Patents

Literature

481 results about "Spatially resolved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spatially resolved metabolic alterations hold the key to defining the dependencies of metabolism that are most limiting for cancer growth and exploring metabolic targeted strategies for better cancer treatment.

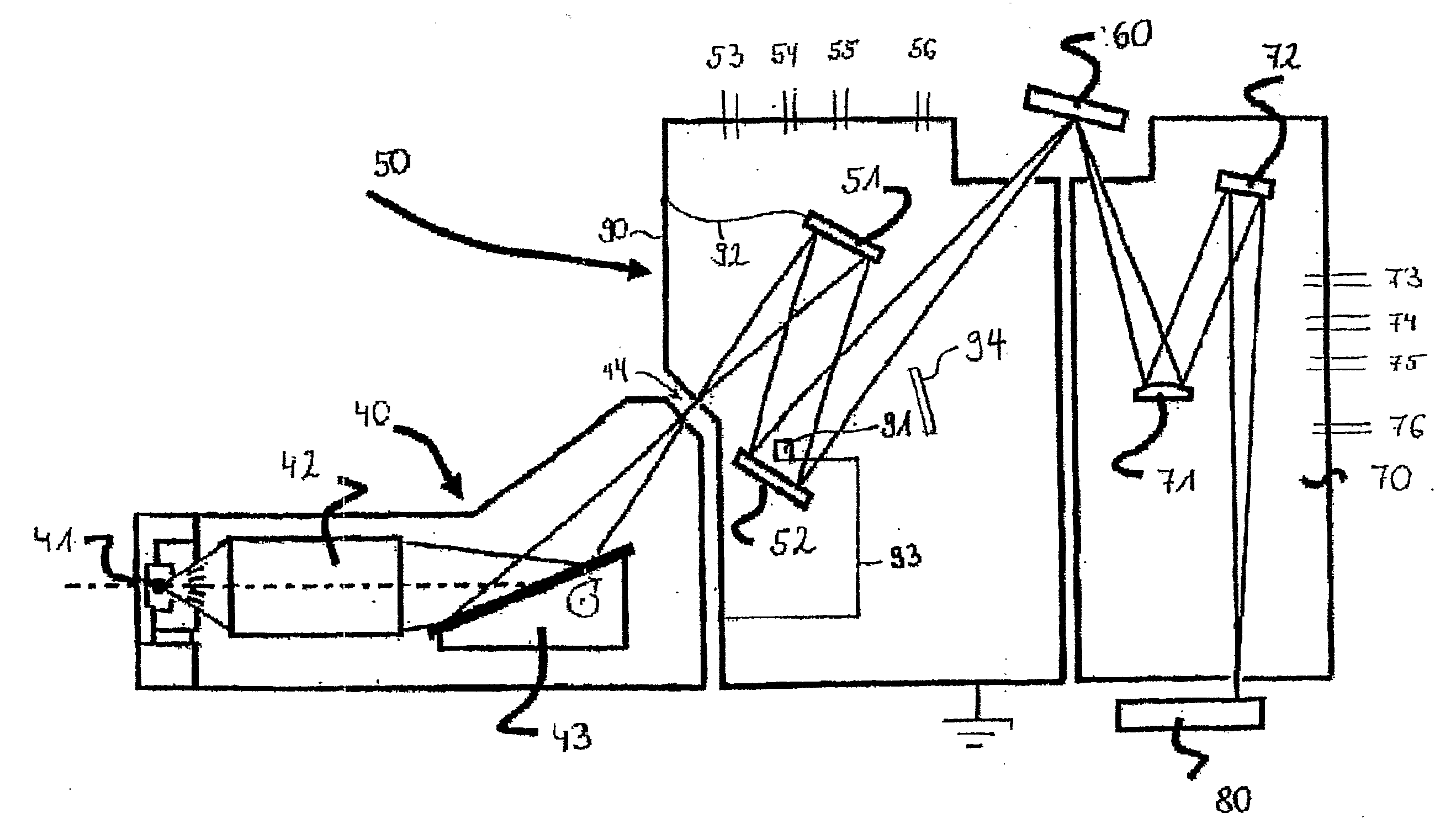

Device and method for spatially resolved photodetection and demodulation of modulated electromagnetic waves

InactiveUS7060957B2Low lighting powerExtend integration timePrismsSolid-state devicesPulse radiationData acquisition

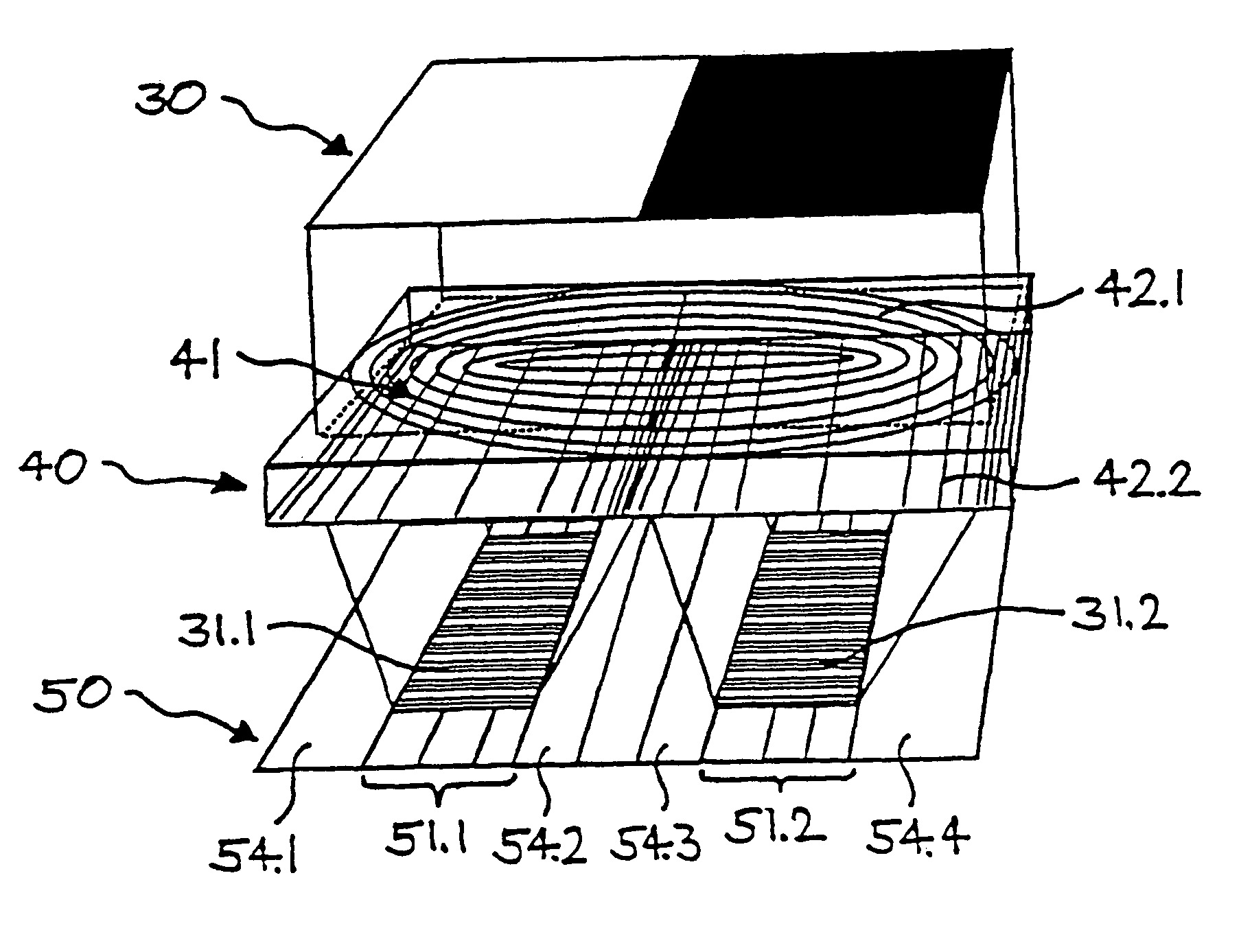

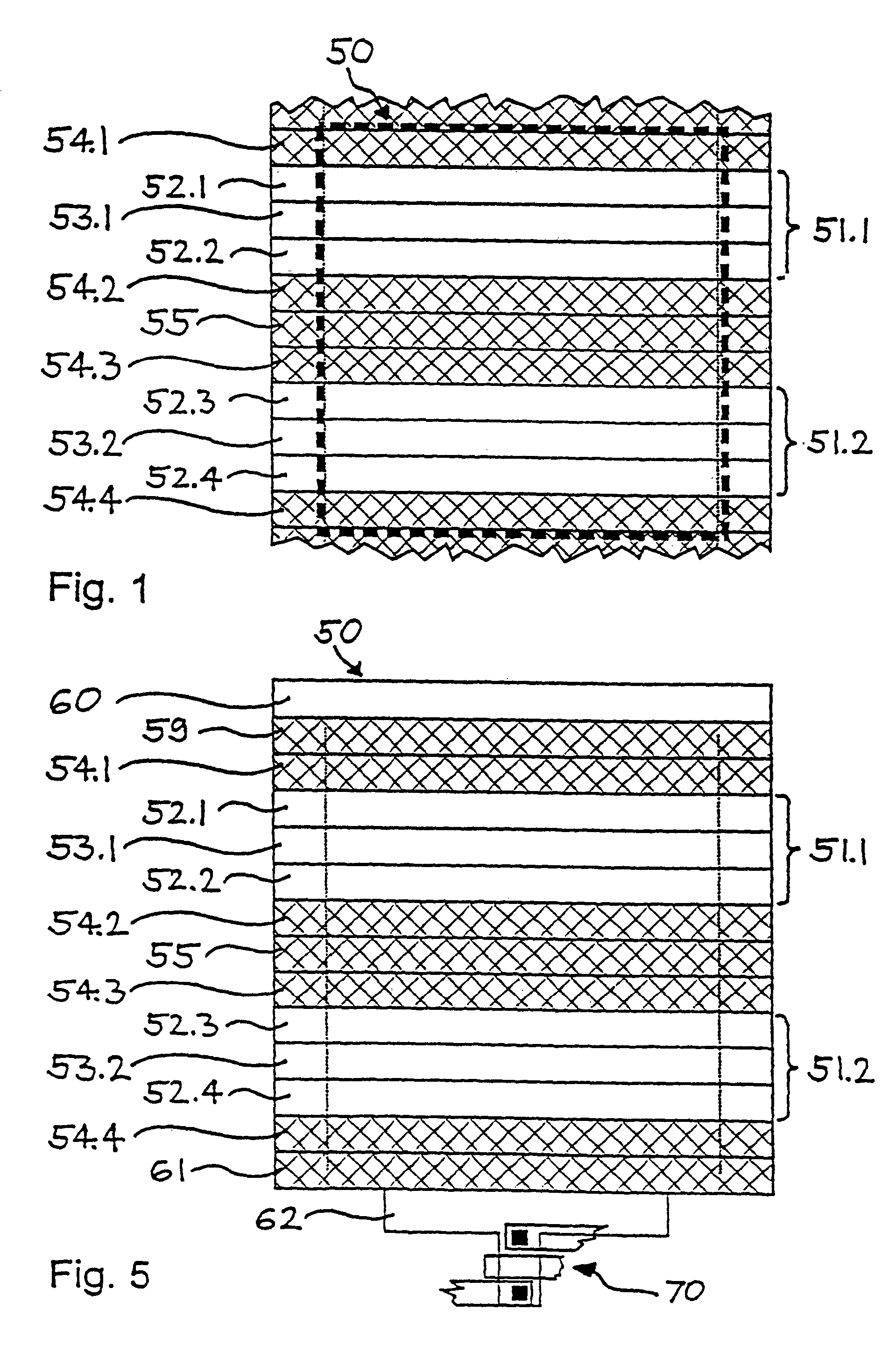

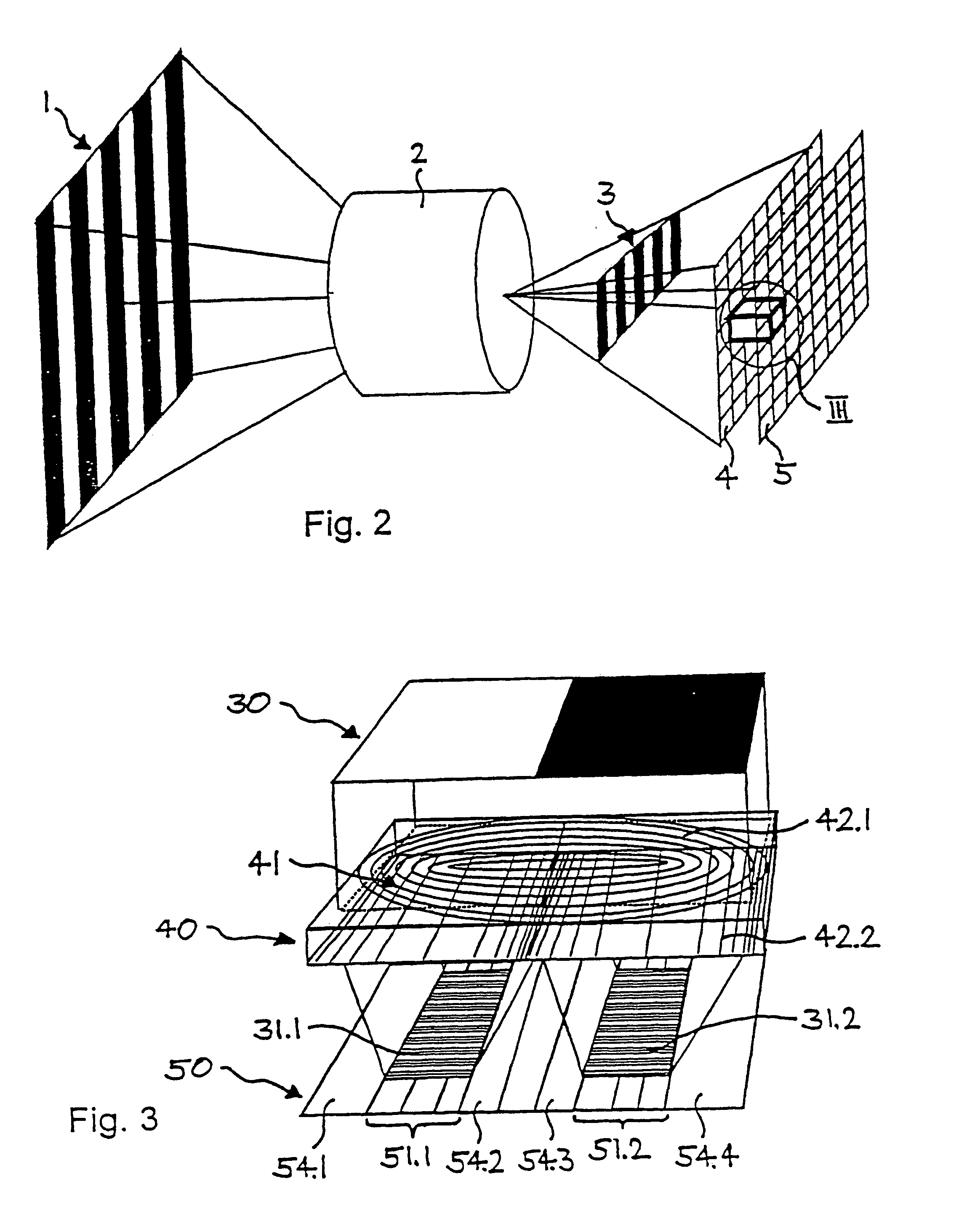

A device and method for spatially resolved photodetection and demodulation of temporally modulated electromagnetic waves makes it possible to measure phase, amplitude and offset of a temporally modulated, spatially coded radiation field. A micro-optical element (41) spatially averages a portion (30) of the scene and equally distributes the averaged intensity on two photo sites (51.1.51.2) close to each other. Adjacent to each of these photo sites (51.1) are two storage areas (54.1, 54.2) into which charge from the photo site can be moved quickly (with a speed of several MHz to several tens or even hundreds of MHz) and accumulated essentially free of noise. This is possible by employing the charge-coupled device (CCD) principle. The device combines a high optical fill factor, insensitivity to offset errors, high sensitivity even with little light, simultaneous data acquisition, small pixel size, and maximum efficiency in use of available signal photons for sinusoidal as well as pulsed radiation signals. The device and method may be used in a time-of-flight (TOF) range imaging system without moving parts, offering 2D or 3D range data.

Owner:AMS SENSORS SINGAPORE PTE LTD

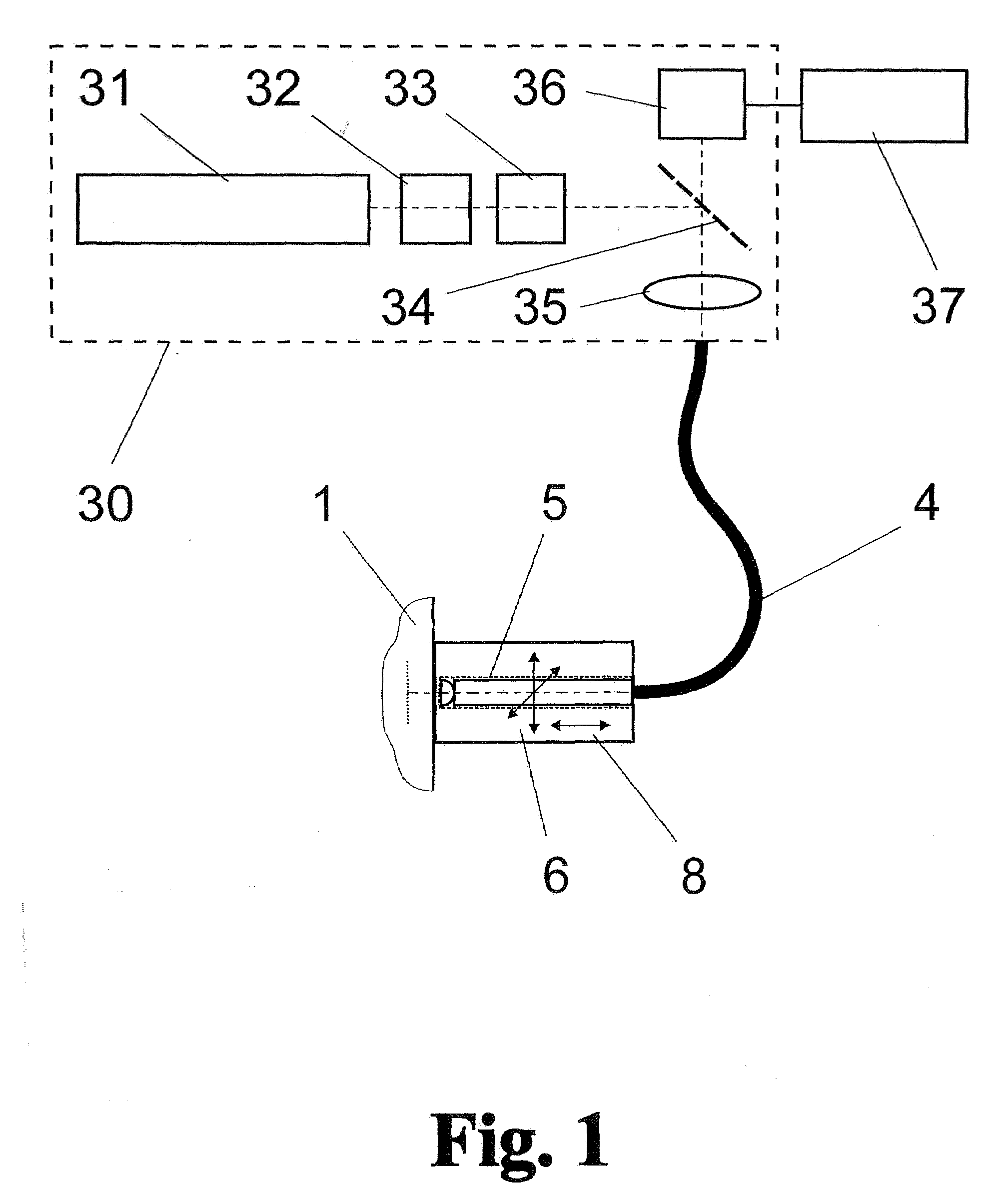

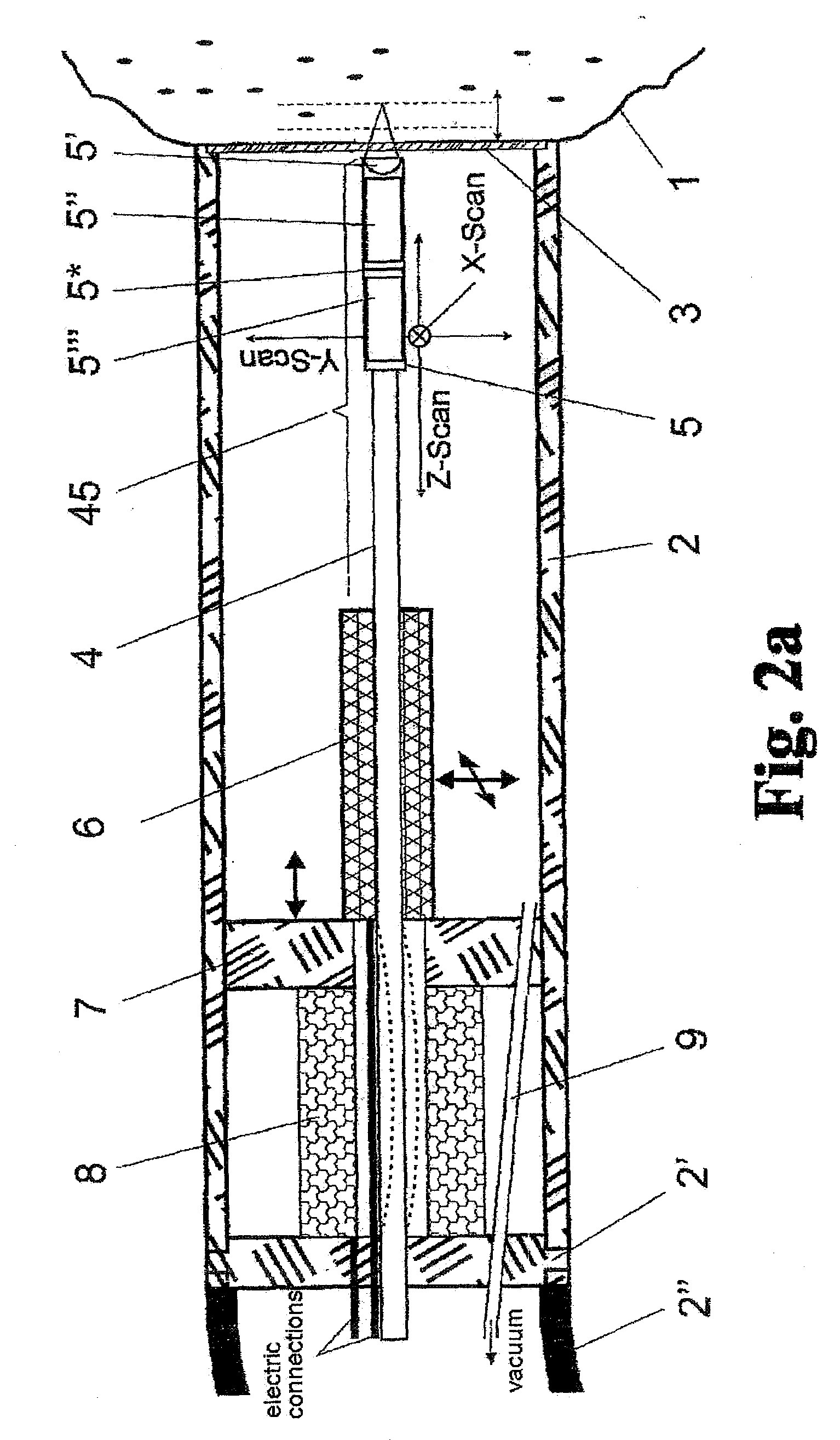

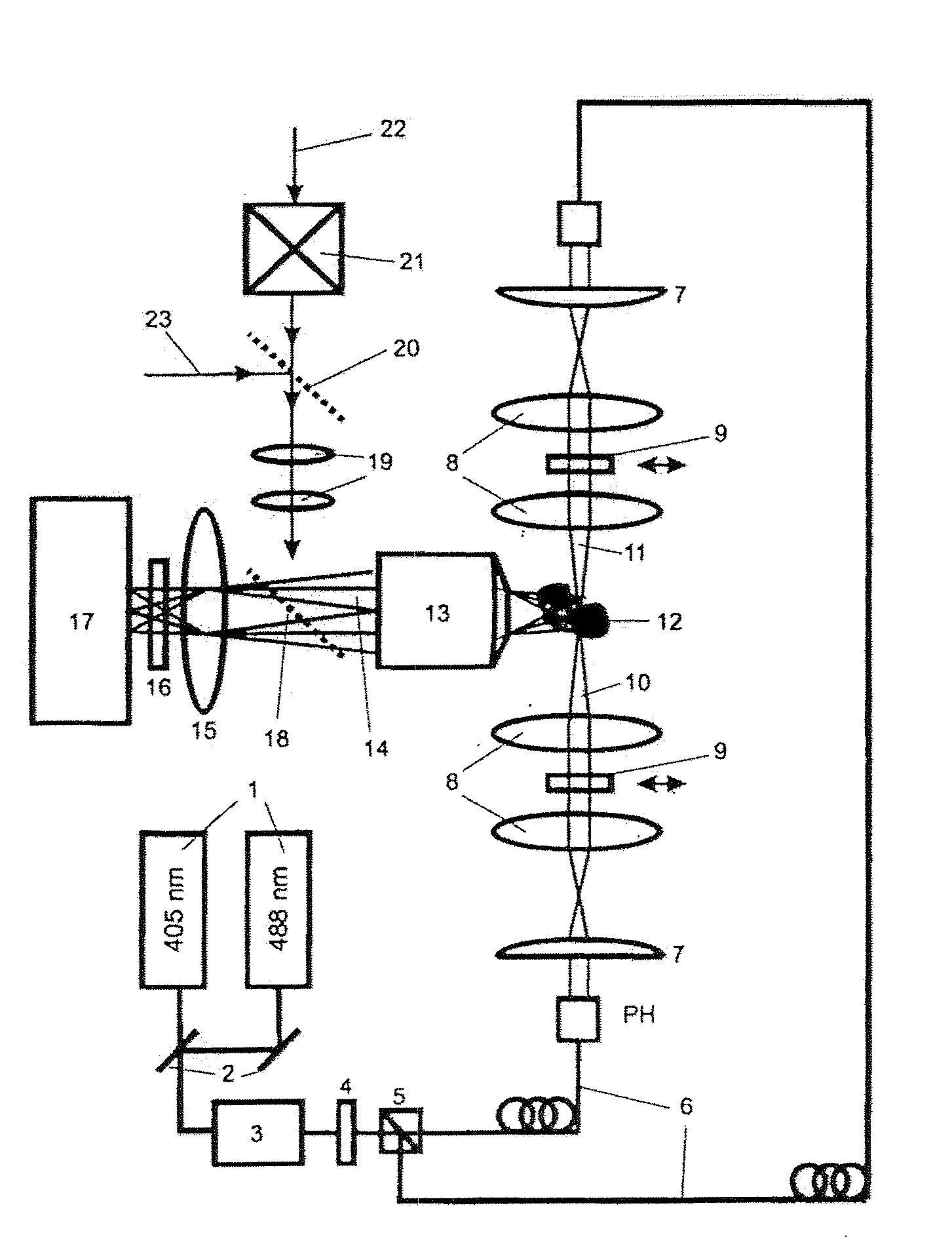

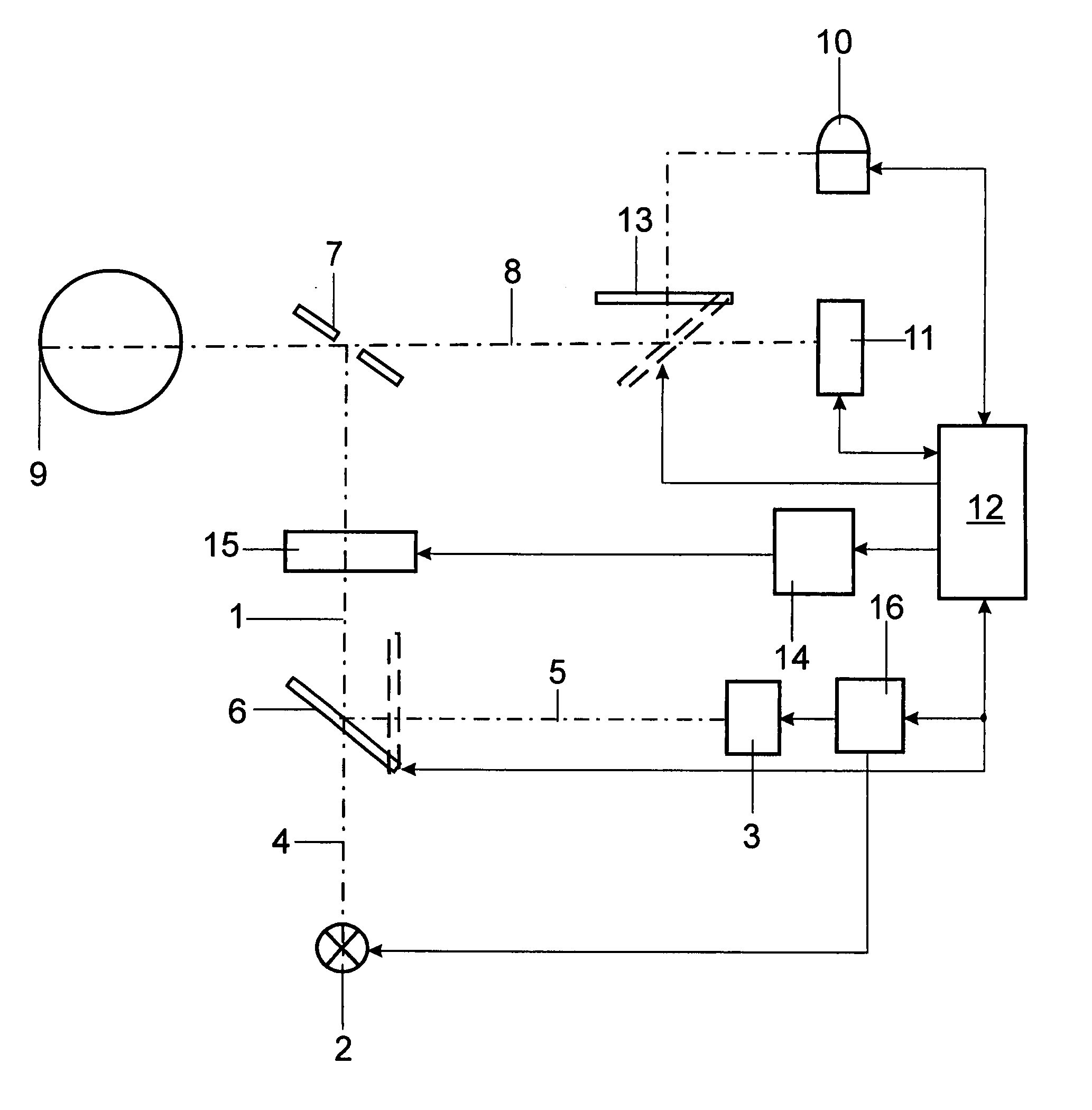

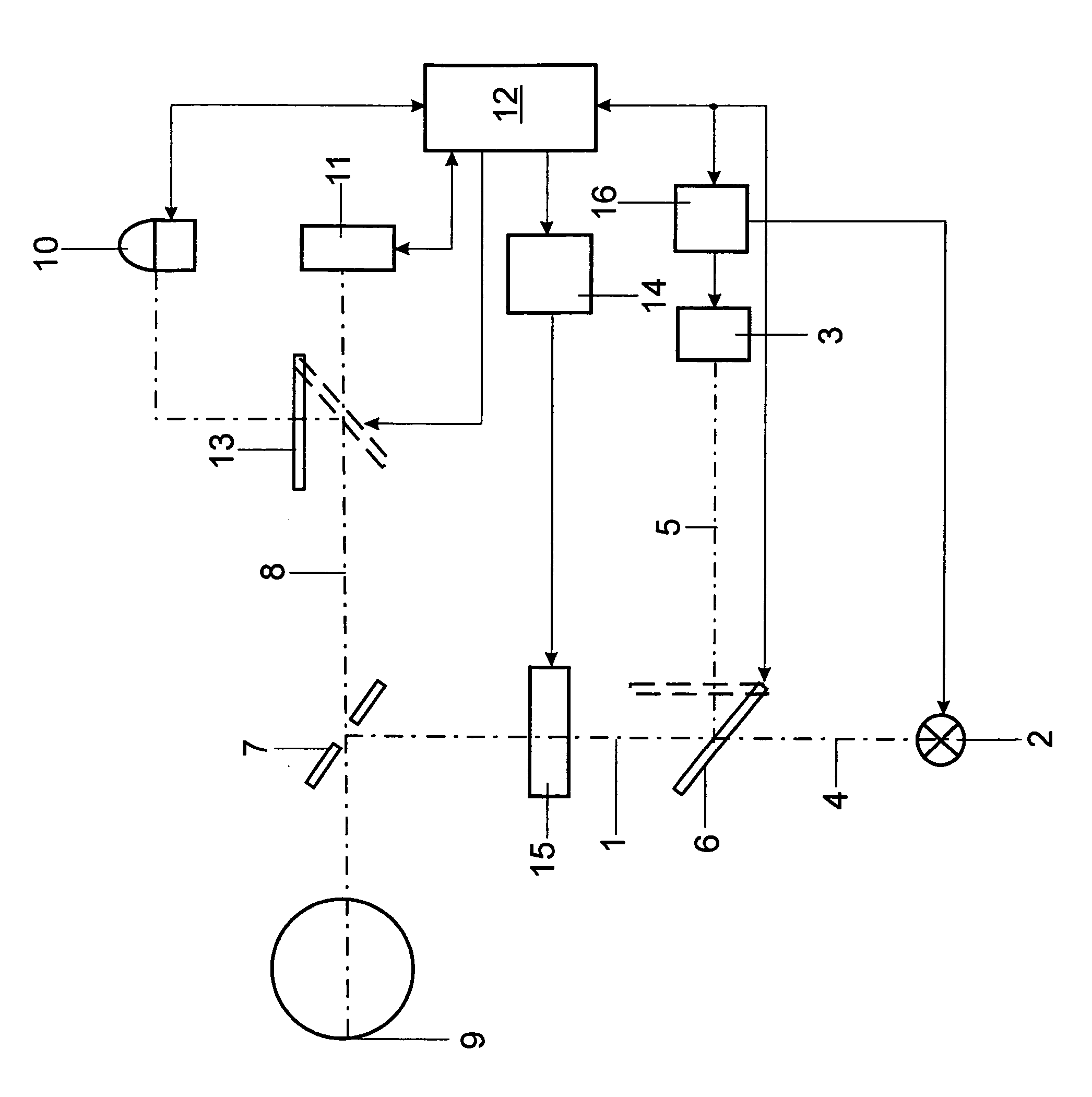

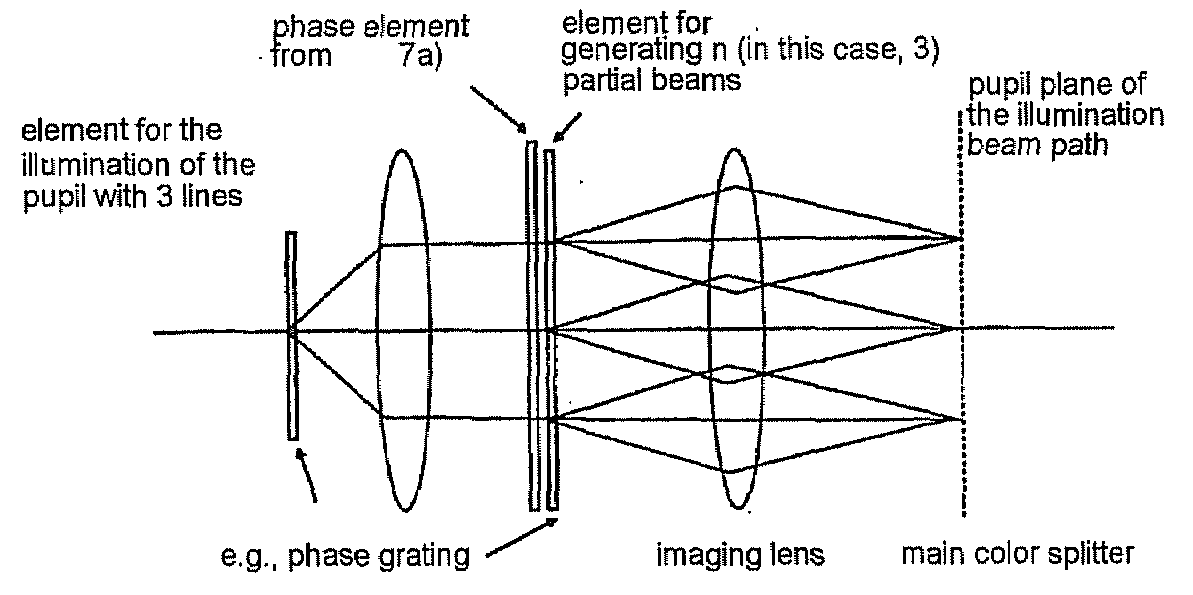

Method and arrangement for high-resolution microscope imaging or cutting in laser endoscopy

ActiveUS20080081950A1Accurate imagingPrecise microcuttingEndoscopesCatheterMicroscopic imageFlexible endoscope

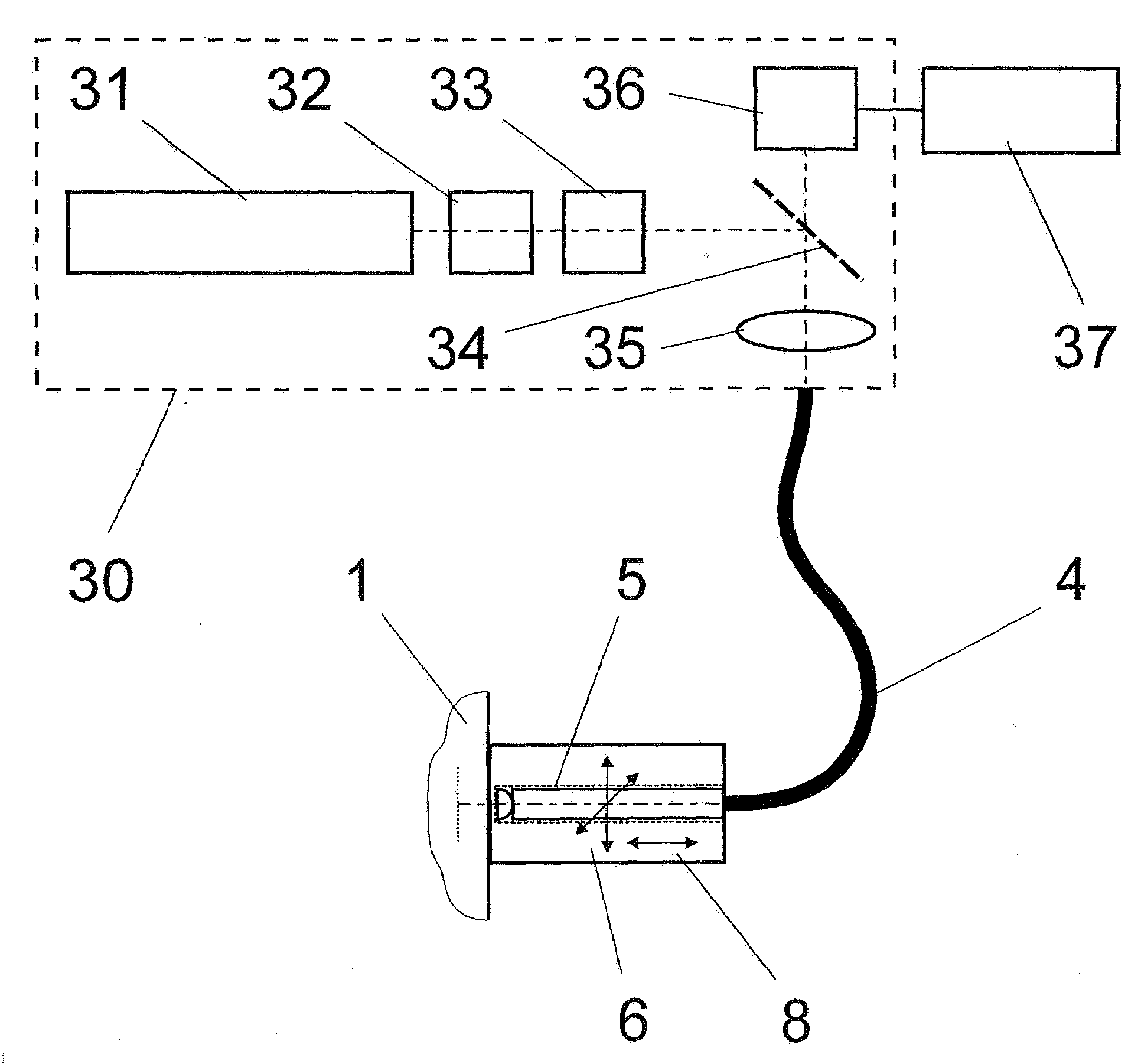

The invention is directed to a method and an arrangement for high-resolution microscopic imaging in laser endoscopy based on laser-induced object reaction radiation and for performing microscopic cuts in biological tissue. In using multiphoton processes for endoscopic applications in biological materials with an accuracy of under one millimeter, radiation of a pulsed femtosecond laser is focused into an object by means of a transmission focusing optics unit comprising a transmission system and miniature focusing optics having a high numerical aperture greater than 0.55 to trigger a local object reaction radiation in the micrometer to nanometer range, and the distal end of the transmission focusing optics unit is moved in at least two dimensions for highly spatially resolved scanning of the object and for transmitting object reaction radiation which is scanned in a locally progressive manner to an image-generating system with a photon detector. In an other embodiment the femtosecond laser radiation is energy enhanced is applied to the same transmission focusing optics unit to perform microendoscopic surgery in biological tissue.

Owner:JENLAB

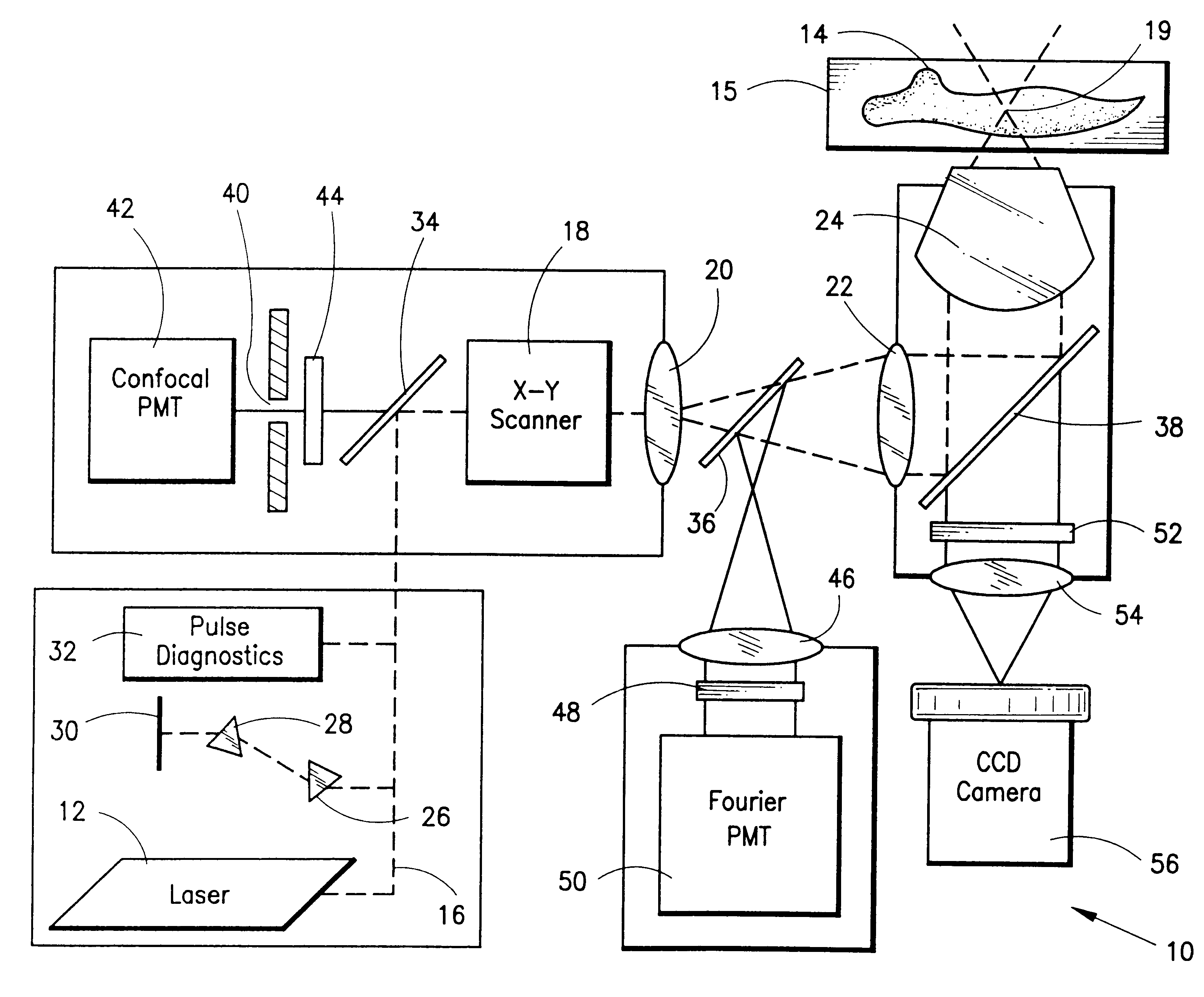

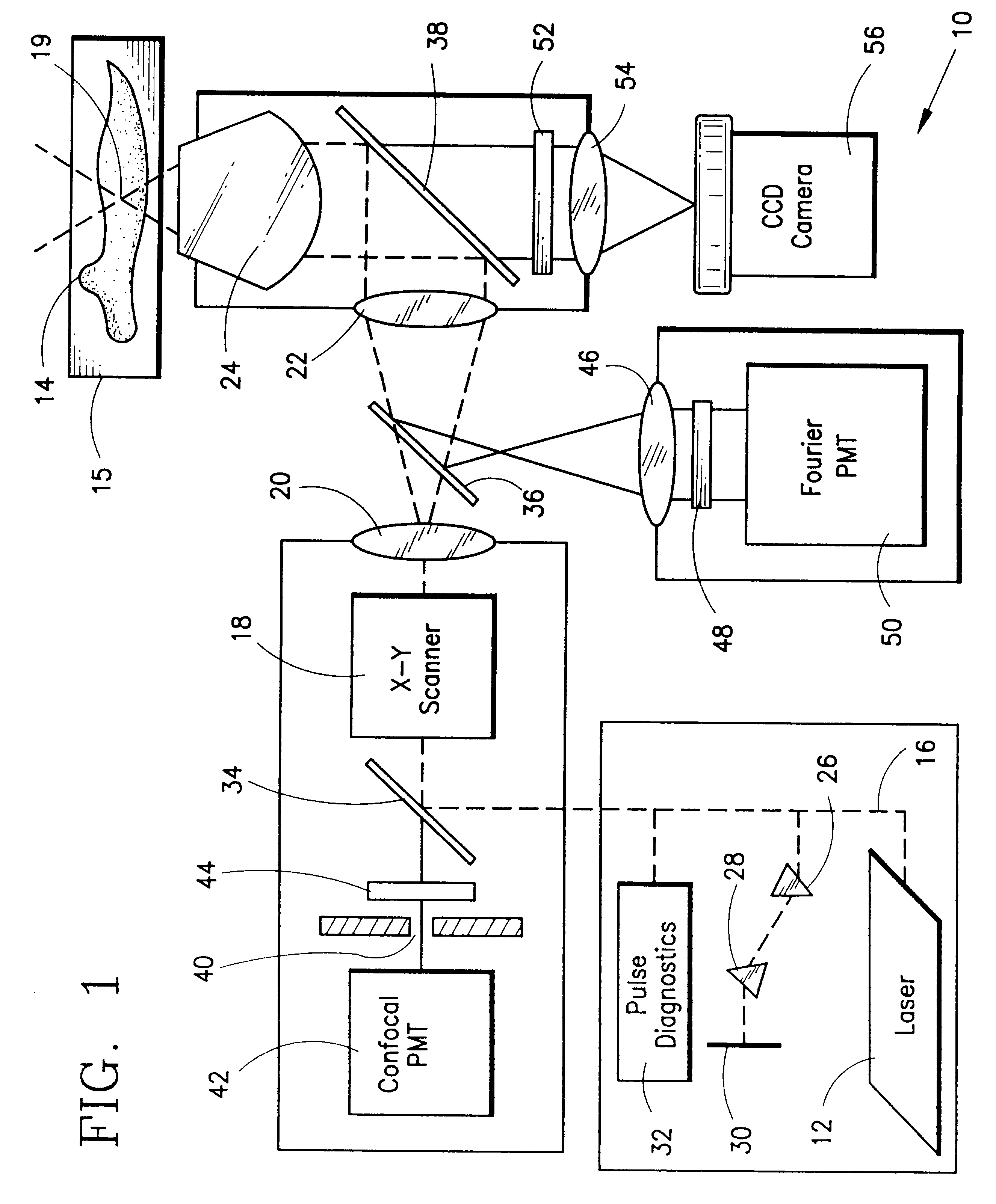

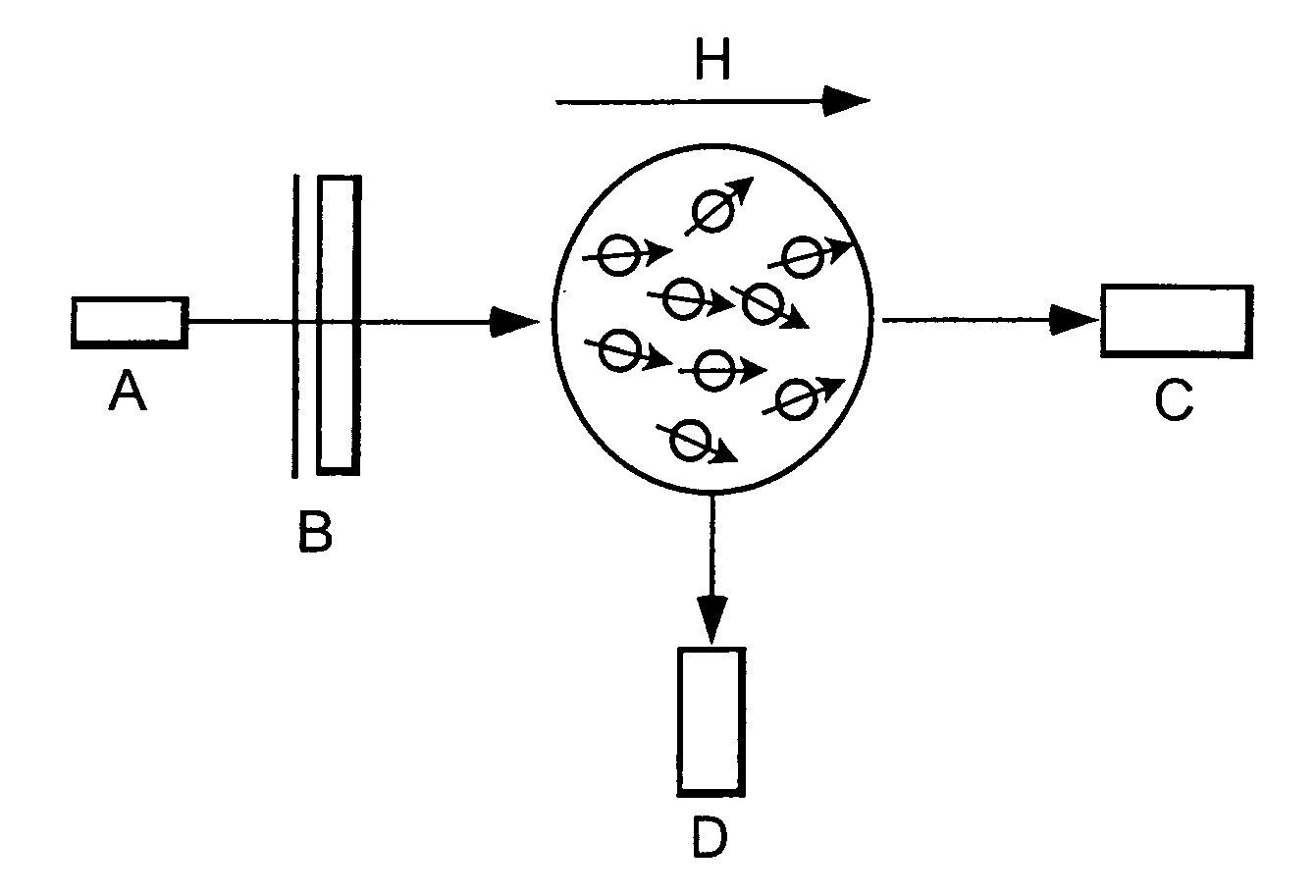

Multi-photon laser microscopy

InactiveUS6344653B1Less photodamageExpand the scope of useLaser detailsPhotometryConfocal laser scanning microscopeLaser scanning microscope

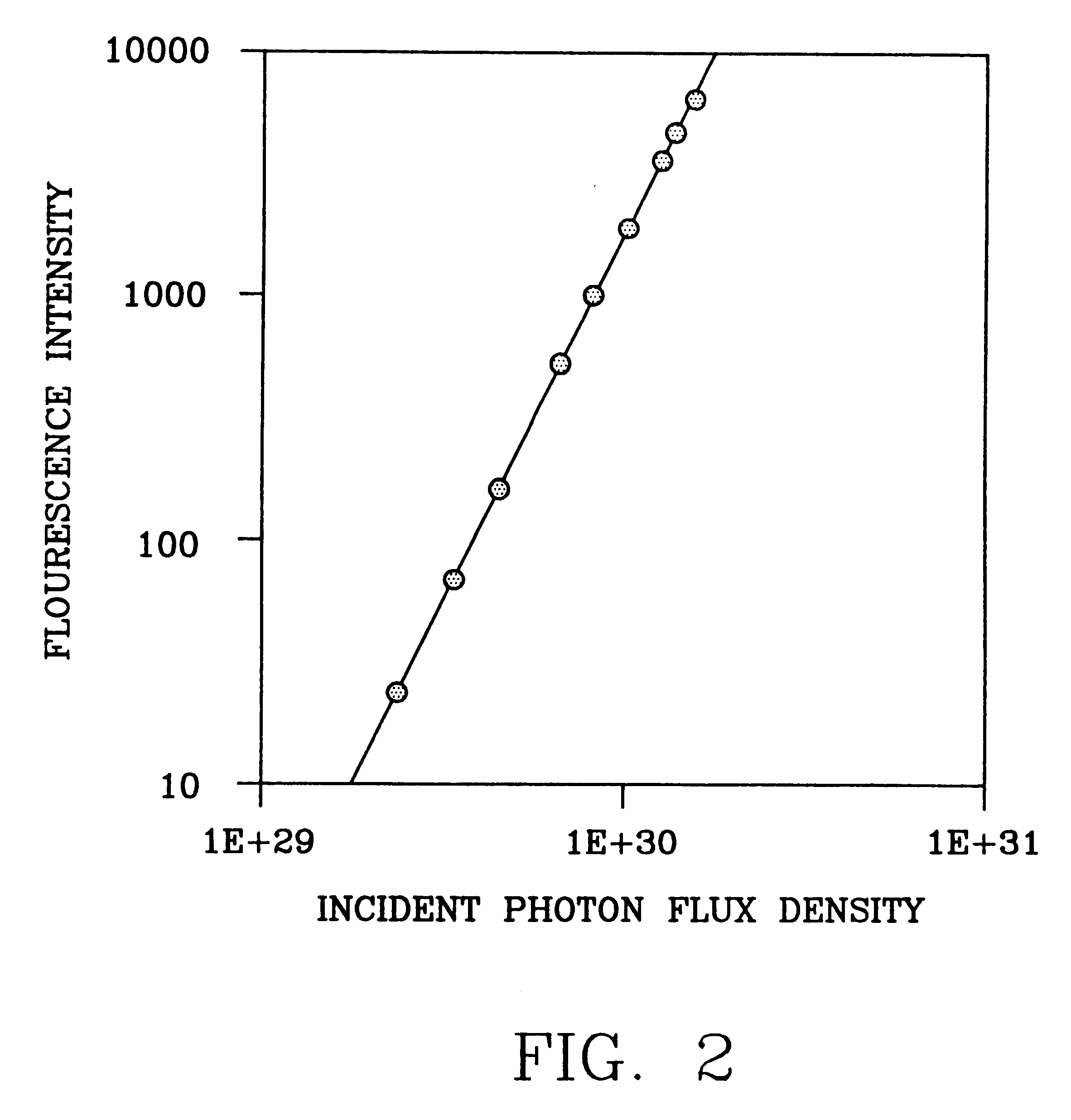

A laser scanning microscope produces molecular excitation in a target material by simultaneous absorption of three or more photons to thereby provide intrinsic three-dimensional resolution. Fluorophores having single photon absorption in the short (ultraviolet or visible) wavelength range are excited by a beam of strongly focused subpicosecond pulses of laser light of relatively long (red or infrared) wavelength range. The fluorophores absorb at about one third, one fourth or even smaller fraction of the laser wavelength to produce fluorescent images of living cells and other microscopic objects. The fluorescent emission from the fluorophores increases cubicly, quarticly or even higher power law with the excitation intensity so that by focusing the laser light, fluorescence as well as photobleaching are confined to the vicinity of the focal plane. This feature provides depth of field resolution comparable to that produced by confocal laser scanning microscopes, and in addition reduces photobleaching and phototoxicity. Scanning of the laser beam by a laser scanning microscope, allows construction of images by collecting multi-photon excited fluorescence from each point in the scanned object while still satisfying the requirement for very high excitation intensity obtained by focusing the laser beam and by pulse time compressing the beam. The focused pulses also provide three-dimensional spatially resolved photochemistry which is particularly useful in photolytic release of caged effector molecules, marking a recording medium or in laser ablation or microsurgery. This invention refers explicitly to extensions of two-photon excitation where more than two photons are absorbed per excitation in this nonlinear microscopy.

Owner:WEBB WATT W +1

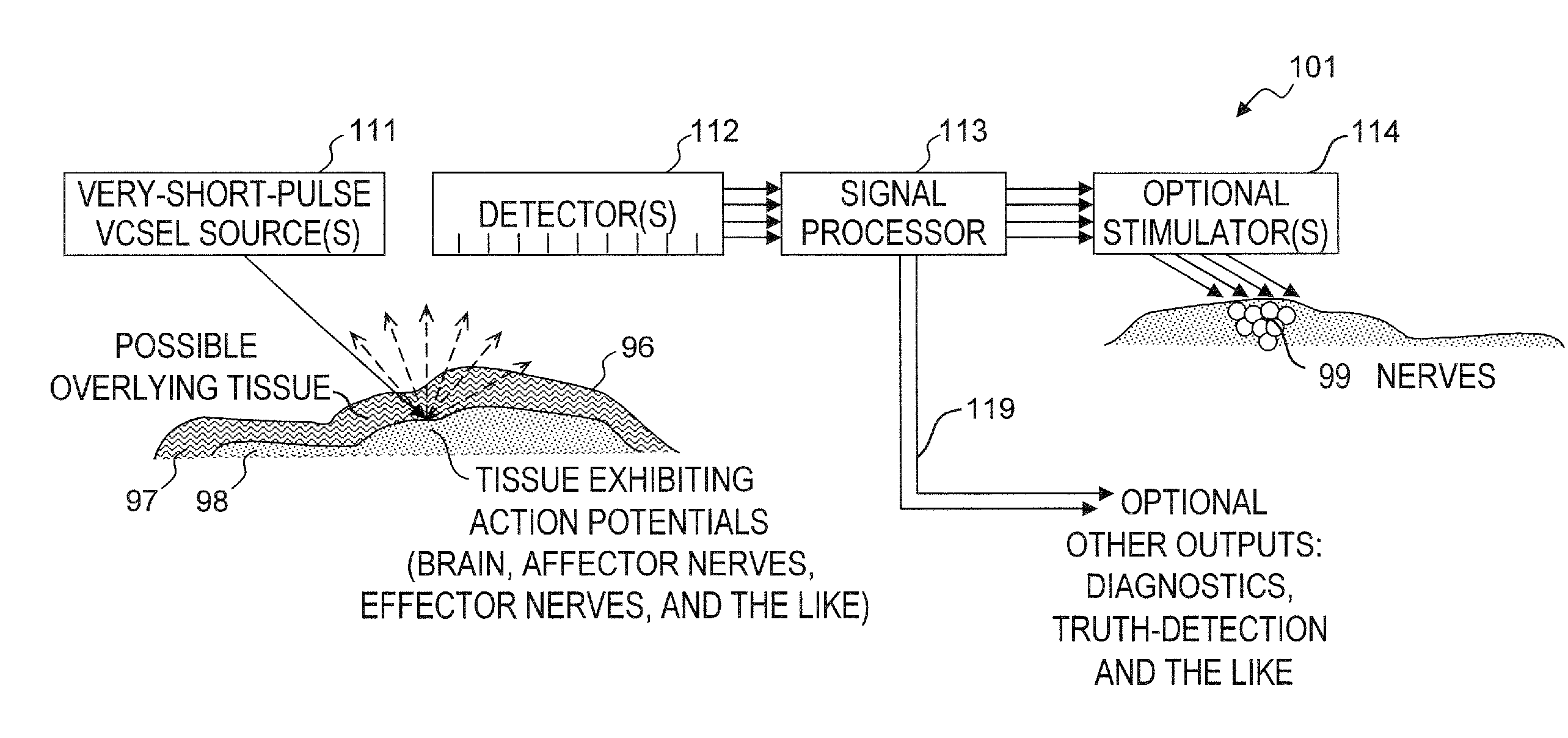

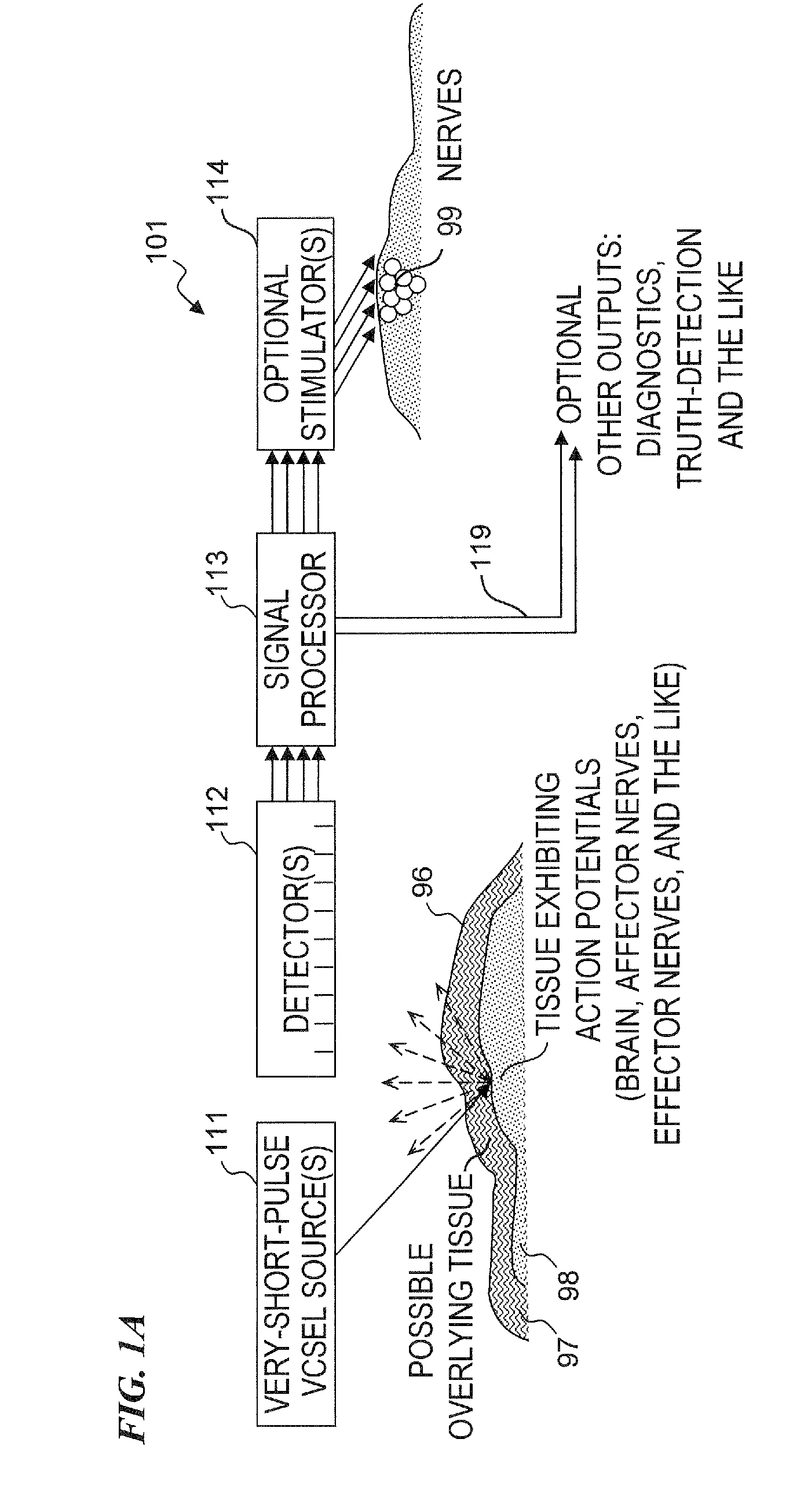

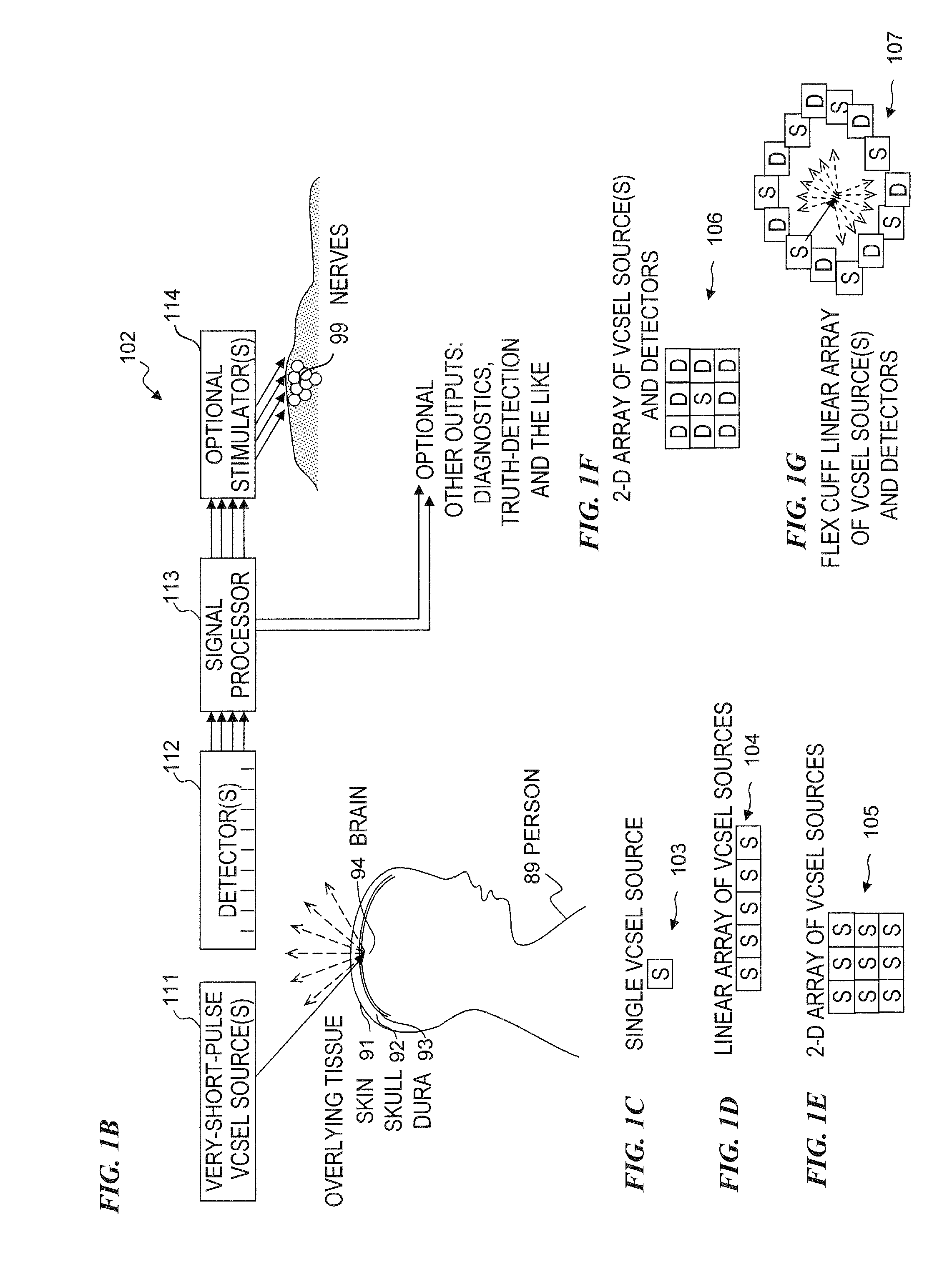

Apparatus and method for neural-signal capture to drive neuroprostheses or control bodily function

Method and apparatus for detecting nerve activity of an animal. Some embodiments include outputting a light pulse having a wavelength onto a volume of animal tissue such that the light pulse interacts with active nerves of the tissue; measuring a light signal resulting from the interaction of the light pulse with the tissue; transmitting an electrical signal based on the measured light signal; signal-processing the electrical signal; and outputting a response signal, which can optionally be used to control a prosthetic device, stimulate another nerve, or display / diagnose a condition. Some embodiments output a plurality of light wavelengths and / or pulses, which are optionally high-frequency intensity modulated. Some embodiments analyze DC, AC, and phase components of signals to spatially resolve locations of neural activity. Some embodiments output light pulse(s) and detect the resultant light from outside a human skull to detect neural activity of human brain tissue inside the skull.

Owner:LOCKHEED MARTIN CORP

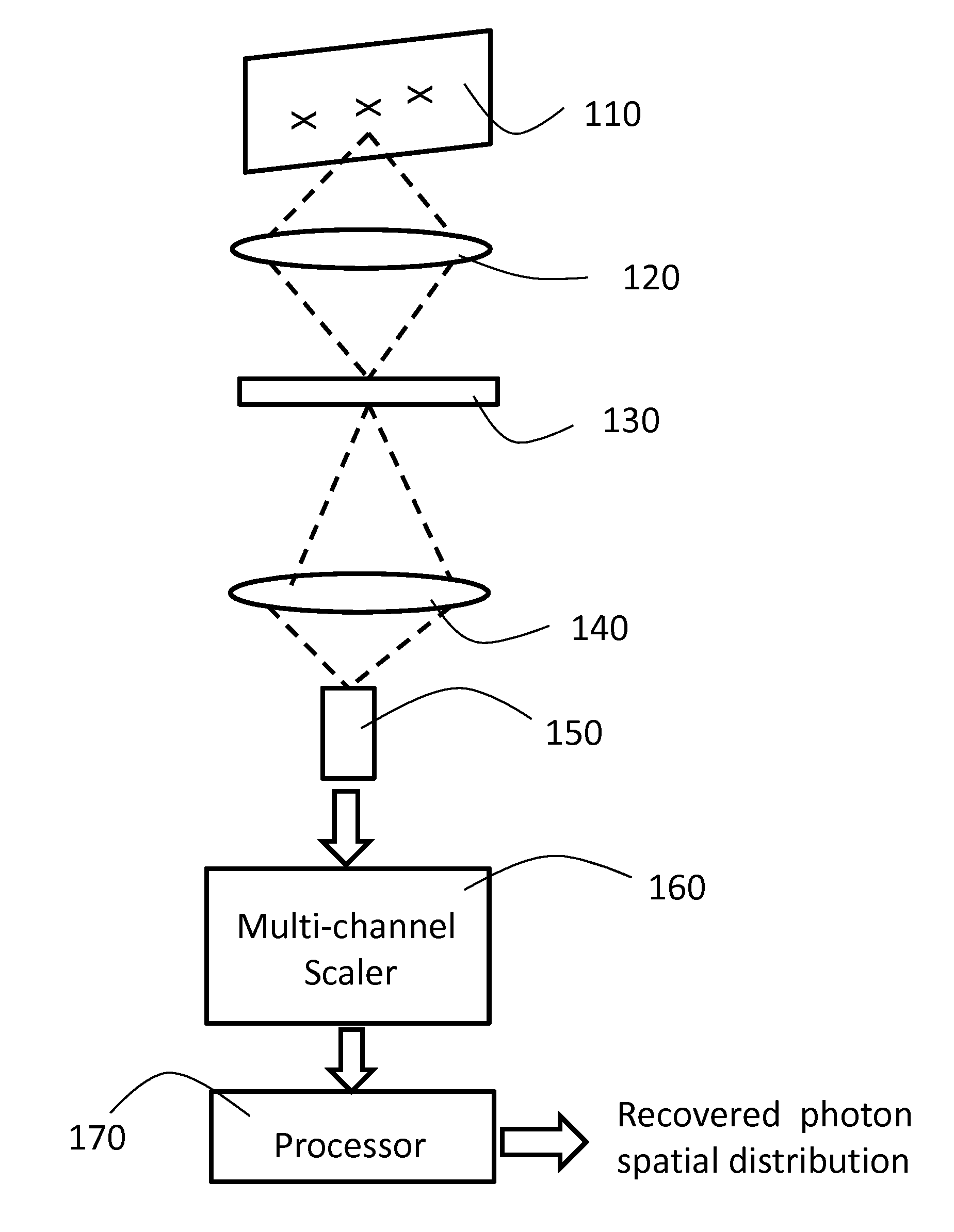

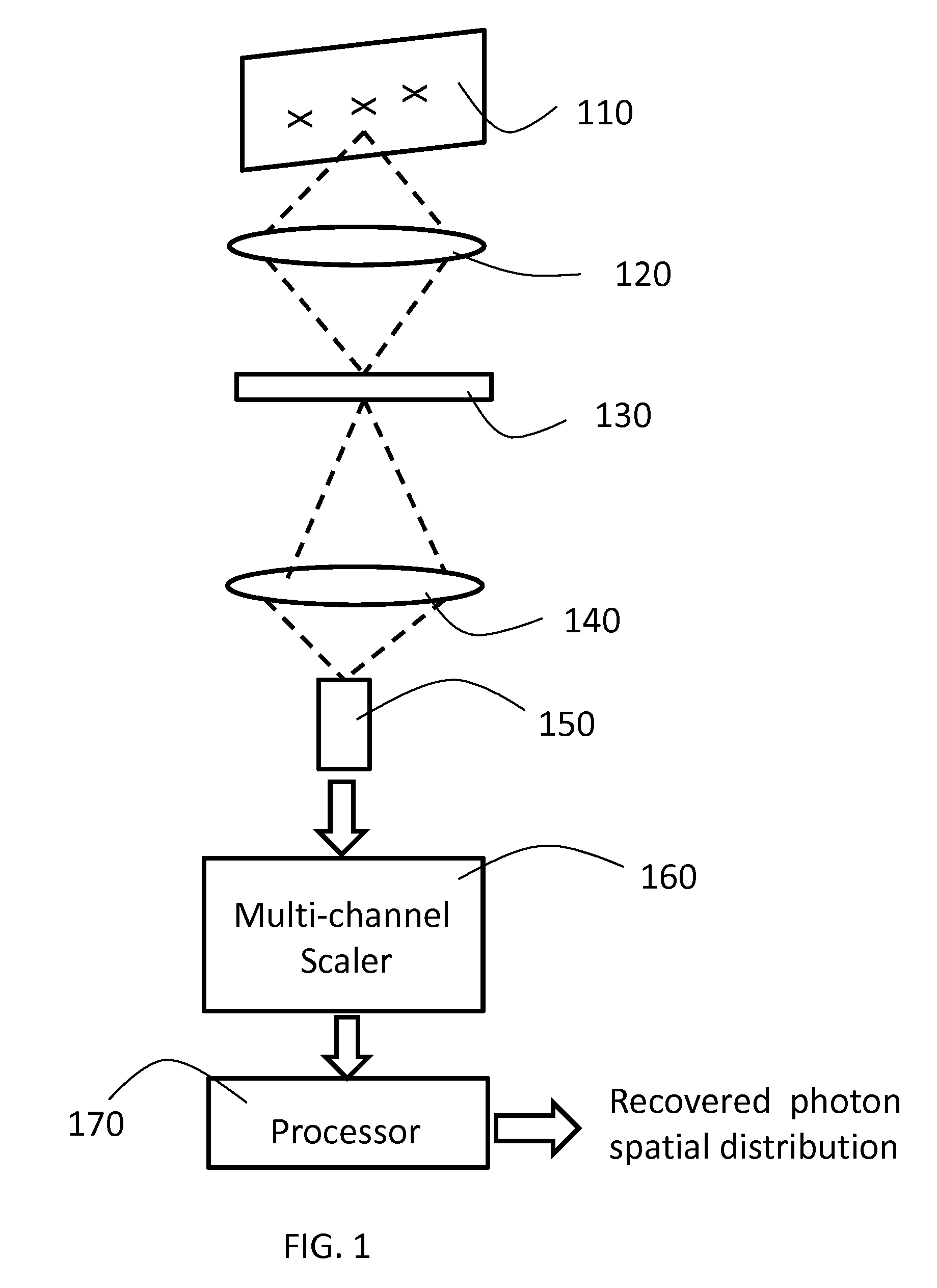

Temporally- And Spatially-Resolved Single Photon Counting Using Compressive Sensing For Debug Of Integrated Circuits, Lidar And Other Applications

InactiveUS20110260036A1Improve instrument performanceFast acquisition timeTelevision system detailsSolid-state devicesPhoton counting detectorSpatially resolved

A method for photon counting including the steps of collecting light emitted or reflected / scattered from an object; imaging the object onto a spatial light modulator, applying a series of pseudo-random modulation patterns to the SLM according to standard compressive-sensing theory, collecting the modulated light onto a photon-counting detector, recording the number of photons received for each pattern (by photon counting) and optionally the time of arrival of the received photons, and recovering the spatial distribution of the received photons by the algorithms of compressive sensing (CS).

Owner:BARANIUK RICHARD G +2

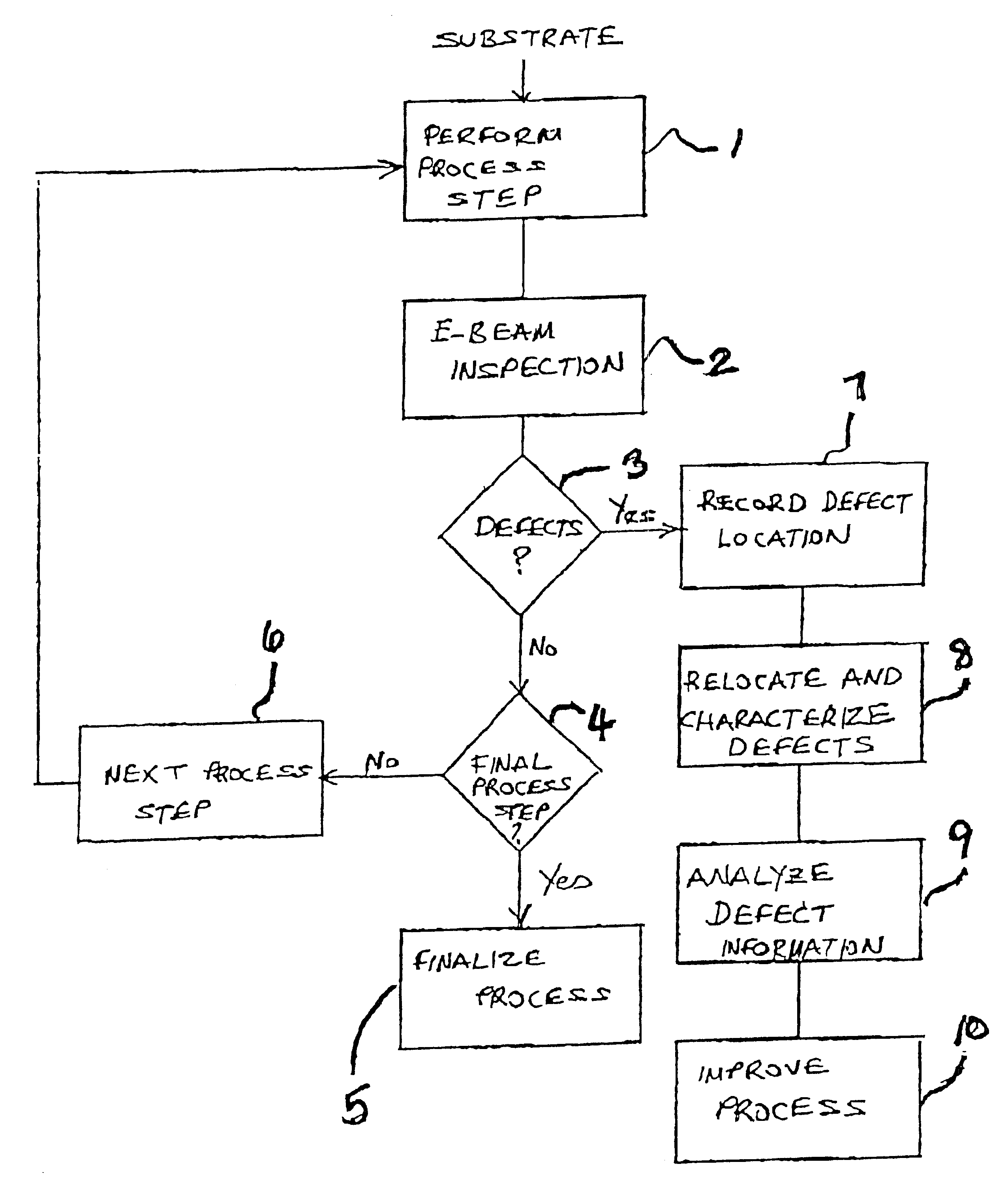

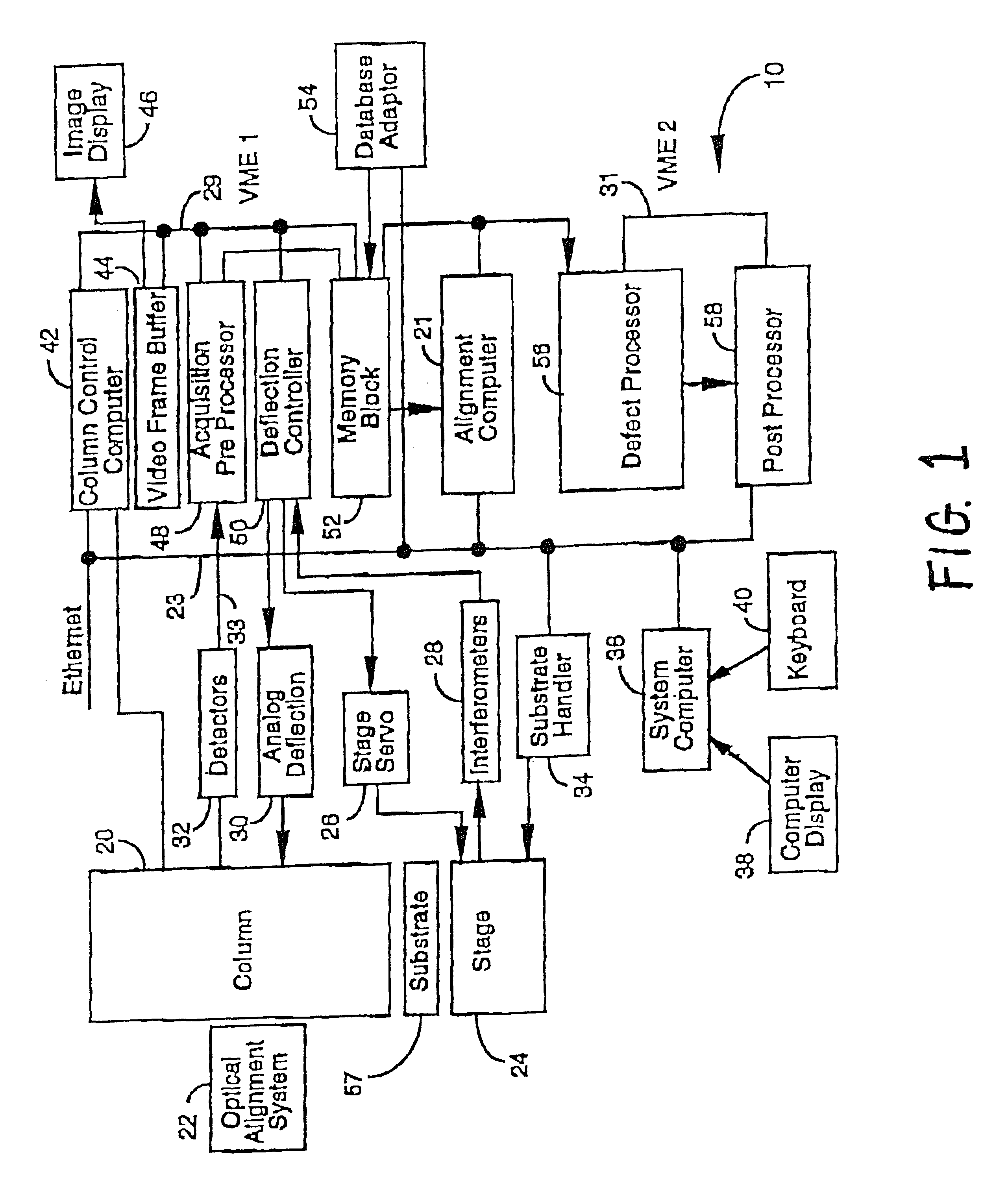

Methods and apparatus for generating spatially resolved voltage contrast maps of semiconductor test structures

InactiveUS6445199B1Reduce pressureSemiconductor/solid-state device testing/measurementElectric discharge tubesSpatially resolvedEngineering

Disclosed is a method of inspecting a sample. The sample is illuminated with an incident beam, thereby causing voltage contrast within structures present on the sample. Voltage contrast is detected within the structures. Information from the detected voltage contrast is stored, and position data concerning the location of features corresponding to at least a portion of the stored voltage contrast information is also stored. In a specific embodiment, the features represent electrical defects present on the sample. In another embodiment, the stored position data is in the form of a two dimensional map. In another aspect, the sample is re-inspected and the stored position data is used in analyzing data resulting from the re-inspection.

Owner:KLA CORP

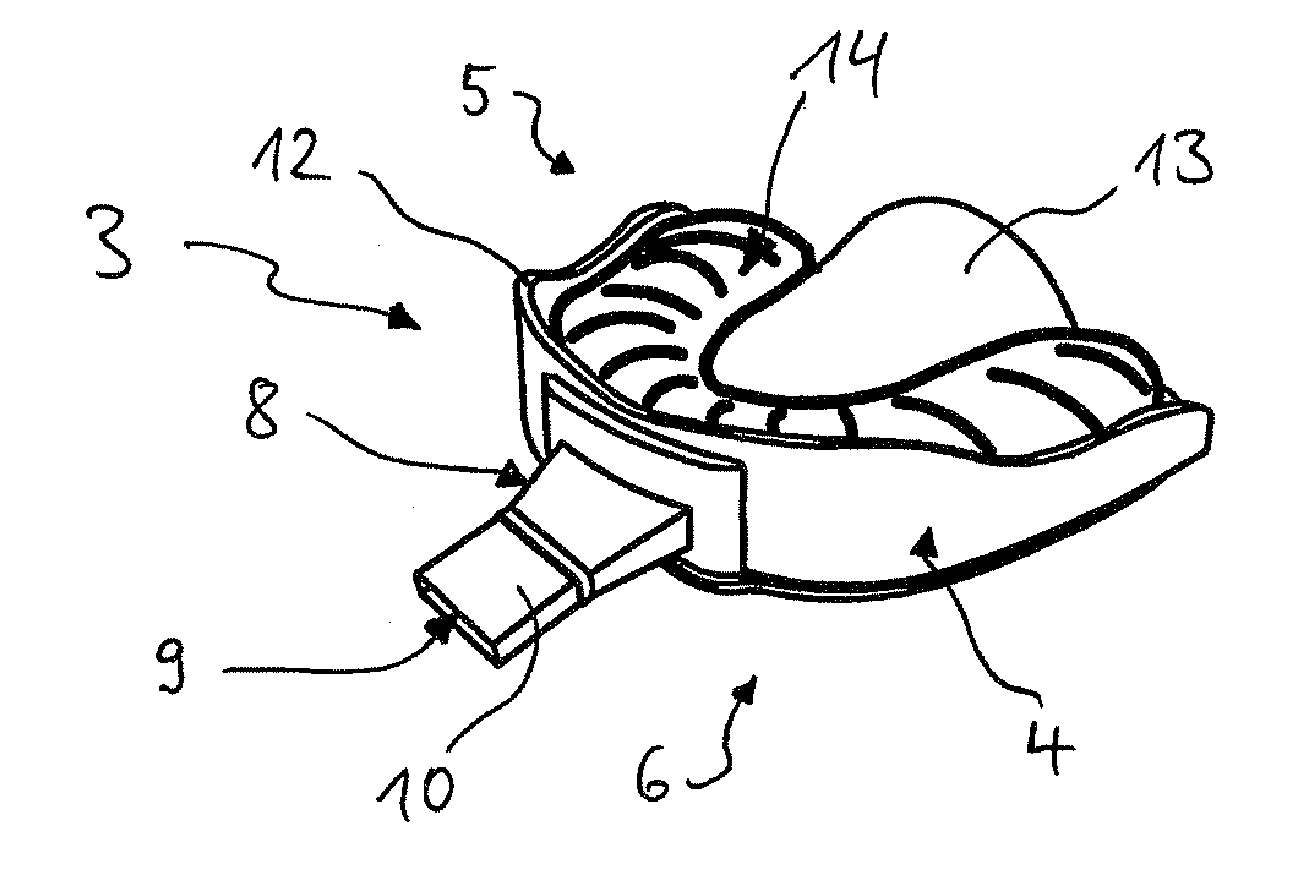

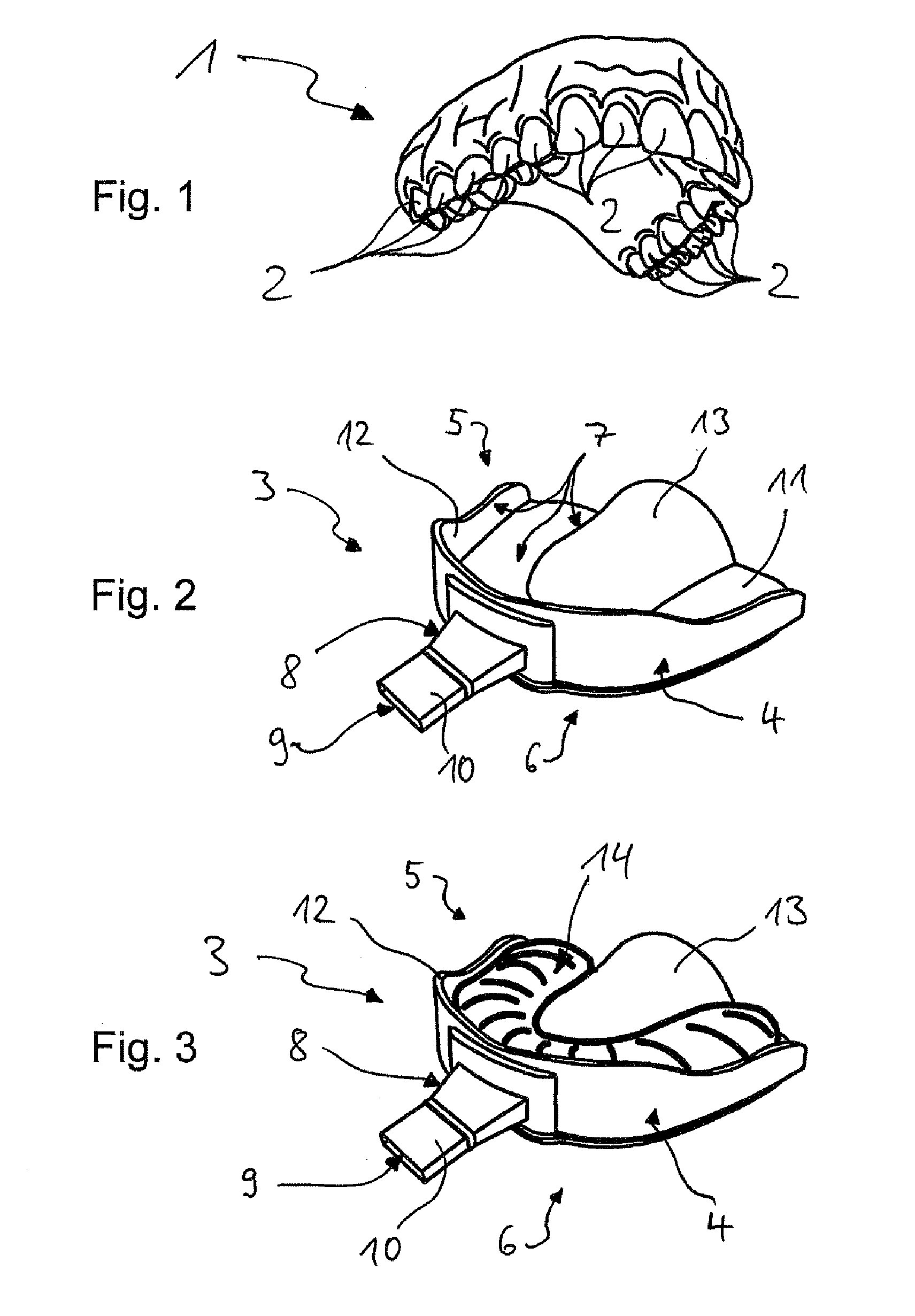

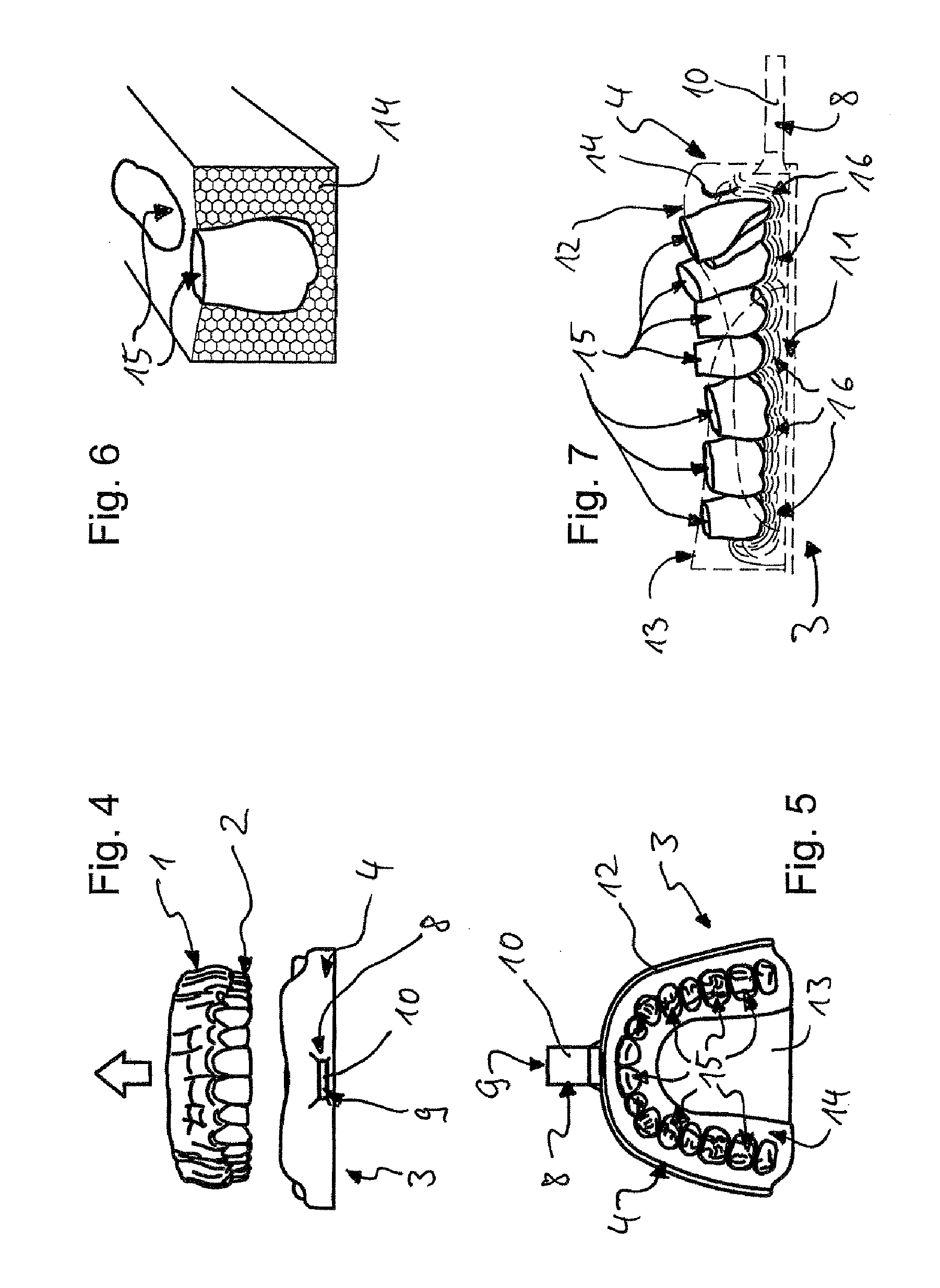

Impression tray, and method for capturing structures, arrangements or shapes, in particular in the mouth or human body

InactiveUS20120064477A1Easy, dependable and accurateImpression capsTeeth fillingSpatially resolvedHuman body

The invention relates to an impression tray, such as in particular a dental impression tray, which carries a deformable impression mass in order to prepare an impression of arrangements, shapes and / or dimensions, in particular in or on the human body, preferably in the mouth, and further preferred an impression of at least part of a tooth or of dental structures, wherein furthermore sensor devices are present, by means of which a change of at least one physical property and / or variable of the impression mass can be captured in a spatially resolved manner when preparing an impression and can be provided in a form that is suited for electronic data processing. The invention further relates to a method for capturing structures, arrangements or shapes, such as preferably for capturing dental structures, arrangements or shapes in the mouth or in the human body, whereby a deformable impression compound is brought onto or into the structures, arrangements or shapes in particular, is introduced, into the mouth or body and a change of at least one physical property and / or variable of the impression compound is transmitted there in a spatially resolved manner directly to sensor devices when preparing an impression and is captured by the sensor devices and, furthermore, provided in a form that is suitable for electronic data processing.

Owner:MEDENTIC

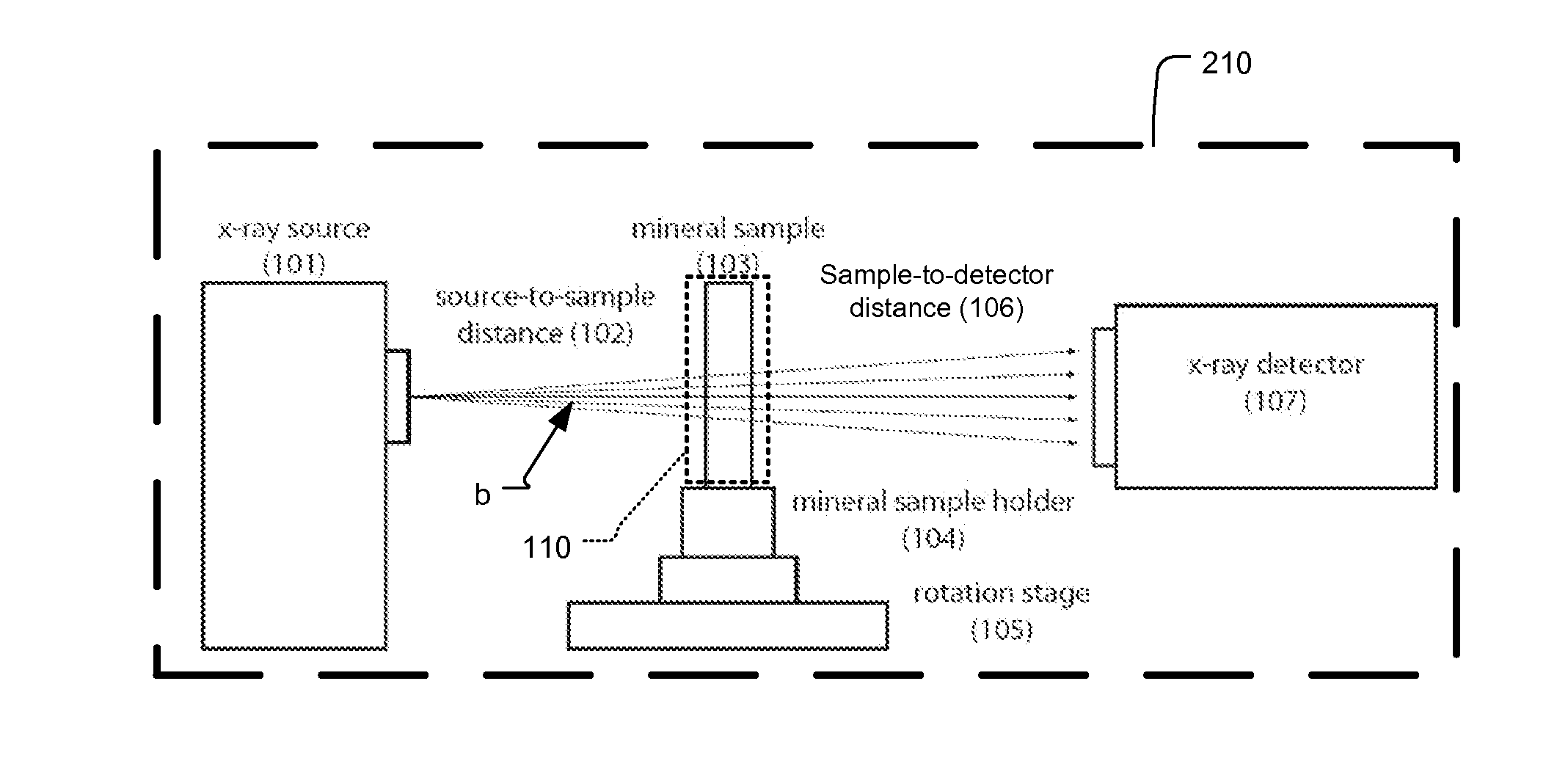

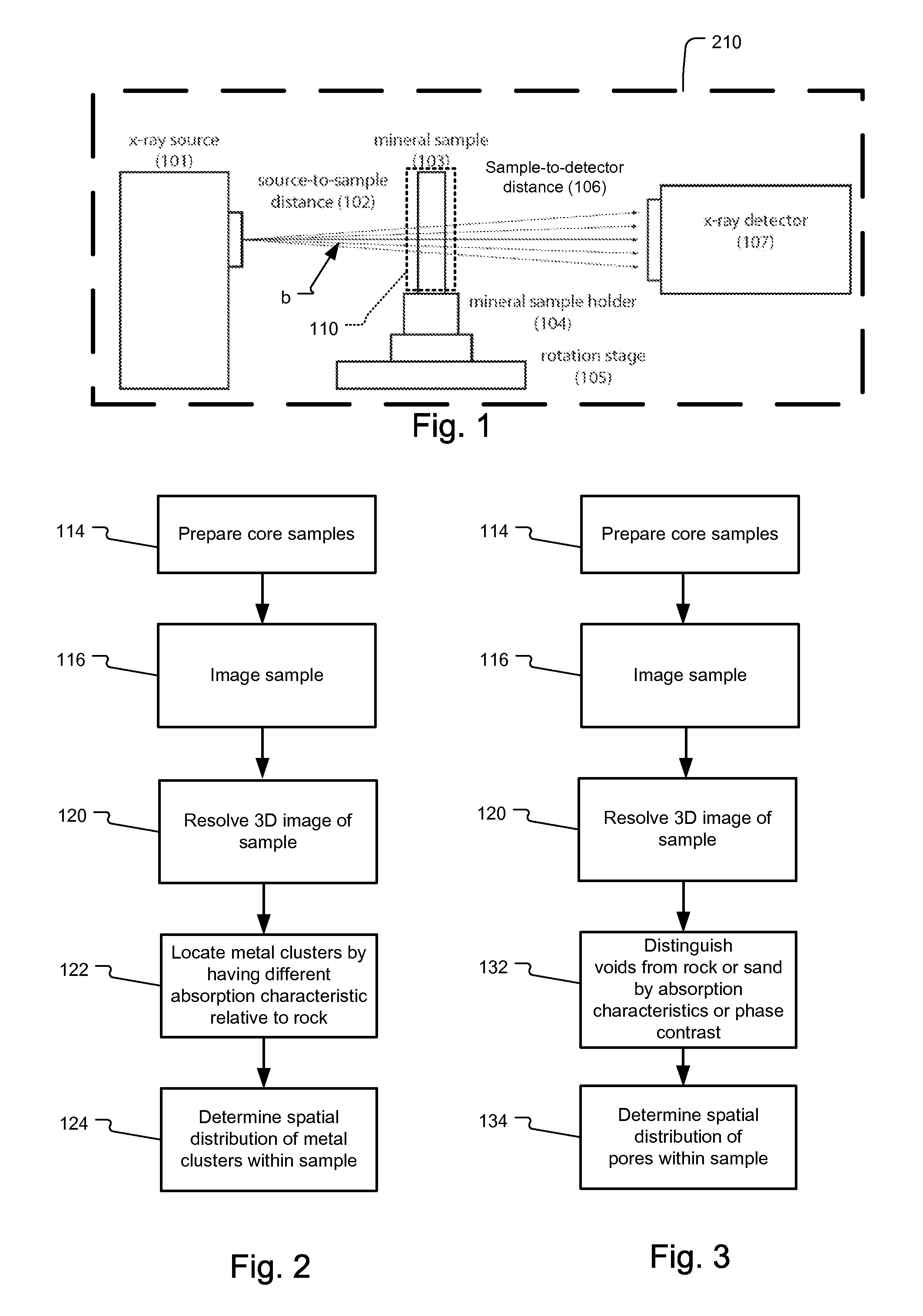

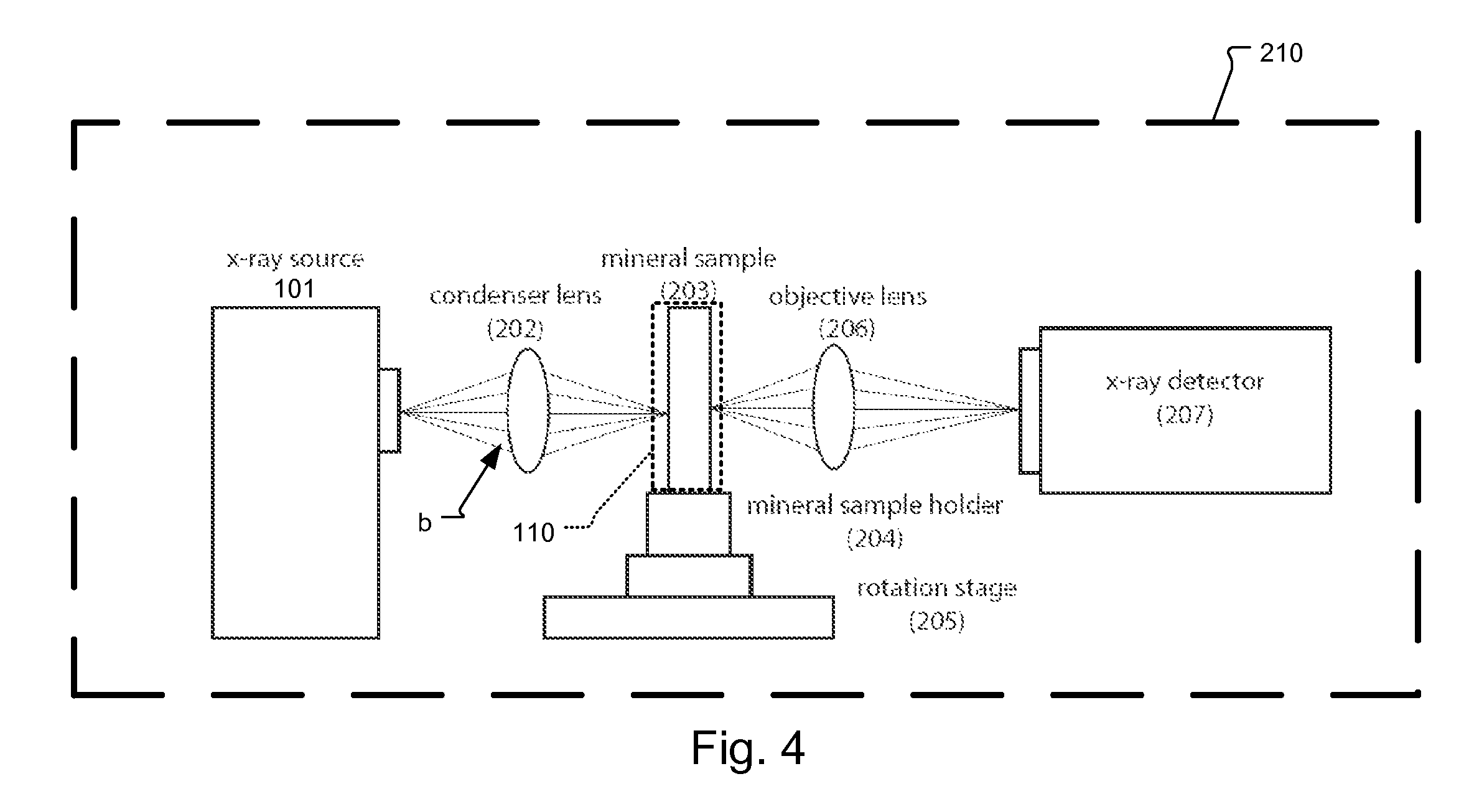

Process for examining mineral samples with X-ray microscope and projection systems

ActiveUS8068579B1Material analysis using wave/particle radiationRadiation/particle handlingPorosityData acquisition

A process to determine the porosity and / or mineral content of mineral samples with an x-ray CT system is described. Based on the direct-projection techniques that use a spatially-resolved x-ray detector to record the x-ray radiation passing through the sample, 1 micrometer or better resolution is achievable. Furthermore, by using an x-ray objective lens to magnify the x-ray image in a microscope configuration, a higher resolution of up to 50 nanometers or more is achieved with state-of-the-art technology. These x-ray CT techniques directly obtain the 3D structure of the sample with no modifications to the sample being necessary. Furthermore, fluid or gas flow experiments can often be conducted during data acquisition so that one may perform live monitoring of the physical process in 3D.

Owner:CARL ZEISS X RAY MICROSCOPY

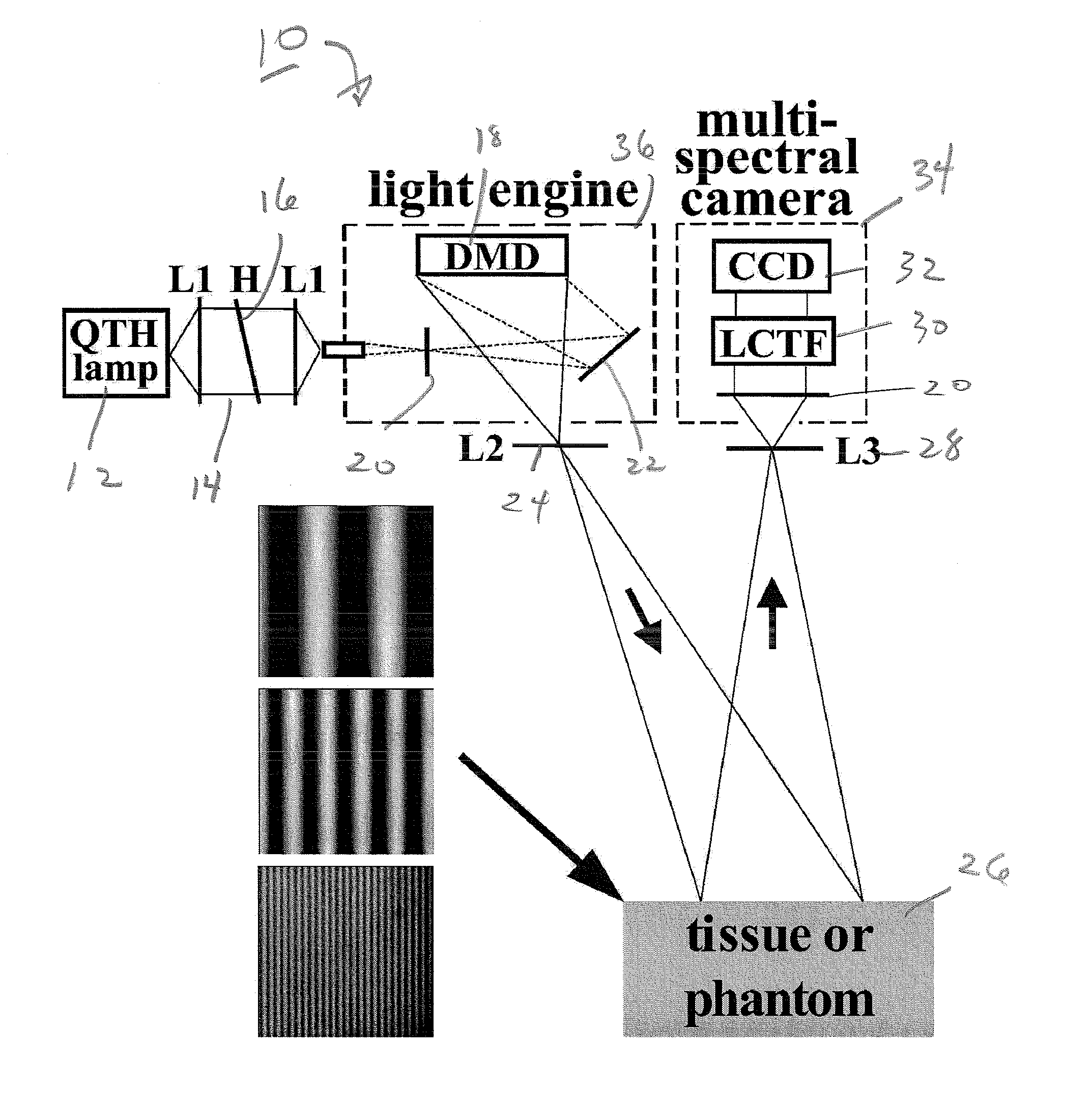

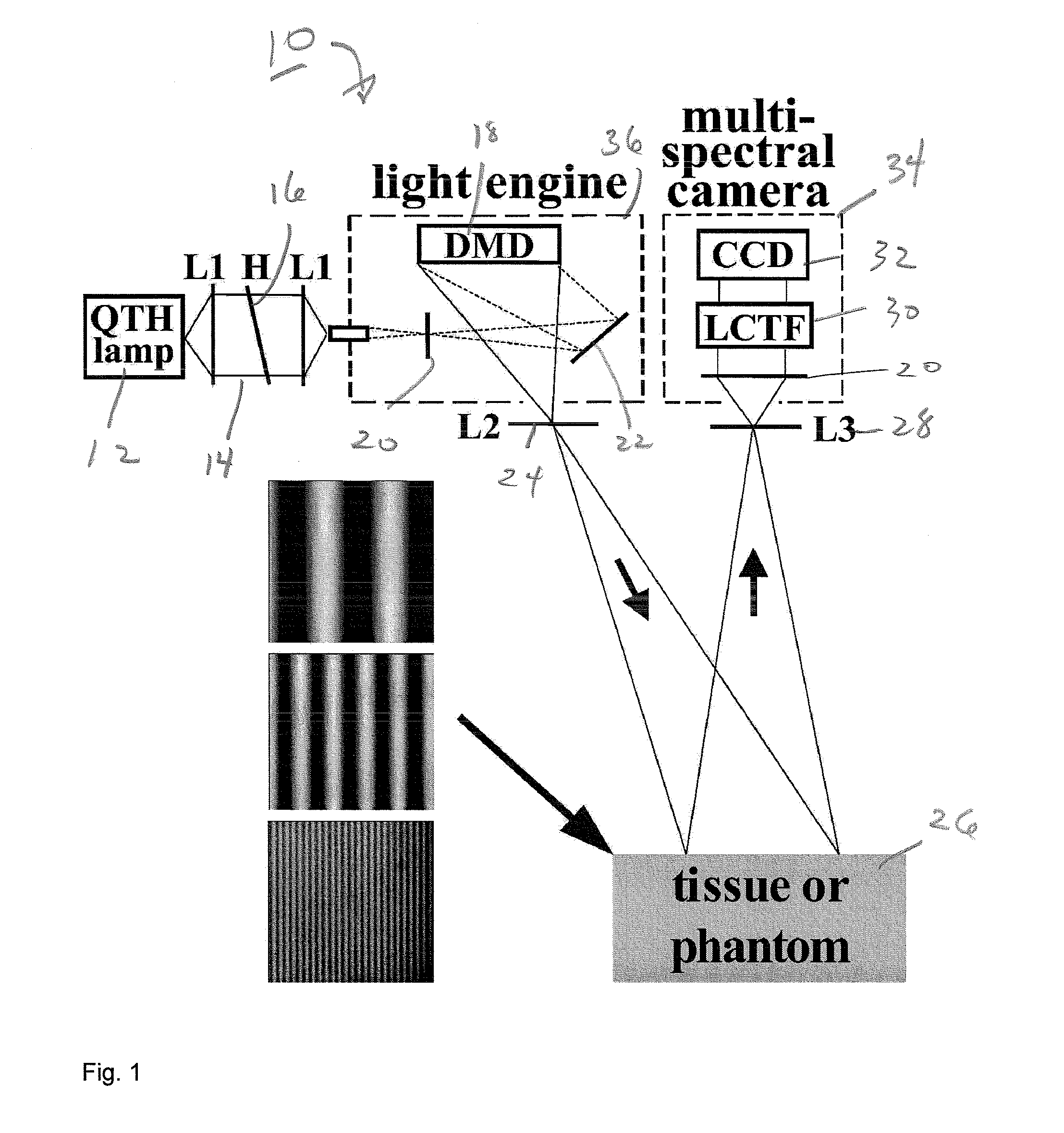

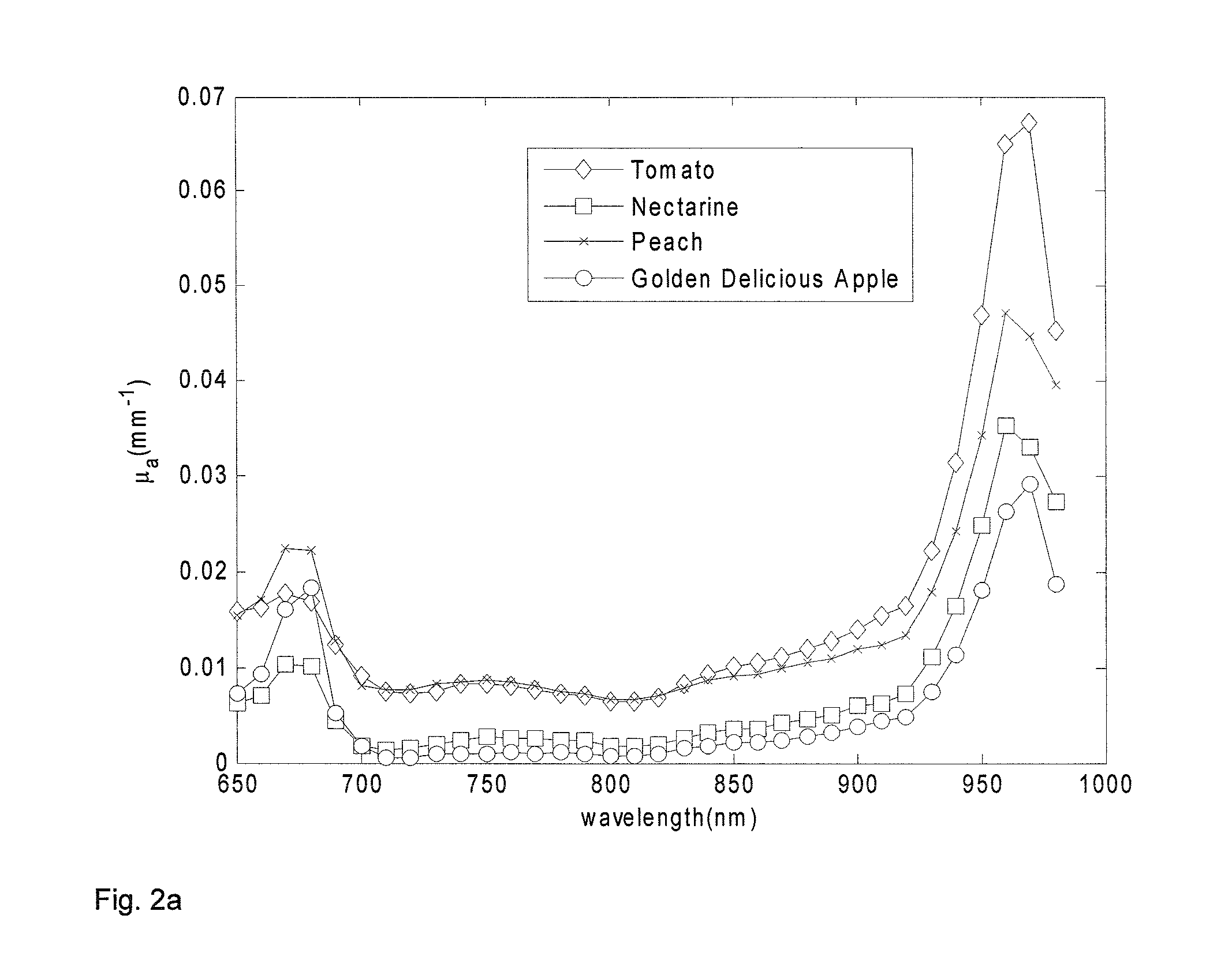

Method and apparatus for performing qualitative and quantitative analysis of produce (fruit, vegetables) using spatially structured illumination

ActiveUS20080101657A1Reduction factorEnhance the imageRaman/scattering spectroscopyCharacter and pattern recognitionDomain imagingSpatial frequency

A method and an apparatus for noninvasively and quantitatively determining spatially resolved absorption and reduced scattering coefficients over a wide field-of-view of a food object, including fruit or produce, uses spatial-frequency-domain imaging (SFDI). A single modulated imaging platform is employed. It includes a broadband light source, a digital micromirror optically coupled to the light source to control a modulated light pattern directed onto the food object at a plurality of selected spatial frequencies, a multispectral camera for taking a spectral image of a reflected modulated light pattern from the food object, a spectrally variable filter optically coupled between the food object and the multispectral camera to select a discrete number of wavelengths for image capture, and a computer coupled to the digital micromirror, camera and variable filter to enable acquisition of the reflected modulated light pattern at the selected spatial frequencies.

Owner:RGT UNIV OF CALIFORNIA

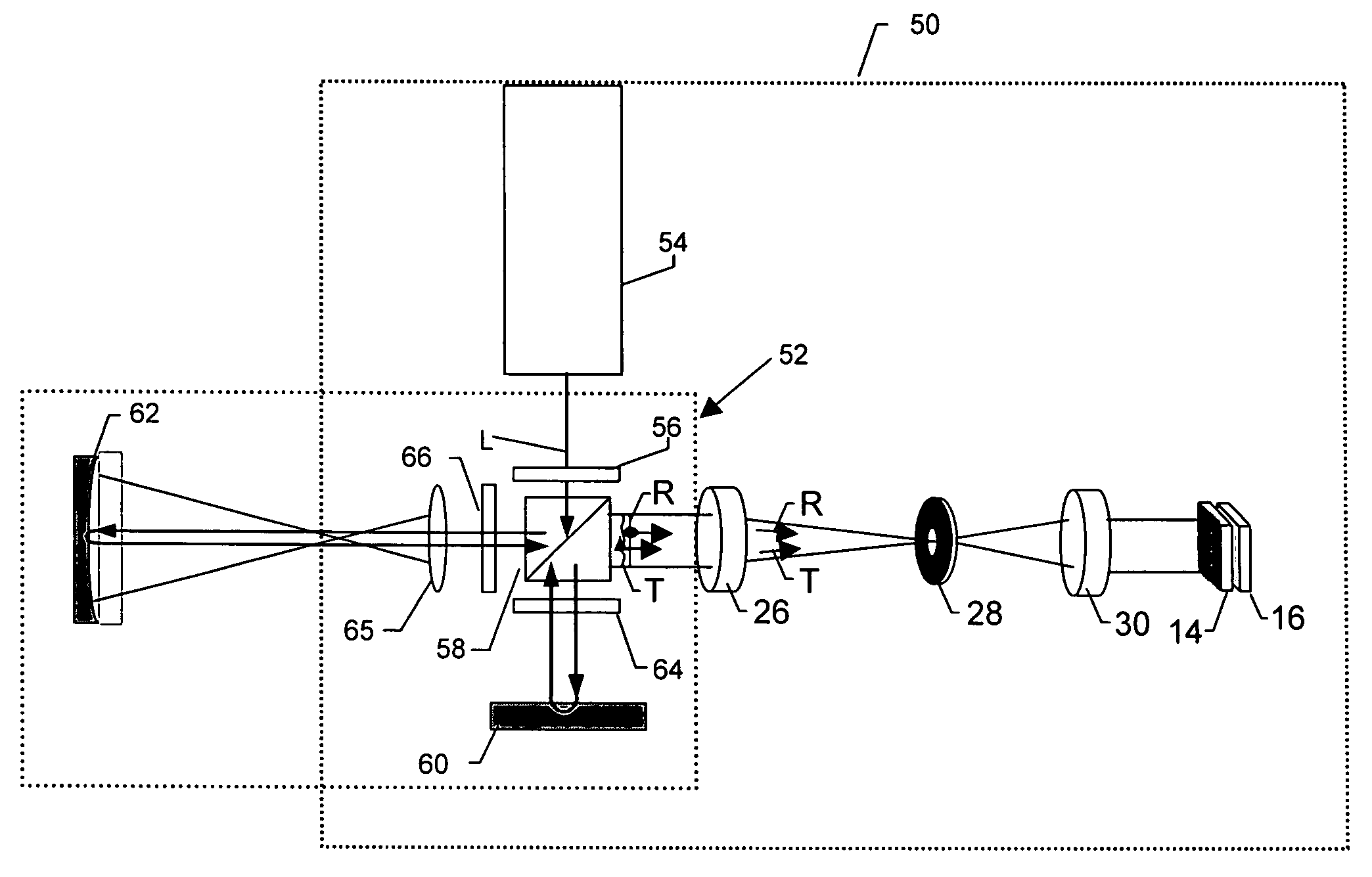

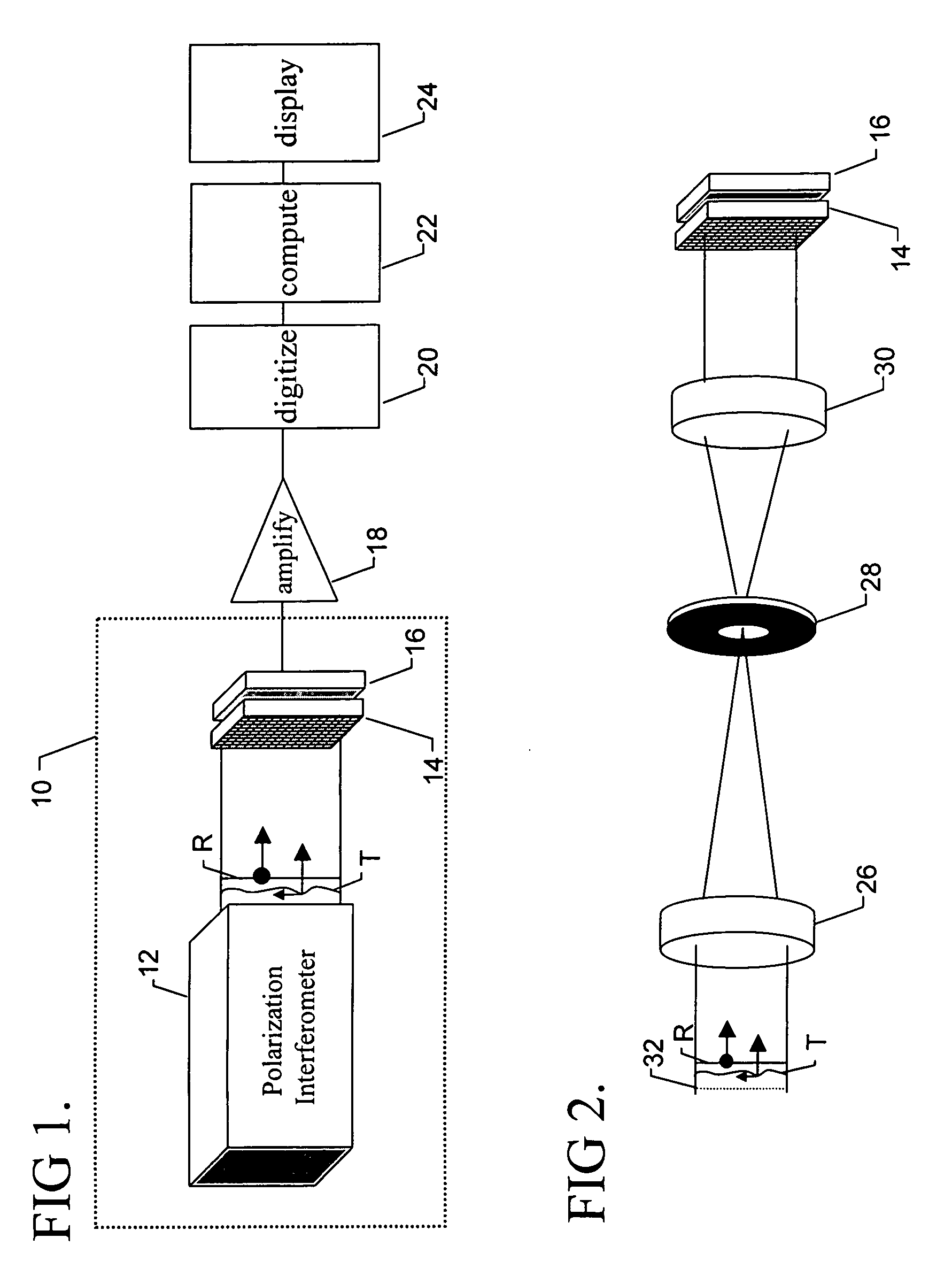

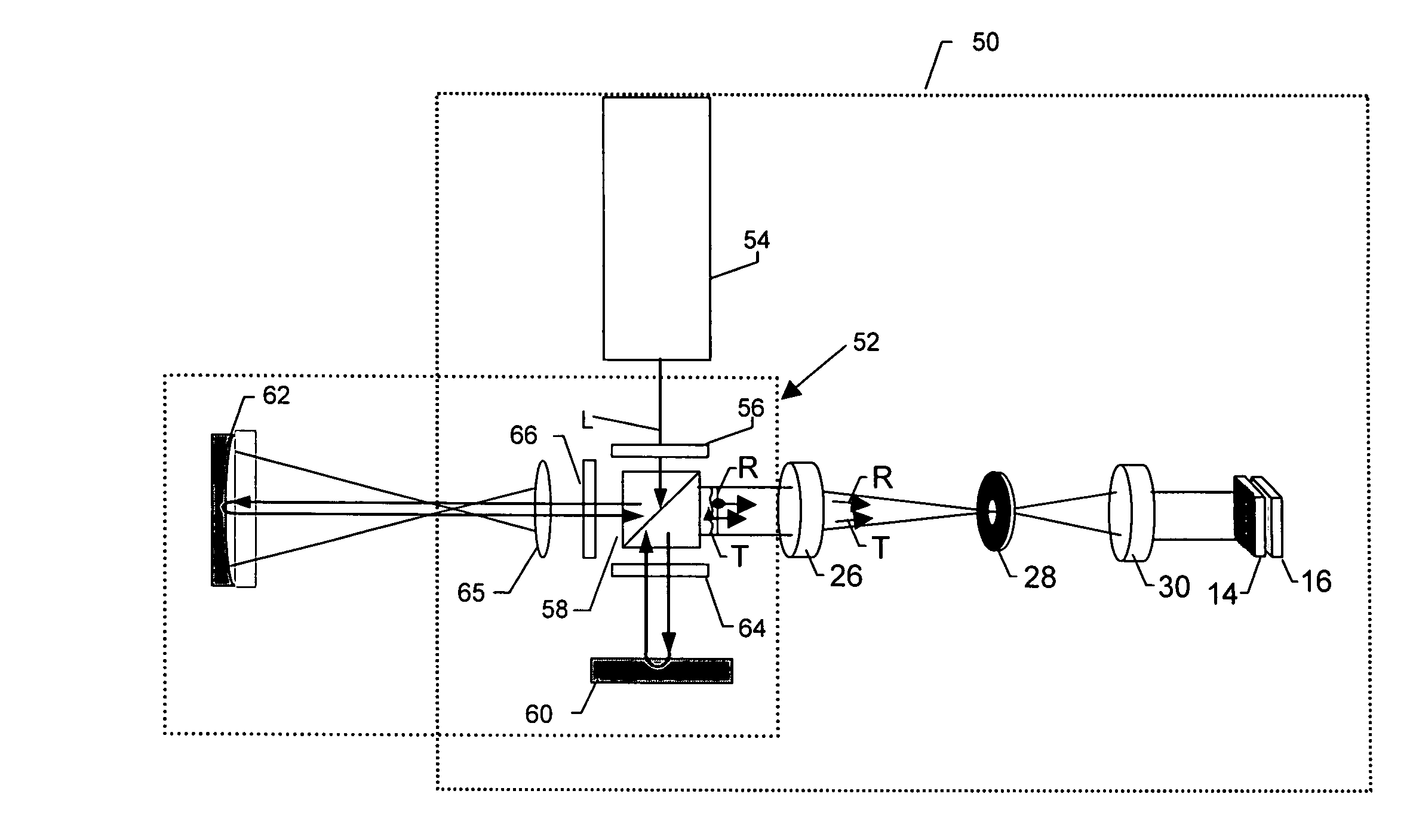

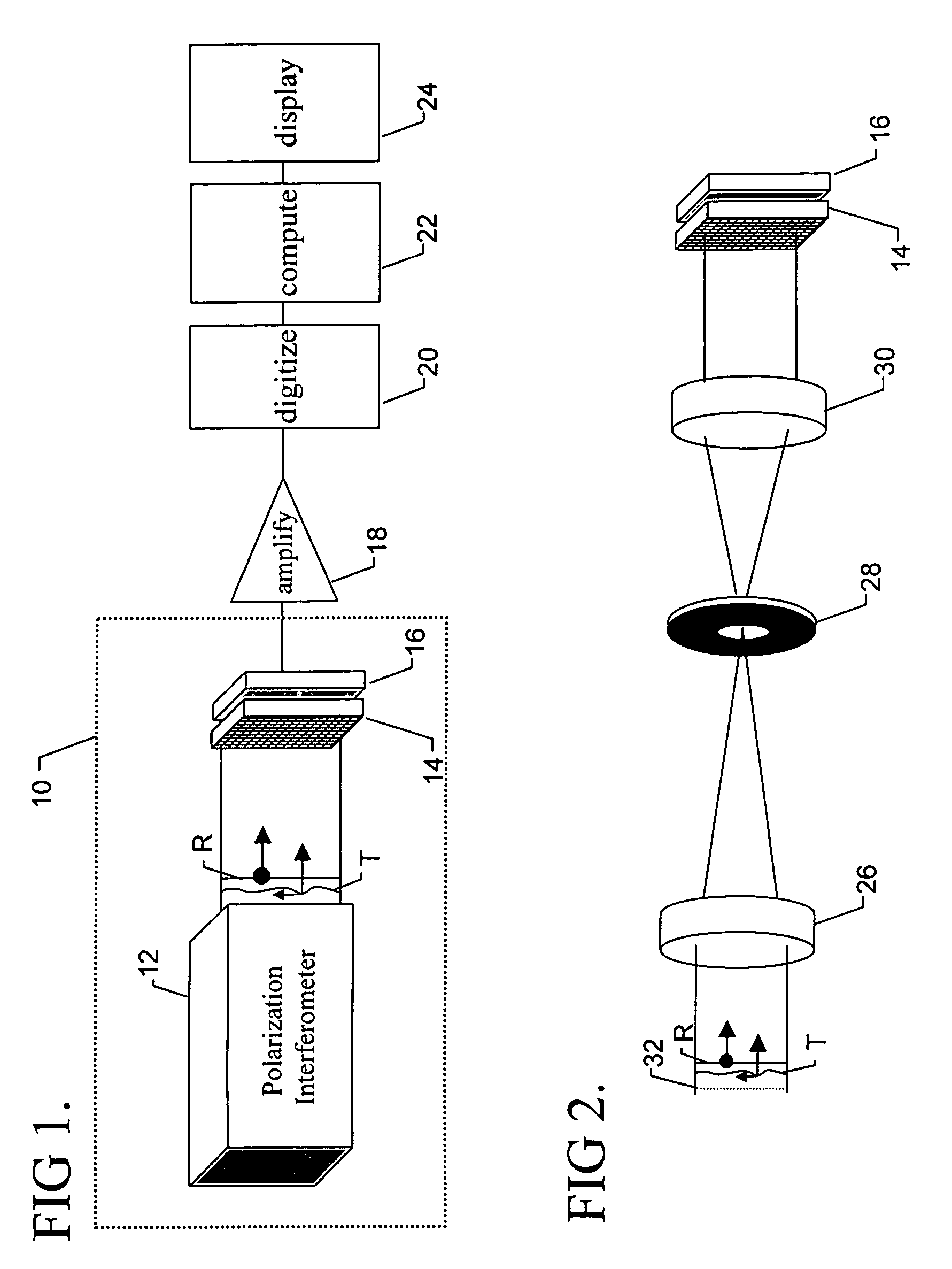

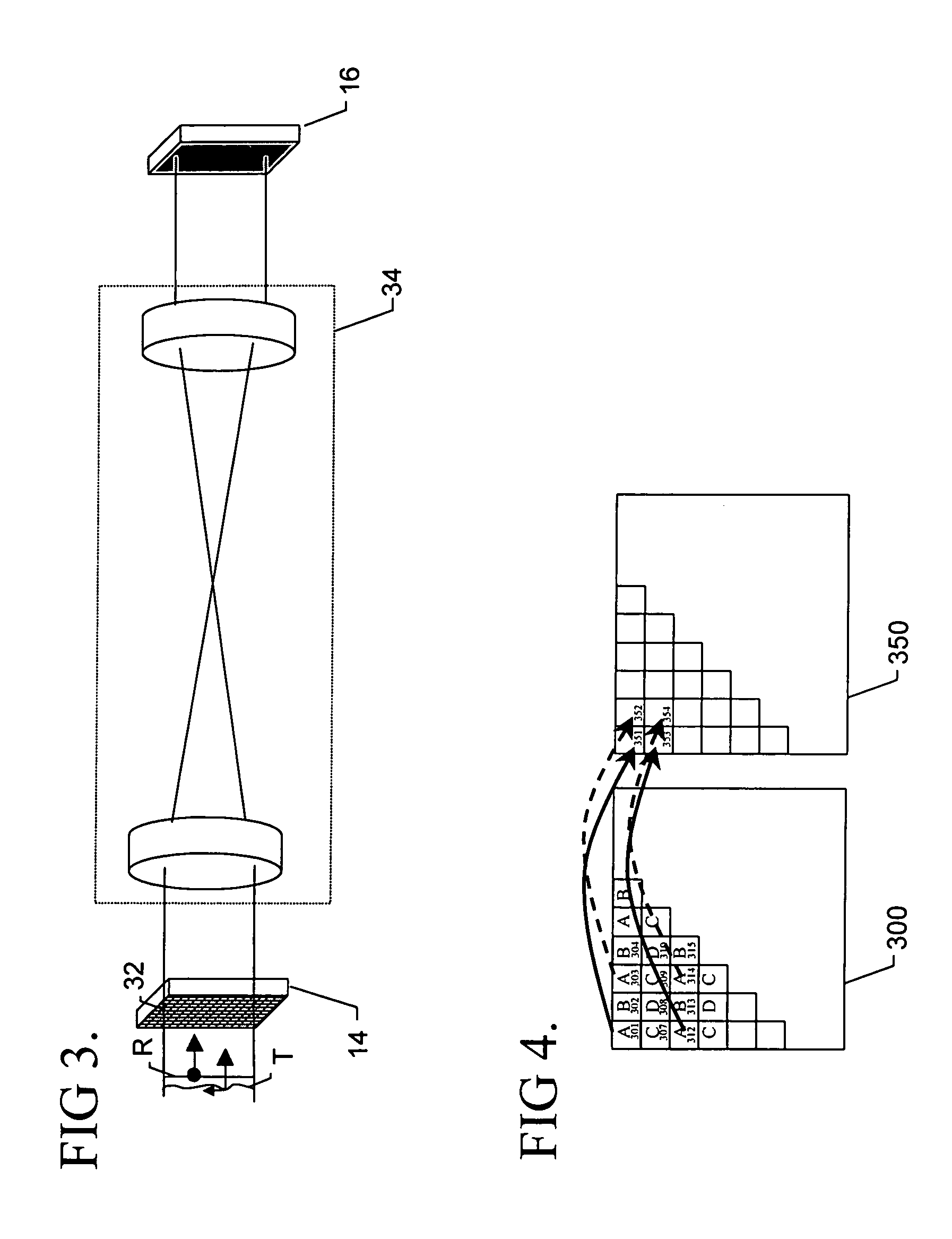

Pixelated phase-mask interferometer

ActiveUS20050046865A1Avoiding chromatic dispersionAvoid complexityInterferometersUsing optical meansPhase differenceDetector array

A phase-difference sensor measures the spatially resolved difference in phase between orthogonally polarized reference and test wavefronts. The sensor is constructed as a pixelated phase-mask aligned to and imaged on a pixelated detector array. Each adjacent pixel of the phase-mask measures a predetermined relative phase shift between the orthogonally polarized reference and test beams. Thus, multiple phase-shifted interferograms can be synthesized at the same time by combining pixels with identical phase-shifts. The multiple phase-shifted interferograms can be combined to calculate standard parameters such as modulation index or average phase step. Any configuration of interferometer that produces orthogonally polarized reference and object beams may be combined with the phase-difference sensor of the invention to provide, single-shot, simultaneous phase-shifting measurements.

Owner:ONTO INNOVATION INC

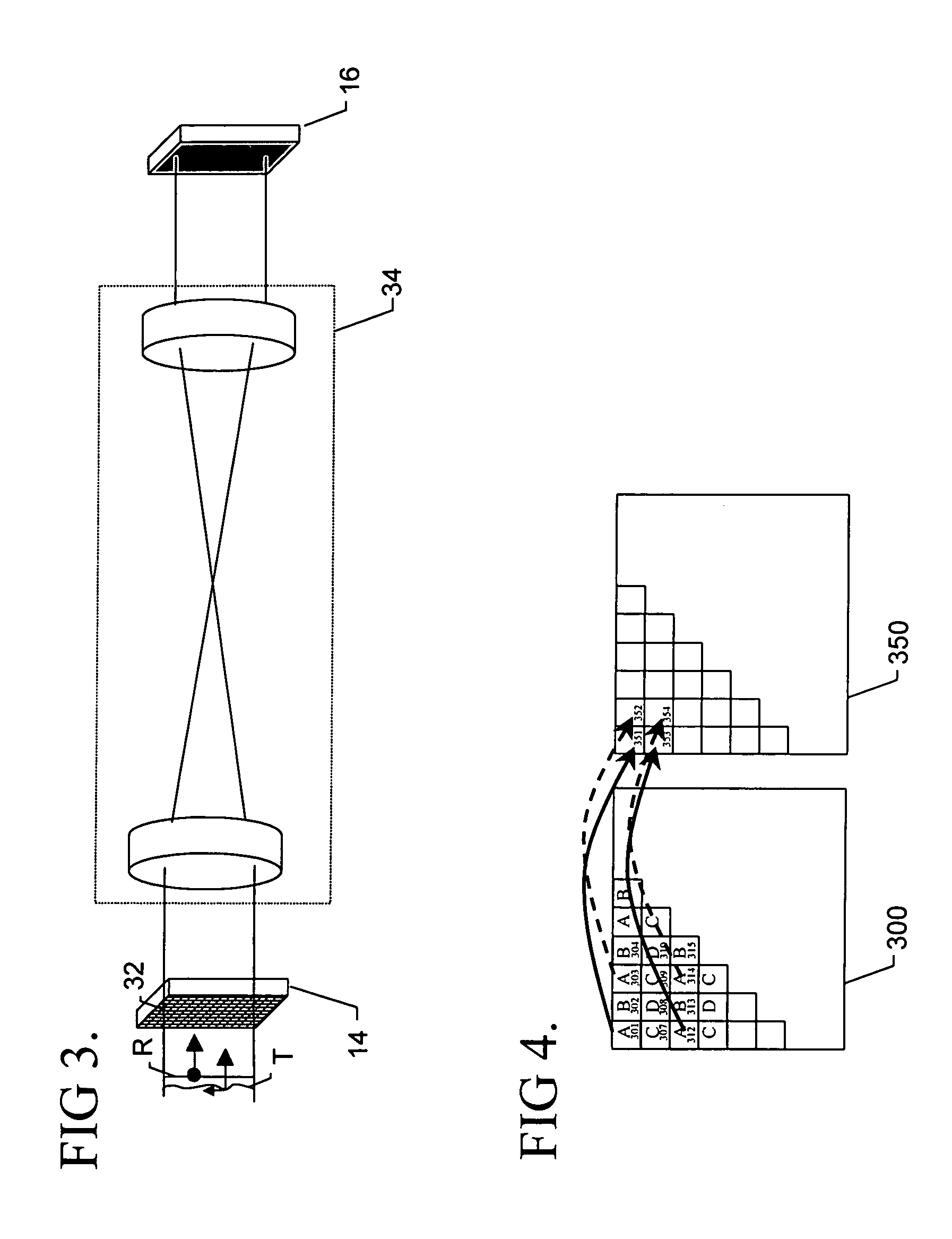

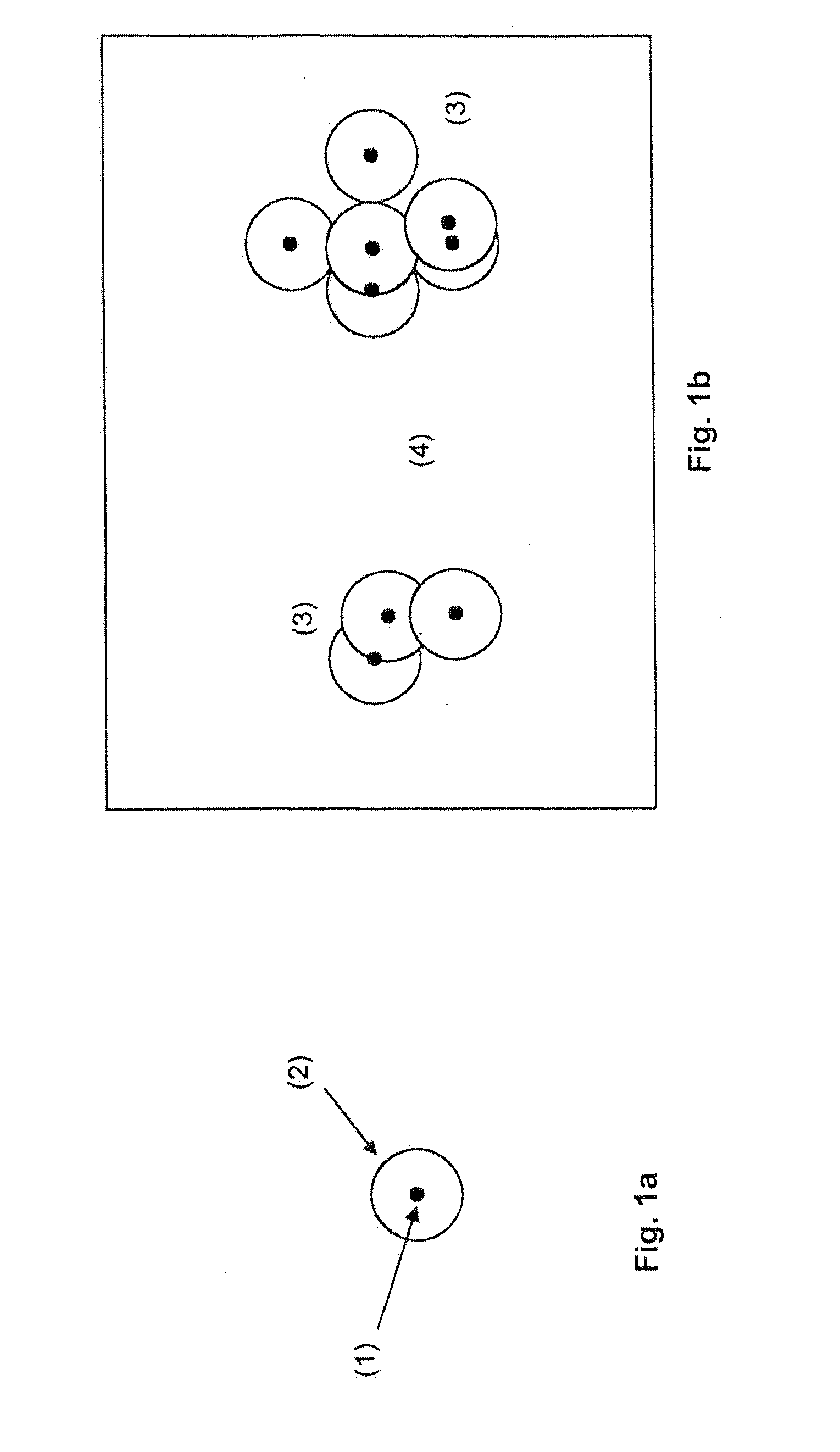

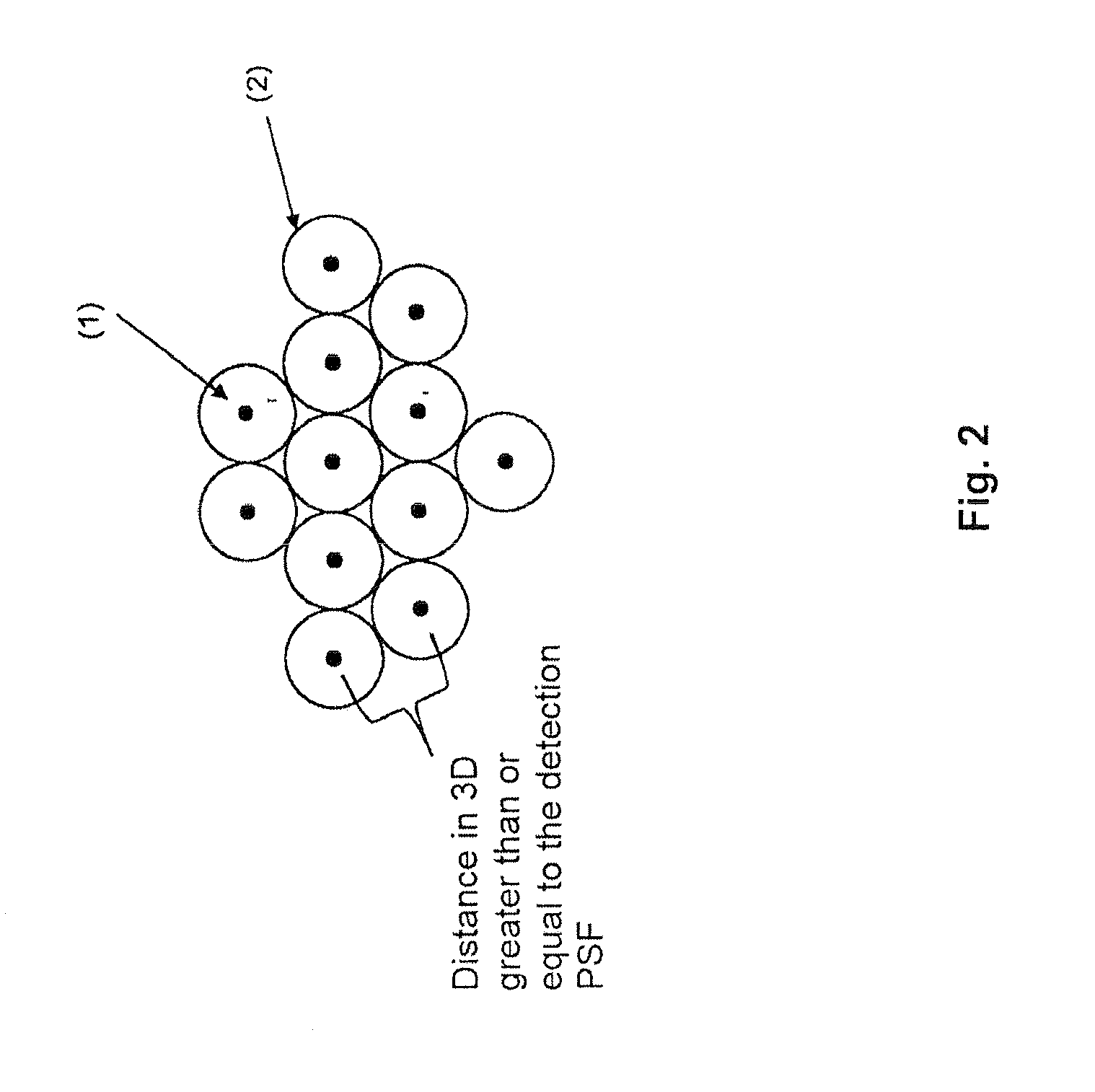

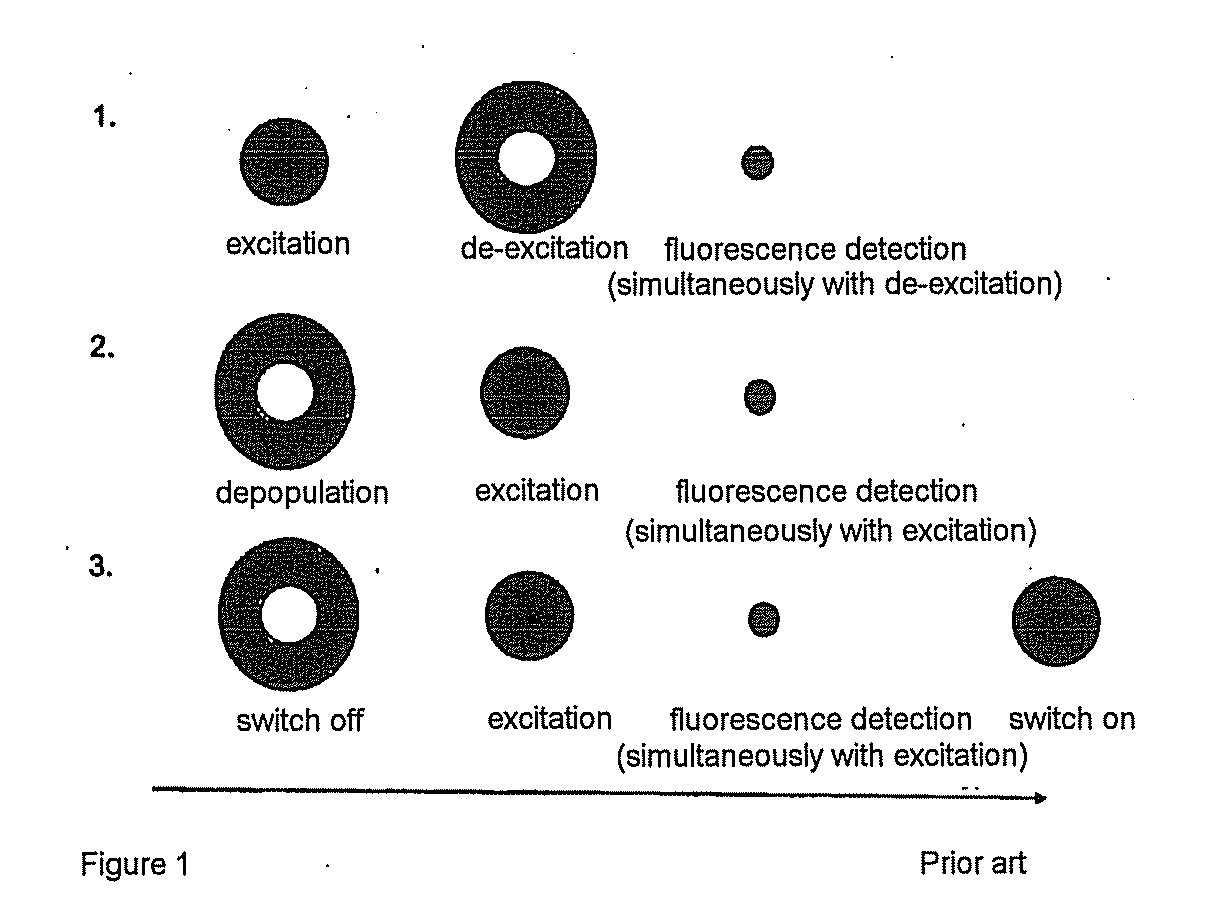

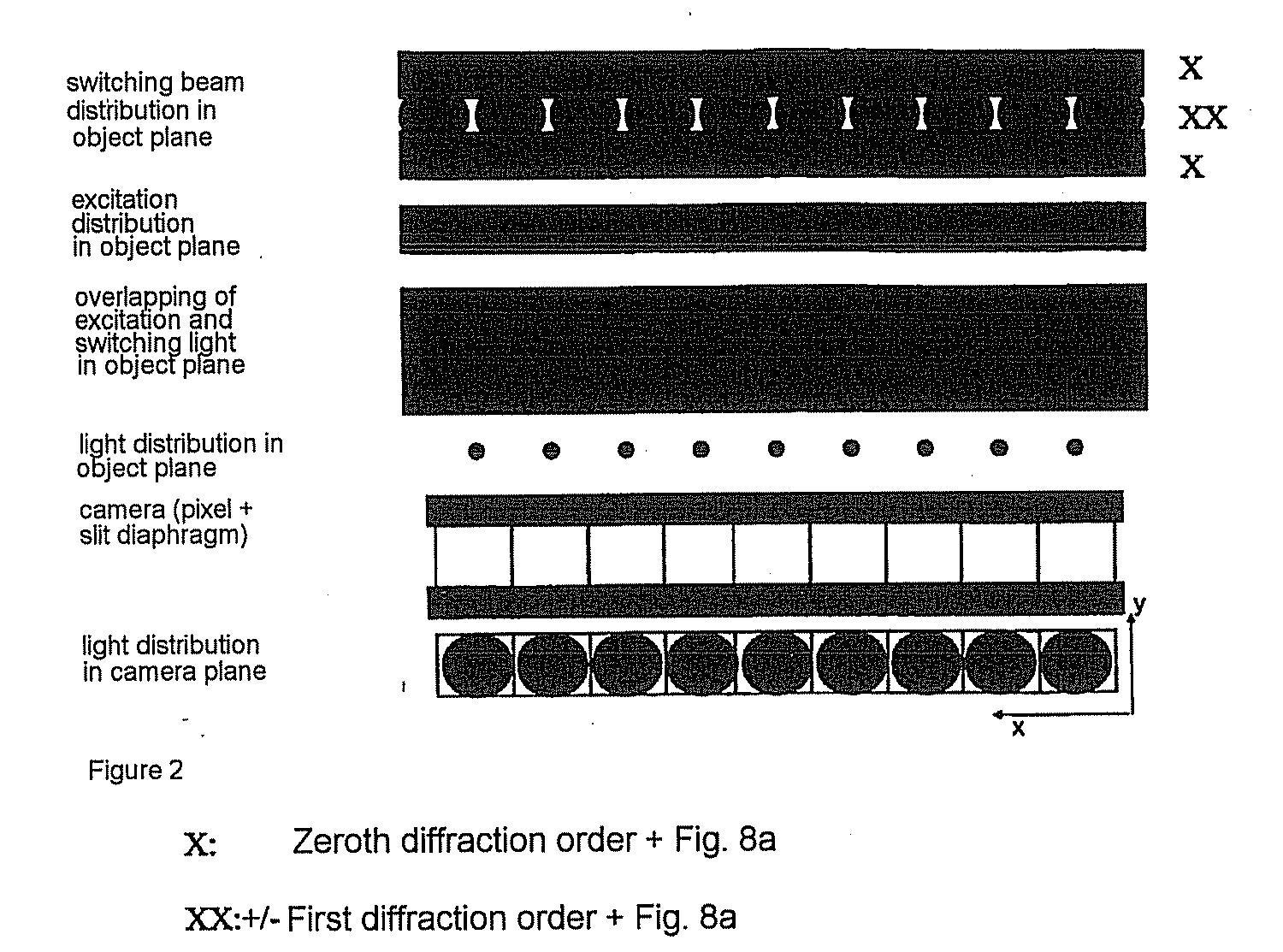

Apparatus and method for high spatial resolution imaging of a structure of a sample

ActiveUS20110036996A1High image rateReducing out-of-focus autofluorescencePhotometryMaterial analysis by optical meansSpatially resolvedImage resolution

Apparatus and method for high spatial resolution imaging of a sample's structure, including a diffraction-limited resolution volume with a plurality of dye molecules which can be switched between different states and have a distribution density which is greater than the inverse of the diffraction-limited resolution volume, where at least one state is fluorescing, the fluorescence being collected by an objective lens and imaged on a spatially resolving detector by an optical system. At least one light source provided for emitting a switching radiation and for emitting an excitation radiation. At least one of the light sources is arranged to radiate through the sample, and a switching and / or fluorescence excitation of the dye molecules is carried out. The switching is a photoactivation or a photodeactivation of the dye molecules. A focusing arrangement is provided for switching and / or for excitation to generate a line-like illumination region extending in a direction of illumination.

Owner:CARL ZEISS MICROSCOPY GMBH

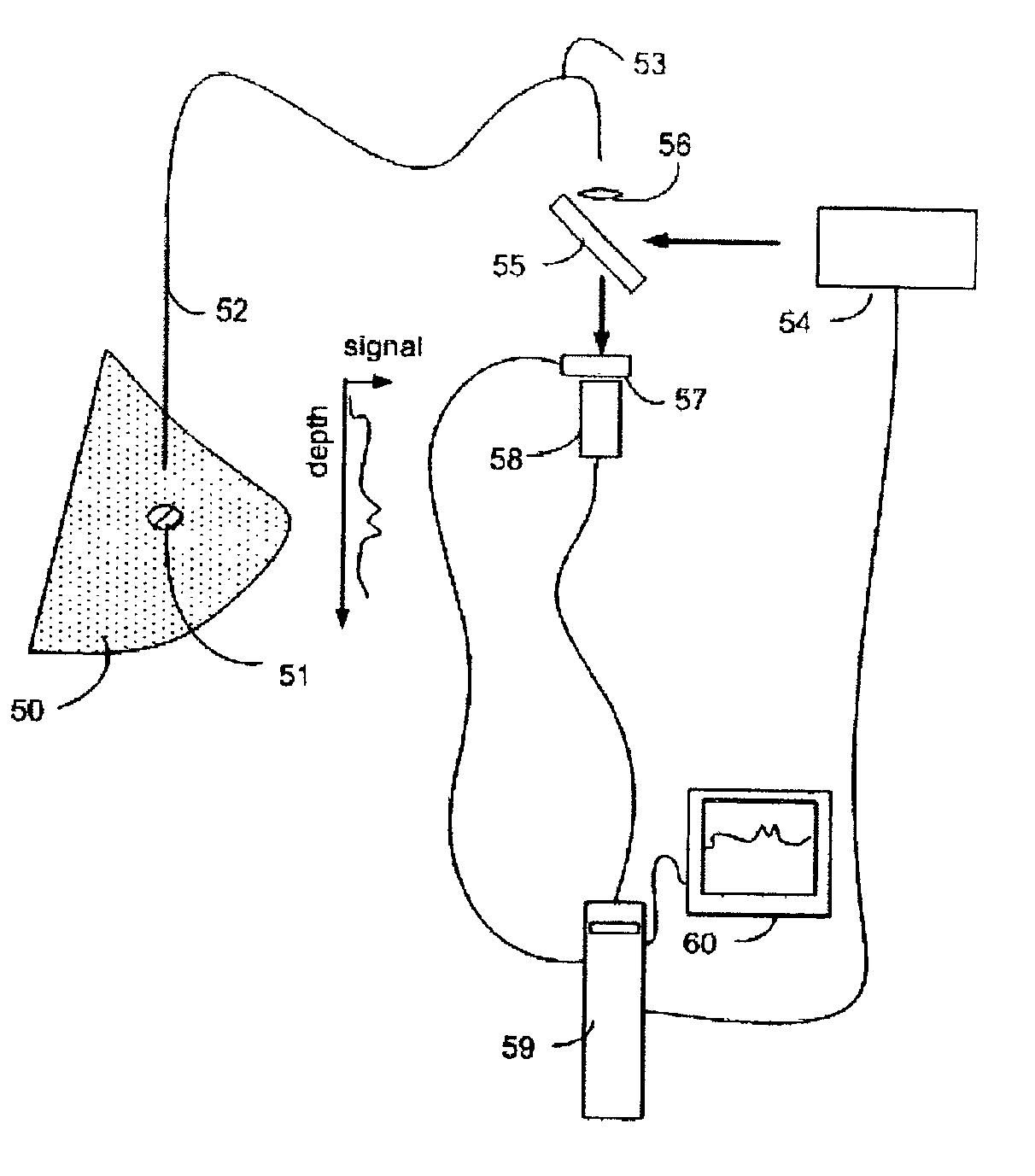

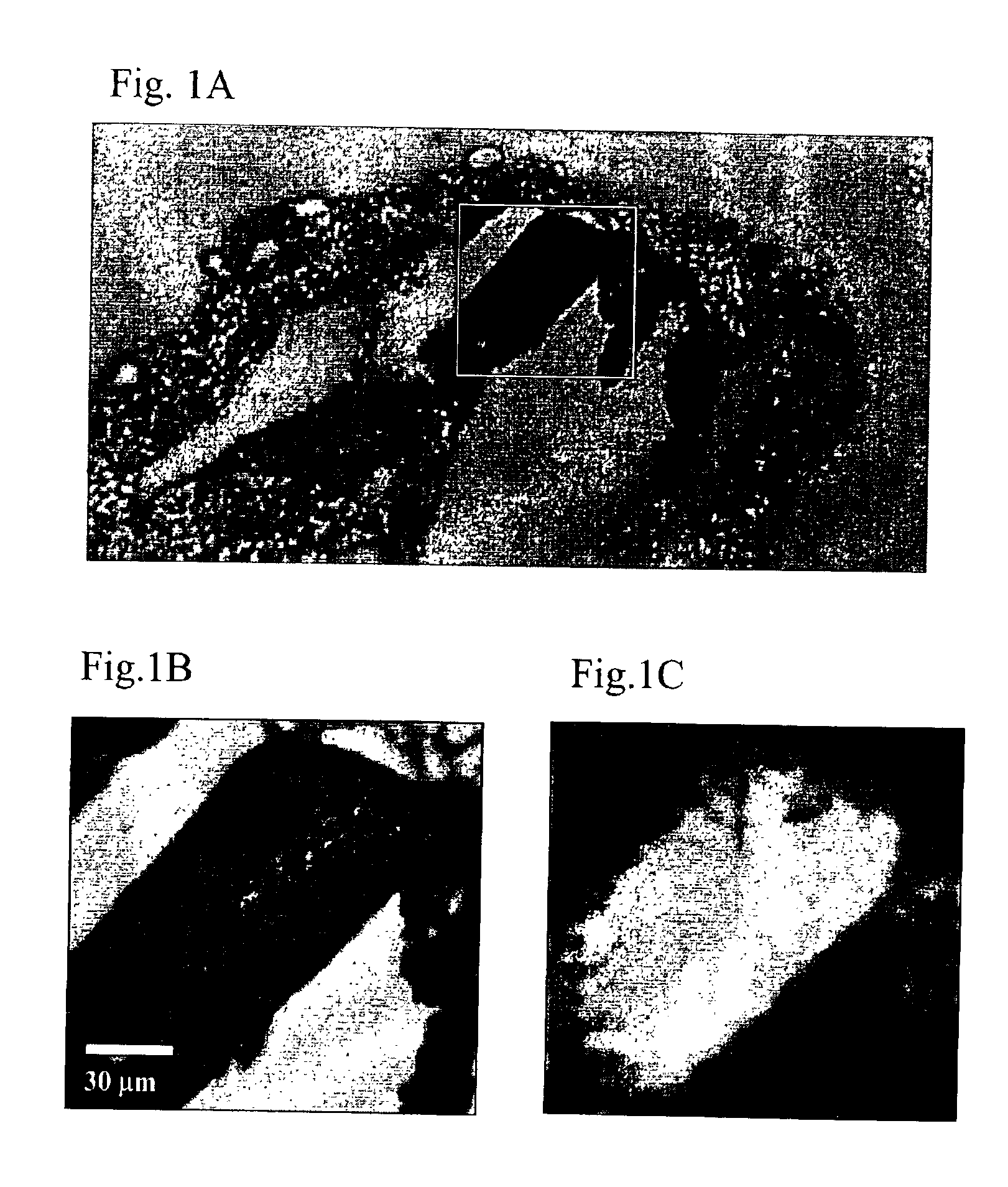

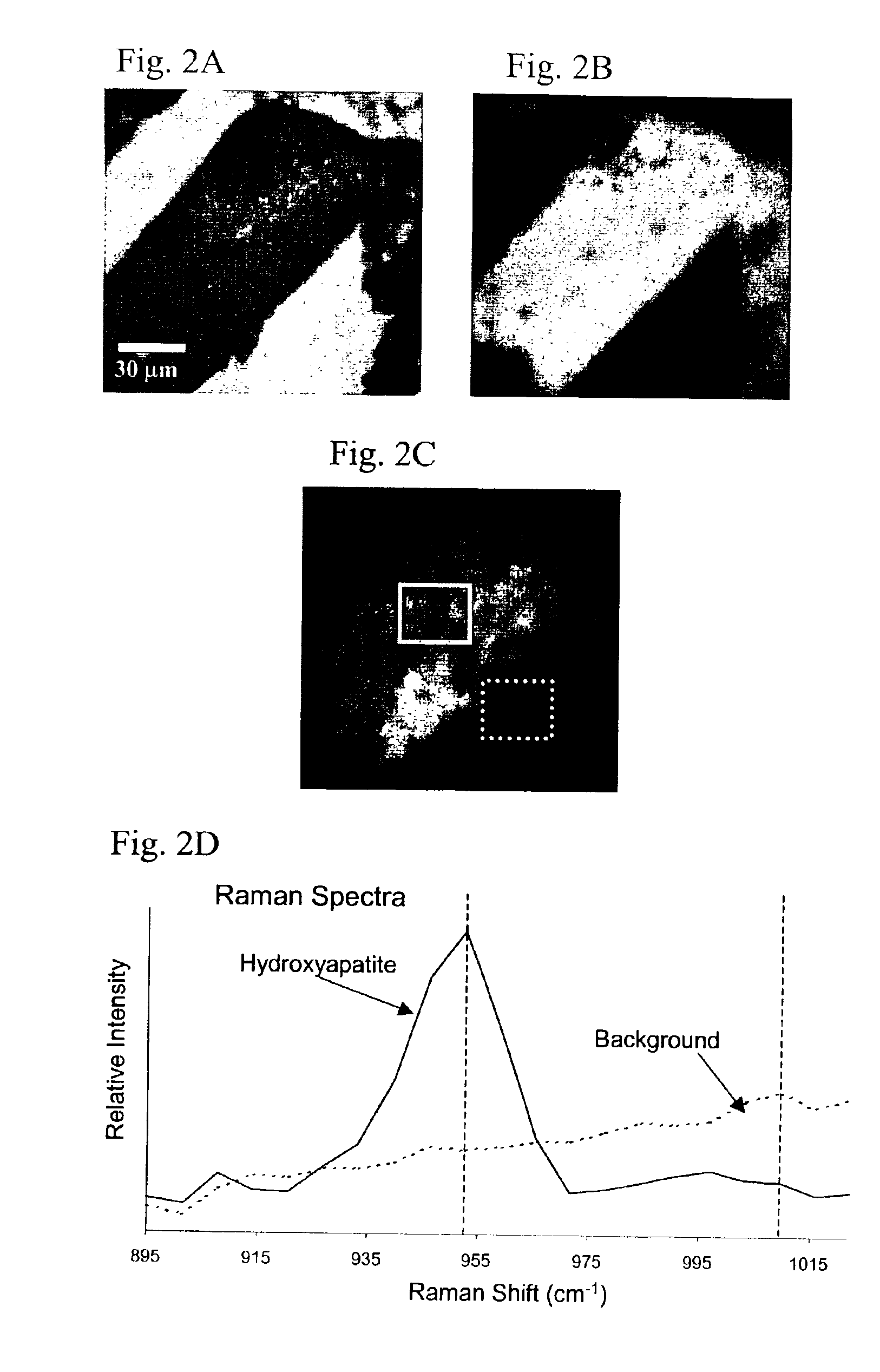

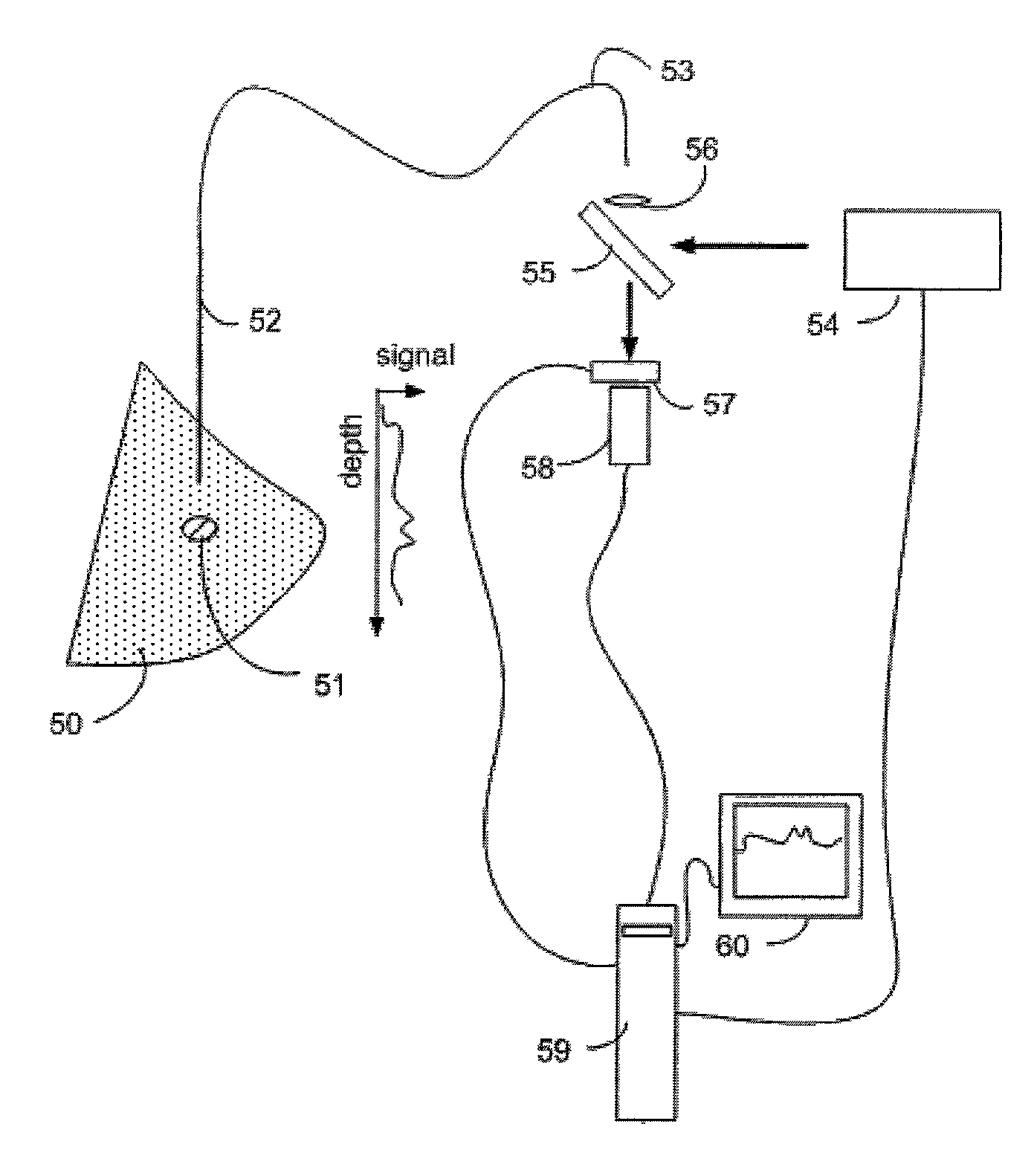

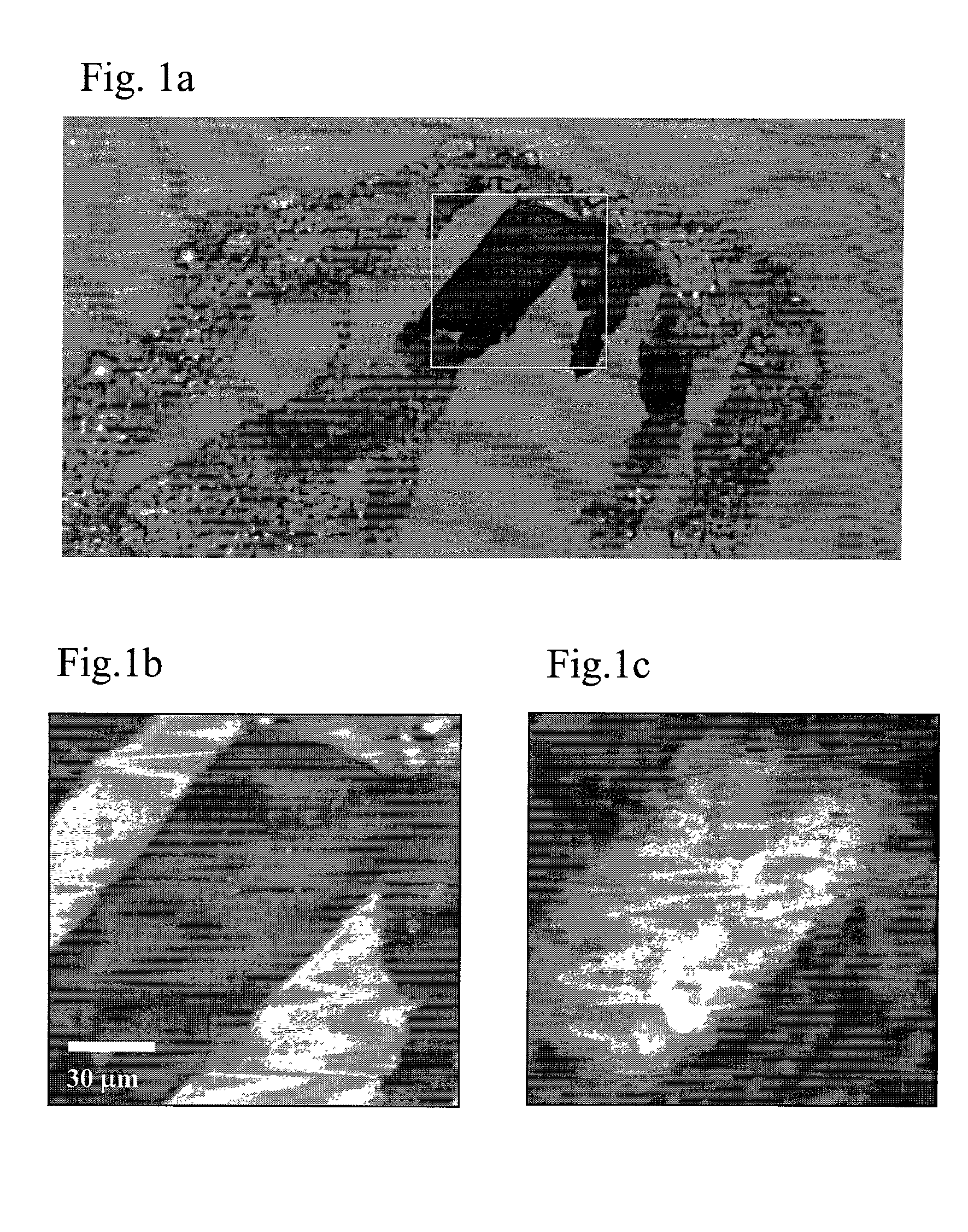

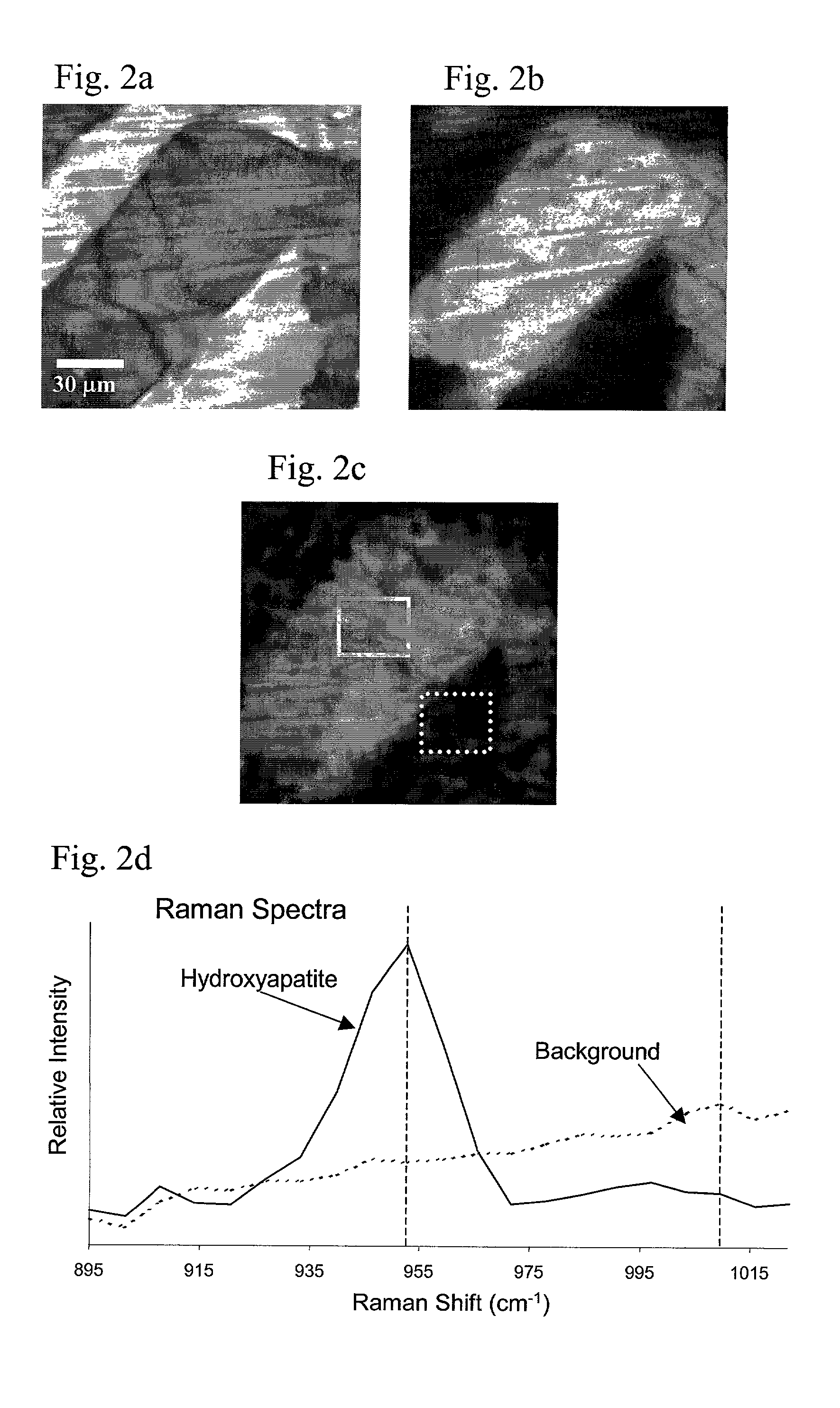

Method for Raman chemical imaging and characterization of calcification in tissue

Apparatus and methods for spatially resolved Raman detection of calcification in tissues are disclosed. A region of soft non-arterial biological tissue is illuminated with monochromatic light. A spatially organized first area of calcified tissue is then detected in the region by detecting a Raman shifted light signal. The Raman shifted light signal is spatially resolved in at least one direction.

Owner:CHEMIMAGE

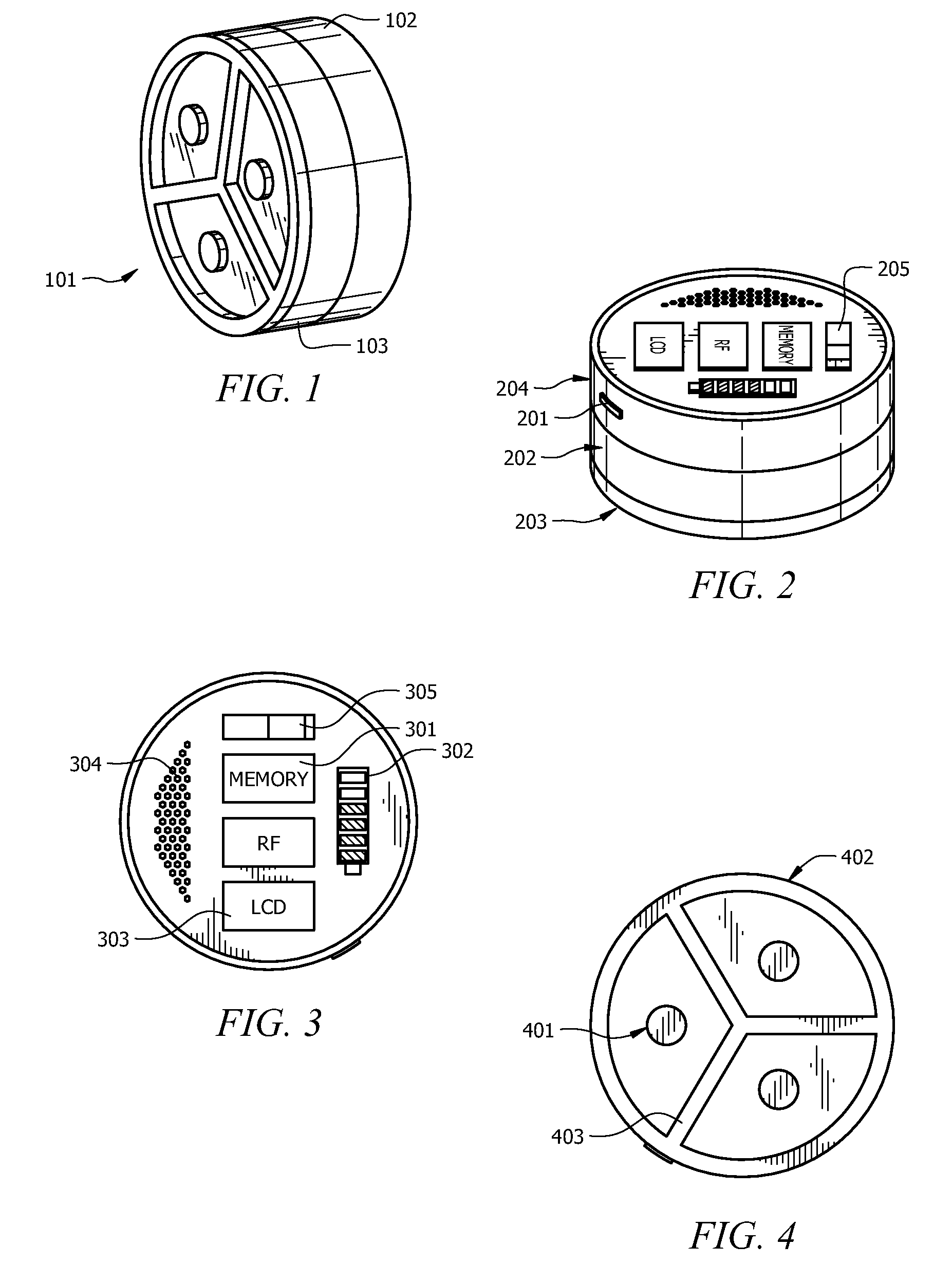

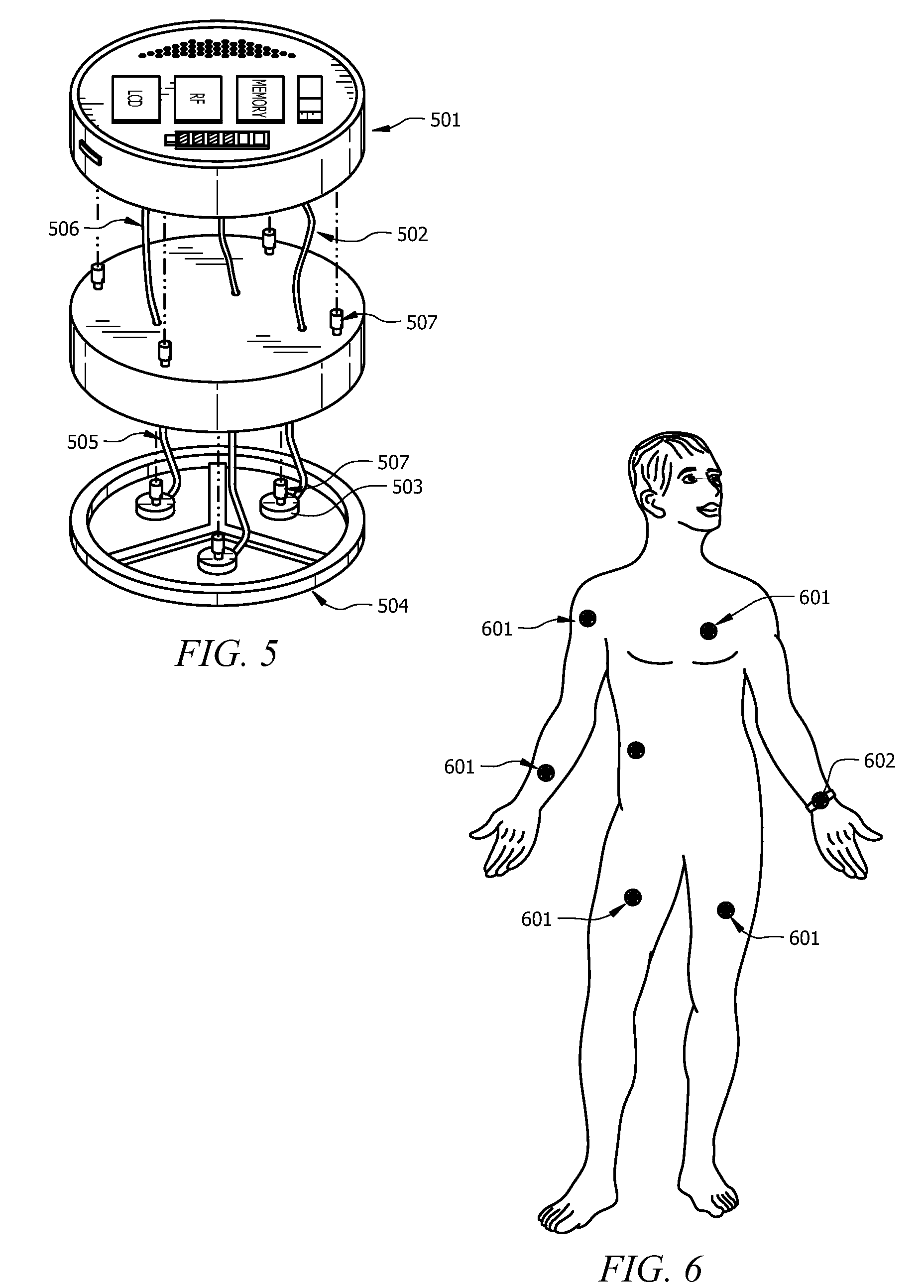

Diagnostic device for remote sensing and transmitting biophysiological signals

InactiveUS20100042012A1Noise minimizationMaximize signalElectrocardiographySensorsSpatially resolvedWireless transmission

A diatrophic, bio-physiological interface is self-contained with onboard intensification, filtering, and signal processing and is wirelessly enabled (idio-electrode), with multiple sensory system for bio-physiological measurements, described herein utilizes spatially resolved potential profiles from a cluster of mini electrodes to form constituent sets comprising mini sensorial electrodes. The sets of sub electrodes containing the clusters are jointly optimized to attain measurable gradient of some diagnostic value. The present invention provides a distinct lead-free single electrode that is rotationally invariant with onboard Digital Signal Processor for arrhythmia detection, source encoding, and passive and active wireless transmission. Additionally, in one aspect of the present invention the lead-free idio-electrode bio-physiological adapter allows for utmost clinical operational freedom and dramatically obviates the needs for leads of any length that invariably encumber the acquisition and performance of electrocardiogram recordings of any sort.

Owner:ALHUSSINY KARIM

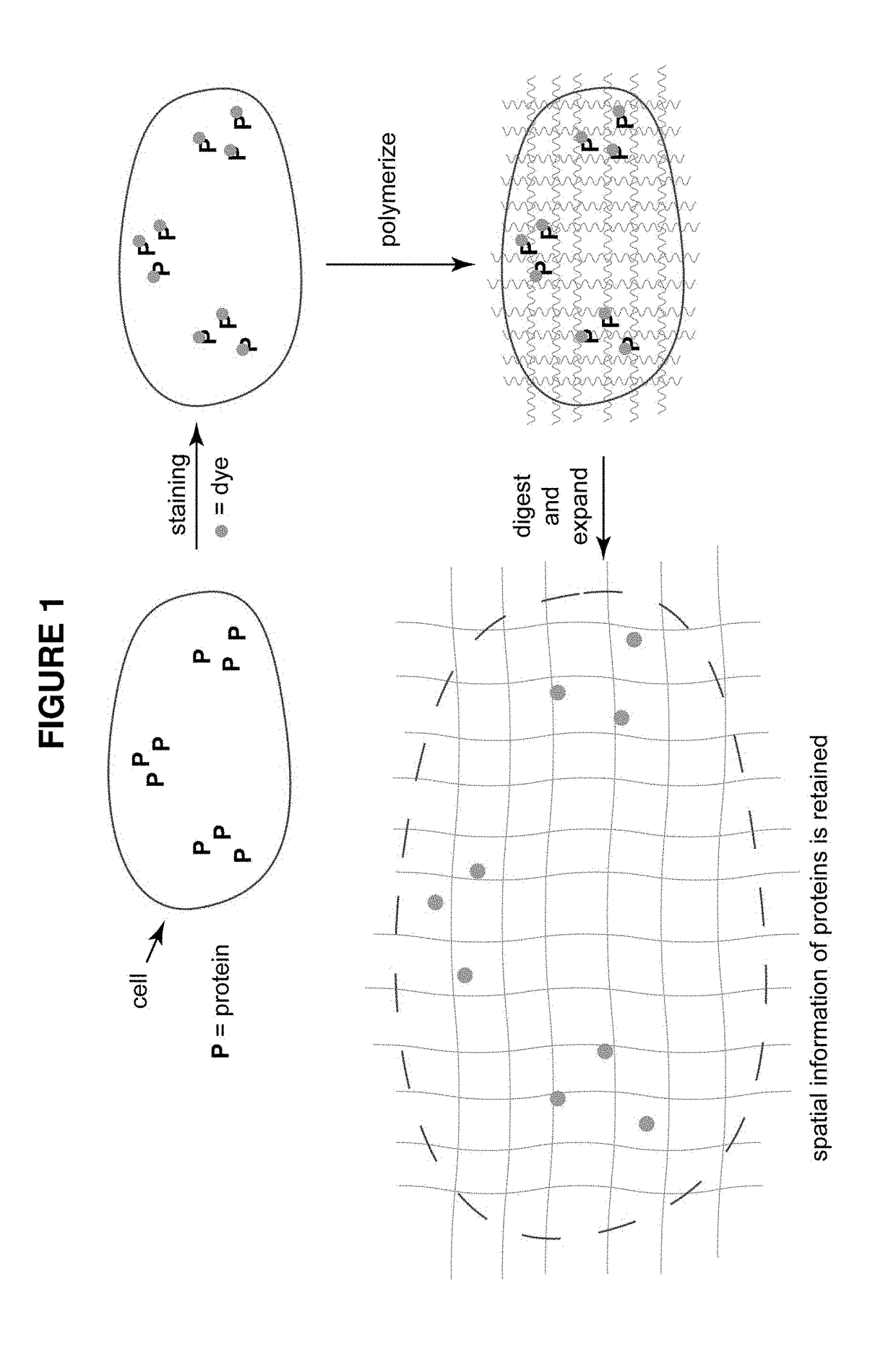

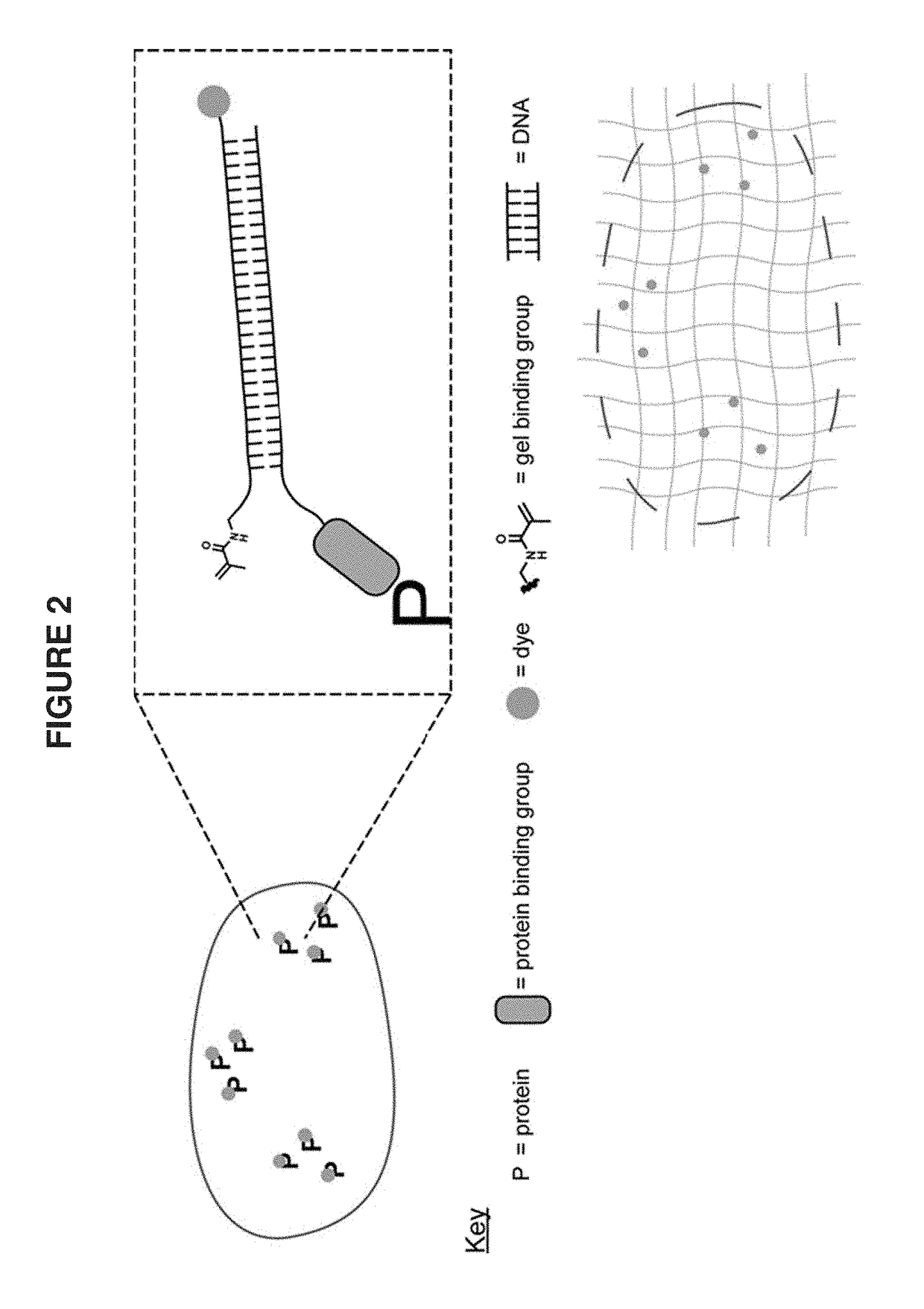

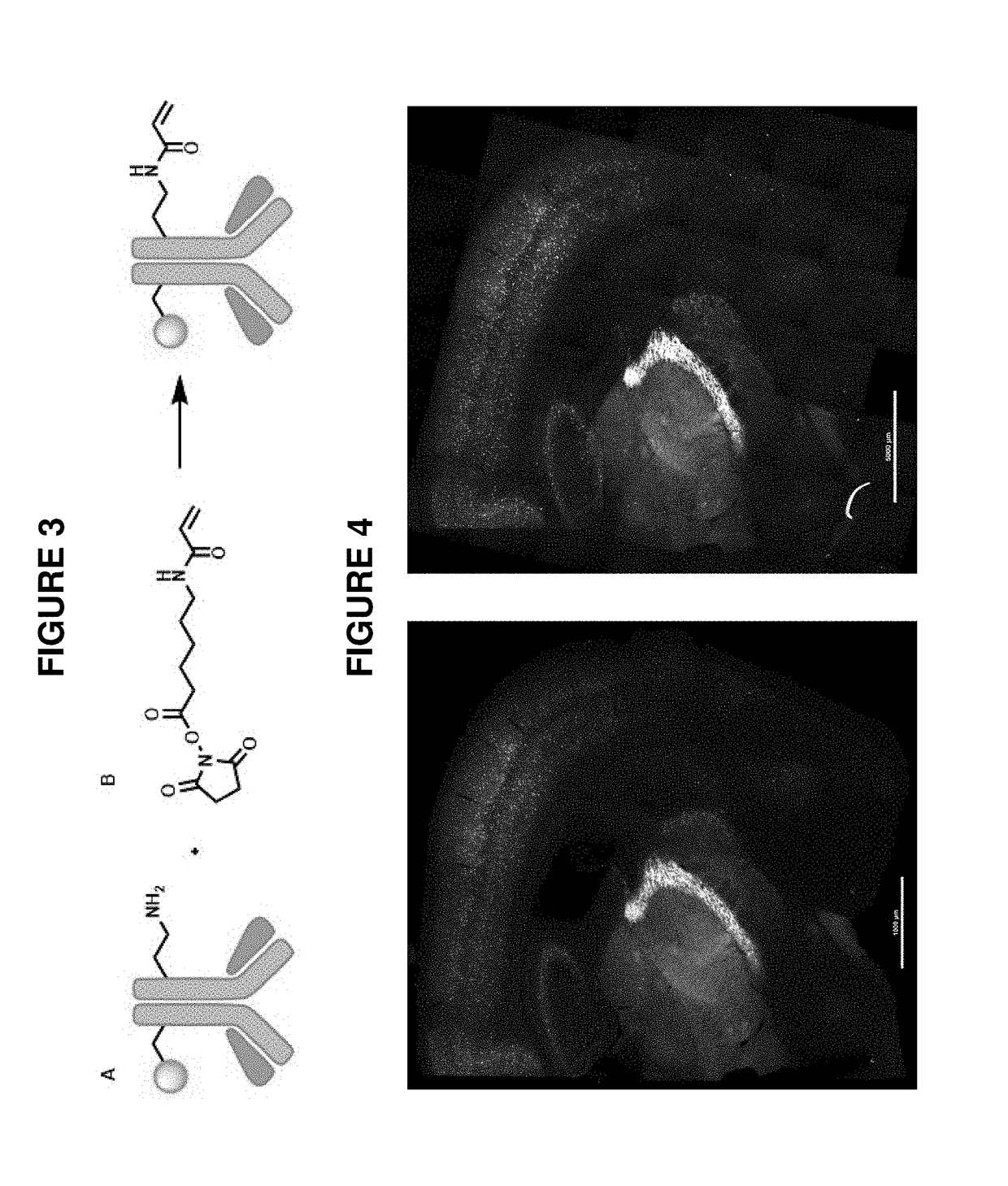

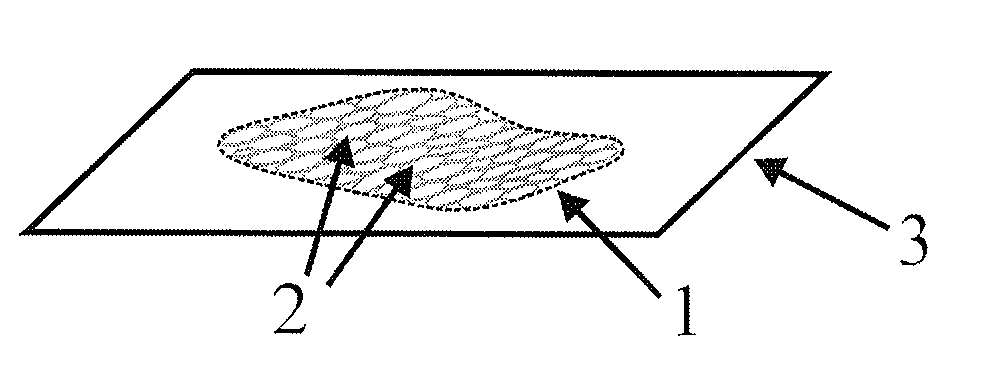

Combining modified antibodies with expansion microscopy for in-situ, spatially-resolved proteomics

InactiveUS20180052081A1Preparing sample for investigationBiological testingSpatially resolvedAntibody

This invention relates to imaging, such as by expansion microscopy, labelling, and analyzing biological samples, such as cells and tissues, as well as reagents and kits for doing so.

Owner:EXPANSION TECH

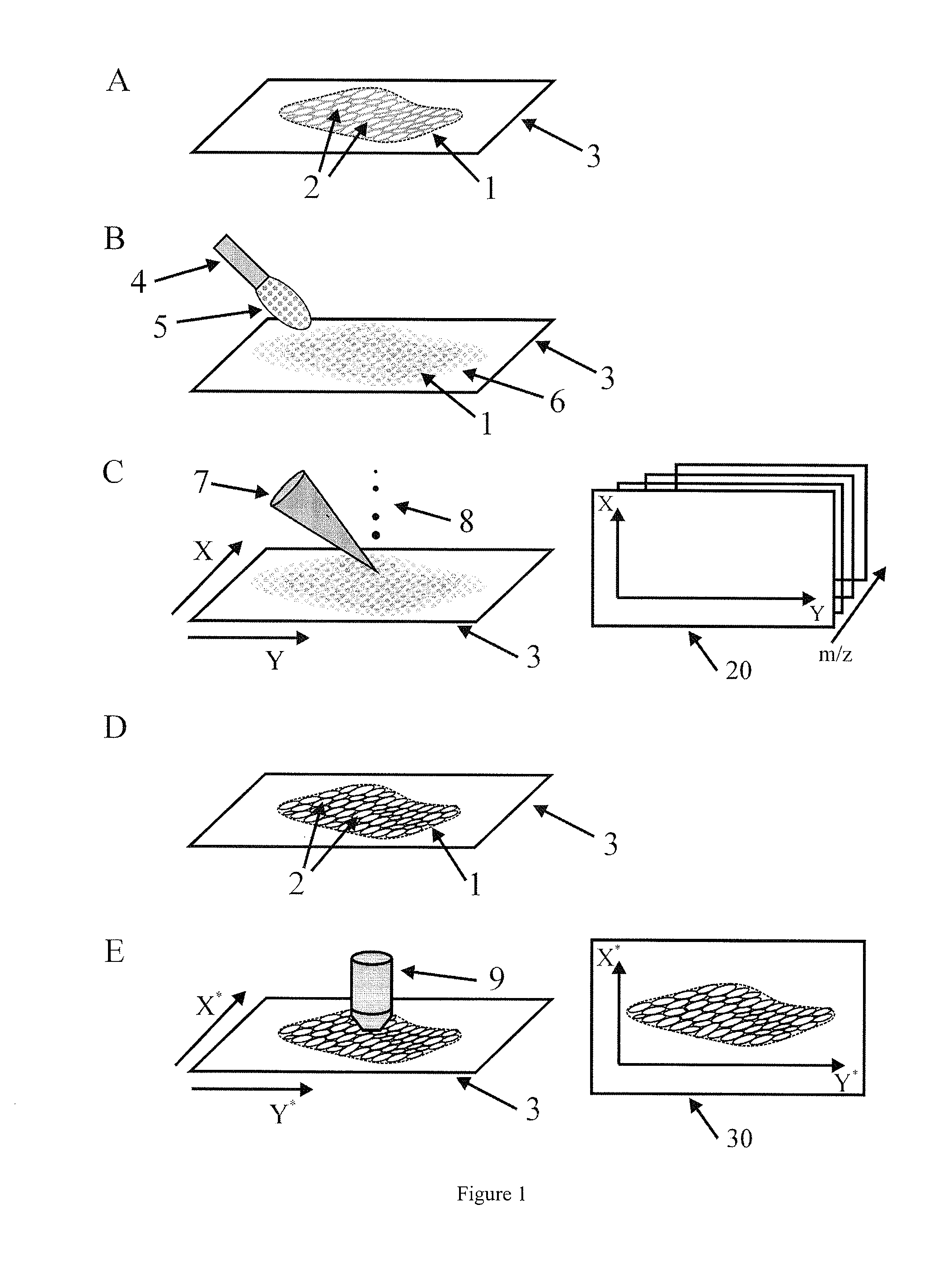

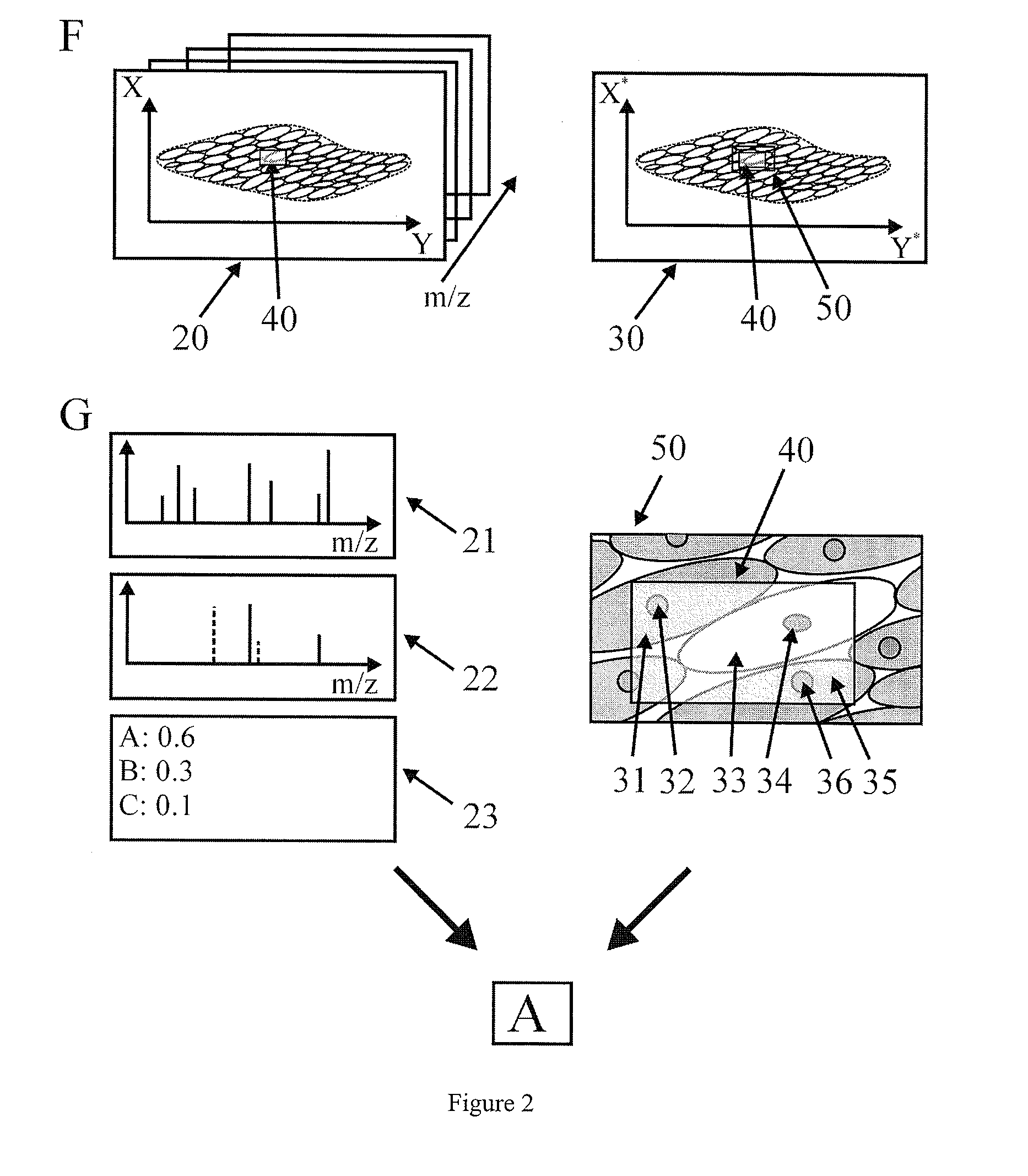

Method for the analysis of tissue sections

InactiveUS20090289184A1Reduce spatial resolutionIncrease contentImage enhancementImage analysisSpatially resolvedImage resolution

The present invention relates to a method for the histologic classification of a tissue section. The method includes acquiring a mass spectrometric image and a light-optical image of the same tissue section (the optical image having a higher spatial resolution than the mass spectrometric image) and combining optical information on the structures of a subarea of the tissue section with mass spectrometric information on the subarea (the structures not being spatially resolved in the mass spectrometric image).

Owner:BRUKER DALTONIK GMBH & CO KG

Pixelated phase-mask interferometer

ActiveUS7230717B2Increase rangeReduce complexityInterferometersUsing optical meansPhase differenceDetector array

A phase-difference sensor measures the spatially resolved difference in phase between orthogonally polarized reference and test wavefronts. The sensor is constructed as a pixelated phase-mask aligned to and imaged on a pixelated detector array. Each adjacent pixel of the phase-mask measures a predetermined relative phase shift between the orthogonally polarized reference and test beams. Thus, multiple phase-shifted interferograms can be synthesized at the same time by combining pixels with identical phase-shifts. The multiple phase-shifted interferograms can be combined to calculate standard parameters such as modulation index or average phase step. Any configuration of interferometer that produces orthogonally polarized reference and object beams may be combined with the phase-difference sensor of the invention to provide, single-shot, simultaneous phase-shifting measurements.

Owner:ONTO INNOVATION INC

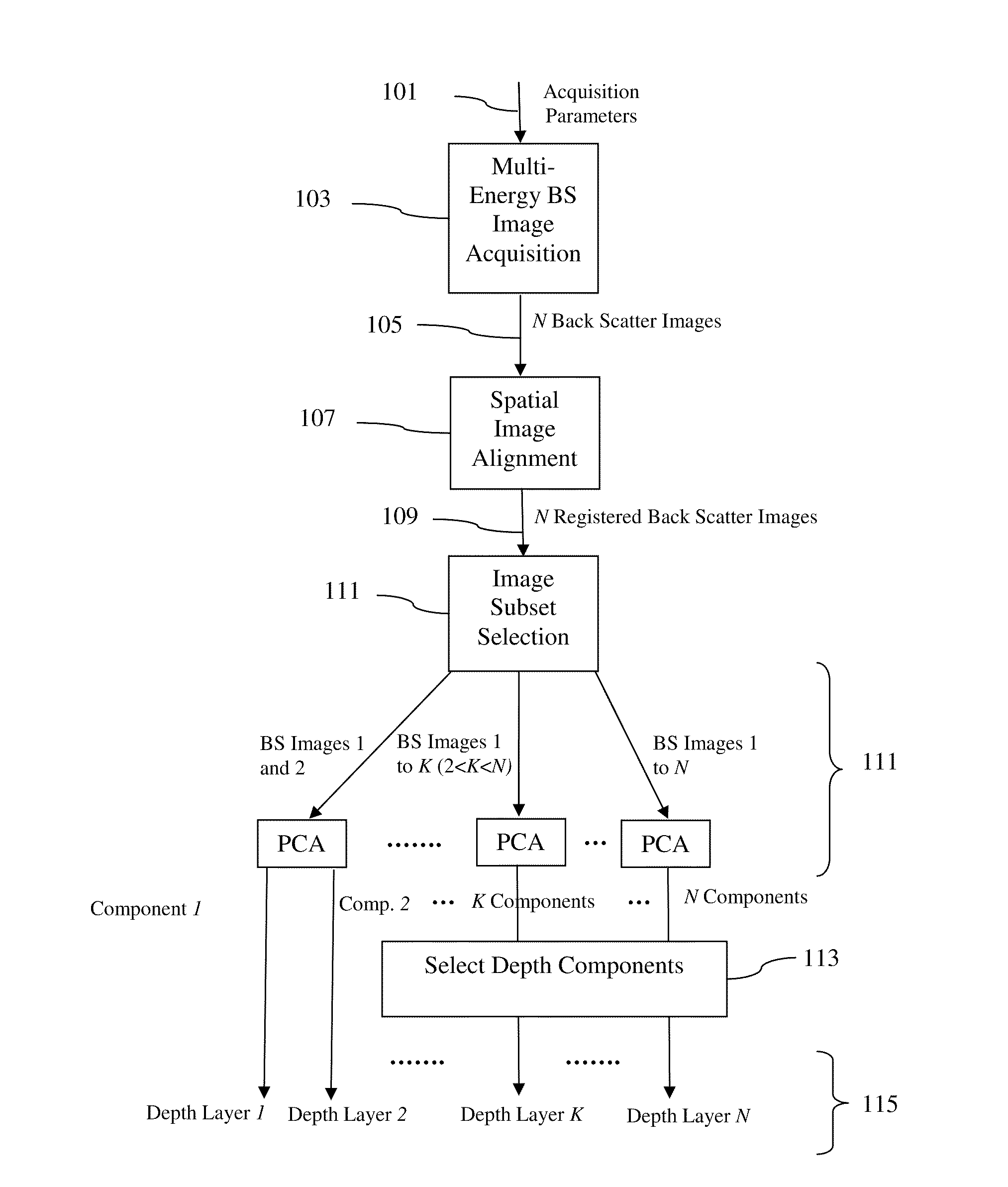

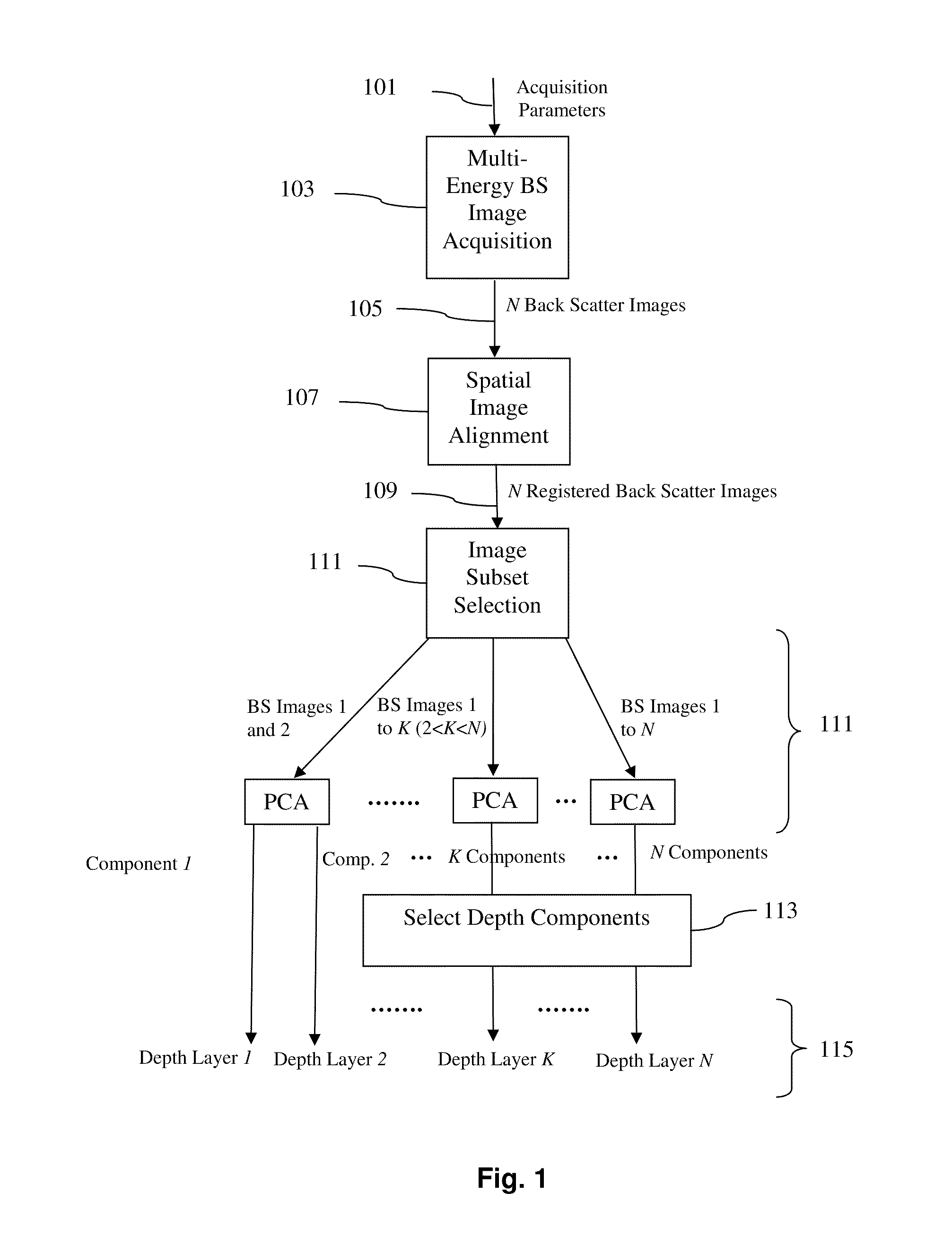

SEM imaging method

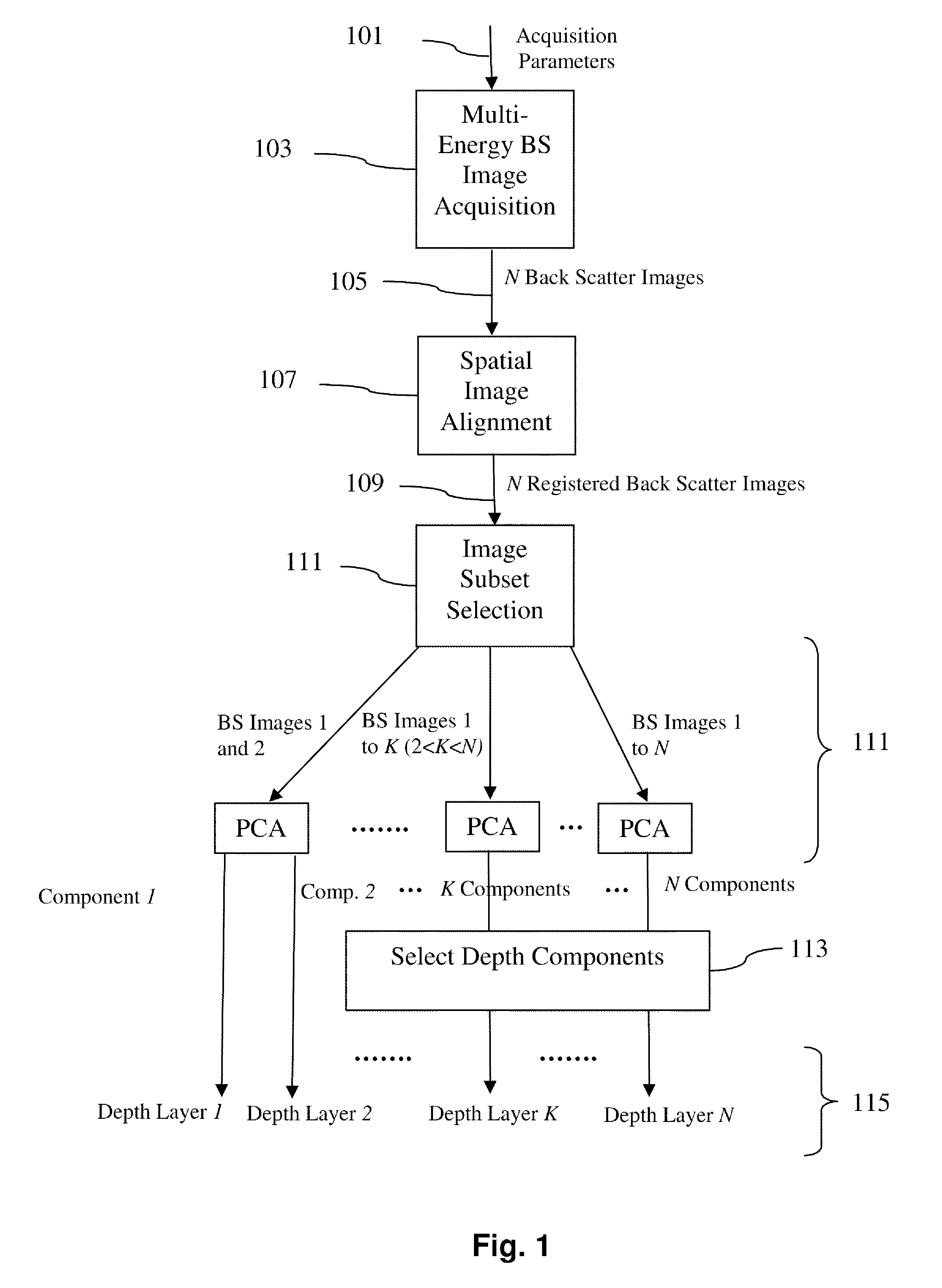

ActiveUS8232523B2Material analysis using wave/particle radiationElectric discharge tubesSpatially resolvedDepth level

Owner:FEI CO

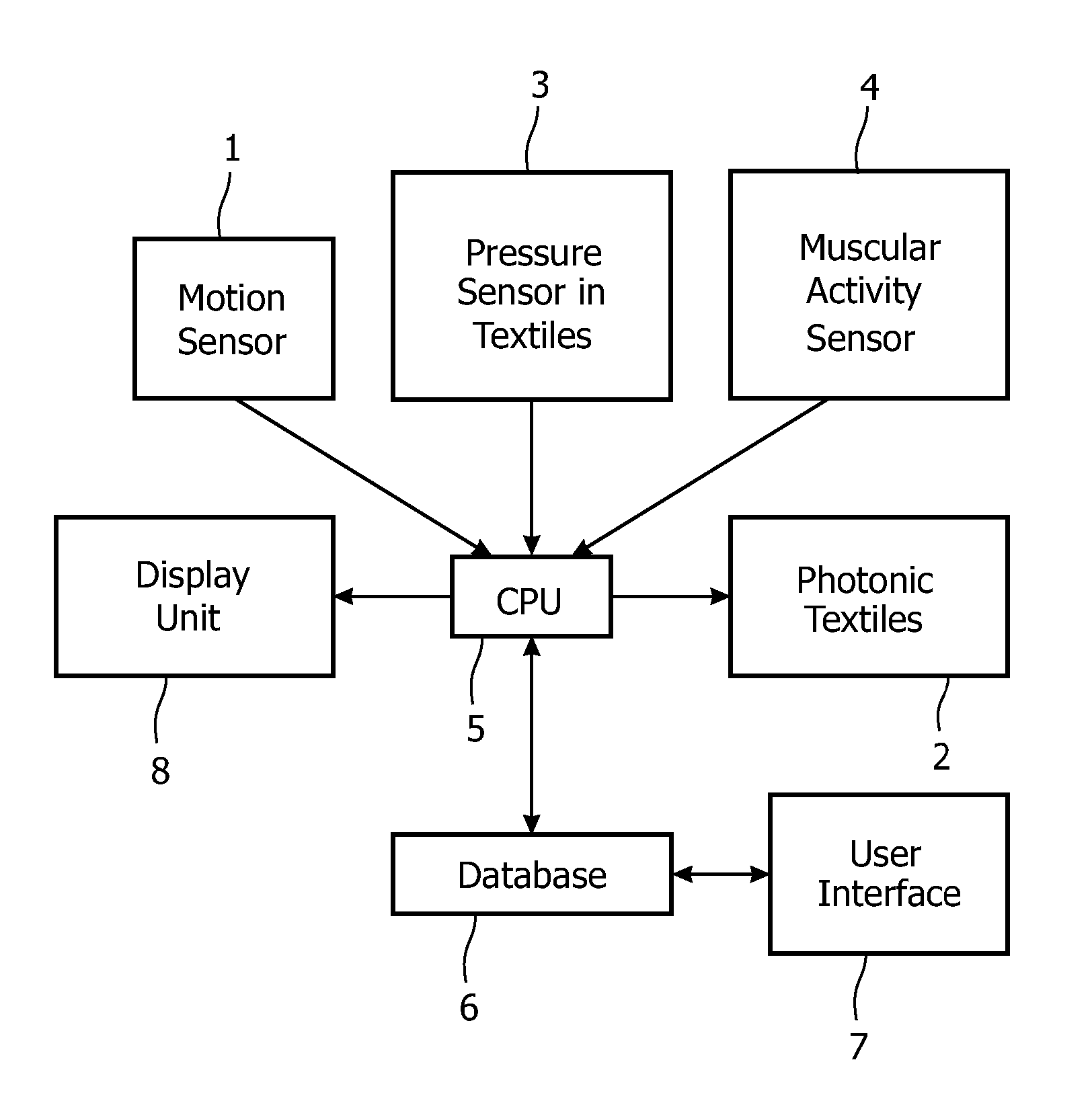

Limb movement monitoring system

A limb movement monitoring system, comprising a motion sensor, a garment comprising spatially addressable photonic textiles and spatially resolving pressure-sensitive textiles and furthermore a muscular activity sensor, a processing unit processing the data from the sensors and issuing illumination commands to the spatially addressable photonic textiles and a database. There is furthermore a process for monitoring limb movement by the system.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Method for Raman chemical imaging of endogenous chemicals to reveal tissue lesion boundaries in tissue

Apparatus and methods for spatially resolved Raman detection of molecules indicative of the borders of lesions with normal tissue are disclosed. A region of biological tissue was illuminated with monochromatic light. A Raman shifted light signal is detected from endogenous molecules in the region, the molecules being spatially organized in a localized first area of the region. These molecules are indicative of a border between normal tissue and a lesion. The Raman shifted light signal is then spatially resolved in at least one direction.

Owner:CHEMIMAGE CORP

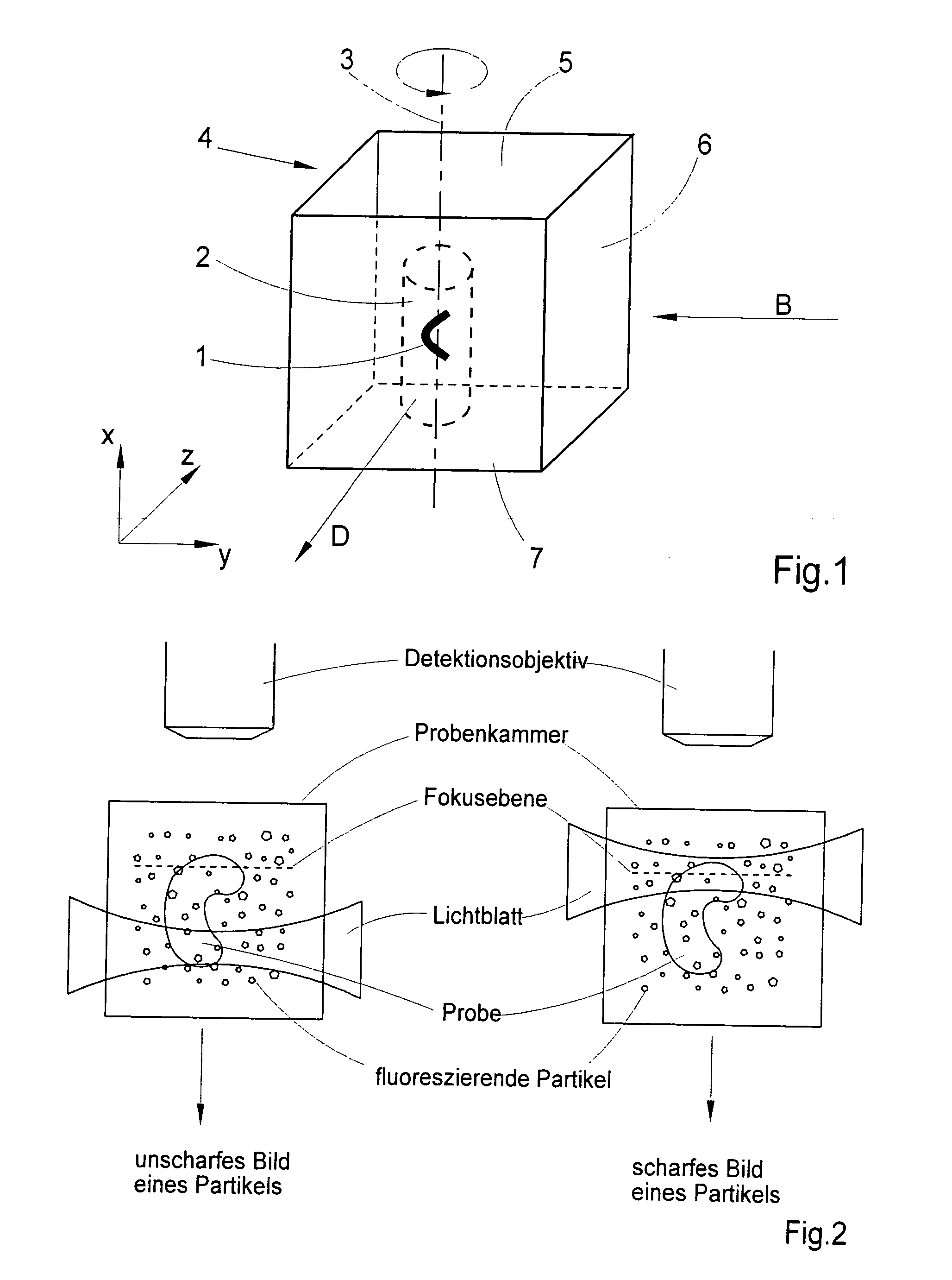

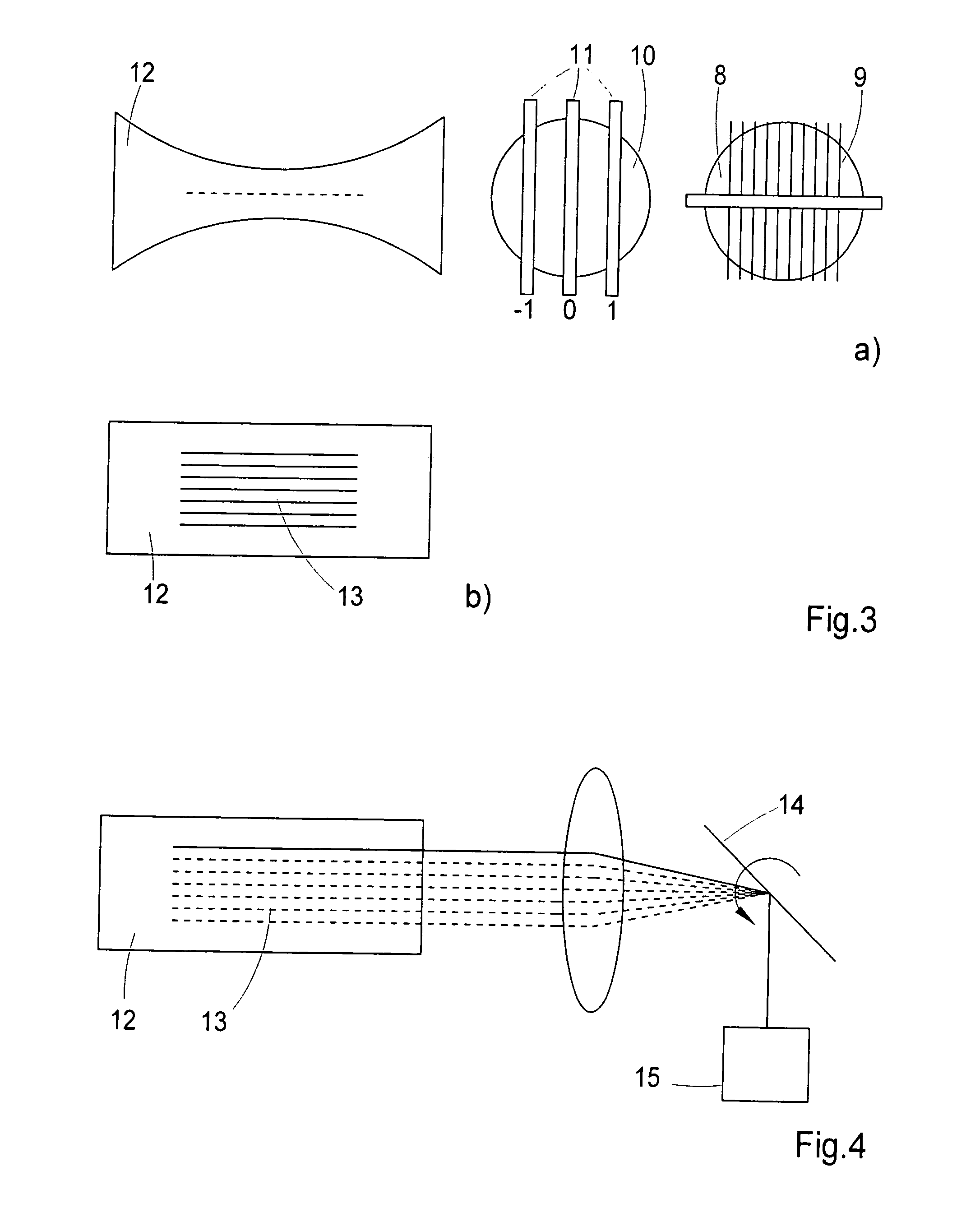

Method for the microscopic three-dimensional reproduction of a sample

InactiveUS20100201784A1Avoid shadow effectMore resolutionImage analysisMicroscopesSpatially resolvedFluorescence

A method for the three-dimensional imaging of a sample in which image information from different depth planes of the sample is stored in a spatially resolved manner, and the three-dimensional image of the sample is subsequently reconstructed from this stored image information is provided. A reference structure is applied to the illumination light, at least one fluorescing reference object is positioned next to or in the sample, images of the reference structure of the illumination light, of the reference object are recorded from at least one detection direction and evaluated. The light sheet is brought into an optimal position based on the results and image information of the reference object and of the sample from a plurality of detection directions is stored. Transformation operators are obtained on the basis of the stored image information and the reconstruction of the three-dimensional image of the is based on these transformation operators.

Owner:CARL ZEISS MICROSCOPY GMBH

SEM Imaging Method

ActiveUS20110266440A1Material analysis using wave/particle radiationElectric discharge tubesSpatially resolvedData set

A method of investigating a sample using Scanning Electron Microscopy (SEM), comprising the following steps:Irradiating a surface (S) of the sample using a probing electron beam in a plurality (N) of measurement sessions, each measurement session having an associated beam parameter (P) value that is chosen from a range of such values and that differs between measurement sessions;Detecting stimulated radiation emitted by the sample during each measurement session, associating a measurand (M) therewith and noting the value of this measurand for each measurement session, thus allowing compilation of a data set (D) of data pairs (Pi, Mi), where 1≦i≦N,wherein:A statistical Blind Source Separation (BSS) technique is employed to automatically process the data set (D) and spatially resolve it into a result set (R) of imaging pairs (Qk, Lk), in which an imaging quantity (Q) having value Qk is associated with a discrete depth level Lk referenced to the surface S.

Owner:FEI CO

Universal ophthalmic examination device and ophthalmic examination method

A universal ophthalmic examination device and an ophthalmic examination method have the object of combining in an inexpensive apparatus in a simple manner the device-related requirements for image generation, measurement and functional imaging for carrying out visual stimulation and highly time-resolved and highly spatially resolved image documentation using continuous illumination and flash mode and the requirements for measurements in the infrared spectral region and visible spectral region with a time regime that can be freely selected to a great extent. The light of at least one light source is modified in a program-oriented manner with respect to its intensity curve and / or time curve with a temporally defined relationship to the adjustments of the at least one light source, of the image recording and of the evaluation for purposes of adaptive matching to an examination task in the illumination beam path by an individual, shared light manipulator and is used as modified light for illumination and for selective stimulation.

Owner:IMEDOS INTELLIGENTE OPTISCHE SYST DER MEDIZIN & MESSTECHNIK GMBH

Detection with evanescent wave probe

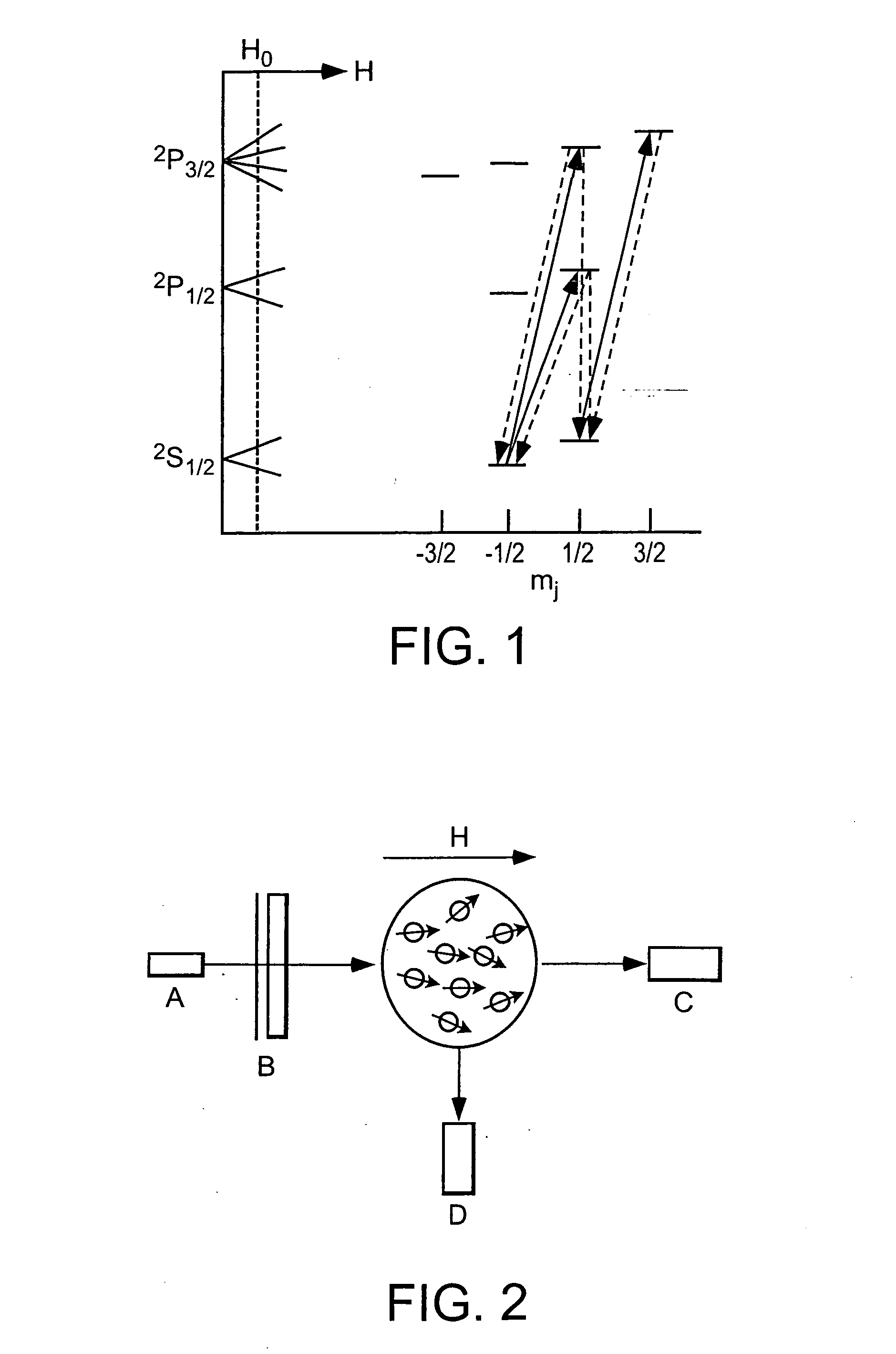

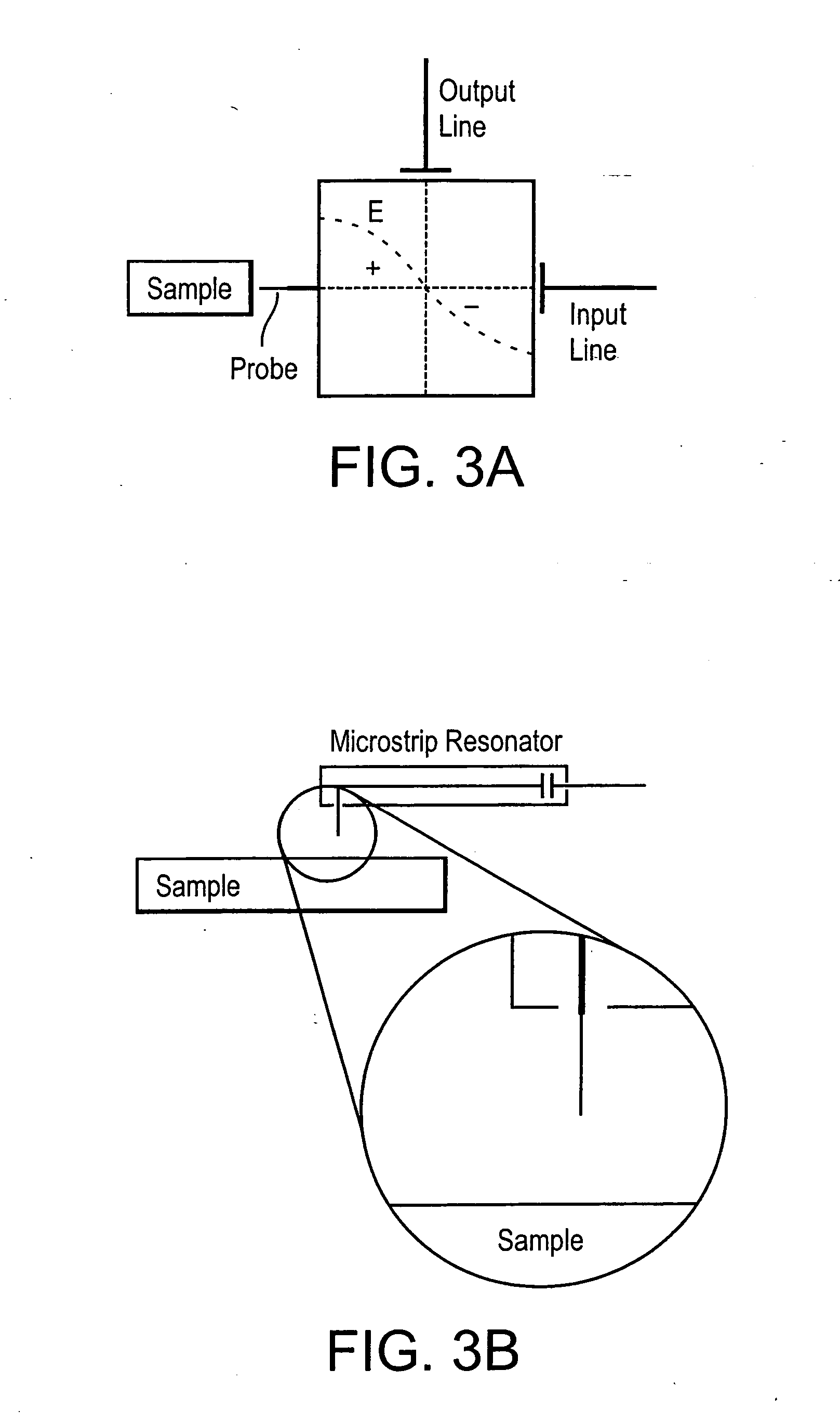

InactiveUS20070090836A1Improve spatial resolutionReduce background noiseMeasurements using electron paramagnetic resonanceAnalysis using optical pumpingSpatially resolvedResonance

Methods and systems for spatially resolved spin resonance detection in a sample of material are disclosed. Also disclosed are methods and systems for spatially resolved impedance measurements in a sample of material. The disclosed methods and samples can be used in screening of plurality of biological, chemical and material samples.

Owner:INTEMATIX

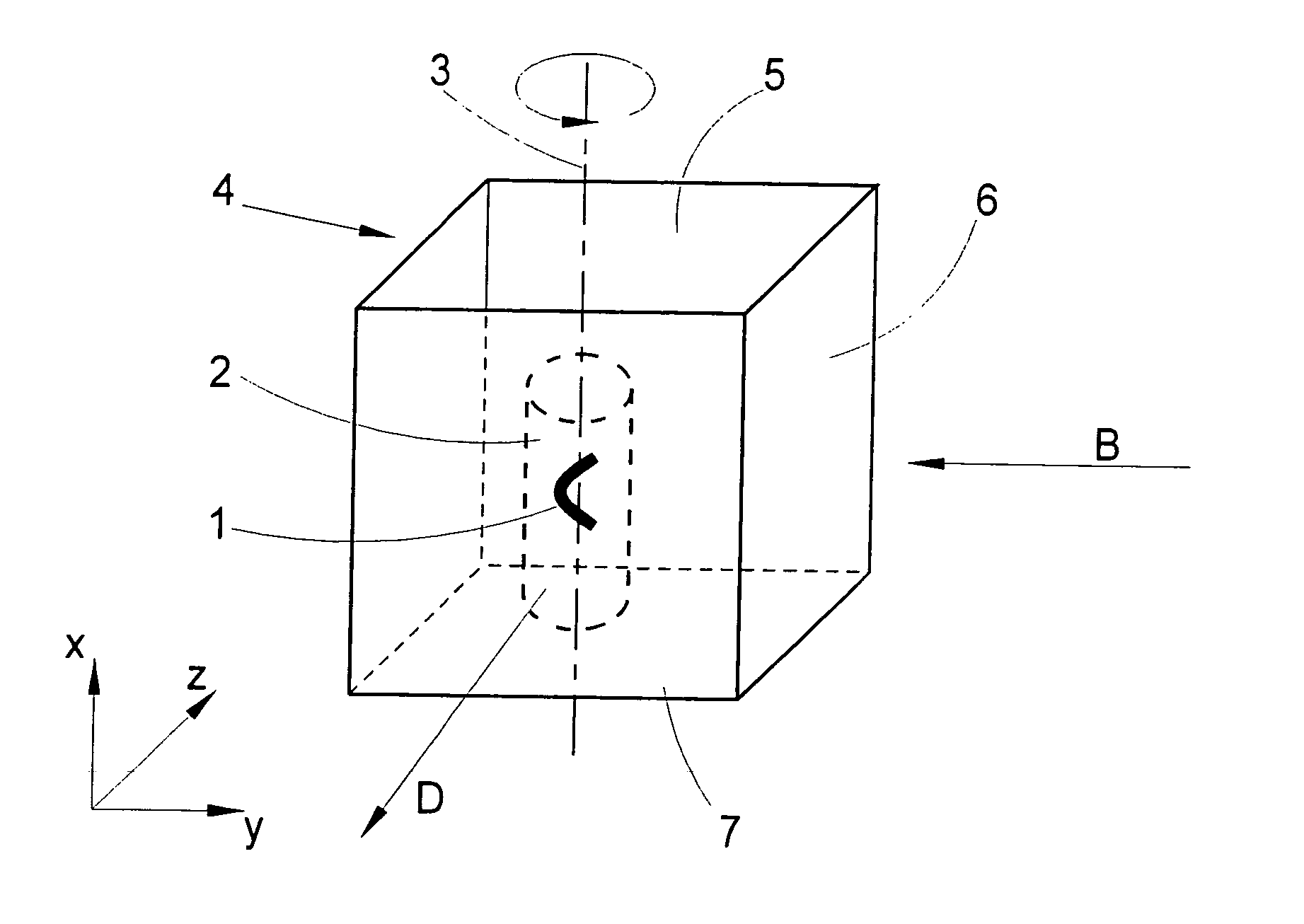

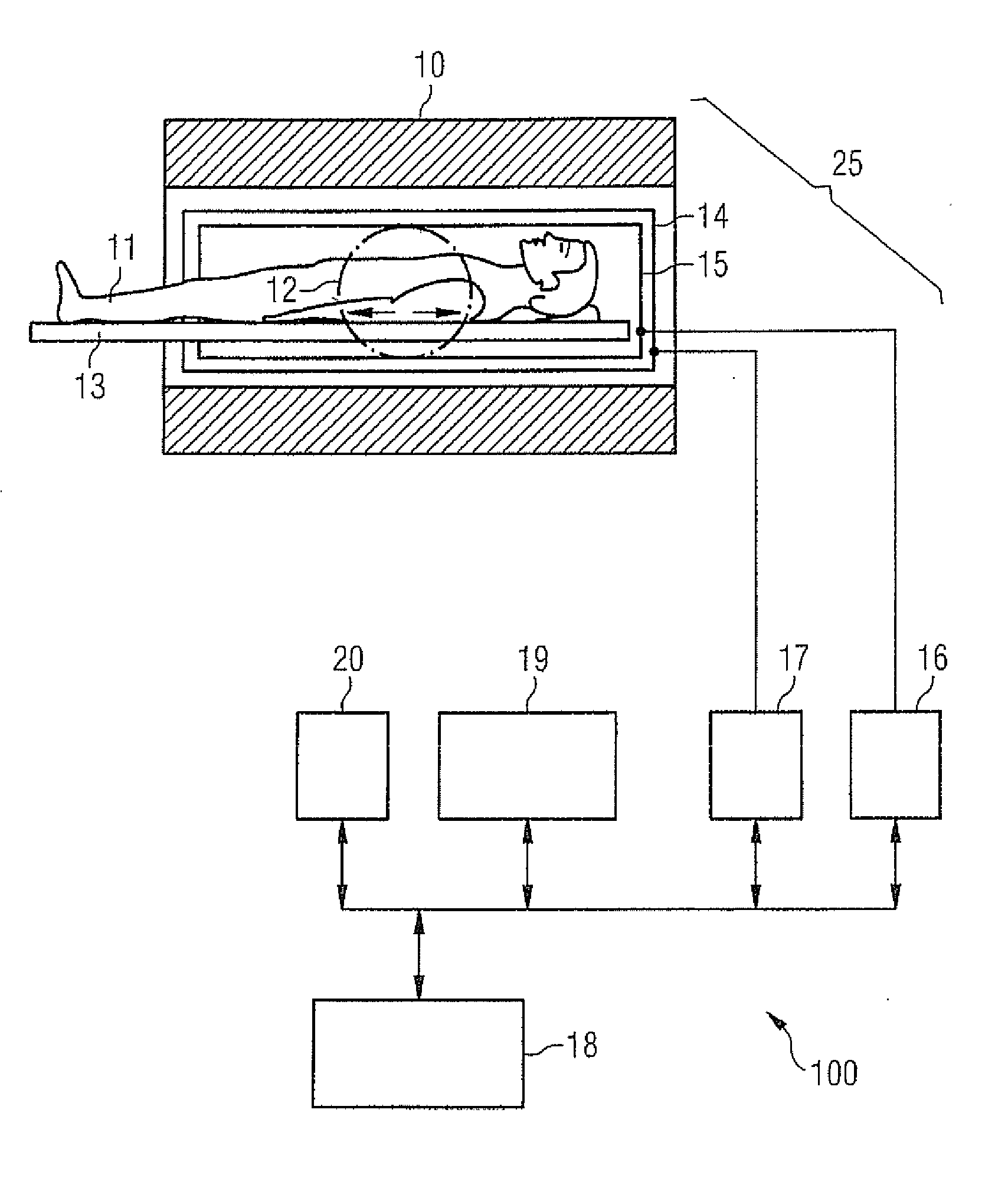

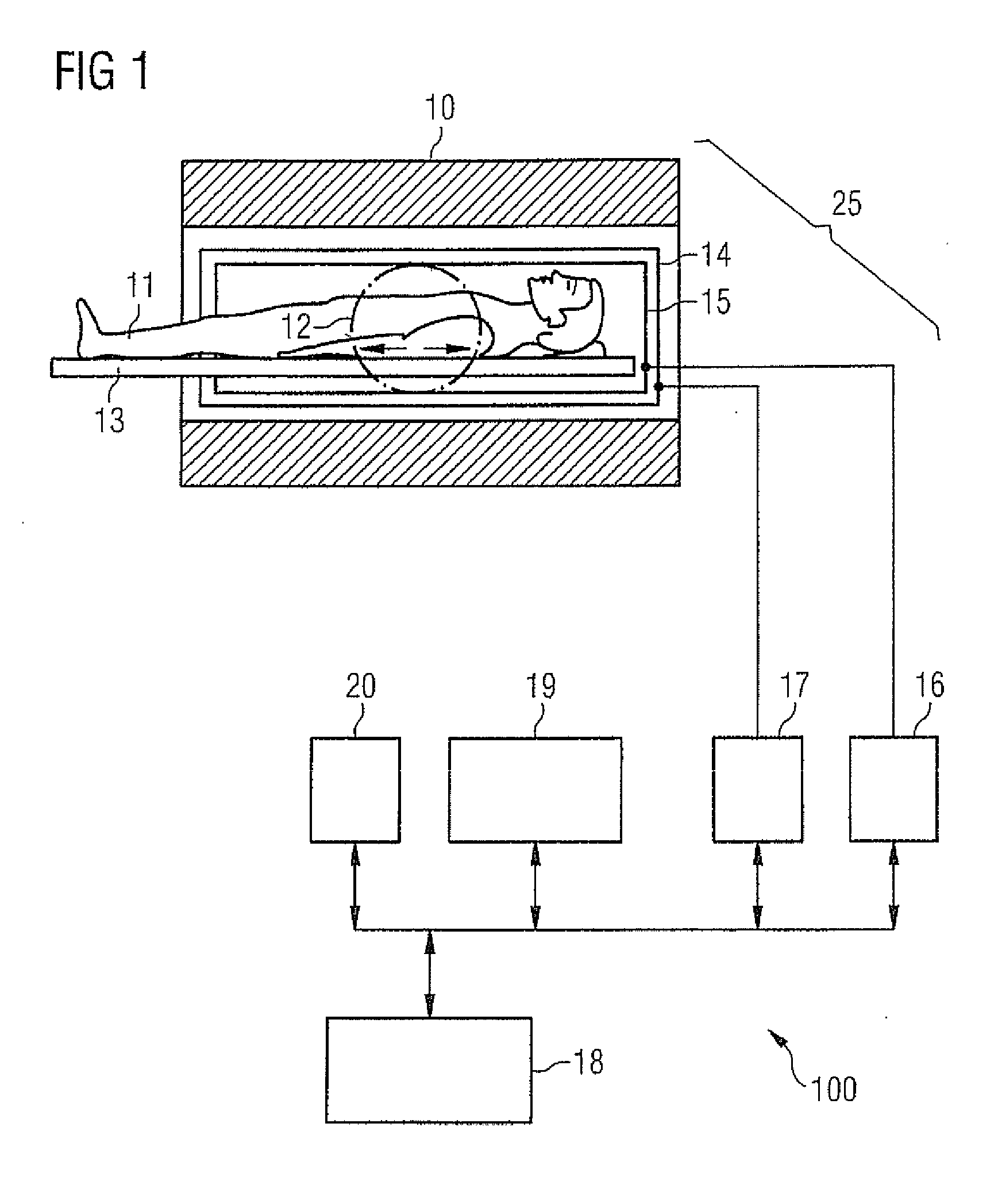

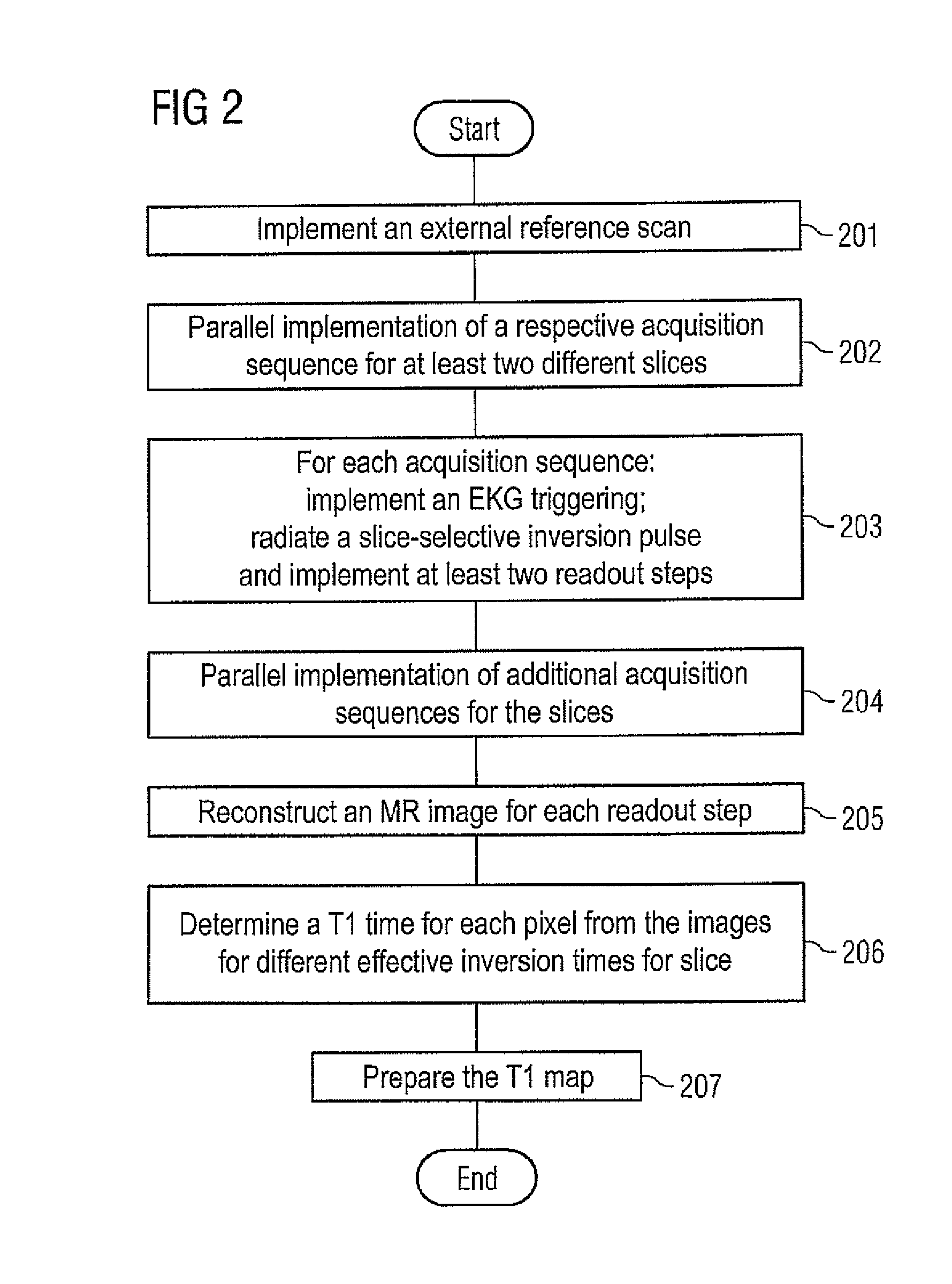

Method and apparatus for magnetic resonance imaging to create t1 maps

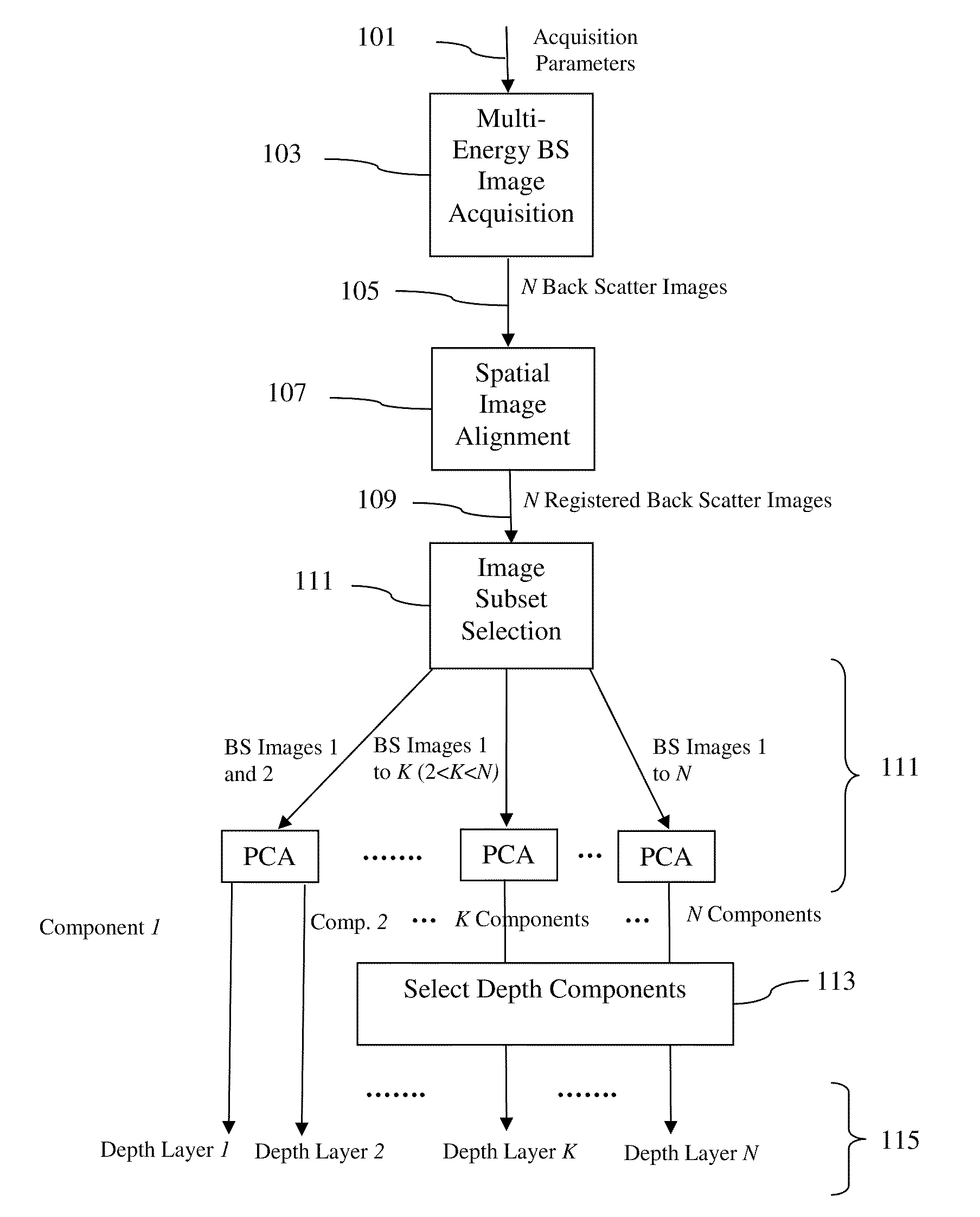

ActiveUS20110181285A1Diagnostic recording/measuringSensorsSpatially resolvedProton magnetic resonance

In a method and apparatus for MR imaging, a data acquisition sequence is executed wherein at least two slices of an examination subject are imaged in parallel with a gradient echo method for spatially resolved quantification of the T1 relaxation time.At least one first acquisition sequence is implemented to acquire MR data from a first slice of the examination subject and at least one second acquisition sequence is implemented to acquire MR data from a second slice of the examination subject. The acquisition sequences each include an inversion pulse and at least two successive readout steps. The first and second acquisition sequences are temporally offset from one another such that they at least partially overlap.

Owner:SIEMENS HEALTHCARE GMBH

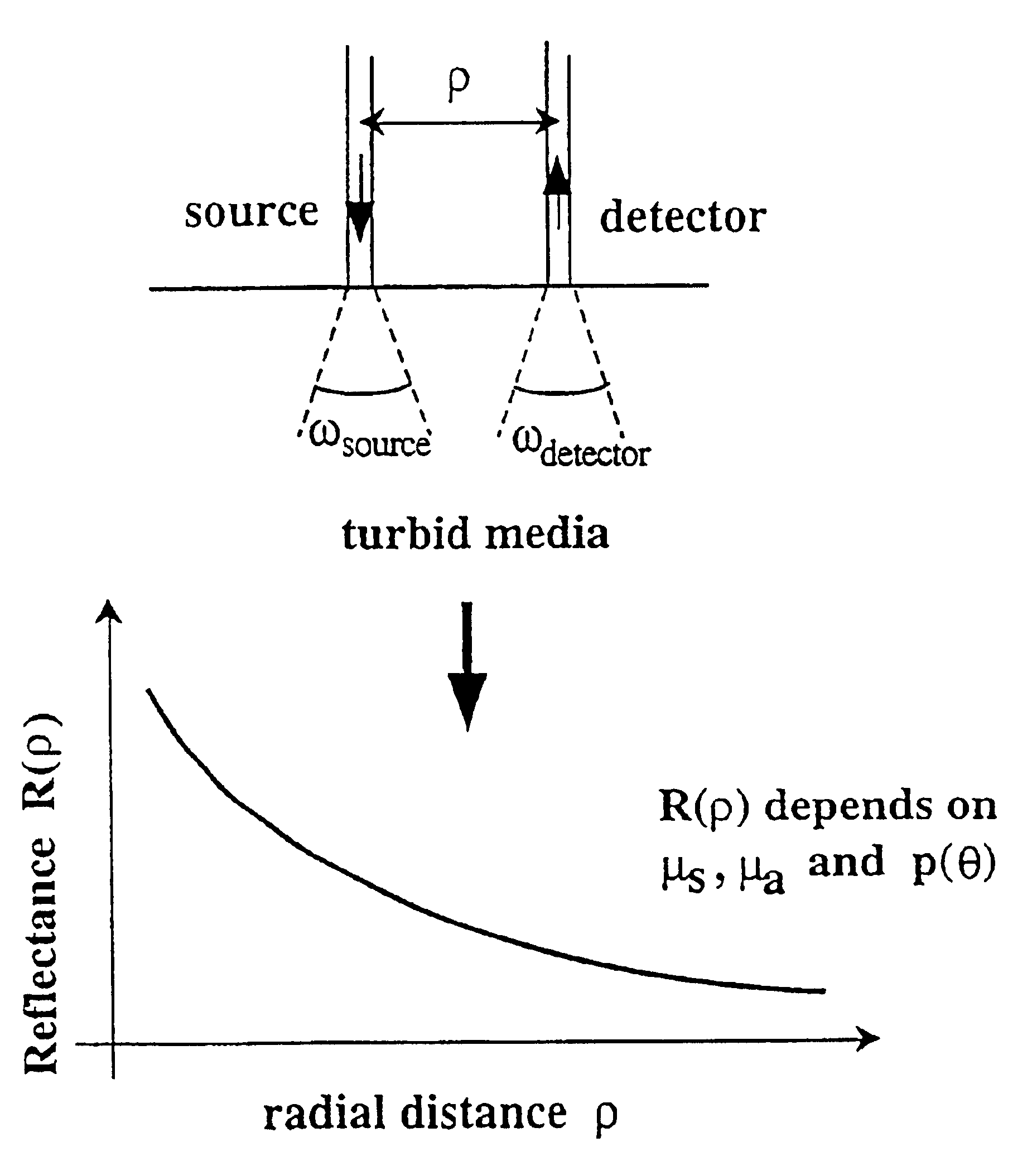

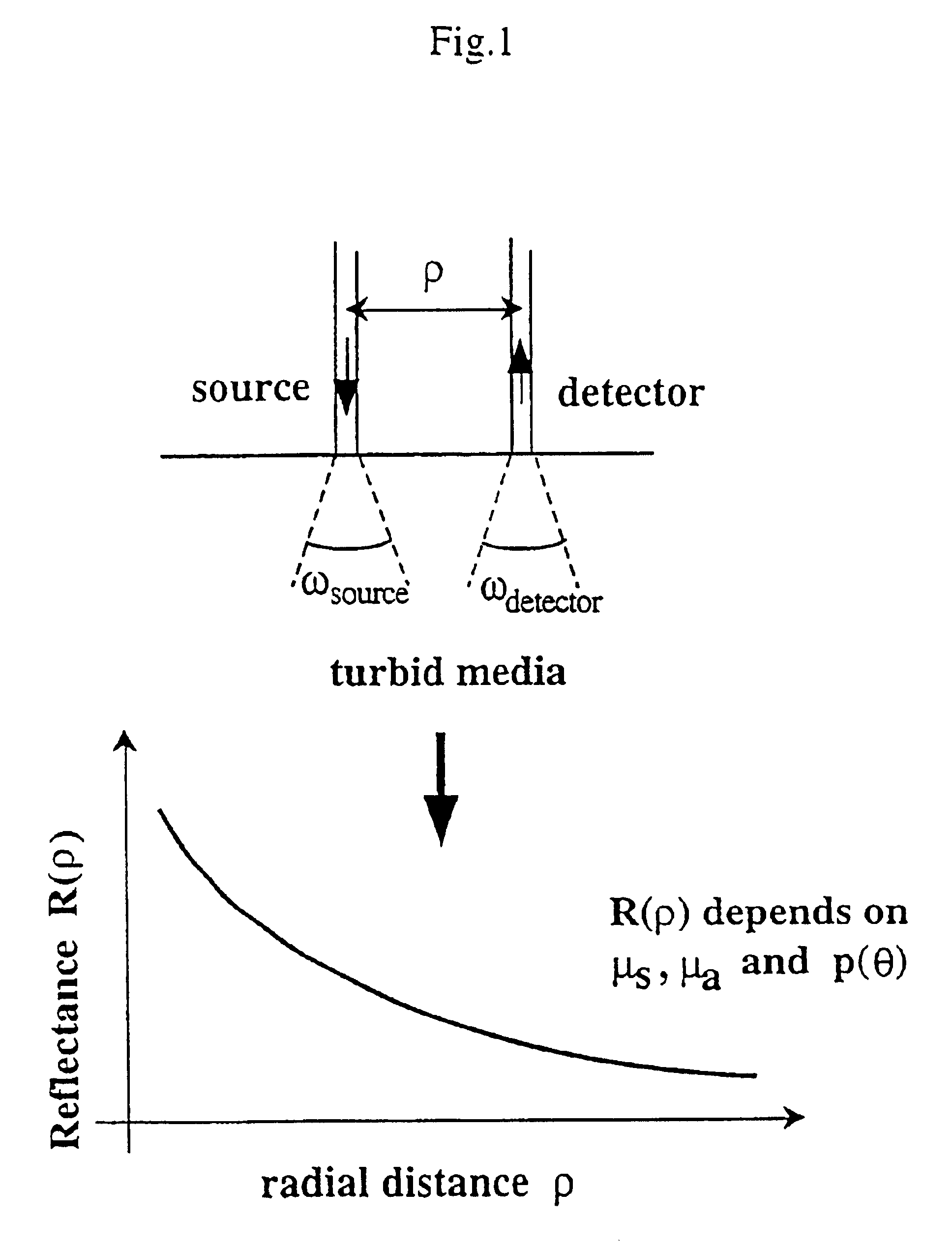

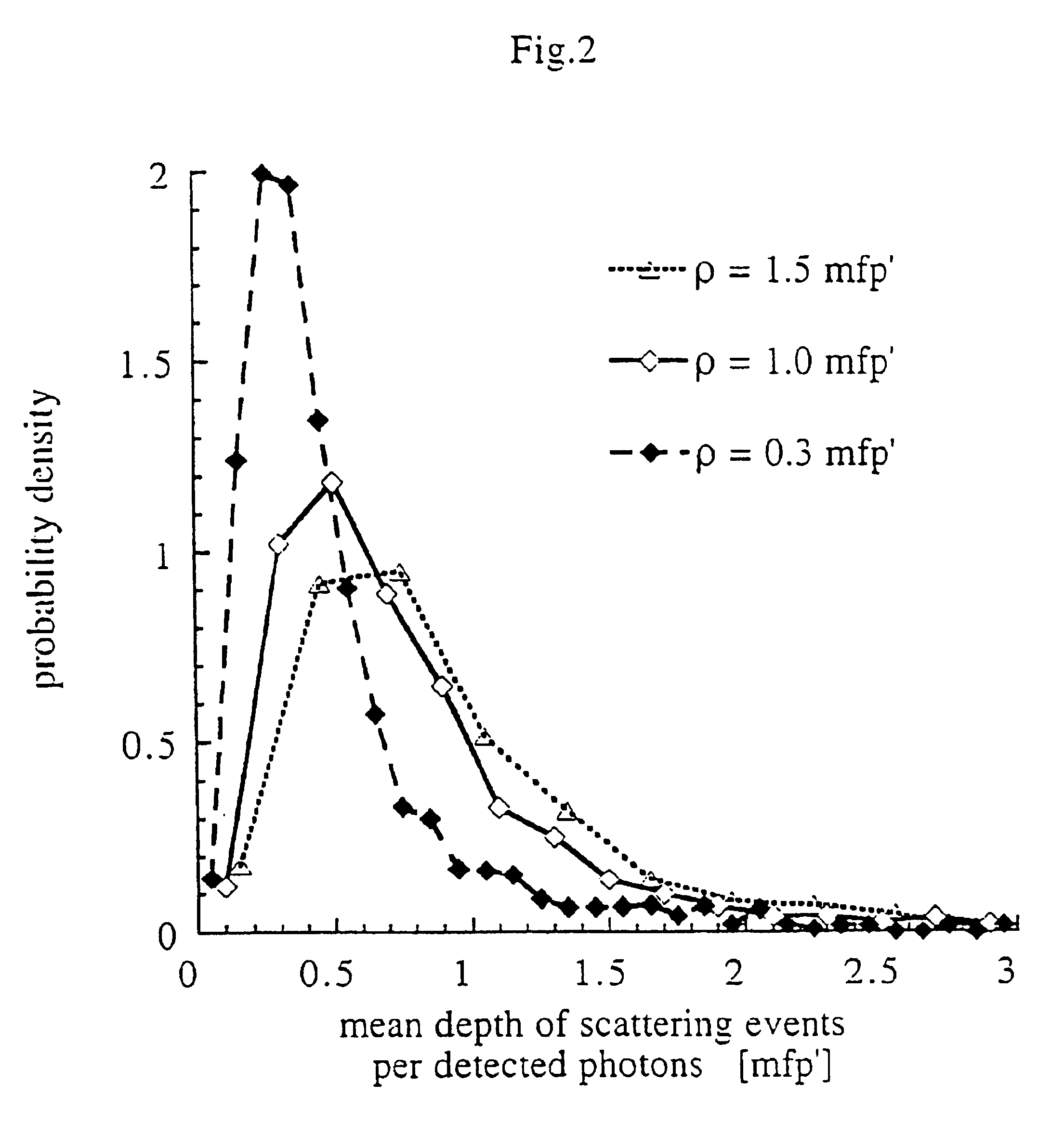

Method and apparatus for measuring locally and superficially the scattering and absorption properties of turbid media

We present a method and apparatus for local and superficial measurement of the optical properties of turbid media. The depth probed is on the order of 1 transport mean free path of the photon. The absorption coefficient, reduced scattering coefficient and the phase function parameter γ=(1−g2) / (1−g1) are optical parameters computed from a single measurement of the spatially resolved reflectance close to the source. Images of superficial structures of the medium can be obtained by performing multi-site measurements. An important application of this technique is the characterization of biological tissues, for example for medical diagnostic purposes. Measurements on biological tissues can be achieved using a probe of diameter less than 2 mm, and the average volume probed is on the order of 1 mm3. Separate images of absorption and tissue structure can be achieved with a resolution of approximately one transport mean free path of the considered tissue.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

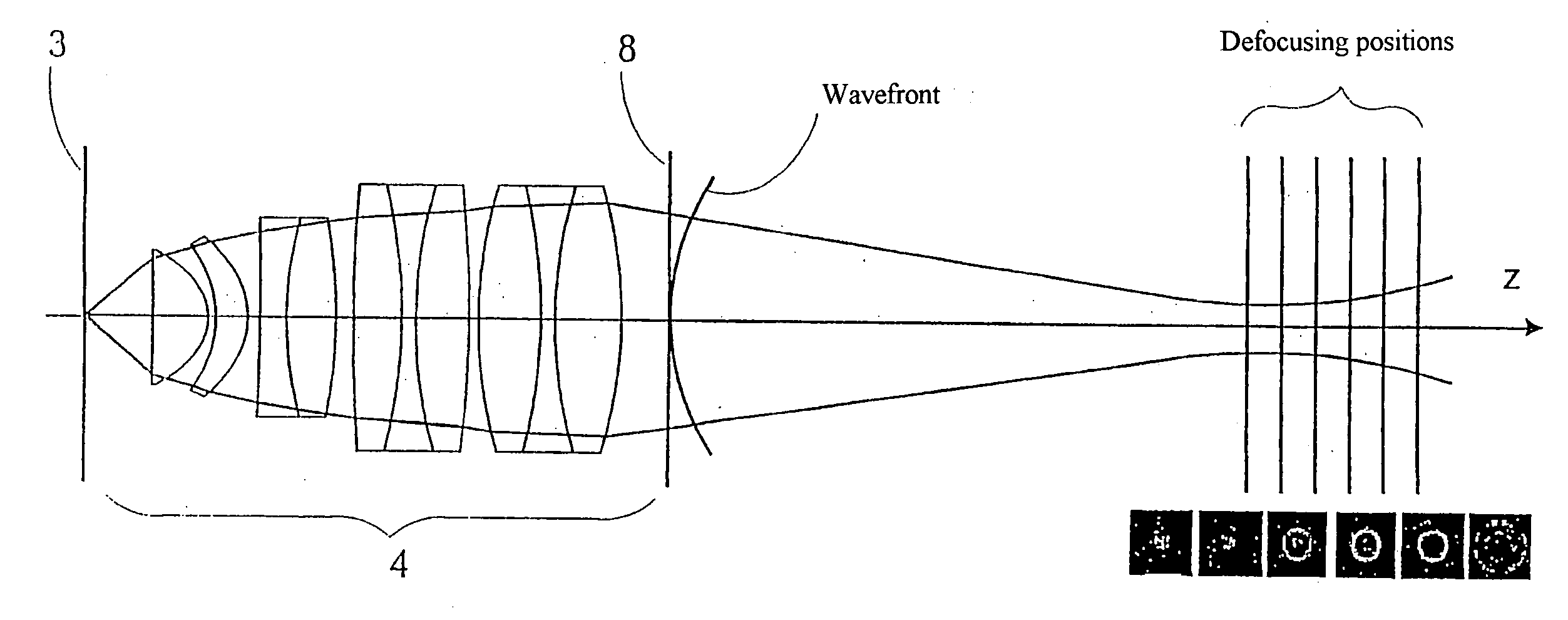

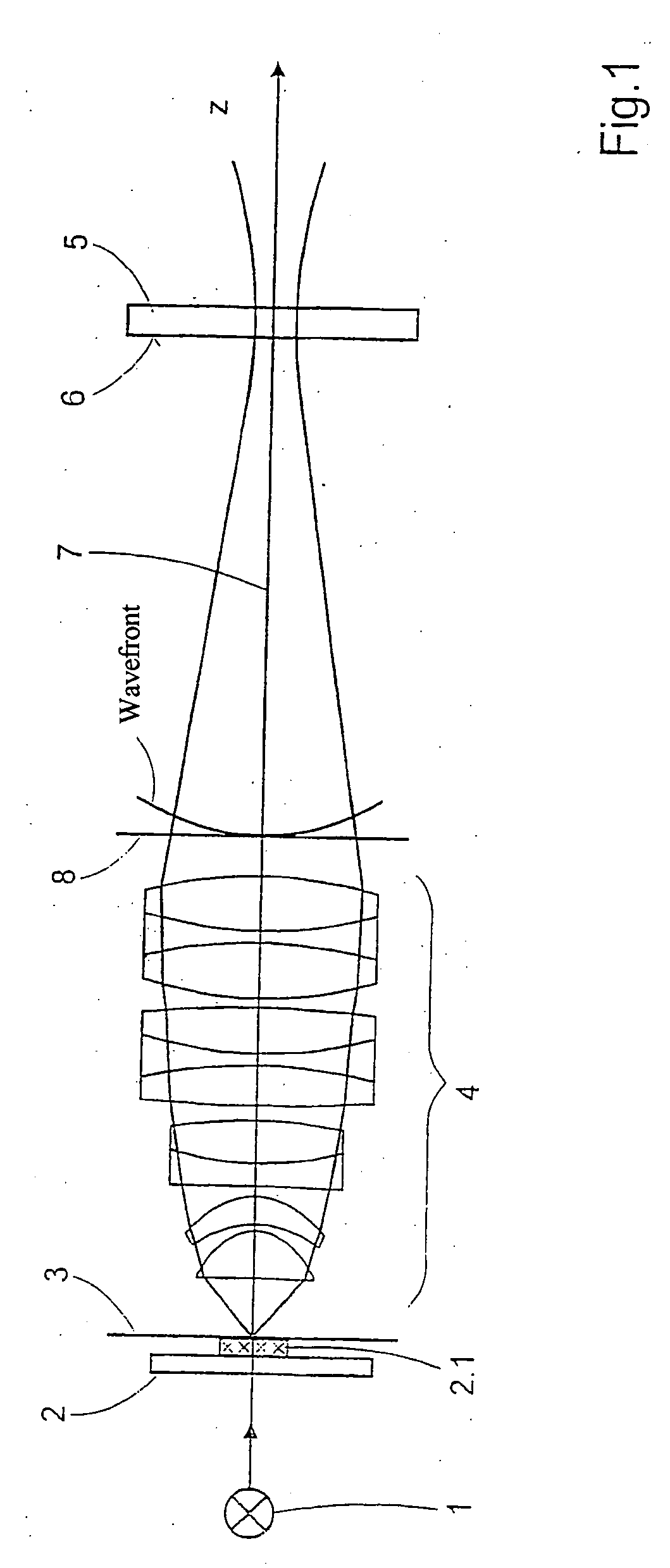

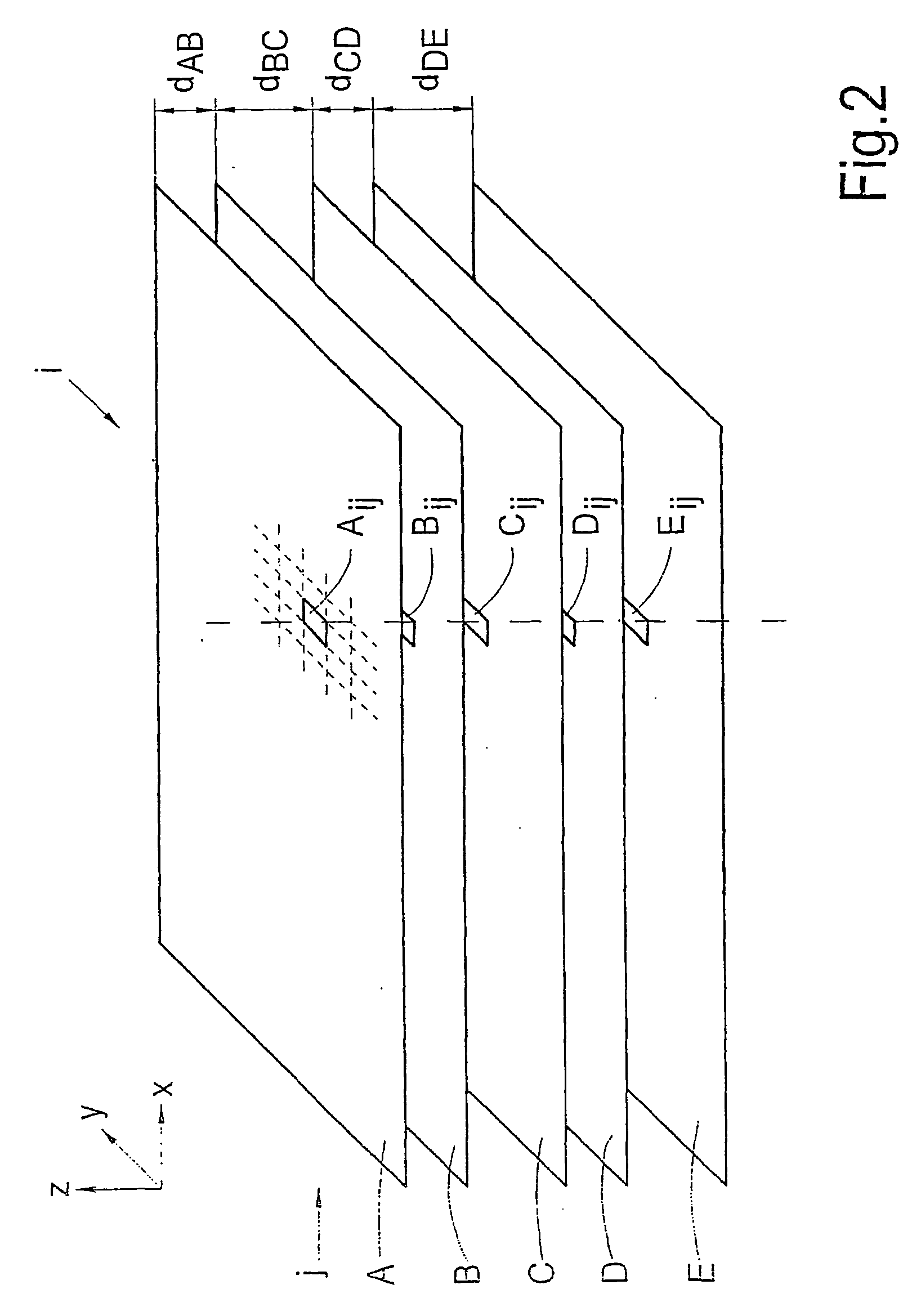

Method for determining the image quality of an optical imaging system

InactiveUS20060072104A1Avoid loweringImprove image qualityPhotometry using reference valueMaterial analysis by optical meansSpatially resolvedImaging processing

The invention is directed to a method for determining the image quality of an optical imaging system and to the use of the method according to the invention for determining the influence of samples on the amplitude distribution and phase front distribution of the illumination light, of which the amplitude distribution is known in particular. The invention comprises the following steps: adjusting the subassemblies relative to one another in such a way that it is possible to project images of a sample on the detection device; recording a plurality of images of the sample from different reference planes near the focus plane; improving the image quality by image processing, particularly to reduce noise, to compensate for local variations in sensitivity of the detection device, and to center the intensity centroids respectively on a predetermined location in the images; computational linking of the spatially resolved image information, of adjustment values and system variables relating to the optical imaging system, and of information concerning the sample with the aim of determining characteristic numbers that are characteristic of the wavefront deformation caused by the imaging system; and outputting the characteristic numbers and associating them with the imaging system for describing the image quality.

Owner:CARL ZEISS SMT GMBH

Reinforcement Element With Sensor Fiber, Monitoring System, And Monitoring Method

A reinforcement element, comprises at least one sensor fiber adapted for strain measurements based on stimulated Brillouin scattering within said sensor fiber. Furthermore, a system for monitoring strain within a structure comprises a reinforcement element comprising at least one sensor fiber adapted for strain measurements based on stimulated Brillouin scattering within said sensor fiber, a pump laser for coupling in laser radiation of a pump frequency into said at least one sensor fiber, a Stokes laser for coupling in laser radiation of a Stokes laser radiation into said at least one sensor fiber, wherein the pump frequency and the Stokes frequency are different from one another and wherein the frequency difference between the pump and Stokes frequencies is within the range of acoustical phonons within said sensor fiber, a sensor adapted to obtain a stimulated Brillouin backscattering signal, and a network analyzer adapted for determining the complex transfer function of the sensor fiber to determine a spatially resolved strain measurement.

Owner:GLOTZL GES FUR BAUMESSTECHN +2

Method and Arrangement for Collimated Microscopic Imaging

InactiveUS20090250632A1Technology is easy to implementHigh-resolution imagePhotometryLuminescent dosimetersSpatially resolvedFluorescence

A method and arrangement for collimated microscopic imaging, including a first illumination of a sample in at least one region for exciting fluorescence, and a spatially resolving detection of the sample light by detector elements, the detection being associated with the region, wherein by means of a second illumination a sub-division of the region into separate fluorescent partial regions occurs, which are associated with the detector elements. The separation of the partial regions is carried out by the spatial separation of the fluorescent regions by means of intermediate regions having reduced fluorescence or no fluorescence, and / or by means of different spectral properties of the fluorescence from the partial regions.

Owner:CARL ZEISS MIKROLMAGING

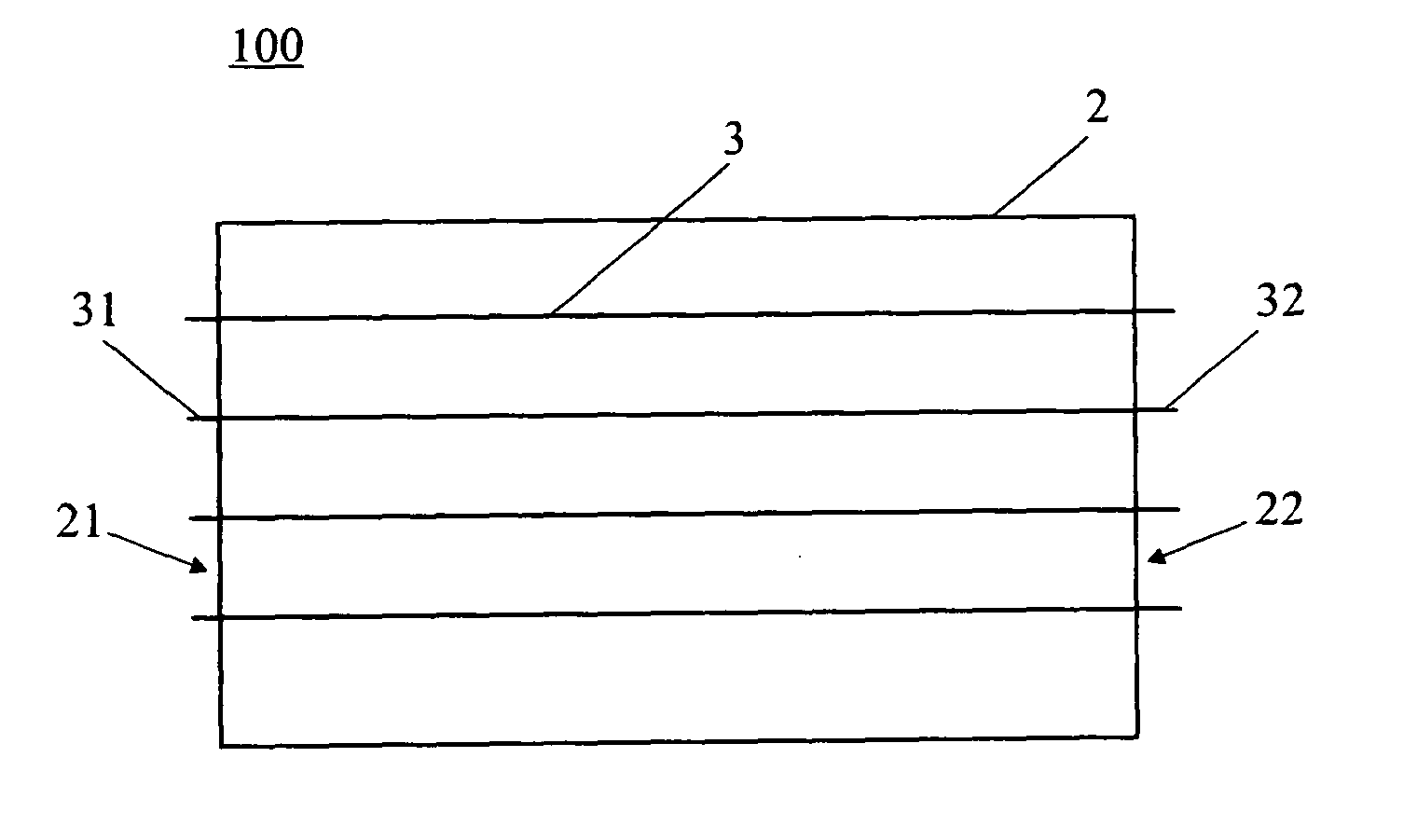

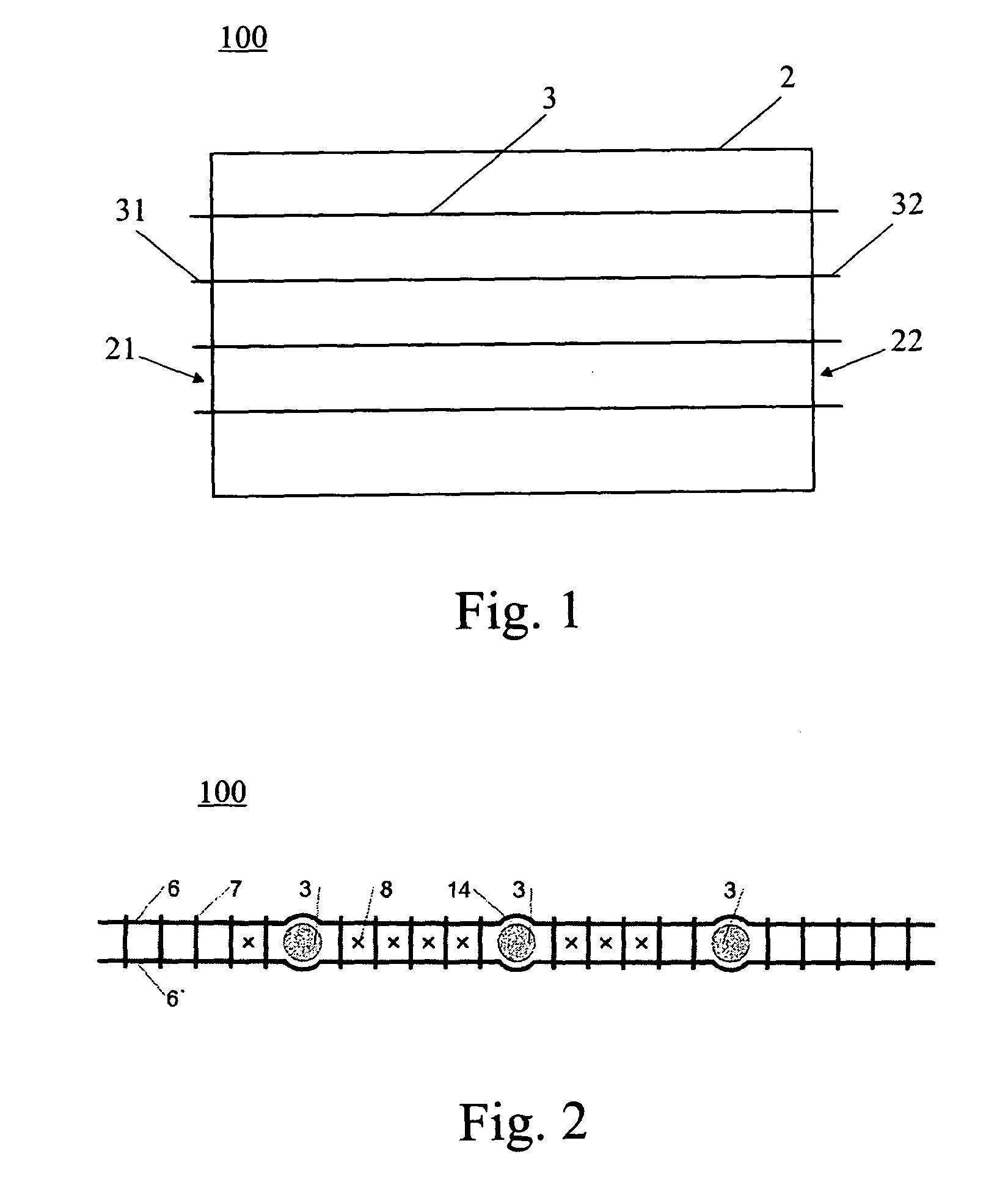

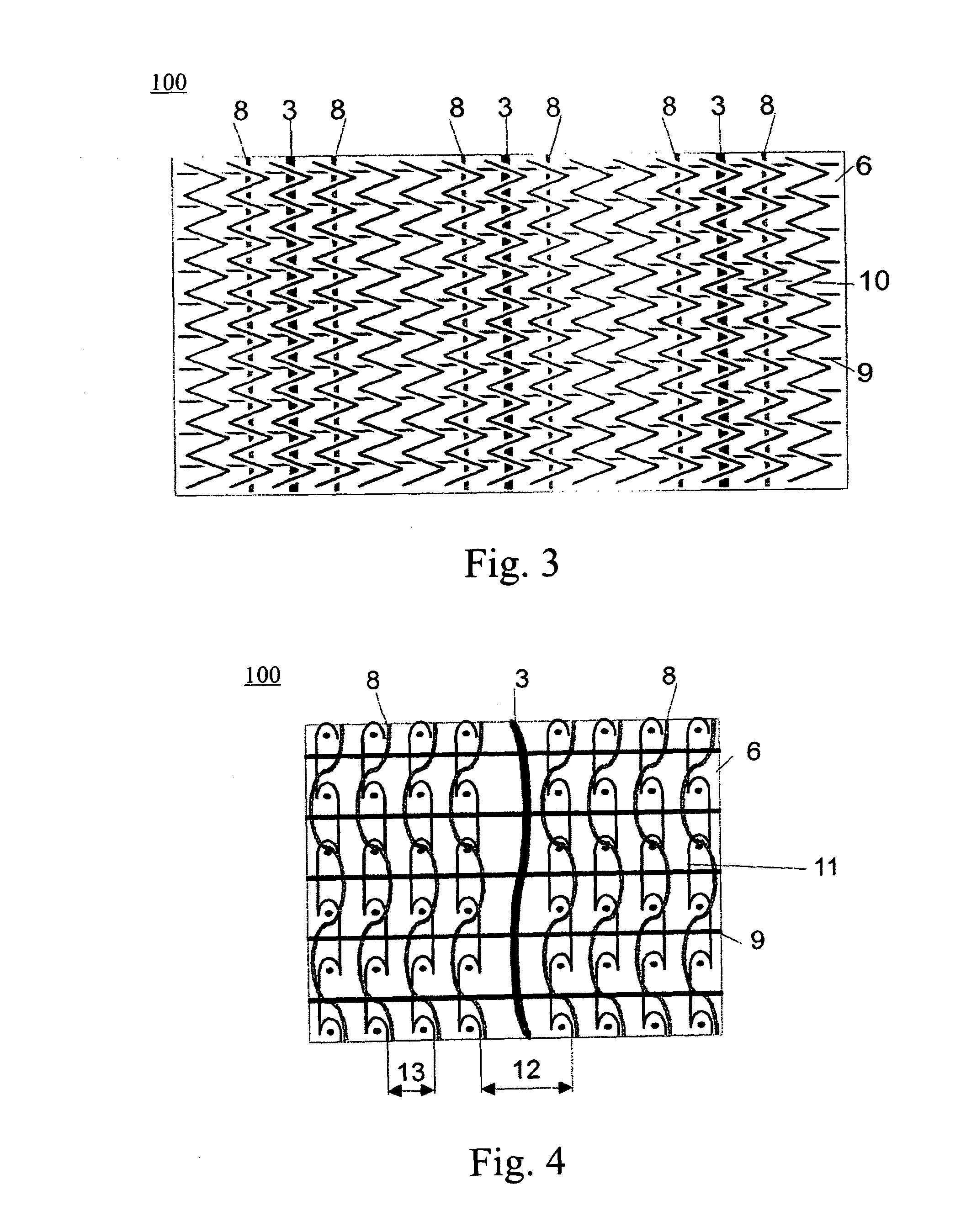

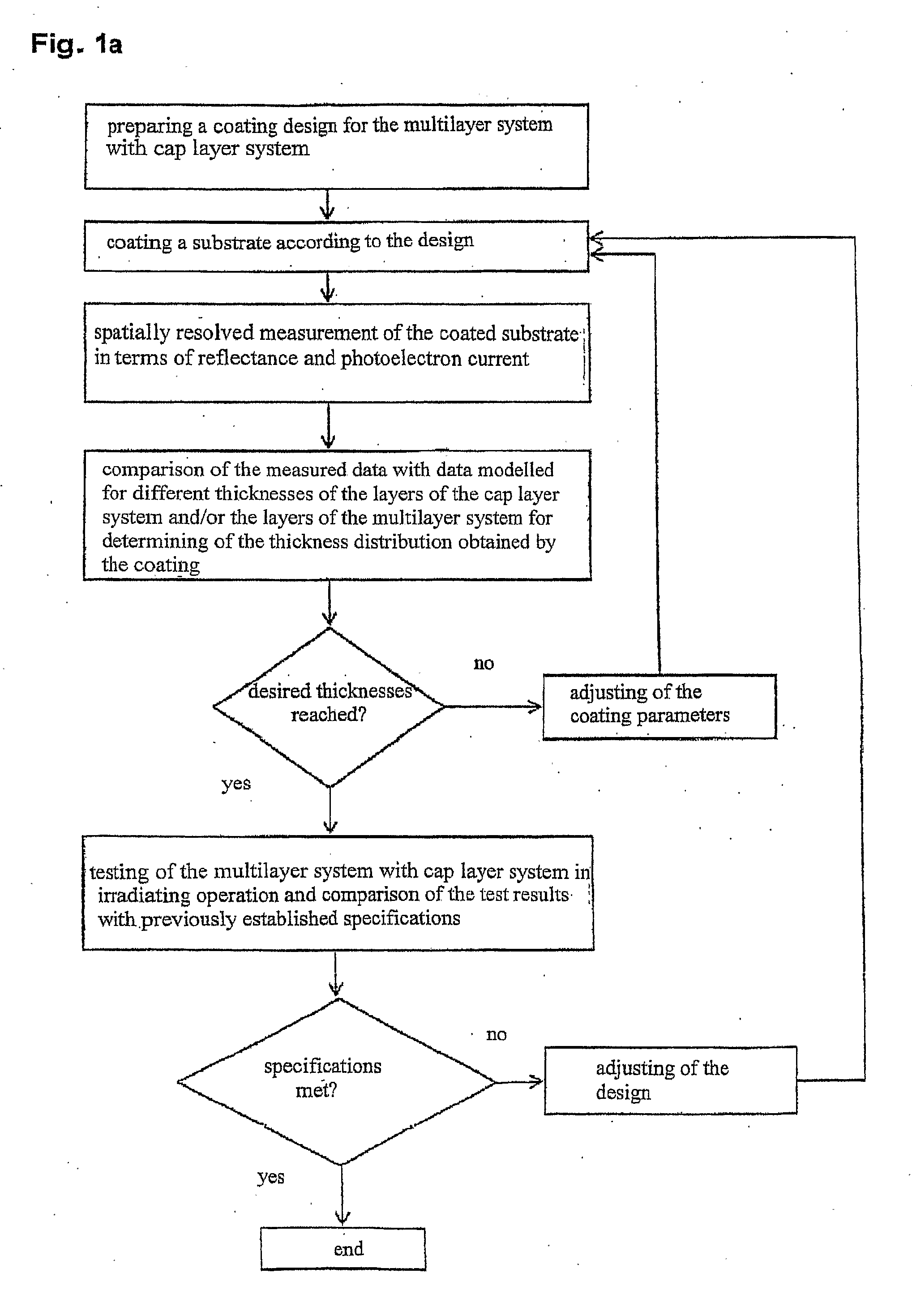

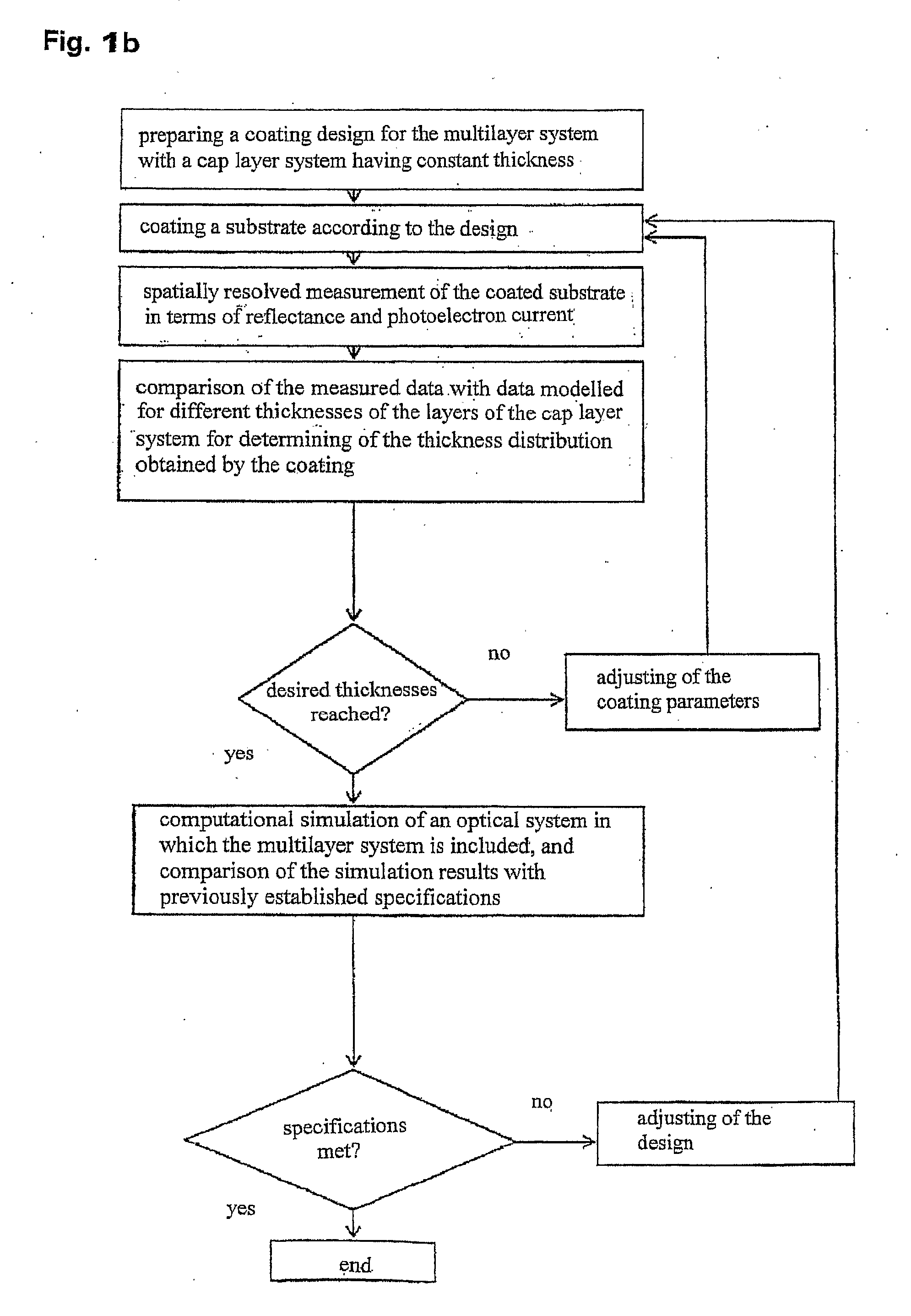

Method For Manufacturing Reflective Optical Element, Reflective Optical Elements, Euv-Lithography Apparatus And Methods For Operating Optical Elements And Euv-Lithography Apparatus, Methods For Determining The Phase Shift, Methods For Determining The Layer Thickness, And Apparatuses For Carrying Out The Methods

InactiveUS20070285643A1Large intensityPhotomechanical apparatusUsing optical meansCatoptricsLayer thickness

The invention relates to a method for manufacturing of a multilayer system (25) with a cap layer system (30), in particular for a reflective optical element for the extreme ultraviolet up to the soft x-ray wavelength range, comprising the steps of: 1. preparing a coating design for the multilayer system (25) with cap layer system (30); 2. coating a substrate (20) with the multilayer system (25) with cap layer system (30); 3. spatially resolved measurement of the coated substrate in terms of reflectance and photoelectron current in at least one surface point; 4. comparison of the measured data with data modelled for different thicknesses of the layers (31, 32, 33) of the cap layer system (30) and / or the layers (21, 22, 23, 24) of the multilayer system (25) for determining of the thickness distribution obtained by the coating; 5. if necessary, adjusting of the coating parameters and repeating steps 2 to 5 until the coated thickness distribution coincides with the design. The invention also relates to further manufacturing methods, reflective optical elements, EUV-lithography apparatuses, and methods for operating optical elements and EUV-lithography apparatuses as well as methods for determining the phase shift, methods for determining the layer thickness, and apparatuses for carrying out the methods.

Owner:CARL ZEISS SMT GMBH

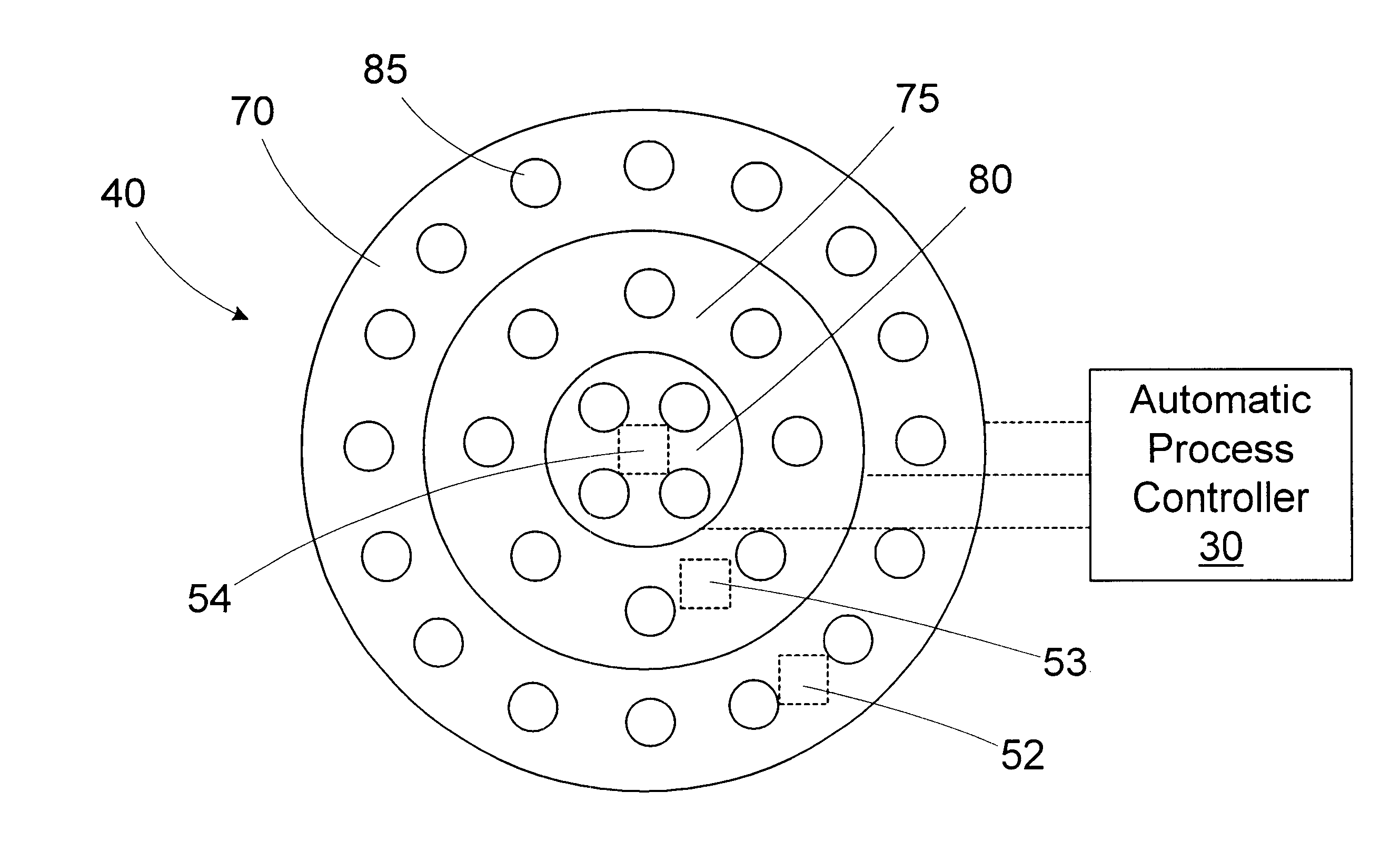

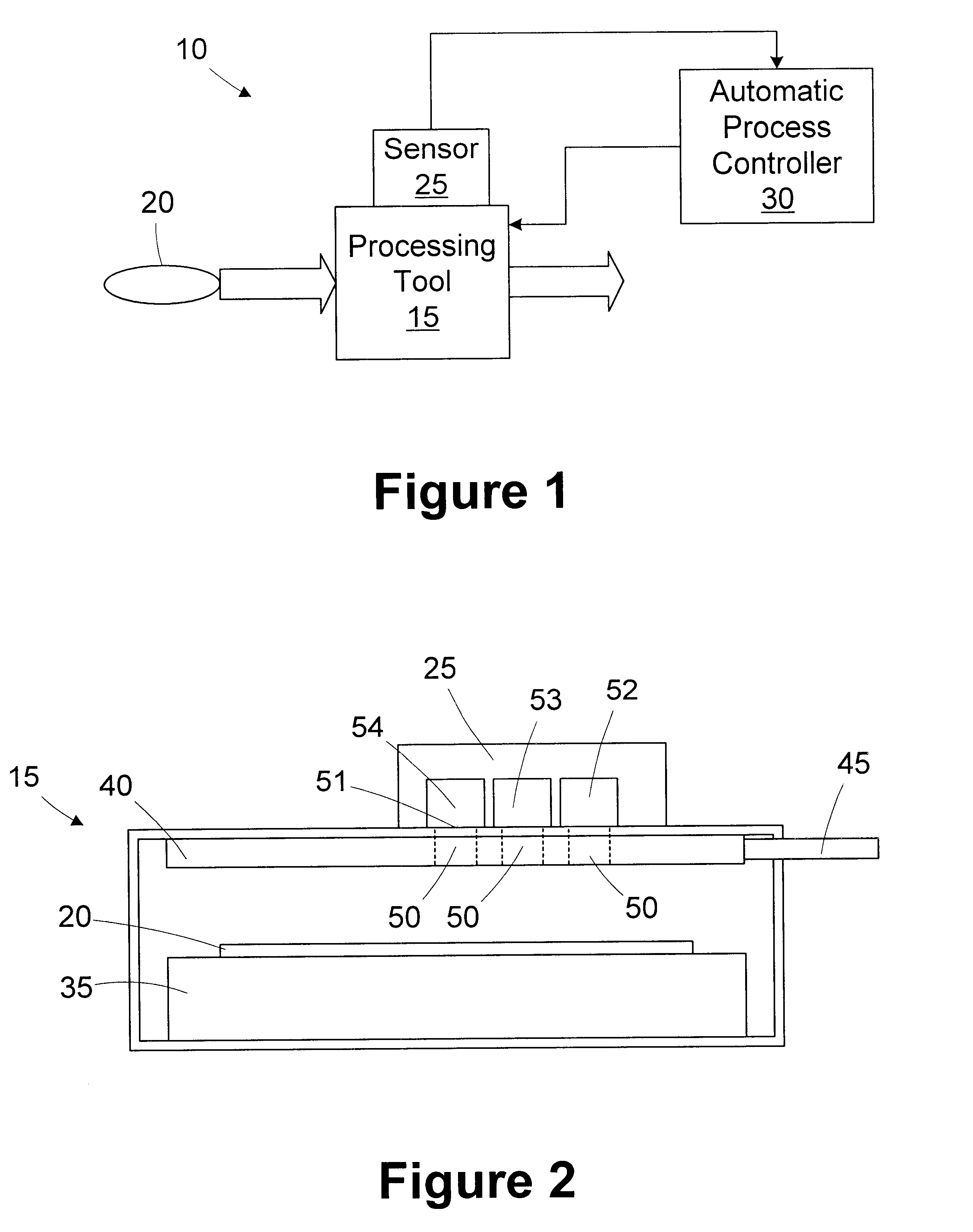

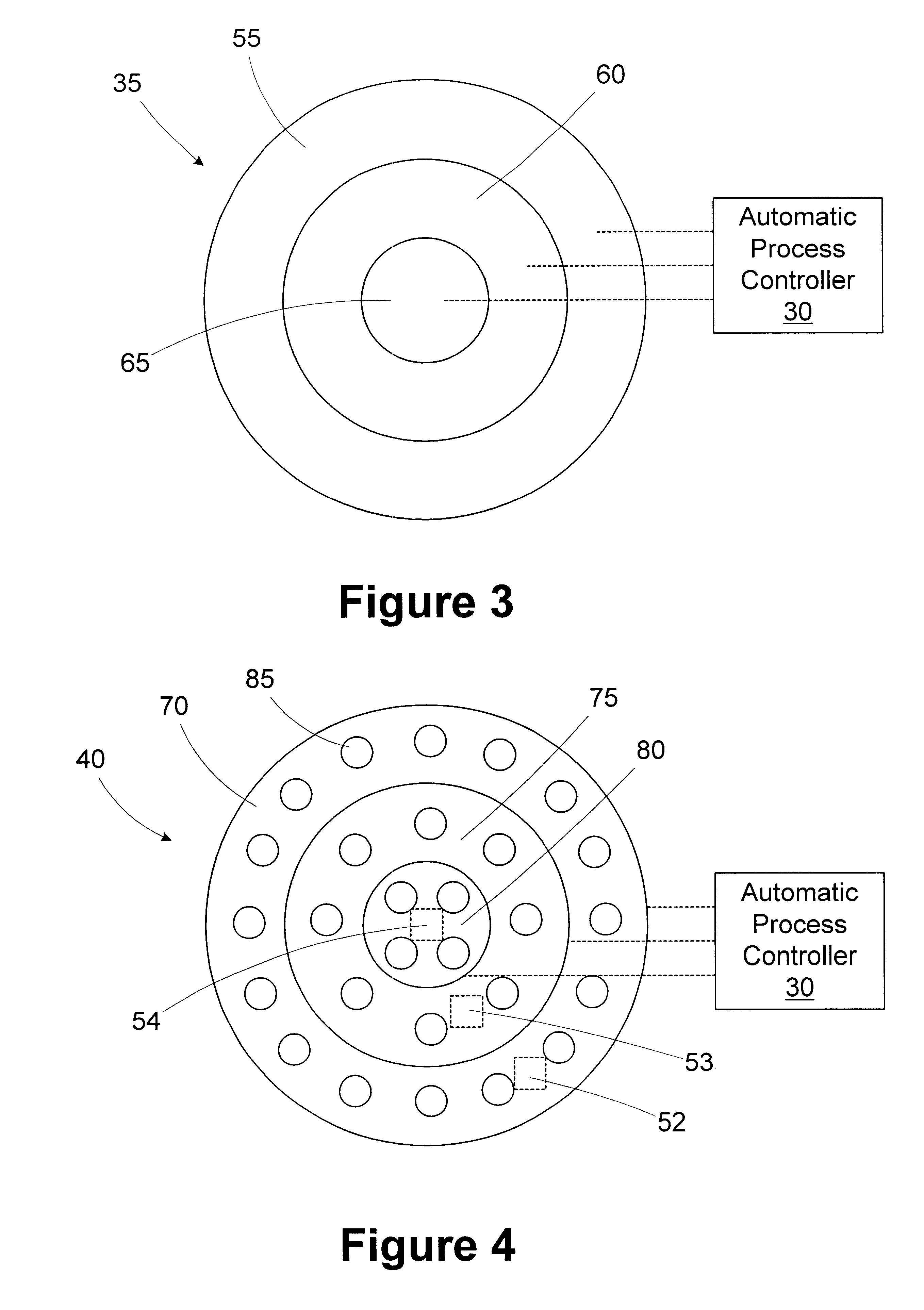

Method and apparatus for controlling wafer uniformity using spatially resolved sensors

InactiveUS6706541B1Semiconductor/solid-state device testing/measurementElectric discharge tubesSpatially resolvedProcess engineering

A processing system includes a sensor, a processing tool, and an automatic process controller. The sensor has a plurality of sensing regions. The processing tool is adapted to process at least one process layer on a wafer. The process tool includes a process control device controllable by a process control variable. The sensor is adapted to measure a process layer characteristic of the process layer in a selected one of the sensing regions. The automatic process controller is adapted to receive the process layer characteristics measured by the sensor and adjust the process control variable in response to the process layer characteristic measured in one sensing region differing from the process layer characteristic measured in another sensing region. A method for controlling wafer uniformity includes processing a process layer on a wafer; measuring a characteristic of the layer in a plurality of sensing locations; and changing a process control variable of a process control device in response to the process layer characteristic measured in one sensing location differing from the process layer characteristic measured in another sensing location to affect the rate of processing the process layer in at least one of the sensing locations.

Owner:ADVANCED MICRO DEVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com