Patents

Literature

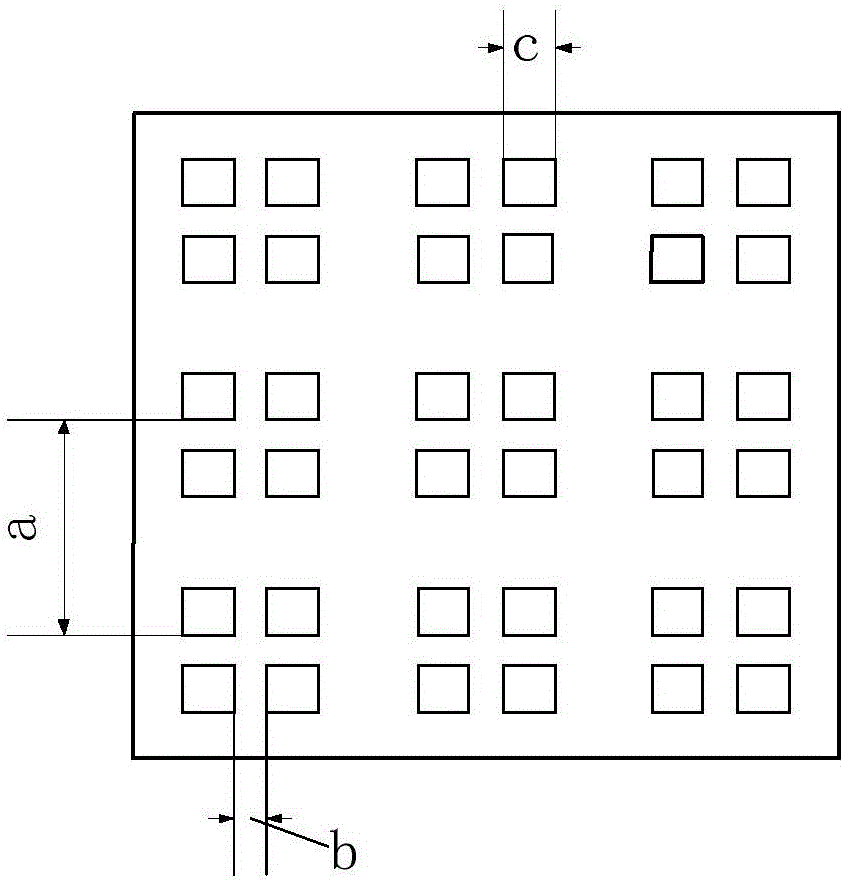

206 results about "Electromagnetic wave absorber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

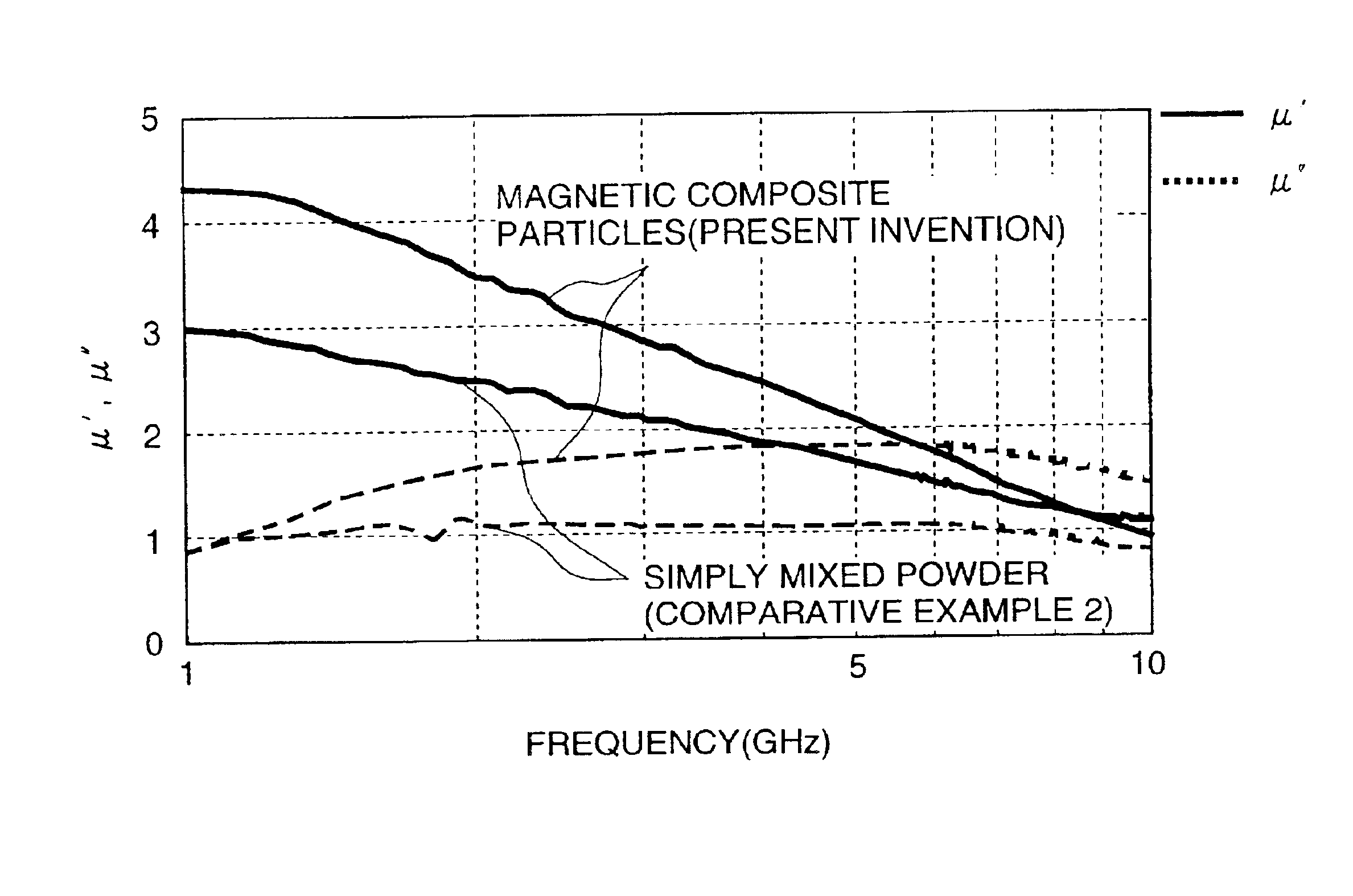

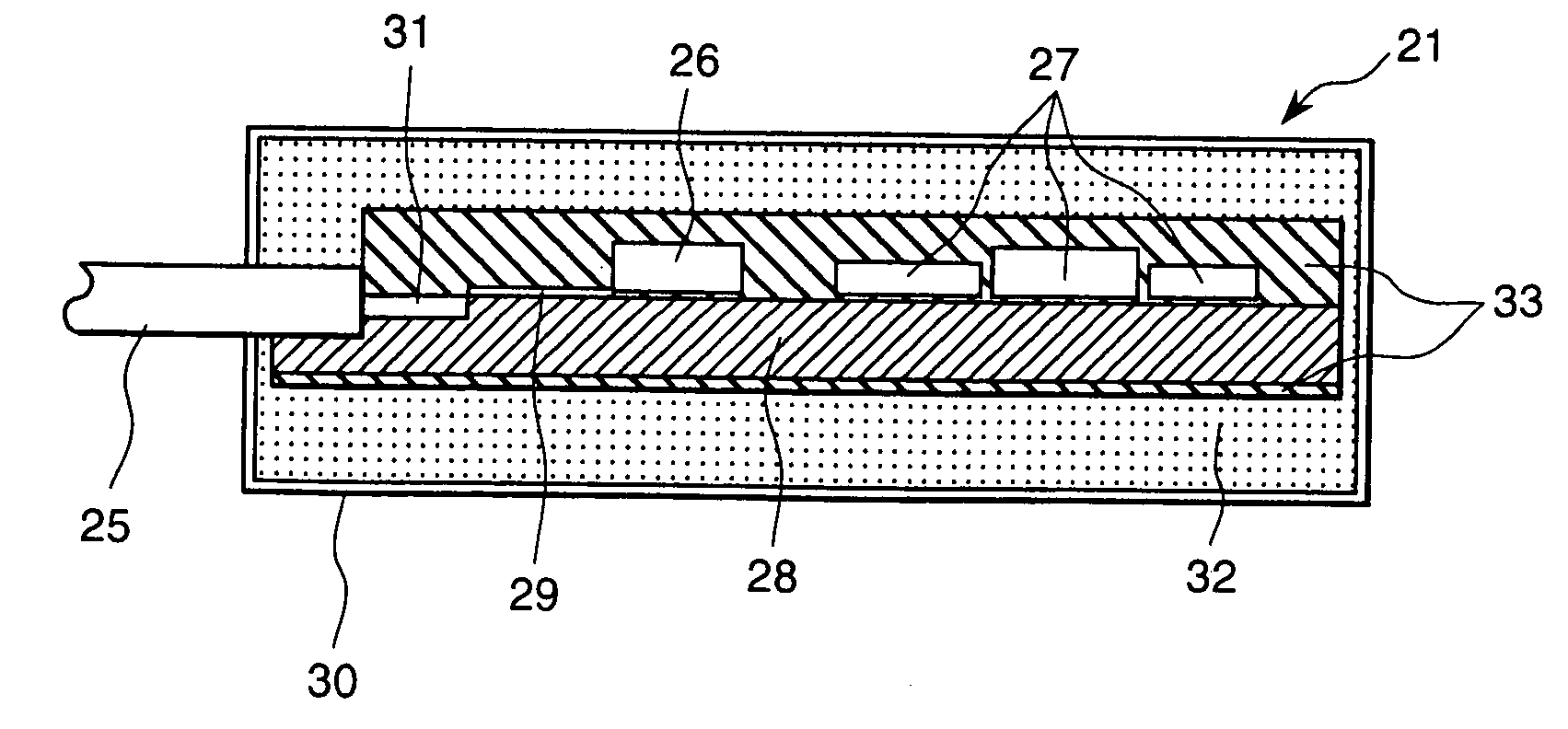

Electromagnetic wave absorber

InactiveUS20090135042A1High loss characteristicStrong absorption capacityMaterial nanotechnologyShielding materialsElectromagnetic wave absorberCarbon fibers

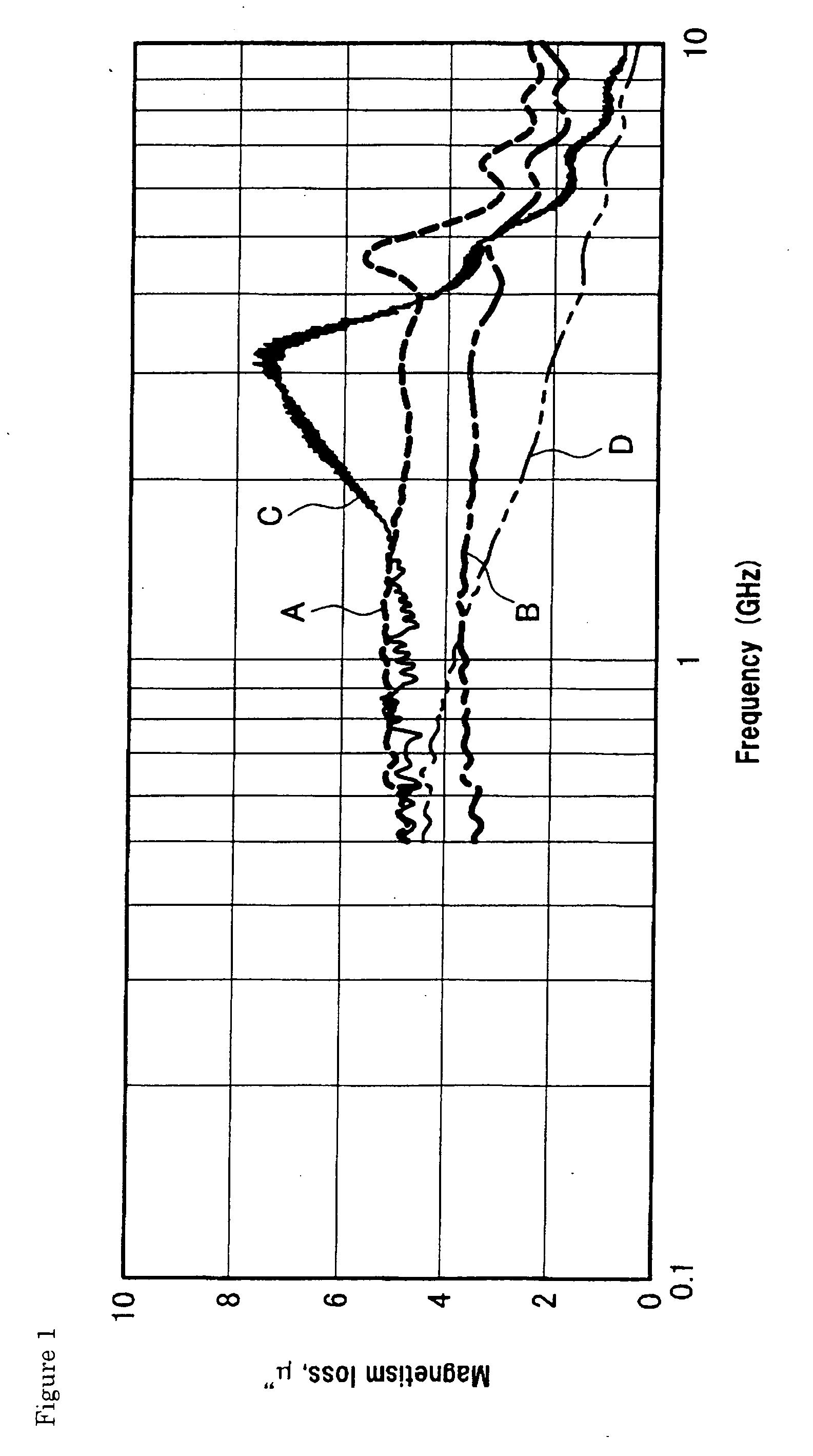

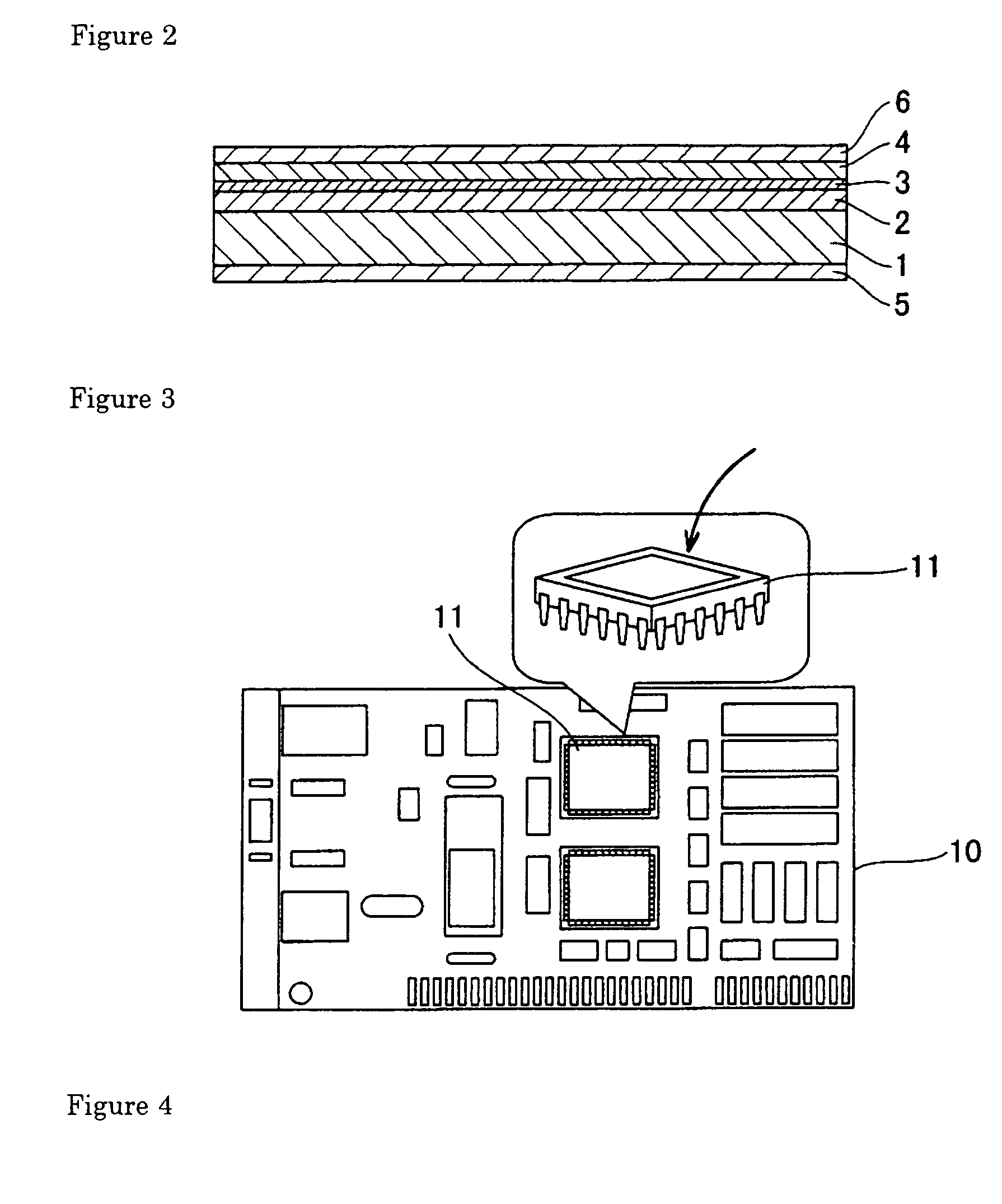

By using a high electromagnetic wave absorbing loss material and adding it in a small amount to a matrix, an electromagnetic wave absorber useful for GHz band, which can demonstrate the electromagnetic wave absorption capability without ruining characteristics of the matrix, and can enjoy a good formability and a low manufacturing cost, is provided.The disclosed is an electromagnetic wave absorber which is characterized in that carbon fibrous structures are contained in the matrix, at a rate of 0.01-25% by weight based on the total weight, wherein the carbon fibrous structure comprises a three dimensional network of carbon fibers each having an outside diameter of 15-100 nm, wherein the carbon fibrous structure further comprises a granular part with which the carbon fibers are tied together in the state that the concerned carbon fibers are externally elongated therefrom, and wherein the granular part is produced in a growth process of the carbon fibers.

Owner:MITSUI & CO LTD

Electromagnetic wave absorber

InactiveUS20070196671A1Improve rendering capabilitiesImprove flame retardant performancePigmenting treatmentNanomagnetismHigh resistanceElectromagnetic wave absorber

Owner:GELTEC

Porous materials embedded with nanoparticles, methods of fabrication and uses thereof

InactiveUS8378877B2Dissolve fastLow costShielding materialsCeramicwareElectromagnetic wave absorberNanoparticle

The present invention relates to porous structures embedded with nanoparticles, methods of forming the structures, and methods of using the structures. In most general form, the invention relates to porous materials embedded with nanoparticles having characteristics, such as magnetic, enabling to align or arrange the nanoparticles in the material by exposure, e.g. to a magnetic field. Therefore, a method according to the invention provides manufacturing materials having variable magnetic and electromagnetic properties which can be adapted during manufacture for various applications, such as electromagnetic wave absorbers, lens, concentrators, etc.

Owner:TISHIN ALEKSANDR METTALINOVICH +1

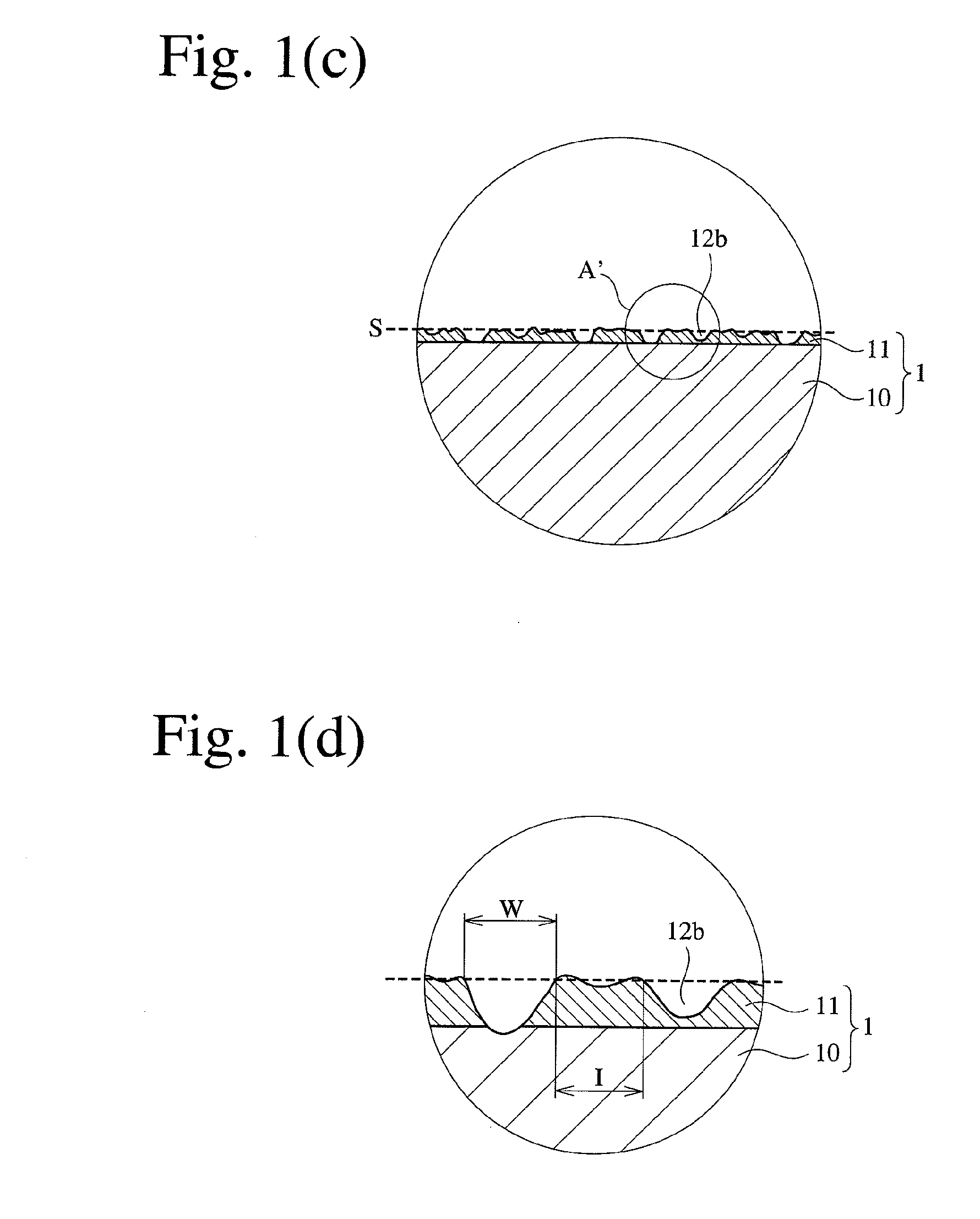

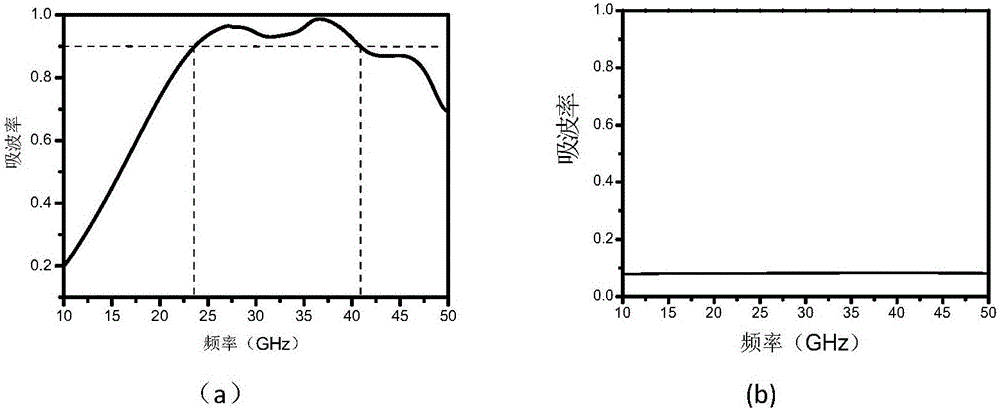

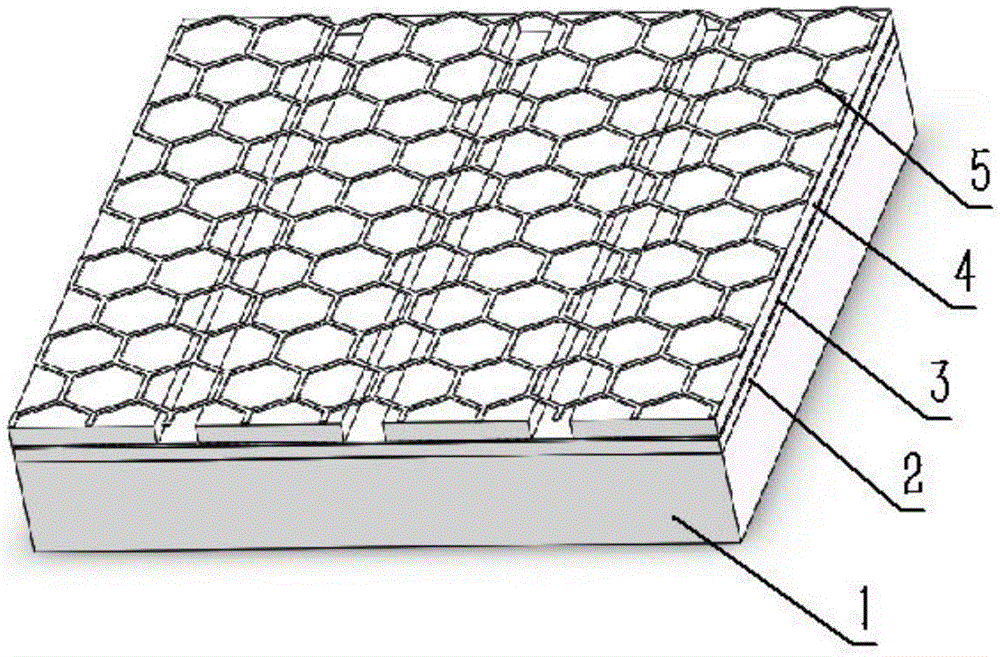

Double-layer conductive thin film-based transparent broadband electromagnetic wave absorber

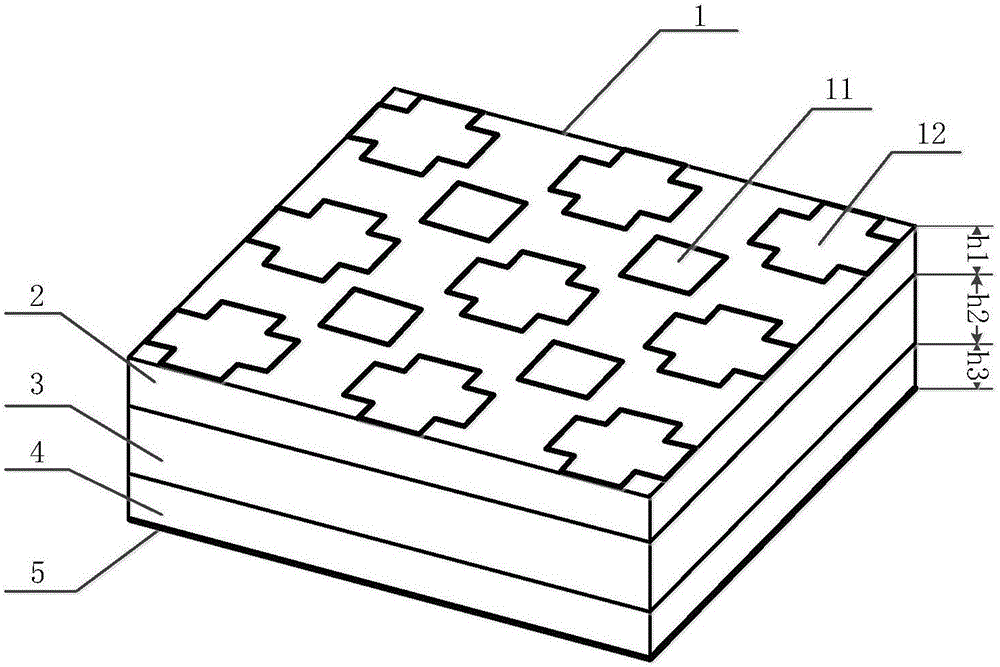

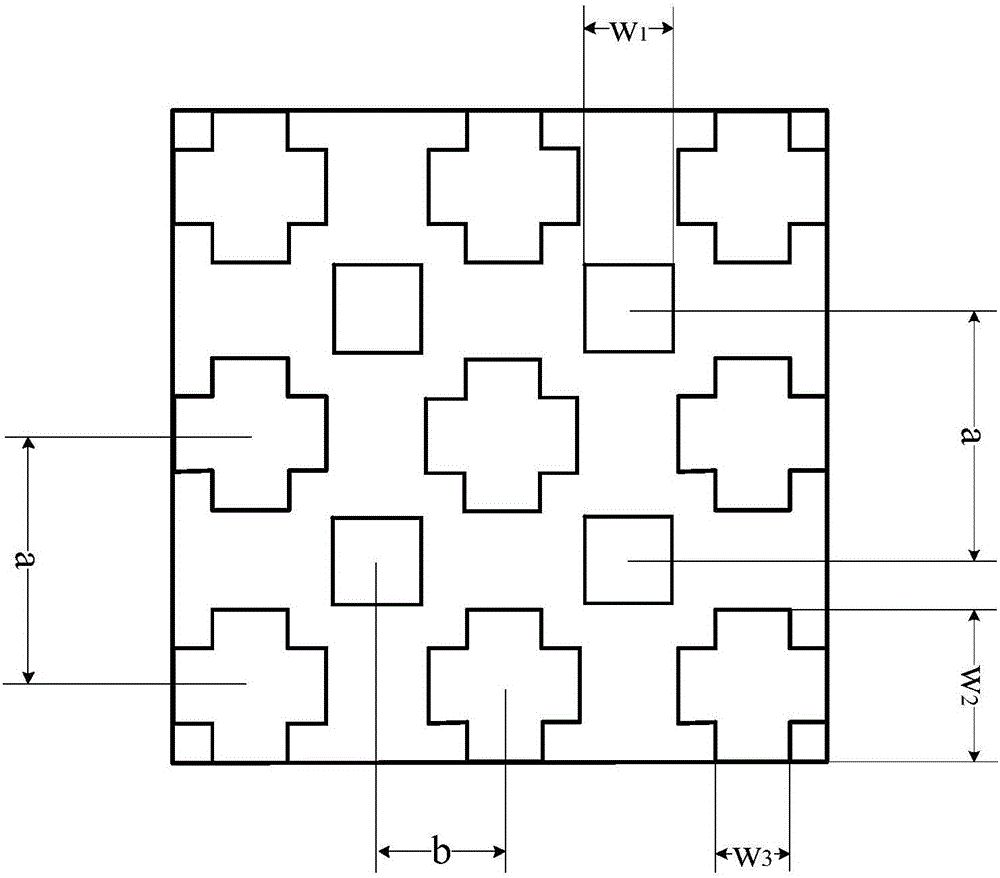

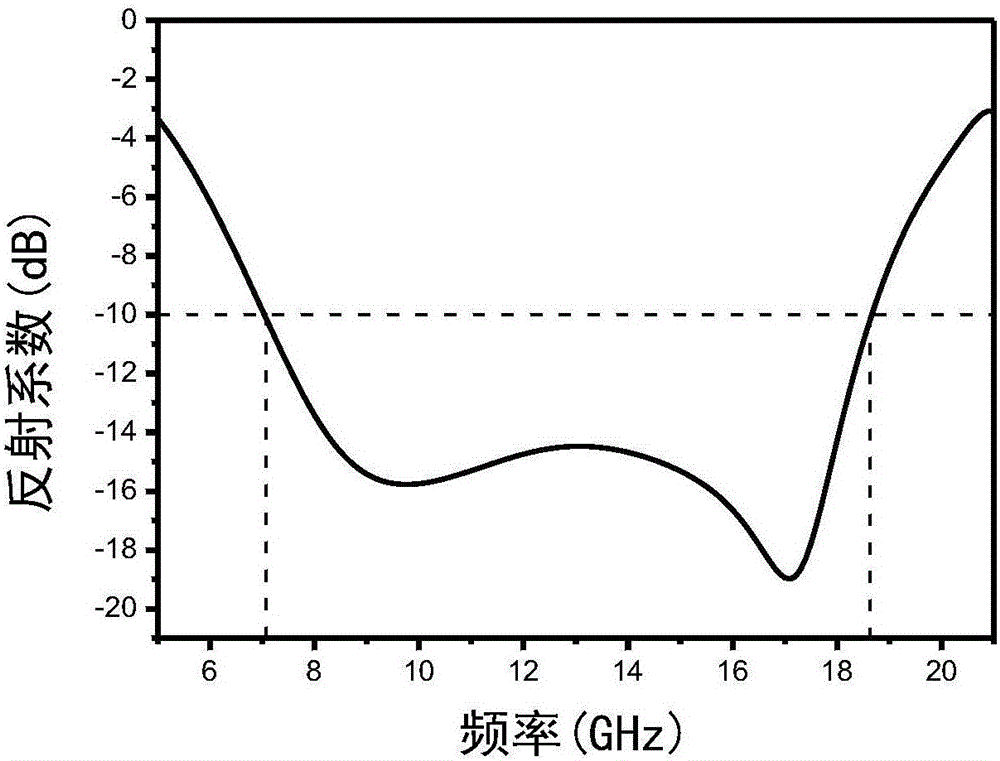

ActiveCN106058482AGood light transmissionHigh resistivityAntennasElectromagnetic wave absorberMicrowave

The invention provides a double-layer conductive thin film-based transparent broadband electromagnetic wave absorber and aims at solving the technical problem of a narrow application range of an existing wave absorber. The double-layer conductive thin film-based transparent broadband electromagnetic wave absorber comprises a conductive thin film, a first dielectric layer, a second dielectric layer, a third dielectric layer and a bottom plate, wherein transparent dielectric plates are adopted as the first dielectric layer and the third dielectric layer; the transparent dielectric plate or an air dielectric is adopted as the second dielectric layer; the three dielectric layers are arranged from top to bottom to form the dielectric layers with a stacked structure; a transparent conductive thin film is adopted as the bottom plate and is printed on the lower surface of the third dielectric layer; and the conductive film is formed by compounding m*n arrays formed by square transparent conductive thin films and (m+1)*(n+1) arrays formed by cross-shaped transparent conductive thin films and is printed on the upper surface of the first dielectric layer. High light transmission is achieved while the wave absorption bandwidth and the wave absorption rate are ensured; and the double-layer conductive thin film-based transparent broadband electromagnetic wave absorber can be applied to electromagnetic anti-interference of microwave systems, of aircraft cabin glass, a PCB-based novel inter-chip wireless interconnection system and the like, requiring the high light transmission.

Owner:XIDIAN UNIV

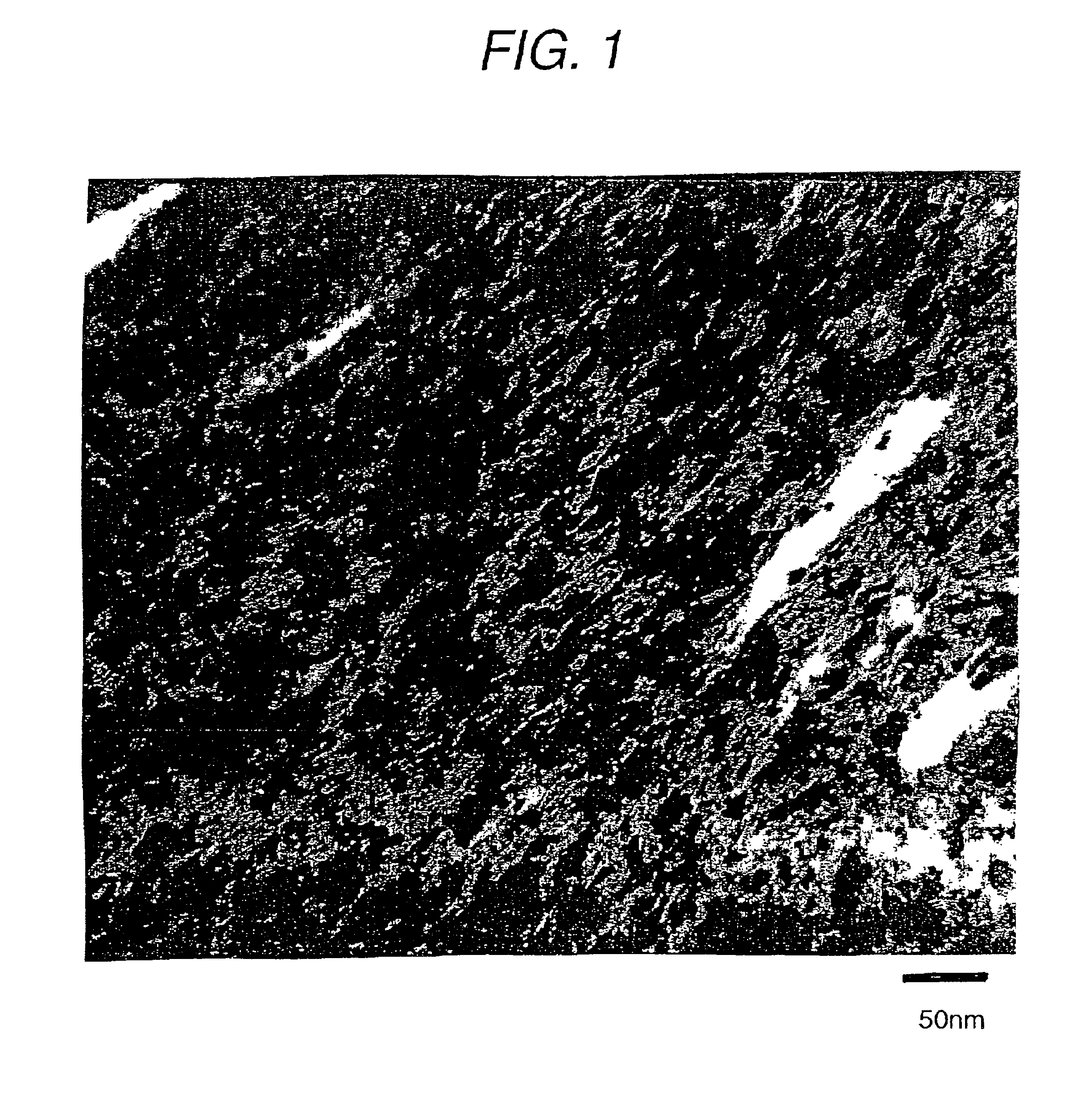

Waveband electromagnetic wave absorber and method for manufacturing same

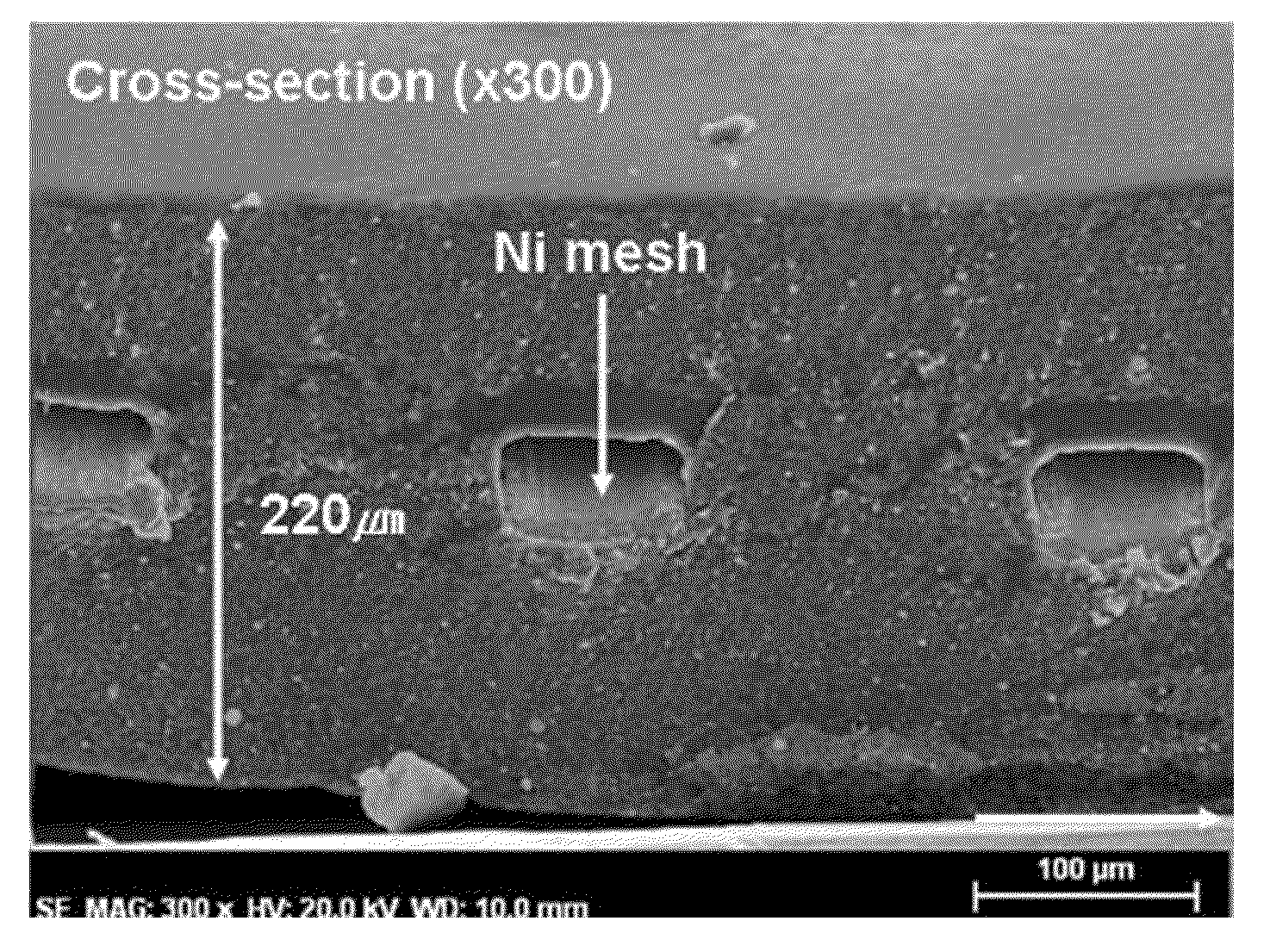

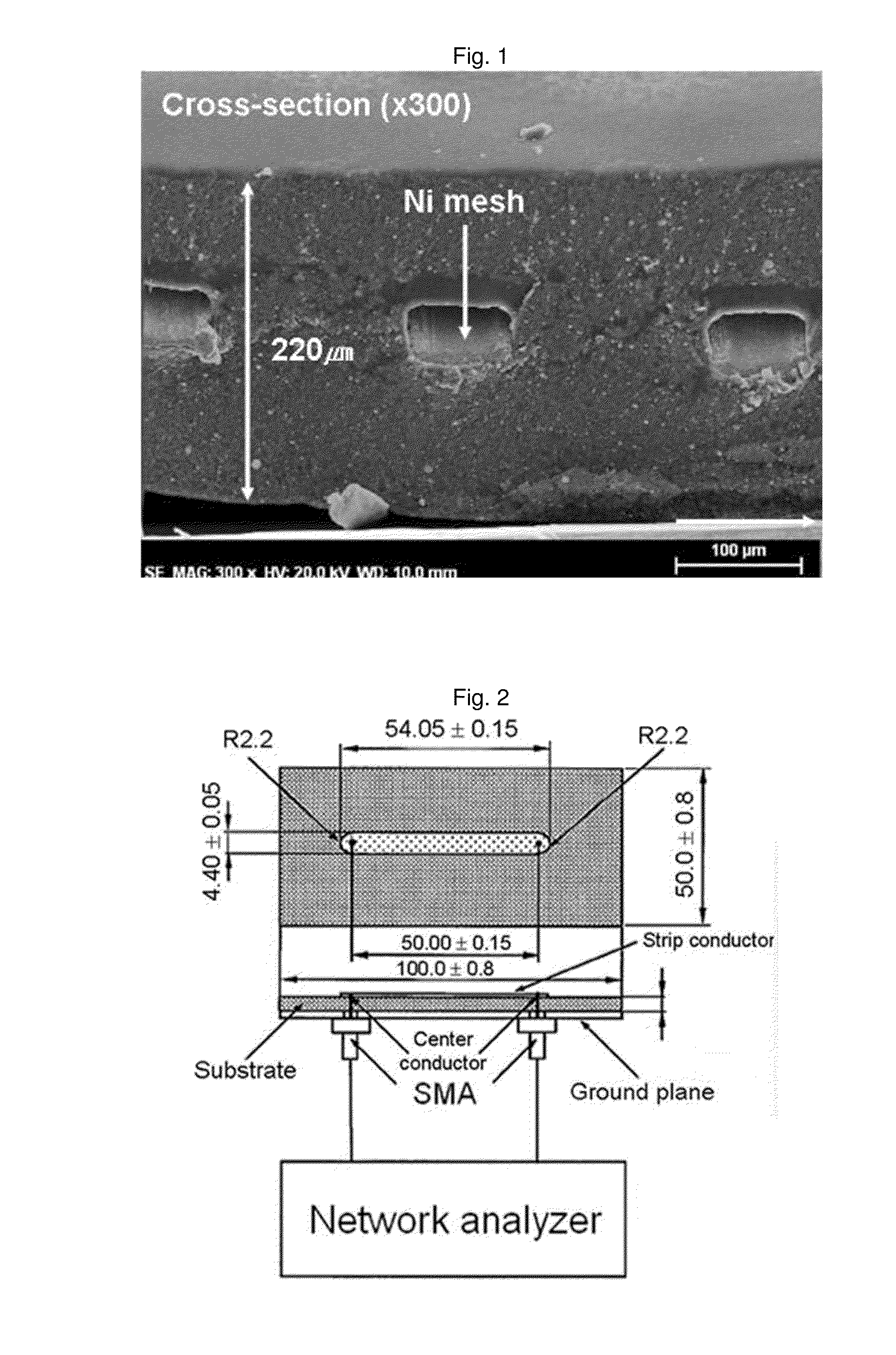

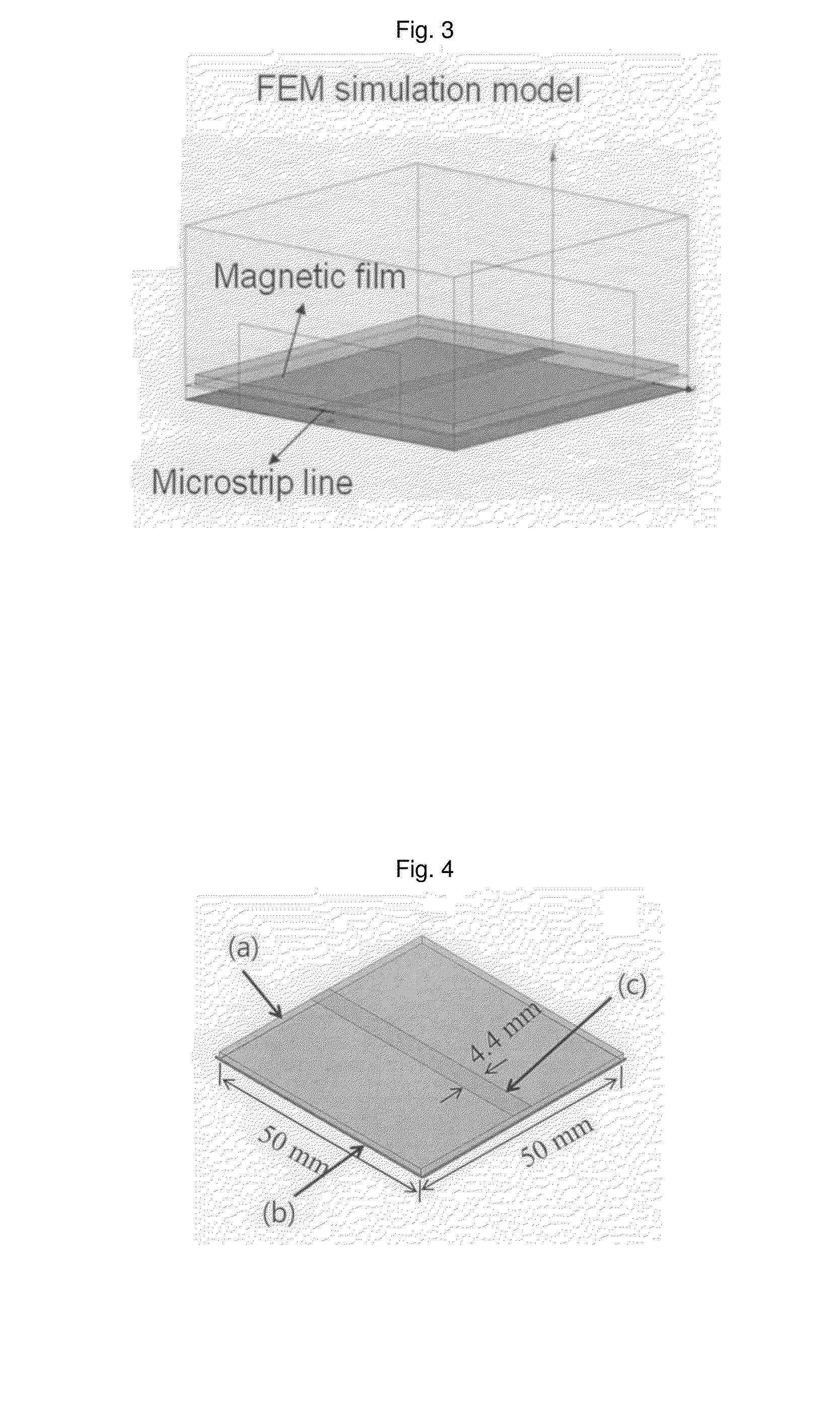

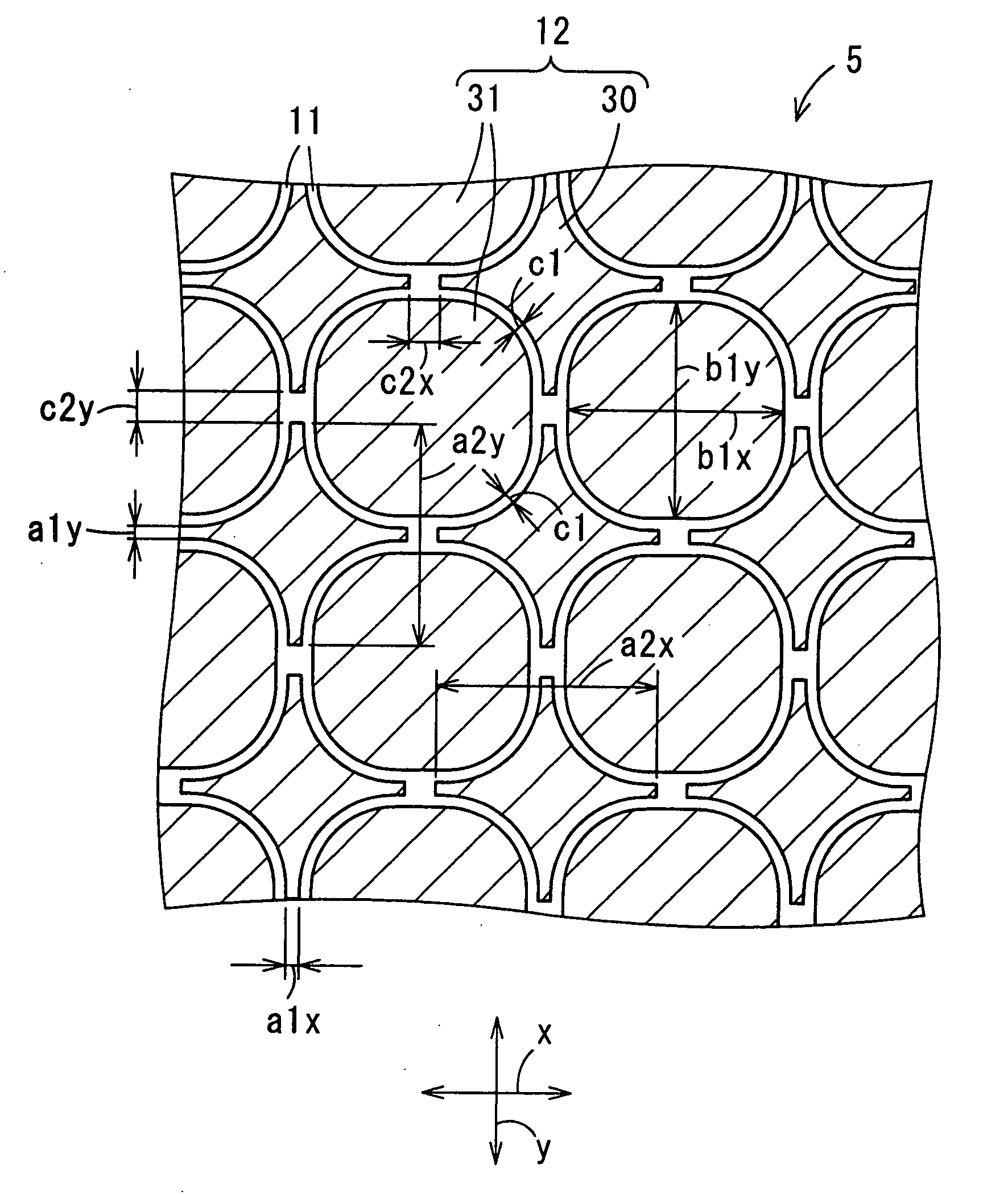

ActiveUS20130140076A1Effective absorptionAvoid interferenceLine/current collector detailsMagnetic/electric field screeningElectromagnetic wave absorberPolymer resin

Provided is a wideband electromagnetic wave (EMW) absorber including a magnetic composite having a structure in which magnetic particles are dispersed in a polymer resin, and a plurality of conductive lines arranged in the magnetic composite, and a method of manufacturing the same. The wideband EMW absorber can be used for a device configured to emit EMWs and effectively absorb wideband EMWs.

Owner:KOREA INST OF MATERIALS SCI

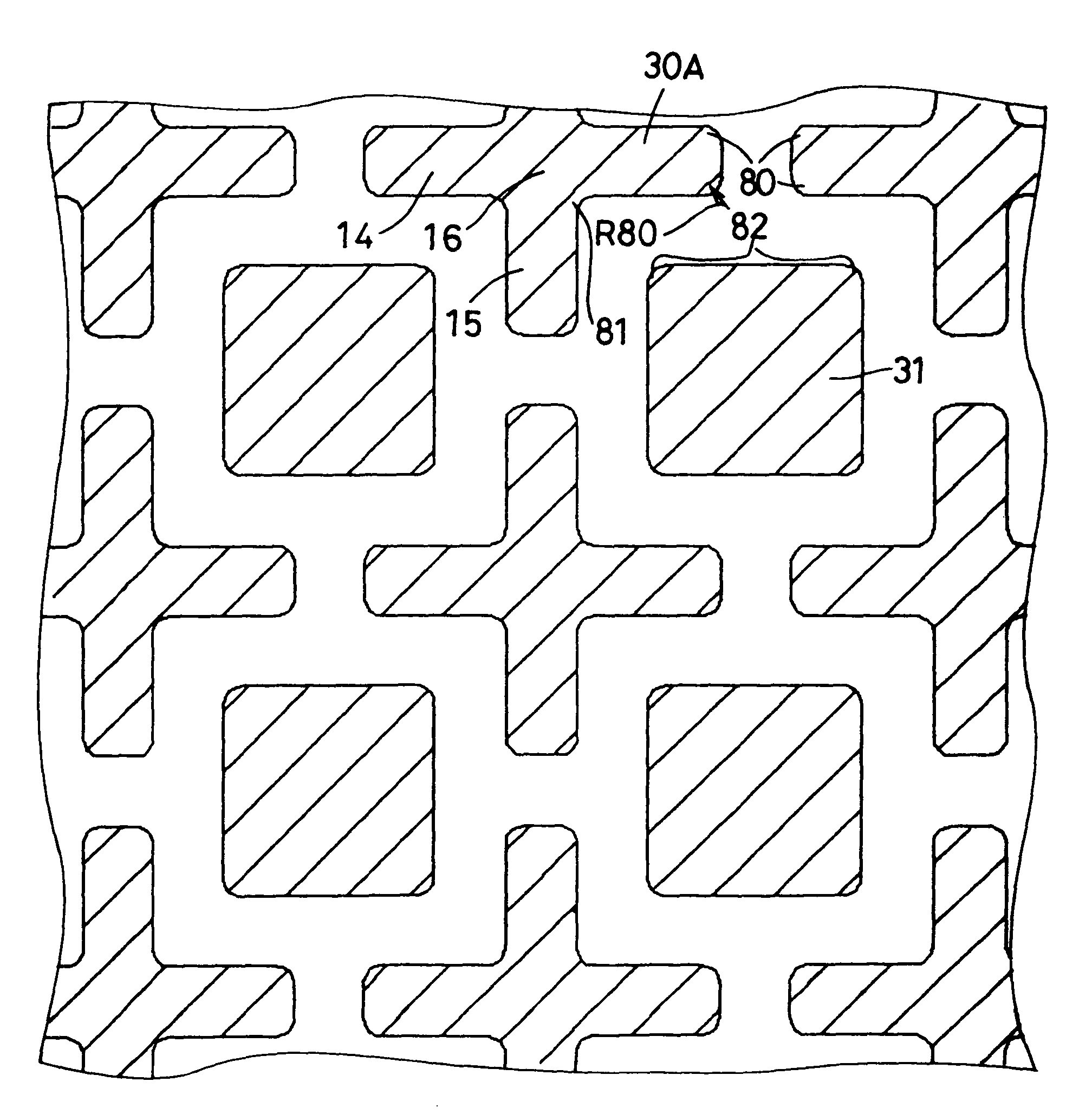

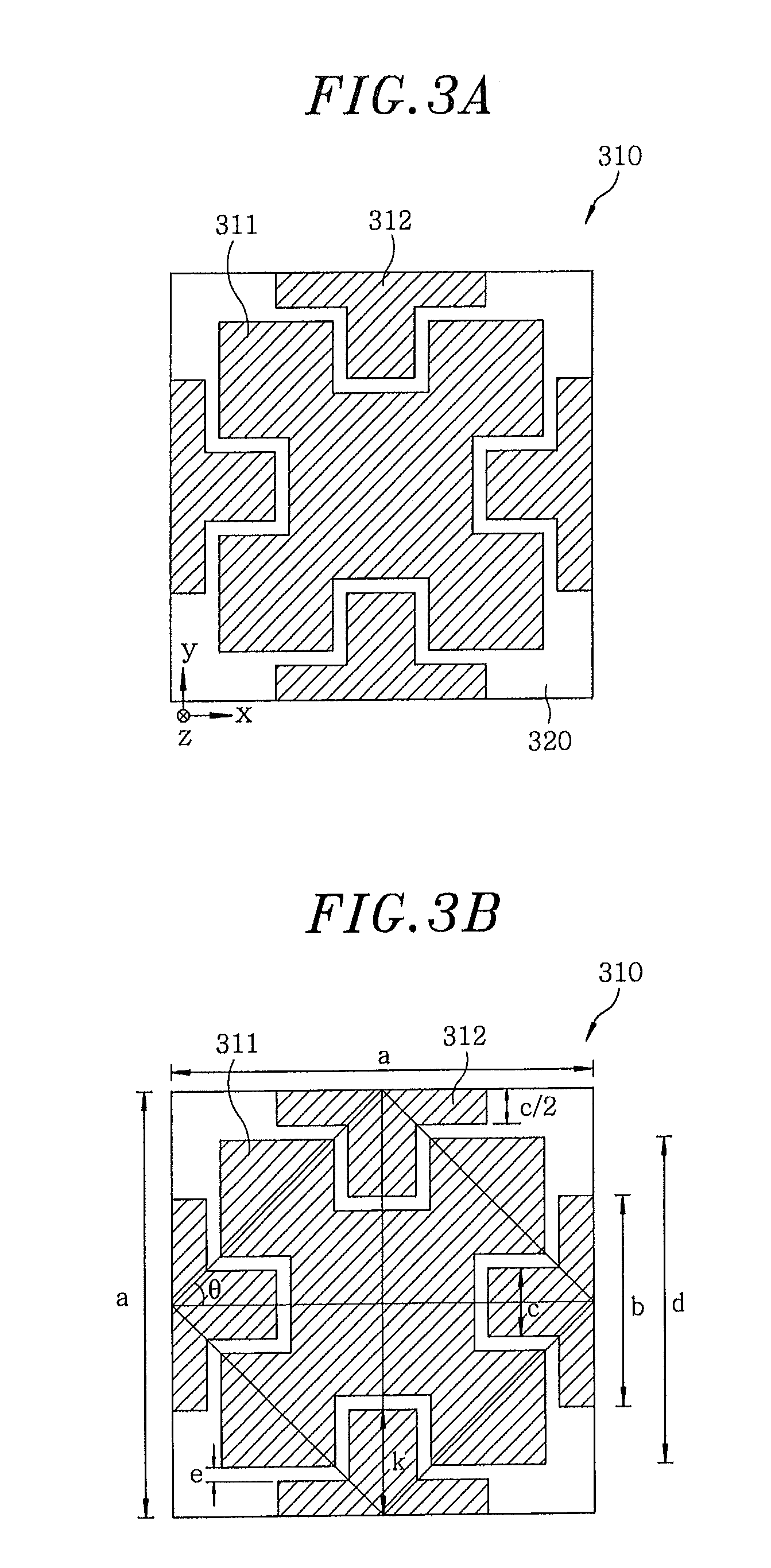

Electromagnetic Wave Absorber

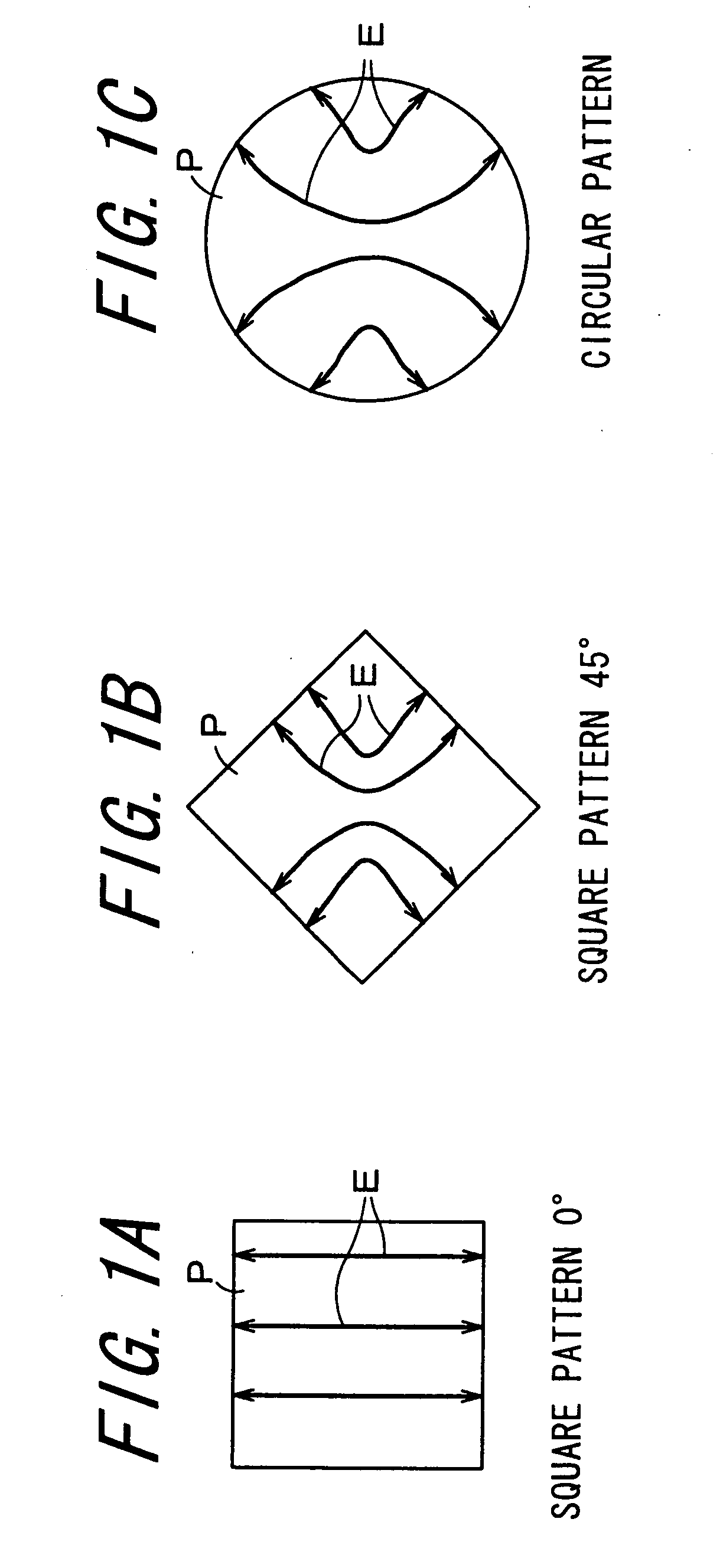

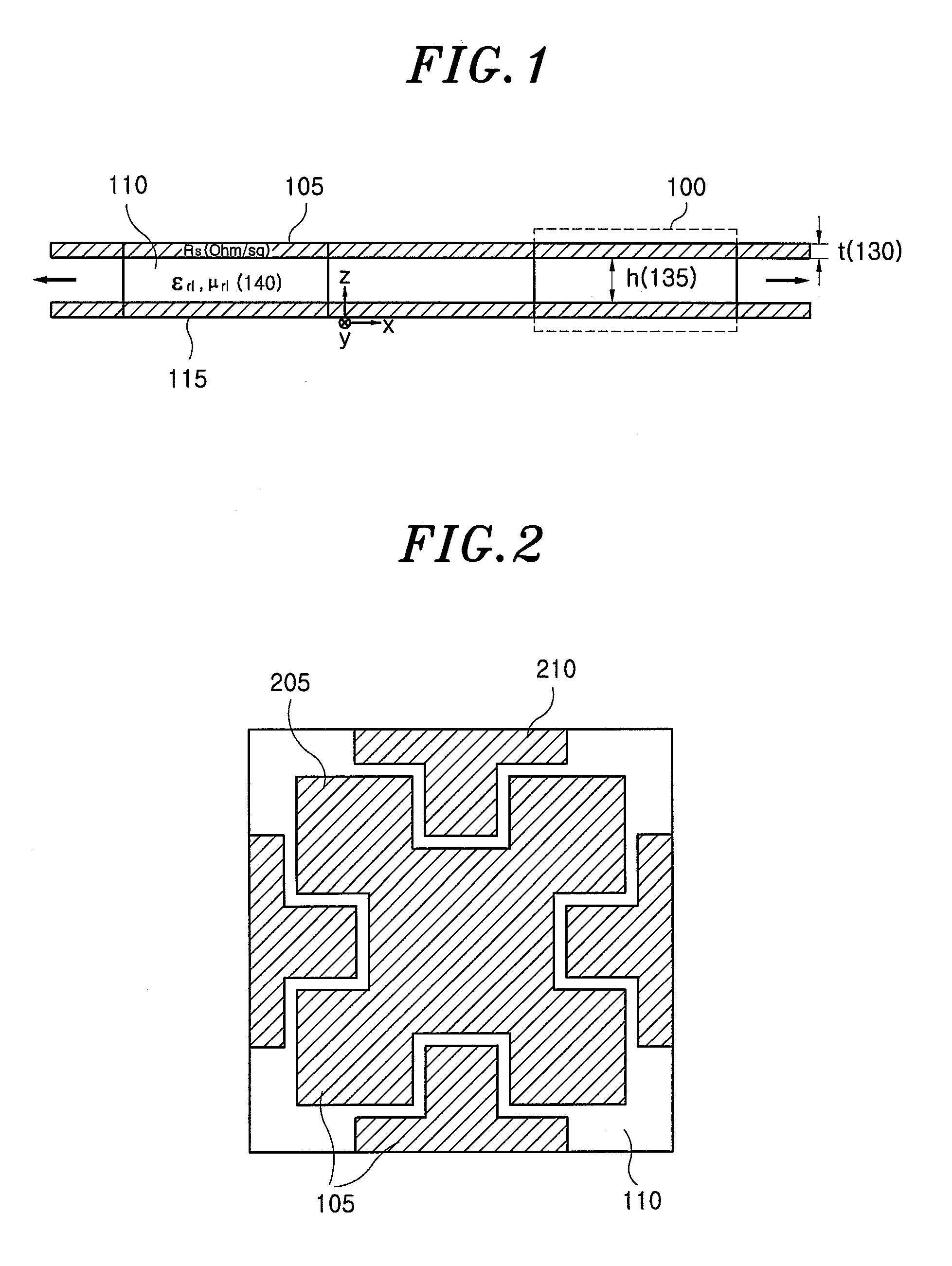

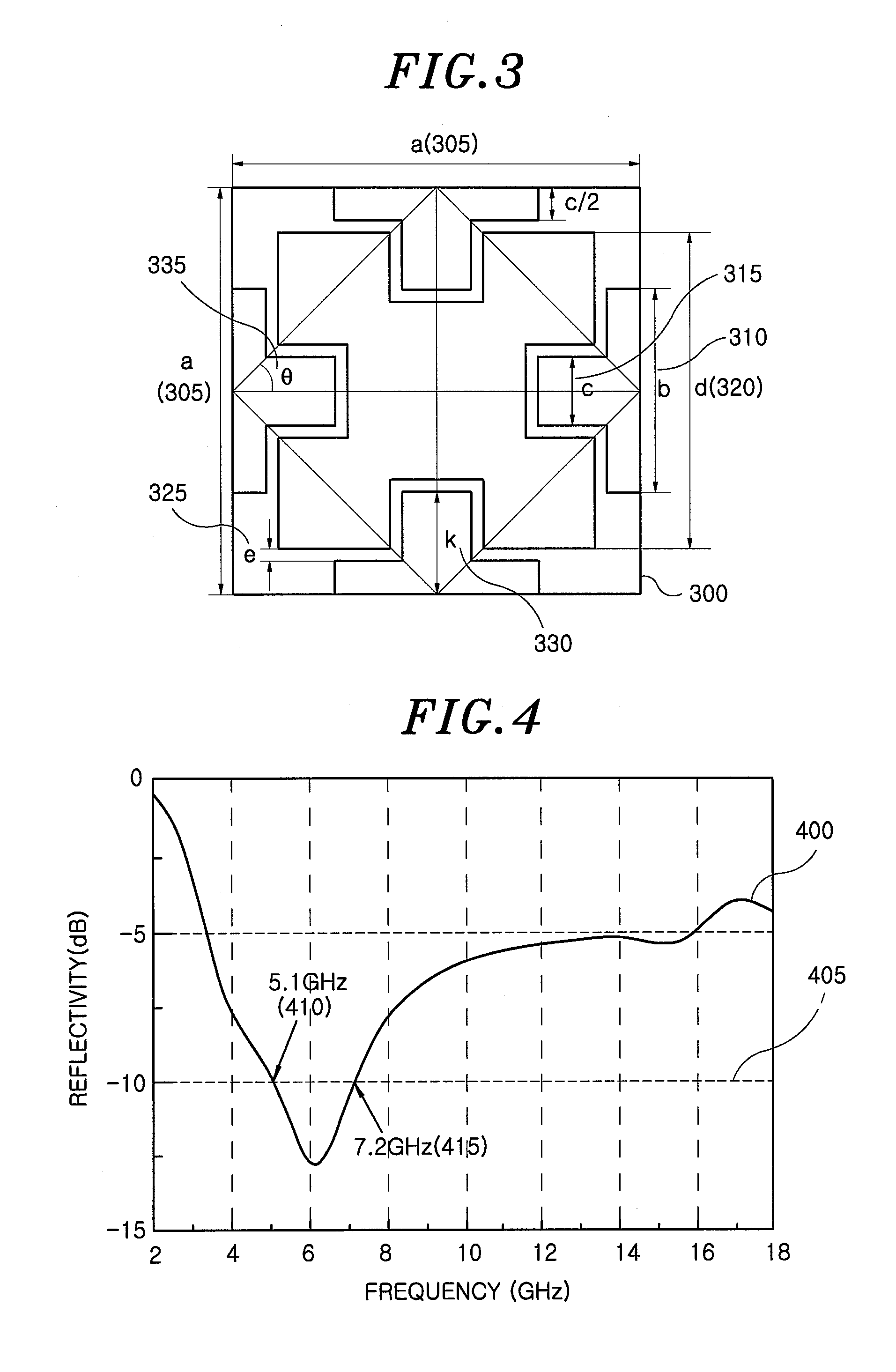

InactiveUS20080257599A1High peak value of absorption amountAvoid large displacementMagnetic/electric field screeningAntennasElectromagnetic wave absorberElectromagnetic absorbers

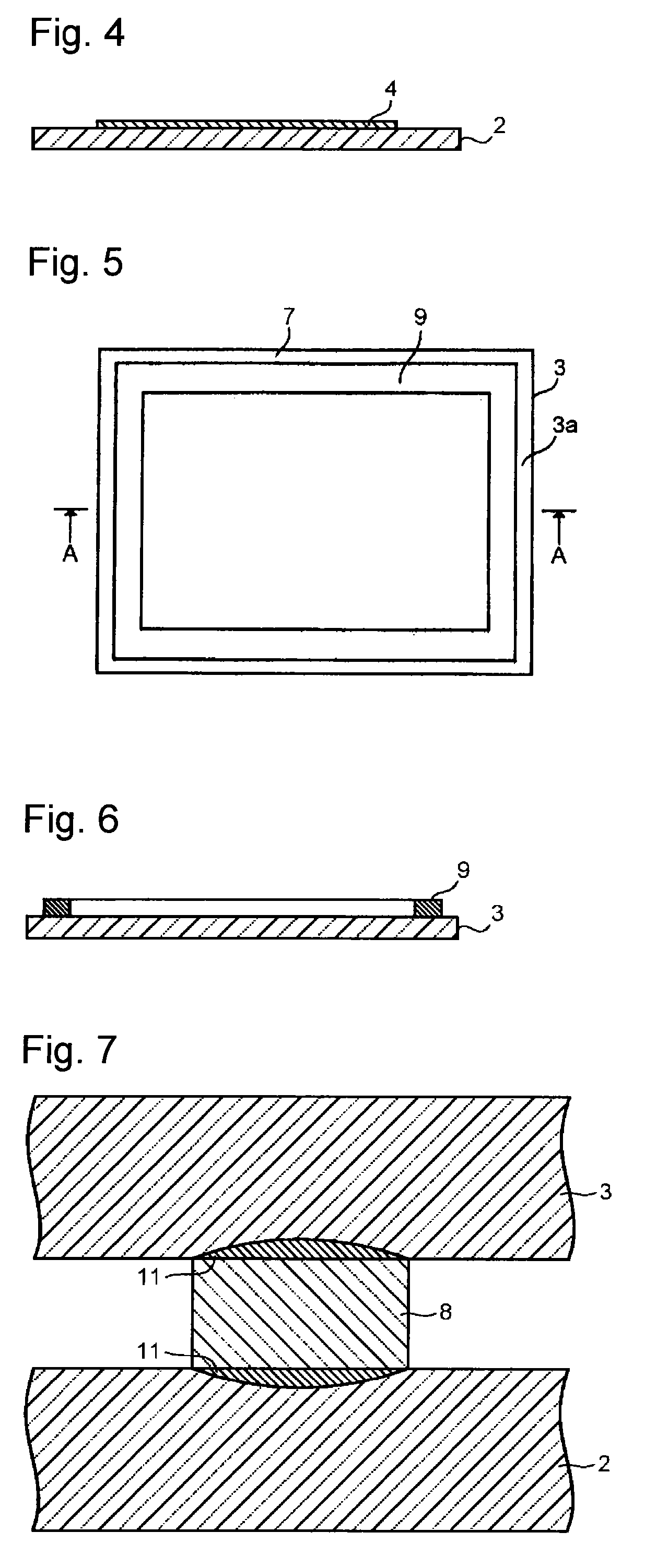

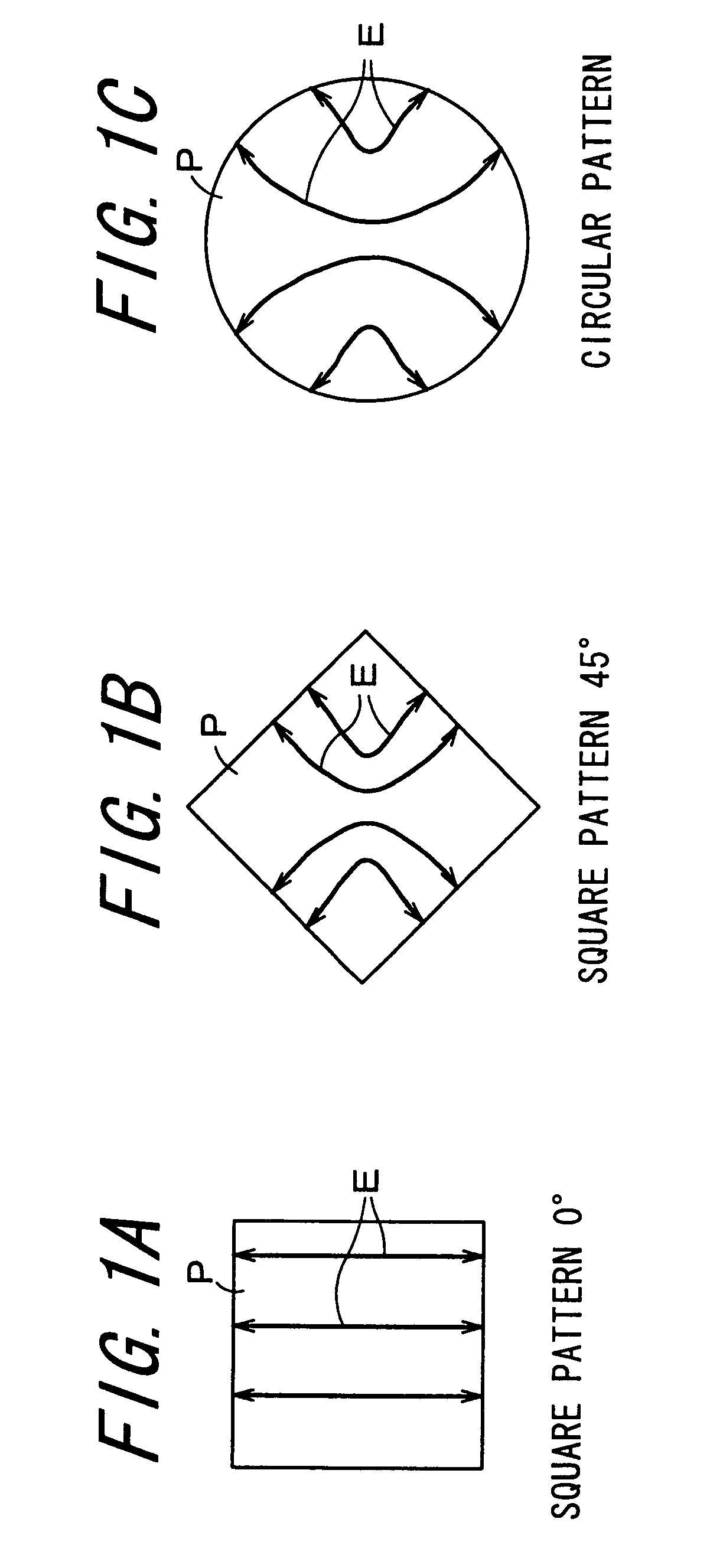

A conductive pattern basically has a substantially polygonal outline shape which is a polygon and can have a high peak value of the electromagnetic wave absorption amount as compared to a case when the conductive pattern has a circular outline shape. Thus, the conductive pattern is basically a polygon and at least one corner portion is shaped in curve. This reduces or even minimizes the shift of the frequency at which the absorption amount becomes a peak value by the polarization direction of the electromagnetic wave. Accordingly, in at least one embodiment, it is possible to realize an electromagnetic absorber having an excellent electromagnetic wave absorption characteristic exhibiting a high peak value of the absorption amount of the electromagnetic wave and a small shift of frequency at which the absorption amount becomes a peak value by the polarization direction of the electromagnetic wave.

Owner:NITTA CORP

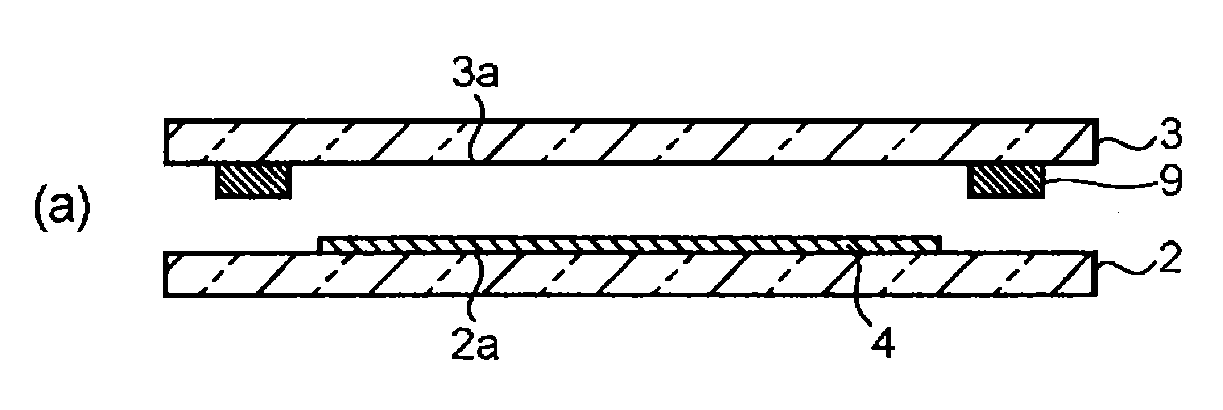

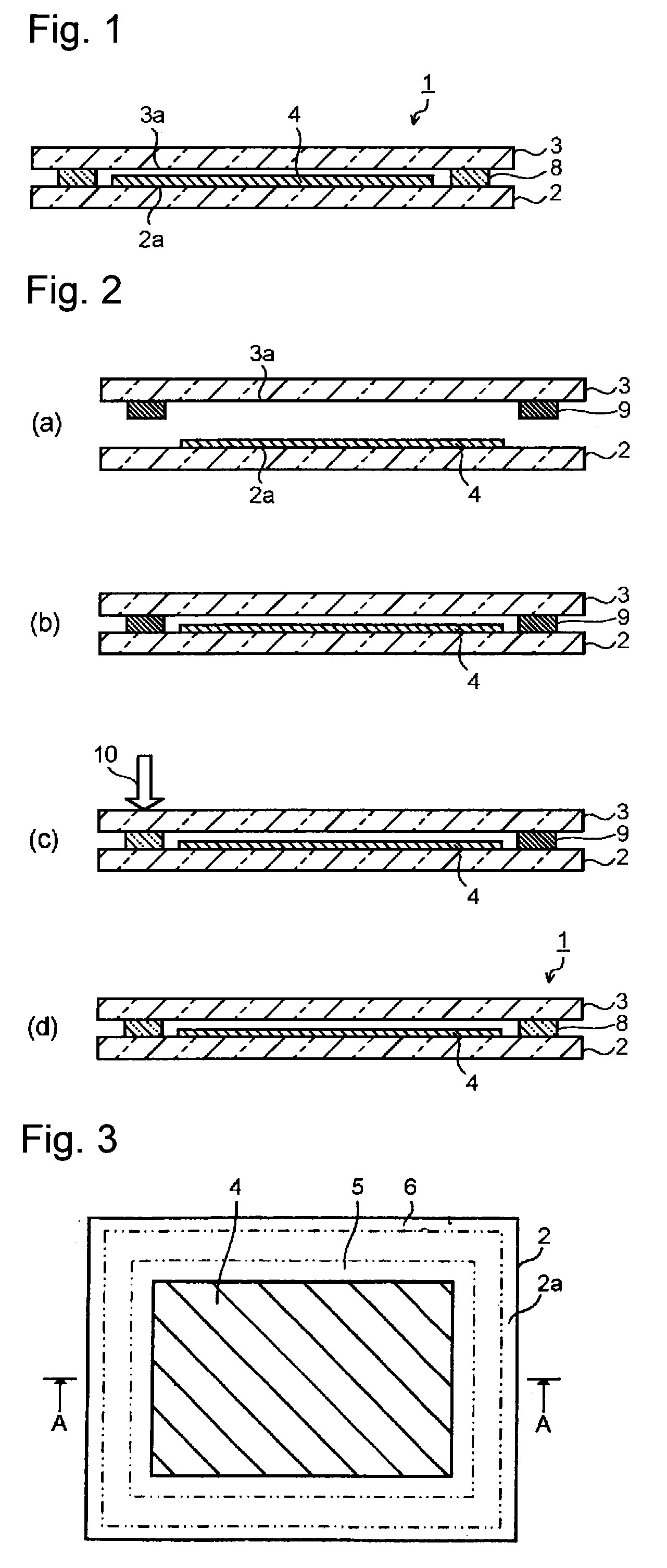

Electronic device and method for manufacturing same

ActiveUS20130011598A1High bonding strengthGood reproducibilityElectric discharge tubesElectrolytic capacitorsElectromagnetic wave absorberMaximum depth

When local heating by use of laser sealing or the like is applied, the bonding strength between glass substrates and a sealing layer is improved to provide an electronic device having increased reliability. An electronic device includes a first glass substrate, a second glass substrate, and a sealing layer to seal an electronic element portion disposed between these glass substrates. The sealing layer is a layer obtained by locally heating a sealing material by an electromagnetic wave, such as laser light or infrared light, to melt-bond the sealing material, the sealing material containing sealing glass, a low-expansion filler and an electromagnetic wave absorber. In the first and second glass substrates, each reacted layer is produced to have a maximum depth of at least 30 nm from an interface with the sealing layer.

Owner:ASAHI GLASS CO LTD

Electromagnetic wave absorber

InactiveUS7495181B2Reduce the amount of solutionSmall displacementSparking plugsMagnetic/electric field screeningElectromagnetic wave absorberElectromagnetic absorbers

A conductive pattern basically has a substantially polygonal outline shape which is a polygon and can have a high peak value of the electromagnetic wave absorption amount as compared to a case when the conductive pattern has a circular outline shape. Thus, the conductive pattern is basically a polygon and at least one corner portion is shaped in curve. This reduces or even minimizes the shift of the frequency at which the absorption amount becomes a peak value by the polarization direction of the electromagnetic wave. Accordingly, in at least one embodiment, it is possible to realize an electromagnetic absorber having an excellent electromagnetic wave absorption characteristic exhibiting a high peak value of the absorption amount of the electromagnetic wave and a small shift of frequency at which the absorption amount becomes a peak value by the polarization direction of the electromagnetic wave.

Owner:NITTA CORP

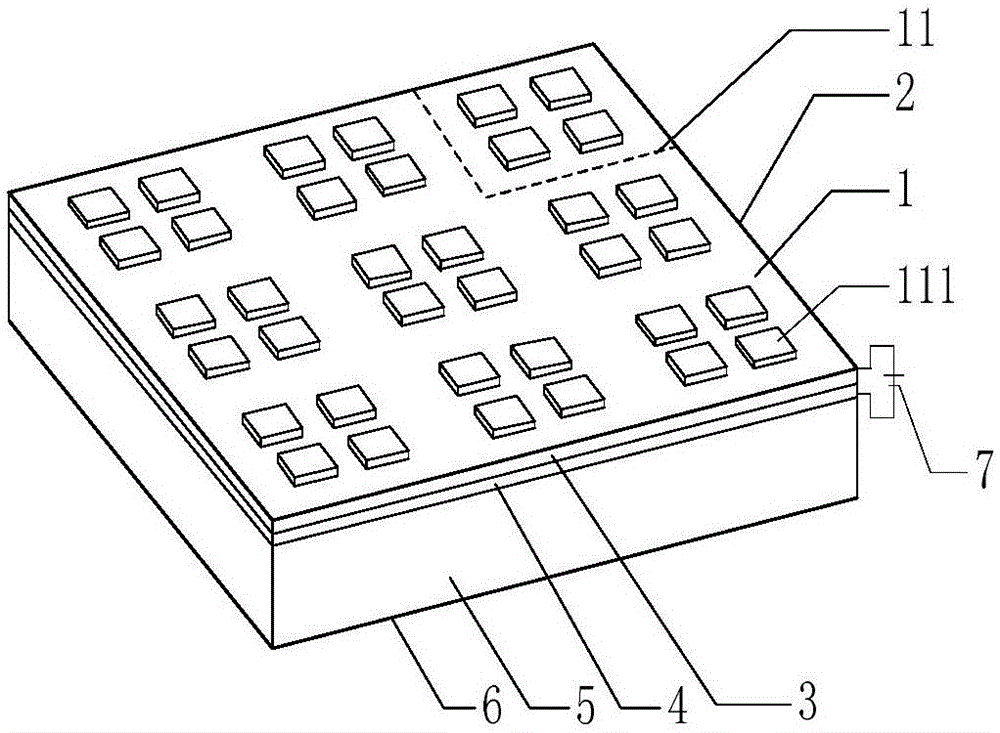

Electromagnetic wave absorber using resistive material

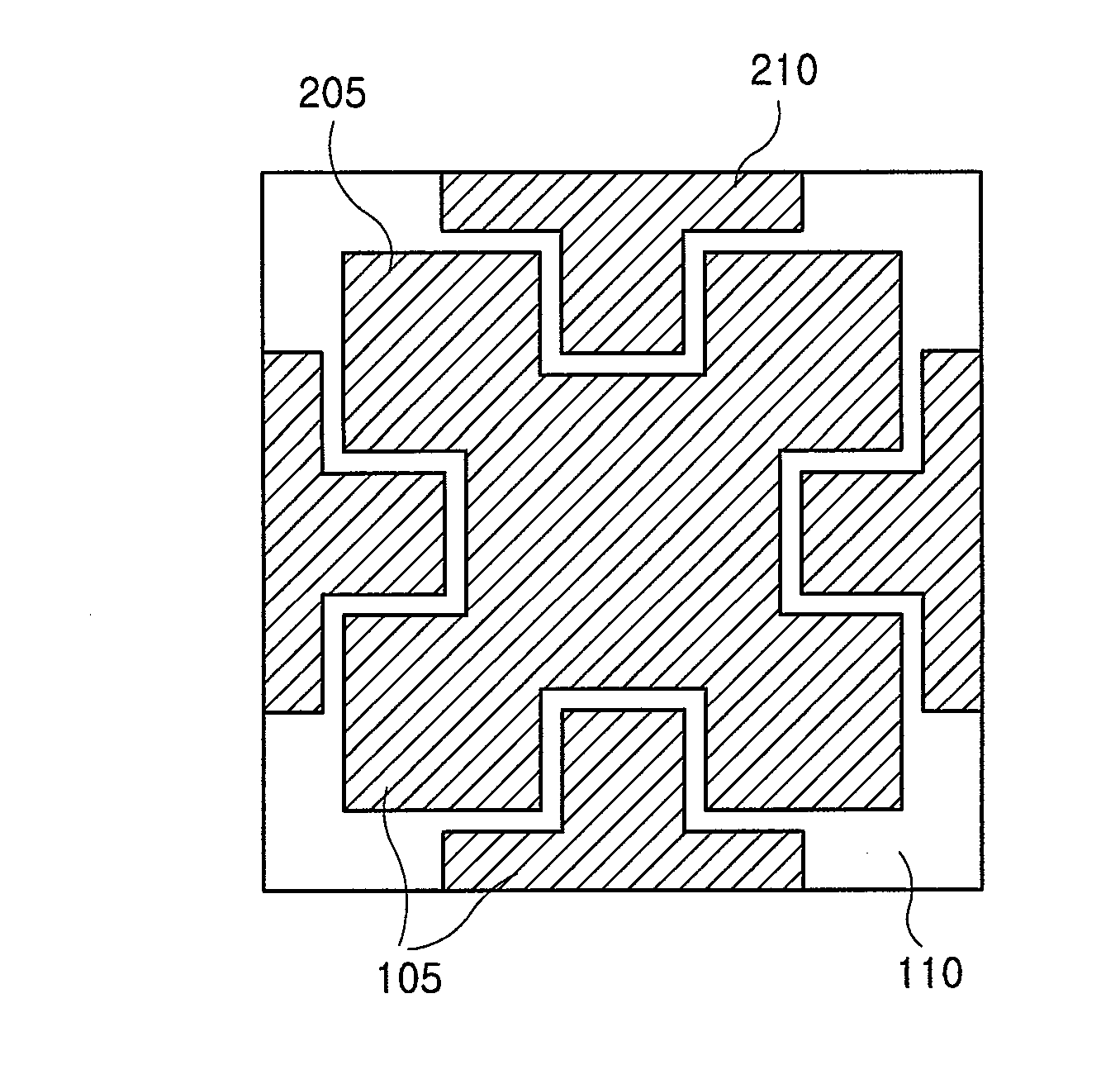

InactiveUS20090284404A1Simple manufacturing processEasy to adjustMagnetic/electric field screeningAntennasElectromagnetic wave absorberCell pattern

An electromagnetic wave absorber includes a ground layer made of a metal conductor, a dielectric layer formed on the ground layer, and a unit cell pattern made of a resistive material, and formed on the dielectric layer. The unit cell pattern includes a fundamental patch having a regular square shape, in which a rectangular recess is formed on the center of each of the respective sides, the fundamental patch being located at the center of each of the unit cell pattern, and half cross dipole patches, which are respectively disposed at the four sides of the fundamental patch at a regular angle so as to be engaged with the recesses formed on the respective sides of the fundamental patch at a regular interval.

Owner:ELECTRONICS & TELECOMM RES INST

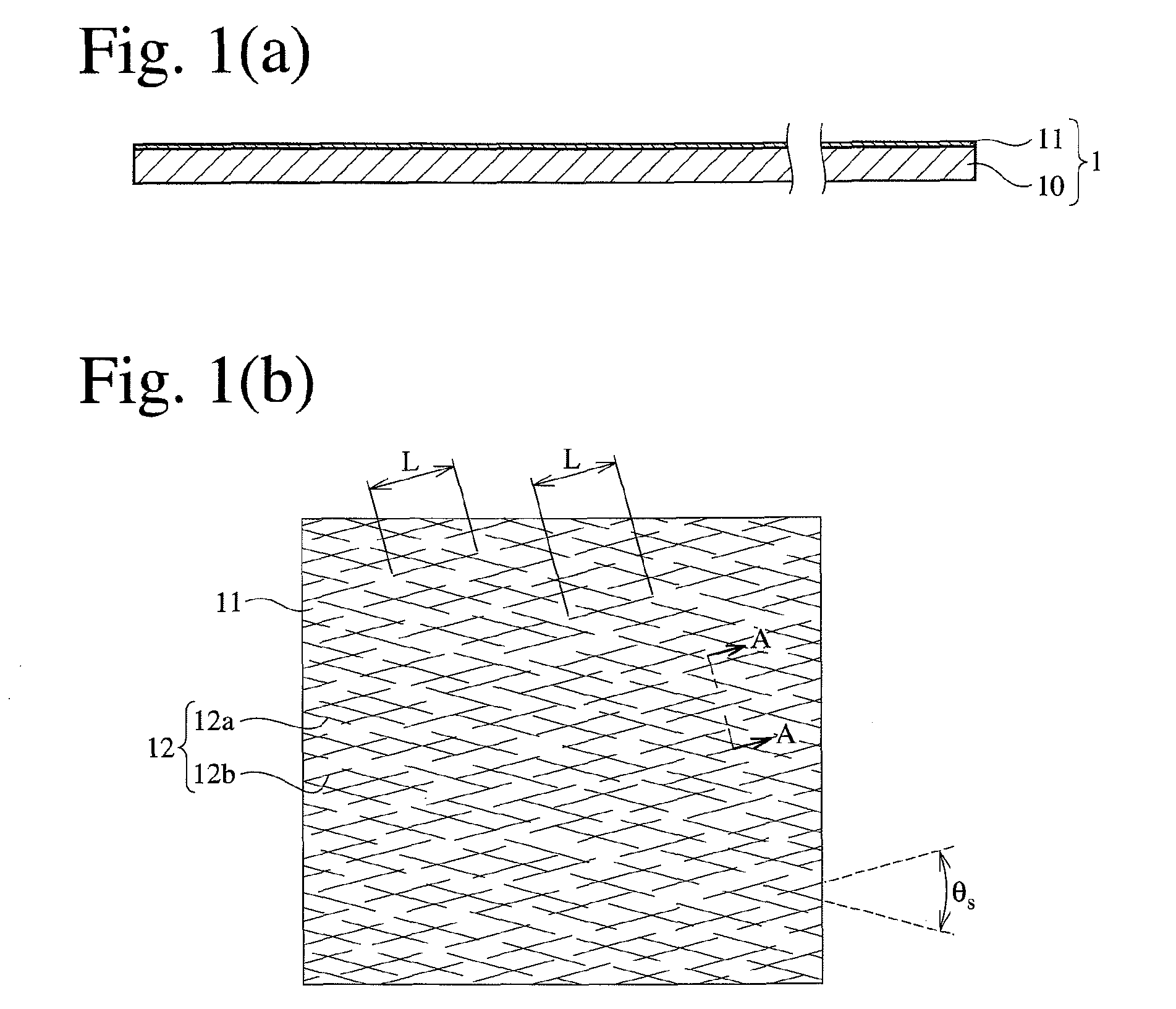

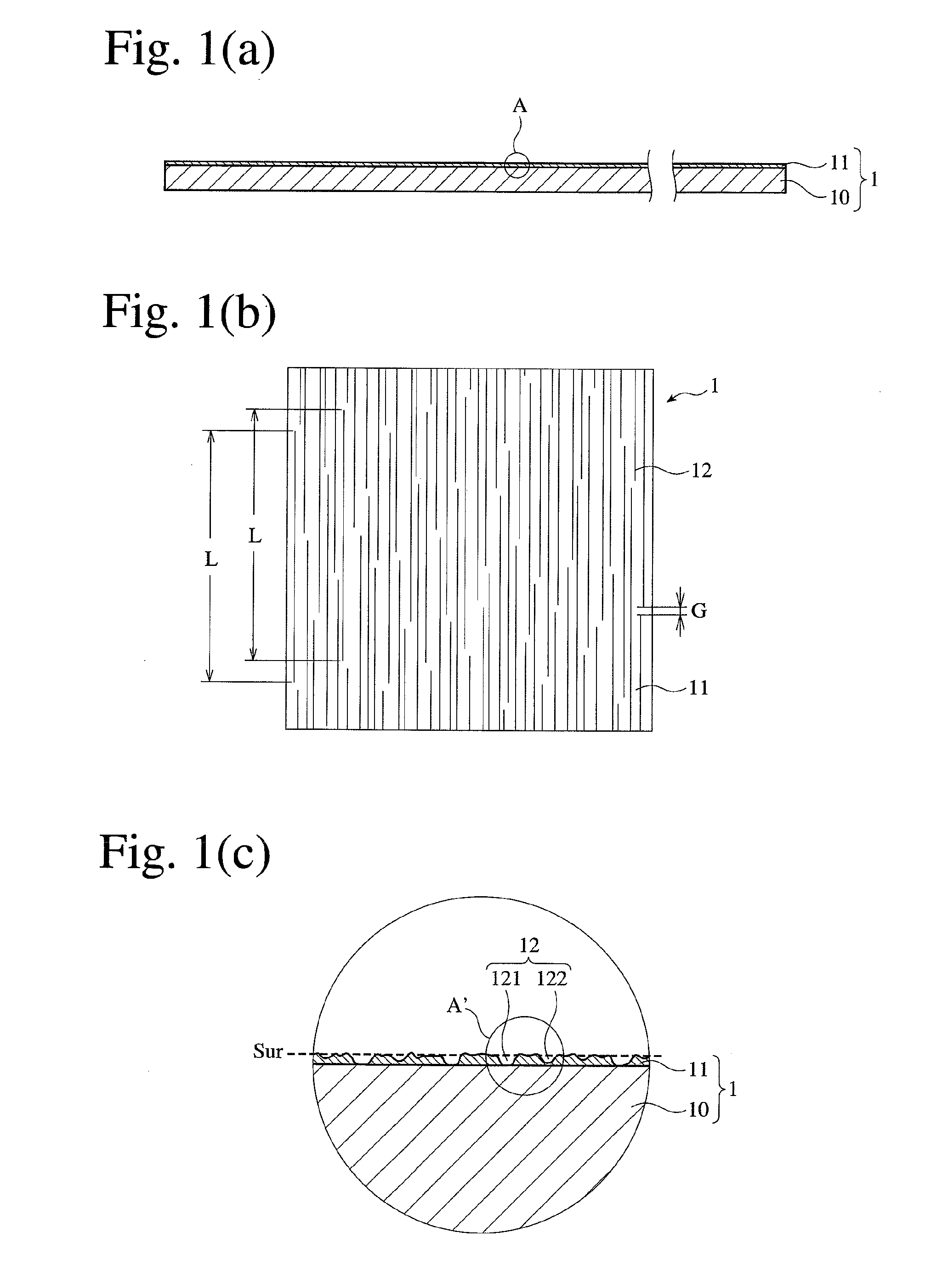

Composite film of linearly-scratched, thin metal film and plastic film, and its production apparatus

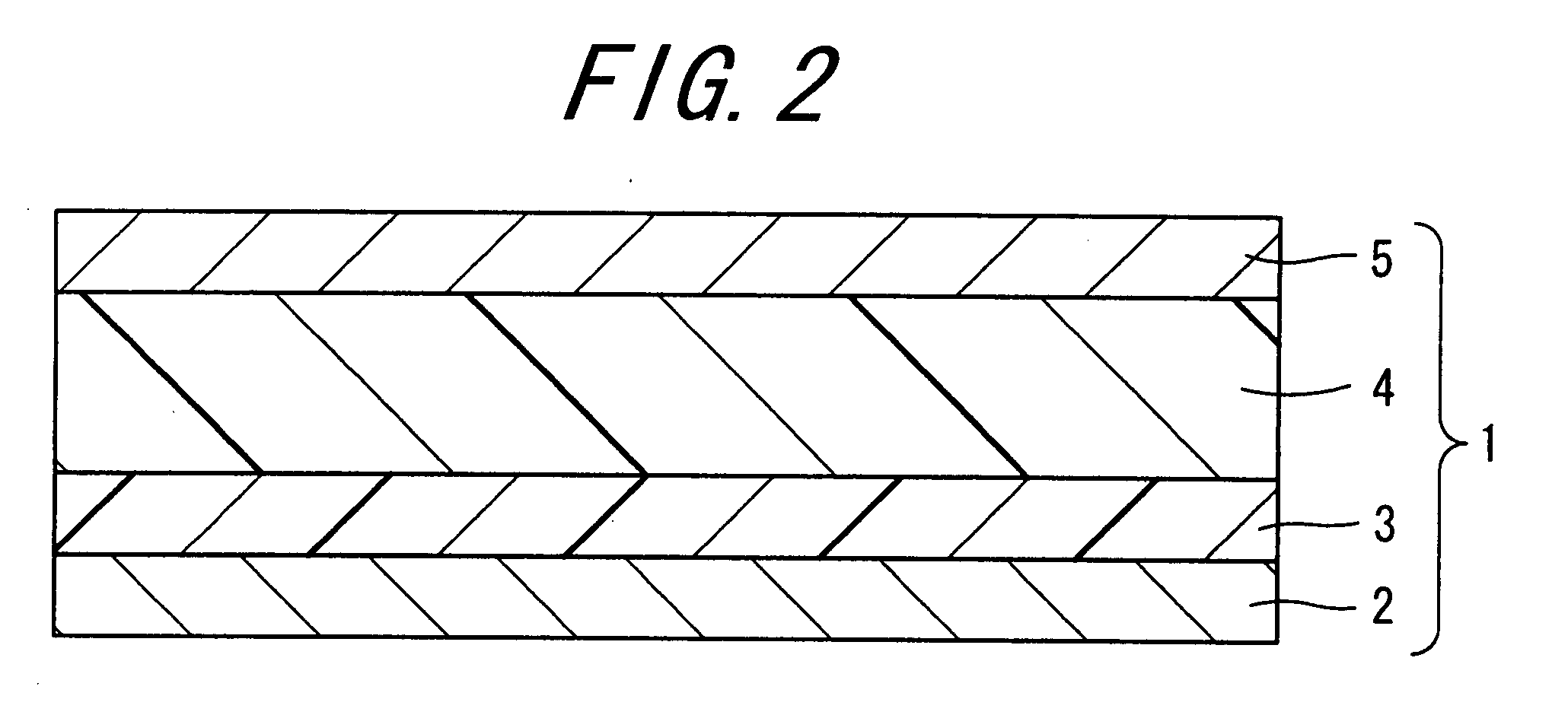

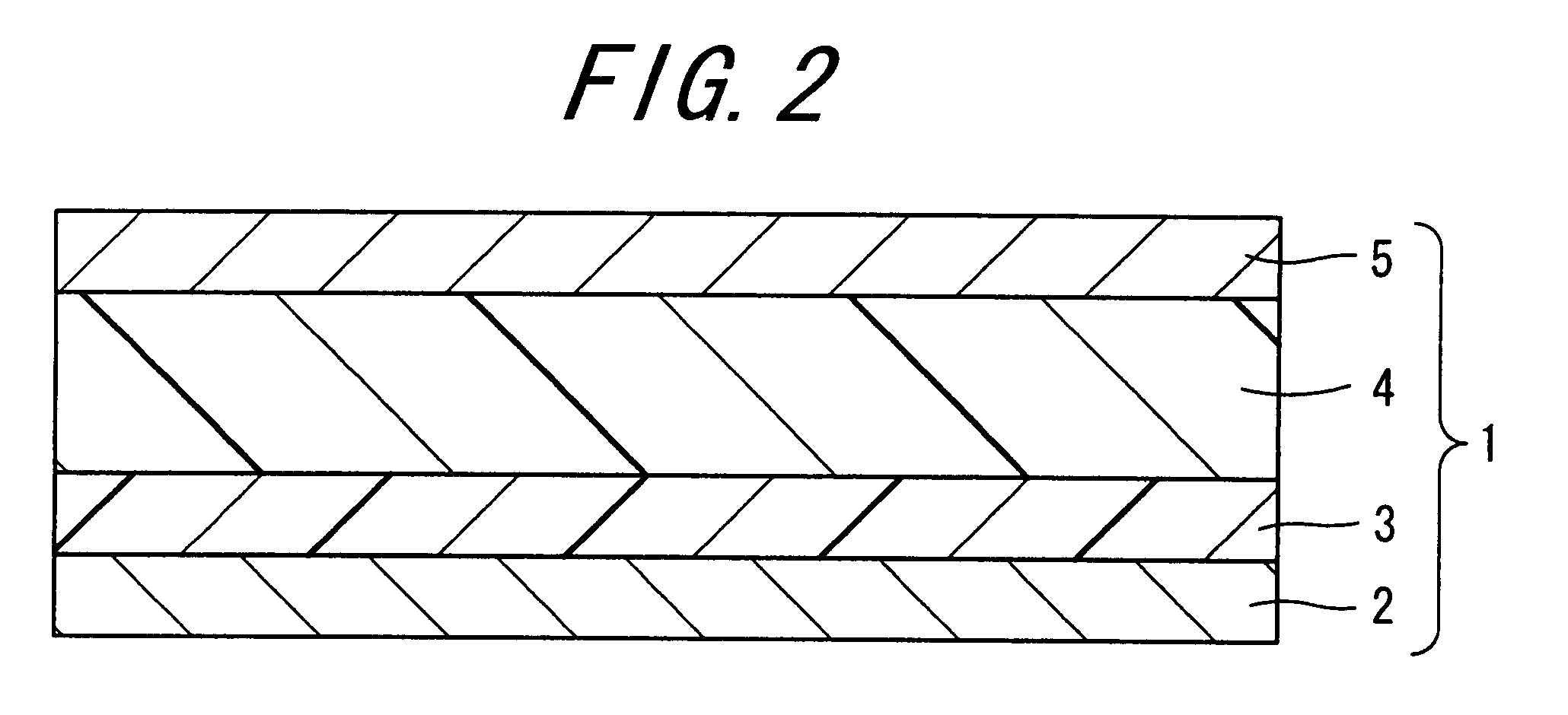

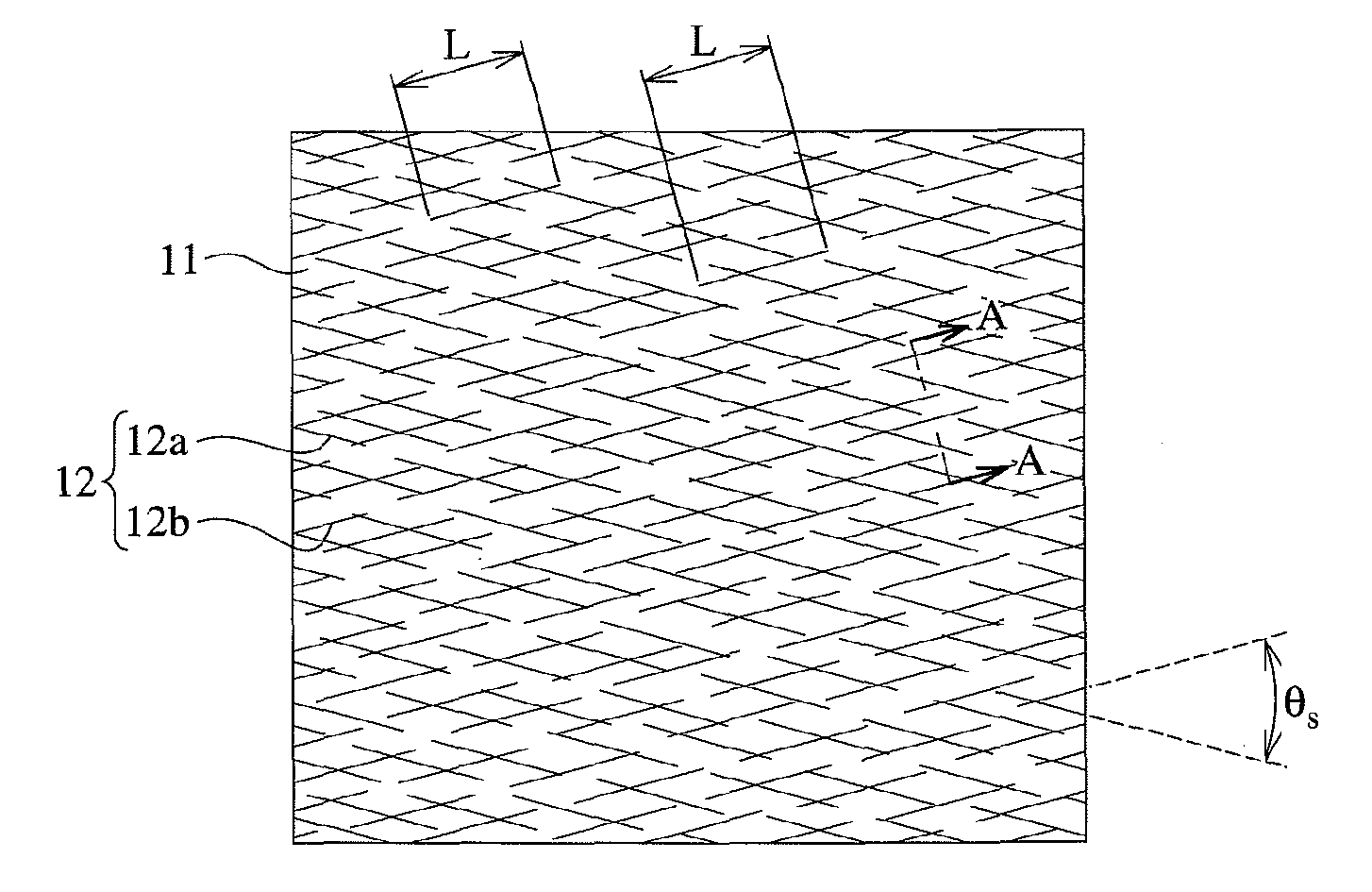

ActiveUS20110008580A1Promote absorptionReduce anisotropyMagnetic/electric field screeningSynthetic resin layered productsElectromagnetic wave absorberThin metal

The present invention provides a composite film having a linearly-scratched, thin metal film and a plastic film, which has good absorbability to electromagnetic waves in various frequencies, as well as reduced anisotropy in electromagnetic wave absorbability, suitable for electromagnetic wave absorbers, and its production apparatus. The composite film having a linearly-scratched, thin metal film and a plastic film according to the present invention comprises a plastic film, and a single-or multi-layer, thin metal film formed on at least one surface of the plastic film, the thin metal film being provided with large numbers of substantially parallel, intermittent, linear scratches with irregular widths and intervals in plural directions. Its production apparatus comprises pluralities of pattern rolls each having large numbers of fine, high-hardness particles on the surface, which are arranged to form linear scratches on the thin metal film side of a thin metal film-plastic composite film, and means each pressing the pattern roll to the composite film, and pluralities of the pattern rolls being oriented in different directions in a plane in which they are in sliding contact with the thin metal film of the composite film.

Owner:KAGAWA SEIJI

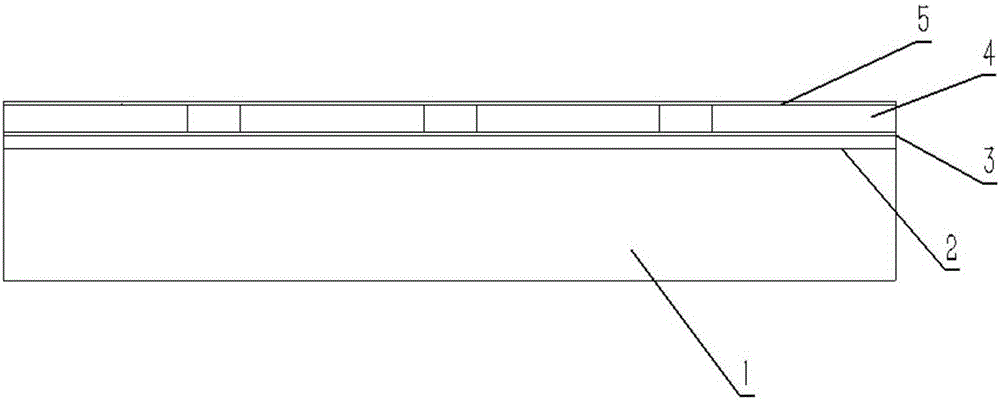

Absorption-rate-adjustable bandwidth electromagnetic wave absorber based on graphene film

ActiveCN106356638AImplement tunable featuresChange input impedanceAntennasElectromagnetic wave absorberDielectric plate

The invention provides an absorption-rate-adjustable bandwidth electromagnetic wave absorber based on a graphene film, and aims to solve the technical problems of high cost and poor practicability in the conventional absorption-rate-adjustable bandwidth electromagnetic wave absorber based on the graphene film. The absorption-rate-adjustable bandwidth electromagnetic wave absorber comprises a conductive layer and a dielectric layer which are laminated one above the other, wherein the conductive layer comprises a metal patch and a graphene film attached to the lower surface of the metal patch; a plurality of cross-shaped gaps of different forms are etched into the metal patch to form M*N patch units; each patch unit consists of m*n patches; the dielectric layer comprises a first dielectric plate, a second dielectric plate and a third dielectric plate which are laminated from top to bottom; a bottom plate is printed on the lower surface of the third dielectric plate; a direct-current power supply is connected between the graphene film and the second dielectric plate, and is used for adjusting surface conductivity of the graphene film. The absorption-rate-adjustable bandwidth electromagnetic wave absorber has the advantages of low cost and high practicability, and can be applied to occasions requiring an intermittent wave-absorbing feature such as a paraboloid antenna and an aircraft surface.

Owner:XIDIAN UNIV

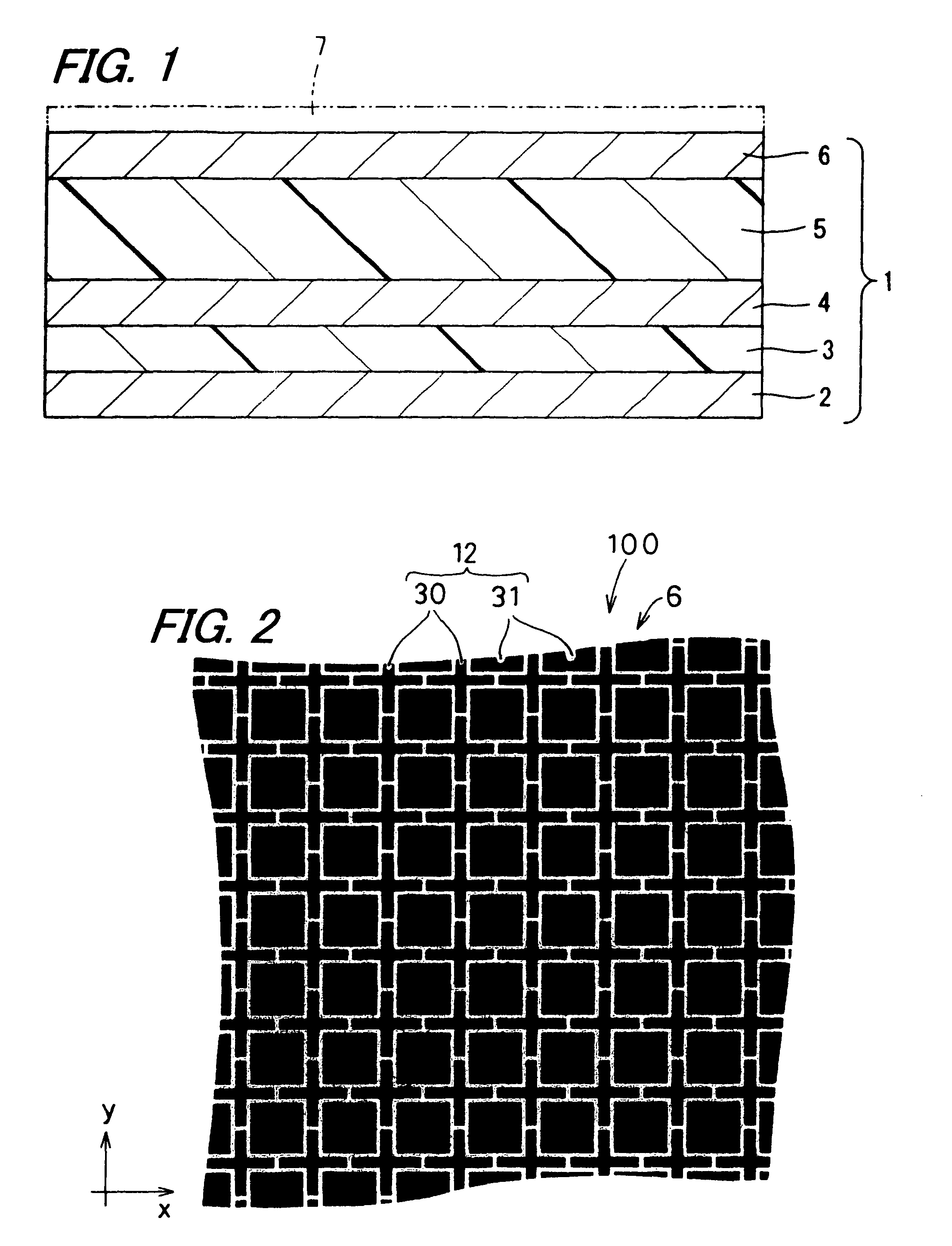

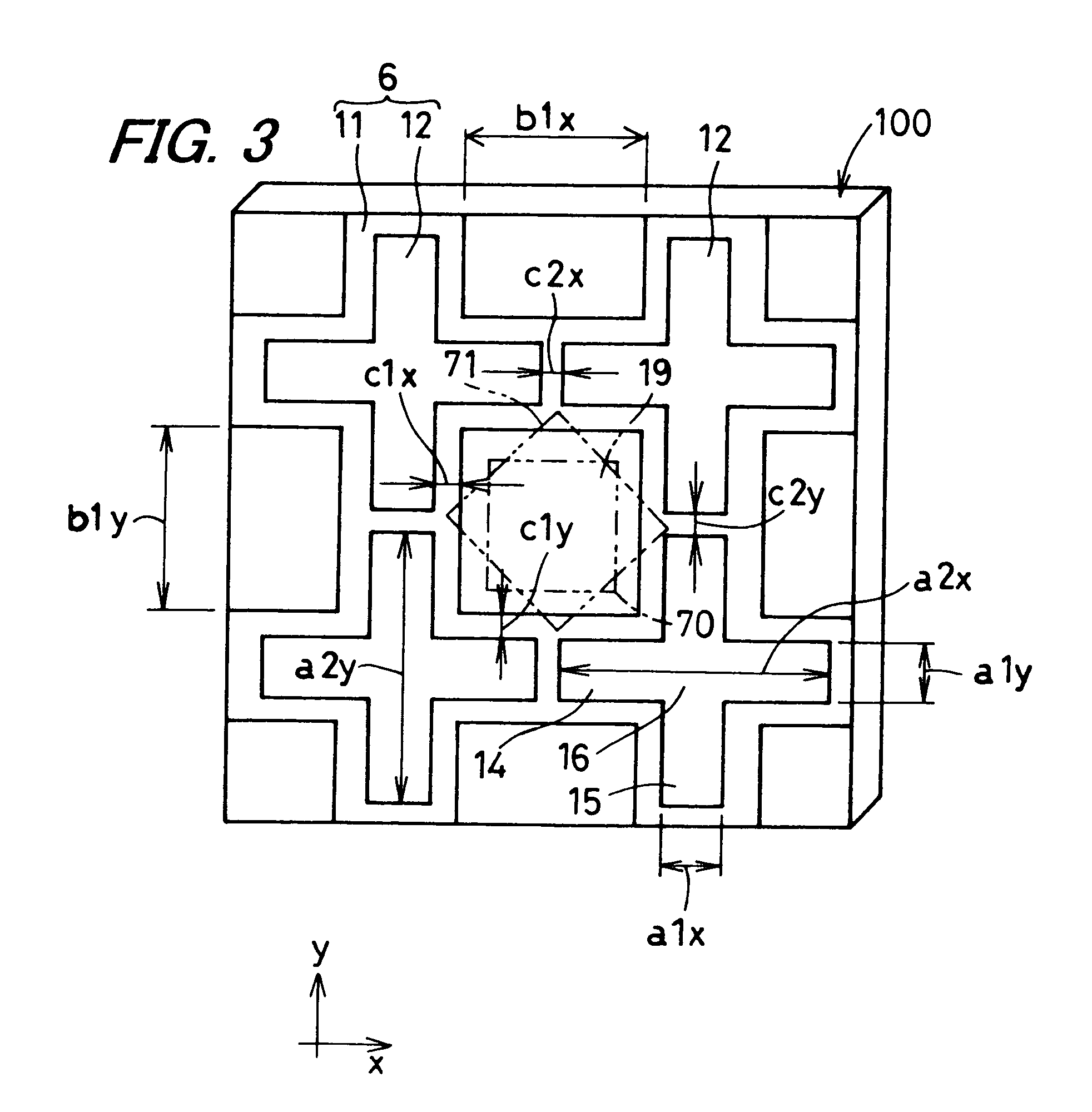

Electromagnetic wave absorber

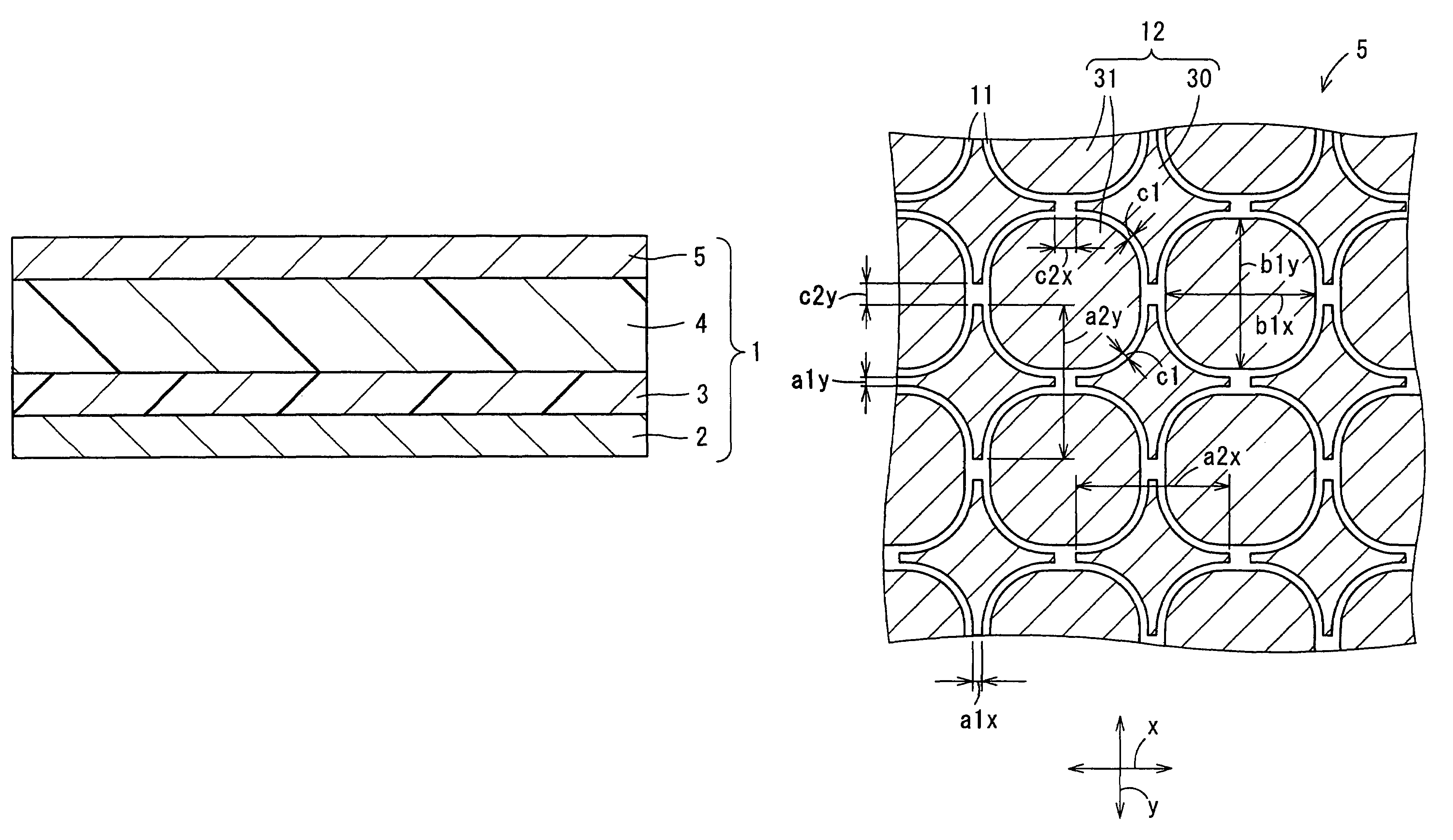

InactiveUS7804439B2High strengthImprove workabilityScreening rooms/chambersWaveguidesElectromagnetic wave absorberElectrical conductor

A thin, light and soft electromagnetic wave absorber is disclosed exhibiting an excellent workability. The first conductor element group of a first conductor element layer consists of aligned cross conductor elements and square conductor elements in regions surrounded by cross conductor elements. A radio wave incident from the first conductor element layer side is received by each element, internally subjected to multiple reflection and then absorbed by a first loss material layer. Since the first conductor element group is realized by the cross conductor elements and the square conductor elements, receiving effect is enhanced and the radio wave can be collected with a high collection efficiency.

Owner:NITTA CORP

Electromagnetic wave absorber

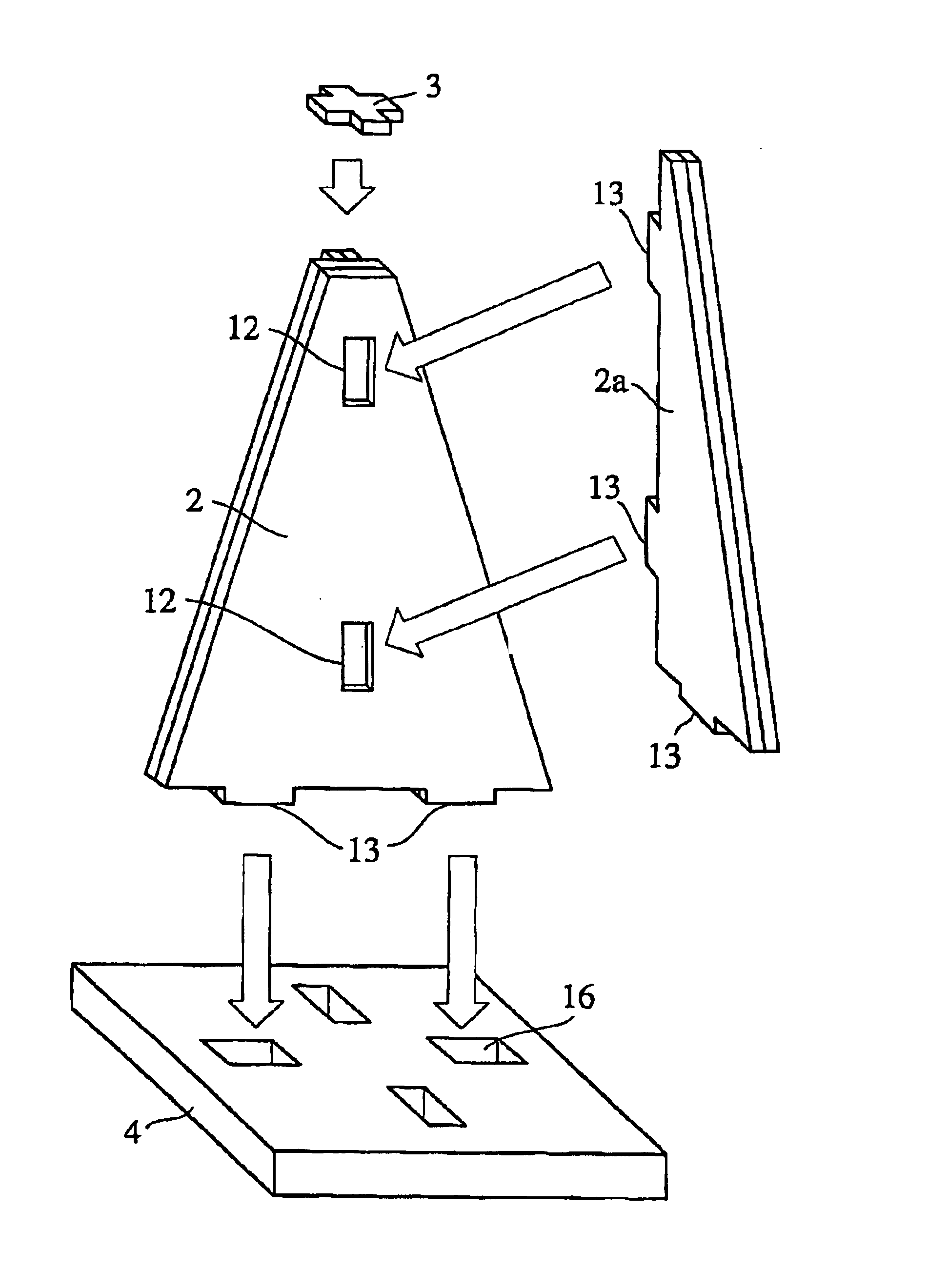

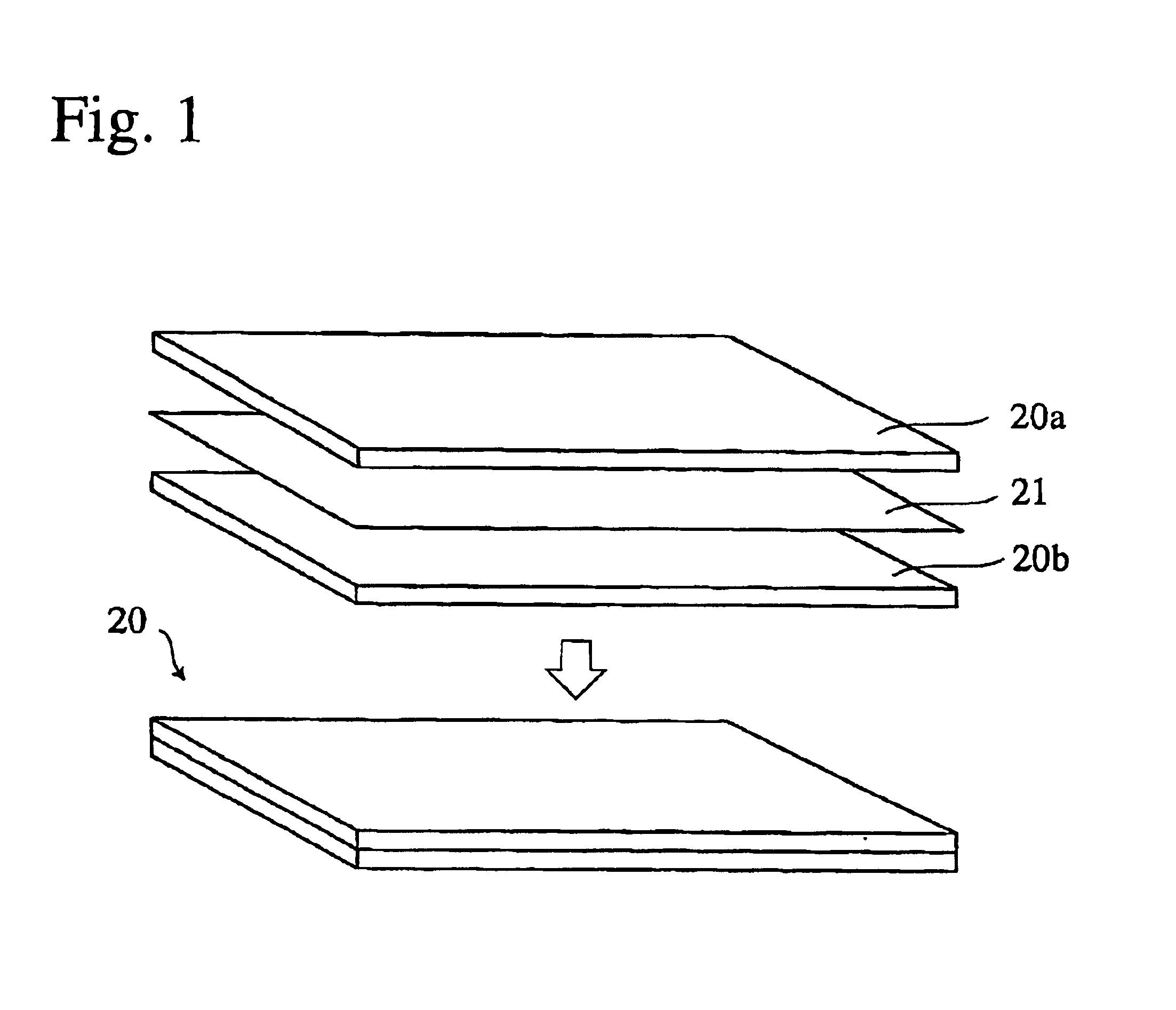

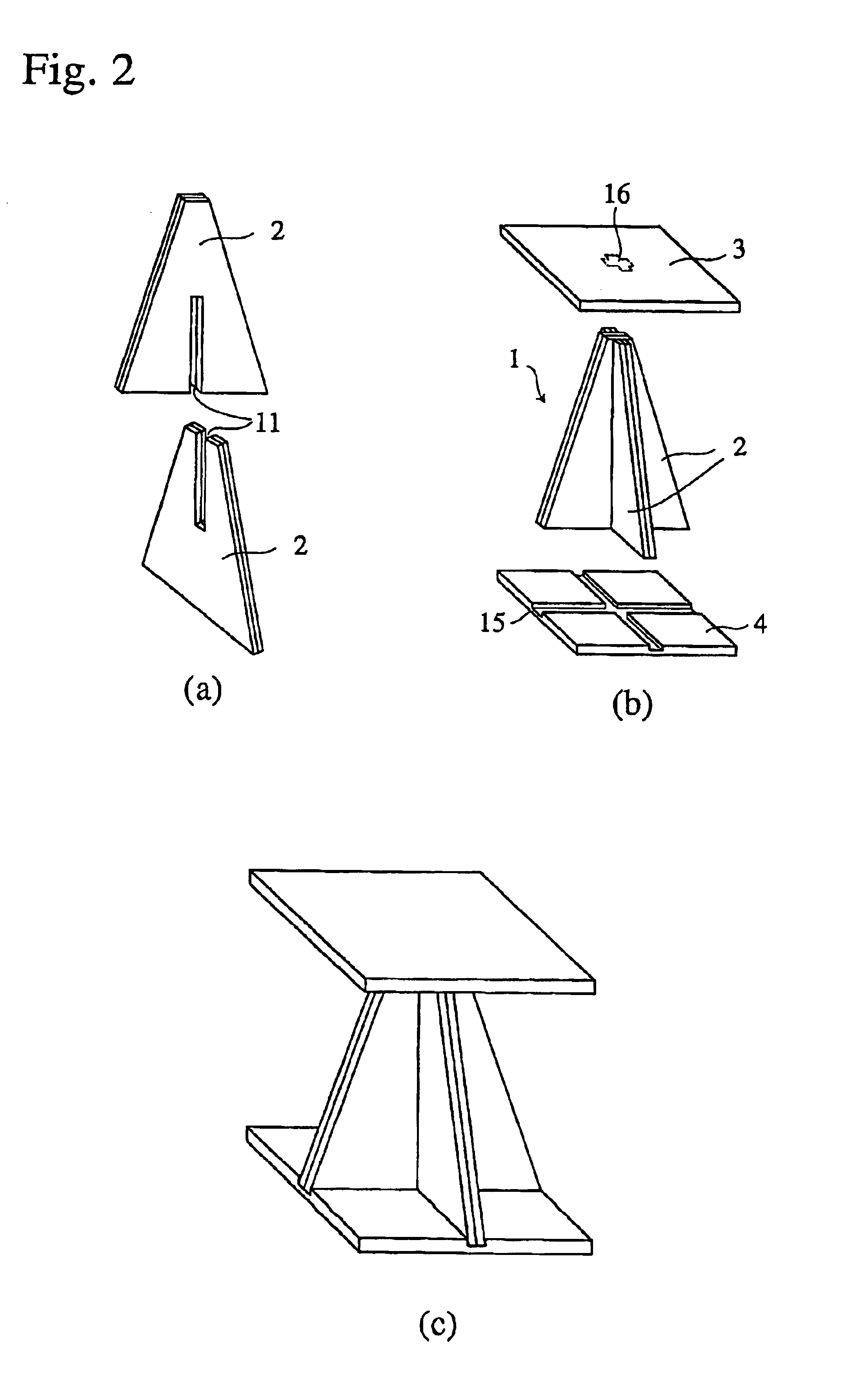

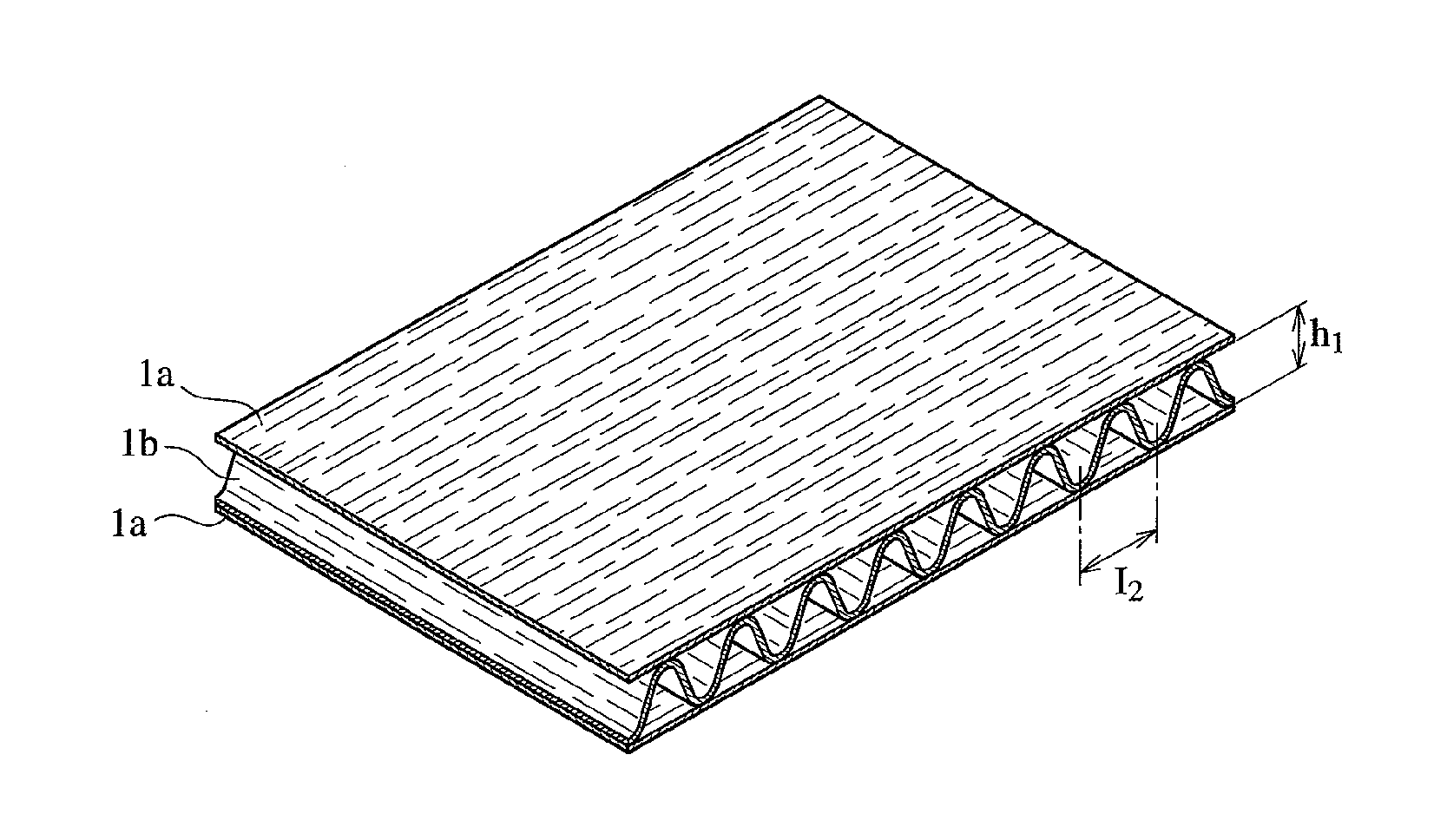

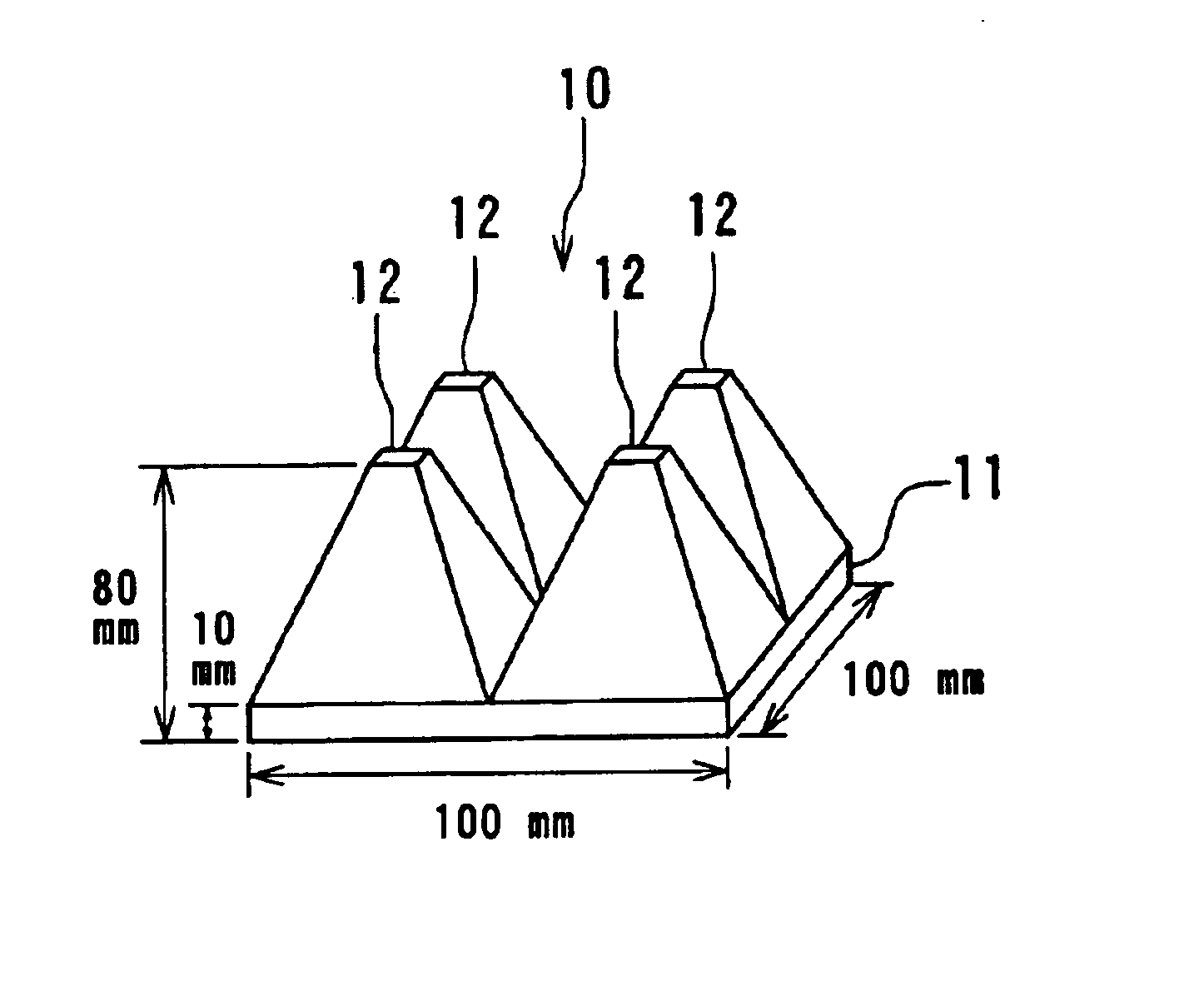

InactiveUS6784419B1Good formabilityExcellent electromagneticMagnetic/electric field screeningScreening apparatusElectromagnetic wave absorberClassical mechanics

The present invention provides a flame-retardant electromagnetic wave absorber that exhibits excellent formability and electromagnetic wave-absorbing properties, and can be easily assembled and constructed. The electromagnetic wave absorber comprises a wave-absorbing body and a base plate supporting the bottom thereof, wherein the wave-absorbing body is formed in a pyramid shape by fitting polygonal wave-absorbing plates into each other.

Owner:RIKEN CO LTD

Electromagnetic-wave-absorbing film and electromagnetic wave absorber comprising it

InactiveUS20110031008A1Excellent electromagnetic wave absorption performanceReduce anisotropyMagnetic/electric field screeningSynthetic resin layered productsElectromagnetic wave absorberThin metal

An electromagnetic-wave-absorbing film comprising a plastic film, and a single- or multi-layer, thin metal film formed on at least one surface of the plastic film, the thin metal film being provided with large numbers of substantially parallel, intermittent, linear scratches with irregular widths and intervals.

Owner:KAGAWA SEIJI

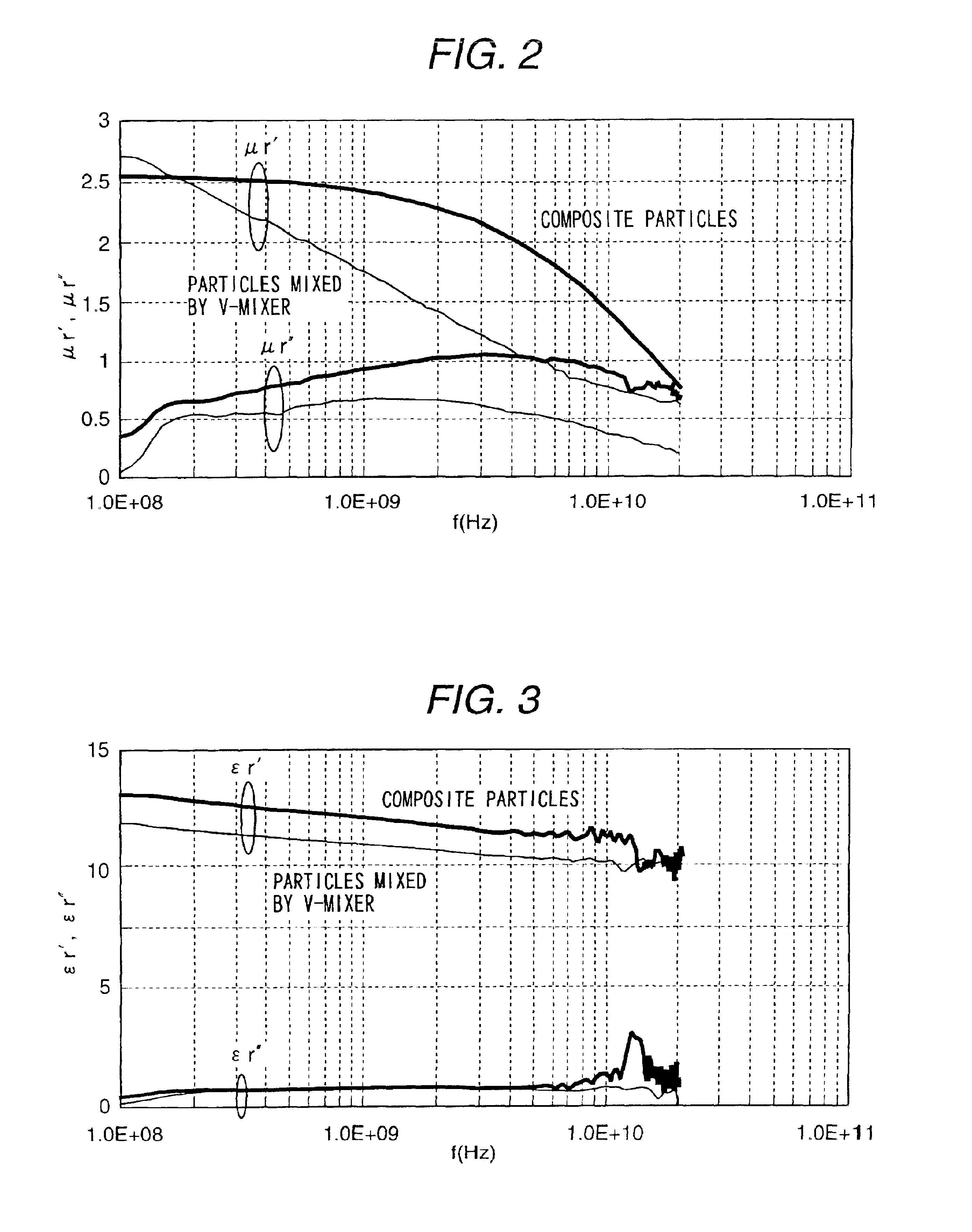

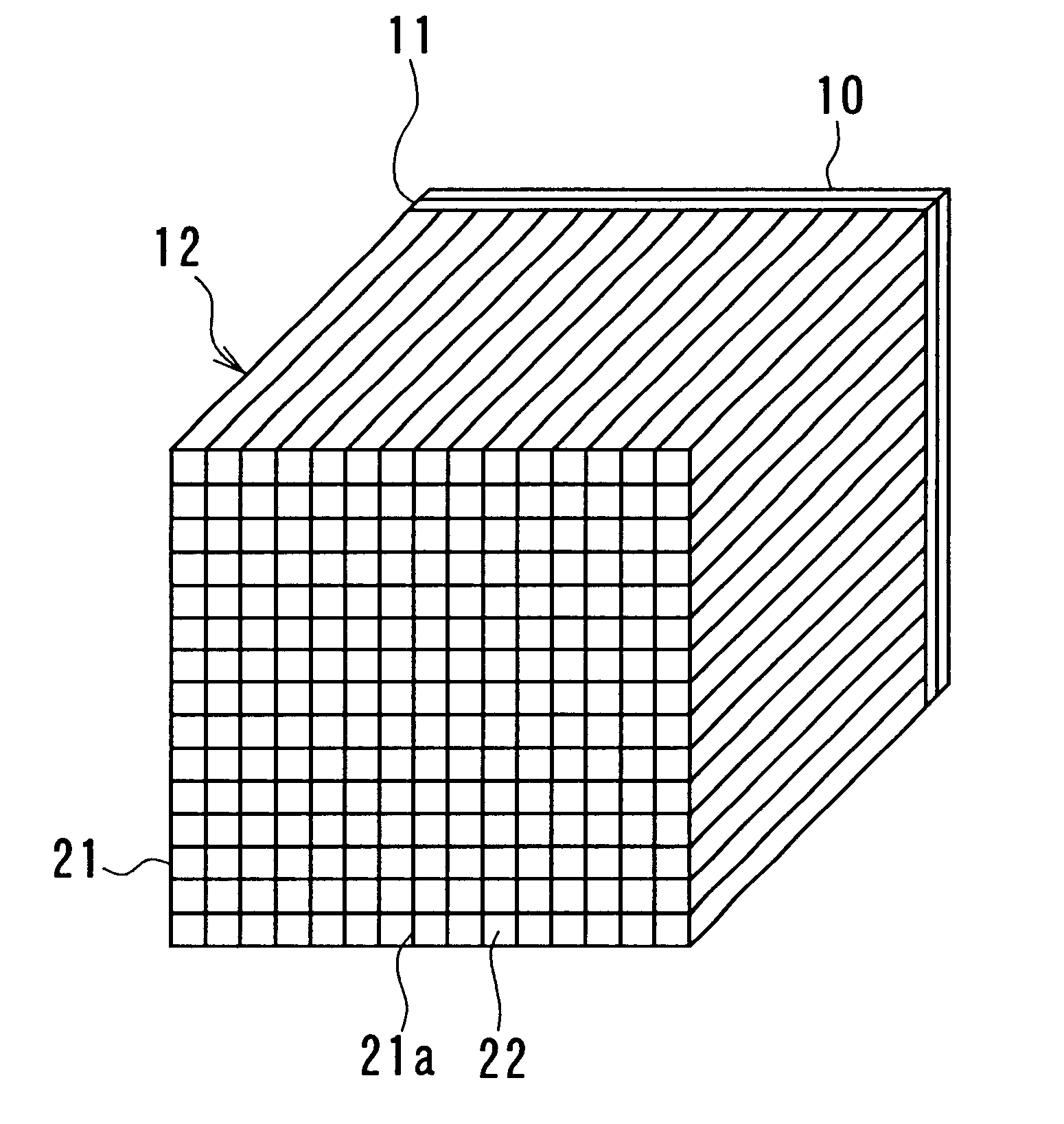

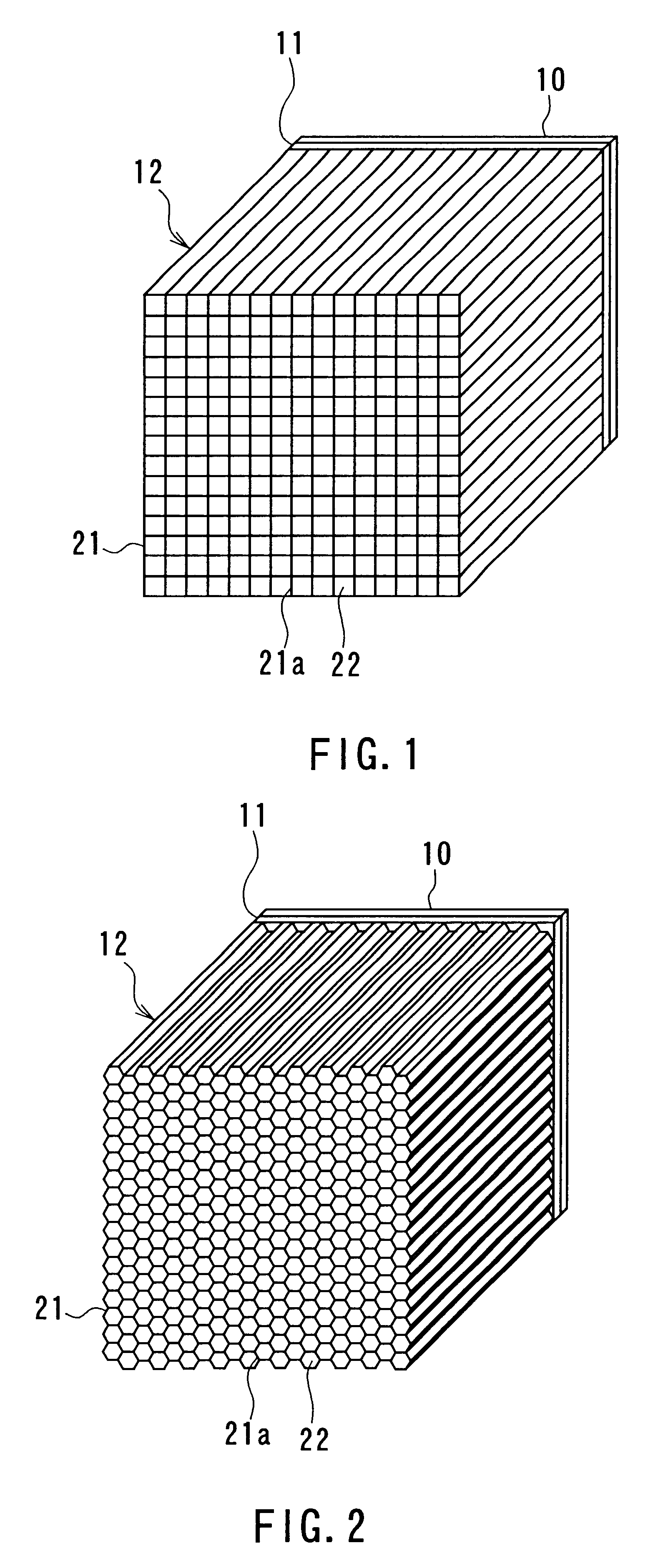

Electromagnetic wave absorber, method of manufacturing the same and appliance using the same

InactiveUS6919387B2Excellent electromagnetic wave absorbing characteristicIncrease heightMagnetic/electric field screeningRoad vehicles traffic controlElectromagnetic wave absorberElectromagnetic absorbers

Owner:HITACHI LTD

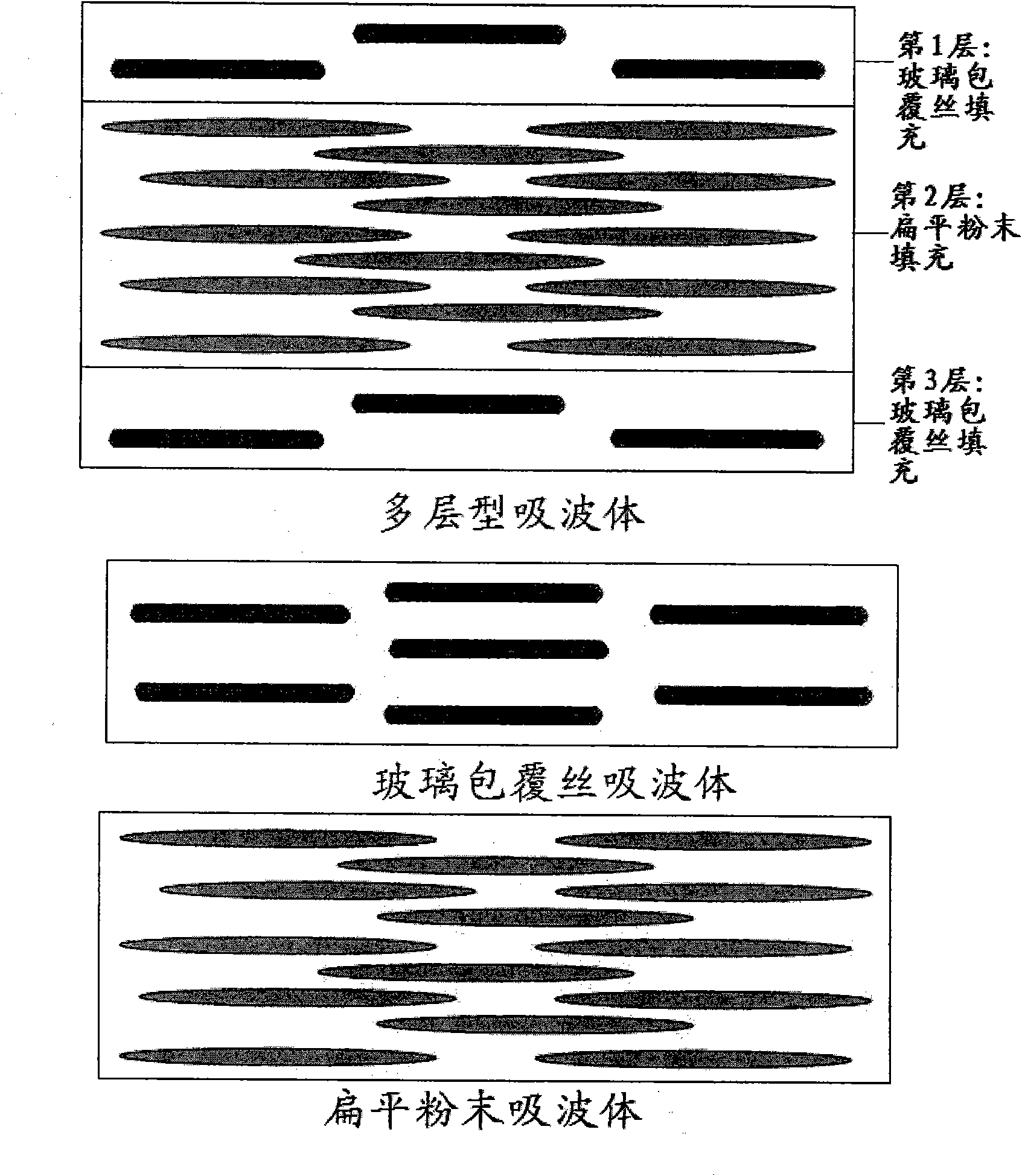

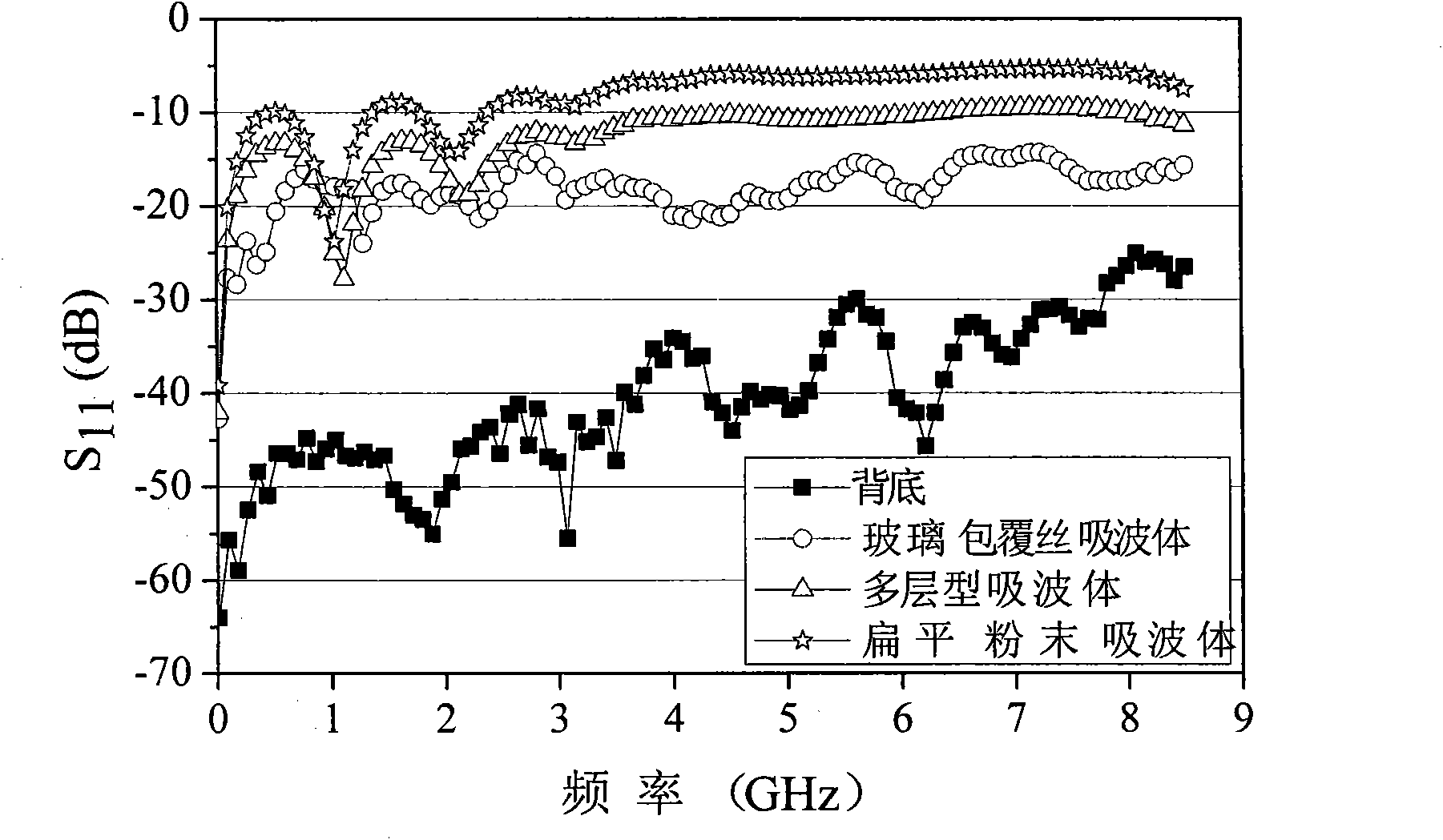

Multilayer type electromagnetic wave absorber and manufacturing method thereof

ActiveCN101902898ASmall reflection coefficientImprove flexibilityOther chemical processesMagnetic/electric field screeningElectromagnetic wave absorberYarn

The invention provides a multilayer type electromagnetic wave absorber which comprises (a) two surface layers and (b) an intermediate layer, wherein the two surface layers mainly comprise a glass-coated yarn wave absorbent and a polymer substrate; the intermediate layer is positioned between the surface layers, and the intermediate layer mainly comprises a flat type amorphous alloy powder wave absorbent and a polymer substrate. The invention also provides a method for preparing the multilayer type electromagnetic wave absorber.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

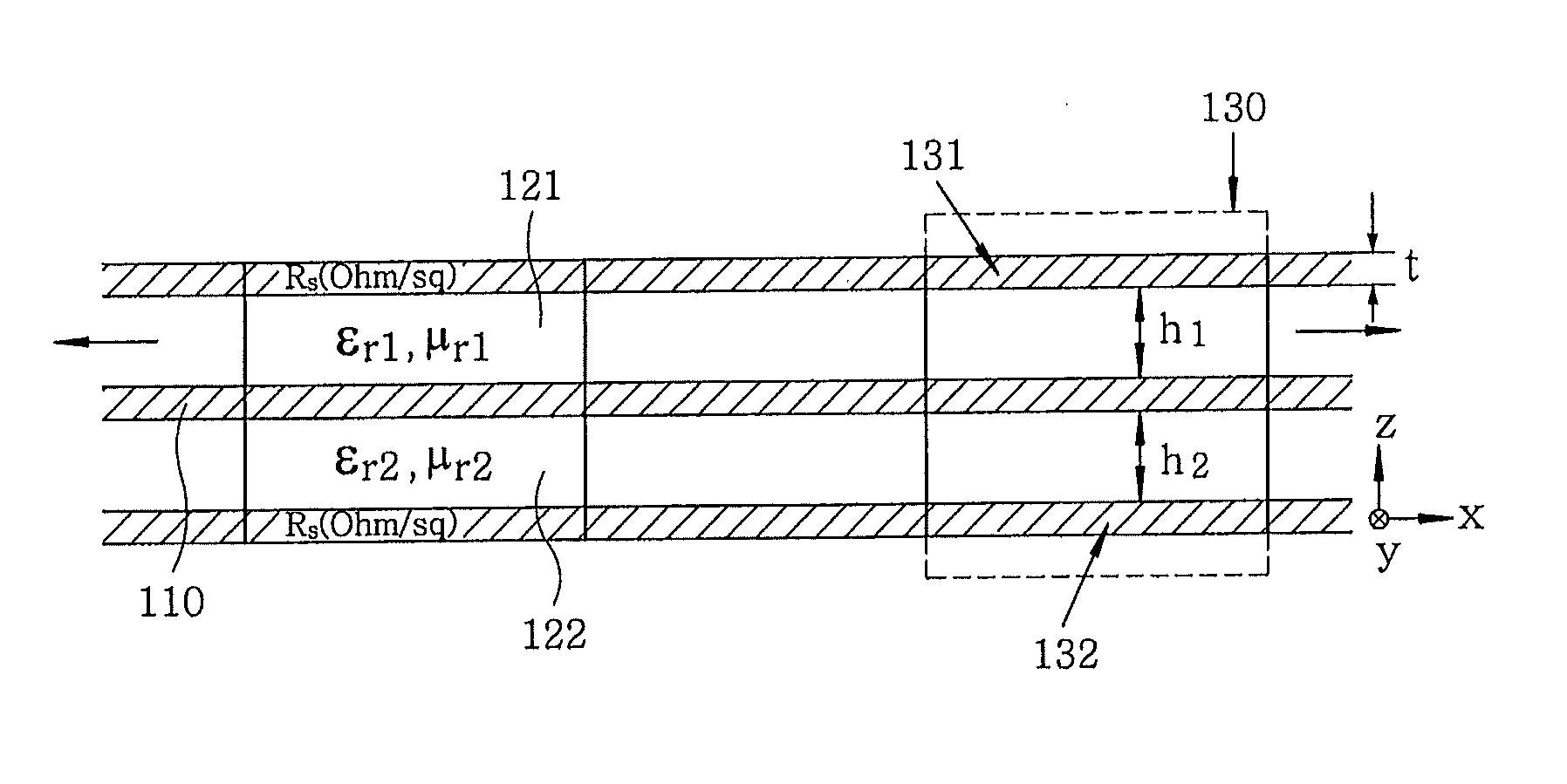

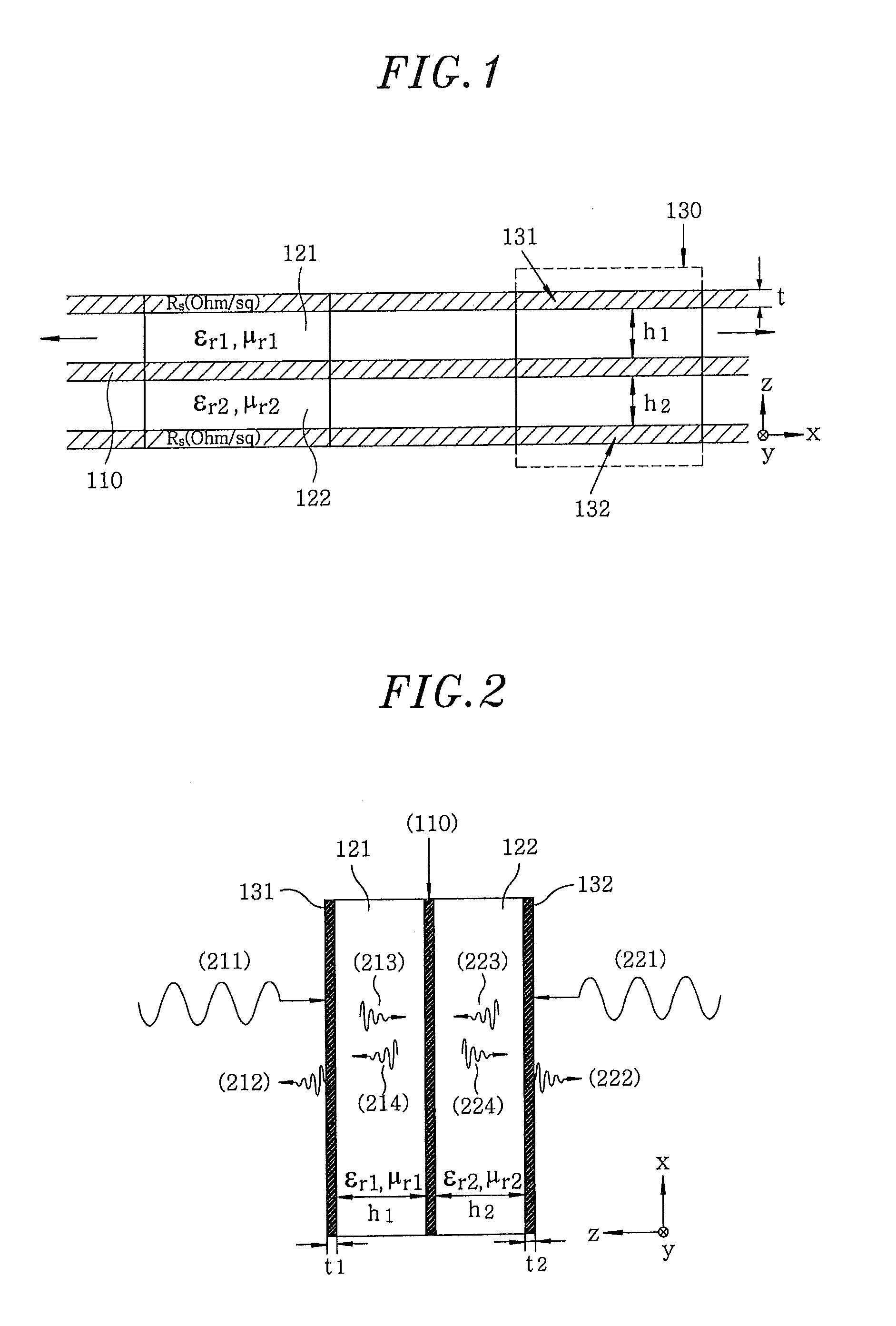

Multi-directional resonant-type electromagnetic wave absorber, method for adjusting electromagnetic wave absorption performance using the same and manufacturing method of the same

InactiveUS20110133978A1Easy to manufactureEasy to adjustMagnetic/electric field screeningCoatingsElectromagnetic wave absorberElectrical resistance and conductance

A multi-directional resonant-type electromagnetic wave absorber includes: at least one ground layer; a first dielectric layer and a second dielectric layer respectively formed on different outer surfaces of the ground layer; a first resistive pattern layer formed on an outer surface of the first dielectric layer; and a second resistive pattern layer formed on an outer surface of the second dielectric layer. Herein, the electromagnetic absorption performance is adjusted by changing one or more of thicknesses, permittivities, and permeabilities of the dielectric layers, thicknesses of the resistive pattern layers, and a reflection coefficient of the ground layer.

Owner:ELECTRONICS & TELECOMM RES INST

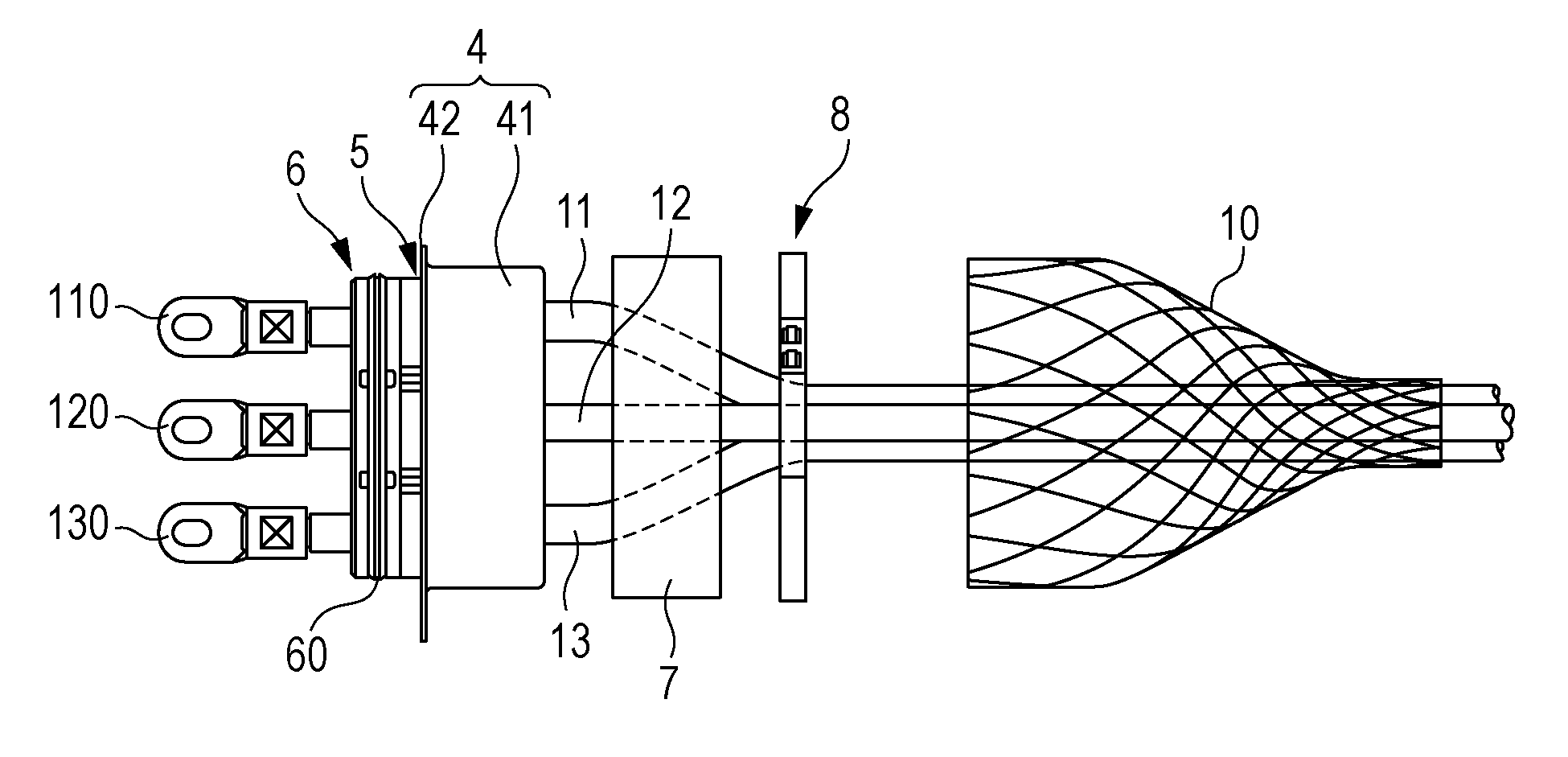

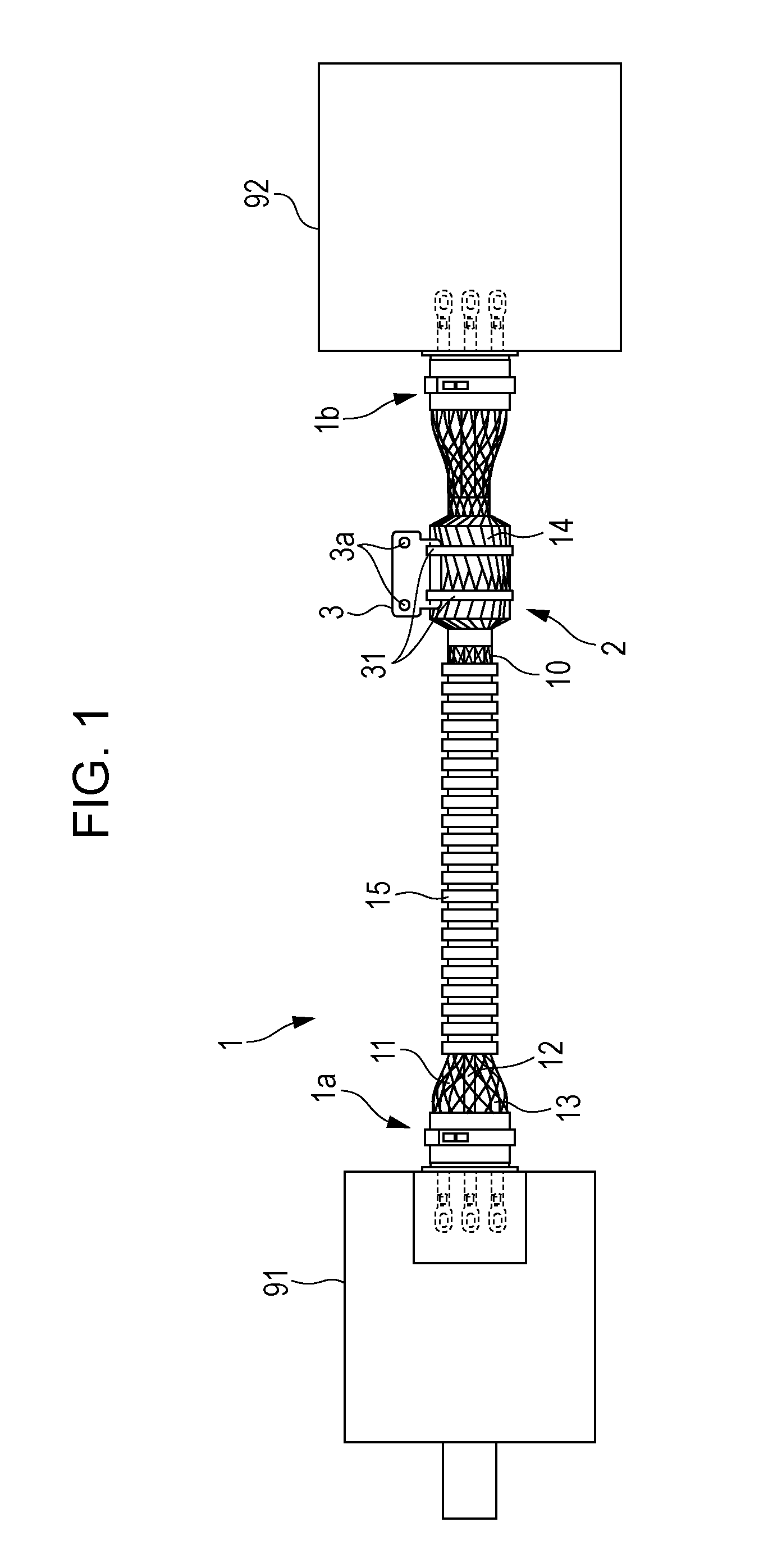

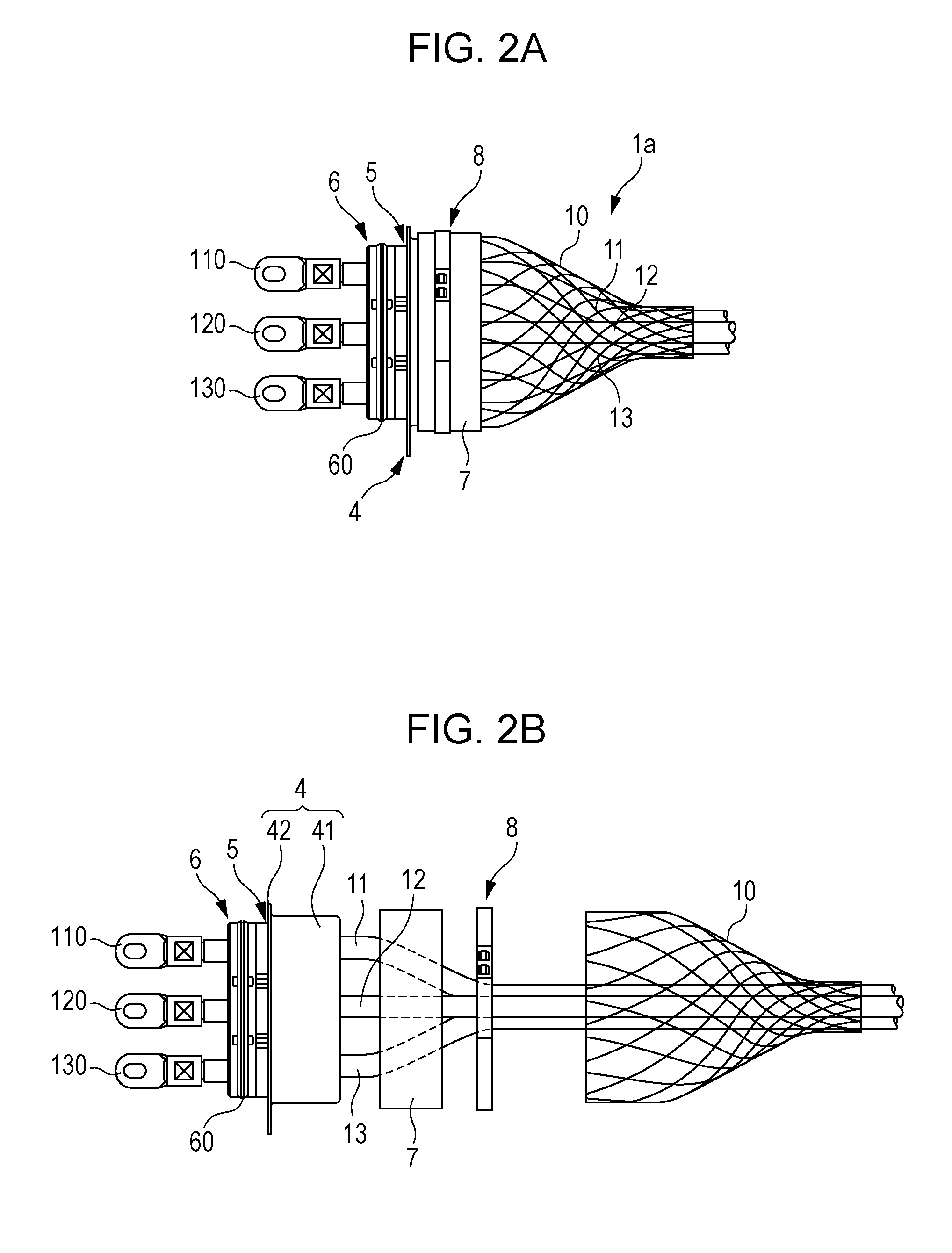

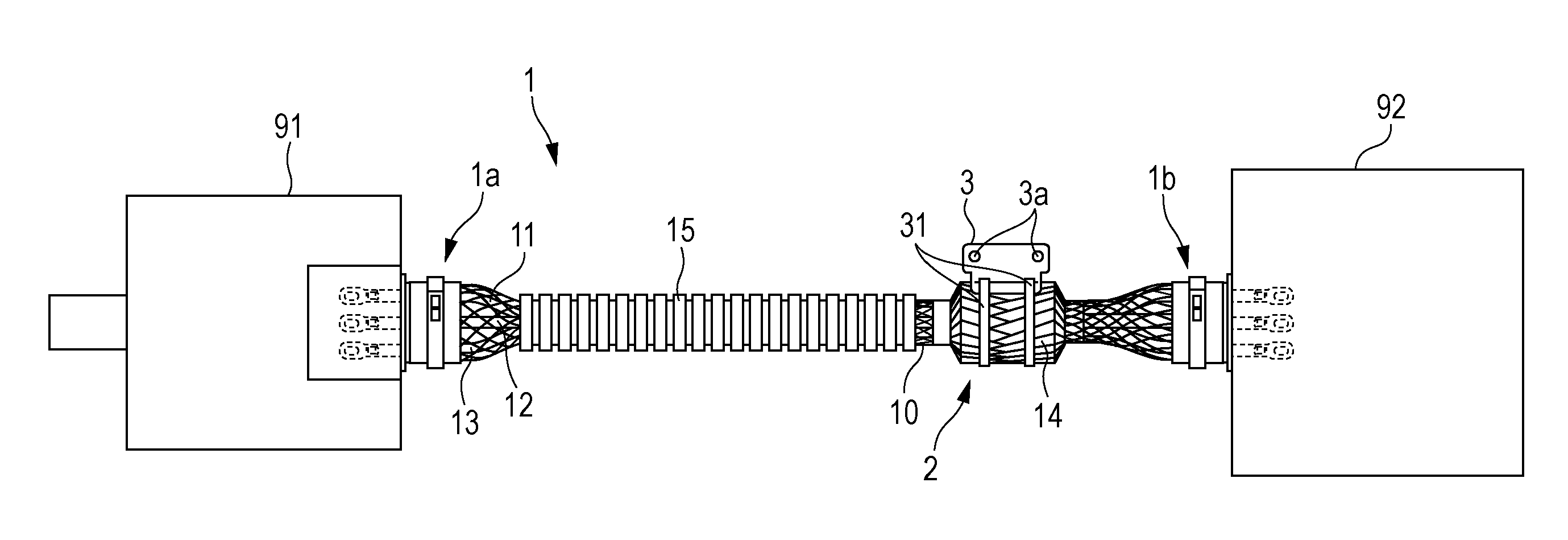

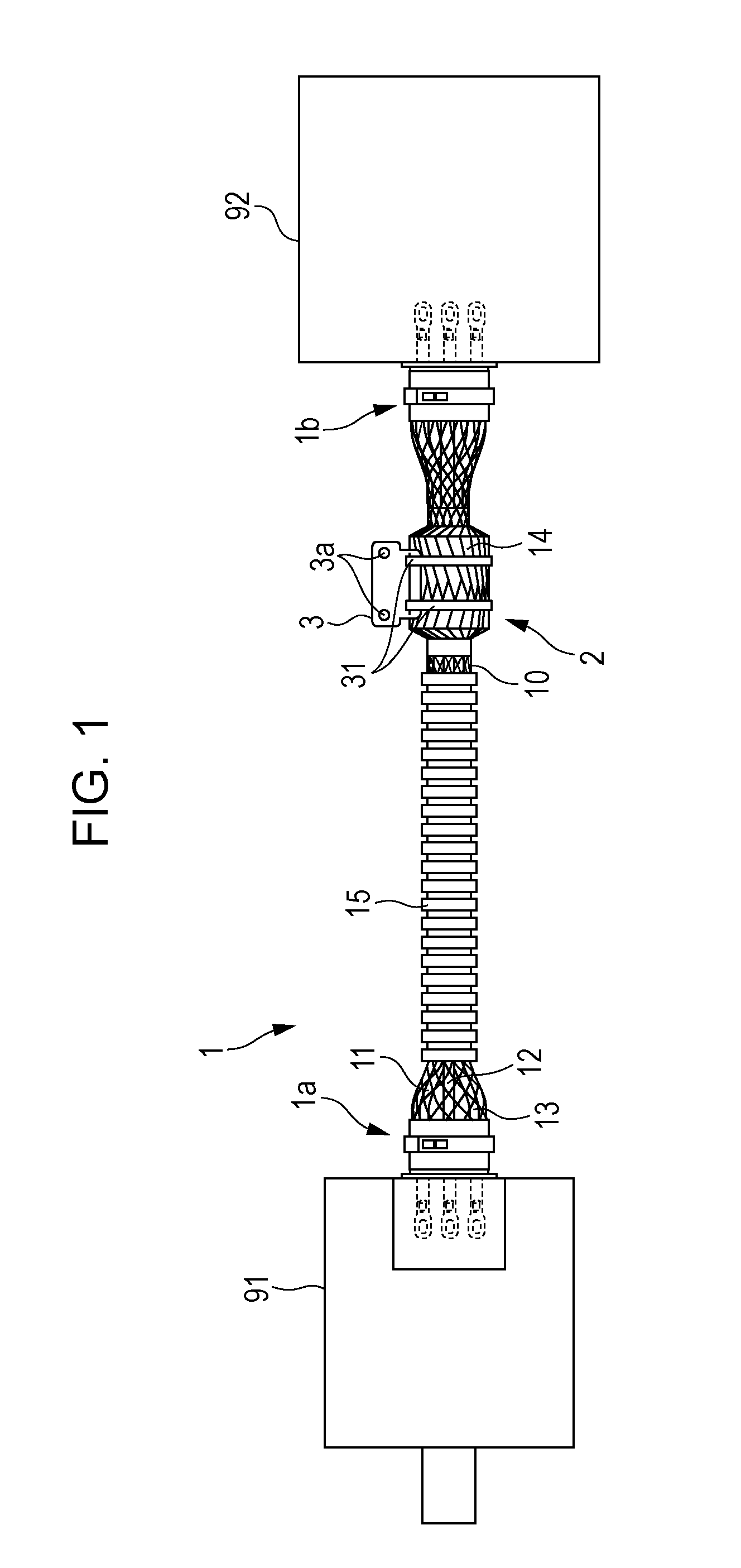

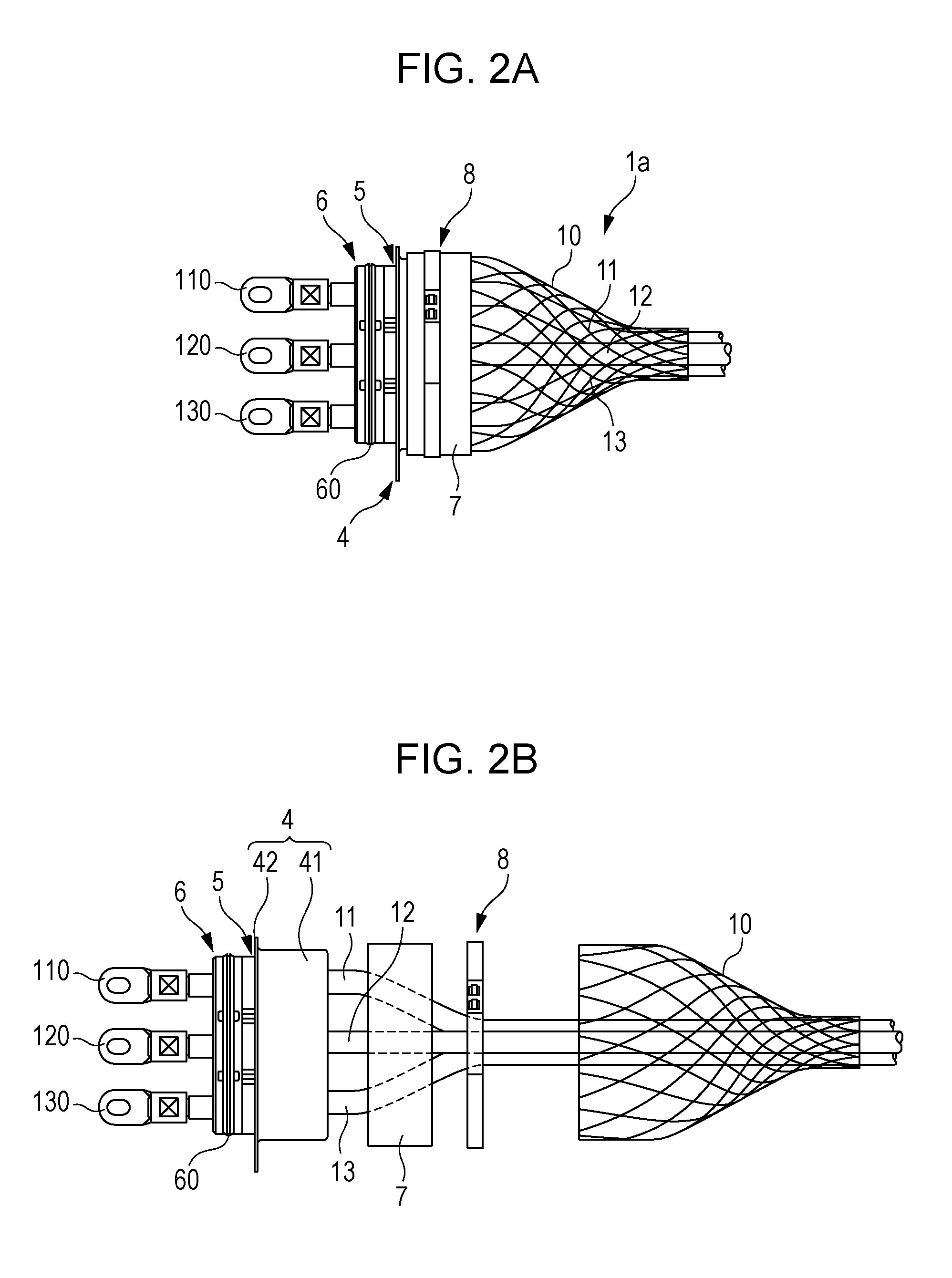

Wiring member

ActiveUS20150289420A1Restrict movementVehicle connectorsAperture leaage reductionElectromagnetic wave absorberEngineering

A wire harness includes first to third electric wires, a braid shield that covers the first to third electric wires, and a tube-shaped electromagnetic wave absorber having a through hole that allows the first to third electric wires to be inserted therethrough, the electromagnetic wave absorber absorbing electromagnetic waves emitted from the first to third electric wires. The braid shield covers an outer circumferential surface and two axial end surfaces of the electromagnetic wave absorber to restrict movement of the electromagnetic wave absorber in an axial direction. The braid shield satisfies 1≦n≦15 and 10≦m≦50 where the number of carriers of the braid shield is denoted by n and the number of ends of the braid shield is denoted by m.

Owner:HITACHI METALS LTD

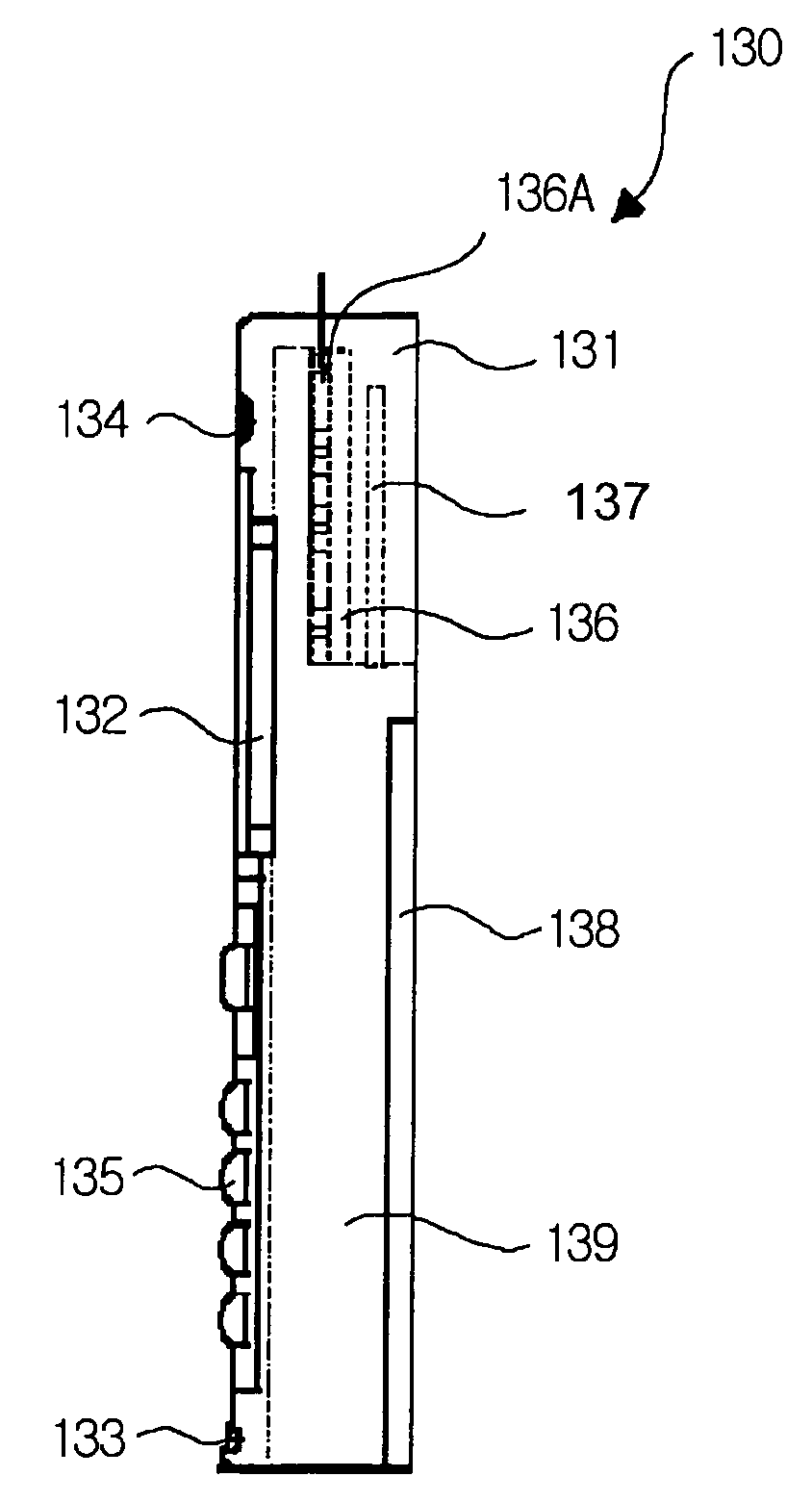

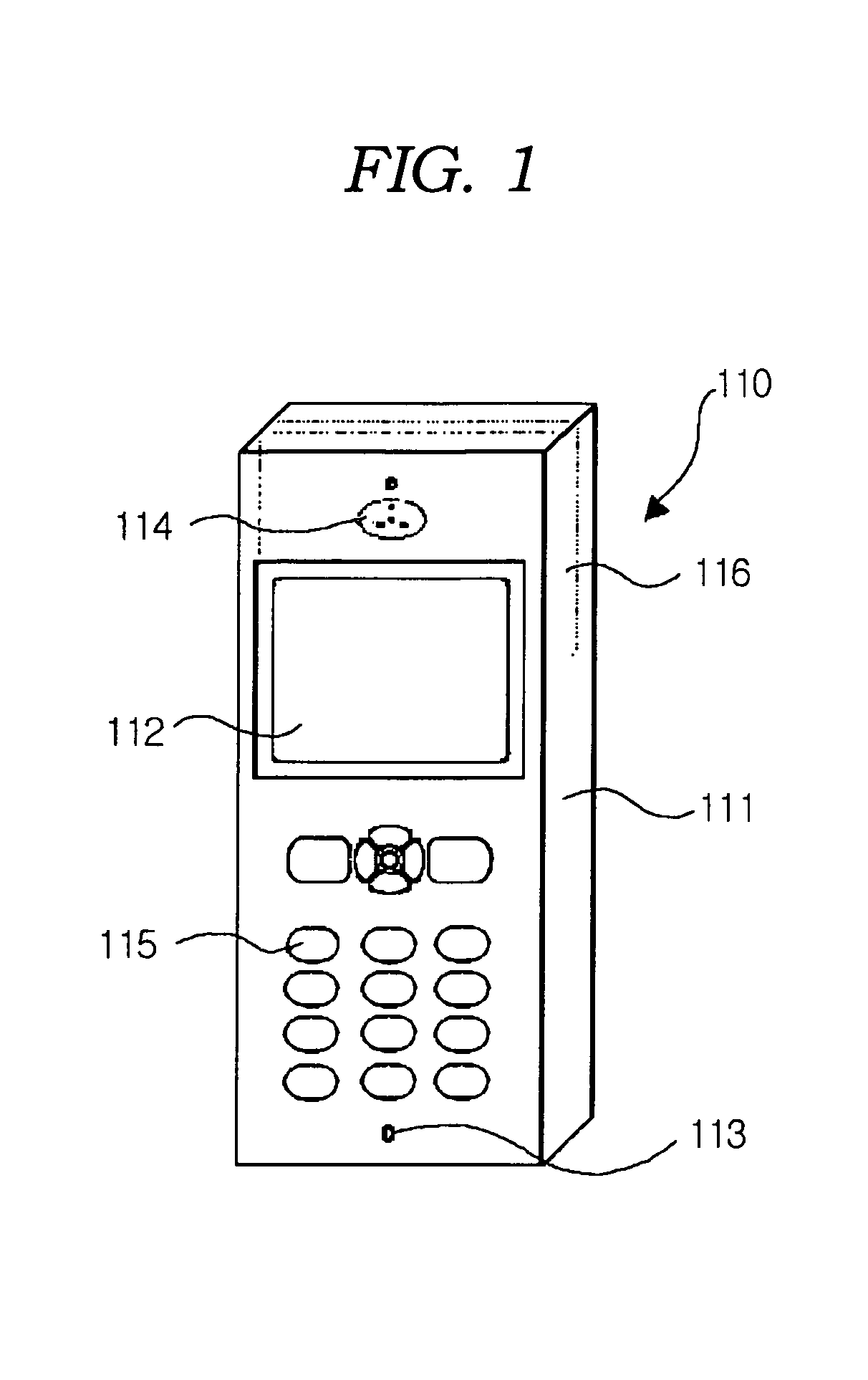

Mobile phone having reduced specific absorption rate (SAR) using an antenna housed to ensure enhanced antenna gain

InactiveUS7099631B2Effectively loweringConvenient to accommodateAntenna supports/mountingsSubstation equipmentElectromagnetic wave absorberAntenna gain

The present invention relates to a structure of an antenna and its shielding structure for a mobile phone which may significantly reduce the hazardous electromagnetic wave transmitted to the user's body. The present invention arranges a monopole antenna inside of the mobile phone housing, and installs an electromagnetic wave absorber between the antenna and the circuit board. The electromagnetic wave absorber can absorb the electromagnetic wave reflected form conductive plate constituting the circuit board. Thus, the adverse effect of the reflected electromagnetic wave to the performance of antenna is prevented and the amount of the electromagnetic wave to which the users is exposed can be significantly reduced as well.

Owner:ELECTRONICS & TELECOMM RES INST

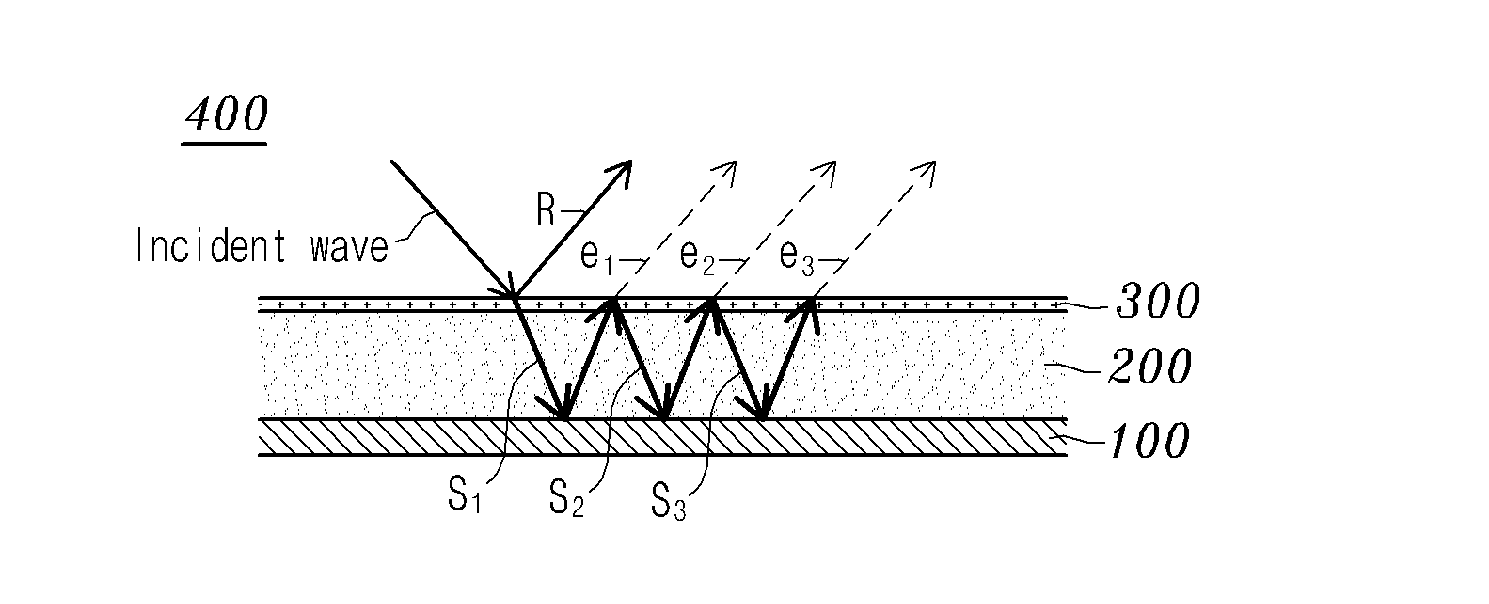

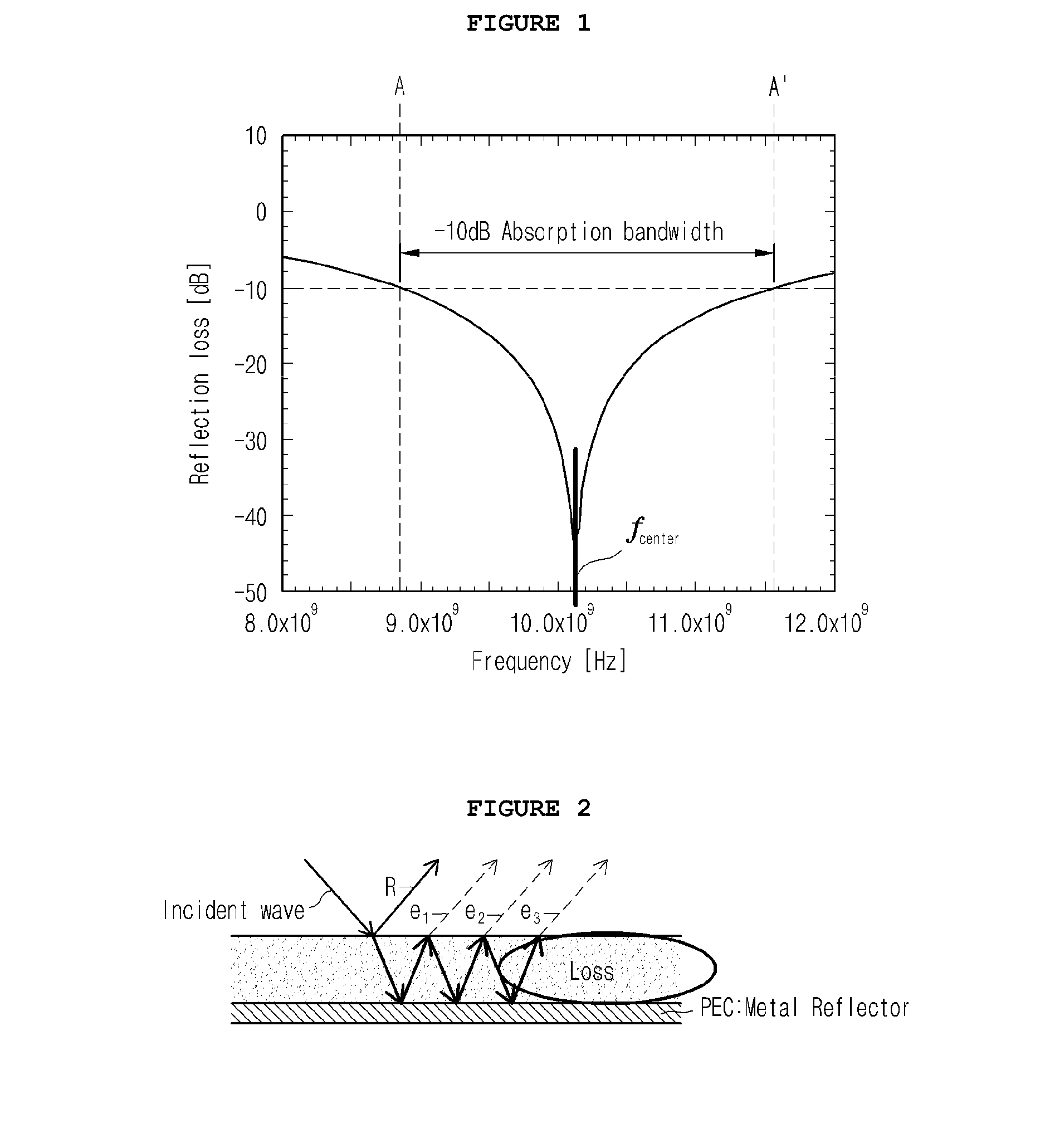

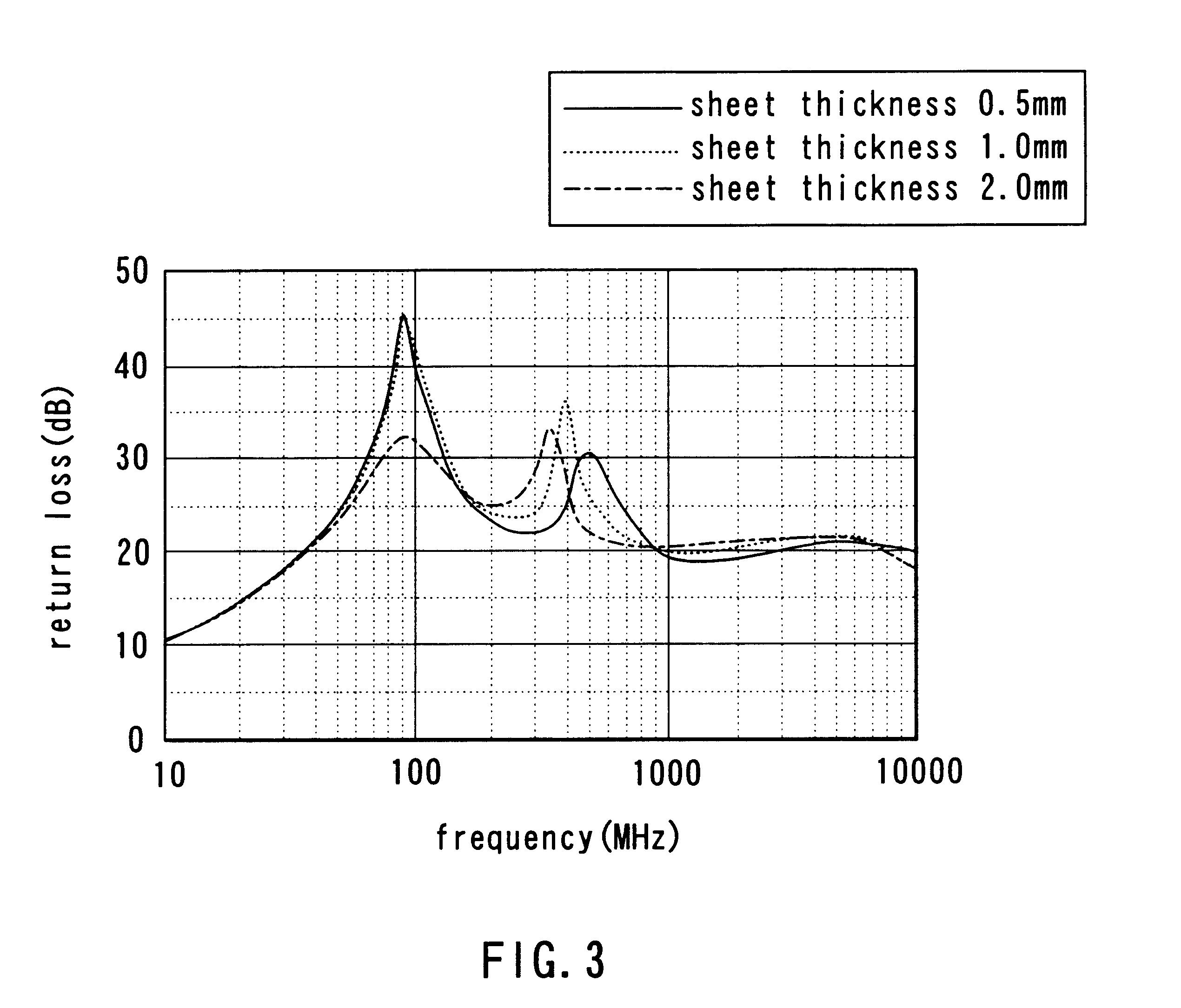

Electromagnetic Wave Absorber Using A Dielectric Loss Sheet, Method For Forming The Electromagnetic Wave Absorber, And Rotary Blade For A Wind Turbine Having An Electromagnetic Wave Function Using Same

InactiveUS20130224023A1Wide absorption bandwidthAvoiding radar interferenceAdhesive processesPropellersElectromagnetic wave absorberElectricity

Disclosed are an electromagnetic wave absorber using a dielectric loss sheet, a method for fabricating the same, and a wind turbine blade having an electromagnetic wave function. The electromagnetic wave absorber comprises: a support layer for providing a resonant space of electromagnetic waves; a highly conductive backing layer assigned to a back surface of the dielectric support layer; and a dielectric lossy composite sheet layer formed on a front surface of the dielectric support layer, said dielectric lossy composite sheet layer having such a dielectric permittivity so as to generate a resonant peak with the electromagnetic waves reflected from the highly conductive backing layer.

Owner:KOREA INST OF MACHINERY & MATERIALS

Electromagnetic-wave absorber

InactiveUS20050008845A1Reduced angle dependenceEasy to processShielding materialsRadiation/particle handlingElectromagnetic wave absorberAngle dependence

An electromagnetic wave absorber characterized by comprising from 50 to 85% by weight of inorganic hollow material, from 0.01 to 35% by weight of conductive material, from 5 to 47.5% by weight of binder, and from 0.1 to 47.5% by weight of filler. It has a reduced angle dependence of electromagnetic wave absorption and has the property of absorbing electromagnetic waves over a wide range of angles. It further has satisfactory processability and workability.

Owner:NITTO BOSEIKI CO LTD

Broadband electromagnetic wave-absorber and process for producing same

ActiveUS20110168440A1Improve shielding effectSimple, highly productive and cost effectiveShielding materialsFibre typesElectromagnetic wave absorberDopant

Disclosed is an electromagnetic wave absorbent which exhibits high electromagnetic wave absorption performance over a wide band. The electromagnetic wave absorbent contains a conductive fiber sheet which is obtained by coating a fiber sheet base with a conductive polymer and has a surface resistivity within a specific range. The conductive fiber sheet is formed by impregnating a fiber sheet base such as a nonwoven fabric with an aqueous oxidant solution that contains a dopant, and then bringing the resulting fiber sheet base into contact with a gaseous monomer for a conductive polymer, so that the monomer is oxidatively polymerized thereon.

Owner:TAYCA CORP

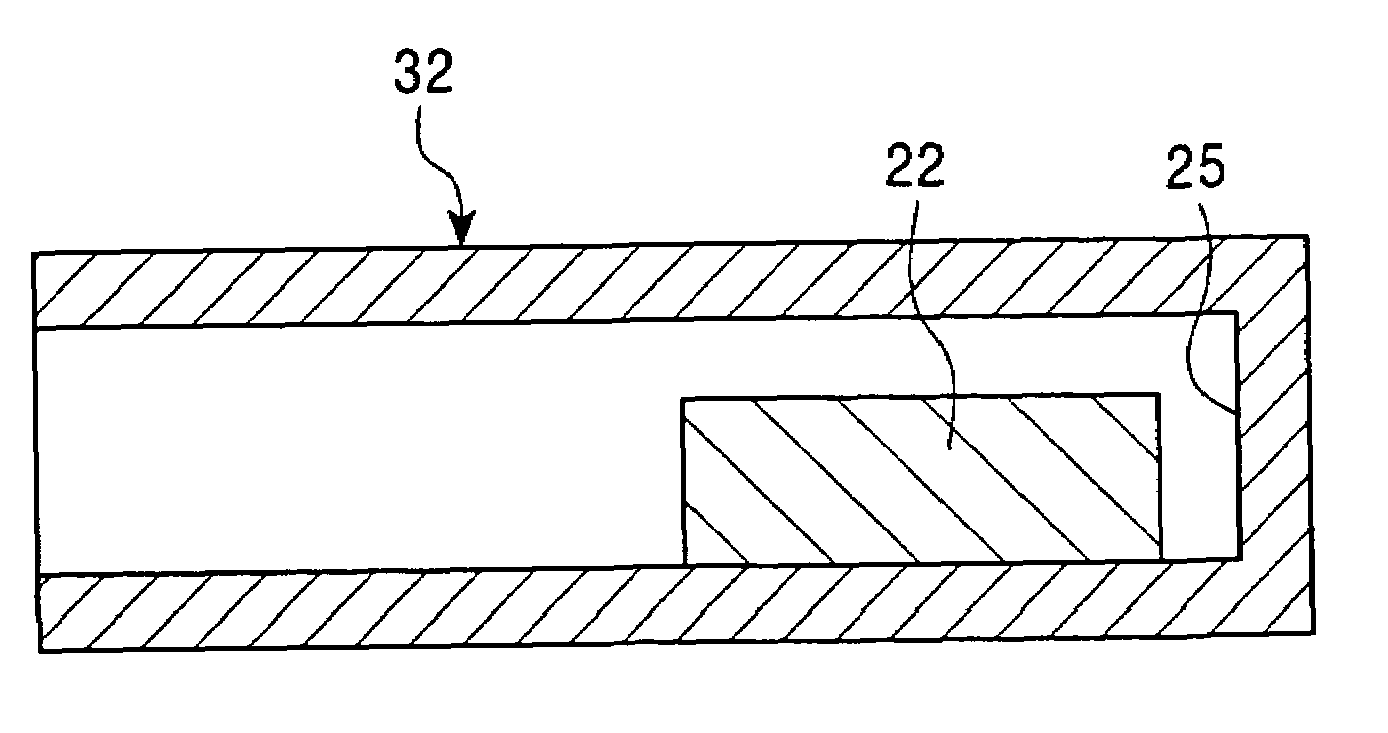

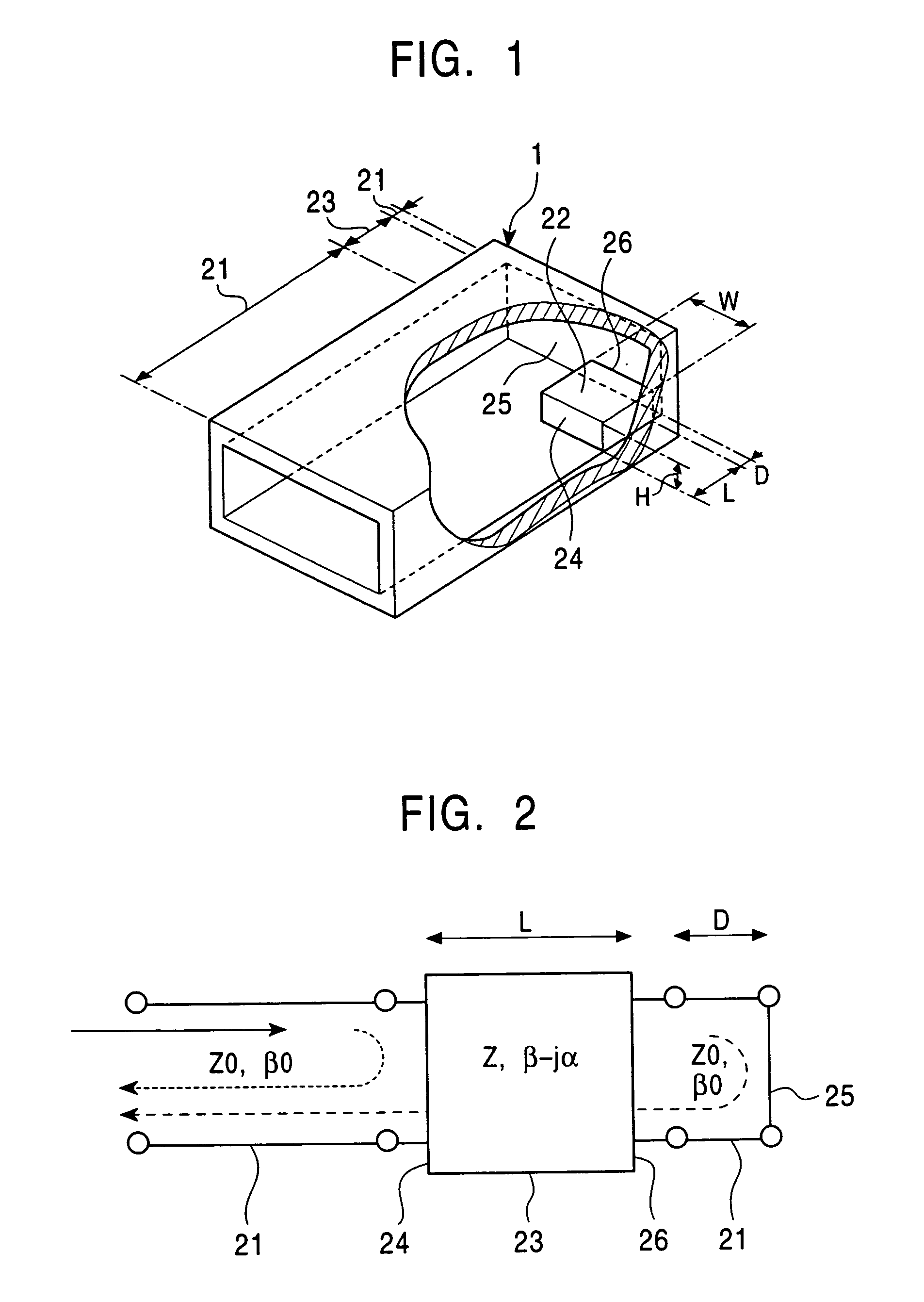

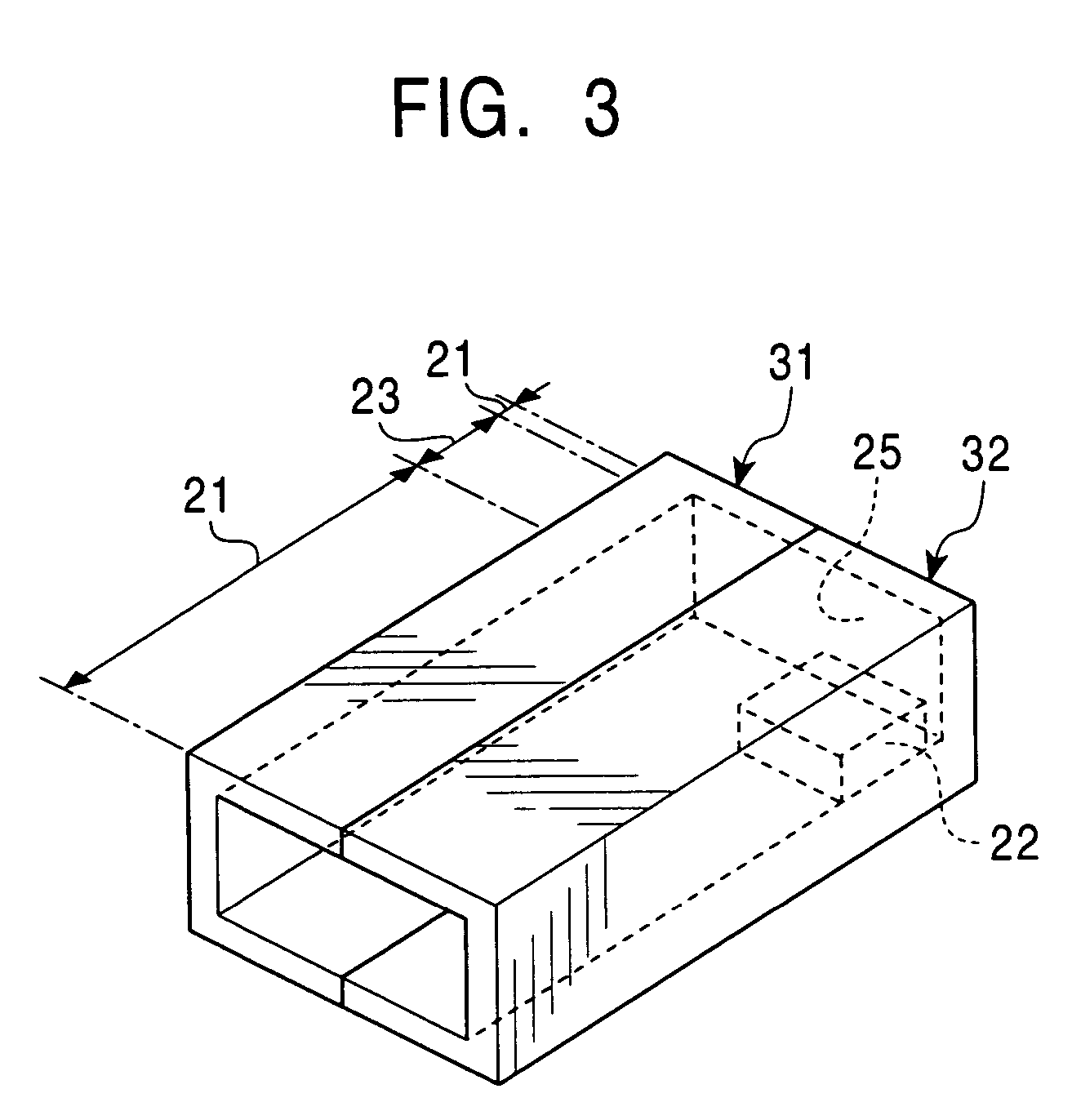

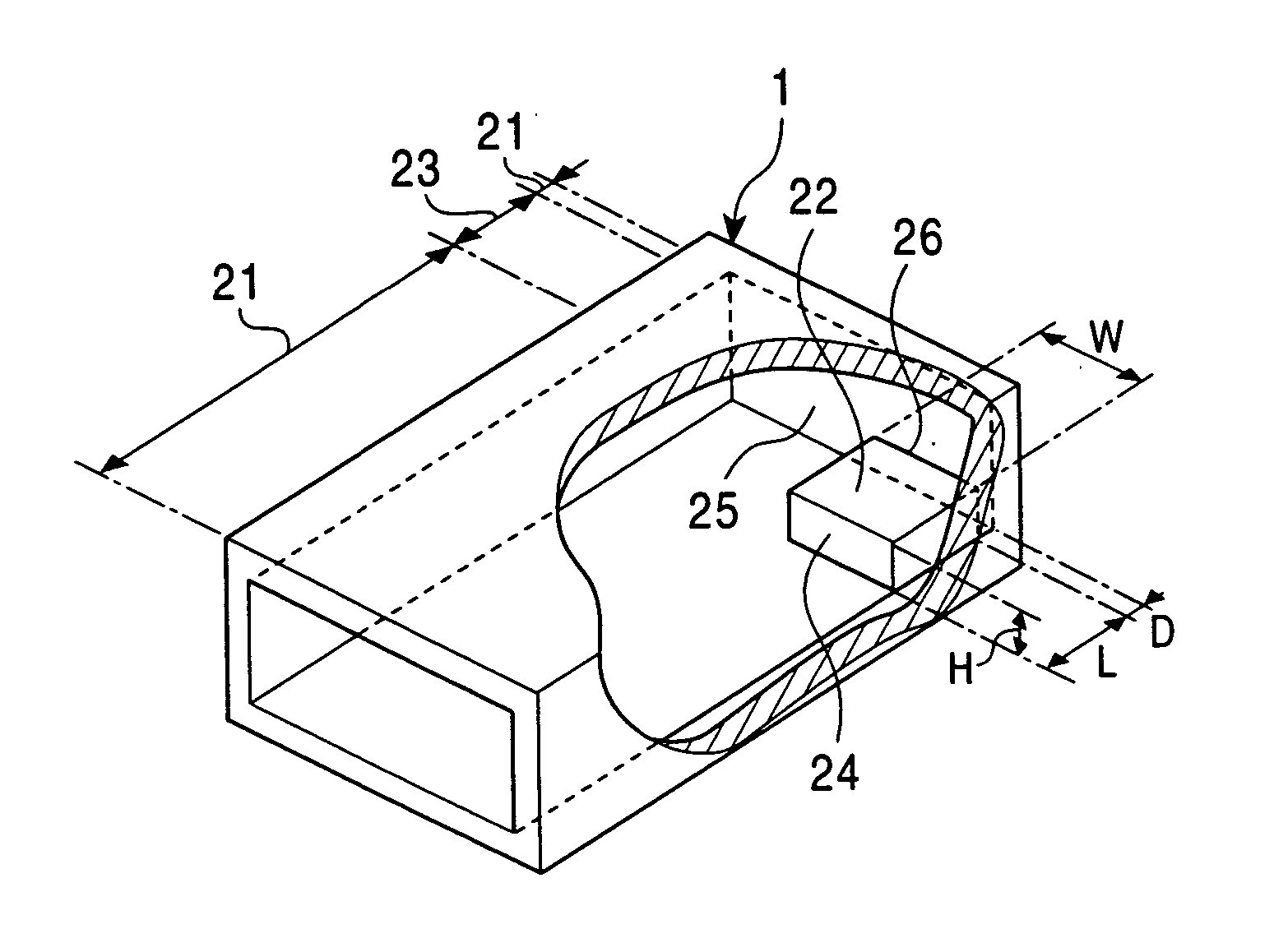

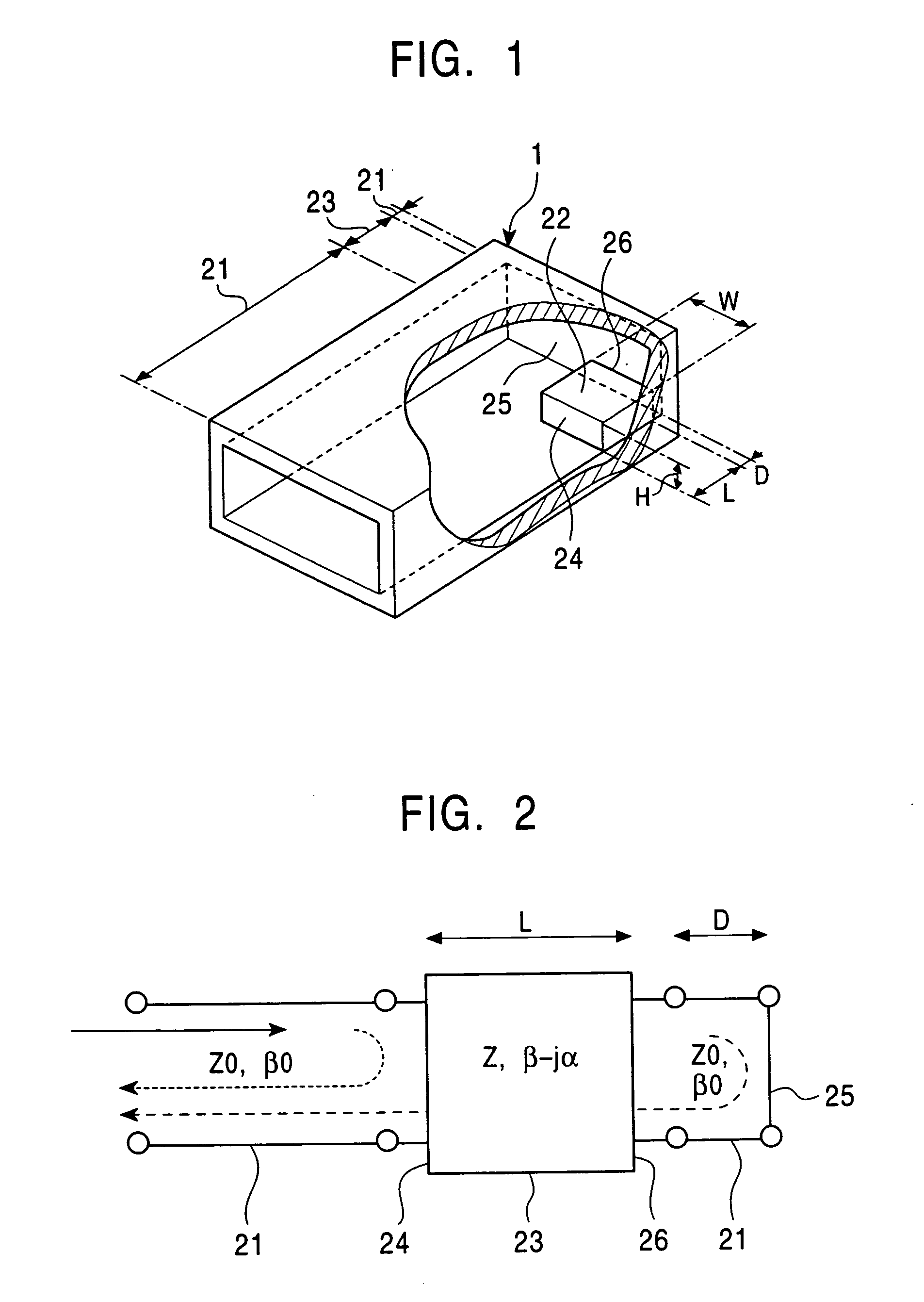

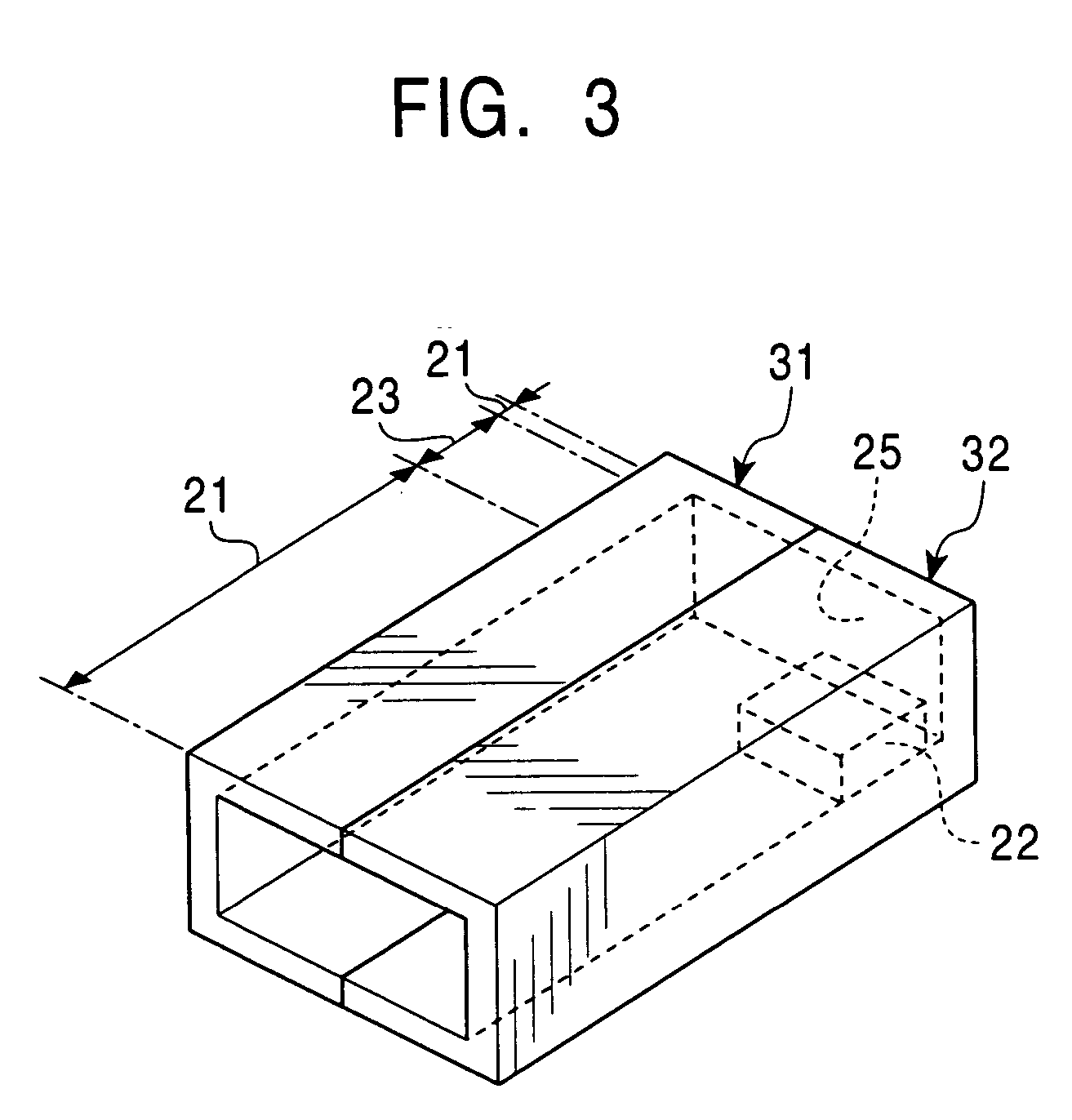

Nonreflective waveguide terminator and waveguide circuit

InactiveUS7002429B2Good high-power tolerant performanceLow production costElectromagnetic wave modulationWaveguide type devicesElectromagnetic wave absorberWaveguide

A nonreflective waveguide terminator includes a waveguide portion and an electromagnetic wave absorber. The portion has a rectangular opening in a plane perpendicular to a radio-wave propagation direction. The portion has one open end in the direction and the other end closed by a terminating metal internal wall. The portion has a radio-wave propagation space surrounded by first and second metal internal walls parallel to a radio-wave electric field, and third and fourth metal internal walls perpendicular to the field. The exterior shape of the absorber is a parallelepiped. The absorber has a rear-end surface positioned at a predetermined distance from the terminating wall and parallel to the terminating wall or is provided against the terminating wall. The surface of the absorber having the largest rectangular area is on the third or the fourth metal internal wall.

Owner:MITSUBISHI ELECTRIC CORP

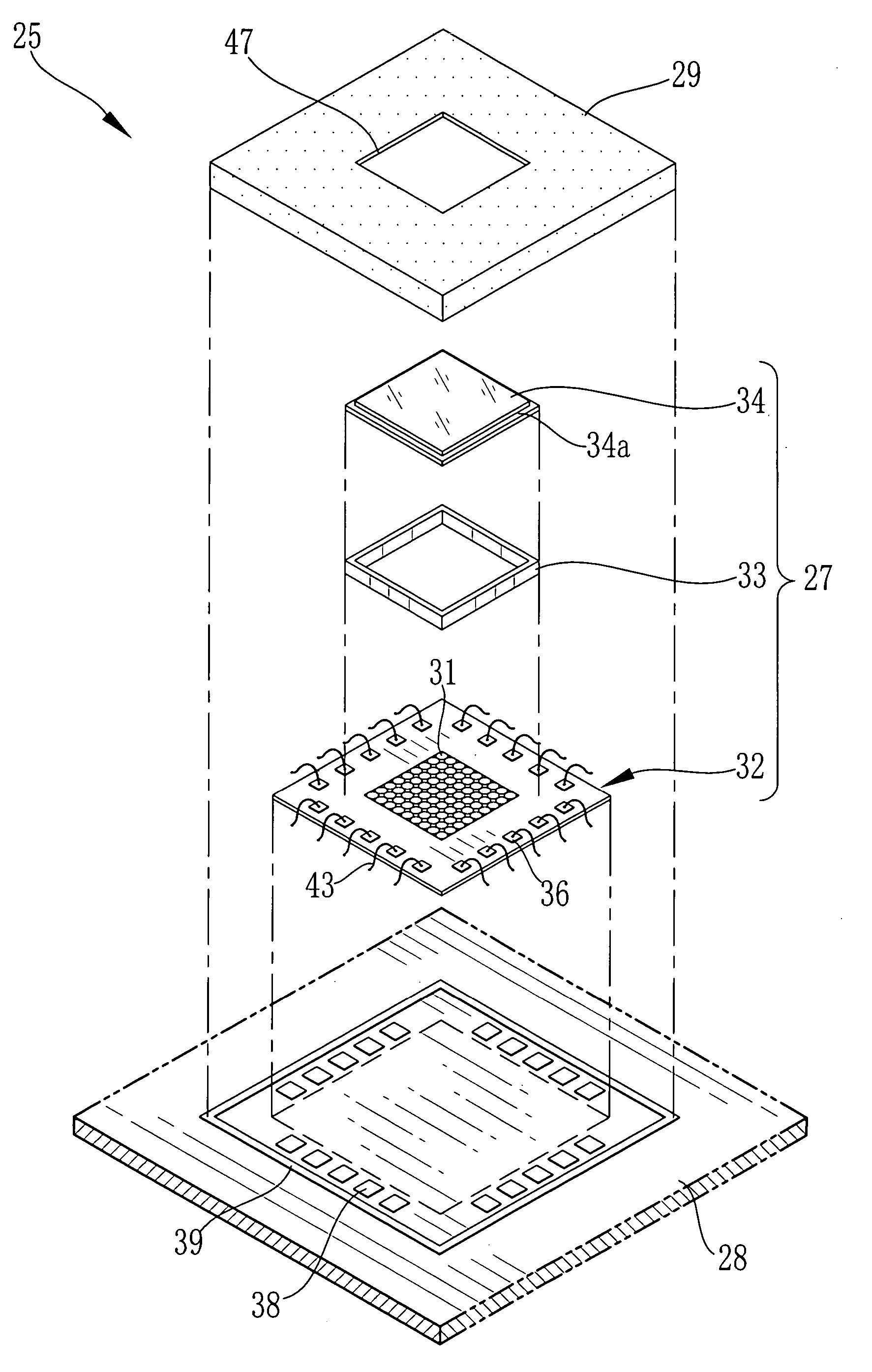

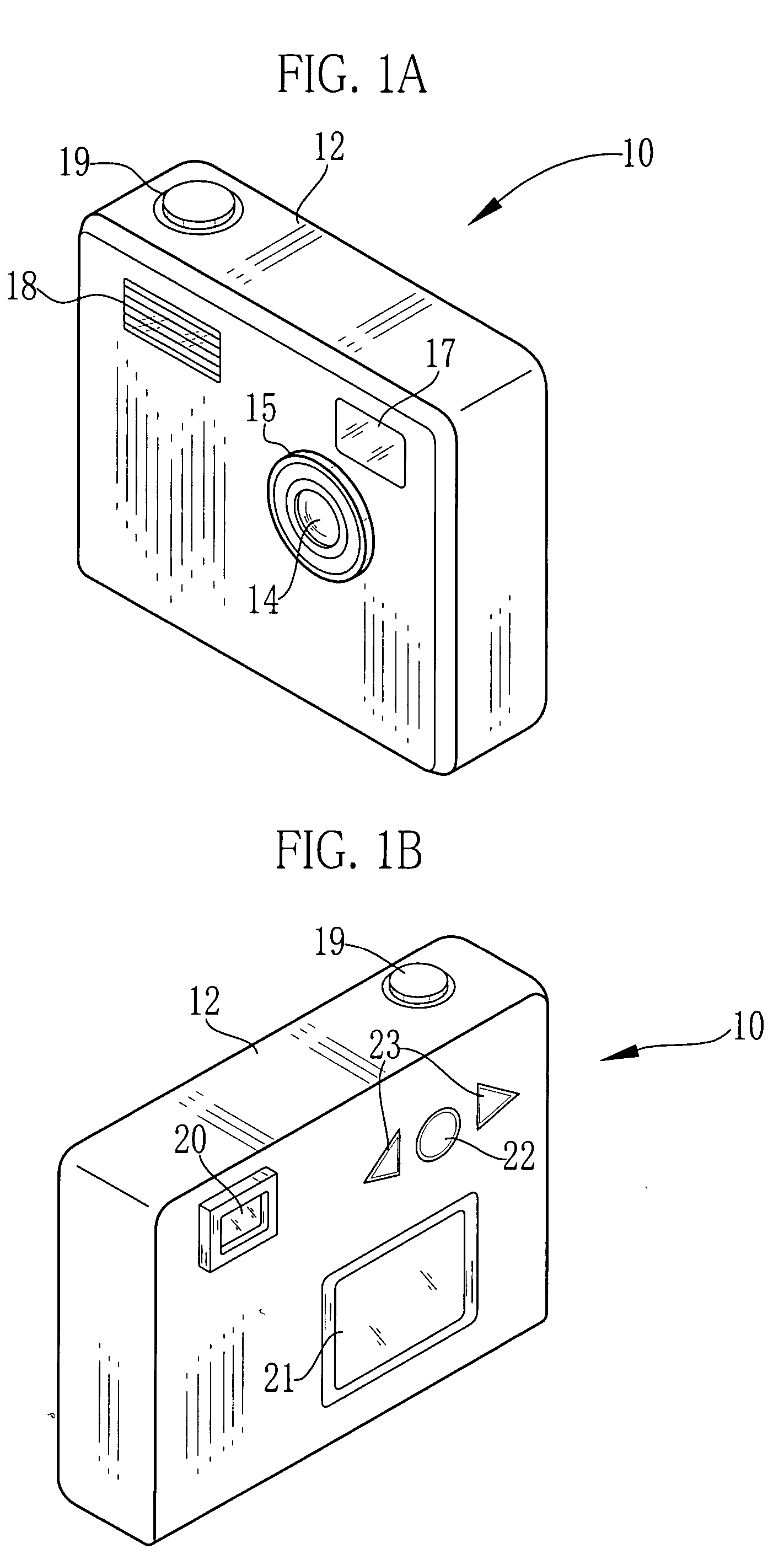

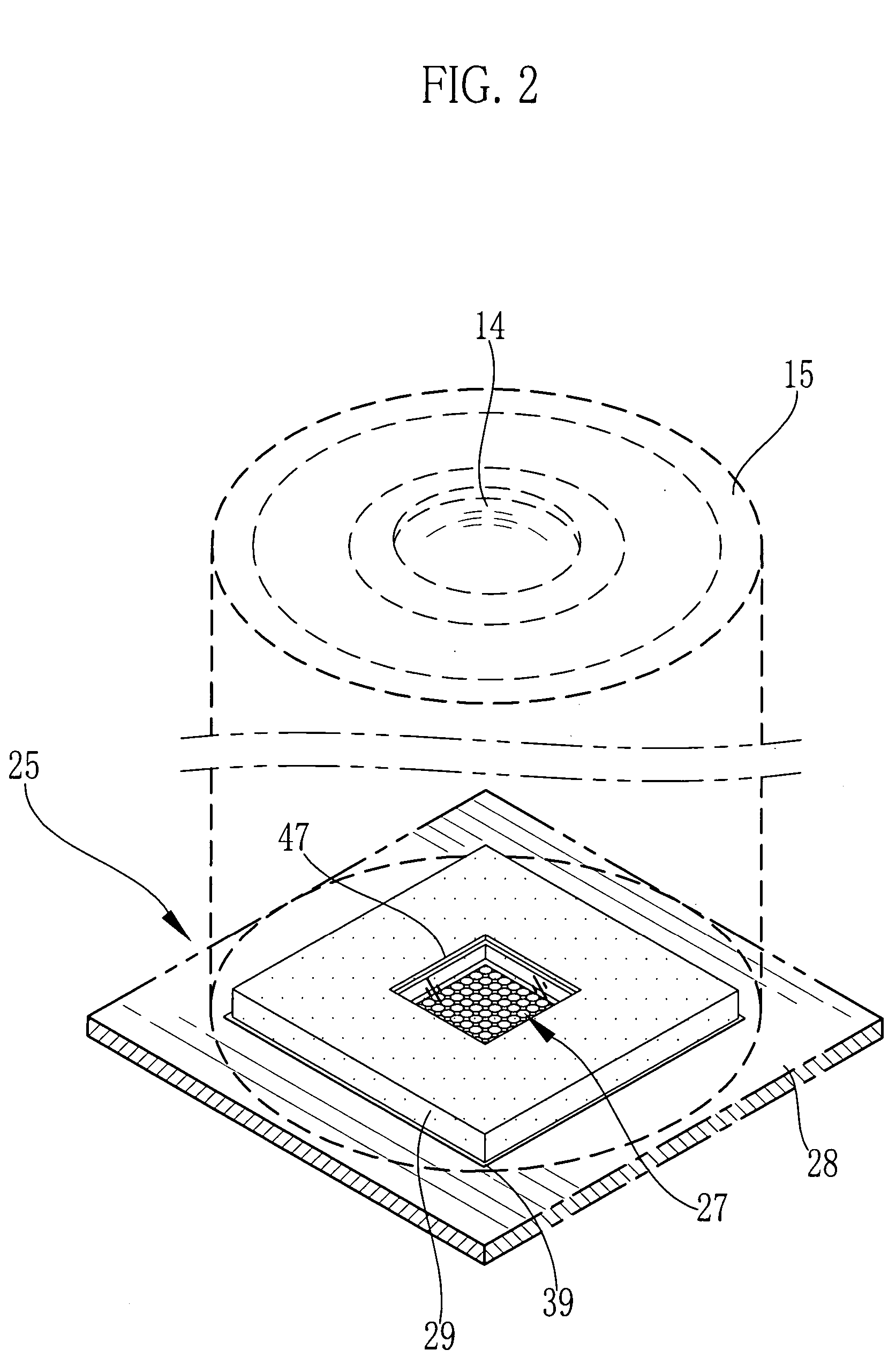

Solid state imaging device

InactiveUS20050211888A1Avoid failurePrevent growth sizeTelevision system detailsSemiconductor/solid-state device detailsElectromagnetic wave absorberEngineering

A solid state imaging device is constituted of an image sensor chip, a circuit board, and an electromagnetic-wave absorber formed of copper. The image sensor chip is constituted of a bare chip, a spacer, and a cover glass. First contact terminals are formed on the bare chip, and second contact terminals and GND wires are formed on the circuit board. When manufacturing, the image sensor chip is mounted at a predetermined position on the circuit board, and the first contact terminals and the second contact terminals are connected with bonding wires. The electromagnetic-wave absorber is formed to cover the bonding wires, while its end contacts to the GND wires.

Owner:FUJIFILM CORP

Wiring member

ActiveUS20150289423A1Increase output powerIncrease flow rateElectric devicesElectric powerElectromagnetic wave absorberEngineering

A wire harness includes first to third electric wires; a braid shield that covers the first to third electric wires; a tube-shaped electromagnetic wave absorber having a through hole that allows the first to third electric wires to be inserted therethrough, the electromagnetic wave absorber absorbing electromagnetic waves emitted from the first to third electric wires; and a resin tape and fasteners that fix the positions of the electromagnetic wave absorber and the braid shield relative to each other. The electromagnetic wave absorber is movable in an axial direction of the first to third electric wires relative to the first to third electric wires as a result of extension and contraction of the braid shield in the axial direction.

Owner:HITACHI METALS LTD

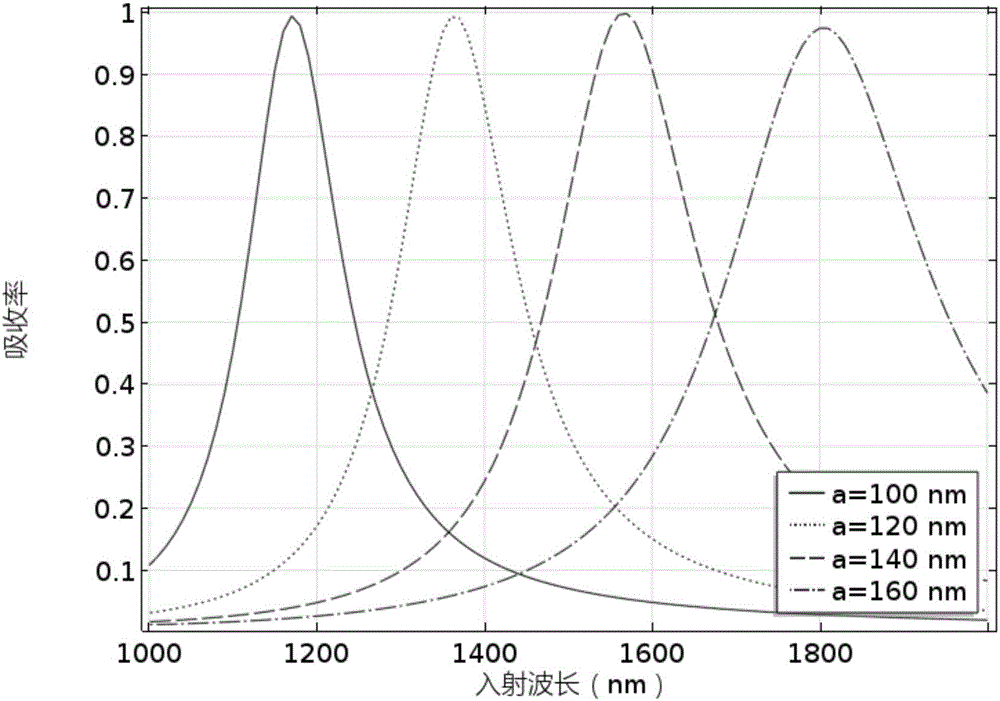

Near infrared absorber based on graphene/metal nanometer belt structure

InactiveCN107436192ACompact structureEasy to processNanoopticsPhotometry using electric radiation detectorsElectromagnetic wave absorberInsulation layer

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Electromagnetic wave abosrber

InactiveUS6359581B2Reduce thicknessExcellent electromagnetic wave absorbing characteristicMagnetic/electric field screeningMagnetic materialsElectromagnetic wave absorberElectricity

Owner:TDK CORPARATION

Nonreflective waveguide terminator and waveguide circuit

InactiveUS20050017815A1Low production costGood high-power tolerant performanceWaveguide type devicesElectromagnetic wave absorberWaveguide

A nonreflective waveguide terminator includes a waveguide portion and an electromagnetic wave absorber. The portion has a rectangular opening in a plane perpendicular to a radio-wave propagation direction. The portion has one open end in the direction and the other end closed by a terminating metal internal wall. The portion has a radio-wave propagation space surrounded by first and second metal internal walls parallel to a radio-wave electric field, and third and fourth metal internal walls perpendicular to the field. The exterior shape of the absorber is a parallelepiped. The absorber has a rear-end surface positioned at a predetermined distance from the terminating wall and parallel to the terminating wall or is provided against the terminating wall. The surface of the absorber having the largest rectangular area is on the third or the fourth metal internal wall.

Owner:MITSUBISHI ELECTRIC CORP

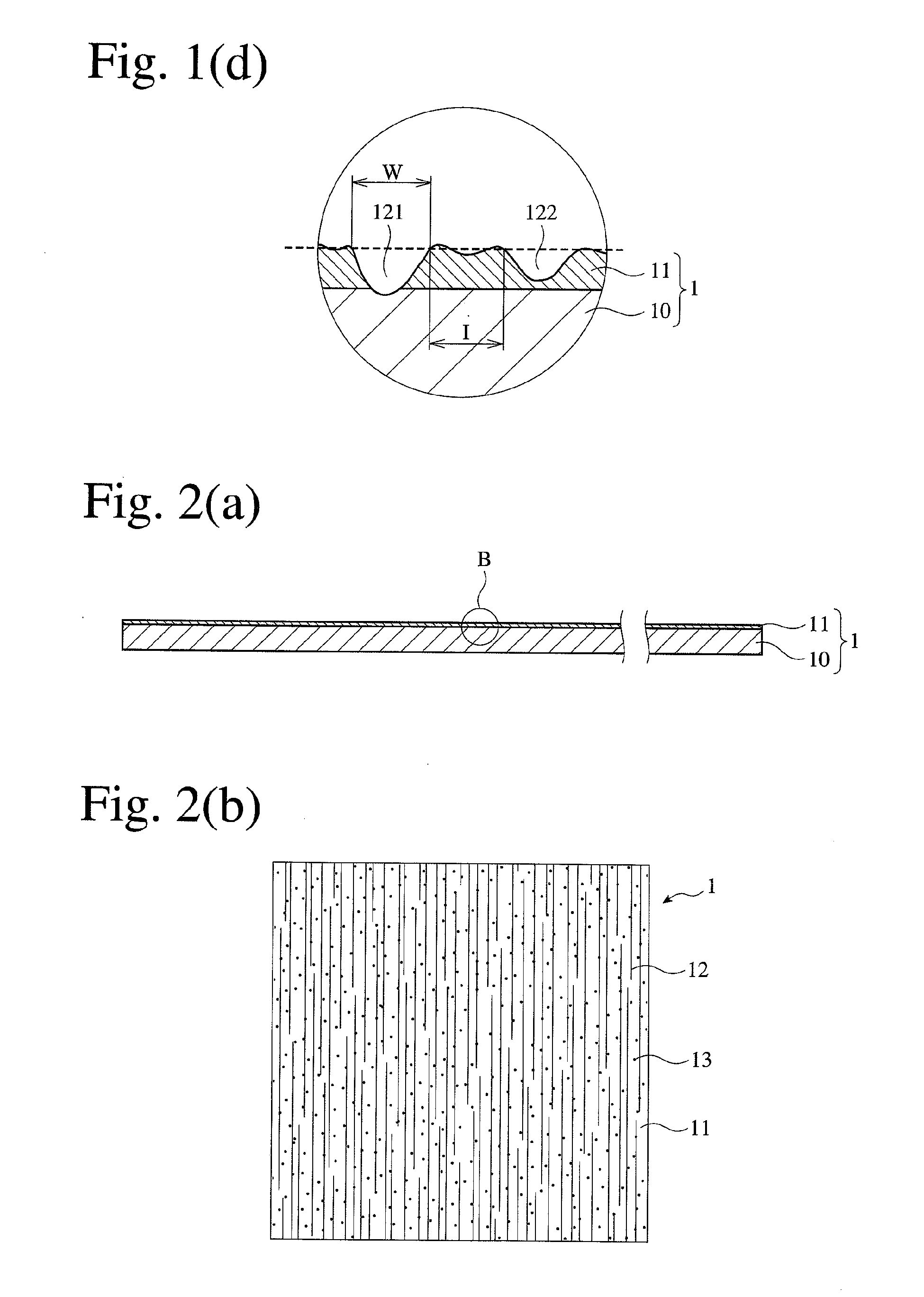

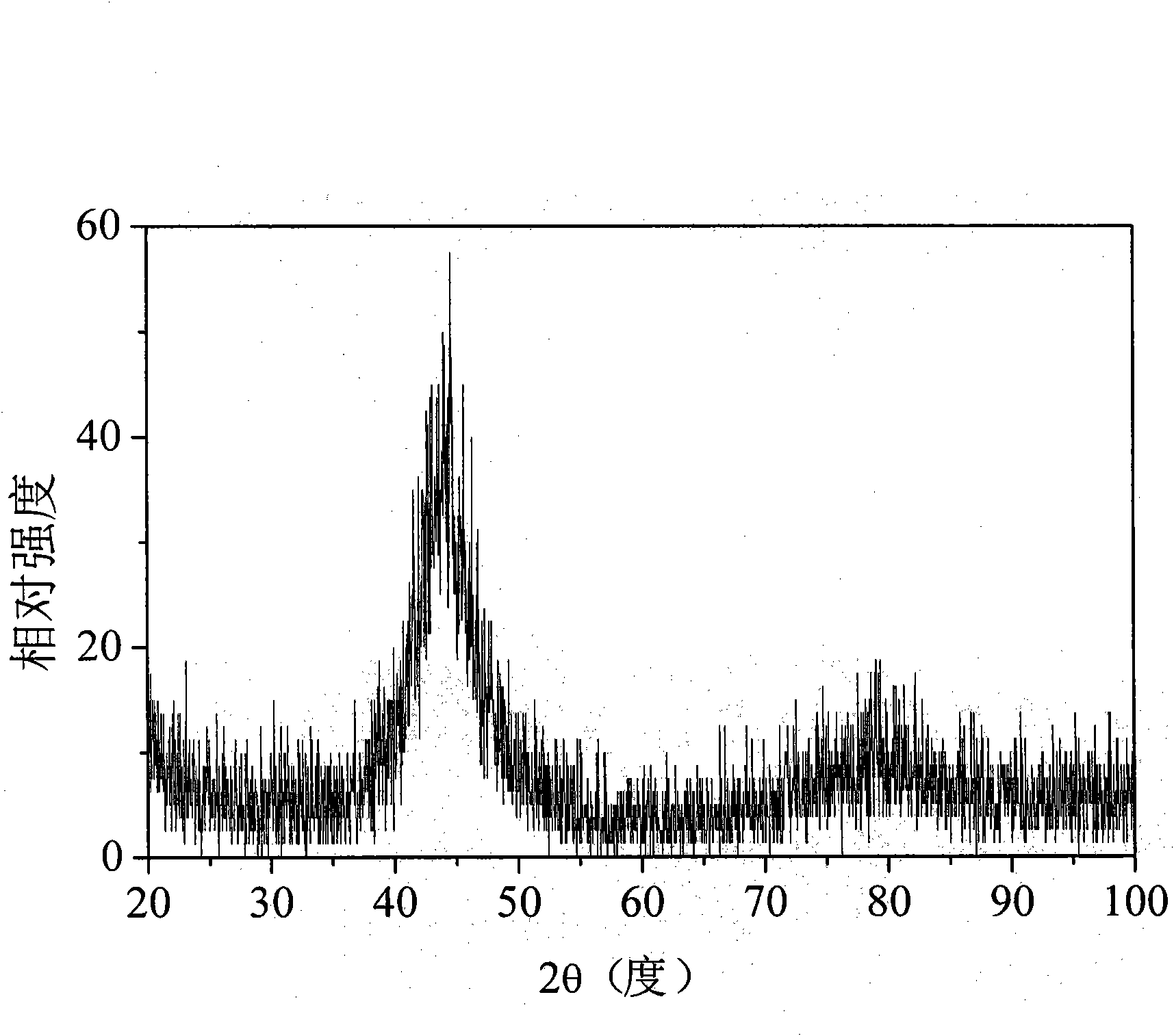

Electromagnetic wave absorber, method of manufacturing the same and appliance using the same

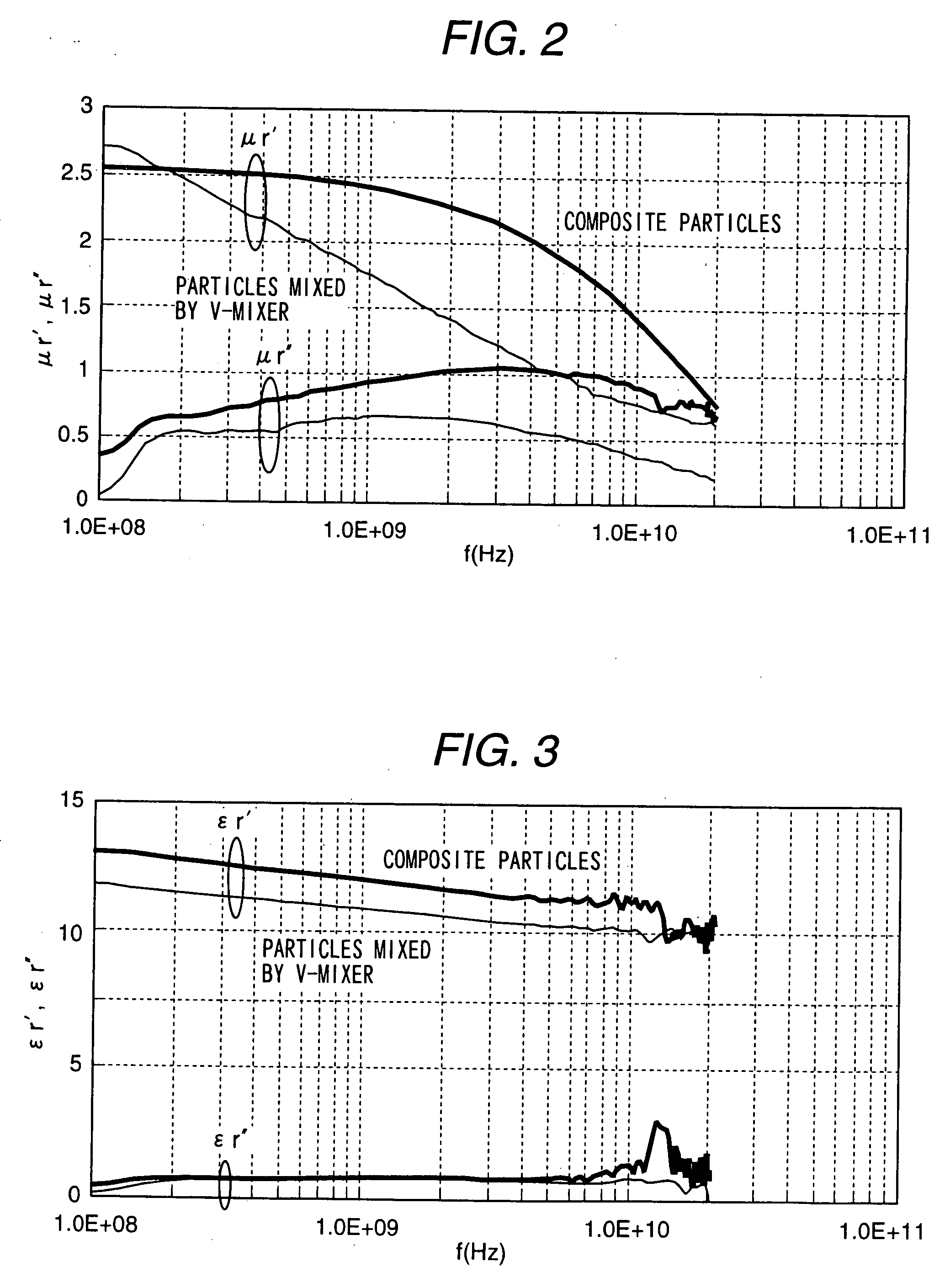

InactiveUS20050140539A1Suppress noise interferenceExcellent electromagnetic wave absorption characteristicMagnetic/electric field screeningCross-talk/noise/interference reductionElectromagnetic wave absorberElectromagnetic absorbers

An electromagnetic wave absorber for use in the high frequency range above 1 Ghz and a composite member are characterized by the fact that magnetic metal grains are covered with ceramic above 20 volume %. Further, a method of manufacturing the electromagnetic absorber and the composite member is characterized by the fact that composite magnetic particles, in which a plurality of magnetic metal grains and ceramic are unified, are formed through a mechanical alloying method applied to a composite powder composed of magnetic metal powder and ceramic powder. The electromagnetic wave absorber can be used in a semiconductor device, an optical sending module, an optical receiving module, an optical sending and receiving module, an automatic tollgate in which erroneous operation due to electromagnetic wave disturbance is provided by use of the electromagnetic wave absorber.

Owner:HITACHI LTD

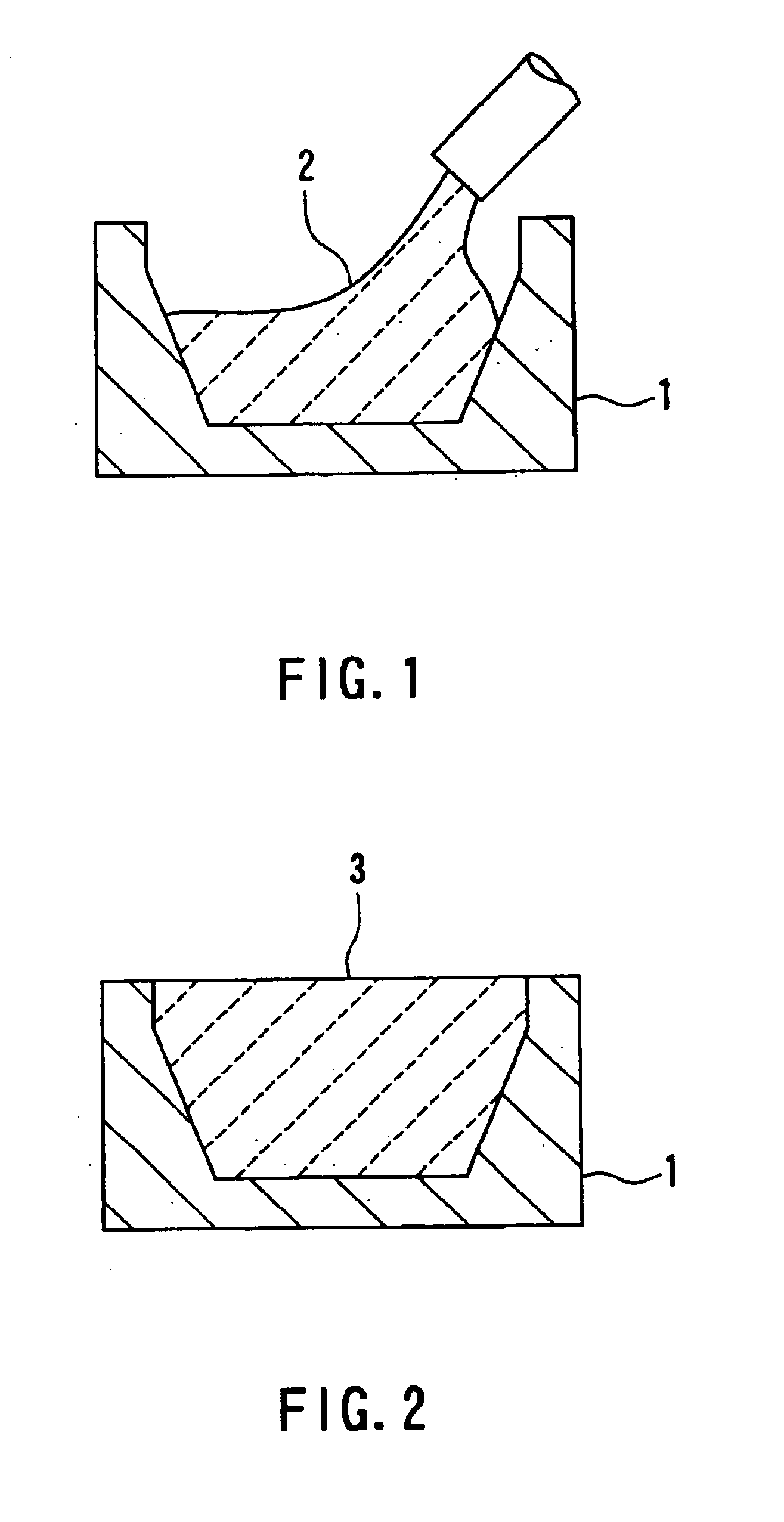

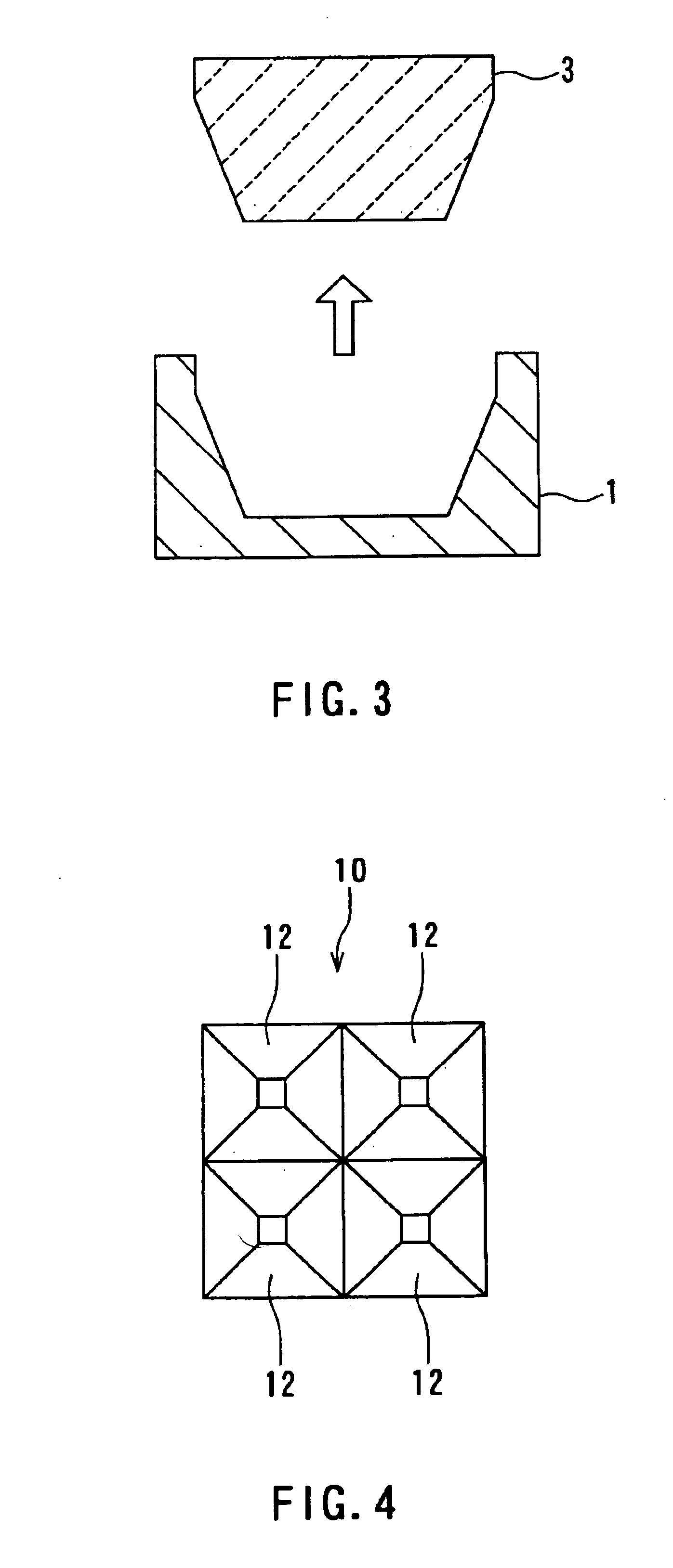

Electromagnetic wave absorber molding material, electromagnetic wave absorber molded element and method of manufacturing same, and electromagnetic wave absorber

InactiveUS6943286B1Easy to manufactureShielding materialsLayered productsElectromagnetic wave absorberFiber

An electromagnetic wave absorber comprises an electromagnetic wave absorber molded element, plate-shaped sintered ferrite, and a metal plate. The molded element incorporates a tile-shaped base portion and a wedge-shaped apex portion disposed on the base portion. The molded element is formed by injecting slurry into a mold, the slurry being obtained through mixing a molding material for the wave absorber with water, and curing the slurry. The molding material includes a magnetic material, an inorganic fiber and an inorganic binder. When these ingredients are mixed with water, the molding material first exhibits fluidity and then a curing reaction in a temperature range of 1 to 40° C.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com