Imaging system of atomic force microscope on the basis of quartz tuning fork probe

An atomic force microscope and quartz tuning fork technology, applied in the field of experimental instruments, can solve the problems that it is difficult for students to quickly understand the working principle of the atomic force microscope, the high cost of the experiment, and the complicated operation of the instrument, so as to reduce the teaching cost, large scanning range and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings.

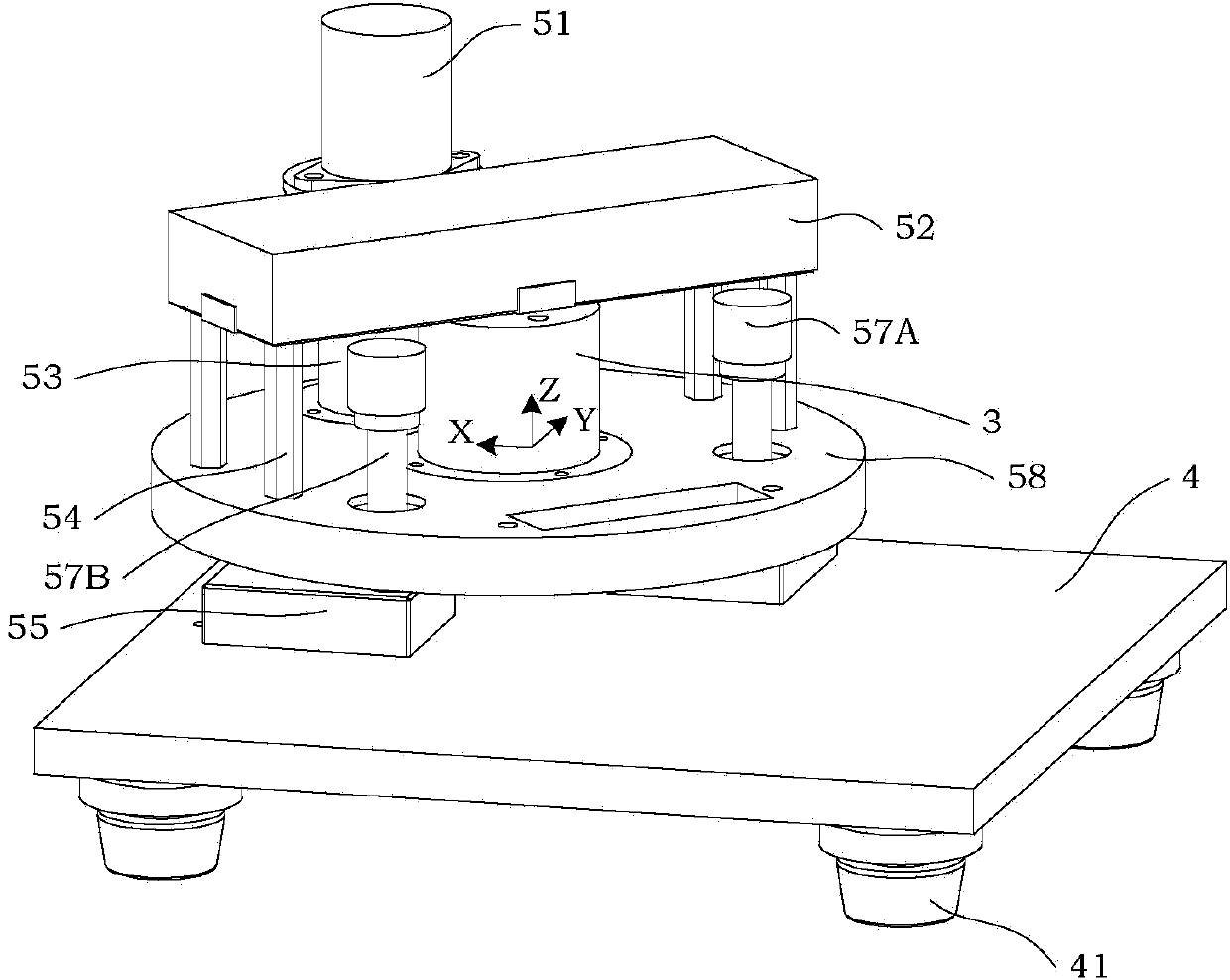

[0047] The imaging system of the atomic force microscope based on the quartz tuning fork probe designed by the present invention is a teaching instrument designed to allow students to master the basic principles and applications of the atomic force microscope, improve the students' hands-on ability in experiments, and enhance the experimental effect. By actually operating the imaging system of the atomic force microscope based on the quartz tuning fork probe designed by the present invention, the students can scan and obtain the surface topography map of the sample 4A on the sample stage 4 . The atomic force microscope plays an important role in characterizing the surface structure and properties of substances, and it will be of great help to students in their future research and study through this experiment.

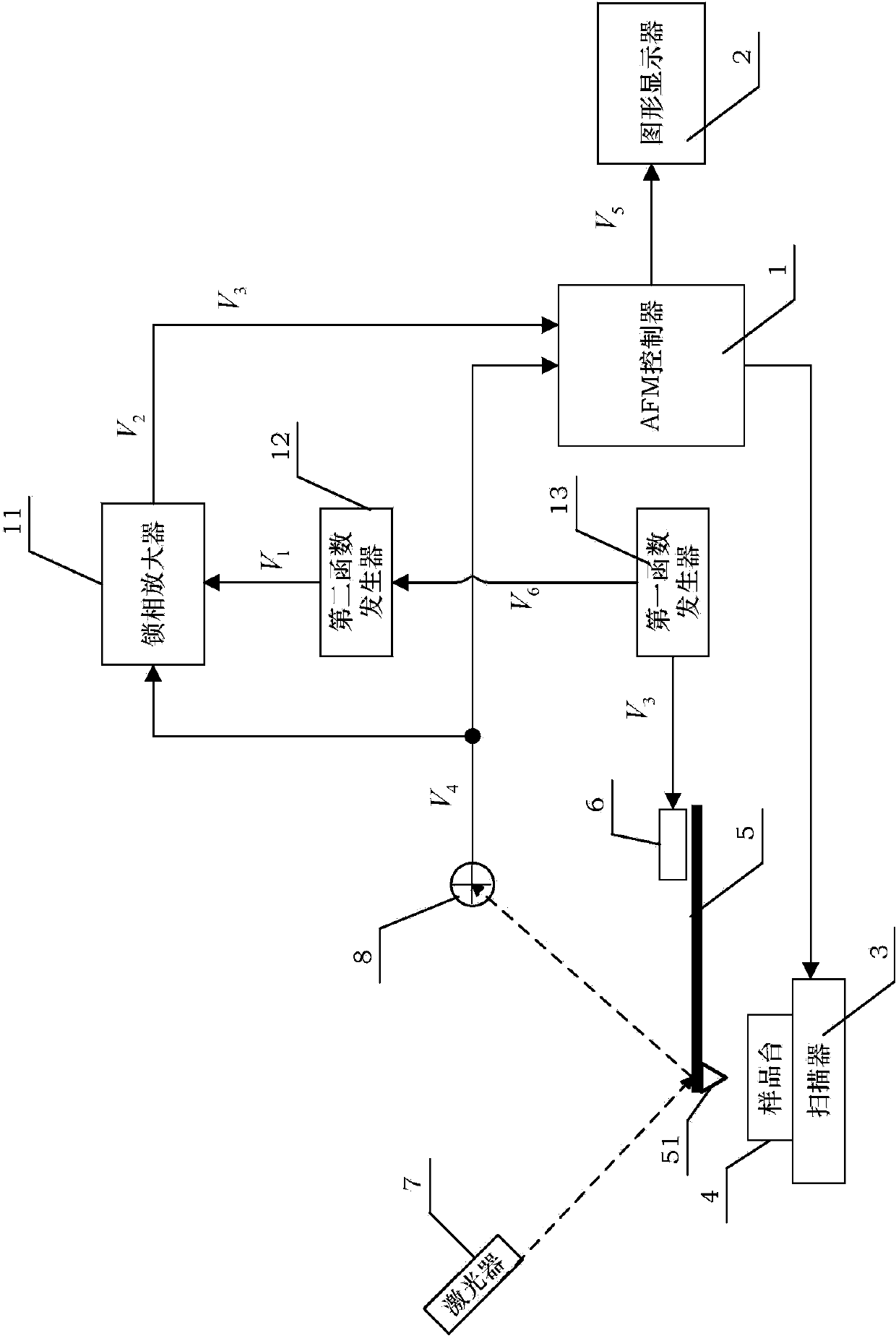

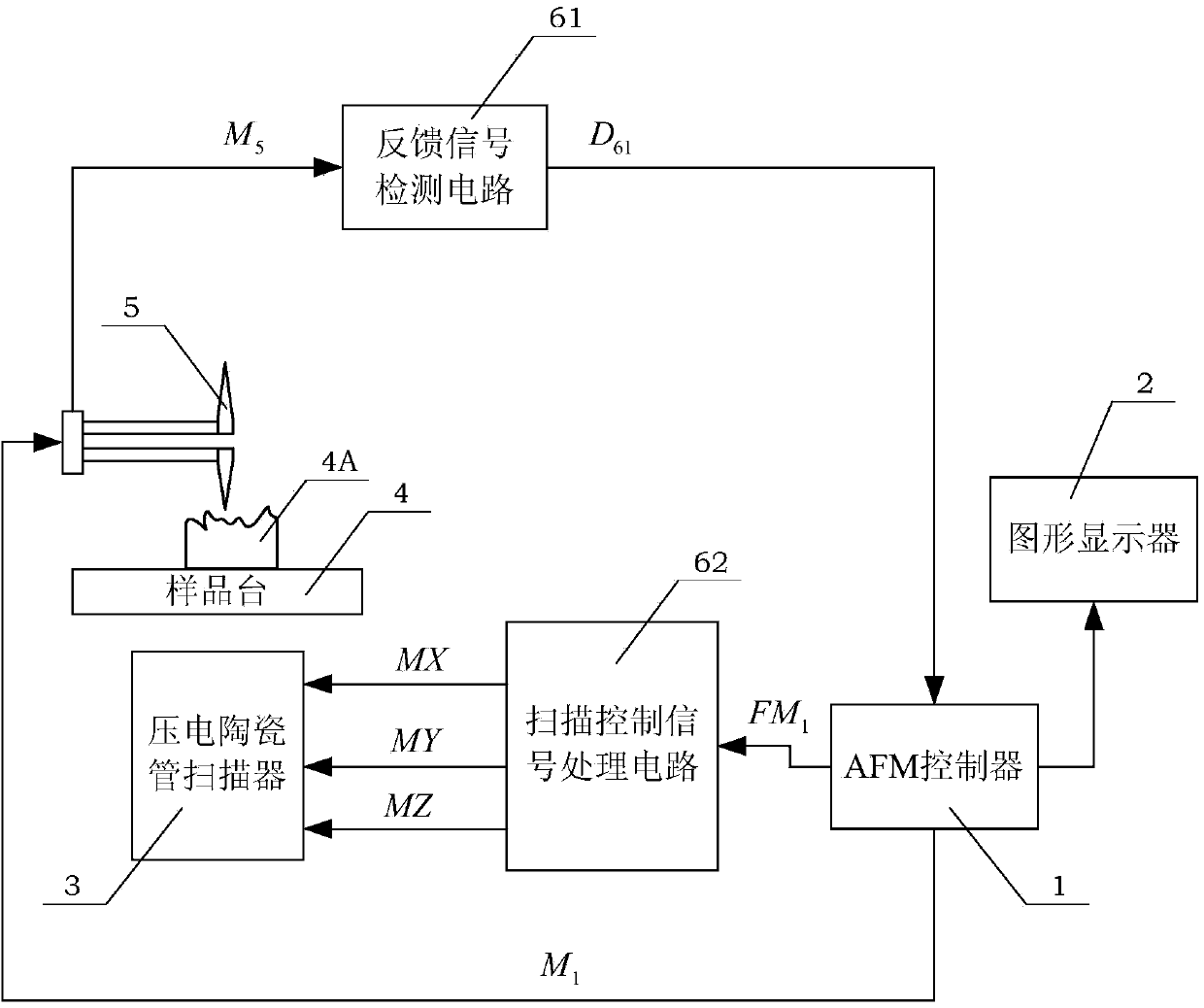

[0048] see figure 2 Shown, the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com