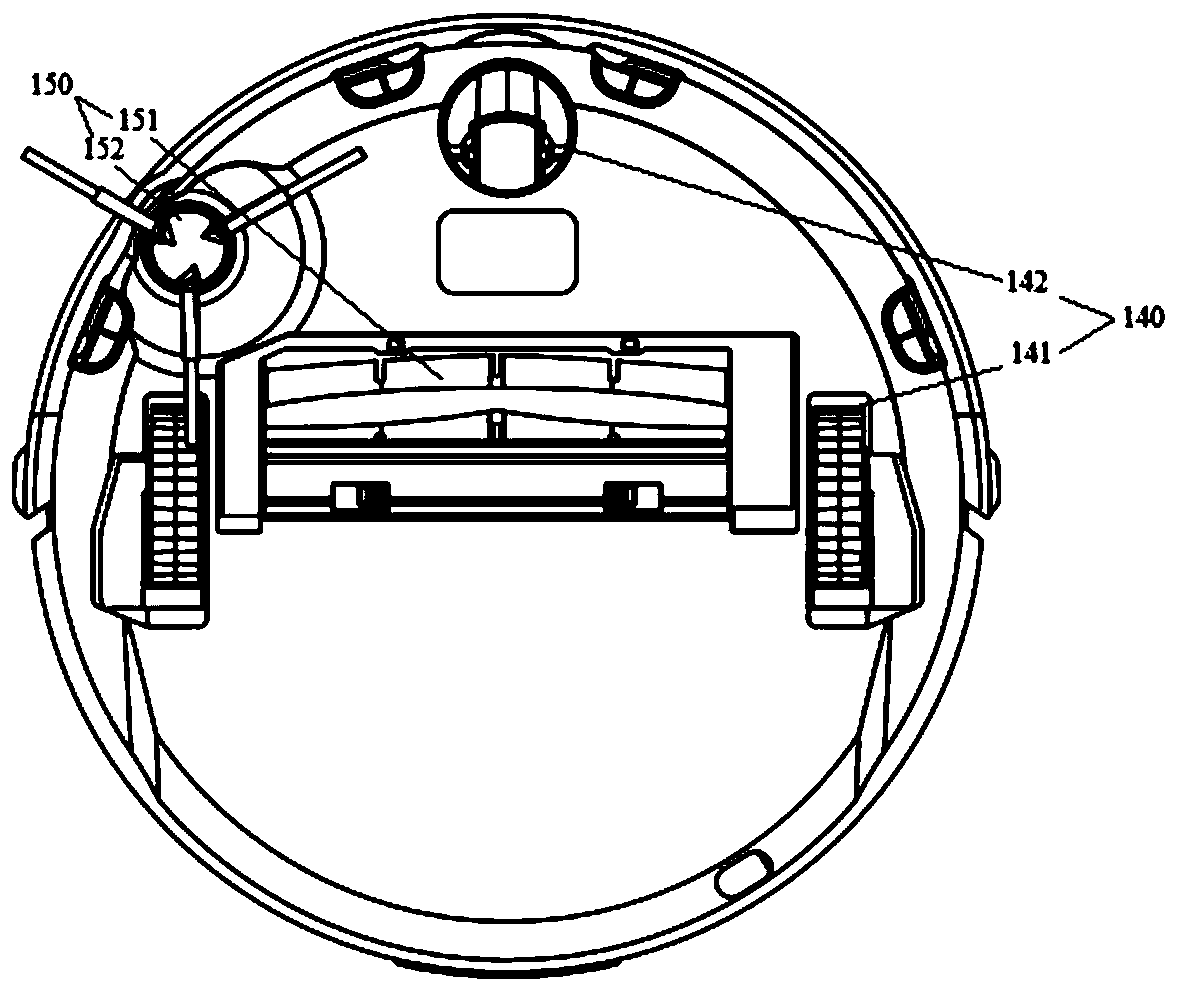

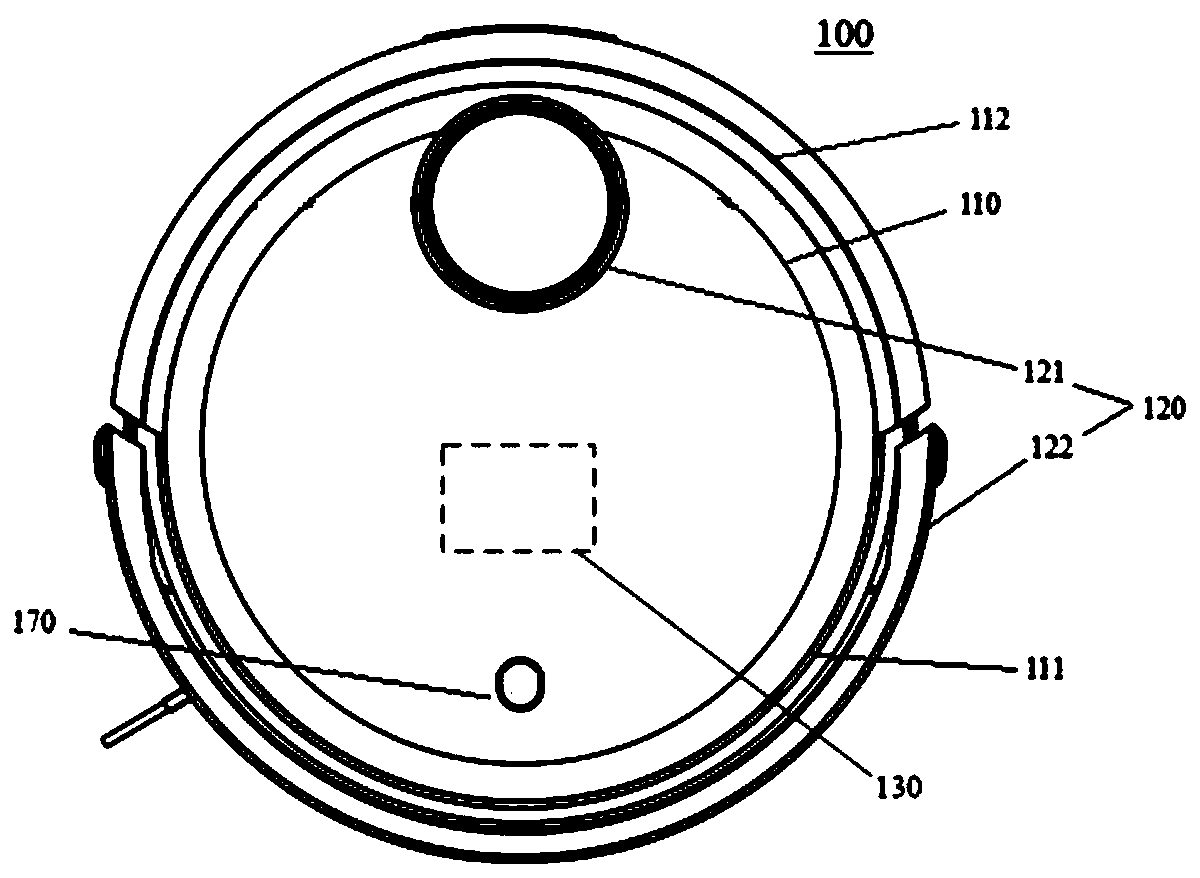

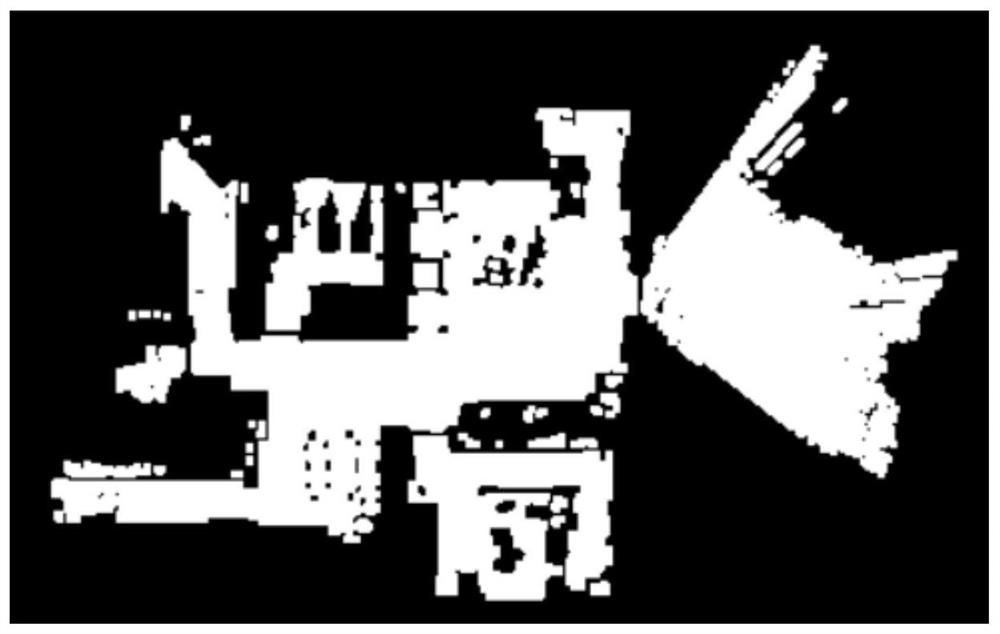

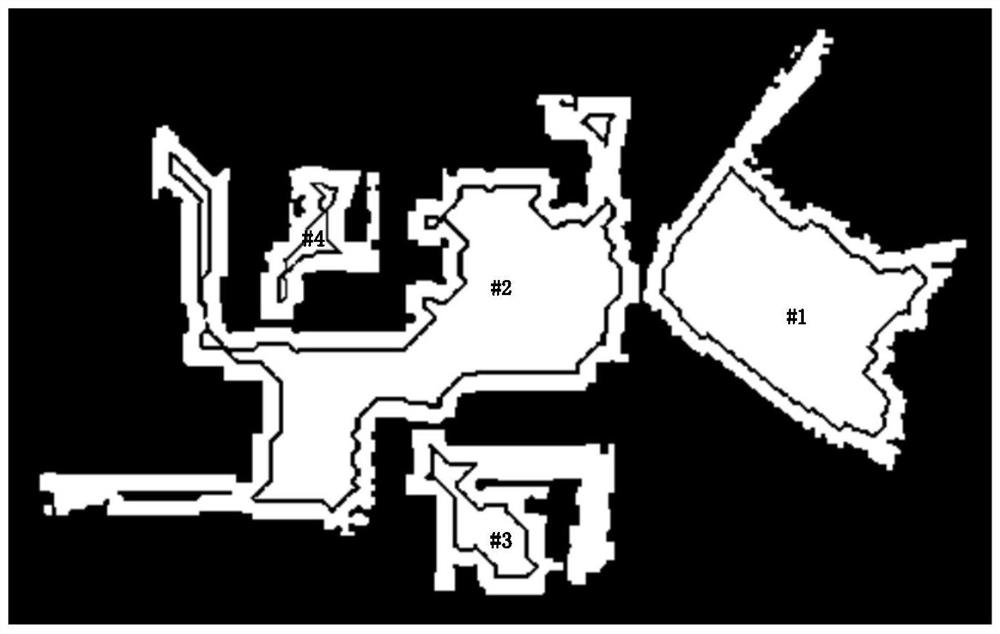

Method and device for building robot work area map, robot and medium

ActiveCN109947109AAvoid segmentation confusionImprove recognition accuracyImage enhancementAutomatic obstacle detectionComputer graphics (images)Radar

The embodiment of the invention provides a method and a device for building a robot work area map, a robot and a medium. The method comprises the following steps: scanning a barrier in a driving routein real time and recording a position parameter of the barrier; acquiring image information of the barrier in the driving route in real time; determining benchmark information of the barrier based onthe work area according to the position parameter and the image information; dividing the work area into a plurality of subareas based on the benchmark information. Through a radar scanning and camera shooting double-insurance mode, the identification accurate rate of a room door is greatly increased and room segmentation disorder caused by misidentification of the room door is avoided.

Owner:北京石头创新科技有限公司

Robot voice control method and device thereof as well as robot and medium

PendingCN109920424AIncrease precision voice controllabilityImprove work efficiencySpeech recognitionInternal memoryContent determination

The embodiment of the invention provides a robot voice control method and a device thereof as well as a robot and a medium. The robot voice control method comprises the following steps: receiving a voice command; identifying content of the voice command and determining an operation area of the robot according to the content; and executing the voice command in the operation area. The robot voice control method is capable of adopting a voice specifying manner, enabling the robot to accurately operate according to commands of users; especially, for example, when a floor sweeping robot is used forsweeping for a first time, the floor sweeping robot is capable of automatically dividing indoor layout and then recording in an internal memory or a cloud terminal; when a user wants to sweep one area in a next time, the user can control the floor sweeping robot to sweep the area; the robot can carry out purposeful operations according to the desires of the users; the accurate voice controllability of the robot is improved; the operating efficiency is improved.

Owner:北京石头创新科技有限公司

Intelligent robot for cleaning water waste through pumping and filtering and control method thereof

ActiveCN109533211AImprove collection effectAvoid entanglementWater cleaningWaterborne vesselsRefuse collectionFiltration

The invention provides an intelligent robot for cleaning water waste through pumping and filtering and a control method thereof, which comprises a shell assembly, a power assembly, a garbage collection assembly, a pumping and drainage assembly, a buoyancy regulating assembly and required electronic elements. The robot eliminates the structures of a prior waste-cleaning robot, such as a brush, a suction port and the like. or a crawler structure adopted by a water waste cleaning ship, and adopts a method of pump-suction filtration, the robot is more suitable for the requirements of water waste cleaning and oil pollution treatment, and solves the problems that some waste and oil pollution cannot be absorbed and the treated waste is wound on the crawler. The power assembly is added, and two modes of manual remote control and automatic cruise are developed. The robot can not only move freely in the water body by remote control, but also be similar to a land-sweeping robot to carry out autonomous cruising and garbage collecting on the water surface, the problems of small working area, low efficiency and high requirement on water environment of a prior cleaning robot are solved.

Owner:SHANGHAI JIAO TONG UNIV +1

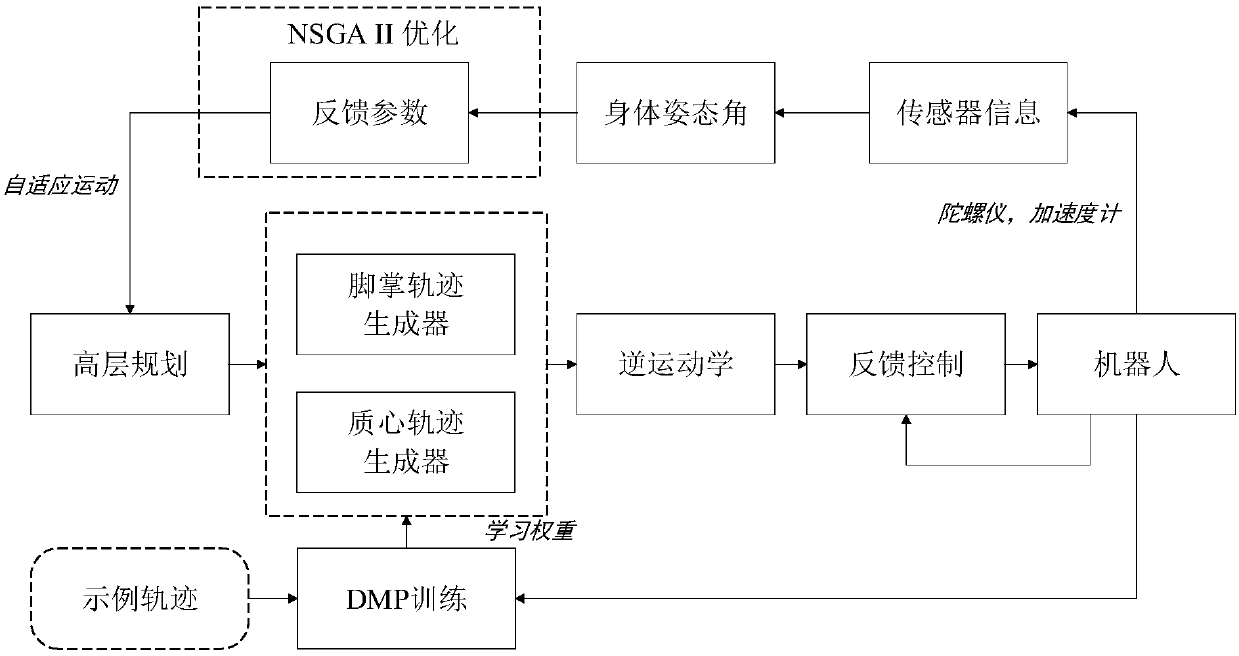

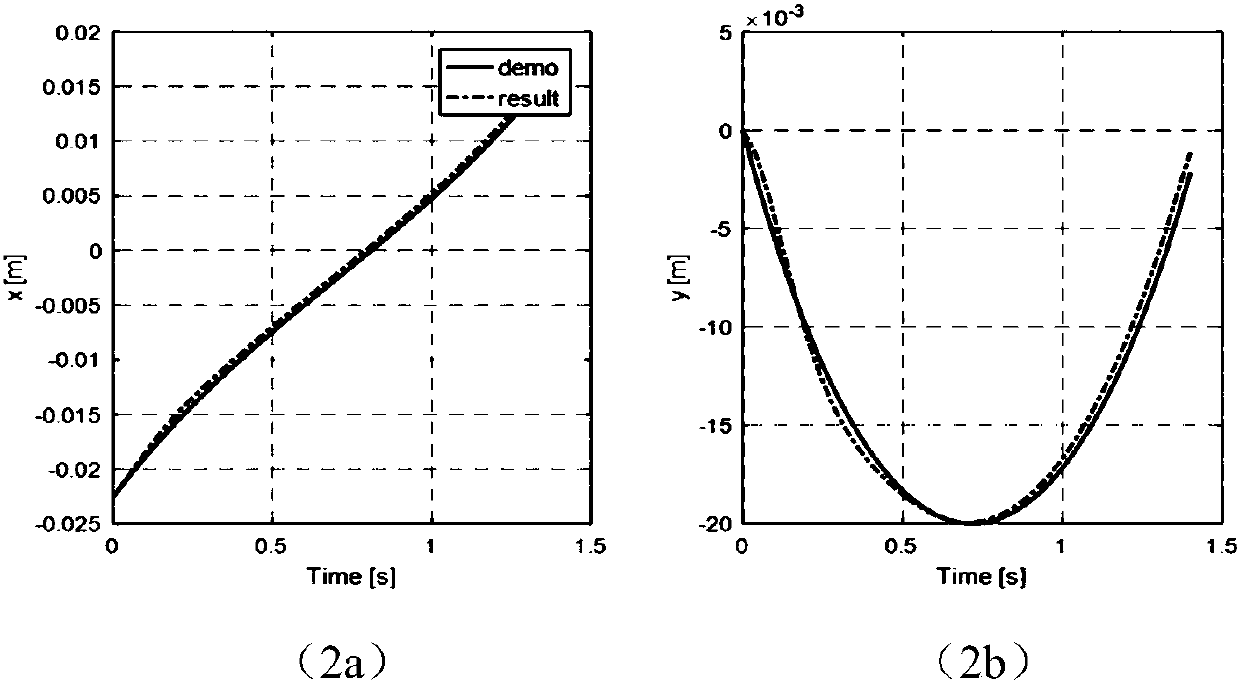

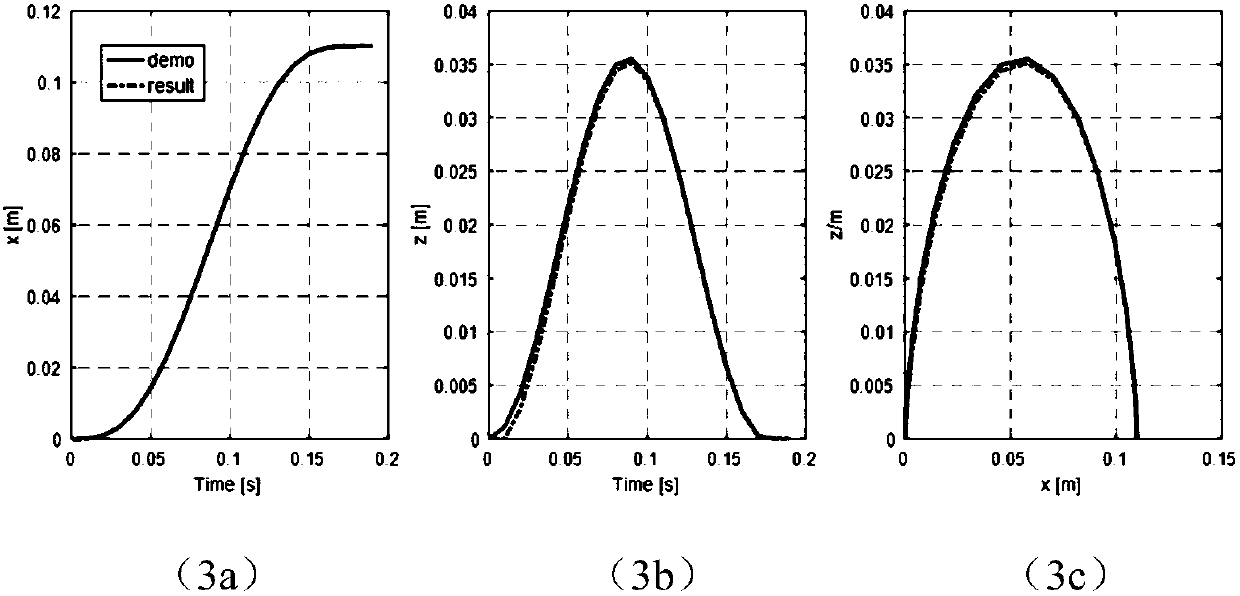

DMP-based robot workspace adaptive walking control system and method

The invention relates to a DMP-based robot workspace adaptive walking control system and method. The control system comprises: a DMP centroid track generator which generates a centroid track of a humanoid robot based on DMP training according to a planning target and feedback information; a DMP foot sole track generator which generates a foot sole track of the humanoid robot based on DMP trainingaccording to the planning target and the feedback information; and a joint mapping module which performs inverse kinematic calculation on the centroid track and the foot sole track, and uses a motionengine to map the adaptability of the workspace to a joint space, so as to achieve the adaptive walking control of the humanoid robot. The DMP centroid track generator and the DMP foot sole track generator are obtained based on the example track training study of the robot working space. Compared with the prior art, the system and the method have the advantages of adjusting the gait and body posture in real time, and enhancing the environmental adaptability of the humanoid robot walking.

Owner:TONGJI UNIV

Drying type intelligent floor sweeping robot

InactiveCN107432719AAvoid phenomena that cannot be removedImplement spot cleanupAutomatic obstacle detectionTravelling automatic controlRadarWaste collection

A dry-type intelligent sweeping robot is provided, including a sweeping robot main body, a drying mechanism and a radar mechanism, wherein a garbage collection device is arranged in the sweeping robot main body, and an inner cavity matched with the garbage collection device is arranged in the sweeping robot main body. There is a drying fan of the drying mechanism and a lidar of the radar mechanism. The drying mechanism includes a drying fan and a humidity sensor. The humidity sensor is installed on the bottom surface of the cleaning robot body. The radar mechanism includes a lidar. The lidar is connected to the main control board in the cleaning robot body. , and the top of the lidar protrudes from the top surface of the main body of the sweeping robot; the invention dries the ground through the drying mechanism, so that the garbage can be separated from the ground, and the cleaning can be cleaned more cleanly, and the laser radar is configured to clean the obstacles in the working area of the sweeping robot. identify.

Owner:SHAANXI LAIFU TECH DEV CO LTD

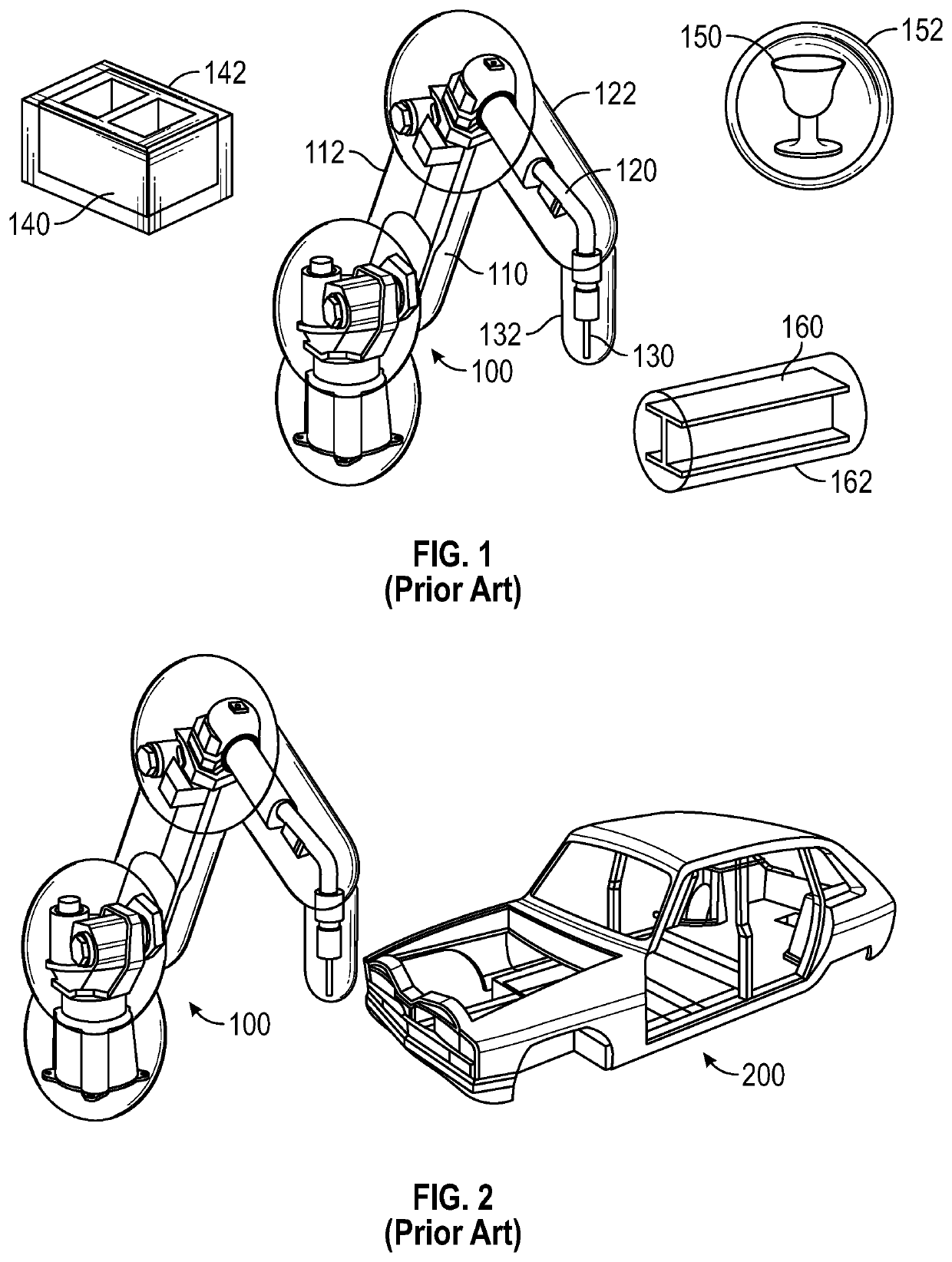

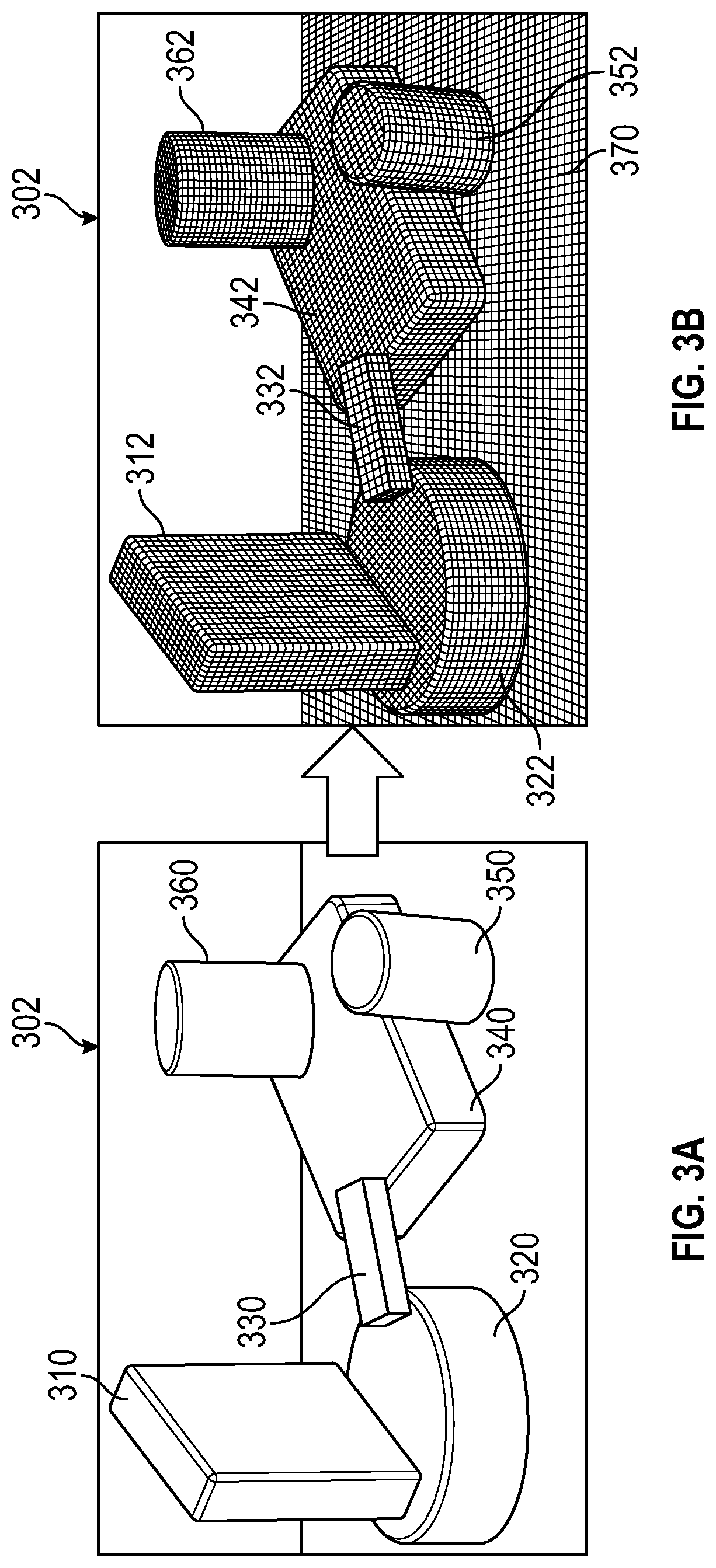

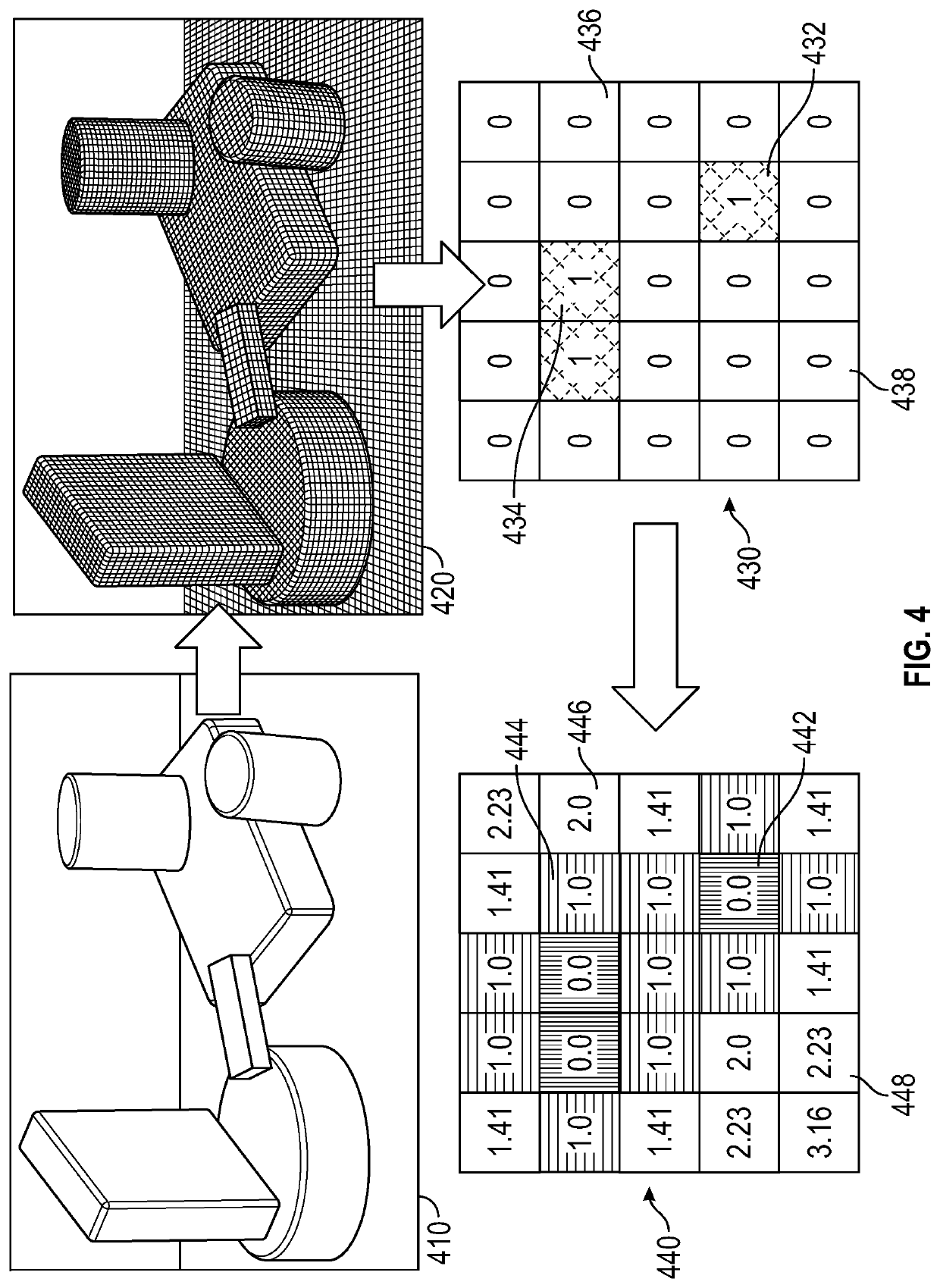

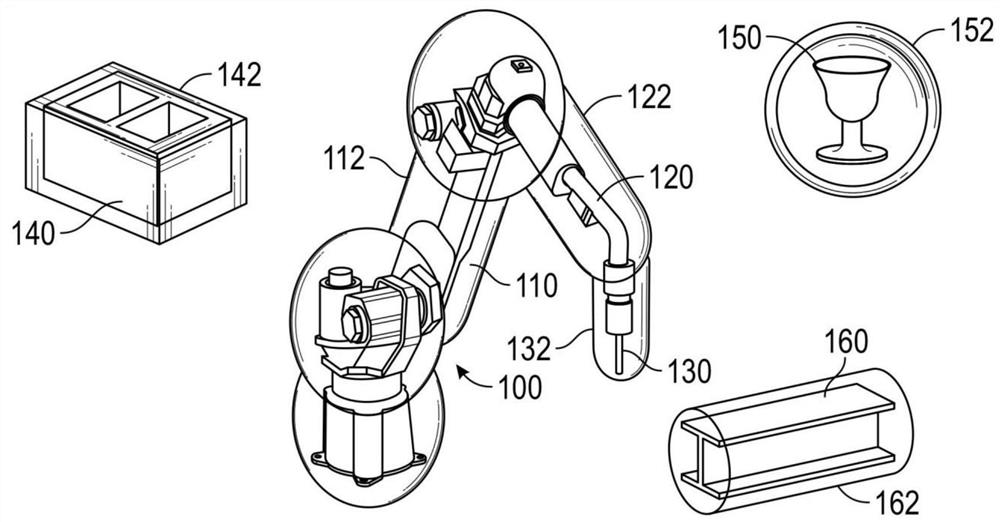

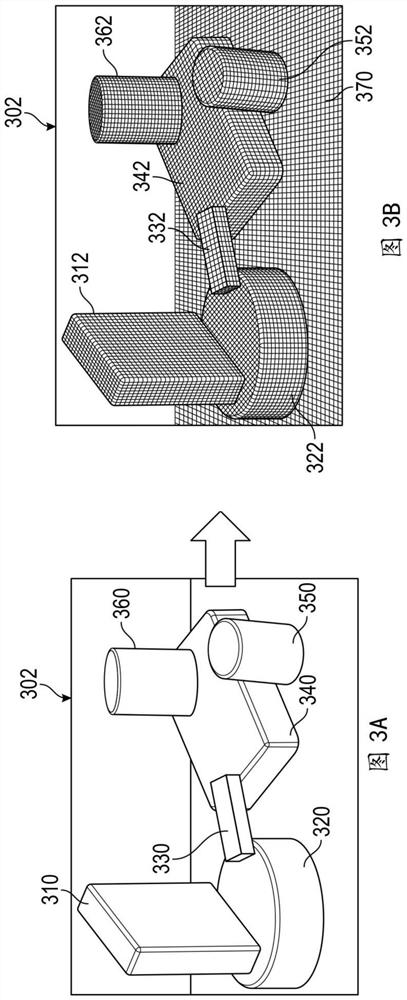

Fast robot motion optimization with distance field

ActiveUS20210308862A1Minimize objective functionFast computerProgramme controlProgramme-controlled manipulatorVoxelRobot workspace

A robot collision avoidance motion optimization technique using a distance field constraint function. CAD or sensor data depicting obstacles in a robot workspace are converted to voxels, and a three-dimensional binary matrix of voxel occupancy is created. A corresponding distance map matrix is then computed, where each cell in the distance map matrix contains a distance to a nearest occupied cell. The distance map matrix is used as a constraint function in a motion planning optimization problem, where the optimization problem is convexified and then iteratively solved to yield a robot motion profile which avoids the obstacles and minimizes an objective function such as distance traveled. The distance field optimization technique is quickly computed and has a computation time which is independent of the number of obstacles. The disclosed optimization technique is easy to set up, as it requires no creation of geometry primitives to approximate robot and obstacle shapes.

Owner:FANUC LTD

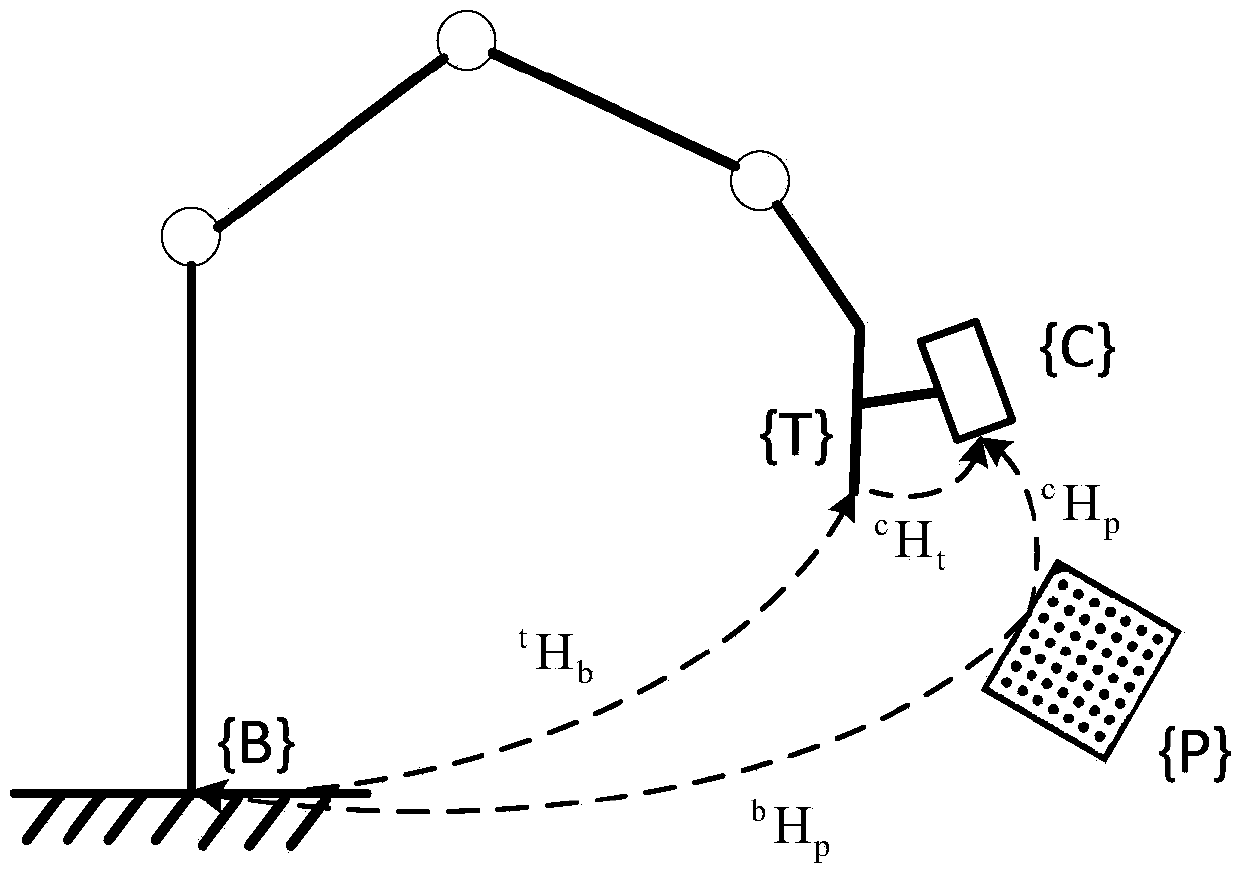

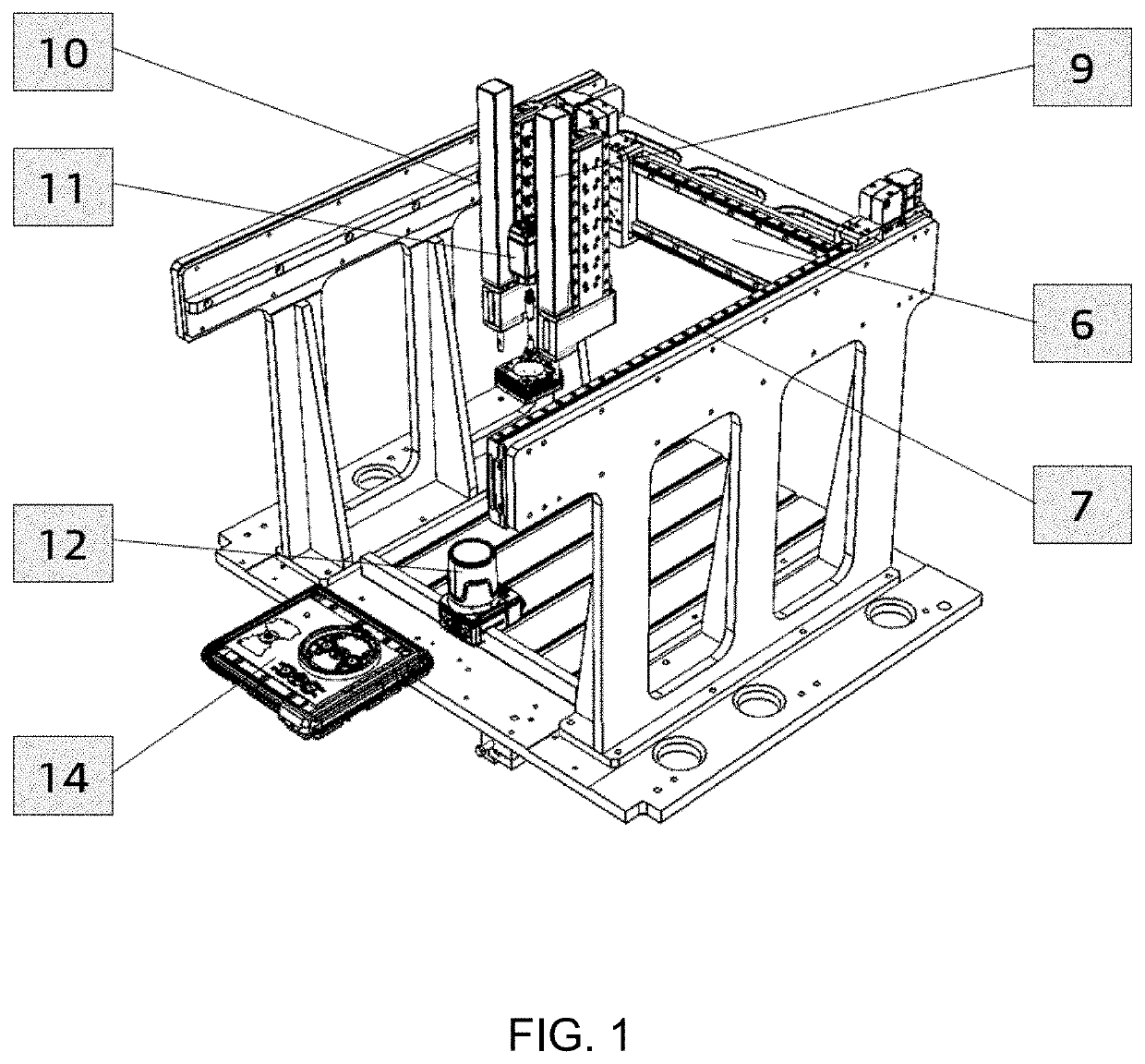

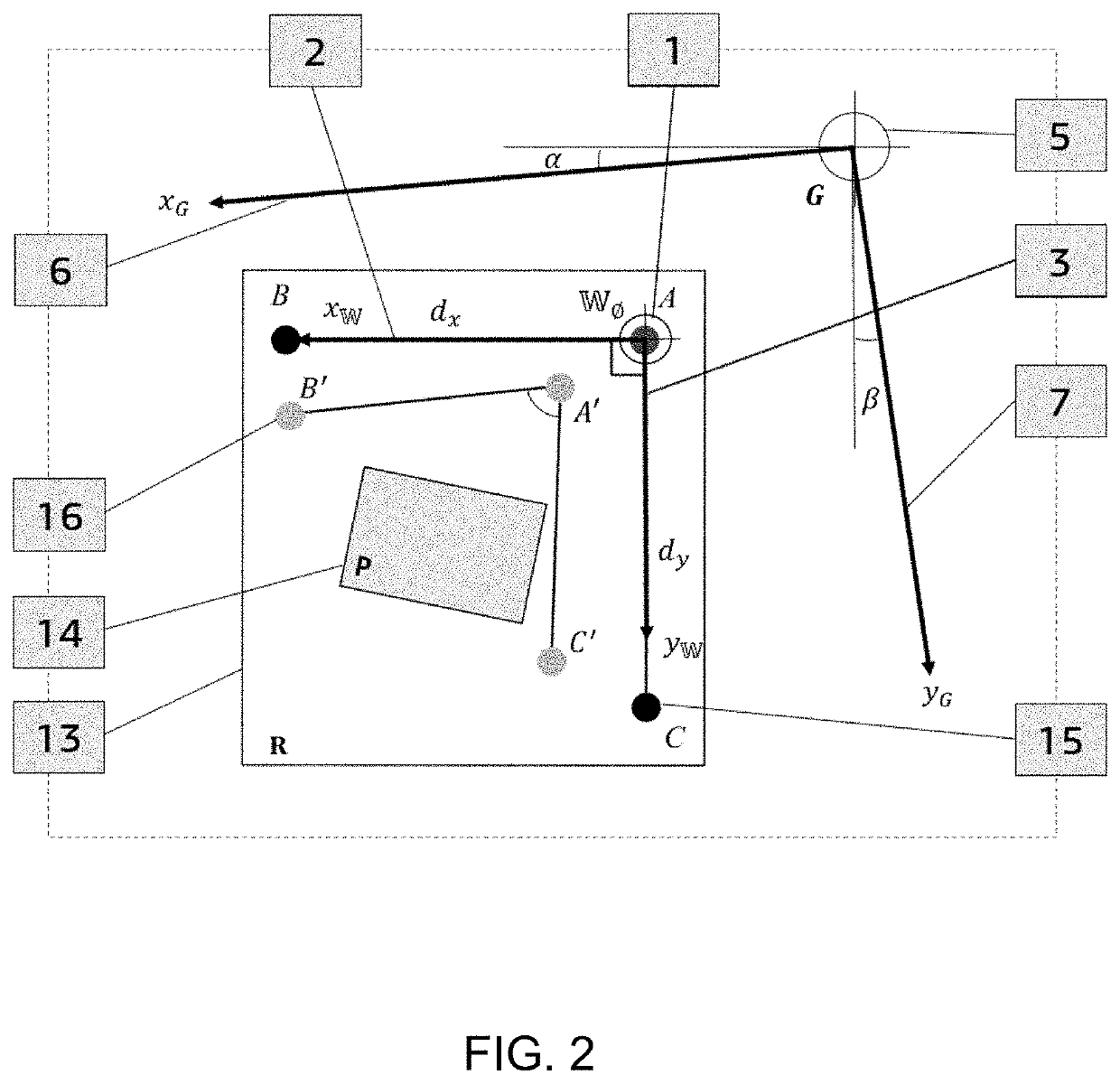

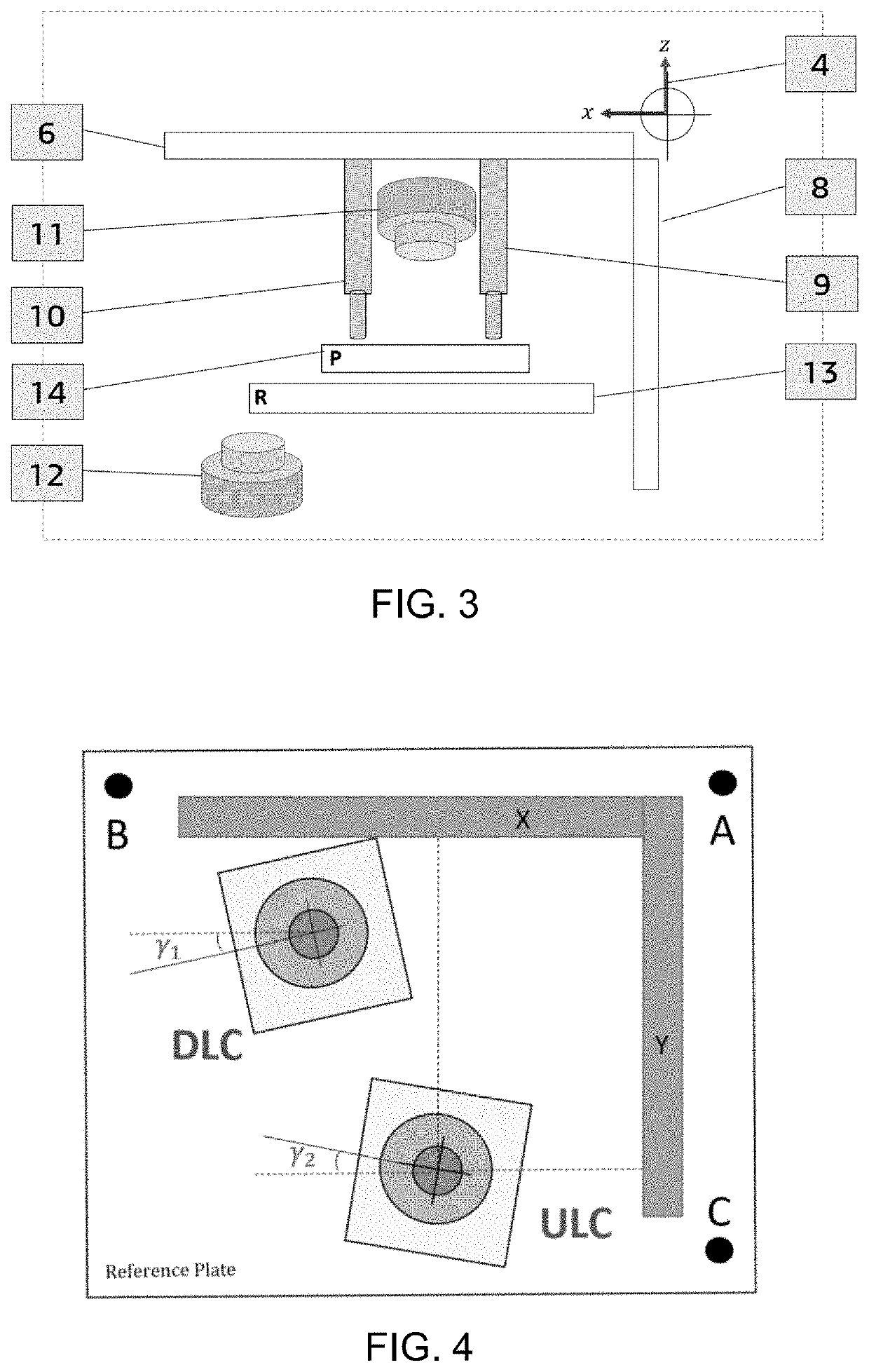

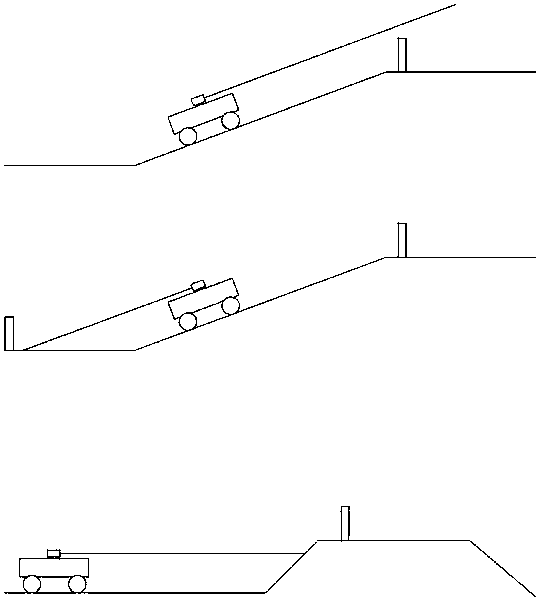

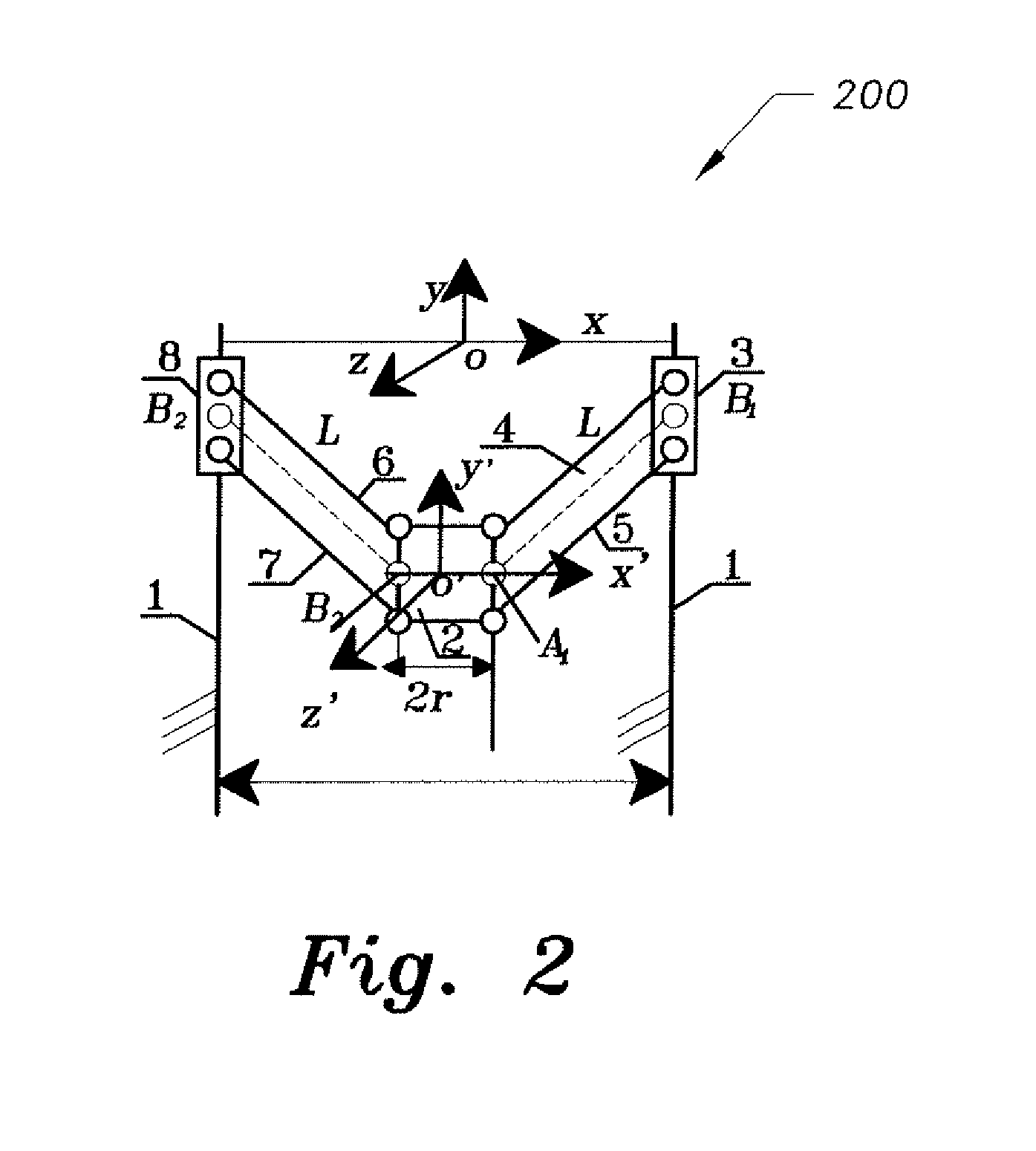

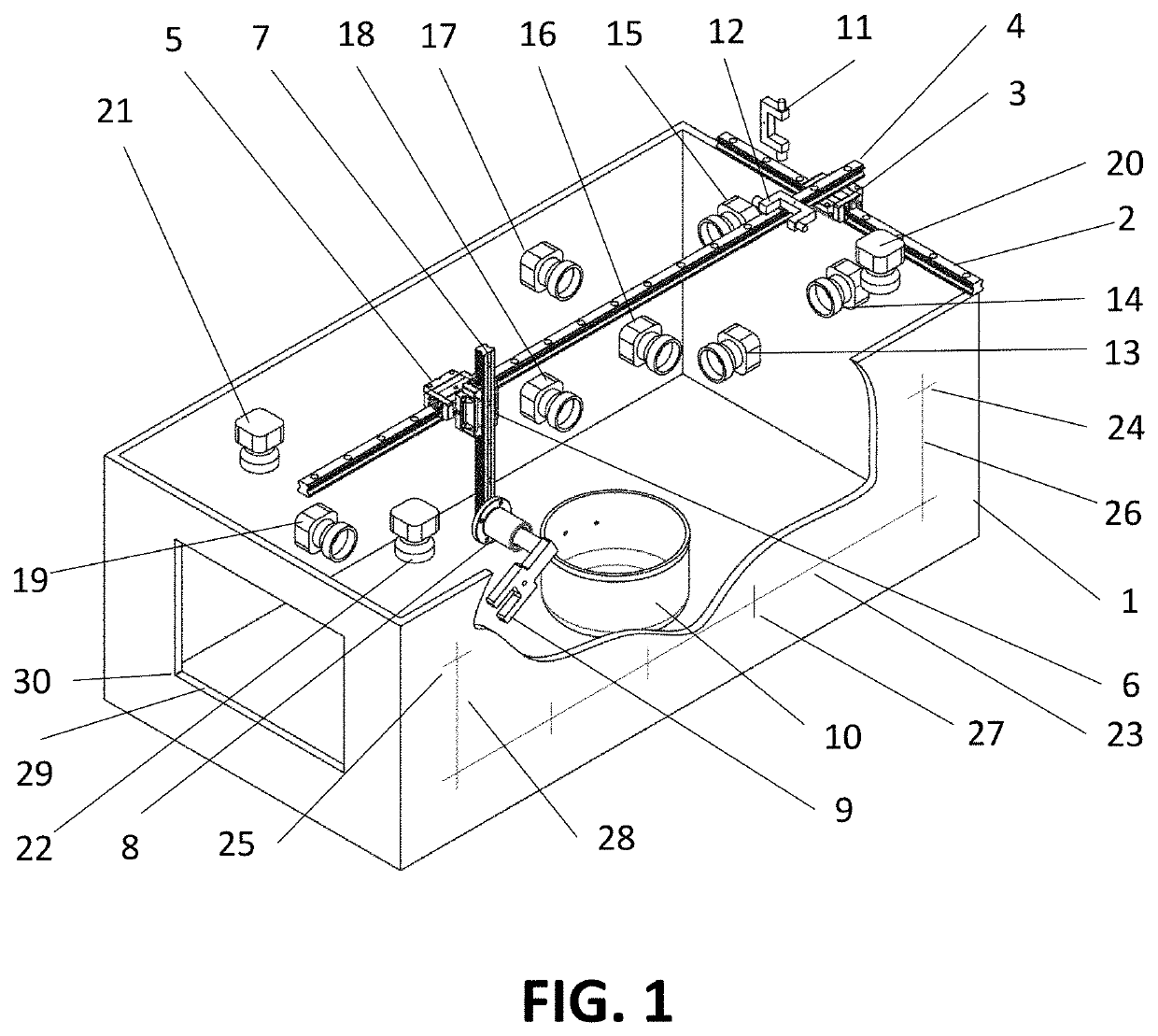

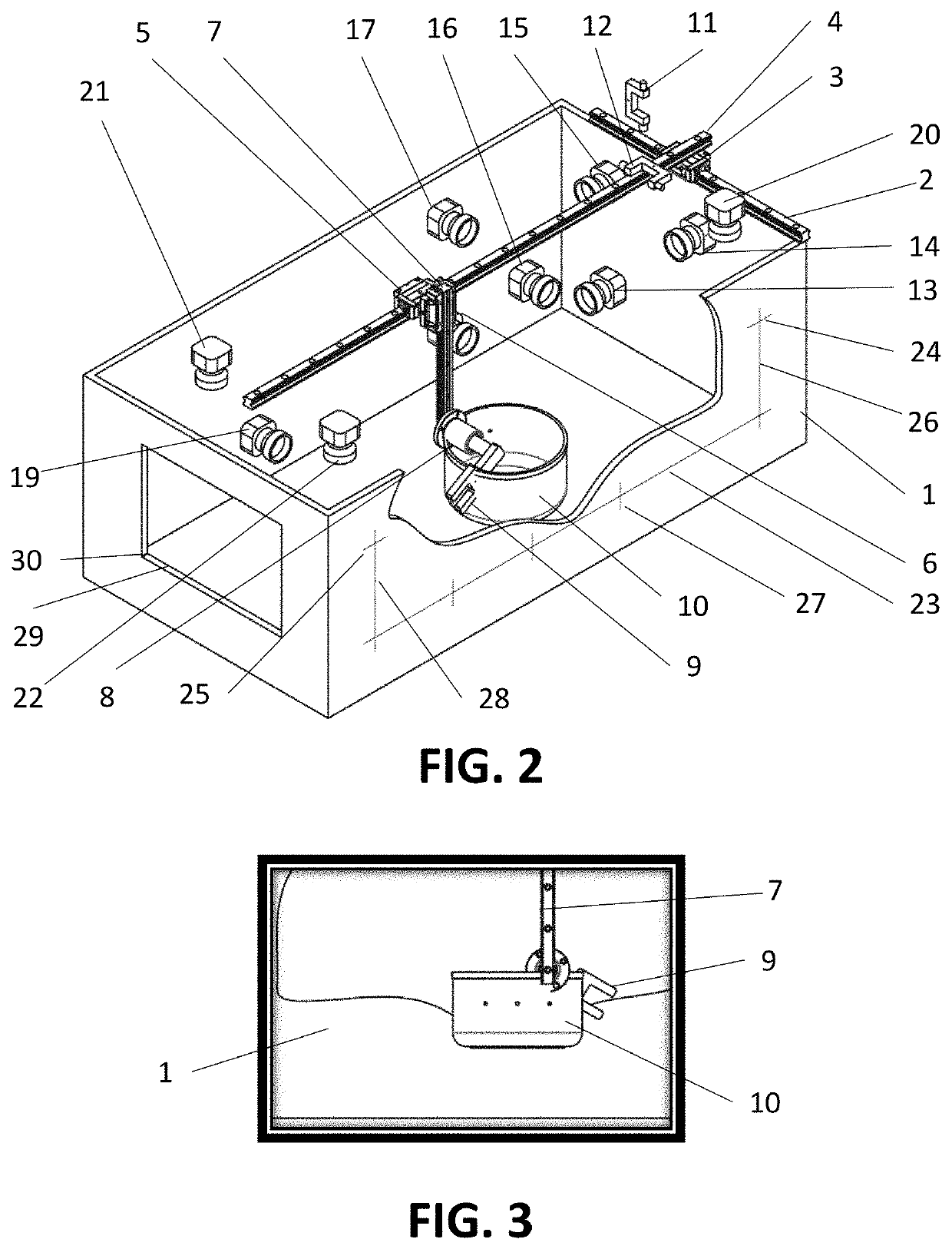

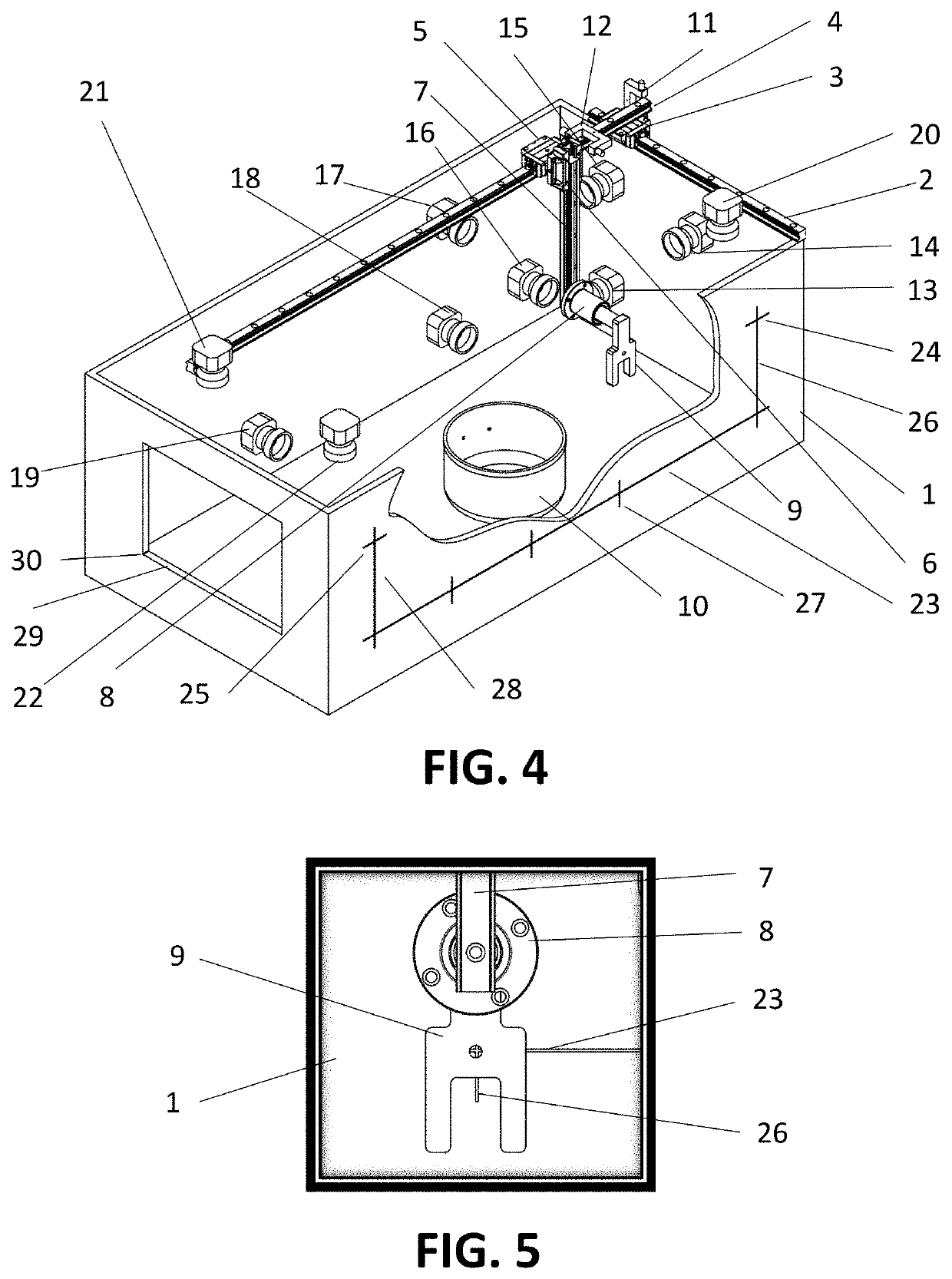

Comprehensive model-based method for gantry robot calibration via a dual camera vision system

InactiveUS20200262080A1Fast and accurate methodReduced commissioning timeProgramme-controlled manipulatorComputer graphics (images)Engineering

A comprehensive model-based mathematical method for calibration of a gantry robot and a tool via a dual camera vision system may employ an automatic calibration process that includes: (i) Camera Internal and External Calibration (ULC and DLC), (ii) Camera Installation, (iii) Robot Workspace Calibration, and (iv) Tool Calibration. The method may provide an accurate, fast and affordable method for robot calibration which may significantly reduce the commissioning time, such that the time-consuming, cumbersome, conventional trial-and-error method may be reduced to a time-efficient automatic procedure with no human interference.

Owner:INTUNE PROD LLC

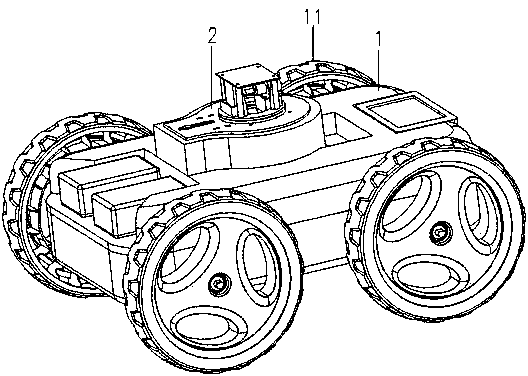

Laser-positioning automatic robot

The invention discloses a laser-positioning automatic robot. The laser-positioning automatic robot comprises a robot body and a laser scanning mechanism, wherein the laser scanning mechanism comprises a laser transmitting part, a laser receiving part, a reflector, a first power motor and a second power motor; the second power motor is used for driving a rotating part to rotate; the reflector is arranged on a rotating shaft of the first power motor; the first power motor is arranged on the rotating part; the first power motor drives the reflector to form swing laser; meanwhile, the first power motor rotates along with the rotating part to form scanning laser; the scanning laser can form a continuous inclined grating scanning track with certain height around the automatic robot; the track is formed by connecting densely-arrayed oblique lines; when the working area of the robot is positioned on a non-horizontal plane, the inclined grating scanning track extends in the vertical direction, and the scanning laser can be projected on a reflecting element.

Owner:SUZHOU CLEVA PRECISION MACHINERY & TECH

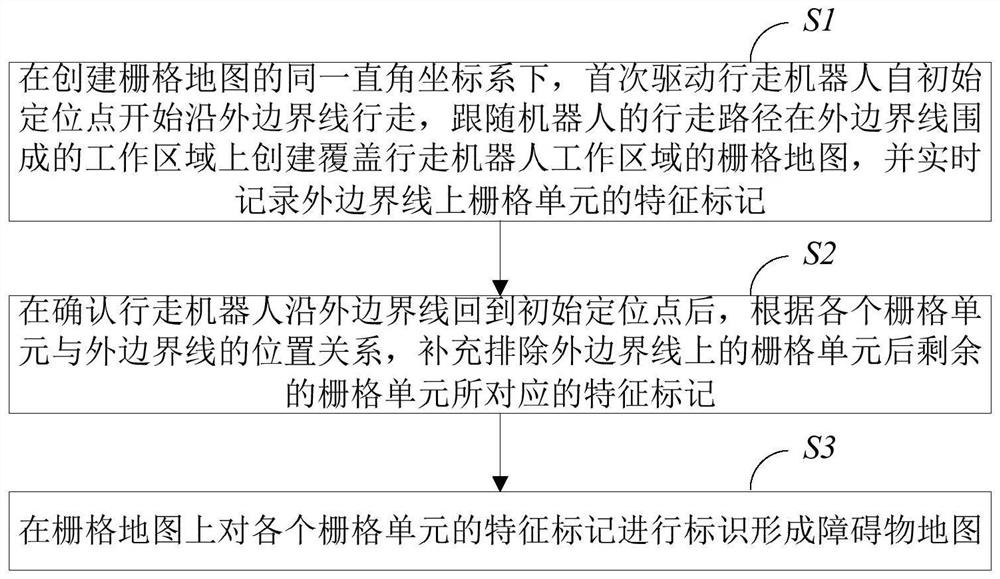

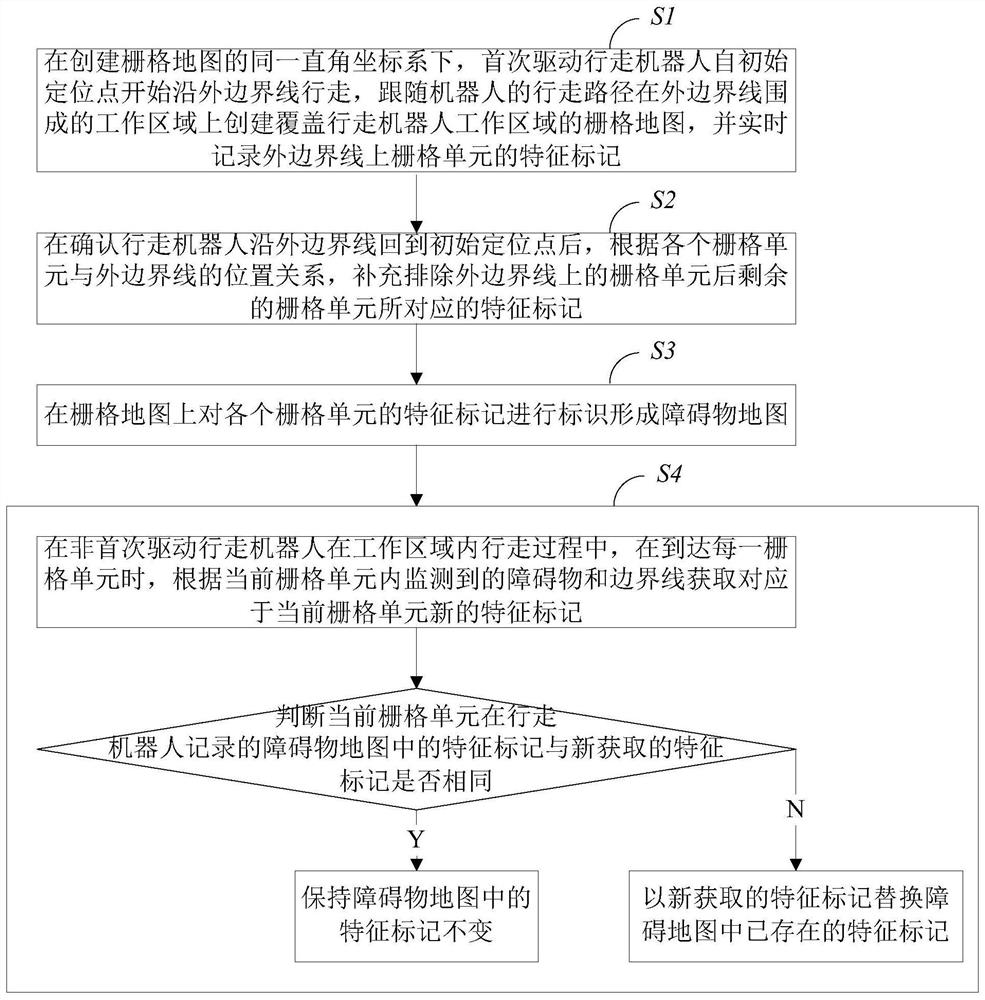

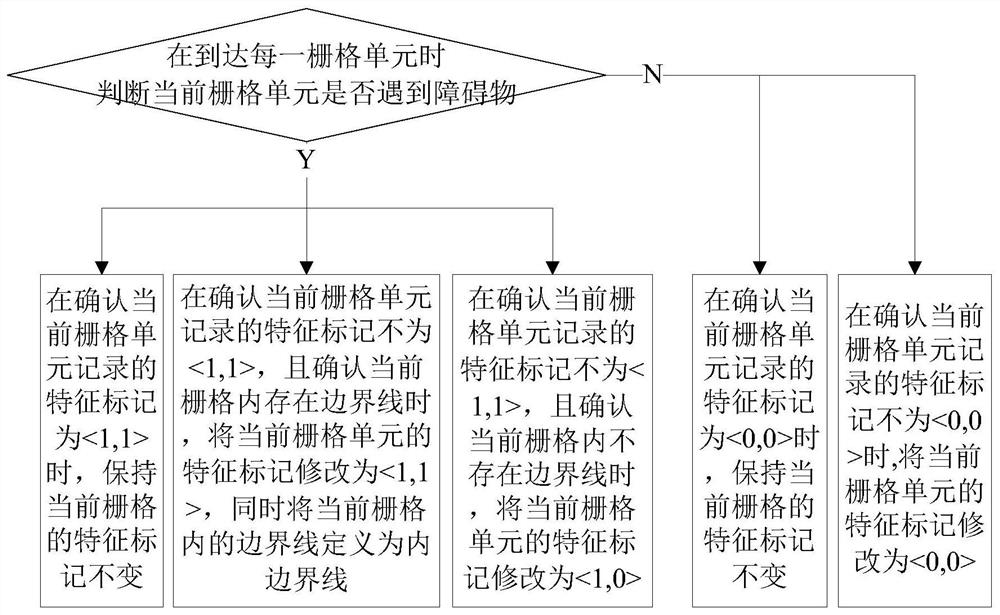

Obstacle map creation method and system, robot and readable storage medium

PendingCN112393737AEasy to walkImprove work efficiencyInstruments for road network navigationComputer graphics (images)Rectangular coordinates

The invention provides an obstacle map creation method and system, a robot and a readable storage medium. The method comprises the steps: driving a walking robot to walk along an outer boundary line from an initial positioning point for the first time under the same rectangular coordinate system of a created grid map, and creating the grid map covering the working area of the walking robot on a working area defined by the outer boundary line along with the walking path of the robot; recording feature marks of the grid units on the outer boundary line in real time; after the walking robot is confirmed to return to the initial positioning point along the outer boundary line, supplementing feature marks corresponding to the remaining grid units after the grid units on the outer boundary lineare removed according to the position relation between the grid units and the outer boundary line; and identifying the feature mark of each grid unit on the grid map to form an obstacle map. The working efficiency of the robot can be improved.

Owner:SUZHOU CLEVA PRECISION MACHINERY & TECH +1

Multi-station robot automatic board contracting and releasing machine provided with robot

The invention discloses a multi-station automatic board contracting and releasing machine. The multi-station automatic board contracting and releasing machine is characterized in that the multi-station robot automatic board contracting and releasing machine is composed of an outer frame and a bottom frame arranged in the outer frame; the bottom frame is divided into a conveying area, a robot work area and a placing area; the conveying area is provided with a conveying platform; the robot work area is provided with a six-shaft robot; the placing area is provided with at least two circuit board carrier placing platforms arranged along the conveying area and the robot work area; an adsorption device matched with the six-shaft robot is arranged below the six-shaft robot; the position of the six-shaft robot and the position where the adsorption device is arranged are both matched with the circuit board carrier placing platforms; at least two sets of circuit board carrier carts are arranged along the outer frame; and the positions of the circuit board carrier carts correspond to the positions of the circuit board carrier placing platforms one to one. According to the multi-station automatic board contracting and releasing machine, a plurality of components are designed into standard modules, the multi-station automatic board contracting and releasing machine can meet the standard arrangement required by most of industries, and a series of multi-station board contracting and releasing machines are derived on the basis.

Owner:SHANGHAI KAISER ELECTRONICS

Parallel kinematic machine trajectory planning method

InactiveUS8719212B2Minimizing energyMinimize timeProgramme-controlled manipulatorDigital data processing detailsData setParallel kinematics

The parallel kinematic machine (PKM) trajectory planning method is operable via a data-driven neuro-fuzzy multistage-based system. Offline planning based on robot kinematic and dynamic models, including actuators, is performed to generate a large dataset of trajectories, covering most of the robot workspace and minimizing time and energy, while avoiding singularities and limits on joint angles, rates, accelerations and torques. The method implements an augmented Lagrangian solver on a decoupled form of the PKM dynamics in order to solve the resulting non-linear constrained optimal control problem. Using outcomes of the offline-planning, the data-driven neuro-fuzzy inference system is built to learn, capture to and optimize the desired dynamic behavior of the PKM. The optimized system is used to achieve near-optimal online planning with a reasonable time complexity. The effectiveness of the method is illustrated through a set of simulation experiments proving the technique on a 2-degrees of freedom planar PKM.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

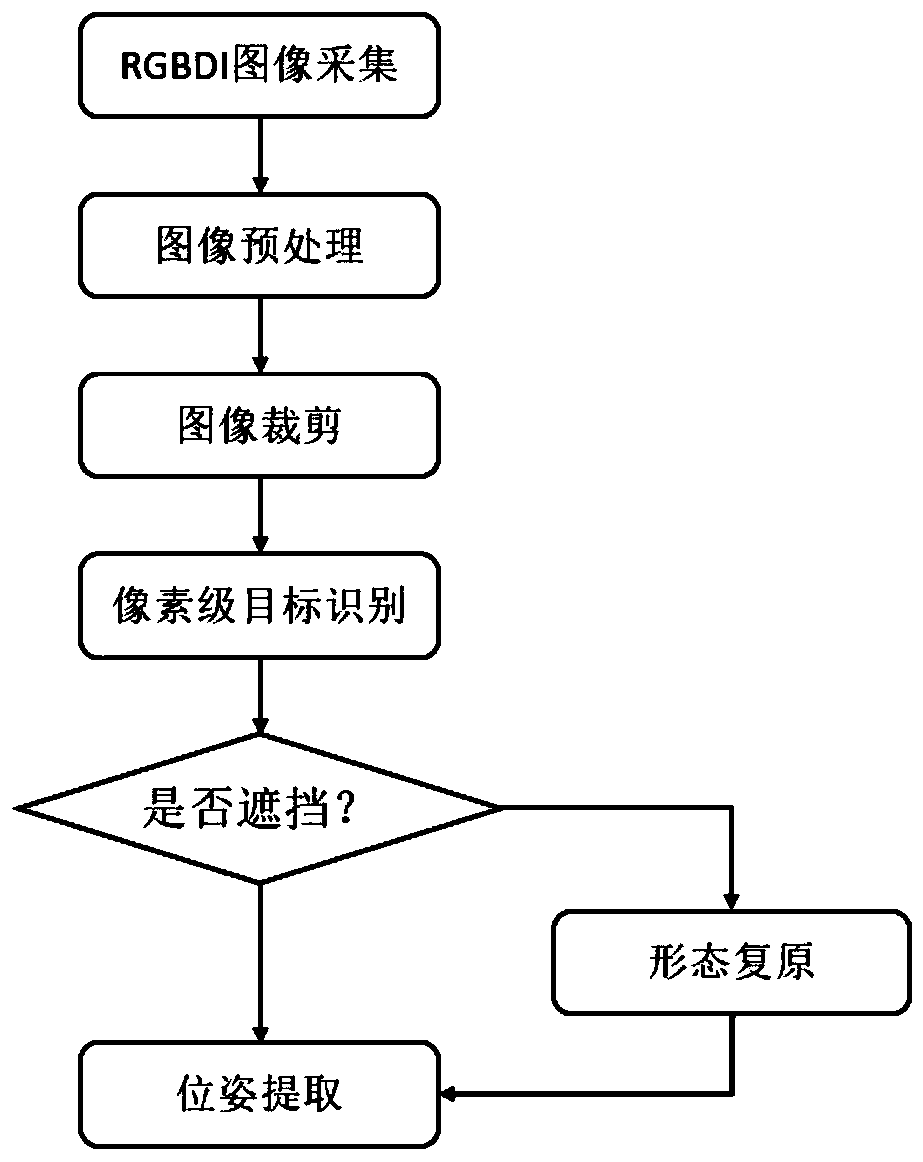

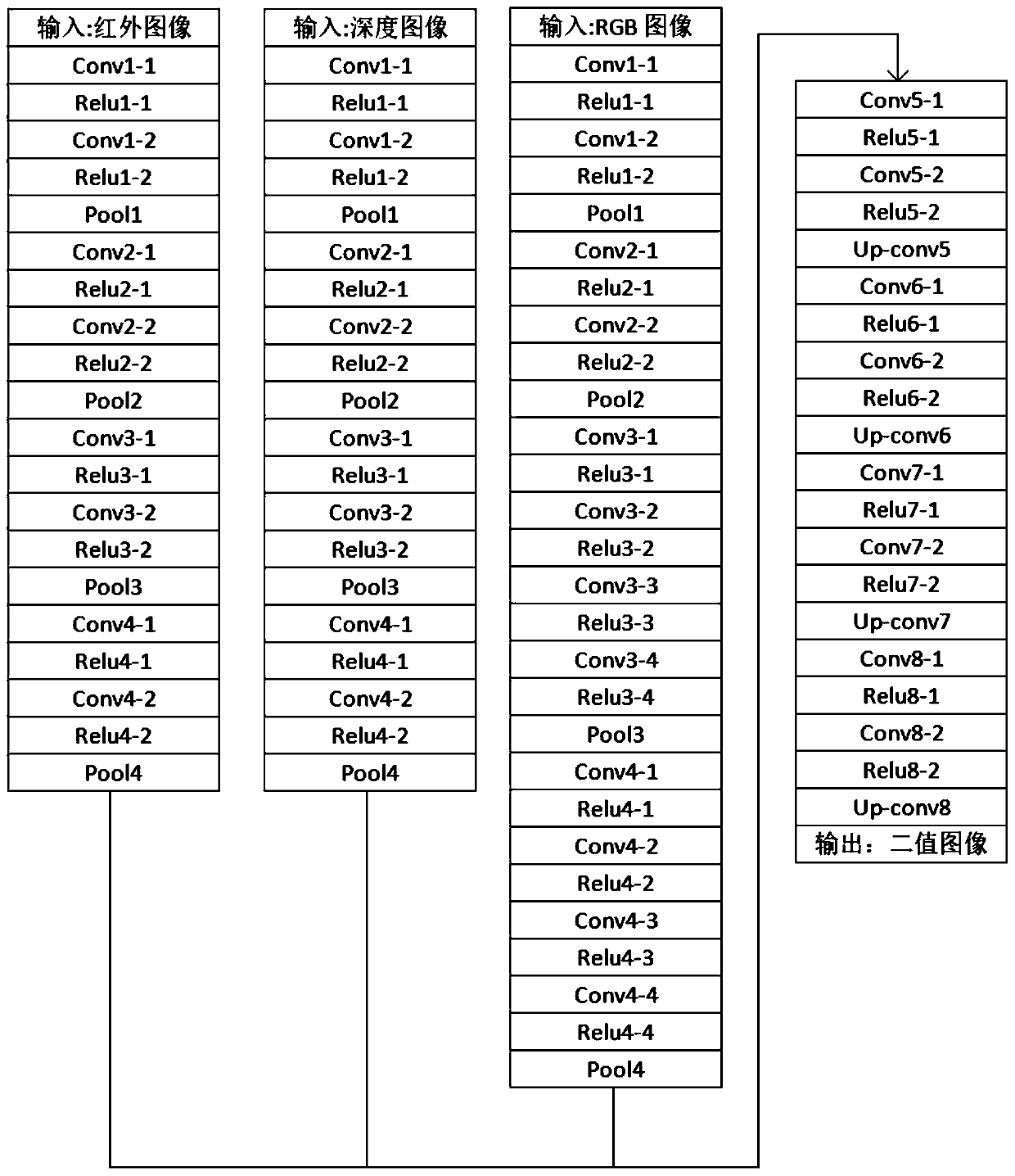

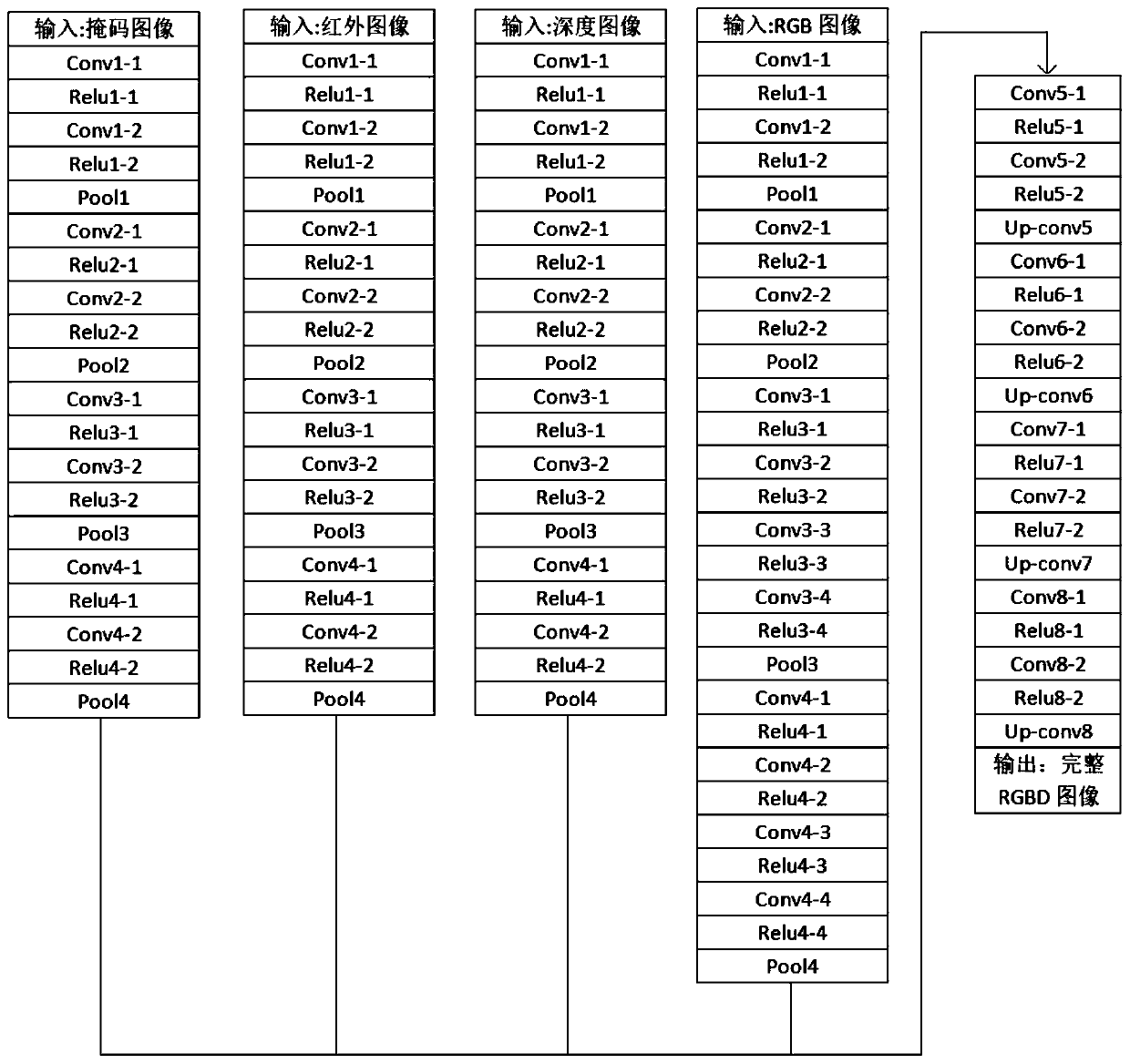

Shielded vegetable and fruit harvesting method based on depth association perception algorithm

InactiveCN110033487AReduce distractionsStable jobImage enhancementImage analysisColor imageImage resolution

The invention provides a shielded vegetable and fruit harvesting method based on a depth association perception algorithm. The shielded vegetable and fruit harvesting method comprises the steps of collecting an RGB channel color image, a D channel depth image and an I channel infrared image; unifying the resolution of the acquired image; removing areas except the working area of the harvesting robot in the image with the uniform resolution; identifying a mature target, and marking each pixel of the mature target in the cut image; judging whether the mature target is shielded or not, restoringthe images of the RGBD four channels of the complete mature target under the condition that the mature target is shielded, and directly obtaining the images of the RGBD four channels of the complete mature target under the condition that the mature target is not shielded; and according to the images of the four channels of the RGBD of the complete mature target, extracting the position and postureof the mature target to a harvesting robot. The device is less interfered by the environment and works more stably; the complete RGBD information of the target can be estimated; robot harvesting success rate can be improved.

Owner:SHANGHAI JIAO TONG UNIV

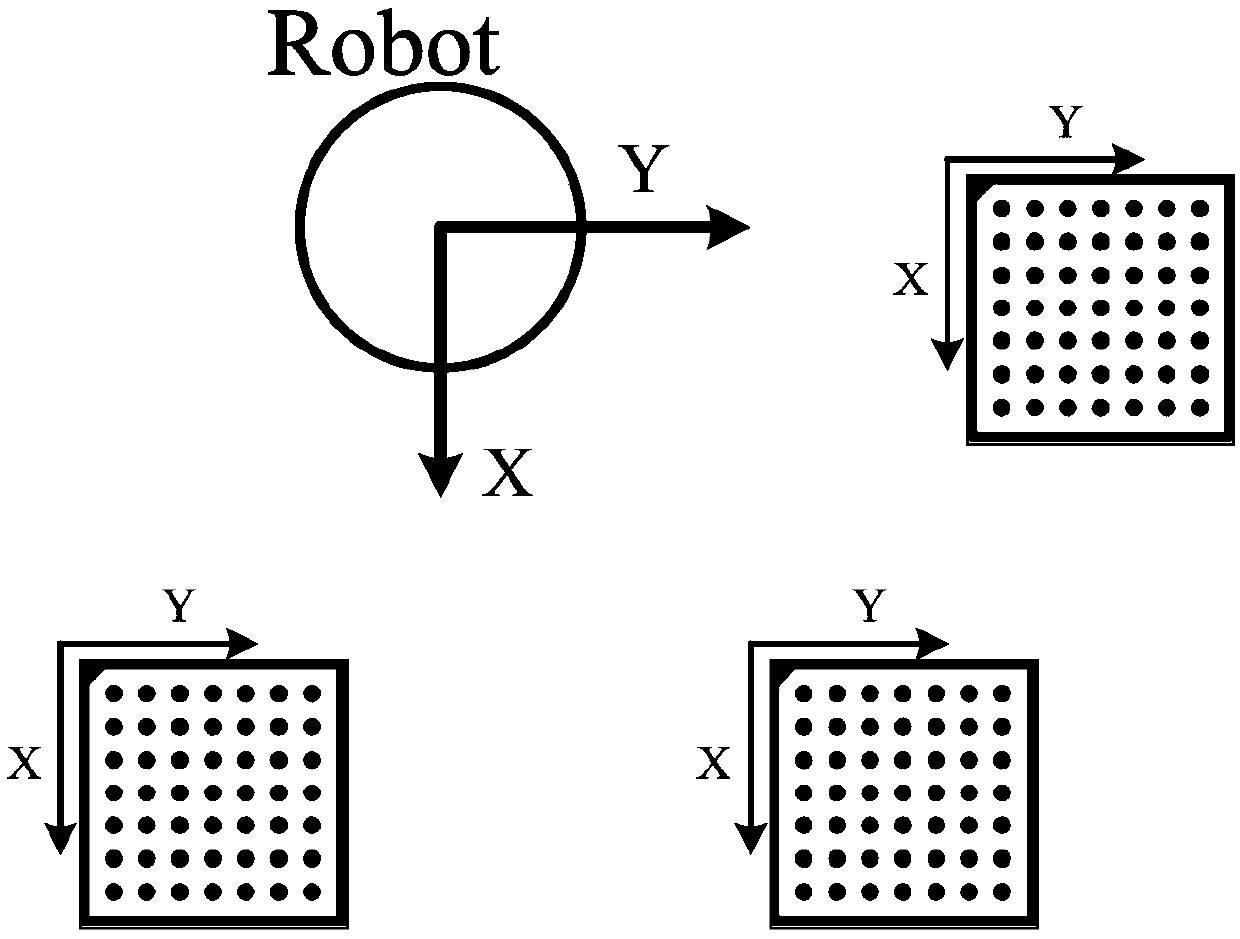

Robot vision supervisor for hybrid homing, positioning and workspace ufo detection enabling industrial robot use for consumer applications

A robot vision supervisor system for use with industrial robots being placed with average home consumers or at restaurants that is capable of guiding the robot to its horning position for initial homing or when a loss of reference has occurred. Further the robot vision supervisor is able to detect presence of unidentified foreign objects in the workspace and guide the robot to navigate around and prevent collisions. Image processing algorithms are used with primary, orthogonal and cross camera arrays to increase reliability and accuracy of the robot vision supervisor. Lookup tables of images are captured and stored by controller for discretized positions in the full robot workspace when robot is in known good calibration to compare with images during regular operation for detecting anomalies.

Owner:ROY SHAMBHU NATH

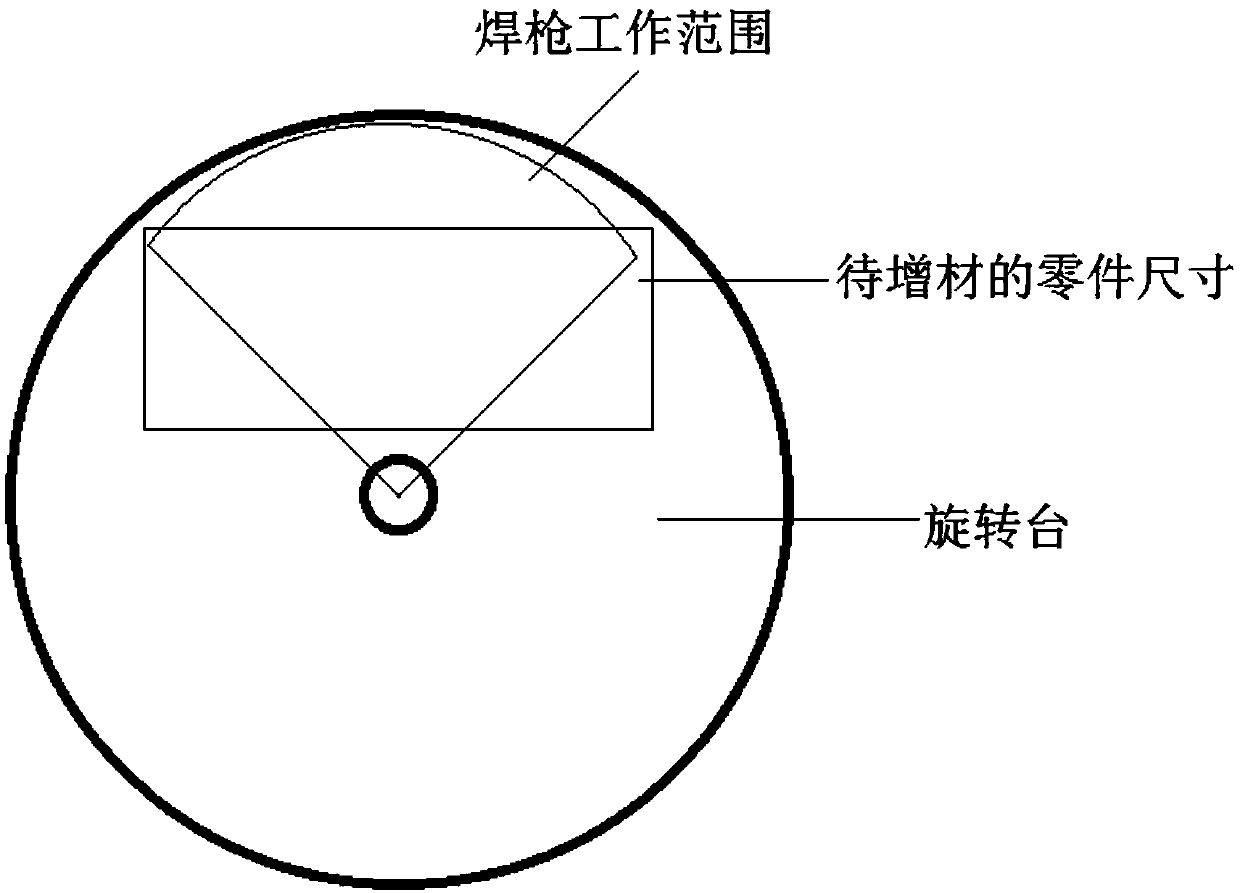

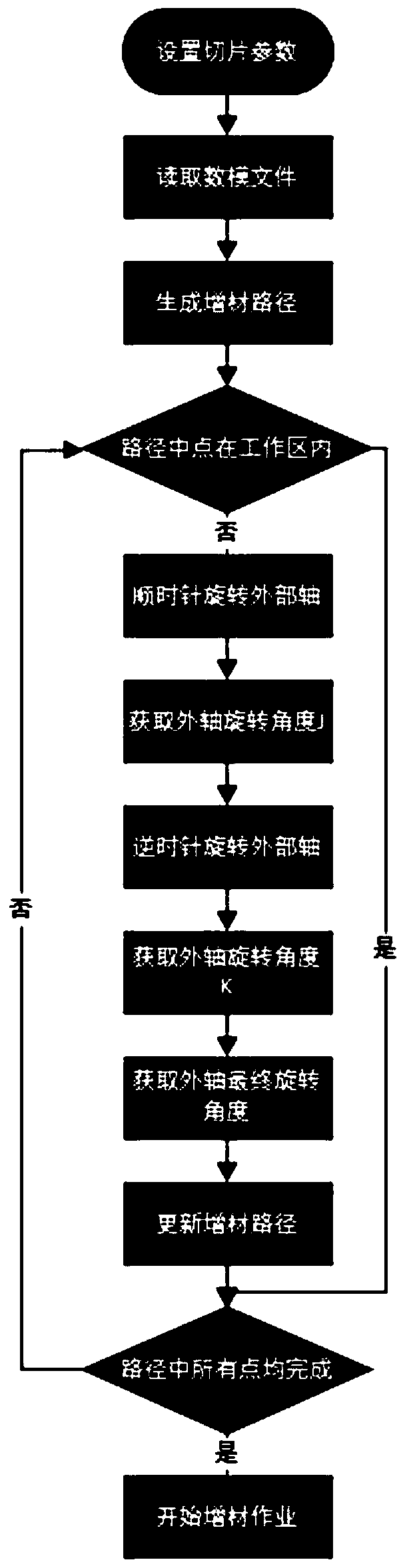

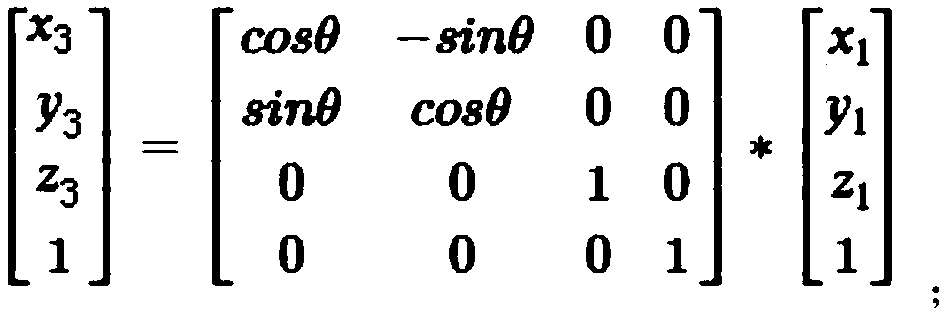

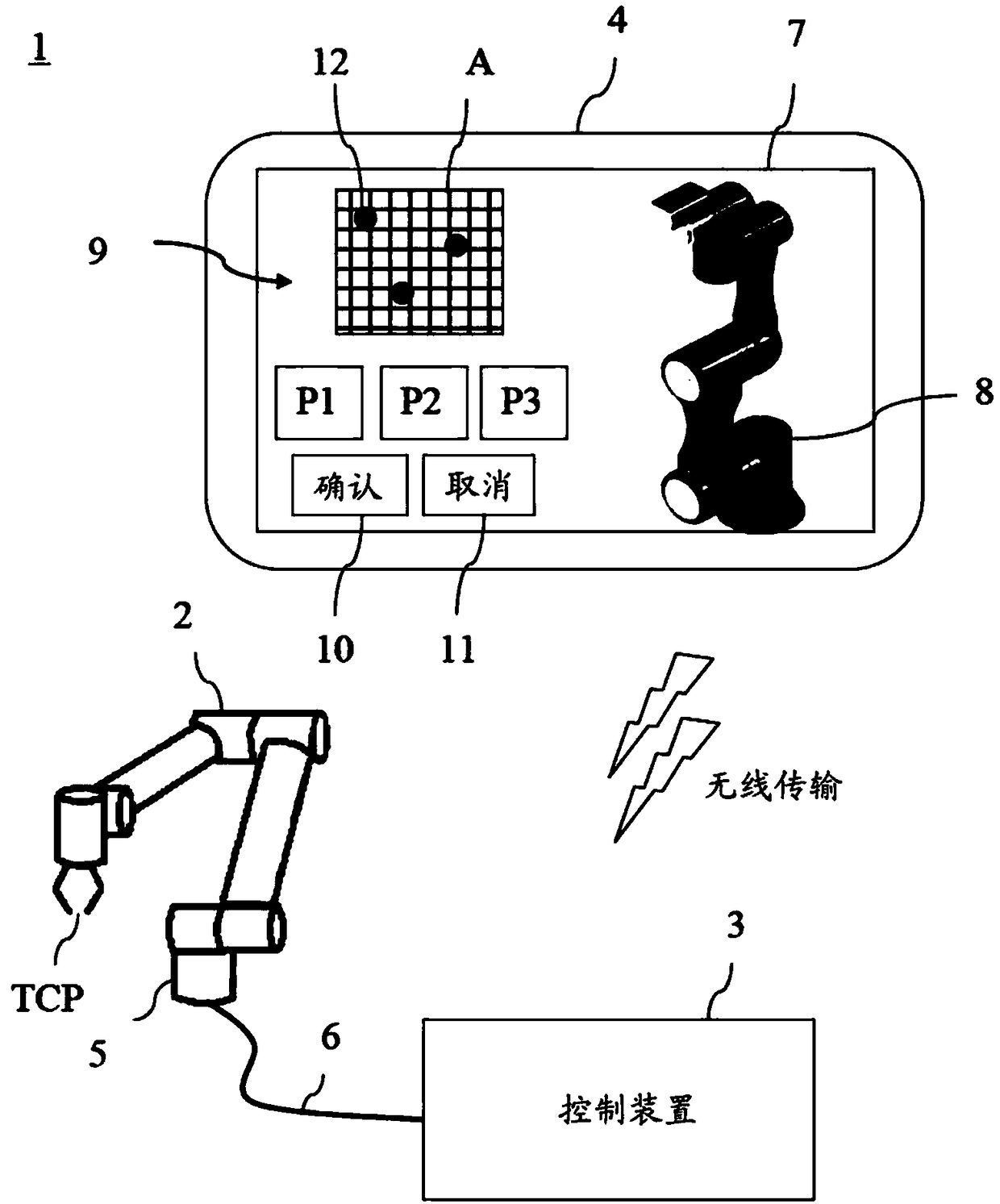

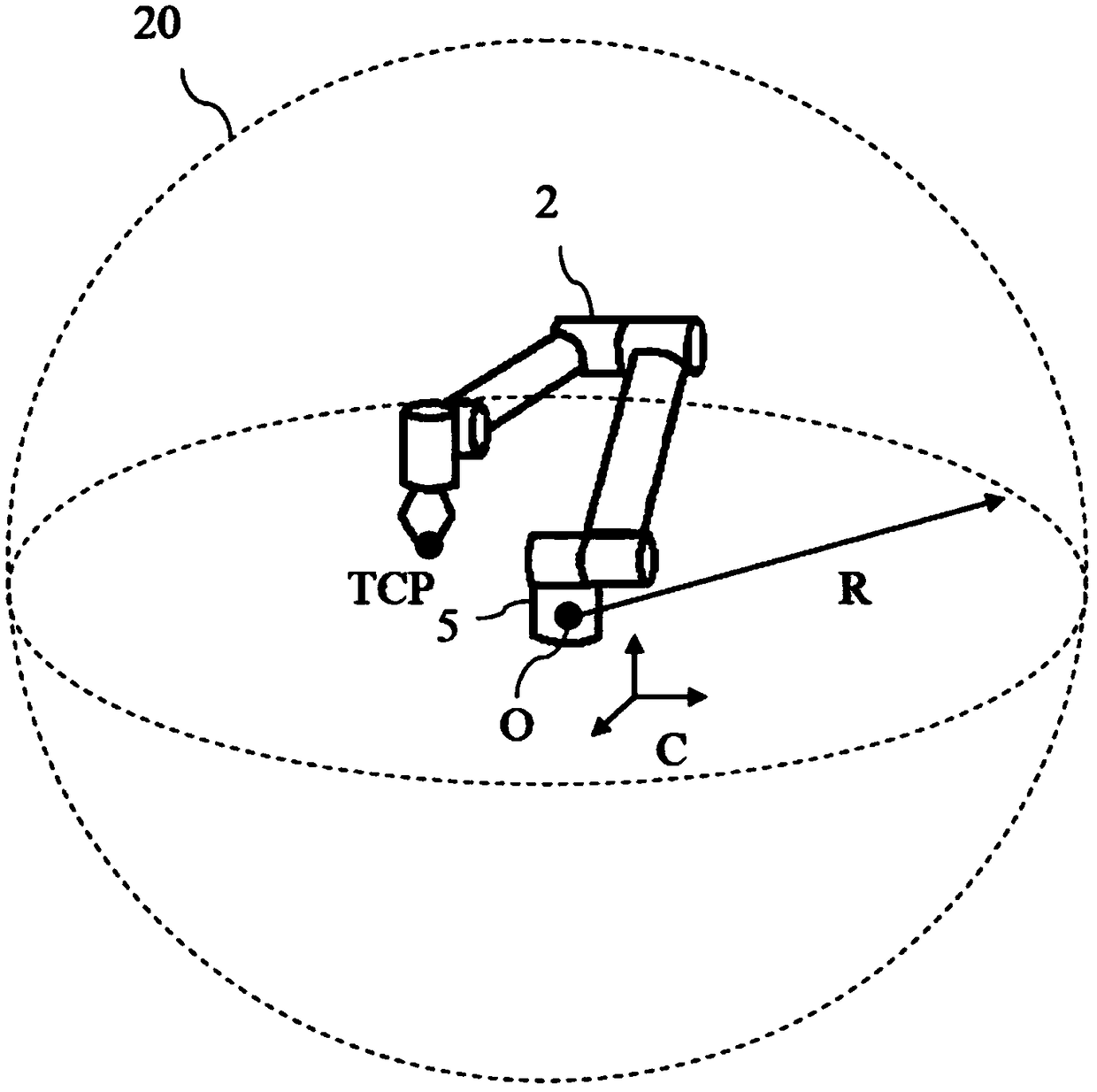

Electric arc additive manufacturing method capable of being used for large-size parts manufacturing

The invention discloses an electric arc additive manufacturing method capable of being used for large-size parts manufacturing. According to the method, the additive manufacturing of parts is carriedout on a rotatable rotating table, the mode that the rotatable rotating table is combined with a slicing program is realized, so that the large-size parts are firstly sliced and analyzed, whether therunning track of the program is located in the working area of the robot body or not is judged, the running track is matched with the rotating table to rotate in the program running process, the working area of the welding robot is expanded, so that the original unreachable region of the robot can be changed into a reachable region so as to achieve the purpose of manufacturing large-size parts; the method can be used for forming and manufacturing the large-size aviation structural parts.

Owner:南京衍构科技有限公司

Method for dividing working area of robot

The invention discloses a method for dividing a working area of a robot. The method comprises the following steps that the working area of the robot is defined, a plurality of separation interfaces are built in the working area by taking non-collinear three points, when the separation interfaces are built, the separation interfaces are mutually crossed to form separation lines, the separation lines divide the separation interfaces into punctuating section surfaces and extending section surfaces, the punctuating section surfaces are connected to form a full separation interface, the full separation interface divides the working area into two operation areas, and the operation area comprising an origin coordinate of the robot is selected as a moving area so as to simplify the dividing operation.

Owner:TECHMAN ROBOT INC

Laser map region segmentation method

PendingCN111681246AImprove work efficiencyEffective segmentationImage enhancementImage analysisLaser scanningLaser sensor

The invention discloses a laser map area segmentation method comprising the following steps: 1, denoising a grayed laser map, wherein the laser map is a map pre-constructed through rotary scanning ofa laser sensor assembled on a robot, and the laser map comprises map environment contour information obtained through laser scanning; step 2, according to distance information between a white pixel point of the grayed laser map and a black pixel point marked by a nearest obstacle, obtaining a laser map, determining central points of at least two robot working areas, secondly, segmenting the imageof the laser map processed in the first step into closed map areas with the center point of the robot working area as a local minimum value point and meeting the requirement for the optimal working area of the robot through a watershed algorithm, wherein each closed map area is an influence area obtained through outward expansion of the center point of the corresponding robot working area. Therefore, the situation that the working efficiency of the robot is reduced after the map is divided into multiple areas is avoided.

Owner:AMICRO SEMICON CORP

Fast robot motion optimization with distance field

A robot collision avoidance motion optimization technique using a distance field constraint function. CAD or sensor data depicting obstacles in a robot workspace are converted to voxels, and a three-dimensional binary matrix of voxel occupancy is created. A corresponding distance map matrix is then computed, wherein each cell in the distance map matrix contains a distance to a nearest occupied cell. The distance map matrix is used as a constraint function in a motion planning optimization problem, wherein the optimization problem is convexified and then iteratively solved to yield a robot motion profile which avoids the obstacles and minimizes an objective function such as distance traveled. The distance field optimization technique is quickly computed and has a computation time which is independent of the number of obstacles. The disclosed optimization technique is easy to set up, as it requires no creation of geometry primitives to approximate robot and obstacle shapes.

Owner:FANUC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com