Patents

Literature

13485results about "Fireproof paints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Desiccant entrained polymer

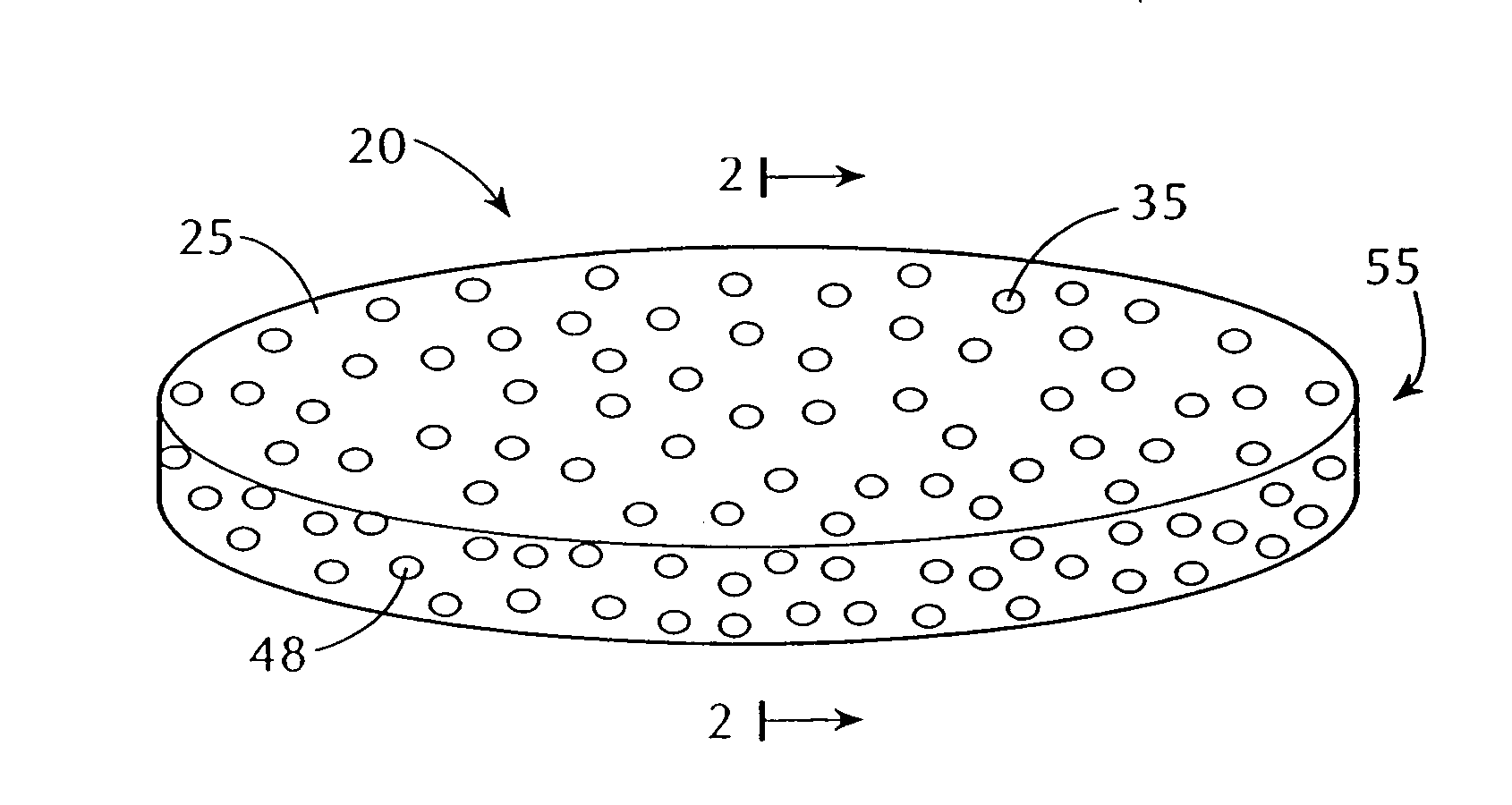

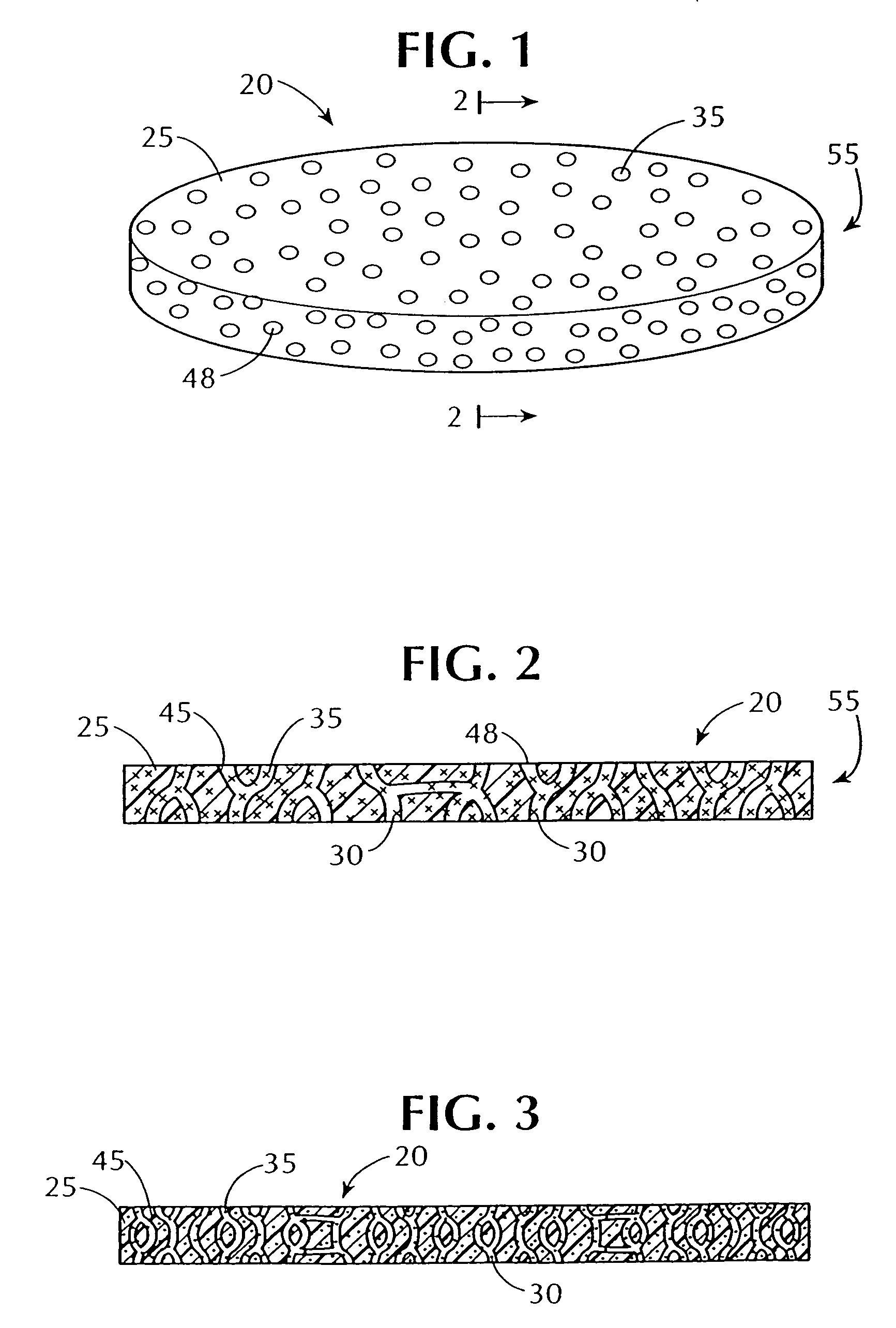

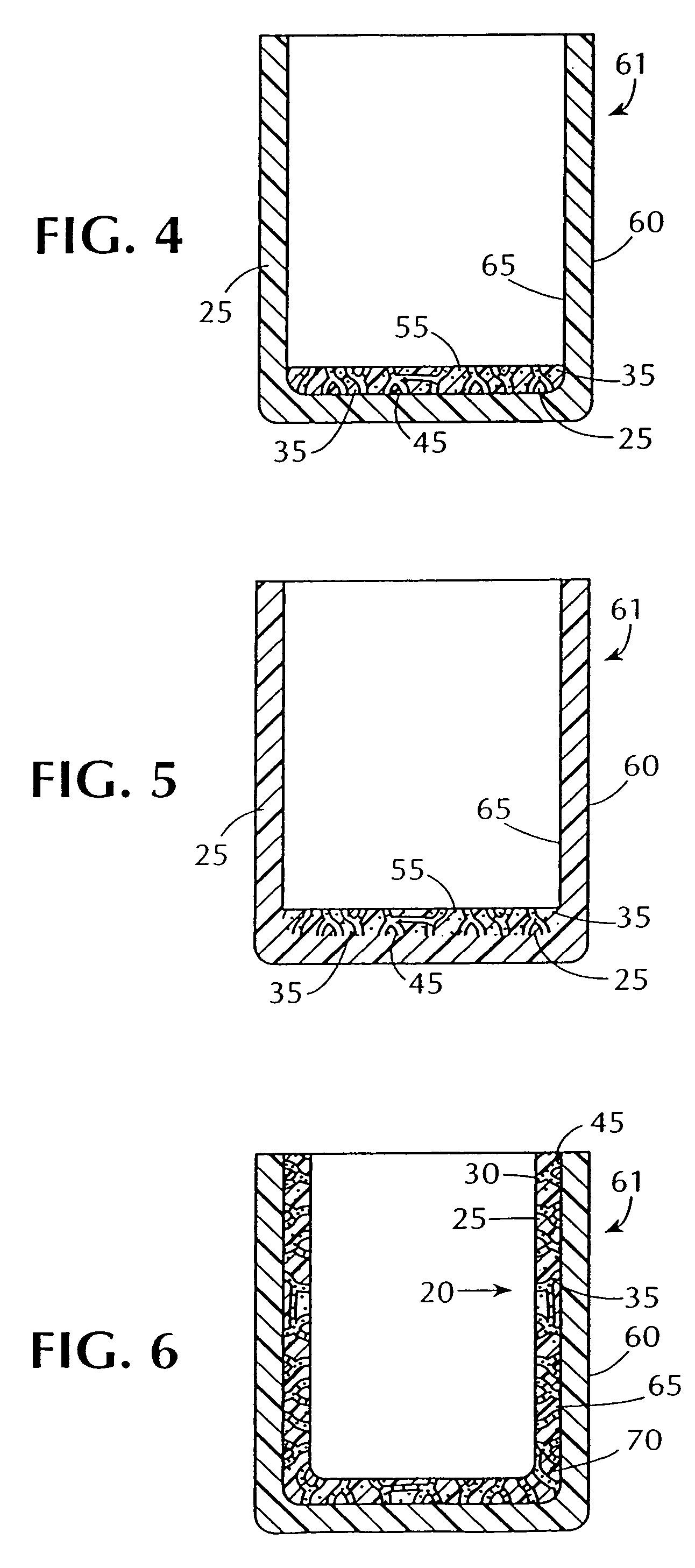

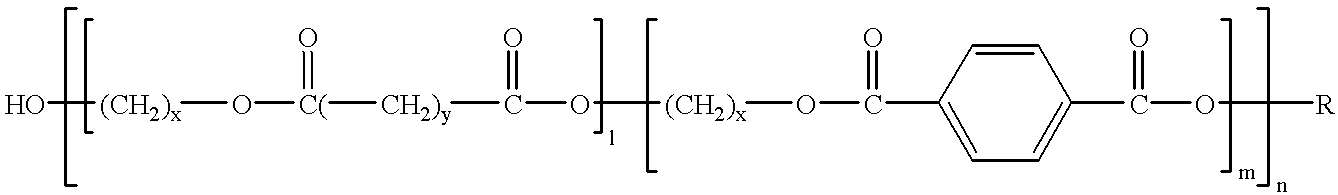

The present invention includes a composition having a co-continuous interconnecting channel morphology. These co-continuous interconnecting channels are predominately occupied with a polymer and particles that control the percolation through the composition. The particles are composed of a material such as an absorbing agent, releasing agent and / or activation agent. The polymer composition may be used to form a desired shaped article such as plug type inserts and liners for closed containers, or it may be formed into a film, sheet, bead or pellet.

Owner:CSP TECH NORTH AMERICA

Compositions and methods for manufacturing thermoplastic starch blends

InactiveUS6235816B1Improved chemical and physical propertyPromote degradationFireproof paintsPaper coatingPolyesterPolymer science

A biologically degradable polymer mixture containing at least one biopolymer made from renewable raw materials and a polymer selected from the following materials: an aromatic polyester; a polyester-copolymer with both aliphatic and aromatic blocks; a polyesteramide; a polyglycol; a polyester urethane; and / or mixtures of these components. The preferred renewable raw material is starch, more preferably native starch, most preferably native starch that has been predried.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

Flame retardant resin compositions

This invention relates to flame retardants for polyester and polyamide compositions, and specifically relates to compositions containing (1) about 30 to about 70 weight percent of a polyester or a synthetic, aliphatic polyamide and synthetic aliphatic, aromatic polyamide copolymers or a mixture thereof; (2) about 15 to about 40 weight percent of glass or mineral reinforcing agent; and (3) a flame retardant of (a) about 5 to about 45 weight percent of melamine polyphosphate; (b) about 15 to about 30 weight percent of melamine polyphosphate and up to about 10 weight percent of a charring catalyst; (c) about 15 to about 30 weight percent of melamine polyphosphate, up to about 10 weight percent of a charring catalyst and up to about 10 weight percent of a char former, wherein all percents by weight are based on the total weight of (1)+(2)+(3) only.

Owner:EI DU PONT DE NEMOURS & CO

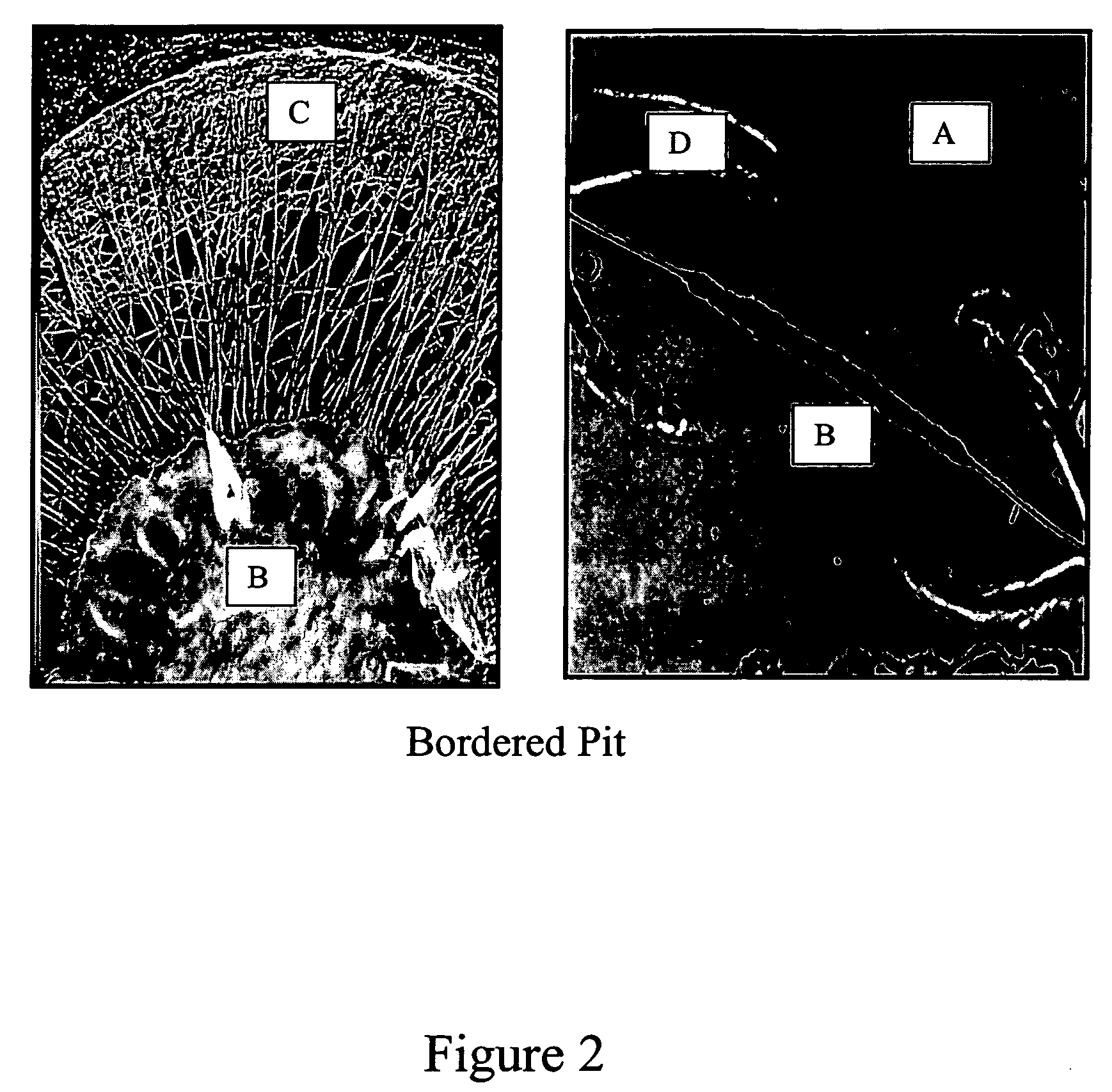

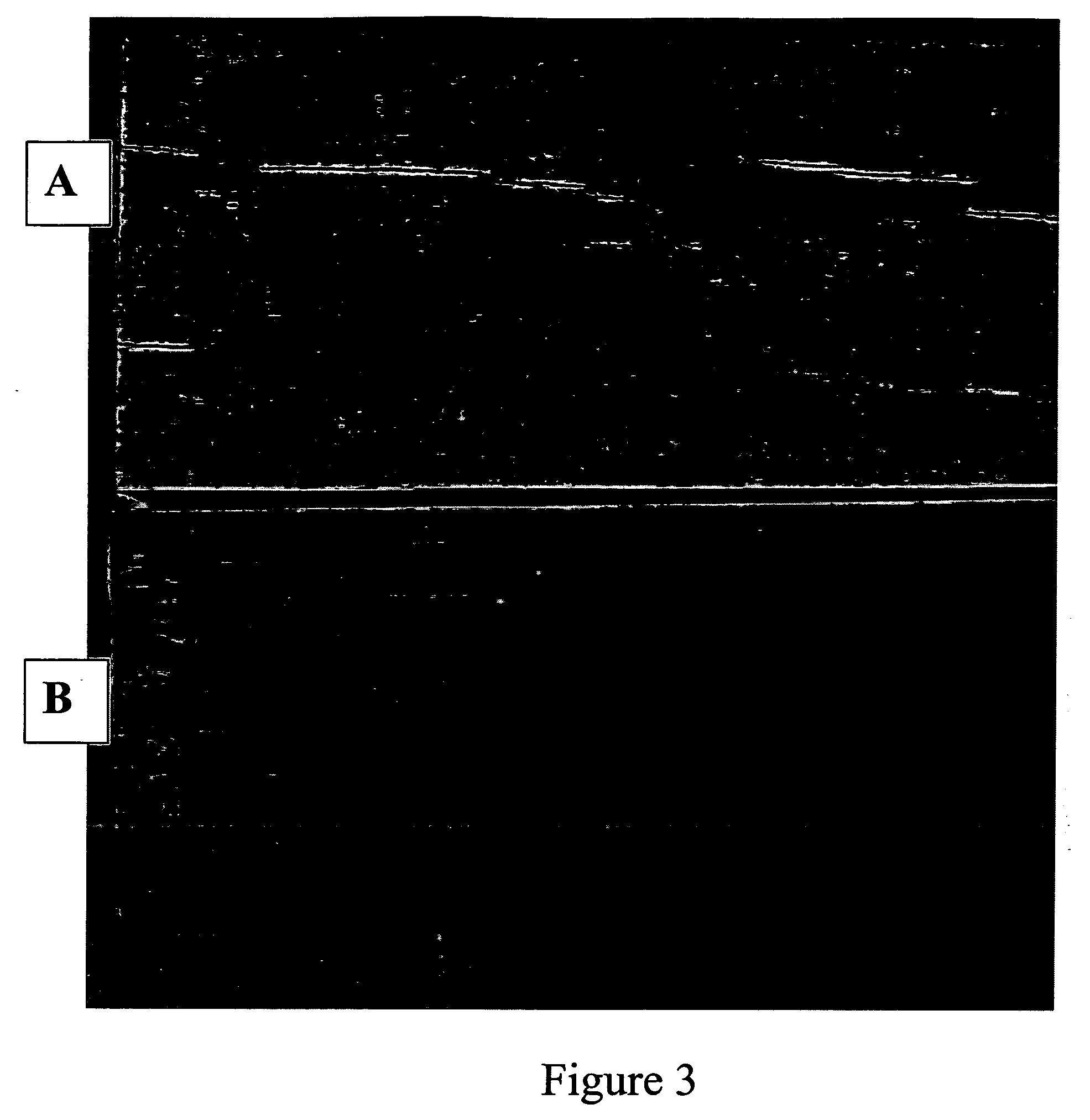

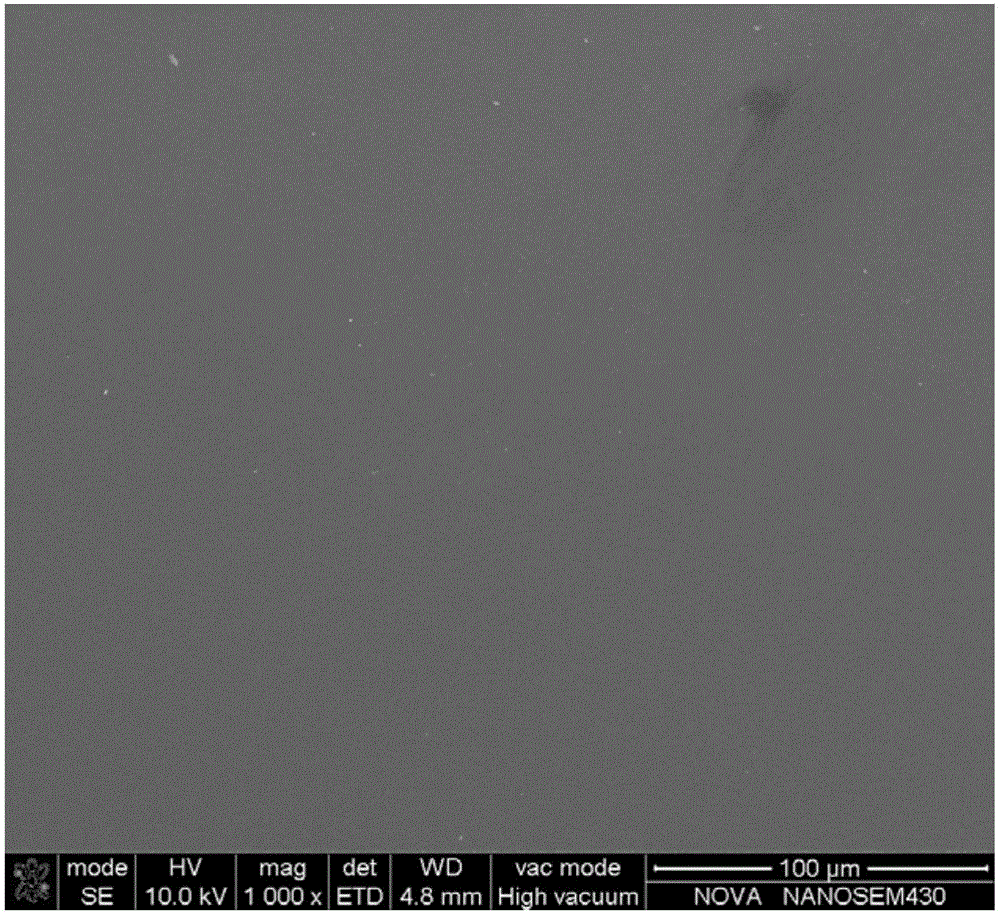

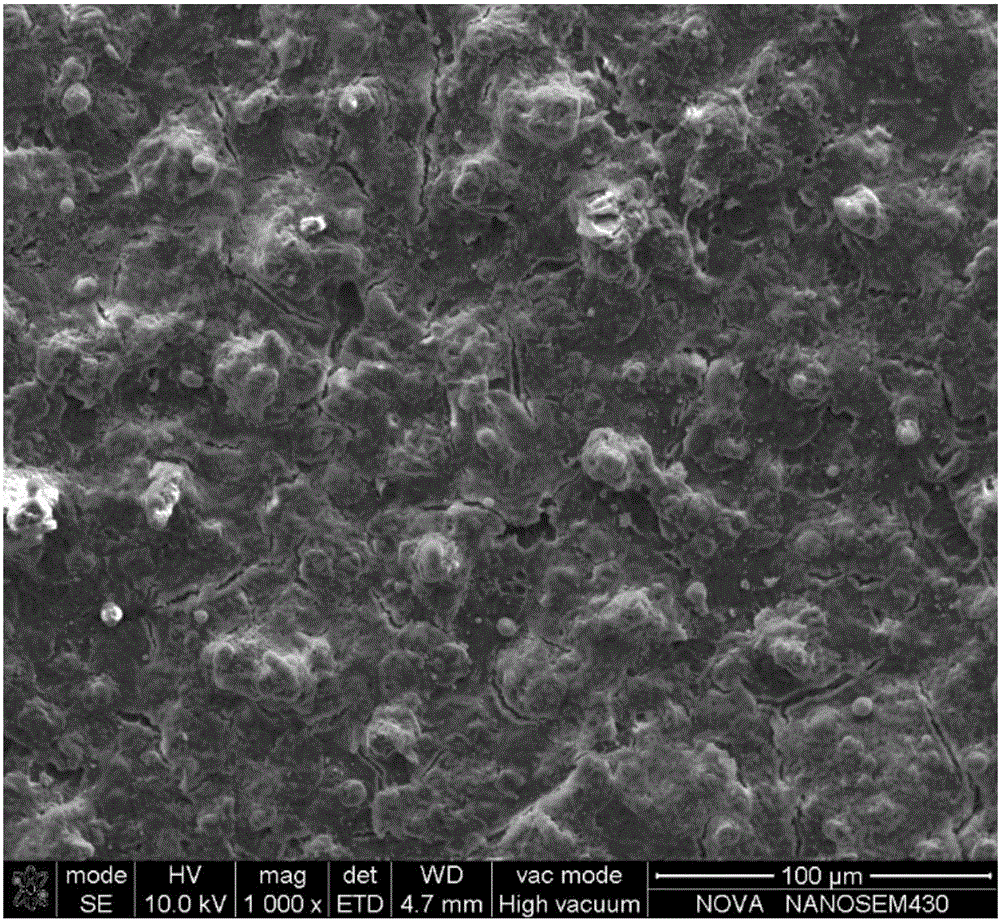

Composition, method of making, and treatment of wood with an injectable wood preservative slurry having biocidal particles

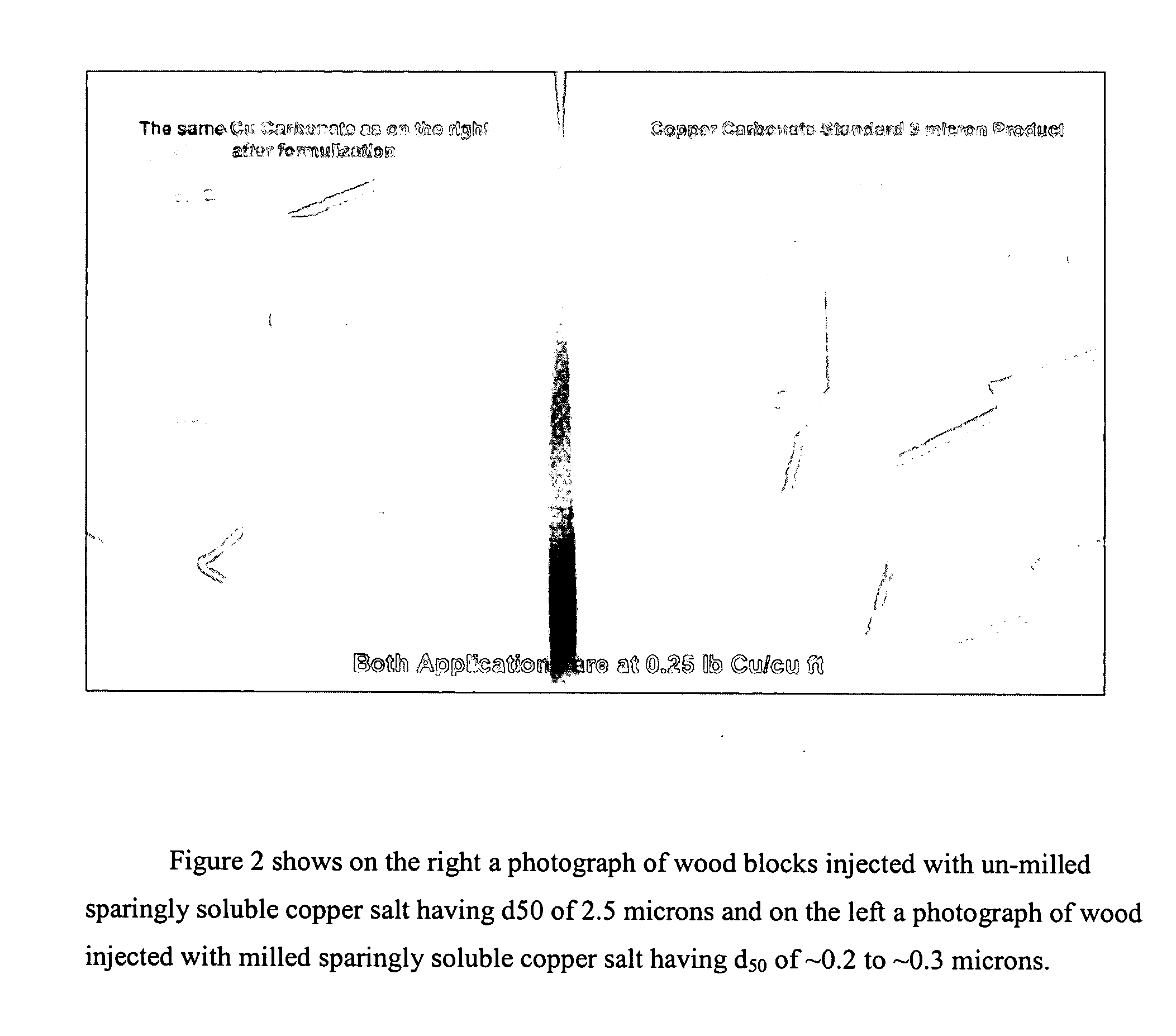

A method of preserving wood includes injecting into the wood an effective amount of a aqueous wood-injectable biocidal slurry, said a wood-injectable biocidal slurry containing dispersants and sub-micron biocidal particles selected from at least one of the following classes: 1) a plurality of particles containing at least 25% by weight of a solid phase of sparingly soluble salts selected from copper salts, nickel salts, tin salts, and / or zinc salts; 2) a plurality of particles containing at least 25% by weight of a solid phase of sparingly soluble metal hydroxides selected from copper hydroxide, nickel hydroxide, tin hydroxide, and / or zinc hydroxide; 3) a plurality of particles containing at least 25% by weight of a solid phase comprising a substantially-insoluble organic biocide selected from triazoles, chlorothalonil, iodo-propynyl butyl carbamate, copper-8-quinolate, fipronil, imidacloprid, bifenthrin, carbaryl, strobulurins, and indoxacarb; 4) a plurality of particles containing on the outer surface thereof a substantially-insoluble organic biocide; 5) a plurality of particles containing a solid phase of a biocidal, partially or fully glassified composition comprising at least one of Zn, B, Cu, and P. The particles may advantageously contain metallic copper, a leachability barrier, pigments, dyes, or other adjuvants disposed on the outer surface thereof.

Owner:OSMOSE

Building materials with bioresistant properties

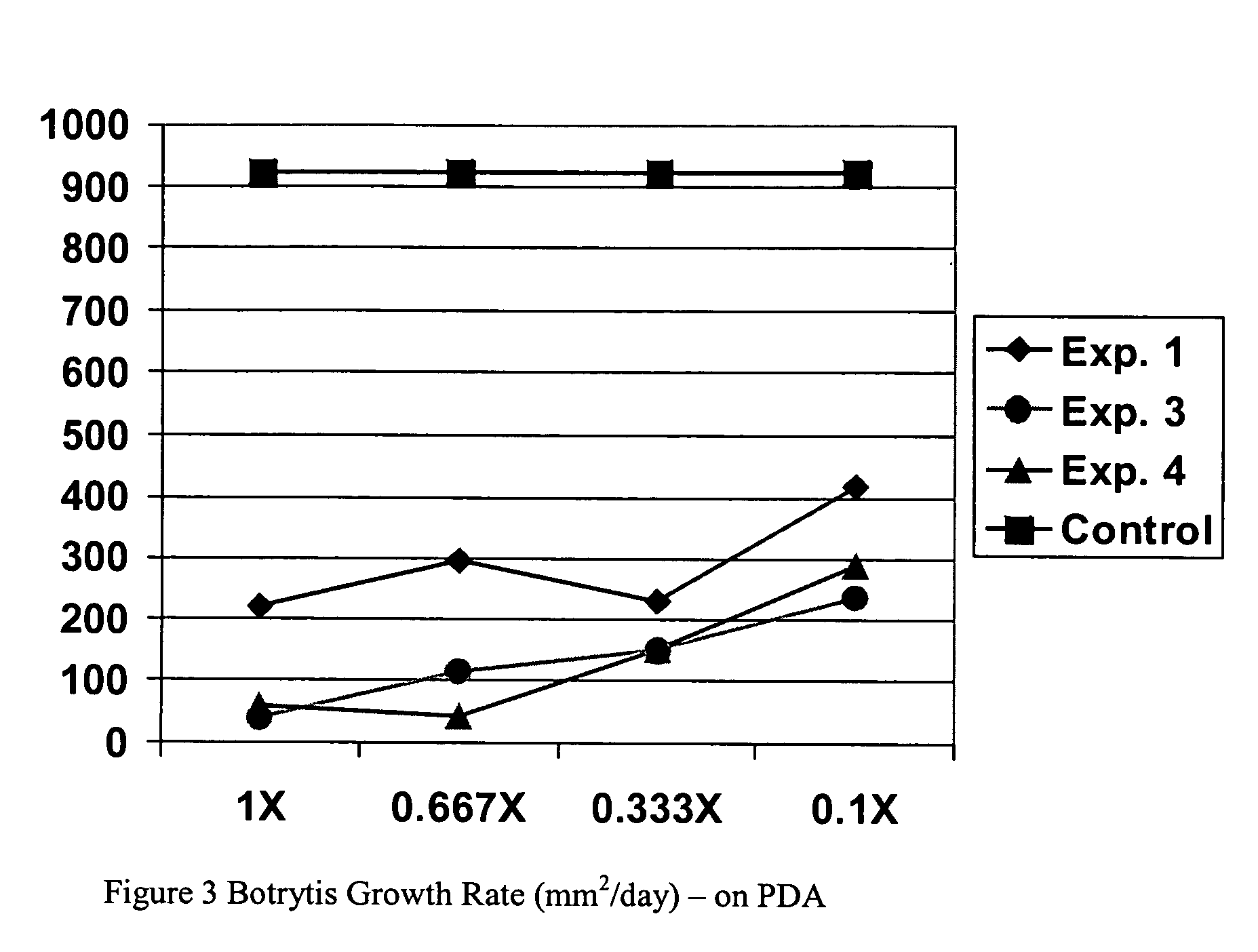

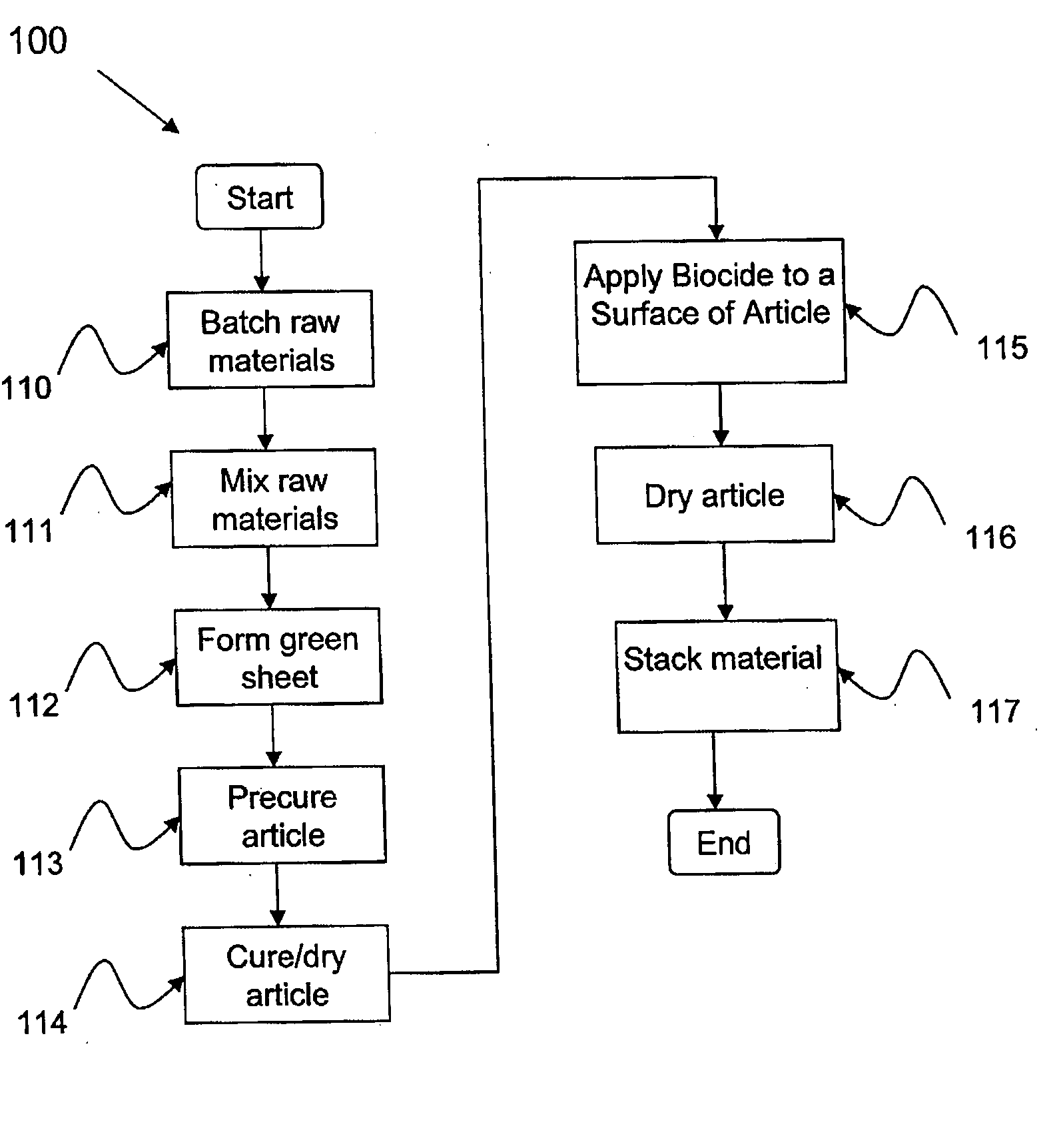

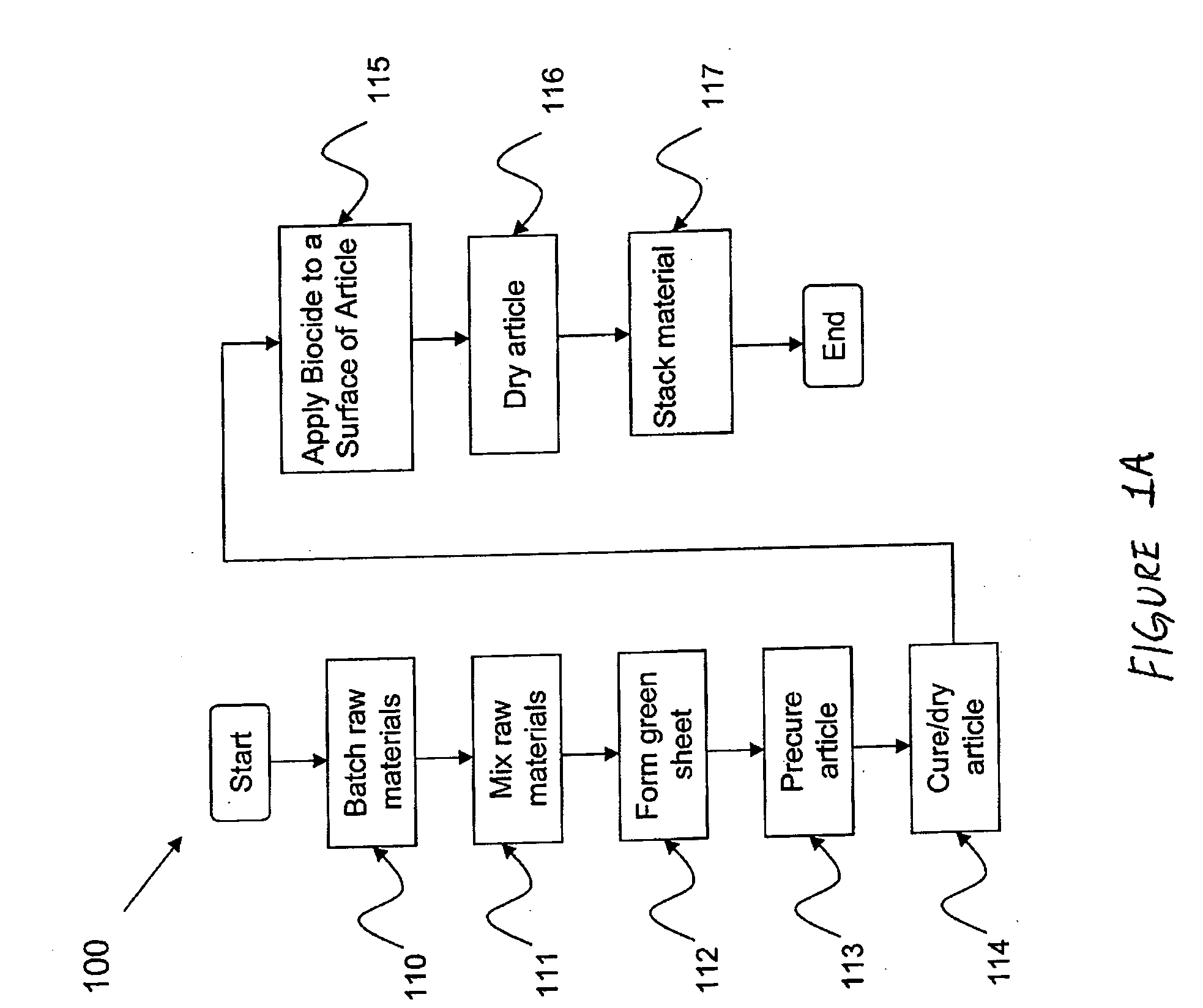

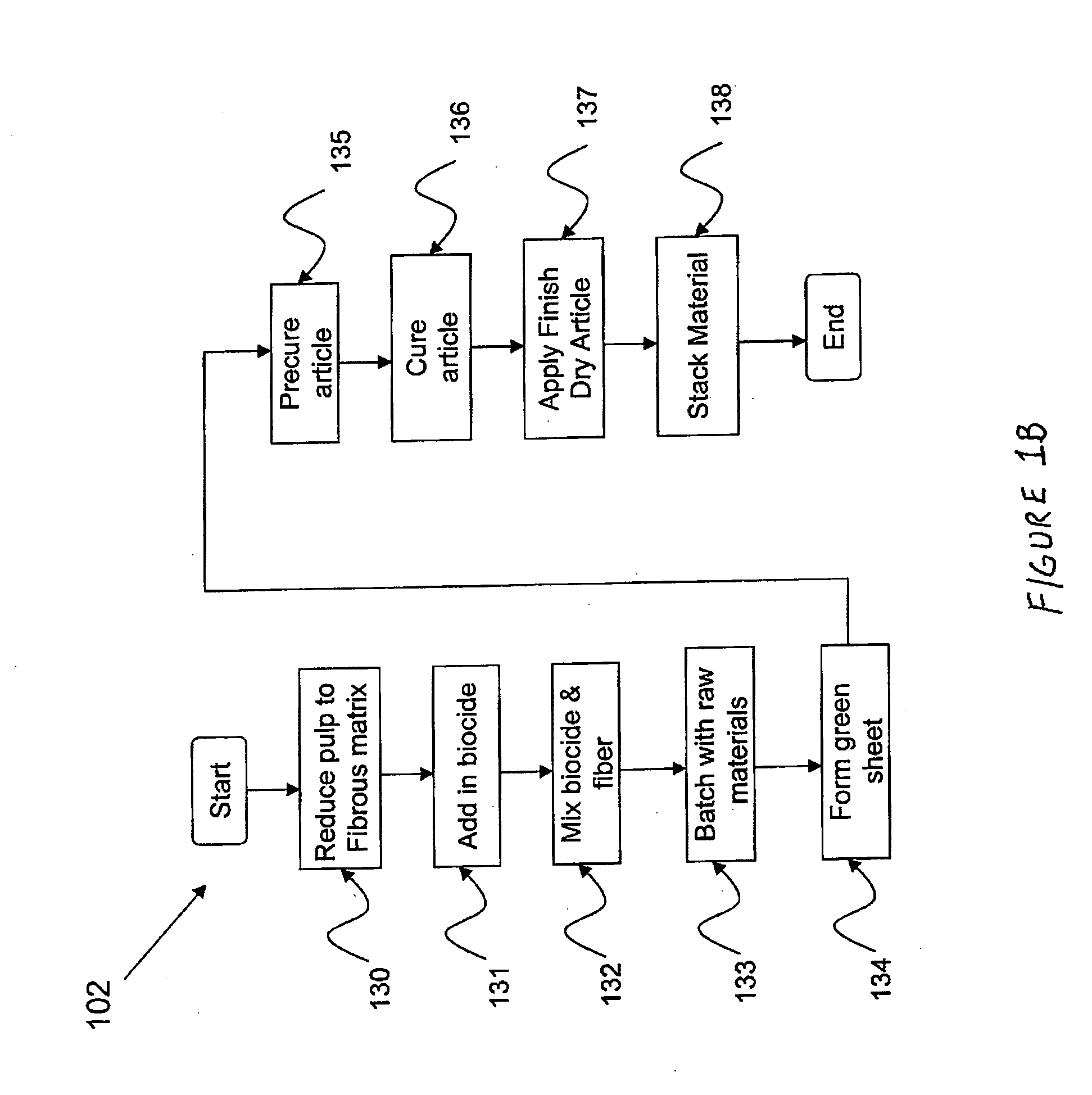

InactiveUS20050126430A1Effective biocide treatmentAffecting performanceFireproof paintsAntifouling/underwater paintsFiberBiological resistance

A building article incorporating a biocidal agent, such as copper oxine, that inhibits the growth of mold, fungi, algae, mildew, bacteria, lichen, and other undesirable biological growth is provided. The biocidal agent can be a biocide, fungicide, germicide, insecticide, mildewcide, or the like. The biocidal agent can be interspersed throughout the matrix of the article; applied as a surface treatment to the article; or applied as a treatment to the fibers reinforcing the article. The building article can include tile backer boards, decks, soffits, trims, decking, fencing, roofing, cladding, sheathing, and other products. The building article can also include a variety of different composite materials such as cement, gypsum, wood, and wood / polymer composites.

Owner:JAMES HARDIE TECH LTD

Mold-resistant gypsum panel and method of making same

InactiveUS6893752B2Reduce the growth of moldImprove anti-mold performancePretreated surfacesRecord information storageSodium PyrithioneEvaporation

A mold-resistant gypsum panel includes a core of an interlocking matrix of calcium sulfate dihydrate crystals, a facing material on at least one side of the panel and a salt of pyrithione dispersed through both the core and the facing materials. A method of making a mold-resistant gypsum product is also provided. A slurry of calcined gypsum, water and a water-soluble pyrithione salt is formed, then deposited on a sheet of facing material. The slurry on the facing material is shaped into a panel and maintained under conditions sufficient for the calcined gypsum to react with the water to form a core comprising an interlocking matrix of set gypsum crystals. Heating of the panel causes evaporation of the water that did not react with the calcined gypsum.

Owner:UNITED STATES GYPSUM CO

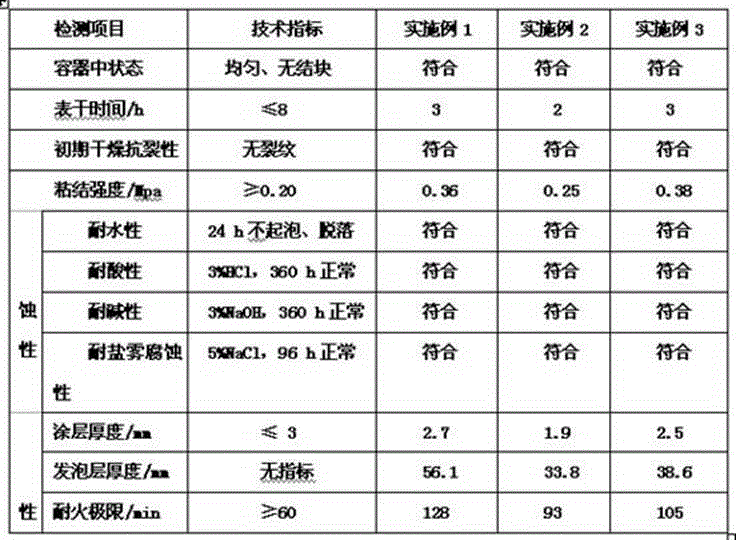

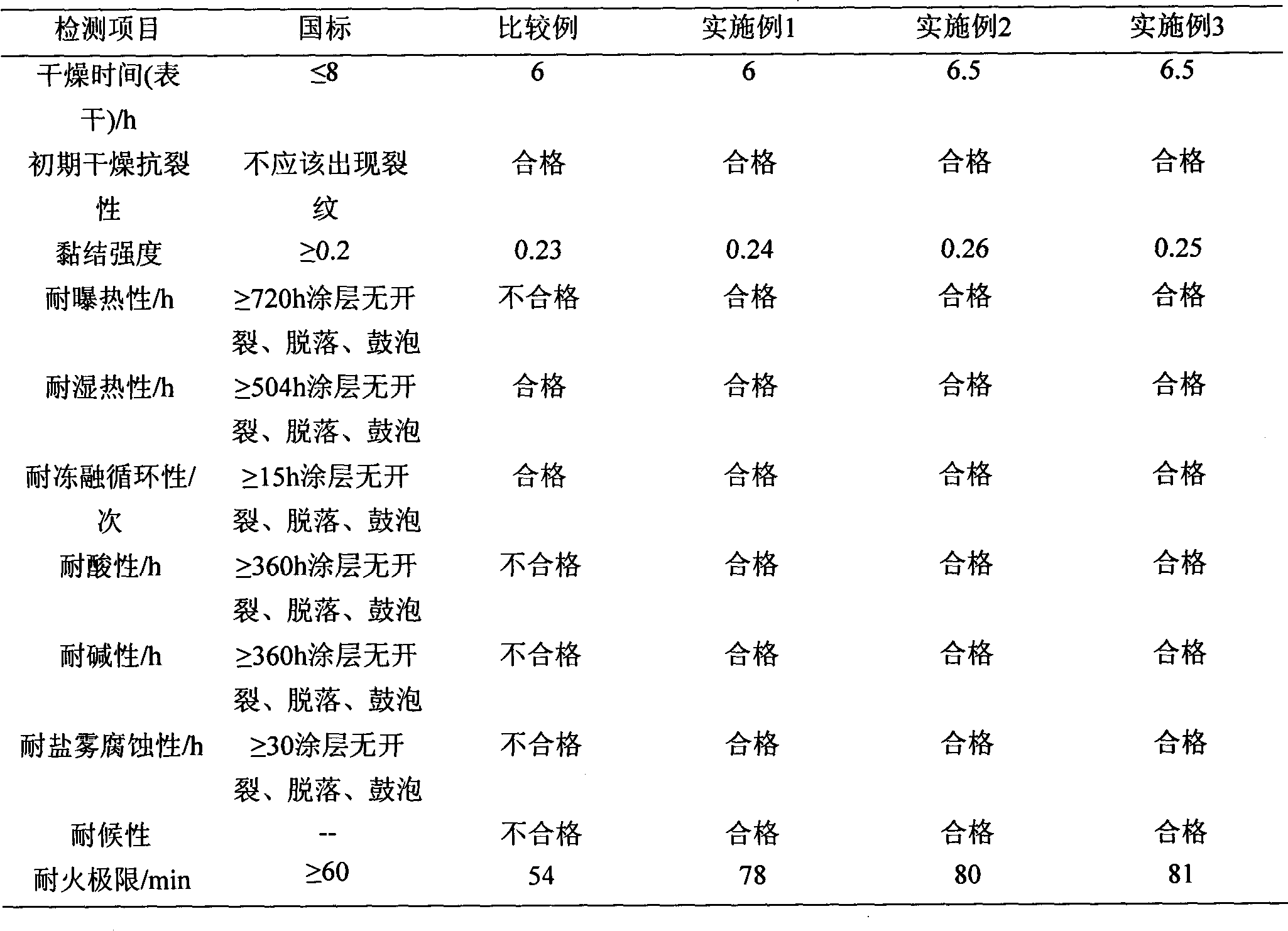

Aqueous fire-proof corrosion-proof paint for steel structure and preparation method thereof

ActiveCN104130638ATaking into account fire resistanceCompatible with anti-corrosionFireproof paintsAnti-corrosive paintsPtru catalystFoaming agent

The invention discloses aqueous fire-proof corrosion-proof paint for a steel structure and a preparation method thereof, and belongs to the technical field of paint. The aqueous fire-proof corrosion-proof paint comprises, by mass, 20-45% of a composite emulsion, 12-25% of a charring catalyst, 6-12% of a foaming agent, 8-17% of a charring agent, 5-10% of a fire retardant, 1-5% of layered double hydroxide, 8-18% of an corrosion-proof filling material, 4-12% of a strengthening filling material, 1-5% of modified nano-powder, 0.5-6% of an assistant and 10-30% of water. Through use of the composite modified emulsion as a base material, coating flame resistance, corrosion resistance and decorativeness are obtained and coating defects caused by a single emulsion as a base material are overcome. Through use of a small amount of the nano-powder, the coating is compact because of filling effects of the nano-powder, the coating corrosion caused by O2, H2O and Cl <-> is avoided, good fire-proof and corrosion-proof effects are obtained under the condition of a small addition amount and a cost is reduced. The aqueous fire-proof corrosion-proof paint has the characteristics of green environmental protection and simple preparation processes.

Owner:山东七维新材料有限公司

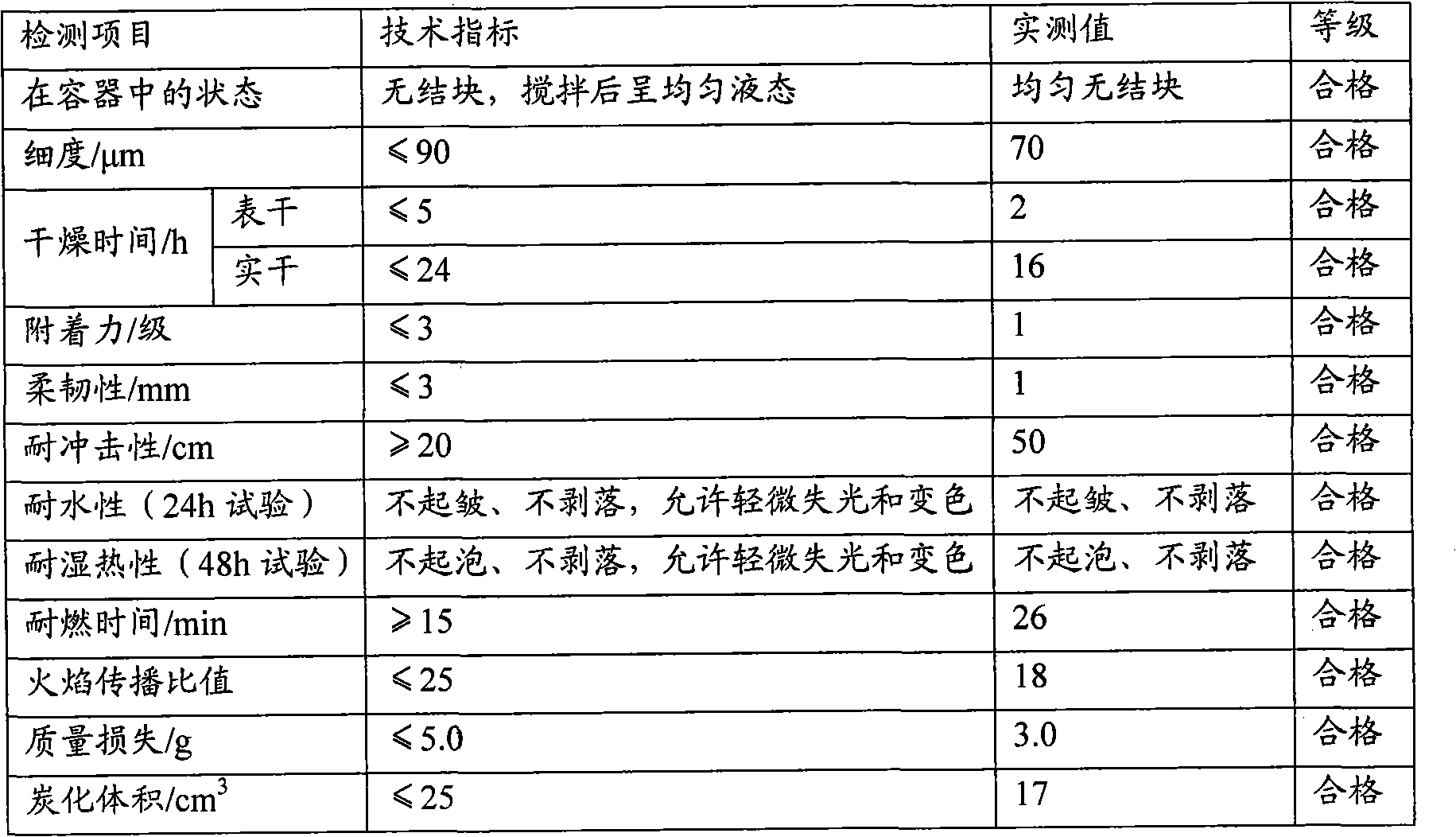

Expanded type fireproof coating and preparation method thereof

ActiveCN101659823AReduce usageLow costFireproof paintsPolyurea/polyurethane coatingsSolventAnti ageing

The invention discloses an expanded type fireproof coating and a preparation method thereof, which are characterized by comprising the steps of grinding and dispersing 15-35 percent of microcapsule flame retardants, 5-10 percent of fillers and 10-30 percent of solvent according to the percentage of the total mass of the coating after preparation until the fineness thereof is less than 90 microns;then adding and dispersing coating matrixes and additives which respectively take up 20-40 percent and 1-5 percent of the total mass of the coating after preparation until the system is uniform; and alternatively adding flame retardant synergist agents which account for 0-10 percent of the total mass of the coating after preparation before grinding. The obtained expanded type fireproof coating hasgood stability, overcomes the defects of poor high-temperature resistance, poor anti-aging performance, poor water resistance and the like in the traditional organic expanded type fireproof coating,lowers the use amount and cost of the flame-retardant additives which all realize non-halogenation, does not cause larger impact on the environment, and has very good application prospects.

Owner:UNIV OF SCI & TECH OF CHINA

Heat resistant molded or extruded thermoplastic articles

InactiveUS20100029819A1Improve thermal stabilityFireproof paintsThin material handlingChemical compositionAlcohol

Disclosed is a molded or extruded thermoplastic article having high heat stability over at least 500 hours at least 170° C. including a thermoplastic composition including a thermoplastic resin; one or more polyhydric alcohols having more than two hydroxyl groups and a having a number average molecular weight (Mn) of less than 2000; one or more reinforcement agents; and optionally, a polymeric toughener; wherein 4 mm test bars prepared from said thermoplastic composition, and exposed at a test temperature at 170° C. for a test period of 500 hours, have, on average, a retention of tensile strength of at least 50 percent, as compared with that of an unexposed control of identical composition and shape. Further disclosed is a molded or extruded thermoplastic article, including a thermoplastic polyamide composition, wherein 4 mm test bars of said thermoplastic polyamide composition, when exposed at 210° C. for a test period of 500 hours, have a retention of tensile strength of at least 70 percent.

Owner:EI DU PONT DE NEMOURS & CO

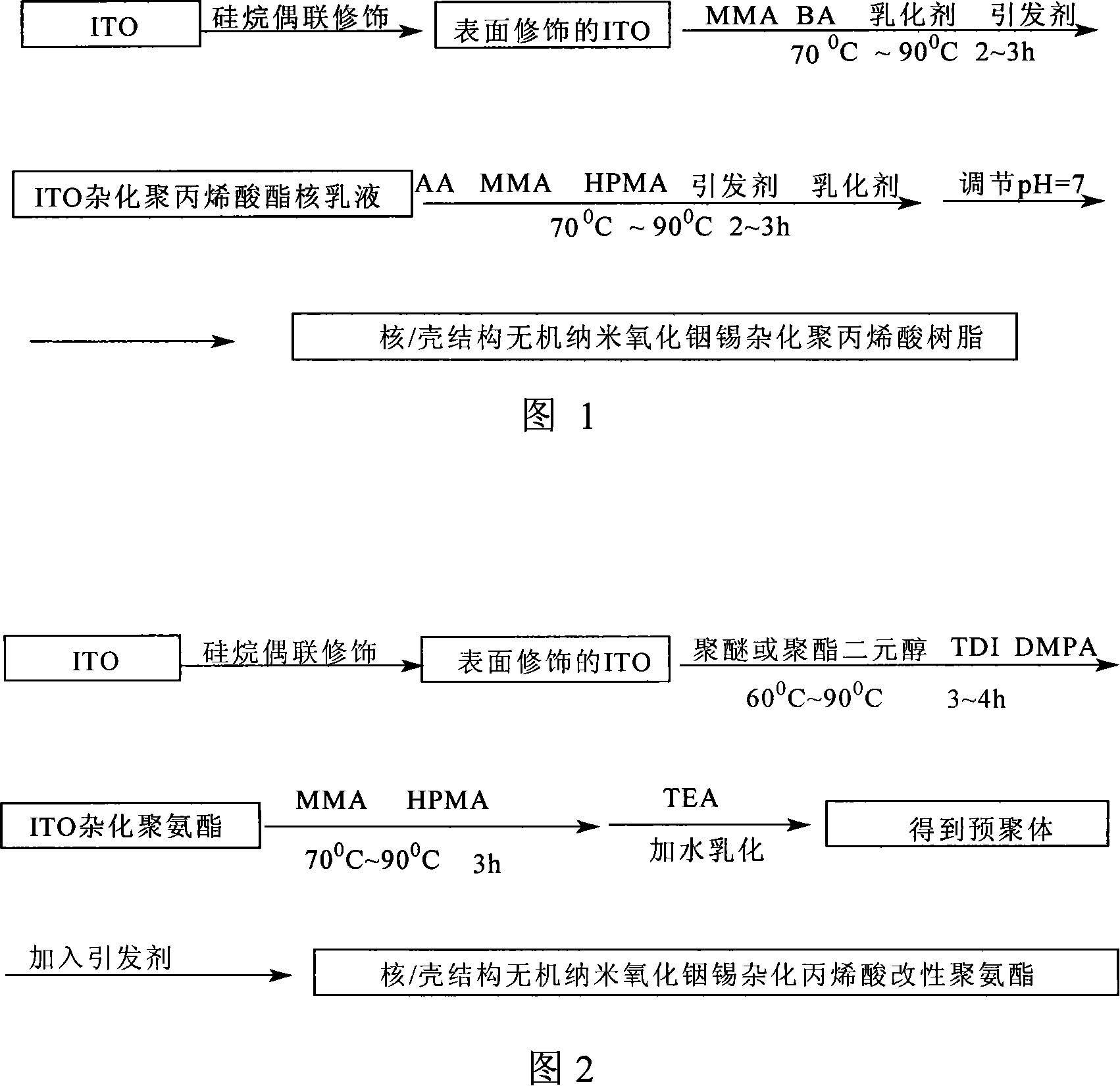

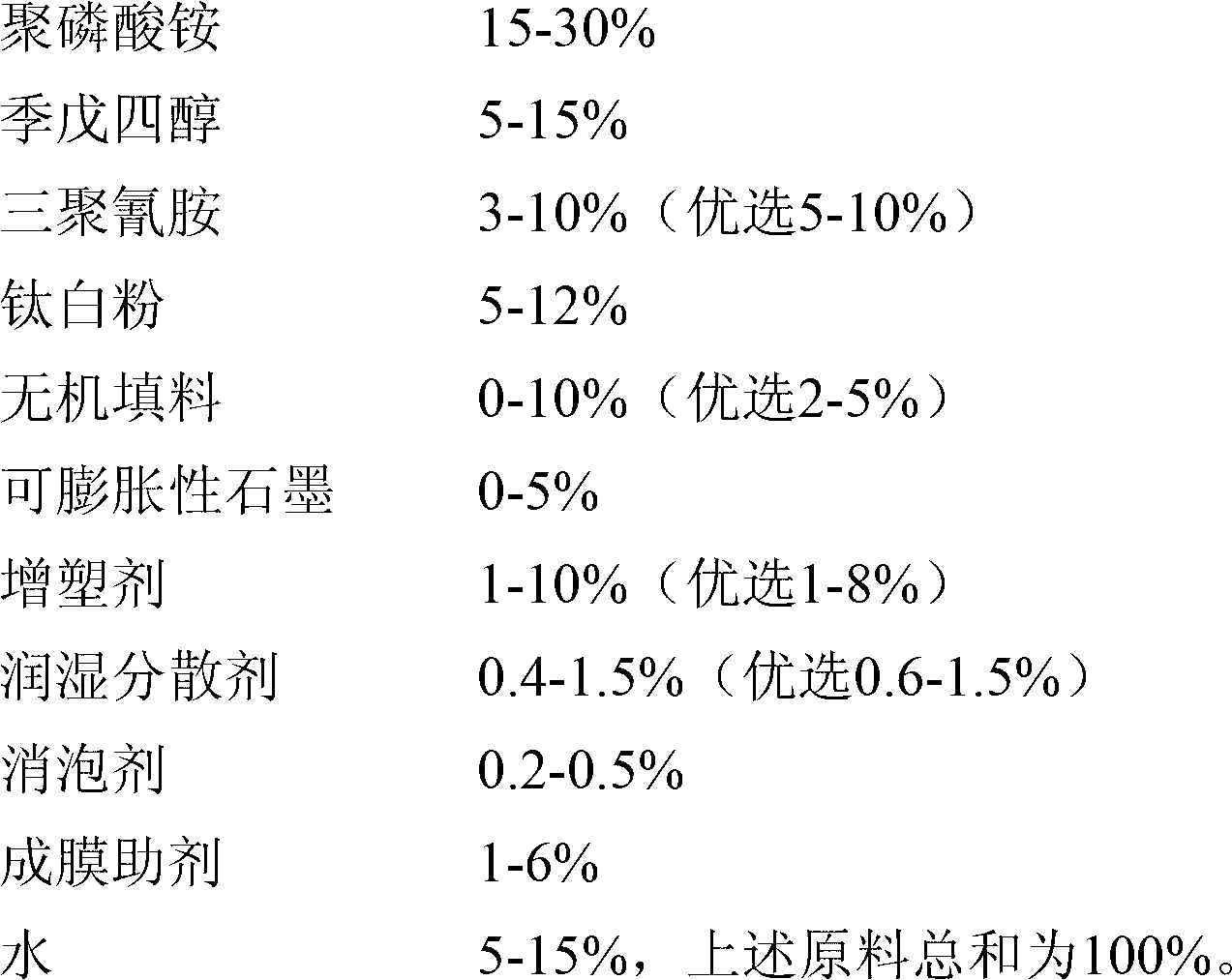

Nano transparent insulating paint and its preparing process

InactiveCN101108946AGood dispersionImprove stabilityFireproof paintsPolyurea/polyurethane coatingsInfraredIn situ polymerization

The invention relates to a nano transparent heat insulation coating, which comprises the following components: inorganic nano particle hybrid high molecular resin, coating additive and thinner. Wherein, the inorganic nano particle hybrid high molecular resin is the resin with core / shell structure and synthesized by inorganic nano heat insulation powder and high molecular resin through in-situ polymerization and the high molecular resin covers the nano heat insulation powder. The invention also provides a preparation method of the nano transparent heat insulation coating. The nano transparent heat insulation coating film forming material is the inorganic nano particle hybrid high molecular resin and is characterized by strong adhesive force, transparency and shielding infrared for heat insulation, which can be coated on the surfaces of glass, metals and cement and is especially for glass of cars or buildings. The invention adopts the inorganic nano particle hybrid high molecular resin with core / shell structure prepared through in-situ polymerization, which is simple and easy and has good coating properties.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Expanding fire-proof paint

InactiveCN1380368AGood fire and heat insulationGood adhesionFireproof paintsFoaming agentAcrylic resin

The expansive fire-resisting paint contains the components of acrylic resin, catalyst, carbon-forming agent, foaming agent, fire-resisting agent, reinforcing agent, pigment filling material, adjuvantand smoke inhibiting agent, and is characterized by that it utilizes the modification of acrylic resin, surface treatment of catalyst and addition of smoke inhibiting agent to raise comprehensive property of paint. When the paint film is heated and expanded, it can be formed into fire-resistant carbonized layer with three-D space structure, and can release fire-resisting gas to prevent flame fromspreading. Said paint is suitable for steel structure, and material and electric cable, etc.

Owner:MARINE CHEM RES INST

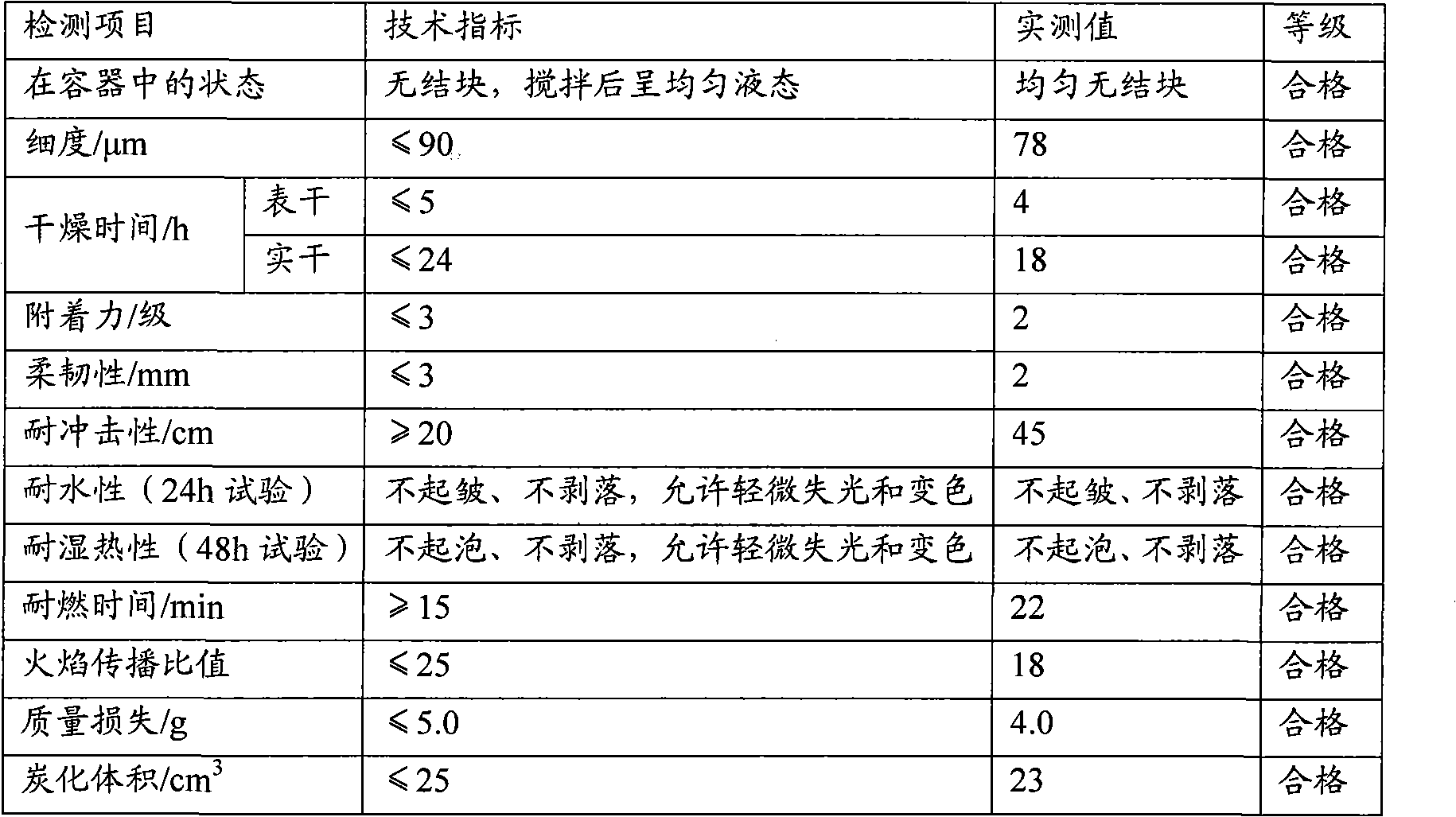

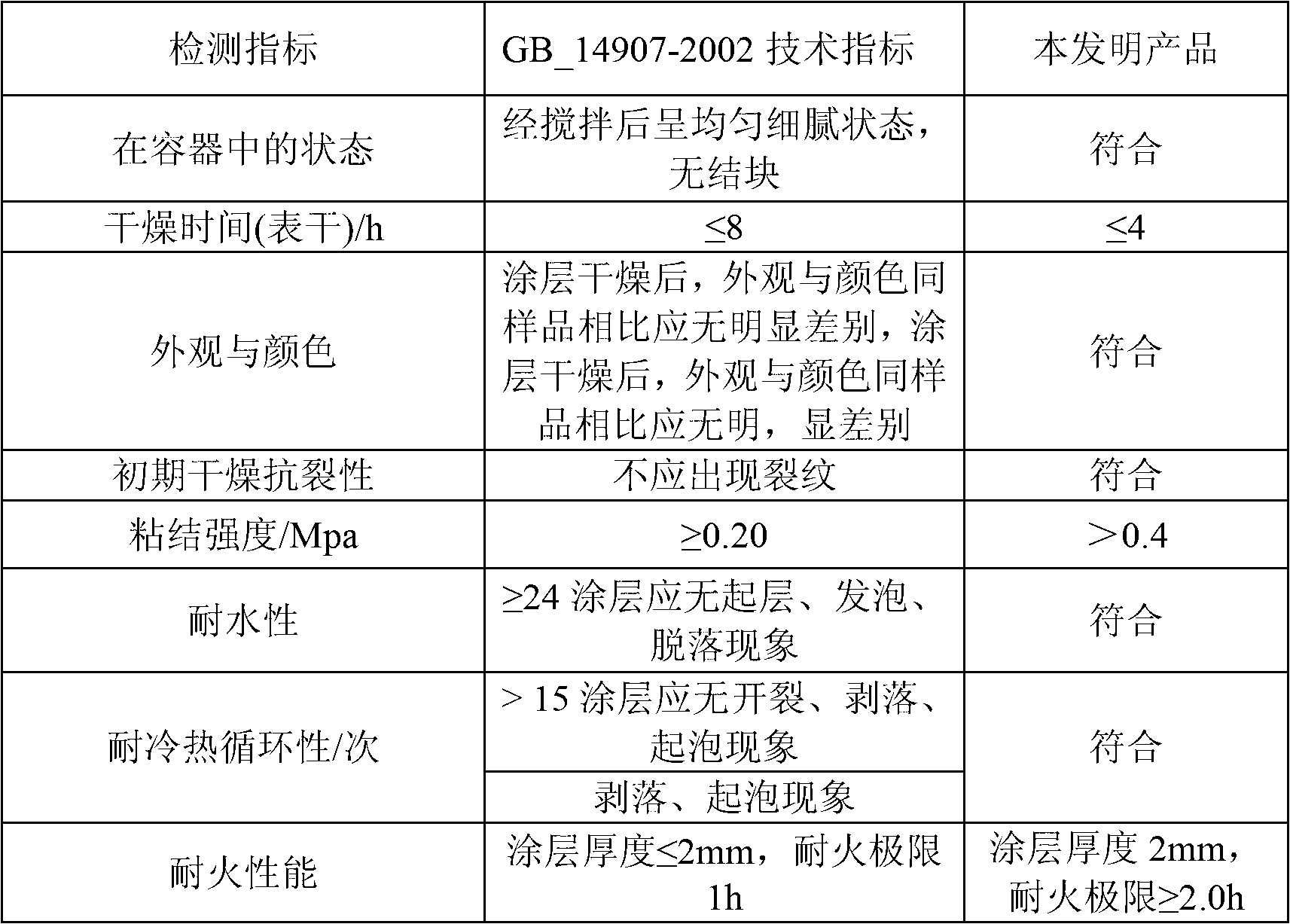

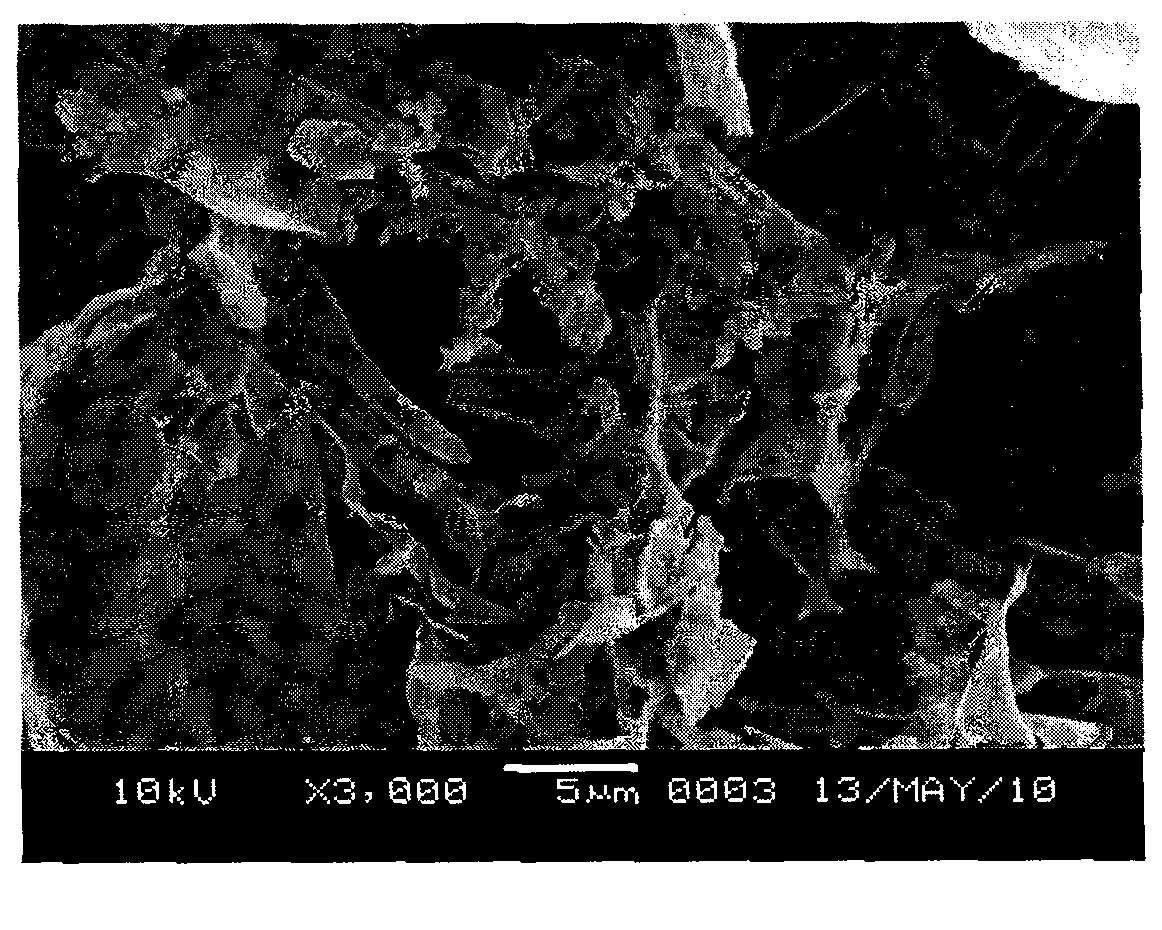

Waterborne ultra-thin steel structure fire retardant coating and preparation method thereof

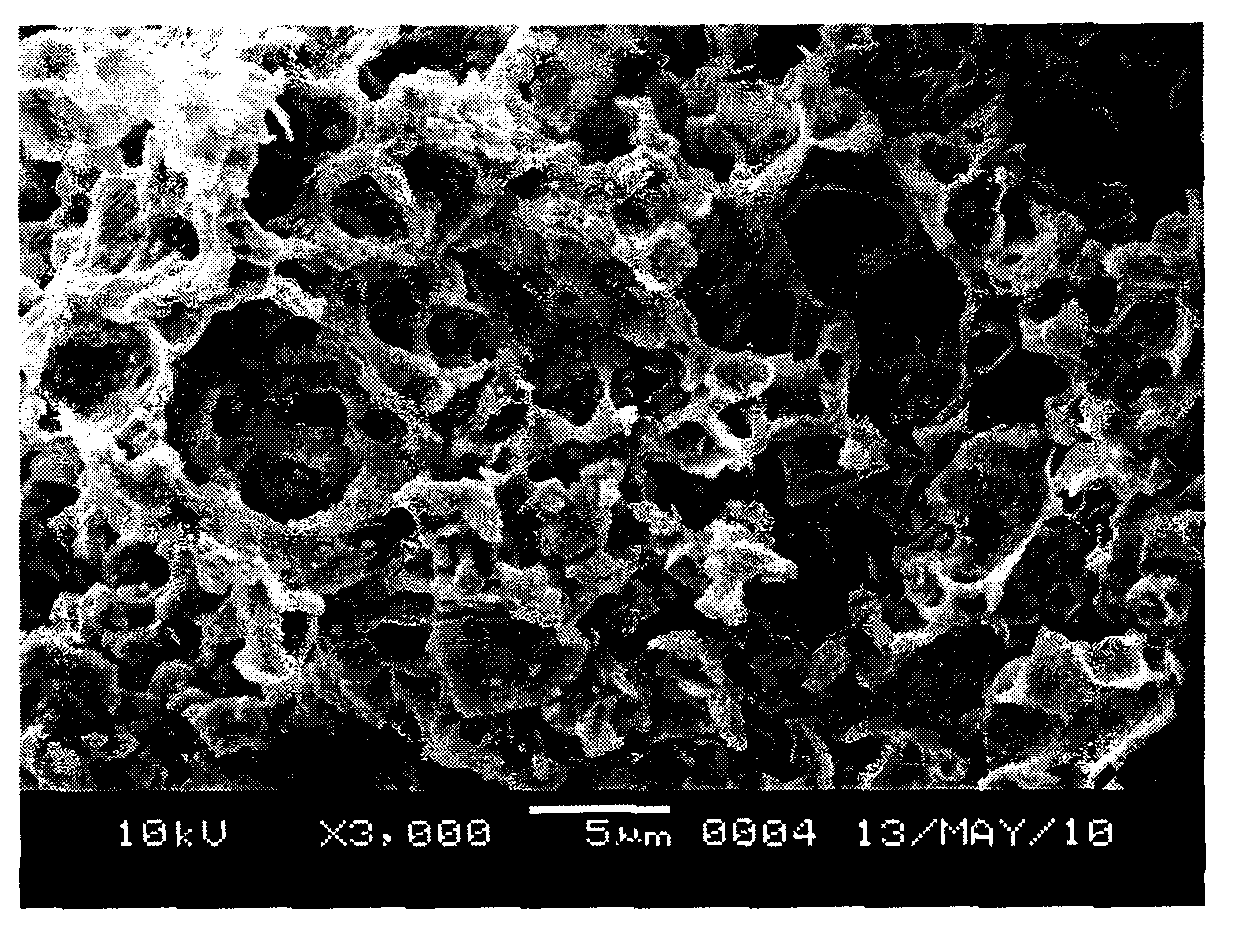

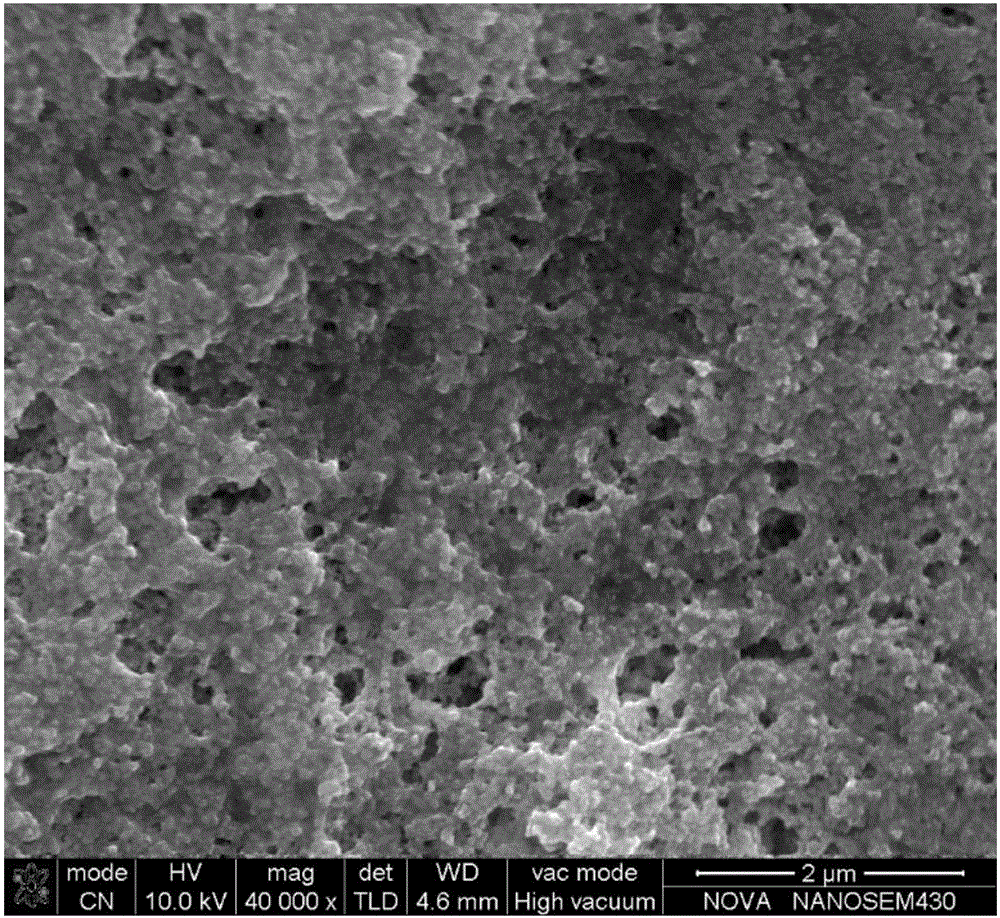

ActiveCN102838907AGood foaming effectThe pores are small and uniformFireproof paintsCarbonizationMaterials science

Provided is a waterborne ultra-thin steel structure fire retardant coating and a preparation method thereof. The raw material ratio of the coating includes 15-50% by weight of polymer latex, 15-30% by weight of ammonium polyphosphate, 5-15% by weight of pentaerythritol, 3-10% by weight of cyanurtriamide, 5-12% by weight of titanium dioxide, 2-13% inorganic filler, 0-5% by weight of expansiveness graphite, 1-10% by weight of plasticizer, 0.4-1.5% by weight of wetting dispersant, 0.2-0.5% by weight of defoamer, 1-6% by weight of coalescing agents and 5-15% by weight of water, and total raw material ratio is 100%. A high-speed dispersion method or a grinding dispersion method is adopted in preparation of the coating. A coating layer of the fire retardant coating can form a carbonization layer which is good in foaming effect, small and uniform in air holes and high in expansion times when in heating. The final fire retardant performance of the coating is far higher than technical requirements of a national standard. The waterborne ultra-thin steel structure fire retardant coating is a waterborne coating product, is non-poisonous and odorless and environment-friendly, and can be coated in a mode of brushing or spraying or roller coating.

Owner:SOUTH CHINA UNIV OF TECH +1

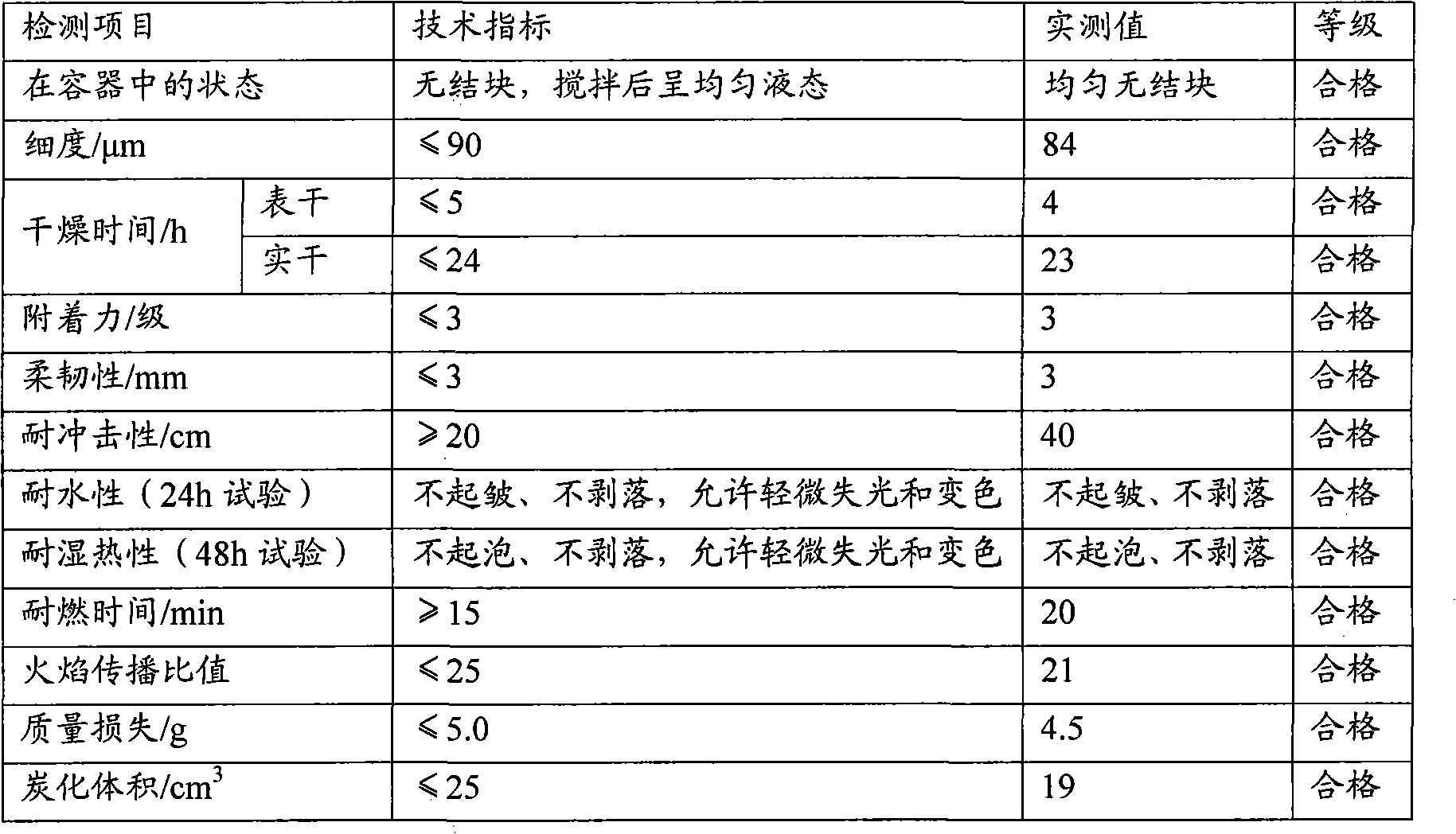

Aqueous ultra-thin expansion type steel structure fire-proof anti-corrosive paint and preparation method thereof

InactiveCN101857760AGuaranteed expansion heightHas anti-rustFireproof paintsAnti-corrosive paintsAcrylic resinRust

The invention relates to an aqueous ultra-thin expansion type steel structure fire-proof anti-corrosive paint and a preparation method thereof. The fire-proof anti-corrosive paint is prepared by adding ammonium polyphosphate, pentaerythritol, melamine, titanium white, expandable graphite, a preservative, a ceramic filler, an antifoaming agent, a dispersing agent, a plasticizer and the like into organic silicon-modified acrylic resin emulsion serving as a film forming base material. The paint has the advantages of high fire-proof performance, anti-corrosion and anti-rust function, and high water resistance, acid-alkali resistance and corrosion resistance, capability of meeting the requirements of various steel structures on the fire-proof and anti-corrosion performance, environmental friendliness, low cost, and readily available raw materials, so the paint can be widely applied to fire-proof protection of various steel structures.

Owner:EAST CHINA UNIV OF SCI & TECH

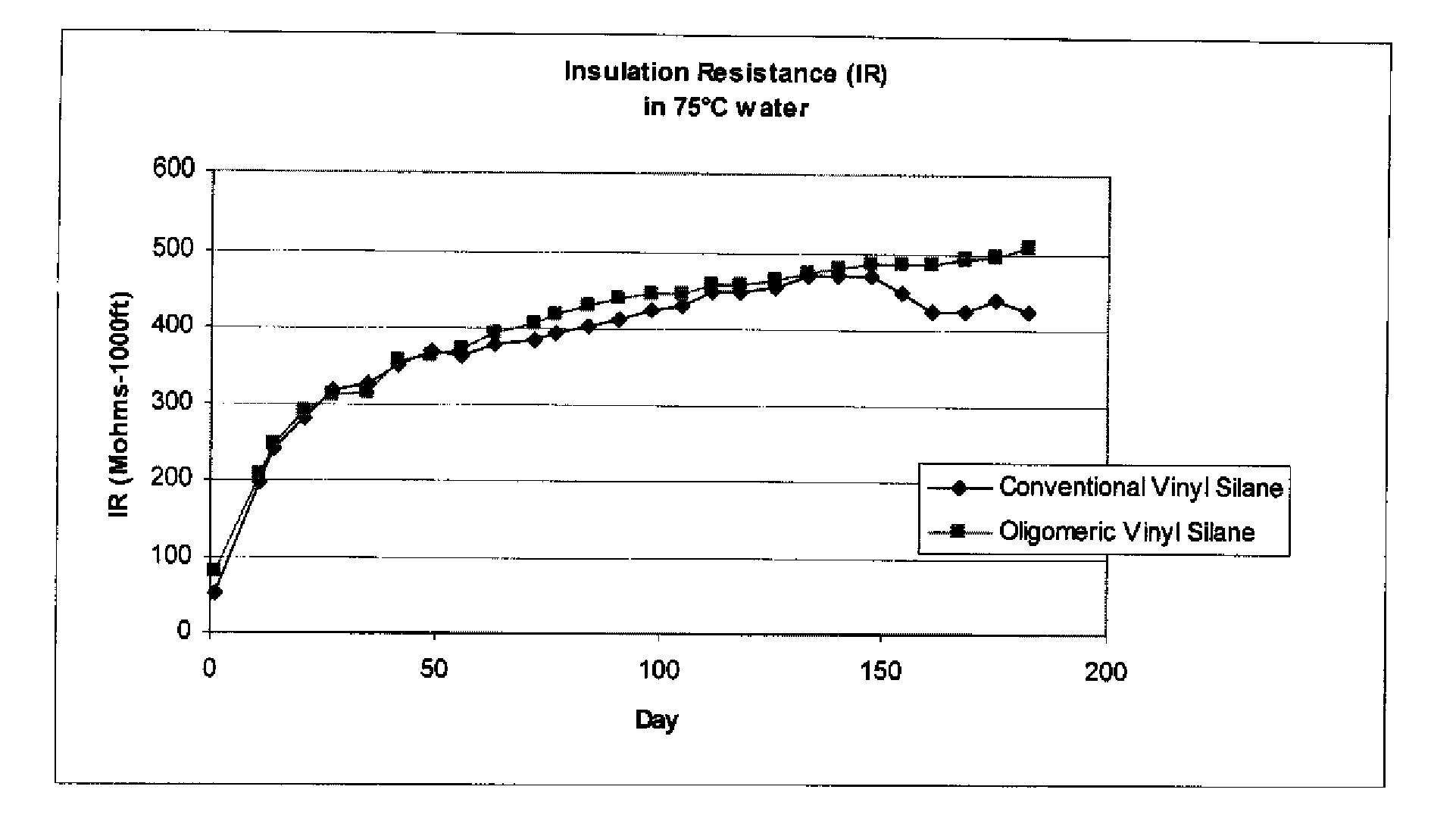

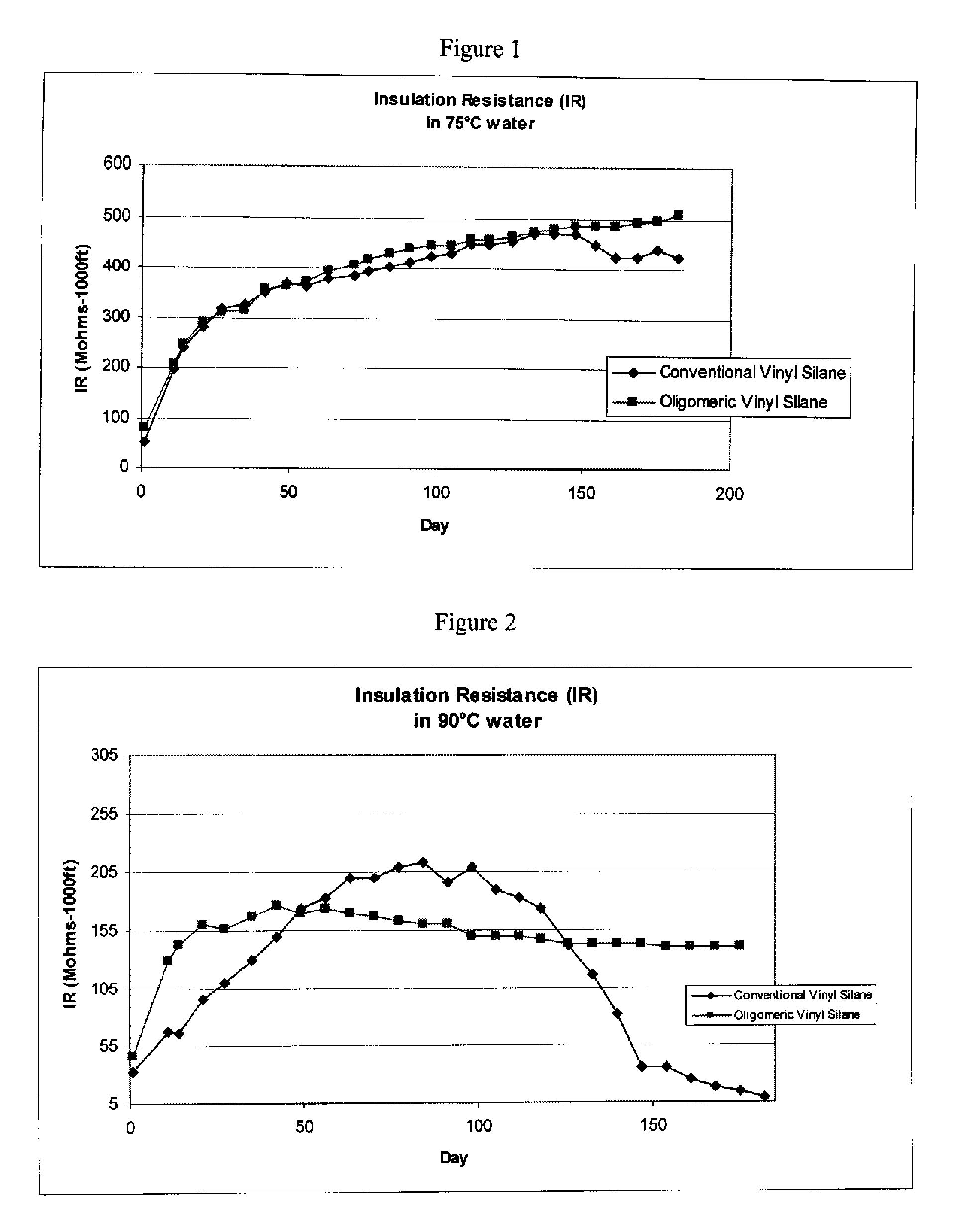

Low smoke, fire and water resistant cable coating

ActiveUS20090238957A1Limited smoke characteristicWet electrical performanceFireproof paintsRubber insulatorsMoisture resistanceOxygen

Cable coatings having effective low-smoke emission, fire resistance and moisture resistance provided by a single layer are described. The cable coatings contain an base polymer, a oxygen containing ethylene copolymer, a fire retardant and a synergistic blend of magnesium hydroxide and aluminum hydroxide. Cables coated with the described coatings have improved wet electrical performance, and satisfactory fire performance and smoke characteristics.

Owner:GENERAL CABLE TECH CORP

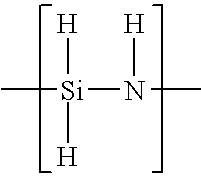

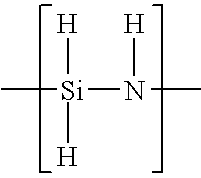

Polysilane-containing coating solution

InactiveUS20050279255A1Easy-to-clean propertyLow shrinkageFireproof paintsImpression capsBrickSolvent

A coating solution comprising 0.1 to 35% by weight of an inorganic or organic polysilazane having repeating units represented by the general formula below and soluble in a solvent and 0.1 to 10% by weight of catalyst such as 4,4′-trimethylenebis(1-methylpiperidine) based on a pure polysilazane content. By applying the coating solution onto the surface of base materials such as metals, plastics, glass, ceramic, wood, cement, mortar, bricks, etc., a silica coating strongly adhered to the base materials can be formed excellent in corrosion resistance and anti-scratch properties and simultaneously excellent in characteristics such as abrasion resistant, long-lasting anti-fouling properties, wetting properties to water, sealing properties, chemical resistance, oxidation resistance, physical barrier effect, heat resistance, fire resistance and antistatic properties.

Owner:CLARIANT INT LTD

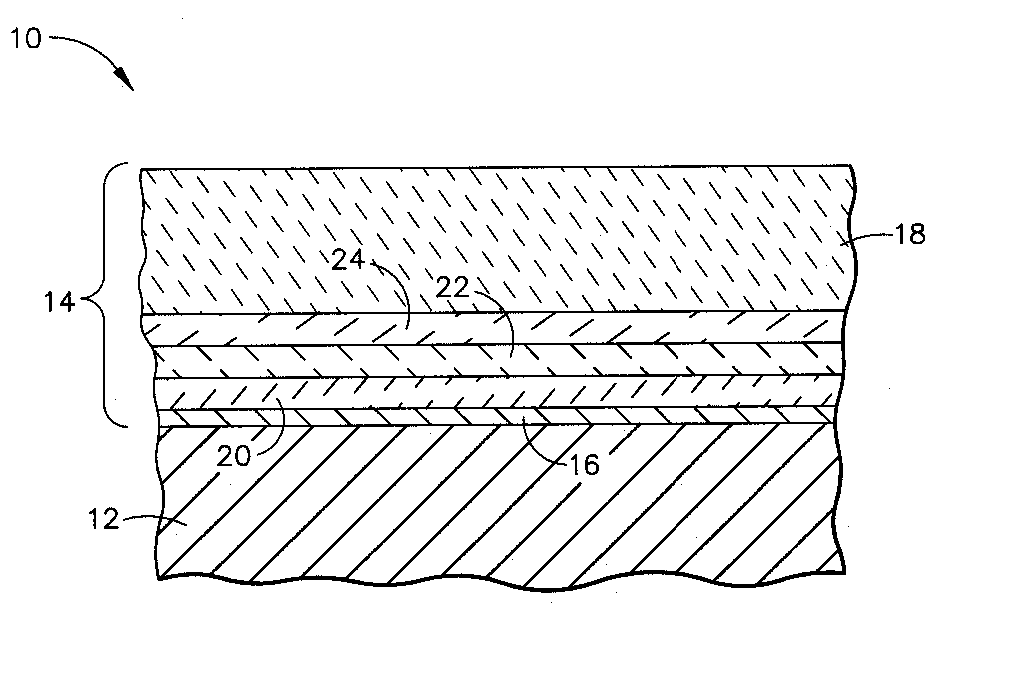

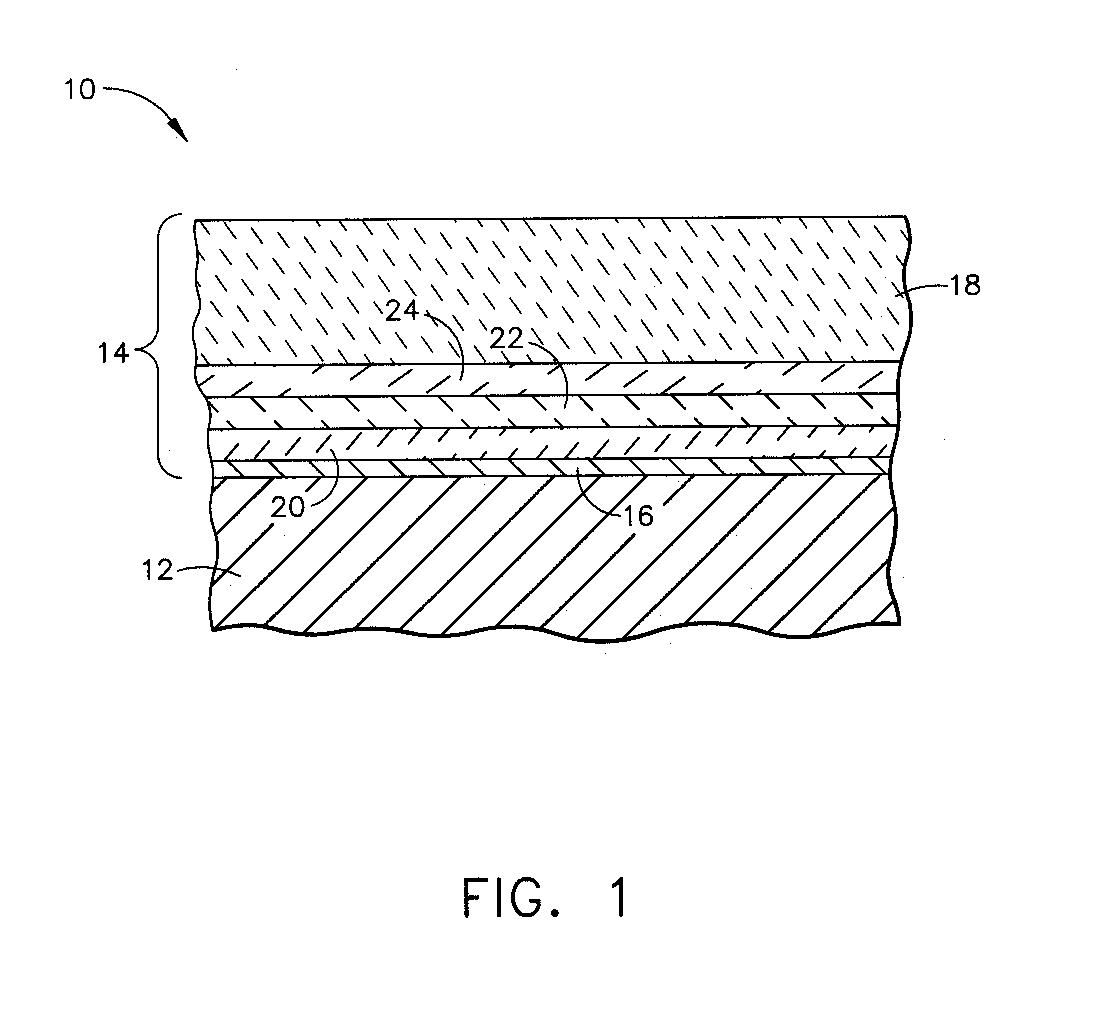

Thermal/environmental barrier coating system for silicon-containing materials

ActiveUS20060280963A1Prolong lifeImprove protectionFireproof paintsBlade accessoriesAluminateCoating system

A coating system for Si-containing materials, particularly those for articles exposed to high temperatures. The coating system exhibits improved resistance to corrosion from sea salt and CMAS as a result of using aluminate compounds to protect silicate-containing layers of the coating system. The coating system includes an environmental barrier coating, a thermal barrier coating overlying the environmental barrier coating and formed of a thermal-insulating material, and a transition layer between the environmental barrier coating and thermal barrier coating, wherein the transition layer contains at least one aluminate compound and / or alumina.

Owner:GENERAL ELECTRIC CO

Fire-retardant coating, method for producing fire-retardant building materials

InactiveUS20050229809A1Simple materialIncrease resistanceFireproof paintsAntifouling/underwater paintsCalcium silicateFire retardant

The present invention relates to a fire-resistant coating and method thereof, which confers enhanced flame and heat resistance to substrate such as building materials. The invented coating is especially applicable to cellulose-based building materials including but not limited to fiberboards, wallboards, roofing materials, particleboards, ceiling tiles, soundproofing boards and hardboards. This novel composition is also useful in providing a fire-resistant coating for concrete, metals, foamed polymeric materials, gypsum and other substrates. A preferred embodiment generally comprising: mono potassium phosphate, magnesium oxide, silica powder, calcium silicate, rice hull ash and water. A method for imparting fire-retardancy to substrates using the invented composition is also described

Owner:BONE SOLUTIONS INC

Thermal protective coating for ceramic surfaces

ActiveUS6921431B2Extended shelf lifeConvenience to workFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

Flame retardant preparation

The present invention relates to preparations composed of metal salts of organic phosphonic acids which feature high thermal stability, for use as flame retardants in engineering thermoplastics, and also to a process for preparation of these preparations.

Owner:LANXESS DEUTDCHLAND GMBH

Intumescent coating

InactiveUS20050139126A1Durable exterior protectionImprove fire resistanceFireproof paintsPigmenting treatmentSteep slopeSolid content

A coating composition useful for building materials products, especially roofing surfaces, is provided. The coating composition provides durable exterior protection to surfaces that it applied to, and it has intumescent and reflective properties. The coating composition includes a mixture of a polymeric binder, at least one intumescent agent, a polymeric carrier and a pigment. The pigment is present in the coating composition in amount that is capable of providing a coating that has an initial energy efficiency rating greater than or equal to 0.65 for a low-sloped roof, or an initial energy efficiency greater than or equal to 0.25 for a steep-sloped roof. The coating composition has a solids content from about 30-80% of which 0.5-35 wt. % is the intumescent agent.

Owner:BUILDING MATERIALS INVESTMENT

Water based hydrophobic self-cleaning coating compositions

InactiveUS20090064894A1Efficient use ofWater-repelling agents additionSemiconductor/solid-state device manufacturingWater basedHydrophobic silica

A coating composition comprising hydrophobic particles having an average size of between 7 nm and 4,000 nm and a wetting agent for promoting dispersion of the hydrophobic particles in water. The hydrophobic particles may be oxides, such as silica, titania, or zinc oxide. In one embodiment, the hydrophobic particles comprise fumed silica. The coating composition may be brushed, spin coated, or dipped onto a surface. In one embodiment, once the coating composition dries, the coating formed thereby is characterized by a contact angle formed with a water droplet in excess of 165 degrees. A method of making a coating composition comprising providing hydrophobic particles having an average size of between 7 nm and 4,000 nm, mixing a wetting agent with the hydrophobic particles to form a paste, and dispersing the paste in water by mixing to form a mixture.

Owner:VALVOLINE LICENSING & INTPROP LLC

Anti-fouling composition comprising an aerogel

InactiveUS20100269731A1High porosityIncrease surface areaFireproof paintsAntifouling/underwater paintsEnzymeChemistry

The present invention also relates to an anti-fouling composition comprising one or more aerogels. In one embodiment the aerogel encapsulate one or more bioactive agents. The one or more encapsulated bioactive agents can in one preferred embodiment be released from the aerogel over time. In one embodiment the encapsulated bioactive agents comprise one or more enzymes. In one preferred embodiment the anti-fouling composition comprising one or more aerogels is a coating composition.

Owner:ENPROS AS +2

Thermal ink jet ink composition

ActiveUS20090246377A1Shorten drying timeLong decap timeFireproof paintsNon-fibrous pulp additionOrganic solventPlasticizer

Disclosed are ink jet ink compositions suitable for use in thermal ink jet printers. The ink jet ink compositions contain one or more volatile organic solvents, one or more humectants, one or more binder resins, and one or more colorants. The ink jet ink compositions may also contain additives such as a plasticizer and / or a surfactant. Embodiments of the ink jet ink compositions have short dry times, good adhesion to a variety of substrates, and / or long decap times.

Owner:VIDEOJET TECH INC

Multifunctional high-efficiency thermal insulation insulating mold paint

The invention relates to a multifunctional high-efficiency heat-preservation heat-insulation coating material. The compositions in percentage by weight of the coating material are: 10 to 20 percent of water, 0.1 to 0.2 percent of multifunctional auxiliary agent, 0.1 to 0.2 percent of wetting agent, 0.5 to 0.8 percent of dispersing agent, 0.3 to 0.5 percent of antifoam agent, 1.5 to 3.0 percent of propylene glycol, 16 to 20 percent of rutile-type titanium pigment, 3 to 5 percent of mica powder, 6 to 8 percent of hollow glass microballoon, 3 to 5 percent of infrared powder, 3 to 4 percent of fire retardant, 35 to 40 percent of elastic acrylic acid emulsion, 3 to 5 percent of opaque polymer, 0.5 to 0.8 percent of film-forming auxiliary agent, 0.2 to 0.3 percent of bactericide and preservative and 0.3 to 0.6 percent of thickening agent. The multifunctional high-efficiency heat-preservation heat-insulation coating material is of aqueous monocomponent and does no harm to human body and the environment so as to be an environment-friendly product; meanwhile, the coating material also has excellent waterproof and fire-retardation functions, convenient and quick construction, excellent adhesion strength, outstanding crack resistance, infrequent pollution and service life as long as 15 years; moreover, during practical use, the coating material can effectively reduce solar heat accumulated in a house by approximately 8 to 15 DEG C, and can greatly reduce energy consumption.

Owner:董善刚

Method for preparing aminosilane coupling agent modifying ammonium polyphosphate

InactiveCN101235221AHigh flame retardant efficiencyReduce solubilityFireproof paintsFibre treatmentSolubilityPolyolefin

The invention discloses a preparation process of modifying ammonium polyphosphate with amino silane coupling agent, relating to the flame-retardant technology in chemical field. The invention provides a surface organic modified technology which can significantly reduce the water-solubility of ammonium polyphosphate, increases the compatibility of ammonium polyphosphate expansion flame-proof macromolecule material and the flame-proof efficiency, aiming to the problems existing the current ammonium polyphosphate flame-retardant that the current ammonium polyphosphate flame-retardant has higher dissolvability in water, and serious mechanical loss after applied on flame-proof plastic. The invention is conducted through two steps that firstly mixing amino silane coupling agent with deionized water according to weight ratio to hydrolyze, and secondly conducting surface organic modifying processing for ammonium polyphosphate (II type) with hydrolyzed amino silane coupling agent, which makes the dissolvability of II type ammonium polyphosphate in water be reduced to 0.43g / 100mL H2O from 1.101g / 100mL H2O, and respectively increases elongation at break and tension strength by 39.4% and 8.0% through applying modified ammonium polyphosphate on expansion flame-proof polypropylene. The modified ammonium polyphosphate can be extensively applied on the expansion flame-proof of polyolefins plastic, textile, lumber, paper and painting.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Heat-insulating energy-saving paint for vehicle and method for producing the same

InactiveCN101195725AIncrease reflectionInsulate heat radiationFireproof paintsPolyester coatingsRadiant heatAbsorption rate

The invention relates to heat insulating and energy saving coating used for the vehicle, and the preparation method thereof. The invention takes organic resin film forming material as the main material, the coating at least includes infrared reflection pigment, hollow ceramic micro-spheres and silicon dioxide aerogel, an organic resin film having low sunlight absorption rate is formed in the coating through the organic resin film forming material with high transparency, the visible light and the near infrared ray in the sunlight are reflected through the infrared reflection pigment, the rutile type titanium dioxide and the hollow ceramic micro-spheres, and simultaneously a compact vacuum layer and an inert gas layer are formed on the surface of a coated object through the hollow ceramic micro-spheres and the silicon dioxide aerogel, so as to effectively isolate the radiant heat of the sun, and to reduce the heat conduction of air, and finally the heat insulating and energy saving coating used for the vehicle is formed, which not only can effectively reflect the energy in the sunlight, but also can effectively isolate the radiant heat of the sun and reduce the heat conduction of air, and simultaneously has good weather resistant performance, chemicals resistant performance, mechanical property and decorative property.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

Intumescent fire retardant composition and method of manufacture thereof

InactiveUS6706793B2Improve flame retardant performanceHigh impact strengthFireproof paintsSpecial tyresGraphiteFire retardant

Owner:APTIV TECH LTD

Fire protection coating composition

InactiveUS20040110870A1Reduce surface burning characteristicProtect the surfaceFireproof paintsPretreated surfacesEngineeringFire protection

The present invention relates to a fire protection coating composition and method of using same on substrate materials for which some degree of fire protection from intense heating and fire is necessary or desirable. The fire protection coating composition will expand upon being exposed to fire or intense heating to provide a protective layer for the substrate material for which protection is required.

Owner:LIU MATTHEW T

Composition and process for coloring and preserving wood

InactiveUS20060147632A1Preserving it from biological degradationGood outdoor weather resistanceFireproof paintsAntifouling/underwater paintsPolymer sciencePolymer chemistry

Provided is a composition which can color and preserve wood. The composition comprises both micronized pigments and inorganic and / or organic biocides, which may be present as a dispersion, emulsion or in solution also provided is a one step method for the coloring and preservation of wood.

Owner:OSMOSE

Organic polysilazane/inorganic nano-material super-hydrophobic coating and preparation method thereof

ActiveCN106189832AHigh hardnessImprove scratch resistanceFireproof paintsLiquid surface applicatorsMetallic materialsChemical stability

The invention discloses an organic polysilazane / inorganic nano-material super-hydrophobic coating and a preparation method thereof. According to the preparation method, firstly, an organic polysilazane solution is prepared, a silane coupling agent containing hydrophobic units is used for carrying out hydrophobization on an inorganic nano-material, and dispersion liquid of the hydrophobic inorganic nano-material is prepared; then, an organic material or an inorganic material or a metal material serves as a base material, and an organic polysilazane and the hydrophobic inorganic nano-material alternatively deposit on the surface of the base material in sequence through a deposition method; finally, appropriate heat treatment is carried out on the surface which is subjected to multiple times of alternative deposition. The obtained coating shows good super-hydrophobic performance, the contact angles of water drops on the surface of the coating are larger than 150 degrees, the rolling angles are smaller than 10 degrees, and the coating has good mechanical and chemical stability and has wide application prospect in the field of waterproof clothes, exterior wall coating, oil-water separation, biomedicine and the like. According to the method, the preparation process is simple, and large hydrophobic coatings can be established on various base material surfaces.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com