Patents

Literature

109results about How to "Meet size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SAPMAC method for preparing sapphire single-crystal with size above 300mm

ActiveCN101580963AHigh purityReduce defect densityPolycrystalline material growthBy pulling from meltSingle crystalLarge size

The invention provides a SAPMAC method for preparing sapphire single-crystal with size above 300mm. In a 300mm sapphire single-crystal growing furnace, technical processes of charging as well as melting material, seeding, shouldering, isometric growing, pulling out, cooling, annealing and discharging are finished. On the basis of the existing SAPMAC method, the invention is greatly improved, so that the SAPMAC method of the invention has the advantages of larger size of crystal, higher quality, more reasonable size, higher utilization rate of material, lower unit production cost and the like, and can produce sapphire single-crystal with the size above Phi320*260mm, high purity, low defect density and favorable optical performance; in addition, the SAPMAC method of the invention can better satisfy demand of sapphire single-crystal with large size and high quality by national defense and military industry field as well as civil field, and reduces defect occurrence probability by controlling seeding structure; meanwhile, the SAPMAC method of the invention controls crystal shoulder structure, decreases shoulder stress and lowers possibility of crystal cleavage by changing pulling speed and cooling rate.

Owner:HARBIN AURORA OPTOELECTRONICS TECH

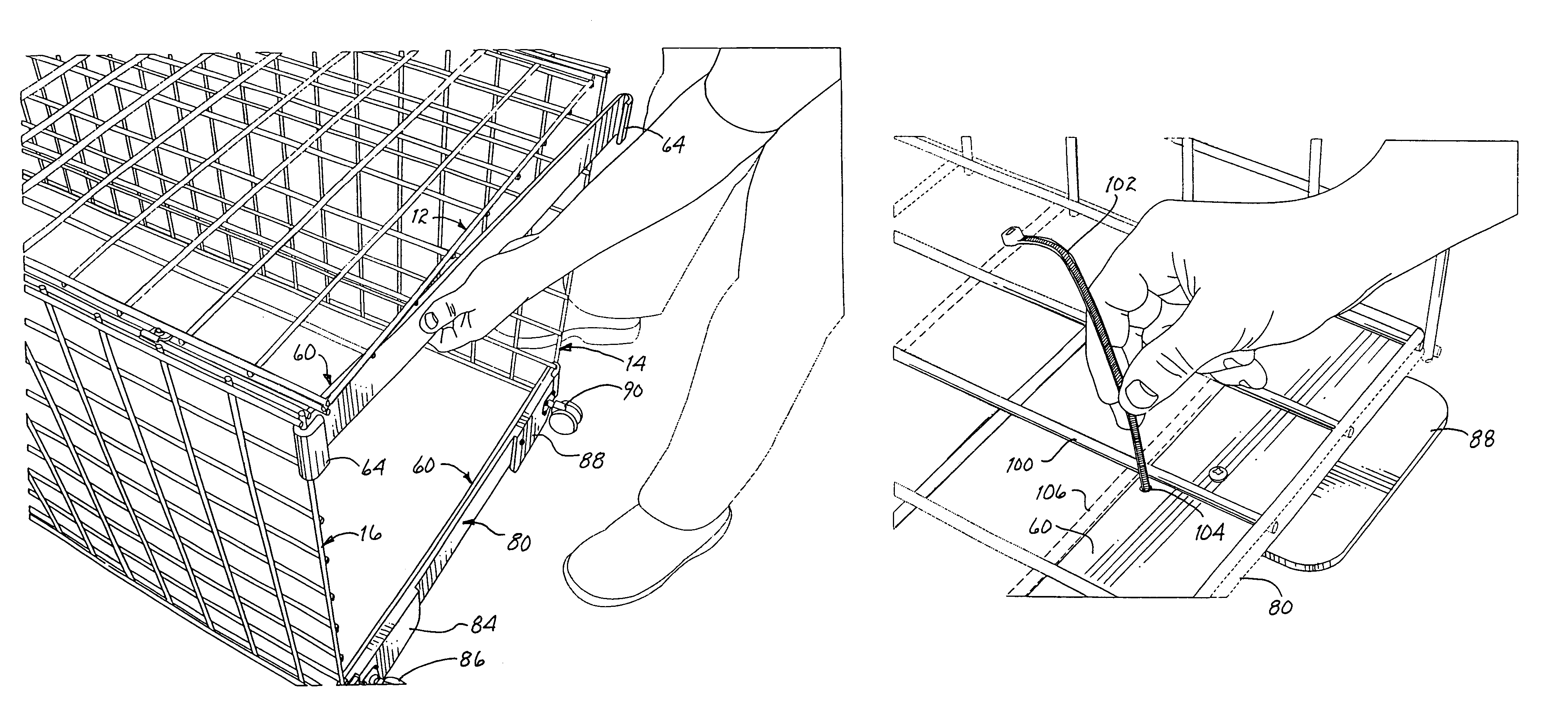

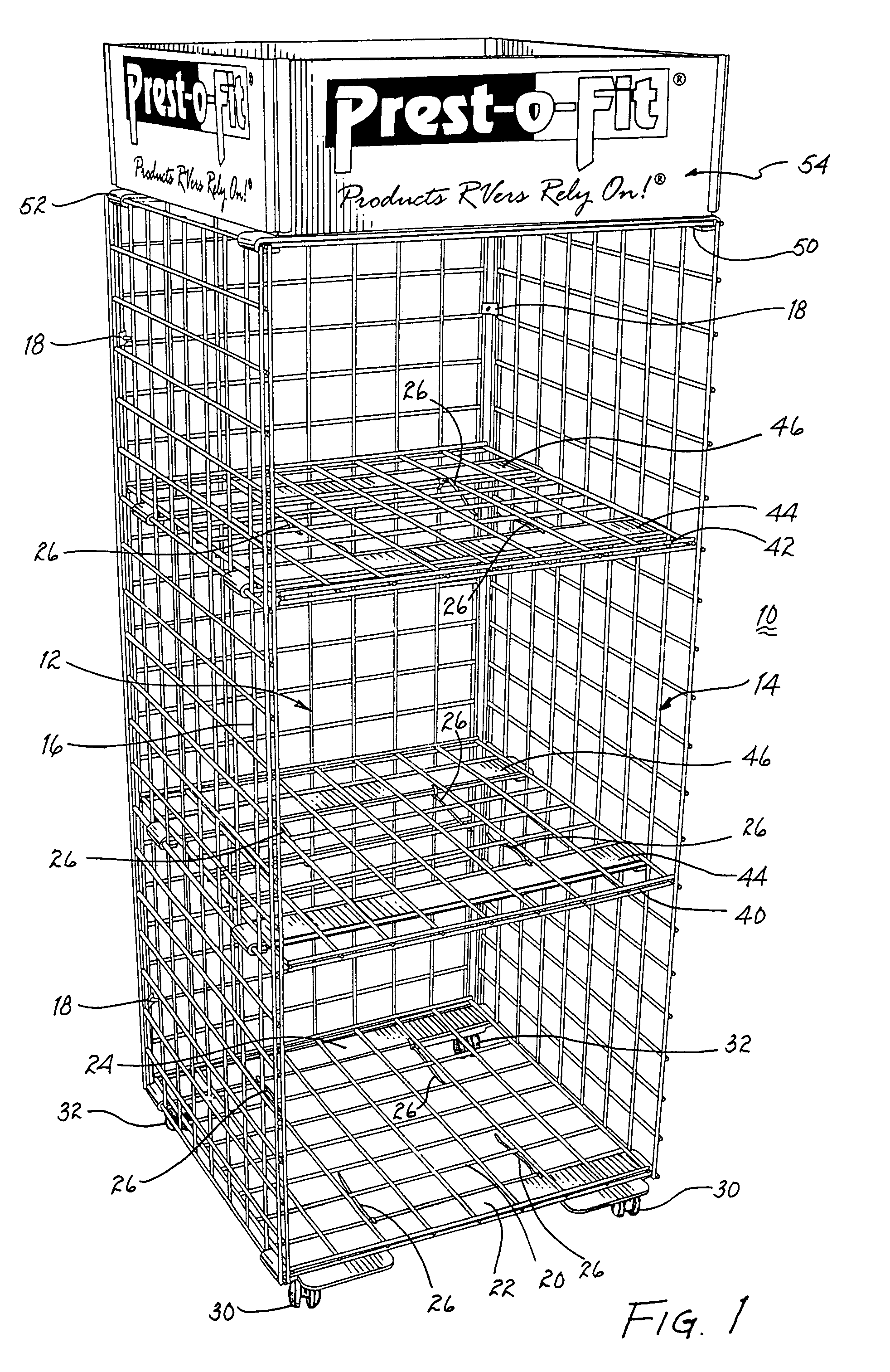

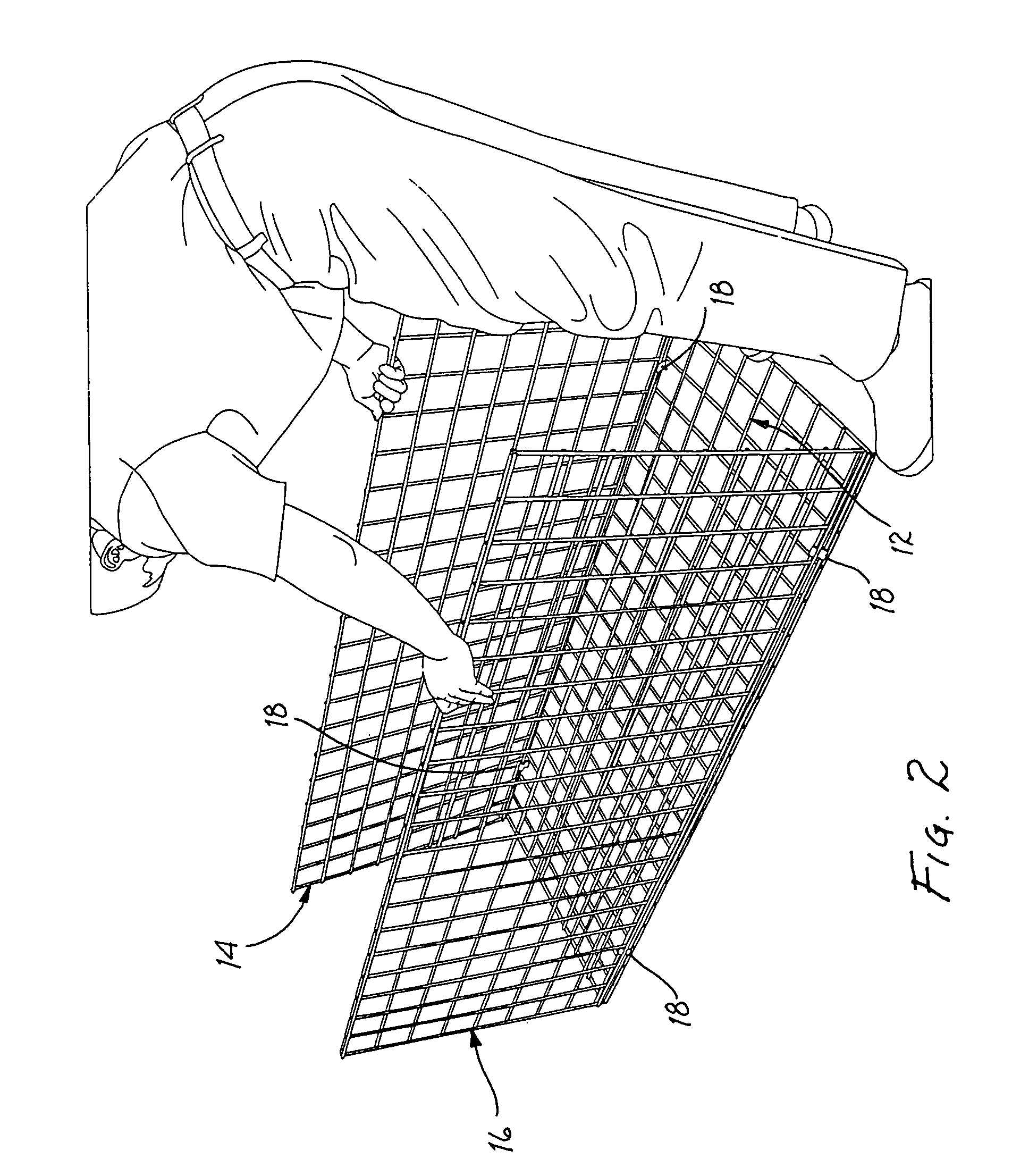

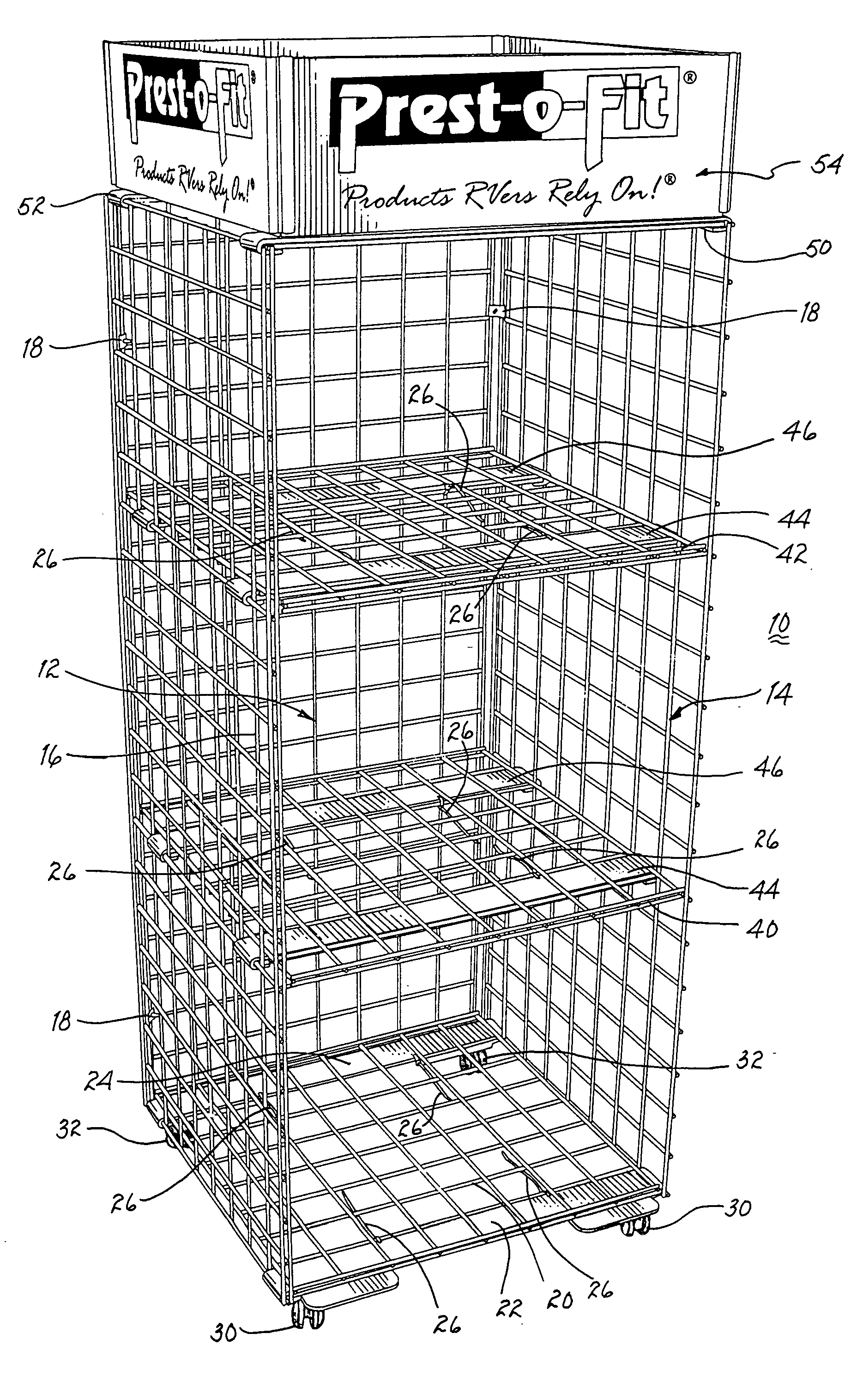

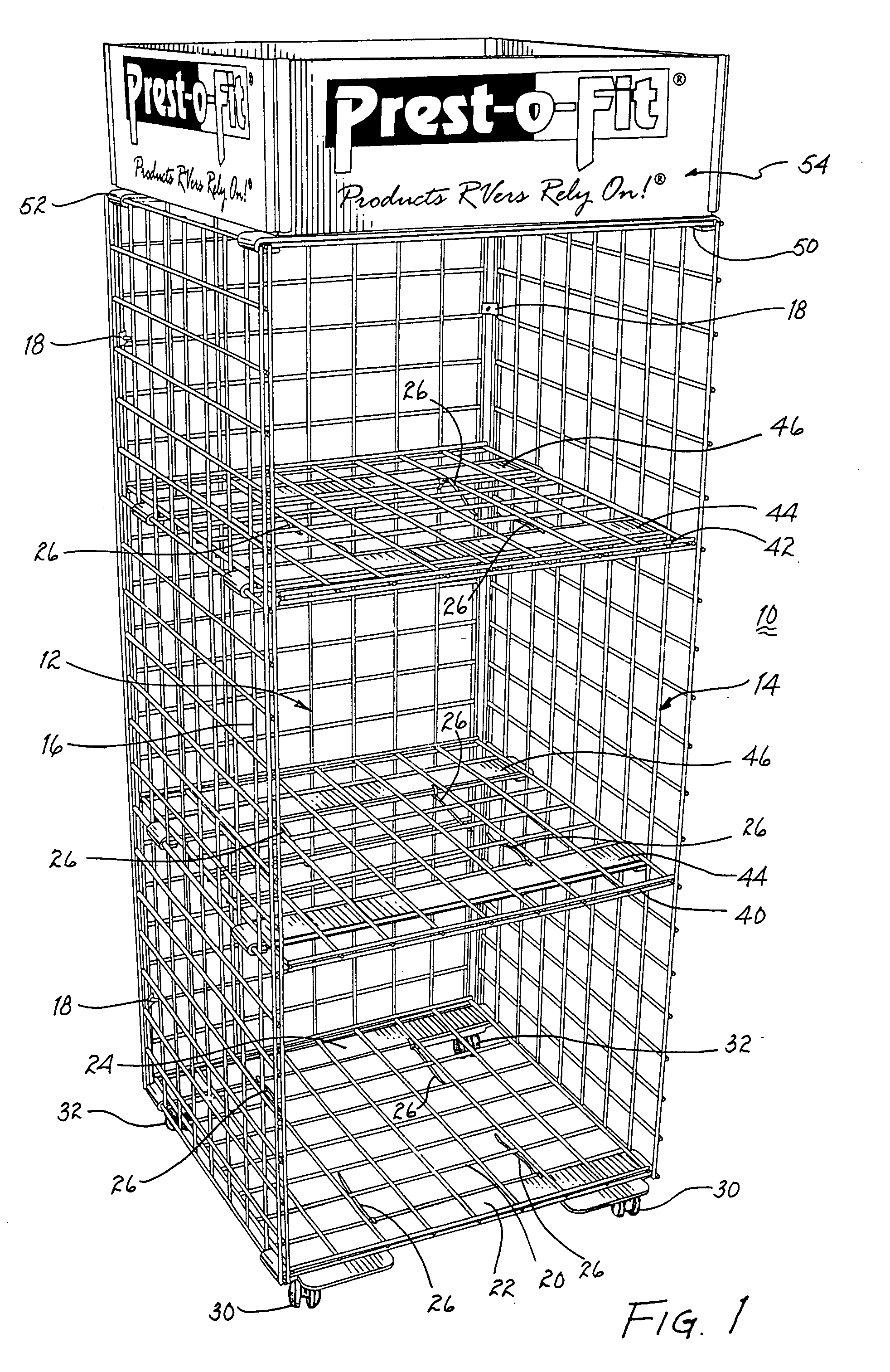

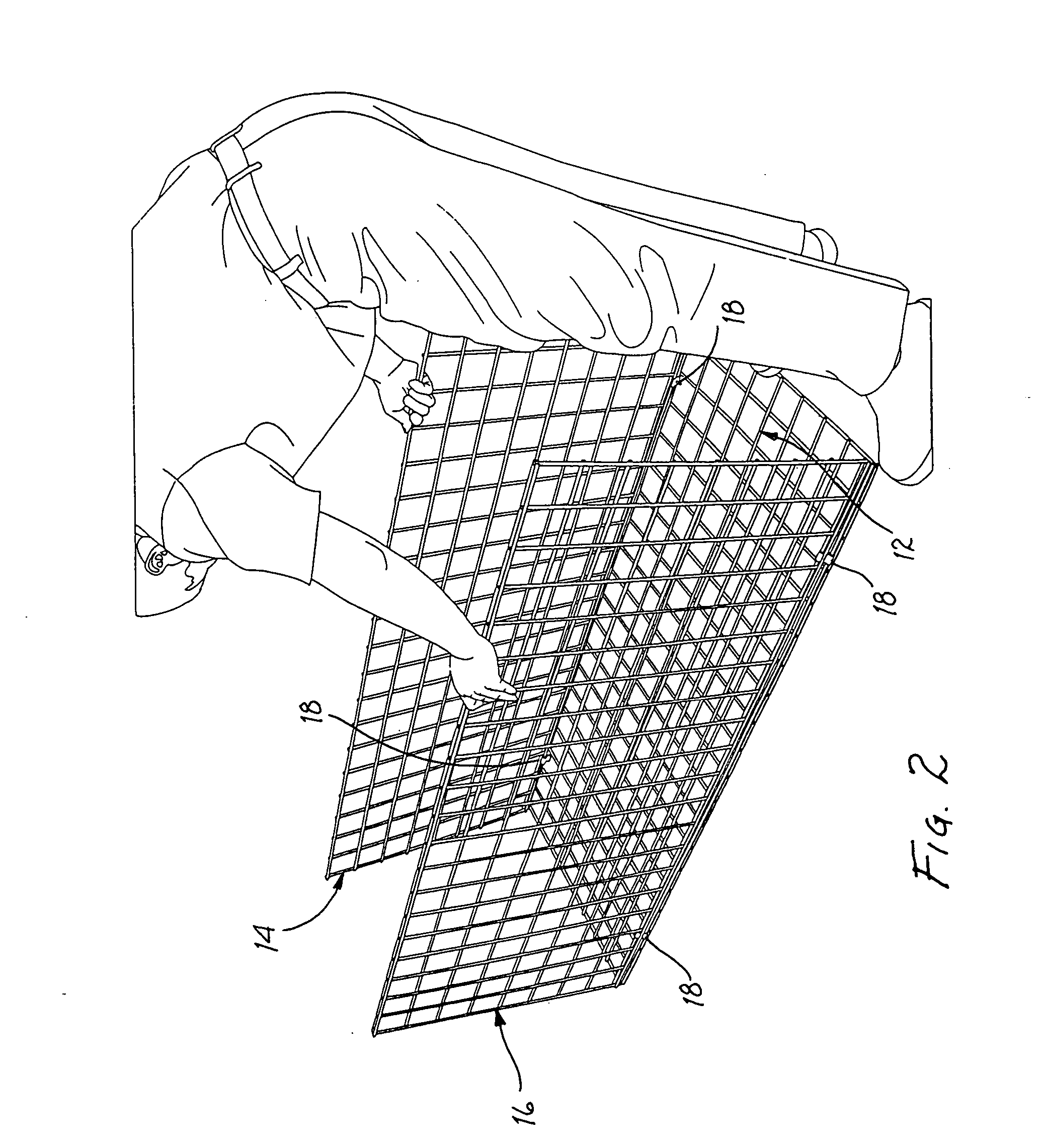

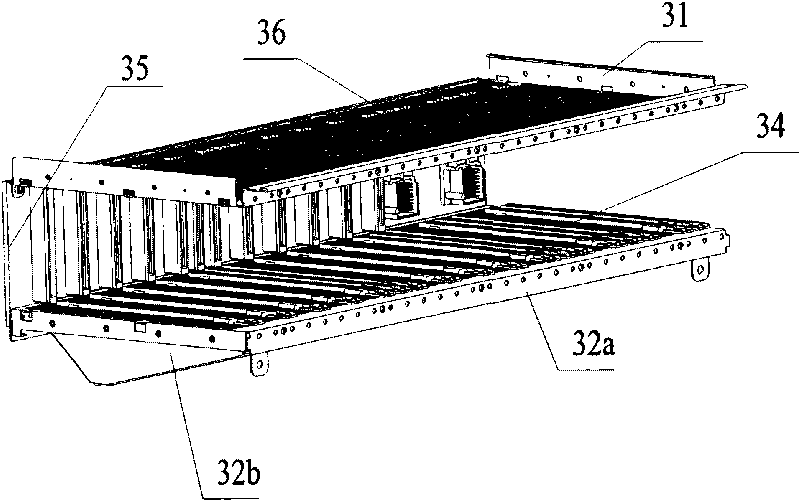

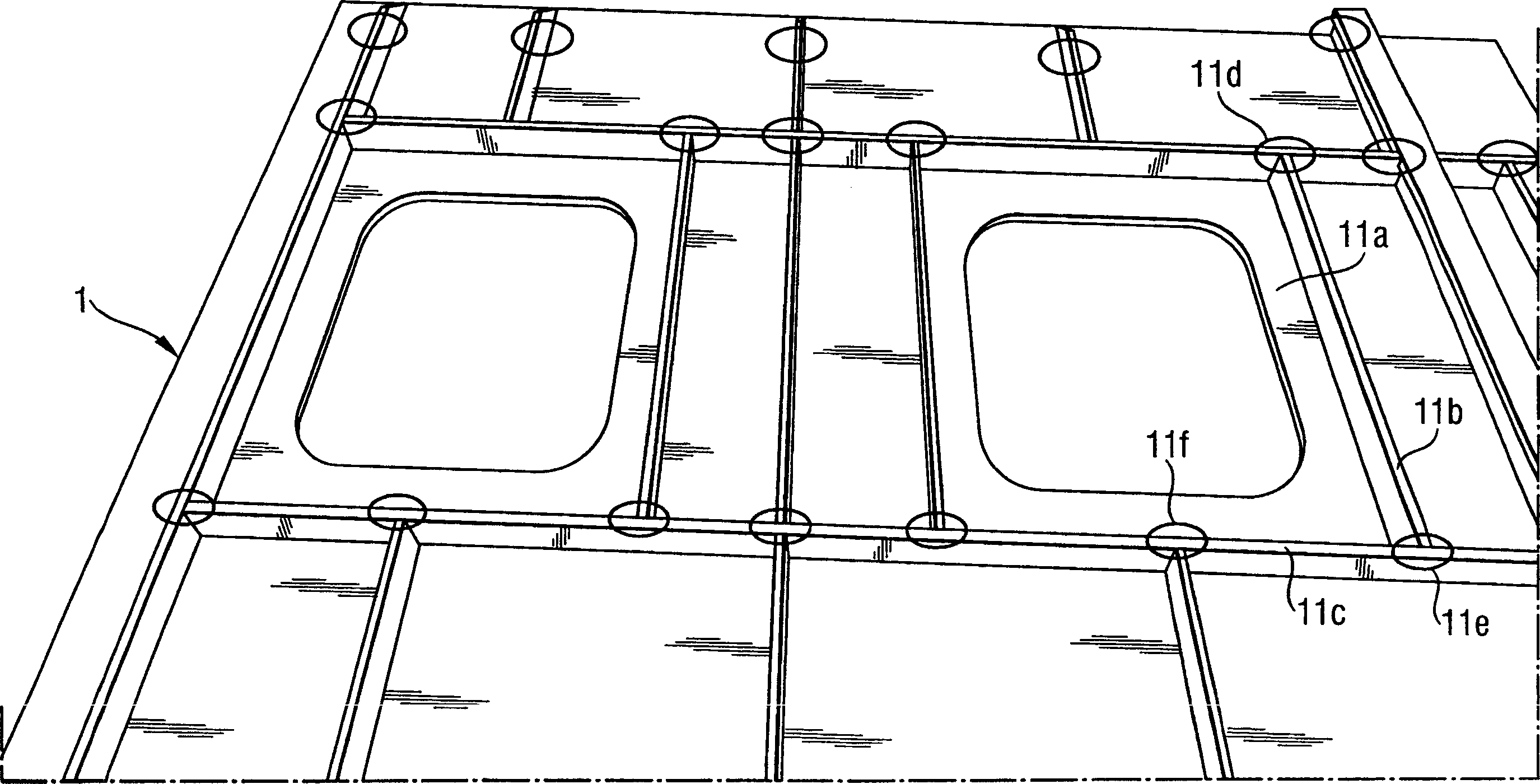

Rapidly assembleable and disassembleable display rack

InactiveUS7611020B2Readily and compactly placed within containerEasily disassembleableFolding cabinetsDismountable cabinetsEngineeringSurface plate

Owner:PREST J DAVID

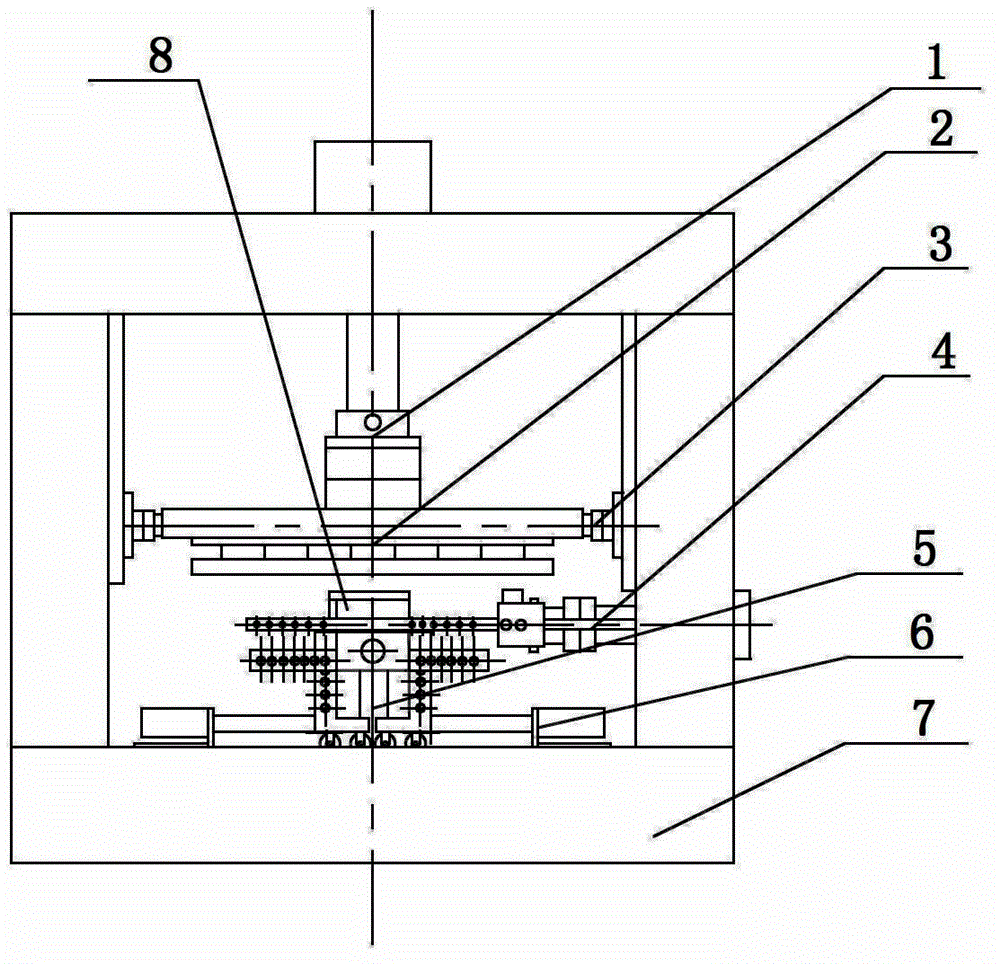

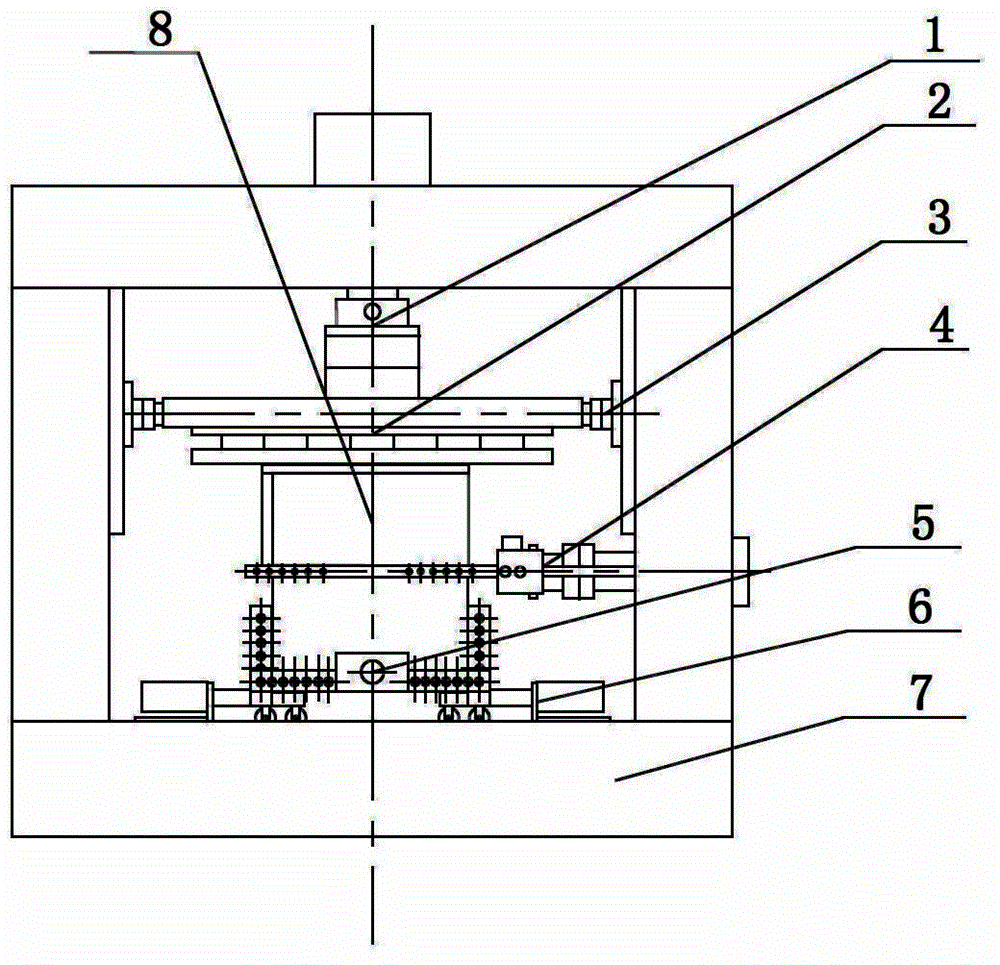

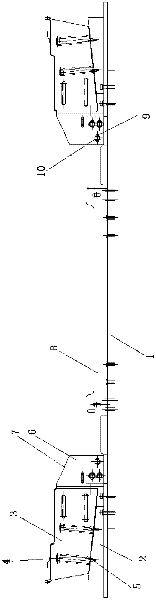

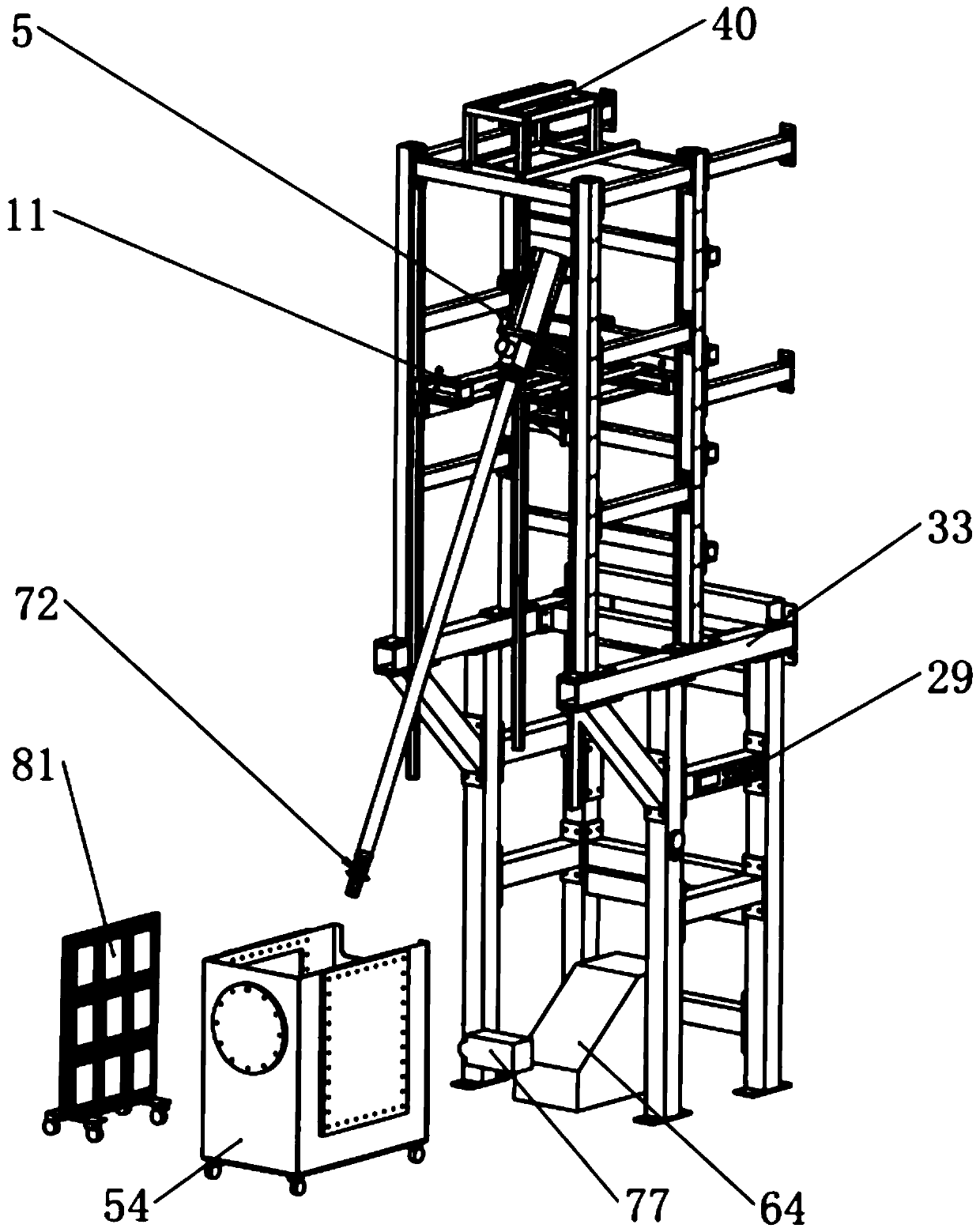

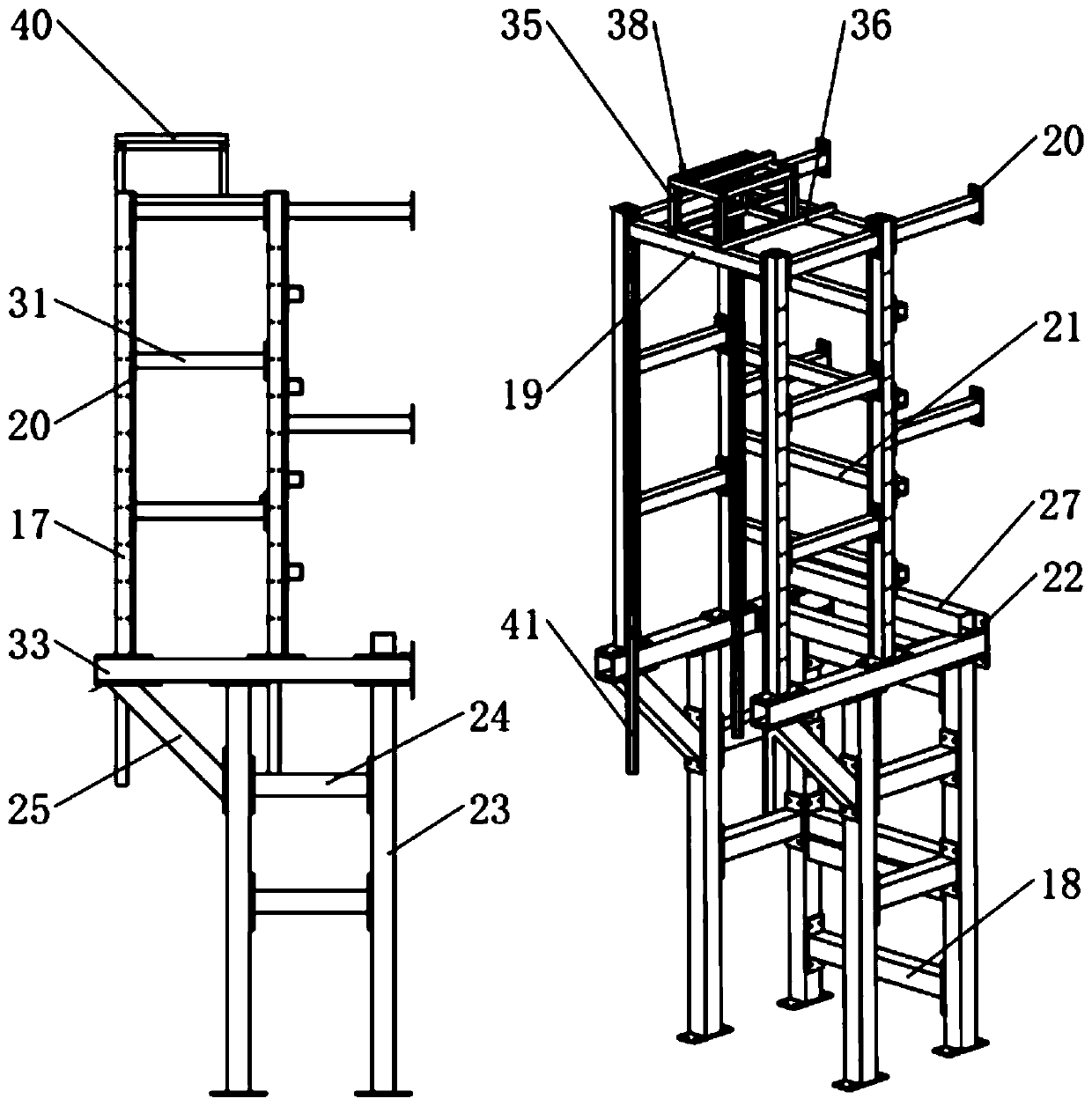

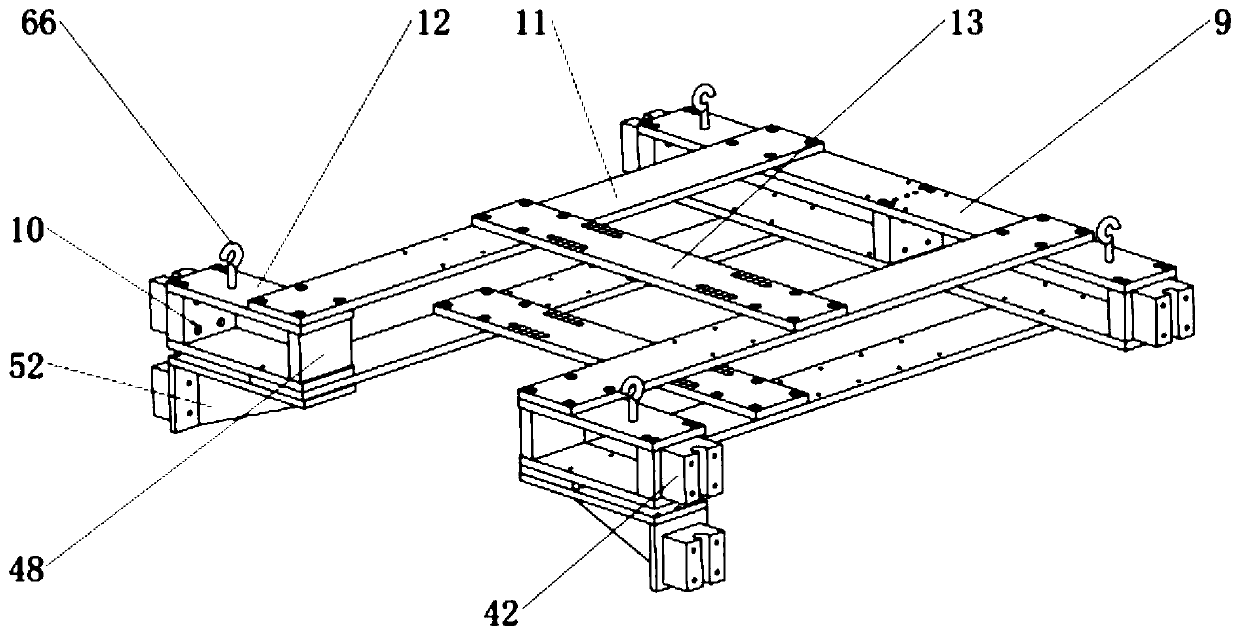

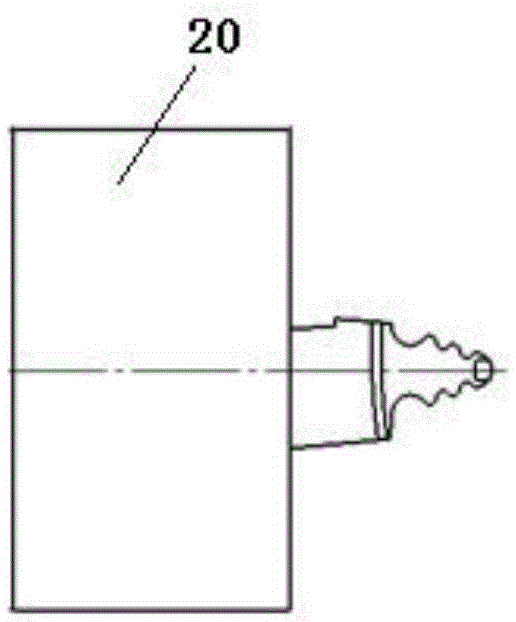

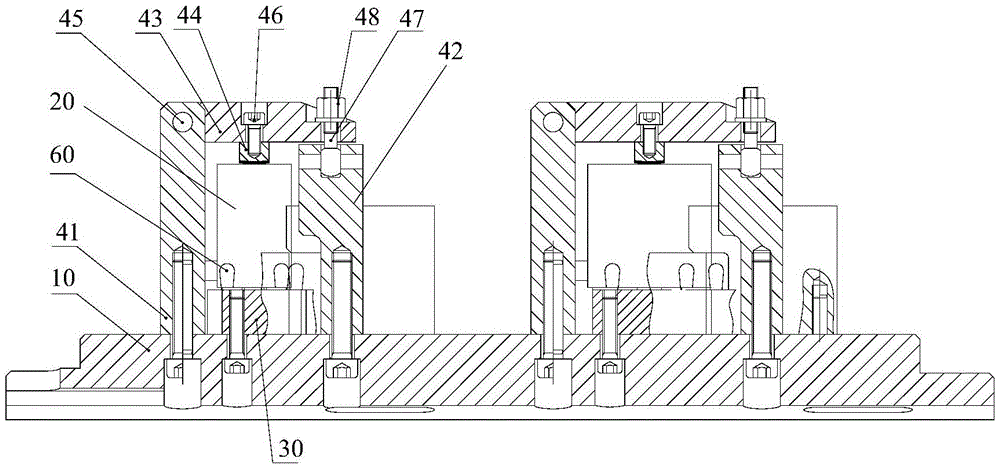

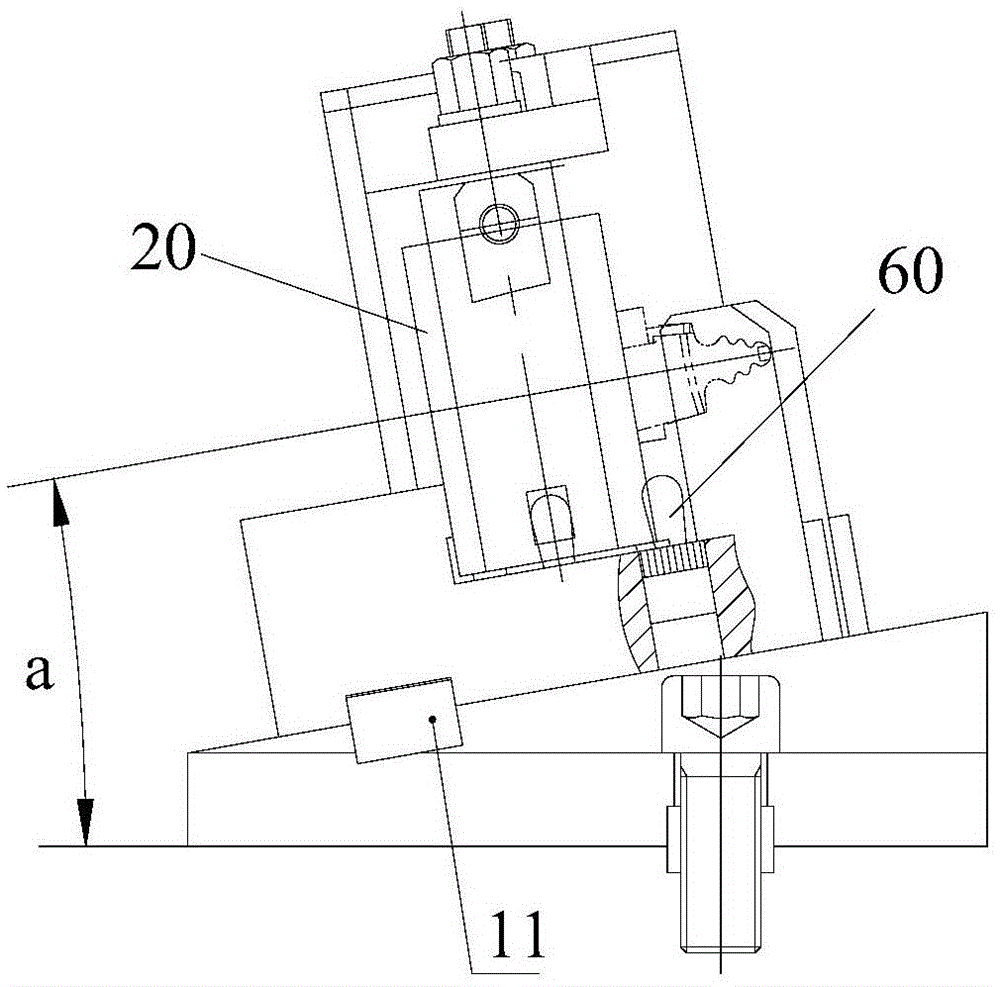

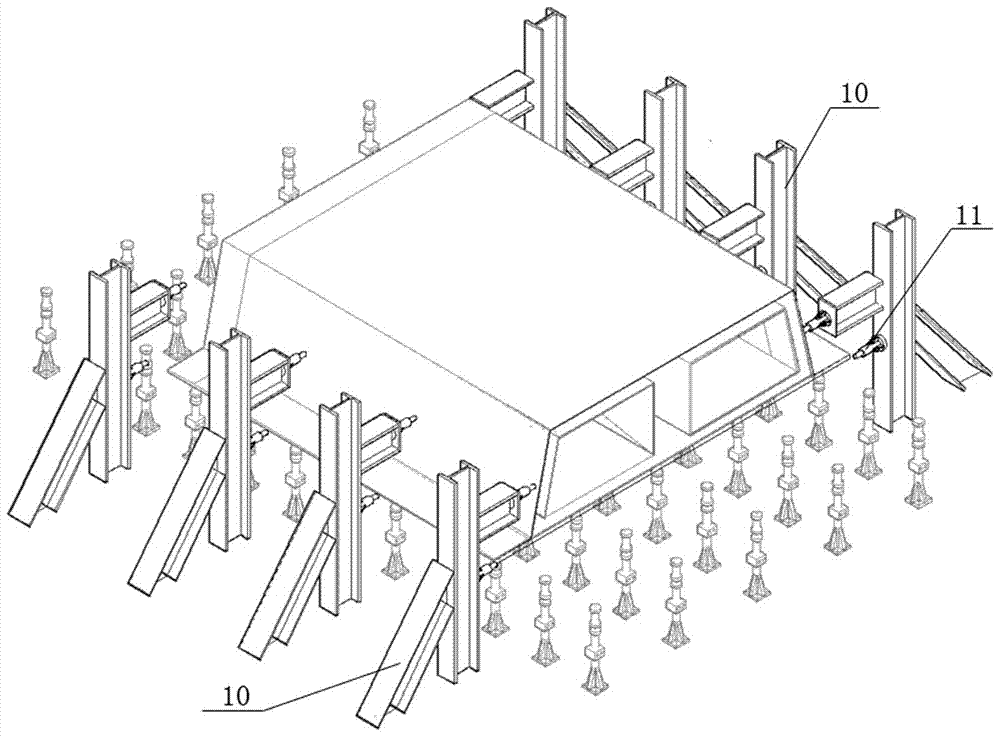

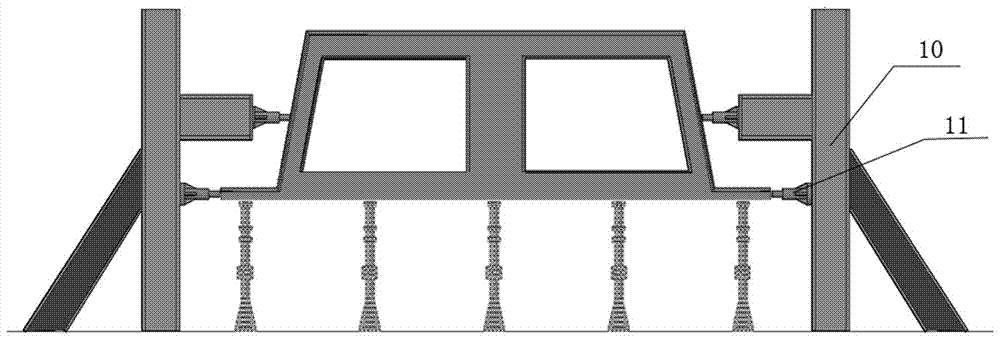

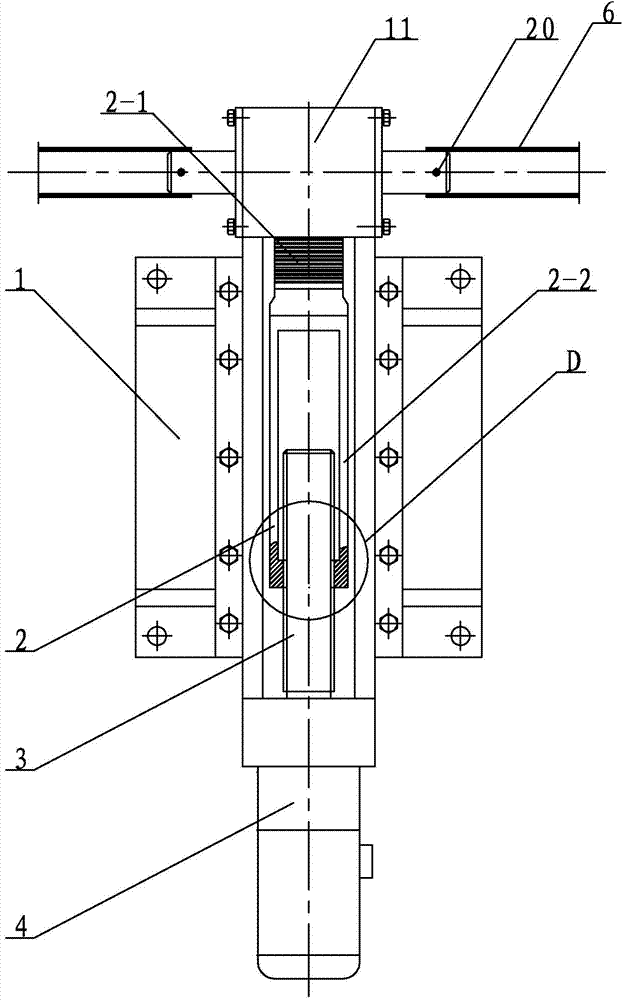

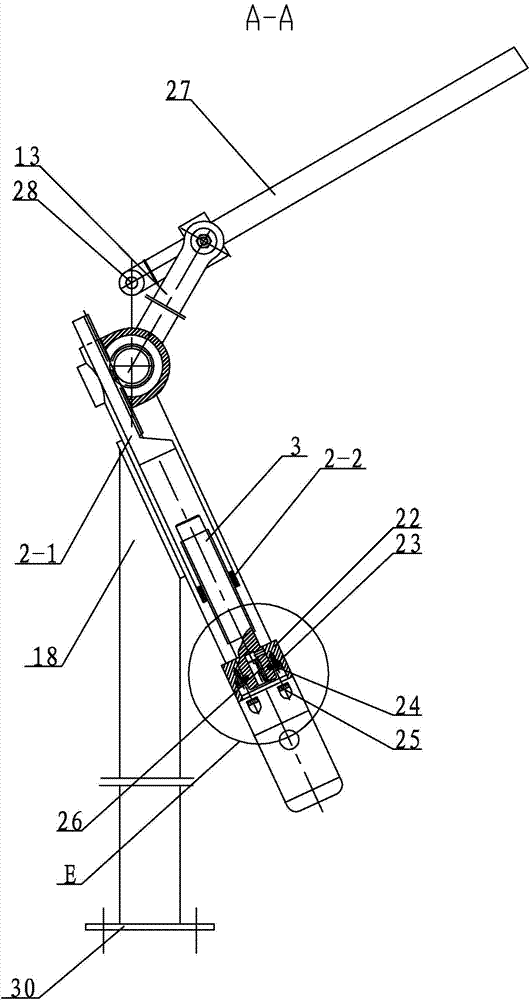

Multi-scale rock direct shear apparatus

ActiveCN103335895AAdaptableFunction increaseMaterial strength using steady shearing forcesTest sampleEngineering

The invention provides a multi-scale rock direct shear apparatus. The multi-scale rock direct shear apparatus comprises a framework, a vertical loading mechanism, a loading and moving mechanism, a transverse load supporting mechanism, a shearing and loading mechanism, a test sample height adjusting mechanism and a lower test sample restraining mechanism, wherein the vertical loading mechanism is connected with the upper end of the loading and moving mechanism; the two sides of the loading and moving mechanism are respectively connected with the transverse load supporting mechanism; the test sample height adjusting mechanism is located below the loading and moving mechanism, and a detection station for placing a test sample to be detected is arranged between the test sample height adjusting mechanism and the loading and moving mechanism; the lower test sample restraining mechanism is connected below the test sample height adjusting mechanism; the side edge of the detection station is provided with the shearing and loading mechanism; the vertical loading mechanism is mounted at the upper part of the framework; the transverse load supporting mechanism is mounted at the upper middle part of the framework; the shearing and loading mechanism is mounted at the lower middle part of the framework; the lower test sample restraining mechanism is mounted at the lower part of the framework. The invention provides the multi-scale rock direct shear apparatus which effectively meets a large-span load and the testing of the size of the test sample, and has good reliability.

Owner:SHAOXING UNIVERSITY

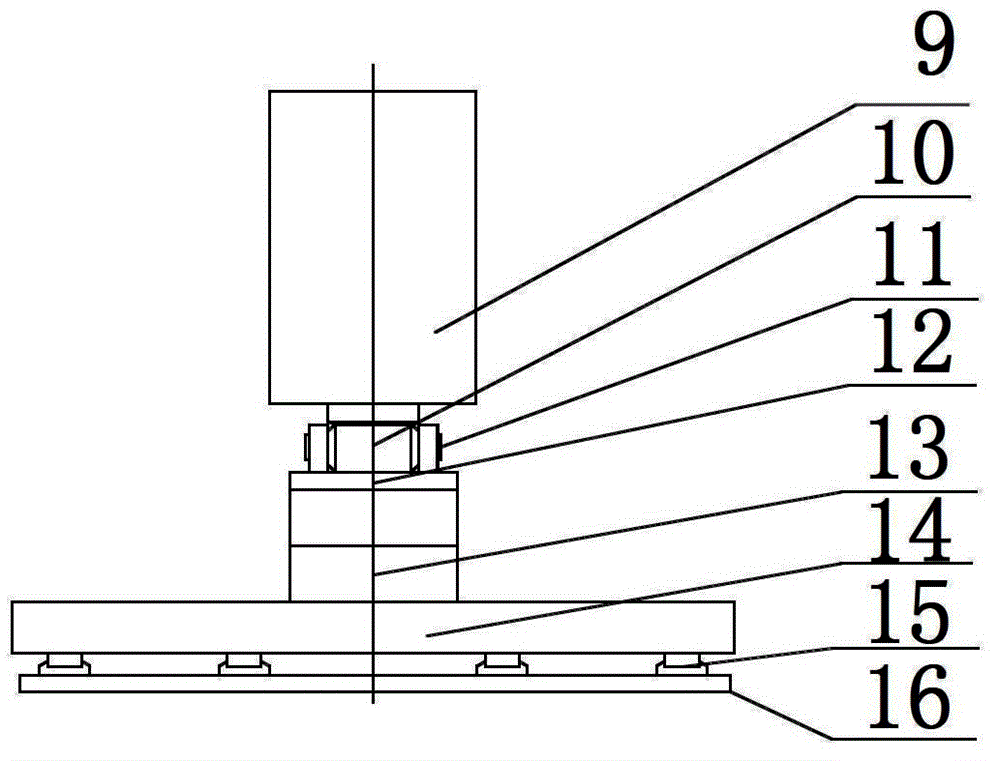

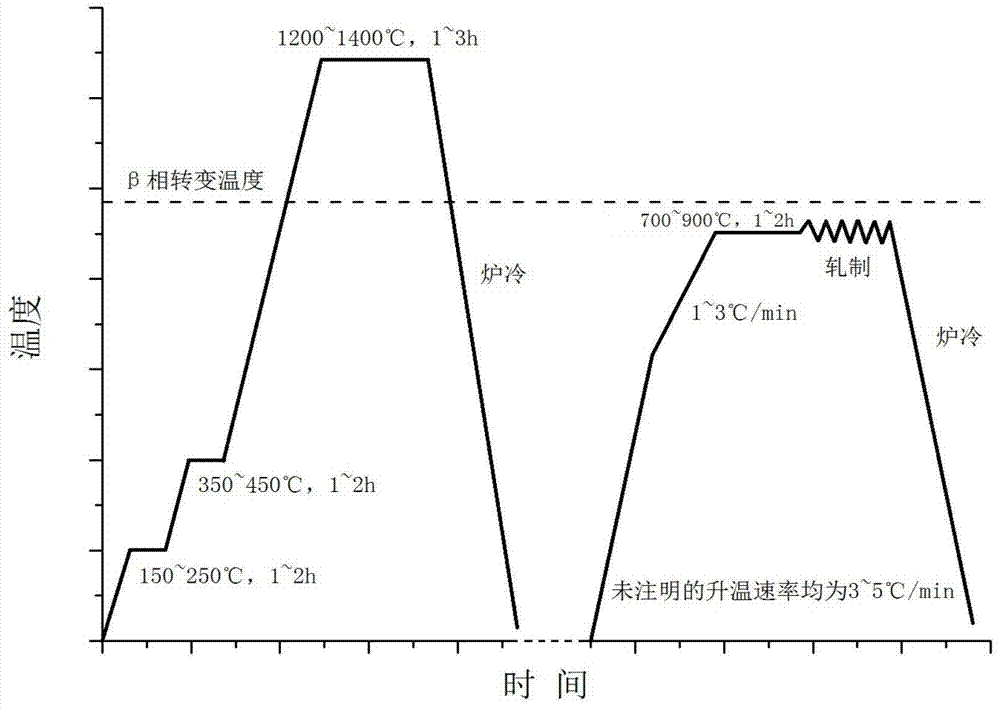

Method for preparing powder metallurgy titanium alloy bar

ActiveCN104263981AThe process steps are simpleShorten the production cycleDiameter ratioTitanium alloy

The invention discloses a method for preparing a powder metallurgy titanium alloy bar. The method comprises the following steps: by taking Ti powder and alloy element powder as raw materials, sufficiently and uniformly mixing the Ti powder and the alloy element powder, and putting the mixed powder into an isostatic cool pressing sleeve for isostatic cool pressing treatment, thereby preparing a crude bar blank; performing vacuum sintering on the prepared crude bar blank, and performing furnace cooling, thereby preparing a sintered bar blank; and performing low-temperature thermoplastic deformation treatment on the prepared sintered bar blank, thereby obtaining the powder metallurgy titanium alloy bar with a large height-diameter ratio, wherein the alloy element powder comprises one or more of Al, V, Mo, Fe, Mn, Zr and intermediate alloy powder of the above elements, and the mass ratio of the alloy element powder is controlled to be within 15%. The method disclosed by the invention is low in cost, small in investment and good in product property, and the powder metallurgy titanium alloy bar can be used for manufacturing high-performance fasteners.

Owner:FUJIAN LONGXI BEARING (GROUP) CO LTD +1

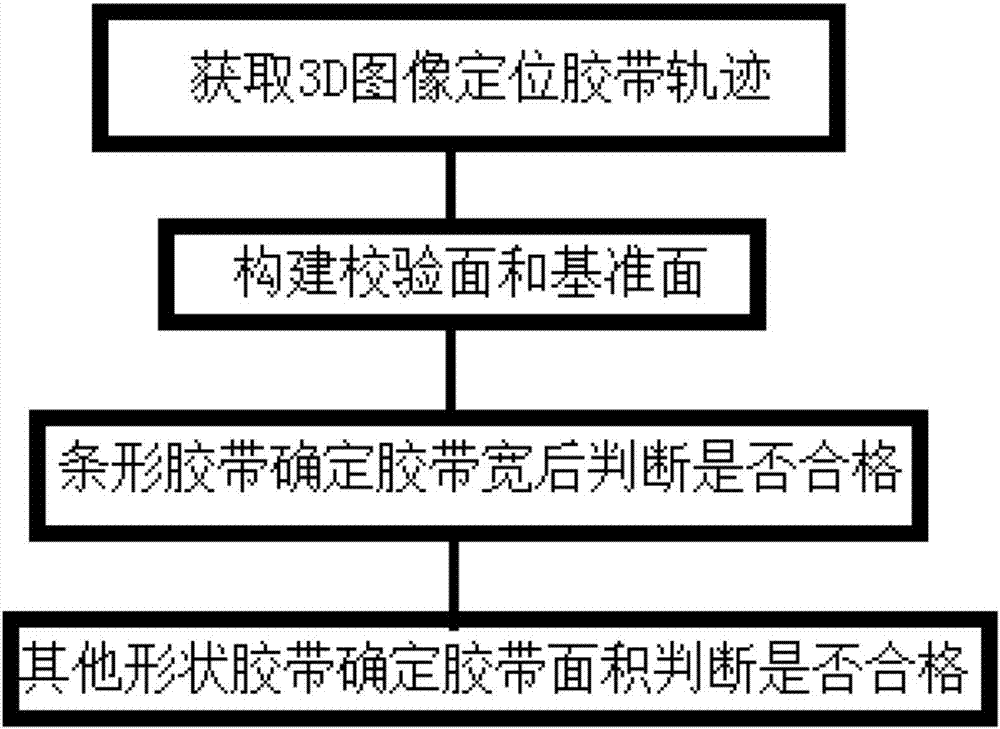

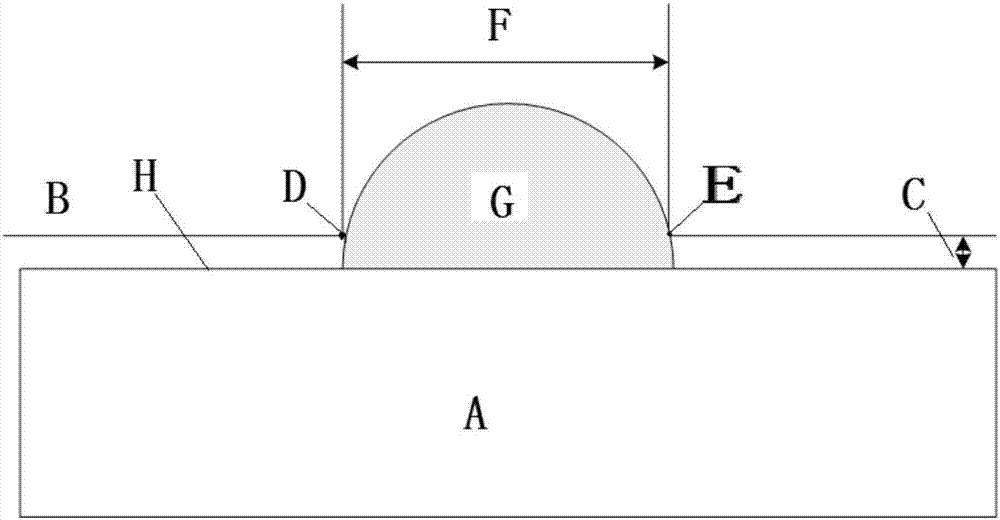

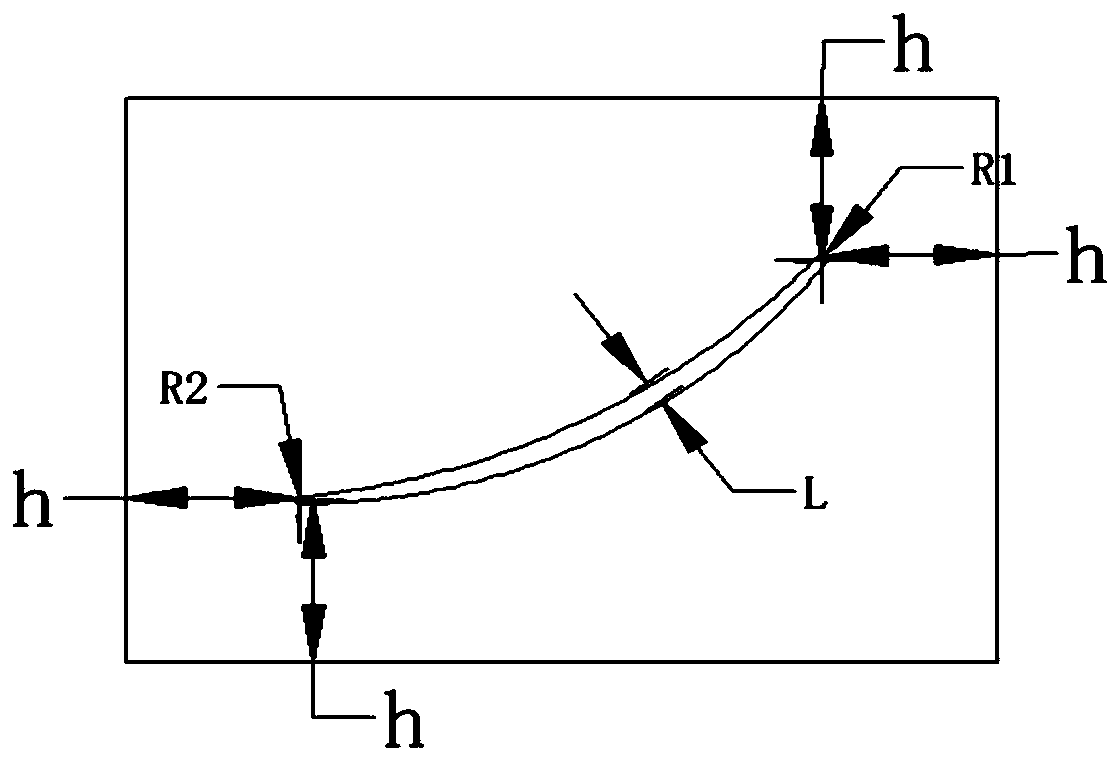

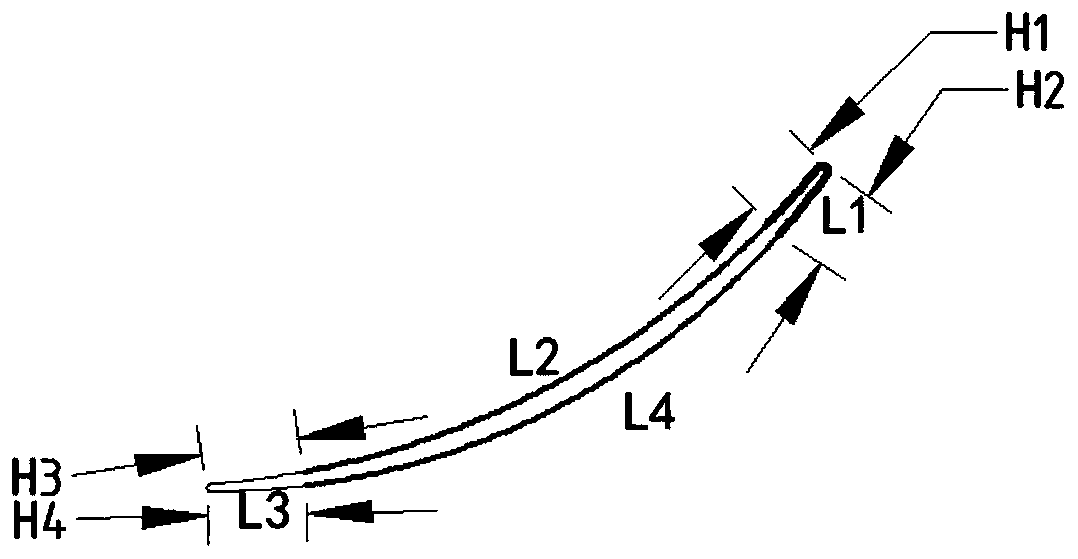

3D visual inspection system and inspection method of gluing quality

InactiveCN107883879AExtend the scan rangeMeet sizeUsing optical meansImaging processingVisual inspection

The invention discloses a 3D visual inspection system of gluing quality. The system comprises a 3D contour scanner, an image processing unit, an encoder, and a computer. The 3D contour scanner consists of an area array CCD and a straight linear laser generator. The image processing unit transmits an adhesive tape 3D image signal shot by the 3D contour scanner to the computer. The encoder fixed with the 3D contour scanner together generates a pulse and triggers the 3D contour scanner to collect an image. The computer with image processing software arranged inside the computer is able to locatean adhesive tape track, calculate the width and area of the adhesive tape, and compare the width and area of the adhesive tape with respective preset threshold values to determine whether the gluing is qualified. In addition, the invention also discloses a 3D visual inspection method of gluing quality. Compared with the prior art, the 3D visual inspection system and method have the following beneficial effects: the continuity and location of glue can be detected accurately and stably; the detection efficiency is improved; and the detection reliability is enhanced.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

Bumper welding fixture

ActiveCN102366869AEasy to debugMeet sizeWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineering

The invention discloses a bumper welding fixture, comprising a base plate, wherein the two ends of the base plate are respectively fixedly provided with wedge blocks, the wedge blocks are respectively provided with a clamping support, each clamping support is provided with a pin shaft through hole, each wedge block is provided with a locating hole, pin shafts pass the pin shaft through holes and the locating holes, the inner side of each clamping support is fixedly connected with a U-shaped support plate, and a connecting plate is connected between the U-shaped support plates the two ends of which are opposite. The bumper welding fixture disclosed by the invention has the characteristics of reliable clamping, convenience in operation and convenience in maintenance and is applicable to various automobile bumper assemblies.

Owner:HEFEI CHANGQING MACHINERY

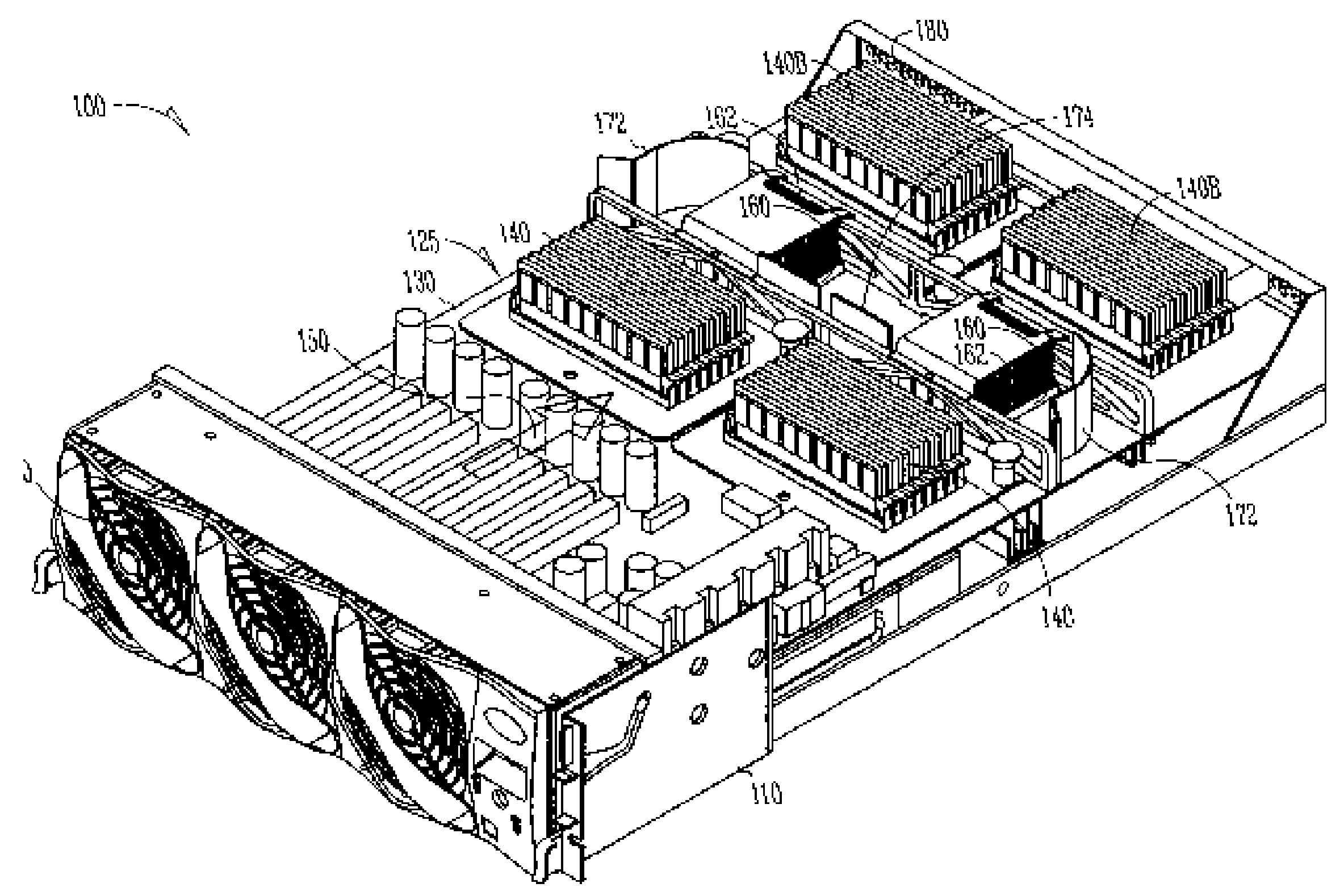

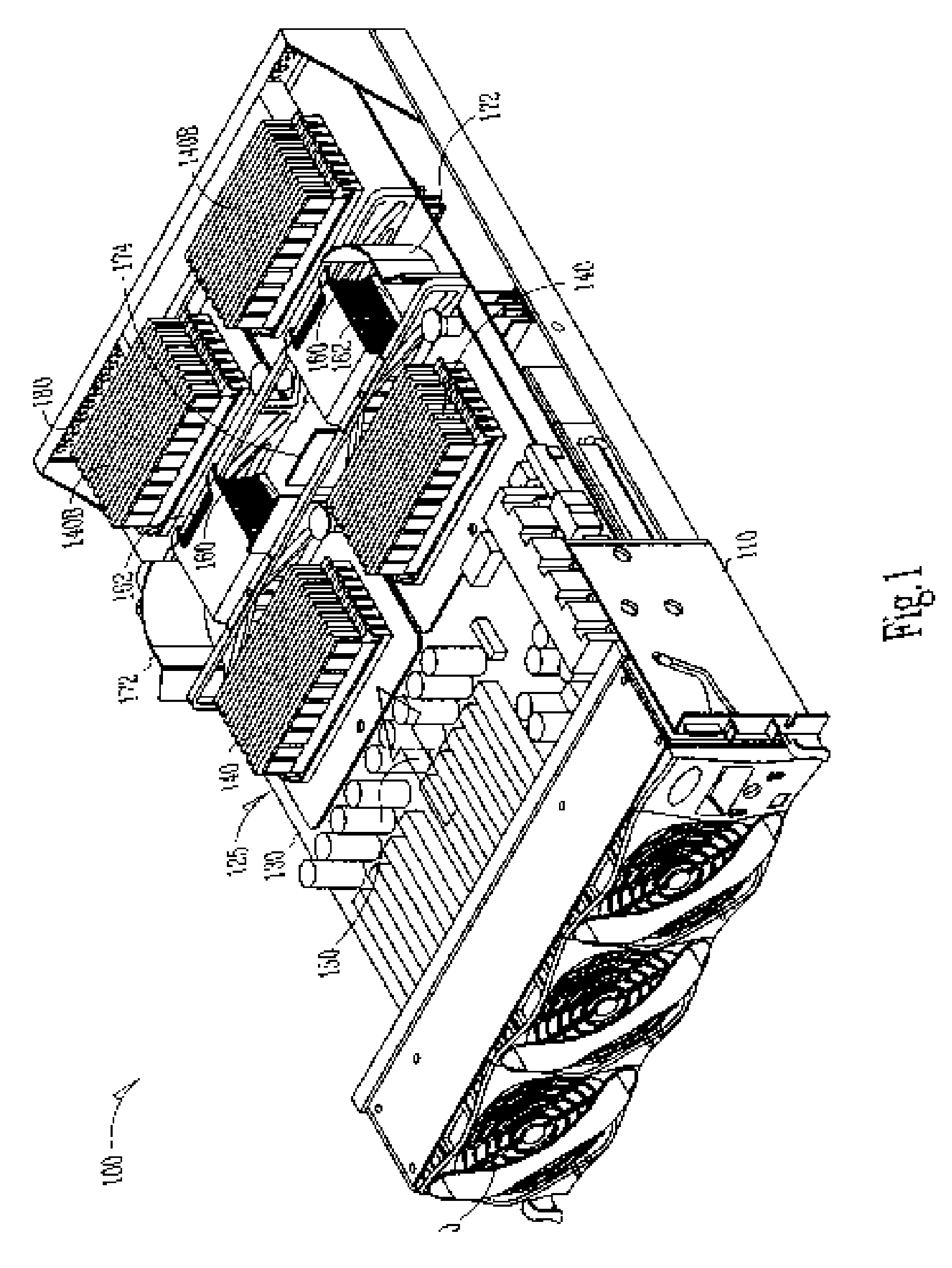

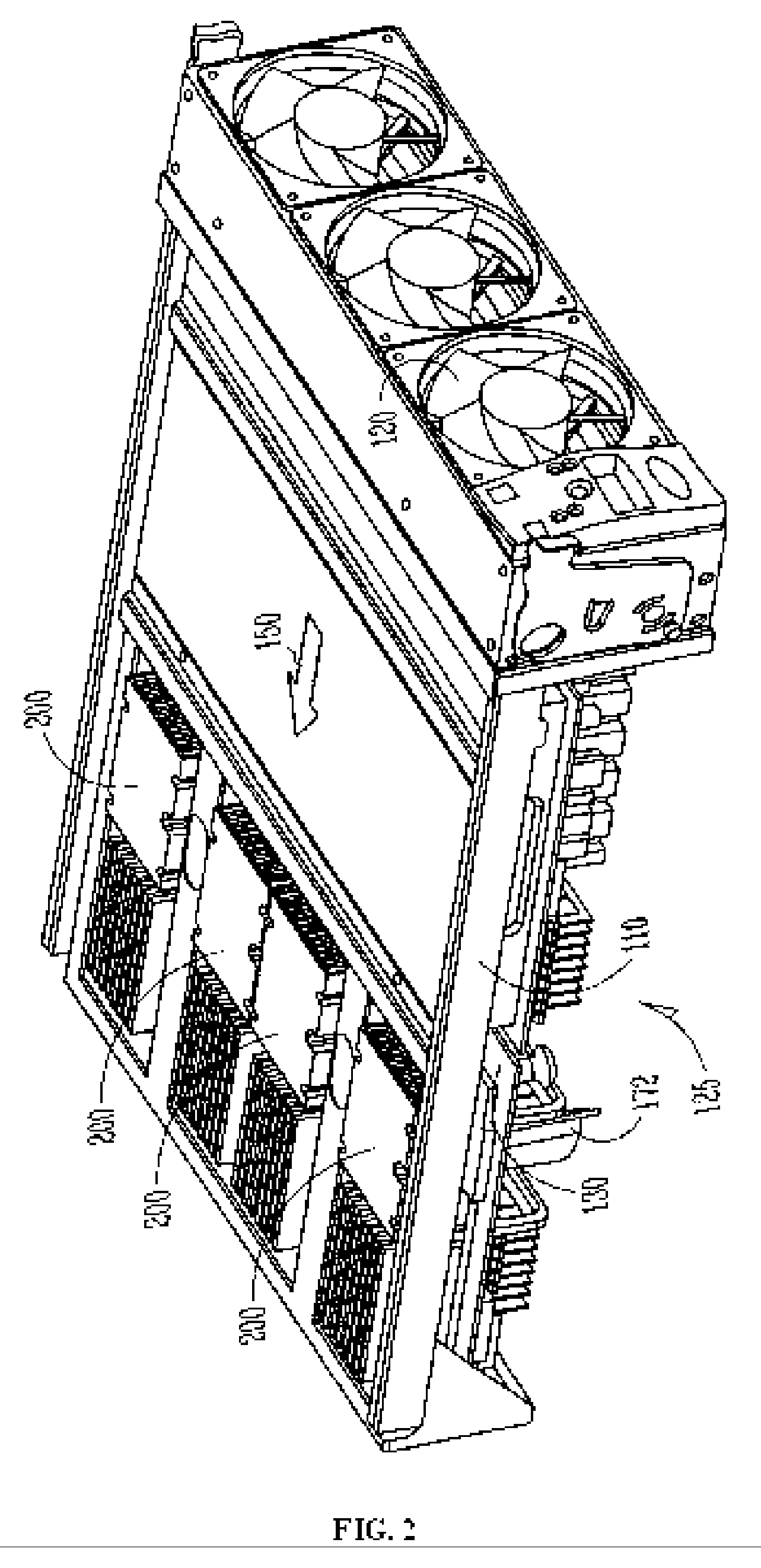

Memory module airflow redirector

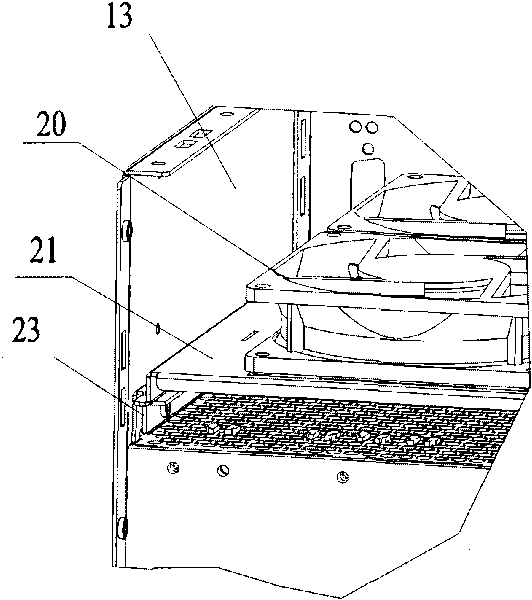

InactiveUS20070121286A1Accelerated dissipationImprove distributionDigital data processing detailsCooling/ventilation/heating modificationsMemory chipEngineering

A method, apparatus and system are disclosed for utilizing a mechanical air redirection device with air cooled computer assemblies in order to evenly distribute airflow to provide balanced cooling of heat producing components, such as memory chips and boards. The present invention improves the thermal distribution and dissipation of heat for computer and memory systems when some memory devices are removed or left uninstalled.

Owner:IBM CORP

Rapidly assembleable and disassembleable display rack

InactiveUS20070175847A1Readily and compactly placed within containerEasily disassembleableFolding cabinetsDismountable cabinetsNuts and boltsSurface plate

Owner:PREST J DAVID

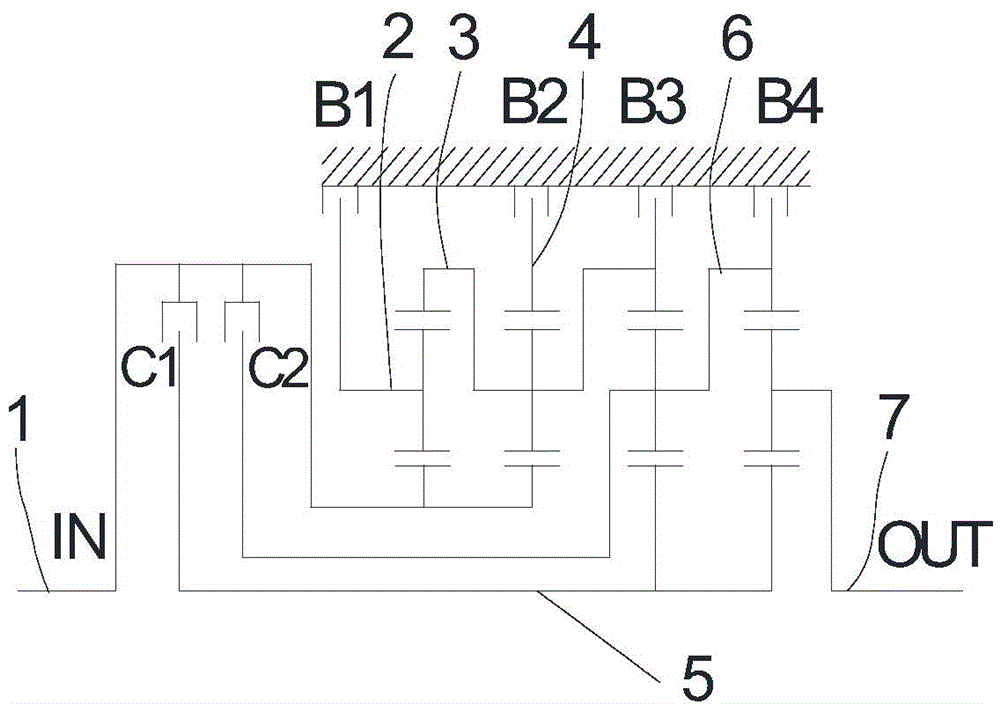

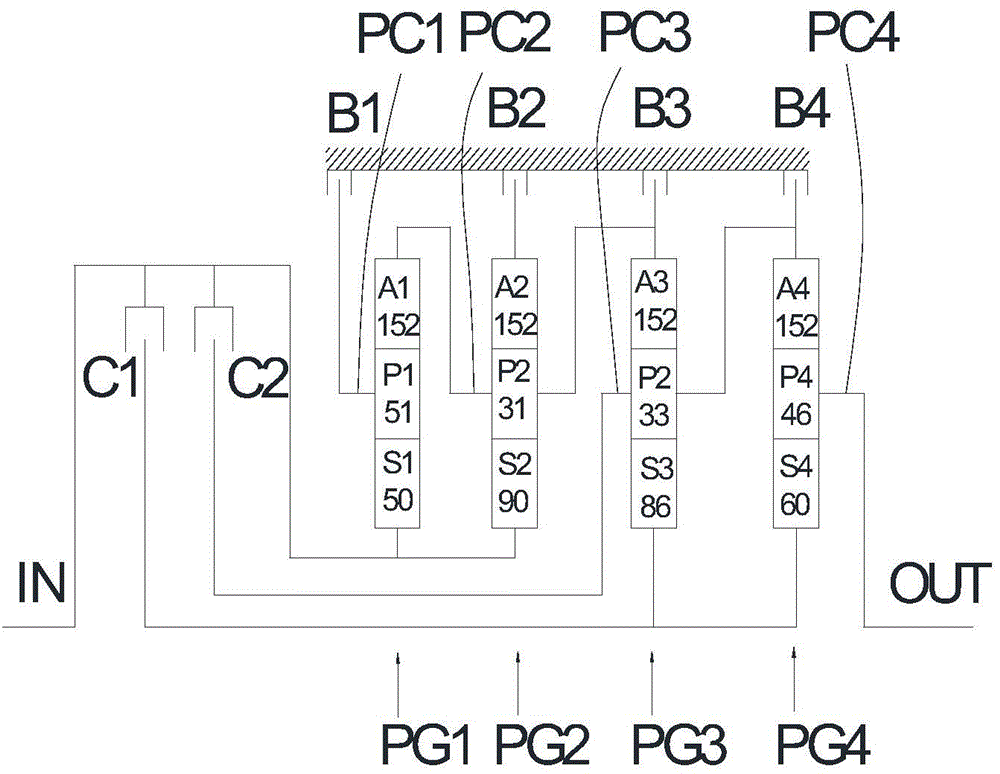

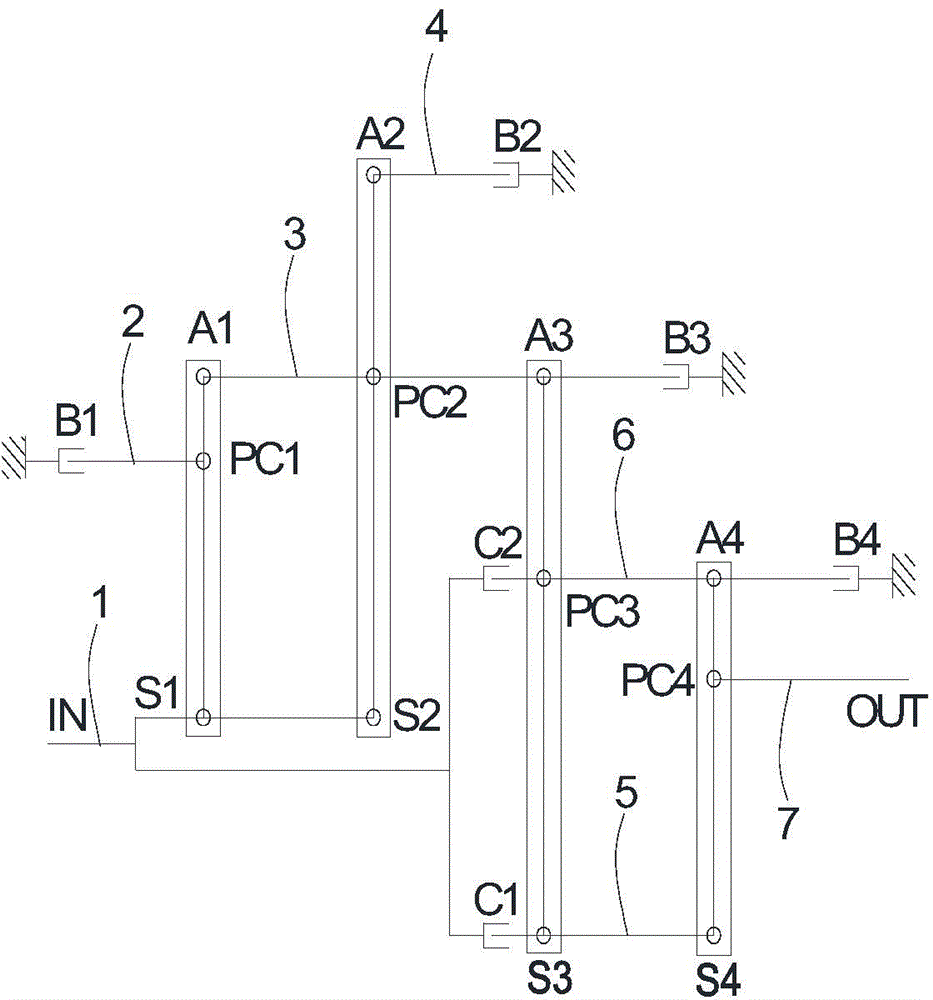

Multi-gear transmission and planetary gear train thereof

ActiveCN104896038AShorten the lengthMeet the durabilityToothed gearingsTransmission elementsAutomatic transmissionGear wheel

The invention discloses a planetary gear train to be used for a multi-gear transmission. At least nine available forward gears and at least one available reverse gear can be obtained. The planetary gear train comprises a first planet row, a second planet row, a third planet row and a fourth planet row. Each planet row comprises a sun gear, a planet carrier and a gear ring. Components and connection members of the planet rows can form seven rotation elements. A gear shifting component comprises two clutches and four brakes. The clutches are arranged among the selected rotation elements of the rotation elements, and the brakes are arranged between the selected rotation elements of the rotation elements and fixing parts. The planetary gear train has more gears and optimal speed ratio, the power transmission performance and the fuel economy of the cars can be improved apparently, and the planetary gear train is short, compact in overall design, capable of meeting requirements of cars for transmission durability, power transmission efficiency, size, costs and the like well. The invention further discloses an automatic transmission with the planetary gear train.

Owner:SHAANXI FAST GEAR CO

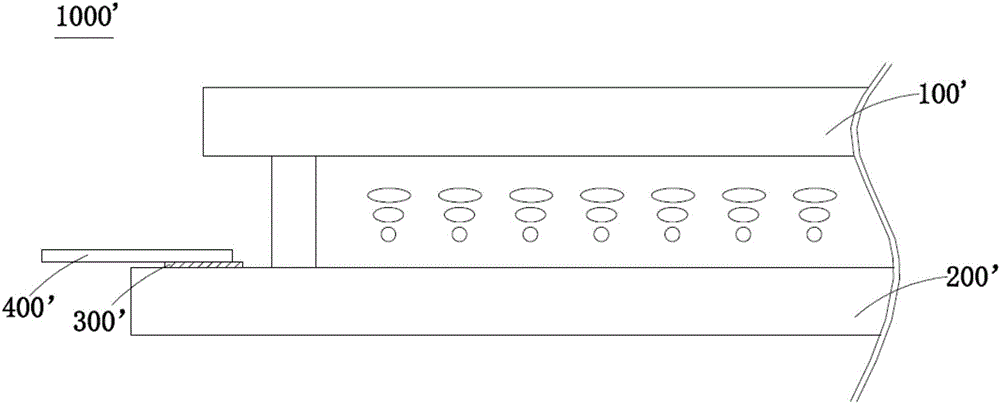

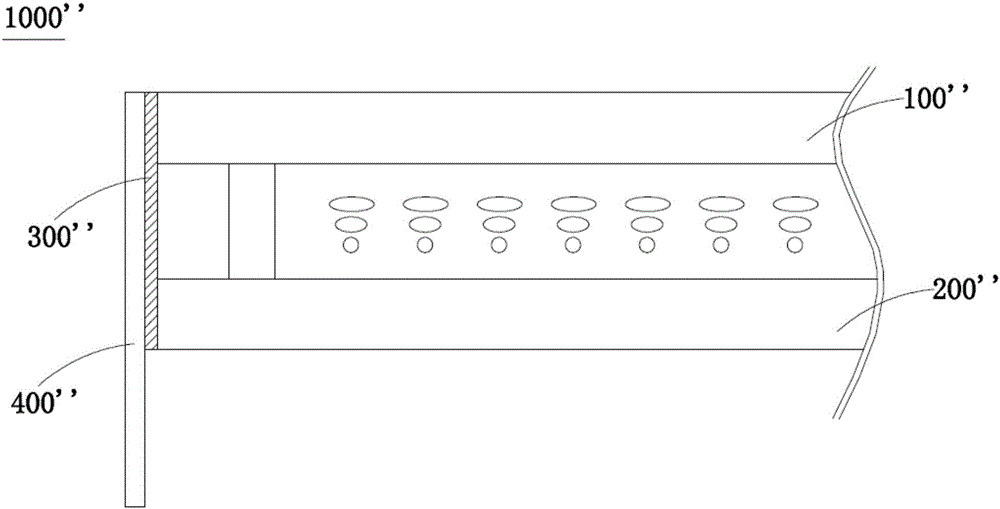

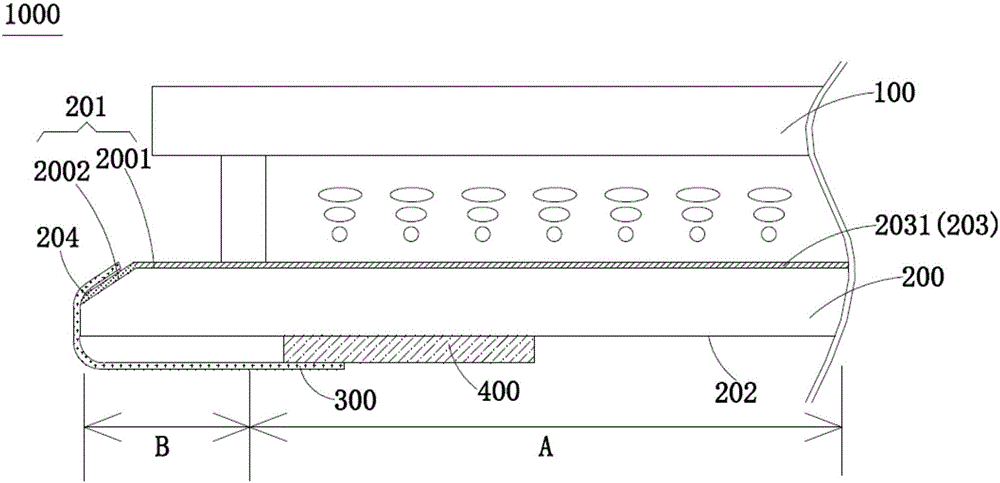

Display apparatus

InactiveCN106558600AEasy to manufactureMeet sizeStatic indicating devicesSolid-state devicesEngineeringElectrical and Electronics engineering

Owner:AU OPTRONICS KUNSHAN CO LTD +1

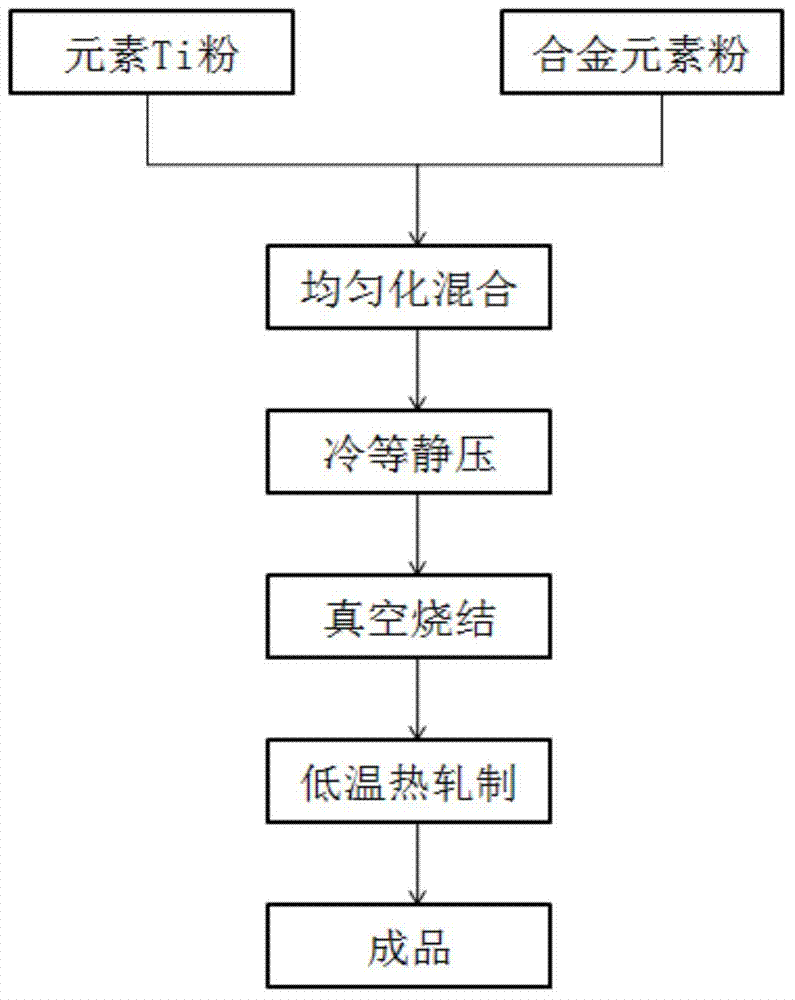

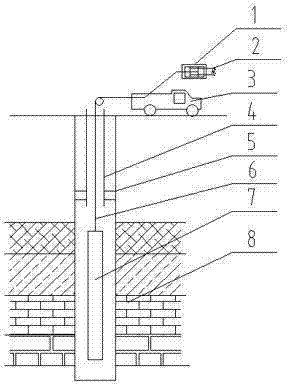

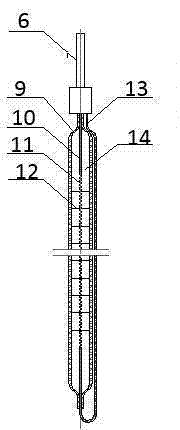

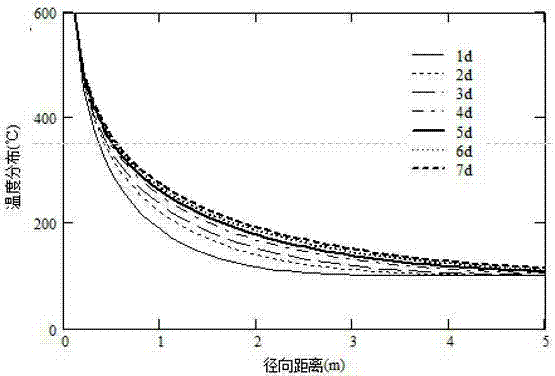

Method for relieving water blocking at high temperature in oil and gas exploitation process

The invention discloses a method for relieving water blocking at a high temperature in the oil and gas exploitation process. According to the method, an electrical heating rod is lowered into a reservoir stratum segment and is heated to a certain temperature, heat is transferred into a formation water blocking area through a casing pipe and a cement sheath, formation fluid in gaps is heated to evaporate and flow into a shaft, and then damages caused by water blocking can be avoided. The diameter of the electrical heating rod is 4 / 5 the inner diameter of the casing pipe of the reservoir stratum segment; the length of the electrical heating rod should be equal to the thickness of the reservoir stratum segment, and the electrical heating rod can be formed by connecting a plurality of fixed-length heating rods in series; the electrical heating rod should be parallel to the reservoir stratum segment when lowered into the reservoir stratum segment; the heating temperature of the electrical heating rod ranges from 300 DEG C to 600 DEG C, and the heating time is estimated. Principles are reliable, and the method is easy and convenient to implement, capable of effectively solving the problem of formation water blocking and suitable for barefoot well completion as well as cased hole completion and has broad application prospects.

Owner:SOUTHWEST PETROLEUM UNIV

Micro TCA exchange platform

InactiveCN101753317AHighly integratedHigh integration, can provide higher system density than ATCAData switching detailsDigital processing power distributionRear quarterComputer module

The invention discloses a Micro TCA exchange platform, comprising a chassis consisting of a top plate, a front panel, a back panel, two side plates and a bottom plate. The upper part of the chassis is provided with a fan module and an alarming monitoring module, the middle part of the chassis is provided with an AMC (automatic message counting) module, a switch fabric card and a power supply module, and the lower part of the chassis is provided with a dustproof filtering device. The invention provides the Micro TCA exchange platform which has the advantages of high flexibility, very high integrated level, high expansion elasticity and management function, no need of a support plate, small dimension and low cost.

Owner:EVOC INTELLIGENT TECH

Object multi-angle high-speed water entry experiment device controlled by high-pressure gas

PendingCN109974966AFree height controlFree control angleHydrodynamic testingCompressed gas gunsOperabilityEngineering

The invention belongs to the object high speed water entry experiment field and especially relates to an object multi-angle high-speed water entry experiment device controlled by a high-pressure gas.In the invention, a same set of device satisfies needs of a plurality of experimental work conditions, the highest water entry speed of an object can be 600m / s, and a water entry angle is 0 to 90 degrees. An emission-object bullet holding device is adopted to clamp an emission object, the emission objects with multiple sizes and shapes can be satisfied, and a bullet holding collector and a deflation device are added at a barrel end of an emission device so as to avoid an influence of the high-pressure gas on a water entry moment of the object. An acceleration sensor is installed in the emission object so as to record an acceleration change process of the object during a water entry process. An array light source makes a water entry process shot by a high-speed camera be clearer so as to satisfy high-precision experiments under different working conditions, and good operability and repeatability are possessed. A manual deflation device is installed on a high pressure gas tank so that manual deflation can be performed, which is safe and reliable. A device structure is compact and flexible and an integral occupied space is small.

Owner:HARBIN ENG UNIV

Blade tenon grinding fixture

ActiveCN105538096ASimplify structural design requirementsEasy to adjustGrinding machinesGrinding work supportsMachining processGrinding wheel

The invention discloses a blade tenon grinding fixture. The blade tenon grinding fixture comprises a baseplate achieving a support positioning effect; the upper surface of the baseplate serves as a mounting surface for mounting a blade to be machined; square boxes for auxiliary positioning are cast at a blade basin and a blade back of the blade to be machined; the mounting surface of the baseplate is a horizontally inclined angle surface; a positioning mechanism for clamping and positioning the square boxes is arranged on the mounting surface; and the baseplate is additionally provided with a drainage mechanism for guiding cooling liquid to a tenon of the positioned blade to be machined to reduce the grinding heat. As the mounting surface of the baseplate is designed as the horizontally inclined angle surface, the tenon symmetry center of the blade is conveniently adjusted in the machining process, and the prolonging of the service life of a formed grinding wheel is facilitated; and the drainage mechanism is arranged on the baseplate, so that the grinding heat is reduced, the quick positioning and clamping requirements are satisfied, the dimensional tolerance and the geometric tolerance of the grinded blade tenon reach the technical requirements, the reliability in the machining process is improved, and the service life of the formed grinding wheel for grinding is prolonged.

Owner:CHINA HANGFA SOUTH IND CO LTD

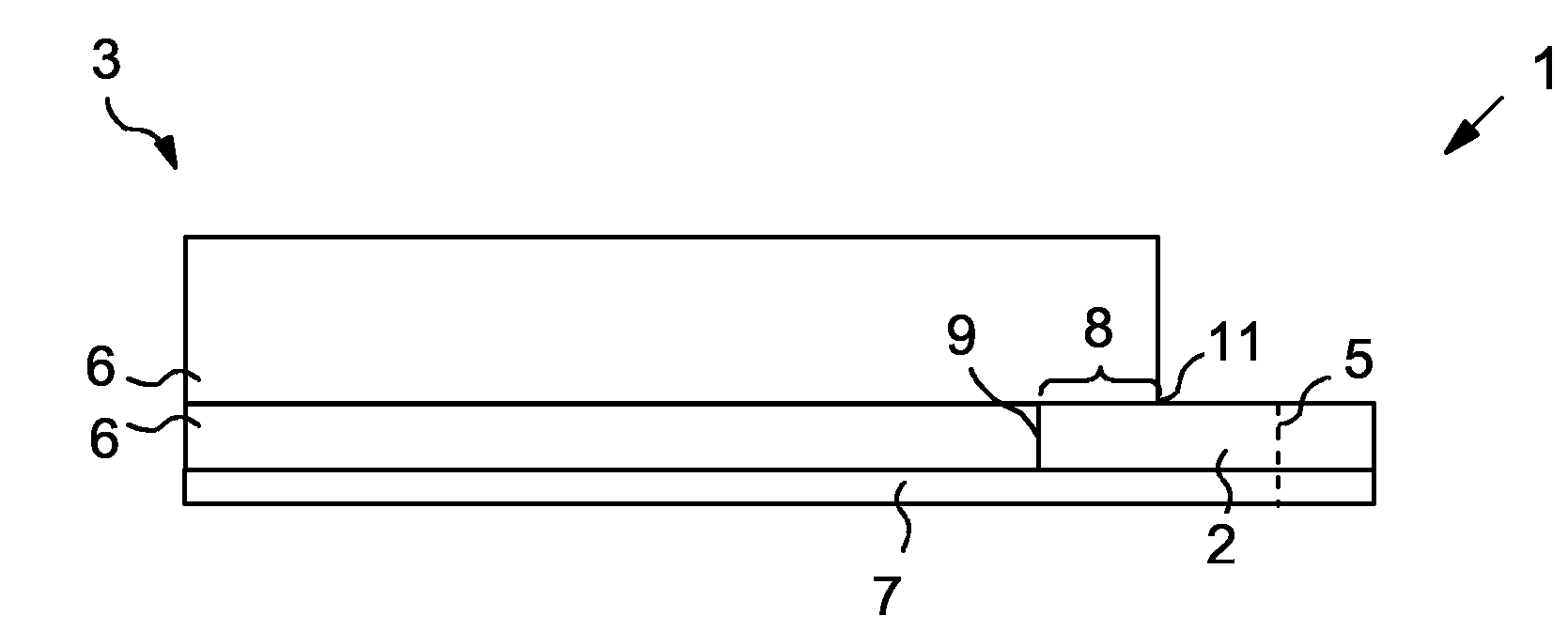

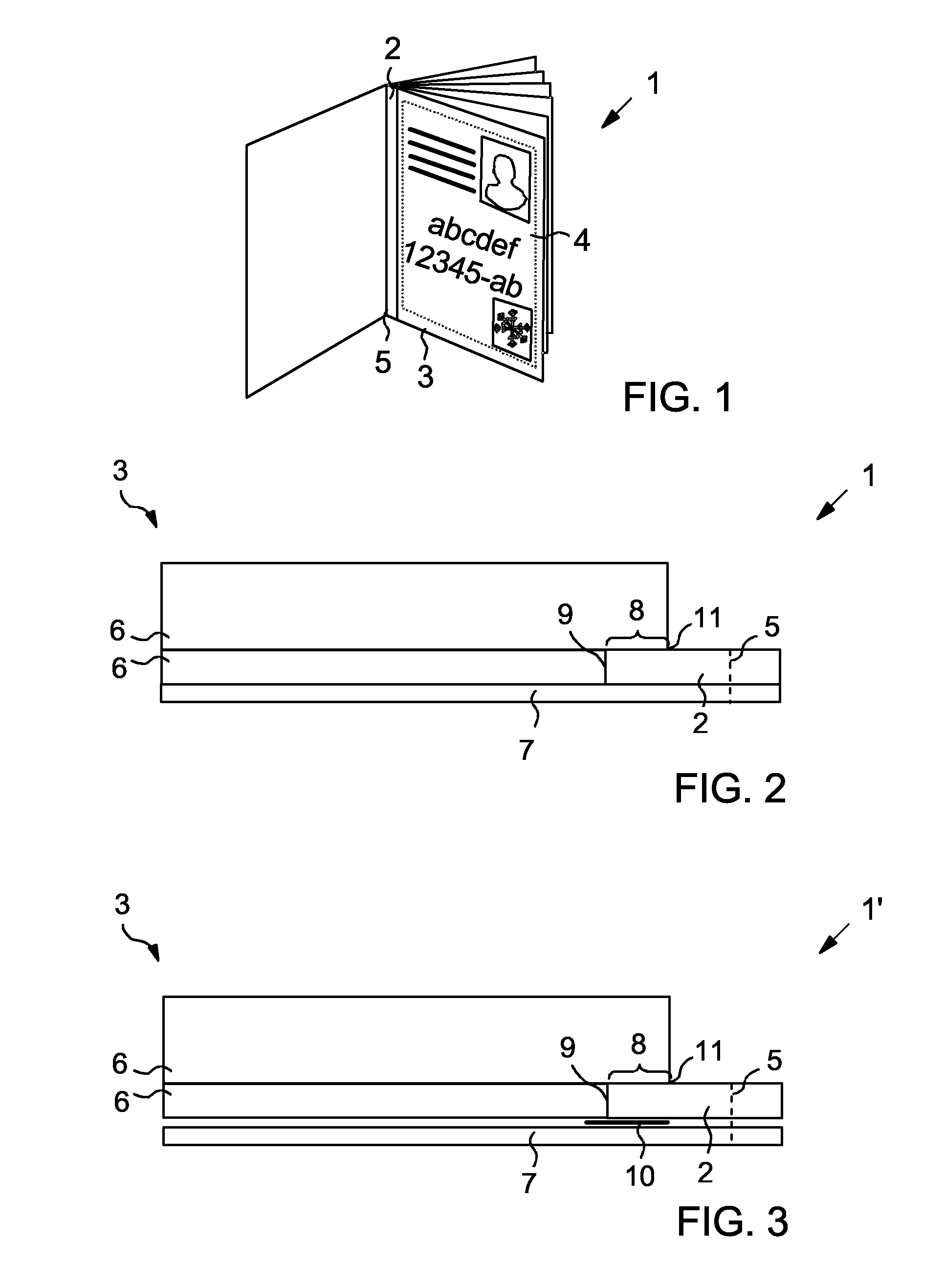

Method of Producing an Information Page For a Security Document

ActiveUS20080191461A1LaboriousEasy to detectRecording apparatusOther printing matterSurface layerLaser engraving

The present invention relates to a multilayer information page (1) for a security document, which includes an information part (3) manufactured from a material allowing at least some identification information of the information page to be entered thereto by utilizing laser engraving, the identification information pro-vided on the information page (1) being readable from an upper surface thereof, and a flexible and bending resistant connecting part (2) for connecting the information page (1) to the security document, the connecting part (2) comprising a fastening end (8) by means of which the connecting part (2) is fastened to the information part (3). In order to ensure that detachment of the information part and the connecting part from one another leaves visible marks, the fastening end (3) of the connecting part (2) is arranged to overlap with a lower surface of the information part (3). Furthermore, the information page (1) includes a transparent surface layer (7) which covers at least the fastening end (8) and at least a part of the lower surface of the information part (3) and through which at least the fastening end (8) is visible.

Owner:THALES DIS FINLAND OY

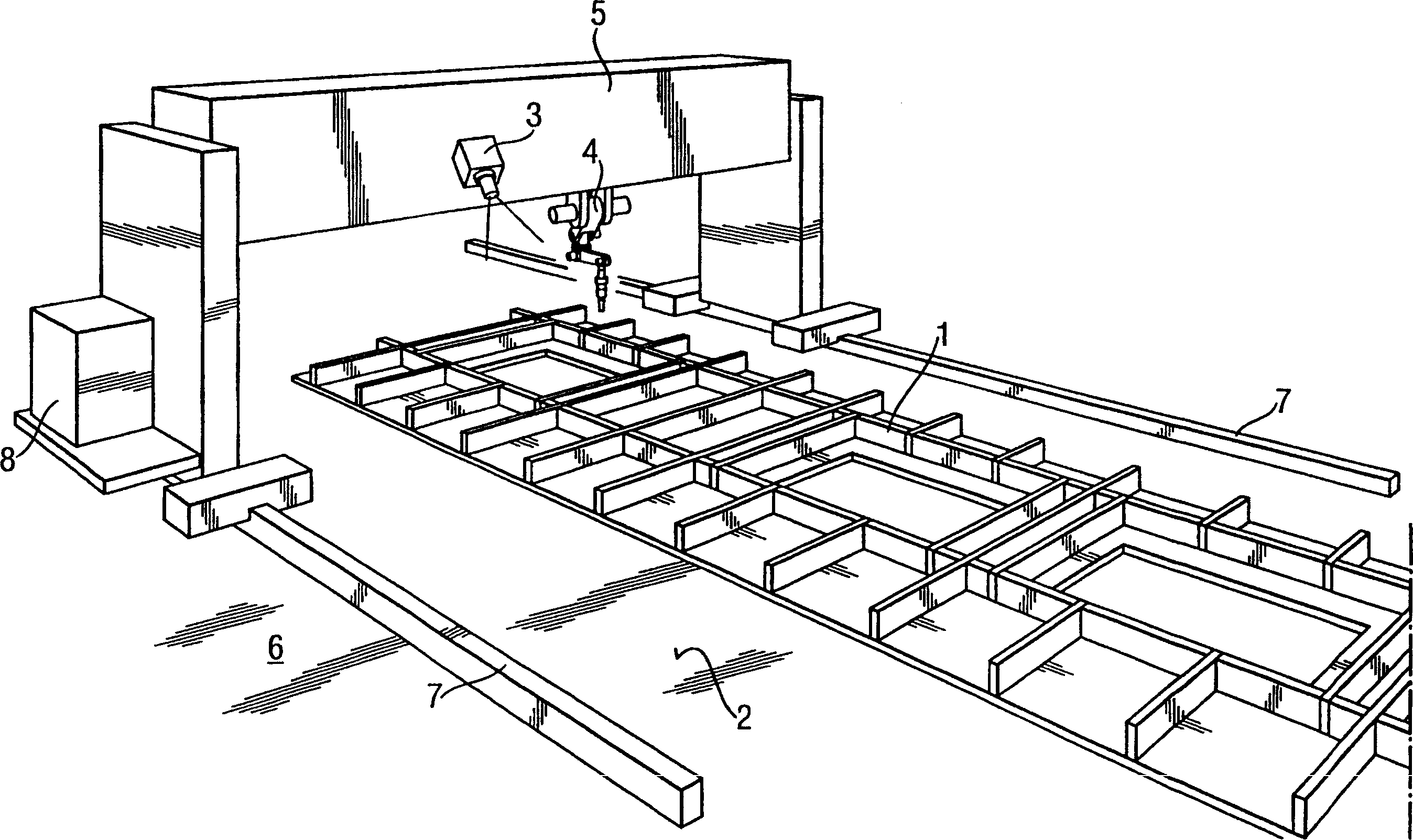

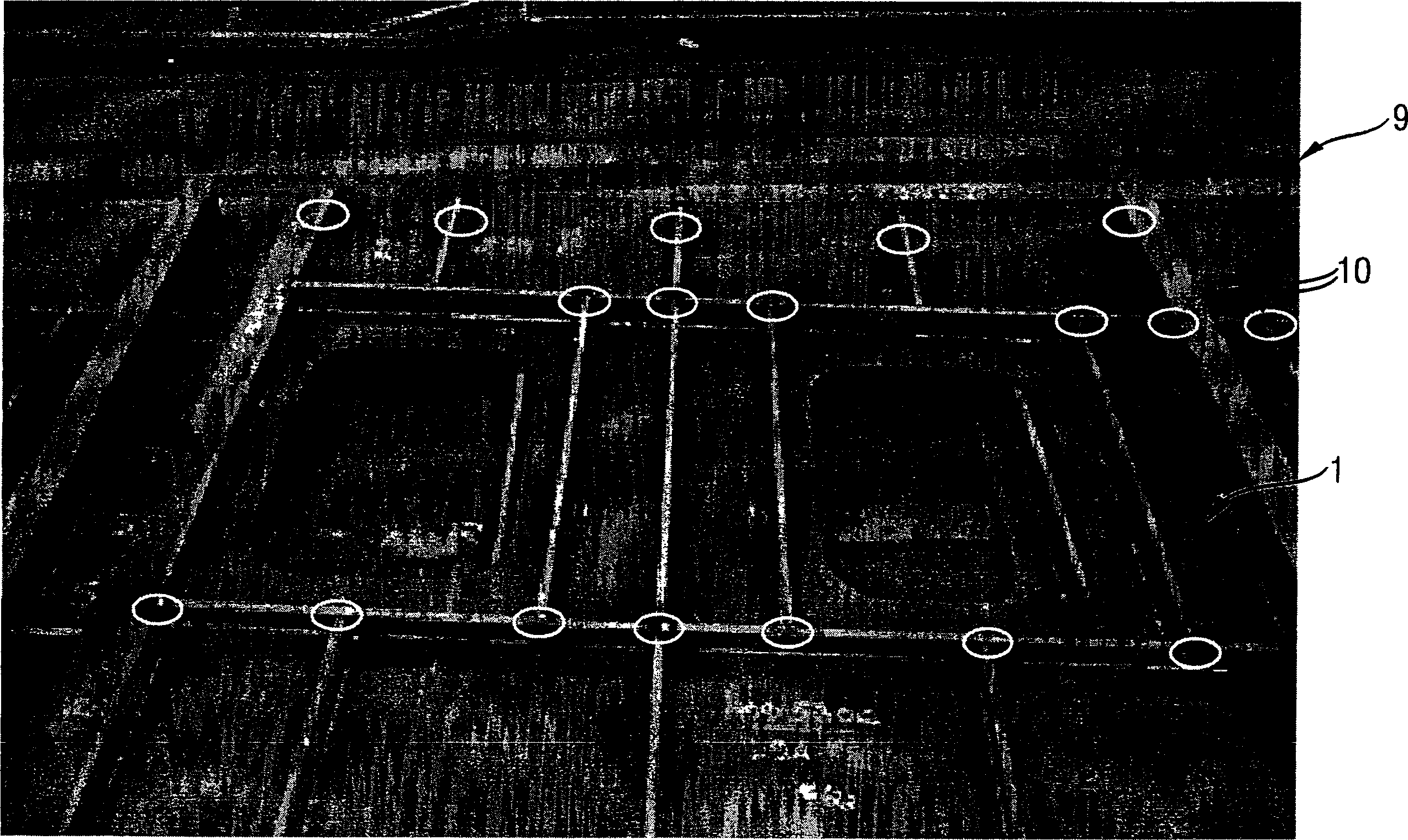

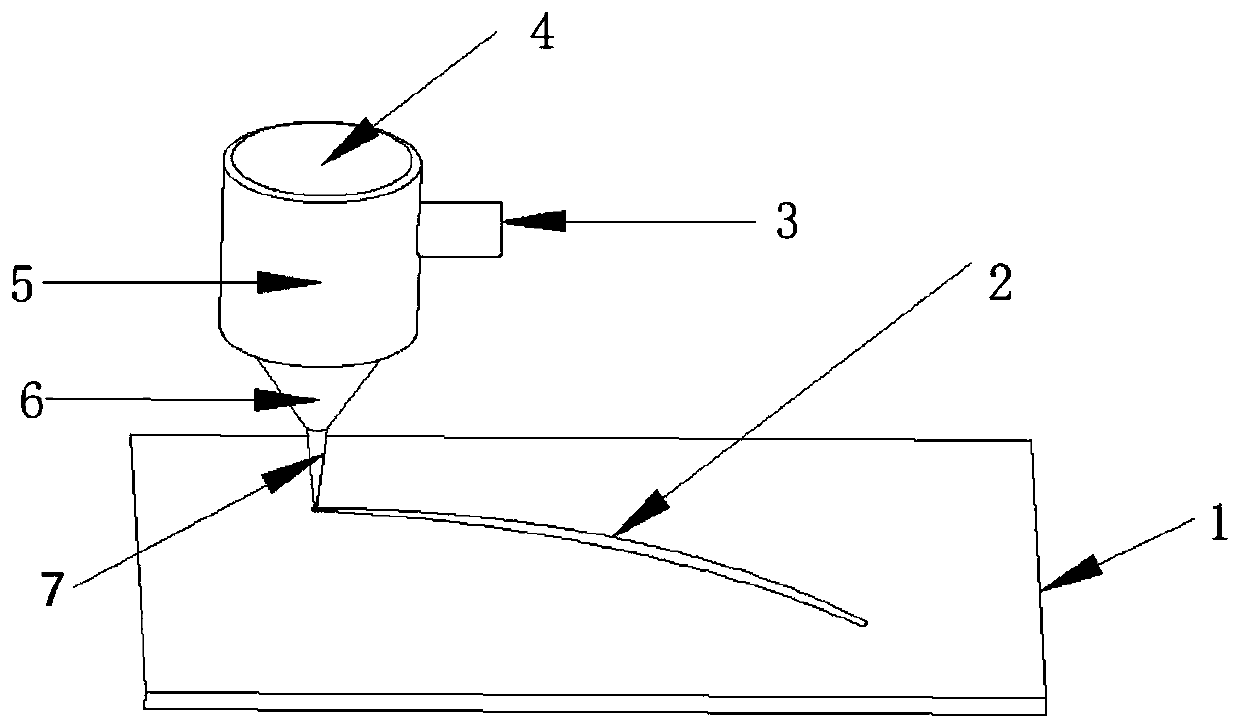

Welding device and method

InactiveCN1408500ALow costSignificant comprehensive benefitsArc welding apparatusPetroleum engineeringSupport plane

The forming process of welded structural member incldues supporting the constituent parts in prospective membrane shape and welding in several welding spots. The welding method includes at least one image of the part arranging positions on the support plane for determining the welding spot positions. The corresponding welding equipment is also disclosed.

Owner:STX FINLAND OY

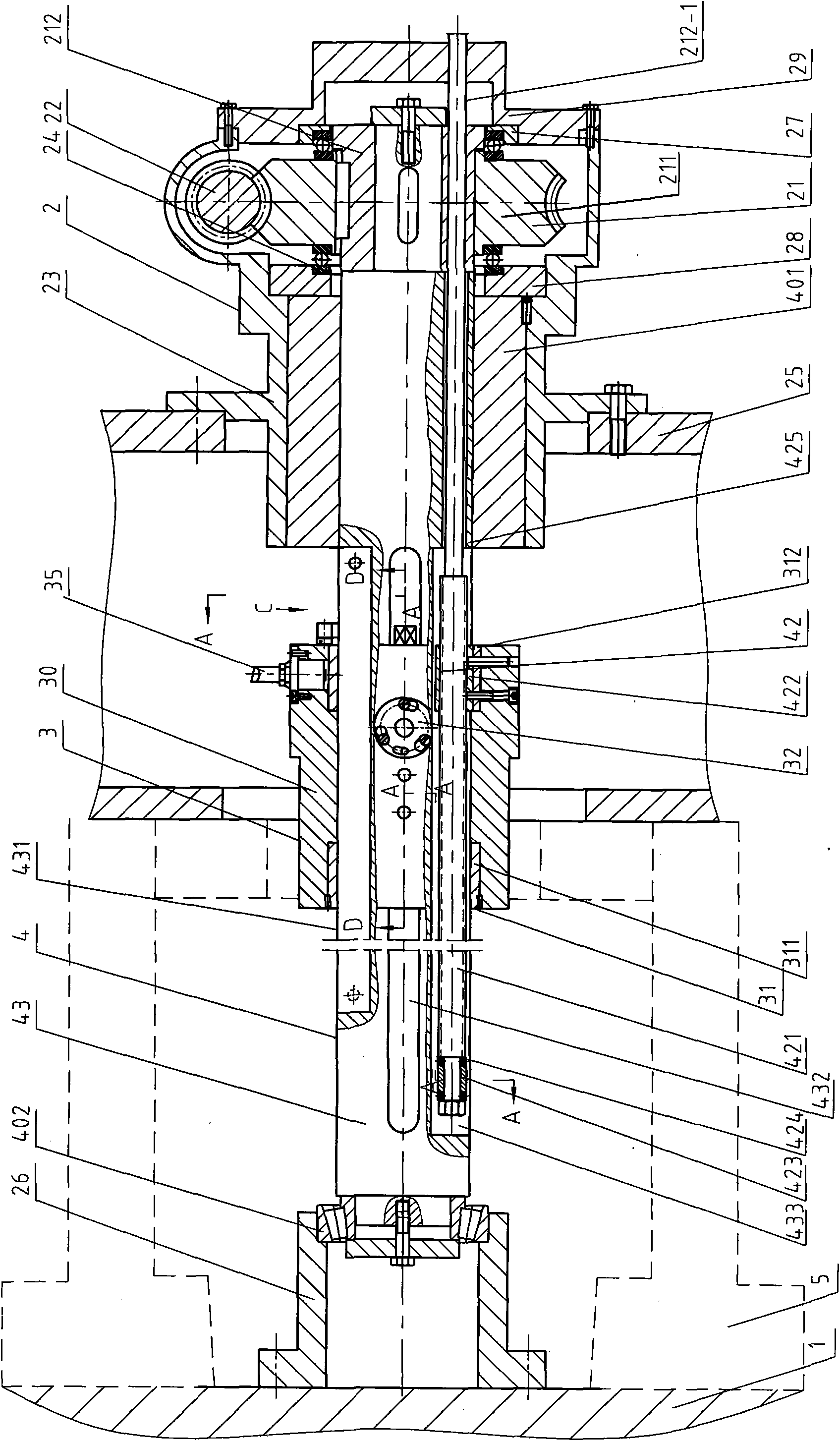

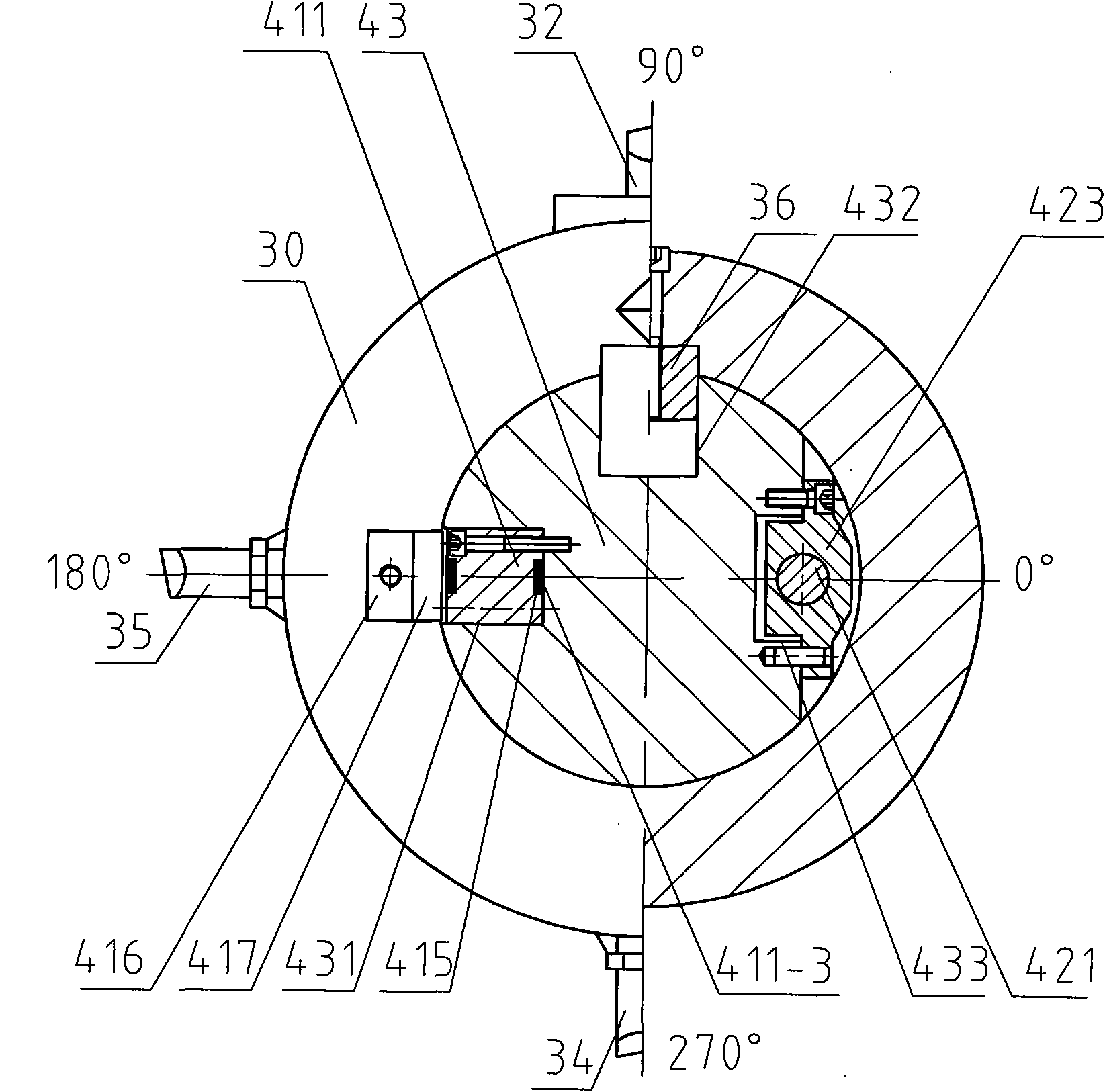

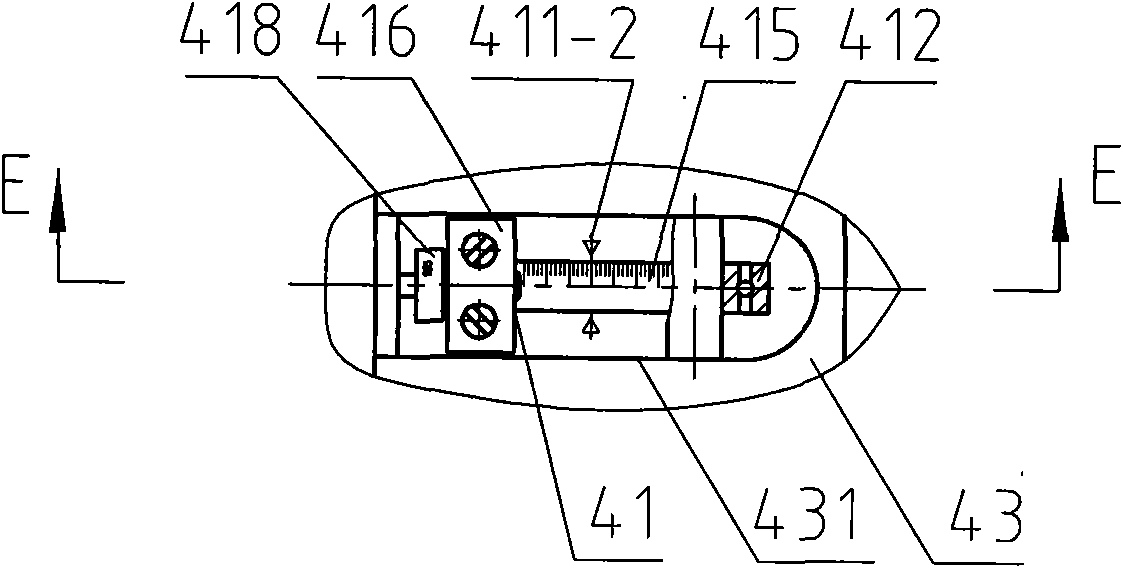

Boring device for cylinder hole of diesel engine stand

InactiveCN101869997AReduce processing costsGuaranteed geometric tolerance requirementsMeasurement/indication equipmentsBoring barsEngineeringBody positions

The invention discloses a boring device for a cylinder hole of a diesel engine stand, which comprises a boring rod transmission mechanism, a boring rod mechanism and a cutter body mechanism, wherein the boring rod transmission mechanism is arranged on one end of a boring rod and comprises a worm gear, a worm, a worm gear case, a pair of supporting bearings, a positioning frame and a positioning seat; the worm gear is fixedly connected with the end of the boring rod; two sides of the worm gear are supported in one end of the worm gear case through the pair of supporting bearings and a retainer ring; the worm is arranged at one side of the worm gear; one end of the boring rod is supported in the other end of the worm gear case through a sliding bearing, and the other end of the boring rod is supported on a machine working table through a conical roller bearing and the positioning seat; the cutter body mechanism can axially move along the boring rod; and a screw rod transmission mechanism and a cutter body position measuring mechanism are also arranged in the boring rod. The invention can enable the cutter body mechanism to automatically and stably feed on the boring rod at constant speed to complete the boring of the cylinder hole, enables the cylinder hole of the diesel engine stand subjected to primary processing to meet the requirements on dimensional tolerance and perpendicularity tolerance of the cylinder hole, and can also measure the boring depth.

Owner:CSSC MARINE POWER

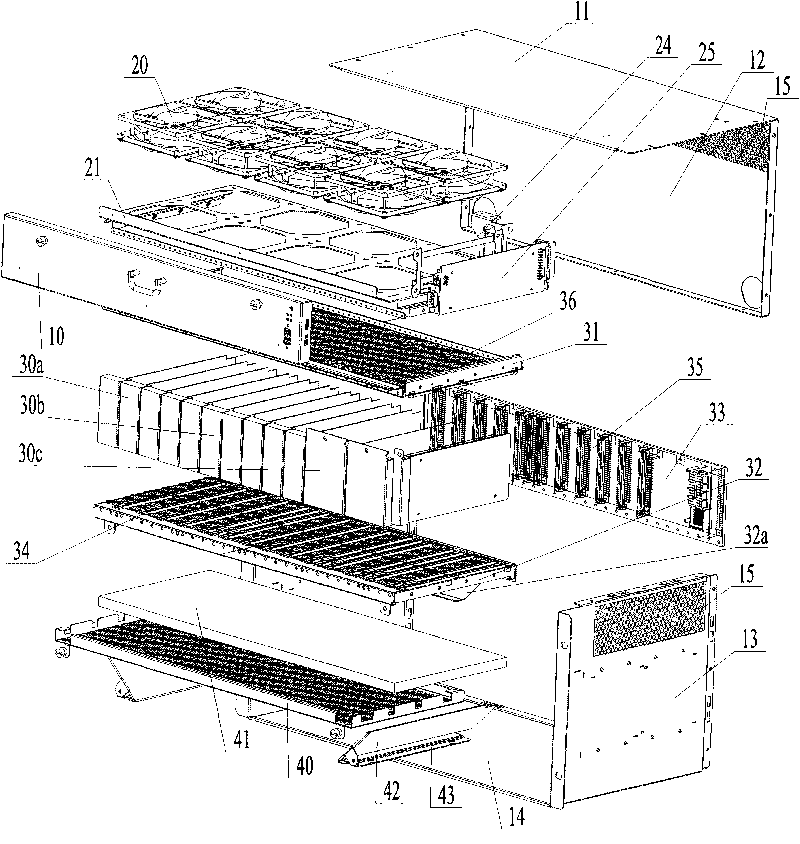

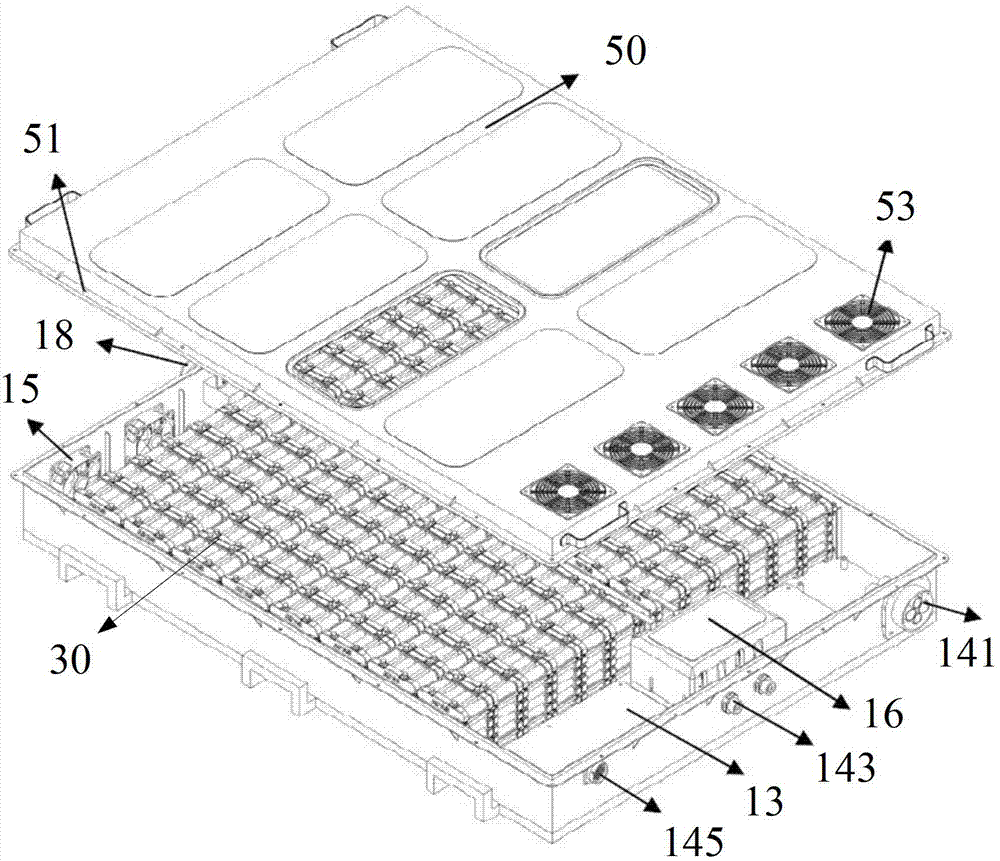

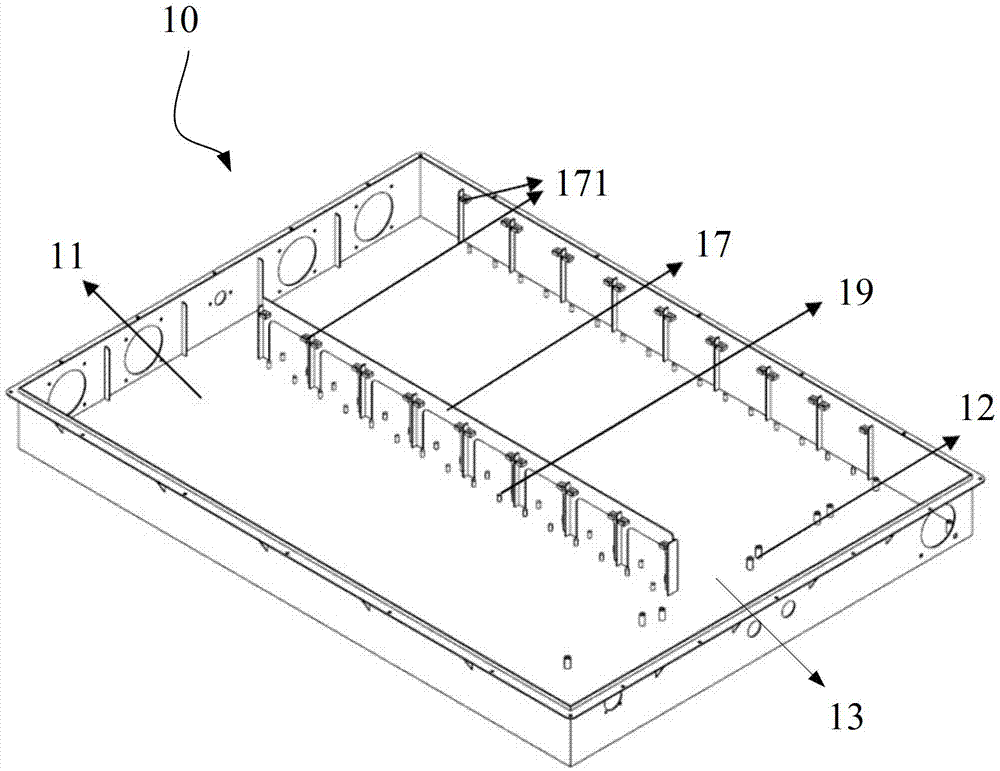

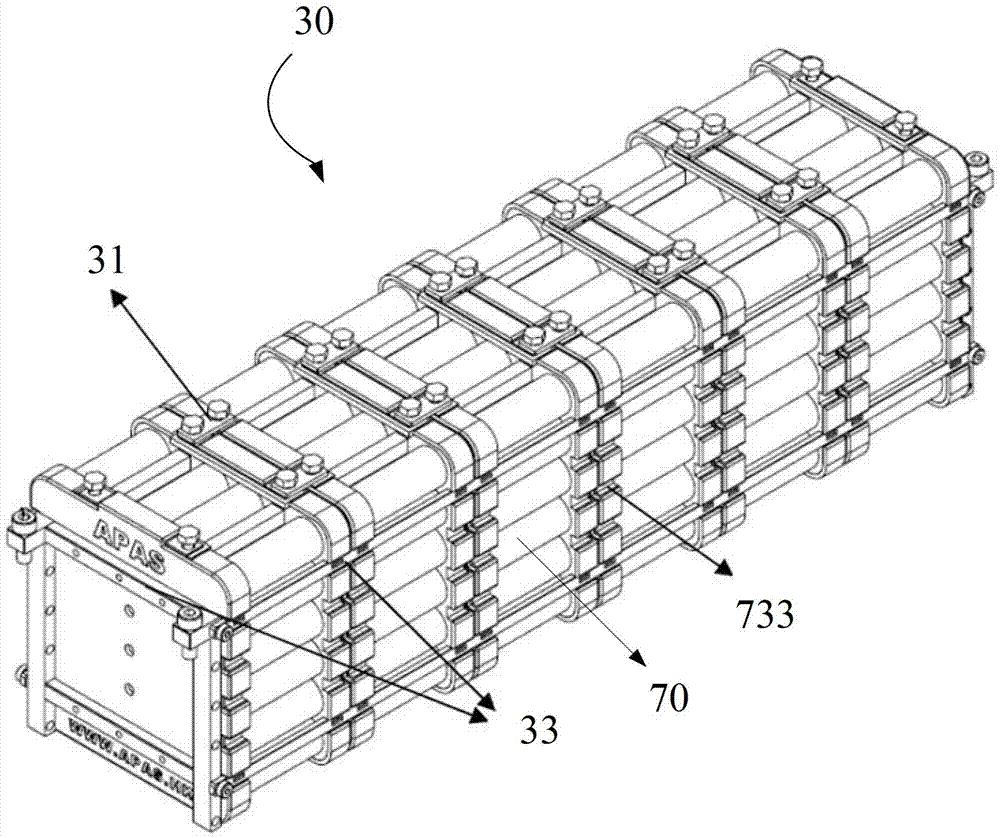

Battery pack for electric vehicle

ActiveCN102903876AMulti-integratedMeet sizeSecondary cellsCell component detailsEngineeringElectric vehicle

The invention discloses a battery pack for an electric vehicle. The battery pack comprises a shell, a battery group and a battery management part, wherein a battery group placement area and an auxiliary part placement area are formed in the shell; a heat dissipation device is arranged on the shell; the battery group comprises a plurality of battery units and is arranged in the battery group placement area of the shell; each battery unit is a basic battery module which comprises a plurality of battery monomers and battery brackets; and the battery management part is connected with the battery group and arranged in the auxiliary part placement area of the shell. According to the battery pack for the electric vehicle, the battery group and various auxiliary parts such as the battery management part can be arranged in the battery pack, so the battery pack has integrated functions; and by adoption of a modular battery unit design method, requirements of different electric vehicles on the size, voltage, capacity, safety and the like of the battery pack can be met according to different combinations of the battery units.

Owner:HONG KONG PRODUCTIVITY COUNCIL

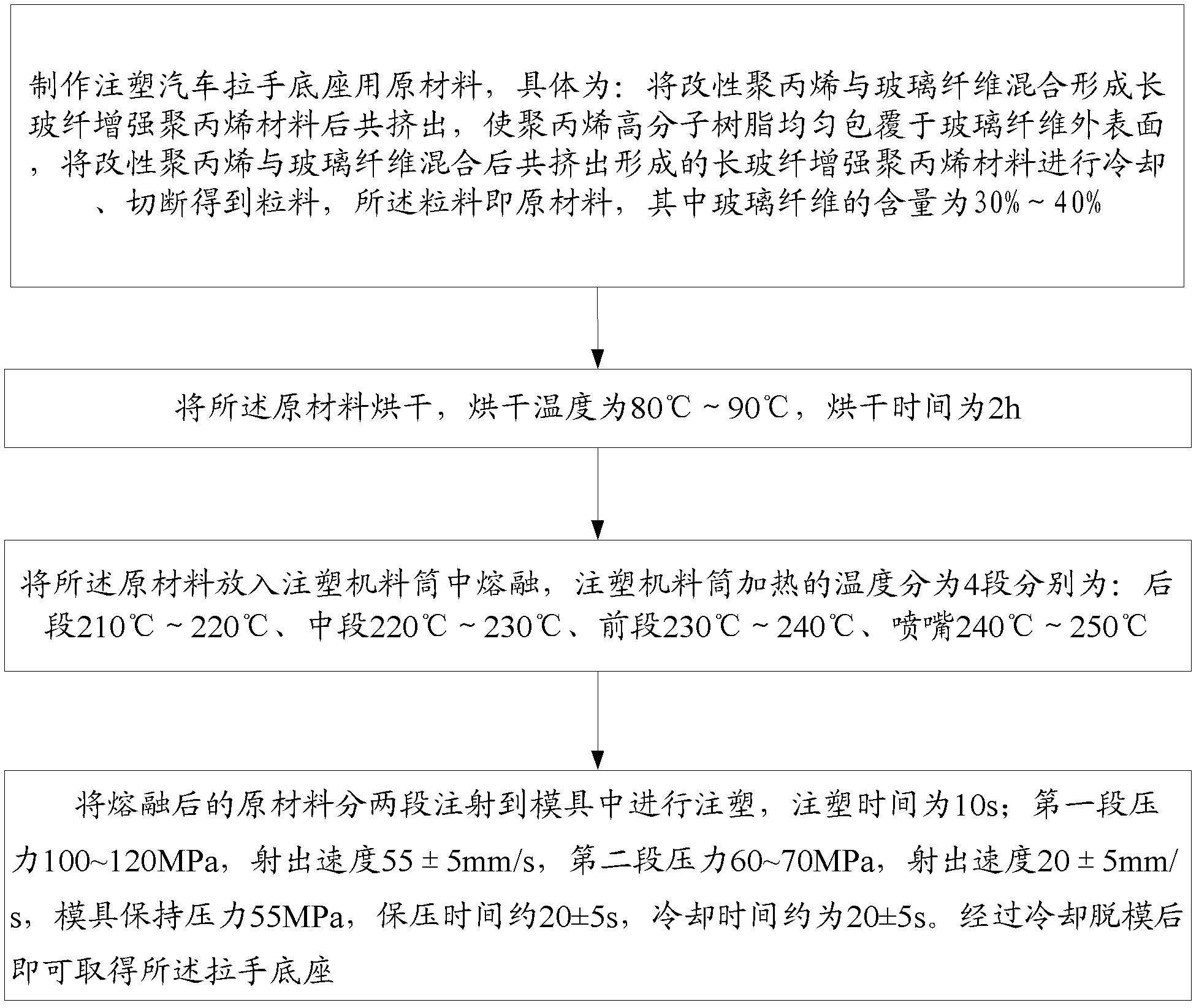

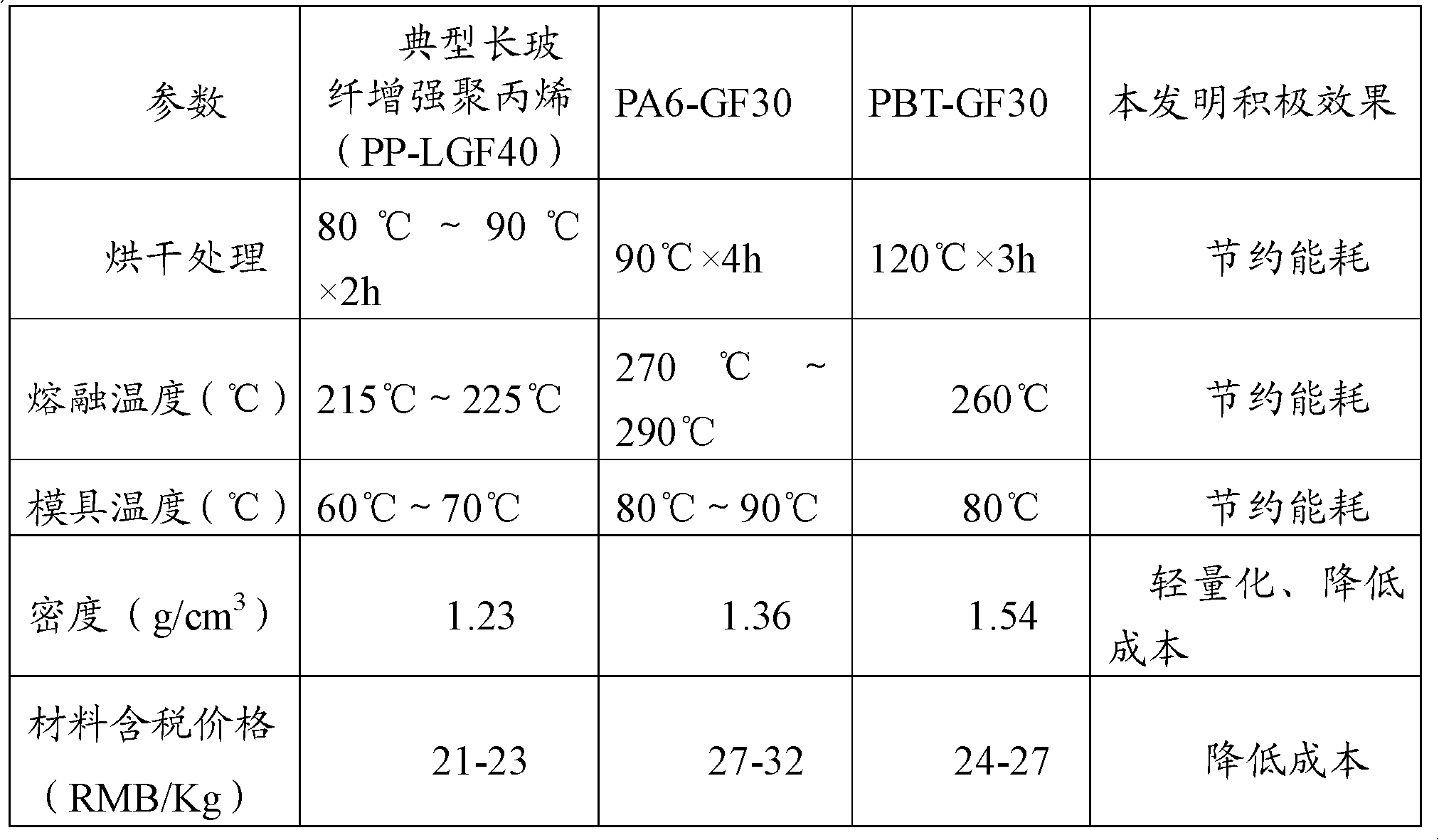

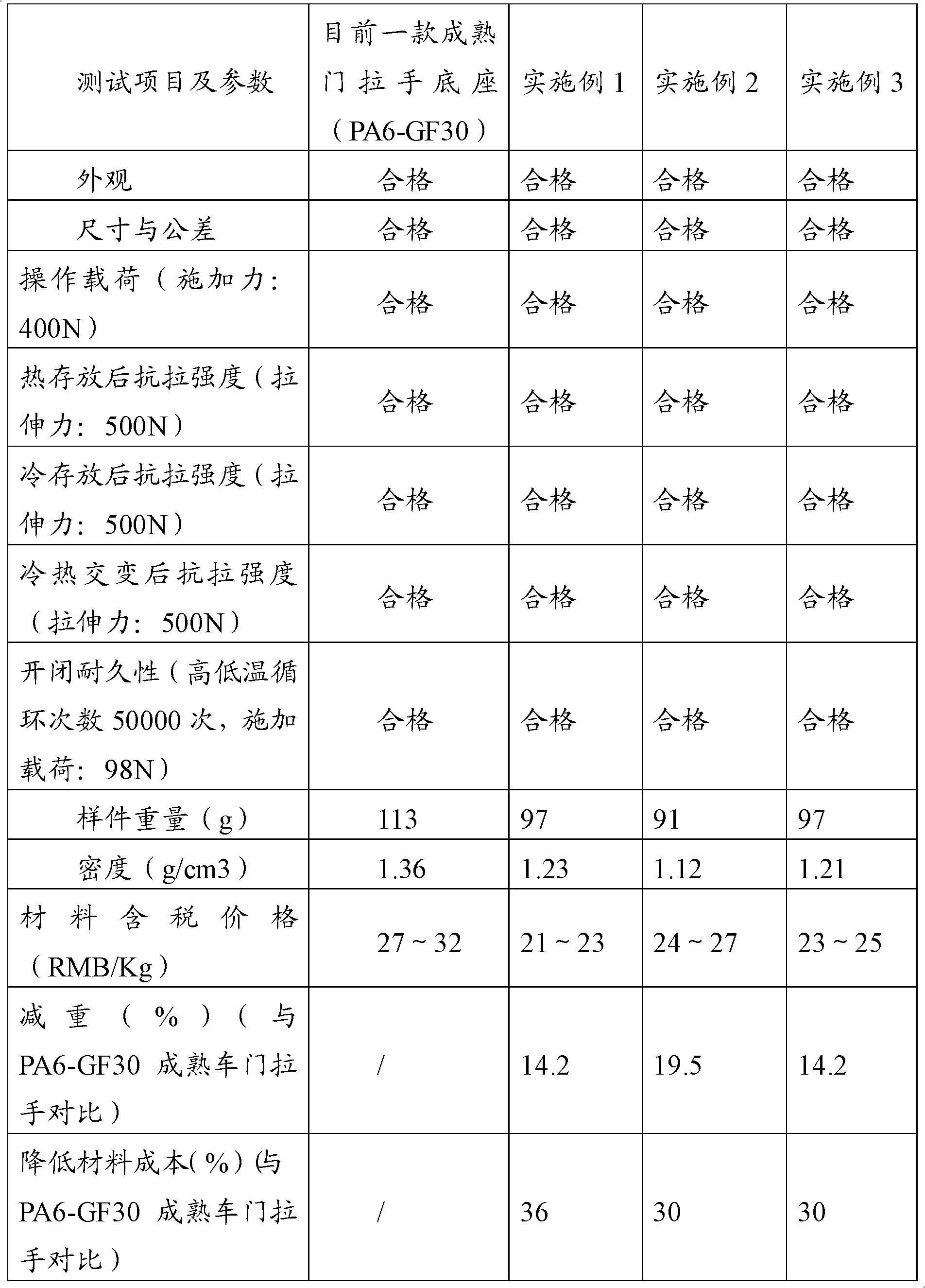

Method for manufacturing handle base of car door

The invention relates to a method for manufacturing a handle base of a car door, in which a LGFRPP (long glass fiber reinforced polypropylene) material is adopted for manufacturing the handle base of the car door. The concrete manufacturing method comprises the following steps: step 1: manufacturing raw material for injection molding the car handle base, and further comprises the steps of mixing modified polypropylene and glass fiber to form the LGFRPP and then co-extruding the LGFRPP, uniformly coating the outer surface of the glass fiber with high polymer resin of polypropylene, cooling and cutting off the LGFRPP after the LGFRPP material is extruded to obtain a granular material which is the raw material, wherein the content of the glass fiber is 30% to 40%; step 2: carrying out oven-drying the raw material; step 3: putting the raw material into a charging barrel of an injection molding machine to melt; and step 4: dividing the melted raw material into two segments and injecting the two segments into a mold for molding, and obtaining the handle base after cooling and demolding. The manufacturing method provided by the invention has the beneficial effects of meeting the requirements for product size, structure and function while reducing weight and cost and significantly saving energy consumption in production.

Owner:BEIJING ELECTRIC VEHICLE

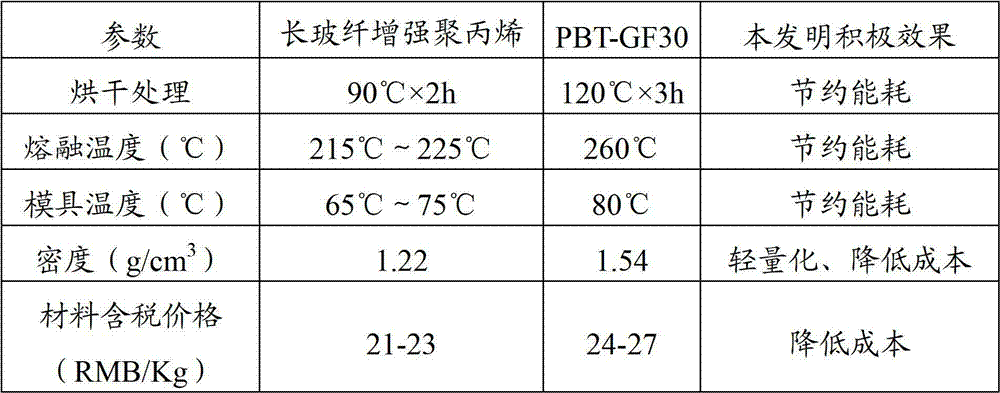

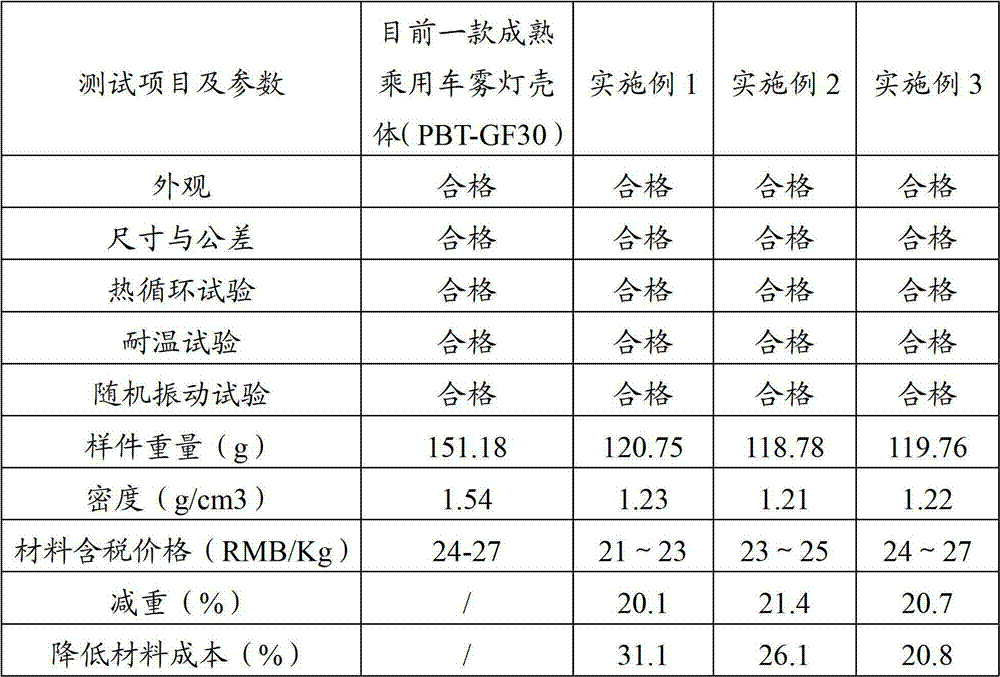

Preparation method of foglight shell of passenger car

The invention relates to a preparation method of a foglight shell of a passenger car. The method comprises the steps of co-extruding mixed modified polypropylene and glass fiber and then cooling and cutting to obtain particles, wherein the content of glass fiber in the particles is 40%, the modified polypropylene is prepared by mixing and stirring polypropylene, antioxidant and ultraviolet absorber, and melting, and weight of the polypropylene is 100 parts, weight of the antioxidant is 0.3-1.2 parts and weight of the ultraviolet absorber is 0.5-0.8 parts; drying the particles; placing the particles into a charging barrel of an injection molding machine to melt; injecting the melted particles in sections to a mould for injection moulding; and cooling and demoulding to obtain the foglight shell. According to the method provided by the invention, the weight is lightened, the cost is reduced and the energy consumption in production is saved to a great extent while size, structure and function of the product are met.

Owner:BAIC MOTOR CORP LTD

Unmanned aerial vehicle based image acquisition system, image acquisition method and unmanned aerial vehicle

InactiveCN105933615AQuality assuranceAchieve stabilityTelevision system detailsColor television detailsUncrewed vehicleEngineering

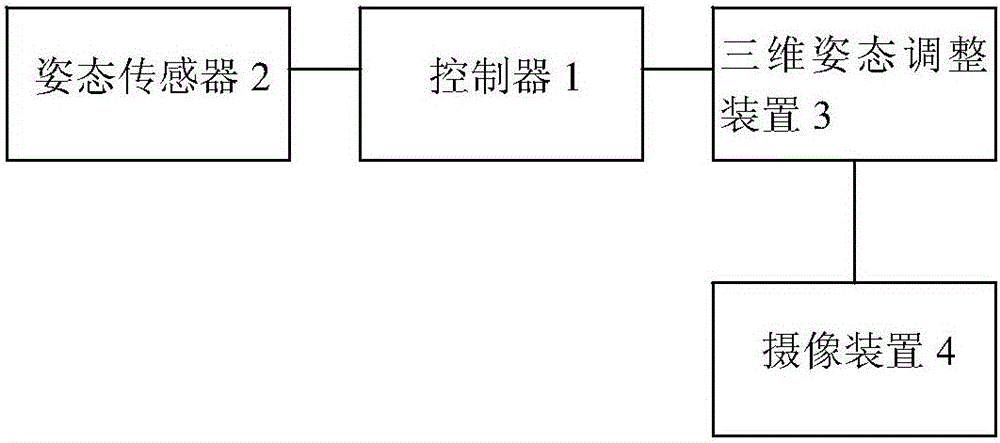

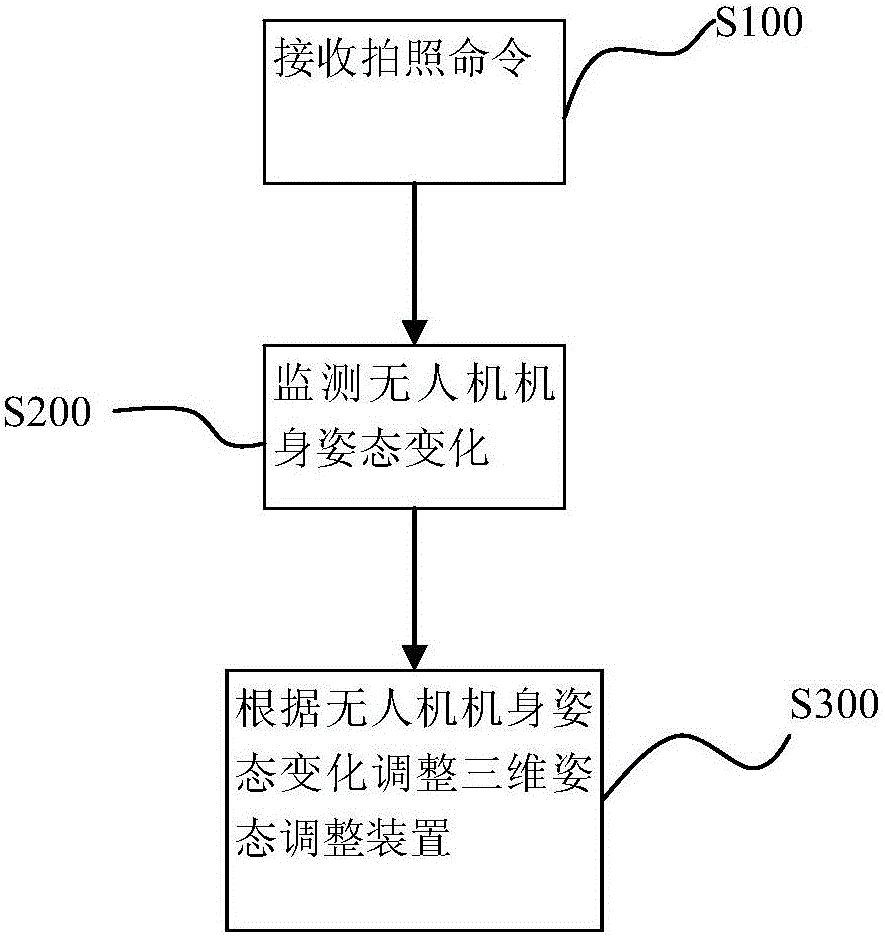

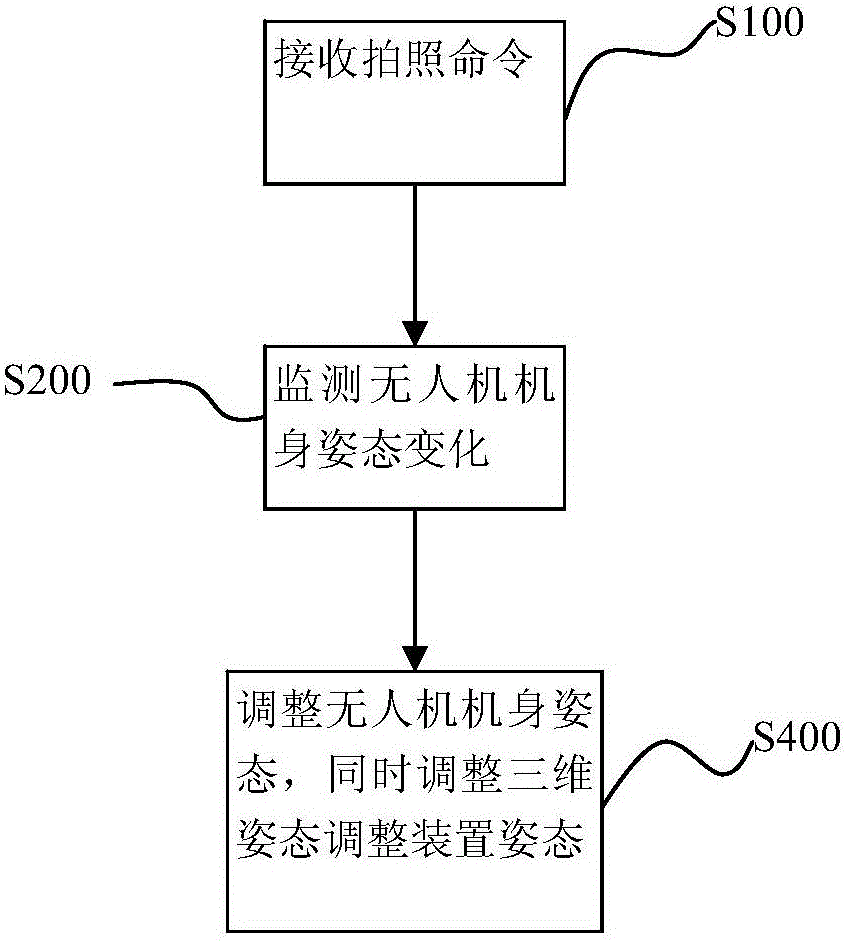

The invention relates to the field of unmanned aerial vehicle control, and particularly relates to an unmanned aerial vehicle based image acquisition system, an image acquisition method and an unmanned aerial vehicle. The unmanned aerial vehicle based image acquisition system comprises a controller, an attitude sensor, a three-dimensional attitude adjustment device and a camera device. According to the unmanned aerial vehicle based image acquisition system provided by the invention, the high-sensitivity three-dimensional attitude adjustment device is arranged, and the camera device is fixedly arranged on the three-dimensional attitude adjustment device; and body attitude variations of the unmanned aerial vehicle when being photographed are sensed, a lens of the camera device is enabled not to be affected by the body attitude variations of the unmanned aerial vehicle through automatically adjusting the three-dimensional attitude adjustment device, thereby being always kept at the same direction and the same angle, thus realizing the lens attitude stability of the camera device of the unmanned aerial vehicle, and ensuring the quality of images.

Owner:BEIFANG UNIV OF NATITIES

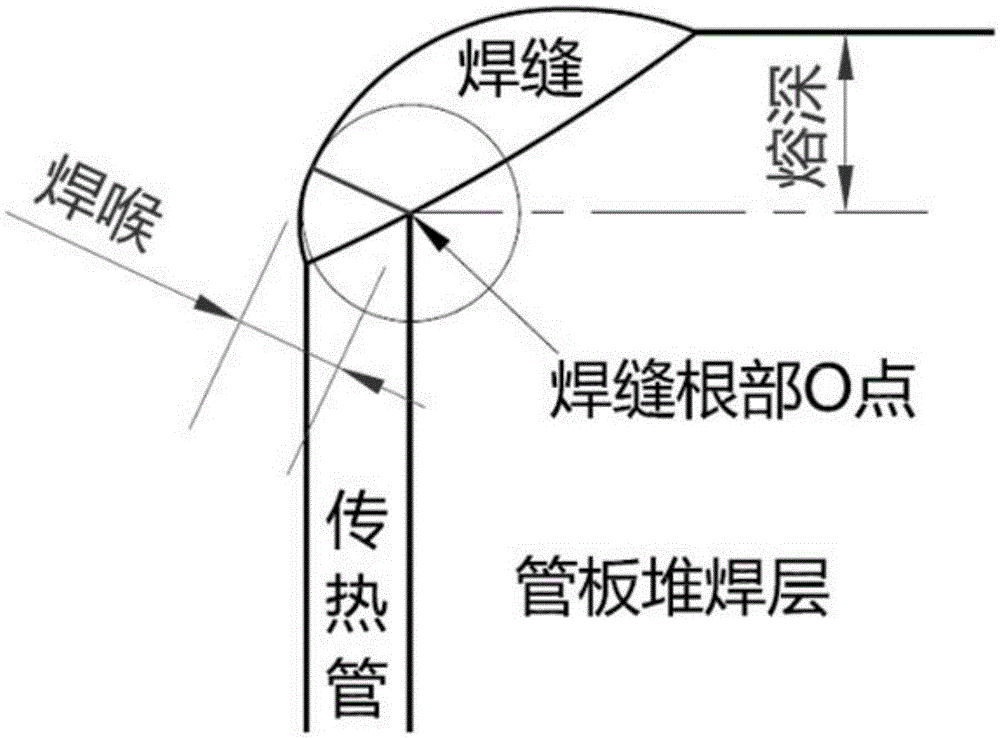

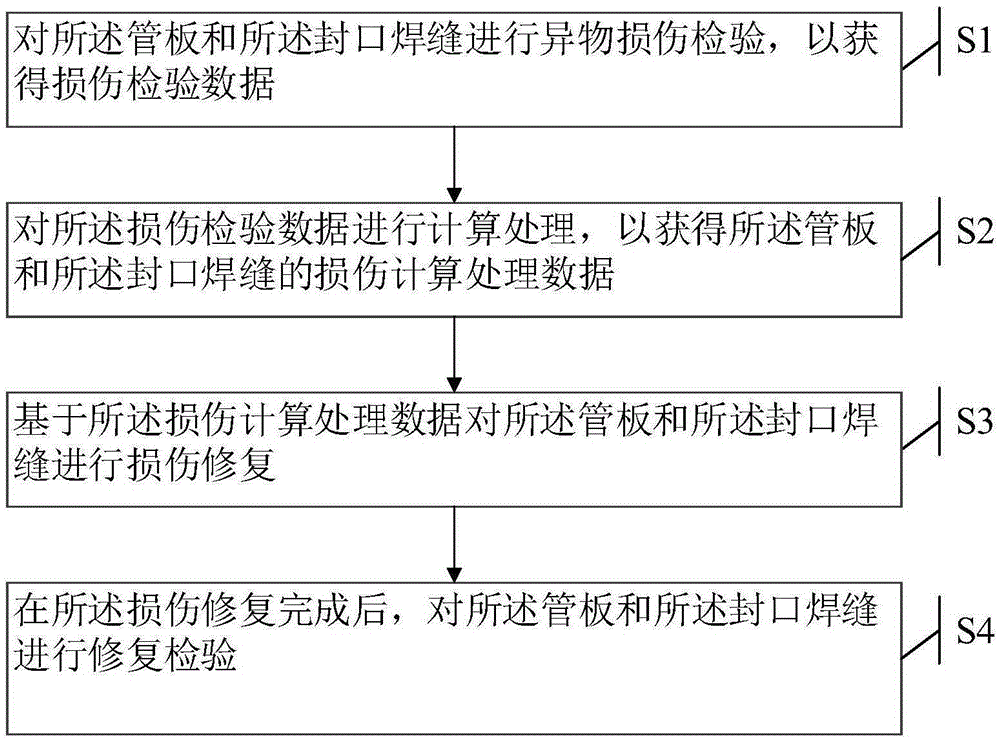

Method and system for damage repair of tube plate and caulk weld of steam generator of nuclear power station

ActiveCN105234573AMeet sizeMeet the hardened layerHeat exchange apparatusMetal working apparatusForeign object damageNuclear power

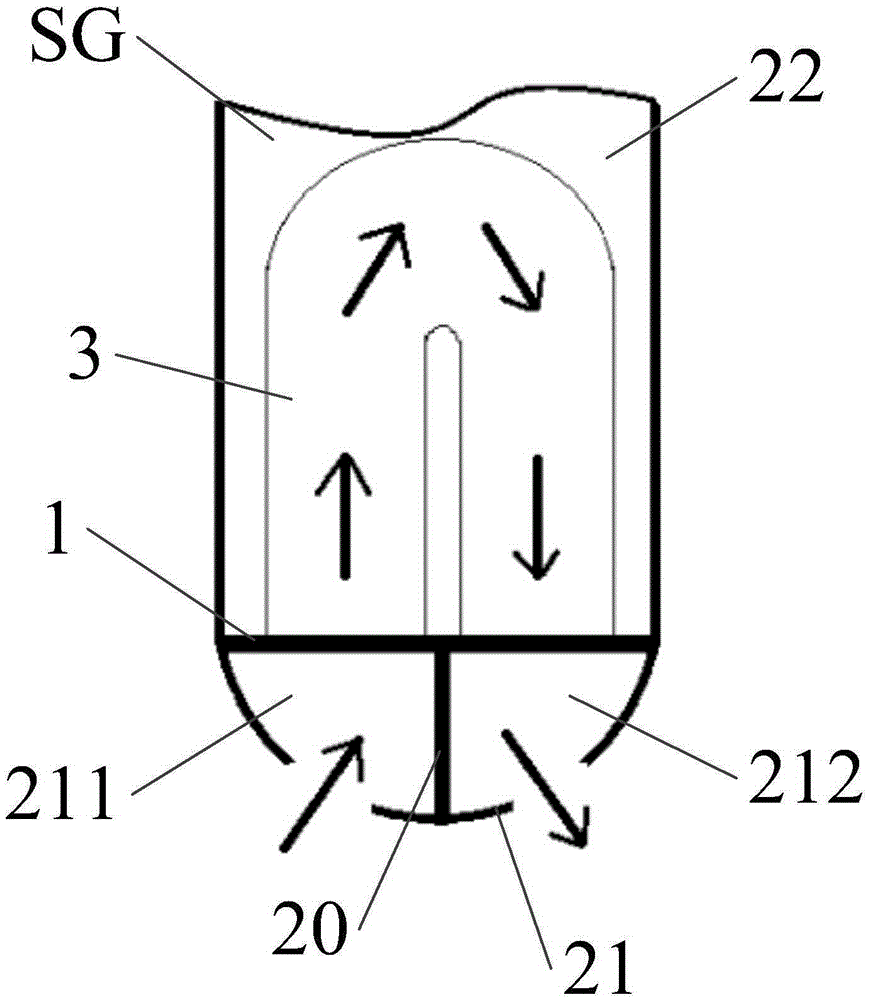

The invention discloses a method and a system for damage repair of a tube plate and a caulk weld of a steam generator of a nuclear power station, and solves the technical problem that a conventional SG site repair technology cannot completely eliminate the influence of foreign object damage on SG. The method comprises the following steps: S1, conducting foreign object damage inspection on the tube plate and the caulk weld to obtain damage inspection data; S2, calculating the damage inspection data to obtain damage calculation data of the tube plate and the caulk weld; S3, conducting damage repair on the tube plate and the caulk weld based on the damage calculation data; and S4, after damage repair is finished, conducting repair inspection on the tube plate and the caulk weld to ensure that the repaired tube plate and the repaired caulk weld meet the equipment code requirement. Through the adoption of the method and the system, that the size of the repaired caulk weld meets the requirement is ensured, and a hardened layer and a stress corrosion risk can be eliminated.

Owner:中广核工程有限公司 +1

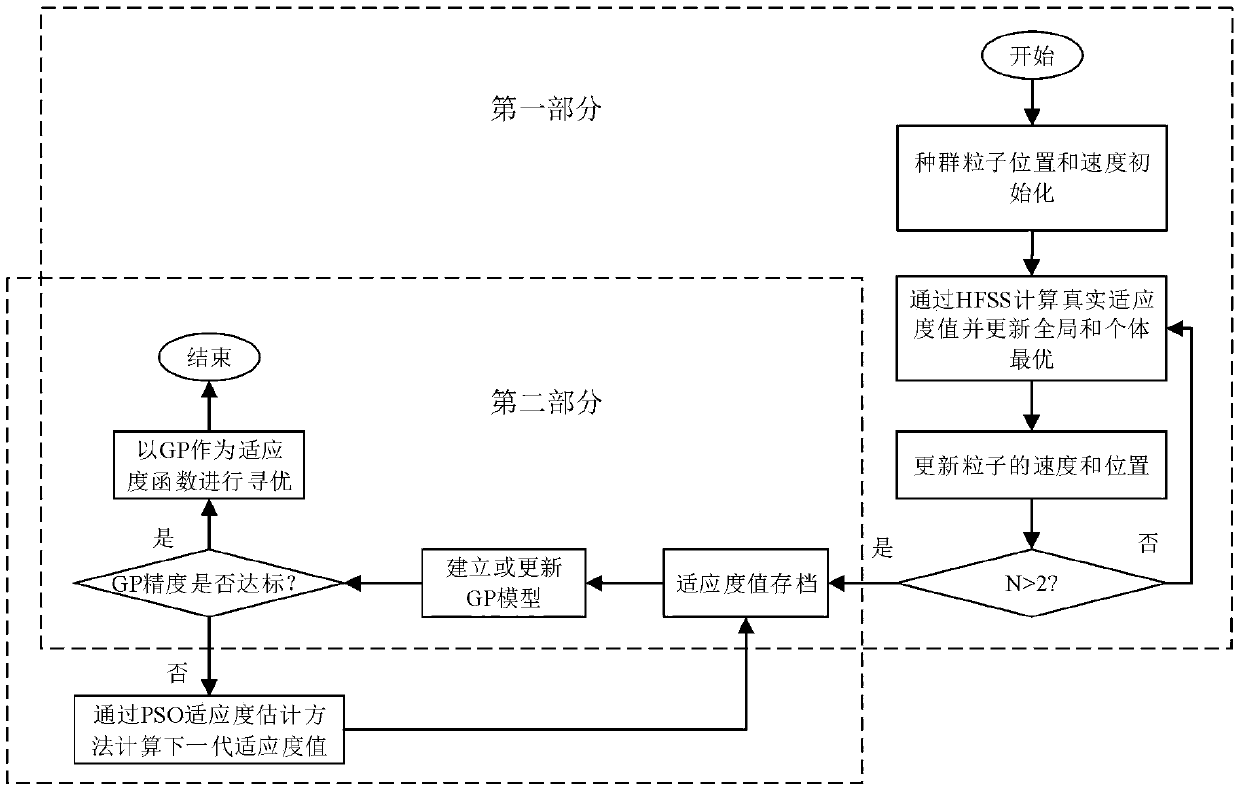

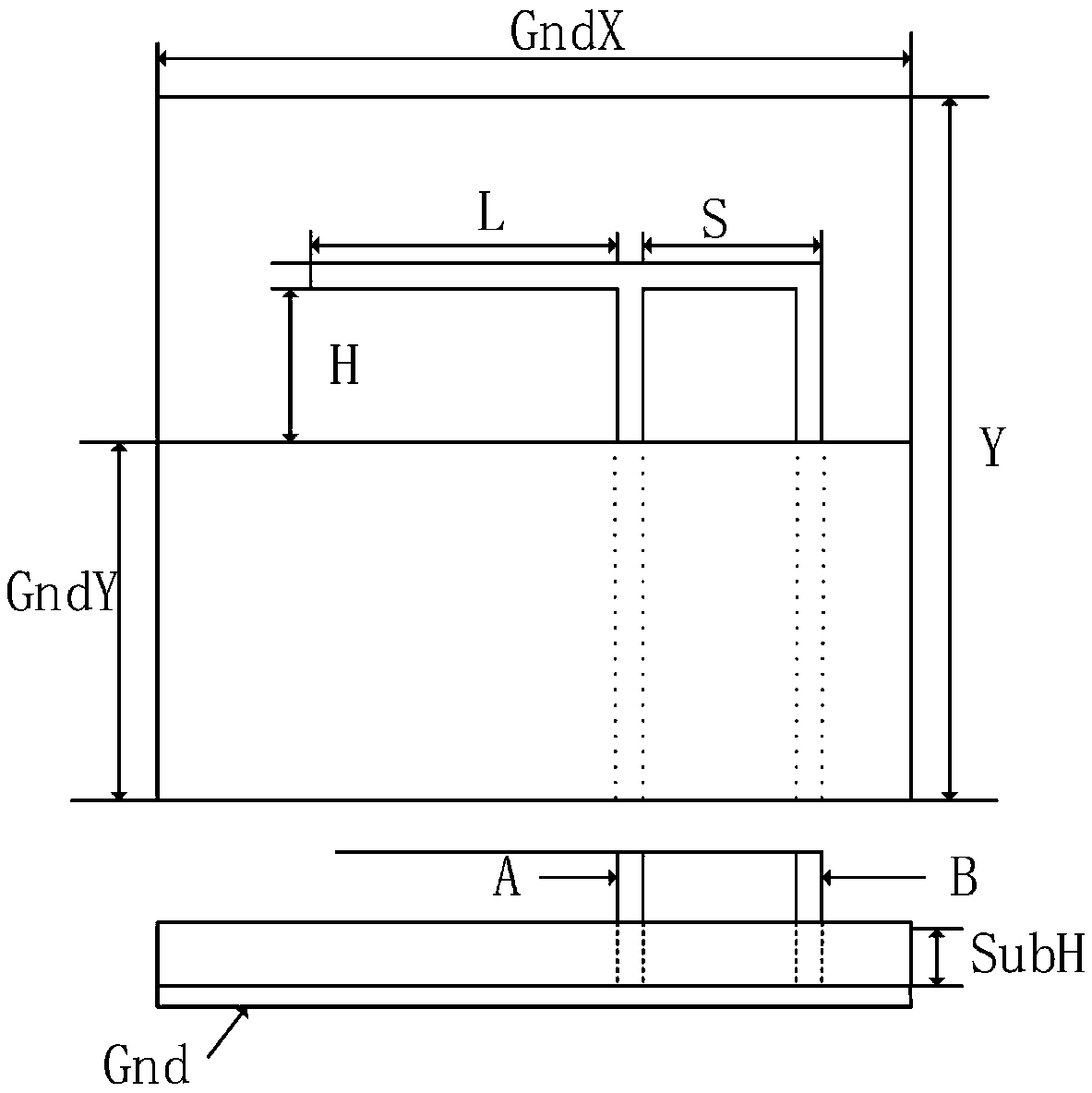

Antenna rapid optimization design method

PendingCN109635343AMeet sizeReduce preparation timeDesign optimisation/simulationSpecial data processing applicationsFull waveDual mode

The invention discloses a Gaussian process (GP) modeling based on PSO (Particle Swarm Optimization) fitness estimation and used for designing an antenna. The Gaussian process (GP) modeling is based onthe PSO fitness estimation. When the GP model is constructed, one part of data comes from the accurate simulation value of the full-wave electromagnetic simulation software, and the other part of data comes from the fitness estimation value of the PSO algorithm, that is, the preparation time for GP modeling data is shortened by reducing the time-consuming accurate simulation times, so that the purpose of efficient and rapid modeling is achieved. And finally, the time-consuming fitness value calculation is replaced by the GP of which the precision reaches the standard to reduce the design time, so that the time required by the whole optimization process is shortened. By optimizing and designing an Inverted-F antenna (Inverted-F Antennae, IFA) and a GPS Beidou dual-mode microstrip antenna (GPS and Beidou Dual-mode Microstrip Antenna), the method is verified, and the high efficiency and accuracy of the method are proved.

Owner:JIANGSU UNIV OF SCI & TECH

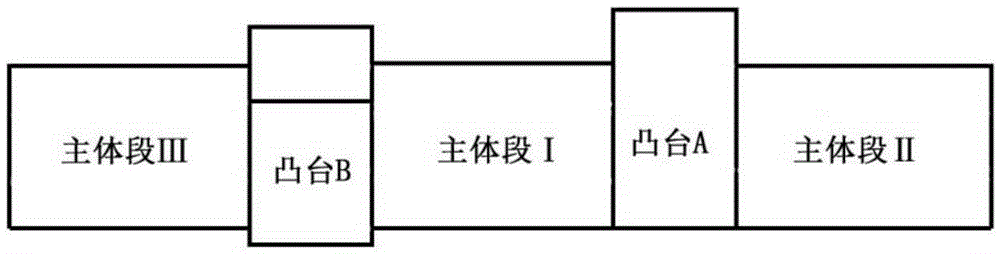

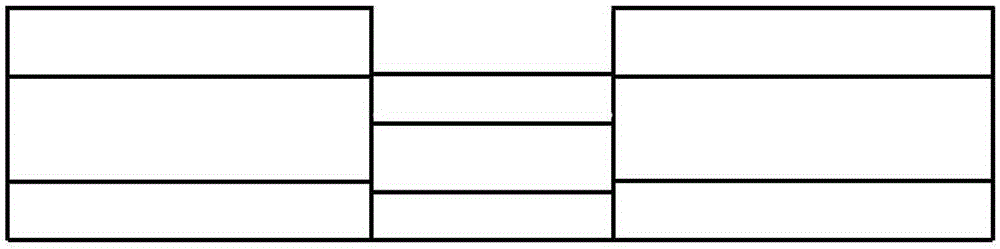

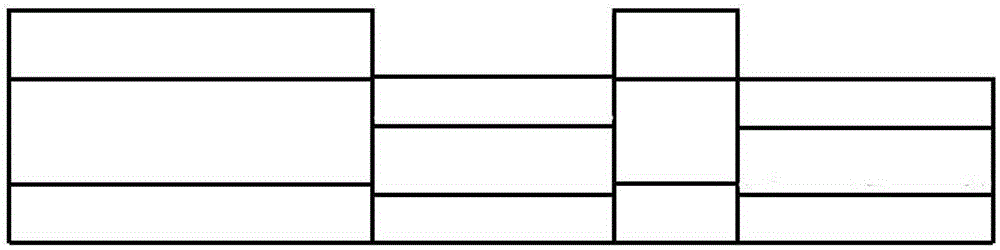

Whole forging method of loop main pipe of AP1000 nuclear power plant

The invention relates to a whole forging method of a loop main pipe of an AP1000 nuclear power plant, and belongs to the technical field of whole forging of stainless steel special-shaped steel blanks. Firstly, an electroslag casting steel ingot is repeatedly upset and lengthened to smash a massive casting structure; then, a main section and a boss of the main pipe are respectively forged; and finally, the boss is forged to obtain fine grain structures. The method can reduce the melted times and time of forgings, improves the forging efficiency, satisfies the shape and size requirements of the forgings, and can refine the structures of the forgings to enable all parts to reach the requirement of grain size above the grade 2.

Owner:UNIV OF SCI & TECH BEIJING

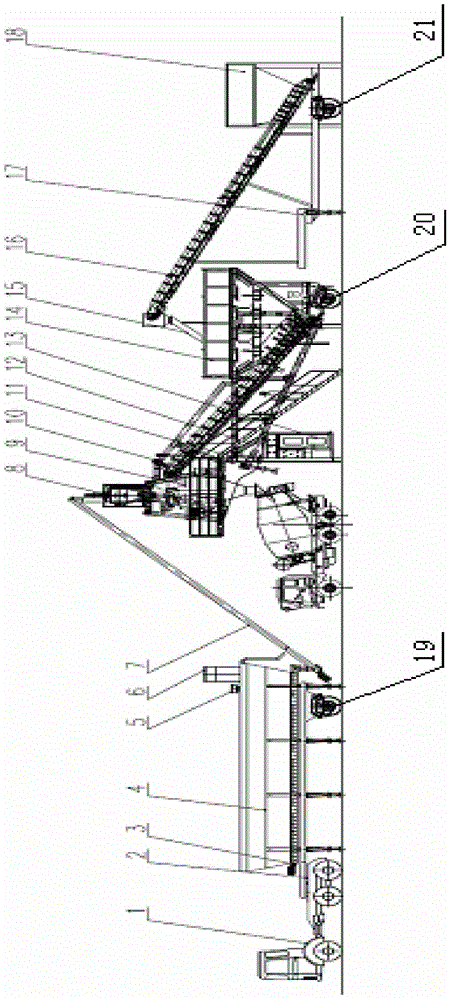

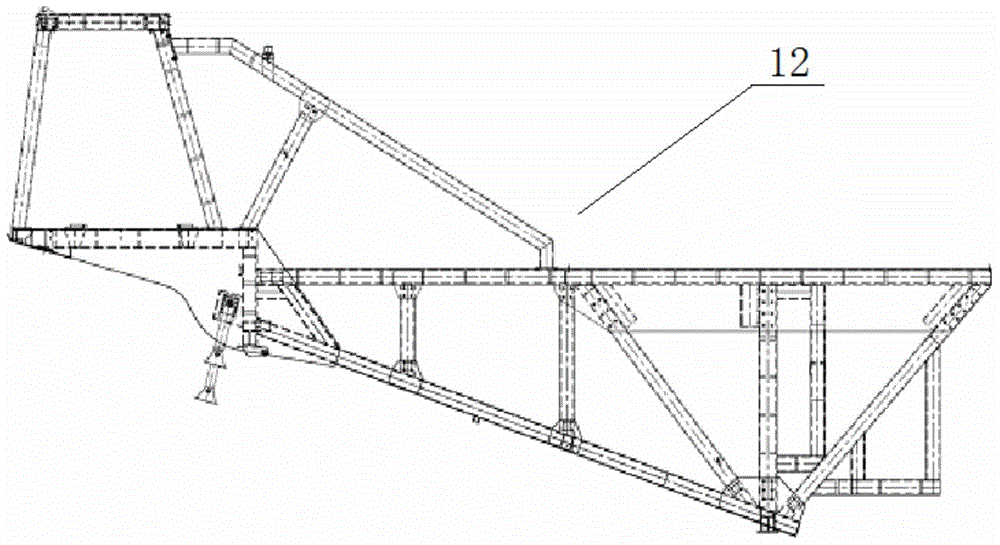

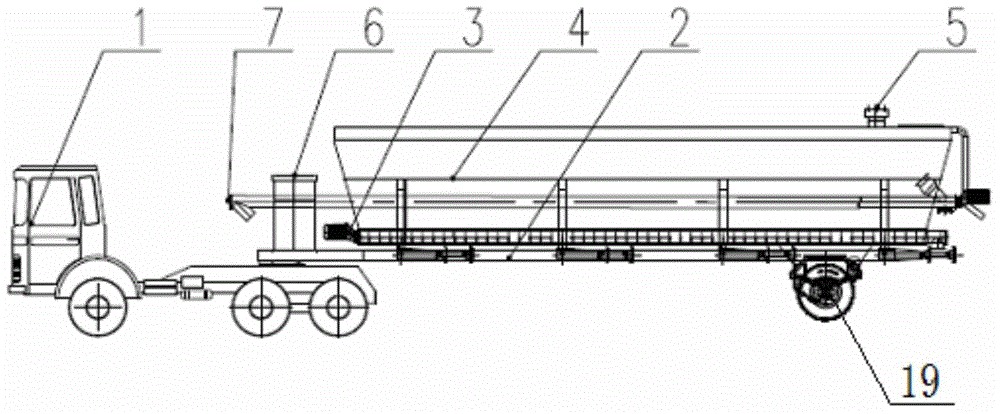

Novel full-movement easy-disassembly-assembly concrete stirring station and transport method thereof

The present invention discloses a novel full-movement easy-disassembly-assembly concrete stirring station and a transport method thereof. The novel full-movement easy-disassembly-assembly concrete stirring station comprises a tractor head, a semi-trailer chassis, a material feeding screw machine, a horizontal cylinder bin, a pressure safety valve, a dust collection machine, a conveying screw machine, a metering module, a stirring module, a sandstone metering conveying module, a control module, a walking main body frame, a control room, a material preparing bin, a material distribution device, a feeding belt machine, a semi-trailing walking chassis and a material receiving hopper. The novel full-movement easy-disassembly-assembly concrete stirring station and the transport method thereof have the following advantageous effects that: the equipment has the complete functions, the schemes capable of being selected by customers are more, the economic performance is high, all the modules of the whole stirring station can move so as to substantially improve the rapidness of the field transferring transportation and reduce the labor intensity and the workload of the transportation splitting and installation, the project requiring often field transportation is met at a maximum, the shipping container packing size can be met, the number of the containers can be reduced at a maximum, and the transportation cost is reduced.

Owner:ZHEJIANG TRUEMAX ENG

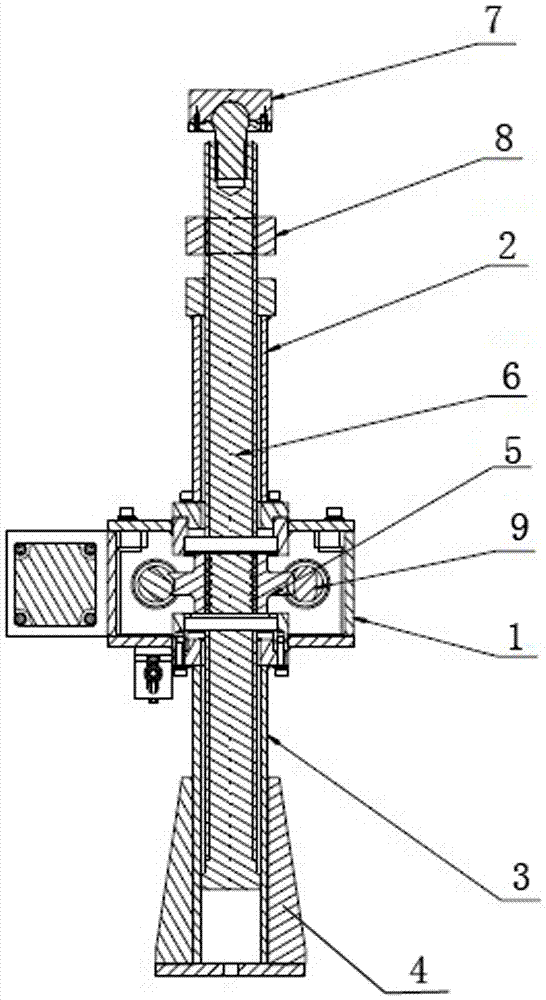

Tool installation mould for upside-down construction of multi-curve superimposed steel box girder and construction method thereof

PendingCN107386130AMeet sizeFulfil requirementsBridge erection/assemblyBridge materialsScrew positionArchitectural engineering

The invention relates to the field of general assembly of girder sections of steel box girders, in particular to a tool installation mould for upside-down construction of a multi-curve superimposed steel box girder and a construction method thereof. The tool installation mould for the upside-down construction of the multi-curve superimposed steel box girder includes a box body, an upper column and a lower column are fixed to the box body and located on and under the box body respectively, and the lower end of the lower column is fixed into a base; the box body is internally provided with a worm wheel and worm mechanism, lead screws positioned inside the upper column and the lower column are arranged on worm wheels, and the top portions of the lead screws are provided with supporting heads. The adjustable mould has excellent universality, and by utilizing the self-locking and adjustable properties of the adjustable mould, the adjustable mould can serve as an adjustable moulding bed support for changes of curved section frame lines and be adjusted in the vertical direction.

Owner:CHINA RAILWAY SIXTH GROUP +1

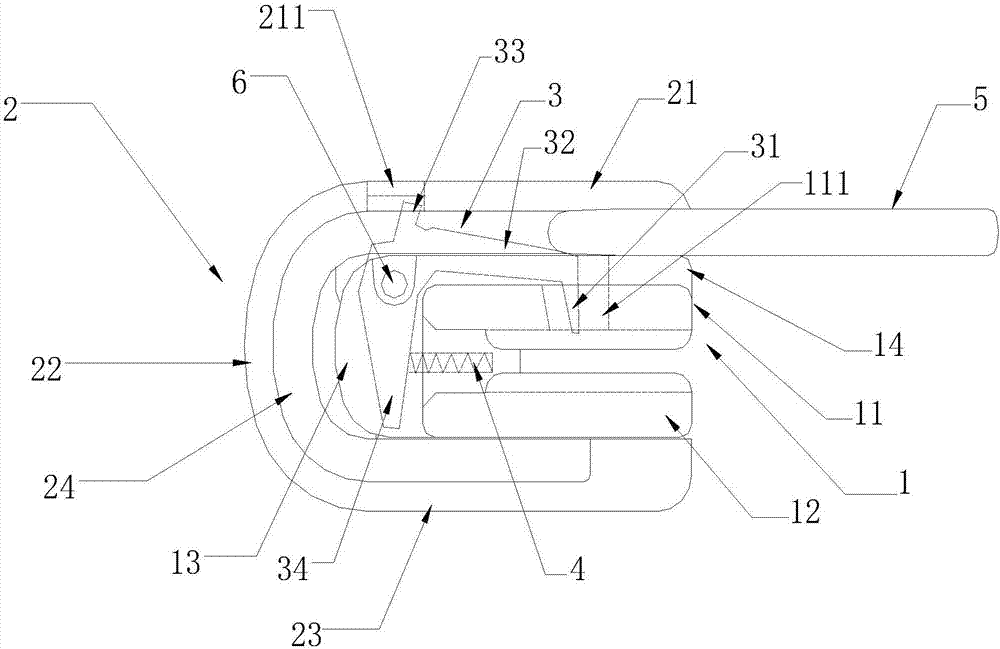

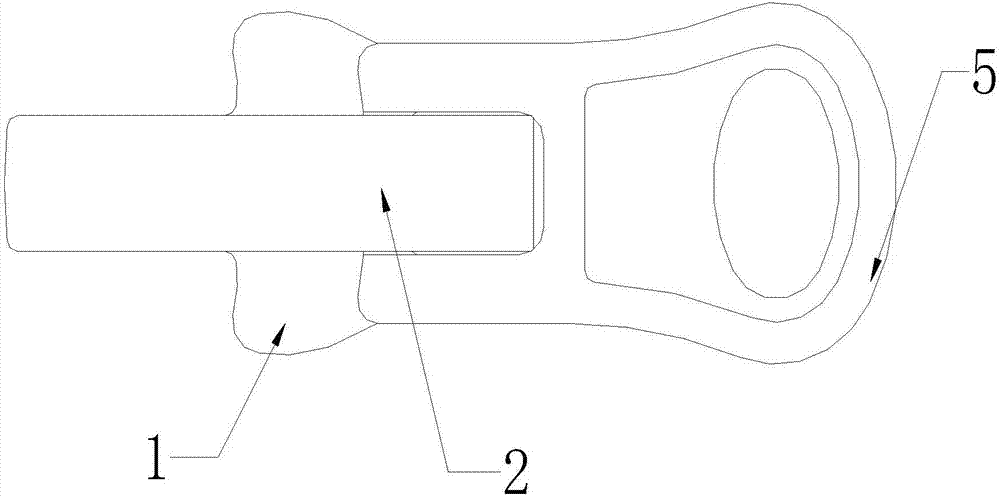

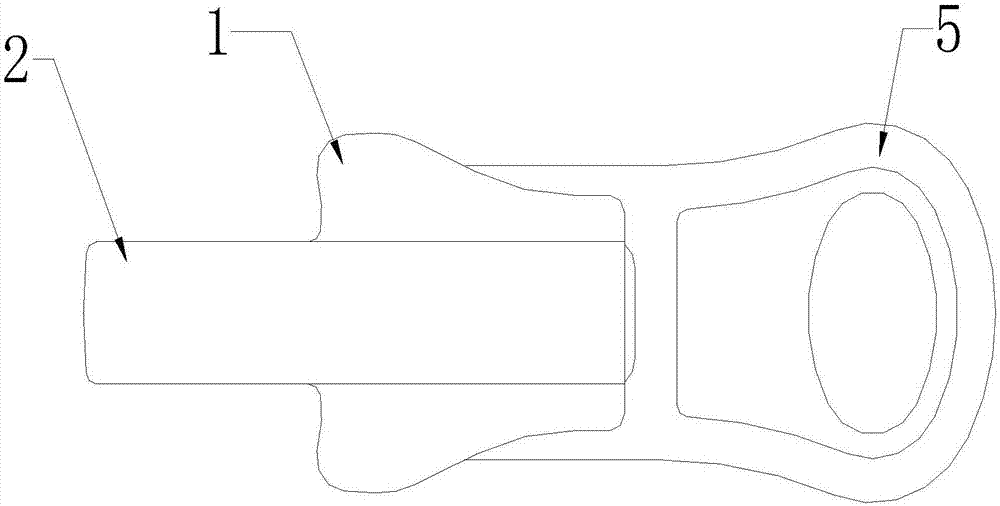

Omni-directional rotary zipper head

The invention discloses an omni-directional rotary zipper head. The zipper head comprises a zipper head body, a multi-rail structure, a locking structure, a spring structure and a pulling piece, the pulling piece is provided with two clamping connection end portions and connected onto the multi-rail structure in a clamping mode, the zipper head body comprises an upper plate and a lower plate, the multi-rail structure and the zipper head body are installed in a perpendicularly crossing mode, the multi-rail structure comprises rails in three directions, the locking structure is arranged between the zipper head body and the multi-rail structure, the spring structure is arranged between the locking structure and the zipper head body, the zipper head body comprises an introduction port and a meshing port, a front baffle plate is arranged at the front end of the zipper head body, and the introduction port is divided symmetrically and equally by the front baffle plate. According to the zipper head, omni-directional 360-degree rotation of the pulling piece can be achieved through the multi-rail structure, and modified polycarbonate composite material has the performance of corrosion resistance and high and low temperature resistance, so that smooth use of the zipper head in a double-faced zipper is guaranteed.

Owner:佛山市南海旺鸿兴拉链配件有限公司

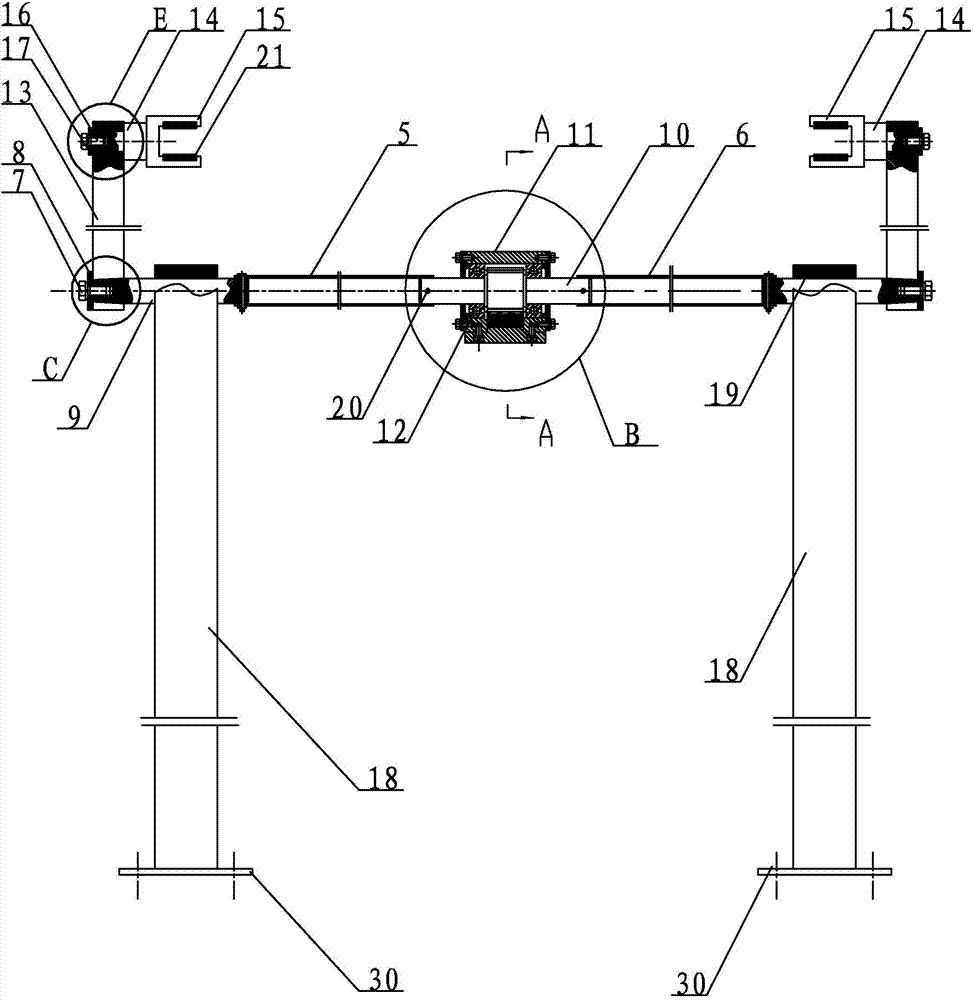

Swing rod and sliding block reciprocating type solar wing auxiliary turnover mechanism

The invention relates to a solar wing auxiliary turnover mechanism, in particular to a swing rod and sliding block reciprocating type solar wing auxiliary turnover mechanism. The problem that a solar wing cannot be freely unfolded and folded in a current ground test is solved. The swing rod and sliding block reciprocating type solar wing auxiliary turnover mechanism comprises a power device, a supporting mechanism, a transitional shaft, a transmission device and two rocker arm mechanisms, the transitional shaft is rotatably arranged on the supporting mechanism, the transmission device is arranged in the middle of the transitional shaft, the power device is connected with the transmission device, and the two ends of the transitional shaft are respectively and rotatably provided with one rocker arm mechanism. A set of the power device and the transmission device is adopted, power is transmitted in two directions, and the two rocker arm mechanisms are driven to control the solar wing to be folded and unfolded. The problem that a solar wing driving mechanism cannot be folded and unfolded on the ground is effectively solved, and high reliability and good expansibility are achieved. The swing rod and sliding block reciprocating type solar wing auxiliary turnover mechanism is used for assisting the solar wing in turning over.

Owner:HARBIN INST OF TECH

Optical fiber laser cutting blade type hole energy regulation method for sheet metal

The invention belongs to the technical field of efficient, high-precision and high-quality laser cutting forming of metal plates, and relates to an optical fiber laser cutting blade type hole energy regulation method for sheet metal. The method comprises the following steps that firstly, a machining graph is reasonably segmented, so that the whole machining graph is divided into four sections, theregion with the larger arc radius difference is divided into an individual line segment, then a method for combining four-section variable-speed and variable-power energy compensation is adopted to reduce erosion and slag adhering of a small arc section in the machining process in a mode of energy regulation and control on separate lines of the sheet metal in the laser cutting process, the energycaused by heat dissipation and heat accumulation is balanced by reducing the laser energy density at a small arc radius part of the sheet metal, the cutting precision is improved, erosion and slag adhering are reduced, and the large arc profile error meets the technical requirements.

Owner:DALIAN UNIV OF TECH

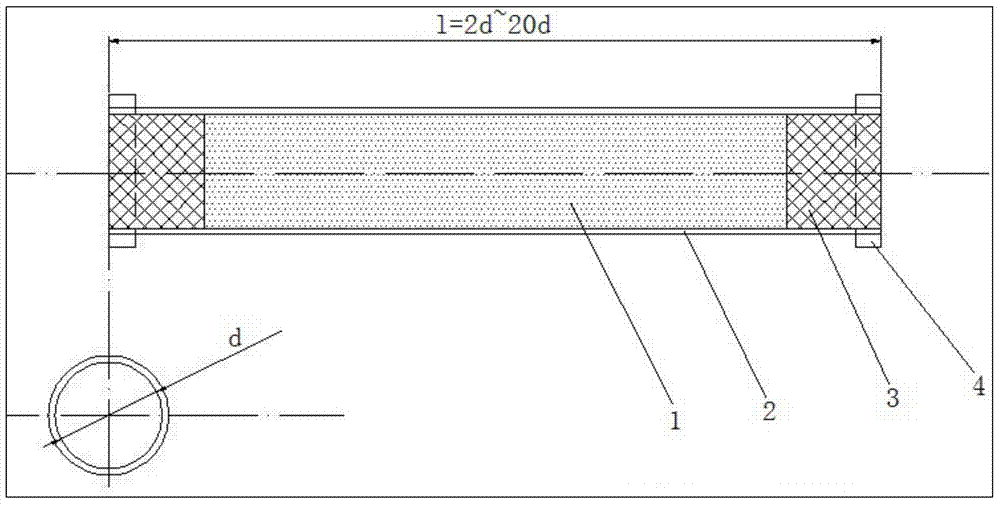

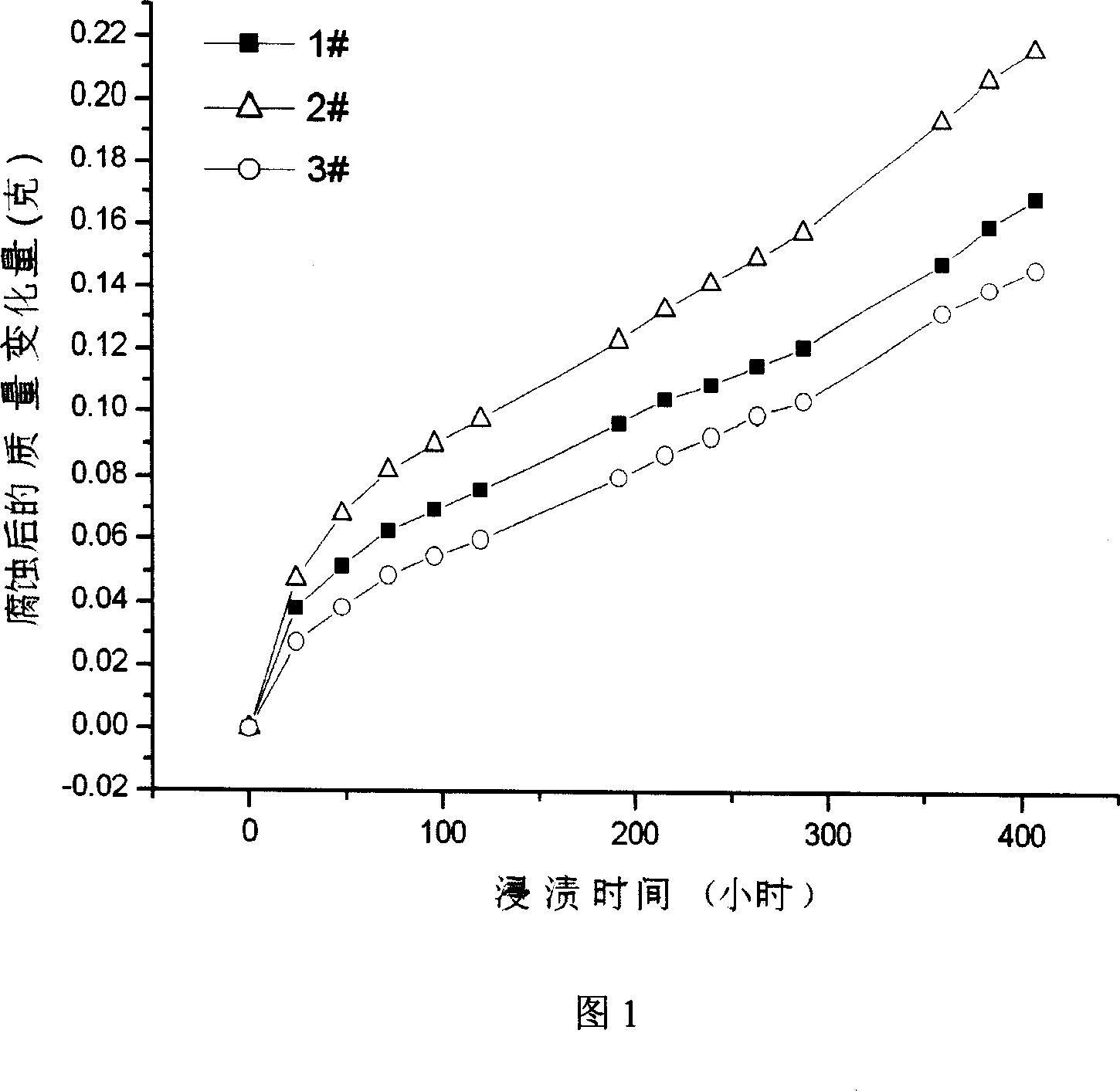

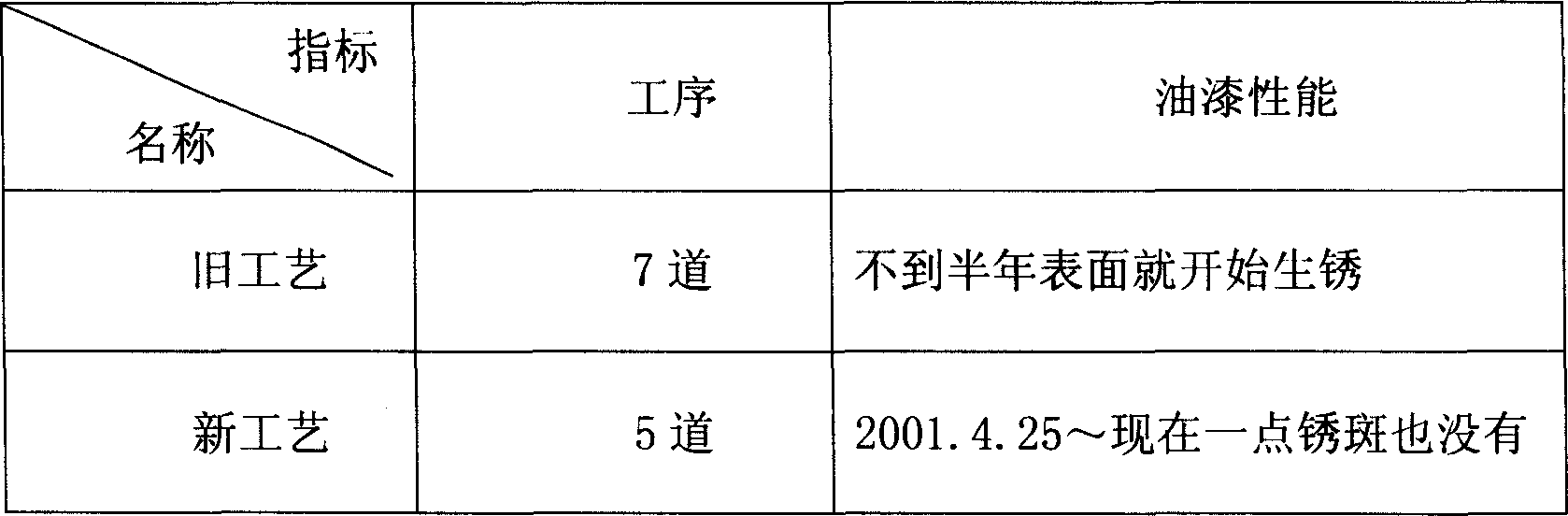

Zinc-aluminium alloy wire, and its manufacturing method and use

The invention supplies allumen and its manufacturing method. The atom percentage of its components metallic aluminum is 41-55%. The rest is zinc. The method includes the following steps: using level continuous casting after smelting for zinc and aluminum to gain Zn Al alloy bar; high temperature rotary swaging or hot rolling; middle temperature drawing to form alloy filament. The invention also supplies the application of the alloy as steel surface anticorrosive.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com