Patents

Literature

711 results about "Surface point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

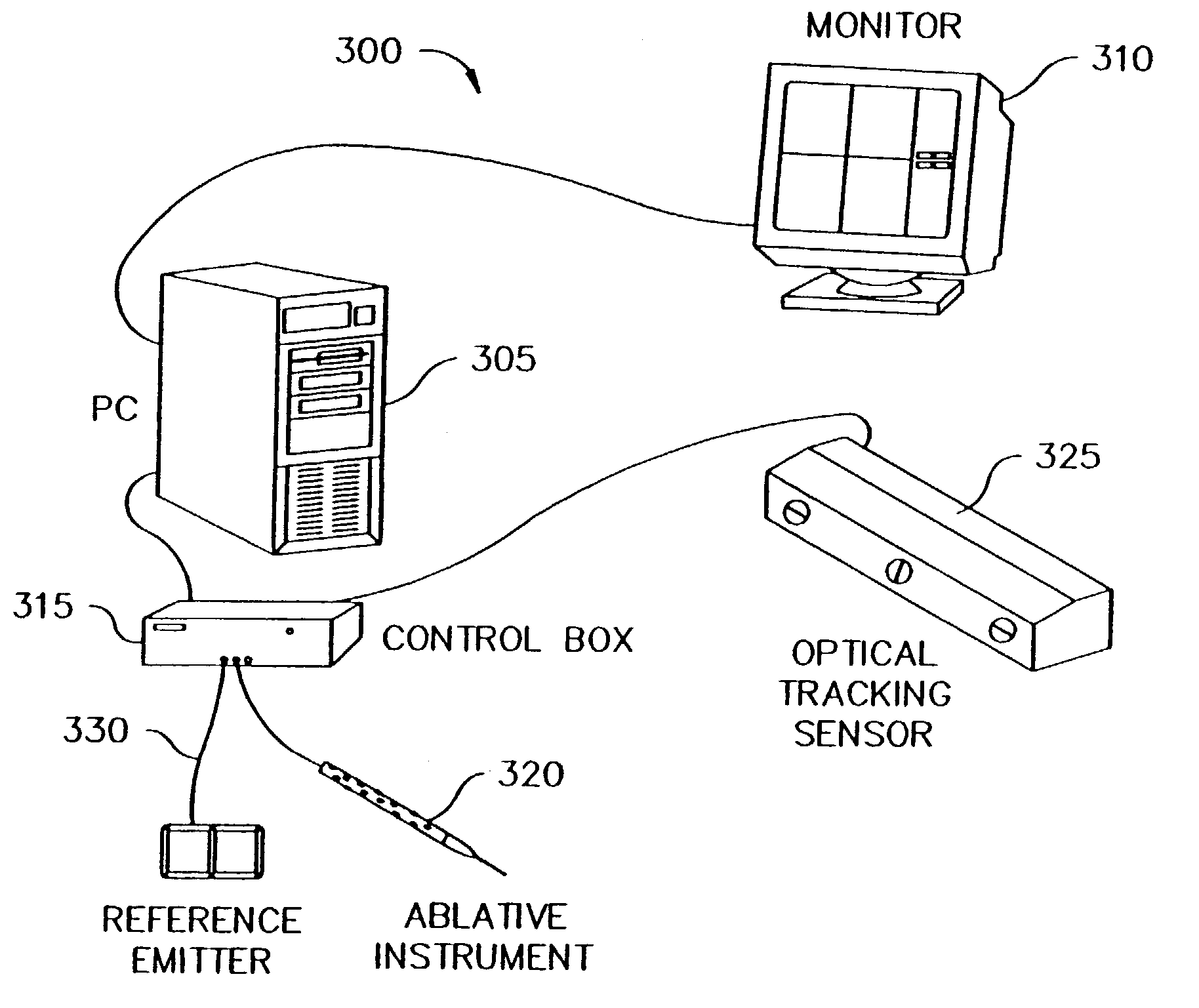

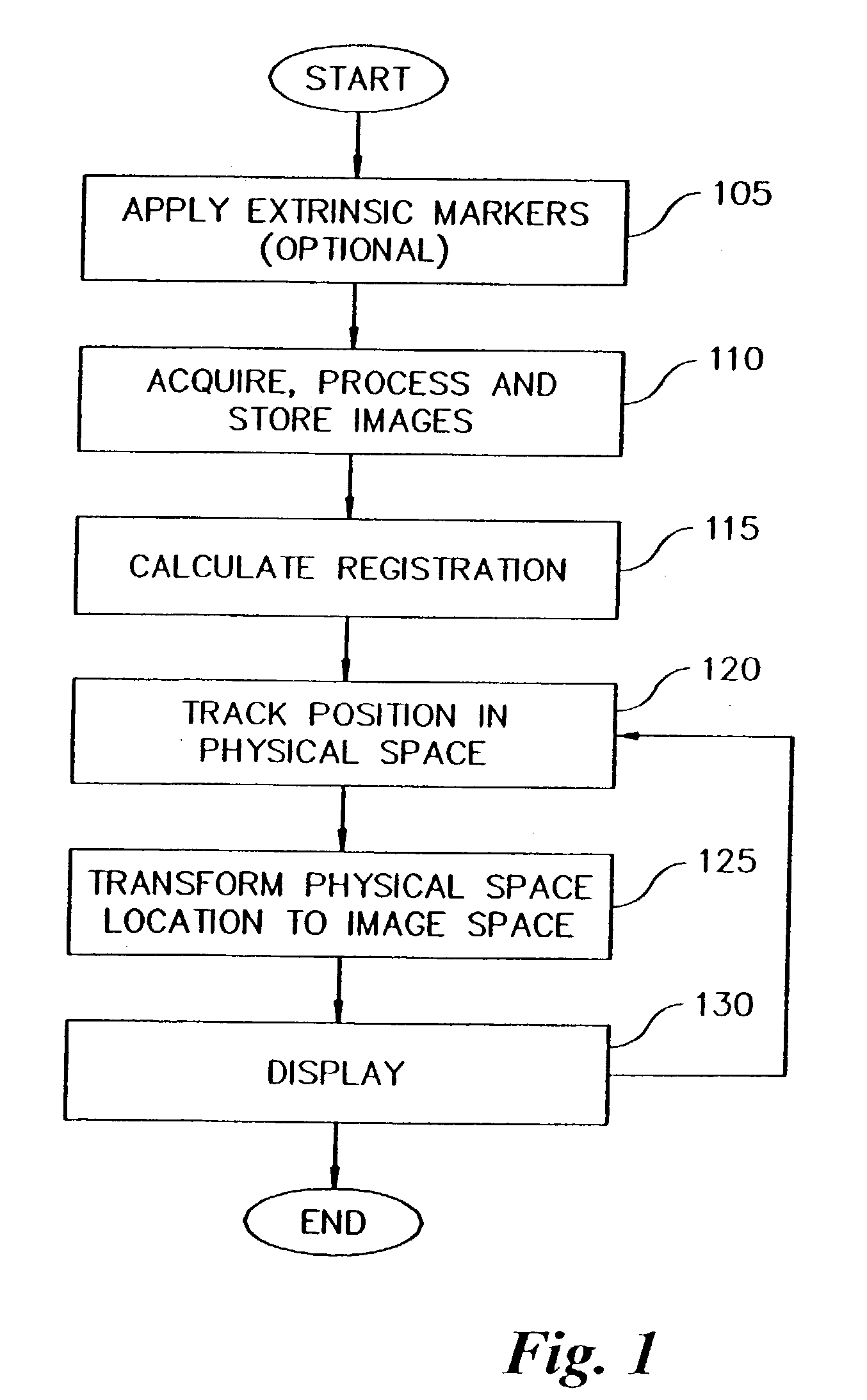

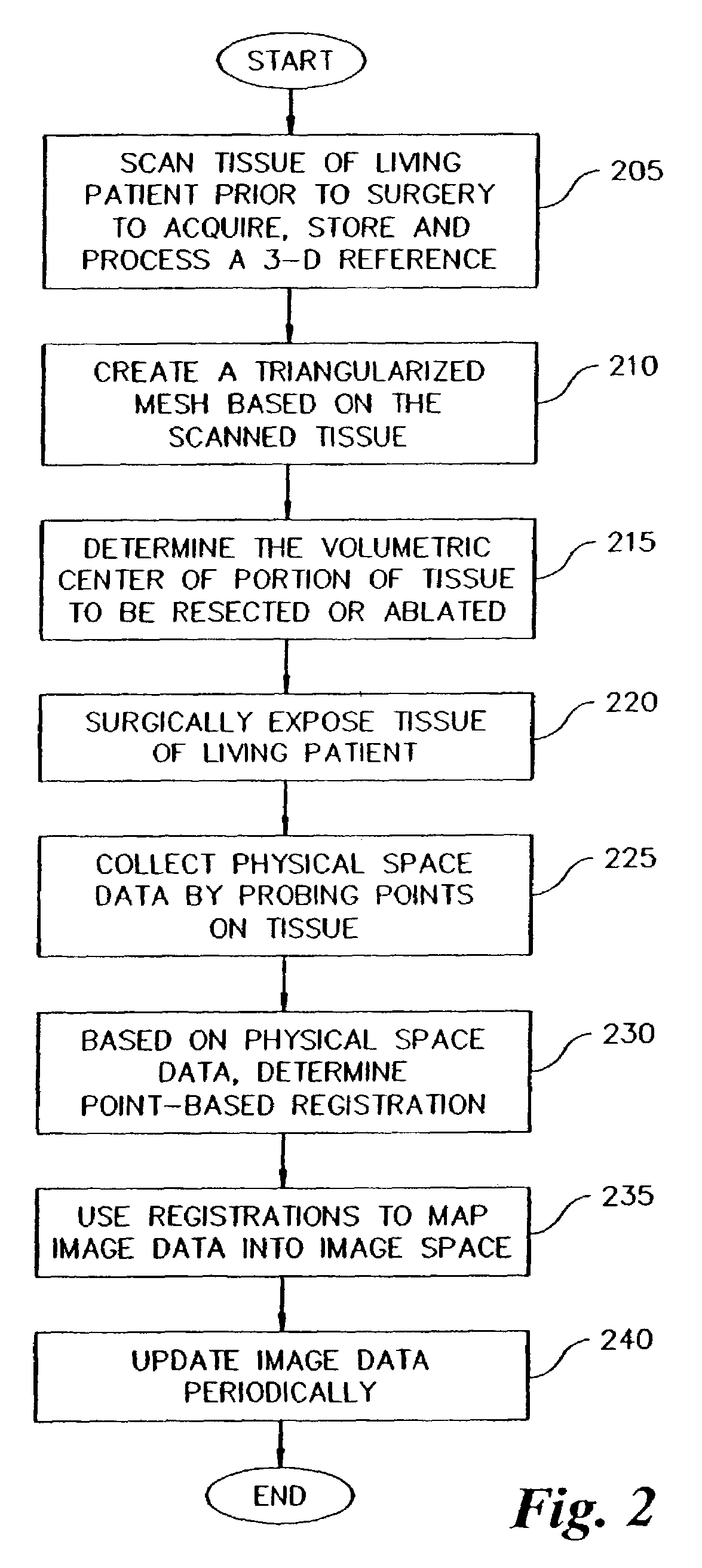

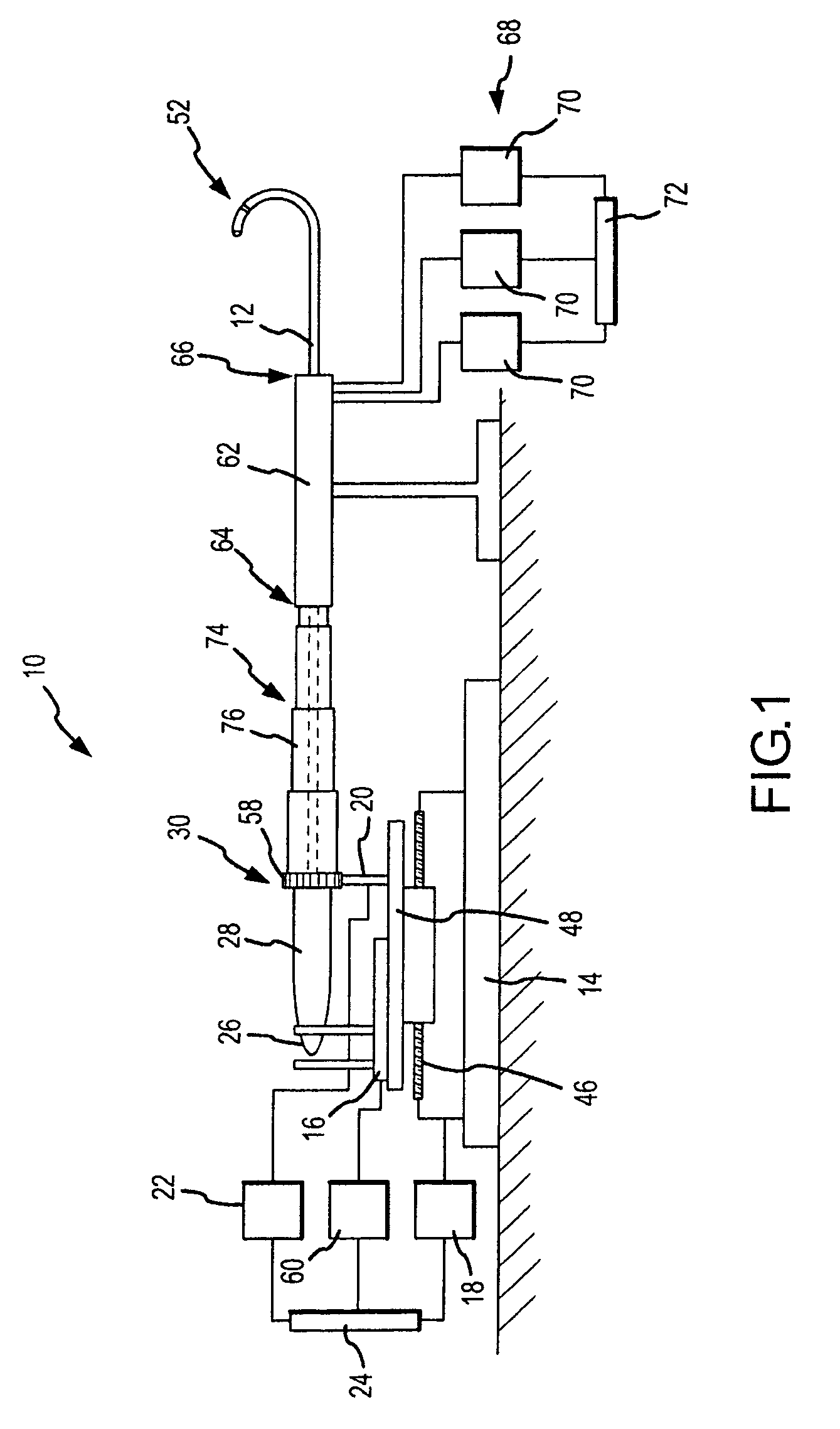

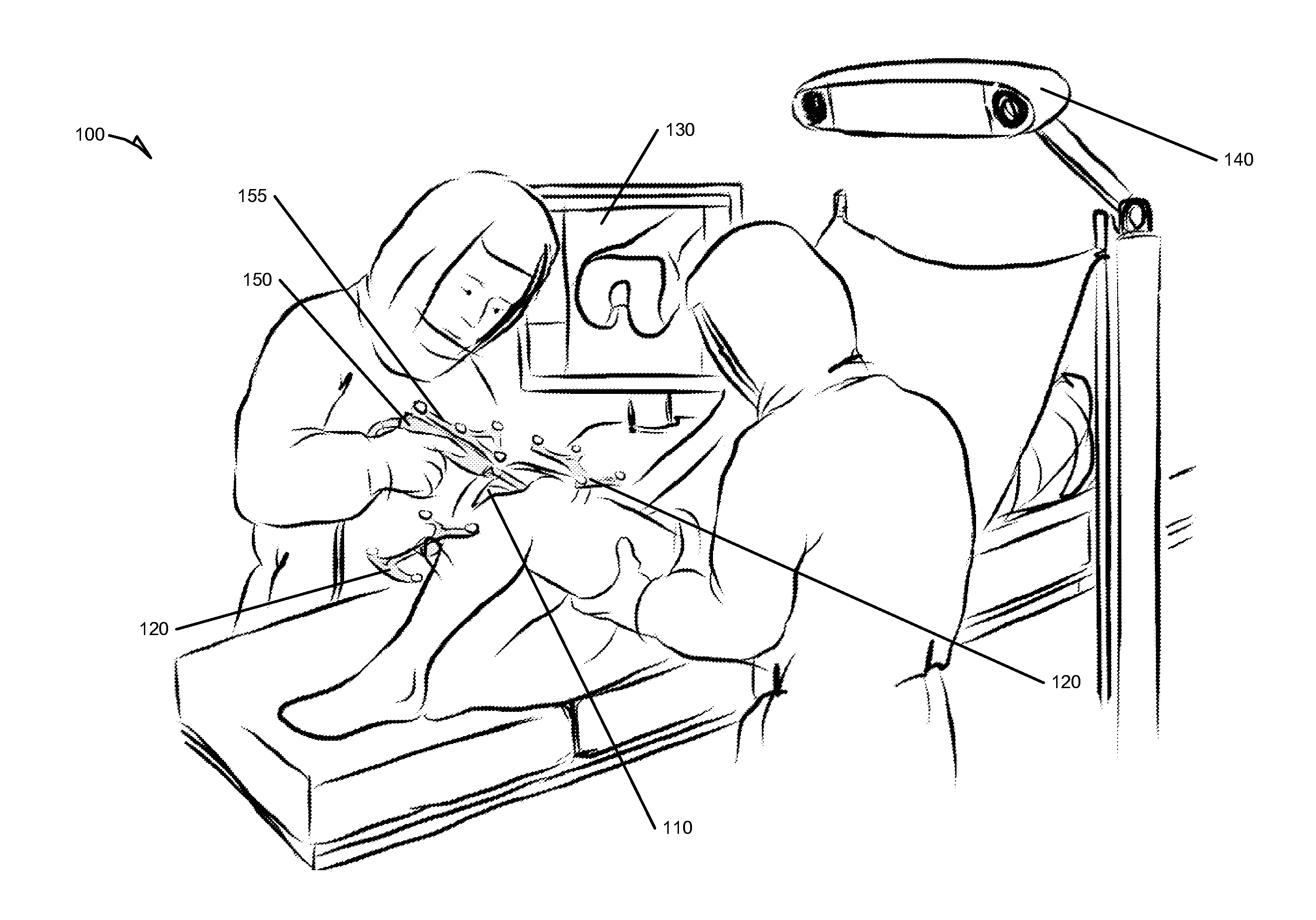

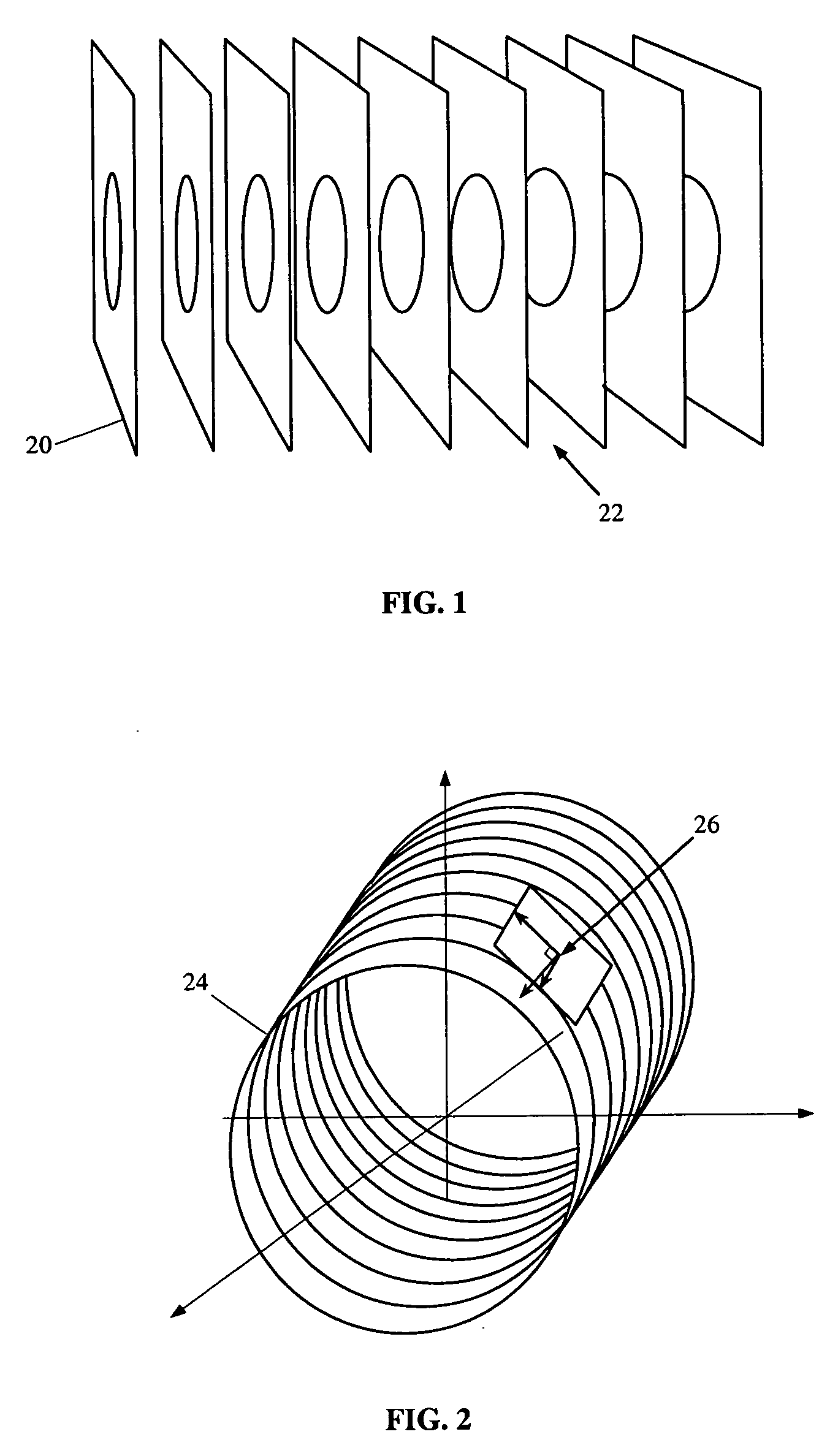

Method and apparatus for collecting and processing physical space data for use while performing image-guided surgery

InactiveUS7072707B2Ultrasonic/sonic/infrasonic diagnosticsSurgical navigation systemsPhysical spaceLaser light

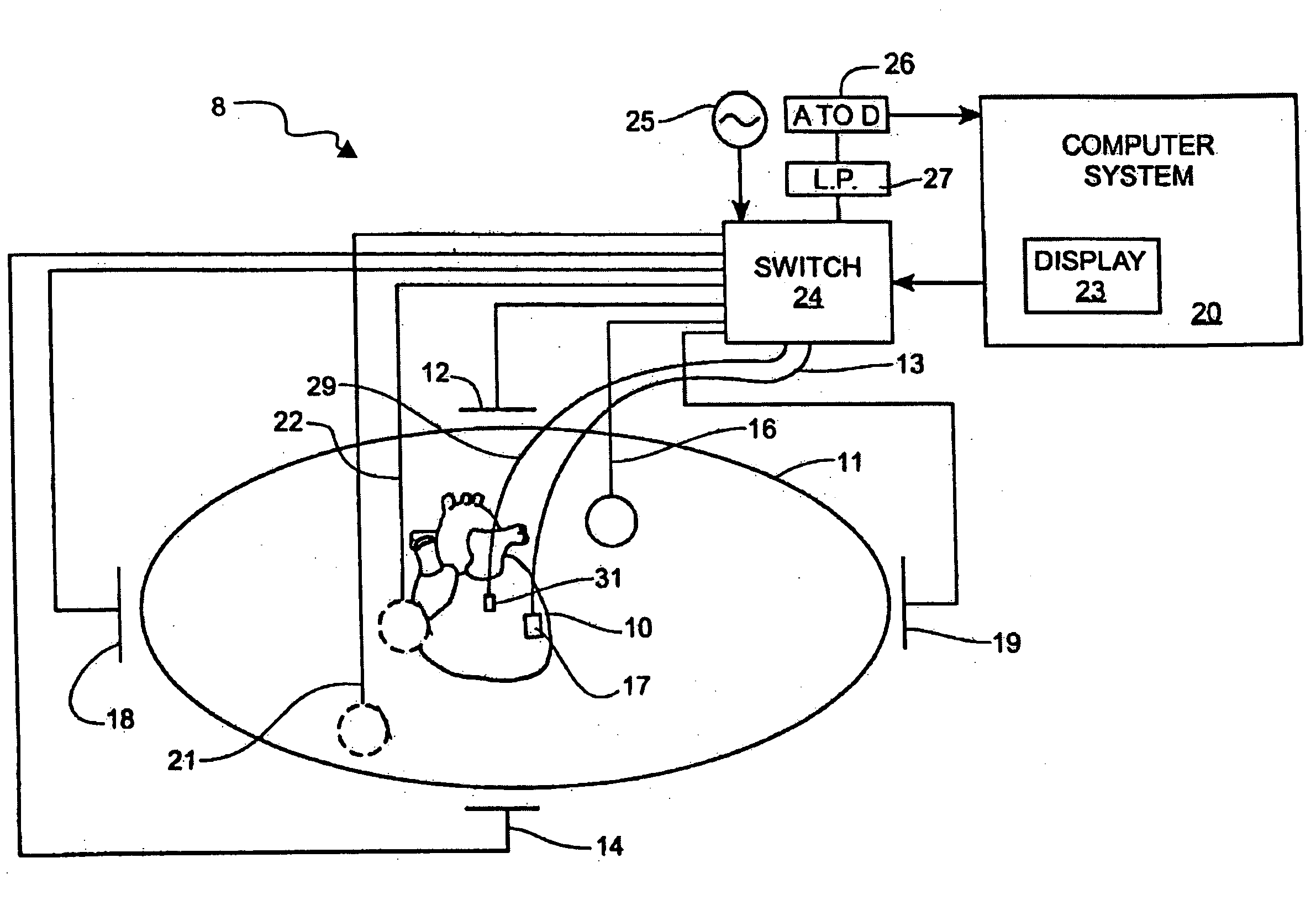

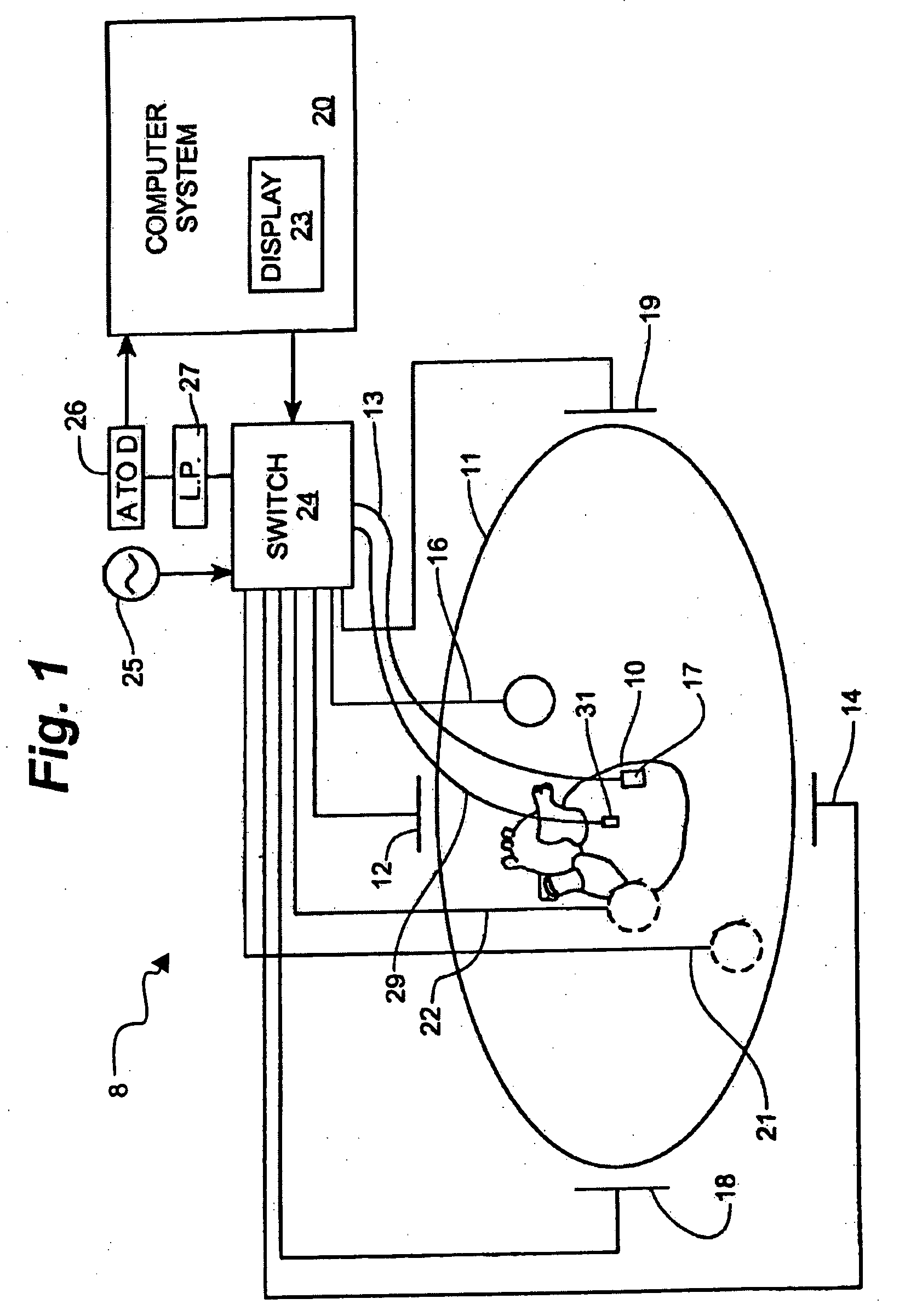

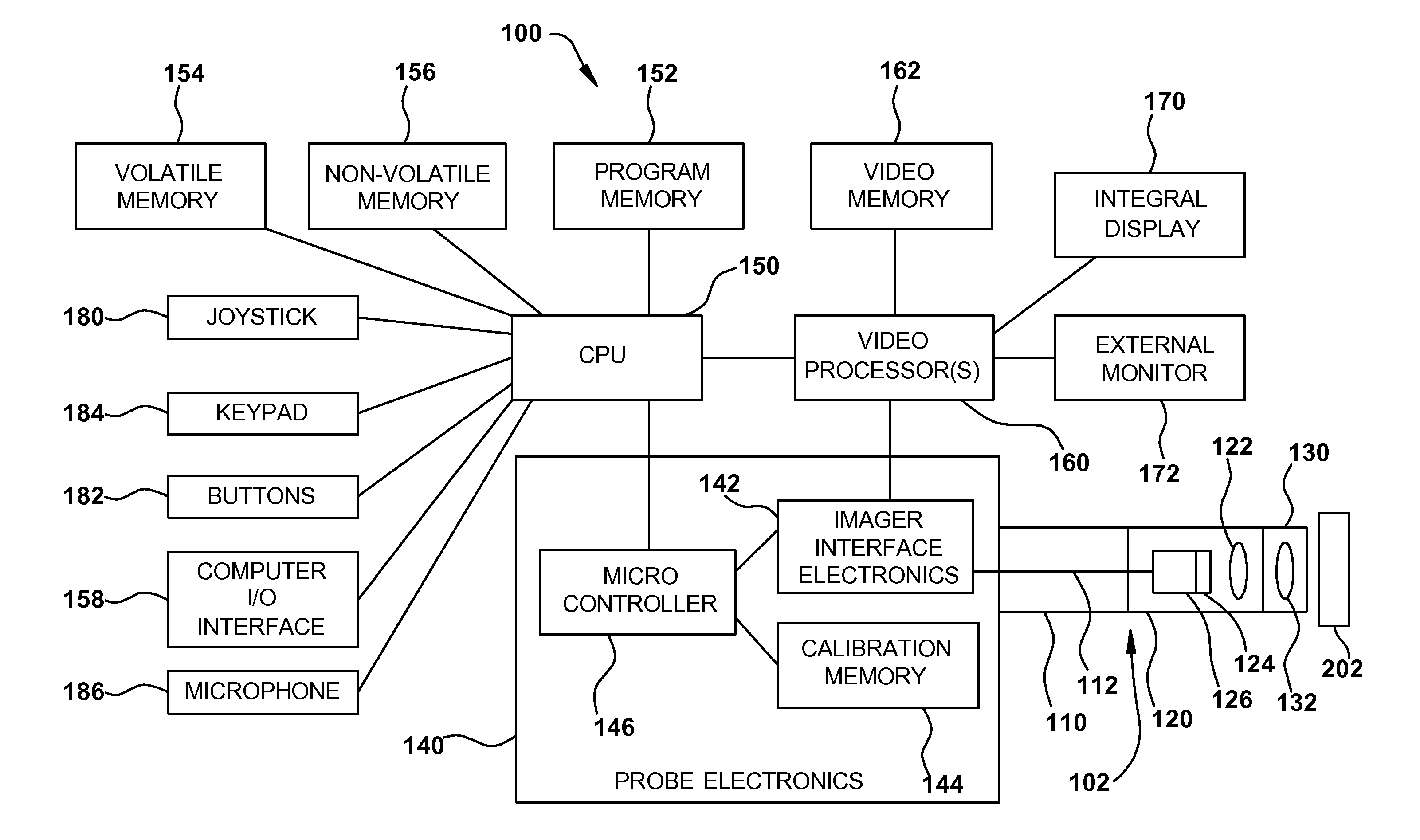

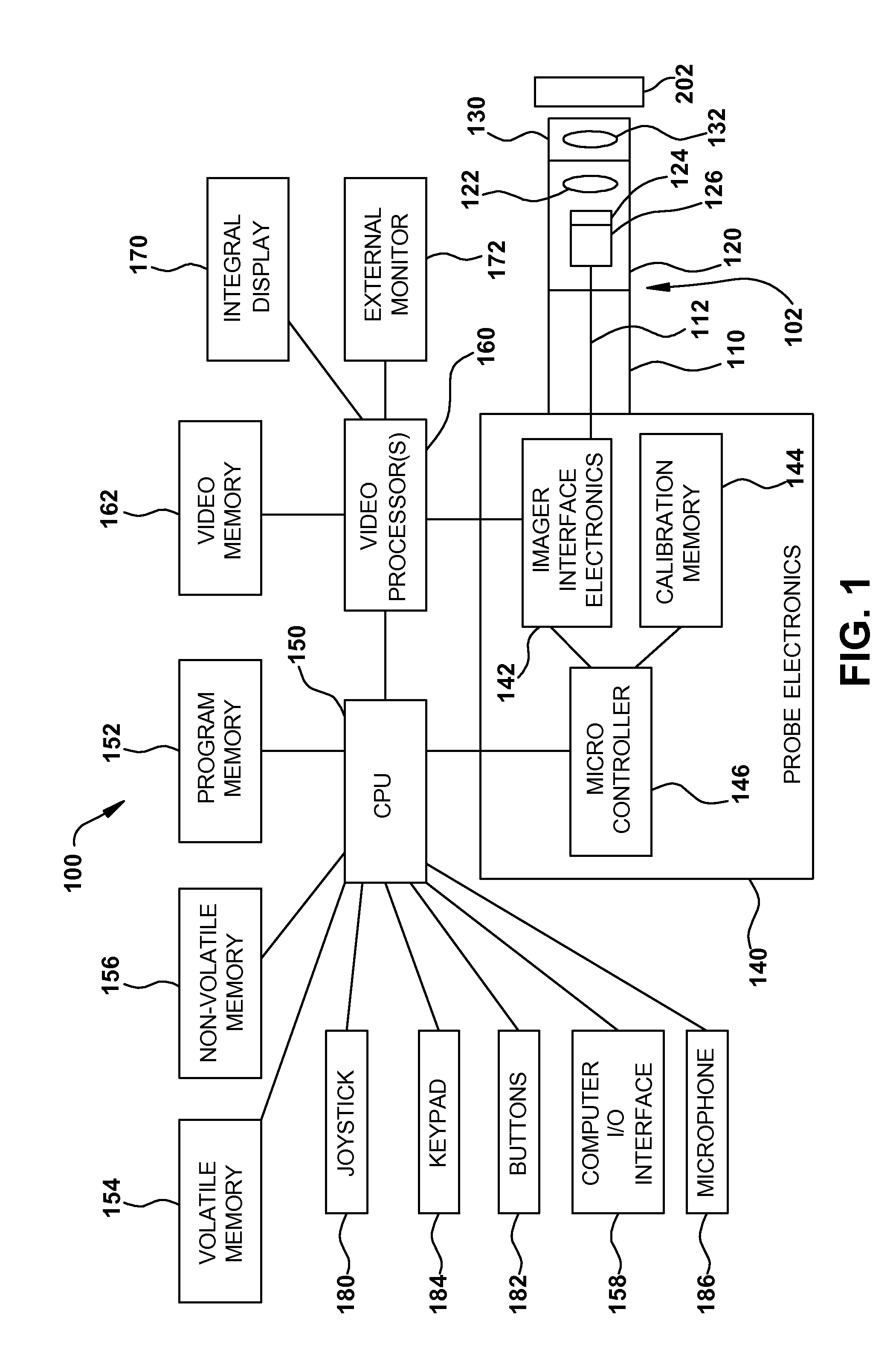

A method and apparatus for collecting and processing physical space data used while performing image-guided surgery is disclosed. Physical space data is collected by probing physical surface points of surgically exposed tissue. The physical space data provides three-dimensional (3-D) coordinates for each of the physical surface points. Based on the physical space data collected, point-based registrations used to indicate surgical position in both image space and physical space are determined. In one embodiment, the surface of surgically exposed tissue of a living patient is illuminated with laser light. Light reflected from the illuminated surface of the exposed tissue is received and analyzed. In another embodiment, one or more magnetic fields of known shape and size are established in the proximity of the exposed tissue. Data associated with the strength of the magnetic fields is acquired and analyzed.

Owner:VANDERBILT UNIV

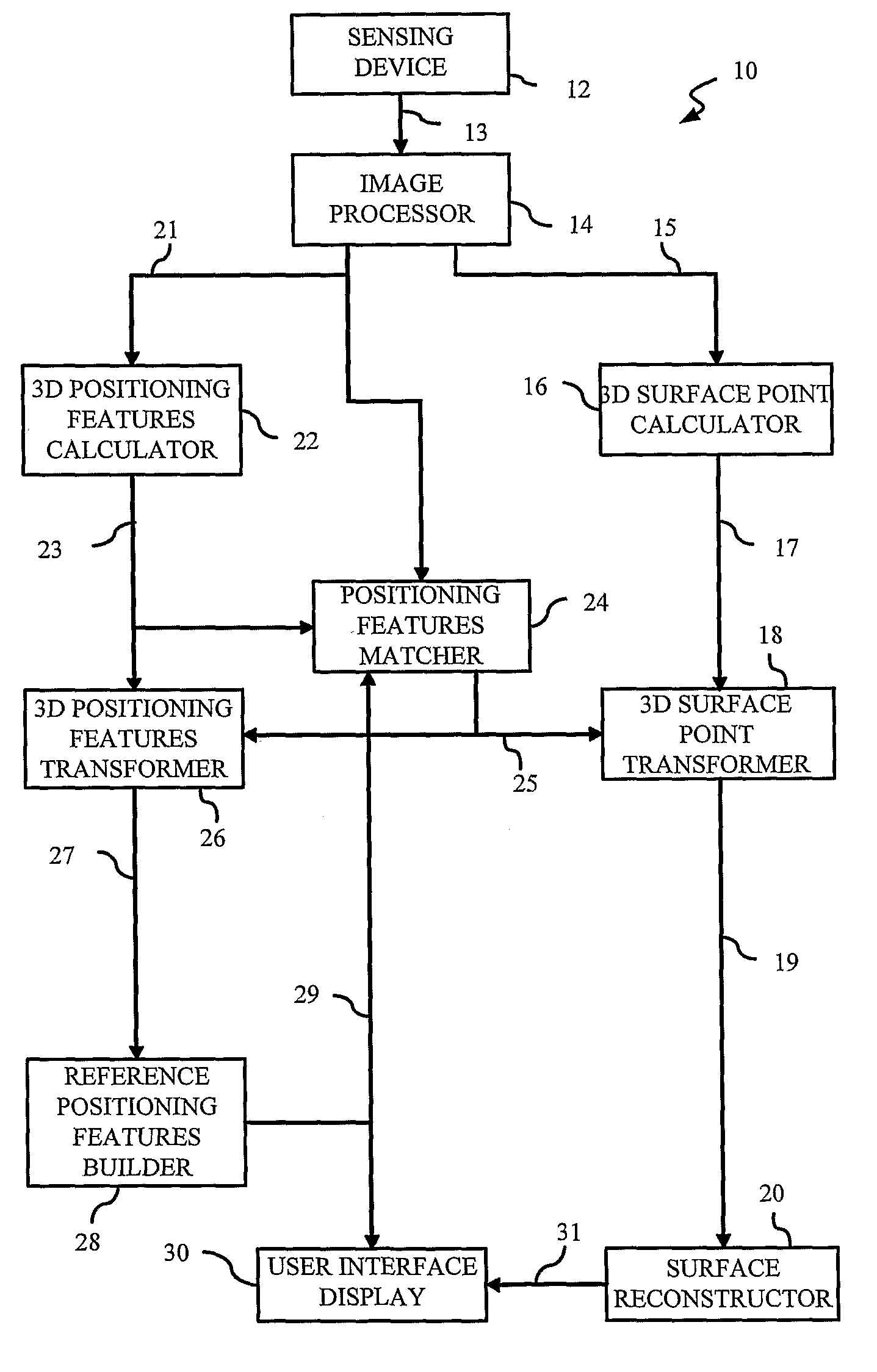

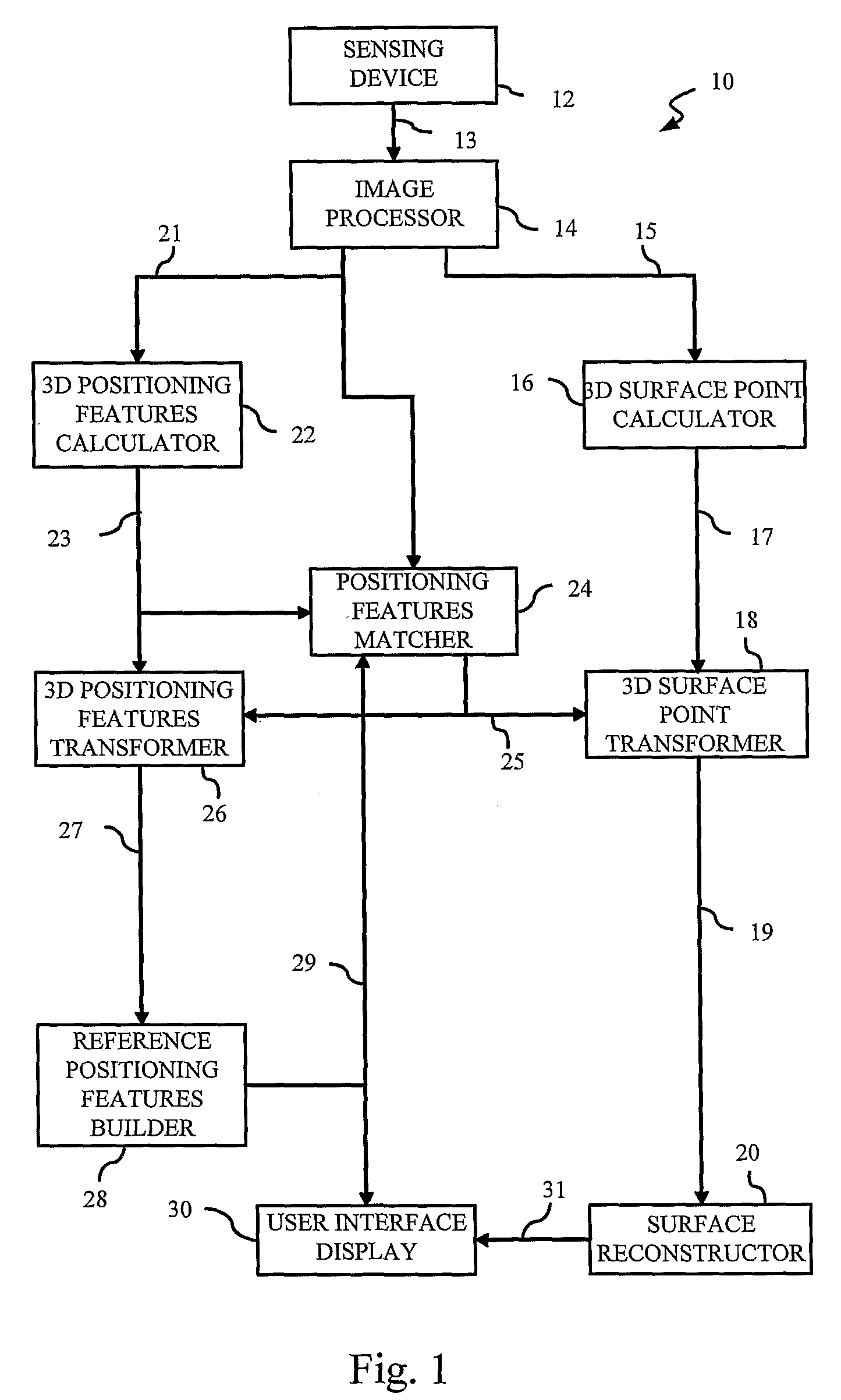

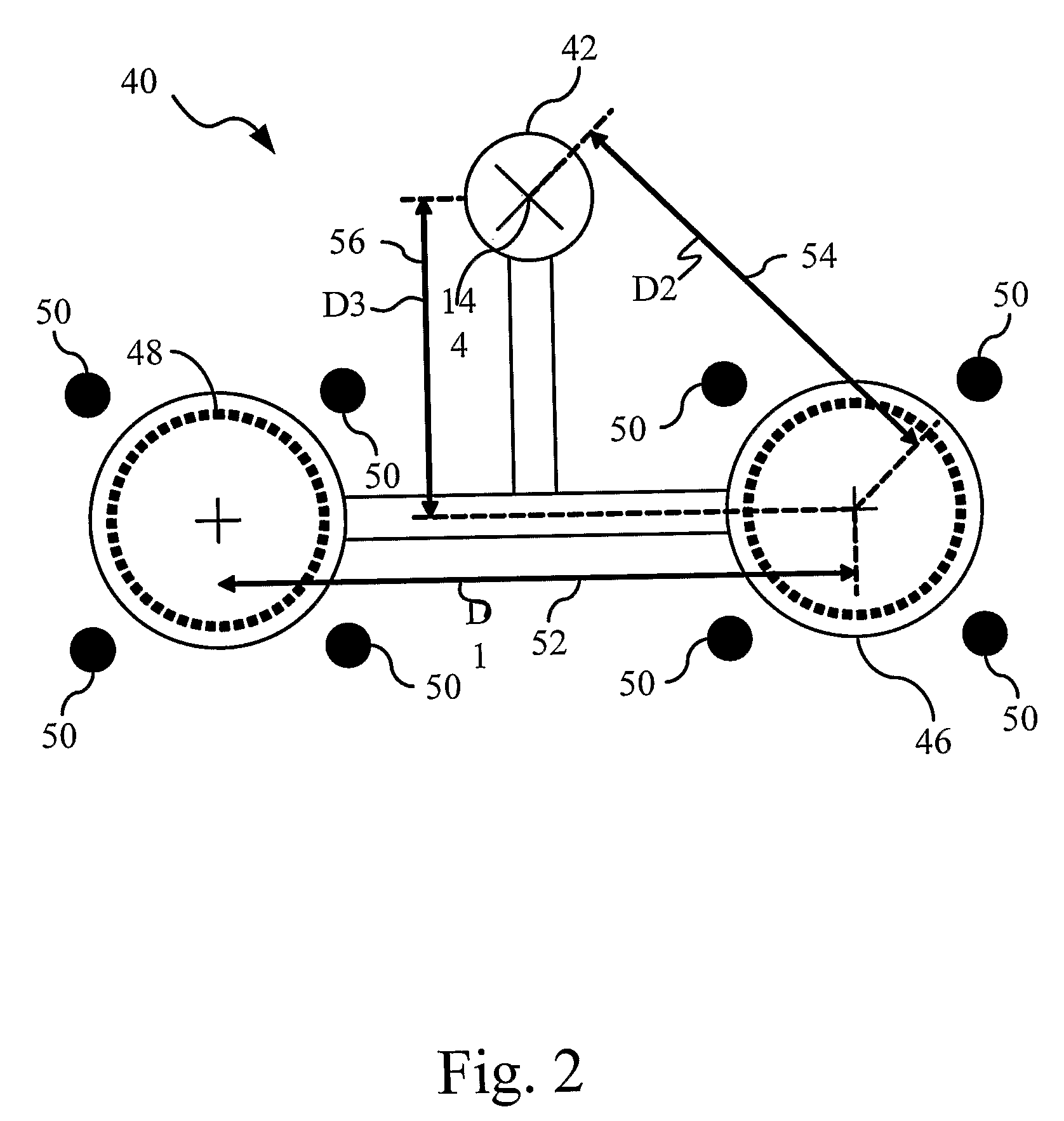

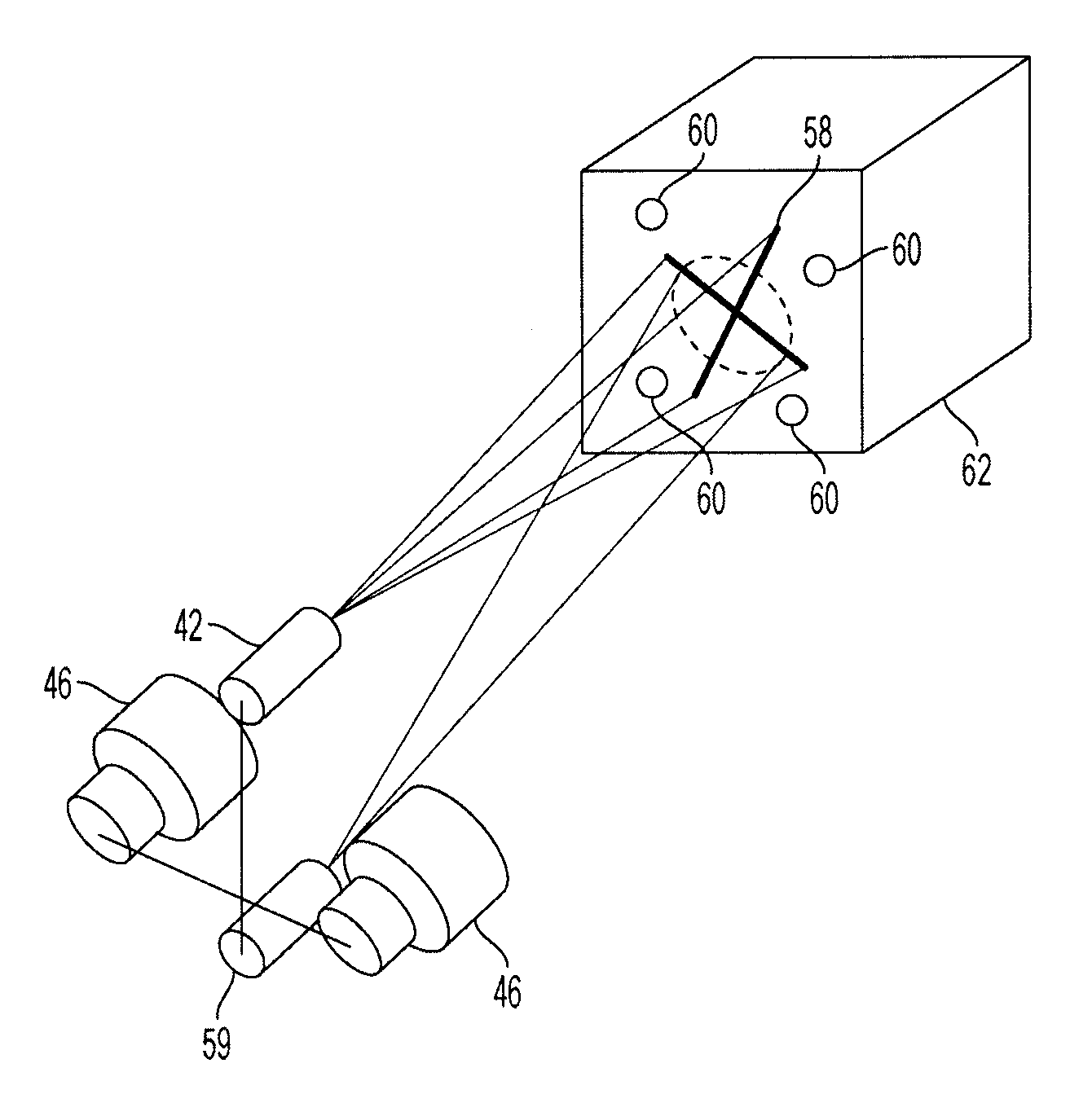

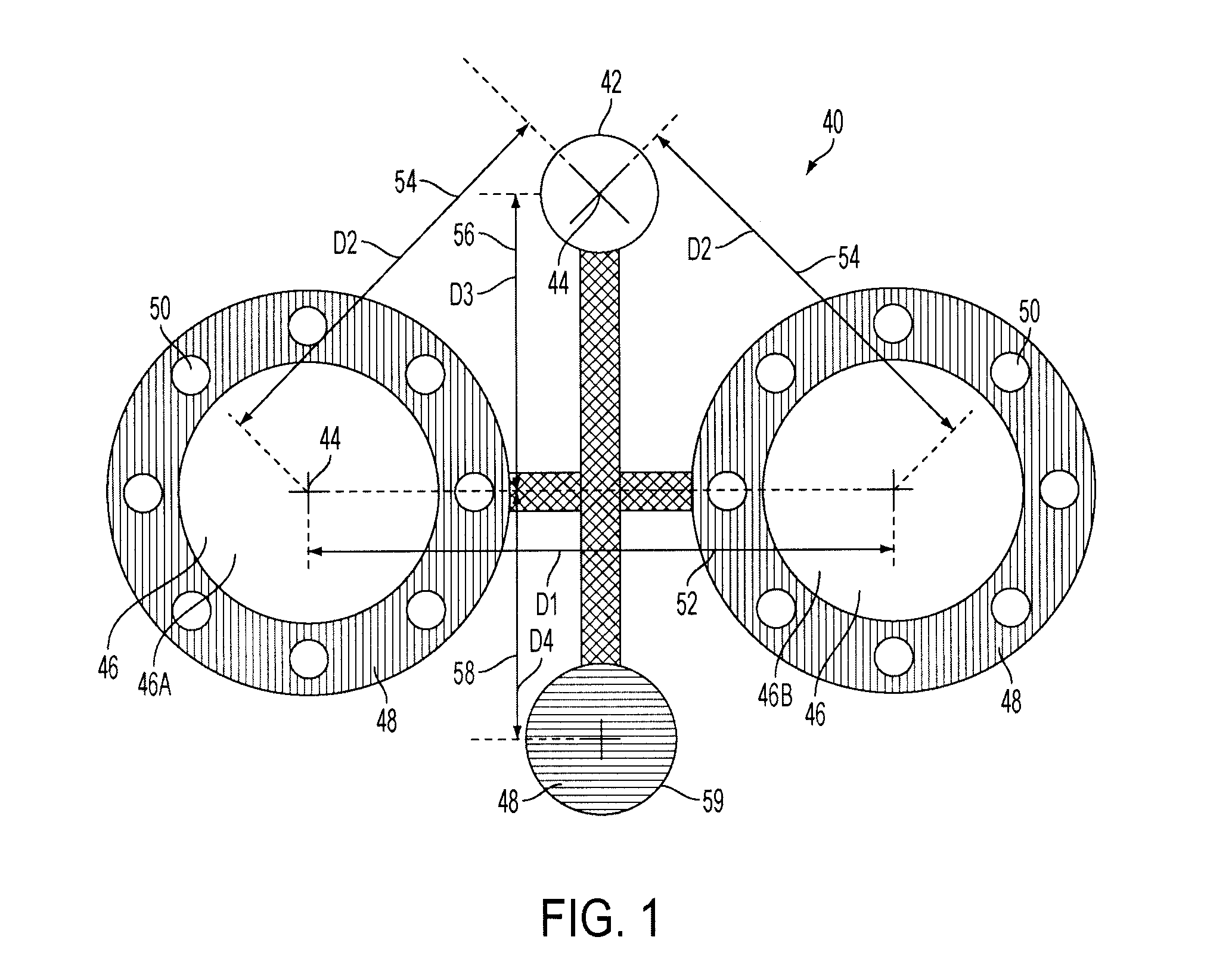

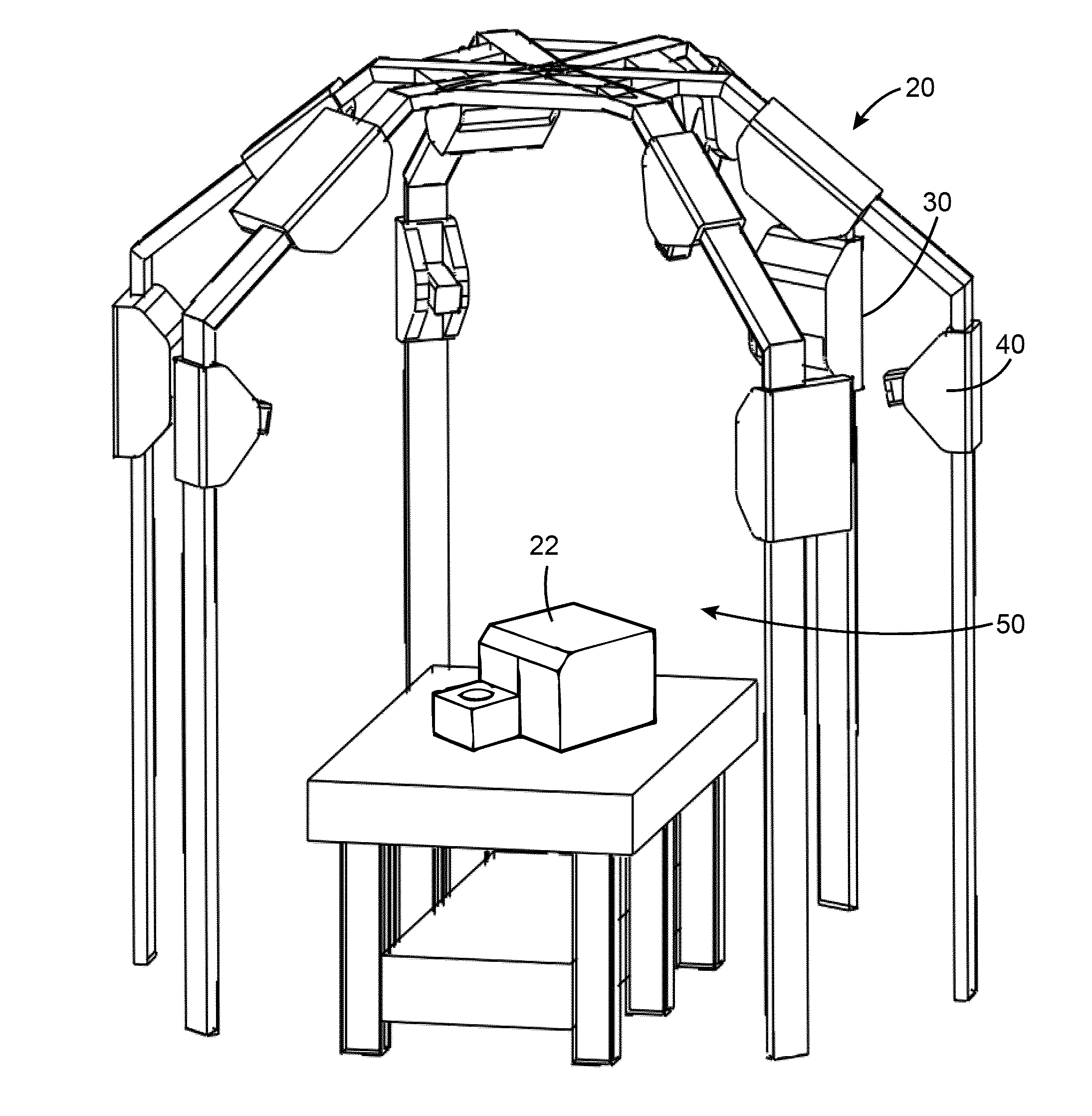

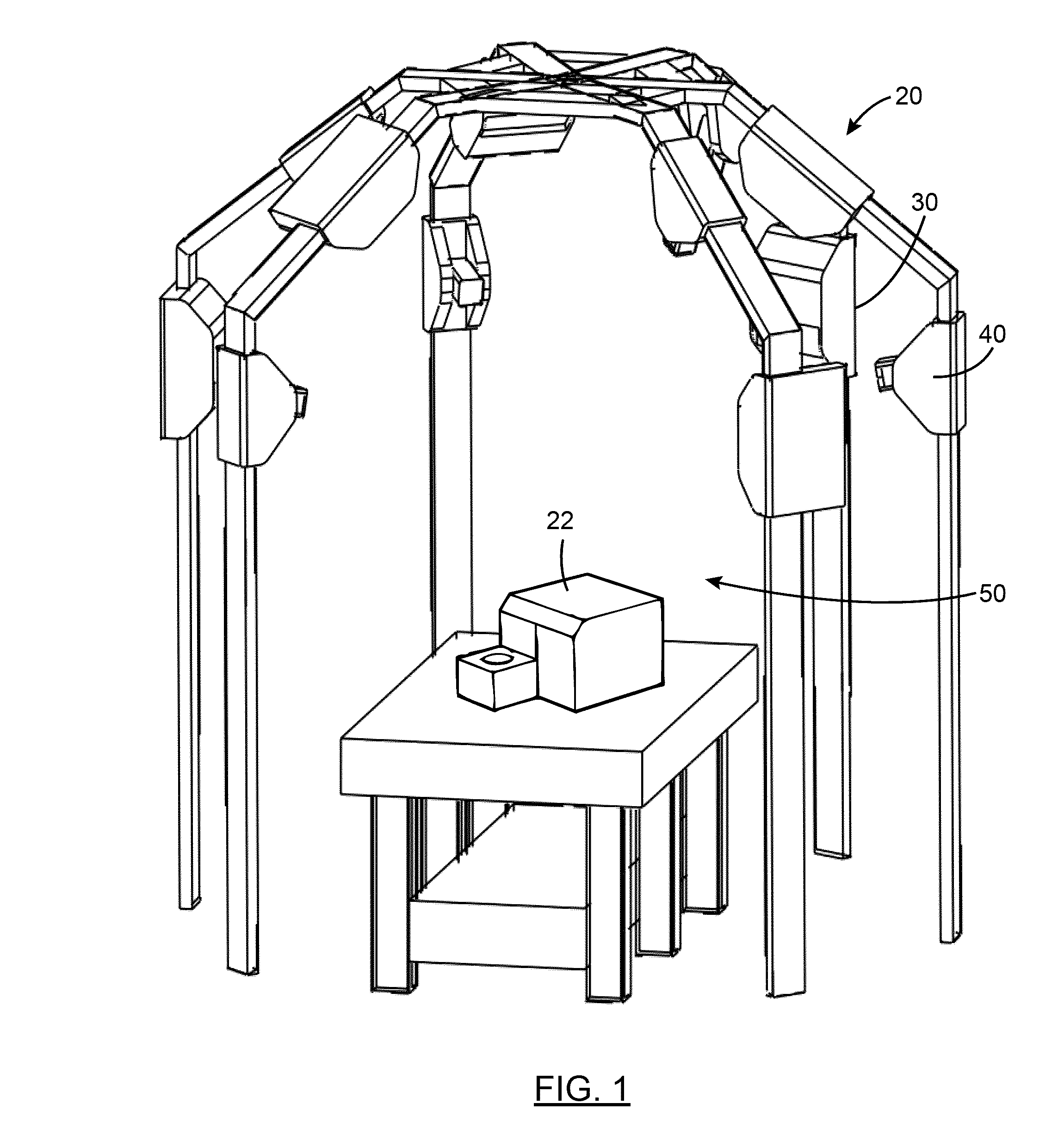

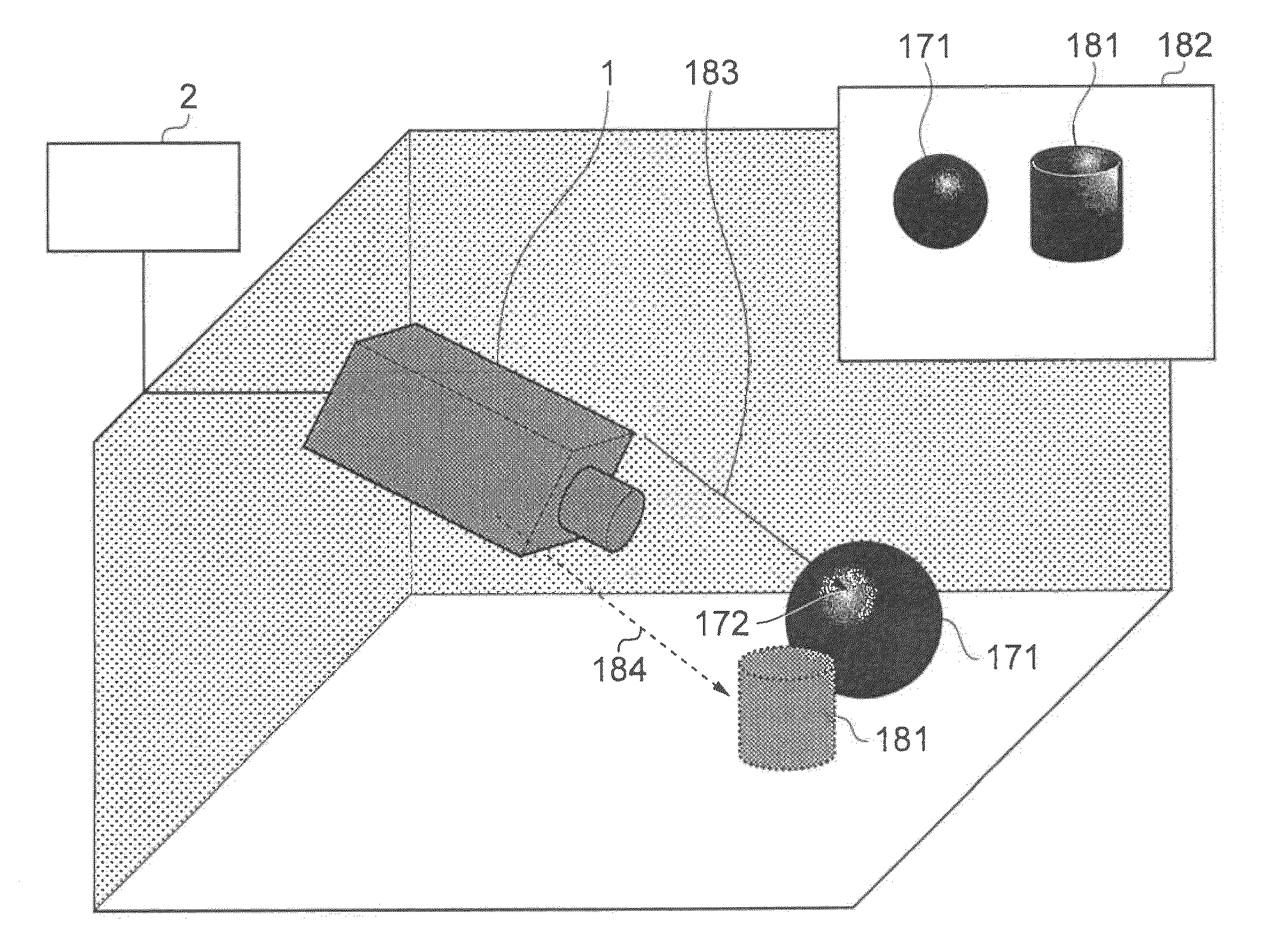

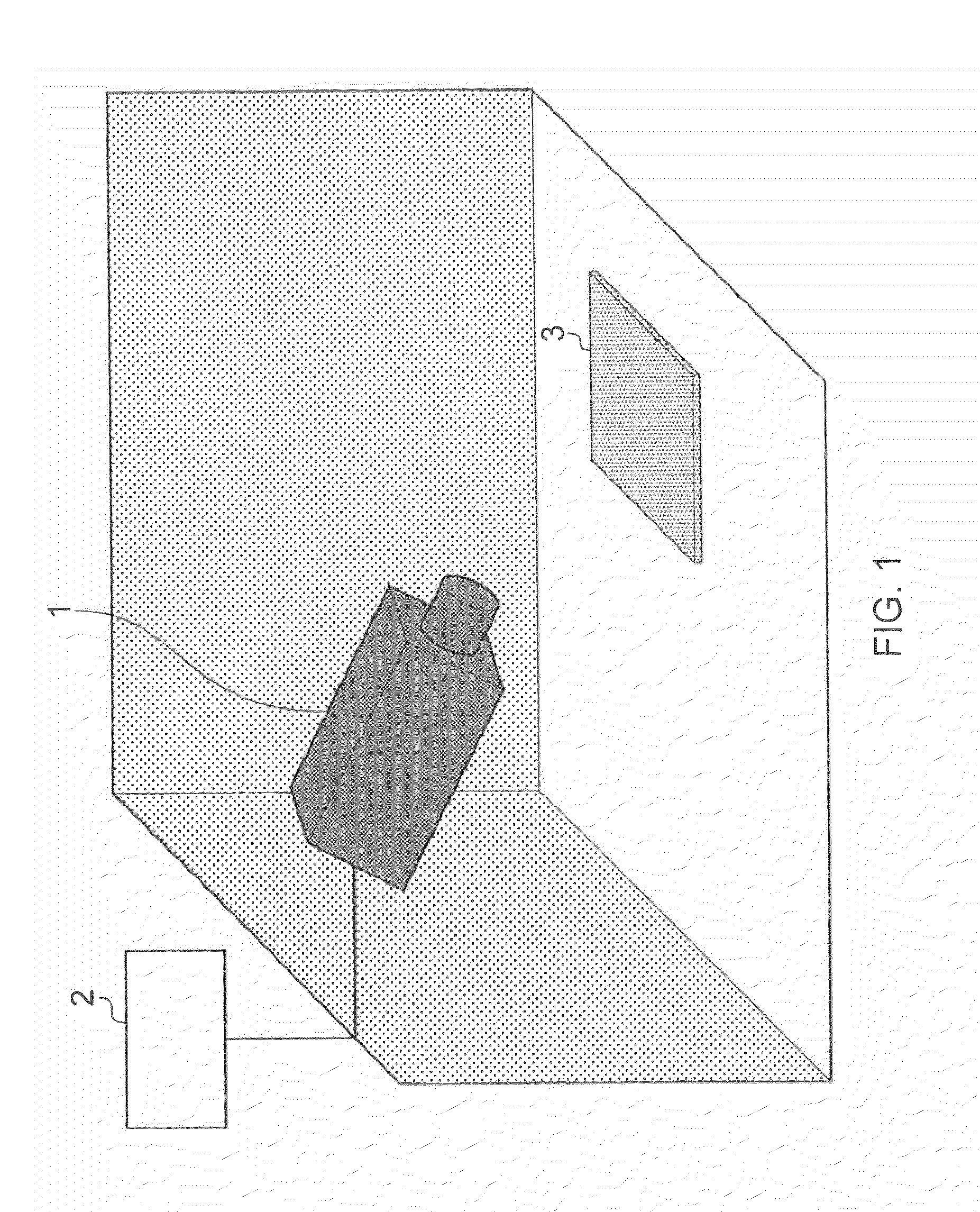

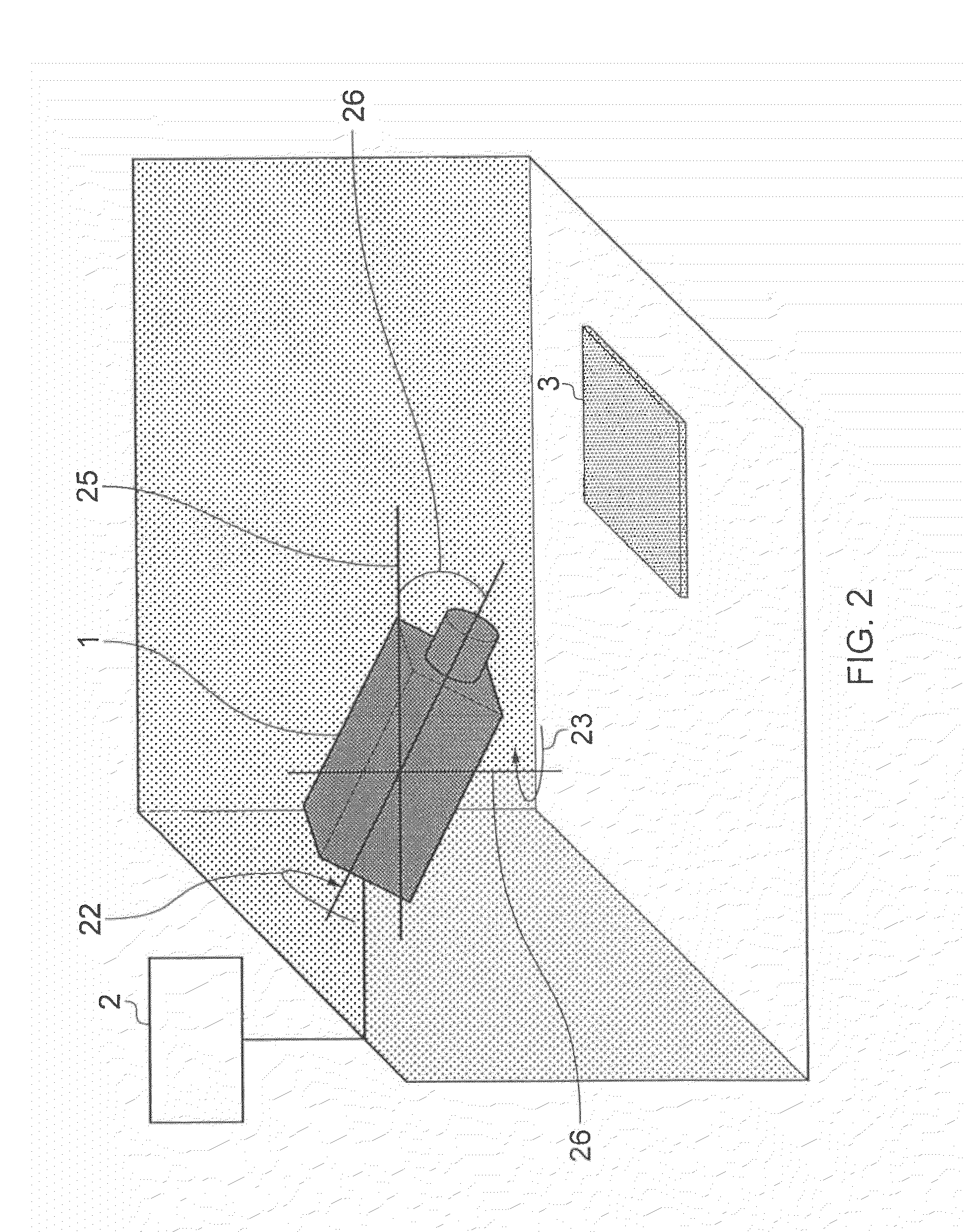

Auto-referenced system and apparatus for three-dimensional scanning

A system, apparatus and method for three-dimensional scanning and digitization of the surface geometry of objects are claimed. The system includes a hand-held apparatus that is auto-referenced. The system is auto-referenced since it does not need any positioning device to provide the 6 degree of freedom transformations that are necessary to integrate 3D measurements in a global coordinate system while the apparatus is manipulated to scan the surface. The system continuously calculates its own position and orientation from observation while scanning the surface geometry of an object. To do so, the system exploits a triangulation principle and integrates an apparatus that captures both surface points originating from the reflection of a projected laser pattern on an object's surface and 2D positioning features originating from the observation of target positioning features.

Owner:CREAFORM INC

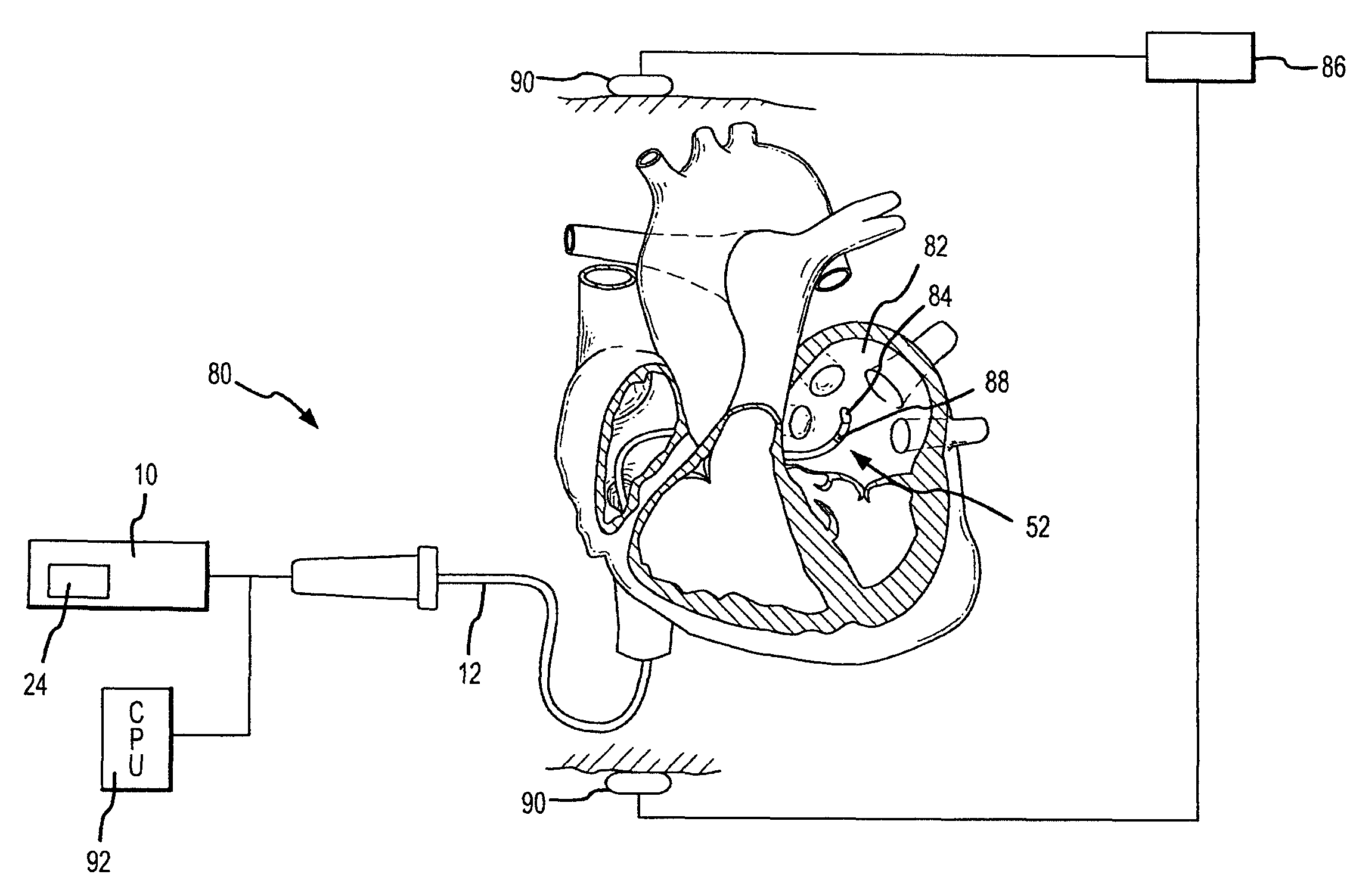

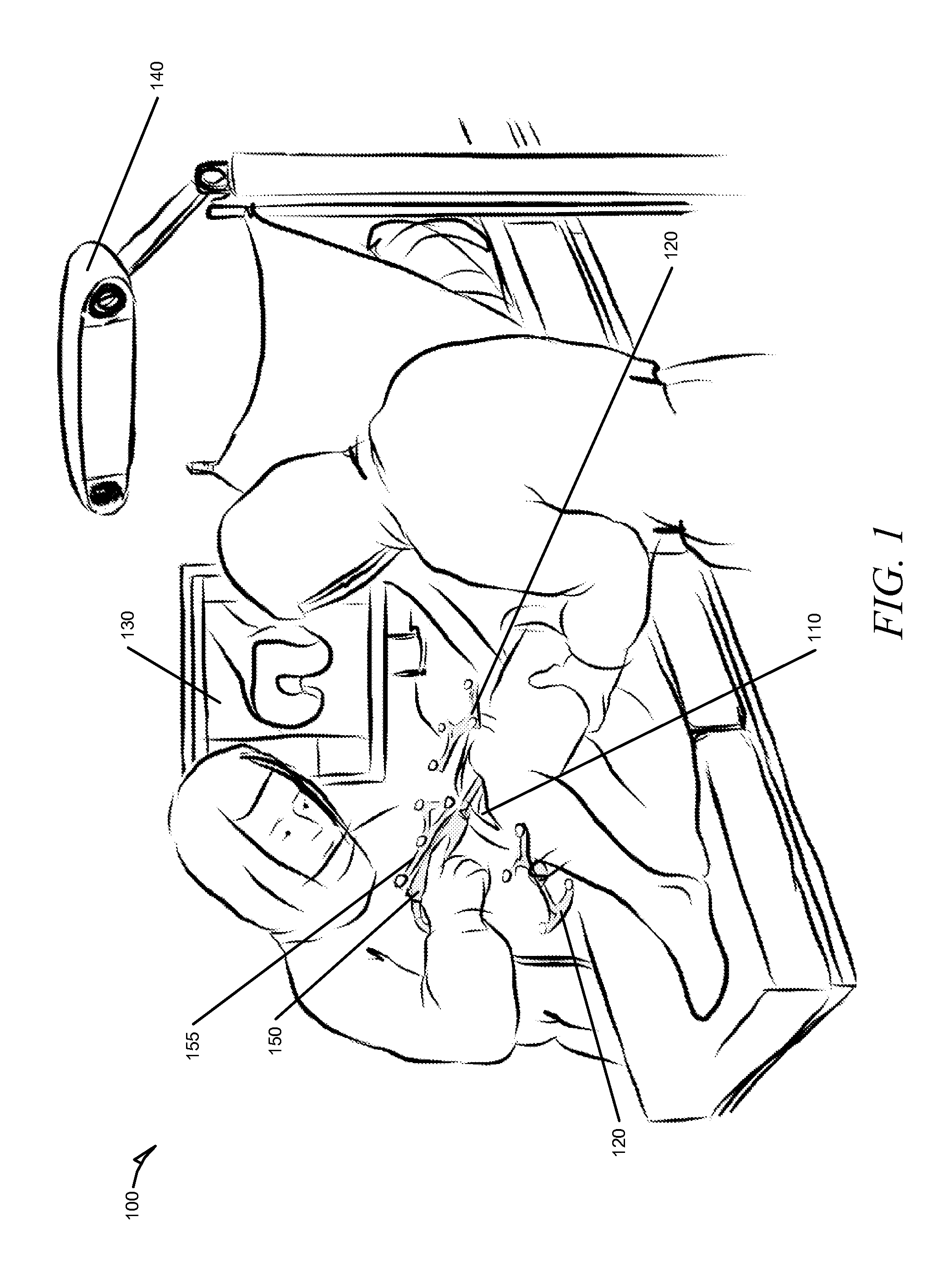

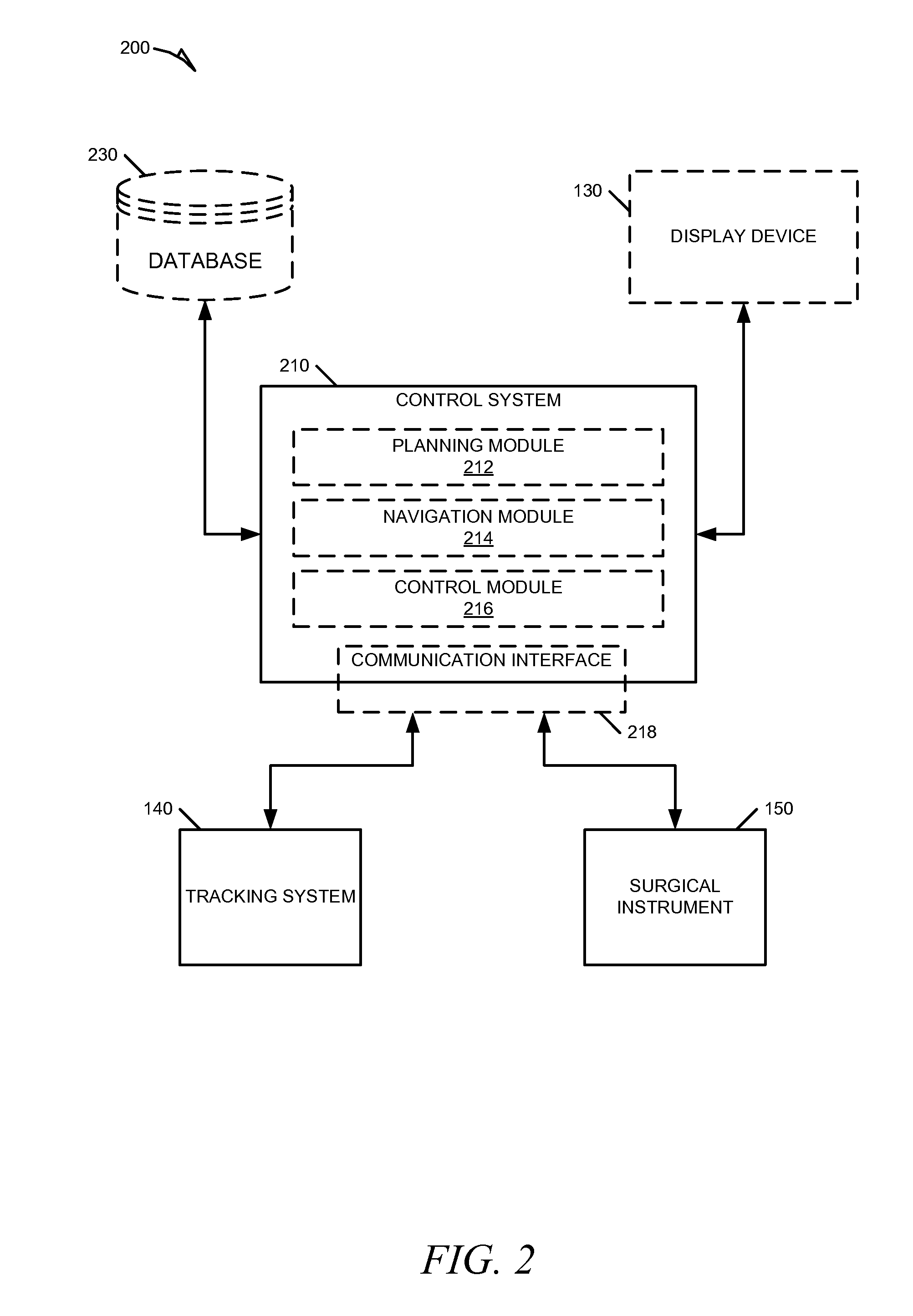

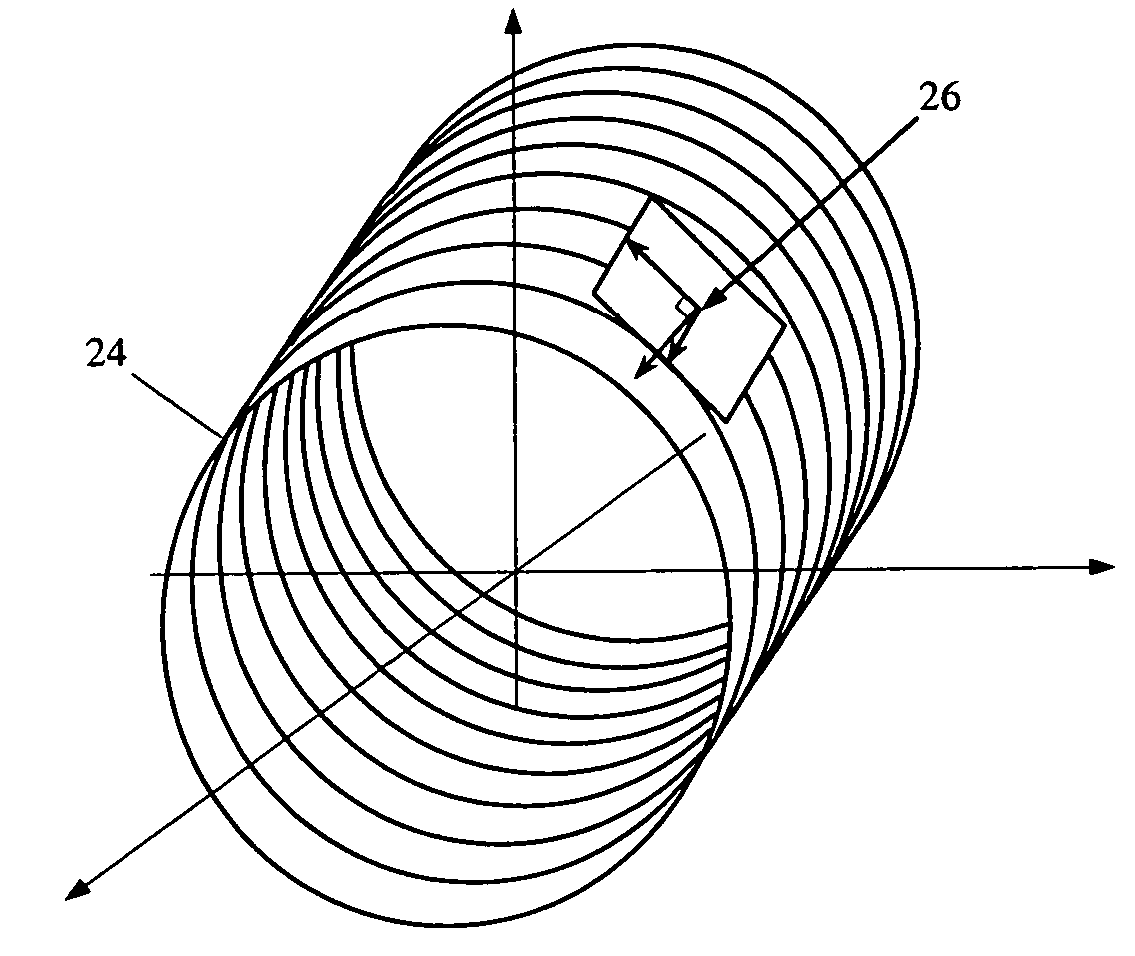

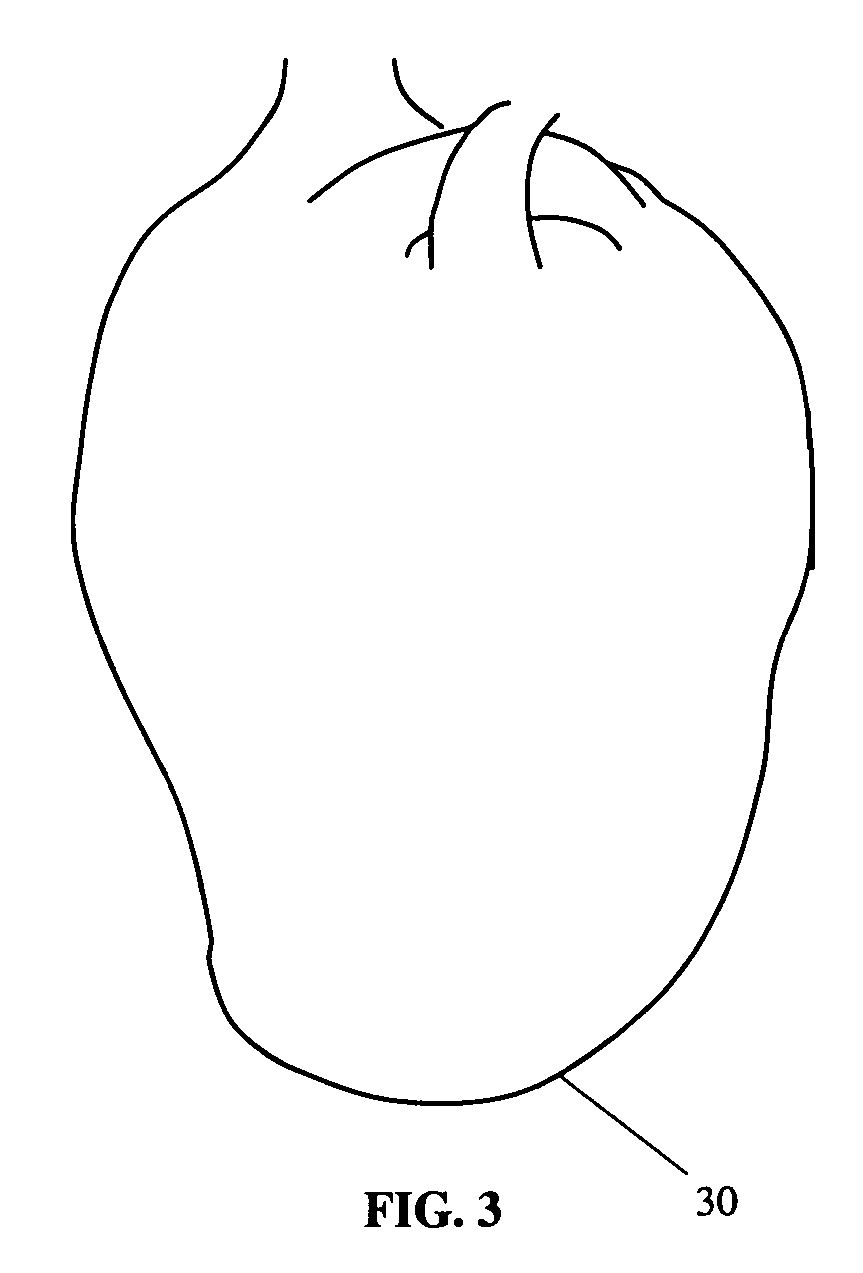

Robotic surgical system and method for surface modeling

ActiveUS7974674B2Reduce exposureMinimization requirementsElectrotherapySurgical navigation systemsCardiac surfaceEngineering

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

System and method for local deformable registration of a catheter navigation system to image data or a model

ActiveUS20080221425A1Surgical navigation systemsComputer-aided planning/modellingCatheterSurface point

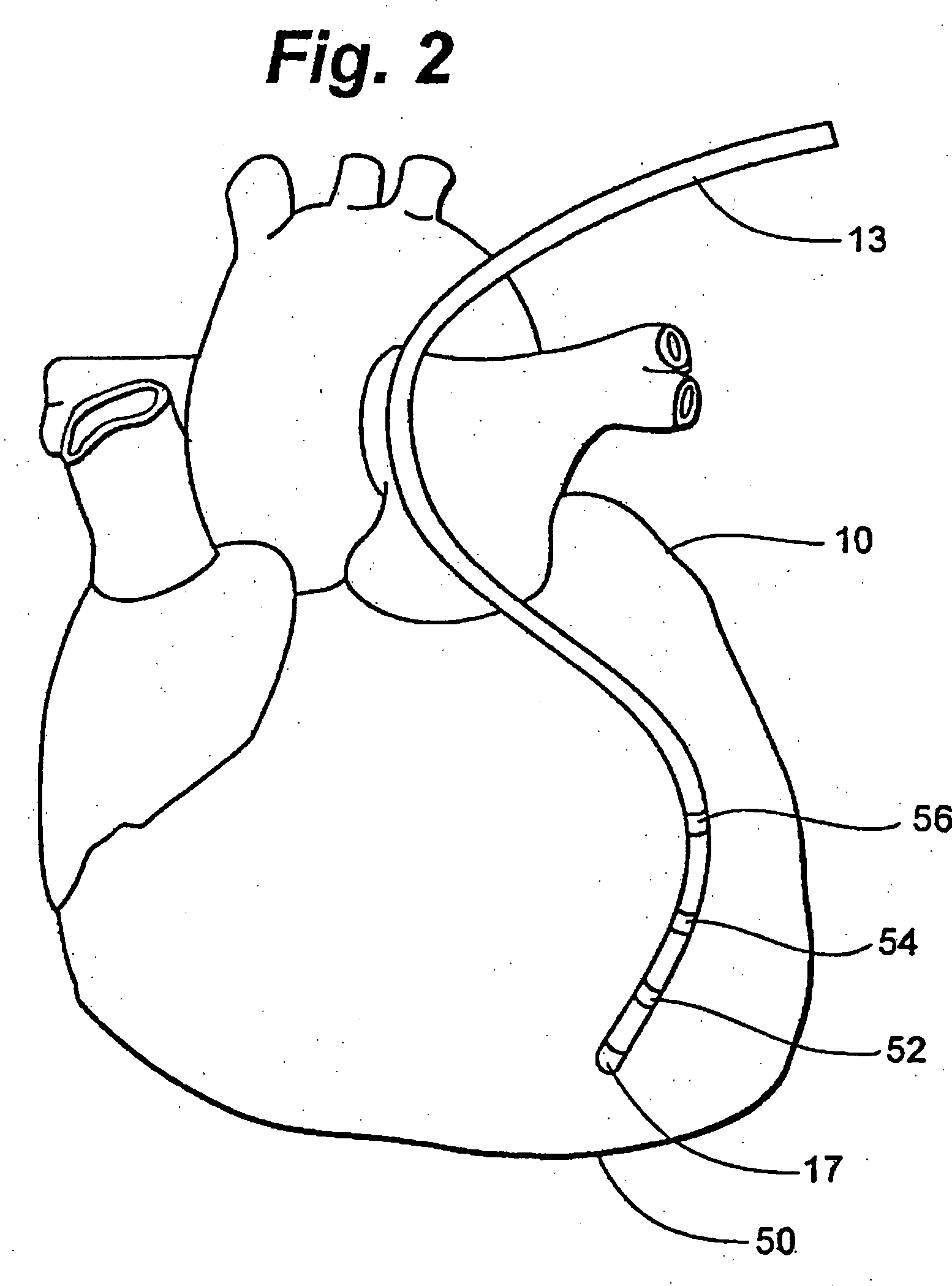

A method for registering a catheter navigation system to a three-dimensional image generally includes obtaining a three-dimensional image including position information for a plurality of surface points on a part of a patient's body, using a catheter navigation system to place a tool at a location on the surface of the patient's body, measuring position information for the surface location, identifying a corresponding location on the image, associating position information for the surface location and the location identified on the image as a fiducial pair, and using at least one fiducial pair to generate a mapping function. The mapping function transforms points within the coordinate system of the catheter navigation to the coordinate system of the three-dimensional image such that, for each fiducial pair, the mapping error is about zero. Suitable warping algorithms include thin plate splines, mean value coordinates, and radial basis function networks.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

System for adaptive three-dimensional scanning of surface characteristics

There are provided systems and methods for obtaining a three-dimensional surface geometric characteristic and / or texture characteristic of an object. A pattern is projected on a surface of said object. A basic 2D image of said object is acquired; a characteristic 2D image of said object is acquired; 2D surface points are extracted from said basic 2D image, from a reflection of said projected pattern on said object; a set of 3D surface points is calculated in a sensor coordinate system using said 2D surface points; and a set of 2D surface geometric / texture characteristics is extracted.

Owner:CREAFORM INC

Systems and methods for planning and performing image free implant revision surgery

Systems and methods for planning and performing image free implant revision surgery are discussed. For example, a method for generating a revision plan can include collecting pre-defined parameters characterizing a target bone, generating a 3D model, collecting a plurality of surface points, and generating a reshaped 3D model. Generating the 3D model of the target bone can be based on a first portion of the pre-defined parameters. Generating the reshaped 3D model can be done based on the plurality of surface points collected from a portion of the surface of the target bone.

Owner:BLUE BELT TECH

System for adaptive three-dimensional scanning of surface characteristics

There are provided systems and methods for obtaining a three-dimensional surface geometric characteristic and / or texture characteristic of an object. A pattern is projected on a surface of said object. A basic 2D image of said object is acquired; a characteristic 2D image of said object is acquired; 2D surface points are extracted from said basic 2D image, from a reflection of said projected pattern on said object; a set of 3D surface points is calculated in a sensor coordinate system using said 2D surface points; and a set of 2D surface geometric / texture characteristics is extracted.

Owner:CREAFORM INC

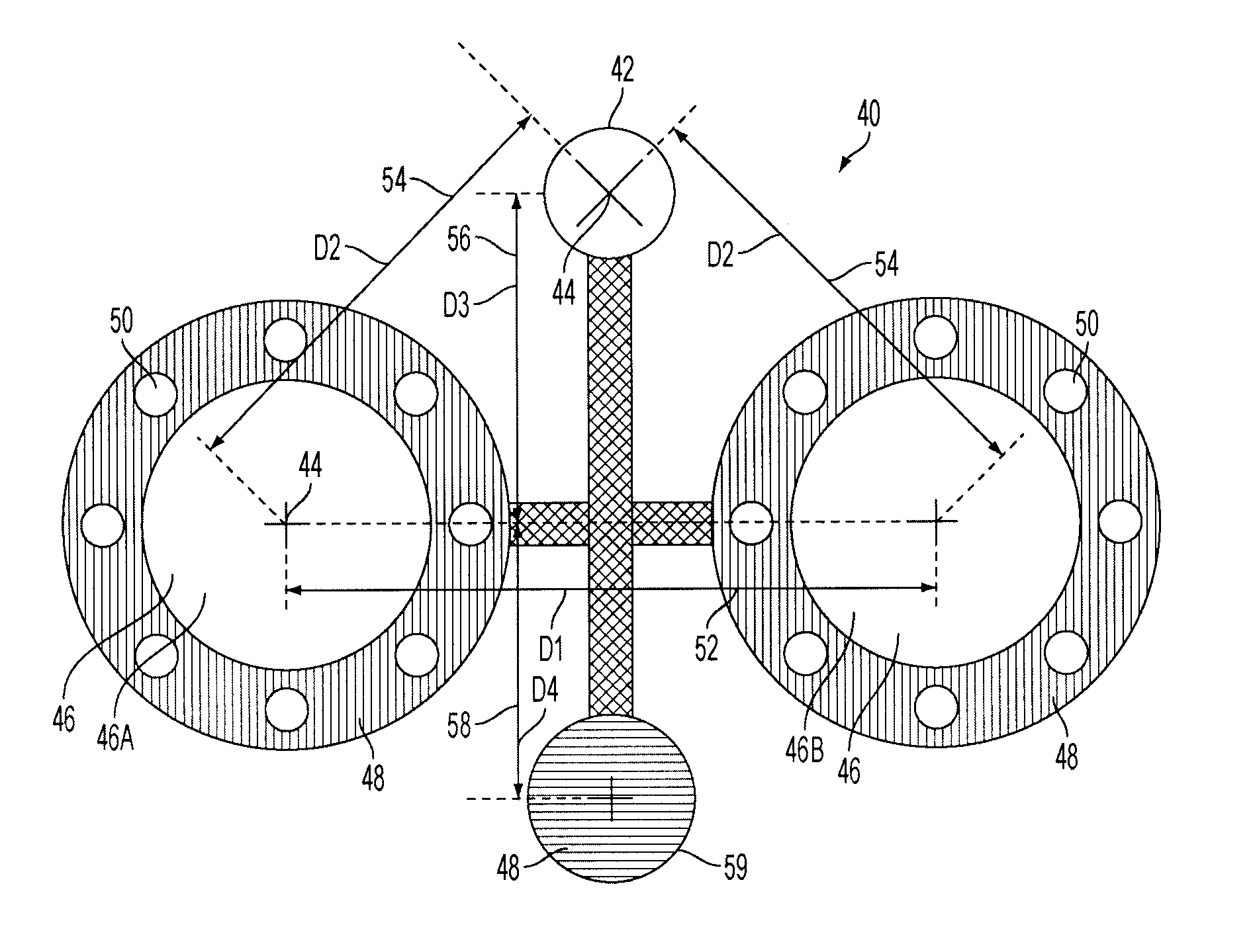

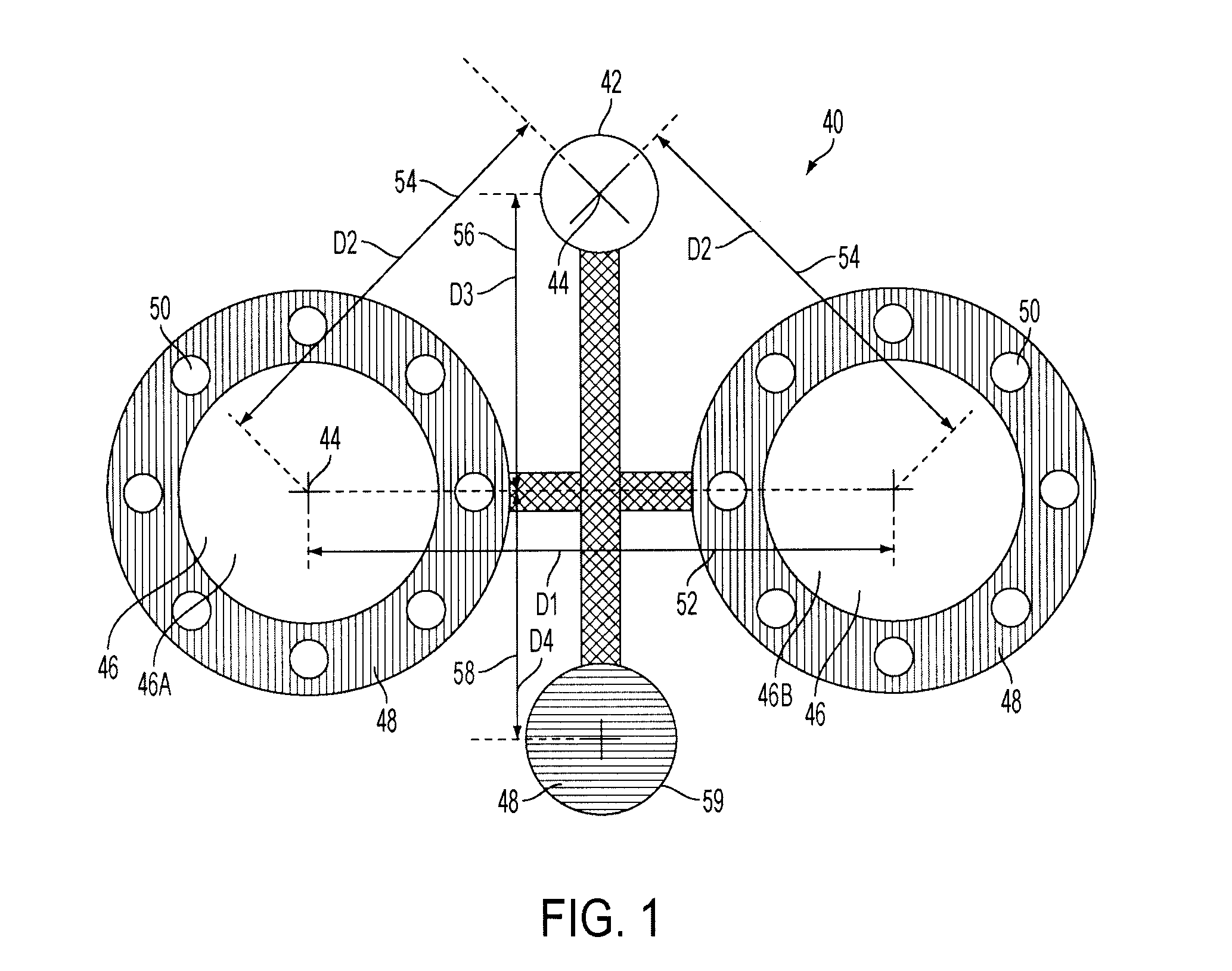

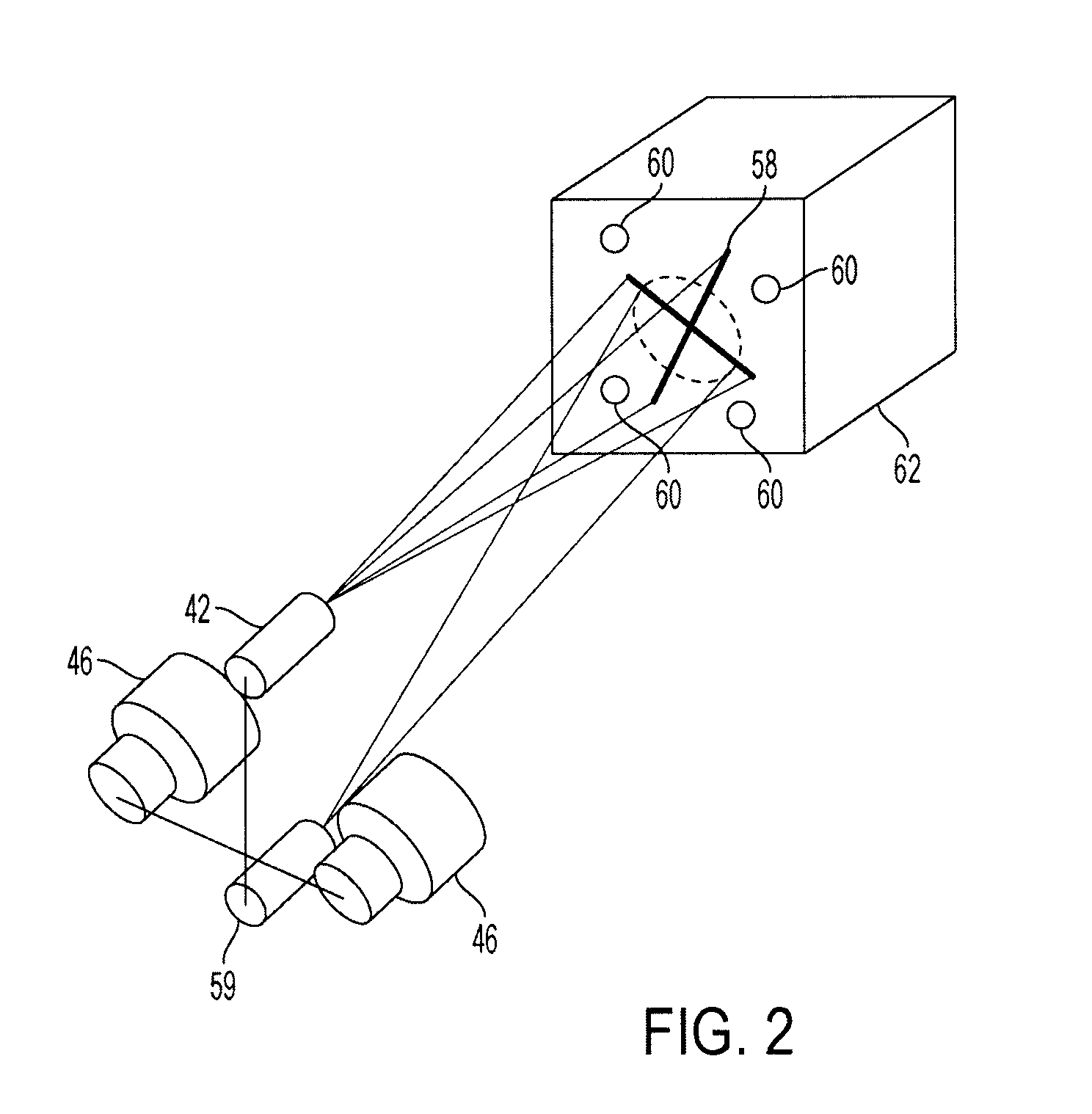

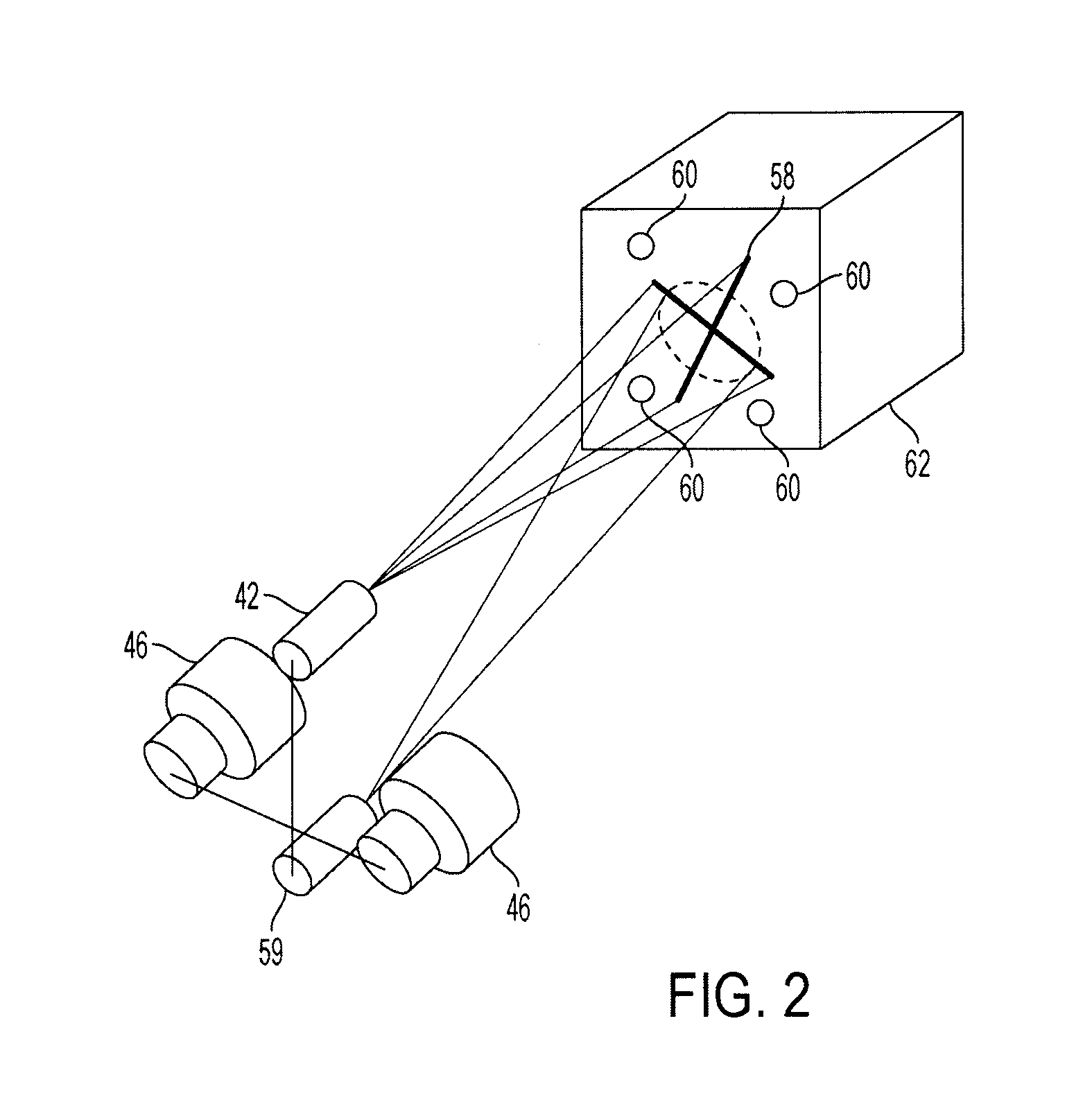

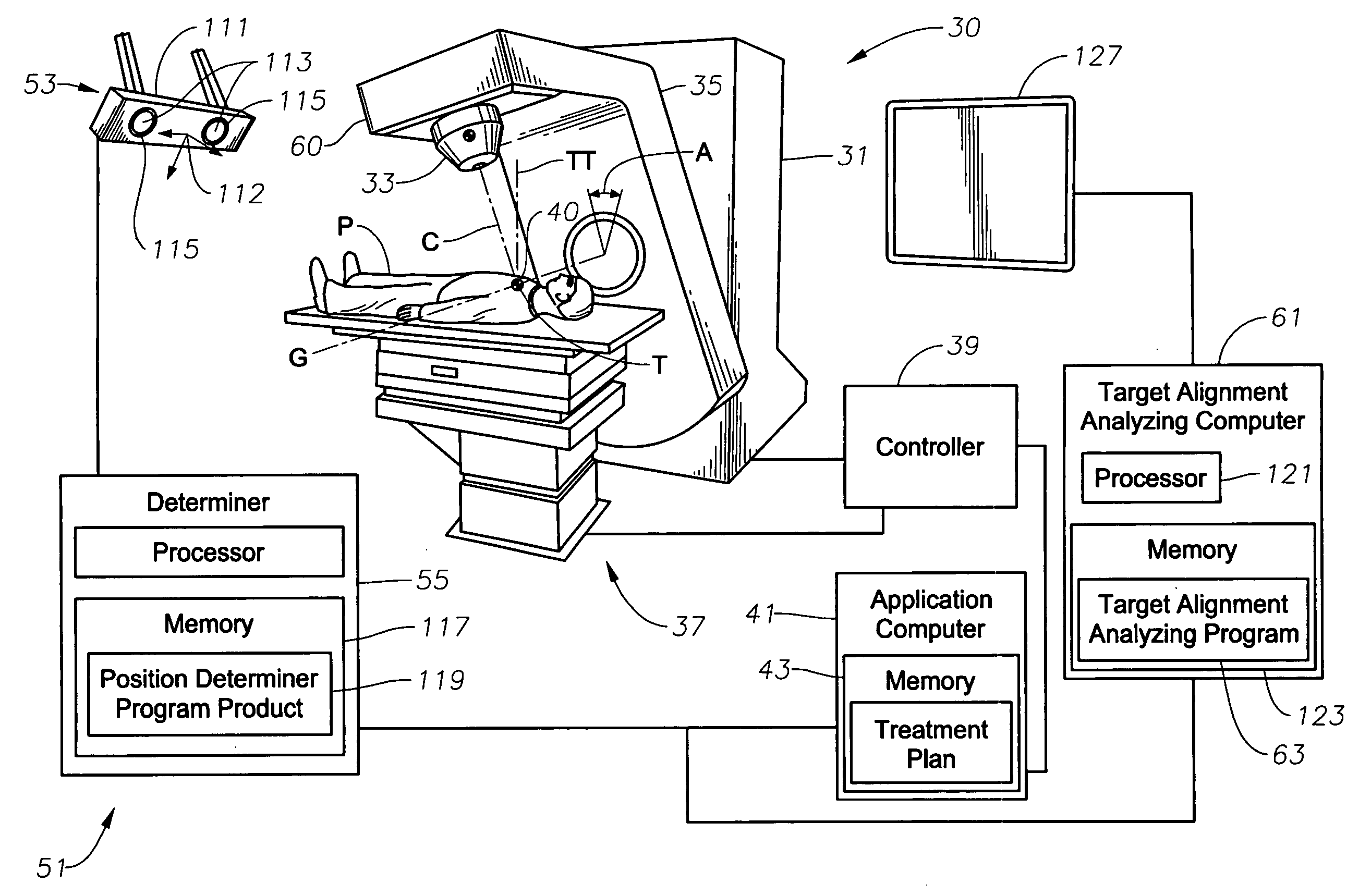

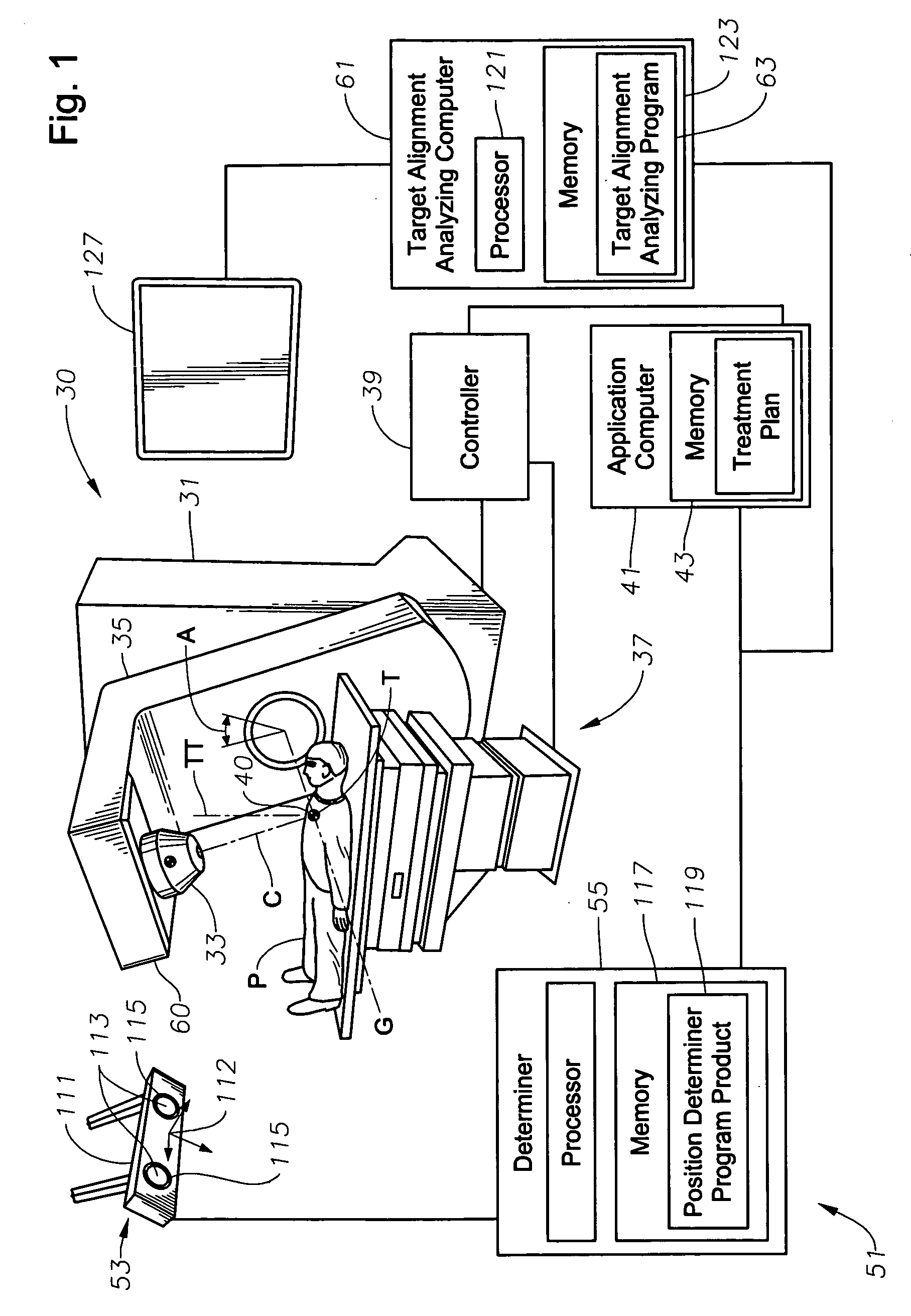

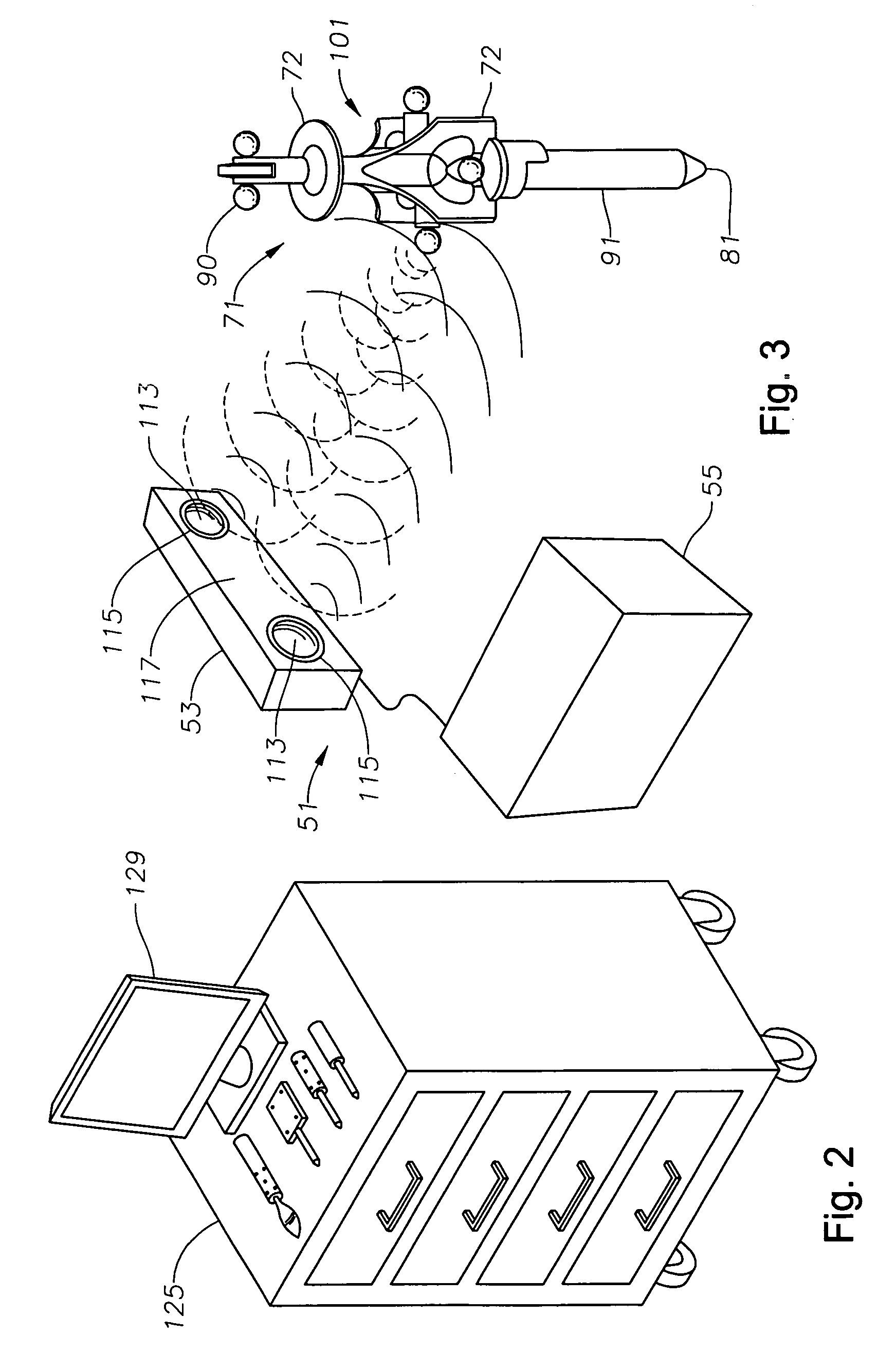

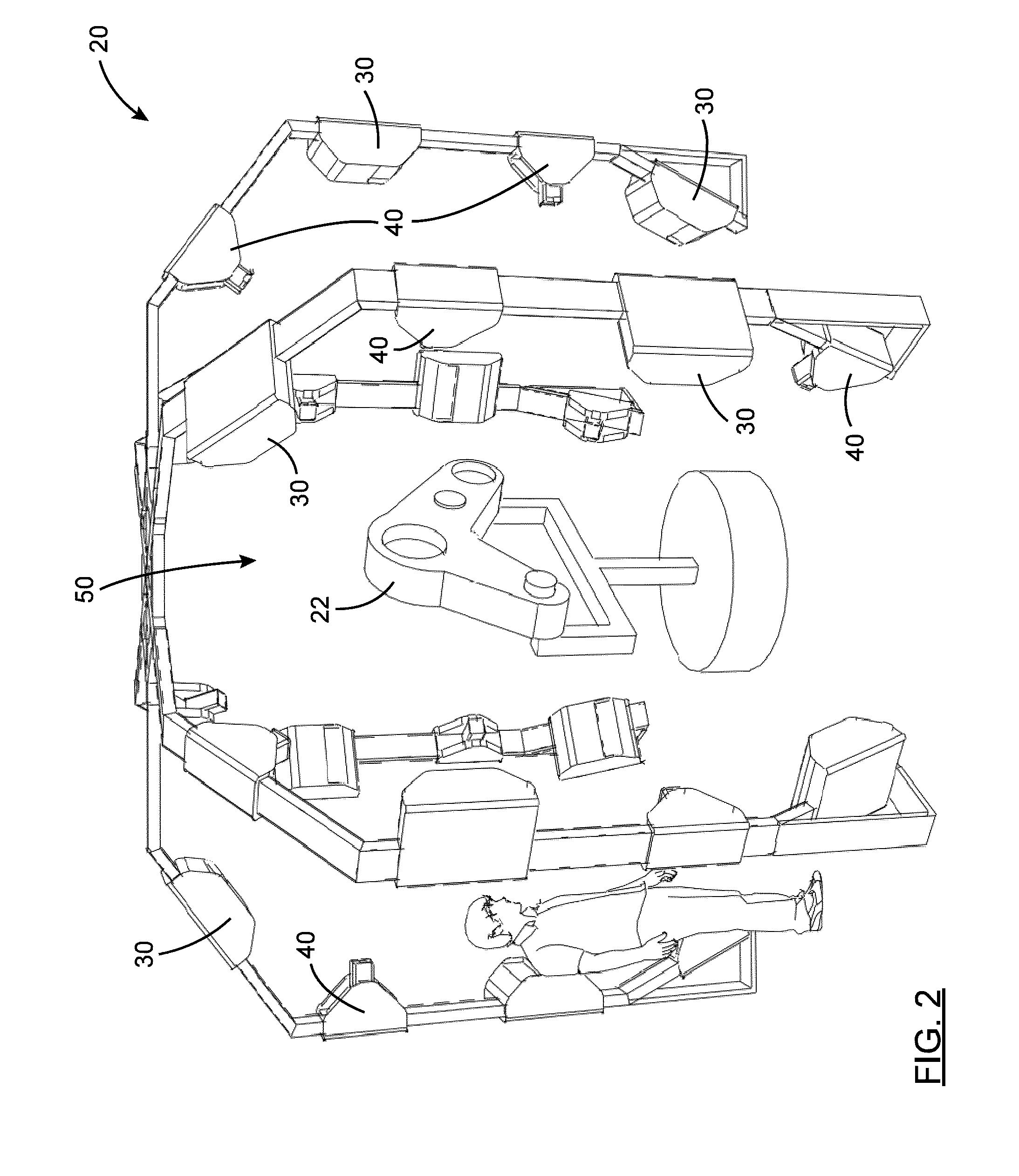

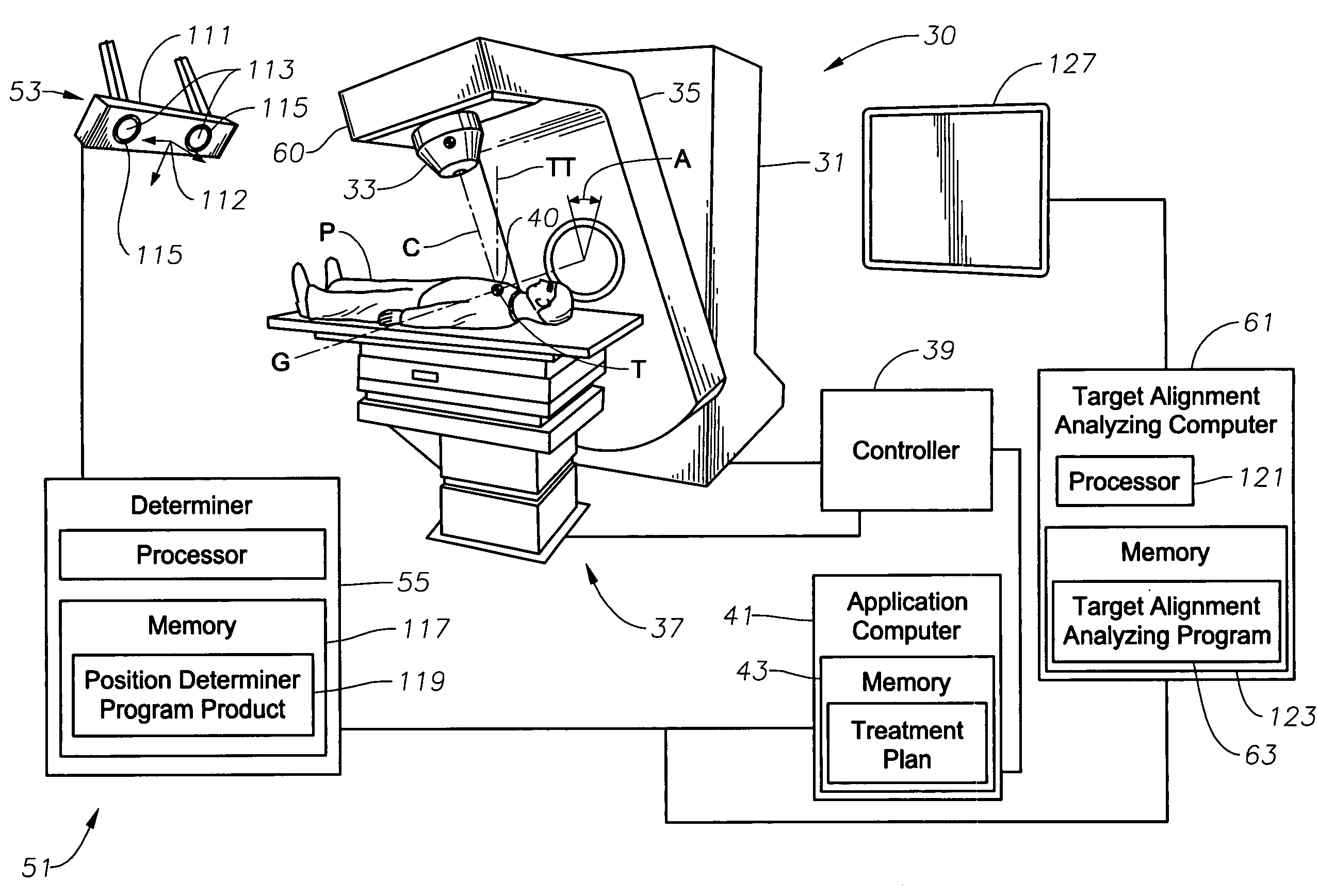

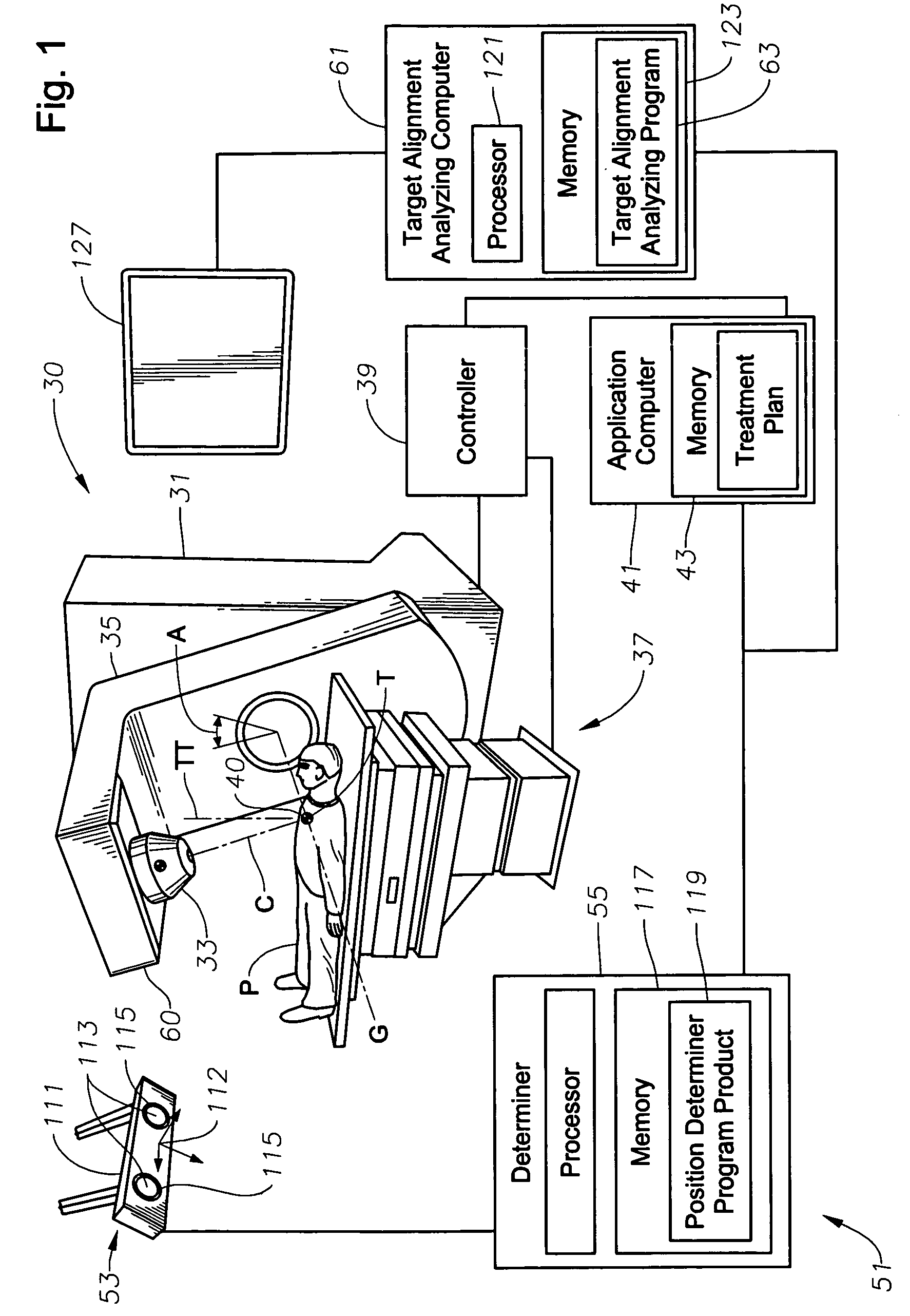

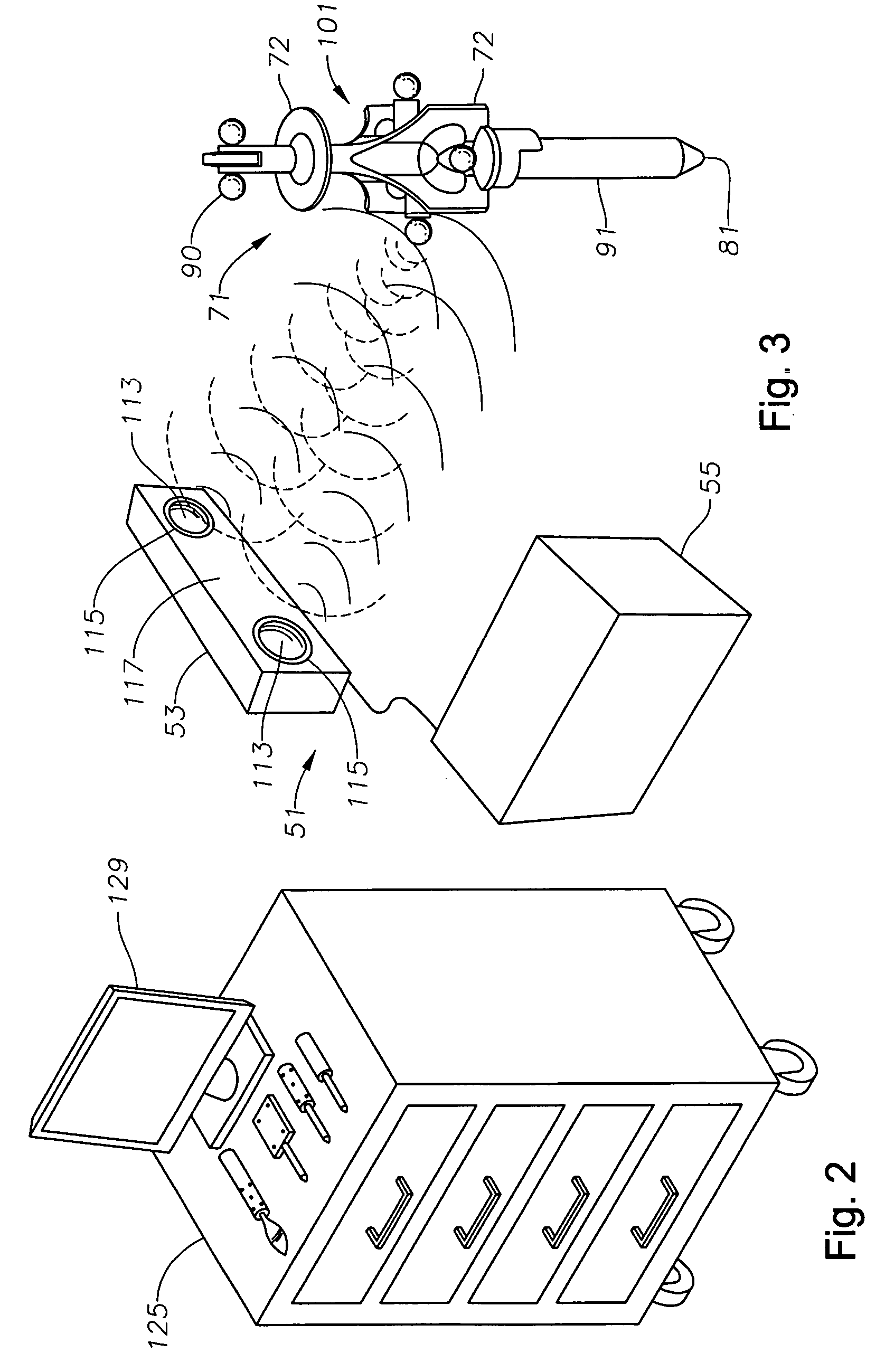

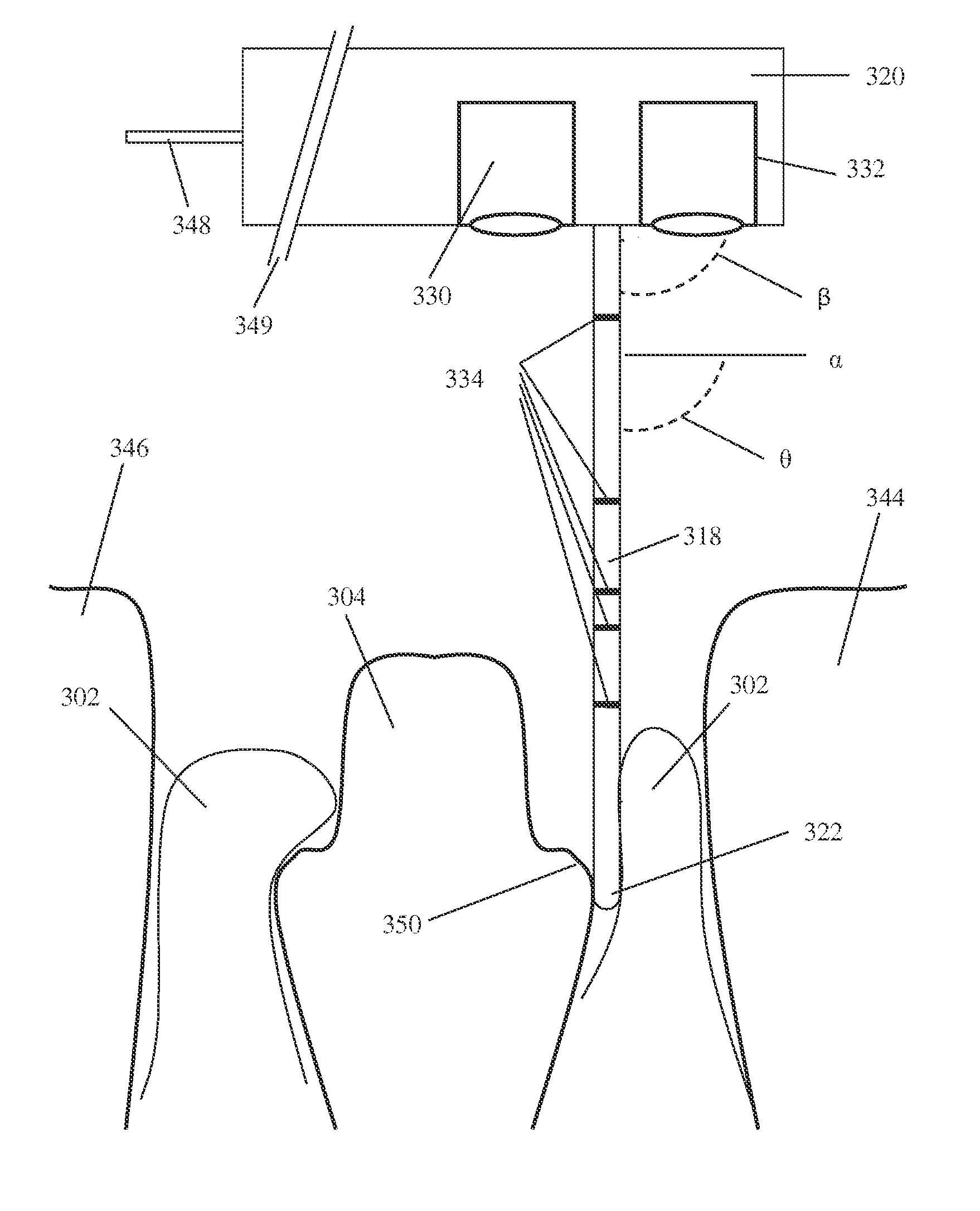

System, tracker, and program product to facilitate and verify proper target alignment for radiation delivery, and related methods

ActiveUS20060285641A1Simple quick applicationEasy to implementDiagnostic recording/measuringSensorsTreatment deliveryApplication computers

A system, tracker, program product, and methods to facilitate and verify proper target alignment for radiation delivery are provided. The system includes a radiation delivery apparatus having a radiation emitter, a rotating assembly controlled by a controller, and an application computer which provides treatment delivery instructions to the controller. The system also includes a trackable body having a trackable body reference point to be positioned adjacent a surface point of a patient to determine a position of such surface point. The system also includes an apparatus to track a trackable body which has a trackable body detector to detect a position of indicators carried by the trackable body and a trackable body determiner to determine a position of the trackable body reference point. The system also includes a target alignment analyzing computer having memory and target alignment analyzing program product stored therein to aid a user of the system to make and display various patient body-surface related measurements.

Owner:BEST MEDICAL INT

Method and device for displaying an indication of the quality of the three-dimensional data for a surface of a viewed object

Owner:BAKER HUGHES INC

Inspection system for inspecting an object and inspection method for same

ActiveUS20160169665A1Avoids combining errorSimple calculationMaterial analysis by optical meansUsing optical meansSurface pointField of view

A system for inspecting an object has at least one light projector and at least one camera jointly defining a field of view and a computer operatively connected thereto. The computer is configured to acquire object data representative of the outer surface of the object through projection of light thereon by the light projector and acquisition of return light by the camera. The object data relates surface points on the outer surface of the object to one or more source point of the light projector. The computer is further configured to generate inspection information data based on the acquired object data and project the inspection information data on at least some of the surface points of the outer surface of the object using the corresponding source points of the at least one light projector. A method inspects an outer surface of an object.

Owner:POLYRIX

System, tracker, and program product to facilitate and verify proper target alignment for radiation delivery, and related methods

ActiveUS7613501B2Facilitate and verify proper target alignmentPrecise applicationDiagnostic recording/measuringSensorsTreatment deliveryApplication computers

Owner:BEST MEDICAL INT

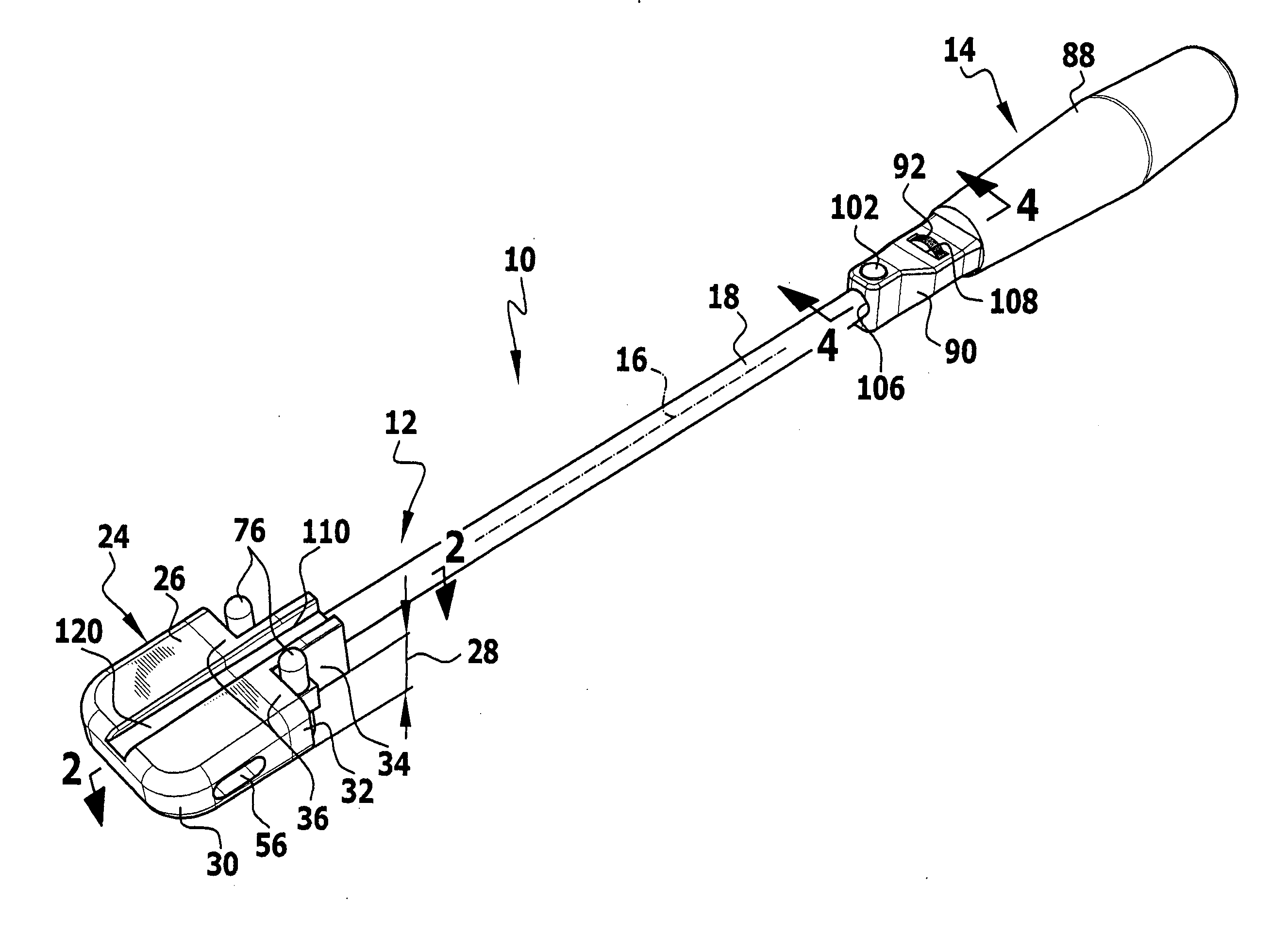

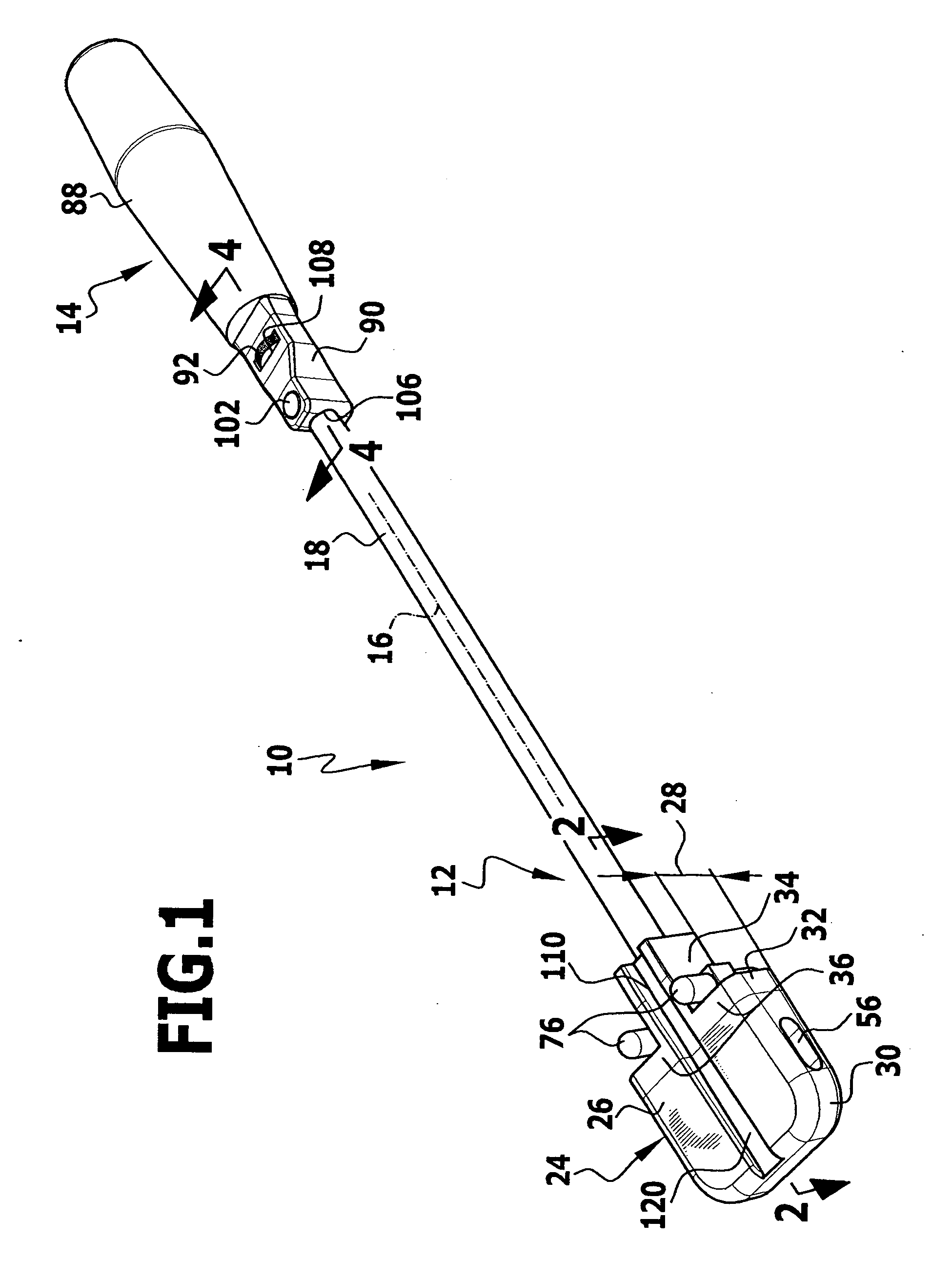

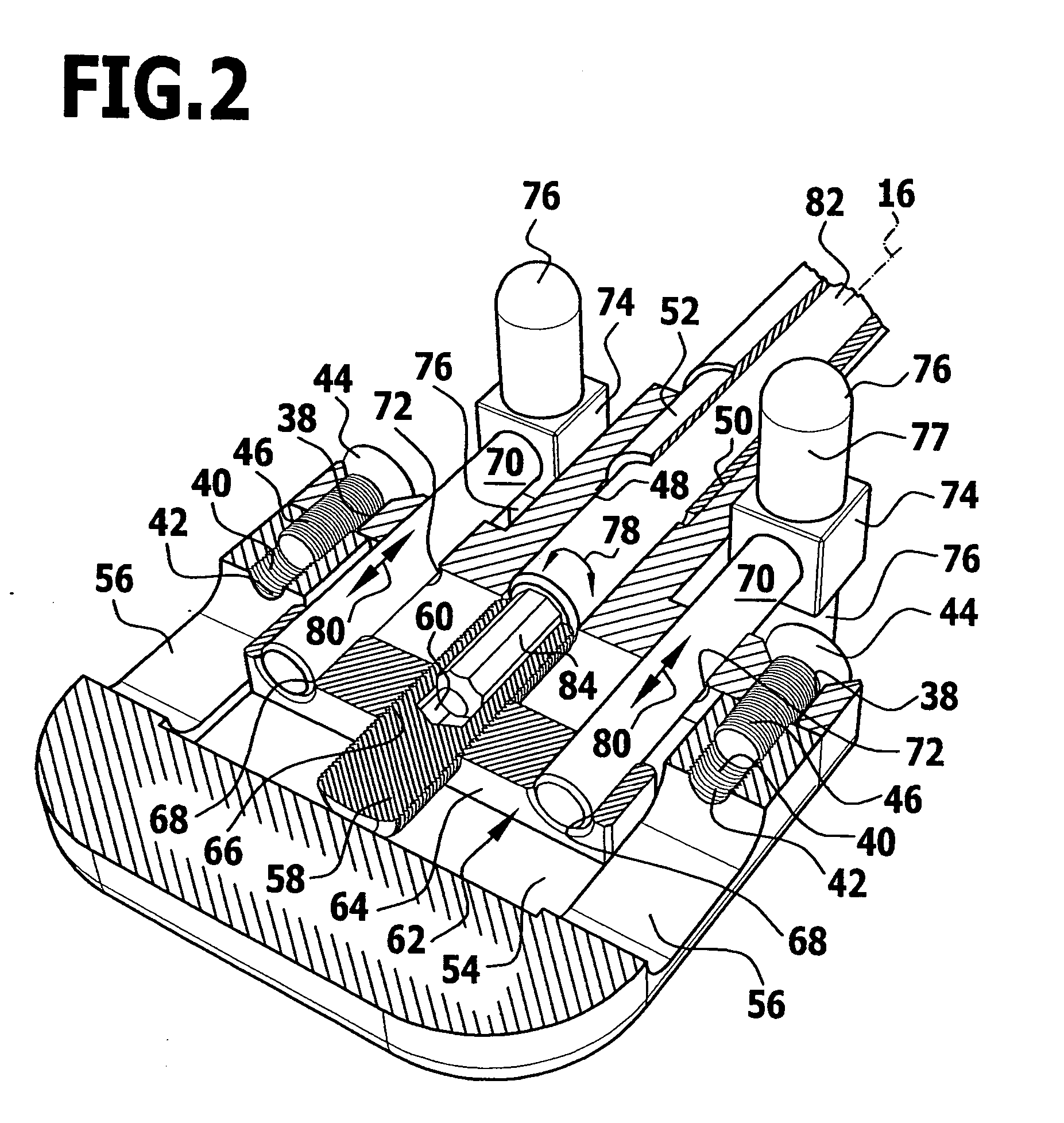

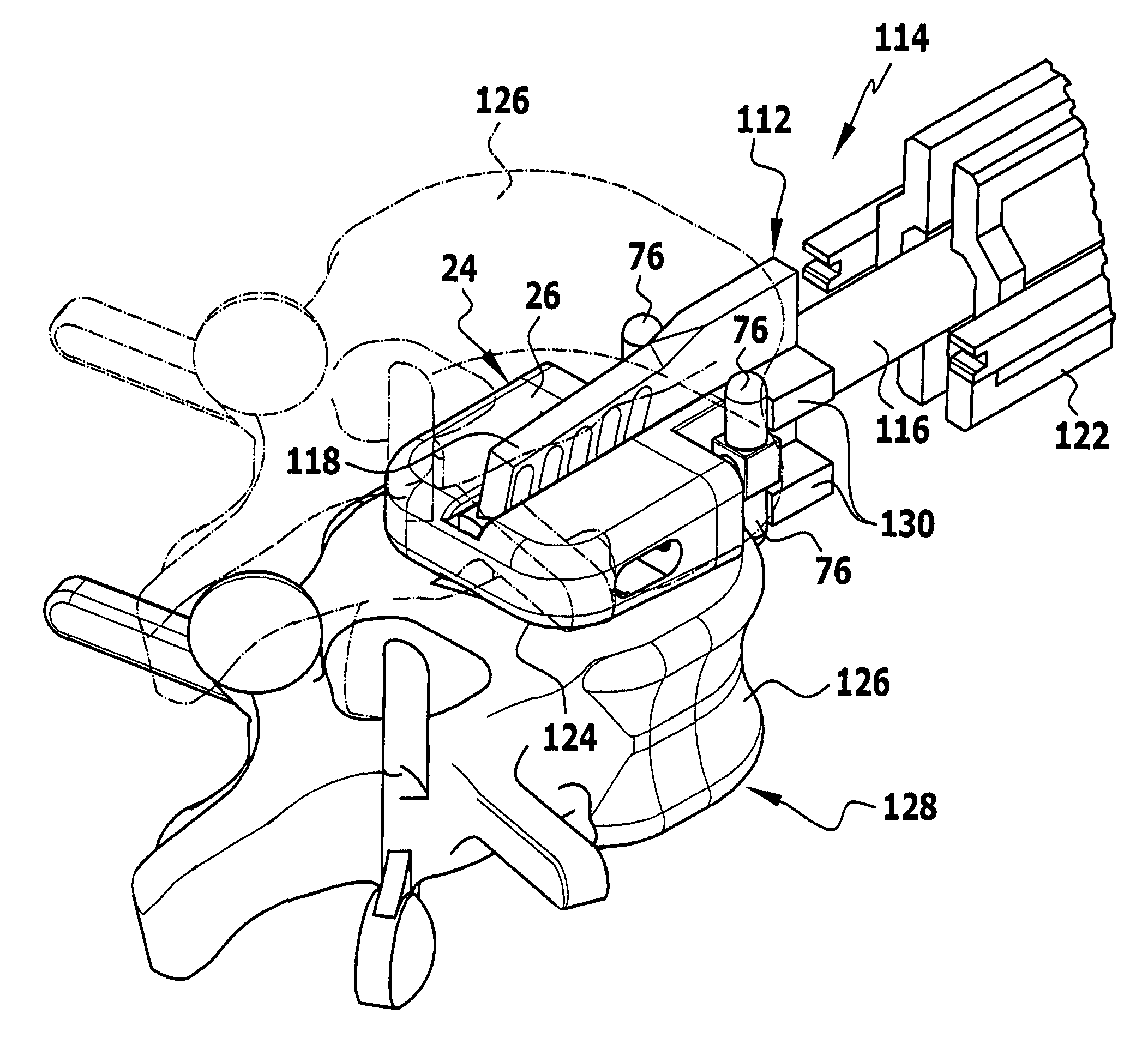

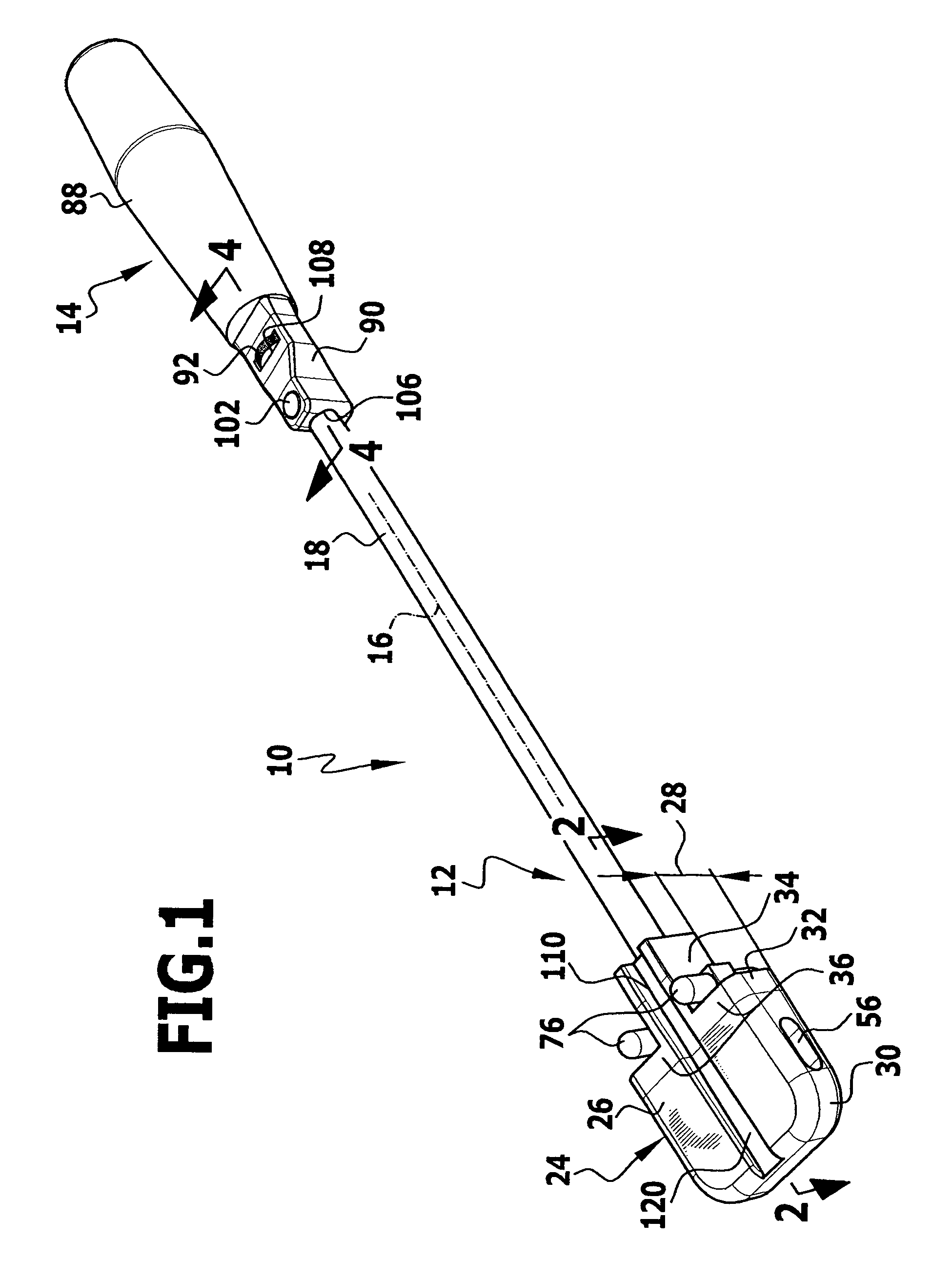

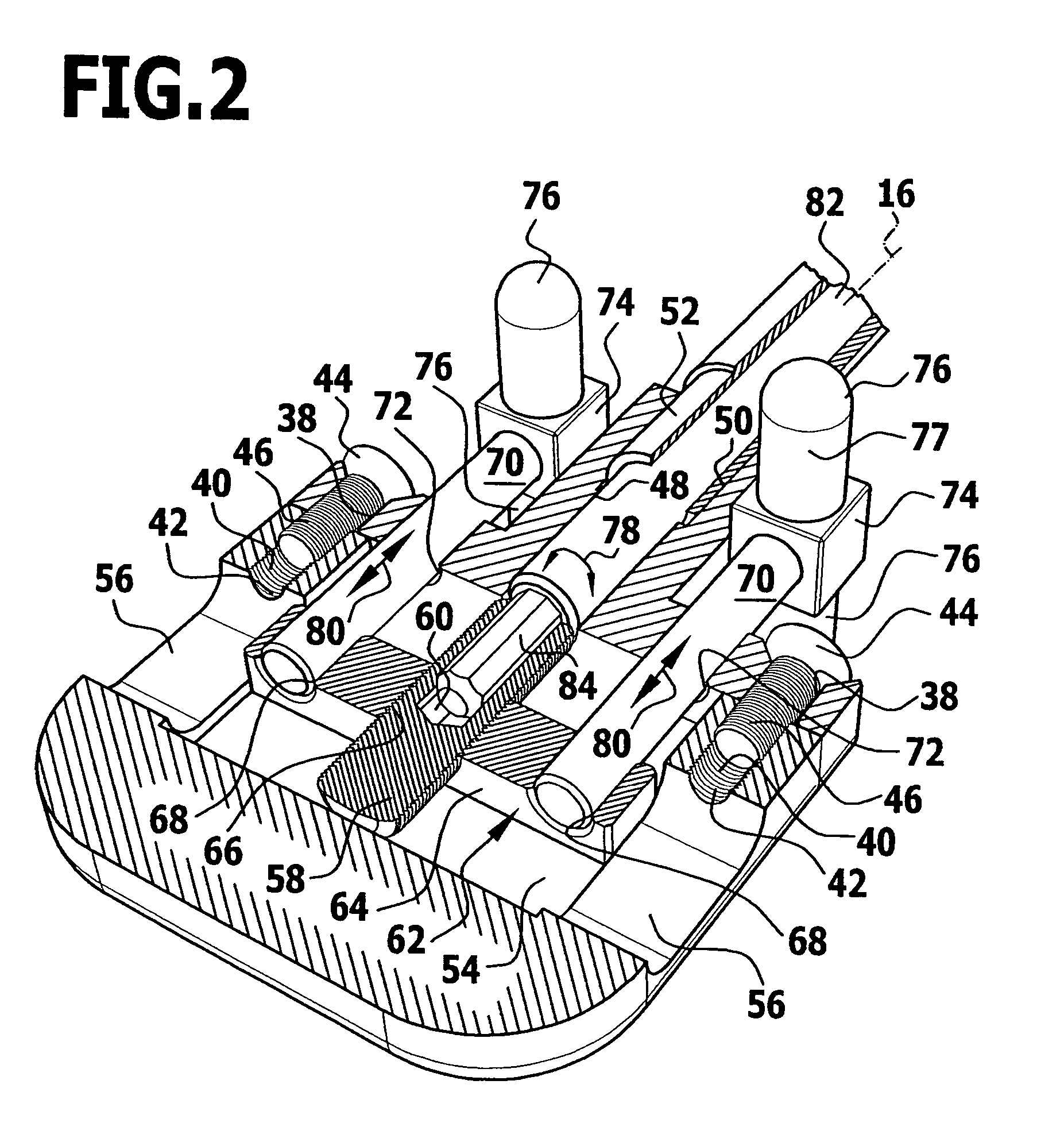

Surgical guiding instrument

ActiveUS20070118145A1Avoid injurySimple preparation processDiagnosticsSpinal implantsChiselInsertion depth

A surgical guiding instrument for use with a chisel and an implant body for insertion into an intervertebral space, included is a shaft with a stop device for delimiting a depth of insertion of the implant body into the intervertebral space. The shaft has a distal end and a proximal end, the implant body being arranged at the distal end of the shaft and defining two bearing surfaces positionable against the adjacent vertebral bodies, the stop device having at least one stop movably mounted at the distal end of the shaft or on the implant body, the stop having a stop surface pointing in distal direction transversely or substantially transversely to at least one of the bearing surfaces, so that an insertion depth for a surgical machining tool can be set in a simple way.

Owner:AESCULAP AG

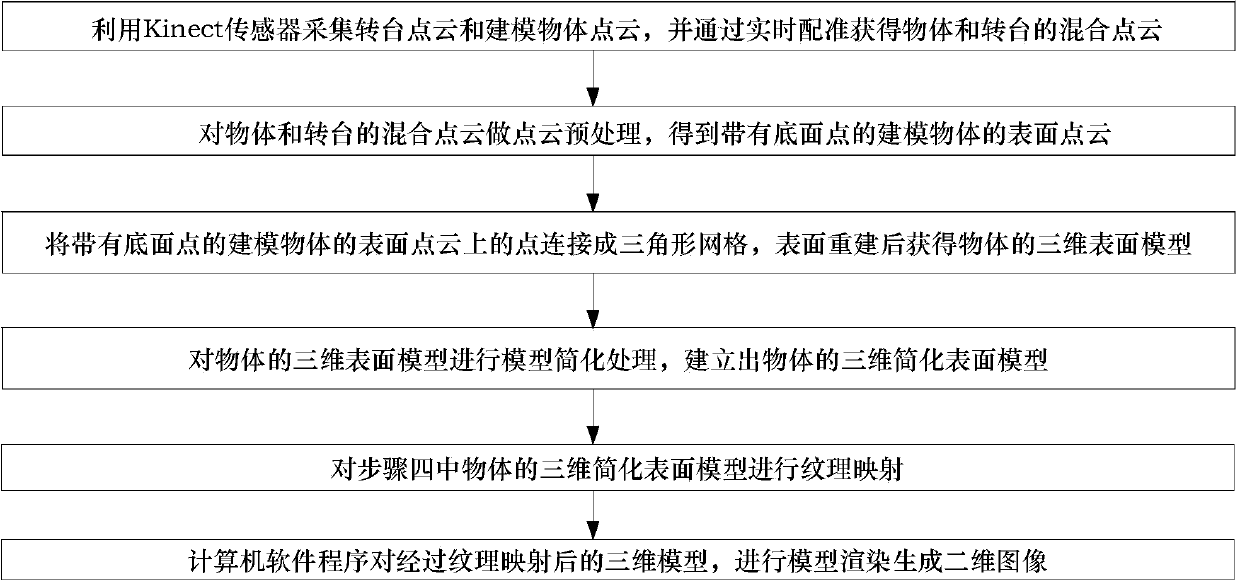

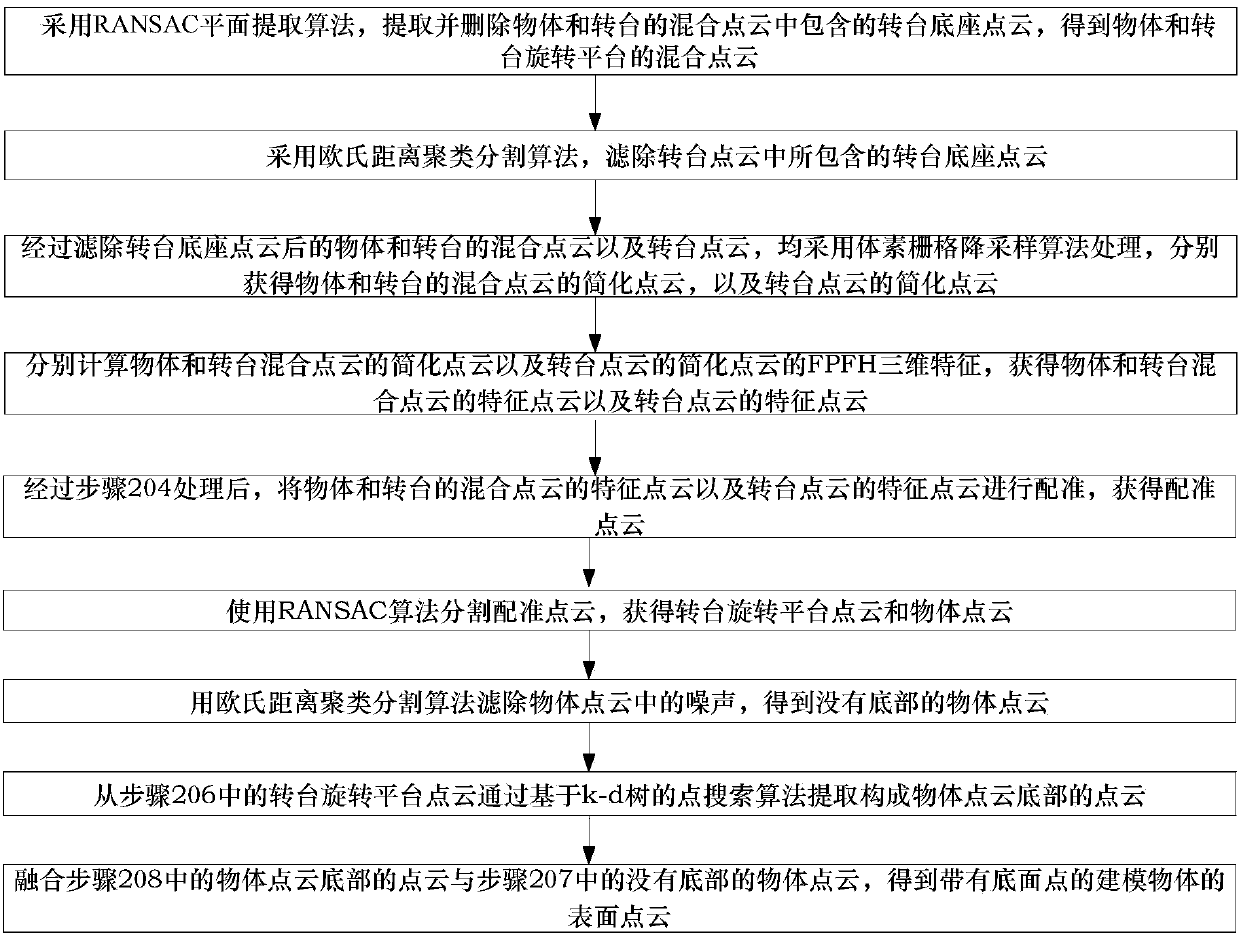

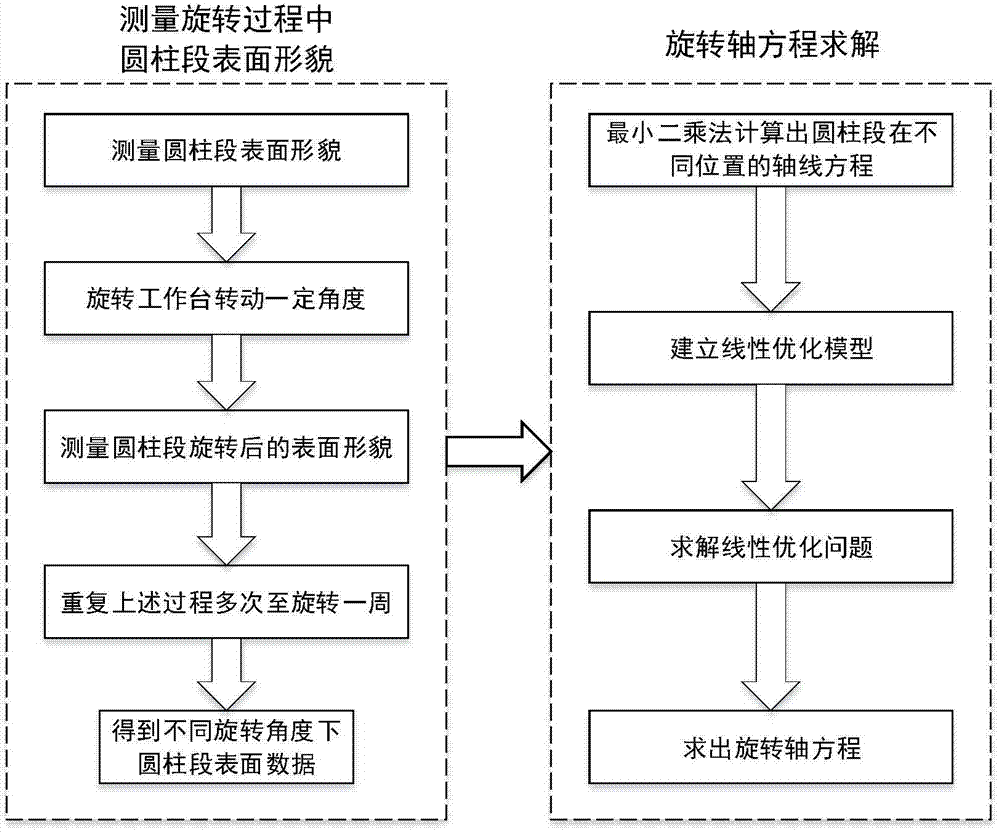

Physical three-dimensional model automatic modeling method

The present invention discloses a physical three-dimensional model automatic modeling method which comprises the following steps of (1) collecting a turntable point cloud and a modeling object point cloud, and carrying out real-time registration to obtain a mixed point cloud of an object and a turntable, (2) carrying out point cloud pretreatment to obtain the surface point cloud of a model object with a bottom surface point, (3) carrying out surface reconstruction to obtain the three-dimensional surface model of the object, (4) carrying out model simplification treatment on the three-dimensional surface model, and establishing the three-dimensional simplified surface model of the object, (5) carrying out texture mapping on the three-dimensional simplified surface model, and (6) carrying out model rendering on the three-dimensional model which is subjected to texture mapping to generate a two-dimensional image. The method has the advantages that the system operation is stable and reliable, the automation is realized in the operation process, a rebuilding effect is good, and the application needs of different simulation scenes can be satisfied by a built multi-granularity three-dimensional model.

Owner:BEIHANG UNIV

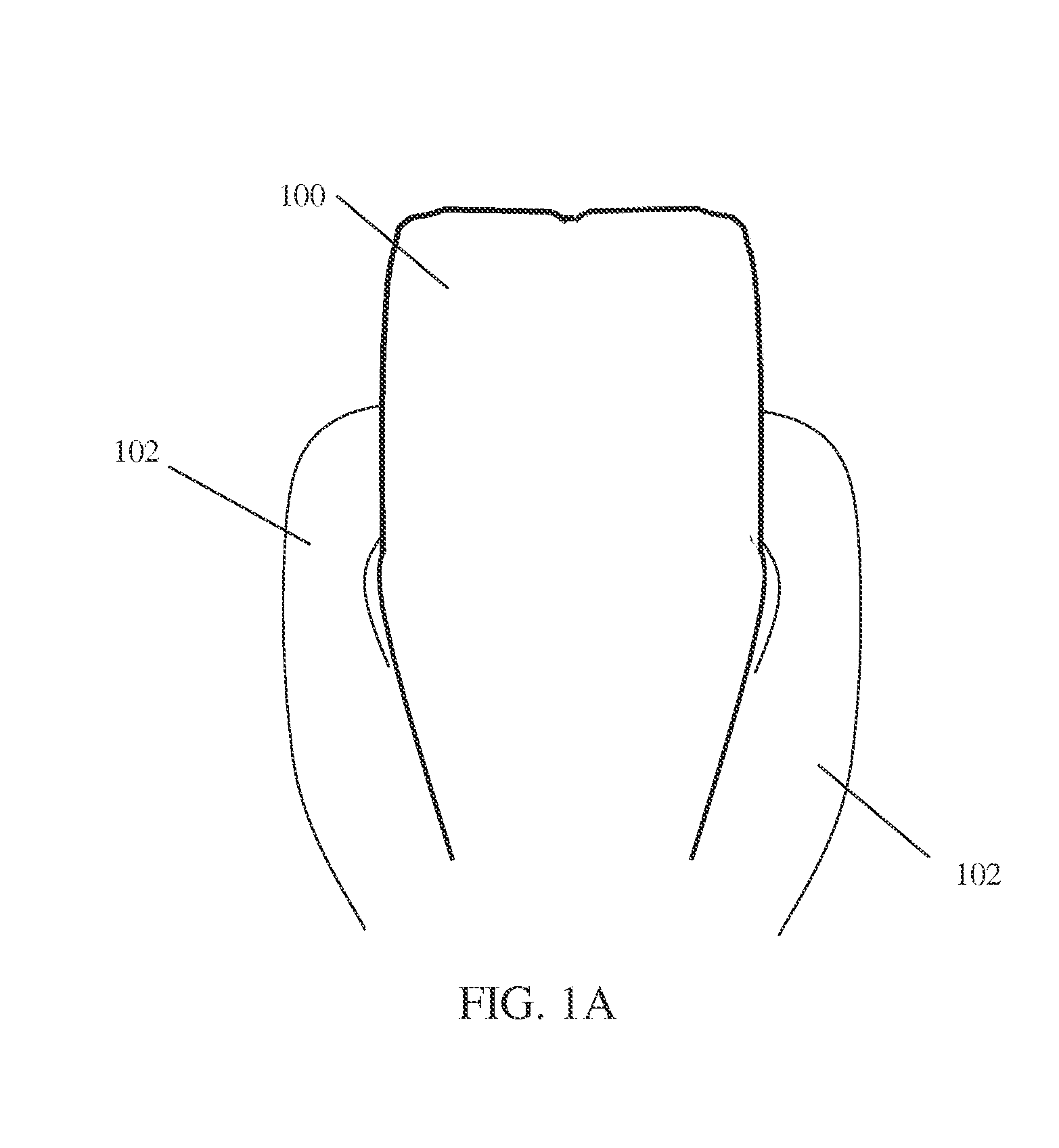

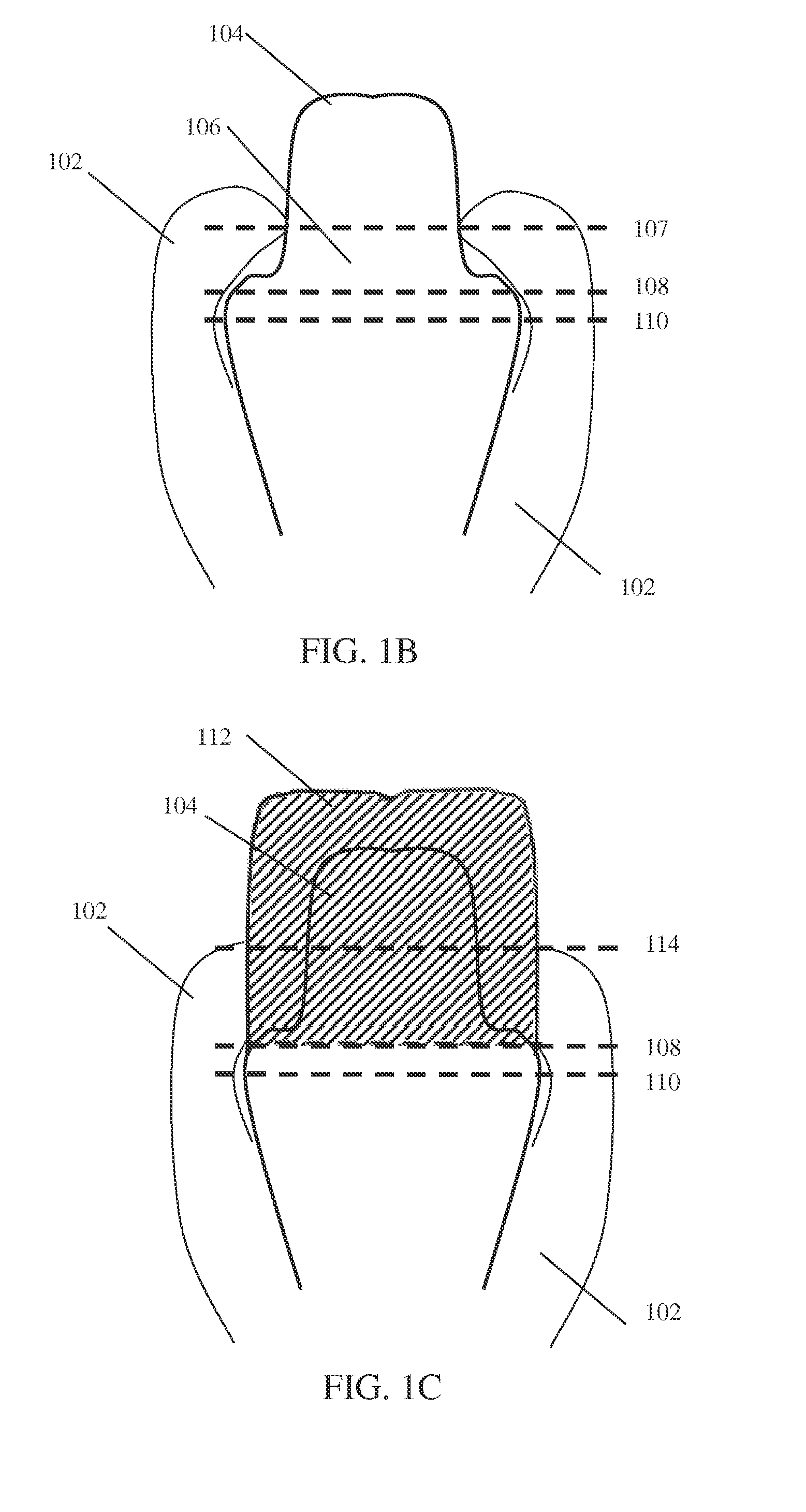

Device and method for subgingival measurement

A method for measuring regions of a tooth in a mouth including: measuring at least one surface point on a surface of the tooth with respect to an element mechanically coupled to said surface point; determining a location of at least one visible reference mechanically coupled to said surface point with respect to said element; estimating a location of said surface point with respect to said visible reference. A device used for such measuring may include a main body comprising a final optical element of an imager which defines an optical field of view directed in a first direction; and a measurement element coupled to said main body extending generally in said first direction; where a tip of said measurement element is sized and shaped to be inserted between a tooth and adjacent gingiva; where said optical field of view is sized to image at least part of a tooth.

Owner:DENTLYTEC G P L

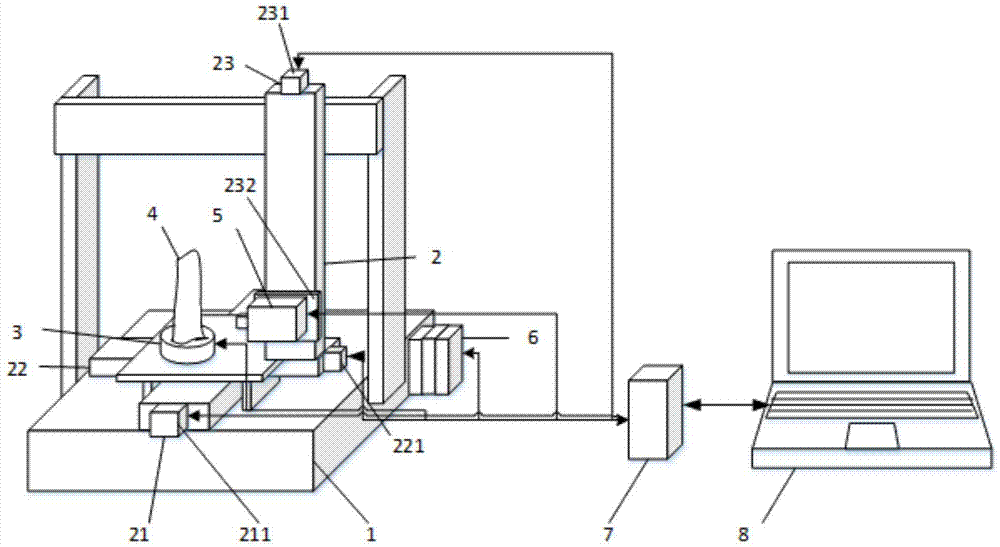

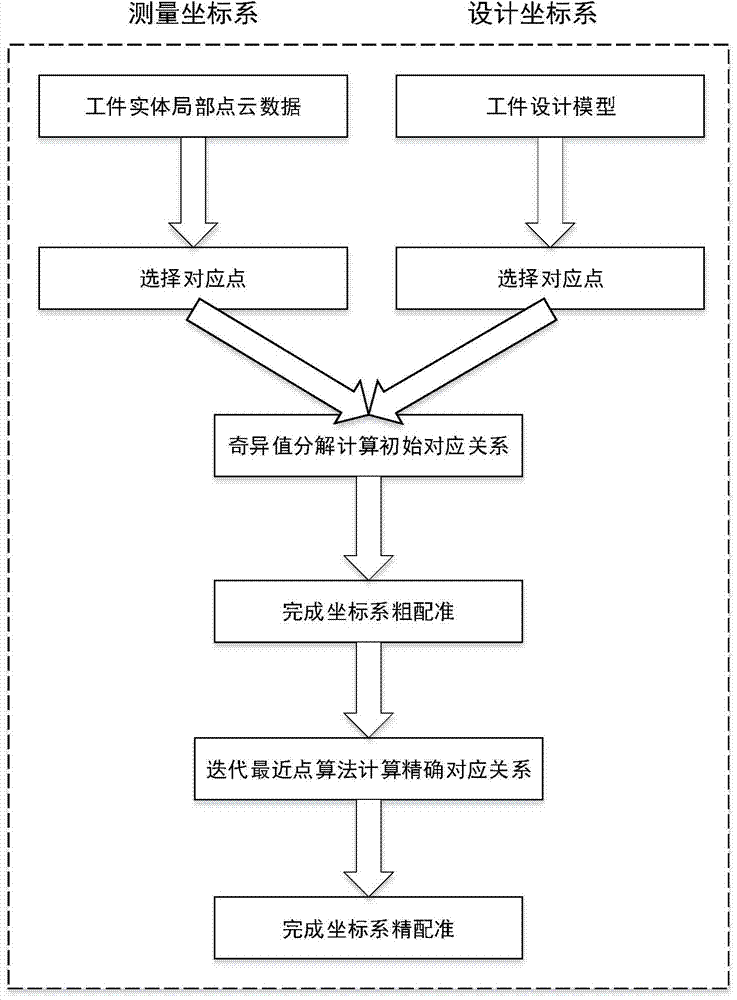

Automatic three-dimensional measuring method and automatic three-dimensional measuring system for high-precision blade of aviation engine

ActiveCN104515478AHigh measurement accuracyImprove measurement resolutionUsing optical meansAviationThree dimensional measurement

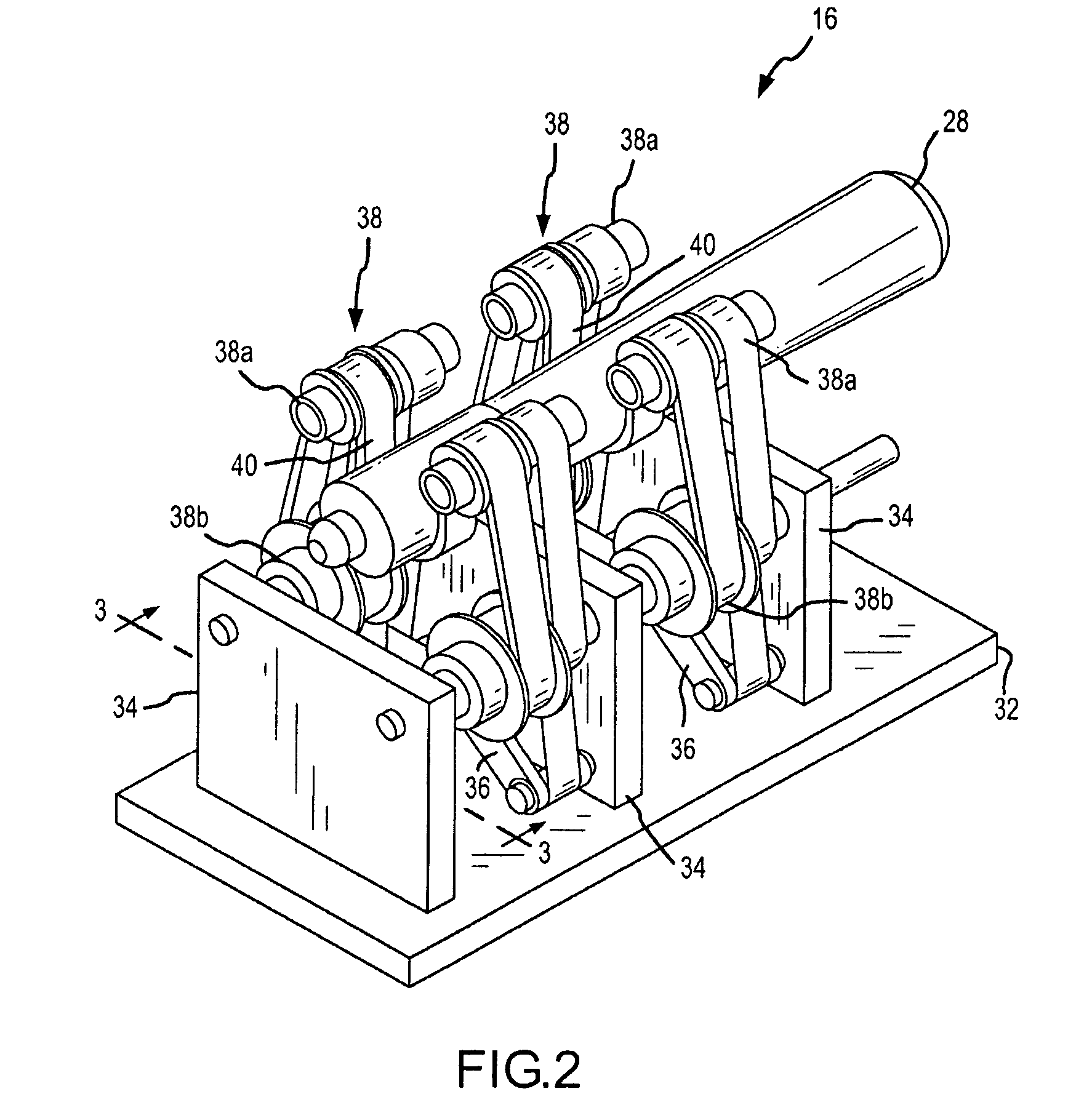

The invention discloses an automatic three-dimensional measuring method for a high-precision blade of an aviation engine. The automatic three-dimensional measuring method comprises the following steps of (1) rectification: performing rectification on a design coordinate system of a design model and a measurement coordinate system of a workpiece entity; (2) path planning: planning a motion path of a distance sensor in a measuring process by using a data processing device so that a measured region of the workpiece entity is in a measurement range of the distance sensor; and (3) automatic measurement: sampling a front region and a reverse region of the workpiece entity by using the distance sensor to obtain a complete surface profile of the workpiece entity. The distance sensor serves as a measuring terminal, and position information of surface points of the measured region can be acquired; and moreover, by a three-axis motion mechanism, measurement on different regions of the workpiece entity can be realized, measured cloud data of points of density of a local range are automatically fused to the same coordinate system, and complete precise measurement on a workpiece and quality testing operation on the workpiece entity are realized.

Owner:HUAZHONG UNIV OF SCI & TECH

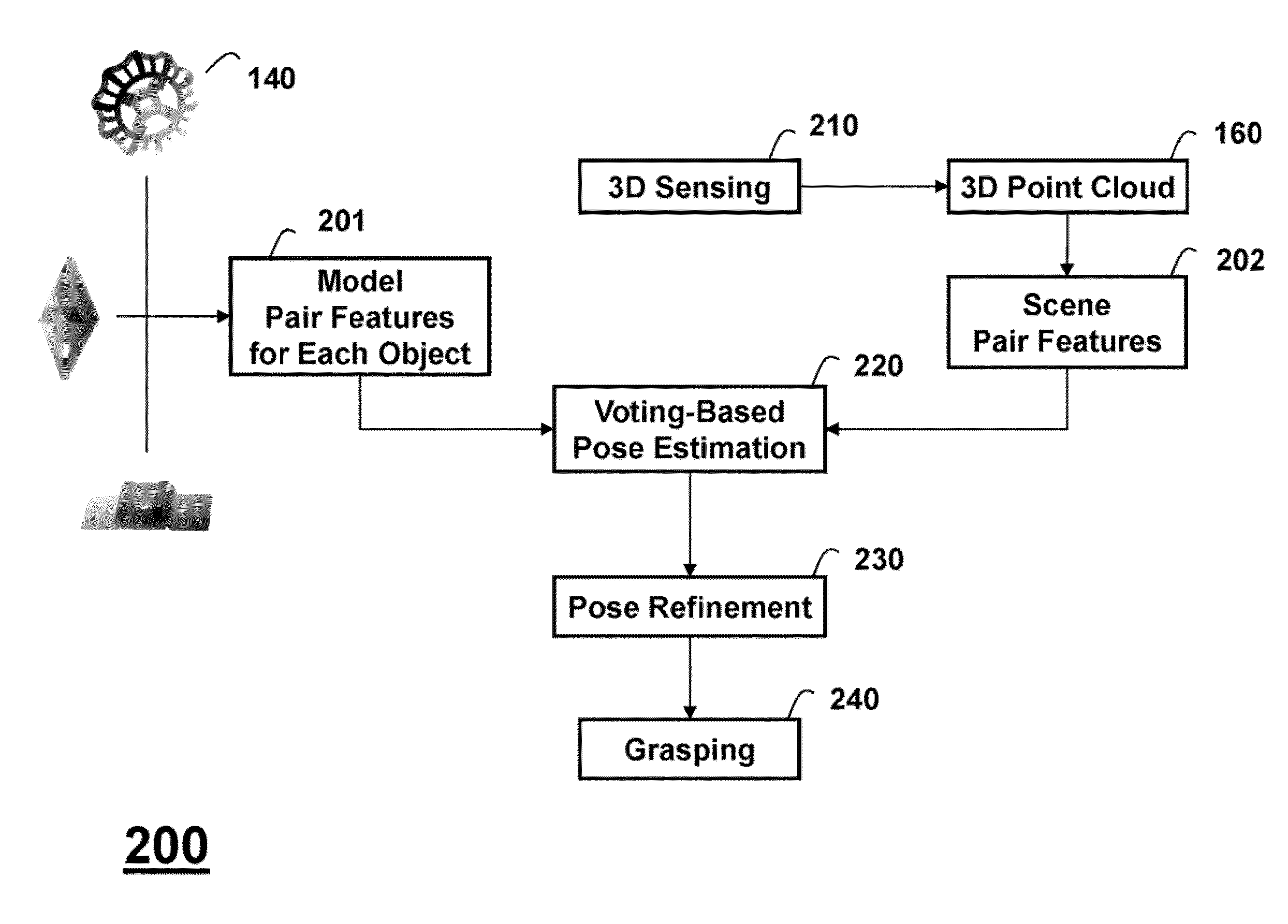

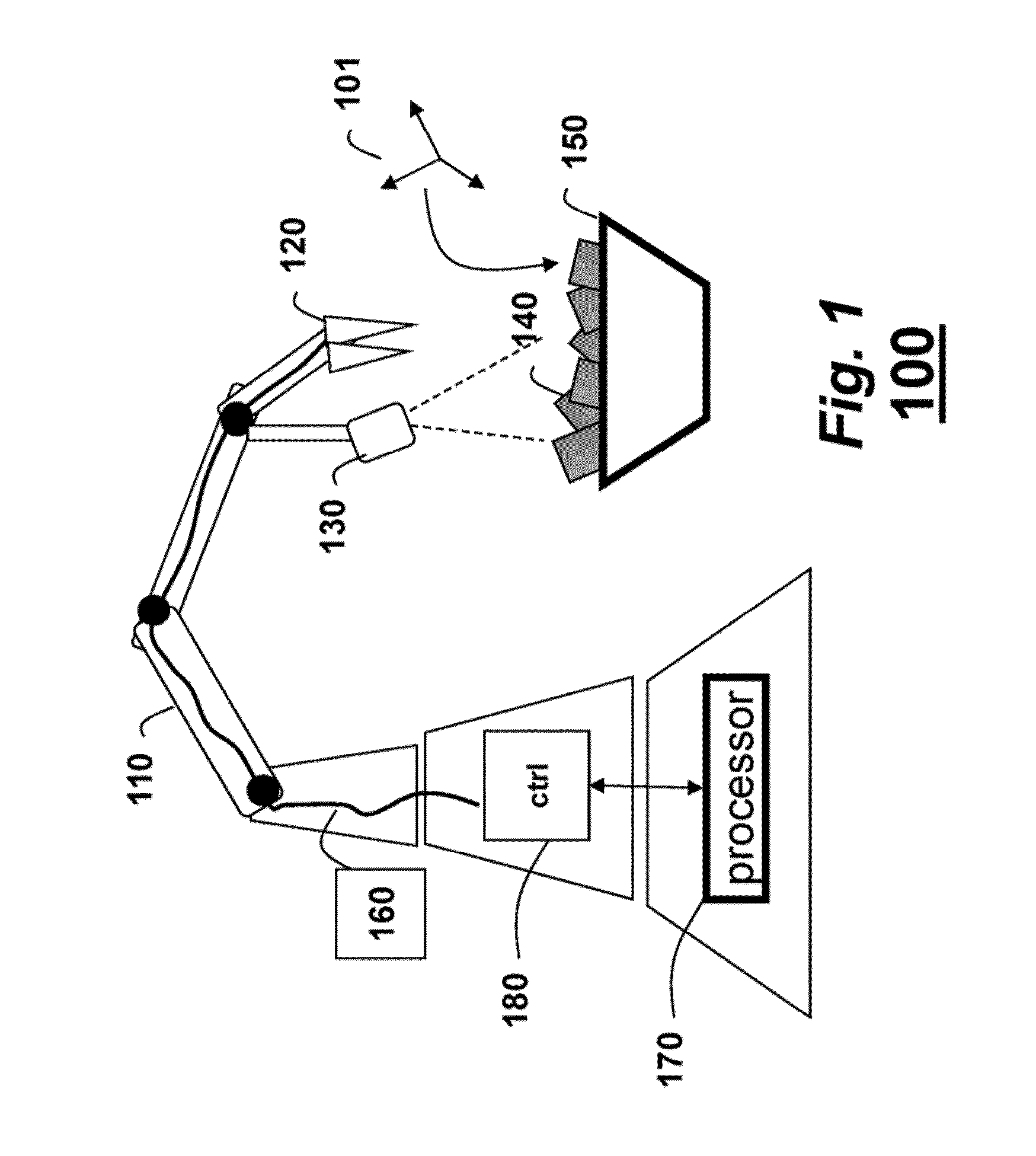

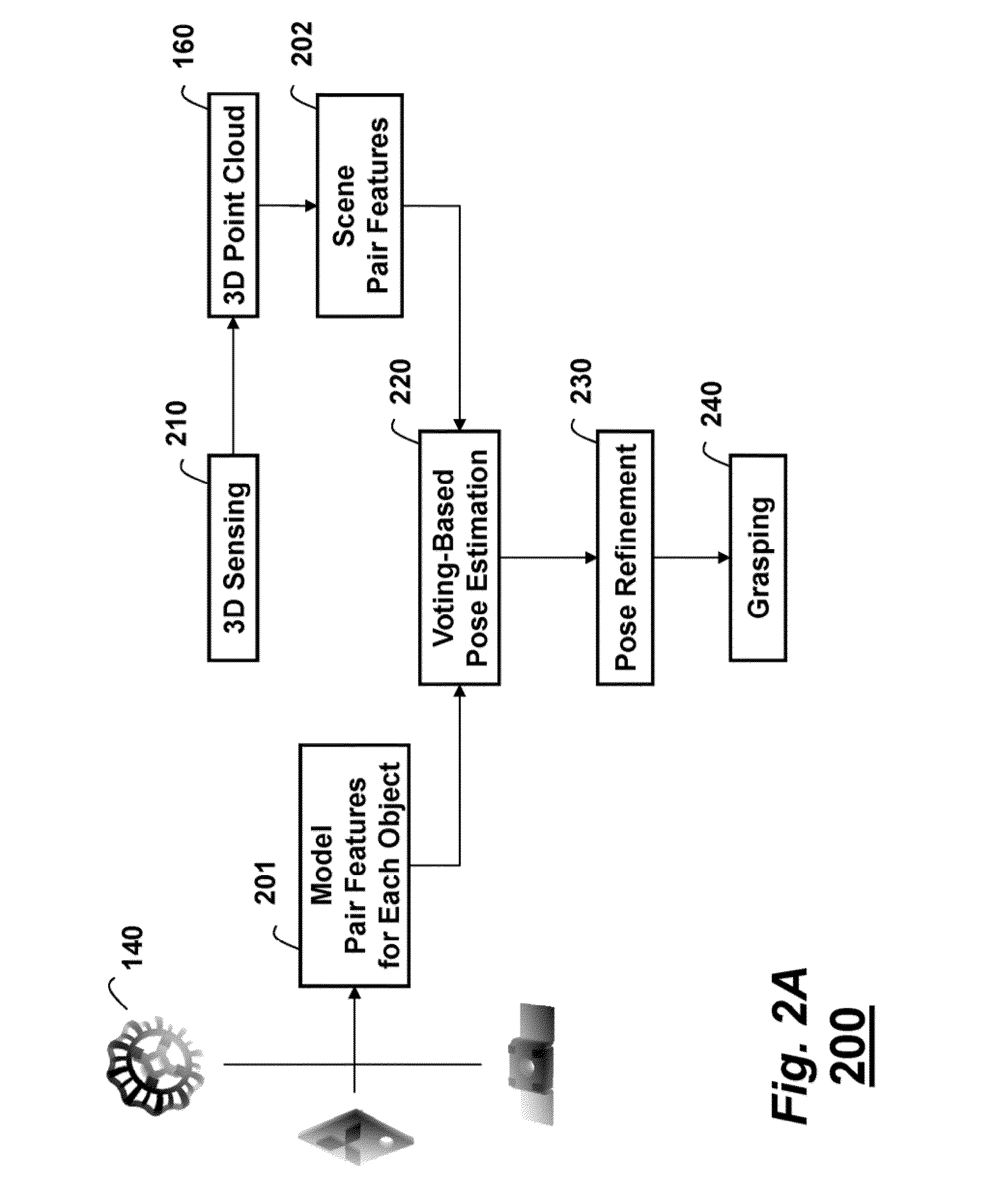

Voting-Based Pose Estimation for 3D Sensors

ActiveUS20130156262A1Improve accuracyFast computerImage enhancementImage analysis3d sensorGeometric primitive

A pose of an object is estimated by first defining a set of pair features as pairs of geometric primitives, wherein the geometric primitives include oriented surface points, oriented boundary points, and boundary line segments. Model pair features are determined based on the set of pair features for a model of the object. Scene pair features are determined based on the set of pair features from data acquired by a 3D sensor, and then the model pair features are matched with the scene pair features to estimate the pose of the object.

Owner:MITSUBISHI ELECTRIC RES LAB INC

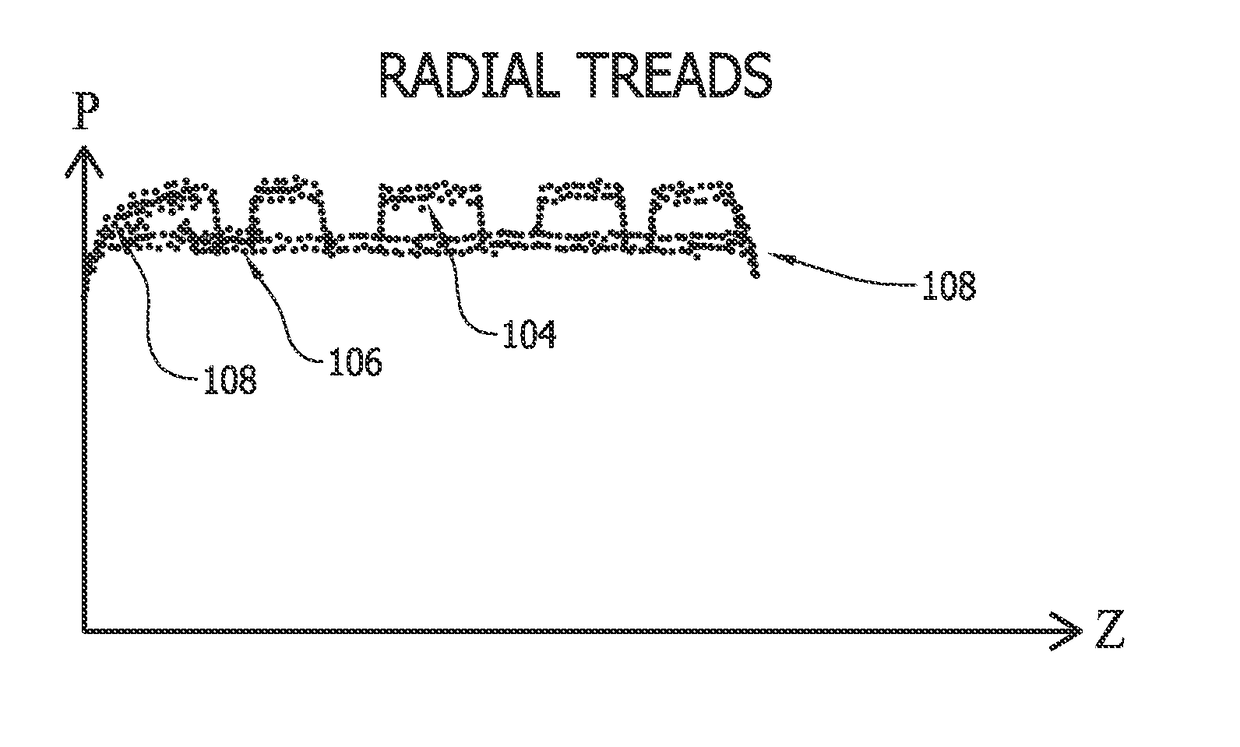

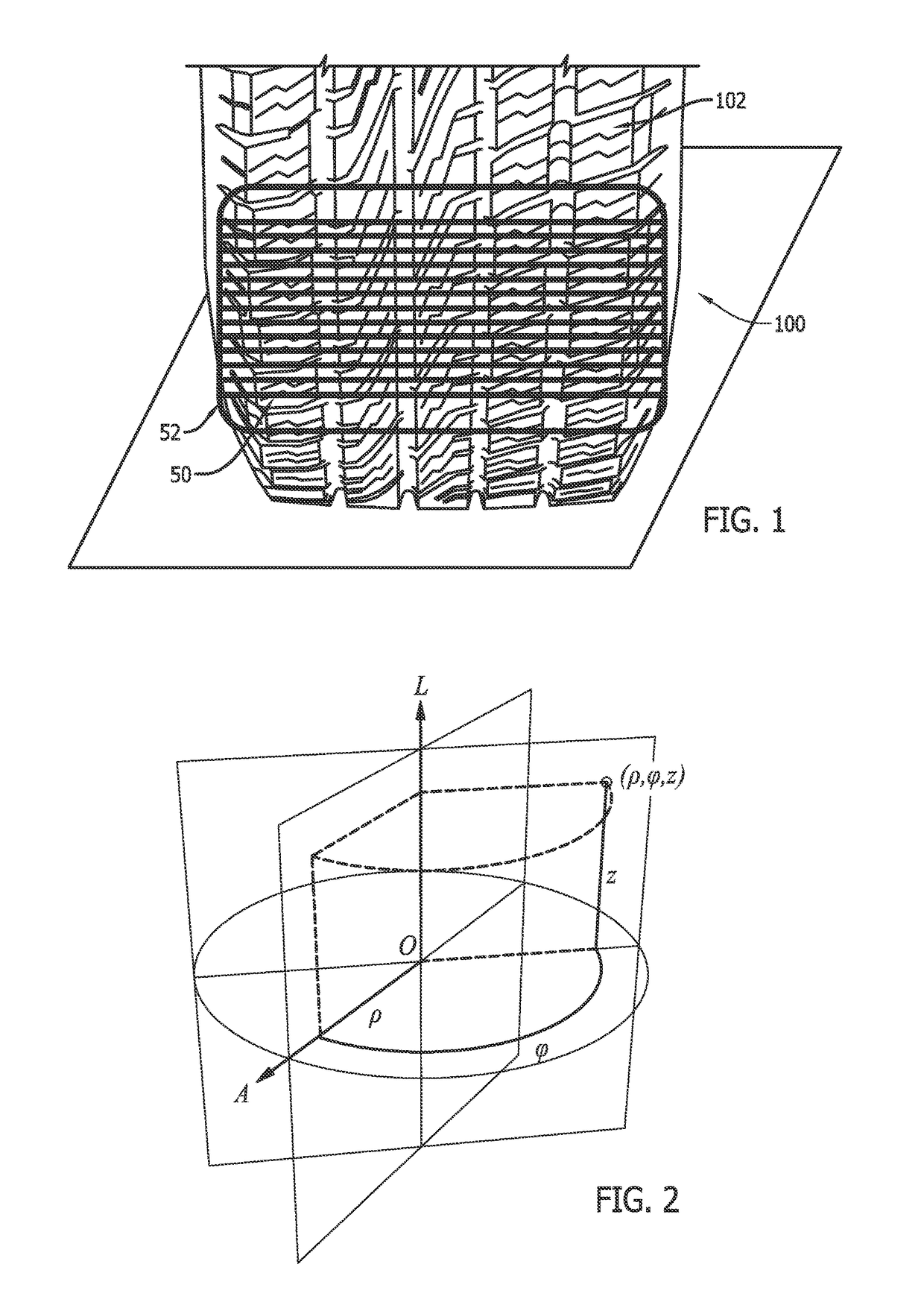

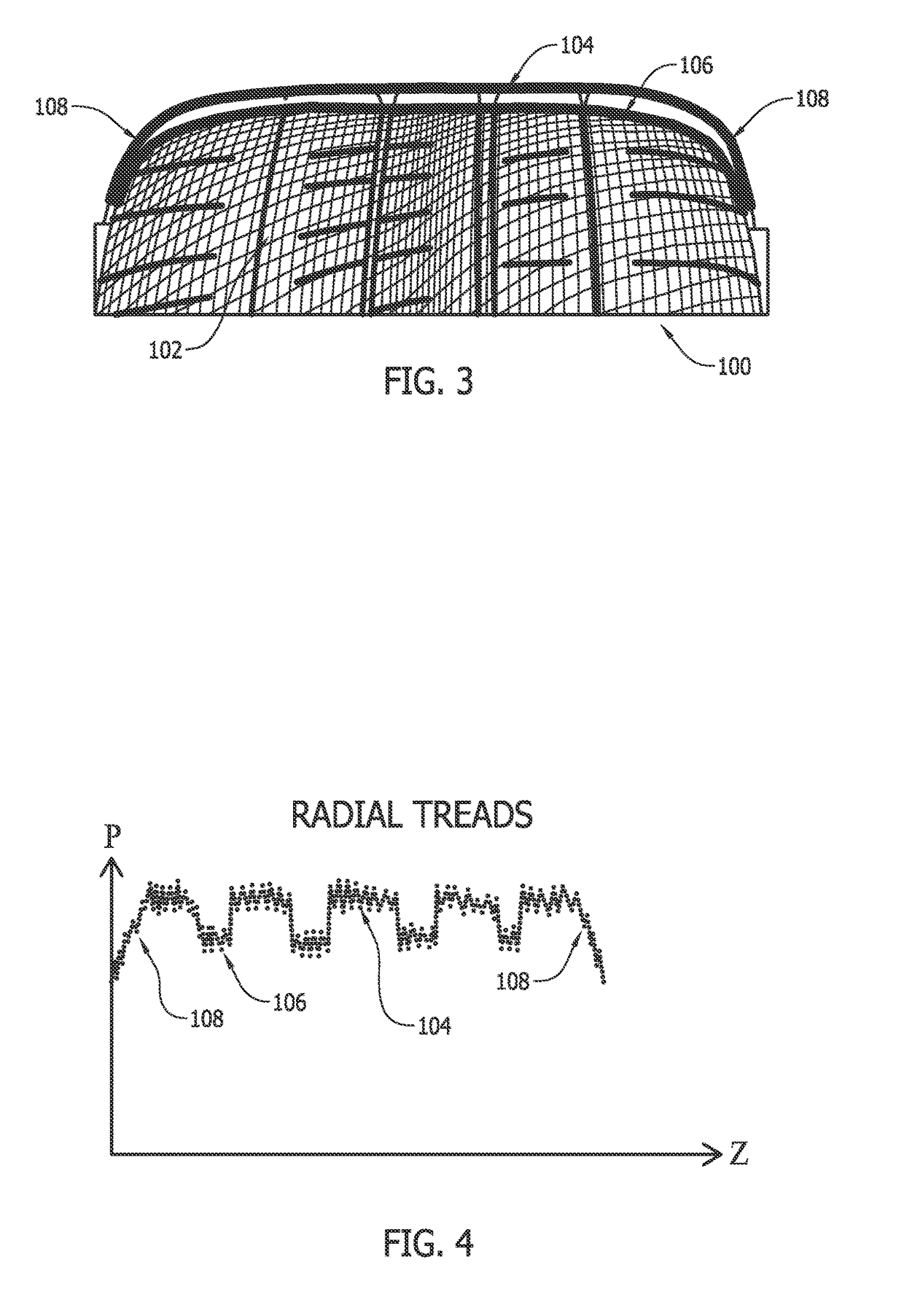

Method for tire tread depth modeling and image annotation

ActiveUS9805697B1Quick identificationImprove handlingTyre partsCathode-ray tube indicatorsGraphicsSurface point

A vehicle service system having a means for acquiring images of a three-dimensional region of a vehicle wheel assembly tire tread surface. The vehicle service system is configured to process the acquired images to produce a collection of data points corresponding to the spatial position of surface points in the region from which tire tread wear characteristics are identified. The acquired images are further utilized to provide both a graphical and a numerical display to an operator, with the numerical display linked to specifically annotated or indexed points or windows within the graphical display, thereby enabling an operator to quickly identify specific focus points or regions on the tire surface which have been measured at the numerically identified tread depths.

Owner:HUNTER ENG

Registration of three dimensional image data to 2D-image-derived data

A method for obtaining registration of a three-dimensional image data set of an anatomical vessel with corresponding two-dimensional image data of the vessel in an X-ray imaging system, where the method comprise the user identifying two points on an anatomical vessel on at least two X-ray image planes, the user identifying two similar points on the surface of the corresponding three-dimensional anatomical image data, determining the orientation direction of the vessel from the two user identified image data surface points, determining the orientation direction of the vessel from the two points obtained from the X-ray image planes, and calculating a transformation of the three-dimensional image data to obtain a best fit registration of the direction derived from the image surface points with the direction derived from the X-ray image data points.

Owner:STEREOTAXIS

Image processing system

InactiveUS20100134688A1Reduce inaccuracyReduce needImage enhancementImage analysisGraphicsImaging processing

A computer graphics generation system combines video images of a scene captured by a camera with one or more rendered computer generated objects. The system comprises a camera which is arranged to generate an image signal representative of a scene including a reference object of a predetermined shape, and an image processor. The image processor is arranged in operation to identify the reference object from the image signal, to detect a luminance distribution across a surface of the reference object by estimating a luminance magnitude at a plurality of surface points on the surface of the reference object, and to estimate a direction of light incident on the reference object derived from the detected luminance distribution across the surface of the reference object by calculating the average of a plurality of luminance vectors, each luminance vector corresponding to one of the surface points and comprising a luminance magnitude of the corresponding surface point and a luminance direction corresponding to a direction perpendicular to the surface at the corresponding surface point, wherein the luminance distribution across the surface of the reference object is detected for luminance above a threshold clipping level. Accordingly a reduction in the “wobble” of the computer generated objects in the scene can be achieved and a more stable image provided from the image light direction estimation.

Owner:SONY CORP

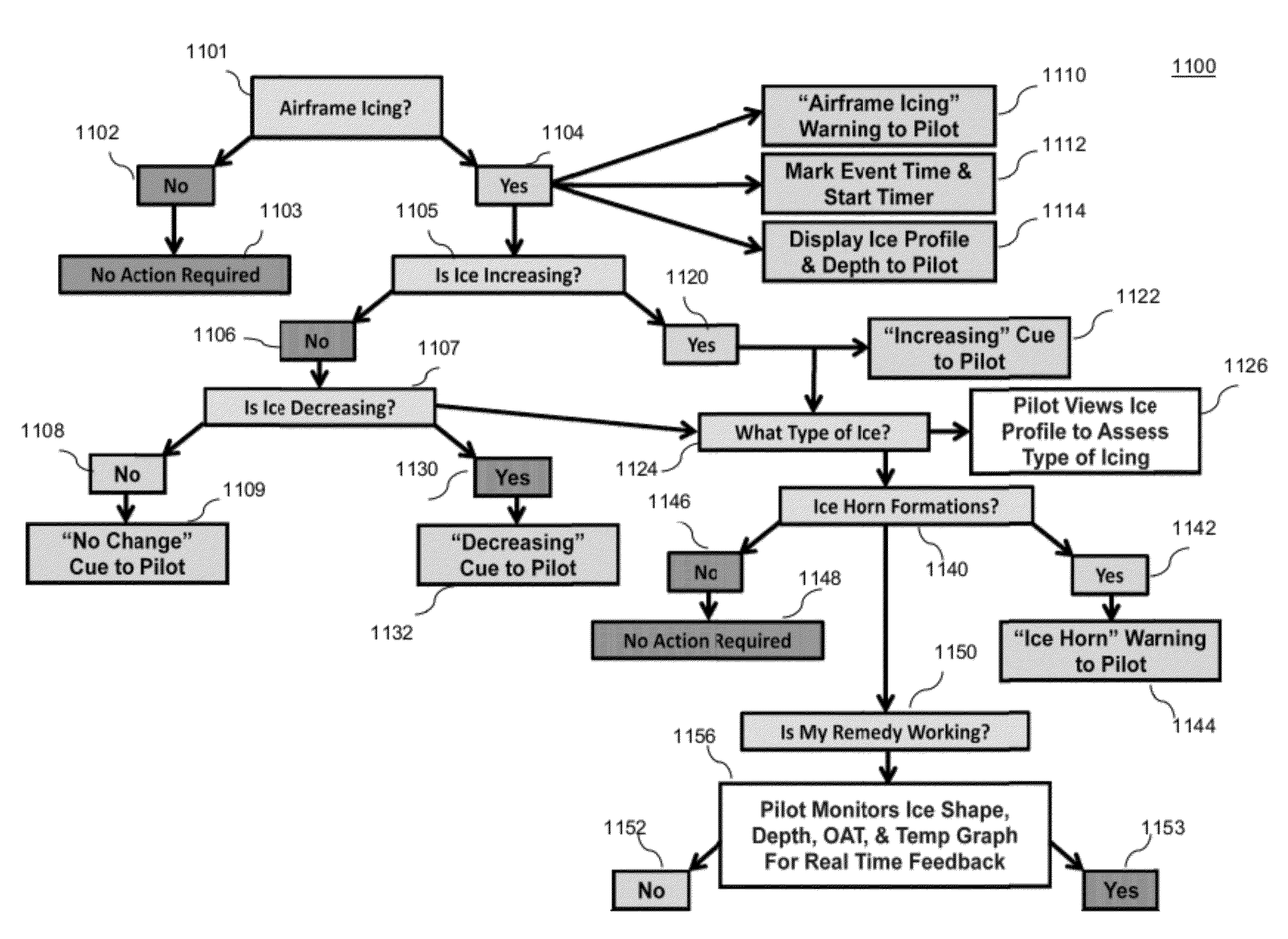

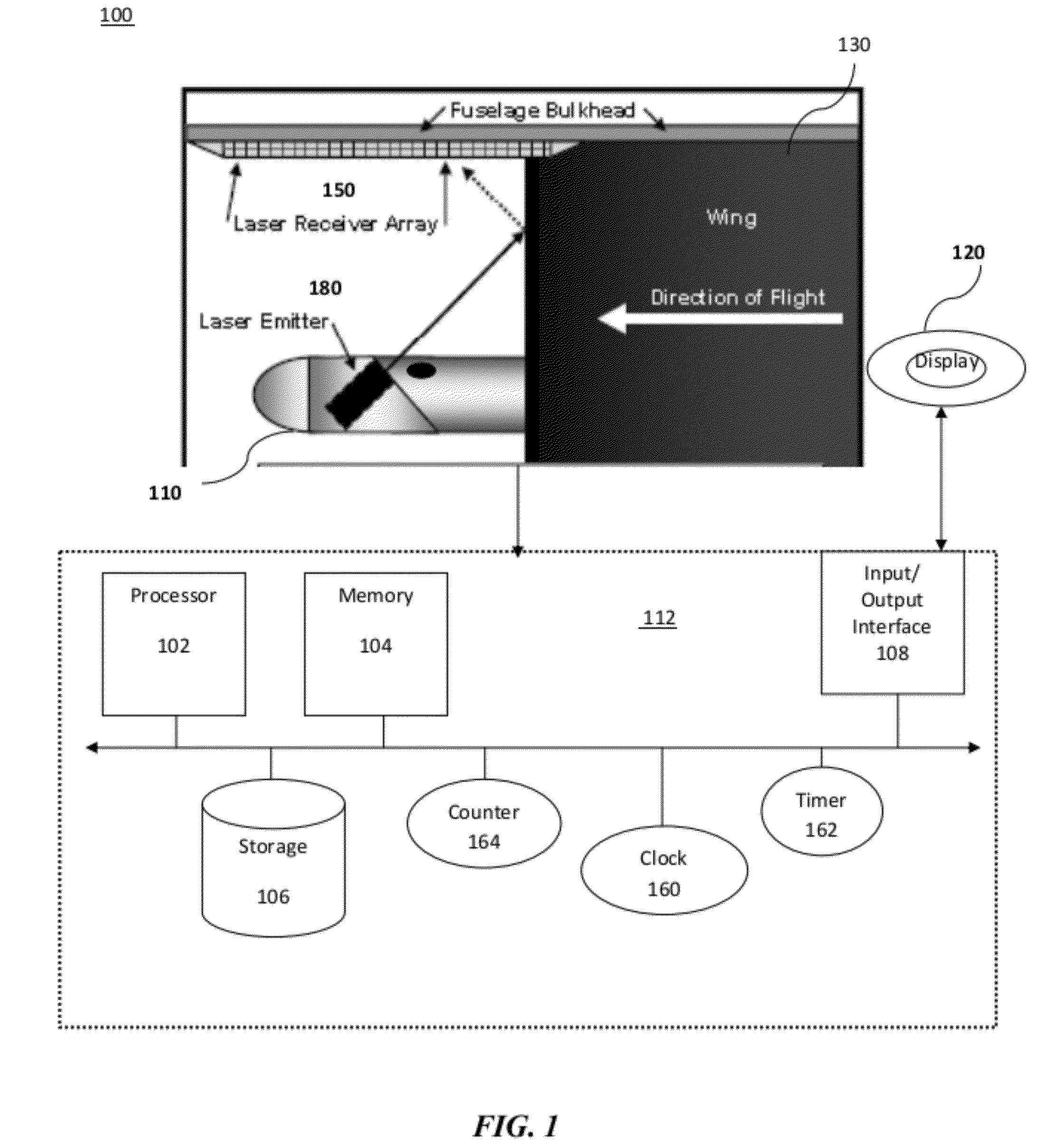

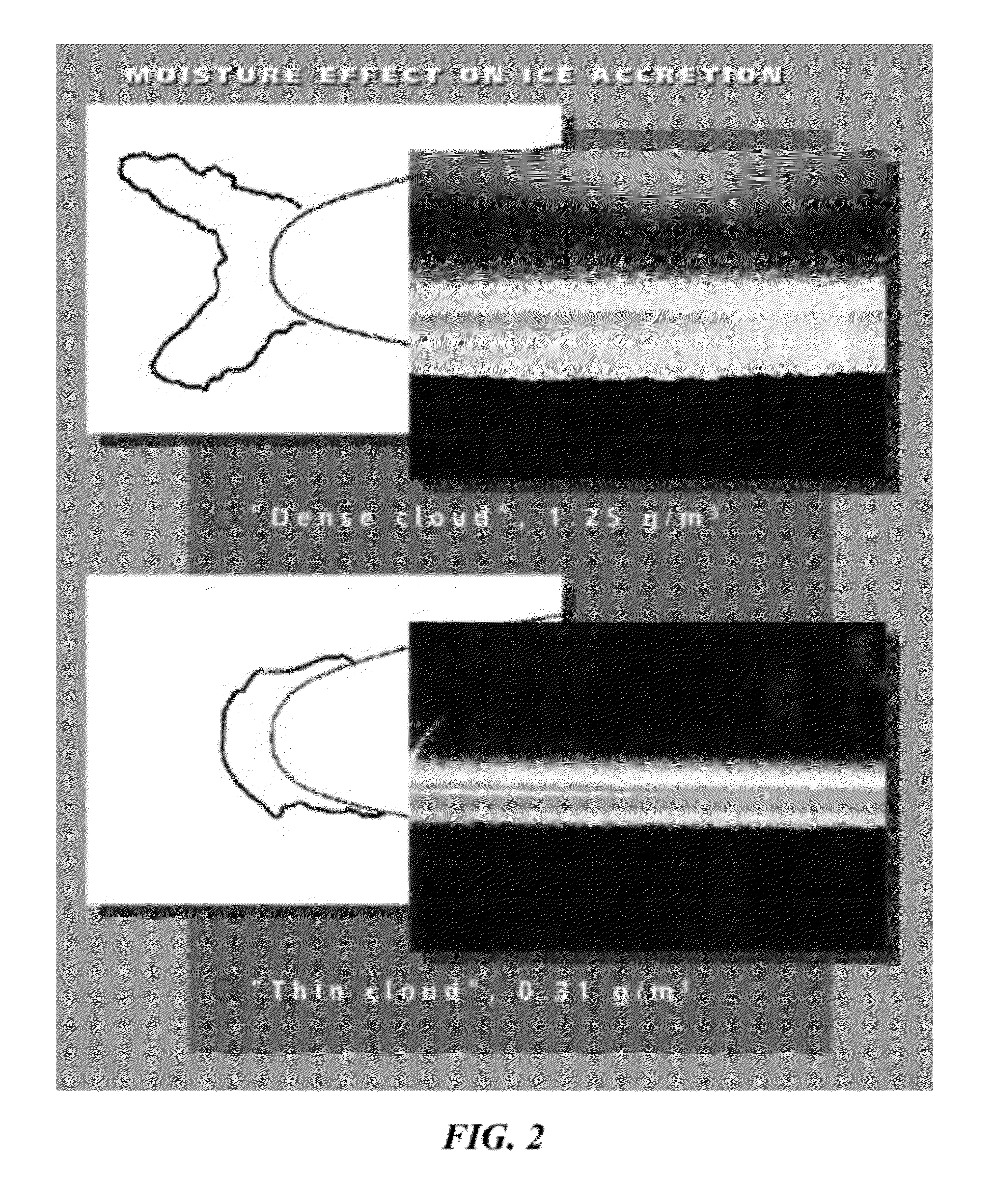

Aircraft icing detector

A method for aircraft surface contamination detection and measurement includes: mounting a laser probe on an airfoil; positioning the laser probe to emit laser energy at multiple pre-determined surface points along the leading edge of the airfoil; and using a processor device for activating the laser probe and obtaining measurement data for generating a surface contour of the shape and accurate measurement of the depth of airfoil icing in the surface target area. The icing data is presented to the pilot in a display that alerts him to the icing and accurately shows the depth and shape of the airfoil icing.

Owner:LUMEN INT

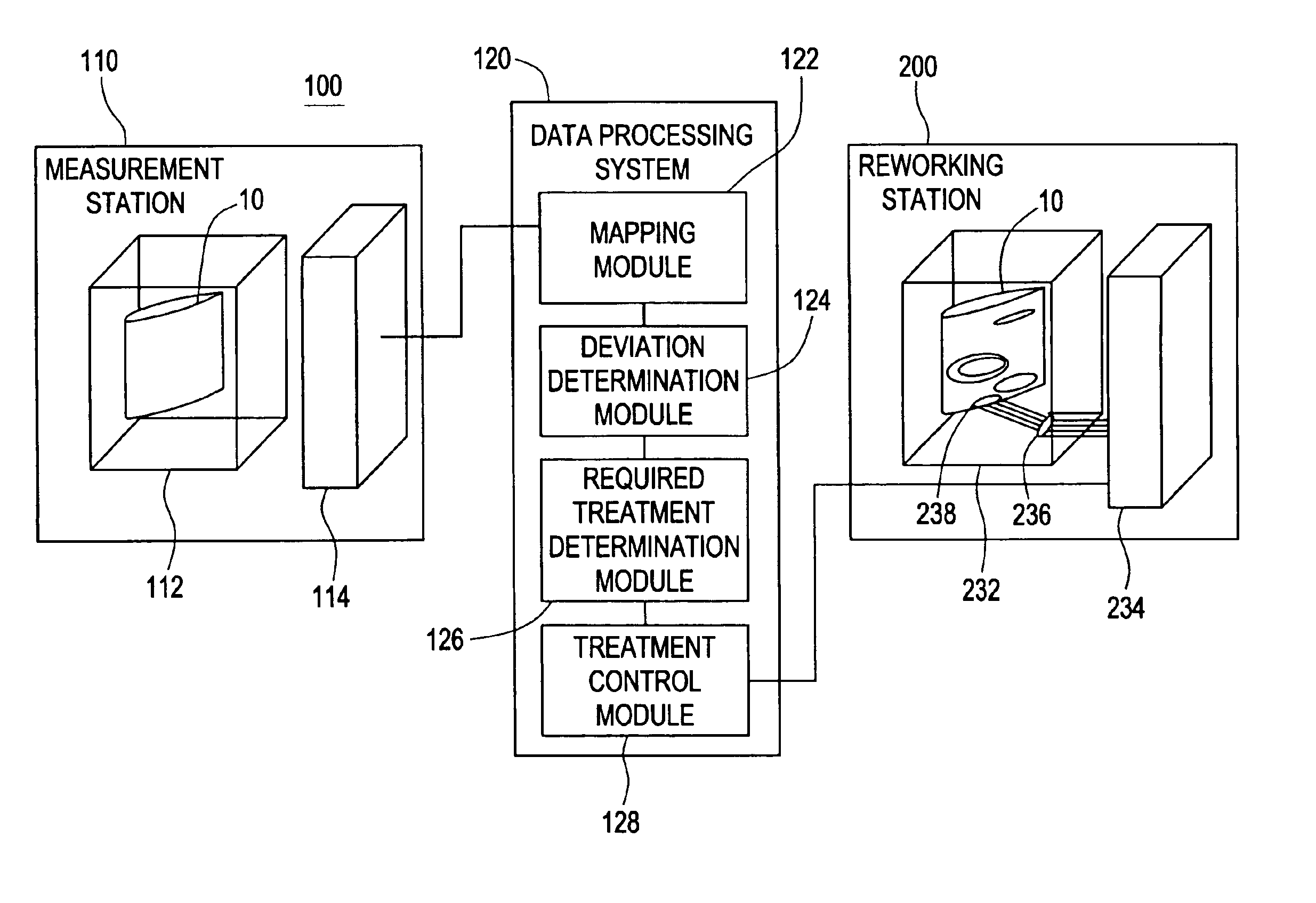

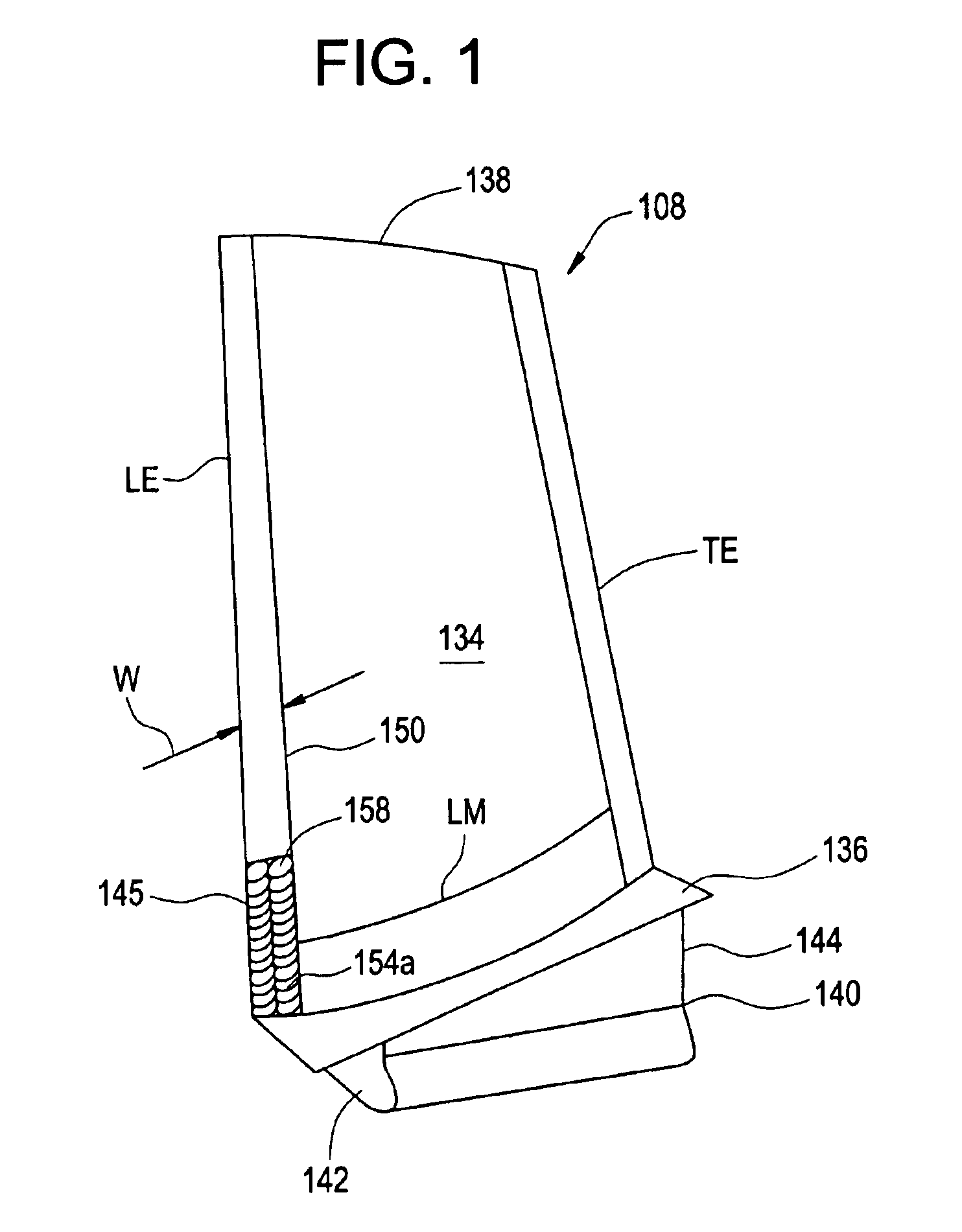

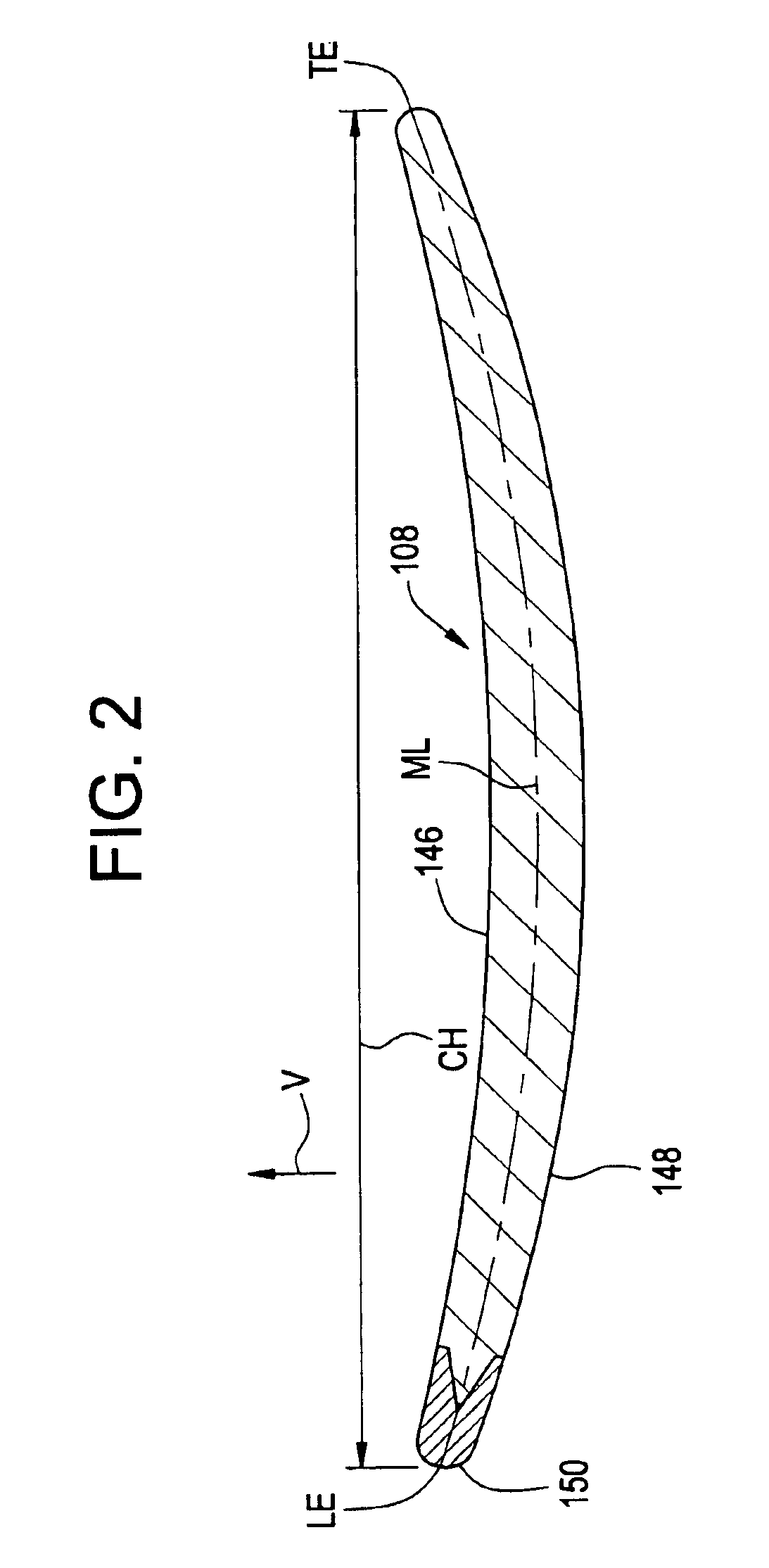

Airfoil qualification system and method

A method for qualifying airfoil blades includes securing an airfoil blade into a fixture, taking digital measurements of the airfoil blade, comparing the digital measurements of the airfoil blade with measurements of a target model, calculating deviations between the digital measurements of the airfoil blade and the measurements of the target model, determining a required treatment for the airfoil blade to conform with the measurements of the target model, directing a reworking system to provide the required treatment to the airfoil blade, and repeating the previous steps until it is determined that no further treatment is required. An airfoil qualification system for performing the method for qualifying airfoil blades includes a measurement station, a data processing system in communication with the measurement station and for determining a point deviation from a surface standard point for each of at least a portion of the plurality of surface points and for determining a required treatment of the airfoil, and a reworking station for directing treatments to the airfoil in response to input from the data processing system.

Owner:GENERAL ELECTRIC CO

Surgical guiding instrument

ActiveUS7749271B2Simple preparation processWithout fear of any undesirable injuryDiagnosticsSpinal implantsChiselInsertion depth

A surgical guiding instrument for use with a chisel and an implant body for insertion into an intervertebral space, included is a shaft with a stop device for delimiting a depth of insertion of the implant body into the intervertebral space. The shaft has a distal end and a proximal end, the implant body being arranged at the distal end of the shaft and defining two bearing surfaces positionable against the adjacent vertebral bodies, the stop device having at least one stop movably mounted at the distal end of the shaft or on the implant body, the stop having a stop surface pointing in distal direction transversely or substantially transversely to at least one of the bearing surfaces, so that an insertion depth for a surgical machining tool can be set in a simple way.

Owner:AESCULAP AG

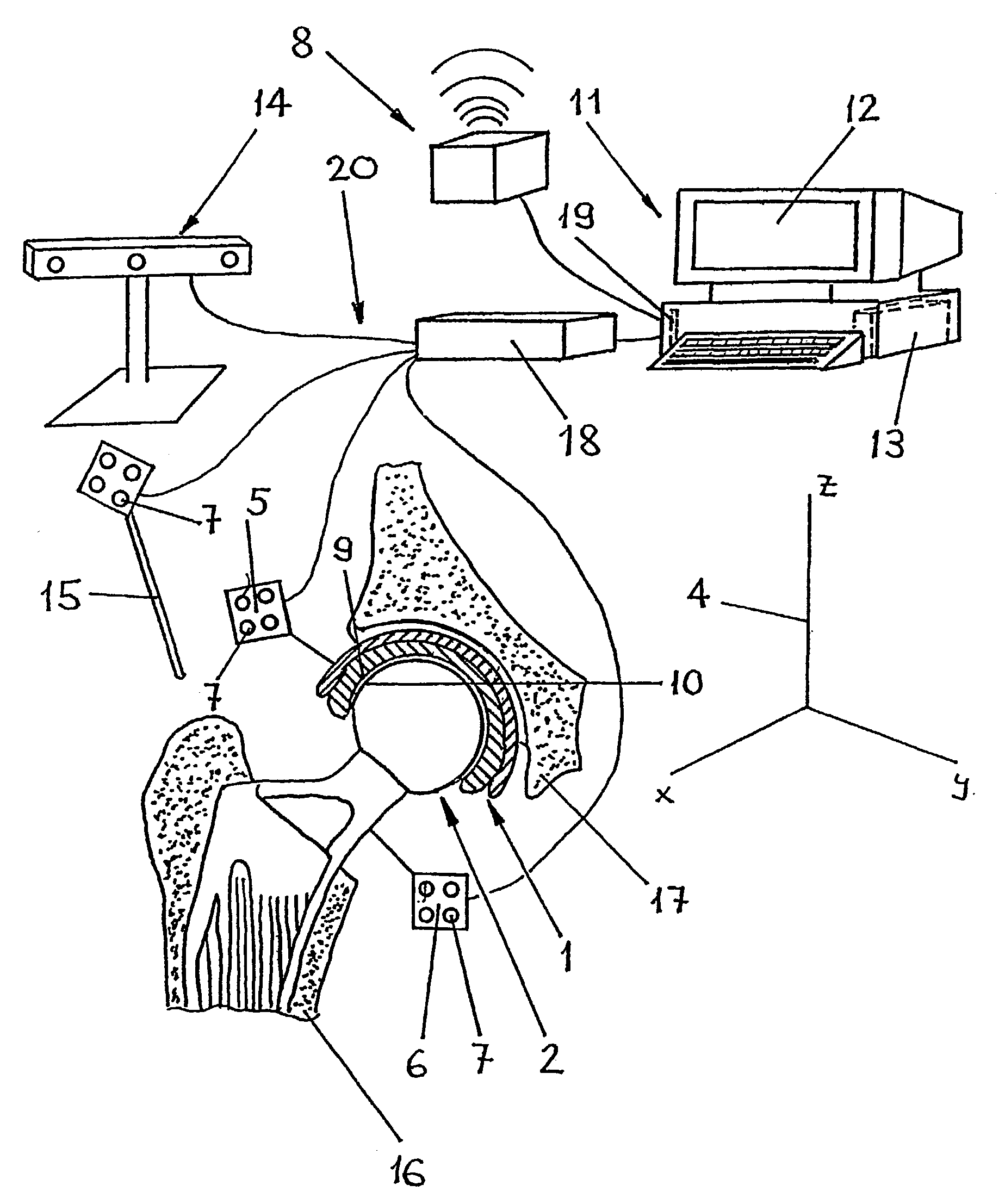

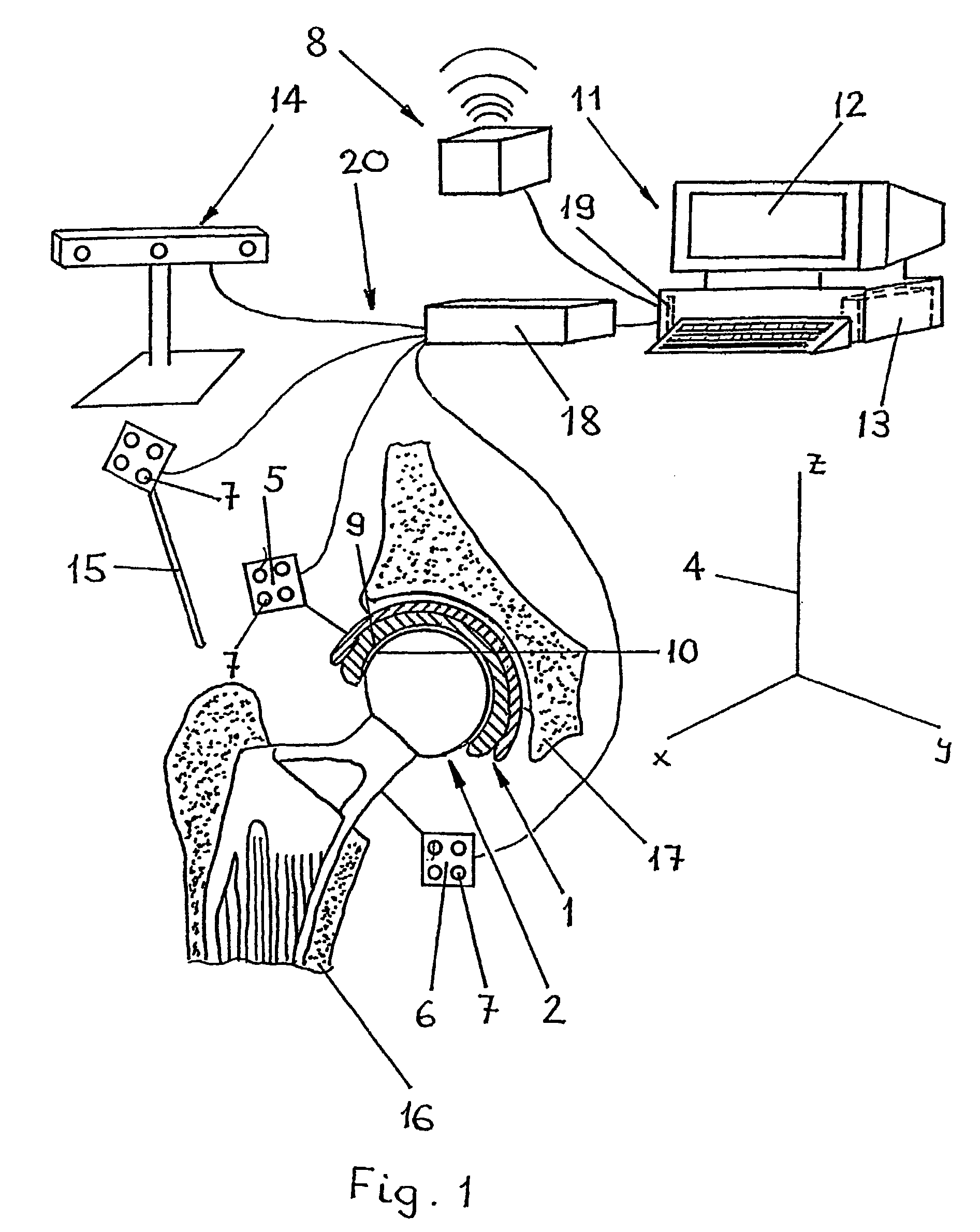

Method and device for impingement detection

InactiveUS7769429B2Ultrasonic/sonic/infrasonic diagnosticsSurgical navigation systemsSurface pointMechanical engineering

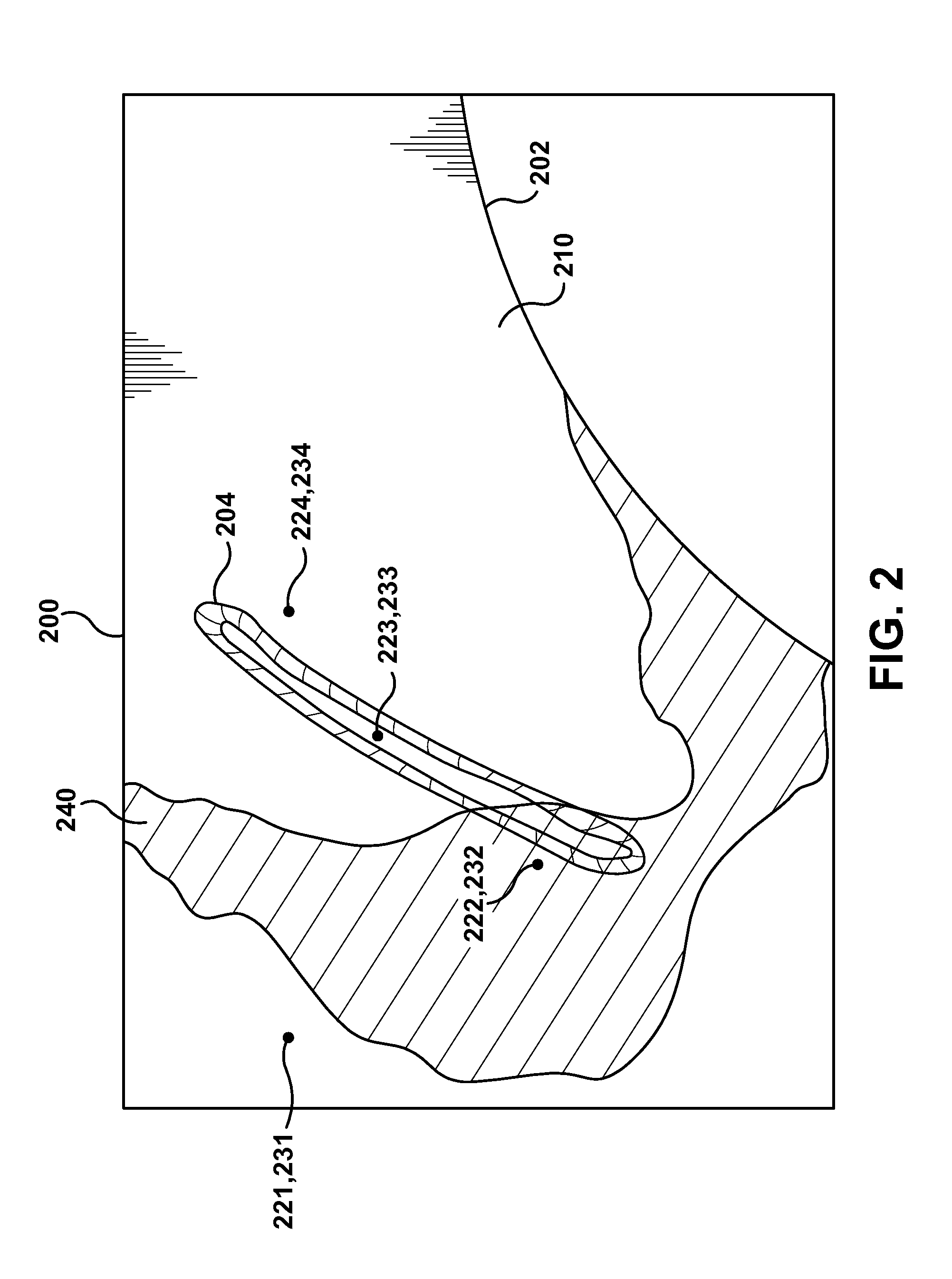

Determining impingement between first and second bodies by determining a spatial relationship between surface points of the first body and markers of a first reference element; determining a spatial relationship between surface points of the second body and markers of a second reference element; displacing the first and second bodies relative to the other body; determining 3D coordinates of the respective pluralities of markers; and using at least (1) the 3D coordinates of the respective pluralities of markers of the reference elements, (2) the determined relationship between surface points of the first body and markers of the first reference elements, and (3) the determined relationship between surface points of the second body and markers of the second reference elements, to determine whether a surface point of one of the first and second bodies coincides with a surface point of the other body.

Owner:AO TECH AG

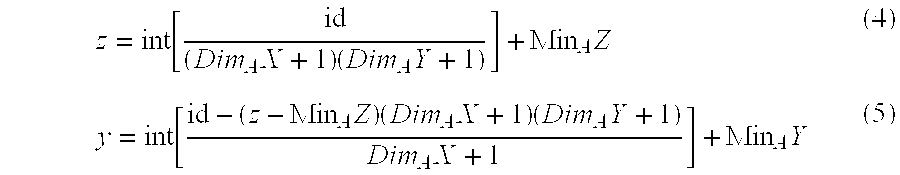

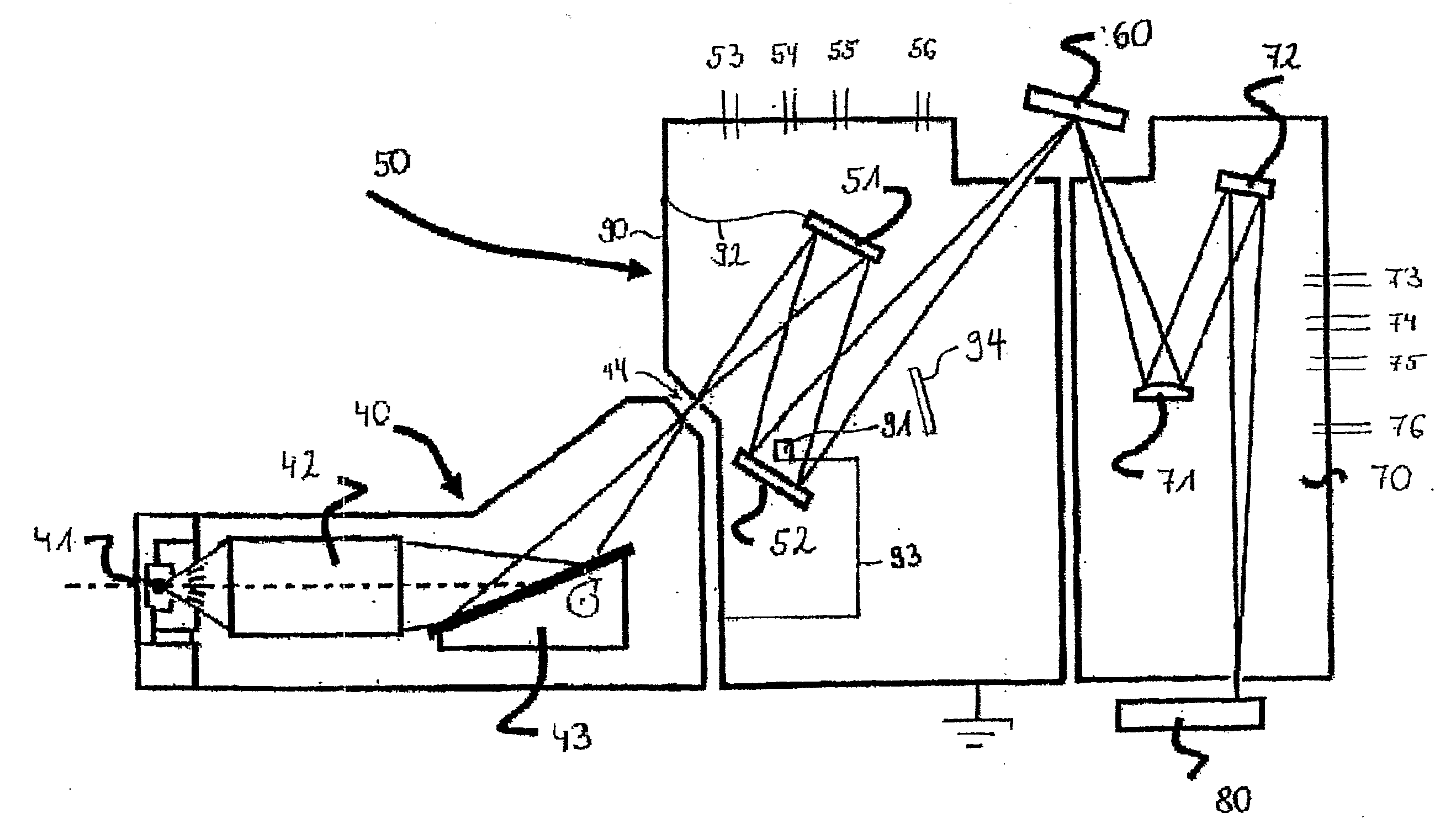

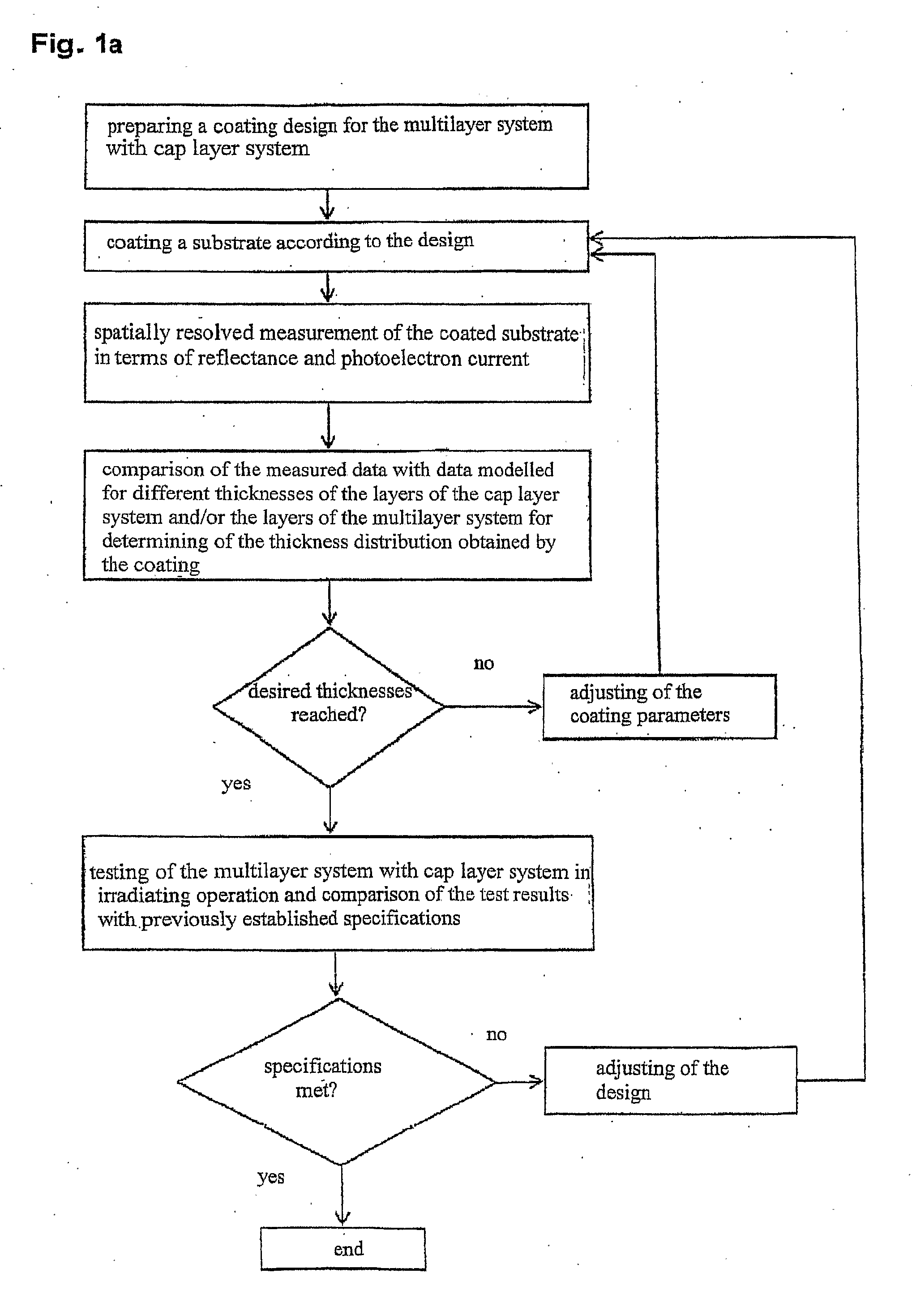

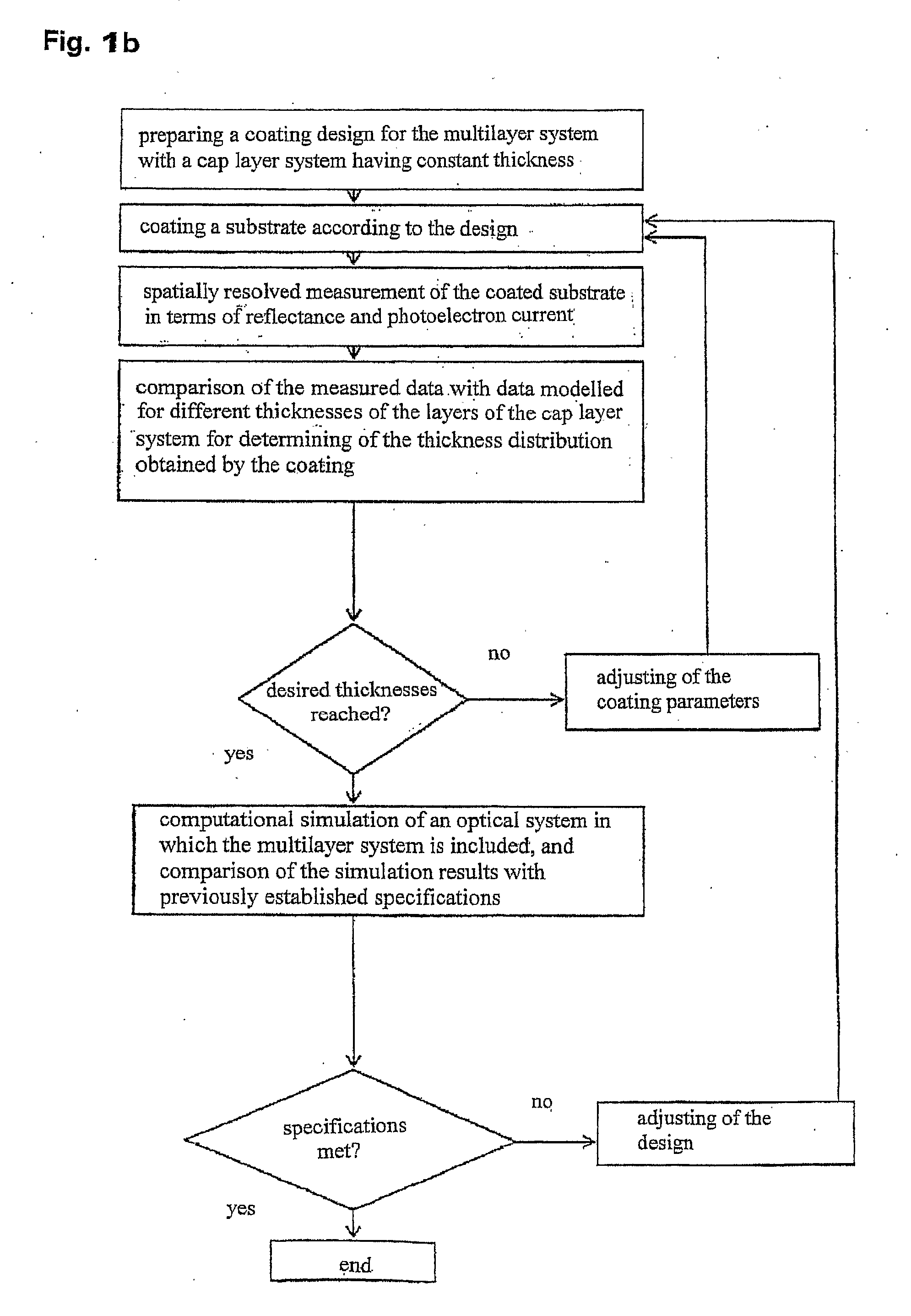

Method For Manufacturing Reflective Optical Element, Reflective Optical Elements, Euv-Lithography Apparatus And Methods For Operating Optical Elements And Euv-Lithography Apparatus, Methods For Determining The Phase Shift, Methods For Determining The Layer Thickness, And Apparatuses For Carrying Out The Methods

InactiveUS20070285643A1Large intensityPhotomechanical apparatusUsing optical meansCatoptricsLayer thickness

The invention relates to a method for manufacturing of a multilayer system (25) with a cap layer system (30), in particular for a reflective optical element for the extreme ultraviolet up to the soft x-ray wavelength range, comprising the steps of: 1. preparing a coating design for the multilayer system (25) with cap layer system (30); 2. coating a substrate (20) with the multilayer system (25) with cap layer system (30); 3. spatially resolved measurement of the coated substrate in terms of reflectance and photoelectron current in at least one surface point; 4. comparison of the measured data with data modelled for different thicknesses of the layers (31, 32, 33) of the cap layer system (30) and / or the layers (21, 22, 23, 24) of the multilayer system (25) for determining of the thickness distribution obtained by the coating; 5. if necessary, adjusting of the coating parameters and repeating steps 2 to 5 until the coated thickness distribution coincides with the design. The invention also relates to further manufacturing methods, reflective optical elements, EUV-lithography apparatuses, and methods for operating optical elements and EUV-lithography apparatuses as well as methods for determining the phase shift, methods for determining the layer thickness, and apparatuses for carrying out the methods.

Owner:CARL ZEISS SMT GMBH

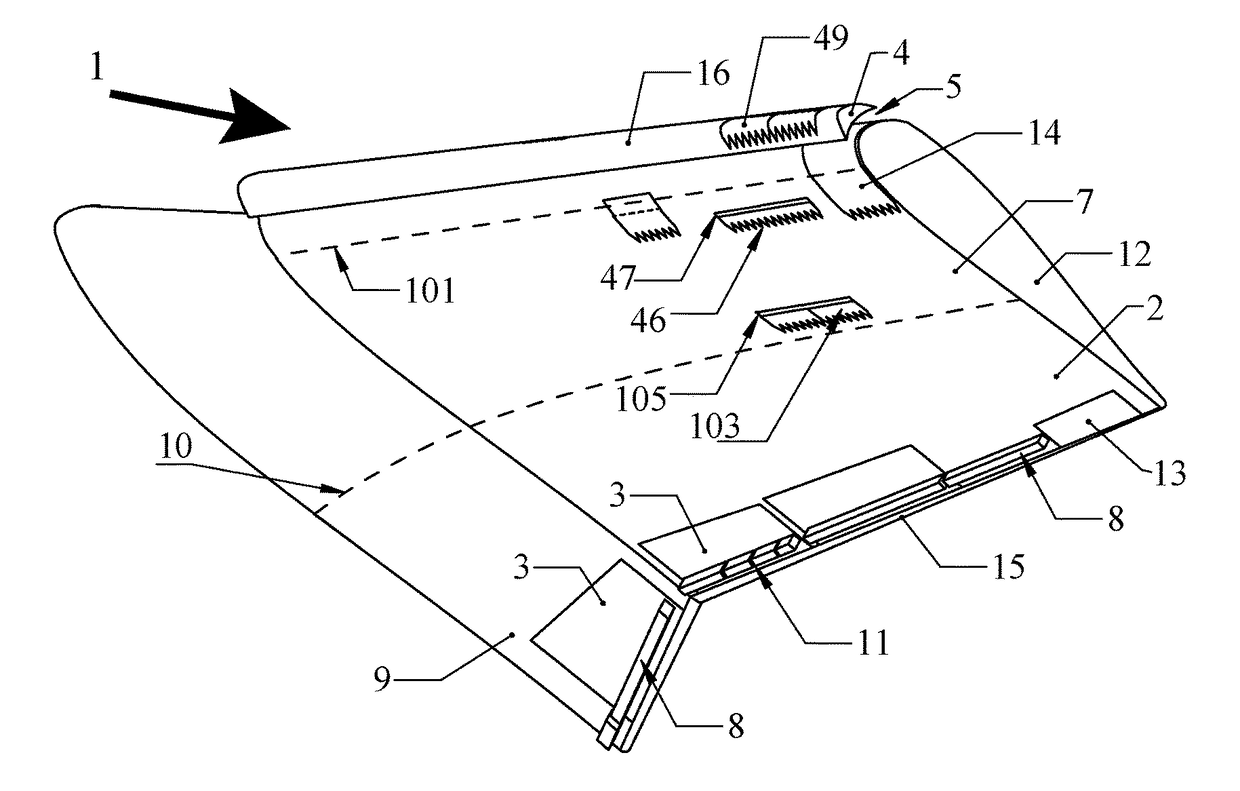

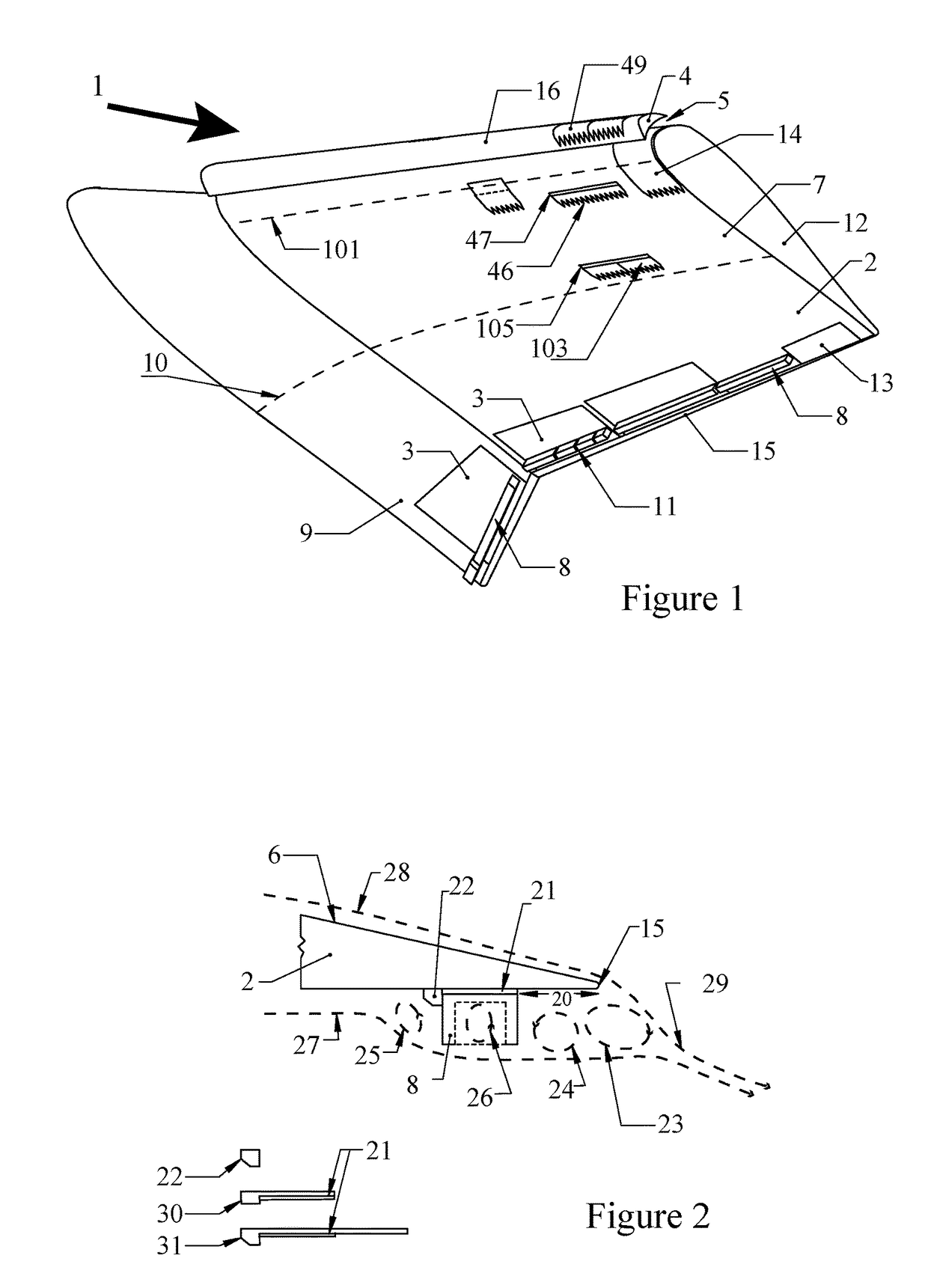

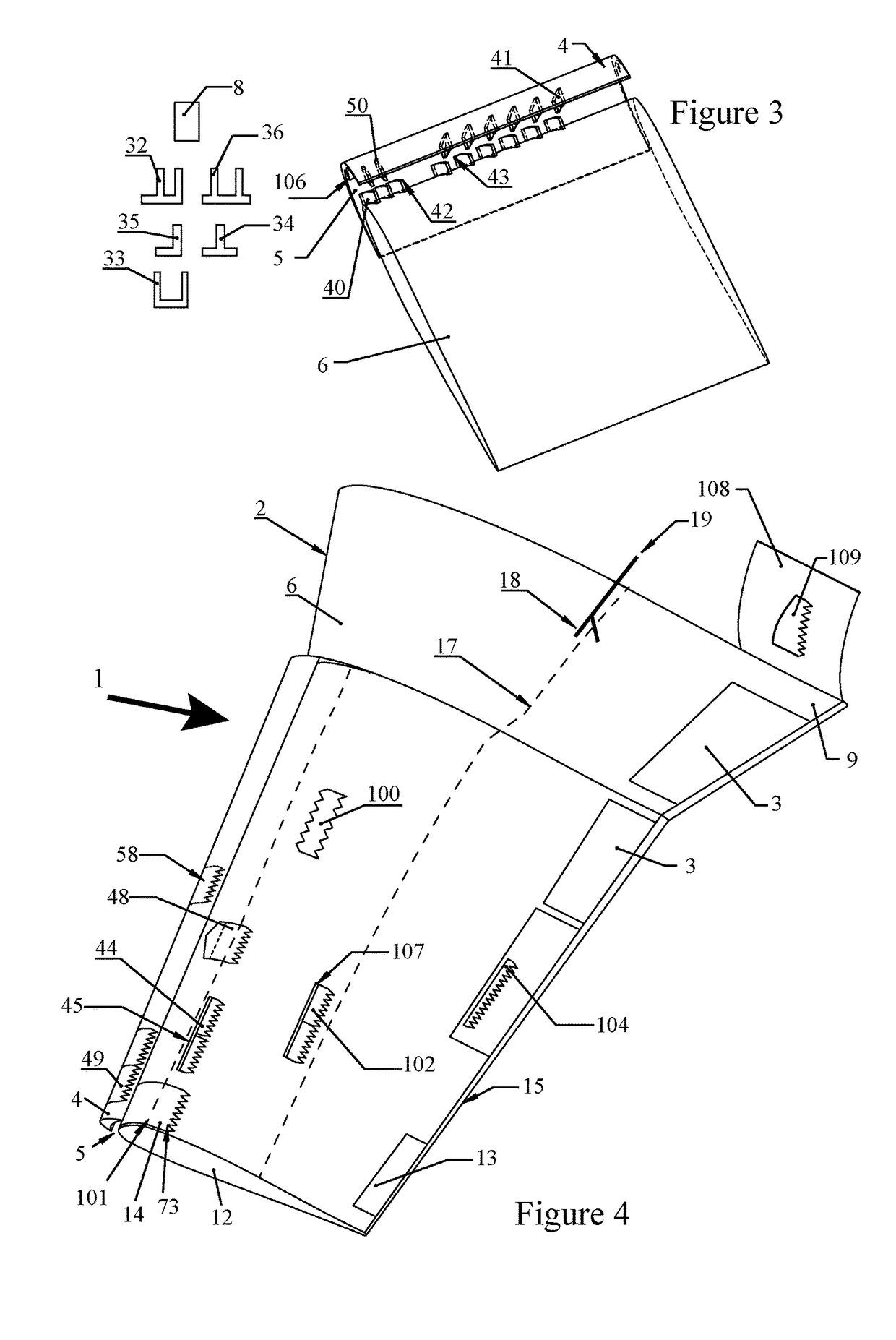

Efficiency improvements for flow control body and system shocks

InactiveUS20170137116A1Mitigate BL lossSolution to short lifeInfluencers by generating vorticesEngine manufactureMomentumEngineering

Methods and related apparatus embodiments are disclosed that allow novel Conformal Vortex Generator and / or Elastomeric Vortex Generator art to improve energy efficiency and control capabilities at many surface points of a body or object moving at speed in aero / hydrodynamic Newtonian fluids, by reducing; shock energy losses, surface flow turbulence, and / or momentum layer thicknesses.

Owner:IRELAND PETER +1

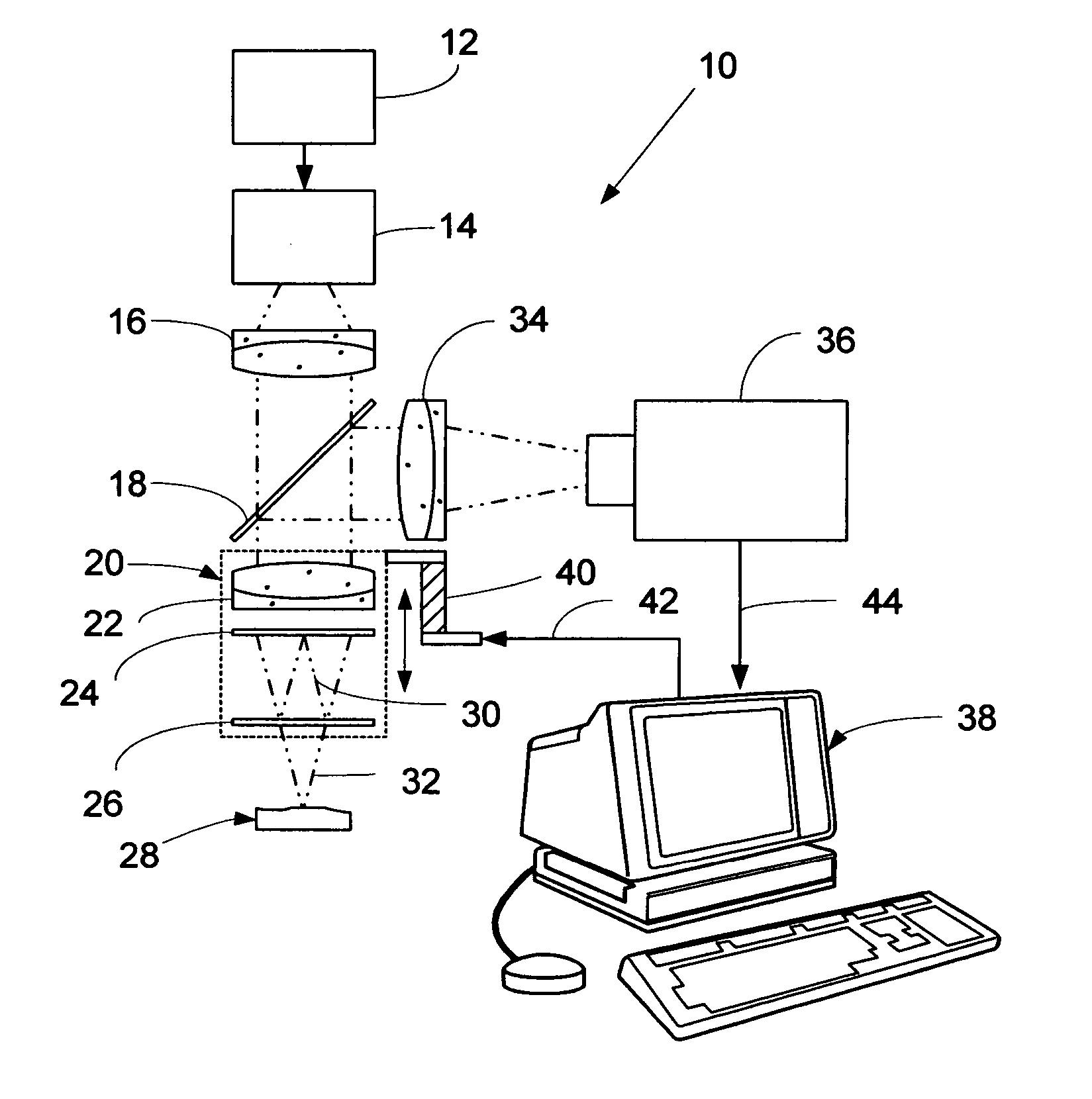

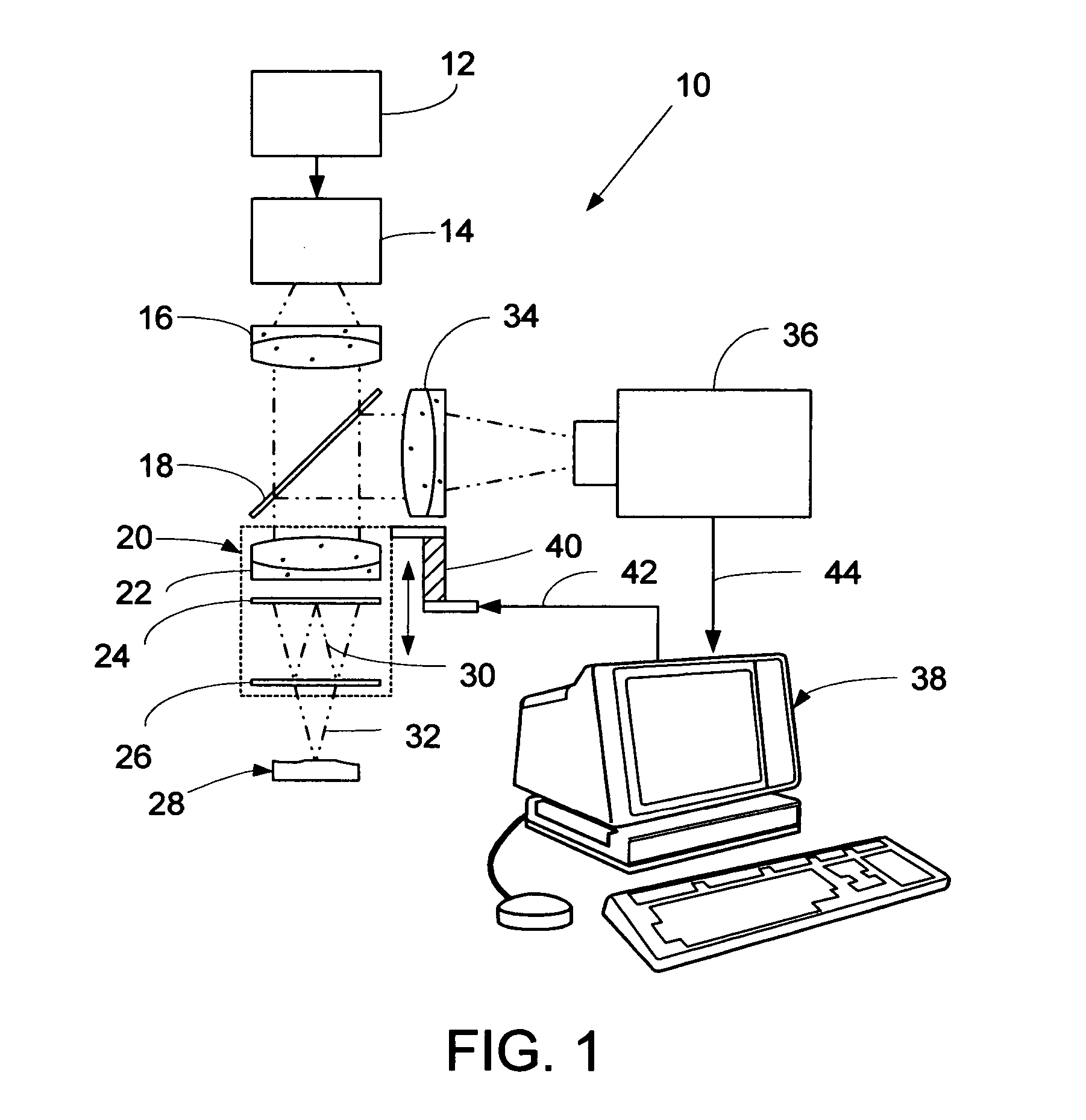

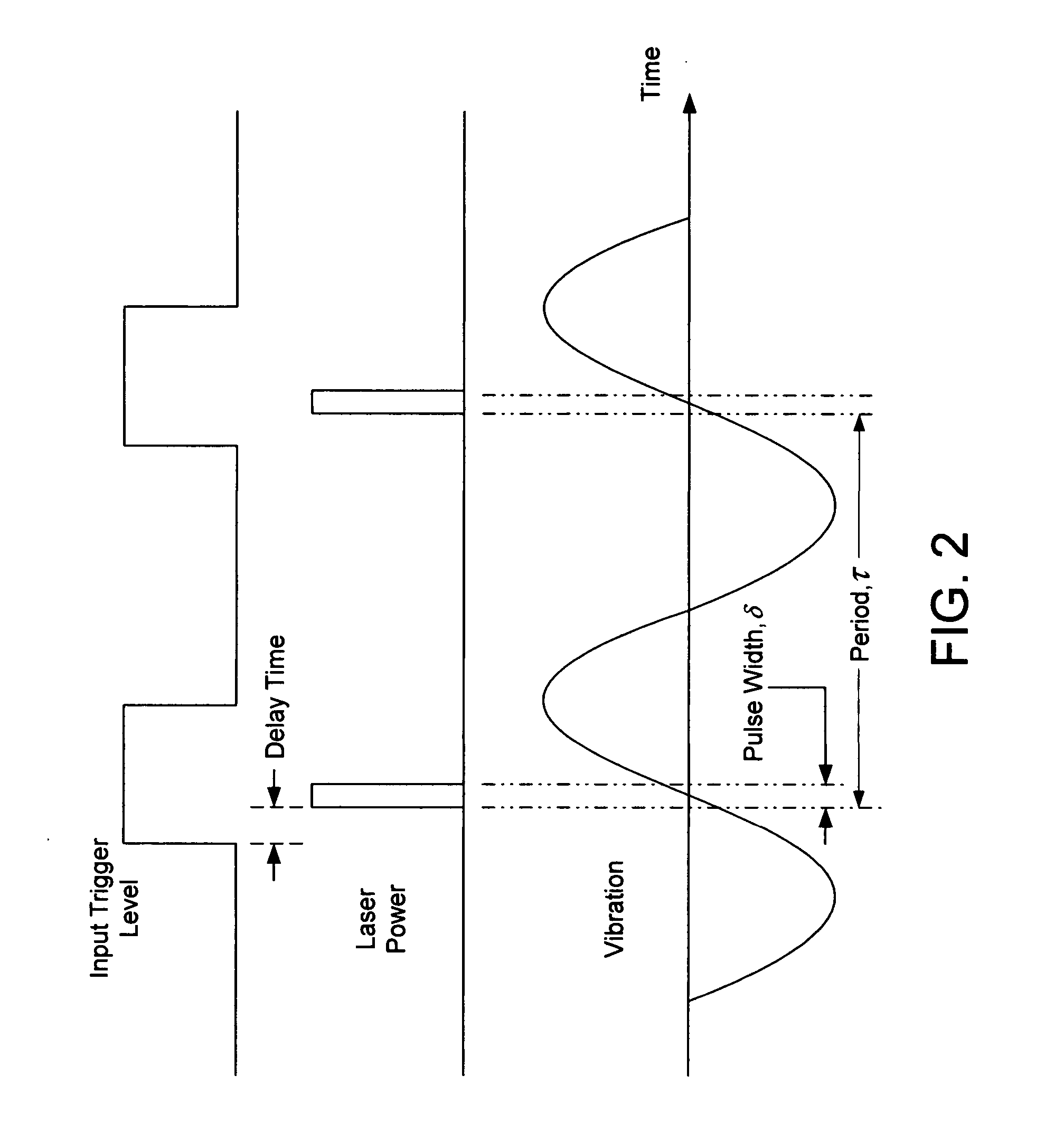

Stroboscopic interferometry with frequency domain analysis

ActiveUS20050007599A1Issue to overcomeSubsonic/sonic/ultrasonic wave measurementUsing optical meansDigital signal processingTwo dimensional detector

A computer-based stroboscopic interferometric microscope system for measuring the topography of a microscopic vibratory object includes an interferometric microscope equipped with a multiple-color (e.g., LED) or white-light source, a mechanical scanning apparatus for varying the optical path difference between the vibratory object and a reference surface, a camera having a two-dimensional detector array, and digital signal processing apparatus for determining surface height from interference data. Interferograms for each of the detector image points in the field of view are generated simultaneously by scanning the object in a direction approximately perpendicular to the object surface illuminated stroboscopically while recording detector data in digital memory. Recorded interferograms for each image point are then transformed into the spatial frequency domain by Fourier analysis, and the surface height for each corresponding object surface point is obtained by examination of the complex phase as a function of spatial frequency. A complete three-dimensional image of the object surface is then constructed from the height data and corresponding image plane coordinates. The three-dimensional image may be presented on a display or hard copy or written to a storage medium.

Owner:ZYGO CORPORATION

Method for preparing to-be-repaired skull flap by 3D printing

ActiveCN103393486ASimplify the surgical processShorten operation timeBone implant3D modellingHeat conductingOperative time

The invention discloses a method for preparing a to-be-repaired skull flap by 3D printing. The method comprises the following steps: three-dimensionally scanning an original flap at a to-be-repaired skull defect part to obtain the three-dimensional data of surface points of an original flap entity; generating a skull flap three-dimensional model matched with the original flap; forming 8-16 drainage holes in the model and circumferentially and uniformly arranging a plurality of tabs protruding from the skull flap edge along the skull flap three-dimensional model; taking medical photosensitive resin as a raw material, and printing the raw material by a 3D printer to obtain a medical resin flap; finally, fixing the resin flap and the to-be-repaired skull by a tapping screw. Through adoption of the method, the medical resin flap matched with the height of the skull defect window of a patient can be prepared, secondary molding is not required in operation, and the operation time is shortened. The medical resin flap is light in weight, solid, excellent in impact resistance, low in heat-conducting property, and heat-insulating, and reduces discomfort caused after head operation.

Owner:TONGJI HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI TECH

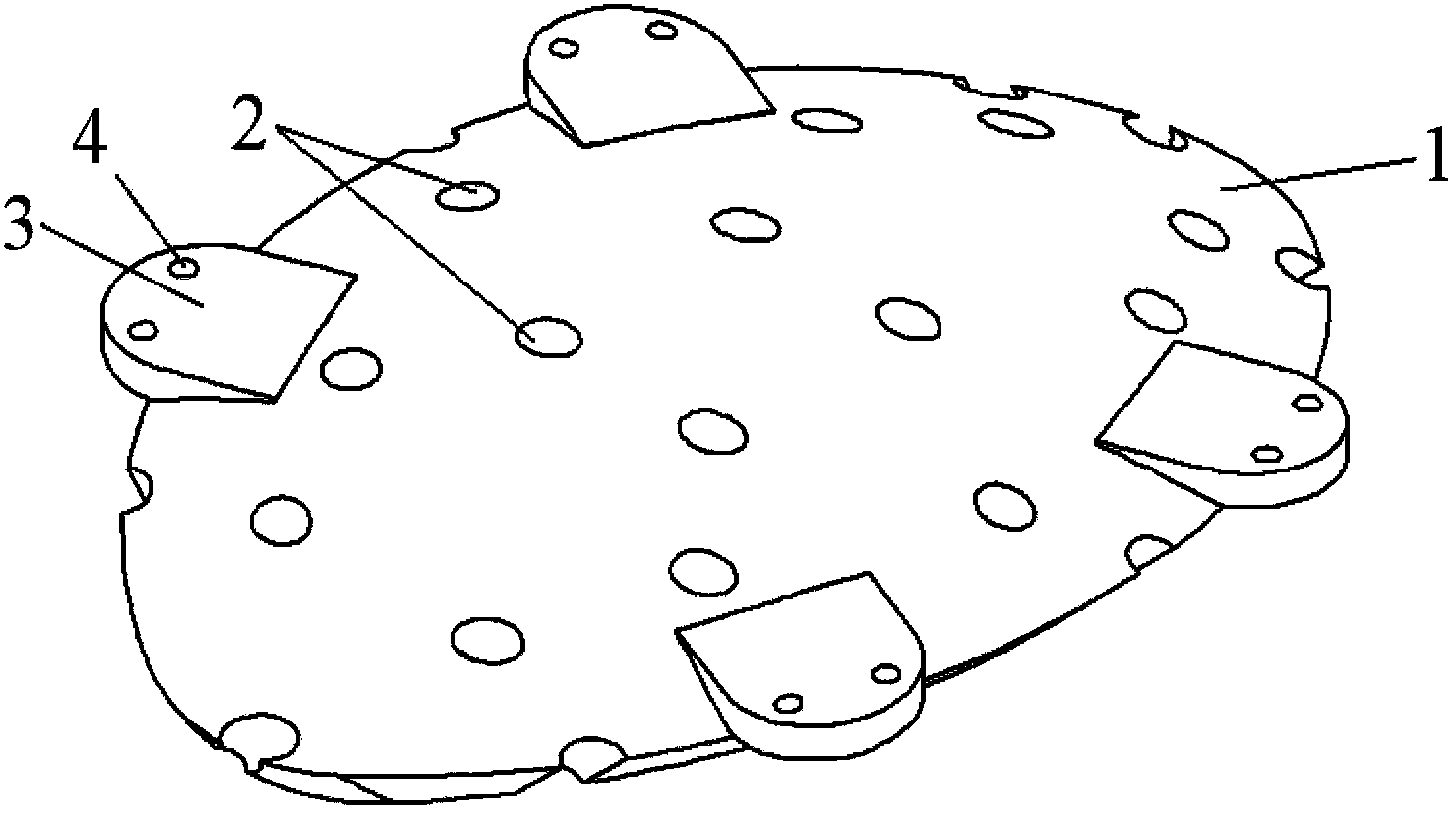

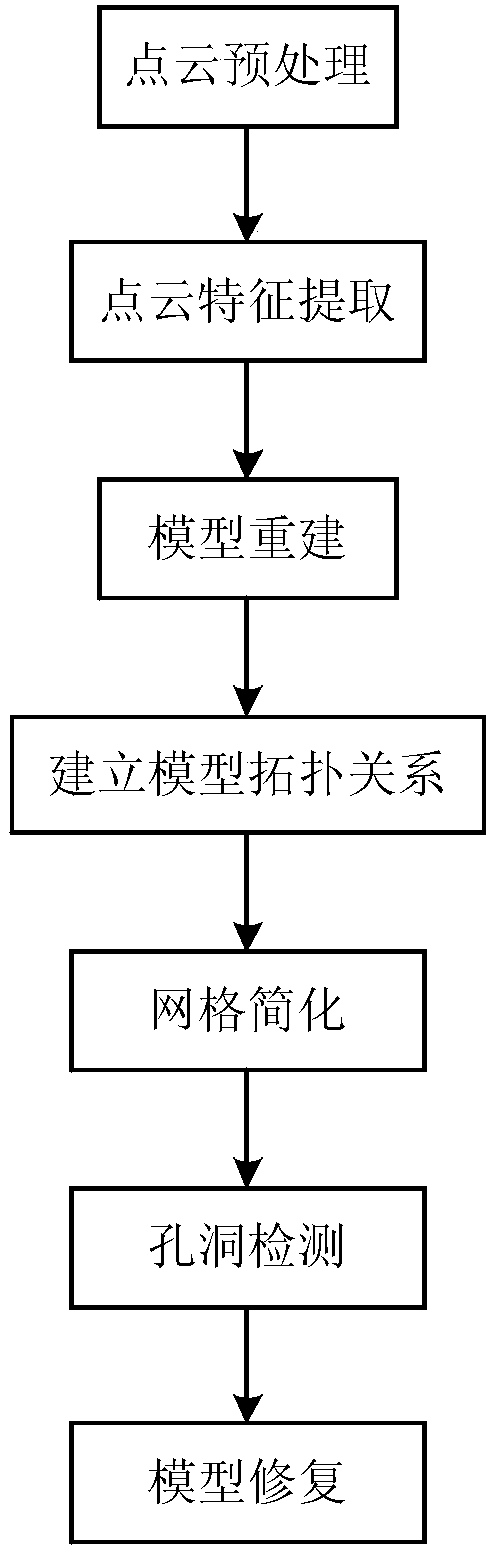

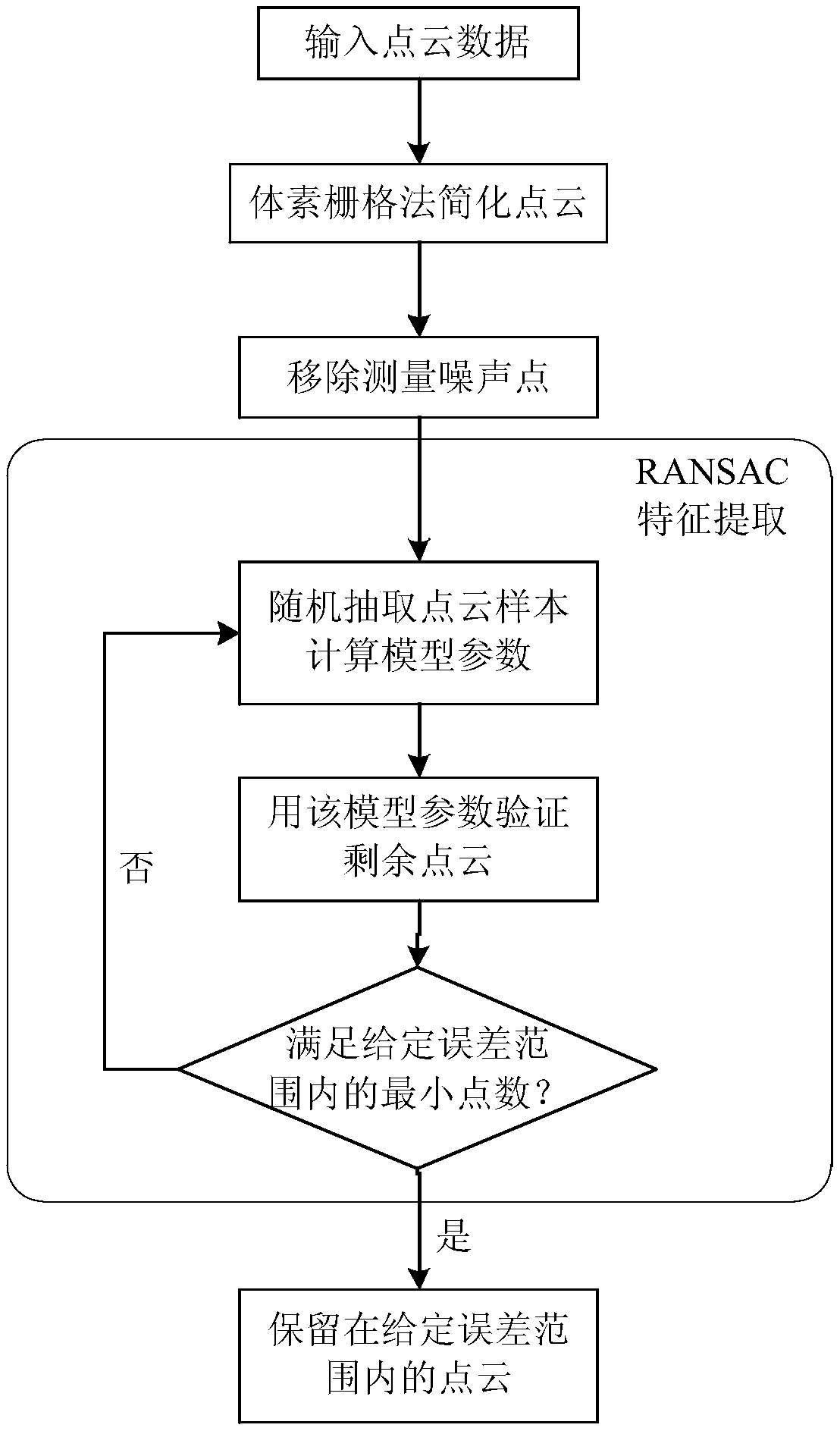

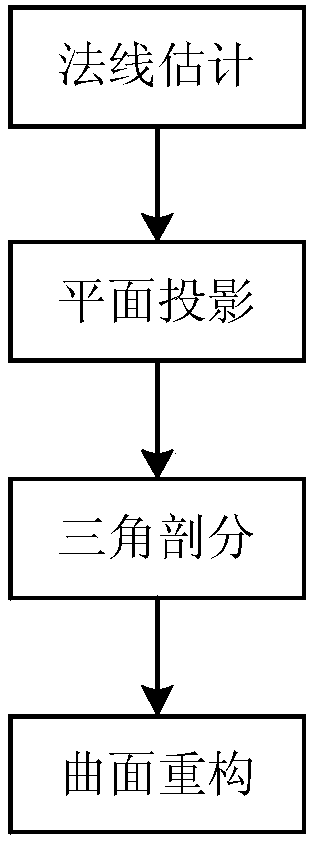

Point cloud based quick reconstruction STL digital model generation method

The invention discloses a point cloud based quick reconstruction STL digital model generation method. The method includes performing simplified filtering and characteristic extraction on input point cloud; performing curve reconstruction on surface point cloud on a digital model; establishing a model topologic relation on the STL digital model and performing grid simplification; performing hole detection and repair on the simplified STL digital model so as to remove defects in the model. According to the invention problems of laser scanning point cloud based STL model reconstruction can be solved effectively. The STL model is generated through steps including point cloud characteristic extraction, model reconstruction and the like and automatic repair of surface defects of the generated STL model is realized through grid simplification and hole repair technology, so that quick reconstruction of the STL digital model is realized and the availability of the reconstructed STL digital model is improved in the premise of keeping basic characteristics of point cloud, and great demands in different fields such as robot offline programming technology, automatic track planning technology and the like in a smart manufacture process can be met.

Owner:SOUTHEAST UNIV

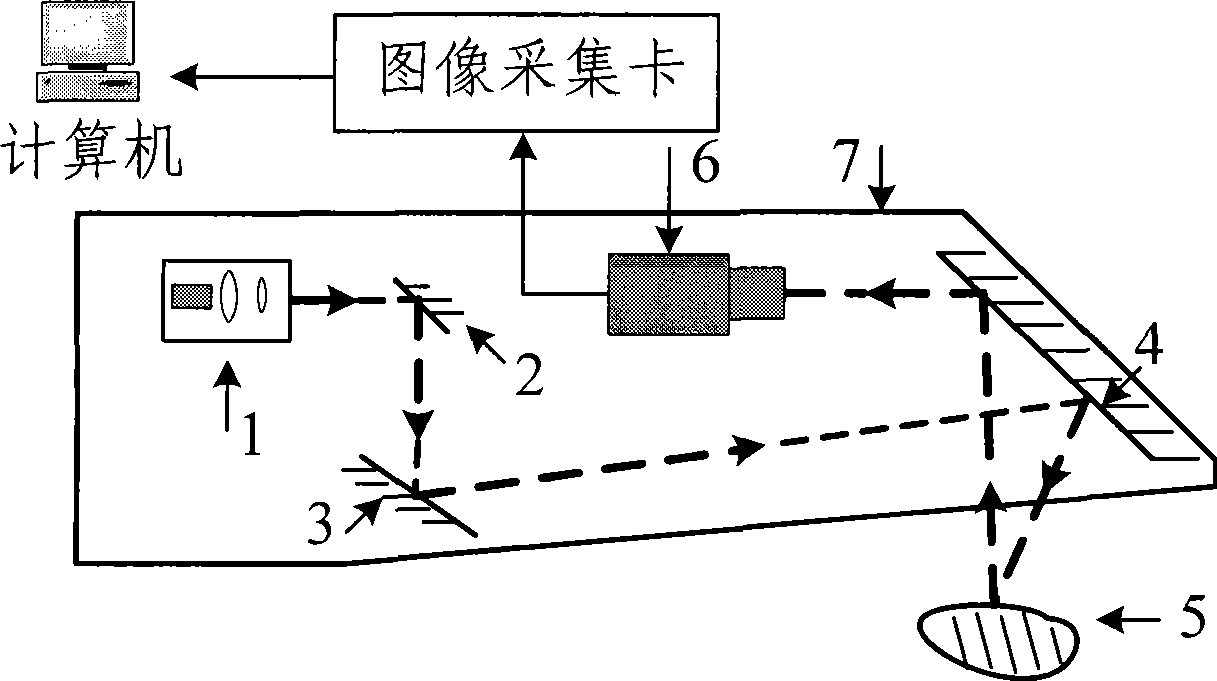

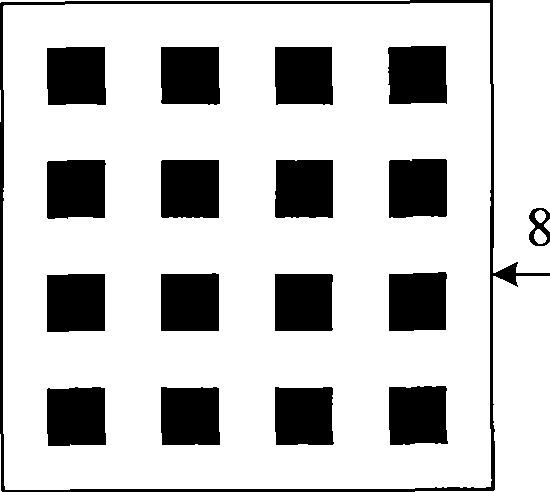

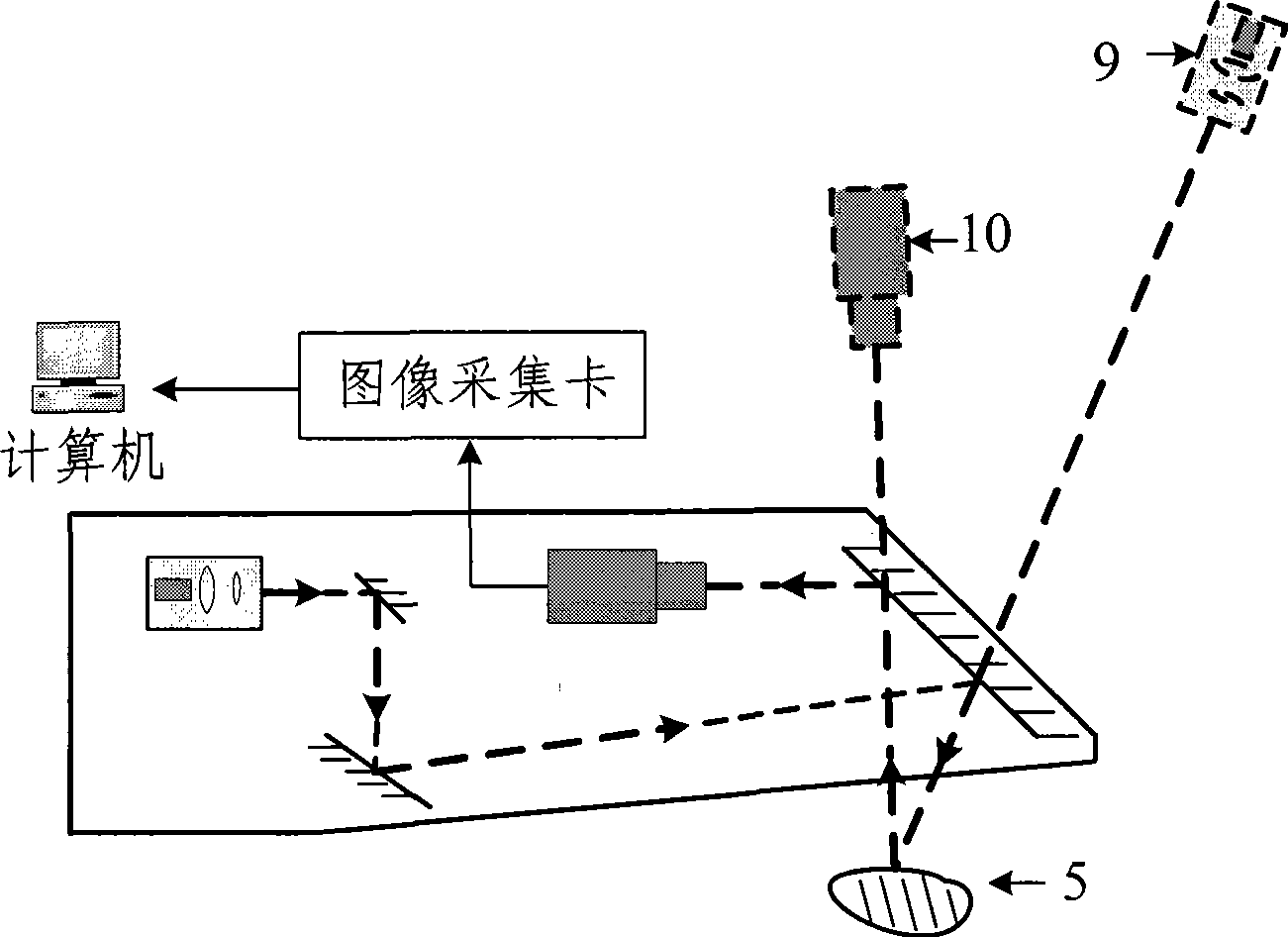

Mirror image type structure light vision measuring systems and measurement method

InactiveCN101419061AReduce lateral spacingMiniaturizationUsing optical meansTriangulationMiniaturization

The invention belongs to the technical field of measurement, and provides a mirror-image type structured light vision measurement system, as well as a measurement method. The measurement system consists of a structured light projector 1, reflectors 2, 3 and 4, a camera 6, a bottom plate 7, a computer, an image acquisition card and a calibration plane target 8. The measurement method comprises the following steps: the structured light is projected through the structured light projector, reflected by the reflectors 2, 3 and 4, and then projected onto the surface of a measured object 5; a reflected light ray is reflected by the reflector 4 and then received by the camera 6; a formed image is acquired into the computer by the high-speed image acquisition card; the acquired image is processed so as to extract an image coordinate of the center line of the structured light; and the three-dimensional coordinate of the surface point of the object is figured out according to a measurement model. The invention adopts a principle that reflector imaging forms triangulation, reduces transverse space between the structured light projector and the camera, compresses system volume, and realizes the miniaturization of structured light vision sensors.

Owner:BEIHANG UNIV

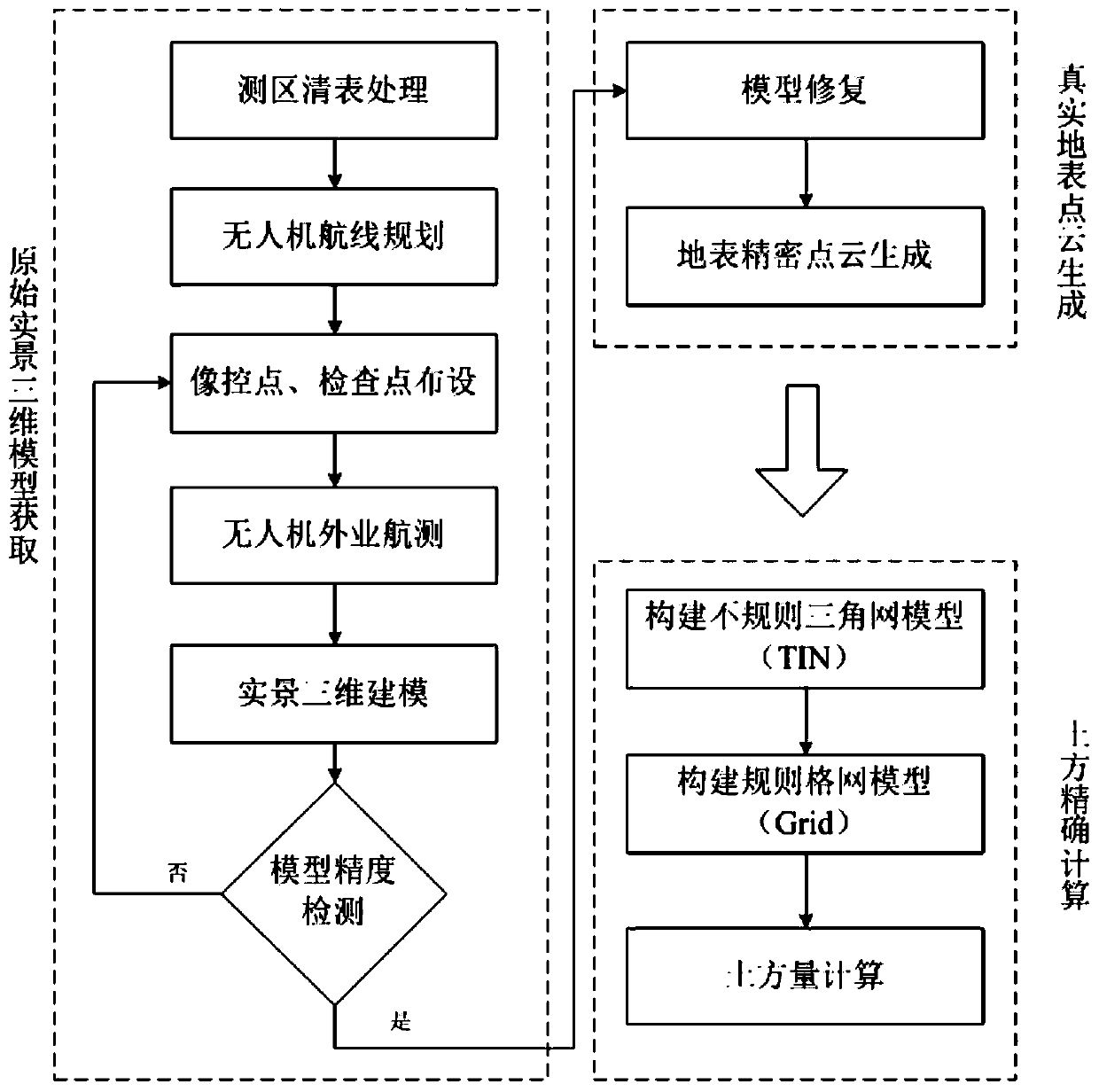

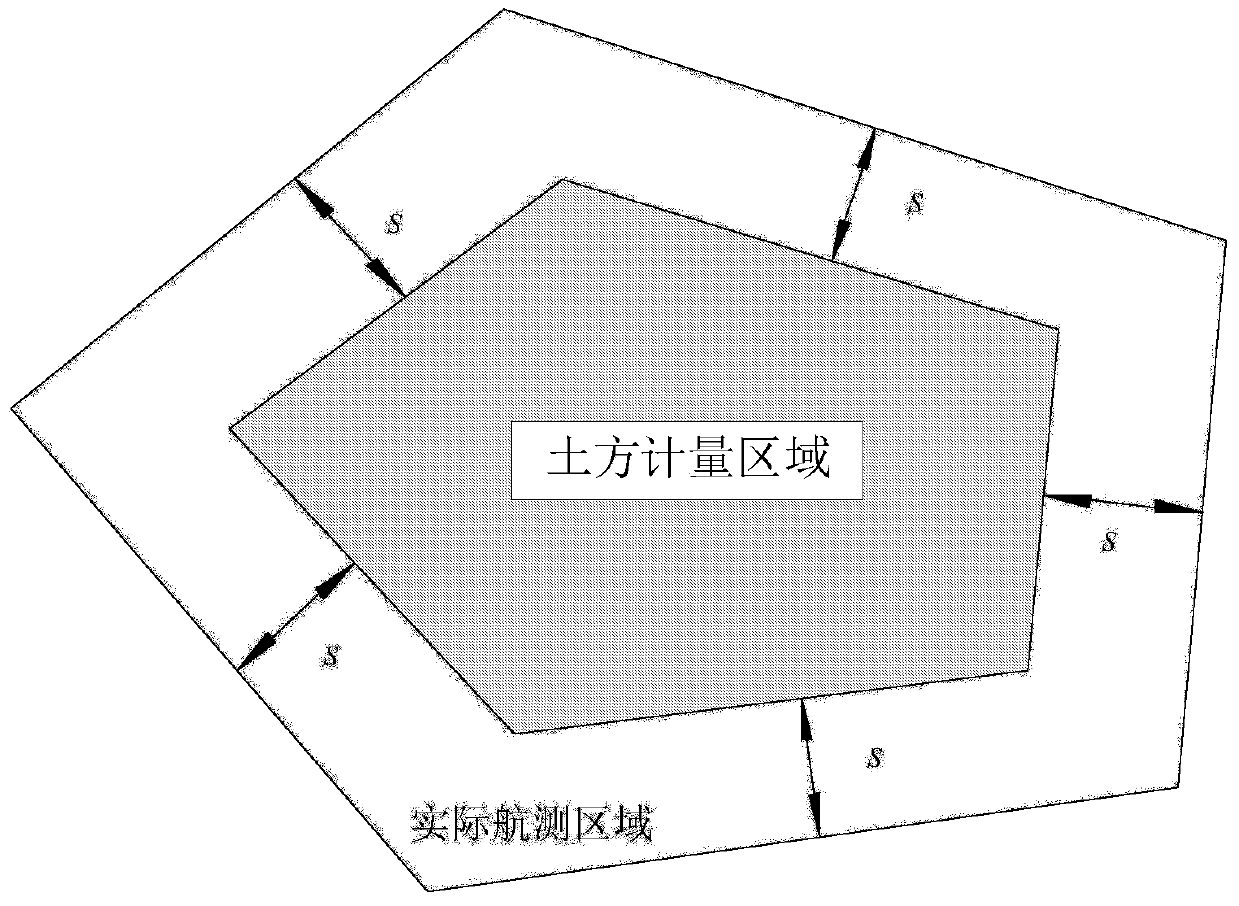

Unmanned aerial vehicle tilt photography fine grid earthwork measurement method

ActiveCN110285792AHigh measurement accuracyReduce intensityPhotogrammetry/videogrammetry3D modellingRegular gridPoint cloud

The invention provides an unmanned aerial vehicle tilt photography fine grid earthwork measurement method. The aerial survey data are obtained by aerial survey of the unmanned aerial vehicle and the data are integrated and processed so as to obtain a three-dimensional model of a real scene; the model restoration technology is applied to eliminate the interference objects such as trees and houses in the real scene three-dimensional model, the elevation around the pores left after the interference objects are deleted is applied to fit the curved surface, and the pores are filled with the curved surface so that the restored real scene three-dimensional model is finally obtained, and the real surface point cloud is generated based on the restored real scene three-dimensional model; and an irregular triangular network model is constructed according to the point cloud and then a regular grid model is further constructed, and the earthwork calculation value is obtained through a fine grid earthwork measurement formula based on the regular grid model. The accurate calculation of earthwork filling and excavation can be realized based on the fine grid, and the method has the advantages of high accuracy, safe operation and saving manpower and time cost.

Owner:SHANDONG TRAFFIC PLANNING DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com