Hot galvanizing steel plate for car and production method thereof

A technology of hot-dip galvanized steel sheet and production method, which is applied in the direction of metal rolling, can solve the problems of unfavorable auxetic forming and low n90 value, and achieve the effect of meeting production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

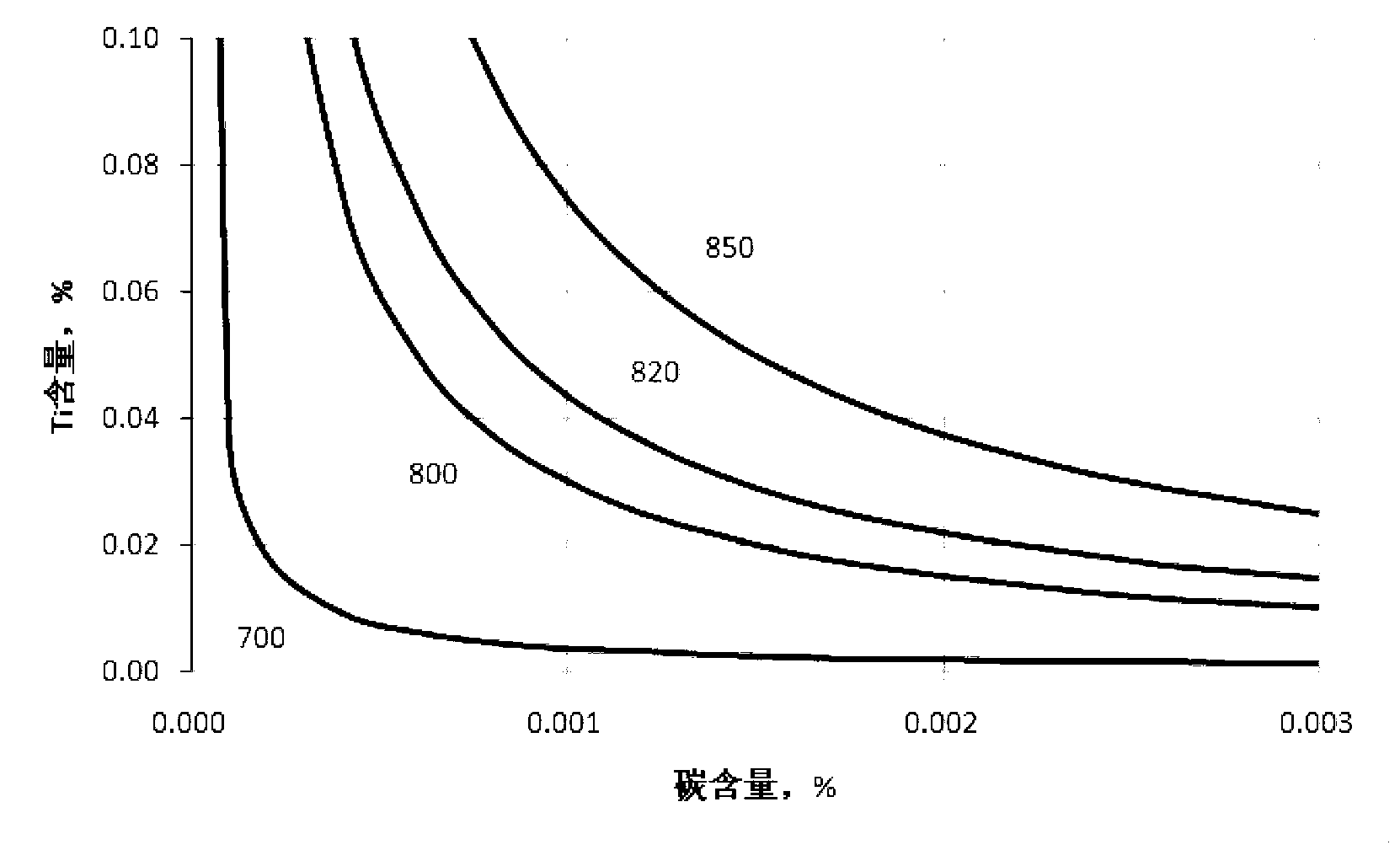

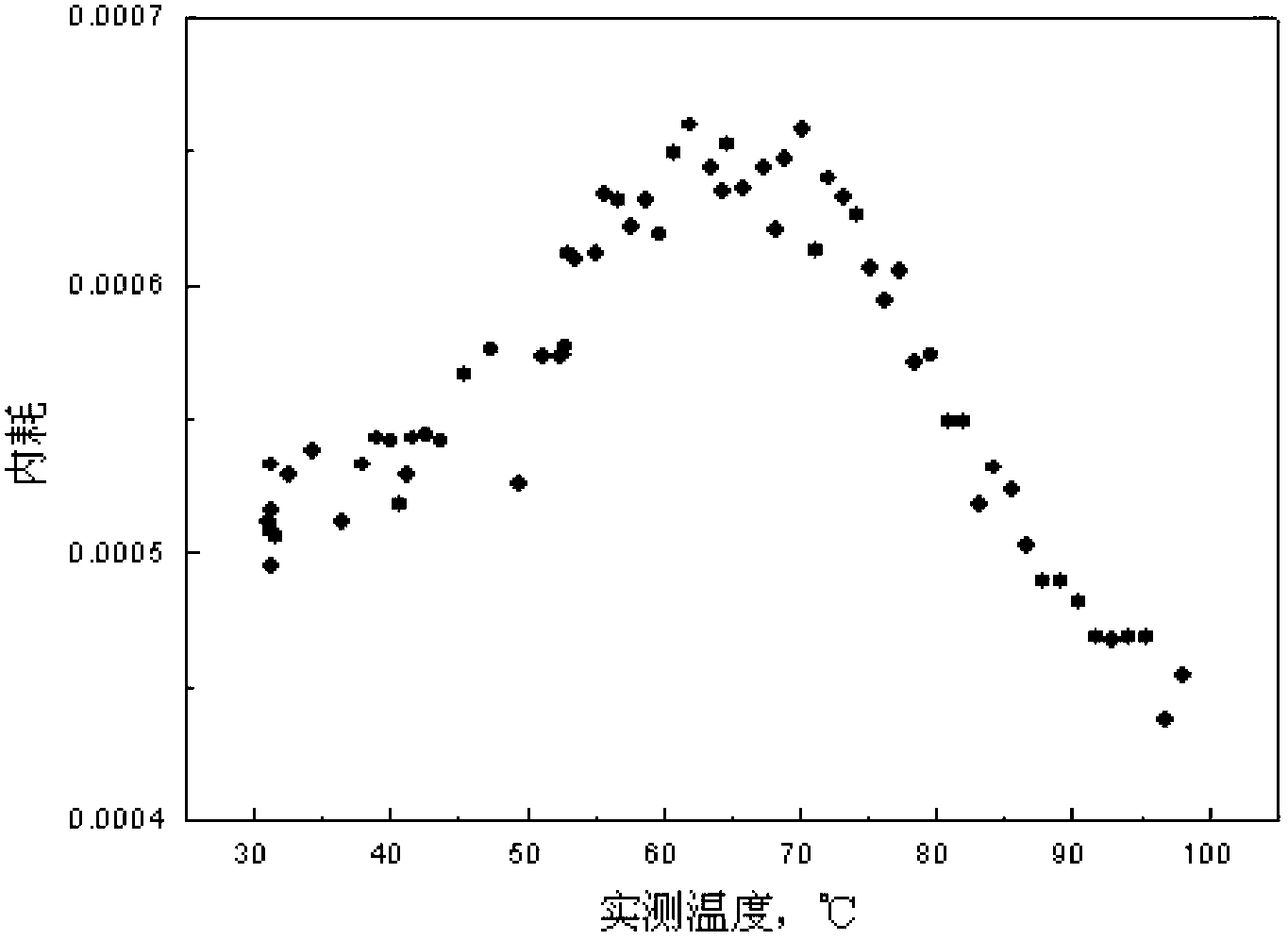

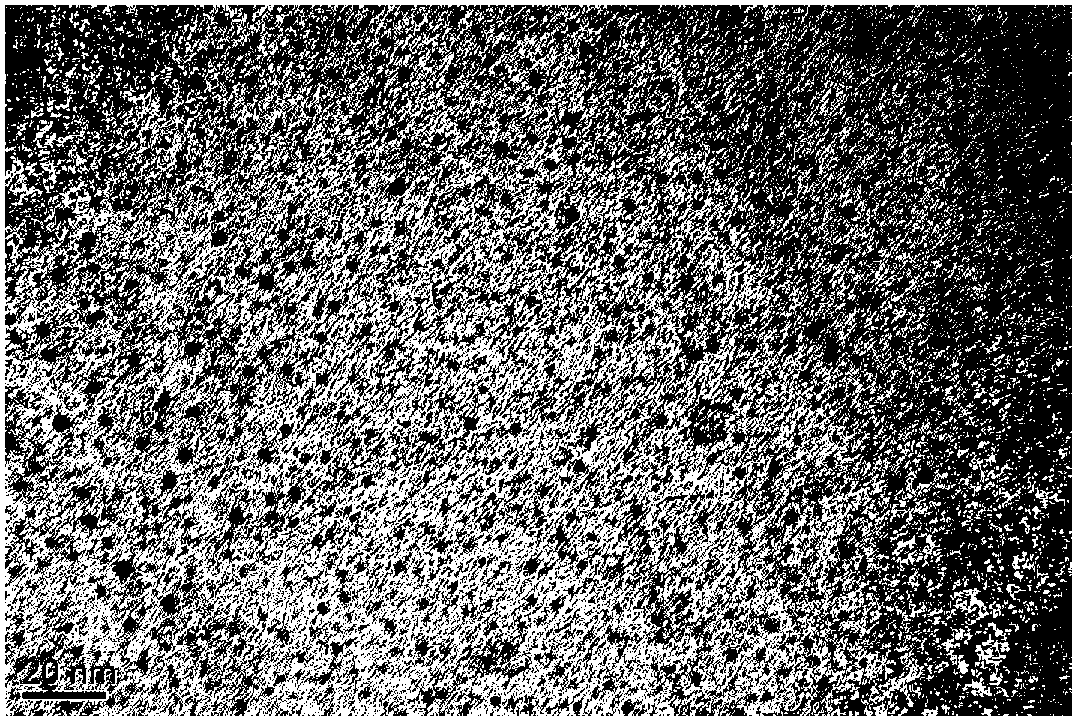

Method used

Image

Examples

Embodiment 1

[0069] According to a method for producing steel sheets for automobiles provided in the present invention, the mass percentages of the chemical components of the steel sheets for automobiles produced are: C: 0.003%, Mn: 0.14%, Si: 0.010%, P: 0.010%, S: 0.008%, Alt: 0.038%, Ti: 0.078%, B: 0.004%, N: 0.004%, and the balance is Fe and trace elements. The production process of the steel for automobile sheet is to first smelt molten iron to obtain a steel slab, and then heat the slab. The heating temperature of the slab is 1160°C, the heating time is 3.2 hours, the final rolling temperature is 920°C, and the curling temperature is 720°C. , and then pickling on the pickling mill to remove the surface oxide scale, and then enter the 5-stand cold rolling mill to obtain chilled coils with a reduction rate of 80%. The chilled coil is finally annealed in a vertical continuous annealing furnace, hot-dip galvanized, and skin-passed (0.5% skin elongation), and finally a steel plate for auto...

Embodiment 2

[0073] The difference between this embodiment and Example 1 is that, according to the method for producing steel sheets for automobiles provided in the present invention, the mass percentages of the chemical components of the steel sheets for automobiles produced are: C: 0.0015%, Mn: 0.10%, Si: 0.01 %, P: 0.02%, S: 0.015%, Alt: 0.07%, Ti: 0.09%, B: 0.001%, N: 0.004%, and the balance is Fe and trace elements. The slab heating temperature was 1180° C., and the heating time was 3.4 hours. The specification of the steel plate is 0.7*1200, the reduction rate of cold rolling is 80%, and the skin elongation rate is 0.7%. Other places are completely consistent with embodiment 1. The temperature and mechanical properties of each stage of the annealing process are shown in Table 2.

[0074] Table 2 Mechanical properties of 0.7×1200mm automotive steel plates

[0075]

Embodiment 3

[0077] The difference between this example and Example 1 is that, according to the method for producing steel sheets for automobiles provided in the present invention, the mass percentages of the chemical components of the steel sheets for automobiles produced are: C: 0.001%, Mn: 0.05%, Si: 0.03 %, P: 0.009%, S: 0.008%, Alt: 0.04%, Ti: 0.066%, B: 0.005%, N: 0.0002%, and the balance is Fe and trace elements. The slab heating temperature is 1130°C, the heating time is 3 hours, the finish rolling temperature is 940°C, the coiling temperature is 750°C, the steel plate size is 0.8*1450, the cold rolling reduction rate is 77%, and the skin elongation rate is 0.8% Other places are completely consistent with embodiment 1. The temperature and mechanical properties of each stage of the annealing process are shown in Table 3.

[0078] Table 3 Mechanical properties of 0.8×1450mm automotive steel plates

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com