3D visual inspection system and inspection method of gluing quality

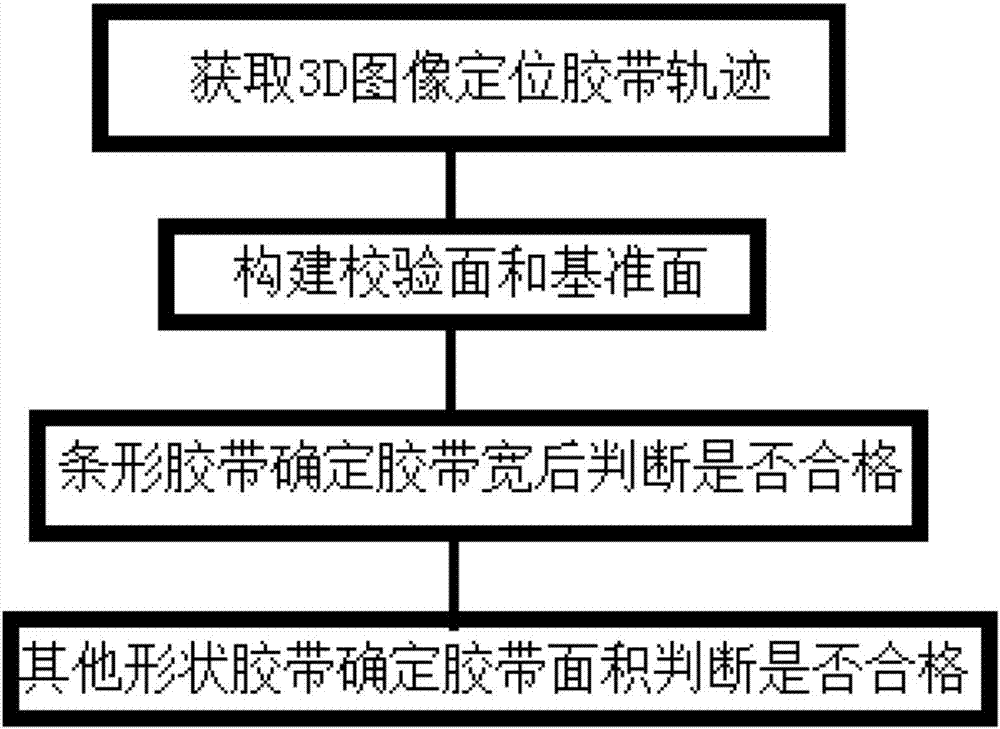

A visual inspection and 3D technology, used in measuring devices, instruments, optical devices, etc., can solve the problem that 2D vision cannot provide height information, the glue quantity of glued products cannot be detected by 2D vision, and the time consumption of servo movement pause detection and other problems to achieve the effect of eliminating image interference, satisfying size, and reducing beats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

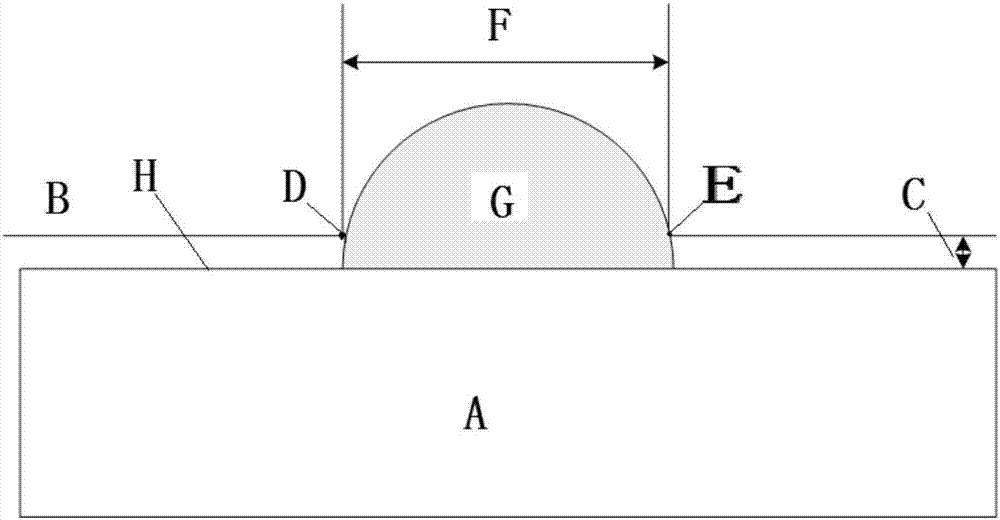

[0052] A 3D visual inspection system for gluing quality provided by the present invention includes: a 3D profile scanner (3D camera), composed of an area array CCD and an in-line laser generator, used to take 3D images of tapes and gluing products ;

[0053] The in-line laser generator emits striped light to irradiate the surface of the object, and the area array CCD is exposed to convert the optical signal into an electrical signal;

[0054] An image processing unit, which transmits the 3D image taken by the 3D contour scanner to the computer memory;

[0055]The encoder is fixed together with the 3D contour scanner, and according to the preset starting conditions of the 3D contour scanner, the encoder generates a pulse signal to start the 3D contour scanner to start shooting; the encoder can be driven by a servo motor, and the 3D contour scanner The starting condition is the moving distance of the 3D contour scanner or a preset time interval. Among them, the time interval f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com