Patents

Literature

427results about How to "Uniform output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

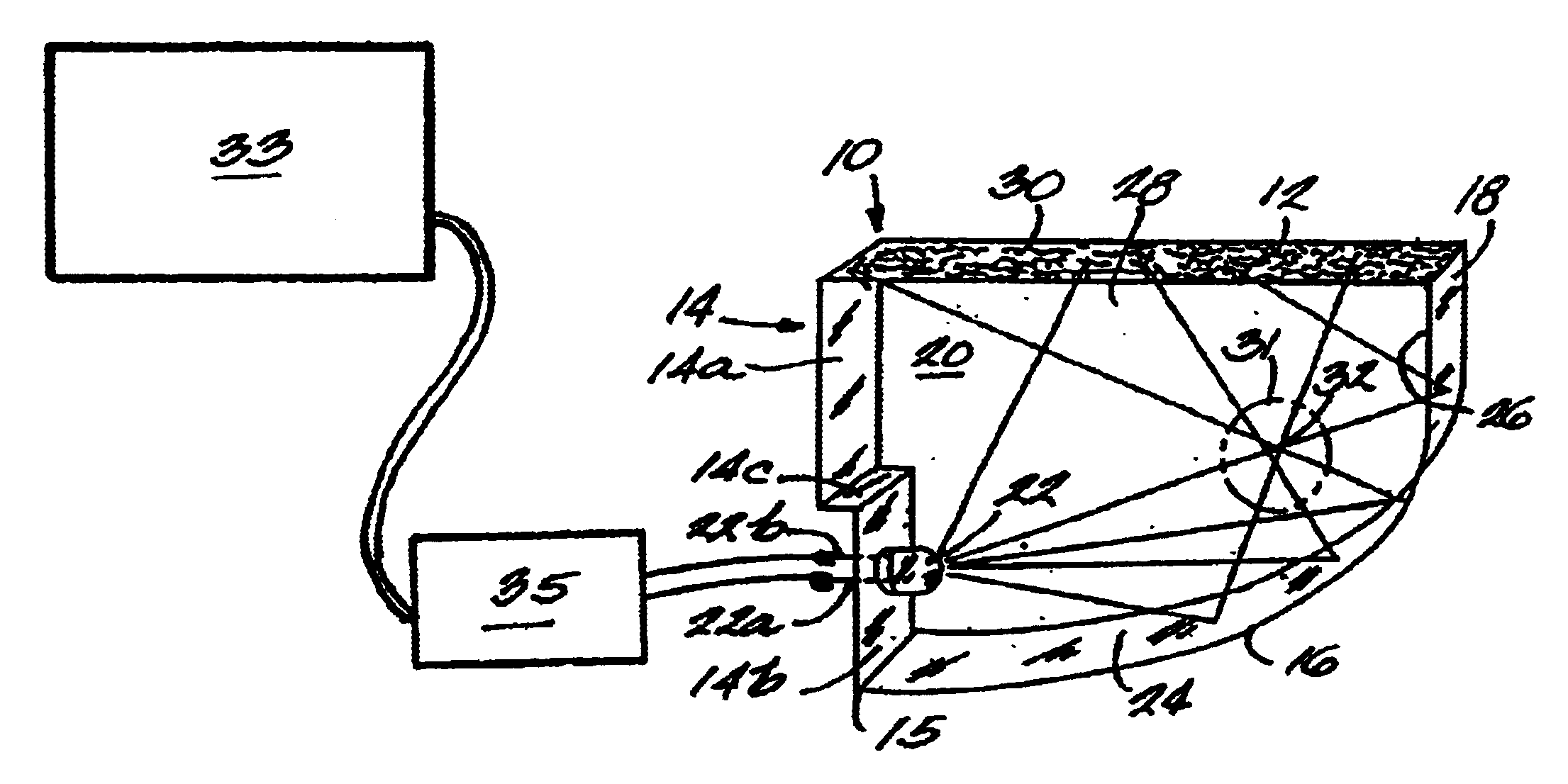

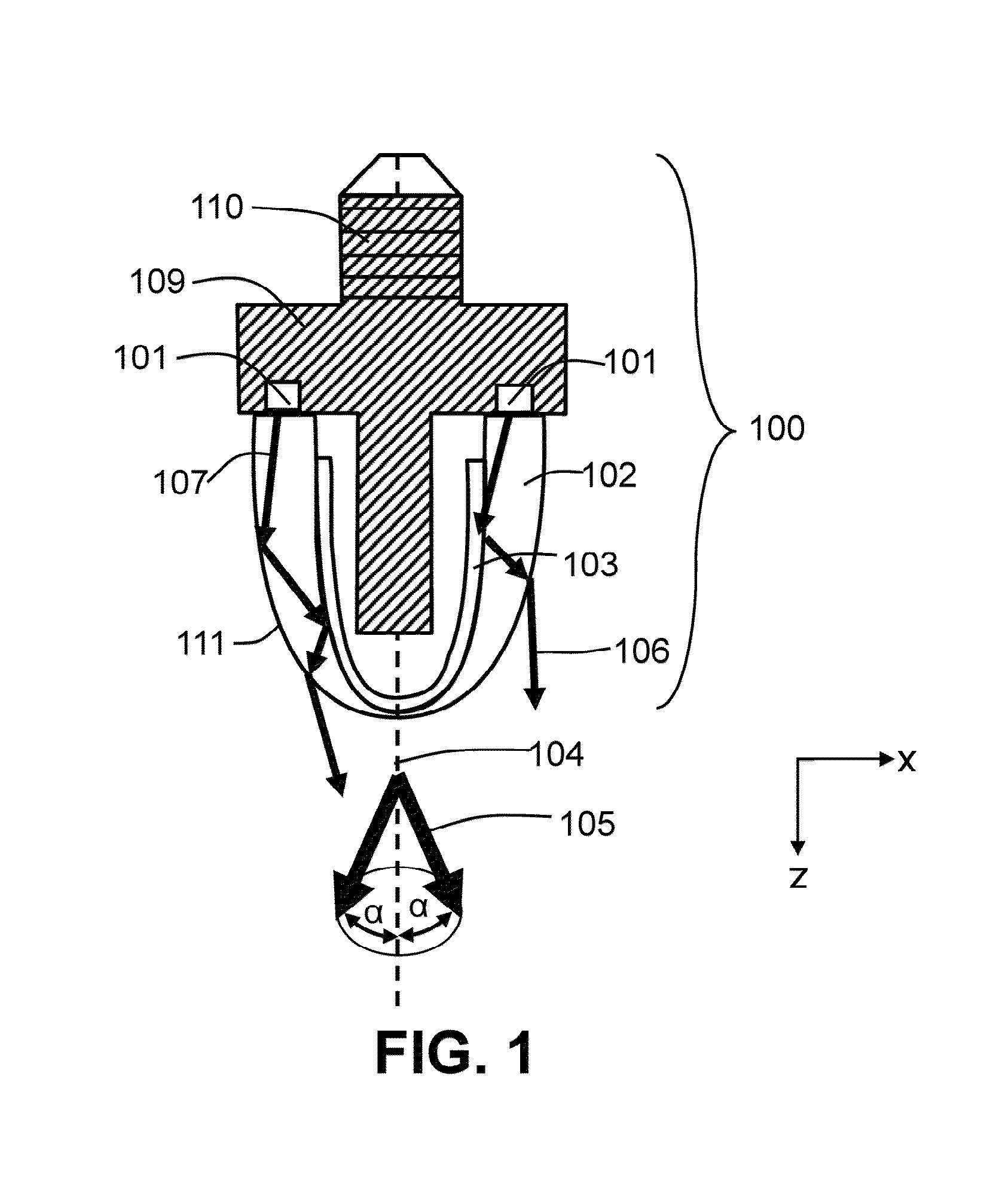

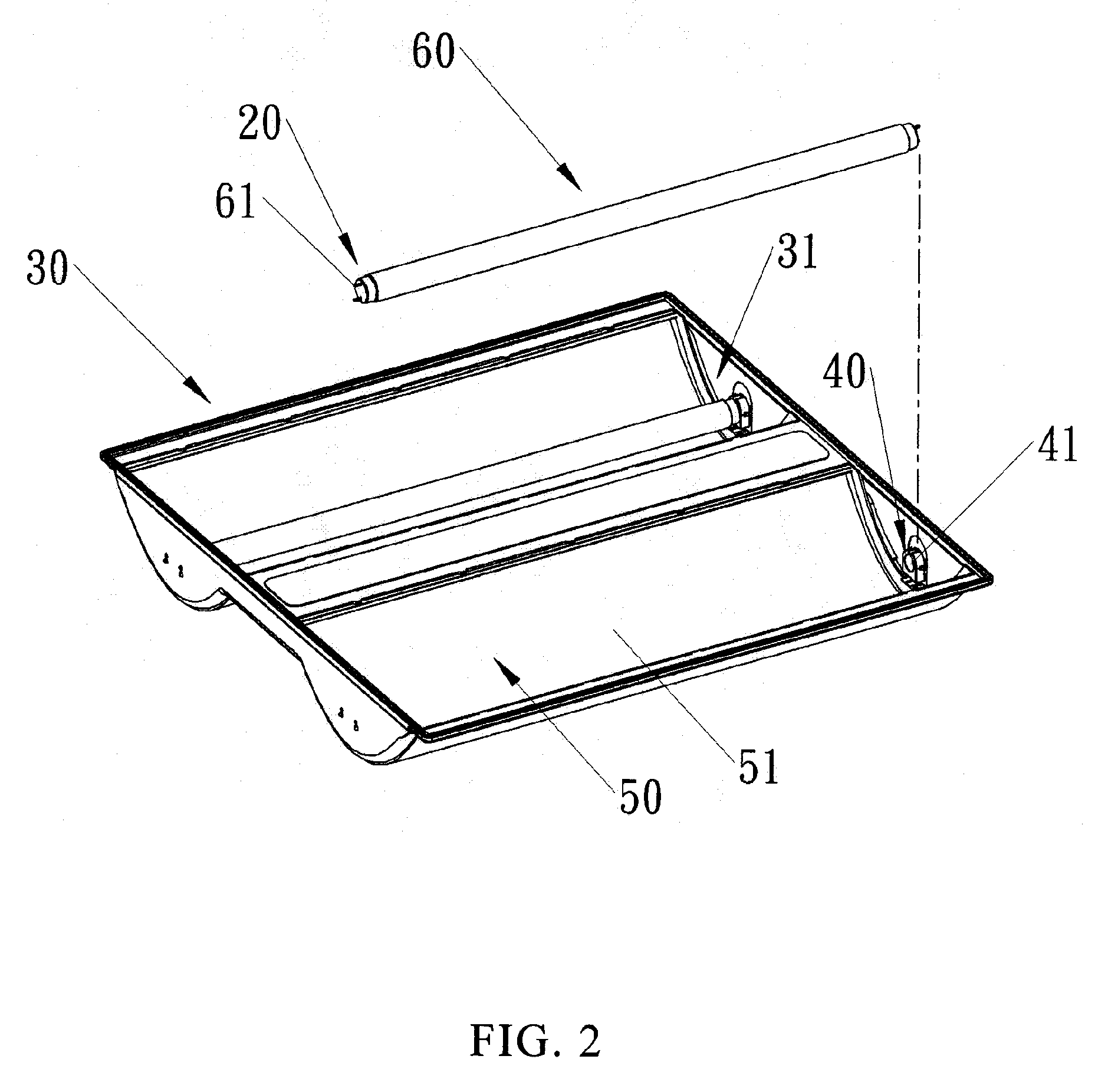

Light emitting diode light bar

InactiveUS6948840B2Low costUniform lightMechanical apparatusMeasurement apparatus componentsEffect lightEngineering

A lighting fixture is disclosed which provides a substantially uniform elongated light output, yet is powered by only a minimum number of inexpensive light emitting diodes. The lighting fixture has a curved back surface and a selected focal area to provide a substantially uniform output. Multiple LEDs may be controlled by a controller to provide special lighting effects. Each of the side surfaces and the back surface may include a reflector. The lighting fixtures preferably have flat end surfaces so they may be placed end-to-end to create an elongated light bar of any desired length.

Owner:EVERBRITE

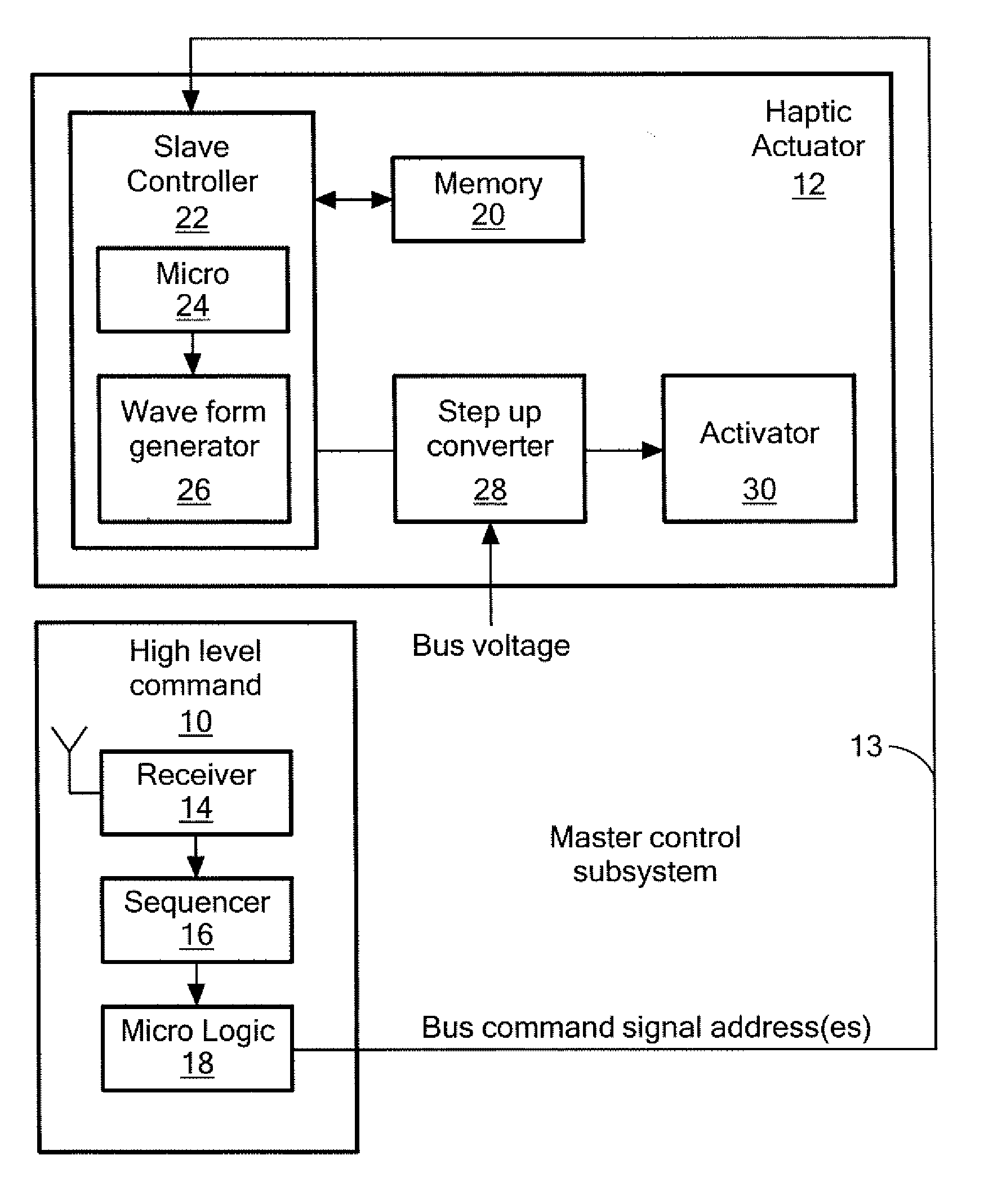

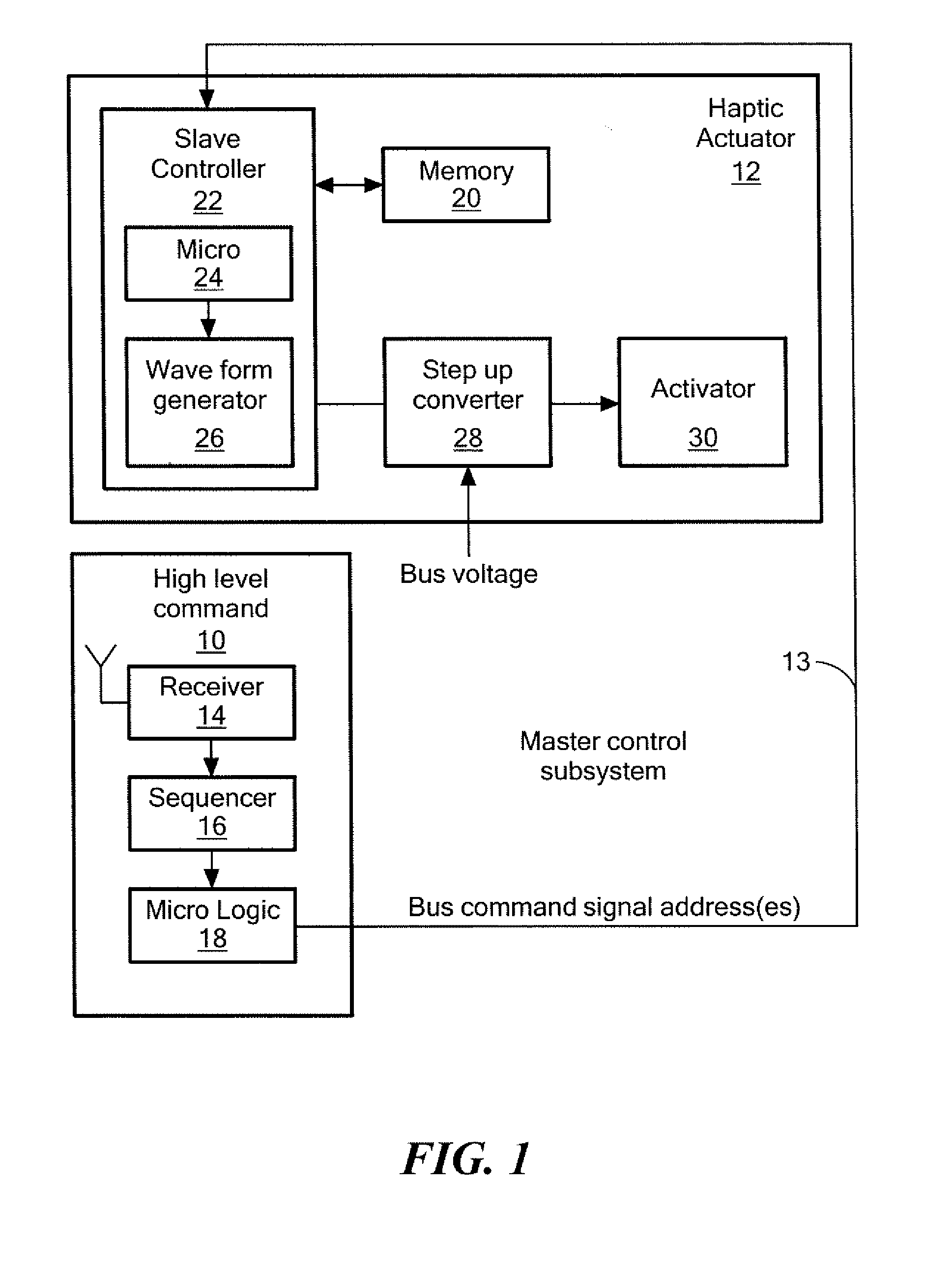

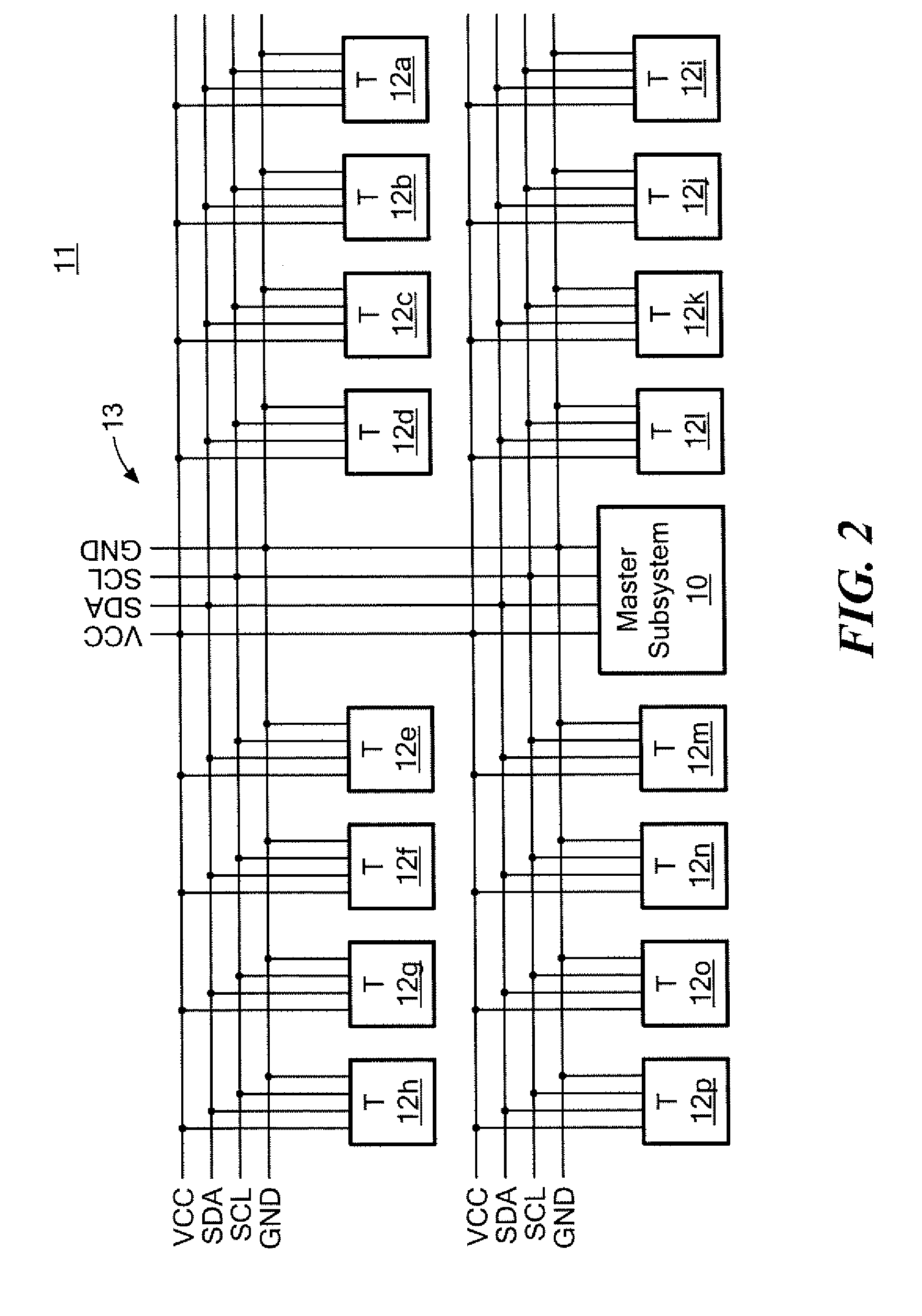

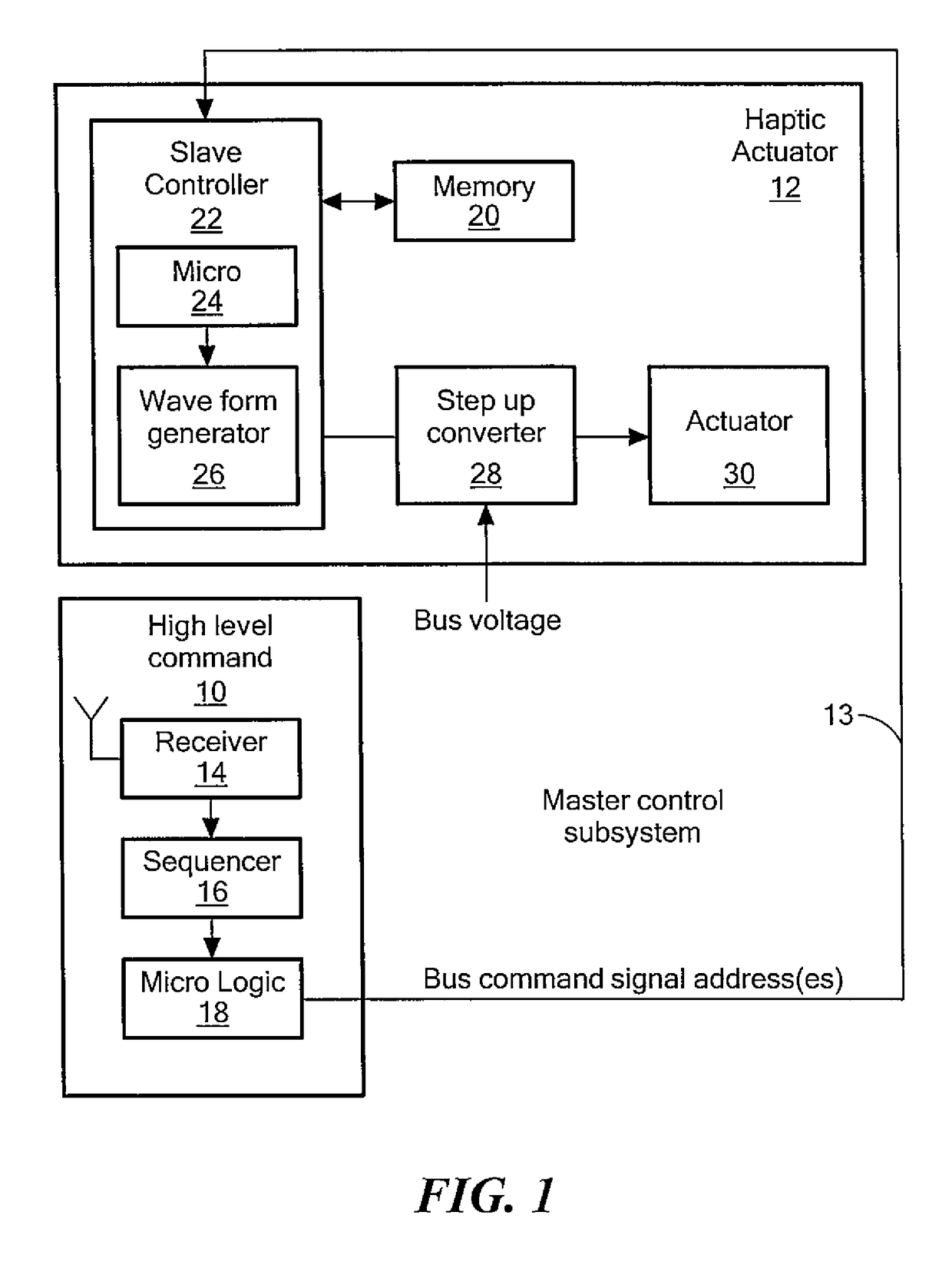

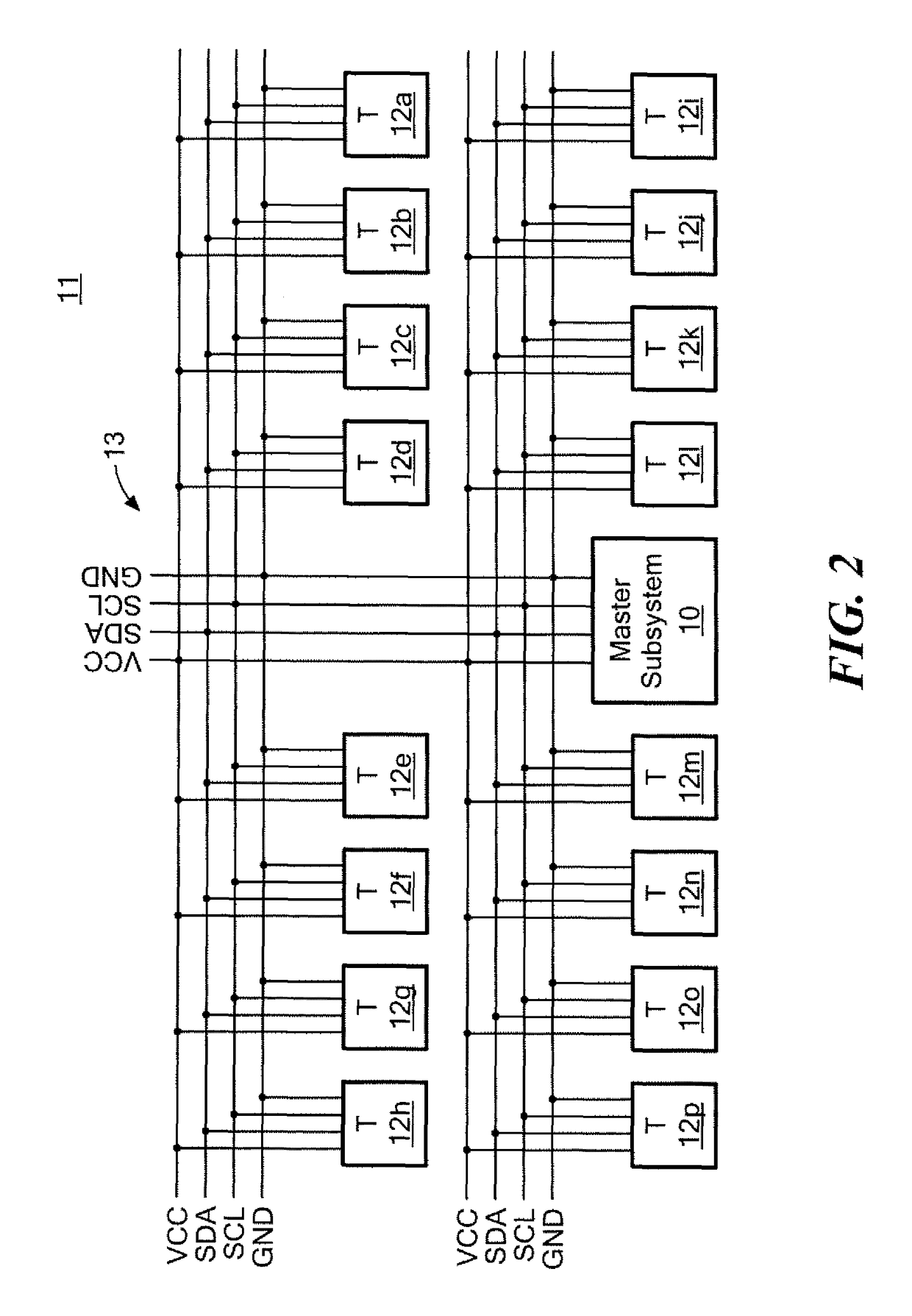

Bussed haptic actuator system and method

ActiveUS20150227204A1Reduced pin countReduce the numberInput/output for user-computer interactionDigital data processing detailsActuatorControl theory

A bussed haptic actuator system includes a plurality of haptic actuators and a master control subsystem. Each haptic actuator includes a memory with an address storable therein and a slave controller subsystem configured to control the actuator in response to a received command signal. The master control subsystem is connected via a bus to the plurality of haptic actuators. The master control subsystem includes sequencer configured to determine which of the plurality of haptic actuators are to be activated and logic configured to provide, on the bus, a command signal including one or more addresses corresponding to haptic actuators to be activated as determined by the sequencer.

Owner:MIDE TECH

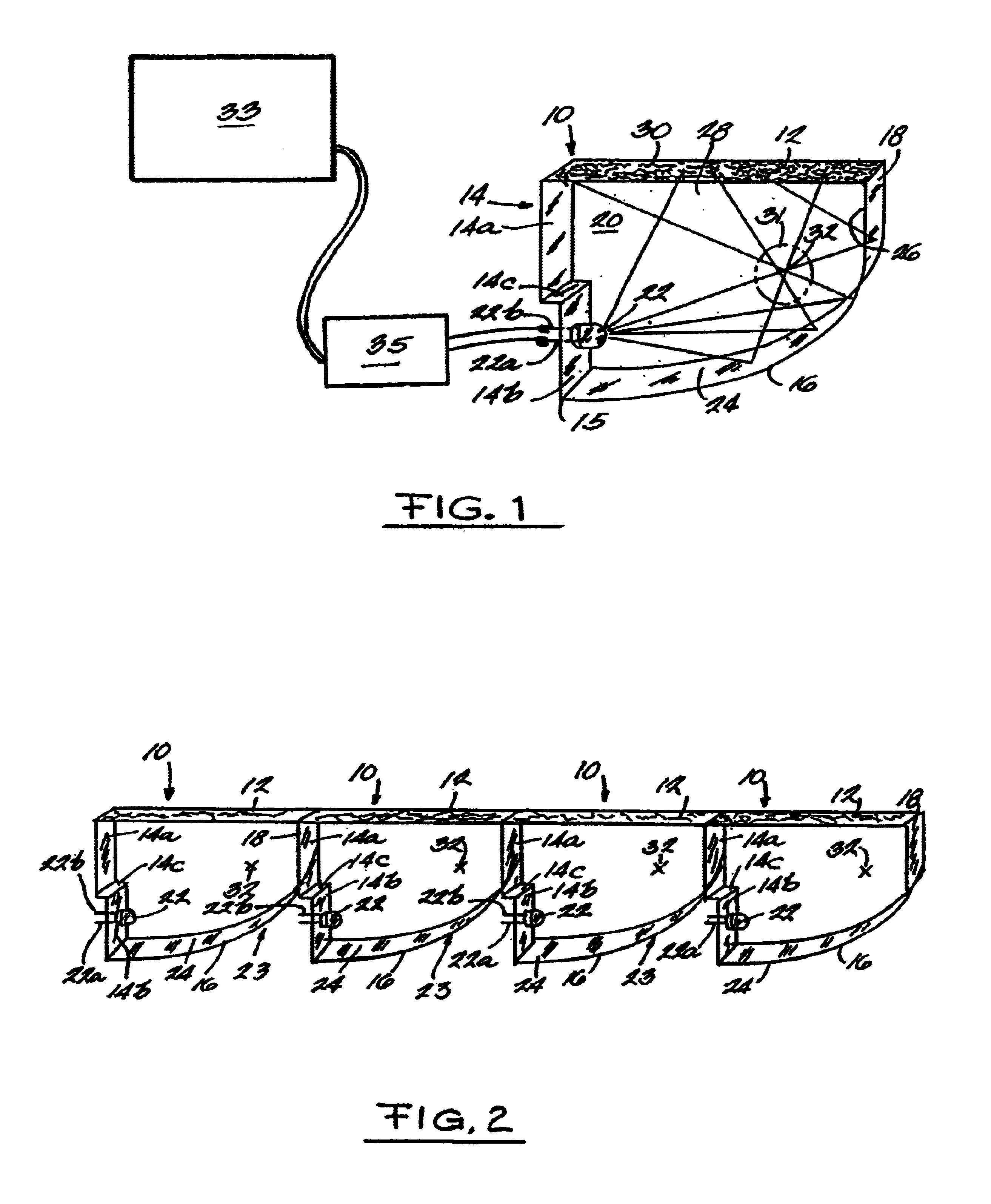

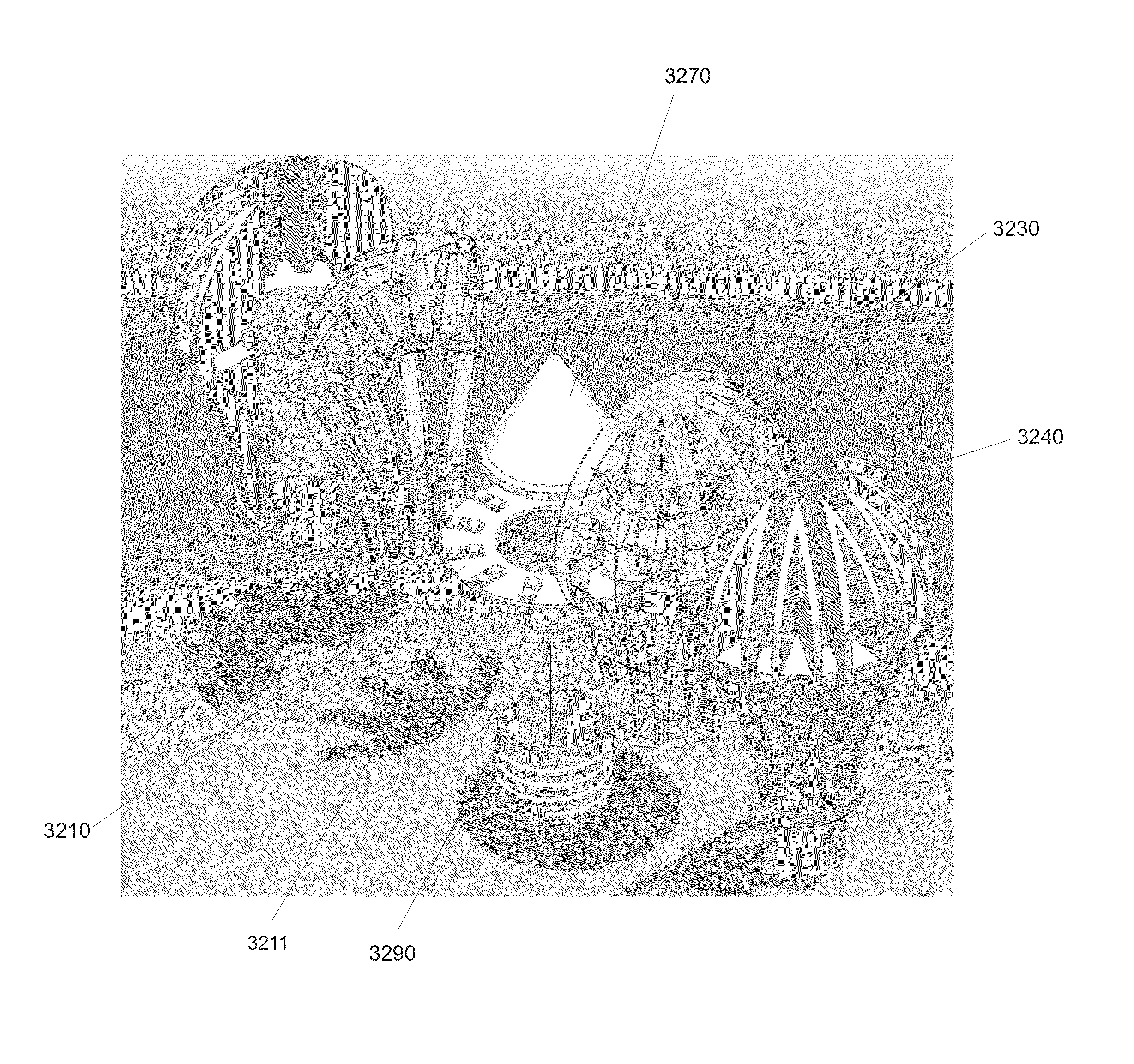

Spline optic and lighting device

ActiveUS8953926B1Improved thermal managementUniform outputElectrical apparatusElectroluminescent light sourcesEngineeringLight source

Owner:MASSACHUSETTS DEV FINANCE AGENCY

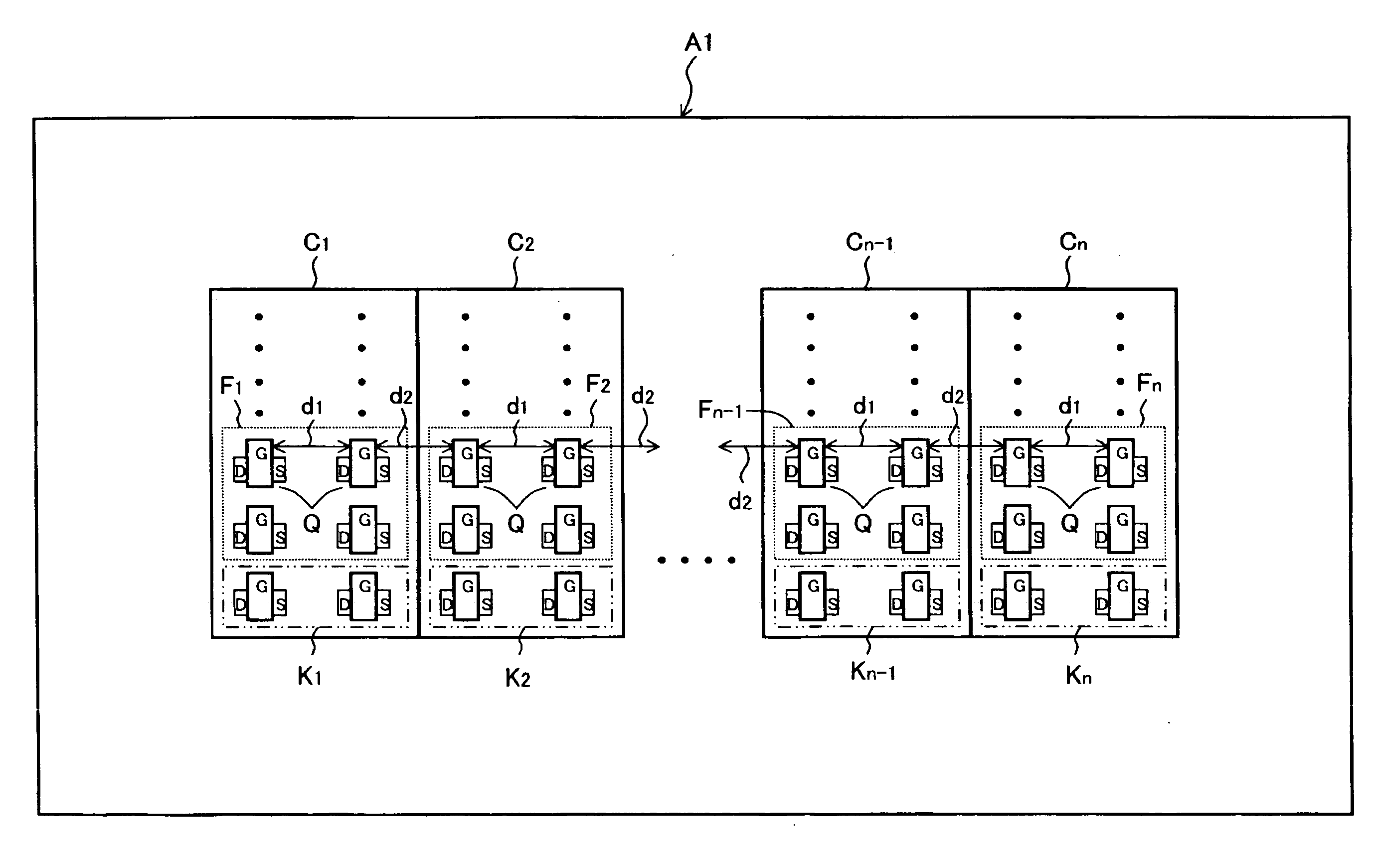

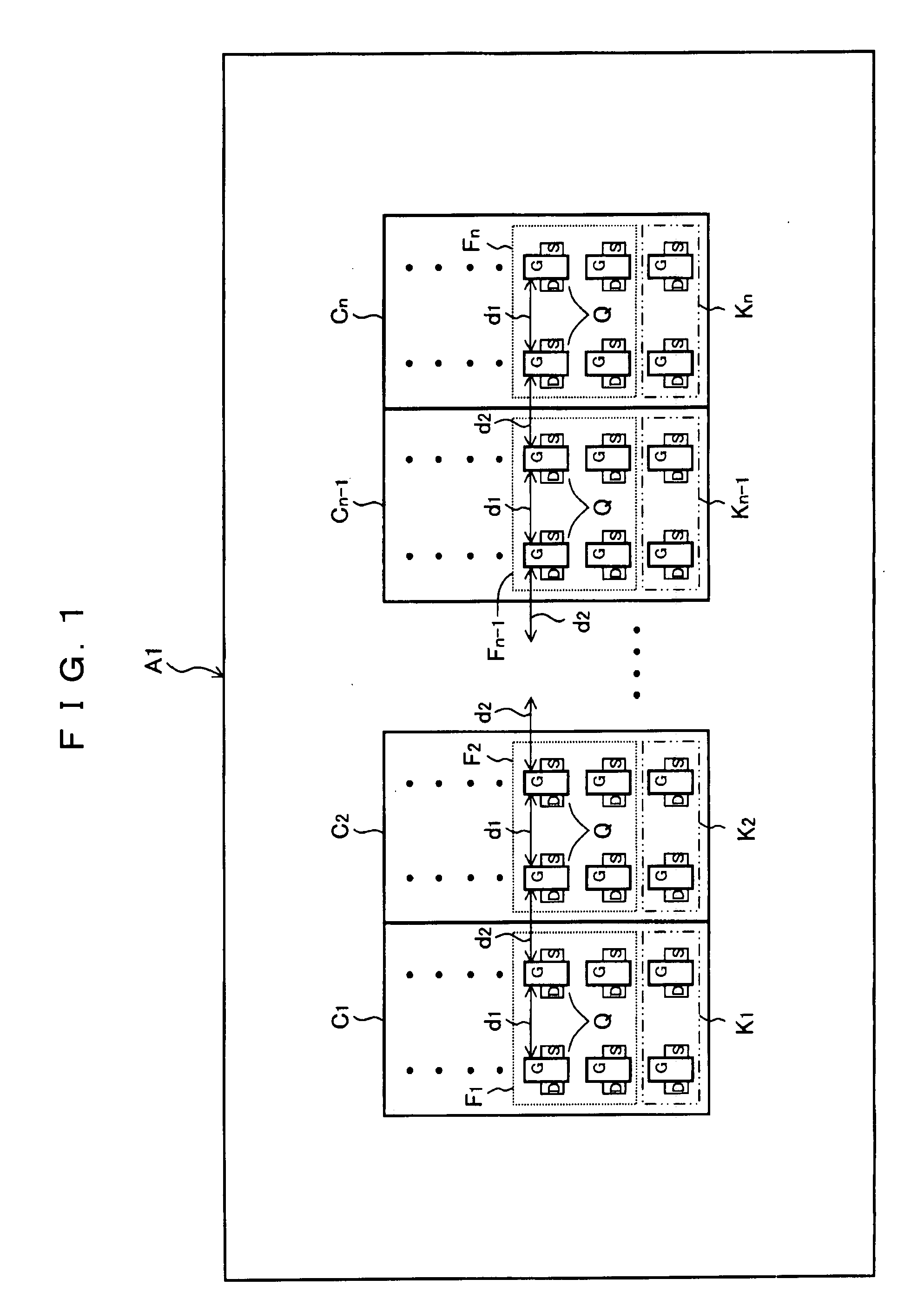

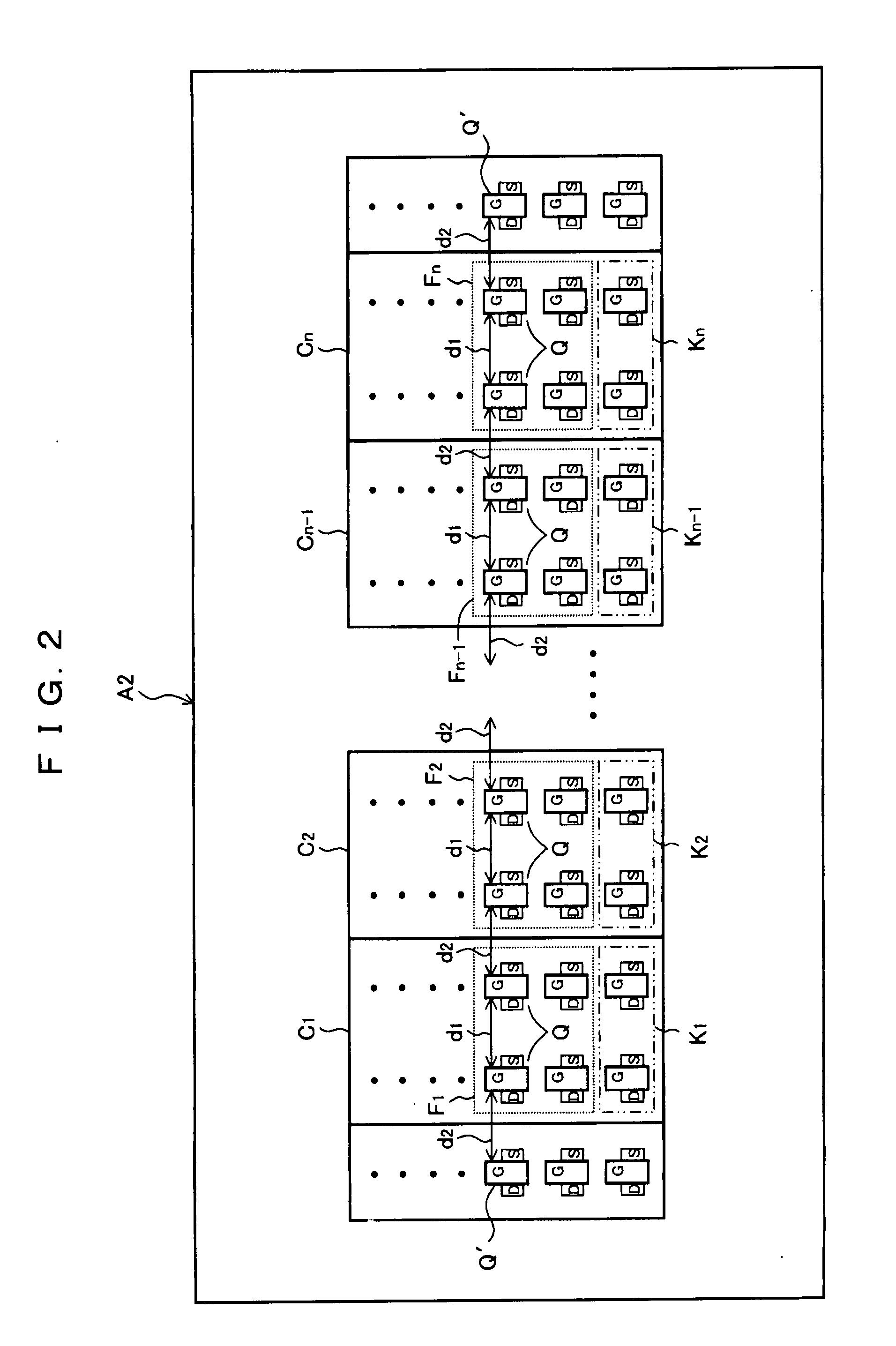

Layout method and semiconductor device

InactiveUS20080022247A1Size of cellIncrease the areaTransistorSolid-state devicesEngineeringSemiconductor

The present invention is provided with a plural cell including a transistor pair. The plural cells are arranged at equal intervals so as to configure a cell group. A inter-cell distance between a transistor in one of the cell and a transistor the other cell in each of adjacent cells in the cell group is equal to a intra-cell distance between one of the transistor and the other transistor in the transistor pair.

Owner:PANASONIC CORP

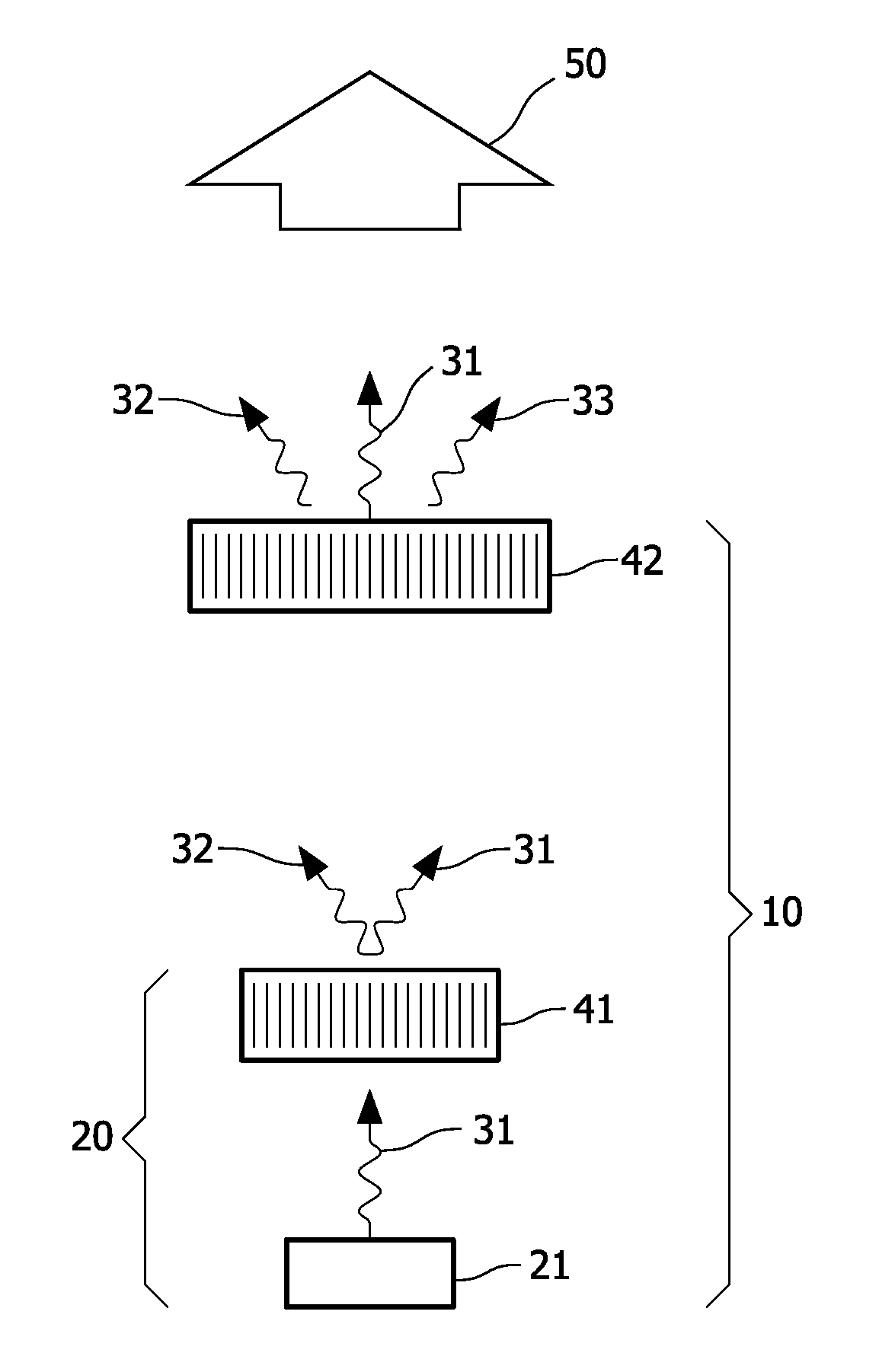

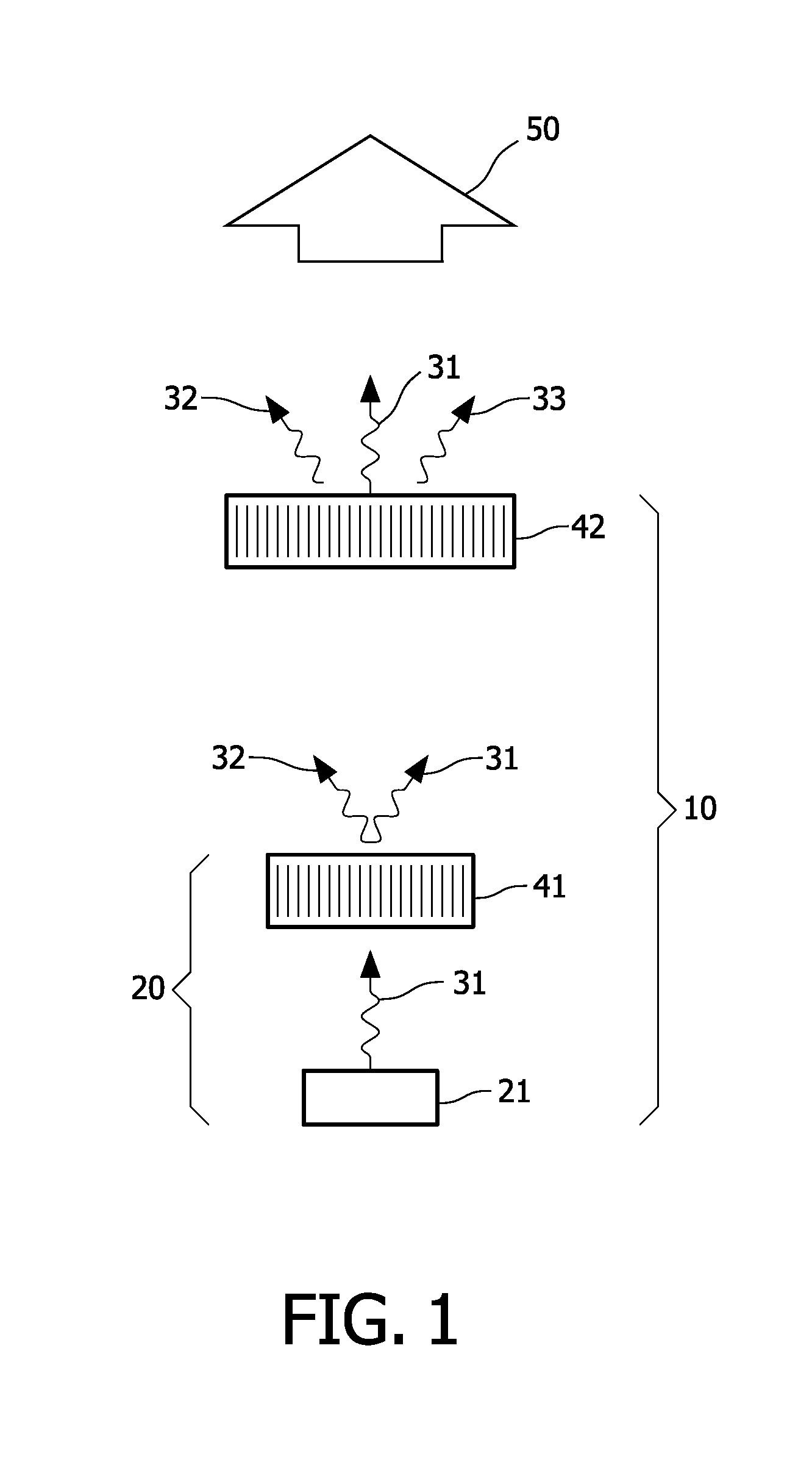

Illumination system

ActiveUS20100142182A1Uniform color outputUniform intensitySpectral modifiersNon-linear opticsLighting systemLight emitting device

The invention provides an illumination system comprising a light-emitting device which excites a first luminescent element, which forms part of the light-emitting device. The light emitted from the first luminescent element and / or the light emitted by the light-emitting device excite a second luminescent element, physically separated from the light-emitting device. By employing two luminescent elements, the first element in the light-emitting device, and the second element physically separated from the light-emitting device, such as on a cover plate, the conversion of light produced by the light-emitting device is performed at both a “local” and a “remote” location, respectively, and the amount of luminescent material required at the remote location may be reduced compared to the situation of the prior art where the light conversion was only performed at a remote location.

Owner:SIGNIFY HLDG BV

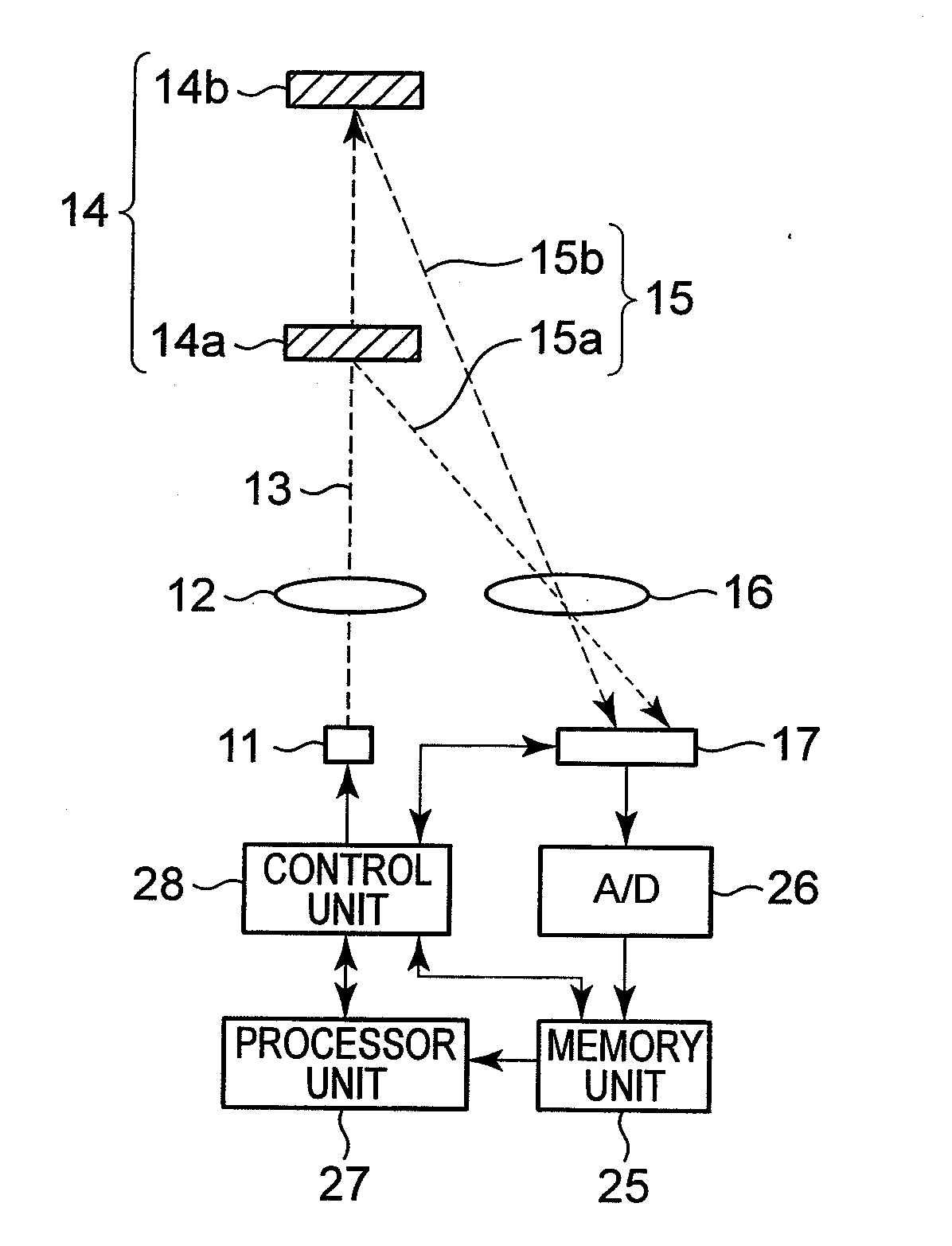

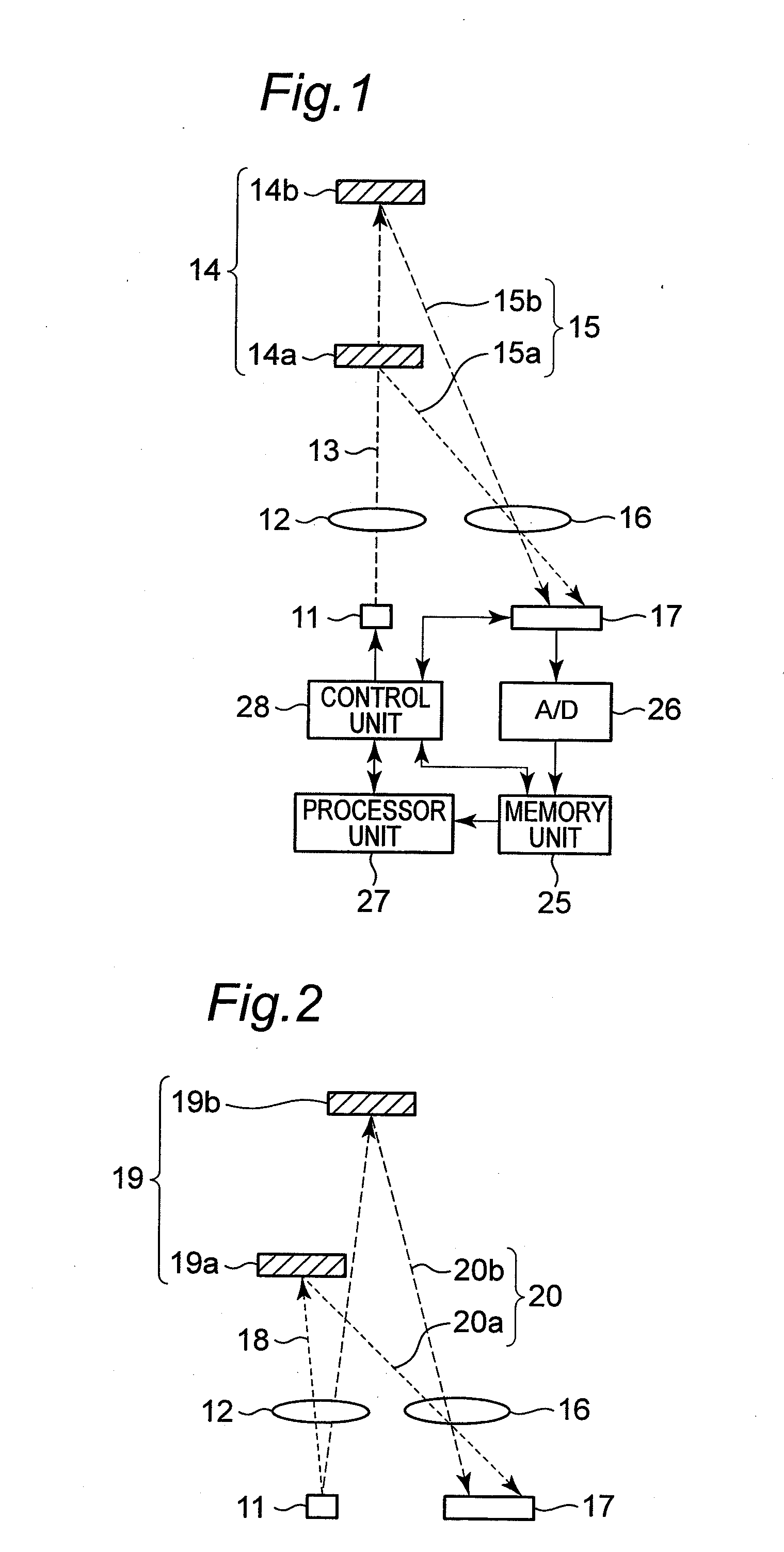

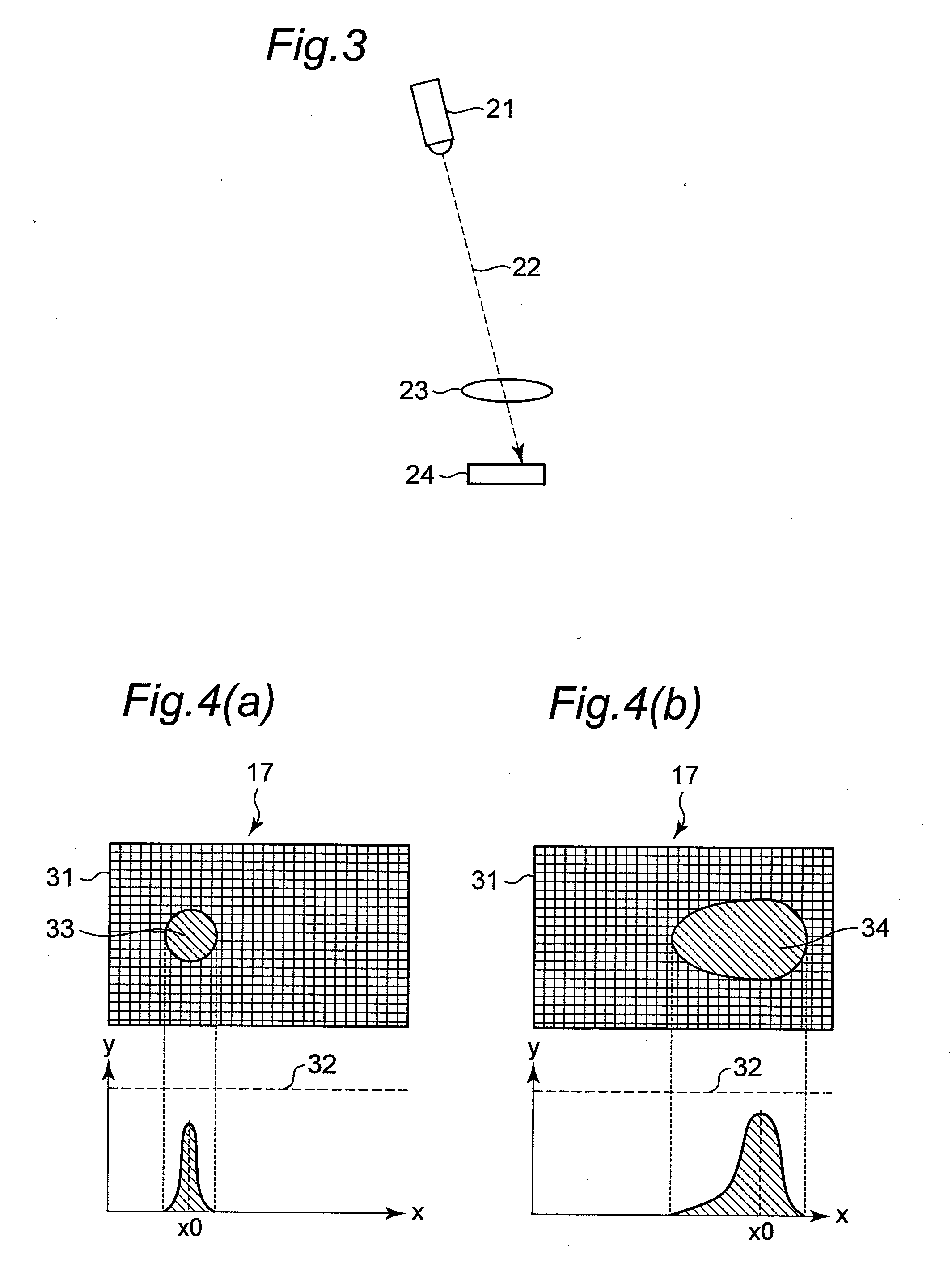

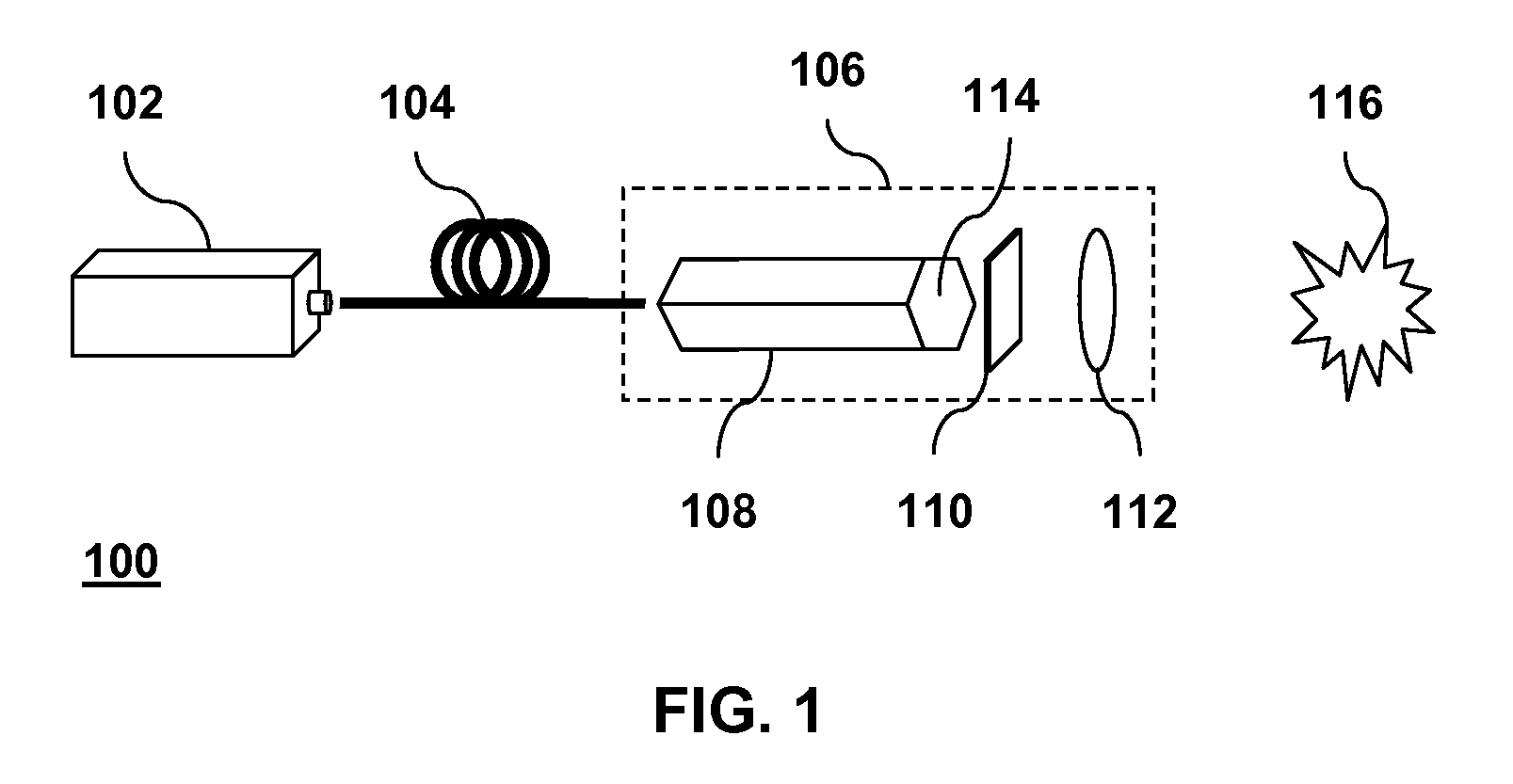

Light spot position detection device, optical device including the same, and electronic equipment including the optical device

ActiveUS20100194942A1Improve accuracyEasy to useTelevision system detailsOptical rangefindersLight spotSignal light

In a light spot position detection device, in one frame of operation, under control of a control unit, pixel data obtained in a pixel section in exposure of a solid-state image sensor in synchronization with light emission of a light emitting element are added to corresponding storage portions in a memory unit, and pixel data obtained in exposure of the image sensor asynchronous to the light emission of the light emitting element are subtracted from the corresponding storage portions, to store pixel data of only signal light in the storage portions. A given number of frames of operation are repetitively performed to accumulate pixel data of only the signal light in the storage portions. The position of a light spot on the pixel section is calculated based on the pixel data of only the signal light and outputted whether the storage portions are saturated or not with the pixel data.

Owner:SHARP KK

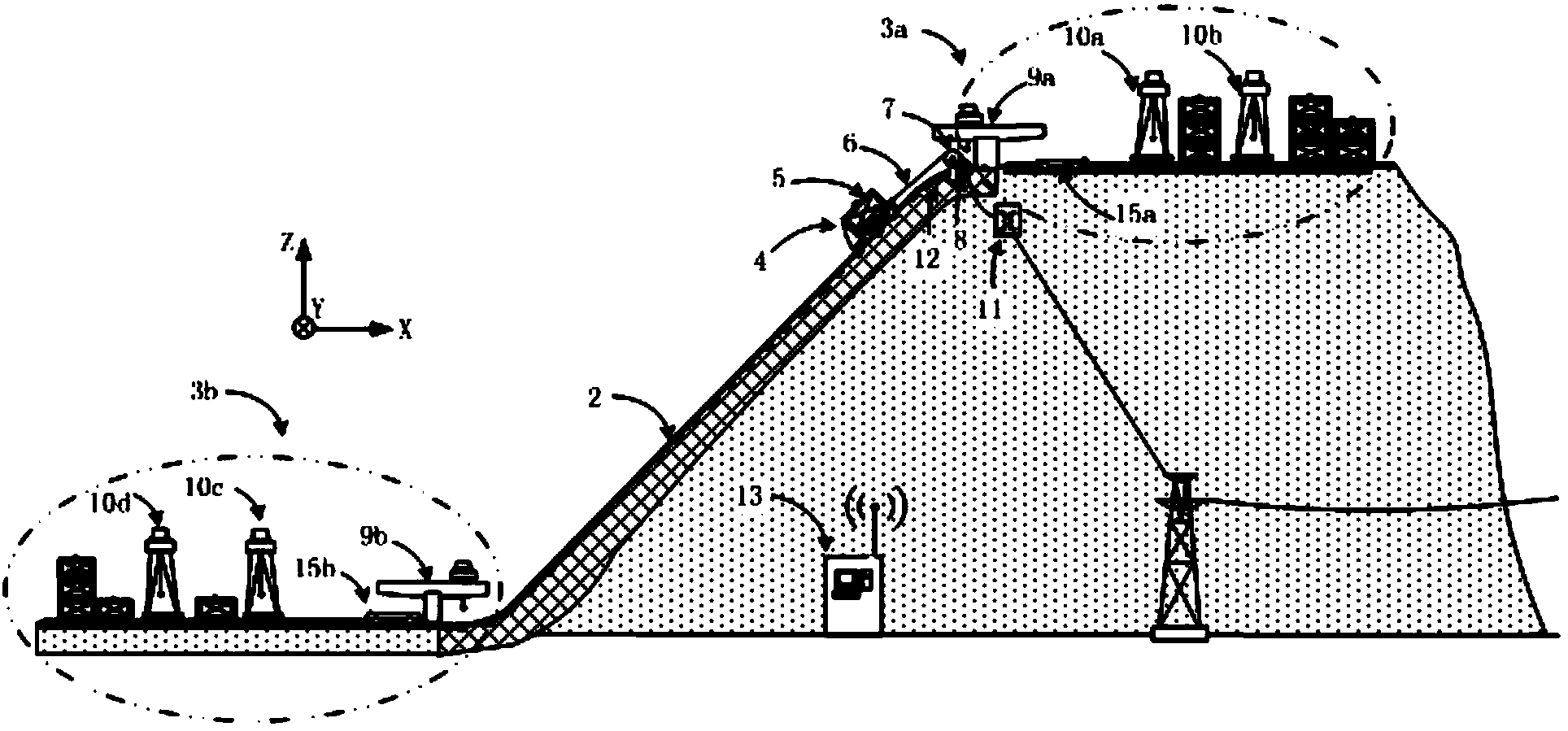

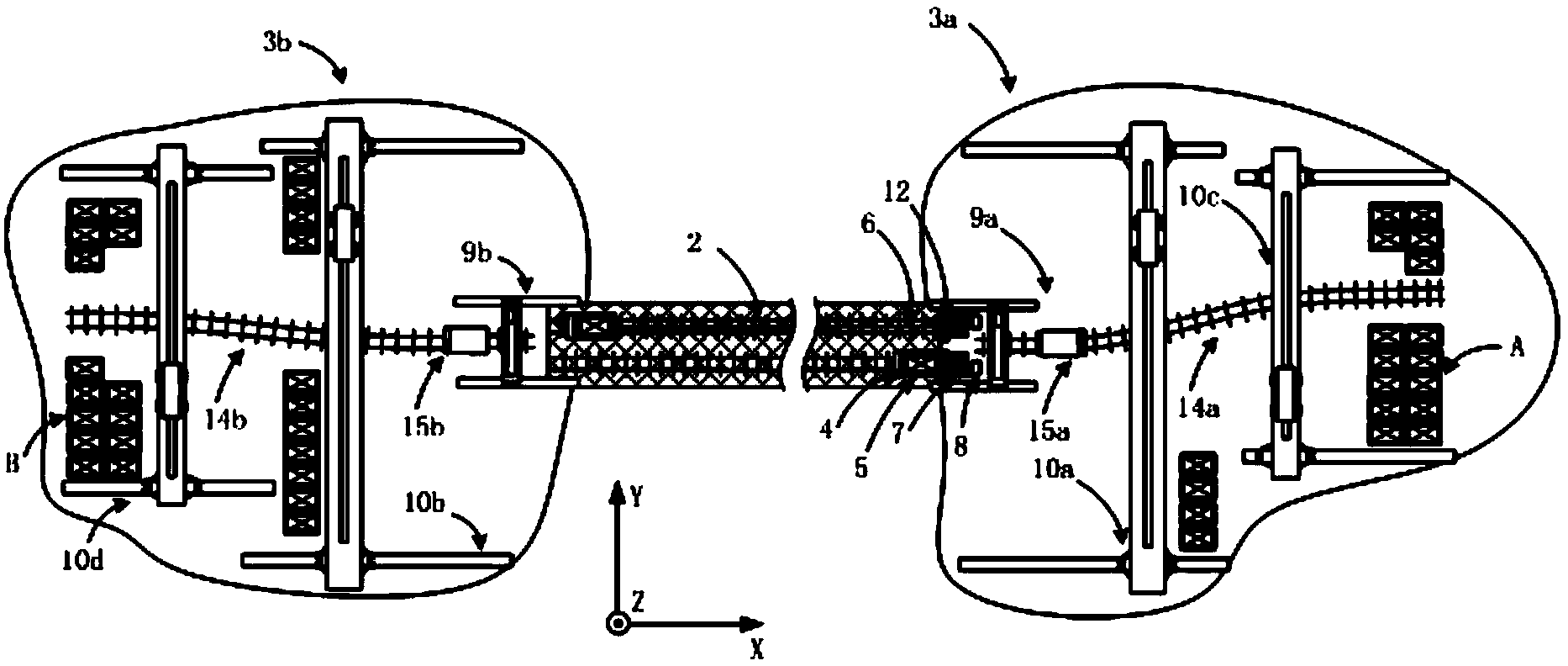

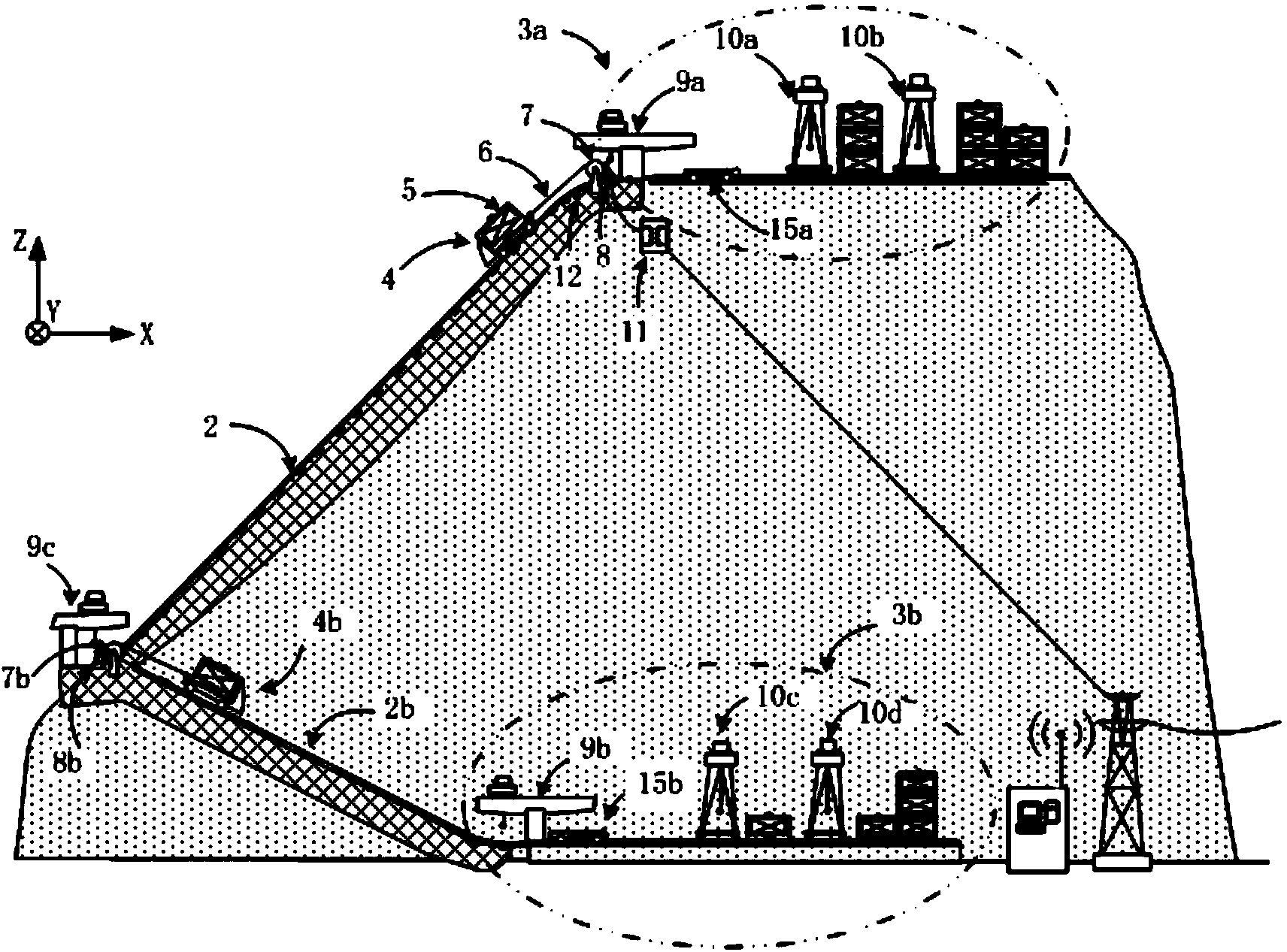

Gravity energy storing system relying on massif

InactiveCN103867408ALow costMature mechanical equipment technologyMachines/enginesMotorsControl systemMassif

The invention discloses a gravity energy storing system relying on a massif. The gravity energy storing system comprises a high-altitude stacking platform, a low-altitude stacking platform, a plurality of standard weights, electric power increasing and generating devices and a control system. The position between the high-altitude stacking platform and the low-altitude stacking platform is paved with at least two inclined tracks, each inclined track is provided with at least one section of continuous track and each section of continuous track is provided with one set of electric power increasing and generating device. Each set of electric power increasing and generating device comprises a trailer, a cable, a cable winch and an electric generating all-in-one machine, wherein the trailer is arranged on the corresponding continuous track and connected with one end of the cable, the cable winch is installed on the edge of the platform at the end of the corresponding continuous track, and the cable winch is connected with the electric generating all-in-one machine. The control system controls the working conditions of transferring, transporting and stacking equipment and the electric power generating all-in-one machine. The gravity energy storing system is high in efficiency, low in cost, small in occupied space and high in safety coefficient.

Owner:TIANJIN UNIV

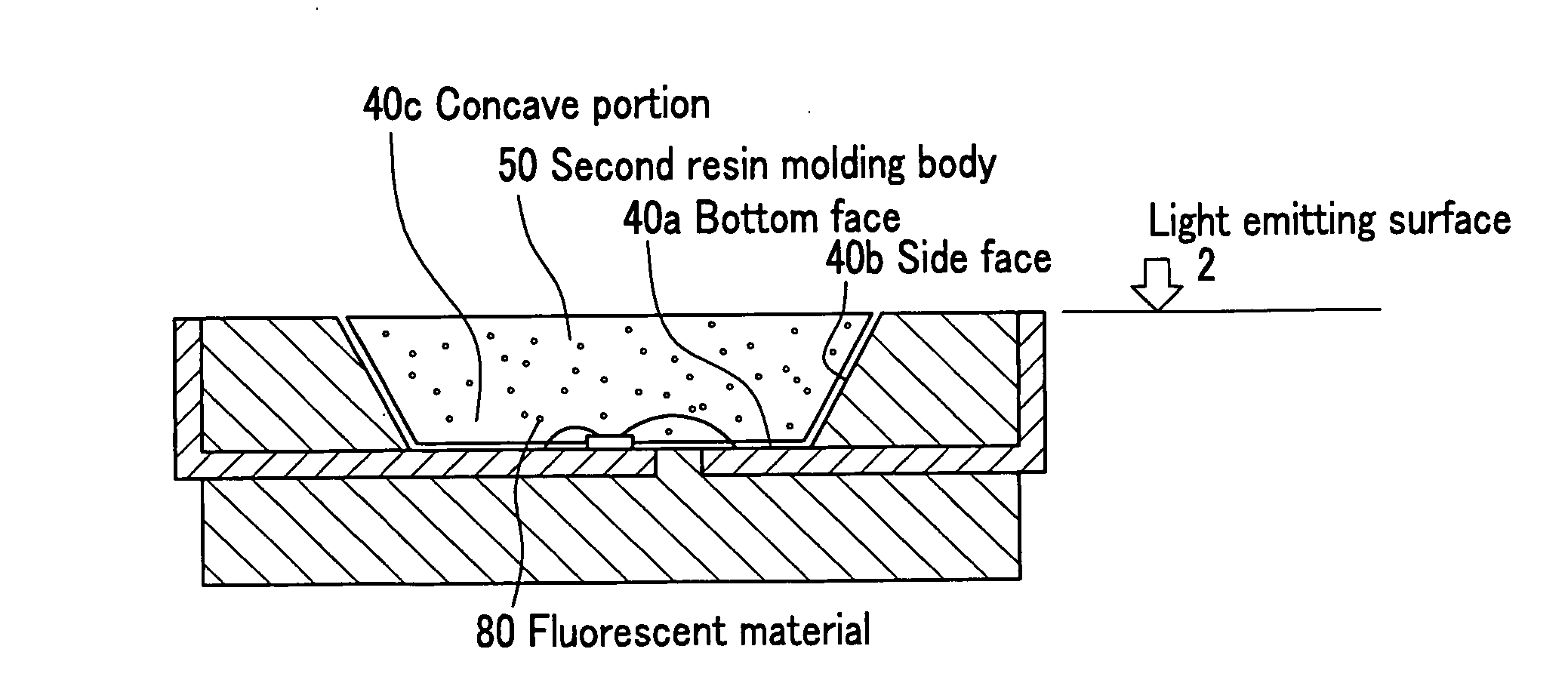

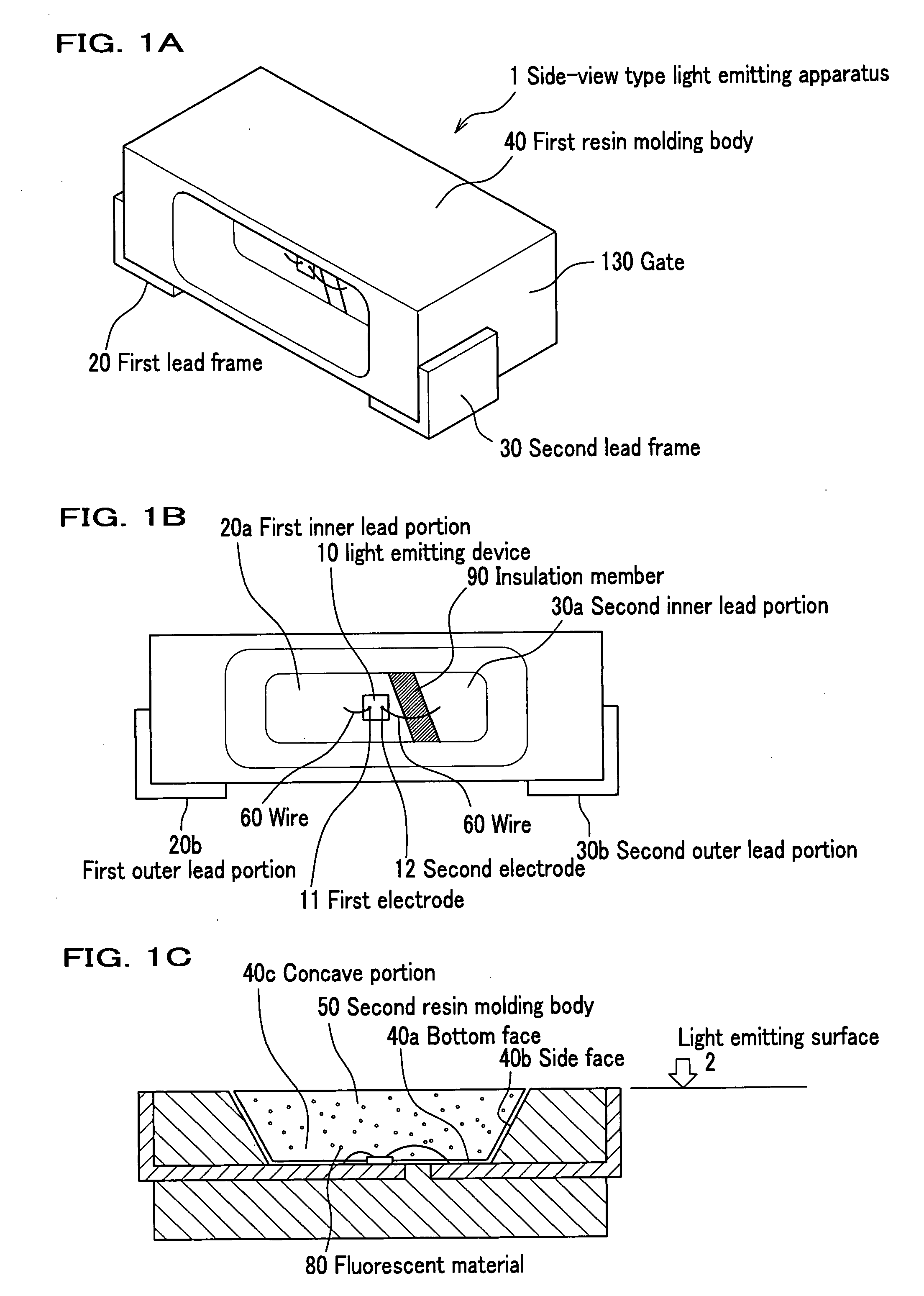

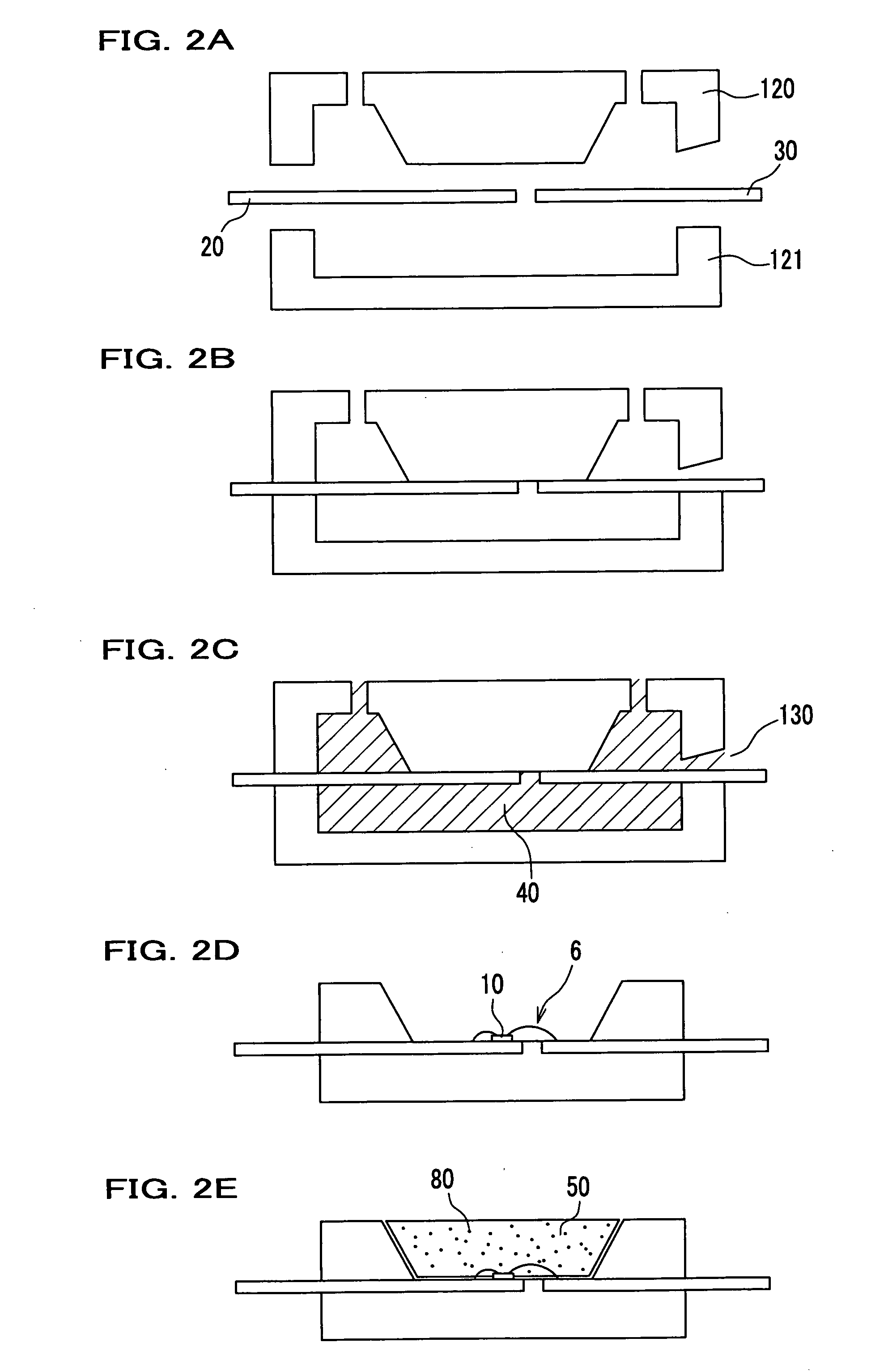

Surface mount lateral light emitting apparatus and fabrication method thereof

ActiveUS20080157113A1Good resin flowSmall sizeSolid-state devicesSemiconductor/solid-state device manufacturingSurface mountingLead frame

A surface mount lateral light emitting apparatus, which includes a light emitting device; a first lead frame connected to the light emitting device; a second lead frame connected to the light emitting device; a first resin molding body in which a concave portion for mounting the light emitting device is formed and the first lead frame and the second lead frame are fixed; and a second resin molding body which covers the light emitting device to form a light emitting surface in the concave portion of the first resin molding body, wherein the first resin molding body contains a filler or a light diffusion agent; wherein in a periphery of the concave portion, a width of at least one side of the first resin molding body is not more than 0.2 mm; and wherein the first resin molding body and the second resin molding body are formed with a thermosetting resin.

Owner:NICHIA CORP

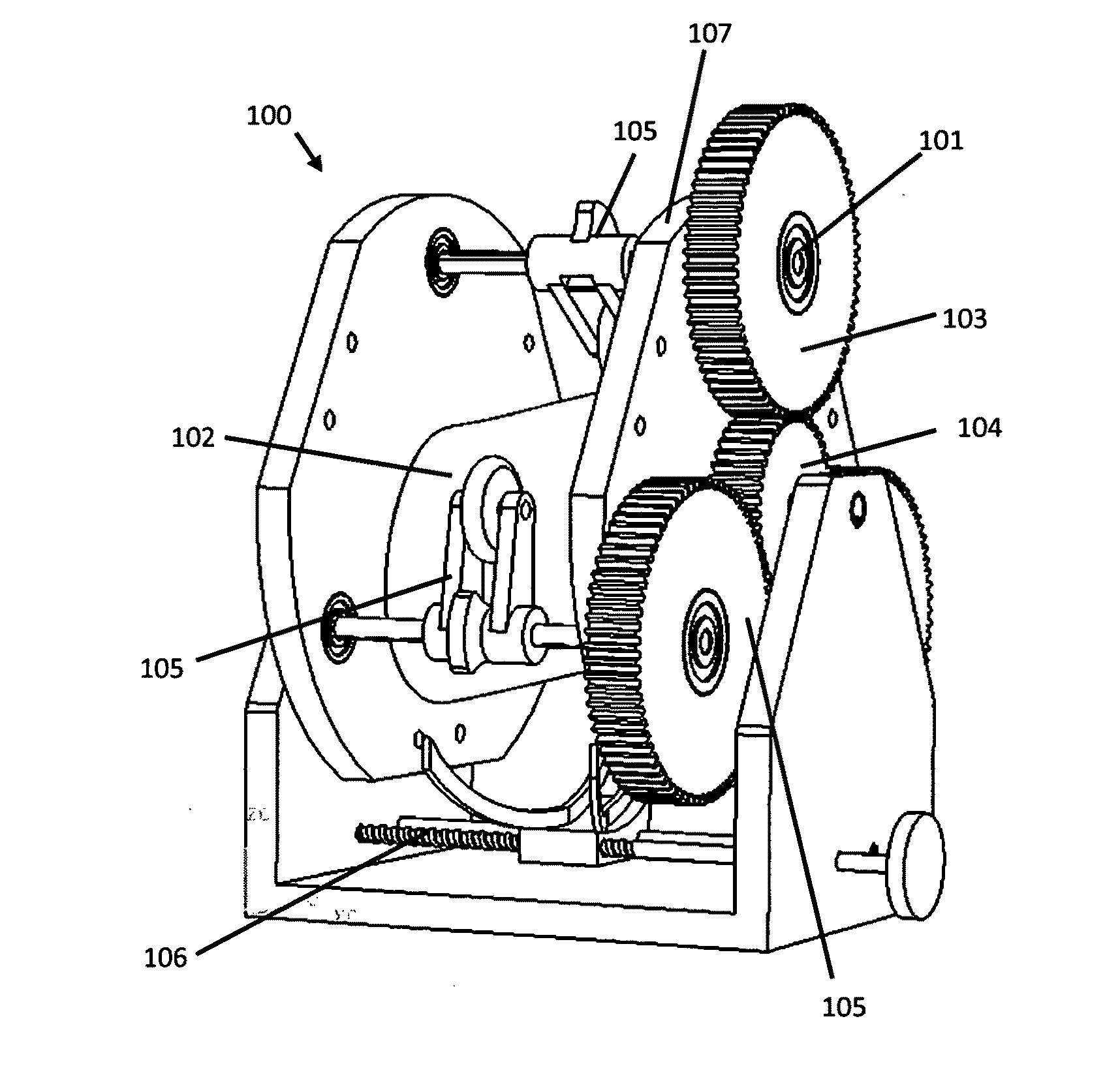

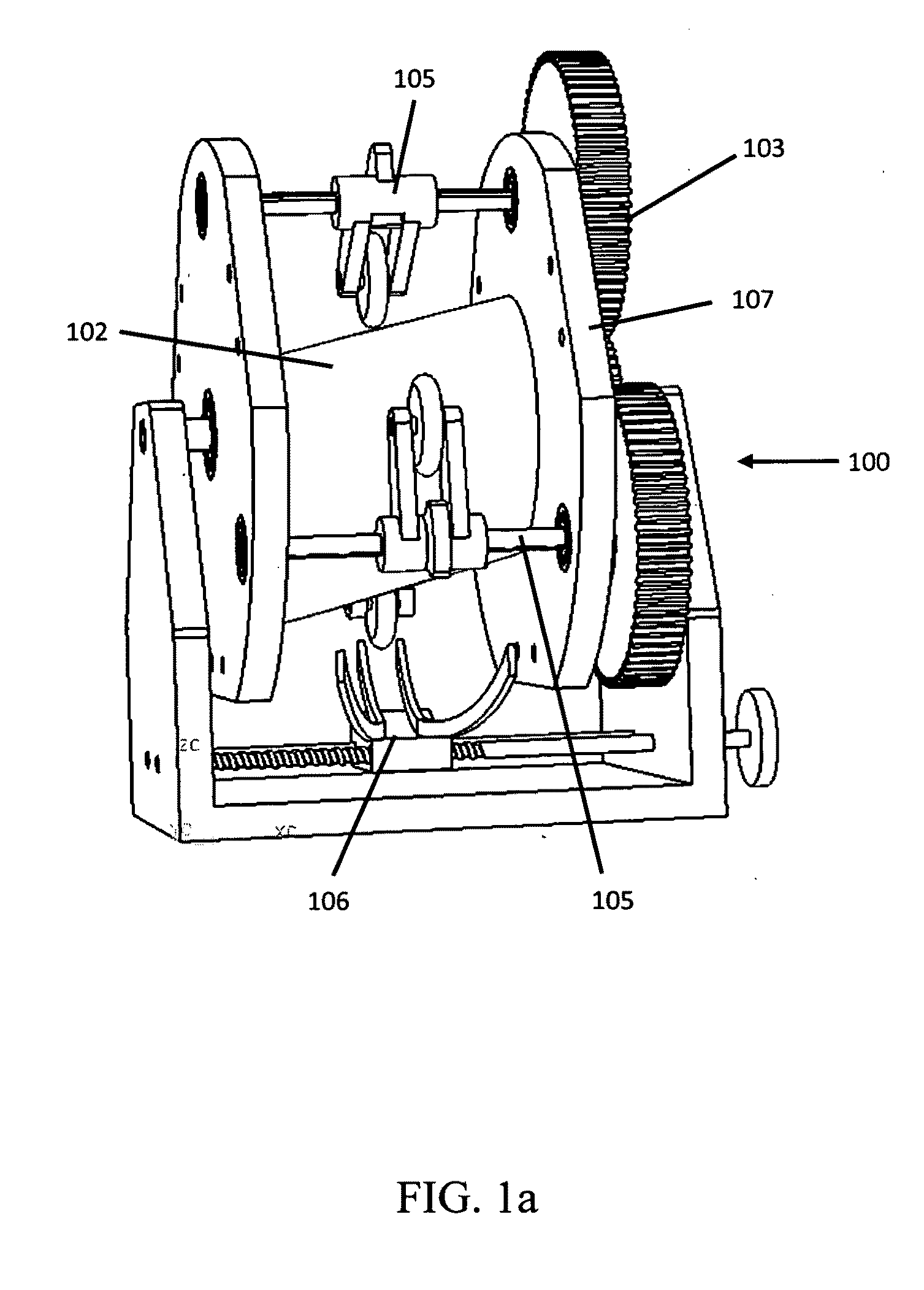

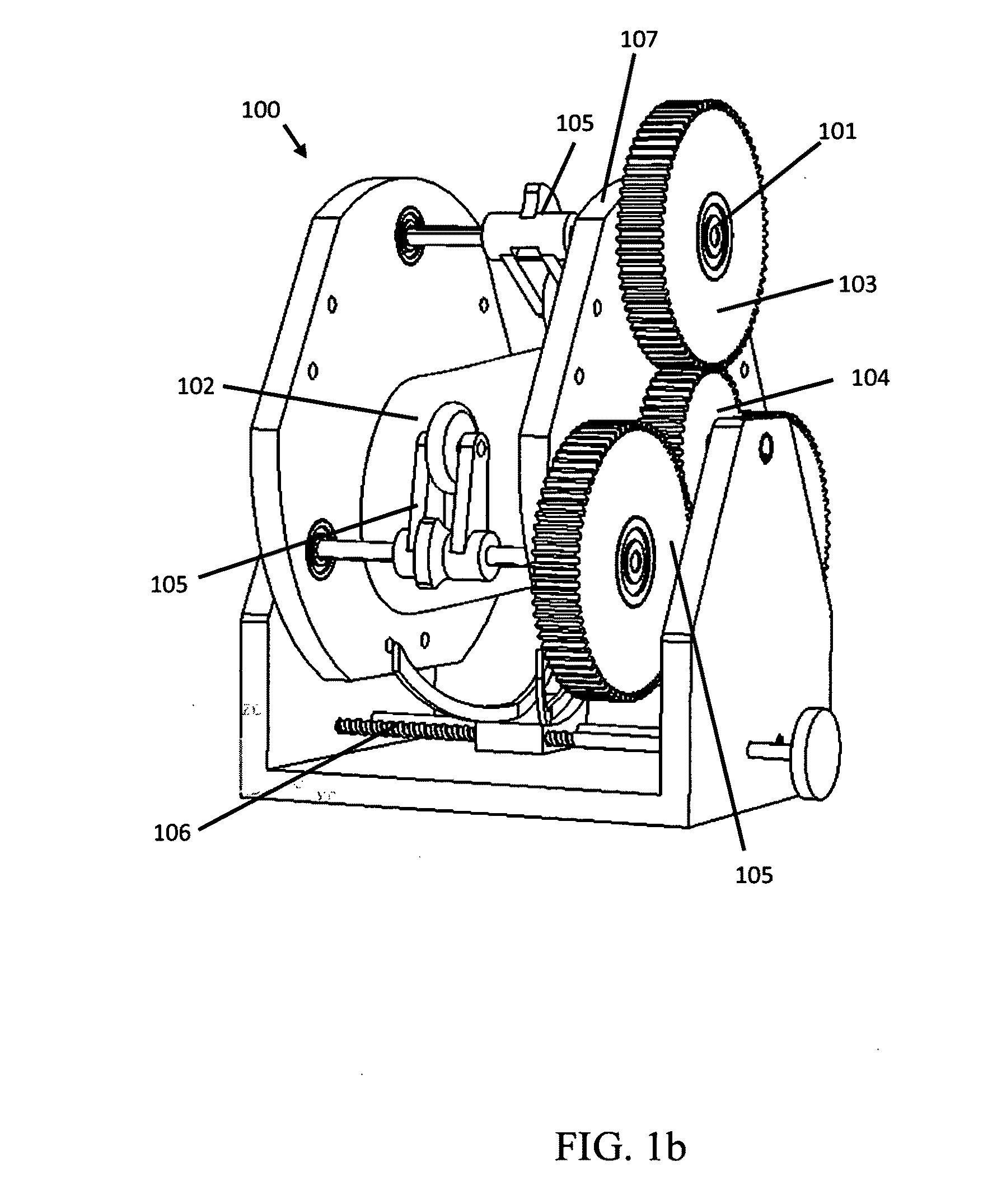

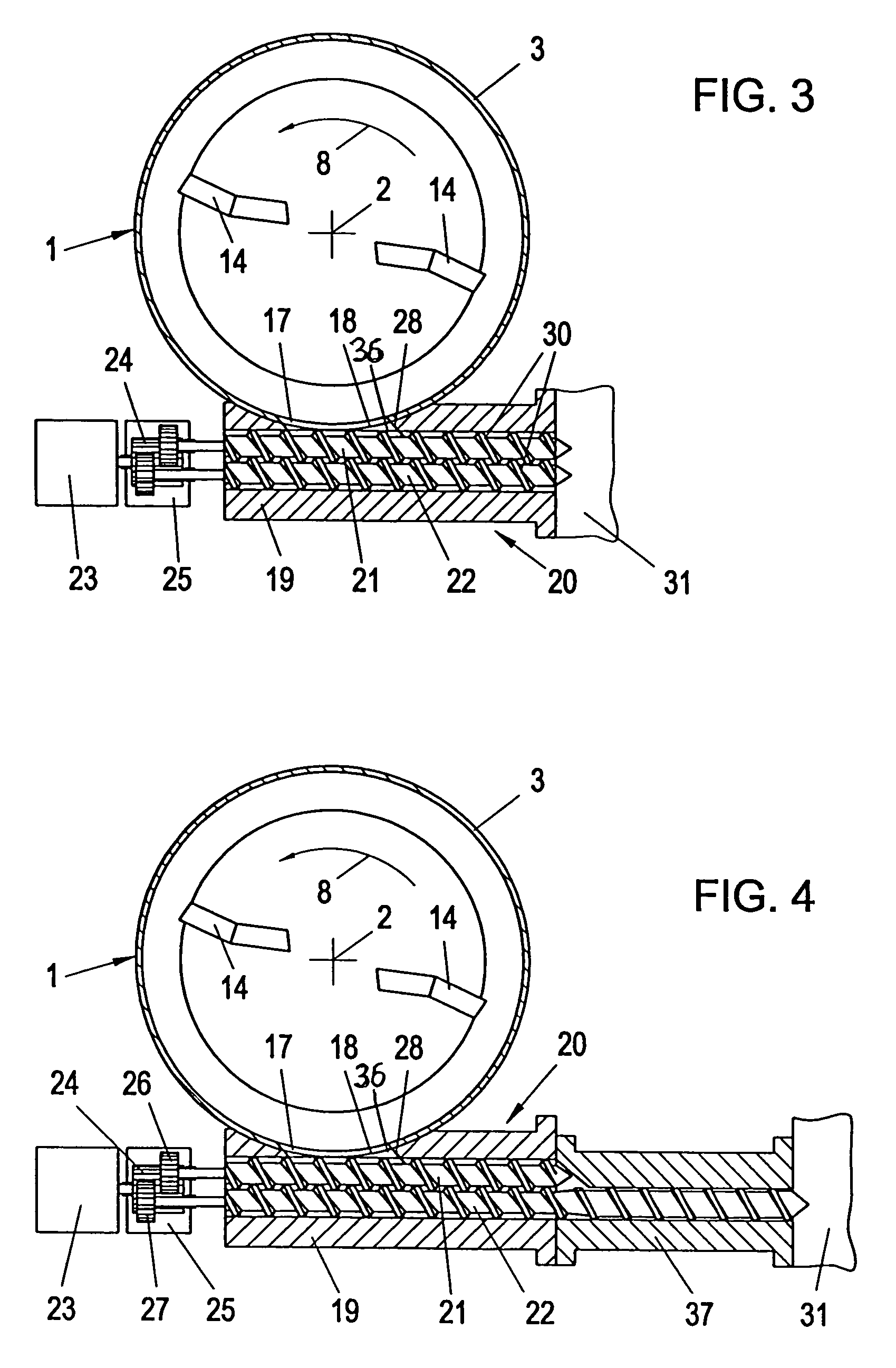

Cam-based infinitely variable transmission

InactiveUS20100304915A1Improved ratcheting variable transmissionUniform outputGearingGearing detailsClutchVariator

A cam based infinitely variable transmission incorporation a ratcheting drive mechanism with one set of planetary gears and a cam with two followers mounted on a carrier with said gears and adapted to in infinitely variable in output but maintain a uniform output for a given uniform input. The followers are can be shifted in relation to the three dimensional cam by a shifter and clutches are used to handle the relative motion of the gears and follower shafts.

Owner:LAHR DEREK

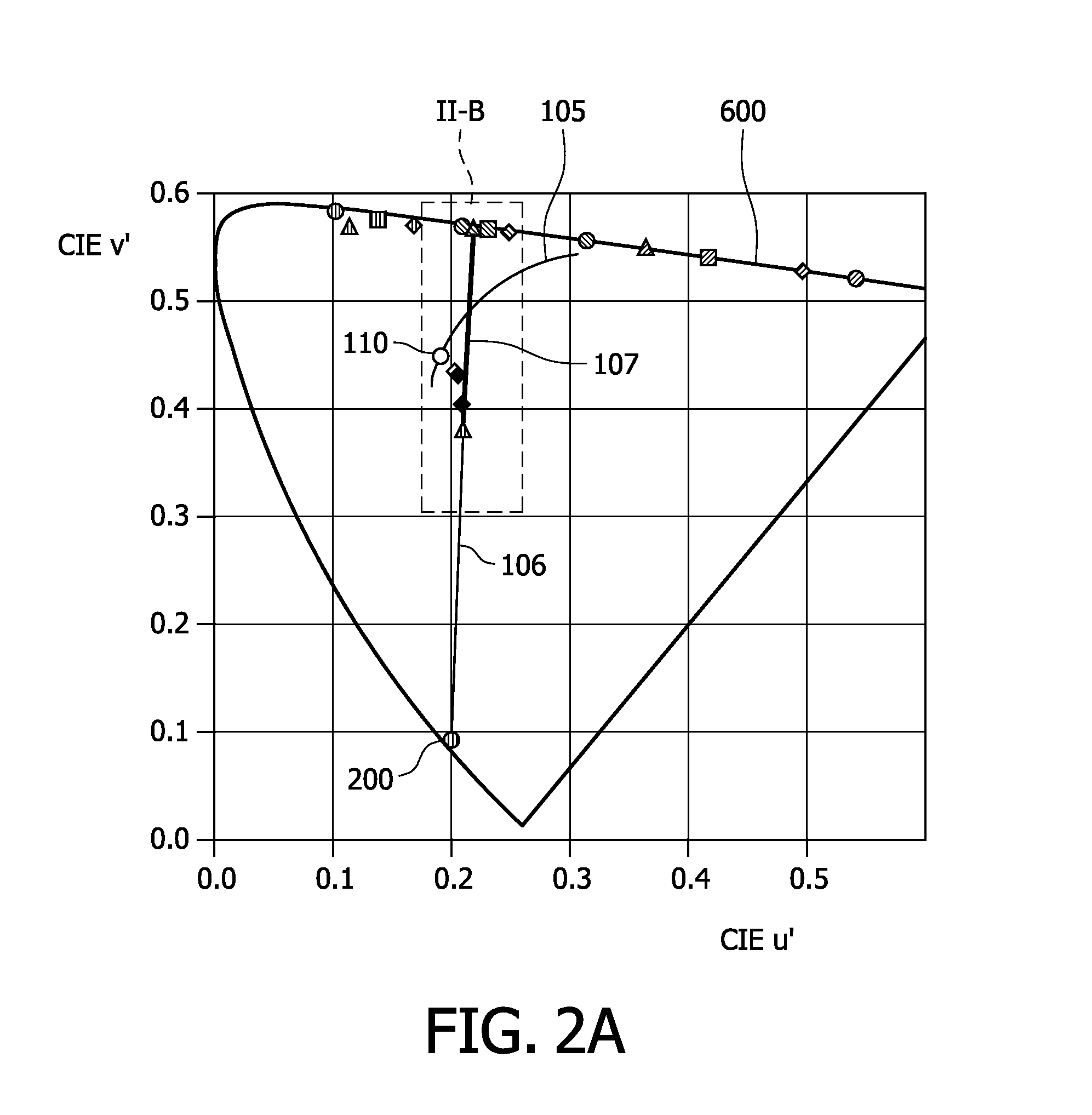

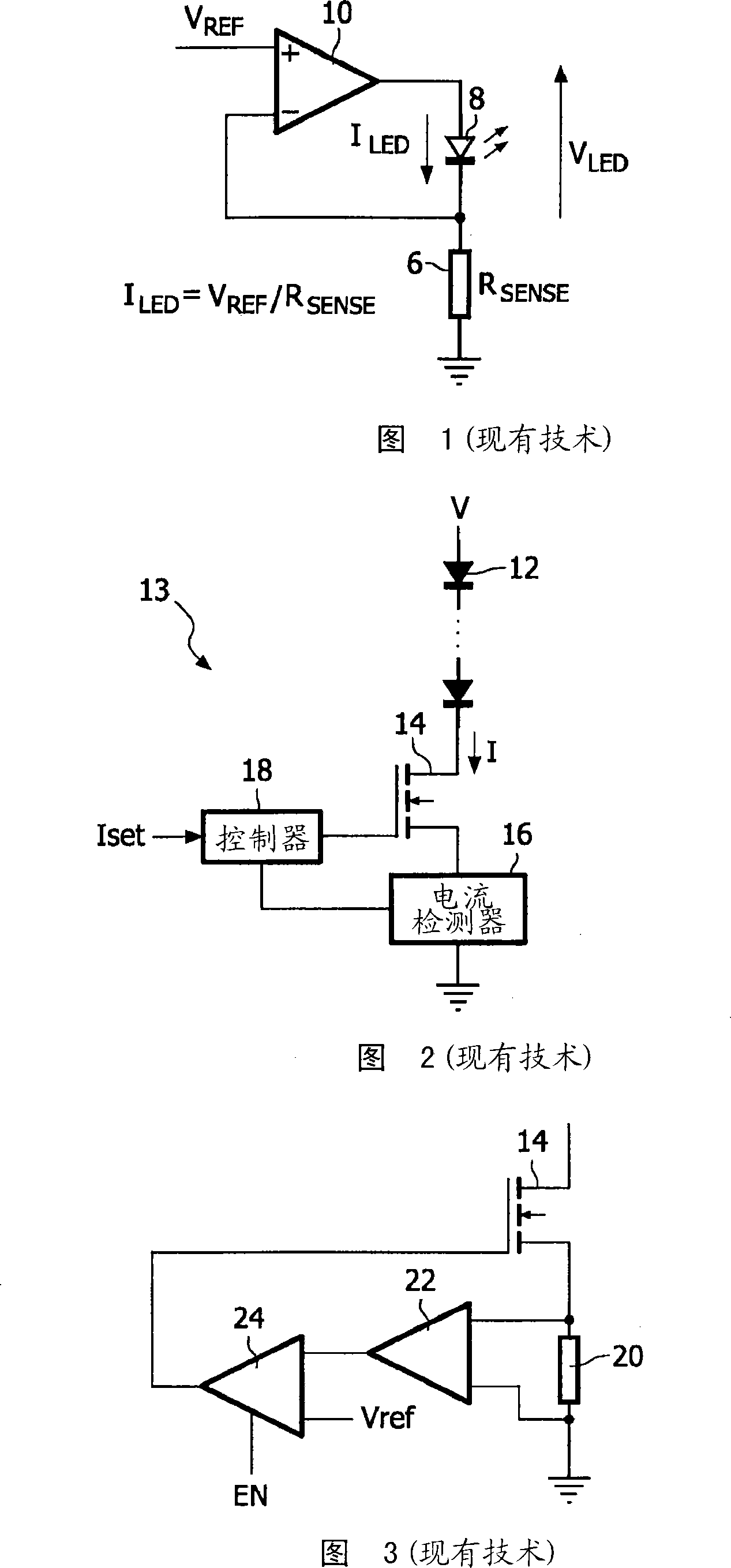

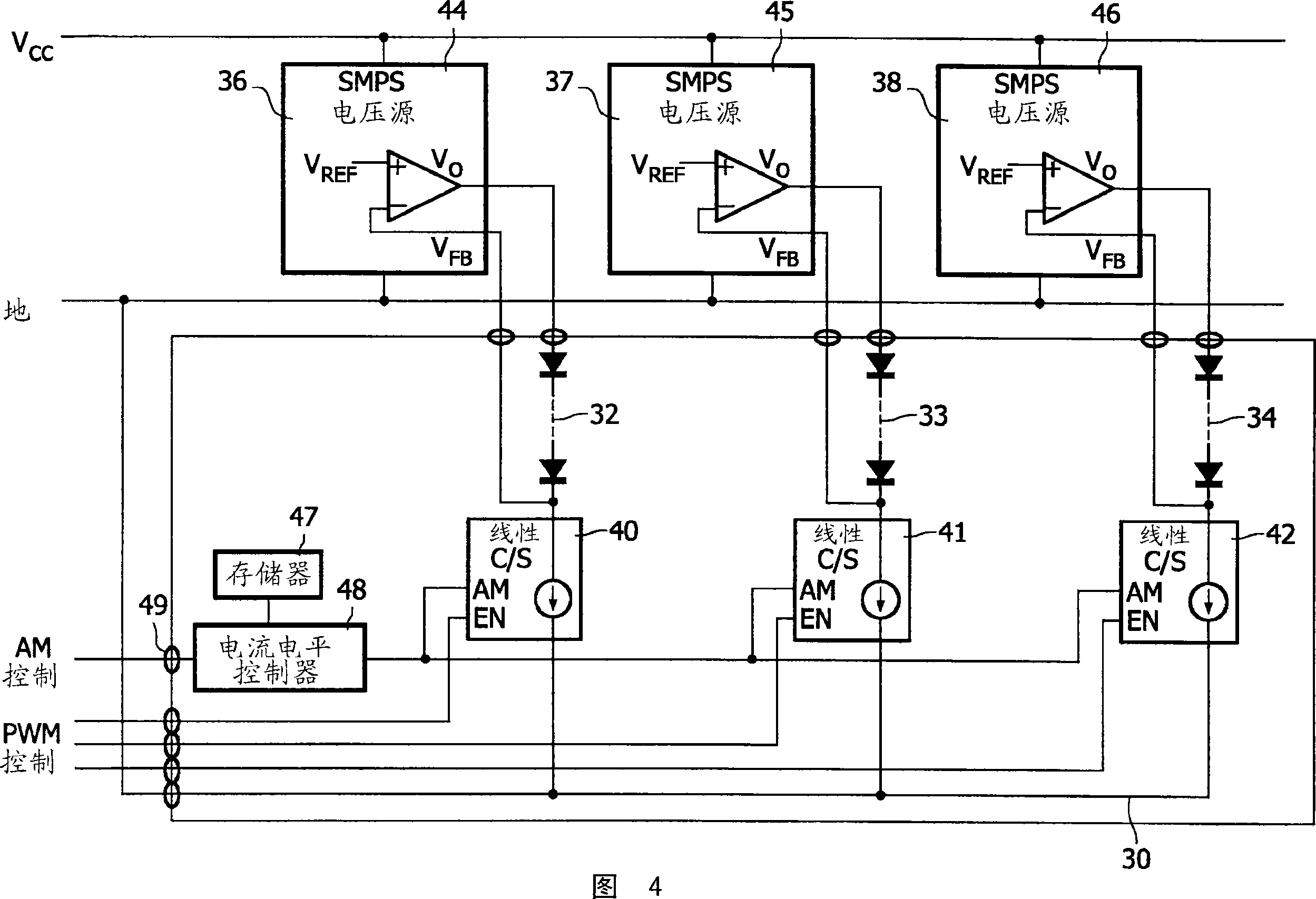

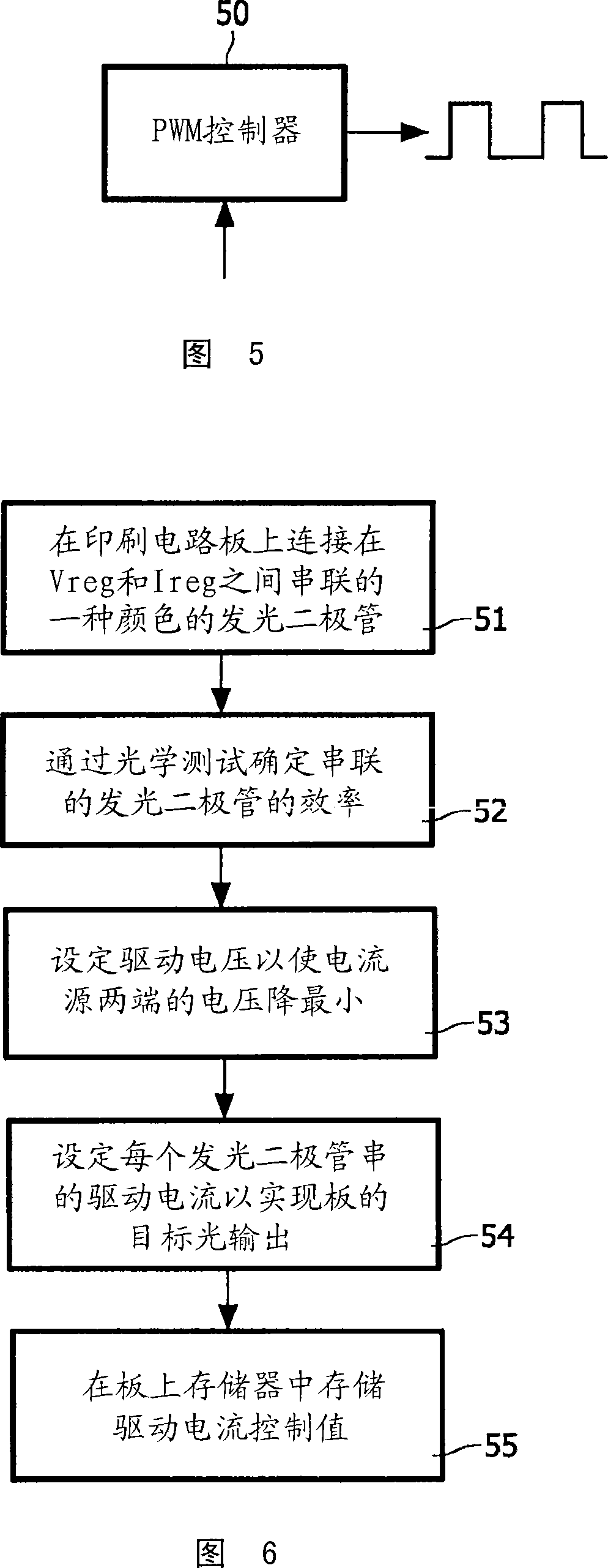

LED light source for backlighting with integrated electronics

ActiveCN101253813AUniform outputAchieve white pointElectroluminescent light sourcesSemiconductor lamp usageConstant current sourceCurrent regulator

An LED backlight structure and technique for setting the voltages and currents for the LEDs are described. In one embodiment, red LEDs are connected in series between a first voltage regulator and a first controllable current source, green LEDs are connected in series between a second voltage regulator and a second controllable current source, and blue LEDs are connected in series between a third voltage regulator and a third controllable current source. The current sources may linear current regulators. After all the LEDs are mounted on a printed circuit board, each voltage regulator is controlled so that there is a minimum voltage drop across the current source to minimize energy dissipation by the current source. Also, after all the LEDs are mounted on the printed circuit board, the current sources are controlled to balance the three colors to achieve a target light output of the board using a light detection chamber. In another embodiment, a constant current source is connected to the series string of LEDs. PWM controllers control transistor switches connected in parallel across groups of LEDs, where the duty cycles set the average current through each group of LEDs. The control values used to achieve the target light characteristics are then stored in a memory on the board. With such a technique, LEDs do not need to be binned to match their efficiencies, since the controllable voltage and current sources compensate for the variety of LED efficiencies. Accordingly, all boards will have the same target light output using the particular values stored on each board. In other embodiments, not all the LEDs of a particular color are connected in series. The brightness levels of the LEDs may be further controlled by a PWM controller. The backlight may be for an LCD television or other color display.

Owner:SIGNIFY NORTH AMERICA CORP

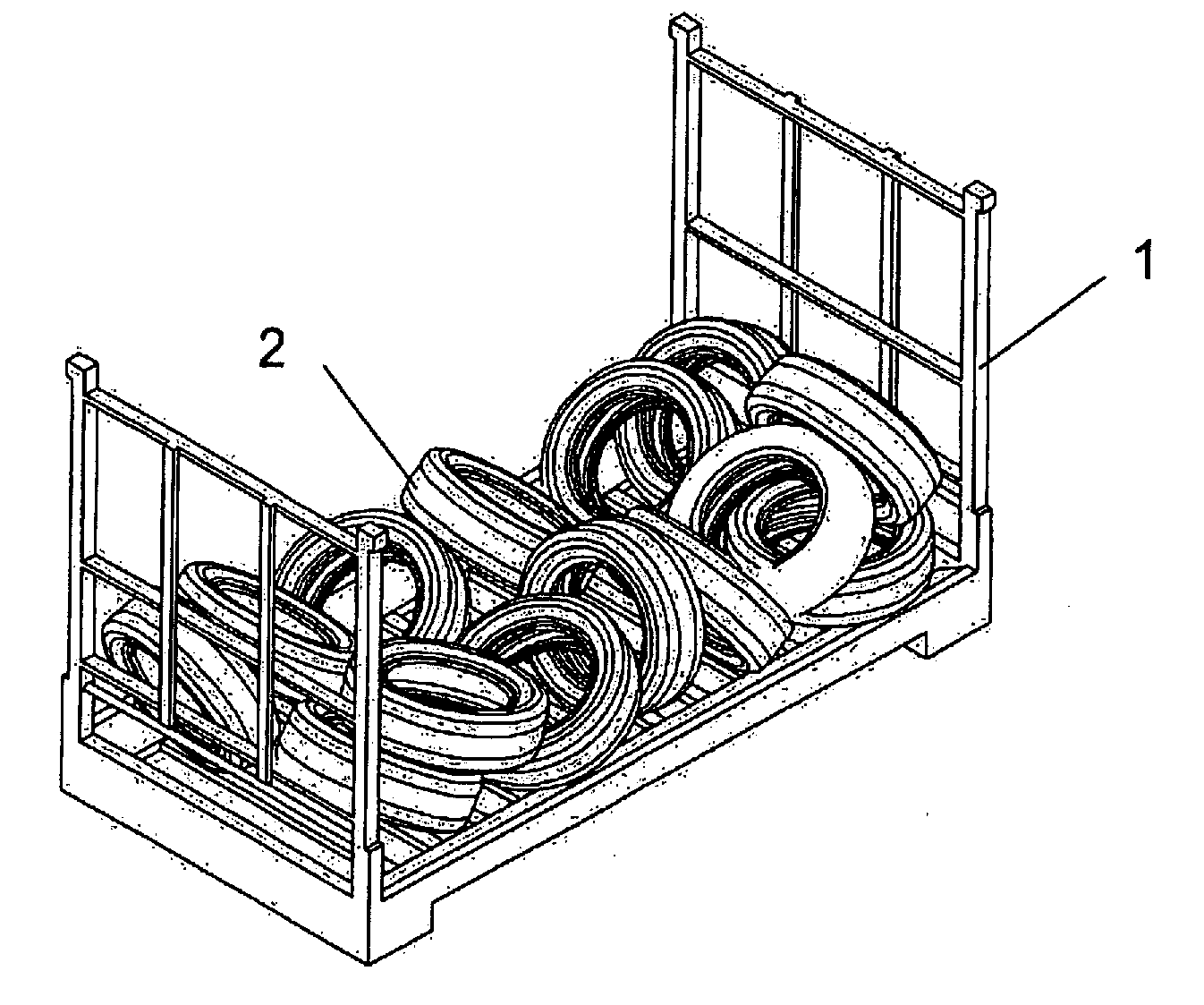

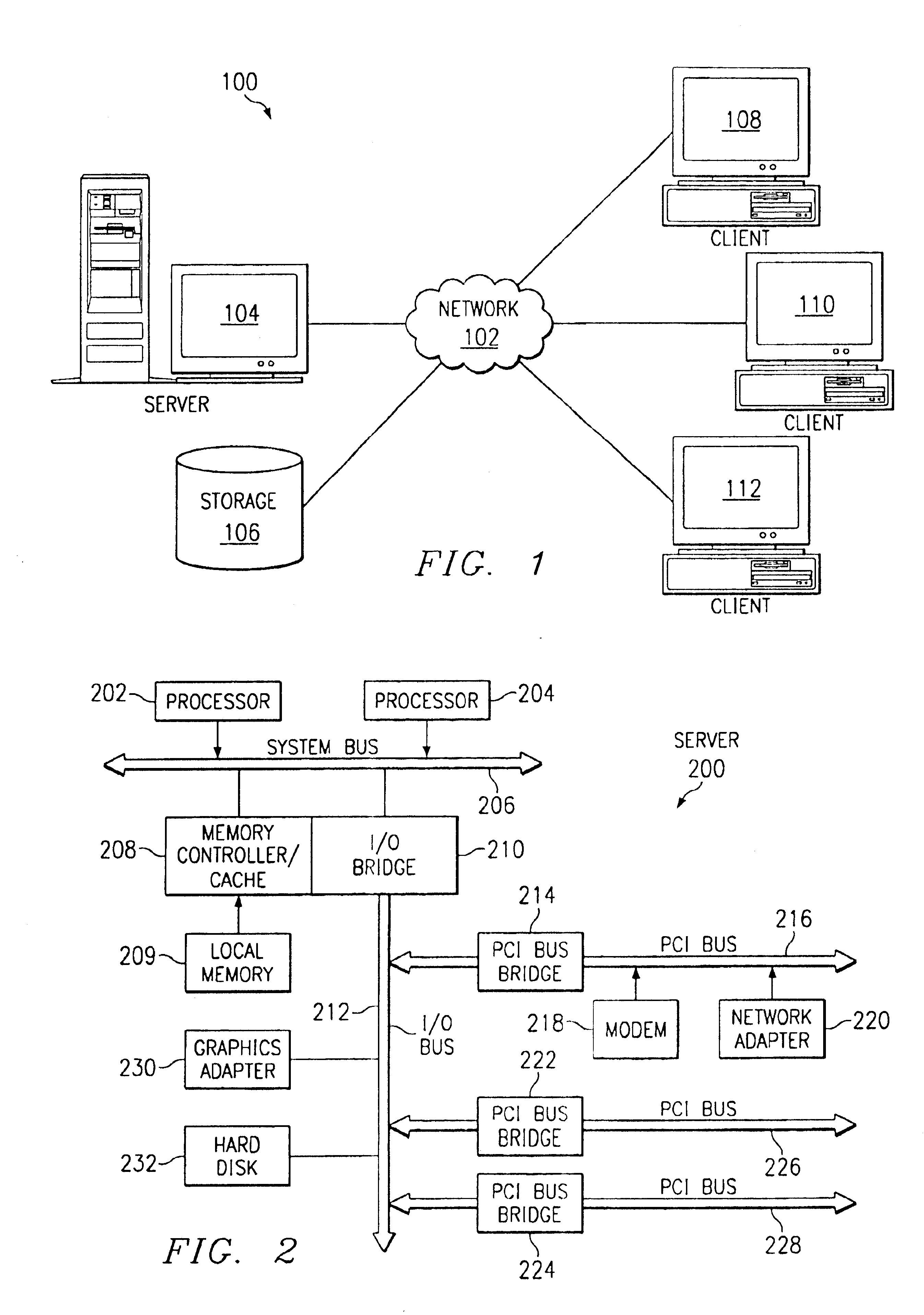

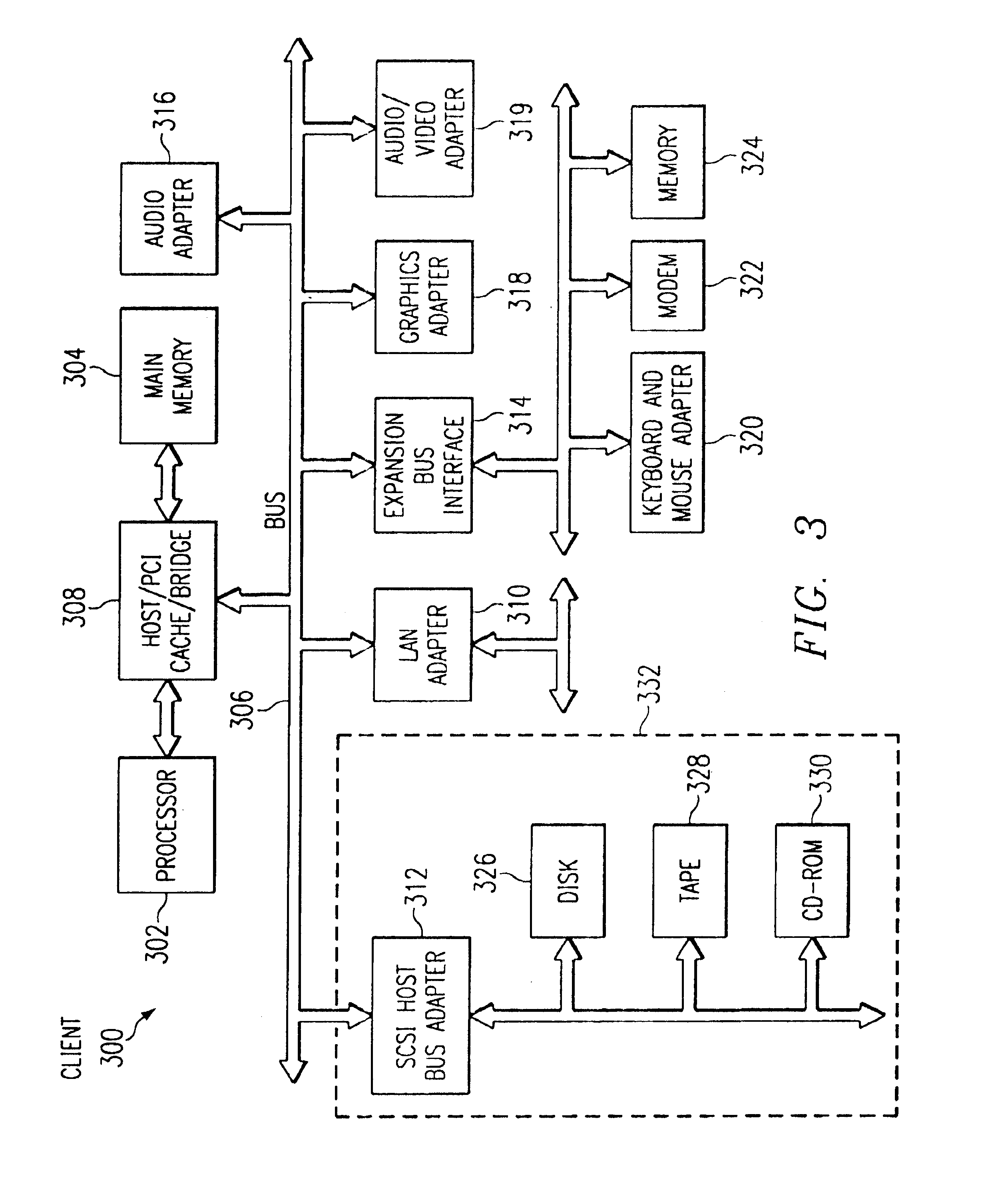

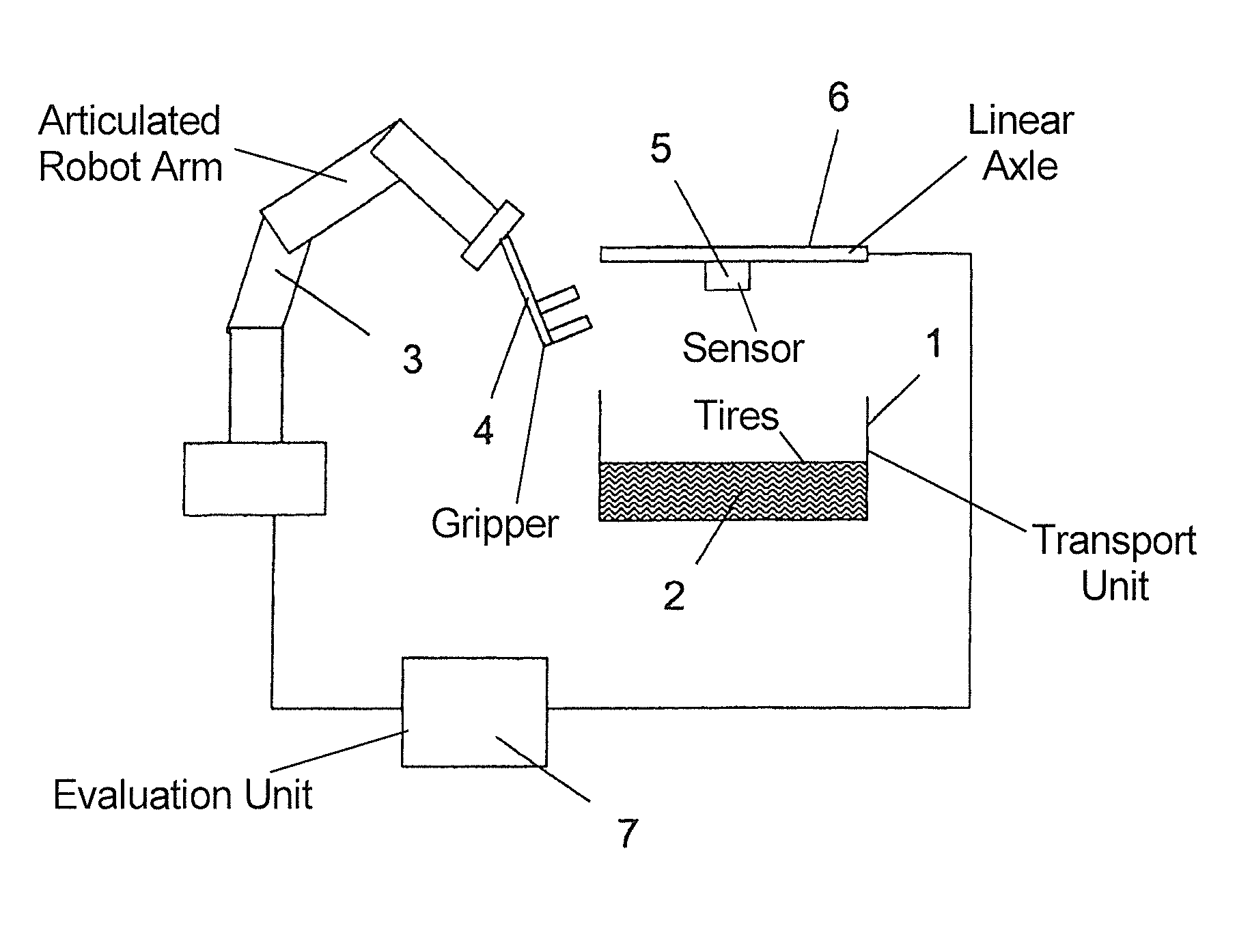

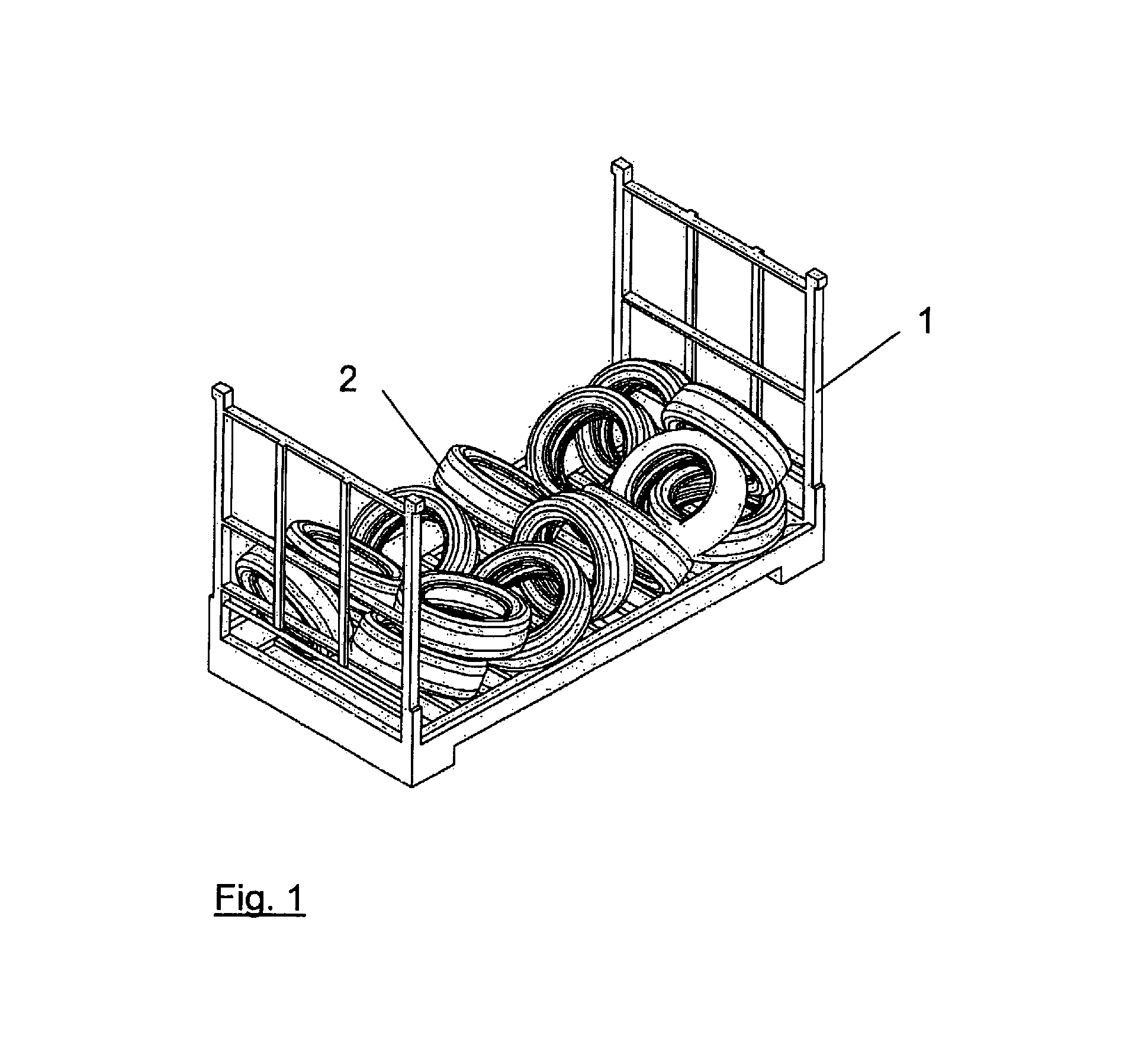

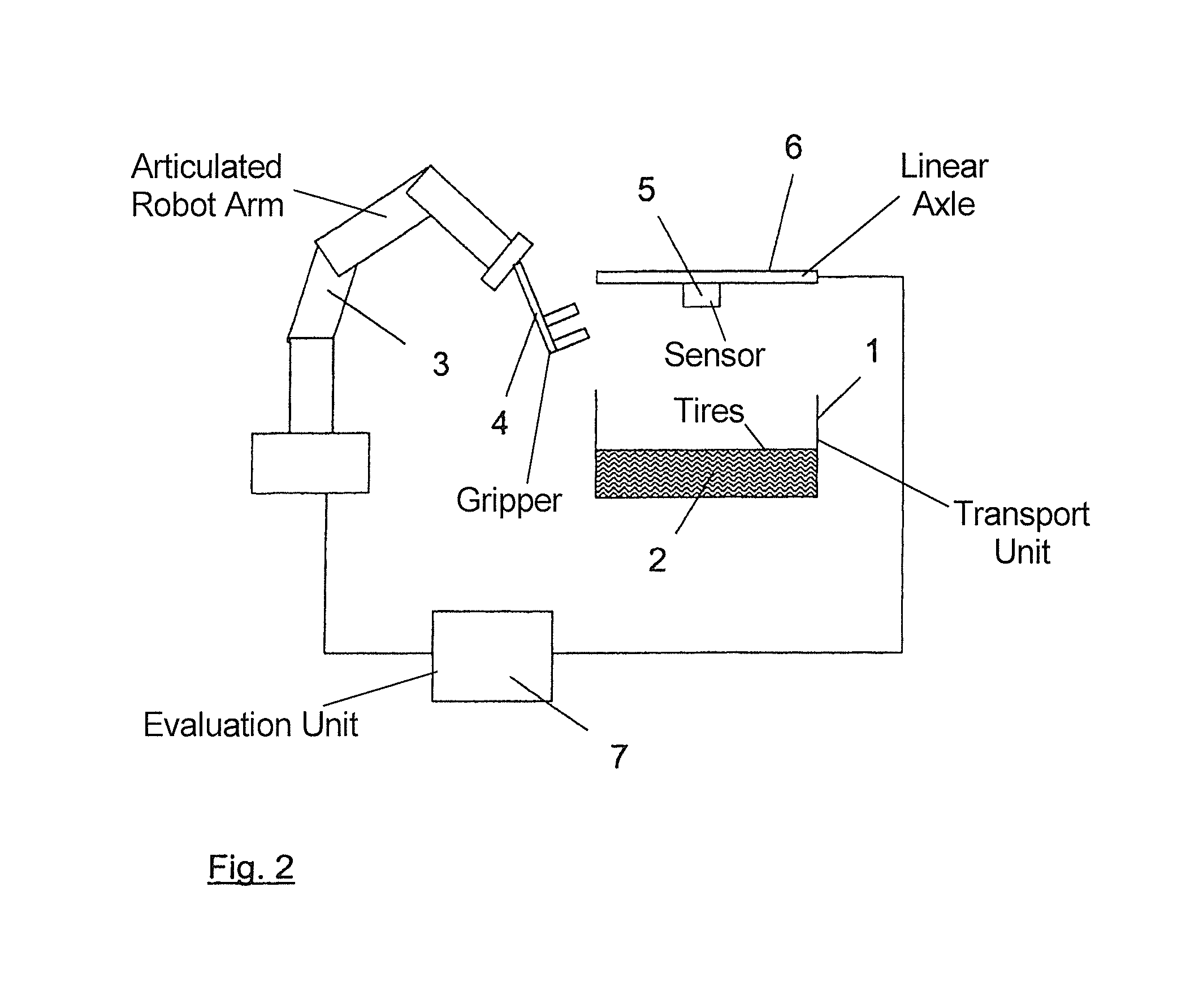

Method And System For Depalletizing Tires Using a Robot

InactiveUS20100272547A1Easy to detectImprove reliabilityProgramme-controlled manipulatorDigital data processing detailsCollision freeIndustrial robot

In a method and system for depalletizing tires using a robot, wherein the tires are randomly located on a carrier, the position and orientation of outer tires on the carrier are detected using a sensor, and a processor, using a signal from the sensor, determines a tire that can be gripped by a gripping tool of an industrial robot, and calculates a movement path for the gripping tool for that tire. If the calculated path is not collision-free, another tire from among the outer tires is selected, and a movement path for depalletizing that tire is determined. The procedure is repeated until a collision-free movement path for a tire from among the outer tires is established. The gripping tool is then guided according to this collision-free movement path to depalletize the tire having the collision-free path associated therewith.

Owner:KUKA ROBOTER

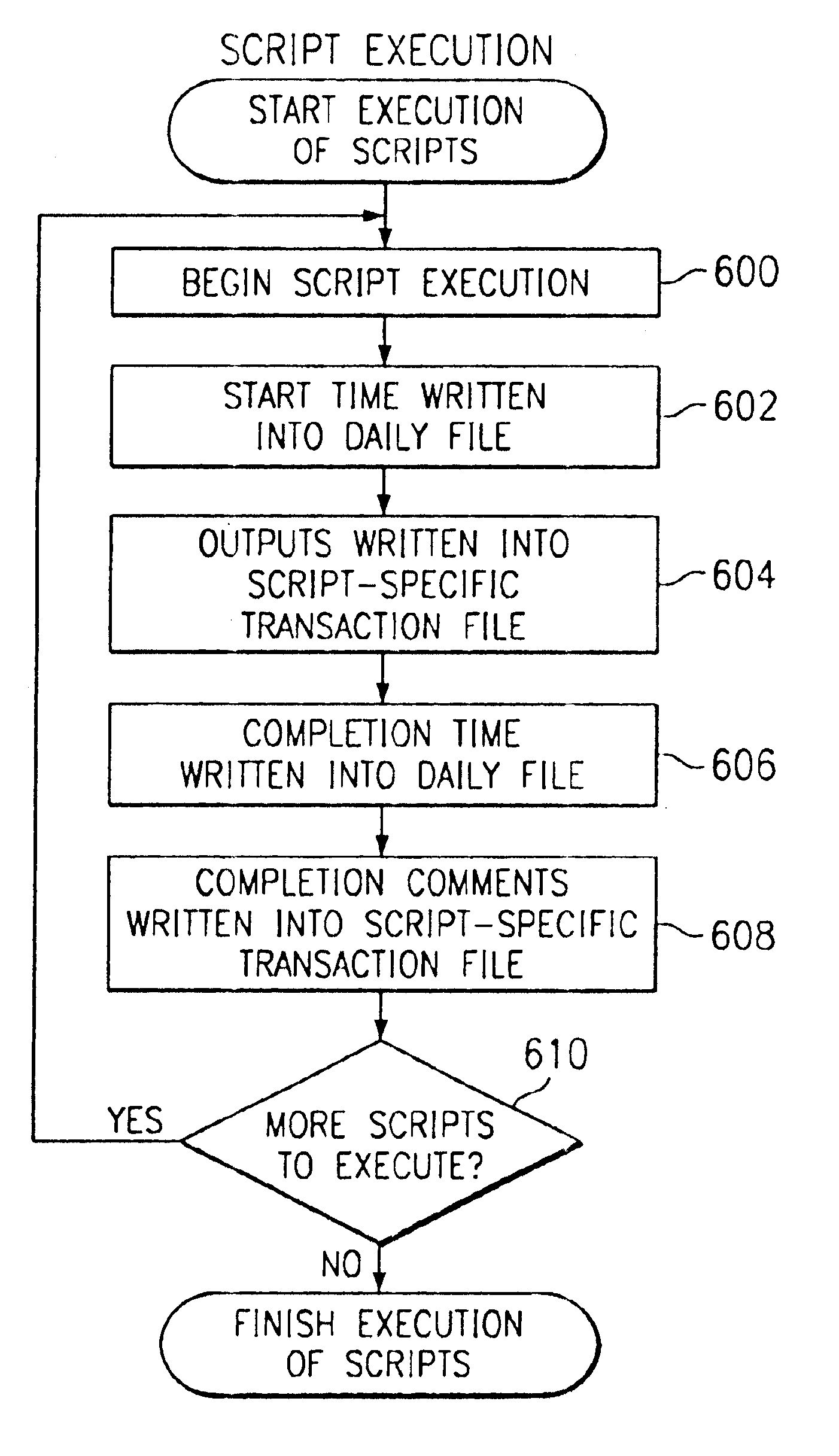

Method and a system for managing shell script file development and execution

InactiveUS6904424B1Simple resultUniform outputData processing applicationsError detection/correctionComputerized systemRunning time

Initially, “libraying” text is inserted on all scripts executed on the computer, allowing administrators to discern at a glance every script that has been executed. Furthermore, administrators can easily ascertain the results of all automatically run programs (such as overnight batch jobs) by looking in a common location rather than all over the computer. All scripts installed on a computer system are required to have the ability to generate uniform output. This output includes the script name, the time it was run, the user name and the script execution results. When a script is executed, it will write this detailed output into a predefined directory. There, a file is generated which lists all the parameters associated with the script execution. The parameters are then available for future review by administrators. Additionally, an executed script writes a summary output to a common file. This file provides a single point of reference and further provides a summary description for all activities.

Owner:IBM CORP

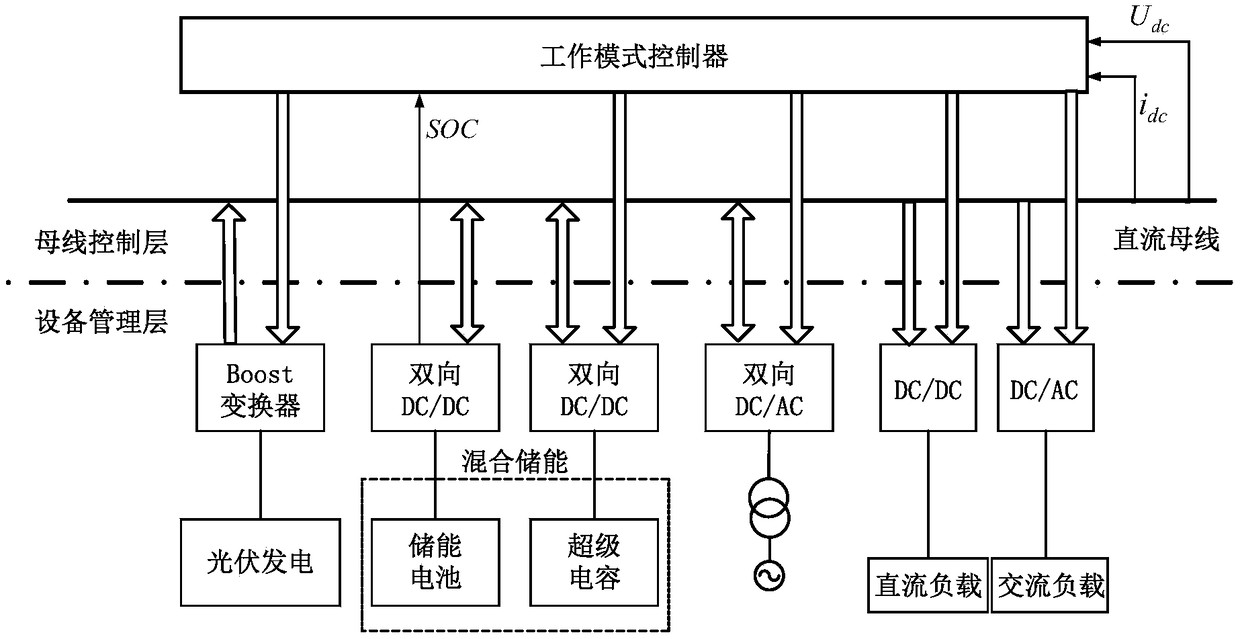

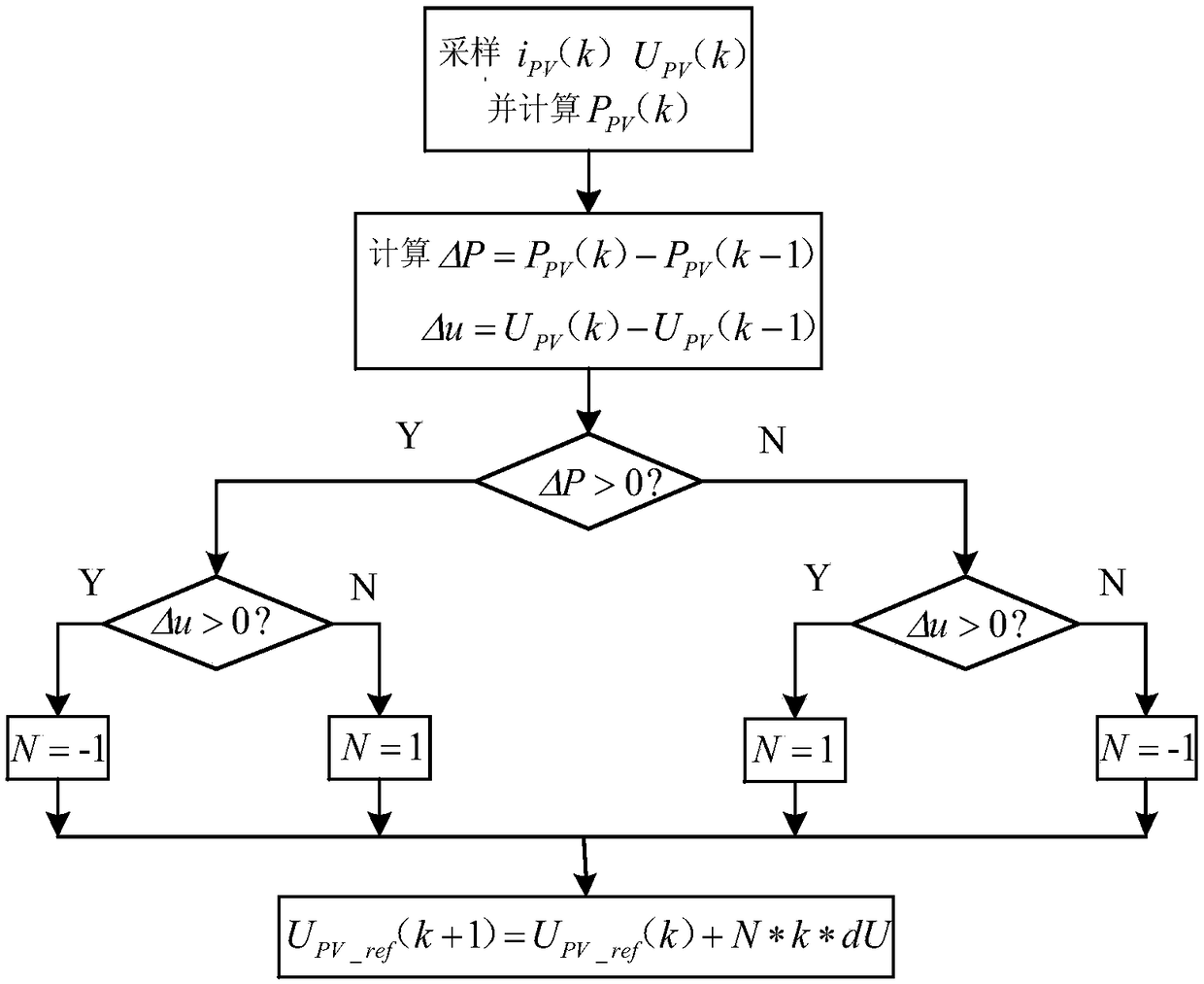

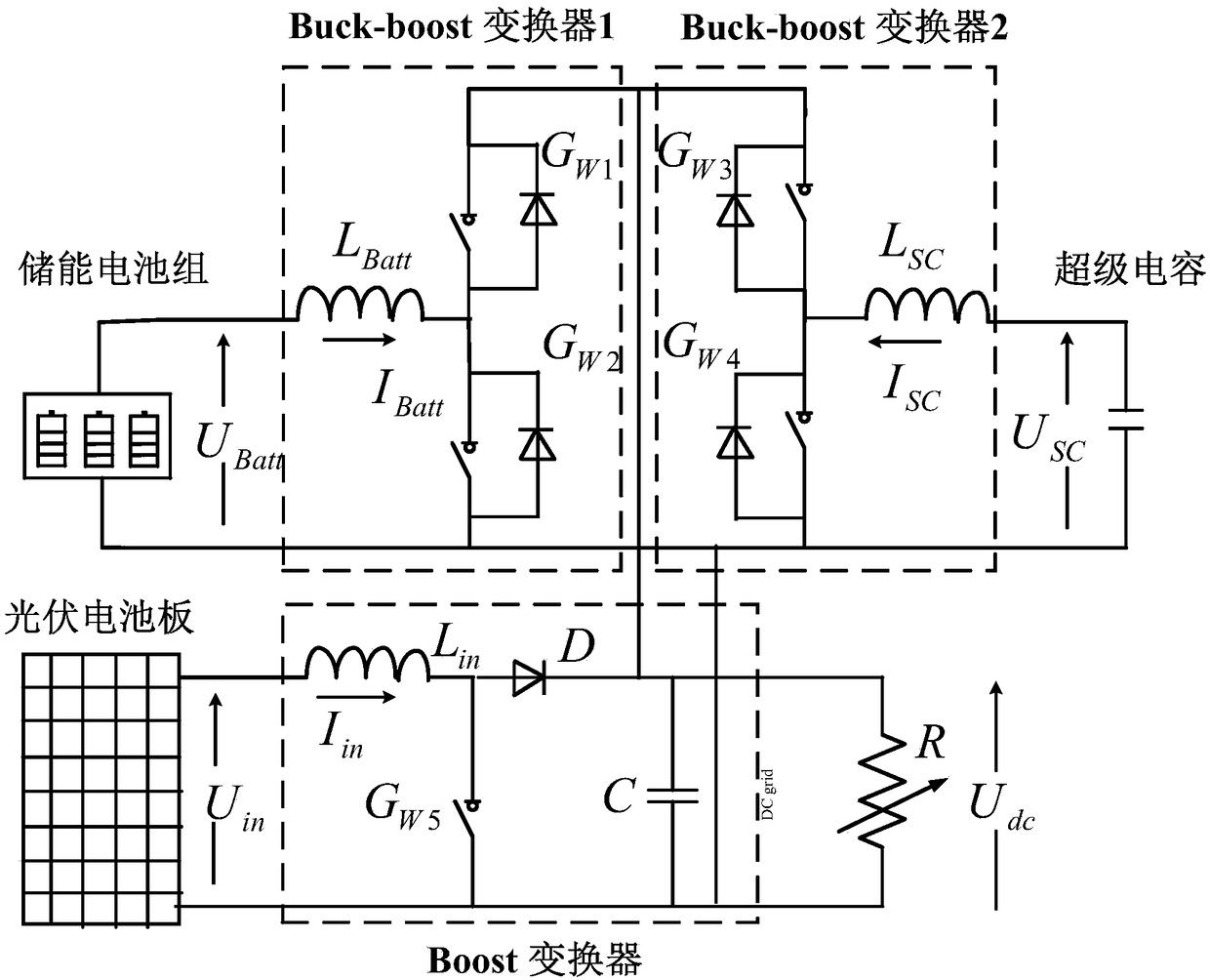

Direct-current microgrid control method and system based on hierarchical management

ActiveCN108832612AImprove reliabilityImprove stabilityBatteries circuit arrangementsDc source parallel operationMicrogridControl layer

The invention provides a direct-current microgrid control method and system based on hierarchical management. An overall control strategy of a direct-current microgrid is decomposed into an equipmentmanagement layer and a bus control layer structure. All parts of the microgrid are regulated based on own characteristics and working modes at the equipment management layer; and at a hybrid energy storage effect link, current controlling without energy storage battery compensation is carried out, so that the energy storage adjustment response speed and stability are improved. At the bus control layer, a set working mode controller carries out working mode division according to a fluctuation range of a bus voltage and the residual power of the battery, so that the system is able to carry out switching in different working states; and the working modes of all units of the equipment management layer are set based on different working modes, so that the stable operation capability of the direct-current microgrid is enhanced. And with consideration of the parallel energy storage control method, an adaptive droop coefficient regulator is established, so that the ring current influence between lines is suppressed and the time of reaching balancing of the parallel energy storage is shortened.

Owner:NORTHEASTERN UNIV

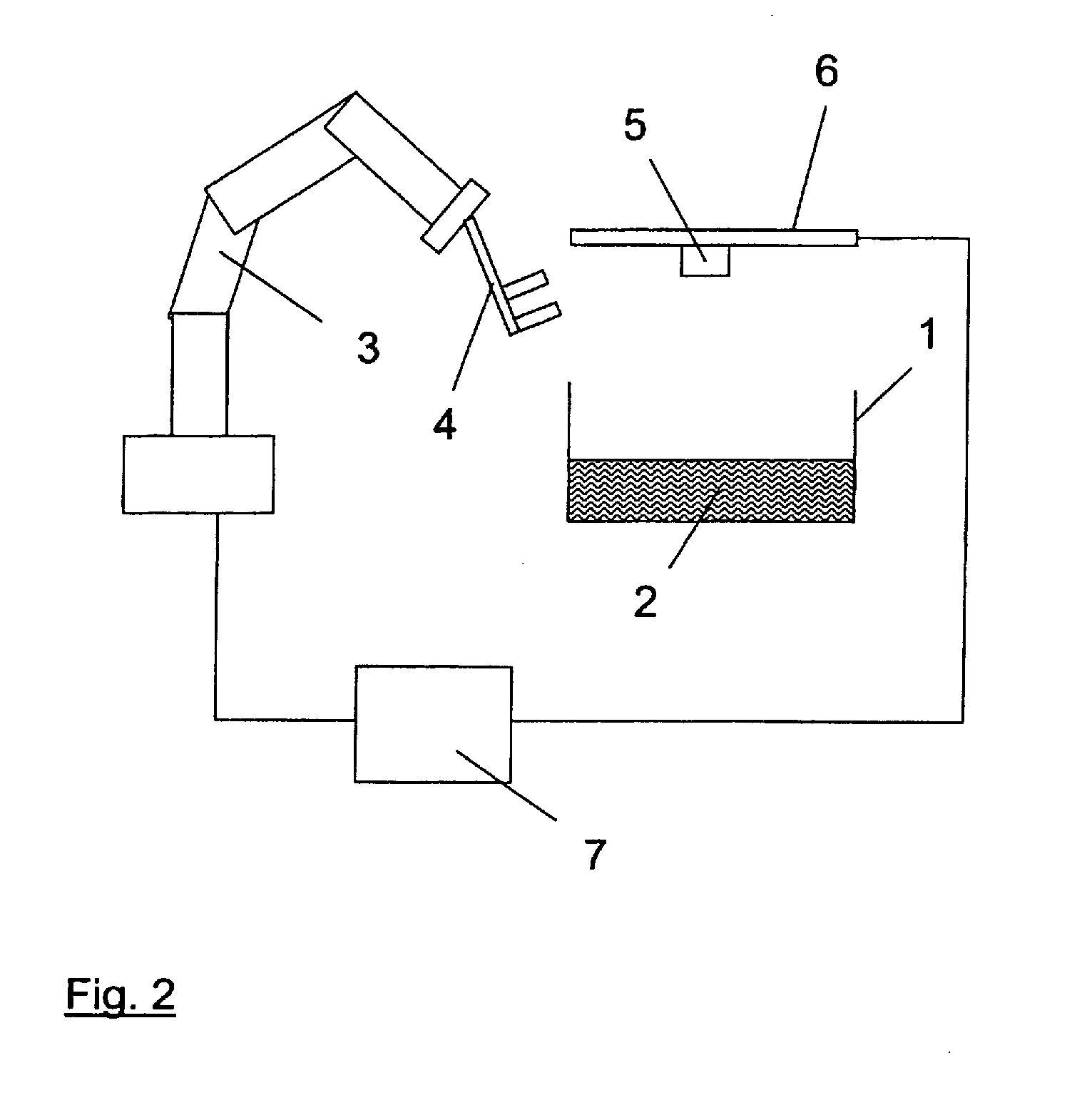

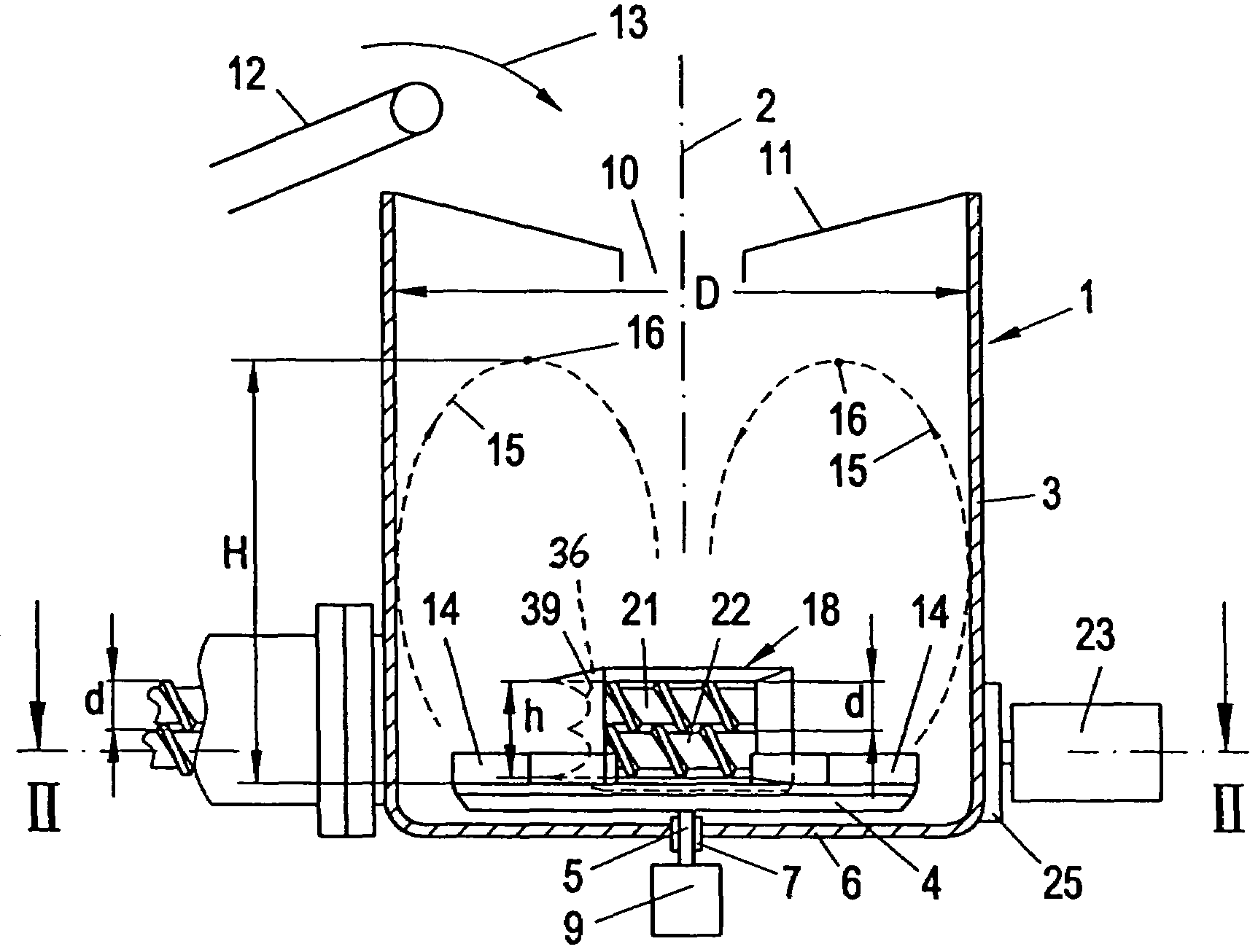

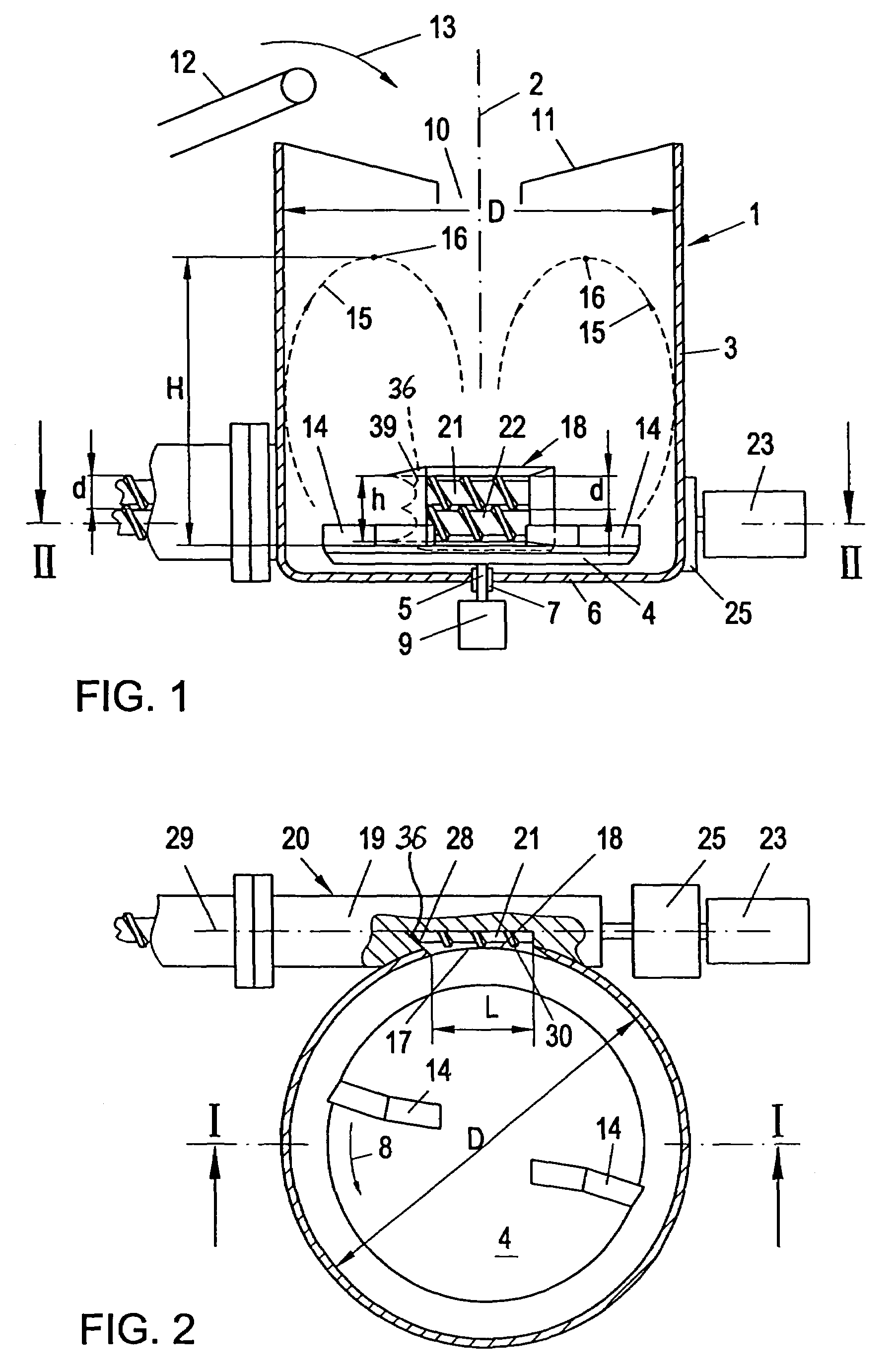

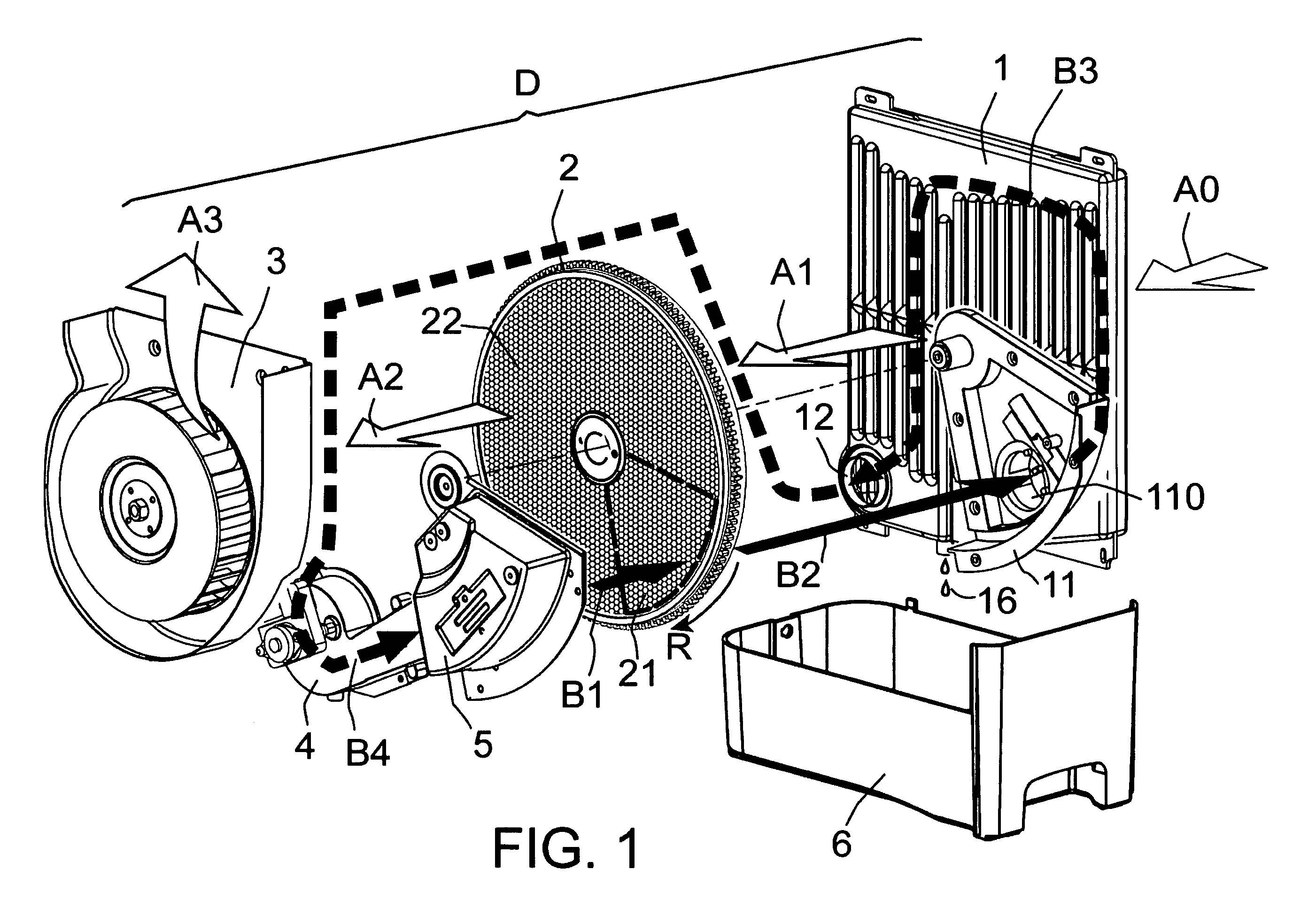

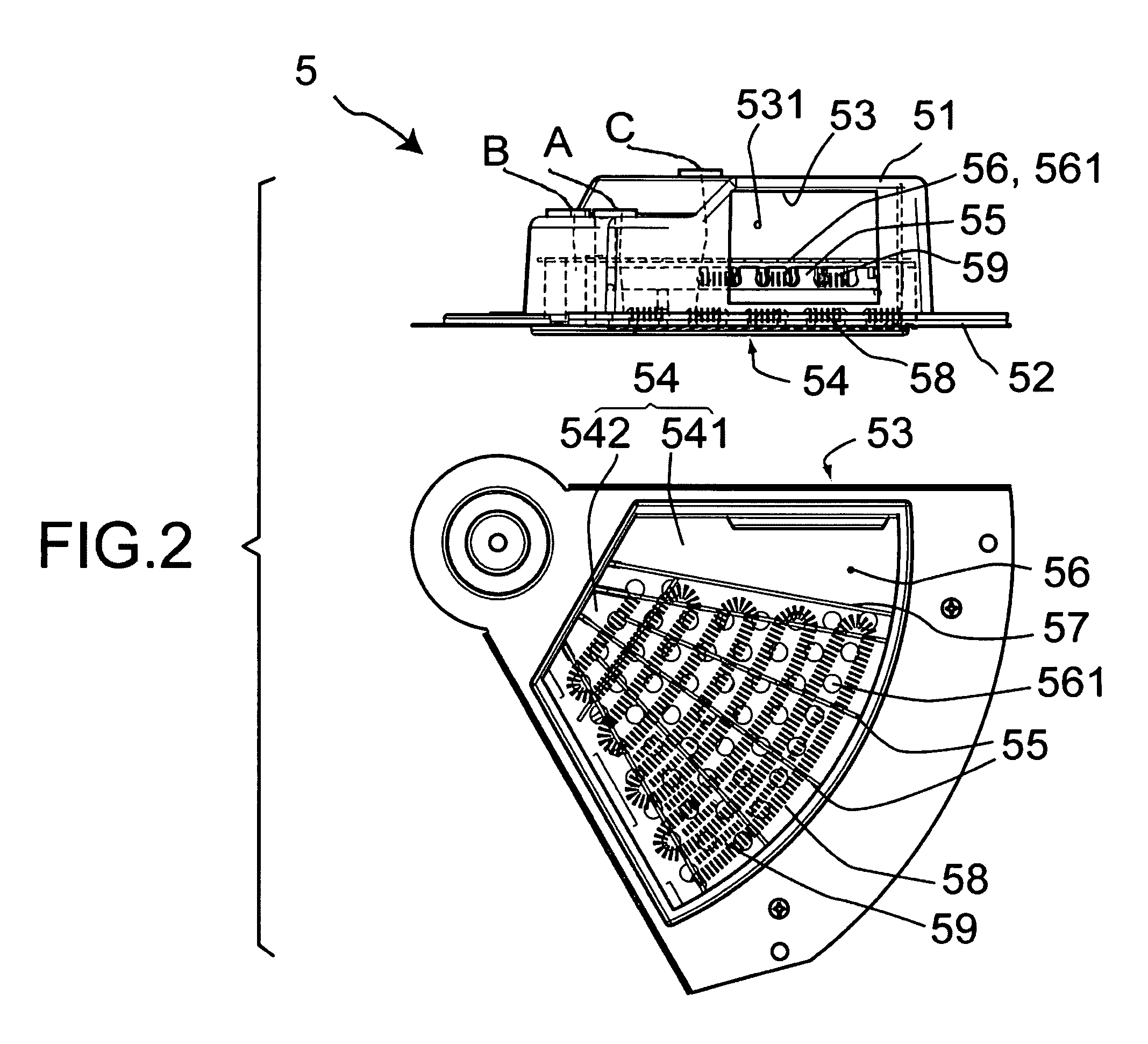

Device for preparation of plastic materials for recycling purposes

ActiveUS7309224B2Starting torqueUniform outputRotary stirring mixersFrozen sweetsPlastic materialsEngineering

A device for the preparation of plastics material for recycling purposes has a container (1) with an upper inlet opening (10) for the material. In the container (1), at least one tool (14) rotates about the vertical container axis. This tool feeds the treated material through an outlet opening (17) which is arranged at the bottom of the container (1) and to which the housing (19) of at least one screw (21, 22) is connected. That side wall (28) of the feed opening (18) at which the tool (14) discharges defines a widening (36) extending continuously towards the screw axis. This widening (36) extends over part of the circumference of the screw turns (30) so that the screw-side edge of this widening (36) forms an uninterrupted shearing edge (39) co-operating with the screw turns (30).

Owner:EREMA ENG RECYCLING MASCH & ANLAGEN GMBH

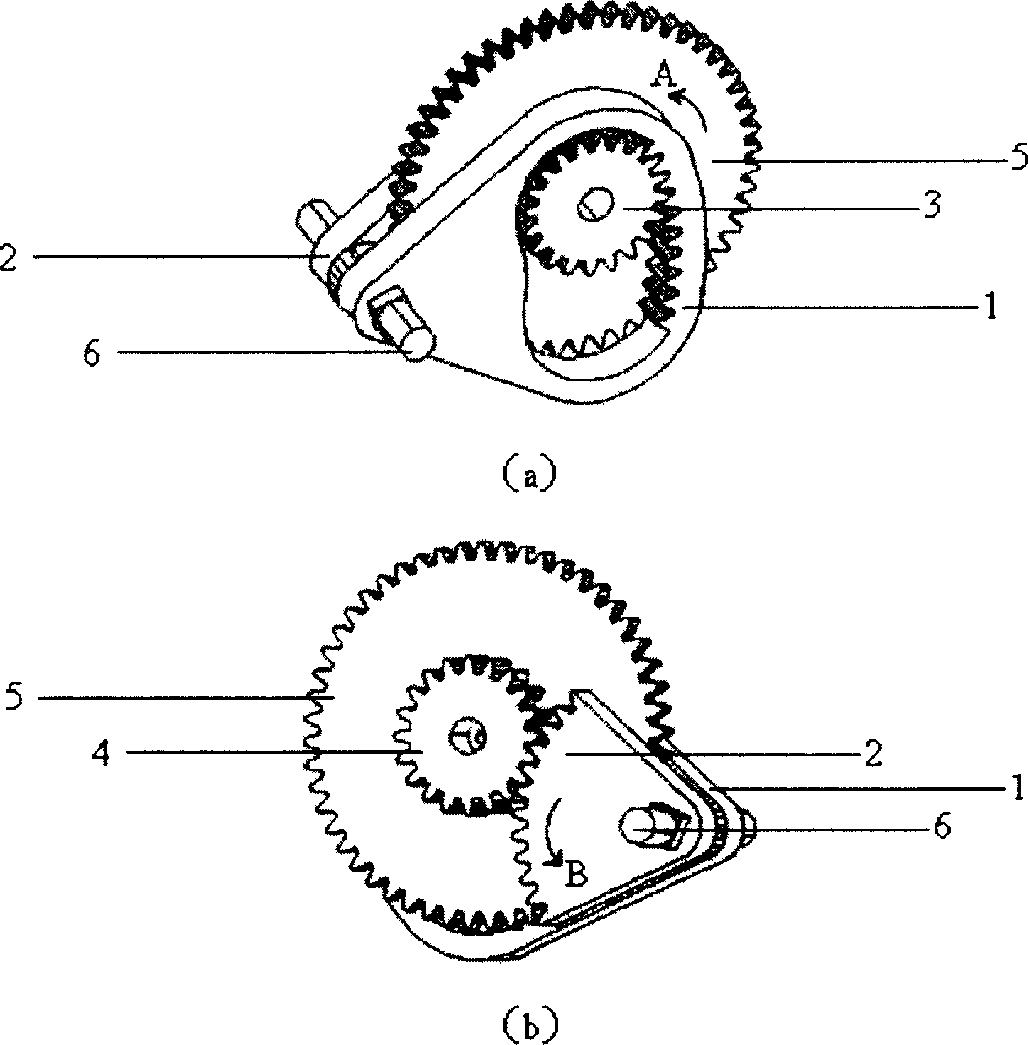

Two-way work doing driving mechanism and portable self-aid generating and lighting device

InactiveCN1683785AUniform outputMeet usage habitsFrom muscle energyLighting elementsReciprocating motionEngineering

The bi-directional work doing transmission mechanism includes power input unit, two single-way transmission parts, and power output unit to drive simultaneously these two single-way transmission parts to move oppositely. The present invention also discloses portable self-aid generating and lighting device with the bi-directional work doing transmission mechanism. The present invention is superior in that two single-way transmission parts are driven in opposite directions so that there is always one single-way transmission part to drive the power output unit during the reciprocating motion, resulting in best utilization of energy and raised transmission efficiency.

Owner:石为民 +2

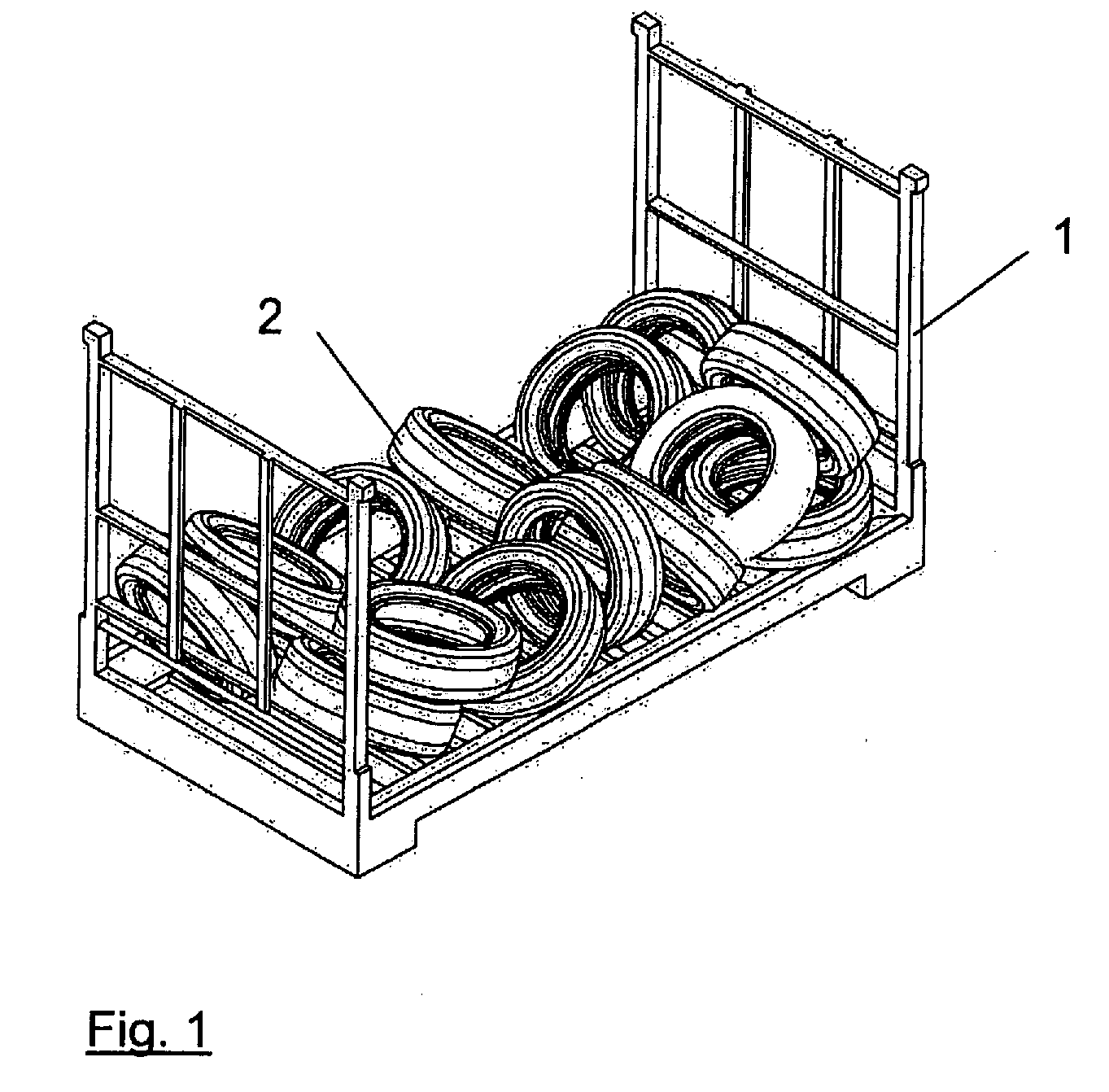

Method and system for depalletizing tires using a robot

InactiveUS8538579B2Easy to detectImprove reliabilityProgramme-controlled manipulatorDigital data processing detailsEngineeringCollision free

In a method and system for depalletizing tires using a robot, wherein the tires are randomly located on a carrier, the position and orientation of outer tires on the carrier are detected using a sensor, and a processor, using a signal from the sensor, determines a tire that can be gripped by a gripping tool of an industrial robot, and calculates a movement path for the gripping tool for that tire. If the calculated path is not collision-free, another tire from among the outer tires is selected, and a movement path for depalletizing that tire is determined. The procedure is repeated until a collision-free movement path for a tire from among the outer tires is established. The gripping tool is then guided according to this collision-free movement path to depalletize the tire having the collision-free path associated therewith.

Owner:KUKA ROBOTER

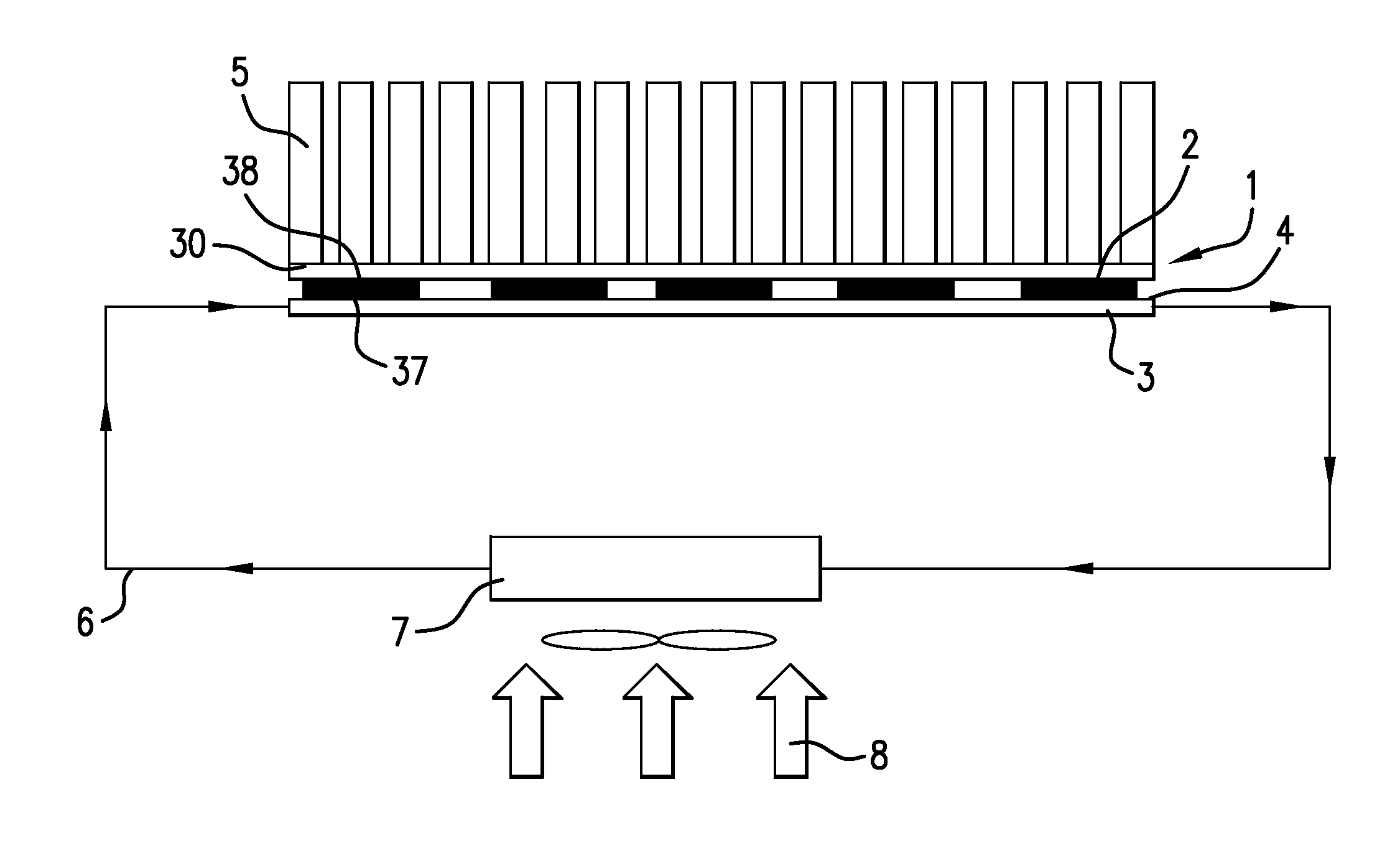

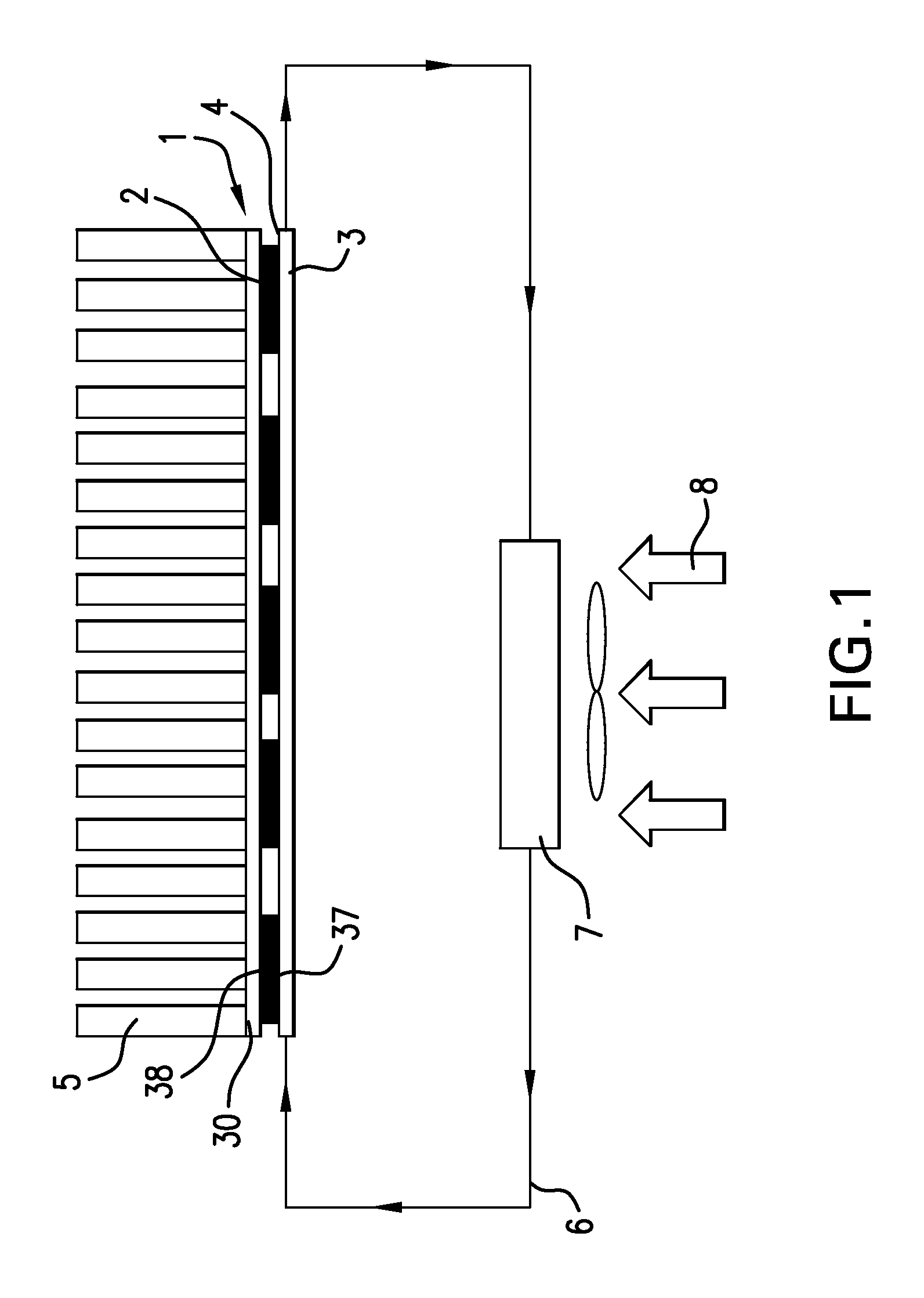

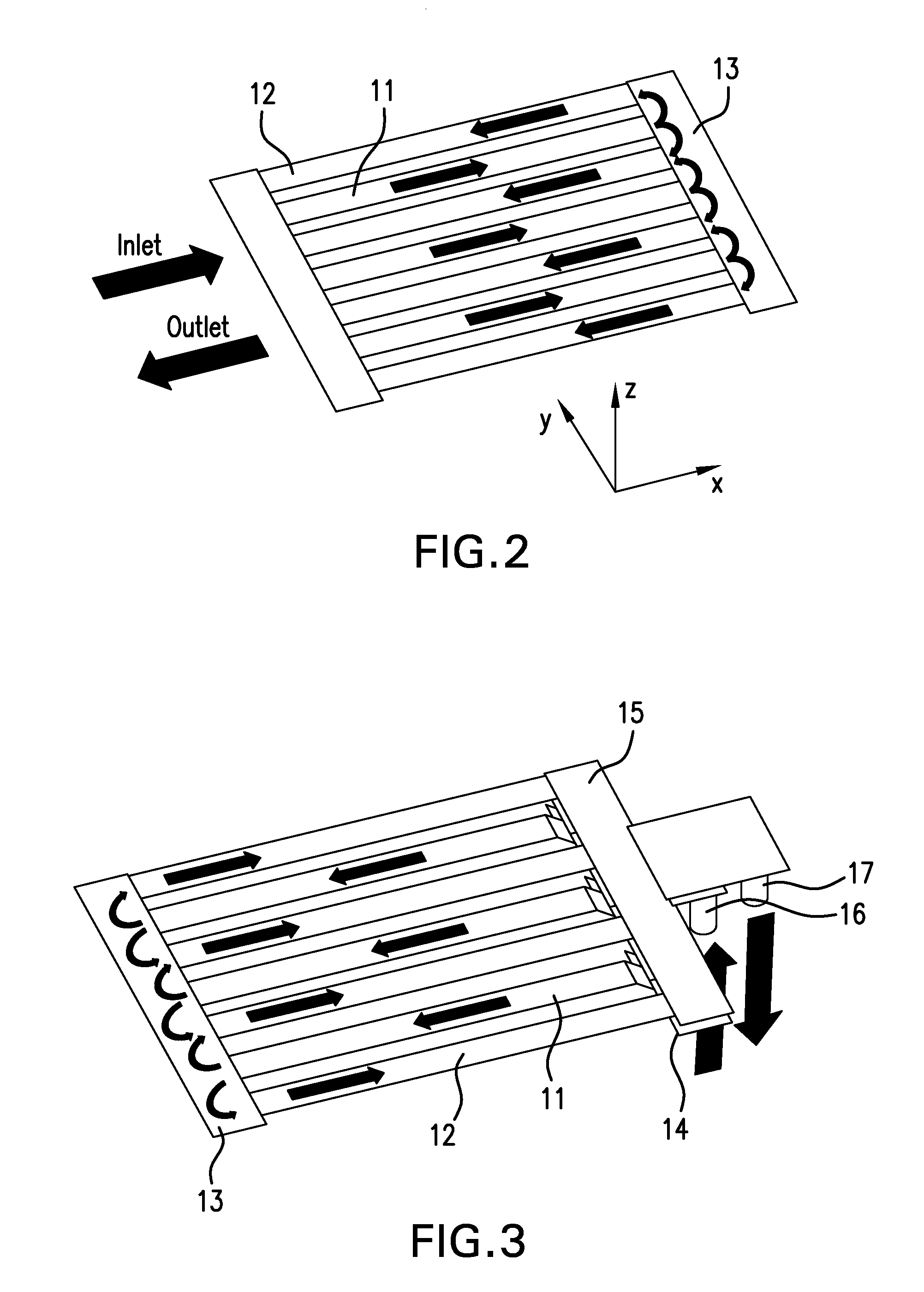

Thermoelectric temperature control unit

InactiveUS20140013774A1Advantageous distribution patternImprove heat transfer performanceSecondary cellsStationary conduit assembliesMobile vehicleTemperature control

The application relates to thermoelectric temperature control units, for example for controlling the temperature of an energy storage device in a motor vehicle. An exemplary embodiment comprises a Peltier element, having a first and a second surface, wherein the second surface is substantially adjacent or opposite to the first. The first surface is connected in a thermally conductive manner to a first and / or second flow duct, through which a fluid can flow. The second surface is connected in a thermally conductive manner to a heat-producing element, wherein the first flow duct is in fluid communication at one of the ends thereof with a first header, and the second flow duct is in fluid communication at one of the ends thereof with a second header, and the first flow duct and the second flow duct are in fluid communication at the respective second ends thereof with a common reversing header.

Owner:MAHLE INT GMBH

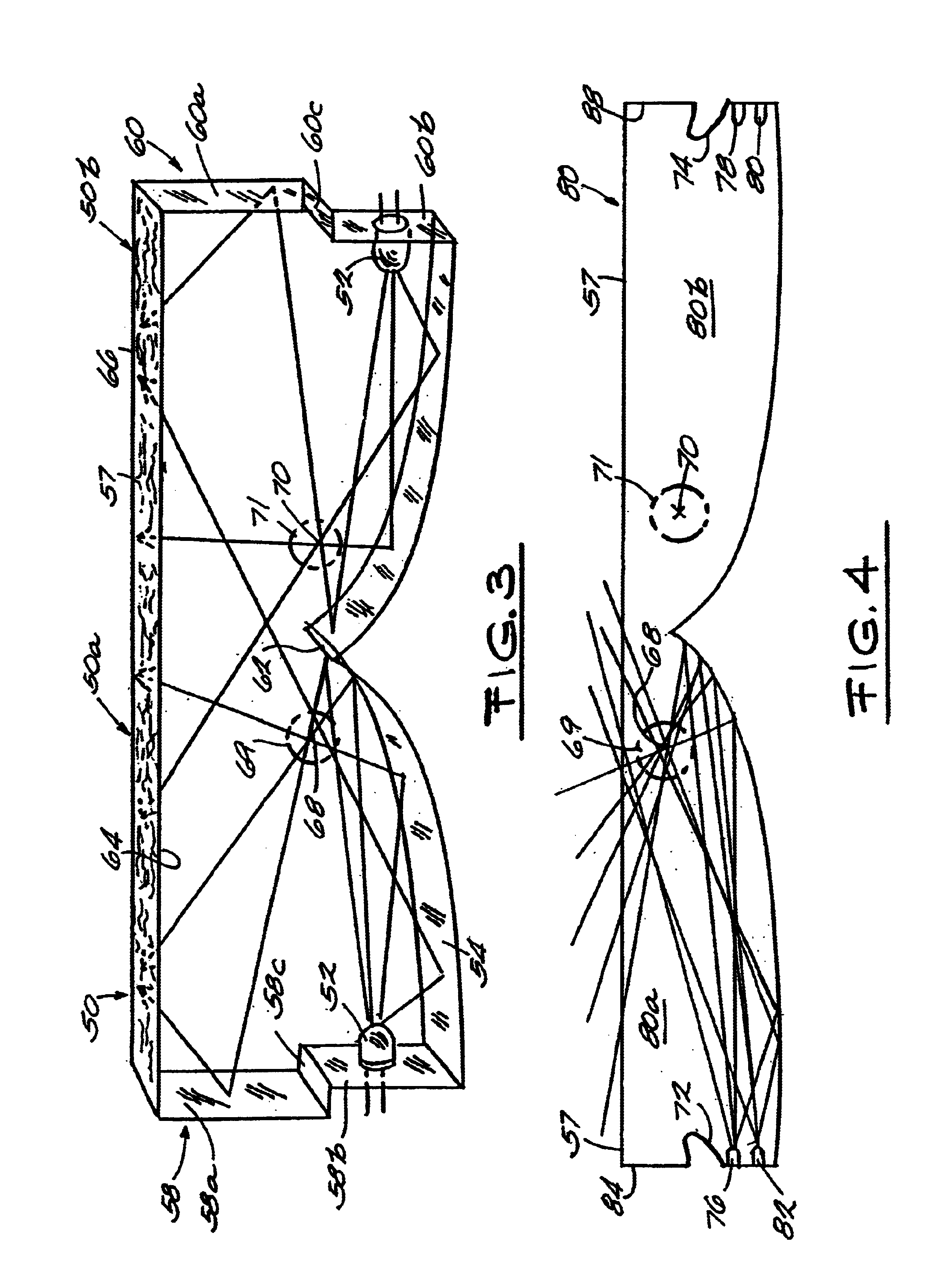

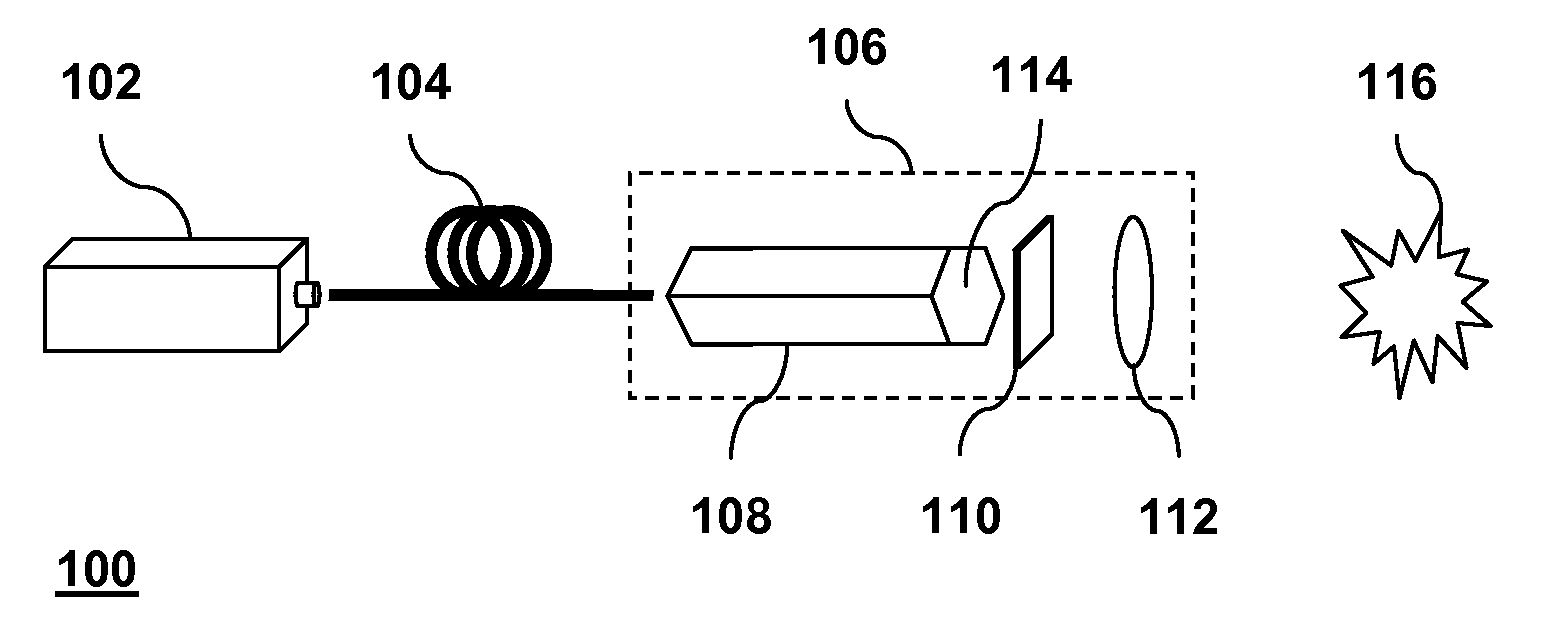

Medical Laser Apparatus with Output Beam Homogenizer

InactiveUS20110034973A1Uniform outputSurgical instrument detailsLight therapyTotal internal reflectionLight pipe

A medical laser apparatus with a beam homogenizer for producing a uniform output beam profile. The beam homogenizer comprises a light pipe which expands the laser beam and mixes the laser light through total internal reflection as well as an optical diffuser to provide further control of the intensity distribution of the laser beam.

Owner:BWT PROPERTY

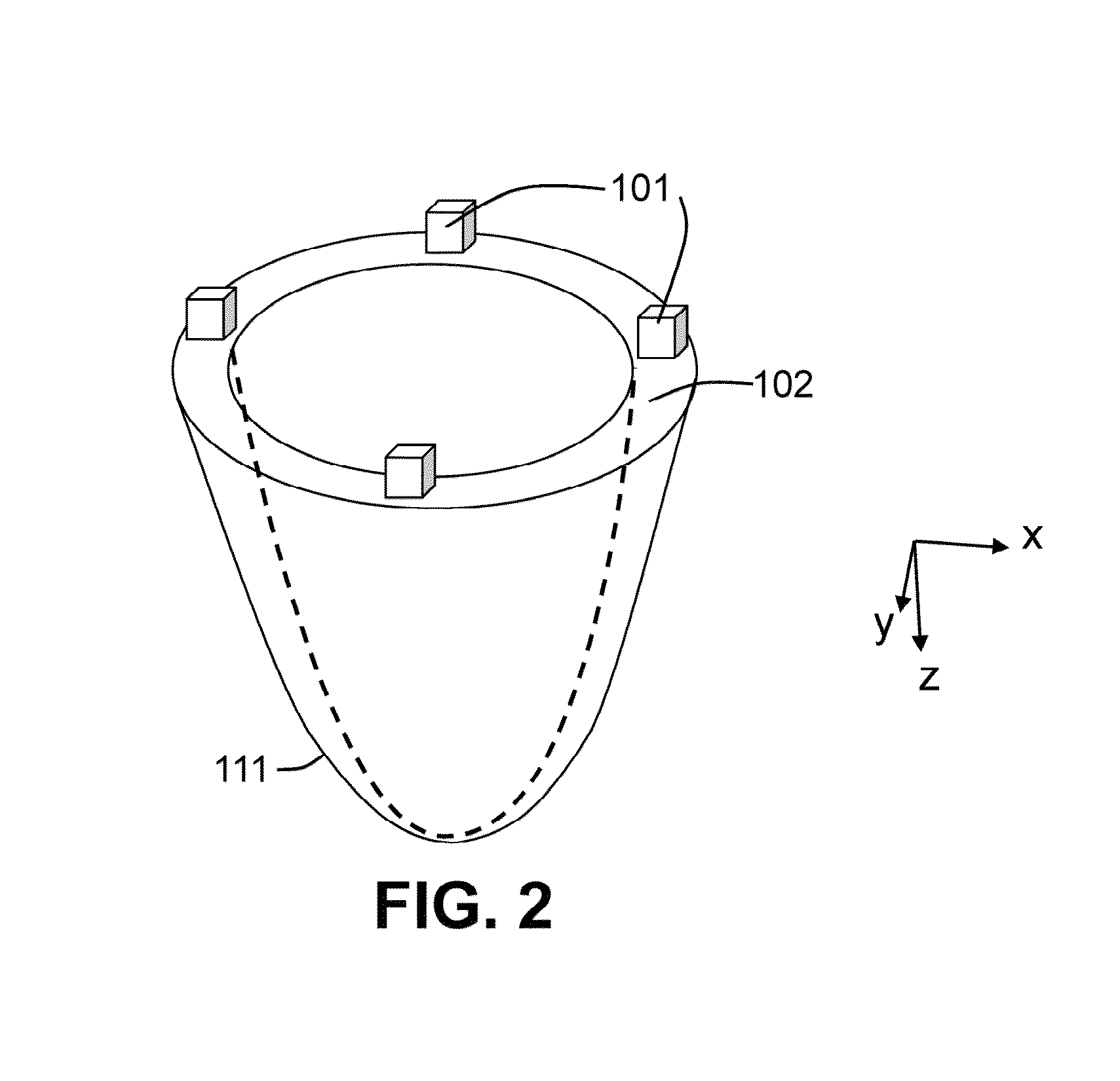

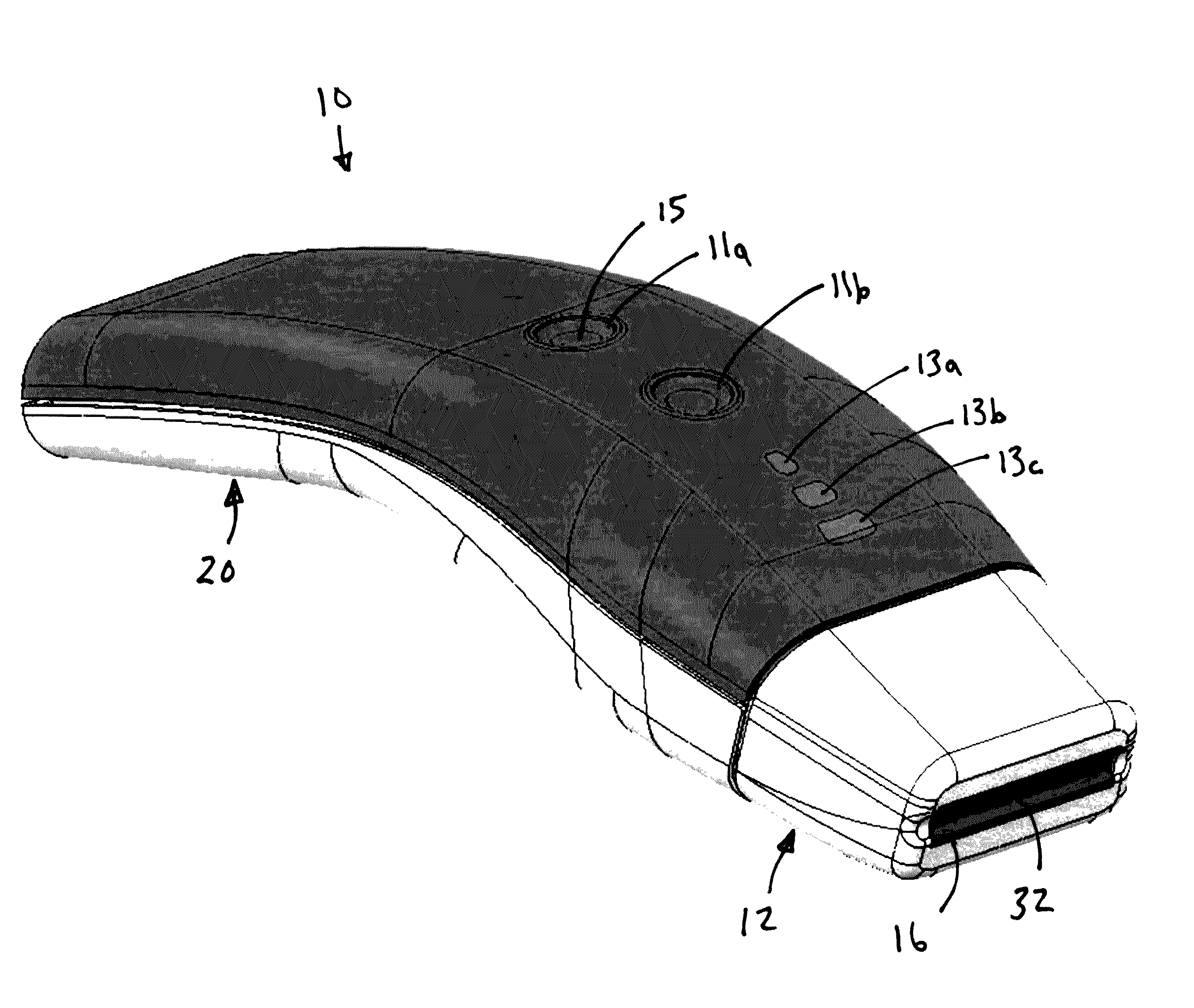

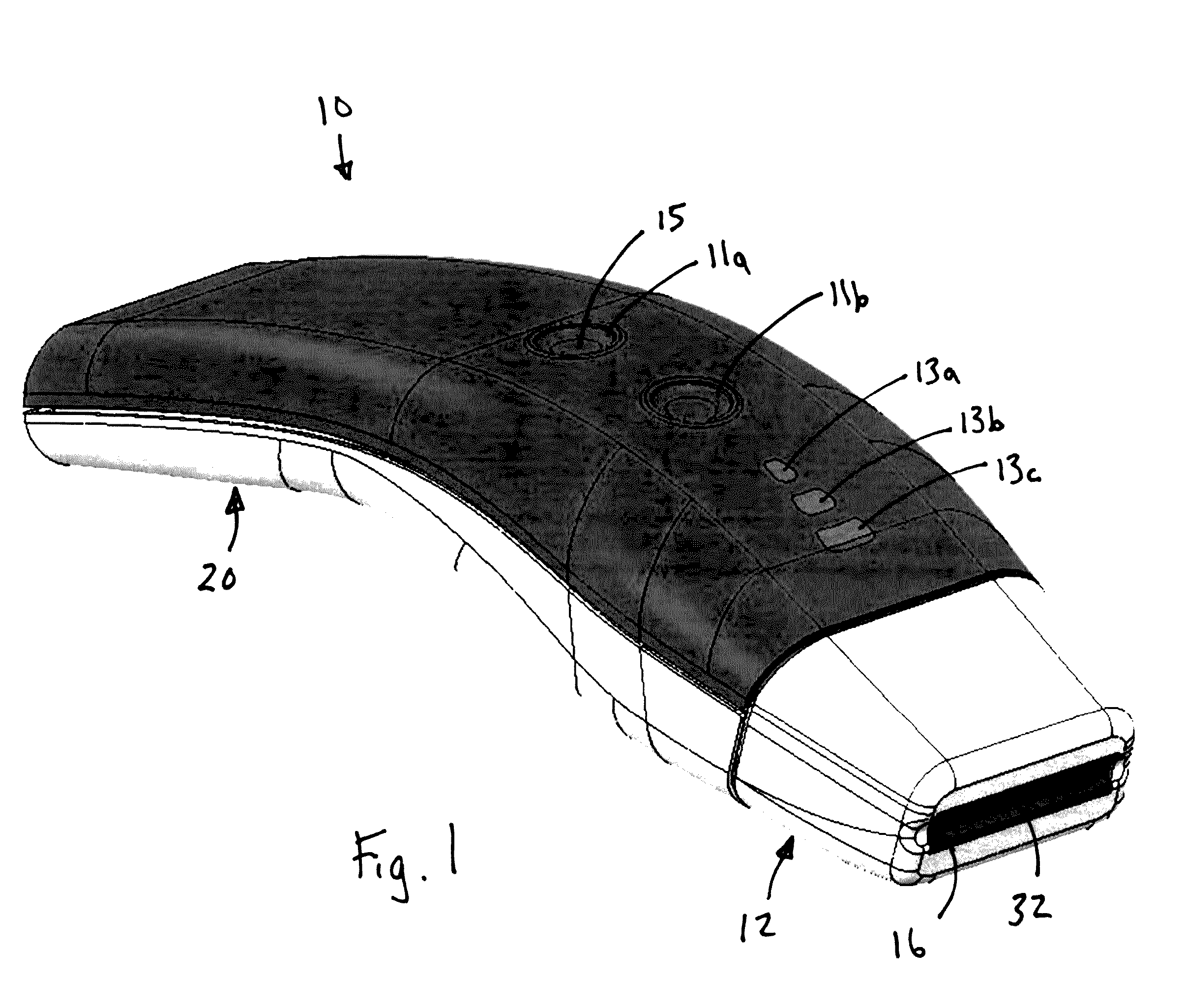

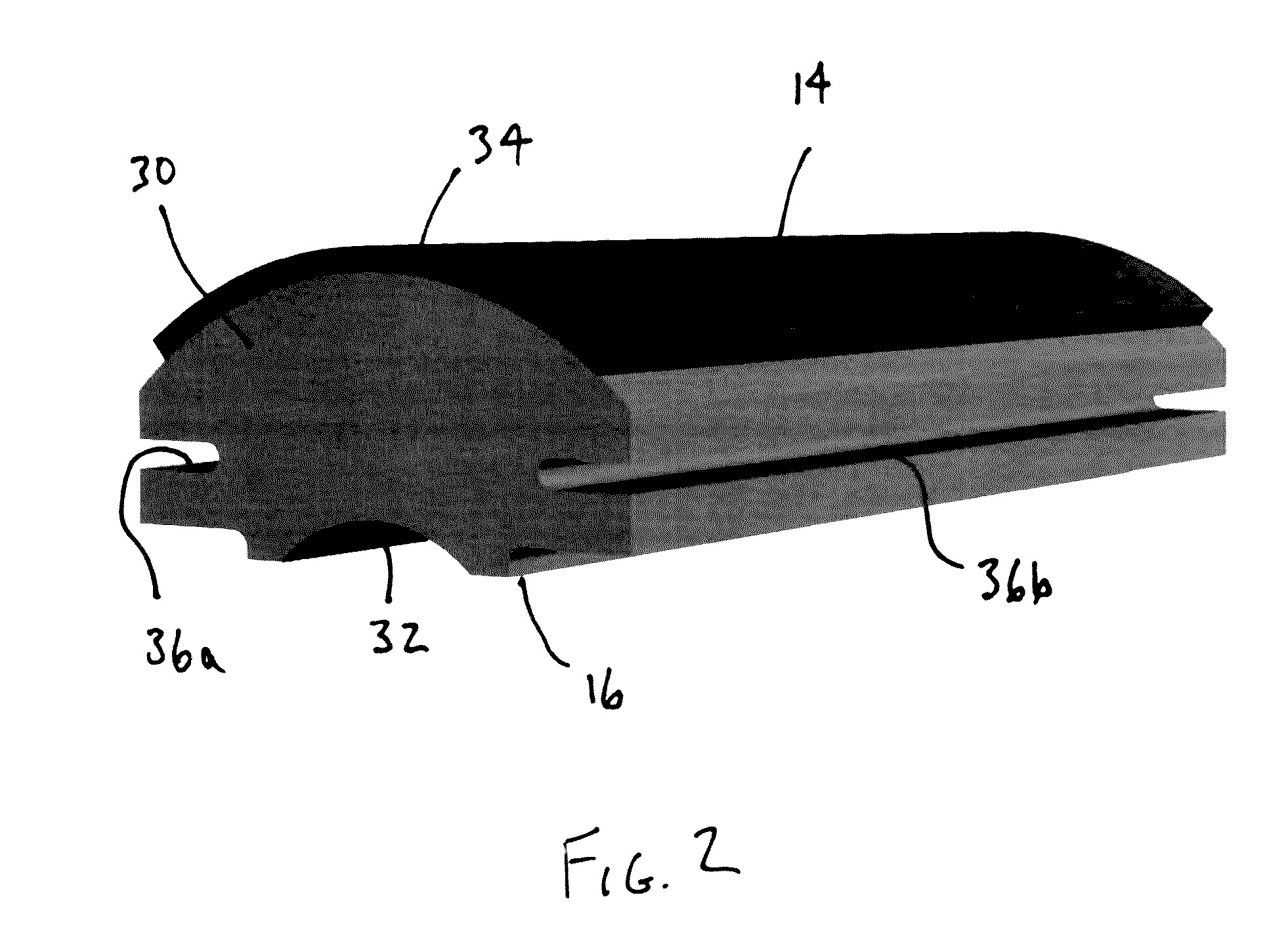

Acoustic module and control system for handheld ultrasound device

ActiveUS20170043189A1Uniformity in acoustic outputImprove overall acoustic uniformityUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyOperating pointAcoustic energy

An acoustic module with a transducer and a solid waveguide. The transducer and waveguide may be curved to focus the acoustic energy along a focal line. The transducer, the top surface of the waveguide and the bottom surface of the waveguide may extend along coaxial curves. The waveguide may include a recess closely receiving the transducer. The waveguide may include an integral skirt that provides a thermal mass. The acoustic module may include a space to accommodate thermal management options. For example, the acoustic module may include a heatsink, an active ventilation system and / or a phase change material. The ultrasound device may include a controller configured to perform a uniformity scan sweep during supply of operating power to the transducer. The uniformity scan sweep can extend through a frequency range that includes the operating point of the acoustic module and does not exceed an acceptable efficiency loss.

Owner:ACCESS BUSINESS GRP INT LLC

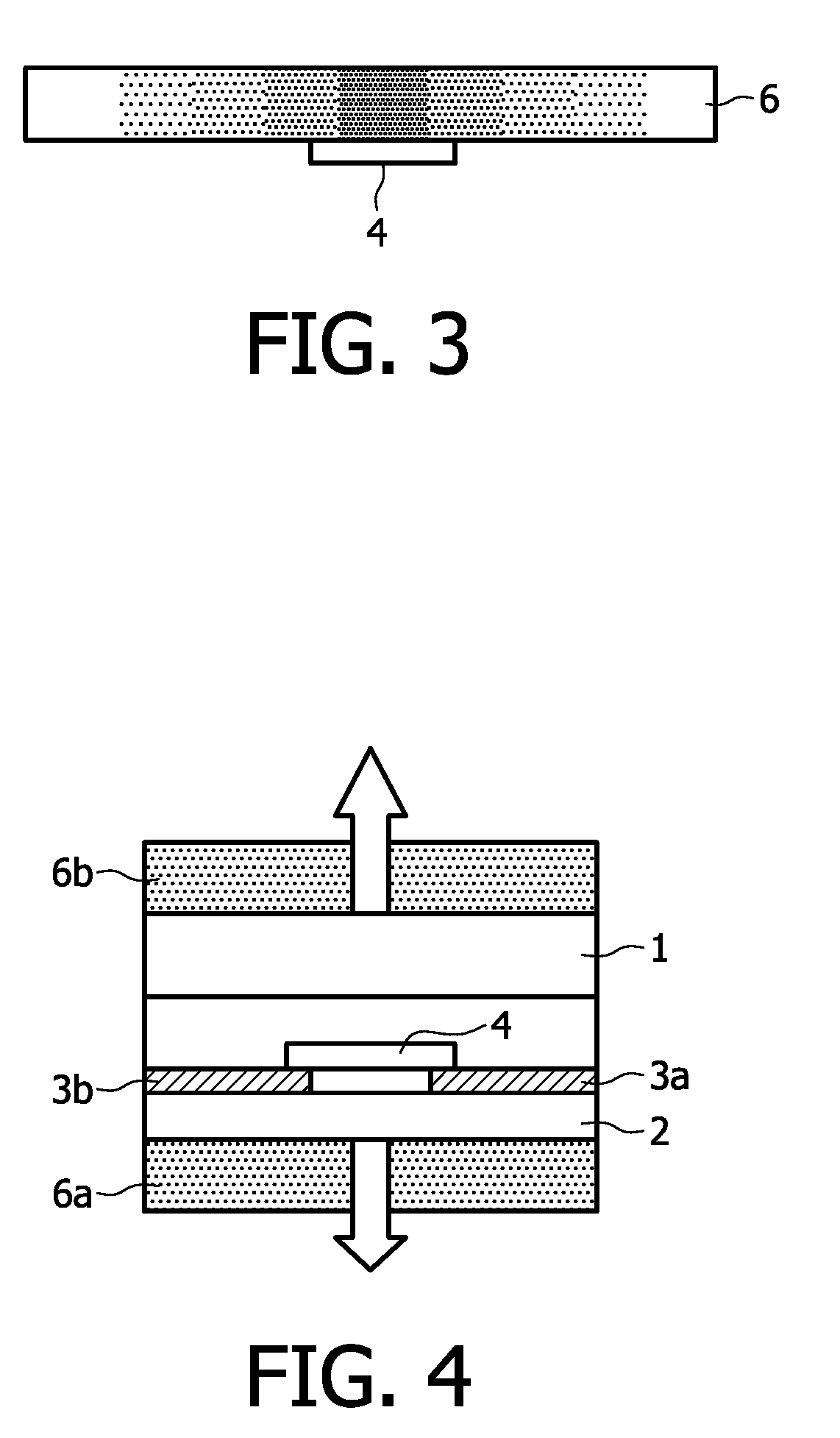

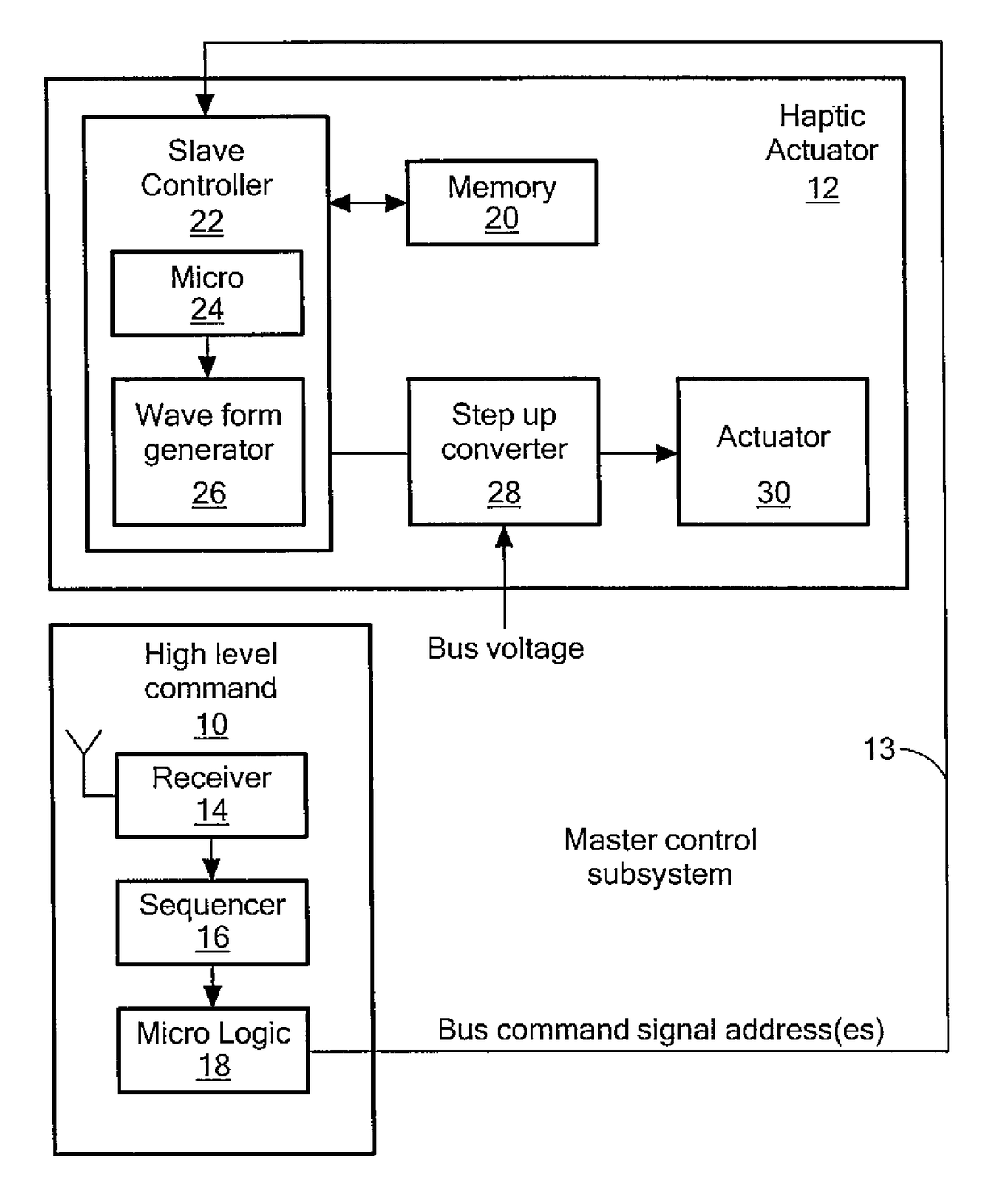

Functional device

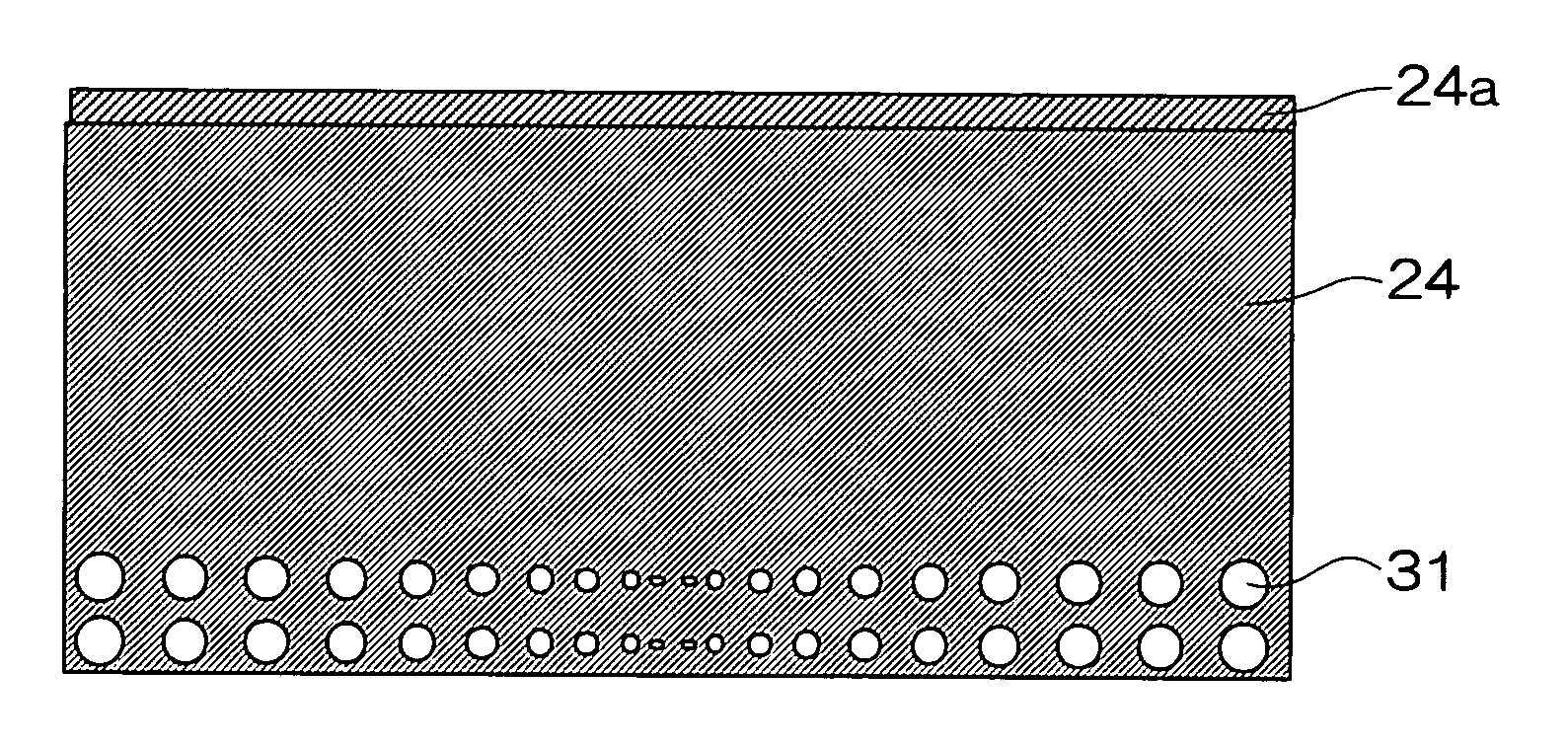

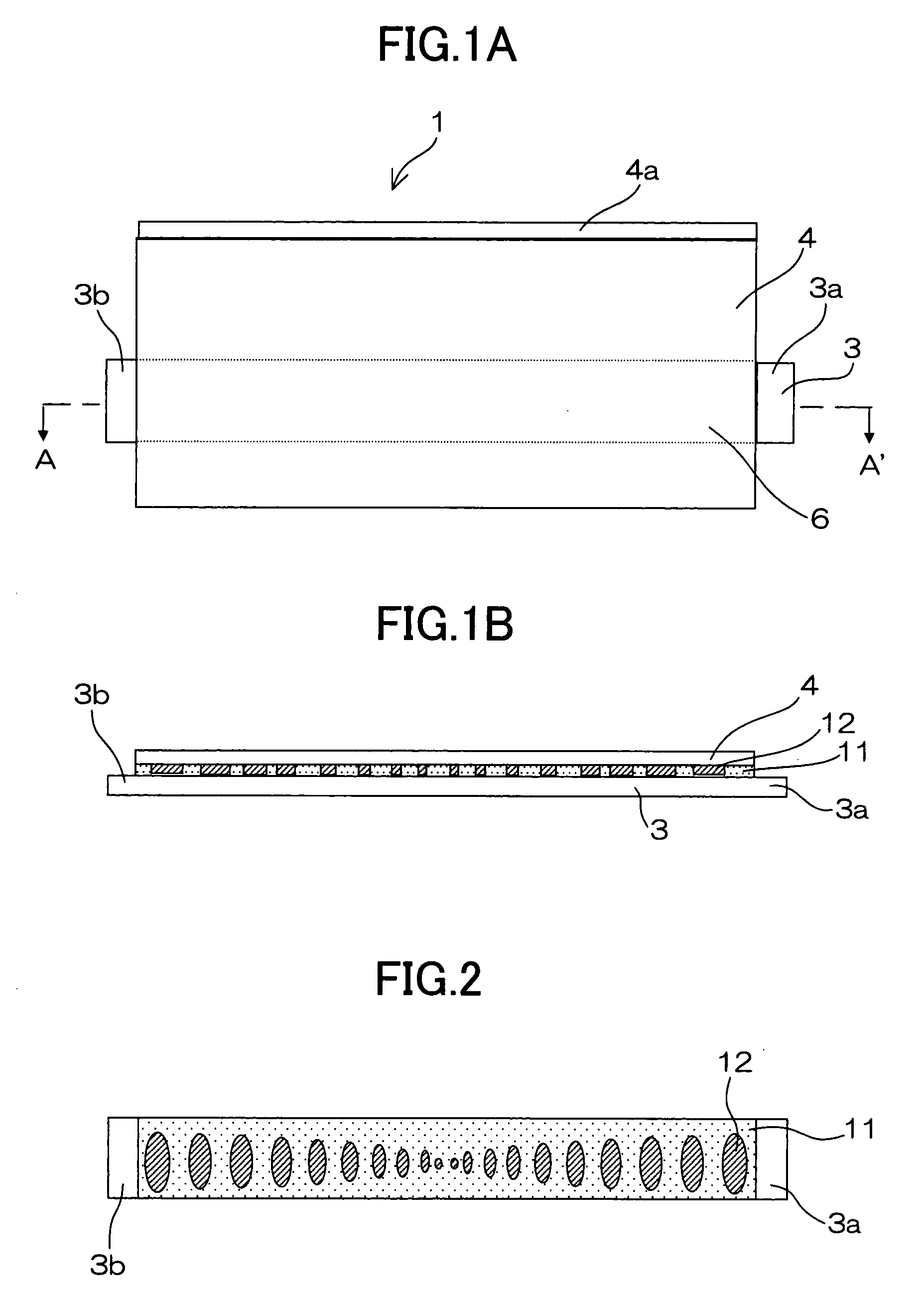

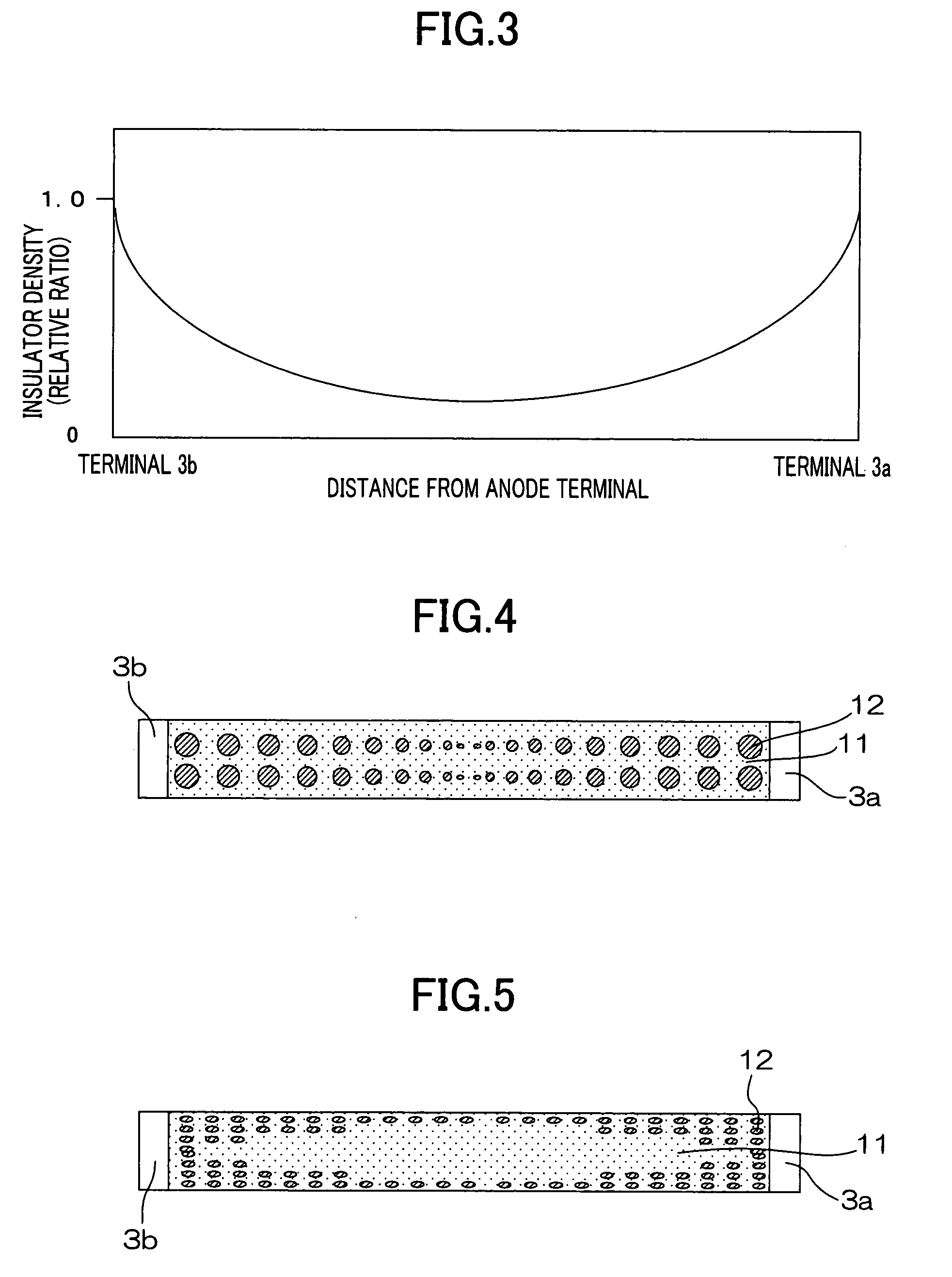

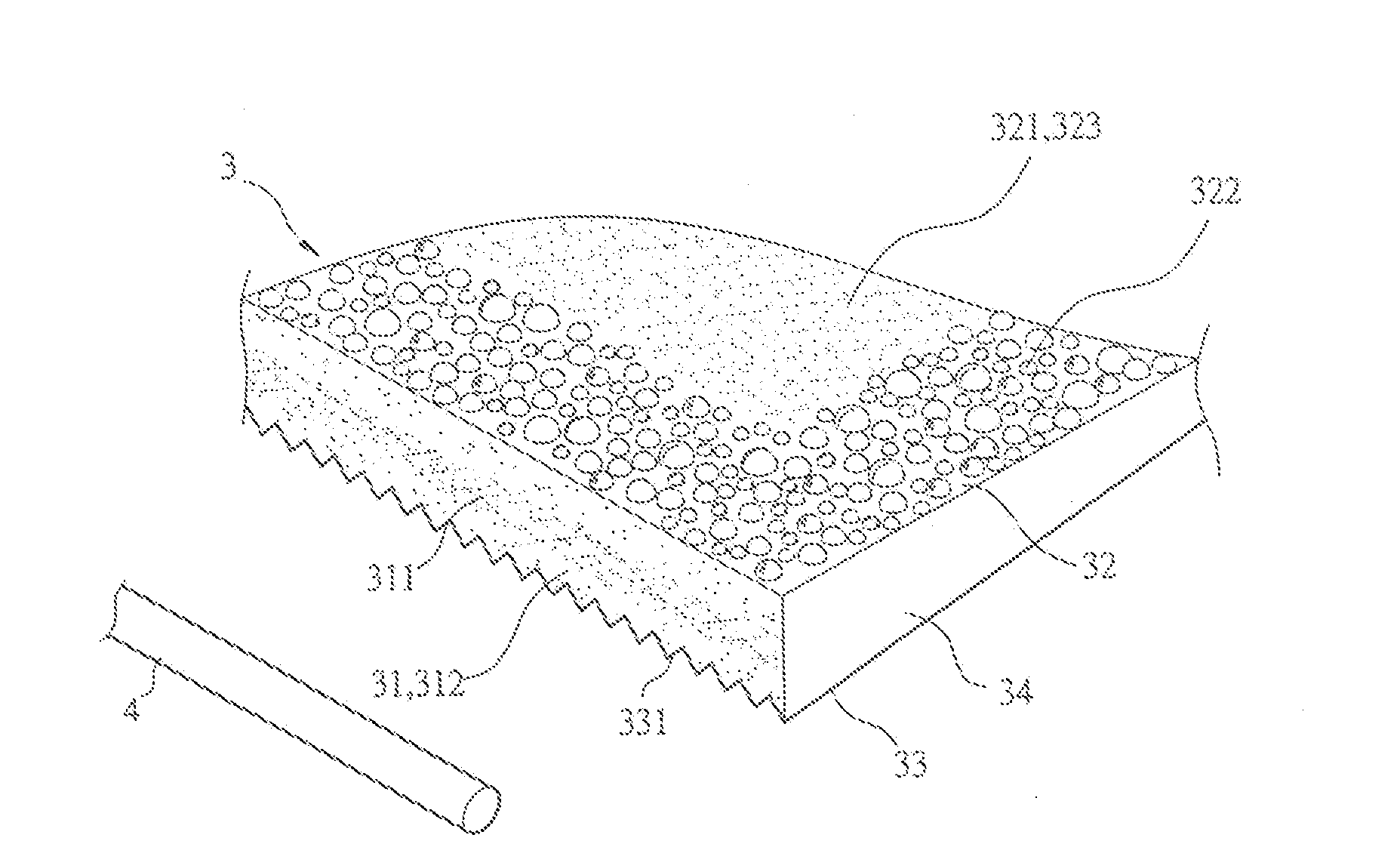

ActiveUS20070228368A1Strong production adaptabilityUniform in-plane outputSolid-state devicesSemiconductor/solid-state device manufacturingIn planeEngineering

A functional device having, on a substrate, a pair of electrodes, a functional layer which is sandwiched between the electrodes and has an output that varies in accordance with an applied electric current, and a terminal arranged to apply an electric current to at least one of the electrodes, wherein an insulator is arranged between the electrodes and the density of the insulator decreases as the distance from the terminal increases, or wherein at least one of the electrodes has a notch section, and the ratio of the area of the notch section to the area of the electrode decreases as the distance from the terminal increases. This is an improved functional device which is excellent in production suitability and gives a uniform in-plane output, and can be rendered, in particular, an organic electroluminescence device.

Owner:UDC IRELAND

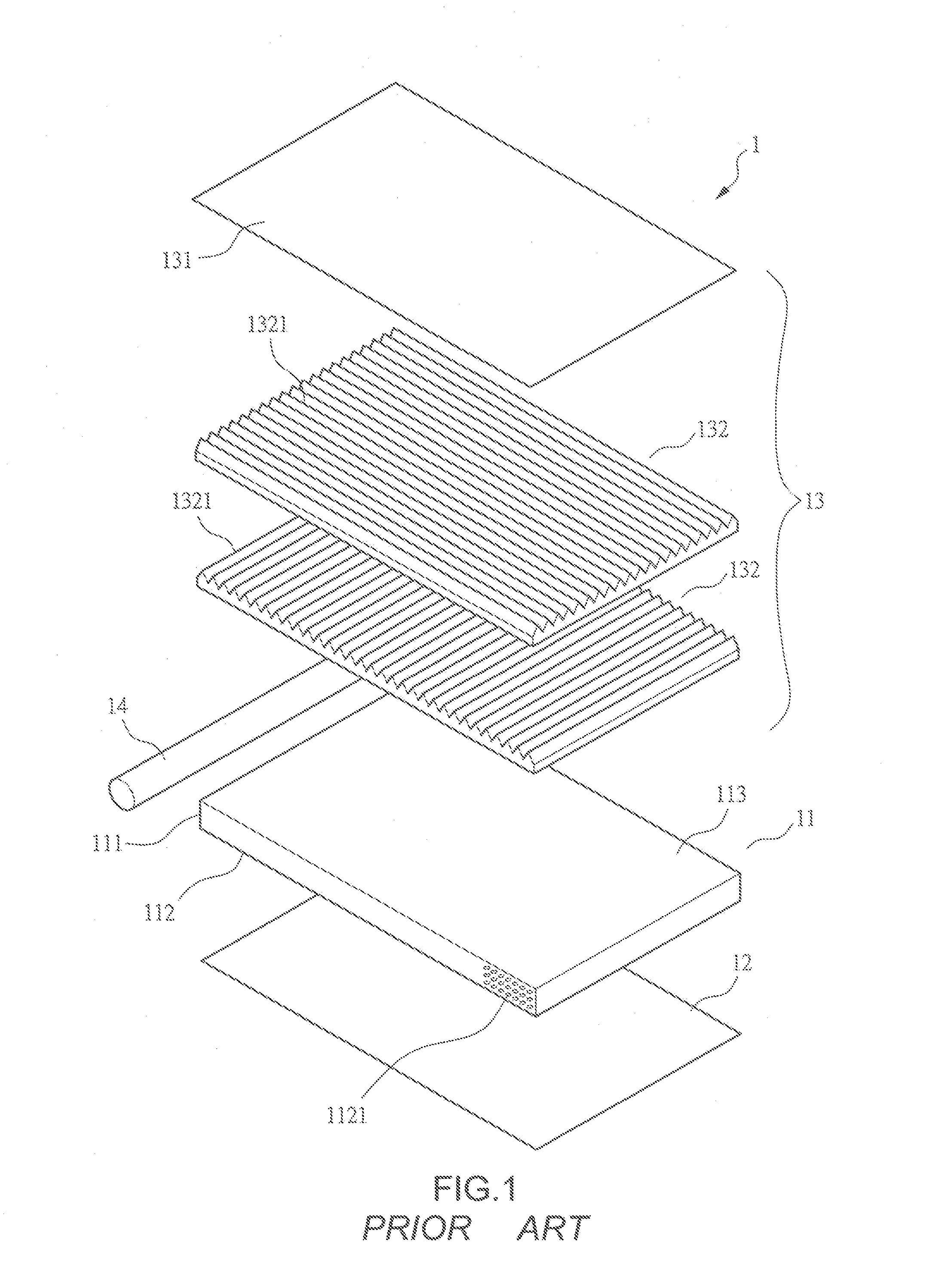

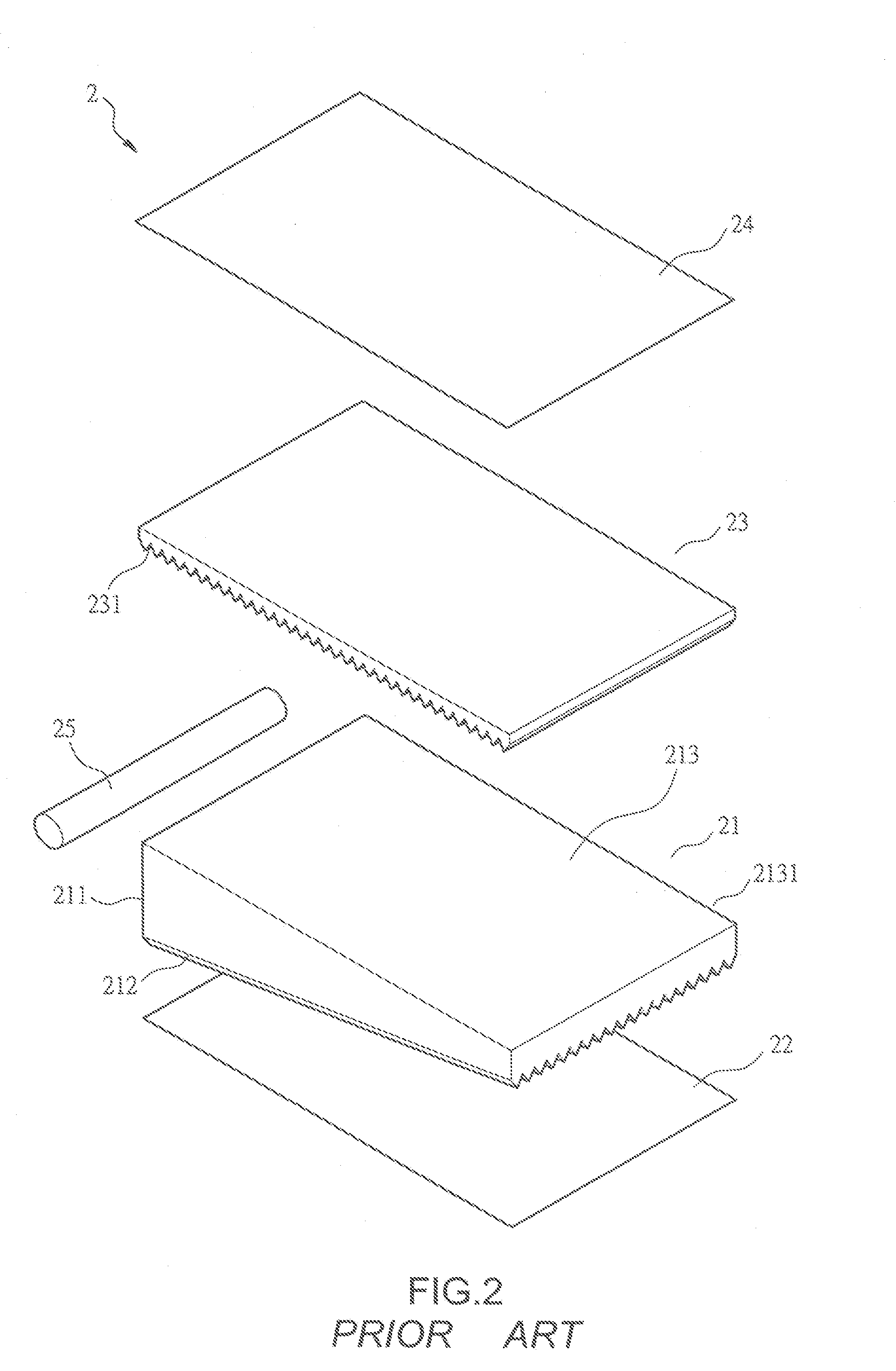

Structure of light guide board

InactiveUS20080123364A1Improve surface roughnessFacilitated DiffusionMechanical apparatusPlanar/plate-like light guidesMicro structureDiffusion

A light guide board includes an incidence surface, an emitting surface, and a reflection surface. The incidence surface is frosted and has a roughness-enhanced zone corresponding in location to a light source. The emitting surface forms micro-structures on portions adjacent to the incidence surface and two opposite end surfaces. The portions of the emitting surface forming the micro-structures have magnitude increased roughness as compared to portions that are not provided with micro-structures so that light transmitting through the micro-structures is subject to further diffusion. The reflection surface forms a plurality of prisms extending from the incidence surface with a small (shallow) depth to an opposite surface with a large (deep) depth, with the height of the prisms increasing with the length thereof so that the prism surface of the prisms changes from minimum to maximum, which ensures uniformity of the light emitted from the light guide board.

Owner:RADIANT OPTO ELECTRONICS

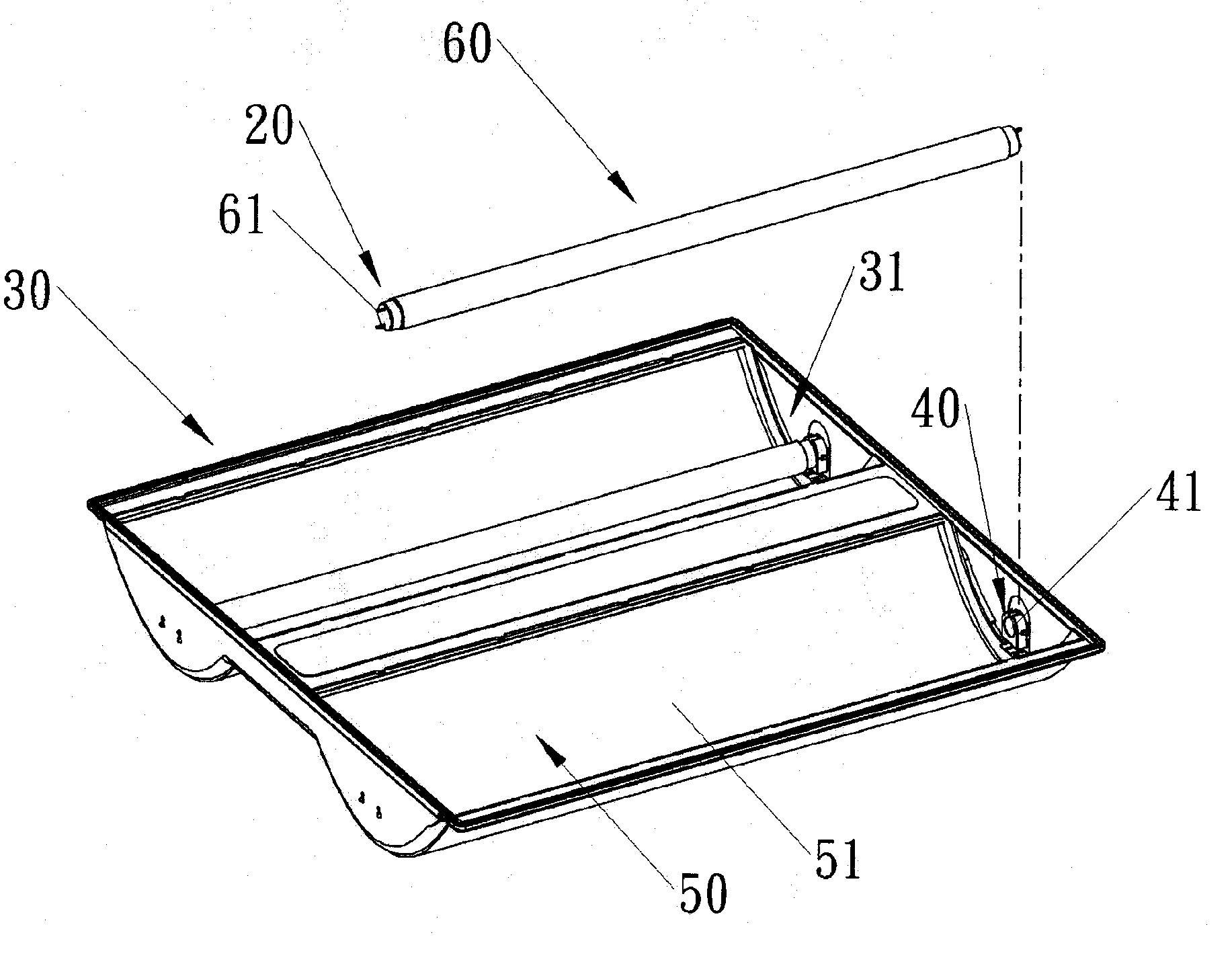

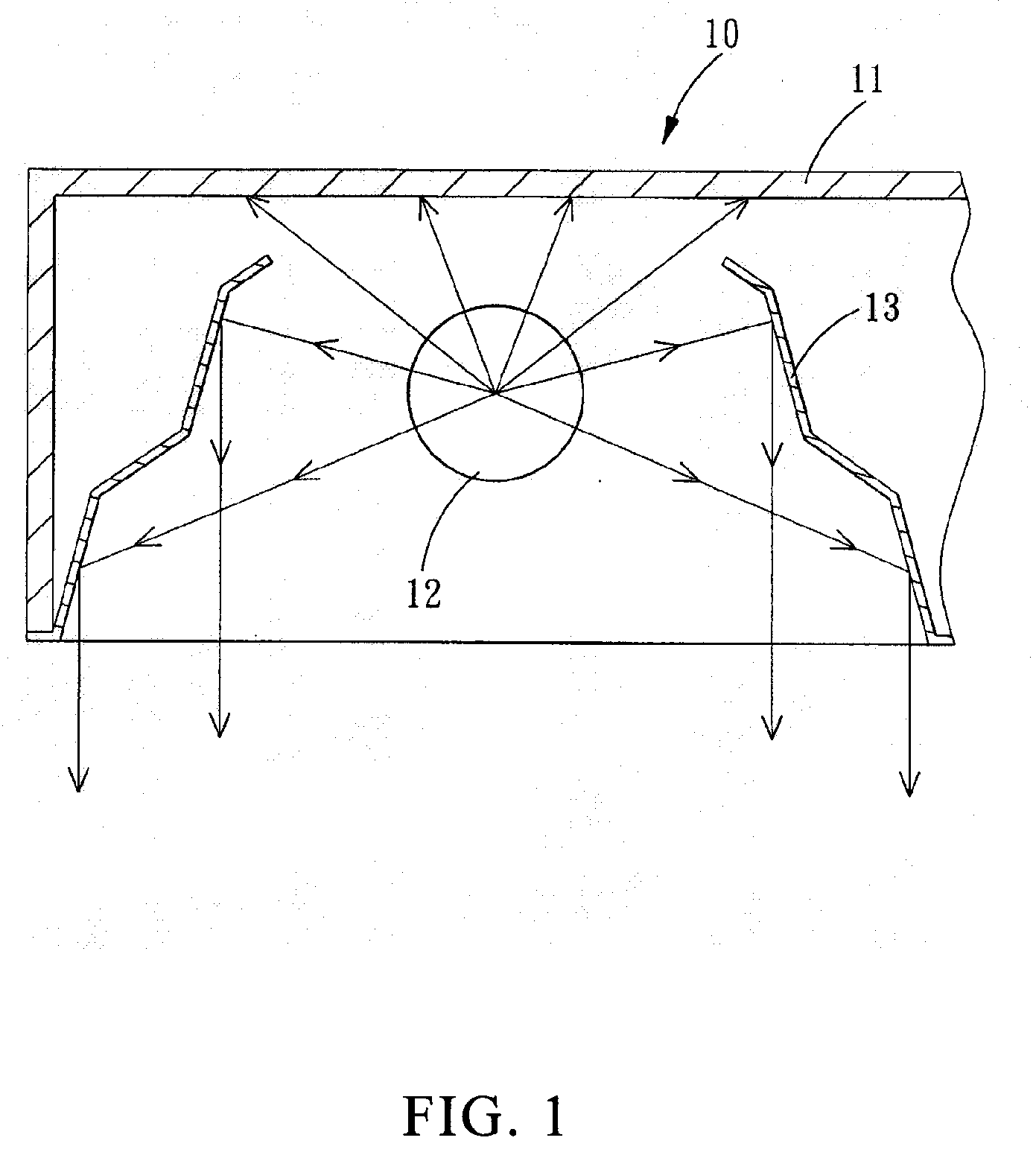

Light fixture with an efficiency-optimized optical reflection structure

InactiveUS20090091935A1Minimize power consumptionReduce energy costsCoatingsReflectorsOptical reflectionLight beam

A light fixture with an optical reflection structure, comprising a lamp housing having at least one open accommodating space for light beam to be emitted outward therefrom; a plurality of connectors for coupling a light tube to the light fixture, the connectors being located at both opposite ends in a longitudinal direction of the accommodating space; a reflector having a curved surface affixed with a composite mirror film for light reflection, the reflector being located in the accommodating space and substantially covering at least a part of a surface of the accommodating space, wherein the curved surface is determined based on law of reflection by optimizing a luminous flux of primary reflection light reflected off the reflector to the extent of 90% or more compared with a naked light source from the light tube. The light fixture of the invention provides sufficient illumination and prolongs the lifespan of the light tube in a cost-economic way, thus directly saving energy and reducing the production of carbon.

Owner:TSAI HUNG YI

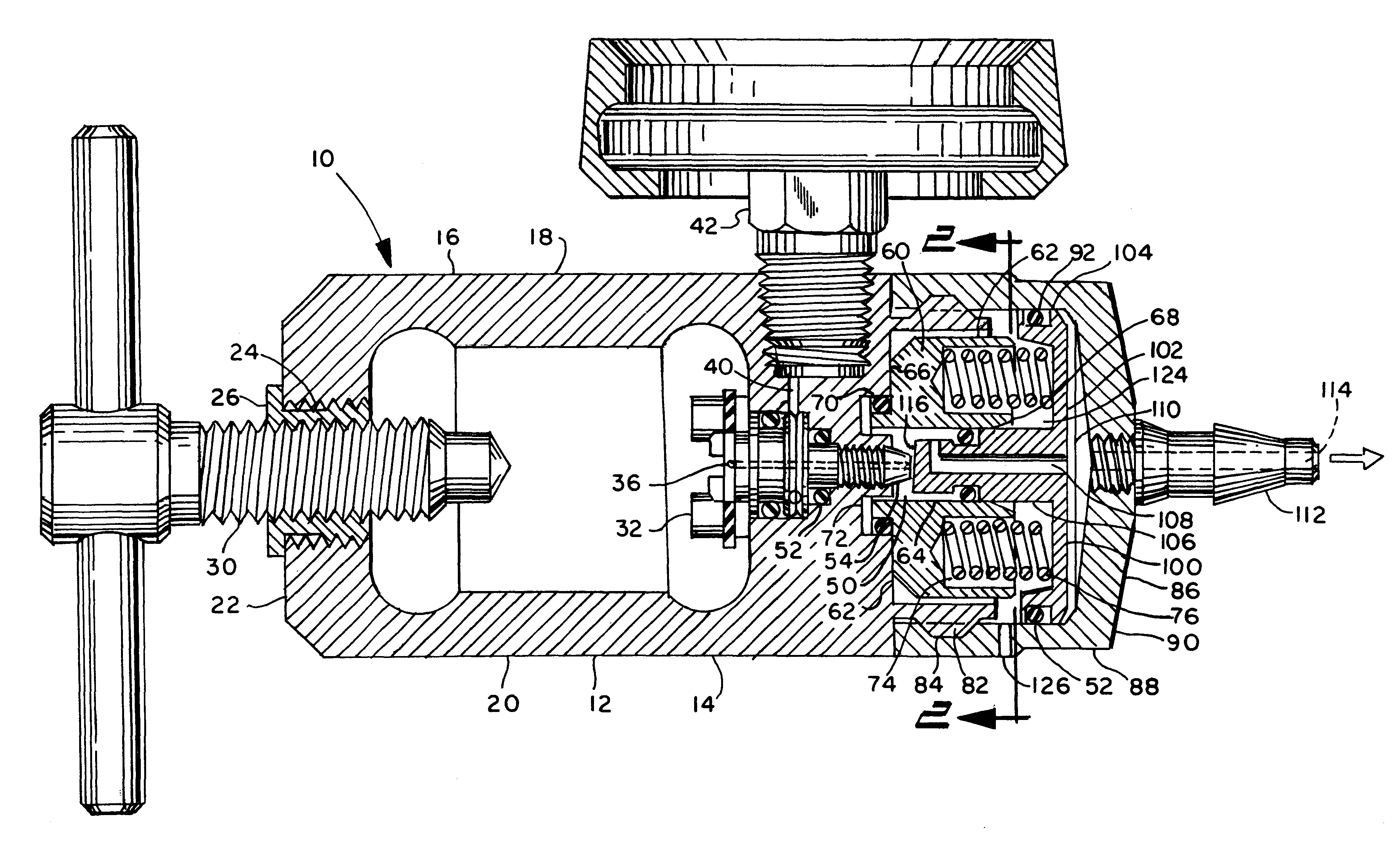

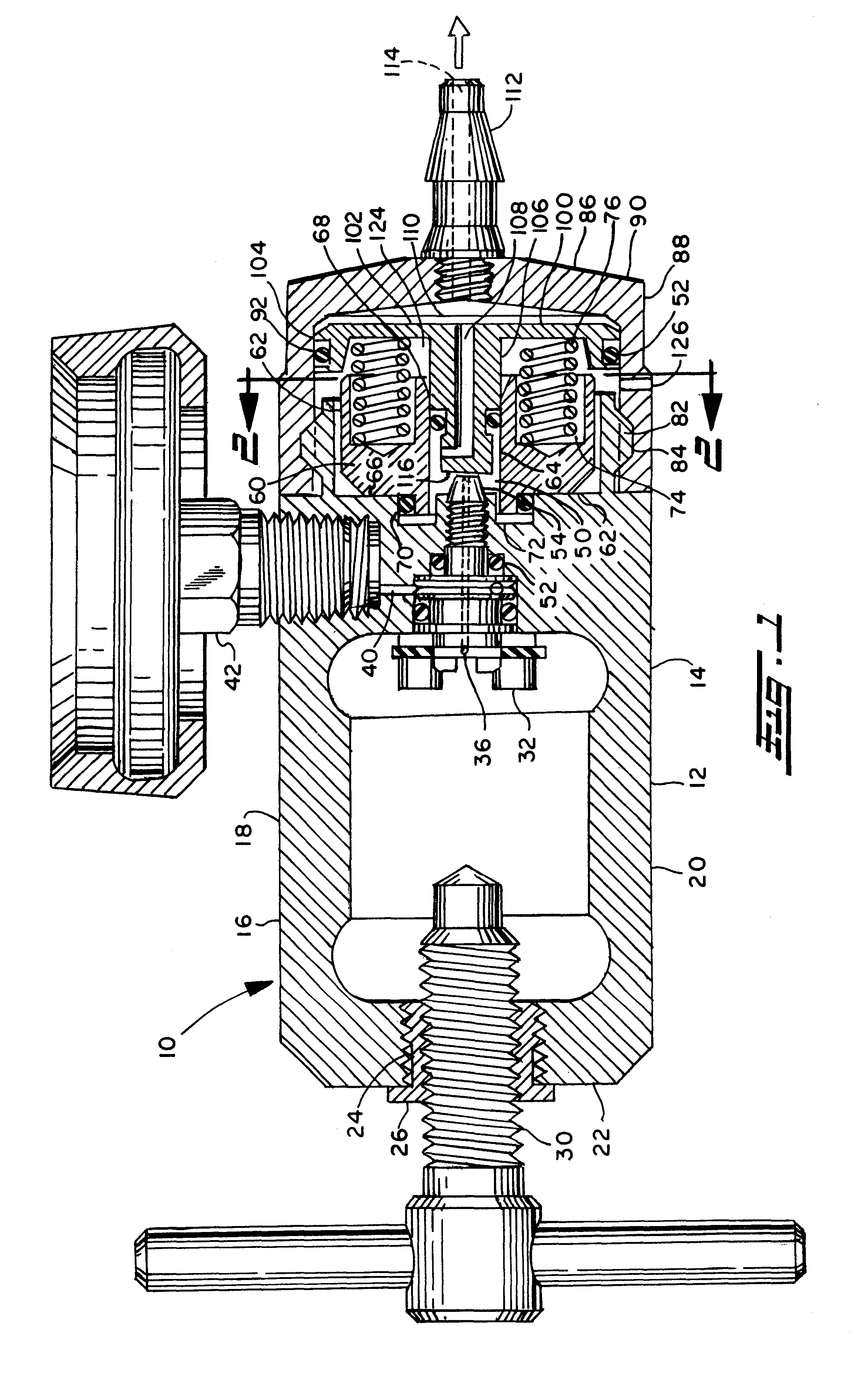

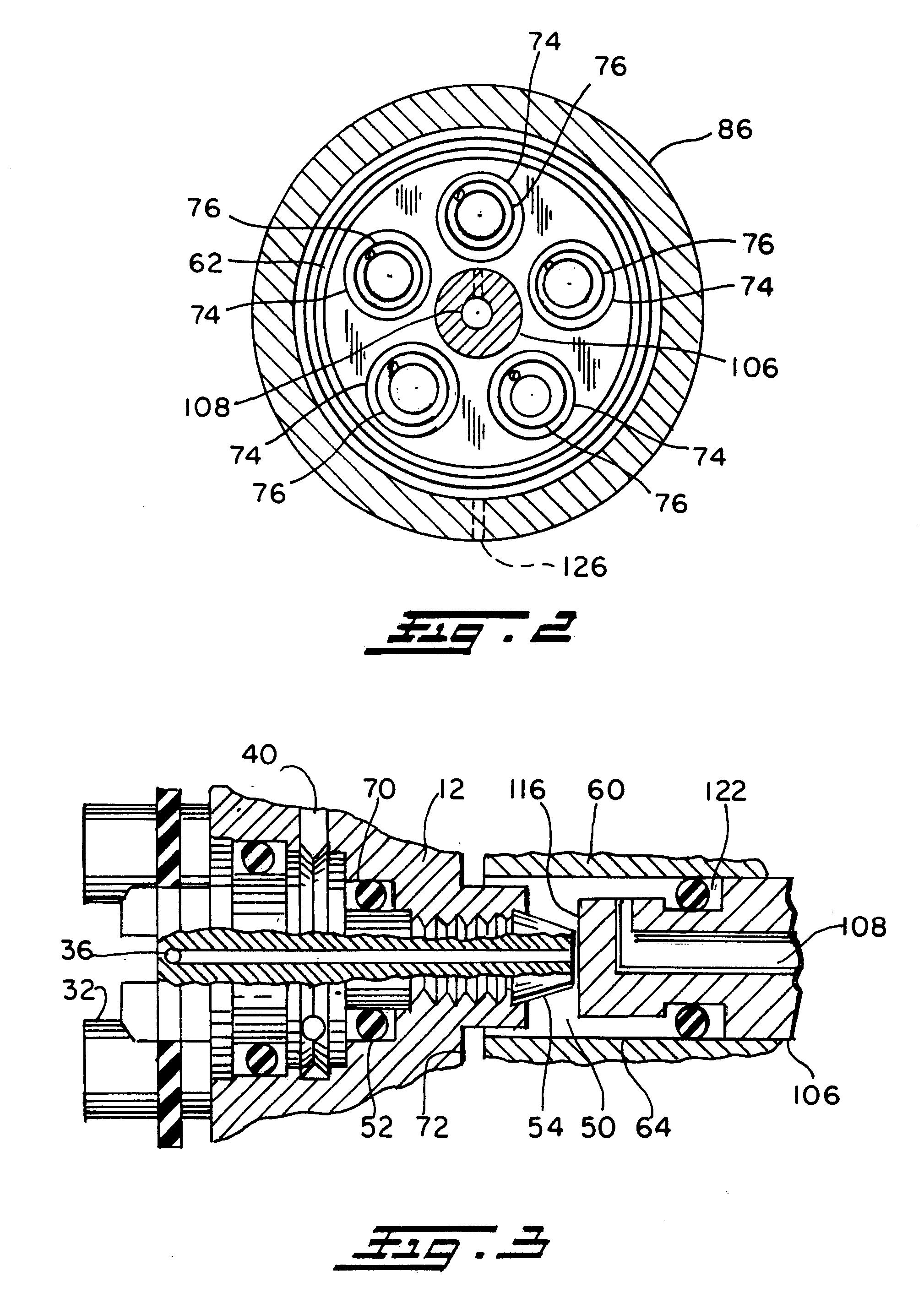

Five spring regulator

InactiveUS6484720B1Reduce manufacturing costEasy maintenanceRespiratory masksCheck valvesControl theoryPiston

Owner:APPLIED MARKETING

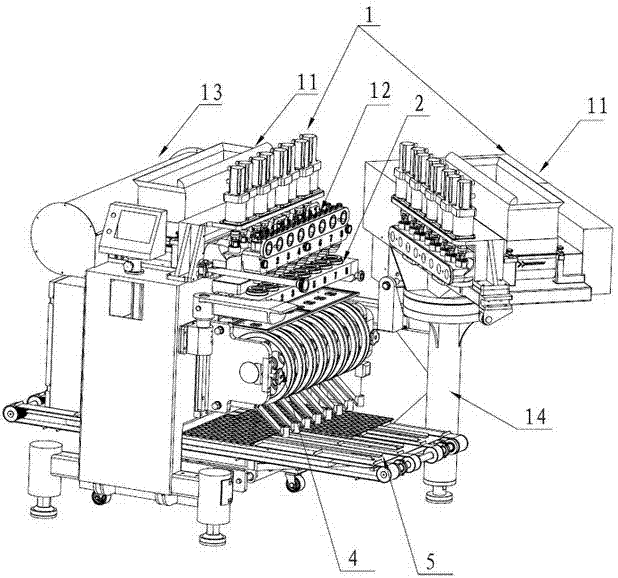

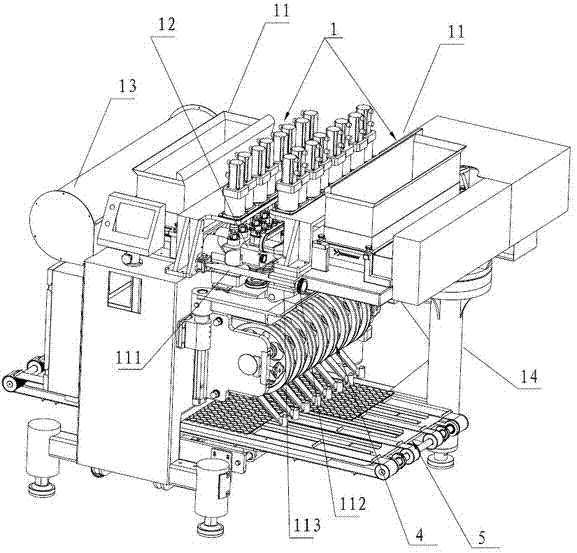

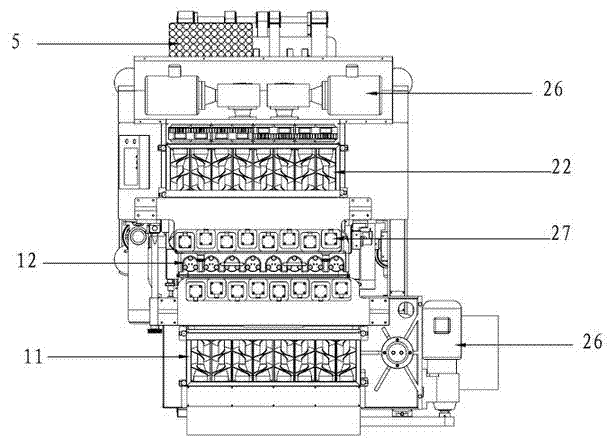

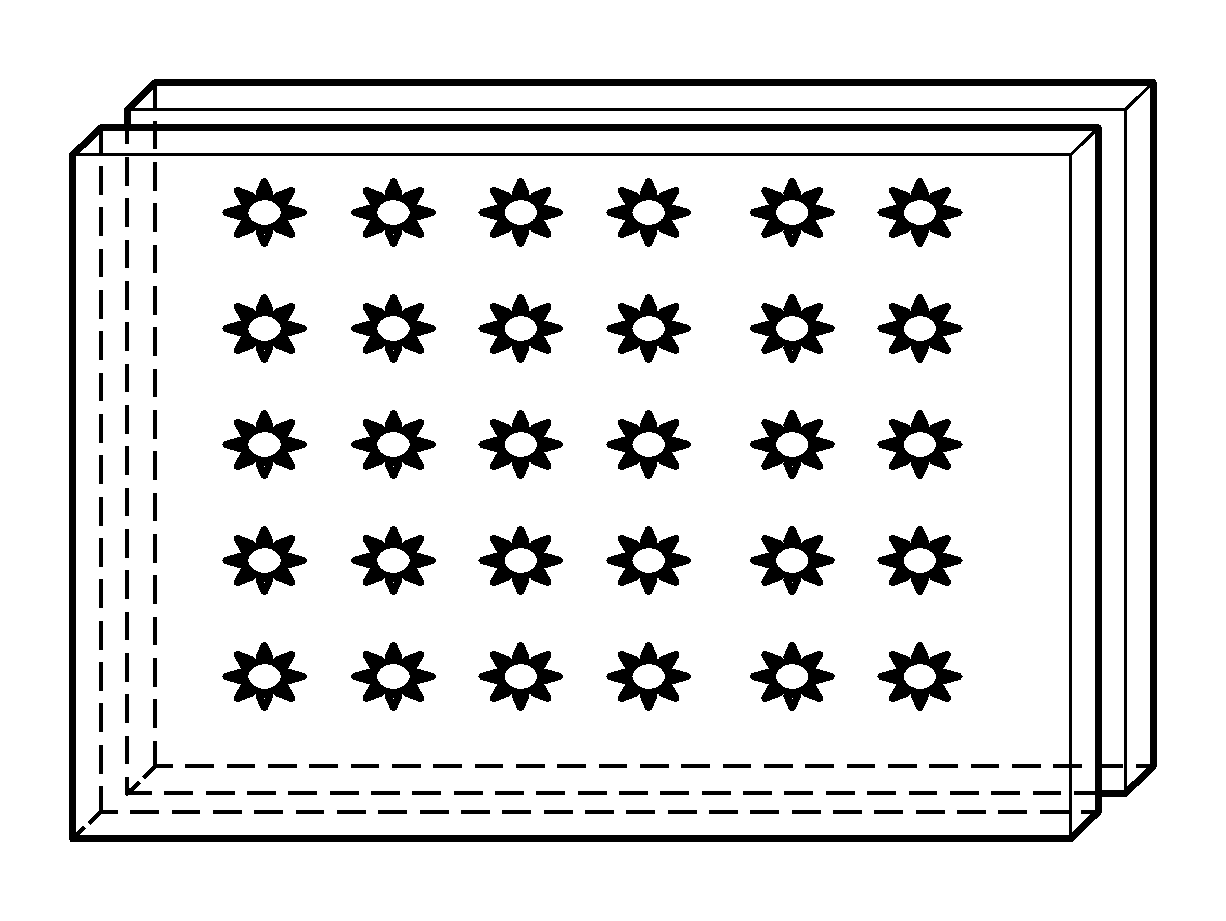

Molding method for food with round shape

ActiveCN102228305AEasy to disassembleEasy to installFood coatingFood shapingEngineeringIndependent feeding

The invention relates to the field of processing filling food, in particular to a molding method for food with round shape, comprising the following steps that: A, charging: skin and stuffing are added in feeding assemblies of a split type feeding system of a molding machine for food with round shape; B, compositing: the skin and stuffing of the feeding assembly are allowed to enter a skin-stuffing complex; C, cutting off: the skin and stuffing output by the skin-stuffing complex are cut off by a cutting assembly which is connected with a cutting lift assembly, the cutting assembly is driven by the cutting lift assembly to realize the cutting function and moving up and down simultaneously; D: ball-kneading: the cutting-off skin and stuffing are put into a ball-kneading device for kneading into balls; and E, discharging on the plate: the products obtained by ball-kneading are transferred to a discharging plate assembly from the ball-kneading device. According to the invention, the two independent feeding assemblies and the skin-stuffing complex have the advantages of simple disassembling and installation, when cleaning or maintaining the parts, only at least one feeding assembly needs be disassembled from the skin-stuffing complex to carry out the cleaning and the maintenance. Because the disassembling is realized by simple rotation, the present disassembling mode is simplified with saving the disassembling time and improving the work efficiency.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

Light output device

ActiveUS20100265707A1Improve uniformityImprove evenlyPlanar light sourcesPoint-like light sourceOptoelectronicsOutput device

A light output device comprises at least one light source having a light source output comprising at least a light output, and a switchable member through which the light output is provided, and which is switchable between at least two optical states. These at least two opticalstates provide different levels of uniformity of the light output. The switching of the switchable member is induced by the light source output.

Owner:SIGNIFY HLDG BV

Bussed haptic actuator system and method

ActiveUS9836123B2Avoid or resolve address conflictsReduced pin countInput/output for user-computer interactionEnergy efficient ICTActuatorControl theory

A bussed haptic actuator system includes a plurality of haptic actuators and a master control subsystem. Each haptic actuator includes a memory with an address storable therein and a slave controller subsystem configured to control the actuator in response to a received command signal. The master control subsystem is connected via a bus to the plurality of haptic actuators. The master control subsystem includes sequencer configured to determine which of the plurality of haptic actuators are to be activated and logic configured to provide, on the bus, a command signal including one or more addresses corresponding to haptic actuators to be activated as determined by the sequencer.

Owner:MIDE TECH

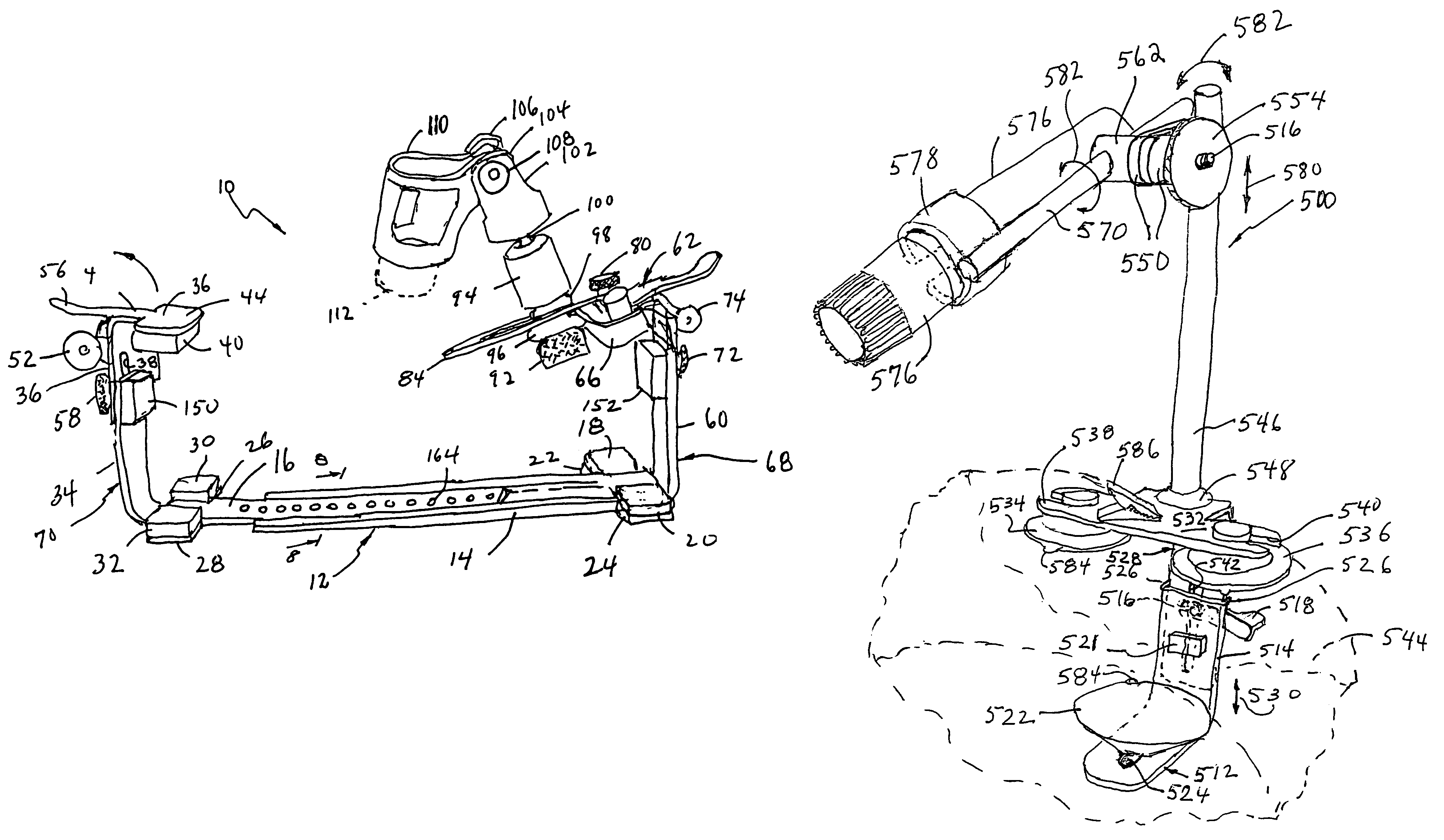

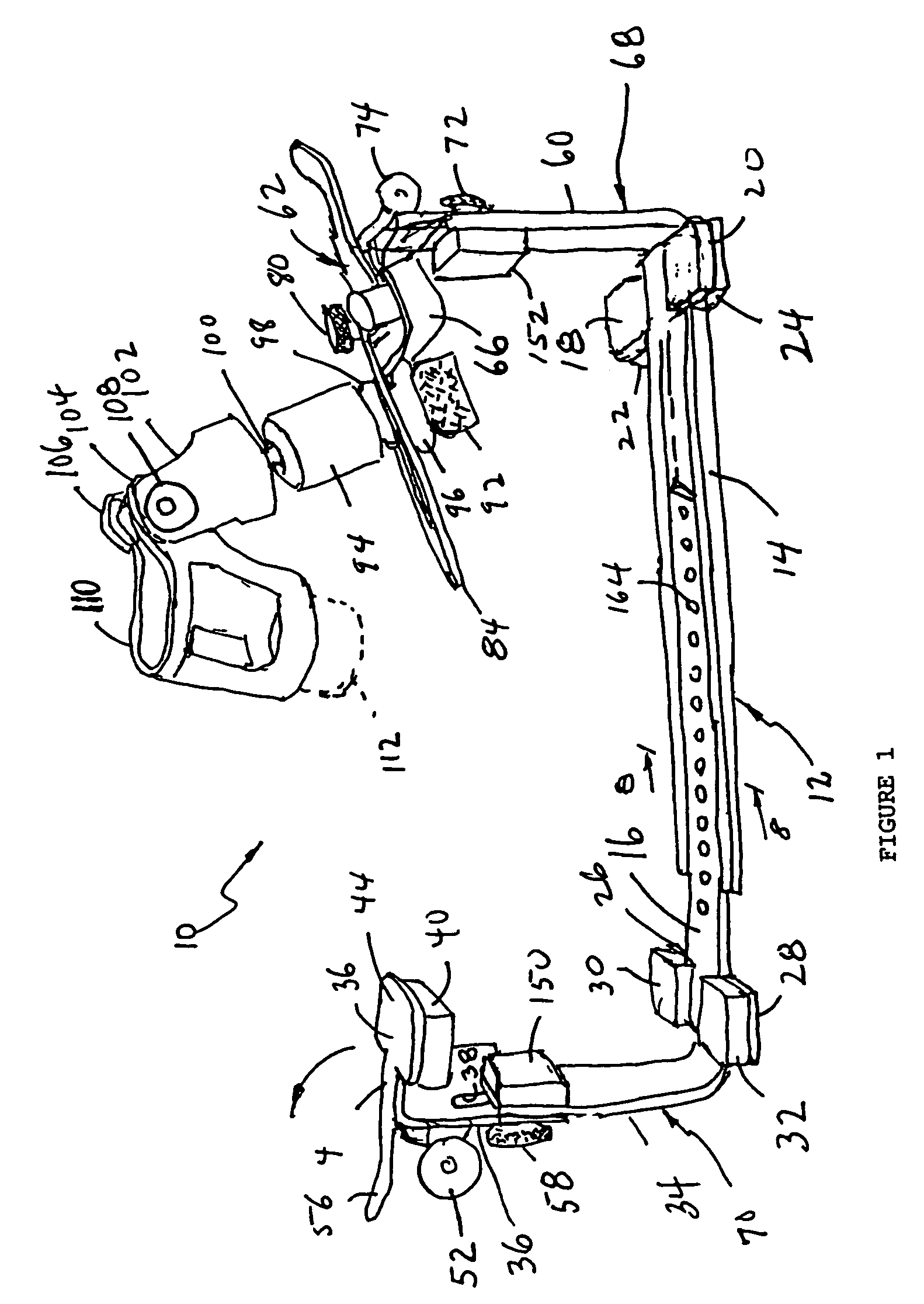

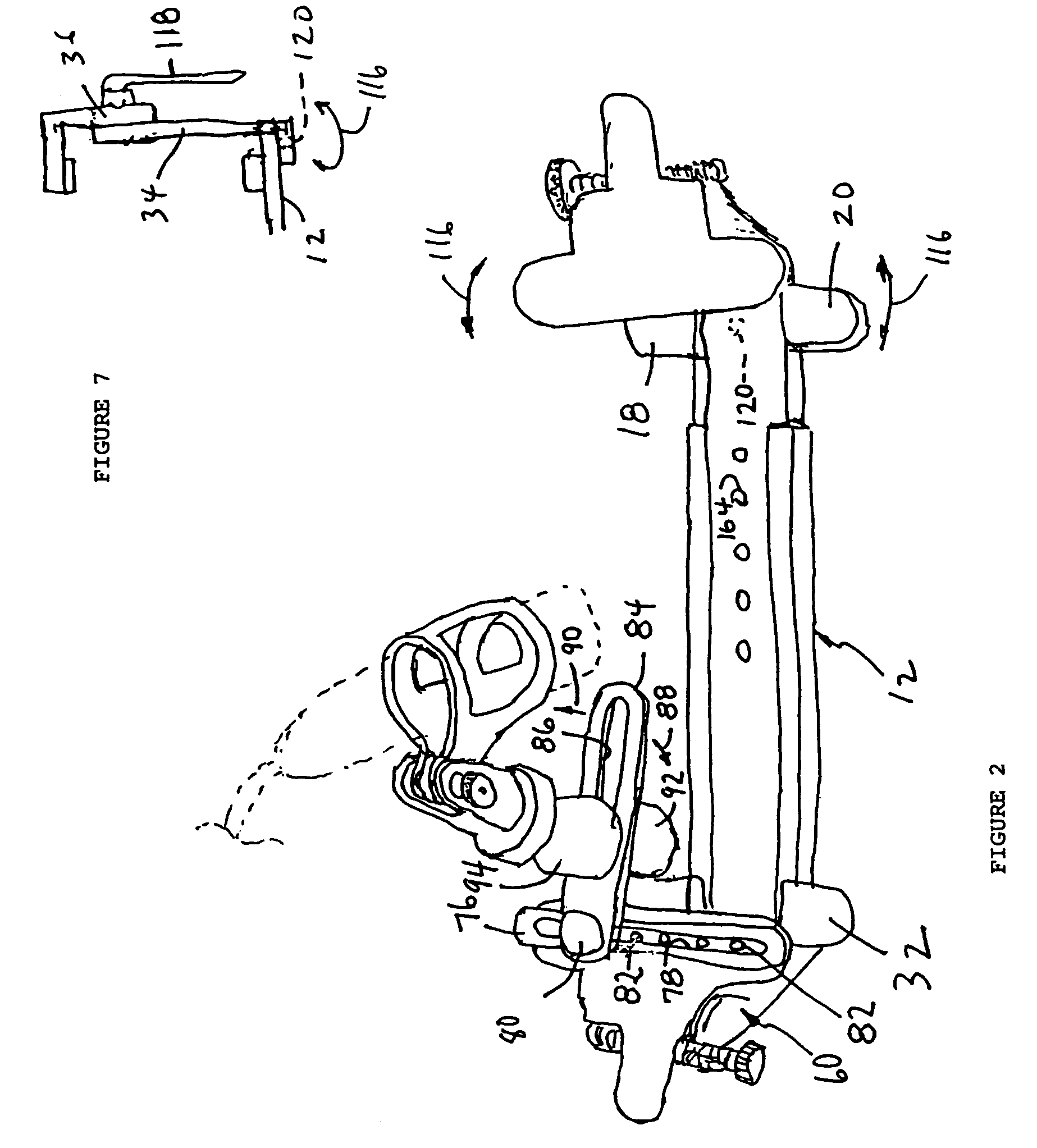

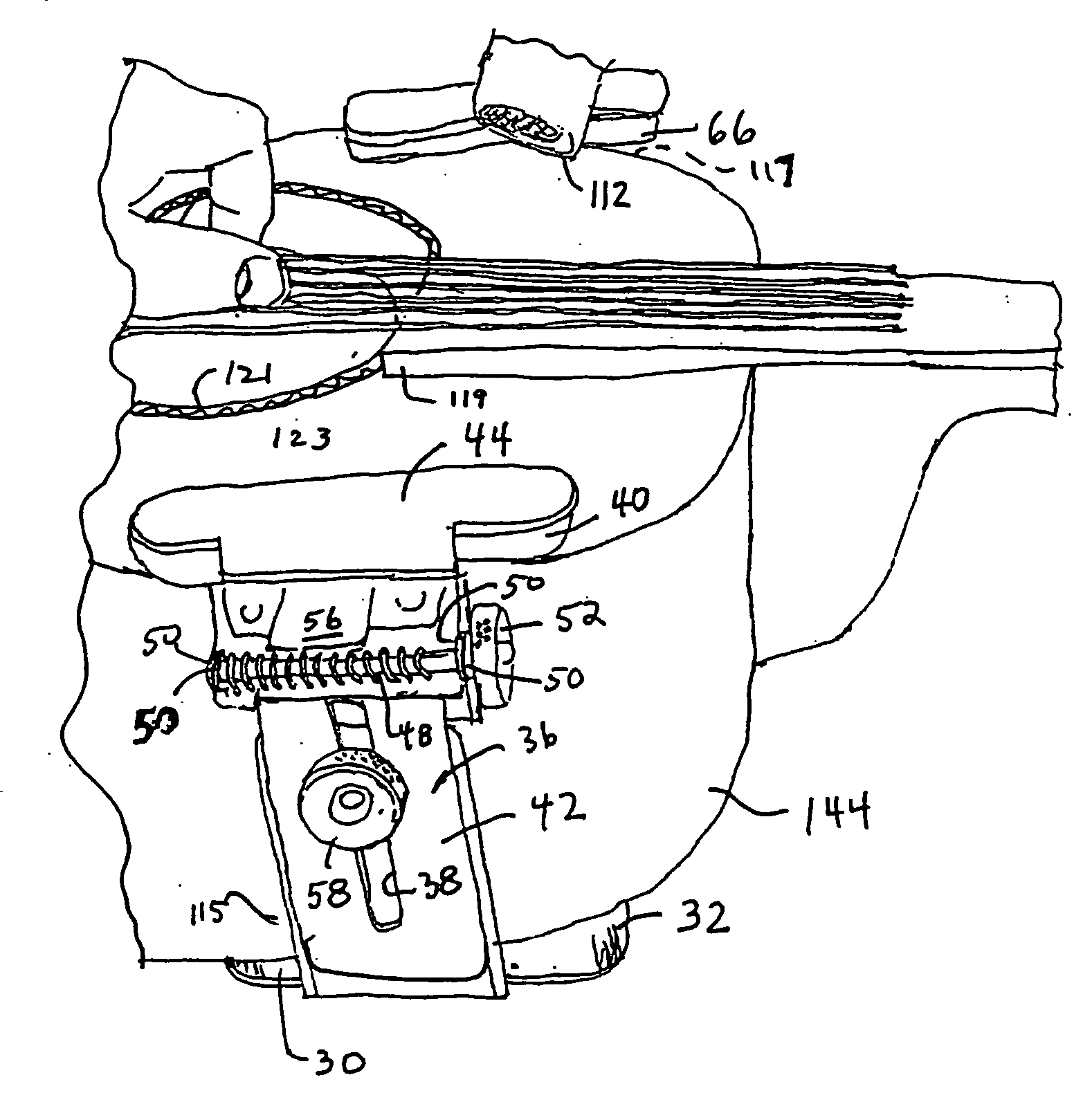

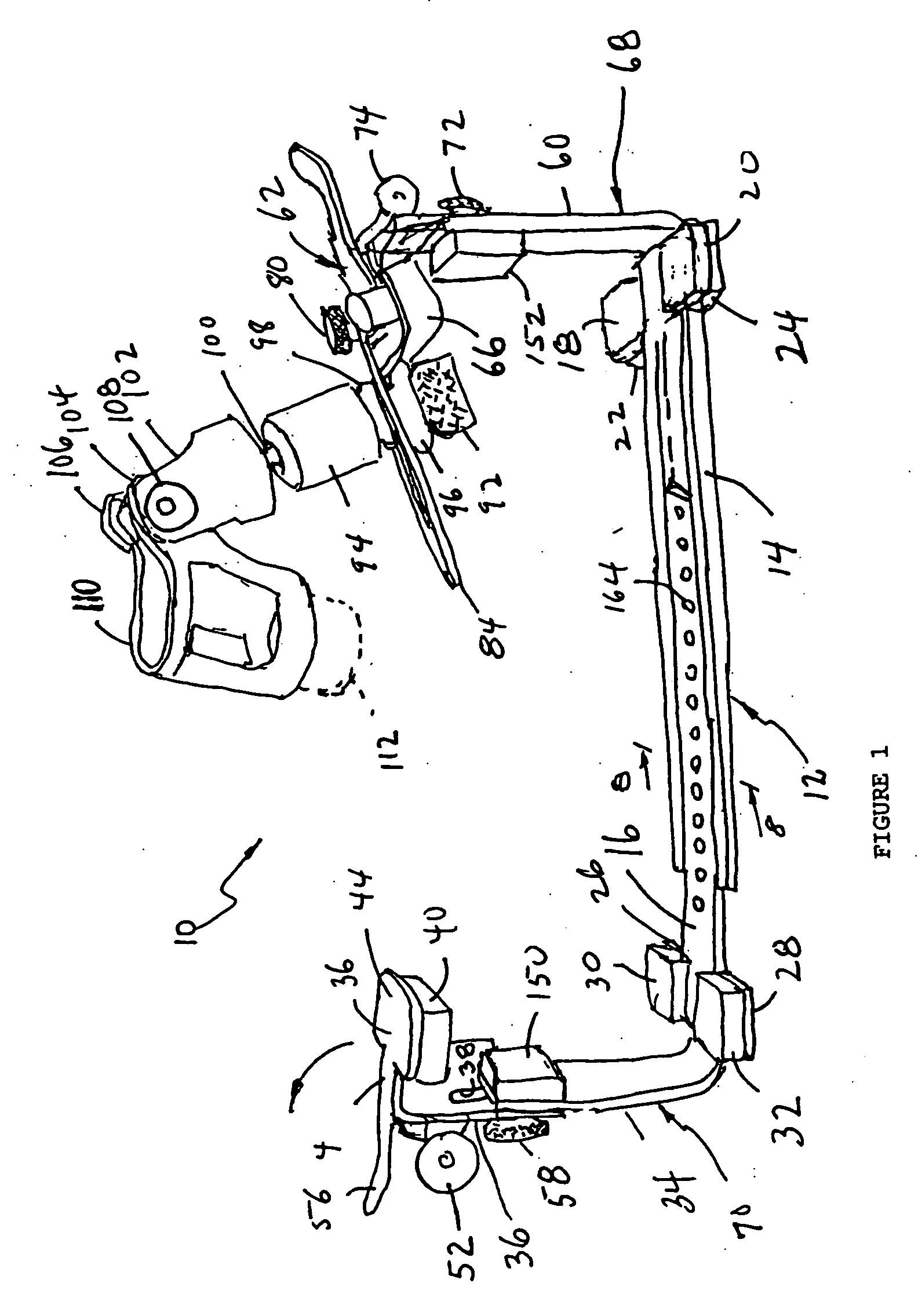

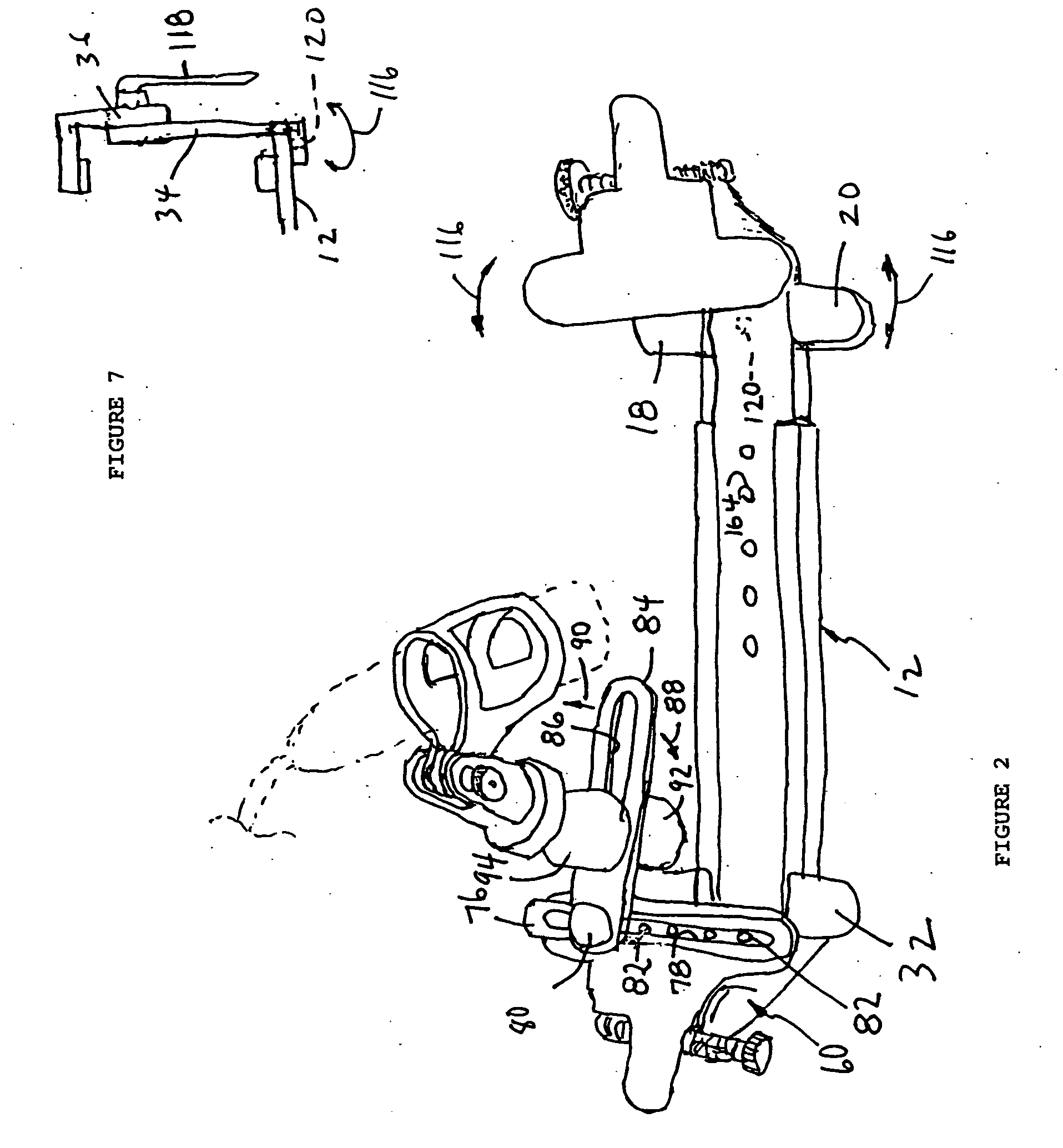

Acoustic microphone support bracket

InactiveUS7390950B2Uniform outputMinimize distortionStringed musical instrumentsMouthpiece/microphone attachmentsResonanceEngineering

A stringed instrument microphone which is particularly optimized for many players of stringed instruments is disclosed. Uniformity and faithfulness of the electrical output is provided by employing a high-quality microphone mounted by a fraction to the sound box at a fixed position in which it does not interfere with the playing of the instrument. At the same time gone variation of this position is accommodated with a structure which maintains position rigorously. This is important because infinitesimally small variations in position will produce clearly audible distortions. In accordance with the invention it has been discovered that such variations may be caused, among other factors, by vibration of the sound box, a flexible or otherwise displaceable bracket structure and resonance in the bracket. The present invention optimizes the solution by providing a mounting configuration, multiple bracket material selections and arrangements, microphone characteristics and bracket configuration which cooperate to minimize distortions.

Owner:HOLLANDER RYAN S

Acoustic microphone support bracket

InactiveUS20070144329A1Minimize distortionUniform outputStringed musical instrumentsMouthpiece/microphone attachmentsDistortionMicrophone

A stringed instrument microphone which is particularly optimized for many players of stringed instruments is disclosed. Uniformity and faithfulness of the electrical output is provided by employing a high-quality microphone mounted by a fraction to the sound box at a fixed position in which it does not interfere with the playing of the instrument. At the same time gone variation of this position is accommodated with a structure which maintains position rigorously. This is important because infinitesimally small variations in position will produce clearly audible distortions. In accordance with the invention it has been discovered that such variations may be caused, among other factors, by vibration of the sound box, a flexible or otherwise displaceable bracket structure and resonance in the bracket. The present invention optimizes the solution by providing a mounting configuration, multiple bracket material selections and arrangements, microphone characteristics and bracket configuration which cooperate to minimize distortions.

Owner:HOLLANDER RYAN S

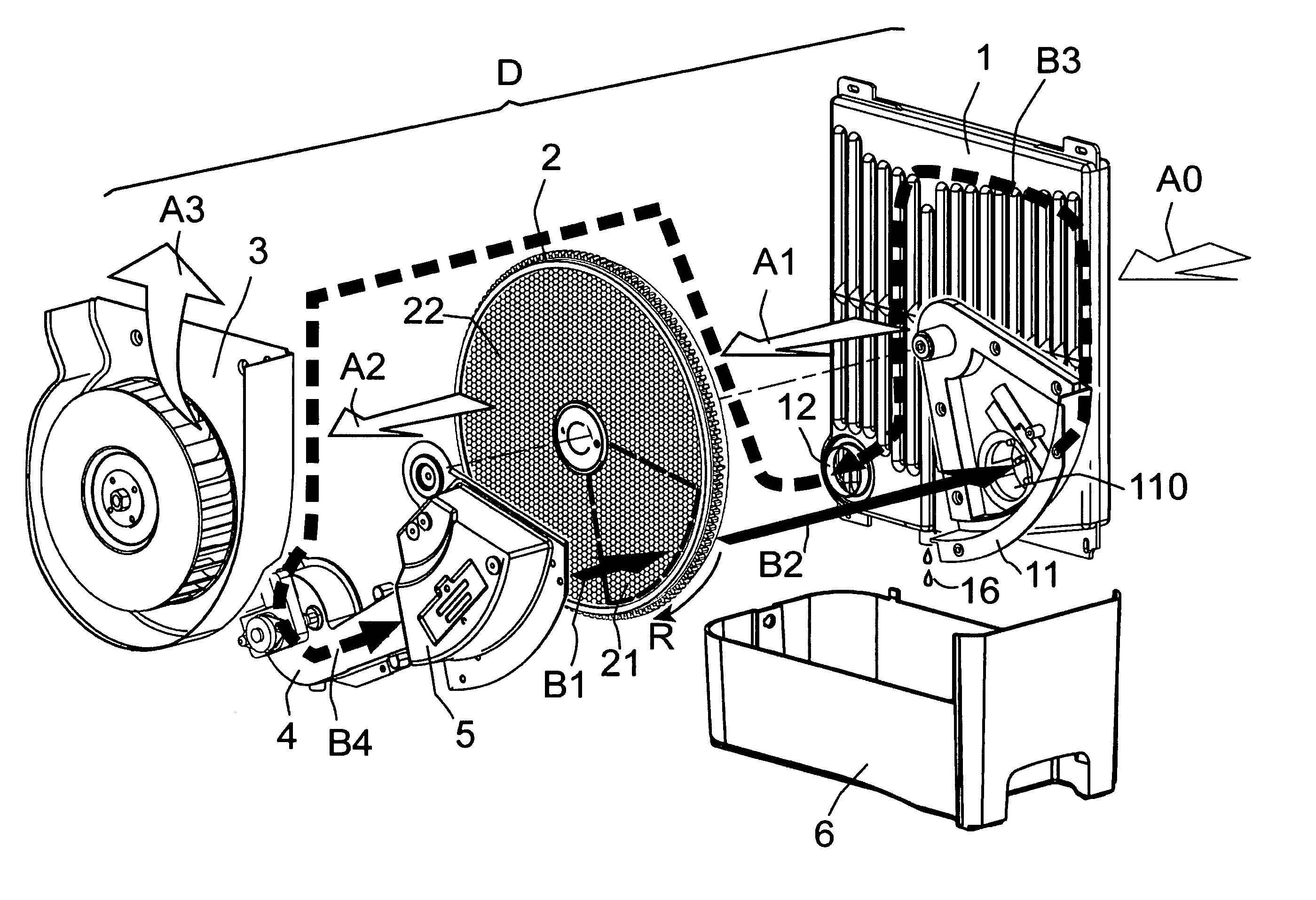

Heater device for desiccant rotor dehumidifier

InactiveUS7050707B1Avoid heat lossUniform airflow outputAir treatment detailsElectric heating systemDesiccantEngineering

A heater device applied in a desiccant rotor dehumidifier for supplying regeneration hot air to the desiccant rotor comprises a metal case having an air inlet and an air outlet; heating elements supported by insulative material and mounted adjacent to the desiccant rotor; and an insulative plate installed in parallel to the heating elements and parting the heating elements with the air inlet. The insulative plate is formed with a plurality of via holes suitably distributed for the intake air coming from the air inlet passing through, being heated by the heating elements and evenly passing the desiccant rotor through the air outlet. The insulative plate also splits and bypasses a part of the intake air to cool down the desiccant rotor that has been heated and regenerated.

Owner:NORM PACIFIC AUTOMATION

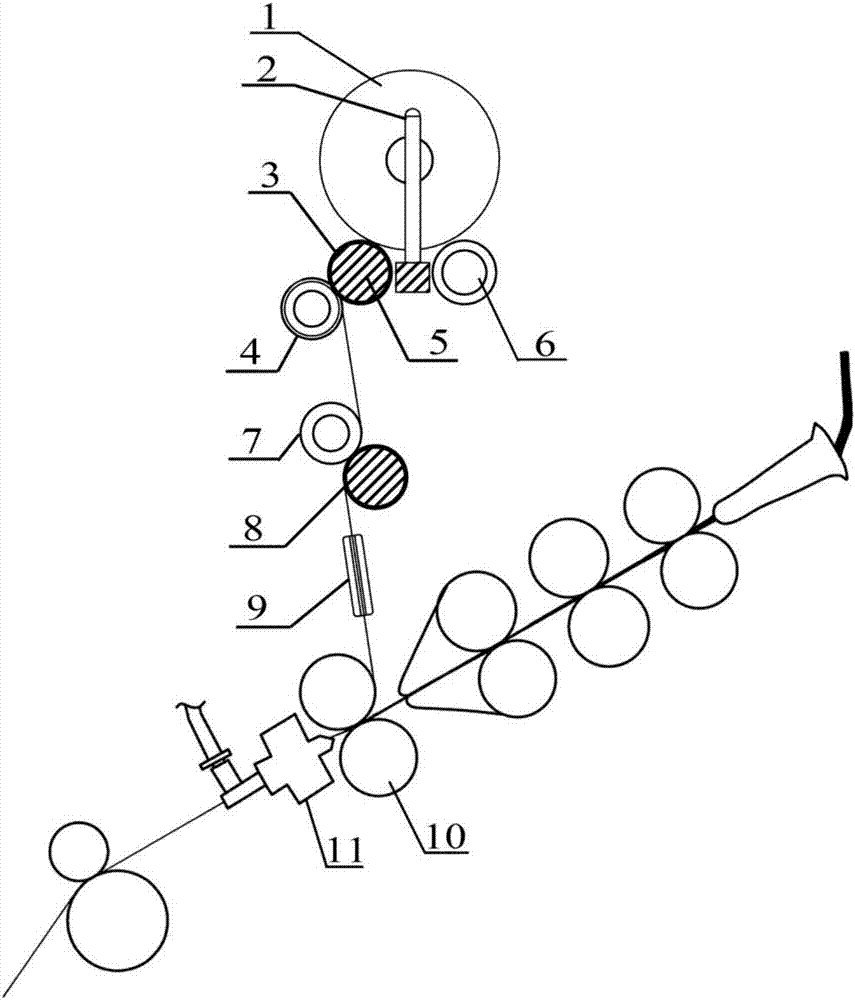

Compound vertex spinning method for film silkening

ActiveCN107059186AUniform outputHigh strengthContinuous wound-up machinesOpen-end spinning machinesMicro nanoFiber

The invention relates to a compound vertex spinning method for film silkening, pertaining to the technical field of weaving. A film cutting drafting device is arranged above a front roller pulling jaw of each drawing mechanism of a vortex flow spinner. A cutting region is formed between a cutting-endurable ring and a cutting roller of a film placing and cutting device. Uniformly-expanded stripped-shaped multifilaments are cut and silken to form a film. The conventional linear discharge and filamentation method for spinneret holes is changed. The multifilaments are drafted and thinned through a first drafting region and a second drafting region to form improved and thinned micro-nano strands. The micro-nano strands of multifilaments and short fibers outputted out of a drafting region of the vortex flow spinner are fully mixed. Short fiber heads of fiber strands clamped by strands enter a hollow yarn-guiding channel of a static spindle of a vortex spinner. The tail ends of short fibers are wounded around strands and short fiber head ends so that vortex compound yarns are formed with micro-nano strands uniformly mixed with the short fibers. The difficulty that filaments, nanofibers and conventional staple fibers are difficult to be mixed uniformly and twisted during vortex compound spinning is solved. Therefore, a film industry and a weaving industry are effectively merged.

Owner:WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com