Patents

Literature

2295 results about "Ink printer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An inkjet printer is a computer peripheral that produces hard copy by spraying ink onto paper. A typical inkjet printer can produce copy with a resolution of at least 300 dots per inch ( dpi ). Some inkjet printers can make full color hard copies at 600 dpi or more.

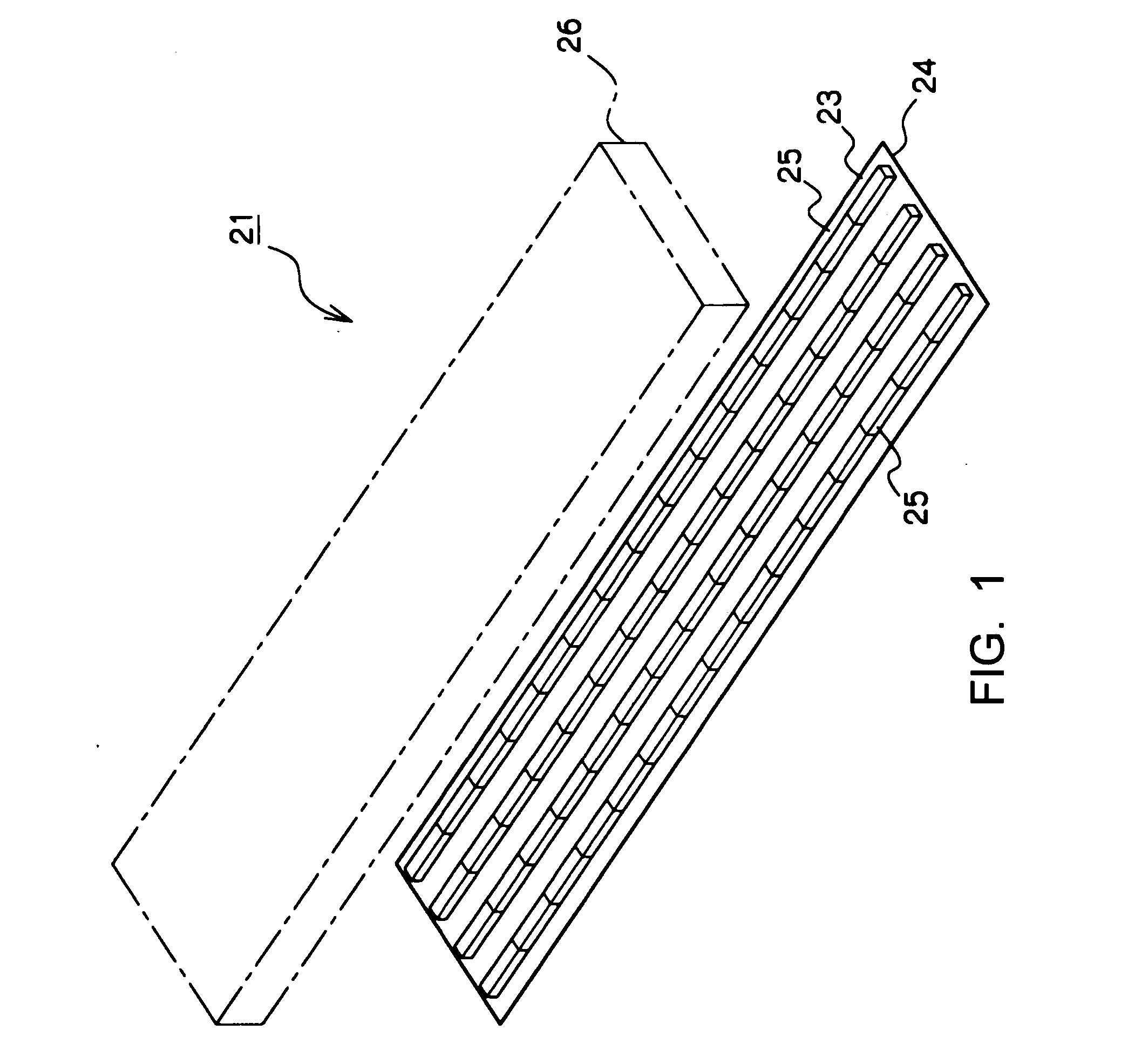

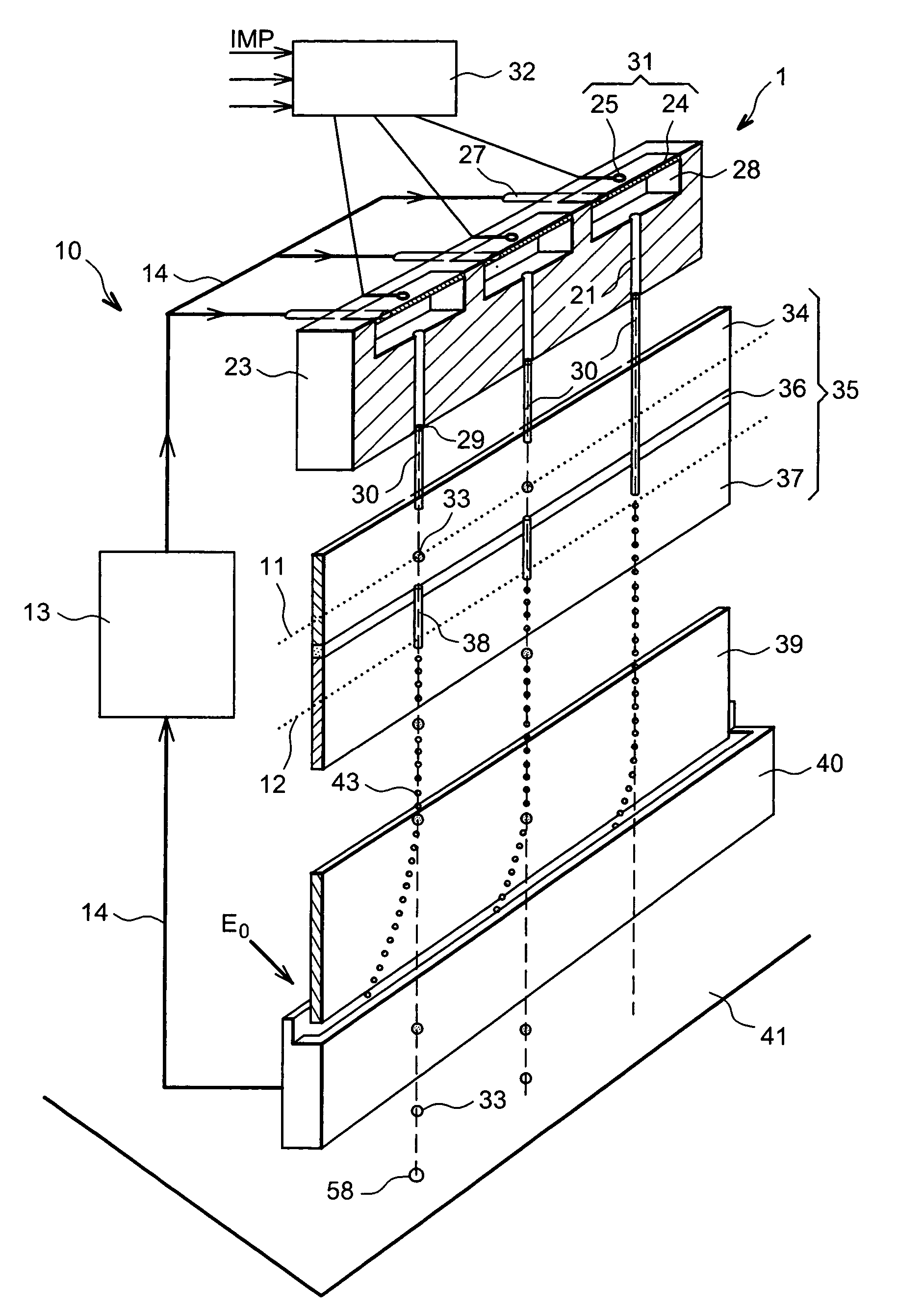

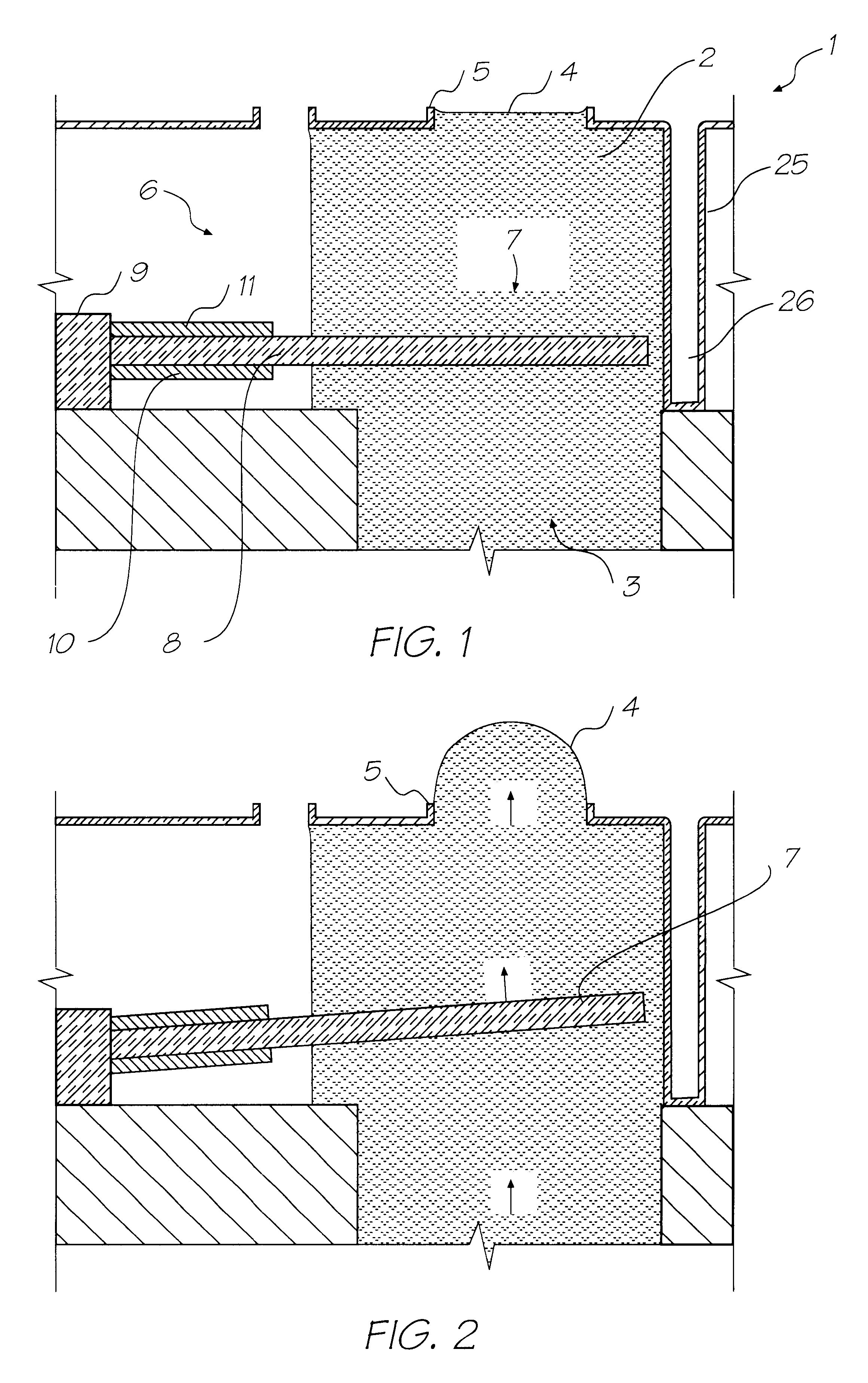

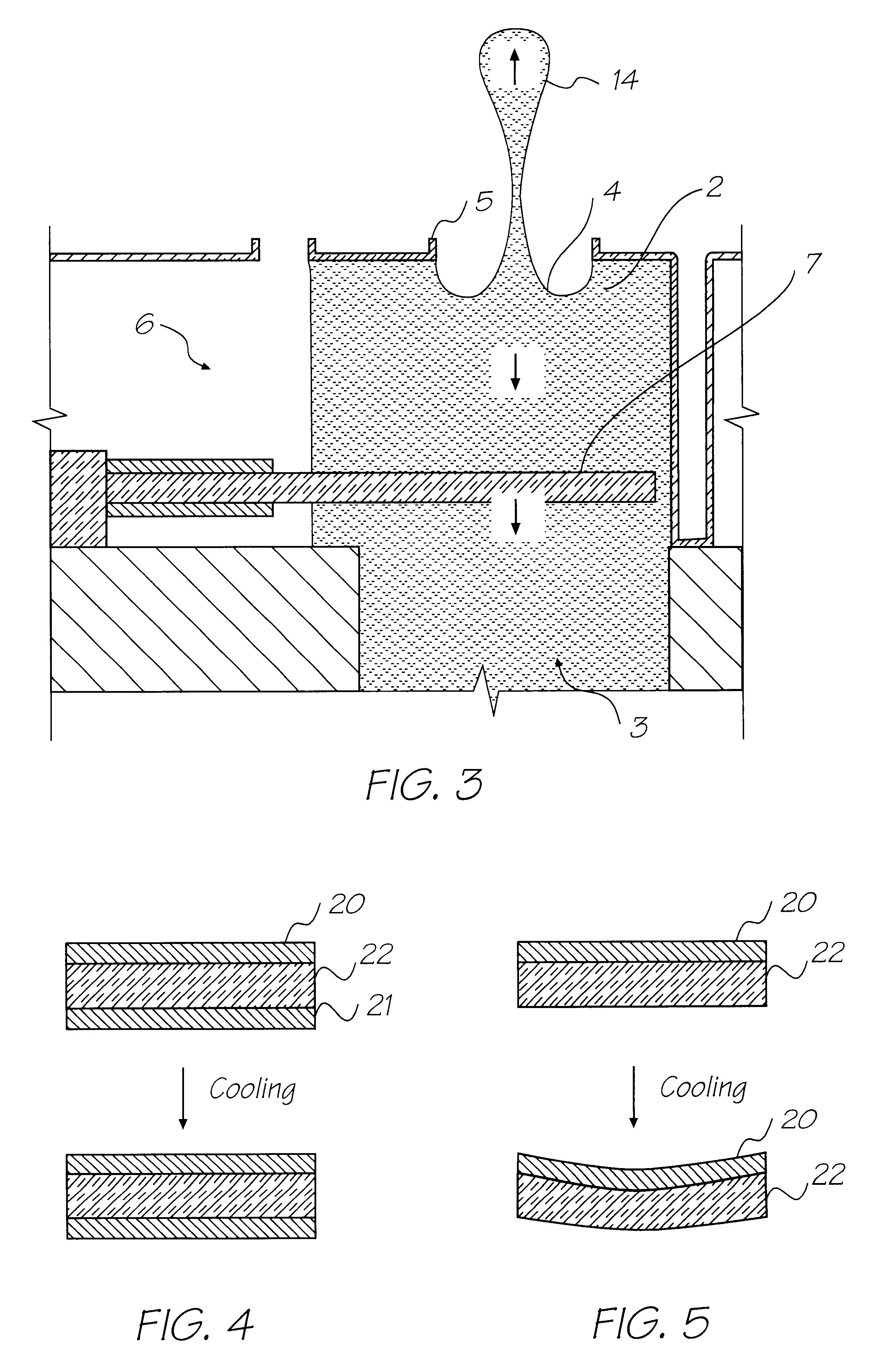

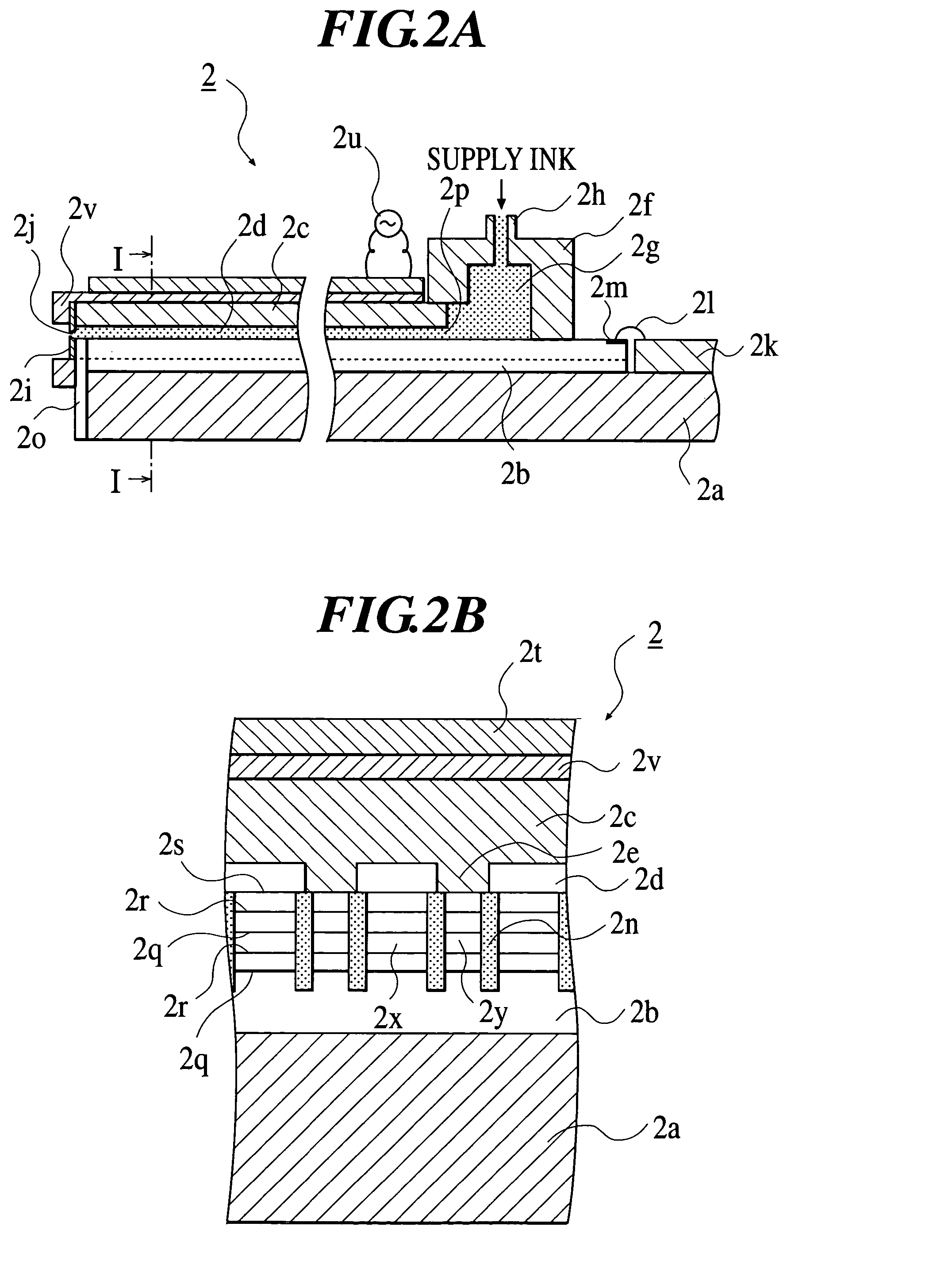

Ink jet print head, inkjet printer including the inkjet print head, and method of manufacturing inkjet print head

An inkjet print head includes one nozzle sheet (23) and a plurality of head chips (25) including a plurality of heaters. The nozzle sheet (23) is formed of an electroformed metal layer made of nickel or a material comprising nickel, and has discharge nozzle rows for respective colors disposed so that the discharge nozzles are in staggered arrangements and so that each set of discharge nozzles partly overlaps another set of discharge nozzles in a sheet-feed direction. The head chips are positioned at and affixed to a growth surface side of the nozzle sheet (23) in staggered arrangements so that the positions of the discharge nozzles and the positions of the heaters correspond to each other. Accordingly, reduction in printing quality caused by displacement of any of the discharge nozzles is prevented from occurring, and landing positions of discharged ink on a recording sheet are stabilized.

Owner:SONY CORP

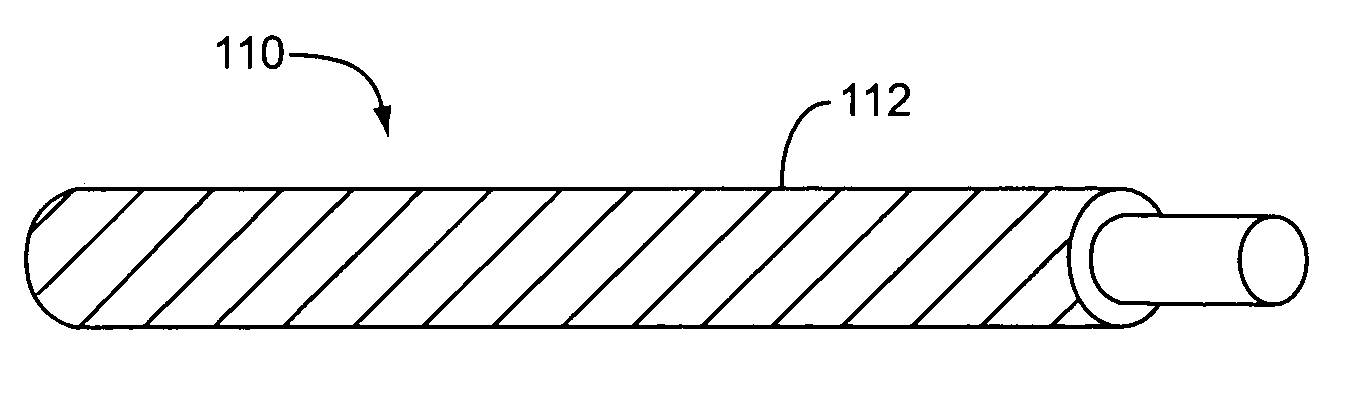

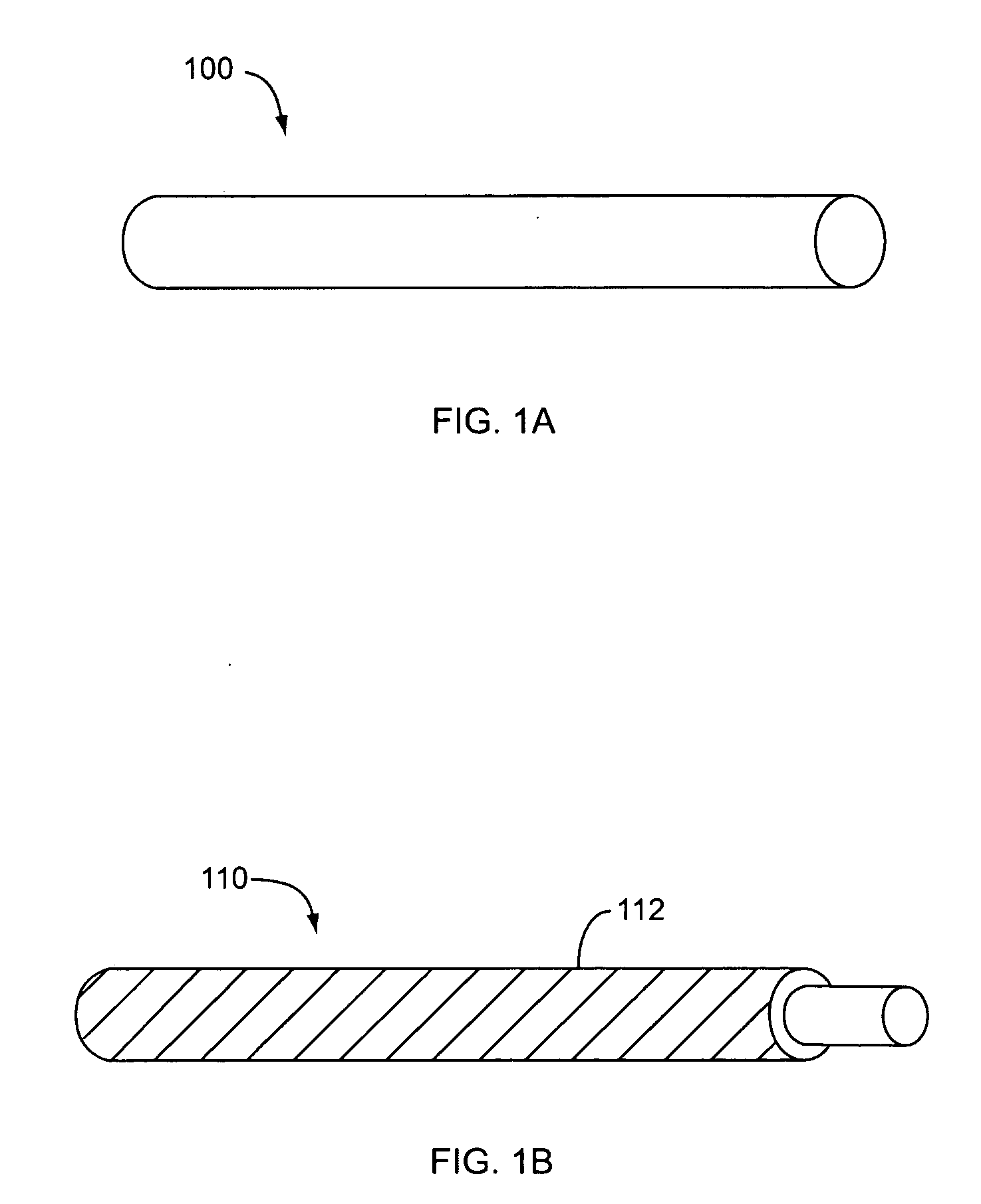

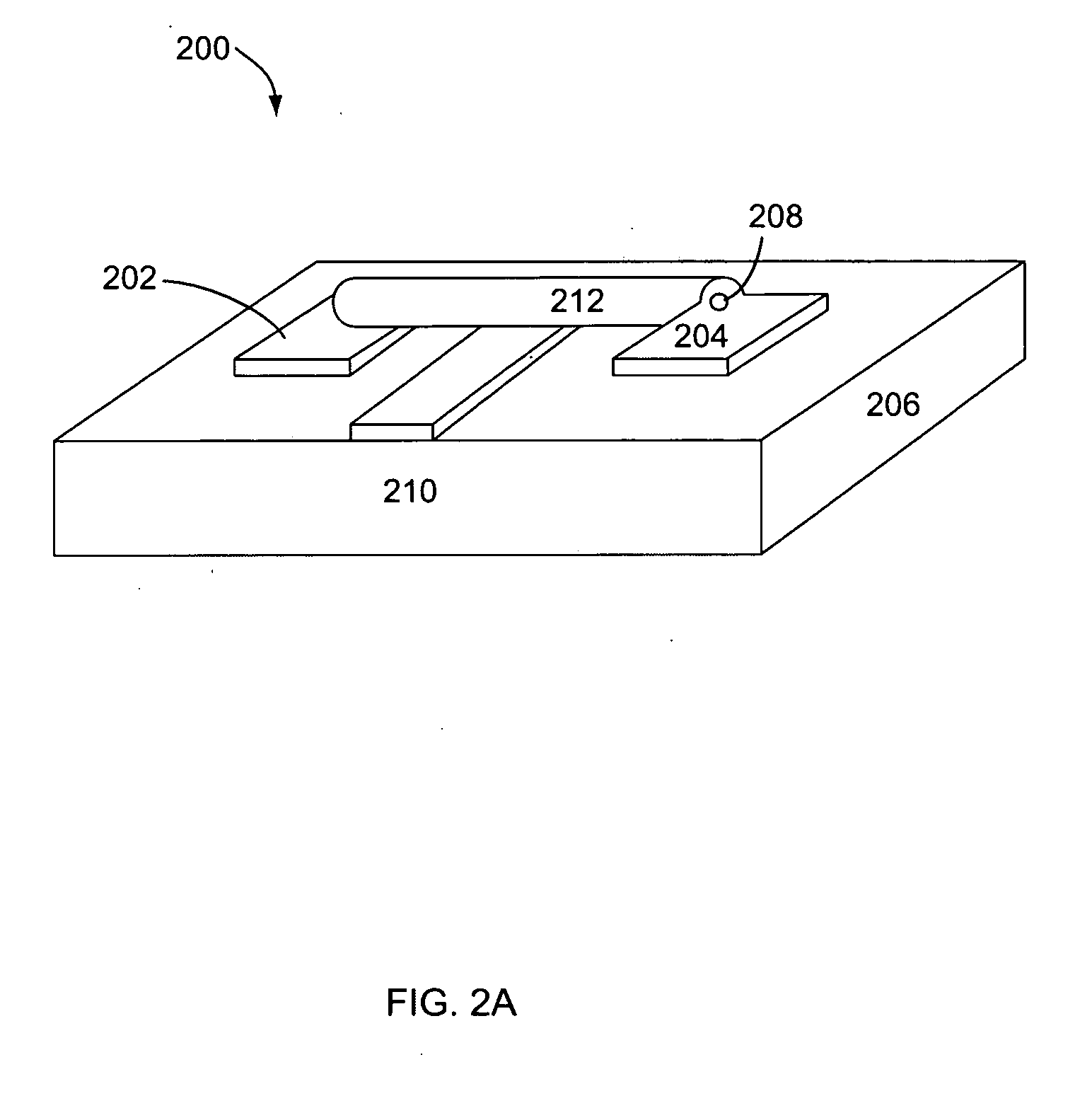

Systems and methods for harvesting and integrating nanowires

ActiveUS20060008942A1Ease of mass productionImprove device performanceLayered productsNanoinformaticsNanowireInk printer

The present invention is directed to methods to harvest, integrate and exploit nanomaterials, and particularly elongated nanowire materials. The invention provides methods for harvesting nanowires that include selectively etching a sacrificial layer placed on a nanowire growth substrate to remove nanowires. The invention also provides methods for integrating nanowires into electronic devices that include placing an outer surface of a cylinder in contact with a fluid suspension of nanowires and rolling the nanowire coated cylinder to deposit nanowires onto a surface. Methods are also provided to deposit nanowires using an ink-jet printer or an aperture to align nanowires. Additional aspects of the invention provide methods for preventing gate shorts in nanowire based transistors. Additional methods for harvesting and integrating nanowires are provided.

Owner:ONED MATERIAL INC

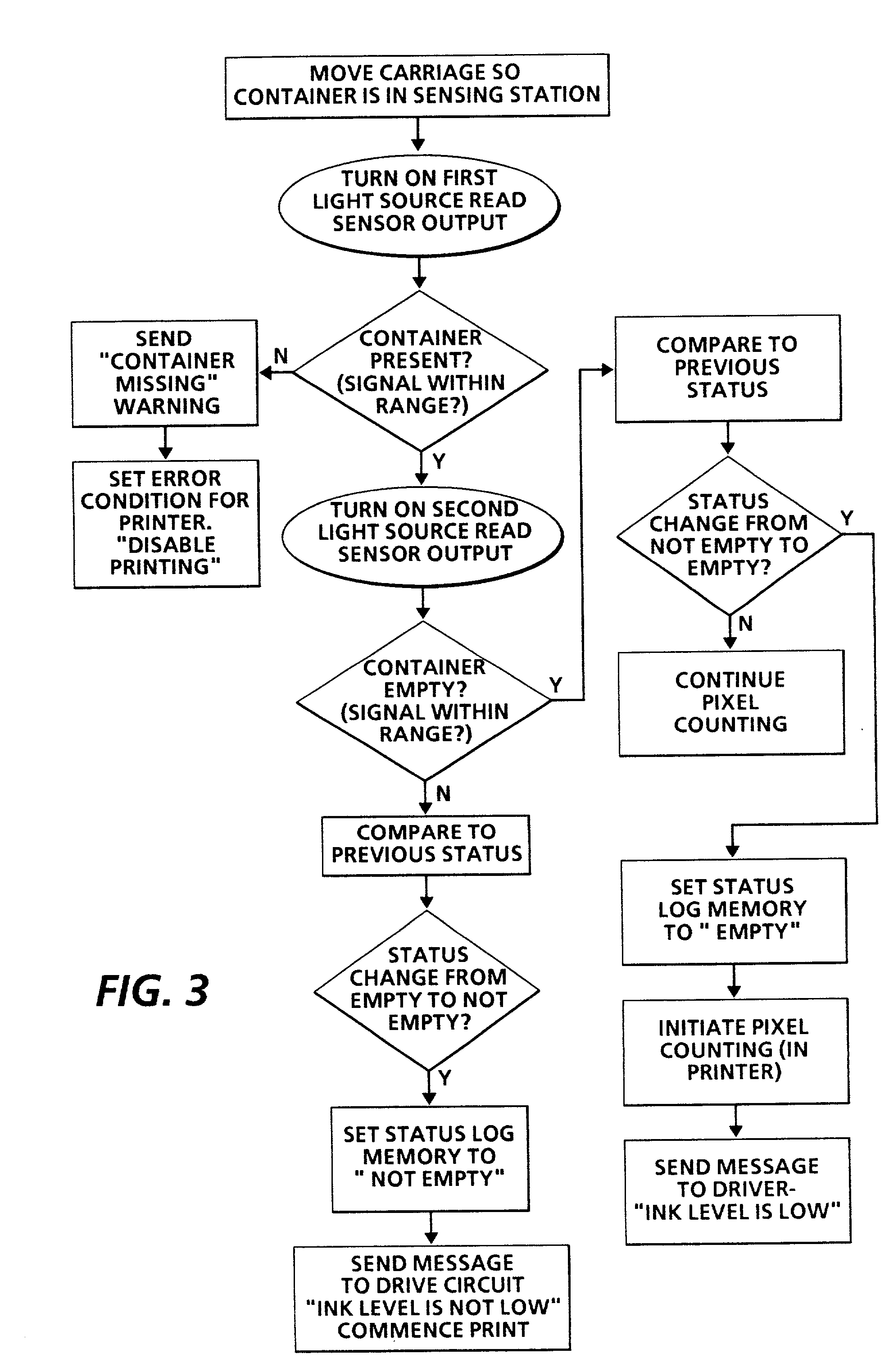

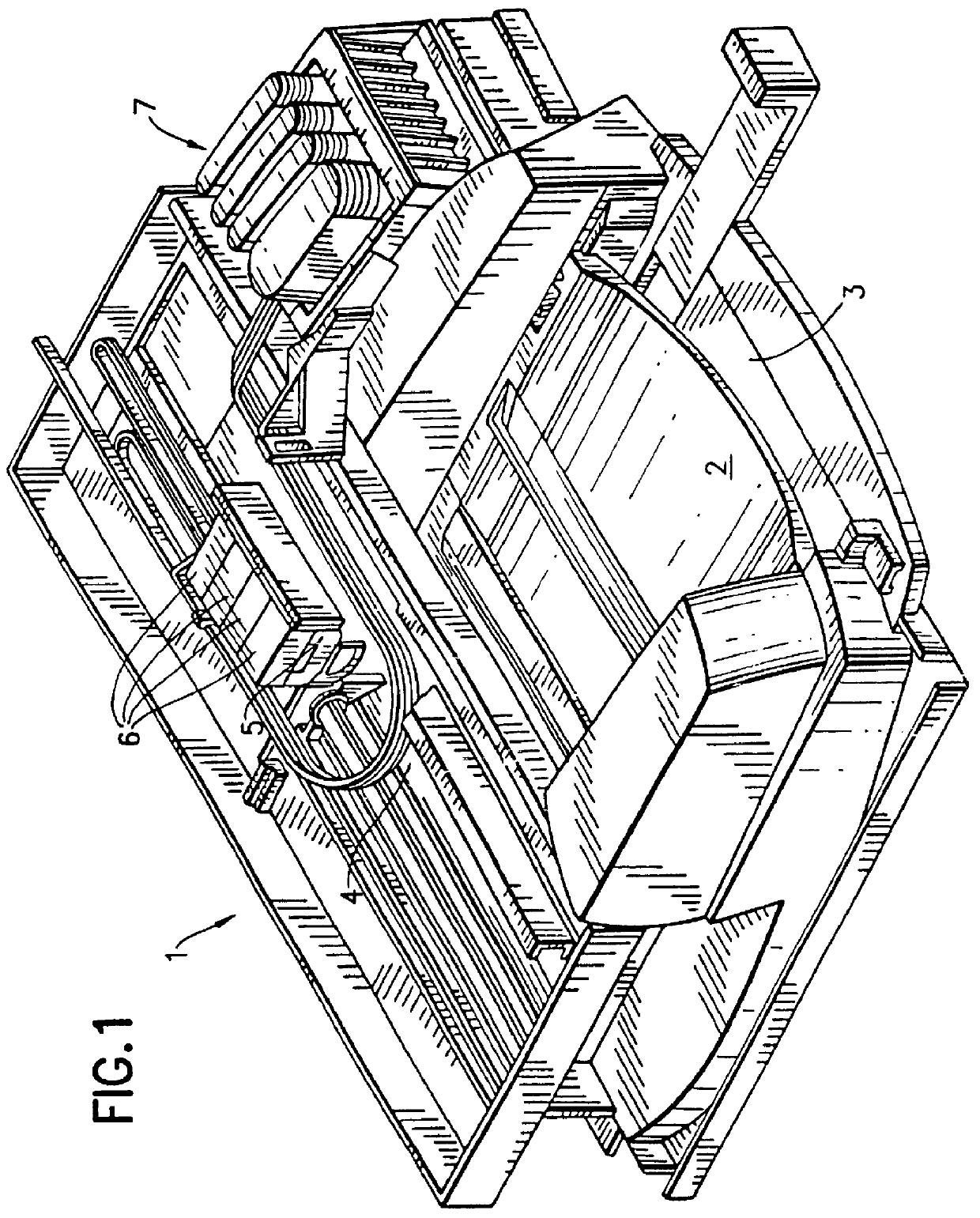

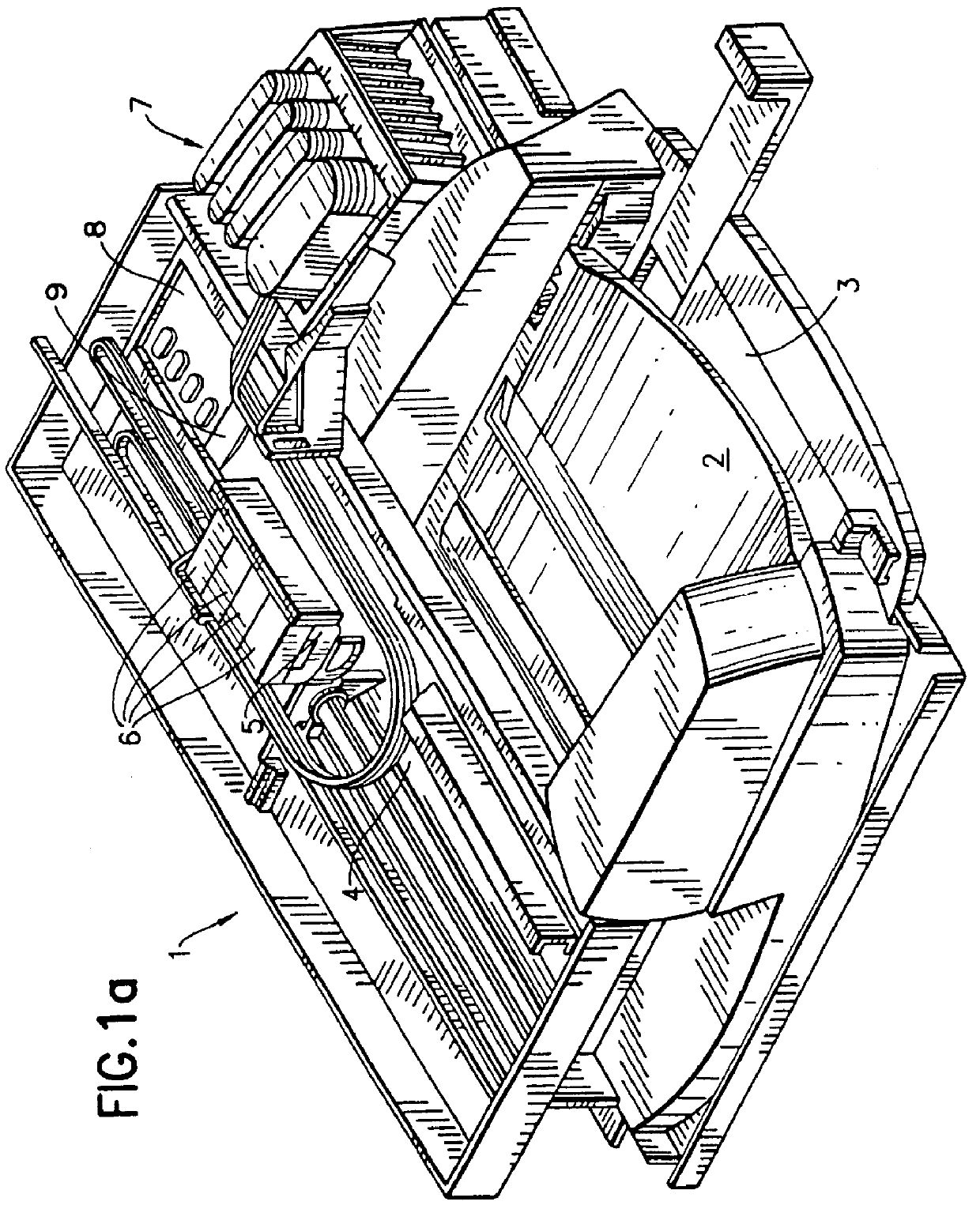

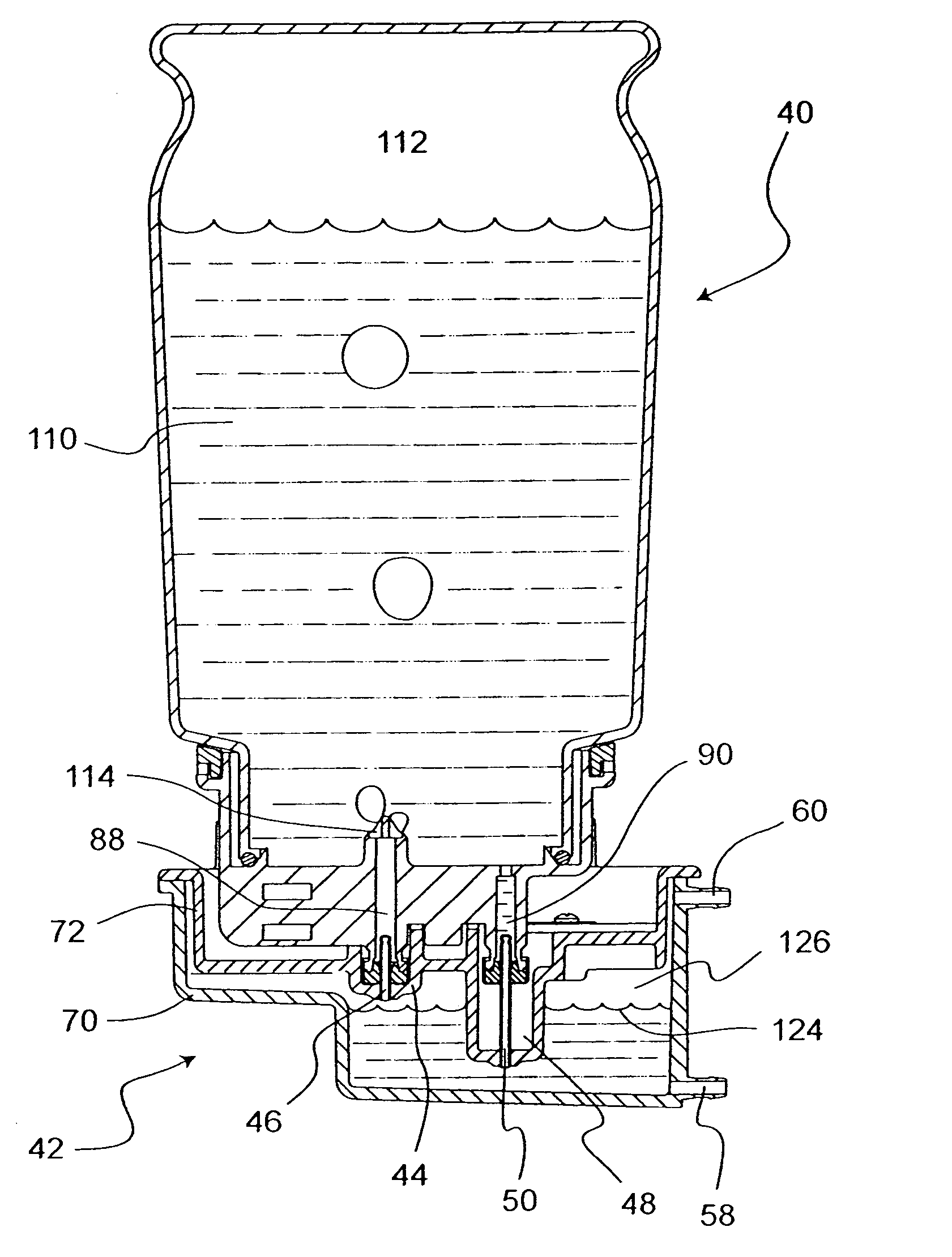

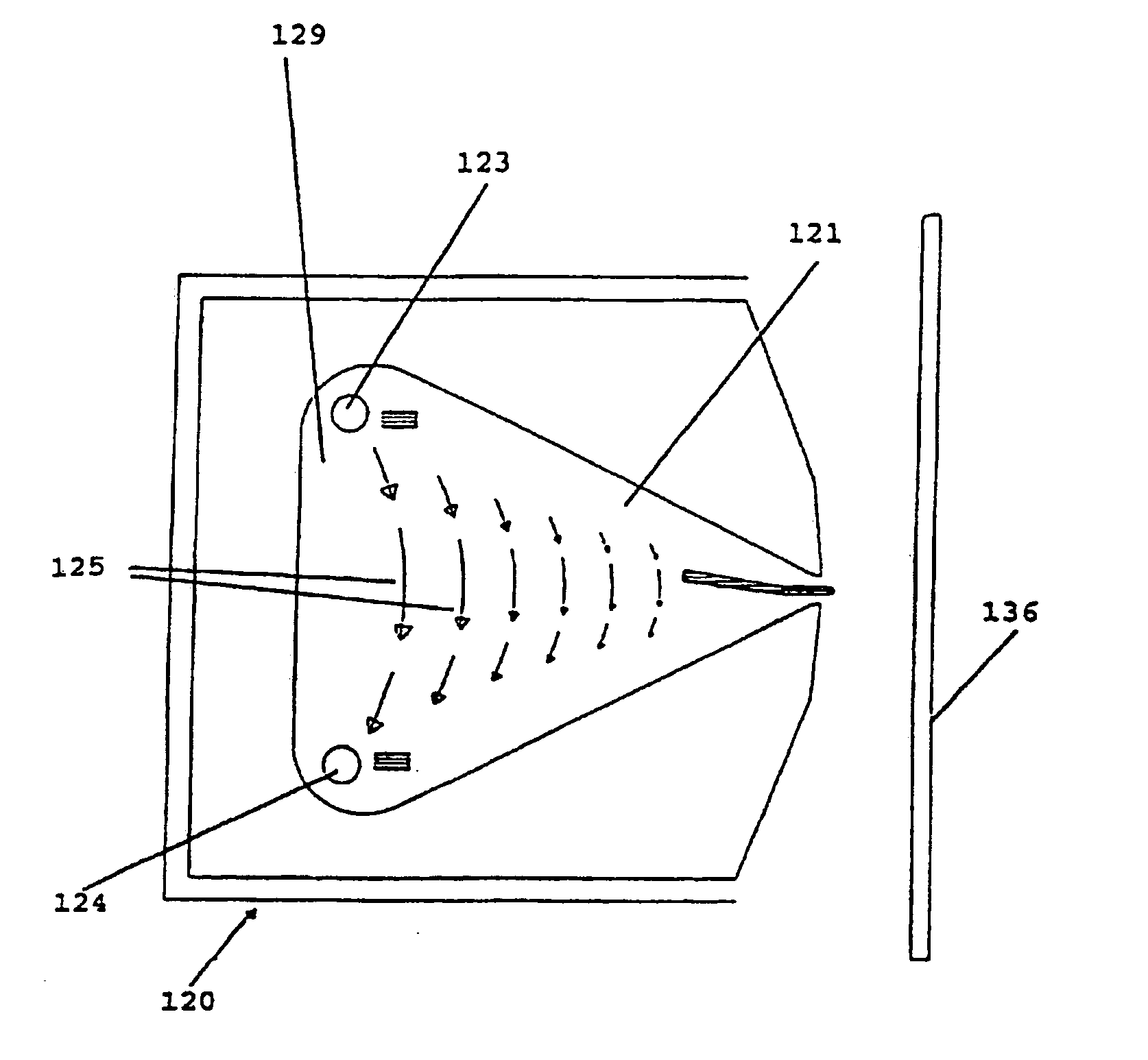

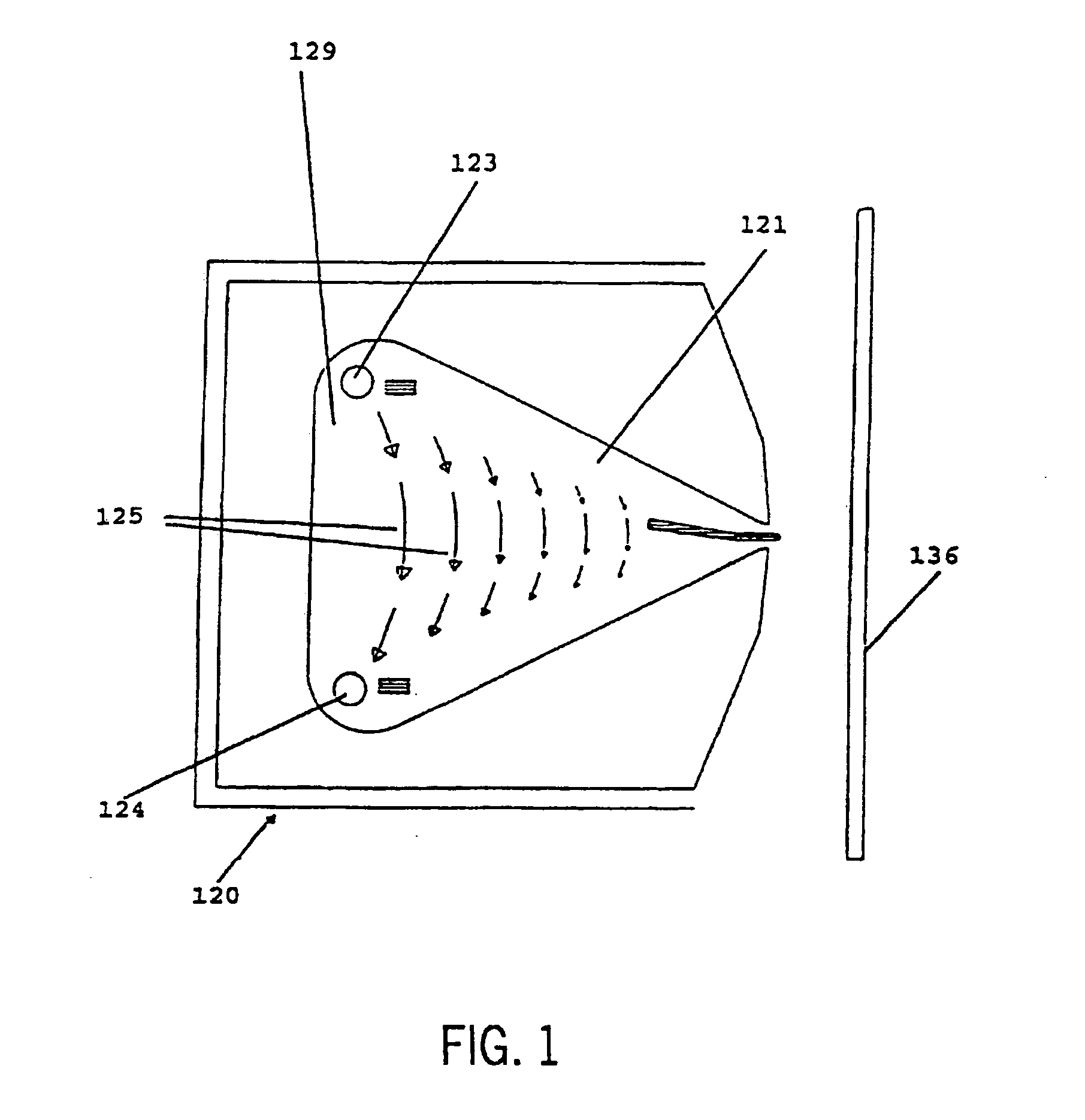

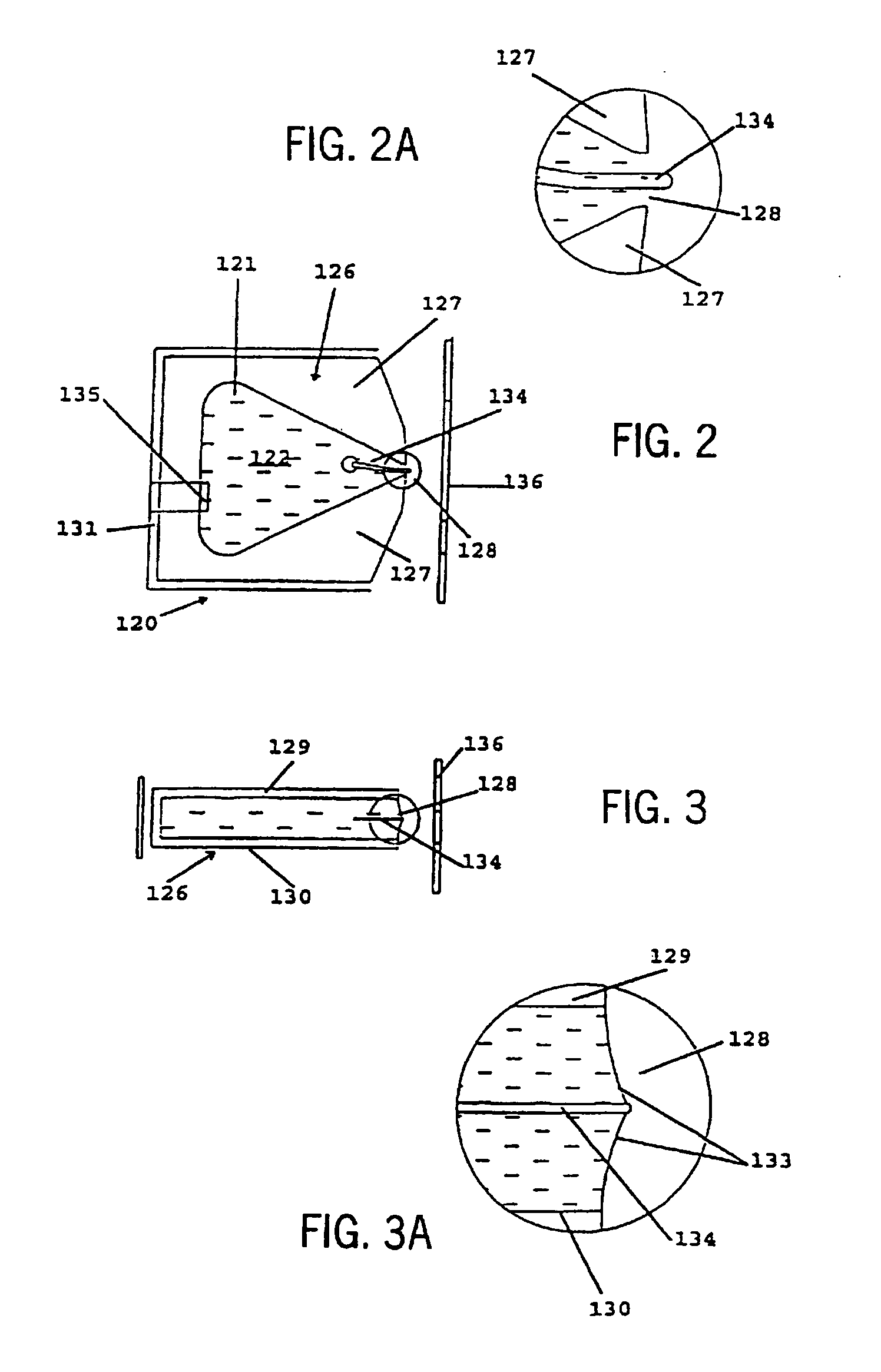

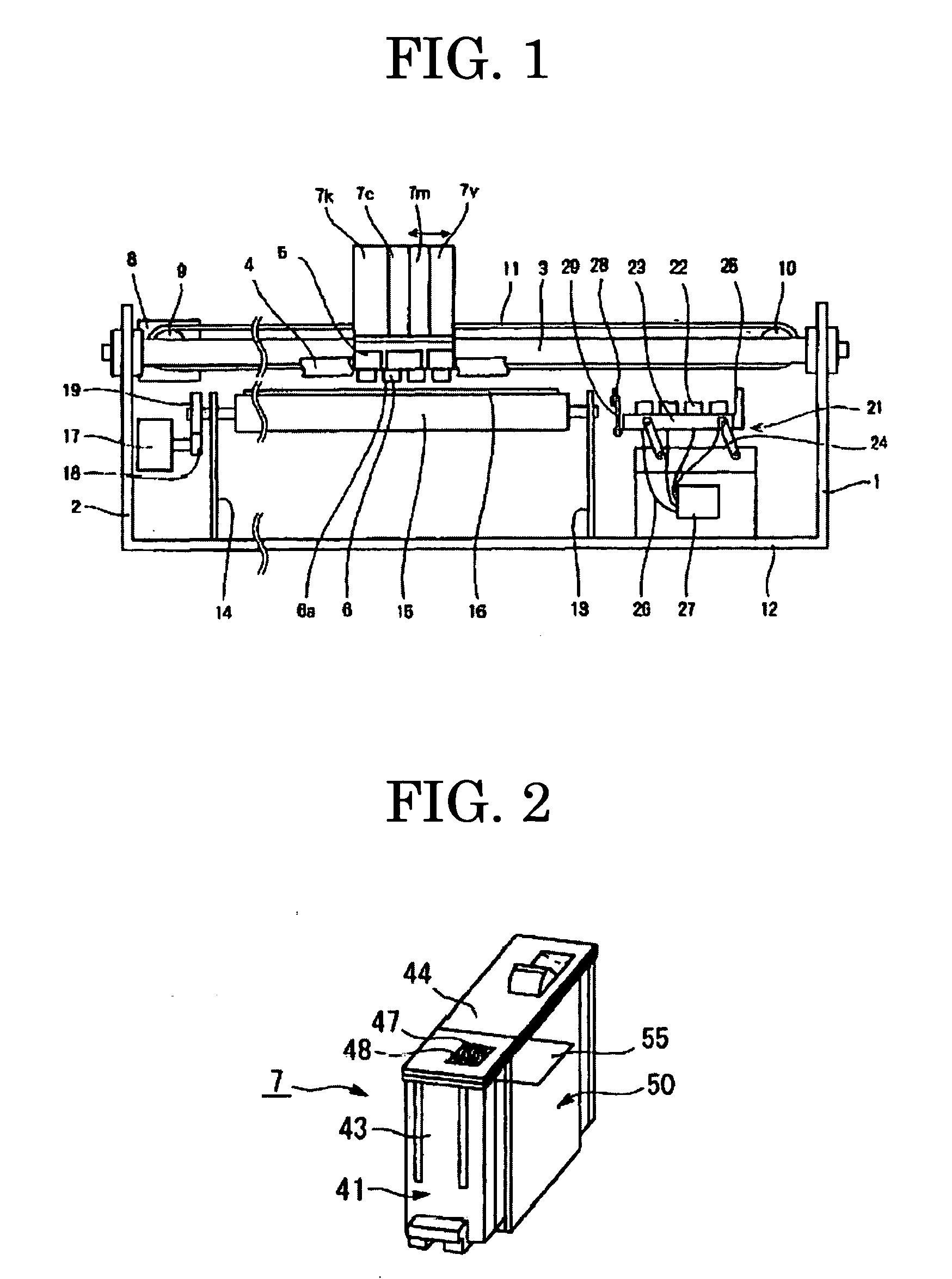

Sensing system for detecting presence of an ink container and level of ink therein

A low ink sensing system is combined with an ink cartridge detection system to enable a more efficient ink jet printer. An ink container which supplies ink to an associated printhead is modified by the incorporation of two light directing elements, in the preferred embodiment, a faceted prism and a roof mirror, into a transparent wall of the container housing. The cartridge, comprising the ink container and associated printhead, is mounted on a scan carriage. Periodically, the carriage is conveyed to a sensing station comprising a pair of light sources and a commonly used photosensor. A first light source is energized and a beam of light is directed to a location where the roof mirror, would be positioned if the cartridge is present. If the cartridge is absent, lack of a reflected return signal is sensed, indicating a cartridge has not been inserted. Print operation is halted until a cartridge is inserted. If a cartridge is properly inserted, the roof mirror returns most of the incident light to the photosensor which generates a signal indicating the presence of the cartridge. A second light source is then energized and directed towards the faceted prism, which is either immersed in ink or exposed to air within the interior of the container. If the latter, light is internally reflected by the prism facets back to the photosensor. If a print operation has been in progress, and the ink level has fallen, the common photosensor detects either a strong or weak redirected light component and initiates a status check and generates appropriate displays of low ink level or out of ink warnings.

Owner:SAMSUNG ELECTRONICS CO LTD

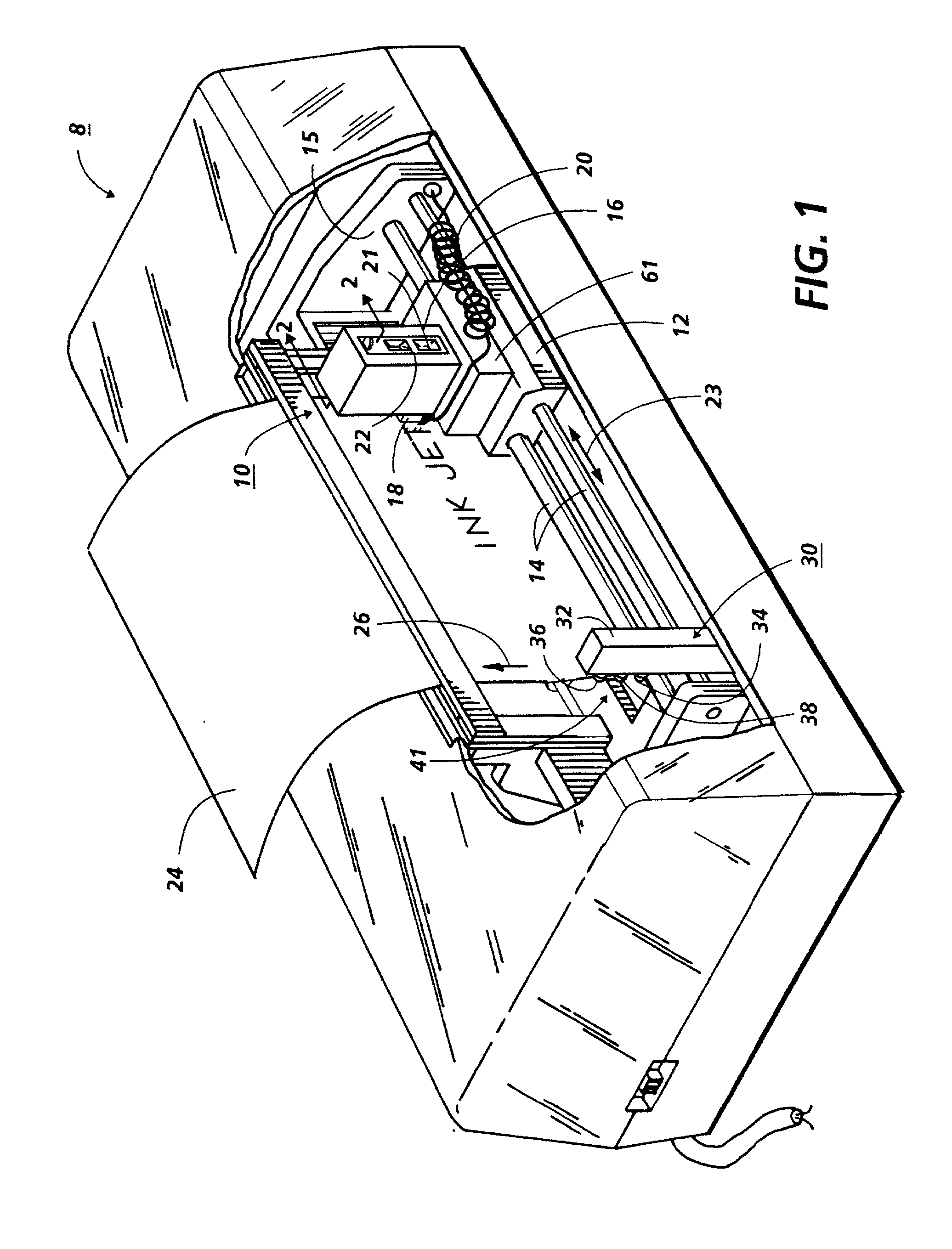

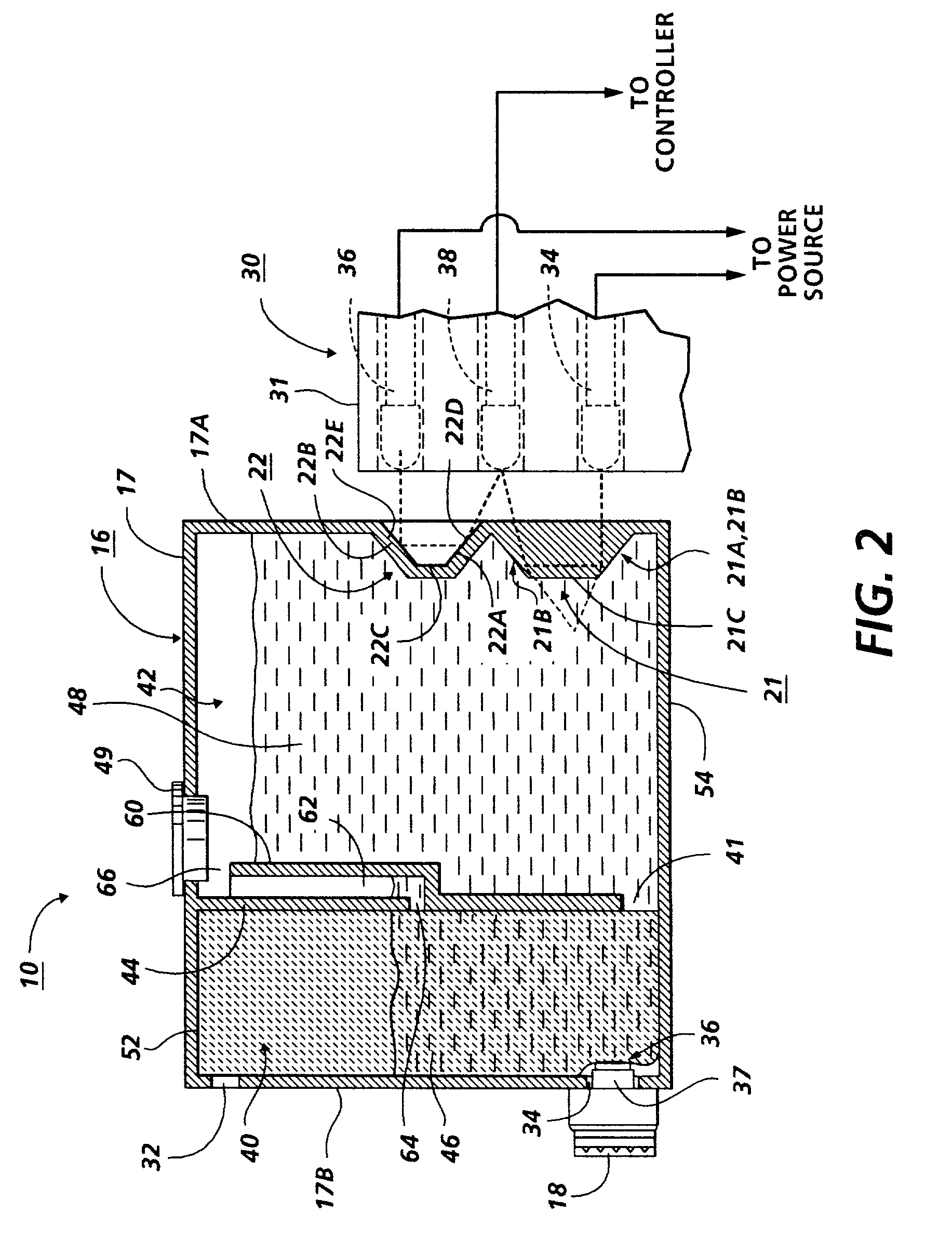

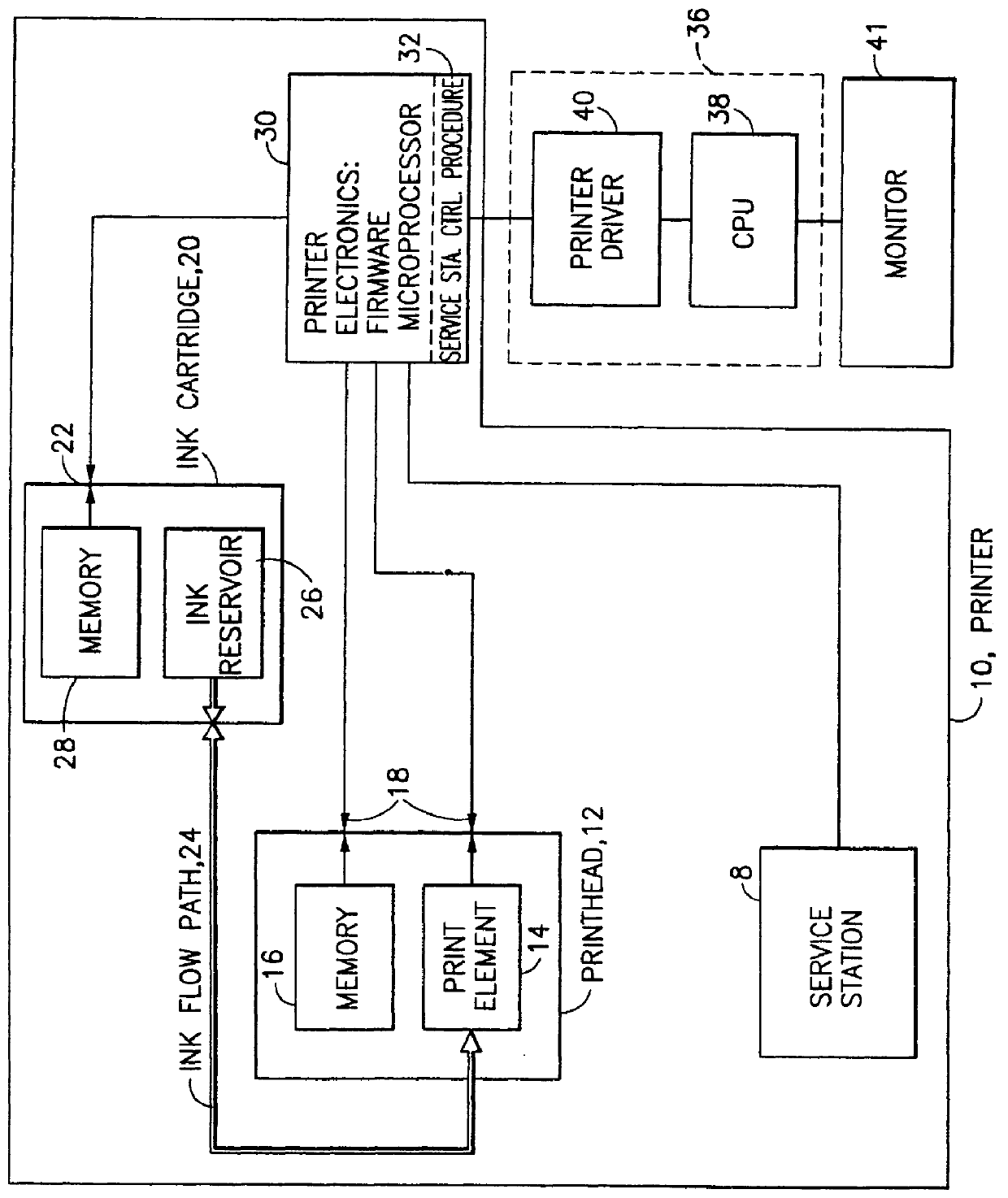

Ink jet printer service station controlled by data from consumable parts with incorporated memory devices

An inkjet printing system includes a replaceable printhead having plural nozzles for ejecting ink droplets, a service station for capping and wiping the plural nozzles, and a replaceable ink cartridge housing a supply of ink and further including a cartridge memory for recording service station-control data. A processor is coupled to the ink cartridge memory and is responsive to service station-control data read from the cartridge memory to derive a service station control value. The printhead further includes a memory which records printhead-related parameters, and the processor is responsive thereto and service station-control data read from said cartridge memory to control the service station. The control data may be service station parameters, one or more subroutines to control the service station and combinations thereof.

Owner:HEWLETT PACKARD DEV CO LP

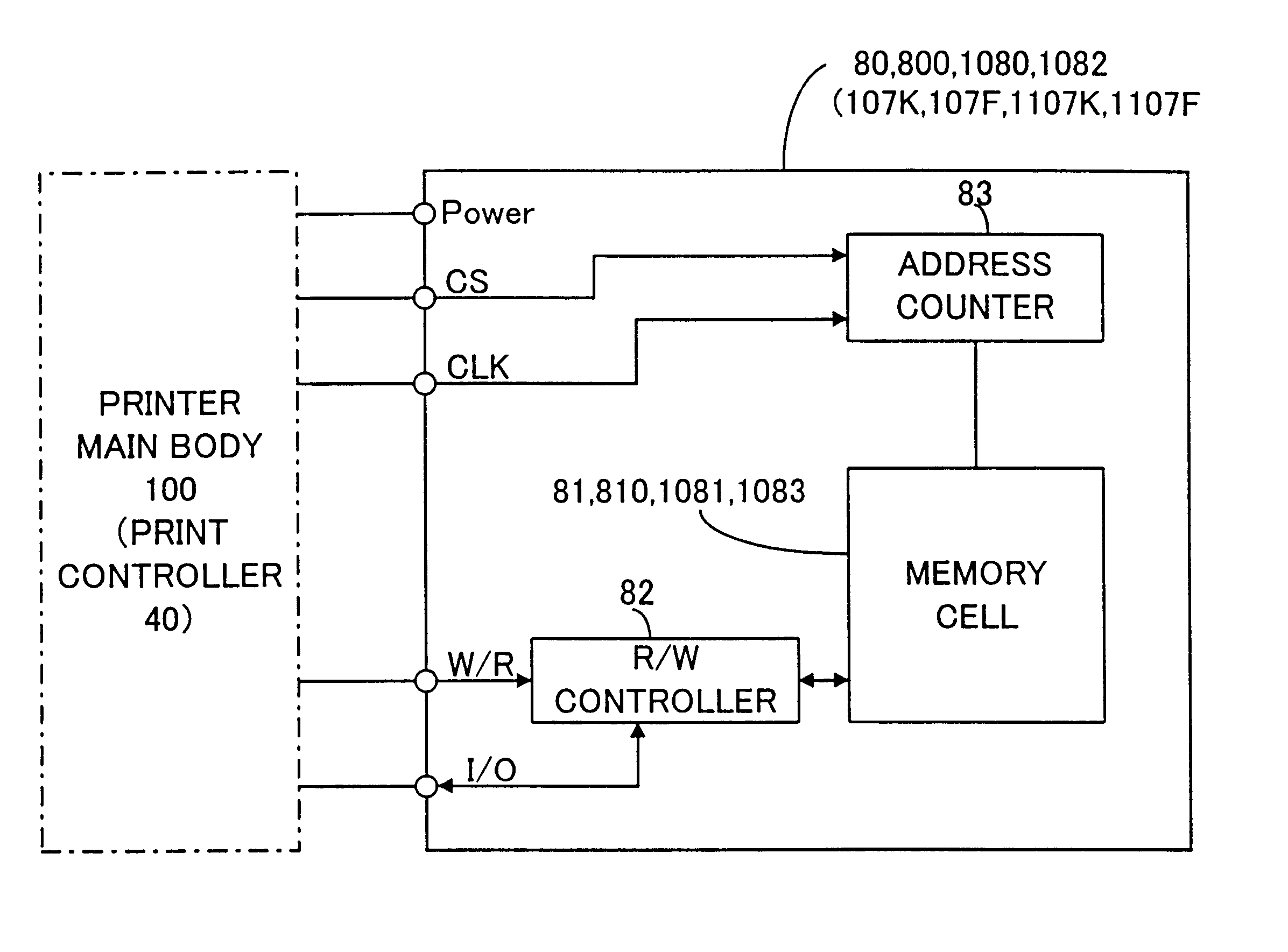

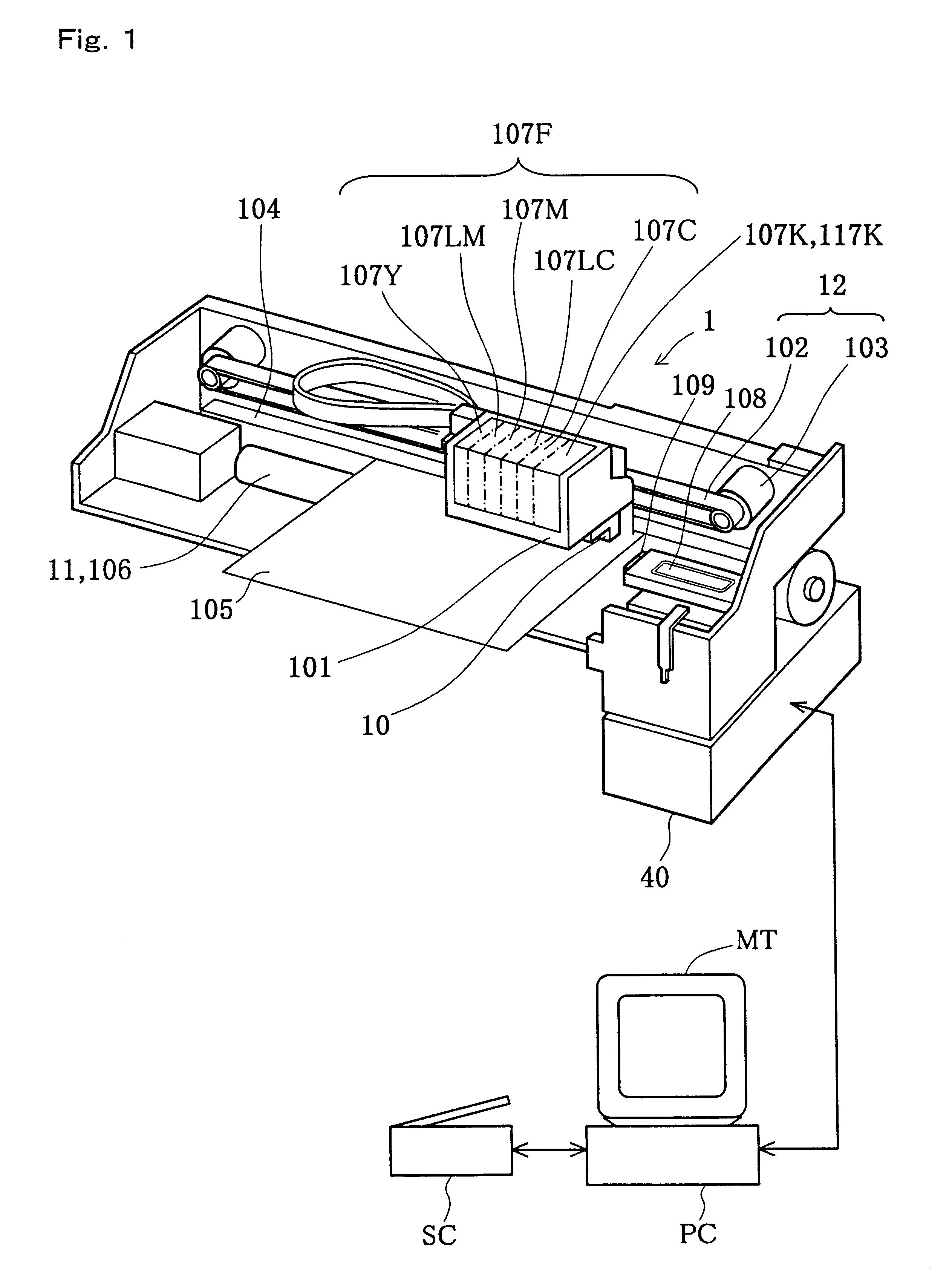

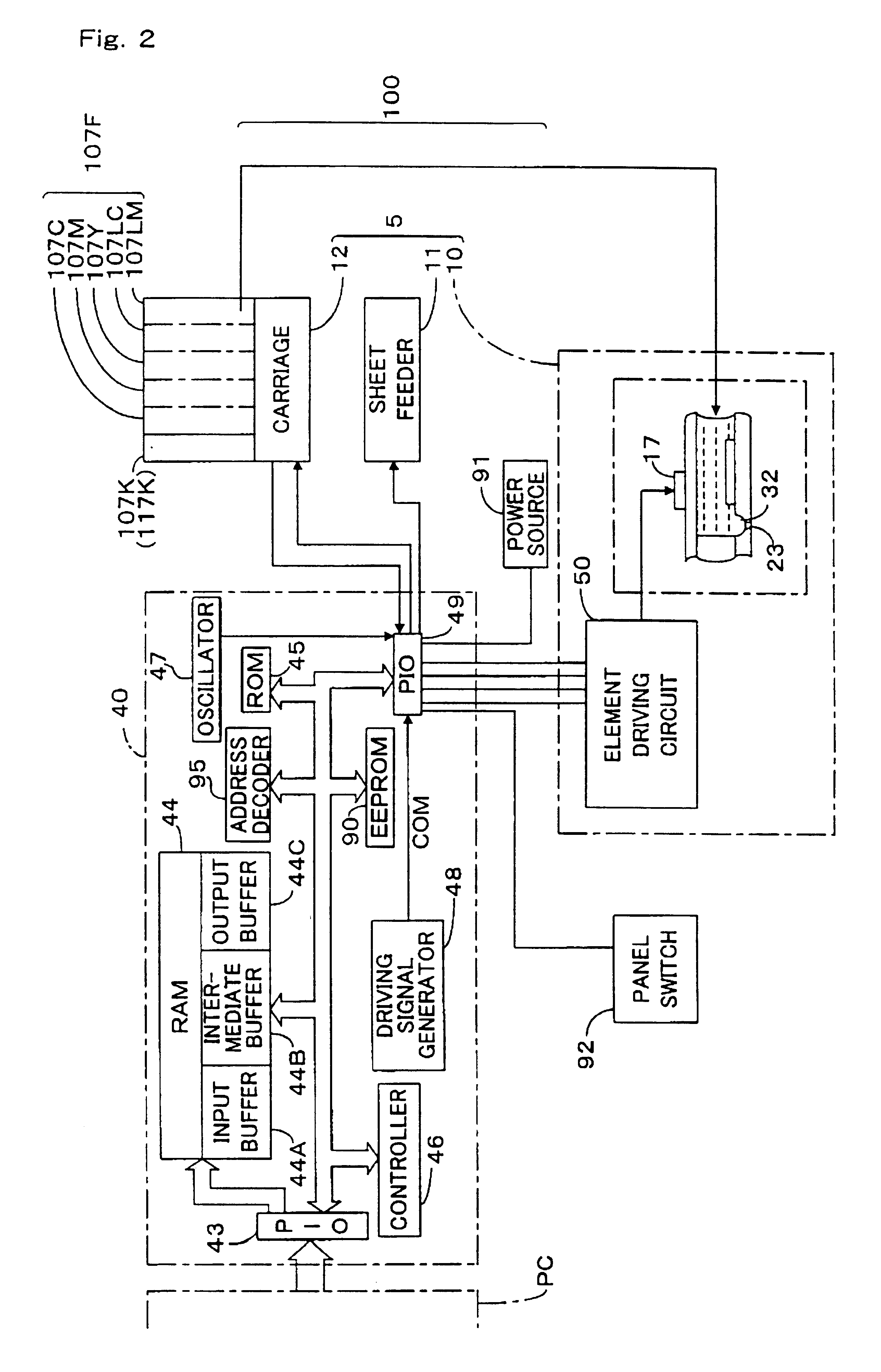

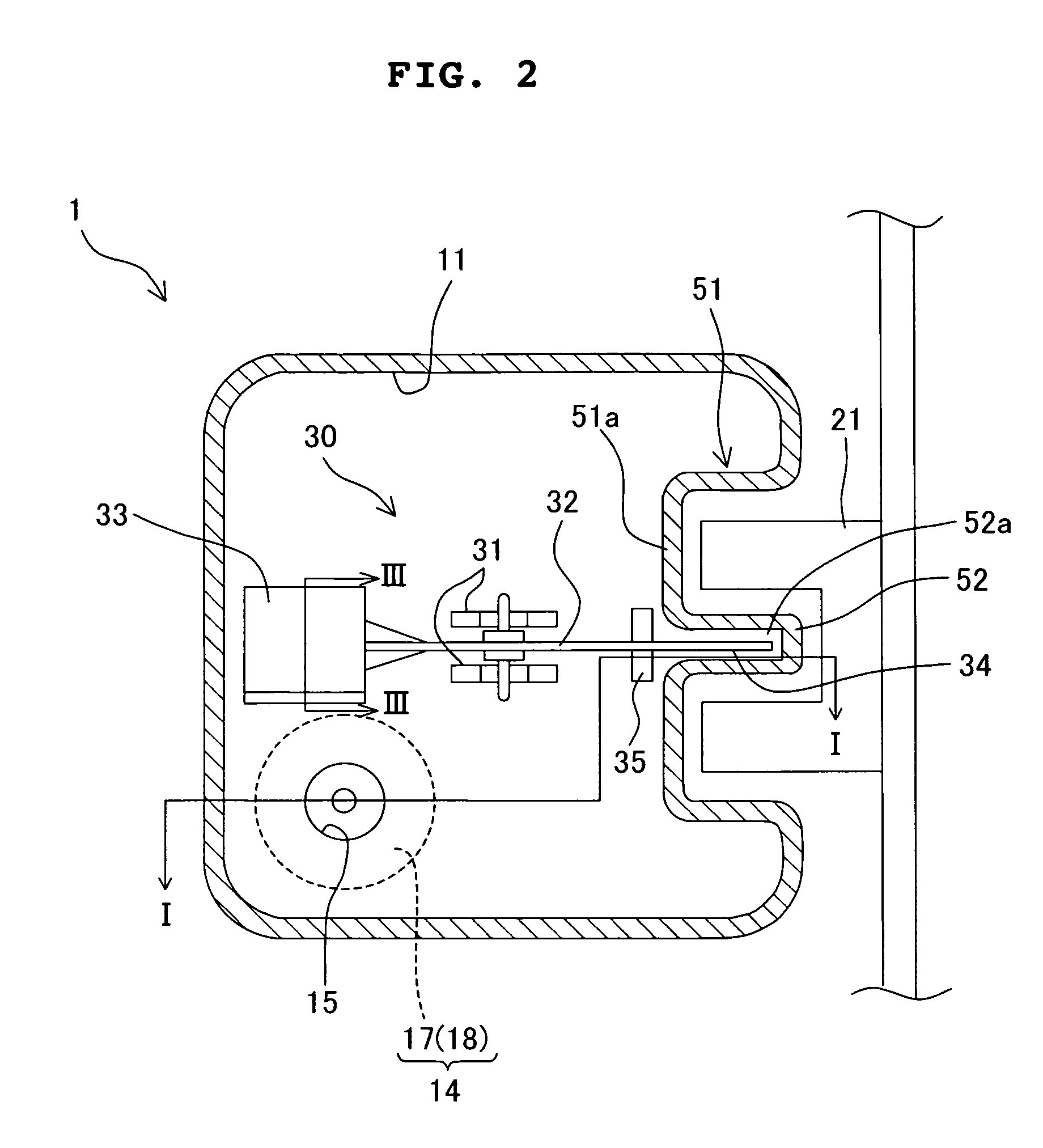

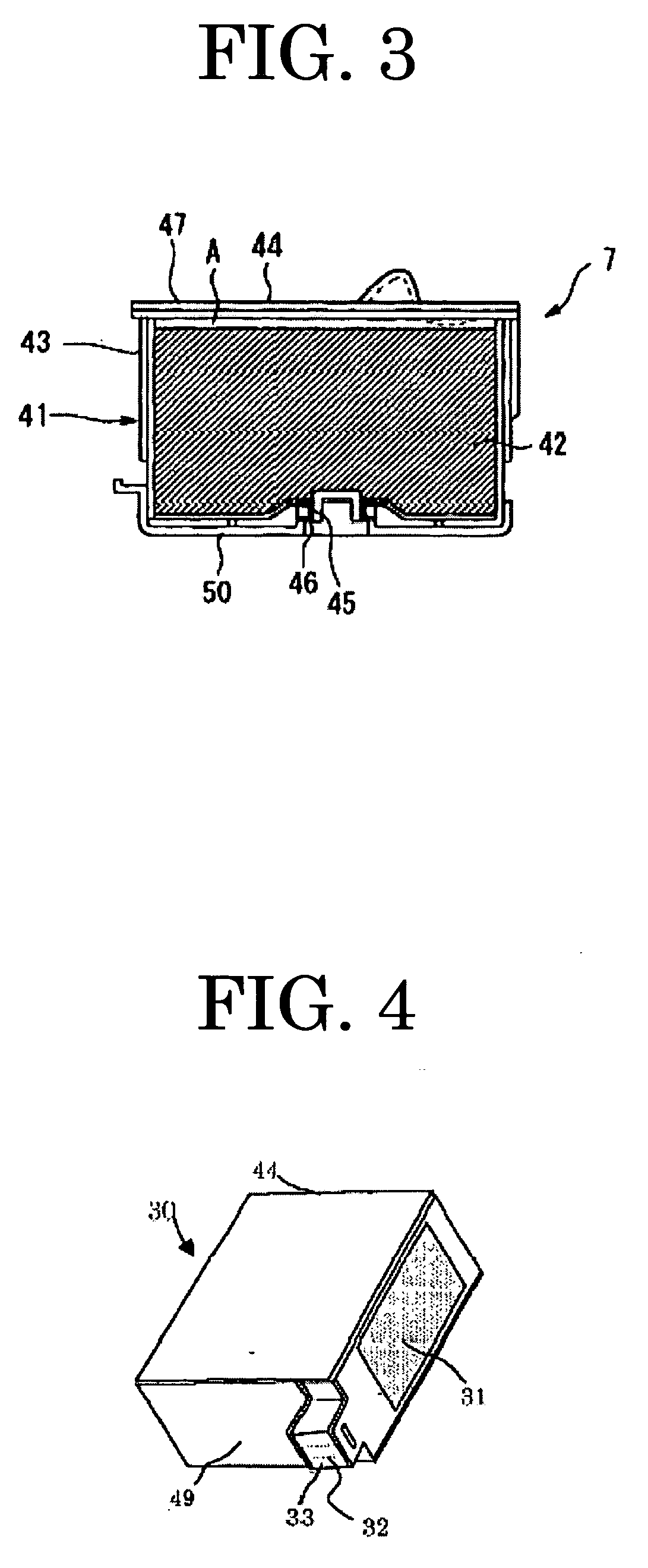

Ink cartridge and printer using the same

InactiveUS6565198B2Low costStored quickly and securelyOther printing apparatusManufacturing cost reductionInk printer

In an ink jet printer of the present invention, in order to reduce the manufacturing cost, an inexpensive EEPROM enabling only sequential accesses is applied for storage elements incorporated in a black ink cartridge and a color ink cartridge. The data array of a memory cell included in each of the storage elements mounted on the ink cartridges is determined in such a manner that a second storage area, in which rewritable data, for example, data on remaining quantities of inks in the ink cartridge, are stored, is accessed prior to a first storage area, in which read only data are stored. This configuration enables the rewritable data to be securely written into the second storage area even after a power-off operation. The second storage area has two memory divisions allocated to each ink, that is, a first ink remaining quantity memory division and a second ink remaining quantity memory division. Latest data on the remaining quantity of each ink is alternately written into these two memory divisions. Alternatively, the latest data on the remaining quantity of each ink is written into these two memory divisions in a duplicated manner. Each ink remaining quantity memory division has a write complete flag to determine whether or not a writing operation has been completed normally in the ink remaining quantity memory division. This arrangement enables the remaining quantities of the respective inks to be monitored accurately and continuously.

Owner:SEIKO EPSON CORP

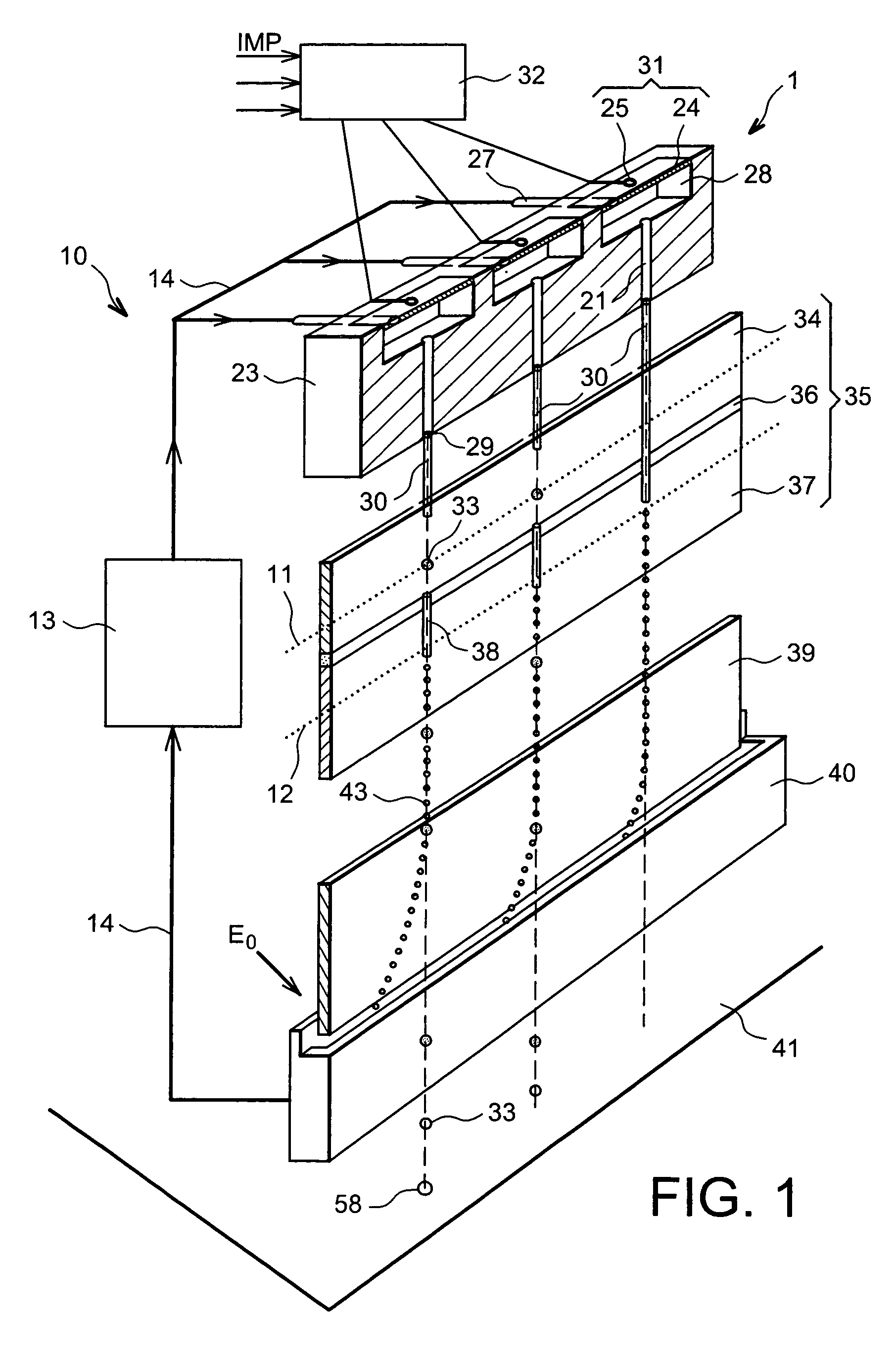

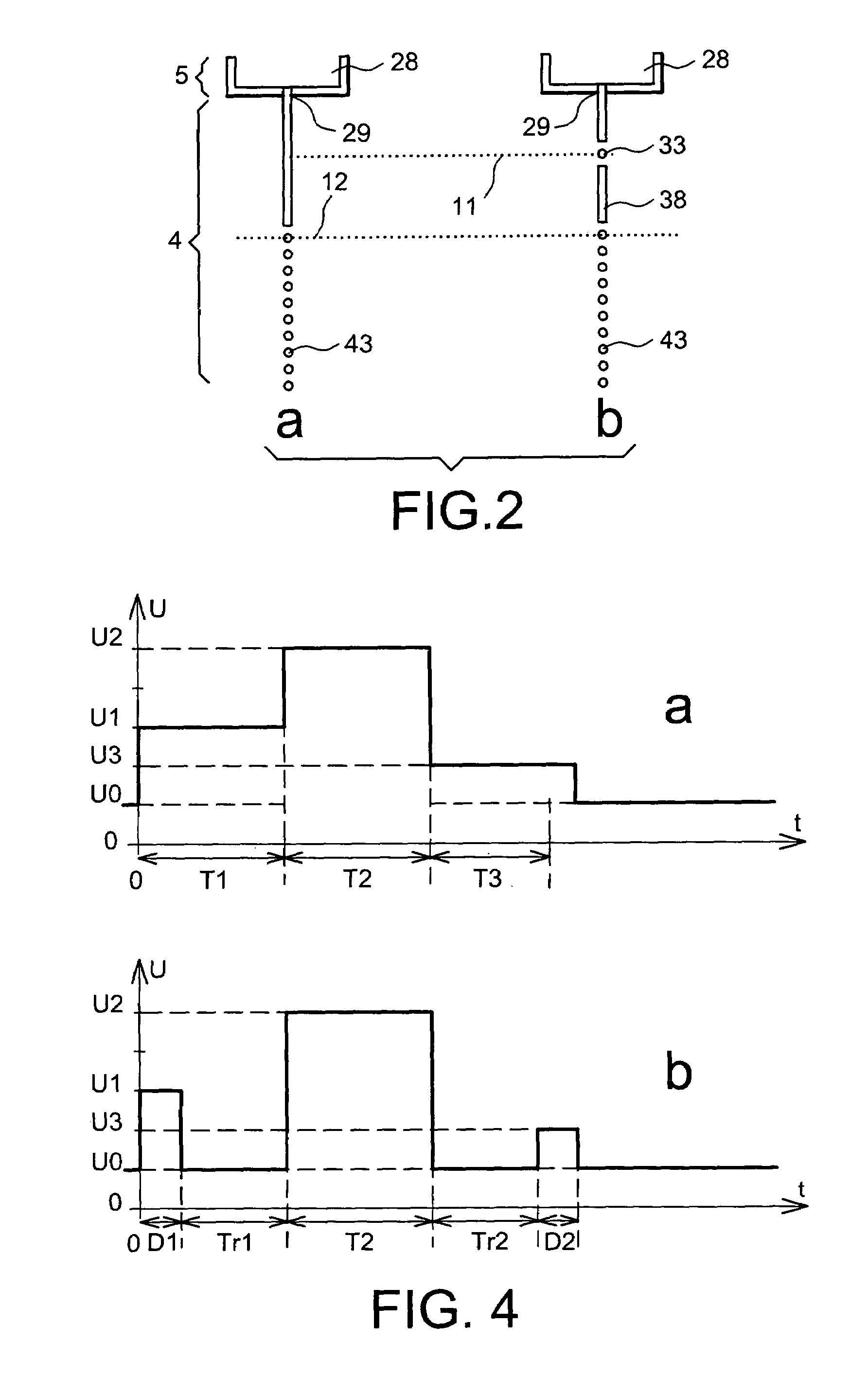

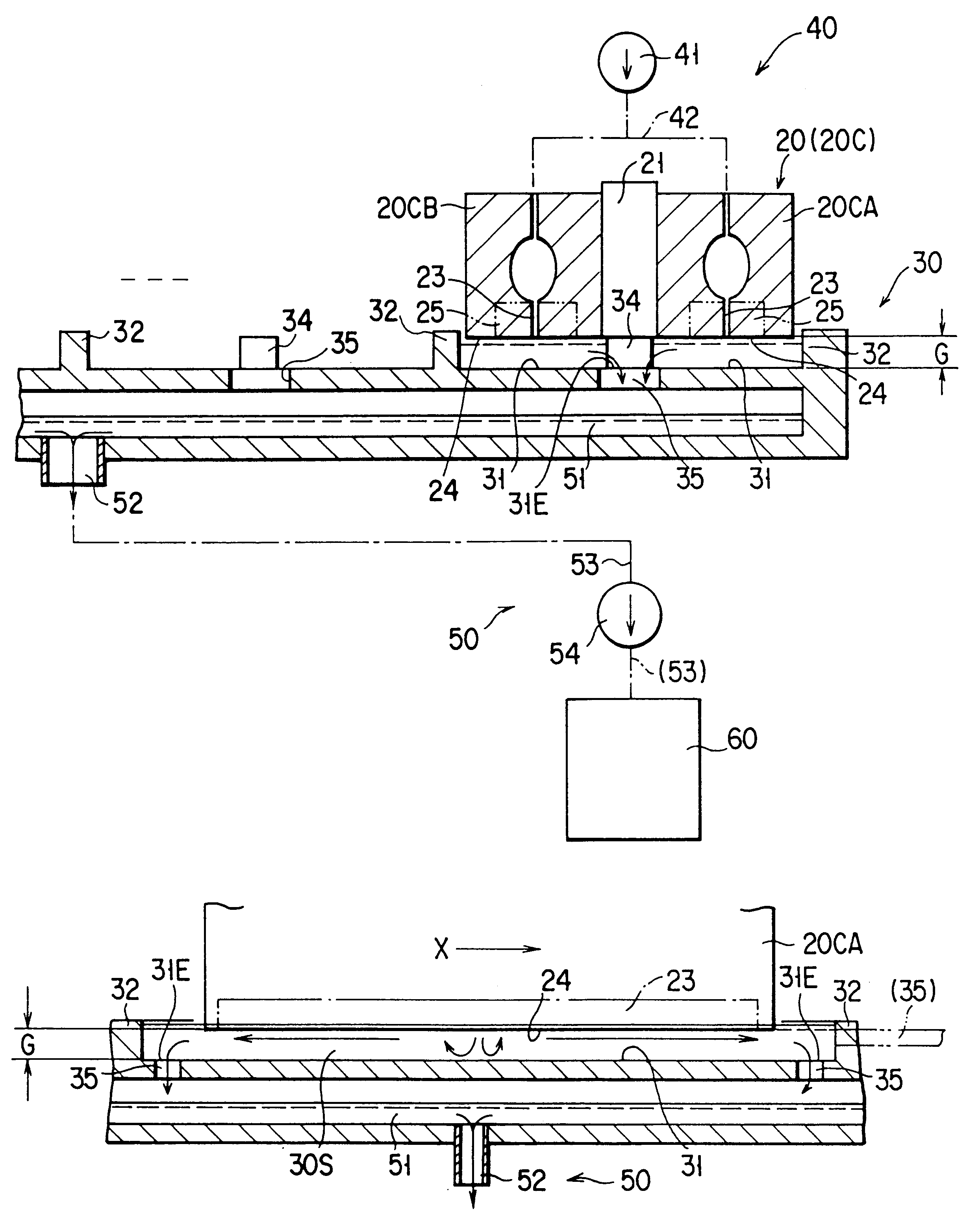

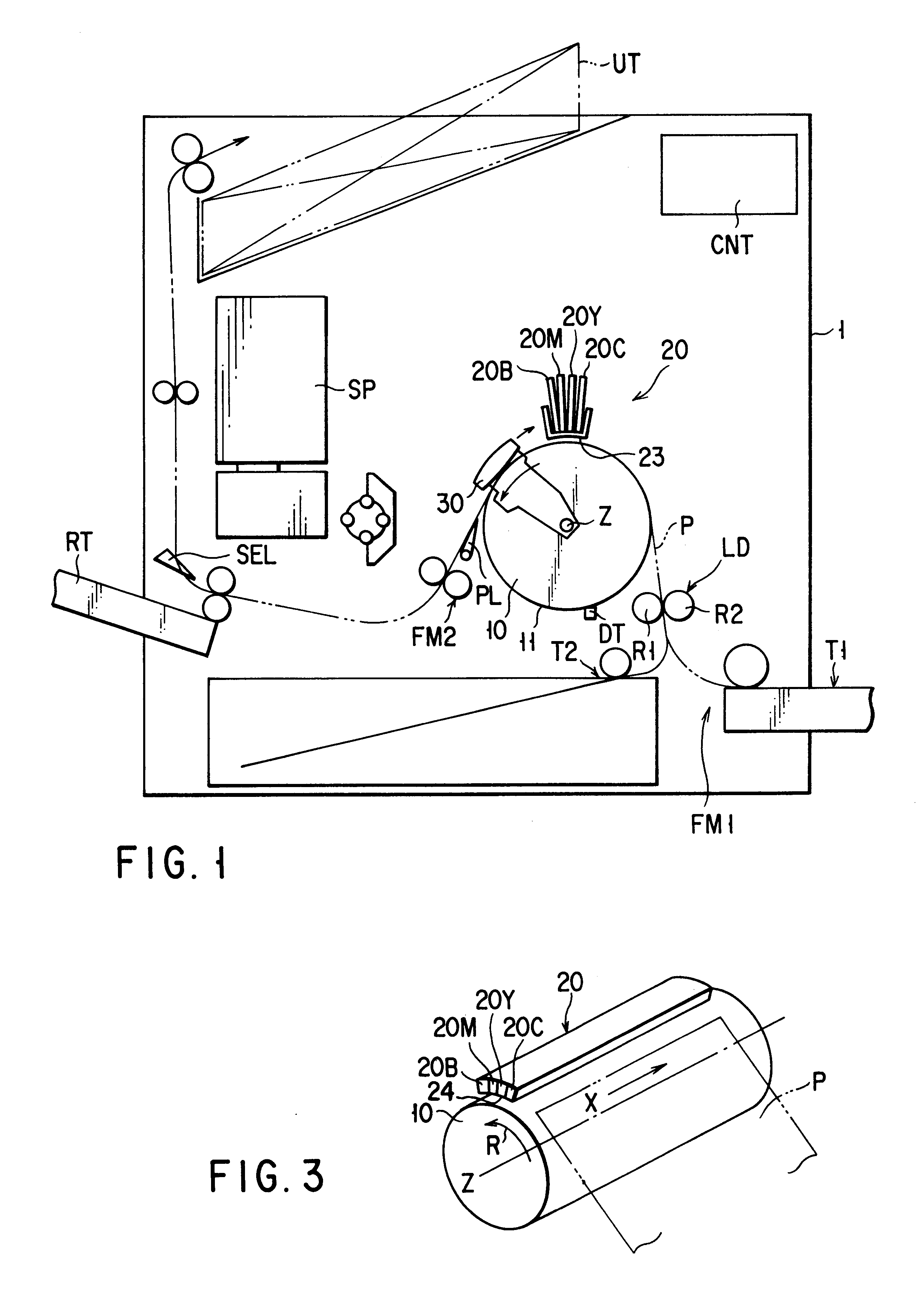

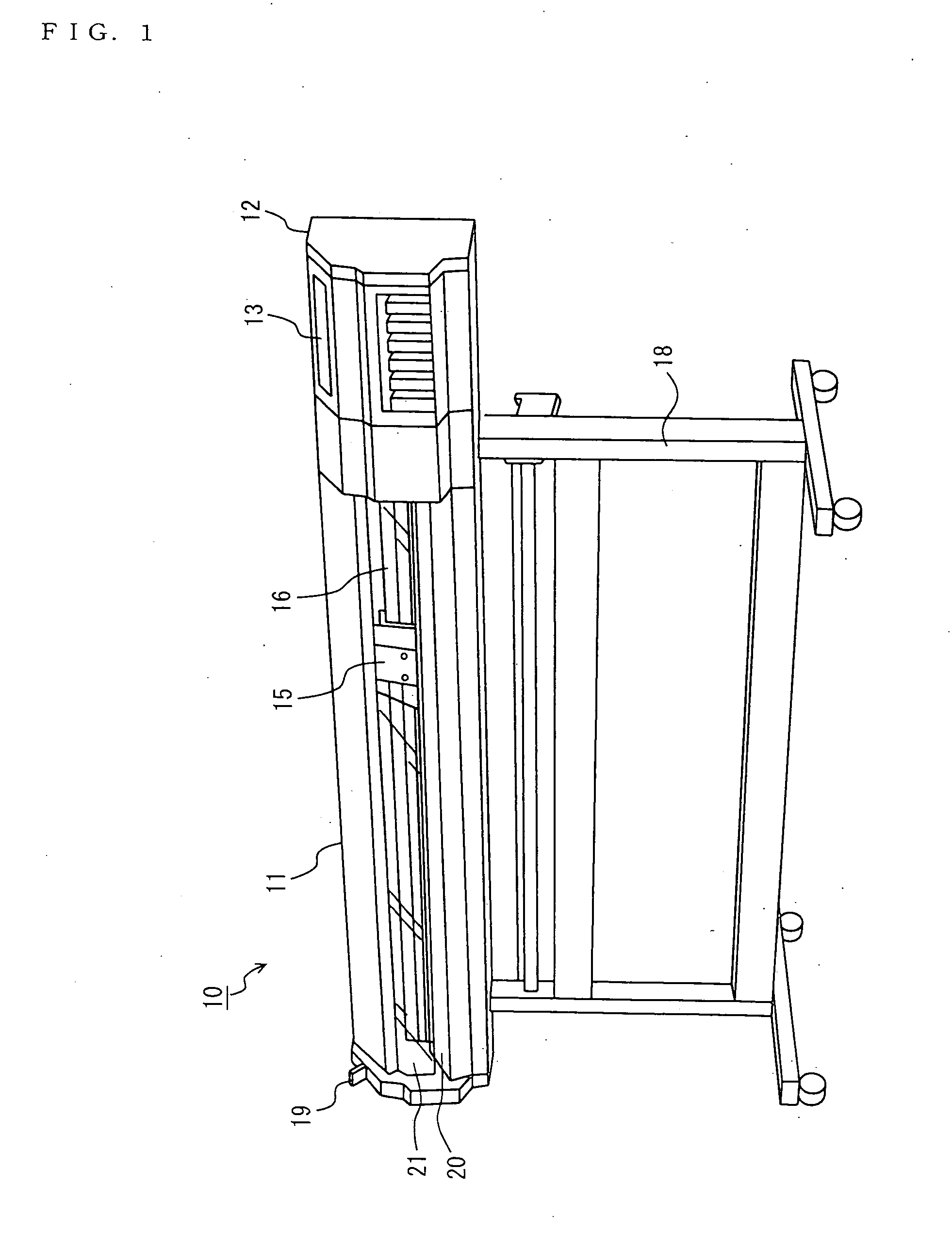

Inkjet printer

A printer head of an ink jet printer is provided with an internal stimulation system with which it is possible to create in an upstream breaking position of a jet, an upstream break-up forming in a zero potential area, drops which will be used for printing, and jet sections on the one hand and in a downstream breaking position, a break-up of the jet or of sections of the jet forming in a non-zero potential area, drops which are recovered on the other hand. A sorting system common to all the jets of the head provides simplification of the head and reduction of its bulkiness.

Owner:MARKEM IMAJE HLDG

Ink-jet printer

InactiveUS6217145B1Quickly and safely removedQuickly and accurately and safely removedPrintingComputer printingInk printer

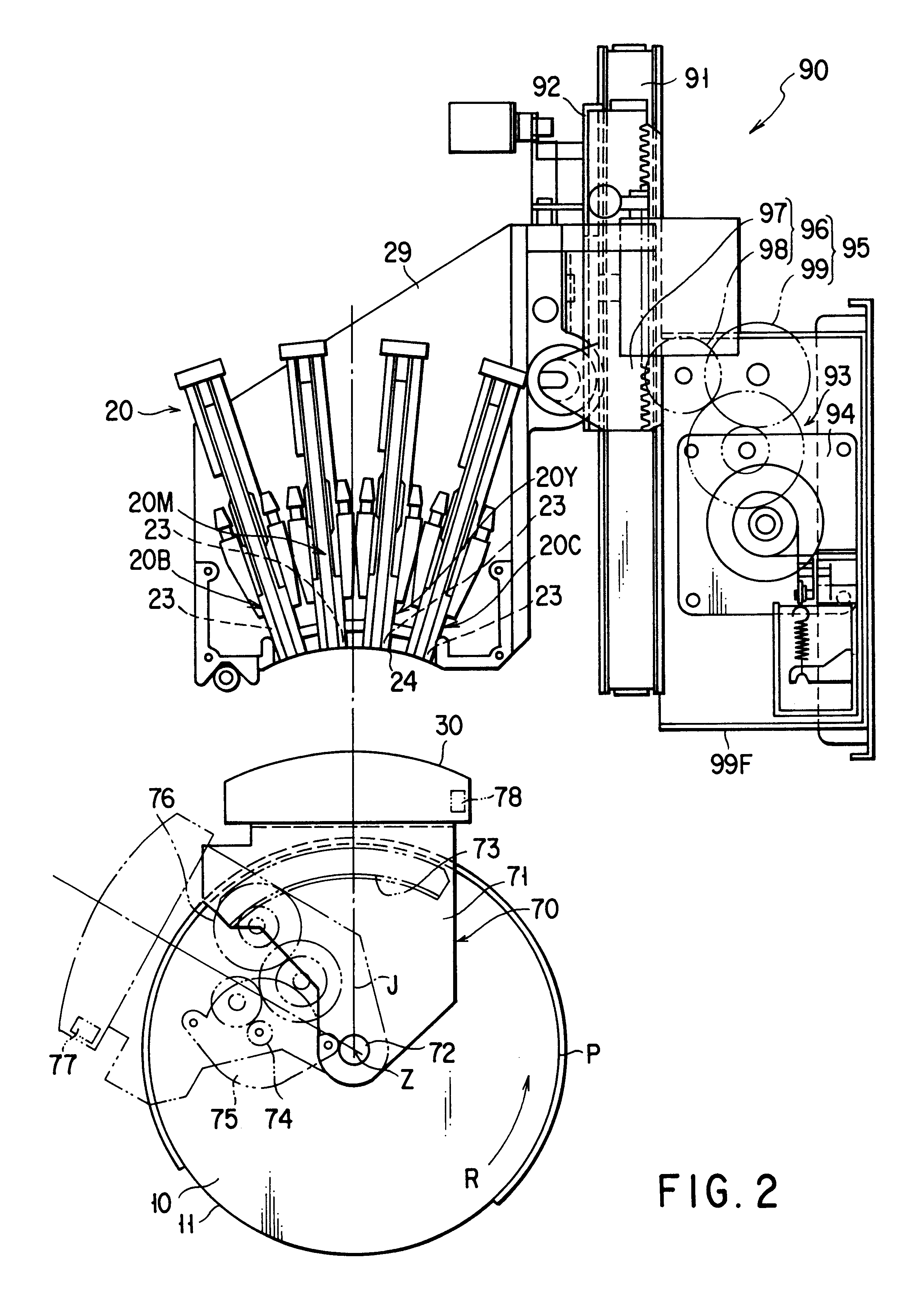

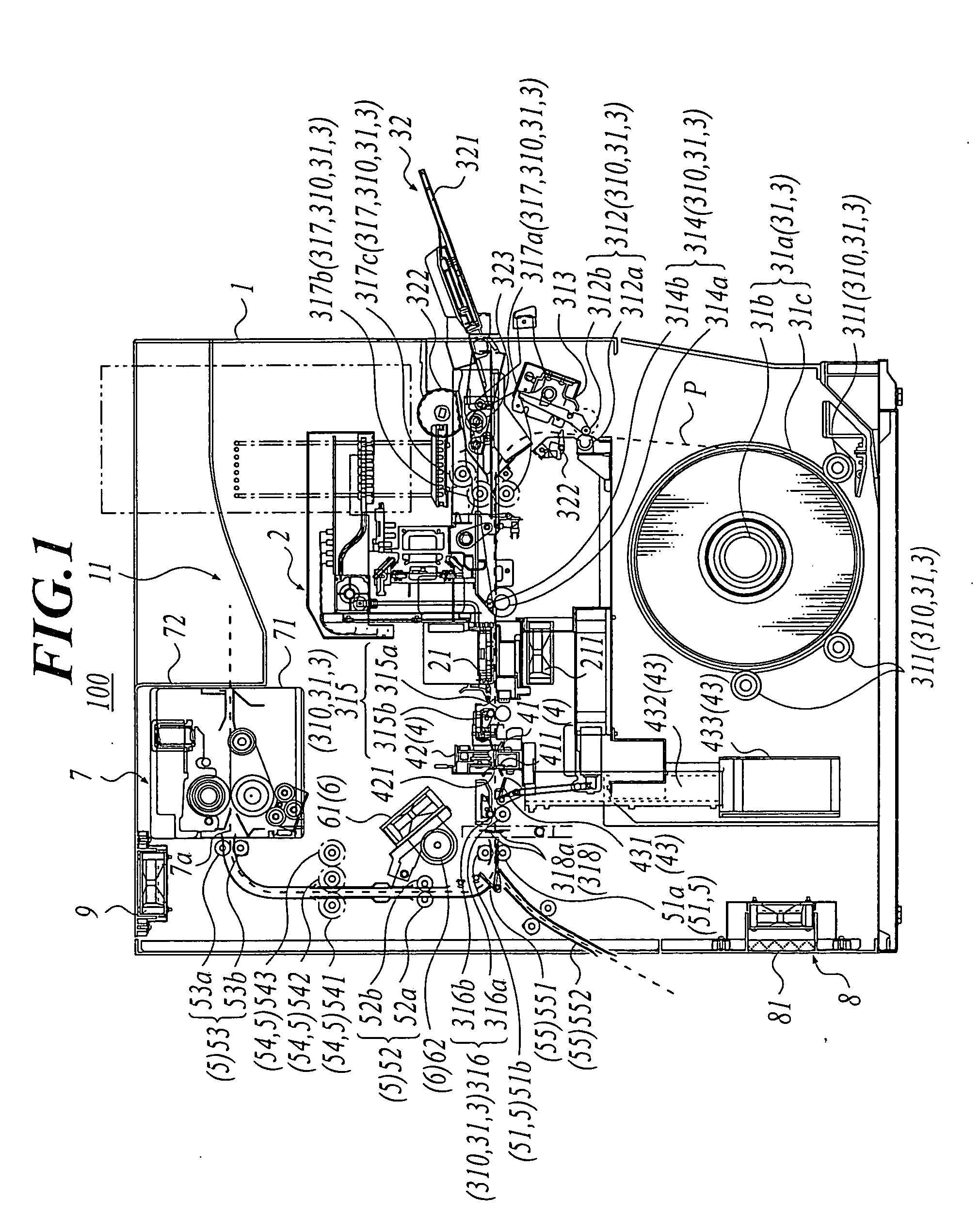

An ink-jet printer includes a rotary drum for carrying a print sheet, a print head arranged above the rotary drum for printing an image by ejecting ink onto the print sheet, a washing board facing the print head to wash an end surface of the print head with ink ejected from the print head, and a control unit for controlling at a non-printing time the washing board to be set at a cleaning position located between the print head and the rotary drum and the print head to eject ink therefrom. Particularly, the washing board has grooves which receives an entire end surface of the print head and a drain section for draining the ink ejected from the print head and flowing in contact with the end surface of the print head within the groove section.

Owner:TOSHIBA TEC KK

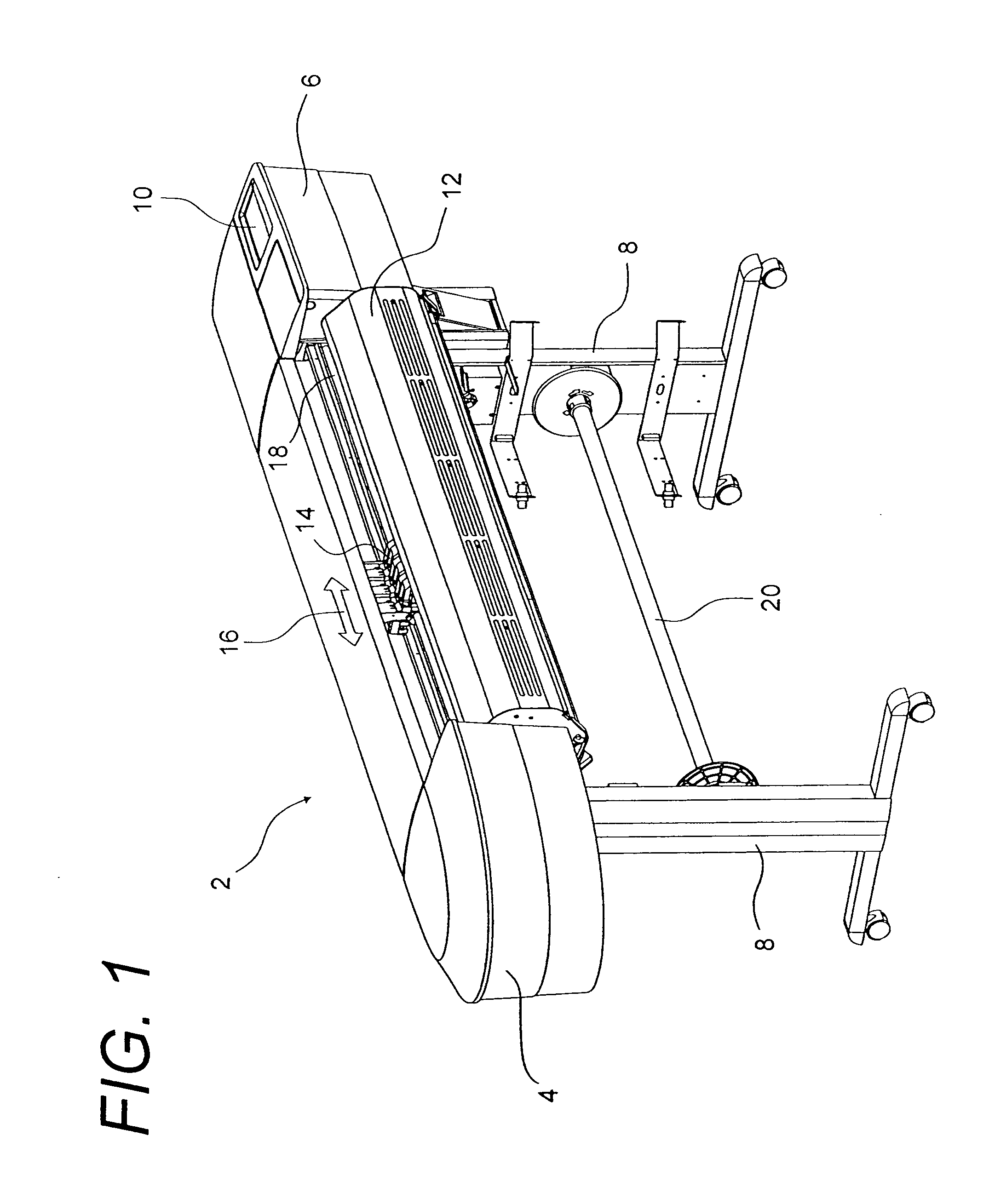

Greeting card feeder module for inkjet printing

InactiveUS6848844B2Easy to useClear imagingPrinting mechanismsRegistering devicesCard stockInk printer

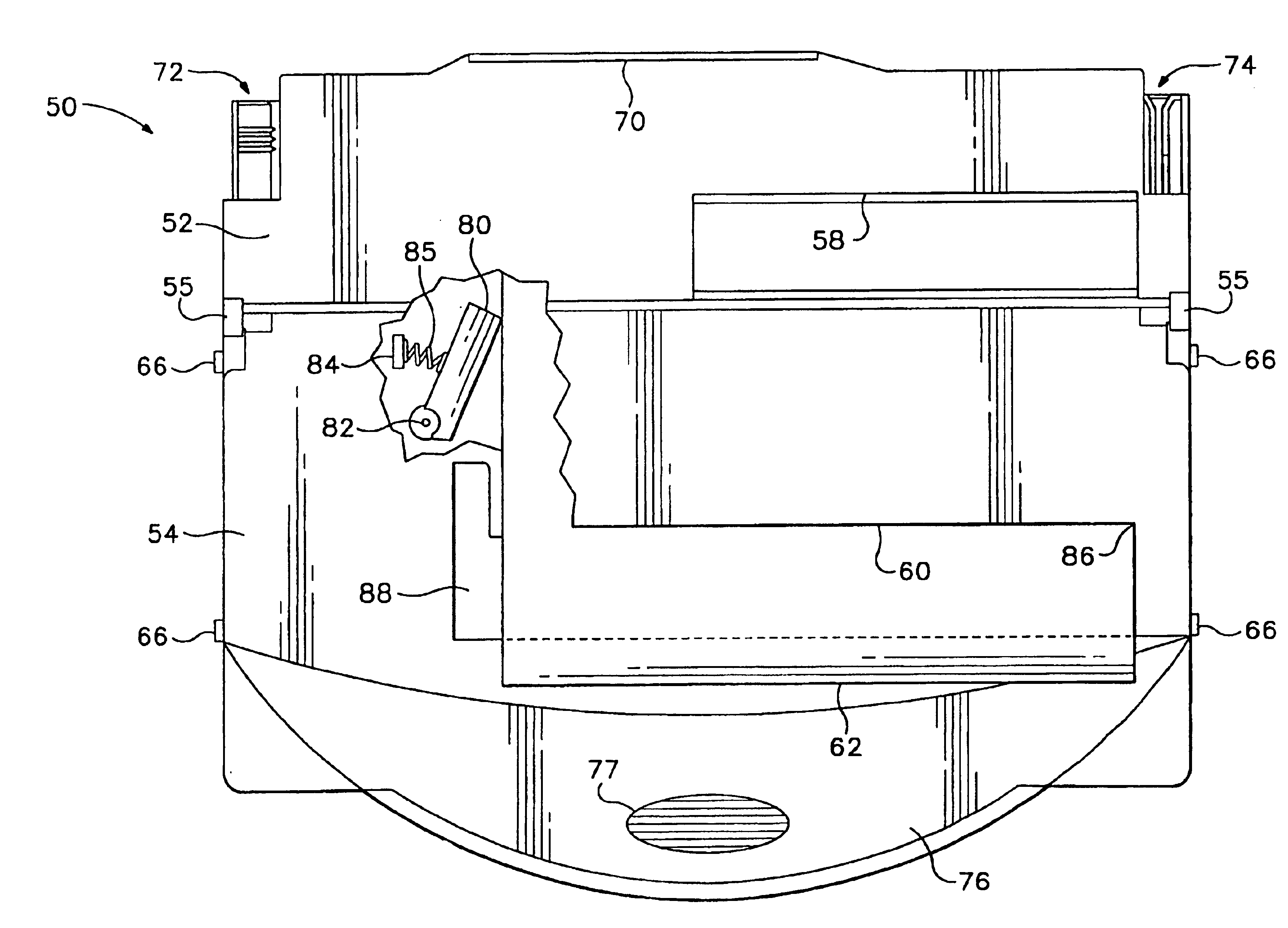

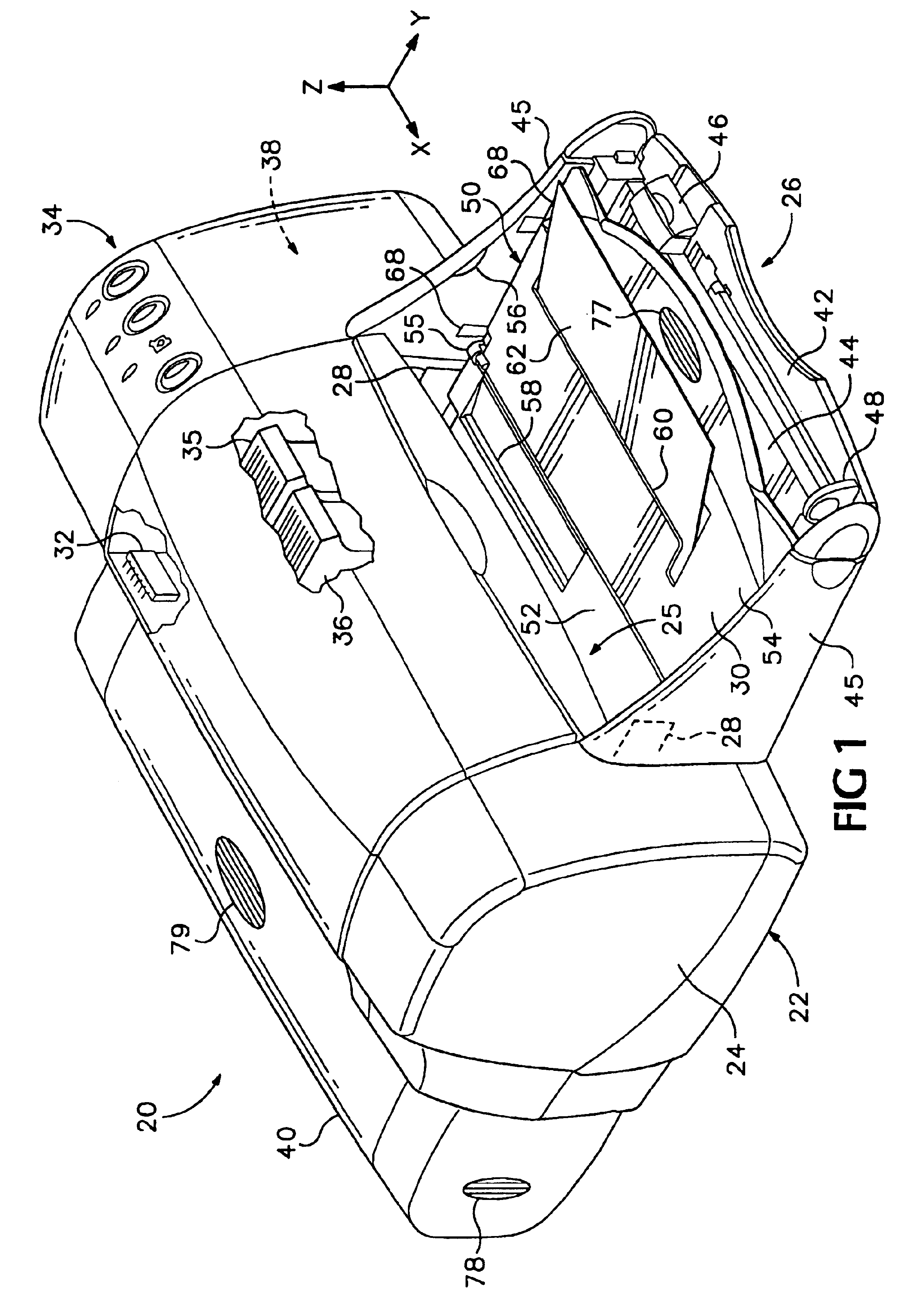

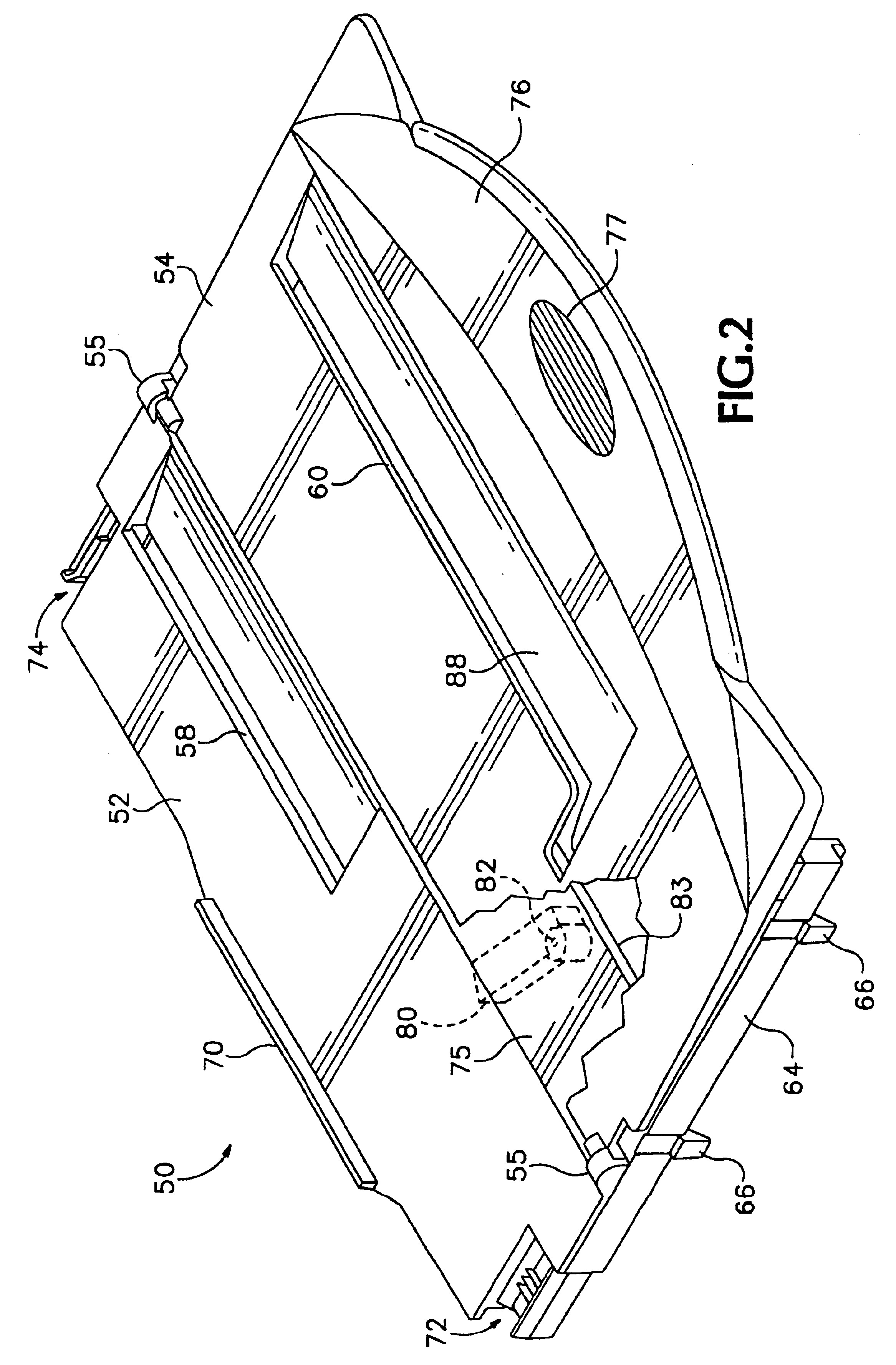

A hardcopy printing mechanism and a greeting card feeder retrofit kit therefor, along with a retrofitting method are provided for printing images on a first-sized media, and on both surfaces a second-sized greeting card media without removing the first-sized media from its normal supply tray. The hardcopy device may be an electrophotographic or inkjet printer preferably equipped with a duplexer module which inverts media from a printed first surface to an opposing second surface for printing an image thereon. For a printer having an alignment surface, and a width adjuster to push the first-sized media against the alignment surface, the greeting card feeder includes a biasing member which pushes the card stock against the alignment surface. The retrofit kit includes a supply of pre-scored greeting card stock and a software program with a group of greeting card images for a consumer to select from to print store-bought quality greeting cards.

Owner:HEWLETT PACKARD DEV CO LP

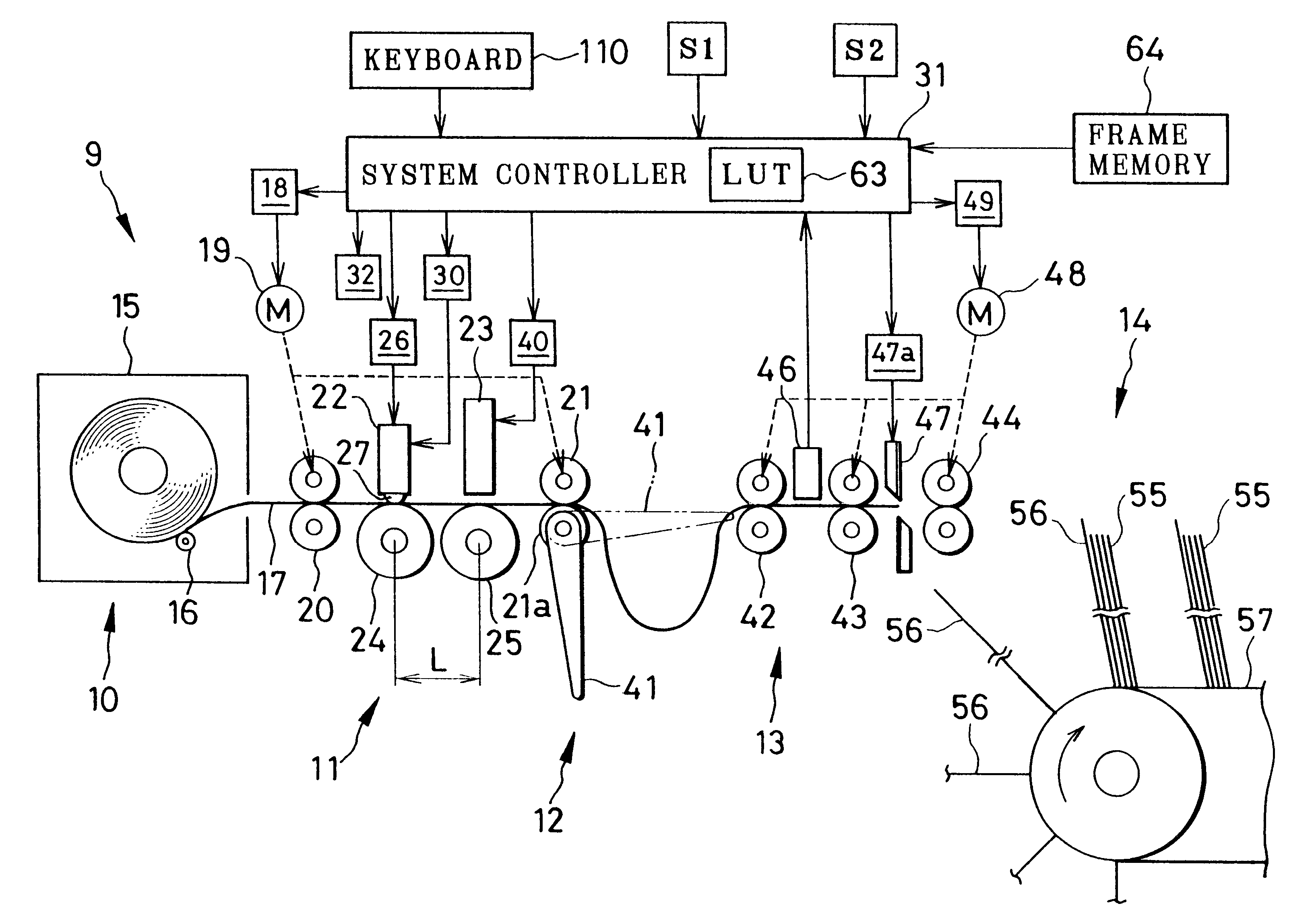

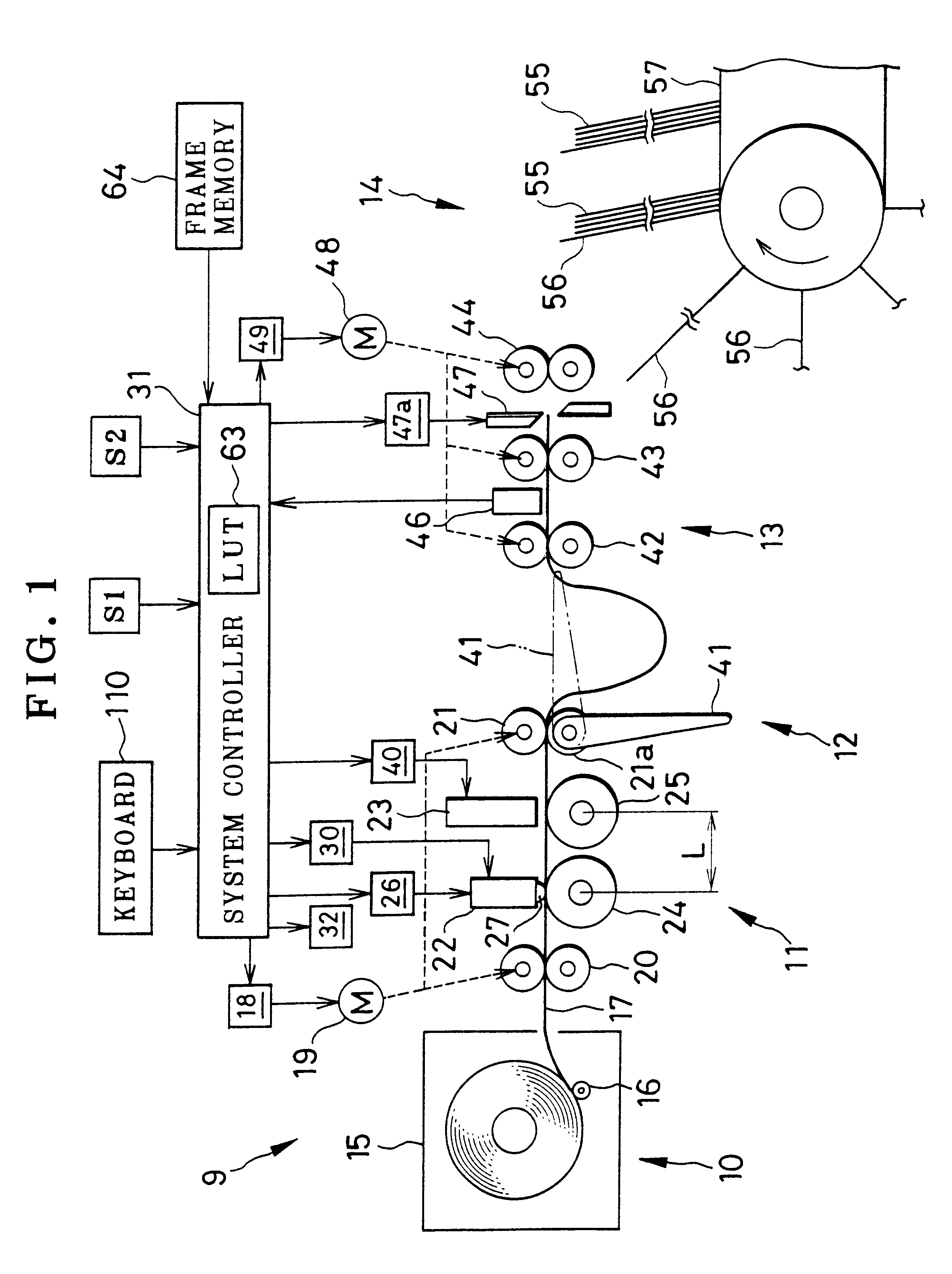

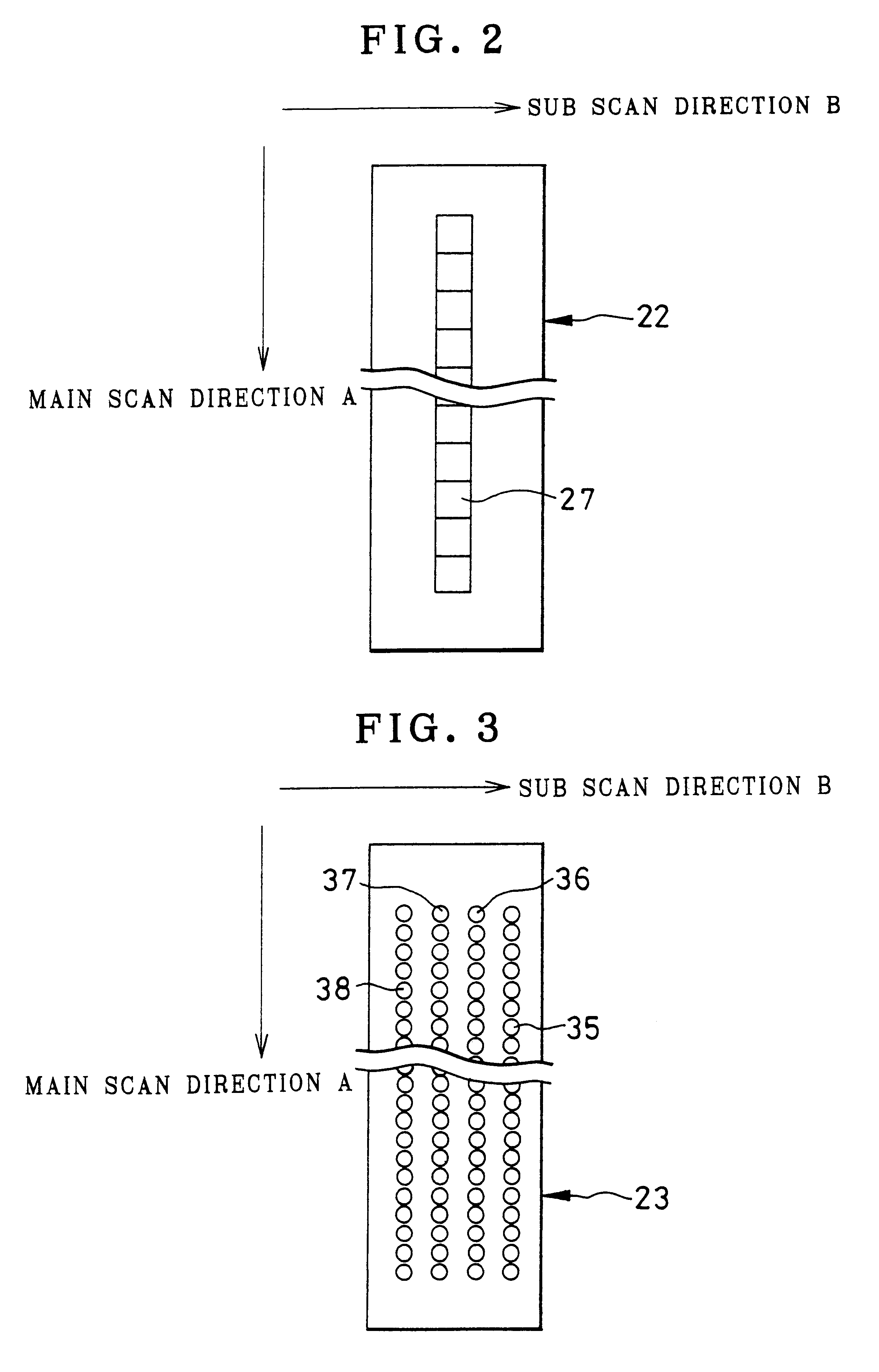

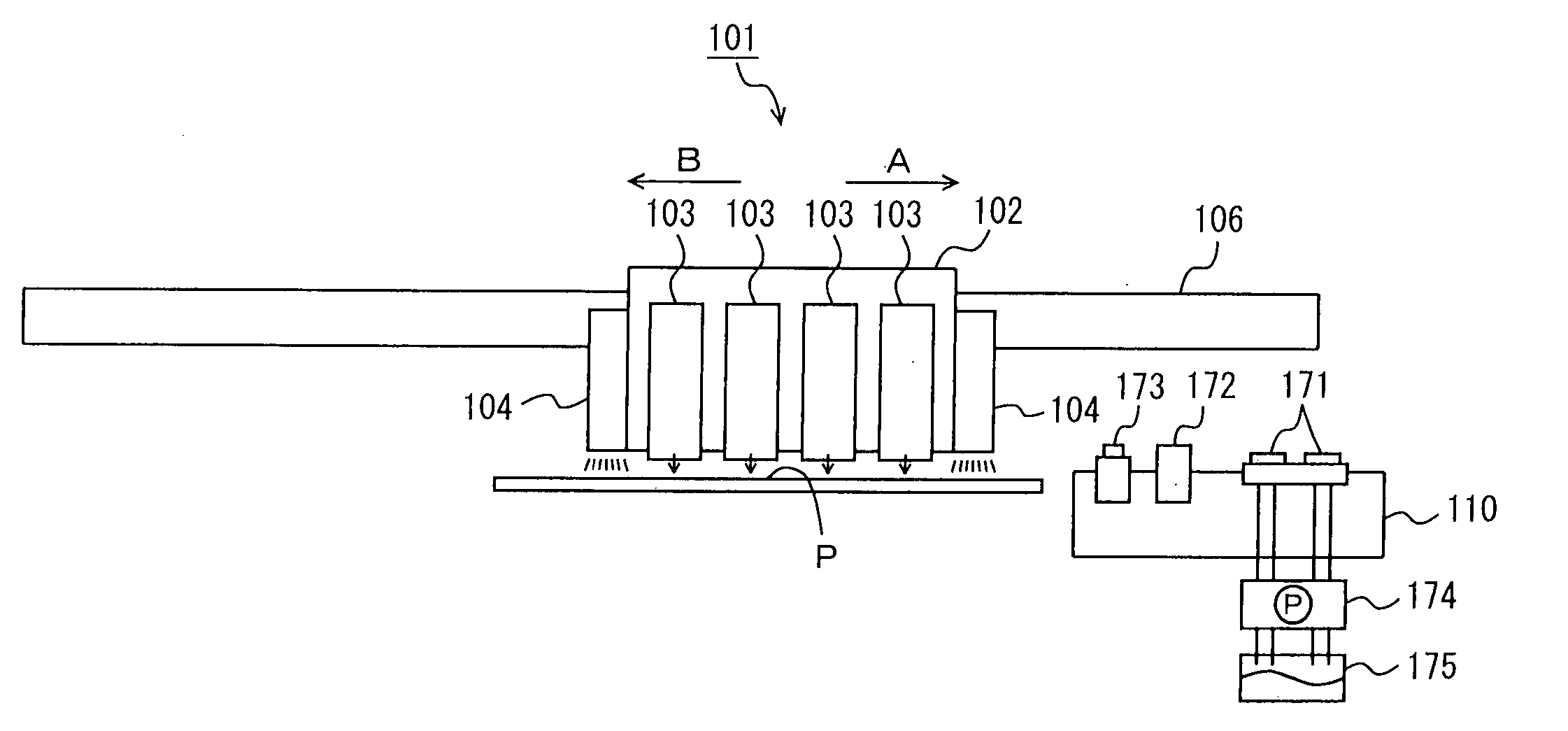

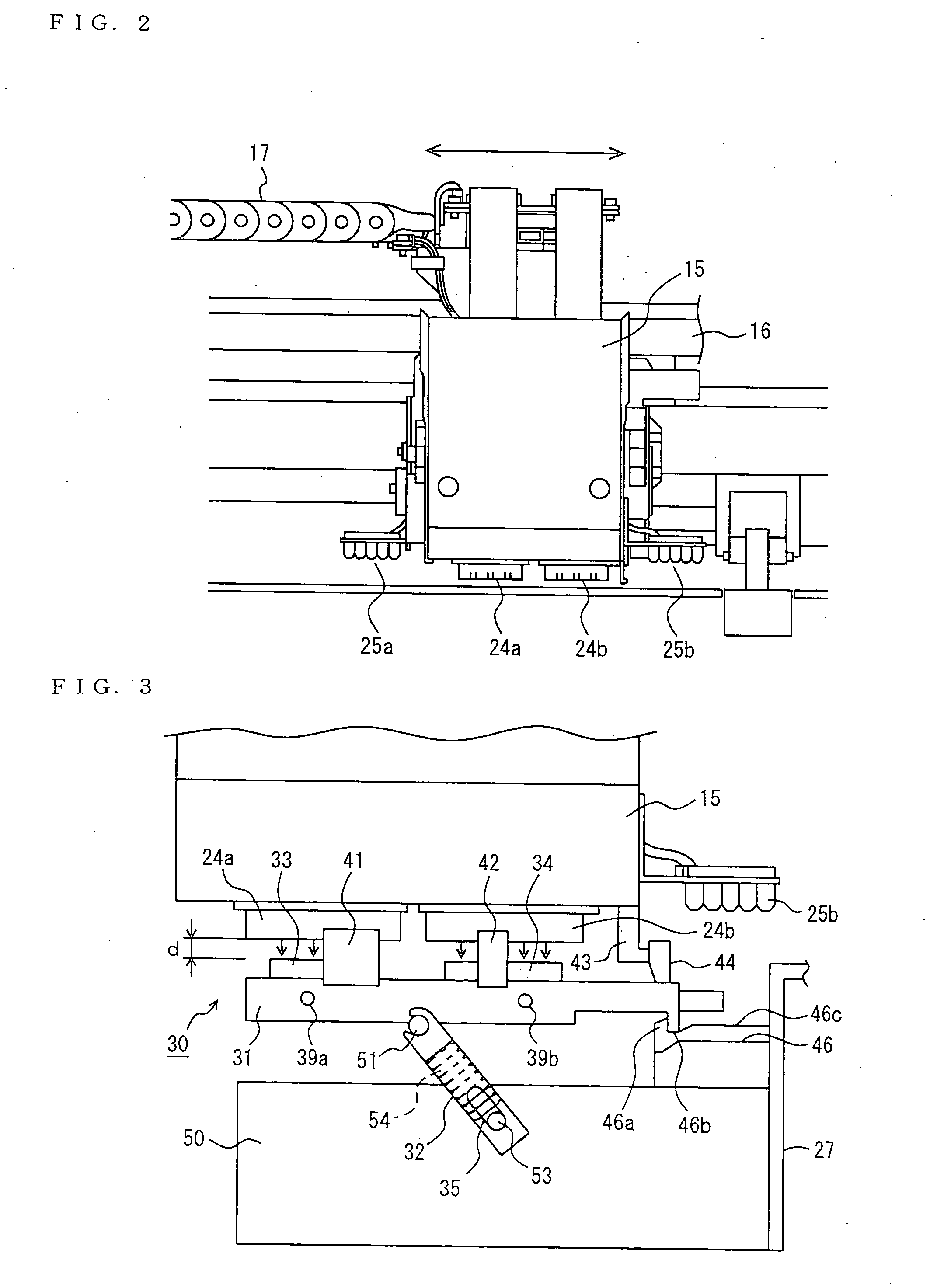

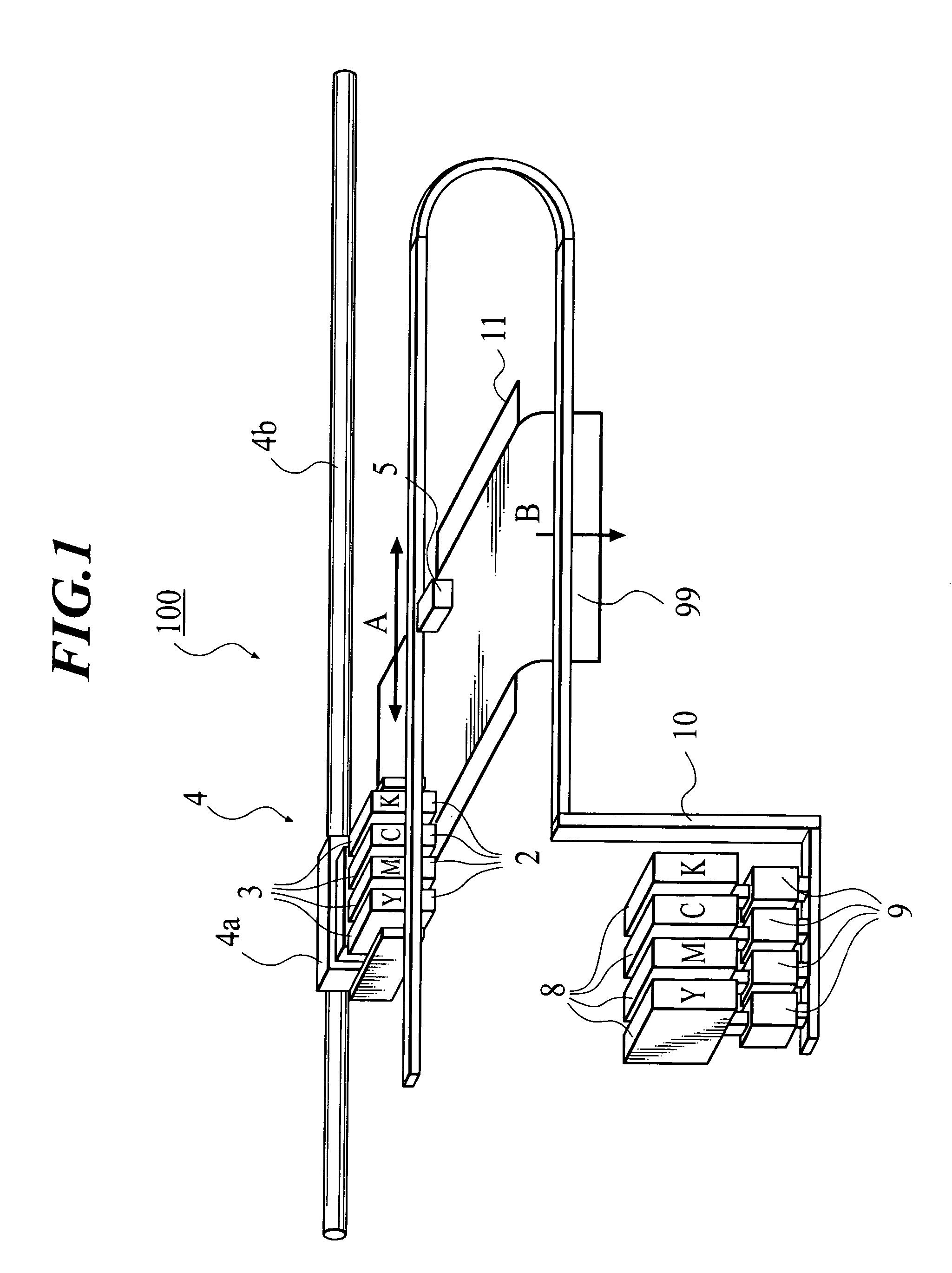

Ink jet printer and ink jet printing method

An ink jet printer comprises at least one ink jet head, in which plural nozzles are arranged in an array in a main scan direction, and eject a droplet of ink to recording material respectively at an ejected amount according to information of an image. Feeder rollers feed the recording material relative to the ink jet head in a sub scan direction, to print the image to the recording material two-dimensionally. A thermal head includes plural heating elements arranged in an array in the main scan direction, for applying heat to the recording material respectively in a heating region. A system controller sets drying heat energy according to the ejected amount, and drives the thermal head to apply the drying heat energy to the heating region, to promote drying of the droplet in the heating region.

Owner:FUJI FILM CO LTD +1

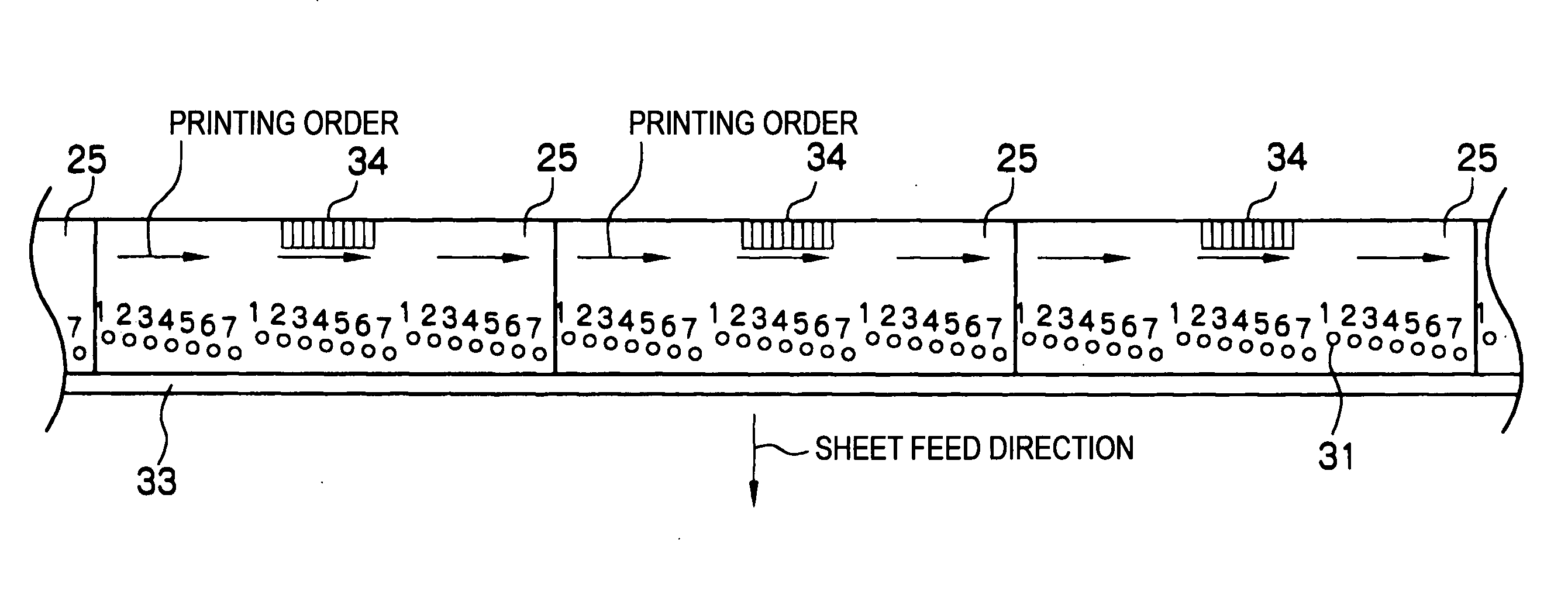

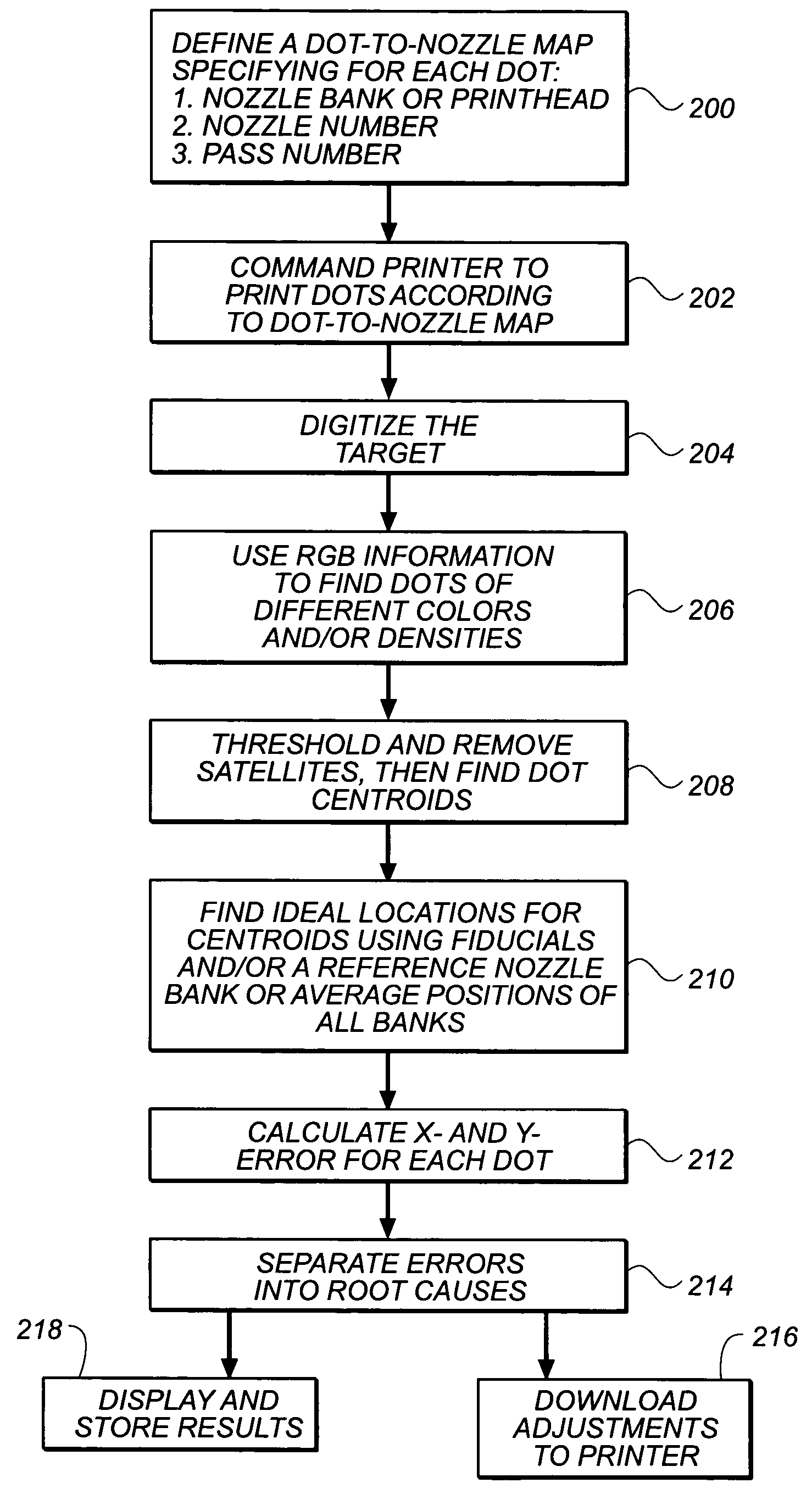

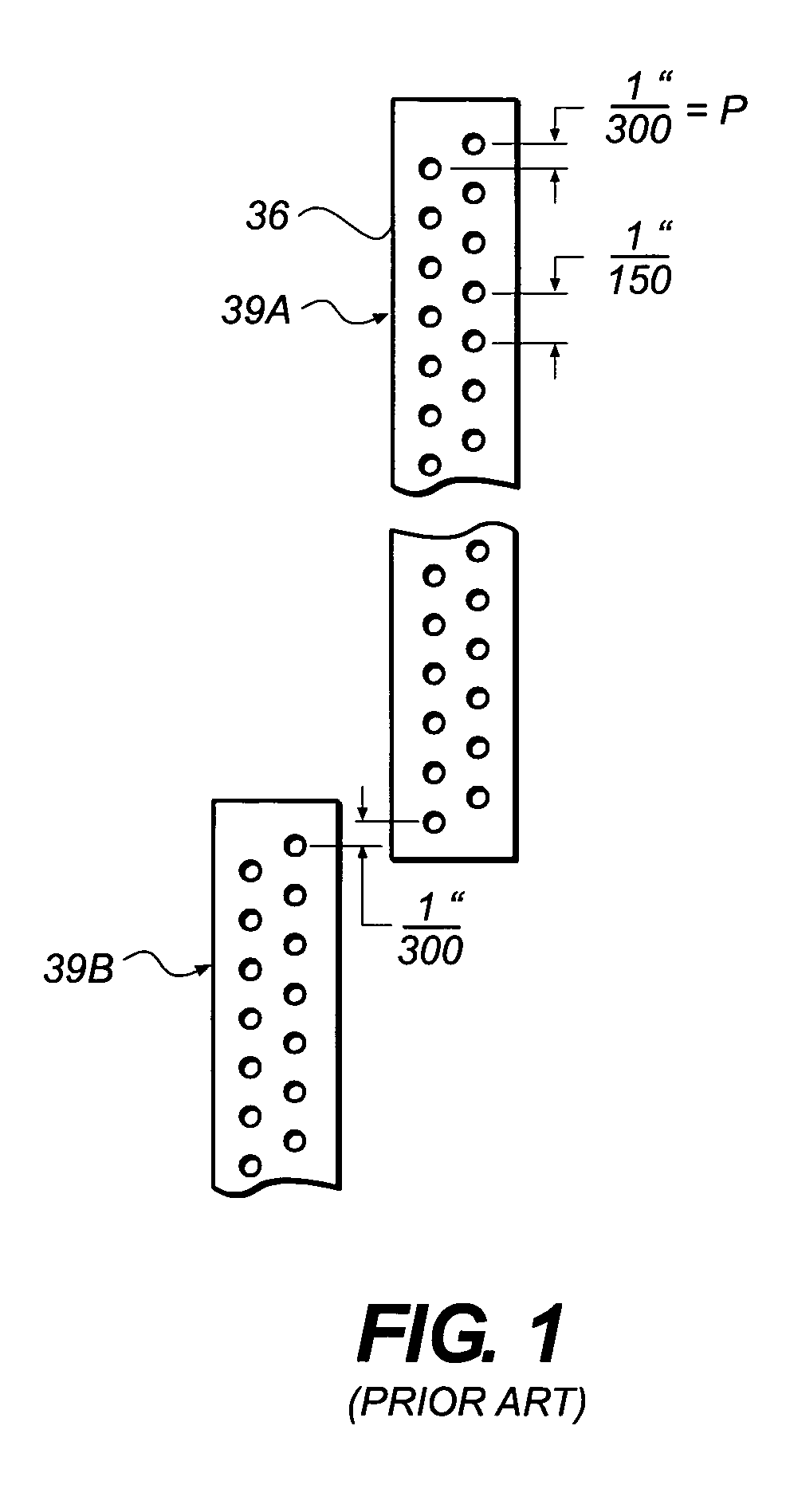

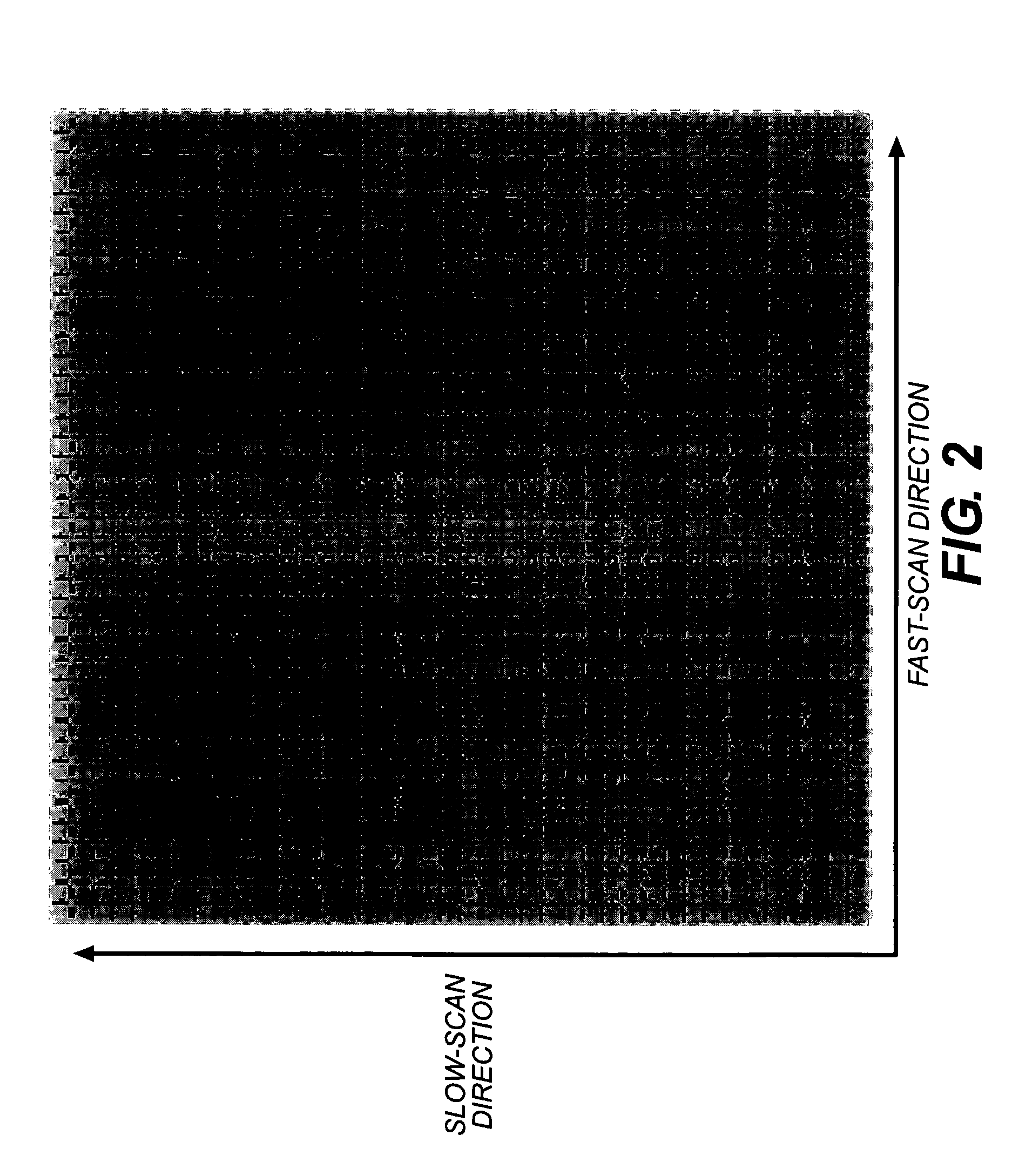

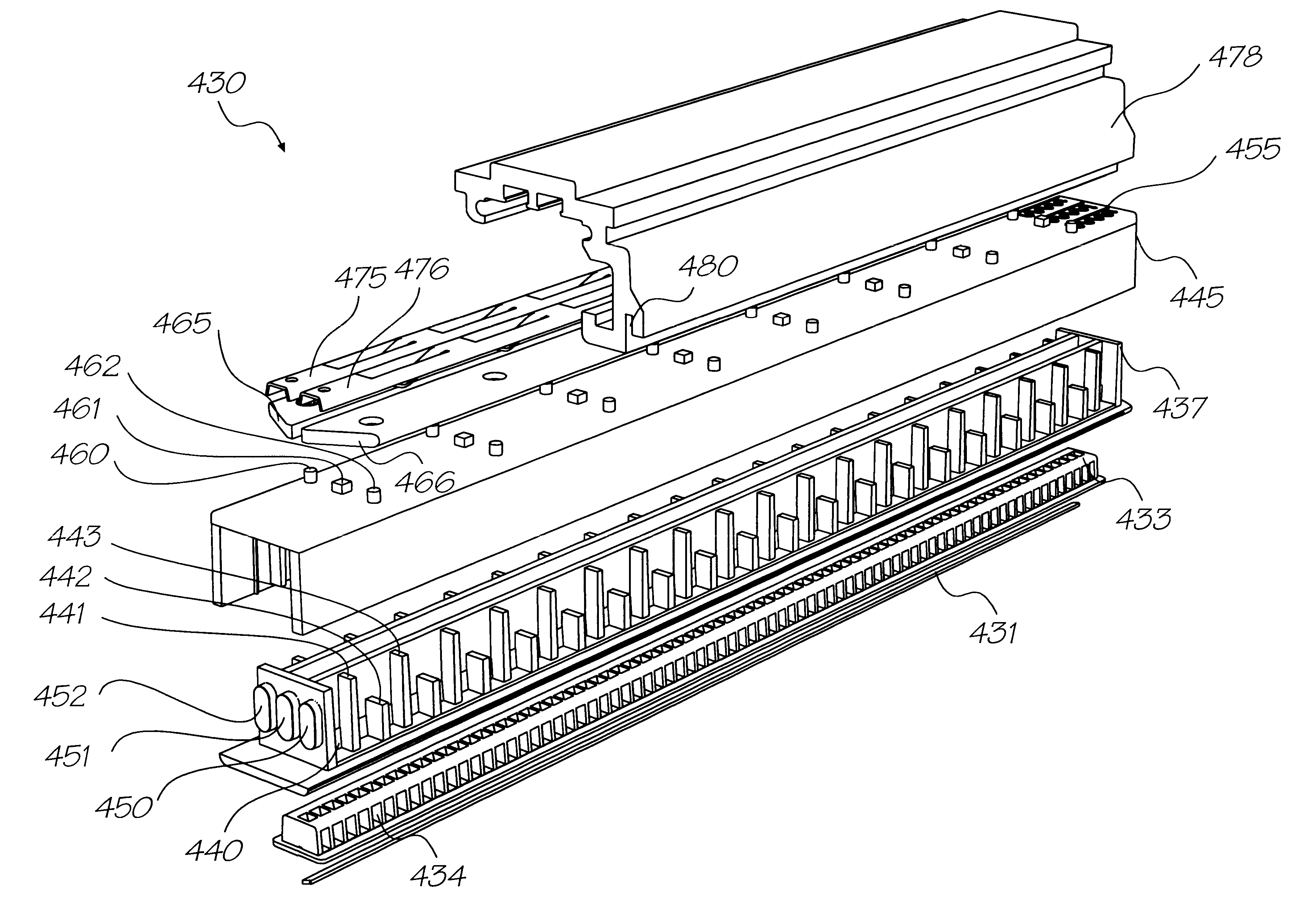

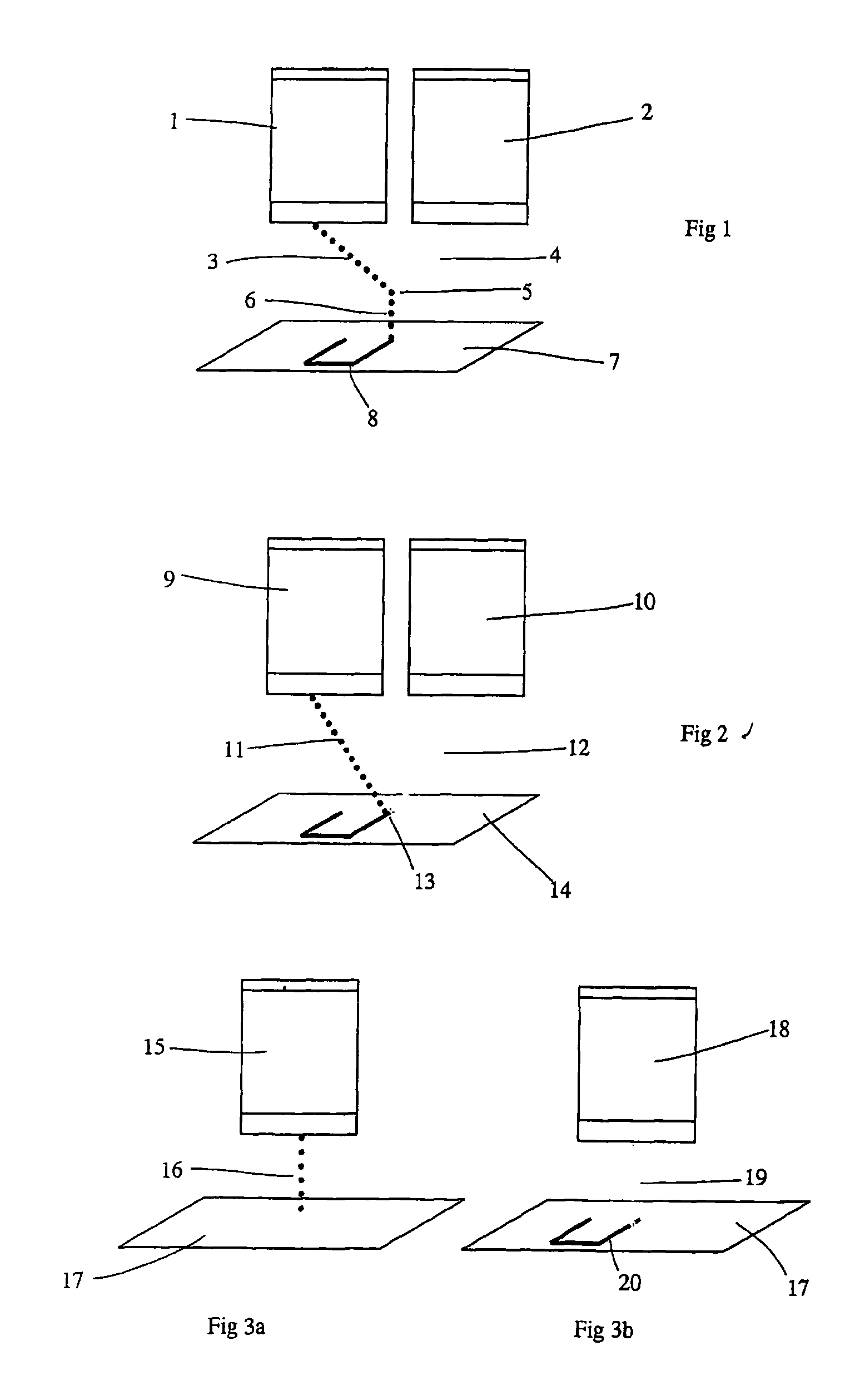

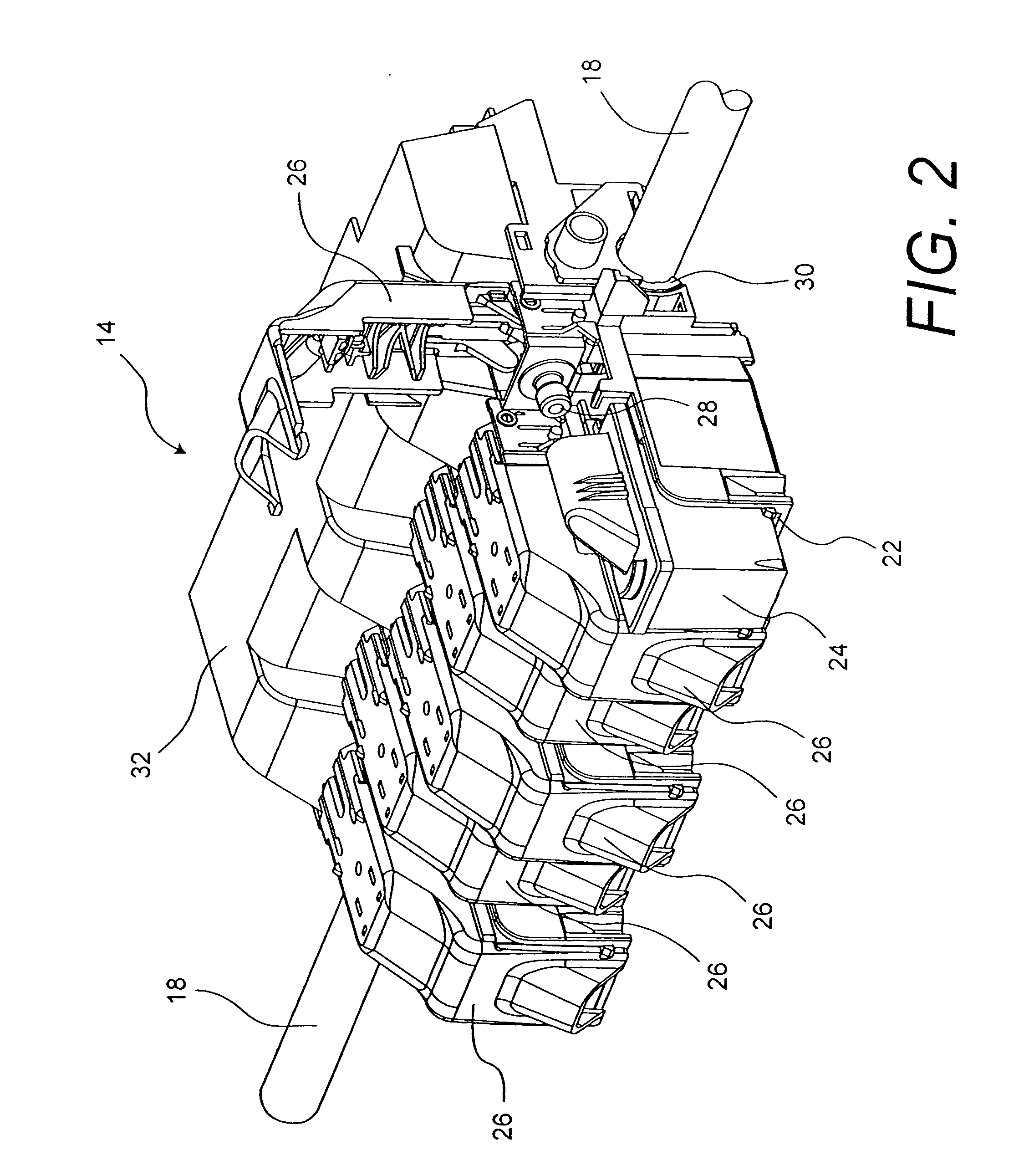

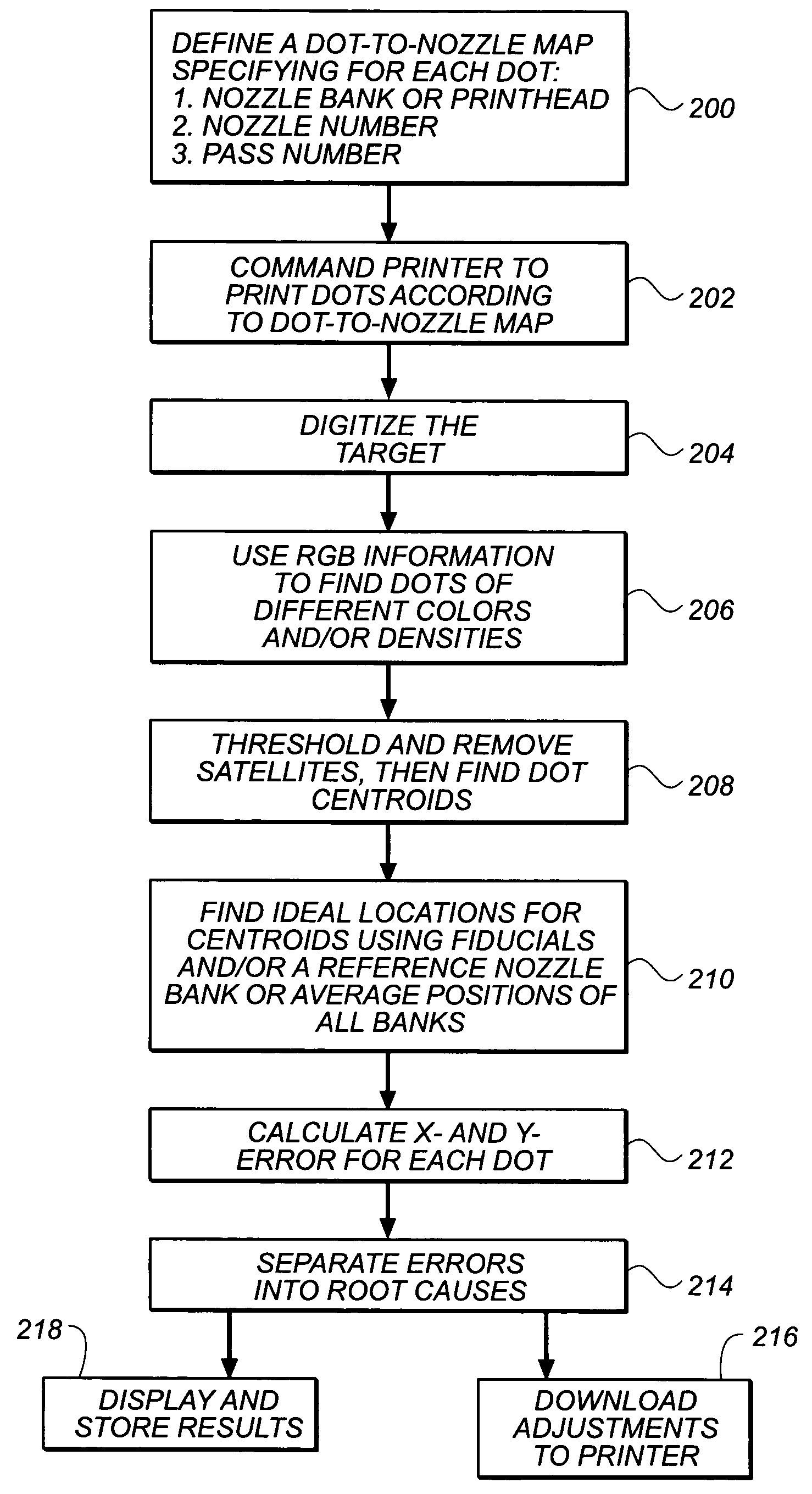

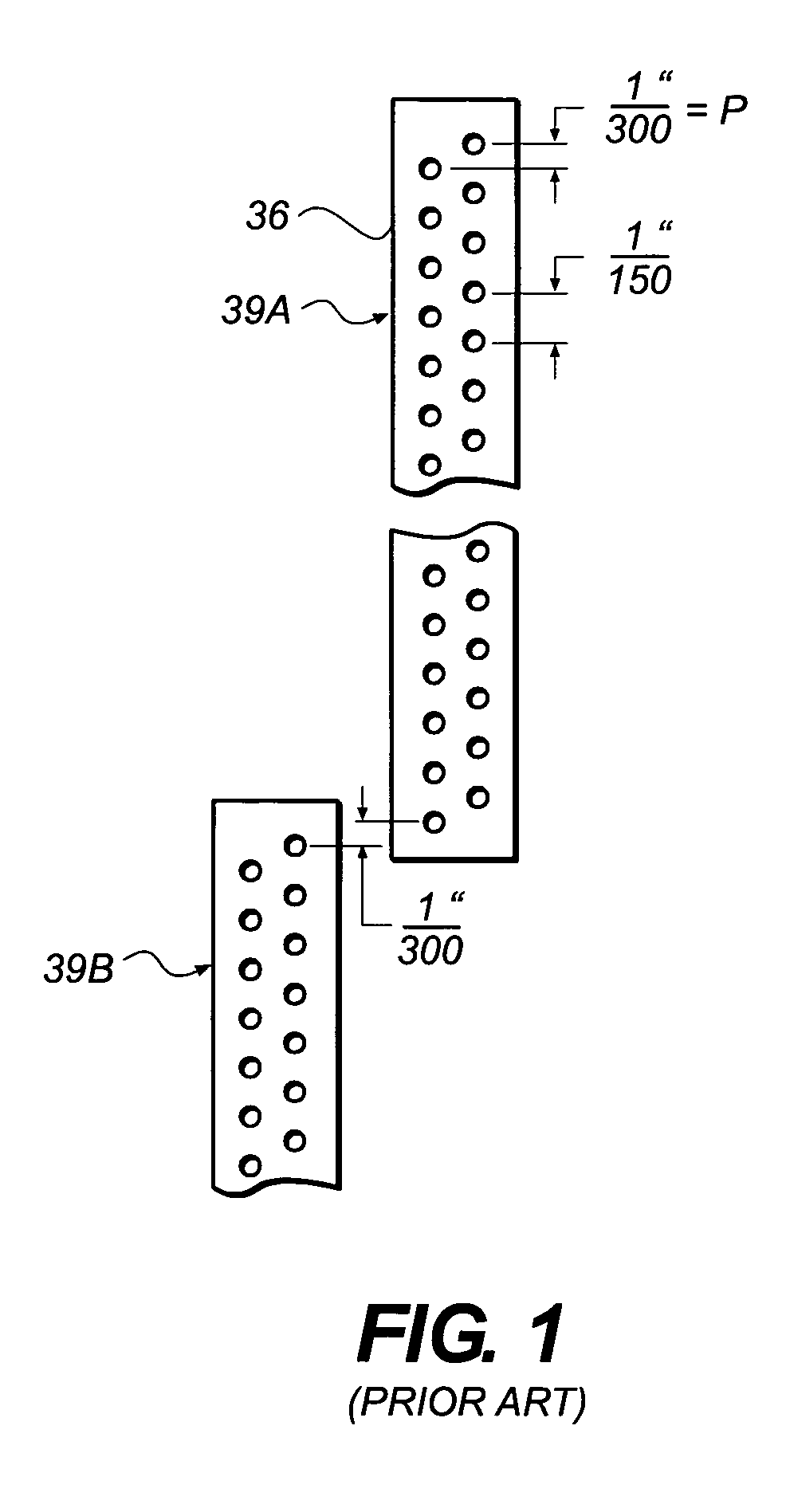

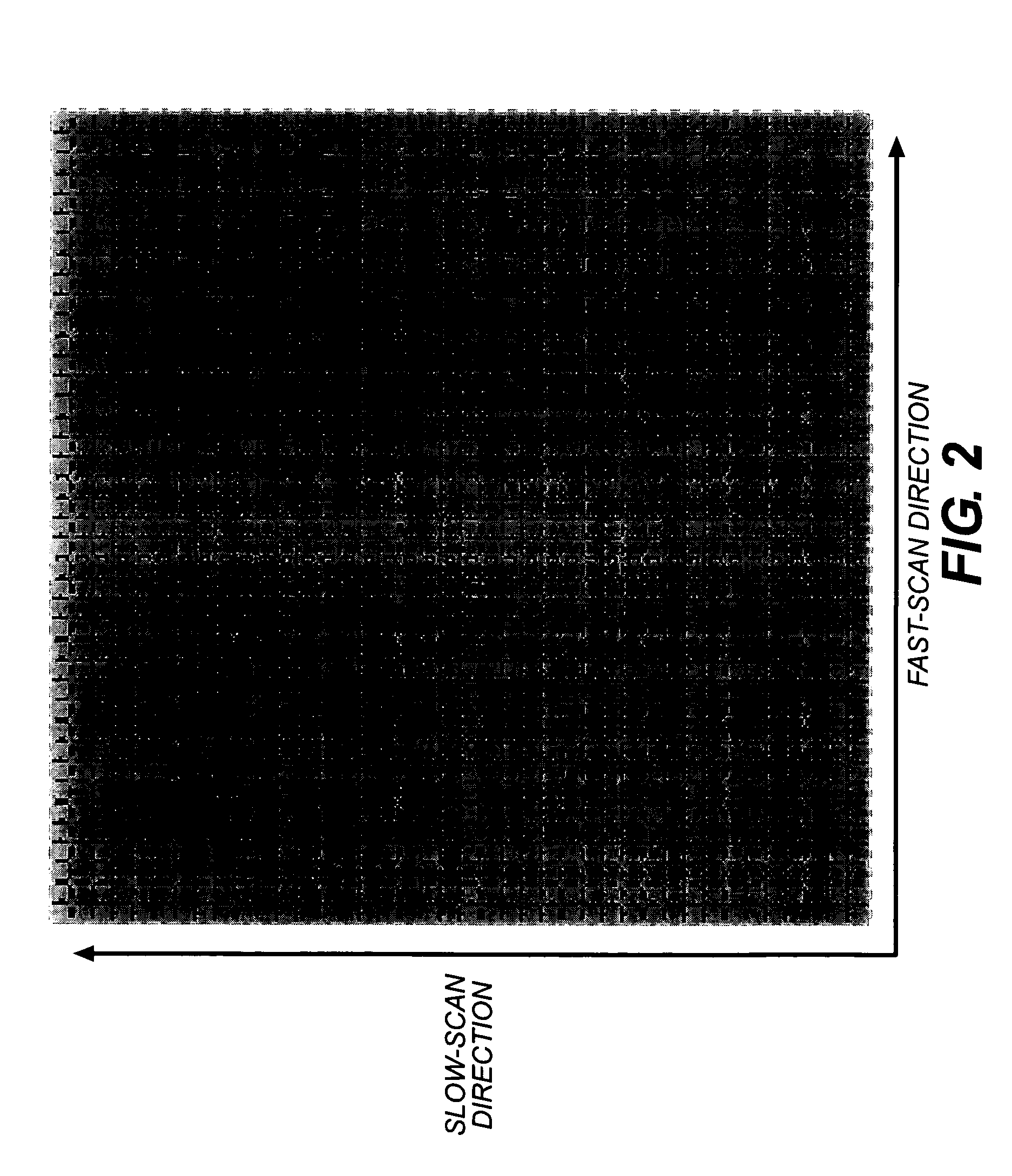

Method of aligning inkjet nozzle banks for an inkjet printer

InactiveUS20050083364A1Reduce Image ArtifactsDecreasing the required receiverSpacing mechanismsPower drive mechanismsComputer printingInk printer

A method is provided for reducing image artifacts in printers that employ two or more printhead nozzle banks that must be aligned and registered with respect to each other either through adjustment of orientation and / or position of one nozzle bank relative to another or through selective control of actuation. In the method, discrete dots are printed by the nozzle banks upon a target receiver medium. Examination of the receiver medium or a reproduction thereof is made by a scanner and information regarding location of the dots is generated. From information regarding location of the dots a determination is made of error placement of the dots from ideal locations. Alignment of the nozzle banks are made in accordance with any errors determined in placement.

Owner:EASTMAN KODAK CO

Ink jet printer

ActiveUS20050099478A1Start fastSolution to short lifeOther printing apparatusUltraviolet lightsInk printer

An ink jet head of an ink jet printer comprises an ink jet nozzle ejecting ultraviolet curing ink, a pair of ultraviolet LEDs provided on both sides of the ink jet nozzle in the moving direction for emitting ultraviolet light in order to cure the ultraviolet curing ink.

Owner:ROLAND DG CORP

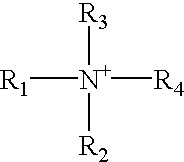

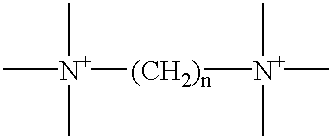

Underprinting fluid compositions to improve inkjet printer image color and stability

InactiveUS6450632B1Measurement apparatus componentsDuplicating/marking methodsPolymer scienceComputer printing

Cationic underprinting fluids, which together with pigment-based ink compositions achieve enhanced durability, chroma, optical density and print quality in inkjet printed images.

Owner:HEWLETT PACKARD DEV CO LP

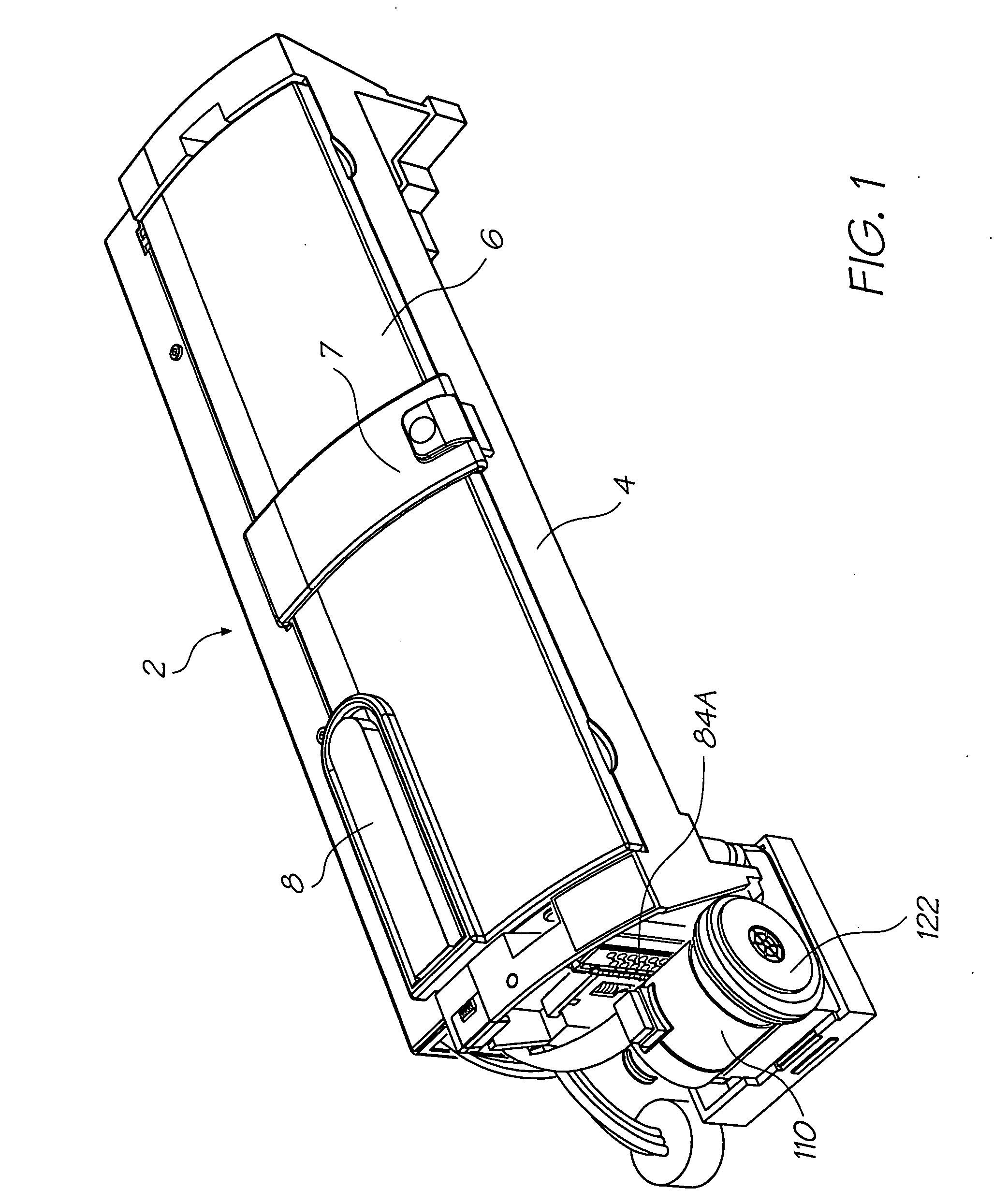

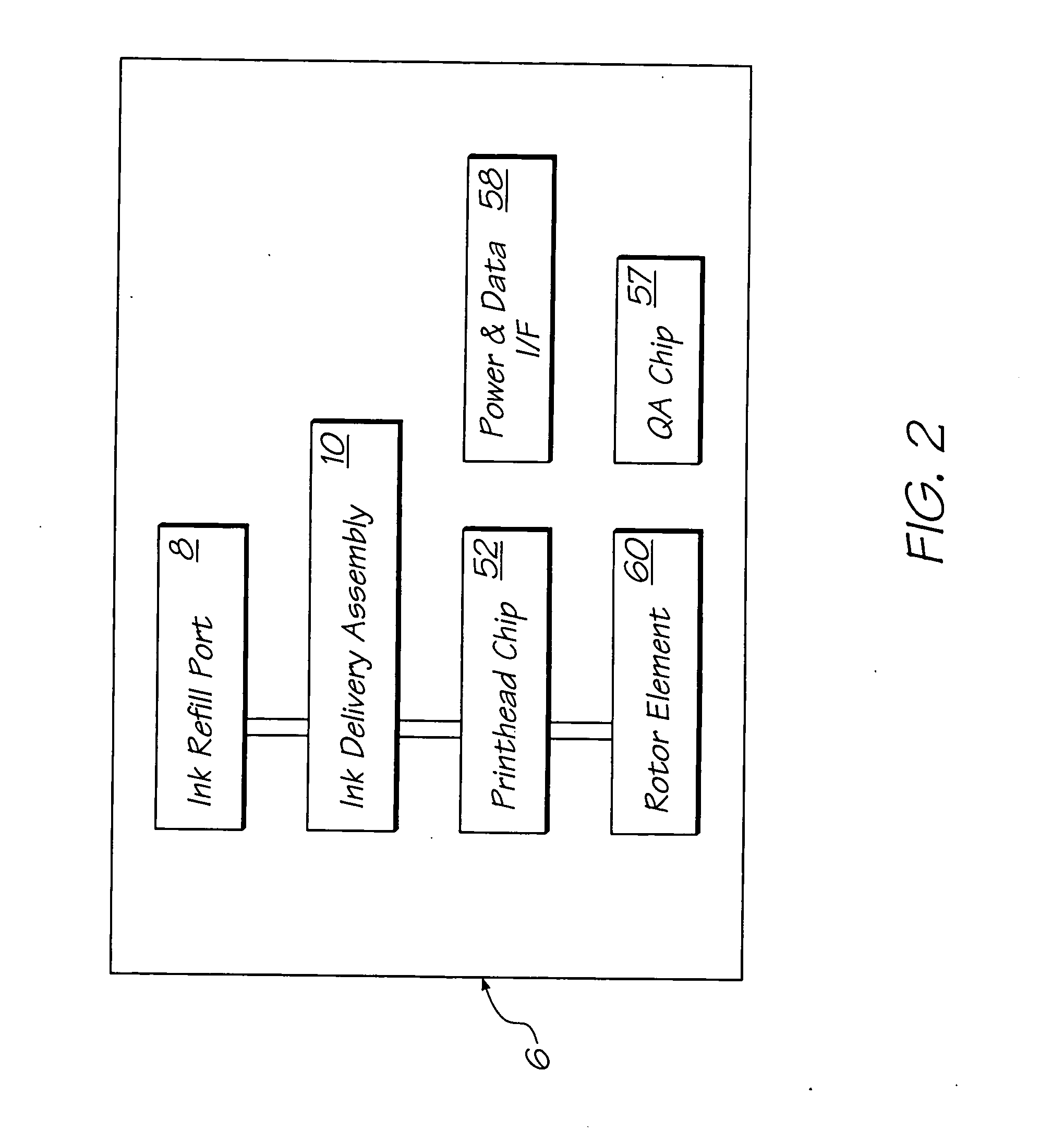

Ink supply arrangement for a portable ink jet printer

Owner:SILVERBROOK RES PTY LTD +1

Inkjet printer cartridge refill dispenser

A printing fluid dispenser including a deformable container of printing fluid having an outlet, a handle arranged to apply pressure to said container in order to force ink through the outlet; and a resilient member arranged to limit pressure applied to the deformable container by the handle in order to prevent rupture of an external reservoir coupled to said dispenser in use.

Owner:SILVERBROOK RES PTY LTD +1

Depositing solid materials

InactiveUS20050174407A1High levelHigh yieldAdditive manufacturing apparatusLiquid surface applicatorsInk printerElectronic component

Material can be deposited directly onto a substrate by using a fluid applicator such as an inkjet printer to apply at least two fluids which react to give the desired material for a range of applications. Thus, multiples of a printing mechanism are used to deposit materials as reagents that react together to form products. The materials may also be advantageously deposited from multiple inkjet heads to prepare a wide range of reaction scenarios in the form of user-defined patterns which may be sequences of differing layers and possibly to build up thicker layers. Thus, a PCB could be printed by the inkjet printer by simply printing the metal salt and the reducing agent directly, instead of two colours from a conventional inkjet printer for example. To print a three dimensional article, a pair of fluids which react to give a precipate can be used instead. Repeated passes can then build up a desired shape. The two processes could be combined to produce composite devices such as electrical components.

Owner:QINETIQ LTD

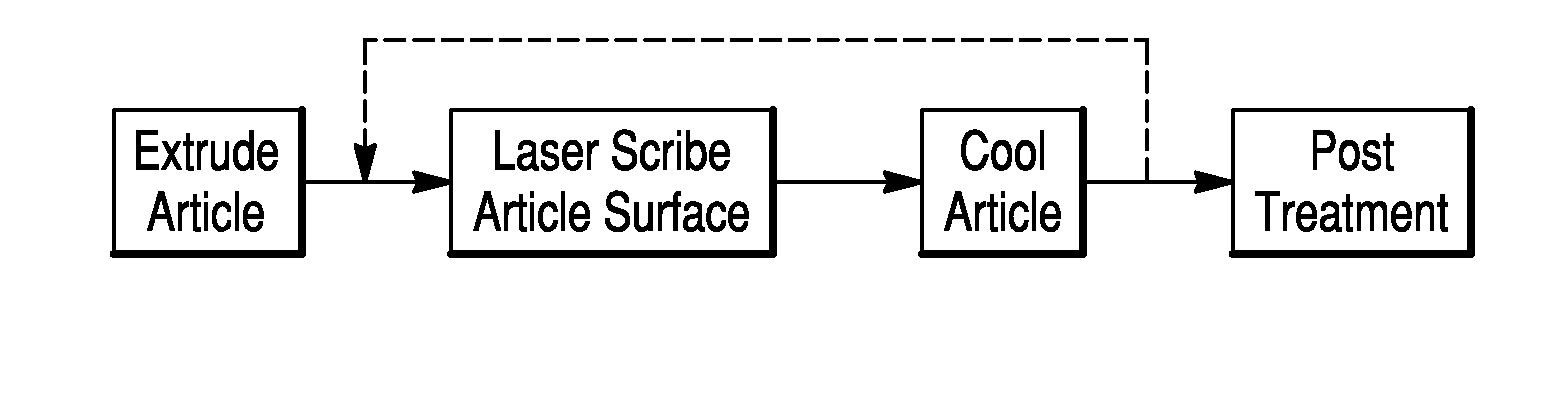

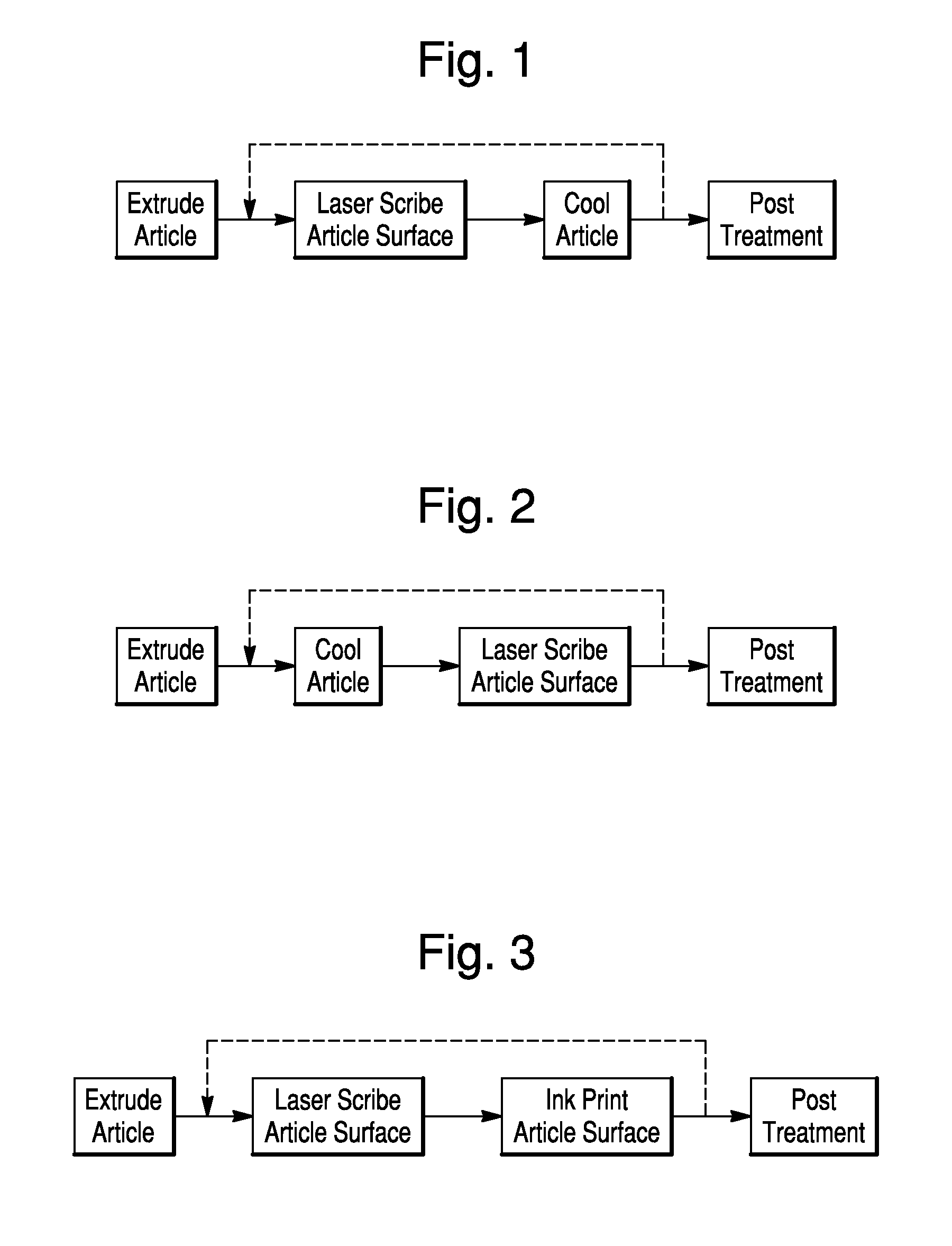

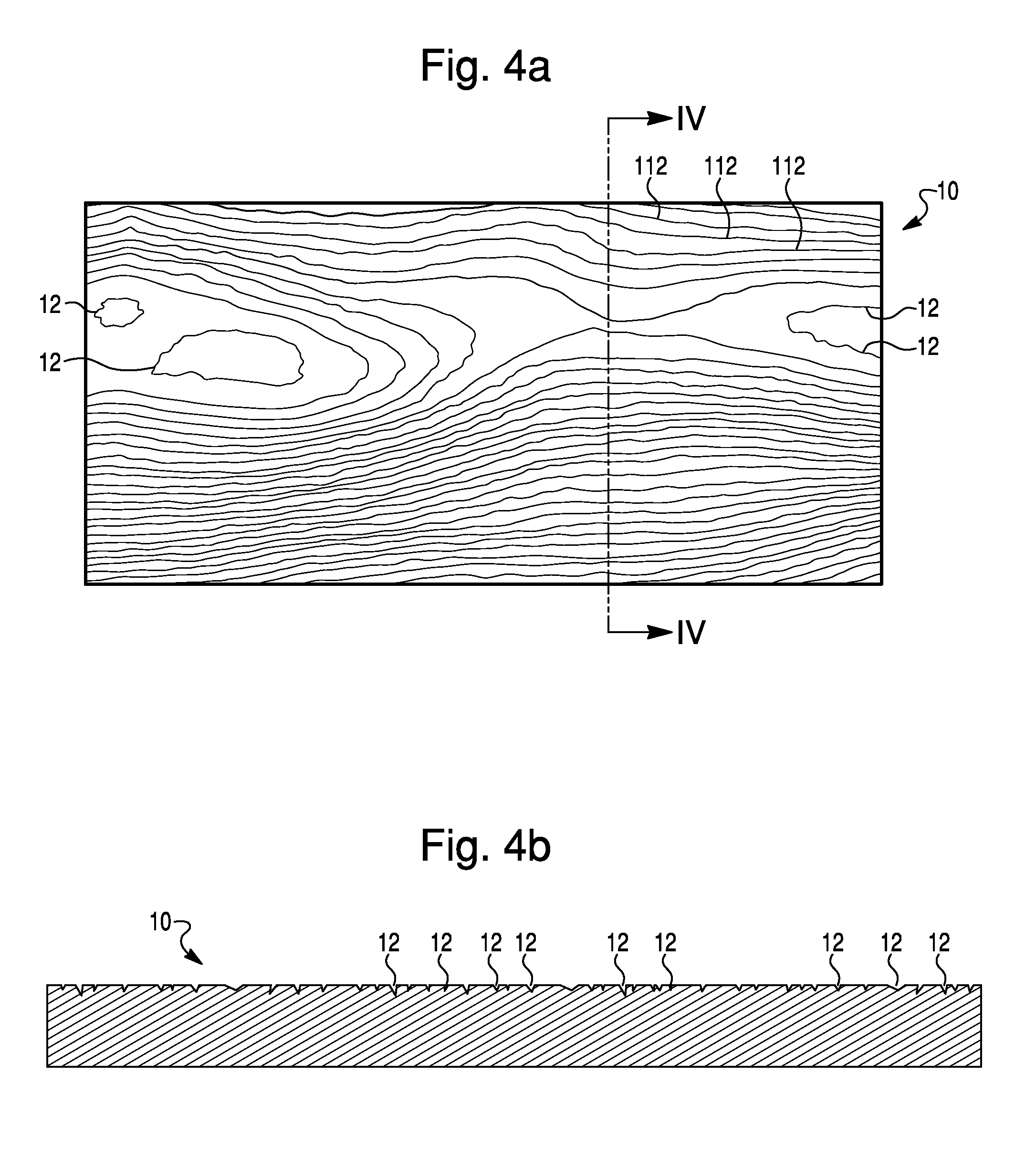

Combination extrusion and laser-marking system, and related method

A combination extrusion and laser marking system and corresponding method are provided for creating an extruded article with a surface graphic image. The system includes an extruder, a laser, and a controller or encoder. The extruder is operable to pass an extrudable material through a die and discharge an extrudate having a markable surface. The laser is operable with the extruder for forming an image on the markable surface of the extrudate discharged from the extruder. The encoding system is operable to measure a rate of speed at which the extrudate is discharged from the extruder and provide a feedback signal for controlling operation of the laser. The combination may further include an ink printer to form an additional image on the extruded article.

Owner:REVOLAZE LLC

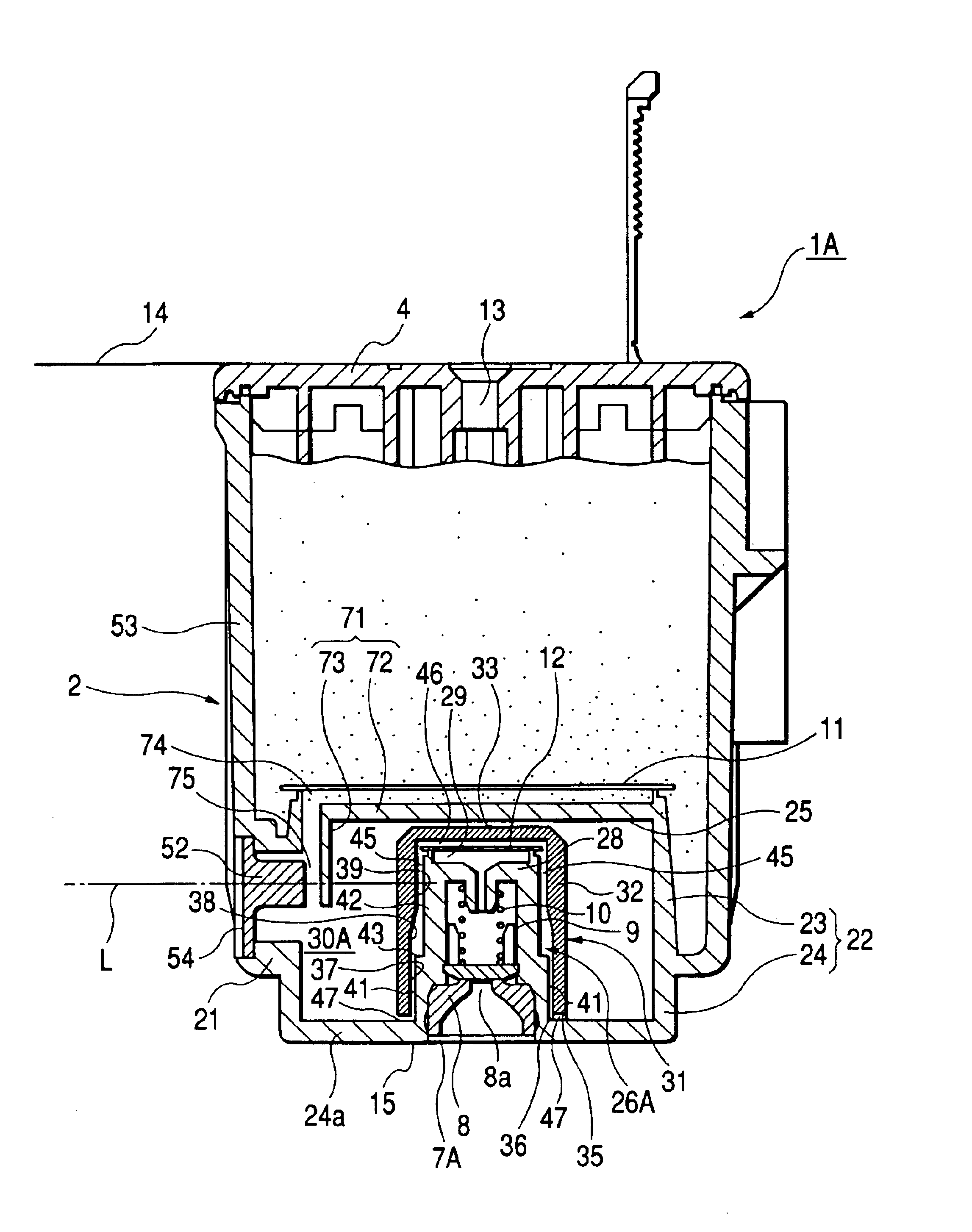

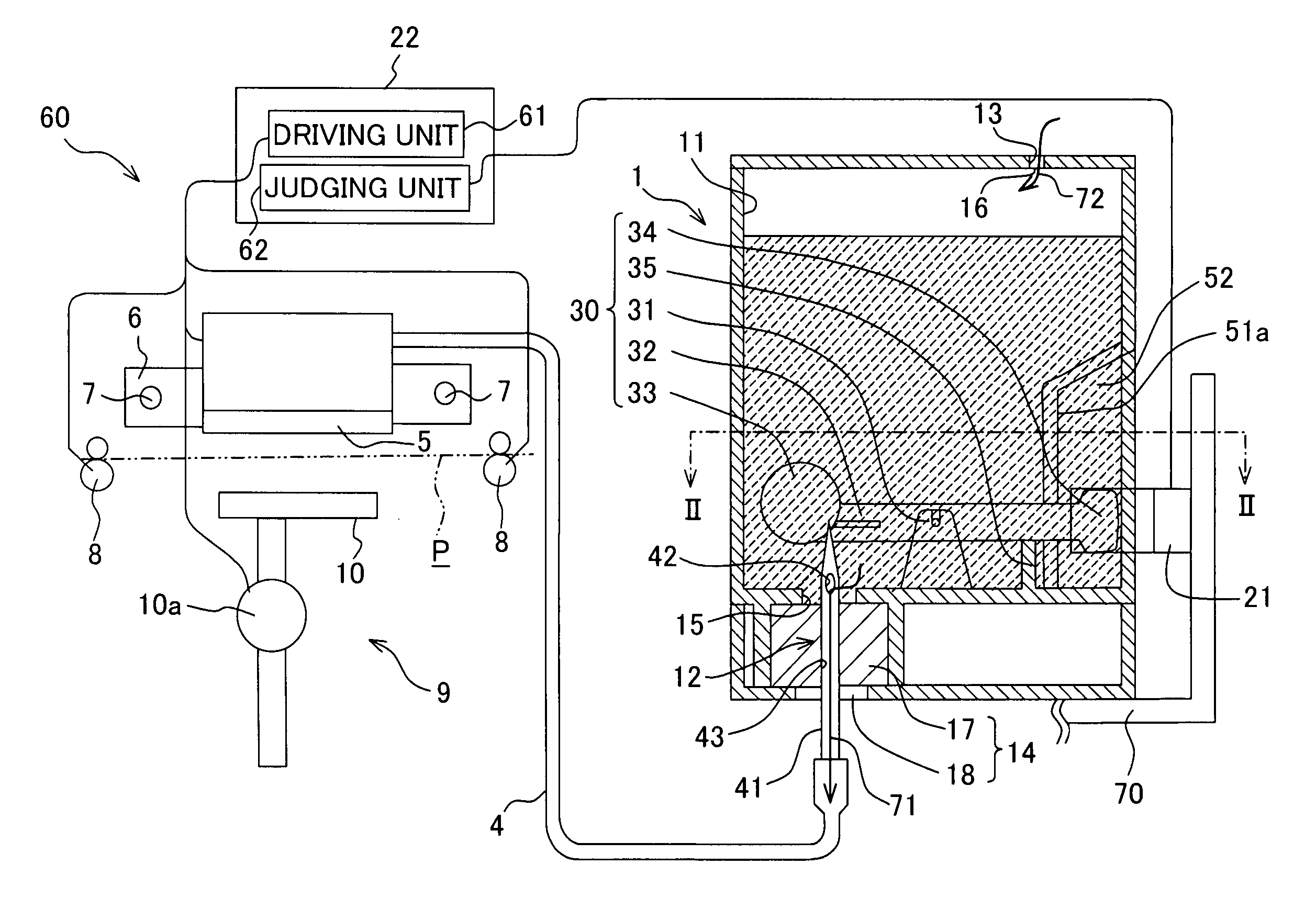

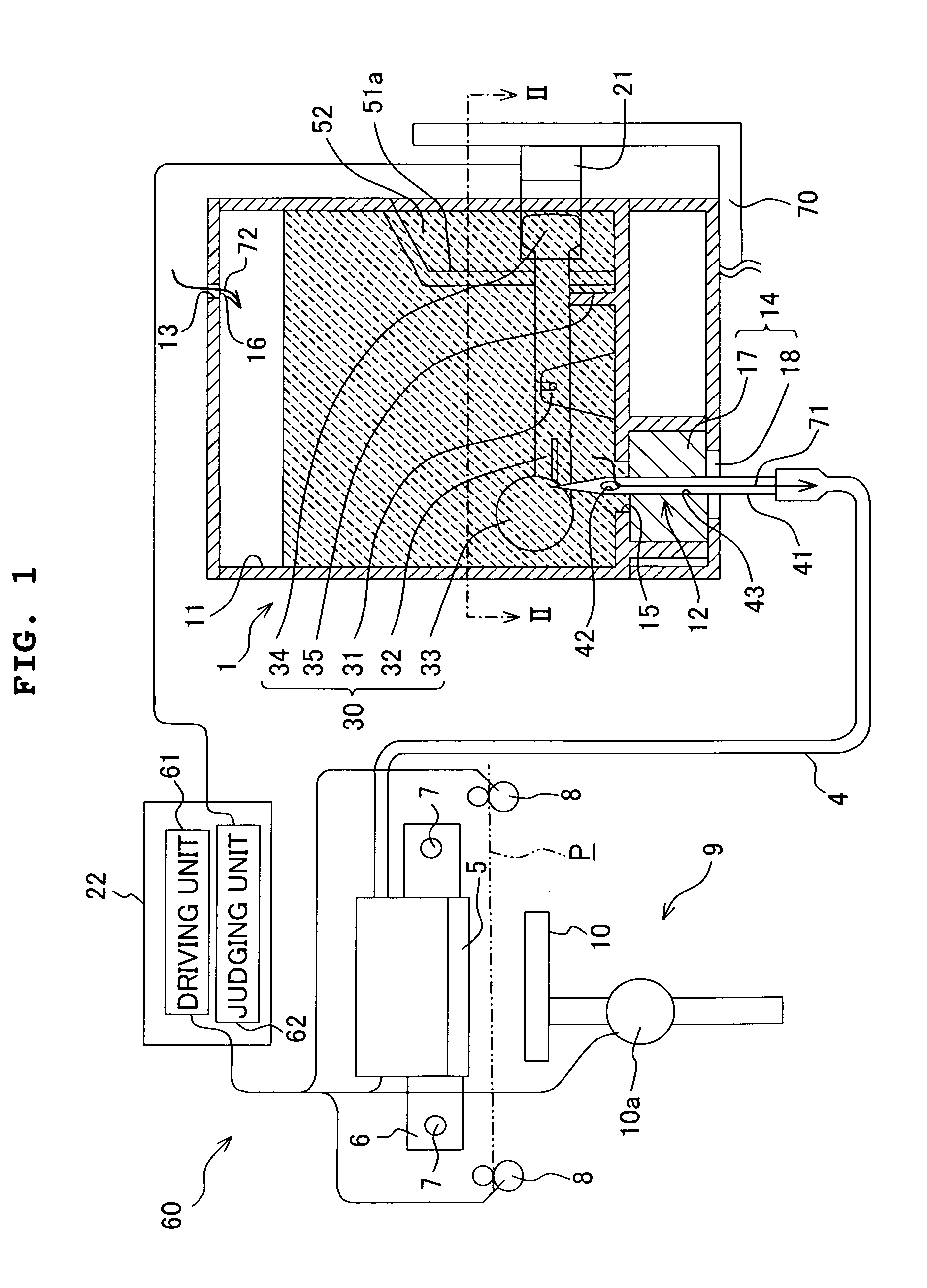

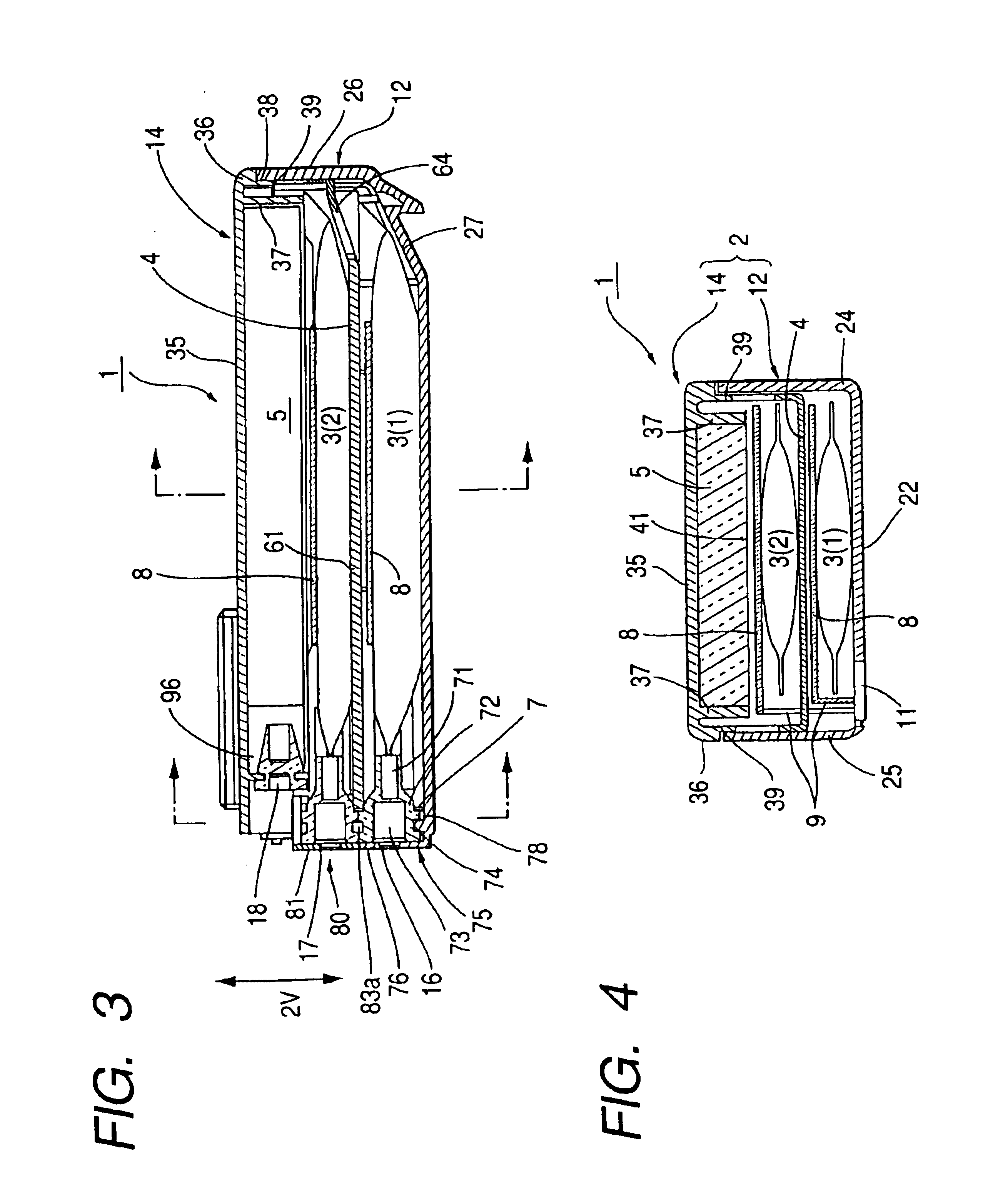

Ink tank and ink jet printer

An ink tank of the foam type which is provided with a detected portion capable of exactly and surely detecting the amount of ink used by the printer or remaining in the ink tank. The ink tank includes a sub ink chamber that is diposed or formed between a main ink chamber and an ink outlet of an ink tank of a foam type. When an amount of air flowing into the sub ink chamber increases, one or more reflecting surfaces of a right-angled prism, which function as ink interfaces, resume their original function of reflecting surfaces, thereby enabling the detection of an ink end. Air bubbles having entered the sub ink chamber are surely led onto the one or more reflecting surfaces by a bubble storage part. At an ink passage having a narrow width, which is defined by the one or more reflecting surfaces, air bubbles are pressed against the one or more reflecting surfaces to be put to a crushed state and in surface contact with the latter. Air bubbles are surely led onto the one or more reflecting surfaces, and are crushed and pressed against the reflecting surfaces. This configuration prevents the one or more reflecting surfaces from being covered with ink retained in spaces among the air bubbles. Therefore, the ink end can be detected surely and exactly.

Owner:SEIKO EPSON CORP

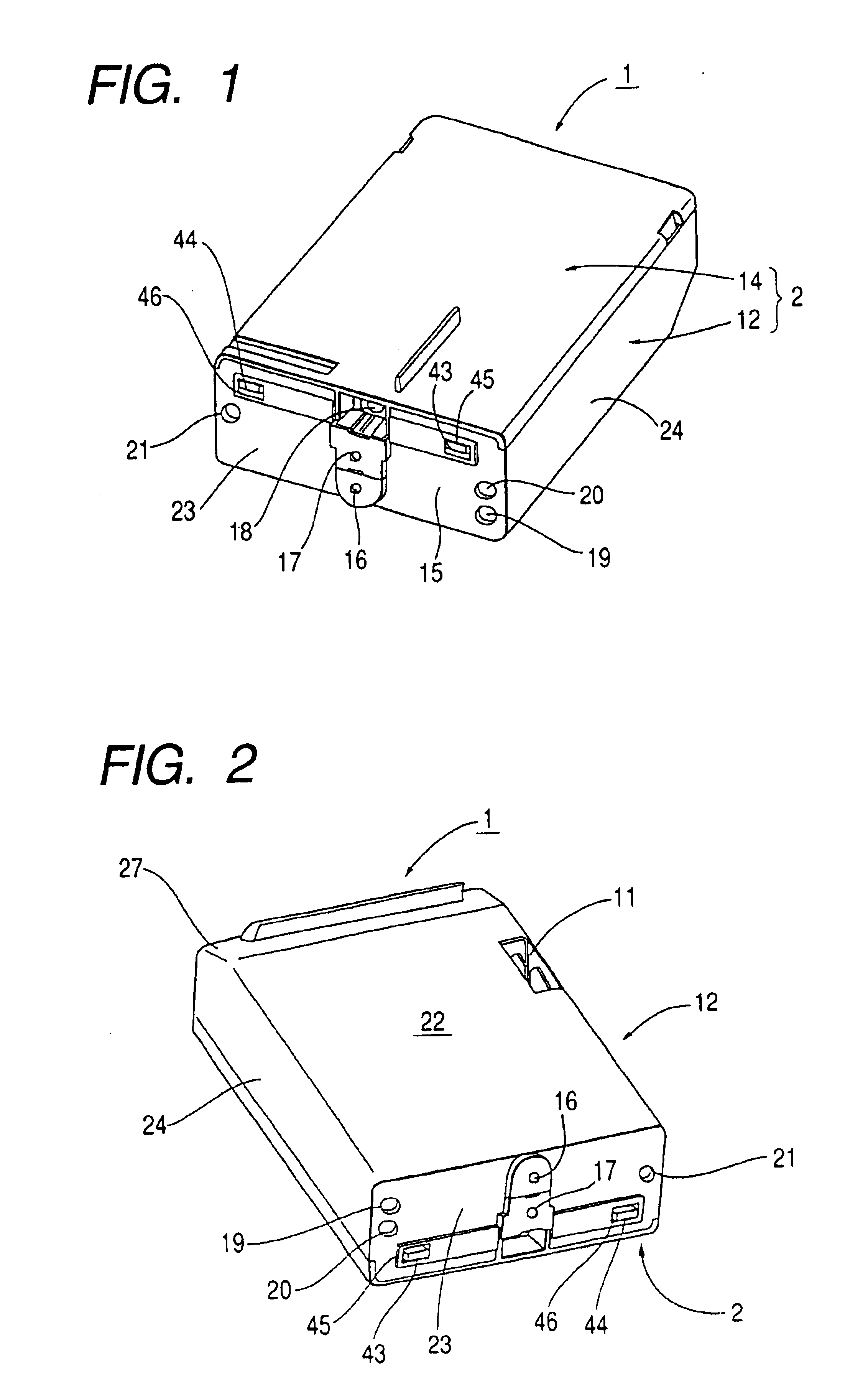

Ink cartridge and ink-jet printer

An ink cartridge has an ink tank in which the ink is stored, and a shutter mechanism which is arranged in the ink tank. The shutter mechanism includes a lever which is supported swingably and which has one end provided with a shutter and the other end provided with a float. The mass and the volume of the float are set so that the first direction, in which the lever moves by the buoyancy and the gravity generated when the entire shutter mechanism is positioned in the ink, is opposite to the second direction in which the lever moves by the buoyancy and the gravity when a part of the float protrudes from the ink liquid surface. A residual amount of an ink is indicated without being excessively affected by any disturbance such as the surface tension of the ink.

Owner:BROTHER KOGYO KK

Liquid level detection method and apparatus

InactiveUS20050151764A1Simple structureEasy to useMachines/enginesLevel indicatorsPhotodetectorInk printer

A sensing system is described for detecting the presence of ink at a predetermined level in an ink reservoir for an ink jet printer. The reservoir includes a perimetric wall having first and second wall sections, wherein at least a portion of said first wall section and a portion of the second wall section are substantially transmissive to light. A light emitter is located proximate to the first wall section and positioned at the predetermined level. A photo detector is positioned at the predetermined level and located proximate to the second wall section for detecting the light emitted from the light emitter, the light emitter being oriented to direct light at the photodetector. The light from the light emitter follows a first path when ink is present in the reservoir at the predetermined level and follows a second path when ink is not present in the reservoir at the predetermined level, the photodetector receiving the light from the light emitter traveling only one of the first path or the second path.

Owner:EASTMAN KODAK CO

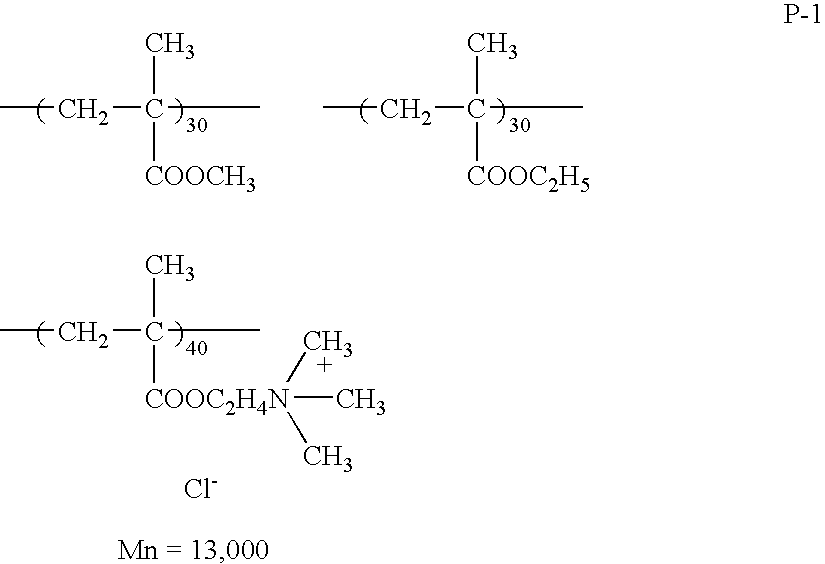

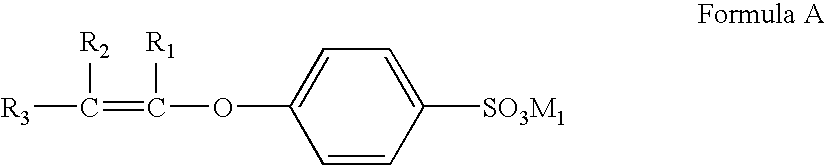

Thermal ink jet ink composition

ActiveUS20090246377A1Shorten drying timeLong decap timeFireproof paintsNon-fibrous pulp additionOrganic solventPlasticizer

Disclosed are ink jet ink compositions suitable for use in thermal ink jet printers. The ink jet ink compositions contain one or more volatile organic solvents, one or more humectants, one or more binder resins, and one or more colorants. The ink jet ink compositions may also contain additives such as a plasticizer and / or a surfactant. Embodiments of the ink jet ink compositions have short dry times, good adhesion to a variety of substrates, and / or long decap times.

Owner:VIDEOJET TECH INC

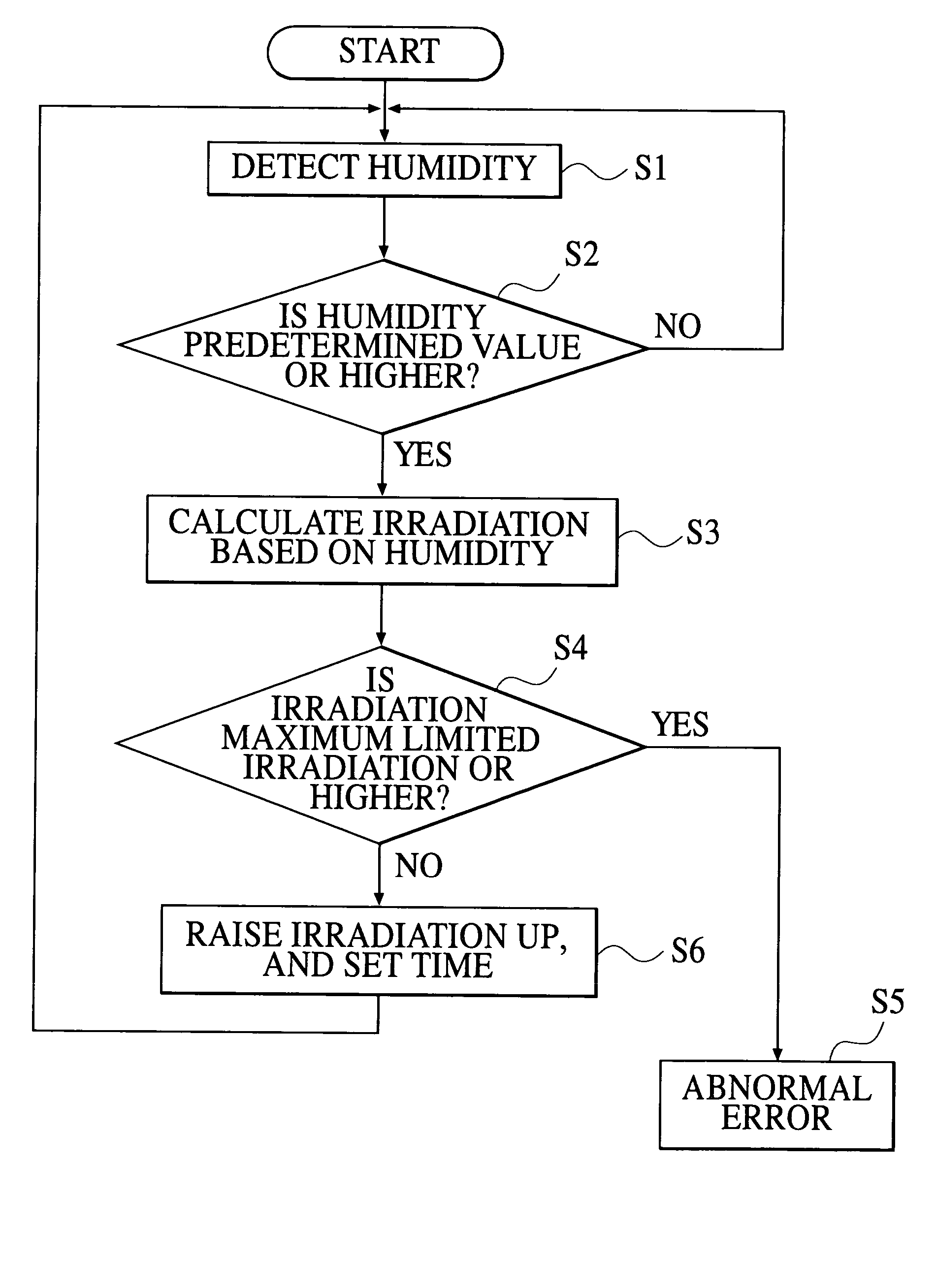

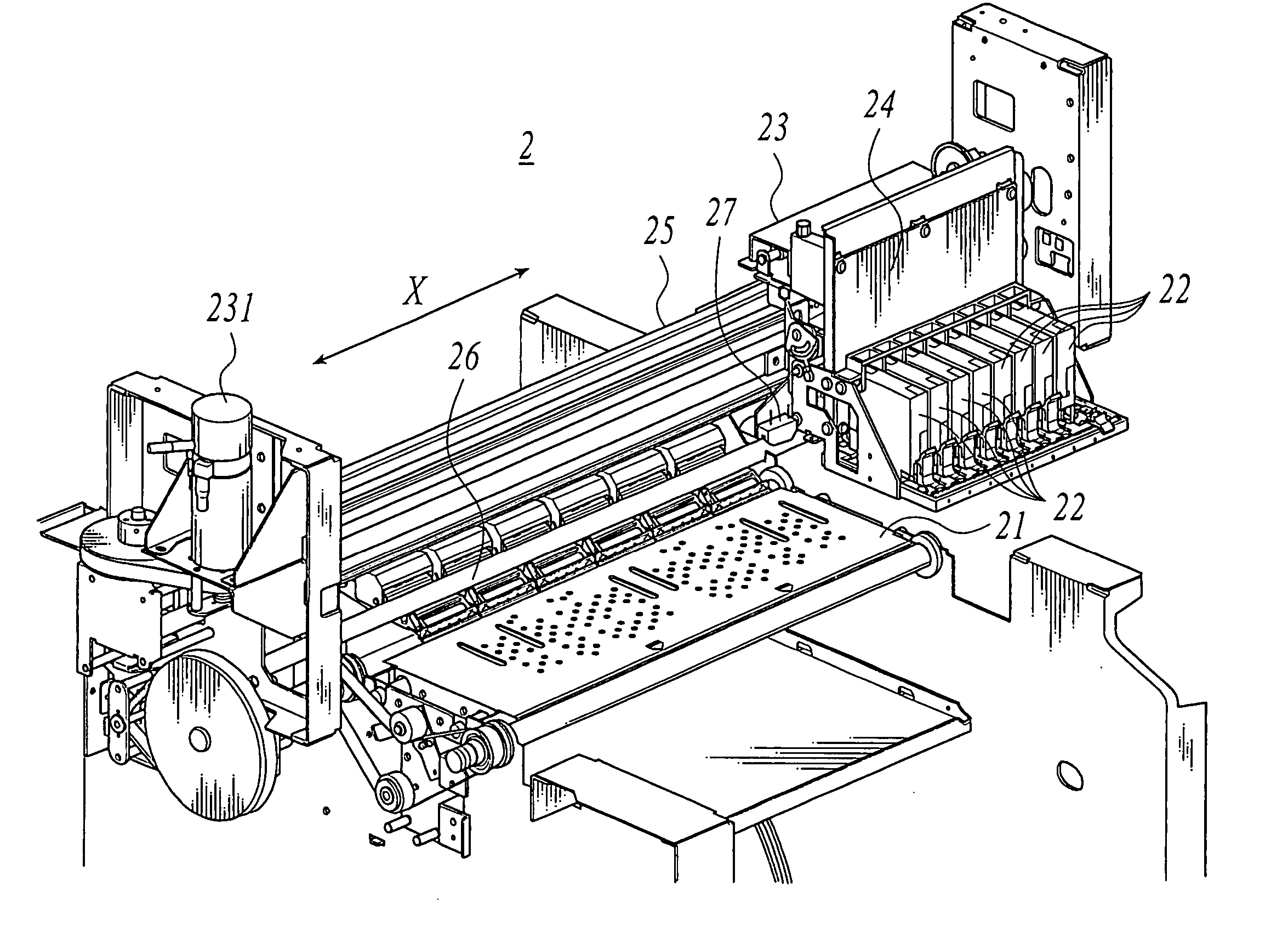

Ink jet printer and image recording method

InactiveUS20040041892A1Improve curing effectIncrease temperatureOther printing apparatusPrinting after-treatmentLight irradiationCationic polymerization

An ink jet printer capable of enhancing curability of cationic polymerization ink in a state that a raise in temperature of a recording medium is prevented as possible. The ink jet printer for recording a desired image on a recording medium by ejecting ink which includes a cationic polymerization component and which is curable when irradiated with light to the recording medium, has: a recording head for ejecting the ink to the recording medium; a light irradiation section for irradiating the light to the ink placed on the recording medium; a humidity detecting section for detecting humidity around the ink placed on the recording medium; and a controller for controlling irradiation of the light to be irradiated from the light irradiation section on the basis of detected humidity detected by the humidity detecting section.

Owner:KONICA CORP

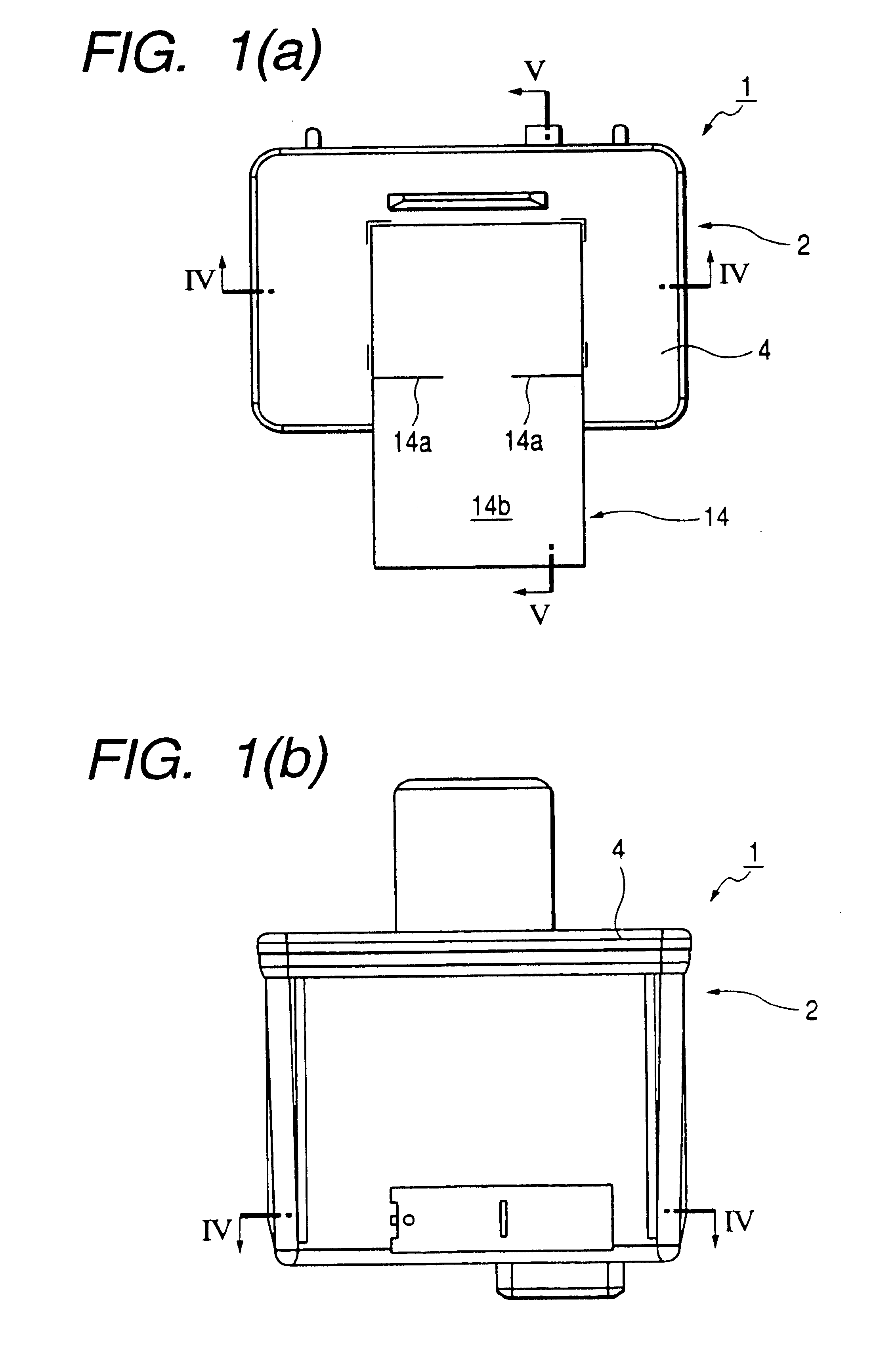

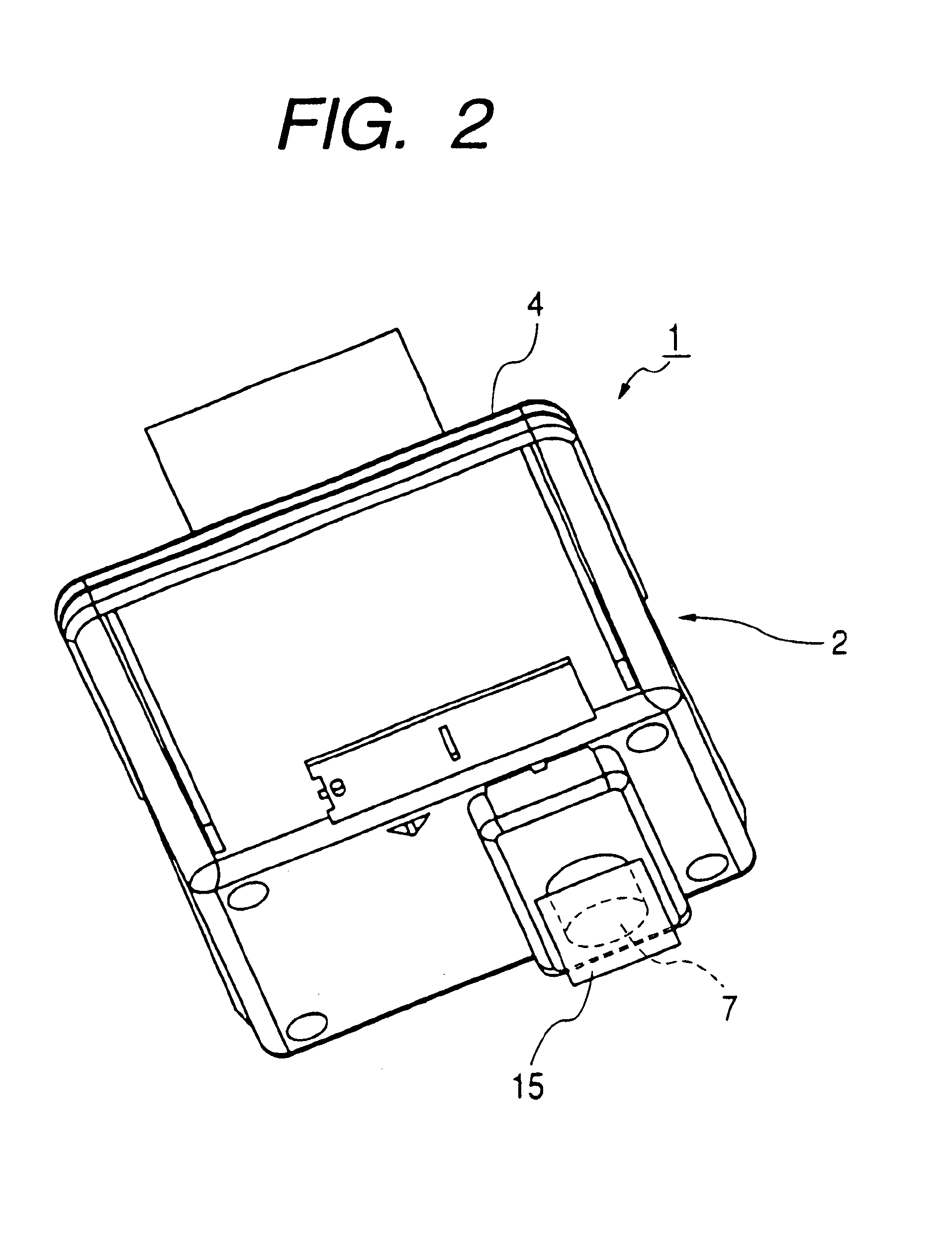

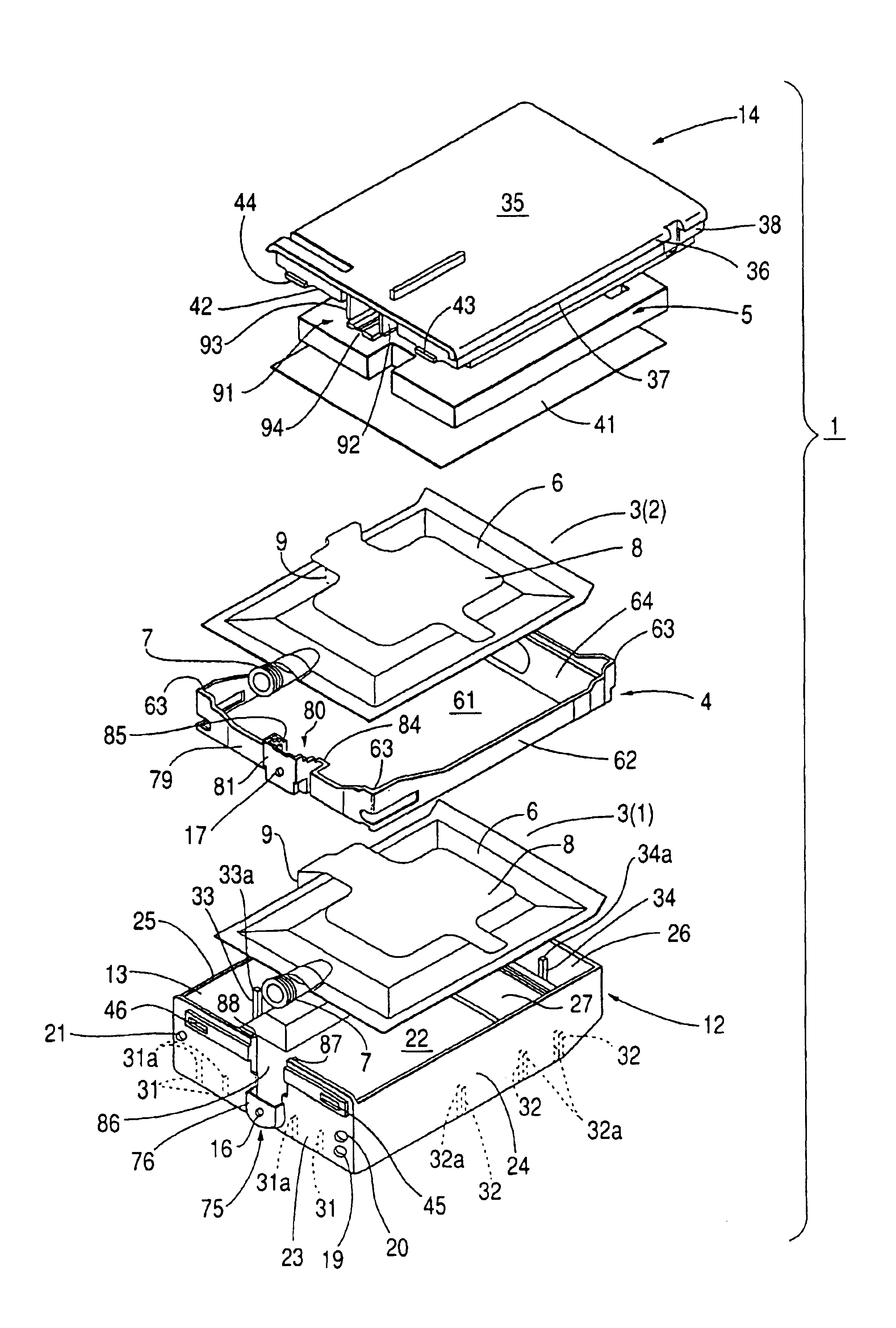

Ink cartridge and ink jet printer

An ink cartridge, for an ink jet printer, having a cartridge case, first and second ink bags housed in the cartridge case, and a partition plate placed between the ink bags. The partition plate is dropped into a case main body of the cartridge case through an upper opening of the case main body. When a case lid is attached to the case main body, the partition plate is sandwiched between rib upper end faces of the case main body and an outer frame end face of the case lid so that the position of the partition plate is fixed. Ink outlet parts, of the ink bags, are overlaid on each other in a case thickness direction so that they are in contact with each other without intervention of the partition plate. Therefore, the ink cartridge is miniaturized and can be easily disassembled when it is recycled.

Owner:SEIKO EPSON CORP

Ink jet printer and image recording method

InactiveUS20040141041A1Add a photographic glossHigh glossOther printing apparatusImage recordingInk printer

An ink jet printer includes: an image forming section for forming an image by ejecting a pigment ink toward a recording medium in which a surficial layer includes thermoplastic fine particles, in a case; a fixing member for fixing the image by heating and pressurizing the recording medium on which the image is formed by the image forming section; a drying member for drying the ink used for forming the image before the image is fixed to the recording medium by the fixing member; a temperature detecting member for detecting a temperature in the case; a humidity detecting member for detecting a humidity in the case; and a drying member control section for controlling an operation of the drying member in accordance with the temperature detected by the temperature detecting member and the humidity detected by the humidity detecting member.

Owner:KONICA MINOLTA INC

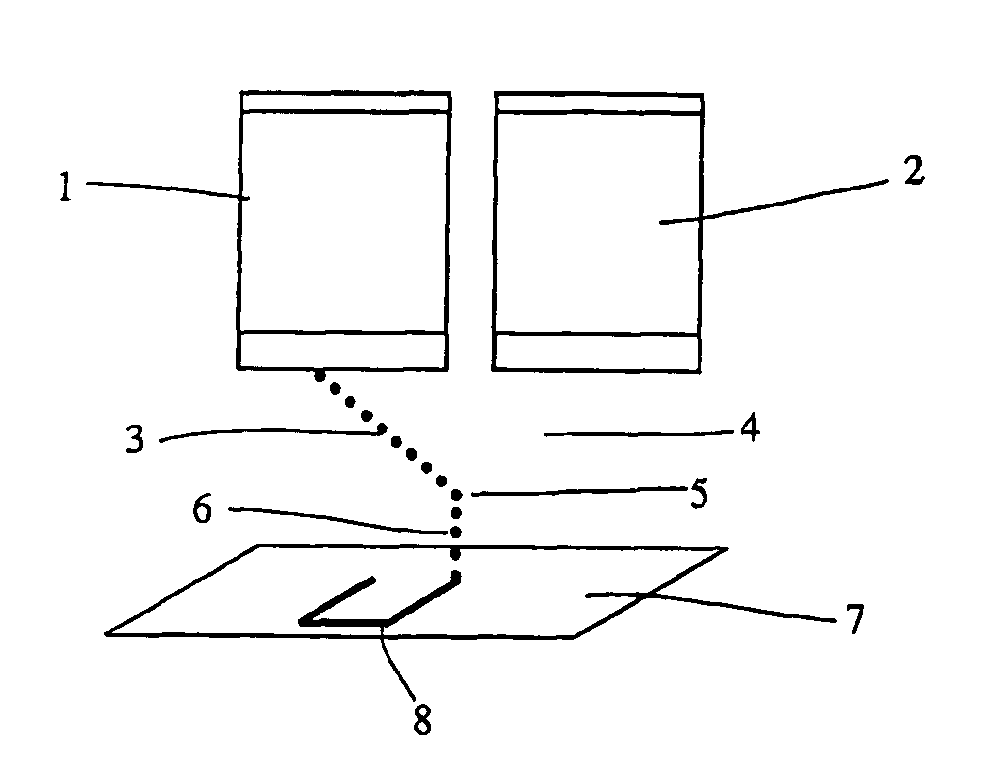

Method of aligning inkjet nozzle banks for an inkjet printer

InactiveUS7073883B2Reduce Image ArtifactsDecreasing the required receiverSpacing mechanismsPower drive mechanismsComputer printingInk printer

A method is provided for reducing image artifacts in printers that employ two or more printhead nozzle banks that must be aligned and registered with respect to each other either through adjustment of orientation and / or position of one nozzle bank relative to another or through selective control of actuation. In the method, discrete dots are printed by the nozzle banks upon a target receiver medium. Examination of the receiver medium or a reproduction thereof is made by a scanner and information regarding location of the dots is generated. From information regarding location of the dots a determination is made of error placement of the dots from ideal locations. Alignment of the nozzle banks are made in accordance with any errors determined in placement.

Owner:EASTMAN KODAK CO

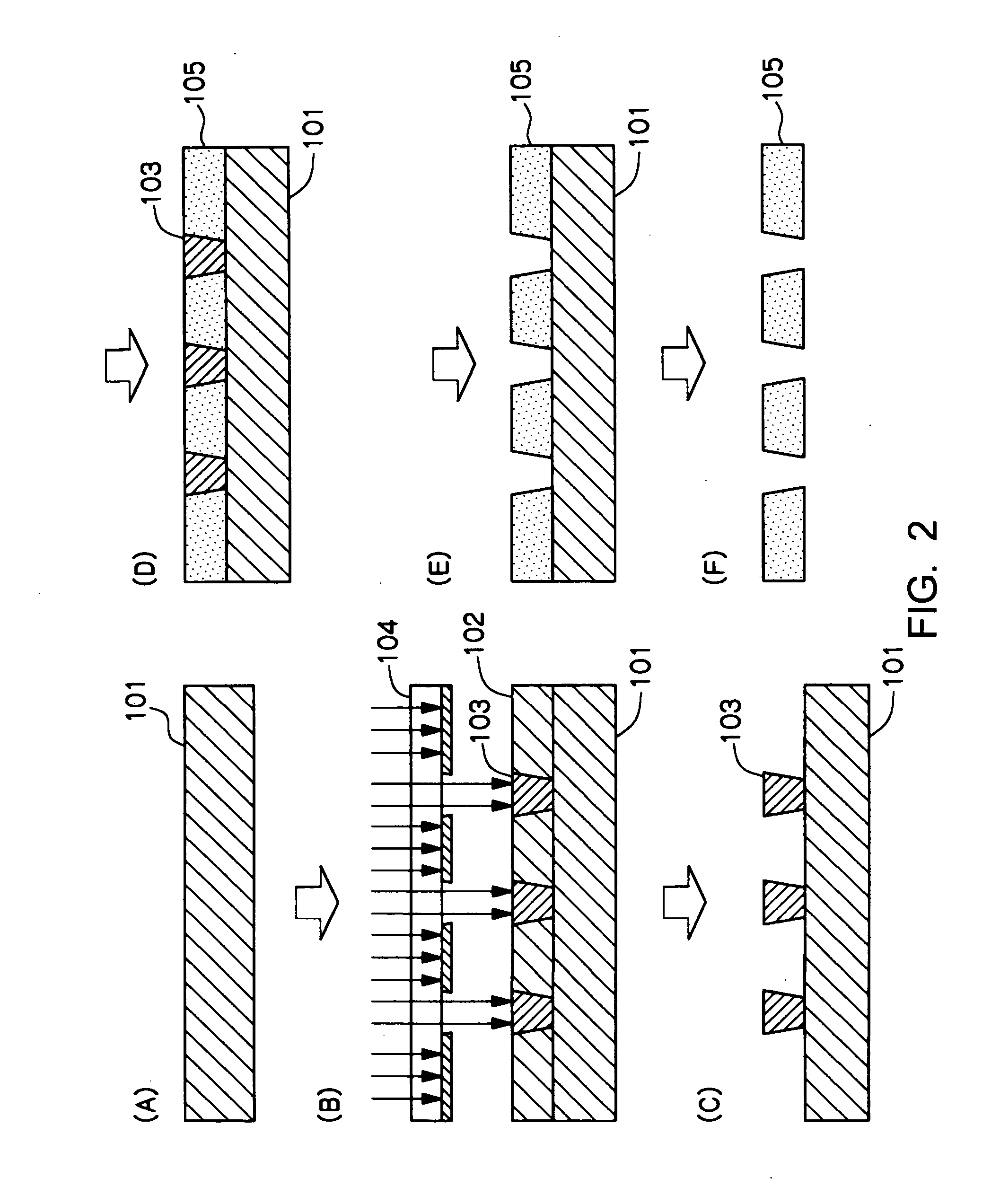

Ink-jet formation of flexographic printing plates

InactiveUS20050153243A1Well formedGood ink absorptionPhotosensitive materialsPhotomechanical apparatusInk printerEngineering

Owner:KODAK POLYCHROME GRAPHICS

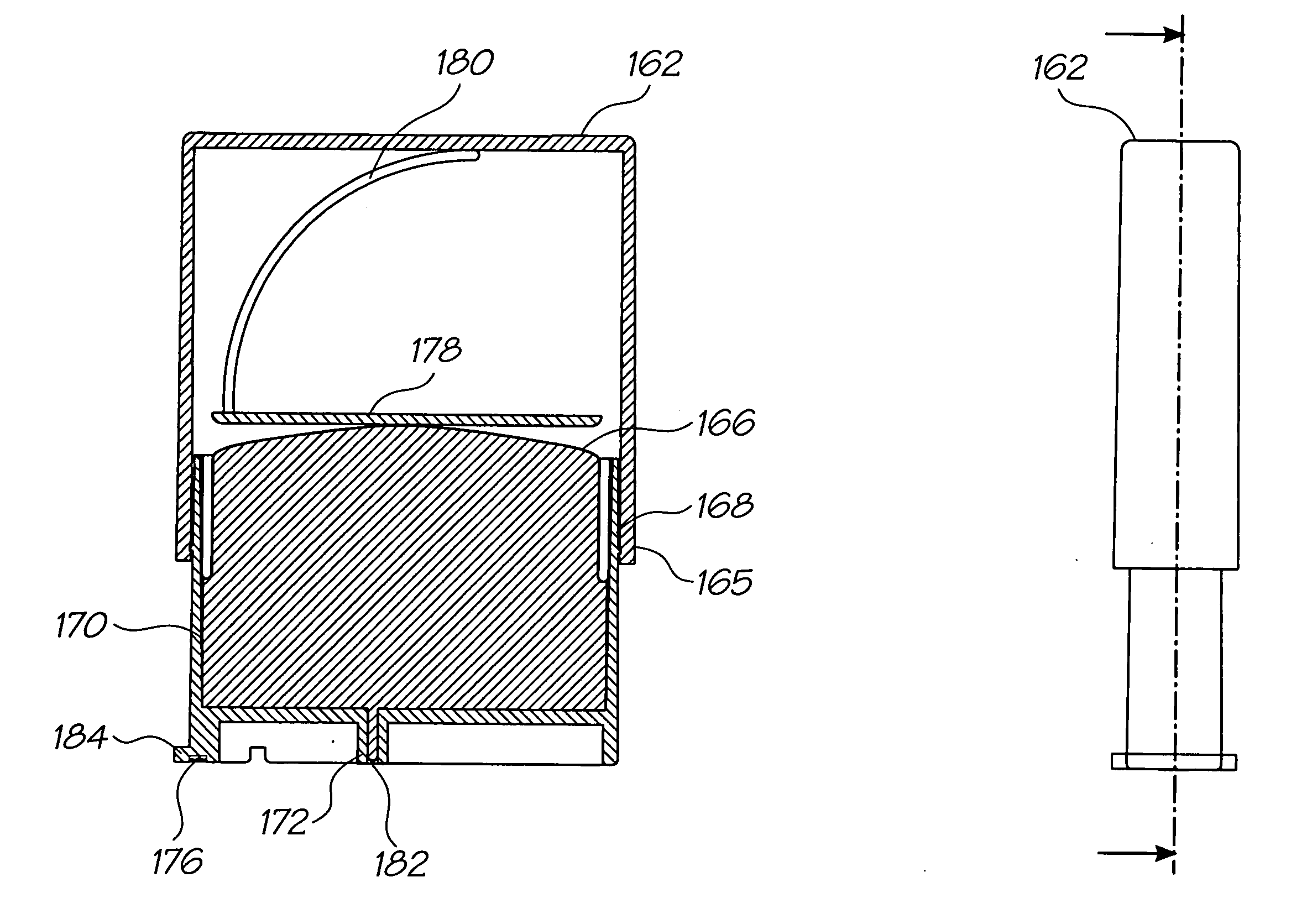

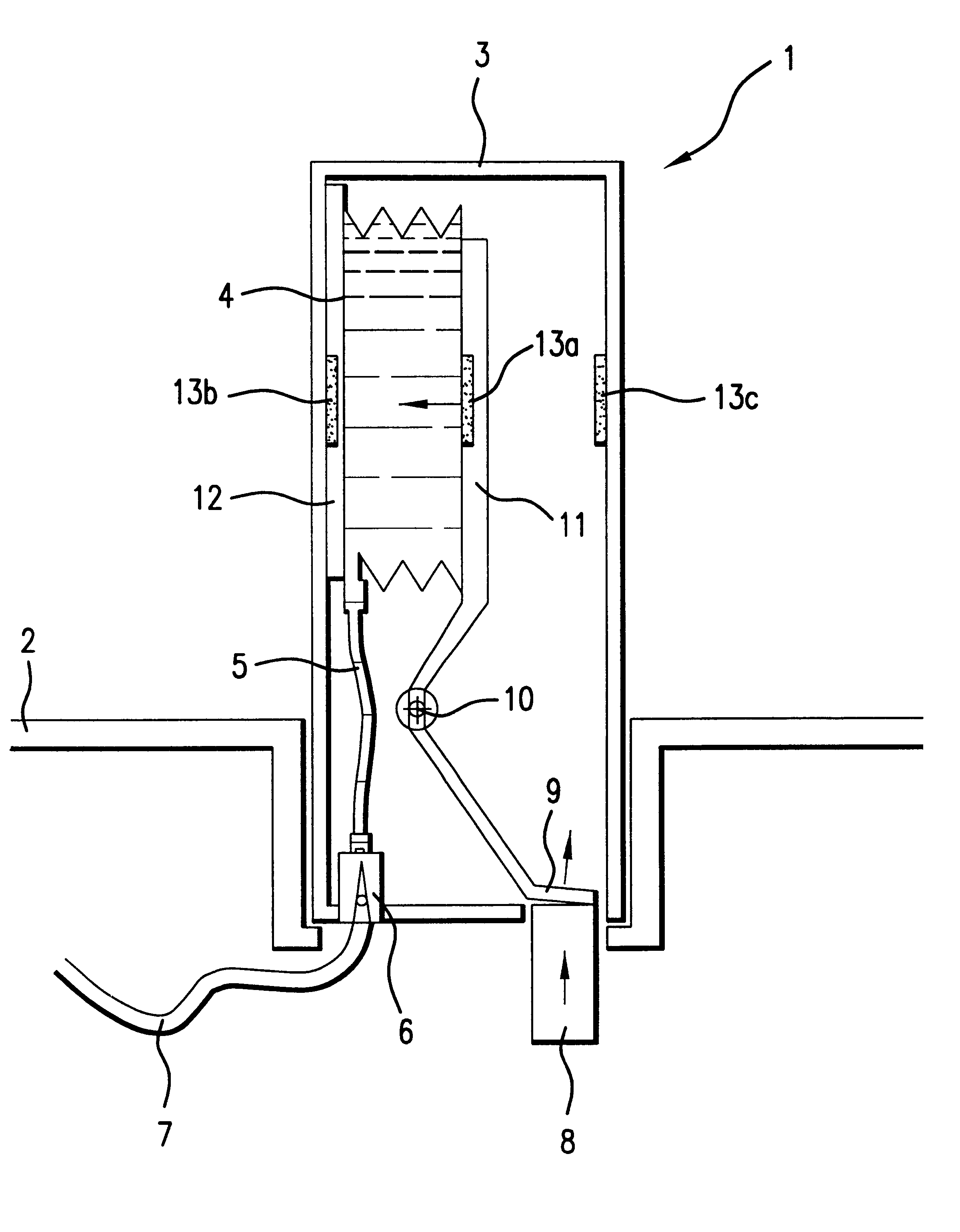

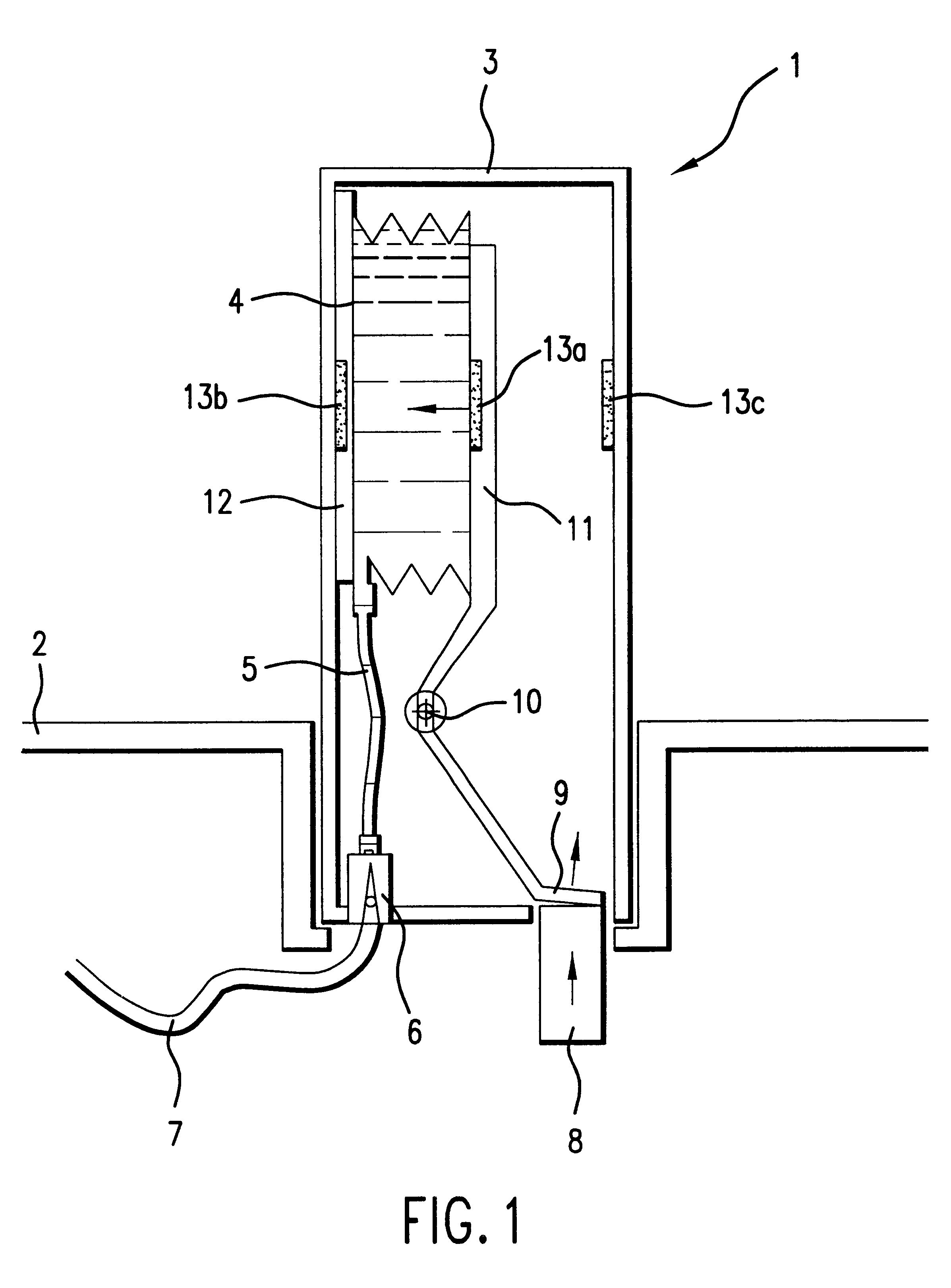

Ink supply tank for an inkjet print head

The present invention pertains to an ink supply tank for an inkjet print head that can be installed in fixed fashion in an inkjet printer, having an ink reservoir that can be connected to an ink supply line leading to an inkjet print head, and having an ink delivery device that has actuating elements accessible from the outside, which can be brought into active engagement with corresponding, motor-powered drive elements of the inkjet printer, in which the ink delivery device feeds ink into the ink supply line at overpressure upon actuation of the actuating elements. In order to reduce the manufacturing effort and ensure a high level of functional reliability with an ink supply tank of such a type, the invention suggests that the ink delivery device have a pressure-generating device that acts on the ink reservoir and is coupled with the actuating elements, and that provides the ink reservoir with overpressure when the actuating elements are driven.

Owner:ARTECH DESIGN PRODN & PLASTIC

Ink-jet recording ink, ink-jet recording ink set, ink cartridge, ink-jet printer, and ink-jet printing method

An ink and ink set characterized in that both a combination of a specific wetting agent, penetrating agent, and water-soluble organic solvent and use of surfactant, particularly fluorine surfactant are enabled by using water dispersion in which polymer fine particles contain coloring material. Even when plain paper is printed at high speed by ink-jet recording by using this ink and ink set, the ink and ink set can realize a pigment ink for ink-jet recording, an ink set, an ink-jet recording method, ink cartridge, and recorder which have an excellent ejection stability and excellent preservability, and provide (1) good color tone, (2) high image density, (3) recorded image free of unsharpness near character or image and feathering and high in sharpness, (4) less boundary color bleedings between different colors, (5) image adaptable to both-side printing and causing less strike-throughs, and (6) image fastness such as water resistance and light resistance.

Owner:RICOH KK

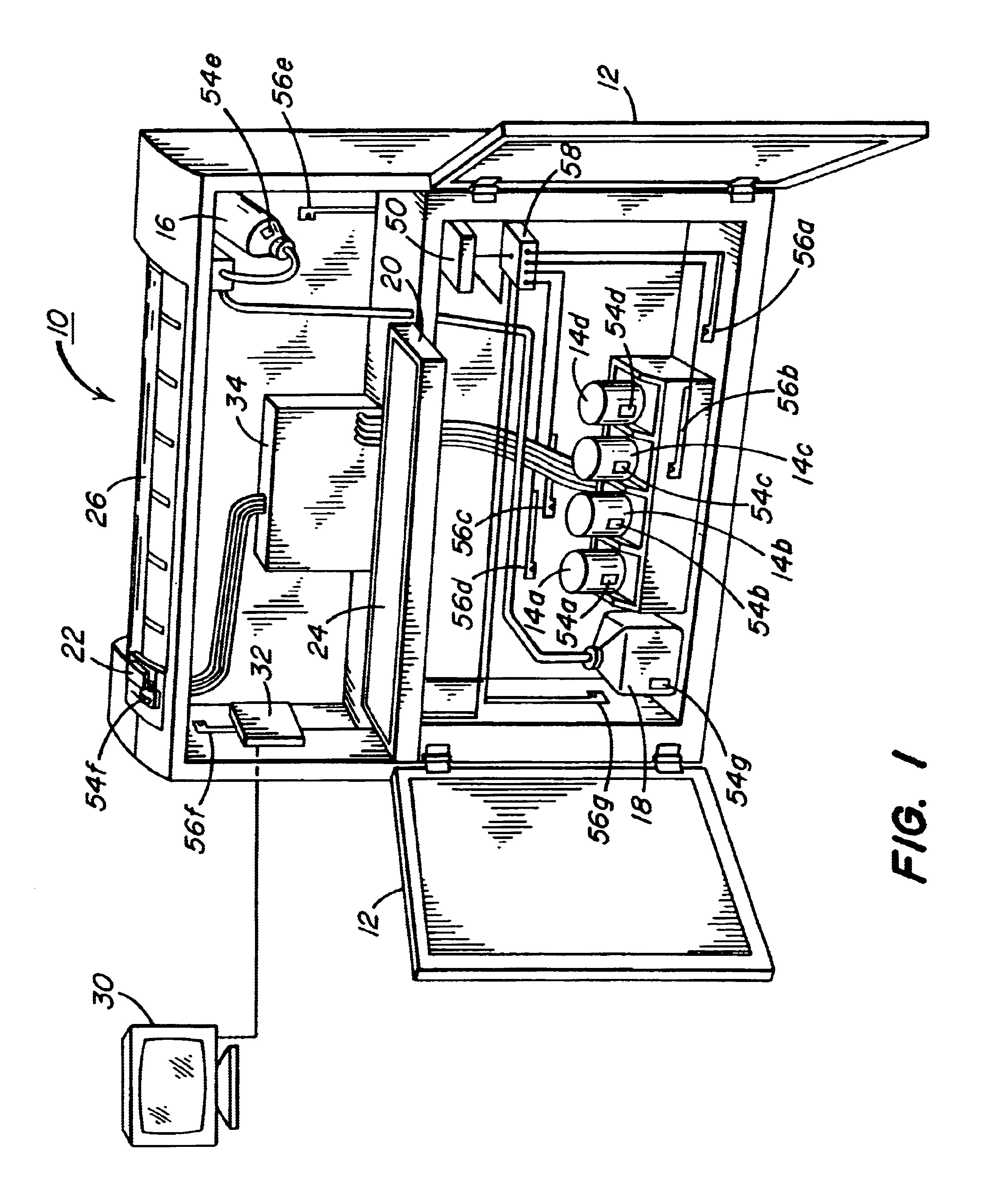

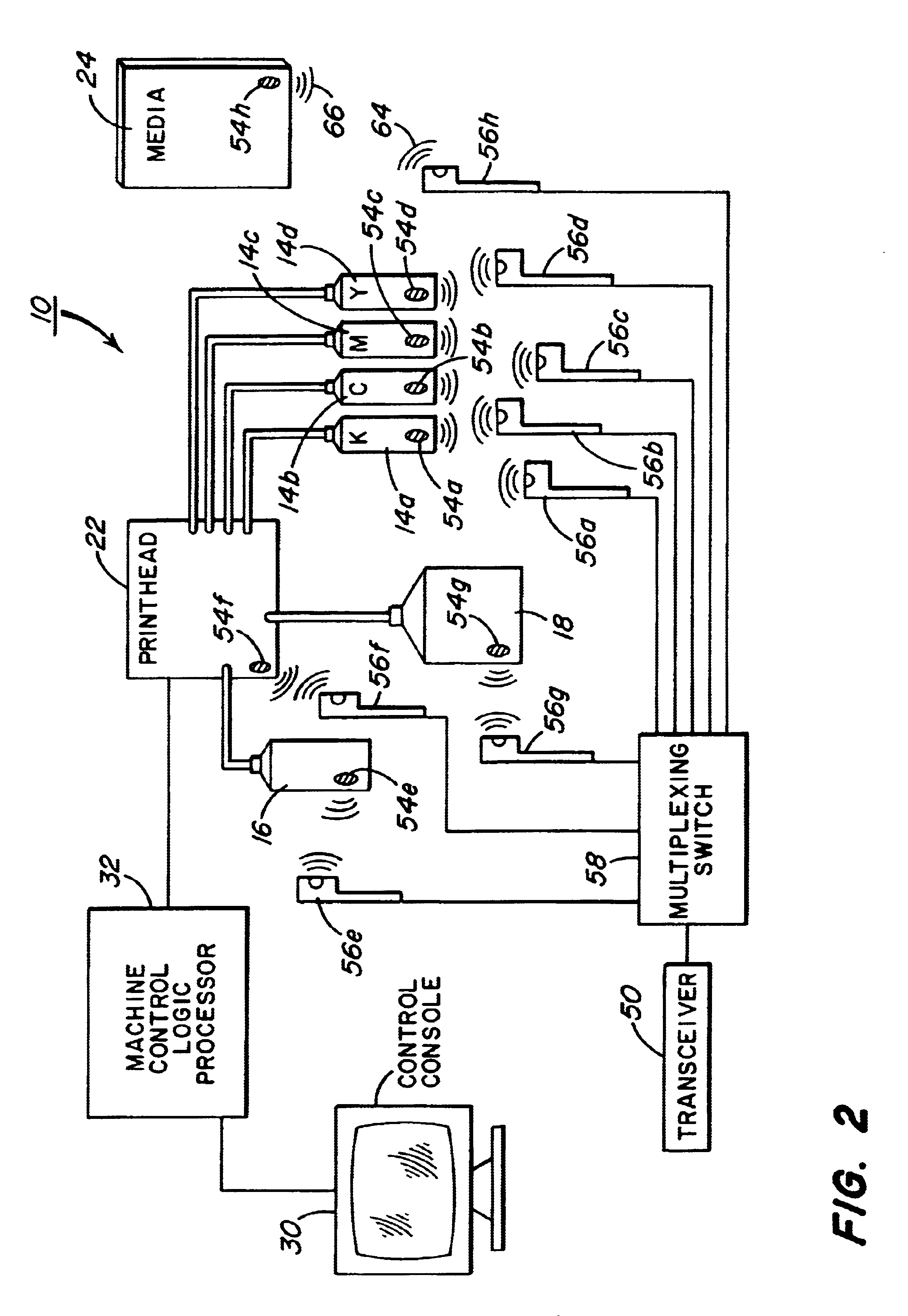

Printer and method therefor adapted to sense data uniquely associated with a consumable loaded into the printer

An inkjet printer adapted to sense type of supplied consumable receiver media, inks, printhead, and cleaning fluid. A transponder attached to a consumable is coupled to a memory device capable of storing information characteristic of the consumable. A transceiver is disposed within the inkjet printer, with antennae disposed for polling an individual transponder attached to each consumable. The transponder is capable of receiving a first RF frequency electromagnetic field from the transceiver and deriving power and address information from the first frequency, then generating a second RF frequency electromagnetic field in response, where the second electromagnetic field is characteristic of the data stored in memory. As instructed by a machine control logic processor, the transceiver can both read manufacturing data from the transponder about the consumable and write usage and processing data to the transponder for storage in memory. The transponder can also be coupled with a transducer for taking measurements from the consumable.

Owner:EASTMAN KODAK CO

Process for making an ink jet ink

A process for making an ink jet ink comprising: a) providing a dispersion containing a pigment, a hydrocarbon carrier, and a polyamine / fatty acid condensation polymer dispersant; b) mixing the pigment dispersion with rigid milling media less than 100 mu m; c) introducing the mixture of step (b) into a mill; d) milling the mixture from step (c) until the pigment particle size is below about 100 nanometers (nm); e) adding to the mixture during or after step d) or f) (below) a stabilizer selected from the group consisting of a polyether polyol; a modified polyester resin; an acrylic polymer; an alkylol ammonium salt of a block copolymer having acidic groups; ethoxylated triethanolamine; a high molecular weight block copolymer having an amine functionality; sorbitan sesquioleate; polyhydroxy stearic acid; butylated polyvinyl pyrrolidone; poly(vinylpyrrolidone / 1-hexadecene); and poly(p-tert-butylstyrene-co-styrene-co-2-sulfoethyl-lithium methacrylate); f) separating the milling media from the mixture milled in step (d); and g) diluting the mixture to obtain an ink jet ink having a pigment concentration suitable for ink jet printers.

Owner:EASTMAN KODAK CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com