Patents

Literature

3468 results about "Formability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formability is the ability of a given metal workpiece to undergo plastic deformation without being damaged. The plastic deformation capacity of metallic materials, however, is limited to a certain extent, at which point, the material could experience tearing or fracture (breakage).

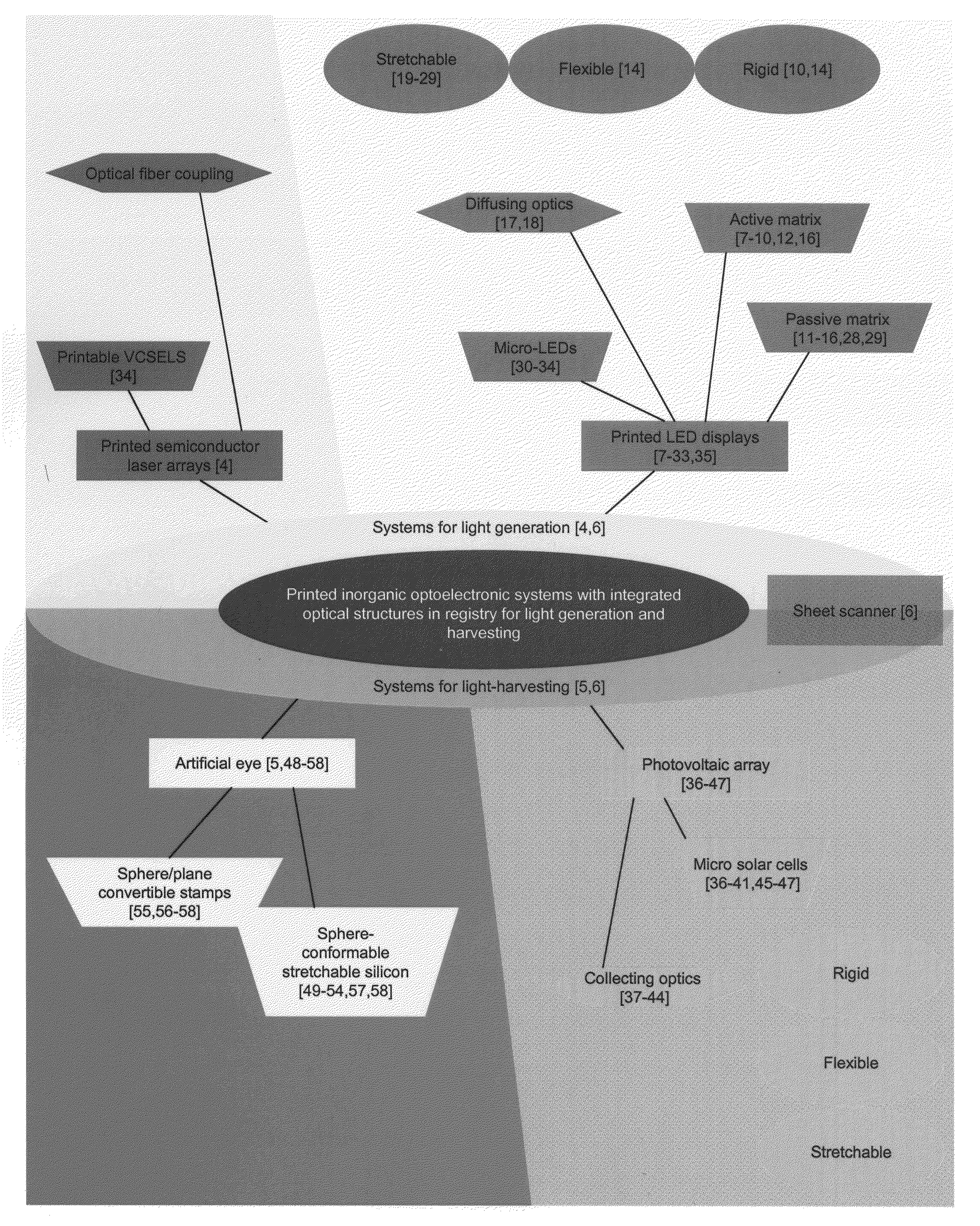

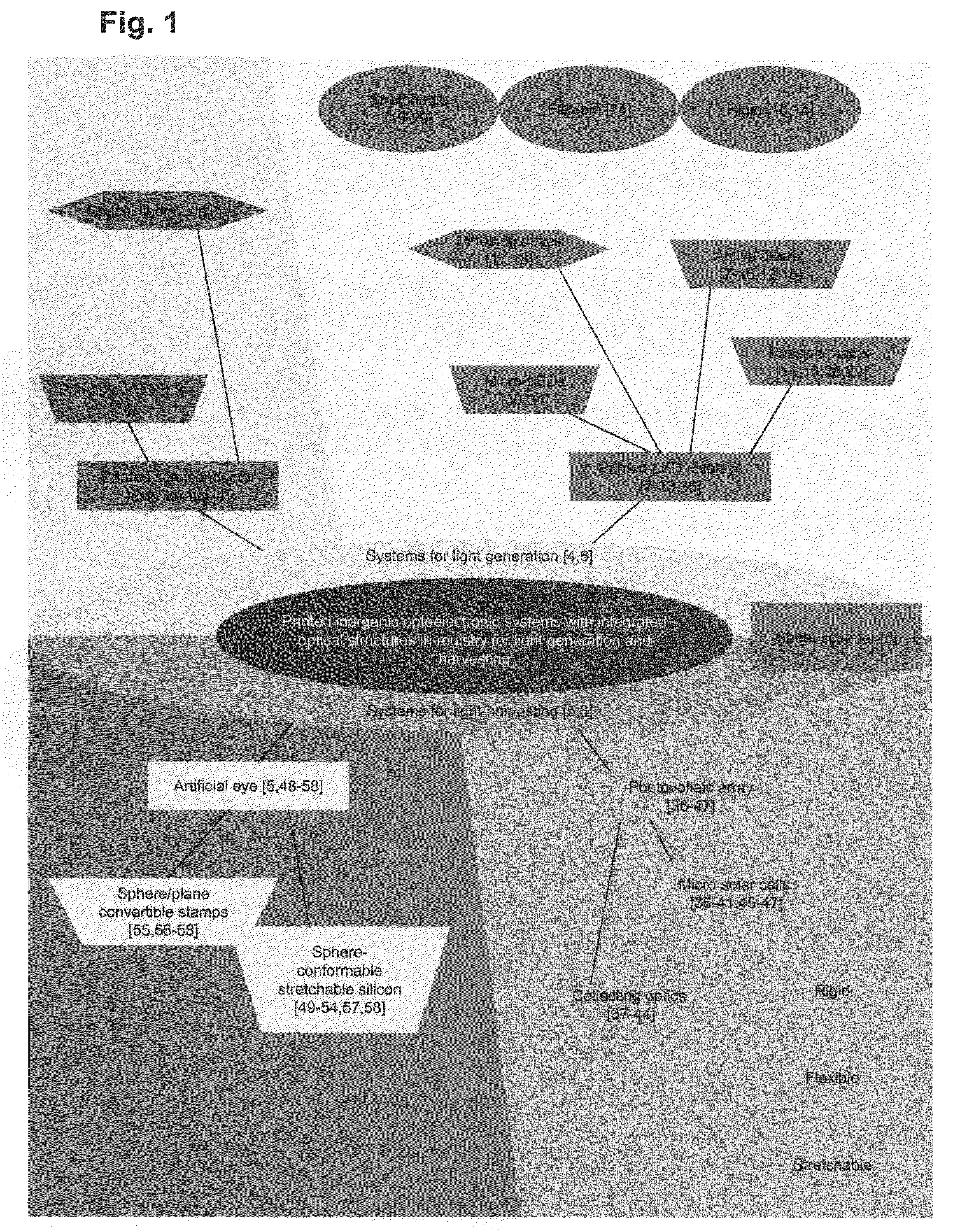

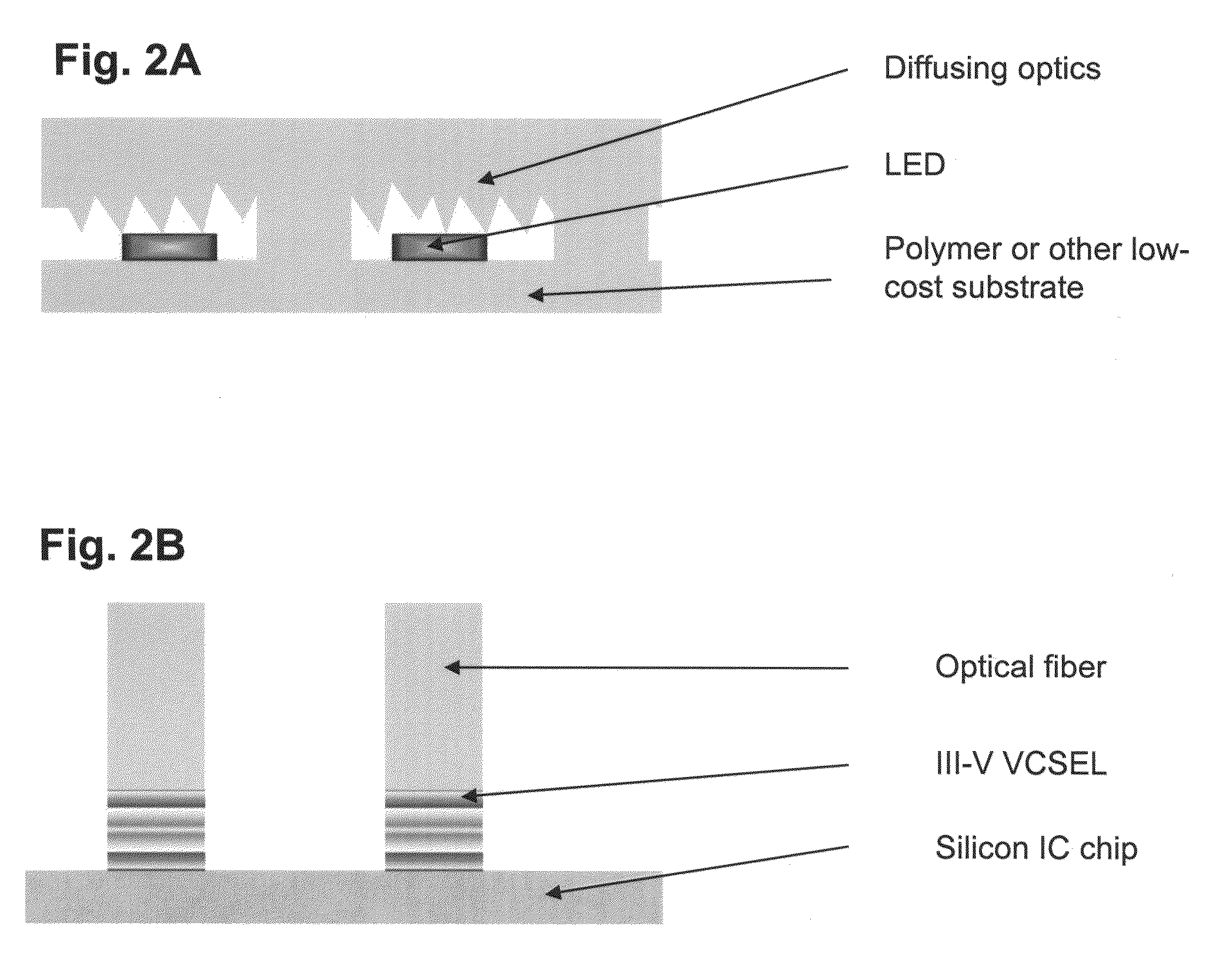

Optical systems fabricated by printing-based assembly

ActiveUS7972875B2Low costImprove performanceFinal product manufactureNanoinformaticsLight sensingSingle crystal

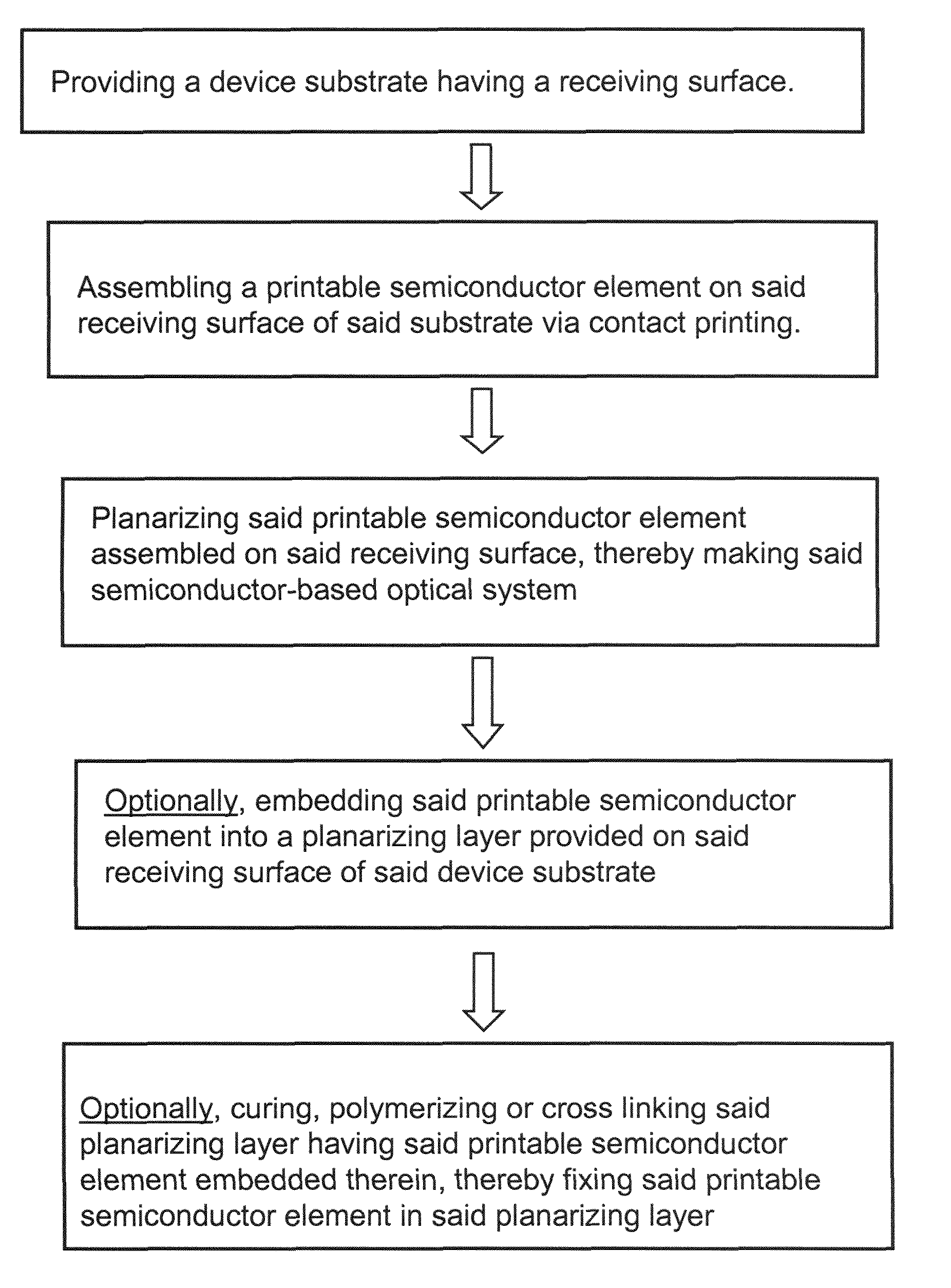

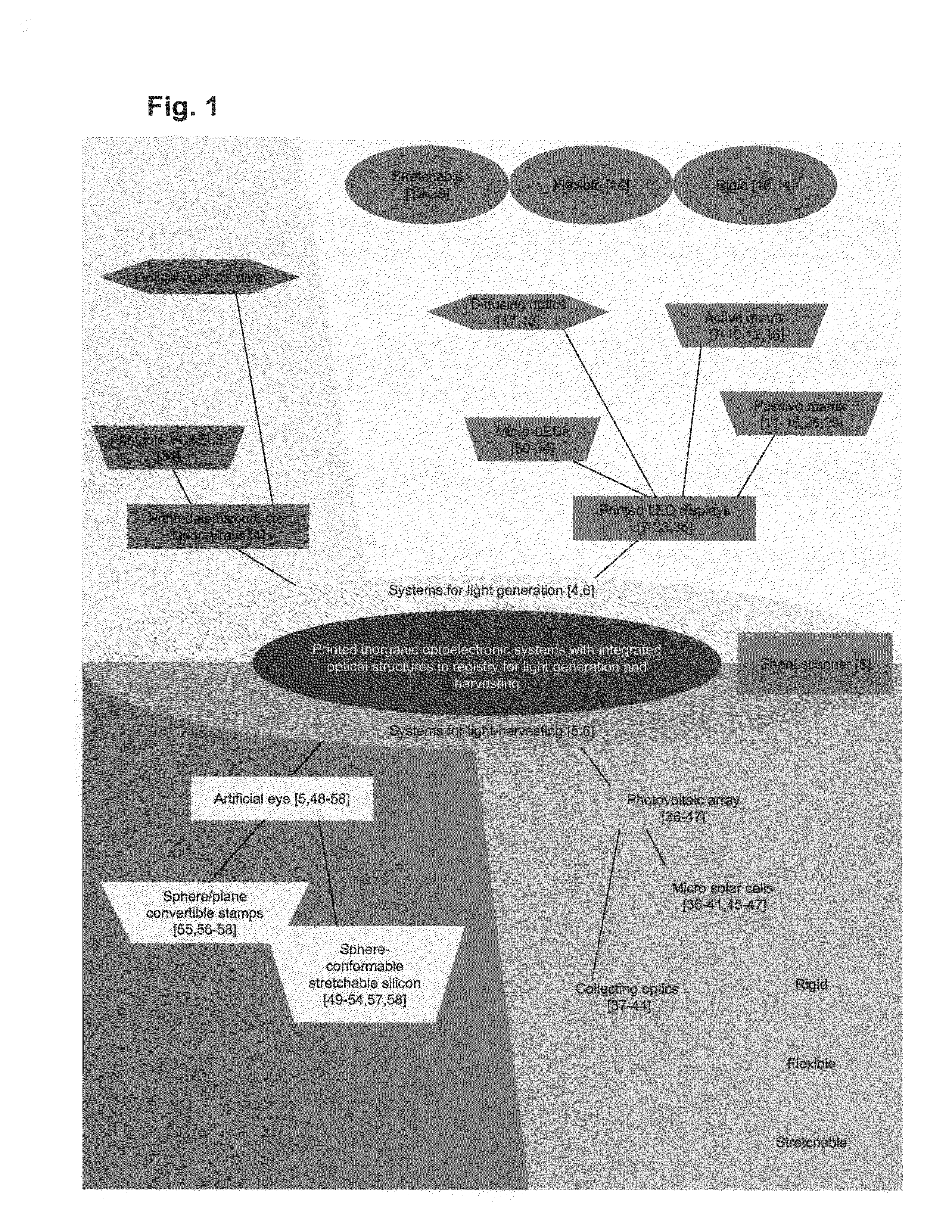

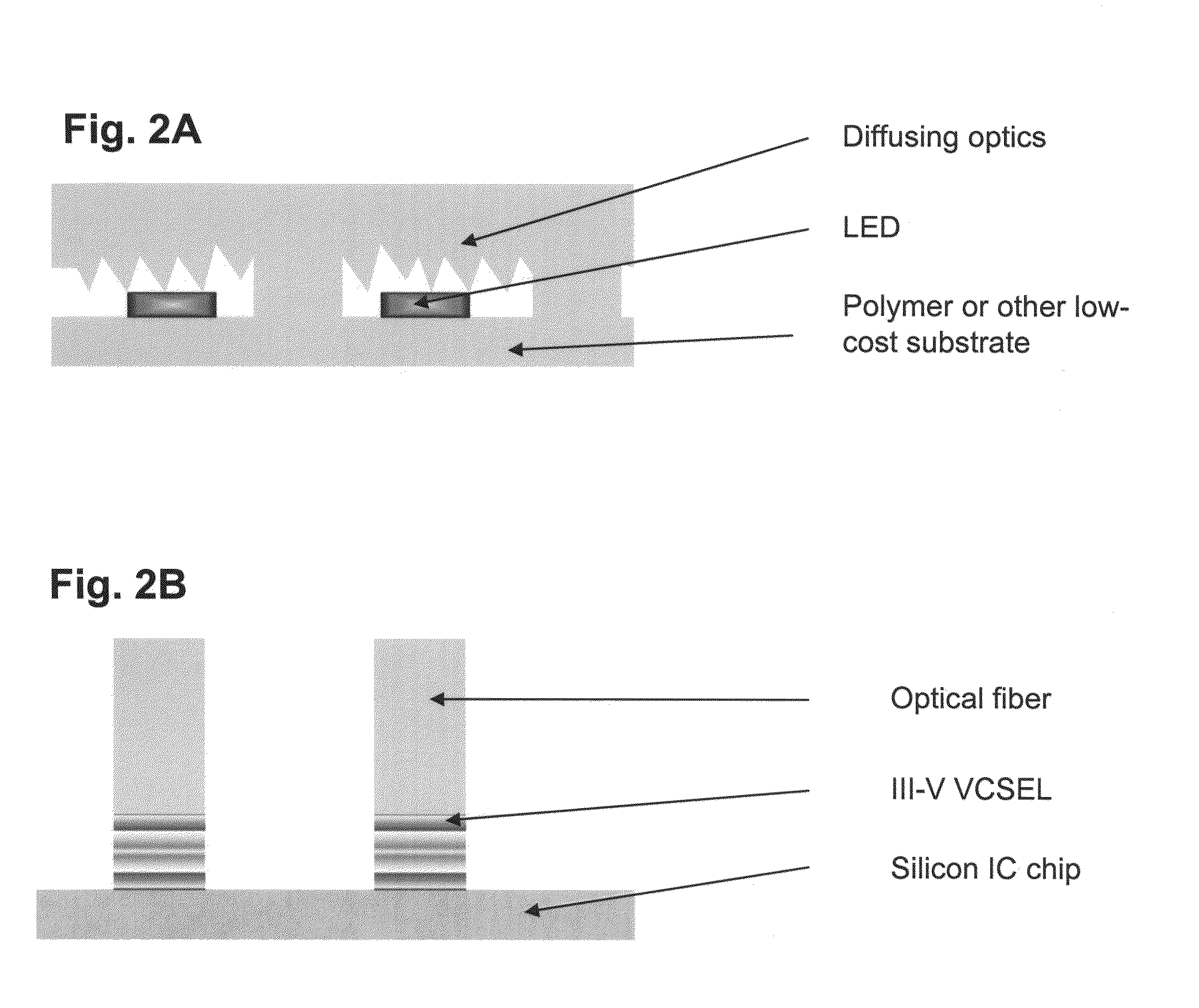

Provided are optical devices and systems fabricated, at least in part, via printing-based assembly and integration of device components. In specific embodiments the present invention provides light emitting systems, light collecting systems, light sensing systems and photovoltaic systems comprising printable semiconductor elements, including large area, high performance macroelectronic devices. Optical systems of the present invention comprise semiconductor elements assembled, organized and / or integrated with other device components via printing techniques that exhibit performance characteristics and functionality comparable to single crystalline semiconductor based devices fabricated using conventional high temperature processing methods. Optical systems of the present invention have device geometries and configurations, such as form factors, component densities, and component positions, accessed by printing that provide a range of useful device functionalities. Optical systems of the present invention include devices and device arrays exhibiting a range of useful physical and mechanical properties including flexibility, shapeability, conformability and stretchablity.

Owner:X DISPLAY CO TECH LTD +1

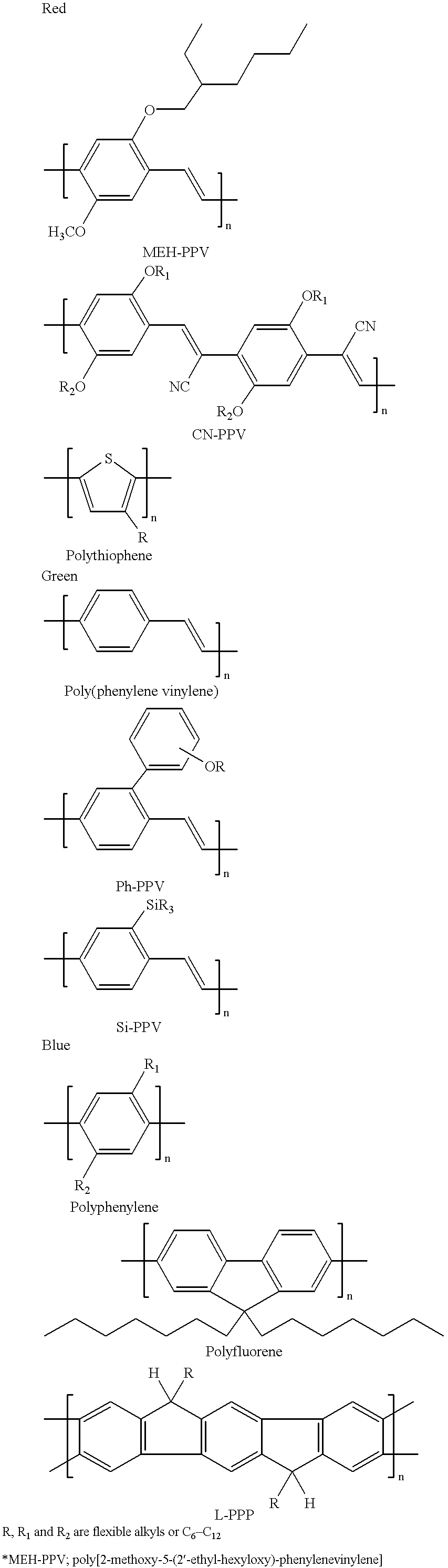

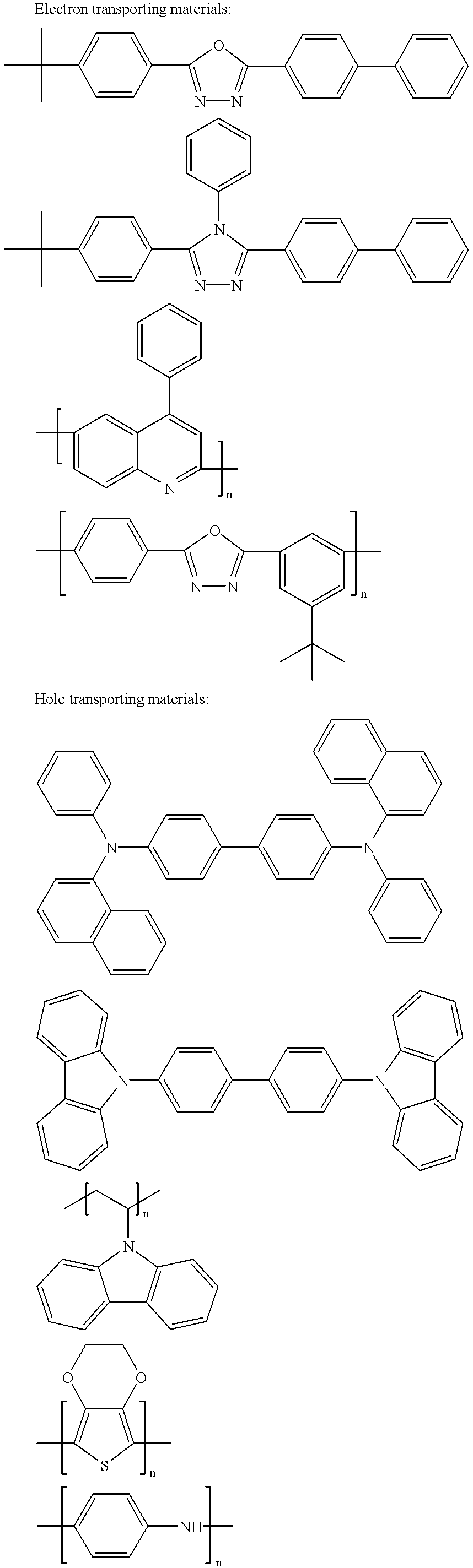

Luminescent ink for printing of organic luminescent devices

InactiveUS6372154B1Improve efficiencyEasy transitionSolid-state devicesSemiconductor/solid-state device manufacturingSolventOrganic compound

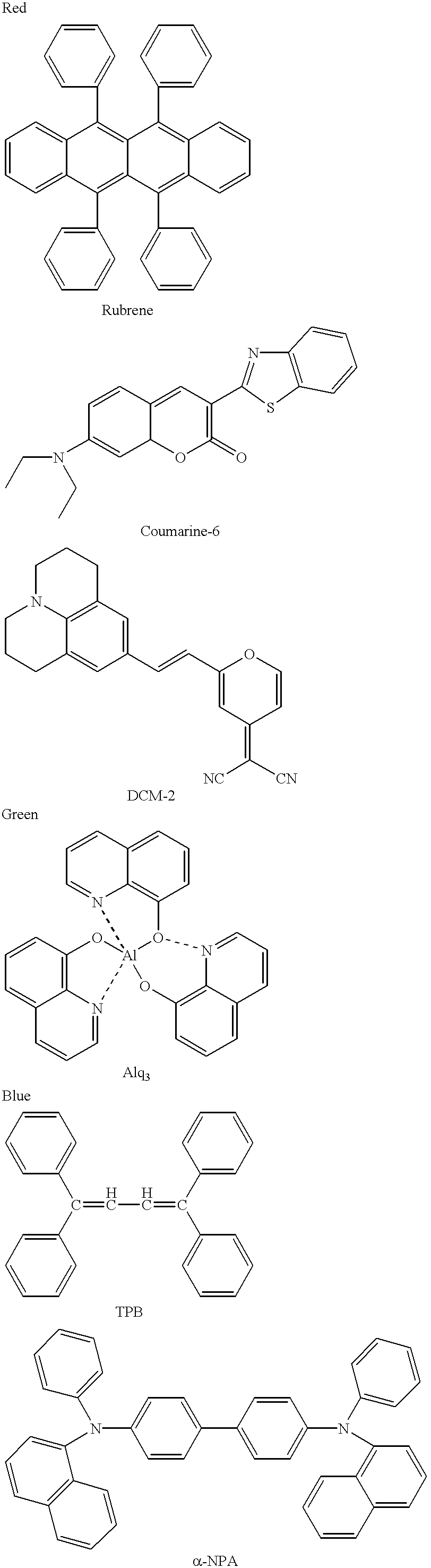

Organic luminescent ink (L-ink) is disclosed for use in printing thin films of organic luminescent material. The L-ink is particularly useful in fabricating organic optoelectronic devices, e.g. organic luminescent devices. The L-ink contains at least one organic luminescent material mixed with a solvent and other functional additives to provide the necessary optical, electronic and morphological properties for light-emitting devices (LEDs). The additives play an important role either for enhanced thin film printing or for better performance of the optoelectronic device. The functional additives may be chemically bound to the luminescent compounds or polymers. Luminescent organic compounds, oligomers, or polymers with relatively low solution viscosity, good thin film formability, and good charge transporting properties, are preferred. The L-inks can be cross-linked under certain conditions to enhance thin film properties. The L-ink can be used in various printing methods, such as screen printing, stamp printing, and preferably ink-jet printing (including bubble-jet printing).

Owner:CANON KK

Optical systems fabricated by printing-based assembly

ActiveUS20100283069A1Low costImprove performanceFinal product manufactureNanoinformaticsLight sensingPliability

The present invention provides optical devices and systems fabricated, at least in part, via printing-based assembly and integration of device components. In specific embodiments the present invention provides light emitting systems, light collecting systems, light sensing systems and photovoltaic systems comprising printable semiconductor elements, including large area, high performance macroelectronic devices. Optical systems of the present invention comprise semiconductor elements assembled, organized and / or integrated with other device components via printing techniques that exhibit performance characteristics and functionality comparable to single crystalline semiconductor based devices fabricated using conventional high temperature processing methods. Optical systems of the present invention have device geometries and configurations, such as form factors, component densities, and component positions, accessed by printing that provide a range of useful device functionalities. Optical systems of the present invention include devices and device arrays exhibiting a range of useful physical and mechanical properties including flexibility, shapeability, conformability and stretchability. Optical systems of the present invention include, however, devices and device arrays provided on conventional rigid or semi-rigid substrates, in addition to devices and device arrays provided on flexible, shapeable and / or stretchable substrates.

Owner:X DISPLAY CO TECH LTD +1

Metal foil with resin and metal-clad laminate, and printed wiring board using the same and method for production thereof

InactiveUS20050121229A1Cost efficiency and handlingCircuit formability highInsulating substrate metal adhesion improvementSynthetic resin layered productsElectrical conductorMetal foil

The present invention provides a metal clad laminate or a resin coated metal foil having a metal foil whose both surfaces are not substantially roughening-treated and an insulating resin composition layer using generally used insulating resin, and a printed wiring board and a manufacturing method thereof, in which the metal clad laminate or the resin coated metal foil is used, the reliability and circuit formability are high, and the conductor loss is extremely low.

Owner:HITACHI CHEM CO LTD

Resin composition, method of its composition, and cured formulation

InactiveUS20060029811A1Improve flame retardant performanceMaintain good propertiesSemiconductor/solid-state device detailsSynthetic resin layered productsCarboxylic acidMicroparticle

It is an object of the present invention to provide a resin composition which can form cured formulations having various excellent properties such as an insulating property, thermal shock resistance, moldability / formability and strength, and exhibit an excellent appearance in which transparency is enhanced, a resin composition whose cured thin film has excellent flame retardancy, good mechanical property and heat resistance, a dispersing element containing an inorganic microfine particle which can give a flame retardancy to a resin, to which the inorganic microfine particle is added, and can reduce a hygroscopic property to the extent possible, a method for producing the same and a cured formulation obtained by using the resin composition. The present invention relates to a resin composition comprising a compound having at least one of a glycidyl group and / or an epoxy group and an inorganic microfine particle, a resin composition comprising three components of a phenolic compound, a compound having at least one of a glycidyl group and / or an epoxy group and an inorganic microfine particle, a flame retardant resin composition comprising a polyhydric phenol and an inorganic microfine particle, and a dispersing element containing an inorganic microfine particle obtained by a hydrolysis condensation reaction of alkoxide and / or metal carboxylate in a dispersion medium.

Owner:NIPPON SHOKUBAI CO LTD

Encapsulation of sensitive liquid components into a matrix to obtain discrete shelf-stable particles

InactiveUS7201923B1Improve hydrophobicityPrevent and delays penetration of waterPowder deliveryBiocideSolid particleHeat sensitive

A liquid encapsulant component which contains an active, sensitive encapsulant, such as a live microorganism or an enzyme dissolved or dispersed in a liquid plasticizer is admixed with a plasticizable matrix material. The matrix material is plasticizable by the liquid plasticizer and the encapsulation of the active encapsulant is accomplished at a low temperature and under low shear conditions. The active component is encapsulated and / or embedded in the plasticizable matrix component or material in a continuous process to produce discrete, solid particles. The liquid content of the liquid encapsulant component provides substantially all or completely all of the liquid plasticizer needed to plasticize the matrix component to obtain a formable, extrudable, cuttable, mixture or dough. Removal of liquid plasticizer prior to extrusion is not needed to adjust the viscosity of the mixture for formability. Release of an active component from the matrix may be delayed or controlled over time so that the active component is delivered when and where it is needed to perform its intended function. Controlled release, discrete, solid particles which contain an encapsulated and / or embedded component such as a heat sensitive or readily oxidizable pharmaceutically, biologically, or nutritionally active component are continuously produced without substantial destruction of the matrix material or encapsulant.

Owner:GENERAL MILLS INC

Solid golf ball

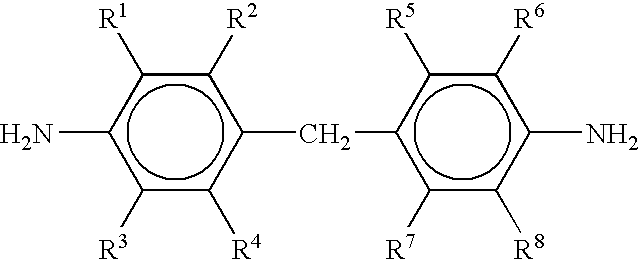

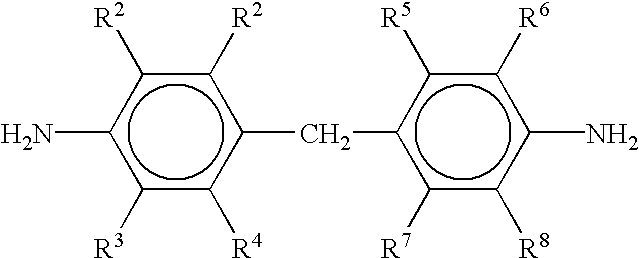

A solid golf ball with a polyurethane cover having satisfactory formability and ball properties. The solid golf ball has a solid core, and a polyurethane cover for covering the solid core, wherein the difference in Shore D hardness between a center portion and a surface portion of the solid core is at least 15; the polyurethane cover has a thickness (t) of not more than 1.0 mm, and is formed from a cured urethane composition having Shore D hardness (D) of from 35 to 60; a product of the thickness(t) and the Shore D Hardness (D) of the cured urethane composition is ranging from 10 to 45(10≦D×t≦45); and the urethane composition contains an isocyanate group-terminated urethane prepolymer having the residual polyisocyanate monomer content of not more than 0.1 mass %, and an aromatic polyamine compound.

Owner:SUMITOMO RUBBER IND LTD

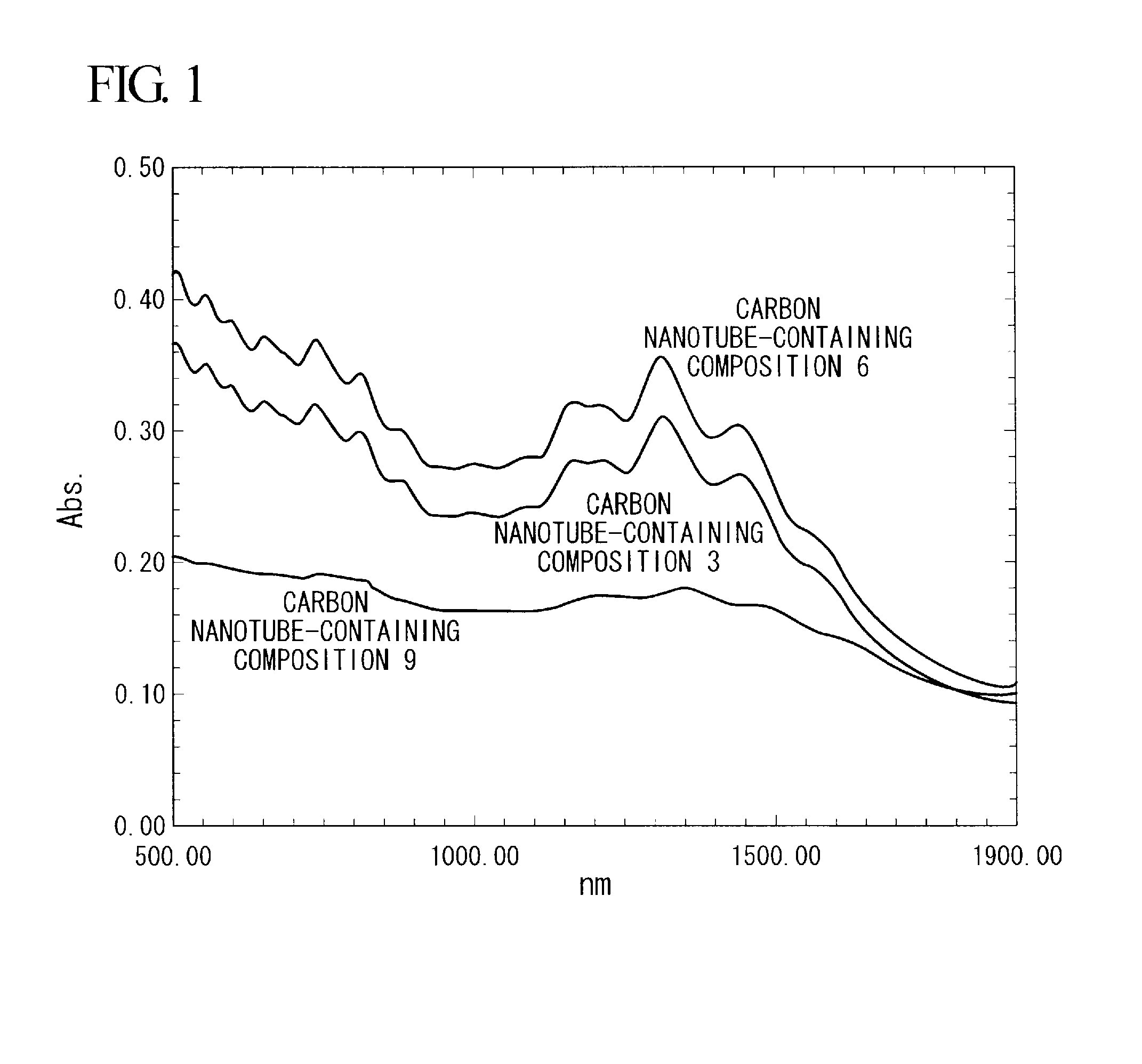

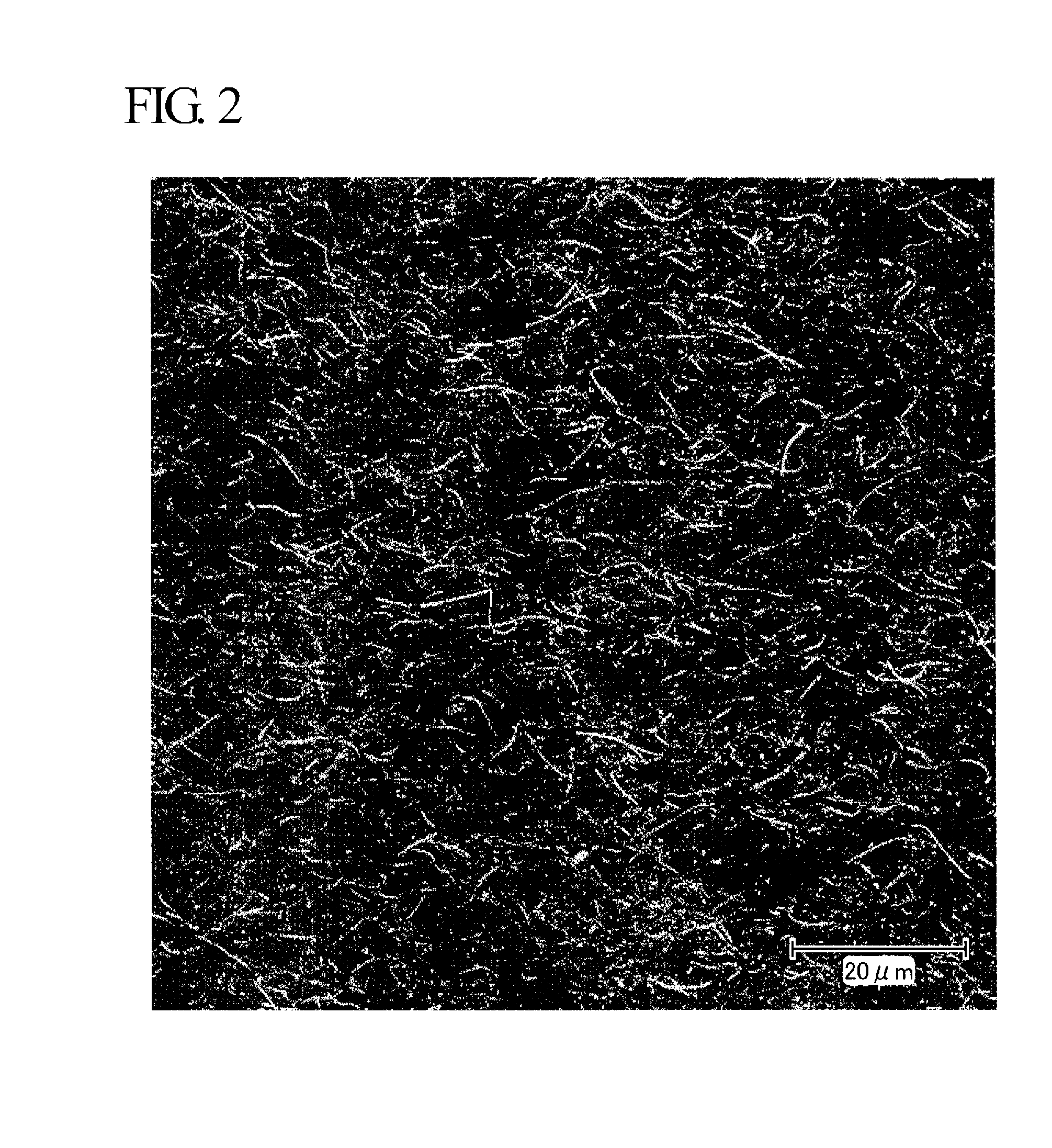

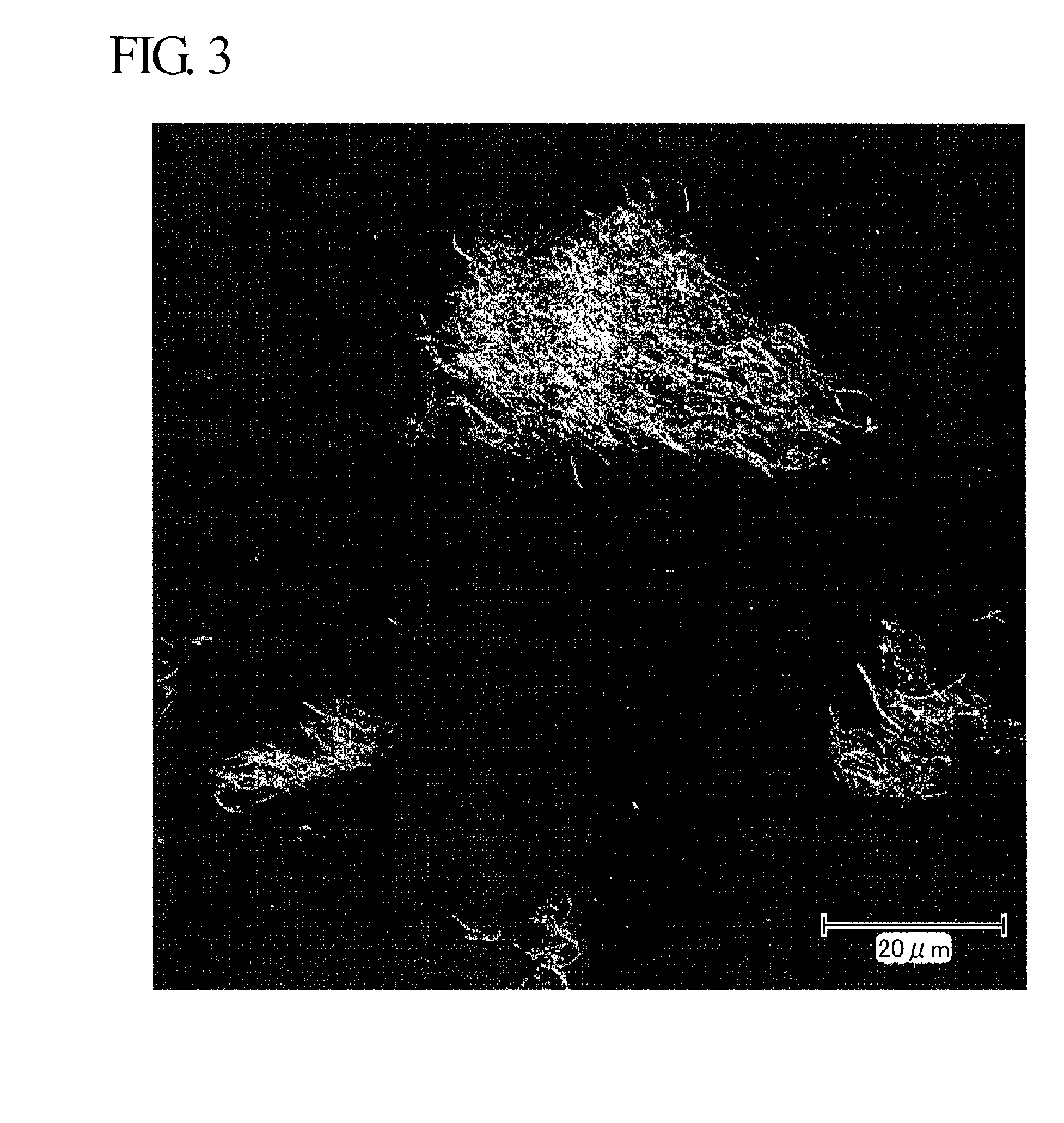

Carbon nanotube-containing composition, composite, and methods for producing them

ActiveUS20100065788A1Improve conductivityInhibit coloringMaterial nanotechnologyConductive materialMeth-Carbon nanotube

Disclosed is a carbon nanotube-containing composition which contains a carbon nanotube and a urethane compound obtained by a reaction between a hydroxyl group-containing (meth)acrylate and a isocyanate compound. Also disclosed is a composite having a coating film or a cured film composed of the carbon nanotube-containing composition on at least one surface of a base material. The carbon nanotube-containing composition and the composite are excellent in electrical conductivity, film-formability, moldability, and transparency without deteriorating the characteristic properties of the carbon nanotube itself.

Owner:MITSUBISHI CHEM CORP

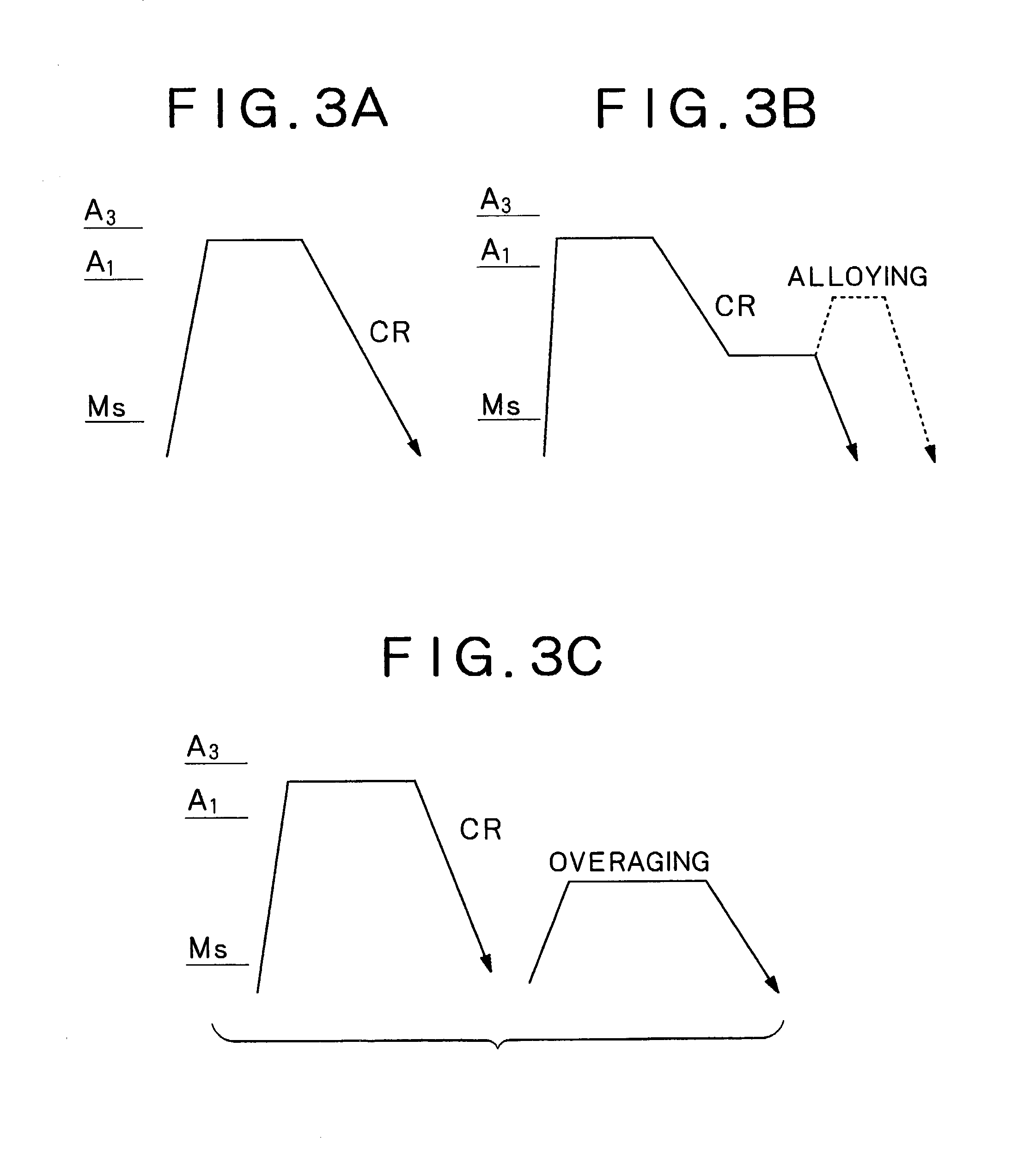

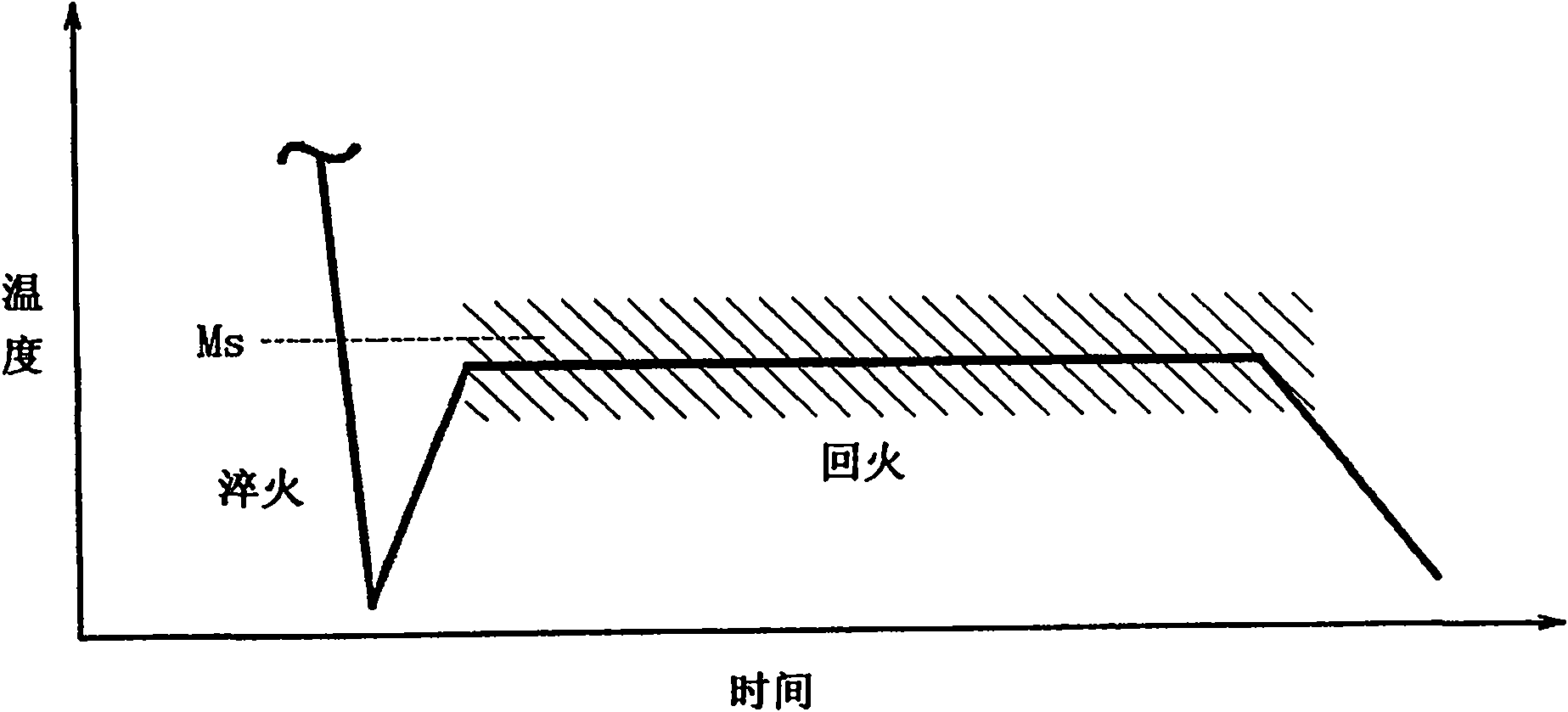

High strength steel sheet having excellent formability and method for production thereof

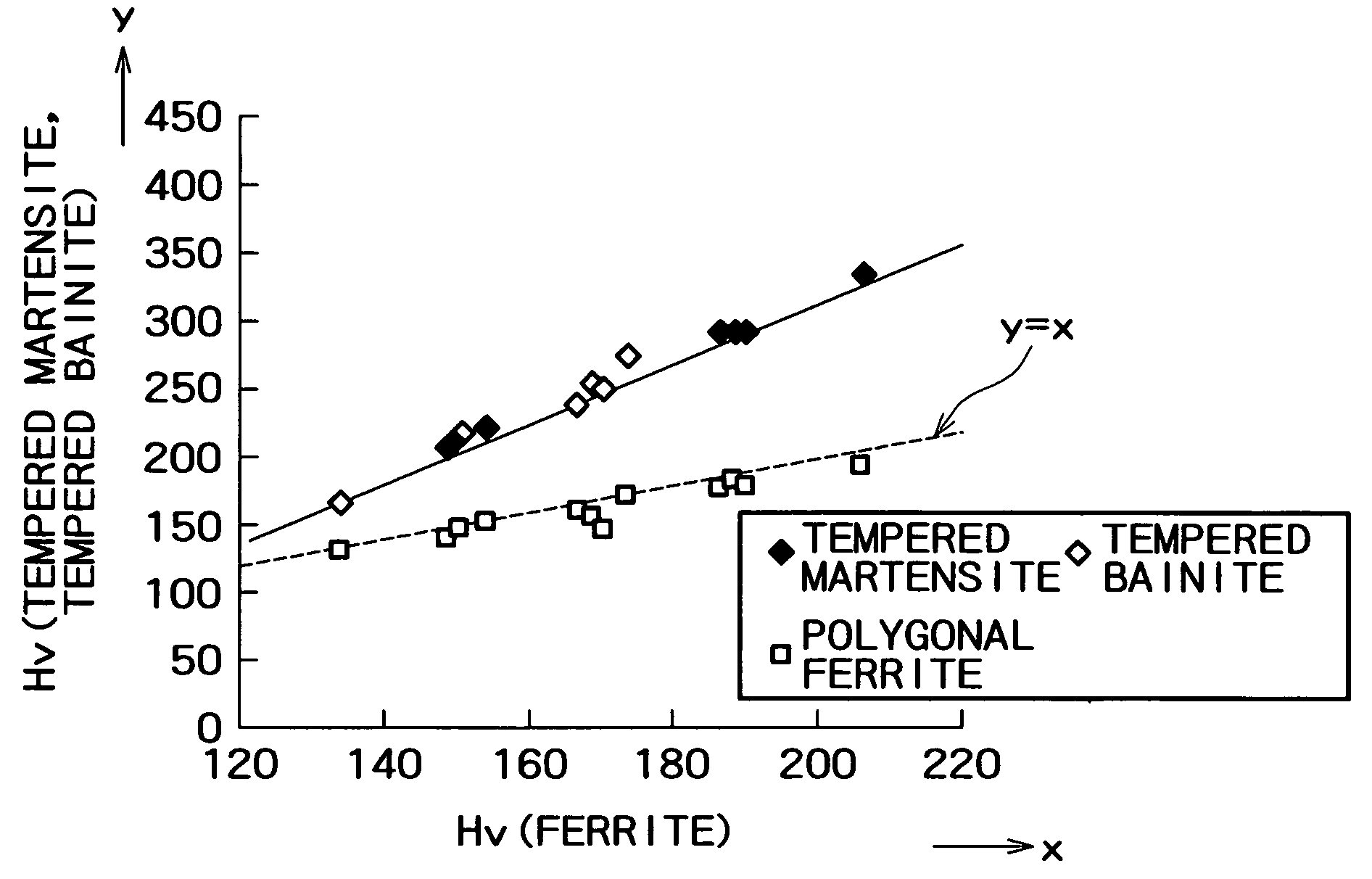

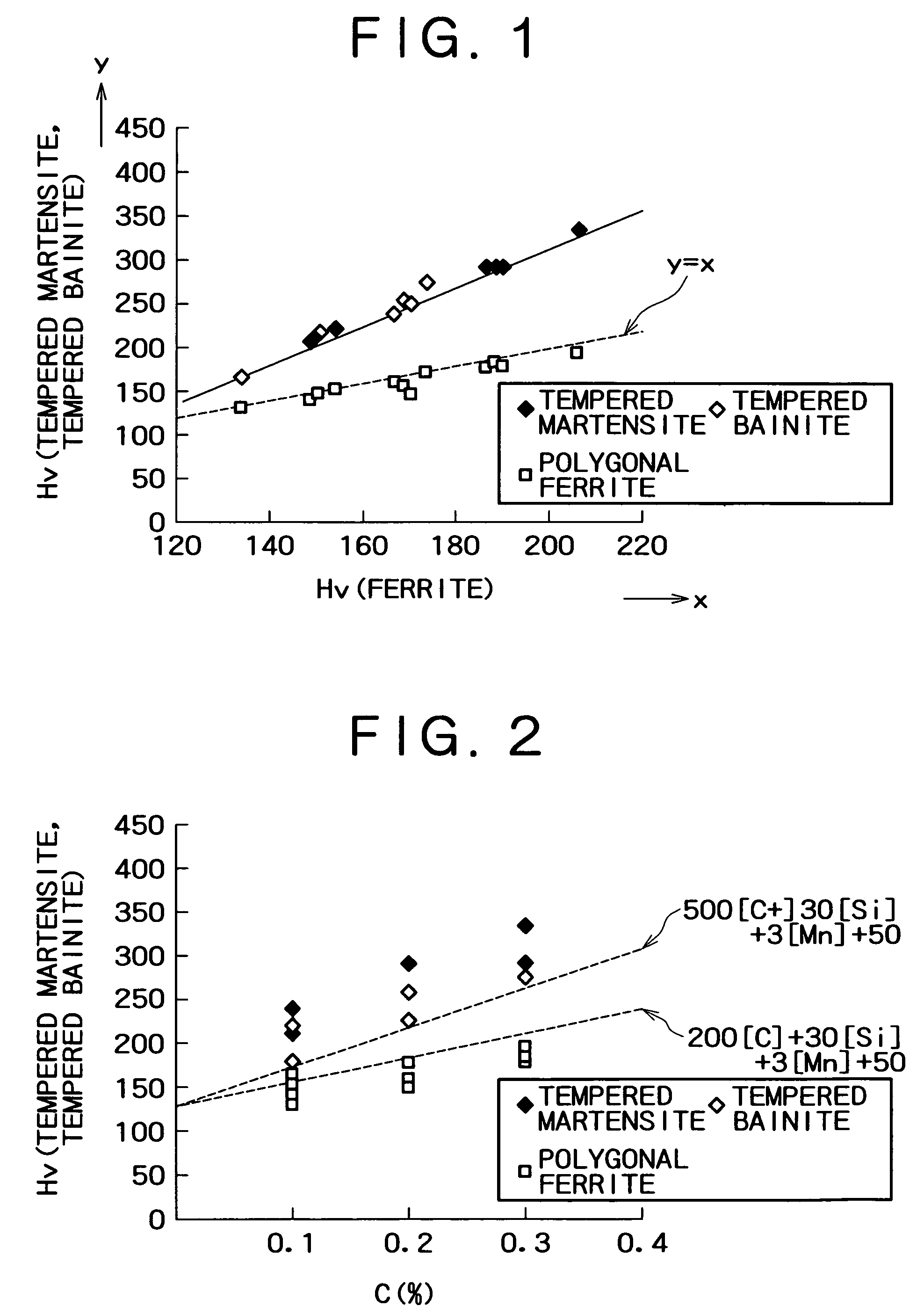

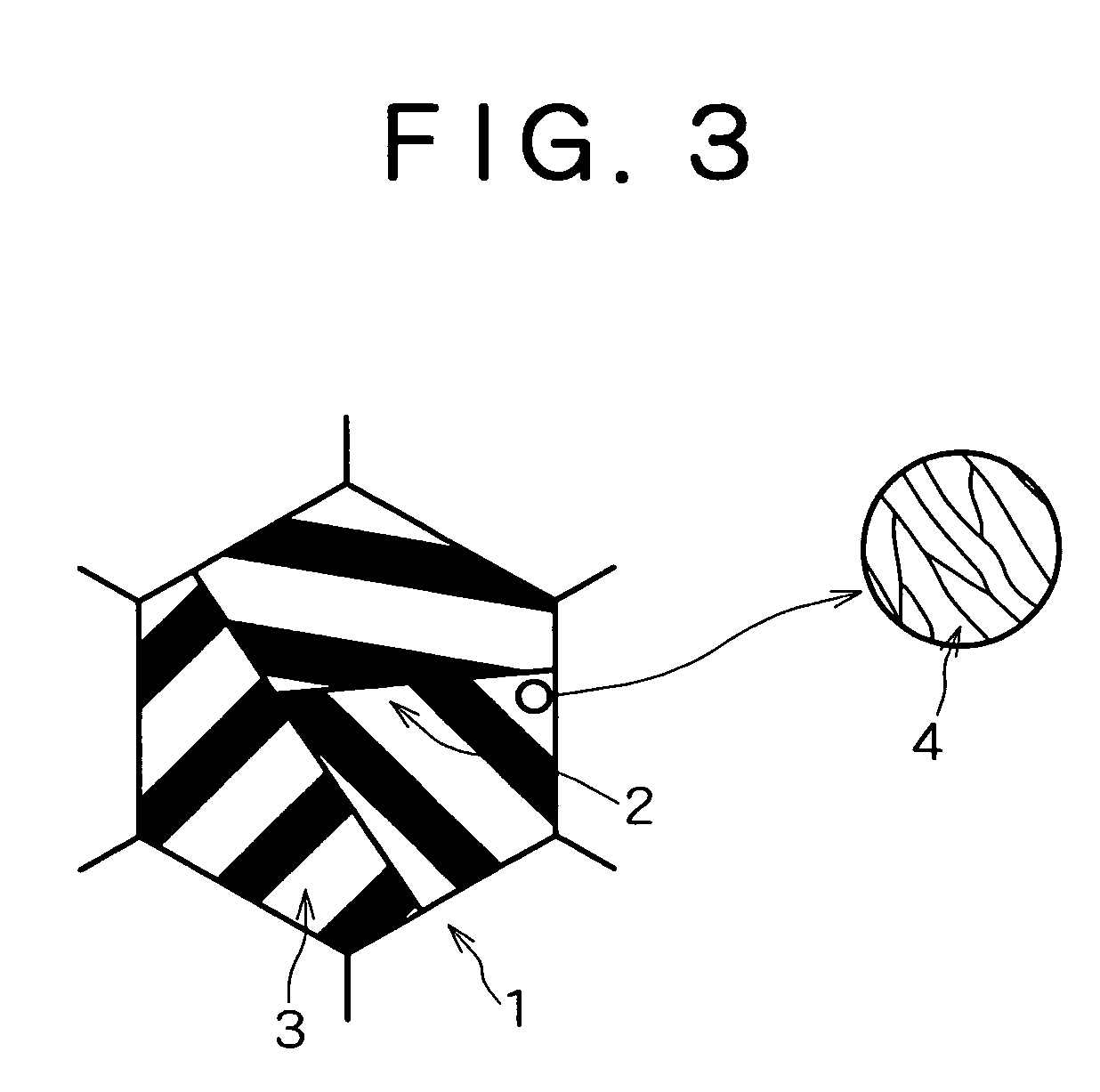

InactiveUS7090731B2Good molding effectHigh strengthHot-dipping/immersion processesFurnace typesHigh intensityHardness

A high strength steel sheet having (2-1) a base phase structure, the base phase structure being tempered martensite or tempered bainite and accounting for 50% or more in terms of a space factor relative to the whole structure, or the base phase structure comprising tempered martensite or tempered bainite which accounts for 15% or more in terms of a space factor relative to the whole structure and further comprising ferrite, the tempered martensite or the tempered bainite having a hardness which satisfies the relation of Vickers hardness (Hv)≧500[C]+30[Si]+3[Mn]+50 where [ ] represents the content (mass %) of each element, and (2-2) a second phase structure comprising retained austenite which accounts for 3 to 30% in terms of a space factor relative to the whole structure and optionally further comprising bainite and / or martensite, the retained austenite having a C concentration (CγR) of 0.8% or more.

Owner:KOBE STEEL LTD

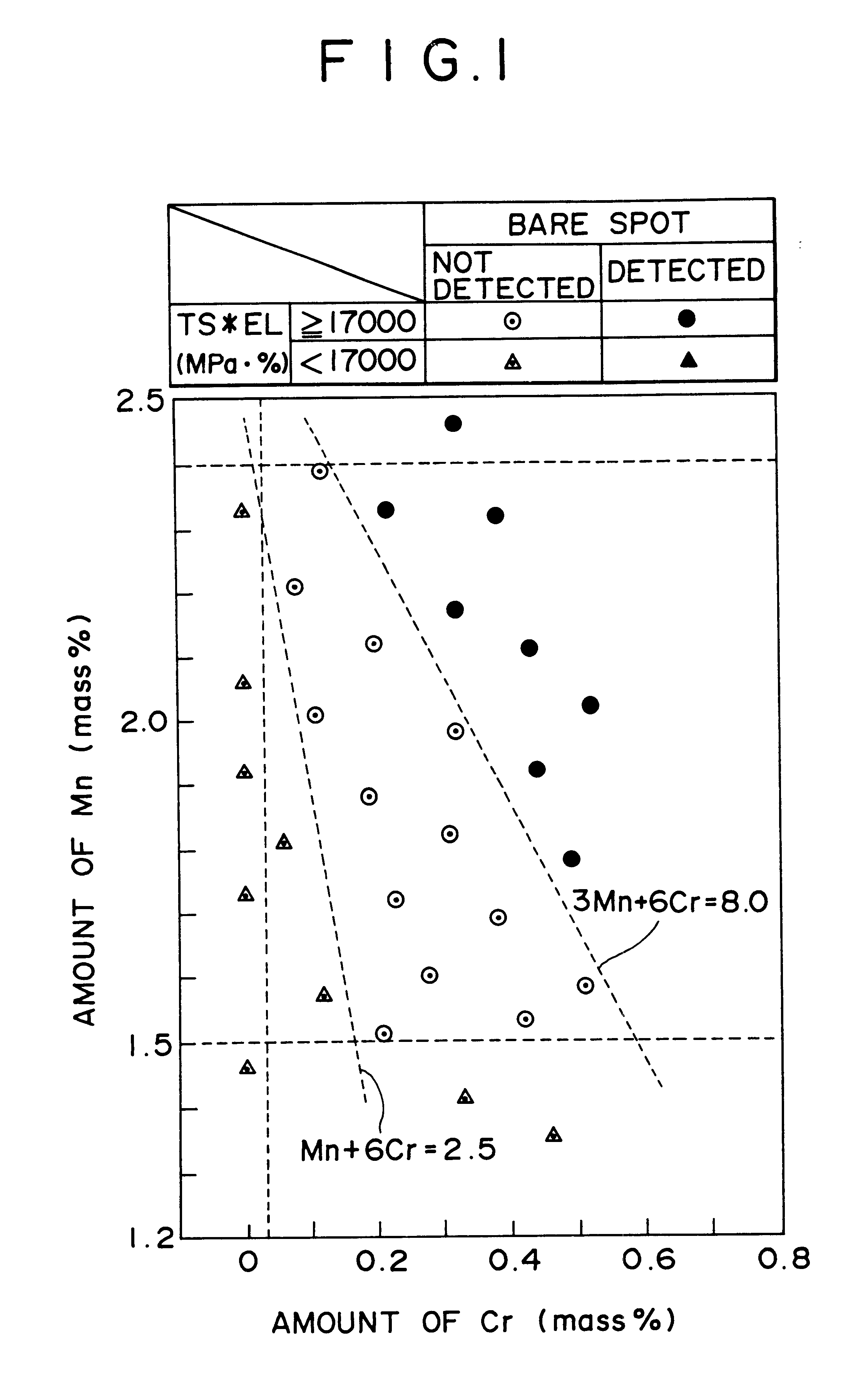

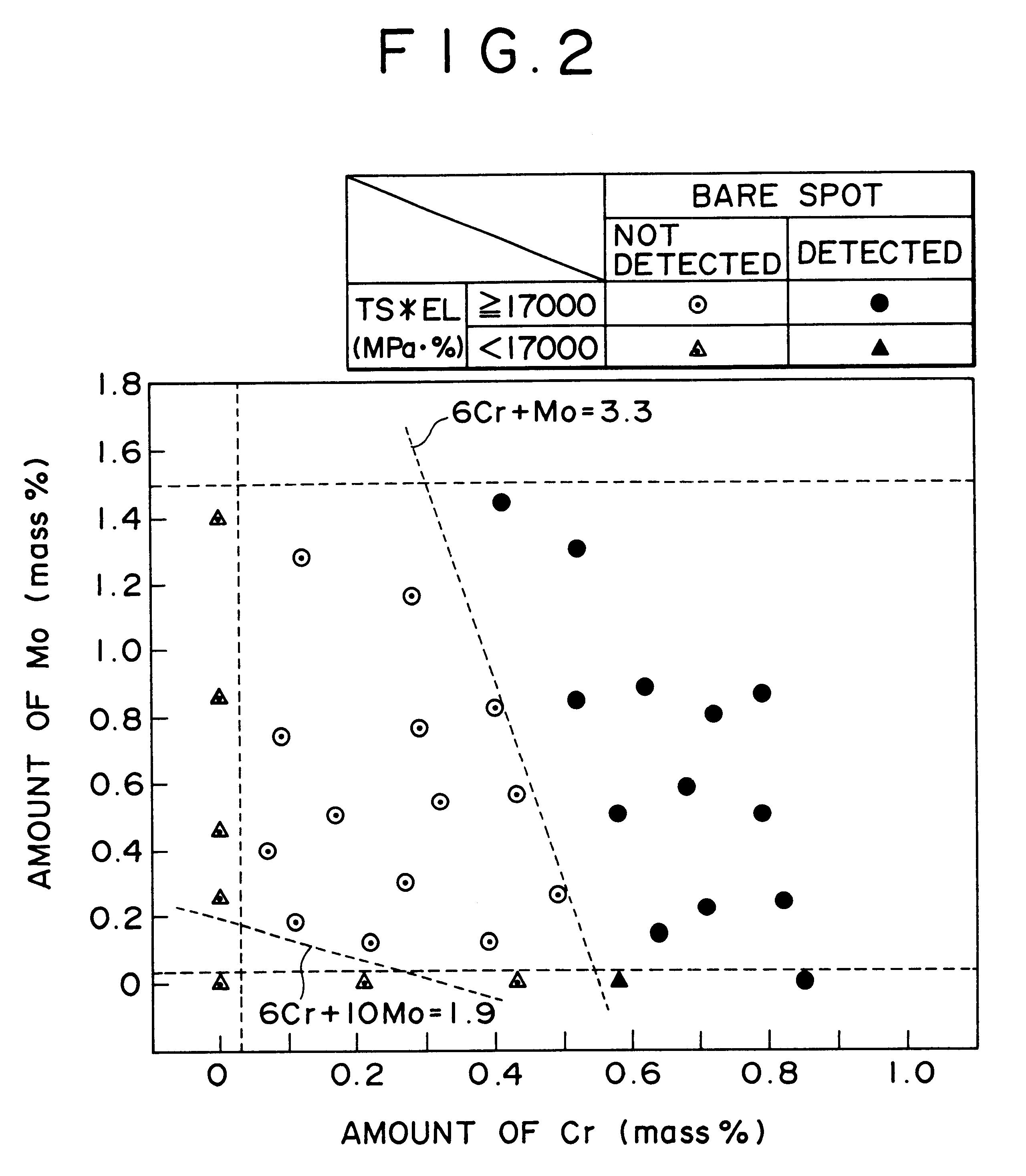

Hot-dip galvanized steel sheet and production thereof

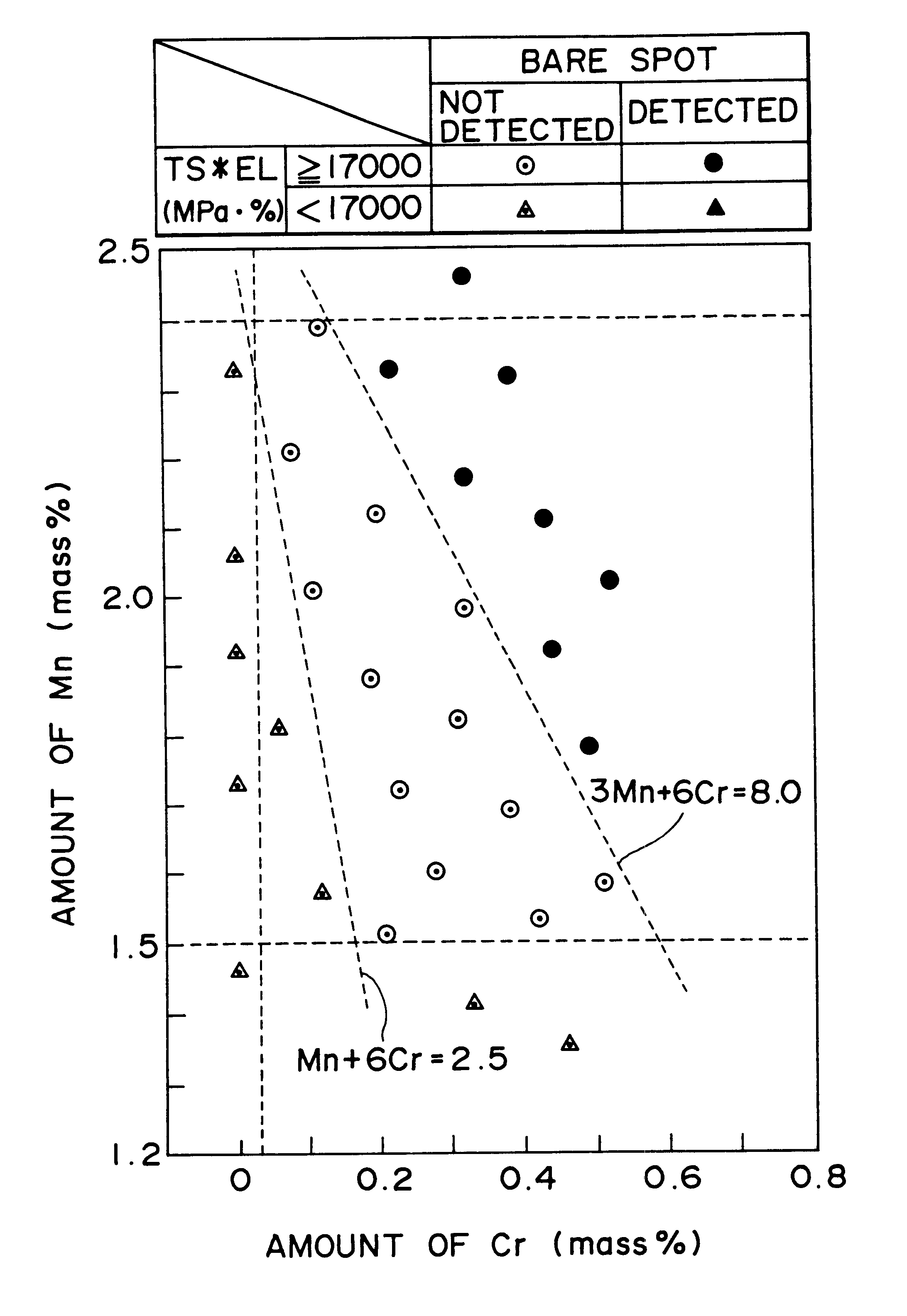

InactiveUS6312536B1High strengthGood formabilityHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

A hot-dip galvanized steel sheet having both high strength and good formability. A process for producing said hot-dip galvanized steel sheet without requiring additional steps of surface grinding and pre-plating.The hot-dip galvanized steel sheet is produced by forming a hot-dip galvanizing layer on a base cold-rolled steel sheet composed of C (0.02-0.20 mass %), Mn (1.50-2.40 mass %), Cr (0.03-1.50 mass %), Mo (0.03-1.50 mass %), 3Mn+6Cr+Mo (no more than 8.1 mass %), Mn+6Cr+10 Mo (no less than 3.5 mass %), Al (0.010-0.150 mass %), and Fe as the principal component, with Ti limited to 0.01 mass % or less, Si limited to 0.04 mass % or less, P limited to 0.060 mass % or less, and S limited to 0.030 mass % or less, and said base steel sheet having the composite microstructure composed mainly of ferrite and martensite.

Owner:KOBE STEEL LTD

Porous thin film and preparation method for porous thin film

The invention discloses a porous thin film and a preparation method for the porous thin film which are easy to achieve the high porosity, guarantee the possible formability in preparation and are simple and practical in preparation technology. The thickness of the porous thin film is 5-200Mum, the average pore size is 0.05-100Mum, and the porosity is 25-75%. The preparation method comprises the steps that 1, a support film is obtained, the support film is provided with a porous-shaped first material, and preliminary pores are formed in the first material; 2, a slurry is prepared, and the slurry contains a powdered second material; 3, the support film is coated with the slurry and then made into a rough-body; 4, the rough-body is sintered, reaction happens between the first material and the second material in sintering, a porous third material is generated, and meanwhile secondary pores communicated with the preliminary pores are generated; 5, the porous thin film is obtained by cooling after the sintering. Due to the fact that at least the preliminary pores and the secondary pores are contained, and therefore the high porosity of the porous thin film is each to be achieve.

Owner:CHENGDU INTERMENT TECH

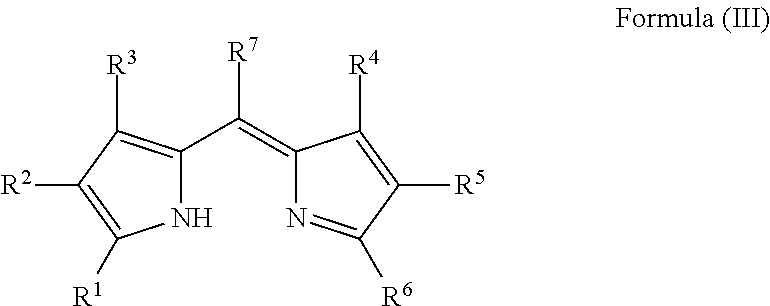

Radiation-sensitive colored composition, color filter, method for producing a color pattern, method for producing color filter, solid-state imaging device, and liquid crystal display apparatus

ActiveUS20120242940A1Improve hydrophilicityImproved development propertyPhotosensitive materialsSolid-state devicesLiquid-crystal displayRadiation sensitivity

Provided is a radiation-sensitive colored composition that enables formation of color cured films in which color concentration unevenness is inhibited and which have uniform color and exhibit a superior development property and excellent pattern formability in the formation of color patterns.The radiation-sensitive colored composition contains (A) a dye polymer containing a structural unit having a dye structure polymerized using a chain-transfer agent having a LogP value of 5 or less, and (B) a solvent.

Owner:FUJIFILM CORP

Bonding wire for semiconductor device

ActiveUS20090188696A1Economical in material costSuperior in ball bondability bondabilityNon-insulated conductorsSolid-state devicesConcentration gradientControllability

The present invention provides a bonding wire improved in formability of a ball part, improved in bondability, good in loop controllability, improved in bonding strength of a wedge connection, securing industrial production ability as well, and mainly comprised of copper which is more inexpensive than gold wire, that is, provides a bonding wire for a semiconductor device comprised of a bonding wire having a core material having copper as its main ingredient and a surface covering layer over the core material and of a conductive metal of a composition different from the core material, characterized in that the surface covering layer has as its main ingredients two or more types of metals selected from gold, palladium, platinum, rhodium, silver, and nickel and the surface covering layer has a concentration gradient of one or both of a main ingredient metal or copper in the wire radial direction.

Owner:NIPPON STEEL CHEMICAL CO LTD

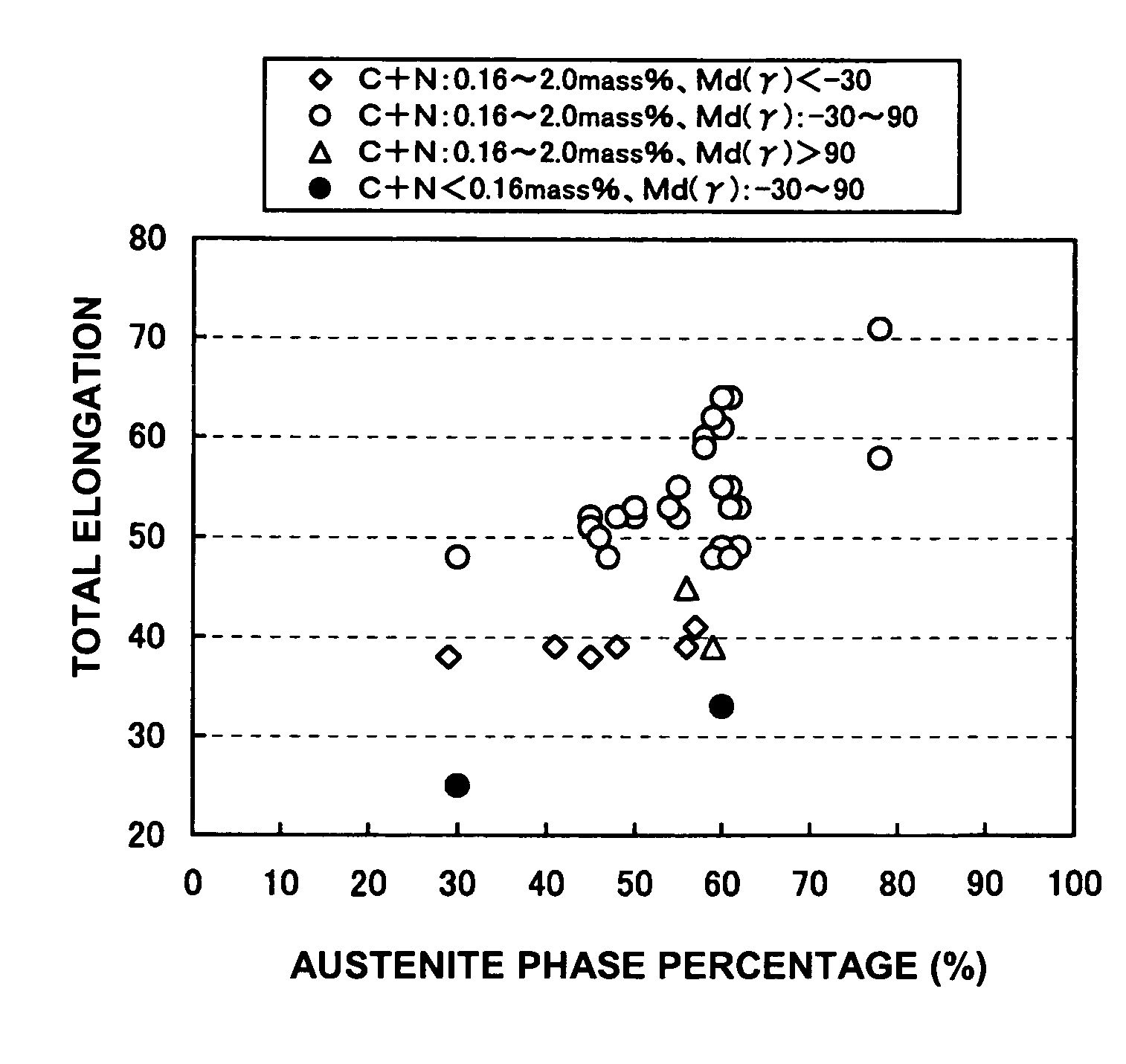

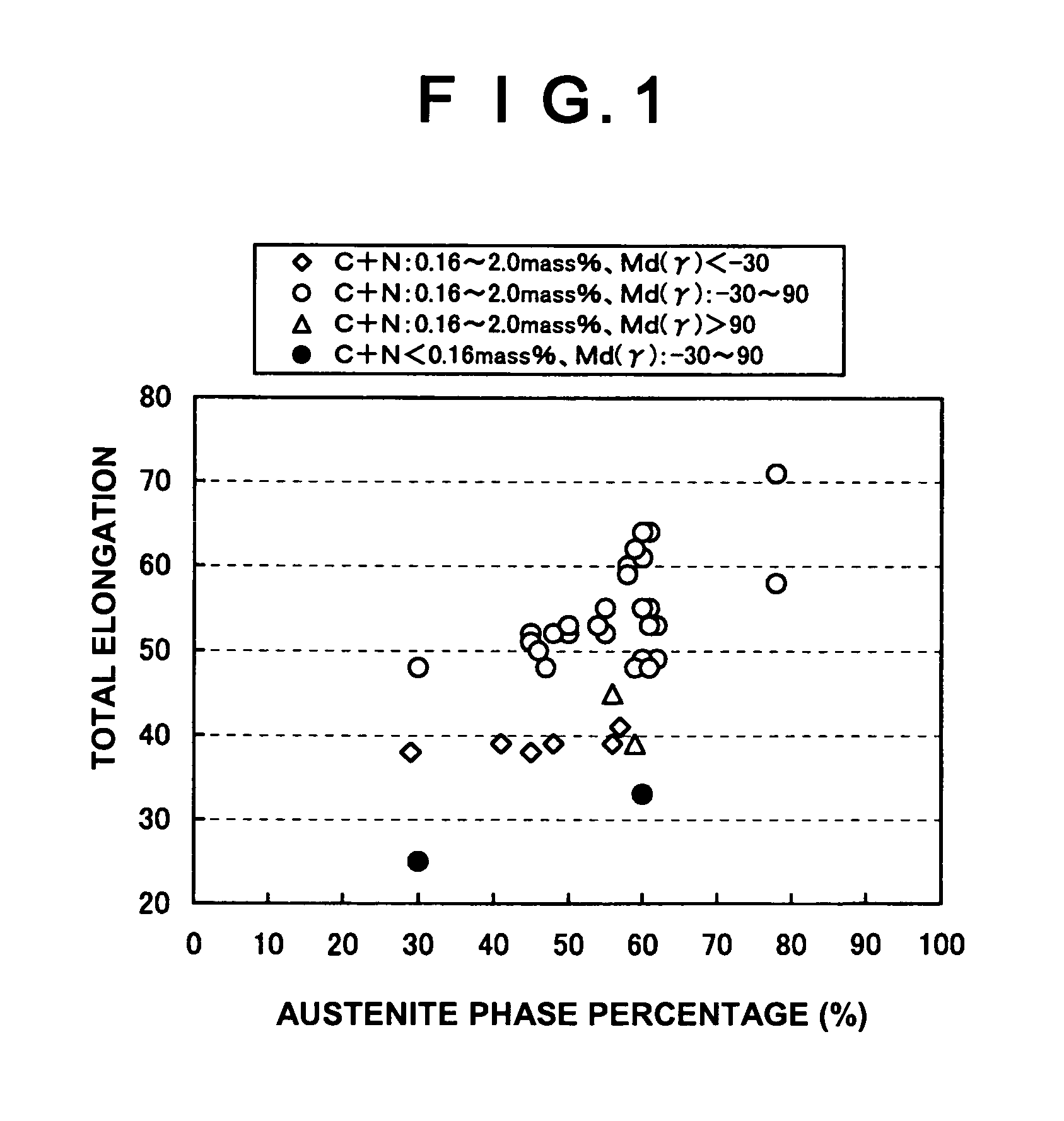

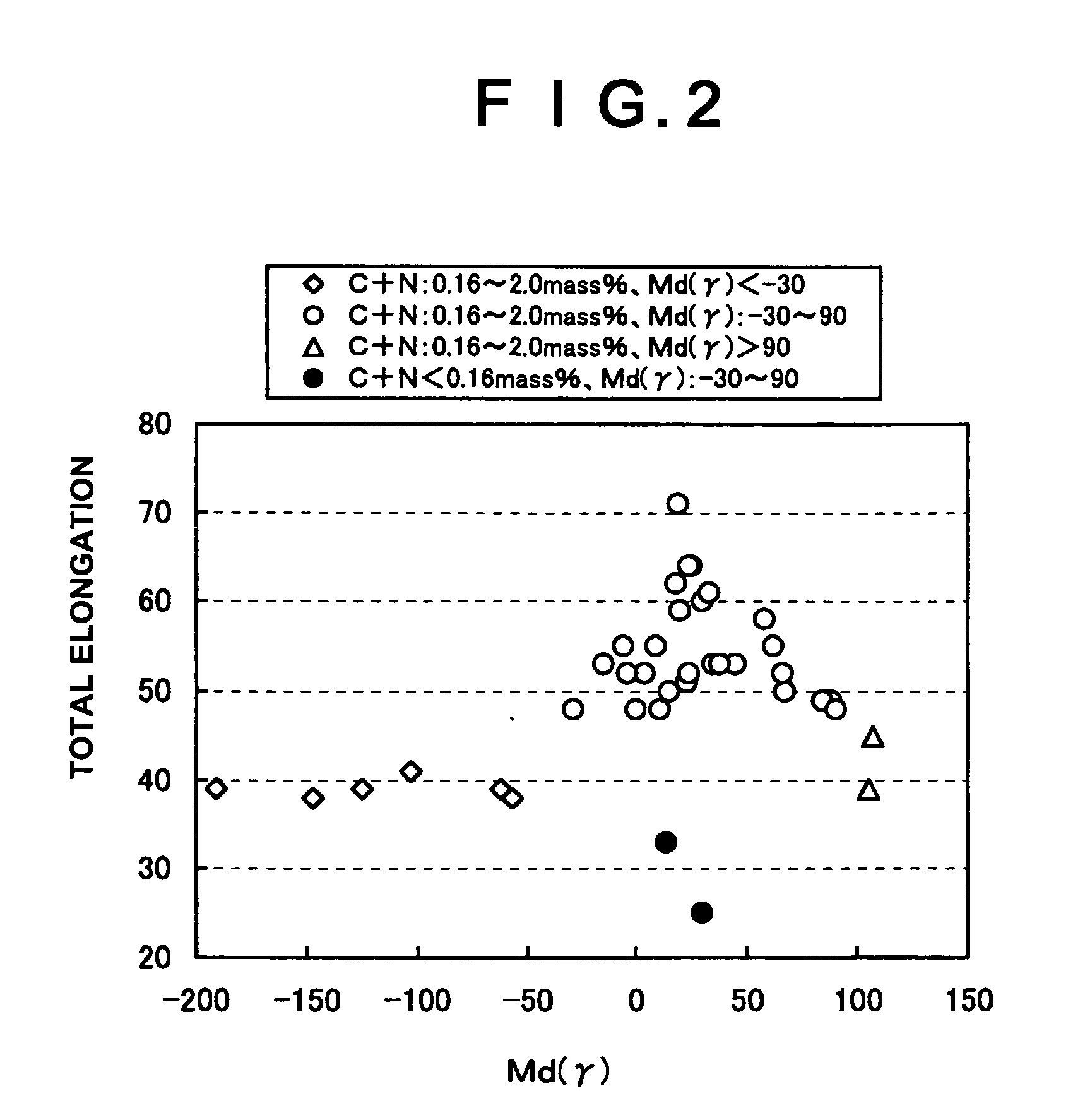

Austenitic-ferritic stainless steel

A low Ni and high N austenitic-ferritic stainless steel is disclosed. It includes an austenitic-ferritic stainless steel having high formability and punch stretchability, crevice corrosion resistance, corrosion resistance at welded part, or excellent intergranular corrosion resistance, from a stainless steel structured by mainly austenite phase and ferrite phase, and consisting essentially of 0.2% or less C, 4% or less Si, 12% or less Mn, 0.1% or less P, 0.03% or less S, 15 to 35% Cr, 3% or less Ni, and 0.05 to 0.6% N, by mass, by adjusting the percentage of the austenite phase in a range from 10 to 85%, by volume. Furthermore, it includes an austenitic-ferritic stainless steel having higher formability by adjusting the amount of (C+N) in the austenite phase to a range from 0.16 to 2% by mass.

Owner:JFE STEEL CORP

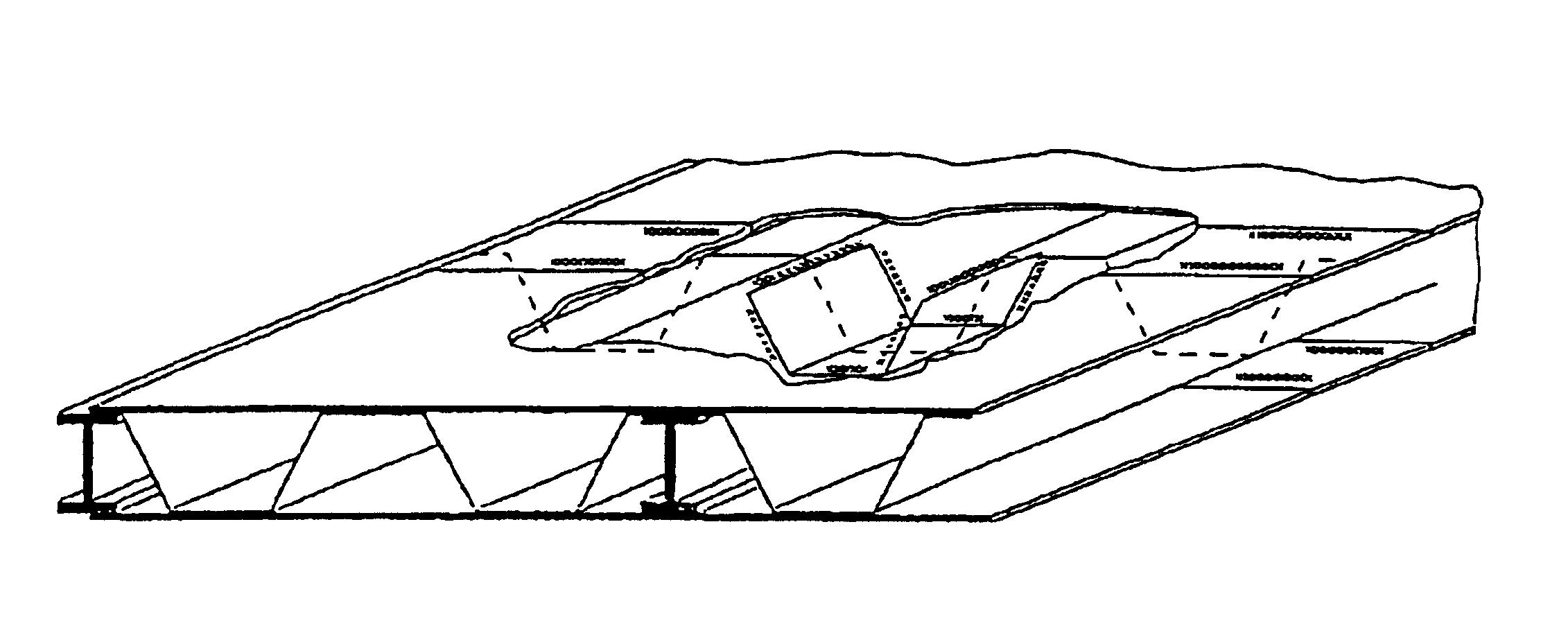

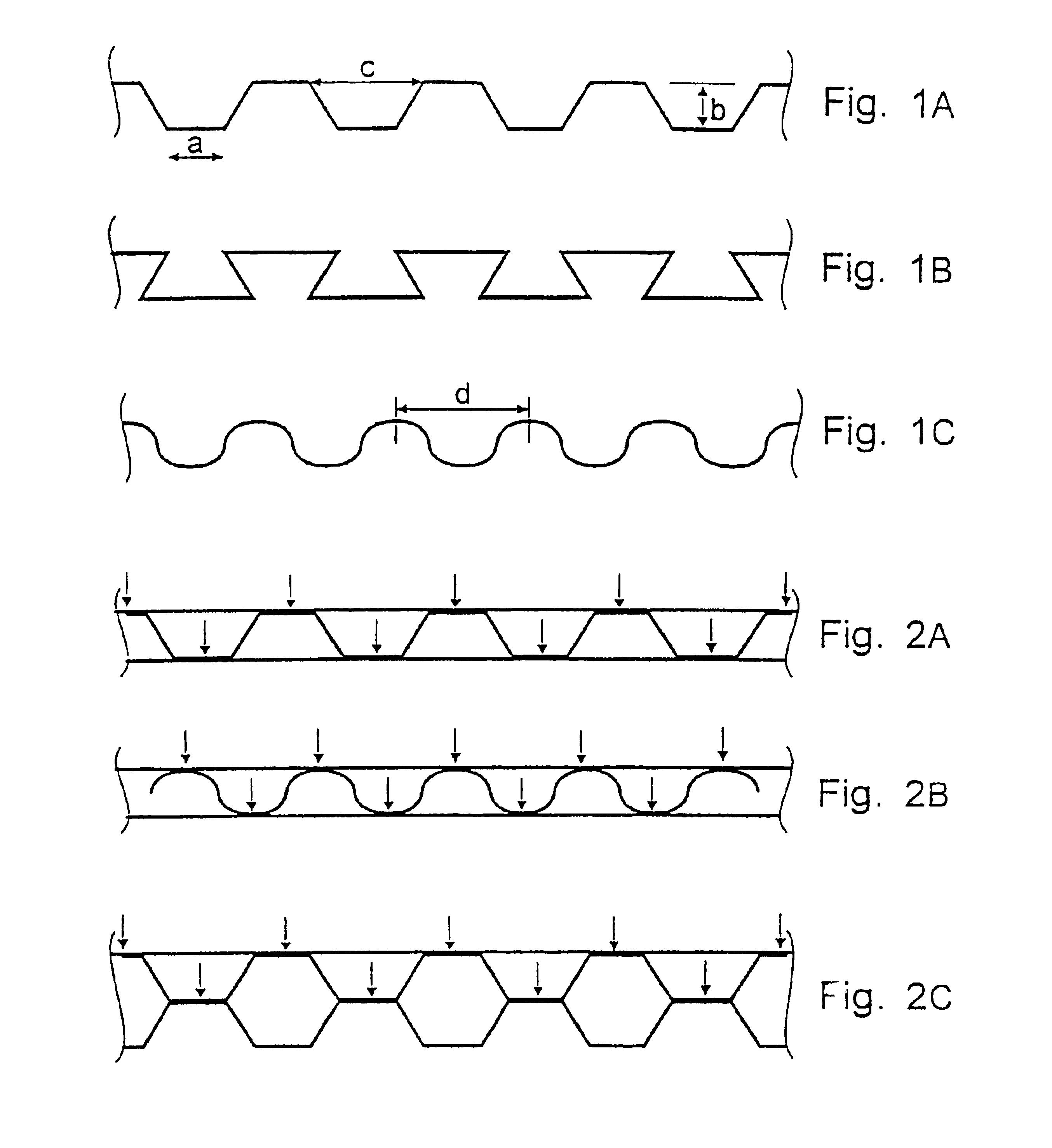

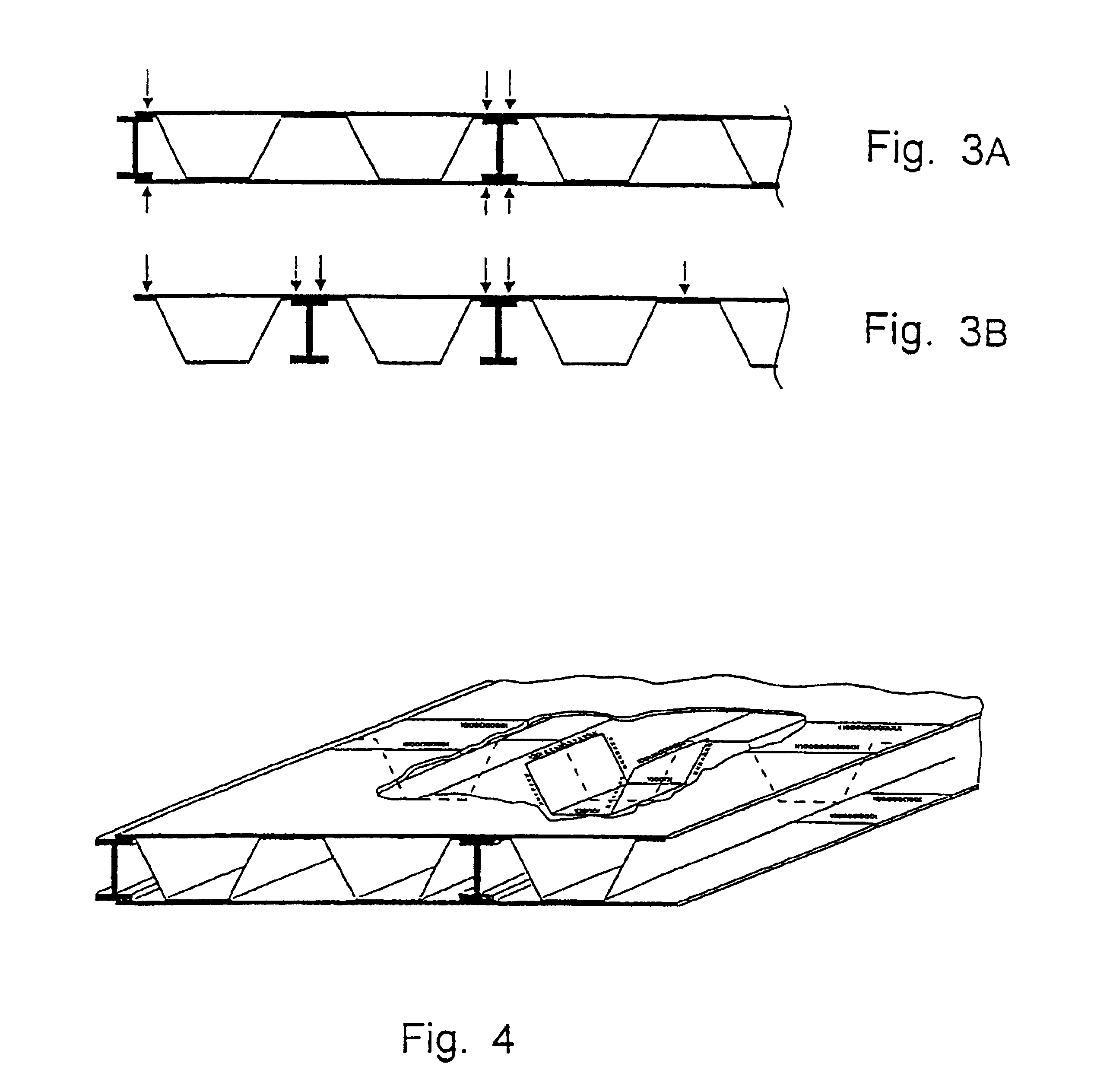

Composite aluminium panel

InactiveUS6848233B1Improve corrosion resistanceReliable and easy to manufactureNon-magnetic metal hullsLayered product treatmentParallel plateMaterials science

A composite aluminium panel comprising two parallel plates and / or sheets secured to the peaks and troughs of a corrugated aluminium stiffener sheet between the parallel plates and / or sheets, wherein the corrugated aluminium stiffener sheet is made from an aluminium alloy rolled sheet of composition (in weight percent): Mg 1.5-6.0, Mn 0.3-1.4, Zn 0.4-5.0, Fe up to 0.5, Si up to 0.5, Zr up to 0.30; optionally one or more of Cr 0.05-0.3, Ti 0.01-0.20, V 0.05-0.25, Ag 0.05-0.40, and Cu up to 0.40; and other elements up to 0.05 each, 0.15 total, with a balance of Al; and having in an H-condition or in an O-condition a ratio of PS / UTS in the range of 0.4 to 0.9 and having good roll formability.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

Porous film and preparation method of porous film

The invention discloses a porous film and a preparation method of the porous film, which can easily achieve high porosity and guarantee the formability during the preparation, and are simple and practical in preparation process. The thickness of the porous film is 200-1500[mu]m, the average aperture of the porous film is 0.05-100[mu]m, and the porosity of the porous film is 25-75%. The preparation method includes (1) acquiring a support film which has a porous first material, and forming primary pores in the first material; (2) preparing slurry containing a powder-like second material; (3) coating the support film with the slurry to prepare a base substrate; (4) sintering the base substrate, generating a porous third material through the reaction between the first material and the second material during the sintering, and further generating secondary pores communicated with the primary pores; and (5) cooling the base substrate to obtain the porous film after the sintering. The porous film at least contains the primary pores and the secondary pores, so that the porous film is easy to achieve high porosity.

Owner:CHENGDU INTERMENT TECH

Dual-phase steel sheet excellent in stretch flange formability and production method thereof

Disclosed is a dual-phase steel sheet having low yield ratio, excellent in the balance for strength-elongation and for strength-stretch flange formability, and also excellent in bake hardening property containing (on the mass% basis). C: 0.01-0.20%, Si: 0.5% or less, Mn: 0.5-3%, sol. Al: 0.06% or less (inclusive 0%), P: 0.15% or less (exclusive 0%), and S: 0.02% or less (inclusive 0''), and in which the matrix phase contains tempered martensite; tempered martensite and ferrite; tempered bainite; or tempered bainite and ferrite, and the second phase comprises 1 to 30% of martensite at an area ratio based on the entire structure.

Owner:KOBE STEEL LTD

Porous thin film and preparation method for porous thin film

The invention discloses a porous thin film and a preparation method for the porous thin film which are easy to achieve the high porosity, guarantee the possible formability in preparation and are simple and practical in preparation technology. The thickness of the porous thin film is 5-200Mum, the average pore size is 0.05-100Mum, and the porosity is 25-75%. The preparation method comprises the steps that 1, a support film is obtained, the support film is provided with a porous-shaped first material, and preliminary pores are formed in the first material; 2, a slurry is prepared, and the slurry contains a powdered second material; 3, the support film is coated with the slurry and then made into a rough-body; 4, the rough-body is sintered, auto-reaction happens to the second material in sintering, a porous third material is generated, and then secondary pores communicated with the preliminary pores are generated; 5, the porous thin film is obtained by cooling after the sintering. Due to the fact that at least the preliminary pores and the secondary pores are contained, the high porosity of the porous thin film is easy to achieve.

Owner:CHENGDU INTERMENT TECH

Aluminum alloy for automobile body of automobile and plate manufacturing method thereof

The invention relates to an aluminum alloy for an automobile body of an automobile and a plate manufacturing method thereof and belongs to the technical field of aluminum alloy. The alloy comprises the following components in percentage by weight: 0.6 to 1.33 percent of Mg, 0.6 to 1.33 percent of Si, 0.3 to 0.7 percent of Cu, less than or equal to 0.3 percent of Zn, less than or equal to 0.15 percent of Fe, 0.2 to 0.8 percent of Mn, 0.01 to 0.3 percent of Cr, 0.01 to 0.3 percent of Ti and the balance of Al, wherein the mass fraction ratio of Mg to Si is 1; the total content of the mass fractions of Mn, Cr and Ti alloy elements is more than or equal to 0.3 percent; and Cu content is more than or equal to 0.3 percent. The method for manufacturing the aluminum alloy for the automobile body of the automobile comprises the following steps of: (1) smelting the alloy; (2) shaping the alloy by casting; (3) performing pre-nucleation treatment; (4) performing homogenization treatment; (5) performing hot rolling; (6) performing intermediate annealing; (7) performing cold rolling; (8) performing solid solution water quenching treatment; (9) standing a product at room temperature; and (10) performing pre-ageing and standing the product at the room temperature for more than two weeks. The aluminum alloy and the method are characterized in that: an alloy casting process and a plate production process of the invention are simple and convenient to control; an alloy plate of the invention has high intensity and excellent stamping forming property; and the stamping yield of a covering part for the aluminum alloy automobile body can be effectively enhanced and stamping cost is lowered.

Owner:NORTHEASTERN UNIV

Magnesium-based alloy

ActiveUS20100161031A1Improve plasticityImprove corrosion resistanceSuture equipmentsStentsInsertion stentHeat resistance

The present invention relates to compositions and structure of deformable alloys on the basis of magnesium with an optimum combination of mechanical properties (strength, plasticity) and a resistance to corrosion, including in vivo. Alloys of the new group possess an excellent formability at room temperature, high corrosion stability in sodium chloride solution, excellent heat resistance and can be used in various technical applications, particularly in vivo as a structural material for stents.

Owner:ACROSTAK CORP

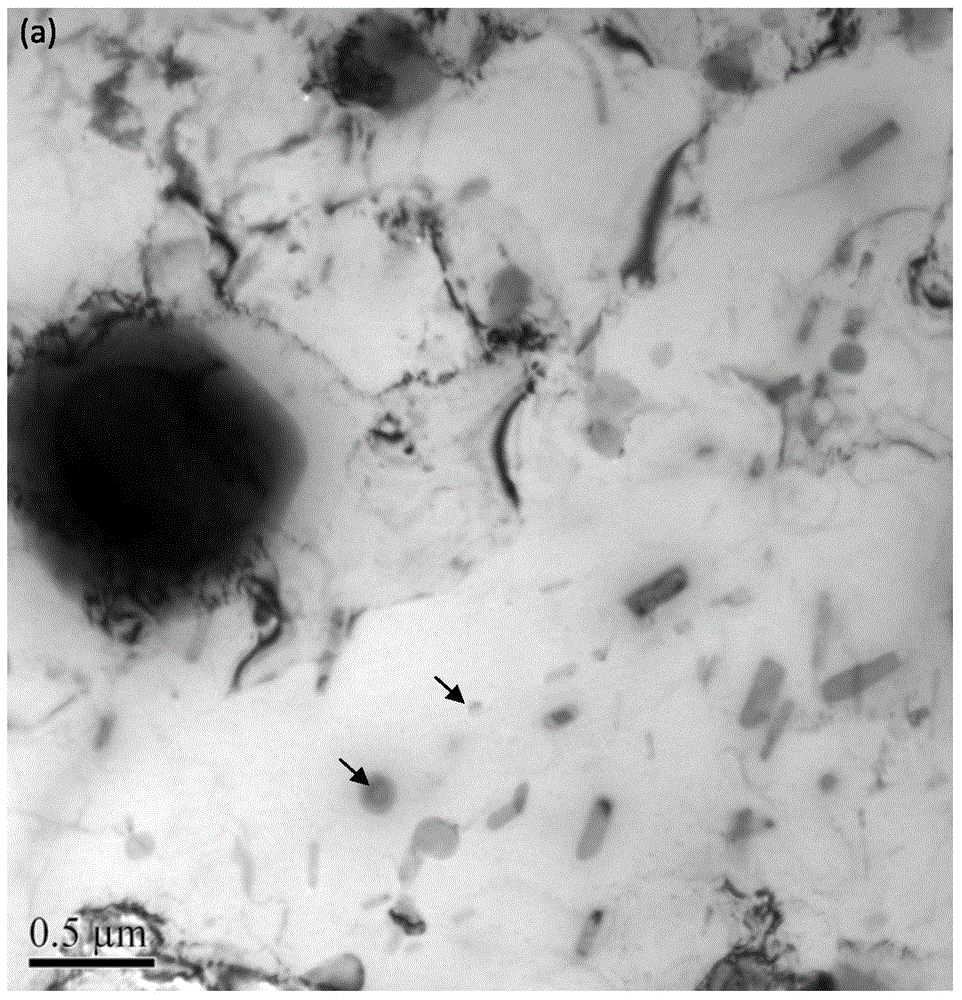

Electromagnetic wave absorber

InactiveUS20090135042A1High loss characteristicStrong absorption capacityMaterial nanotechnologyShielding materialsElectromagnetic wave absorberCarbon fibers

By using a high electromagnetic wave absorbing loss material and adding it in a small amount to a matrix, an electromagnetic wave absorber useful for GHz band, which can demonstrate the electromagnetic wave absorption capability without ruining characteristics of the matrix, and can enjoy a good formability and a low manufacturing cost, is provided.The disclosed is an electromagnetic wave absorber which is characterized in that carbon fibrous structures are contained in the matrix, at a rate of 0.01-25% by weight based on the total weight, wherein the carbon fibrous structure comprises a three dimensional network of carbon fibers each having an outside diameter of 15-100 nm, wherein the carbon fibrous structure further comprises a granular part with which the carbon fibers are tied together in the state that the concerned carbon fibers are externally elongated therefrom, and wherein the granular part is produced in a growth process of the carbon fibers.

Owner:MITSUI & CO LTD

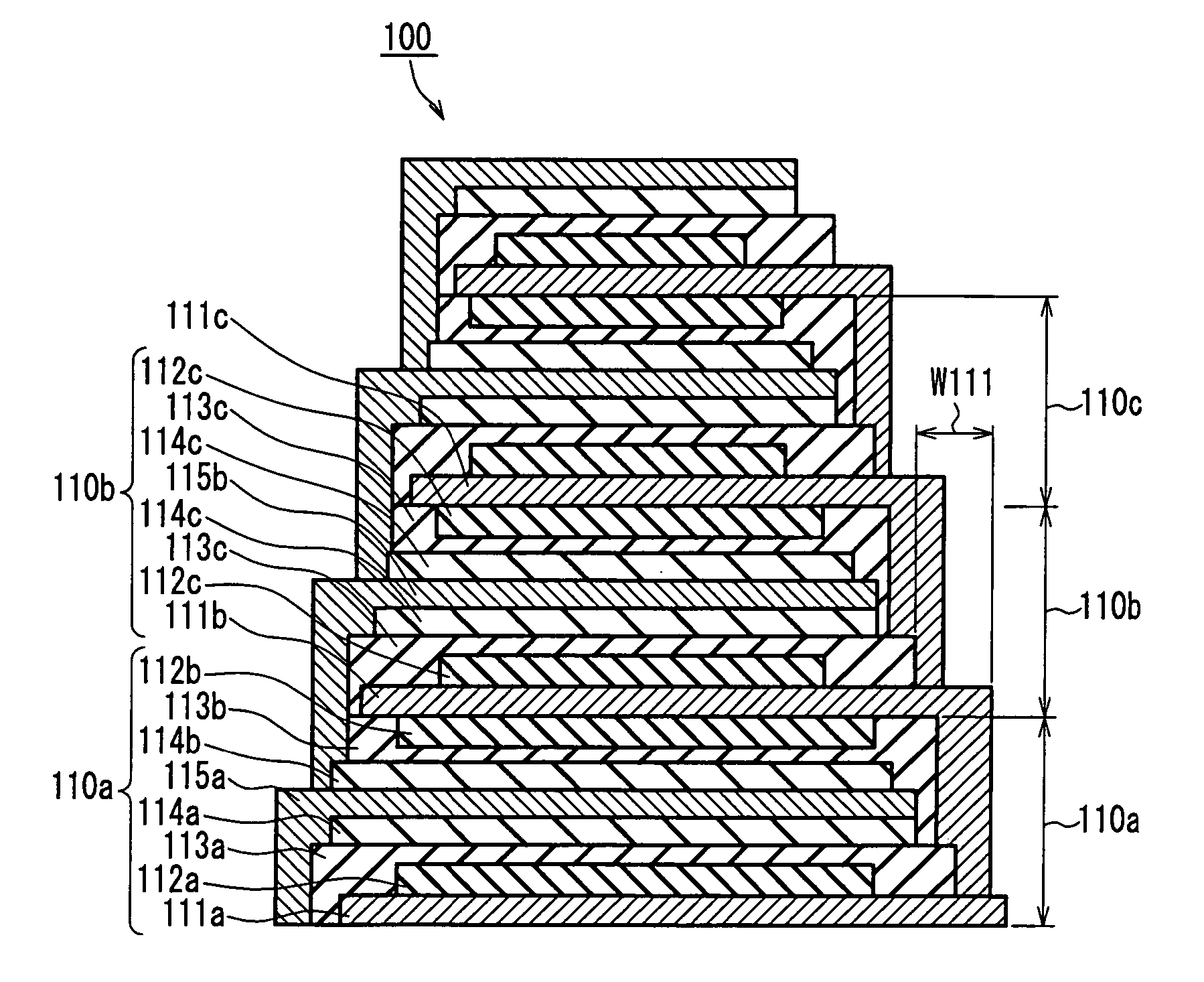

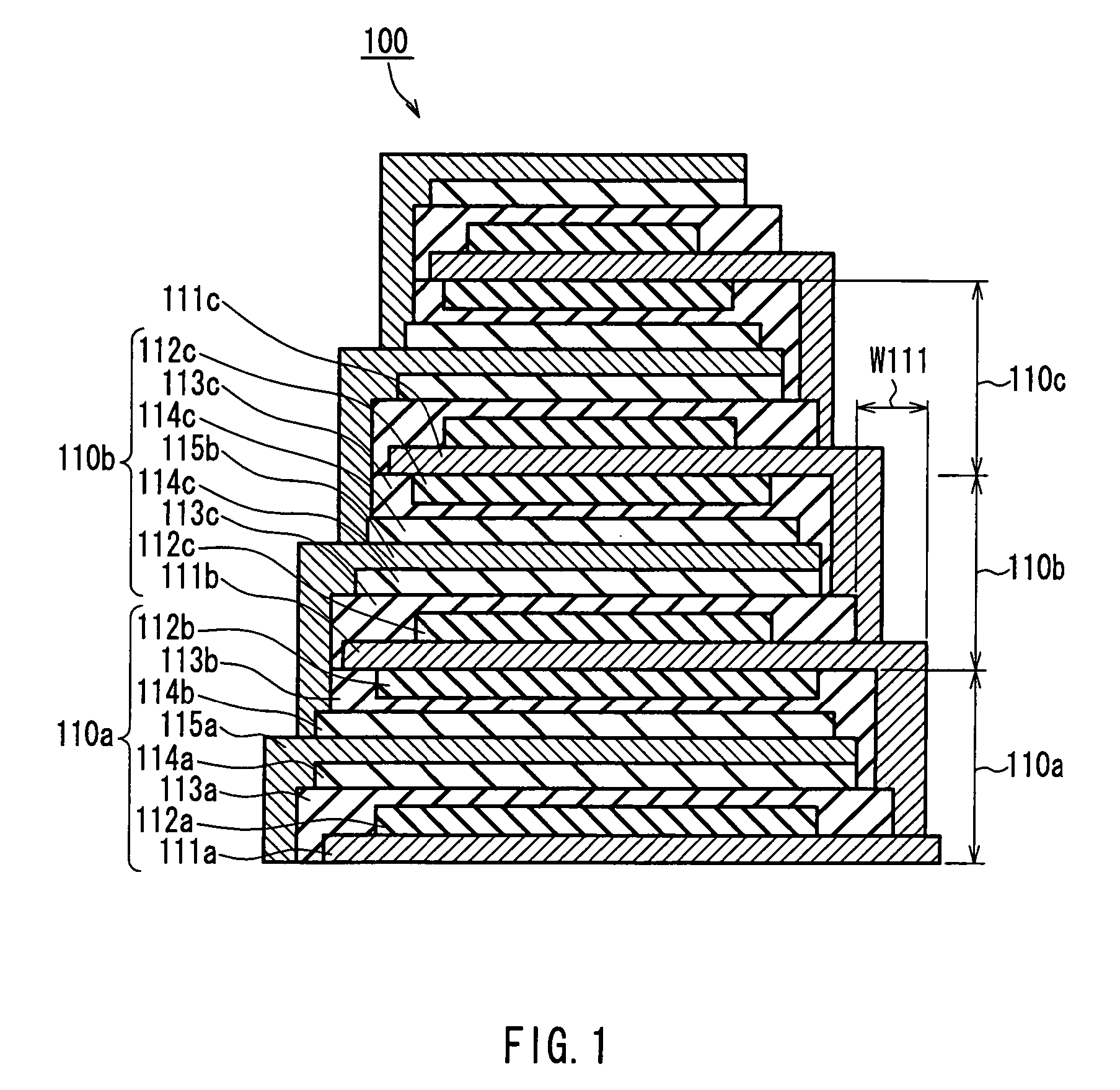

Thin-film laminated body, thin-film cell, capacitor, and method and equipment for manufacturing thin-film laminated body

InactiveUS20050141170A1Improve connection reliabilityQuality improvementCell electrodesFinal product manufactureEngineeringAdhesion strength

A thin film layered product is composed of at least two deposition units, each of which includes at least a first thin film layer and a second thin film layer. At least one of the first thin film layer and the second thin film layer in each of the at least two deposition units is laminated so as to have an area decreased in a direction from a lower layer toward an upper layer. Thus, the reliability of connection between layers can be improved, and when a protective layer is formed on side faces, the formability and adhesion strength can be improved.

Owner:PANASONIC CORP

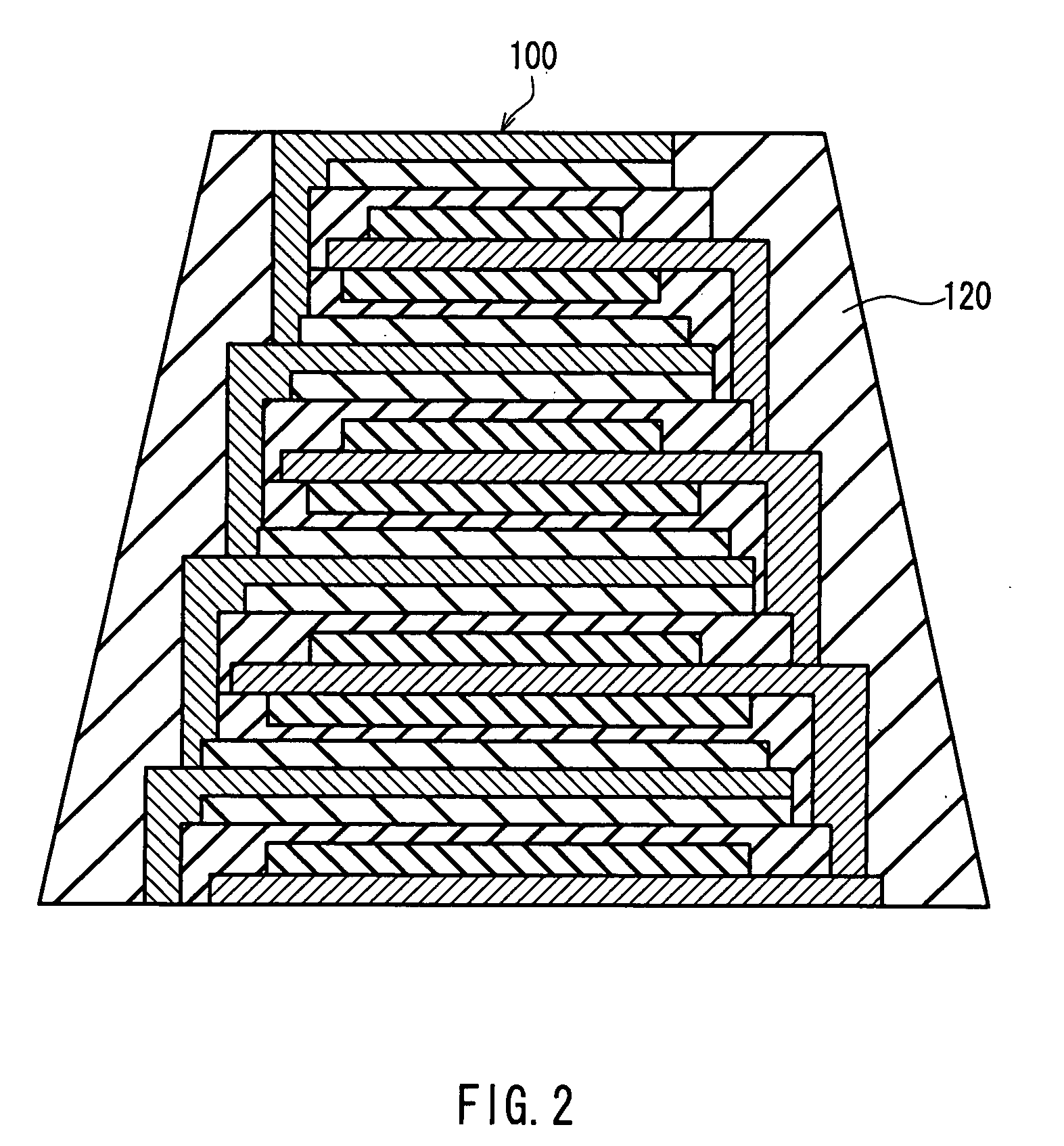

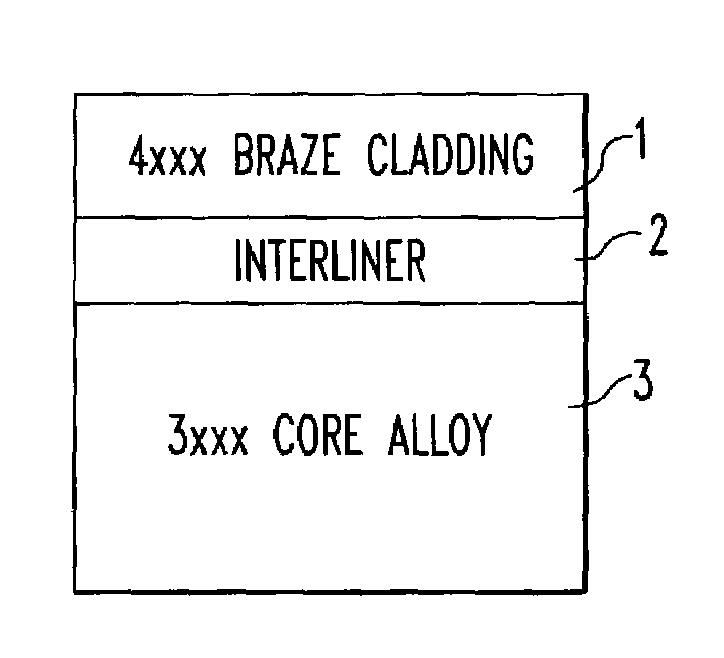

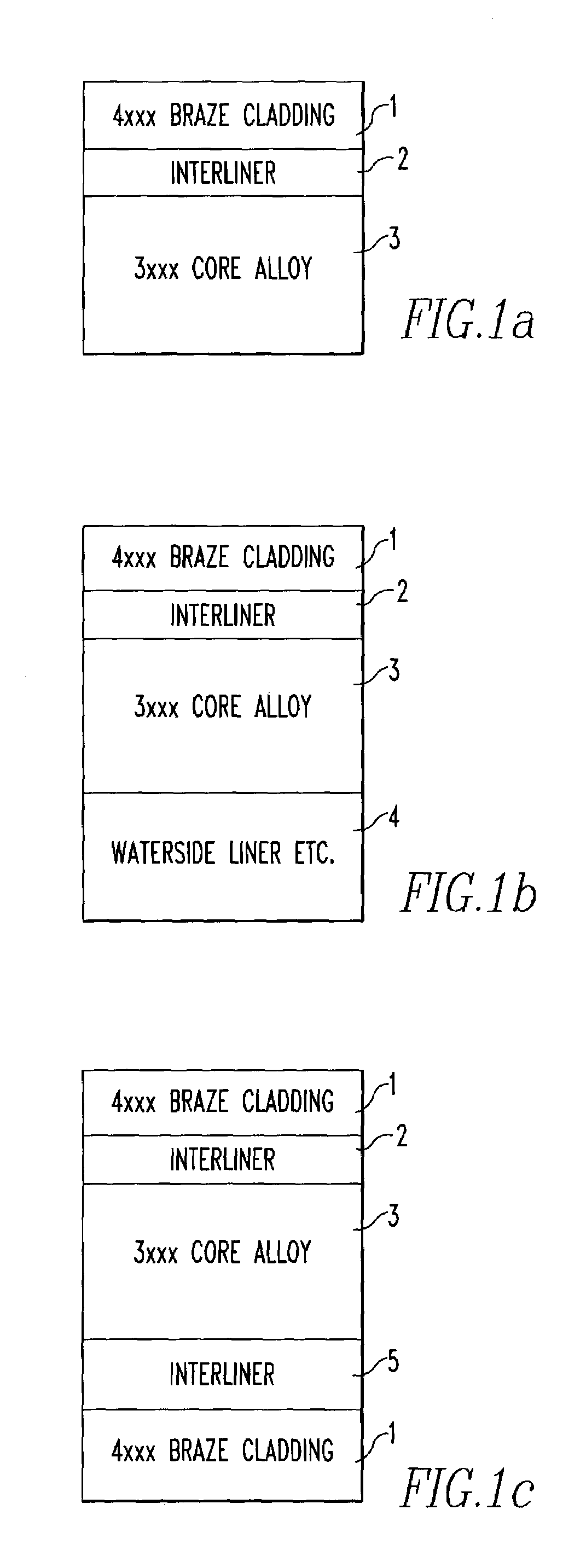

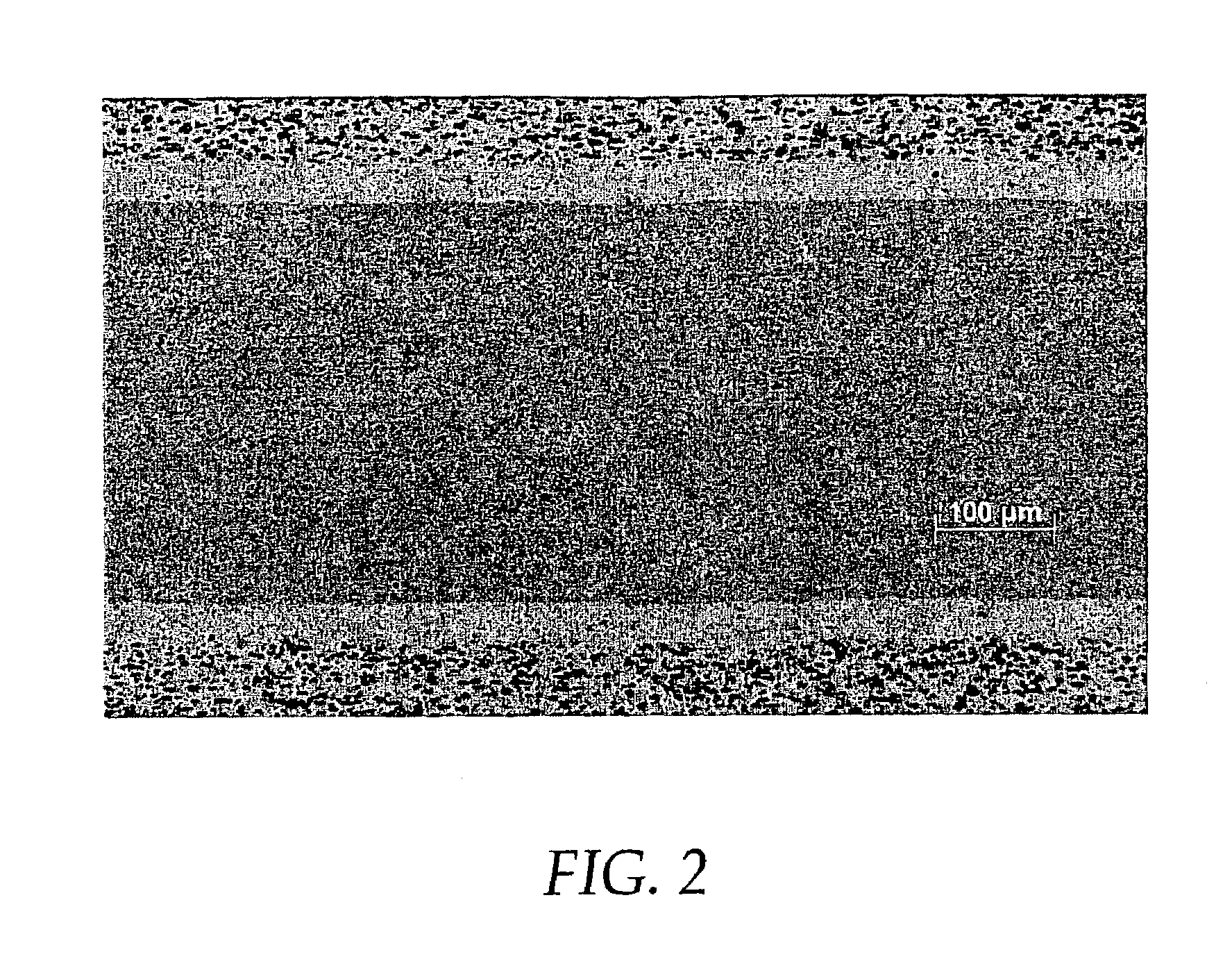

Ultra-longlife, high formability brazing sheet

InactiveUS7255932B1Improve corrosion resistanceWelding/cutting media/materialsHeat exchange apparatusOptoelectronicsMultiple layer

The present invention relates to multiple layer aluminum brazing sheet having a core, a braze cladding, and an interliner therebetween that, when fabricated in the fully annealed condition (O-temper), forms a continuous and dense dispersoid band in the core in addition to having an additional sacrificial layer for exceptional post brazed corrosion resistance. This present invention also relates to the process used to fabricate these alloys.

Owner:ARCONIC TECH LLC

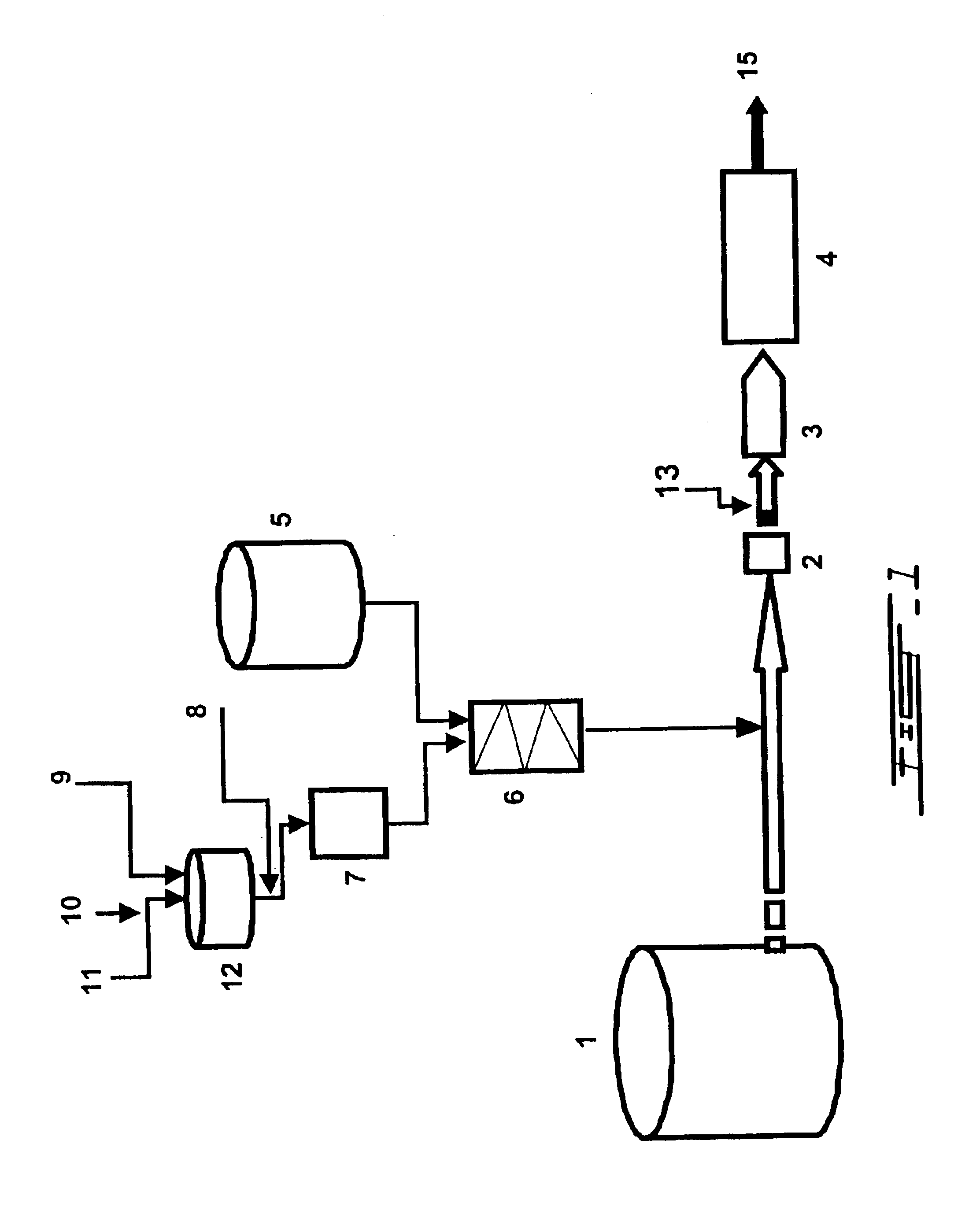

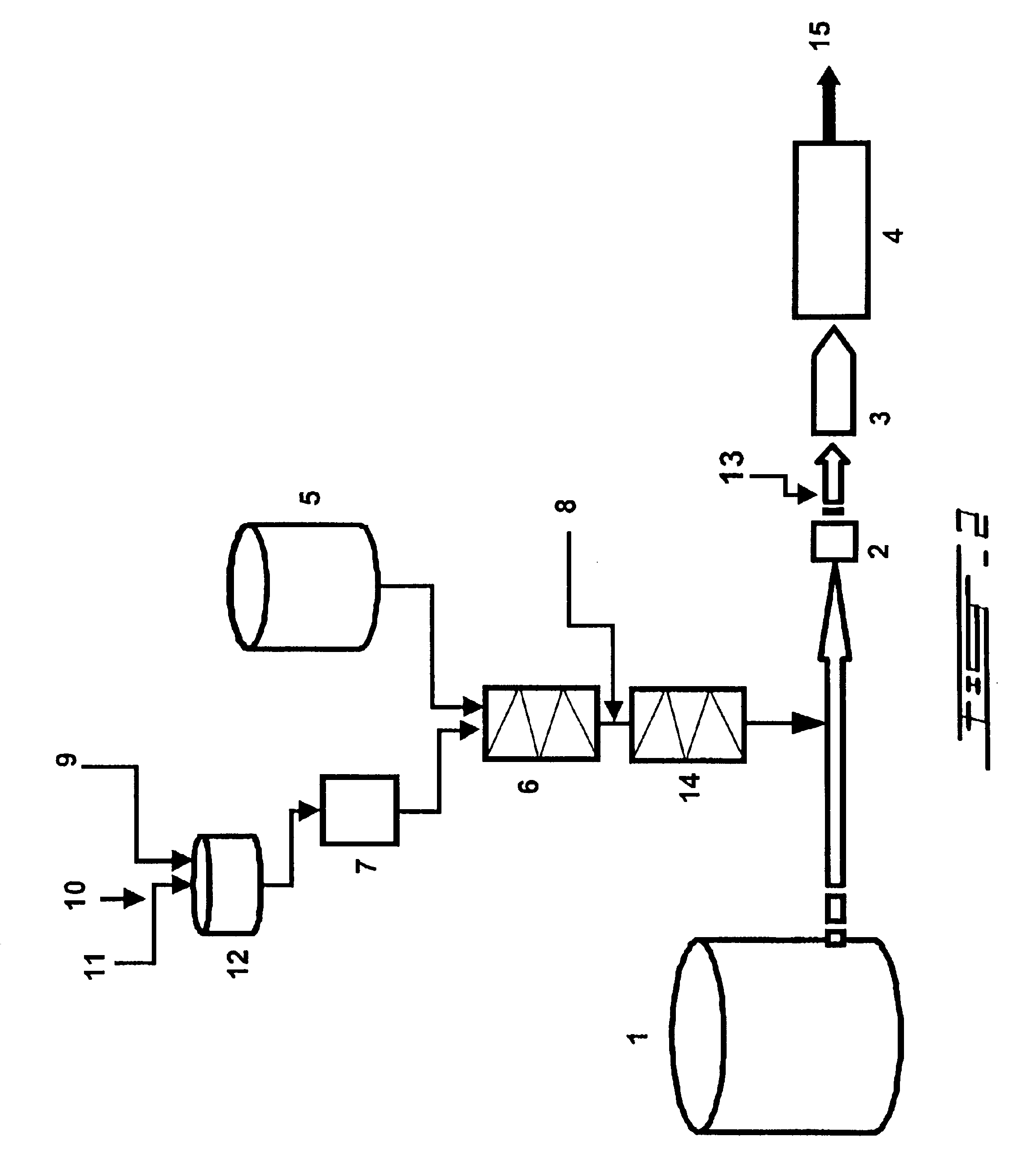

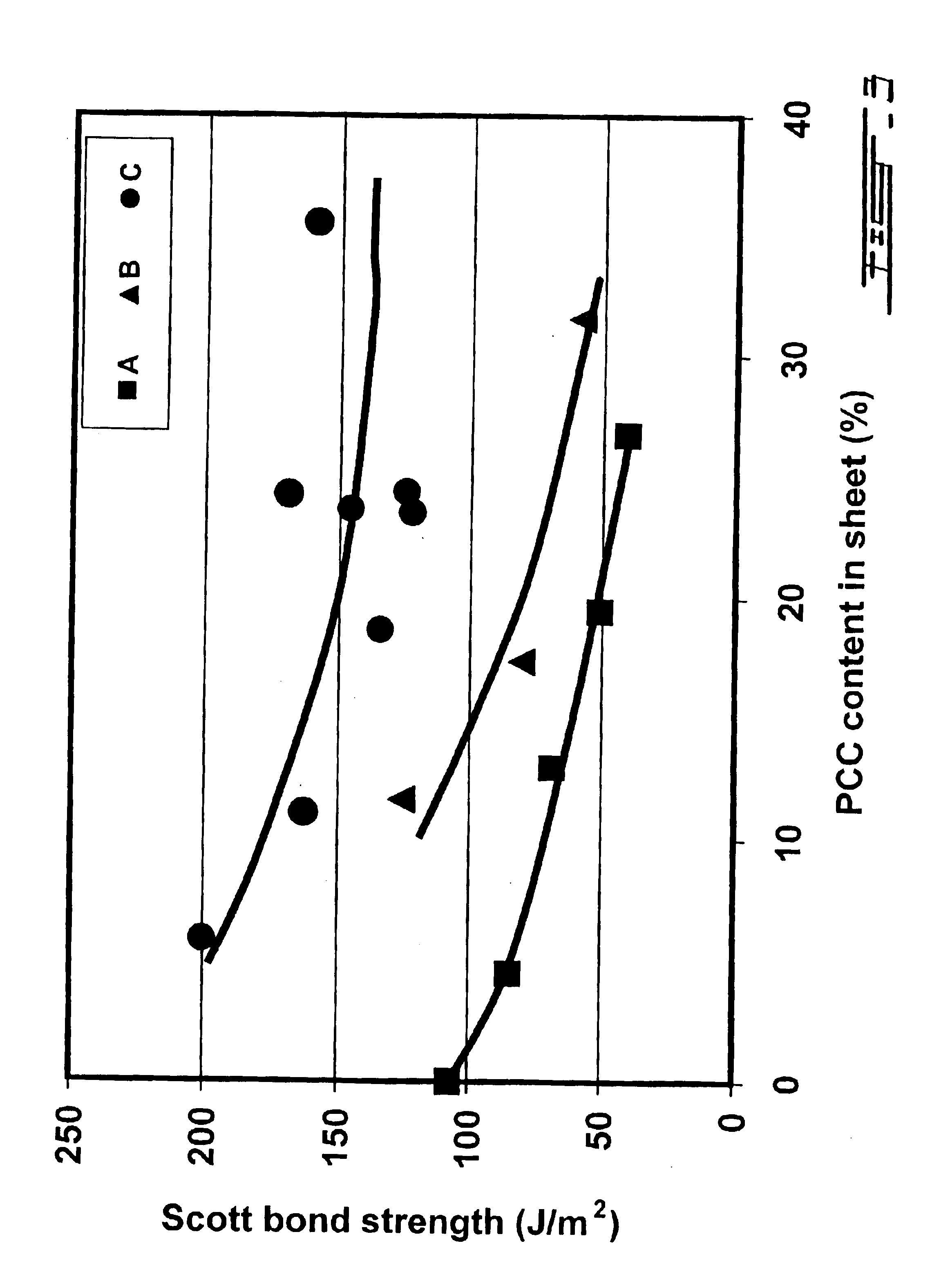

Swollen starch-latex compositions for use in papermaking

InactiveUS7074845B2High retention rateEasy to drainPigmenting treatmentNatural cellulose pulp/paperPaperboardPapermaking

A novel filler treatment comprising the preparation of swollen starch-latex compositions, prepared in the presence or absence of co-additives, and the addition of the said composition to a filler suspension, has been developed. Use of the treated filler during papermaking improves filler retention and produces filled papers where addition of the filler has only a minimal negative effect on strength properties. The swollen starch-latex compositions can be prepared in a batch or jet cooker, or by mixing with hot water under controlled conditions (i.e., temperature, pH, mixing, mixing time) in order to make the starch granules swell sufficiently to improve their properties as a filler additive but avoiding excess swelling leading to their rupture. The swollen starch-latex composition is then rapidly mixed with the filler slurry, preferably in a static mixer, and added to the papermaking furnish at a point prior to the headbox of the paper machine. The starch-latex composition can be used with wood-free or wood-containing furnishes. The treated filler is easily retained in the web during papermaking, improves drainage, and gives sheets having good formation. Sheets made with the treated fillers have higher bonding and tensile strengths than sheets produced using filler treated with either swollen starch alone or latex alone. Retention and drainage are further improved when conventional retention aid chemicals are added to the furnish containing the treated filler. The use of swollen starch-latex compositions could allow the papermaker to increase the filler content of the paper without sacrificing dry strength properties or increasing the amount, and hence the cost, of the retention aid added. The combination of swollen starch and latex could be used as furnish additives in the manufacture of both filled grades and grades that contain no filler such as sack papers and paperboard products.

Owner:FPINNOVATIONS INC

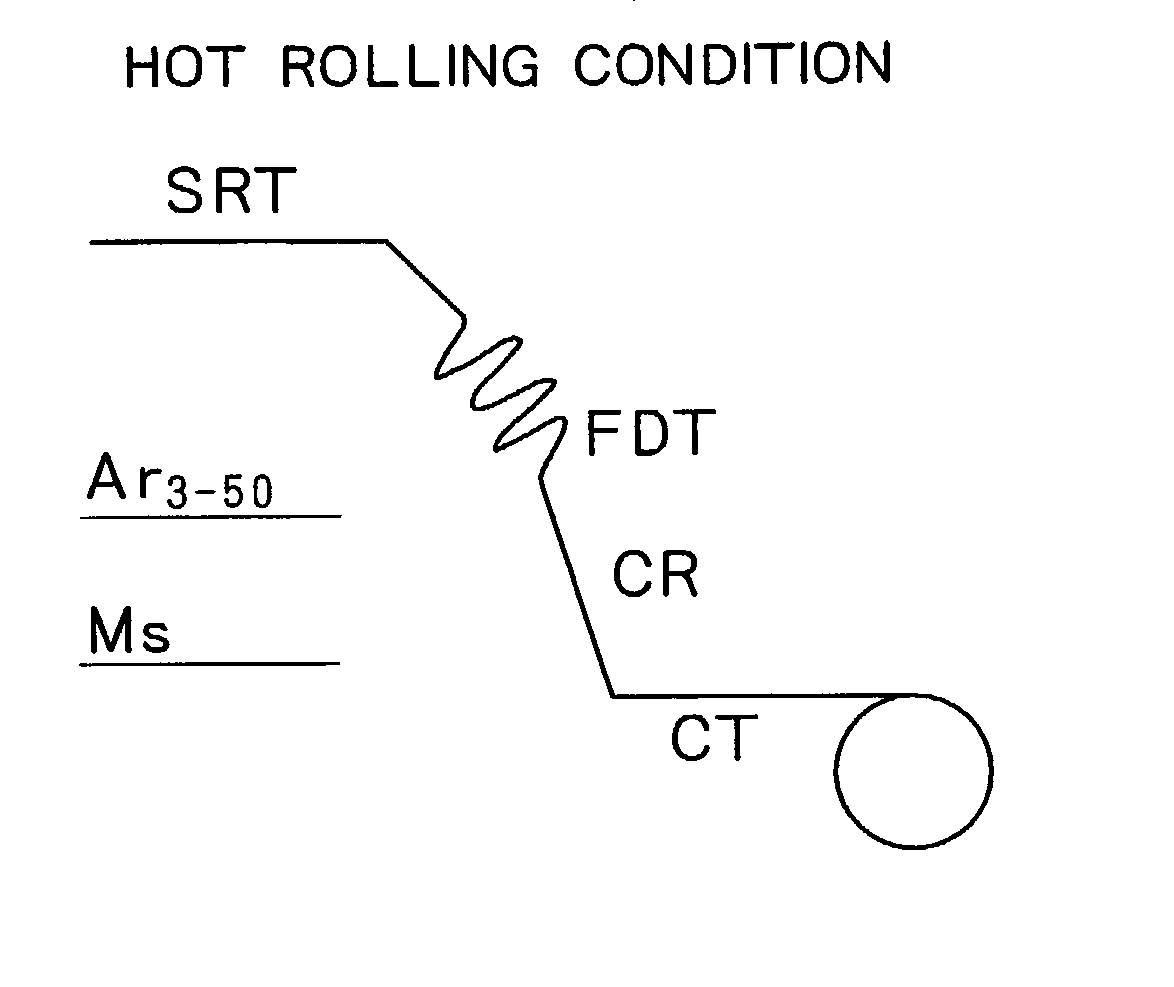

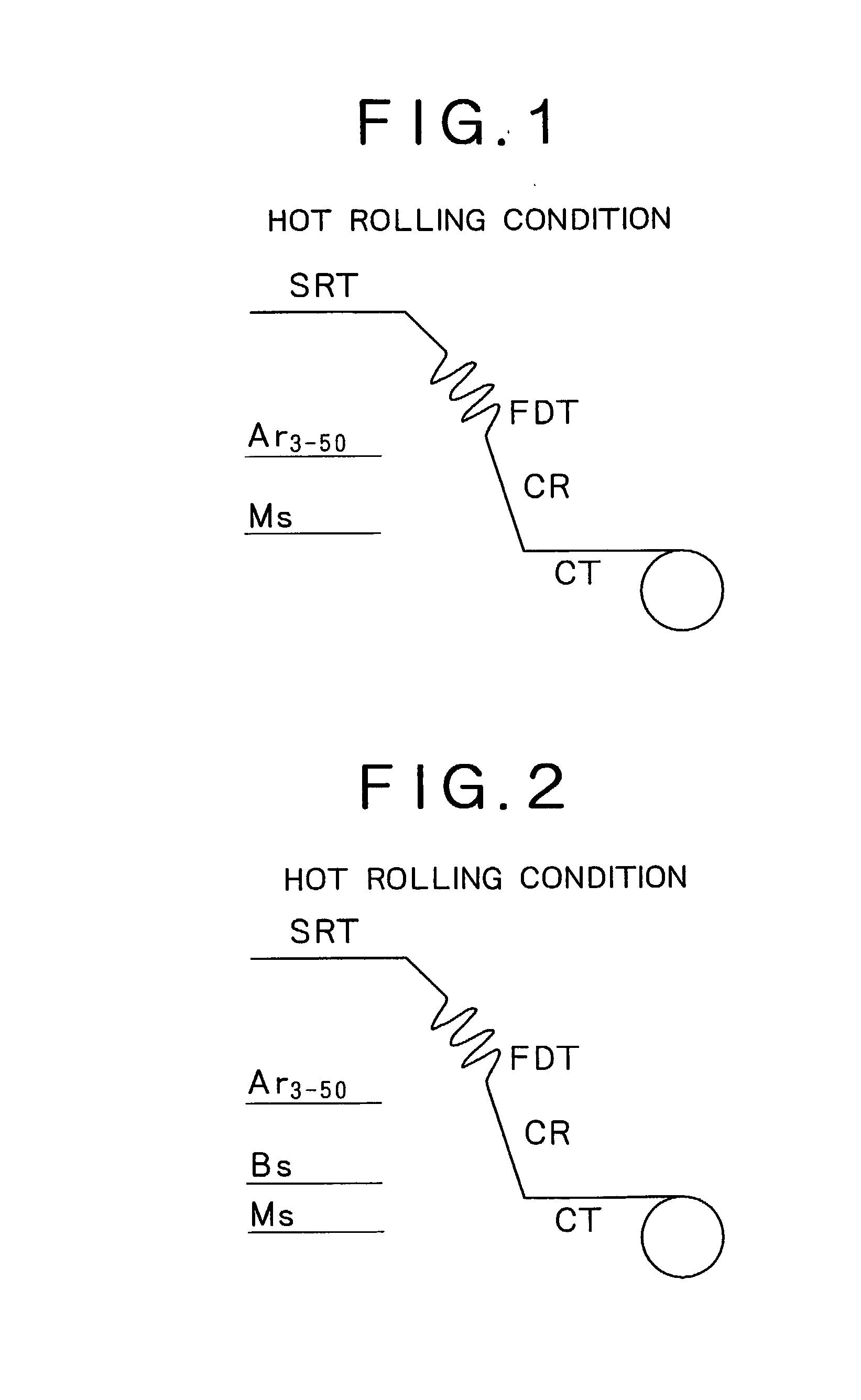

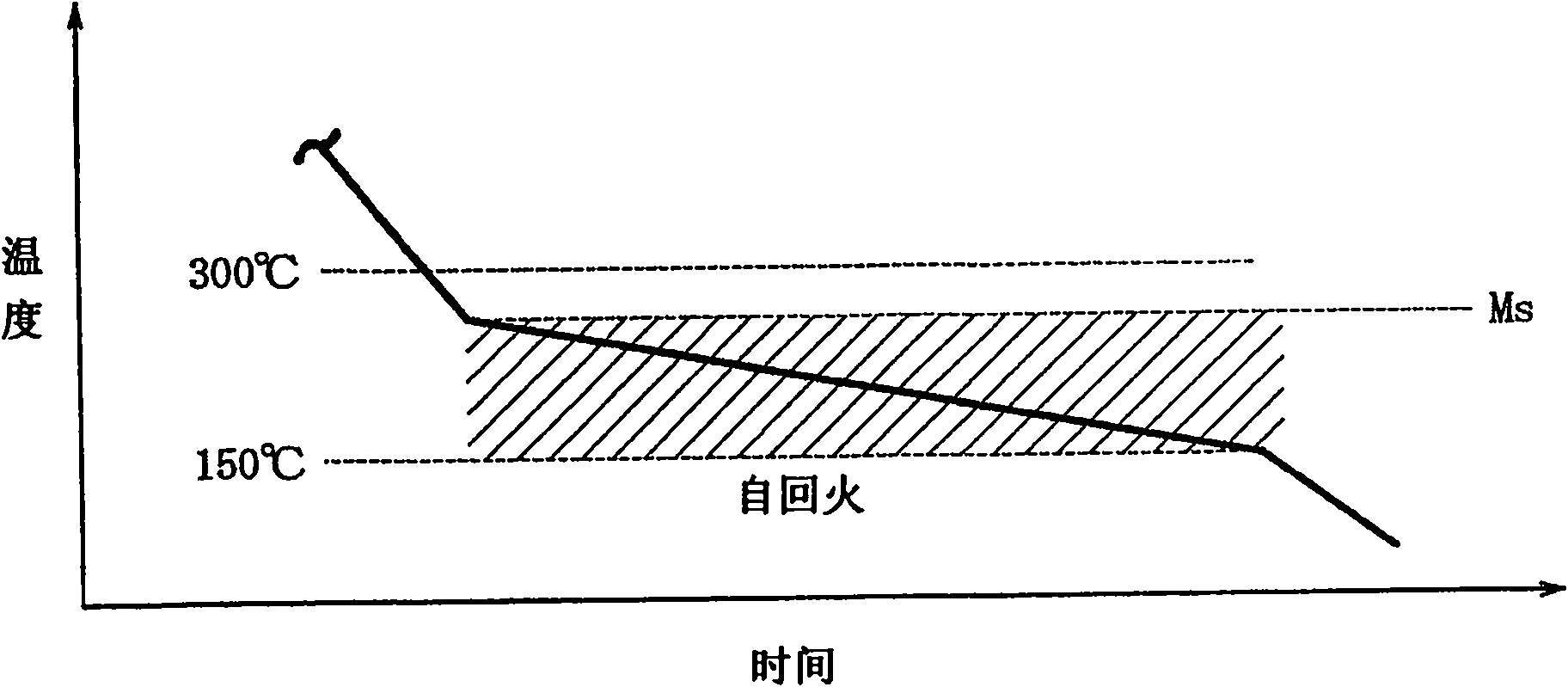

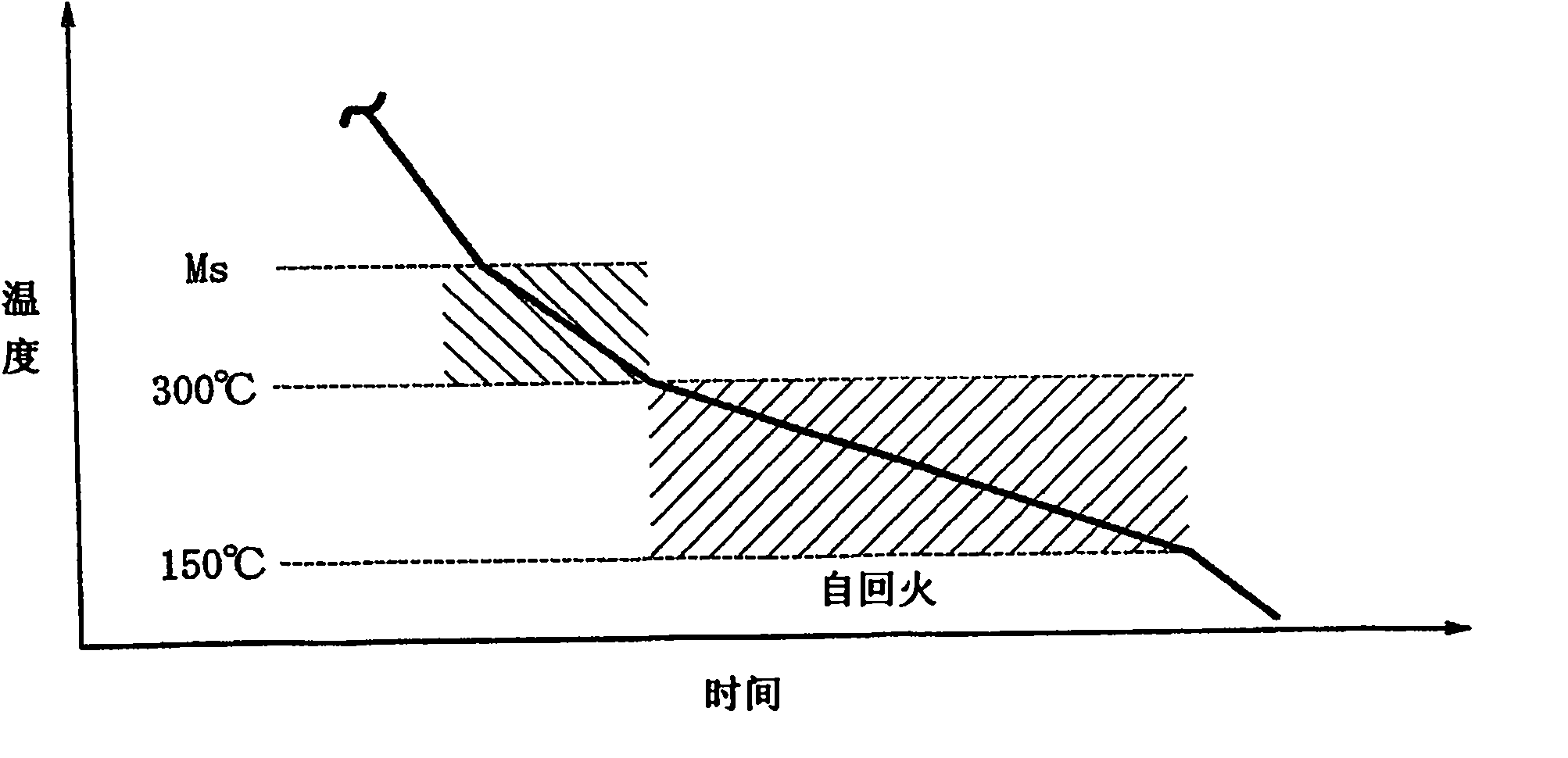

High-strength steel sheet and process for production thereof

ActiveCN101932745AHigh strengthHelps to reduce weightHot-dipping/immersion processesFurnace typesSheet steelCarbide

Disclosed are an ultra-high-strength steel sheet having both a tensile strength of as high as 1400MPa or above and excellent formability and an advantageous process for manufacturing the same. A high-strength steel sheet having both a composition which contains by mass C: 0.12 to 0.50%, Si: 2.0% or less, Mn: 1.0 to 5.0%, P: 0.1% or less, S: 0.07% or less, Al: 1.0% or less, and N: 0.008% or less with the balance being Fe and unavoidable impurities, and a structure which comprises, in terms of area fraction, autotempered martensite: 80% or more, ferrite: less than 5%, bainite: 10% or less, and retained austenite: 5% or less and in which the average number of precipitated iron carbide particles of 5nm to 0.5[mu]m in the autotempered martensite is 5OE04 or above per mm2.

Owner:JFE STEEL CORP

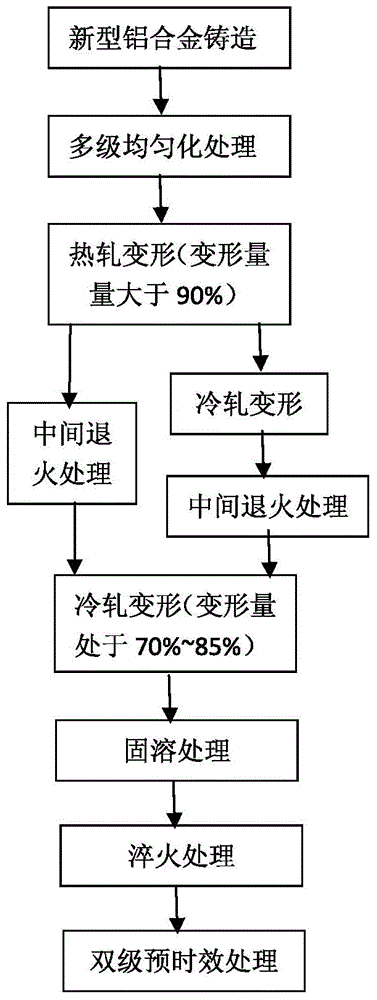

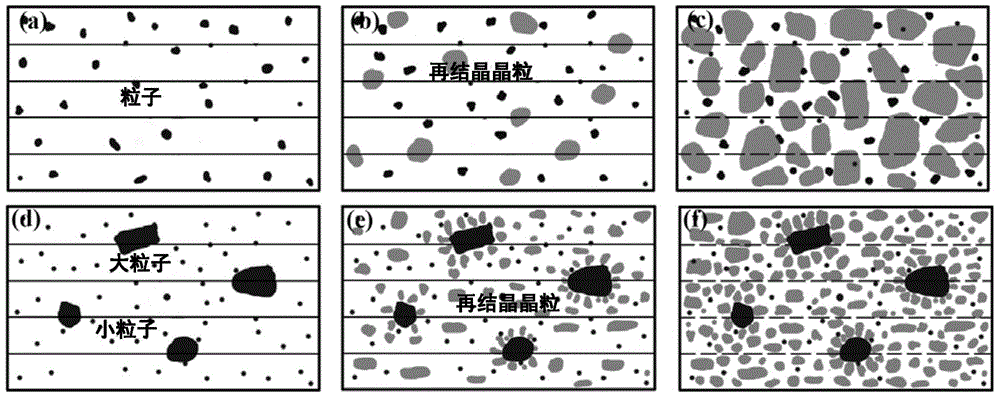

Automotive high-formability aluminum alloy material and preparation method thereof

The invention provides an automotive high-formability aluminum alloy material and a preparation method thereof. The preparation method comprises the steps of selection of novel aluminum alloy components, alloy preparation and melting-casting, homogenization, hot rolling deformation, intermediate annealing or cold rolling deformation and intermediate annealing, intermediate annealing, solution treatment, quenching and multistage pre-ageing treatment. By using the double effects that a certain quantity of multi-scale particles can be formed among different solute elements in the alloy material and then oversize particles are stimulated, re-crystallized and nucleated while fine particles block the growth of the re-crystallized grains in the high-temperature heat treatment process, so that the structure of an alloy plate is formed by the fine and uniformly distributed re-crystallized grains, the anisotropy of the alloy plate is well controlled, and the stamping forming performance is relatively excellent. Meanwhile, the novel aluminum alloy with high formability and high baking varnish hardening increment is very suitable for manufacturing of automotive body outer plates, particularly manufacturing of parts having relatively high requirements for stamping formability and baking varnish hardening increment and having complex shapes.

Owner:UNIV OF SCI & TECH BEIJING

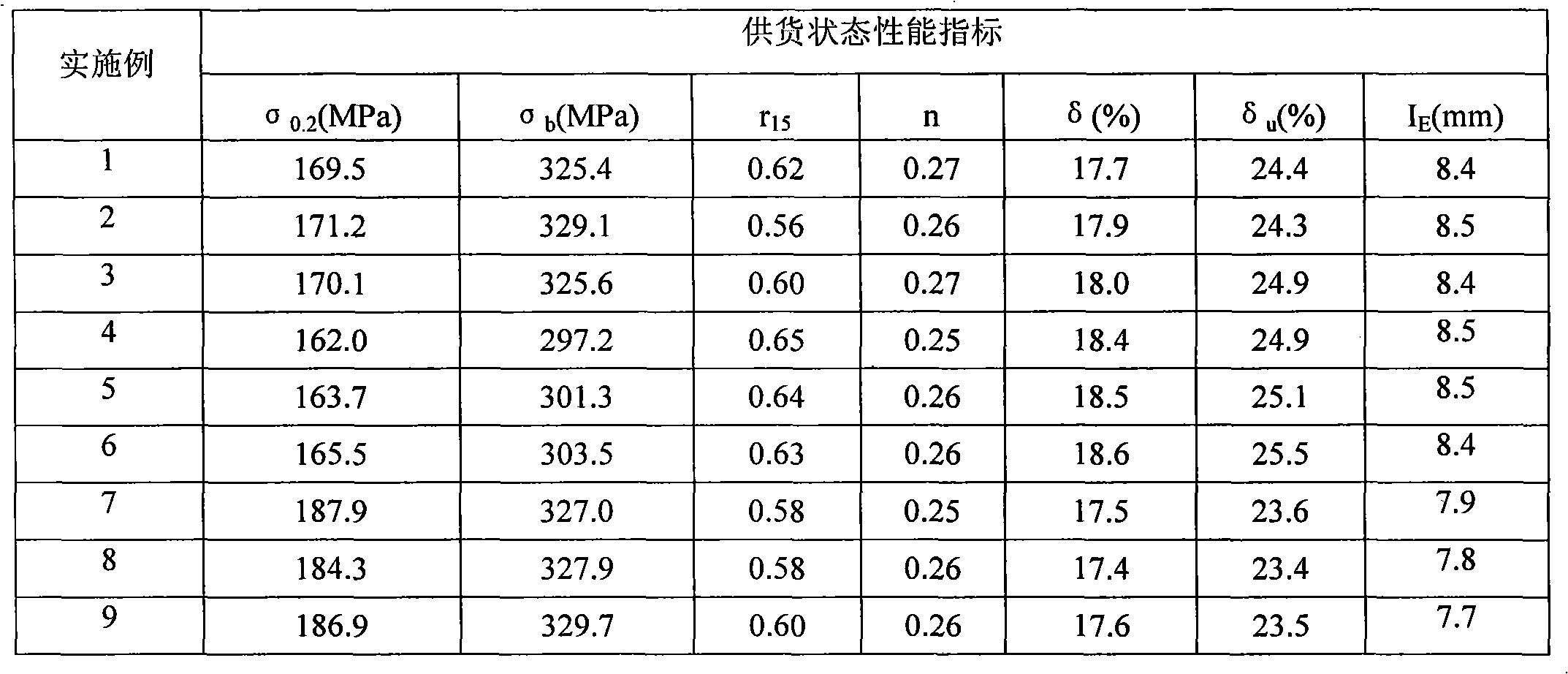

High strength cold-rolled plate with excellent formability and production method thereof

The invention provides a high strength cold-rolled plate with excellent formability, containing: no more than 0.0040% of C, 0.02-0.15% of Si, 0.20-1.00% of Mn, 0.02-0.09% of P, 0.015-0.06% Ti, 0.01-0.05% of Nb, and the rest being Fe. The production method comprises: smelting, continuous casting, hot-rolling, cold rolling and continuous annealing, wherein the heating temperature of the hot-rolled billet is 1170-1270 DEG C, the finishing temperature of hot-rolling is 850-960 DEG C, and the coiling temperature is 650-760 DEG C; the cold rolling reduction percent is 60-82%; the annealing temperature is 760-880 DEG C, the thermal insulation time is 60-210s, the slow-cooling segment temperature is 630-700 DEG C, and the fast-cooling exit temperature is 300-500 DEG C; and the levelling elongationrate is 0.5-1.0%. The high strength steel plate containing phosphorus of the invention has the features of low carbon, microalloying and purity. The steel added with a certain amount of Nb and Ti hashigher plasticity. Using relevant rolling and annealing technique, the indexes of performance of the steel achieves the demand of high strength automobile stamping parts.

Owner:ANGANG STEEL CO LTD

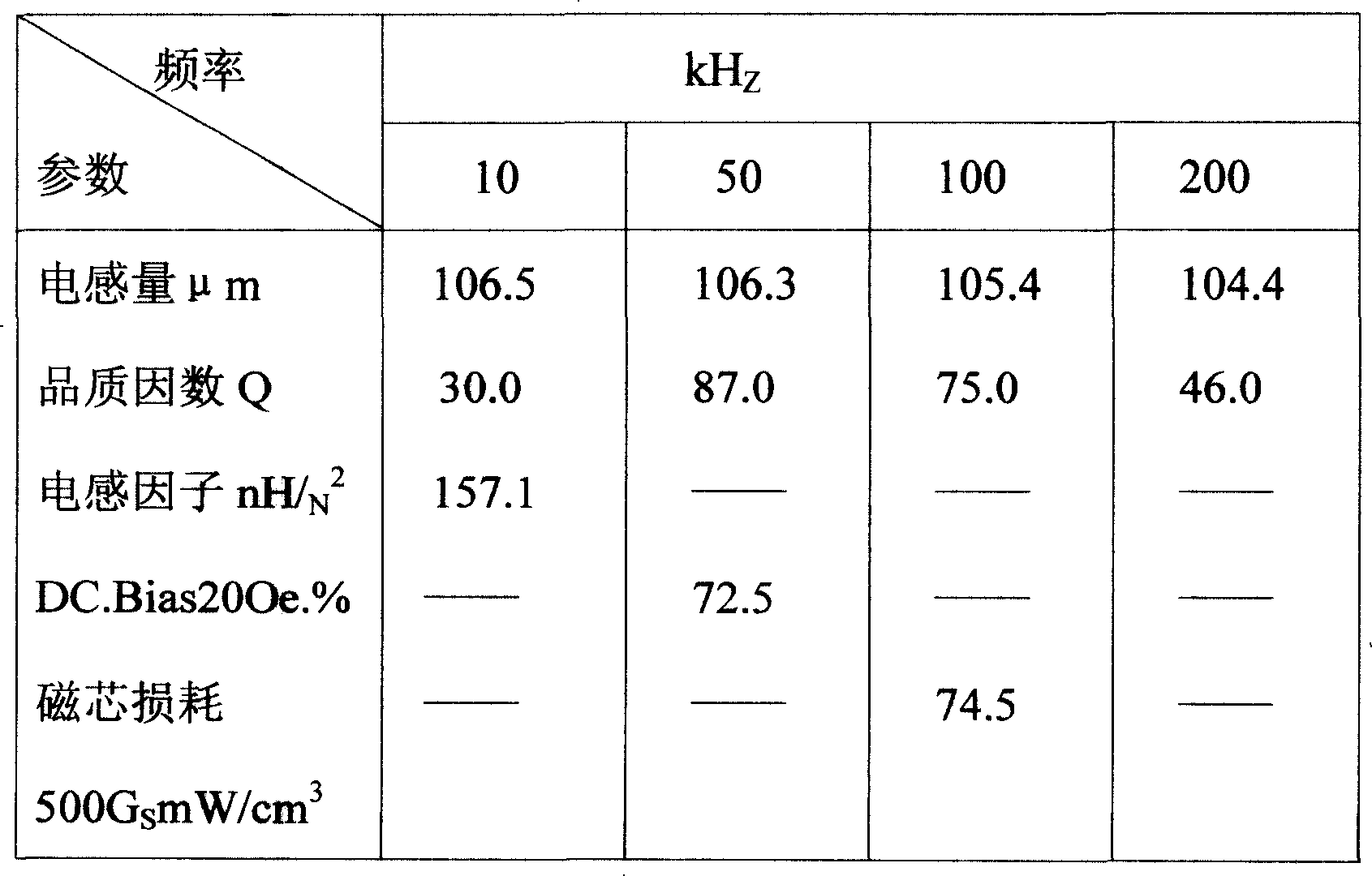

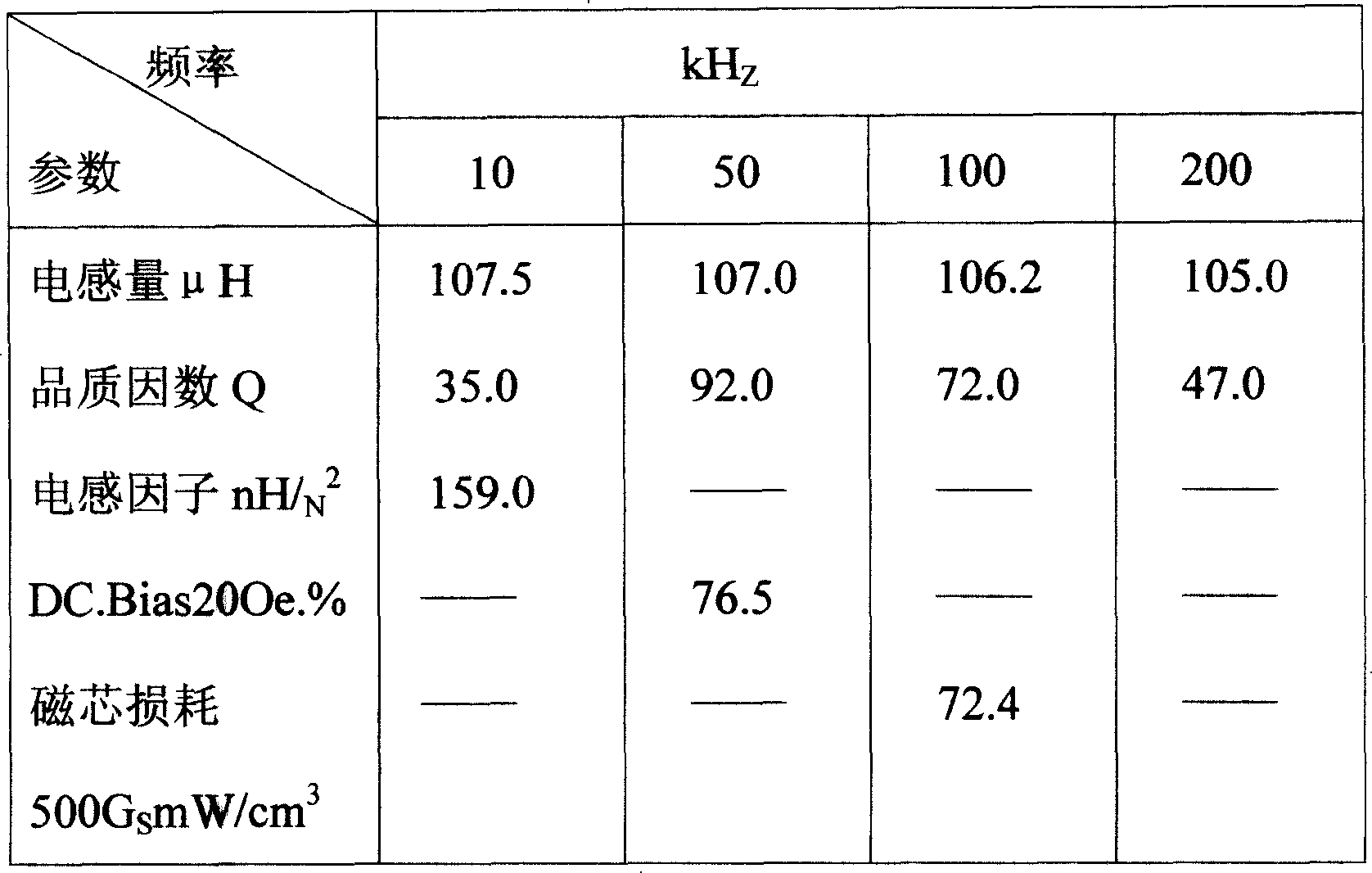

Manufacturing method of Fe-6.5Si alloy powder and manufacturing method of magnetic powder core

The making of Fe-6.5Si alloy magnetic powder core comprises grain proportion, alloy powder inactivating, adding insulation agent to the metal powder, binder, lubricant and stripping agent, compression, heat treatment, solidification, surface coating, with the inactivating treatment getting phosphopyruvic acid with 5-15% phosphate chrome, the rest being acetone, adding alloy powder with 2-6% of mass percentage. Adding small quantity Ti nor Ni, it can reach the saturated alloy magnetic sensing strength BS value of 16000- 18000 Gaussian, coercitive force <=80A / m. It has better forming and compression feature. It reduces broken stress. The made magnetic powder core having magnetic conductivity of 125, with low metal core consumption.

Owner:武汉欣达磁性材料有限公司

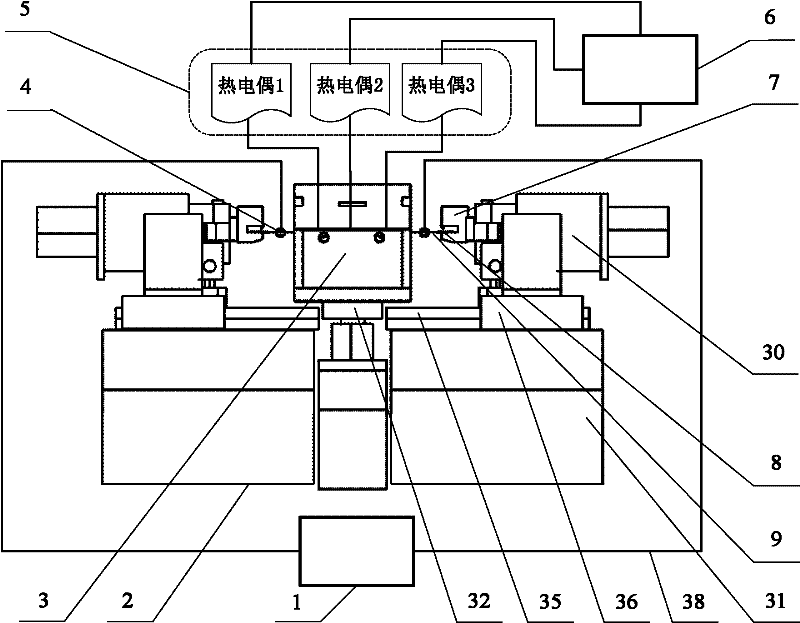

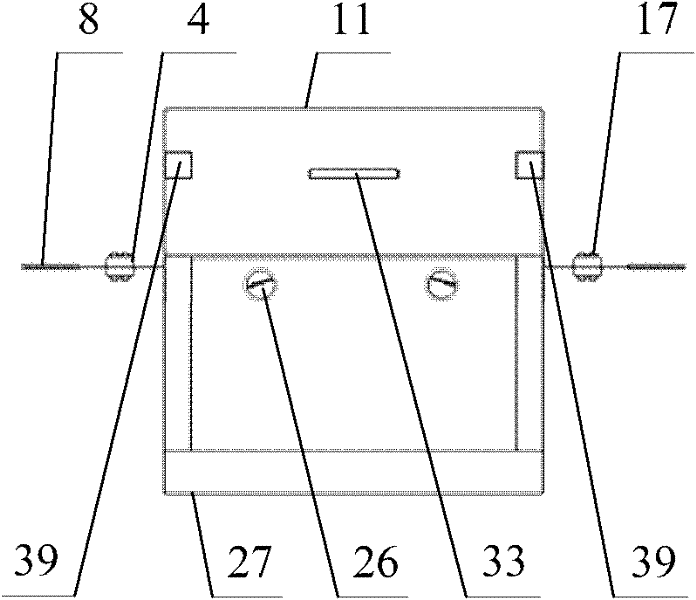

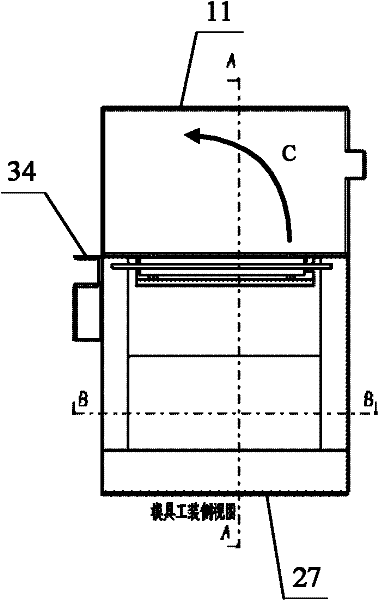

Hot forming tool of titanium alloy thin-wall part and machining method of hot forming tool

ActiveCN102500675AViscoplastic deformation facilitatesAvoid lostShaping toolsTemperature controlProcess integration

The invention provides a hot forming tool of a titanium alloy thin-wall part, comprising five parts, namely stretching equipment, a mould device, a blank, a power supply system and a temperature control system, wherein the mould device is arranged on a central worktable of the stretching equipment; the blank passes through a side wall crack of the mould device; an insulating and heat-insulation cushion layer is used for insulating the blank, a clamp of the stretching equipment, the surface of a mould and a tool of the mould; the power supply system is switched on to electrify an electrode clamping plate and generate a current in the blank; the blank is heated and the temperature of the blank is measured and controlled by the temperature control system; and after the temperature of the blank reaches a target temperature, the part is formed on the surface on the mould by the blank in an adhered manner through carrying out hot forming processes successively including stretching, covering, stretching, heat preservation and creep deformation and the like on the stretching equipment. A machining method of the hot forming tool of the titanium alloy thin-wall part comprises eight steps. According to the invention, the heating efficiency, the process integration, the material formation and the formation precision of the titanium alloy thin-wall part in manufacture are greatly improved, so that the hot forming tool of the titanium alloy thin-wall part and the machining method of the hot forming tool have a practical value and a popularization value.

Owner:BEIHANG UNIV

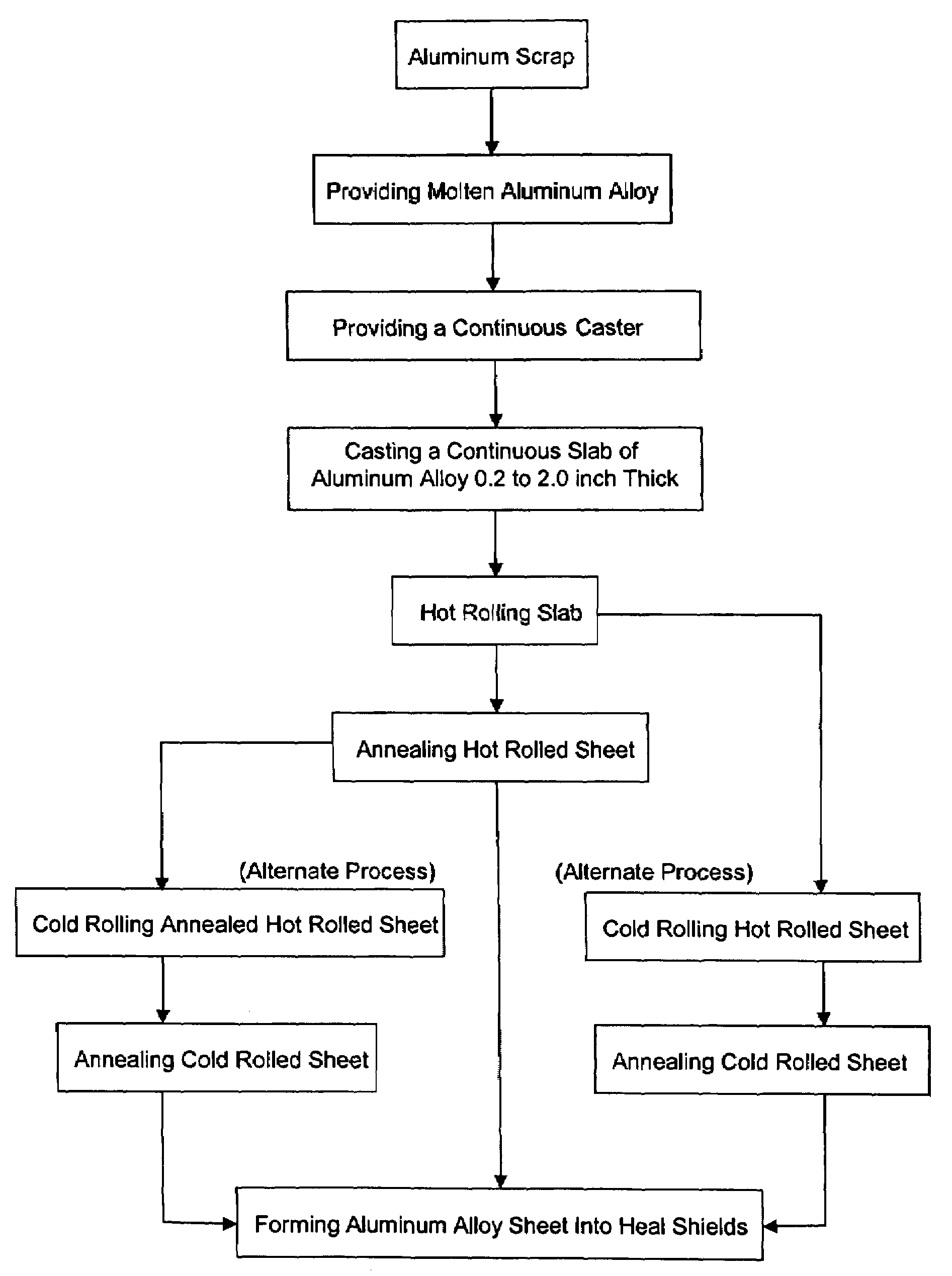

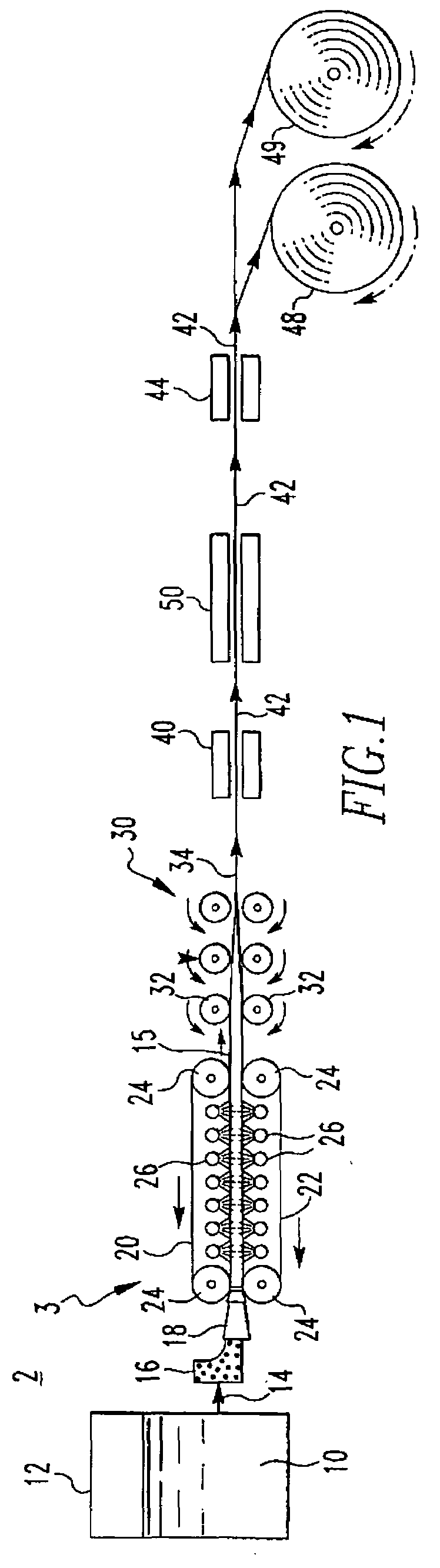

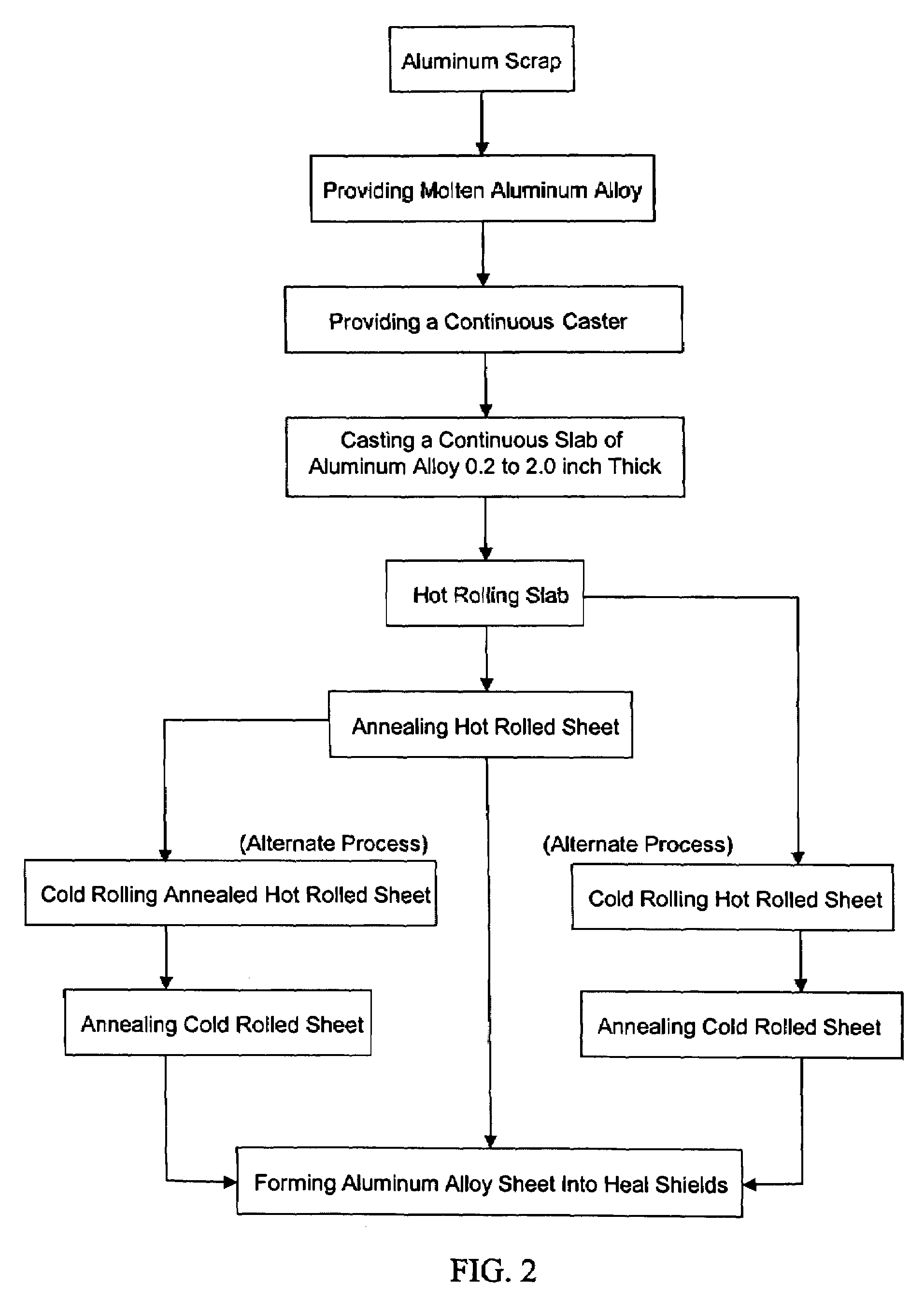

Aluminum automotive heat shields

Disclosed is a method for producing aluminum automotive heat shields or panels such as from scrap derived molten aluminum alloy using a continuous caster to cast the alloy into a slab. The method comprises providing a molten aluminum alloy consisting essentially of 0.1 to 0.7 wt. % Si, 0.2 to 0.9 wt. % Fe, 0.05 to 0.5 wt. % Cu, 0.05 to 1.3 wt. % Mn, 0.2 to 2.8 wt. % Mg, 0.3 wt. % max. Cr, 0.3 wt. % max. Zn, 0.2 wt. % max. Ti, the remainder aluminum, incidental elements and impurities and providing a continuous caster such as a belt caster, block caster or roll caster for continuously casting the molten aluminum alloy. The molten aluminum alloy is cast into a slab which is rolled into a sheet product and then annealed. Thereafter, the sheet product is formed into the automotive heat shield or panel with strength and formability as required by the automotive industry.

Owner:COMMONWELATH IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com