Electric arc additive manufacturing method capable of being used for large-size parts manufacturing

A large-scale, arc technology, applied in the field of arc additive manufacturing using a rotatable external shaft combined with a slicing process, metal arc additive manufacturing, and can solve problems such as limited working area and inability to manufacture large-sized parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with specific embodiments.

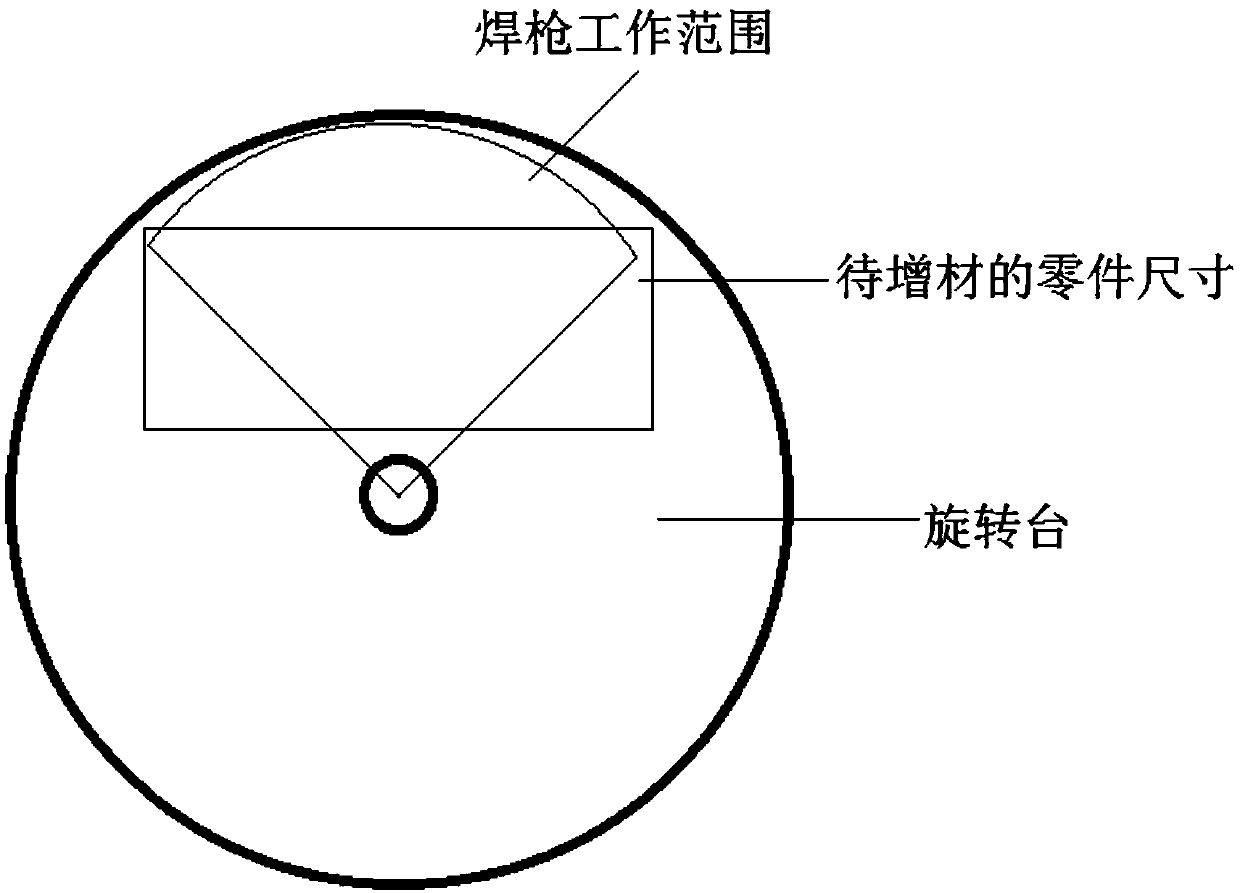

[0035] Such as figure 1 As shown, the present invention can be used in the arc additive method of large-scale parts manufacturing, and a rotating table is arranged under the welding head of the welding robot, and the rotating shaft of the rotating table is parallel to the central axis of the robot base;

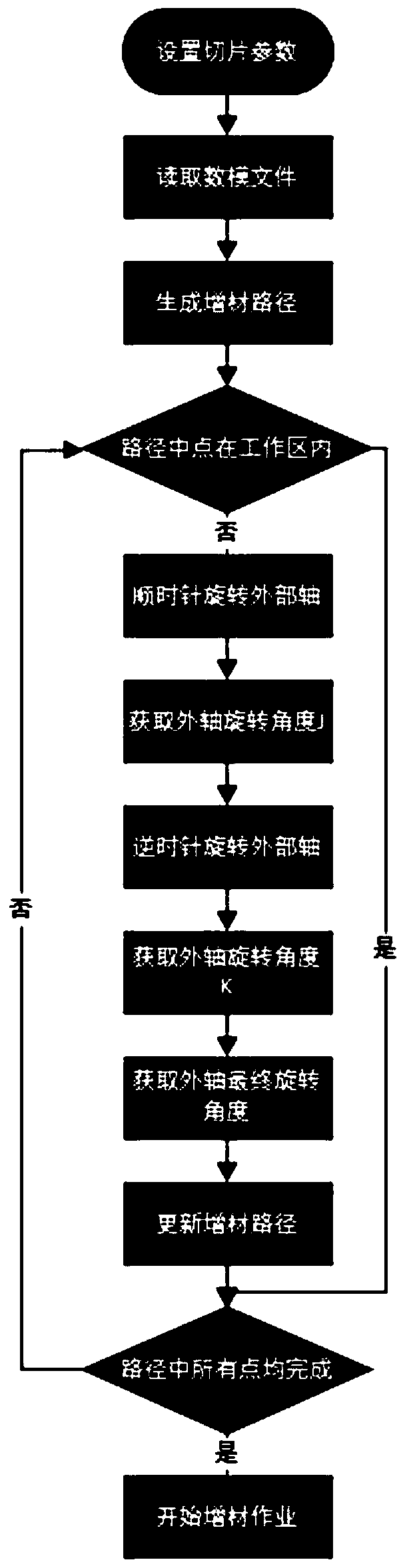

[0036] Such as figure 2 As shown, the above-mentioned arc additive manufacturing method specifically includes the following steps:

[0037] Step 1. Analyze the digital model of the part in the slicing software of arc additive, and use the offset algorithm or parallel line scanning algorithm to generate the additive path;

[0038] Step 2, judging whether the first point in the additive path is within the reachable area of the robot;

[0039] The specific judgment method is:

[0040] Set the reachable area radius of welding torch robot to 1000~1200mm;

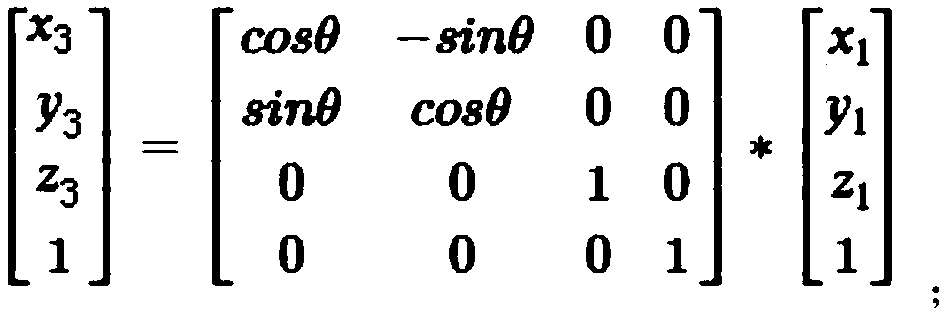

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com