Patents

Literature

2290 results about "Continuous annealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

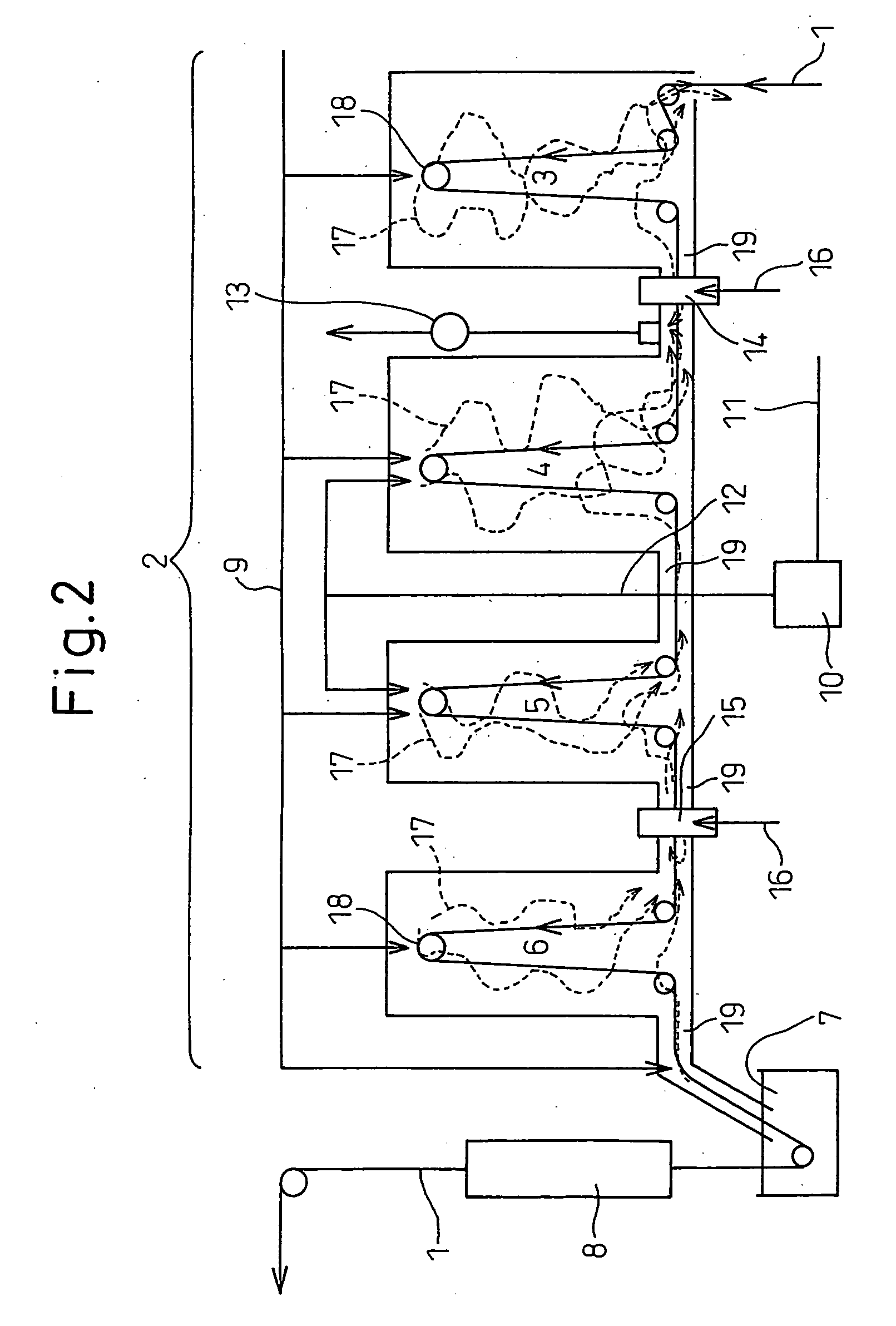

Continuous annealing. Annealing is a process in which metals, glass and other materials are treated to render them less brittle and more workable. Continuous steel annealing subjects rolled strip product to a sequence of furnaces to elevate and profile the strip temperature according to grade and dimension.

High-strength cold-rolled plate with favorable forming property and preparation method thereof

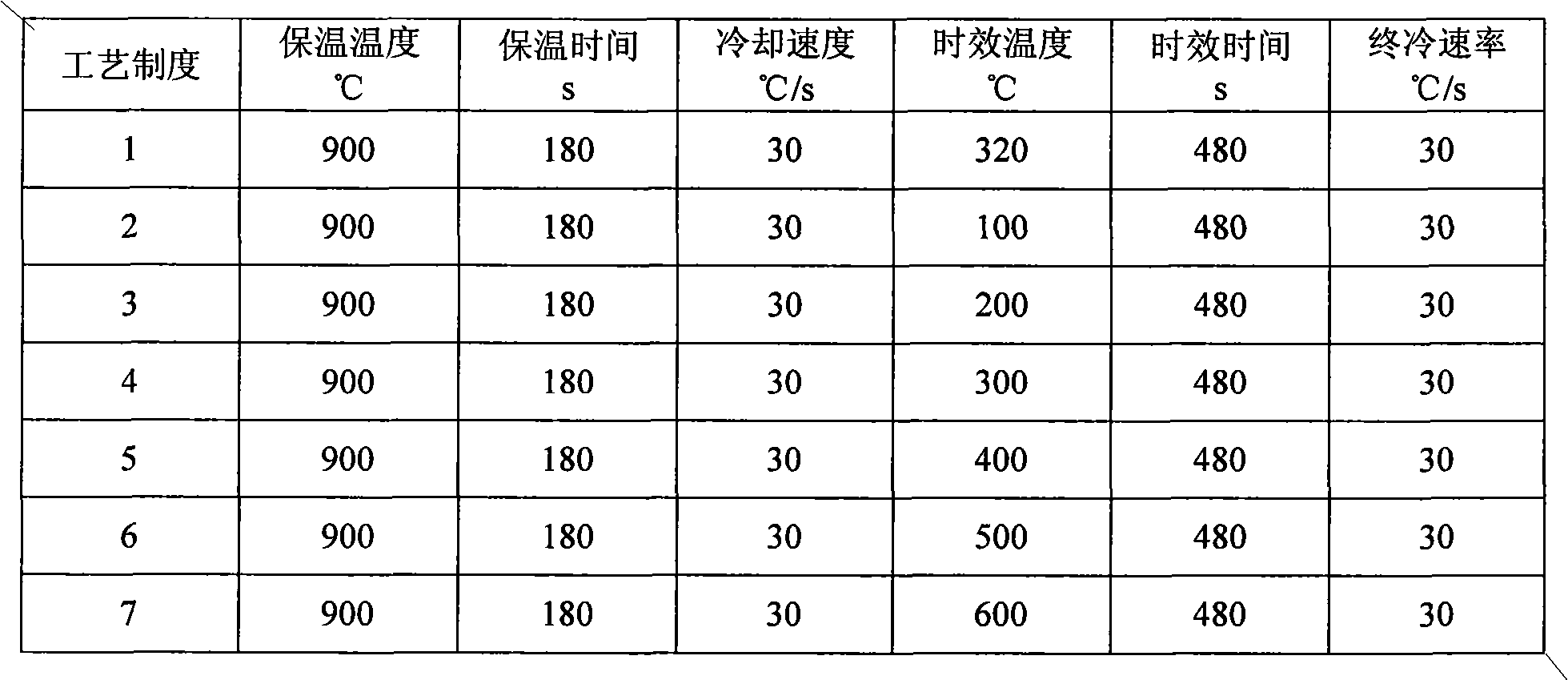

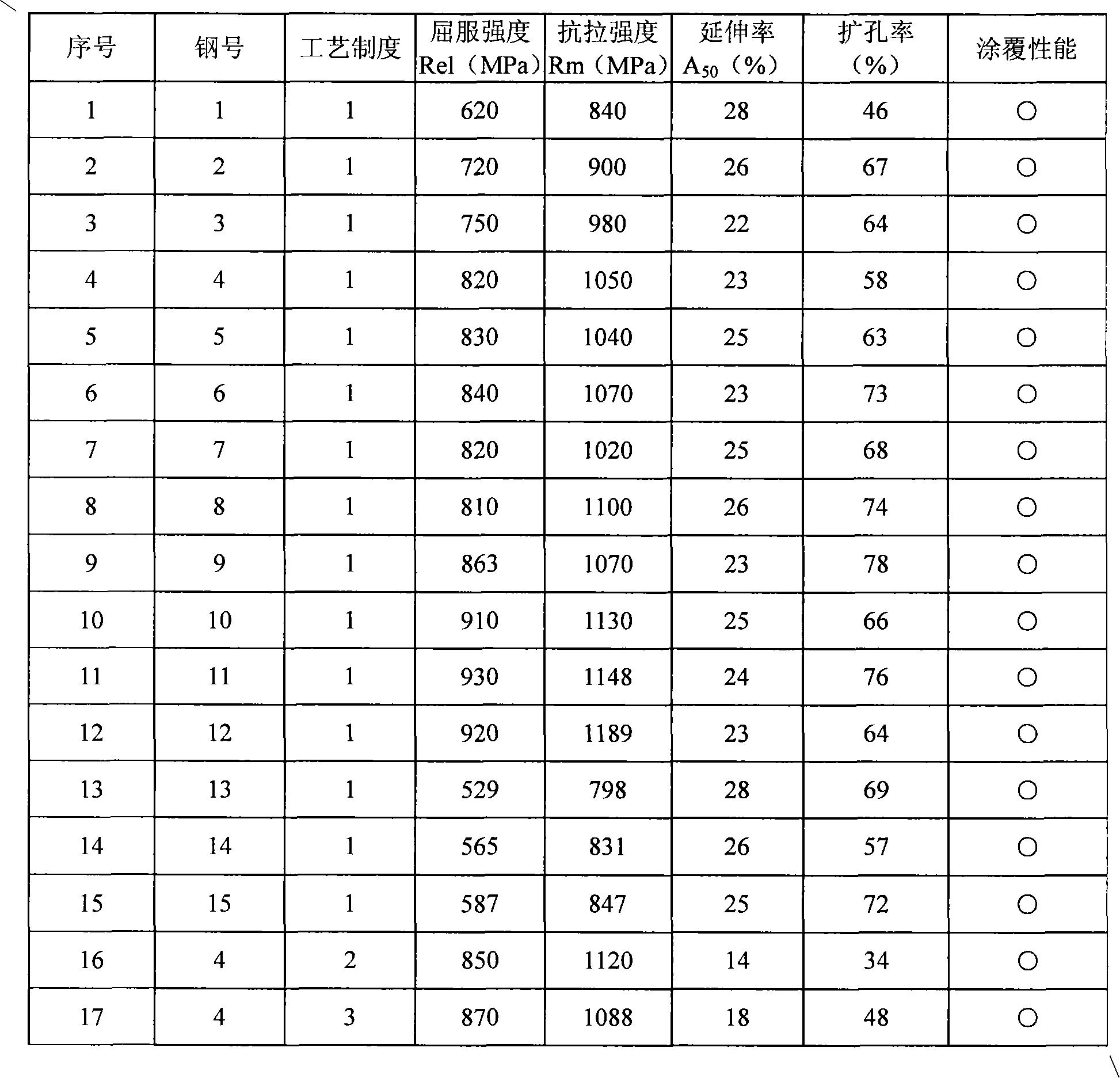

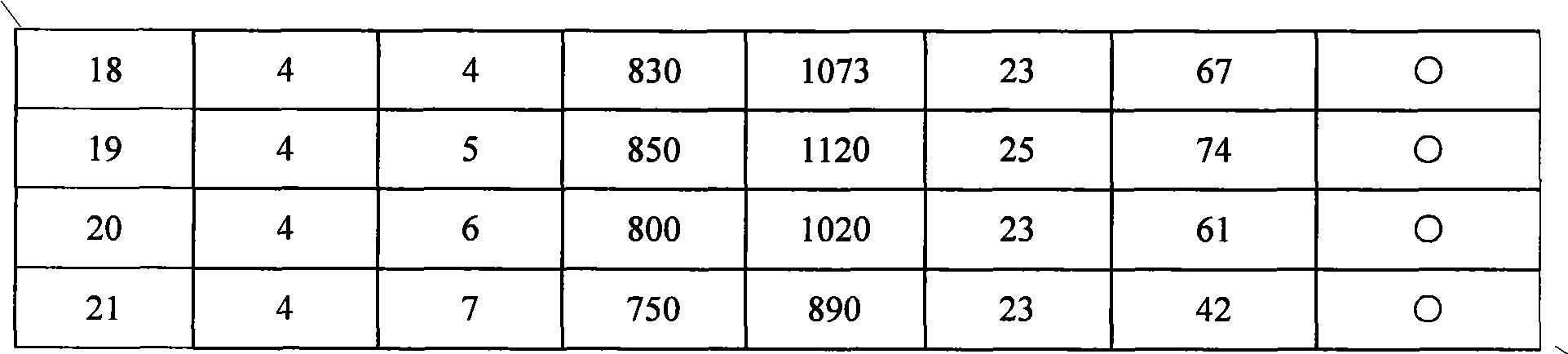

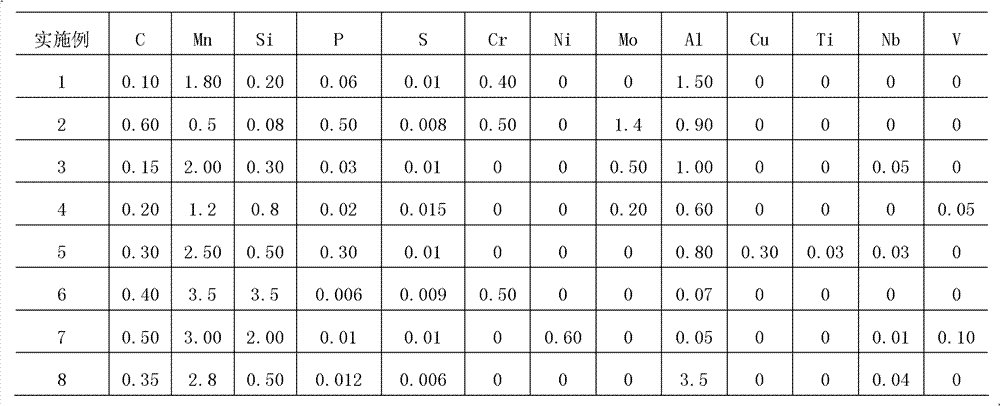

The invention provides a high-strength cold-rolled plate with favorable forming property and a preparation method thereof. The high-strength cold-rolled plate comprises the following chemical components: 0.05-0.6% of C, being more than or equal to 0.3% and being less than 0.8% of Si, 0.5-4.0% of Mn, being more than ore equal to 0.2% of P, being more than or equal to 0.002% of S, being more than or equal to 0.1% of Al, being more than or equal to 0.01% of N, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: smelting, continuous-casting, hot-rolling, cold-rolling and continuous-annealing, wherein annealing temperature is higher than that of Ac3, holding time is 3-30 minutes; quickly cooling to 100-600 DEG C at the rate of 30-100 DEG C / s, keeping the temperature for 3-30 minutes, and finally cooling to room temperature at the rate of 5-30 DEG C / s. The invention adopts low-silicon low-aluminum component design and heat treatment technique; the strength level of the produced bainite TRIP steel is greater than 780 MPa; and the produced bainite TRIP steel has favorable strength, plasticity, extensibility, chambering property and coating property.

Owner:ANGANG STEEL CO LTD

Production method of ultrahigh strength steel plate for cold forming and steel plate

The invention provides a production method of an ultrahigh strength steel plate for cold forming and the steel plate. The method comprises the steps of smelting, casting, hot rolling, cold rolling, heating the cold-rolled steel plate through a continuous annealing production line with rapid cooling treatment to the austenite temperature, holding the temperature for a certain time, carrying out quenching treatment, obtaining a steel plate with the main structure of M+A and carrying out distribution treatment in a bell type annealing furnace. The steel plate comprises the following components in percentage by mass: 0.02-0.60% of C, 0.05-3.5% of Si, 0.20-3.50% of Mn, P more than or equal to 0.005 but less than or equal to 0.50%, S not more than 0.05%, 0.02-3.00% of Al, Cr not more than 0.50%, Ni not more than 3.00%, Cu not more than 0.50%, Mo not more than 1.50%, V not more than 0.50%, Ti not more than 0.20%, Nb not more than 0.20% and the balance of Fe and unavoidable impurities. The steel plate produced by adopting the method provided by the invention has the advantages of high strength and capability of cold forming and the process route of Q&P steel industrial production is effectively solved.

Owner:ANGANG STEEL CO LTD

Low-yield strength anti-ageing continuous annealing cold-roll steel sheet and production method thereof

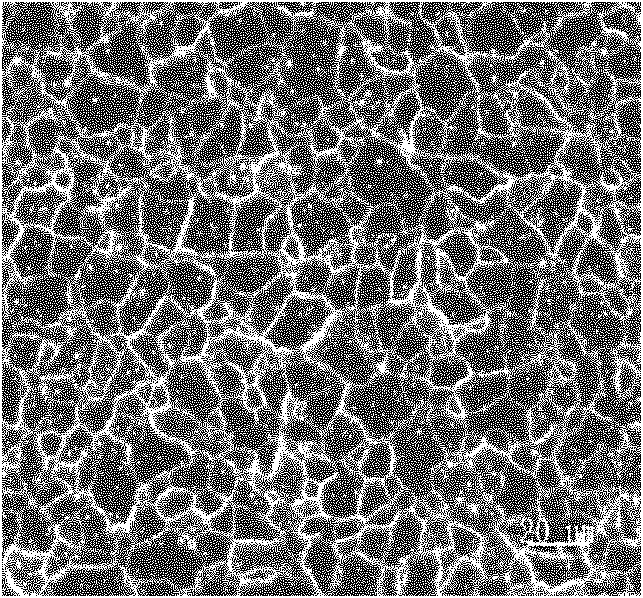

InactiveCN101956133ARefine and stabilize crystal sizeLower yield strengthSheet steelContinuous annealing

The invention belongs to the field of roll steel, in particular to a low-yield strength anti-ageing continuous annealing cold-roll steel sheet and a production method thereof, which solves the technical problem that stable-performance low-yield strength anti-ageing cold-roll steel sheets are difficult to be produced on a machine set with worse equipment level. The technical scheme of the invention is characterized by providing the low-yield strength anti-ageing cold-roll steel sheet and the production method thereof. The method of the invention can be implemented on the machine set with worse equipment level; and by adopting the method of the invention, the stable-performance low-yield strength anti-ageing cold-roll steel sheet can be produced, and the technical problem existing in the field of roll steel for a long term can be overcome.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

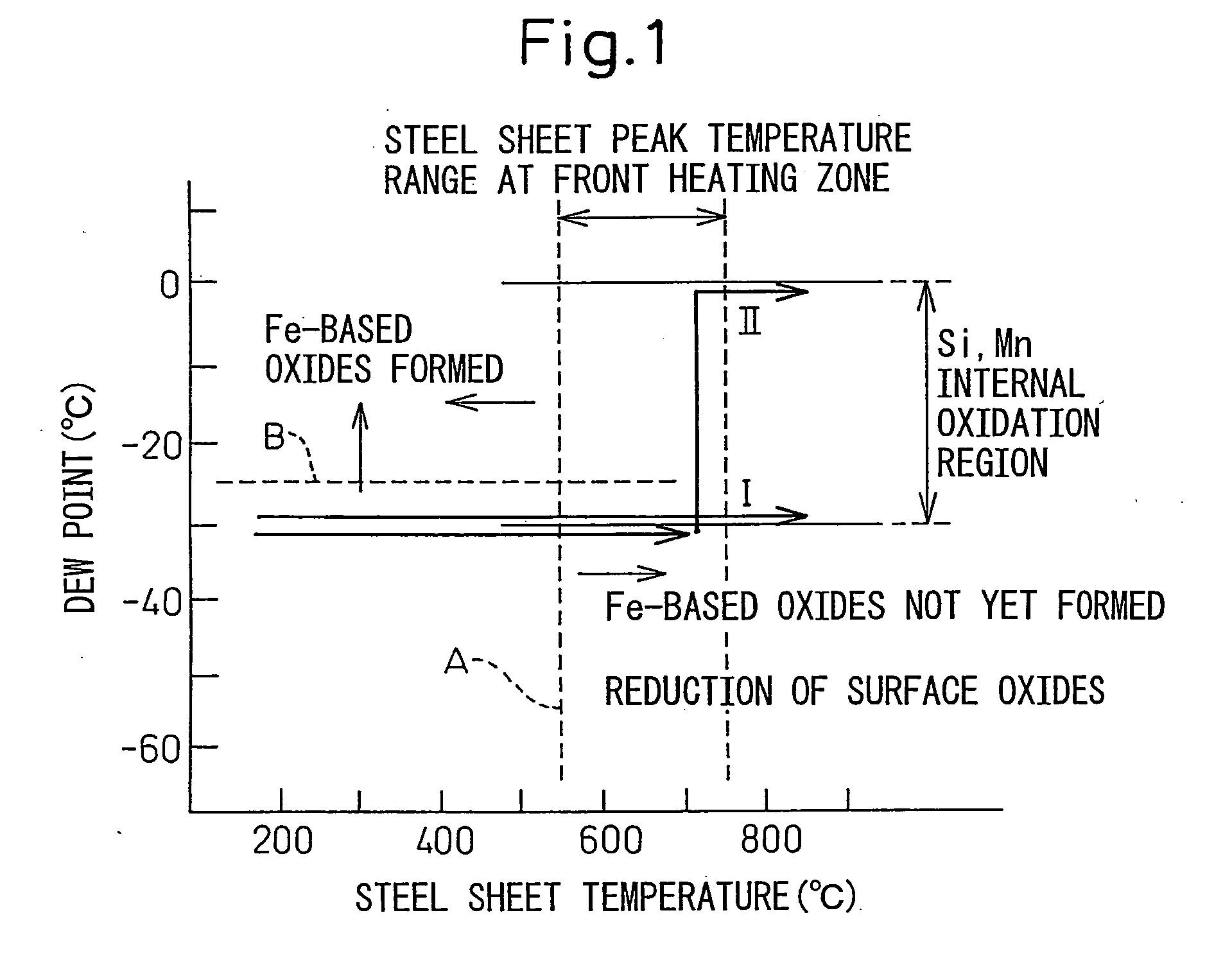

Continuous Annealing and Hot Dip Plating Method and Continuous Annealing and Hot Dip Plating System of Steel sheet Containing Si

InactiveUS20090123651A1Suppress surface concentrationImprove adhesionHot-dipping/immersion processesPretreated surfacesSheet steelHydrogen

The present invention provides, in a hot dip plating system having an annealing furnace for hot dip plating steel sheet containing Si, a continuous annealing and hot dip plating method and system causing internal oxidation without causing surface oxidation of the Si in the steel and avoiding a drop in the plating ability of the steel sheet and retardation of alloying, that is, a continuous annealing and hot dip plating method using an annealing furnace having, in order, a front heating zone, rear heating zone, soaking zone, and cooling zone and a hot dip plating bath, comprising heating or soaking the steel sheet at a steel sheet temperature of a temperature range of at least 300° C. or more by indirect heating, making an atmosphere of the zones one comprised of hydrogen H: 1 to 10 vol % and a balance of nitrogen and unavoidable impurities, making a steel sheet peak temperature during heating at the front heating zone 550 to 750° C. and making the dew point less than −25° C., making dew points of the following rear heating zone and soaking zone −30° C. to 0° C., and making a dew point of the cooling zone less than −25° C.

Owner:NIPPON STEEL & SUMITOMO METAL CORP

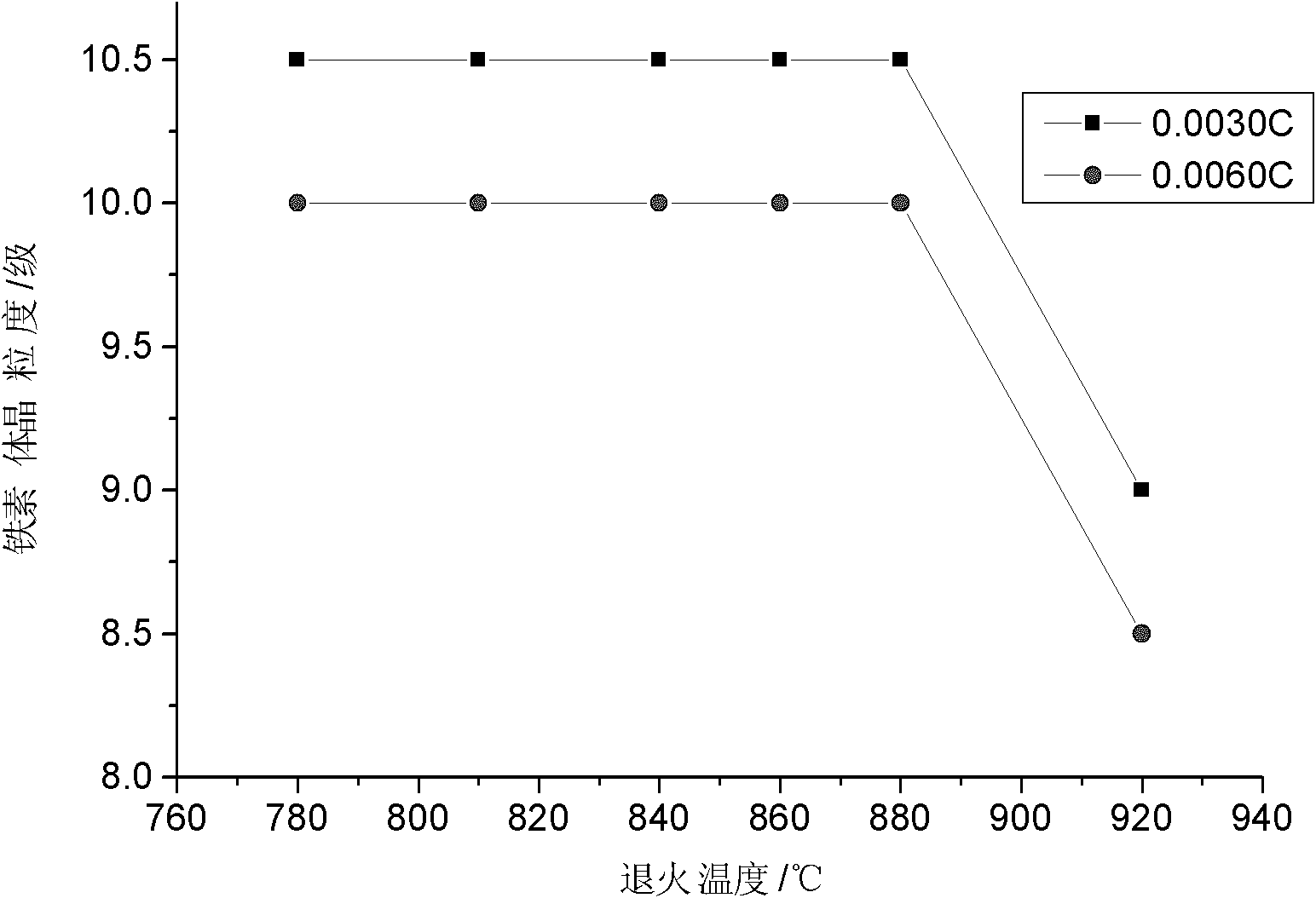

High strength cold-rolled plate with excellent formability and production method thereof

The invention provides a high strength cold-rolled plate with excellent formability, containing: no more than 0.0040% of C, 0.02-0.15% of Si, 0.20-1.00% of Mn, 0.02-0.09% of P, 0.015-0.06% Ti, 0.01-0.05% of Nb, and the rest being Fe. The production method comprises: smelting, continuous casting, hot-rolling, cold rolling and continuous annealing, wherein the heating temperature of the hot-rolled billet is 1170-1270 DEG C, the finishing temperature of hot-rolling is 850-960 DEG C, and the coiling temperature is 650-760 DEG C; the cold rolling reduction percent is 60-82%; the annealing temperature is 760-880 DEG C, the thermal insulation time is 60-210s, the slow-cooling segment temperature is 630-700 DEG C, and the fast-cooling exit temperature is 300-500 DEG C; and the levelling elongationrate is 0.5-1.0%. The high strength steel plate containing phosphorus of the invention has the features of low carbon, microalloying and purity. The steel added with a certain amount of Nb and Ti hashigher plasticity. Using relevant rolling and annealing technique, the indexes of performance of the steel achieves the demand of high strength automobile stamping parts.

Owner:ANGANG STEEL CO LTD

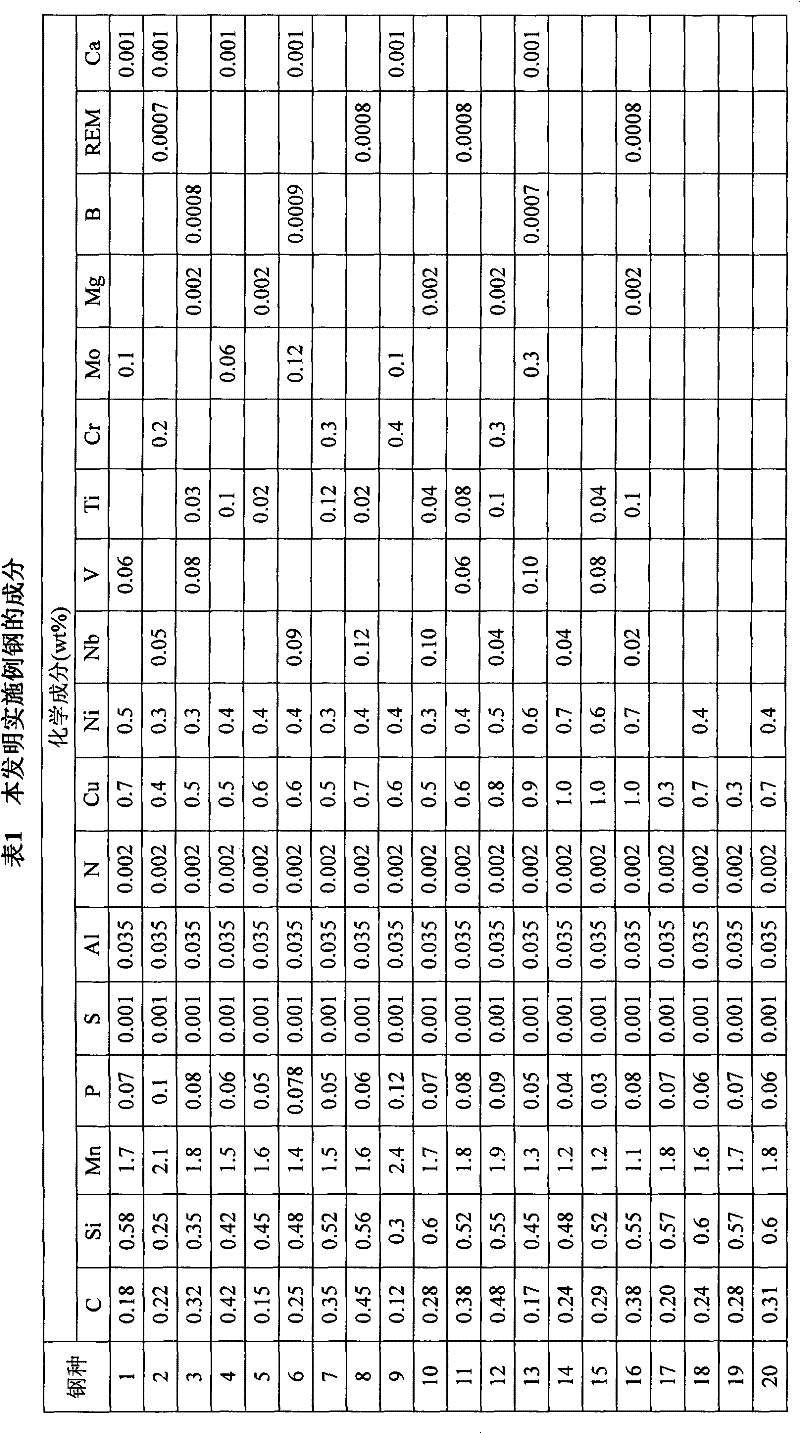

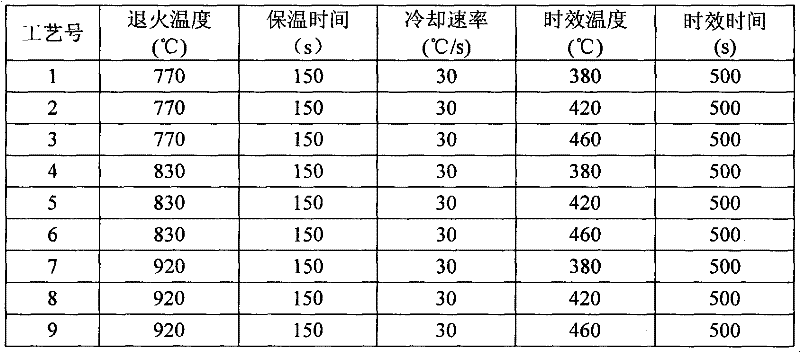

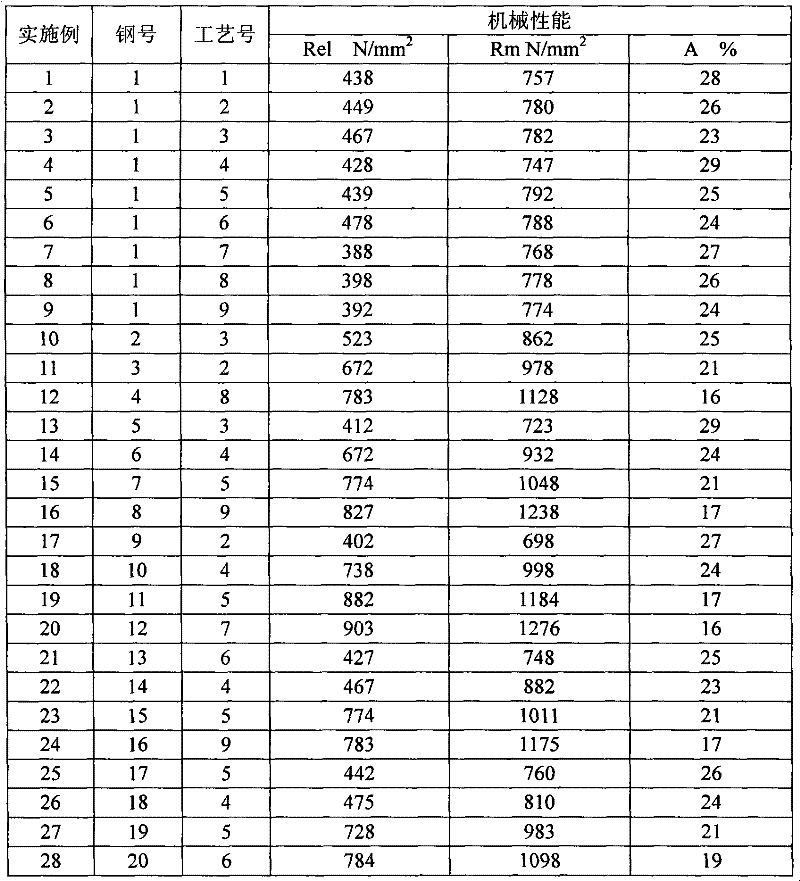

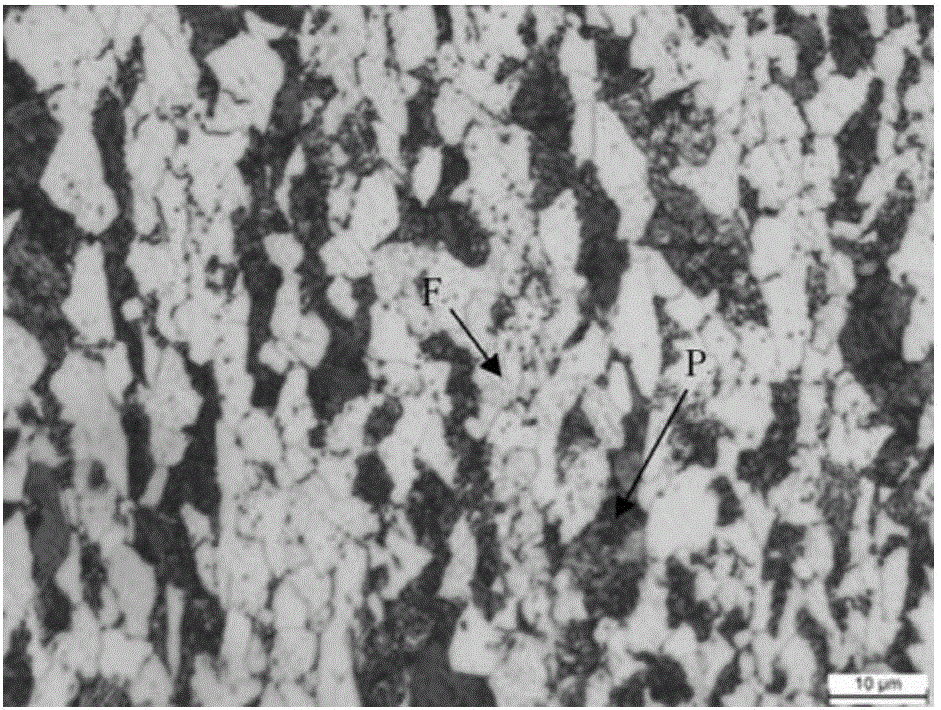

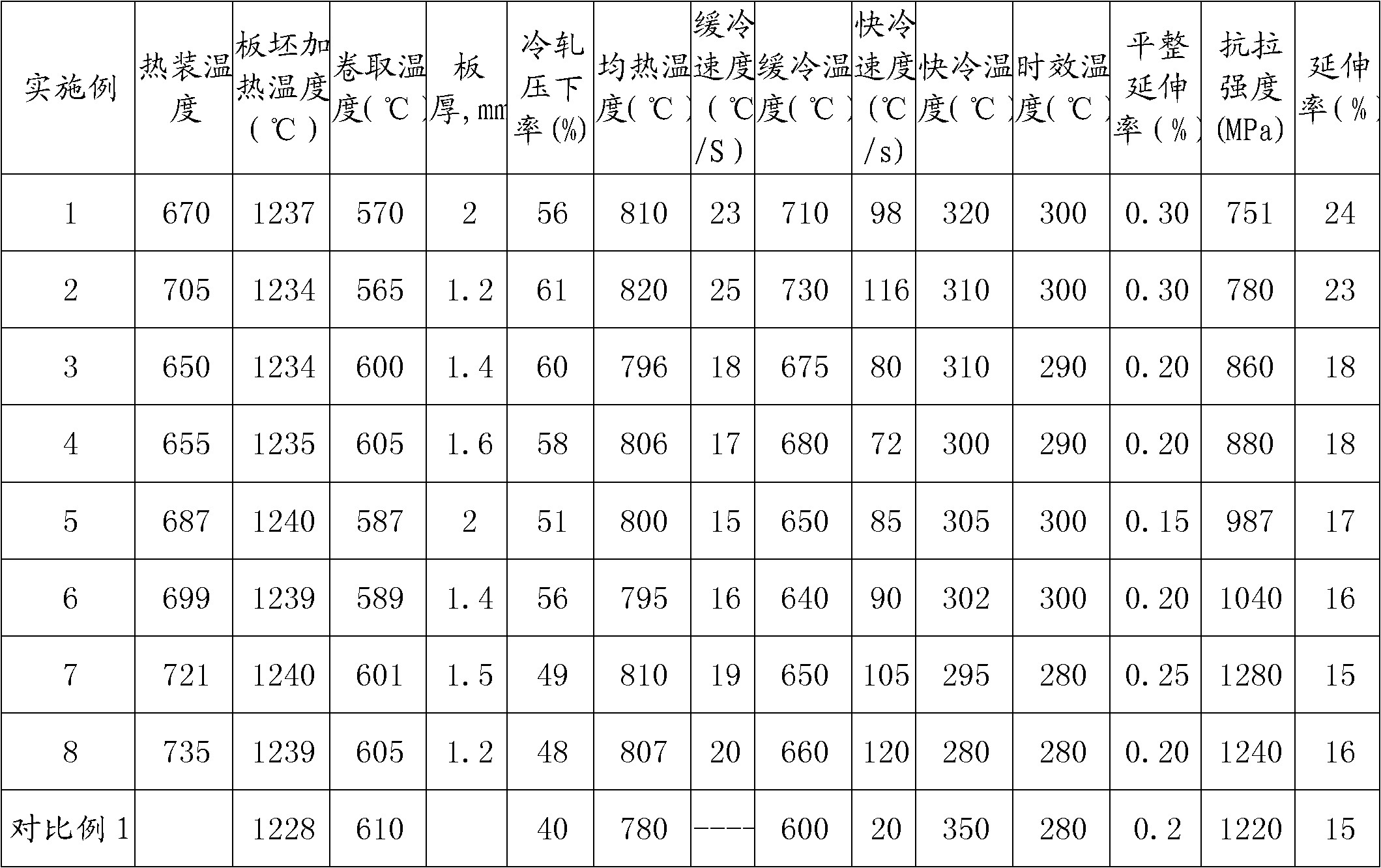

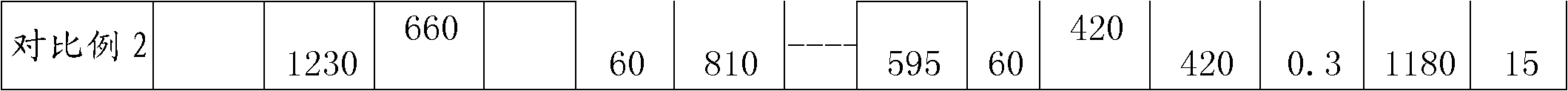

High-strength cold rolling transformation induced plasticity steel plate and preparation method thereof

InactiveCN102409235ASolve Surface Quality IssuesSolve the blockageTemperature control deviceFurnace typesSheet steelRoom temperature

The invention provides a high-strength cold rolling transformation induced plasticity steel plate and a preparation method thereof. The high-strength cold rolling transformation induced plasticity steel plate comprises the following components by weight percentage: 0.1%-0.5% of C, 0.1%-0.6% of Si, 0.5%-2.5% of Mn, 0.02%-0.12% of P, less than or equal to 0.02% of S, 0.02%-0.5% of Al, less than or equal to 0.01% of N, 0.1%-1.0% of Cu and the rest Fe. The preparation method comprises the following steps of: (a) refining molten steel meeting a component condition, and casting into a blank; (b) rolling, wherein the heating temperature is 1,100-1,250 DEG C, the heat preservation time is 1-4h, the initial rolling temperature is 1,100 DEG C, the final rolling temperature is 750-900 DEG C, the coiling temperature is less than 700 DEG C, the thickness of a hot rolled steel plate is 2-4mm, and the cold rolling accumulated pressing amount is 40-80%; and (c) continuous annealing, wherein the annealing temperature is 700-Ac3+50 DEG C, the heat preservation time is 30-360s, the cooling speed is 10-150 DEG C / s, the aging temperature is 250-600 DEG C, the aging time is 30-1,200s, and the hot roller steel plate is cooled at the speed of 5-100DEG C / s to be at the room temperature. The steel plate disclosed by the invention has the bending strength of 380-1,000 MPa, tensile strength of 680-1,280 MPa and elongation of 15-30%.

Owner:ANGANG STEEL CO LTD

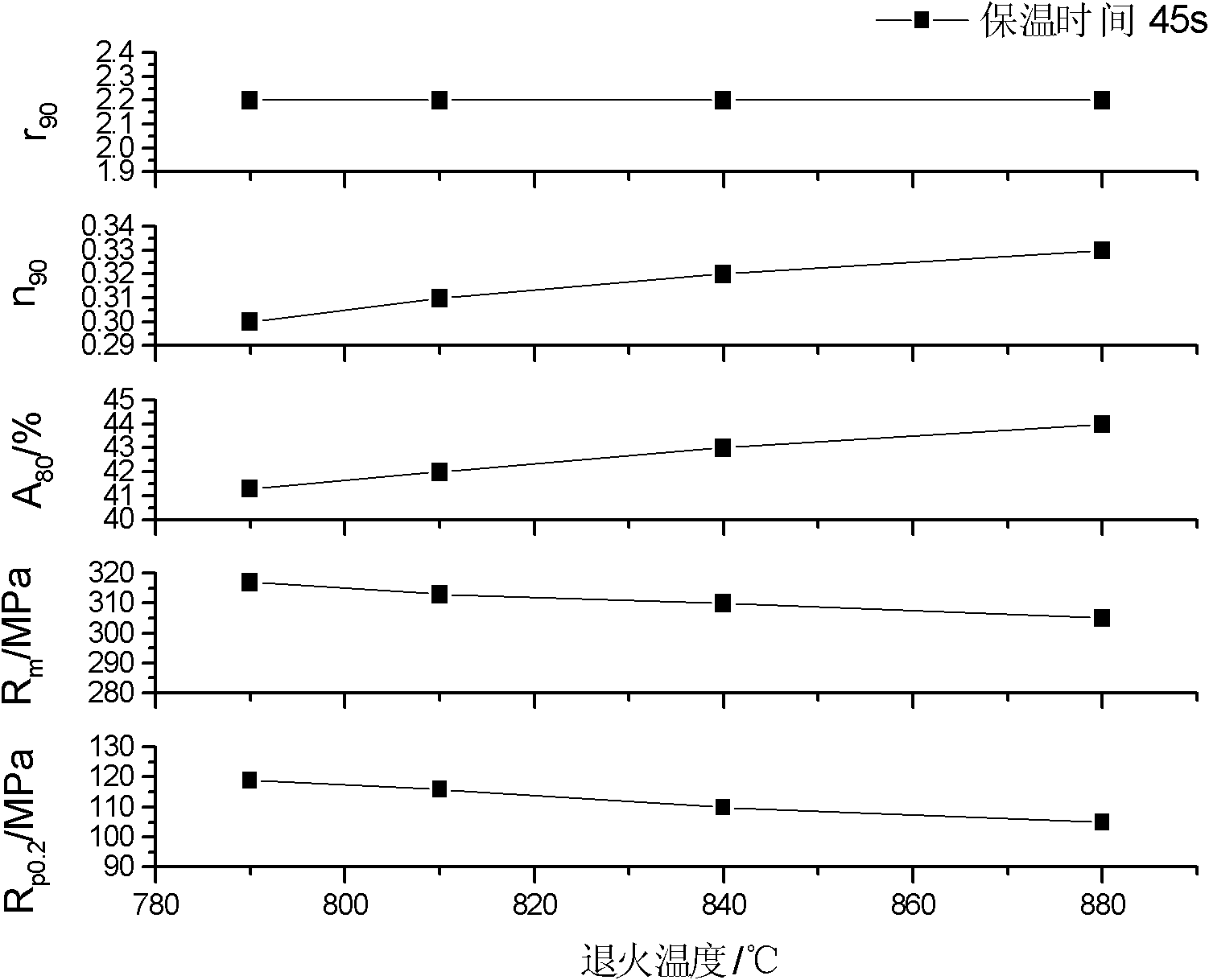

Hot galvanizing steel plate for car and production method thereof

InactiveCN102839322AHigh work hardening indexHigh work hardening index n90 valueMetal rolling arrangementsSheet steelTrace element

The invention discloses a hot galvanizing steel plate for a car. The hot galvanizing steel plate comprises the following chemical components by weight: C is more than or equal to 0.001% and is less than or equal to 0.003%, Mn is more than or equal to 0.05% and is less than or equal to 0. 15%, Si is less than or equal to 0.03%, P is less than or equal to 0.02%, S is more than or equal to 0.008% and is less than or equal to 0.015%, Alt is more than or equal to 0.02% and is less than or equal to 0.07%, Ti is more than or equal to 0.05% and is less than or equal to 0.09%, B is more than or equal to 0.0002% and is less than or equal to 0.010%, N is less than or equal to 0.004% and the balance of Fe and trace element. The invention also discloses a method for producing the hot galvanizing steel plate for the car; according to the hot galvanizing steel plate for the car and the production method of the hot galvanizing steel plate, the sulfur content in steel making can be adjusted based on the mixture ratio of components, and the technology of hot rolling, continuous annealing, hot galvanizing steel and finishing are optimized, thus producing the continuous annealing hot galvanizing steel, so that the steel plate has the characteristics of high processing hardening index of n90 value, and the requirements on demand of expanding-formed car plate are satisfied.

Owner:SHOUGANG CORPORATION

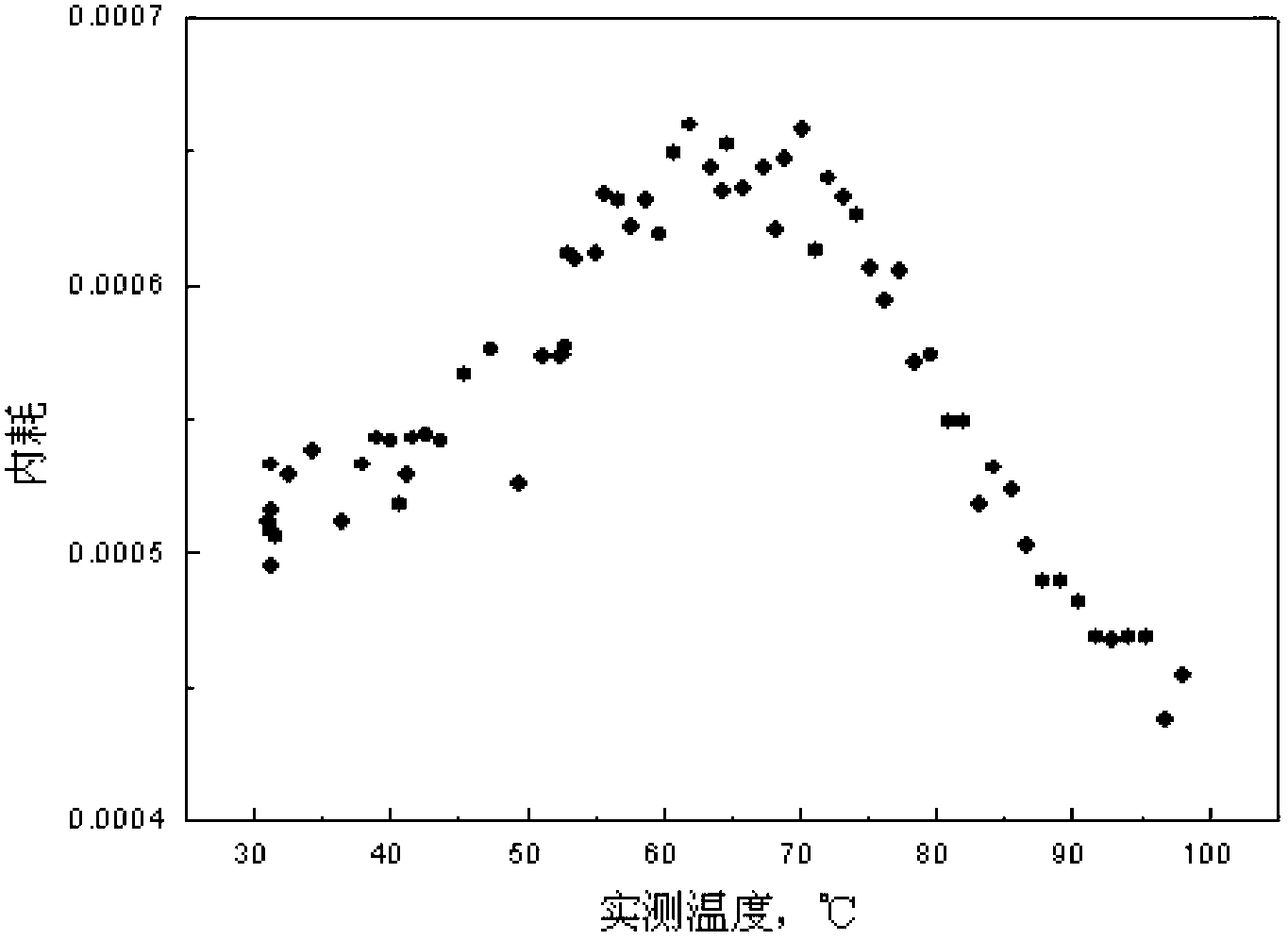

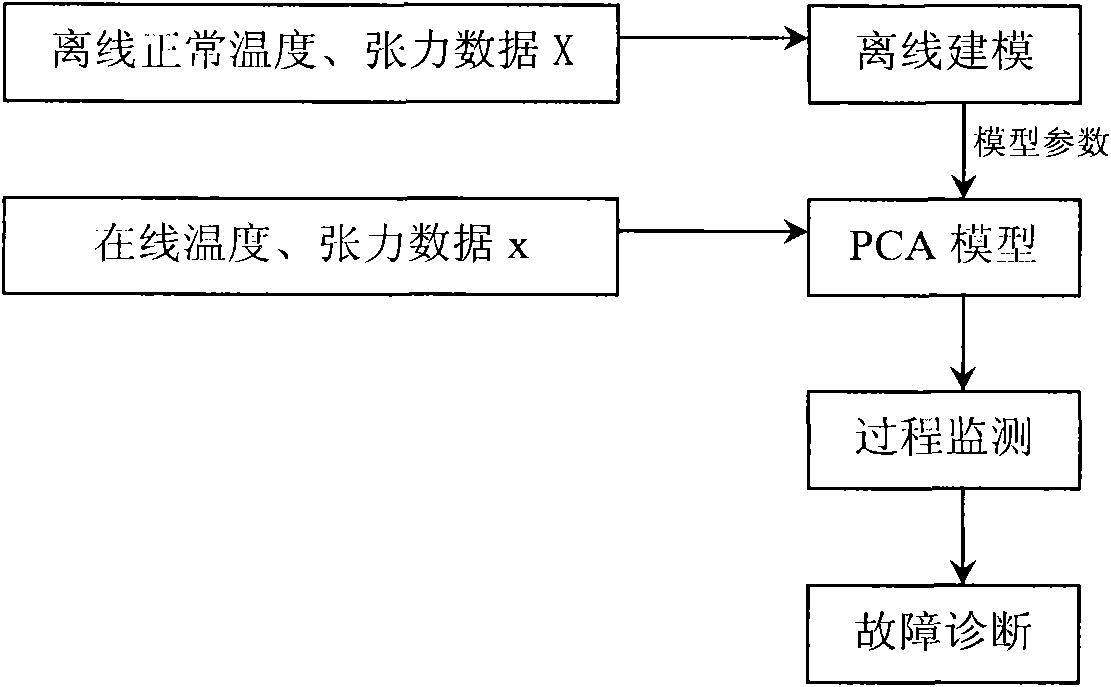

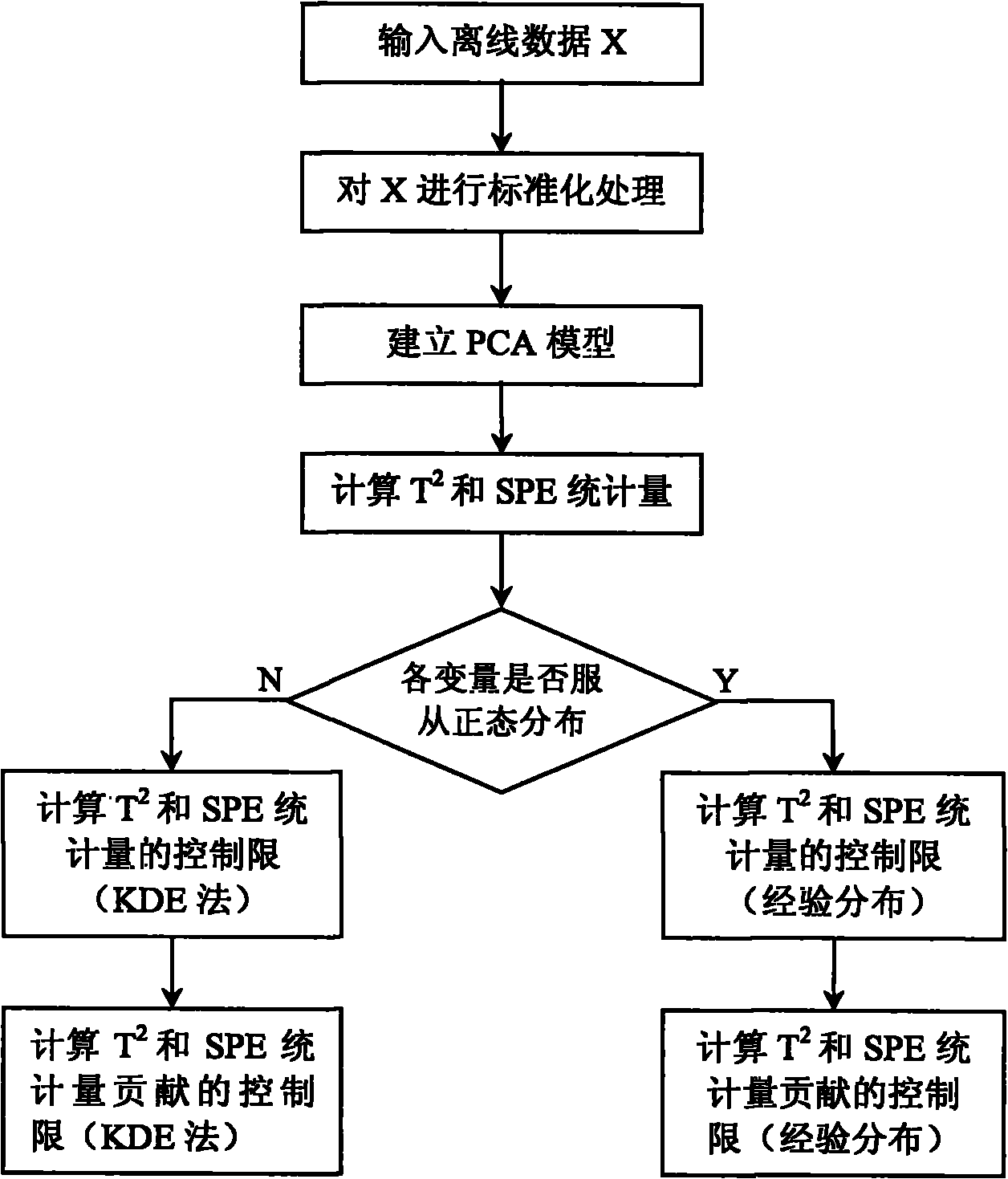

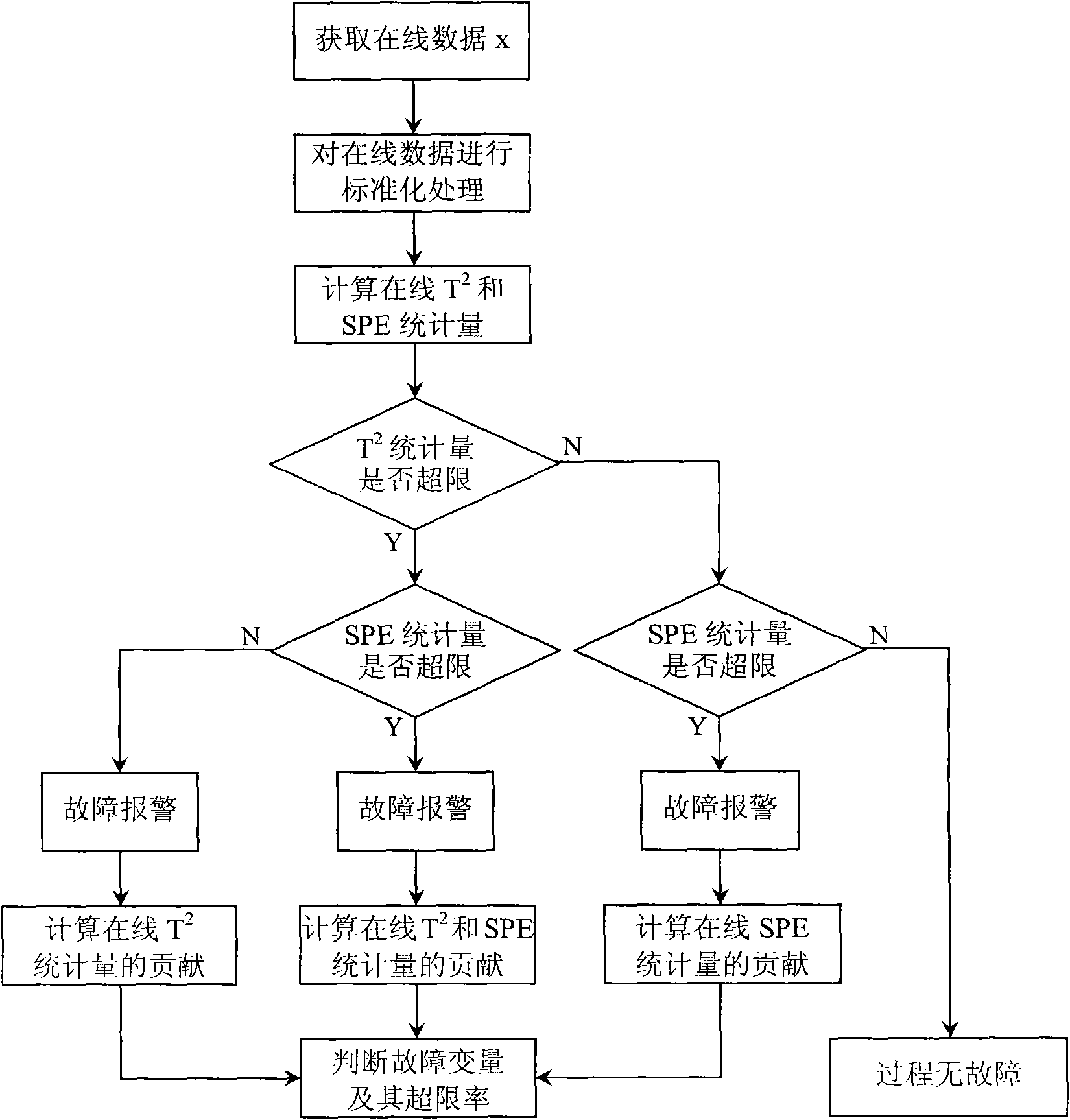

PCA (Principle Component Analysis) model based furnace temperature and tension monitoring and fault tracing method of continuous annealing unit

InactiveCN101899563AClear structureClear relationshipHeat treatment process controlFurnace temperatureOnline model

The invention relates to a fault monitor and diagnosis method of a continuous annealing unit, in particular to a PCA (Principle Component Analysis) model based furnace temperature and tension monitoring of a continuous annealing unit, mainly comprising the following steps of firstly, according to process variable data obtained in the field, and establishing a temperature and tension monitor modelby utilizing a principle component analysis PCA method; secondly, establishing an off-line model and calculating the T2 statistics quantity and the SPE statistics quantity as well as contributed control limits thereof by utilizing the data, obtained in step one, when process variable is in a normal work condition; thirdly, applying an on-line model, calculating the T2 statistics quantity and the SPE statistics quantity of current data, monitoring whether a current state is normal or not according to information supplied by the off-line model, and giving alarm signals if abnormal; fourthly, determining a leading variable which causes a fault by utilizing contribution of the T2 statistics quantity and contribution of the SPE statistics quantity. The invention monitors the furnace temperature and tension in real time in the production process and traces back a fault reason for leading to system abnormality when the abnormality occurs.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE +1

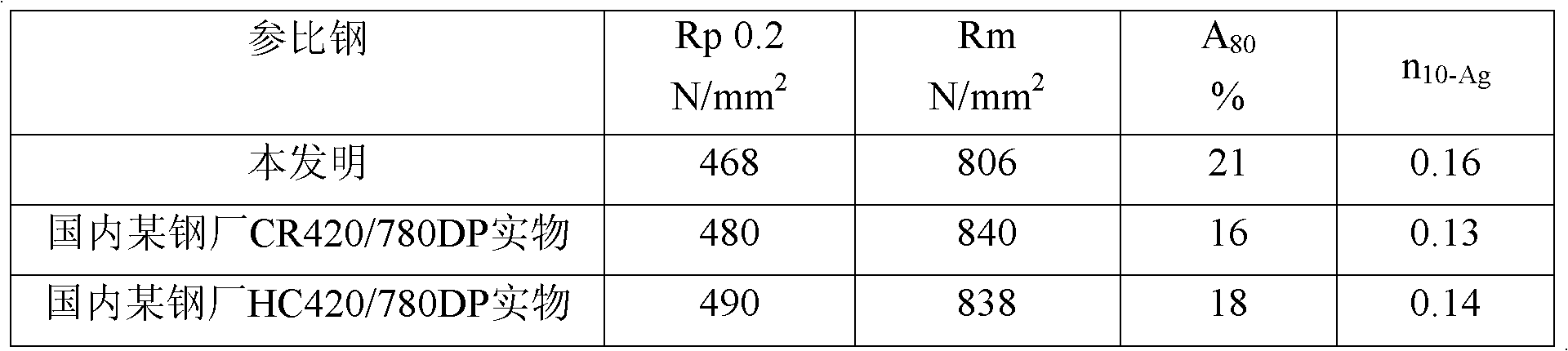

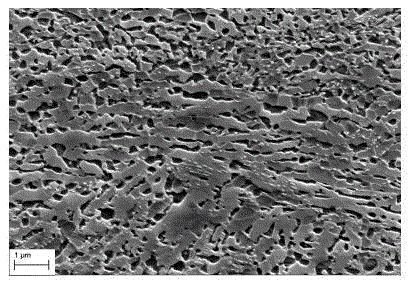

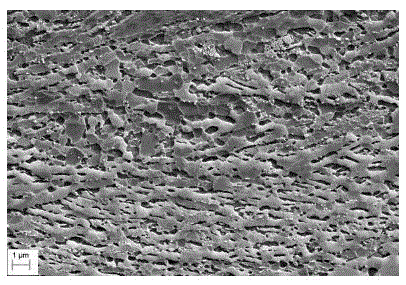

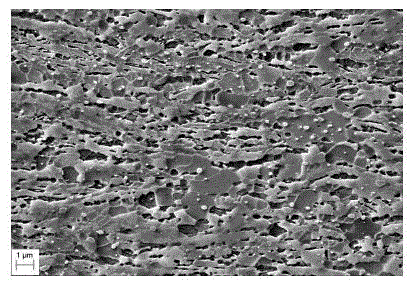

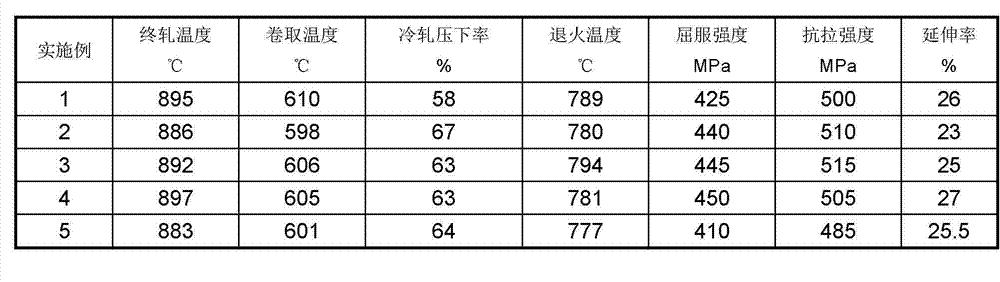

High-plasticity 780MPa-level cold rolled dual-phase steel and preparation method thereof

InactiveCN102212745ANominal C content decreasedGood welding performanceRoll mill control devicesHeat treatment process controlChemical compositionEconomic benefits

The invention discloses a high-plasticity 780MPa-level cold rolled dual-phase steel and a preparation method thereof. The steel comprises the following chemical components in percentage by weight: 0.06 to 0.08 percent of C, 1.0 to 1.3 percent of Si, 2.1 to 2.3 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.01 percent of S, 0.02 to 0.07 percent of Alt, less than or equal to 0.005 percent of N, and the balance of Fe and inevitable impurities. According to the hot rolling process parameters, the heating temperature of a continuously cast bloom is 1,250+ / -30 DEG C, the final rolling temperature is 890+ / -30 DEG C, the coiling temperature is 670+ / -30 DEG C, the cold rolling press-down rate is 50 to 70 percent, and the continuous annealing process is controlled. The invention has the advantages that: the C equivalent weight of the steel is effectively reduced by regulating the components of the alloy based on a conventional gas jet cooling and continuous annealing mode, the elongation of the steel is improved, and considerable economic benefit can be brought.

Owner:SHOUGANG CORPORATION

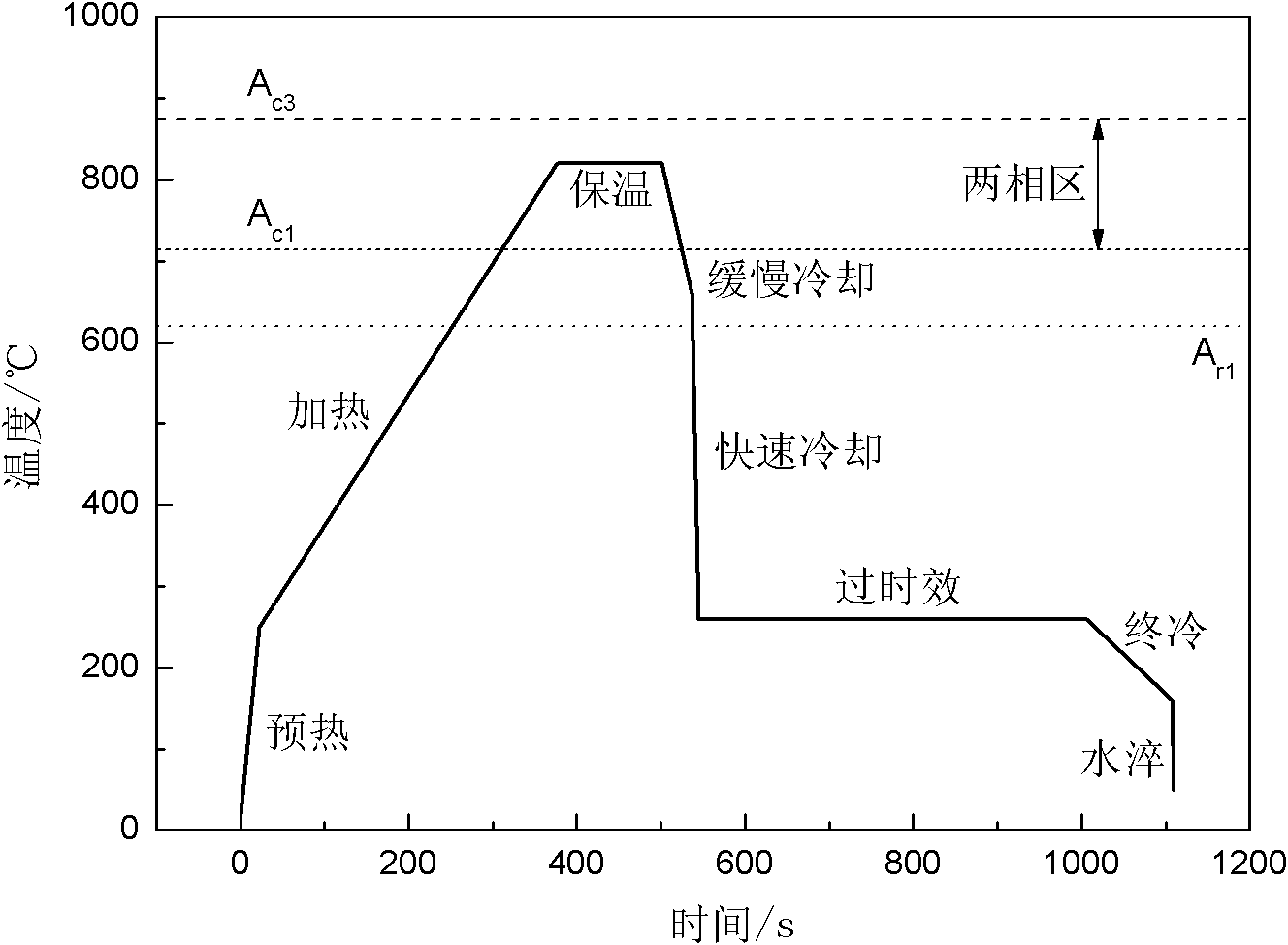

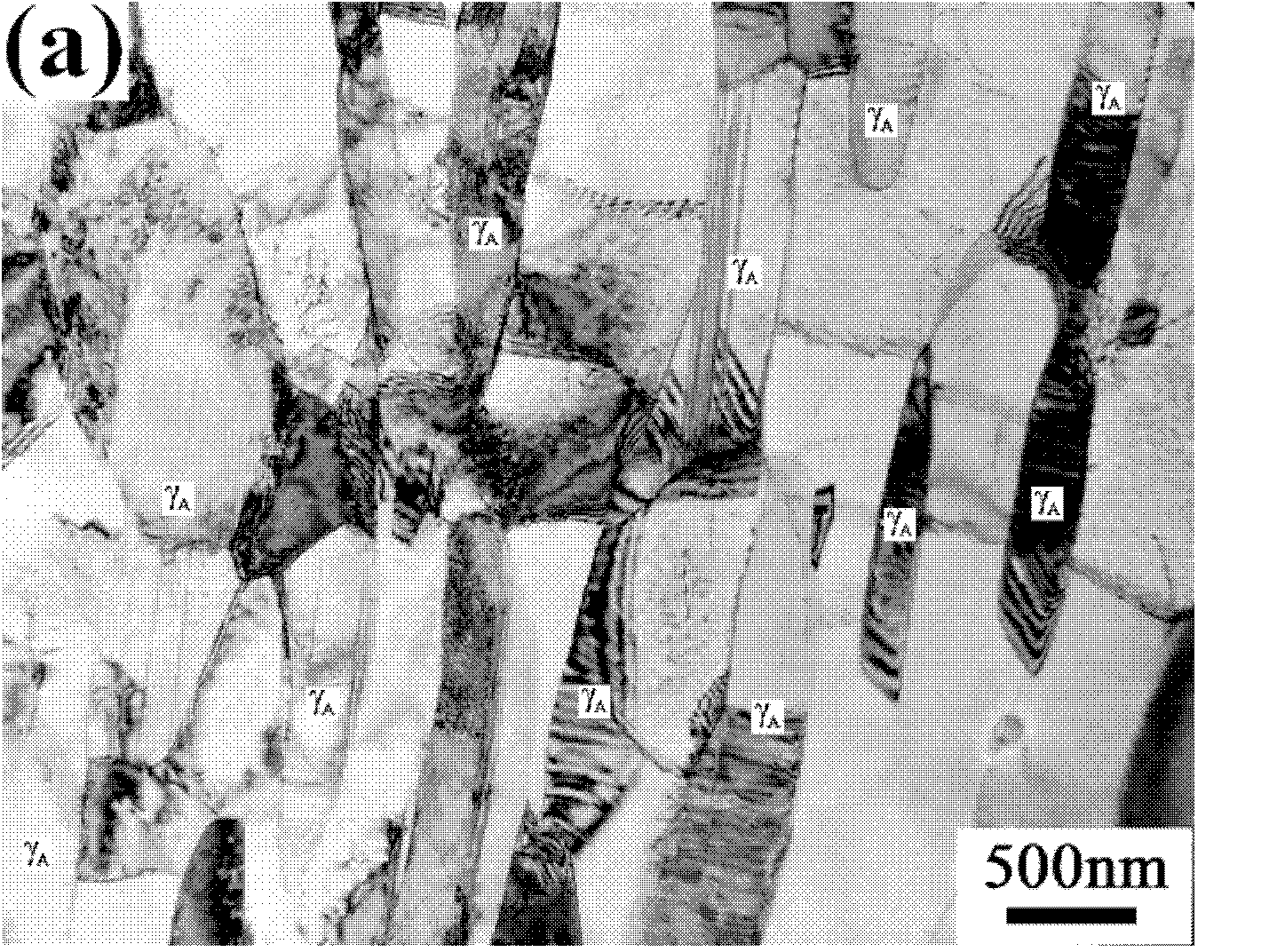

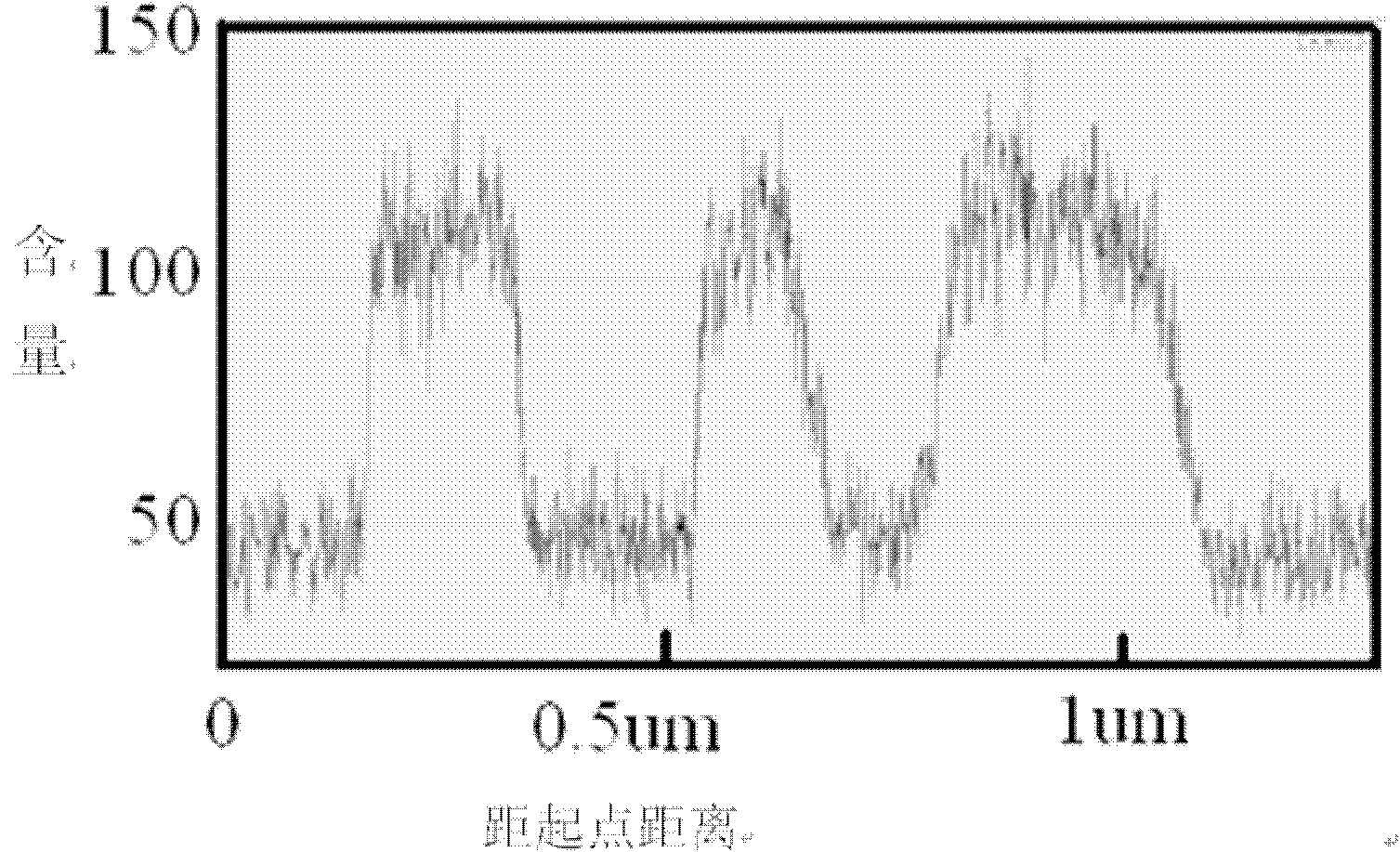

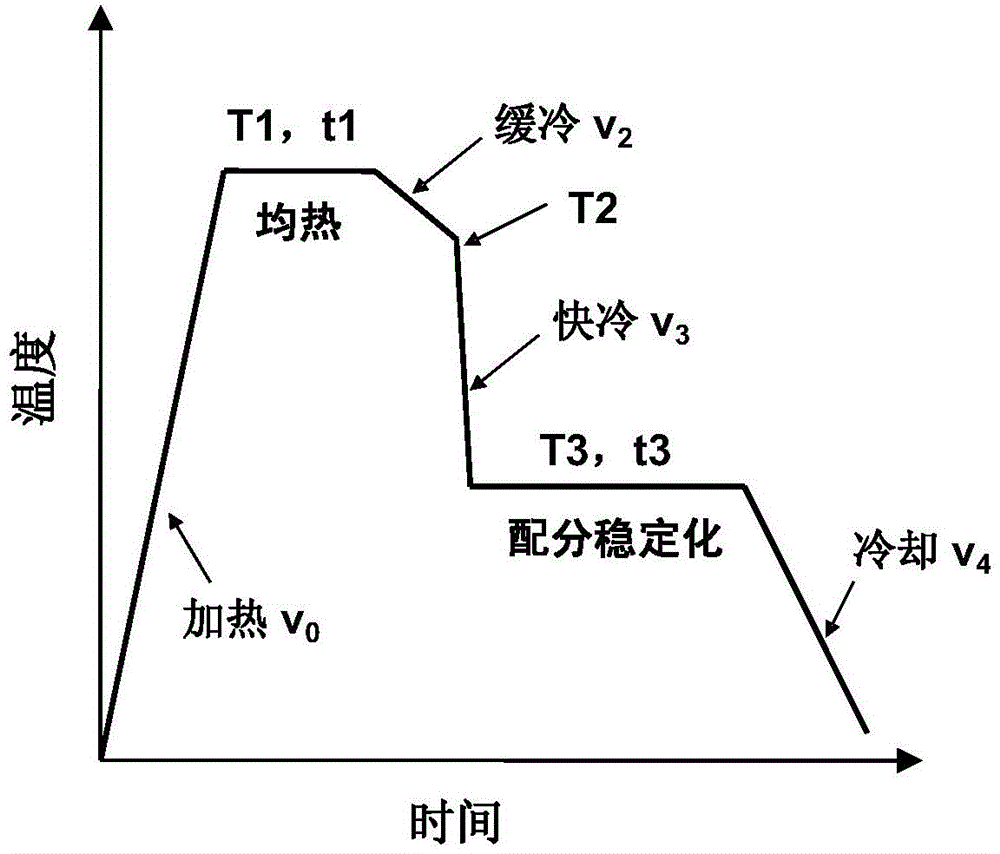

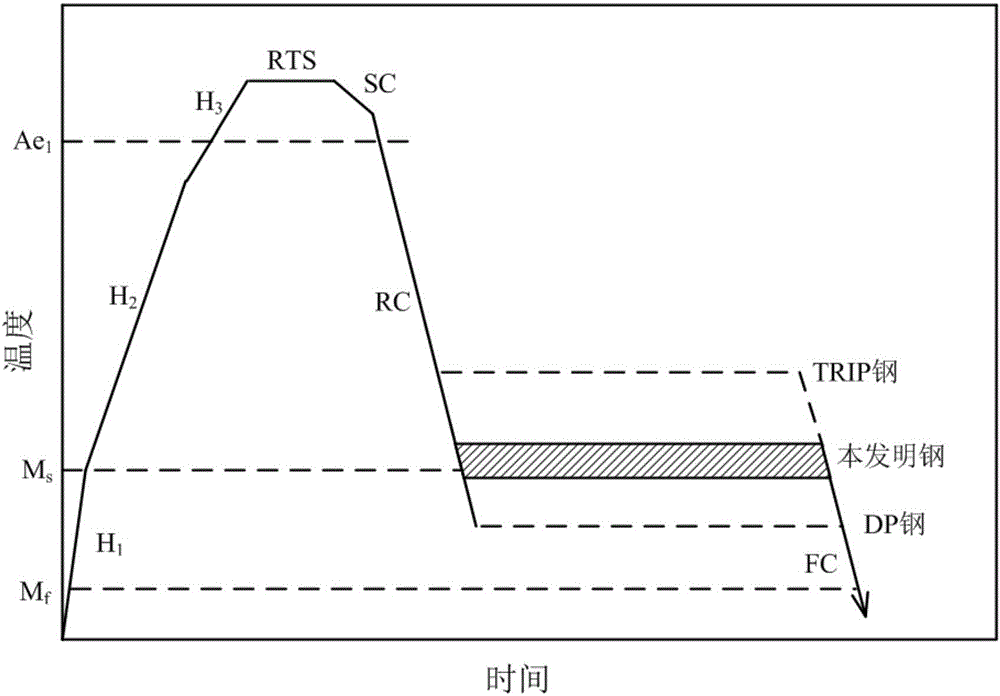

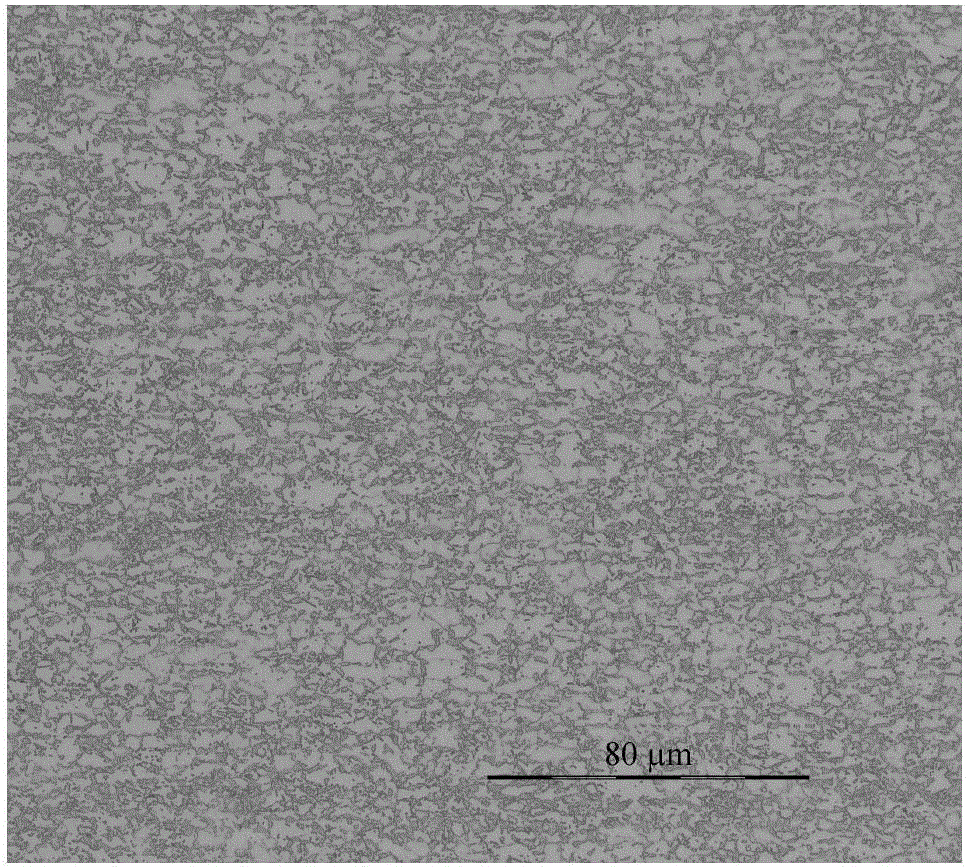

High-strength and high-plasticity medium-manganese Q and P steel cold-rolling annealing plate and preparing technology thereof

ActiveCN105648317AIncrease the content of retained austeniteGuaranteed StrengthManganeseContinuous annealing

The invention discloses a high-strength and high-plasticity medium-manganese Q and P steel cold-rolling annealing plate and a preparing technology thereof. The annealing plate comprises chemical components including, by weight percent, 0.1%-0.3% of C, 0.8%-2.0% of Si, 4.0%-8.0% of Mn, smaller than or equal to 0.01% of P, smaller than or equal to 0.01% of S, smaller than or equal to 0.01% of N, and the balance iron and inevitable impurities. The preparing technology includes smelting, hot rolling, intermediate annealing, cold rolling and final heat treatment. The Q and P technology is applied to the field of medium-manganese steel field, a two-phase region Q and P technology is developed, and finally complex-phase medium-manganese Q and P steel including martensite, retained austenite and a ferritic structure is obtained, wherein the tensile strength ranges from 900 MPa to 1,300 MPa, plasticity ranges from 24% to 37%, and the product of strength and elongation reaches 30 GPa% to 45 GPa%. The continuous annealing treatment of the medium-manganese steel is achieved, the time of traditional cover annealing is shortened, and meanwhile the high-strength medium-manganese steel plate with strength and plasticity well matched is obtained.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Hot-dip aluminizing zincium steel plate/belt for deep drawing and method for producing the same

ActiveCN101352946AImprove corrosion resistanceImprove high temperature resistanceHot-dipping/immersion processesFurnace typesChemical compositionSheet steel

The invention provides a deep drawing hot-dipped al-zn steel plate / strip and a production method thereof. The deep drawing hot-dipped al-zn steel plate / strip comprises an IF steel substrate and an alloy coating and the chemical constituents of the substrate (wt percent) are that C is less than or equal to 0.01, Si is less than or equal to 0.12, Mn is less than or equal to 0.6, P is less than or equal to 0.1, S is less than or equal to 0.045, Ti is less than or equal to 0.3 and the allowance is Fe and inevitable impurities. The production method comprises substrate degreasing treatment, annealing treatment and hot dipping, and the annealing treatment is carried out in a continuous annealing furnace and protective gas contents in the annealing furnace are 10 to 60 percent. The yield strength of the steel plate / strip of the invention reaches 140 to 220 MPa, the tensile strength is 260 to 350 MPa and the elongation is more than 30 percent; the production method of the invention is simple in production process and strong in operability.

Owner:BAOSHAN IRON & STEEL CO LTD

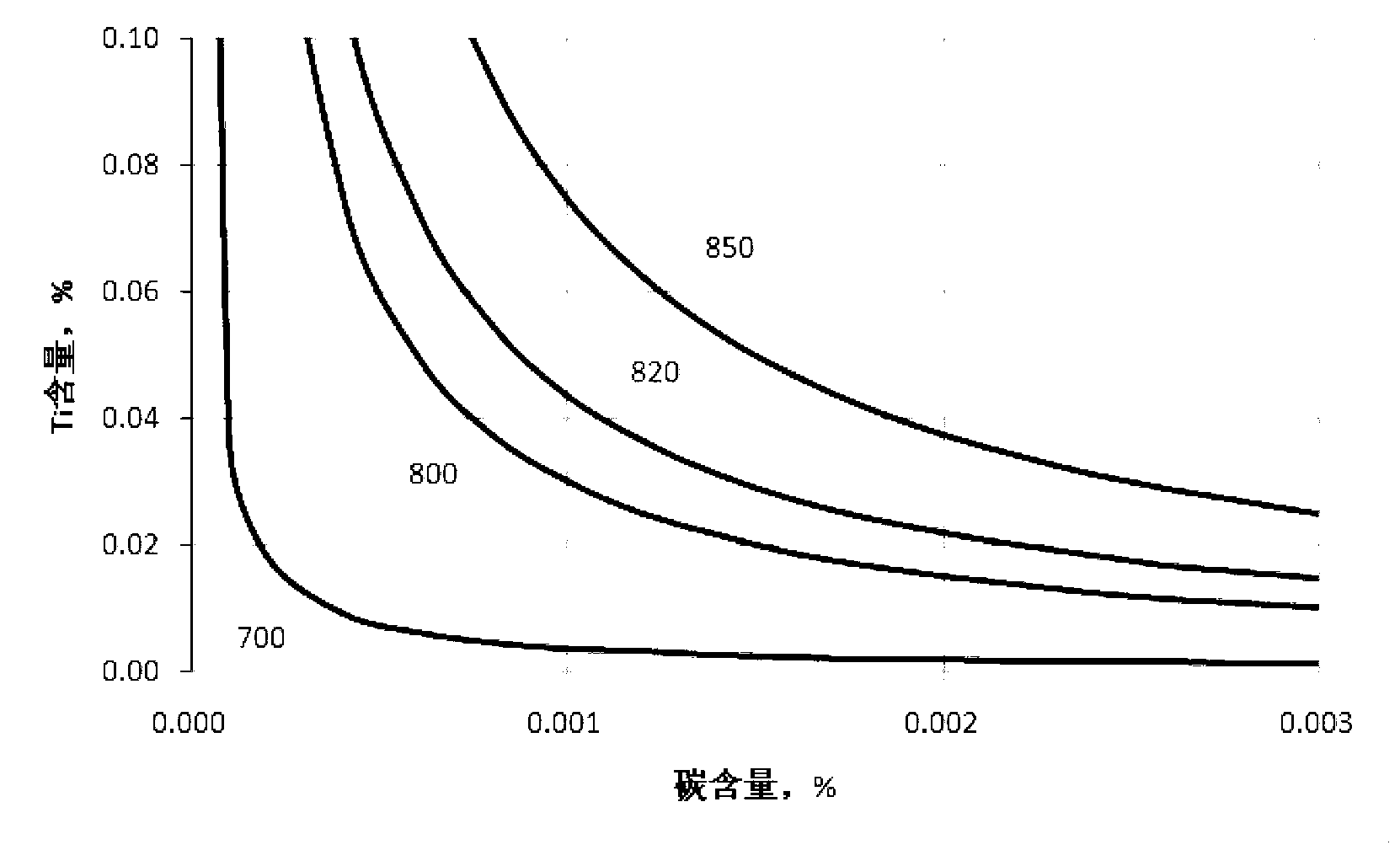

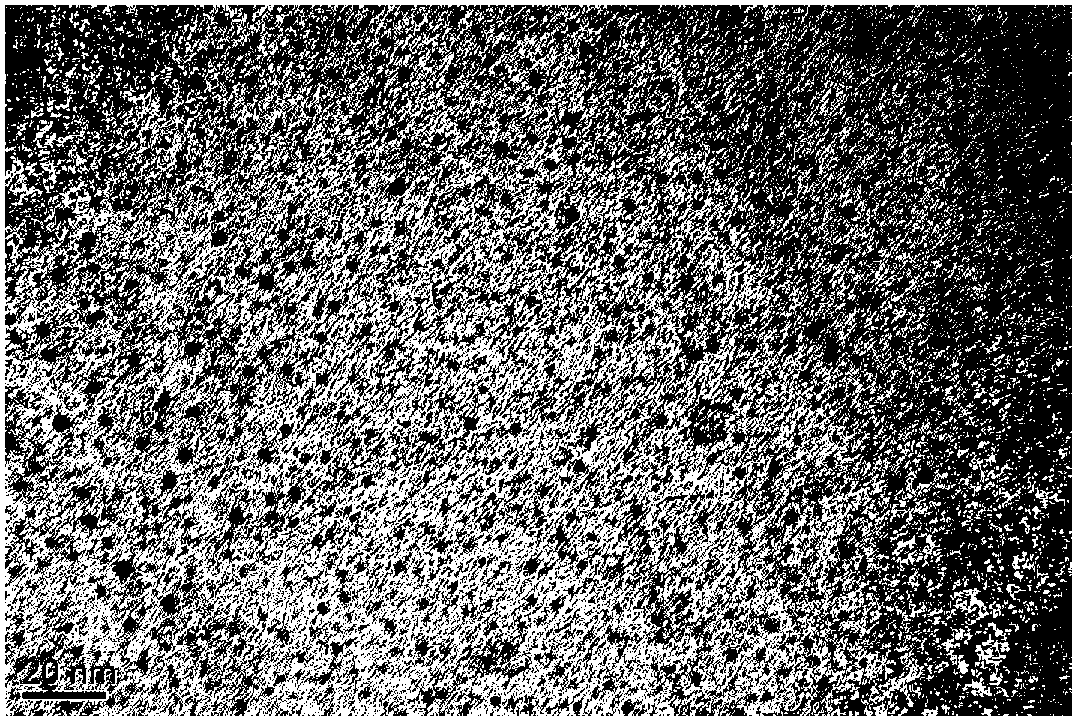

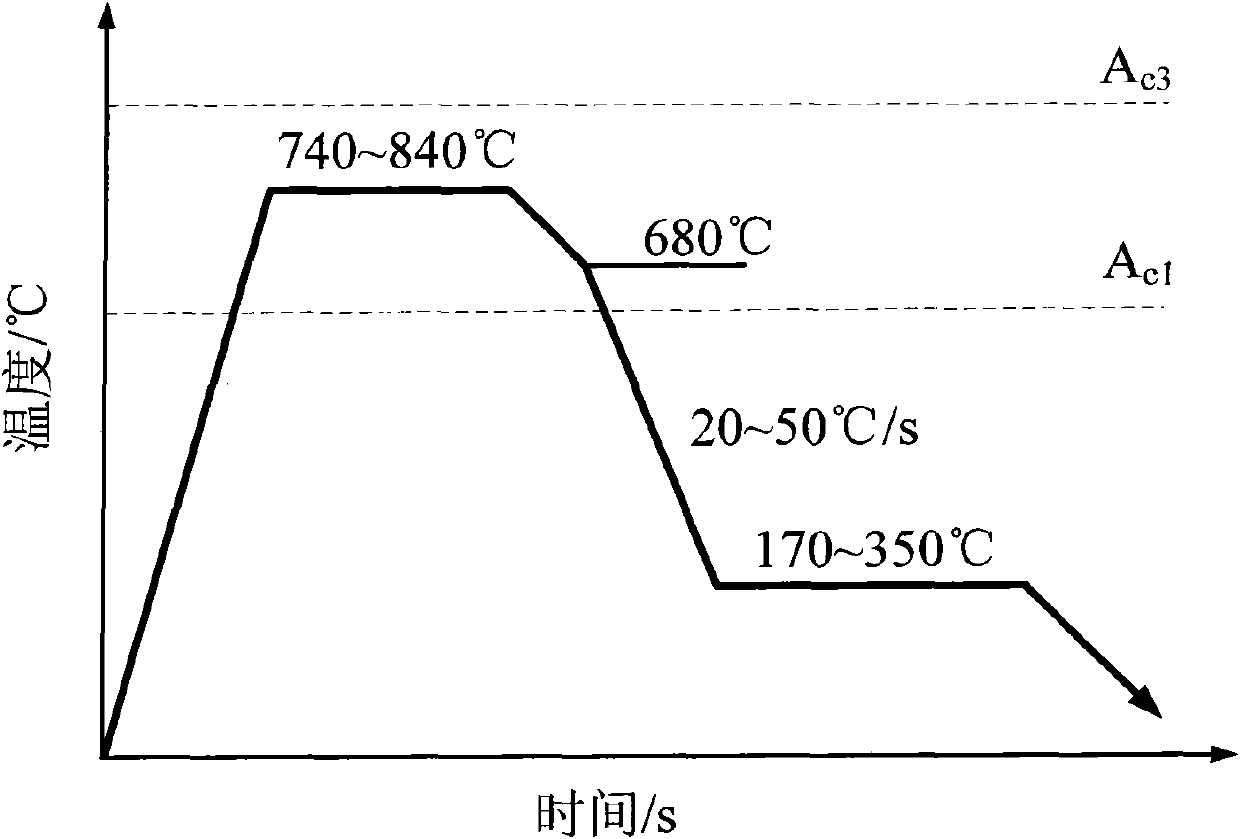

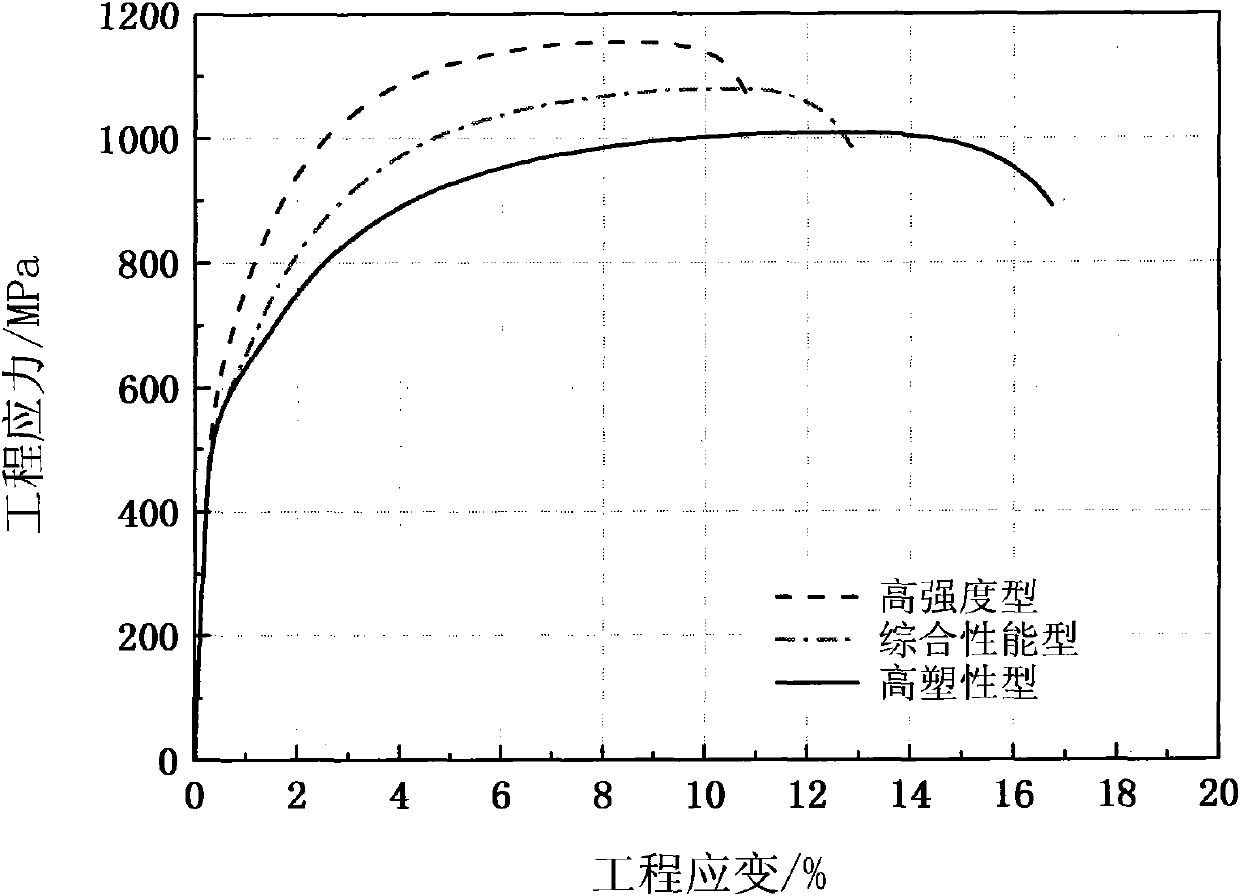

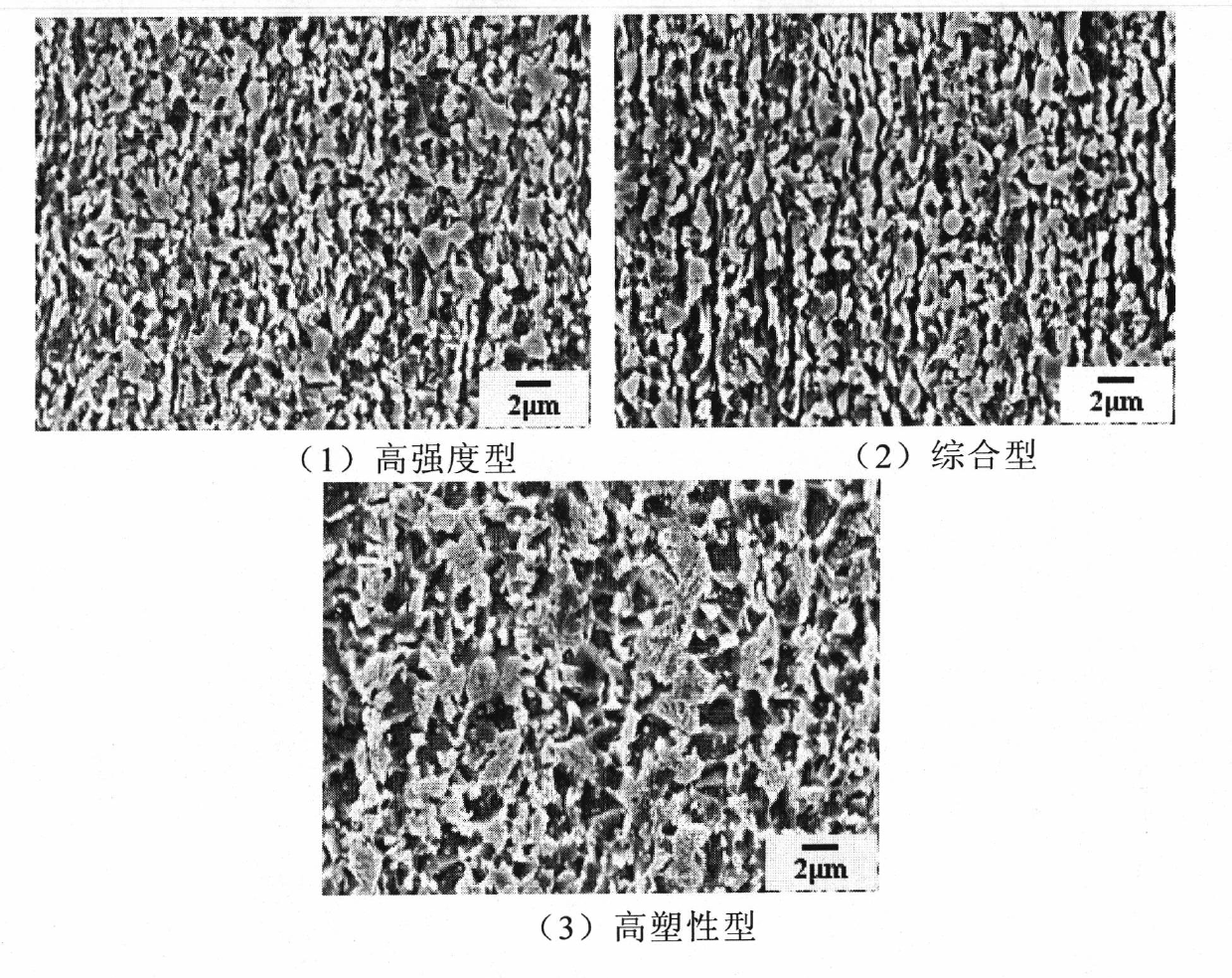

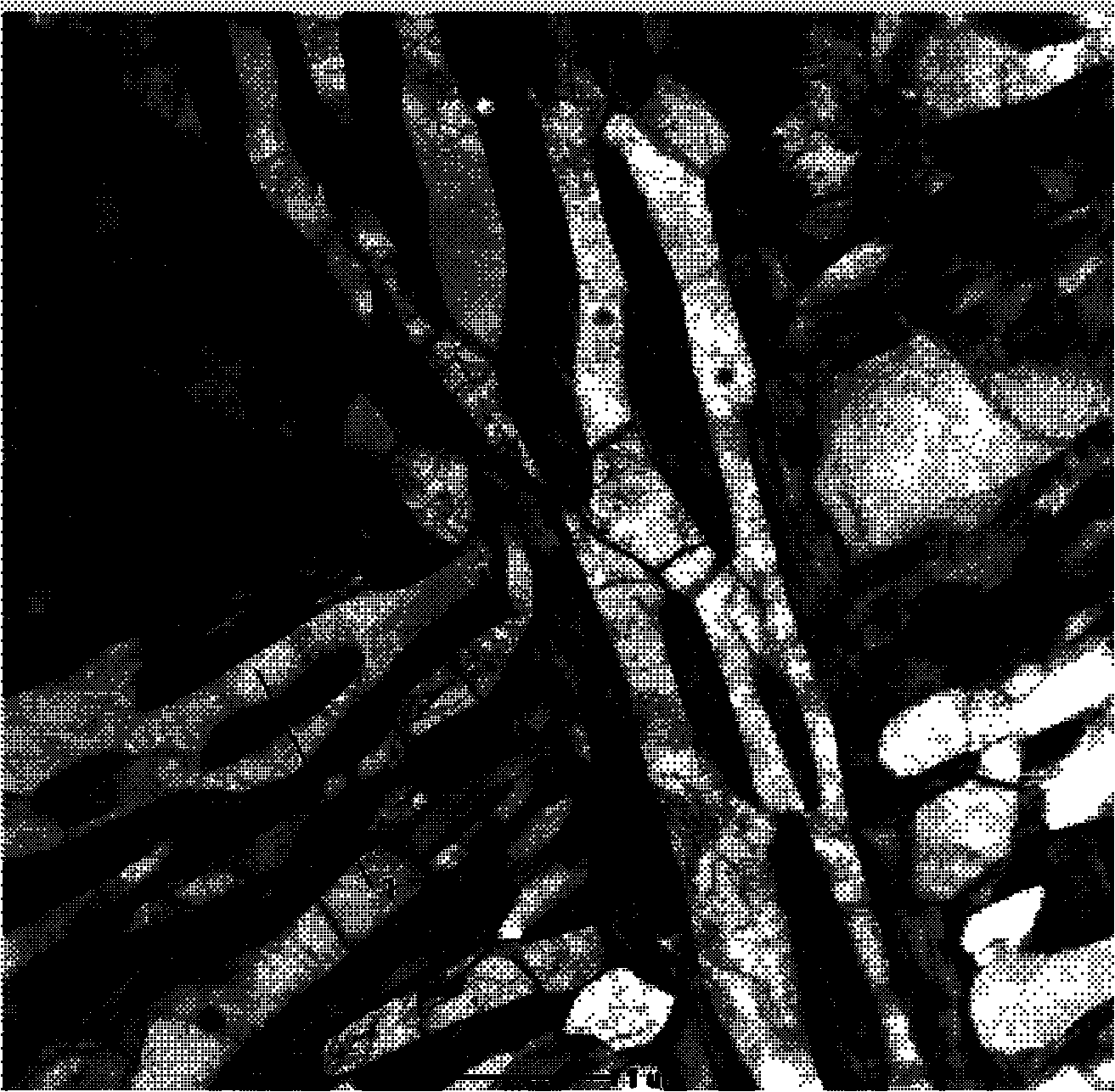

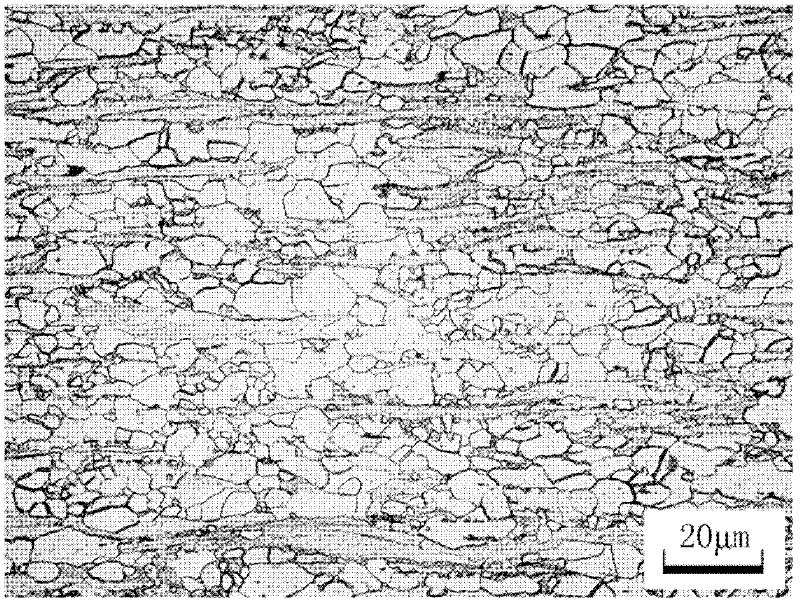

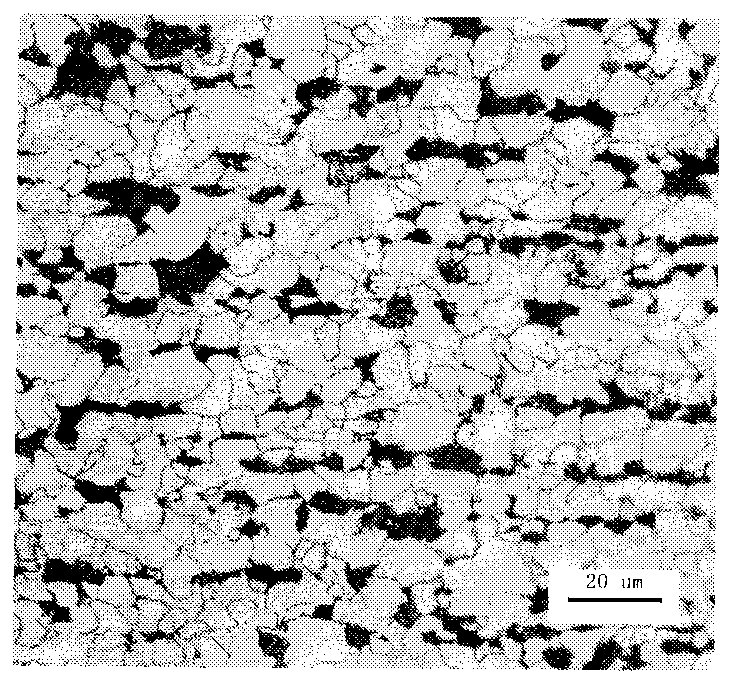

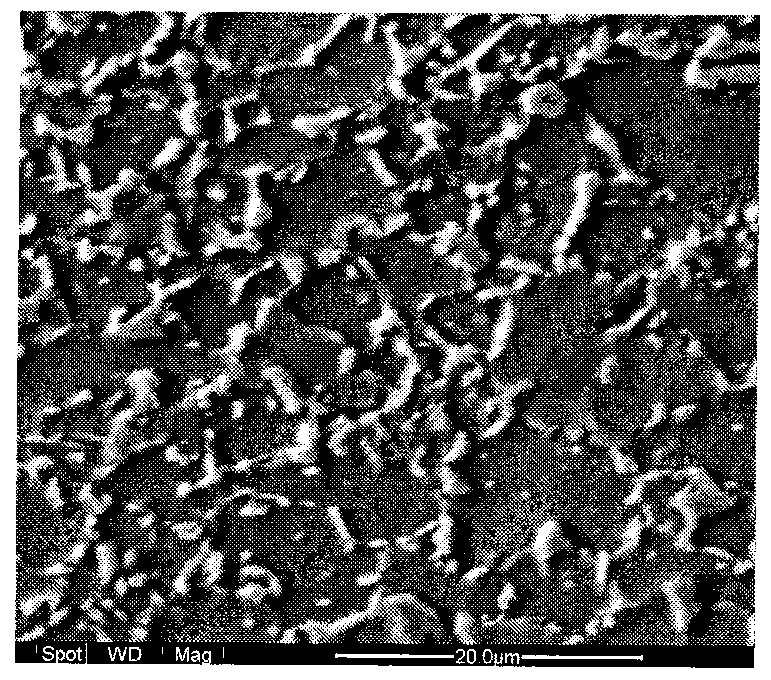

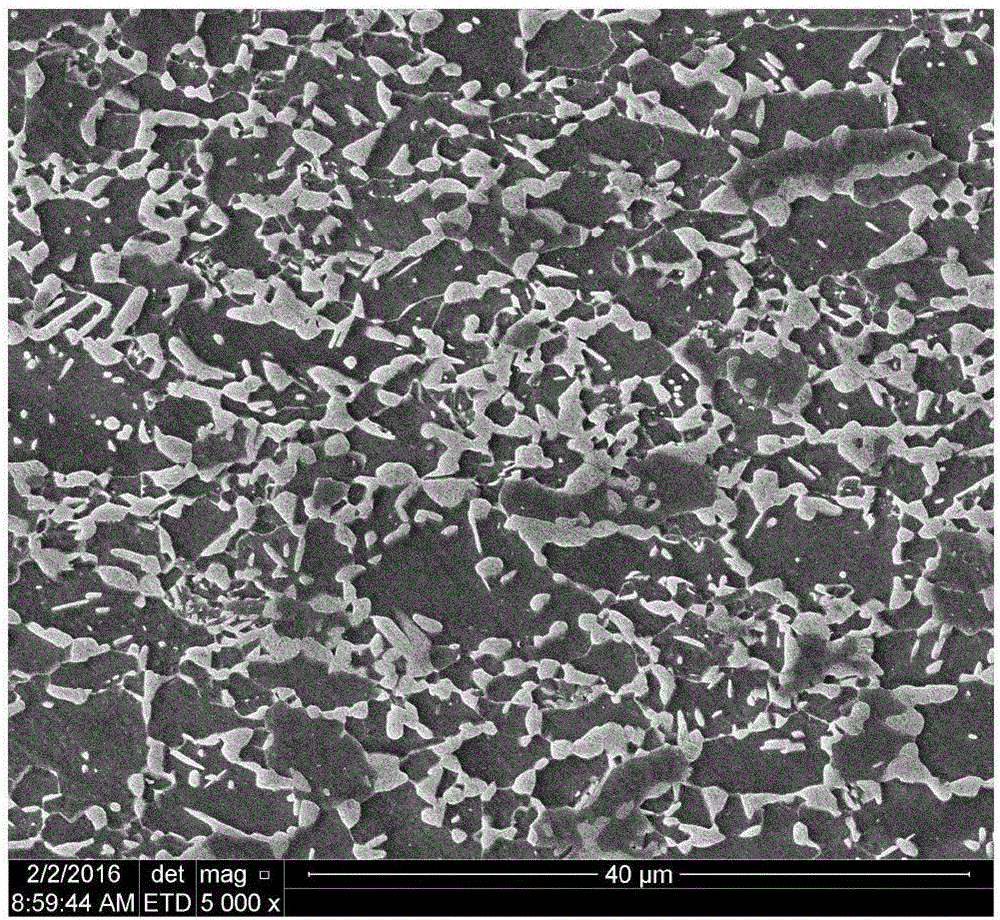

Ti microalloyed ultra-fine grained cold rolling dual-phase steel of 1,000MPa level and preparation method thereof

InactiveCN101768695ALow priceInhibit growthTemperature control deviceFurnace typesChemical compositionMicrometer

The invention relates to Ti microalloyed ultra-fine grained cold rolling dual-phase steel of a 1,000MPa level and a preparation method thereof, belonging to the technical field of cold rolling ultra-high strength steel for automobiles. The steel comprises the following chemical compositions in percentage by weight: 0.03-0.20 percent of C, 0.20-0.80 percent of Si, 1.2-2.0 percent of Mn, 0.03-0.15 percent of Ti, less than 0.15 percent of S, less than 0.020 percent of P, 0.02-0.15 percent of Als and the balance of Fe. In the invention, C-Si-Mn-Ti is used as a basic alloy system, low-price Ti is adopted, and alloy elements such as Cr, Mo, Nb, V, and the like are not added, thereby reducing the production cost; through a flexible continuous annealing process, the size of a martensite island can be controlled to be 1-2 micrometers or increased to about 5 micrometers under the condition that the quick cooling speed is lower than 50 DEG C / s in continuous annealing so as to obtain the following three different types of dual-phase steel: a high strength type (Rm is 980-1,200MPa, and A50 is 10-13 percent), a high plasticity type (Rm is 980-1,100MPa, and A50 is 14-18 percent) and a synthesizing type (Rm is 980-1,150MPa, and A50 is 12-15 percent); and the yield ratio is 0.47-0.65.

Owner:UNIV OF SCI & TECH BEIJING

Production method for continuous annealing process high strength and plasticity product automobile steel plate

ActiveCN102021472AMeet continuous annealing production requirementsIncreased strength and plasticityFurnace typesHeat treatment furnacesSheet steelContinuous annealing

The invention discloses a production method for a continuous annealing process high strength and plasticity product automobile steel plate, which belongs to the technical field of automobile steel. By increasing the deformation energy storage of a cold-rolled steel plate and acquiring nonequilibrium structure, the time for reverting austenite is reduced greatly, a condition for obtaining better strength and plasticity product in an annealing and heat preservation time period of 1 to 10 minutes is created, and the process conditions of the conventional automobile steel cold-rolled plate continuous annealing and continuous galvanizing production equipment are met. In addition, through structural heredity, the strength and plasticity product of a cold-rolled reversed austenite annealing steel plate is improved by over 10 percent compared with that of reversed austenite annealing hot-rolled steel plate.

Owner:CENT IRON & STEEL RES INST

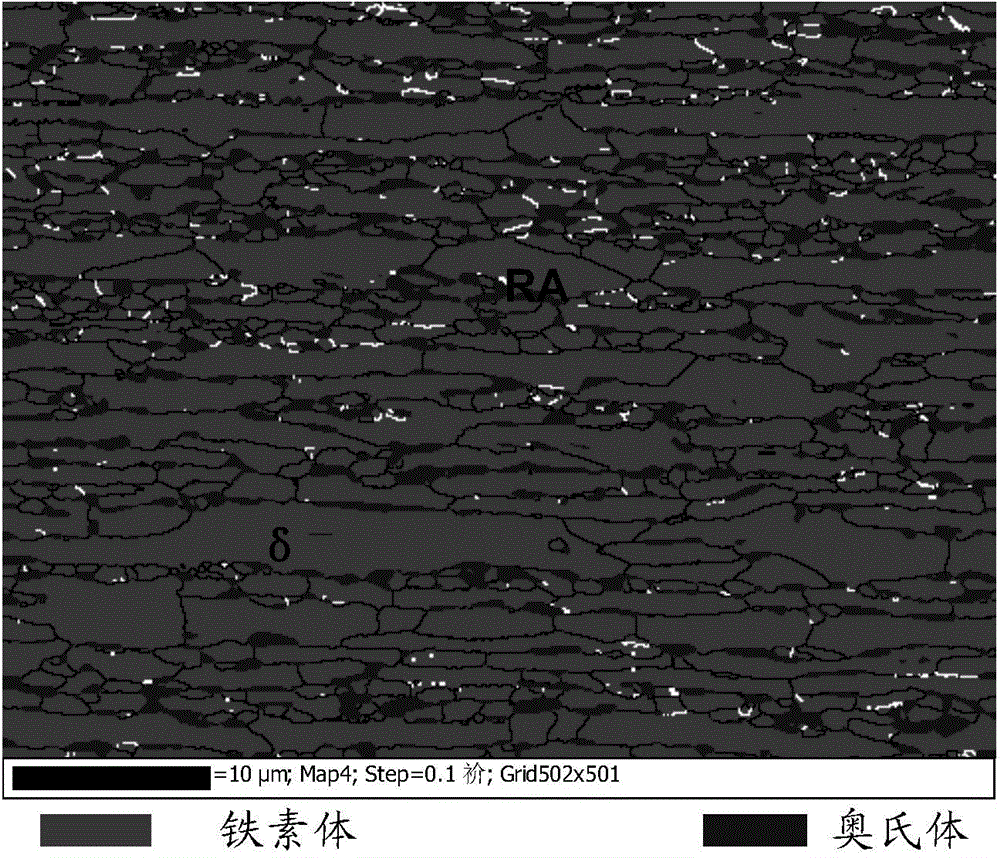

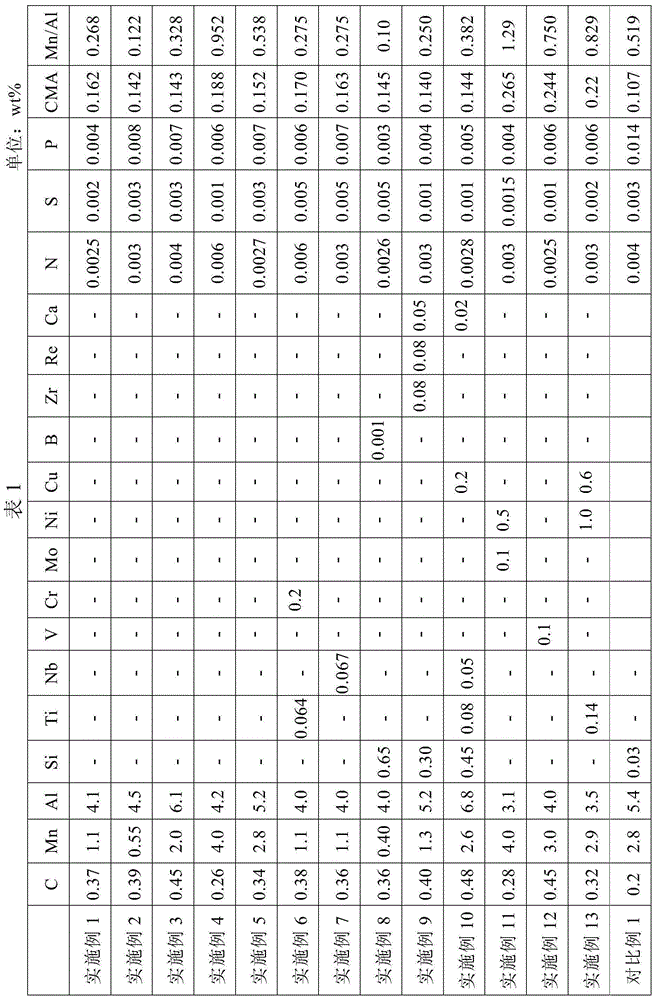

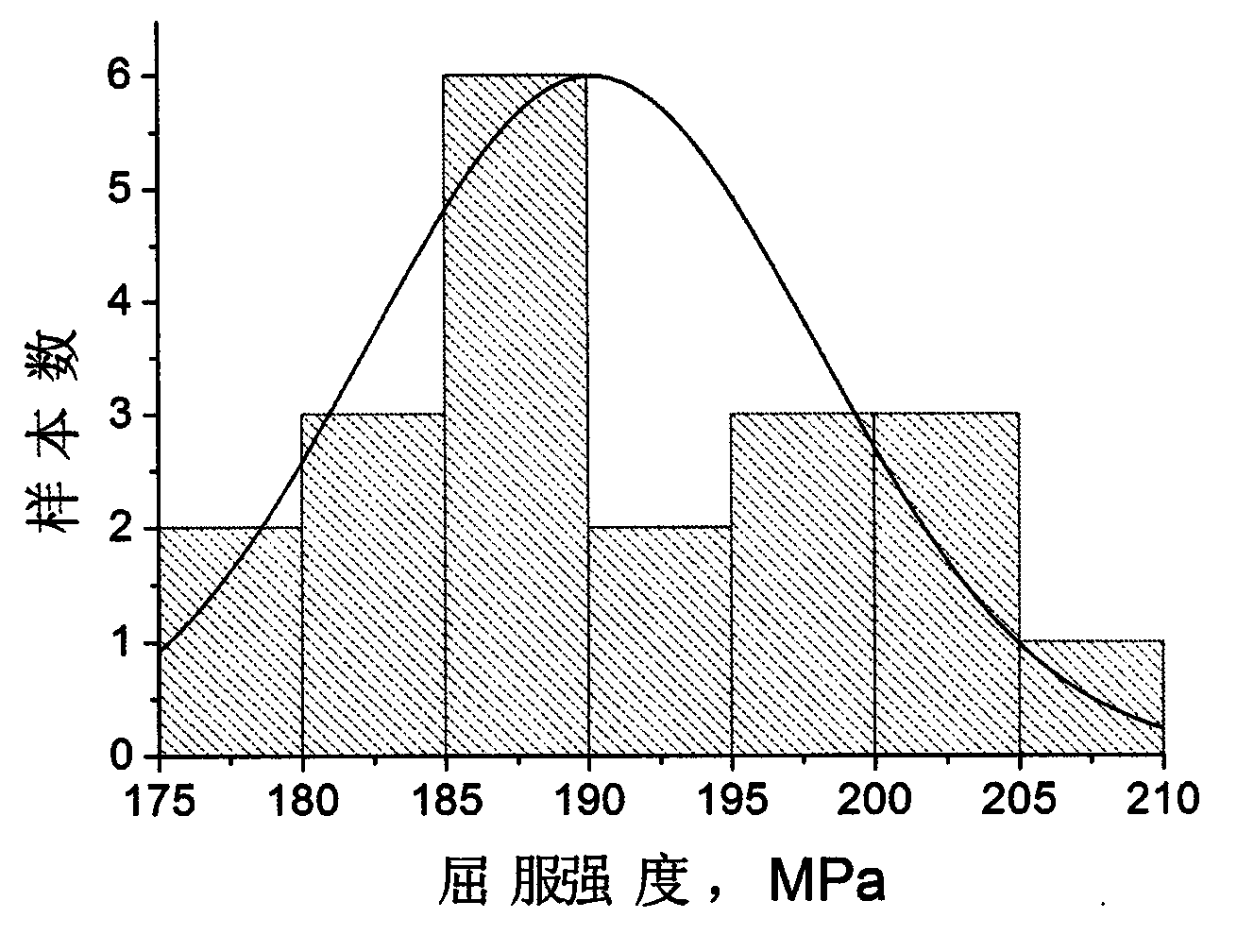

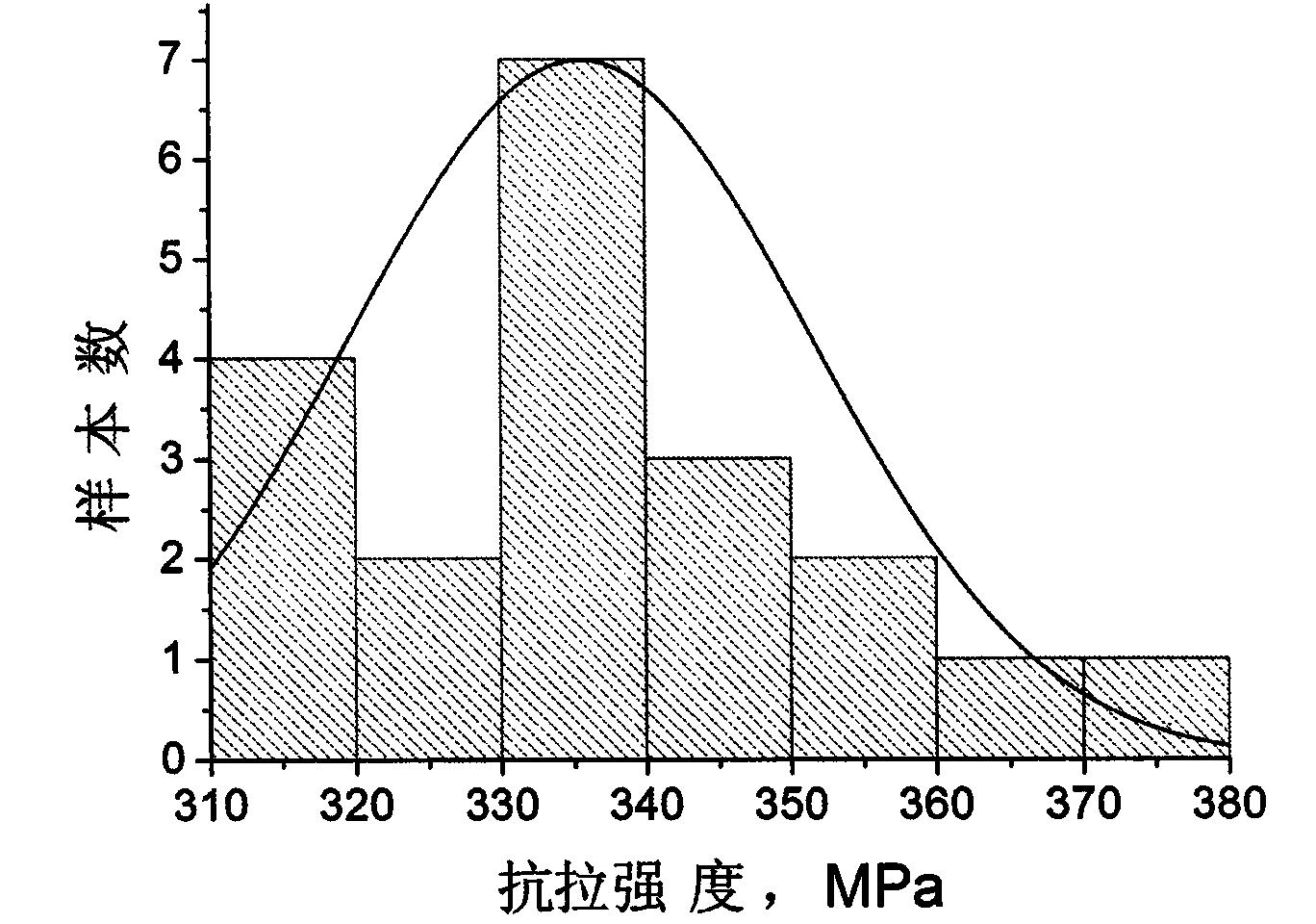

800MPa grade high-ductility low-density steel and manufacturing method thereof

An 800MPa grade high-ductility low-density steel and a manufacturing method thereof. The steel comprises the following chemical composition by weight percentage: 0.25-0.50% of C, 0.25-4.0% of Mn, 3.0-7.0% of Al, no more than 0.02% of P, no more than 0.01% of S, no more than 0.01% of N, and the balance of Fe and inevitable impurity elements, and these elements meet the following relationship: 0.14<= (1.5C + 0.1Mn) / Al<=0.30. The manufacturing method comprises hot rolling, pickling, cold rolling and continuous annealing to prepare a low-density steel plate. In addition to ferrite, the microstructure of the steel plate also contains 6-30% of residual austenite, wherein the content of C in the residual austenite is not less than 0.8%. The steel plate has tensile strength higher than 800MPa, elongation higher than 25%, and density less than 7500kg / m<3>.

Owner:BAOSHAN IRON & STEEL CO LTD

Continuous annealing method of DC01 steel plate with low yield and high tensile strength for automobiles

The invention relates to a continuous annealing method of DC01 steel plate with low yield and high tensile strength for automobiles, belonging to the field of metallic materials processing. The chemical composition of the steel plate is as follows by mass percentage: 0.02-0.04% of C, 0.2-0.35% of Mn, less than or equal to 0.03% of Si, less than or equal to 0.010% of P, less than or equal to 0.010% of S, 0.02-0.06% of Als, 0.0020-0.0050%of N, and the rest being Fe. The hot rolling parameter is as follows: heating temperature at 1250+ / -30 DEG C; finishing temperature at 930+ / -20 DEG C; coiling temperature at 730+ / -20 DEG C; cold rolling reduction ratio being controlled at 75-85%; soaking time for 50-100s; annealing temperature at 780+ / -20 DEG C; outlet temperature of the slow-cooling section at 675+ / -20 DEG C; outlet temperature of the rapid-cooling section at 400+ / -20 DEG C; overaging temperature at 350+ / -20 DEG C; and level elongate ratio being 0.9+ / -0.3%. The generated steel plate has the advantages of low yield strength, high tensile strength, fine formability, high product quality and considerable economic benefit.

Owner:SHOUGANG CORPORATION

Hard tinned sheet steel and its production method

The invention relates to a hard tinned sheet steel produced from low carbon aluminium killed steel so as to solve the technical problems of easy appearance of local edge waves during current pickling rolling production of tinned sheet steel, high incidence of surface iron oxide scale during continuous annealing production, high yield ratio of tin plates, undesirable stamping processing and the like. The hard tinned sheet steel and its raw sheet comprise the following chemical components (by weight): 0.05-0.07% of C, less than or equal to 0.1% of Si, 0.20-0.30% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, 0.010-0.060% of Alt, less than or equal to 0.0060% of N, and the balance Fe and some inevitable impurity elements. The production method of the hard tinned sheet steel includes: steelmaking, continuous casting, hot rolling, combined pickling rolling, continuous annealing, double-stand tempering, and electrotinning. The hard tinned sheet steel produced in the invention has the advantages of small production control difficulty, excellent appearance quality, thin specification, stable hardness, and good stamping processing performance, etc., can meet the use requirements of high-speed canning, and can be widely used as a food cans, beverage cans, aerosol cans and other packaging materials.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

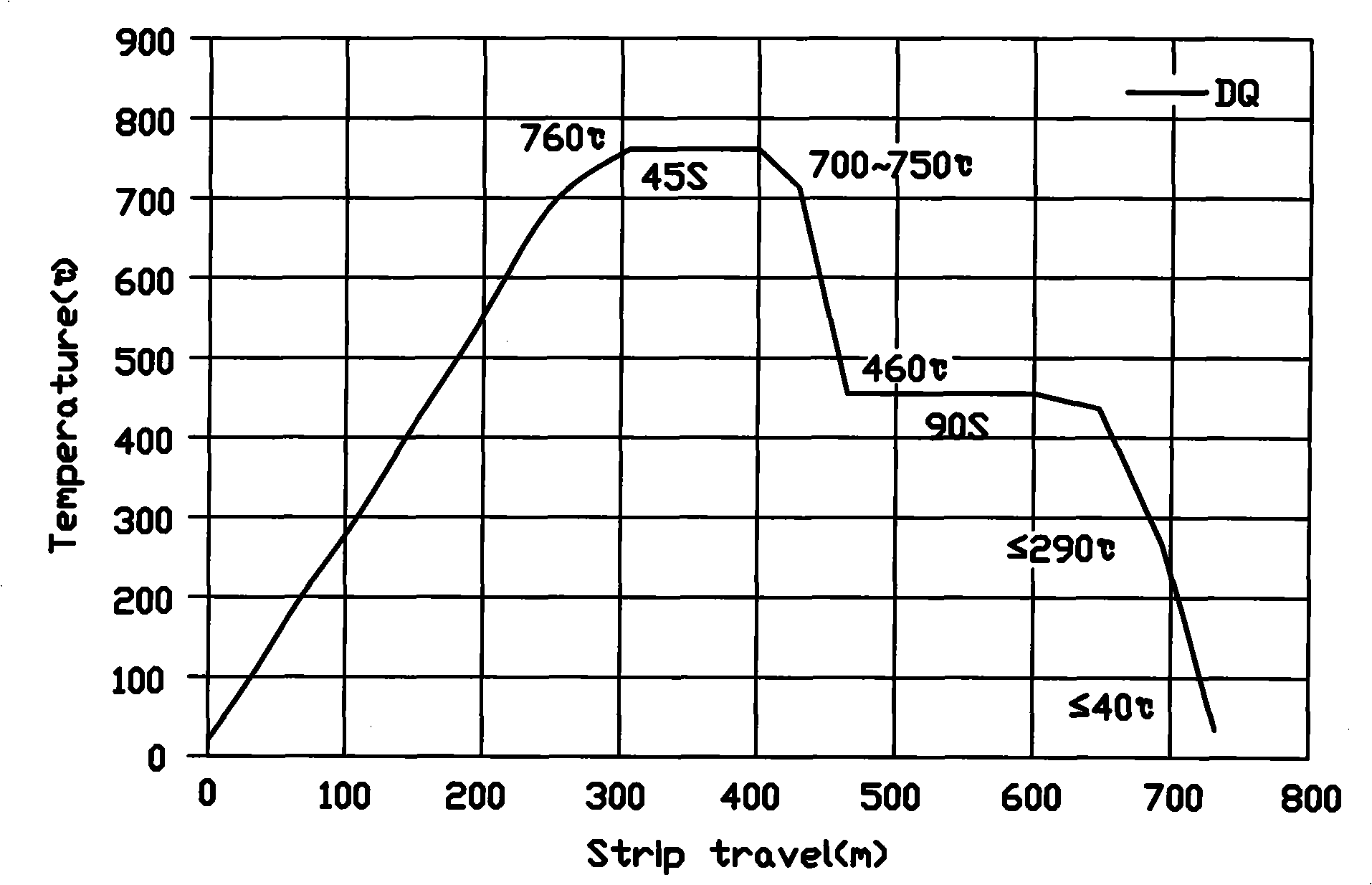

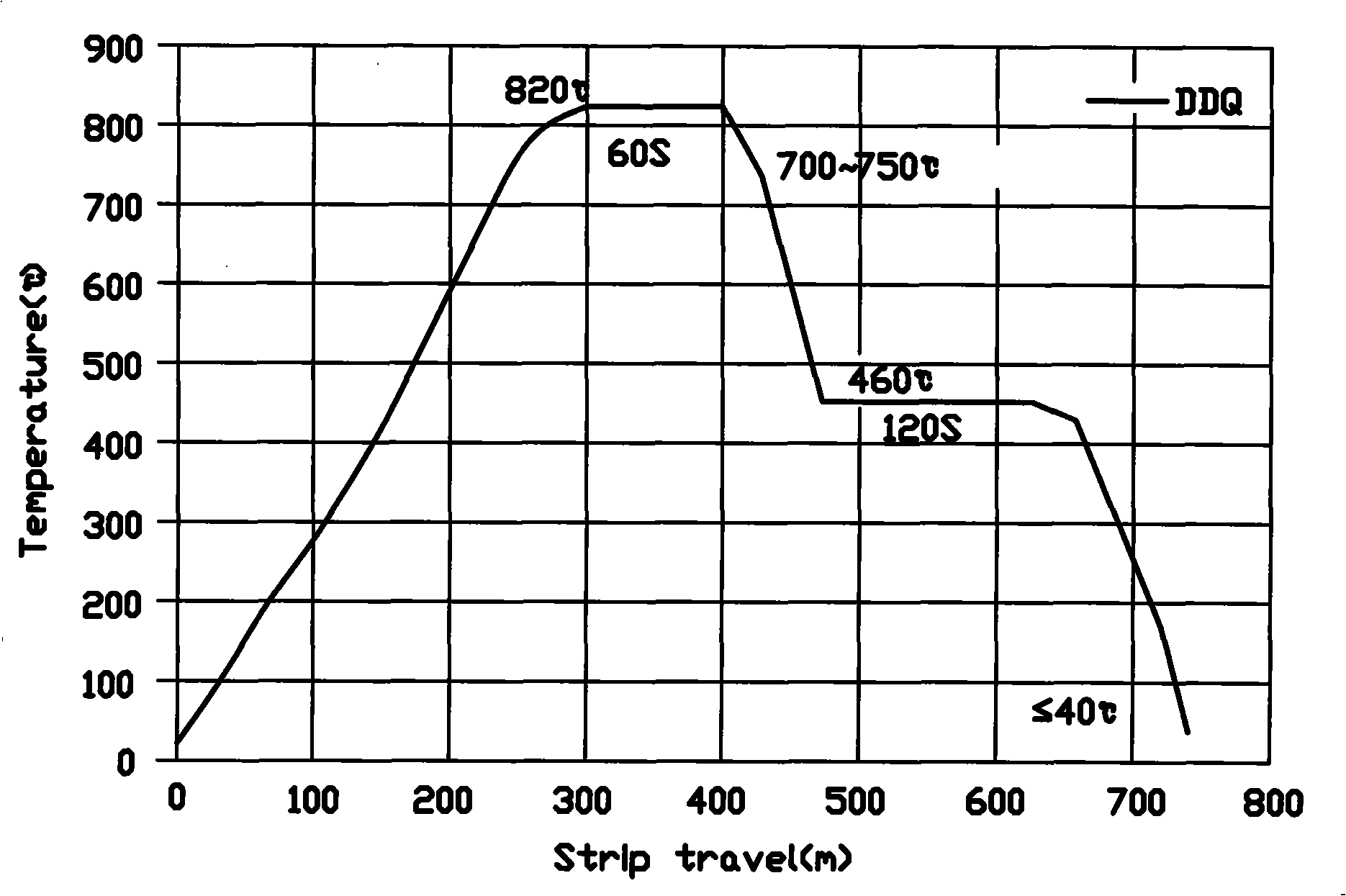

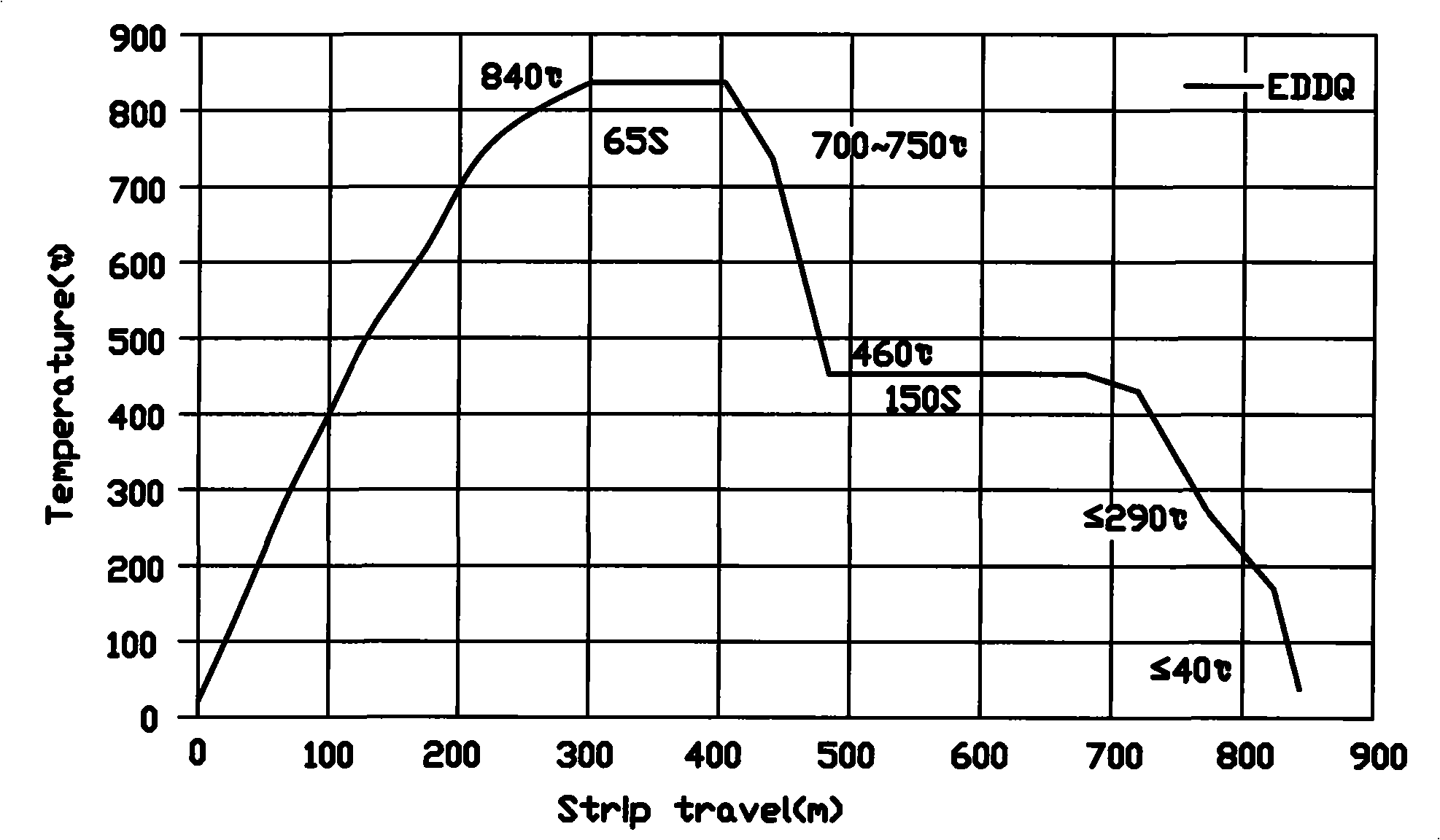

Continuous annealing process of deep drawing and extra-deep drawing steel plates

InactiveCN101514392AGuaranteed stamping effectGuaranteed ultra-deep drawing performanceFurnace typesHeat treatment process controlSheet steelHydrogen

The invention relates to a continuous annealing process of deep drawing and extra-deep drawing steel plates. The steel plate is washed before annealing to cause the contents of rolling oil and iron power on the surface of the steel plate are less than 20mg / m; the steel plate is put into a continuous annealing furnace and walks at the speed of 150-350m / min, mixed gas of nitrogen and hydrogen is used to blow the surface of the steel plate to protect and prevent the steel plate from oxidation, and the steel plate is heated to 120-180DEG C; and then the steel plate is heated again to 750-880 DEG C and the heat is preserved for 40-70 S; then, the steel plate is cooled to 400-460 DEG C and the heat is preserved for 60-300 S to carry out overaging treatment; finally, the steel plate is cooled to normal temperature. Owing to the employment of overaging annealing process, carbide in the steel is fully precipitated, thus guaranteeing the needs of drawing properties and extra-deep drawing properties of plates for household electrical appliances and of automobile plates.

Owner:耿凯

Method for producing cold-rolling low-carbon aluminum killed steel with uniform through plate mechanical property

ActiveCN102174683AImprove the uniformity of the mechanical properties of the plateThe mechanical properties of the plate are uniformMetal rolling arrangementsSteelmakingAcid washing

The invention discloses a method for producing cold-rolling low-carbon aluminum killed steel with a uniform through plate mechanical property, which belongs to the technical field of steel rolling. The method comprises the following process flows of: performing krypton (KR) desulfuration treatment, performing steelmaking by using the conventional converter, performing composition adjustment system (CAS) / relative humidity (RH) refining treatment, continuously casting, and performing hot loading and hot feeding; performing rough rolling, performing precision rolling, performing laminar cooling, and reeling; unreeling, performing acid washing, performing continuous cold rolling, and reeling; and unreeling, washing, continuously annealing, smoothing, and reeling. The method is characterized in that: the cold-rolling low-carbon aluminum killed steel which has the width of 750 to 1,580 mm, the thickness of 0.25 to 2.5 mm and the uniform through plate property is produced by a 2,250 mm or 1,580 mm continuous hot rolling machine set, a 1,700 mm acid rolling machine set and a 1,700 mm continuous annealing machine set. A trace amount of B is added into the low-carbon aluminum killed steel to appropriately improve finish rolling temperatures and appropriately reduce rolling process parameters such as reeling temperatures, annealing temperatures and the like, so that thick boron nitride (BN) is fully separated out; and thin dispersed aluminum nitride (AlN) is effectively prevented from being separated out, so that the uniformity of the through plate mechanical property of the cold-rolling low-carbon aluminum killed steel is improved.

Owner:SHOUGANG CORPORATION

Method for producing color-coated plate for structure with yield strength of more than or equal to 550 MPa

InactiveCN102363857APrevent rustNo foamingHot-dipping/immersion processesAcid washingCooling chamber

The invention relates to a method for producing color-coated steel sheet for a structure. The method comprises the following steps of: smelting, namely desulfurizing by molten iron, smelting by a converter, casting continuously to form a blank and performing hot rolling; performing acid washing; performing cold milling; annealing continuously; performing hot dipping on aluminum and zinc; and polishing, straightening, performing color coating and packaging for later use. In the method, the yield strength RP 0.2 (or ReH) is between 550 and 600 MPa; the tensile strength Rm is between 560 and 610MPa; and the percentage elongation after break A80 mm is more than or equal to 6 percent. A neutral salt mist test is performed for 1,200 hours, a coating does not have bubbling and corrosion phenomena. At present, the annealed color-coated plate of which the metallographic structure is ferrite and pearlite or the ferrite and free cementite or the ferrite and the pearlite and less free cementite cannot achieve the effect, and the production cost can be reduced by 10 to 15 percent. By the method, special occasions which have high-yield strength and are used for cooling chambers of automobiles,arch coverings and the like can be met, and a process is simple and easy to implement.

Owner:武钢集团有限公司

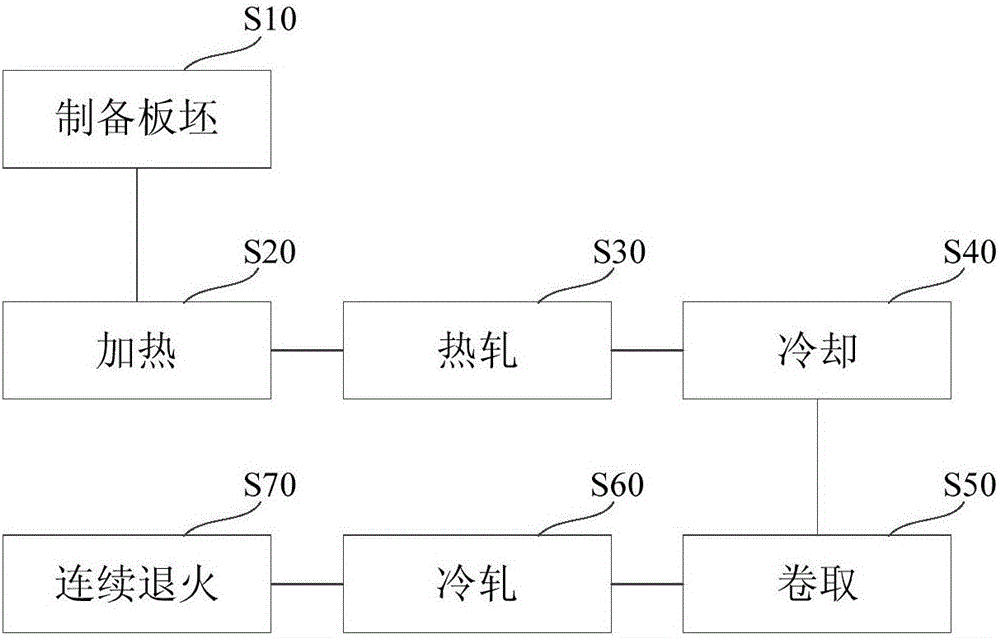

Cold rolled quenched ductile steel and preparation method

The application provides cold rolled quenched ductile steel and a preparation method. The cold rolled quenched ductile steel comprises the following chemical components in mass percent: 0.18 to 0.23 percent of C, 1.5 to 2.2 percent of Mn, 1.3 to 1.8 percent of Si, not greater than 0.02 percent of P, not greater than 0.008 percent of S, 0 to 0.05 percent of Nb, 0 to 0.1 percent of Ti and the balance Fe and inevitable impurities. According to the application, the cold rolled quenched ductile steel prepared by adopting processes of slab preparation, heating, hot rolling, cooling, coiling, cold rolling, continuous annealing and the like reaches 980 to 1200 MPa in tensile strength and reaches more than 25 GPa.% in product of strength and elongation.

Owner:NORTHEASTERN UNIV

High-strength and high-plasticity dual-phase steel and manufacturing method thereof

Owner:SHOUGANG CORPORATION

High-strength cold-rolled hot-galvanized dual-phase steel plate and manufacture method thereof

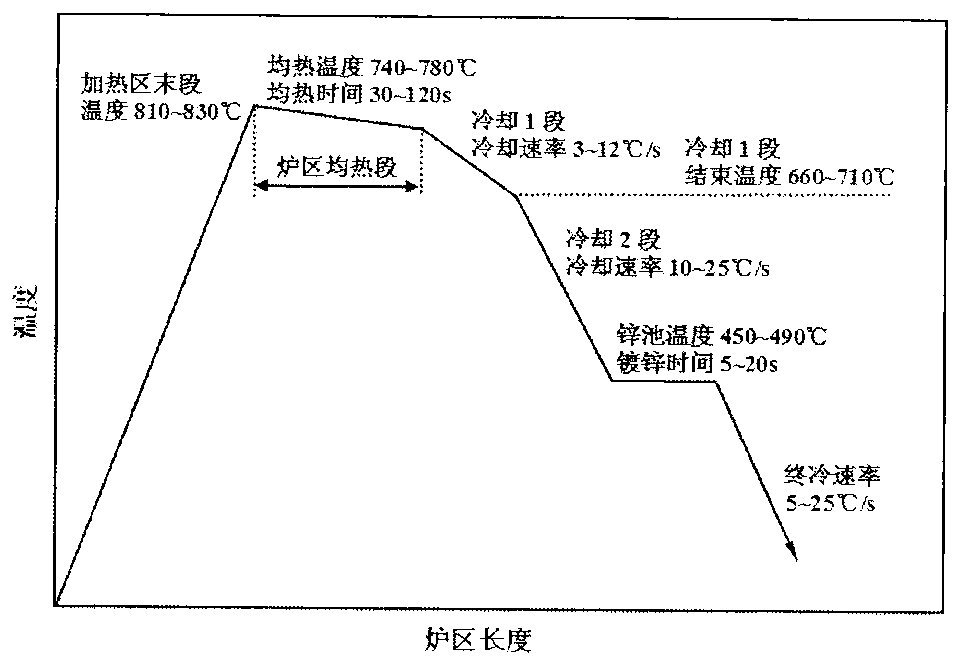

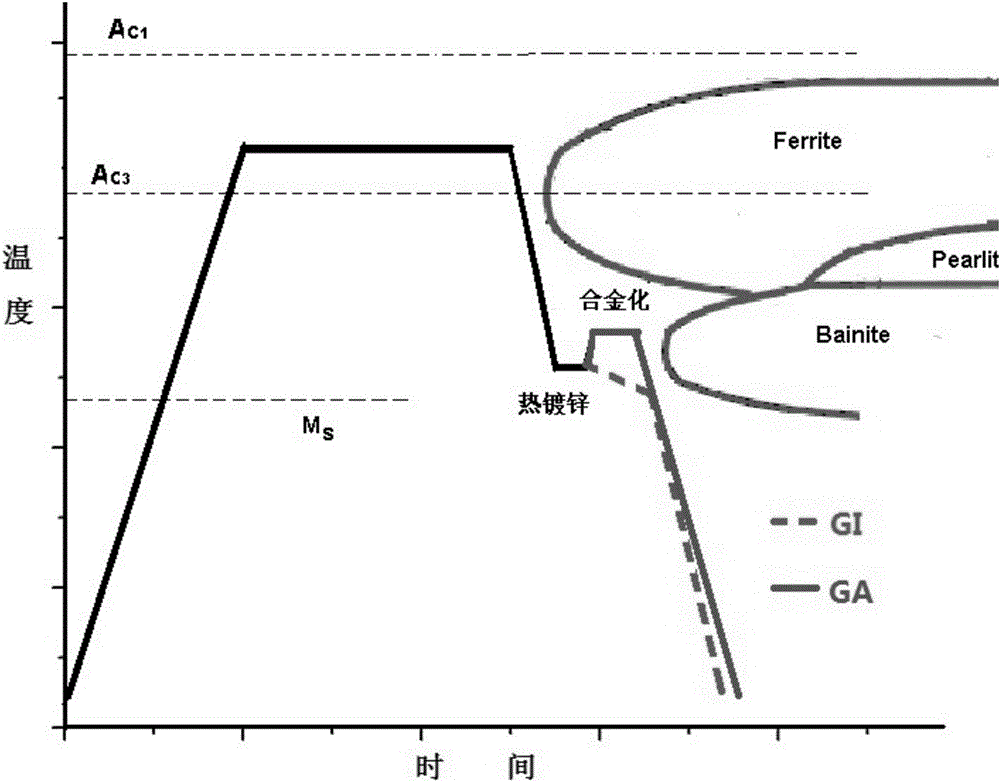

ActiveCN102719751AAdd lessReduce compositionTemperature control deviceContinuous annealingUltimate tensile strength

The invention discloses a high-strength cold-rolled hot-galvanized dual-phase steel plate, characterized in that components, in mass percentage, are: 0.03% to 0.15% of C, less than or equal to 0.15% of Si, 1.00% to 1.75% of Mn, less than or equal to 0.015% of P, less than or equal to 0.012% of S, 0.02% to 0.15% of Al, 0.35% to 0.75% of Cr, 0.02% to 0.15% of Cu, 0.010% to 0.035% of Ti, less than or equal to 0.005% of N, in addition meeting the requirement that the total percentage of Mn, 1.29Cr and 0.46Cu is not less than 1.5% and not more than 2.5%, and the balance being Fe and inevitable impurities. The manufacture method comprises converter smelting, secondary refining, continuous casting, hot continuous rolling, cold acid continuous rolling, annealing galvanizing and hot dipping, wherein a galvanized substrate with a reasonable organization and composition and an excellent plate shape is obtained through controlled rolling and controlled cooling while rolling; and through employing a micro-slowly cooling way for heating from an end segment to an isothermal segment and a secondary fast cooling way for a fast cooling segment during continuous annealing galvanizing, the cold-rolled hot-galvanized dual-phase steel plate is obtained, wherein the steel plate is advantageous by having a tensile strength between 490 to 700 MPa, well-matched strength and ductility, an excellent coating performance, and a thickness between 0.5 to 2.5 mm, and can be used as an automobile cover component, an inner plate, a structural component, etc.

Owner:ANGANG STEEL CO LTD

Production method for Si-contained cold-rolling hot galvanizing dual-phase steel with tensile strength reaching 800MPa level

ActiveCN106399857AStable productionLow costHot-dipping/immersion processesContinuous annealingImpurity

The invention relates to a production method for Si-contained cold-rolling hot galvanizing dual-phase steel with tensile strength reaching 800MPa level. The cold-rolling hot galvanizing dual-phase steel comprises, by mass, 0.08%-0.12% of C, 0.10%-0.18% of Si, 1.5%-2.5% of Mn, 0.2%-0.4% of Cr, 0.12%-0.20% of Mo, 0.03%-0.06% of Als, 0-0.015% of P, 0-0.04% of S, 0-0.005% of N, and the balance Fe and inevitable impurities. Due to the fact that chemical component design is combined with cold rolling, hot rolling, continuous annealing and hot galvanizing technical control, stable production of steel plates can be guaranteed. According to the steel produced through the method, yield strength is 426MPa-540MPa, tensile strength is larger than or equal to 800MPa, and the ductility is larger than or equal to 15%. The production method has the characteristics that cost is low, equipment is simple and product application performance is good.

Owner:马钢(合肥)钢铁有限责任公司

Steel mill continuous annealing galvanized sheet chromium-free compound passivator and preparation method thereof

InactiveCN103834938AImprove corrosion resistanceExcellent coating adhesion performanceAnti-corrosive paintsMetallic material coating processesChromium freeEnvironmental resistance

The invention discloses a steel mill continuous annealing galvanized sheet chromium-free compound passivator which comprises the following raw materials in percentage by weight: 5-20 percent by weight of a main film-forming agent, 0.1-5 percent by weight of a coupling agent, 0.1-0.5 percent by weight of inorganic complex film-forming agent, 0.1-4 percent by weight of silicate, 0.1-0.4 percent of an emulsifying agent, 0.1-0.2 percent of a dispersing agent, 0.1-0.4 percent of a corrosion inhibitor, 0.1-0.3 percent of a protective colloid, 0.1-1 percent of a nanometer sealing agent, 0.1-0.4 percent of phosphate and the balance of water. The steel mill continuous annealing galvanized sheet chromium-free compound passivator disclosed by the invention is uniform in appearance, stabilizes a liquid, has an expiration date of above 90 days, is nontoxic and environment-friendly, and accords with the ROHS (Restriction Of Hazardous Substances) requirement. The steel mill continuous annealing galvanized sheet chromium-free compound passivator is simple in preparation process; a passivated film is uniform in appearance and has certain glossness. A galvanized sheet passivated by using the passivator has the advantages that the corrosion resistance is remarkably improved, the neutral salt mist SST (Sea Surface Temperature) resistant time reaches above 72 hours, the white rust area is less than 5 percent, the blackening resistance delta E is less than 5, the yellowing resistance delta E is less than 3, the alkaline resistance delta E is less than 3, the interlamination resistance R is less than 3 omega / cm, and the conductivity is less than 1 m Omega.

Owner:NORTHEASTERN UNIV

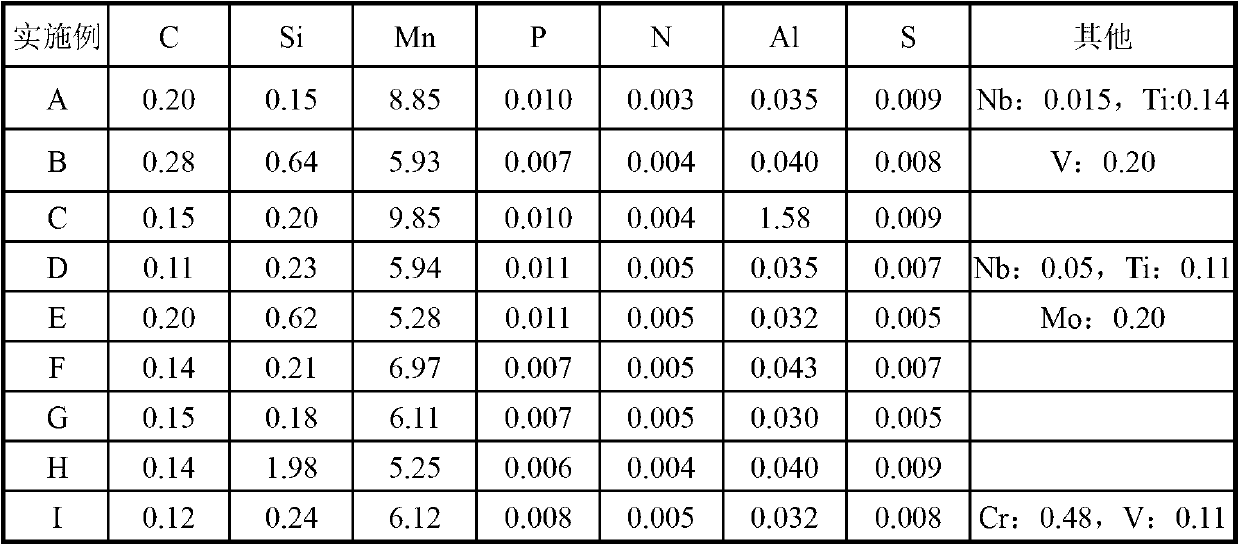

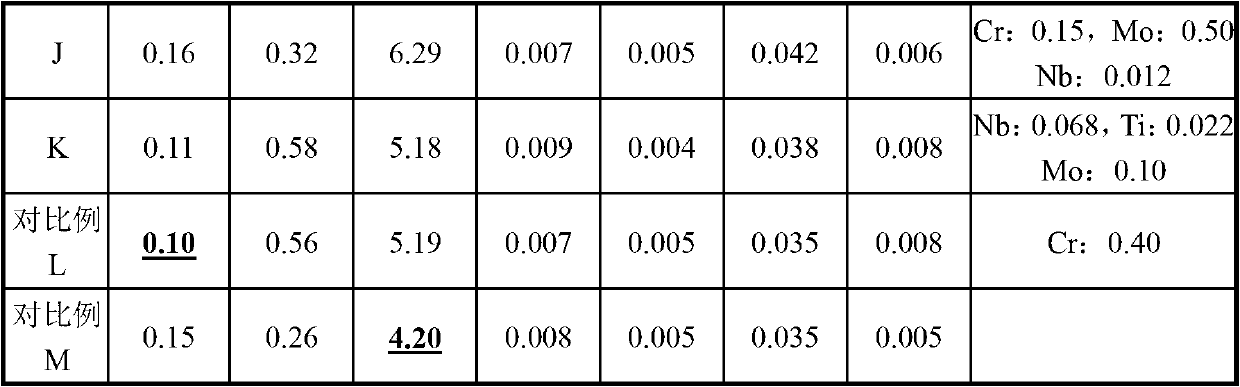

1000MPa-level automobile steel with high product of strength and elongation and manufacturing method thereof

ActiveCN102758133AMeet the requirements of manufacturing automotive structural partsFulfil requirementsChemical compositionHigh intensity

The invention discloses a 1000MPa-level automobile steel with high product of strength and elongation and a manufacturing method thereof. The automobile steel comprises the following chemical components in percentage by mass: 0.11-0.30% of C, 0.1-2.0% of Si, 5-10% of Mn, at most 0.02% of P, at most 0.02% of S, 0.01-2.0% of Al, at most 0.02% of N, and the balance of Fe and other inevitable impurities. Correspondingly, the invention also discloses a manufacturing method of the automobile steel, which comprises the following steps: smelting, casting, hot rolling, coiling, cover annealing, cold rolling and continuous annealing. The tensile strength of the automobile steel is greater than 1000MPa, and the product of strength and elongation is greater than or equal to 30GPa%; the automobile steel has high strength and high elongation percentage; and the manufacturing method is simple and easy to control, and is suitable for routine mass production for steel enterprises.

Owner:BAOSHAN IRON & STEEL CO LTD

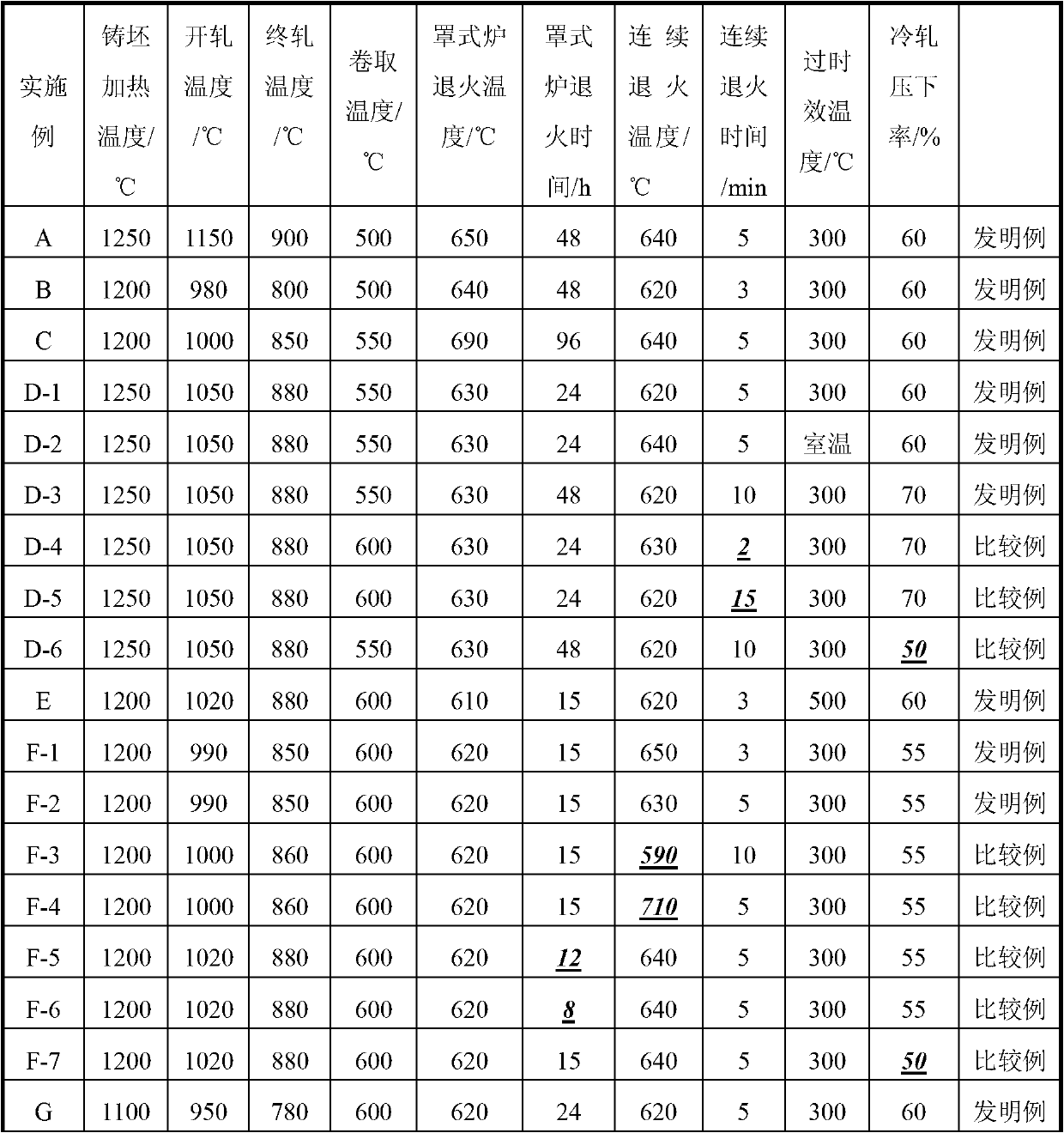

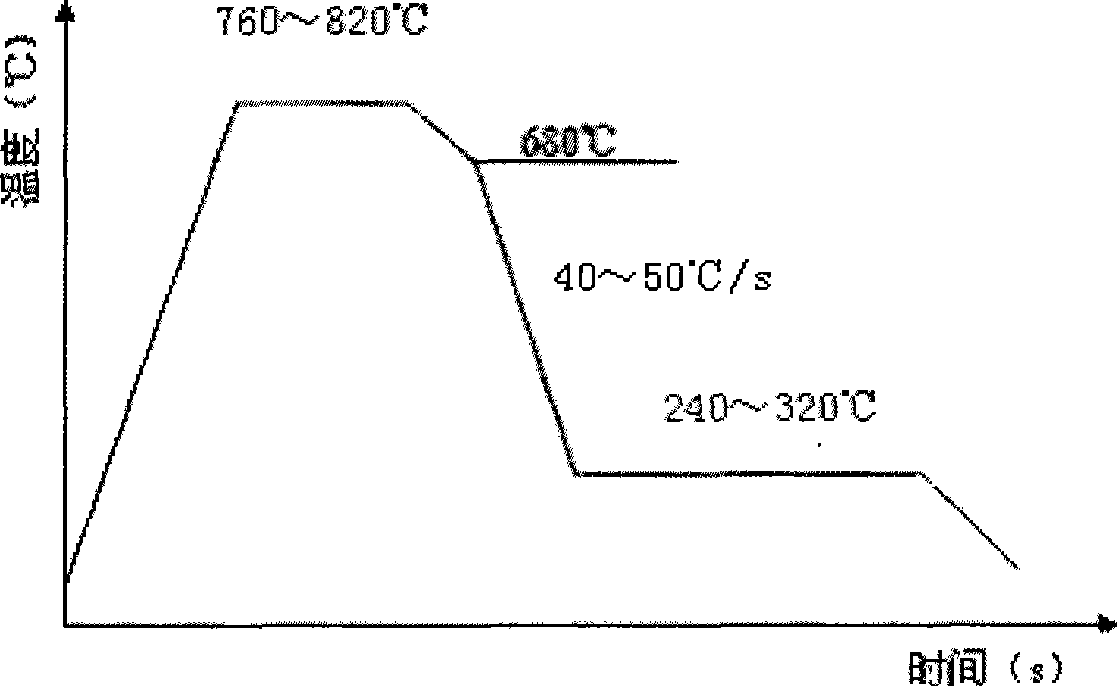

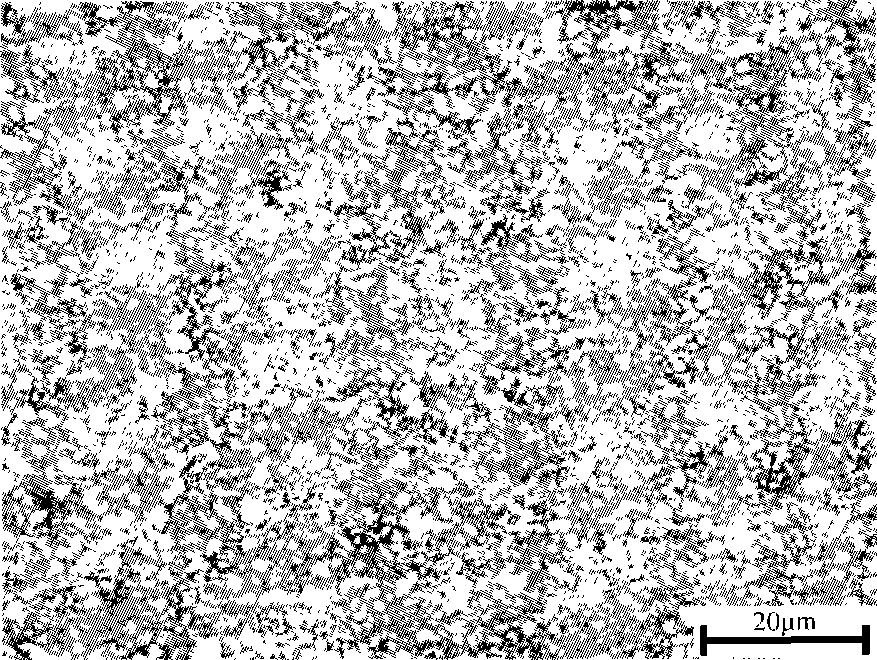

Cold rolled dual-phase sheet steel with 1000MPa grade tensile strength and preparation method thereof

A cold-rolled biphase steel plate with 1000 MPa of tensile strength and a production method thereof belong to the technical field of high-intensity cold-rolled biphase steel. The steel plate comprises the following chemical components by mass percentages: 0.14%-0.21% of C, 0.40%-0.90% of Si, 1.5%-2.1% of Mn, 0.01%-0.05% of Nb, less than 0.02% of P, less than 0.01% of S, and Fe and inevitable impurities. The production method is as follows: a billet is treated by the conventional hot rolling, pickling, cold rolling and continuous annealing, the annealing temperature is 760-820 DEG C and is kept for 70-120s, the fast cooling speed is 40-50 DEG C per second, the aging temperature is 240-320 DEG C and the aging time is 180-300s. The cold-rolled biphase steel plate has the advantages of high tensile strength, low tensile ratio, high initial work hardening rate, no yield elongation which avoids wrinkles on the formed parts. The cold-rolled biphase steel plate has a biphase organization with fine grain ferrite and martensite, wherein, the volume fraction of the martensite is 30%-40% and the average grain size of the ferrite is 2mum.

Owner:UNIV OF SCI & TECH BEIJING +1

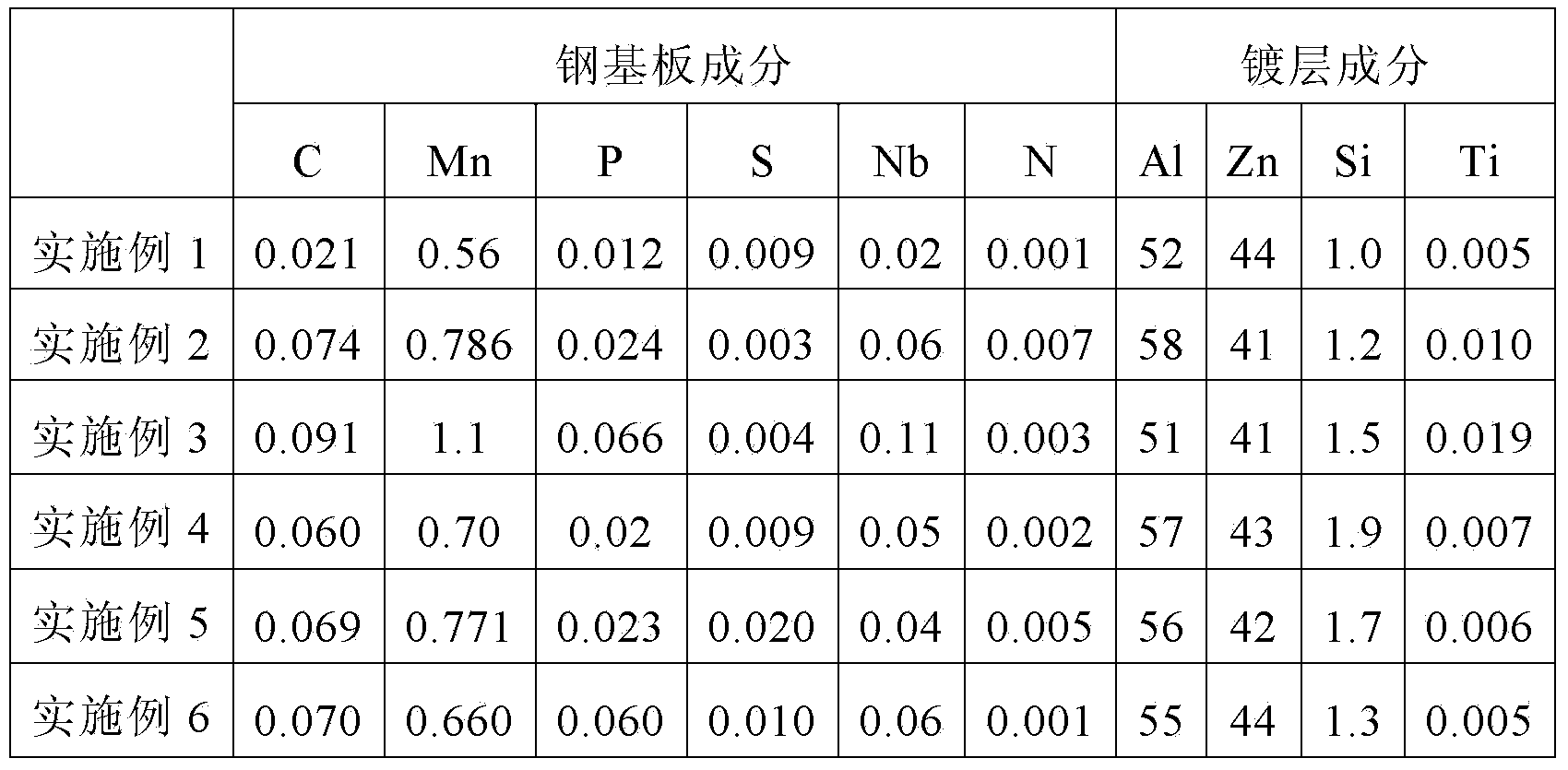

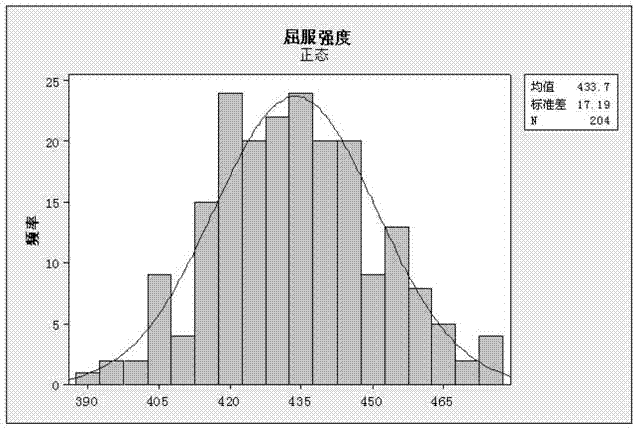

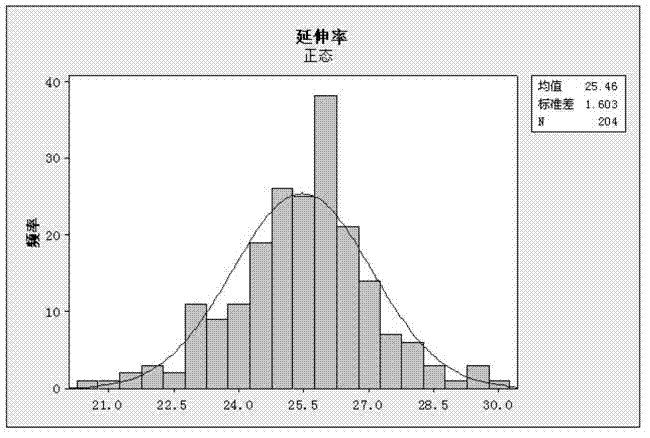

High-strength low-alloy hot-dip aluminized and galvanized steel strip and production method thereof

ActiveCN104264041AHigh strengthLow yield ratioHot-dipping/immersion processesAlloy coatingContinuous annealing

The invention relates to a high-strength low-alloy hot-dip aluminized and galvanized steel strip and a production method thereof. The hot-dip aluminized and galvanized steel strip comprises a steel base plate and an alloy coating, wherein the steel base plate comprises the following chemical components in percentage by weight: 0.02-0.10% of C, 0.5-1.2% of Mn, 0.01-0.07% of P, 0.01-0.12% of Nb, less than or equal to 0.0080% of N, less than or equal to 0.02% of S and the balance of Fe and inevitable impurities, wherein Nb-0.22C-1.1N is equal to or greater than 0.01% and less than or equal to 0.1% and Mn / 1.7S is equal to or greater than 8; the alloy coating comprises the following chemical components in percentage by weight: 50-58% of Al, 40-45% of Zn, 1.0-2.0% of Si, 0.005-0.020% of Ti and the balance of unavoidable impurities. According to the hot-dip aluminized and galvanized steel strip, by virtue of smelting, casting, carrying out hot rolling and cold rolling, continuously annealing and carrying out hot-dip aluminizing and galvanizing, the aluminum-zinc coating is evenly and densely adhered to the steel base plate, the obtained low-alloy hot-dip aluminized and galvanized steel strip has the yield strength of 410-570MPa, the tensile strength equal to or greater than 470MPa and elongation equal to or greater than 15% and has both good strength and toughness and excellent corrosion resistance. The production process is low in cost and high in steel plate yield.

Owner:BAOSHAN IRON & STEEL CO LTD

Production method of 460MPa grade high-surface quality structural hot dipped galvanized steel plate and its product

InactiveCN102787271AReduce C, SiGood adhesionHot-dipping/immersion processesTemperature control deviceMetallurgyHigh surface

The invention relates to a 460MPa grade high-surface quality structural hot dipped galvanized steel plate and its production method. The method consists of steps of: conducting continuous casting on molten steel; carrying out hot continuous rolling on a steel billet; performing cold rolling on the steel billet subjected to hot continuous rolling; implementing continuous annealing; and conducting galvanizing, thus obtaining the galvanized plate. The hot dipped galvanized steel plate comprises, by mass: 0.040%-0.10% of C; less than or equal to 0.060% of Si; 0.60%-0.80% of Mn; less than or equal to 0.035% of P; less than or equal to 0.035% of S; 0.020%-0.060% of Al; less than or equal to 0.080% of Nb and Ti; and the balance Fe.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

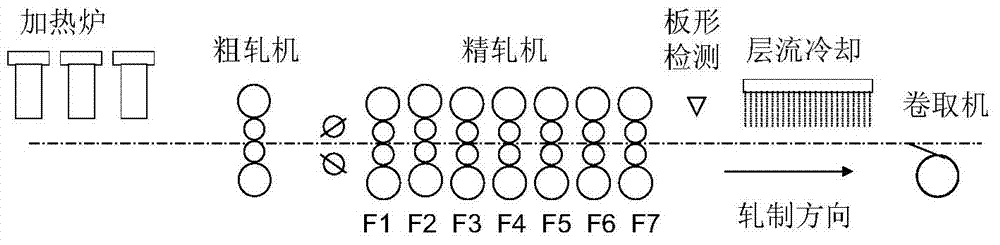

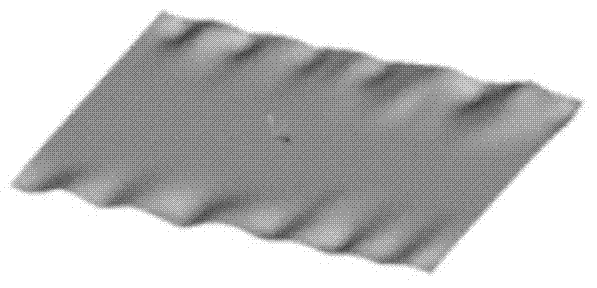

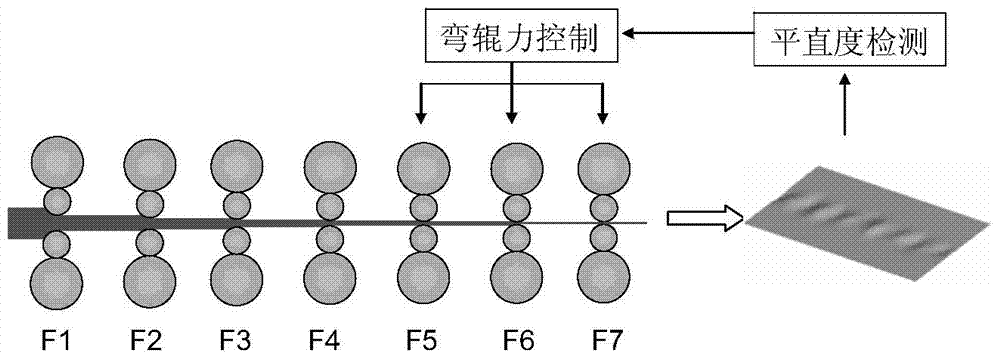

Slight center wave strip-shape control method of hot-rolled strip steel

ActiveCN104511484AFlat thickness distributionEasy to scratchProfile control deviceMartensitic stainless steelEngineering

The invention relates to a slight center wave strip-shape control method of hot-rolled strip steel. The method comprises the following steps: firstly, choosing a strip-shape feedback control frame; utilizing the adjusting manner of upstream frames, namely, adjusting the roll bending forces of the frames F2-F4 to realize the targeted slight center waves at a precision rolled outlet; secondly, controlling and adjusting the roll bending forces; detecting the flatness of the strip steel in real time by a strip-shape instrument and comparing it with a target value; if the deviation exists, adjusting the roll bending forces of the frames F2-F4. The slight center wave strip-shape control method of hot-rolled strip steel is applicable to overcoming strip-shape problems caused by the stages such as cooling and thermal treatment after hot rolling; the strip-shape quality of martensitic stainless steel strips is improved greatly and the scratching on the surface strip-shape in follow-up pickling and continuous annealing production is solved.

Owner:BAOSHAN IRON & STEEL CO LTD +1

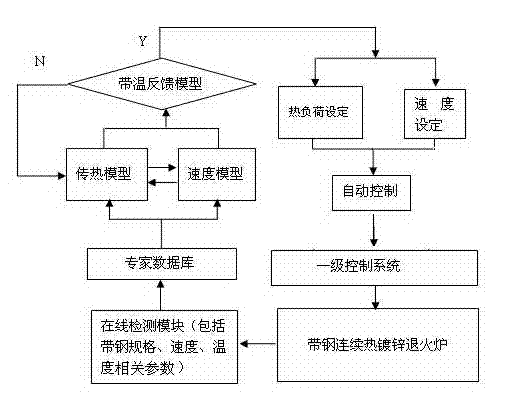

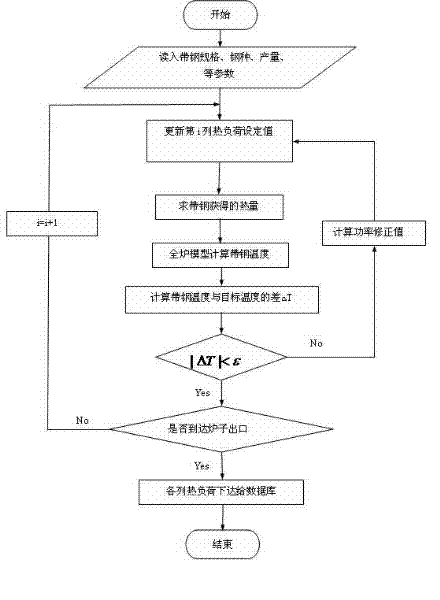

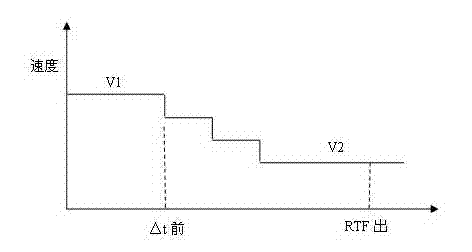

Online comprehensive control method for hot-galvanized continuous annealing furnace

ActiveCN102392119ASimple structureRealize online production controlFurnace typesAdaptive controlAutomatic controlControl system

The present invention discloses an online comprehensive control method for a hot-galvanized continuous annealing furnace. The method collects the operating information, including band steel speed, processing technique, steel coil codes and band steel specifications, of band steel through an online detection module. According to the collected operating information of band steel, the method calls main parameters through an expert database, so as to complete thermal load setting and speed setting by the co-operation of a speed model, a heat transfer model and a band temperature feedback model. Therefore, according to the set parameters, the method automatically controls a primary control system, so as to achieve the online production control of an annealing furnace. Based on heat transfer mechanism analysis, the method achieves the online production control of an annealing furnace by building a one-dimensional math model and the expert database with two cross-control methods: coarse tuning and fining tuning. In addition, the method also provides an additional series of complete control strategies such as a transition control method, so as to form a relative perfect control method. The models can be built conveniently and operate fast. Therefore, the method is suitable for the online production computation and control of an annealing furnace.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com