Patents

Literature

4931results about "Food coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

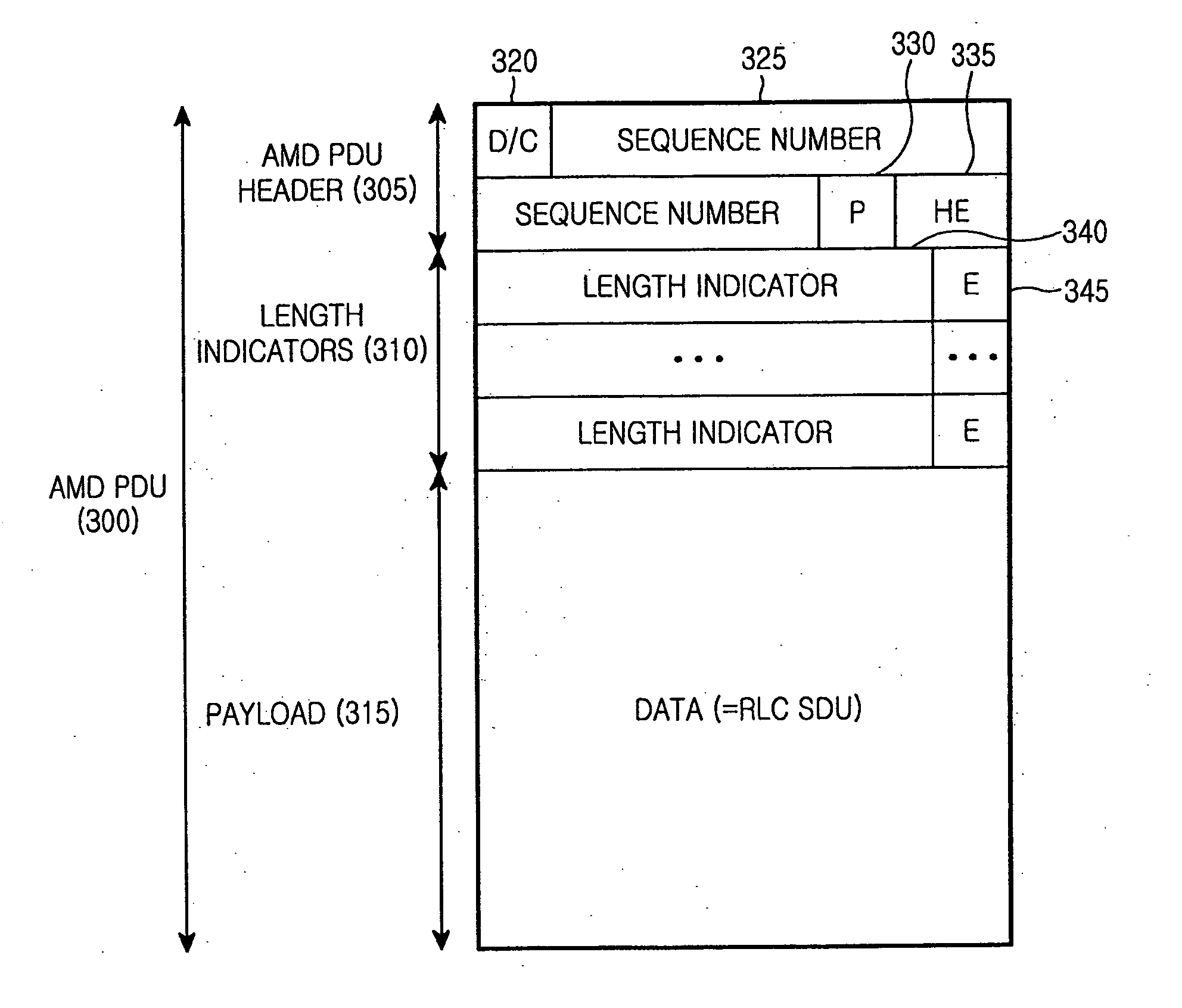

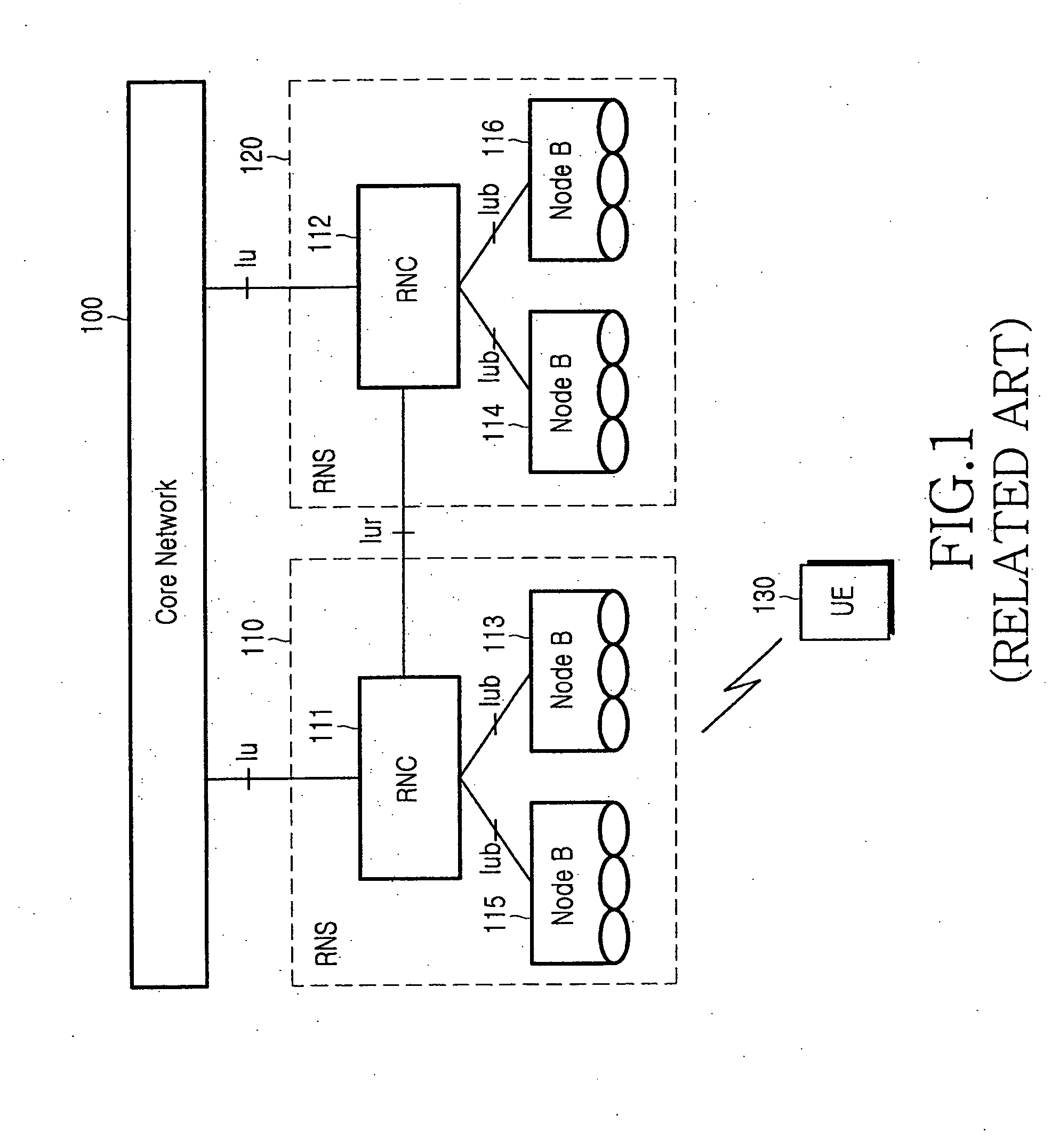

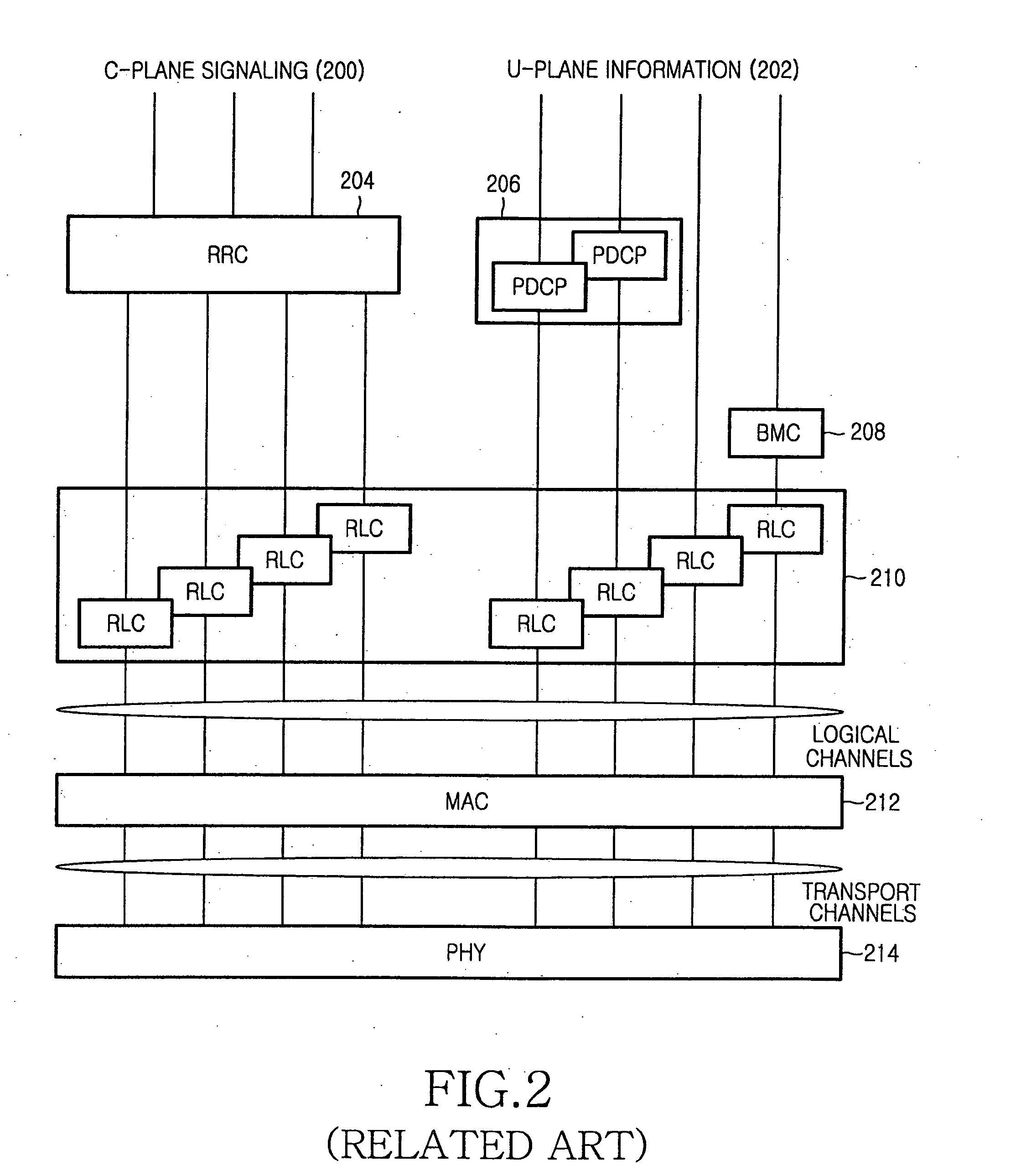

Method and apparatus for requesting/transmitting status report of a mobile communication system

InactiveUS20060251105A1Reducing excessive retransmission delayError preventionNetwork traffic/resource managementCommunications systemMobile communication systems

A method and apparatus are provided for reducing excessive retransmission delays which may occur due to the loss of the last packet of a transmission buffer in a Radio Link Control (RLC) layer of a mobile communication system. The method includes receiving a Service Data Unit (SDU) from a higher layer, dividing the SDU into a plurality of Packet Data Units (PDUs), and storing the PDUs in a buffer, setting a poll bit for a last PDU from among the PDUs stored in the buffer, the poll bit requesting a status report, and repeatedly transmitting the last PDU having the setup poll bit at least twice from a sender to a receiver, regardless of whether there is a request for retransmission of the last PDU.

Owner:SAMSUNG ELECTRONICS CO LTD

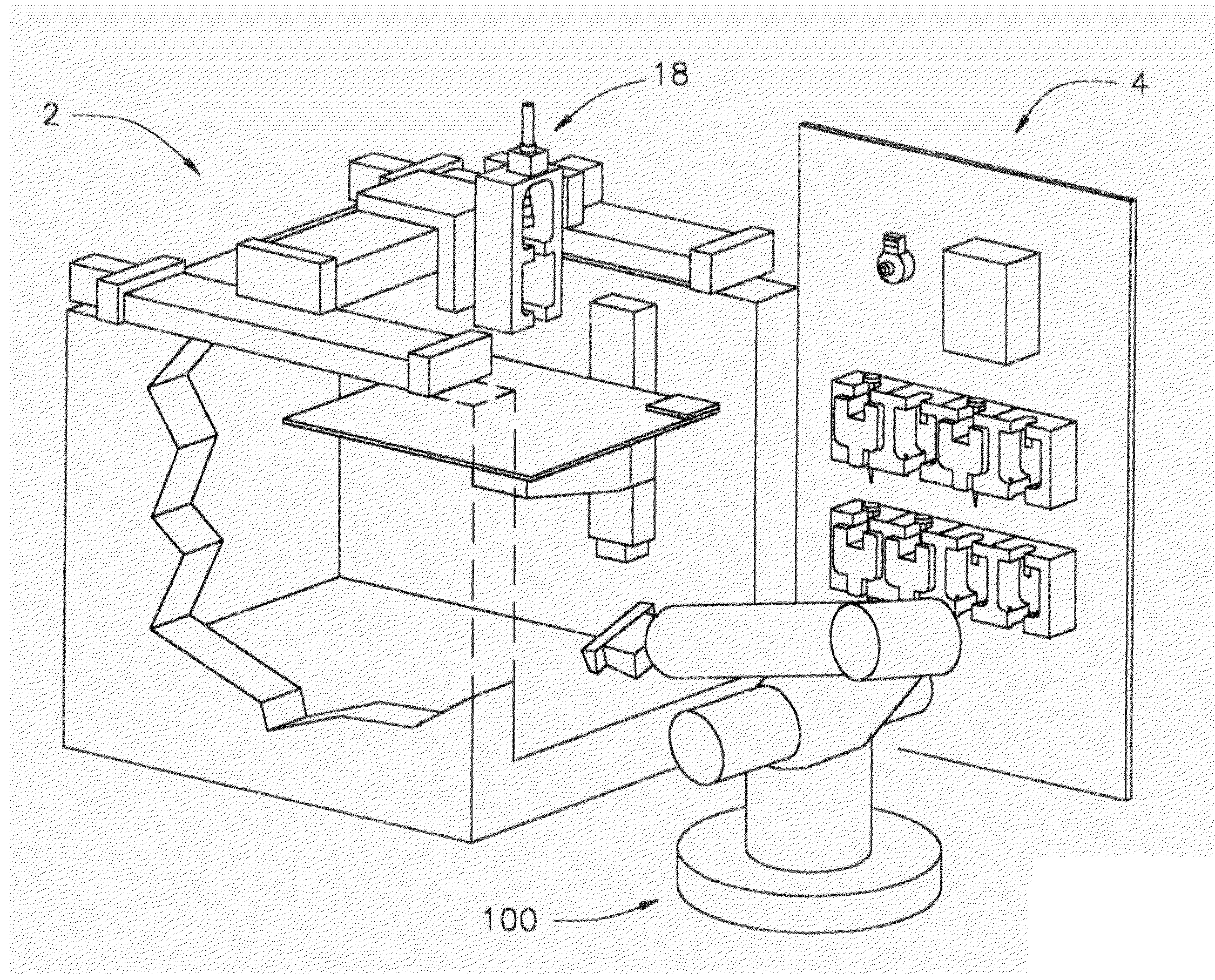

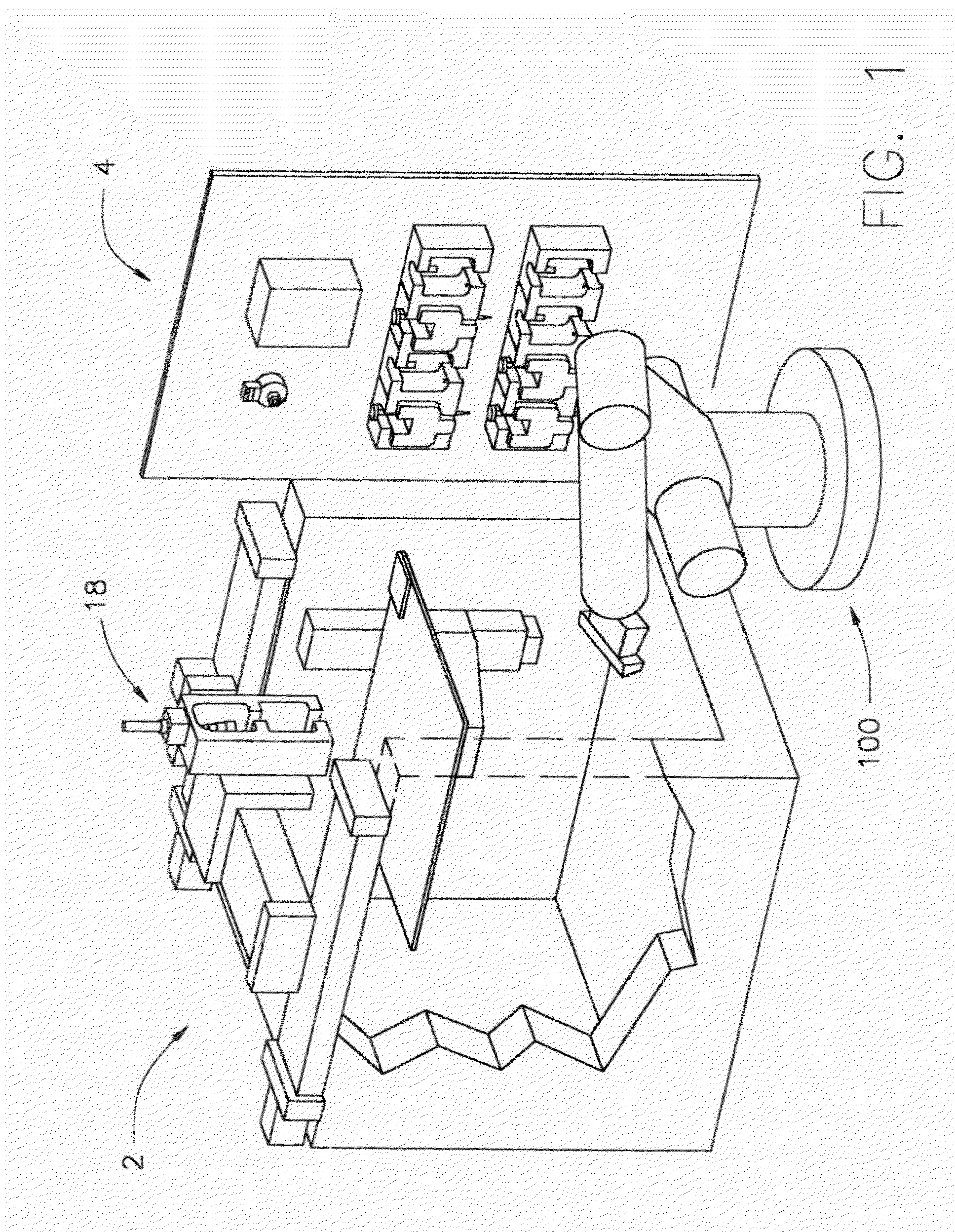

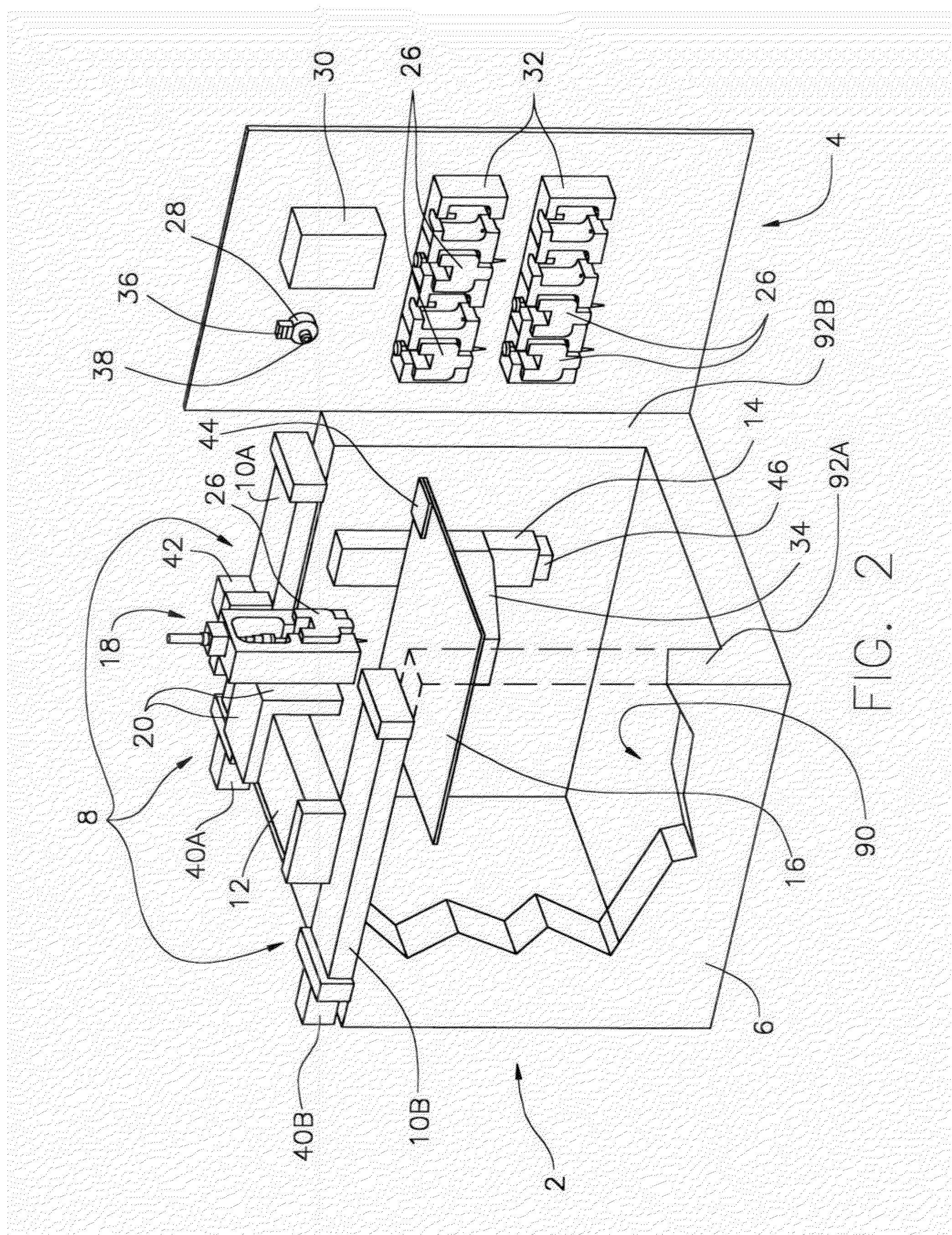

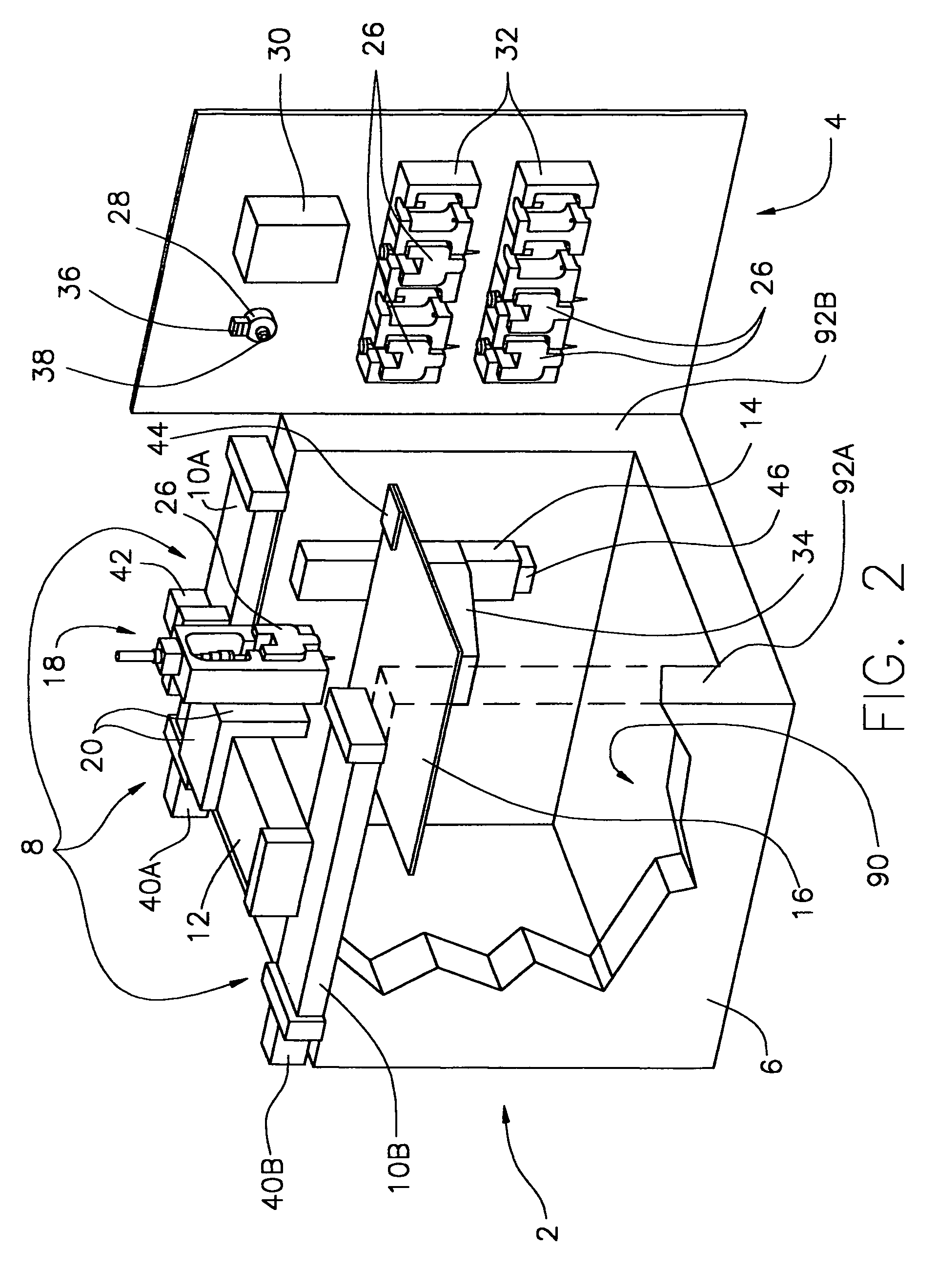

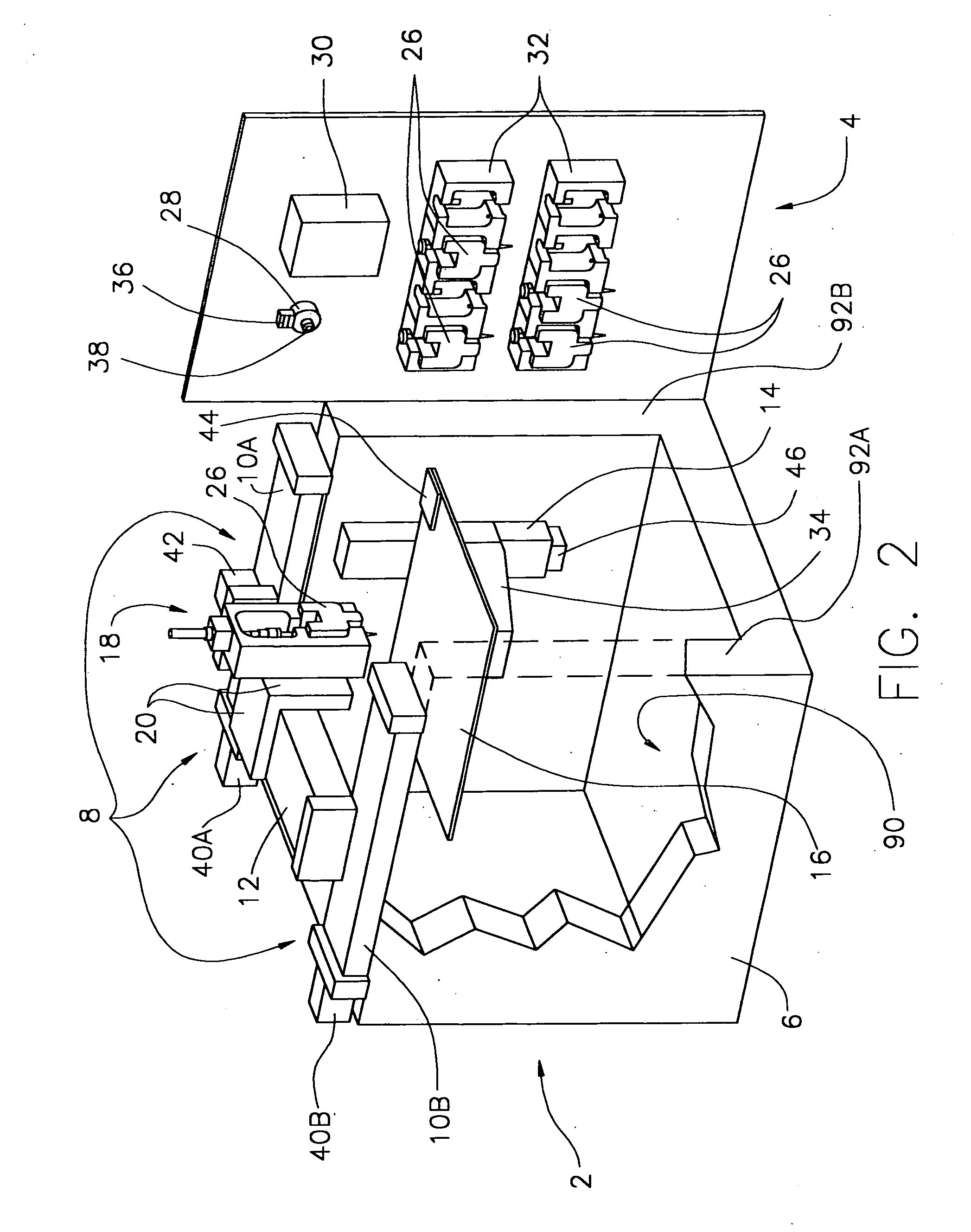

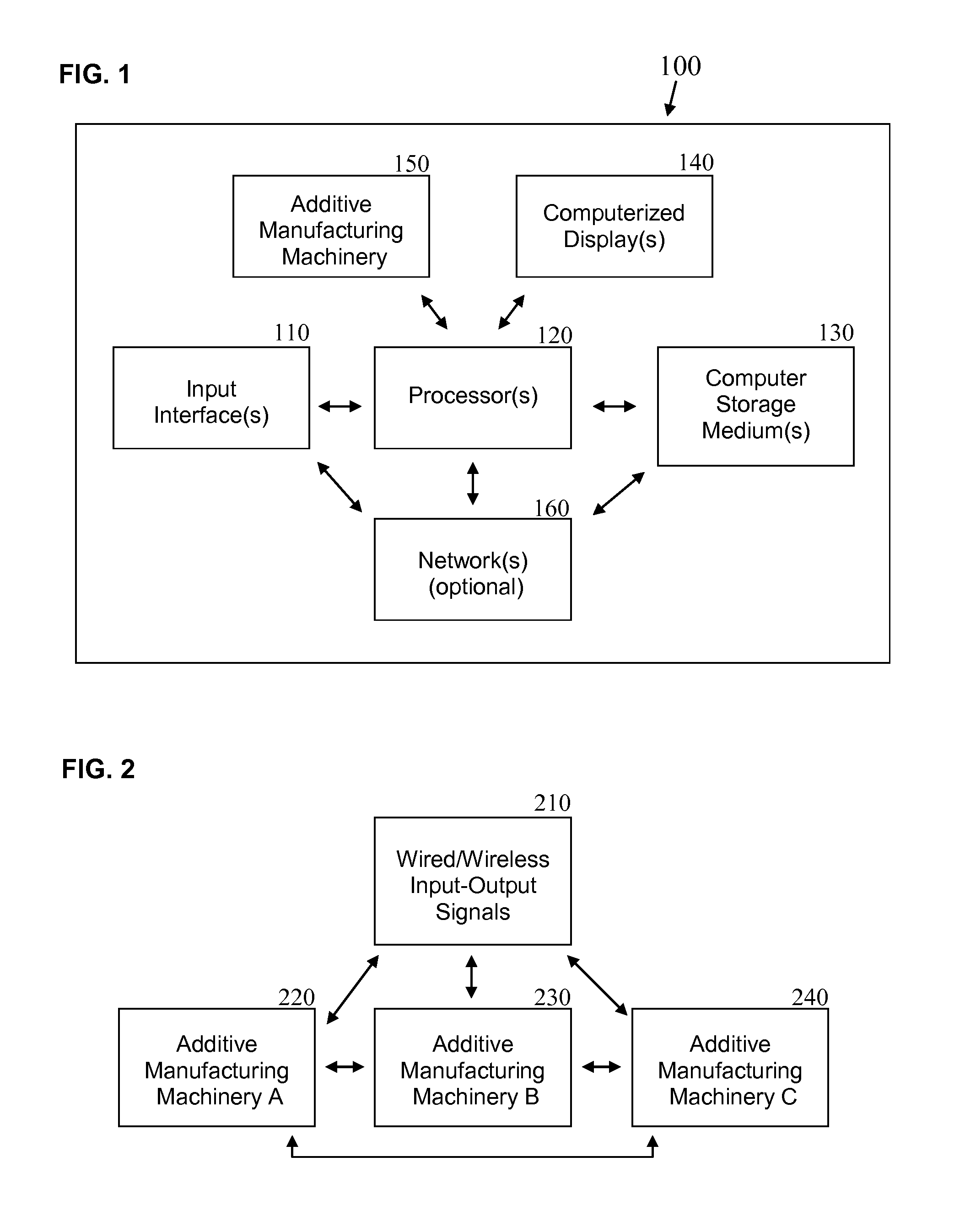

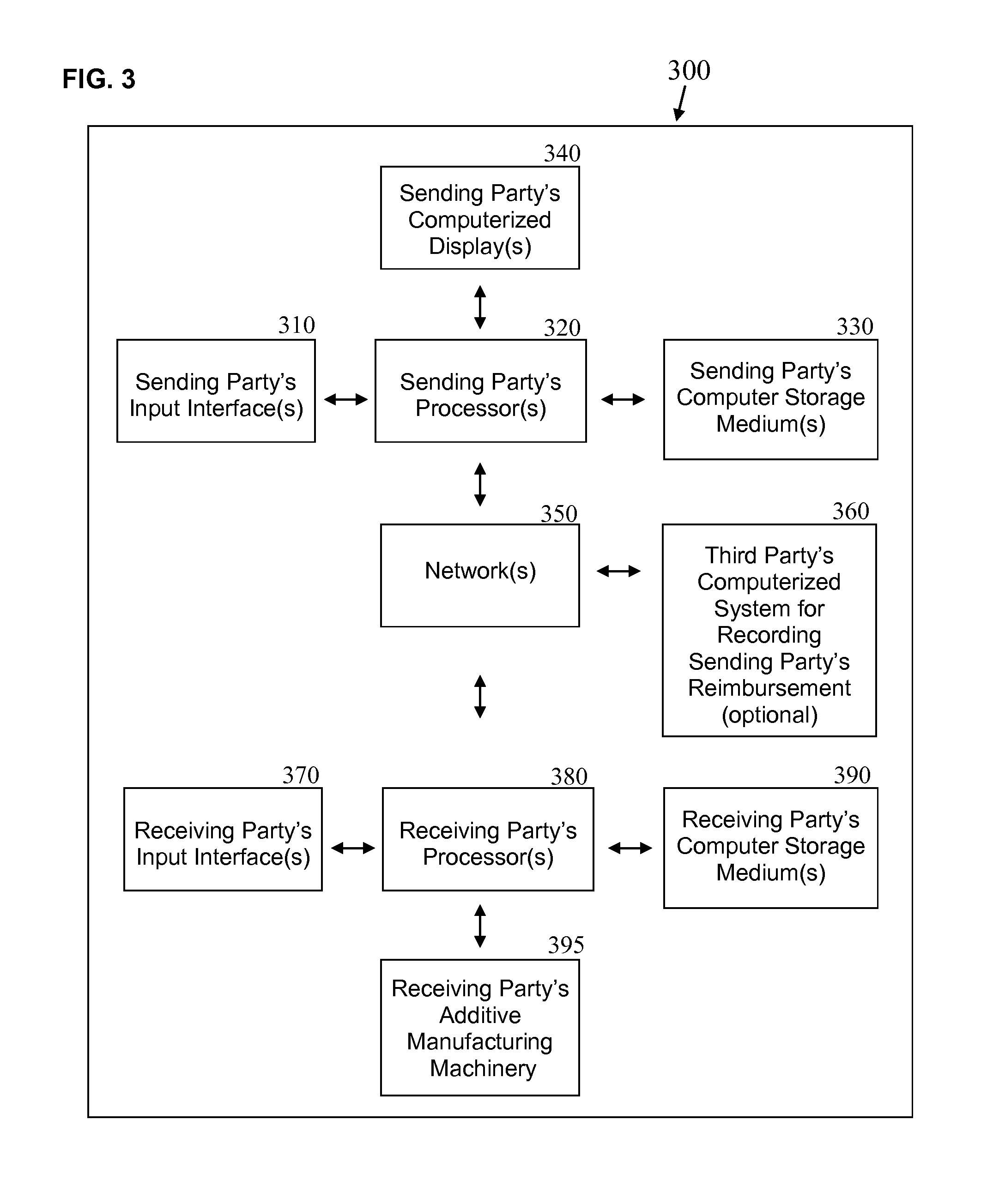

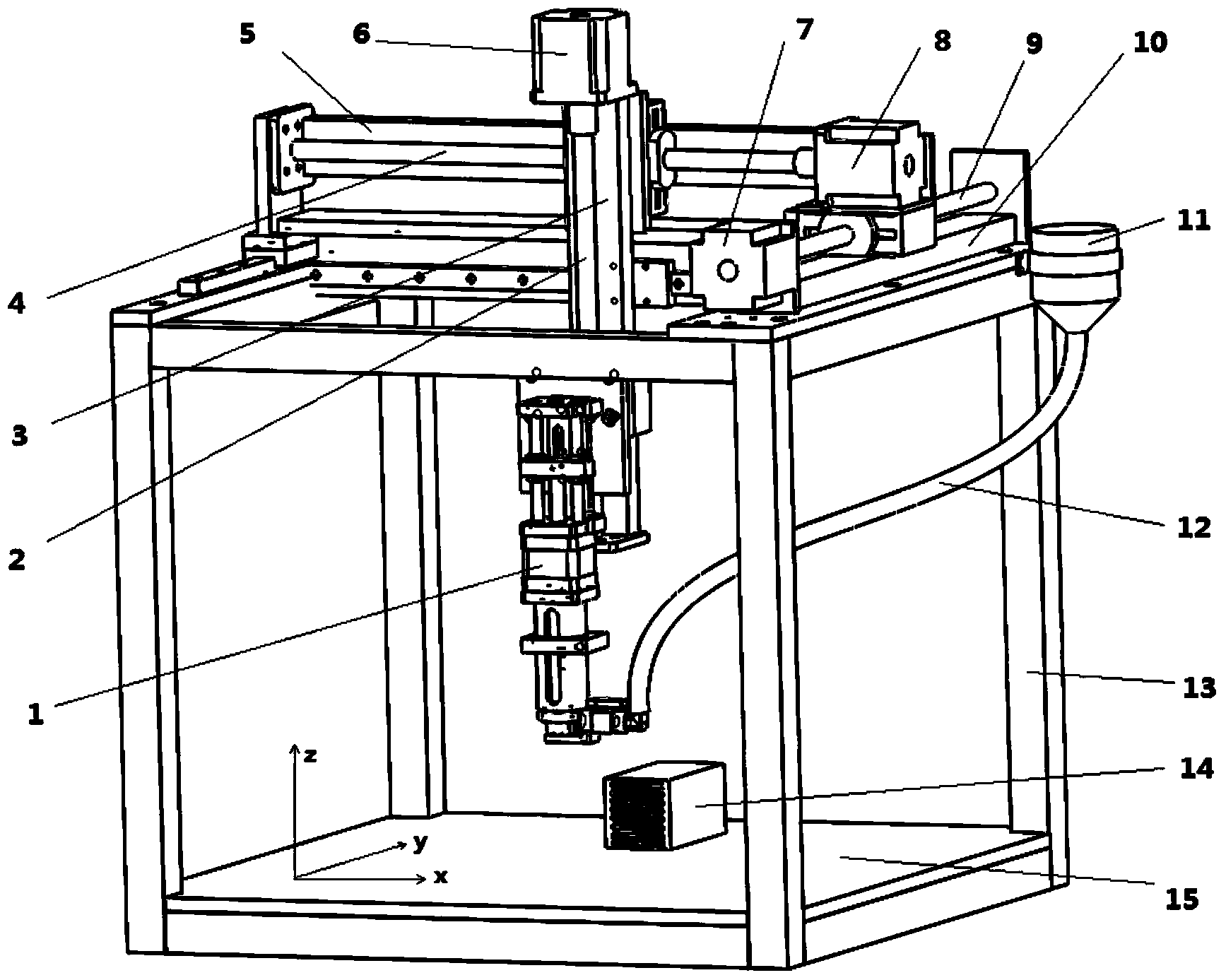

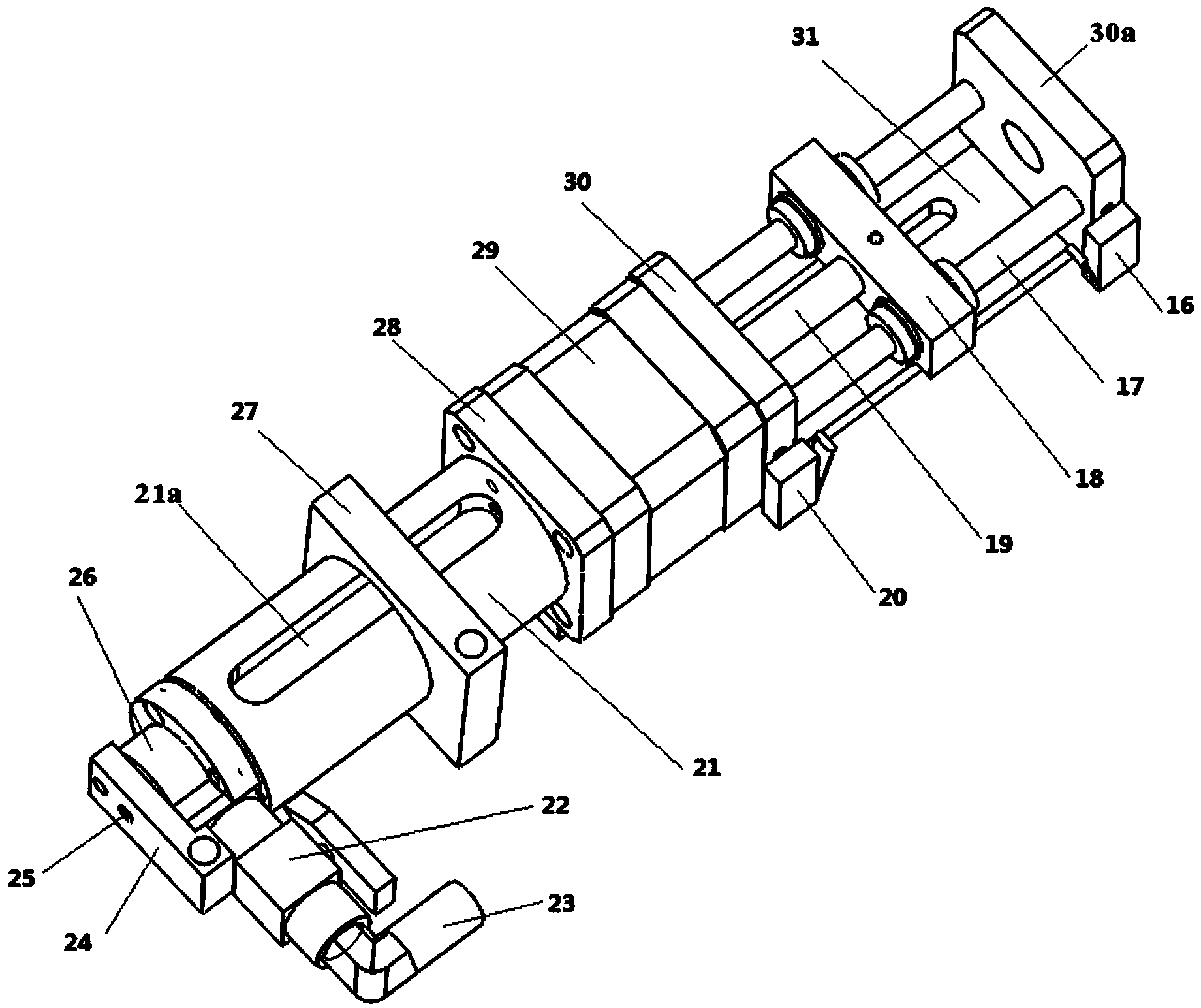

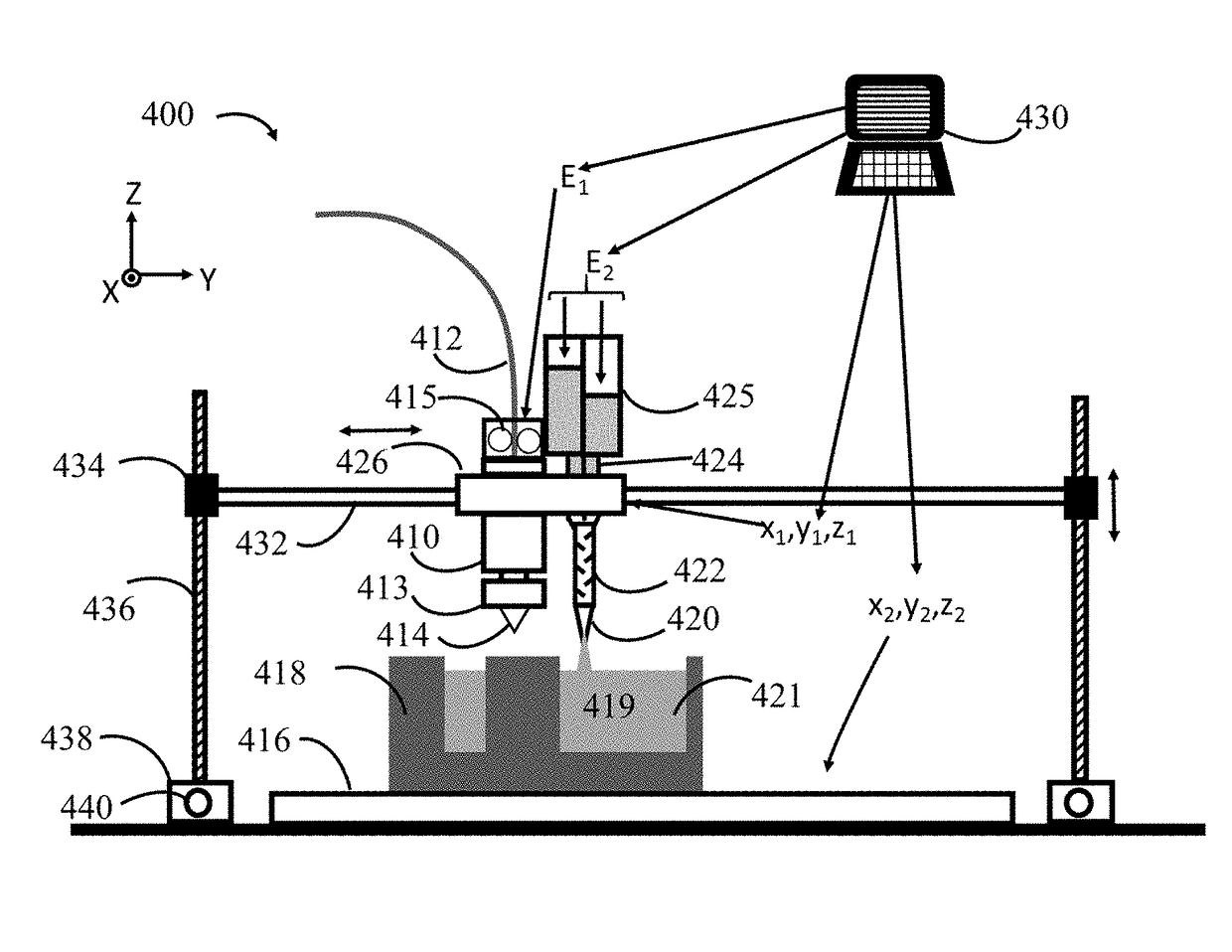

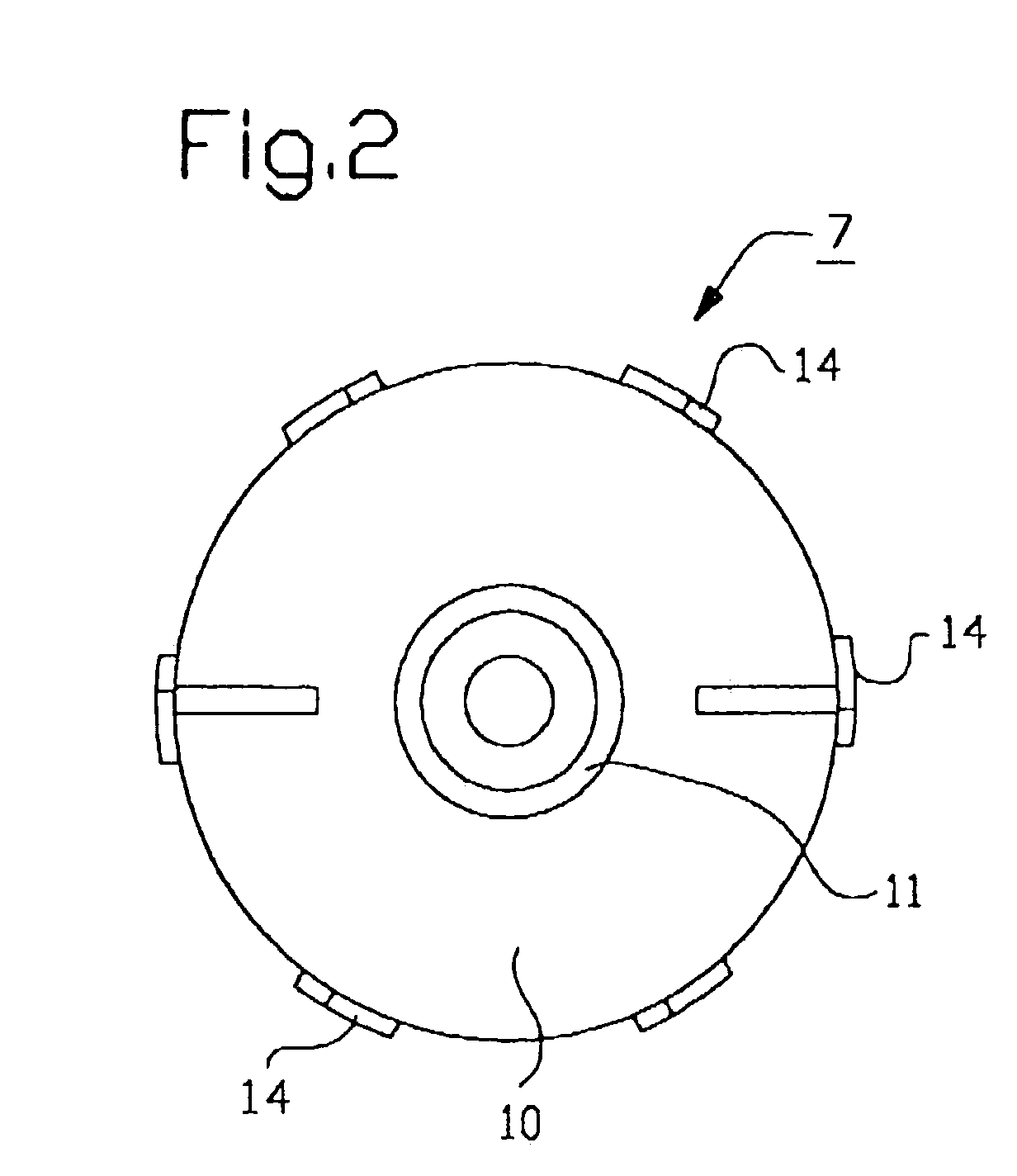

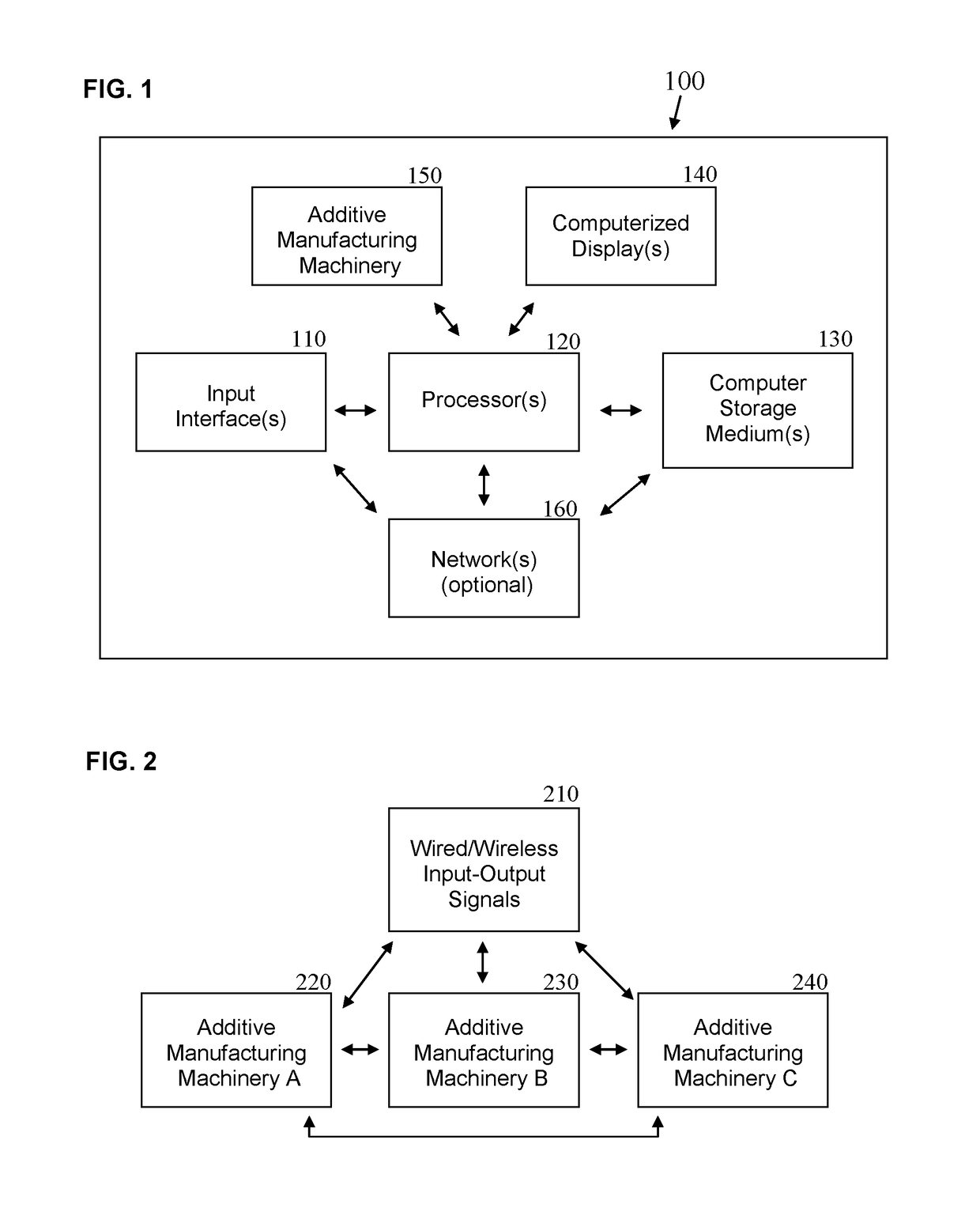

Modular fabrication systems and methods

ActiveUS20130089642A1Improve throughputHigh-throughput applicationsReady-for-oven doughsAuxillary shaping apparatusEngineeringSystem controller

The present invention relates to an article fabrication system having a plurality of material deposition tools containing one or more materials useful in fabricating the article, and a material deposition device having a tool interface for receiving one of the material deposition tools. A system controller is operably connected to the material deposition device to control operation of the material deposition device. Also disclosed is a method of fabricating an article using the system of the invention and a method of fabricating edible foodstuffs.

Owner:CORNELL UNIVERSITY

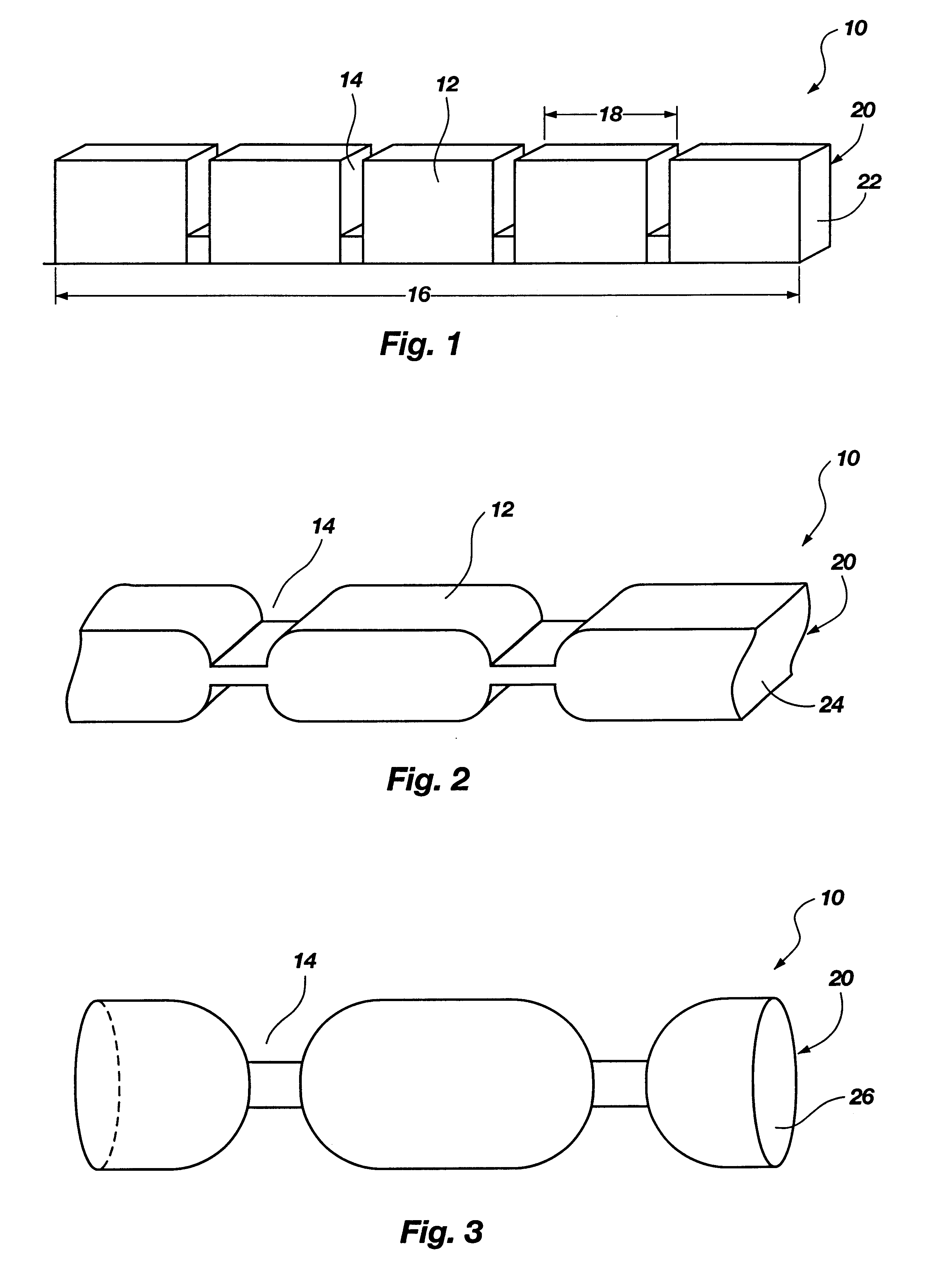

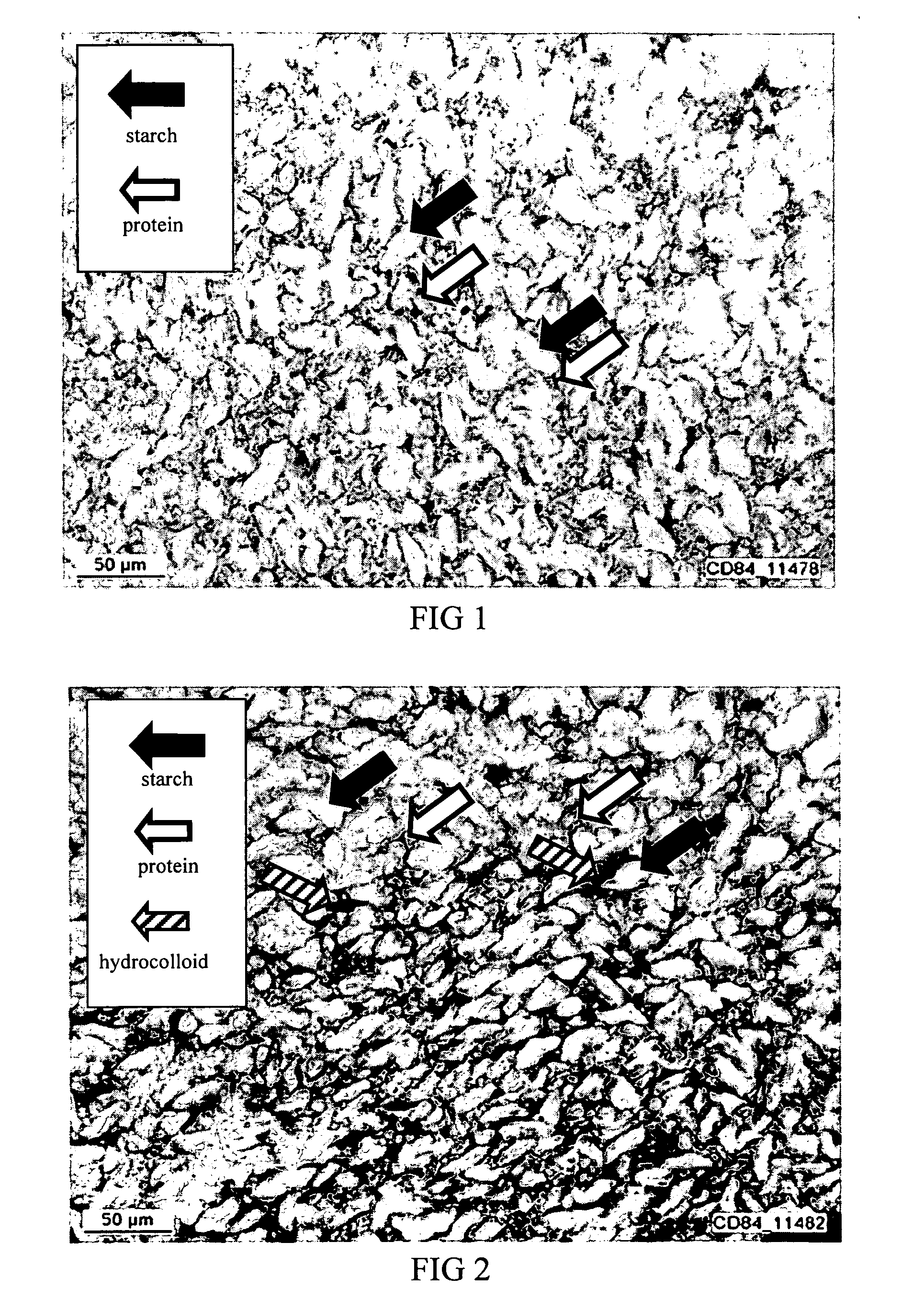

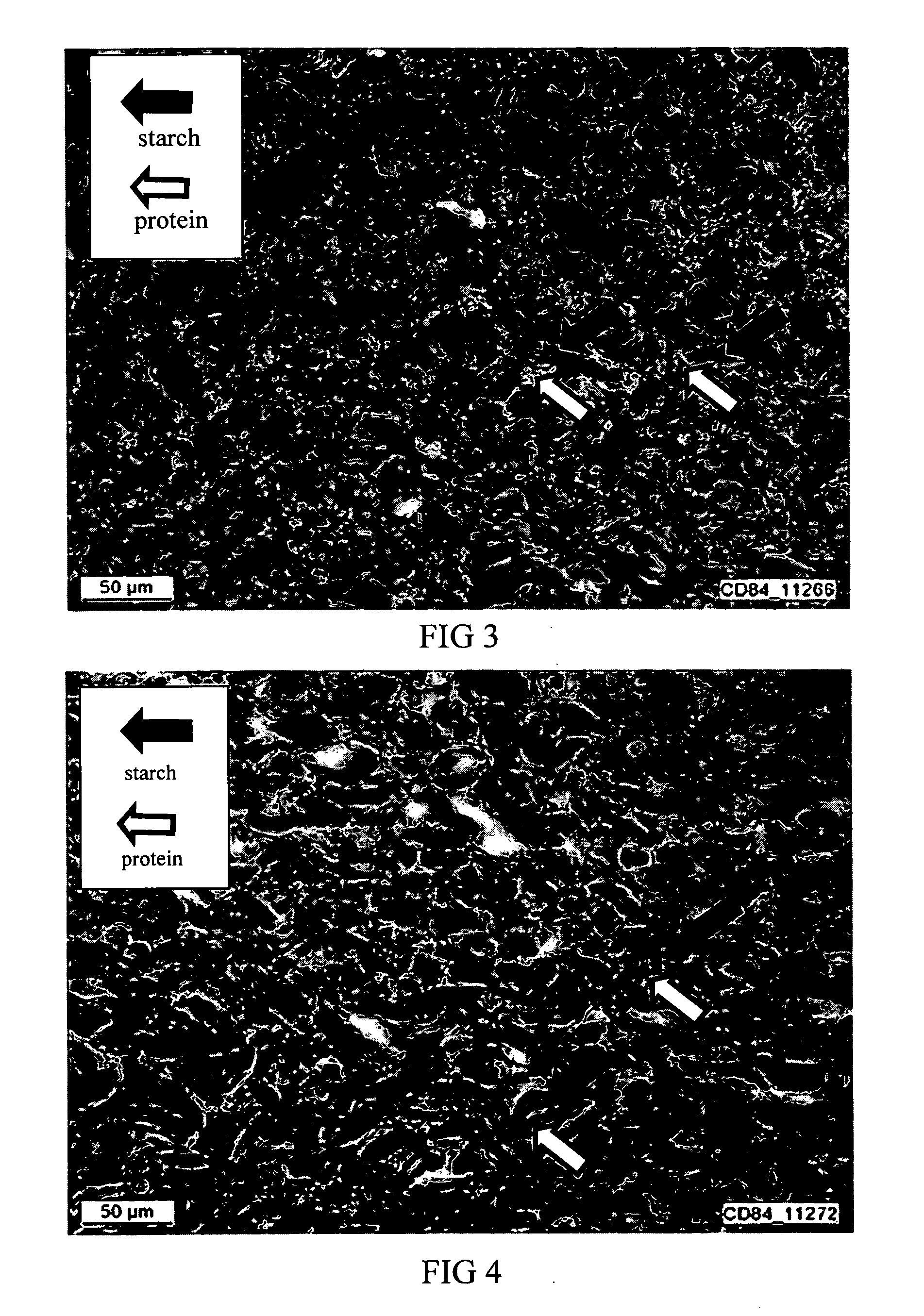

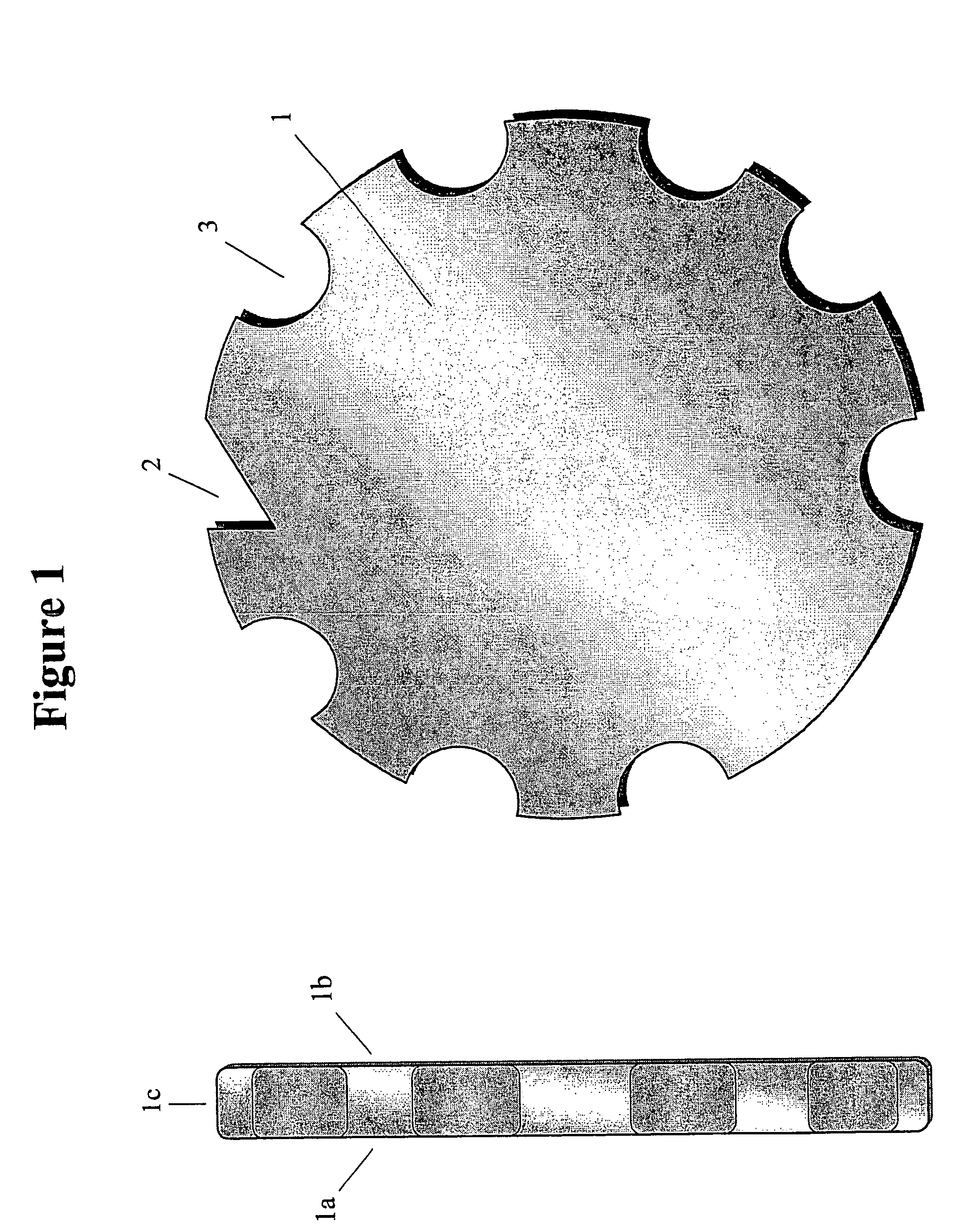

Edible thermoplastic and nutritious pet chew

The present invention relates to an edible thermoplastic made from about 30 to 50 wt. % protein comprising a mixture of plant and animal derived protein, about 20 to 50 wt. % starch about 10 to 20 wt. % water, about 1 to 10 wt. % edible fiber, and about 0.5 to 3 wt. % metallic salt hydrate. When molded, the thermoplastic has good strength and stiffness and other physical properties. The edible thermoplastic may be molded in a variety of shapes including a segmented nutritional pet chew with a plurality of segments separated by a plurality of scores. The scores serve to structurally weaken the pet chew so that it may be broken into smaller pieces. When molded the edible thermoplastic has a density of about 1.2 to 1.5 g / cubic centimeters.

Owner:BISMUTH INVESTMENTS

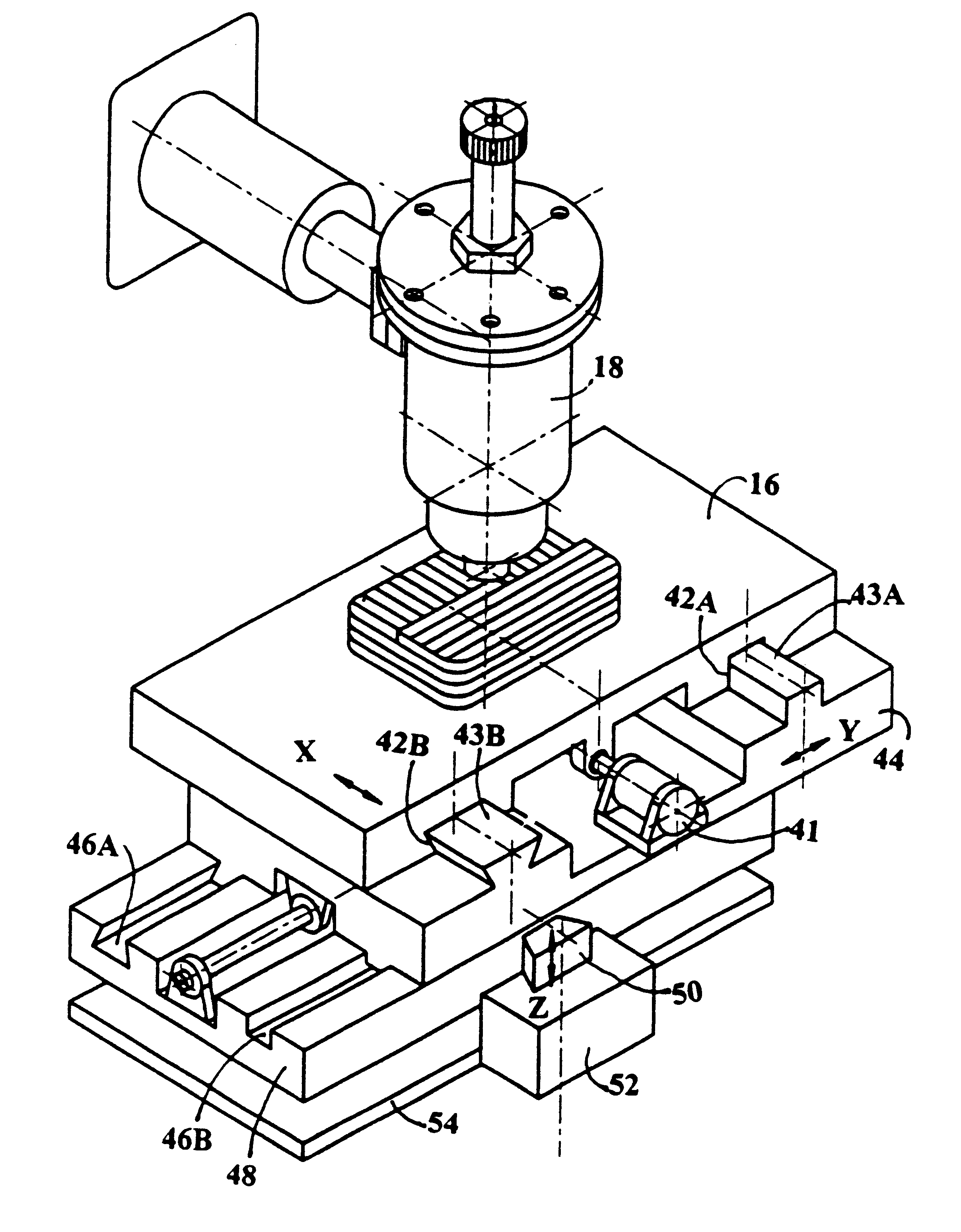

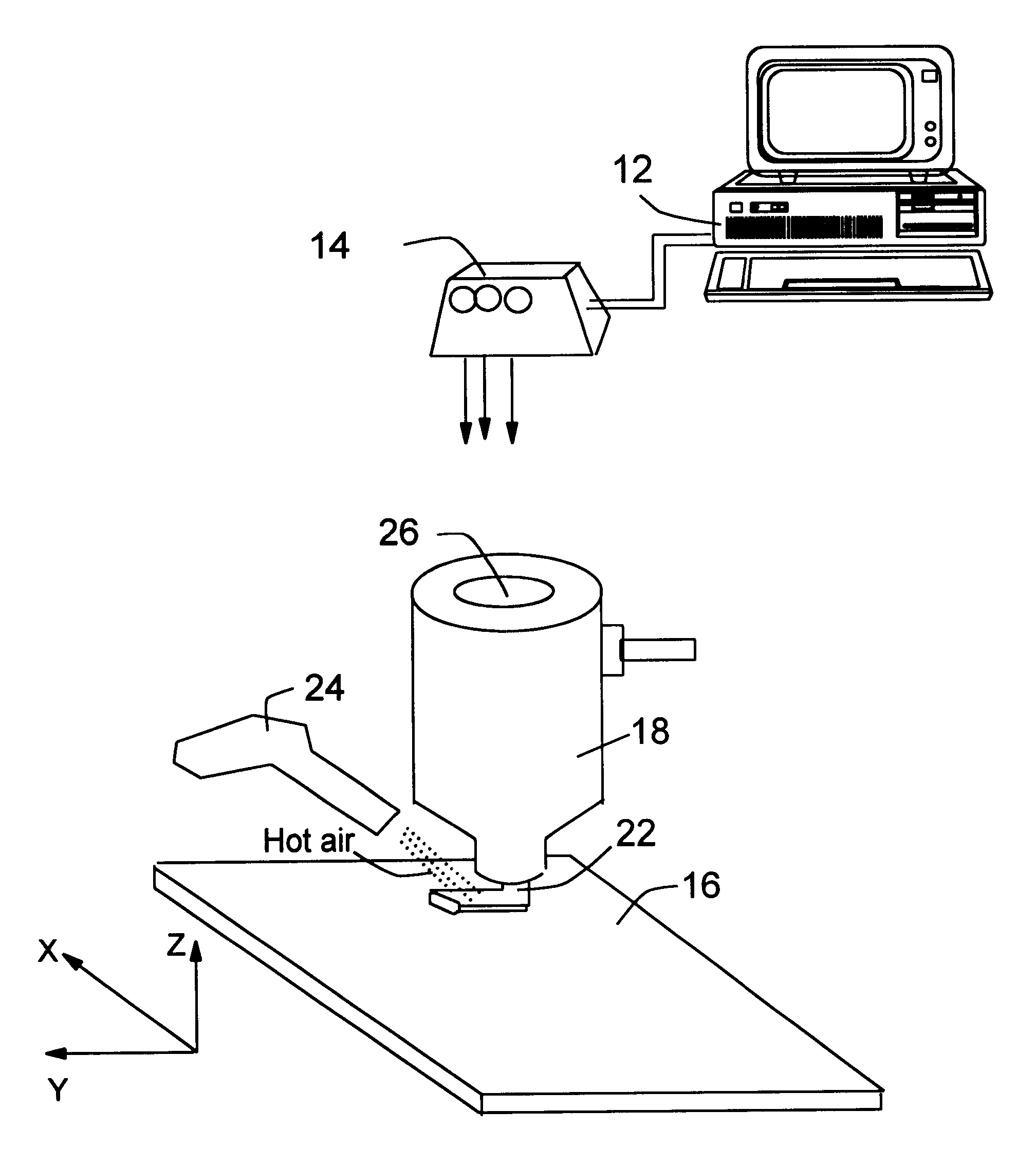

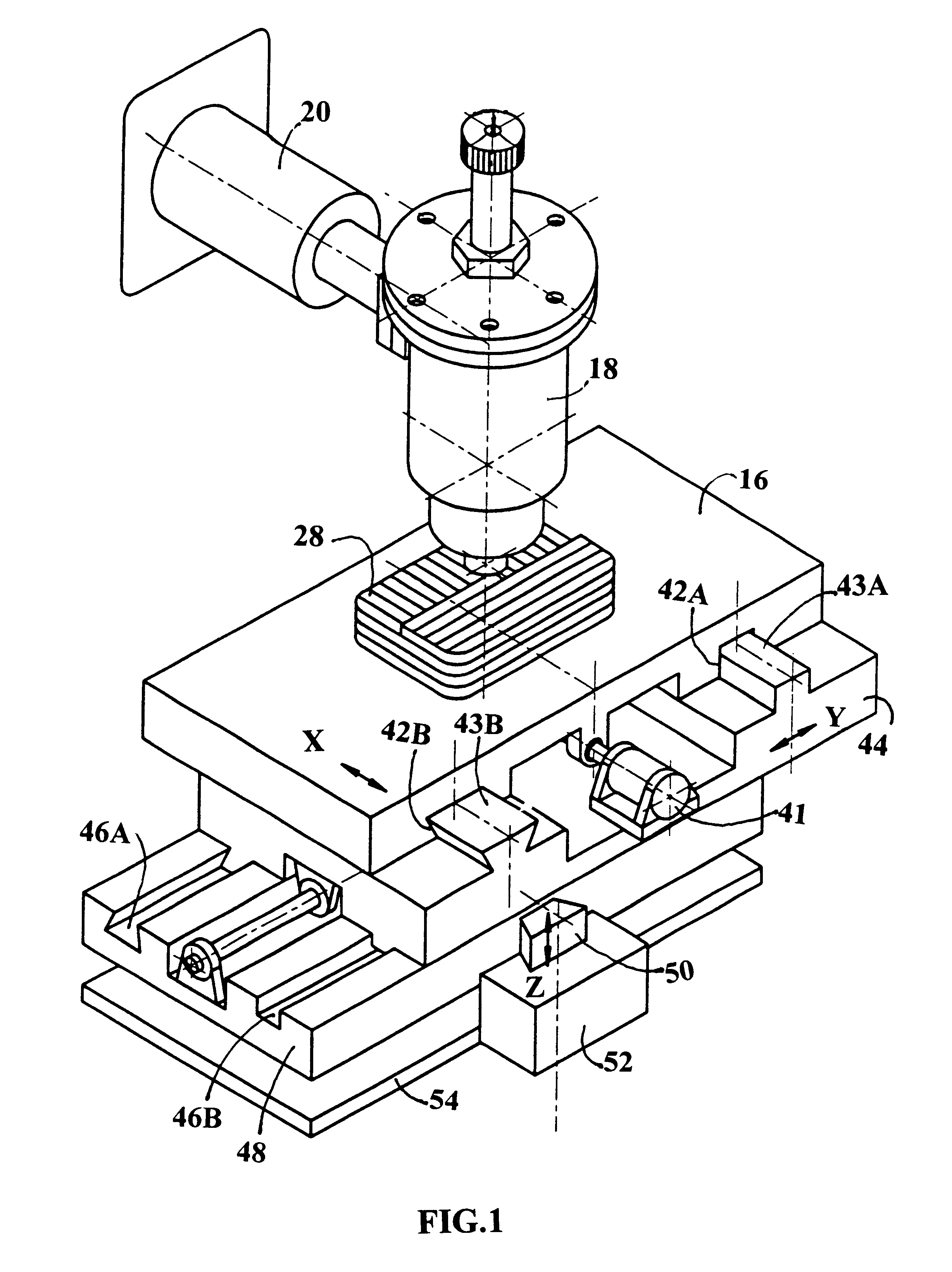

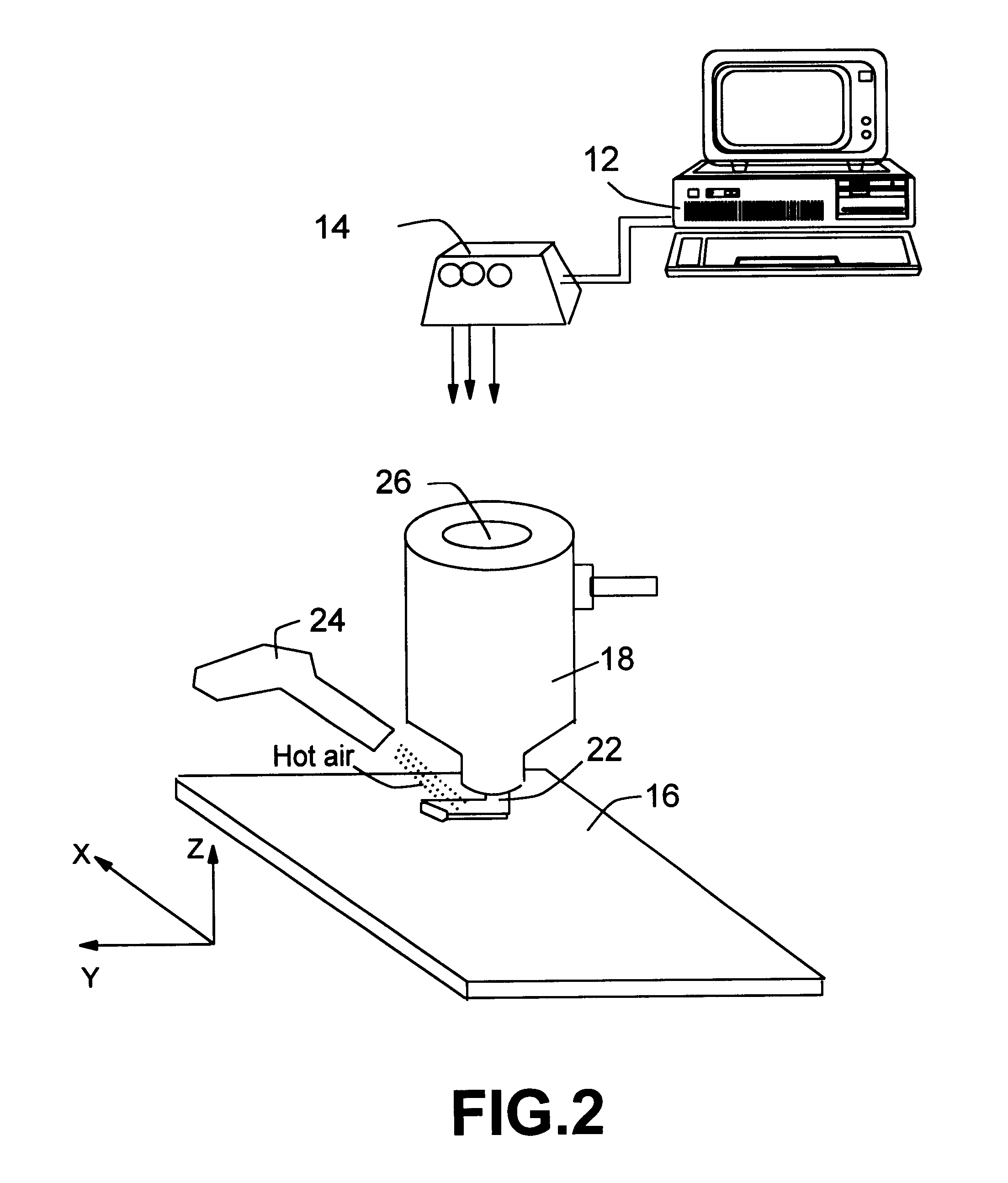

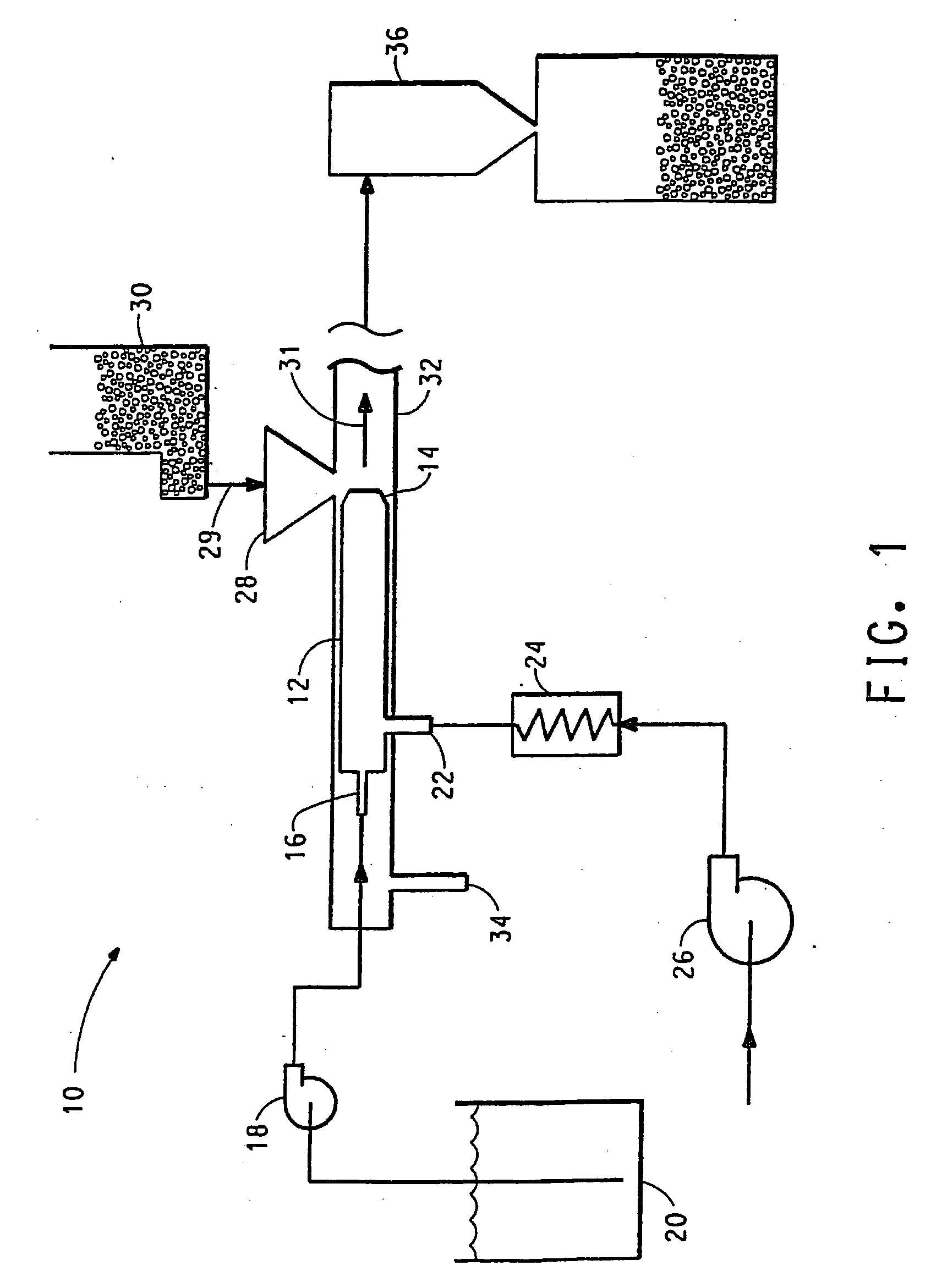

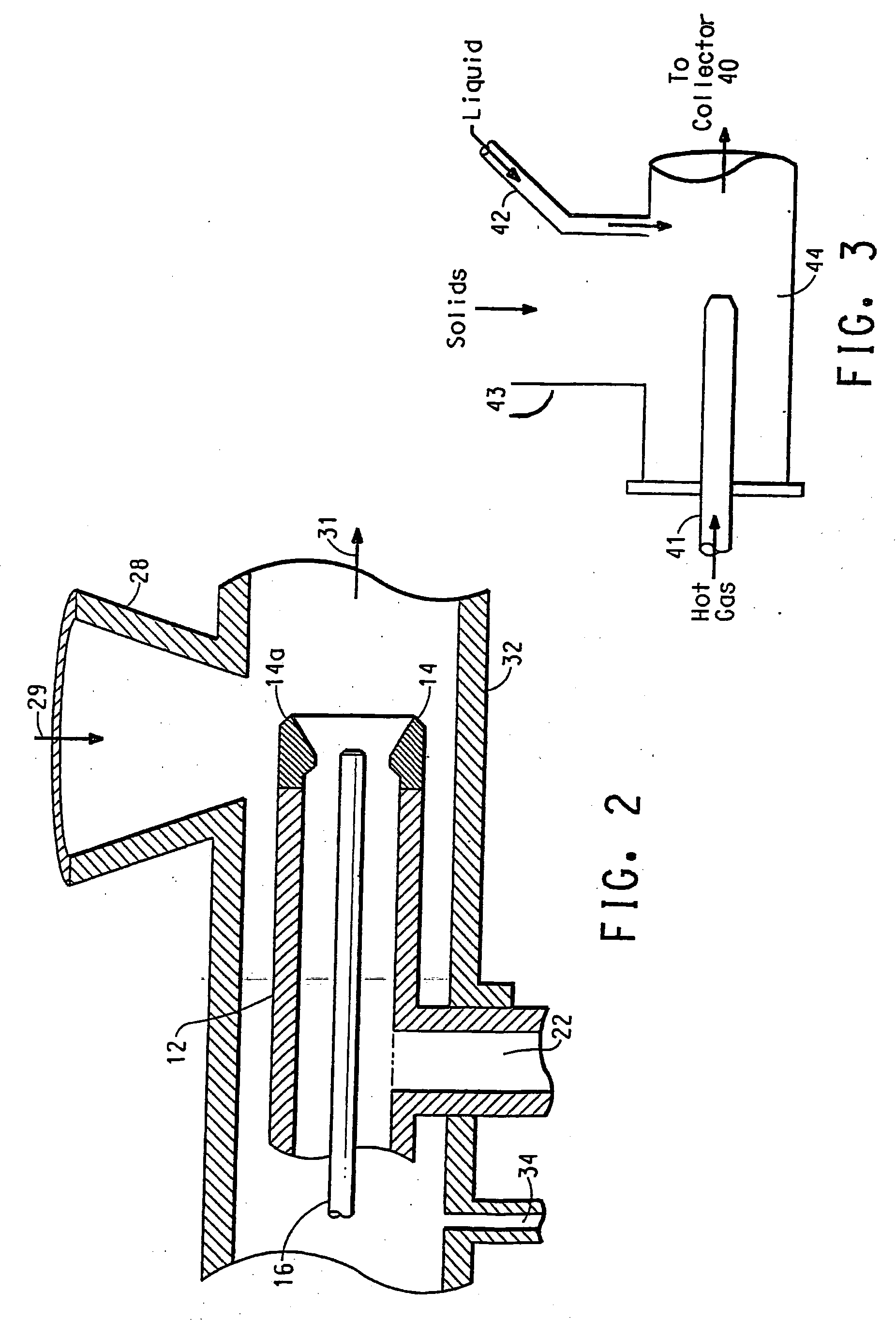

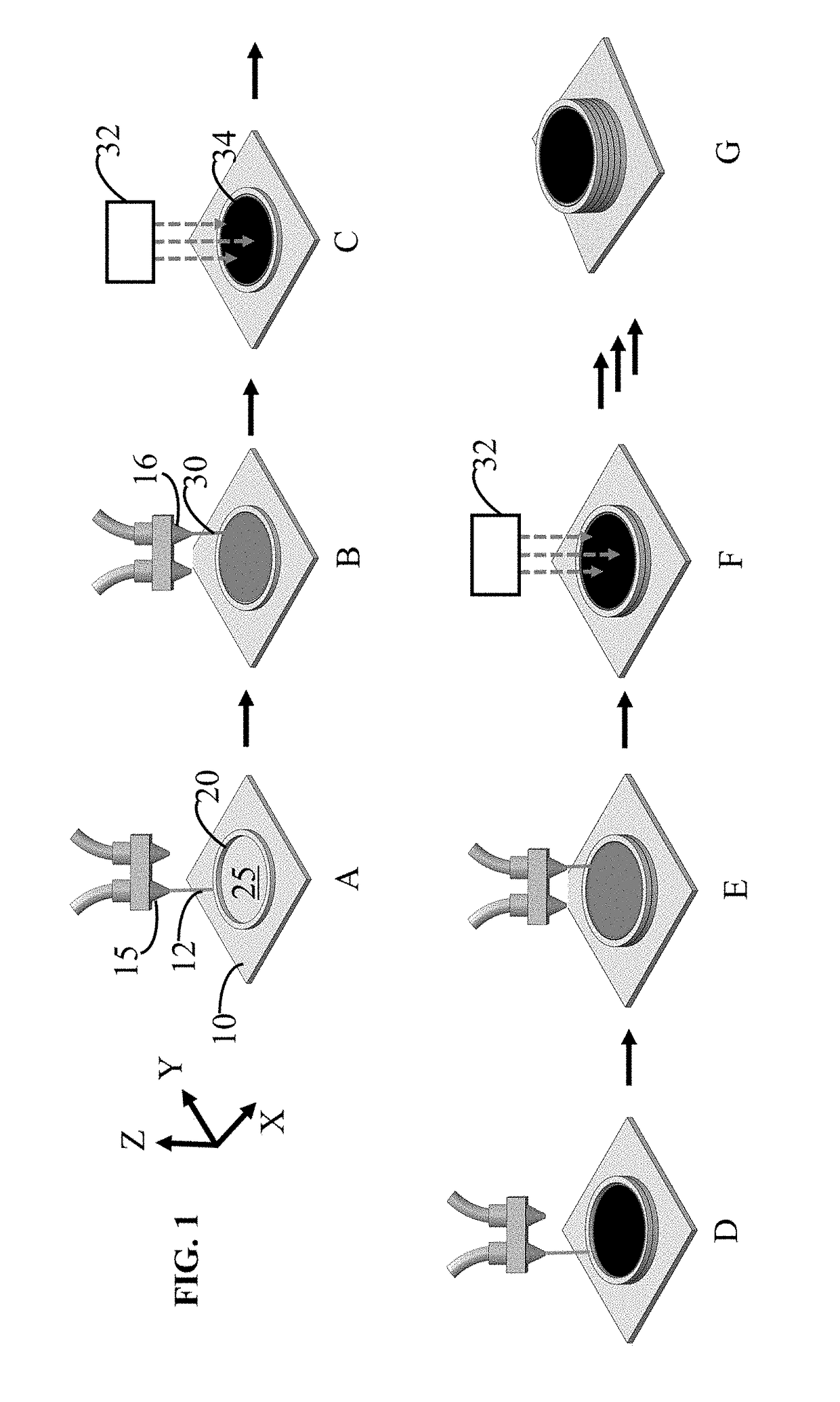

Rapid prototyping and fabrication method for 3-D food objects

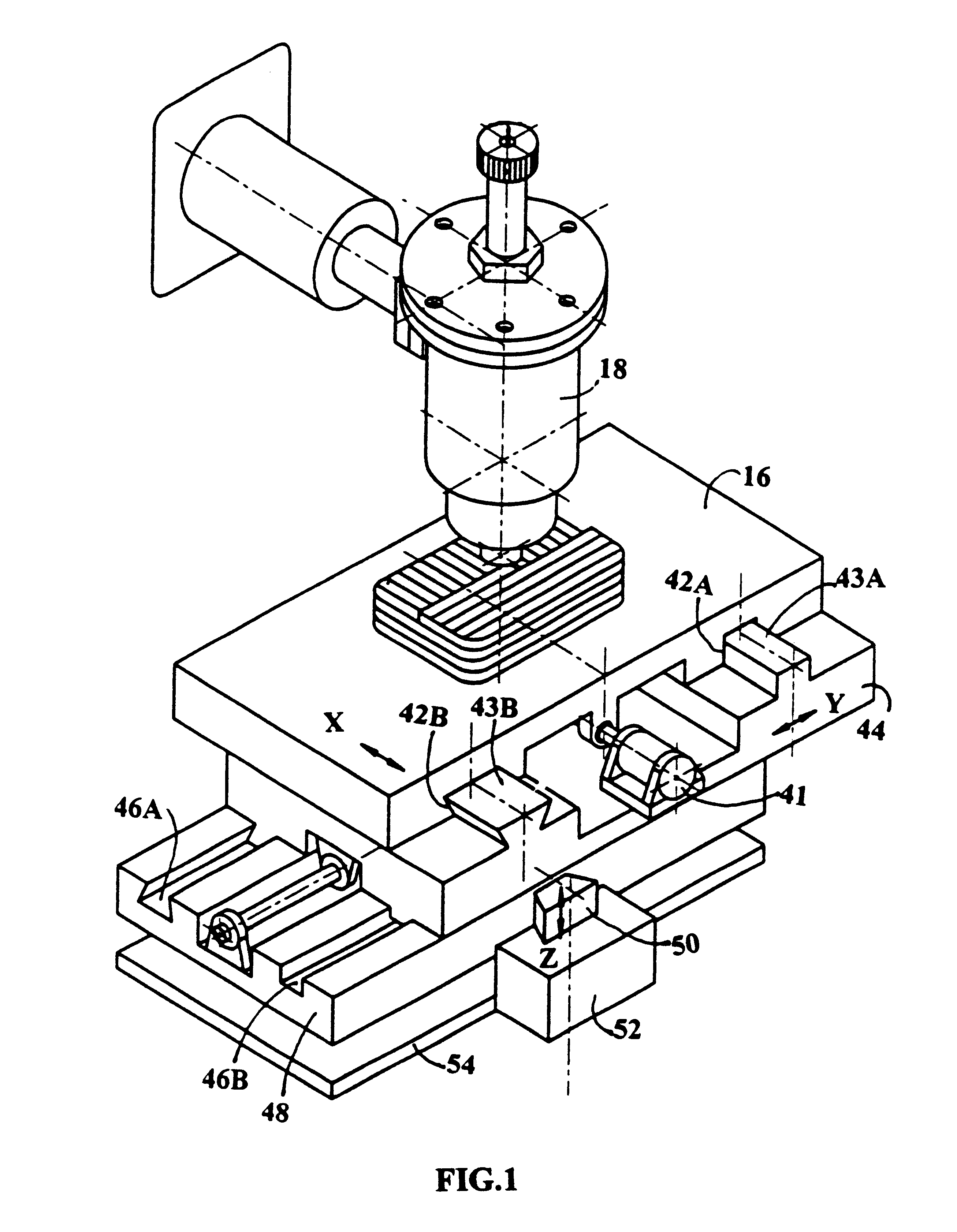

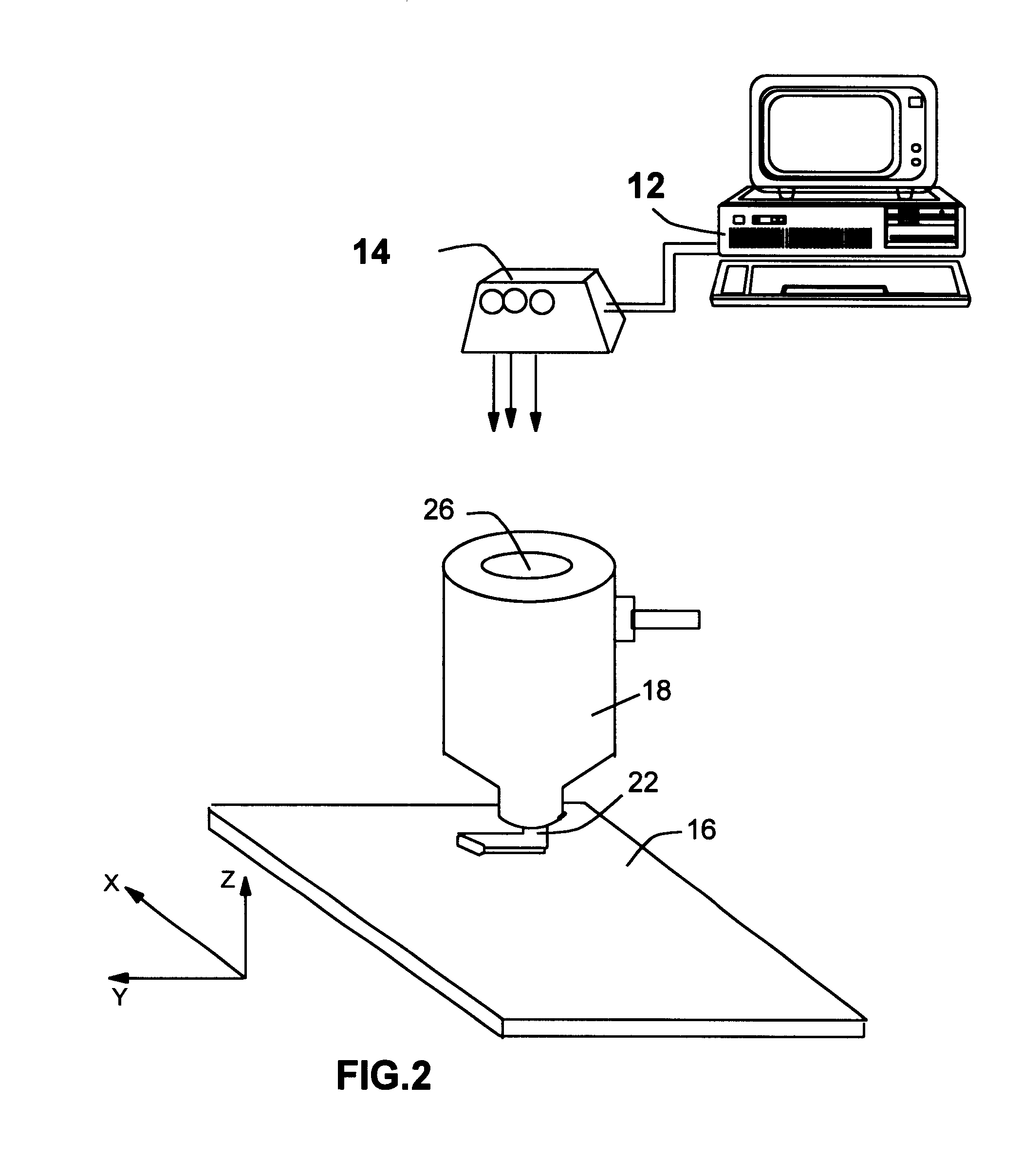

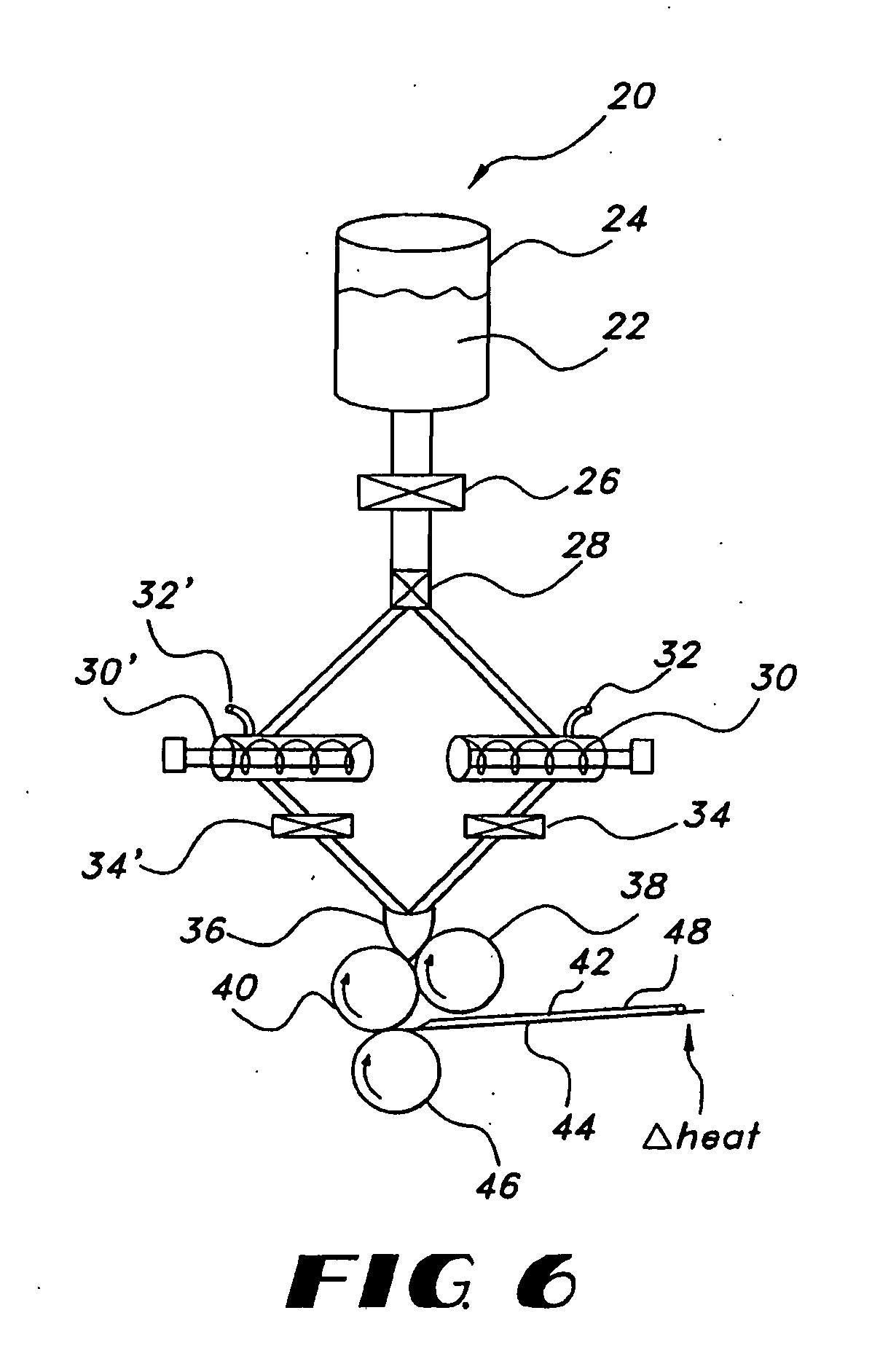

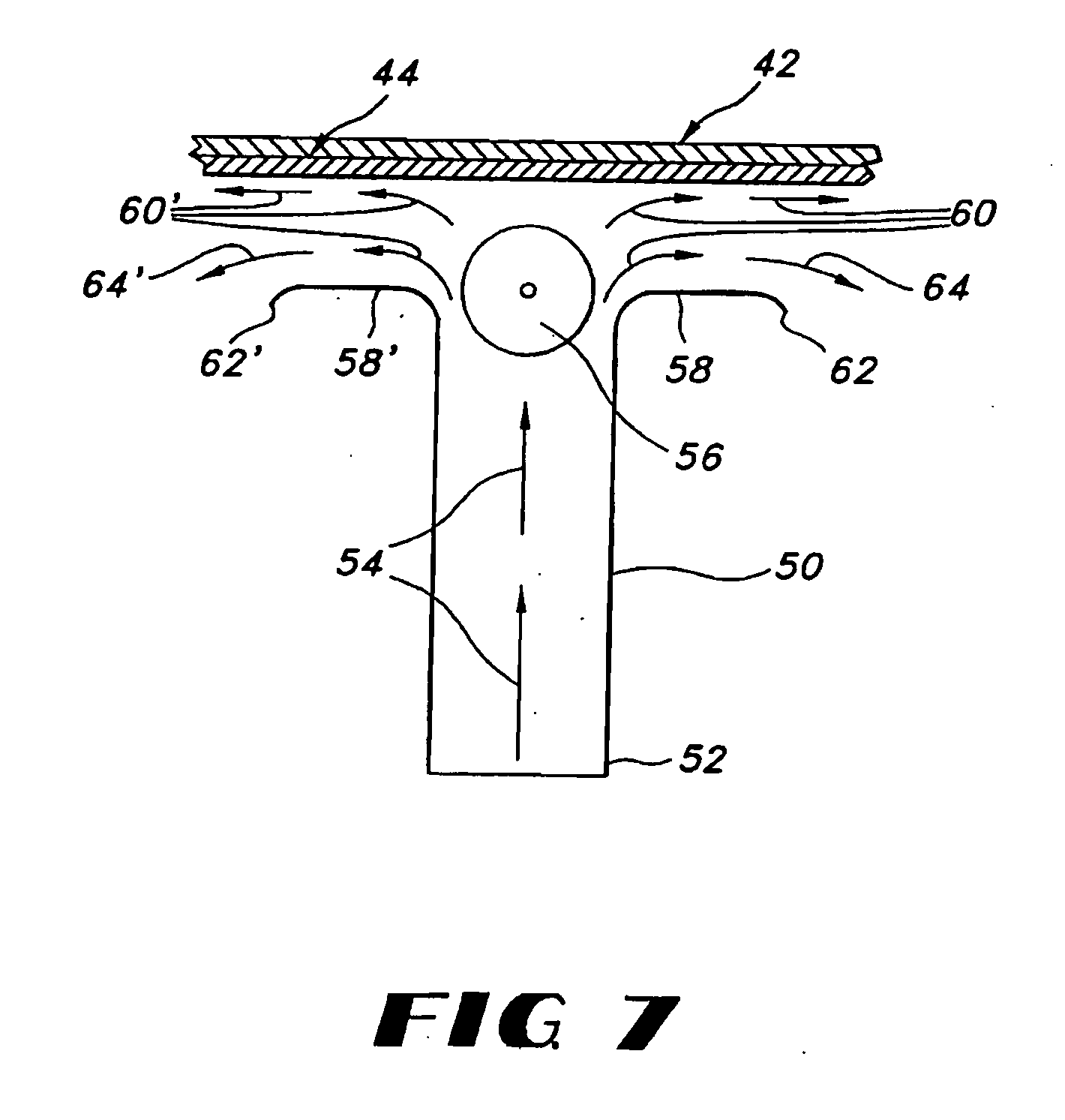

InactiveUS6280785B1Versatile and Realistic Rapid PrototypingRapid productionLayered productsConfectioneryFree formControl signal

A freeform fabrication method for making a three-dimensional food object from a design created on a computer, including: (a) providing a support member by which the object is supported while being constructed; (b) operating a material dispensing head for dispensing a continuous or intermittent strand of food composition in a fluent state; this food composition including a liquid ingredient and a primary body-building food material and the dispensed food composition having a rigidity and strength sufficient for permitting the food composition to be built up layer by layer into a three-dimensional shape in a non-solid state; and (c) operating control devices for generating control signals in response to coordinates of the object design and controlling the position of the dispensing head relative to the support member in response to the control signals to control dispensing of the food composition to construct a 3-D shape of this object. The method optionally includes an additional step of applying a heat treatment to the 3-D shape after this 3-D shape is constructed. This method can be used to form an intricate shape of a cake mix, which is then baked in an oven. It can also be used to form a custom-designed decorative shape on the top surface of a pre-made cake.

Owner:NANOTEK INSTR GRP LLC

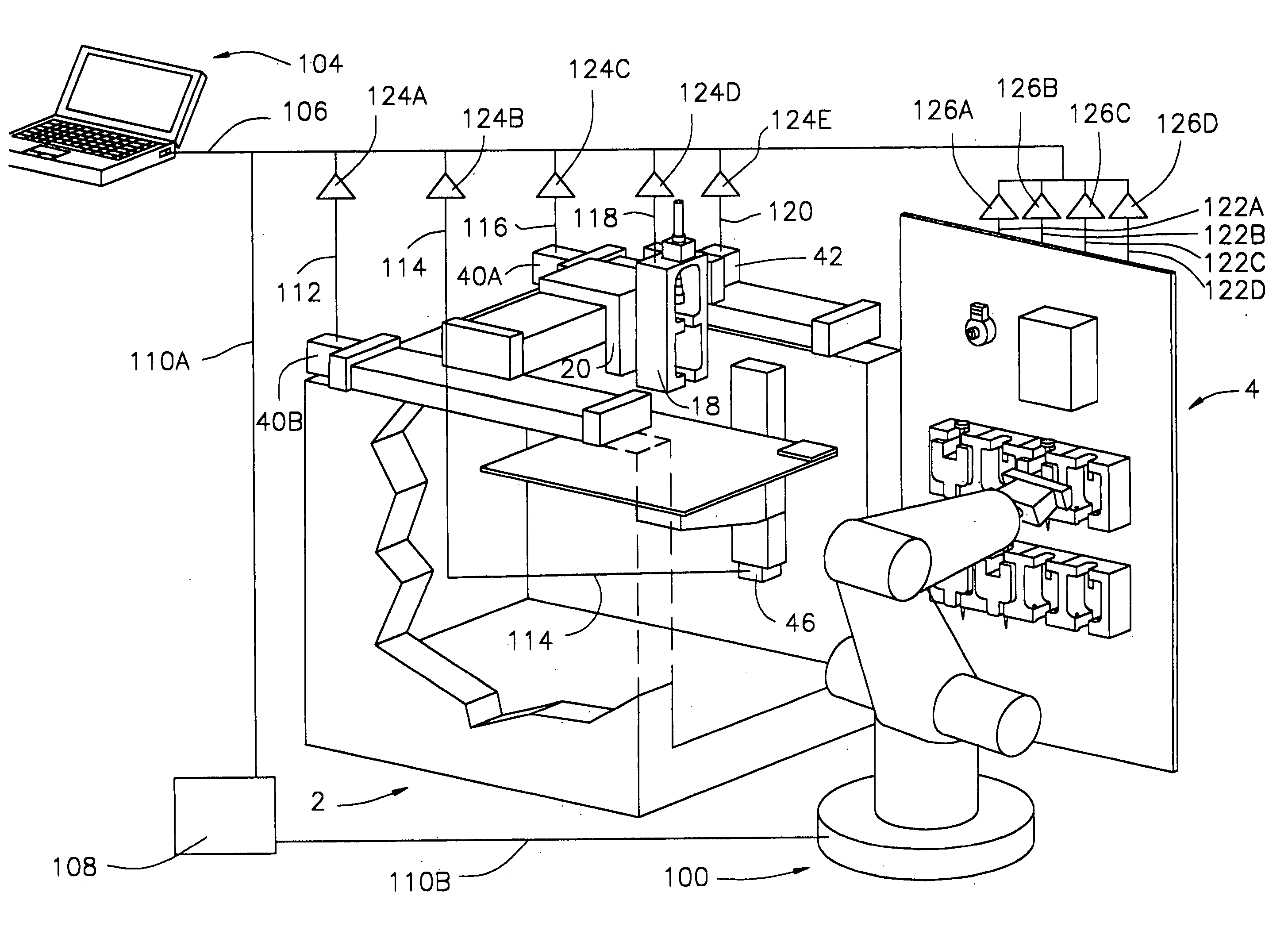

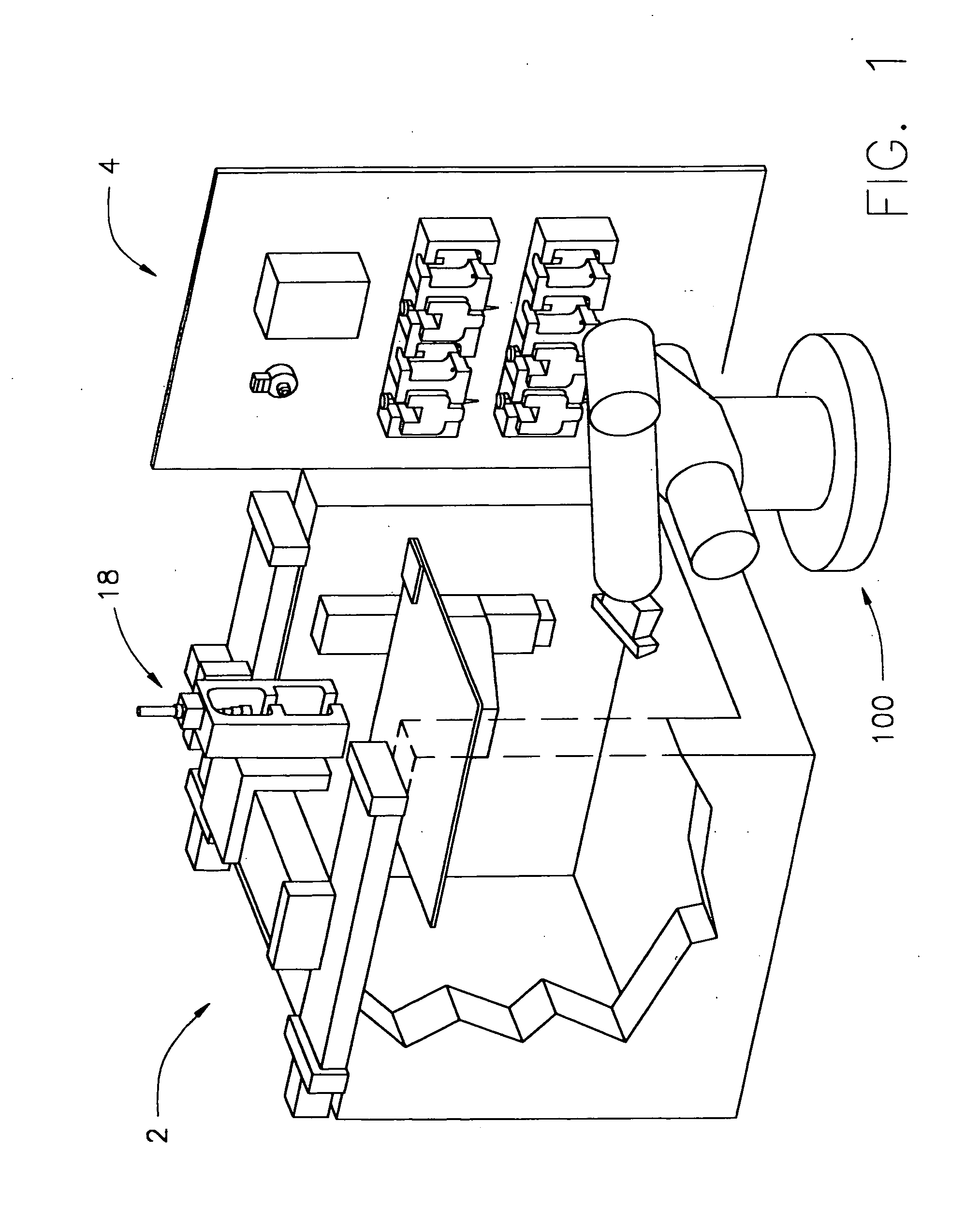

Modular fabrication systems and methods

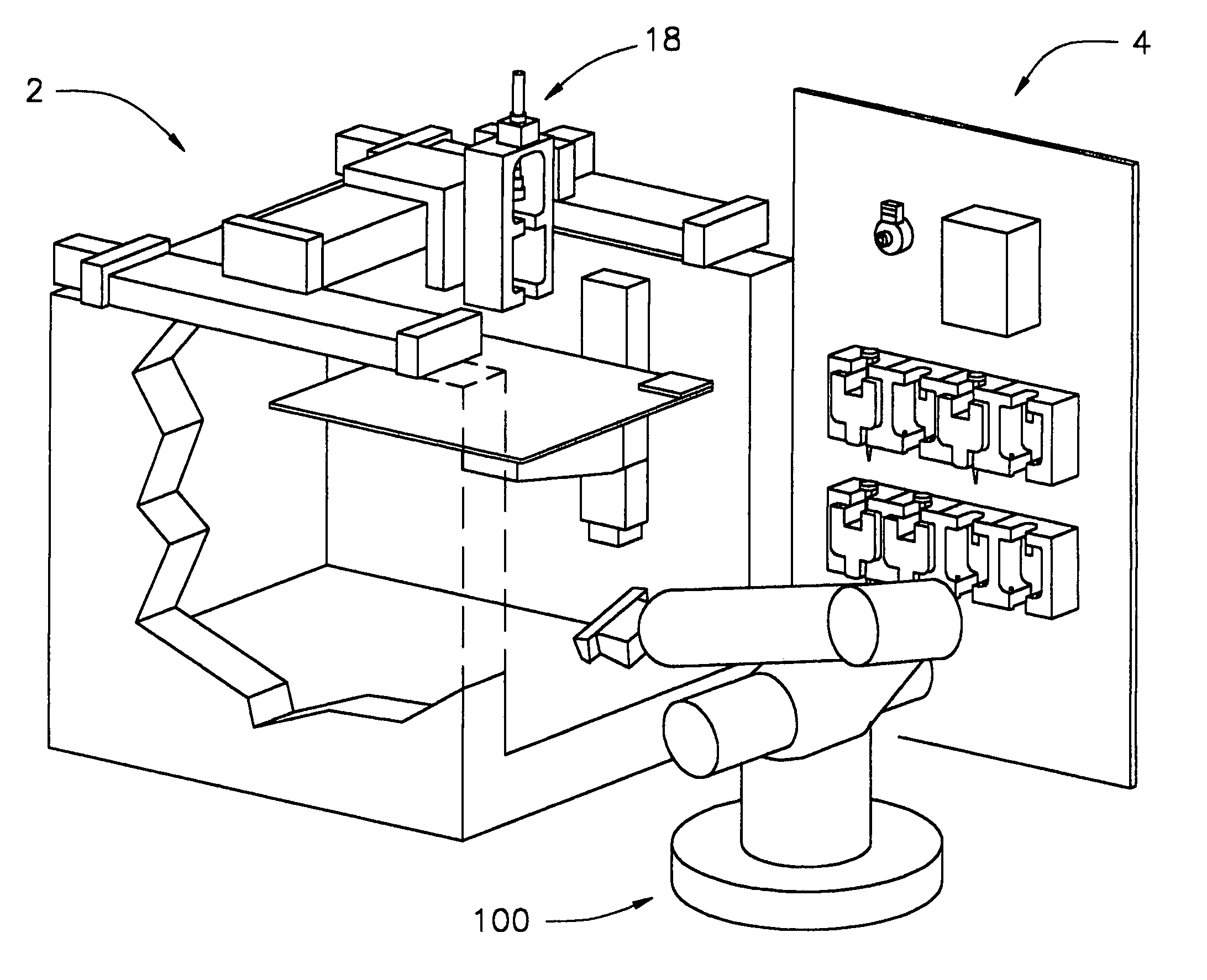

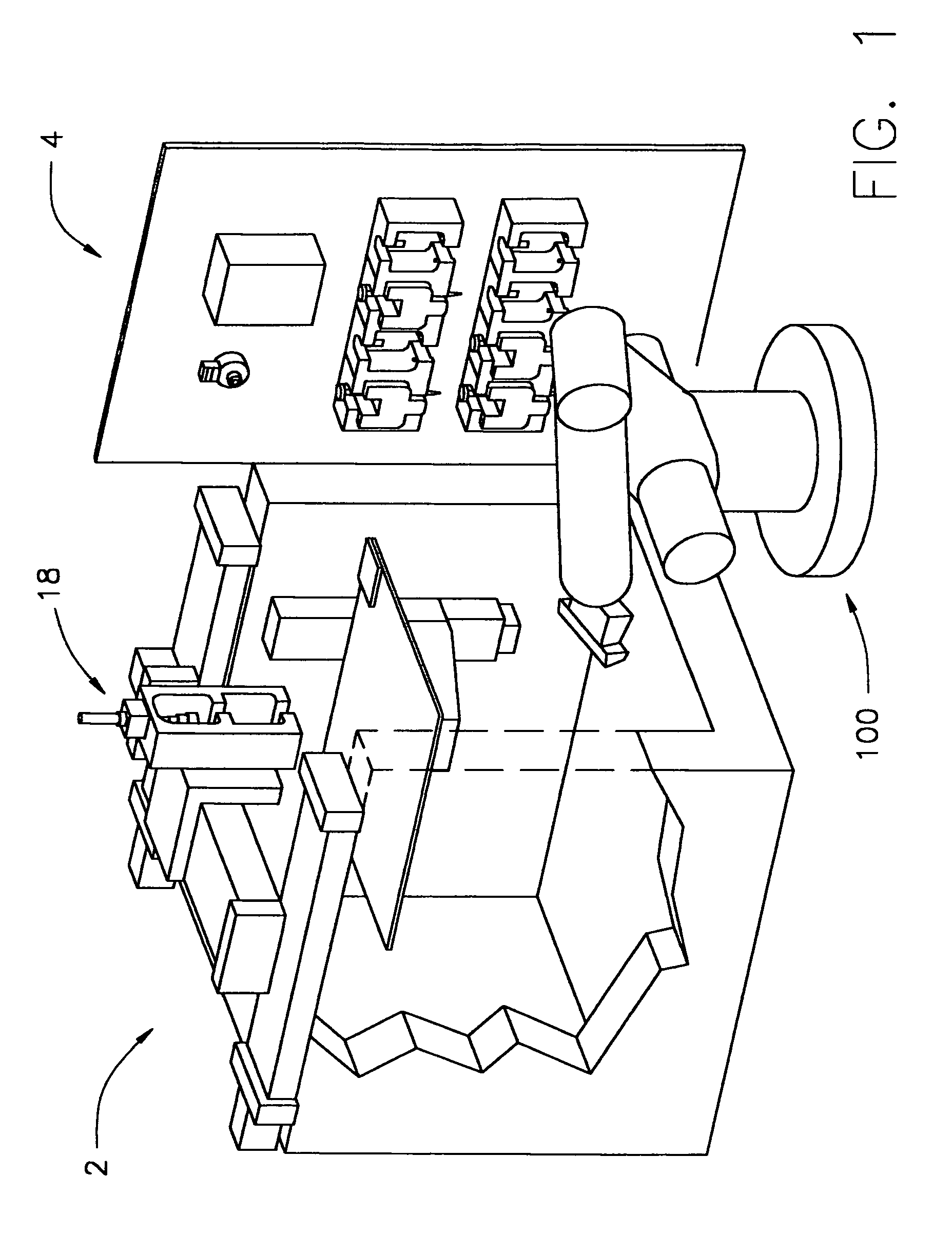

ActiveUS7625198B2Improve throughputAdapt to a wide rangeLiquid surface applicatorsConfectioneryEngineeringSystem controller

The present invention relates to an article fabrication system having a plurality of material deposition tools containing one or more materials useful in fabricating the article, and a material deposition device having a tool interface for receiving one of the material deposition tools. A system controller is operably connected to the material deposition device to control operation of the material deposition device. Also disclosed is a method of fabricating an article using the system of the invention and a method of fabricating a living three-dimensional structure.

Owner:CORNELL RES FOUNDATION INC

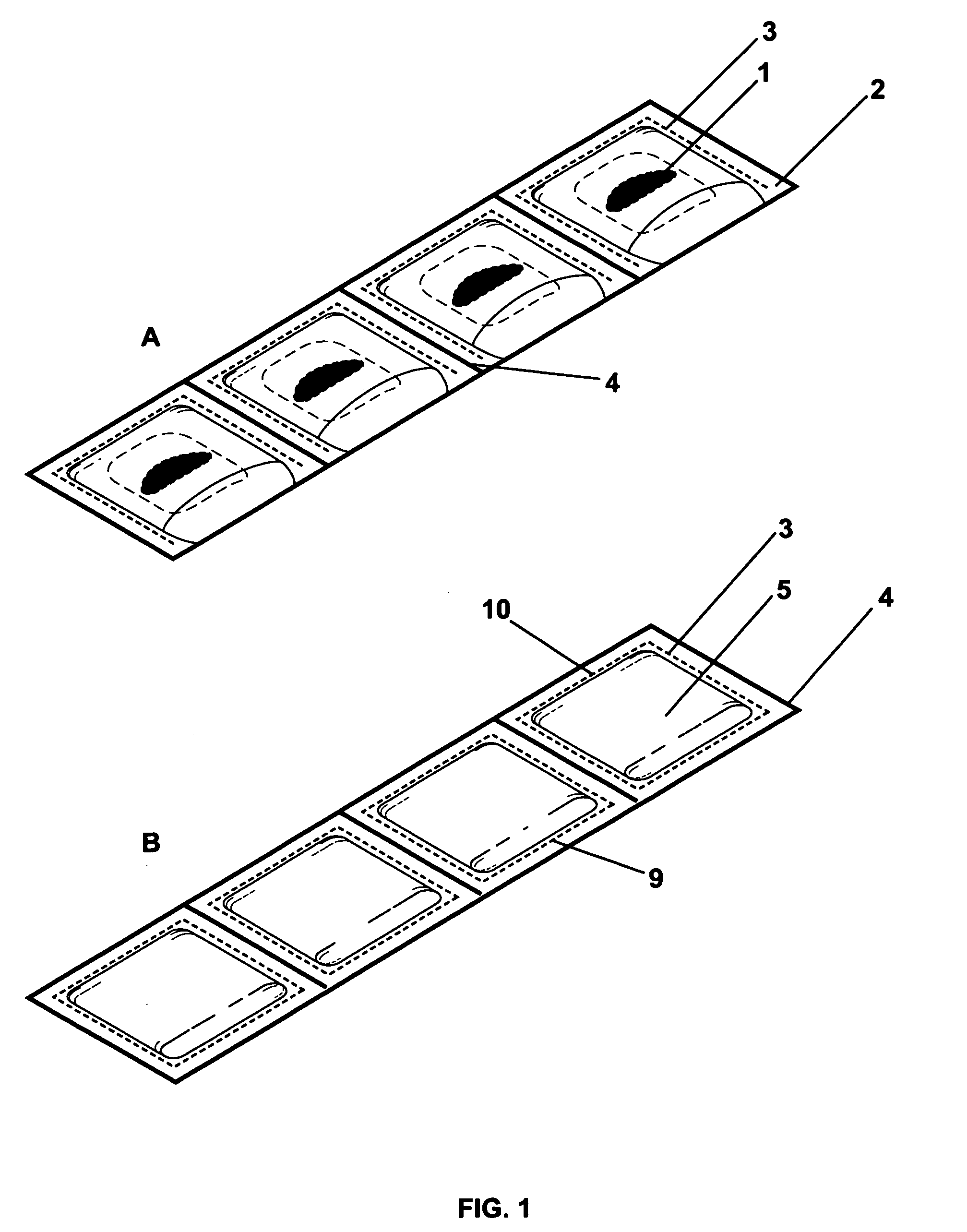

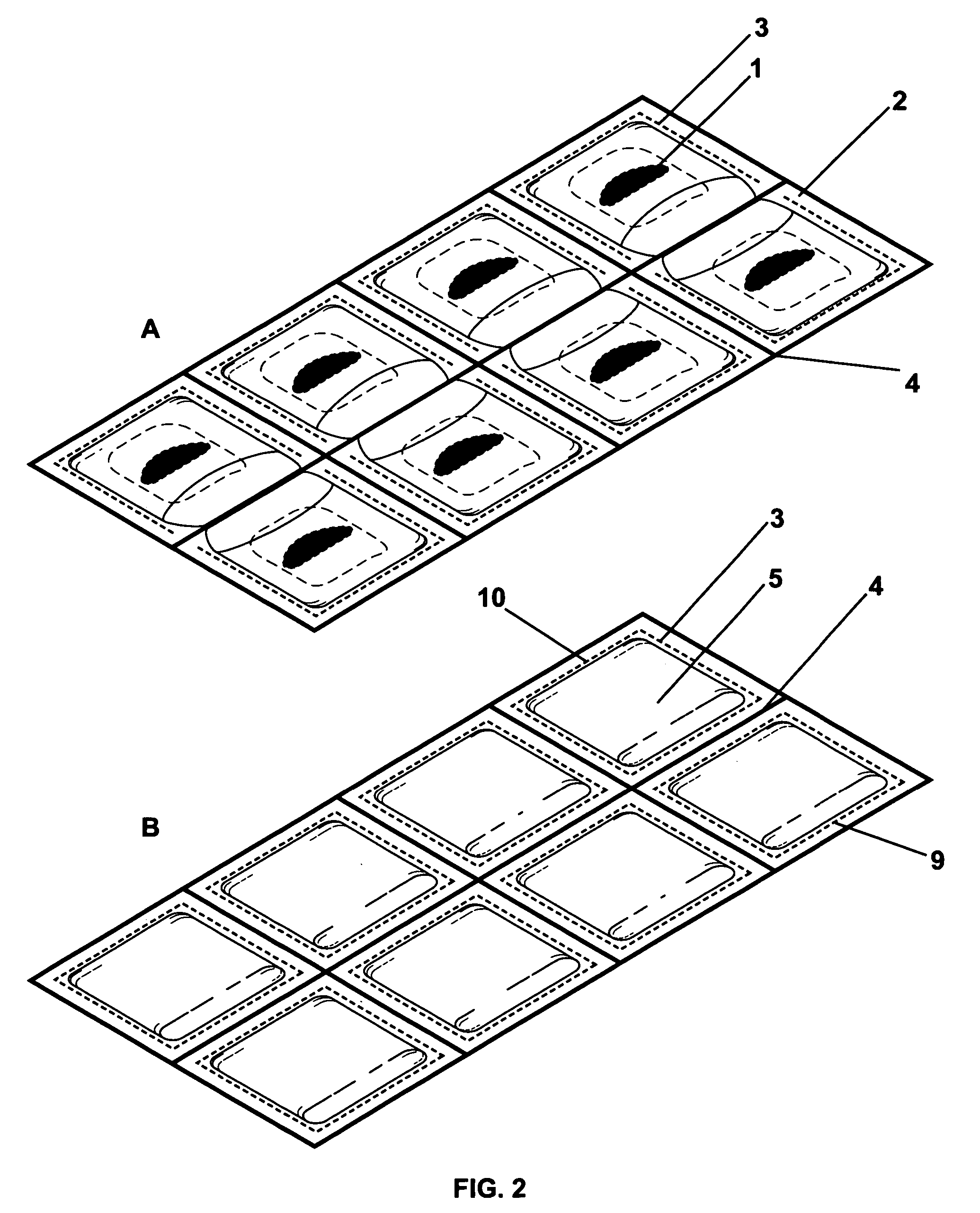

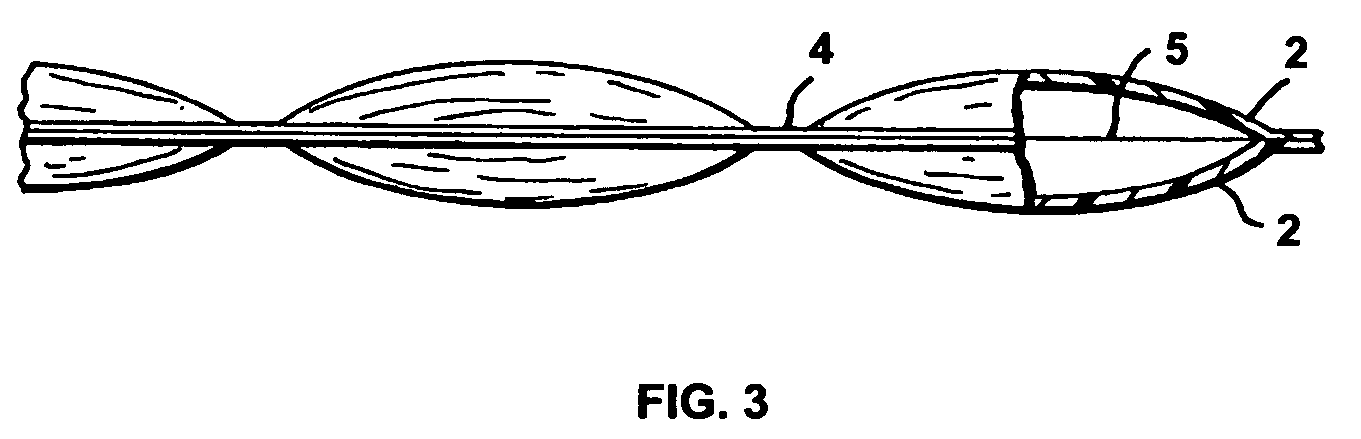

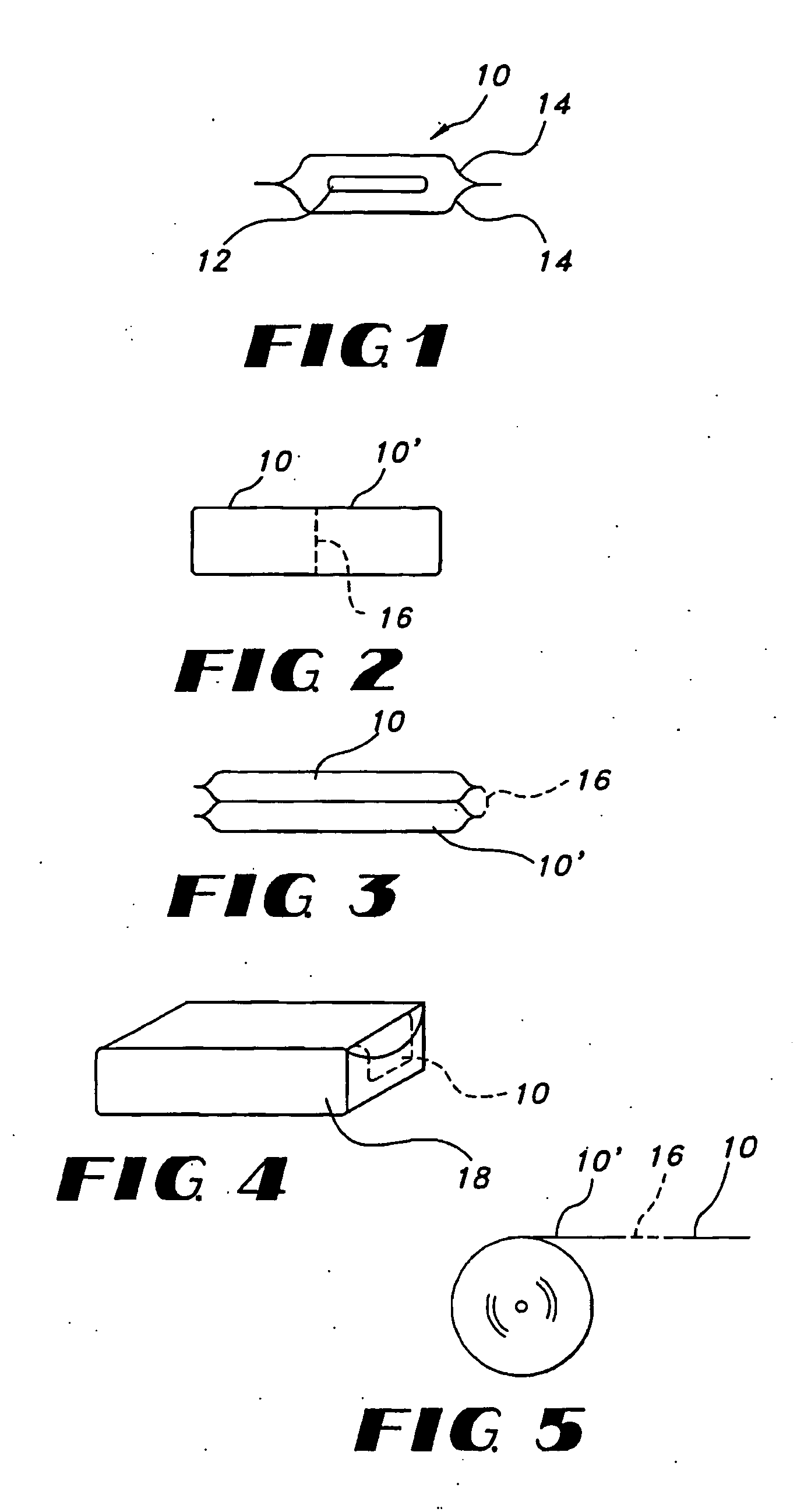

Sealed, edible film strip packets and methods of making and using them

The invention provides, in one aspect, a method of making a confectionery packet or sachet formed with an edible film and enclosing a center composition. The packet or sachet can be designed to be placed in the mouth, where the film dissolves and the center composition is released. In preferred embodiments, the center composition comprises a sugar alcohol, such as xylitol, that creates a cooling sensation. Many other flavors and / or colors or sensates can also be used in the center composition, and some embodiments include breath-freshening, anti-bacterial, nutriceutical, or pharmaceutical compositions in the center composition. The invention also comprises the edible packets or sachets, especially those composed of film with a desired retained water level suitable for producing a self-sealing film and / or an edible film packet that is stable at room temperature for at least six to twelve months.

Owner:CARROLL THOMAS J +5

Reduced digestible carbohydrate food having reduced blood glucose response

ActiveUS20050118326A1Hypoglycemic responseReduced digestibleDough treatmentLeguminous plant bakery productsAdditive ingredientFood material

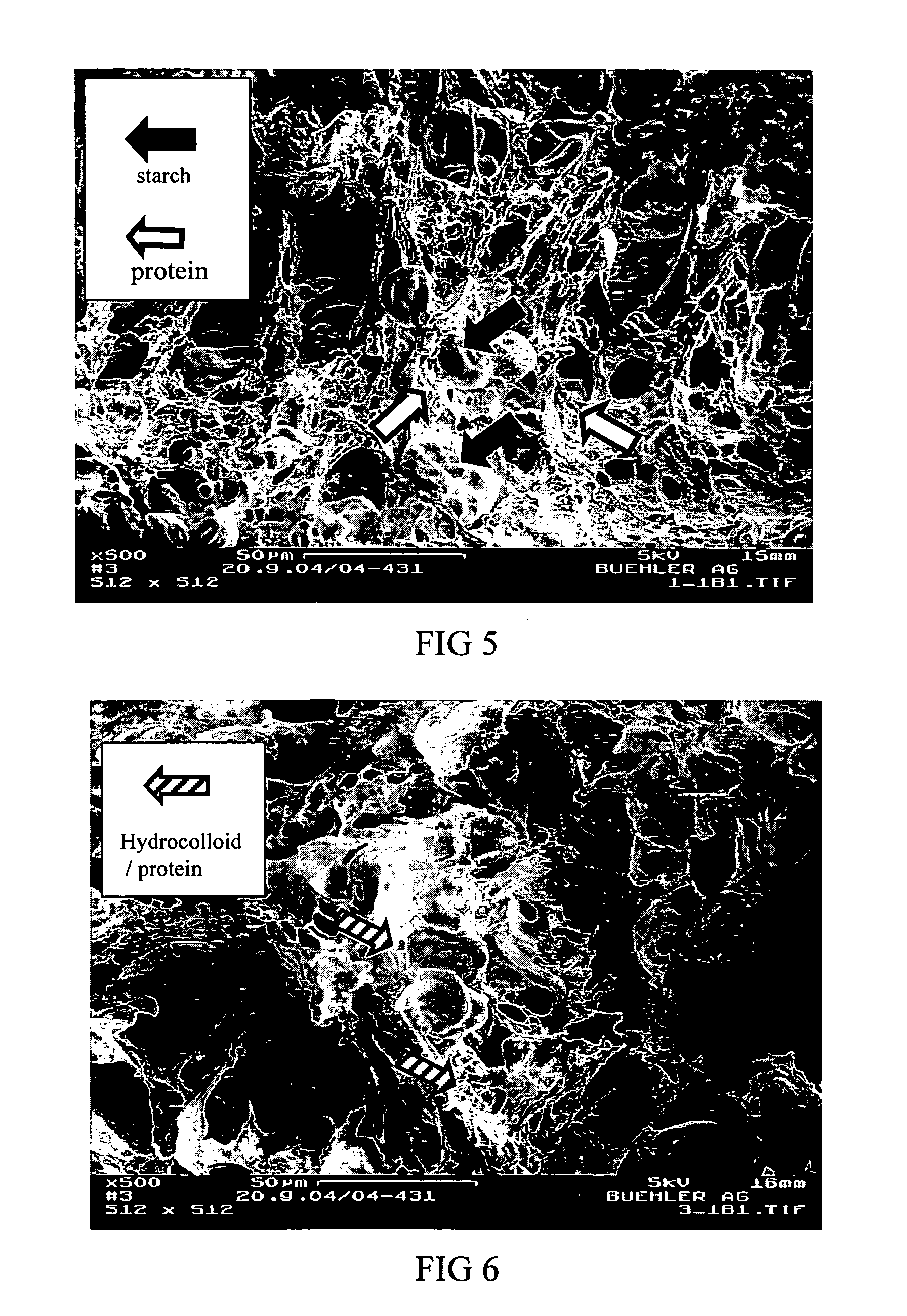

Reducing the digestion of digestible carbohydrates in a digestible carbohydrate-based material, and reducing the absorption of the digestion product(s) of digestible carbohydrates (that is, simple sugars) within the small intestine. The undigested digestible carbohydrate and the unabsorbed digestion products pass through the small intestines and into the colon, where they are fermented. In effect, the food materials made by practicing the present invention cause a controlled amount of digestible carbohydrate to by-pass the small intestine, resulting in the fermentation of digestible carbohydrates in the colon. The invention also provides for processing of a digestible carbohydrate-based ingredient with a non-digestible food film material, to form a reduced digestible carbohydrate food having a protective food film network, which can inhibit or prevent digestion of the digestible carbohydrate. The present invention also provides for processing of a digestible carbohydrate-based ingredient with a non-digestible food film material, to provide a resulting reduced digestible carbohydrate food containing a viscosity-building component that contributes to the formation of a viscous intestinal chyme that can inhibit or prevent digestion of the digestible carbohydrate and can inhibit adsorption of digestion products of digestible carbohydrates in the small intestine.

Owner:TECHCOM GRP LLC

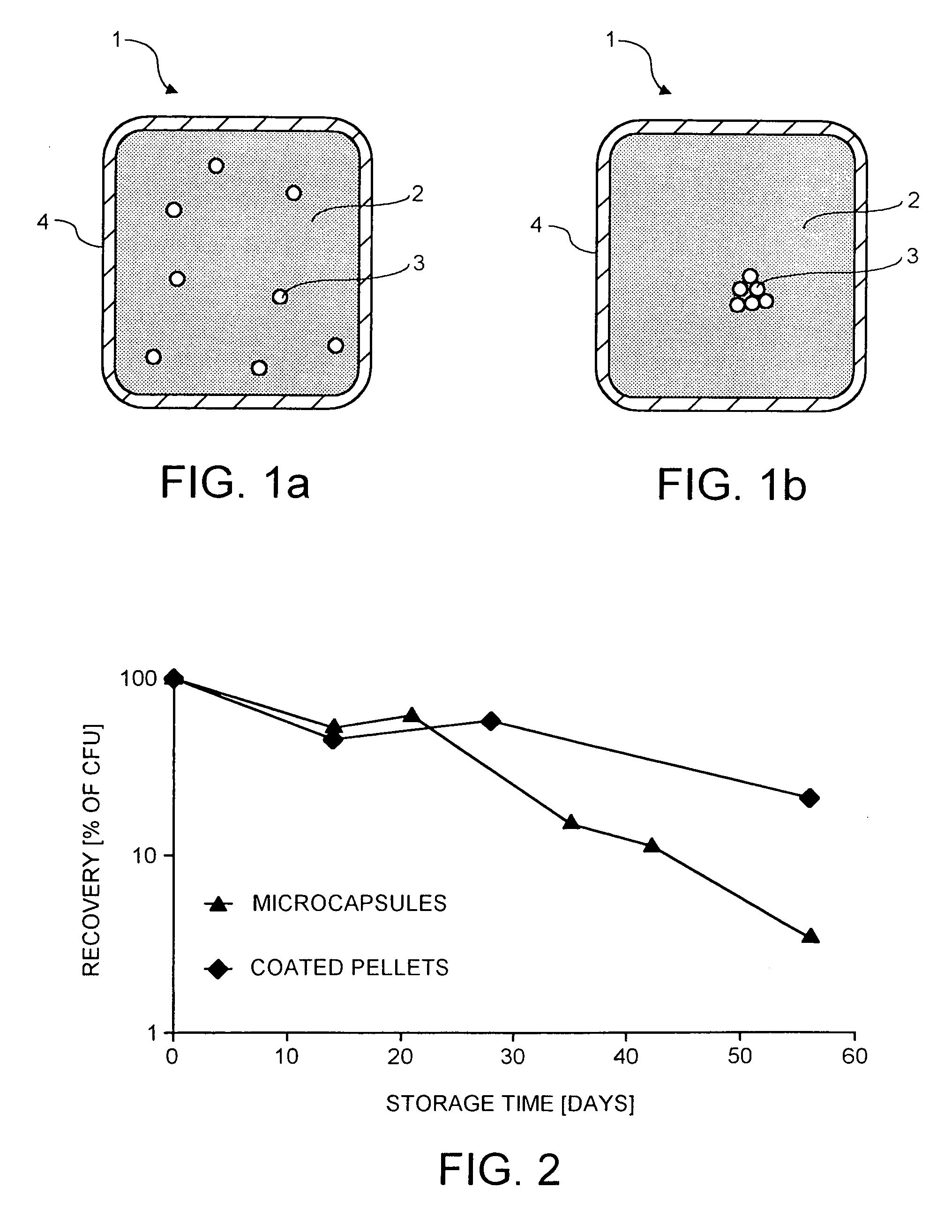

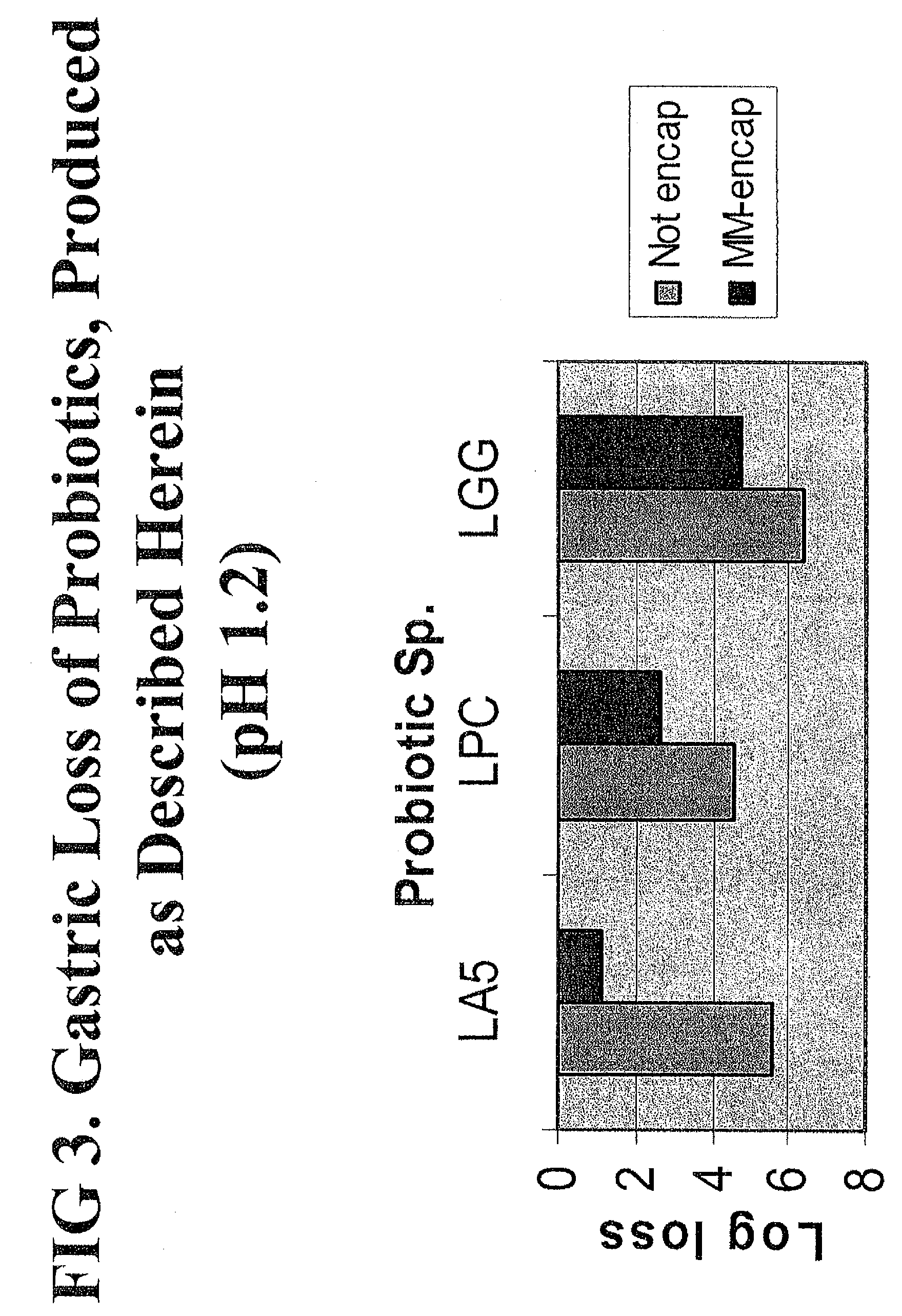

Probiotic delivery system

InactiveUS20050153018A1Improve stabilityProcessing is easy and straightforwardFood ingredient as barrier agentMicroorganism preservationMicroorganismBiotechnology

The present invention relates to a probiotic delivery system that is preferably added to a food product. In particular, the invention shows that compacted pellets having a volume of at least 0.02 cm3, that comprise, besides viable micro-organisms, arbitrary or eligible components, such as fillers, binder, plasticizer, other functional ingredients and a coating may be added to semi-moist, moist or semi-dry products. The micro-organisms remain viable for a longer time than commercially obtainable preparations of probiotics.

Owner:NESTEC SA

Method for rapidly making a 3-D food object

InactiveUS6280784B1Rapid productionBroad spectrumConfectionerySweetmeatsControl signalAdditive ingredient

Owner:NANOTEK INSTR GRP LLC

Uniform films for rapid-dissolve dosage form incorporating anti-tacking compositions

The present invention relates to water-soluble films incorporating anti-tacking agents and methods of their preparation. Anti-tacking agents may improve the flow characteristics of the compositions and thereby reduce the problem of film adhering to a user's mouth or to other units of film. In particular, the present invention relates to edible water-soluble delivery systems in the form of a film composition including a water-soluble polymer, an active component selected from cosmetic agents, pharmaceutical agents, vitamins, bioactive agents and combinations thereof and at least one anti-tacking agent.

Owner:AQUESTIVE THERAPEUTICS INC

Modular fabrication systems and methods

ActiveUS20060160250A1Improve throughputHigh-throughput applicationsLiquid surface applicatorsSemiconductor/solid-state device manufacturingMulti materialEngineering

The present invention relates to an article fabrication system having a plurality of material deposition tools containing one or more materials useful in fabricating the article, and a material deposition device having a tool interface for receiving one of the material deposition tools. A system controller is operably connected to the material deposition device to control operation of the material deposition device. Also disclosed is a method of fabricating an article using the system of the invention and a method of fabricating a living three-dimensional structure.

Owner:CORNELL RES FOUNDATION INC

Coated polyunsaturated fatty acid-containing particles and coated liquid pharmaceutical-containing particles

InactiveUS20060068019A1Powder deliveryLiquid surface applicatorsFatty acids.polyunsaturatedFatty acid

A process for coating a polyunsaturated fatty acid (PUFA)-containing carrier particle or a PUFA matrix particle, or a liquid pharmaceutical-containing carrier particle or a liquid pharmaceutical matrix particle. Also disclosed are such particles made by the process of the invention and foods, pharmaceuticals, beverages, nutritional supplements, infant formula, pet food and animal feed with incorporate such particles.

Owner:SOLAE LLC

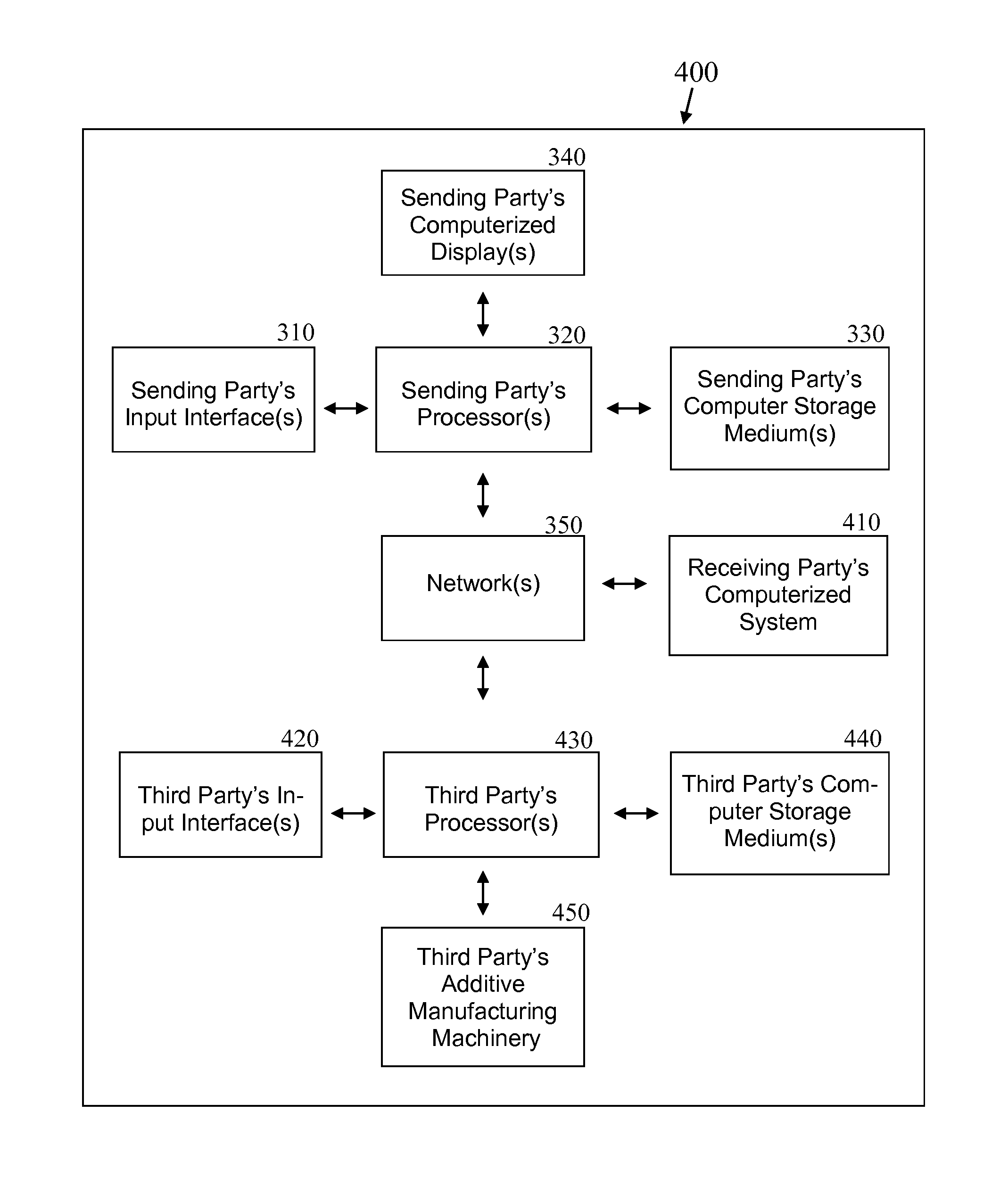

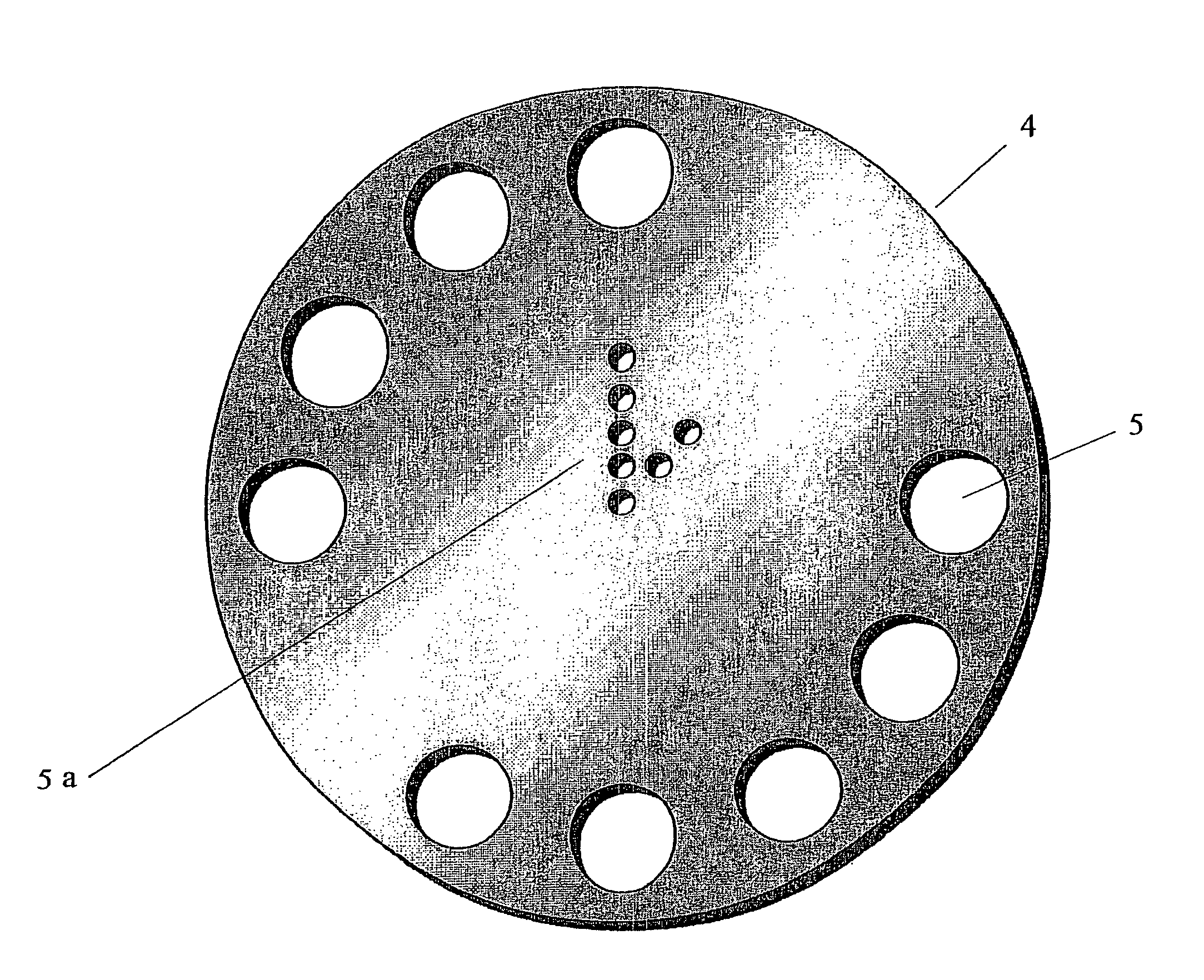

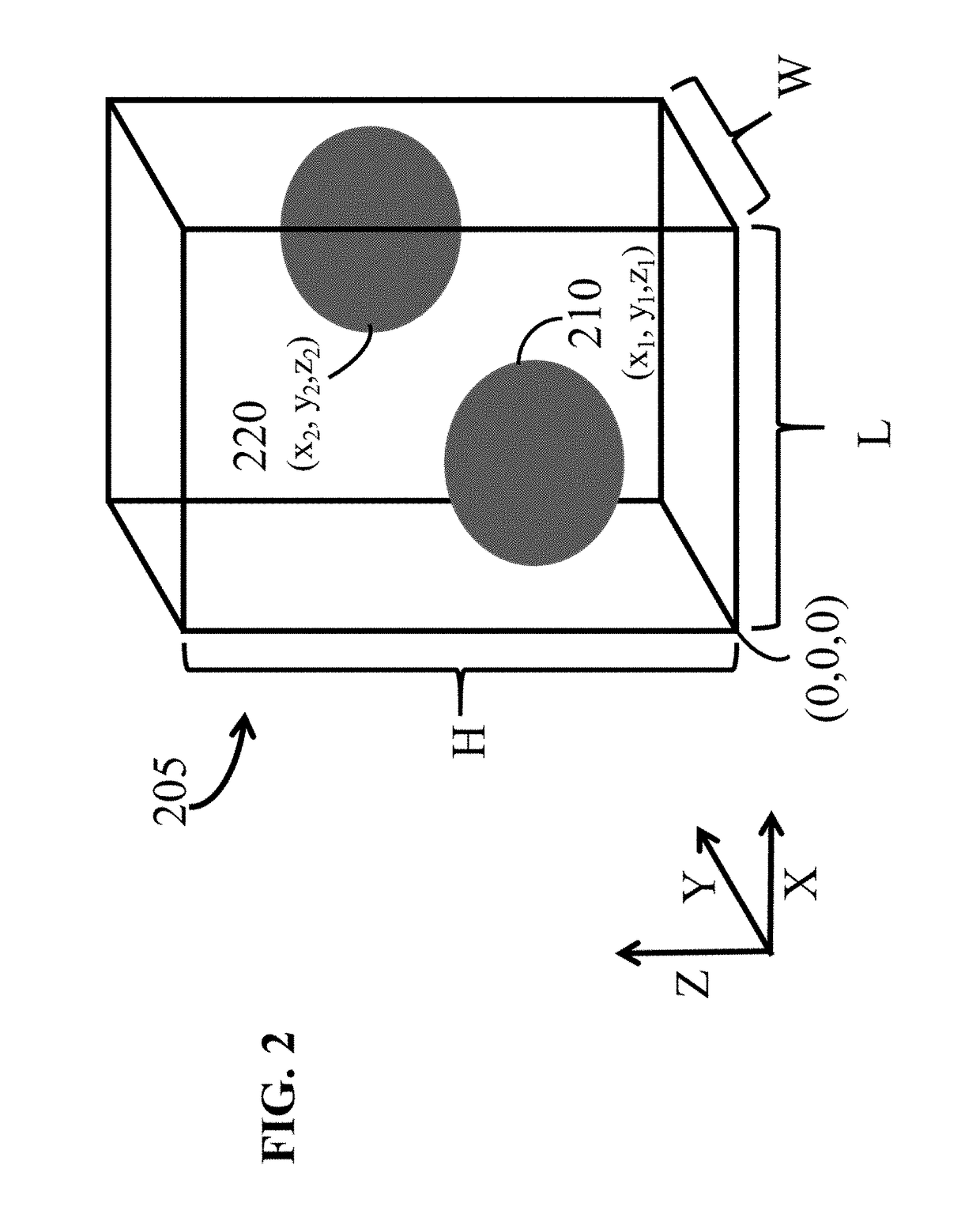

Game object advances for the 3D printing entertainment industry

Embodiments describe constructing game-related objects through additive manufacturing systems. At least one construction configuration for building a game-related object is advanced at least partly due to at least one game task result being attained by a user and / or due to when an object is constructed and / or arranged to be built. Several embodiments demonstrate select game task results leading to determined construction configurations instead of alternative construction configurations, causing, for instance, a differing design, complexity, function, and / or number of constructed object portions. Game task results in certain embodiments lead to multiple distinct portions of one or more objects being constructed concurrently and / or successively, at one or more locations. Selected methods and systems disclose objects constructed as awards, puzzles, other assembly challenges, educational challenges, wagering elements, electronic game elements, in multiple inseparable portions, and / or for other entertainment purposes.

Owner:NEVINS JOEL

Multi-functional product markers and methods for making and using the same

InactiveUS7163744B2Increase information storage capacitySafe, reliable, easily read, and inexpensiveStampsFood coatingEngineeringMulti feature

Owner:BURNTSIDE PARTNERS

Browning agent

A browning agent for foodstuffs having at least two carbonyl groups is disclosed. A method for using the browning agent in or on a substrate is also disclosed. The browning agent may be coated onto foodstuffs such as biscuits, pizza, pie coverings or hash brown potatoes and heated by microwave or convection oven to induce browning.

Owner:GENENCOR INT INC

Three-dimensional printer for printing liquid materials

ActiveCN103876263AAvoid the hassle of frequent cleaning of equipmentAdditive manufacturing apparatusConfectionerySprayerSpray nozzle

Owner:苏州智能制造研究院有限公司

Lacteal coated pizzas

From dietary health to product diversity, Lacteal Coated Pizzas outperform the venerable four-hundred year old ethnic (Italian) pizzas. Lacteal Coated Pizzas are comprised of soft leaven dough / sourdough that is topped with a delicious, nutritious Lacteal Batter, and a conventional topping. The present invention's Lacteal Batters are innovative, heat-stable, hydrocolloidal-proteineous mixtures that possess unique performance-enhancing, rheological properties.

Owner:BODY STRUCTURES

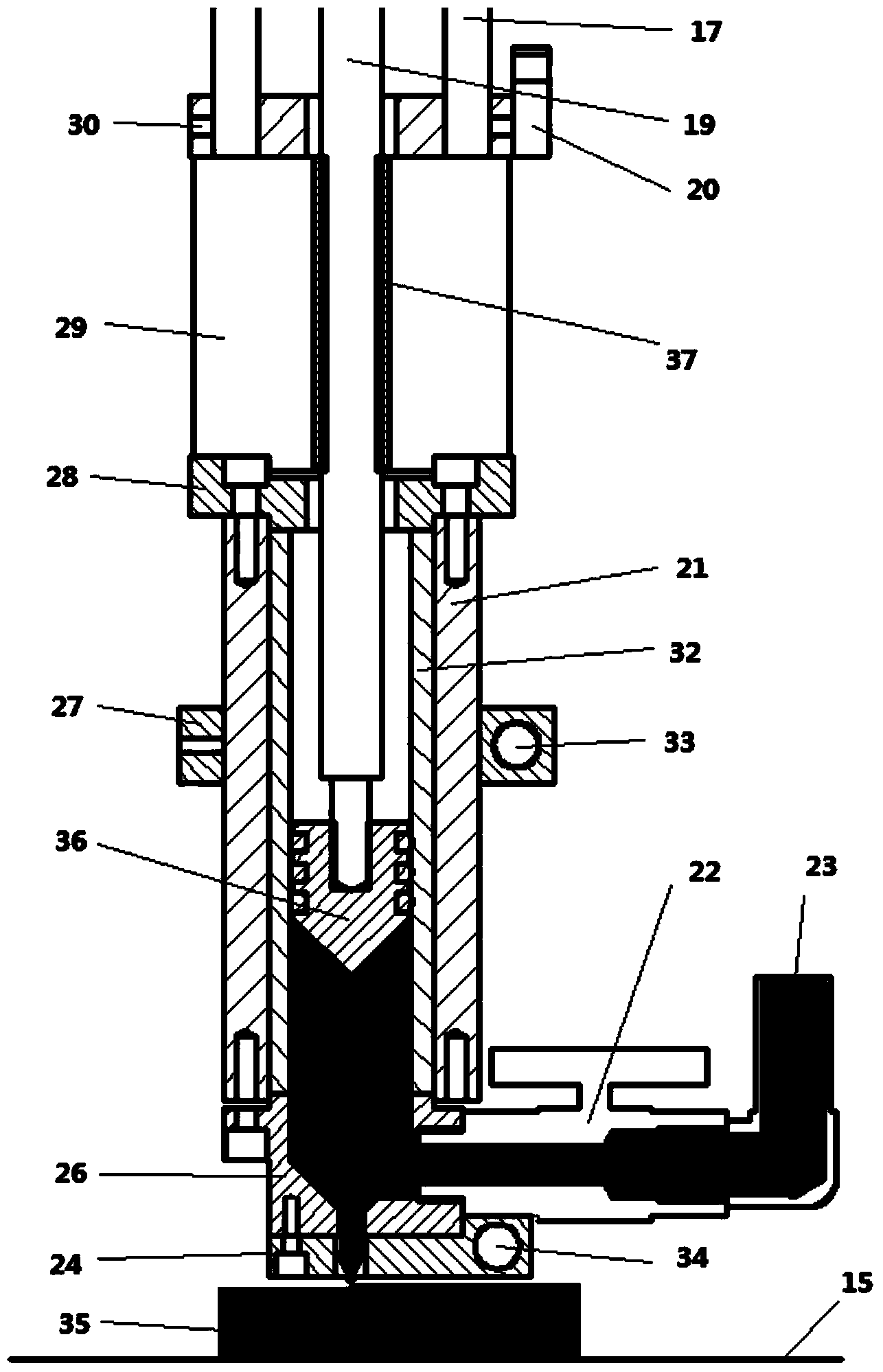

Acid-resistant soft gel compositions

The present disclosure describes a delivery device for administration of nutraceuticals or pharmaceuticals, which device contains a soft gel shell comprising a gelatin-based water soluble film forming polymer, an acid insoluble polymer, and at least one reducing sugar and water, including processes, gel mixtures used for device production, and coatings containing such gel mixtures.

Owner:HASSAN EMADELDIN M

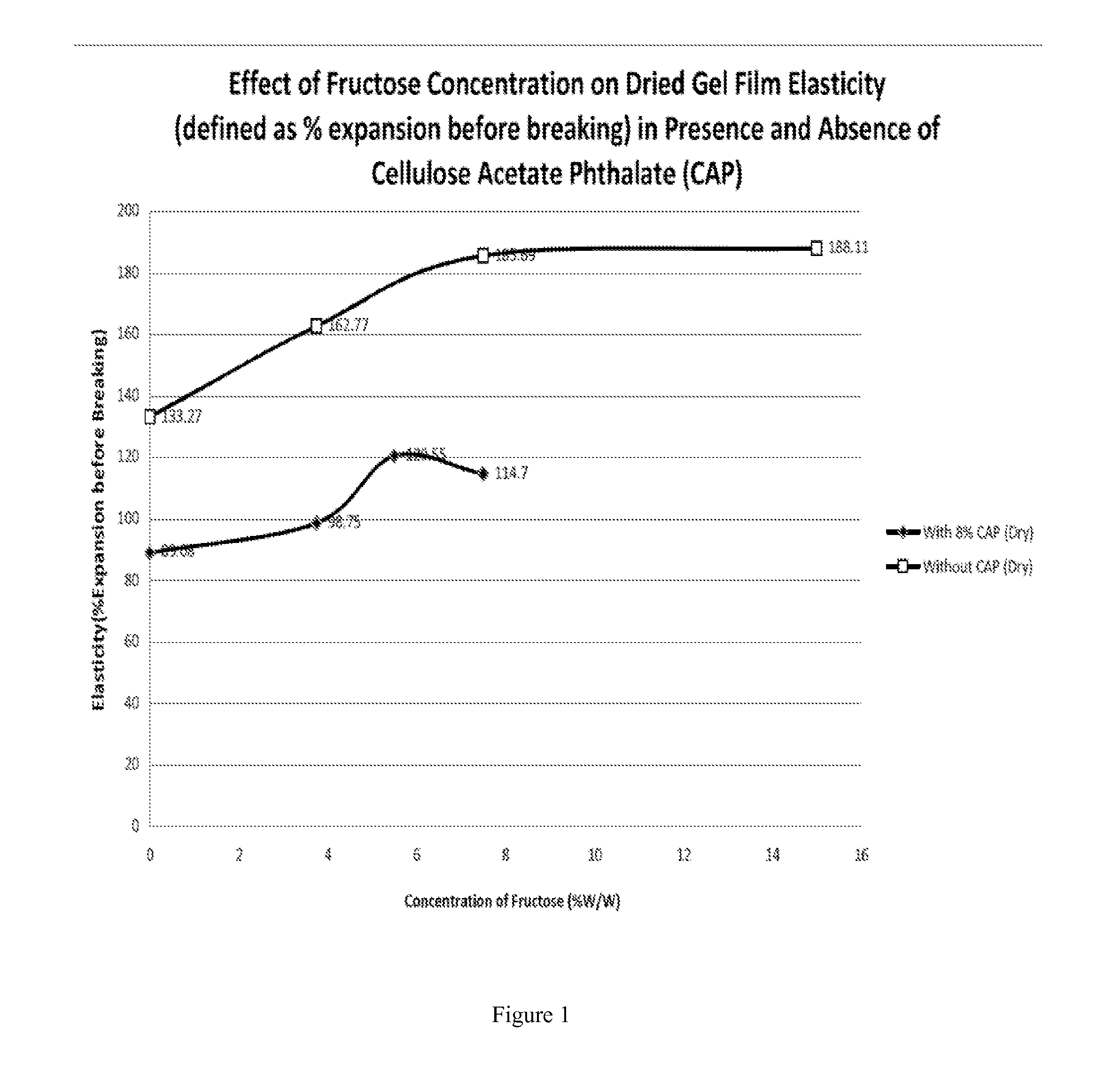

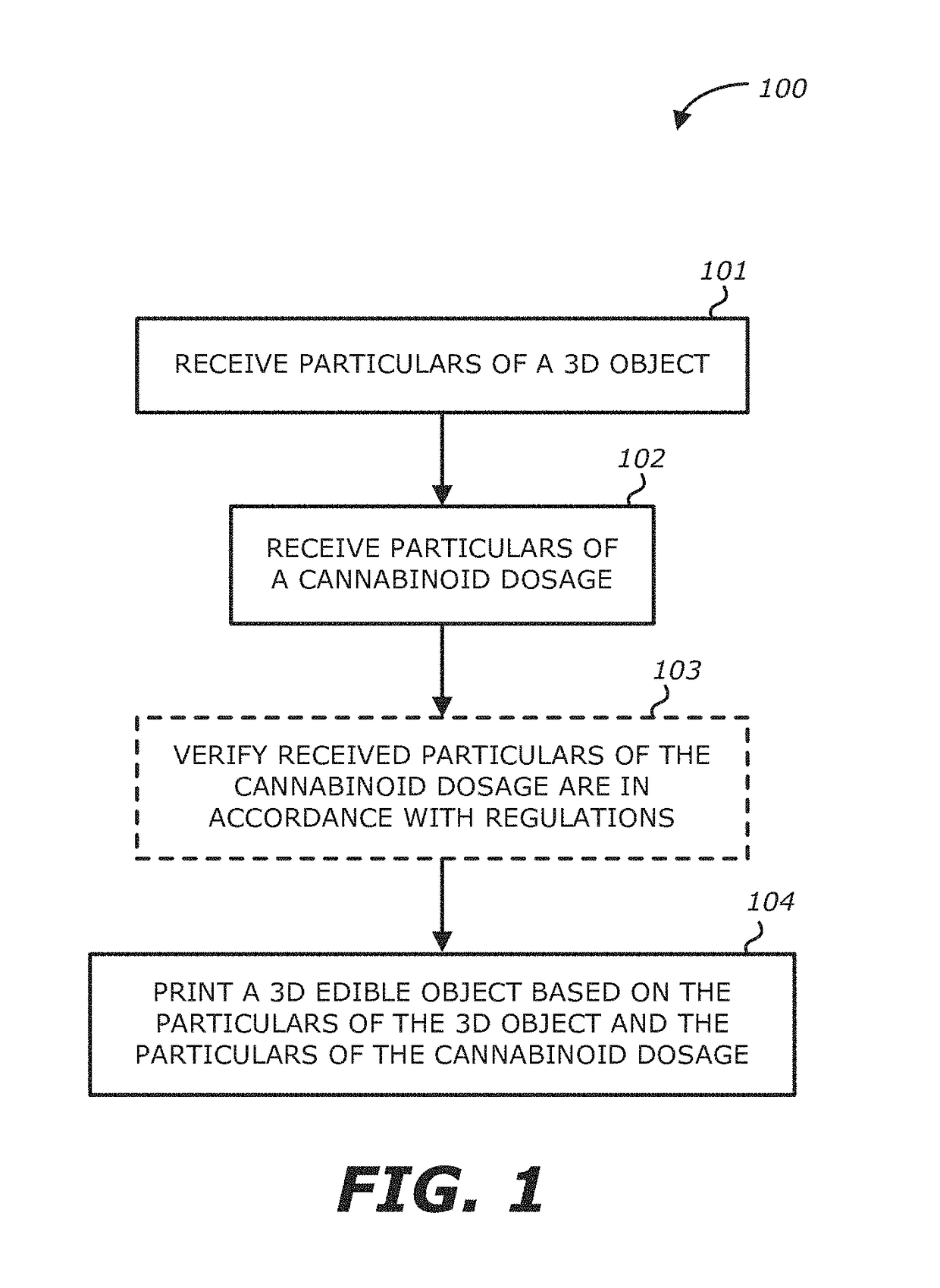

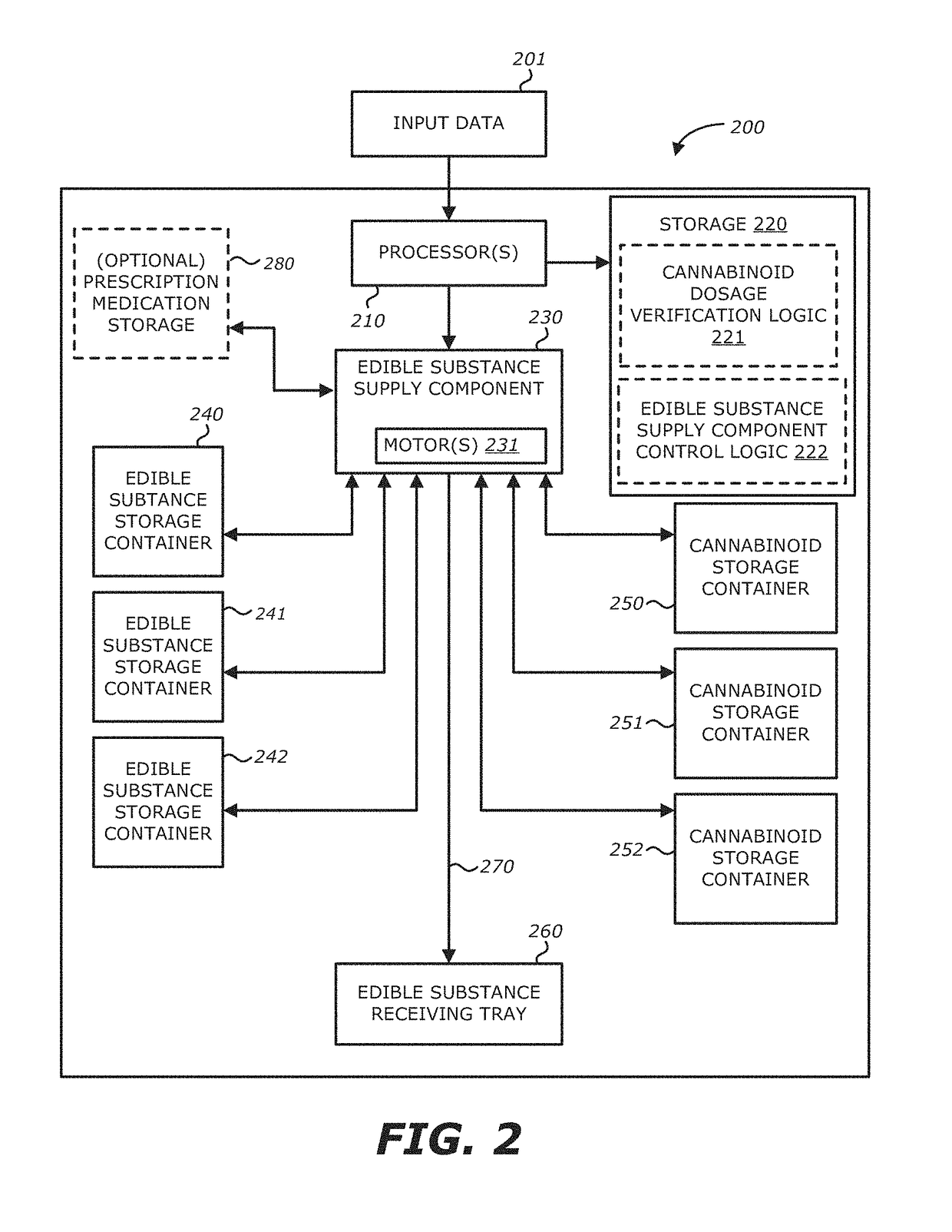

Method, system and apparatus for creating 3D-printed edible objects

InactiveUS9854828B2Additive manufacturing apparatusHydroxy compound active ingredientsObject basedCannabinoid

According to one embodiment, a system of using a three-dimensional (3D) printer to include a cannabinoid comprising: one or more extruders; one or more processors; and a storage module communicatively coupled to the one or more processors, the storage module comprises logic, upon execution by the one or more processors, that receives particulars of a 3D object; receives particulars of a cannabinoid dosage; and instructs the one or more extruders to print the 3D object based on the particulars of the 3D object and the particulars of the cannabinoid dosage, wherein at least a portion of the printed 3D object contains the type of cannabinoid described in the instructions of the particulars of the cannabinoid dosage, and the printed 3D object is edible is provided.

Owner:LANGELAND WILLIAM

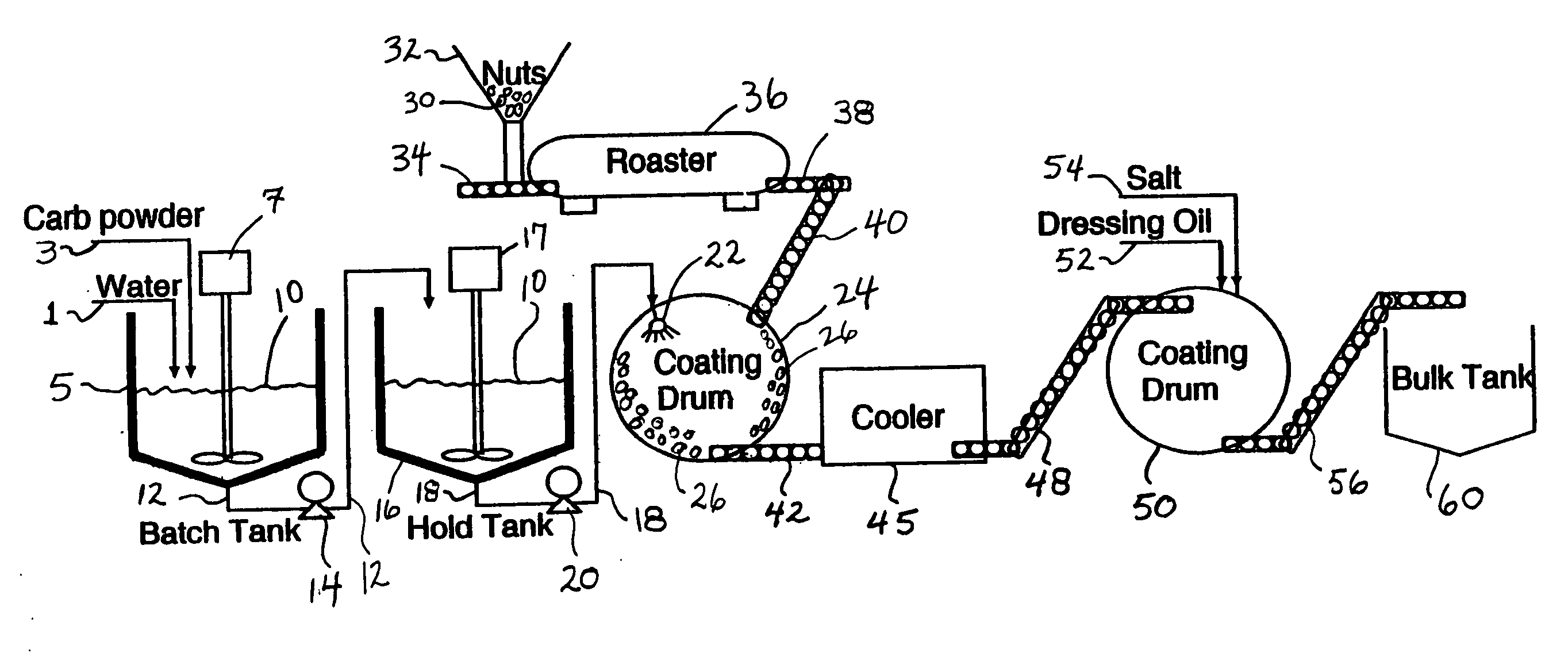

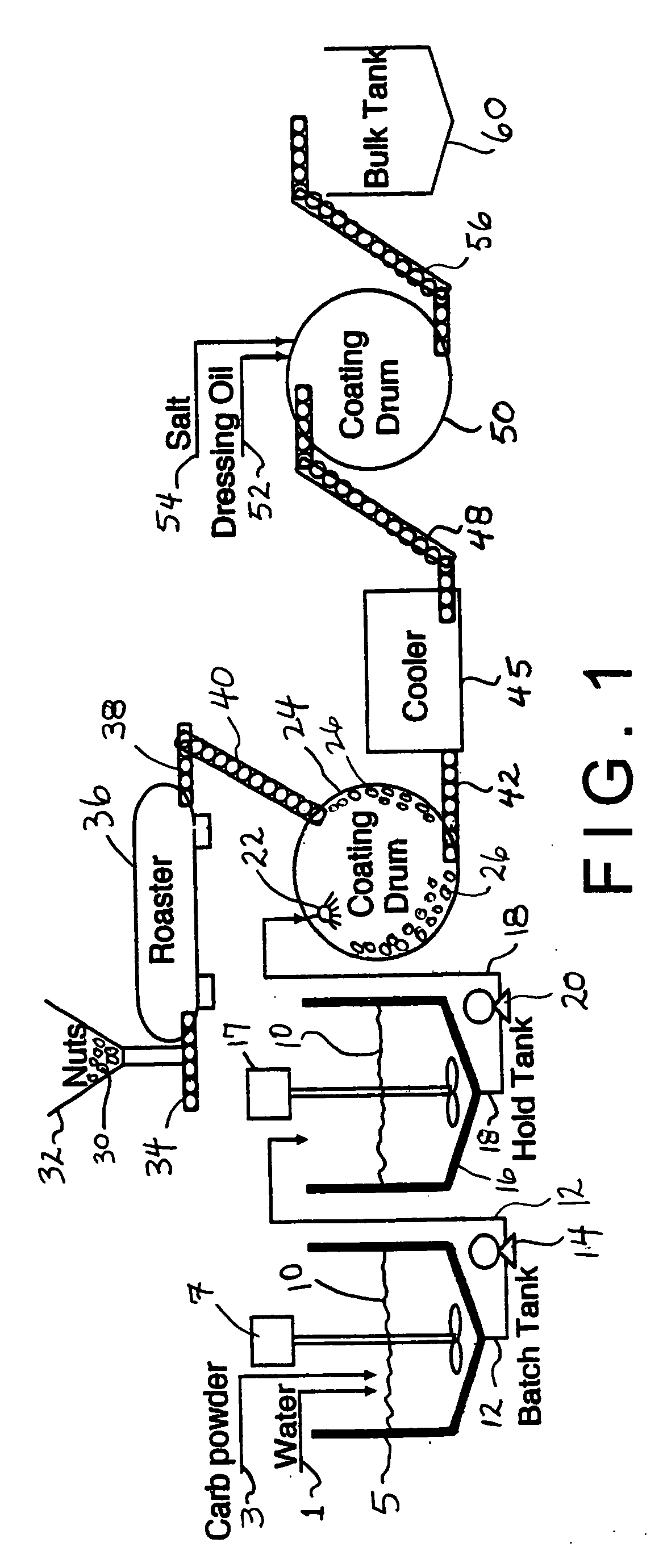

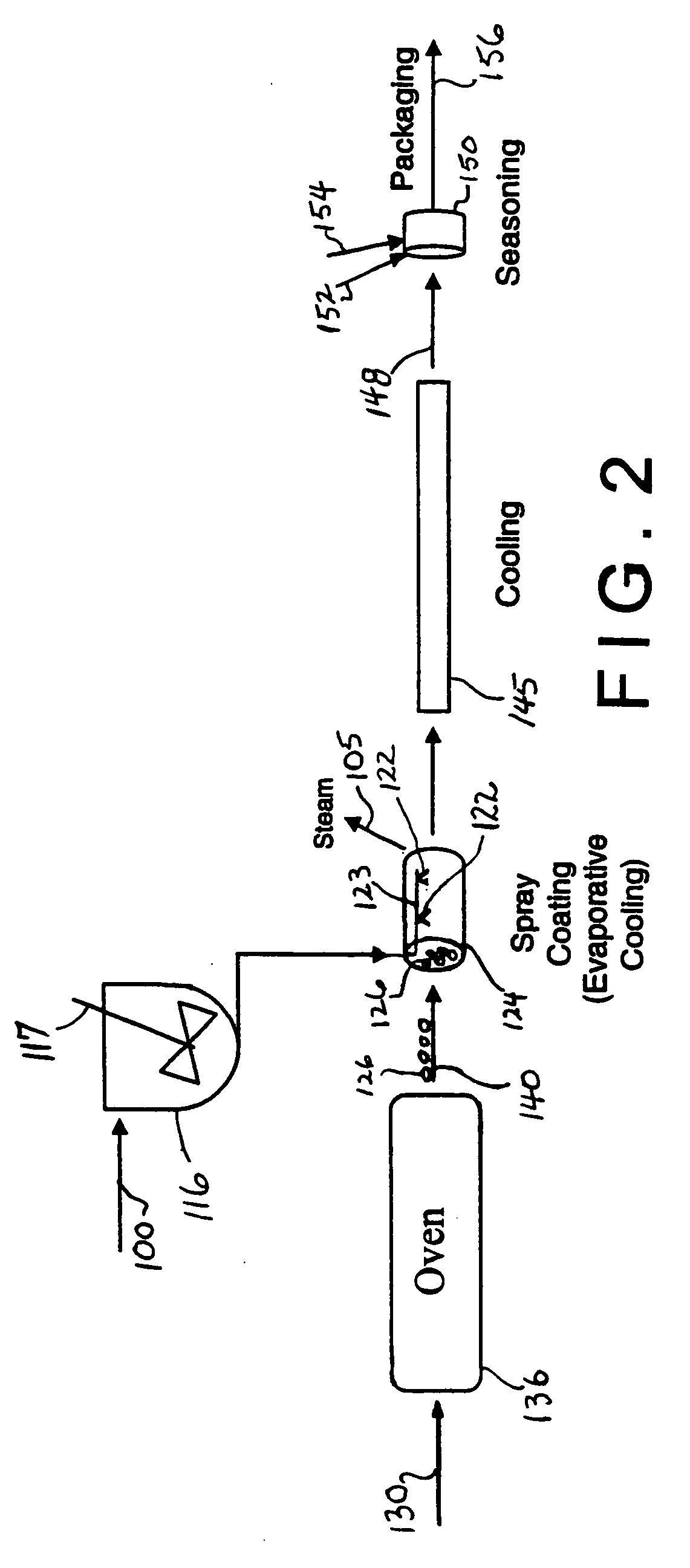

Method and apparatus for applying aqueous coating to cooked foods

A cooked snack food or cooked edible core material, such as roasted nuts, or baked snack chips, while still hot from the cooking step, is tumbled and sprayed with an aqueous solution of a water-soluble, film-forming coating component, such as a maltodextrin. The tumbling and spraying is performed immediately after cooking so that latent heat from the cooked edible core material, reduces the moisture content of the applied aqueous solution to form a dry, thin film coating of the coating component on the edible core material. The need for a separate, subsequent drying step or forced air drying equipment to reduce the moisture content is eliminated by evaporative cooling of the hot cooked snacks and flashing of the applied aqueous coating solution. The dry, coated cooked snack may be cooled to obtain a snack food having a thin, uniform coating which enhances appearance, texture, taste and shelf life.

Owner:KRAFT FOODS GRP BRANDS LLC

3D printer and method for printing an object using a curable liquid

InactiveUS20170251713A1Improve toughnessLow viscosityAdditive manufacturing apparatusFood preservationEngineering3d printer

Owner:TELAMENS INC

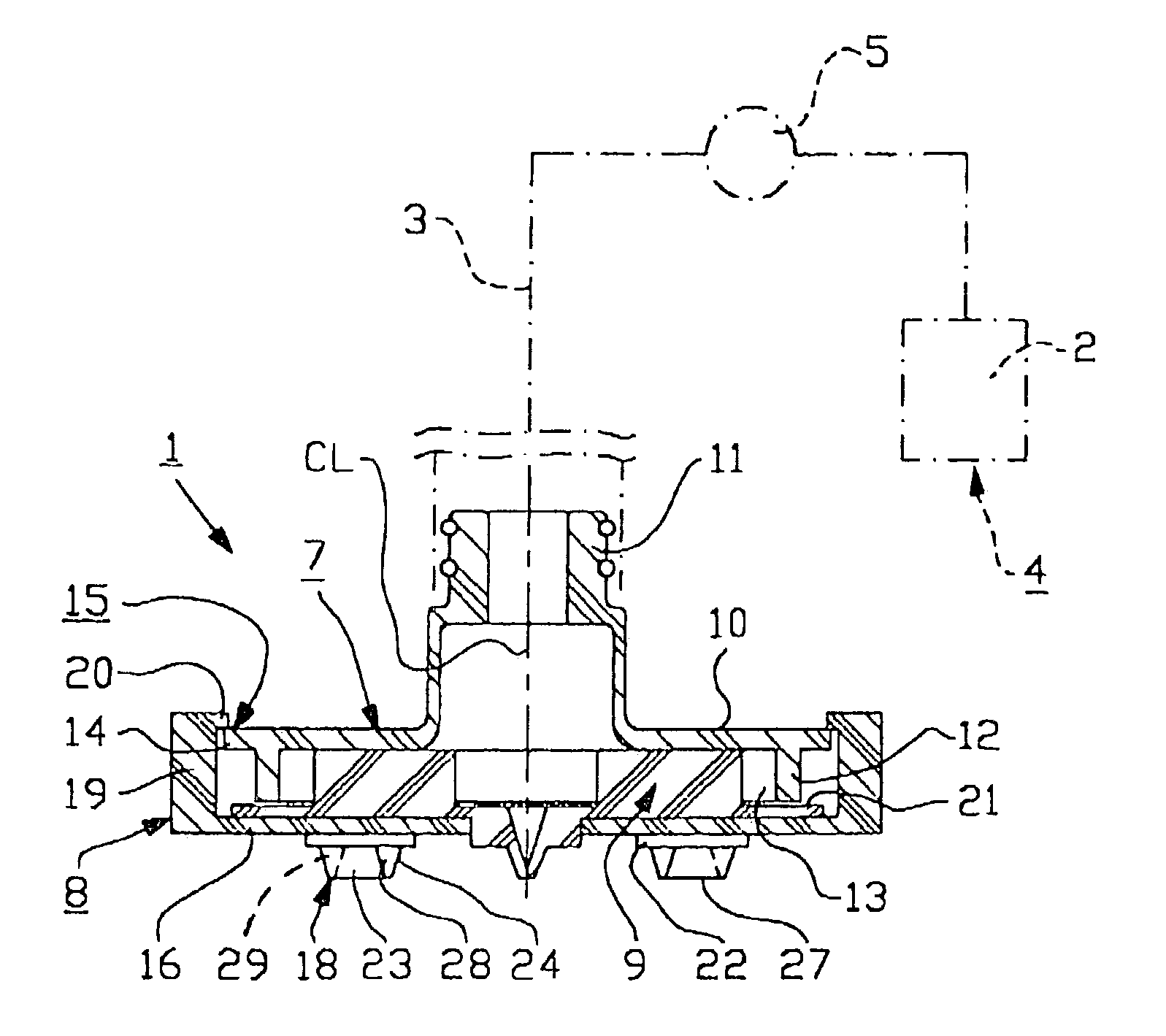

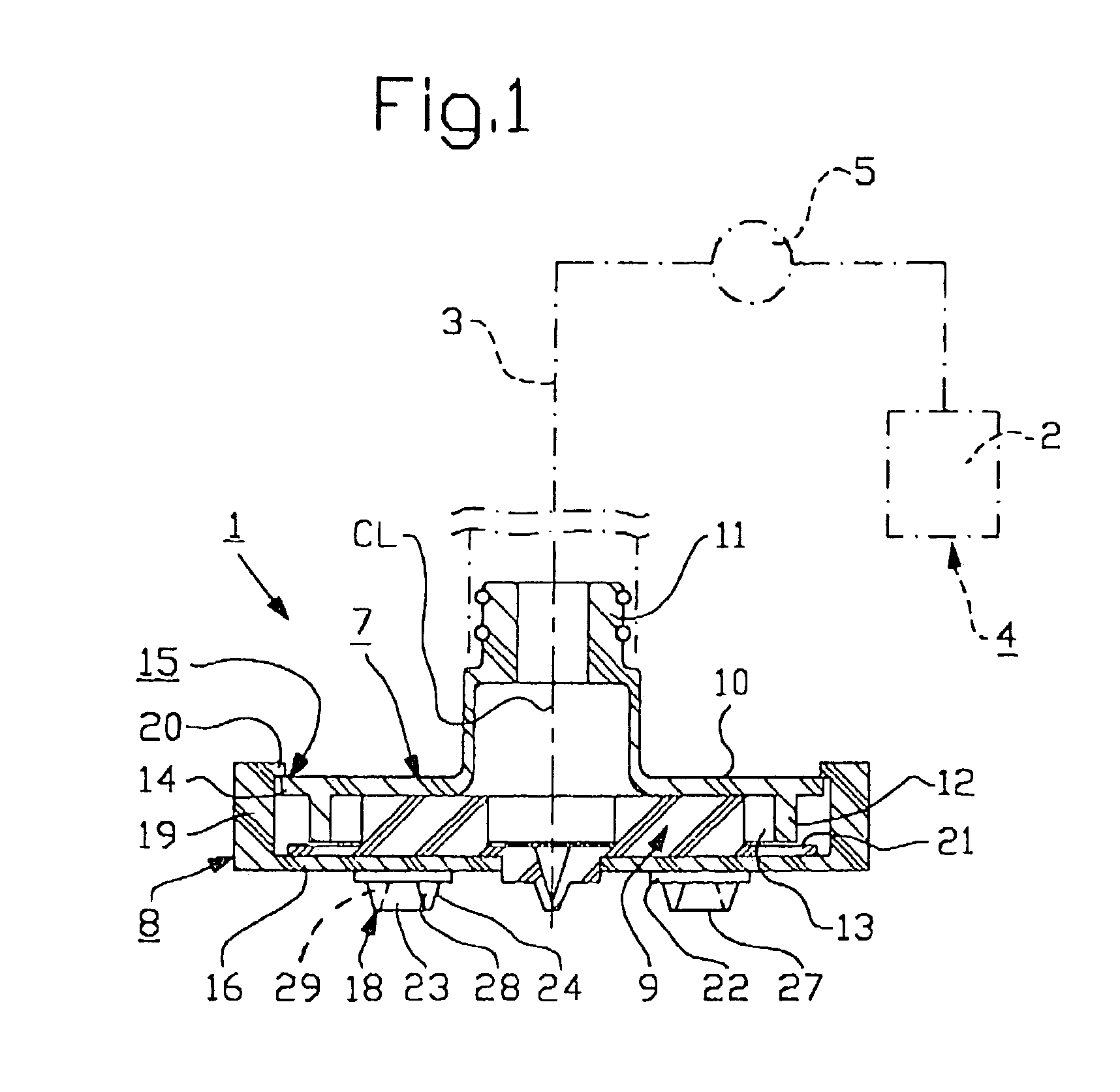

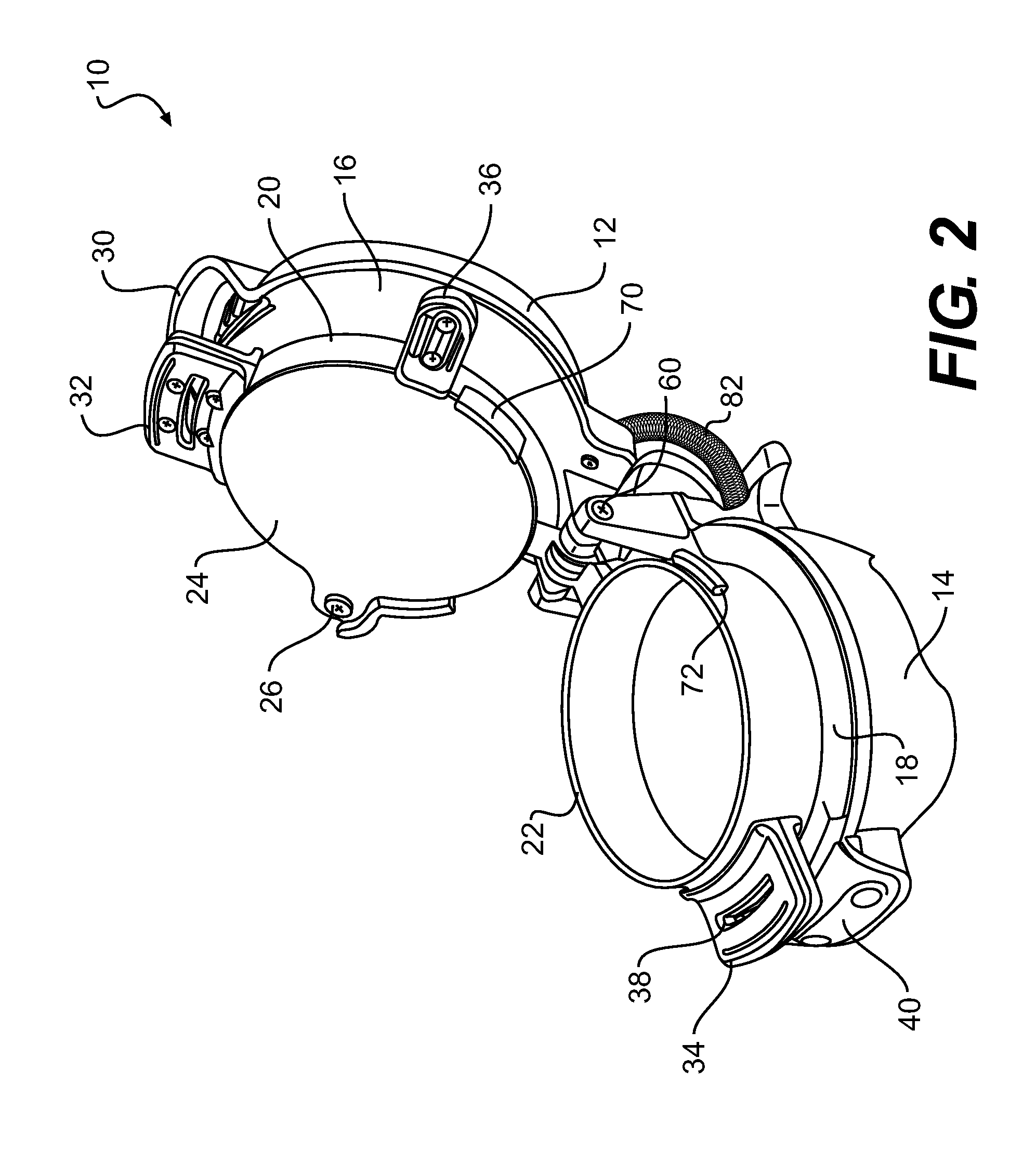

Spray head

InactiveUS7040554B2Eliminate the problemEasy to disassembleLiquid surface applicatorsDust removalLiquid productCoupling

Owner:ASEPT INT

Synchronizing instructional media with object builds to advance the 3D printing industry

Methods and systems are described for constructing media-synchronized objects through additive manufacturing means. At least one construction configuration for at least one object is at least partly synchronized with at least one segment of at least one associated instructional media presentation viewed by a user through at least one media presentation device. Various embodiments demonstrate successive object portions synchronized with successive media presentation segments, at least partly automated object construction synchronized with one or more media presentation segments, and / or user assembly of multiple object portions configured to modify media presentation aspects. In select embodiments, object design modifications by the user are configured to change media presentation aspects. Certain embodiments permit accelerated and / or decelerated object construction being configured to accelerate, decelerate, lengthen, and / or truncate associated media presentations.

Owner:NEVINS JOEL

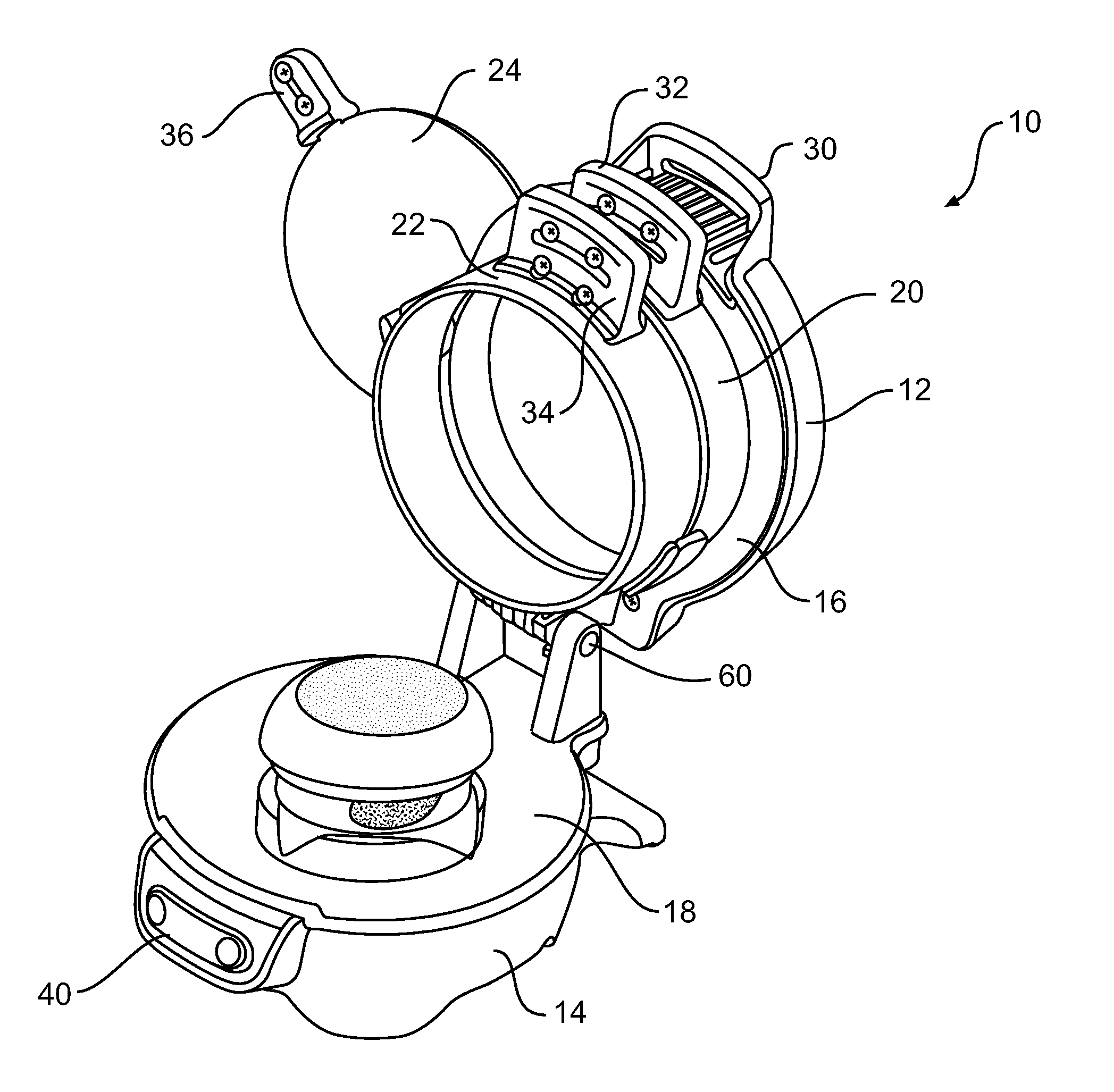

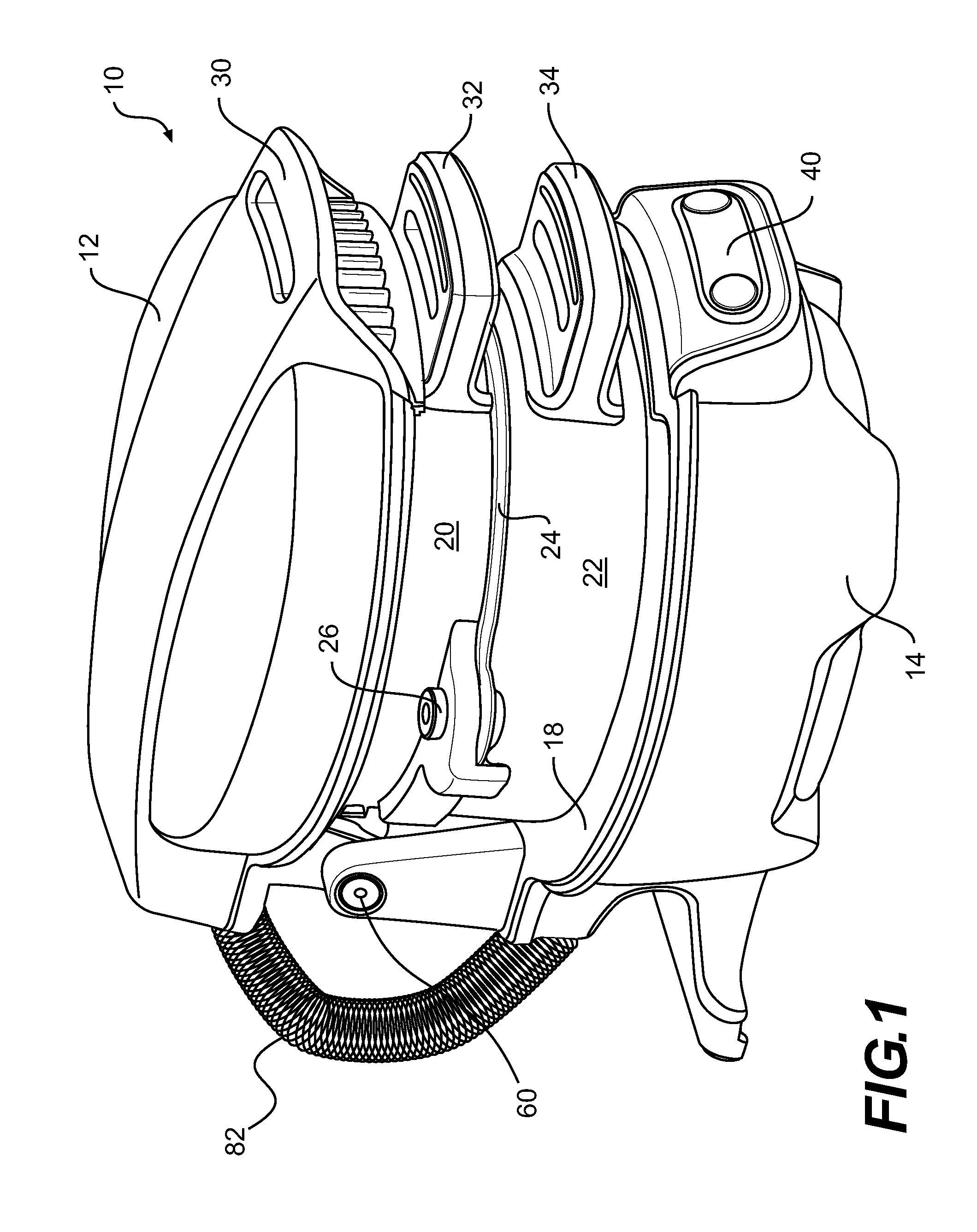

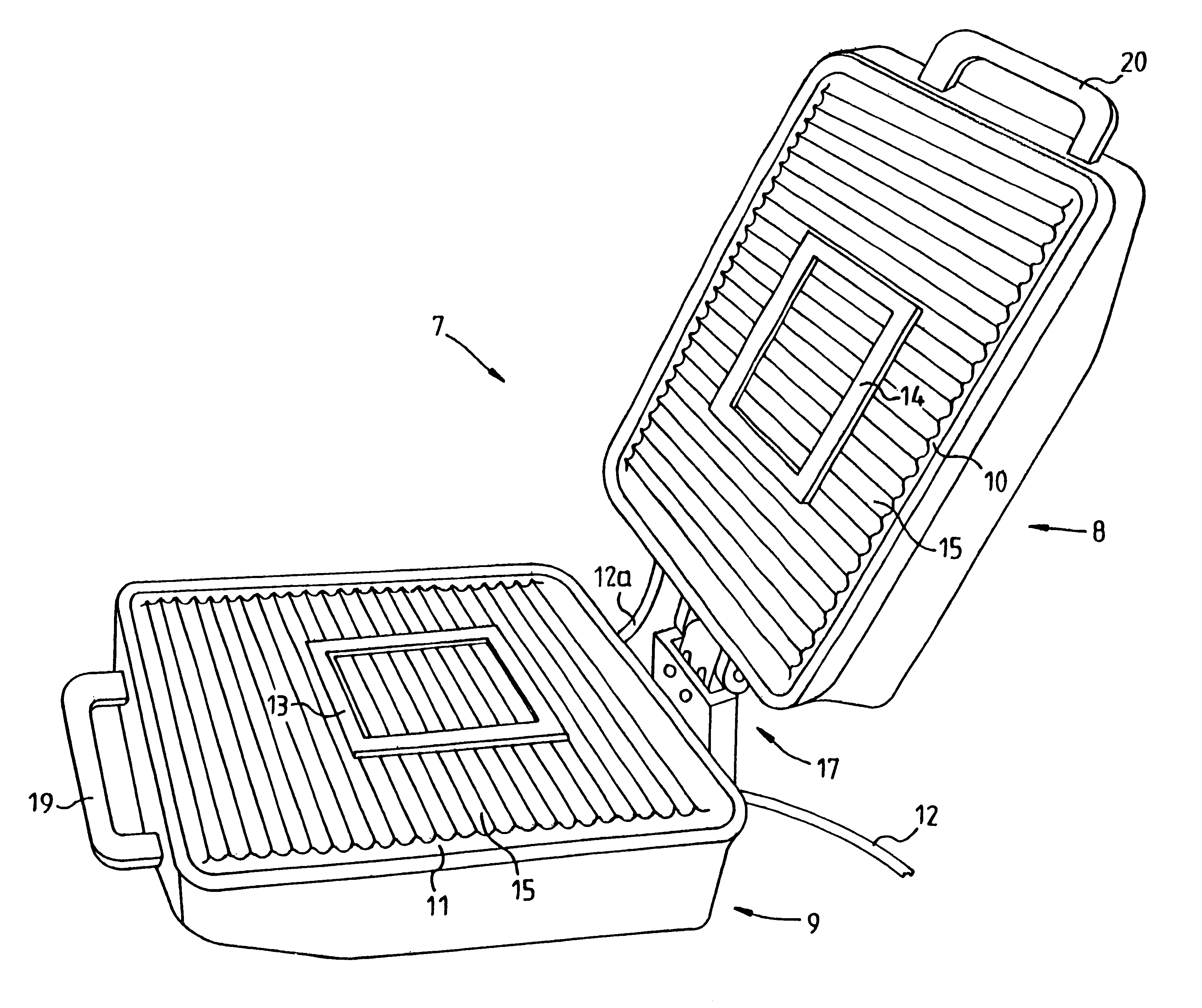

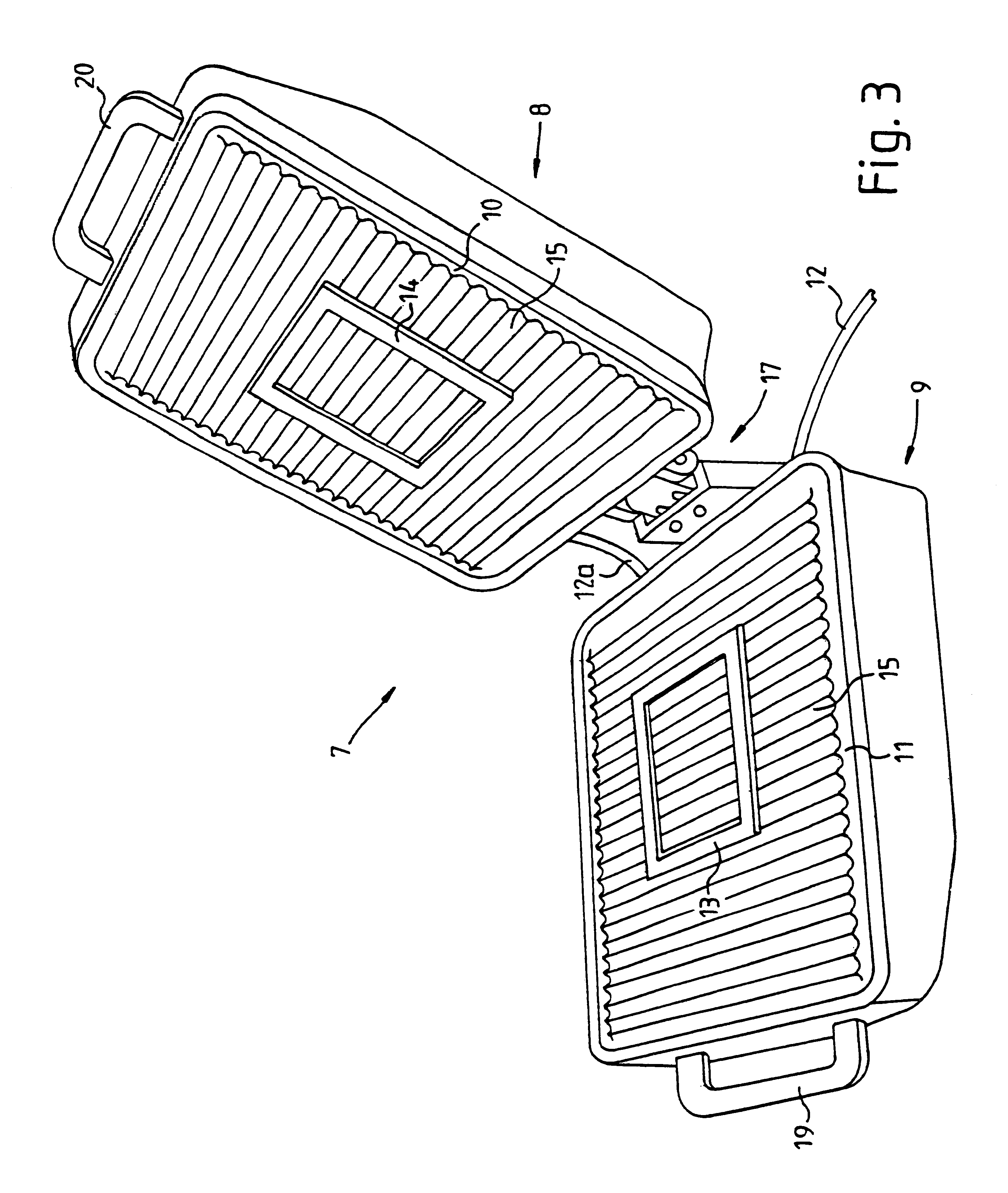

Sandwich Making Appliance and Method of Making a Sandwich with the Same

ActiveUS20140199459A1Reduce heat transferIncrease air spaceMilk preservationMultiple-unit cooking vesselsStructural engineeringCooker

A small cooking appliance comprises a bottom housing, a top housing, and a ring assembly. The bottom housing has a top surface that forms a bottom cooking surface of the appliance. The top housing has a bottom surface that forms a top cooking surface of the appliance. The top housing is movably attached to the bottom housing and moveable between a closed position and an open position. The ring assembly is positionable between the top and bottom cooking surfaces when the top housing is in its closed position. The ring assembly comprises a top ring, a bottom ring, and an optional center cooking plate. The center cooking plate is movable between (i) a closed position in which a space defined by the ring assembly is divided into top and bottom cooking cavities and (ii) an open position.

Owner:HAMILTON BEACH BRANDS

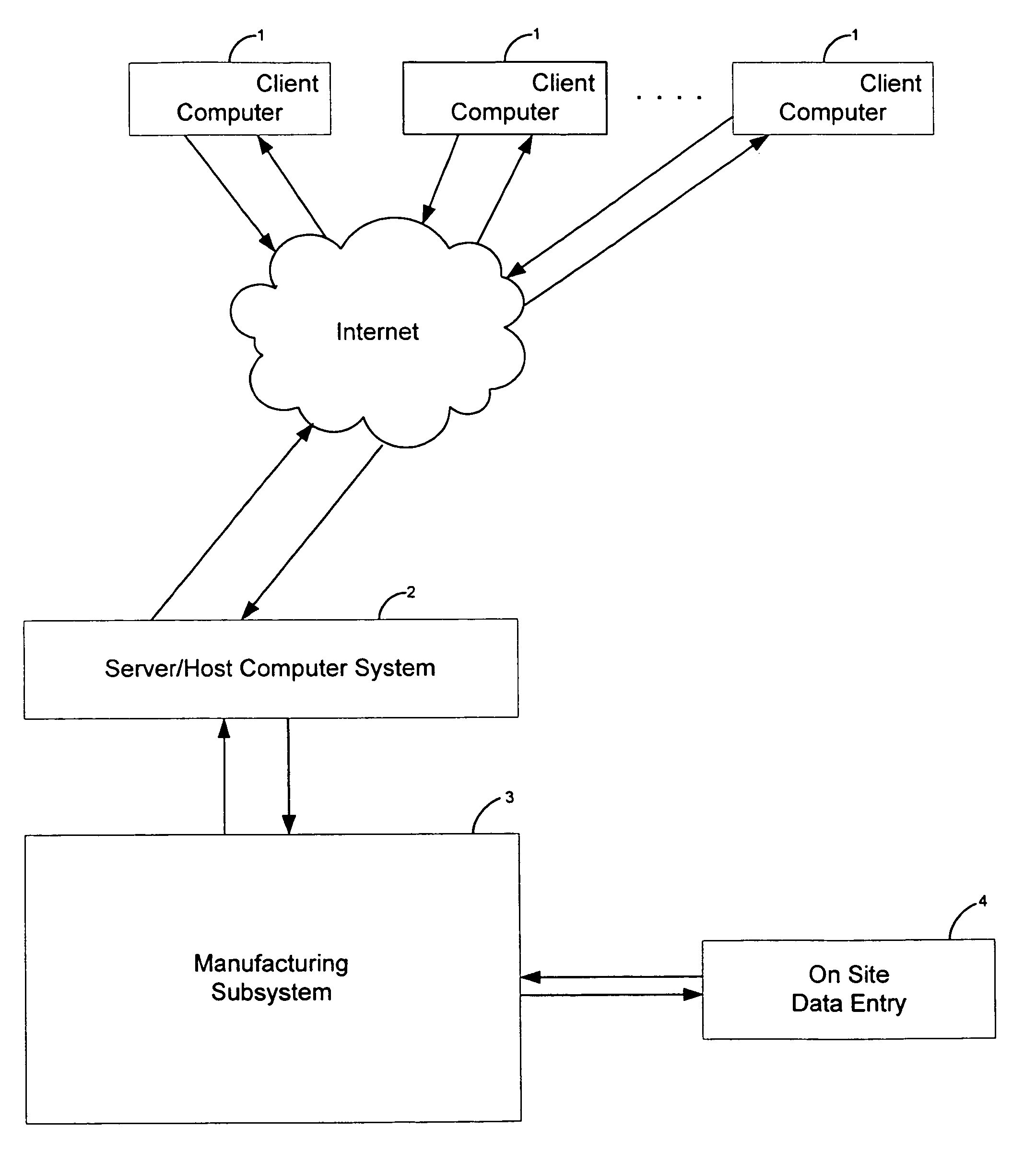

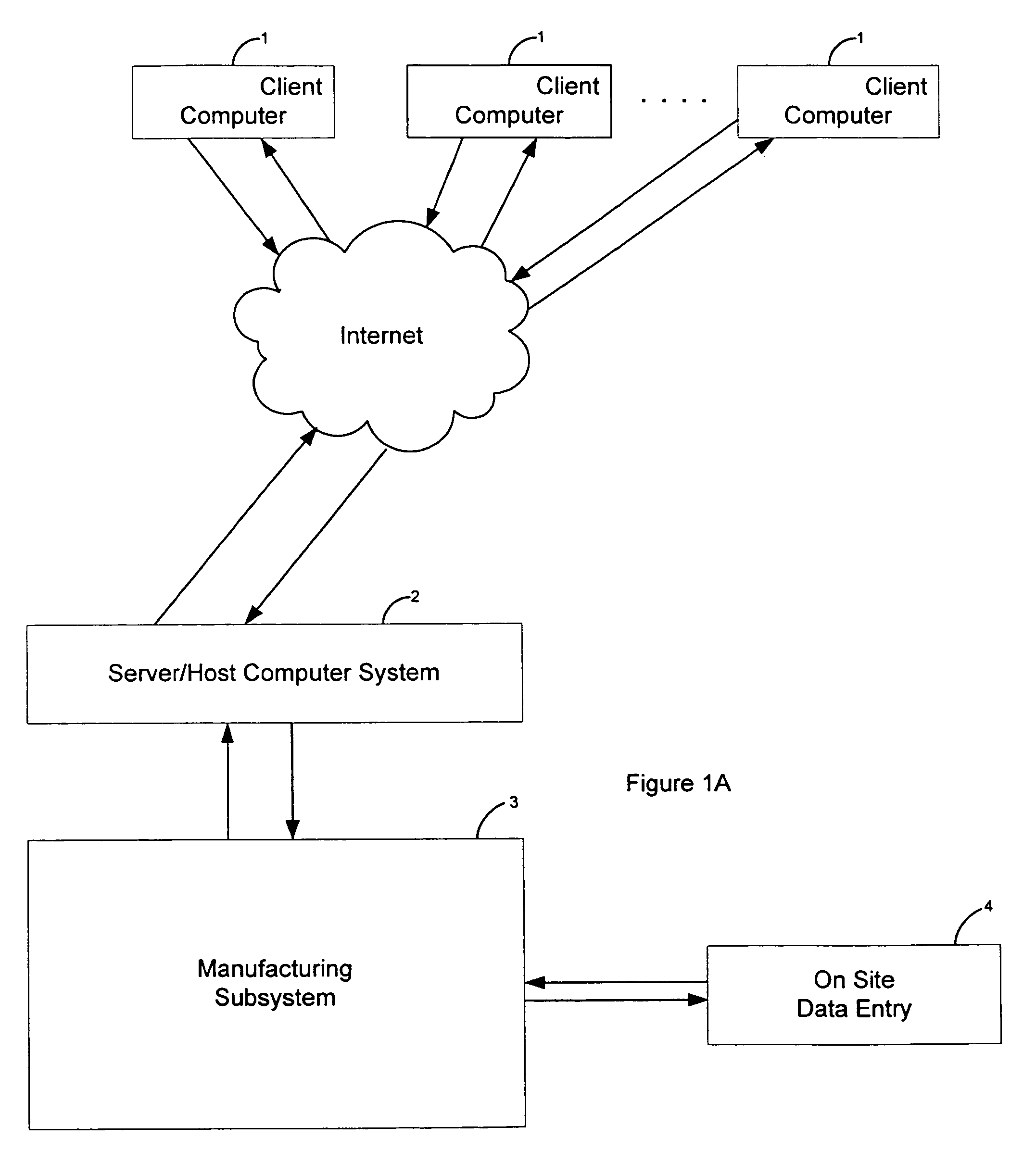

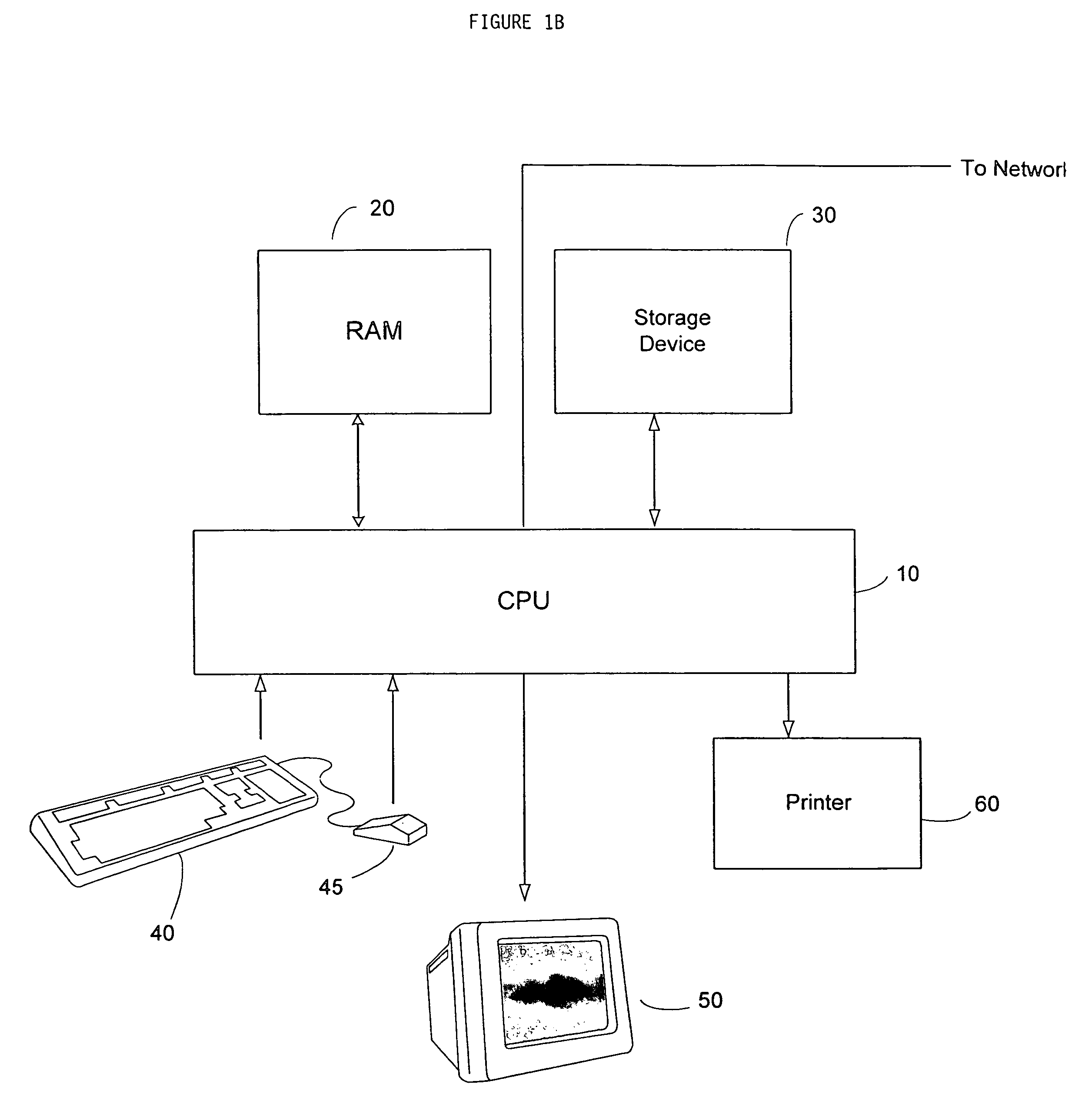

High resolution ink-jet printing on edibles and products made

InactiveUS7884953B1Quality improvementHigh quality imagingDigitally marking record carriersFrozen sweetsImage resolutionInk printer

Disclosed are methods of printing high resolution images on edible substrates with dispersed pigmented inks using a drop-on-demand ink-jet printer. Dispersed pigmented white inks useful with the inventive methods are also disclosed. White images having a resolution greater than 200 dpi can be printed on chocolate using the methods and inks disclosed herein. The inventive methods and inks may also be integrated with a consumer-driven site vending or e-commerce application in which the consumer provides the image to be printed and edibles bearing the printed image are prepared for rapid turnaround.

Owner:MARS INC

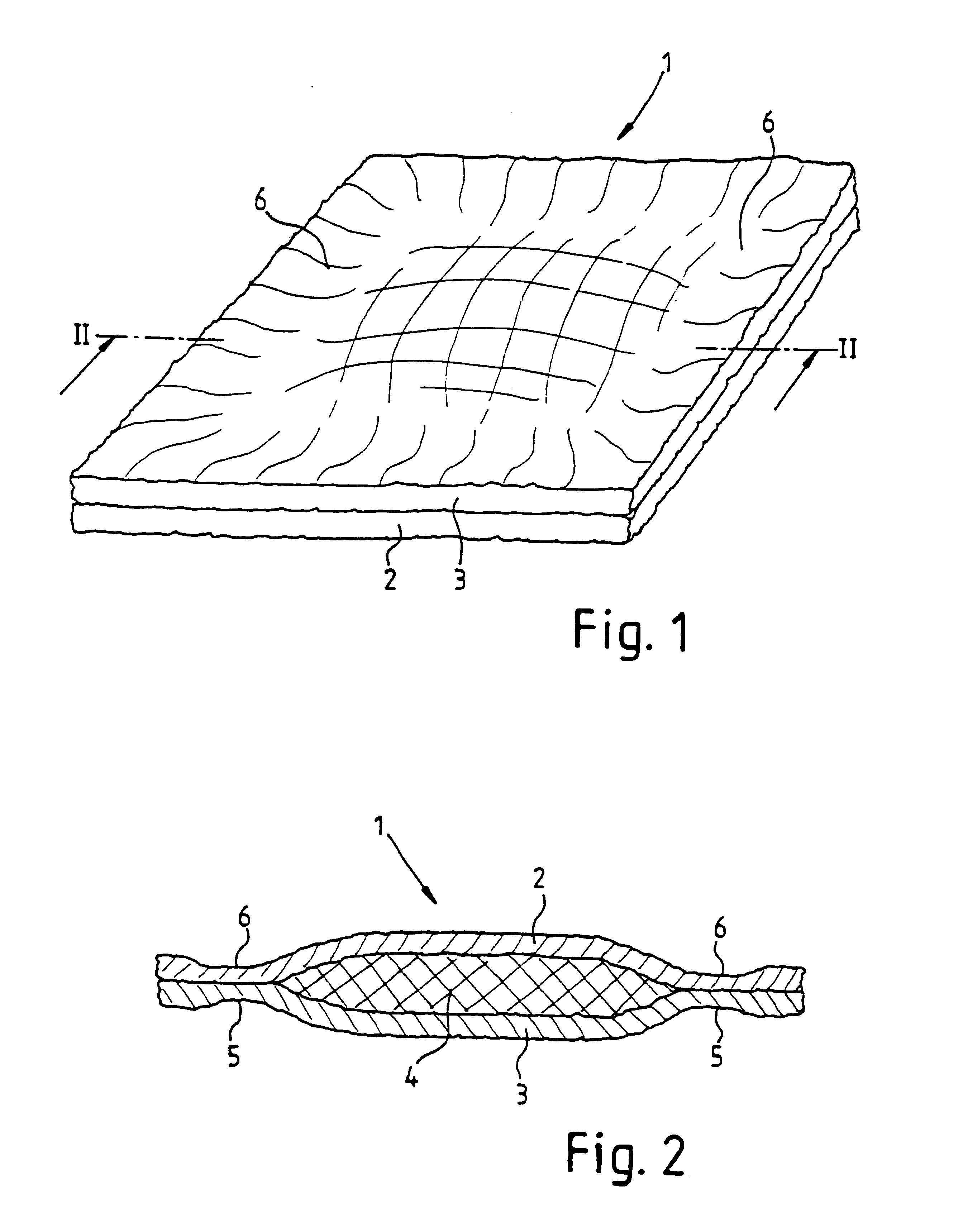

Sandwich and method for the production thereof

The invention relates to a sandwich consisting of two toasted slices of bread and an edible filling placed between said slices. According to the invention, the filling is essentially arranged in the inner region of the surfaces of the slices of bread and the slices of bread are pressed together in a peripheral edge area with greater force than in the inner region so that the slices of bread adhere to each other and form a cohesive sandwich arrangement, whereby the filling is packed between the slices of bread. The invention also relates to a method for the production of a toasted sandwich that consists of two slices of bread and an edible filling placed between said slices. According to the invention, the filling is initially and essentially arranged in the inner region of the surface of a first underlying slice of bread. A second slice of bread is subsequently placed thereon. The sandwich arrangement is pressed together in an edge area with greater force than in the inner region under the effect of heating, whereby the slices of bread and the filling placed therebetween form a cohesive sandwich arrangement whose peripheral edge areas are closed. The invention further relates to a device for the production of an inventive sandwich.

Owner:STEINBACH ORTWIN +1

Trans fat replacement system and method of making a baked good with a trans fat replacement system

The invention provides a trans fat replacement system that is a stable and shelf storable mixture of an edible oil and an expanded, low-density carbohydrate for use in preparing baked goods having a reduced trans fat content. Depending upon formulation and processing, the mixture can have a consistency ranging from generally granular to an almost paste-like consistency. The trans fat replacement system consists of at least one edible oil and an expanded, low-density carbohydrate having a bulk density less than about 0.4 g / cc. The trans fat replacement system can be used to reduce or eliminate the amounts of traditional fats used to make baked goods. In one representative formulation, the trans fat replacement system can take the form of a generally, paste-like mixture that is suitable for spreading and is especially useful for the preparation of laminated dough products such as biscuits and croissants.

Owner:GENERAL MILLS INC

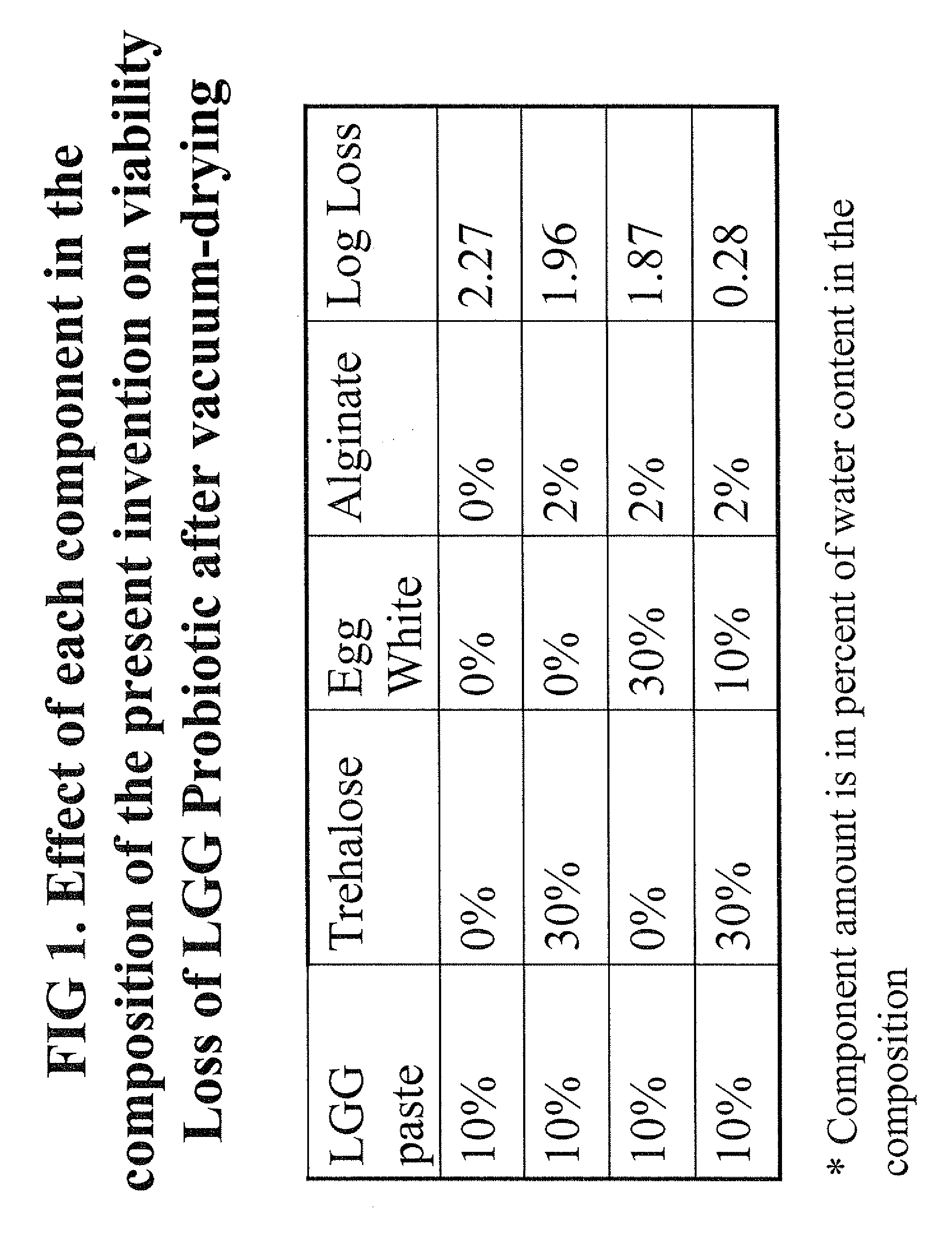

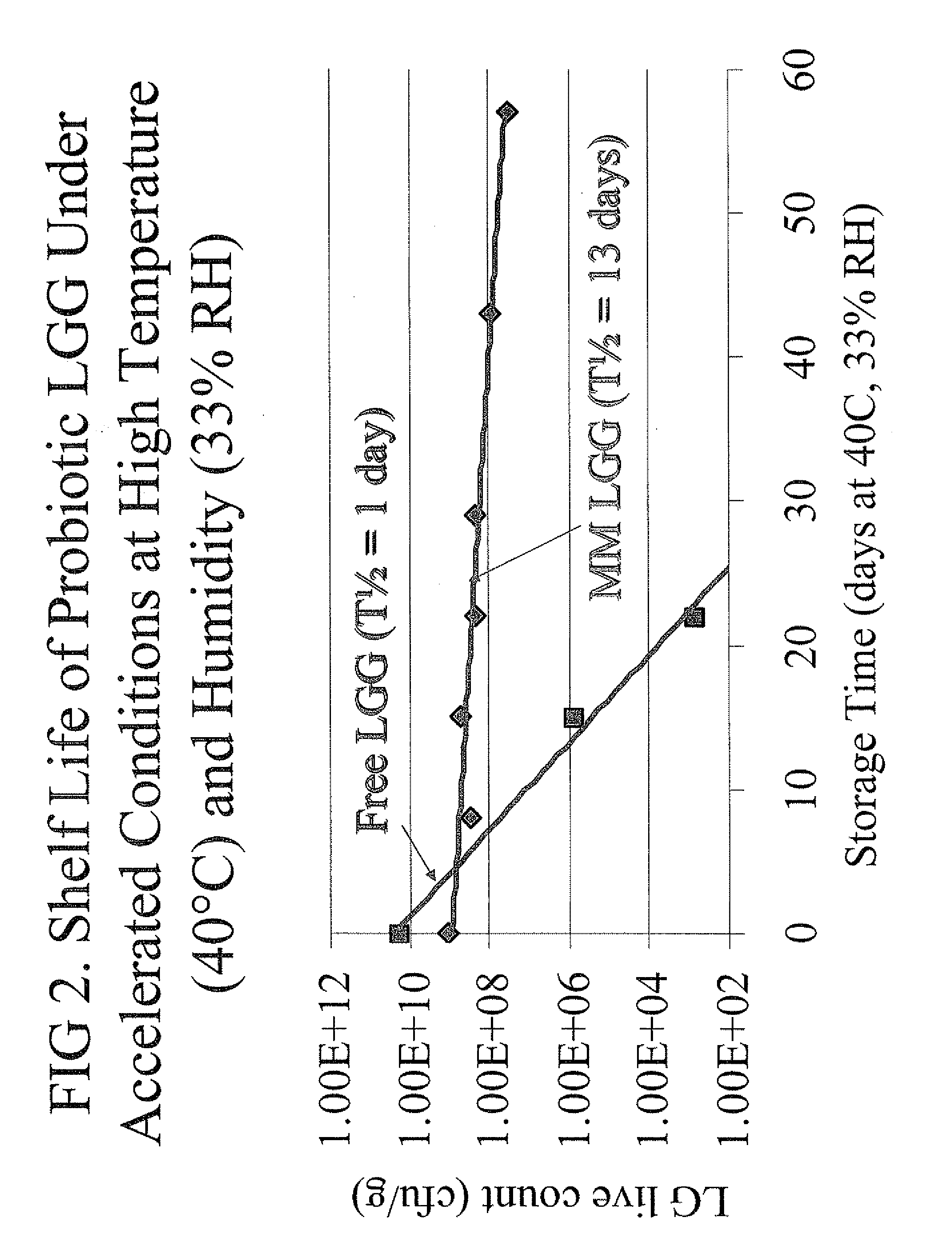

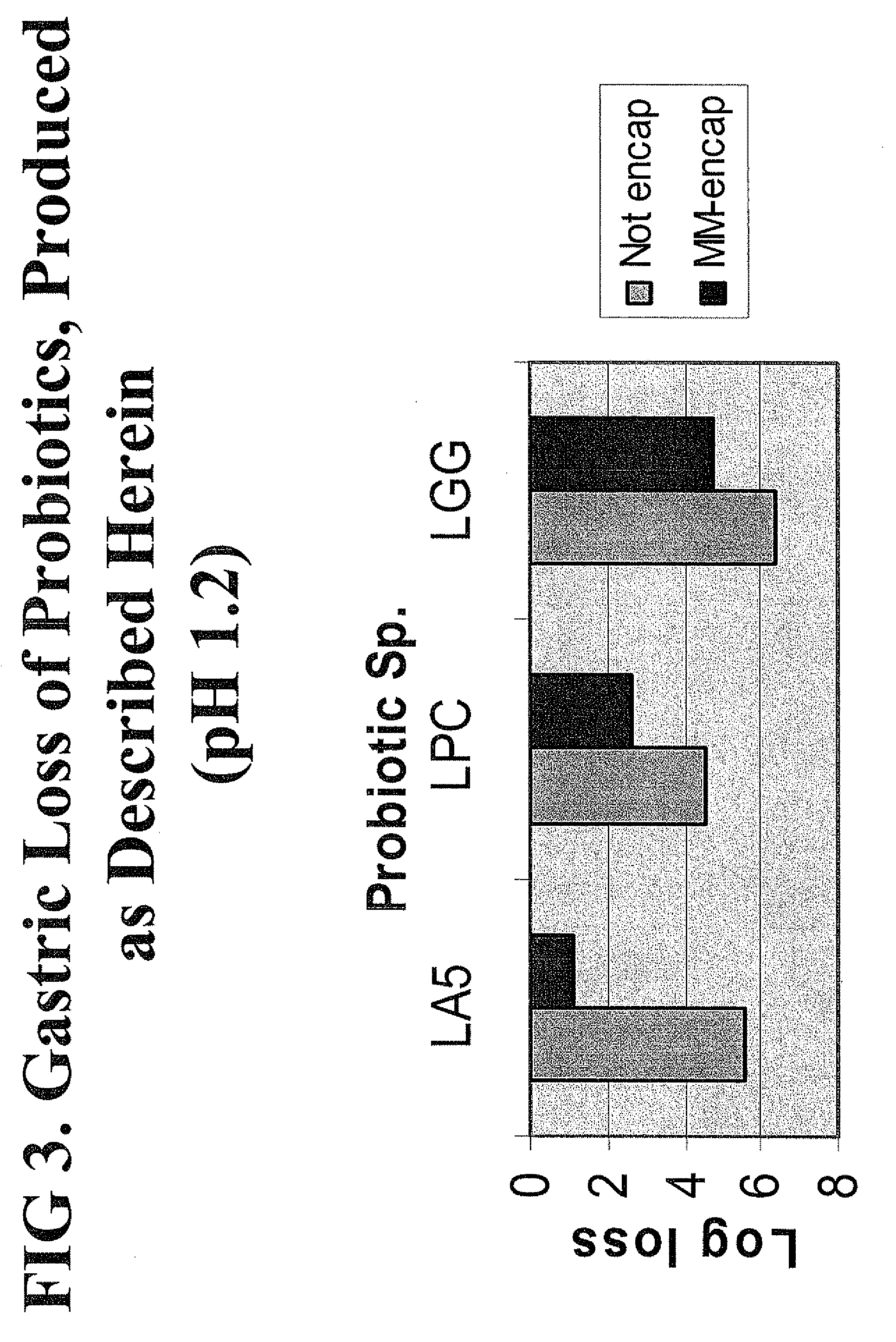

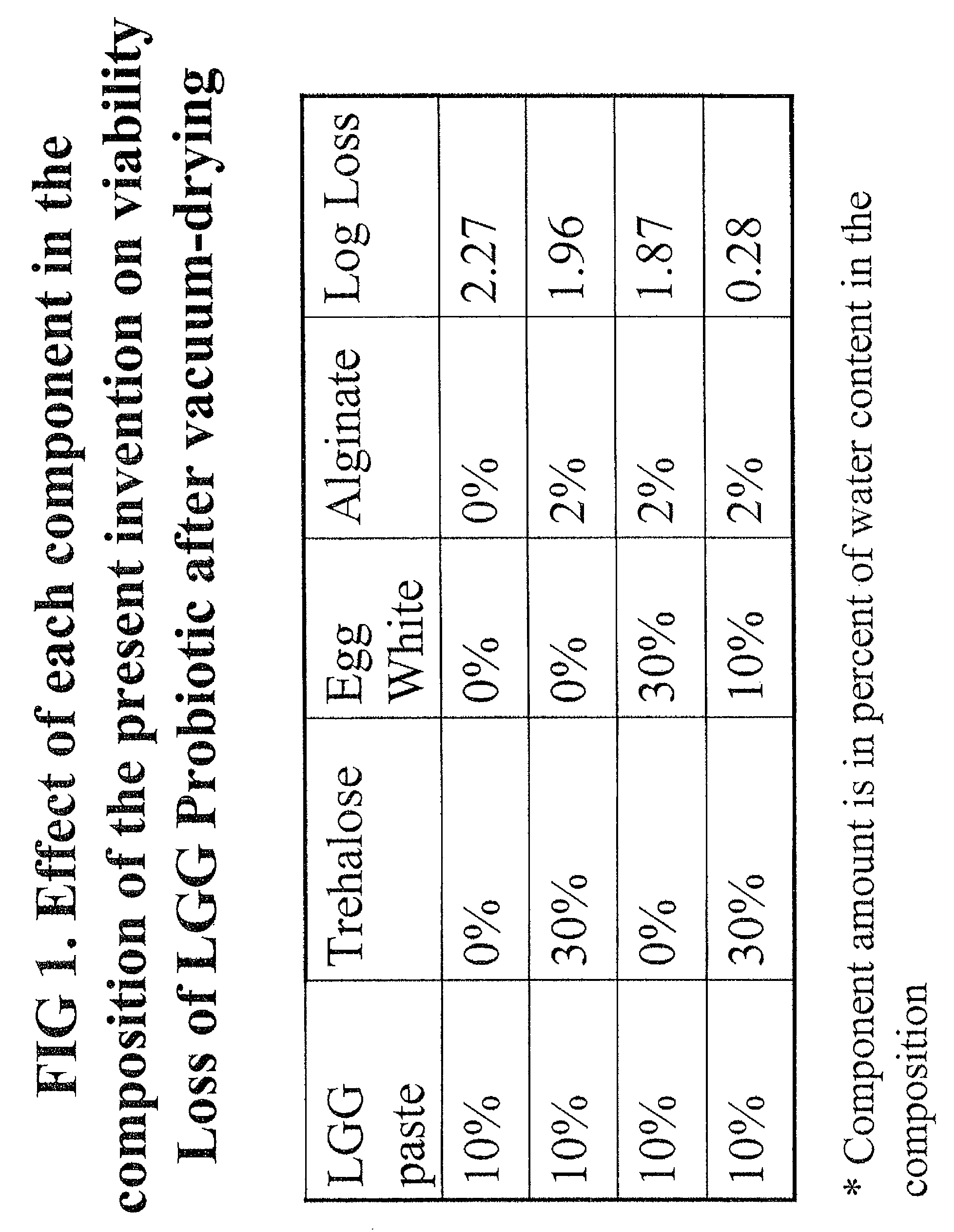

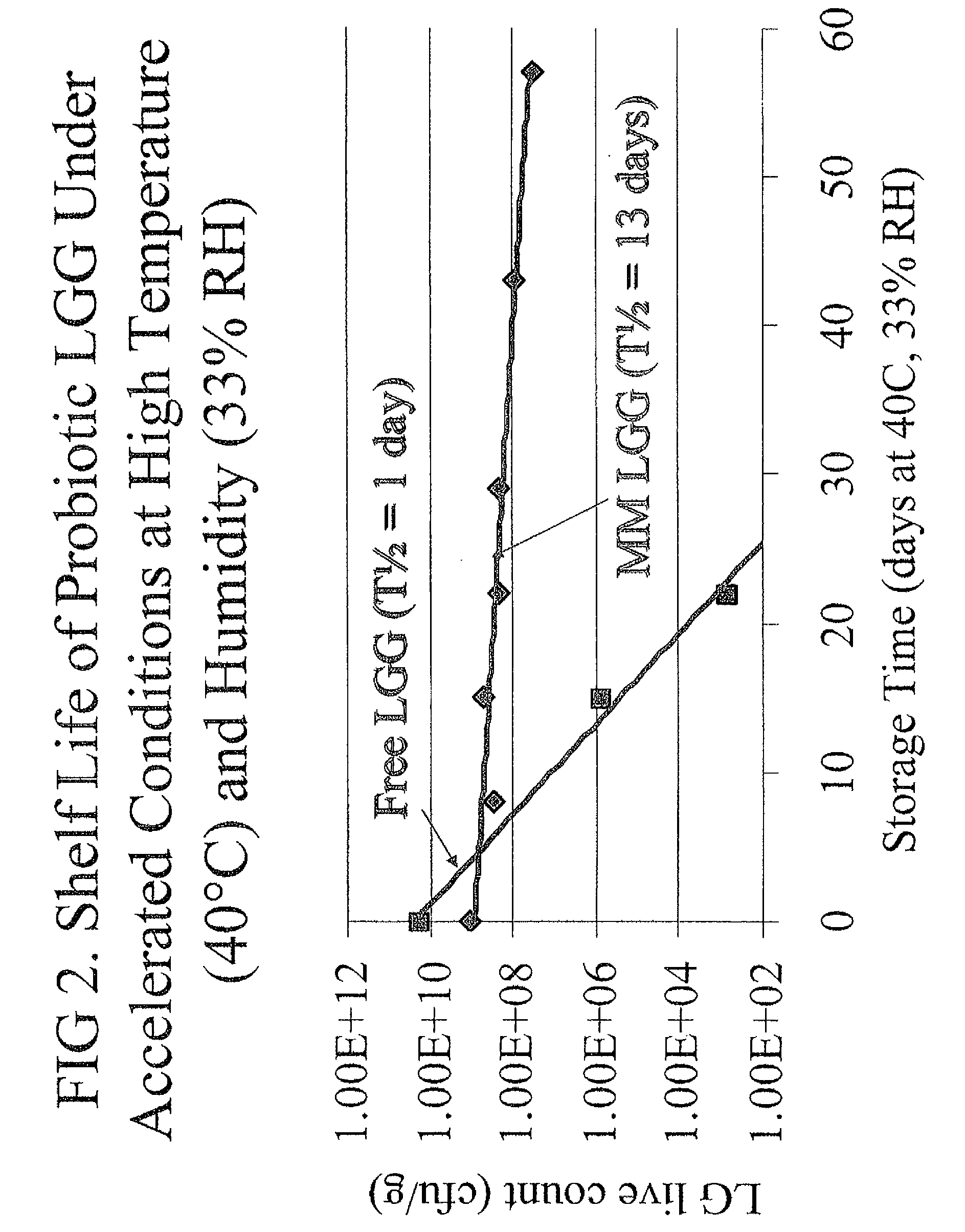

Dry food product containing live probiotic

ActiveUS20100074994A1Promote recoveryImprove stabilityAntibacterial agentsSugar food ingredientsBiotechnologyMicroorganism

The disclosure relates to a probiotic delivery system that can be consumed as a snack-food or added to a food product. In particular, the disclosure describes a crisp and tasty treat that comprises viable probiotic microorganisms preserved in a vacuum dried matrix of sugars, proteins, and polysaccharides. The probiotic remain viable within the treat for a longer time without the need for additional moisture barrier coating. The probiotic also remain viable in the animal gastrointestinal tract.

Owner:ADVANCED BIONUTRITION CORP

Snack system, including interior filing of ingredient, outer coating of ingredient, addition of ingredient, and formation of snack roll

InactiveUS20140212453A1Modest expenseQuickly replenish energy levelBiocideFrozen sweetsAdditive ingredientSnack food

A novel snack system is created in various form, variety, and with various ingredient. The snack system is created being a snack, with at least one ingredient, and at least one texture. The category of snack includes cheese, powdery candy, soft candy, creamy candy, gummy candy, hard candy, liquid candy, fudge candy, chocolate, ice cream, ice milk, sherbet, gelato, yogurt, sorbet, tofu, jelly, pudding, chewing gum, roll, pie, biscuit, cookie, donut, pastry, cake, pancake, crepe, waffle, bread, tortilla, and taco. The snack can be served at room temperature, cold from refrigerator, warm, hot, and reheated. The snack is in form selected from group consisting of interior filing of ingredient, outer coating of ingredient, and formation of snack roll. The snack is also created with addition of various ingredients. The snack is created with at least one ingredient selected from group consisting of flavoring ingredient, nutritional ingredient, health ingredient, and other ingredient.

Owner:CHANG ALICE

Dry food product containing live probiotic

ActiveUS8460726B2Possible formationIncrease load capacityAntibacterial agentsSugar food ingredientsBiotechnologySnack food

The disclosure relates to a probiotic delivery system that can be consumed as a snack-food or added to a food product. In particular, the disclosure describes a crisp and tasty treat that comprises viable probiotic microorganisms preserved in a vacuum dried matrix of sugars, proteins, and polysaccharides. The probiotic remain viable within the treat for a longer time without the need for additional moisture barrier coating. The probiotic also remain viable in the animal gastrointestinal tract.

Owner:ADVANCED BIONUTRITION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com