Patents

Literature

1301results about How to "Expand the scope of use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

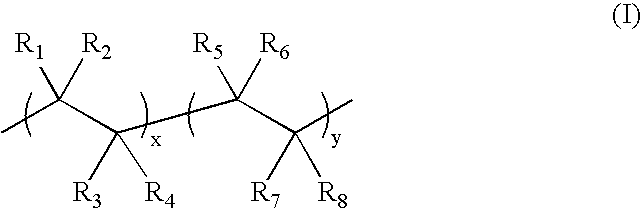

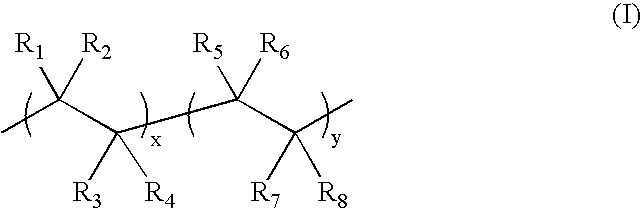

Capsules, materials for use therein and electrophoretic media and displays containing such capsules

InactiveUS20040012839A1Good water solubilityExpand the scope of useMicroballoon preparationNon-linear opticsElectrophoresisDisplay device

An encapsulation material, intended for use in encapsulated electrophoretic displays, comprises the coacervation product of a polyanionic polymer having a vinyl main chain and a plurality of anionic groups bonded to the main chain, with a cationic or zwitterionic water-soluble polymer capable of forming an immiscible second phase on contact with the polyanionic polymer.

Owner:E INK CORPORATION

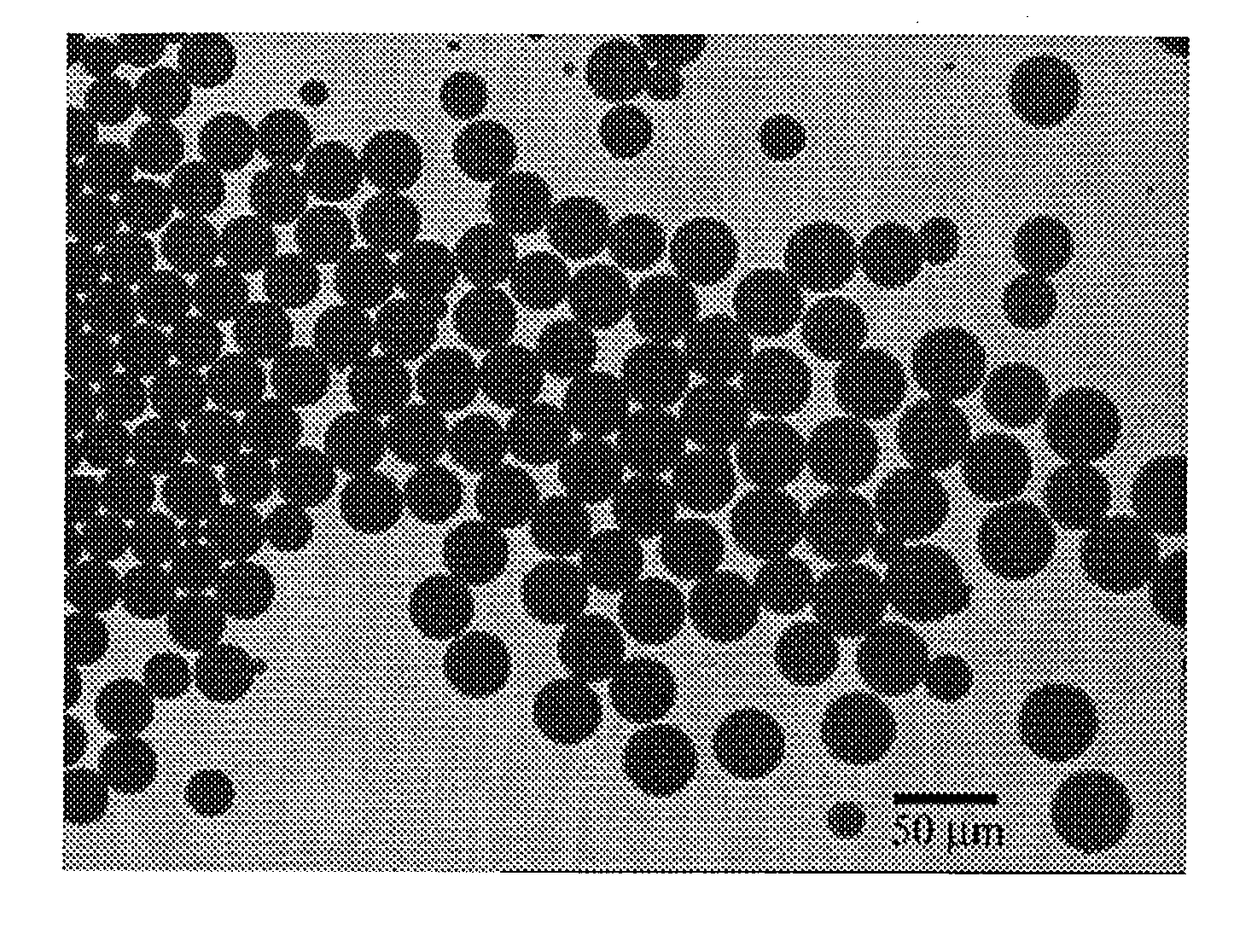

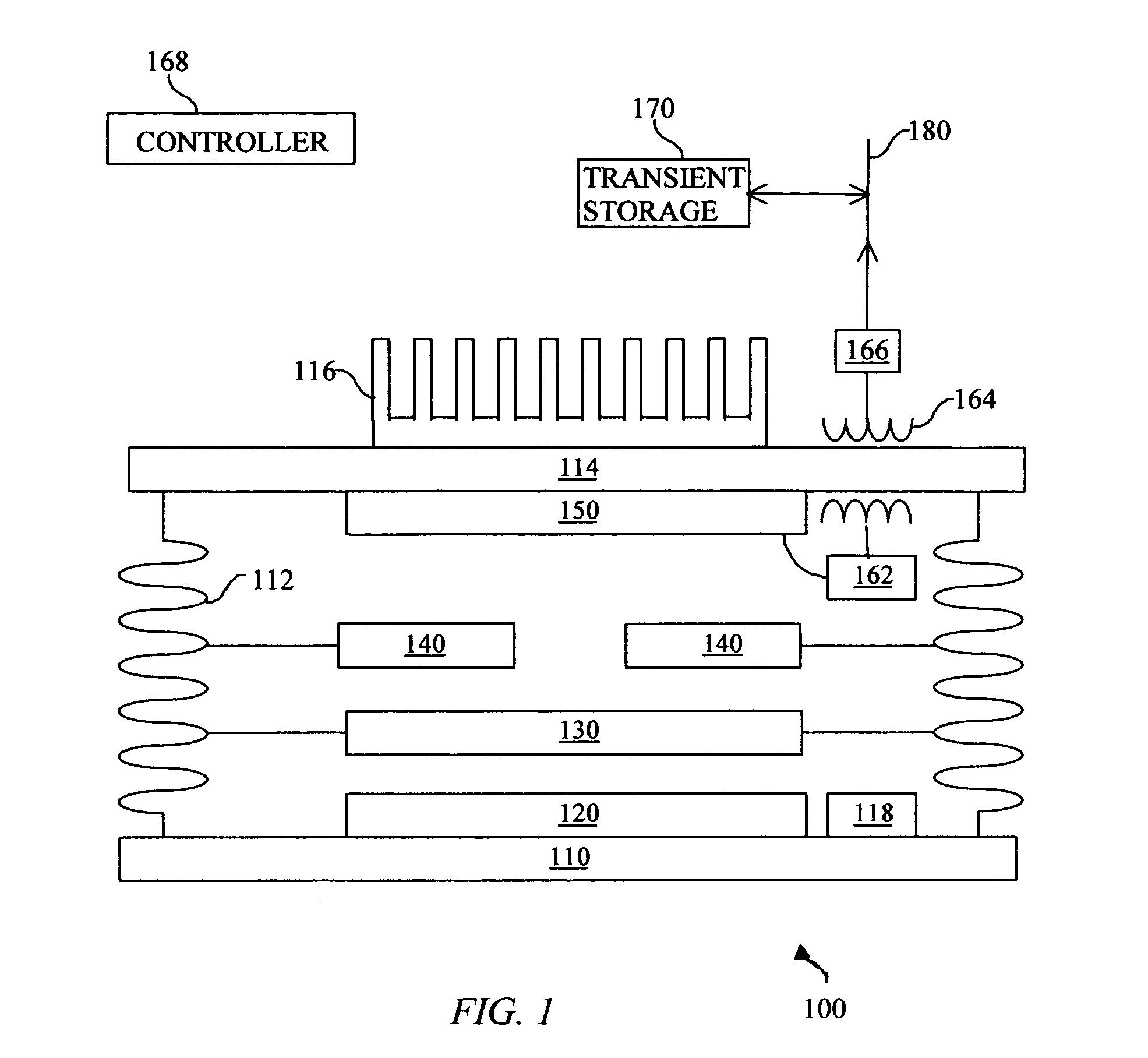

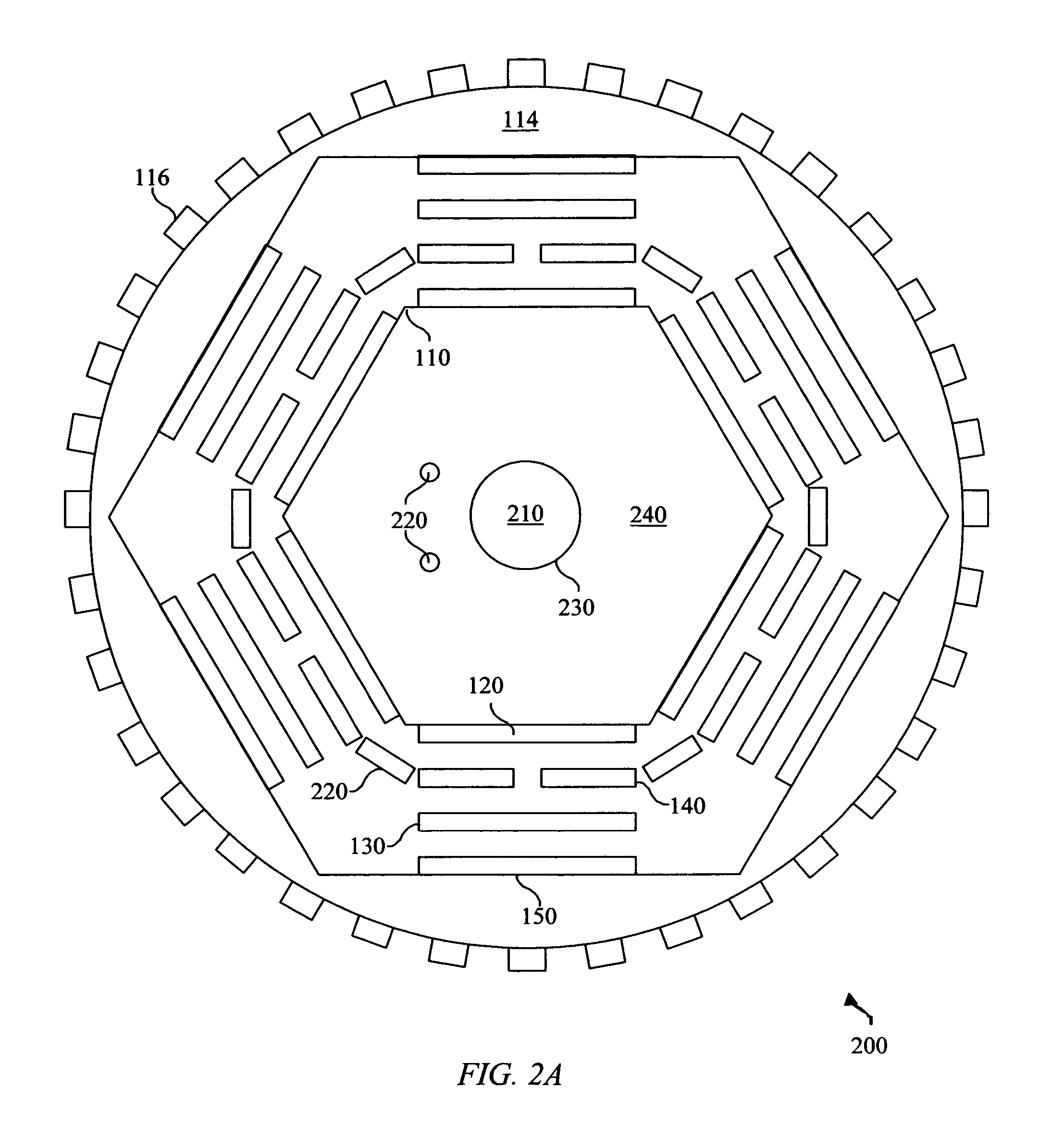

System and method for enhanced thermophotovoltaic generation

InactiveUS20050109386A1Reduce fossil fueled NOx emissionIncreasing burner efficiencyThermoelectric device with peltier/seeback effectPV power plantsThermophotovoltaicDistributed generation

A system and method for lower cost, high efficiency, thermophotovoltaic distributed generation includes: an emitter, a photovoltaic cell, and transient electrical energy storage.

Owner:PRACTICAL TECH

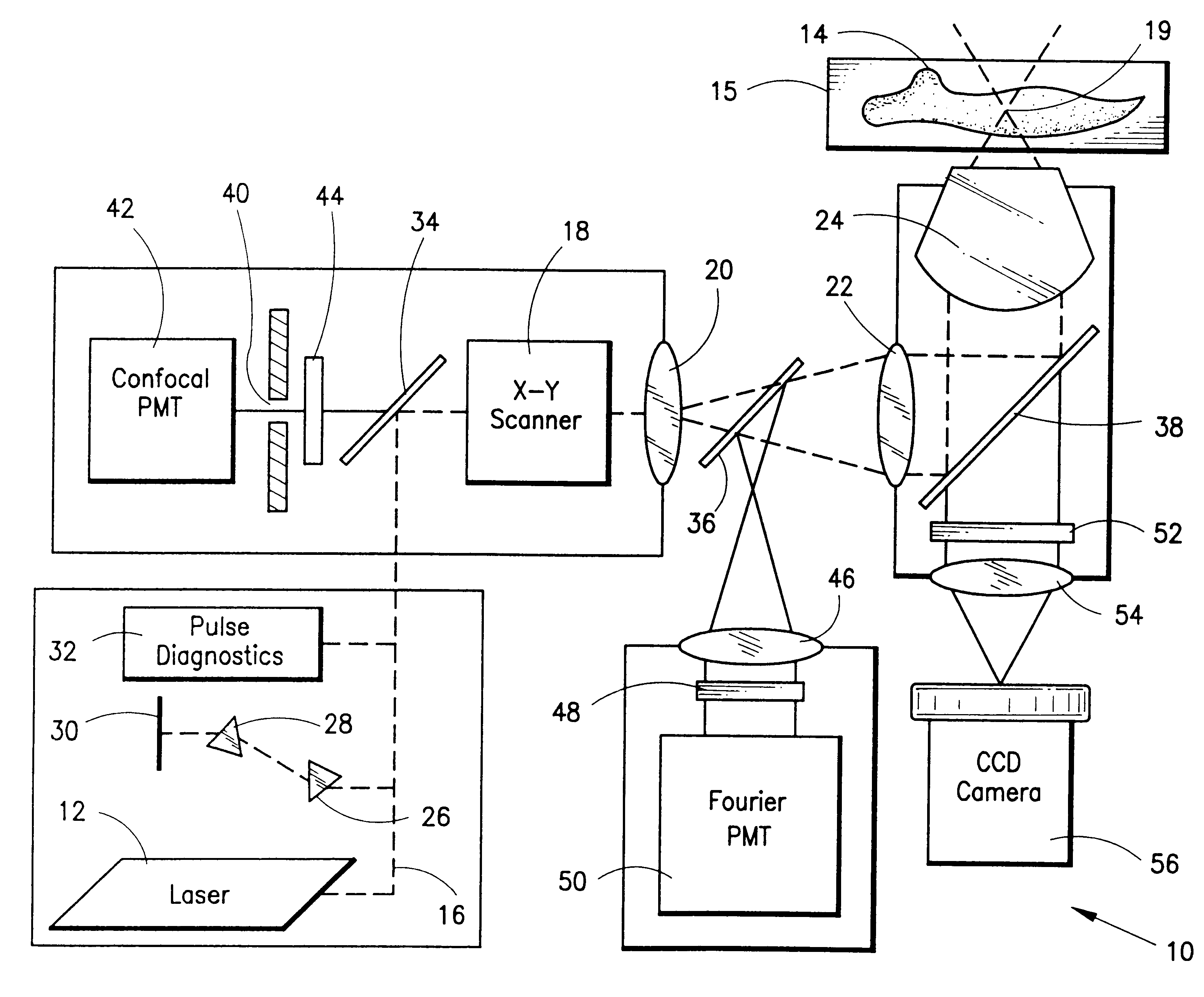

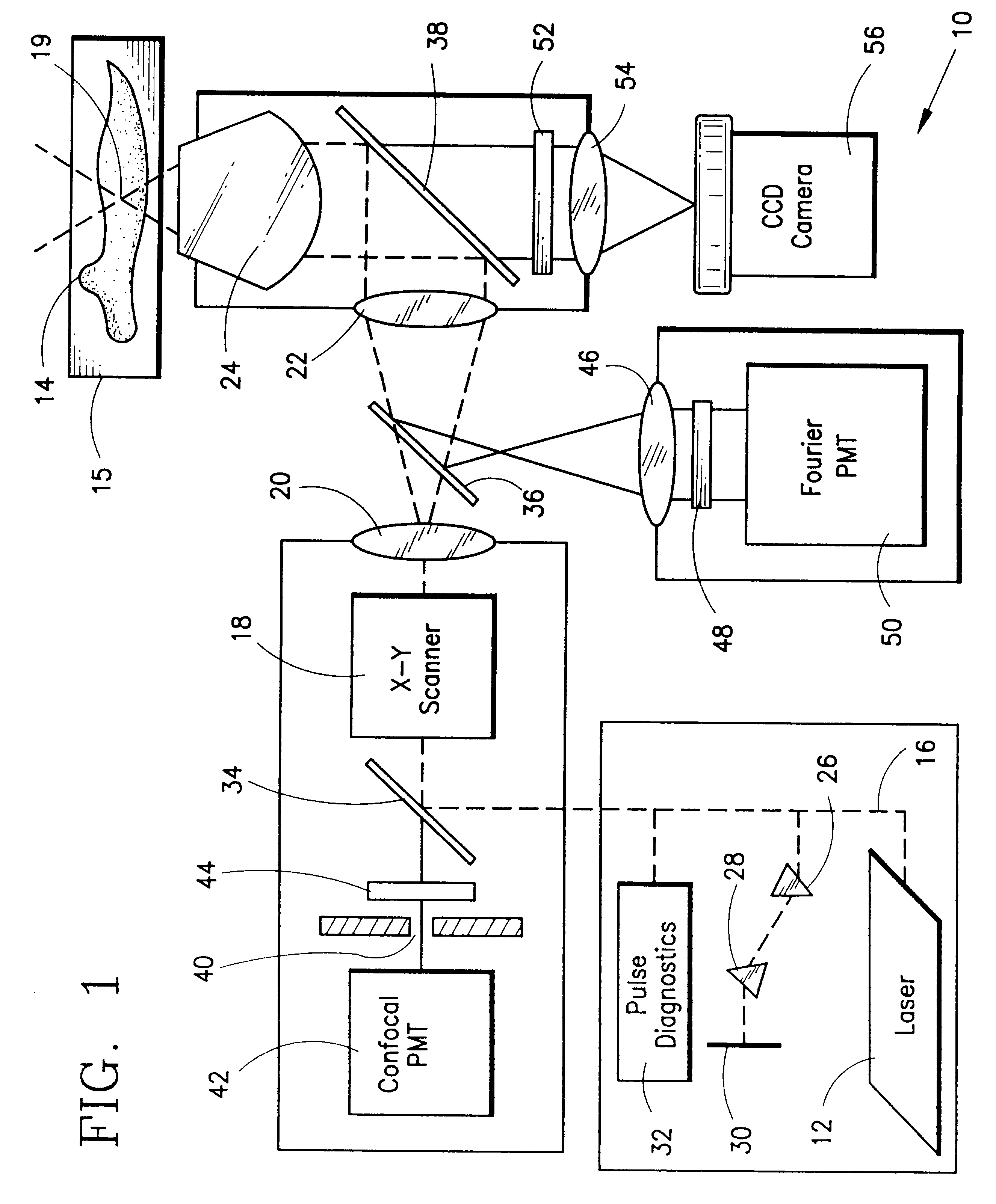

Multi-photon laser microscopy

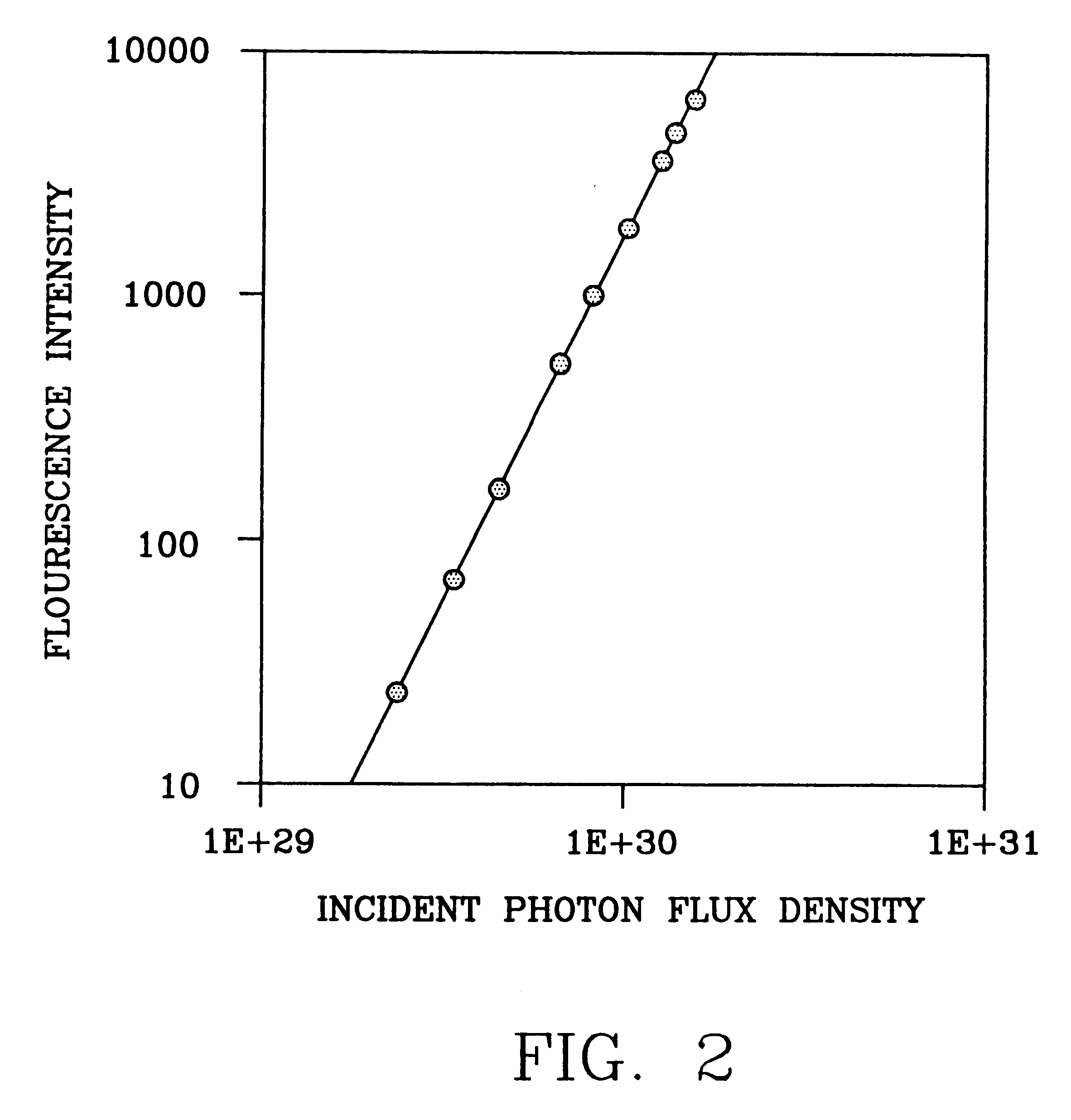

InactiveUS6344653B1Less photodamageExpand the scope of useLaser detailsPhotometryConfocal laser scanning microscopeLaser scanning microscope

A laser scanning microscope produces molecular excitation in a target material by simultaneous absorption of three or more photons to thereby provide intrinsic three-dimensional resolution. Fluorophores having single photon absorption in the short (ultraviolet or visible) wavelength range are excited by a beam of strongly focused subpicosecond pulses of laser light of relatively long (red or infrared) wavelength range. The fluorophores absorb at about one third, one fourth or even smaller fraction of the laser wavelength to produce fluorescent images of living cells and other microscopic objects. The fluorescent emission from the fluorophores increases cubicly, quarticly or even higher power law with the excitation intensity so that by focusing the laser light, fluorescence as well as photobleaching are confined to the vicinity of the focal plane. This feature provides depth of field resolution comparable to that produced by confocal laser scanning microscopes, and in addition reduces photobleaching and phototoxicity. Scanning of the laser beam by a laser scanning microscope, allows construction of images by collecting multi-photon excited fluorescence from each point in the scanned object while still satisfying the requirement for very high excitation intensity obtained by focusing the laser beam and by pulse time compressing the beam. The focused pulses also provide three-dimensional spatially resolved photochemistry which is particularly useful in photolytic release of caged effector molecules, marking a recording medium or in laser ablation or microsurgery. This invention refers explicitly to extensions of two-photon excitation where more than two photons are absorbed per excitation in this nonlinear microscopy.

Owner:WEBB WATT W +1

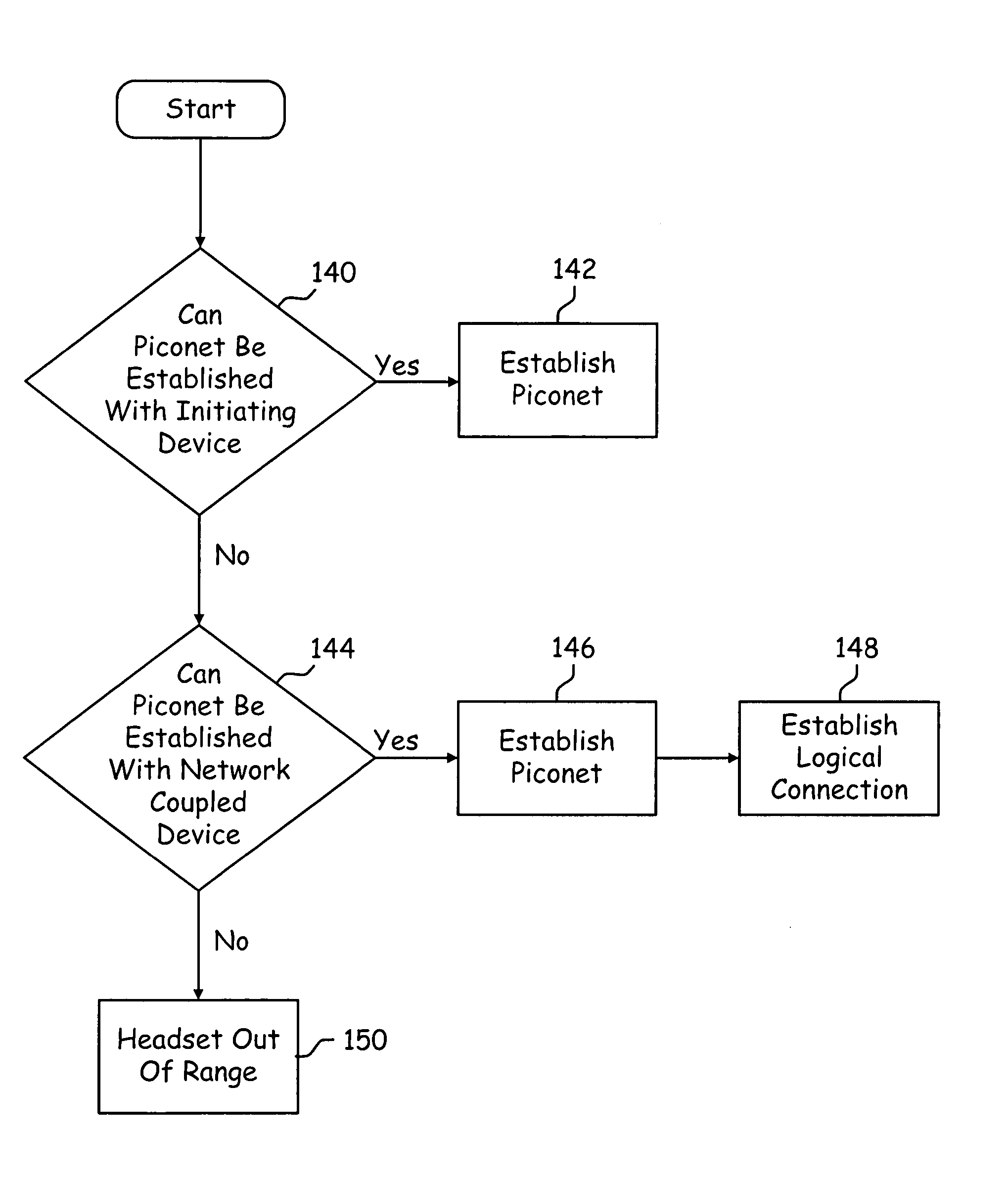

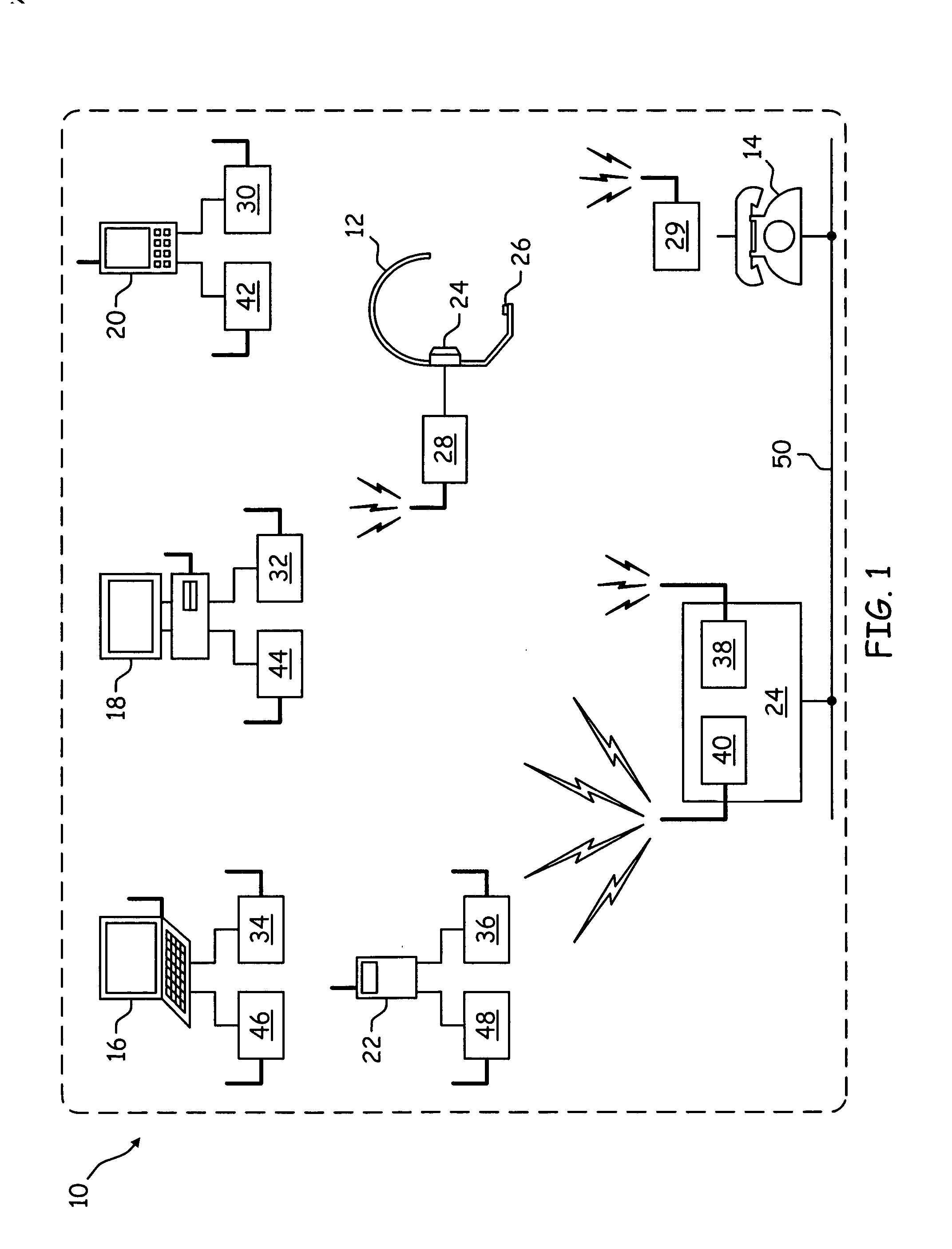

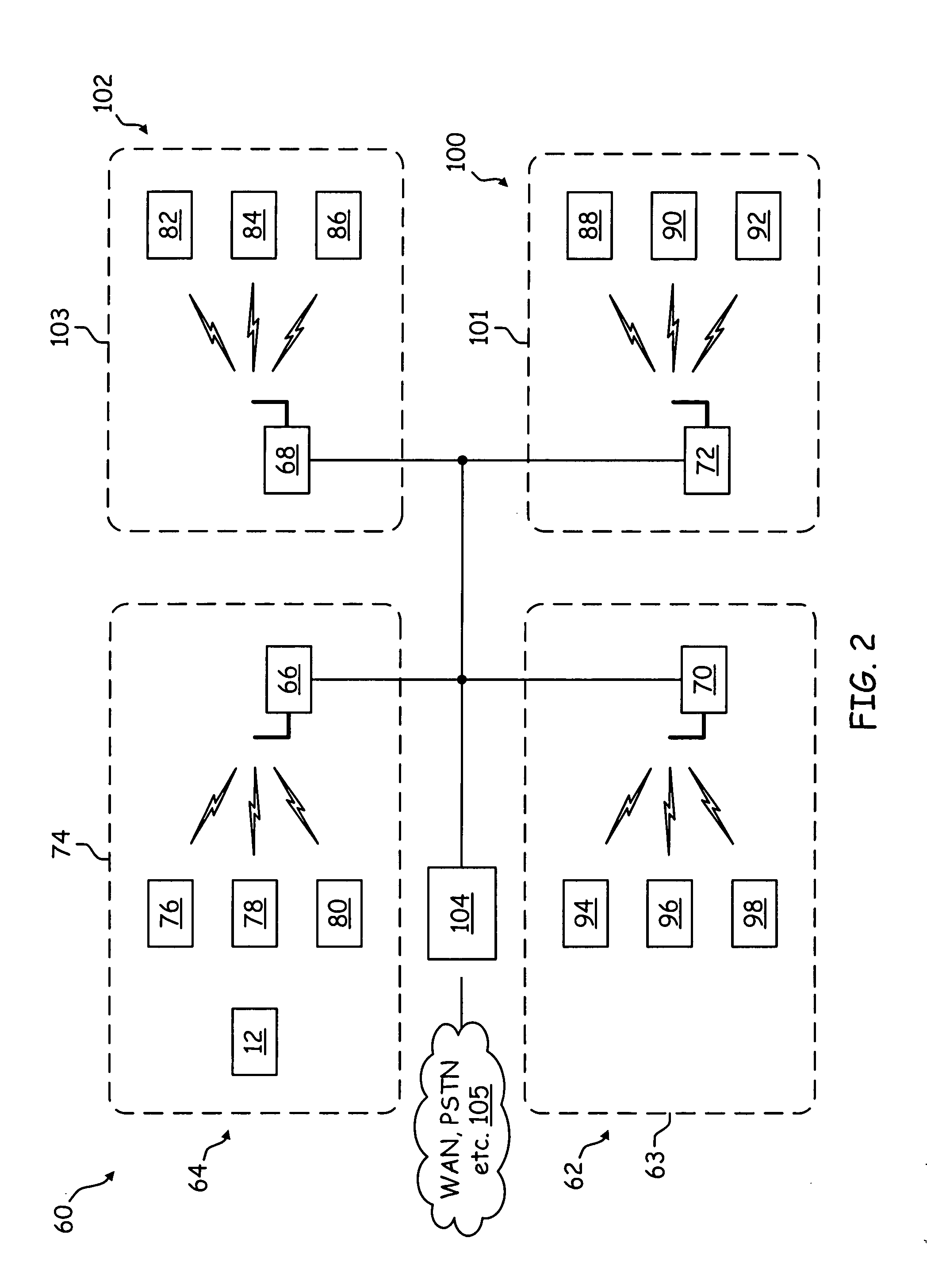

Providing a universal wireless headset

InactiveUS20050037818A1Improving mobility of userExpand the scope of useNetwork topologiesSubstation speech amplifiersHeadphonesComputer science

Providing of a universal wireless headset begins for an incoming call by determining whether a piconet can be established between an initiating device and the wireless headset. If a piconet cannot be established, the processing continues by determining whether the headset can establish a piconet with a device coupled to a network. The network may be a local area network, which includes wireless devices and / or wired devices. When the wireless headset can establish the piconet with a device coupled to the network, the piconet is established. Once the piconet is established, the processing continues by establishing a logical connection between the initiating device and the device coupled to the network. As such, the incoming communication is supported via the logical connection and the piconet.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

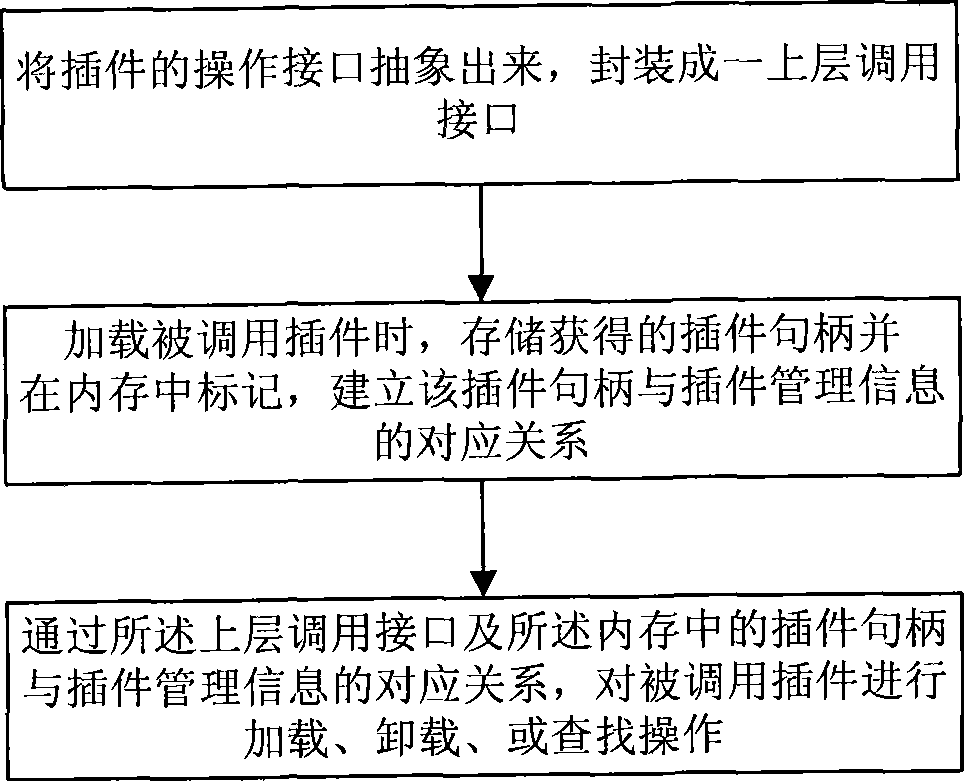

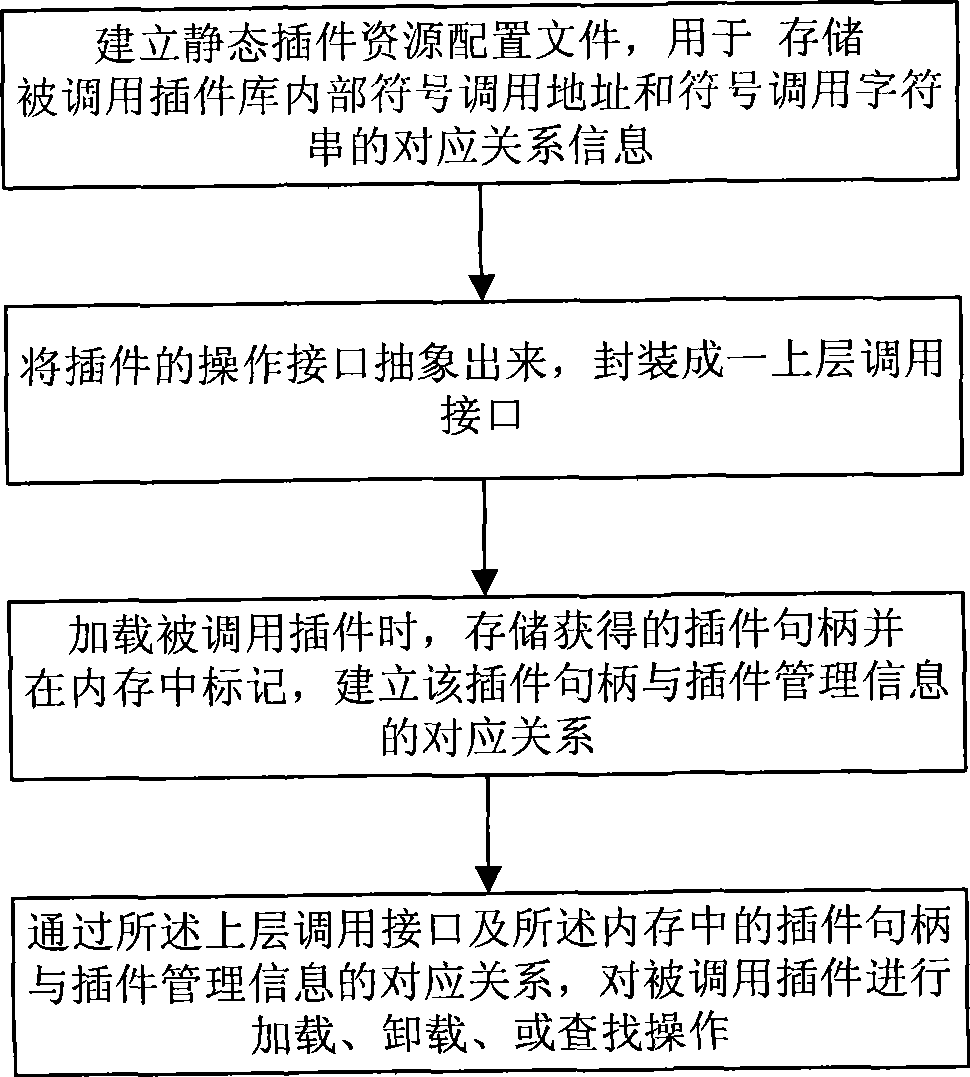

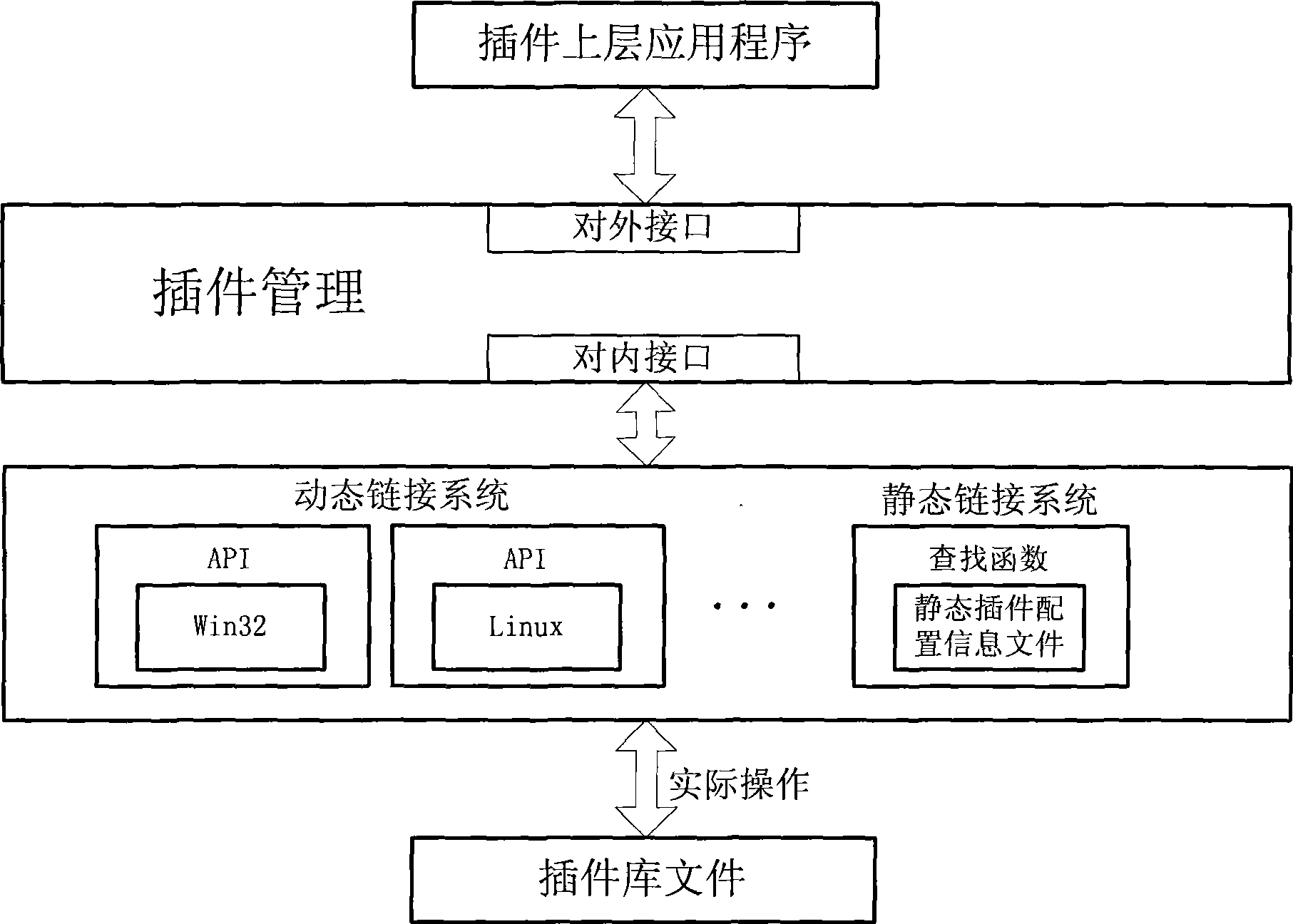

Plug-in management method and system thereof

InactiveCN101464805AExpand the scope of useImprove scalabilityMultiprogramming arrangementsProgram loading/initiatingCross-platformTransplantation

The invention discloses a method for managing a plug-in and a system thereof. The method comprises the following steps: A, abstracting the operation interface of the plug-in and encapsulating the interface into an upper-level invocation interface; B, storing obtained plug-in handle and marking in a memory when loading the plug-in needs to be invoked, and establishing the corresponding relationship between the plug-in handle and the plug-in management information; and C, conducting loading, unloading or searching operation to the plug-in to be invoked according to the upper-level invocation interface and the corresponding relationship between the plug-in handle and the plug-in management information in the memory. The invention realizes unified storage, operation and management to the plug-in, and particularly aims to solve the difference between static loading and dynamic loading of a shared library, thereby enlarging use range of programs to plug-ins, improving the cross-platform expansibility of programs, and facilitating the transplantation of programs.

Owner:ZTE CORP

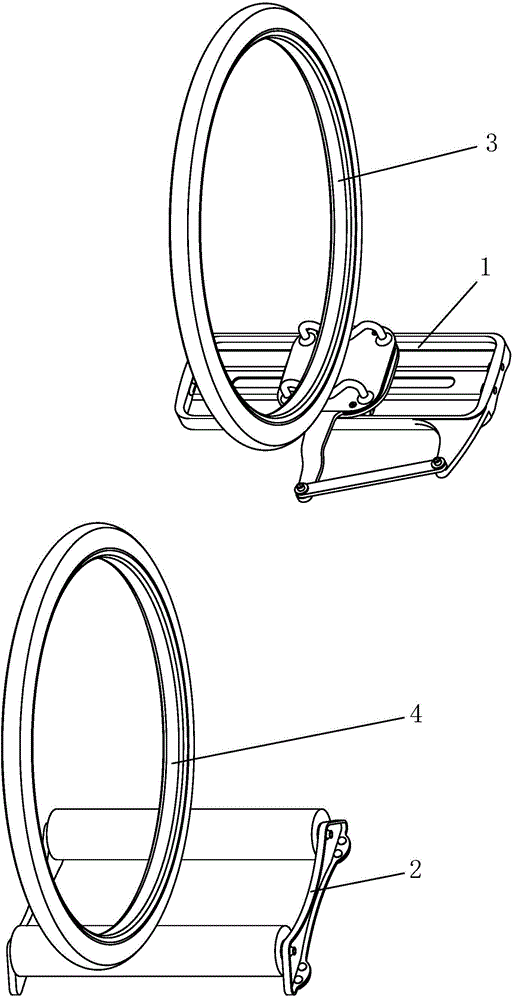

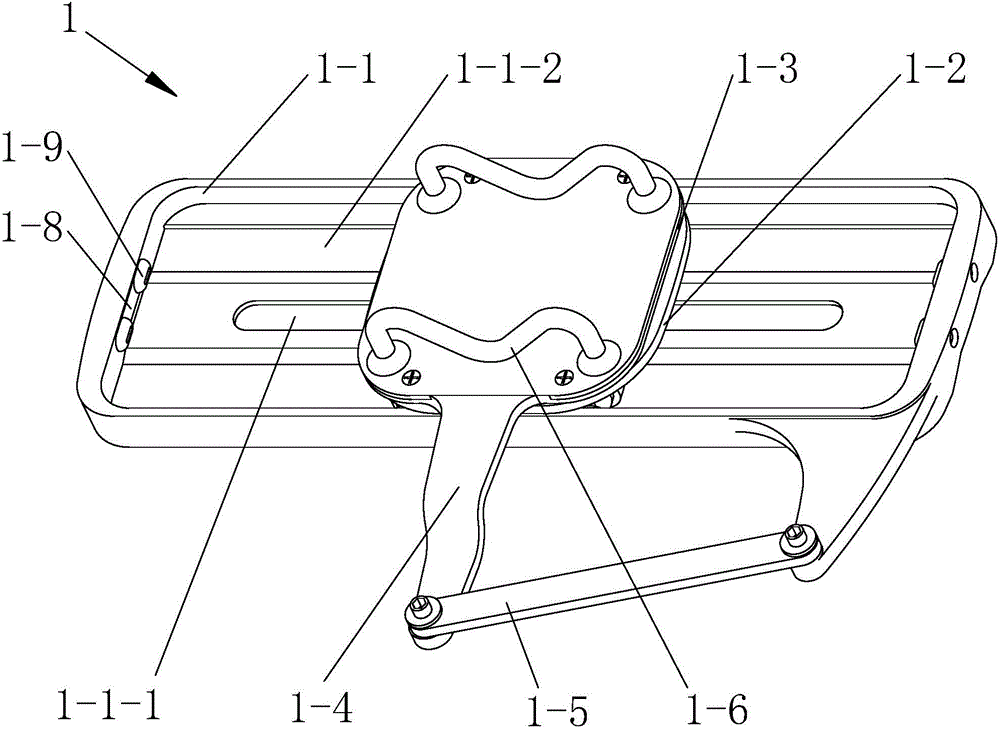

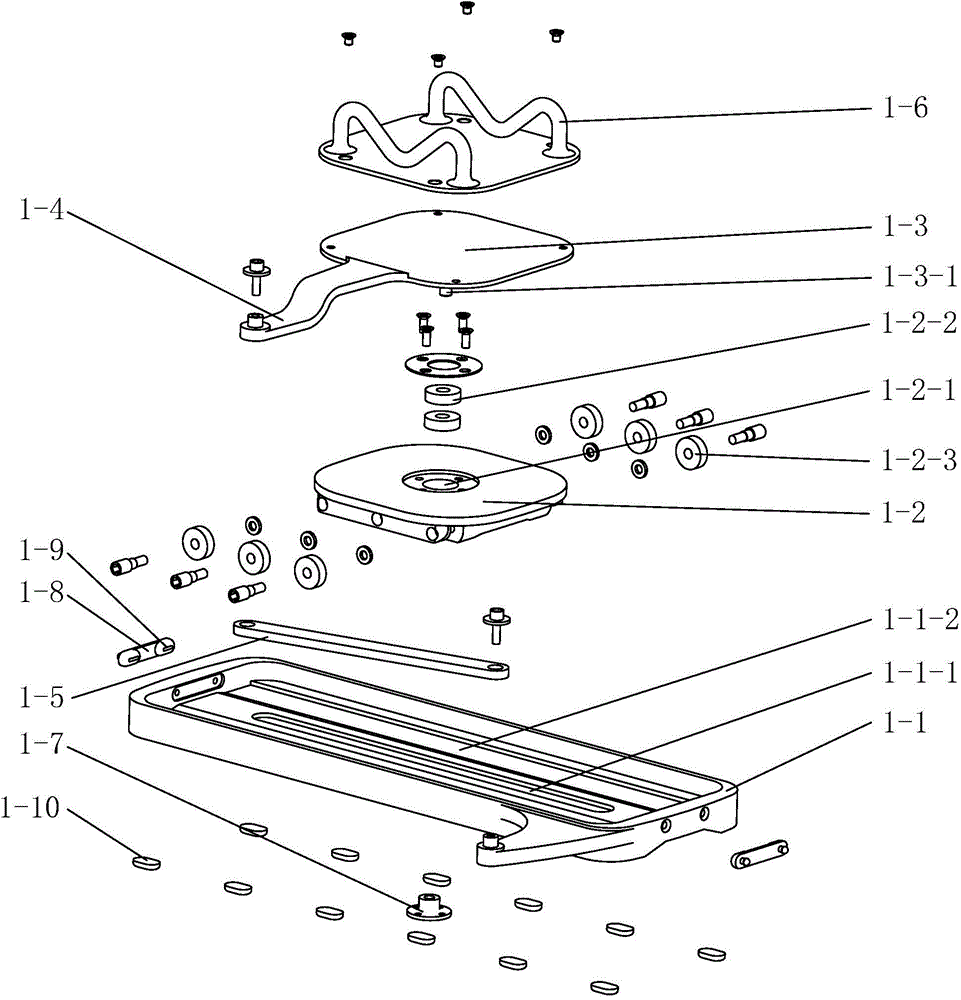

Push-pull rod type bicycle riding balance simulator

InactiveCN104147769AHigh degree of simulationIncrease flexibilitySport apparatusPush pullEngineering

The invention relates to a push-pull rod type bicycle riding balance simulator which comprises a balancing device used for accommodating a front wheel of a bicycle, and a roller device located behind the balancing device and used for accommodating a rear wheel of the bicycle, wherein the balancing device comprises a base, a sliding part connected to the base in a sliding mode, a rotary part connected to the sliding part in a rotary mode, a swing rod fixedly connected to the rotary part, and a push-pull rod connected between the swing rod and the base in a rotary mode, and a limiting device used for restraining the front wheel of the bicycle from sliding leftwards and rightwards is arranged on the rotary part. The simulator is high in simulation degree, simple in structure and low in manufacturing cost.

Owner:HEZE BOILER FACTORY

Method for blending and setting wood

ActiveCN101596730AAlleviate the prominent contradiction between supply and demandExpand the scope of useWood compressionWood treatment detailsPulp and paper industryDistortion

The invention relates to the technique field of wood processing treatment, in particular to a method for blending and setting wood. The method for blending and setting wood comprises steps of sorting treatment, softening process, blending and deforming, setting, temperature reduction and humidifying, and cooling and health preserving. The method solves the problems existing in the existing traditional wood blending and distortion technique that wood utilization ratio is low, obtained products have poor size stability and high recovery rate of radius of curvature and is easy to crack, deform, decay and go moldy, etc.

Owner:ZHEJIANG SHIYOU TIMBER

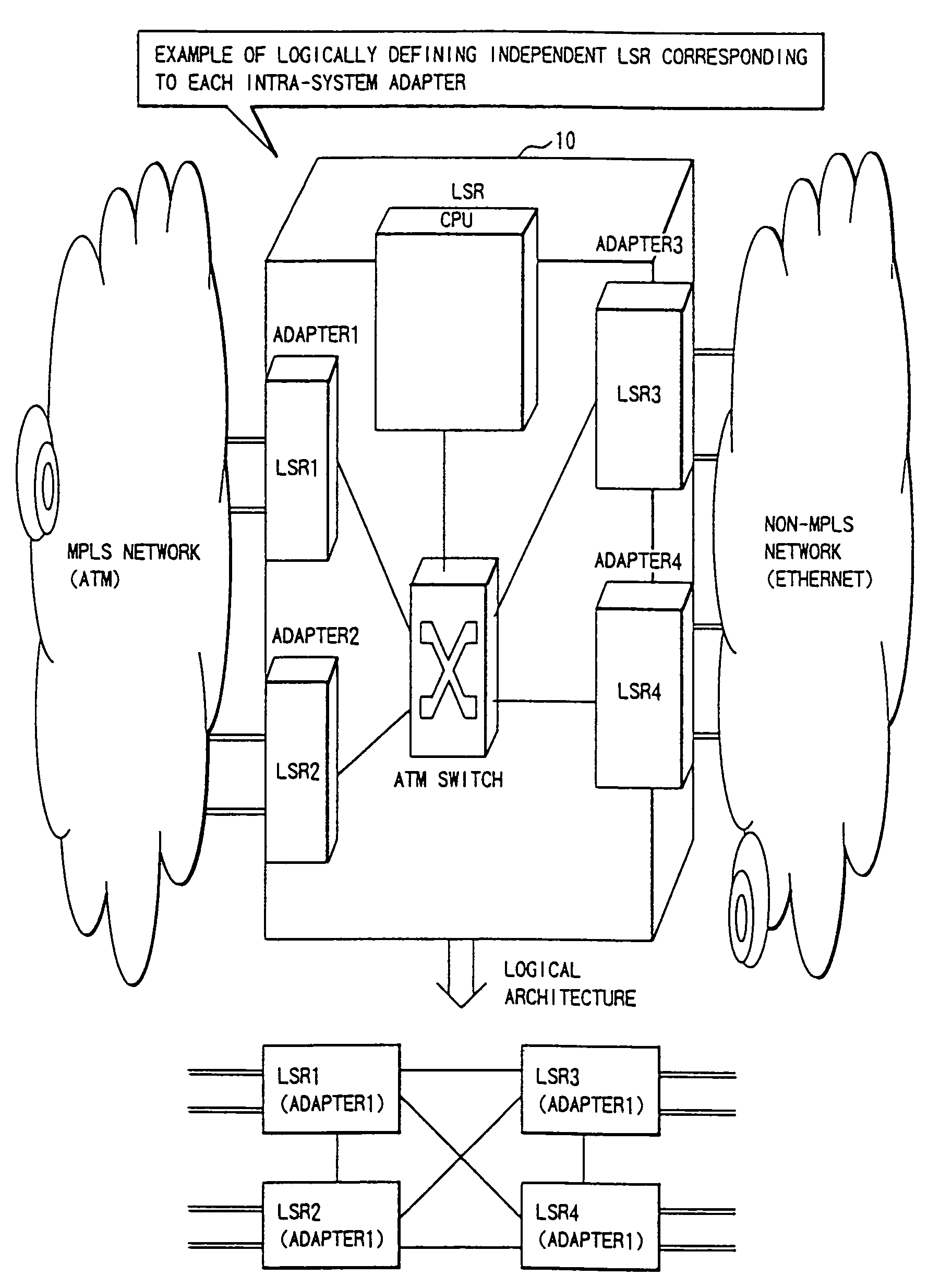

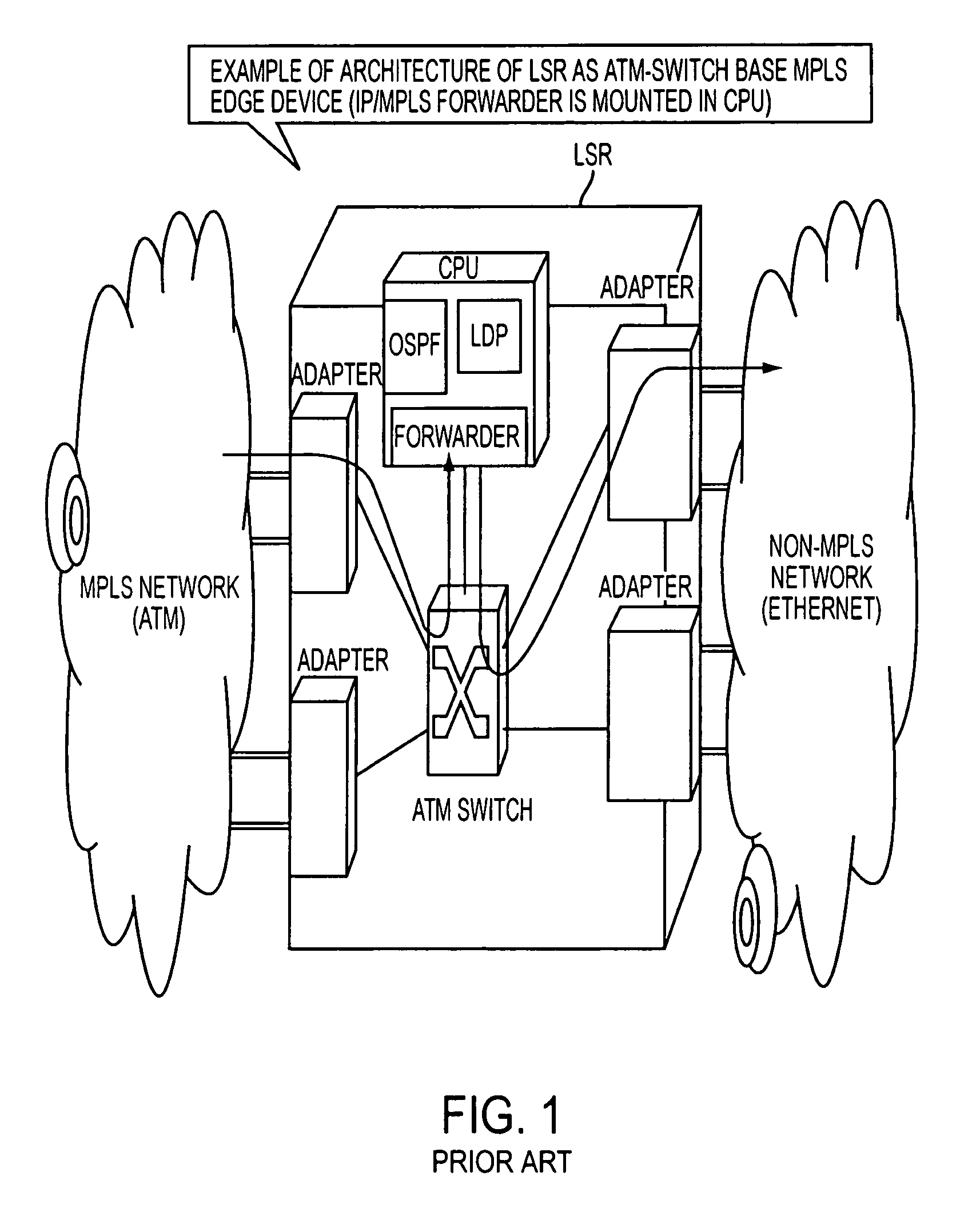

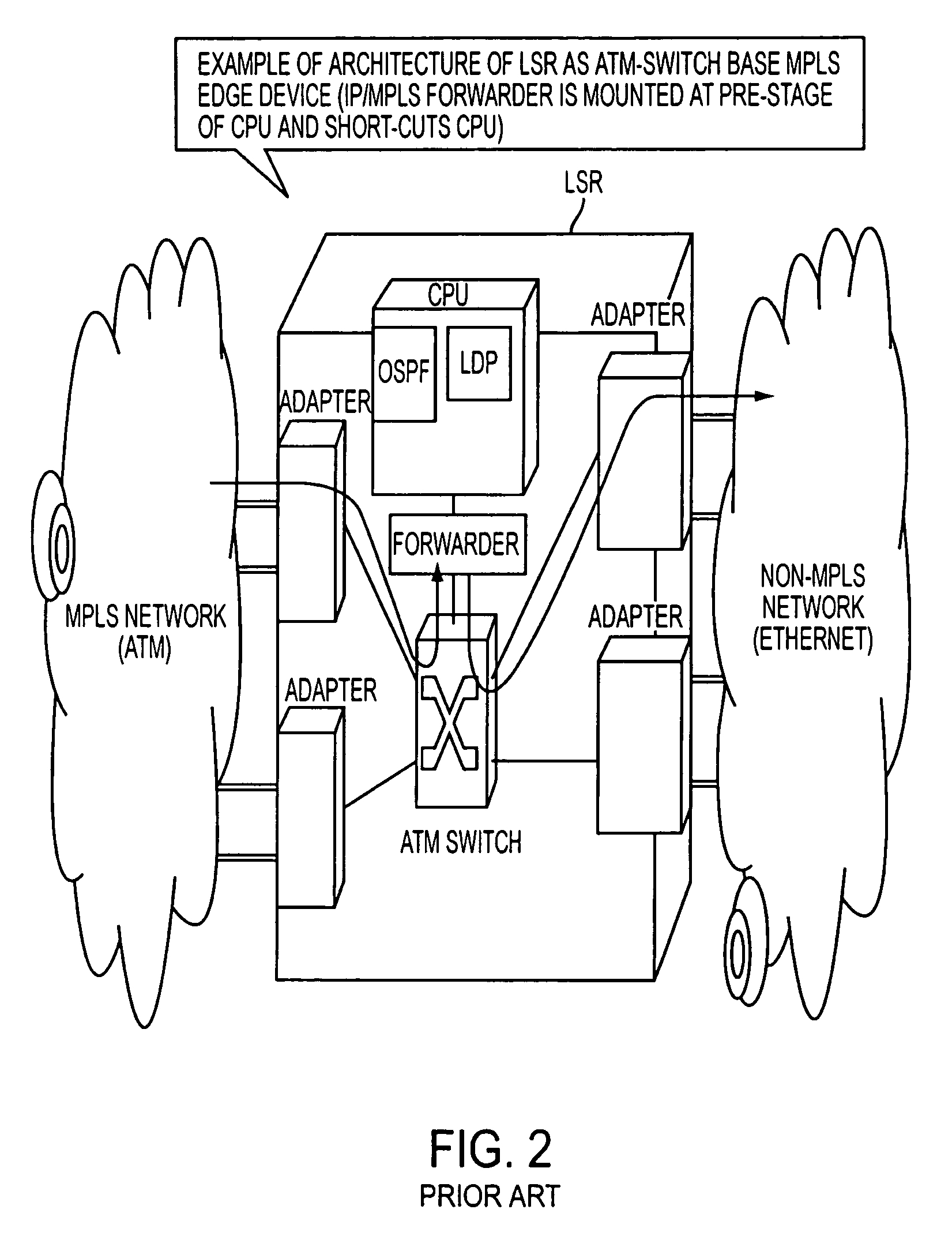

Label switching system

InactiveUS7336648B1Easy to installExpand the scope of useError preventionFrequency-division multiplex detailsGranularityLabel switch router

A packet router in a label switching system includes a logical router configuring module for logically dividing a label switching router (LSR) into a plurality of LSRs each having a label switching function, and a module for specifying, when setting a label switched path on the basis of an explicit route specified, a port or a port group of an egress node. With this construction, a label switching architecture in an ATM network for actualizing MPLS (label switching) can be mapped to an ATM-Switch base system architecture, and a granularity or function (Constraint Base Routing) of specifying a variety of routes provided by MPLS can be attained.

Owner:FUJITSU LTD

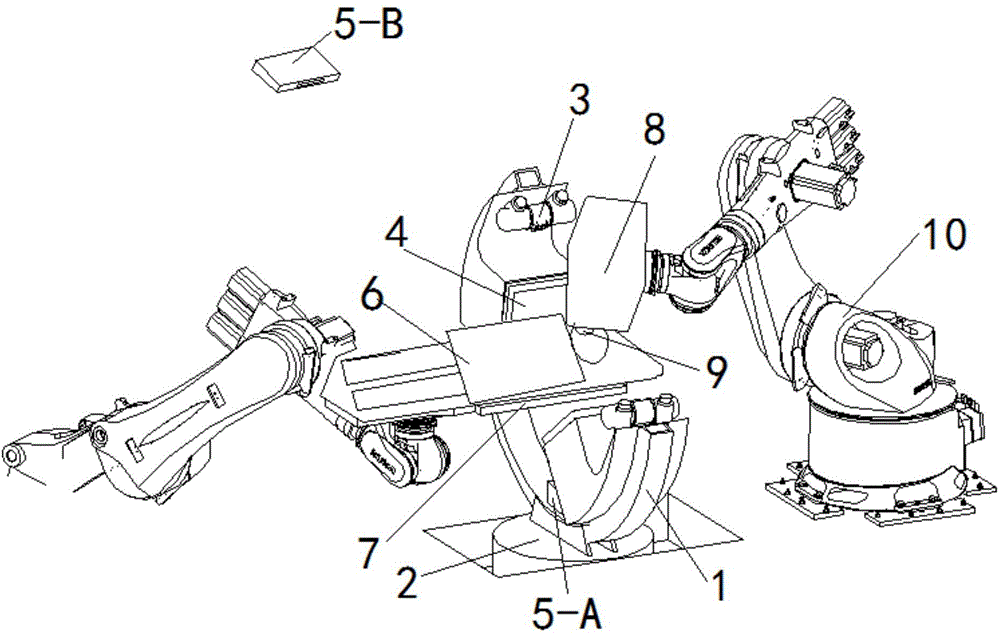

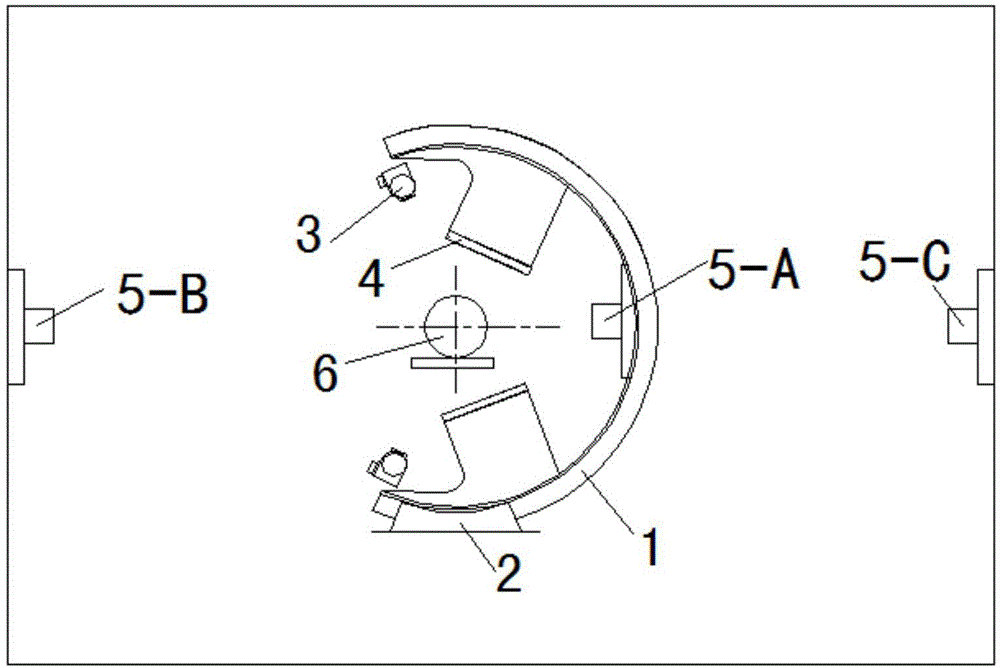

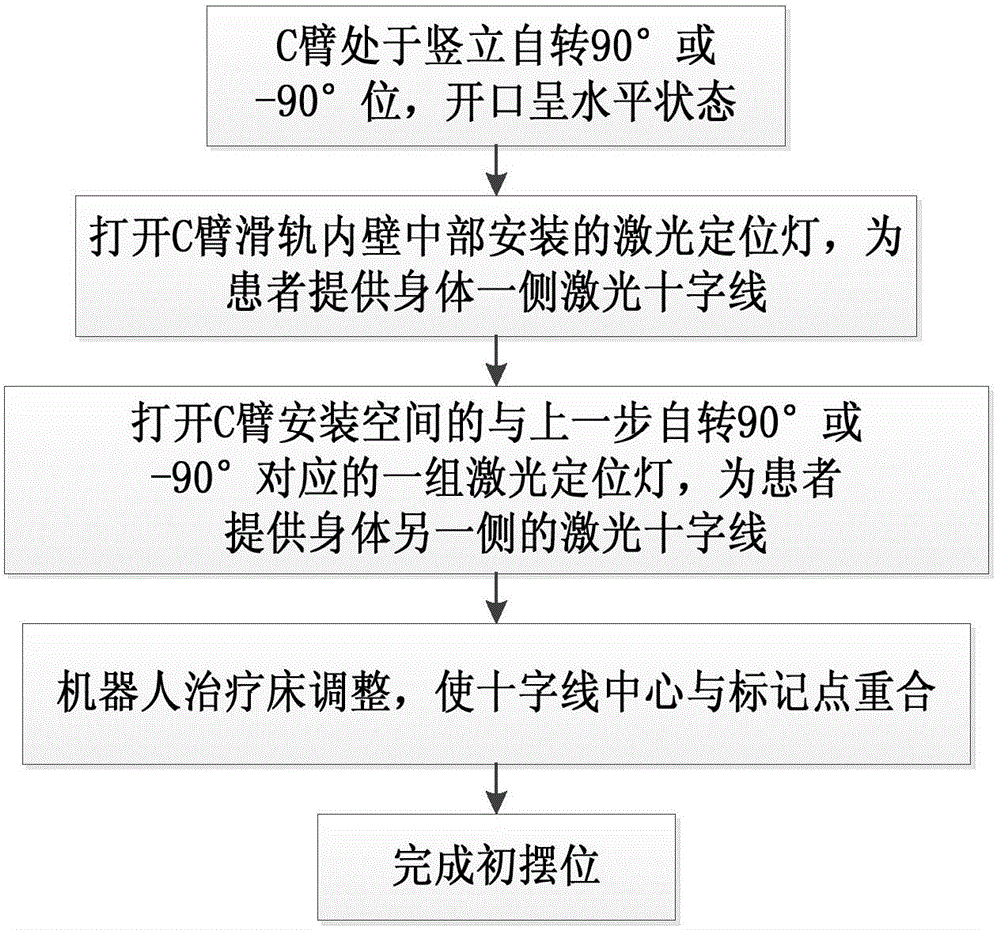

Positioning and locating device for radiotherapy and positioning method of dynamic target region

ActiveCN104587609AFast cross imagingExpand the scope of useComputerised tomographsTomographyEngineeringX ray image

The invention discloses a positioning and locating device for radiotherapy and a positioning method of a dynamic target region. A therapy robot has an operating arm, wherein a compact linear electronic accelerator is arranged at one end of an operating arm of the therapy robot, and a secondary collimator is installed at one end of the compact linear electronic accelerator; a robot treatment table is arranged on a corresponding position of a double-image C-arm system, an C-arm sliding rail laser locator is arranged inside the double-image C-arm system, and a left side locator for an C-arm installation space is arranged on a corresponding position at the outer part of the double-image C-arm system. The positioning and locating device provided by the invention is provided with two groups of X-ray image systems, so as to realize binocular imaging; when the C-arm sliding rail rotates and a group of X-ray image systems is started, and CBCT (Cone Beam Computed Tomography) imaging can be realized; according to the positioning method, different imaging ways are adopted for a static target region and a dynamic target region, the rapidity and timeliness of the binocular imaging, the high quality, high definition and image registration of the CBCT imaging can be fully exerted.

Owner:RADIATION THERAPY MEDICAL SCI & TECH CO LTD

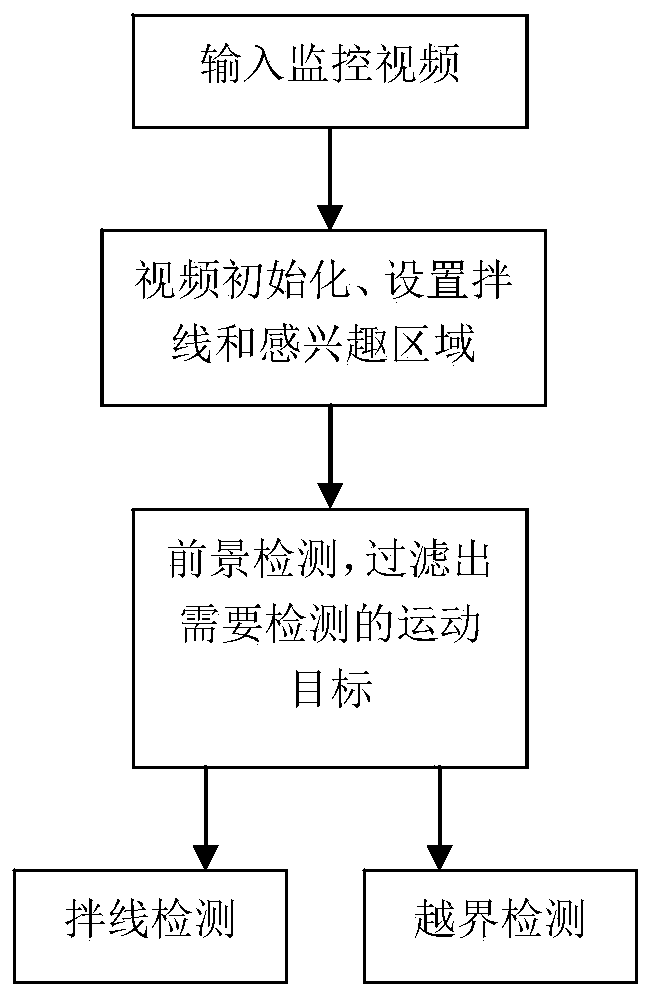

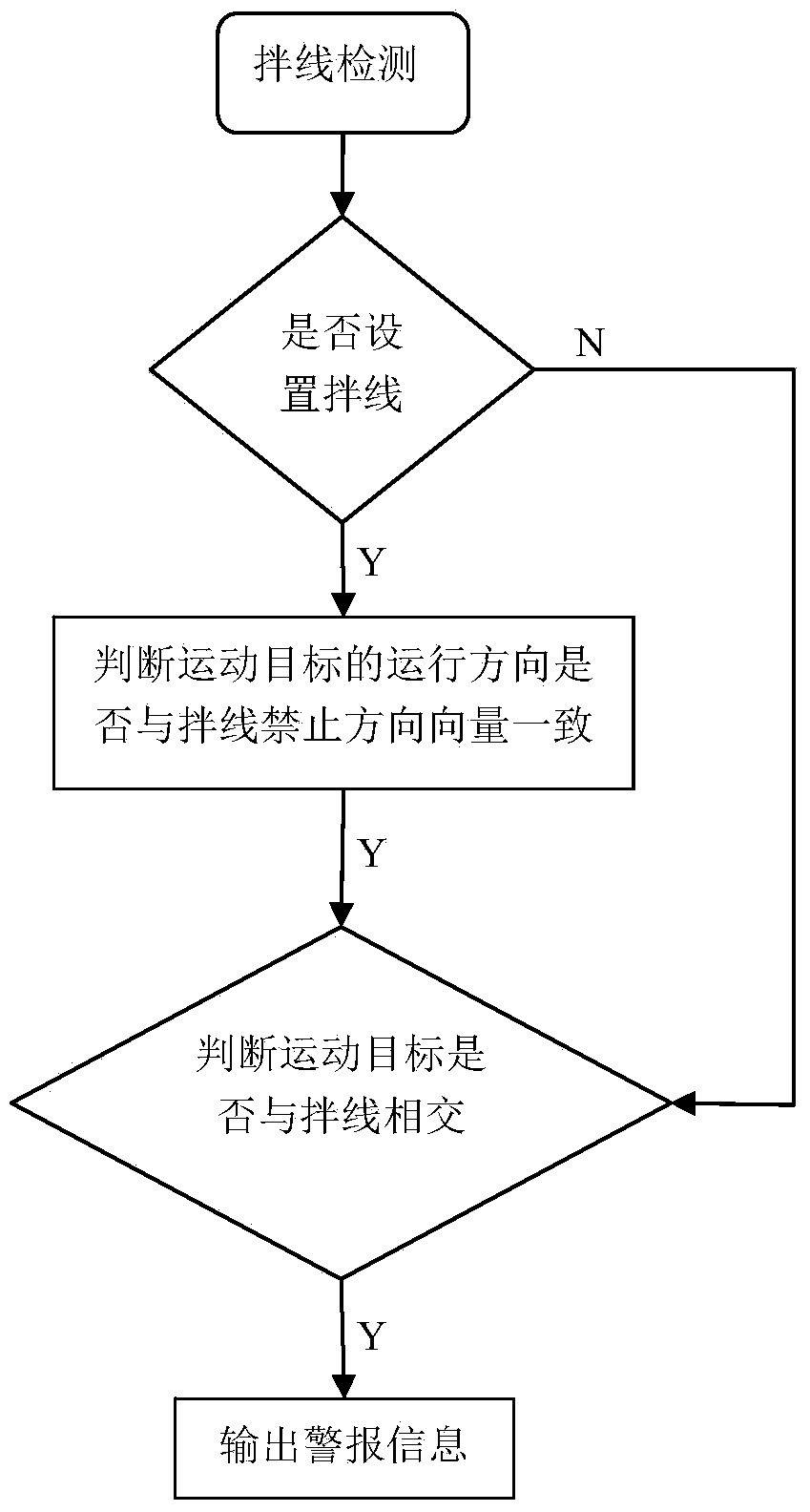

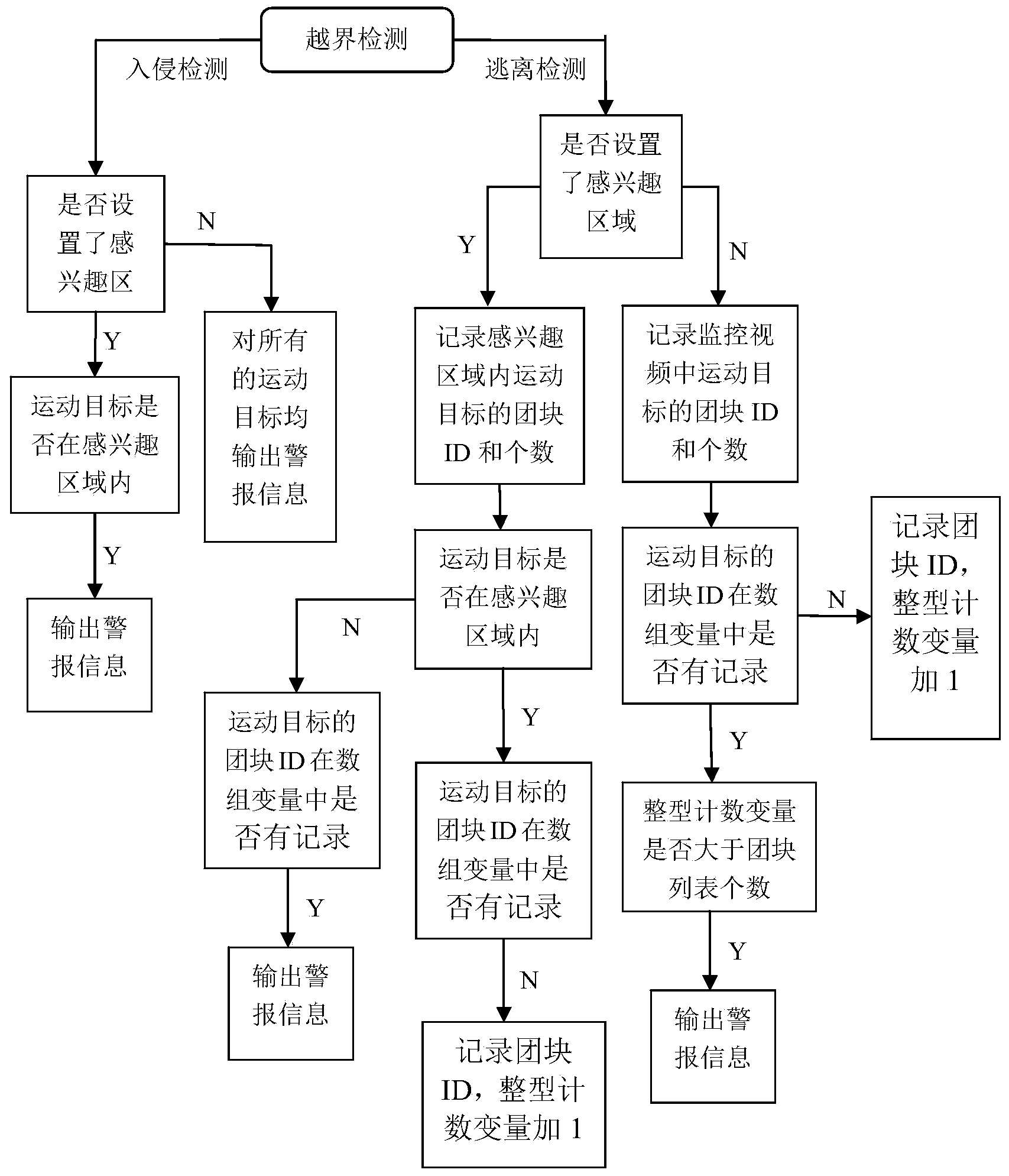

Method for directional cross-border detection and mixing line detection in video

InactiveCN104021570AExtended functional scopeExpand the scope of useImage analysisCharacter and pattern recognitionSmall animalImage resolution

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

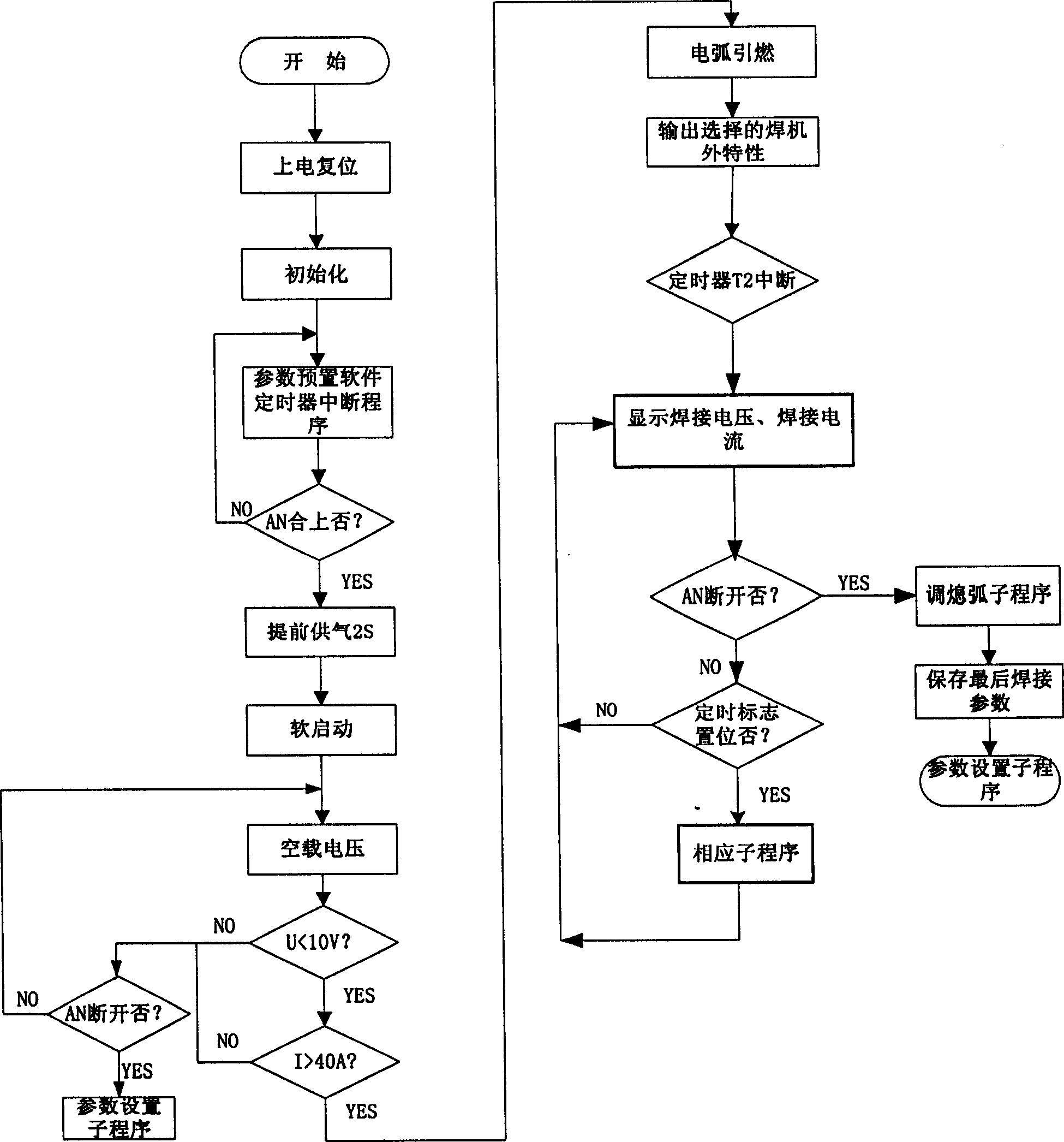

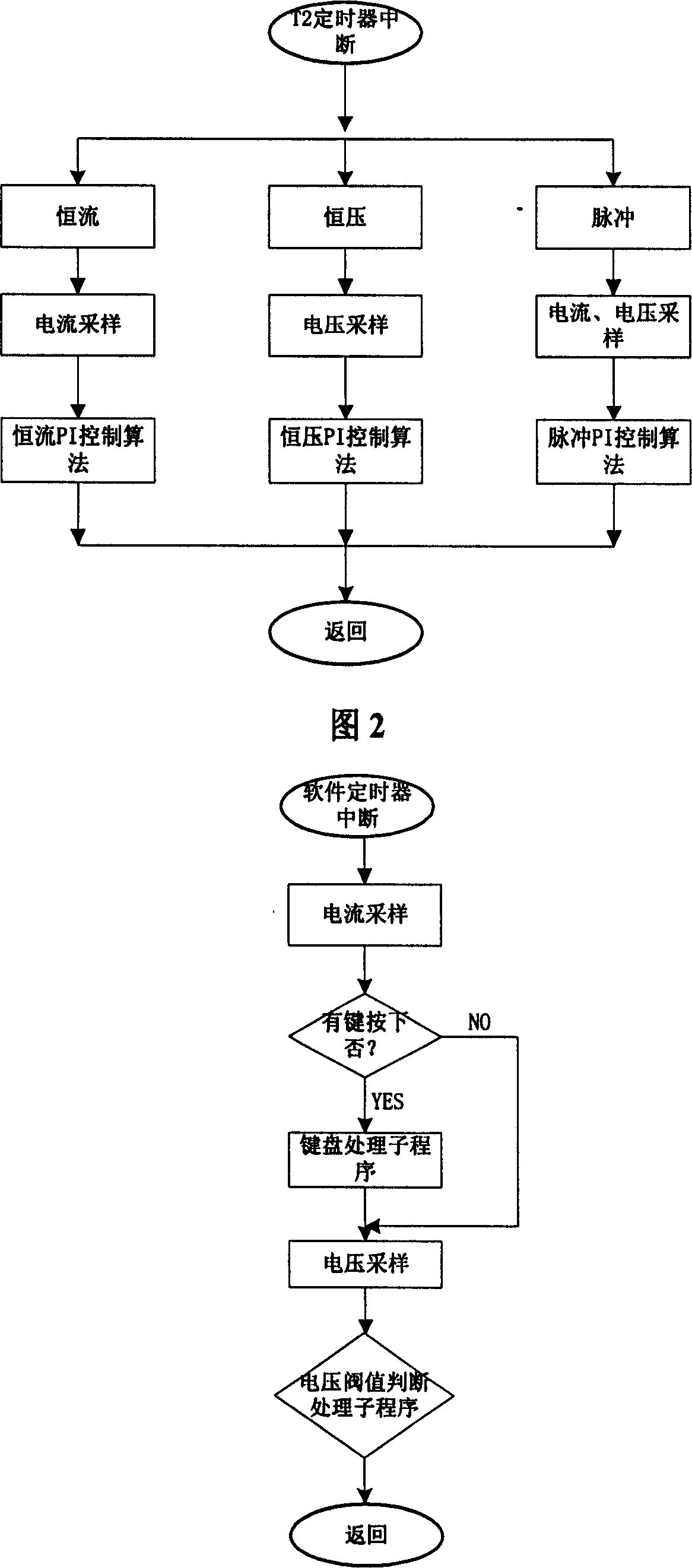

Welding machine output characteristic control method

InactiveCN1640603AAdd presetEnhance memoryArc welding apparatusNumerical controlControl theorySelf adaptive

The present invention relates to an output characteristic control method of welding machine. Said method includes the following steps: 1. preselecting correspondent welding method and presetting correspondent parameter; 2. judging that the welding operation is started or not; 3. electric arc is ignited or not; 4. judging that the welding proces is stable or not, namely, is identical to the preset parameter or not, and according to the concrete welding process adaptatively regulating welding machine output to obtain required output characteristics; and 5. judging state of welding gun with and combining welding mode, judging that the arc is blown out or not, otherwise, repeating step 4 to step 5.

Owner:SHANGHAI WTL WELDING EQUIP MFG CO LTD

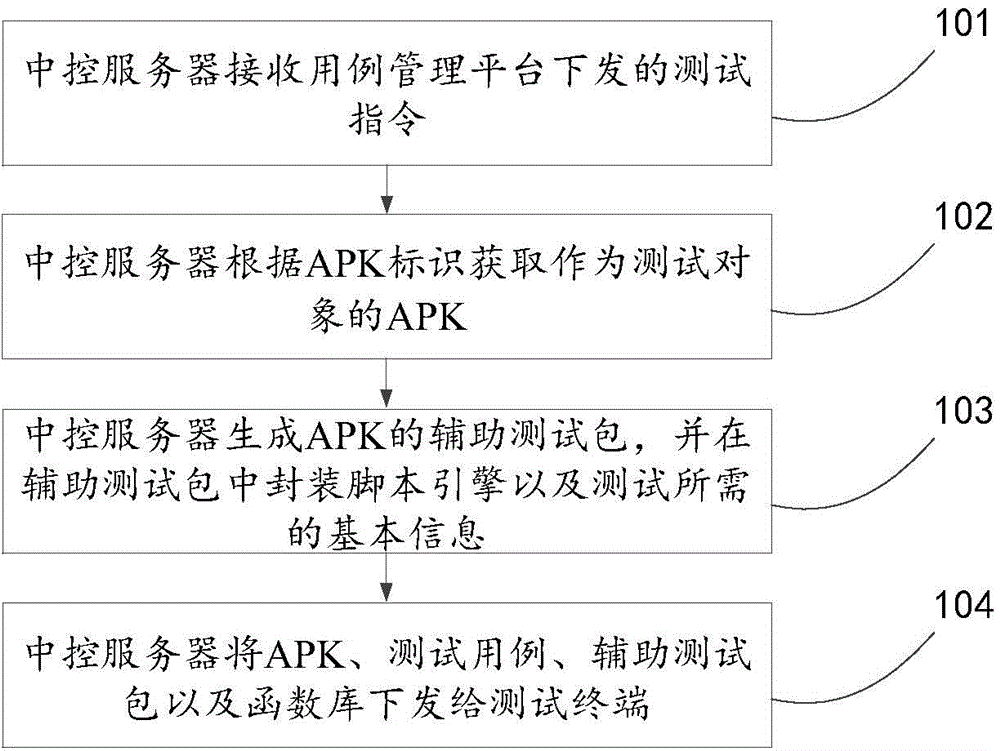

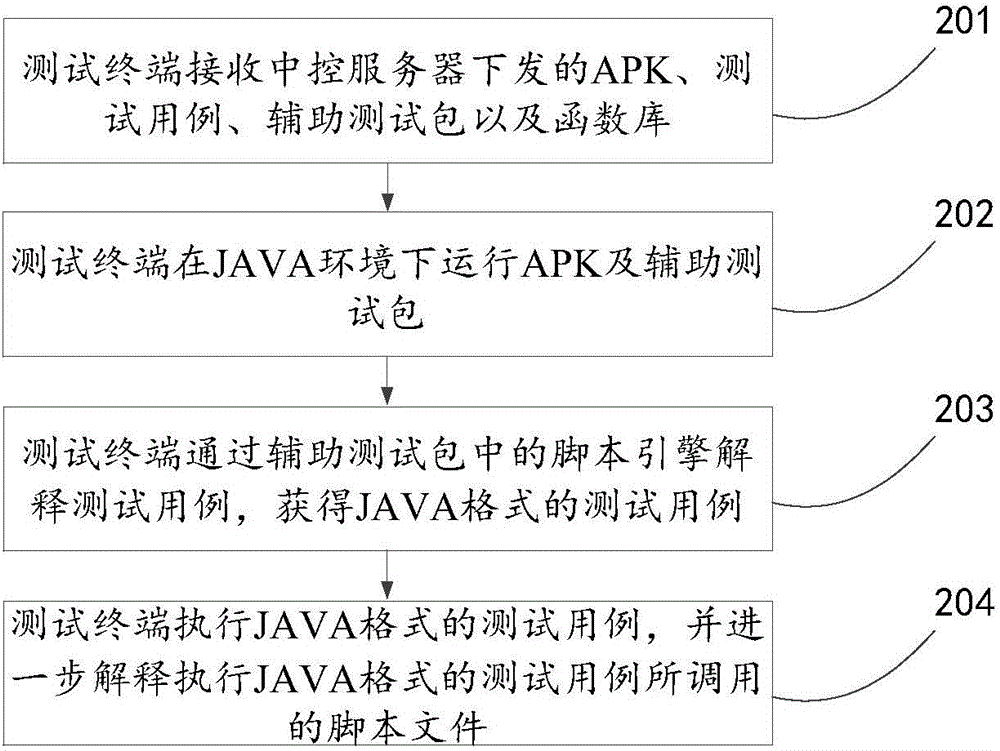

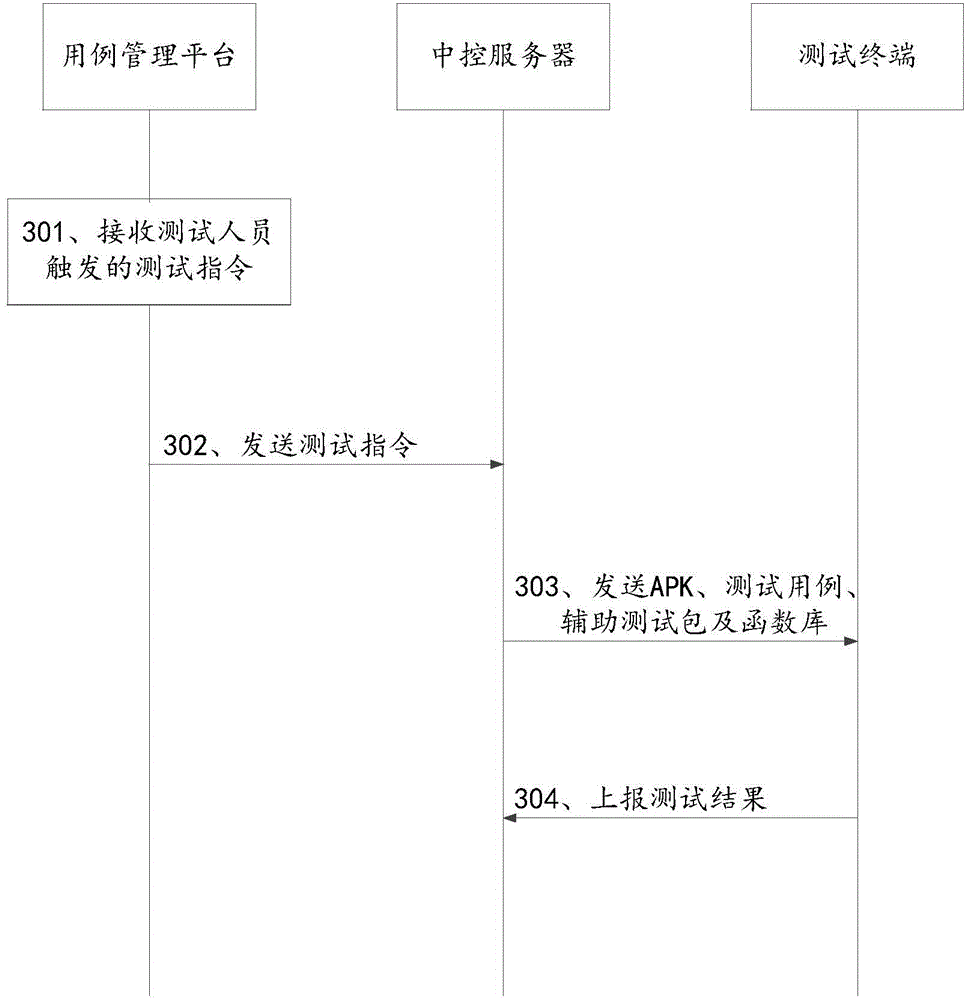

Application testing method, center control server, test terminal and system

ActiveCN104461898ARemove obscurityExpand the scope of useSoftware testing/debuggingTest objectAncillary test

The invention discloses an application testing method, a center control server, a test terminal and a system and relates to the field of automated testing. The application testing method, the center control server, the test terminal and the system aim to solve the problems that an existing testing process is complex, cumbersome and poor in usability. The method comprises the steps that a testing instruction issued by a use case management platform is received, wherein the testing instruction carries an APK identifier and a testing use case written in a scripting language; an APK used as a test object is obtained according to the APK identifier, an auxiliary test pack of the APK is generated, and a scripting engine and basic information required by testing are packaged in the auxiliary test pack; the APK, the testing use case, the auxiliary test pack and a function library are issued to the test terminal. The application testing method, the center control server, the test terminal and the system are mainly applied to the application testing process in a public cloud environment.

Owner:BEIJING QIHOO TECH CO LTD

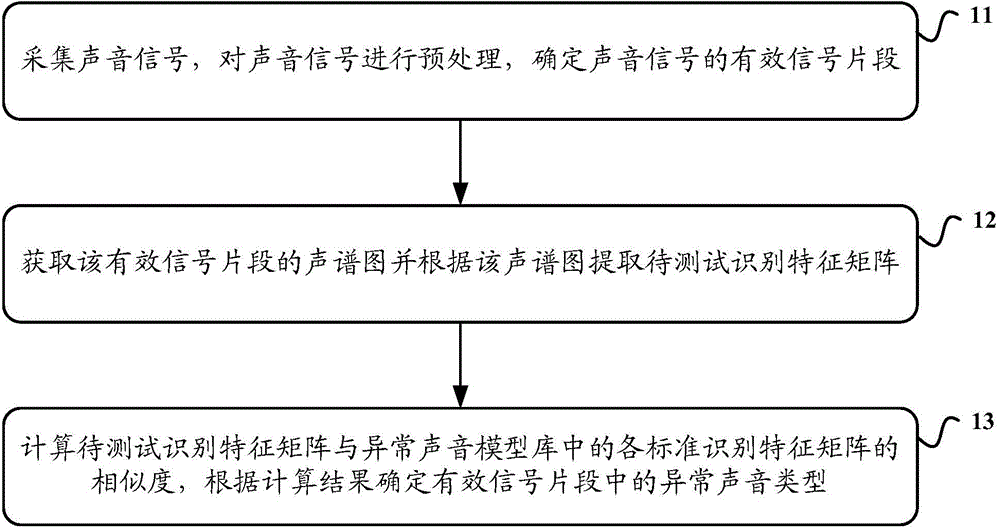

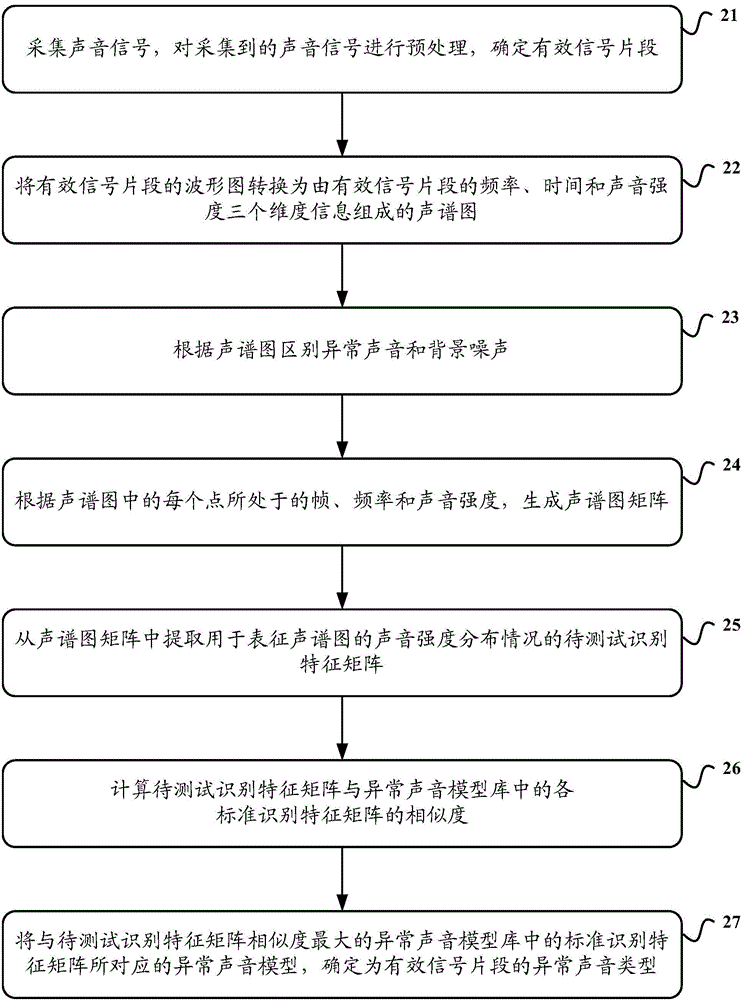

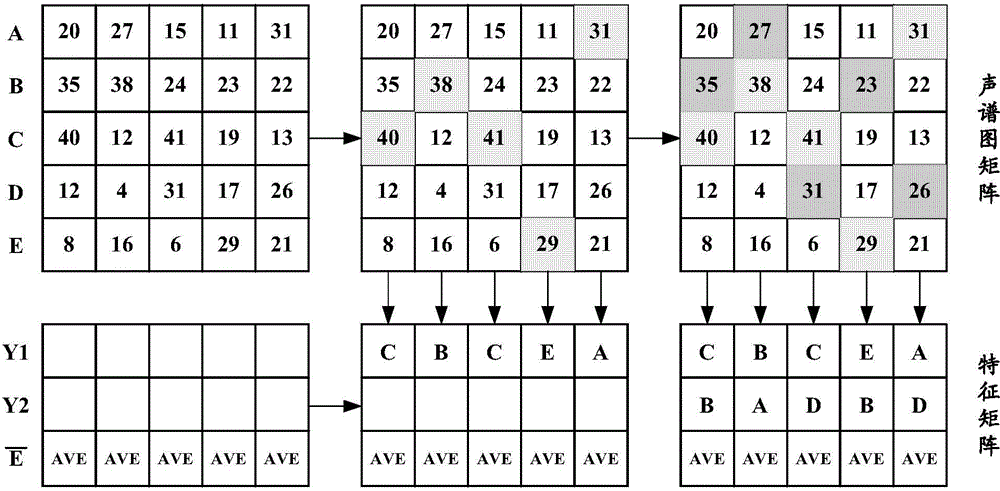

Typical abnormal sound detection method and device

InactiveCN105810213AReduce computational complexityExpand the scope of useSpeech analysisSignal onTime frequency domain

The invention discloses a typical abnormal sound detection method and a device, relates to the voice signal processing field and particularly provides an abnormal sound detection method based on spectrograms. According to the method, a sound signal is acquired, the sound signal is pre-processed, and effective signal segments of the sound signal are determined; the spectrograms of the effective signal segments are acquired, a to-be-tested identification characteristic matrix is determined, and the to-be-tested identification characteristic matrix is used for representing sound intensity distribution of the sound signal on the time-frequency domain; similarities between the to-be-tested identification characteristic matrix and each standard identification characteristic matrix in an abnormal sound model database are calculated, and abnormal sound types of the effective signal segments are determined according to calculation results; computational complexity in an abnormal sound identification process is simplified, and detection accuracy is improved.

Owner:ZHEJIANG DAHUA TECH

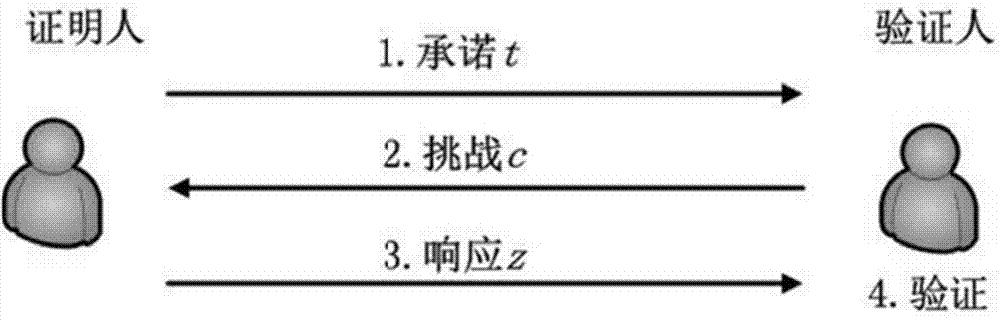

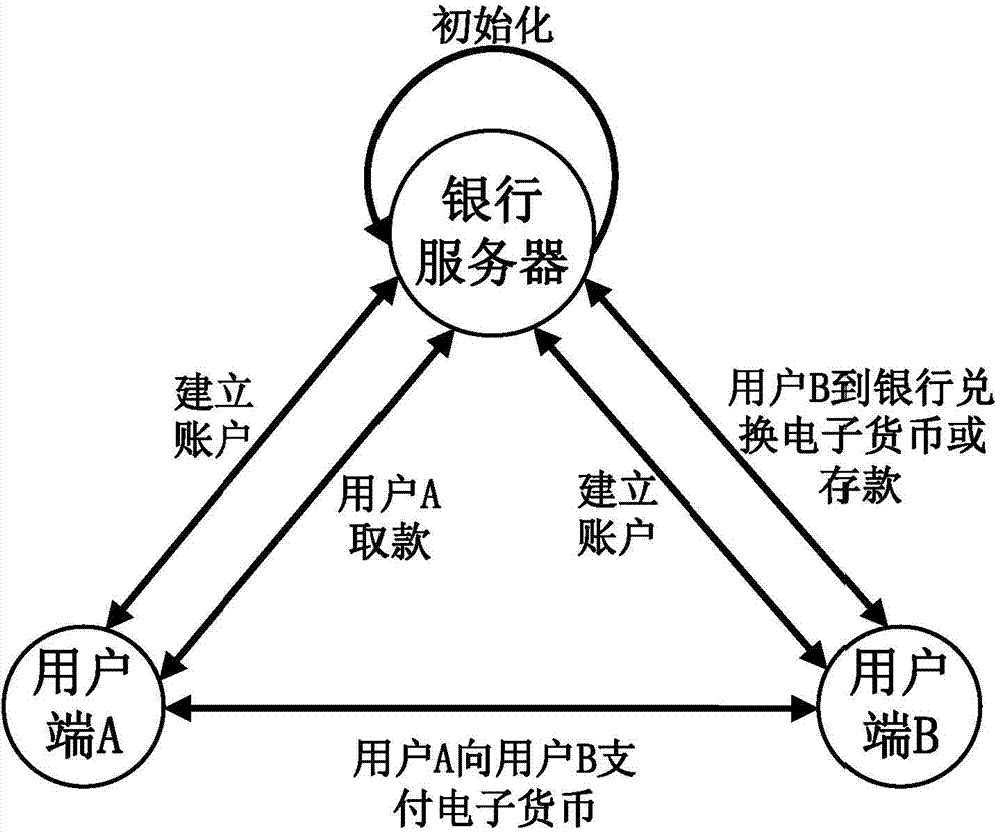

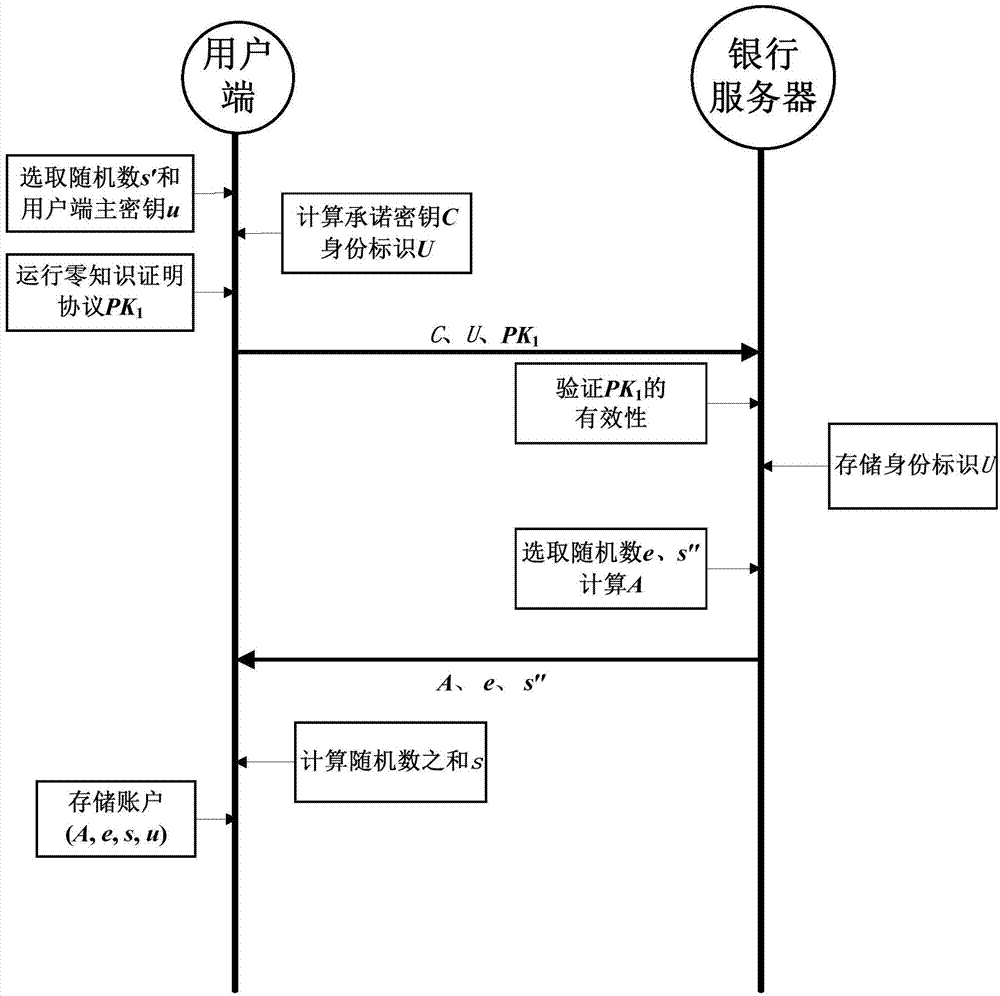

Safe operation method for offline payment of electronic money

InactiveCN104850984AWide range of paymentsExpand the scope of usePayment protocolsPayment circuitsMobile electronicsProtocol for Carrying Authentication for Network Access

The present invention discloses a safe operation method for the offline payment of electronic money and belongs to the technical field of network security. According to the method, system parameters are initialized by a bank server, and a client interacts with the bank server to create an account. After that, the client verifies the identity thereof based on the zero-knowledge proof protocol to withdraw money. During the transaction process, the payment process between a gathering client and a paying client is realized in the privacy protection manner based on the zero-knowledge proof protocol again. When the gathering client receives an evidence of the electronic money, the gathering client interacts with the bank server in an anonymous manner based on the randomized protocol to change the electronic money or store the money in the bank. The safe operation method is applicable to mobile e-commerce environments with weak network signals, and protects the both-side privacies of both paying users and gathering users. The free domination of electronic money by gathering users is enabled, and the realistic money is perfectly simulated. Meanwhile, the functions of privacy, balance and incapable escape of crimes are realized. Therefore, the security of the e-commerce payment is ensured.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

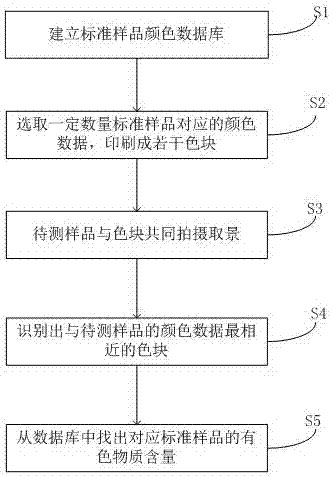

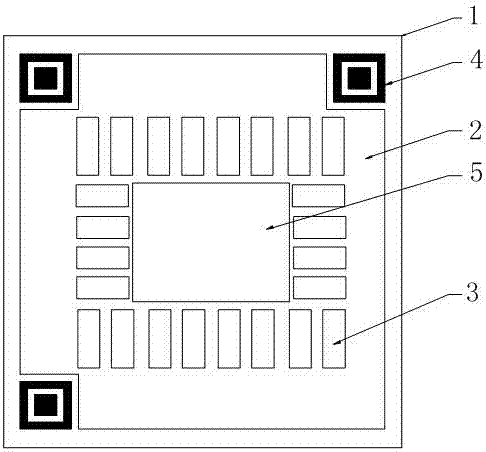

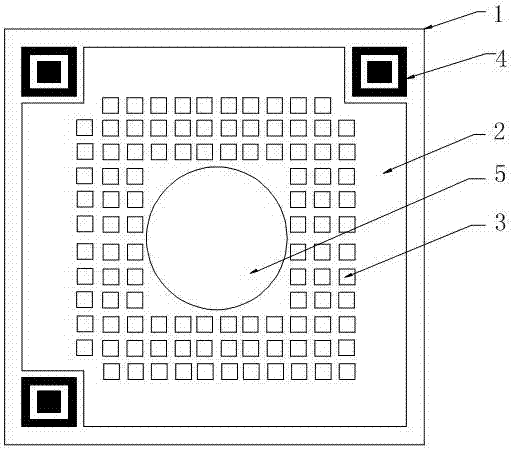

Substance content detection method, system and device based oncolordata analysis

InactiveCN107144531AExpand the scope of useReduce use costMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsStandard samplesAmount of substance

The invention belongs to the field of content detection of color-changed substances, and specifically relates to a substance content detection method, system and devicebased on color data analysis. According to the technical scheme, the method mainly comprises the following steps: S1, creating a standard sample color database; S2, selecting color data corresponding to a certain amount of standard samples according to a detection result accuracy demand, and printing a plurality of color blocks; S3, shooting and frame the to-be-detected samples and the plurality of color blocks in onesame horizontal plane; S4, recognizing the color blocks inthe color the most close to the color data of the to-be-detected samples; and S5, finding out the substance content corresponding to the color blocks from the standard sample color database, and then defining to be the substance content in theto-be-detected sample. With the adoption of the method, the problems that a colourimetric card is used for visually comparing the color in case of little color difference, subjective factors highly influence the result, and the visual color difference comparing capability is limited, can be solved; the detection process is objective; the detecting accuracy is high; the field detection is convenient; the detection cost is low; and the result is accurate and clear.

Owner:UCHEER PURIFICATION & POLLUTION CONTROL TECH ZHEJIANG CO LTD

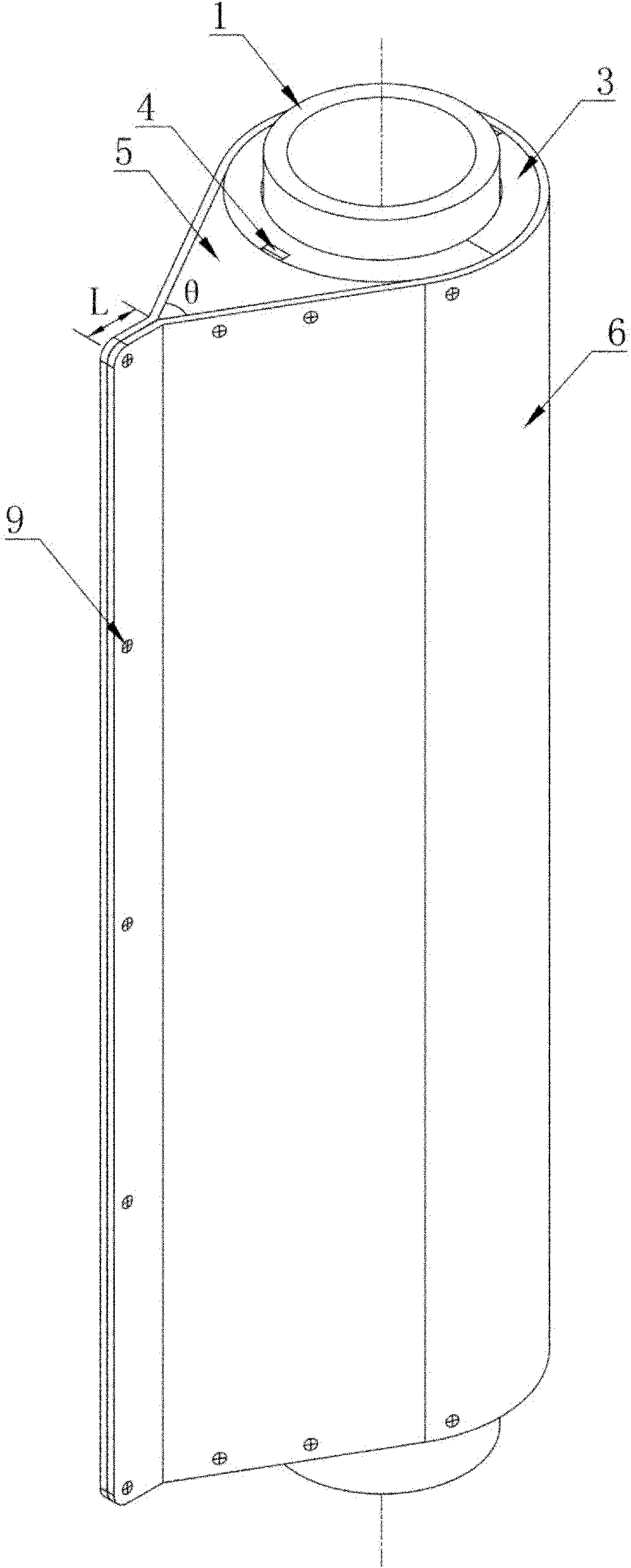

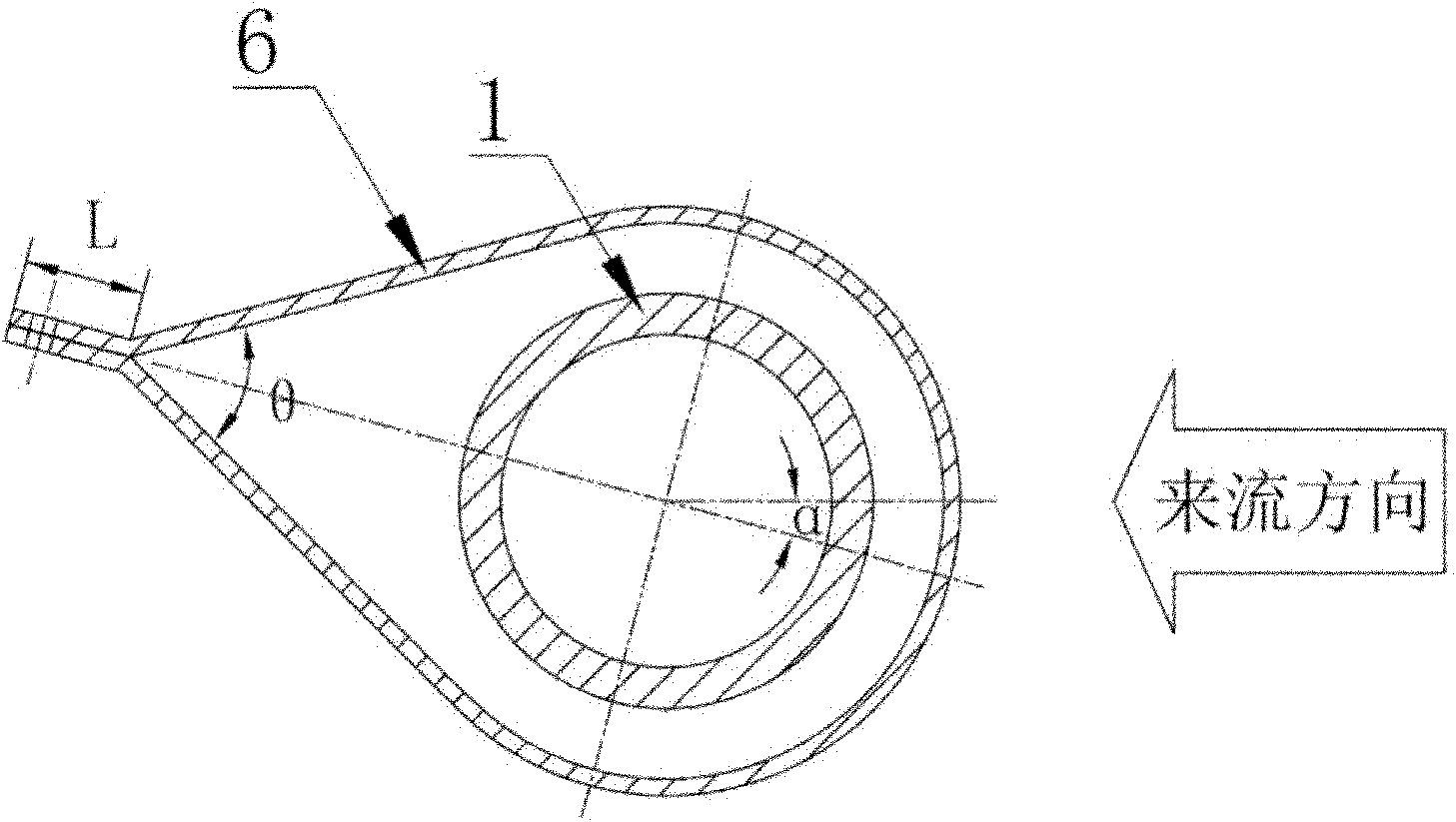

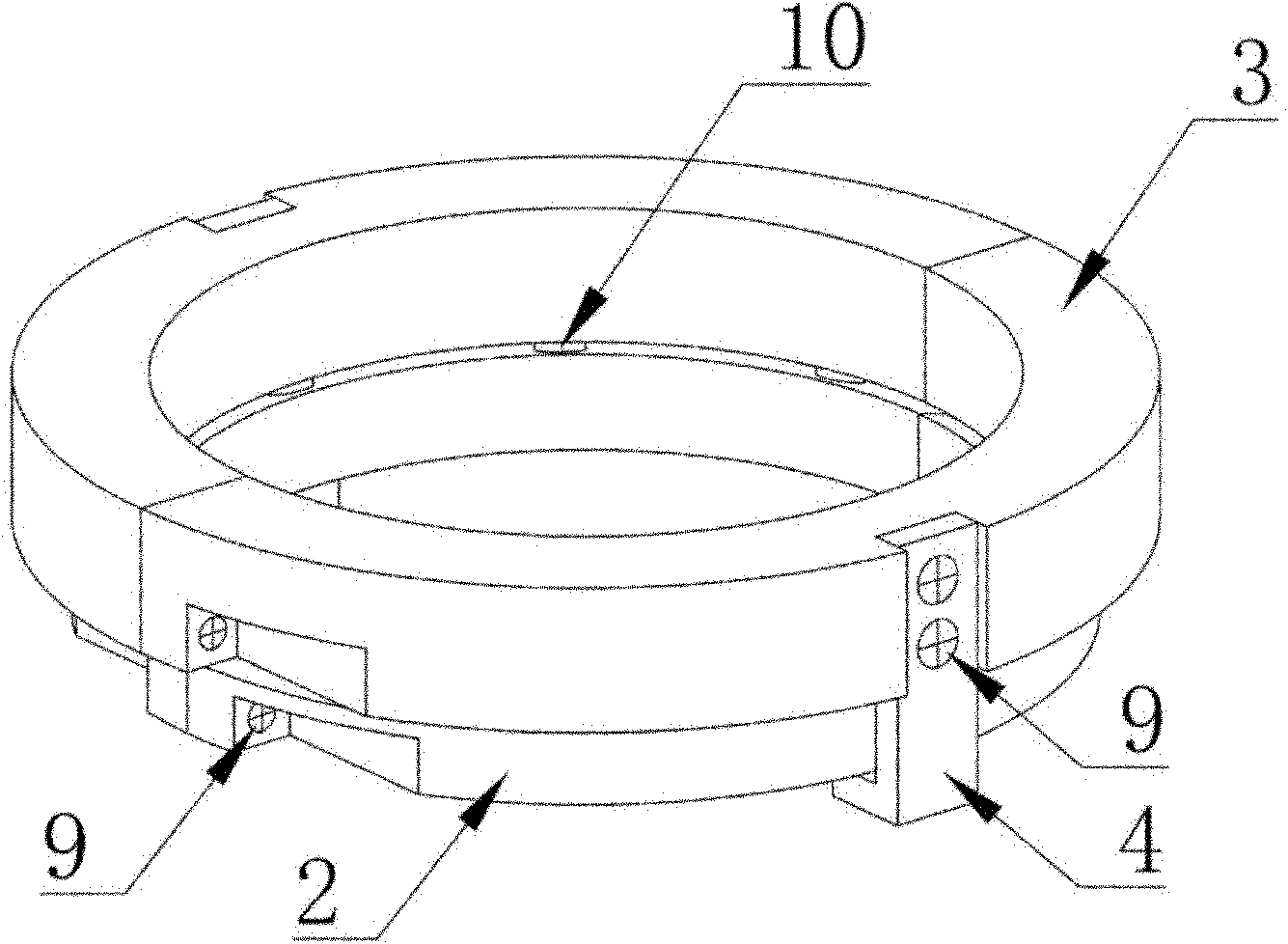

Underwater stand pipe vortex induced vibration inhibiter adopting rotatable cowling

InactiveCN102071883ASuppression of vortex induced vibrationExpand the scope of useDrilling rodsFluid dynamicsStructural deformationGravitation

The invention discloses an underwater stand pipe vortex induced vibration inhibiter adopting a rotatable cowling, belonging to the technical field of ocean stand pipe facility laying. In the invention, the rotatable cowling capable of changing own direction along with the current flow direction is installed on an underwater stand pipe and comprises a pair of rotating modules, a cowling fixing pad and a cowling. The inhibiter is characterized in that the front part of the cowling is round, the rear part of the cowling is pointed, the surface of the cowling is smooth, and the shape of the cowling is similar to a water drop. The circular arc part of the cowling is coaxial to the stand pipe and is connected with a main pipe by the rotating module which is convenient to install and disassemble to cause the circular arc part to freely rotate around the stand pipe. A small-density buoyant material is added in the hollow part of the cowling, and the structural deformation and pivoting friction resistance brought by the asymmetric gravity of the cowling can be eliminated. Because of effectively inhibiting vortex induced vibration, the underwater stand pipe vortex induced vibration inhibiter can improve the fatigue resistance of the underwater stand pipe, thus greatly lowering the engineering cost. Meanwhile, the inhibiter overcomes limitation on incoming flow directions by various vortex induced vibration inhibiters, and has high application value in the environments with frequently changed flow directions of oceans, rivers and the like.

Owner:SHANGHAI JIAO TONG UNIV

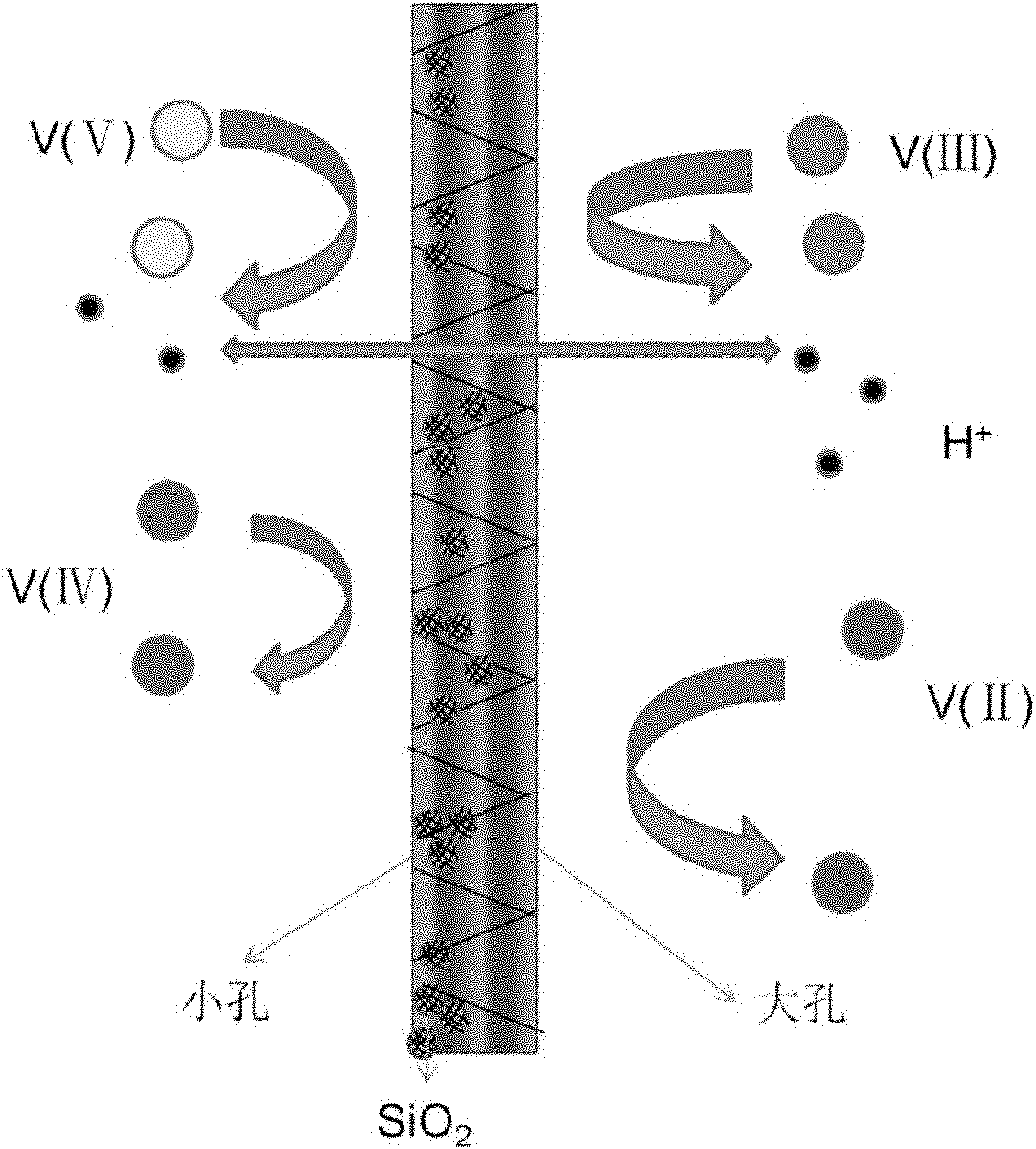

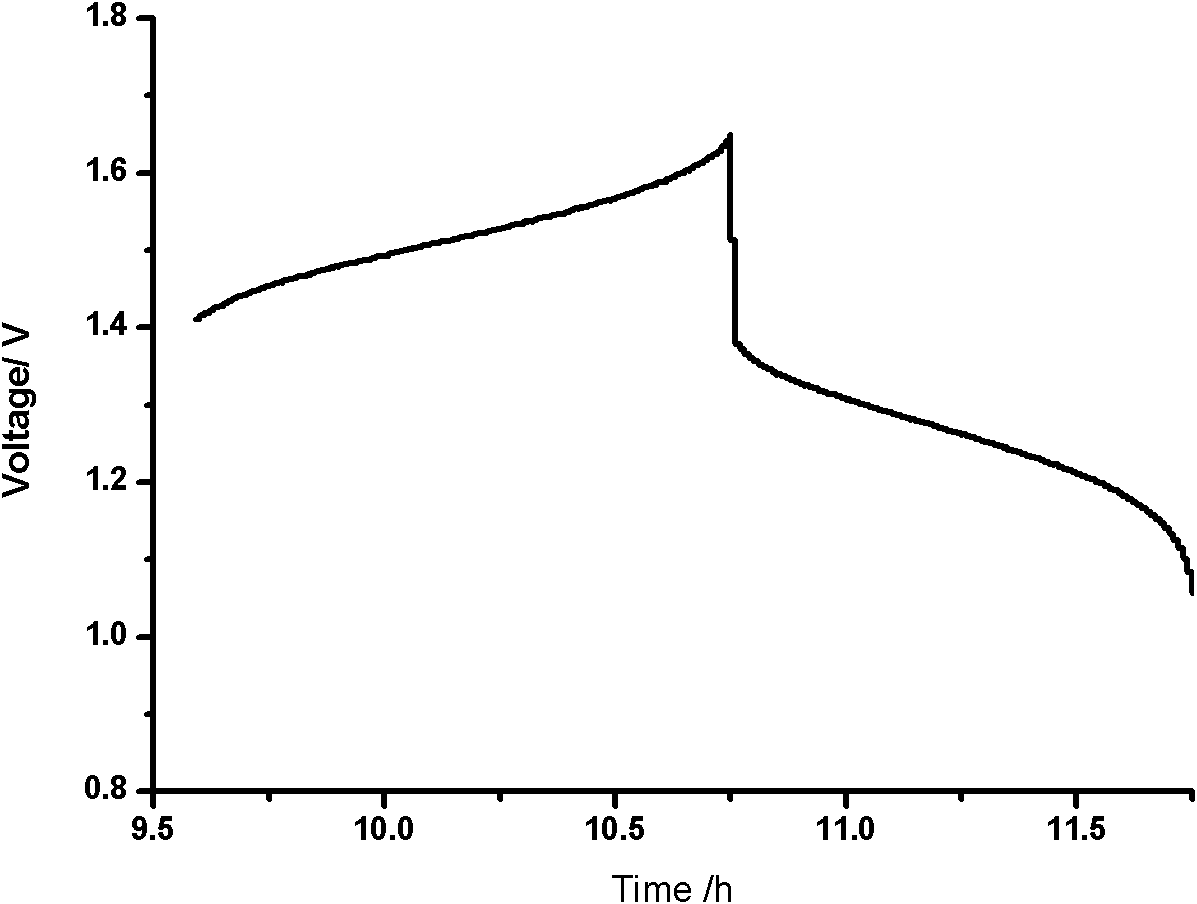

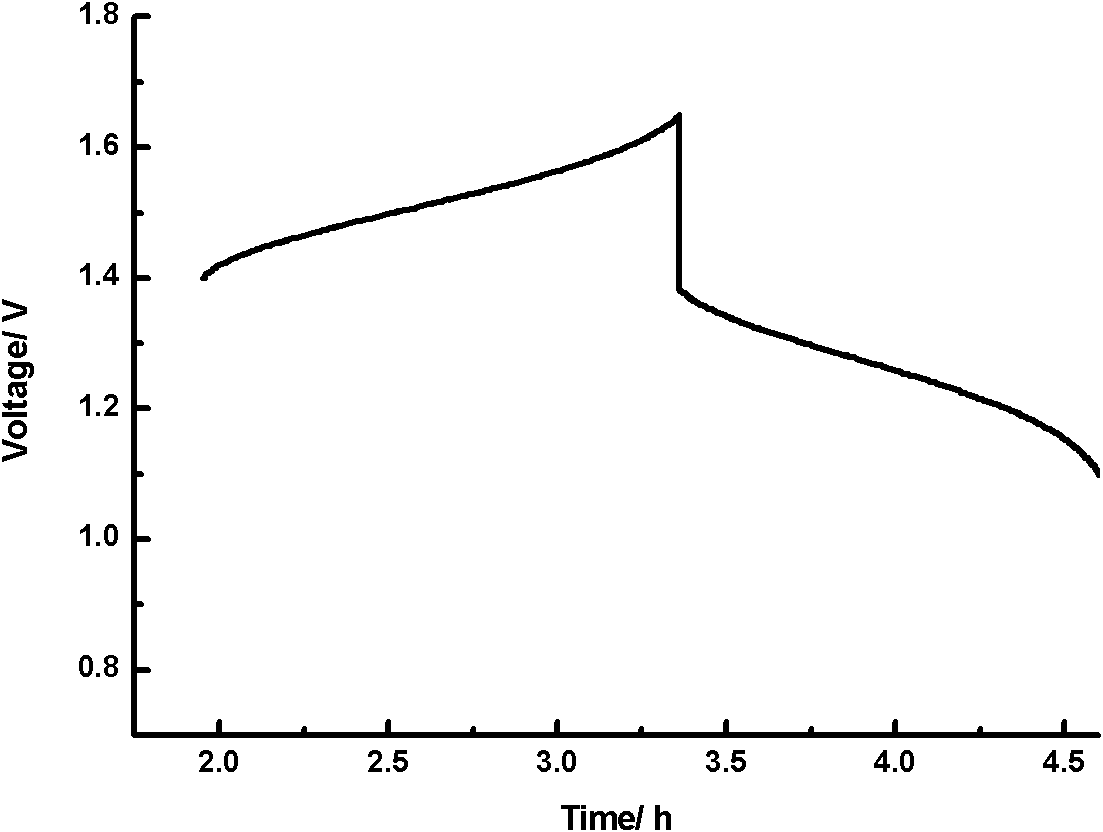

Inorganic matter-filled poriferous composite membrane for liquid flow energy-storage cell and use thereof

ActiveCN102569839ASelection throughEasy to prepareFinal product manufactureCell component detailsIon exchangeSilicon oxide

The invention discloses an inorganic matter-filled poriferous composite membrane for a liquid flow energy-storage cell and a use thereof. The inorganic matter-filled poriferous composite membrane for a liquid flow energy-storage cell is characterized in that one or more of organic polymer resins and sulfonated organic polymer resins are prepared into a poriferous diaphragm as a matrix; inorganic matter particles are filled into apertures of the matrix so that the inorganic matter-filled poriferous composite membrane is obtained; and the inorganic matter particles are prepared from one or more of silicon oxide, zirconia, titanium oxide, lead oxide, tungsten oxide and zirconium phosphate. The inorganic matter-filled poriferous composite membrane can be prepared by simple processes, has controllable apertures, is suitable for large-scale production, has high ion selectivity, hydrophily and ion conductivity, can realize ion transport without introduction of any ion exchange groups, and broadens a selection scope of liquid flow energy-storage cell membrane materials.

Owner:DALIAN RONGKE POWER

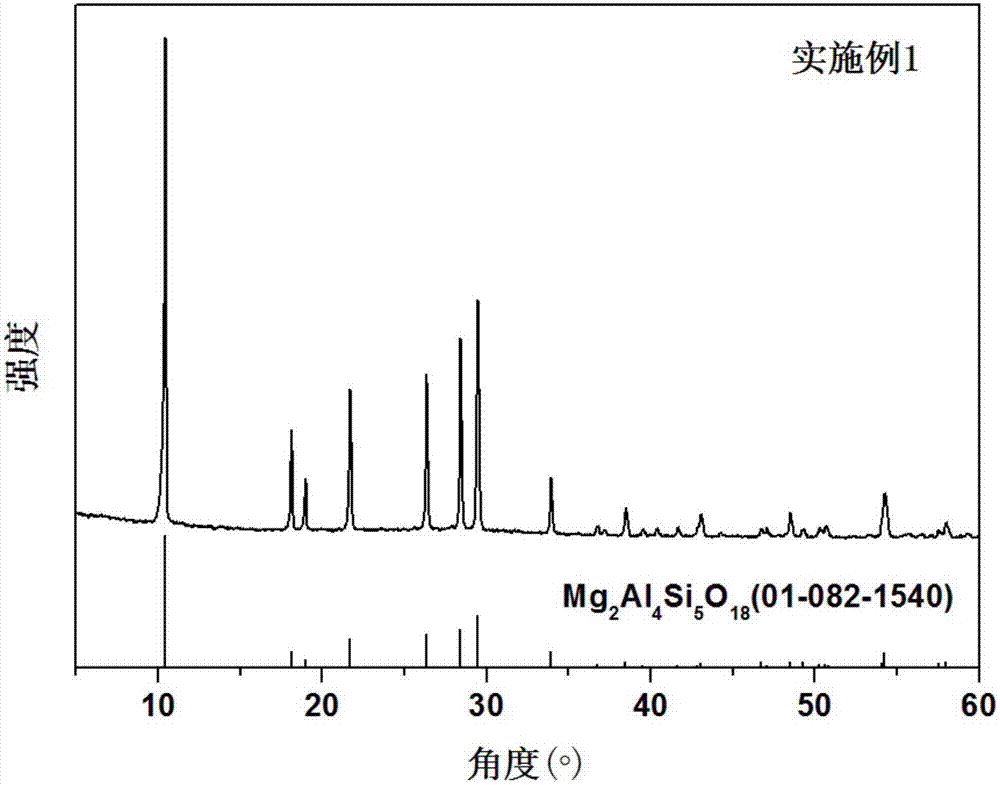

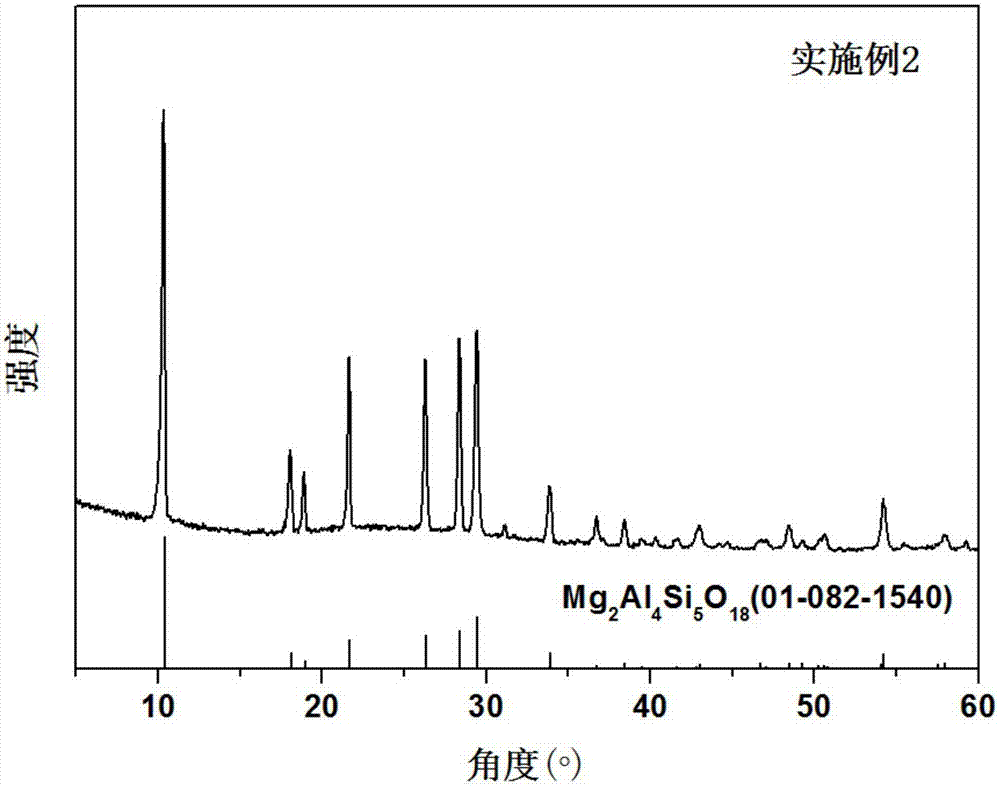

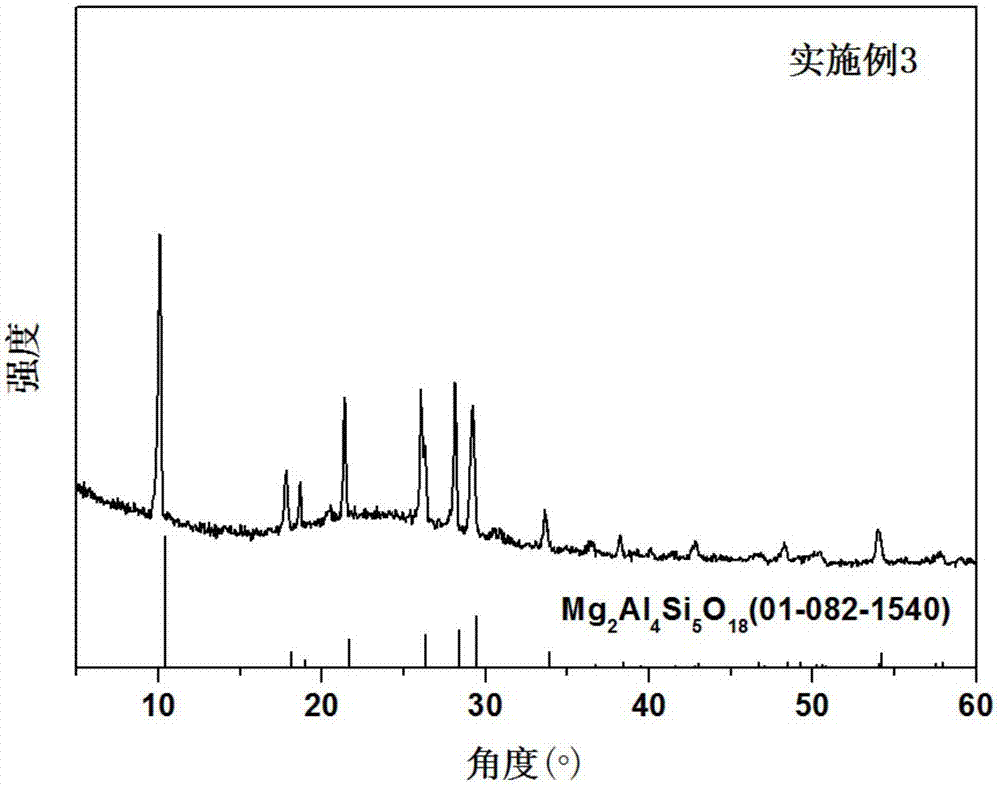

High-abrasion-resistance ceramic glazed brick and manufacturing method thereof

The invention discloses a high-abrasion-resistance ceramic glazed brick and a manufacturing method thereof. The ceramic brick surface is provided with a glaze layer; the glaze layer of the high-abrasion-resistance ceramic glazed brick is characterized in that a cordierite crystal is taken as a main crystal phase; the glaze layer contains 10 to 60 percent of the cordierite crystal; the glaze layer is mainly prepared from the following chemical components in percent by weight: 50 to 65 percent of SiO2, 10 to 25 percent of Al2O3, 6 to 15 percent of MgO, 2 to 10 percent of CaO, 0 to 2 percent of Li2O, 0 to 4 percent of Na2O, 0 to 4 percent of K2O, 0 to 3 percent of ZnO, 0 to 3 percent of BaO, 0 to 2 percent of SrO, 0 to 2 percent of B2O3 and 0 to 2 percent of TiO2. The prepared glazed layer containing the cordierite crystal has the advantages of remarkably improving the hardness and abrasion resistance of a glaze surface, and enlarging the application range of the glazed brick under the condition of keeping the transparency of the glaze layer.

Owner:佛山市大千色釉料有限公司

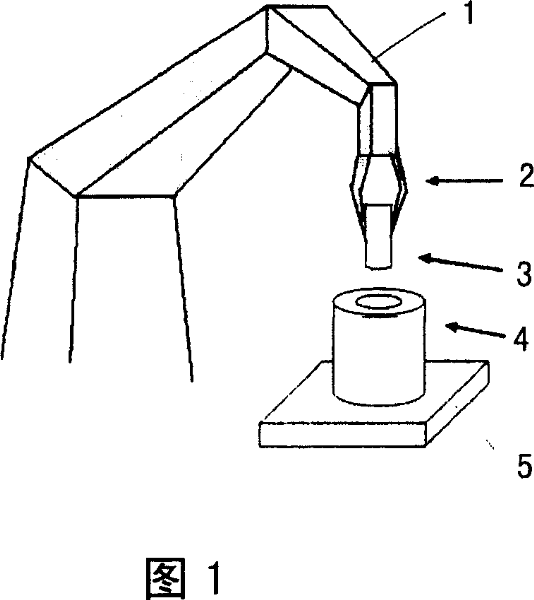

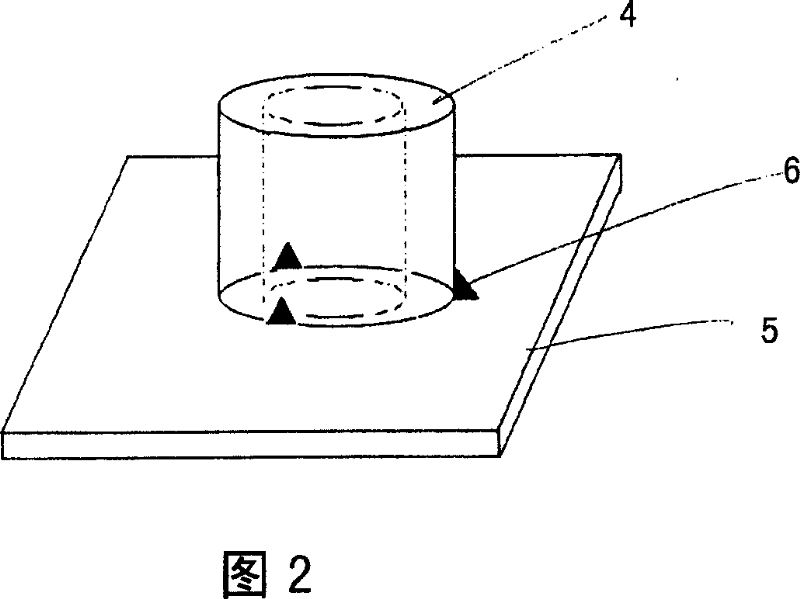

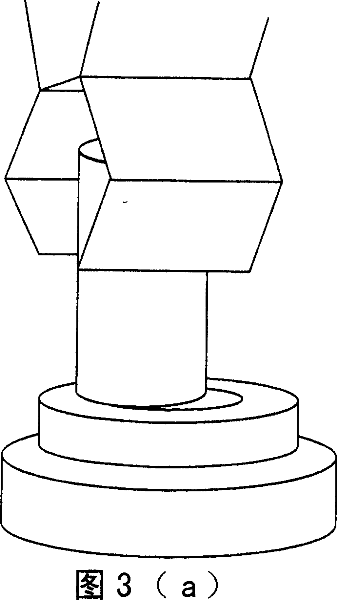

Method for realizing the assembly of shaft hole having high-precision by using robot having low precision

ActiveCN101041220AExpand the scope of useAvoid destructibilityProgramme-controlled manipulatorMetal working apparatusEngineeringAngular error

Owner:惠州中科先进制造有限公司

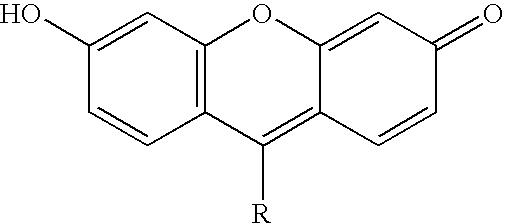

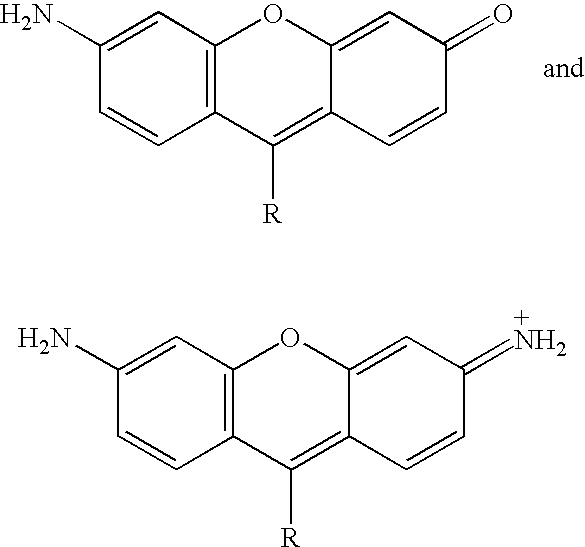

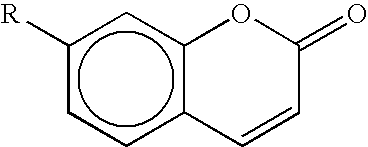

Novel dyes for the detection or quantification of desirable target molecules

ActiveUS20060269926A1Fluorescence enhancementHigh affinity bindingMethine/polymethine dyesPeptide/protein ingredientsCombinatorial chemistryOrganic chemistry

The present invention provides dyes, reactive dyes and labeled reagents that may be used in the detection or quantification of desirable target molecules, such as proteins and nucleic acids. Dyes are provided that may be used free in solution where the binding of the dye to the target molecule provides signal generation. Dyes are also provided that comprise reactive groups that may be used to attach the dyes to probes that will bind to desirable target molecules. The novel dyes of the present invention have been modified by the addition of charged and polar groups to provide beneficial properties.

Owner:ENZO LIFE SCI INC

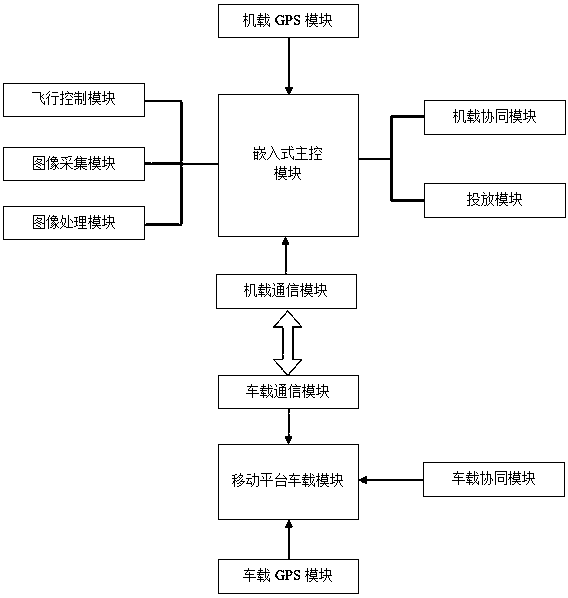

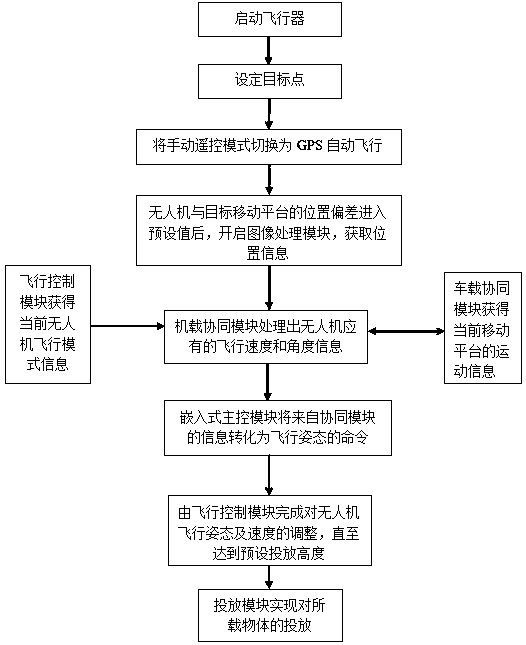

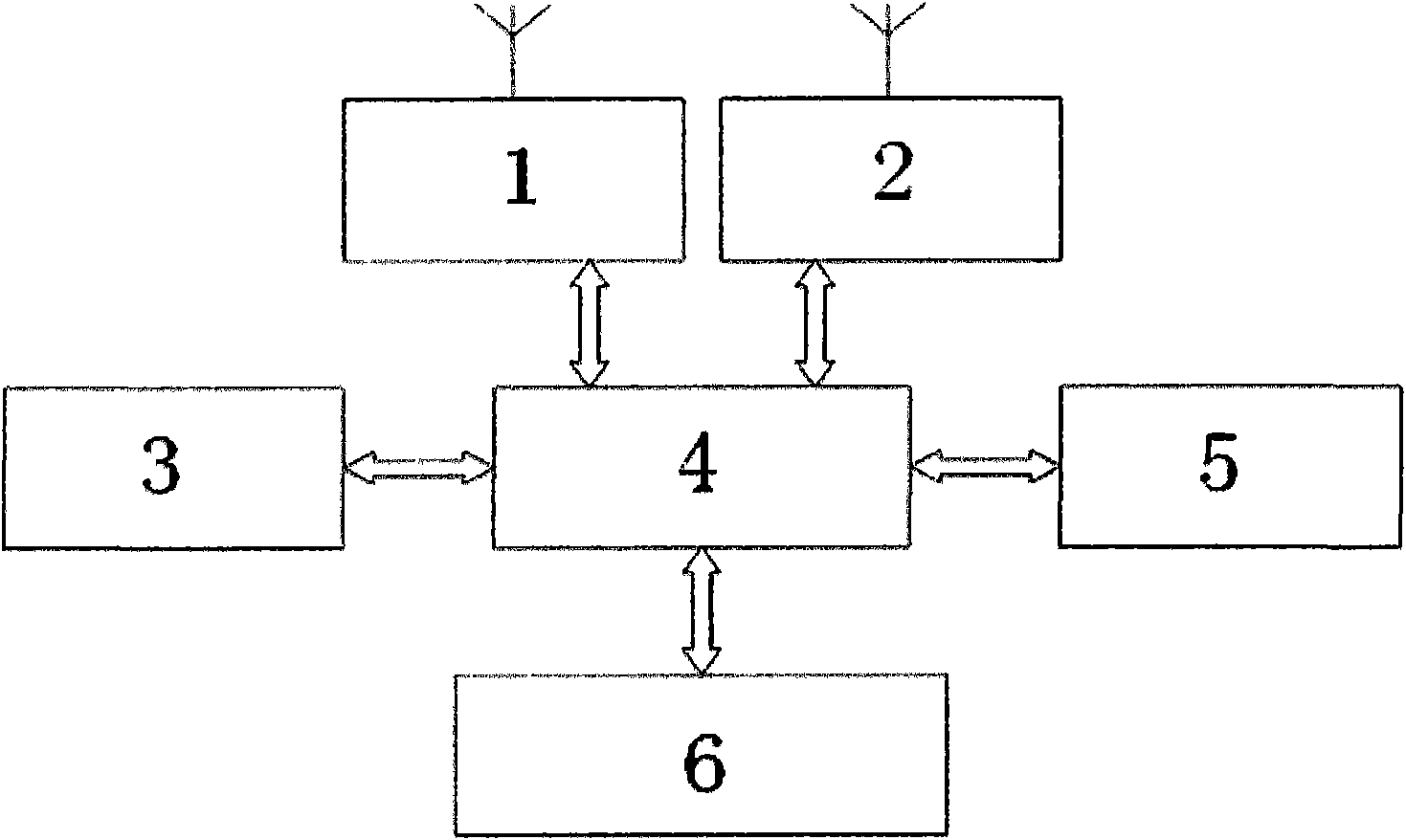

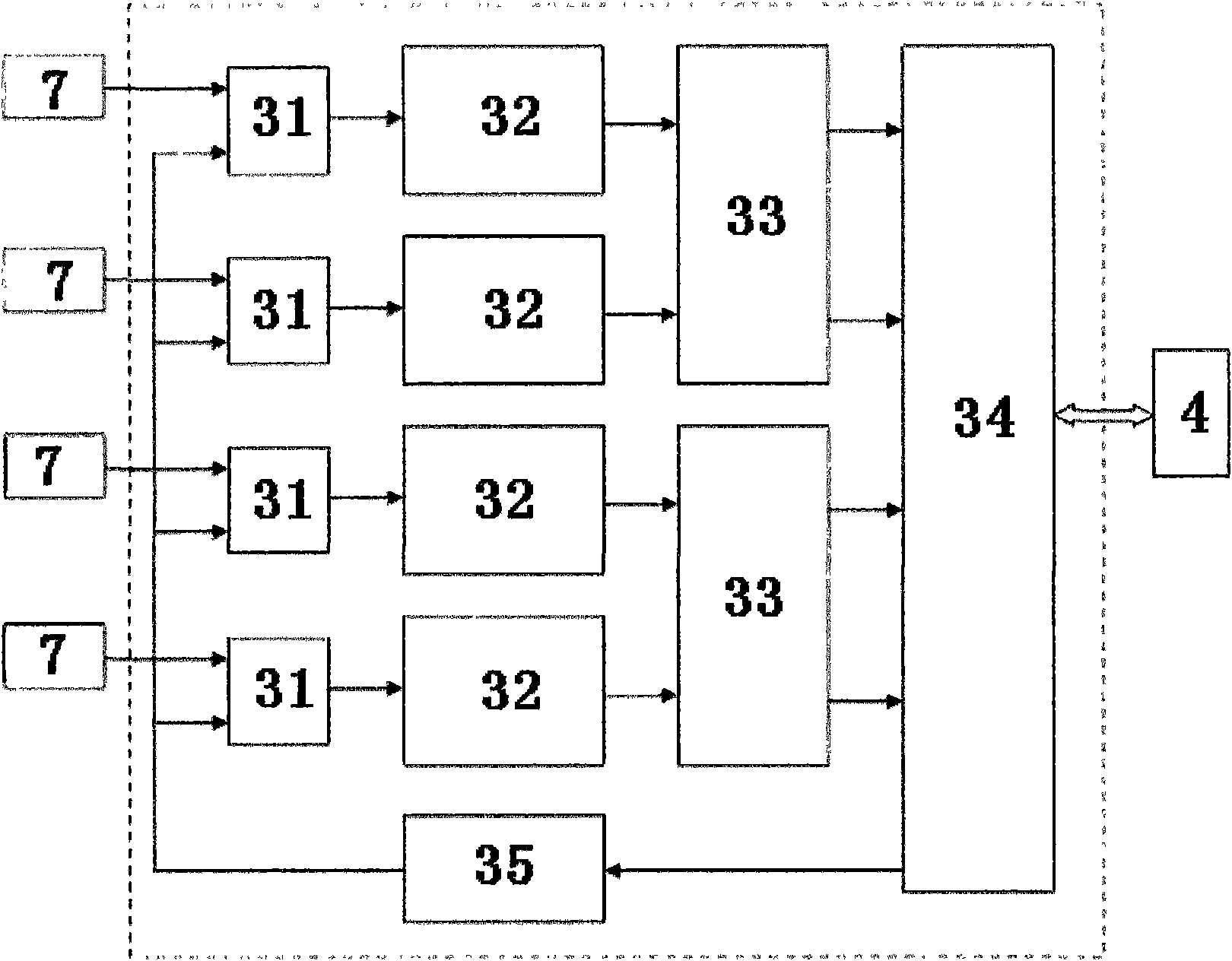

System and method for flight control of automatic putting of unmanned aerial vehicle for mobile platform

InactiveCN108459618AAir supportExpand the scope of usePosition/course control in three dimensionsImaging processingFlight control modes

The present invention provides a system and a method for flight control of automatic putting of an unmanned aerial vehicle for a mobile platform. The control system comprises an unmanned aerial vehicle and a mobile platform. The unmanned aerial vehicle is provided with an unmanned aerial vehicle airborne module and an airborne communication module, the unmanned aerial vehicle airborne module comprises an airborne location module, a flight control module, an embedded main control module, an image collection module, an image processing module, a distance measurement module and a putting module.The mobile platform is provided with a mobile platform vehicle module, a vehicle communication module, a vehicle location module and a location mark, and the location mark is arranged at the upper portion of the mobile platform. The present invention further discloses corresponding enforcement method. On the basis of fixed point targets based on image processing being subjected to the secondary location technology in the prior art, the system and the method add a collaborative module and a collaborative algorithm matchingly used with the collaborative module to push the automatic fixed point putting of the unmanned aerial vehicle to the put of the mobile platform of the unmanned aerial vehicle so as to enlarge the automatically controlled actual usage value of the unmanned aerial vehicle.

Owner:HENAN UNIVERSITY +1

Method for performing seismograph control and data transmission by using short message and short message control and transmission type cableless seismograph

InactiveCN101661111AExpand the scope of useImprove construction efficiencySeismic signal receiversSeismic signal transmissionQuality controlSeismometer

The invention relates to a method for performing seismograph control and data transmission by using a short message and a short message control and transmission type cableless seismograph. Aiming at solving the problem of no real-time quality control to the prior cableless seismograph, the method for seismograph control and data transmission introduces a mobile phone unit into an acquisition station for the prior cableless seismograph, and utilizes the short message to conduct state control and data transmission to the acquisition station for the cable-less seismograph. The acquisition stationfor the cableless seismograph comprises a main control unit, an acquisition unit, a storage unit, a GPS unit, a power management control unit and a mobile phone unit. The invention has the advantagesthat the work load of measurement can be reduced, the laying of the acquisition equipment is more flexible, simpler and more convenient, the synchronous collection mode for blasting at the fixed timeis convenient, the construction efficiency is favorable for improving, the data recovery is flexible, an SPS file can be automatically generated, the coordinate with cm-level accuracy can be automatically calculated, the difficult problem of no real-time quality control to the cableless seismograph is solved in a simple and inexpensive way, and the application range and the construction efficiency of the cableless seismograph are greatly improved.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

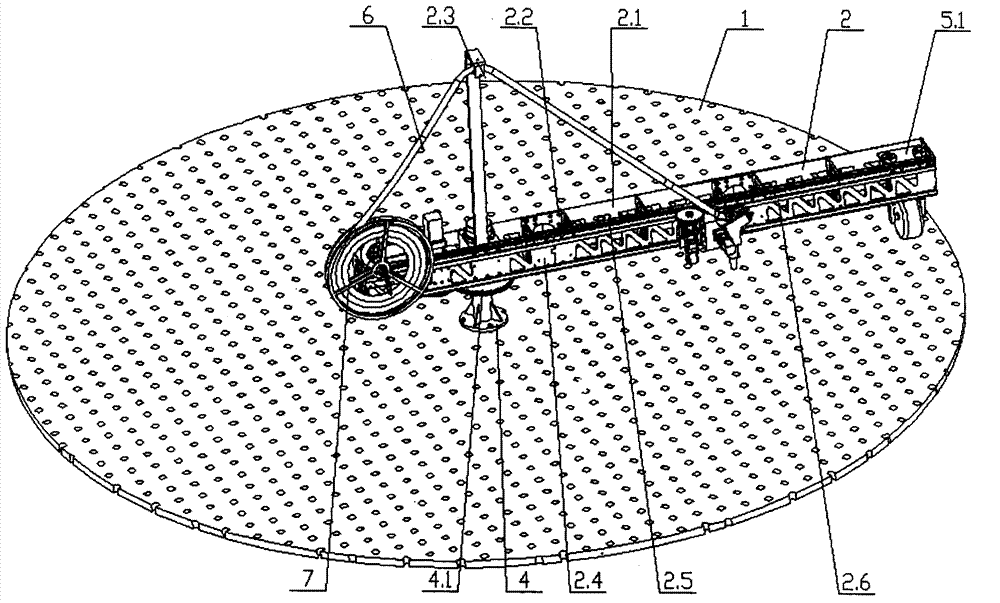

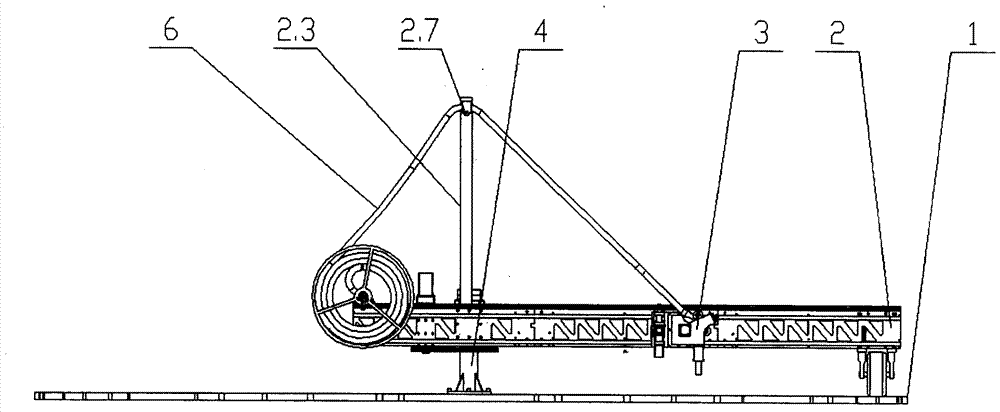

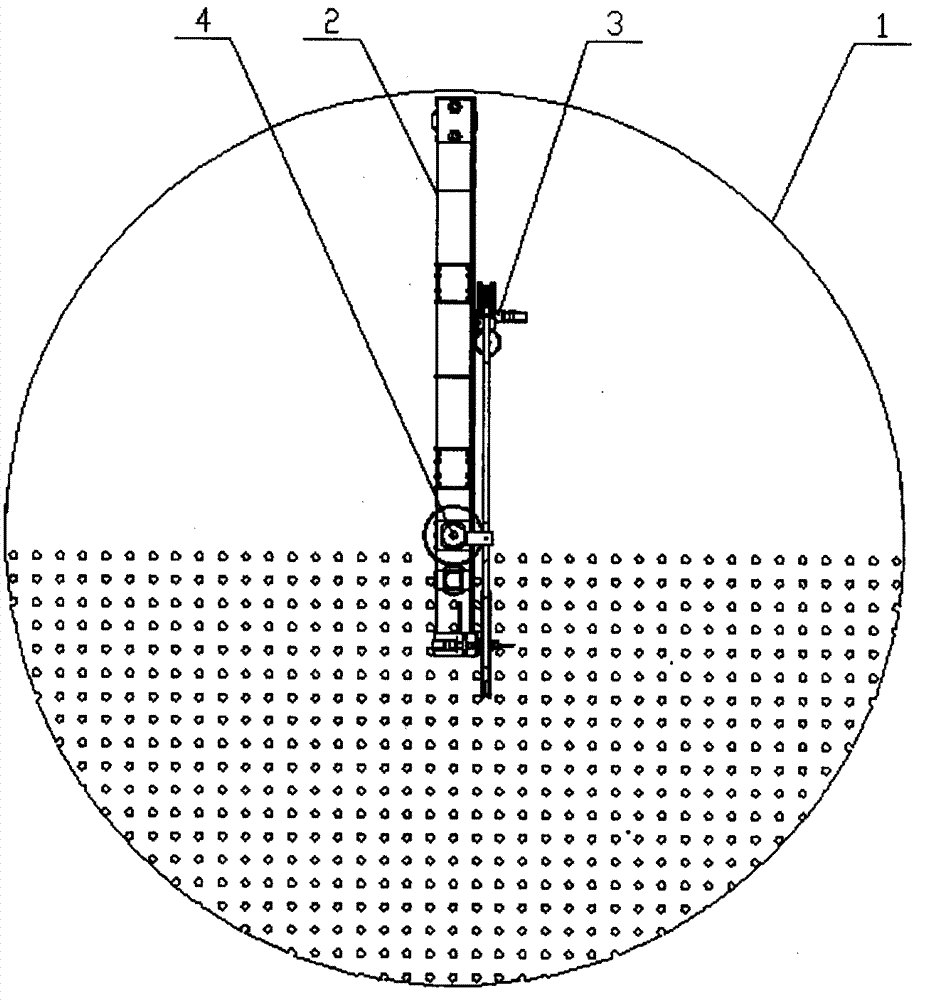

Automatic cleaning device for evaporating pot heat exchange tube

The invention discloses an automatic cleaning device for an evaporating pot heat exchange tube. The automatic cleaning device comprises a center column, a sliding fame driving mechanism, a machine frame portion, a machine frame wheel portion, a machine frame driving portion, a water pipe clamping wheel mechanism and a water pipe conveying mechanism; one end of the machine frame portion is hinged to the center column, the other end of the machine frame portion is connected with the machine frame wheel portion in a positioned mode, and the length of the machine frame portion can be changed by adding a connection machine frame portion; the machine frame driving mechanism is arranged a front machine frame of the machine frame portion and drives the machine frame portion to rotate around the center column, the sliding frame driving mechanism drives the water pipe clamping mechanism to slide on the side face of the machine frame portion, and the heat exchange tube is positioned in a polar coordinate mode; the water pipe conveying mechanism and the water pipe clamping mechanism are combined to achieving conveying and retracting of a water pipe. The automatic cleaning device for the evaporating pot heat exchange tube can achieve automatic cleaning, the length of the machine frame portion can be enlarged according to the size of an evaporating pot, no cleaning dead space exist in a cleaning range, and the phenomenon that machine frame wheels are blocked because of walking on the surface of an irregular evaporating pot can be avoided.

Owner:GUANGXI UNIV

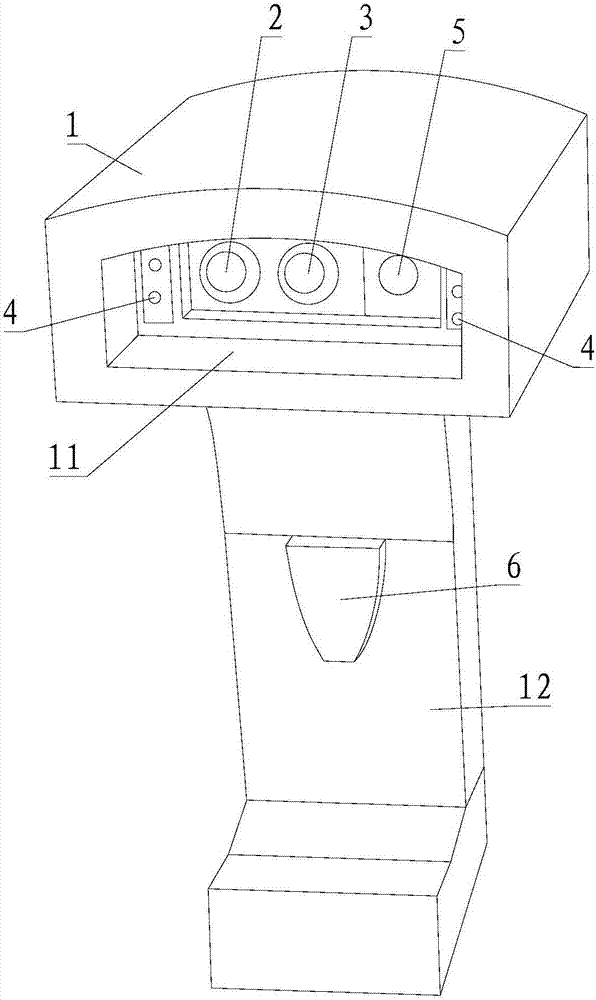

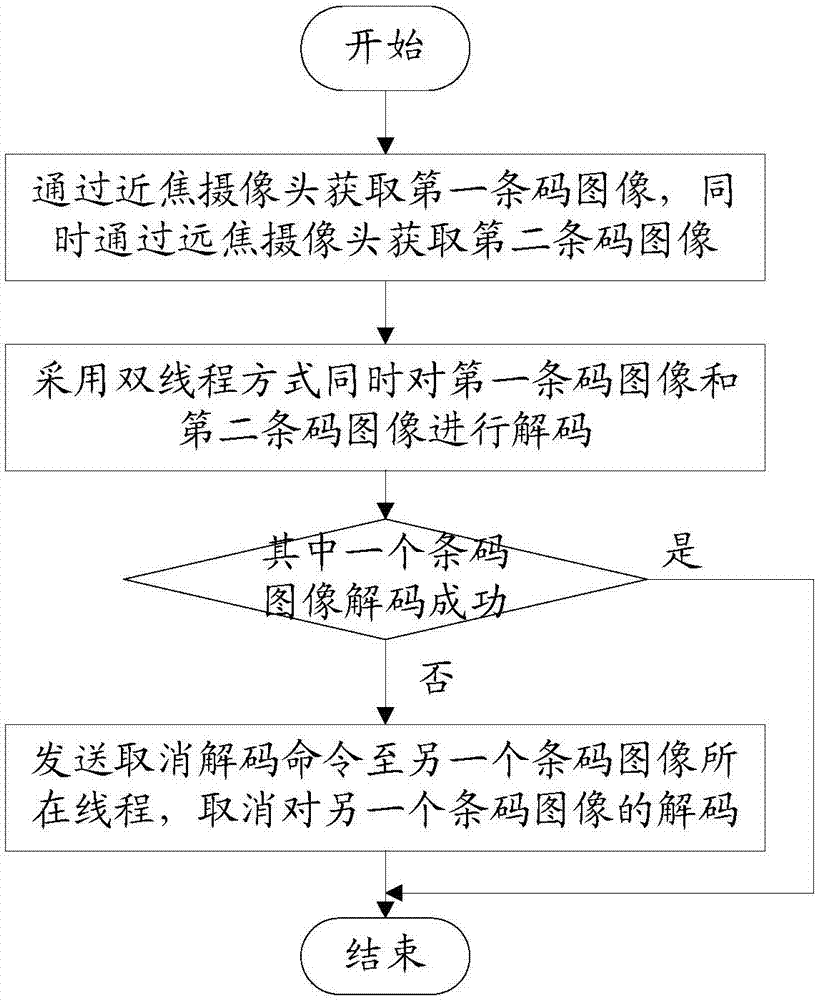

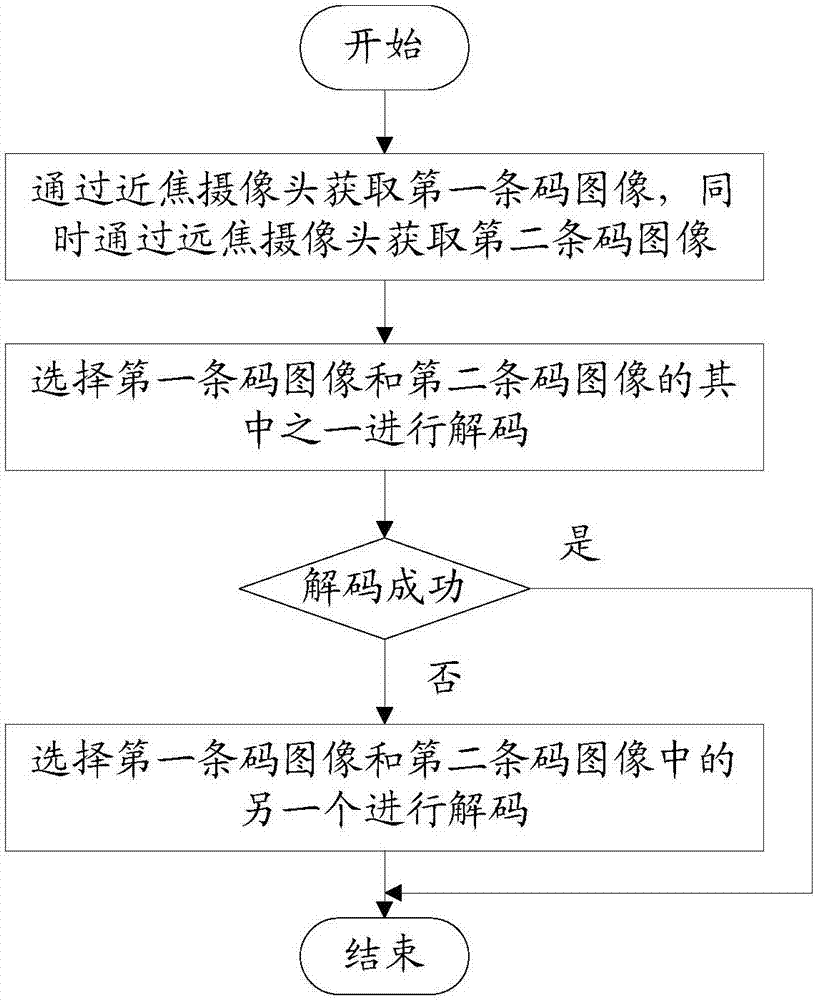

Bi-camera scanner gun and scanning method thereof

ActiveCN107111737AExpand the scope of useShorten scanning timeSensing by electromagnetic radiationDepth of fieldDepth of focus

The invention provides a bi-camera scanner gun and a scanning method thereof. The bi-camera scanner gun includes a housing, a near-focus camera and a far-focus camera. The housing is provided with a scanning window thereon. The near-focus camera and the far-focus camera are both installed on the scanning window. The method includes the following steps: the near-focus camera acquiring a first bar code image, and at the same time the far-focus camera acquiring a second bar code image; decoding the first bar code image and / or the second bar code image. The bar code images are acquired by the near-focus camera and the far-focus camera having different depths of focus, and the bar code images are decoded, such that the usage of the scanner gun is expanded, the time for manual adjustment of the scanner gun is shortened, the time for code scanning of the scanner gun is reduced, and the sensitivity of code scanning is increased.

Owner:FUJIAN LANDI COMML EQUIP CO LTD

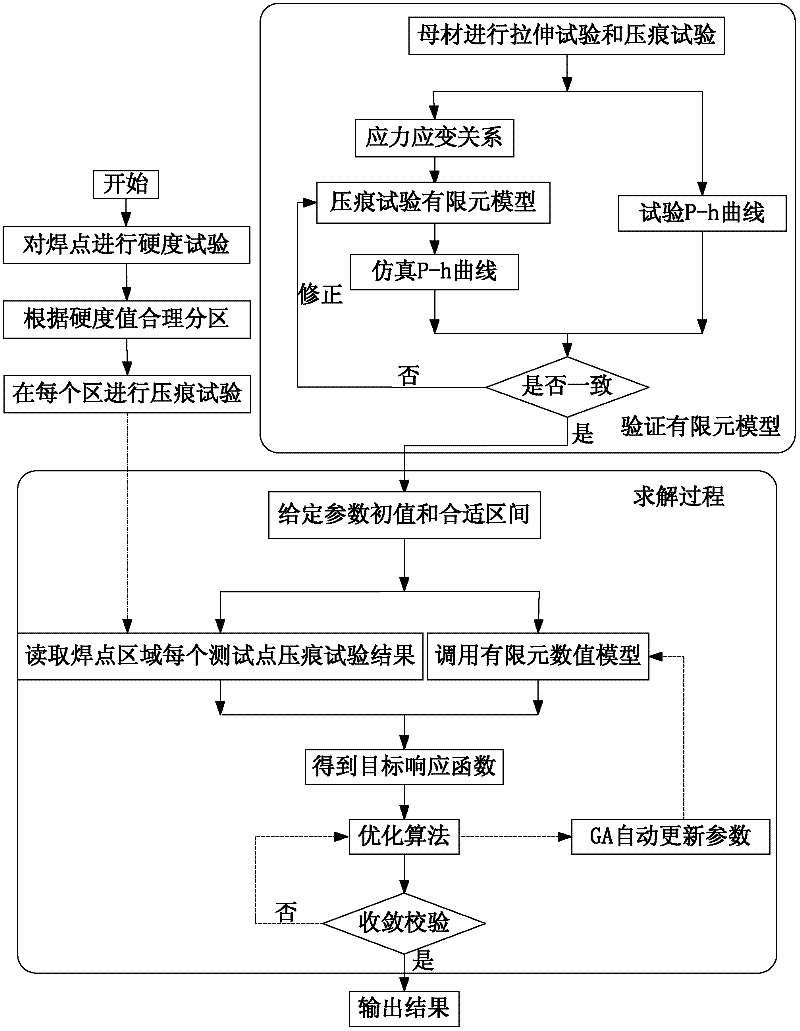

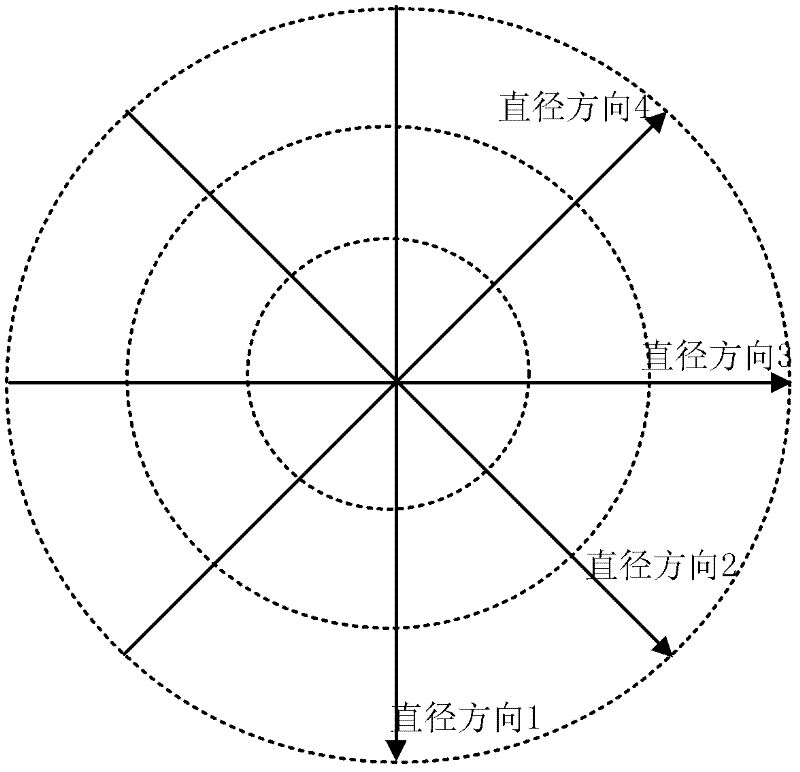

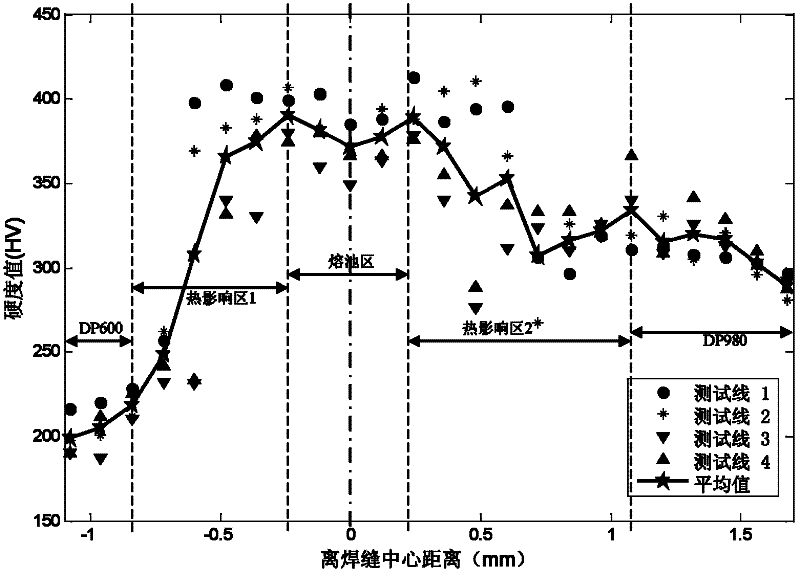

Detection method for identifying material static mechanical property parameters in different areas of solder joints

InactiveCN102313676AStrong engineering use valueExpand the scope of useInvestigating material hardnessJoint sampleNumerical models

A detection method for identifying material static mechanical property parameters in different areas of solder joints comprises the following steps of: (1) preparing a solder joint sample used for a hardness test; (2) selecting a plurality of points in the whole solder joint area along the direction of the solder joint diameter to carry out the hardness test, and regionalizing according to hardness number; (3) carrying out an indentation test in the regionalized areas to obtain a load-depth curve of different test points; (4) establishing a finite element model of the indentation test and verifying; (5) forming optimization mathematical models in different areas of the solder joints according to a simulation result of the finite element method numerical model in the indentation test and acorresponding experimental result; (6) calculating the static mechanical property parameters in different areas of the solder joints by the combination of genetic algorithm. The detection method provided by the invention has a simple principle, is convenient to operate, and can be used to determine local mechanical property parameters of a material with millimeter even micrometer dimensions and expand the application range of the indentation test.

Owner:HUNAN UNIV

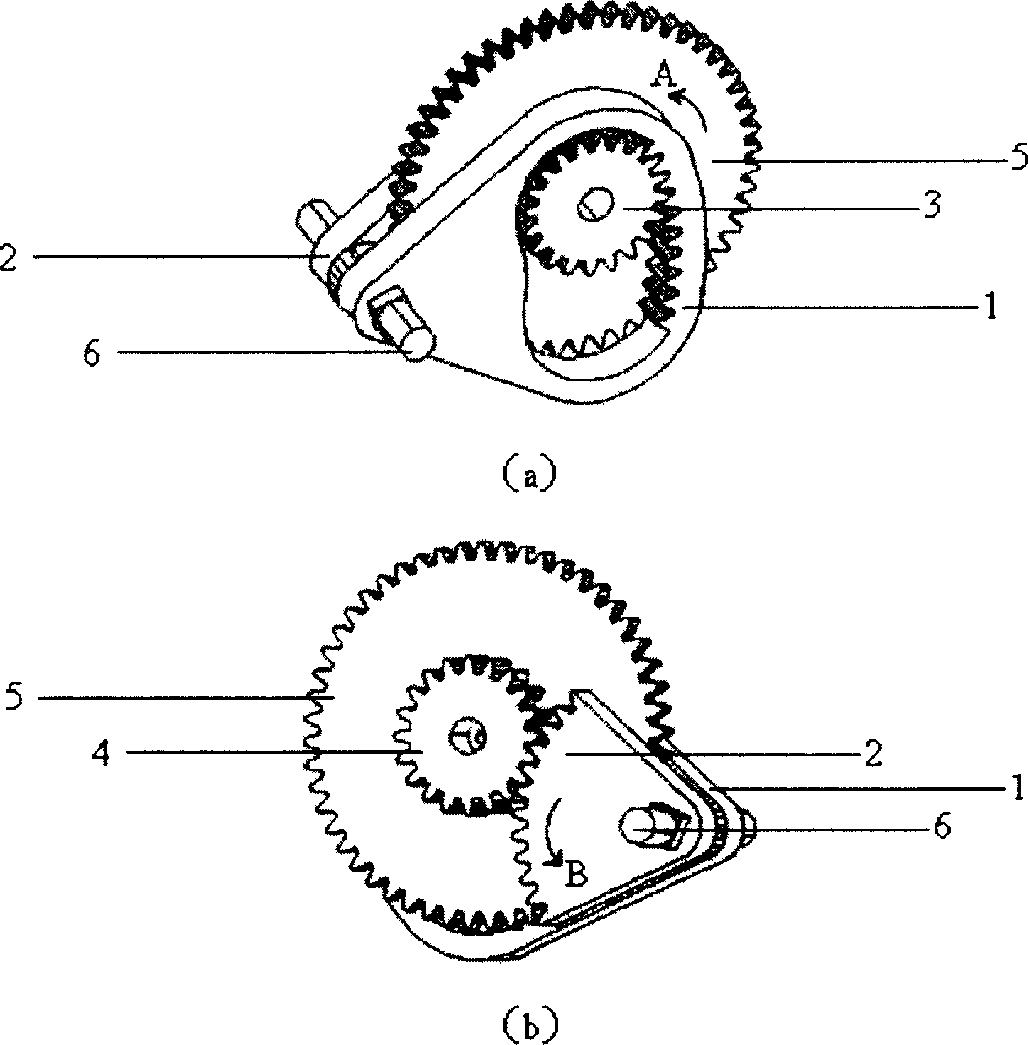

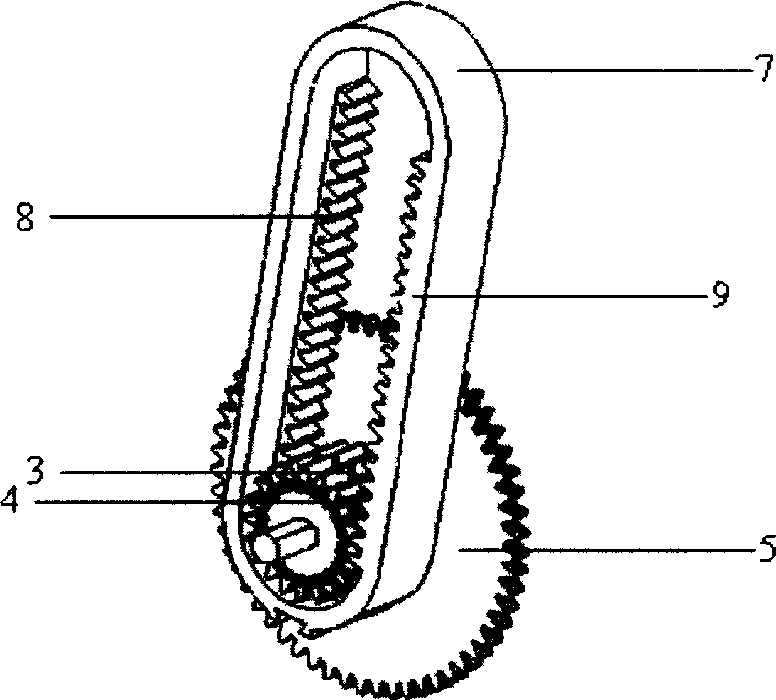

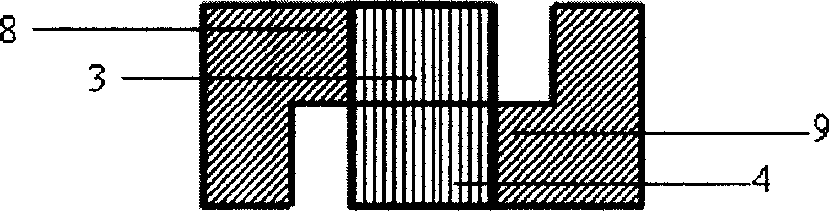

Two-way work doing driving mechanism and portable self-aid generating and lighting device

InactiveCN1683785AUniform outputMeet usage habitsFrom muscle energyLighting elementsReciprocating motionEngineering

The bi-directional work doing transmission mechanism includes power input unit, two single-way transmission parts, and power output unit to drive simultaneously these two single-way transmission parts to move oppositely. The present invention also discloses portable self-aid generating and lighting device with the bi-directional work doing transmission mechanism. The present invention is superior in that two single-way transmission parts are driven in opposite directions so that there is always one single-way transmission part to drive the power output unit during the reciprocating motion, resulting in best utilization of energy and raised transmission efficiency.

Owner:石为民 +2

Ultraviolet light/sunlight cured fluorine-free antifouling coating and preparation method thereof

ActiveCN108504269AEasy to industrializeImprove system compatibilityAntifouling/underwater paintsPaints with biocidesUltraviolet lightsSolvent

The invention discloses an ultraviolet light / sunlight cured fluorine-free antifouling coating and a preparation method thereof. The preparation method is characterized in that firstly, the synthesis of a low surface energy prepolymer is performed; an isocyanate type compound and hydroxyl containing polysiloxane are uniformly mixed and are heated to 50 to 90 DEG C; a catalyst is added for reaction;a solvent and / or a reactive diluent are / is added; then, a hydroxyl containing acrylate monomer and a polymerization inhibitor are added; the temperature is maintained to be 50 to 90 DEG C; the reaction is performed for 0.5 to 4h; the low surface energy prepolymer is prepared; then, the reactive diluent or a photosensitive group containing urethane acrylate affixture is added into the low surfaceenergy prepolymer; a photoinitiator is added; through ultraviolet light curing or sunlight curing, the fluorine-free antifouling coating is obtained. The use of expensive fluorine-containing compoundsand fluorine-containing solvents is avoided; the coating can be cured under the room temperature condition; the ultraviolet light curing time is short; the production cost is effectively reduced; thecoating has excellent antifouling performance and is applicable to various substrates.

Owner:SOUTH CHINA UNIV OF TECH

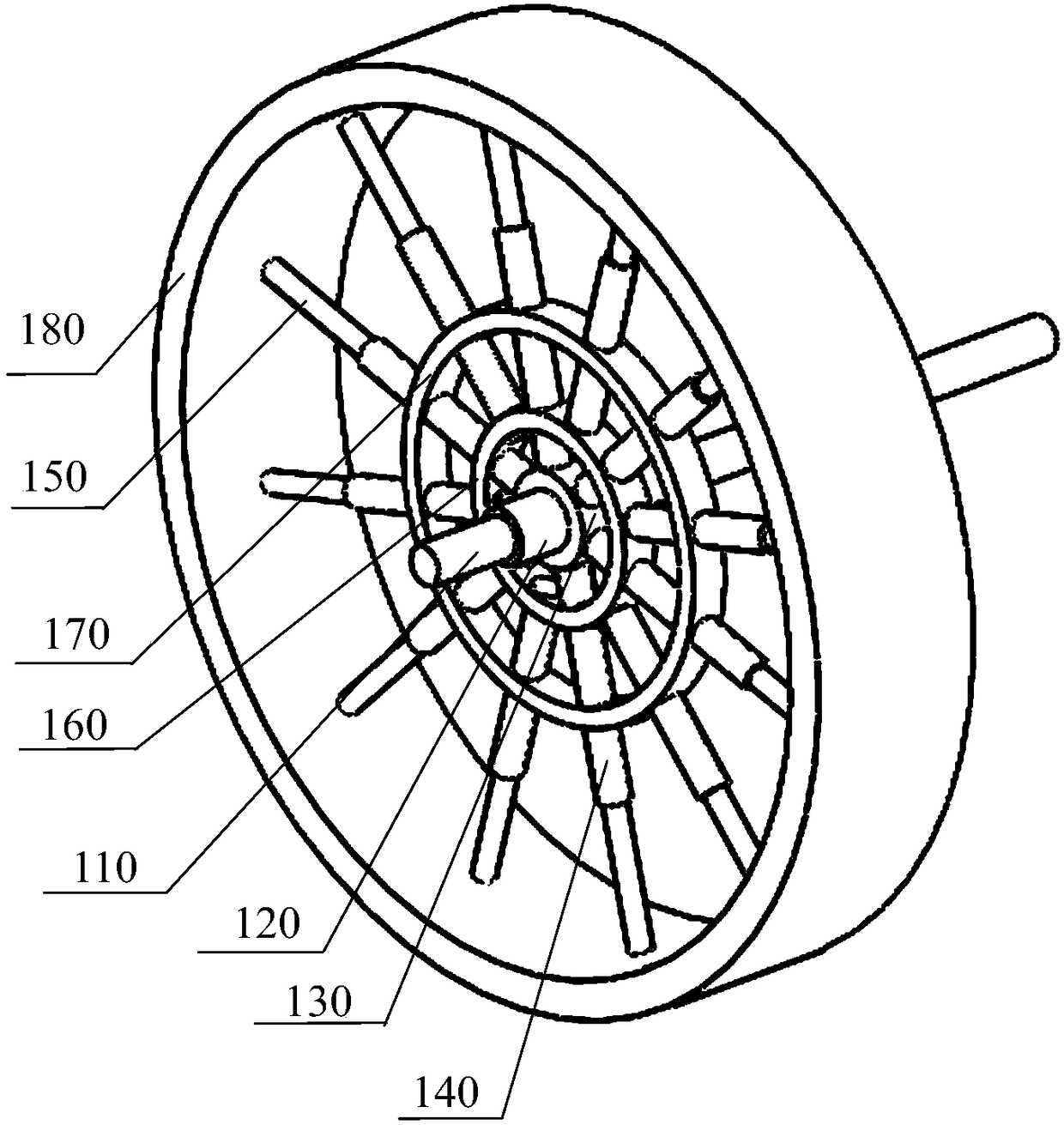

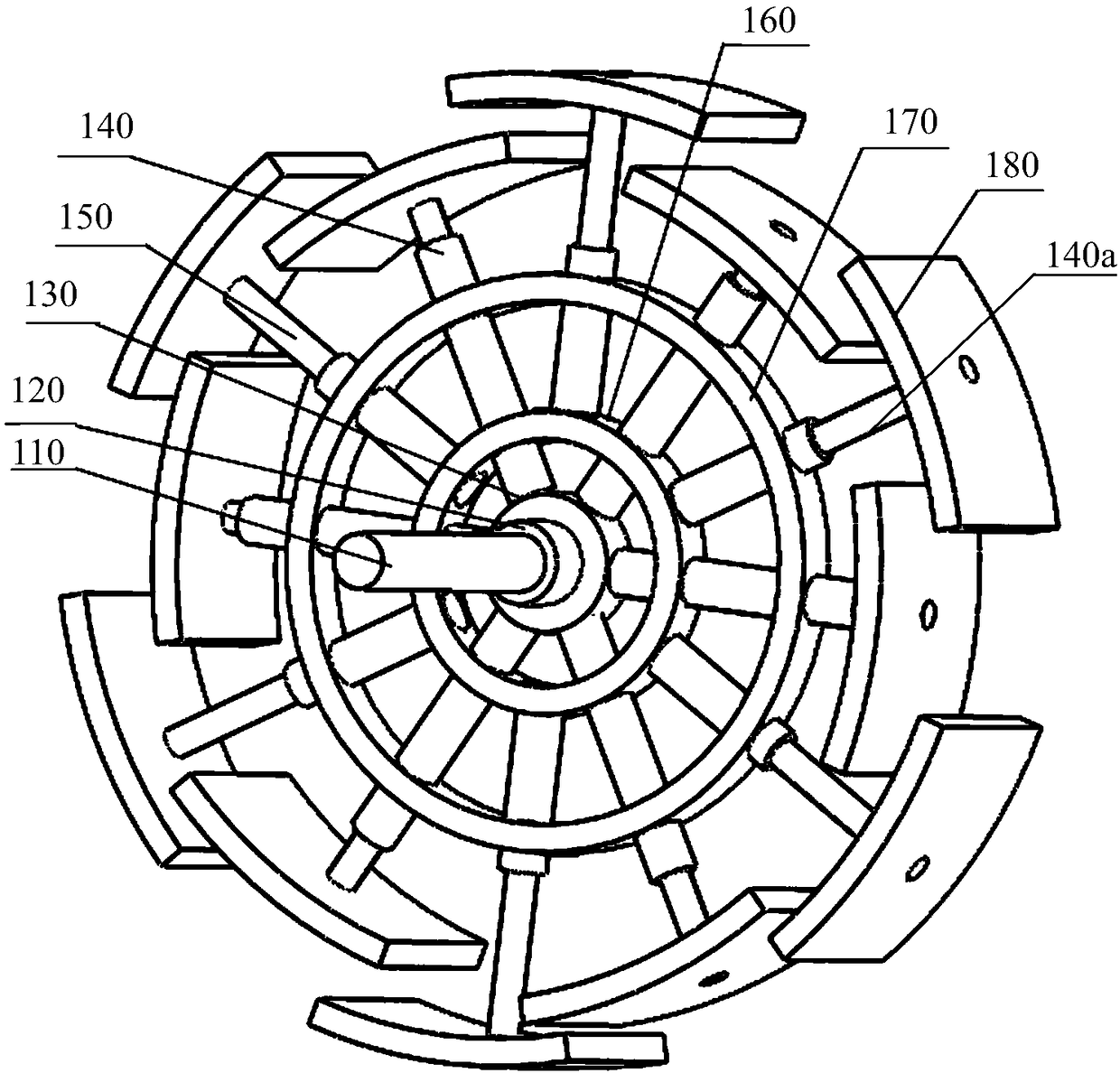

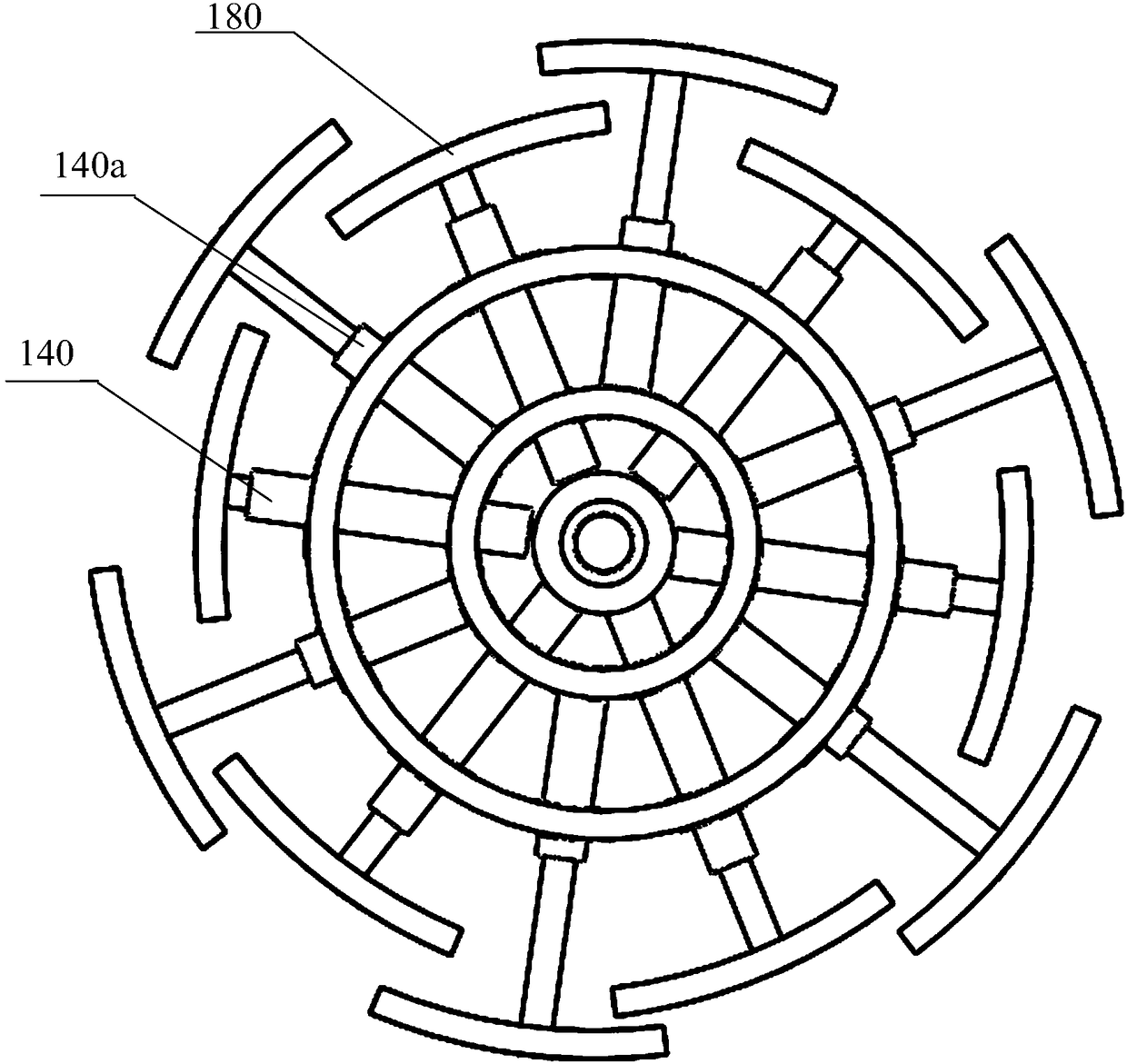

Staggered spoke type stretchable tool for friction stir welding and adjusting method of tool

PendingCN108213829AGood adaptabilityExpand the scope of useWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFriction stir welding

The invention discloses a staggered spoke type stretchable tool for friction stir welding. The staggered spoke type stretchable tool comprises a bearing, a bearing sleeve, a first supporting ring, a second supporting ring, a third supporting ring and a plurality of supporting plates, the bearing is used for connecting the spoke type tool with a cross-shaped operation machine type dislodgement machine, the bearing sleeve is rotationally arranged on the bearing in a sleeving manner, the first supporting ring is annular, an inner ring fixing sleeve is arranged on the bearing sleeve and can rotatealong with the bearing sleeve, the multiple first air cylinder assemblies are arranged on the outer ring of the first supporting ring and distributed on the outer side of the first supporting ring ina circumferential array equal-interval manner, the second supporting ring is annular, is concentric with the first supporting ring and is arranged on the outer side of the first supporting ring, a plurality of round holes are formed in the second supporting ring, air cylinders can penetrate the round holes, the supporting plates are arc-shaped plates, and the first air cylinder assemblies can bedetached to be far away from one end of the third supporting ring. The invention further discloses an adjusting method of the staggered spoke type stretchable tool for friction stir welding.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

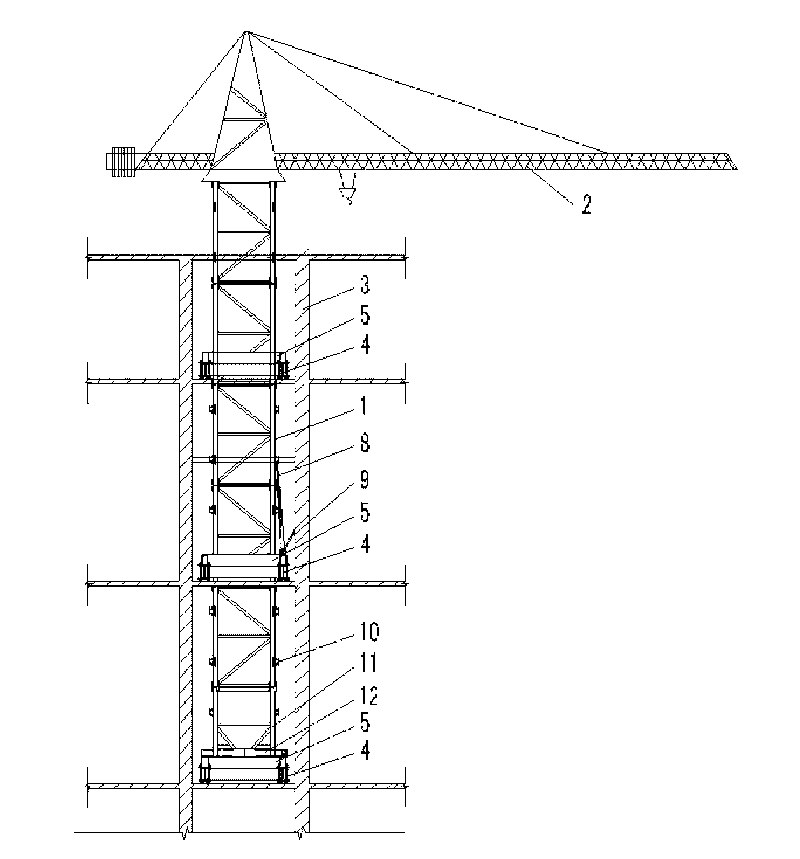

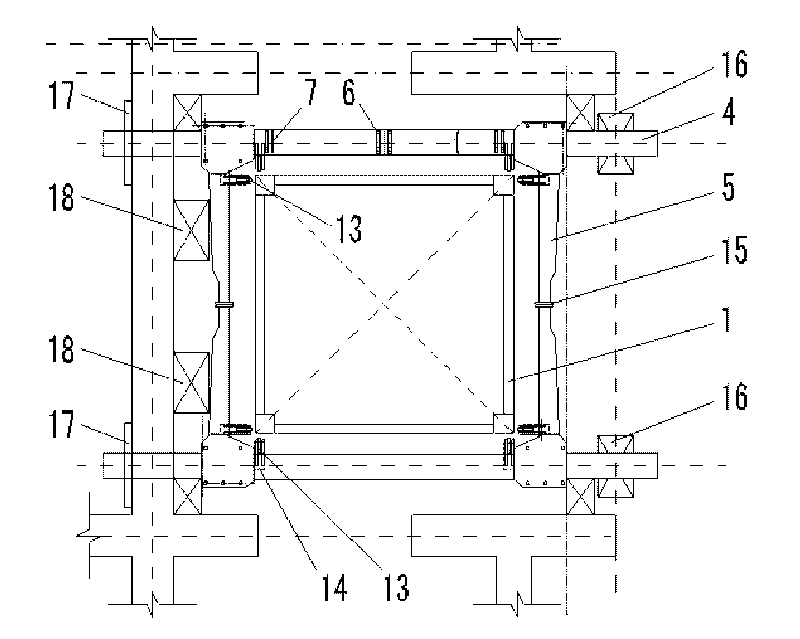

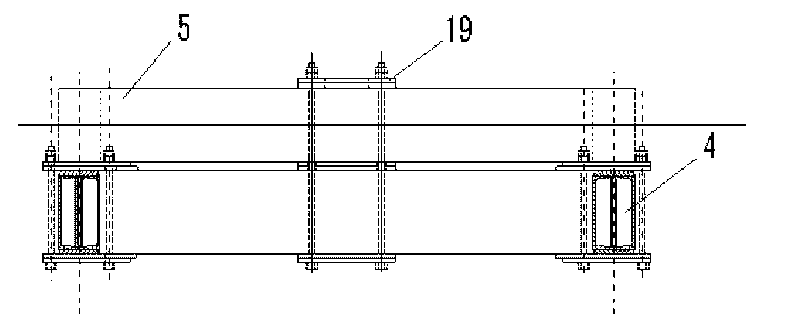

Self-climbing tower crane

InactiveCN101691191AHave vertical transportation requirementsMeet vertical transportation requirementsCranesSocial benefitsTower crane

The invention discloses a self-climbing tower crane, which comprises a tower body (1), a hoisting arm (2) and a climbing mechanism, wherein the climbing mechanism comprises a main stressed supporting steel beam (4) and a steel structure climbing attached frame (5); the steel structure climbing attached frame (5) is fixedly connected on the main stressed supporting steel beam (4) and is provided with a jacking cylinder (8) and a supporting steel beam (9); and a tower body supporting tread (10) is arranged on a tower body (1), and the bottom of the tower body (1) is provided with a climbing base section (11). The self-climbing tower crane can climb upward along a constructed structure by using the constructed building structure as a support, meet the requirements of superhigh-rise and out-of-code tall buildings on vertical transportation at the whole construction height, contribute to construction efficiency, construction period reduction, steel conservation and energy conservation and create obvious economic and social benefits.

Owner:CHINA CONSTR FOURTH ENG DIV

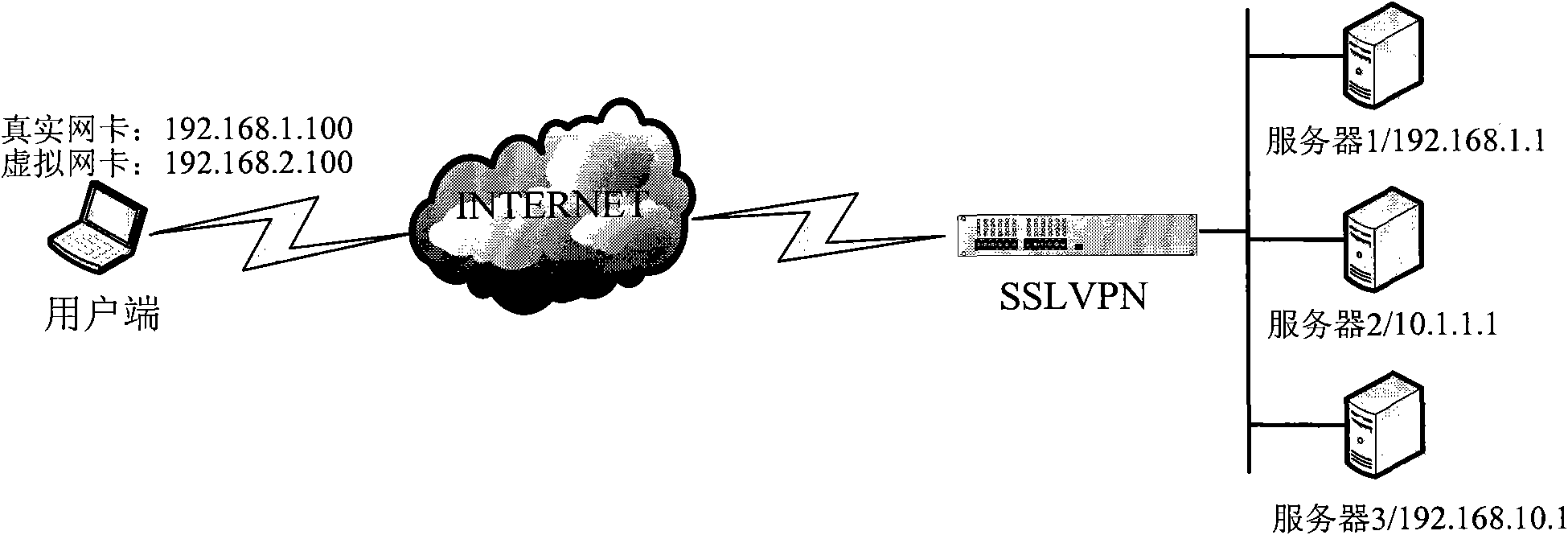

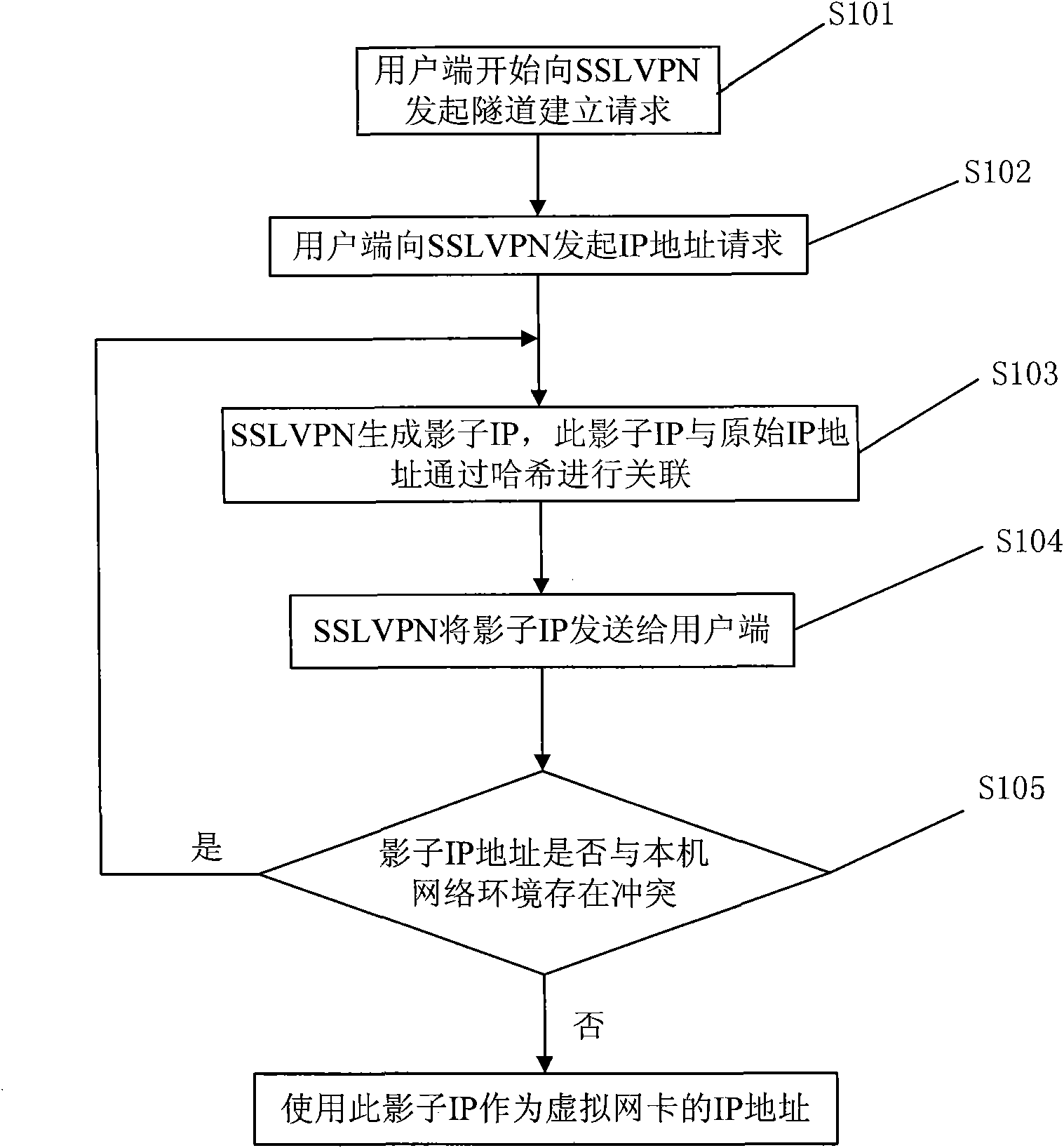

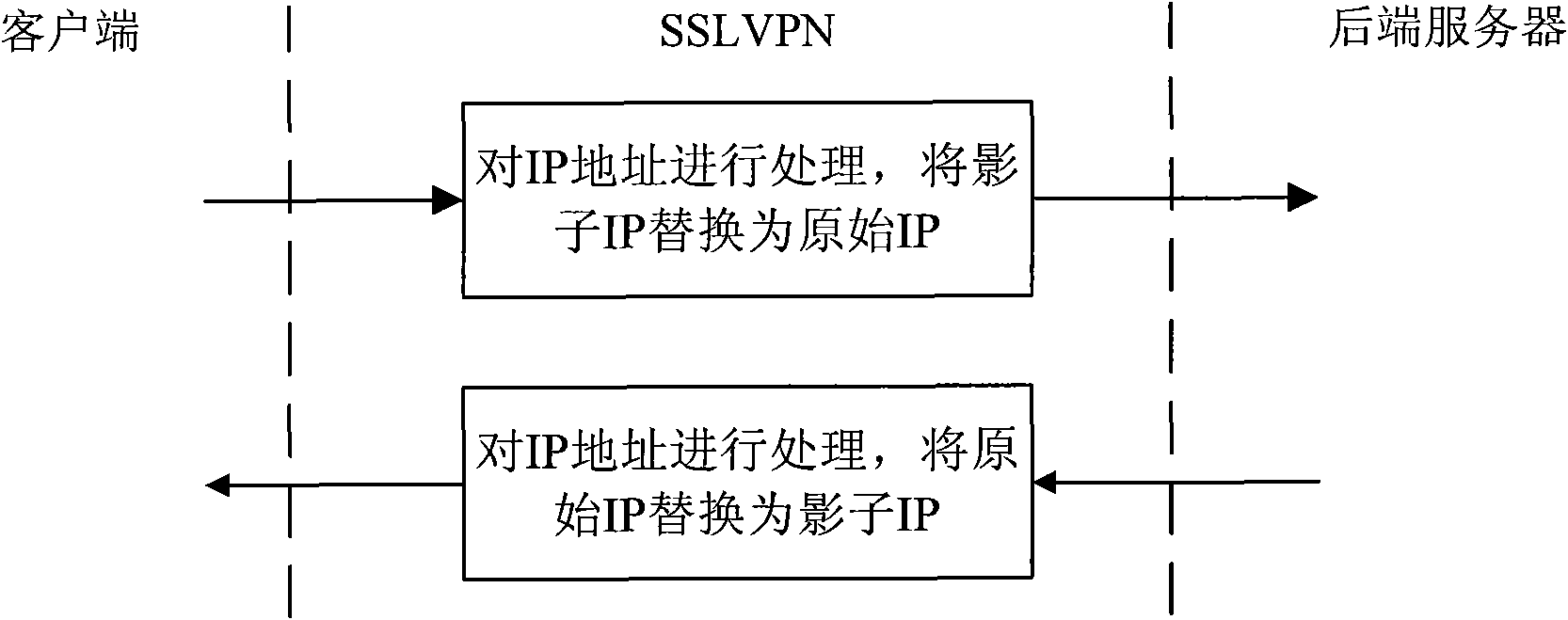

Solution method of address conflict in point-to-network tunnel mode

ActiveCN101964799AExpand the scope of useResolve Address ConflictsNetworks interconnectionClient-sideIp address

The invention discloses a solution method of an address conflict in a point-to-network tunnel mode. In the solution method, a client side starts to launch a tunnel establishing request to an SSLVPN (Secure Sockets Layer / Virtual Private Network); the client side launches an IP address request to the SSLVPN; the SSLVPN generates a shadow IP, and the shadow IP is associated with an original IP address through Hashing; the SSLVPN sends the shadow IP to the client side; the client side judges whether the shadow IP has a conflict with the local network environment or not; if the conflict exists, the SSLVPN regenerates a shadow IP; and if the conflict does not exist, then the shadow IP is used as the IP address of a virtual network card. The solution method can be used for successfully solving the problem that the virtual network card of the client side is required to use a specific IP address in certain circumstances and the IP address of the virtual network card allocated by the SSLVPN has a conflict with the specific IP address. Thus, a point-to-network tunnel can meet various network topology requirements, and the use range of the application is widened.

Owner:北京神州数码云科信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com