Patents

Literature

347 results about "Additive process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Additive process. (Photography) a photographic process in which the desired colours are produced by adding together appropriate proportions of three primary colours.

Surface modified particulate and sintered or injection molded products

ActiveUS20150080495A1Simple technologyWeaken energyConductive materialCeramic shaping apparatusParticulatesPolymer science

Disclosed are interfacially modified particulate and polymer composite material for use in injection molding processes, such as metal injection molding and additive process such as 3D printing. The composite material is uniquely adapted for powder metallurgy processes. Improved products are provided under process conditions through surface modified powders that are produced by extrusion, injection molding, additive processes such as 3D printing, Press and Sinter, or rapid prototyping.

Owner:TUNDRA COMPOSITES LLC

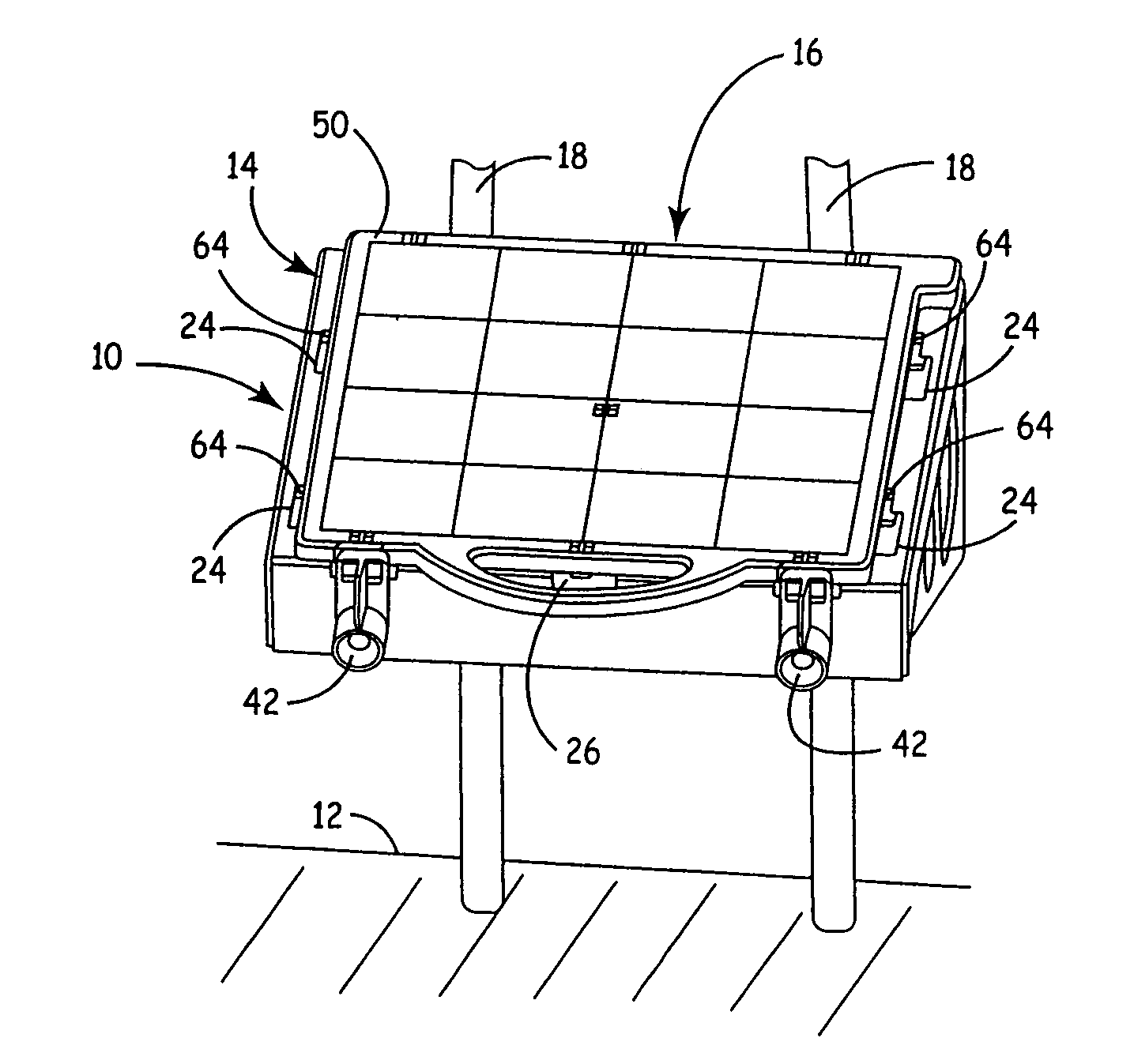

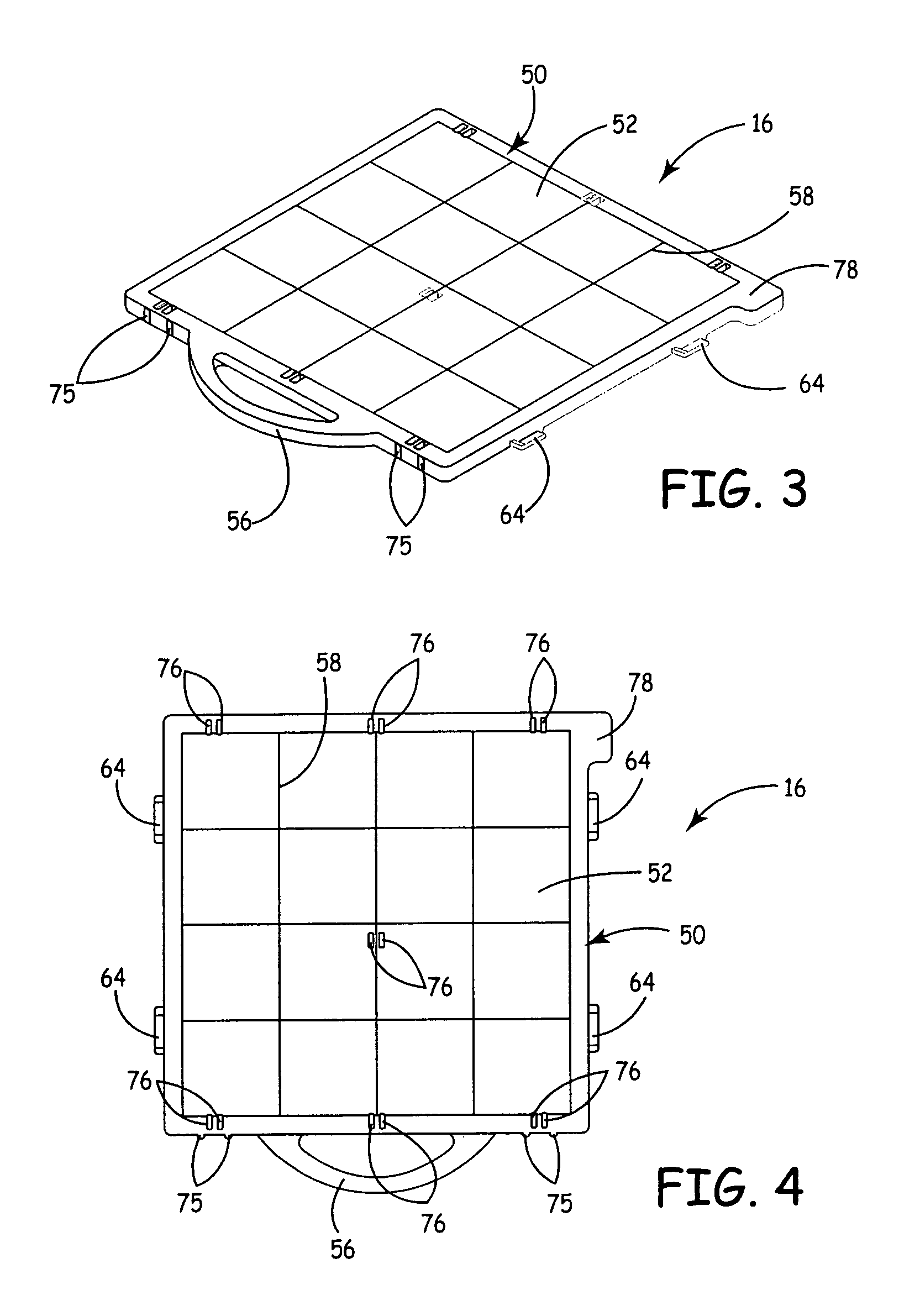

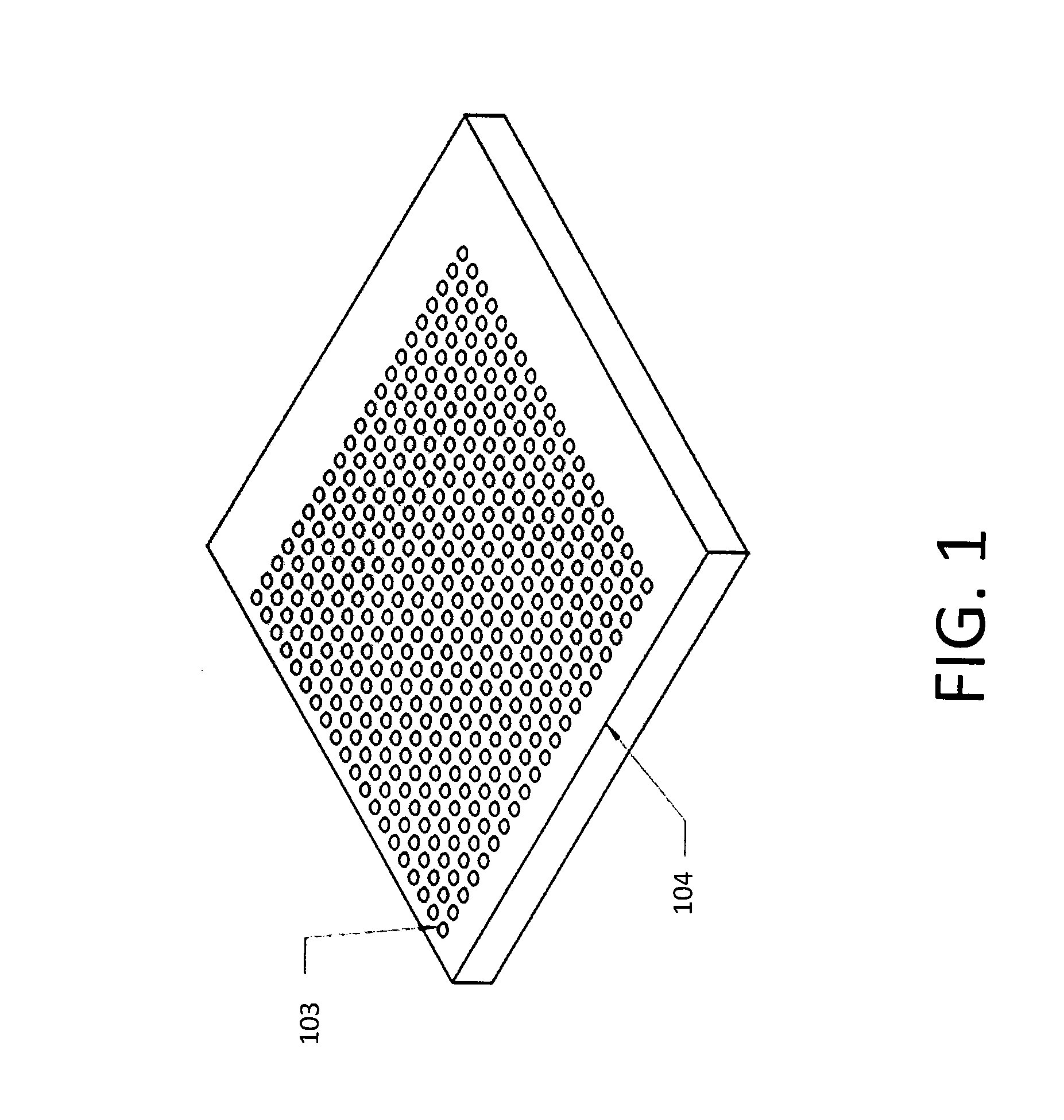

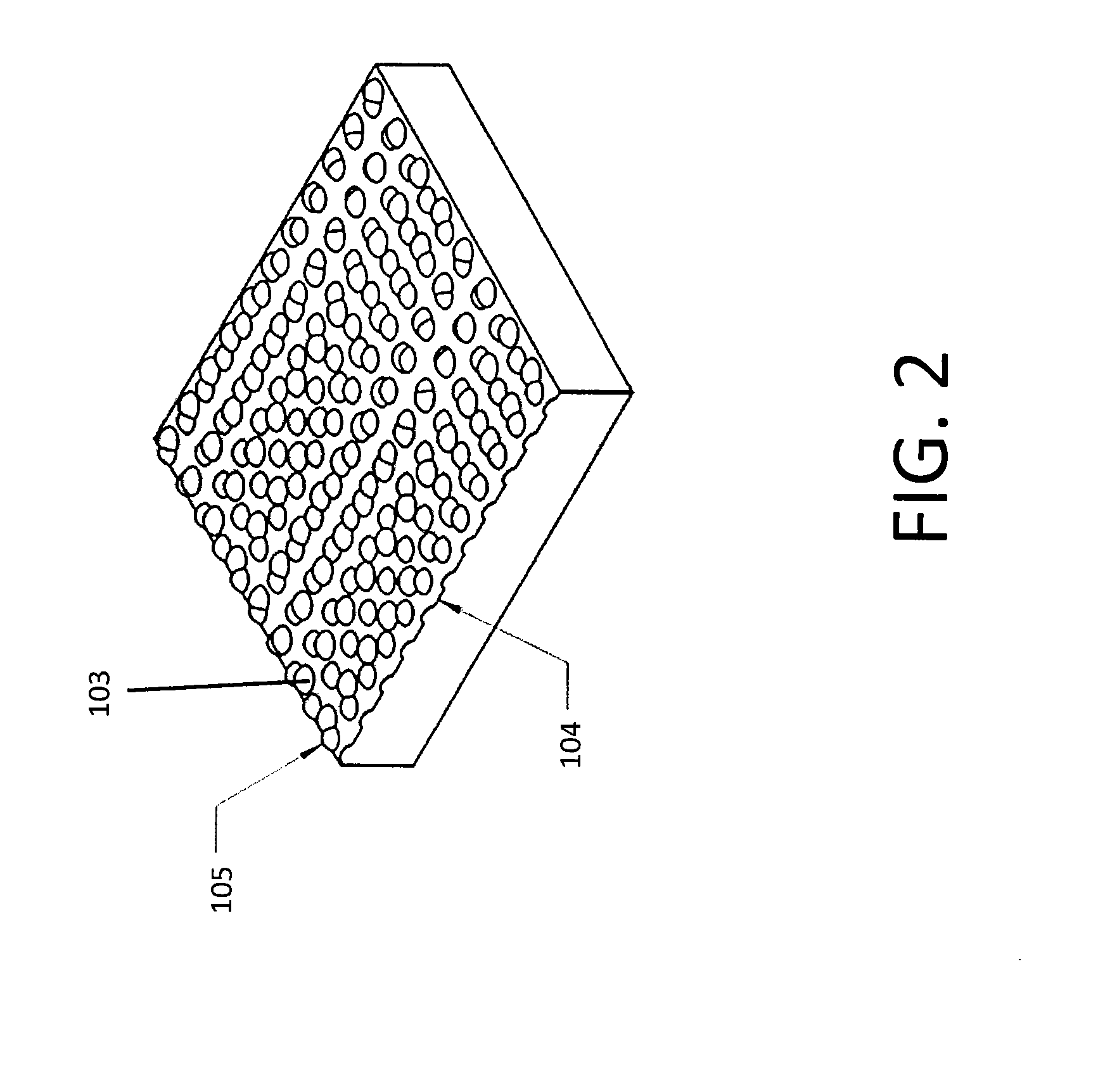

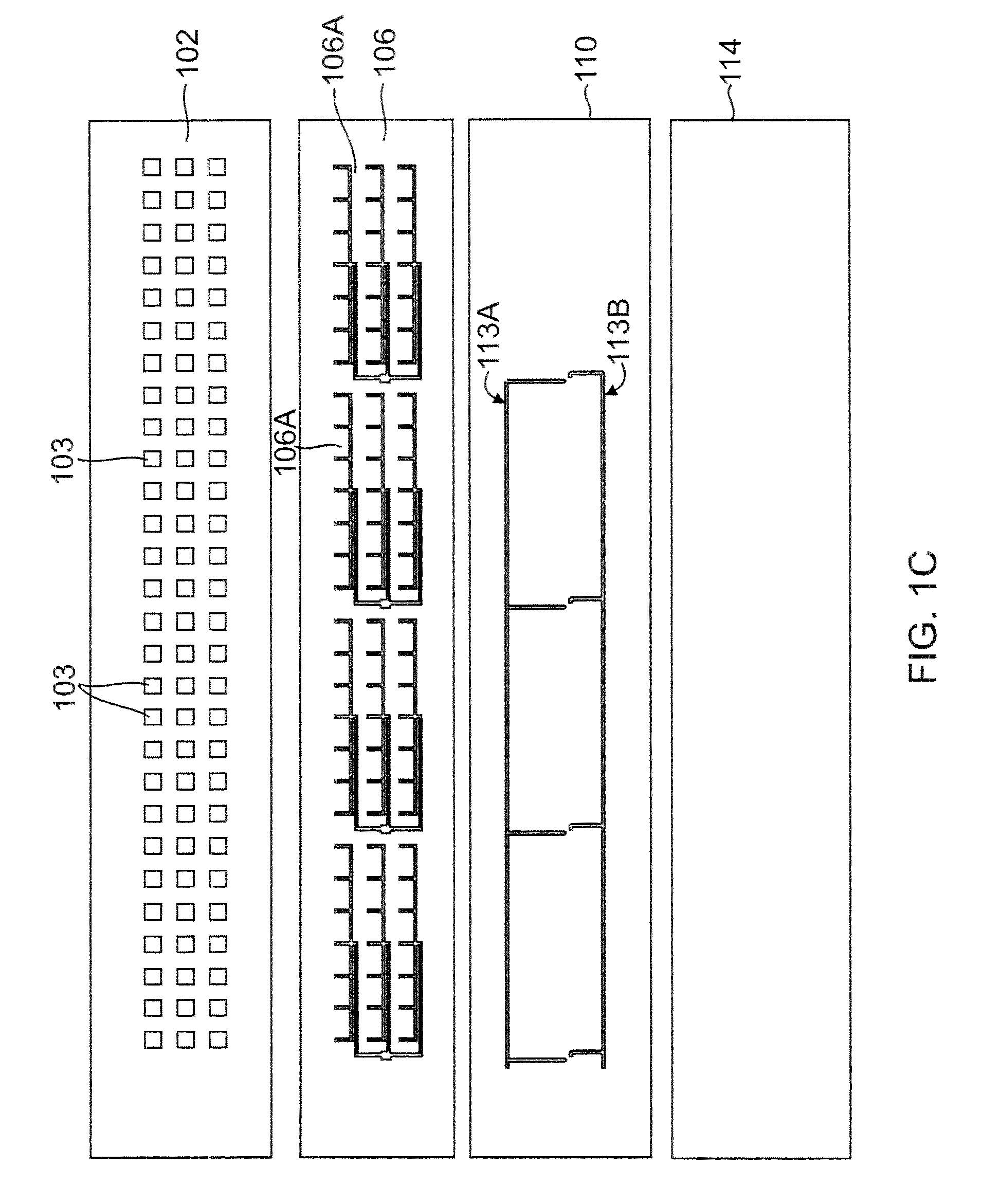

Modeling apparatus with tray substrate

ActiveUS7127309B2Reduce usageAdditive manufacturing apparatusLarge fixed membersDimensional modelingEngineering

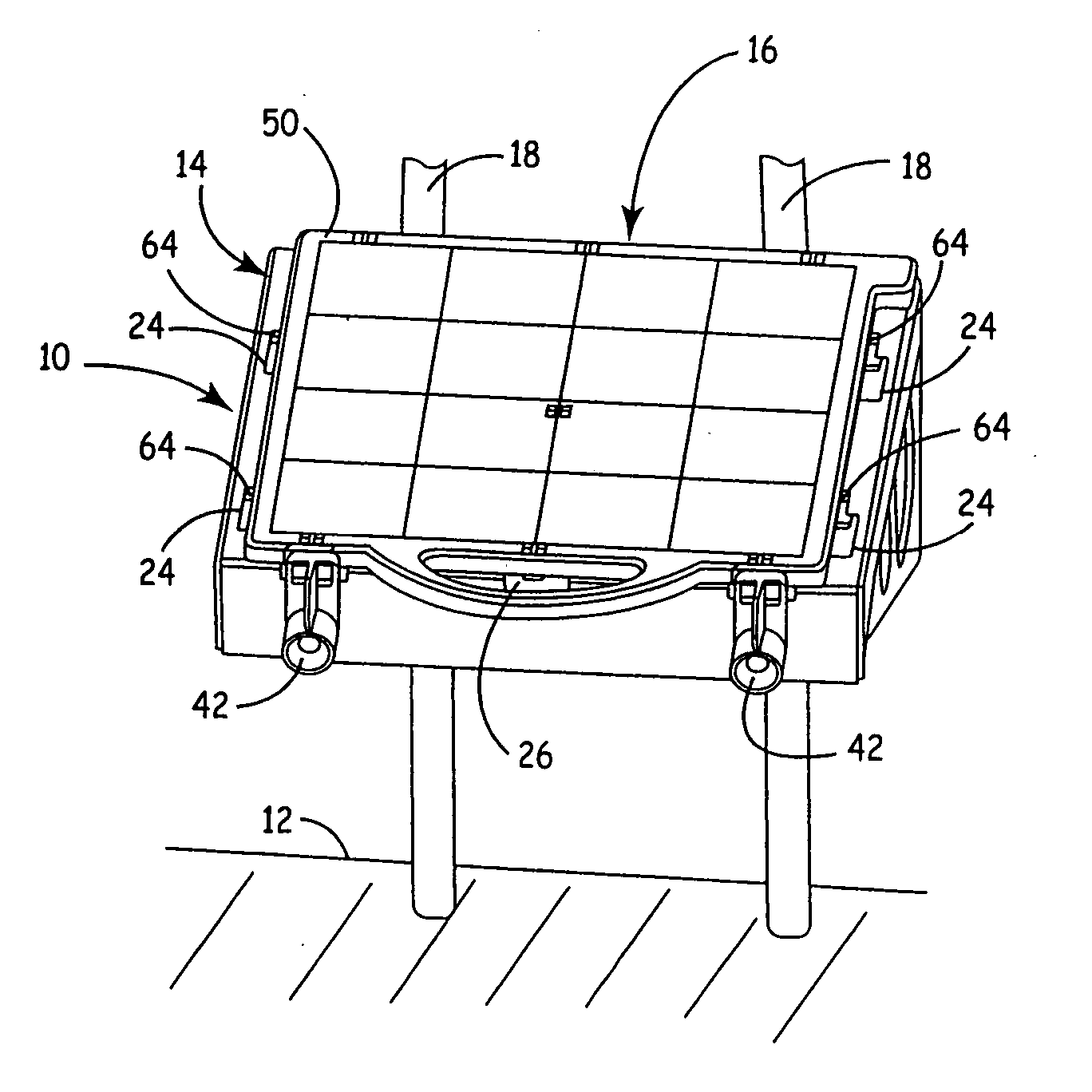

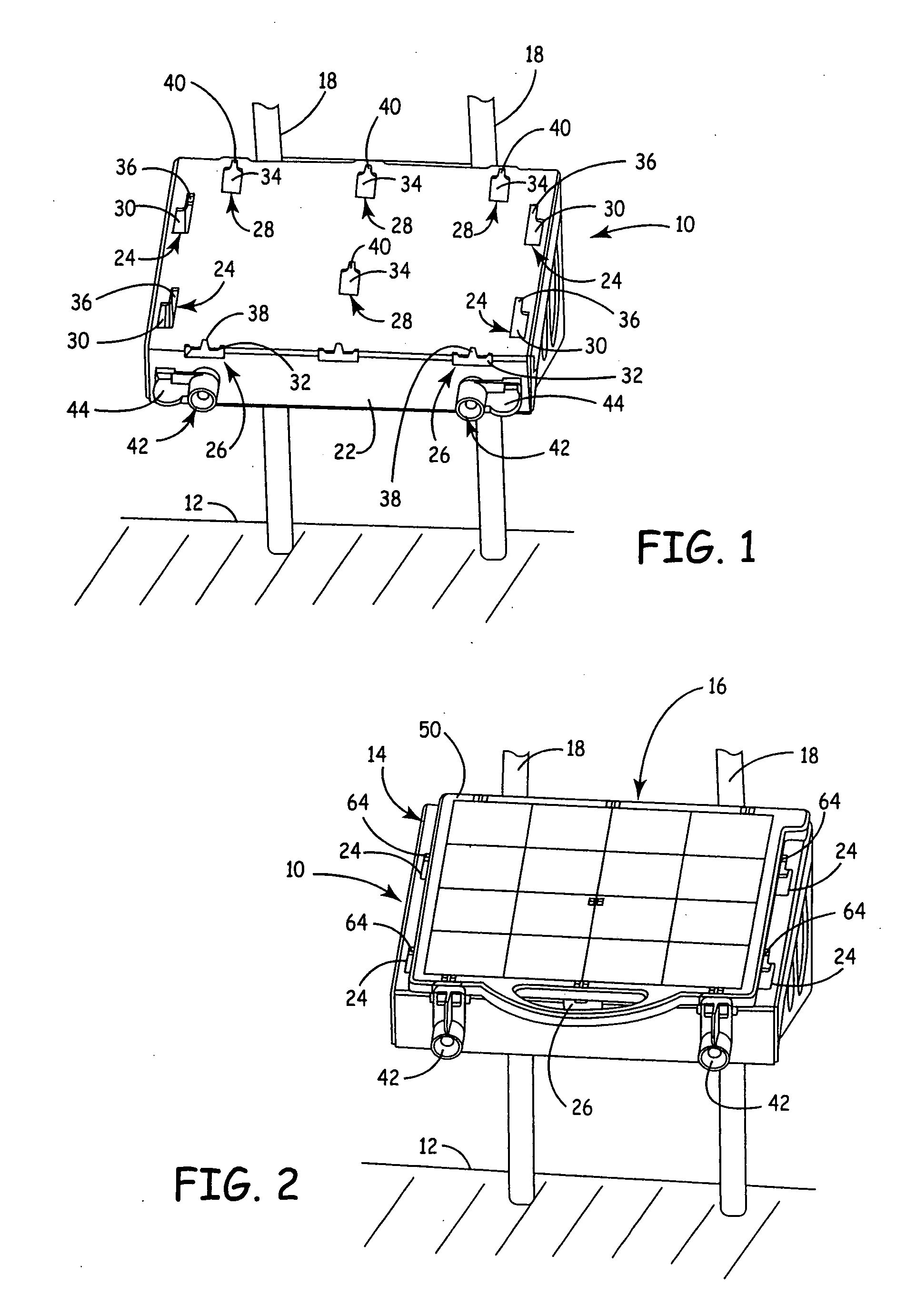

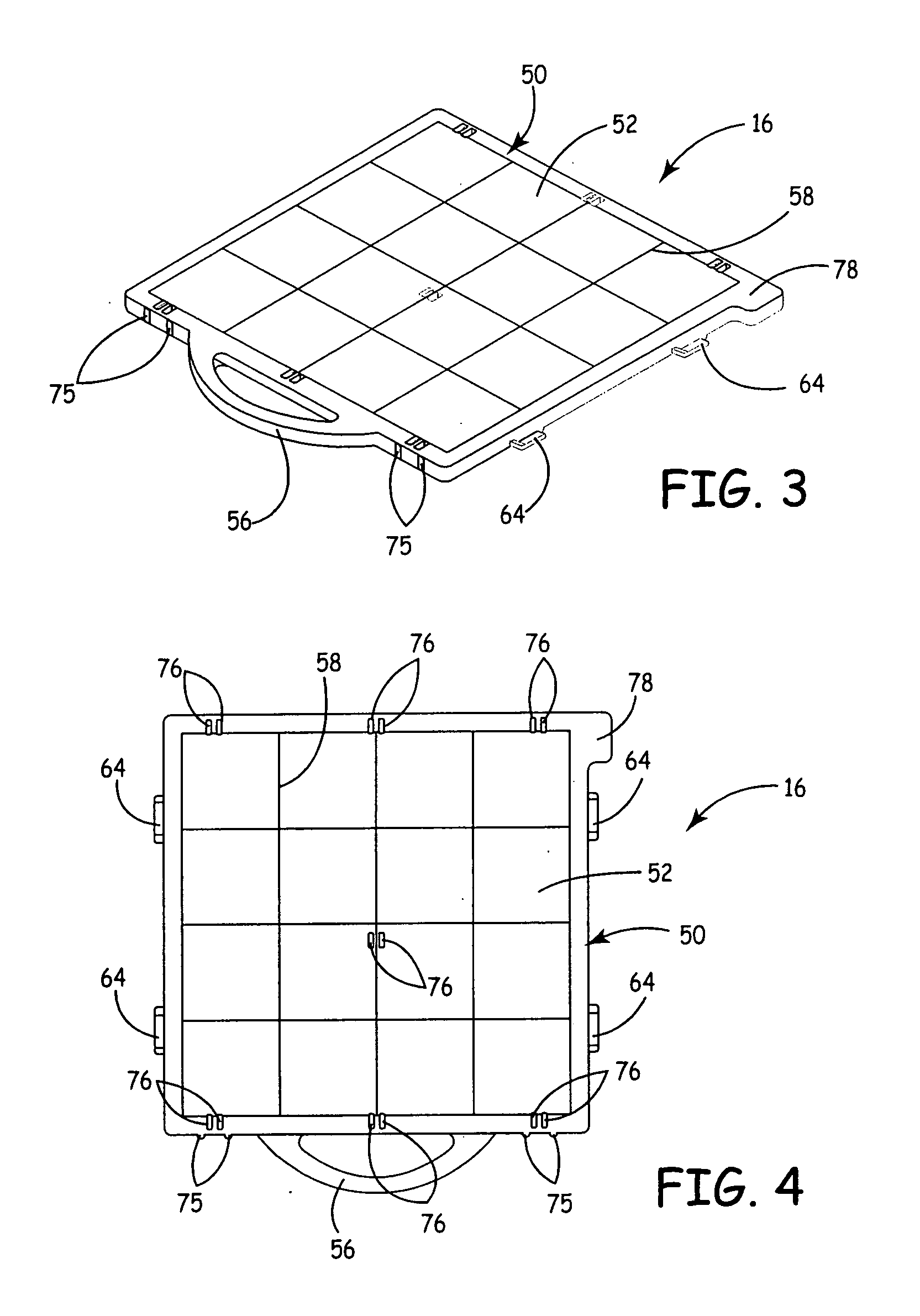

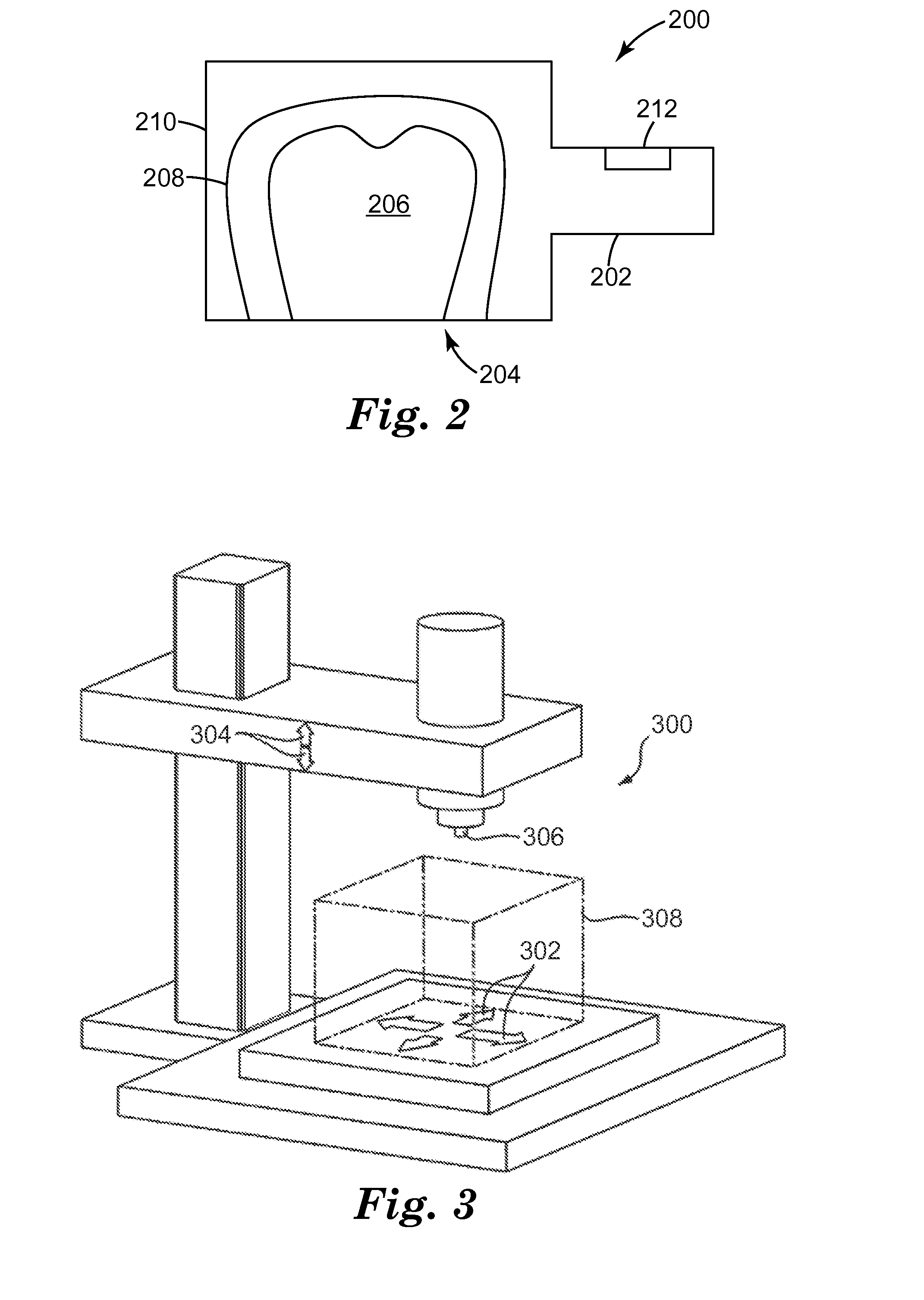

A modeling apparatus includes a platform and a substrate, which are adapted to be releasably locked together to provide a surface for building up models in an additive-process three-dimensional modeling machine. The substrate comprises a substantially rigid, non-dusting tray providing a modeling surface. Male connectors extending from the tray are seated in female connectors in the platform, to engage the substrate to the platform. The engaged substrate is locked to the platform, maintaining accurate positioning of the substrate while a model is built. After modeling is complete, the substrate is released from the platform, the model is removed, and the substrate may be reused.

Owner:STRATSYS INC

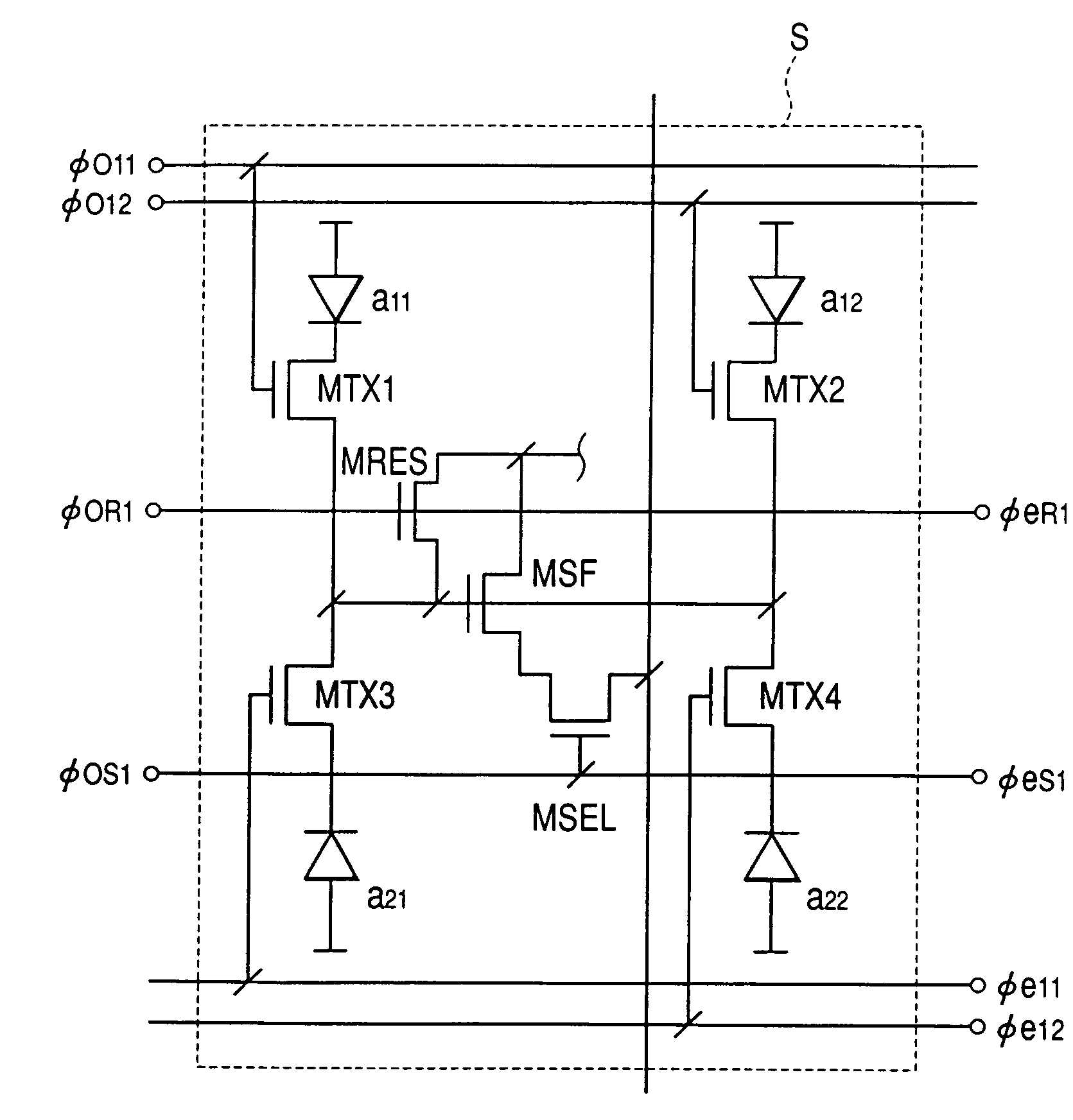

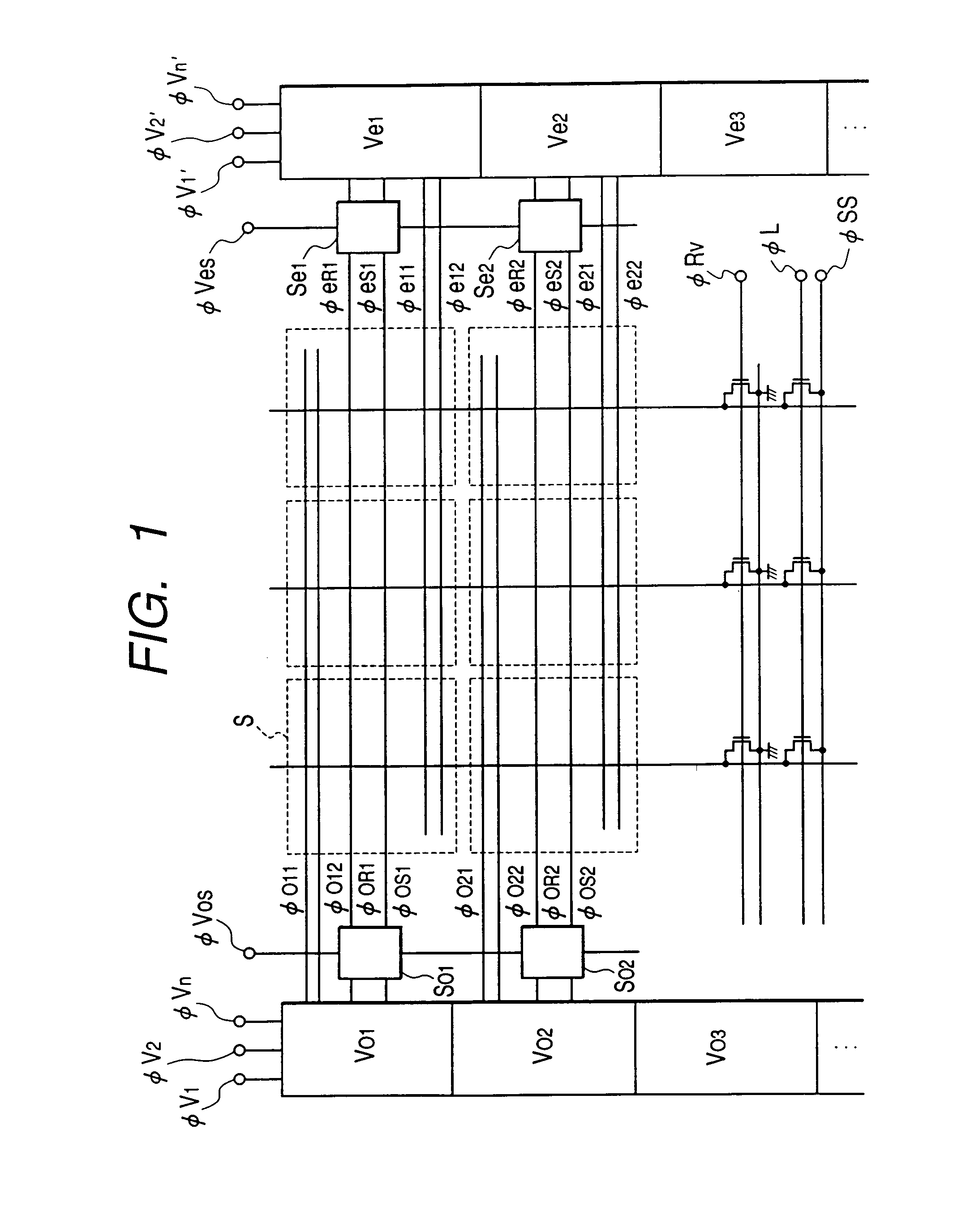

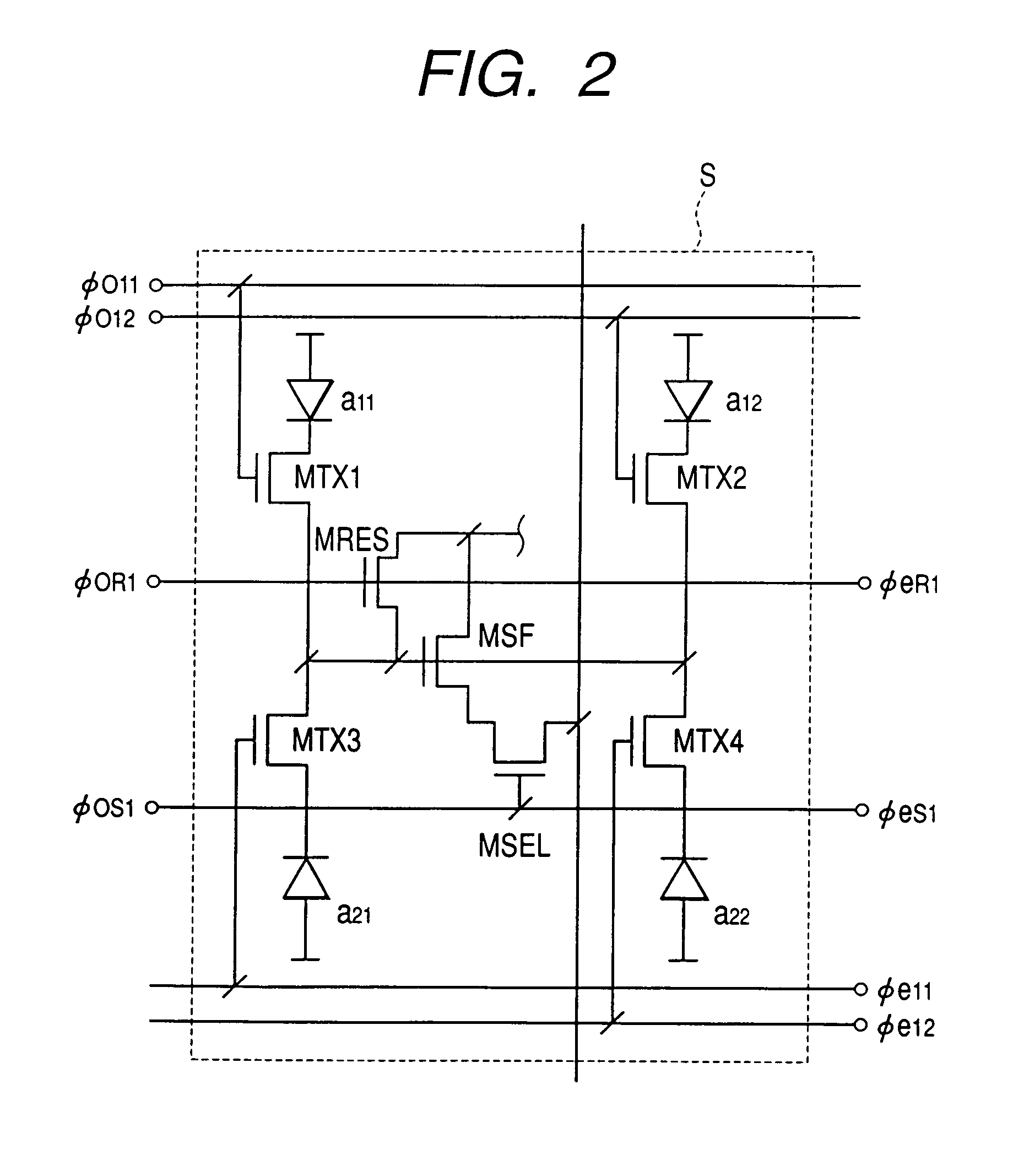

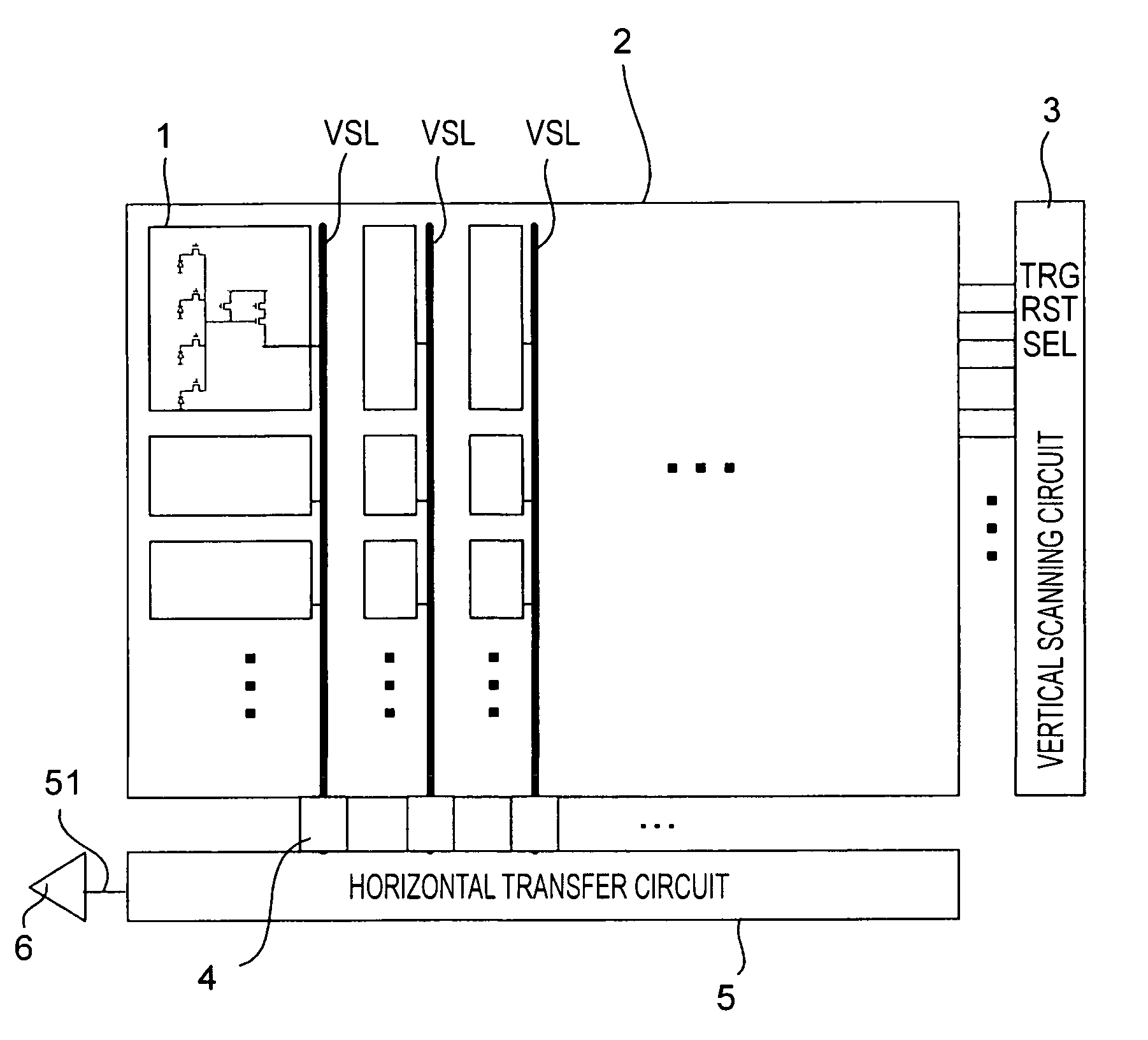

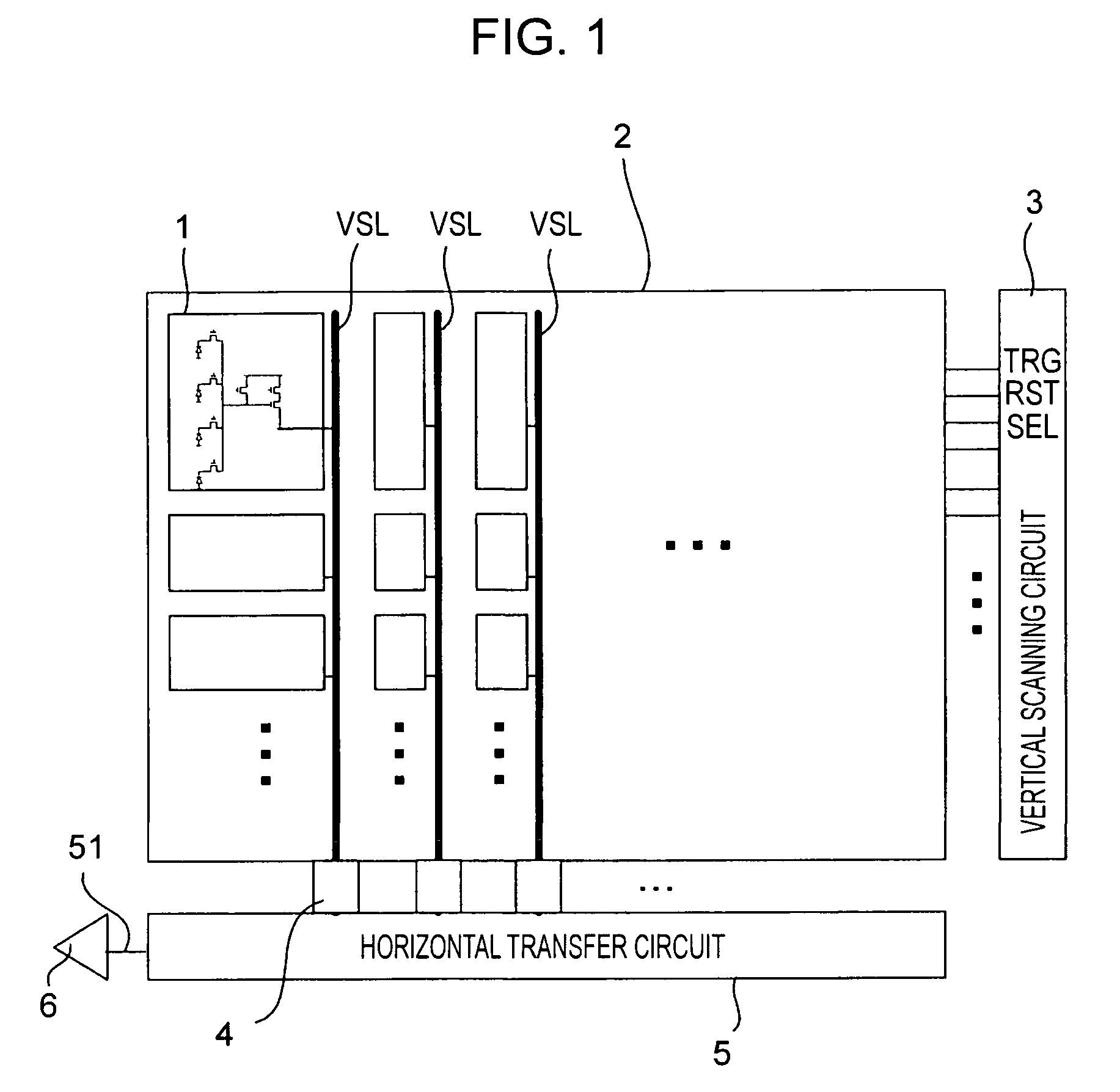

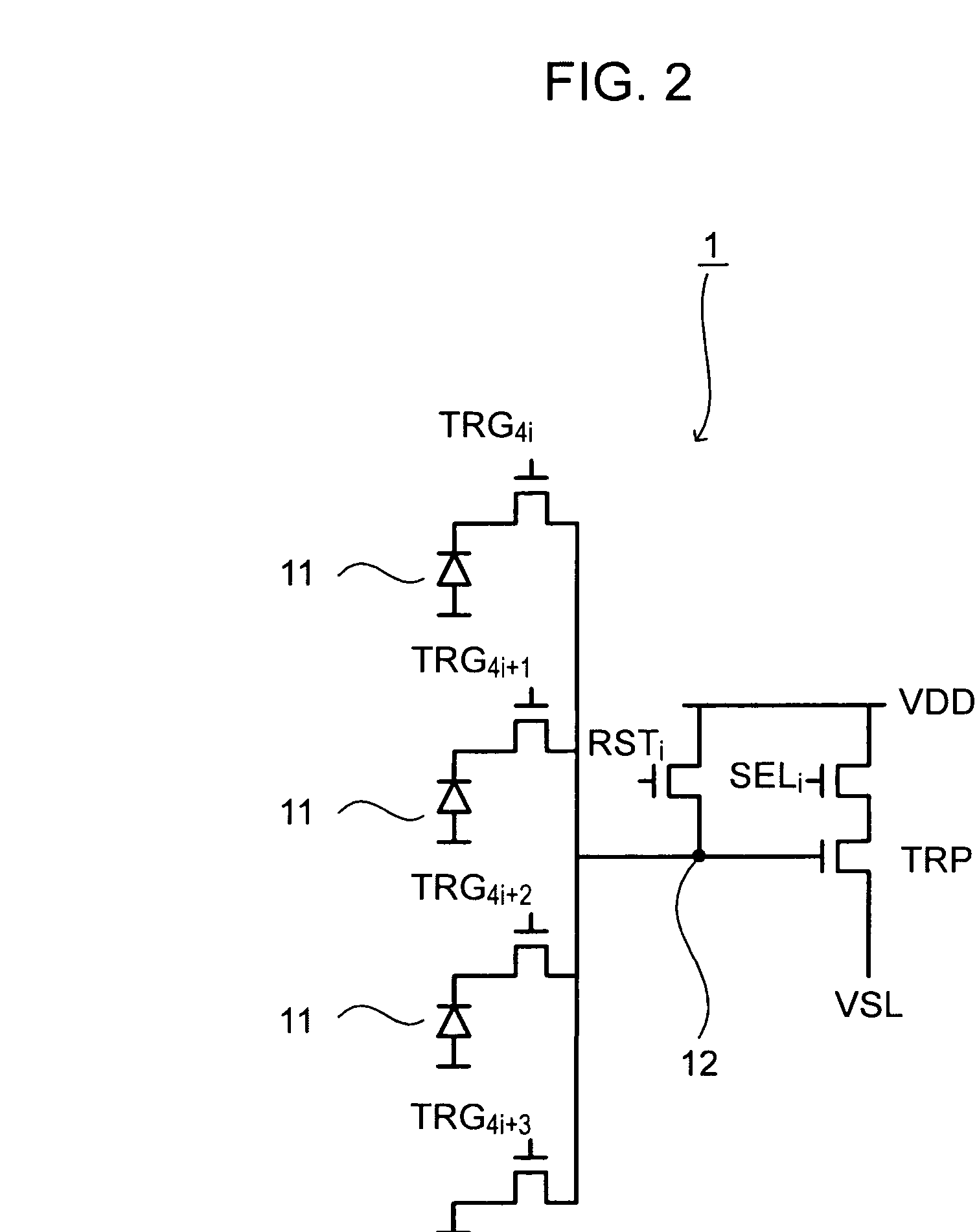

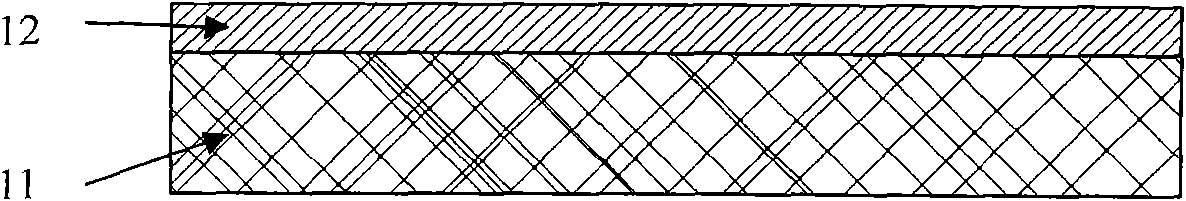

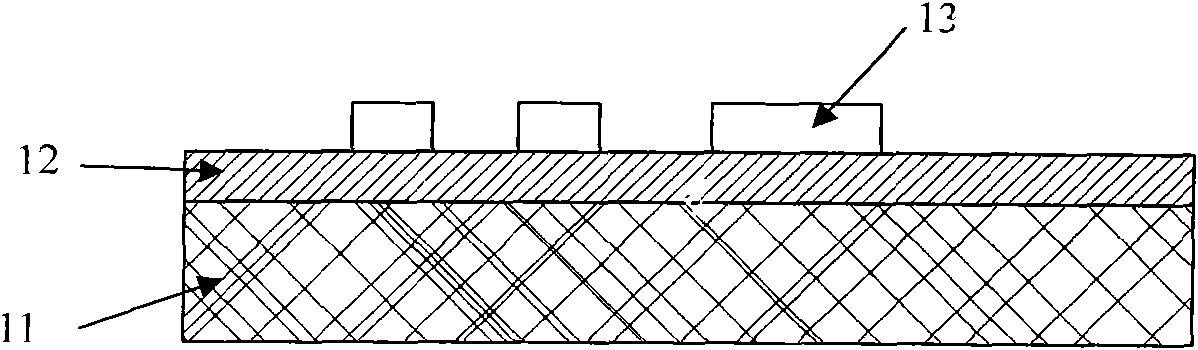

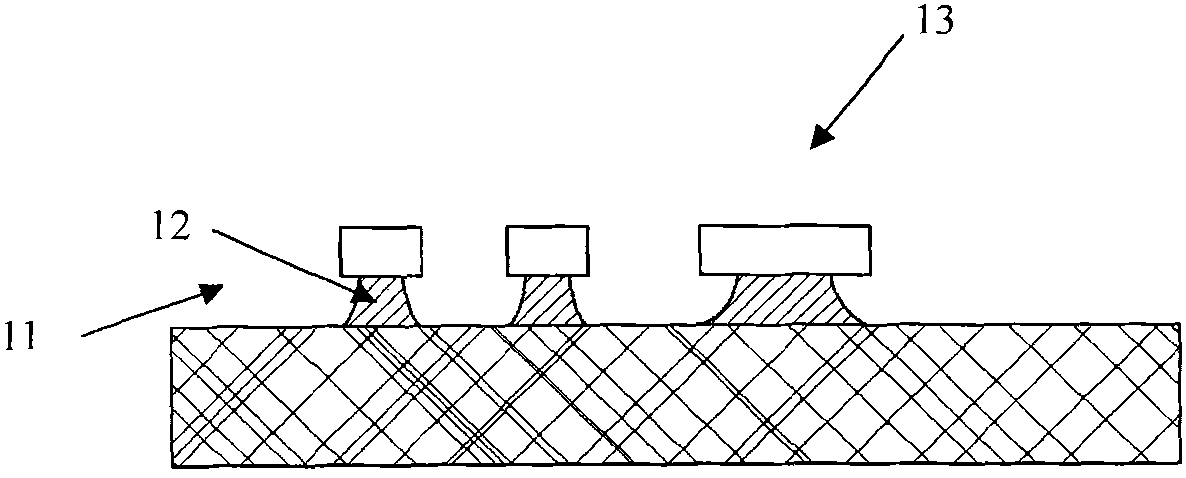

Image pickup apparatus

InactiveUS6956605B1Television system detailsTelevision system scanning detailsPhotoelectric conversionEngineering

To provide an image pickup apparatus capable of adding signals from a plurality of photoelectric conversion portions, an image pickup apparatus including a plurality of unit cells arranged in an array, each unit cell including a plurality of photoelectric conversion portions and a common circuit for inputting signals from the plurality of photoelectric conversion portions and outputting the signals from the unit cell, a first addition circuit for adding the signals from the plurality of photoelectric conversion portions in the unit cell, and a second addition circuit for adding the signals from the plurality of photoelectric conversion portions outside the unit cell is provided.

Owner:CANON KK

Processes for producing regular repeating patterns on surfaces of interbody devices

ActiveUS20120312778A1Sufficient bioactivityHigh positioning accuracyDecorative surface effectsVacuum evaporation coatingRough surfaceMedicine

Processes for producing interbody spinal implants having a body with a top surface, a bottom surface, opposing lateral sides, opposing anterior and posterior portions, a substantially hollow center, and a single vertical aperture; and optionally, one or two integration plates affixed to the body. The processes include applying an additive process, a subtractive process, or both processes to at least one surface of the interbody spinal implant to form a roughened surface topography having a regular repeating pattern. The roughened surface topography is specifically designed to provide certain frictional characteristics, load dispersion, and to influence the biological responses that occur during bone healing and fusion.

Owner:TITAN SPINE

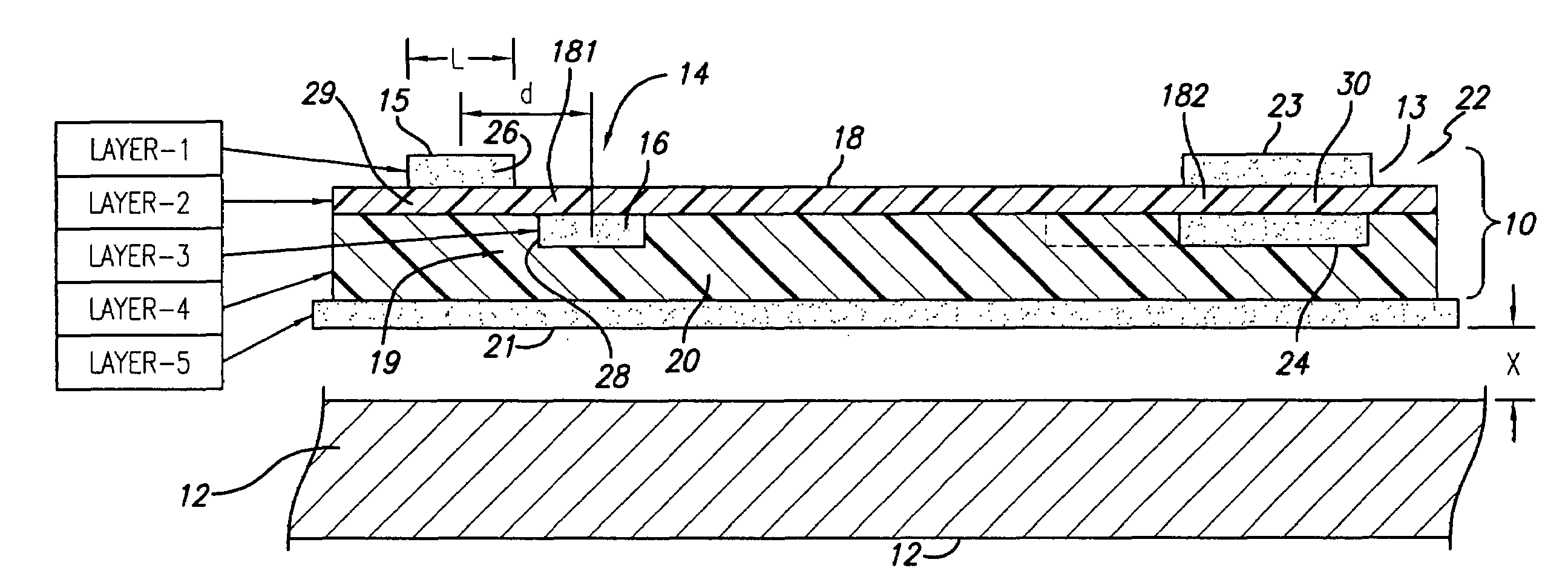

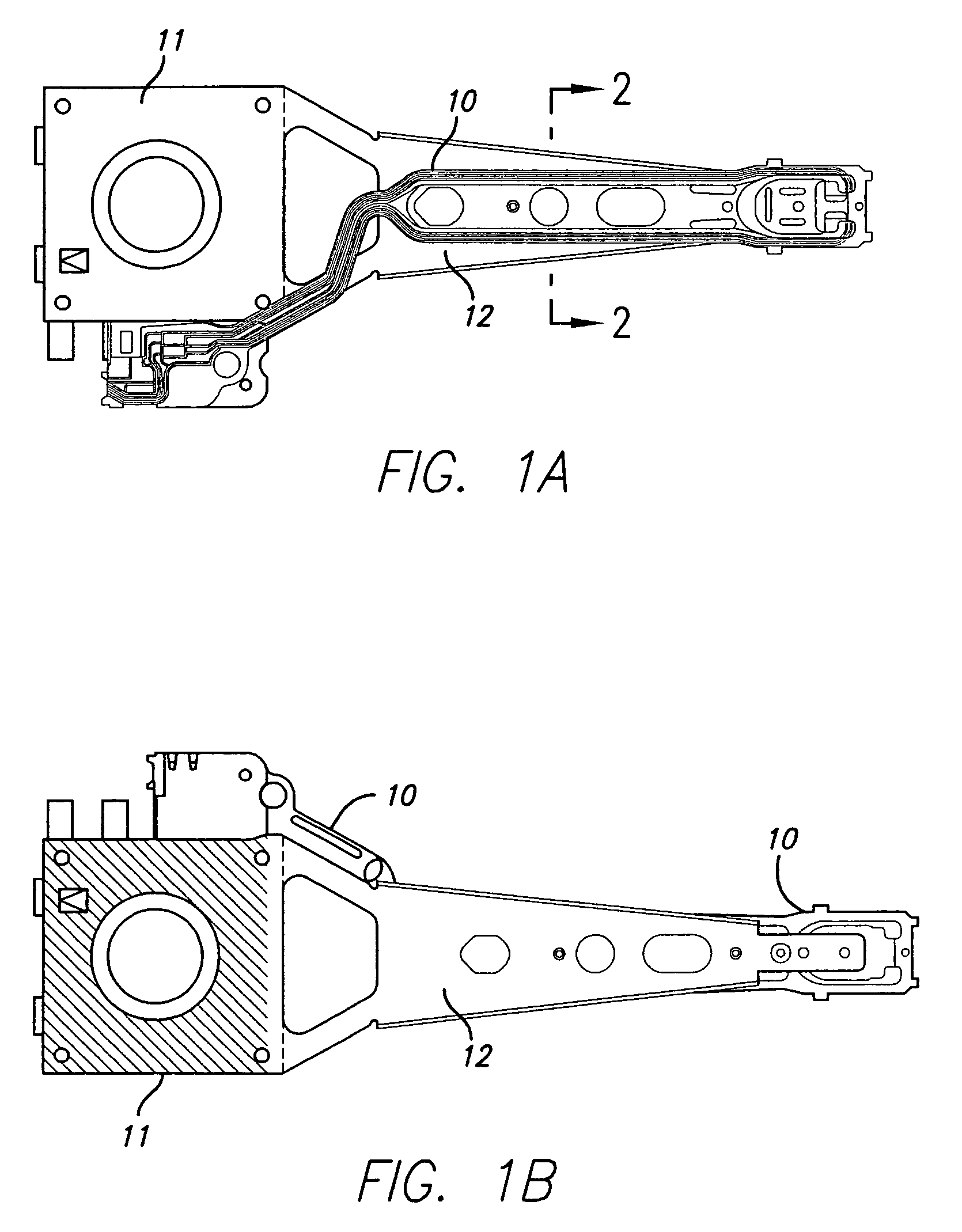

Additive-process suspension interconnect with controlled noise

InactiveUS7079357B1Increase electrical couplingLess sensitiveRecord information storageStructure of arm assemblyAdditive processElectrical interconnect

A disk drive electrical interconnect assembly and additive method therefor. The interconnect assembly has a supporting or fifth layer of metal, a fourth layer of a polyimide precursor or a polyimide with a first face directed away from the fifth layer, a third layer directly attached to the first face and defining a first subset of one or more conductive trace pair members, a second layer on the third and fourth layers of a polyimide precursor or a polyimide with a second face directed away from the third layer, and a first layer directly attached to the second layer and defining a second subset of one or more conductive trace pair members in spaced, paired and laterally offset relation respectively with one or more of the first subset pair members.

Owner:MAGNECOMP

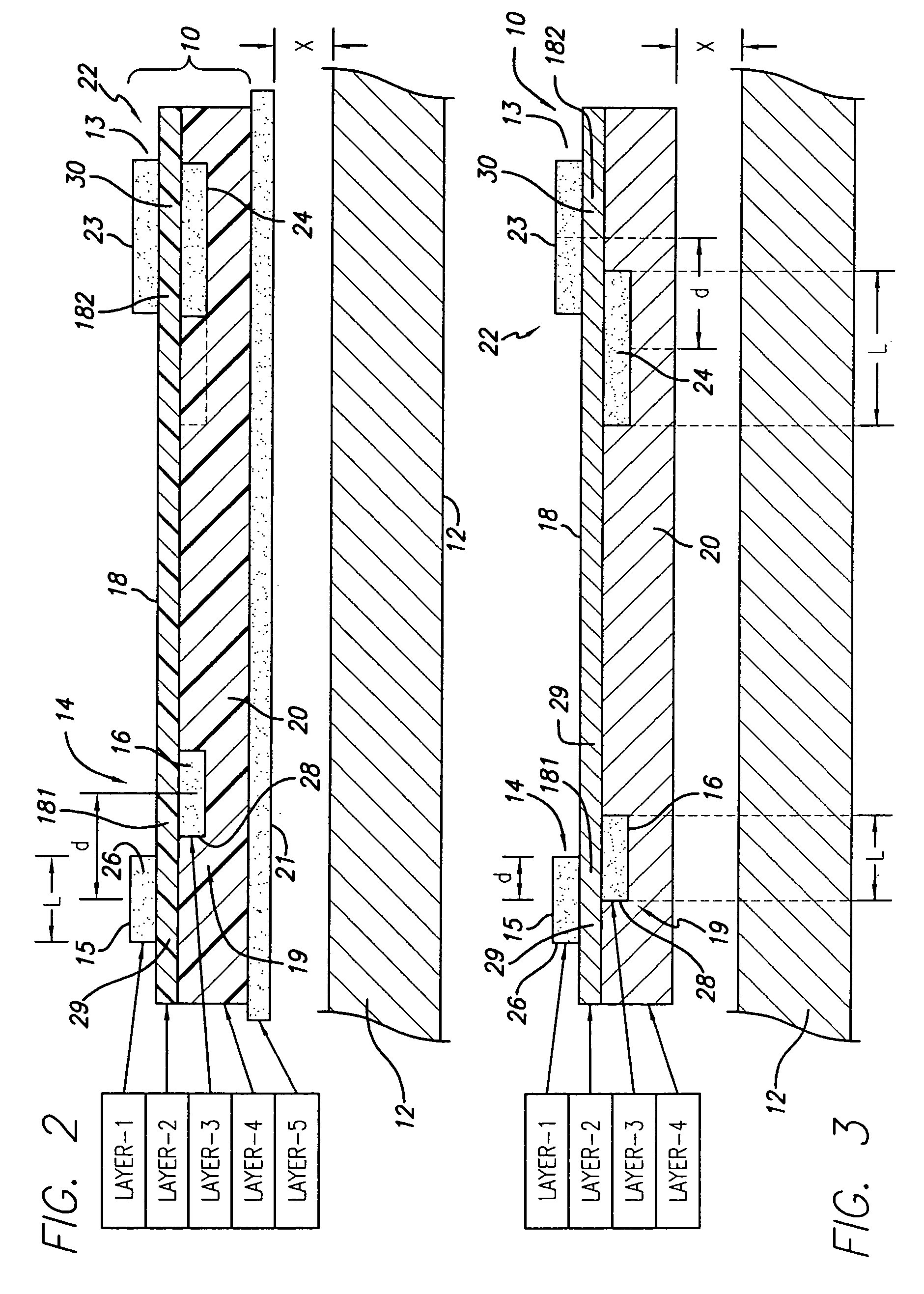

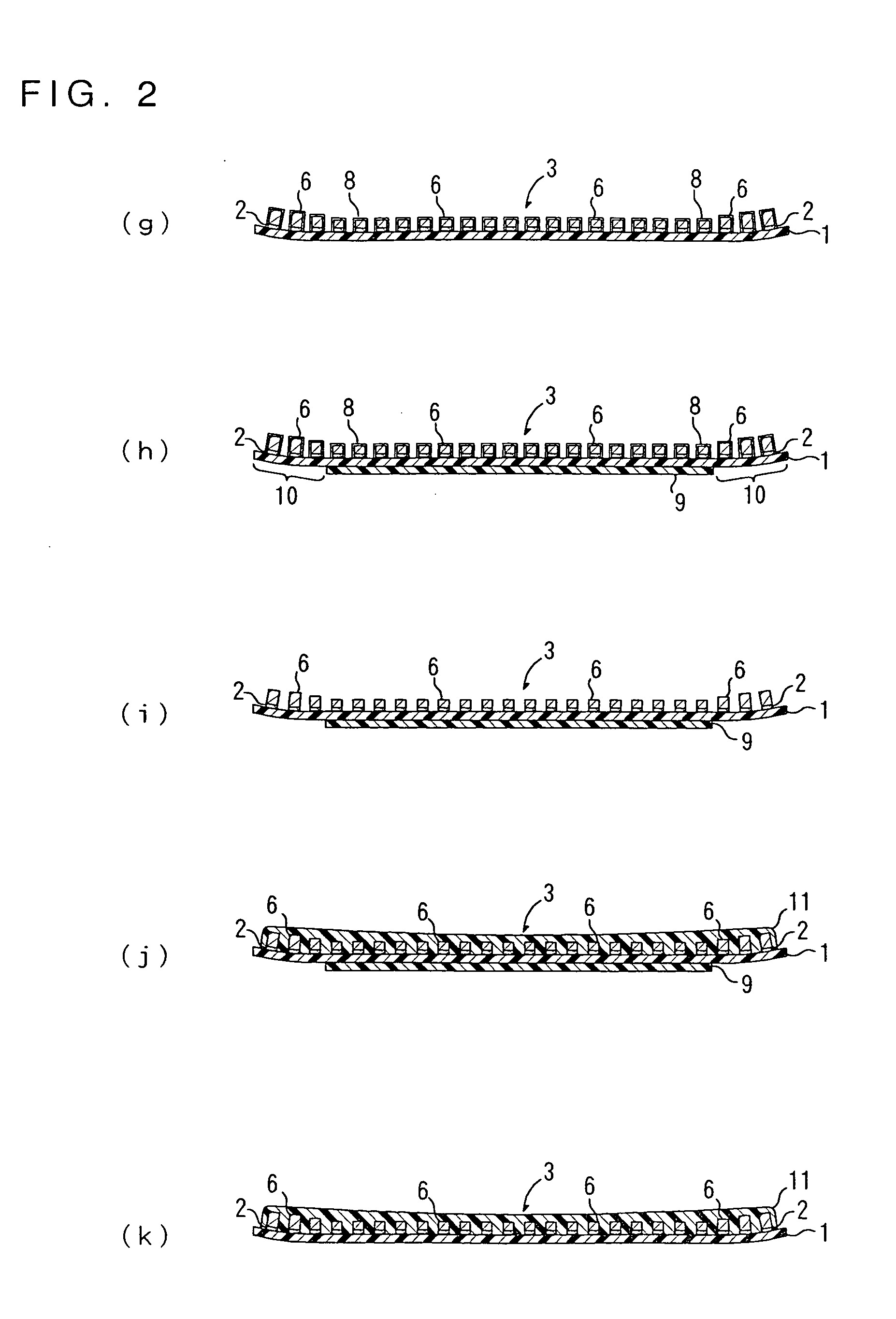

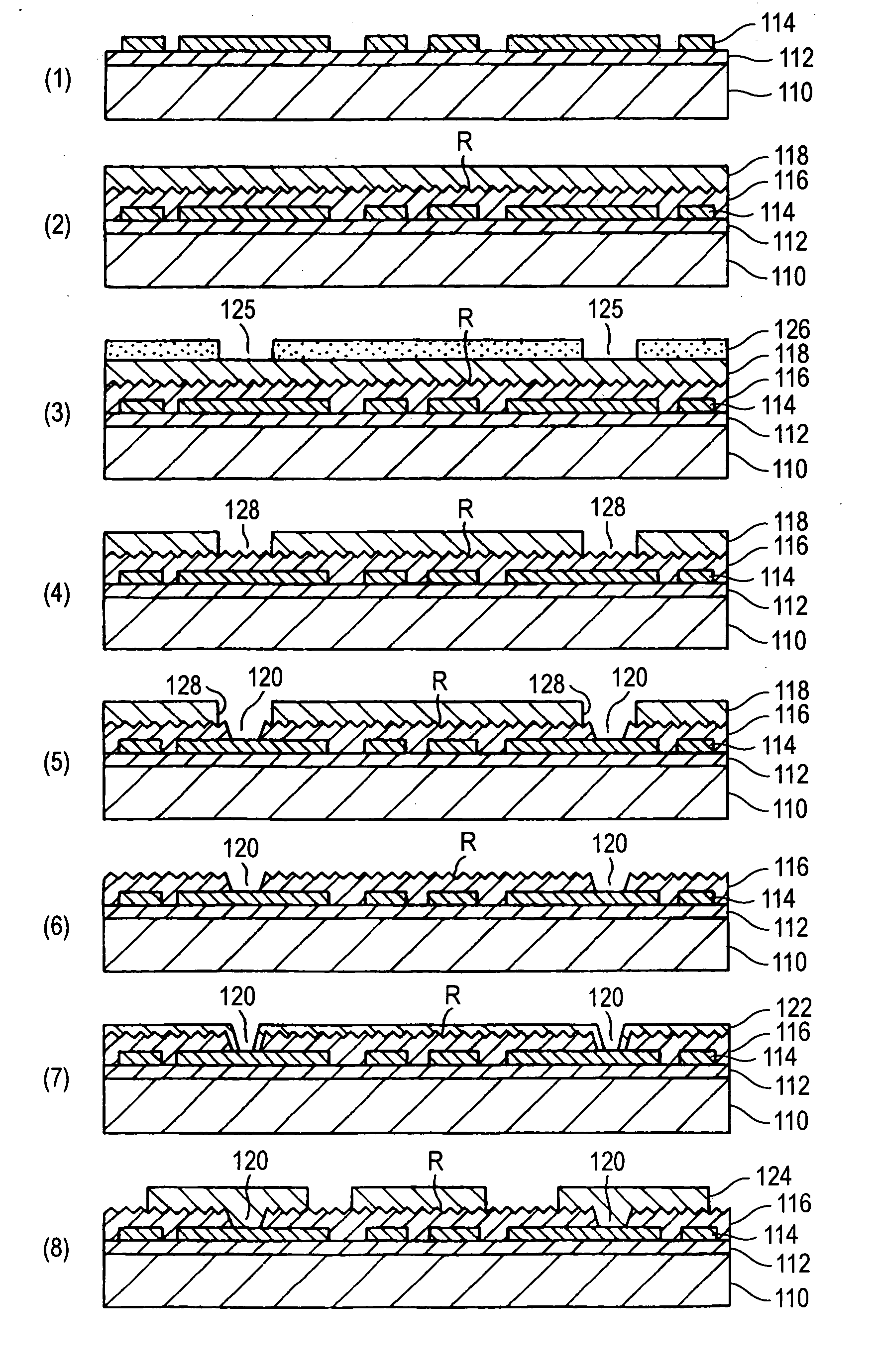

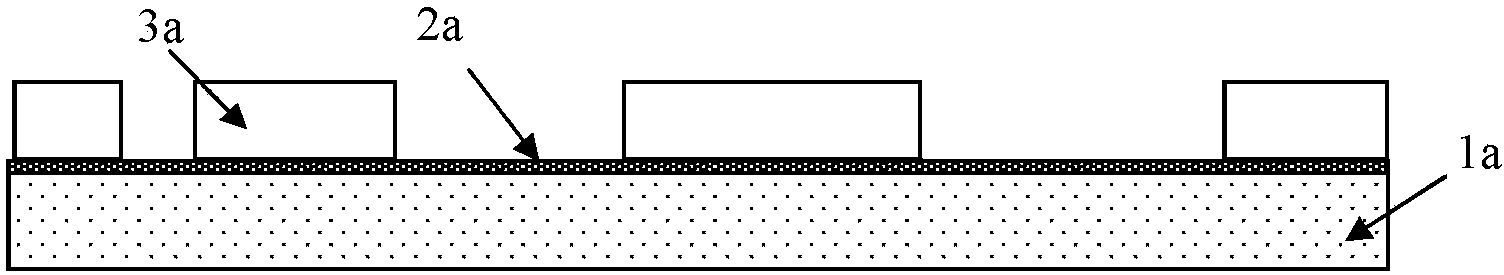

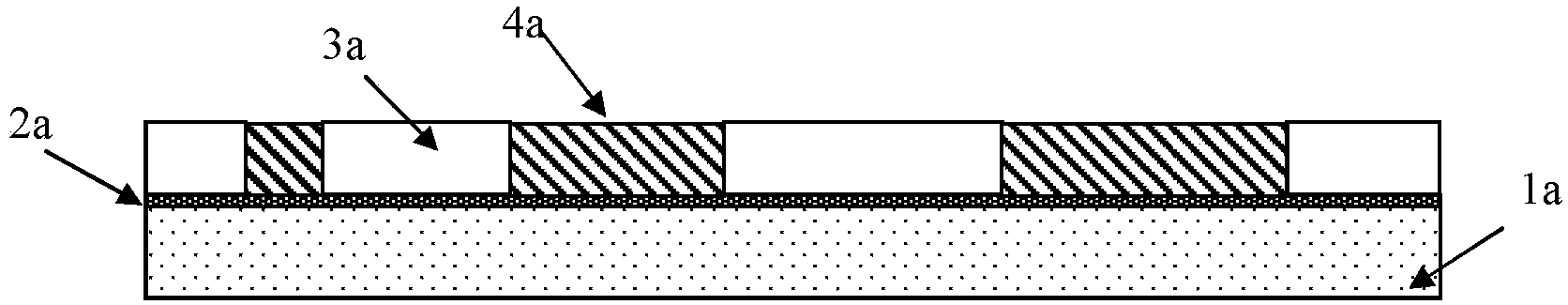

Producing method of flexible wired circuit board

InactiveUS20050067293A1Large thicknessAvoid it happening againPrinted circuit detailsDecorative surface effectsResistElectrolysis

A producing method of a flexible wired circuit board that can prevent the formation of a gap between an elongate substrate and a stiffener sheet bonded thereto to prevent contamination of the flexible wired circuit board obtained. In the process subsequent to the process of forming a conductive pattern 3 on a surface of the elongate substrate 1 by the semi-additive process using electrolysis plating and then annealing the elongate substrate 1 with the conductive pattern 3 in its wound up state, a stiffener sheet 9 having a width narrower than the elongate substrate 1 is bonded to the back side of the elongate substrate 1. Thereafter, an oxidized film formed on a surface of the conductive pattern 3 is removed and then a solder resist 11 is formed thereon. This prevents the strip of the stiffener sheet 9 from the elongate substrate 1 and in turn prevents etching solution or developing solution from entraining in a gap therebetween.

Owner:NITTO DENKO CORP

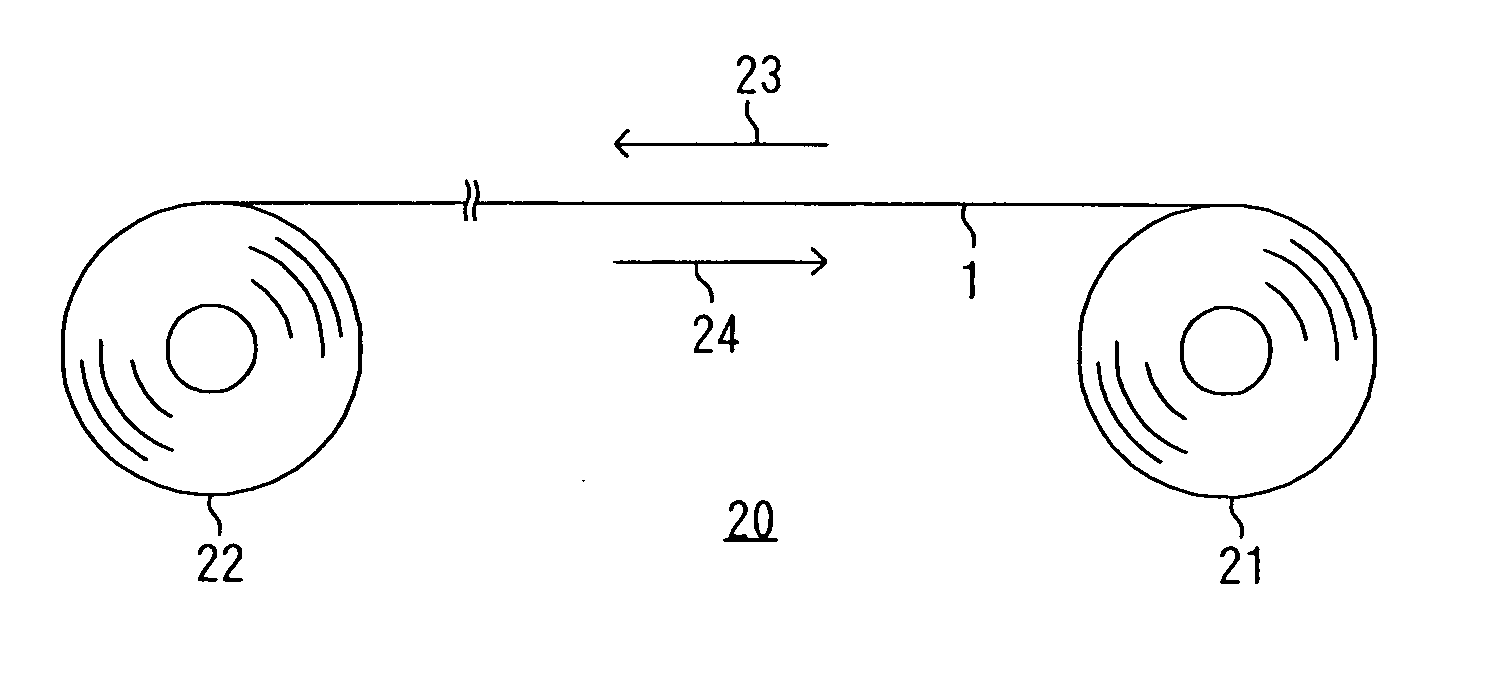

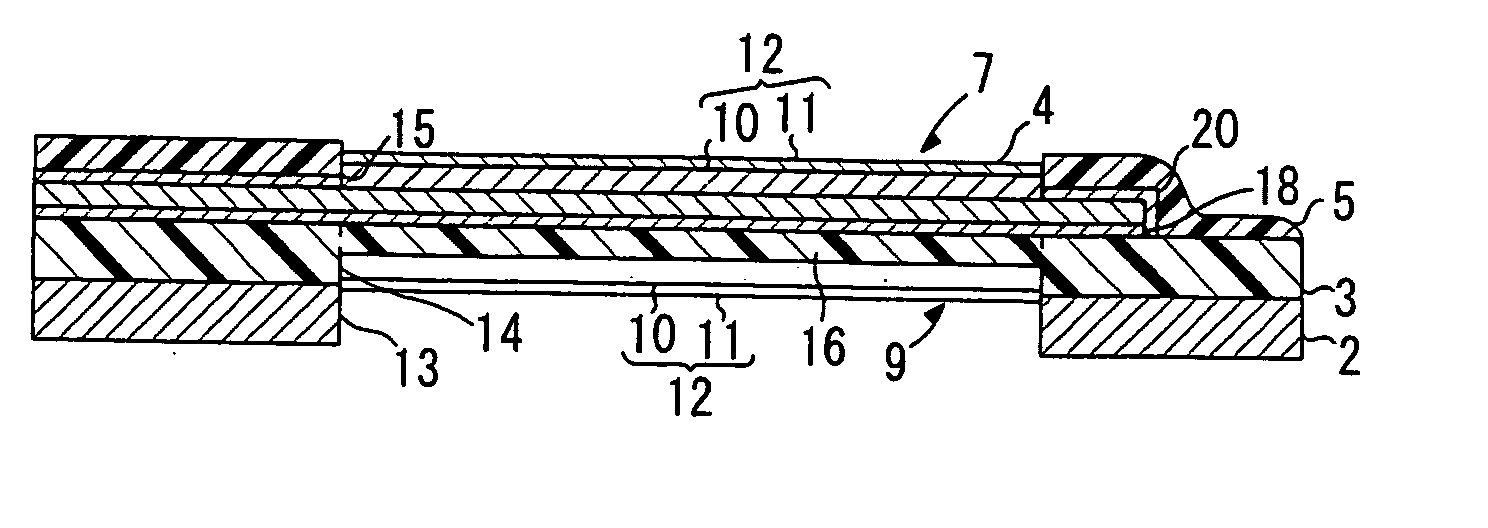

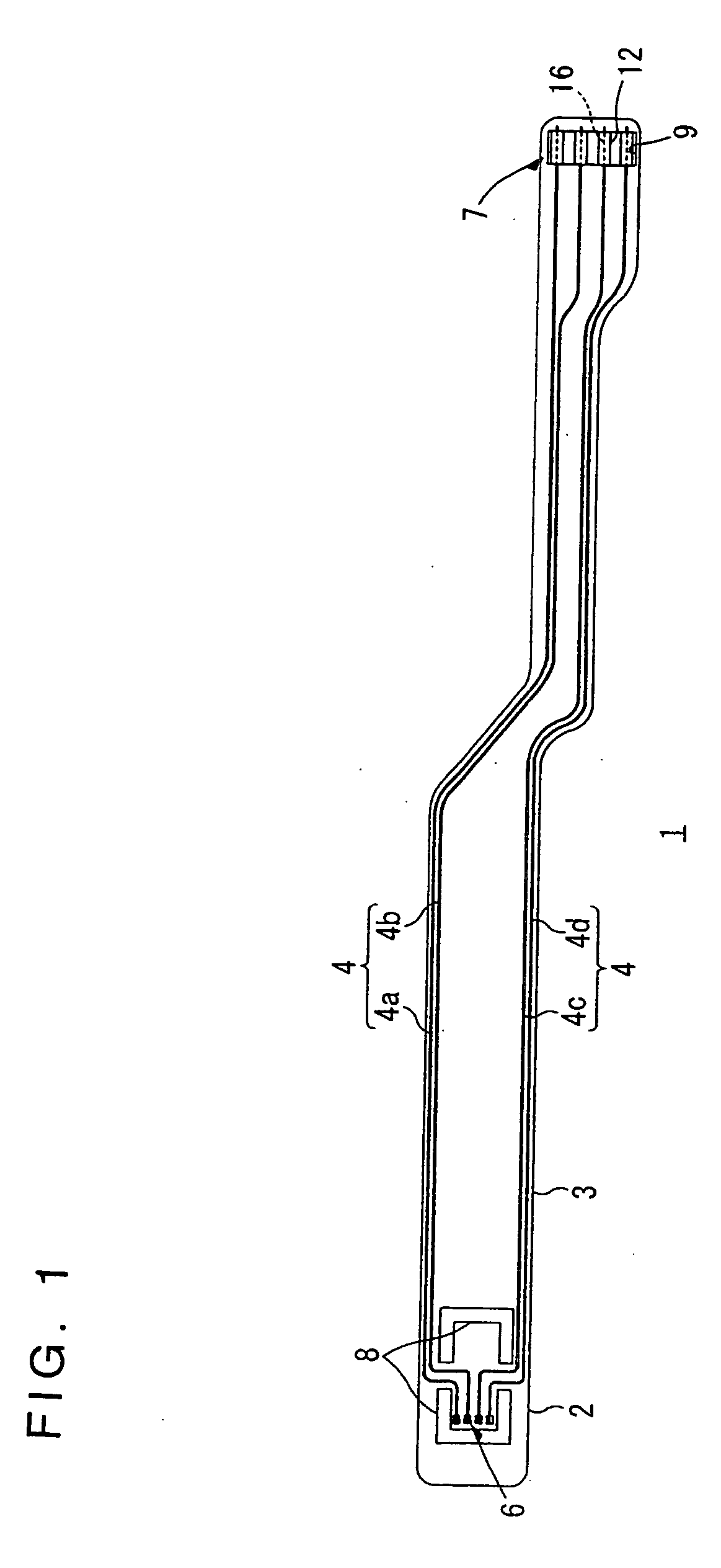

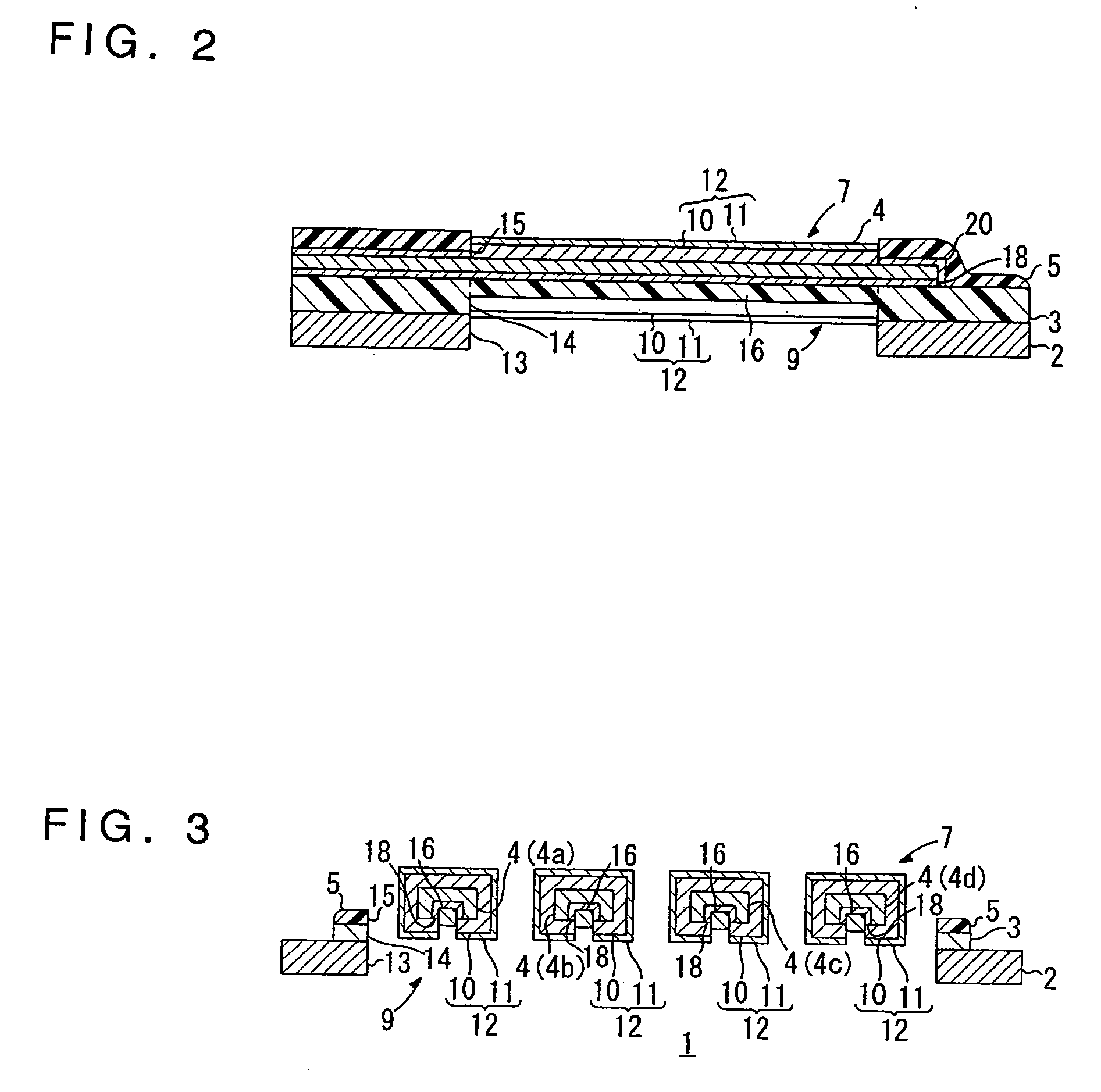

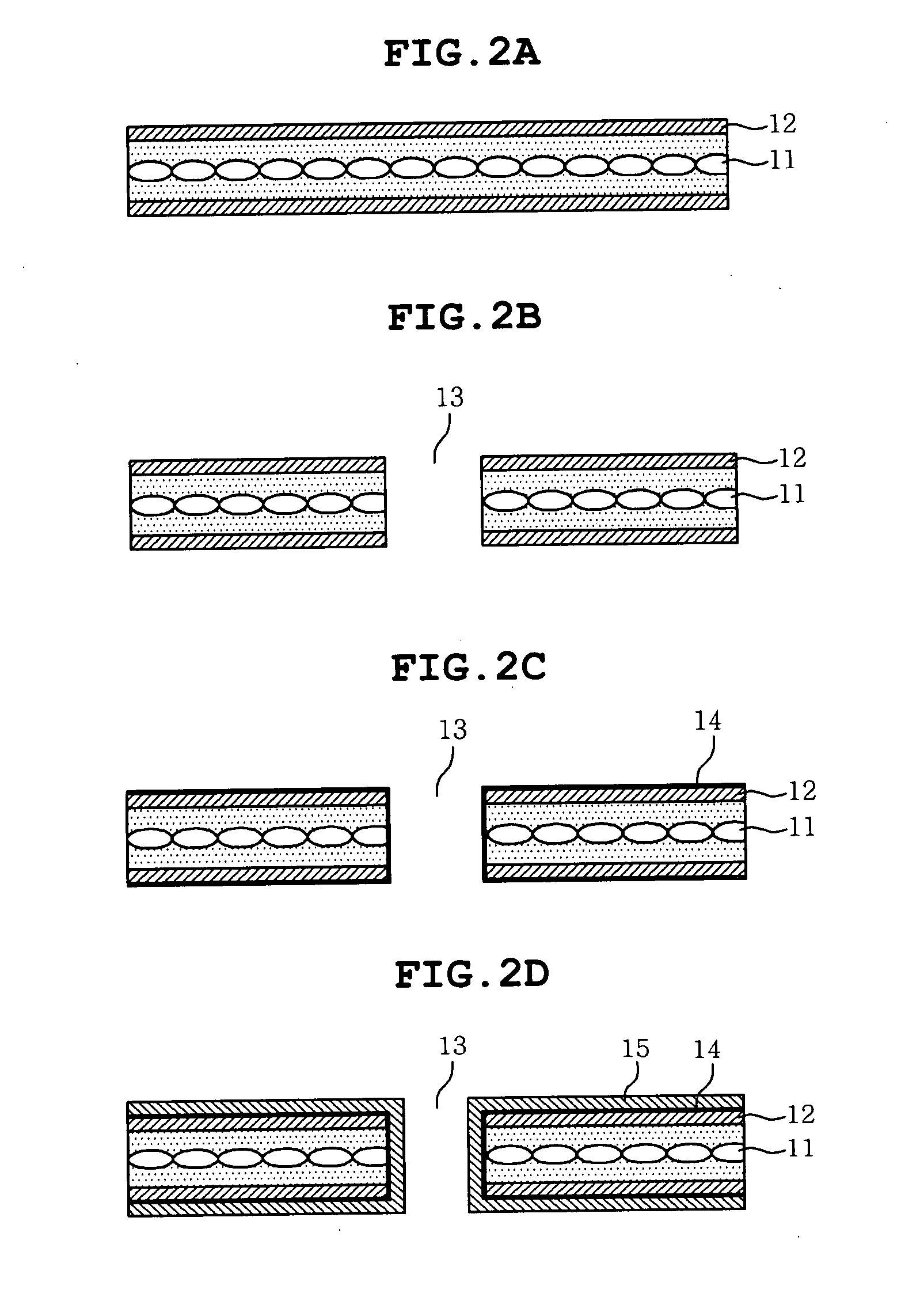

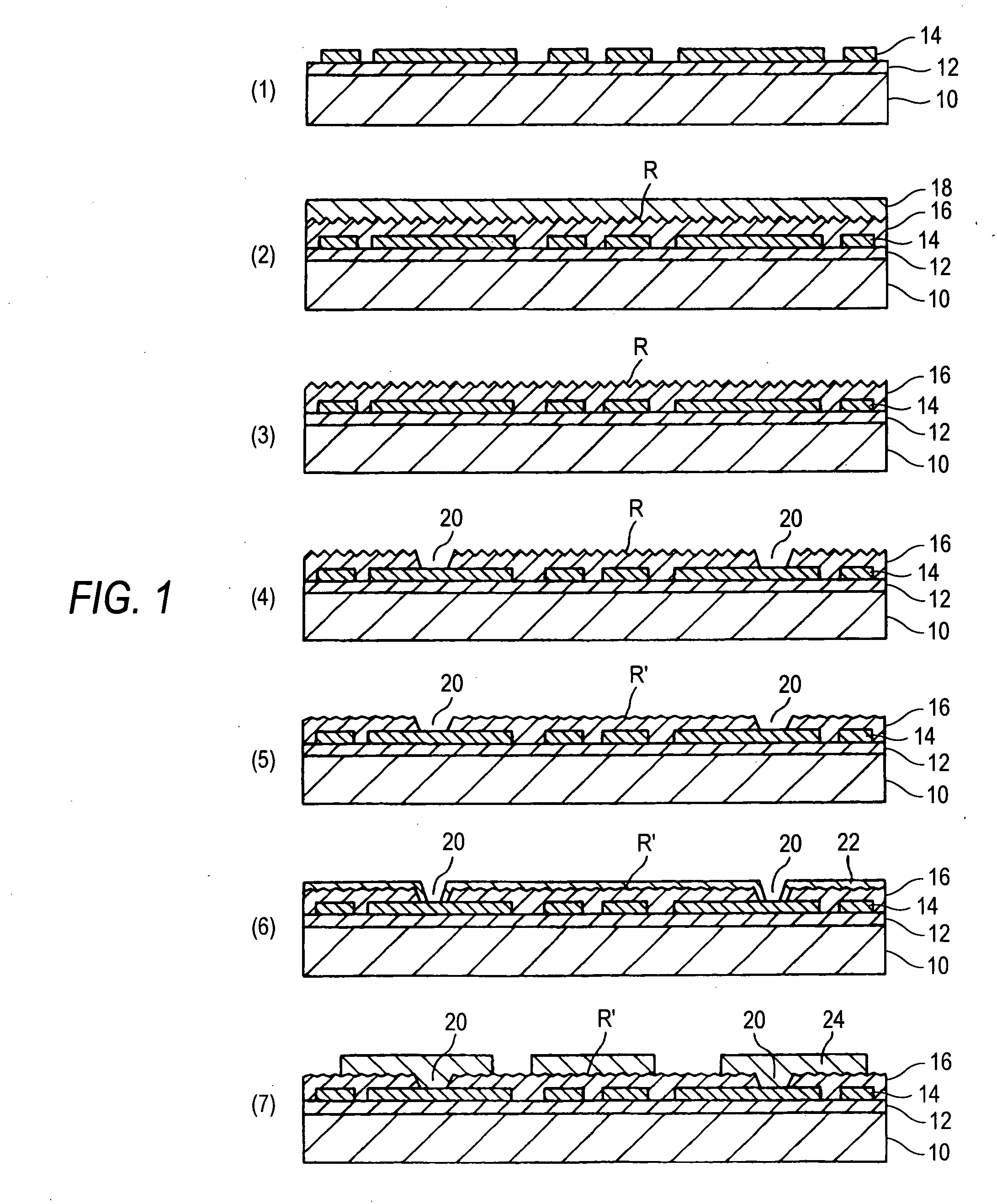

Suspension board with circuit

InactiveUS20050122627A1Reduce risk of damageImprove reliabilityDriving/moving recording headsPrinted circuit aspectsElectrical conductorAdditive process

A suspension board with circuit having a conductor layer formed in the form of a fine wiring circuit by an additive process, while providing a reduced risk of damage and breaking of the conductor layer in a flying lead portion. The suspension board with circuit comprises a supporting board 2, an insulating base layer 3 formed on the supporting board 2, a conductor layer 4 formed on the insulating base layer 3, an insulating cover layer 5 formed on the conductor layer 4, and a flying lead portion 9 in which a supporting-board-side opening 13, a base-layer-side opening 14, and a cover-layer-side opening 15 are formed so that both sides of the conductor layer 4 can be exposed therefrom. A reinforcing portion 16 or 23 for reinforcing the conductor layer 4 formed continuously from at least either of the insulating base layer 3 and the insulating cover layer 5 along the longitudinal direction of the conductor layer 4 is included in the flying lead portion 9.

Owner:NITTO DENKO CORP

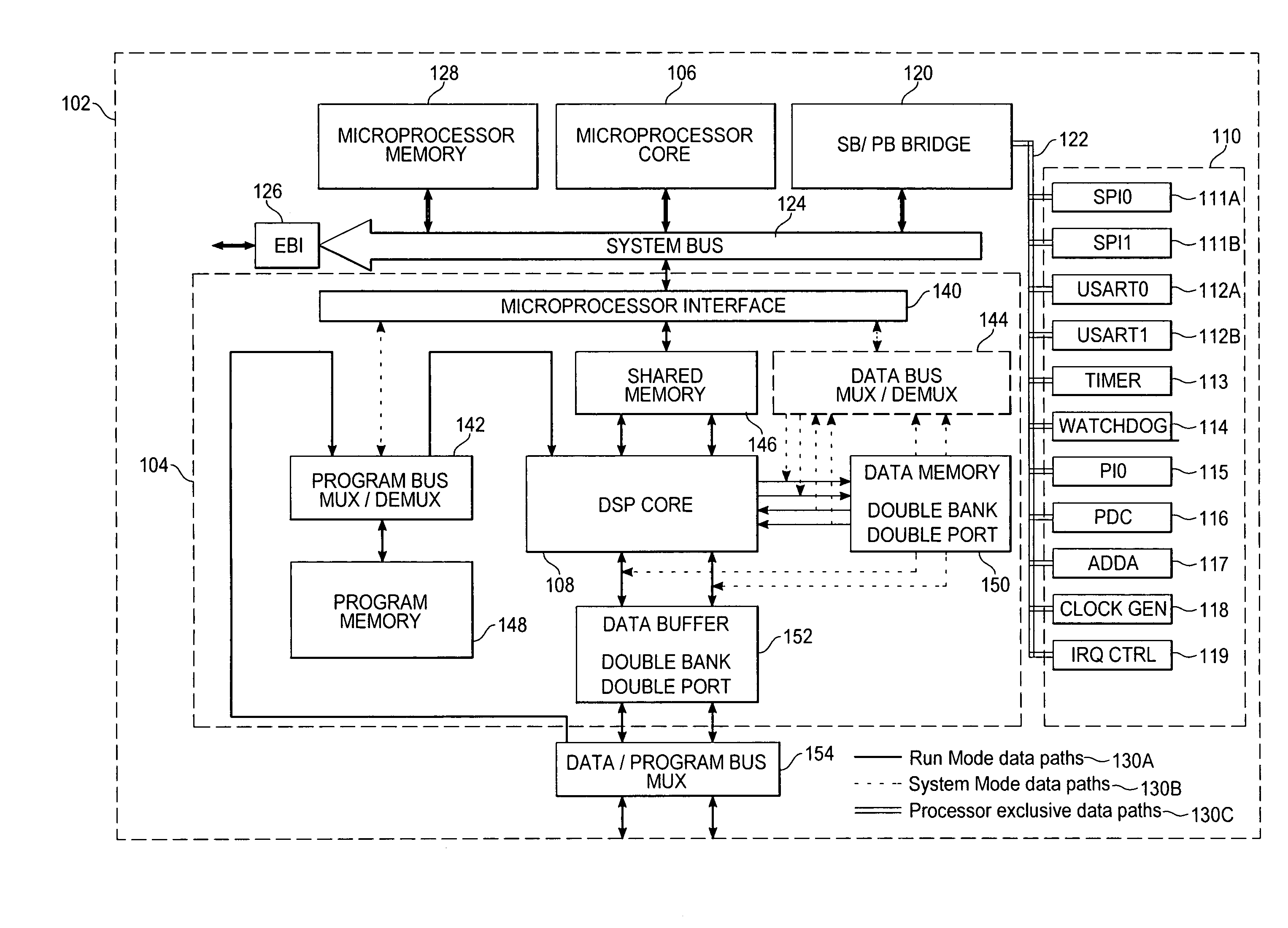

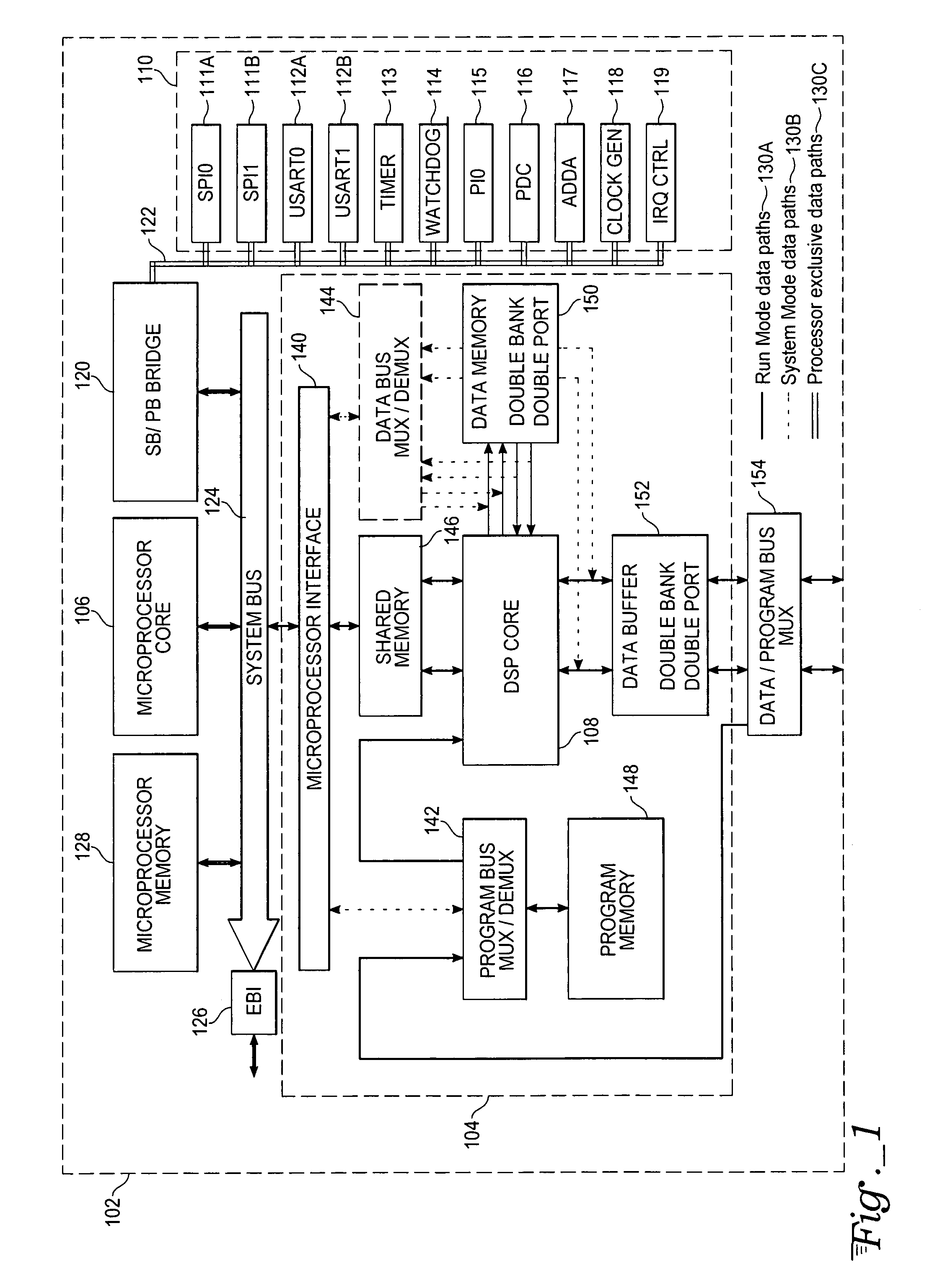

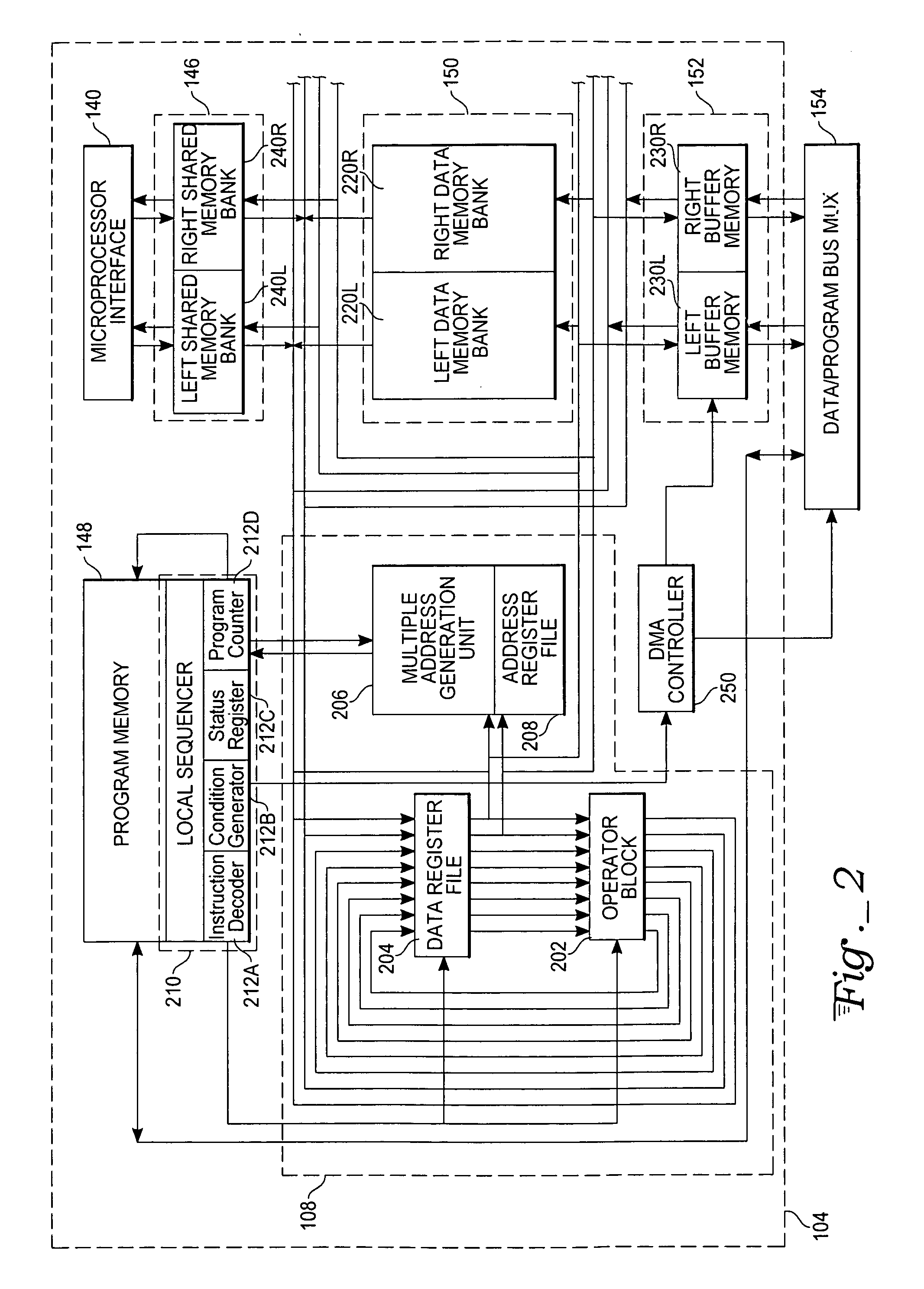

Complex domain floating point VLIW DSP with data/program bus multiplexer and microprocessor interface

ActiveUS7437540B2No performance lossReduce in quantityArchitecture with single central processing unitSpecific program execution arrangementsDigital signal processingProcessing core

A system for digital signal processing, configured as a system on chip (SoC), combines a microprocessor core and digital signal processor (DSP) core with floating-point data processing capability. The DSP core can perform operations on floating-point data in a complex domain and is capable of producing real and imaginary arithmetic results simultaneously. This capability allows a single-cycle execution of, for example, FFT butterflies, complex domain simultaneous addition and subtraction, complex multiply accumulate (MULACC), and real domain dual multiply-accumulators (MACs). The SoC may be programmed entirely from a microprocessor programming interface, using calls from a DSP library to execute DSP functions. The cores may also be programmed separately. Capability for programming and simulating the entire SoC are provided by a separate programming environment. The SoC may have heterogeneous processing cores in which either processing core may act as master or slave, or both cores may operate simultaneously and independently.

Owner:ATMEL CORP

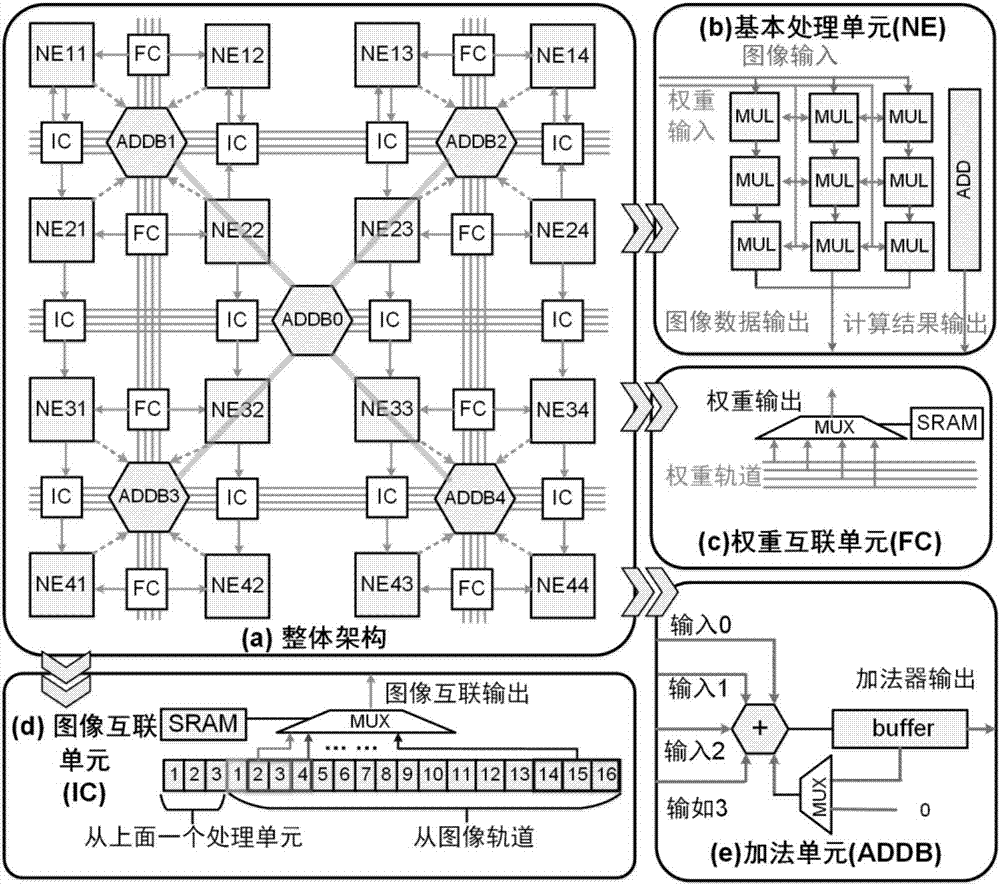

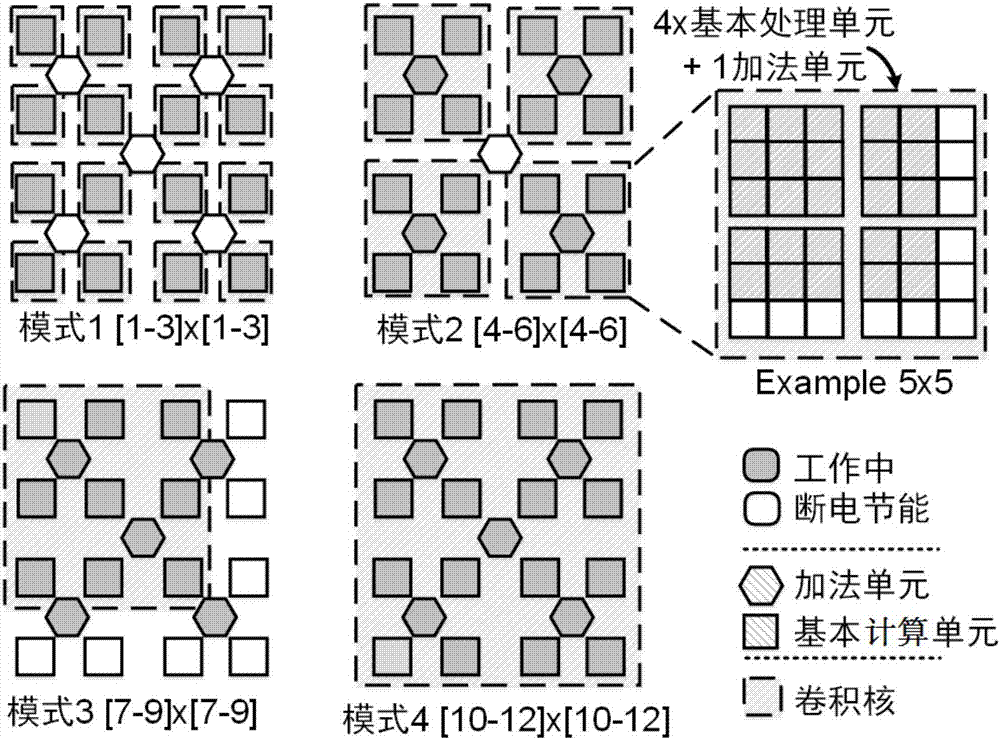

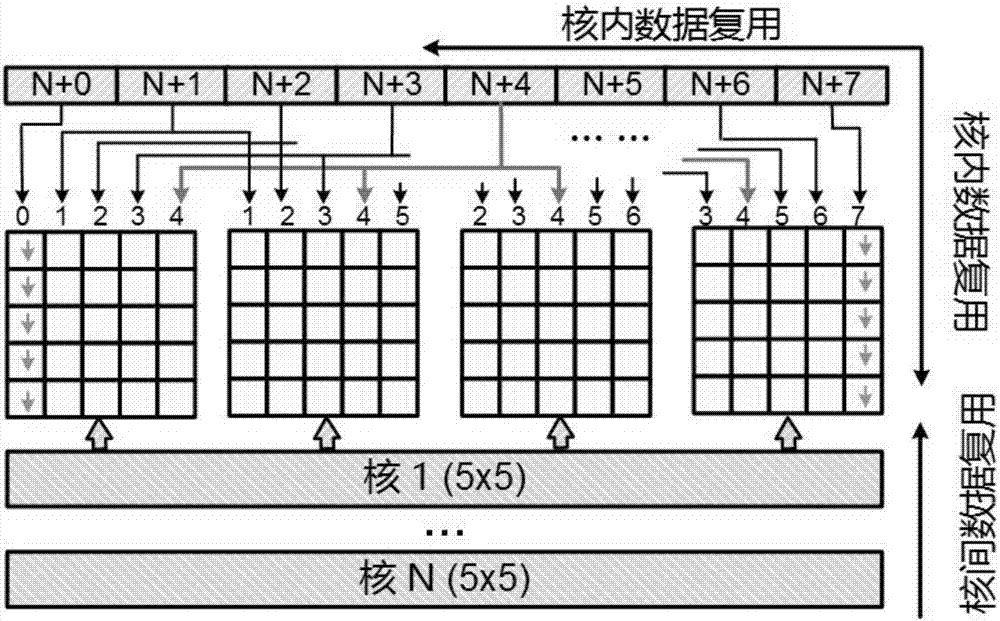

Coarse-grained reconfigurable convolution neural network accelerator and system

ActiveCN106951961AEfficient supportReduce overheadImage memory managementProcessor architectures/configurationGranularityParallel computing

The invention provides a coarse-grained reconfigurable convolution neural network accelerator and a system. The accelerator comprises a number of processing unit clusters. Each processing unit cluster comprises a number of basic computing units which are connected through a sub-addition unit. The sub-addition units of a number of processing unit clusters are respectively connected with a mother addition unit. Each sub addition unit is used for generating partial sum of a number of adjacent basic computing units. The mother addition unit is used for accumulating the sub-addition units. According to the invention, a coarse-grained reconfigurable way is adopted to link different weights and image tracks through SRAM or other interconnection units to realize different convolution kernel processing structures; the accelerator can effectively support networks and convolution cores of different sizes; and the cost of reconfiguration is significantly reduced.

Owner:TSINGHUA UNIV

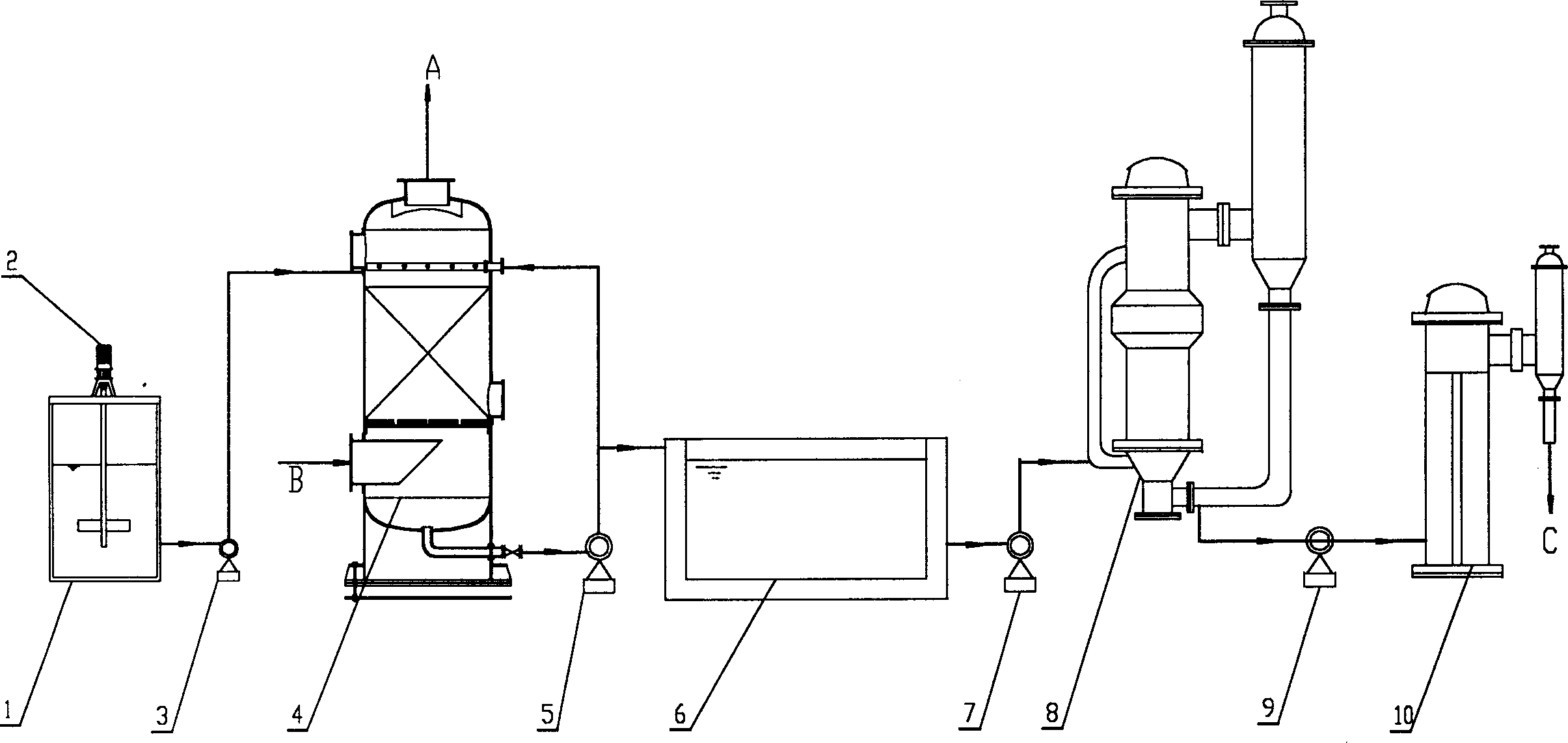

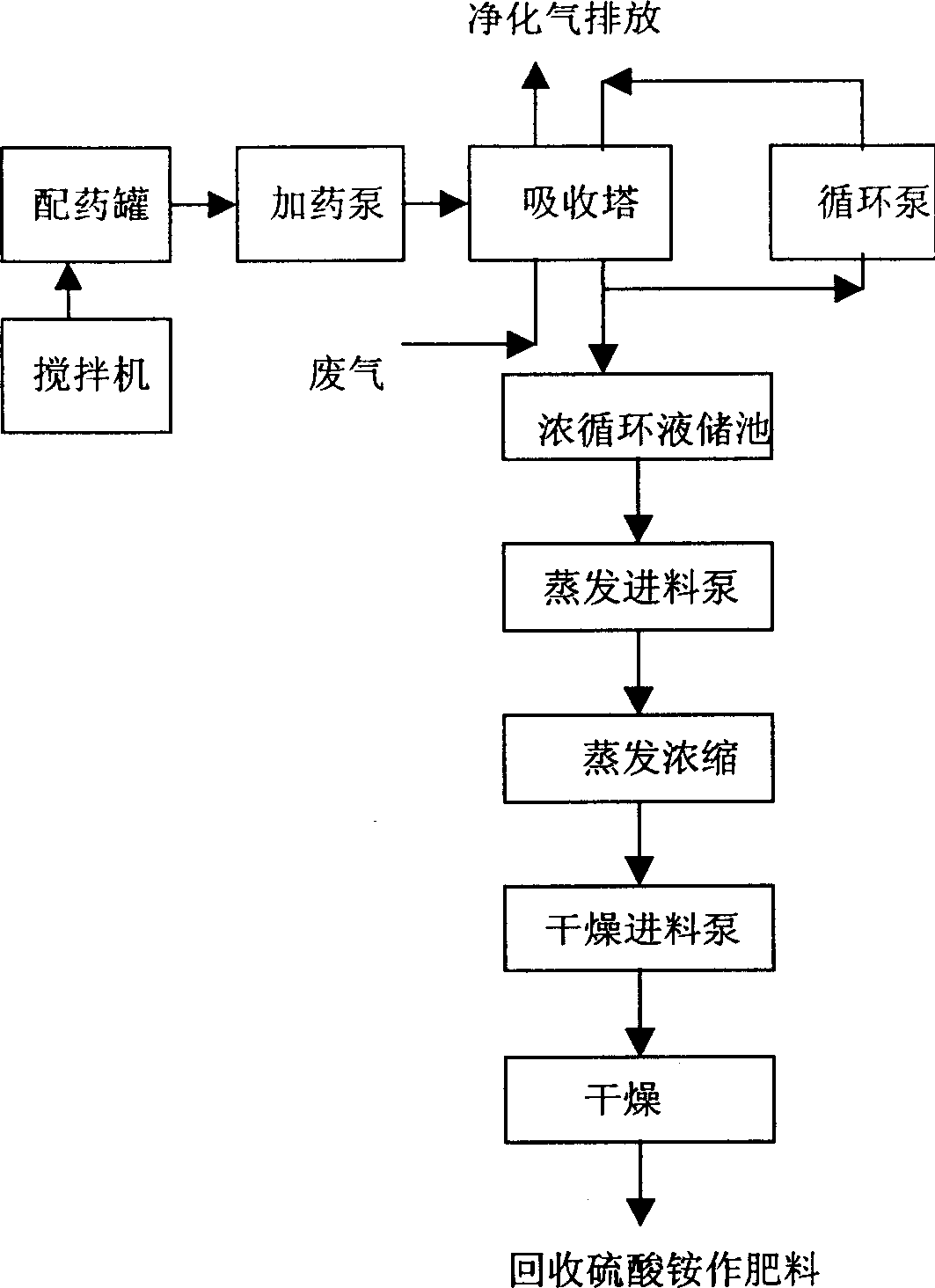

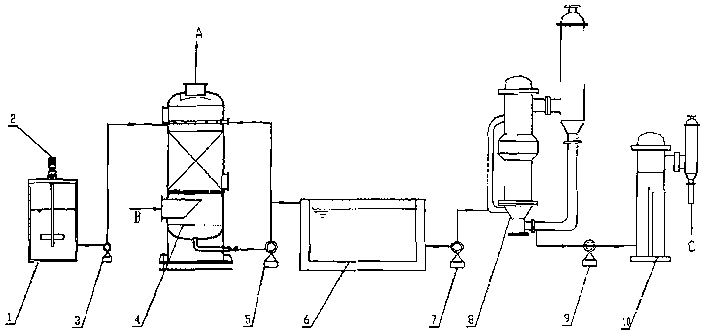

Wet urea additive process for simultanously desulfurizing and denitrification

InactiveCN1377722AReduce volumeGuarantee sustainableDispersed particle separationAir quality improvementEthylenediaminePhosphate

The present invention relates to flue gas purifying treatment technology. The equipment consists of chemical compounding tank with stirrer, chemical adding pump, adsorber tower, circulating pump, storing pond for concentrated absorbent liquid, evaporating inlet pump, evaporator, drying inlet pump and drying machine connected via pipeline. It desulfurizes and denitrificates simultaneously through the mixed reaction of flue gas and absorbent liquid in the absorber tower with urea as absorbent and organic amine or phosphate as additive. It has an SO2 eliminating rate up to 95% and NOx eliminating rate up to 80%, with the recovered ammonium sulfate being used as fertilizer.

Owner:国家环境保护总局华南环境科学研究所

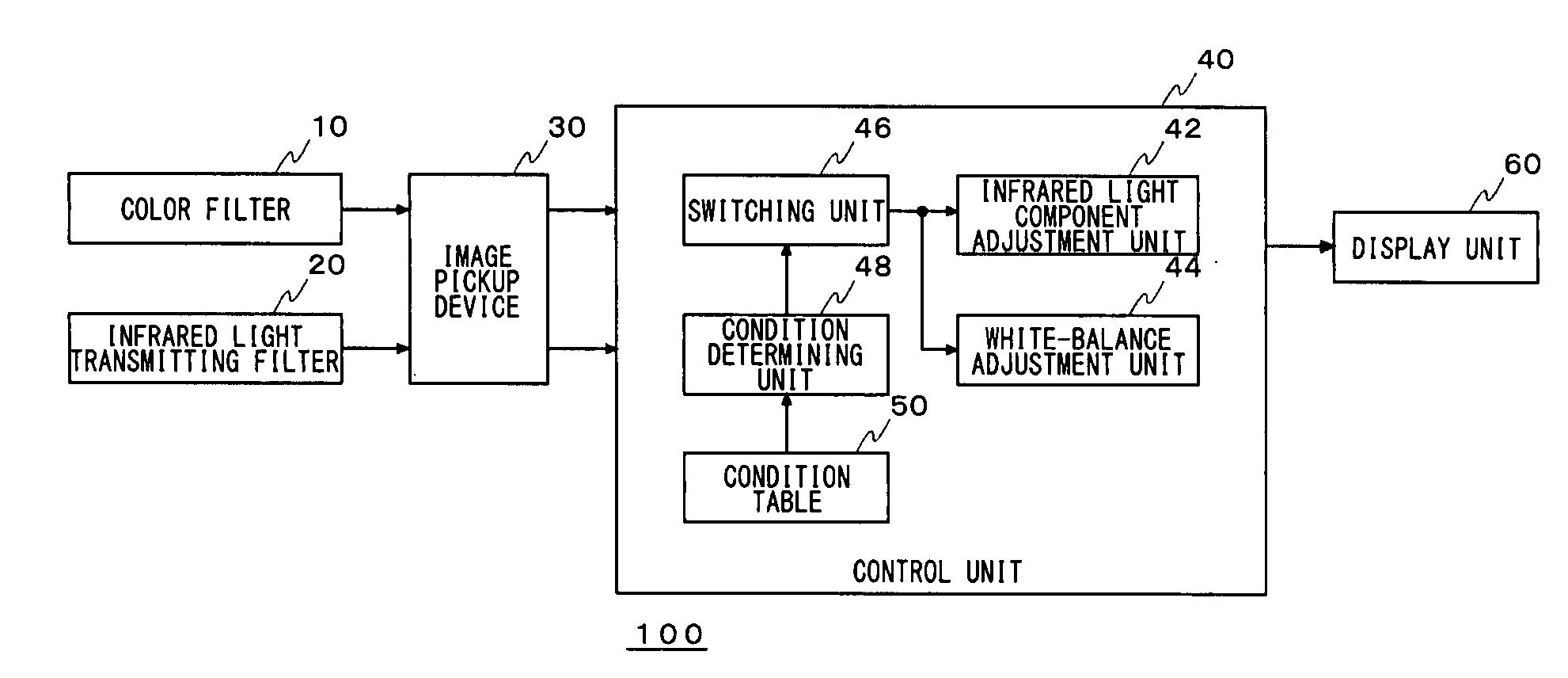

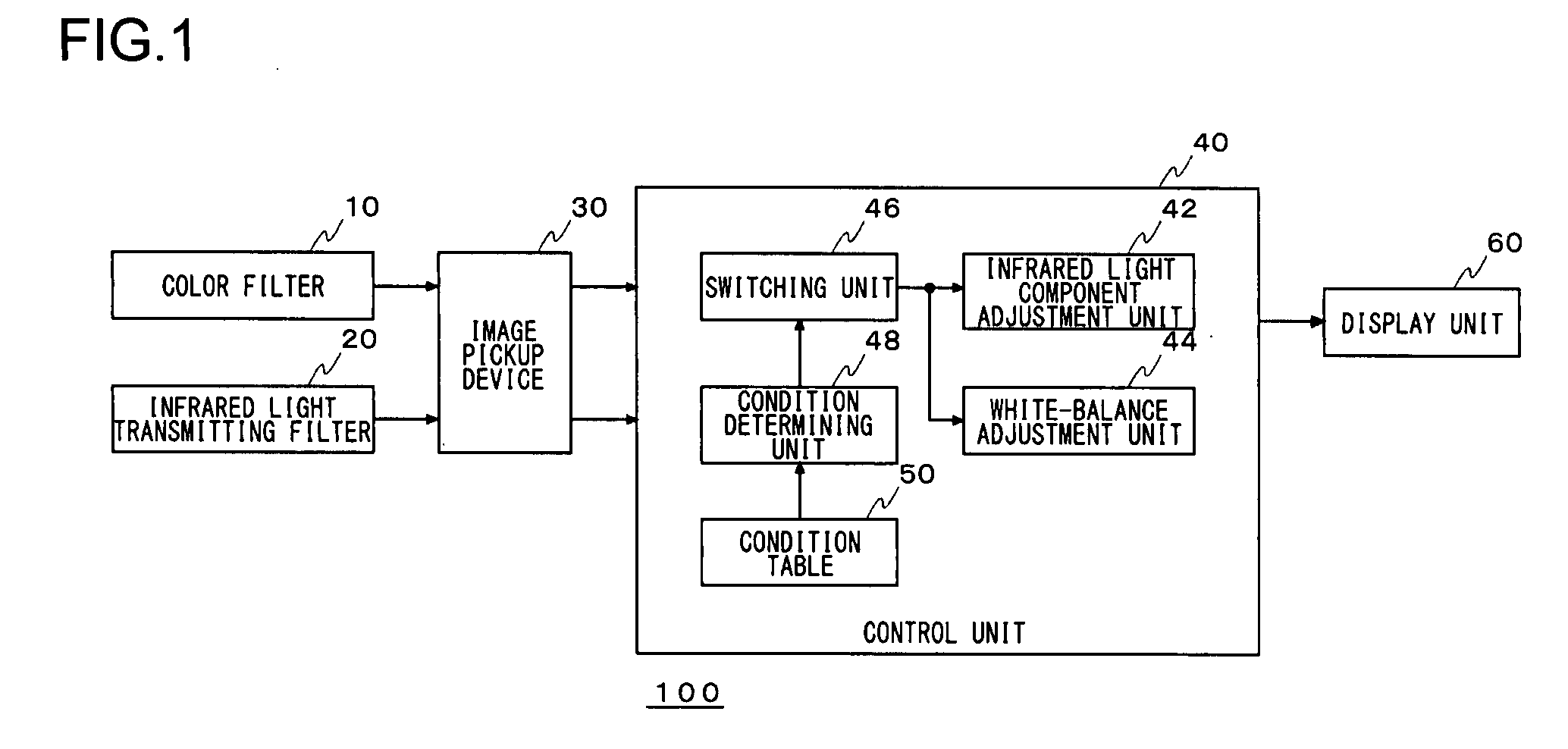

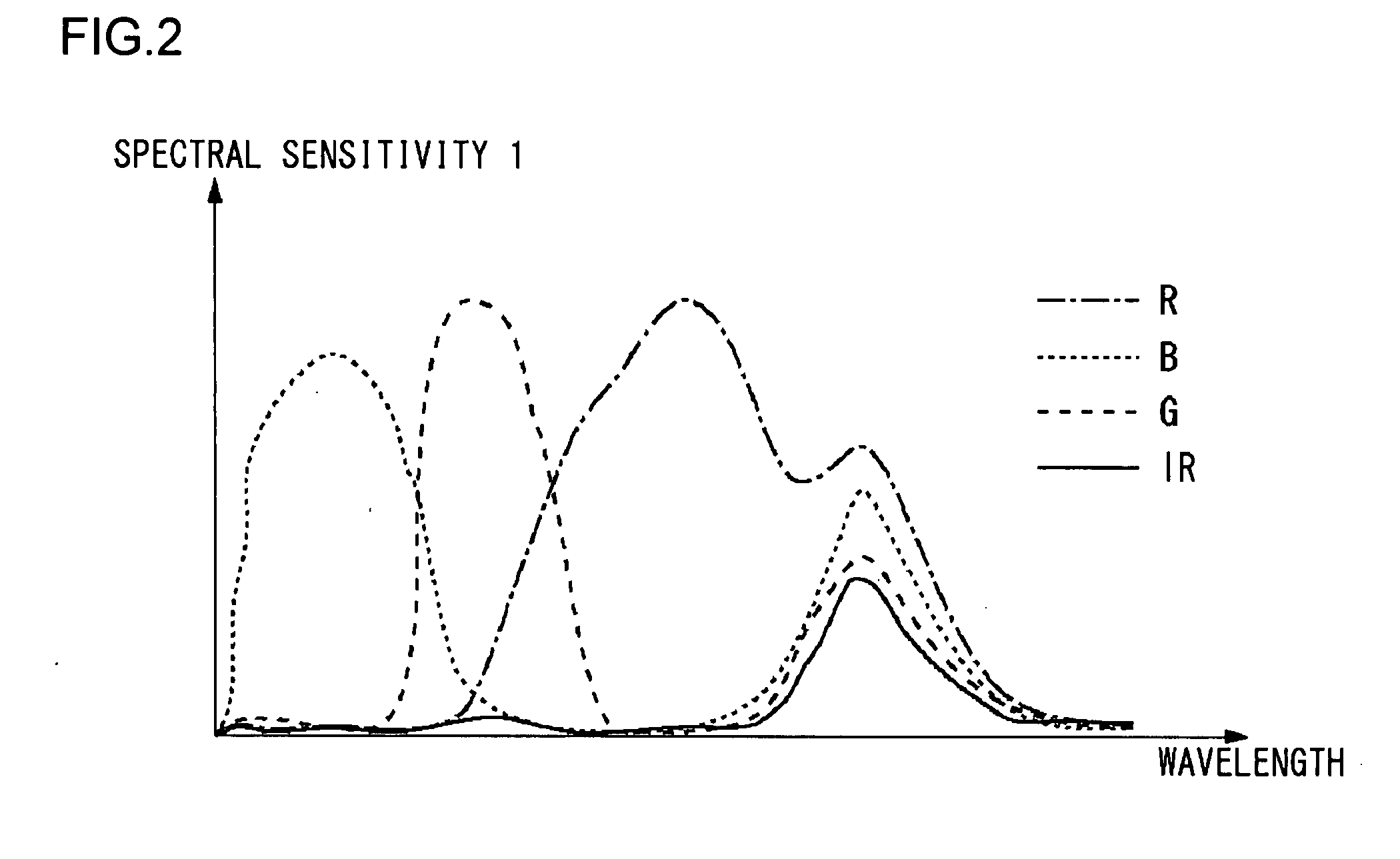

Image pickup apparatus and image pickup method

ActiveUS20080049115A1Television system detailsTelevision system scanning detailsOptoelectronicsColor filter array

An image pickup device receives an incident light by way of the color filter that also transmits an infrared light component. For the purpose of correcting an infrared light component contained in an output signal, a control unit adds correcting infrared light components to image signals of multiple colors supplied from the image pickup device, respectively. To remove the infrared light components contained in the output signals, the correcting infrared light components are subtracted from the image signals of multiple colors supplied from the image pickup device. The control unit switches between an addition processing where an infrared light component is added and a subtraction processing where the infrared component is subtracted, according to a predetermined condition.

Owner:SEMICON COMPONENTS IND LLC

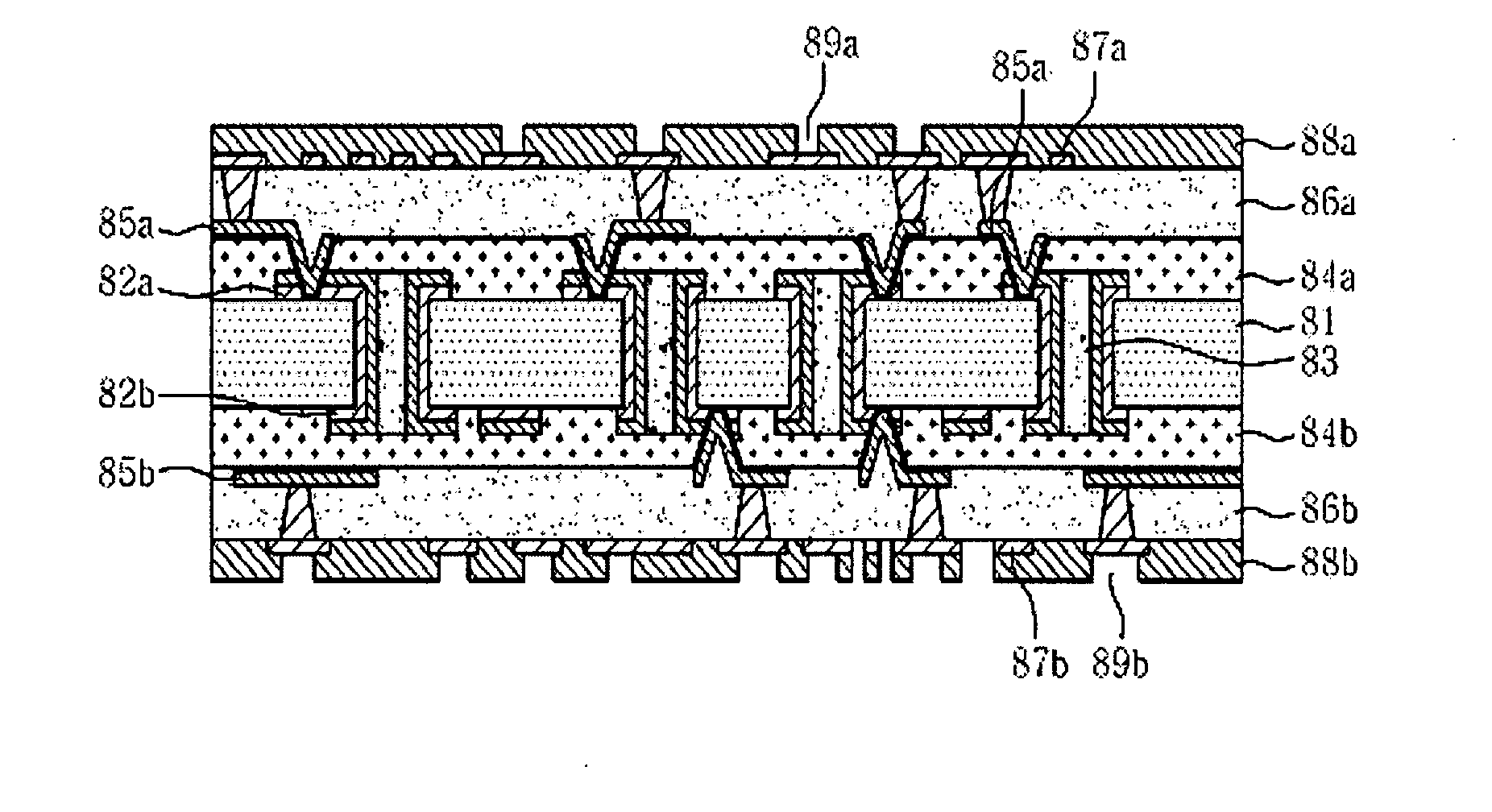

Method of manufacturing build-up printed circuit board

InactiveUS20070261234A1Fine circuitHigh peel strengthPrinted circuit assemblingPrinted circuit detailsIon beamEngineering

Disclosed is a method of manufacturing a build-up printed circuit board, in which the circuit of a build-up printed circuit board including a core layer and an outer layer is realized by forming the metal seed layer of the core layer using a dry process, consisting of ion beam surface treatment and vacuum deposition, instead of a conventional wet process, including a wet surface roughening process and electroless plating. When the wet process is replaced with the dry process in the method of the invention, the circuit layer can be formed in an environmentally friendly manner, and as well, all circuit layers of the substrate including the core layer and the outer layer can be manufactured through a semi-additive process. Further, the peel strength between the resin substrate and the metal layer can be increased, thus realizing a highly reliable fine circuit.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Surface modified particulate and sintered or injection molded products

ActiveUS20160256925A1Additive manufacturing apparatusInorganic material artificial filamentsParticulatesRapid prototyping

Owner:TUNDRA COMPOSITES LLC

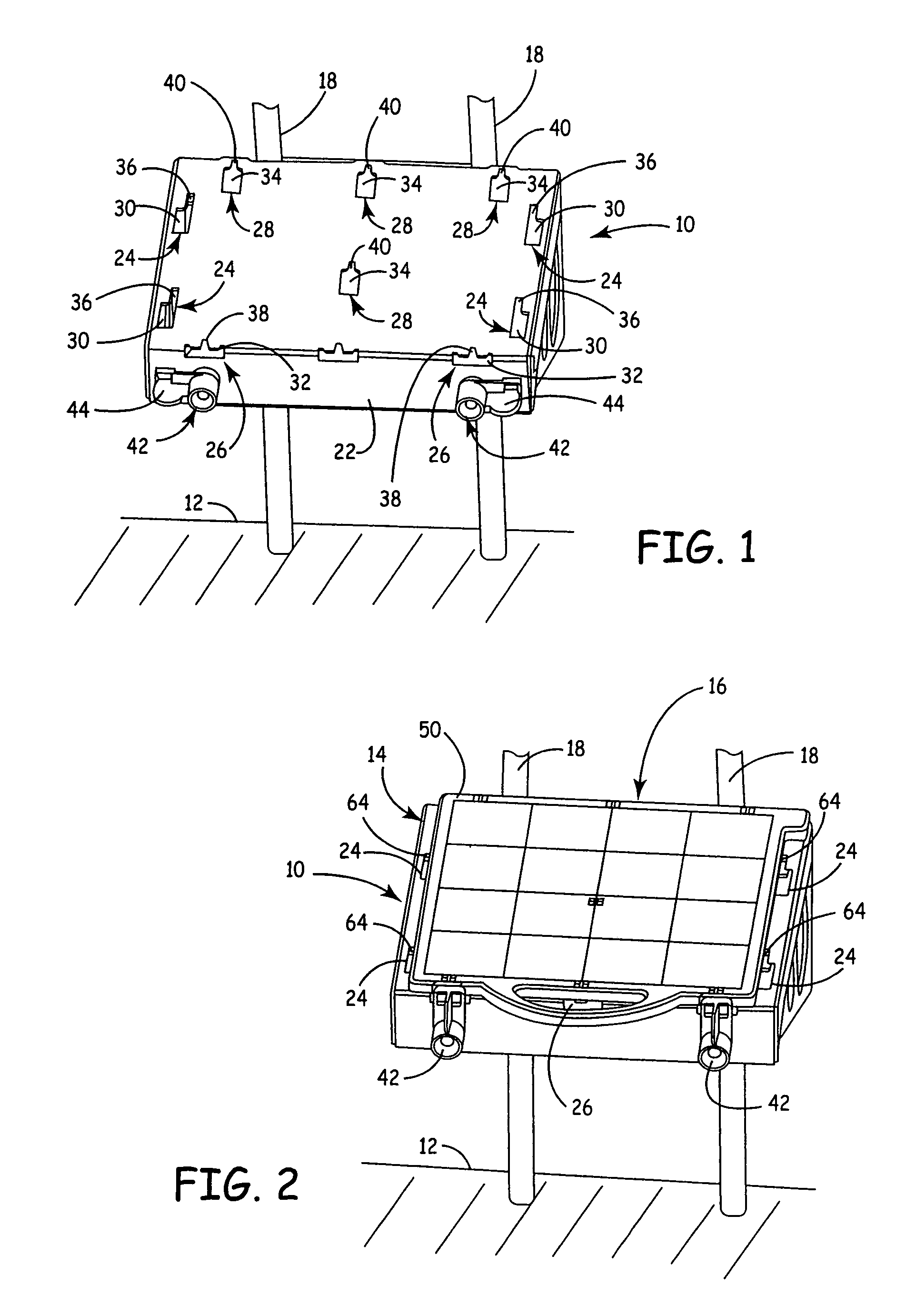

Modeling apparatus with tray substrate

ActiveUS20050173855A1Reduce usageAdditive manufacturing apparatusLarge fixed membersEngineeringDimensional modeling

A modeling apparatus includes a platform and a substrate, which are adapted to be releasably locked together to provide a surface for building up models in an additive-process three-dimensional modeling machine. The substrate comprises a substantially rigid, non-dusting tray providing a modeling surface. Female connectors extending from the tray are seated in male connectors in the platform, to engage the substrate to the platform. The engaged substrate is locked to the platform, maintaining accurate positioning of the substrate while a model is built. After modeling is complete, the substrate is released from the platform, the model is removed, and the substrate may be reused.

Owner:STRATSYS INC

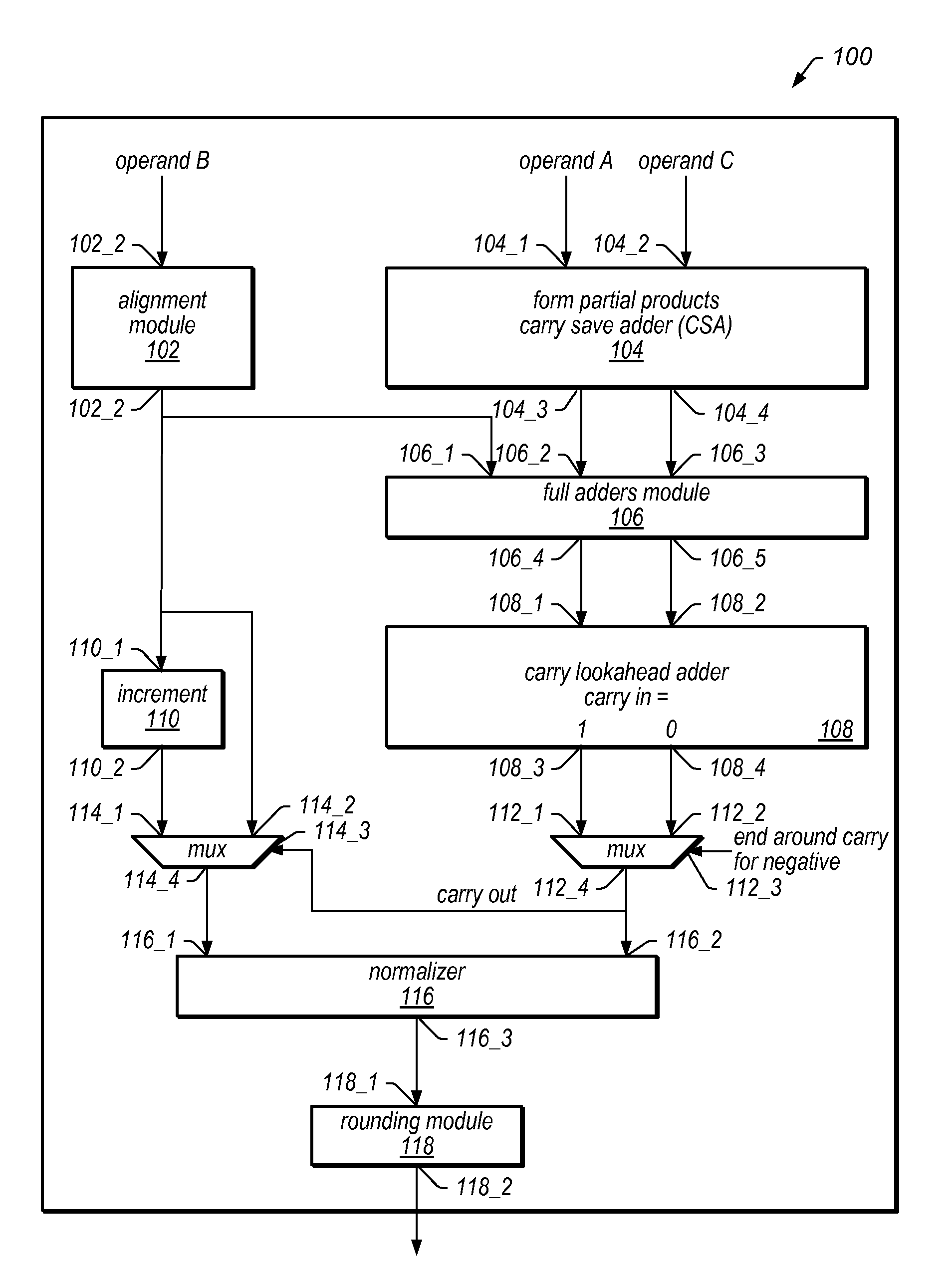

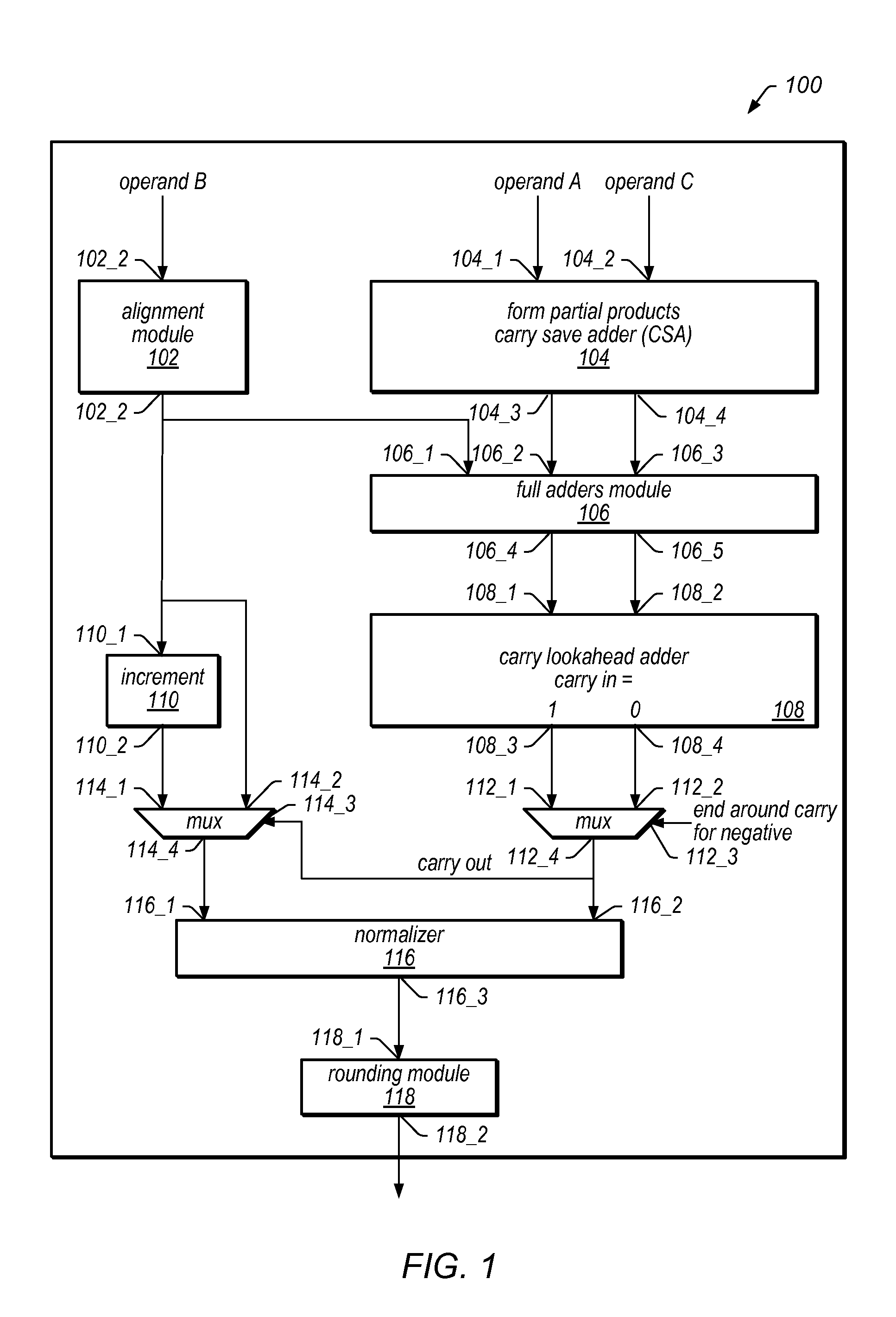

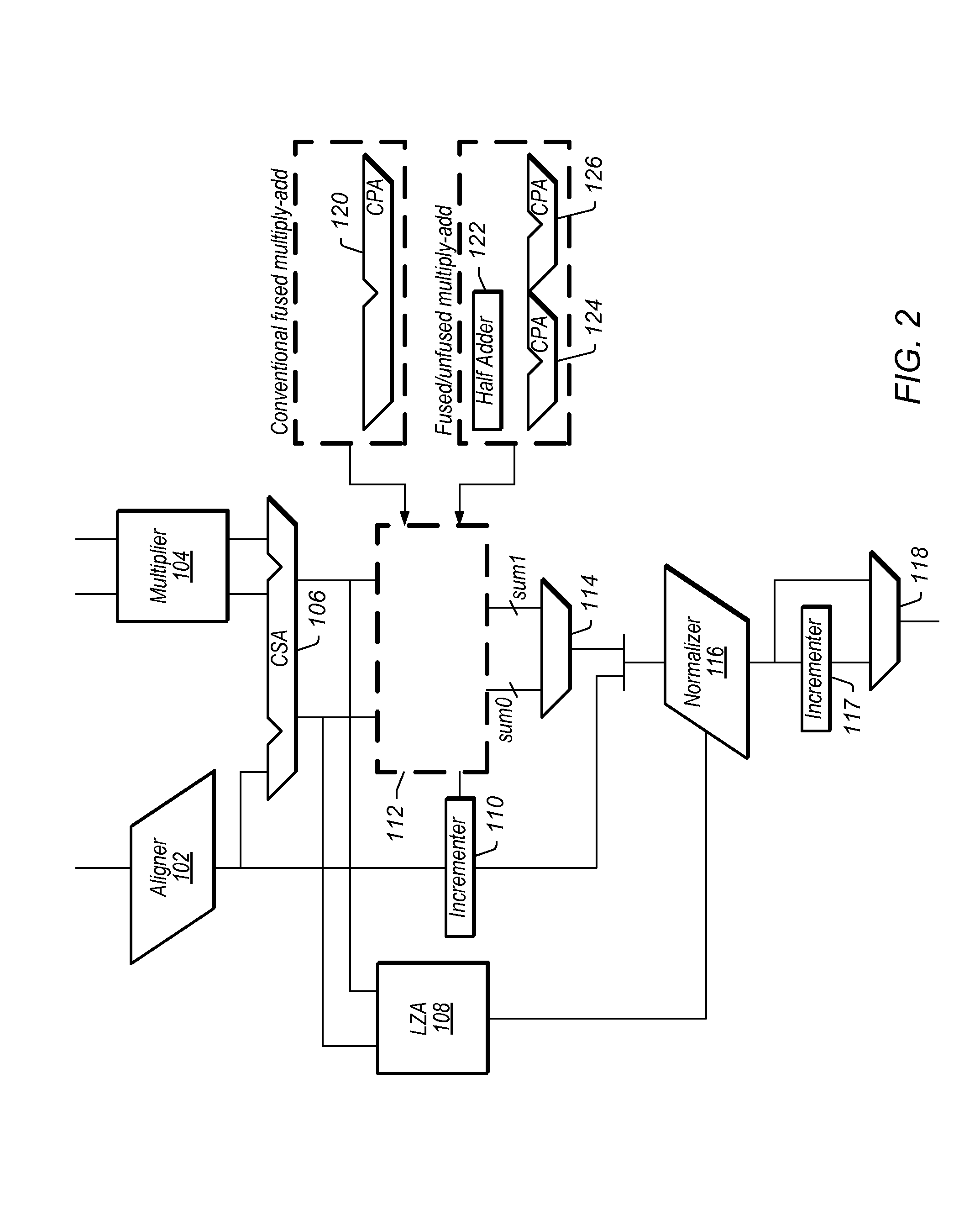

Processor which Implements Fused and Unfused Multiply-Add Instructions in a Pipelined Manner

ActiveUS20090248779A1Computations using contact-making devicesBinary multiplierTheoretical computer science

Implementing an unfused multiply-add instruction within a fused multiply-add pipeline. The system may include an aligner having an input for receiving an addition term, a multiplier tree having two inputs for receiving a first value and a second value for multiplication, and a first carry save adder (CSA), wherein the first CSA may receive partial products from the multiplier tree and an aligned addition term from the aligner. The system may include a fused / unfused multiply add (FUMA) block which may receive the first partial product, the second partial product, and the aligned addition term, wherein the first partial product and the second partial product are not truncated. The FUMA block may perform an unfused multiply add operation or a fused multiply add operation using the first partial product, the second partial product, and the aligned addition term, e.g., depending on an opcode or mode bit.

Owner:ORACLE INT CORP

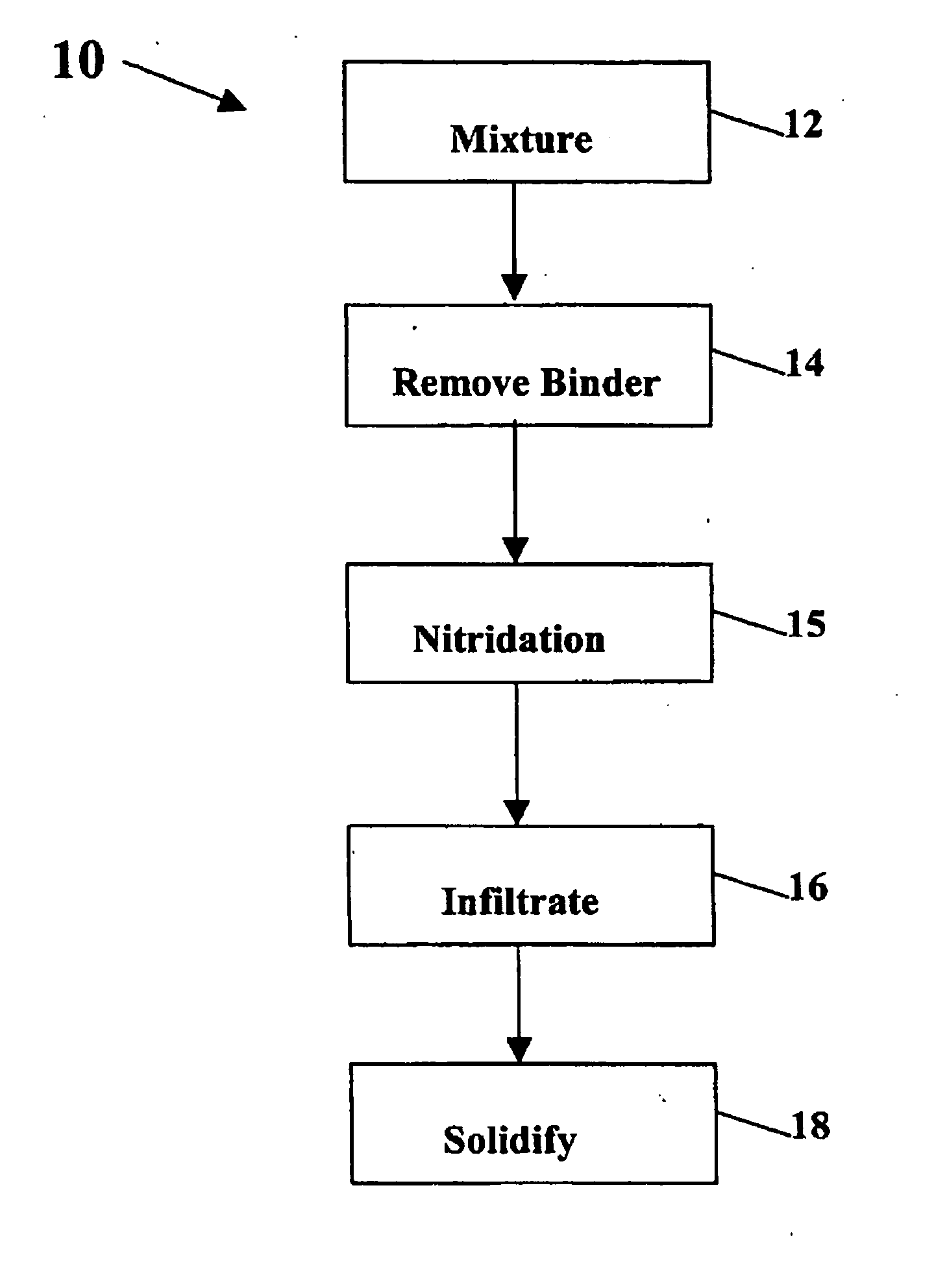

Infiltrated aluminum preforms

InactiveUS20050161189A1Easy to manufactureGood dimensional stabilityAdditive manufacturing apparatusTransportation and packagingSelective laser sinteringHigh density

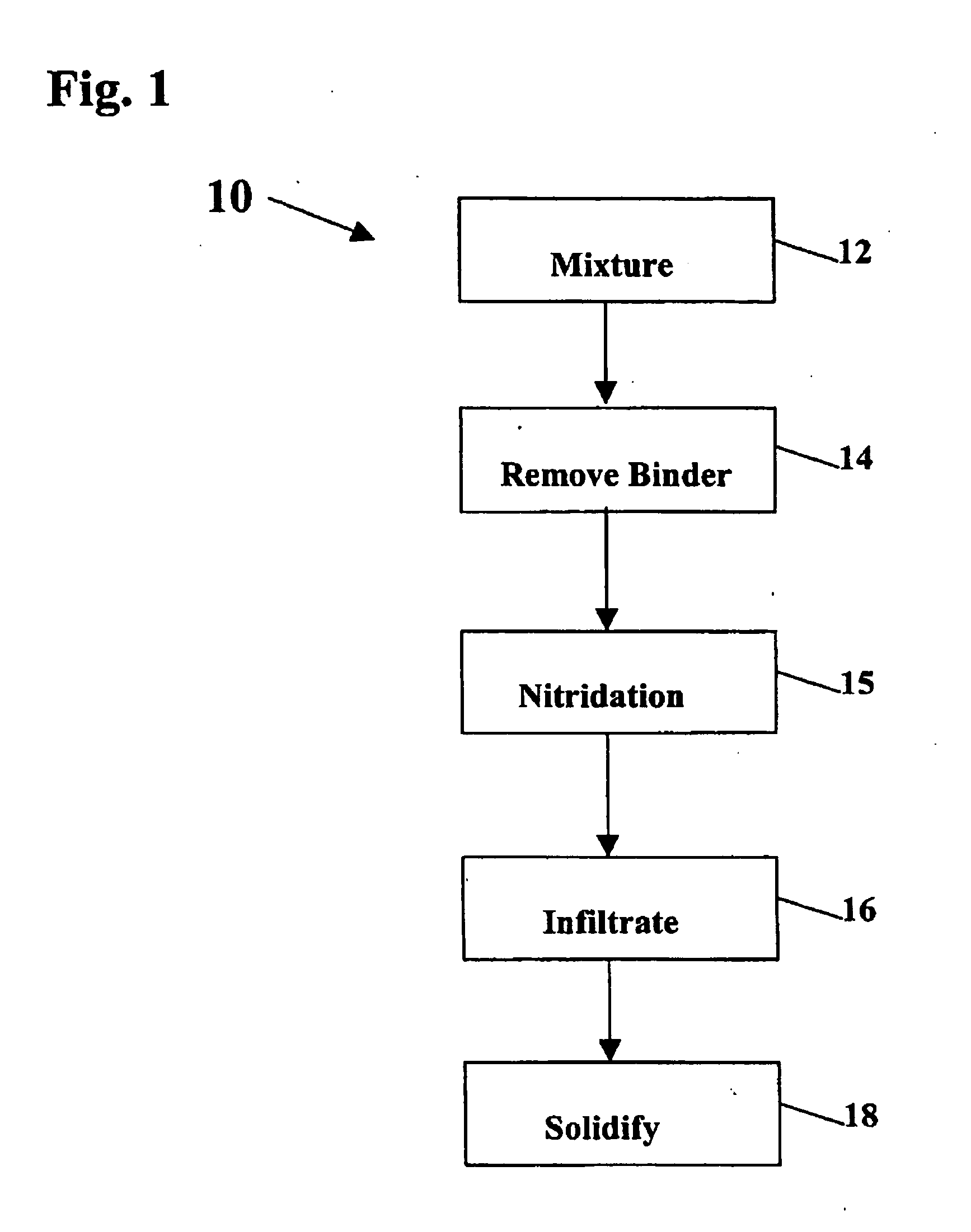

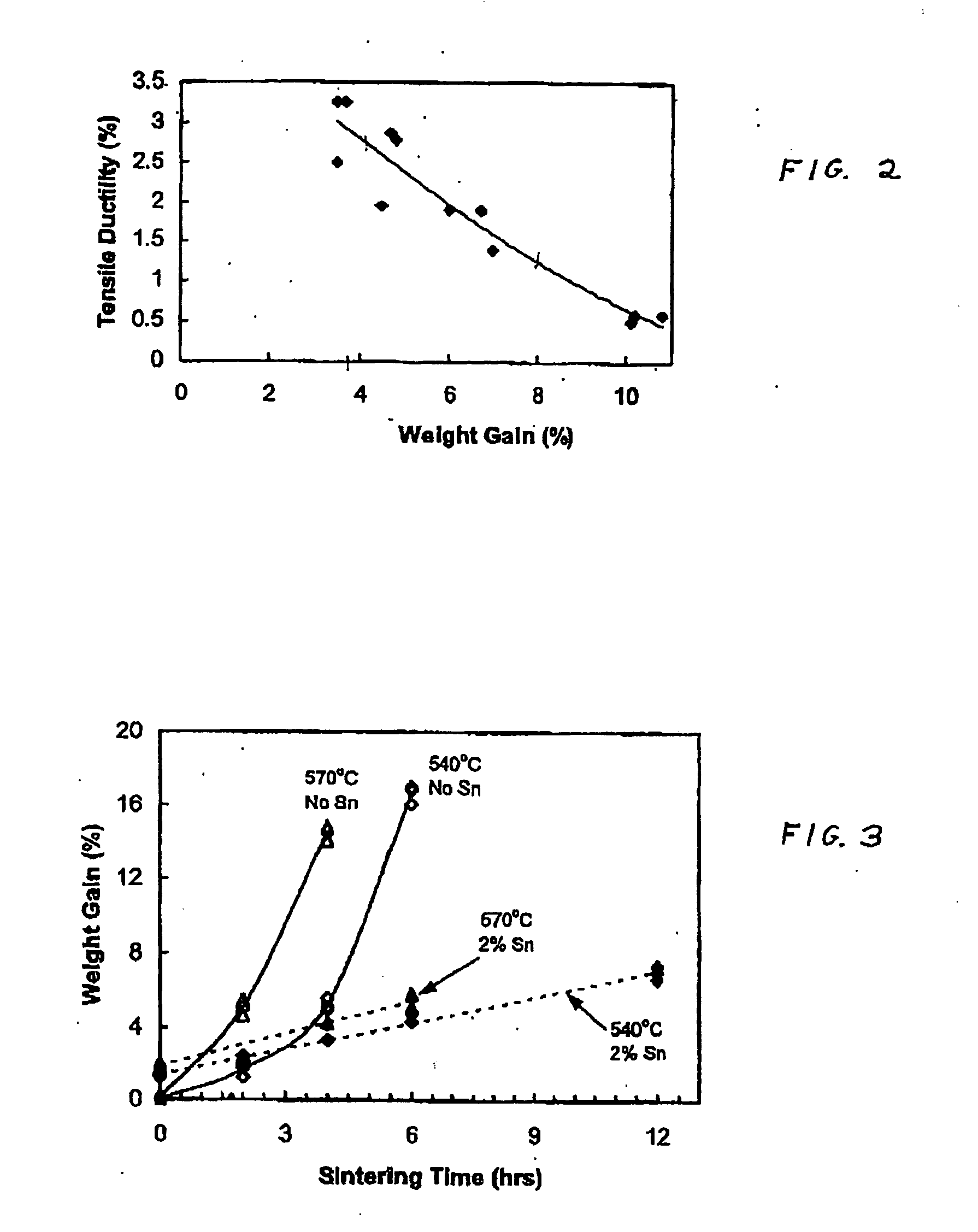

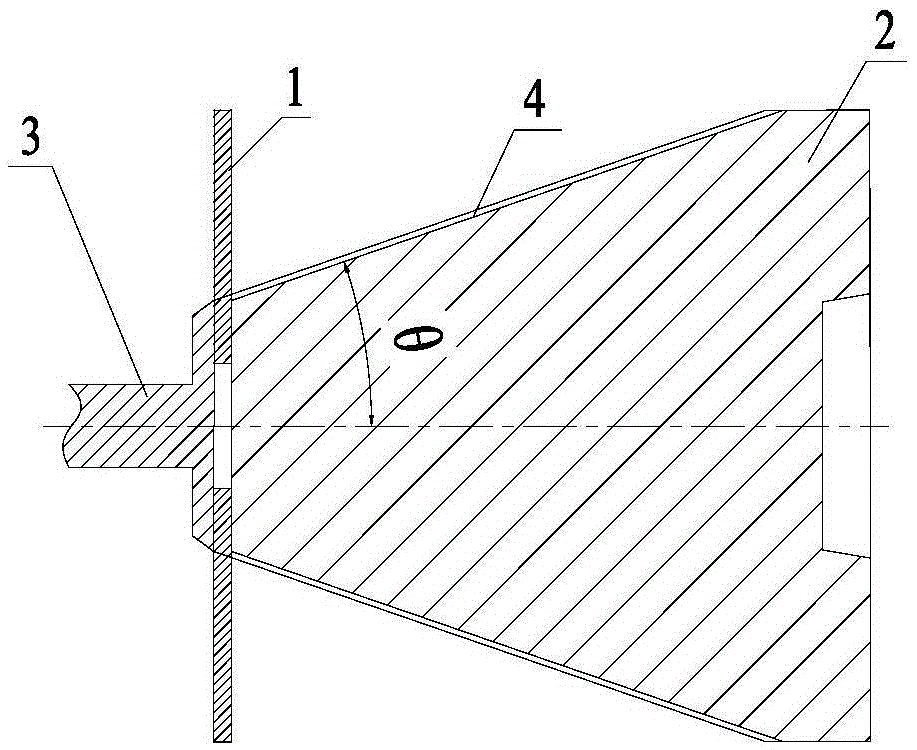

A method for the manufacture of a three-dimensional object includes the steps of forming a mixture that contains a binder and a least one of aluminum or a first aluminum-base alloy into a green composite, removing the binder from said green composite, forming a porous preform structure, reacting the aluminum or first aluminum base alloy with nitrogen to form a rigid skeleton and infiltrating the porous structure with molten aluminum or second aluminum base alloy to form the three-dimensional object with near theoretical density. The green composite may be formed by an additive process such as computer aided rapid prototyping, for example selective laser sintering. The method facilitates the rapid manufacture of aluminum components by an inexpensive technique that provides high dimensional stability and high density.

Owner:THE UNIV OF QUEENSLAND

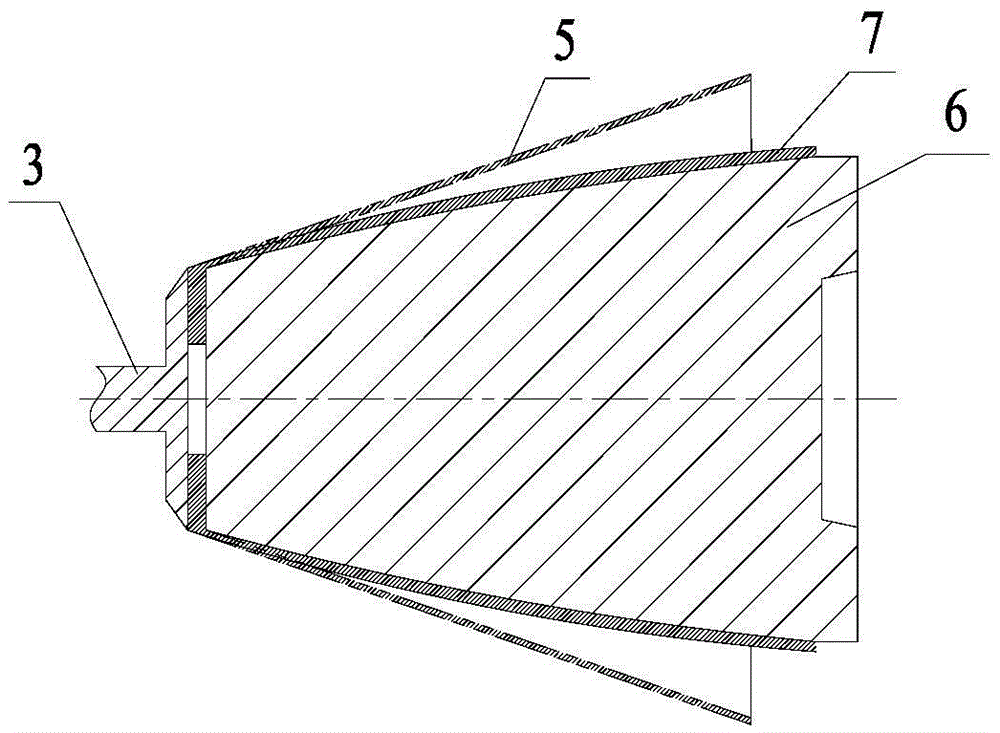

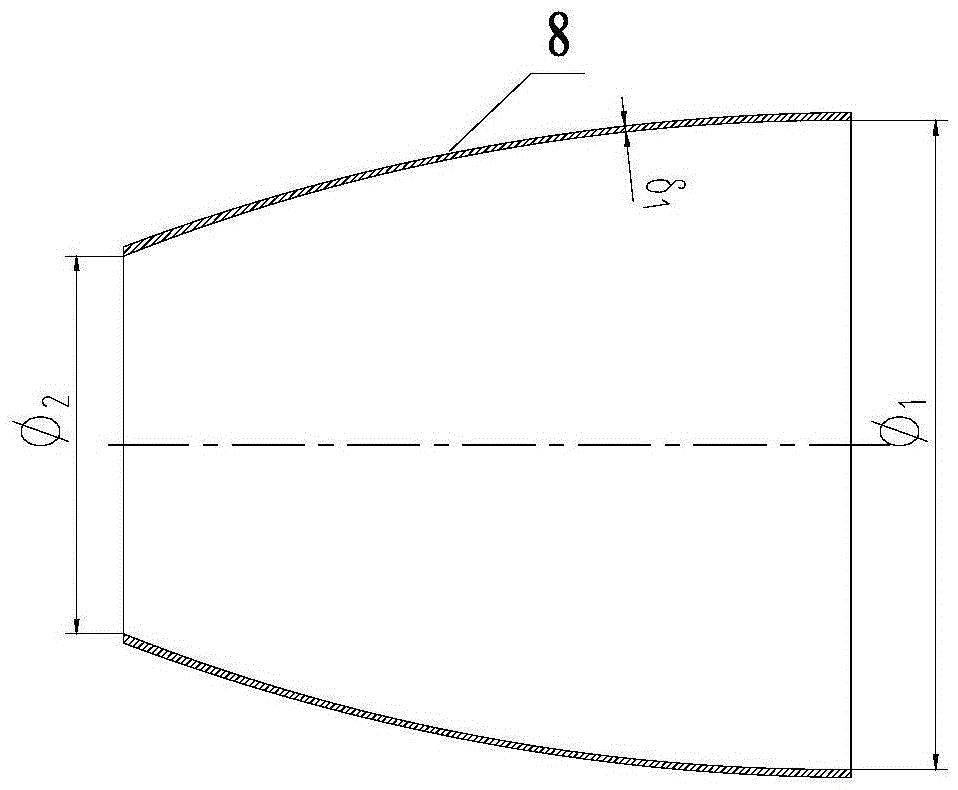

Spinning machining method for aluminium alloy thin-walled revolution body

ActiveCN105537449AMeet sizeFulfil requirementsHollow articles5005 aluminium alloy5052 aluminium alloy

The invention discloses a spinning machining method for an aluminium alloy thin-walled revolution body. The spinning machining method comprises the following steps: producing an aluminium alloy spun blank with required dimensions, and carrying out annealing treatment on the aluminium alloy spun blank; carrying out shearing spinning on the aluminium alloy spun blank to obtain a primary conical barrel; carrying out annealing treatment on the primary conical barrel, and cutting a process allowance at a large end to form a secondary conical barrel; carrying out common spinning on the secondary conical barrel on a spinning machine to obtain a pre-spun aluminium alloy thin-walled revolution body; and carrying out annealing treatment and surface polishing treatment on the pre-spun blank, and then cutting process allowances at the two ends of a spun part by using a plasma cutting machine, so as to obtain the aluminium alloy thin-walled revolution body meeting process requirements. According to the invention, the aluminium alloy thin-walled revolution body is machined by virtue of the technologies of shearing spinning and common spinning; the dimension and structural performance requirements of a bullet shell are met; a machining method and a stamping-welding method can be replaced; and a low-cost and efficient machining method is provided for machining for an aluminium alloy shell of a bullet.

Owner:湖北三江航天江北机械工程有限公司

Method for forming wiring on insulating resin layer

InactiveUS20070051459A1High joining strengthHigh strengthLamination ancillary operationsArtificial flowers and garlandsMetallic foilHigh energy

The method for forming wiring includes: laminating a thermosetting resin film in a semi-cured state and a metallic foil in this order on an insulating substrate where base-layer wiring is formed, a mat surface of the metallic foil facing the resin film, pressing the film and the foil with application of heat; forming an opening in the metallic foil so as to expose a part of the insulating resin layer in which a via hole is to be formed; forming the via hole in the insulating resin layer by irradiating high-energy beams on to insulating resin layer by using as a mask the metallic foil in which the opening is formed; performing a desmear process of the via hole via the opening of the metallic foil; removing the metallic foil by etching; forming an electroless-plated layer that continuously covers the top surface of the insulating resin layer, a side surface of the via hole and a top surface of the base-layer wiring corresponding to the bottom of the via hole; and forming wiring including an electroplated layer on the electroless-plated layer by a semi-additive process.

Owner:SHINKO ELECTRIC IND CO LTD

Organic silicon-acrylate nano emulsion

InactiveCN1385447AHigh glass transition temperatureLow minimum film forming temperatureAdhesiveAlloy

Owner:SOUTH CHINA UNIV OF TECH

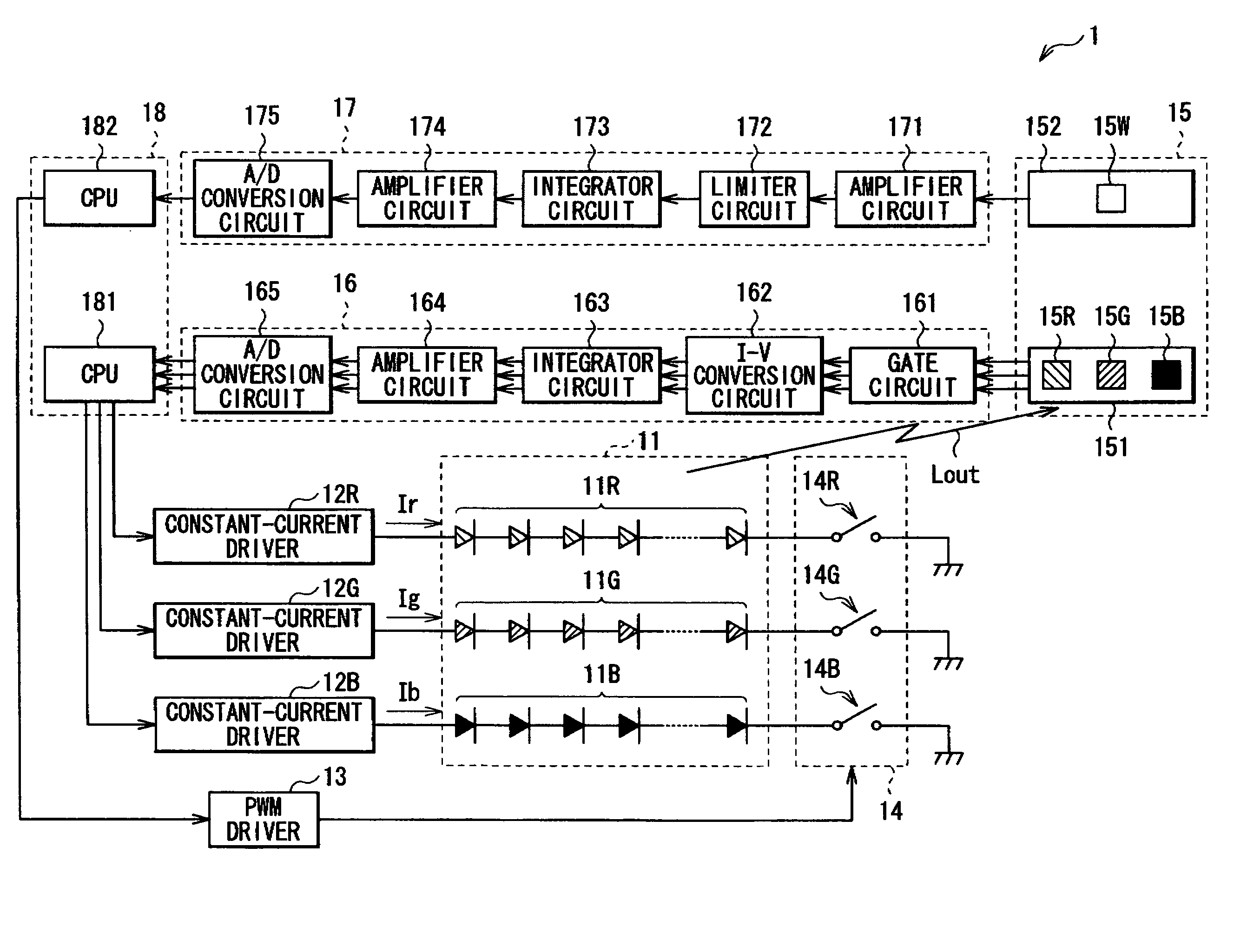

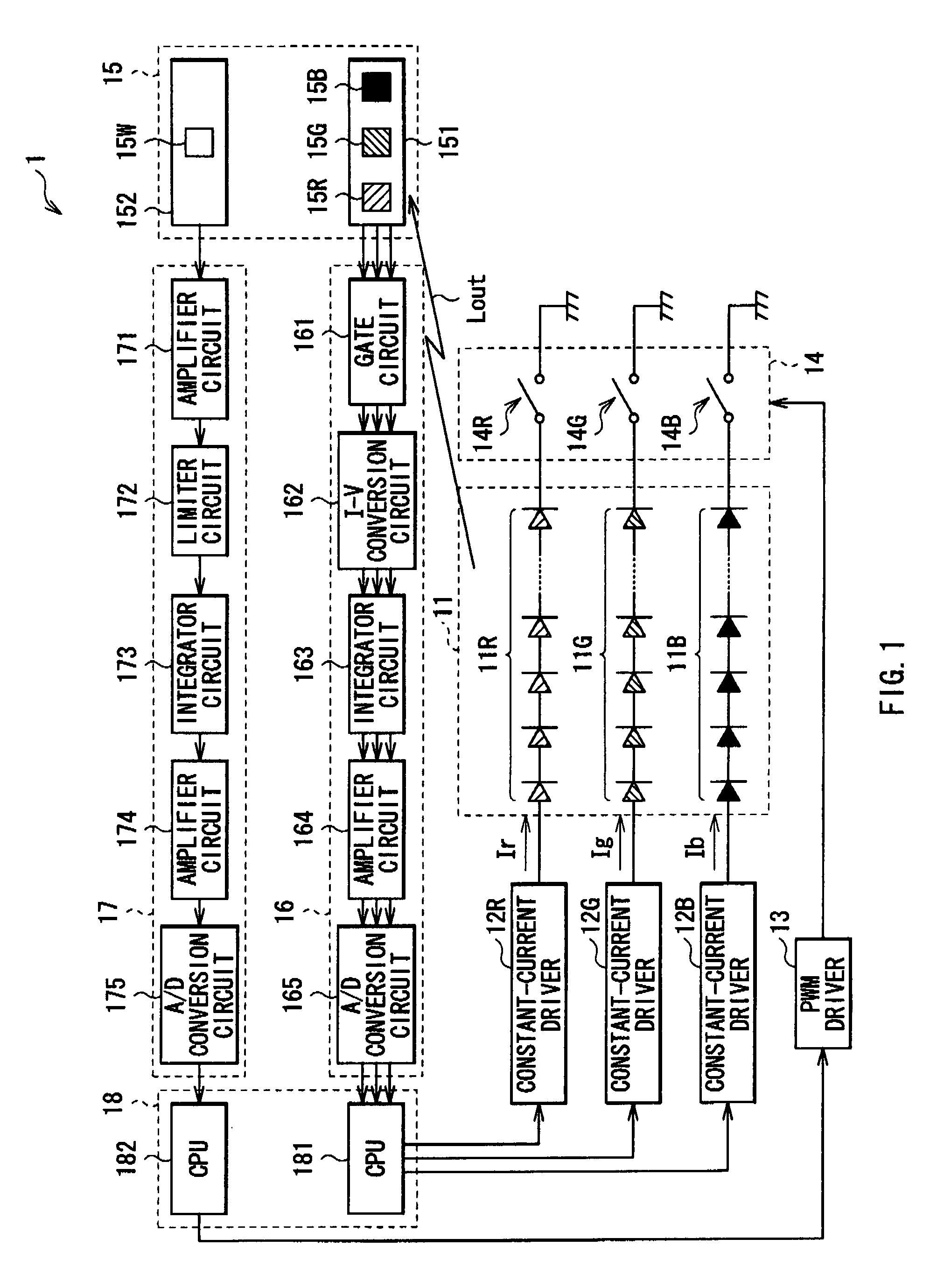

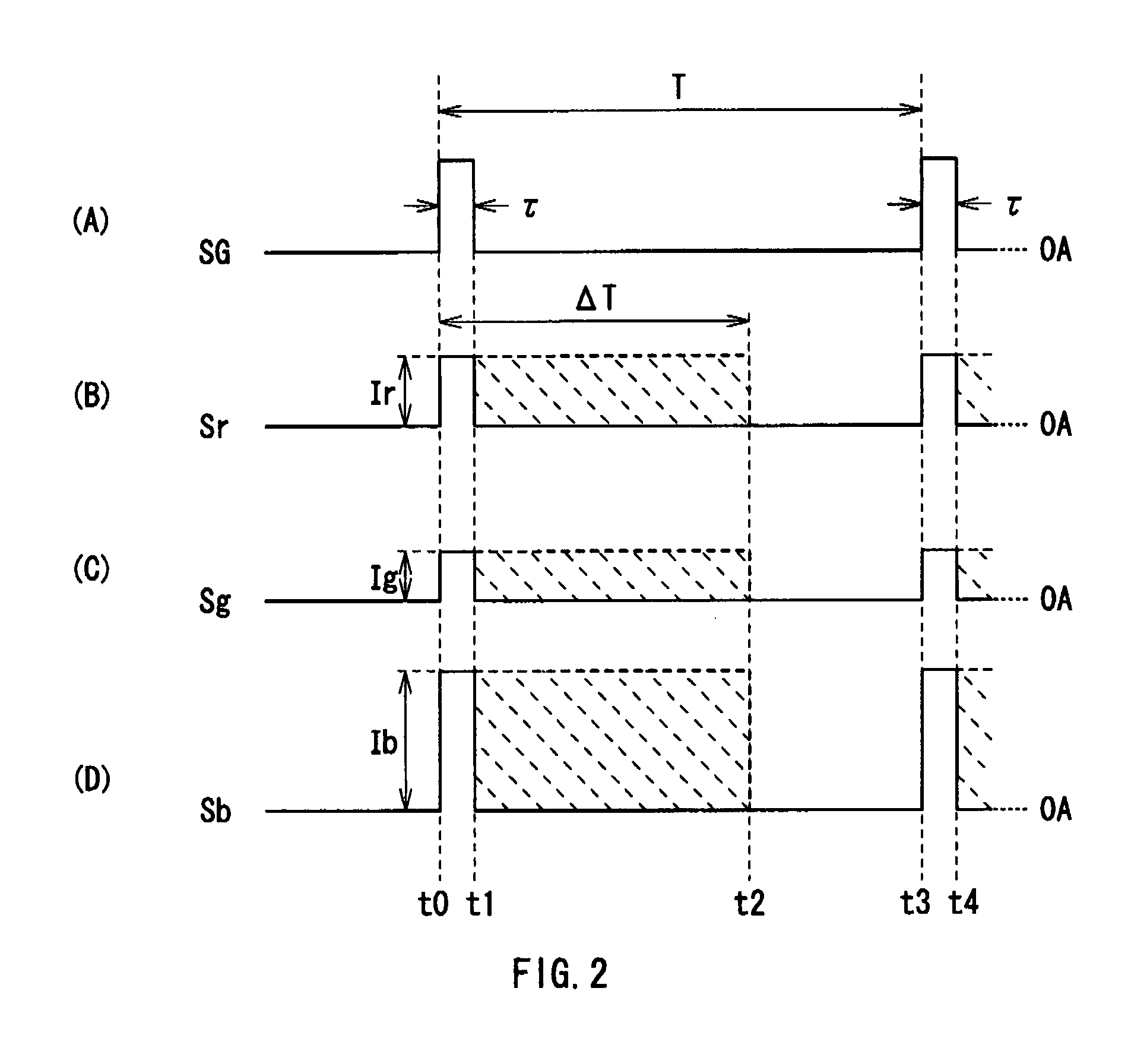

Illumination system and liquid crystal display

InactiveUS8035603B2Improve display image qualityQuality improvementStatic indicating devicesNon-linear opticsLuminous intensityLiquid-crystal display

An illumination system capable of varying the light emission intensity of illumination light while maintaining the color balance of the illumination light is provided. An additive process illumination system obtaining a specific color light by mixing a plurality of color lights, the illumination system may include a plurality of light sources each emitting a different color light; a lighting period varying means for varying the lighting period of each light source; a light emission intensity varying means for varying the light emission intensity of each light source; and a control means for controlling the lighting period varying means and the light emission intensity varying means to control the light emission amount of each light source.

Owner:SONY CORP

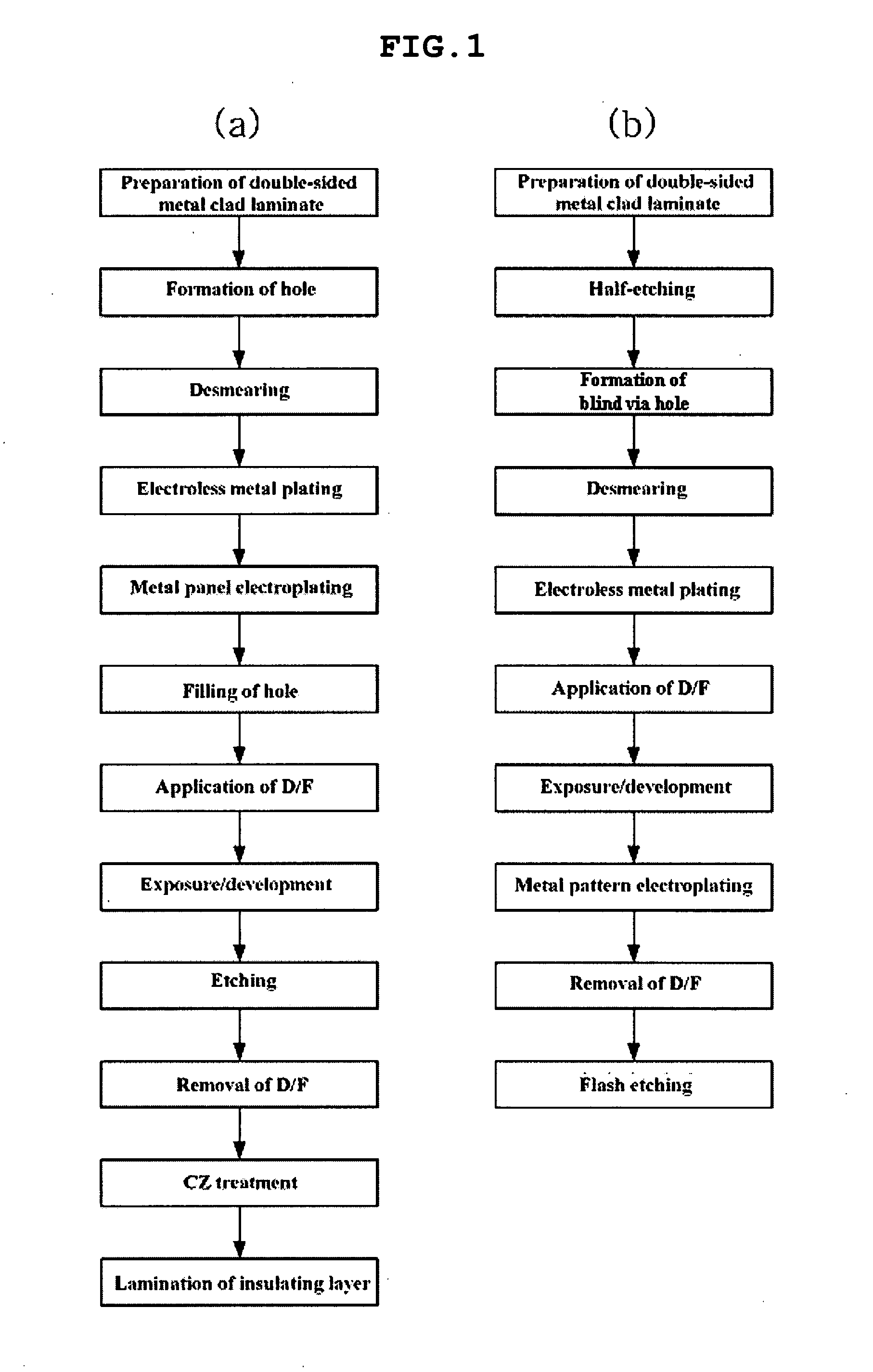

Method for manufacturing printed circuit board by using novel and improved semi-additive process

InactiveCN104113994AEasy to handleReduce the amount of flash erosionMultilayer circuit manufacturePrinted element electric connection formationRough surfaceChemical plating

The invention relates to a method for manufacturing a printed circuit board by using a novel and improved semi-additive process. The method includes the following steps that: a) a dielectric layer is prepared, and copper foil is pressed on the dielectric layer, so that a copper foil conductive layer can be formed, and as a result, a composite structure substrate can be formed, the roughness of the rough surface of the copper foil being smaller than 4 microns; b) the thickness of the copper foil conductive layer is reduced to 0.2 to 5 microns; c) through holes or blind holes are formed in the dielectric layer and the copper foil conductive layer; d) conductive treatment is performed on the copper foil conductive layer and the hole walls of the blind holes or through holes, so that a seed layer can be formed; e) a photosensitive film is bonded on the surface of the substrate, and an electroplating barrier layer is formed on the substrate through pattern transfer; f) electroplating is performed on the substrate; g) a metal protective layer is formed on the surface of a circuit pattern through using a chemical plating or electroplating method; h) the electroplating barrier layer is removed; i) the bare seed layer and copper foil conductive layer are removed through adopting a flash rusting method, and the circuit pattern formed through electroplating is reserved; j) the metal protective layer is removed; and k) processing in steps from a) to j) is performed on the circuit board repeatedly, so that a multi-layer circuit board can be formed.

Owner:SHANGHAI MEADVILLE SCI & TECH

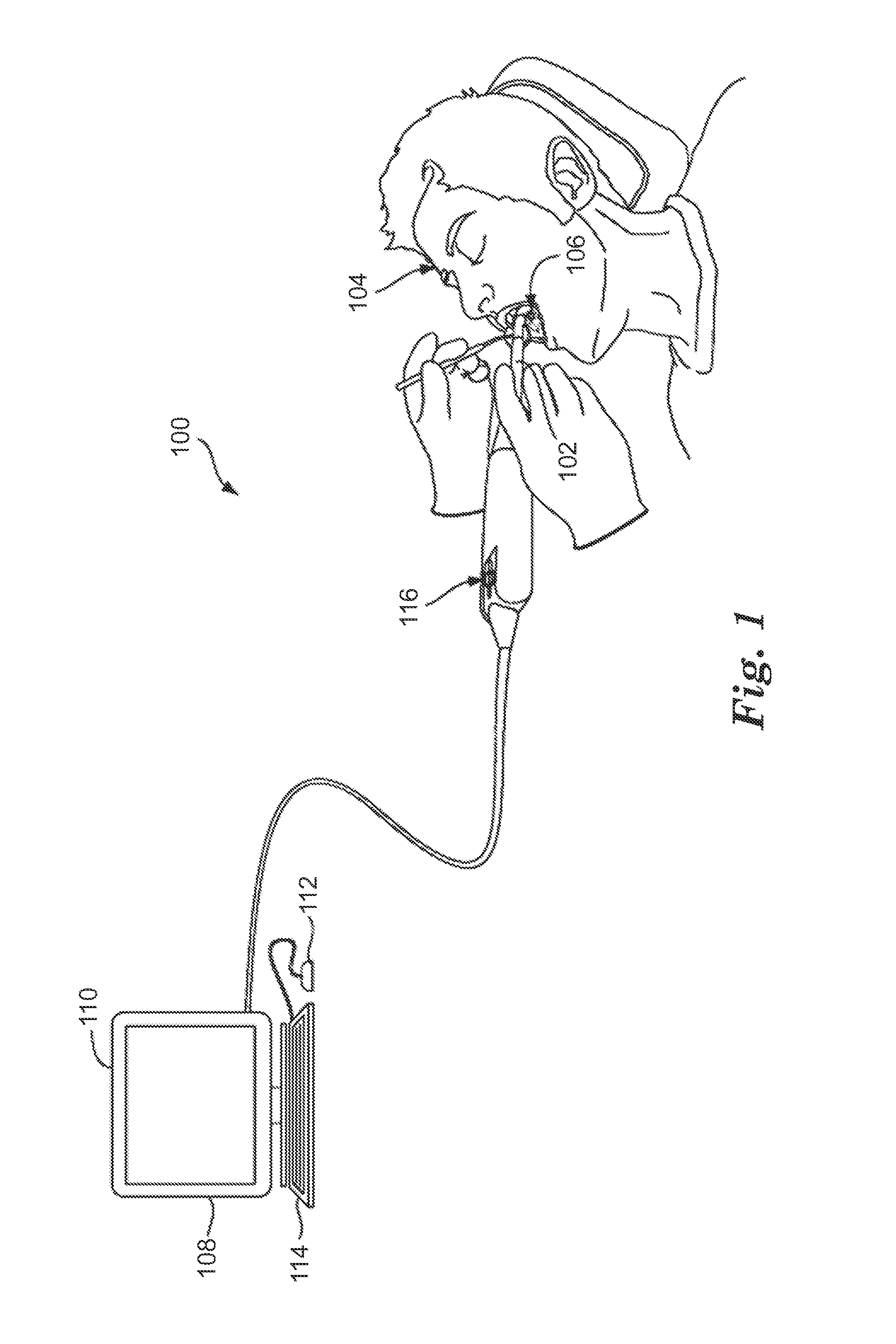

Fabrication of dental articles using digitally-controlled reductive and digitally-controlled additive processes

By capturing a highly detailed three-dimensional digital model of dentition, a suitable replacement dental article be fabricated with a combination of digitally-controlled reductive processes such as milling and digitally-controlled additive processes such as digital painting. A dental article so-manufactured can provide an aesthetically pleasing, multi-chromatic appearance that closely matches surrounding dentition.

Owner:3M INNOVATIVE PROPERTIES CO

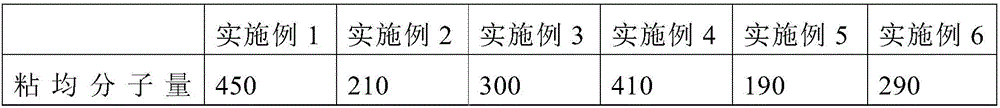

Preparation method of injection molding grade UHMWPE (Ultra-High Molecular Weight Polyethylene)

The invention relates to a preparation method of injection molding grade UHMWPE (Ultra-High Molecular Weight Polyethylene). The preparation method comprises the following steps: adding a certain amount of solvent oil in a dispersion medium, and polymerizing, thus obtaining UHMWPE containing the solvent oil; extruding through a screw extruder after mixing a flow modifier, a function additive processed by a coupling agent, an antioxidant and the UHMWPE containing the solvent oil at high speed, thus obtaining the injection molding grade UHMWPE. Compared with the prior art, the injection molding grade UHMWPE prepared by the method has good liquidity and good mechanical performance, can be machined and formed on a common injection molding and extrusion device, the machining efficiency is increased, and the injection molding grade UHMWPE can be widely applied to many fields of spaceflight, military industry, automobiles, high-speed rails, rail transit, spinner accessories and the like.

Owner:SHANGHAI RES INST OF CHEM IND

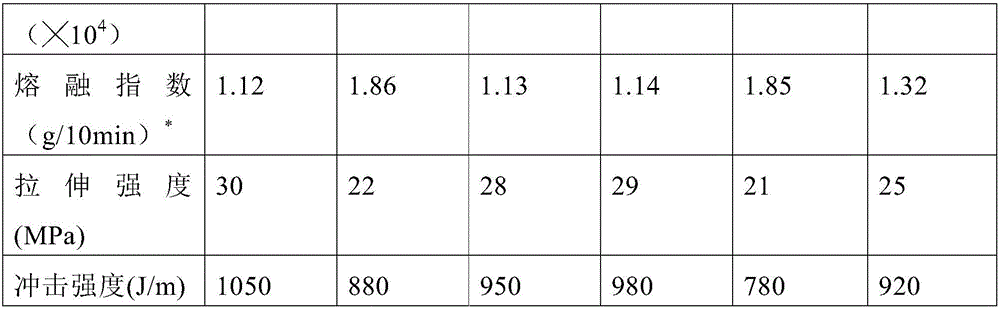

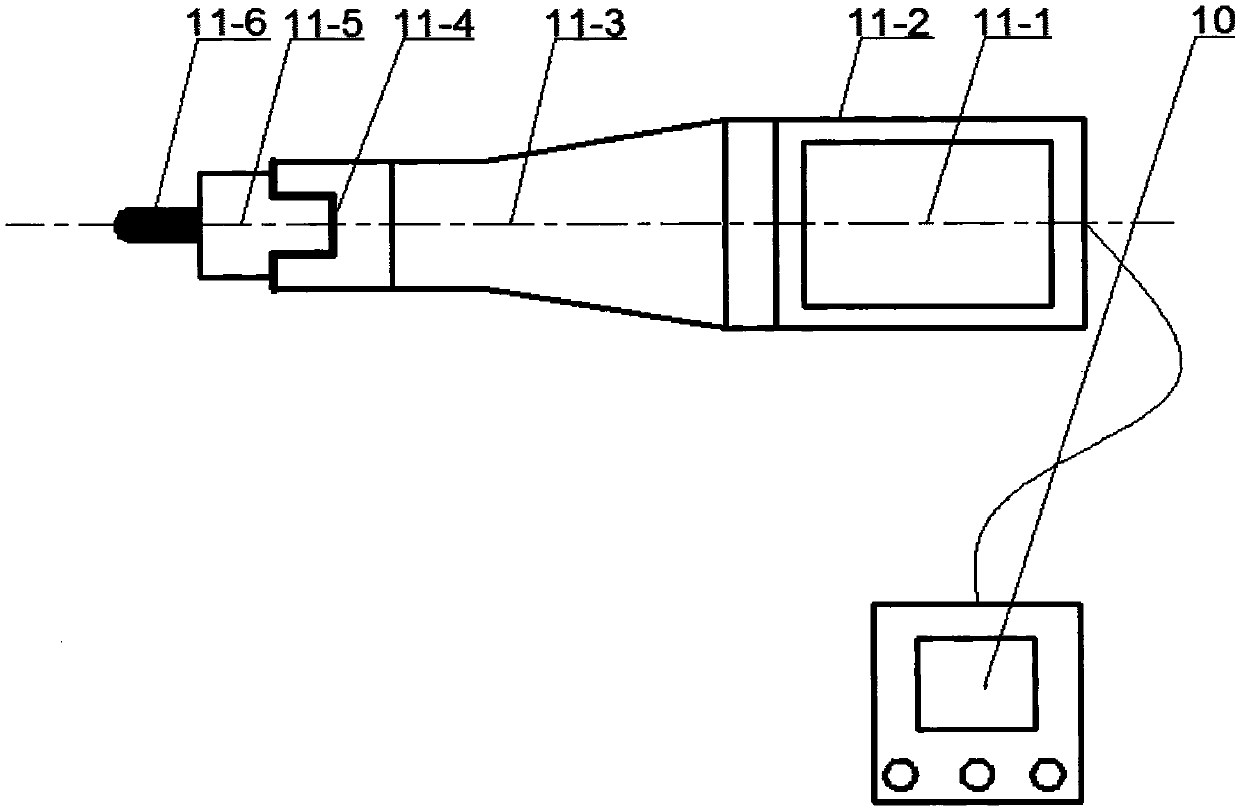

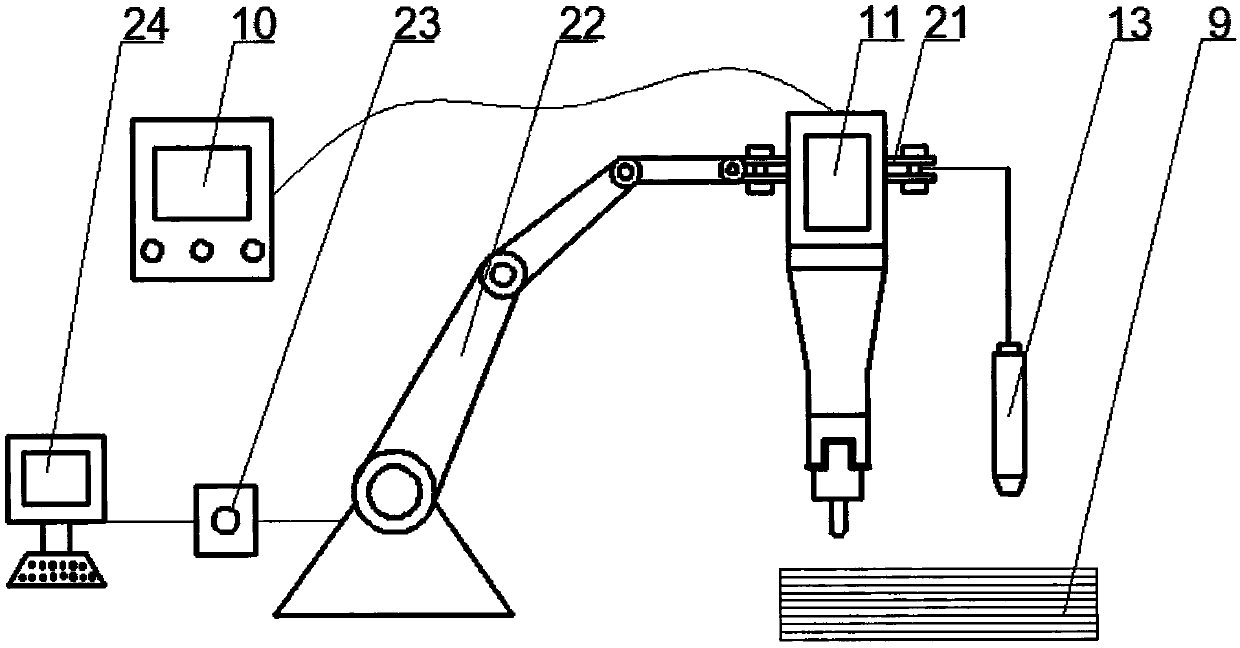

Electric arc additive and electric auxiliary ultrasonic impact reinforcing composite manufacturing method and device

InactiveCN109623100AReduce peakLow densityAdditive manufacturing apparatusArc welding apparatusMulti fieldPulse power supply

The invention relates to an electric arc additive and electric auxiliary ultrasonic impact reinforcing composite manufacturing method and device. The method is characterized in that an electric arc isused for melting a metal wire material; after the wire material is settled on a base sheet by one or more layers through a welding gun and a wire feeding mechanism, the base sheet and the settled layer are heated through a direct-current pulse power supply; and the temperature of the surface of the settled layer is acquired by a temperature sensor, and an ultrasonic impact device is used for carrying out ultrasonic impact on the surface of the settled layer when the temperature reaches a preset value. The device comprises the base sheet, a clamp, a workbench, the welding gun, the wire feedingmechanism, the temperature sensor, an ultrasonic generator, the ultrasonic impact device, an electrode, a wire, the direct-current pulse power supply and an insulating spacer. According to the method, pulse current auxiliary heating, ultrasonic impact reinforcing and an electric arc additive process are organically combined, the multi-field coupling effect of electricity, heat, sound and force isused for improving the forming precision of the settled layer and refining the grain size, so that the defects such as air holes and cracks and internal residual tensile stress generated in the electric arc additive process are eliminated, and the mechanical property of material is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

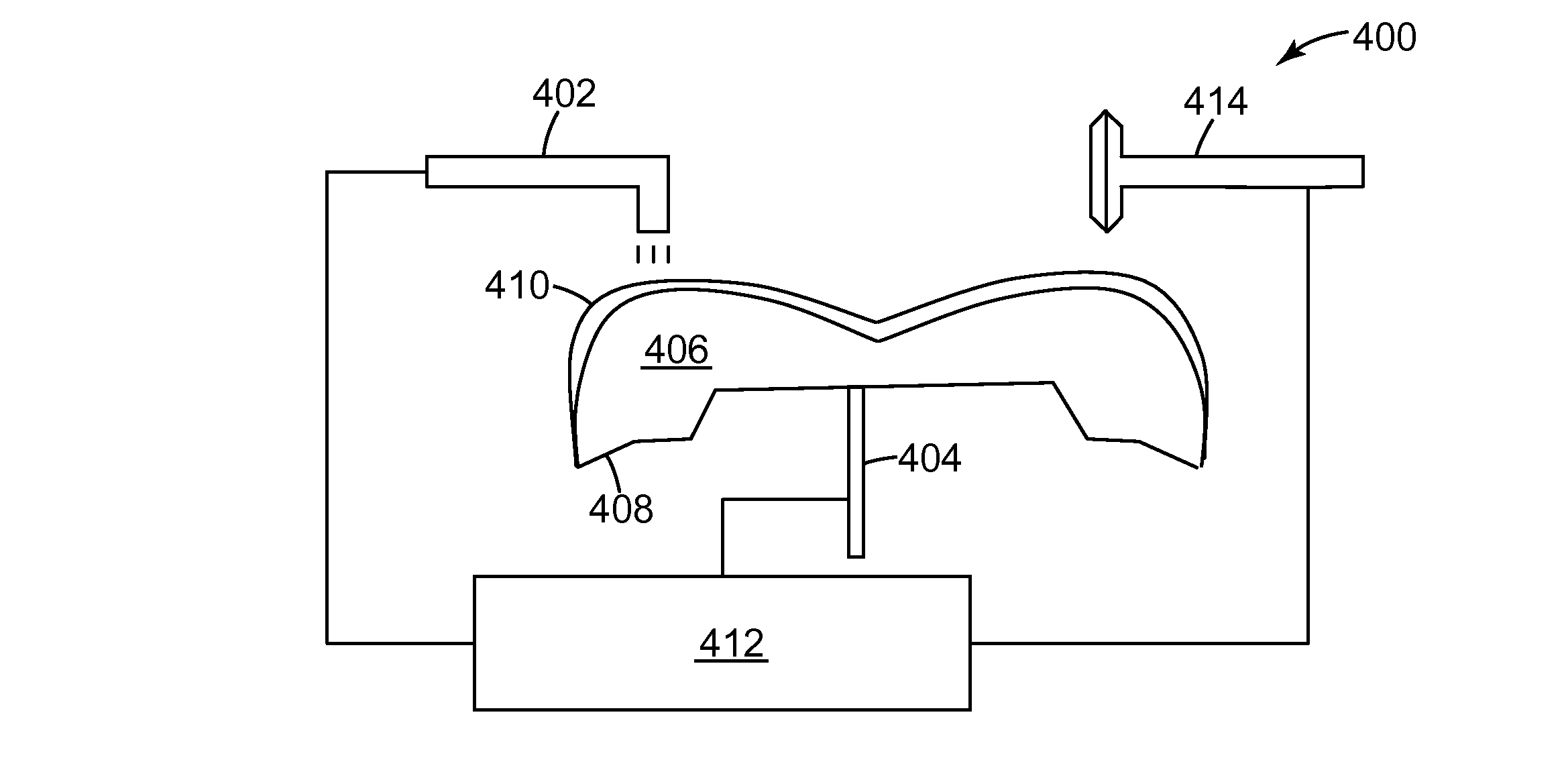

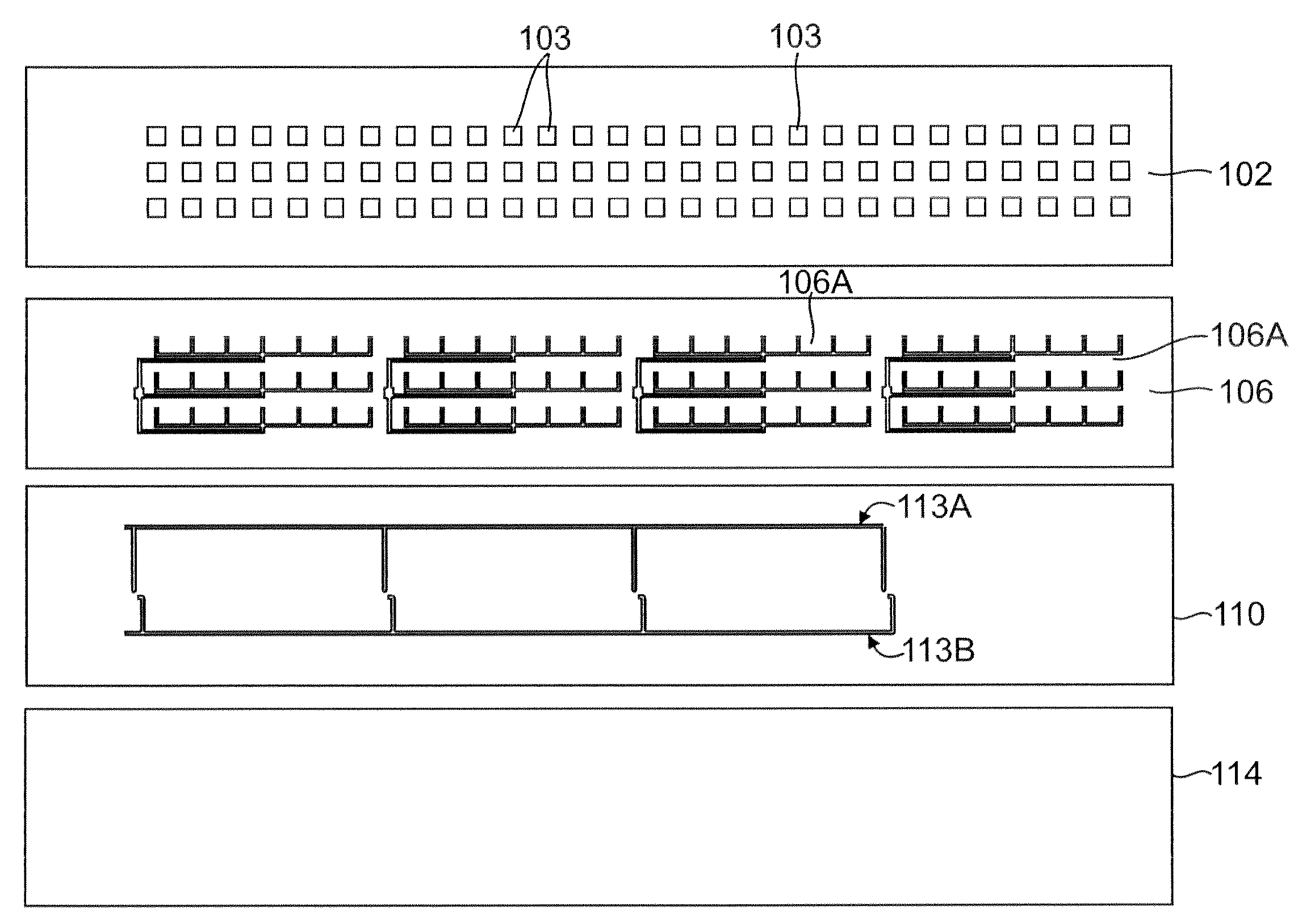

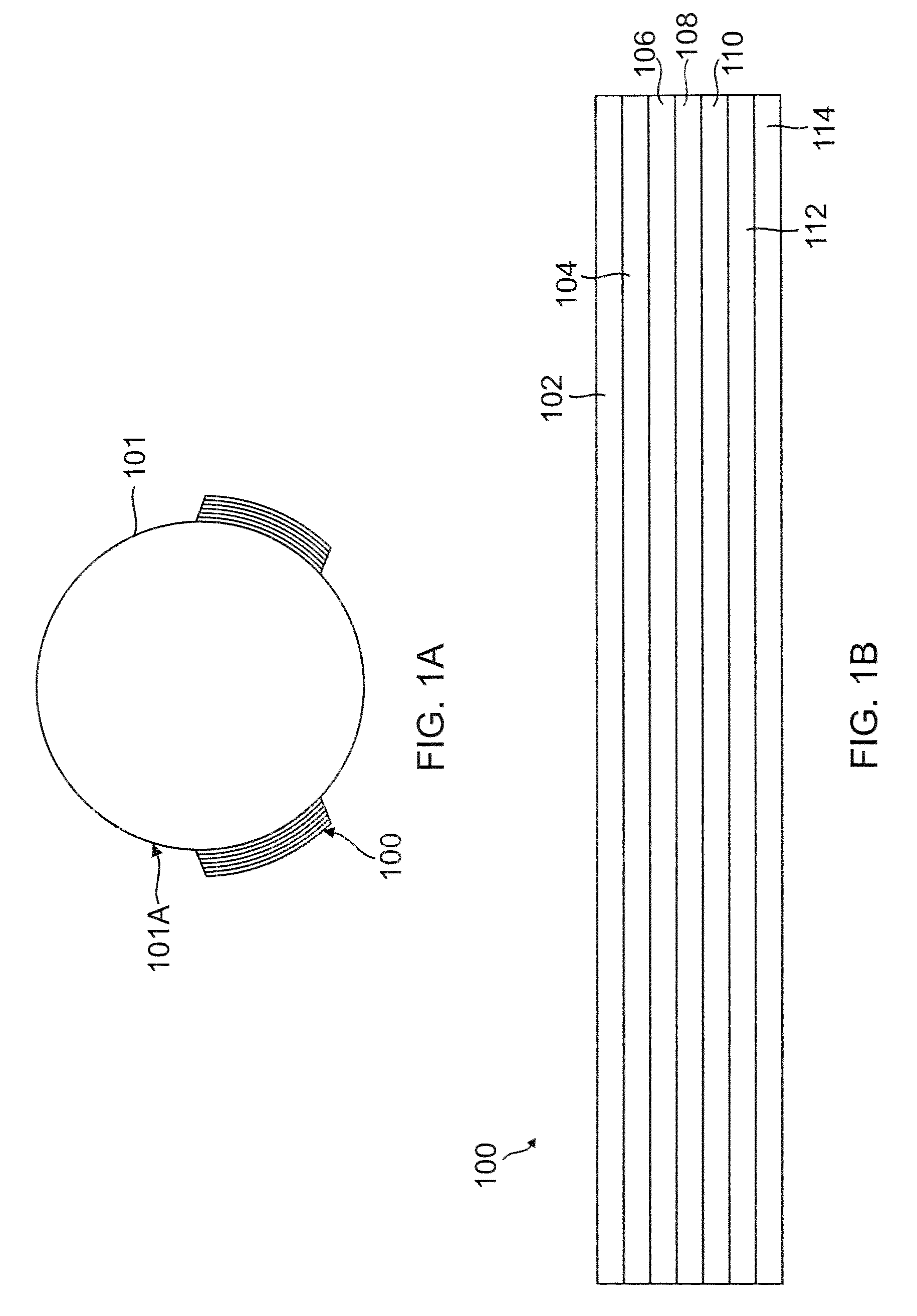

Flexible phased array antennas

InactiveUS20100177011A1Antenna adaptation in movable bodiesIndividually energised antenna arraysControl layerDielectric layer

A phased array antenna (PAA) is provided. The PAA includes a plurality of layers fabricated using an additive process such that the PAA conforms to a curvilinear surface. The plurality of layers include: a radiating layer placed on a first surface of a first dielectric layer; a feed layer operationally coupled to a second surface of the first dielectric layer; and a second dielectric layer having a first surface operationally coupled a power and control layer and a second surface operationally coupled to a ground layer. An adhesive layer operationally couples the feed layer to the power and control layer.

Owner:THE BOEING CO

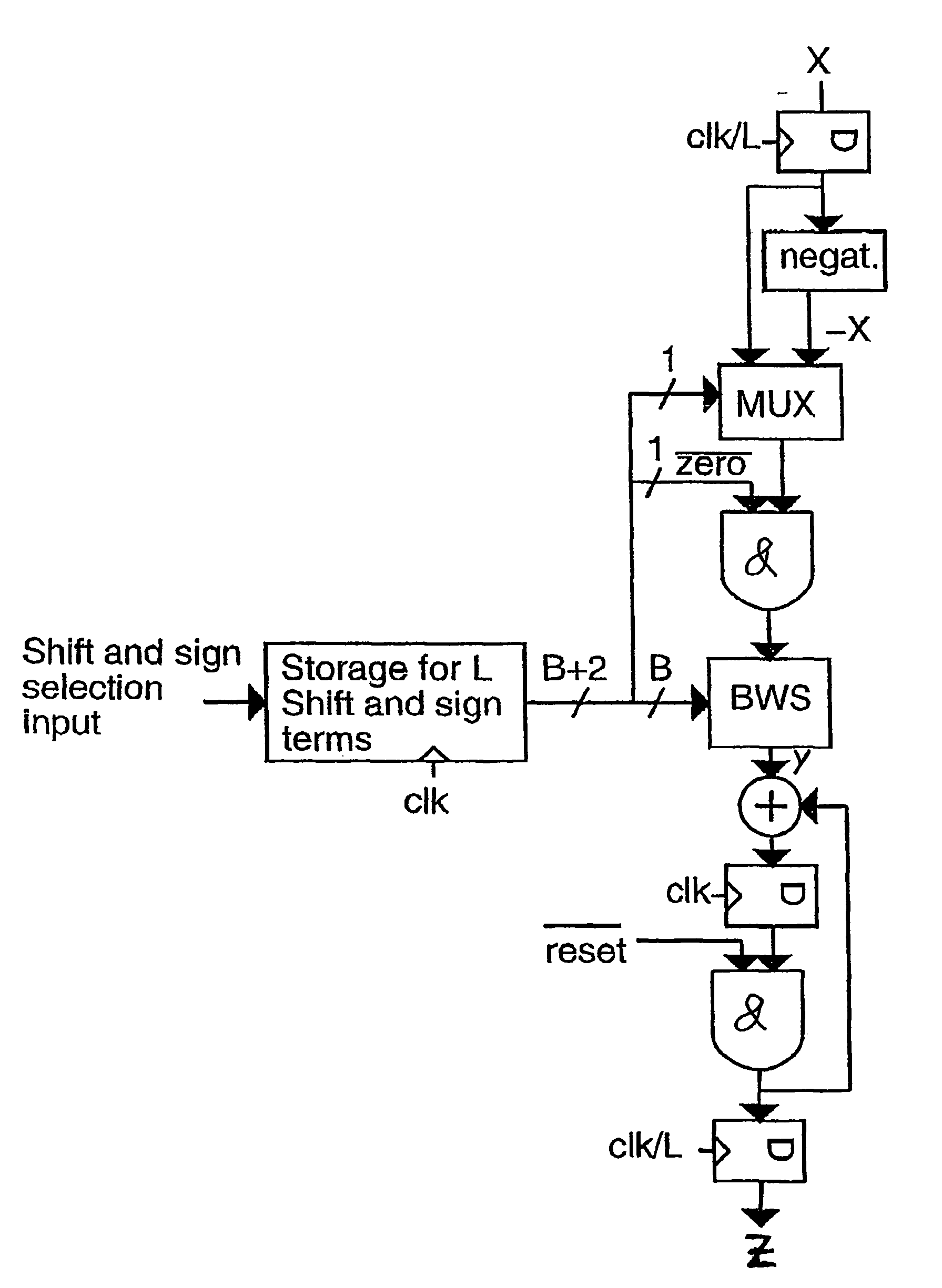

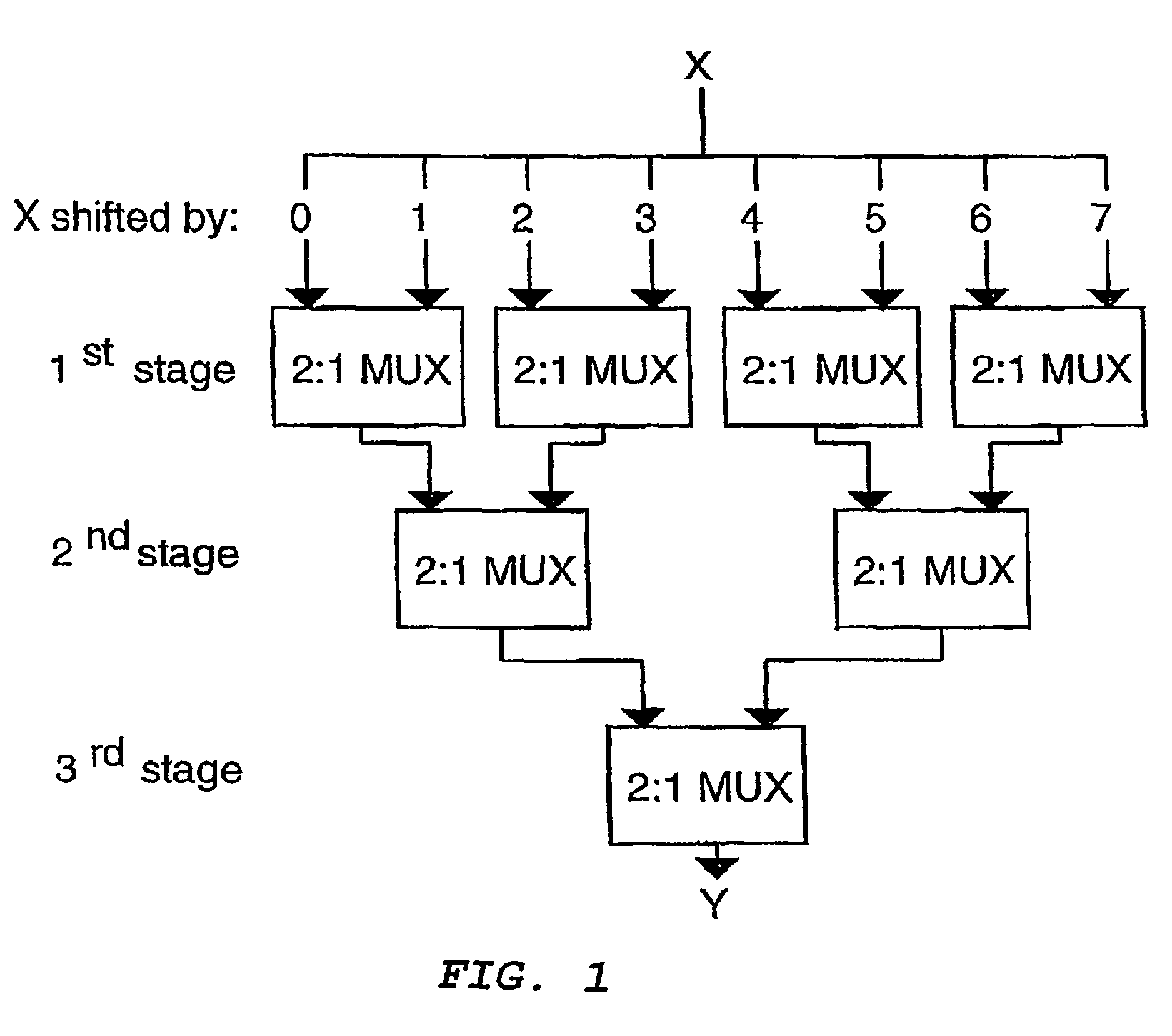

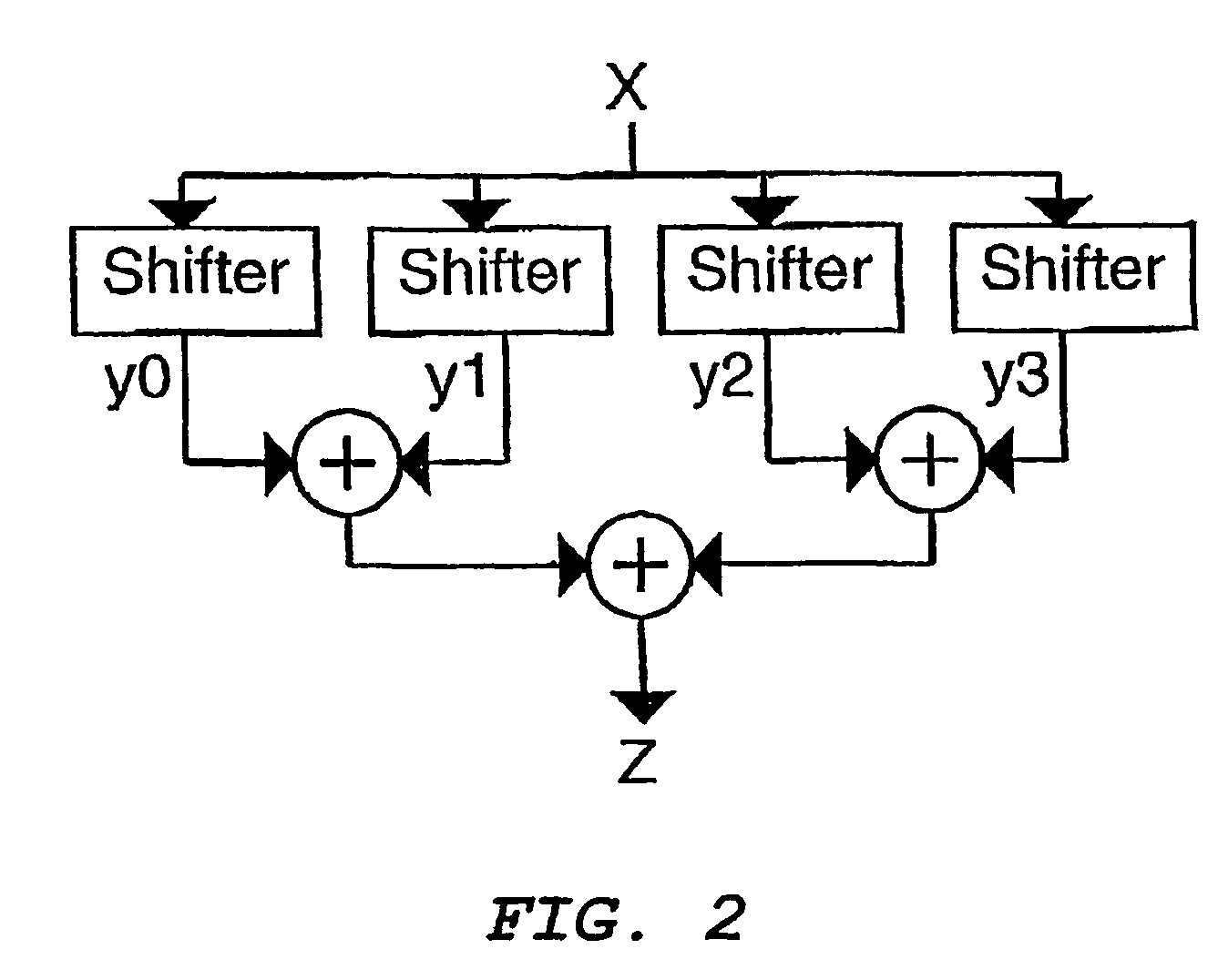

Multiplier and shift device using signed digit representation

InactiveUS7257609B1Consuming only a minimum area of semiconductor chip areaReduce in quantityComputation using non-contact making devicesDigital computer detailsFinite impulse responseSigned-digit representation

The present invention proposes a multiplier device performing multiplication of different powers of two serially in time (not in parallel) in order to further reduce the area needed for a hardware realization. By virtue thereof, it is enabled to use only one adder in connection with the multiplication which contributes to a reduced hardware amount and reduced required area for the hardware. A shifter means based on binary weighted shifting is used for shifting in connection with the multiplication, thereby reducing the required hardware amount (number of multiplexers and hardwired shifting elements) and thus reducing the area for hardware implementation still further. The present invention can be used in applications using digital multiplication, such as in digital signal processing DSP, digital filters and / or finite impulse response filters FIR filters as well as programmable and / or adaptive digital filters. As the multiplier is represented in CSD coding, the number of necessary shifting operations can be reduced and the number of necessary additions can be reduced, thus contributing to a reduced area needed for a hardware realization of a shifting means and a multiplier device on a silicon chip.

Owner:NOKIA SOLUTIONS & NETWORKS OY

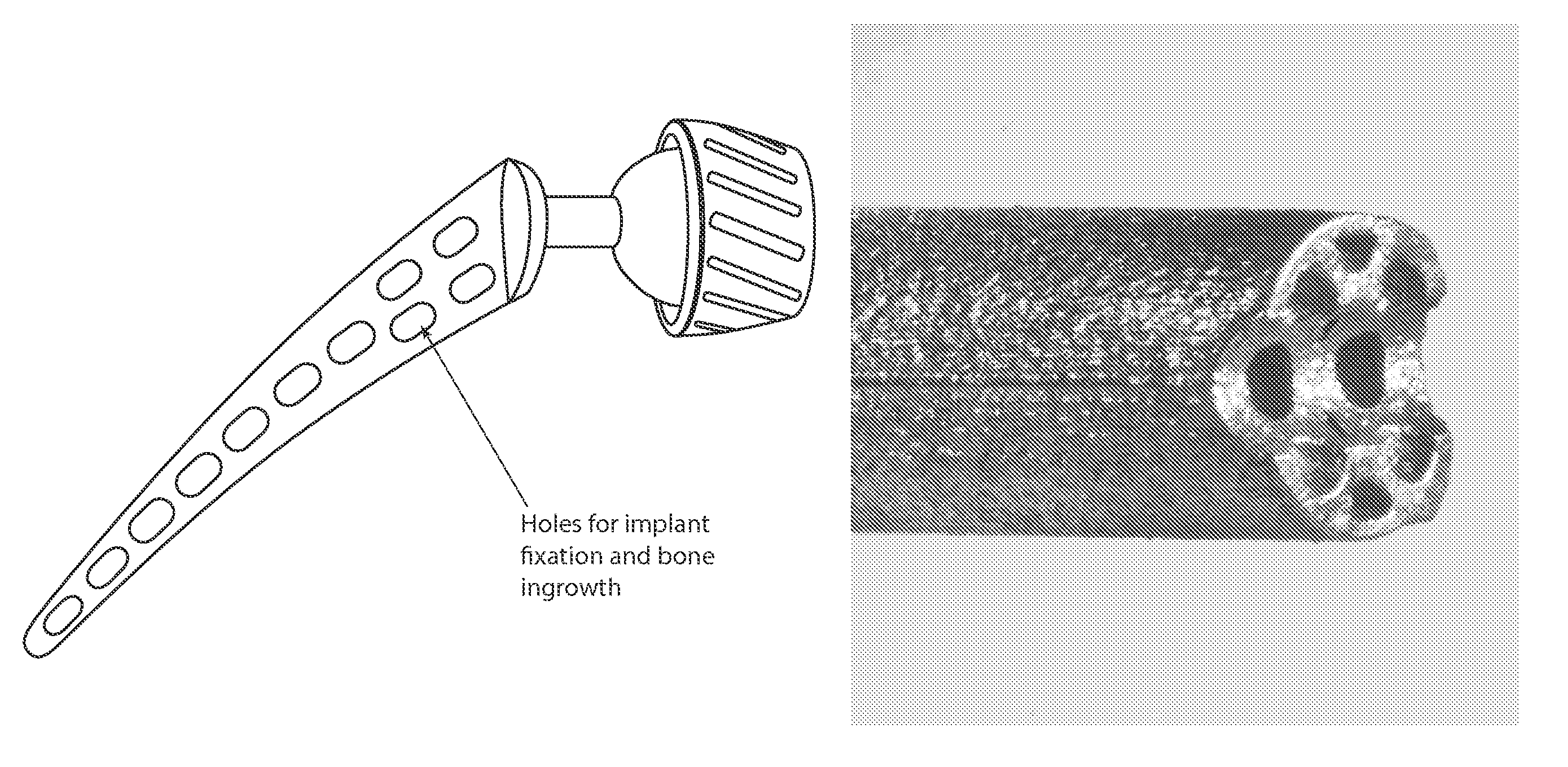

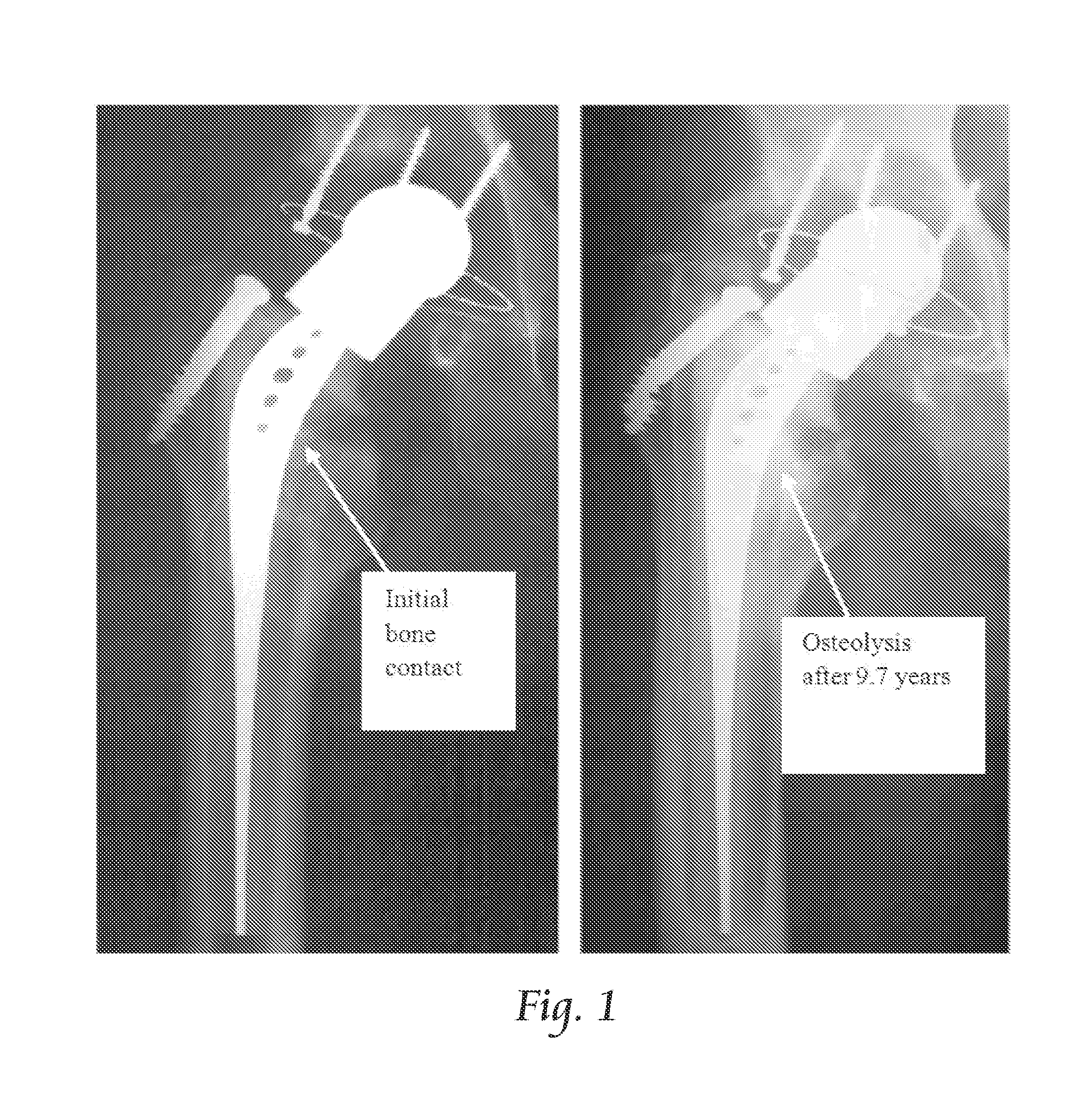

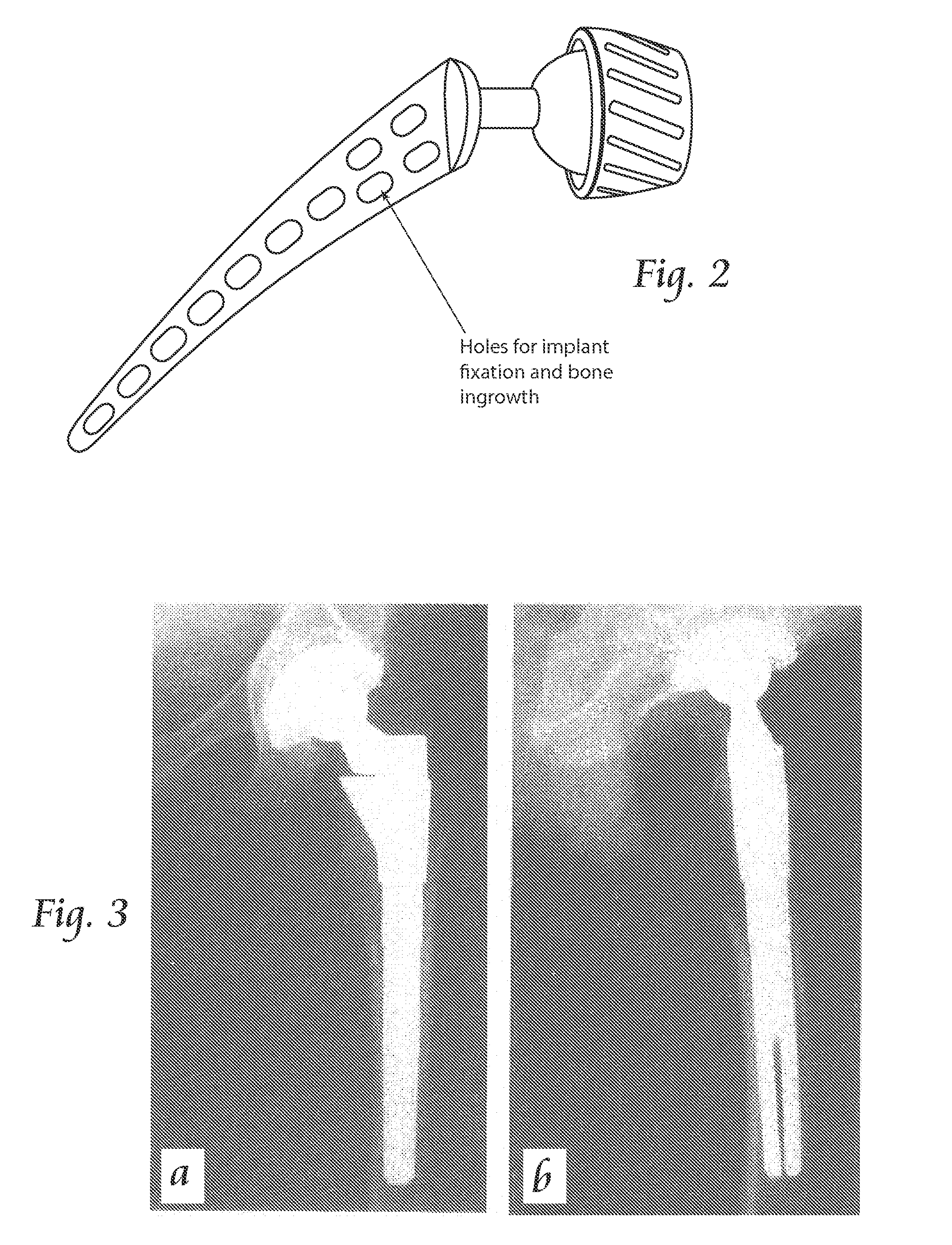

Orthopaedic implants and methods of forming implant structures

InactiveUS9034048B2Improve mechanical propertiesPrecise designJoint implantsFemoral headsMedicinePlastic surgery

Additive processes and novel implant designs provide precise pore design and positioning for clinically useful microstructures exhibiting the appropriate rigidity for orthopaedic implants.

Owner:CHOREN JOHN A

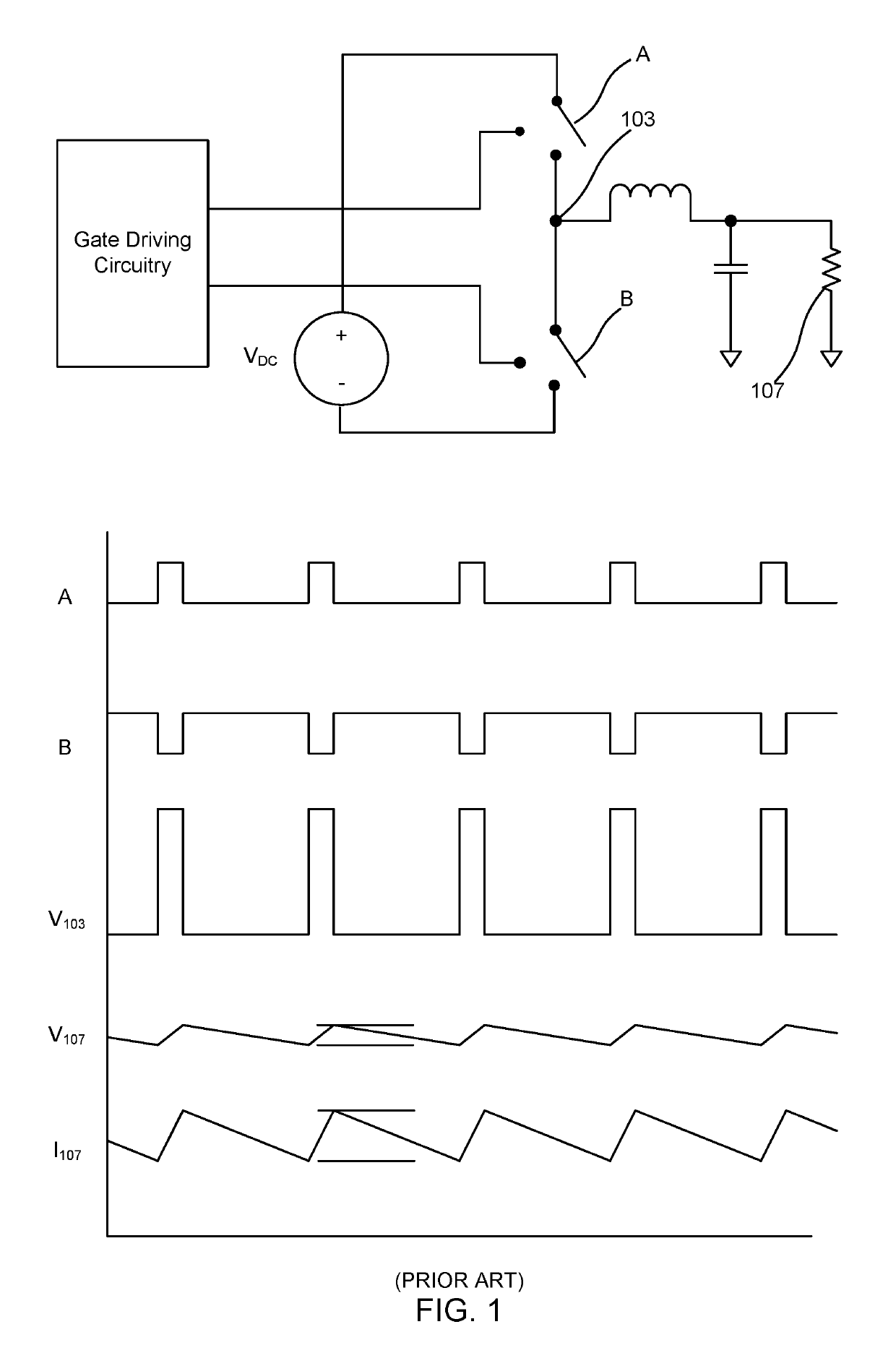

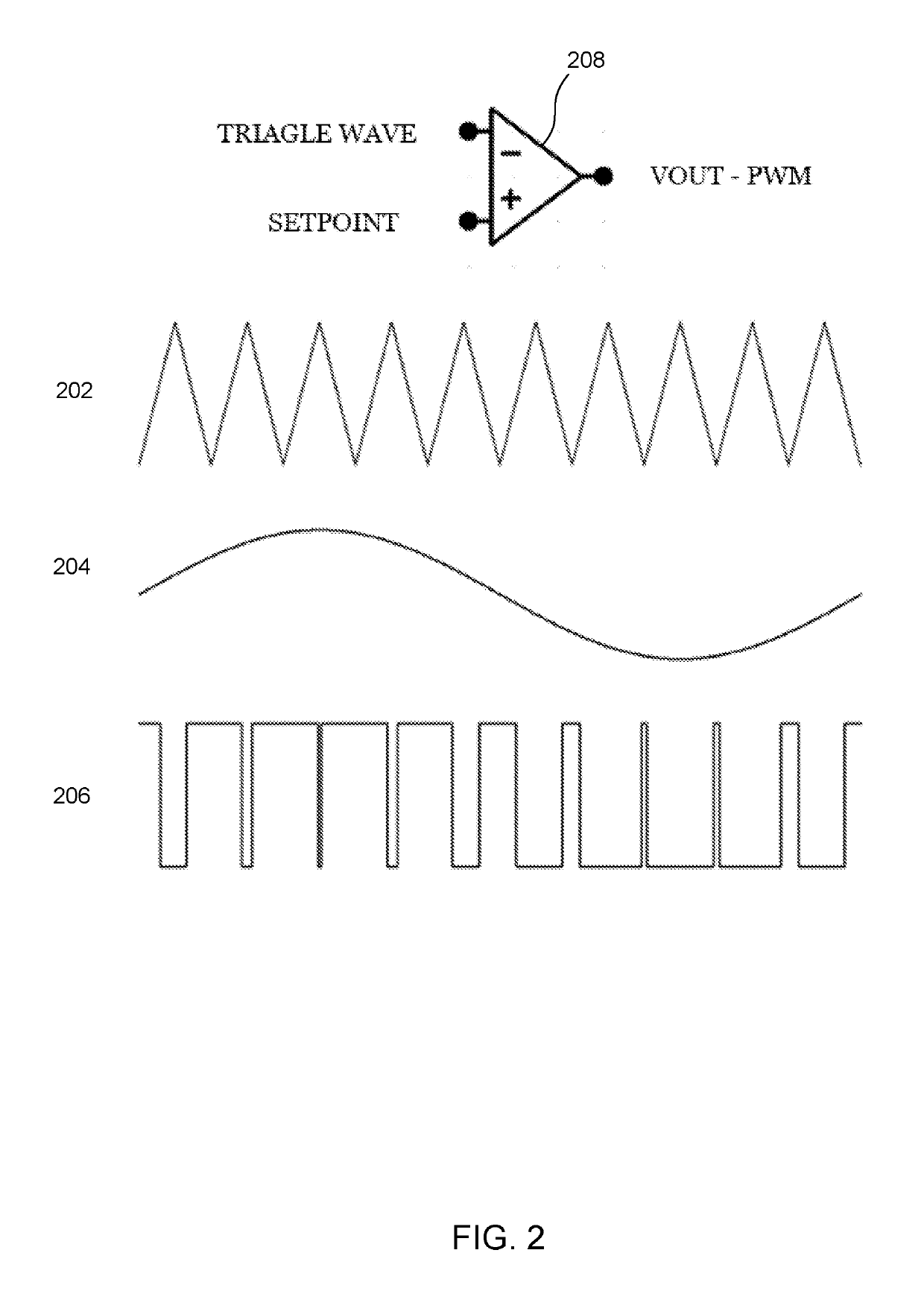

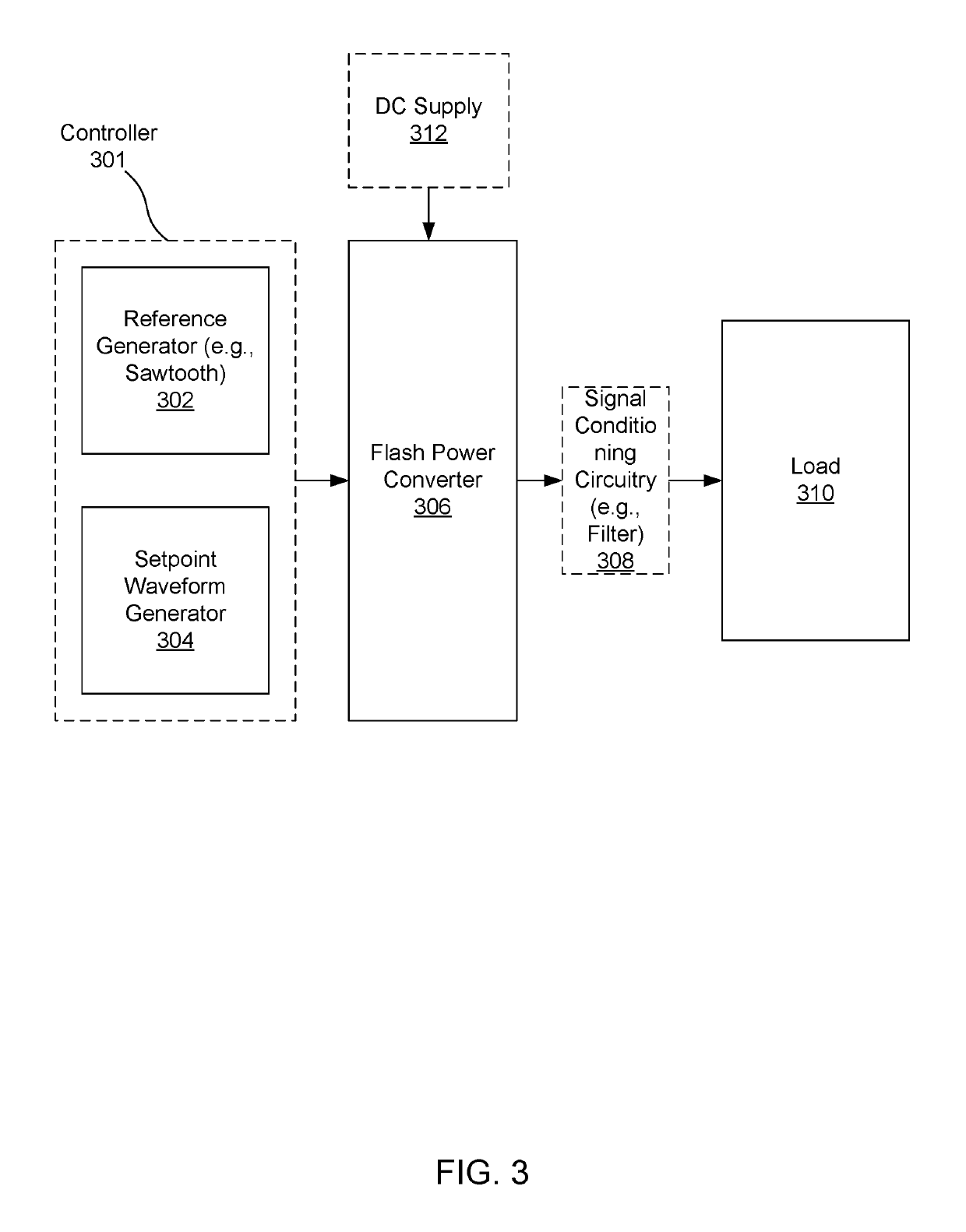

Additive synthesis of interleaved switch mode power stages for minimal delay in set point tracking

An apparatus utilizing additive interleaved switchmode (PWM) power conversion stages, having minimal or no output filter, to achieve high bandwidth or even ideally instantaneous power conversion. The additive process may involve voltage stacking of isolated PWM converters, which are interleaved in time, or may involve a single input power supply and inductively combining output currents of PWM power converters interleaved in time, with either additive circuit having minimal or no output filtering. This circuit may overcome limitations for the frequency of feedback control loops once thought to be physical limitations, such as, fundamental switching frequency, output filter delay and the Nyquist criteria.

Owner:ADVANCED ENERGY IND INC

Solid-state imaging device and method for driving the same

InactiveUS20060132634A1Television system detailsTelevision system scanning detailsEngineeringPhotoelectric conversion

A solid-state imaging device includes a pixel array in which a plurality of pixel cells, each of which includes a plurality of photoelectric conversion elements, is arranged, and an adder for performing an addition operation on a plurality of signals output from the photoelectric conversion elements of the pixel array in a predetermined combination of the photoelectric conversion elements, while setting between the signals to be added a ratio determined according to the arrangement of the photoelectric conversion elements.

Owner:SONY CORP

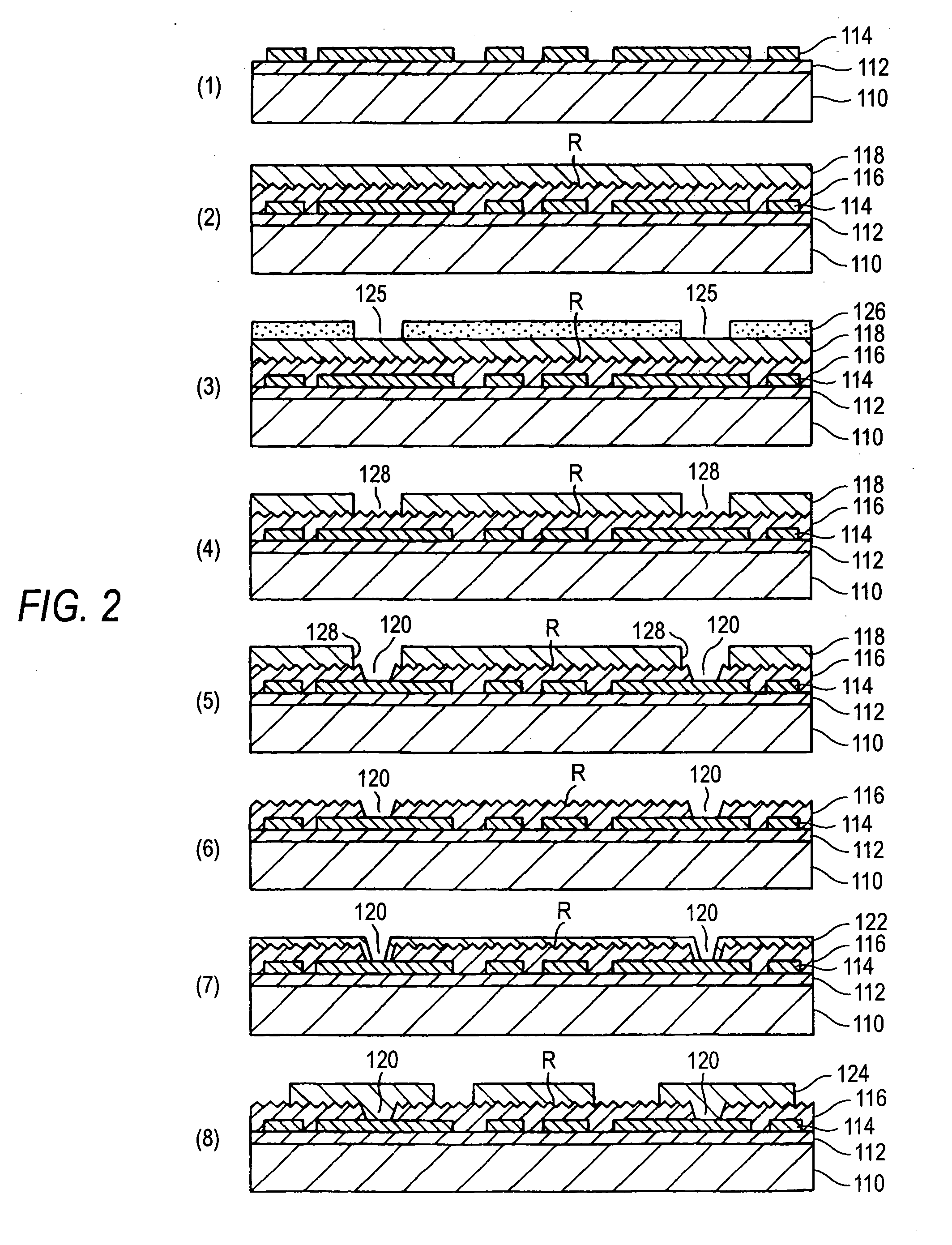

Manufacturing method of novel printed circuit board

ActiveCN101790288AAvoid the problem of low binding forceImprove routing densityPrinted element electric connection formationElectrical conductorInterconnection

The invention relates to a manufacturing method of a novel printed circuit board, which can form fine circuits and laminated interconnection based on the improved semi-additive process and the process of pore filling under pattern plating. The specific steps of the method are as follows: a) preparing a dielectric layer and laminating a conductive layer on the dielectric layer, thereby forming a substrate of a composite structure with the dielectric layer and the conductive layer; b) manufacturing conduction blind holes on the dielectric layer and the conductive layer; c) carrying out conduction treatment for the conductive layer and the walls of the conduction blind holes, thereby forming a seed layer; d) adhering a light-sensitive film to the surface of the substrate and forming a plated blocking layer on the substrate through pattern transfer; e) plating the substrate with the plated blocking layer, forming a conductor pattern, and filling the conduction blind holes through plating, thereby forming a solid conductive pole; f) removing the plated blocking layer; g) removing the exposed seed layer and the conductive layer below the seed layer, and reserving the conductor pattern and circuits formed through plating, thereby forming a circuit board; and h) repeating the steps from Step a) to Step g) on the circuit board, so as to realize the multi-layer superposition.

Owner:SHANGHAI MEADVILLE SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com