Patents

Literature

2425 results about "Adhesion strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The strength of adhesion depends on many factors, including the means by which it occurs. Methods of adhesion include: Chemical bond may occur between the adhesive and substrate. Electrostatic forces, as in static electricity, hold the substances together. Van der Waals forces may develop between molecules.

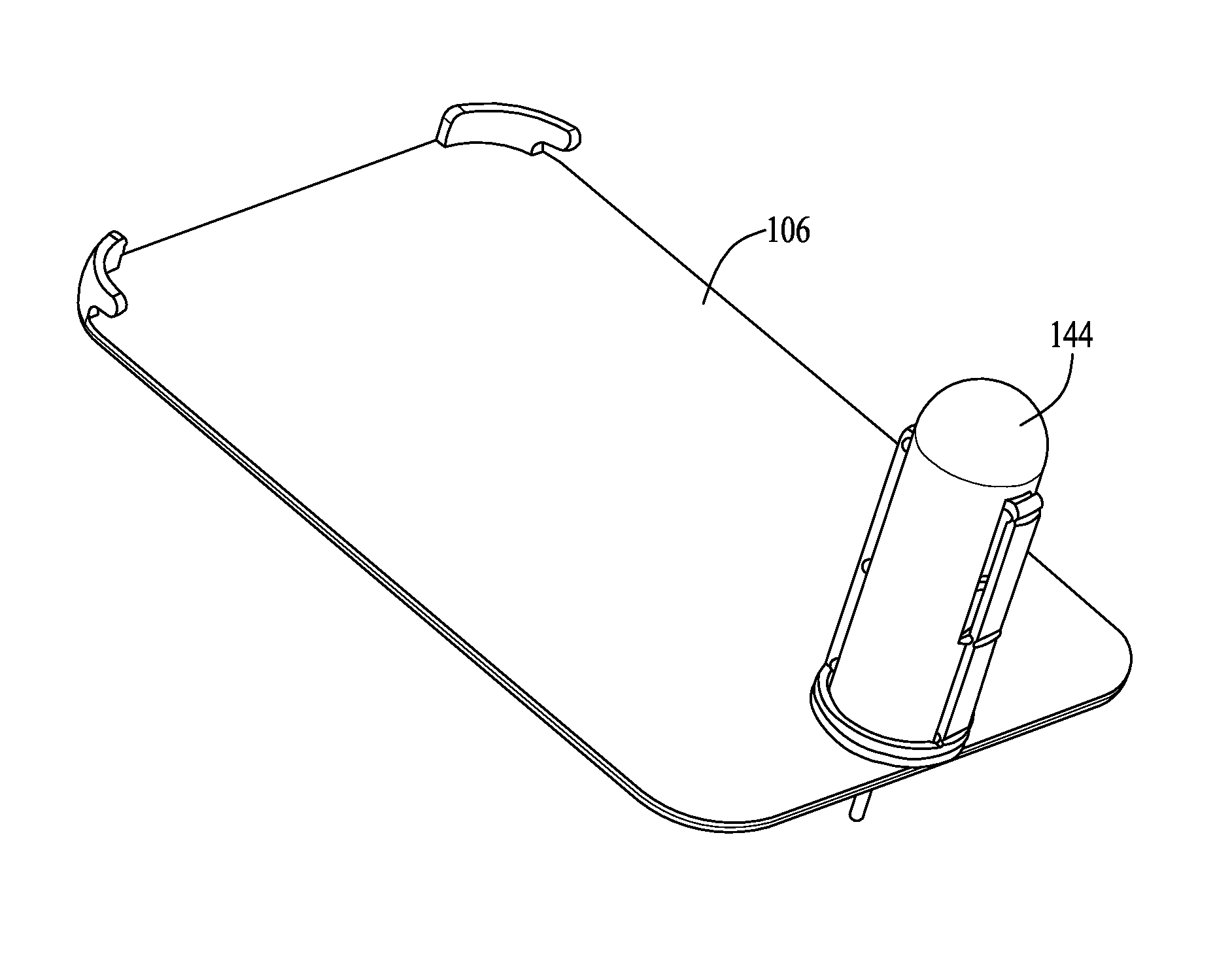

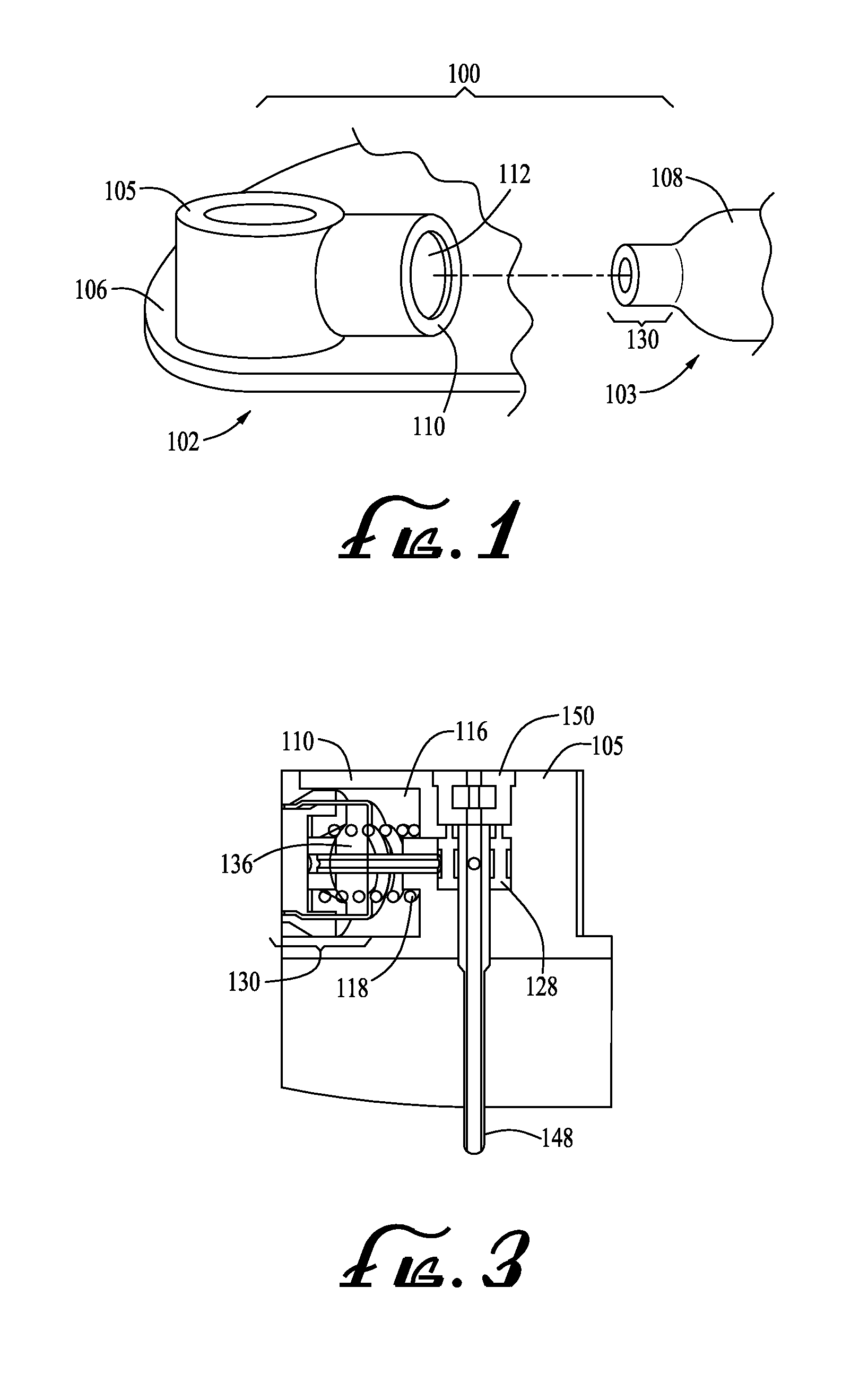

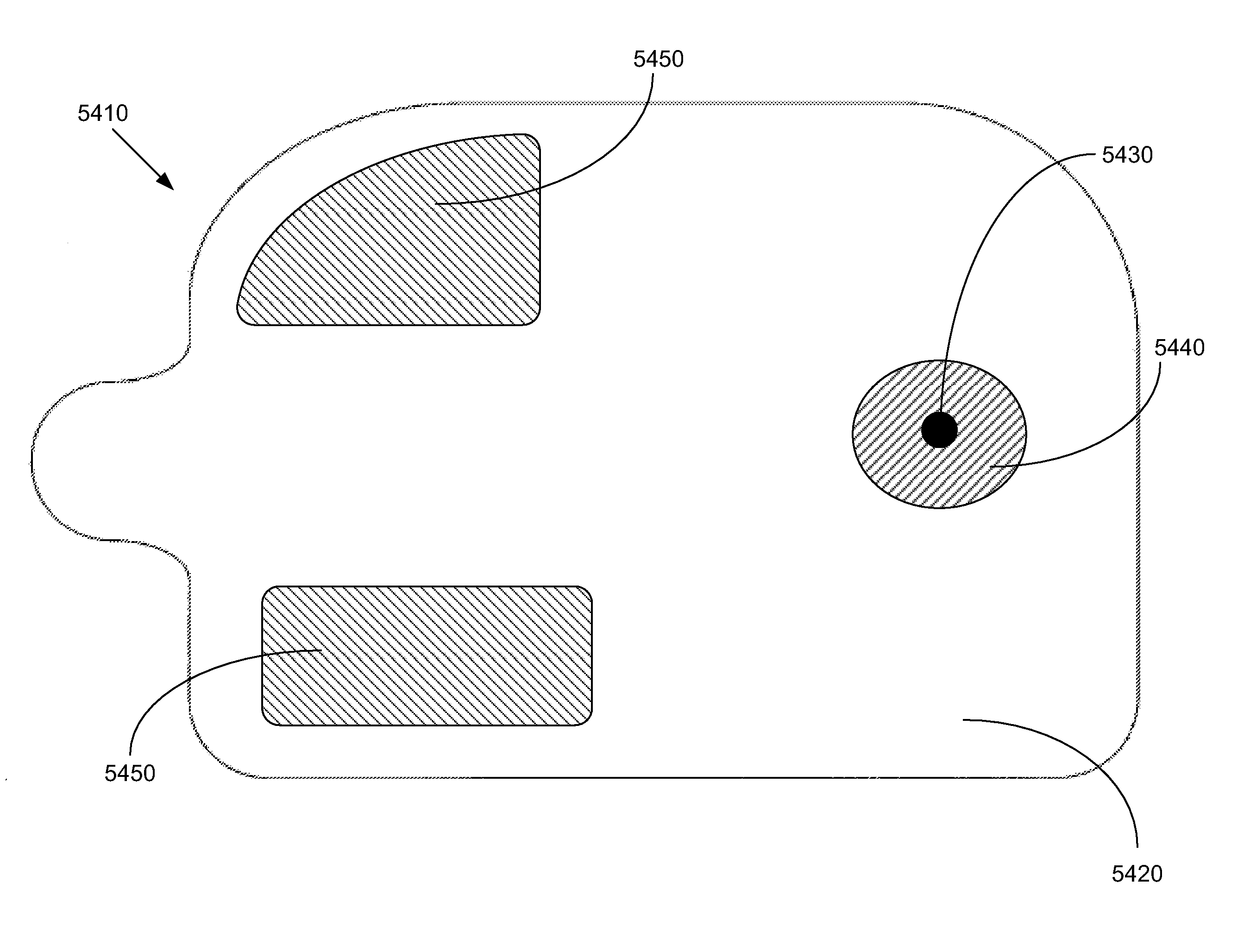

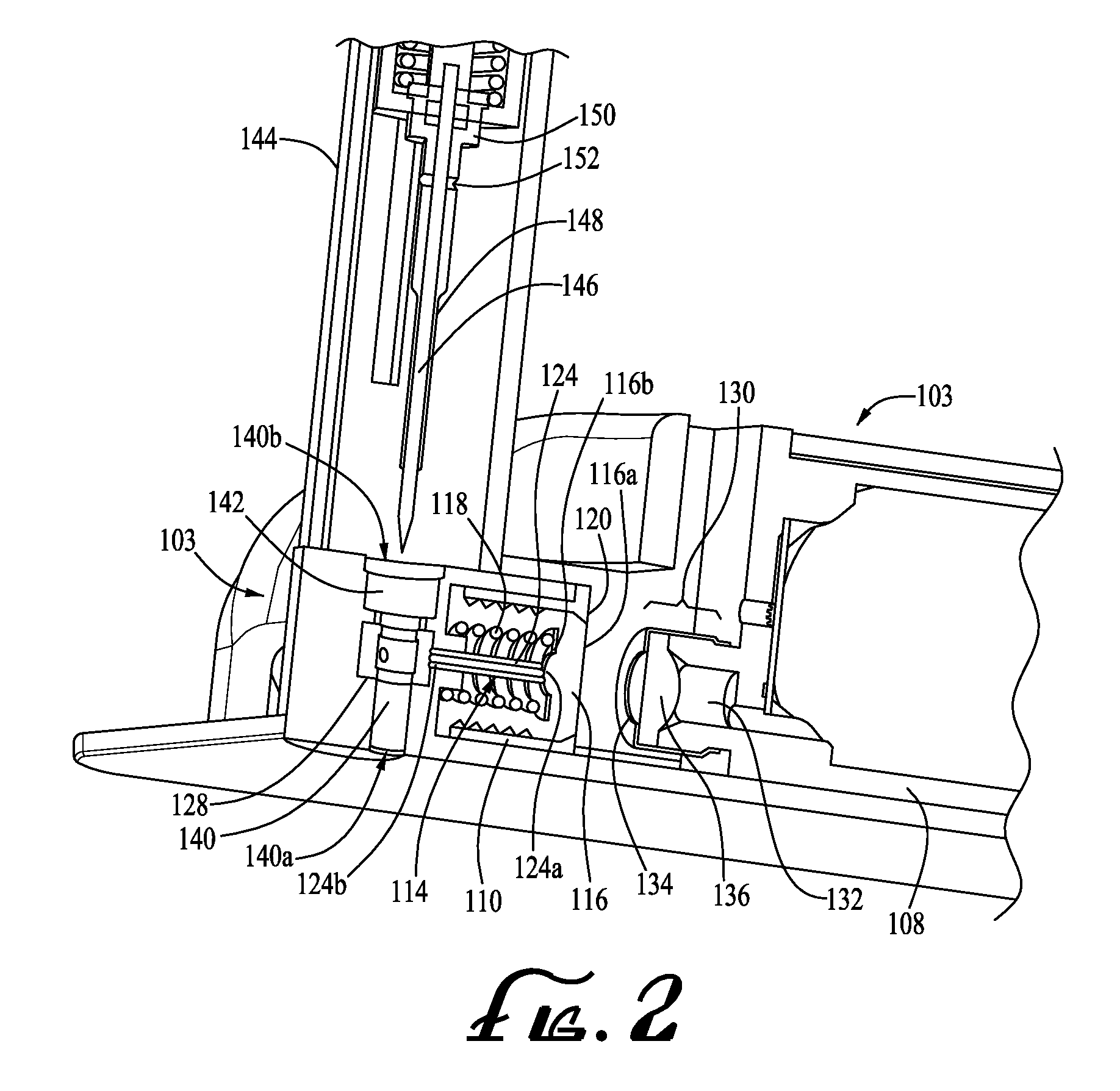

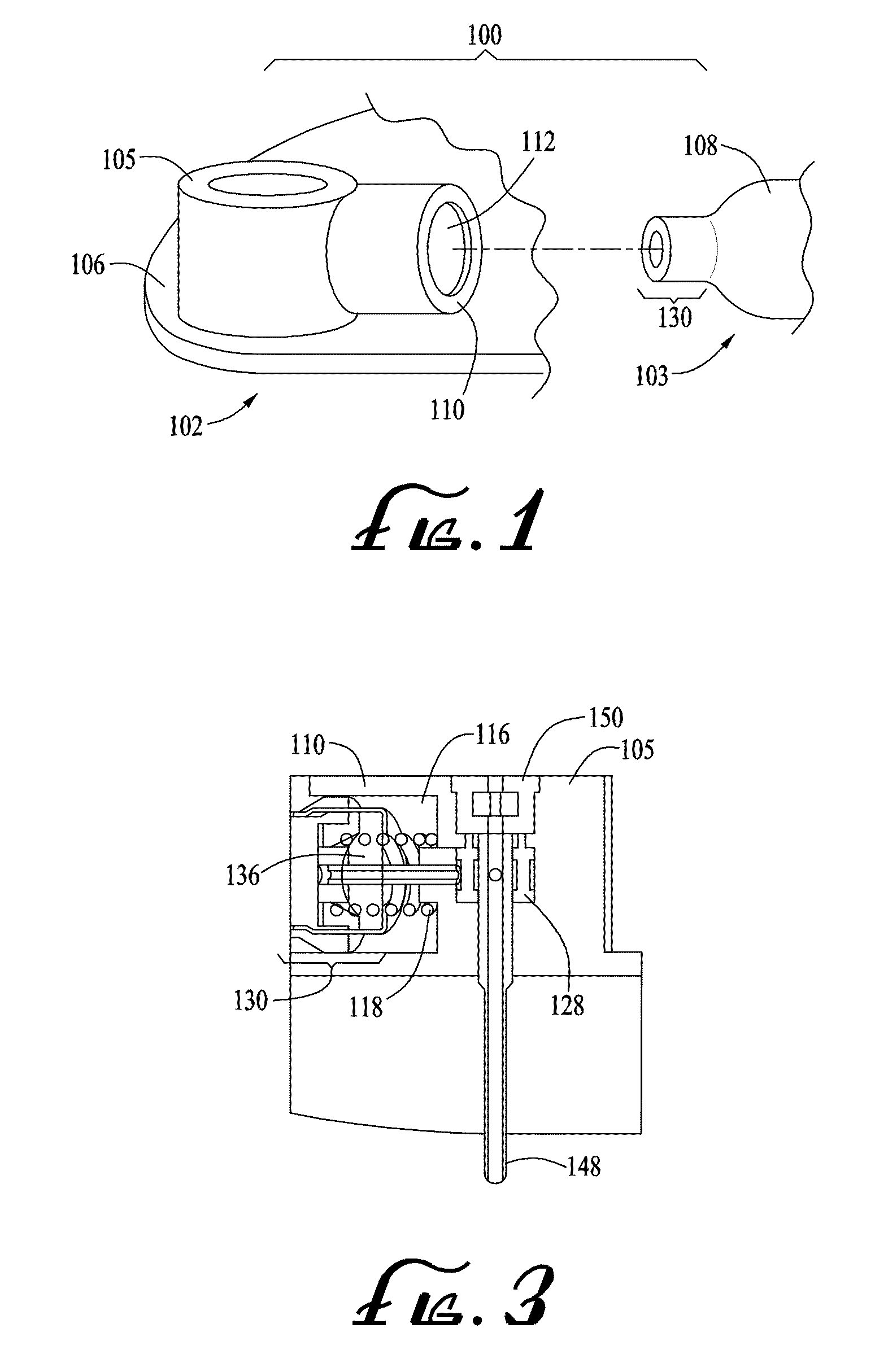

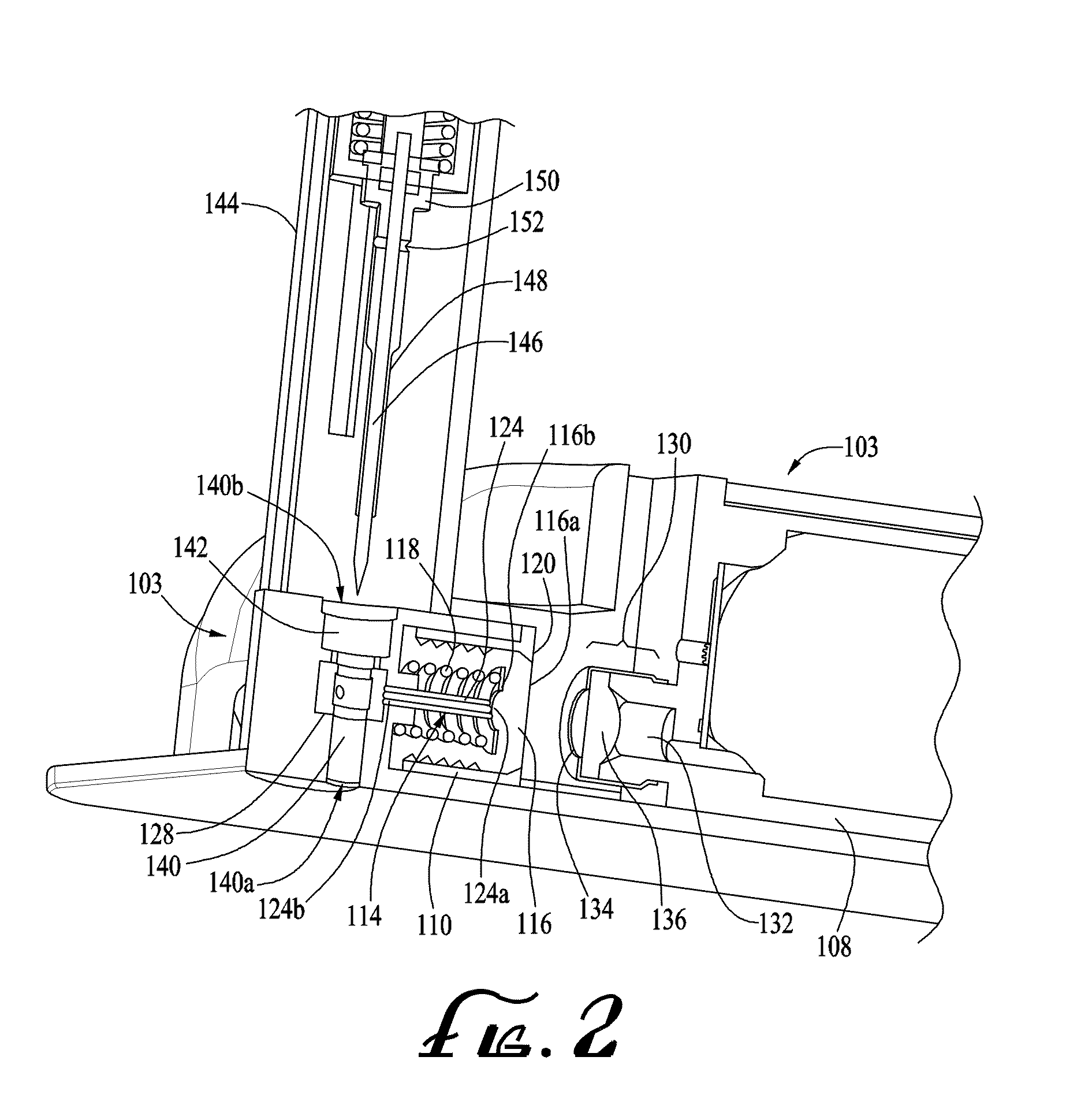

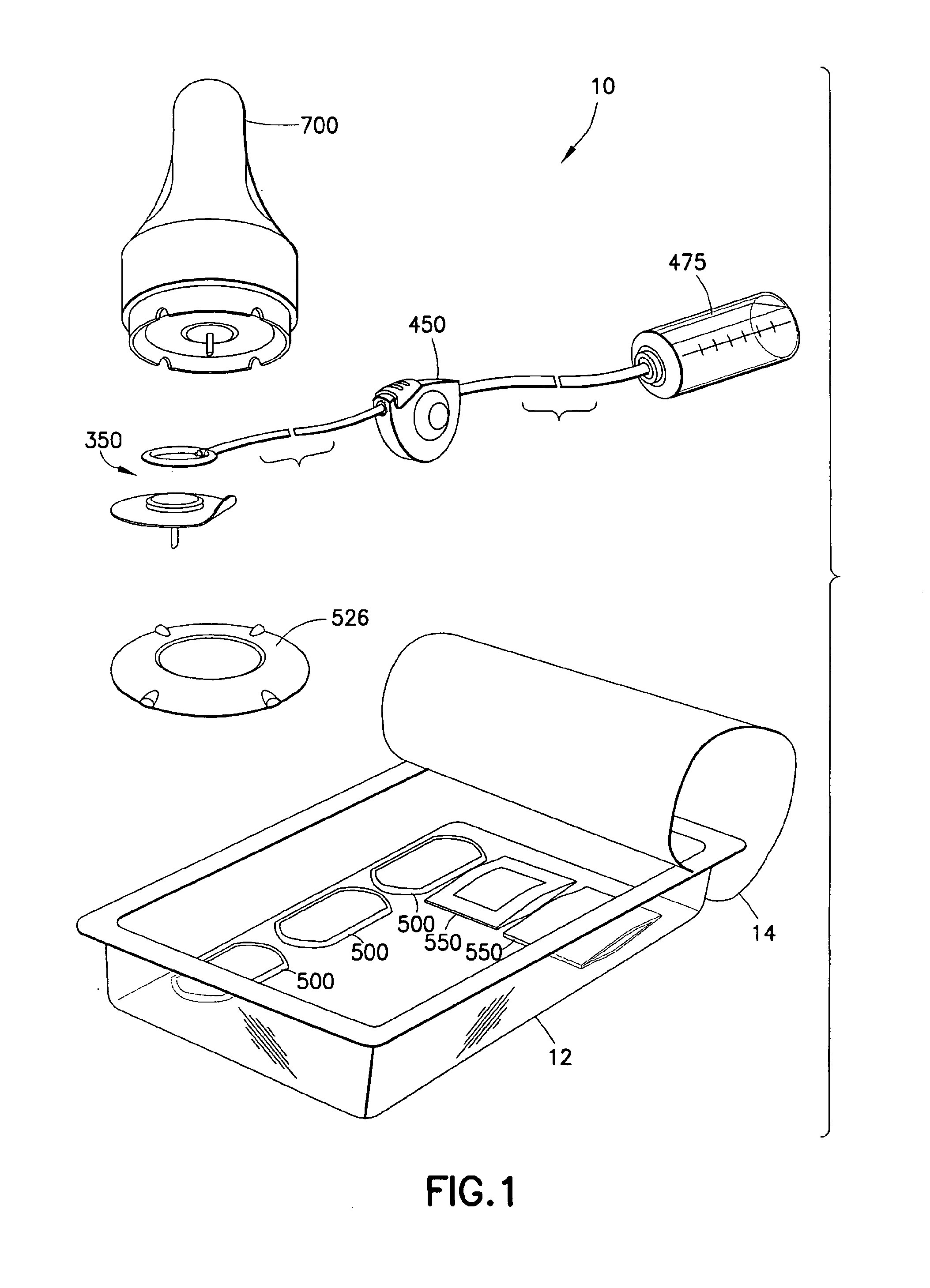

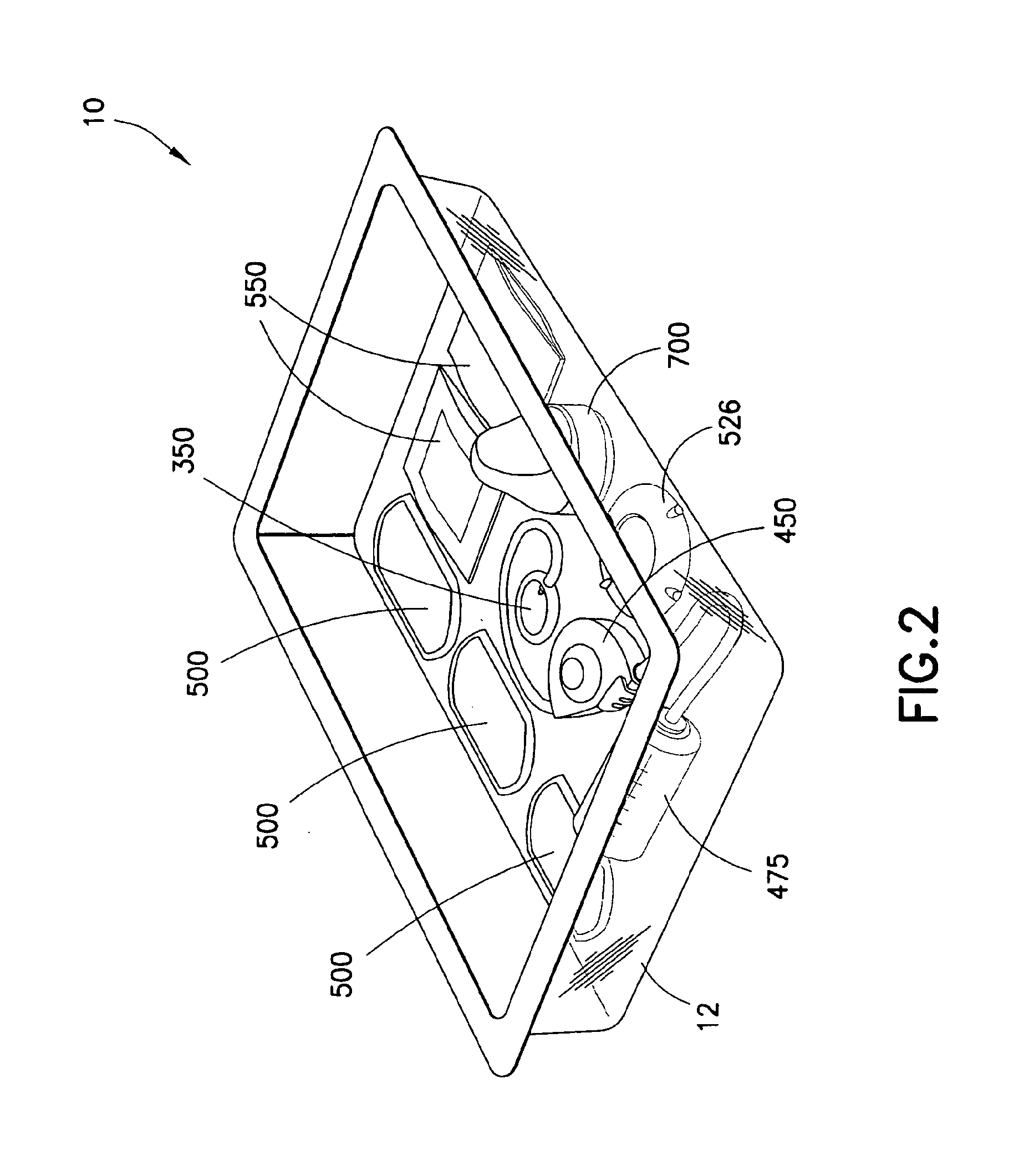

Adhesive Patch Systems and Methods

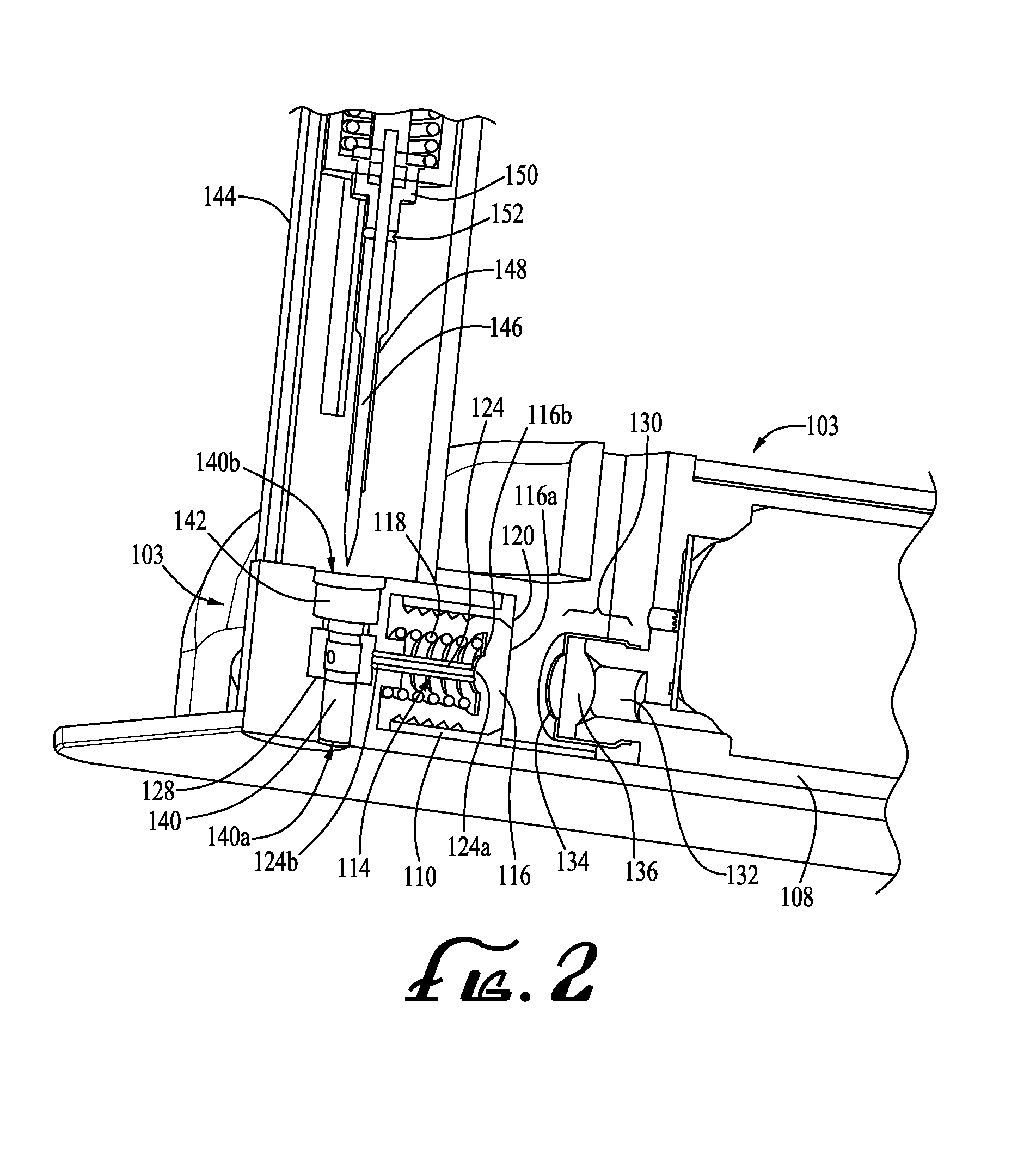

ActiveUS20080269687A1High bonding strengthReduced adhesion strengthInfusion syringesFiltering accessoriesAdhesion strengthUltimate tensile strength

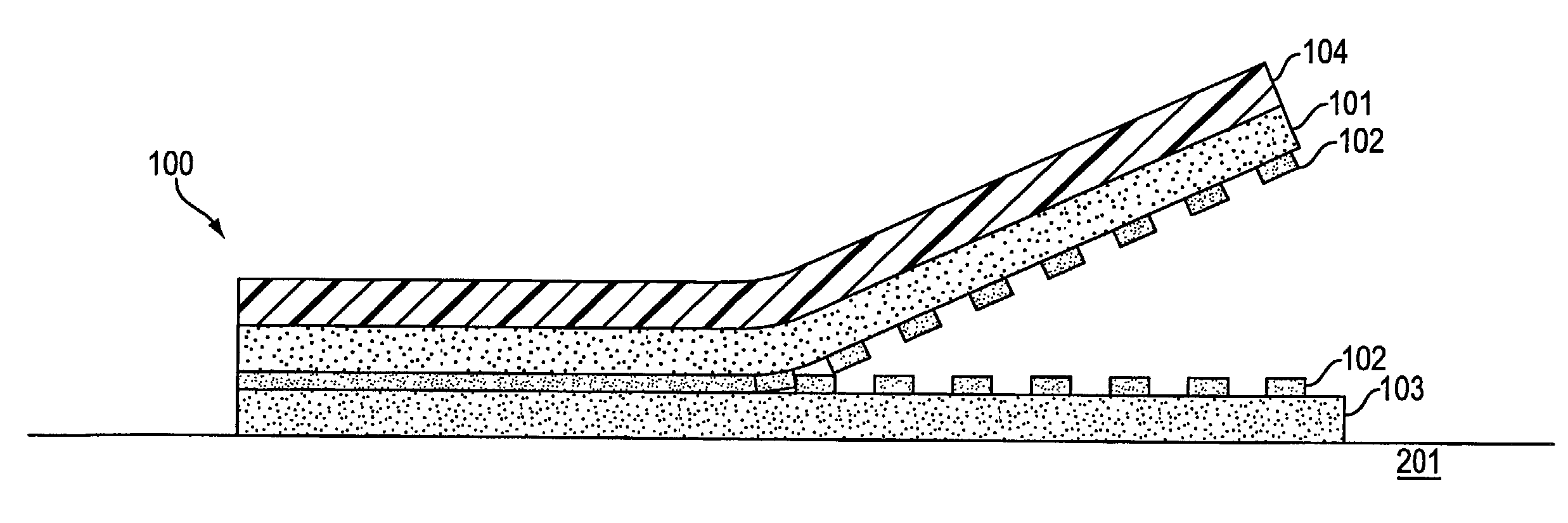

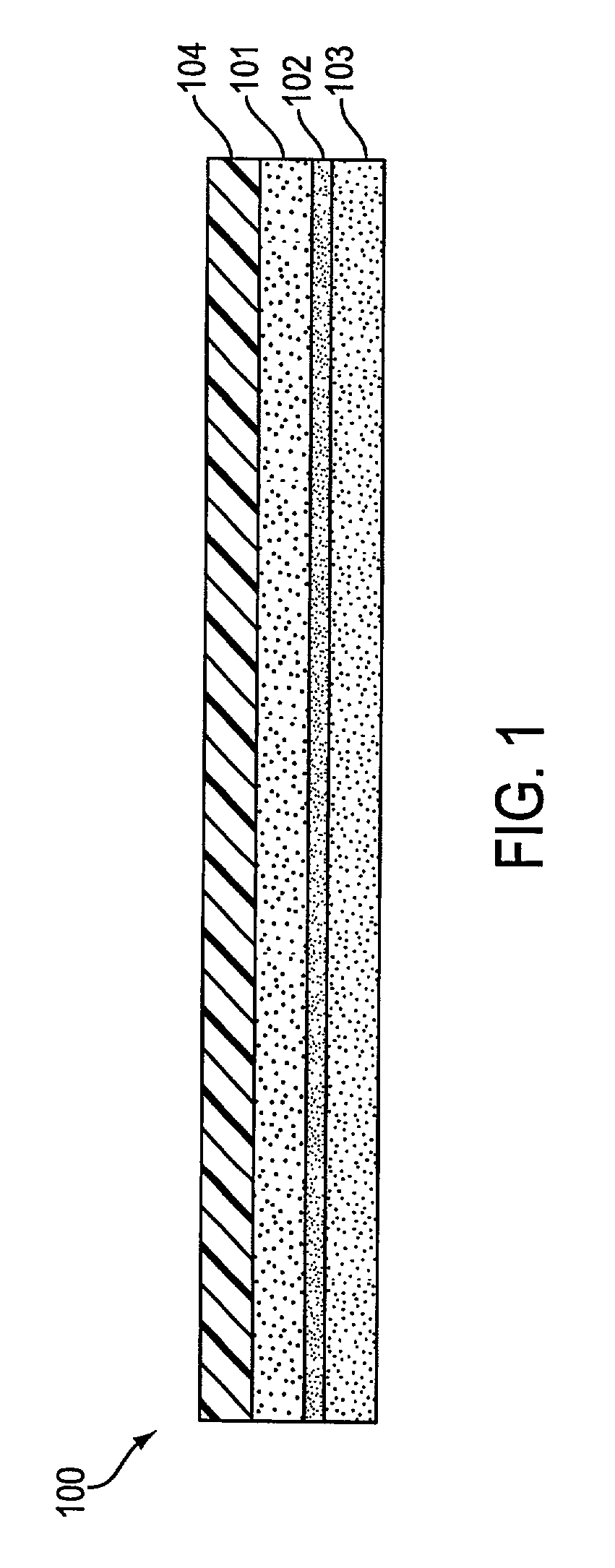

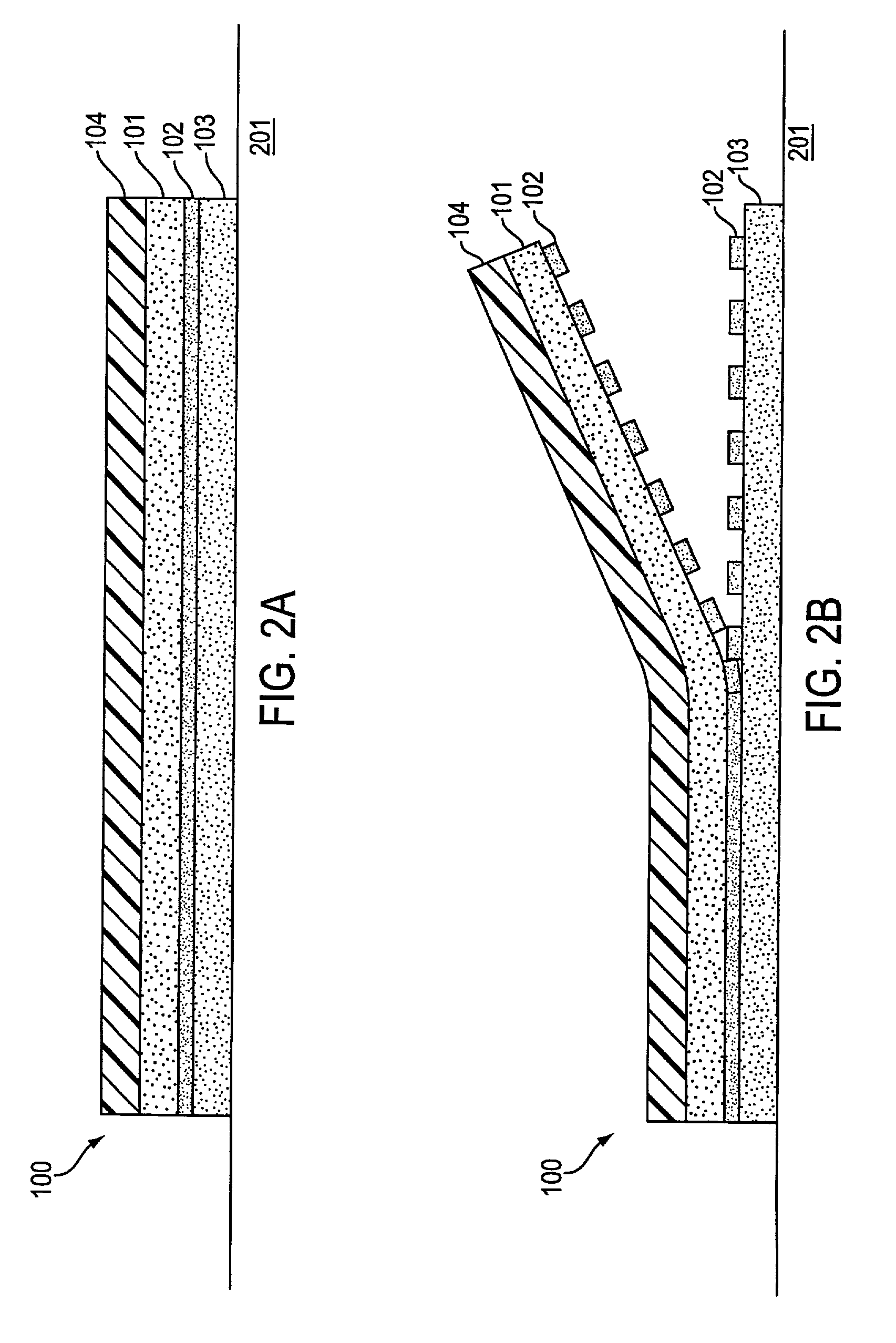

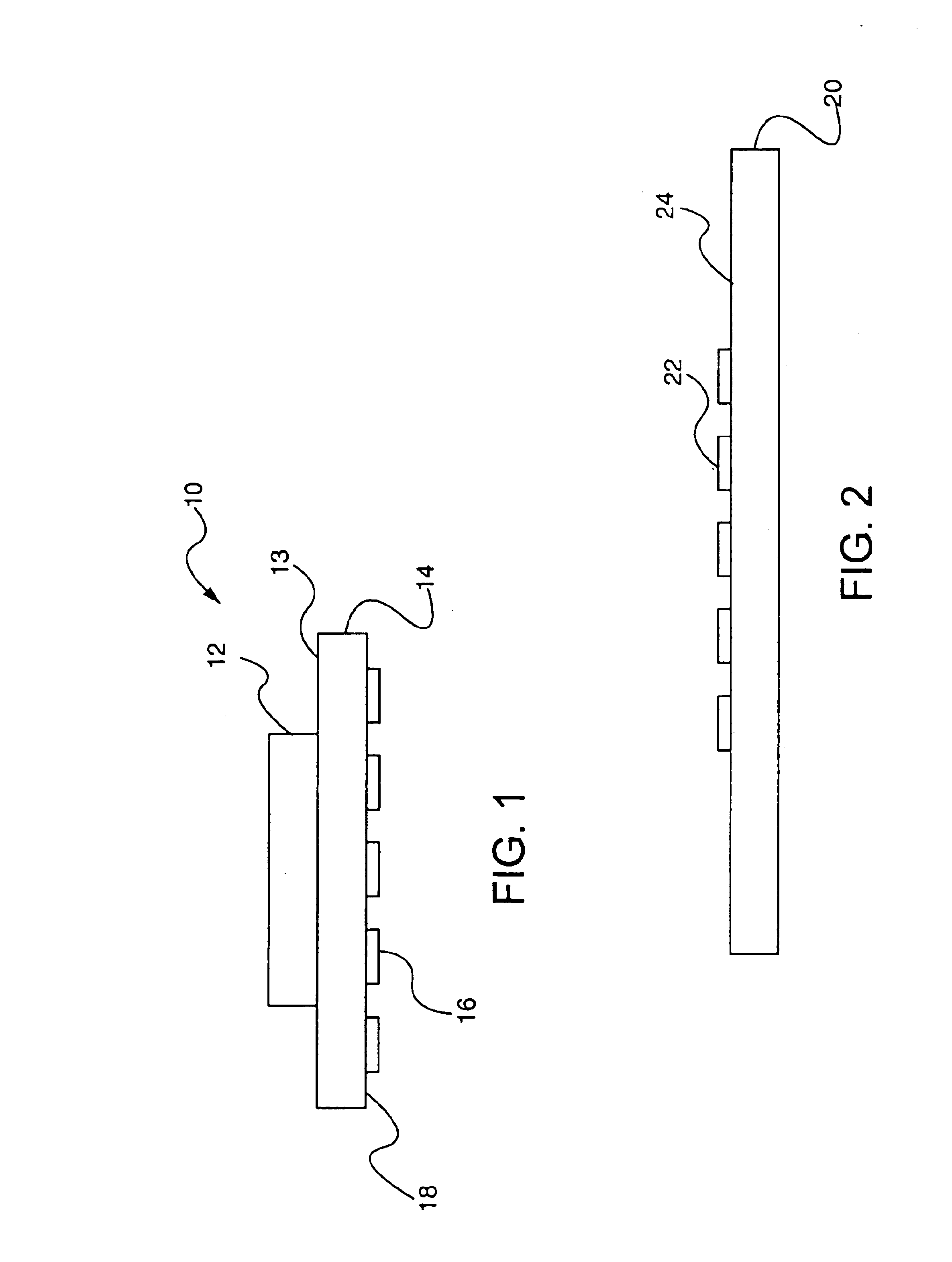

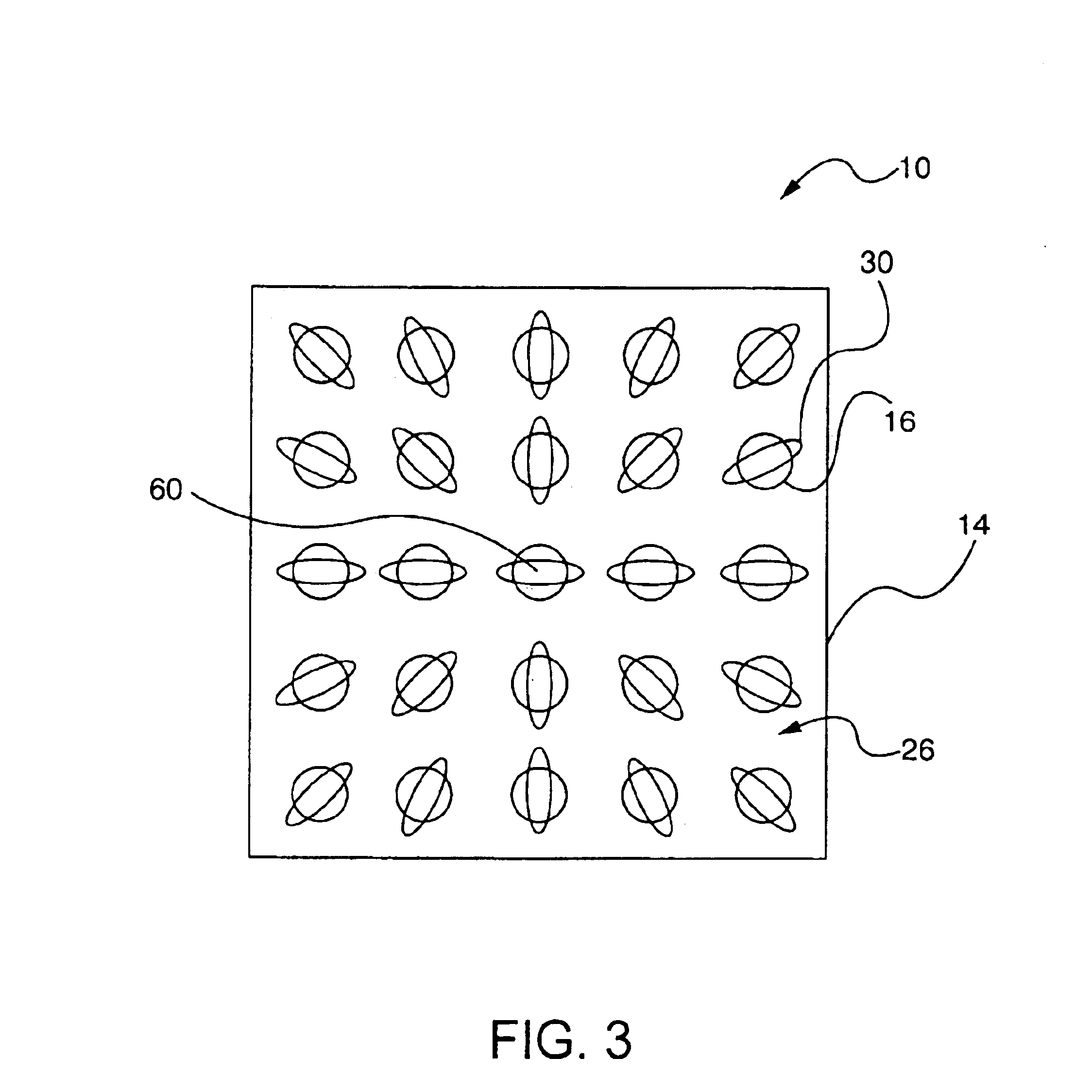

Various embodiments of the present invention are directed to patches for medical devices. In various embodiments, an adhesive patch of a medical device may have selective areas with adhesive material of varying adhesion strengths. In other embodiments, an adhesive patch of a medical device may include adhesive material that may be activated by a catalyst to increase or decrease the adhesion strength of the adhesive material. In further embodiments, a medical device may include a pierceable membrane containing an agent, the pierceable membrane positioned to be pierced by a needle and to cause some of the agent to be carried to the user-patient.

Owner:MEDTRONIC MIMIMED INC

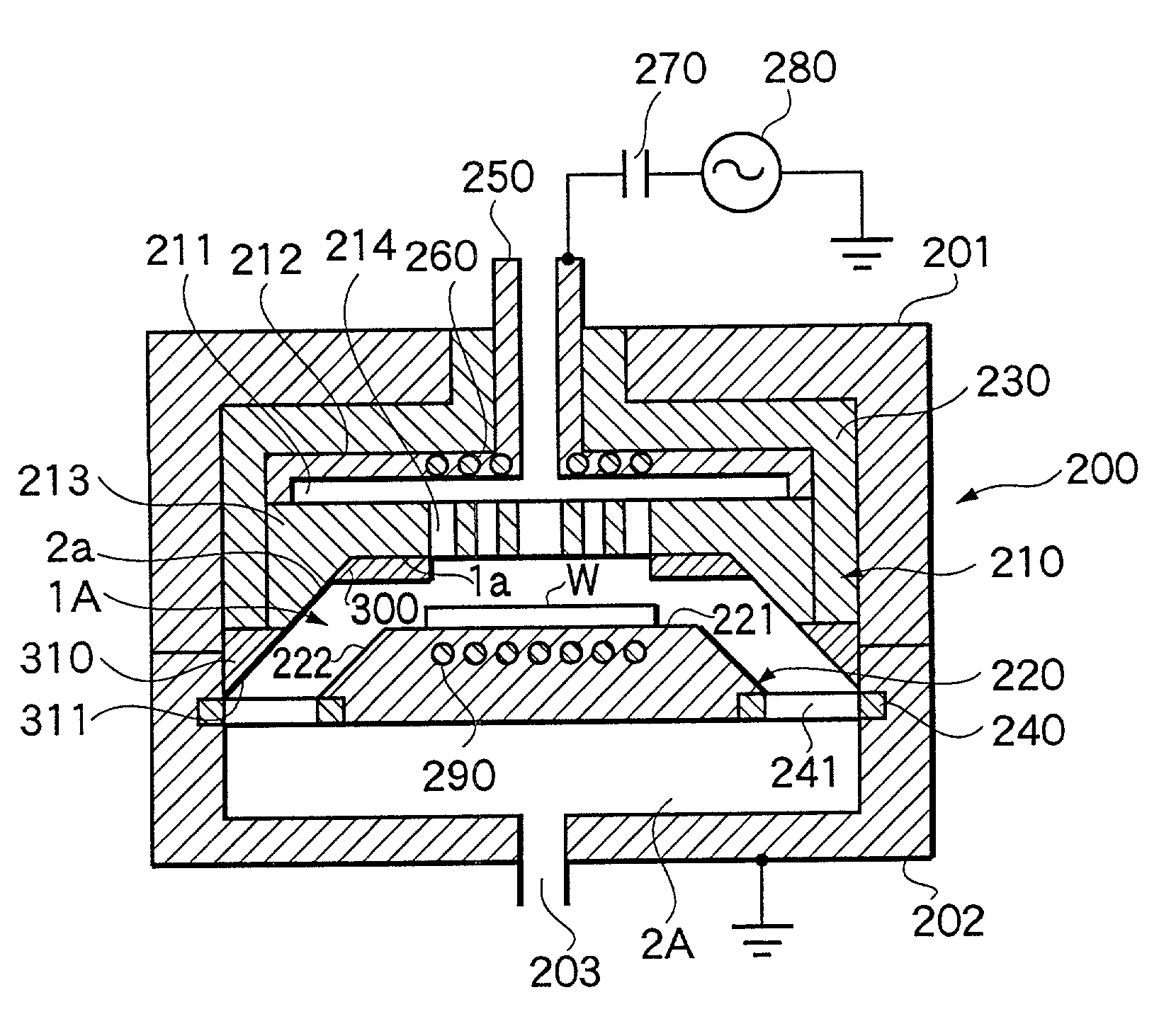

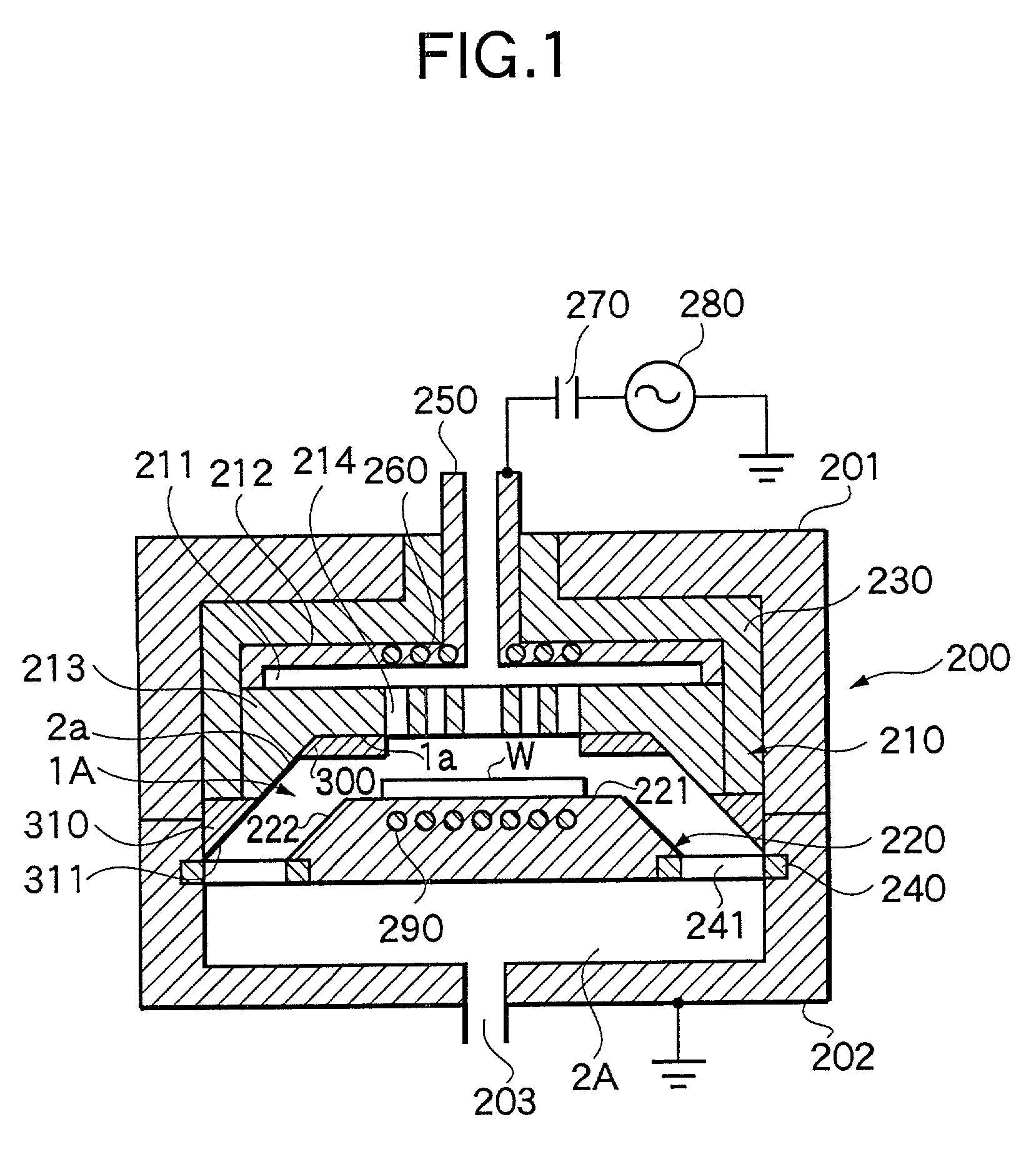

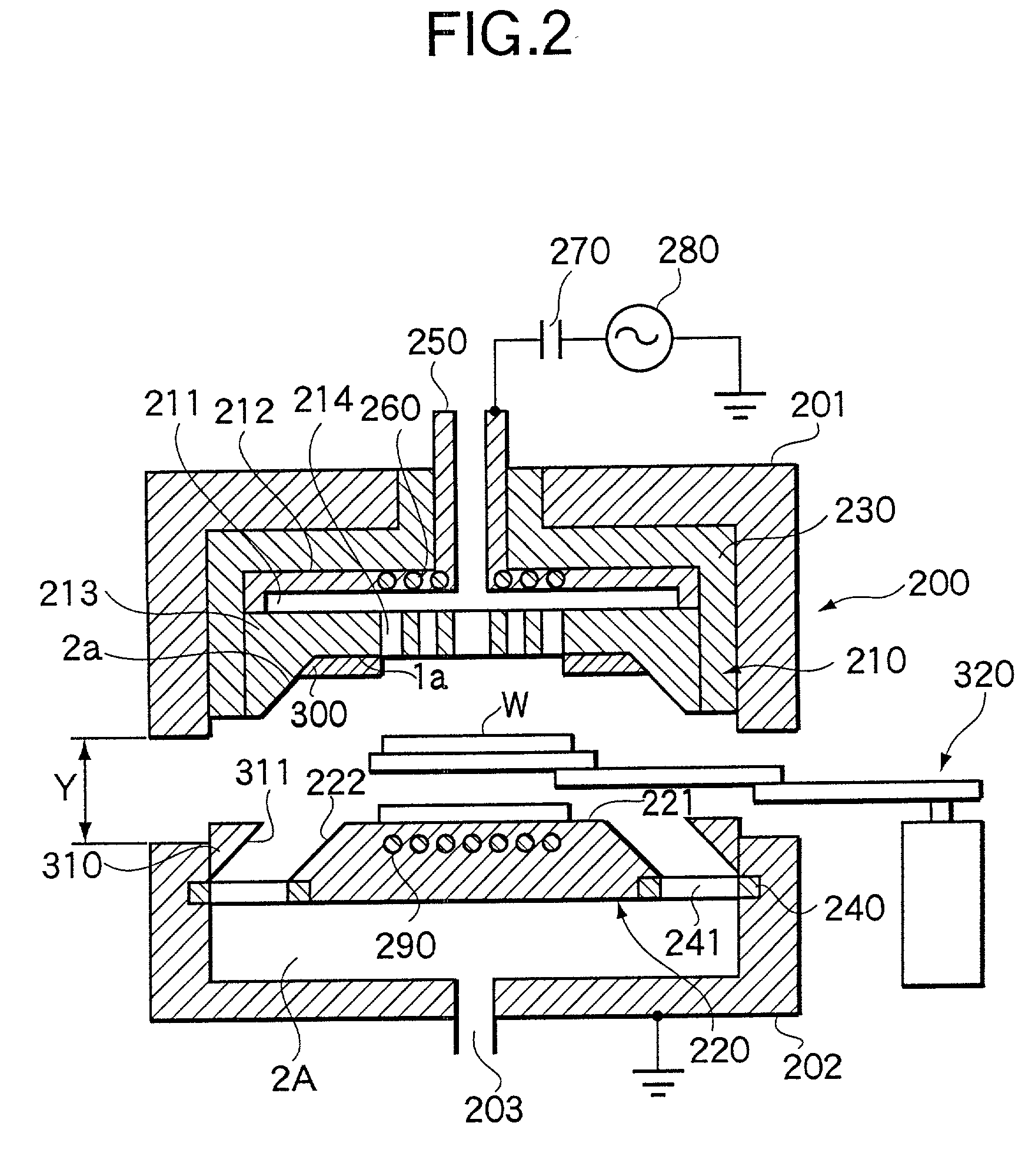

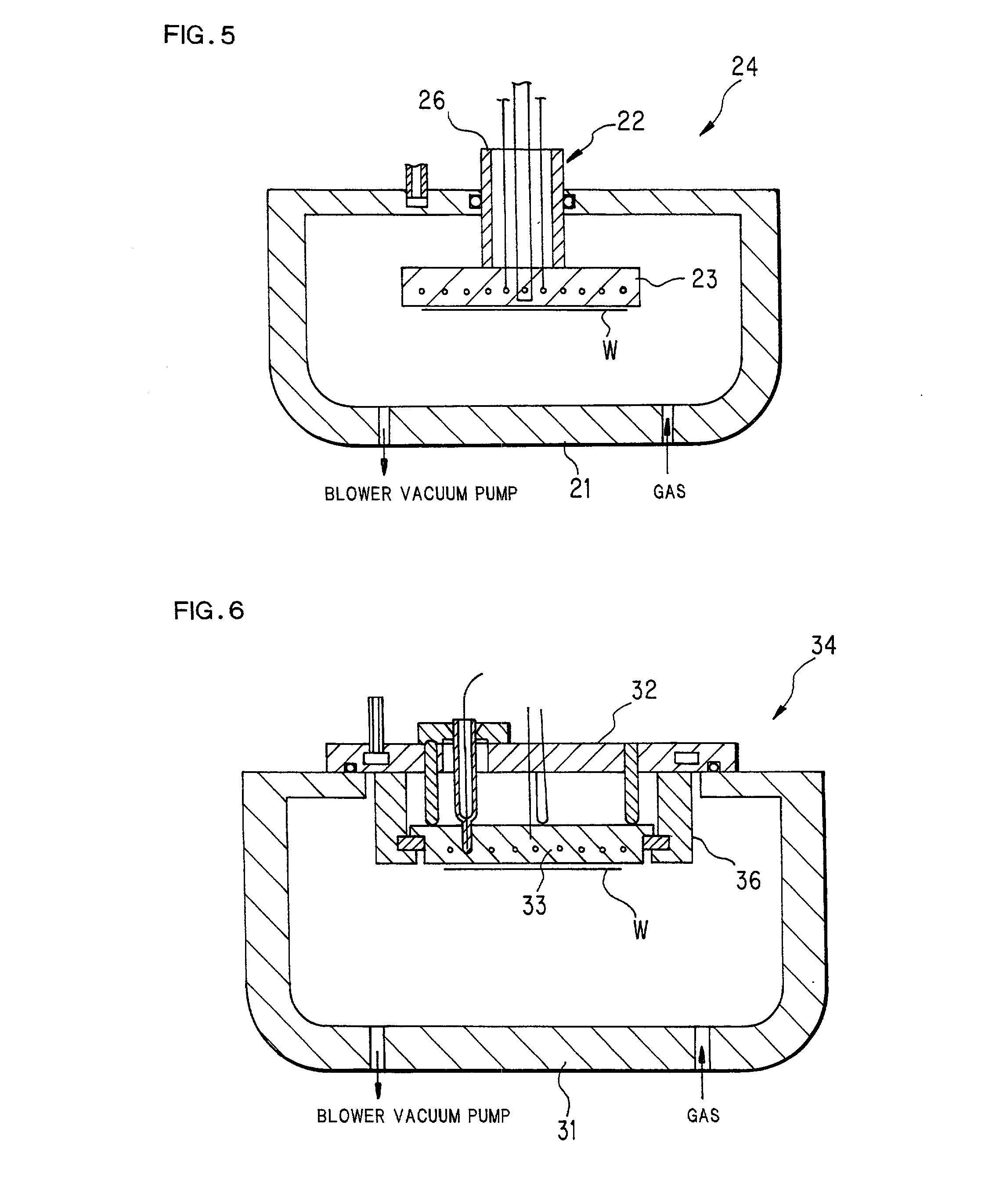

Plasma CVD device

InactiveUS20030205202A1Reduce the amount requiredIncrease productionElectric discharge tubesSemiconductor/solid-state device manufacturingSurface mountingEngineering

It is an object of the present invention to provide a plasma CVD device in which it is possible to inhibit the formation of particles resulting from the adhesion of reaction by-products of poor adhesive strength around the upper electrode. The plasma CVD device has a vacuum container 200, an upper electrode 210 and a lower electrode 220. The edge of the gas dispersion plate 213 of the upper electrode 210 is formed in the shape of an upturned bowl, the edge of which extends below the upper surface of the treatment substrate W mounted on the substrate-mounting surface 221 of the lower electrode 220.

Owner:KOKUSA ELECTRIC CO LTD

Adhesive patch systems and methods

Owner:MEDTRONIC MIMIMED INC

Adhesive patch systems and methods

ActiveUS20090198215A1High bonding strengthReduced adhesion strengthInfusion syringesFiltering accessoriesUltimate tensile strengthAdhesion strength

Various embodiments of the present invention are directed to patches for medical devices. In various embodiments, an adhesive patch of a medical device may have selective areas with adhesive material of varying adhesion strengths. In other embodiments, an adhesive patch of a medical device may include adhesive material that may be activated by a catalyst to increase or decrease the adhesion strength of the adhesive material. In further embodiments, a medical device may include a pierceable membrane containing an agent, the pierceable membrane positioned to be pierced by a needle and to cause some of the agent to be carried to the user-patient.

Owner:MEDTRONIC MIMIMED INC

Materials and construction for a tamper indicating radio frequency identification label

InactiveUS7049962B2Maintain abilityRecord carriers used with machinesBurglar alarm by hand-portable articles removalEngineeringAdhesion strength

Materials and construction for a tamper indicating radio frequency identification (RFID) label are provided to permit the destruction of the label or its properties in the event of attempts to remove the label from a surface to which it has been applied. An adhesion modifying coating is applied to a label surface or portions thereof to affect the relative adhesion strengths between different layers or areas of the label. The adhesion modifying coating can be applied in selected patterns to achieve differential adhesion strengths and resulting differential separation of the label from a surface on which it has been applied.

Owner:MAJKOKH CORP +1

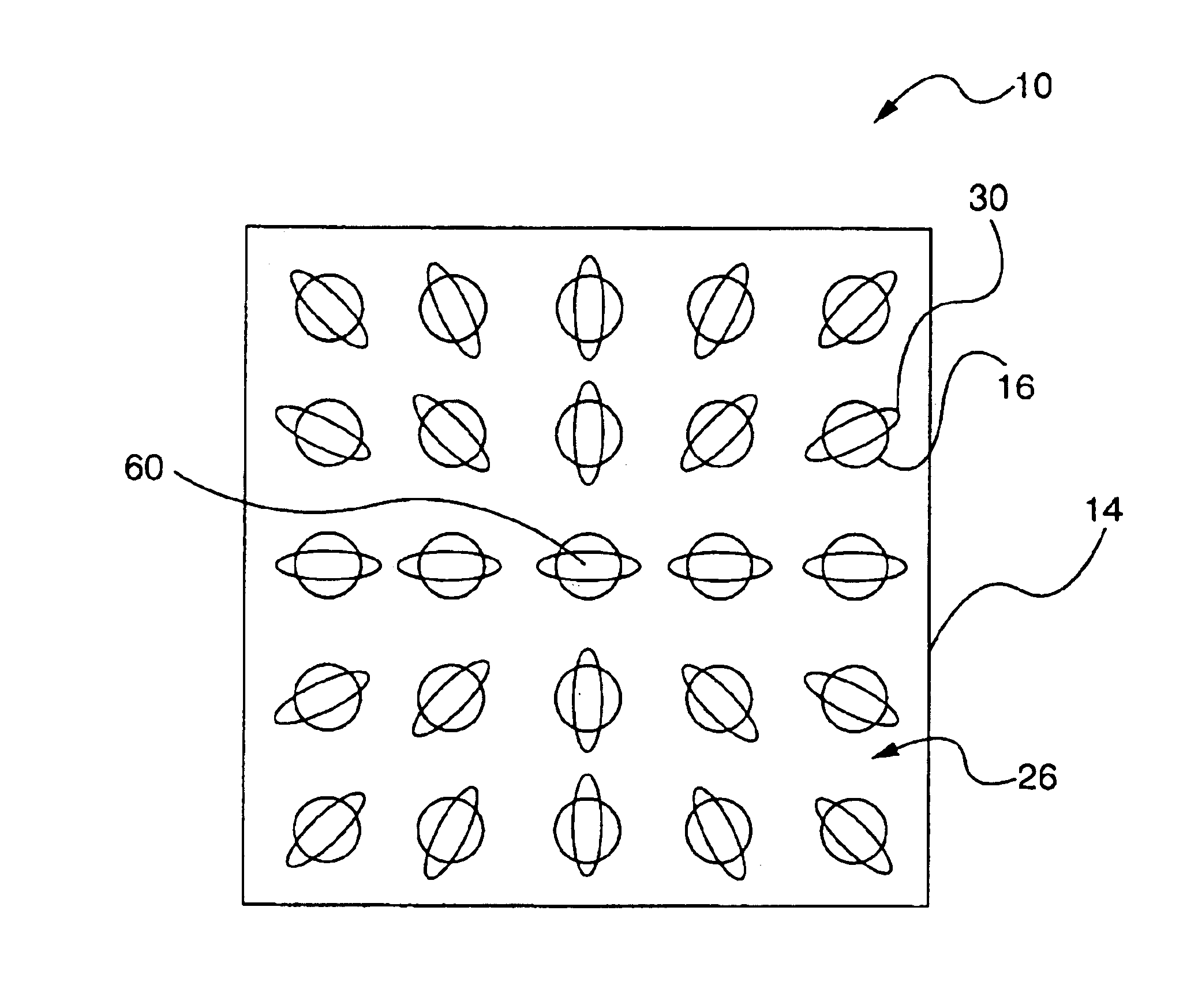

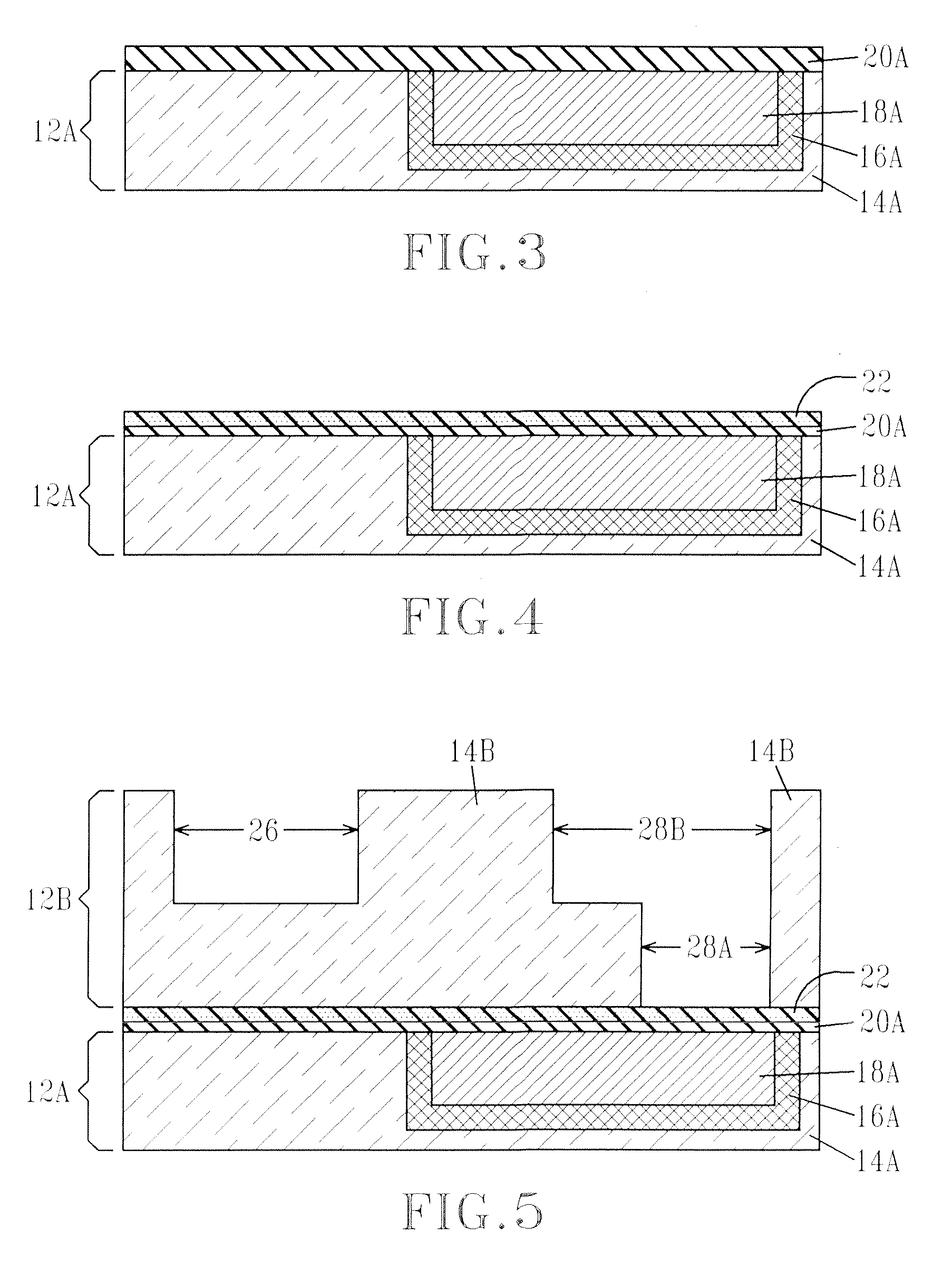

Partially captured oriented interconnections for BGA packages and a method of forming the interconnections

InactiveUS6913948B2Improve fatigue lifeEnhanced pad adhesionPrinted circuit assemblingSemiconductor/solid-state device detailsIncreased fatigueEngineering

A Ball Grid Array package having an increased fatigue life and improved conductive pad adhesion strength, as well as providing sufficient wiring space within the package, is disclosed. In particular, solder joints having a combination of mask-defined and pad-defined solder joint profiles are formed using a mask having non-circular elongated openings. The non-circular elongated openings of the mask have a major axis and a minor axis, such that the dimension of the openings along the major axis is greater than the diameter of the conductive pads, and the dimension of the openings along the minor axis is less than the diameter of the conductive pads. In addition, the major axis of the openings within the mask are selectively oriented in the direction of highest stress for each solder joint within the package, while providing ample wiring space therein.

Owner:IBM CORP

Adhesive patch systems and methods

Various embodiments of the present invention are directed to patches for medical devices. In various embodiments, an adhesive patch of a medical device may have selective areas with adhesive material of varying adhesion strengths. In other embodiments, an adhesive patch of a medical device may include adhesive material that may be activated by a catalyst to increase or decrease the adhesion strength of the adhesive material. In further embodiments, a medical device may include a pierceable membrane containing an agent, the pierceable membrane positioned to be pierced by a needle and to cause some of the agent to be carried to the user-patient.

Owner:MEDTRONIC MIMIMED INC

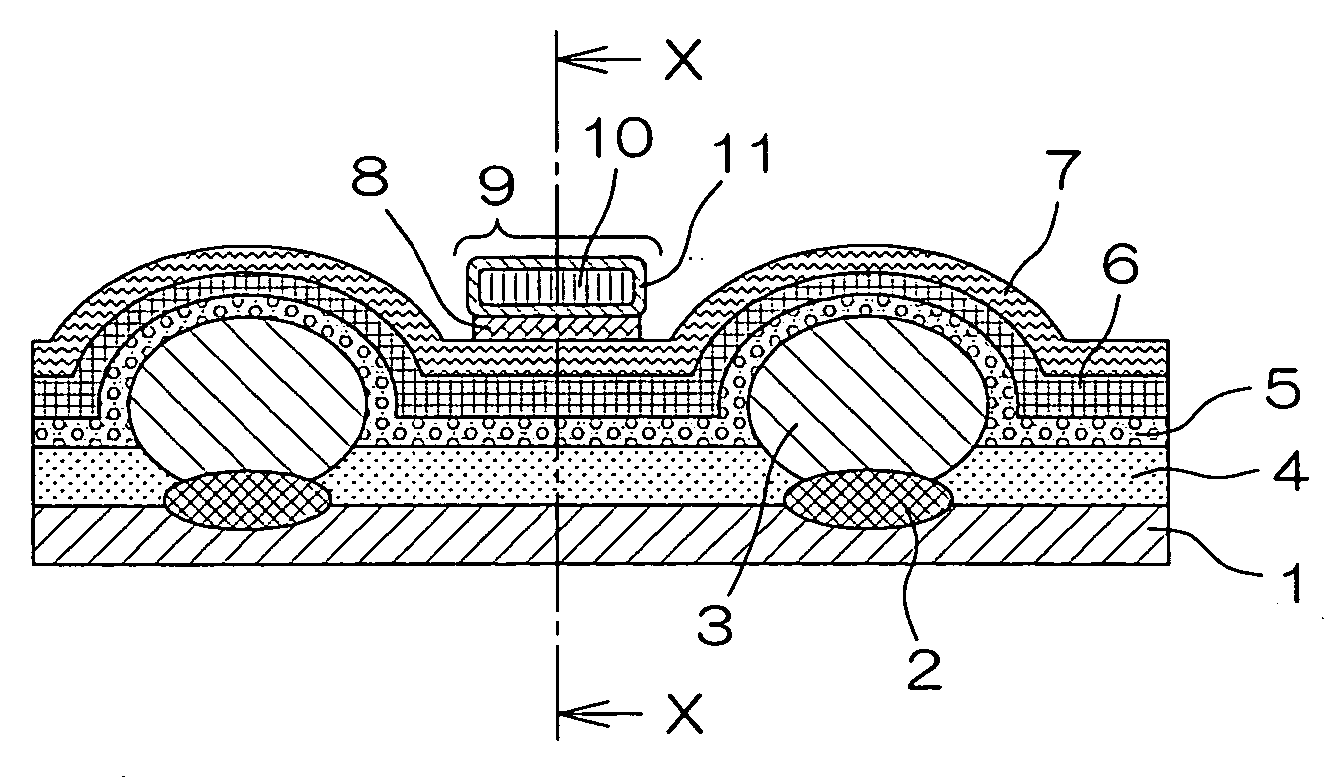

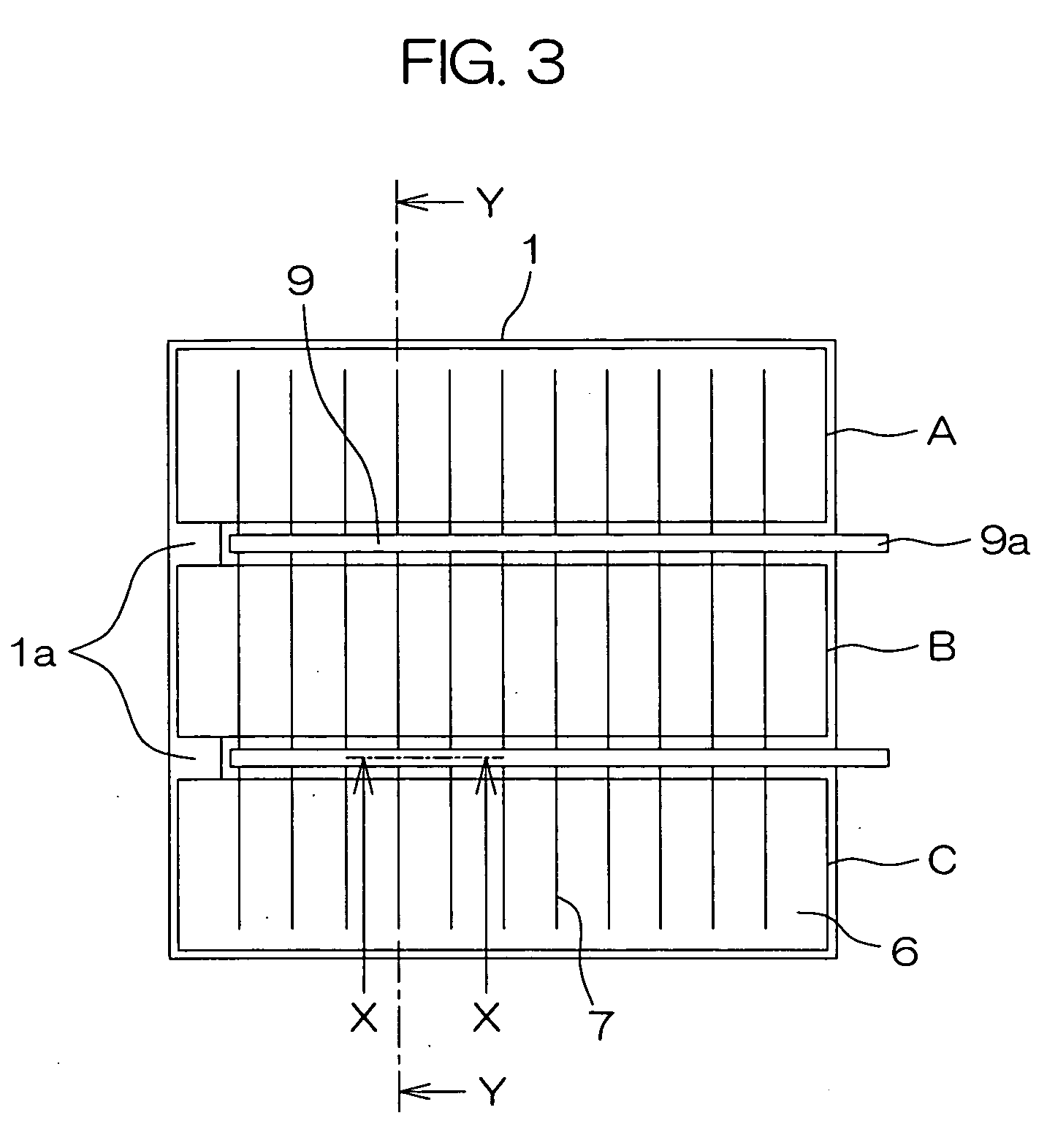

Photo-electric conversion cell and array, and photo-electric generation system

InactiveUS20050115602A1Practical to useHigh economic valuePV power plantsPhotovoltaic energy generationElectricityElectrical conductor

A photo-electric conversion array is formed by connecting photo-electric conversion cells in series. Each photo-electric conversion cell includes: a substrate, at least one main surface of which is made of a conductor layer; plural crystalline semiconductor particles provided on the conductor surface of the substrate; an insulation layer filled in clearances among the crystalline semiconductor particles; a transparent electric conducting layer provided above the plural crystalline semiconductor particles; a collector electrode, formed on the transparent electric conducting layer, to collect electricity from the transparent electric conducting layer. The substrate is provided with a substrate electrode portion at one end portion, through which the conductor surface of the substrate is exposed, and a connection electrode is formed by extending the collector electrode, so that the connection electrode in a given photo-electric conversion cell is connected to the substrate electrode portion in another photo-electric conversion cell. It is thus possible to provide a photo-electric conversion array capable of maintaining the reliability as to the adhesion strength, with a good outward appearance as well as excellent reliability and power generation efficiency.

Owner:KYOCERA CORP

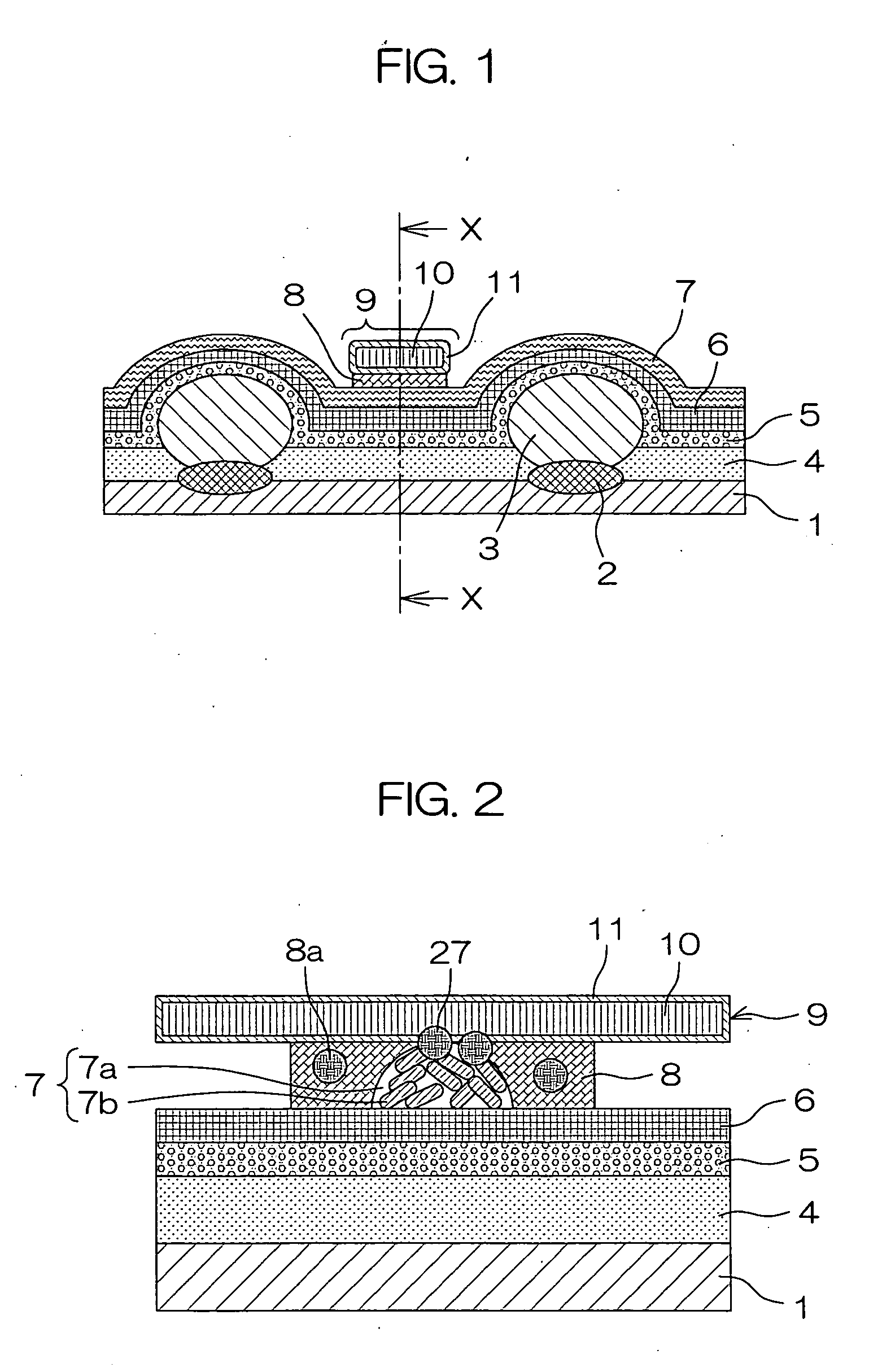

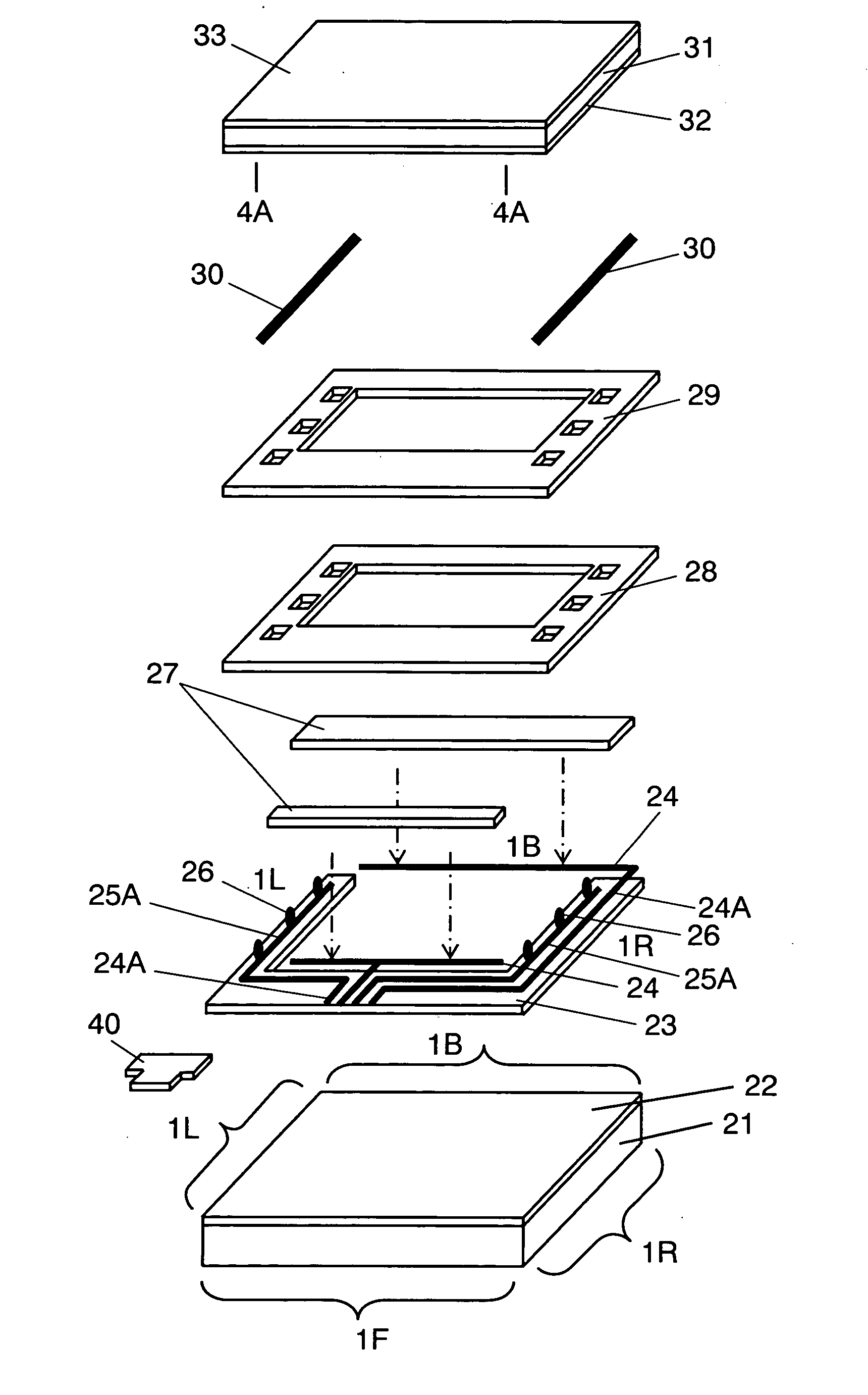

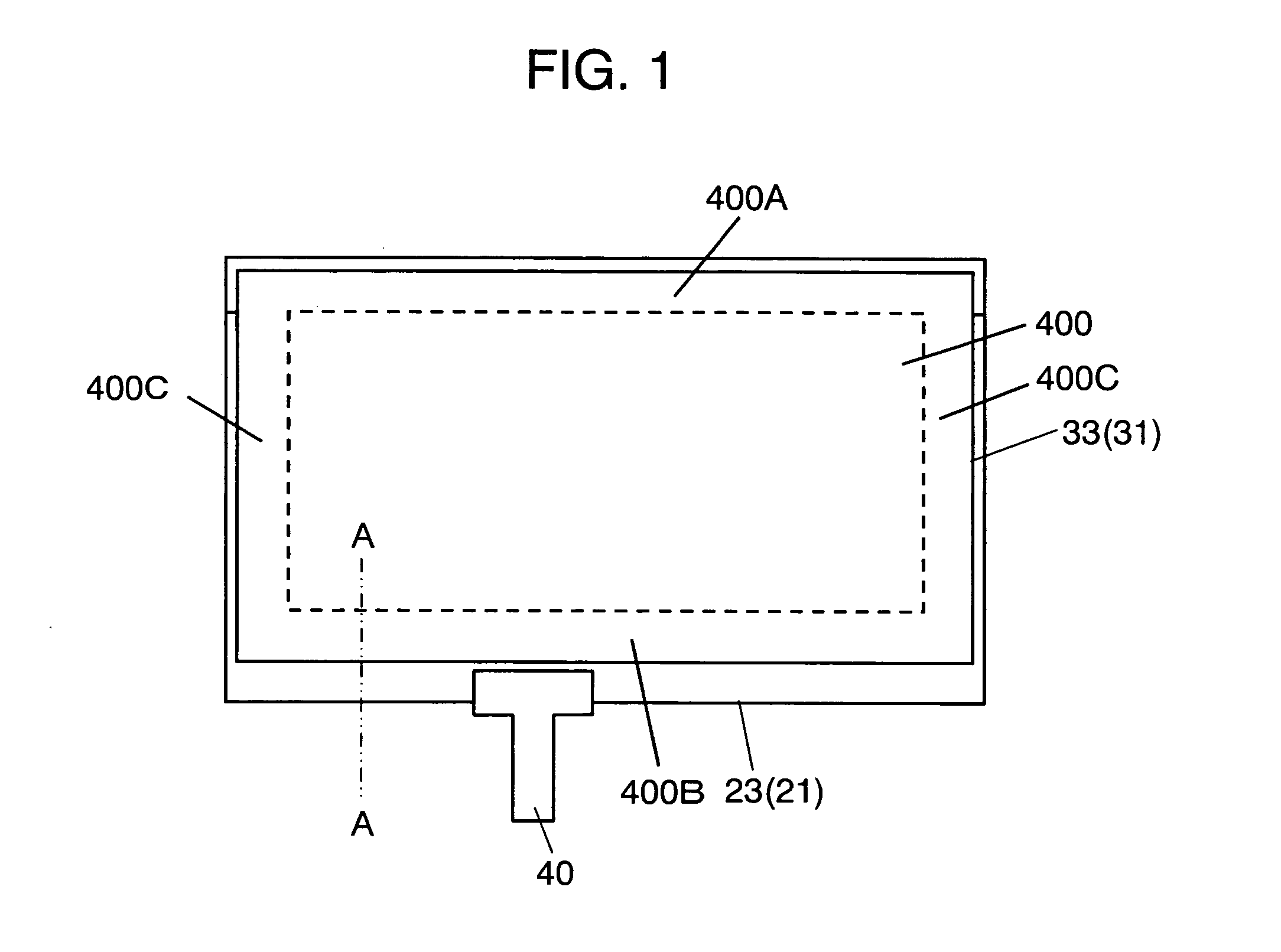

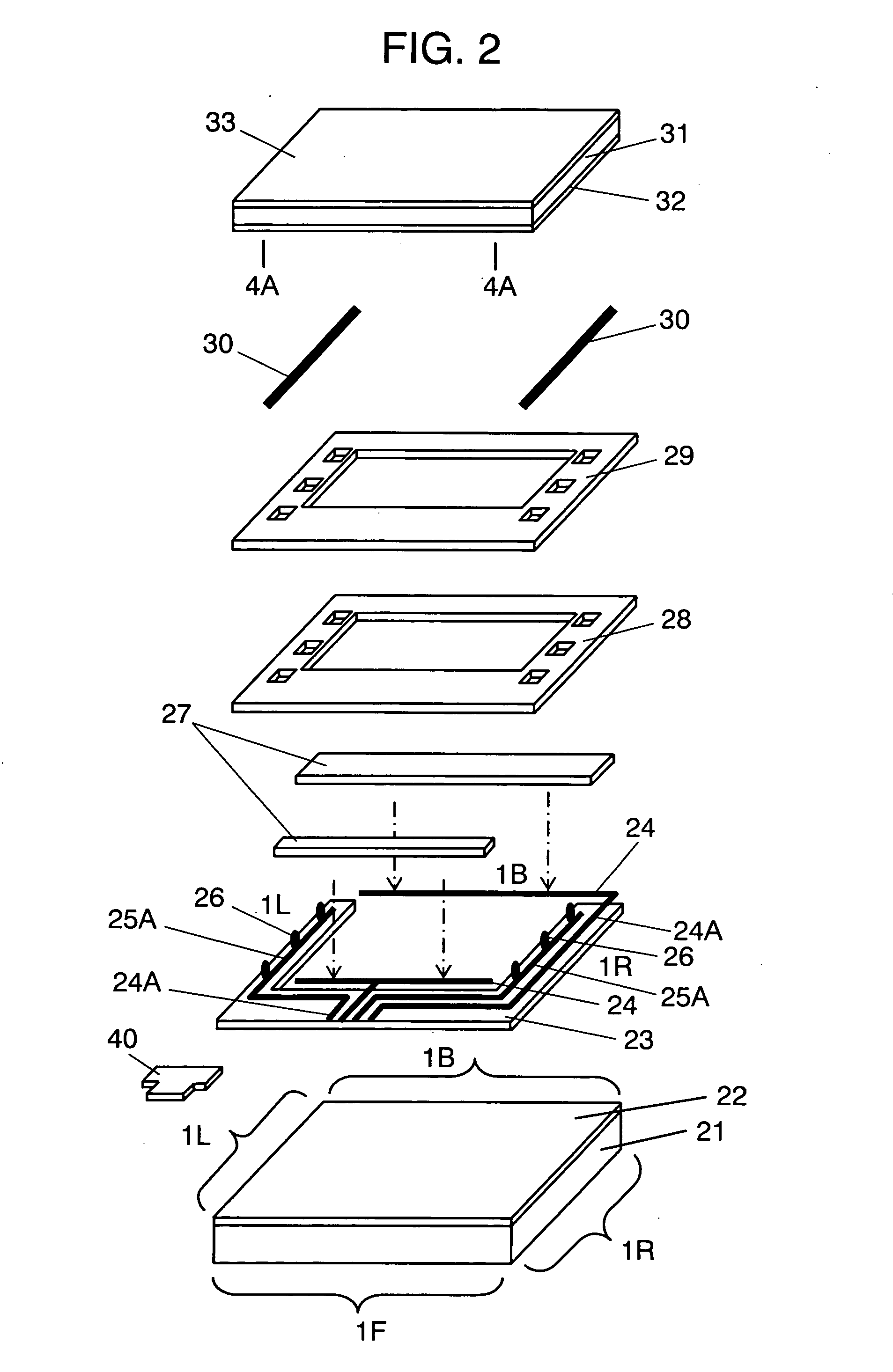

Touch panel and electronic device using the same

InactiveUS20050046622A1Avoid contactWell formedCathode-ray tube indicatorsInput/output processes for data processingEnvironmental resistanceLiquid-crystal display

The invention presents a touch panel disposed at the display screen side of a liquid crystal display device or the like, and excellent in surface smoothness and environmental resistance. In marginal outer circumferential part 400B for adhering and fixing first transparent substrate 21 and second transparent substrate 31 face to face, insulating layer 27 for correction of step difference is disposed in order to make uniform the film thickness. Adhesive layer 29 is disposed on insulating layer 27, and first transparent substrate 21 and second transparent substrate 31 are adhered to each other. As a result, the adhesion fixing state if stabilized, and the adhesion strength is enhanced, and a touch panel suitable for car-mount unit excellent in surface smoothness and environmental resistance can be presented.

Owner:PANASONIC CORP

Adhesive polyethylene compositions and multi-layer laminated films using the same

InactiveUS6210765B1Improve adhesion strengthHigh heat sealing strength heatWrappers shrinkageShrinkage connectionsElastomerPolyamide

Disclosed is a specific adhesive polyethylene composition comprising [1] a modified ethylene / alpha-olefin copolymer resin or elastomer obtained by modifying a specific ethylene / alpha-olefin copolymer resin or elastomer, each of which comprises ethylene and an alpha-olefin of 3 to 20 carbon atoms, with an unsaturated carboxylic acid or anhydride, ester, amide, imide or metallic salt derivative of a unsaturated carboxylic acid thereof, [2] an unmodified ethylene / alpha-olefin copolymer resin and / or an unmodified ethylene / alpha-olefin copolymer elastomer and [3] a tackifier. Also disclosed is a multi-layer laminated film of 3 or more layers in which a layer of the above composition is interposed between an ethylene polymer layer and either a polyamide resin layer, an ethylene / vinyl alcohol copolymer layer or a layer of a mixture of polyamide resin and ethylene / vinyl alcohol copolymer. The adhesive polyethylene composition shows excellent adhesion strength to ethylene polymers, polyamide resins and ethylene / vinyl alcohol copolymers, high heat-sealing strength and heat resistance. The multi-layer laminated film shows excellent strength, heat resistance and gas barrier properties, and besides this film has heat shrinkability, so that the film is suitably used as a shrink film.

Owner:MITSUI CHEM INC

Multifunctional high-efficiency thermal insulation insulating mold paint

The invention relates to a multifunctional high-efficiency heat-preservation heat-insulation coating material. The compositions in percentage by weight of the coating material are: 10 to 20 percent of water, 0.1 to 0.2 percent of multifunctional auxiliary agent, 0.1 to 0.2 percent of wetting agent, 0.5 to 0.8 percent of dispersing agent, 0.3 to 0.5 percent of antifoam agent, 1.5 to 3.0 percent of propylene glycol, 16 to 20 percent of rutile-type titanium pigment, 3 to 5 percent of mica powder, 6 to 8 percent of hollow glass microballoon, 3 to 5 percent of infrared powder, 3 to 4 percent of fire retardant, 35 to 40 percent of elastic acrylic acid emulsion, 3 to 5 percent of opaque polymer, 0.5 to 0.8 percent of film-forming auxiliary agent, 0.2 to 0.3 percent of bactericide and preservative and 0.3 to 0.6 percent of thickening agent. The multifunctional high-efficiency heat-preservation heat-insulation coating material is of aqueous monocomponent and does no harm to human body and the environment so as to be an environment-friendly product; meanwhile, the coating material also has excellent waterproof and fire-retardation functions, convenient and quick construction, excellent adhesion strength, outstanding crack resistance, infrequent pollution and service life as long as 15 years; moreover, during practical use, the coating material can effectively reduce solar heat accumulated in a house by approximately 8 to 15 DEG C, and can greatly reduce energy consumption.

Owner:董善刚

Biocolloid hemostatic prepared by aldehyde-modified sodium alginate and amine-modified gelatine

InactiveCN101716366AEasy to prepareRapid hemostasisAbsorbent padsBandagesFibrin glueBiocompatibility Testing

The invention relates to a biocolloid hemostatic prepared by aldehyde-modified sodium alginate and amine-modified gelatine. Sodium alginate and gelatine as raw materials; according to ratio, aldehyde-modified sodium alginate solution with the concentration of 5-25% and the same volume of amine-modified gelatine solution with the concentration of 5-40% are mixed; sodium alginate is modified by aldehyde through sodium periodate oxidation; and then gel is obtained by mixing with gelatine modified by ethanediamine. The adopted gelatine and sodium alginate are safe and stable, have good biocompatibility and can be absorbed and degraded by organism. Gel is rapidly formed through Schiff base reaction of aldehyde-modified sodium alginate and amine-modified gelatine, and the gel has the same gel-forming time as fibrin glue but better adhesion property and adhesion strength, can be acted on any part of body through simple local spraying or injection, and can be used as substitute product of fibrin glue.

Owner:TIANJIN UNIV

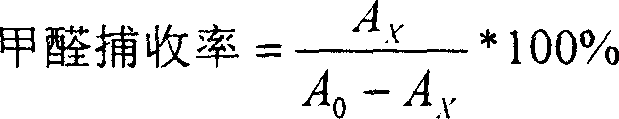

Adhesive and paint for absorbing formol

ActiveCN101045847AEffective absorptionAdhesive strength effectMonocarboxylic acid ester polymer adhesivesHydrocarbon polymer adhesivesBULK ACTIVE INGREDIENTUltimate tensile strength

This invention relates to a adhesive and a dope used for catching formaldehyde, both takes formaldehyde collector as active ingredient. This adhesive is used for gluing outer layer or kerf section of panel, can efficiently absorb formaldehyde liberated by panel, and has no impact to adhesion strength of panel. This dope is used for washing indoor wall; to absorb formaldehyde in the indoor air; also be used for surface washing of panel, absorb formaldehyde gas, reduce releasing of formaldehyde. Comparing with existing technology, this invention has such merit: cheapness, efficiently, and can generate stable compound, no longer discharge formaldehyde gas, thus unable to generate other secondary pollutant.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

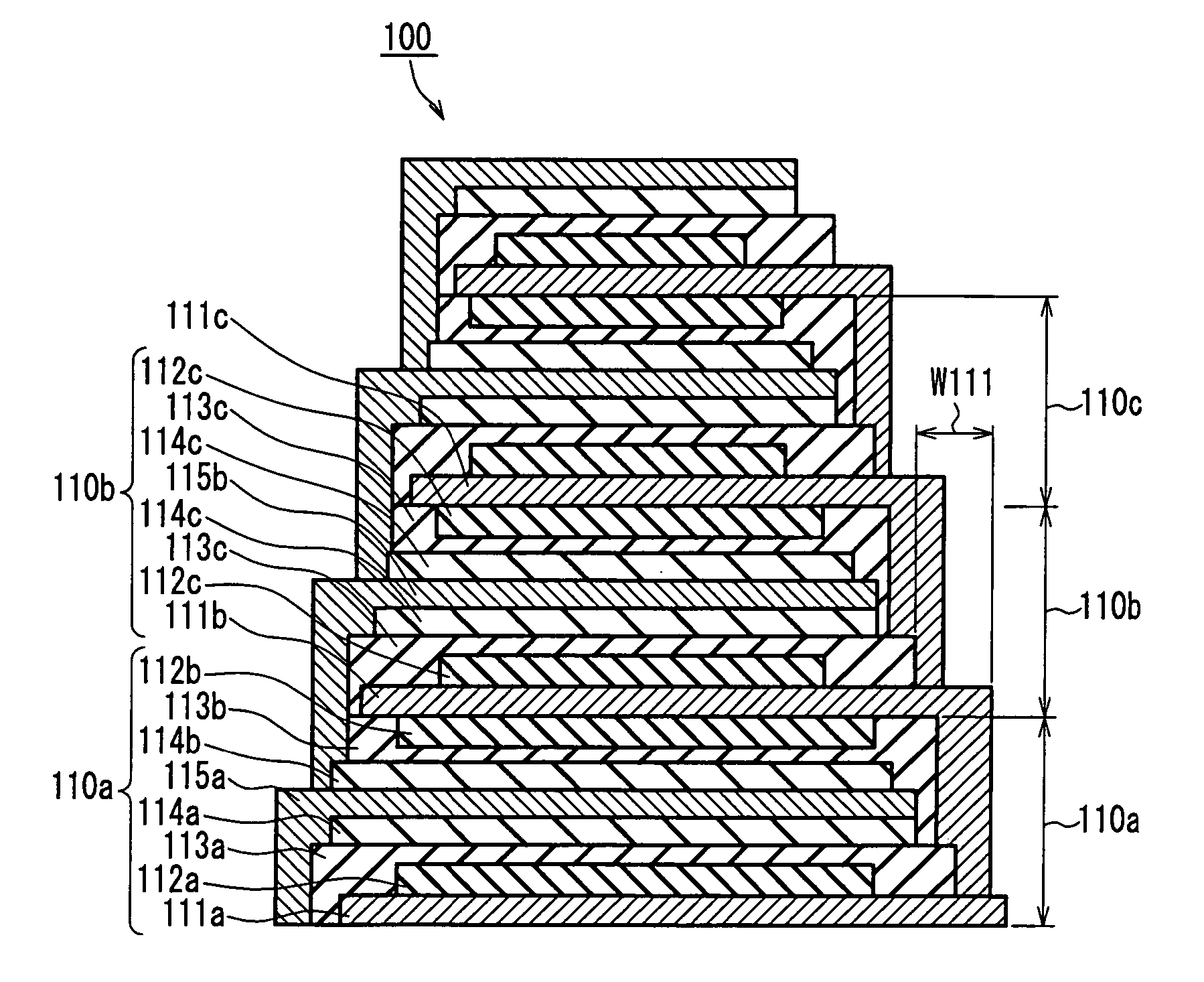

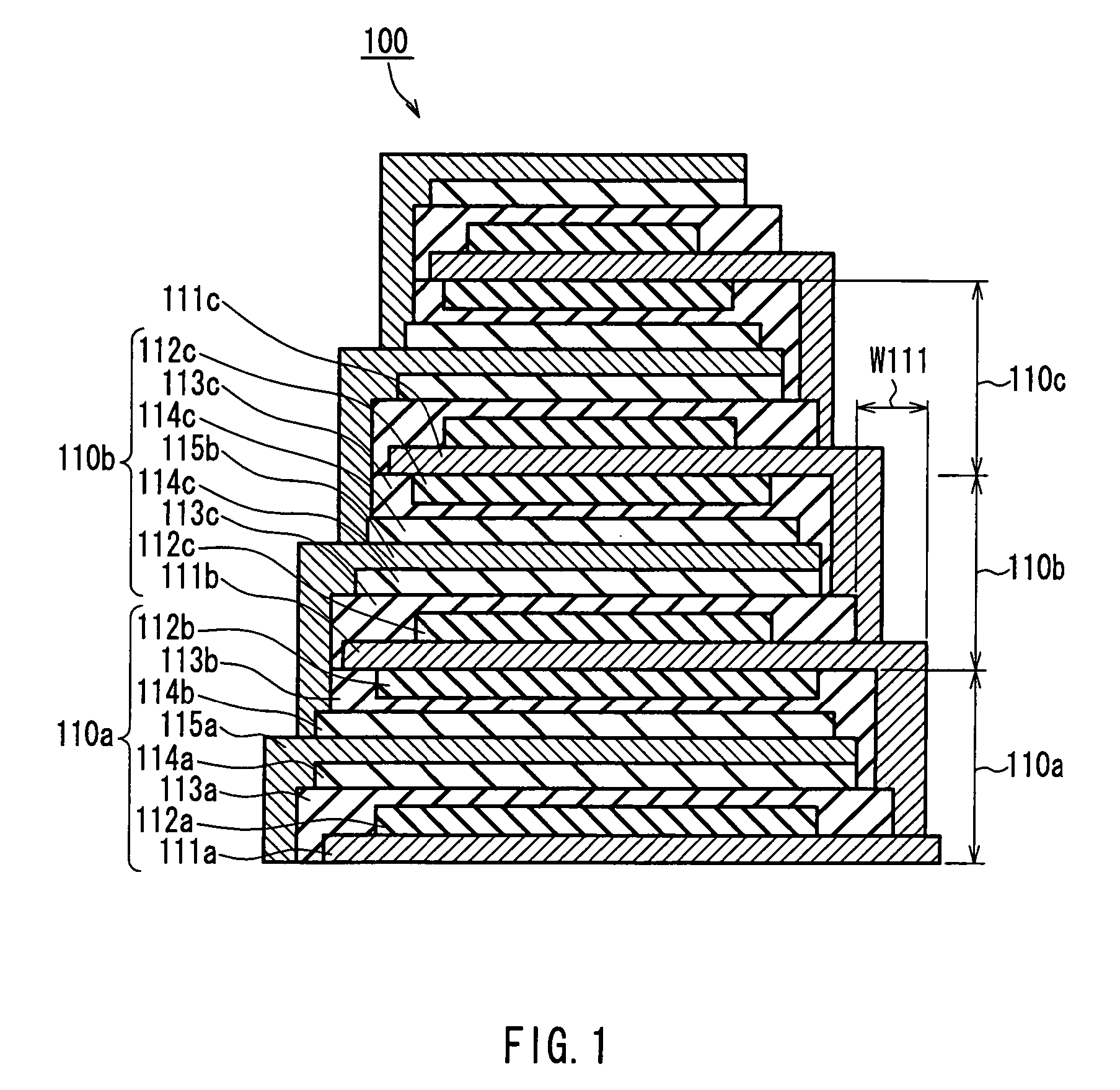

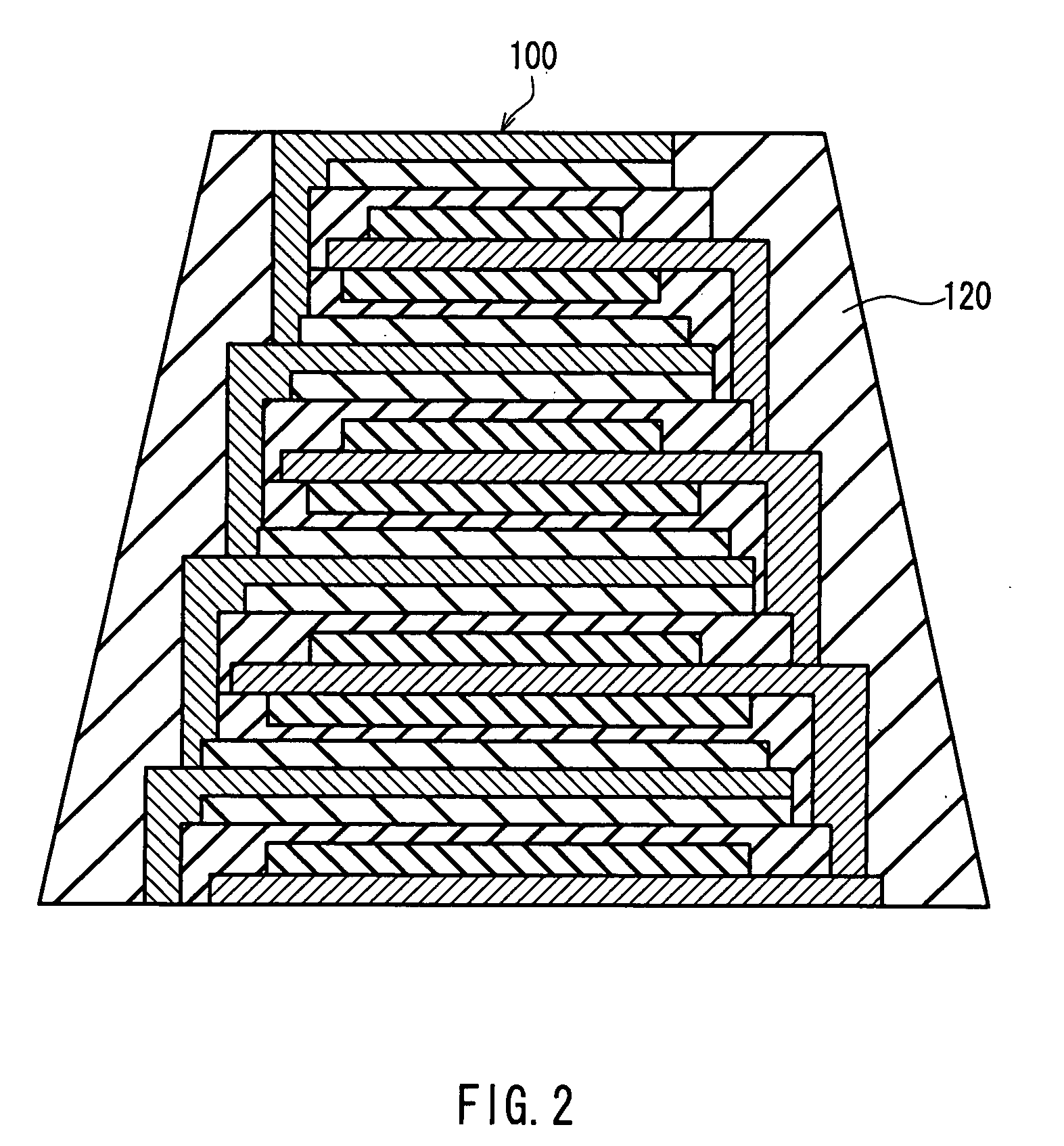

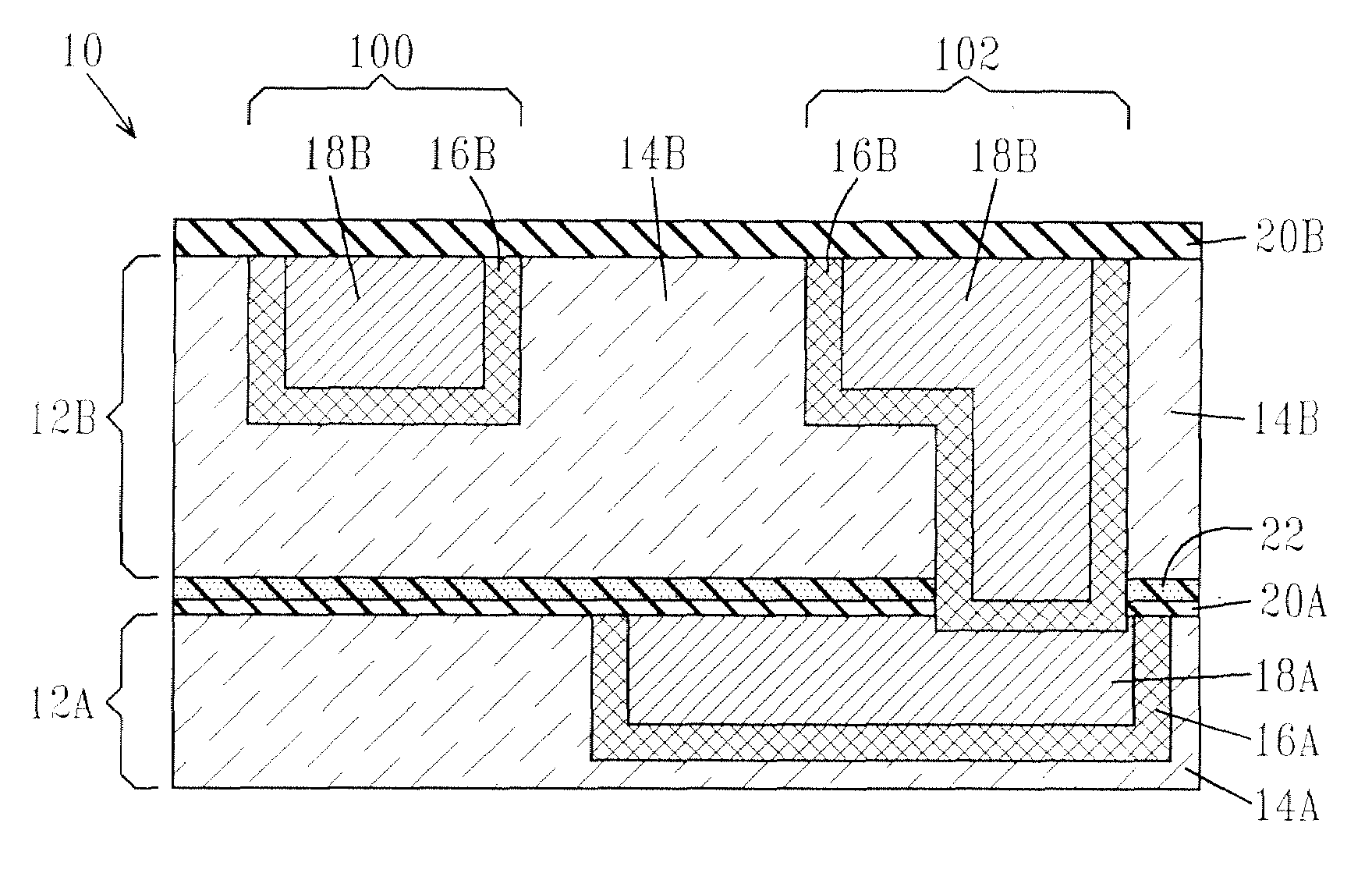

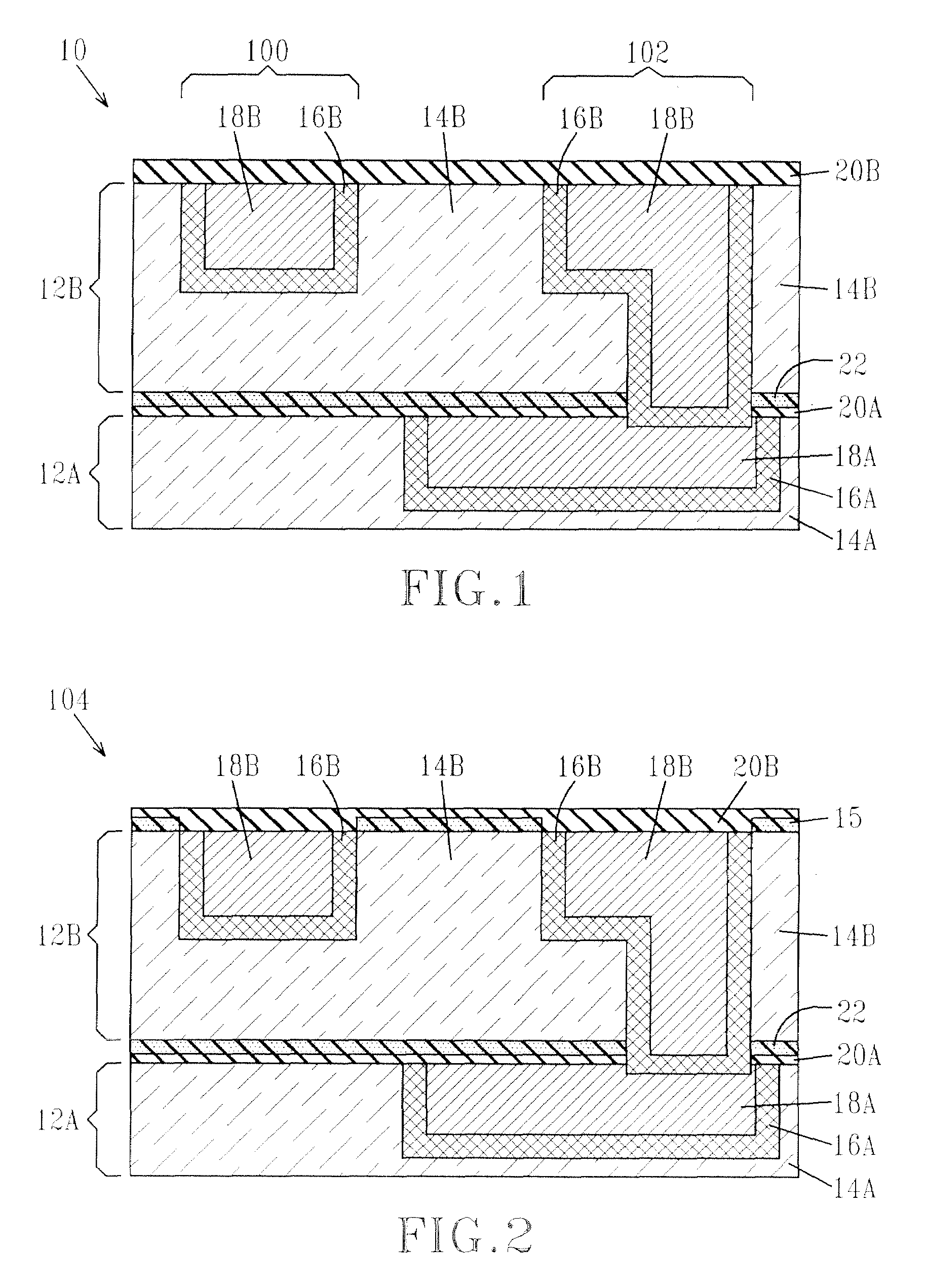

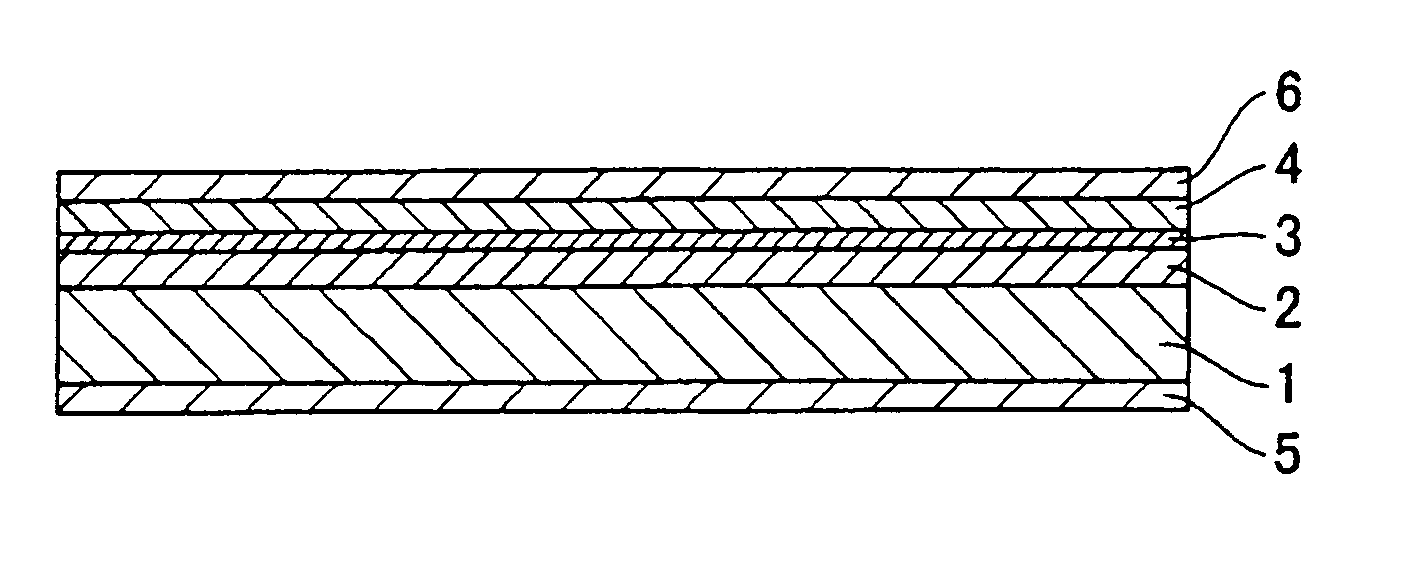

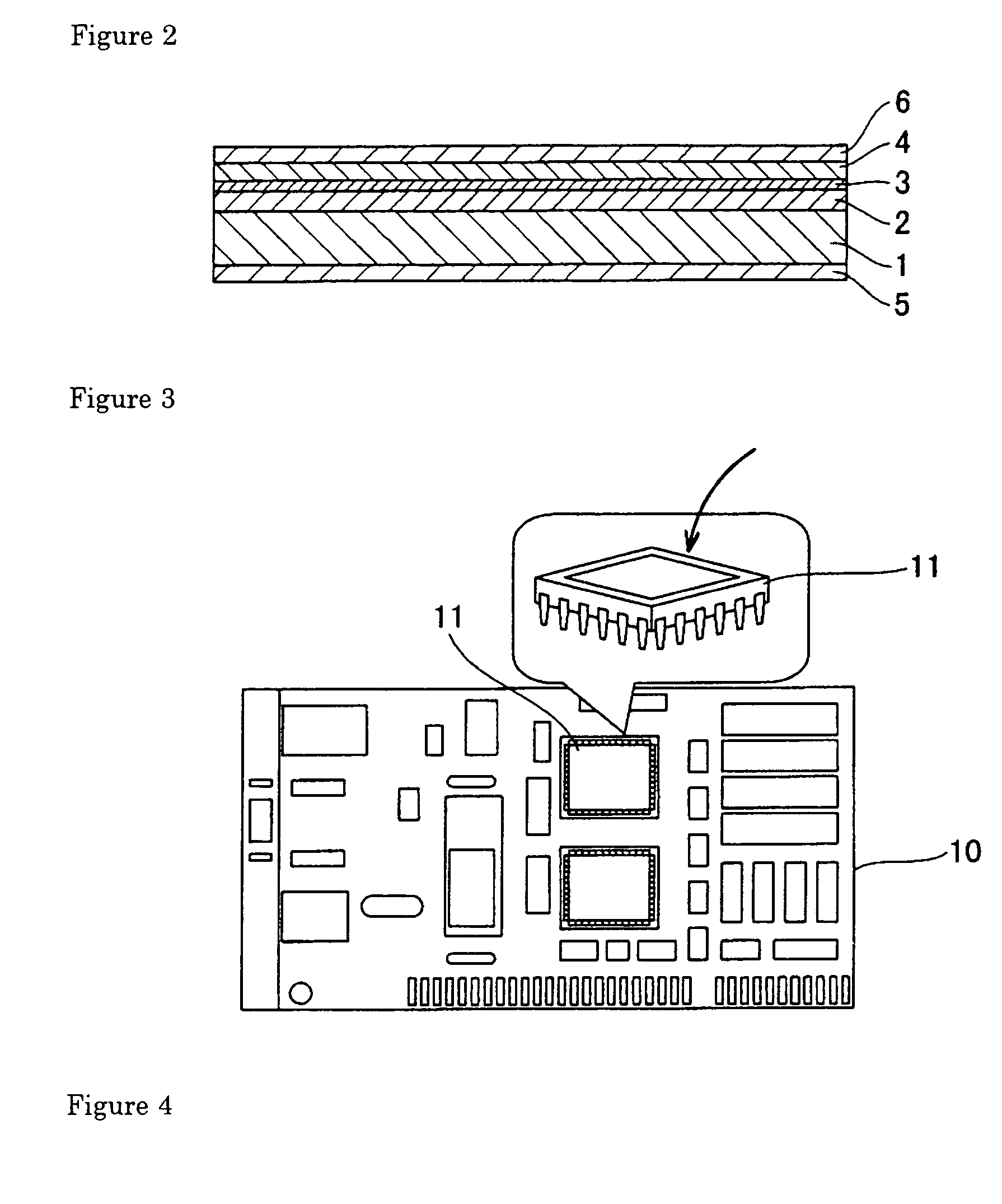

Thin-film laminated body, thin-film cell, capacitor, and method and equipment for manufacturing thin-film laminated body

InactiveUS20050141170A1Improve connection reliabilityQuality improvementCell electrodesFinal product manufactureEngineeringAdhesion strength

A thin film layered product is composed of at least two deposition units, each of which includes at least a first thin film layer and a second thin film layer. At least one of the first thin film layer and the second thin film layer in each of the at least two deposition units is laminated so as to have an area decreased in a direction from a lower layer toward an upper layer. Thus, the reliability of connection between layers can be improved, and when a protective layer is formed on side faces, the formability and adhesion strength can be improved.

Owner:PANASONIC CORP

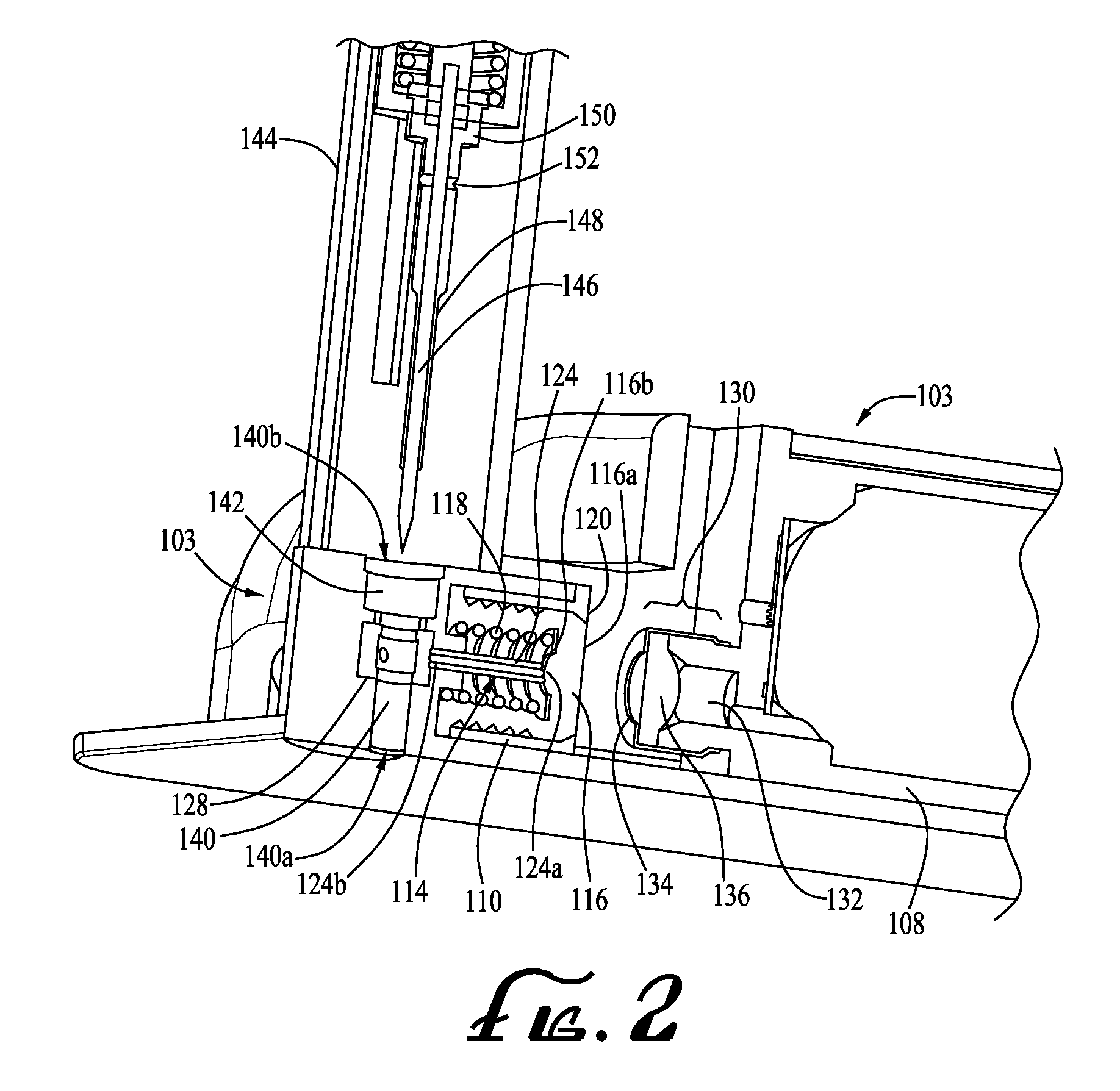

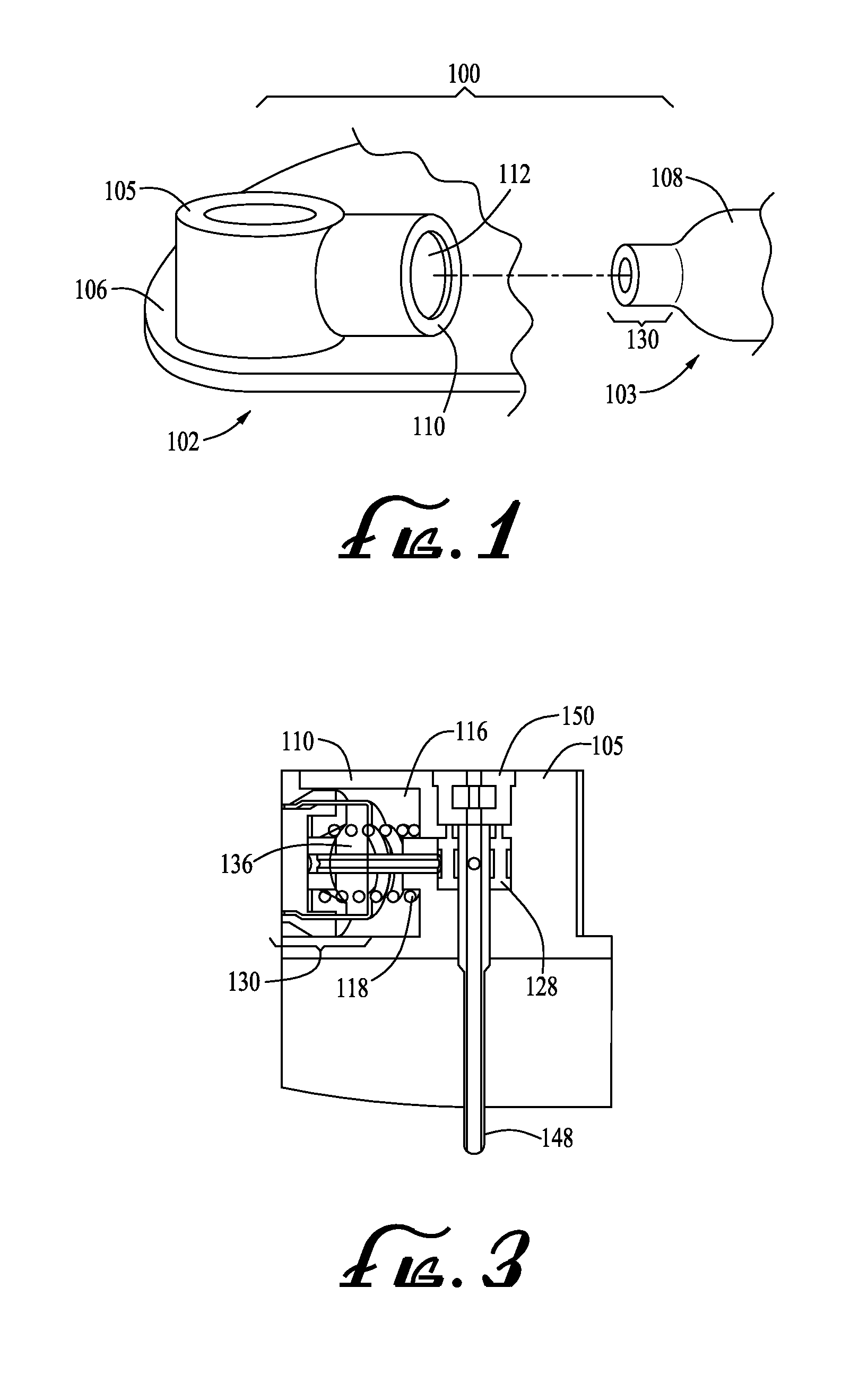

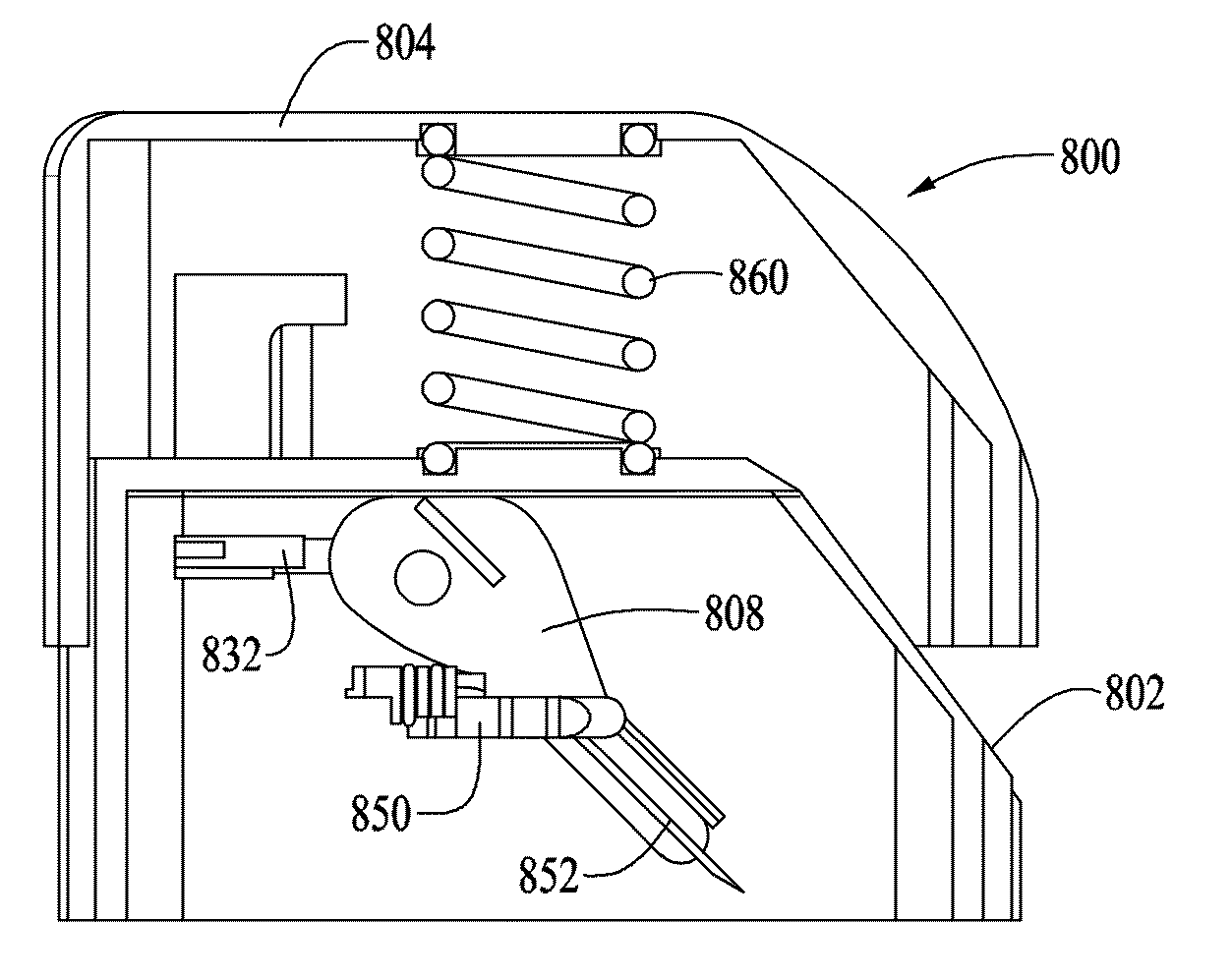

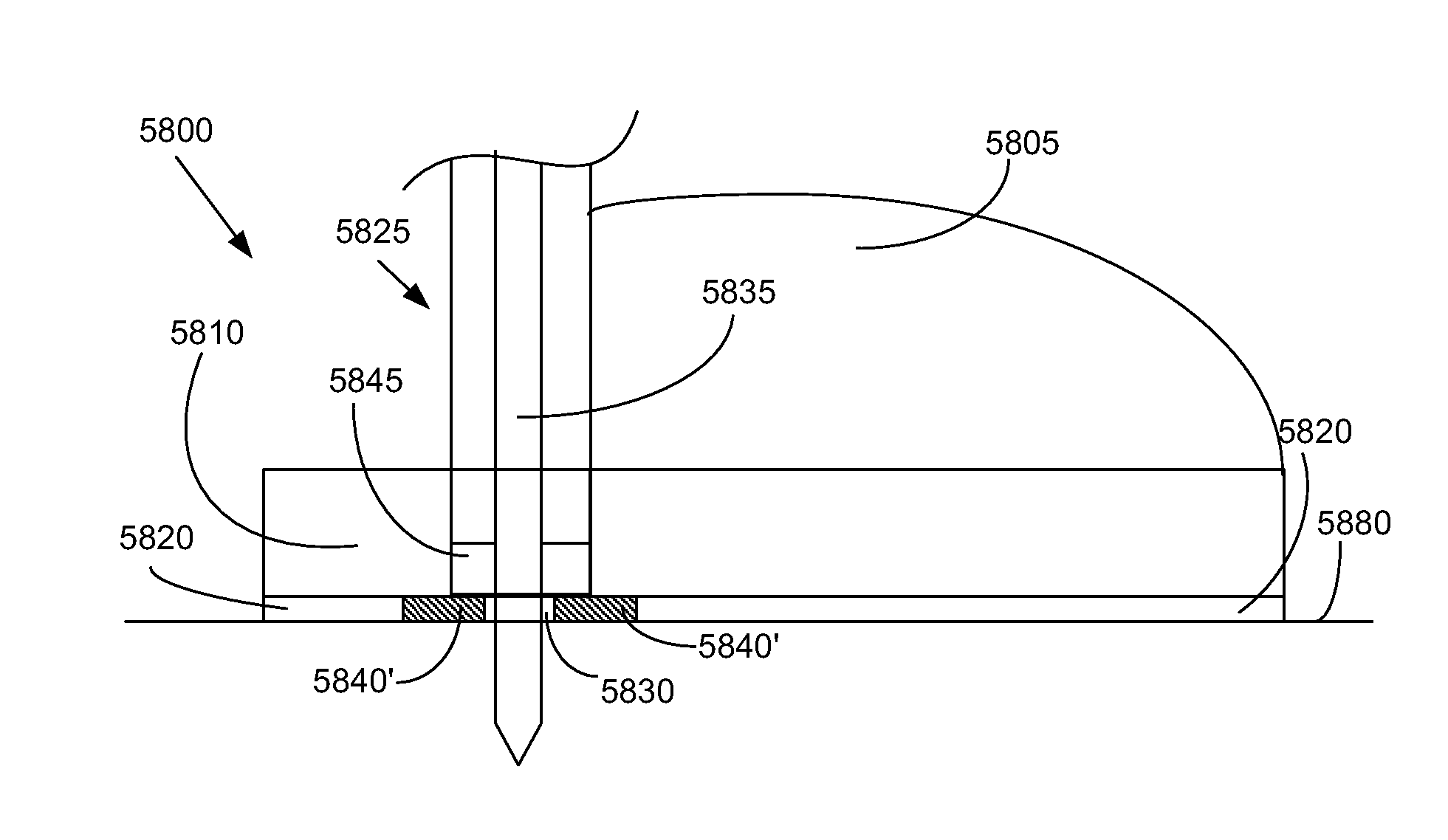

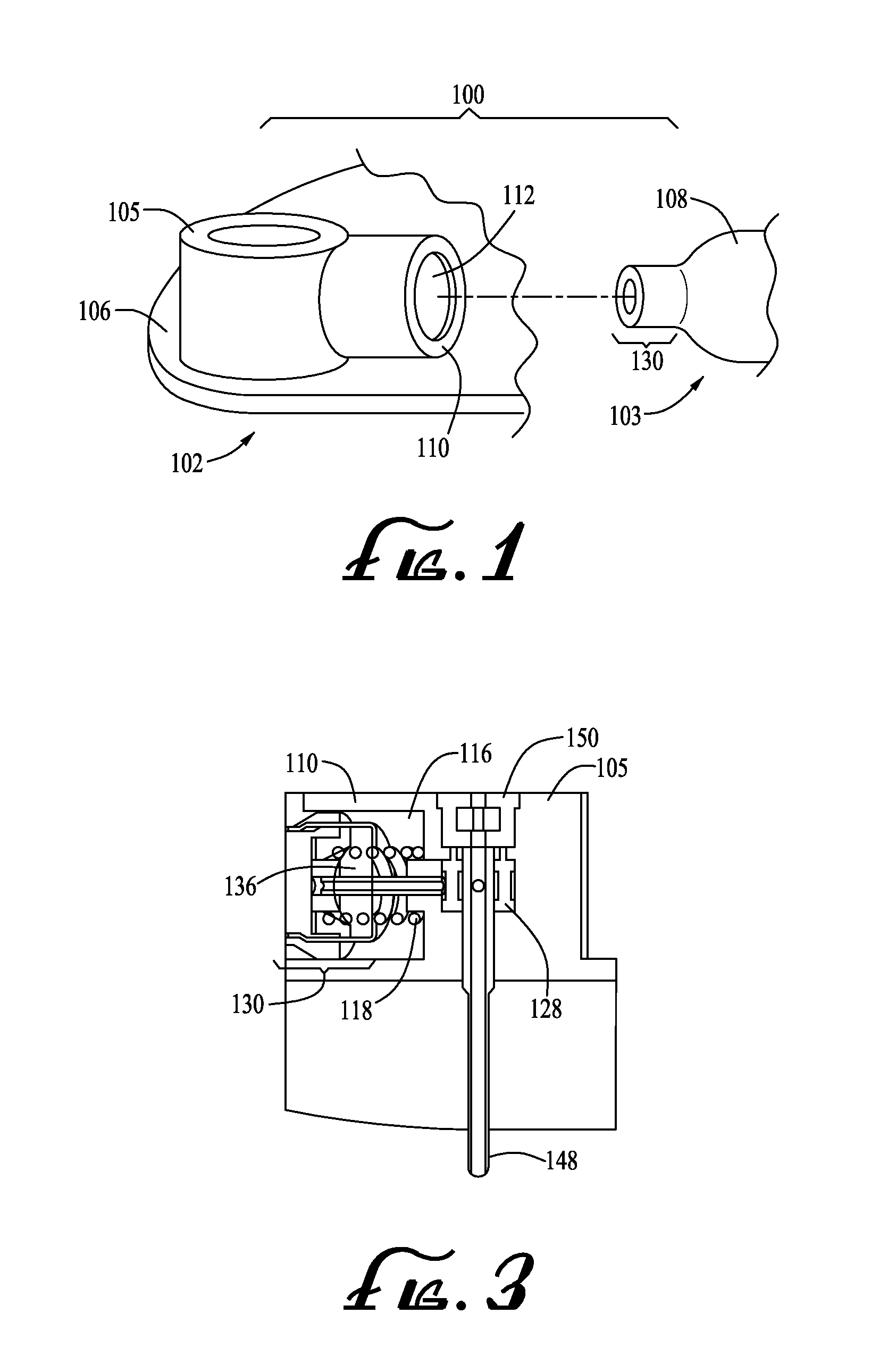

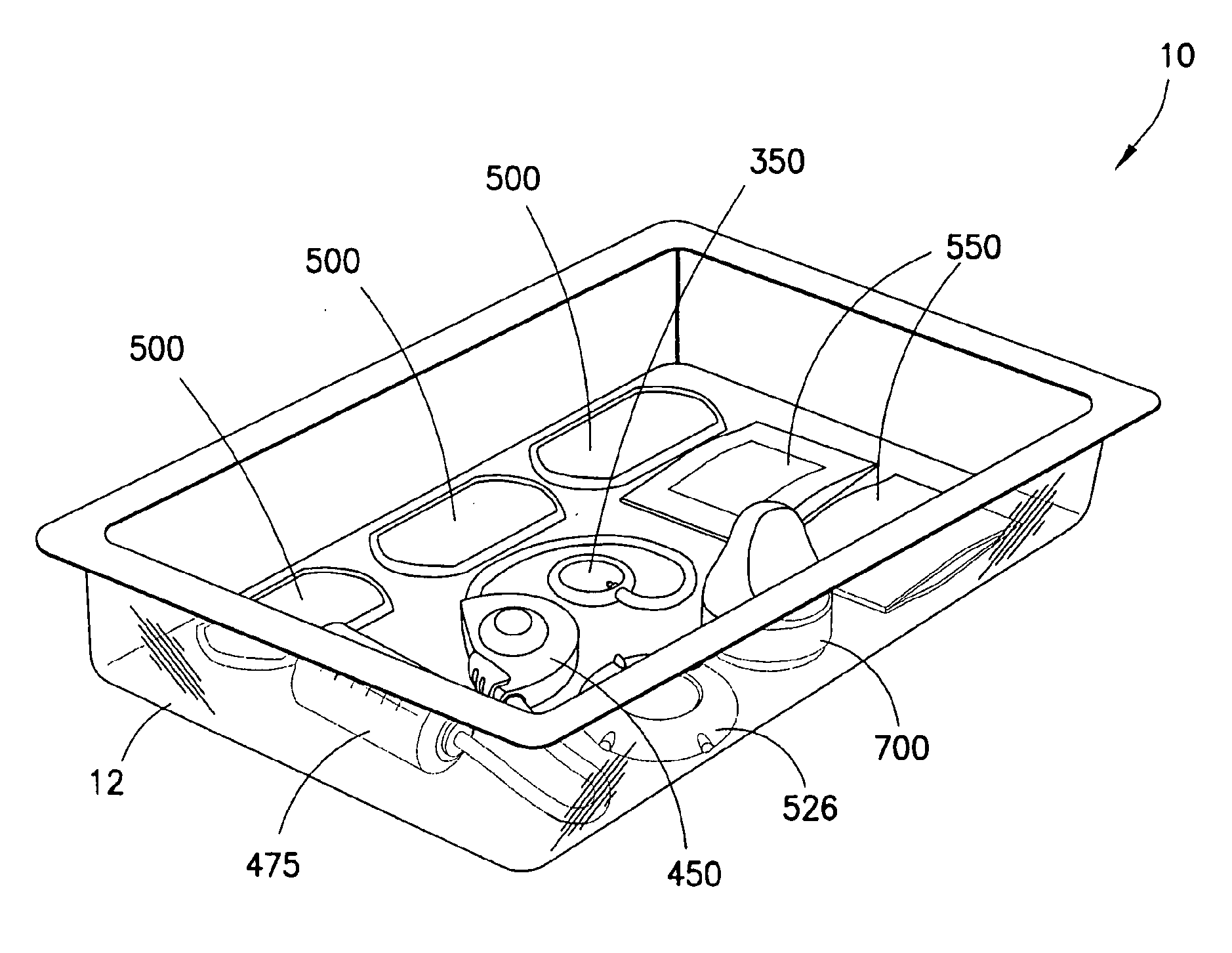

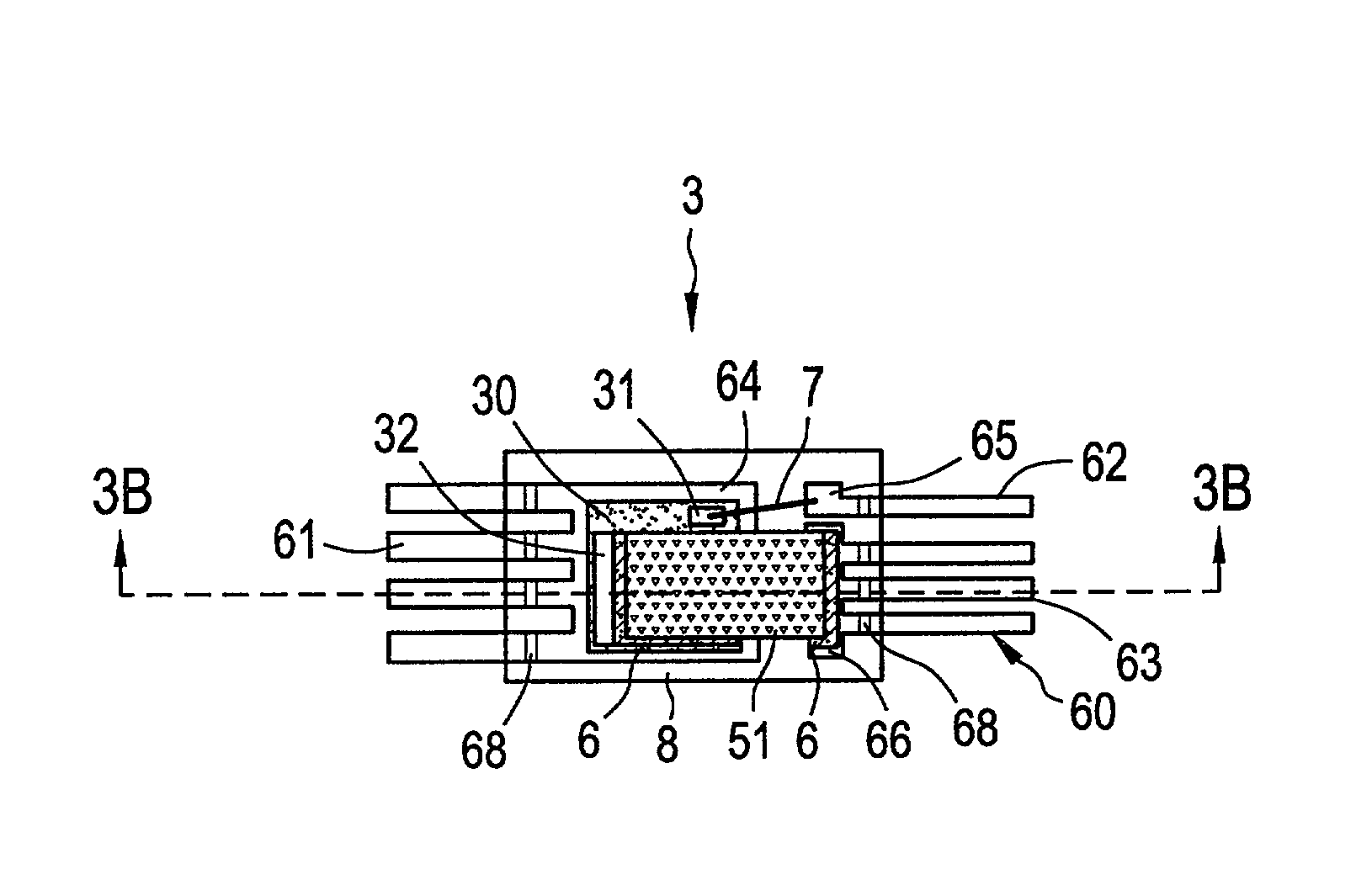

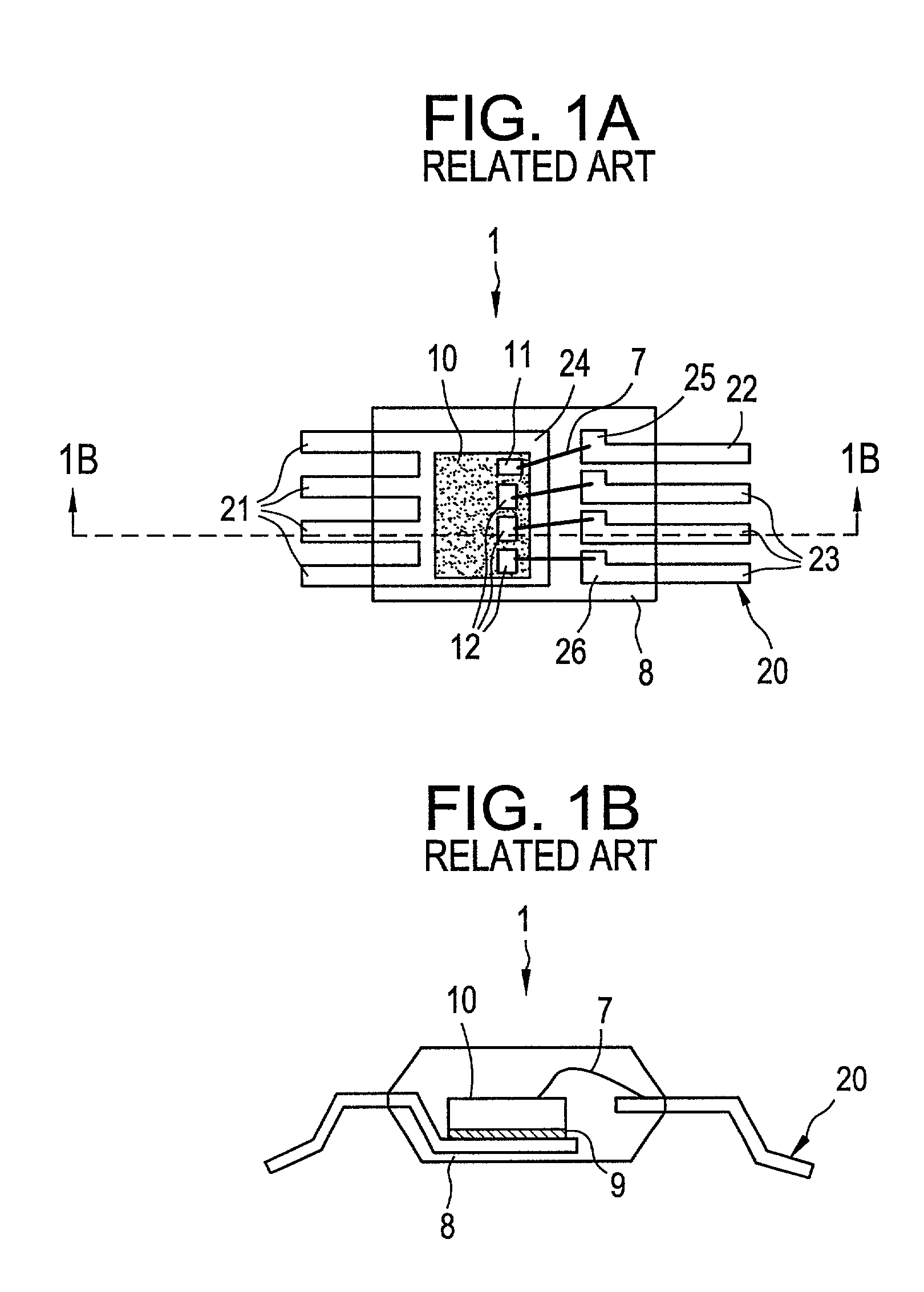

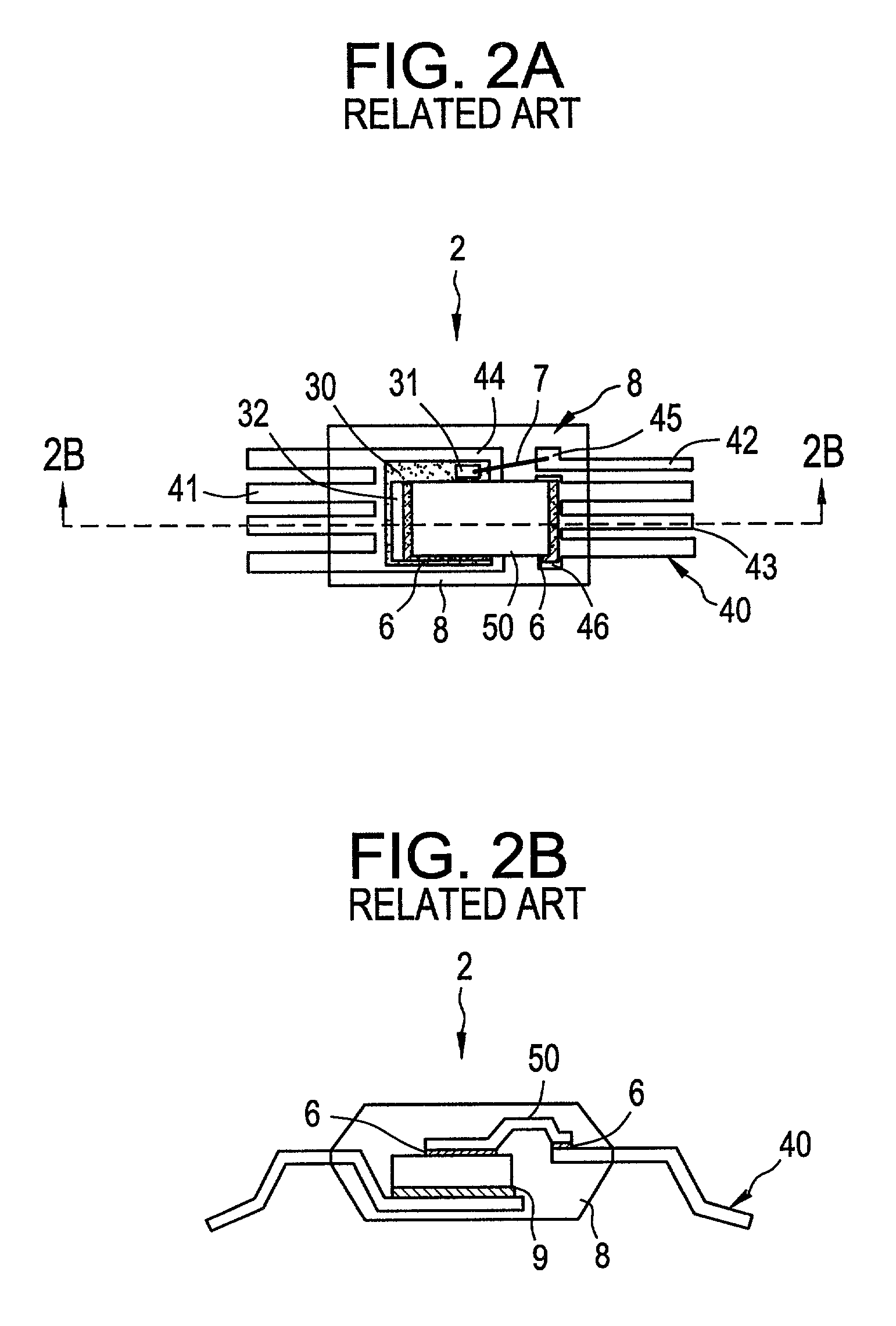

Infusion set

ActiveUS20120150123A1Easy to assembleSimplify useDispensing apparatusDiagnosticsMedicineInfusion set

A single package infusion set is provided, including one or more of the following inserters: pushbutton-type, squeeze-type, contact-type, skin pinching-type, folding retraction-type, or multistage-type inserter having at least one reusable stage. The infusion set further includes adhesion means with user-selectable degrees of adhesion strength, self-sealing tube connection means, a lens feature to view, a site beneath the set, exemplary tube management and connection elements, insulin supply, adhesion concealment means, finger loops on the inserter and site preparation wipes or sprays, optionally provided as part of the inserter. The system further includes a package which may hold a number of easily released sets, retrievable by an inserter, an exemplary insertion needle handle and shroud, an exemplary squeeze-type latch between an upper portion and a lower portion of the set, and / or a tool removable upper portion of the set.

Owner:BECTON DICKINSON & CO

MECHANICALLY ROBUST METAL/LOW-k INTERCONNECTS

InactiveUS20080173984A1Improve adhesionSemiconductor/solid-state device detailsSolid-state devicesSurface layerSemiconductor structure

A mechanically robust semiconductor structure with improved adhesion strength between a low-k dielectric layer and a dielectric-containing substrate is provided. In particular, the present invention provides a structure that includes a dielectric-containing substrate having an upper region including a treated surface layer which is chemically and physically different from the substrate; and a low-k dielectric material located on a the treated surface layer of the substrate. The treated surface layer and the low-k dielectric material form an interface that has an adhesion strength that is greater than 60% of the cohesive strength of the weaker material on either side of the interface. The treated surface is formed by treating the surface of the substrate with at least one of actinic radiation, a plasma and e-beam radiation prior to forming of the substrate the low-k dielectric material.

Owner:GLOBALFOUNDRIES INC

Three-dimensional printing forming material with toughness and high adhesive property and preparation method thereof

The invention discloses a three-dimensional printing forming material with toughness and high adhesive property. The three-dimensional printing forming material comprises a powder material and an adhesive material and is characterized in that the powder material comprises the following components in parts by weight: 40-85 parts of polyamide resin, 5-40 parts of pigments, 5-30 parts of filler, 1-6 parts of pigment and filler dispersing and wetting aid, 0.1-1.5 parts of flatting agent and 0.1-0.5 part of degassing agent; the adhesive material comprises the following components in parts by weight: 60-95 parts of epoxy resin, 5-40 parts of filler, 1-10 parts of toughening agent, 0.1-1.5 parts of flatting agent, 1-4 parts of pigment and filler dispersing and wetting aid, 0.1-0.5 part of degassing agent and 0.1-0.5 parts of powder flowing aid; and when the three-dimensional printing forming material is used, 1 part by weight of powder material and 0.01-0.5 part by weight of adhesive material are cooperatively used. A solid component printed by using the material disclosed by the invention has the advantages of higher adhesion strength and firmness, good flexibility and scratching resistance.

Owner:ZHONGSHAN POLYTECHNIC

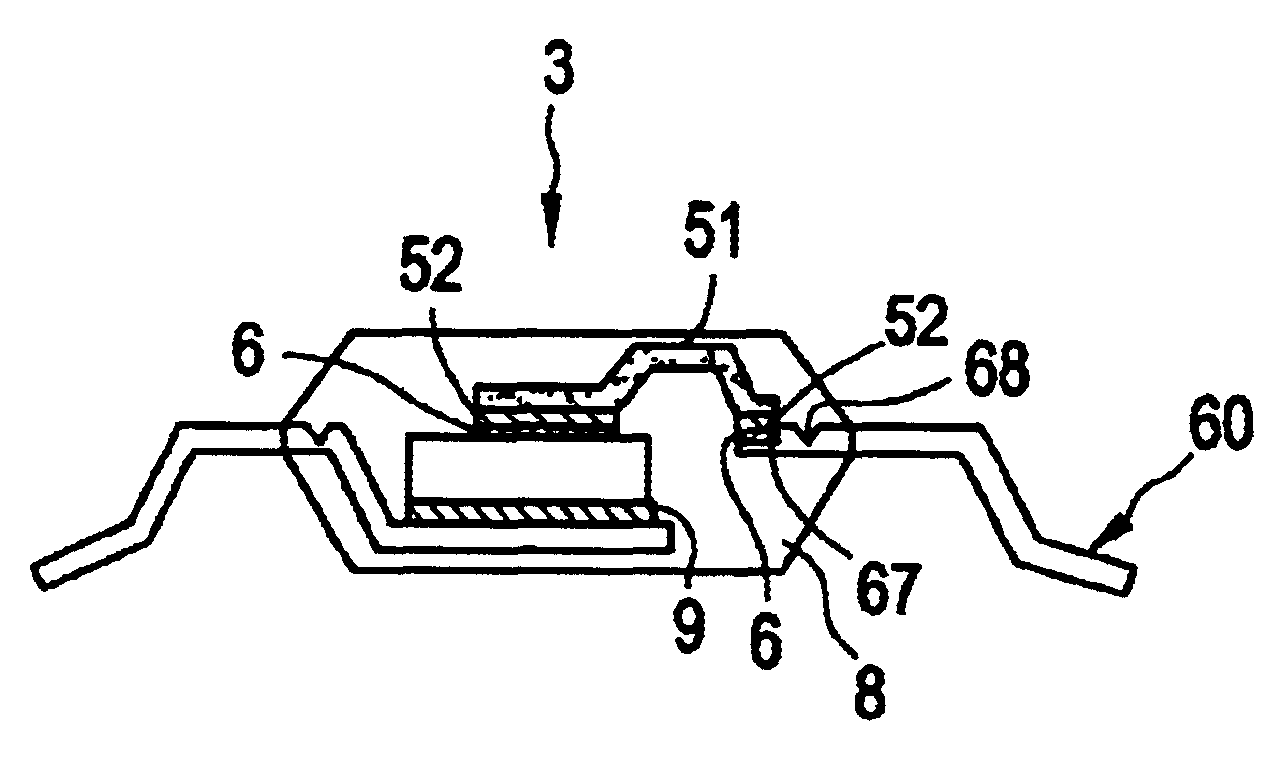

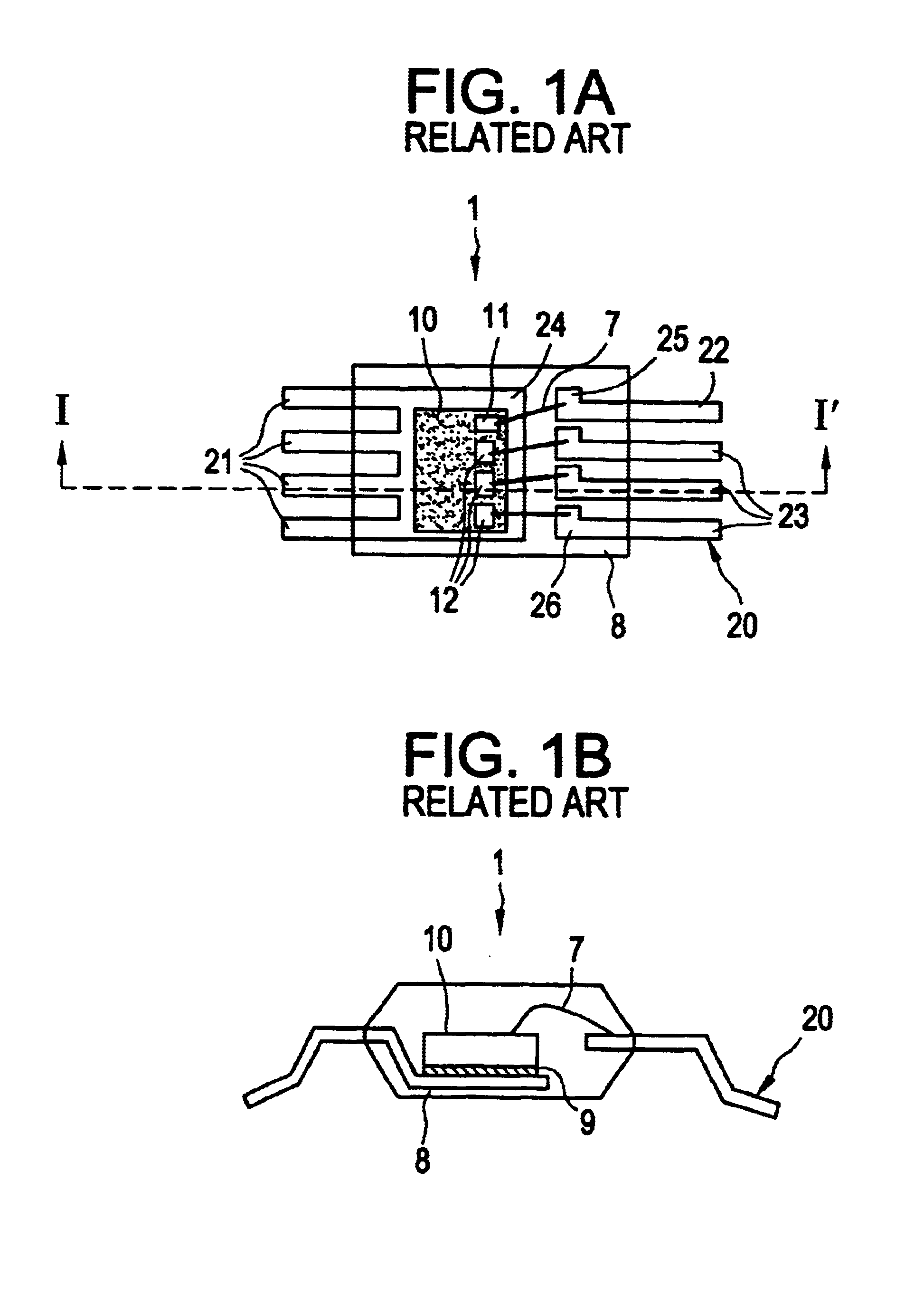

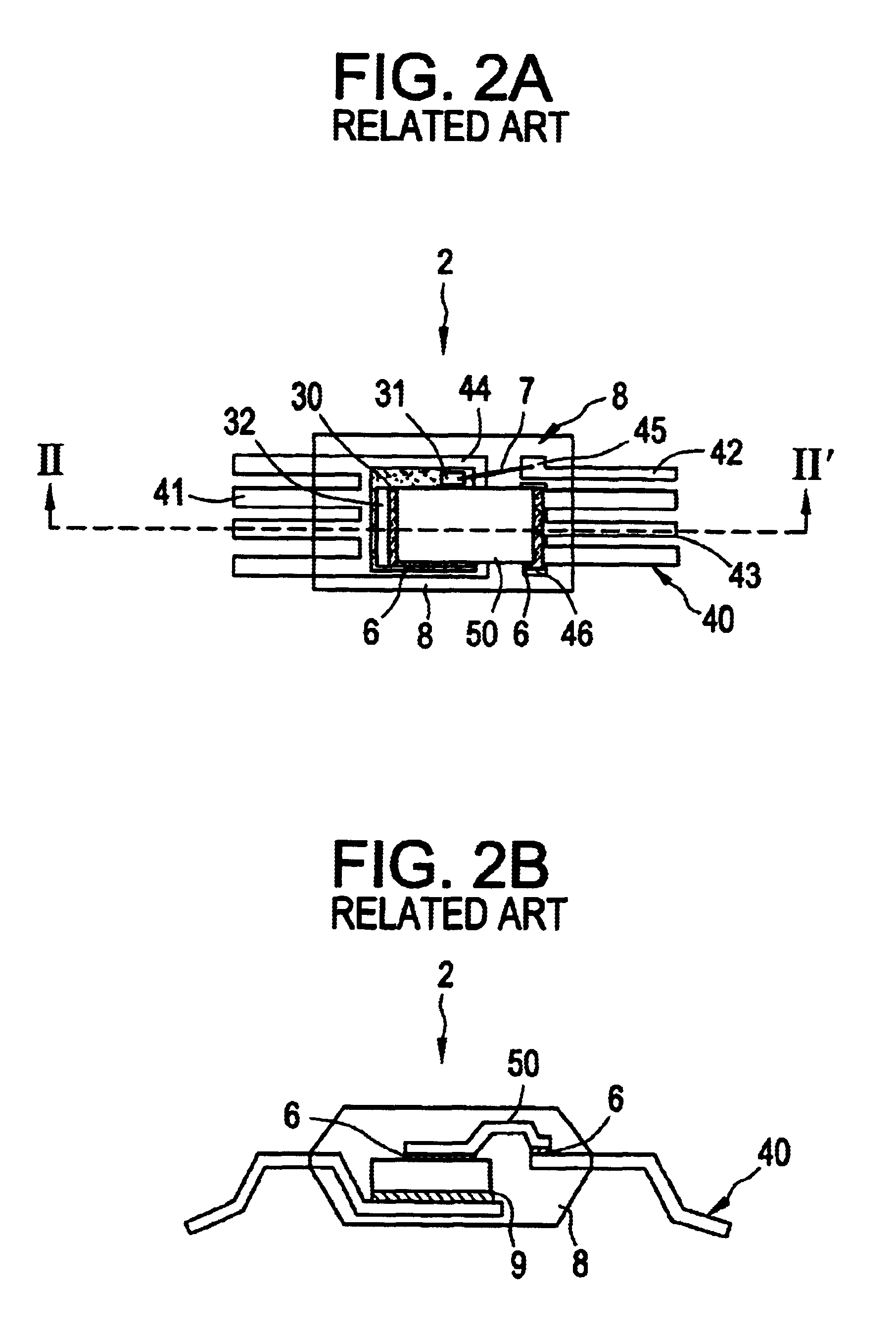

Semiconductor device with uneven metal plate to improve adhesion to molding compound

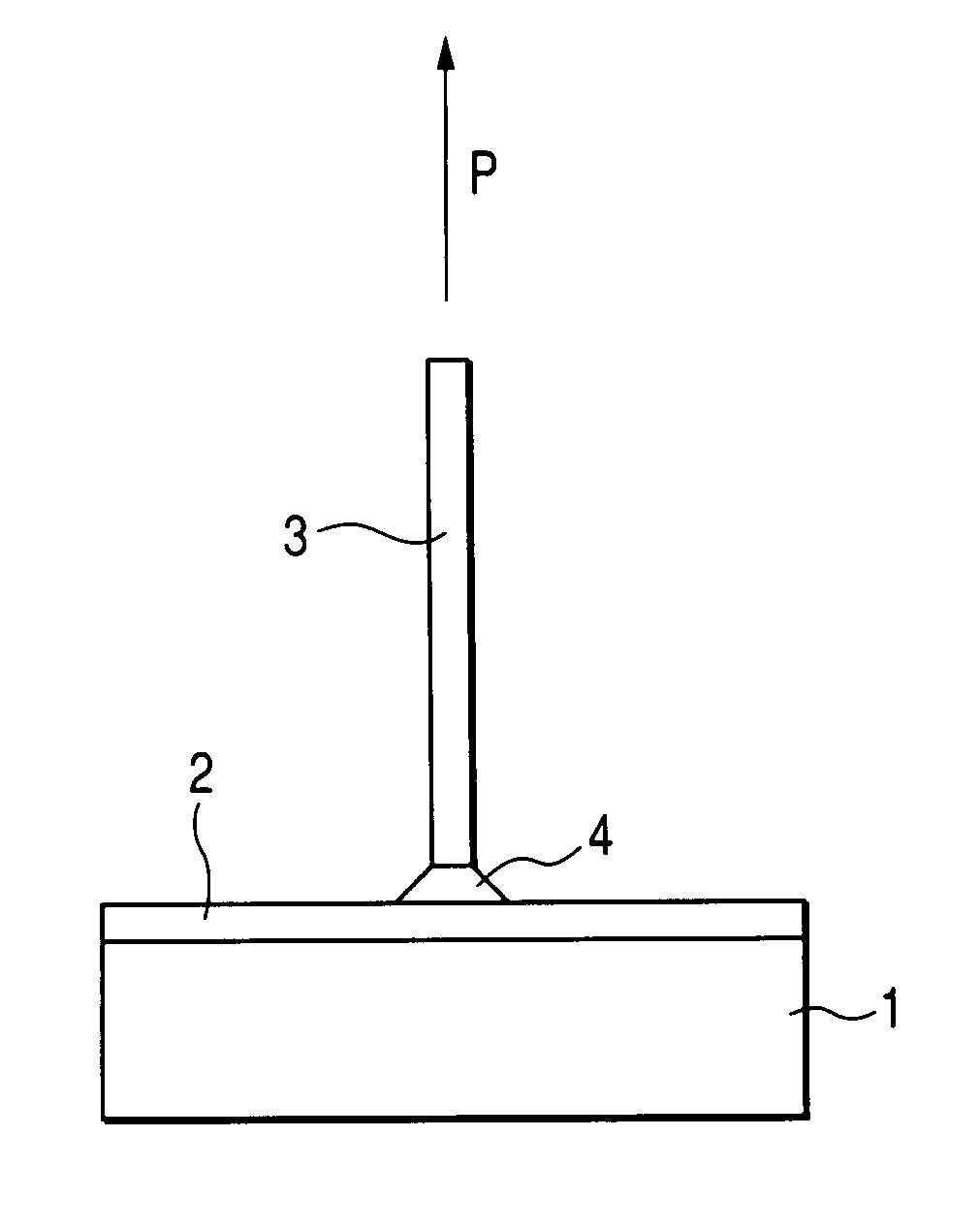

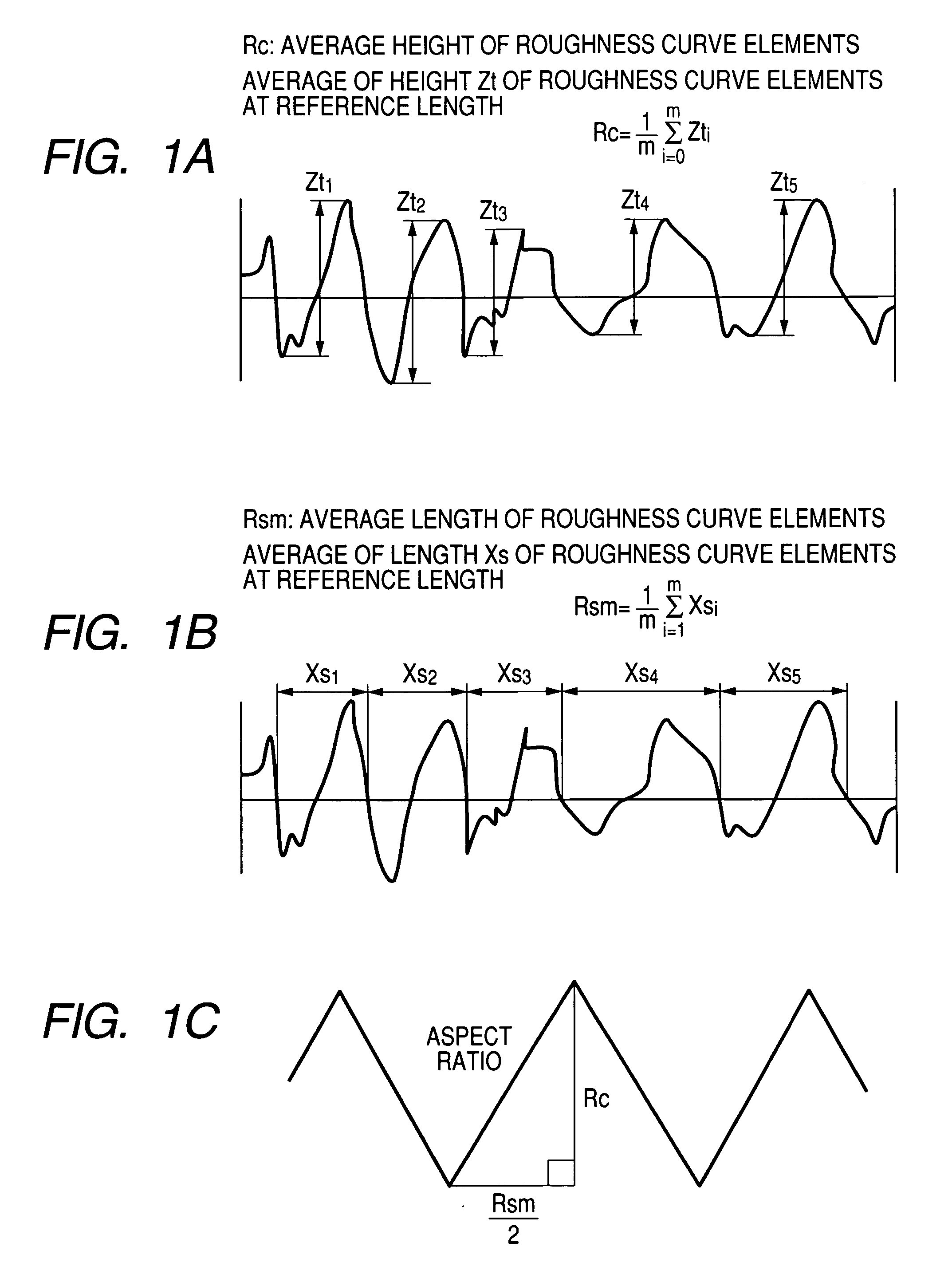

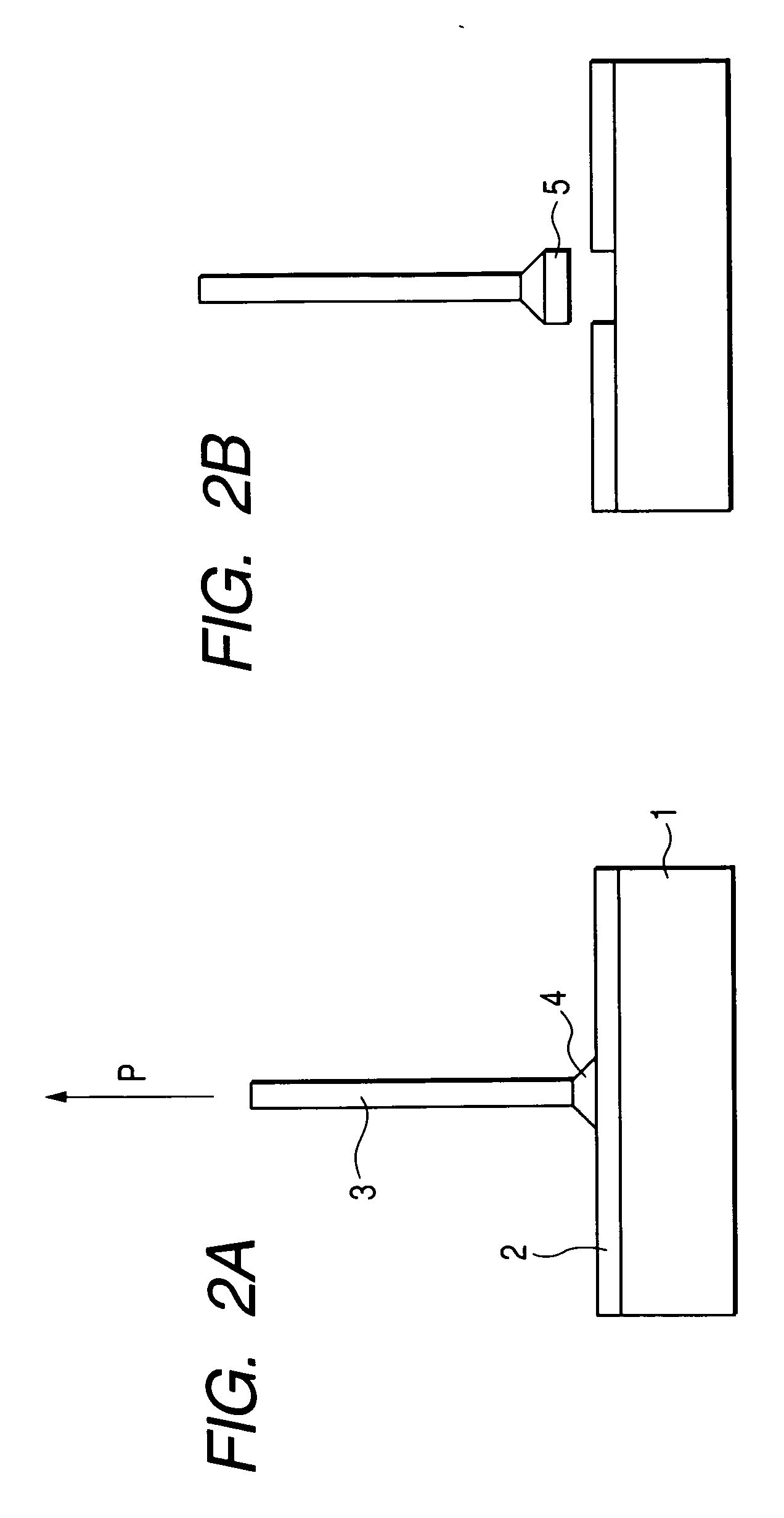

InactiveUS6849930B2Adhesive strengthImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesConductive pasteSemiconductor chip

The present invention provides a semiconductor device whose reliability is improved by improving the adhesion strength of a metal plate or connecting chip, said plurality of electrodes and a lead frame with a molding resin. Further, the semiconductor device of the present invention prevents flow out of a conductive joining material to be employed for joining a lead terminal and the metal plate other than the joining range of the metal plate and the lead terminal, and mounts the metal plate at high precision. In a semiconductor device (a plastic package) in which a source electrode of a semiconductor chip and source terminal of a lead frame are electrically connected by a copper plate and sealed by a resin, the surface of the copper plate is roughened to improve the adhesion strength to a molding resin. Further, a stepped part is formed in the source terminal to prevent a conductive paste from flowing out. The structure is so formed as to fit claw parts in the lead frame.

Owner:RENESAS ELECTRONICS CORP

Phenolic resin/phosphate hybrid adhesive and preparation method thereof

InactiveCN101875830AEasy to prepareImprove thermal stabilityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPhosphateWorking temperature

The invention provides a phenolic resin / phosphate hybrid adhesive and a preparation method thereof, relating to an adhesive and a preparation method thereof. The invention solves the problems of low working temperature, rigorous curing process and low adhesion strength of the conventional high-temperature resisting phenolic resin adhesive. The adhesive is prepared from phenolic resin, heat-resistant reinforced resin, a coupling agent, a toughening agent, phosphate, a curing agent, a framework material, fillers and a dispersing agent. The preparation method comprises the following steps of: mixing the phenolic resin, the heat-resistant reinforced resin, the coupling agent and the toughening agent and then evenly stirring to obtain a phenolic resin component; then mixing the phosphate, the curing agent, the framework material and the fillers and then evenly stirring to obtain a phosphate component; and then adding the phosphate component and the dispersing agent into the phenolic resin component and evenly stirring. The adhesive can be applied in aerospace, military and machining industries with the working temperature above 800 DEG C.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

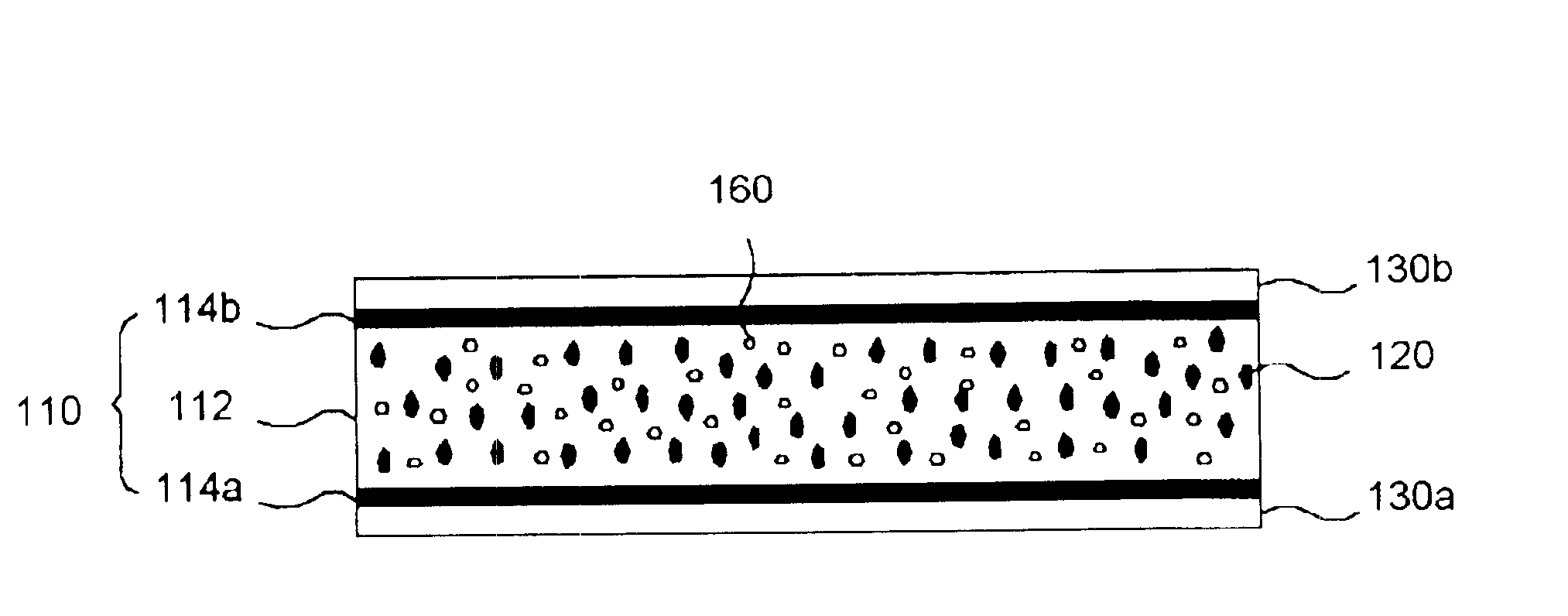

High adhesion triple layered anisotropic conductive adhesive film

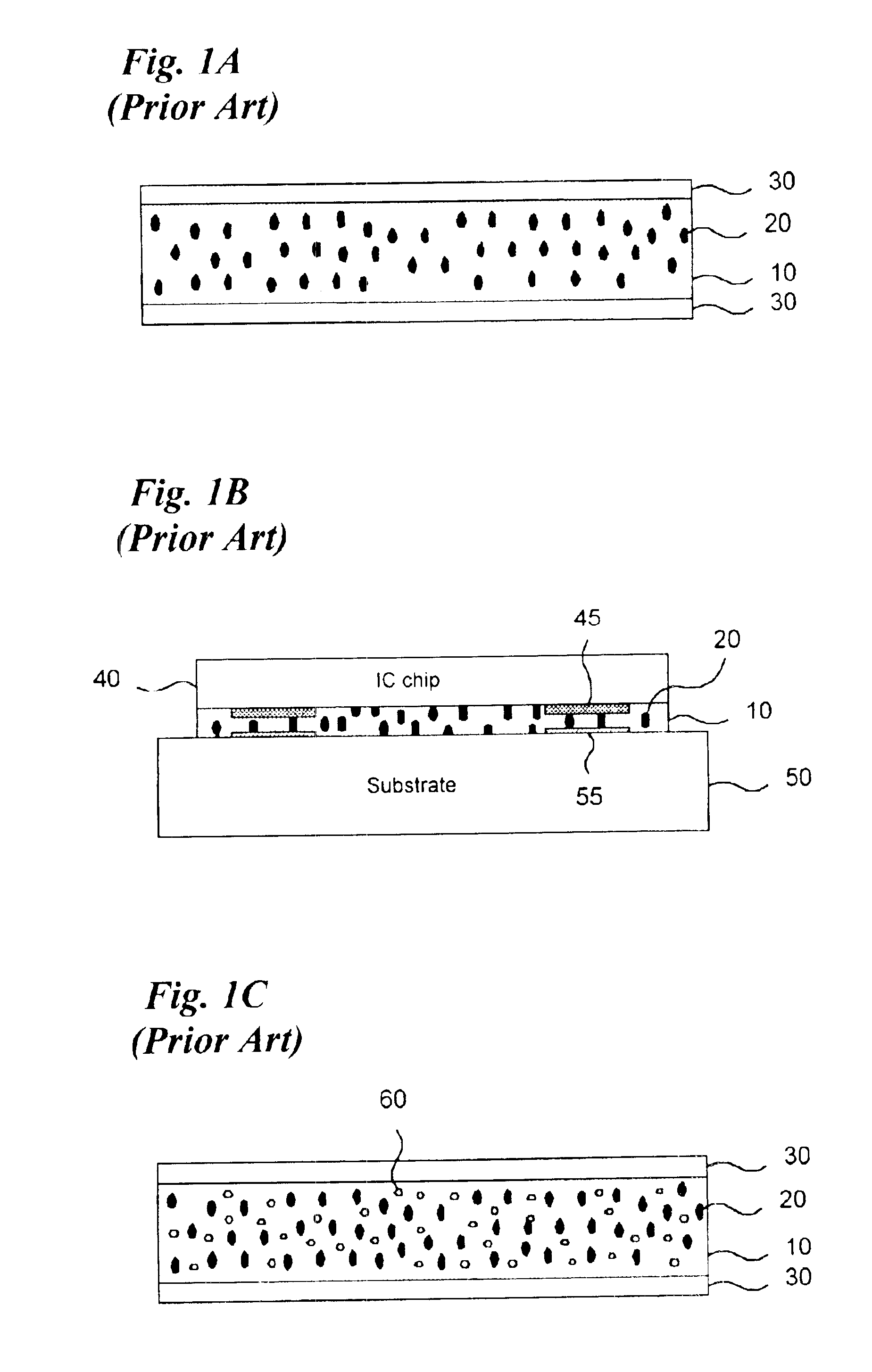

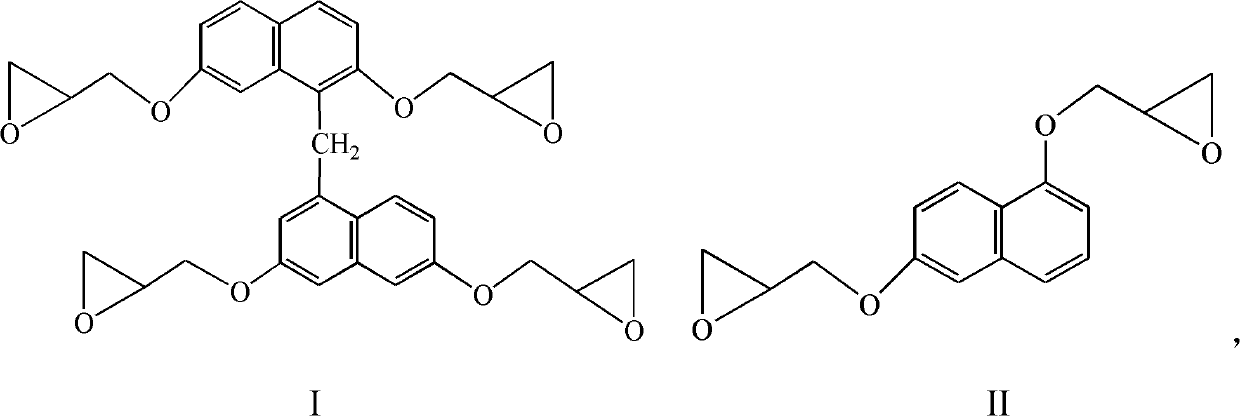

InactiveUS6878435B2High bonding strengthImprove adhesionNon-insulated conductorsSolid-state devicesEpoxyAnisotropic conductive film

Disclosed is a triple layered ACA film adapted for enhancing the adhesion strength of a typical single layer Anisotropic Conductive Film or for enhancing the adhesion strength of the ACA film in flip chip bonding. The triple layered ACA film of the invention comprises: a main ACA film based upon epoxy resin and containing conductive particles having a particle size of 3 to 10 μm and optionally non-conductive particles having a particle size of 0.1 to 1 μm; and adhesion reinforcing layers based upon epoxy resin and formed at both sides of the main ACA film.

Owner:KOREA ADVANCED INST OF SCI & TECH

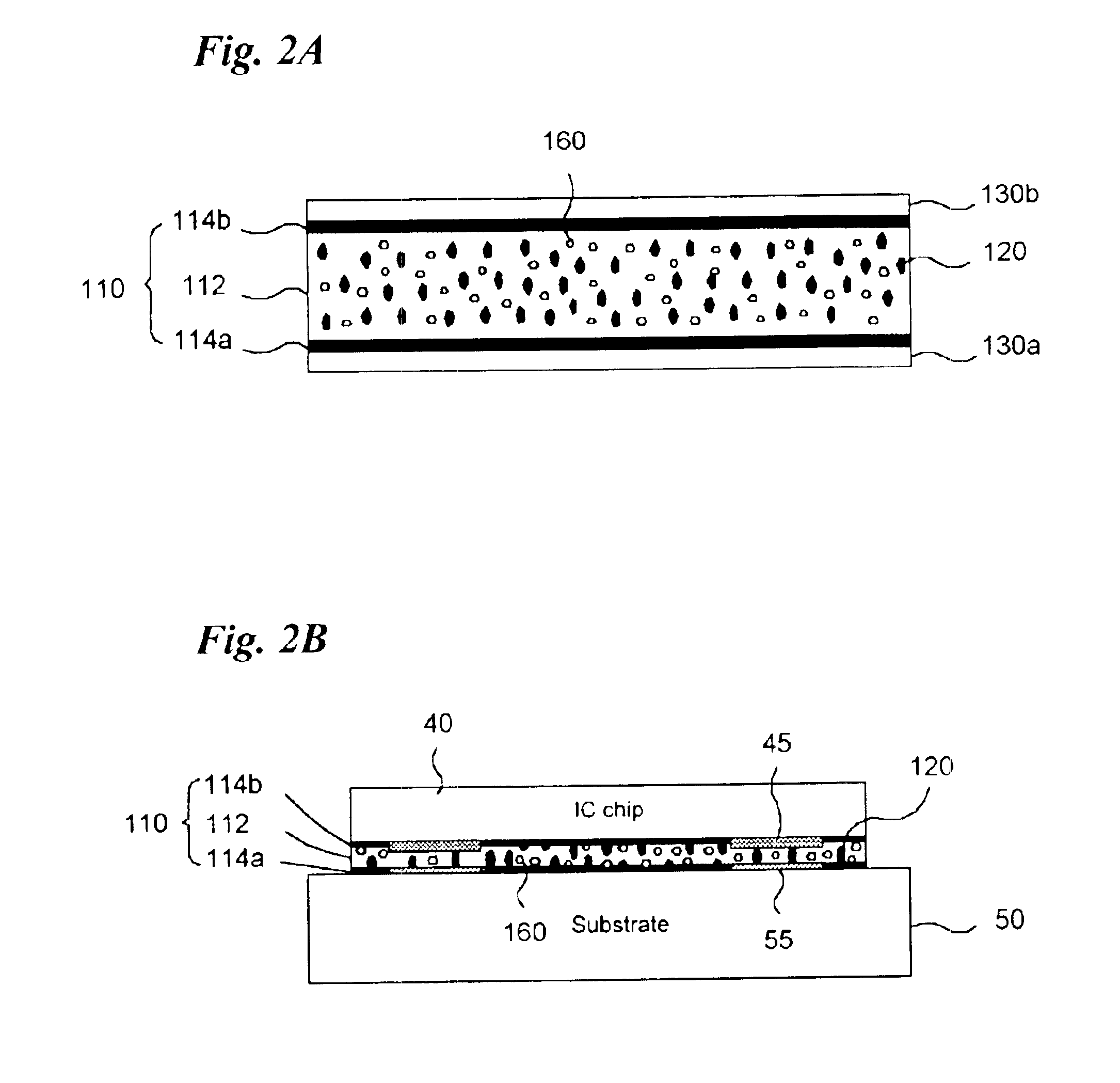

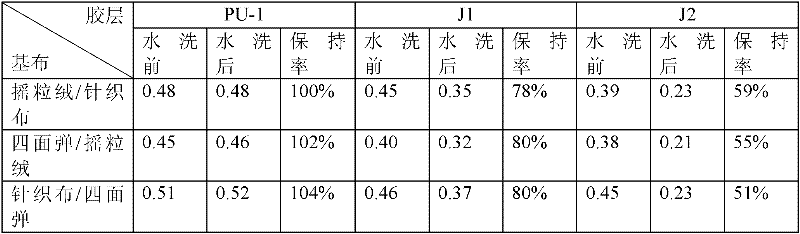

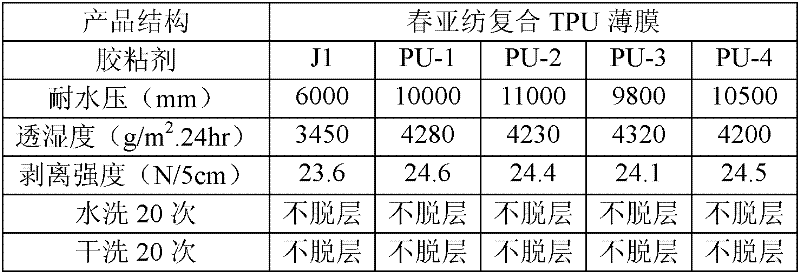

Preparation method of reactive polyurethane hot melt adhesive for fabric lamination

ActiveCN102336883AApplicable fitExcellent enzyme-resistant bacteria performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPliability

The invention relates to a preparation method of a reactive polyurethane hot melt adhesive for fabric lamination, relates to a reactive polyurethane hot melt adhesive, and belongs to the technical field of polyurethane hot melt adhesive preparation. The reactive polyurethane hot melt adhesive for fabric lamination is prepared by the following steps: heating and melting polyester polyol, polyether polyol, a chain extender, an adhesive force accelerant and an antioxidant and mixing uniformly, drying in vacuum for dewatering, adding isocyanate, a catalyst and a silane coupling agent, and reacting under nitrogen protection. The prepared reactive polyurethane hot melt adhesive for fabric lamination has the characteristics that: after being heated, the hot melt adhesive becomes molten thick state because of physical crosslinking generated under the action of hydrogen bonds, and then becomes original physical property after being cooled; the hot melt adhesive not only has excellent enzyme bacteria resistance, higher adhesion strength and good flexibility, water resistance, waterproof and moisture permeable properties and the like, but also does not contain volatile organic solvents, has excellent environmental friendliness, and is suitable for the lamination of various fabrics and the lamination of fabrics and waterproof and moisture permeable thin films.

Owner:WUXI WANLI ADHESION MATERIALS

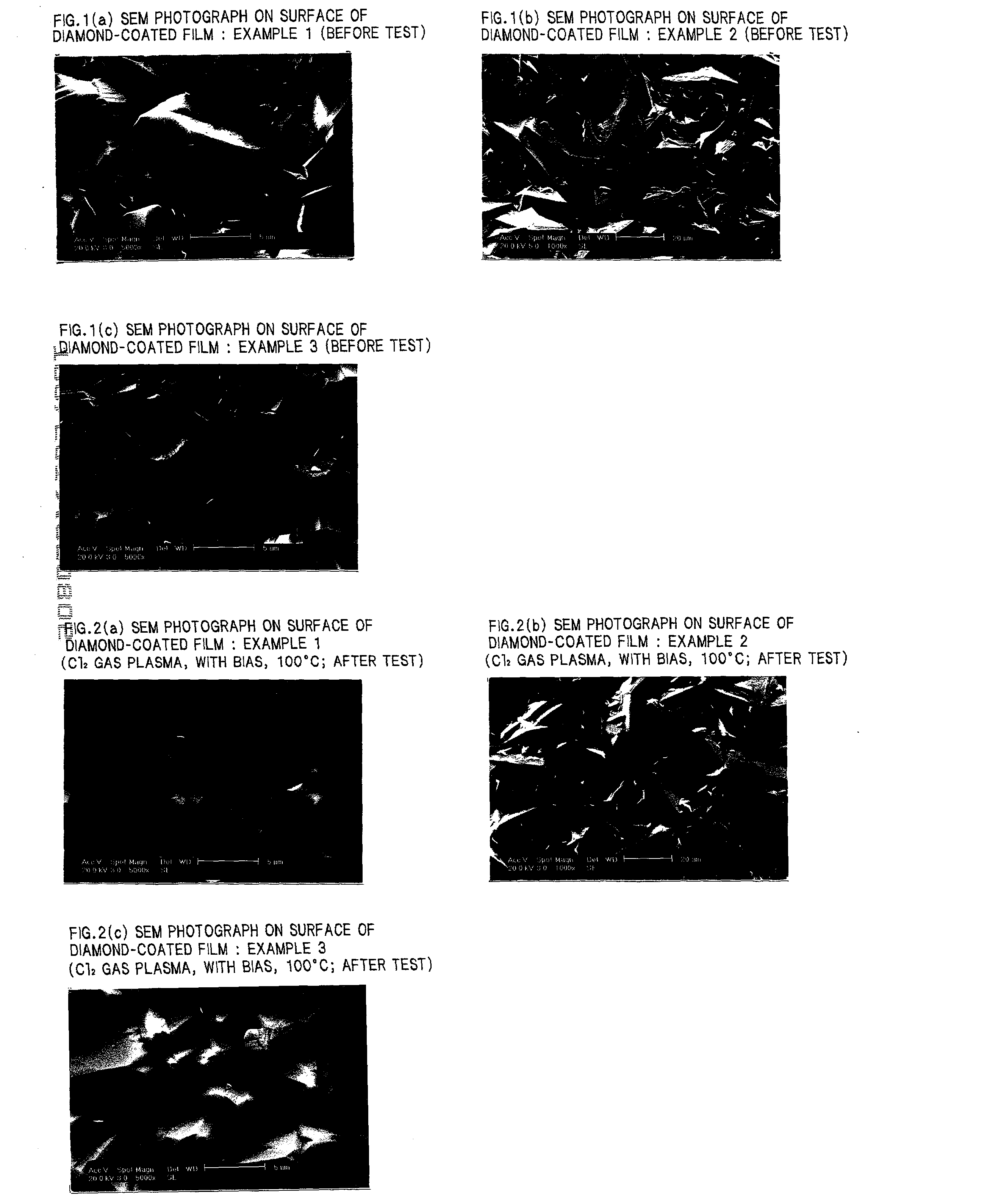

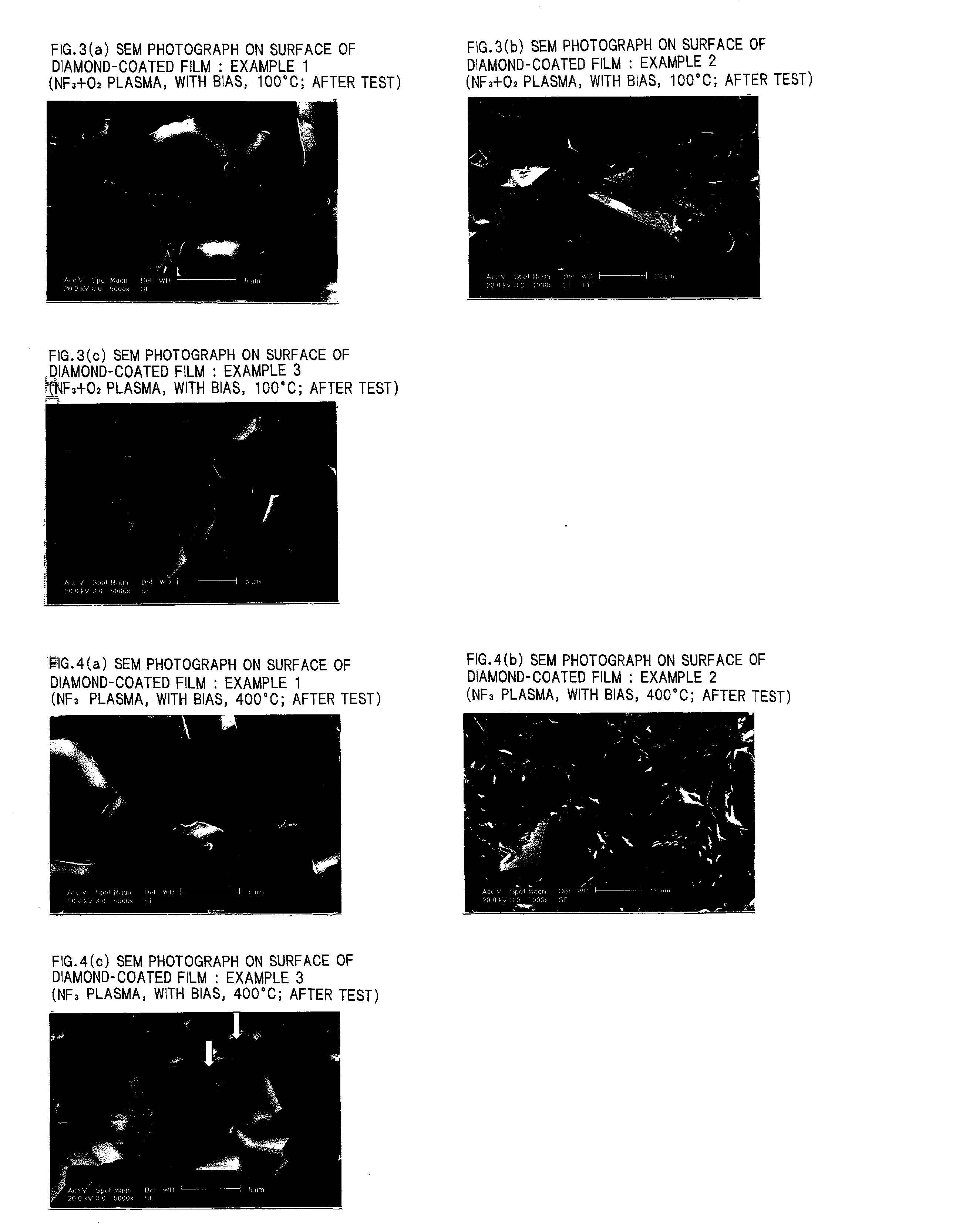

Diamond-coated member

InactiveUS20030064225A1Polycrystalline material growthElectric discharge tubesSusceptorAdhesion strength

A diamond-coated member includes a basal material such as aluminum nitride, and a diamond thin film coating at least one part of a surface of the basal material, being adhered thereto, and has corrosion-erosion resistance. Adhesion strength between the thin film and the basal material is 15 MPa or more. Or, in diamond thin film, degree of orientation of diamond {220} plane present in faces parallel to the basal material is expressed by following formula: [Im220 / (Im220+Im111)] / [Ip220 / (Ip220+Ip111)]<1. The diamond-coated corrosion-erosion resistant member has excellent corrosion-erosion resistance, and is used mainly for a semiconductor producing apparatus; being preferably applied as a member inside a reaction chamber where a substrate, represented by silicon wafer, is exposed to plasma, corrosion gas or the like, inclusive of rings, a chamber inner lining, a gas shower plate, nozzles, a susceptor, an electrostatic chuck, a heater, or the like.

Owner:NGK INSULATORS LTD

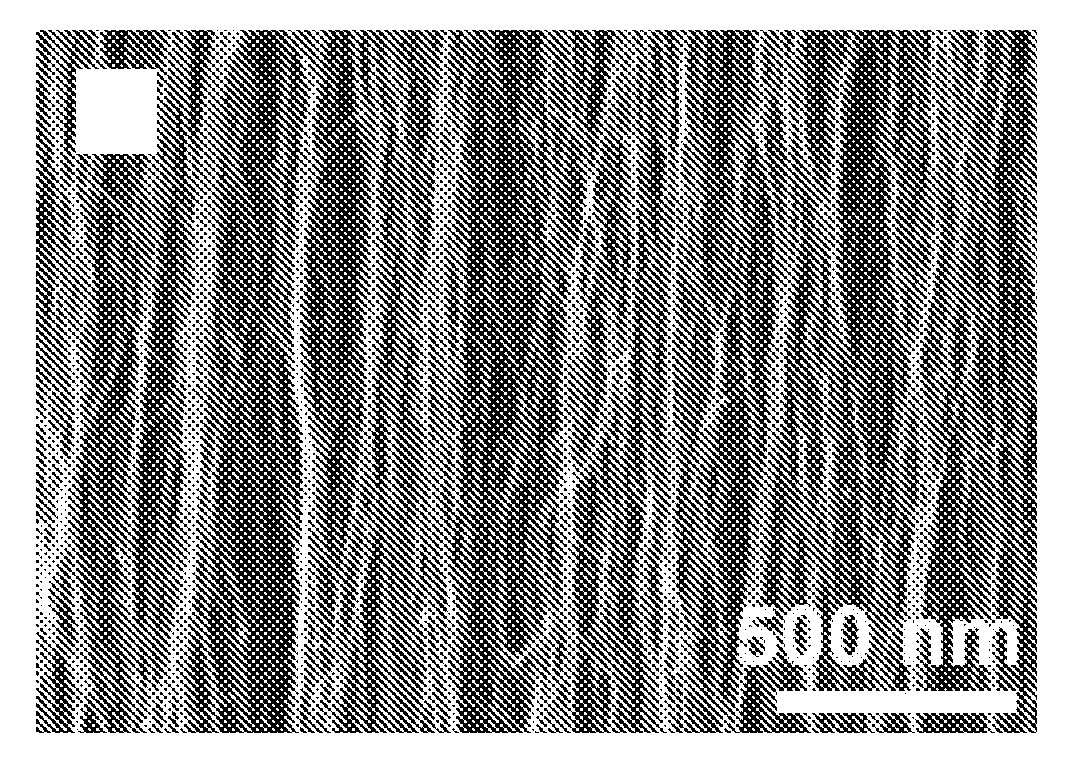

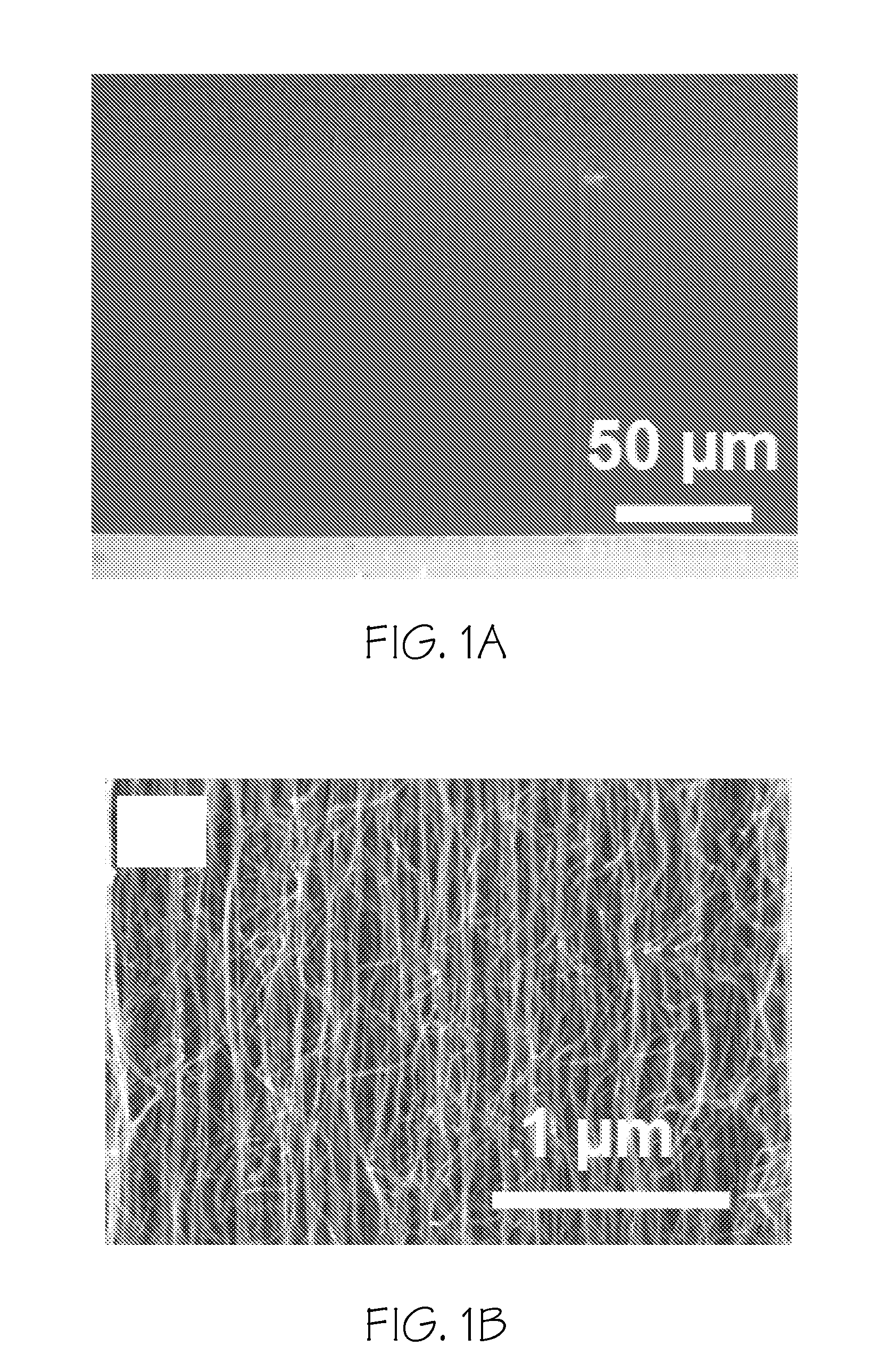

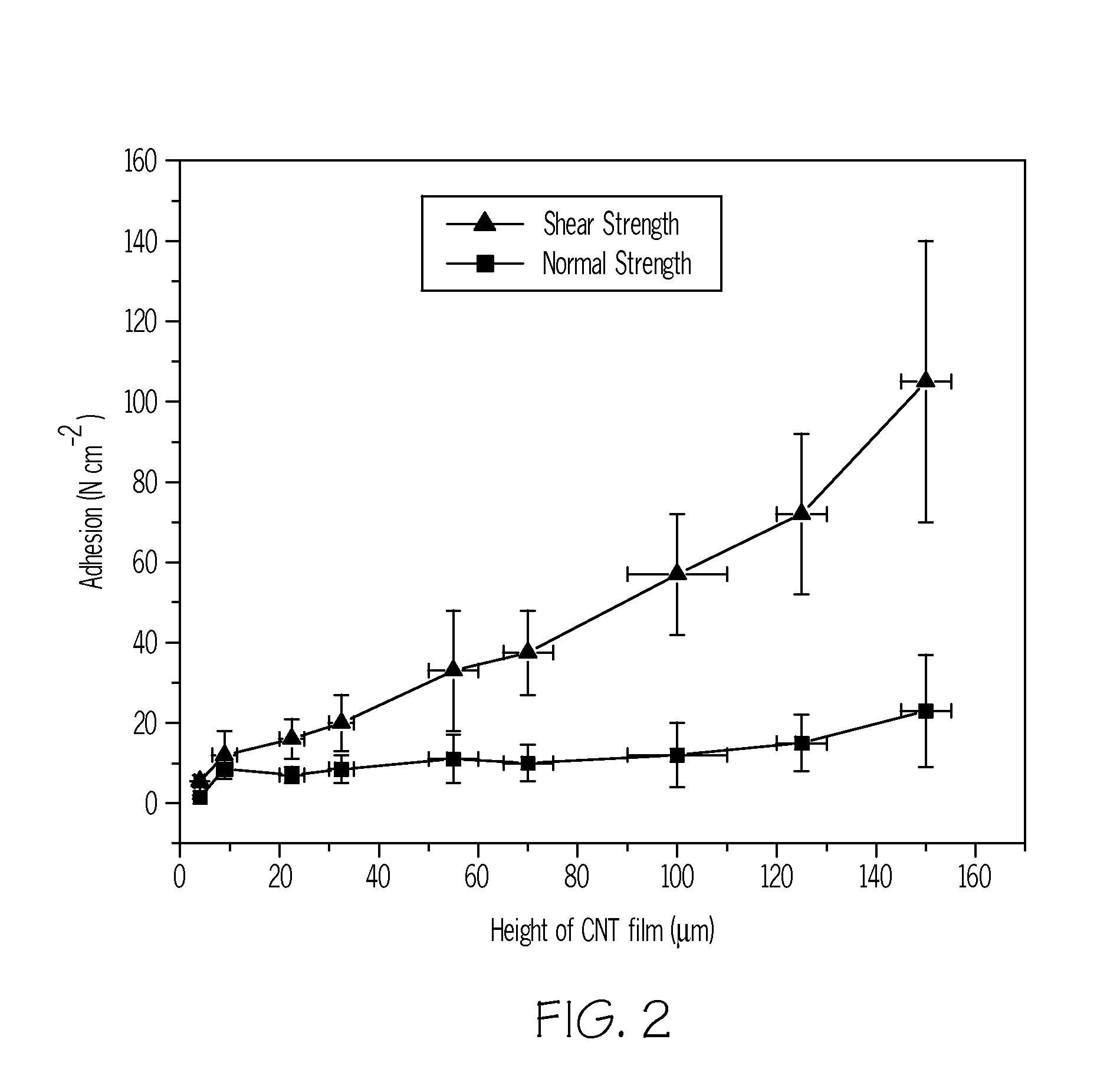

Aligned carbon nanotubes for dry adhesives and methods for producing same

A nanocomposite dry adhesive. The nanocomposite dry adhesive includes a substrate; and an array of vertically aligned single-walled carbon nanotubes or vertically aligned multi-walled carbon nanotubes on the substrate, wherein the nanocomposite dry adhesive utilizes the array of single-walled carbon nanotubes or multi-walled carbon nanotubes as synthesized, the as synthesized single-walled carbon nanotubes being substantially free of randomly entangled nanotube segments on top of the vertically aligned single-walled carbon nanotubes, the as synthesized multi-walled carbon nanotubes having randomly entangled nanotube segments on top of the vertically aligned multi-walled carbon nanotubes; wherein the dry adhesive has a normal adhesion strength of at least about 5 N·cm−2, and a shear adhesion strength of at least about 13 N·cm−2. Methods of making a nanocomposite dry adhesive are also described.

Owner:UNIV OF DAYTON

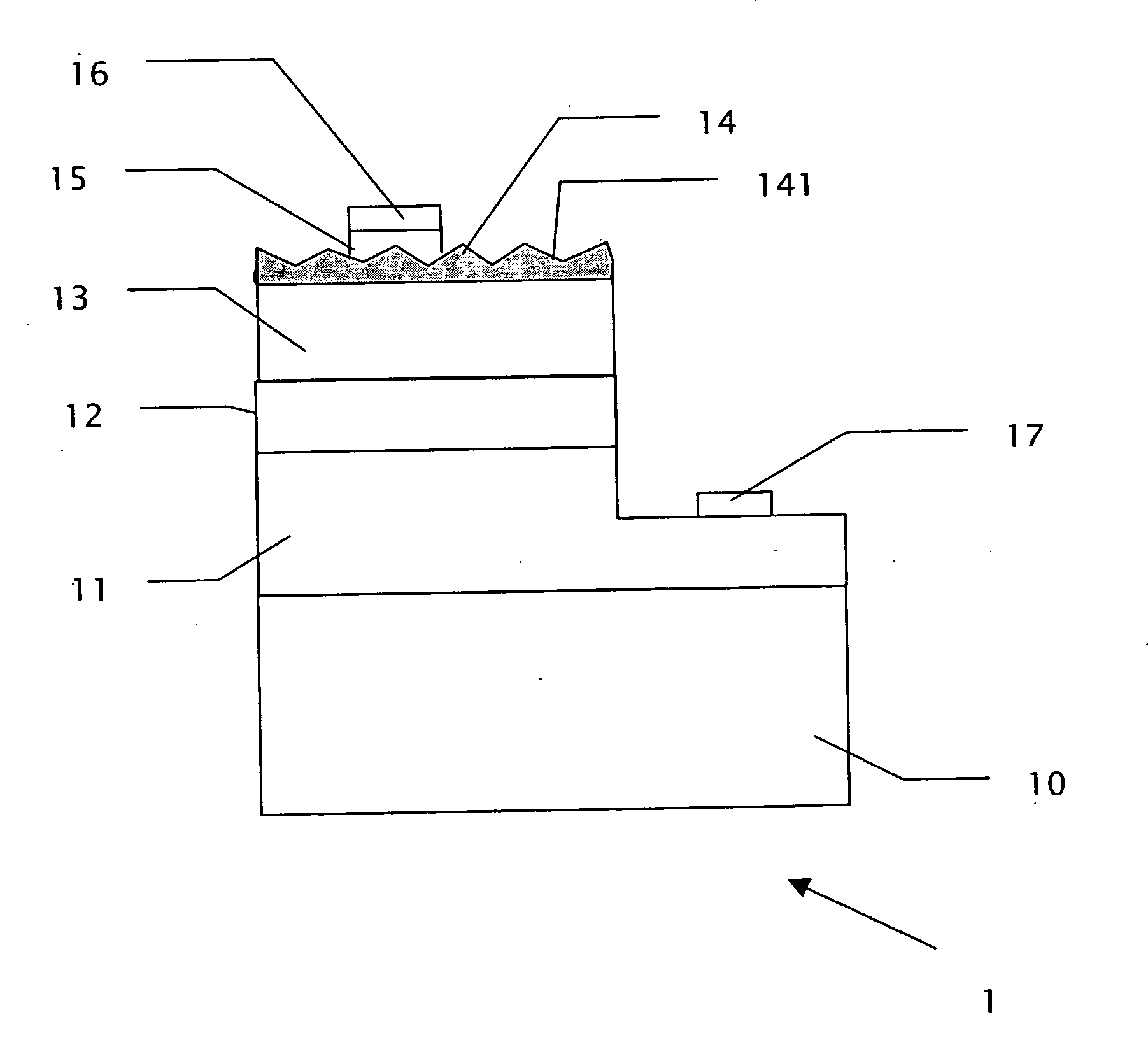

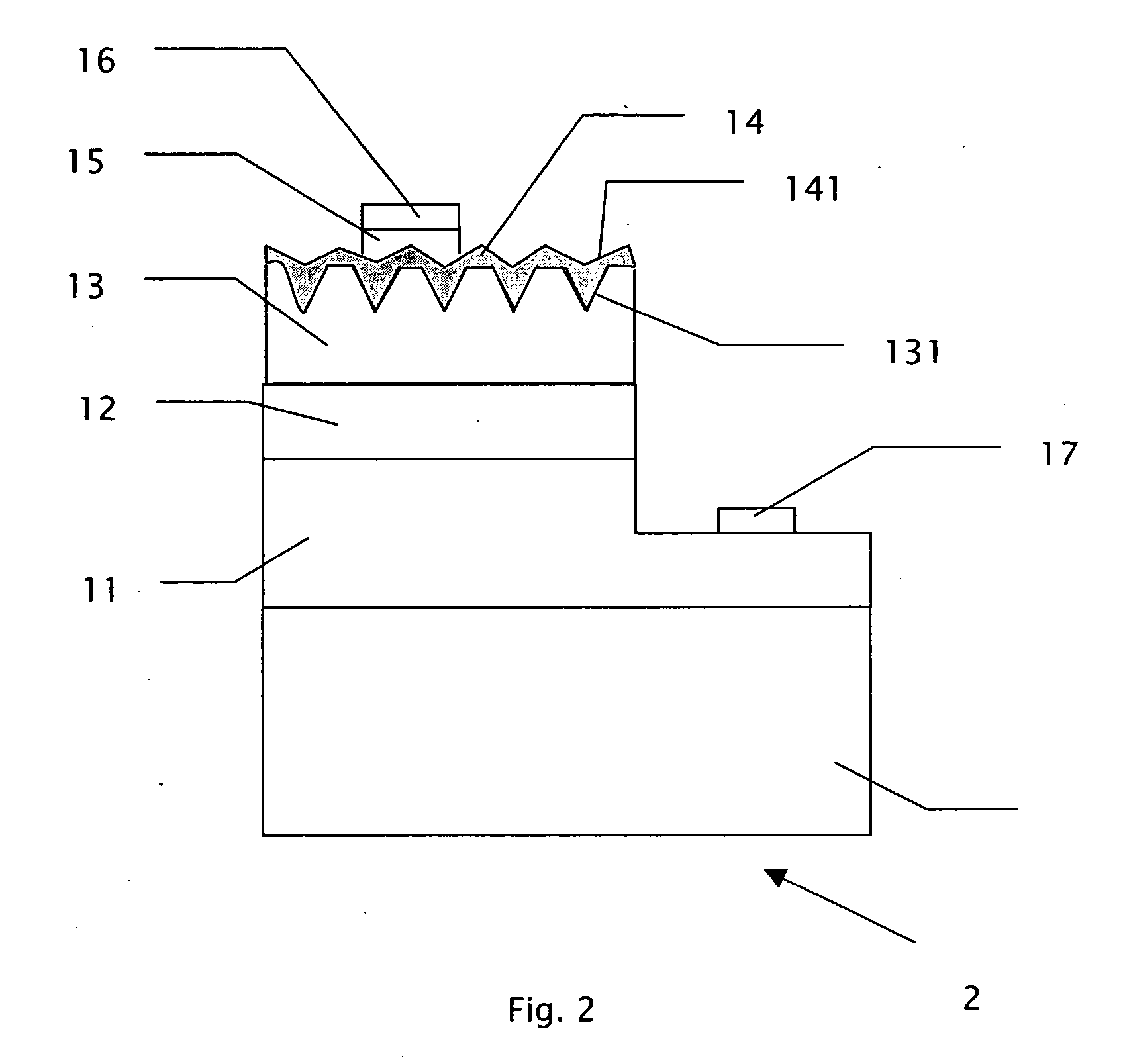

Light-emitting apparatus

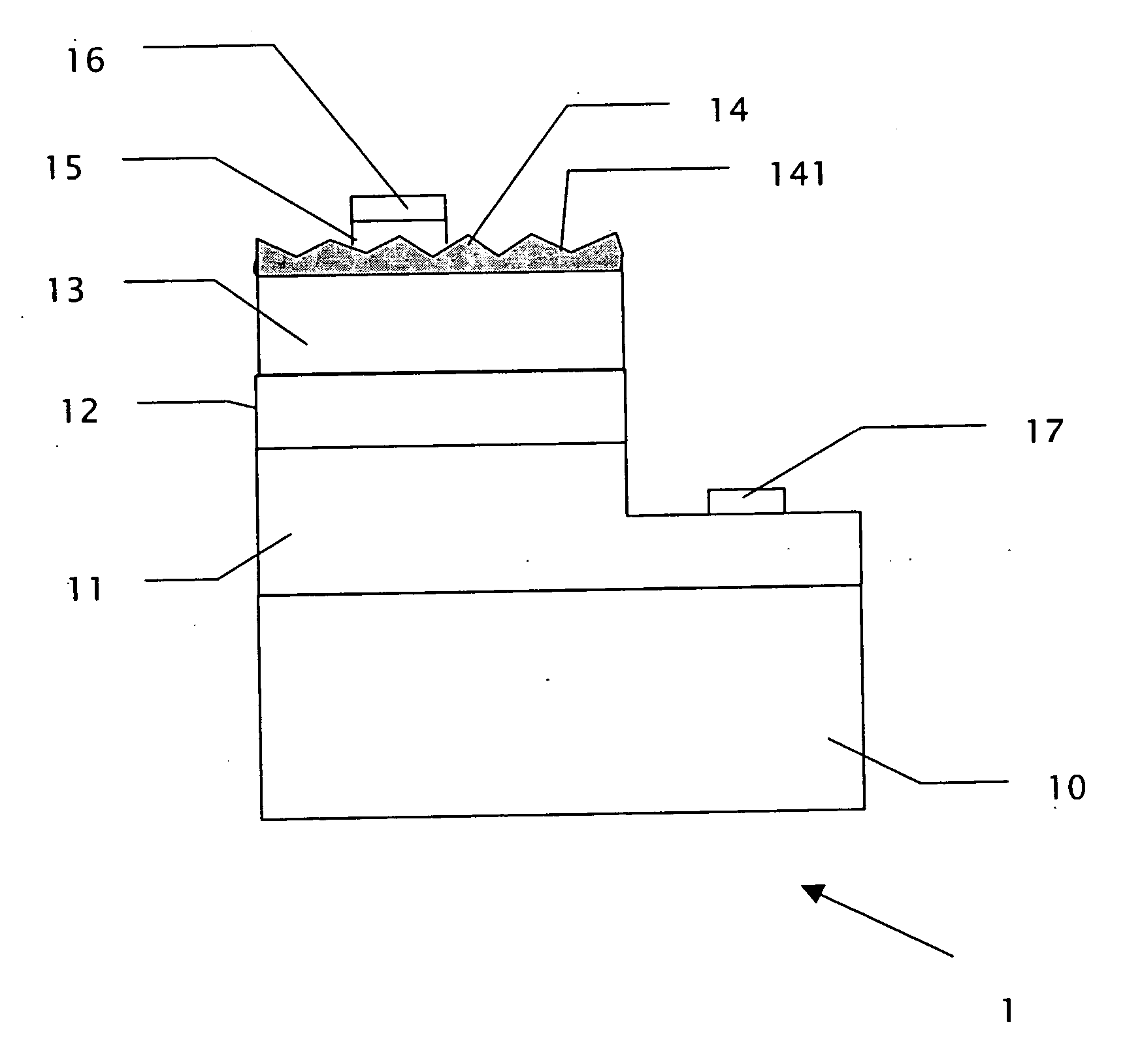

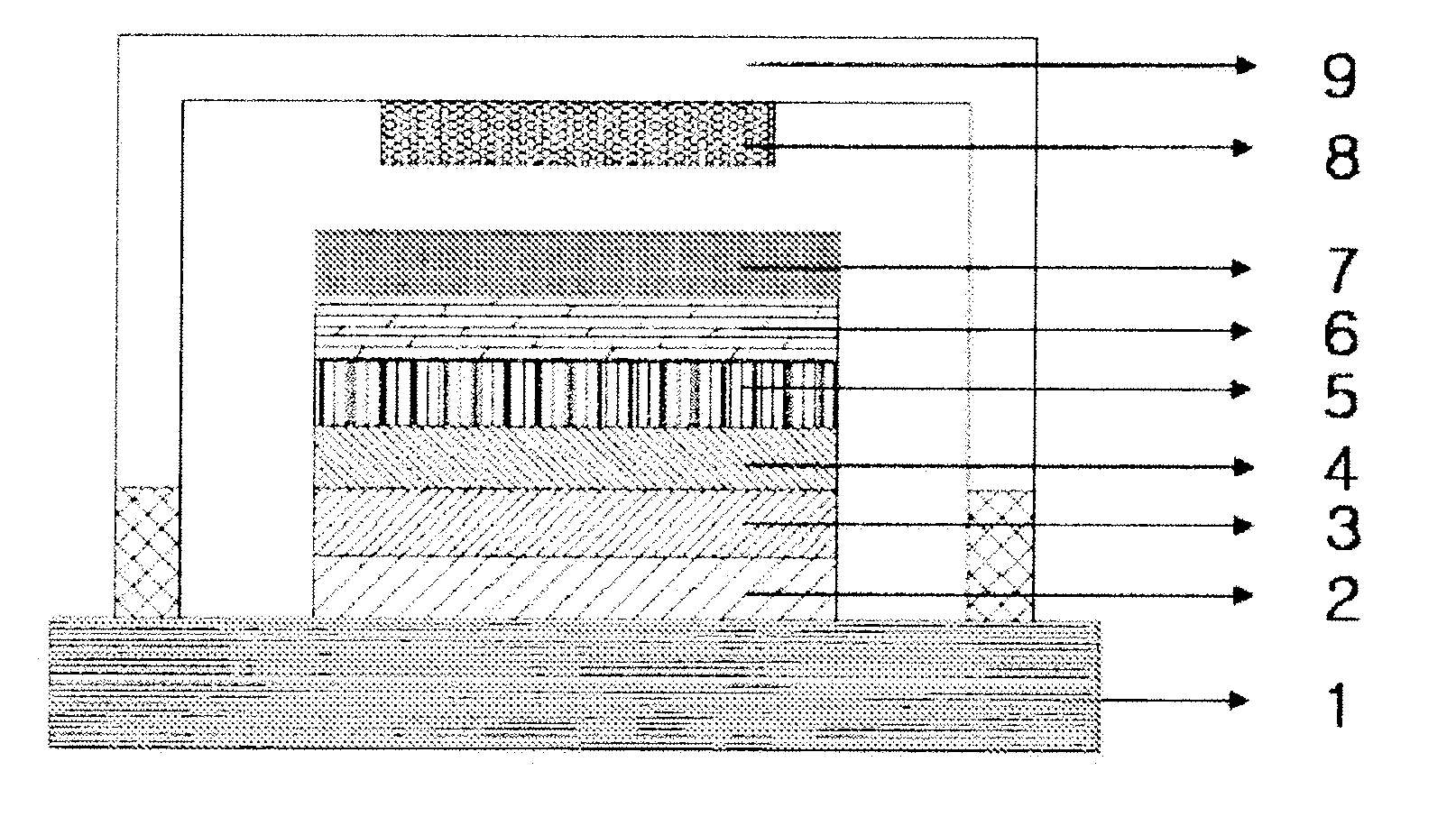

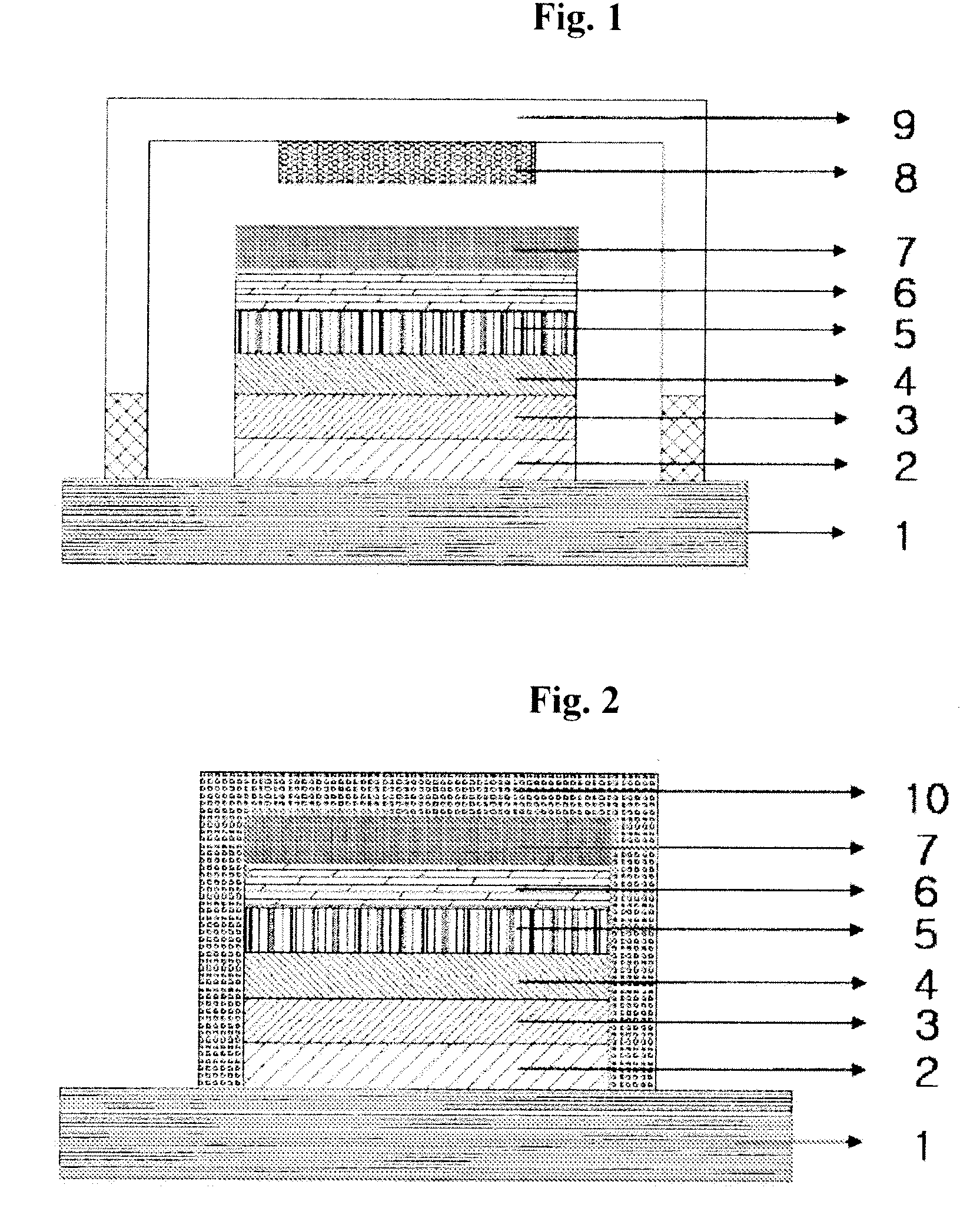

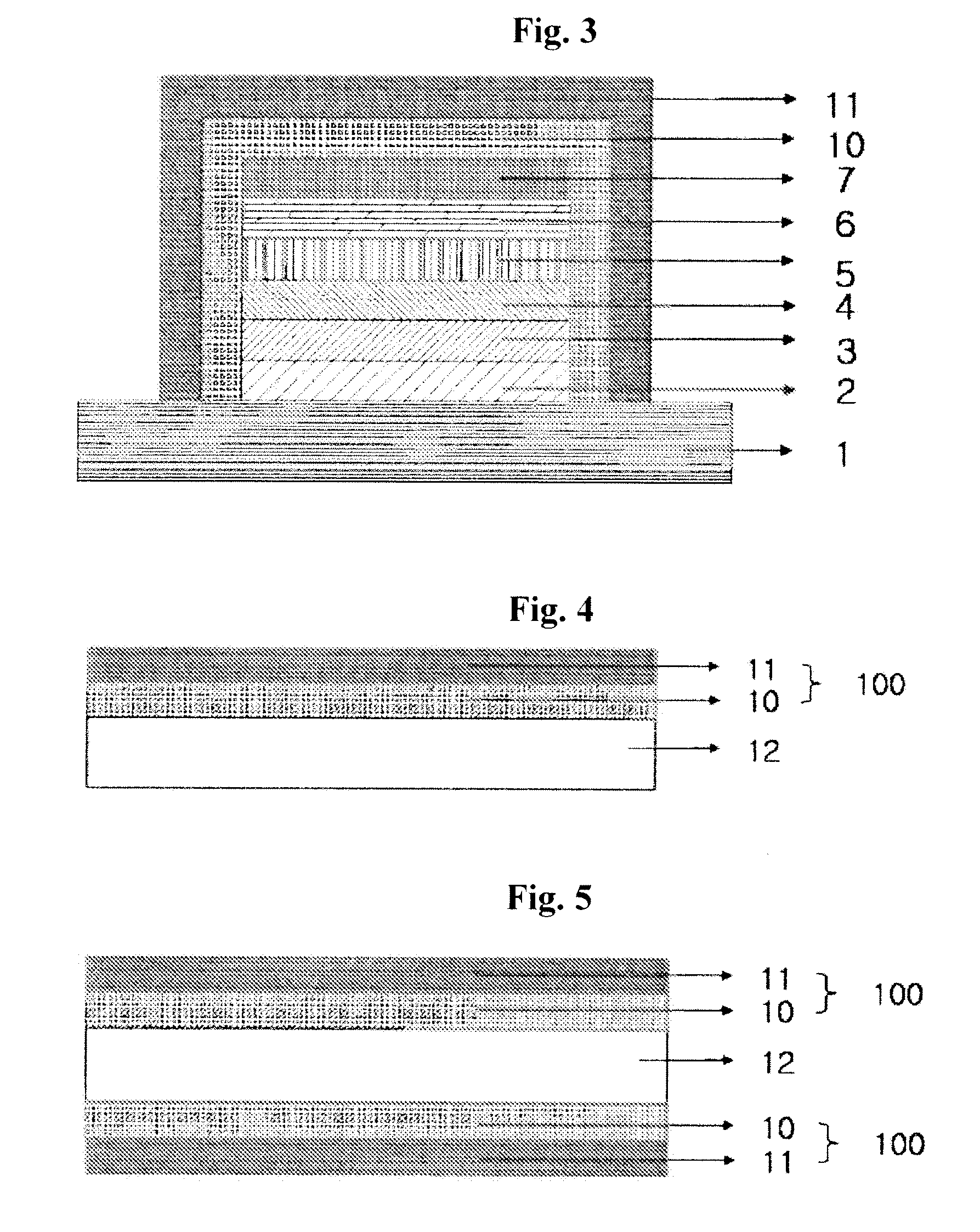

InactiveUS20070200493A1Improve light extraction efficiencyReduce light areaDischarge tube luminescnet screensLamp detailsAdhesion strengthLight emitting device

The light-emitting apparatus comprises a substrate, a first semiconductor layer formed on the substrate, a light-emitting layer formed on the first semiconductor layer, a second semiconductor layer formed on the light-emitting layer, a first transparent conductive oxide layer formed on the second semiconductor layer, a reflective metal layer form on the transparent conductive oxide layer, and a first electrode formed on the reflective metal layer; characterized in that the first transparent conductive oxide layer is formed with a plurality of cavities on the interface between the first transparent conductive oxide layer and the reflective metal layer for improving the adhesion strength therebetween.

Owner:EPISTAR CORP

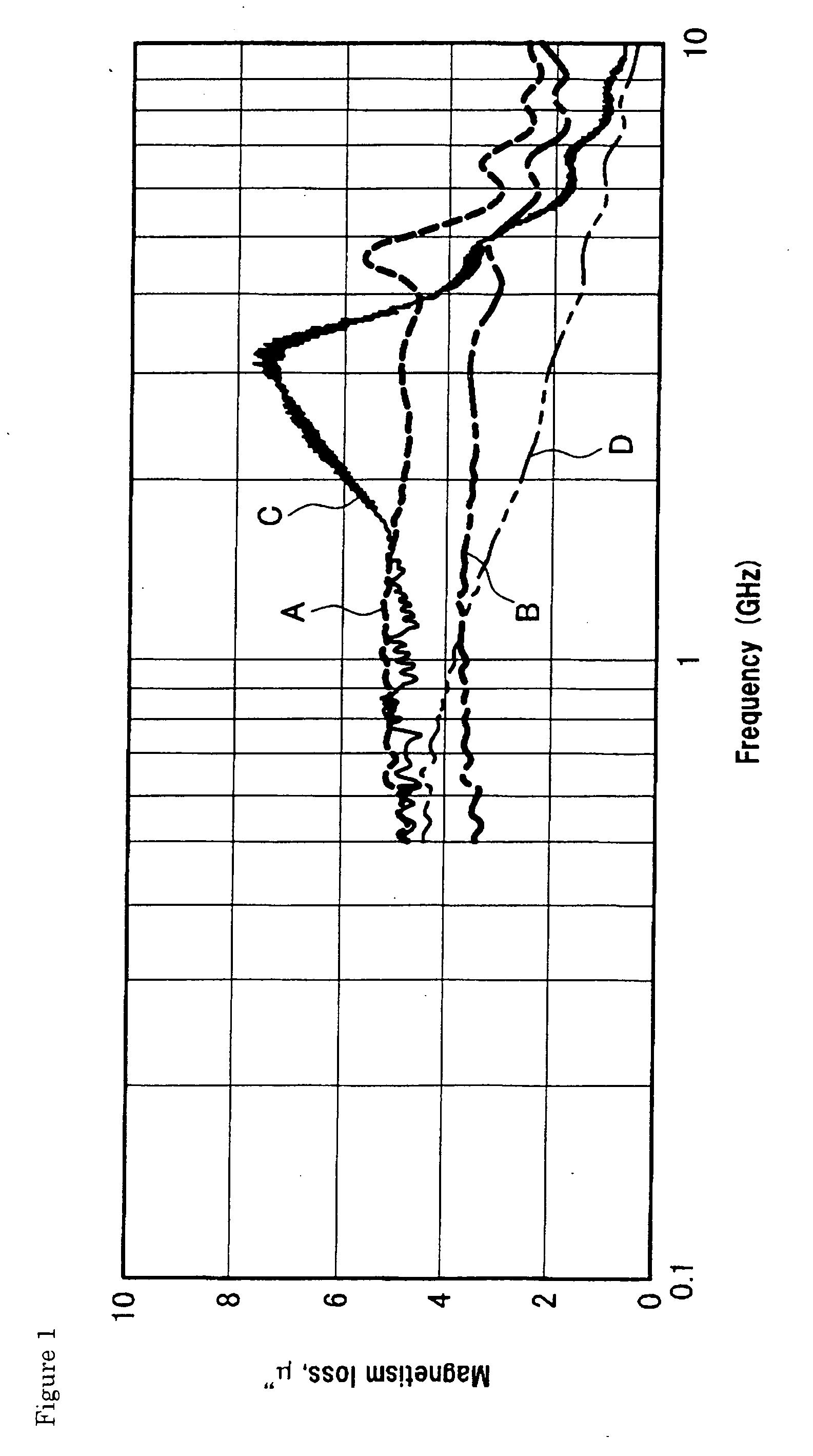

Electromagnetic wave absorber

InactiveUS20070196671A1Improve rendering capabilitiesImprove flame retardant performancePigmenting treatmentNanomagnetismHigh resistanceElectromagnetic wave absorber

Owner:GELTEC

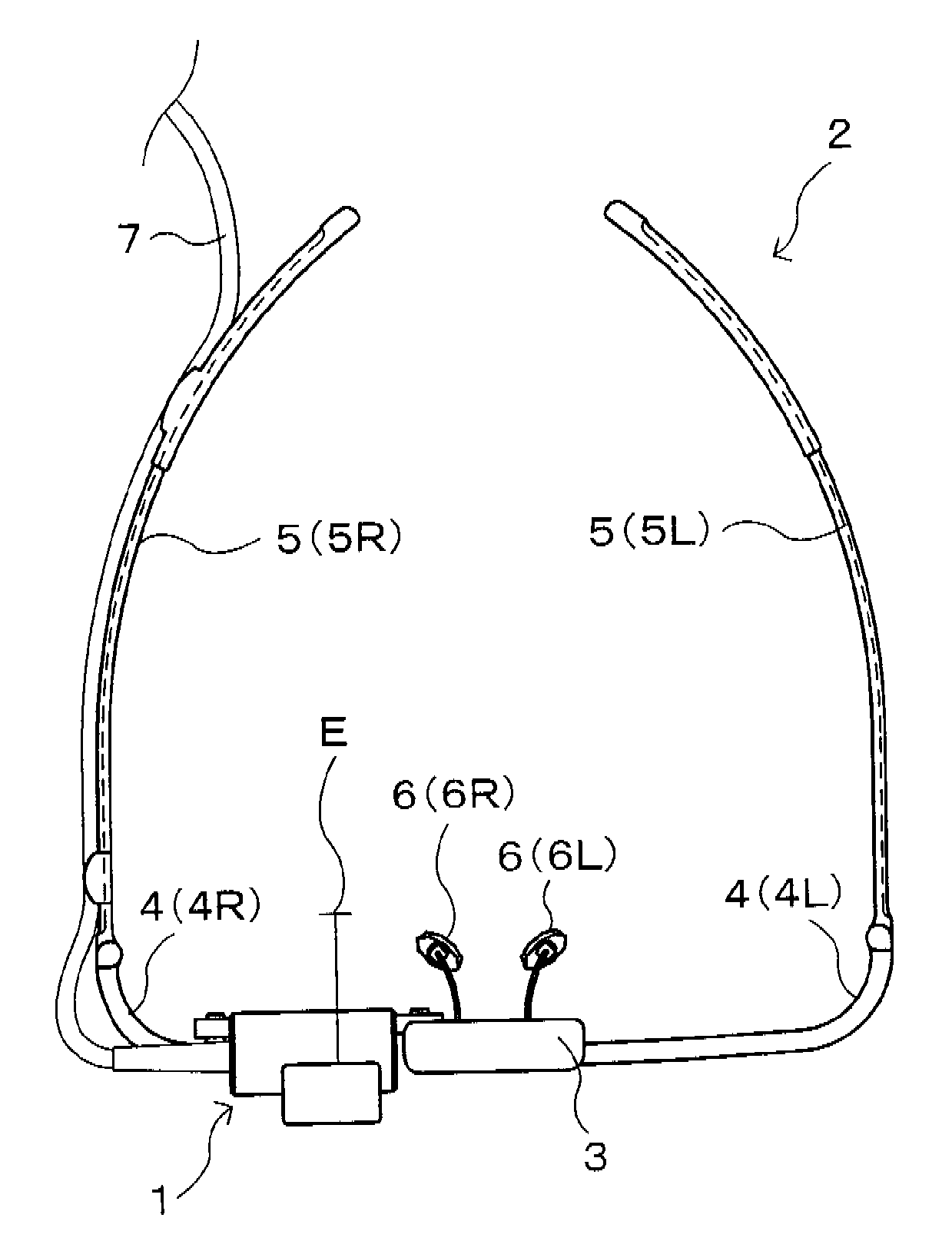

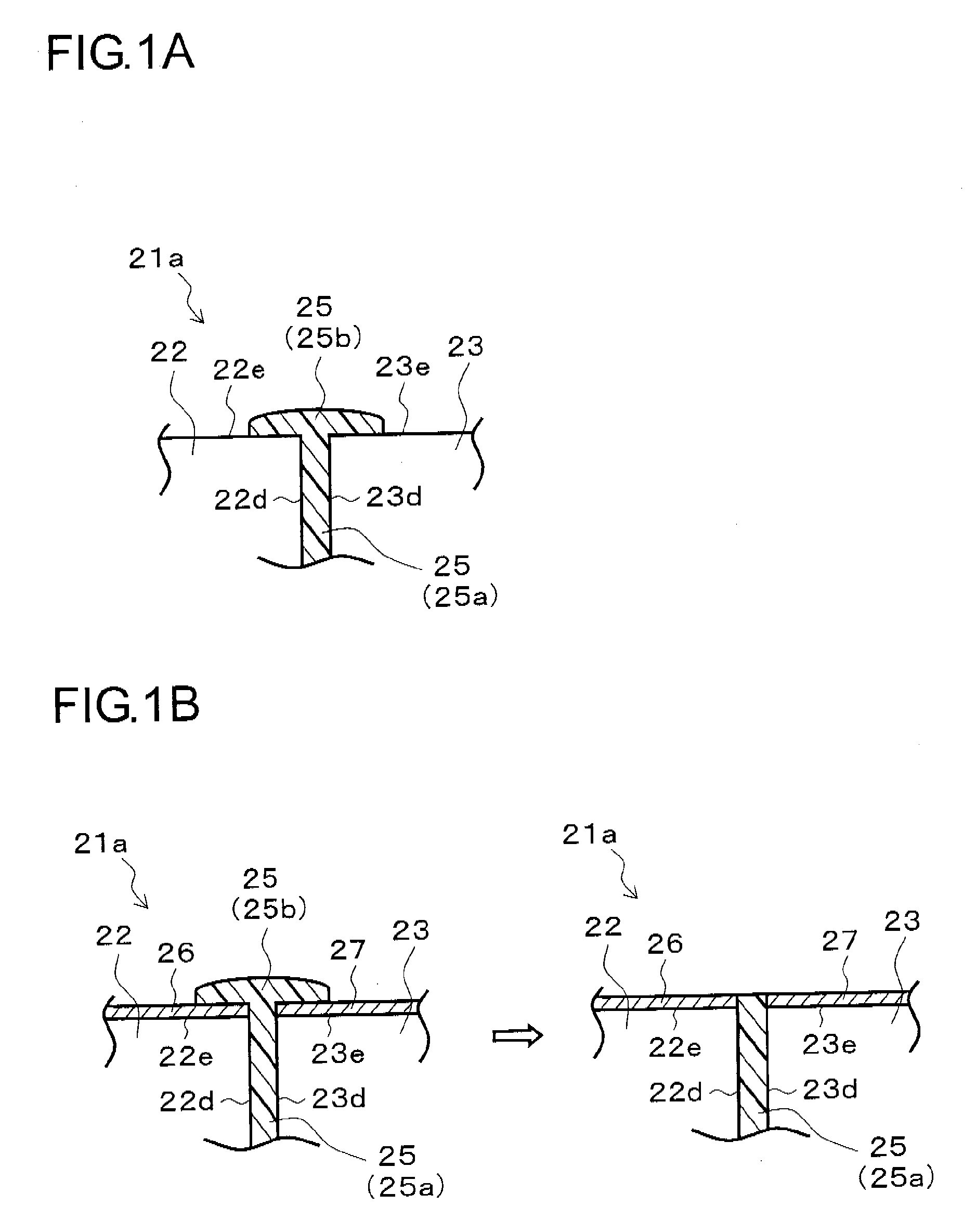

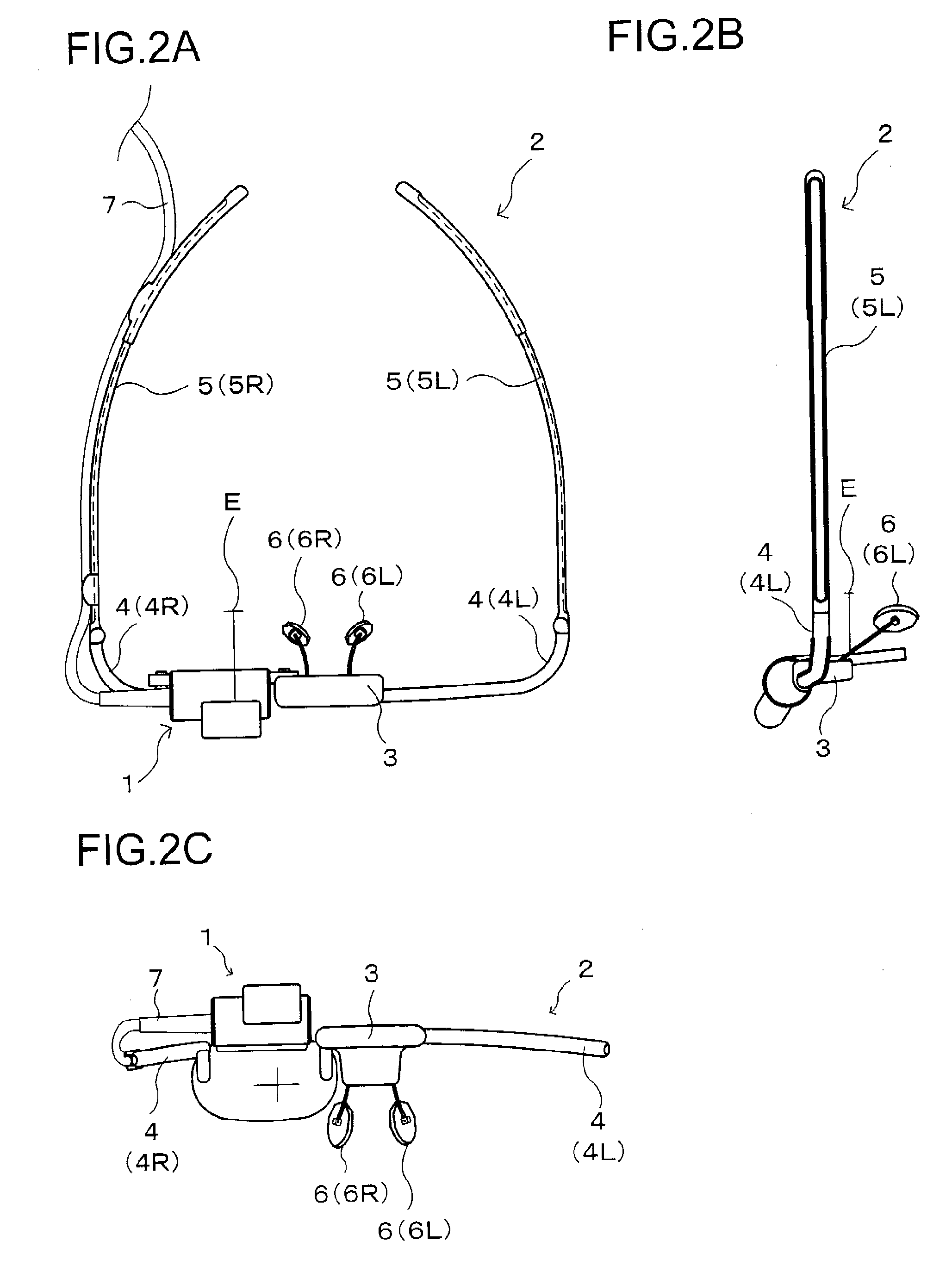

Joined optical member, image display apparatus, and head-mounted display

InactiveUS20080239422A1Good optical performanceStrong effect of preventingOptical articlesPolarising elementsEyepieceDisplay device

In a joined optical member, let the adhesion strength between a surface coating layer and an eyepiece prism be A1, the adhesion strength between the surface coating layer and a deflector prism be A2, the adhesion strength between the surface coating layer and adhesive be A3, and the adhesion strength between, at one end, the adhesive and, at the other, the eyepiece prism and the deflector prism be A4, then A1 (A2)>S3 and simultaneously A4>A3. This makes removal of superfluous adhesive on the surface coating layer easy, and prevents scratches on the exterior surfaces. Even after removal of superfluous adhesive, the surface coating layer remains on the exterior surfaces of the eyepiece prism and the deflector prism. This prevents scratches on the exterior surfaces in actual use, and prevents degradation of optical performance.

Owner:KONICA MINOLTA INC

Plasma resistant member, manufacturing method for the same and method of forming a thermal spray coat

InactiveUS20060037536A1High bonding strengthAvoid it happening againLiquid surface applicatorsMolten spray coatingPorositySurface layer

The present invention concerns a plasma resistant member comprising Y2O3 or YAG thermal performed thermal spray on an alumina base material, wherein the surface roughness Ra of the alumina base material is 5 μm or more and 15 μm or less. By rendering the surface layer of the alumina base material porous to a porosity of 20% or more and 60% or less to a depth of ranging from 10 μm to 1O0 μm, aplasma resistant member having an enhanced adhesion strength can be provided. The aforementioned plasma resistant member can be produced by subjecting the surface of analumina base material to chemical etching, and then performing thermal spray Y2O3 or YAG on the roughened surface of the alumina base material to form a plasma resistant layer.

Owner:COVALENT MATERIALS CORP

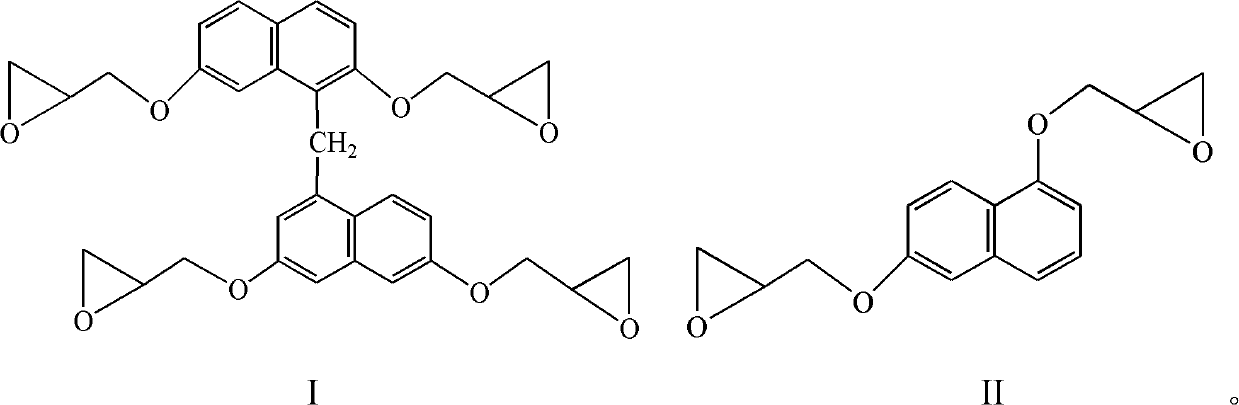

Bi-component adhesive composition and preparation method thereof

ActiveCN103305170AHigh bonding strengthImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesNitrile rubberHeat resistance

The invention provides a bi-component adhesive composition composed of an A component and a B component. The A component contains an epoxy resin mixture, a first toughening agent, filler and a thixotropic agent; the B component contains a second toughening agent, a normal temperature curing agent, a high-temperature curing agent and an accelerant; the epoxy resin mixture contains a first epoxy resin, a second epoxy resin and a third epoxy resin, the first epoxy resin is a bisphenol A epoxy resin or a bisphenol A epoxy resin, the second epoxy resin is a chelate modified epoxy resin, and the third epoxy resin is a naphthalene-nucleus modified epoxy resin; the first toughening agent is a core-shell structure rubber nano particle, the second toughening agent is an end-isocyanate polyurethane and / or end-carboxy nitrile rubber. The invention further provides a preparation method of the bi-component adhesive. The adhesive composition provided by the invention is high in adhesion strength, high in heat resistance, low in water adsorption, high in impact resistance, and capable of satisfying the use requirement of structural adhesive for connecting structural members of an automobile.

Owner:BYD CO LTD

Semiconductor device

InactiveUS20020047187A1Semiconductor/solid-state device detailsSolid-state devicesConductive pasteSemiconductor chip

The present invention provides a semiconductor device whose reliability is improved by improving the adhesion strength of a metal plate or connecting chip, said plurality of electrodes and a lead frame with a molding resin. Further, the semiconductor device of the present invention prevents flow out of a conductive joining material to be employed for joining a lead terminal and the metal plate other than the joining range of the metal plate and the lead terminal, and mounts the metal plate at high precision. In a semiconductor device (a plastic package) in which a source electrode of a semiconductor chip and source terminal of a lead frame are electrically connected by a copper plate and sealed by a resin, the surface of the copper plate is roughened to improve the adhesion strength to a molding resin. Further, a stepped part is formed in the source terminal to prevent a conductive paste from flowing out. The structure is so formed as to fit claw parts in the lead frame.

Owner:RENESAS ELECTRONICS CORP

Organic/inorganic hybrid thin film passivation layer for blocking moisture/oxygen transmission and improving gas barrier property

ActiveUS20090215279A1Avoid transmissionEnsure stabilityMaterial nanotechnologyElectroluminescent light sourcesLayer interfaceTransmittance

The present invention relates to an organic / inorganic hybrid thin film passivation layer comprising an organic polymer passivation layer prepared by a UV / ozone curing process and an inorganic thin film passivation layer for blocking moisture and oxygen transmission of an organic electronic device fabricated on a substrate and improving gas barrier property of a plastic substrate; and a fabrication method thereof. Since the organic / inorganic hybrid thin film passivation layer of the present invention converts the surface polarity of an organic polymer passivation layer into hydrophilic by using the UV / ozone curing process, it can improve the adhesion strength between the passivation layer interfaces, increase the light transmission rate due to surface planarization of the organic polymer passivation layer, and enhance gas barrier property by effectively blocking moisture and oxygen transmission.

Owner:KOREA INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com