Patents

Literature

4822 results about "Sulfur content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfur Content. Sulfur content of crude oils is the second most important property of crude oils next to API gravity. Sulfur content is expressed as weight percent of sulfur in oil and typically varies in the range from 0.1 to 5.0%wt.

Sorbent composition, process for producing same and use in desulfurization

Particulate sorbent compositions comprising a mixture of zinc oxide, silica, alumina and a substantially reduced valence nickel are provided for the desulfurization of a feedstream of cracked-gasoline or diesel fuels in a desulfurization zone by a process which comprises the contacting of such feedstreams in a desulfurization zone followed by separation of the resulting low sulfur-containing stream and sulfurized-sorbent and thereafter regenerating and activating the separated sorbent before recycle of same to the desulfurization zone.

Owner:CHINA PETROLEUM & CHEM CORP

Sorbent composition, process for producing same and use in desulfurization

A particulate adsorbent composition comprising a mixture of zinc oxide, silica, alumina and substantially reduced valence cobalt for use in desulfurizing a cracked gasoline or diesel fuel feed stream in a desulfurization zone by: The desulfurization zone contacts the feed stream, then separates the resulting low sulfur content stream and the sulfurized adsorbent, regenerates and activates the separated adsorbent, and then returns to the desulfurization zone.

Owner:CHINA PETROLEUM & CHEM CORP

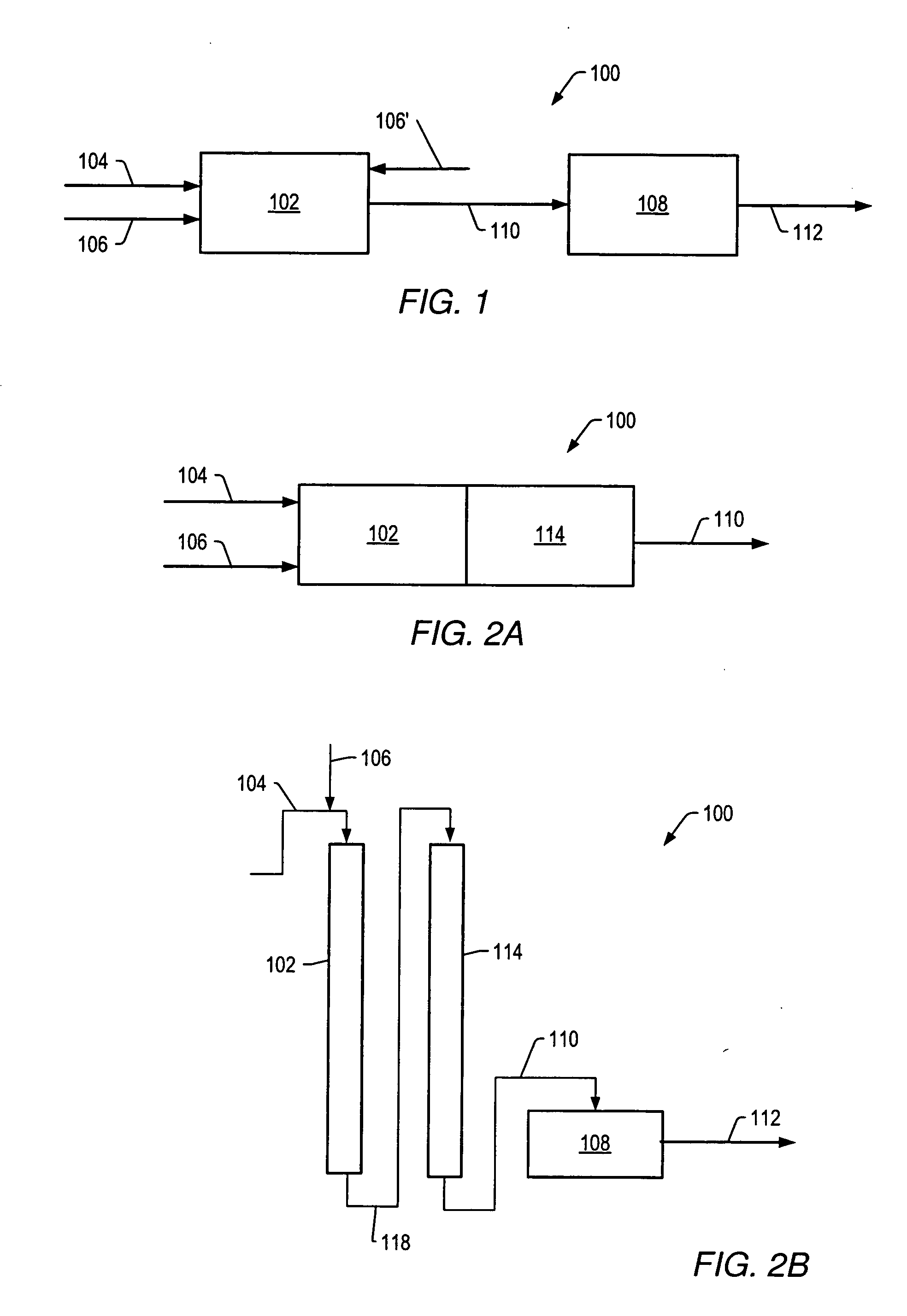

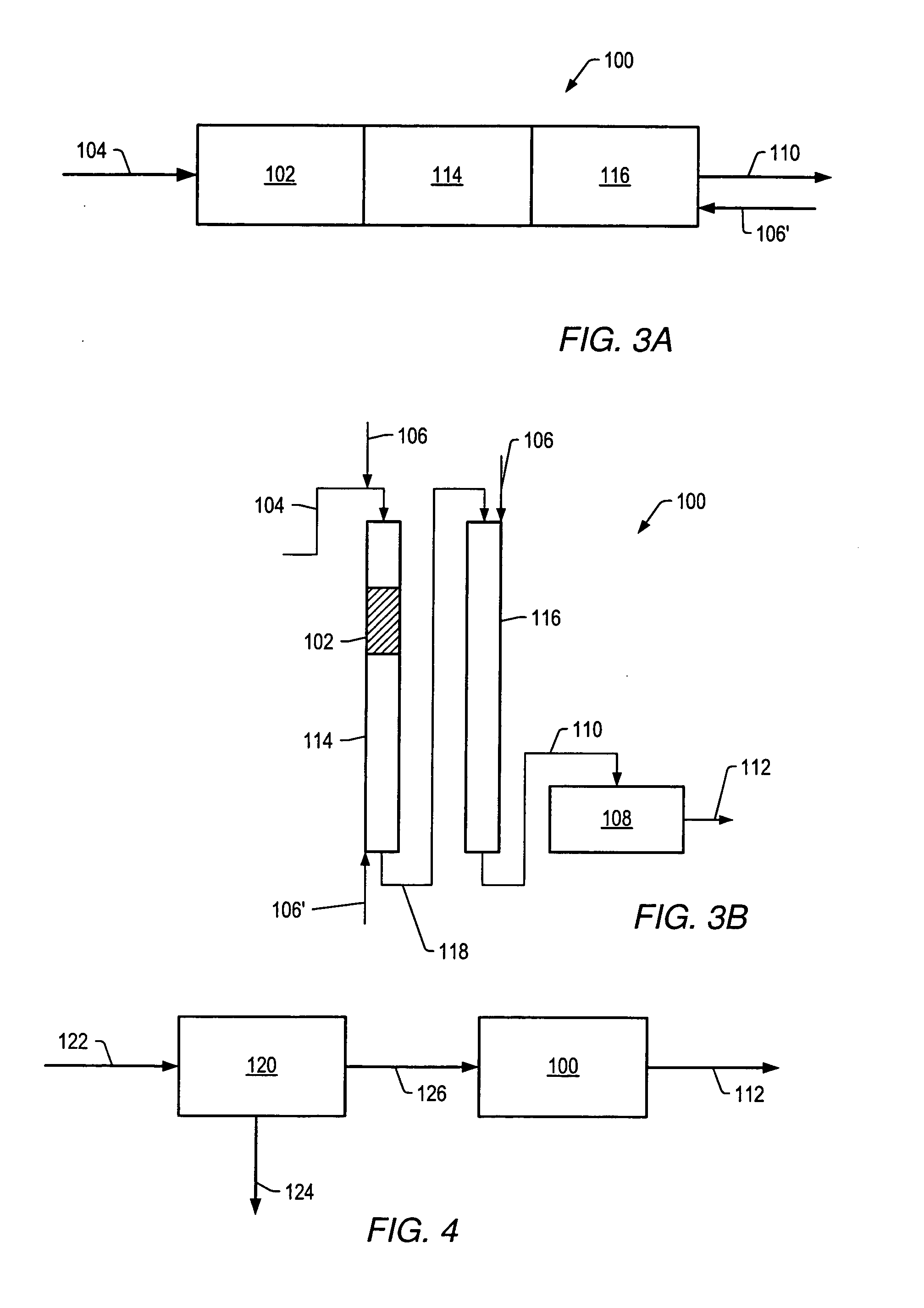

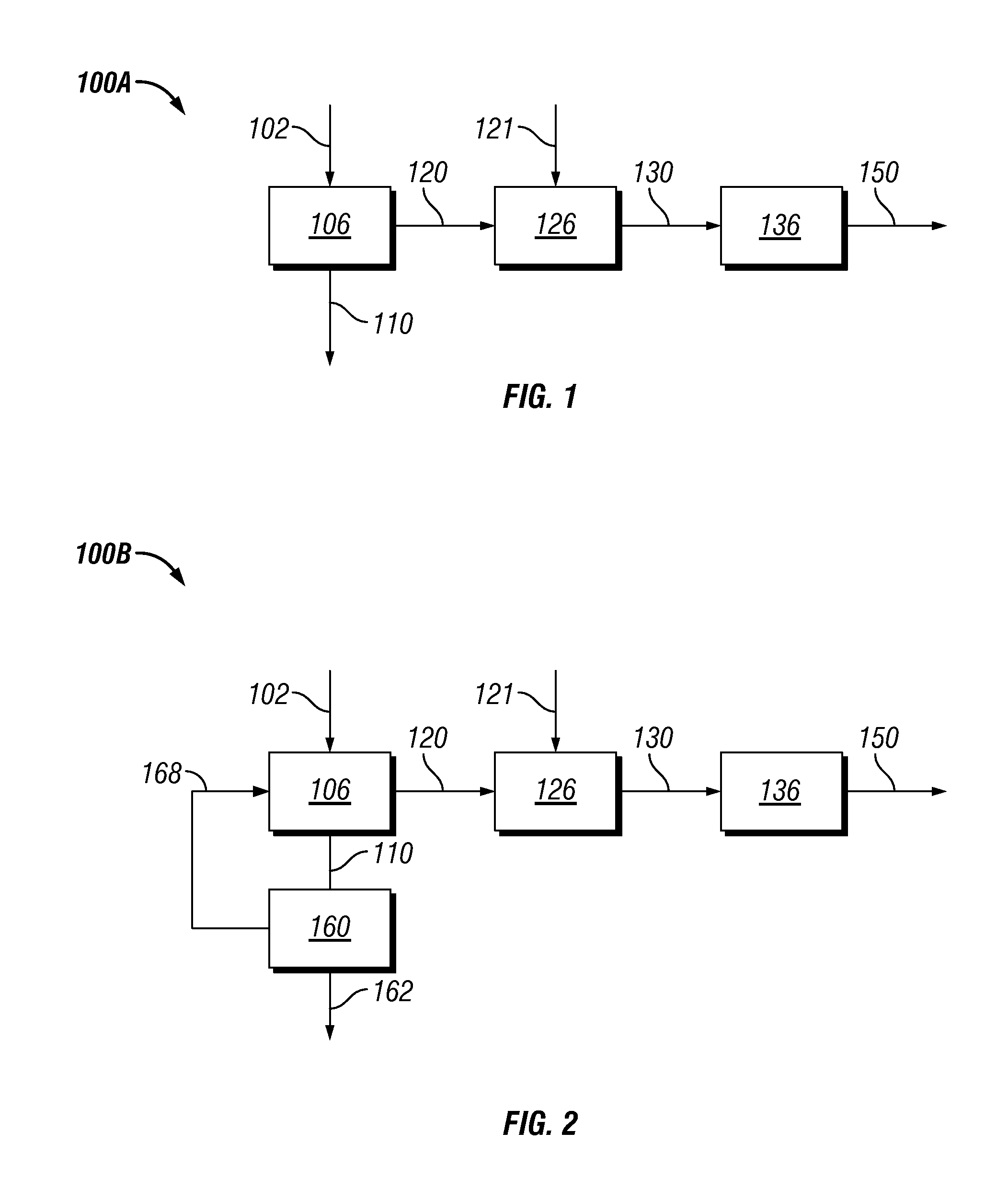

Systems, methods, and catalysts for producing a crude product

InactiveUS20050133414A1Reduce contentCatalytic crackingRefining with metal saltsOxygen contentChemistry

Contact of a crude feed with one or more catalysts produces a total product that includes a crude product. The crude feed may include Micro-Carbon Residue (MCR), oxygen, sulfur, or mixtures thereof. The crude product is a liquid mixture at 25° C. and 0.101 MPa. The crude product may have a MCR residue and / or oxygen content of at most 90% of the MCR residue content and / or oxygen content of the crude feed. In some instances, the crude product may have a sulfur content of about 30% to about 70% of the sulfur content of the crude feed. One or more other properties of the crude product may be changed by at least 10% relative to the respective properties of the crude feed.

Owner:SHELL OIL CO

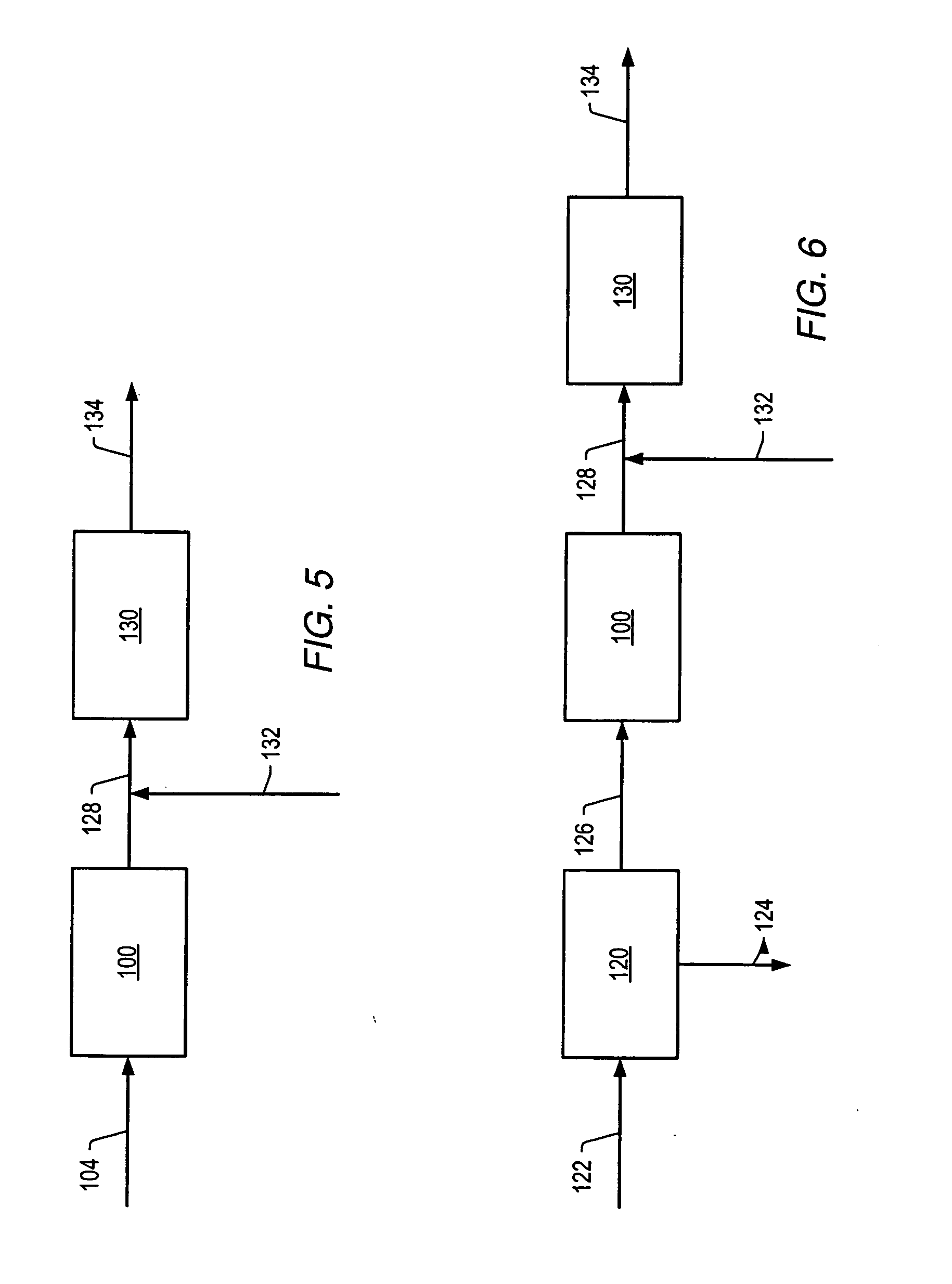

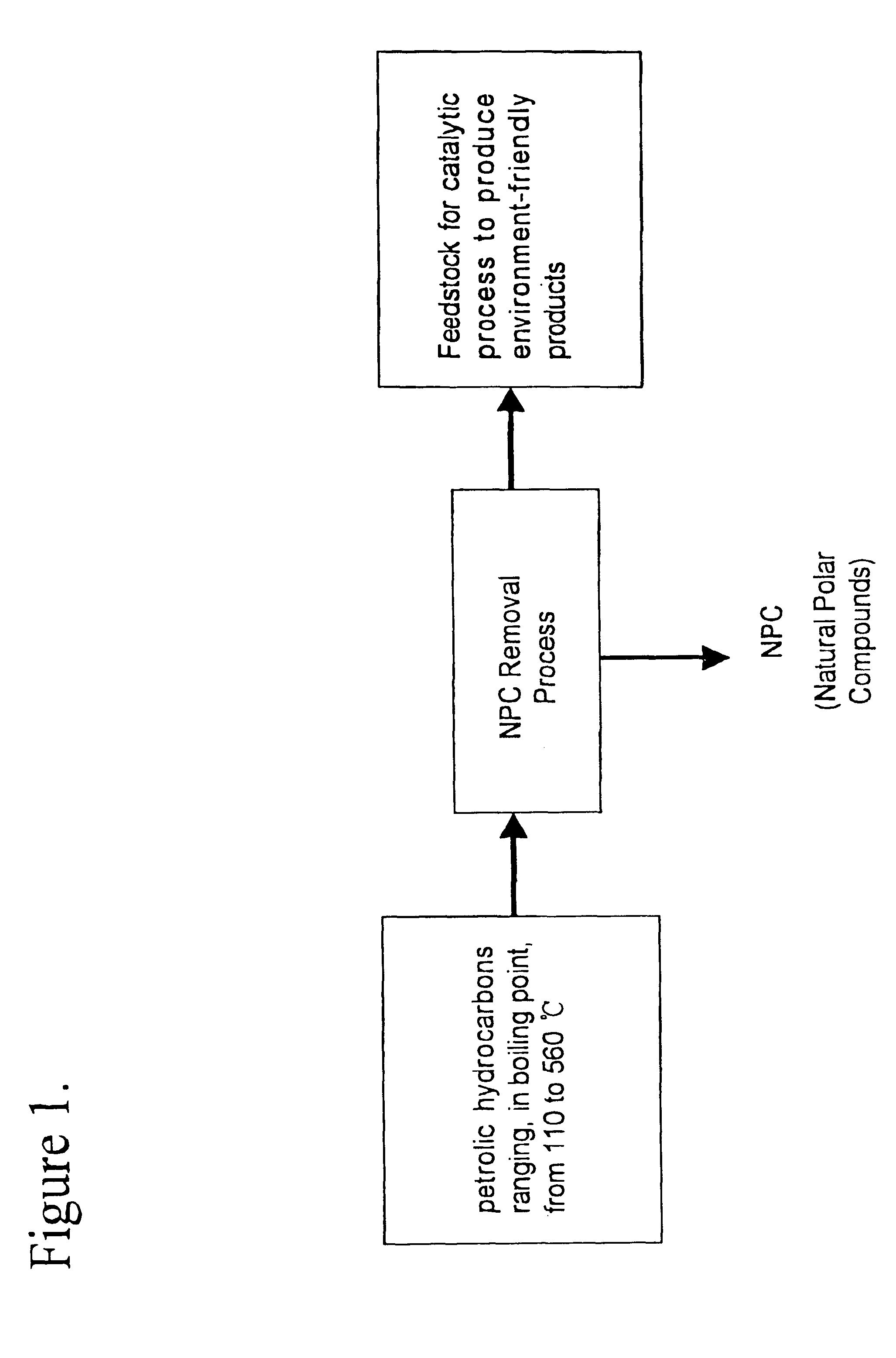

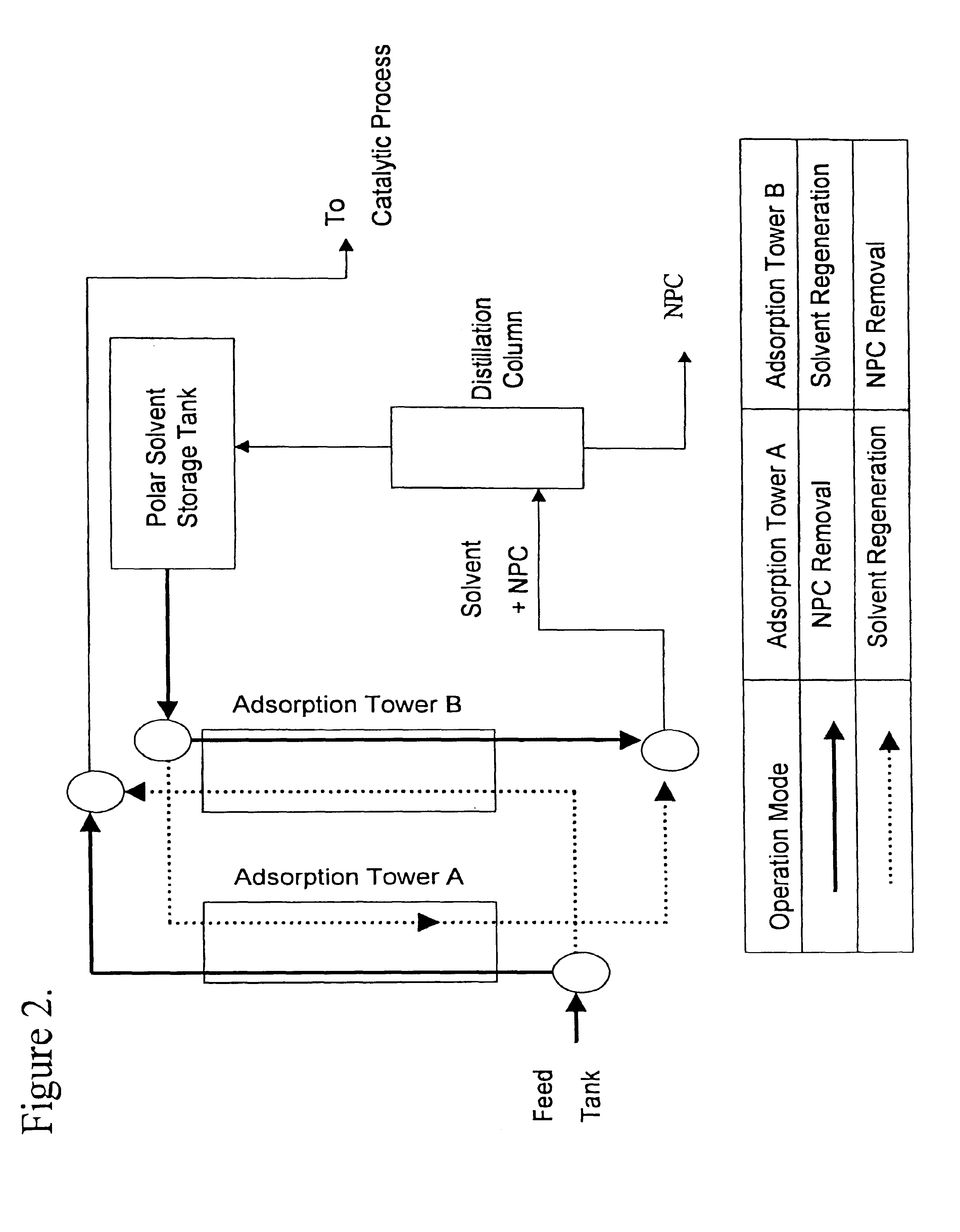

Method for manufacturing cleaner fuels

InactiveUS6248230B1Long catalyst lifeReduce hydrogen consumptionLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesBoiling pointGasoline

A method is provided for manufacturing cleaner fuels, in which NPC (Natural Polar Compounds), naturally existing in small quantities within various petrolic hydrocarbon fractions, are removed from the petrolic hydrocarbon fractions ranging, in boiling point, from 110 to 560° C. and preferably from 200 to 400° C., in advance of catalytic hydroprocessing. The removal of NPC improves the efficiency of the catalytic process and produces environment-friendly products, such as diesel fuel with a sulfur content of 50 ppm (wt) or lower. Also, the NPC can be used to improve fuel lubricity.

Owner:SK ENERGY CO LTD (KR)

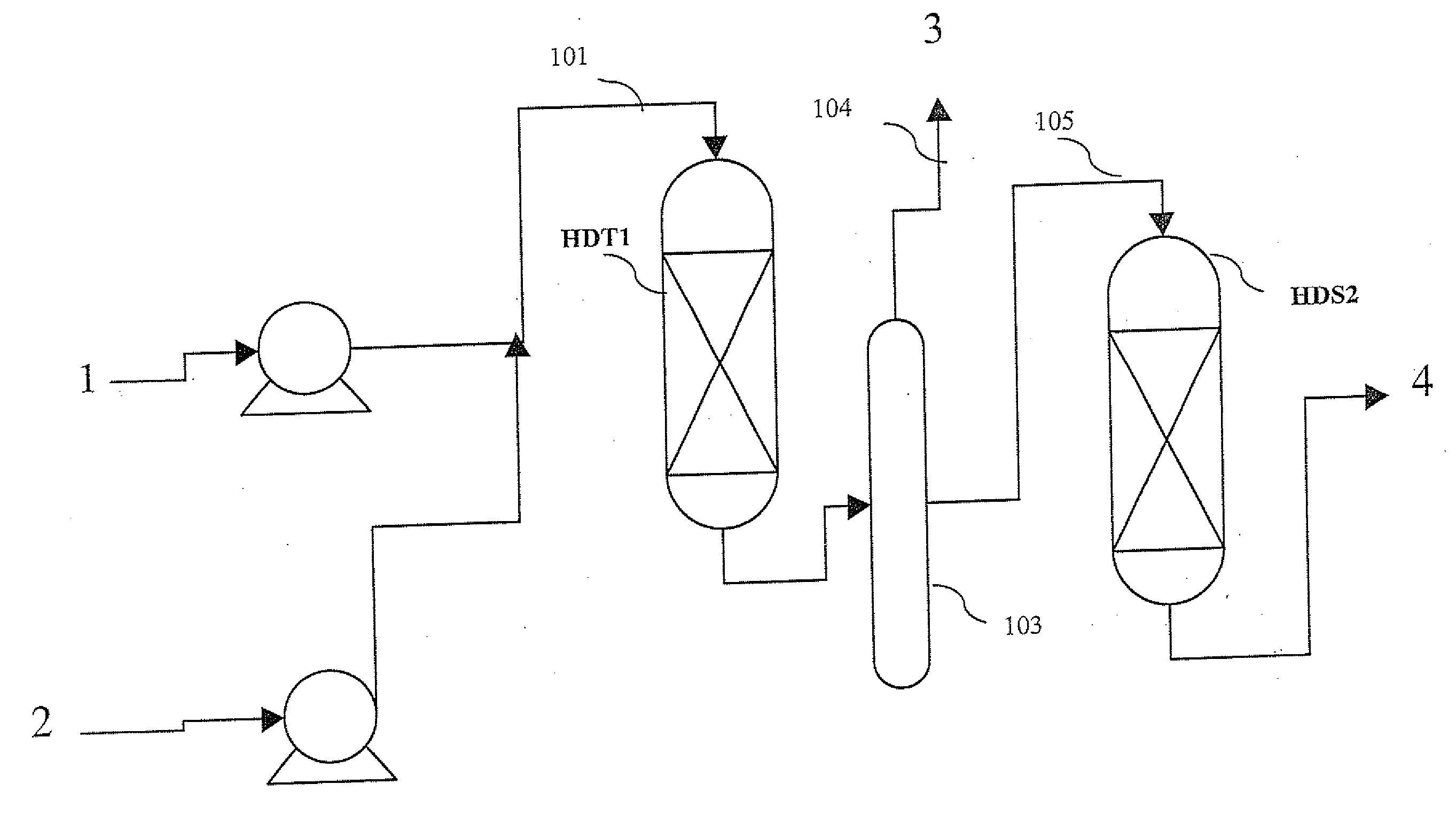

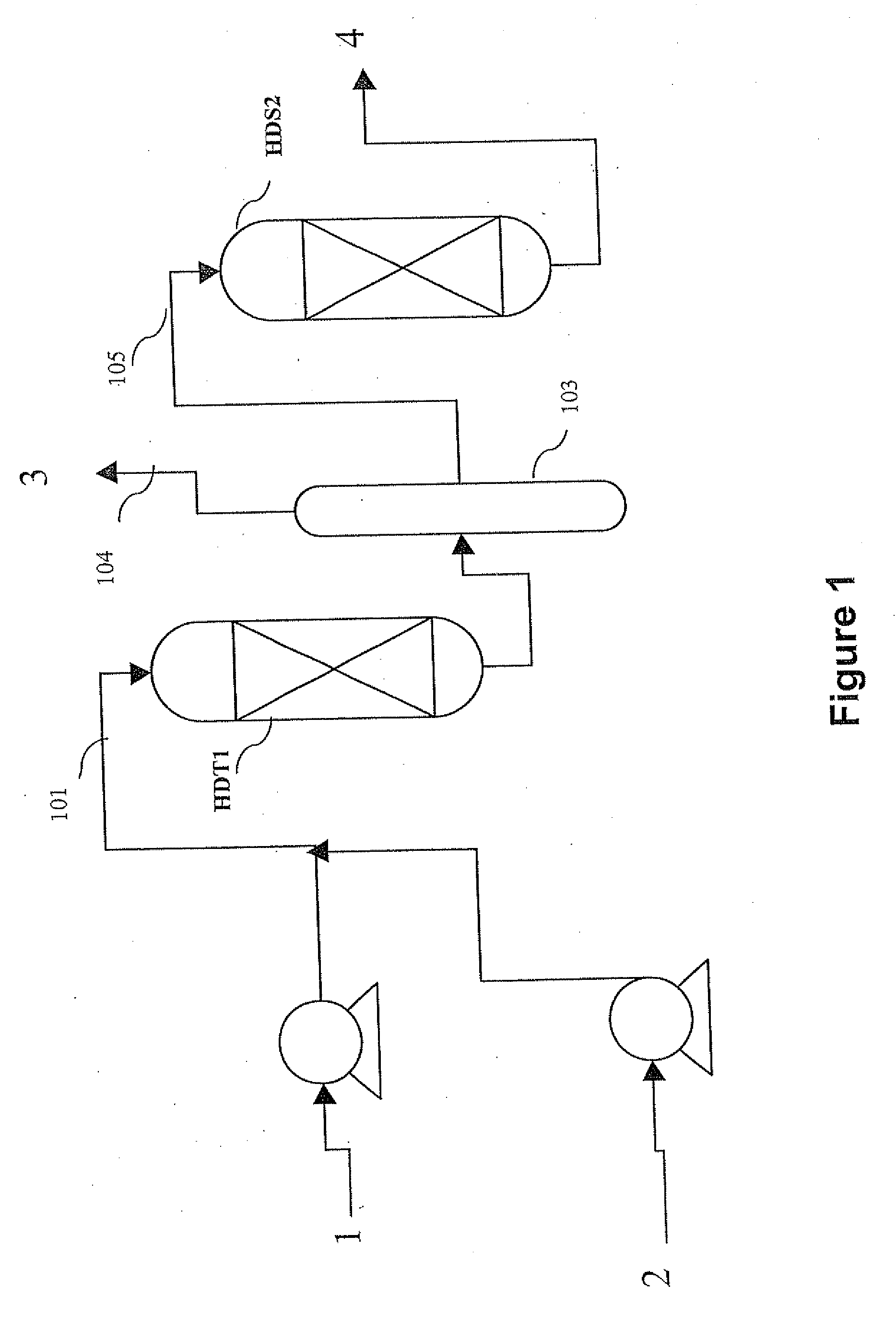

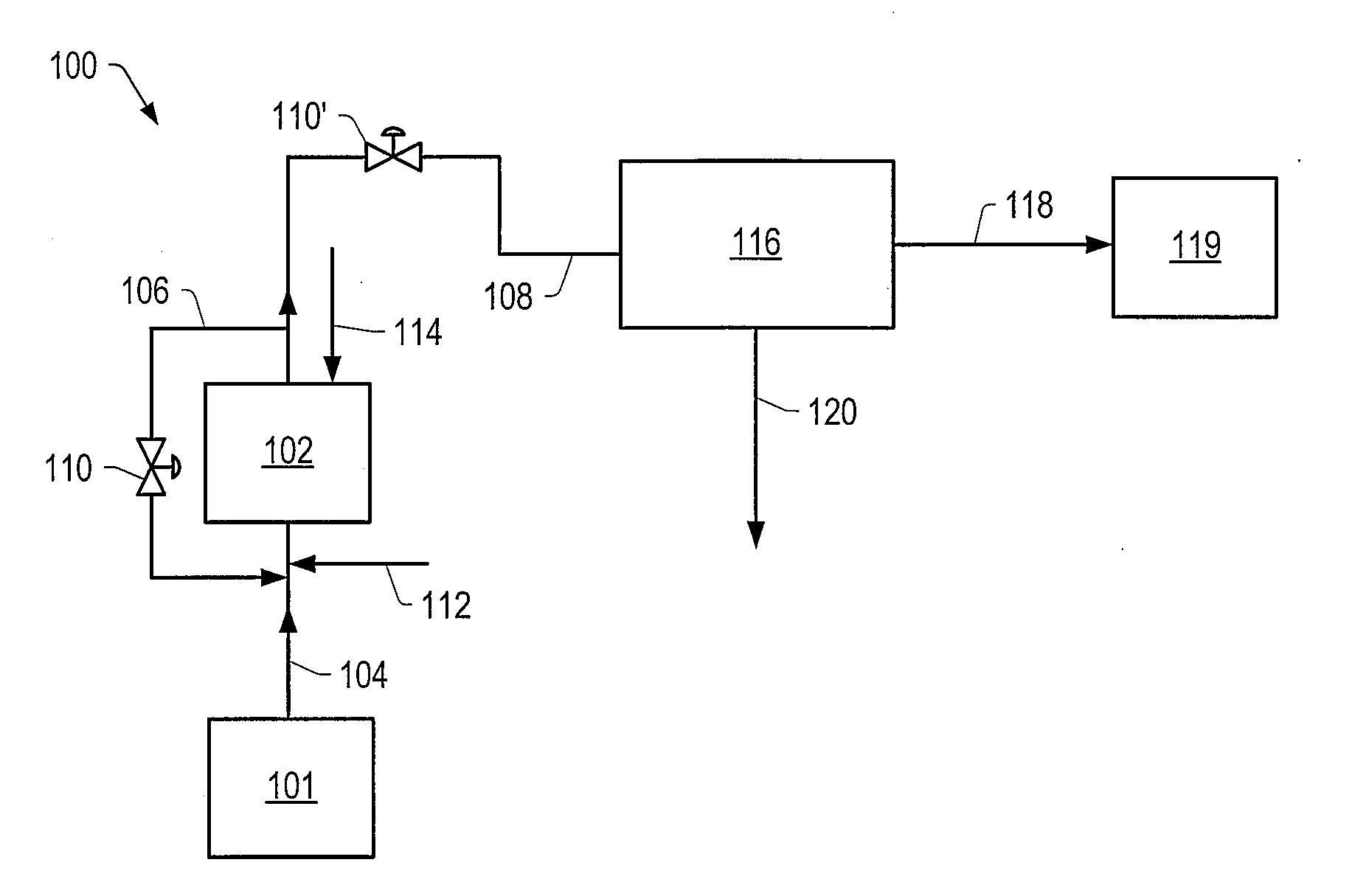

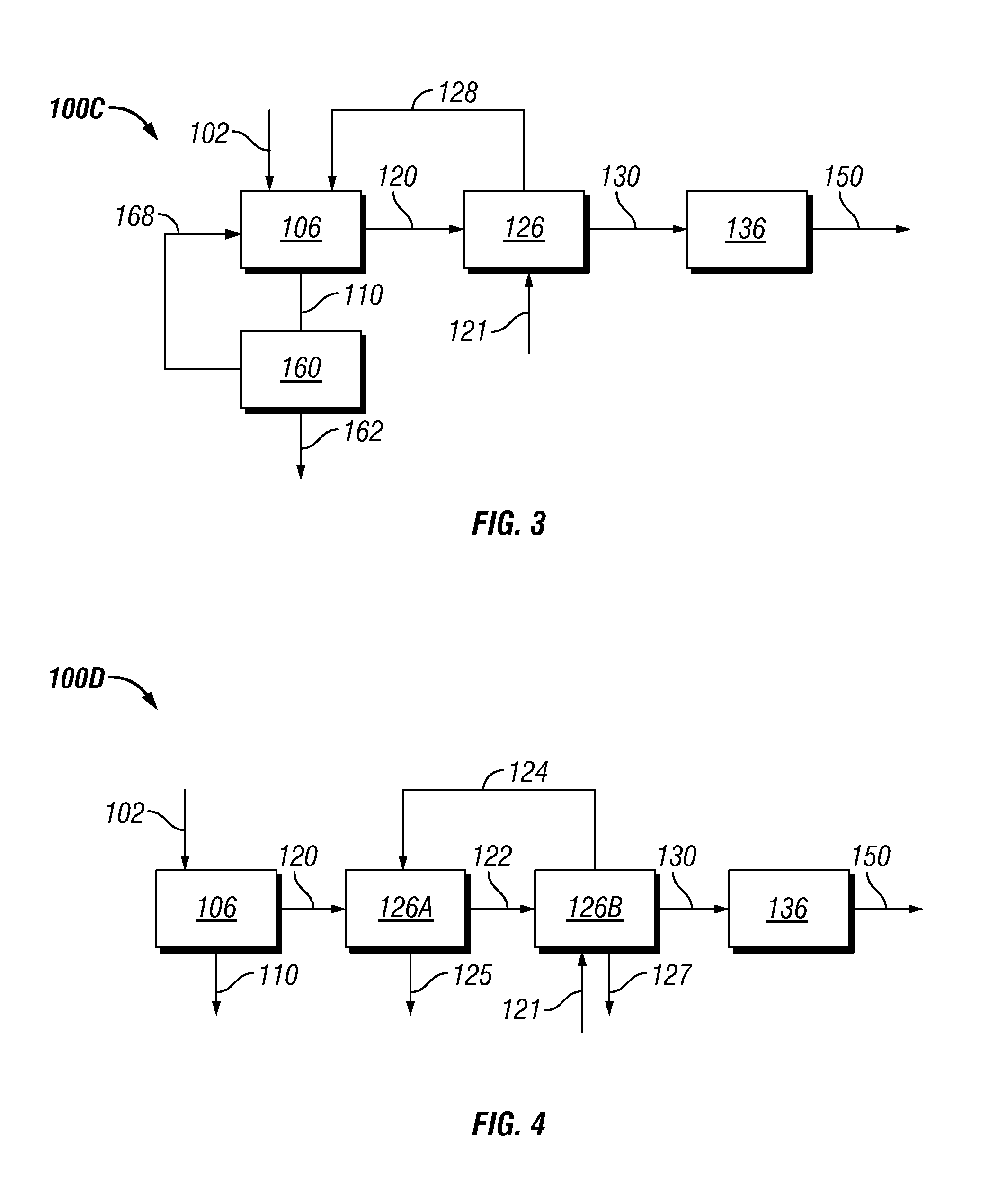

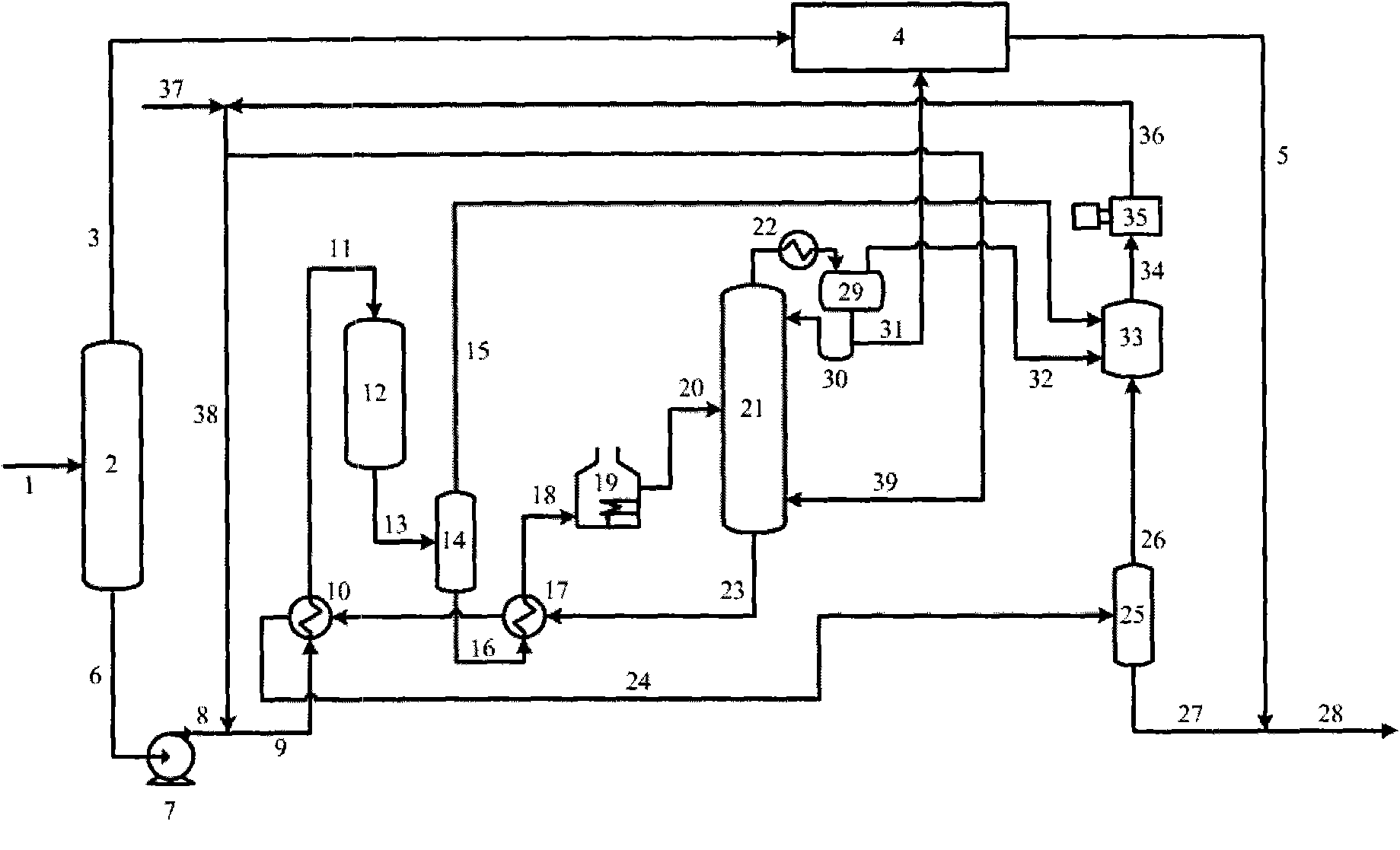

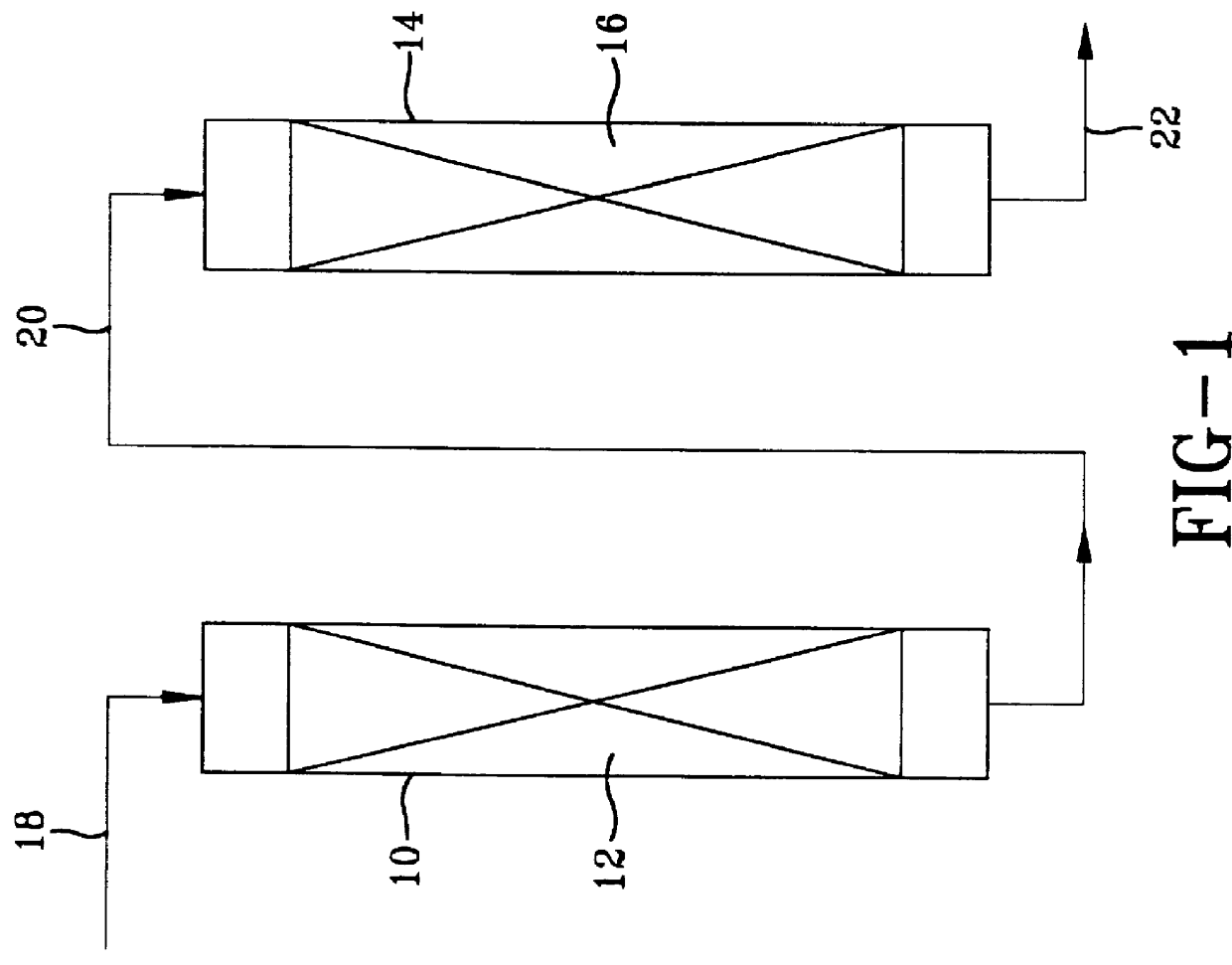

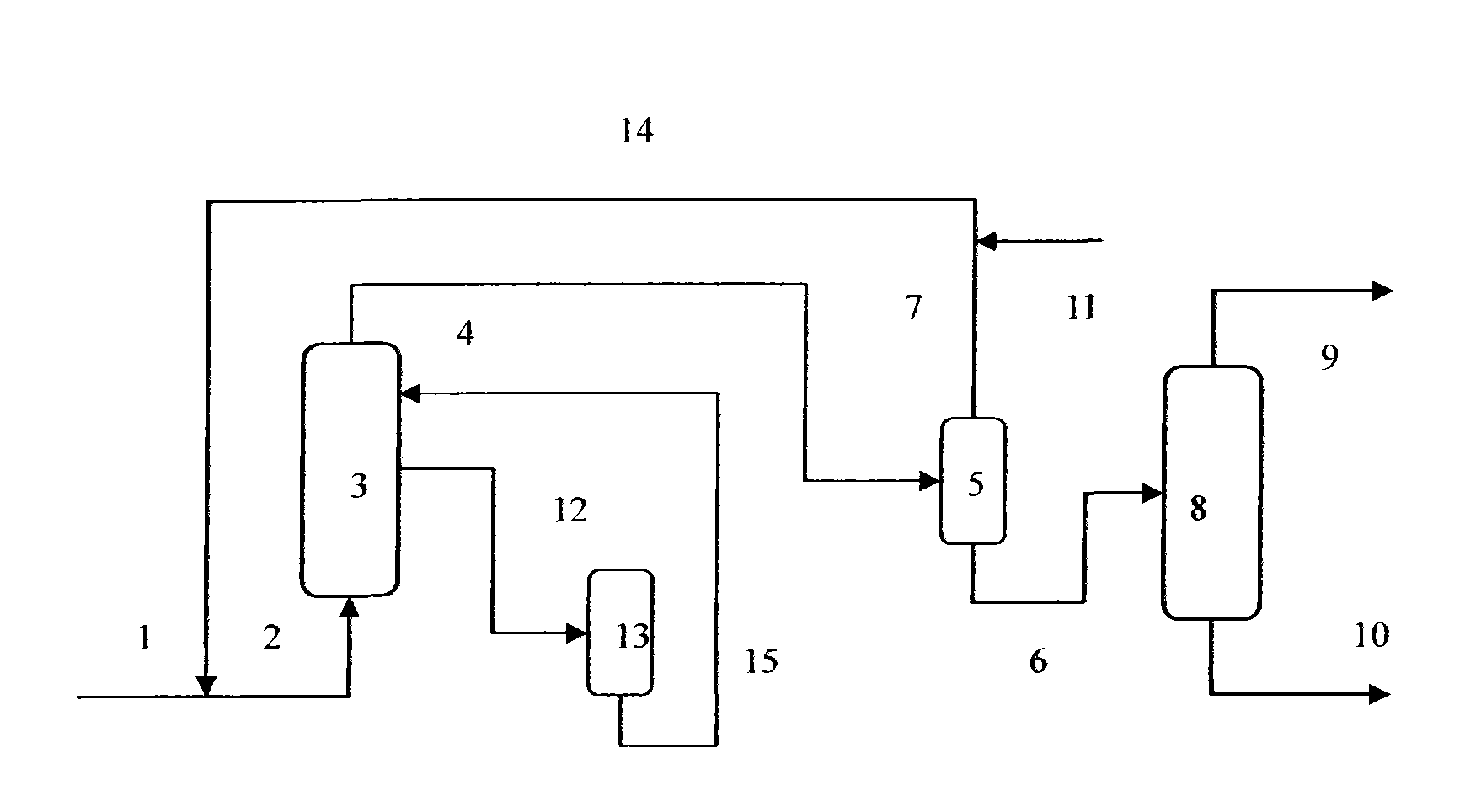

Methods of hydrotreating a mixture made up of oils of animal or vegetable origin and of petroleum cuts with intermediate stripping

ActiveUS20080161614A1Low costLimit consumption of hydrogenThermal non-catalytic crackingCatalytic crackingVegetable oilVolumetric Mass Density

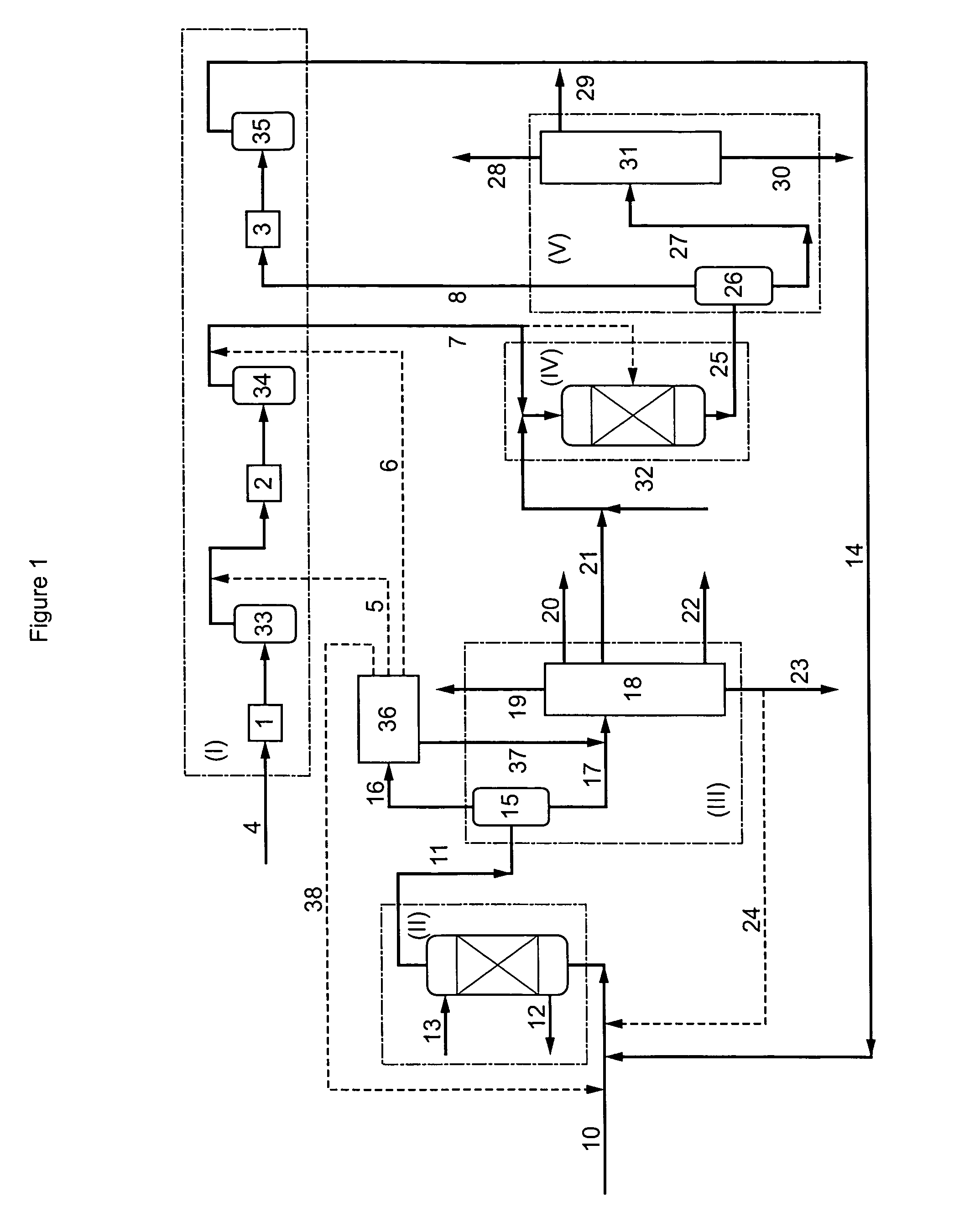

The invention relates to a hydrotreating method (HDT) using two plants working under different operating conditions with an intermediate stripping for co-treating a mixture made up of oils of vegetable or animal origin and petroleum cuts (gas oil cuts (GO) and middle distillates) in order to produce gas oil fuel bases meeting specifications. The first plant (HDT1) is more particularly dedicated to the reactions concerning oils of vegetable or animal origin in comixture while pretreating the hydrocarbon feed, whereas the second plant (HDS2) works under more severe conditions to obtain diesel fuel according to standards, in particular in terms of effluent sulfur content, density and cold properties. The process economy, the activity and the stability of the catalyst of the second plant are greatly improved by the intermediate stripping.

Owner:INST FR DU PETROLE

Methods for producing a total product in the presence of sulfur

Methods of producing a total product are described. A method includes continuously contacting a feed with a hydrogen source in the presence of one or more inorganic salt catalysts and steam to produce a total product, wherein the feed has at least 0.02 grams of sulfur, per gram of feed; and producing a total product that includes coke and the crude product. The crude product has a sulfur content of at most 90% of the sulfur content of the feed.

Owner:SHELL OIL CO

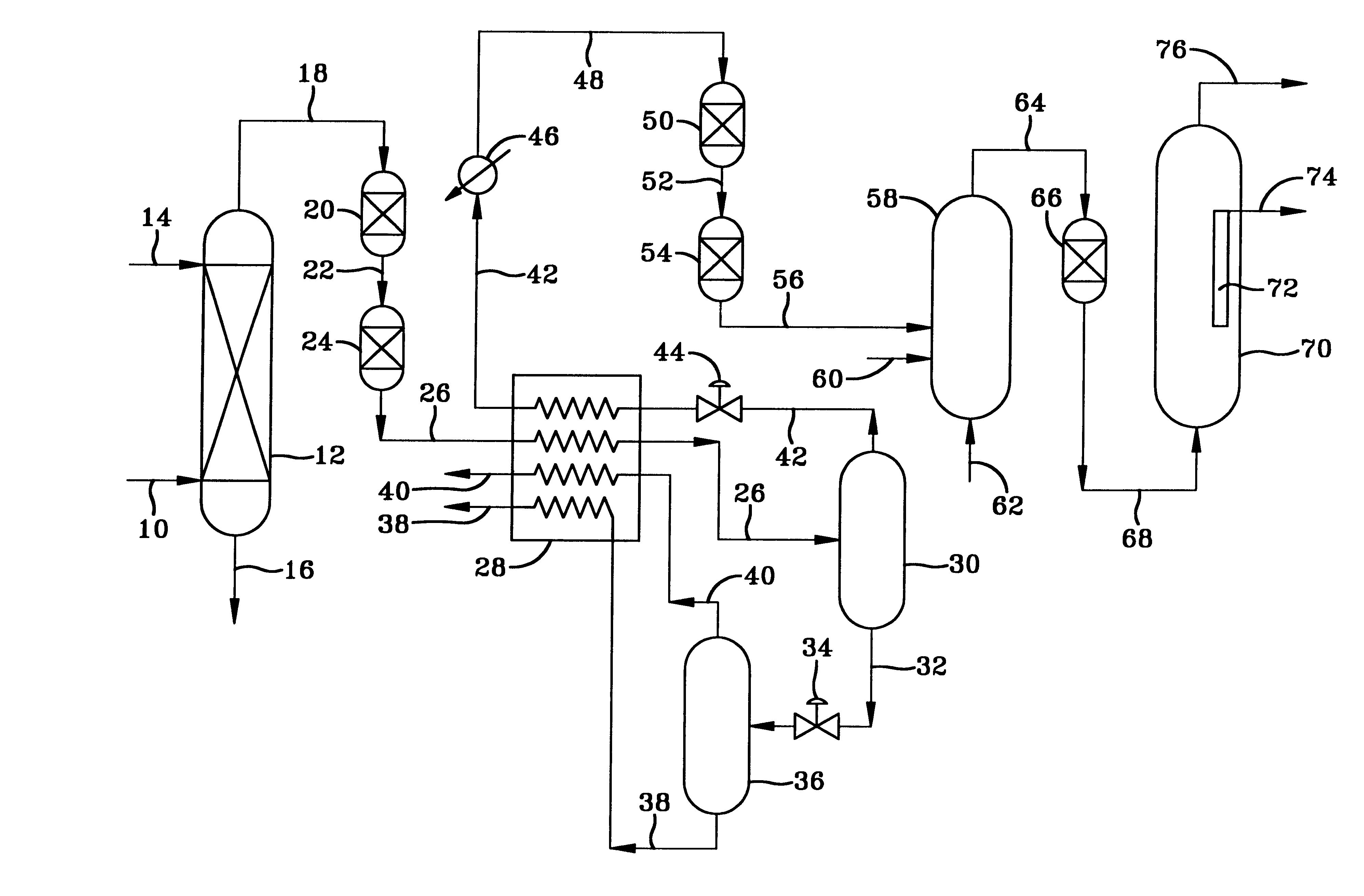

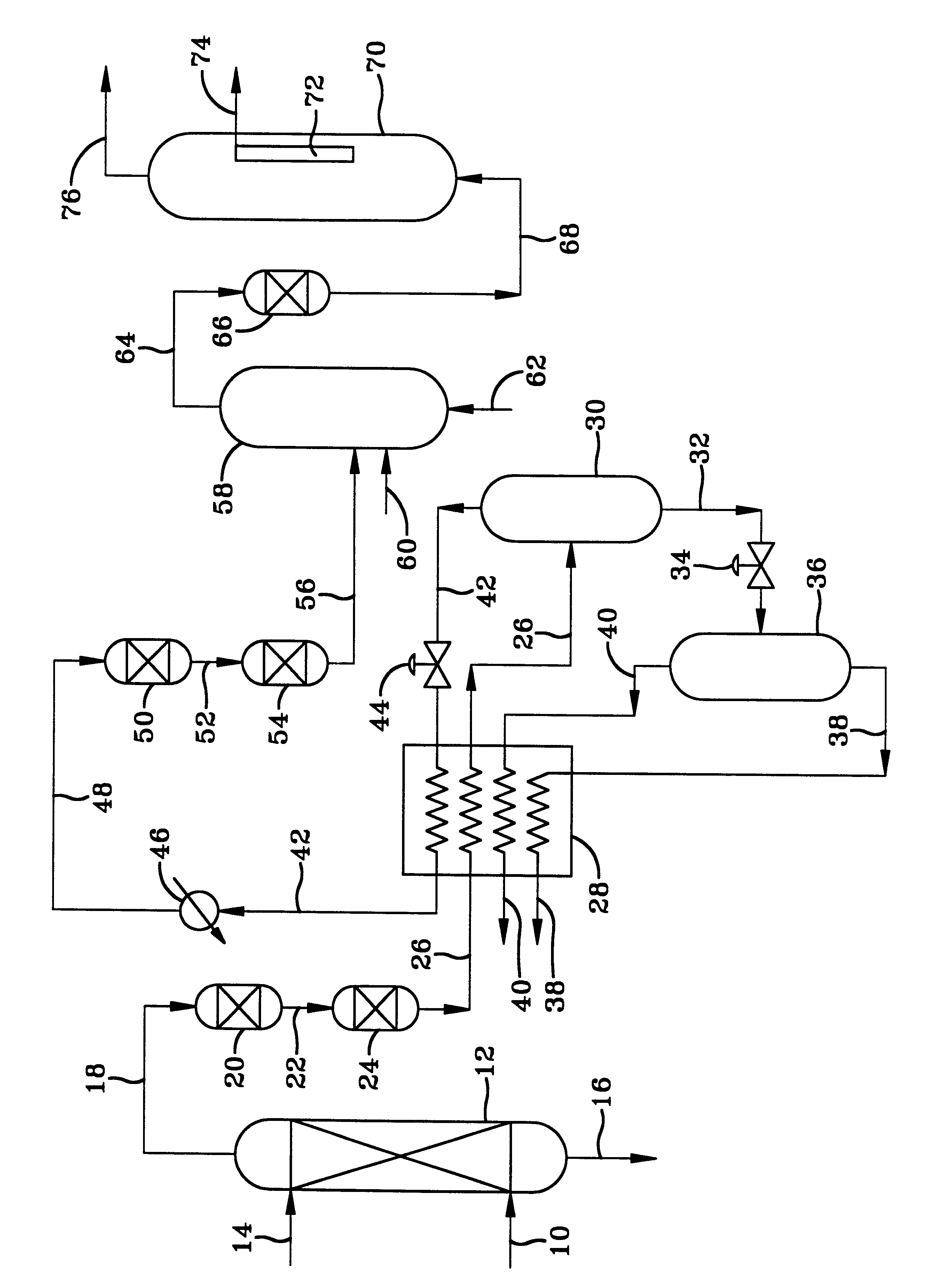

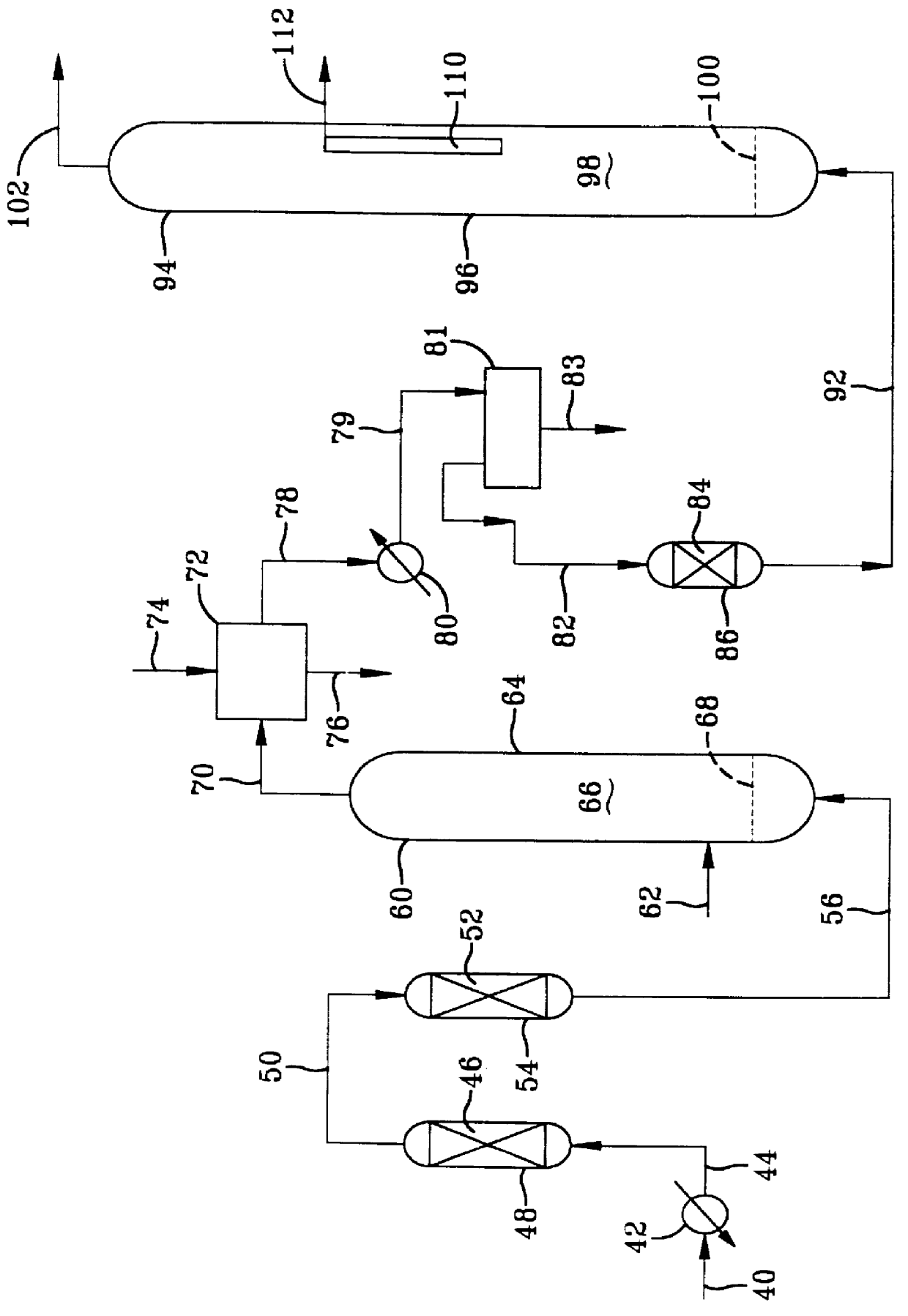

Production of low sulfur syngas from natural gas with C4+/C5+ hydrocarbon recovery

Sour natural gas is processed to remove the sulfur compounds and recover C4+ / C5+ hydrocarbons by scrubbing the gas with an amine solution to remove most of the sulfur, followed cooling the gas to remove C4+ / C5+ hydrocarbons and more sulfur compounds as liquid condensate to produce a gas having less than 20 vppm of total sulfur. The condensate is sent to a fractionator to recover the C4+ / C5+ hydrocarbons. The sulfur and hydrocarbon reduced gas is contacted first with zinc oxide and then nickel, to produce a gas having less than 10 vppb of total sulfur which is passed into a synthesis gas generating unit to form a very low sulfur synthesis gas comprising a mixture of H2 and CO. This synthesis gas is useful for hydrocarbon synthesis with increased life of the hydrocarbon synthesis catalyst and greater hydrocarbon production from the hydrocarbon synthesis reactor. Contacting the synthesis gas with zinc oxide further reduces the sulfur content to below 3 vppb.

Owner:EXXON RES & ENG CO

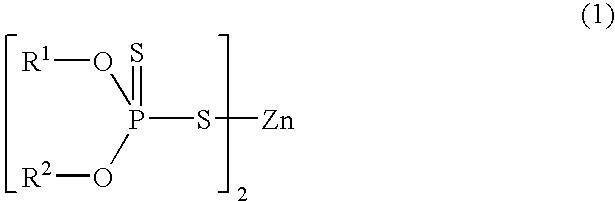

Low ash, low phosphorus and low sulfur engine oils for internal combustion engines

InactiveUS6730638B2Reduce friction and wearReduce frictionOrganic chemistryOrganic compound preparationCombustionSulfur

A lubricating composition for internal combustion engines especially useful with fuels having less than 350 ppm sulfur comprises a lubricating oil basestock, a boron containing ashless dispersant, a molybdenum containing friction reducing agent, a metal type detergent and zinc dithiophosphate.

Owner:EXXON RES & ENG CO

Process to produce biofuels from biomass

Biofuels can be produced by: (i) providing a biomass containing celluloses, hemicelluloses, lignin, nitrogen compounds and sulfur compounds; (ii) removing sulfur compounds and nitrogen compounds from the biomass by contacting the biomass with a digestive solvent to form a pretreated biomass containing carbohydrates and having less than 35% of the sulfur content and less than 35% of the nitrogen content of untreated biomass on a dry mass basis; (iii) contacting the pretreated biomass directly with hydrogen in the presence of a hydrogenolysis catalyst to form a plurality of oxygenated intermediates, and (vi) processing at least a portion of the oxygenated intermediates to form a liquid fuel.

Owner:SHELL OIL CO

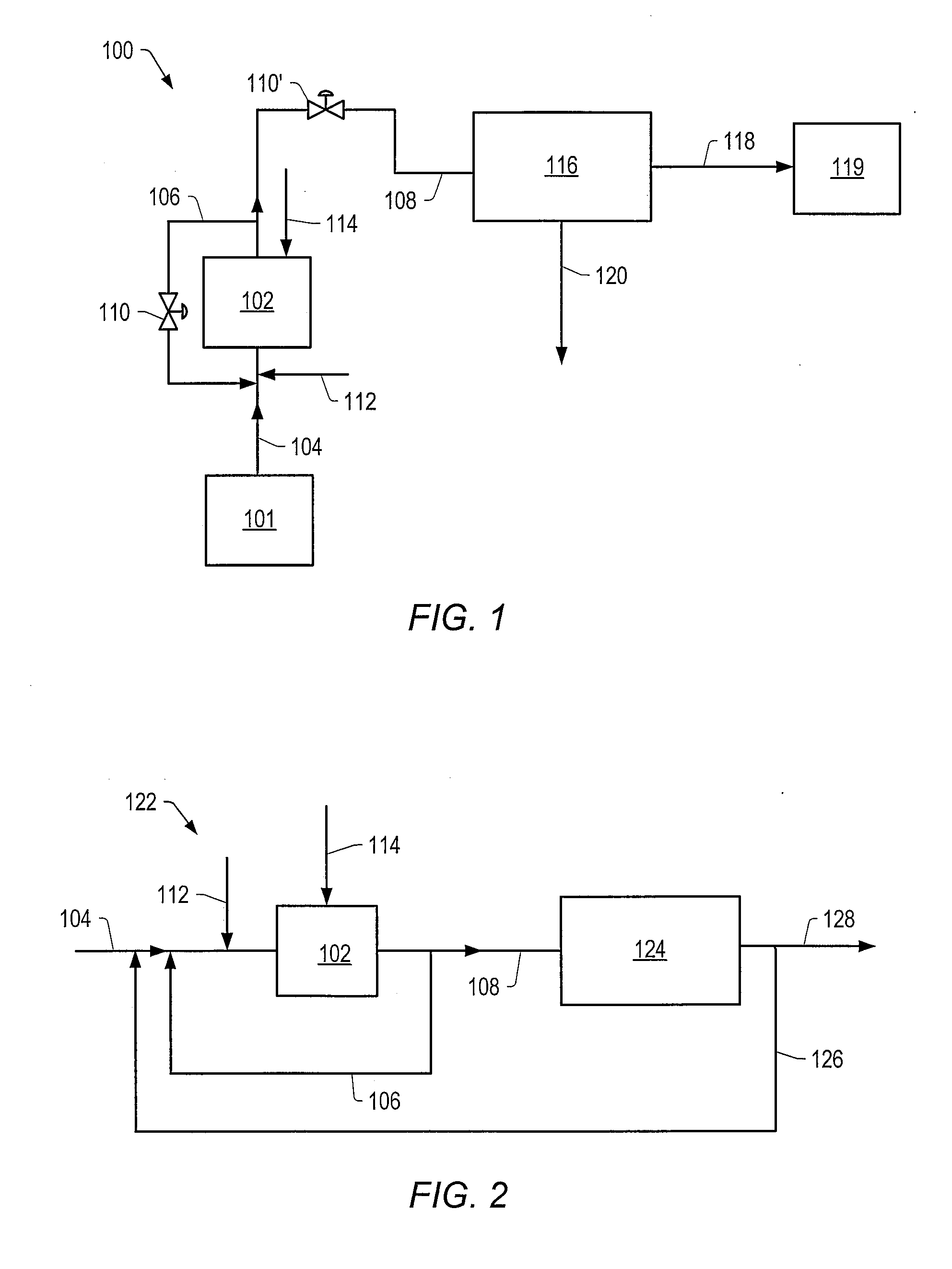

Methods of hydrotreating a mixture made up of oils of animal or vegetable origin and of petroleum cuts with quench injection of the oils on the last catalyst bed

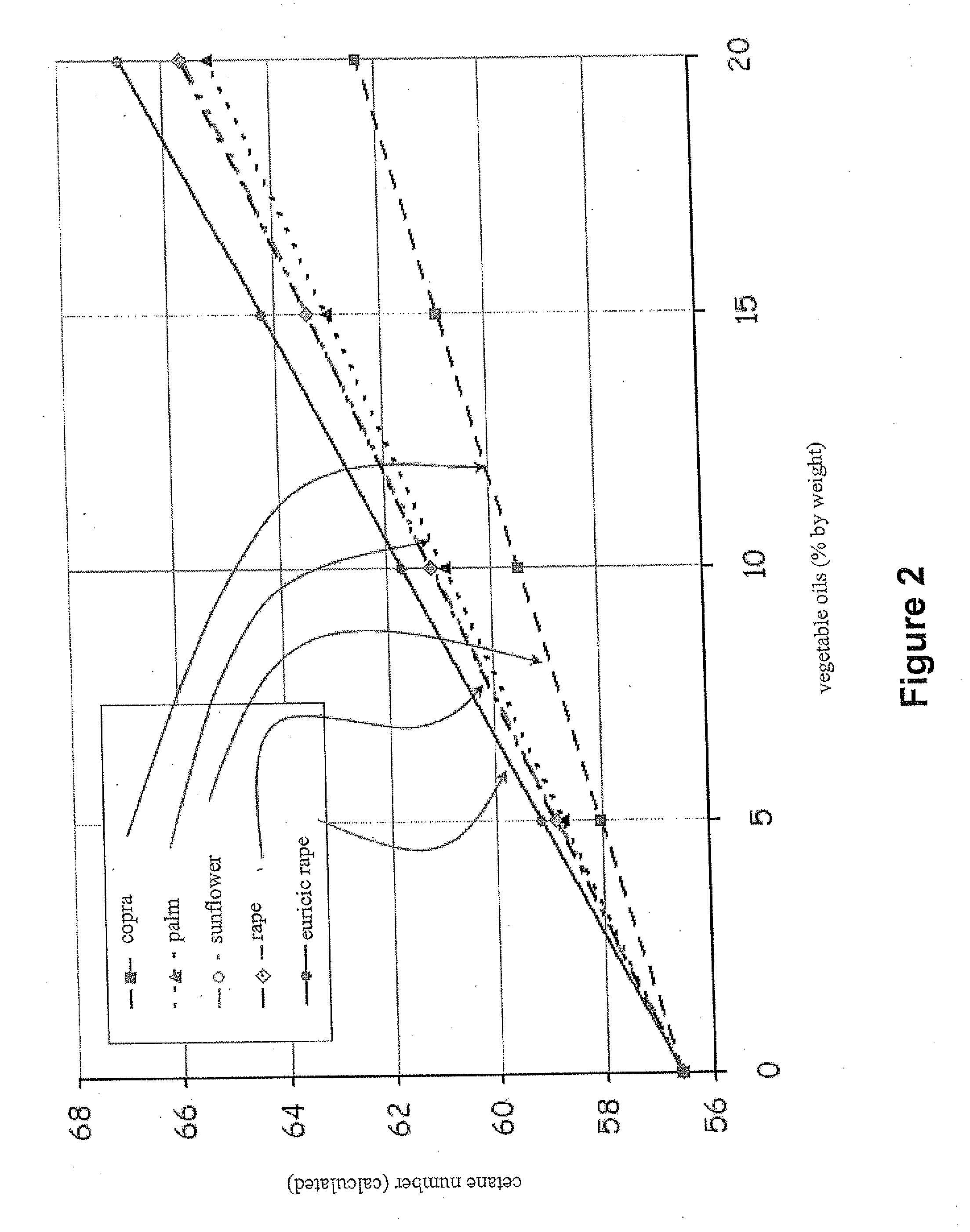

ActiveUS20080173570A1Low costReduce use costCatalytic crackingHydrocarbon oil crackingDistillates petroleumVegetable oil

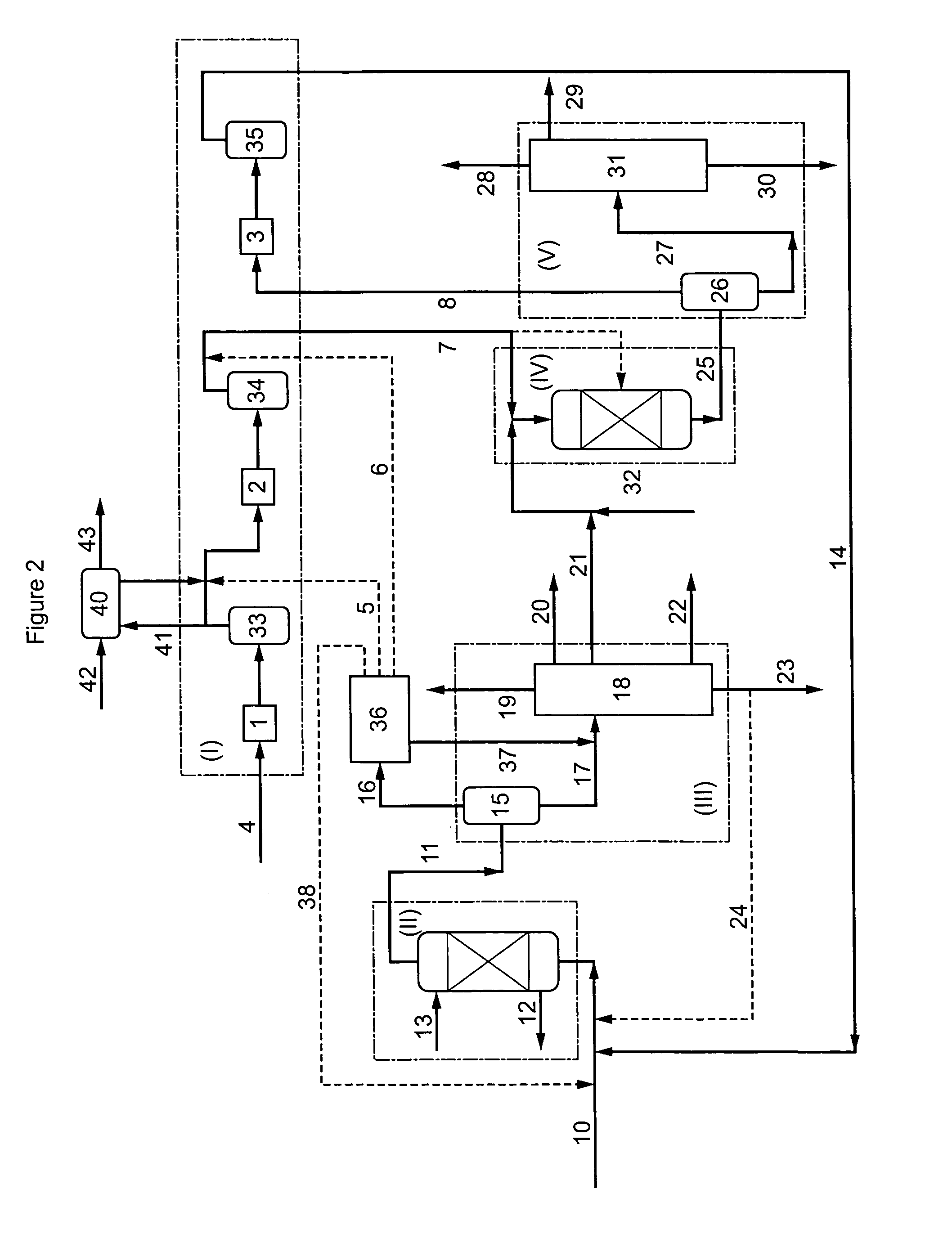

A hydrotreating method uses two catalyst beds with the introduction, on the last catalyst bed, of oils of animal or vegetable origin for co-treating a mixture made up of oils of vegetable or animal origin and of petroleum cuts (gas oil cuts (GO) and middle distillates) in order to produce gas oil effluents meeting specifications with an improved cetane number. The first catalyst bed is dedicated to only the deep desulfurization reactions (HDS1) of a petroleum type feed. The effluents of the first catalyst bed having an effluent sulfur content below or equal to 50 mg / kg are separated into two streams. The first stream, which is predominant, is sent to the gas oil pool. The second stream is mixed with oils of vegetable or animal origin. The resultant oil-petroleum cut mixture is then subjected to a milder hydrotreatment (HDT2). The effluents obtained at the outlet of the second catalyst bed can optionally be mixed with the predominant stream from the first bed. The process economy, the tolerance to the specifications relative to oils of animal or vegetable origin and the quality of the products obtained are thus greatly improved.

Owner:INST FR DU PETROLE

Methods for producing a total product in the presence of sulfur

Methods of producing a total product are described. A method includes continuously contacting a feed with a hydrogen source in the presence of one or more inorganic salt catalysts and steam to produce a total product, wherein the feed has at least 0.02 grams of sulfur, per gram of feed; and producing a total product that includes coke and the crude product. The crude product has a sulfur content of at most 90% of the sulfur content of the feed.

Owner:SHELL OIL CO

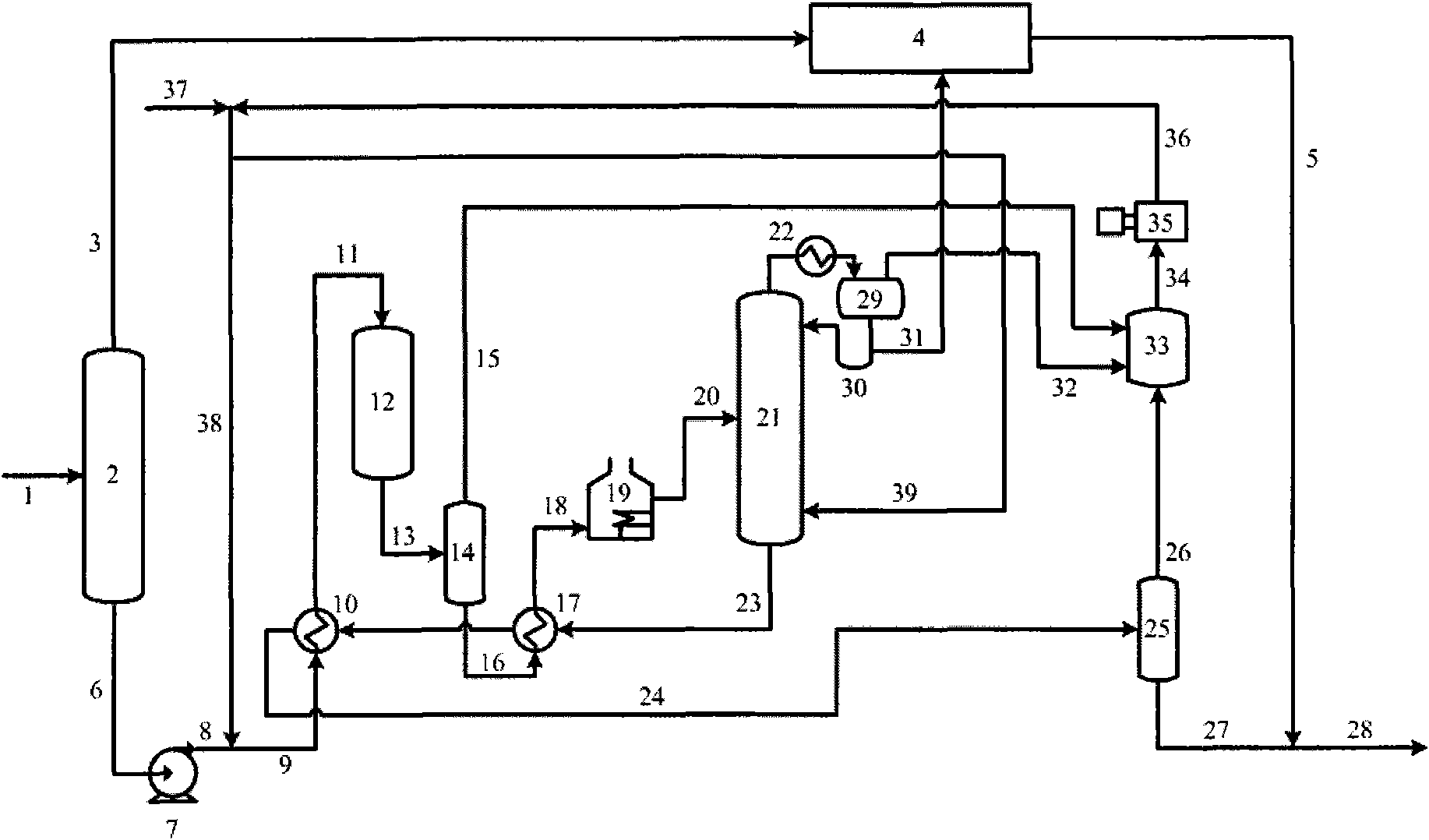

Method for producing low sulfur gasoline

InactiveCN1465668AReduce sulfur contentReduce saturationTreatment with hydrotreatment processesHydrogenHydrodesulfurization

The method for producing low-sulfur gasoline includes the following steps: cutting gasoline raw material into light fraction and heavy fraction, making the light fraction undergo the processes of alkali refinement treatment and removing mercaptans, making the heavy fraction and hydrogen gas together by contacted with hydrogenation desulfurization catalyst to make selective hydrogenation desulfurization reaction, then hydrogenated gasoline fraction undergo the process of hydrogenation or non-hydrogenation to remove mercaptans, then mixing the above-mentioned desulfurized light and heavy fractions so as to obtain the invented gasoline product whose olefine saturation rate is less than 30%, and sulfur content is less than 200 ppm.

Owner:CHINA PETROLEUM & CHEM CORP +1

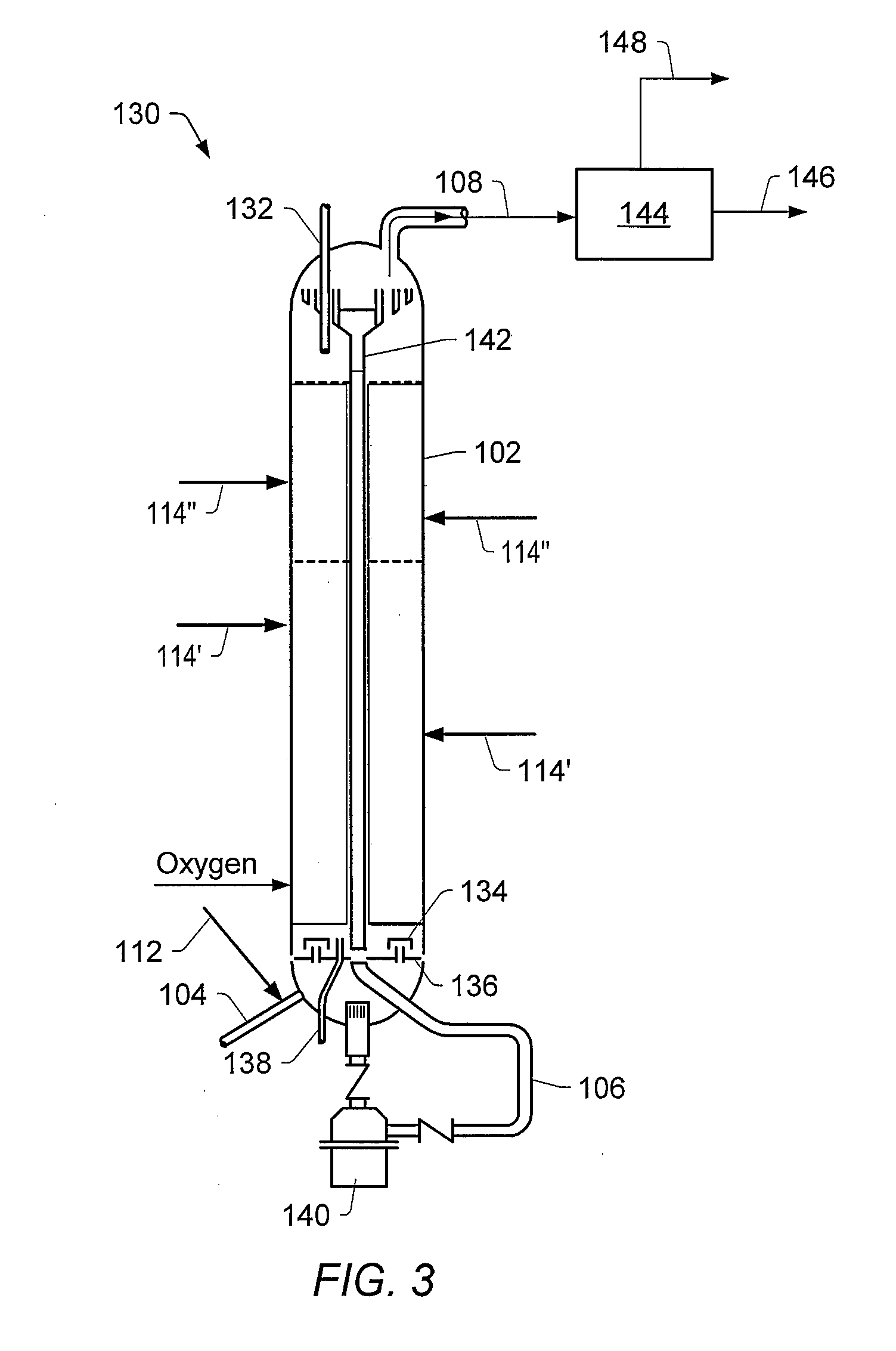

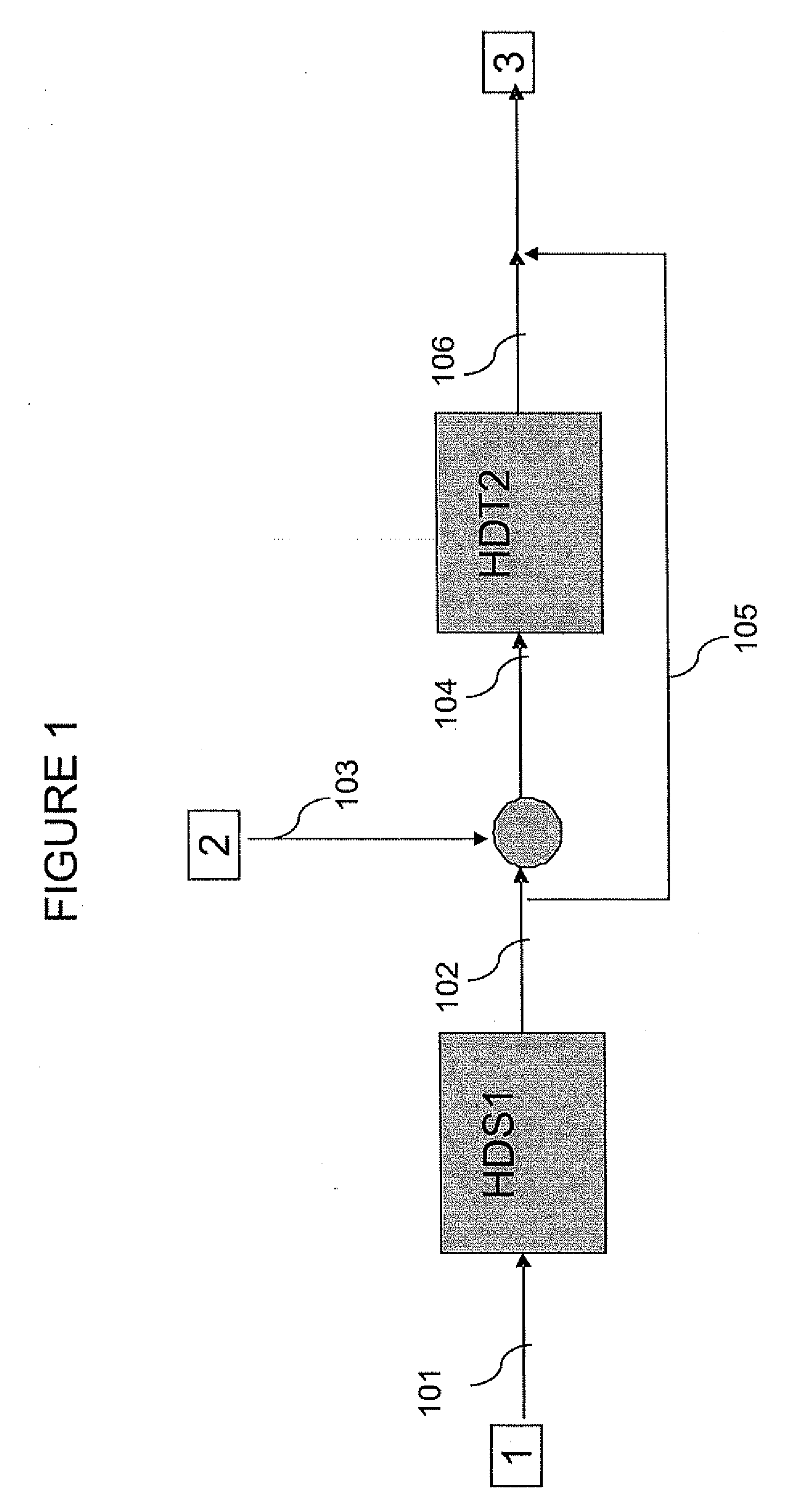

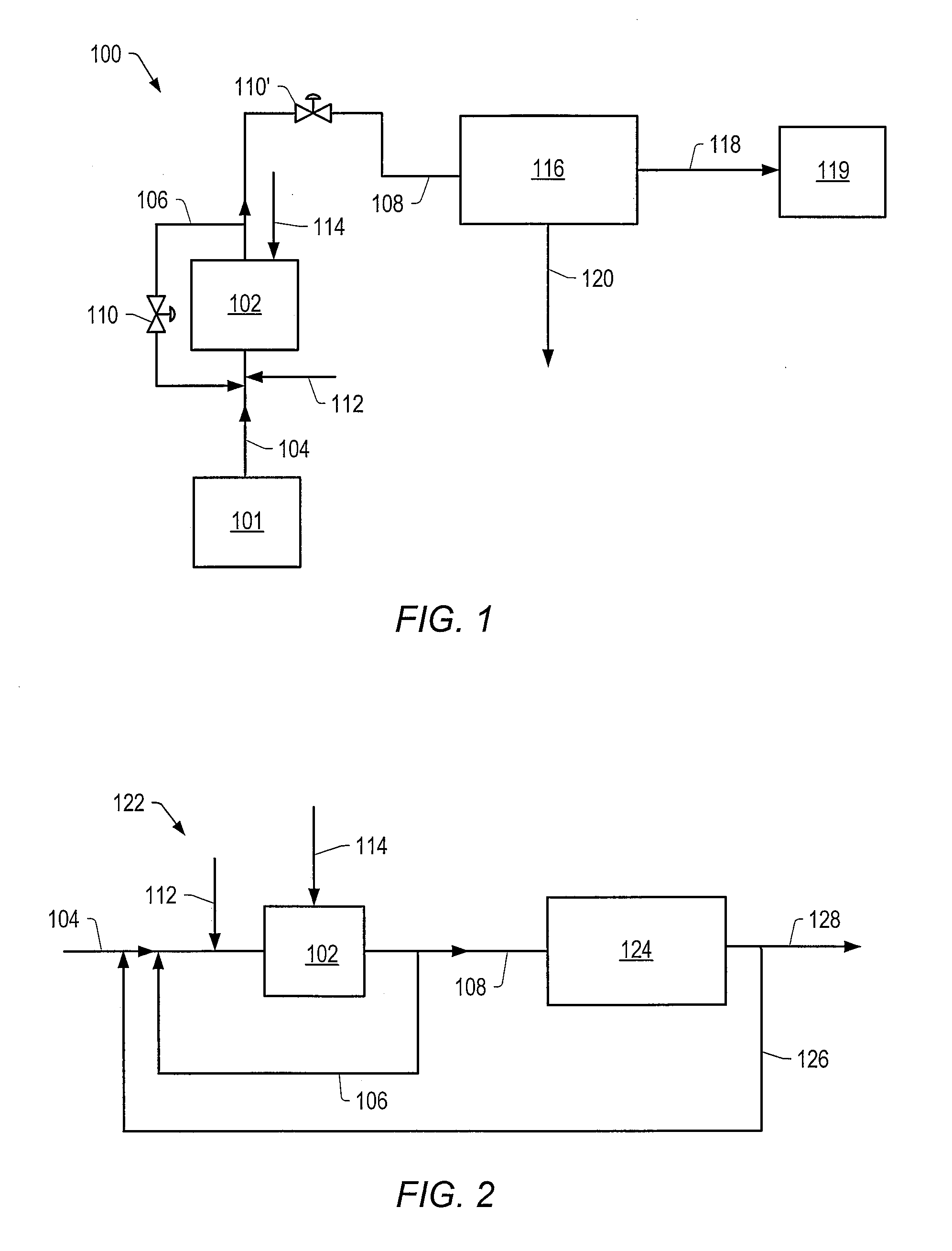

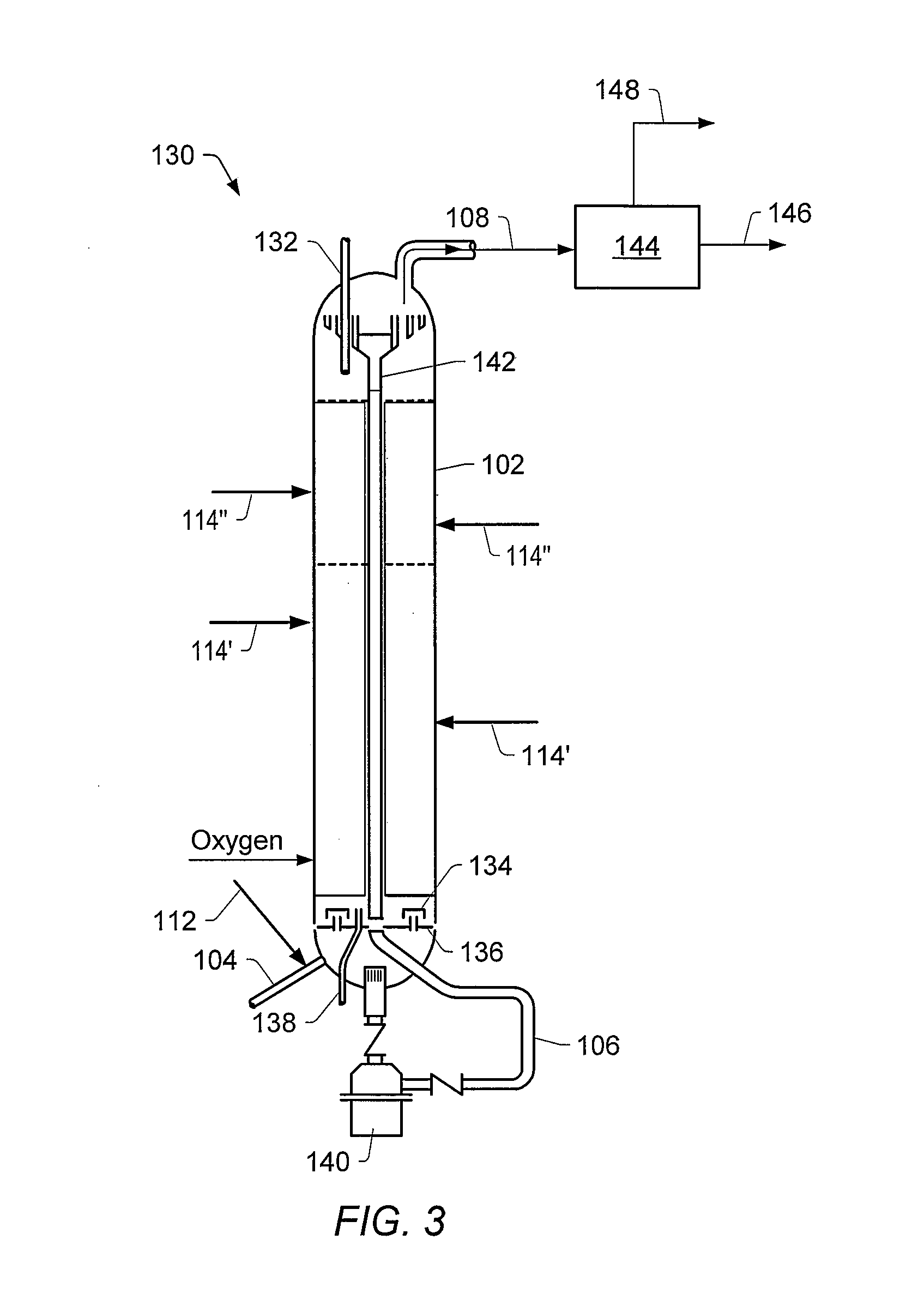

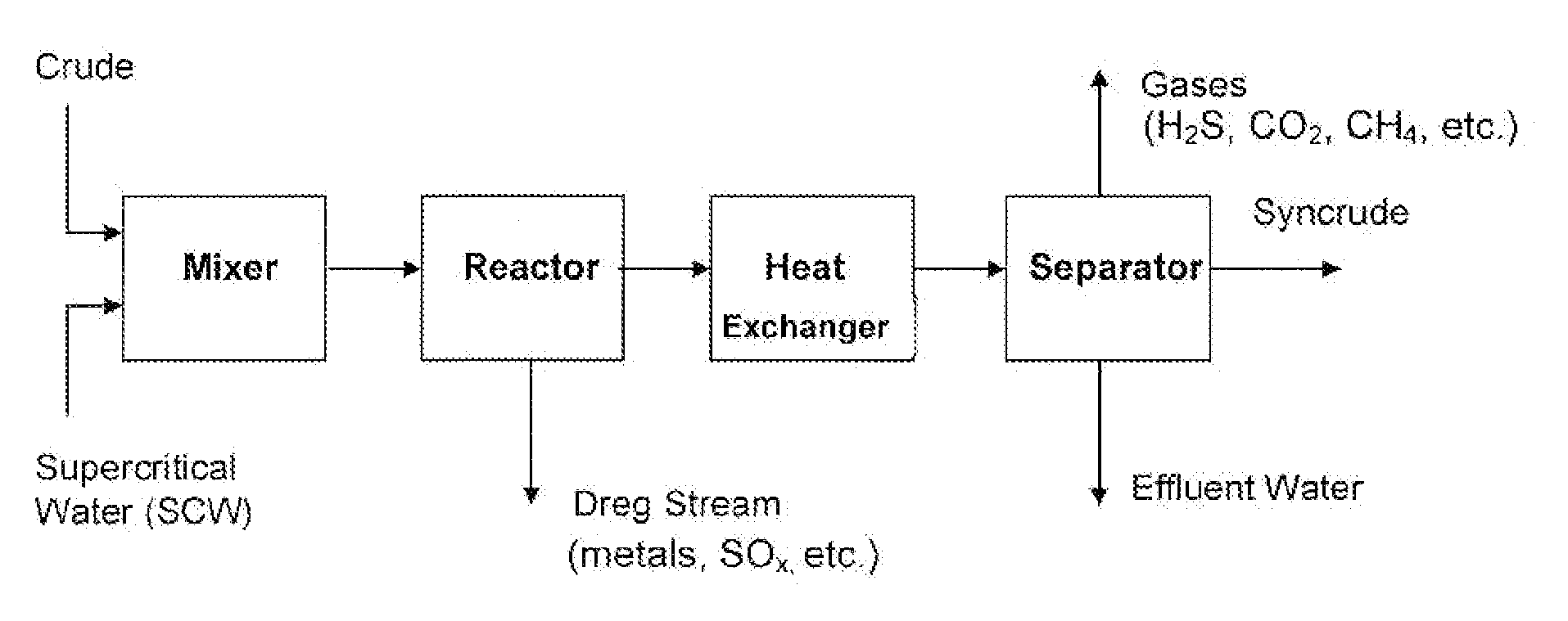

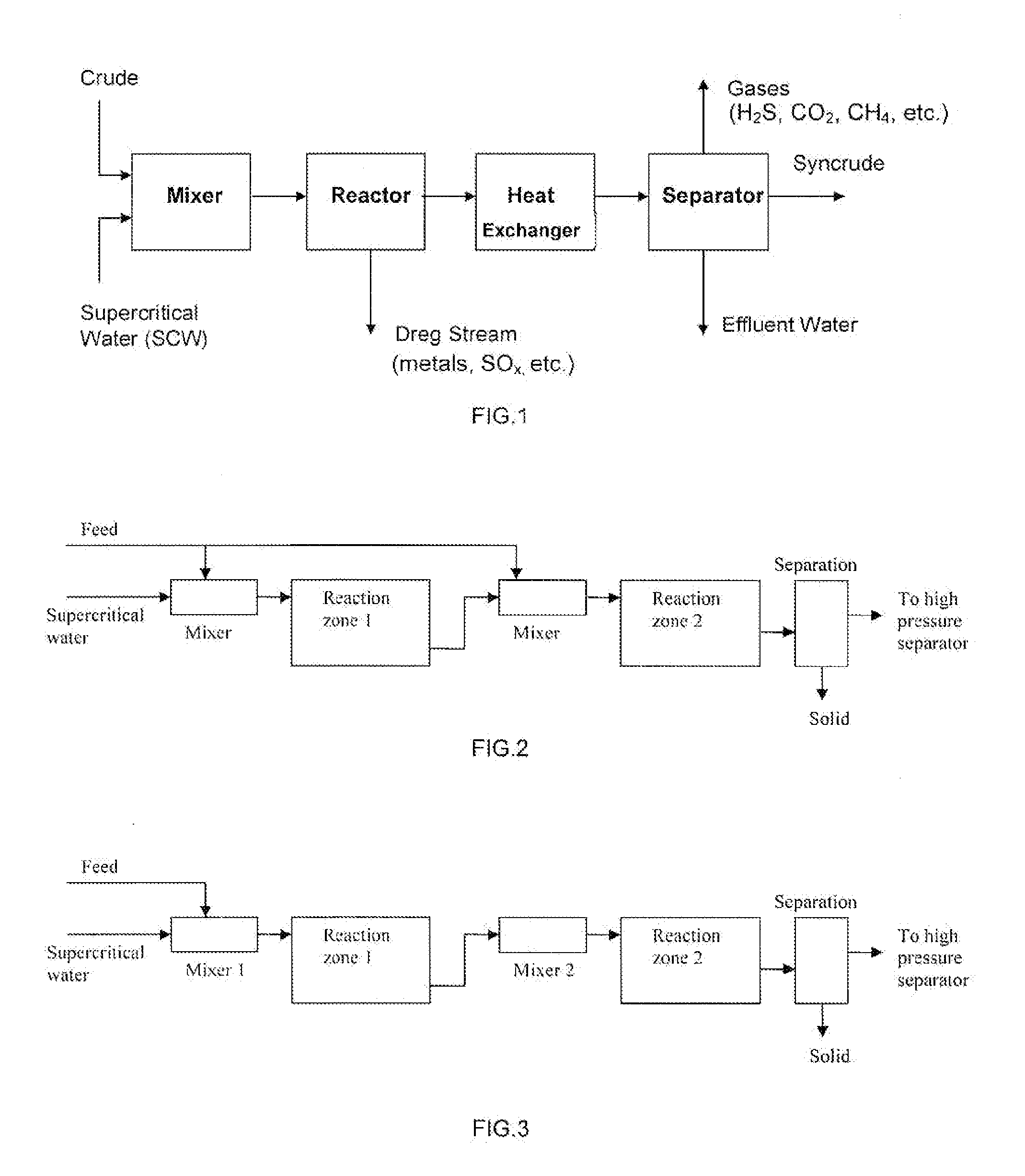

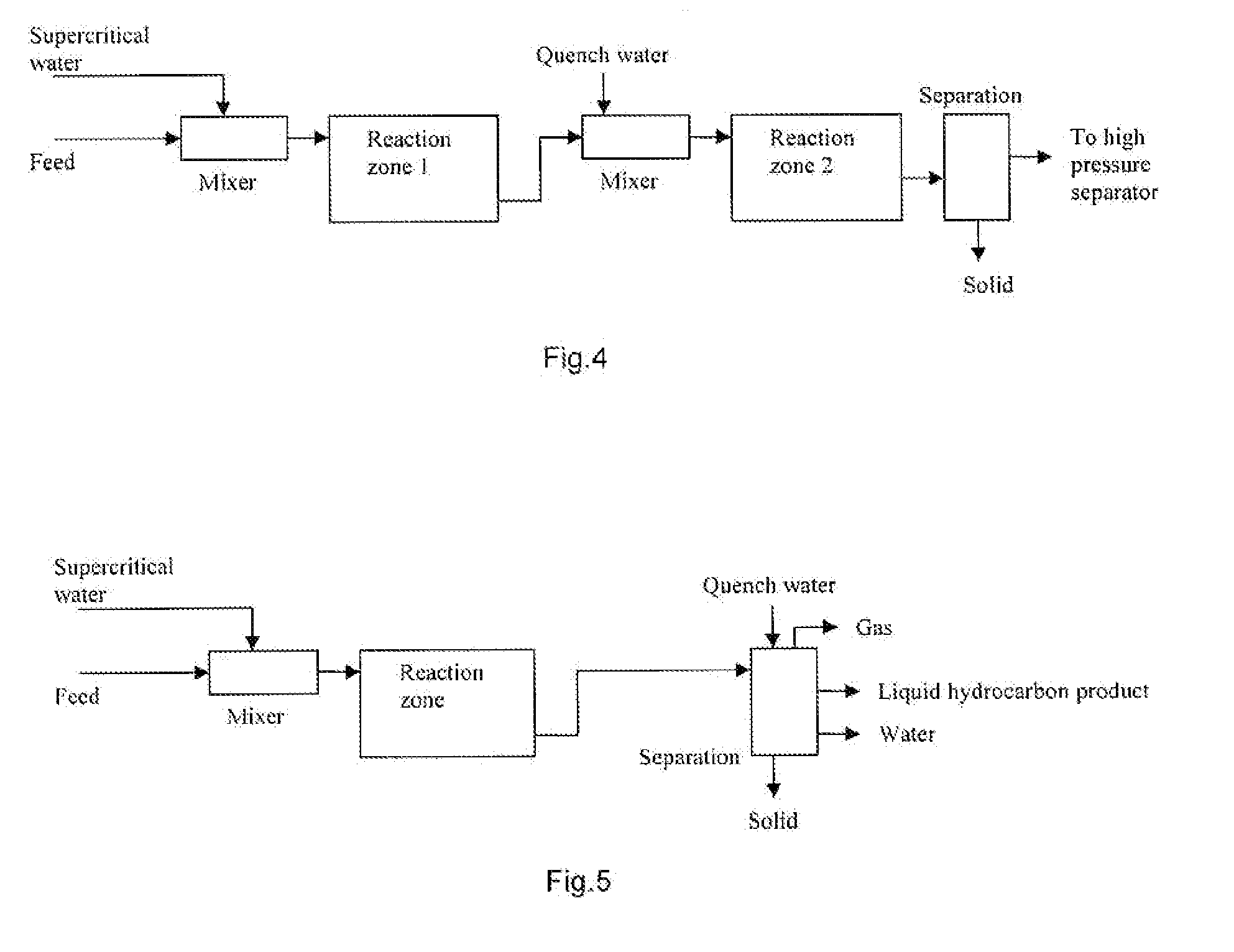

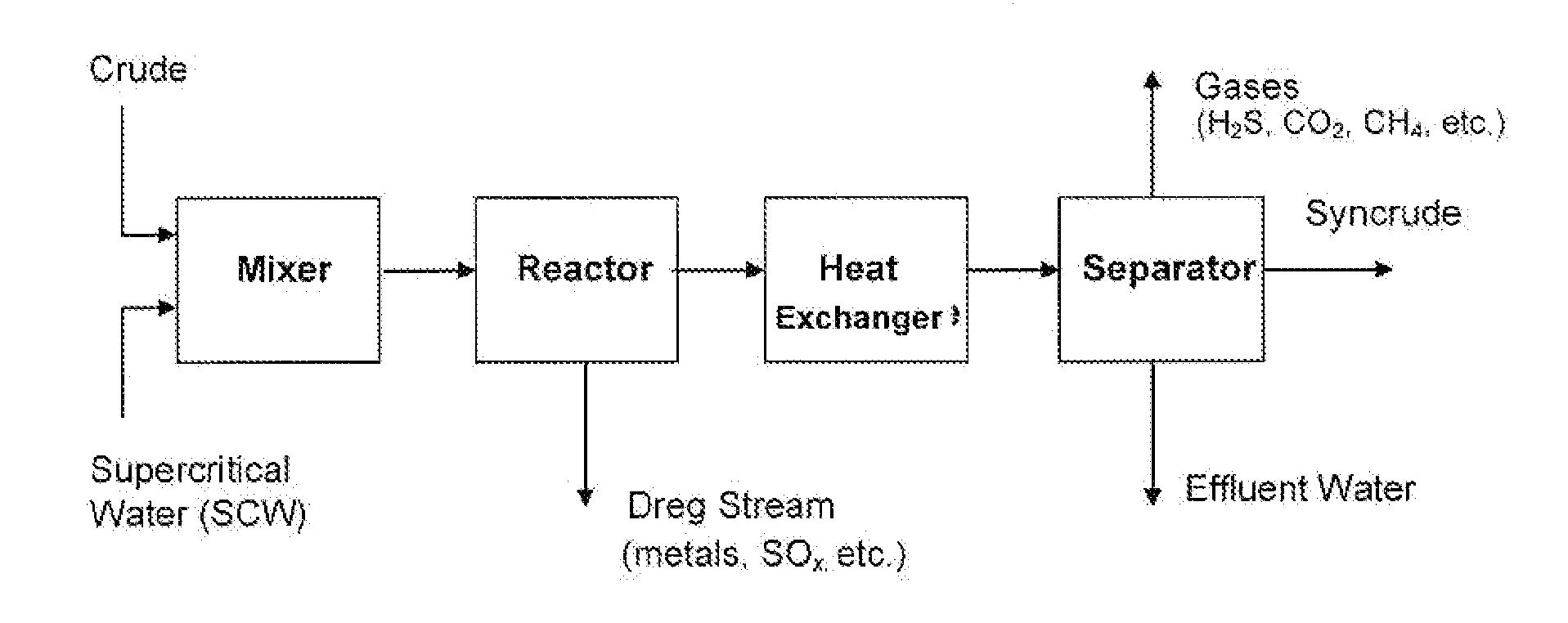

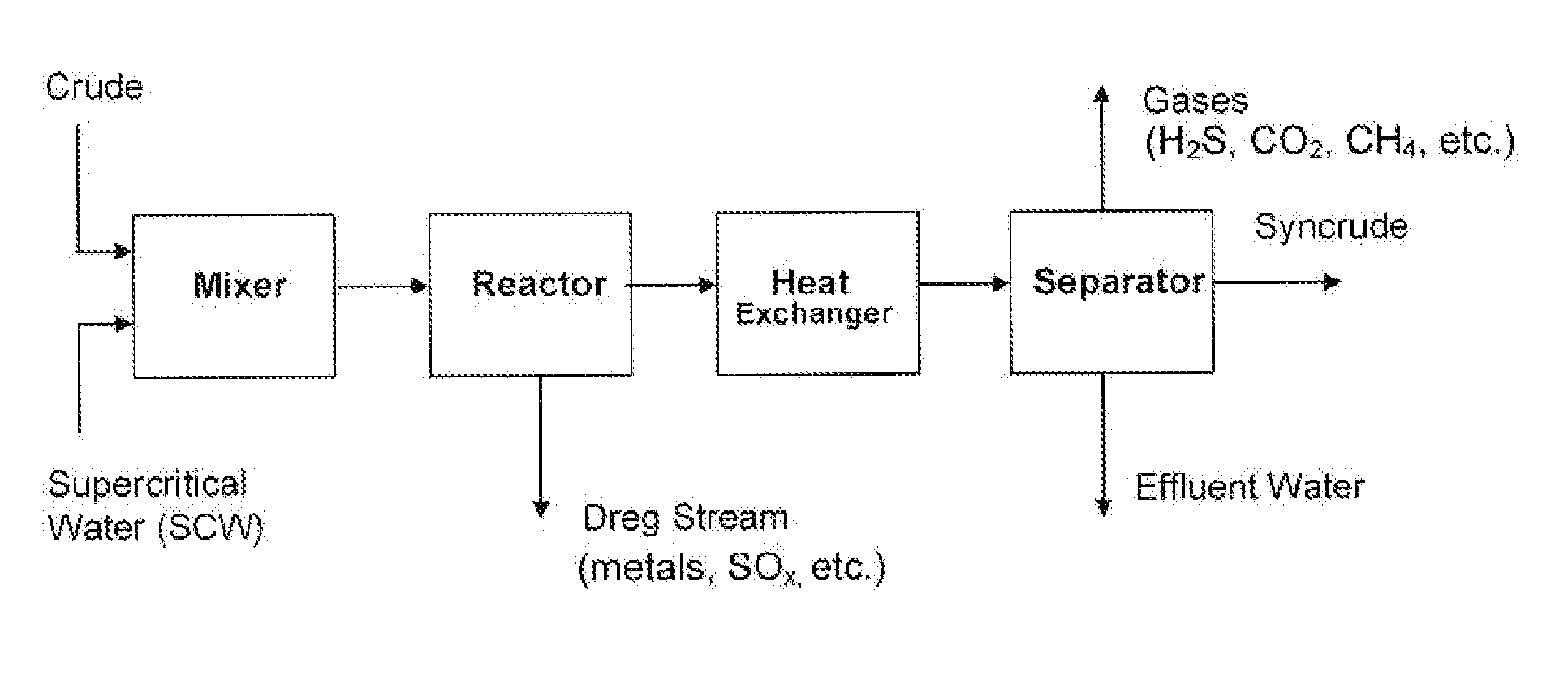

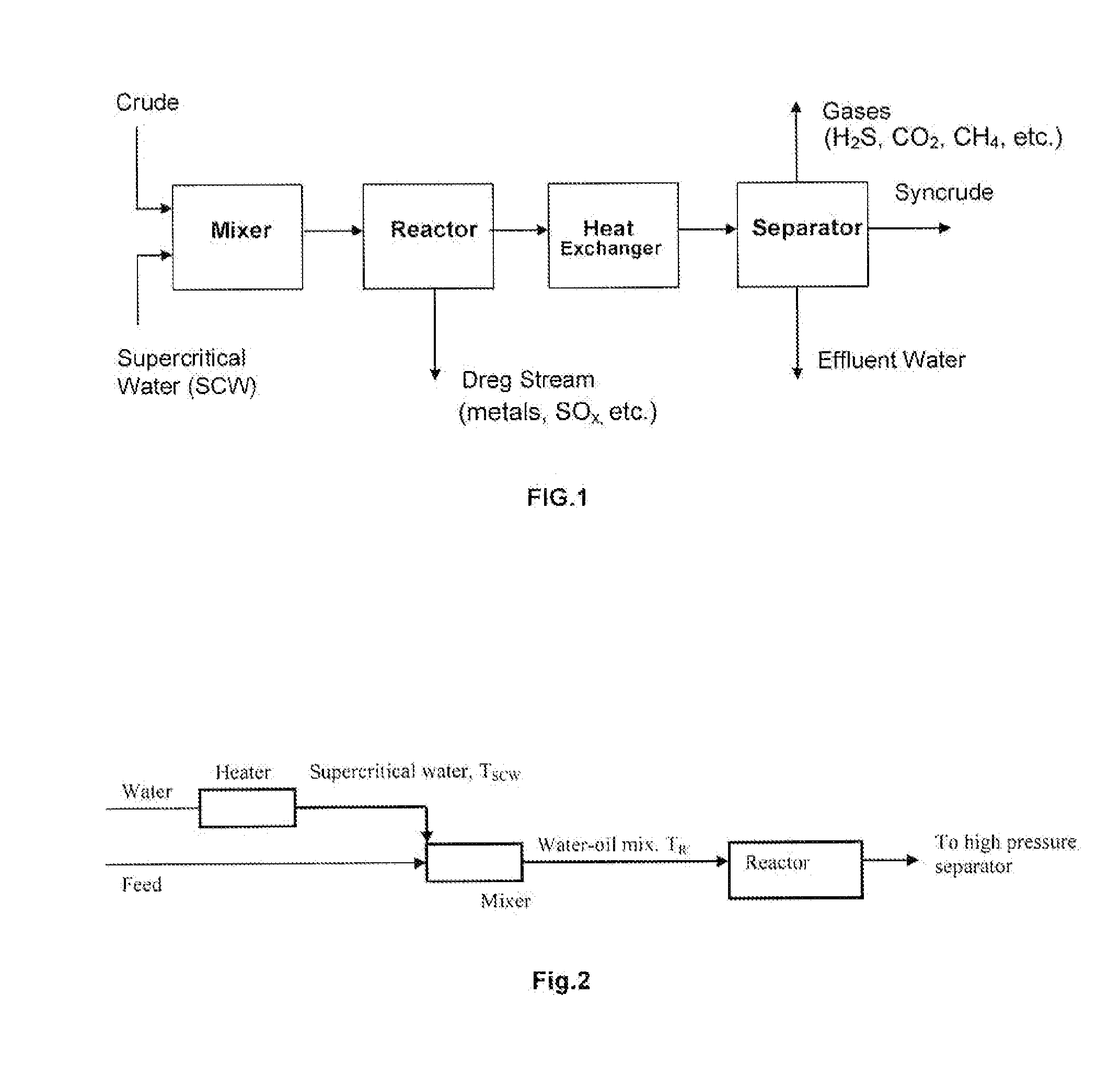

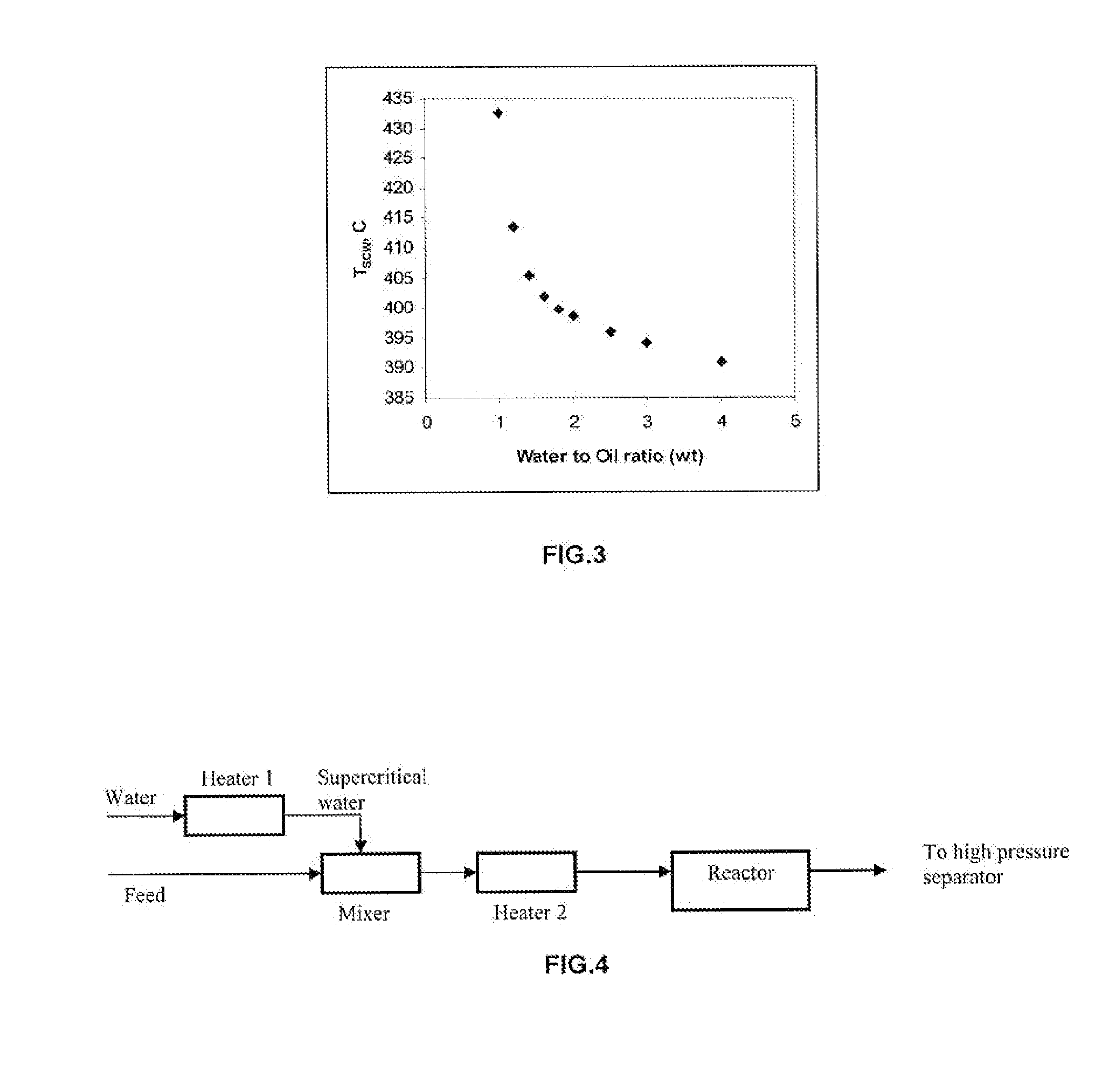

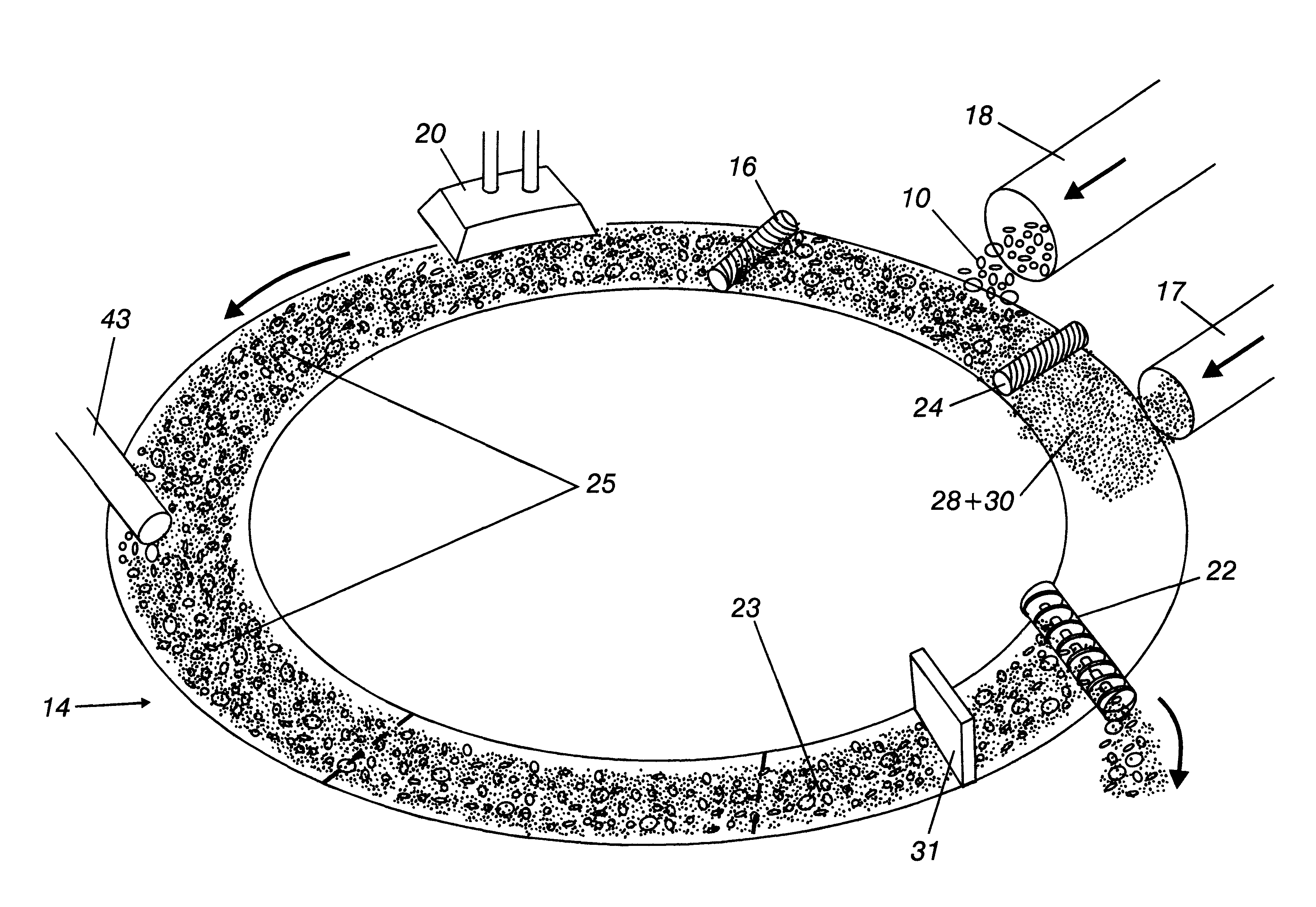

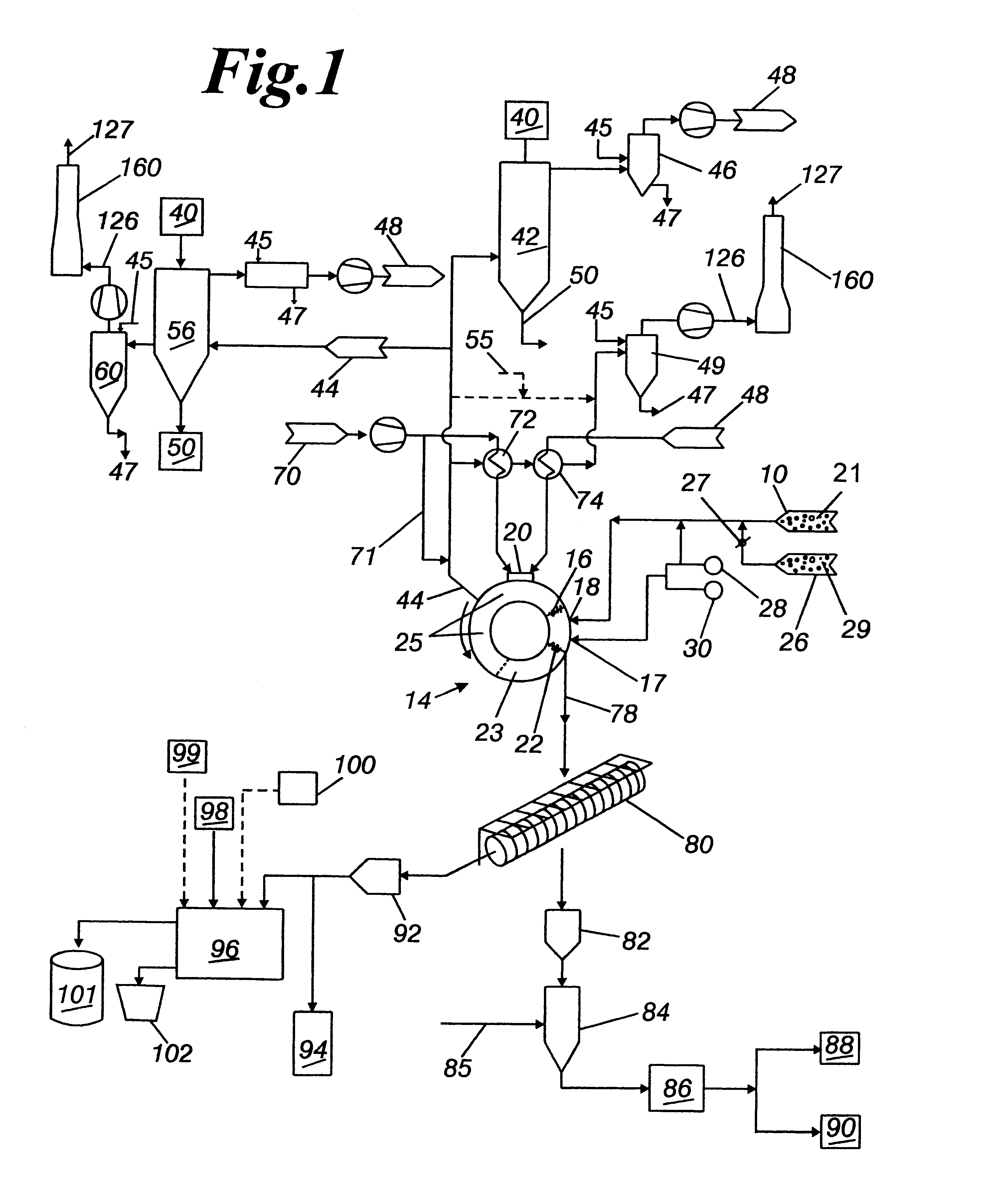

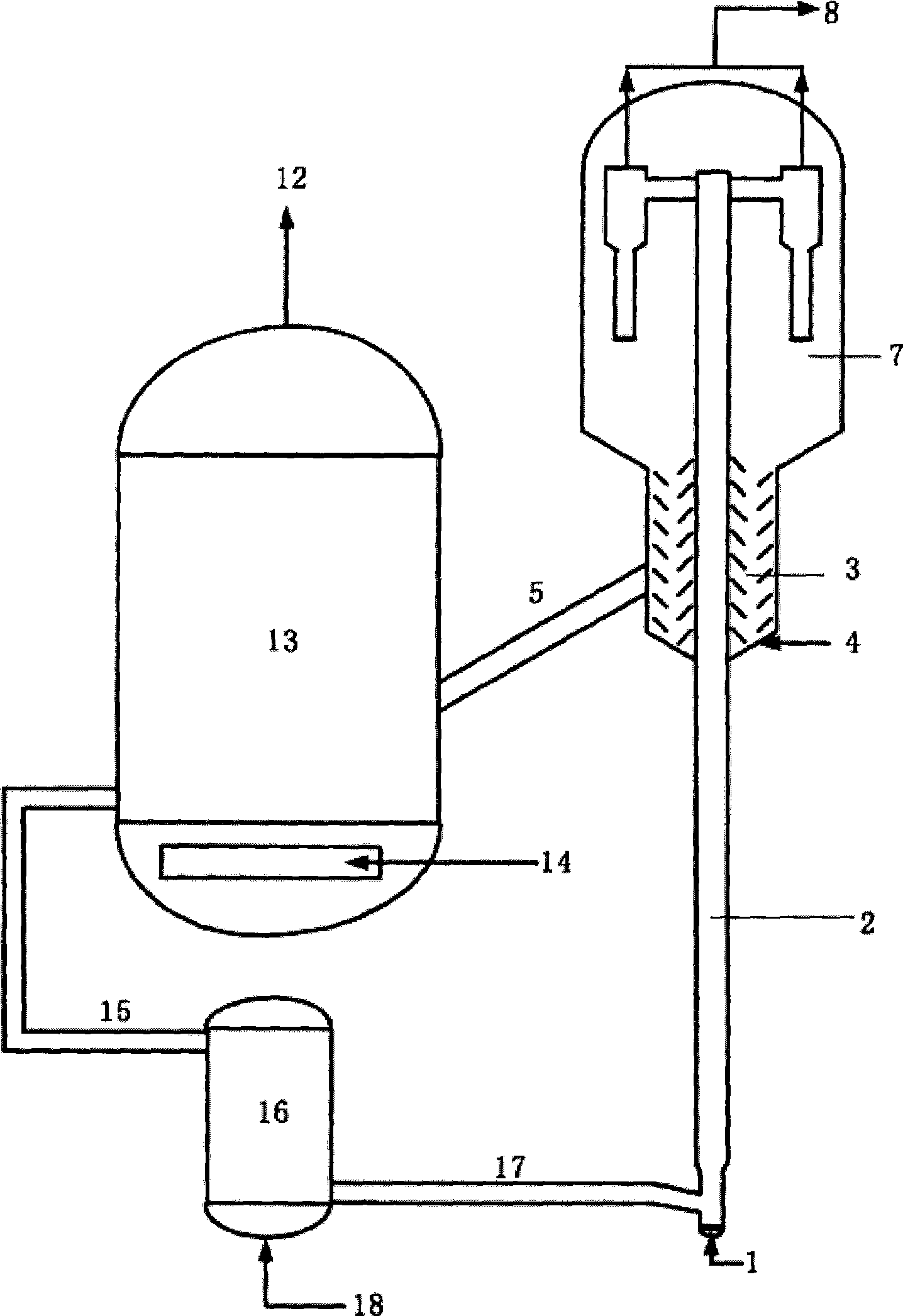

Reactor and process for upgrading heavy hydrocarbon oils

InactiveUS20080099374A1Prevent subsidenceRefining by water treatmentFeed devicesMomentumVolumetric Mass Density

A reactor for conducting a process using supercritical water to upgrade a heavy hydrocarbon feedstock into an upgraded hydrocarbon product or syncrude with highly desirable properties (low sulfur content, low metals content, lower density (higher API), lower viscosity, lower residuum content, etc.) is described. The reactor is operable under continuous) semi-continuous or batch mode and is equipped with means to enable momentum, heat and mass transfer in and out of and within the reactor.

Owner:CHEVROU USA INC

Process for the production of gasolines with low sulfur contents

InactiveUS6692635B2Increase chanceMinimizing the octane lossHydrocarbon by hydrogenationHydrocarbon purification/separationDecompositionGasoline

Process for the production of gasoline with a low sulfur content that comprises at least the following two stages:a) a hydrogenation stage of the unsaturated sulfur containing compounds,b) a decomposition stage of saturated sulfur containing compounds,and optionally a preliminary stage for pretreatment of the feedstock such as selective hydrogenation of dienes.

Owner:INST FR DU PETROLE

Novel carbon-sulfur compound for lithium-sulfur battery

InactiveCN101587951AIncrease profitIncrease specific energyCell electrodesSulfur compoundsElectric capacityInternal resistance

The invention relates to a novel carbon-sulfur compound for an anode material of a lithium-sulfur battery and a preparation method thereof. Sulfur is filled into a nano and micron hole of a matrix in an elementary substance way by taking a macroporous carbon material with high pore volume, electrical conductivity and specific surface area as the matrix, and the sulfur and carbon can also carry out combination reaction so as to prepare the novel carbon-sulfur compound of which the sulfur exists in one or more chemical states in a carbon material. The novel carbon-sulfur compound used as the anode material of the lithium-sulfur battery has the advantages that the high pore volume has large contained sulfur contents and can ensure high electric capacity; the small granularity of the sulfur can reduce a conductive distance between ions and electrons and increase the utilization ratio of the sulfur; and the adsorption characteristics of the high specific surface of the carbon material can inhibit a discharging intermediate product from dissolving and moving towards a cathode, reduce the self discharge, prevent a nonconductive discharging product, namely lithium sulfide from largely accumulating outside carbon particles and reduce internal resistance, therefore, the material can improve the specific energy, the specific power and the cycle performance of the lithium-sulfur battery.

Owner:NO 63971 TROOPS PLA

Process and reactor for upgrading heavy hydrocarbon oils

A process using supercritical water to upgrade a heavy hydrocarbon feedstock into an upgraded hydrocarbon product or syncrude with highly desirable properties (low sulfur content, low metals content, lower density (higher API) lower viscosity, lower residuum content, etc.) is described. The process does not require external supply of hydrogen nor does it use externally supplied catalysts. A reactor design to carry out the process is also described,

Owner:CHEVROU USA INC

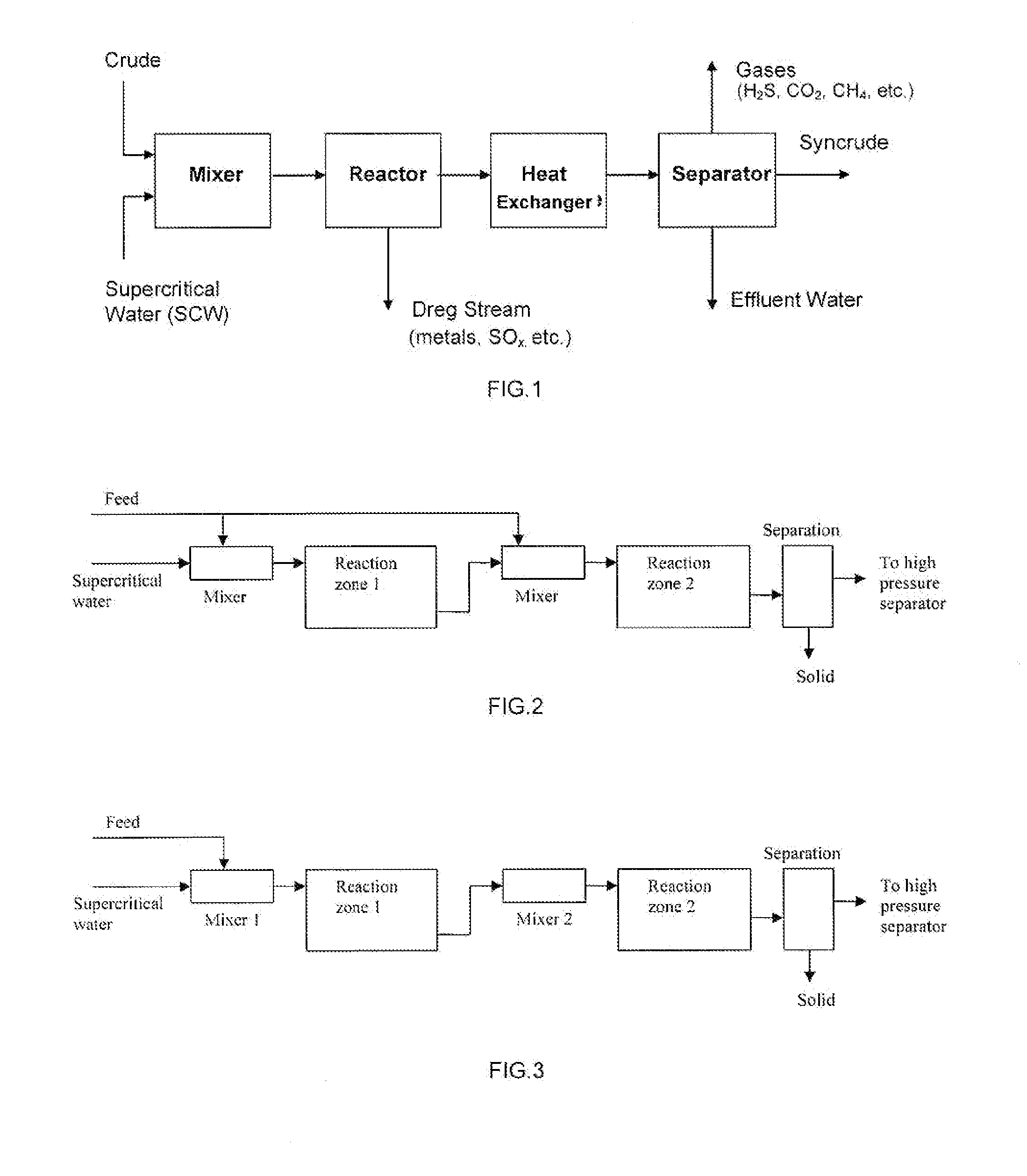

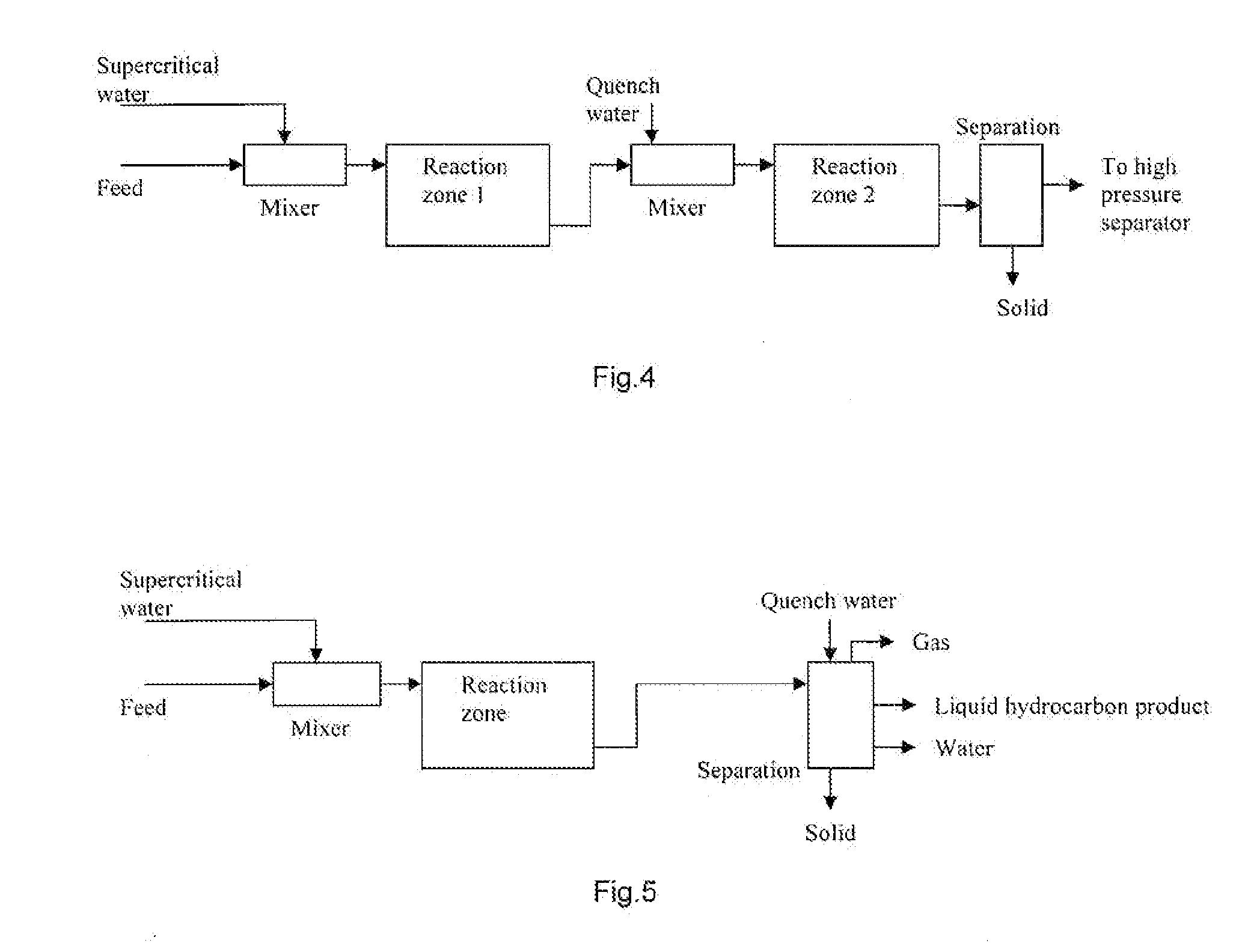

Process for upgrading heavy hydrocarbon oils

InactiveUS20080099377A1Increase gravityHigh yieldLiquid hydrocarbon mixture productionHydrocarbon oils refiningHydrogenLow density

A process using supercritical water to upgrade a heavy hydrocarbon feedstock into an upgraded hydrocarbon product or syncrude with highly desirable properties (low sulfur content, low metals content, lower density (higher API), lower viscosity lower, residuum content, etc.) is disclosed. The process does not require external supply of hydrogen nor does it use externally supplied catalysts. Improved methods of mixing the reactants are also disclosed.

Owner:CHEVROU USA INC

Method of direct iron-making / steel-making via gas or coal-based direct reduction and apparatus

The invention is a method and apparatus for iron-making / steel-making using a modified rotary hearth furnace, that is a finisher-hearth-melter (FHM) furnace. In the method the refractory surface of the hearth is coated with carbonaceous hearth conditioners and refractory compounds, where onto said hearth is charged with pre-reduced metallized iron. The pre-reduced metallized iron is leveled, then heated until molten, and then reacted with the carbon and reducing gas burner gases until any residual iron oxide is converted to iron having a low sulfur content. Nascent slag separates from the molted iron forming carburized iron nuggets. The nuggets are cooled, and then the iron nuggets and the hearth conditioners, including the refractory compounds, are discharged onto a screen, which separate the iron nuggets from the hearth conditioner. The hearth conditioner is recycled, and the iron nuggets are either prepared for sale or for additional treatment, such as alloying, in a final melter, where the final melter is preferably an electric furnace. Exhaust gases from the FHM furnace are recovered for calcining coal into fuel gases and coke.

Owner:KOBE STEEL LTD

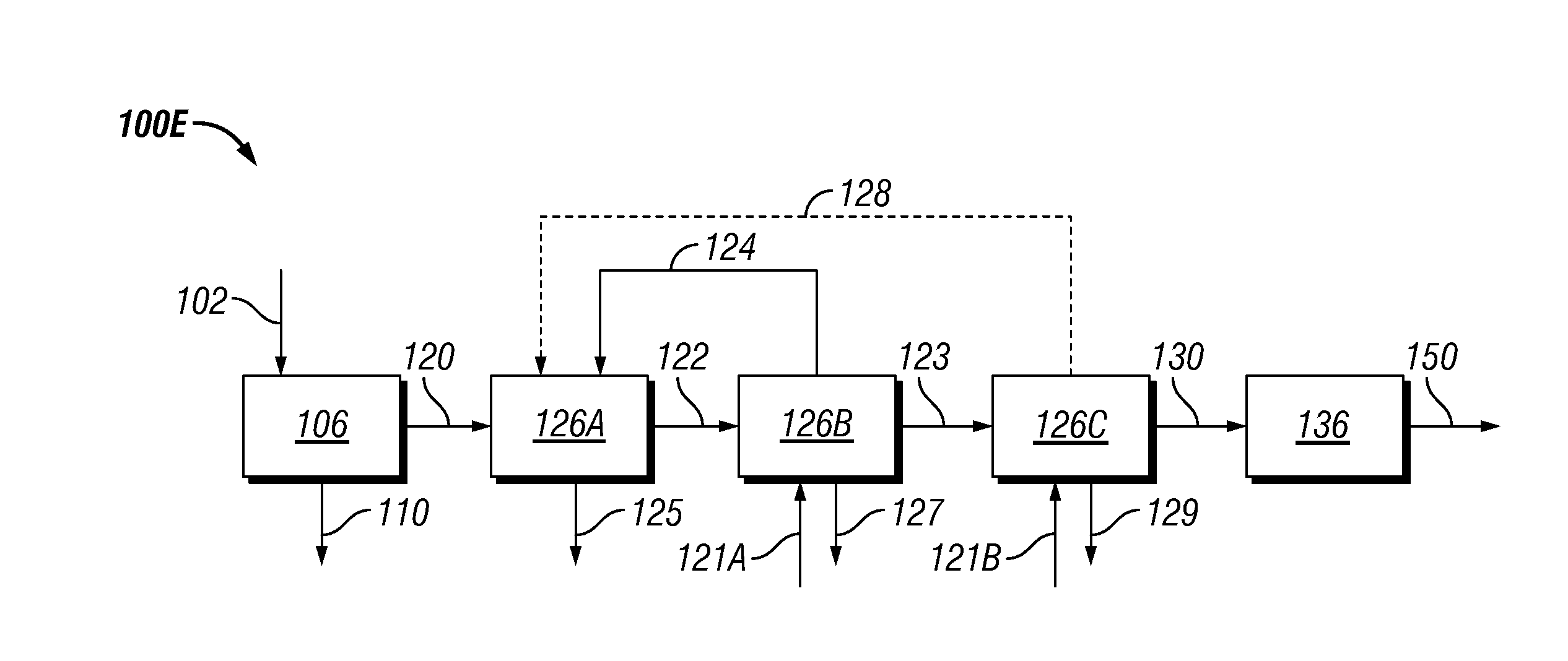

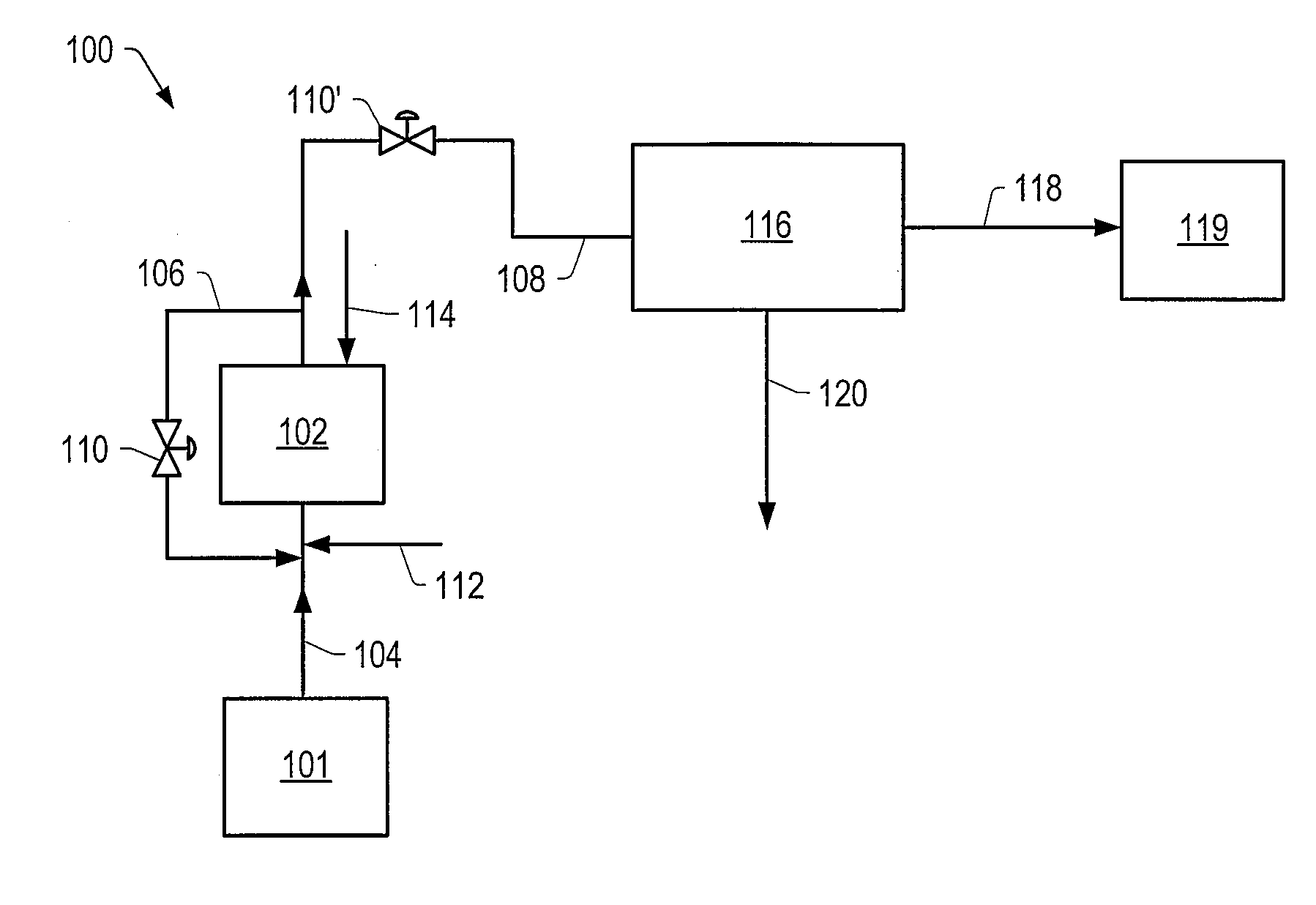

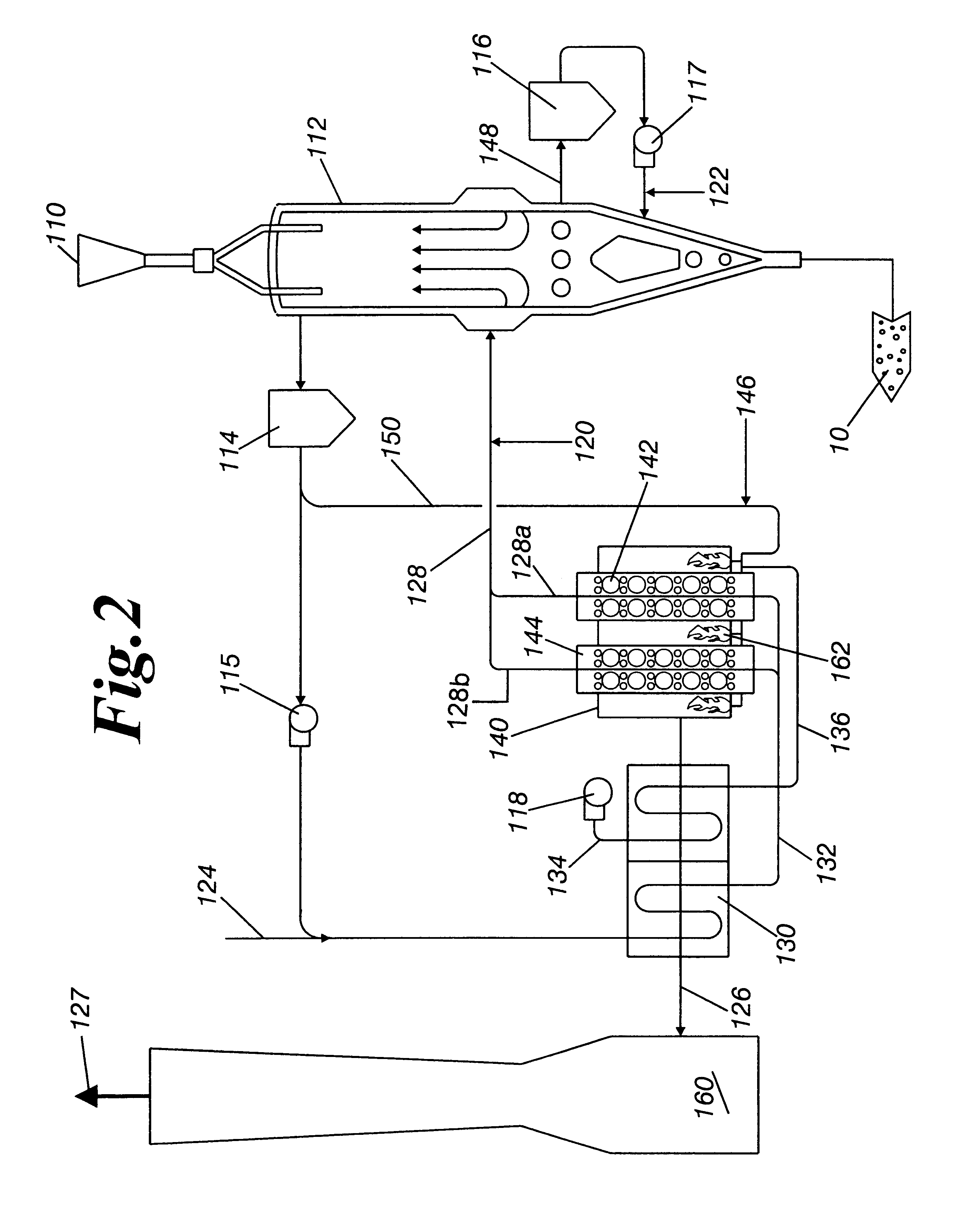

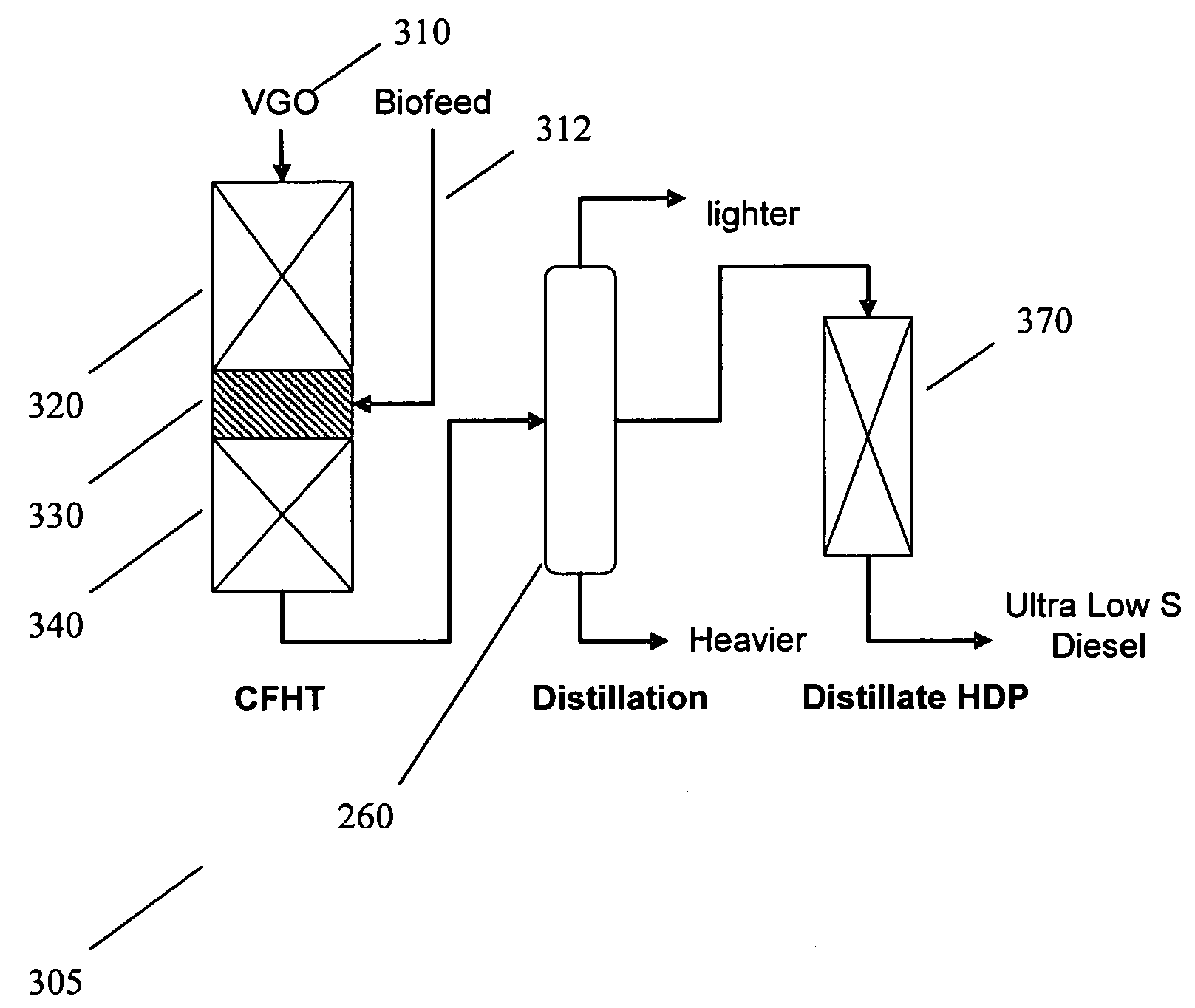

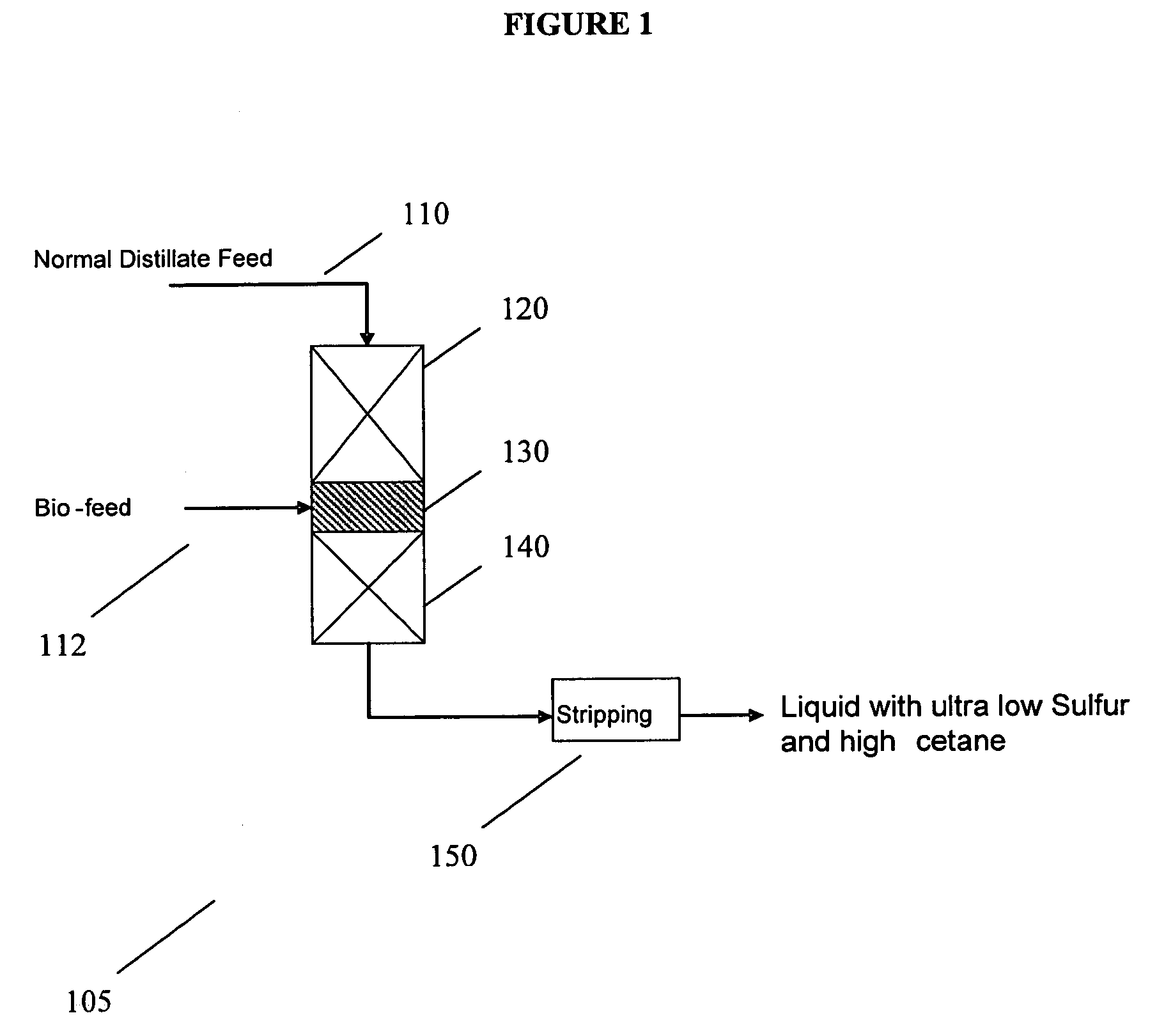

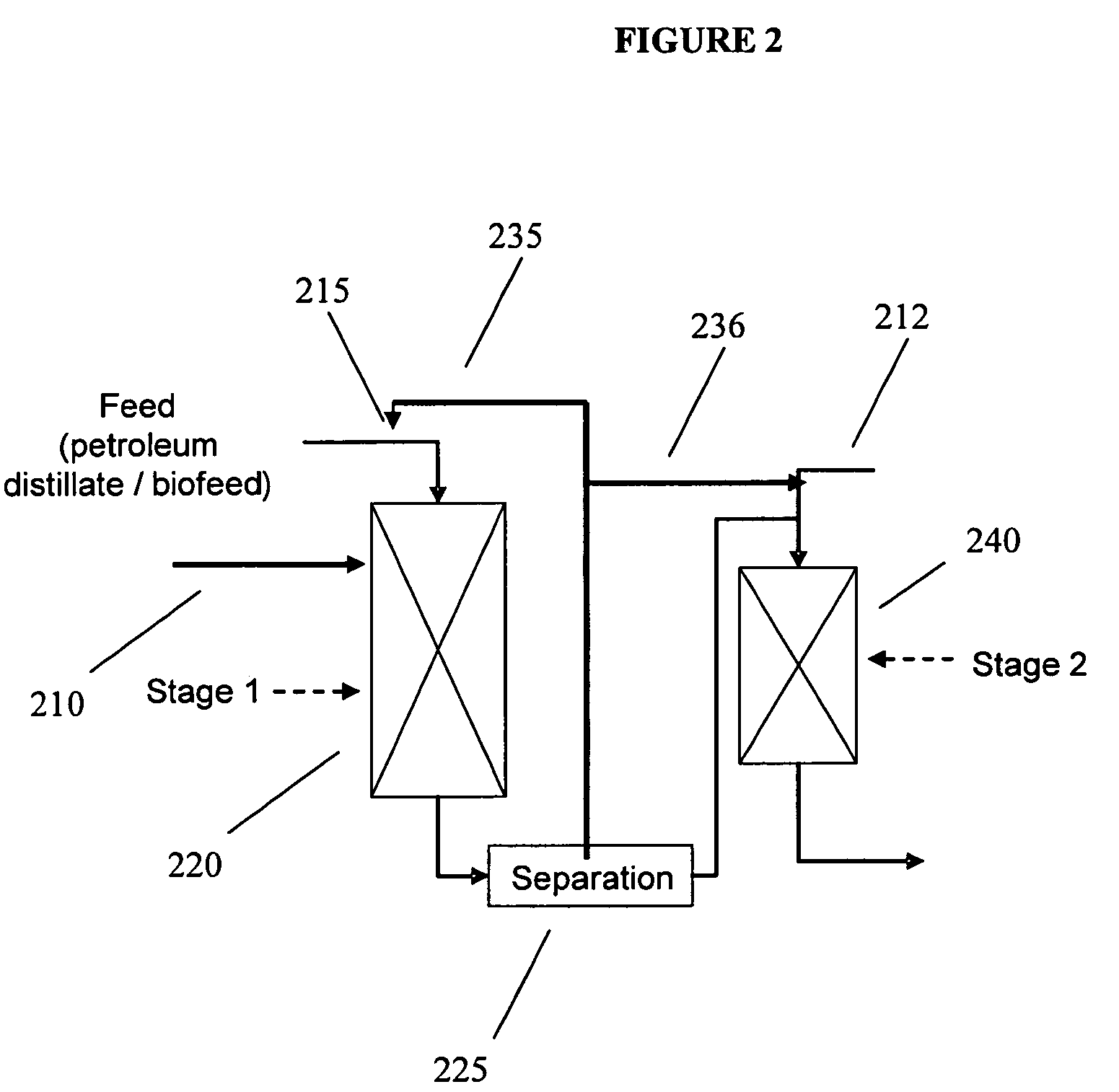

Staged co-processing of biofeeds for manufacture of diesel range hydrocarbons

ActiveUS20090166256A1Liquid hydrocarbon mixture productionTreatment with hydrotreatment processesCo-processingMaceral

Processes are provided for producing a diesel fuel product having a sulfur content of 10 ppm by weight or less from feed sources that include up to 20% by weight of a biocomponent feedstock. The mineral hydrocarbon portions of the feed sources can be distillate or heavier feed sources.

Owner:EXXON RES & ENG CO

Gasoline sulfur reduction in fluid catalytic cracking

InactiveUS6852214B1Reduce sulfur contentLow sulfurCatalytic crackingMolecular sieve catalystsOxidation stateGasoline

The sulfur content of liquid cracking products, especially the cracked gasoline, of the catalytic cracking process is reduced by the use of a sulfur reduction additive comprising a porous molecular sieve which contains a metal in an oxidation state above zero within the interior of the pore structure of the sieve. The molecular sieve is normally a large pore size zeolite such as USY or zeolite beta or an intermediate pore size zeolite such as ZSM-5. The metal is normally a metal of Period 4 of the Periodic Table, preferably zinc or vanadium. The sulfur reduction catalyst may be used in the form of a separate particle additive or as a component of an integrated cracking / sulfur reduction catalyst.

Owner:MOBIL OIL CORP +1

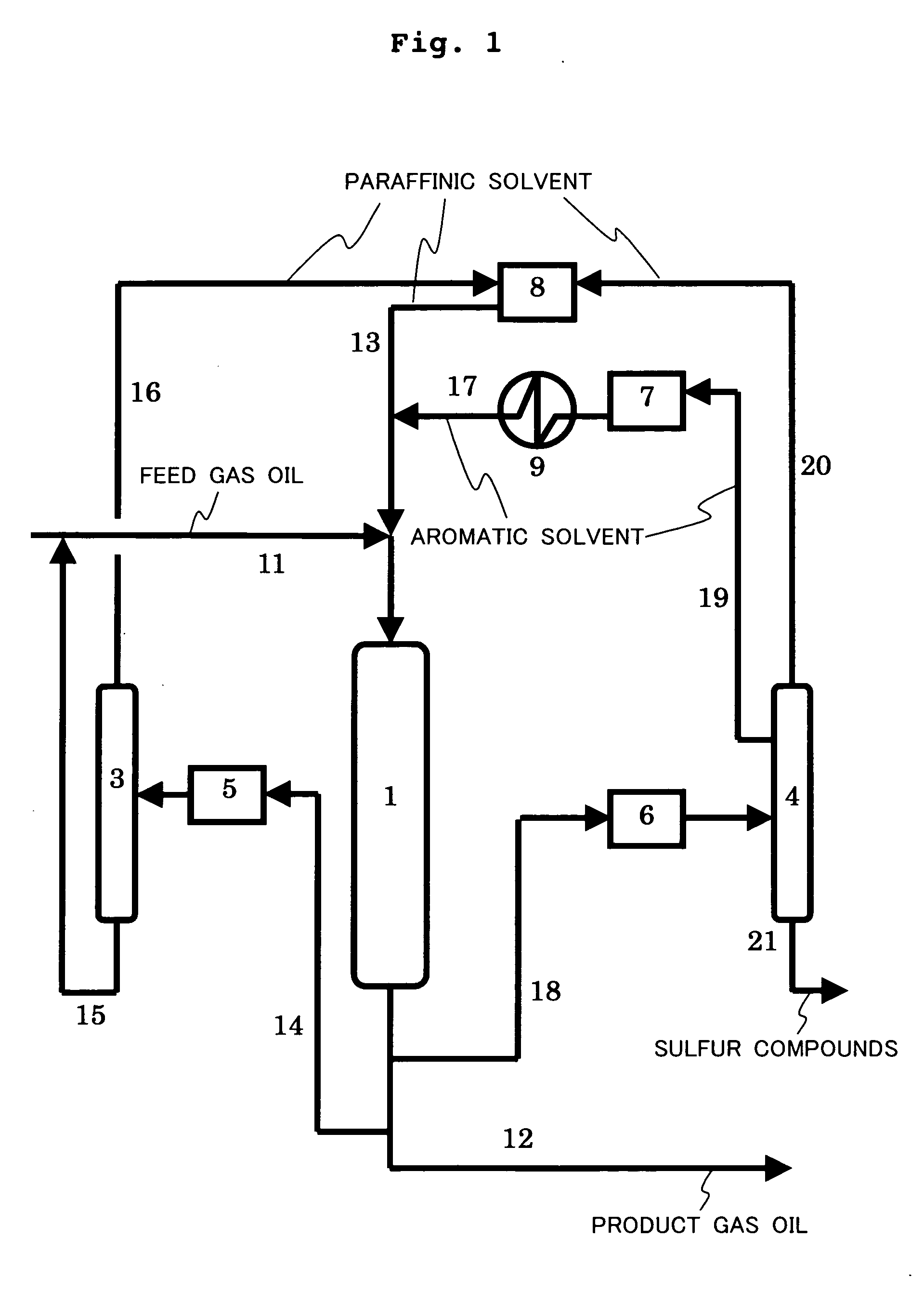

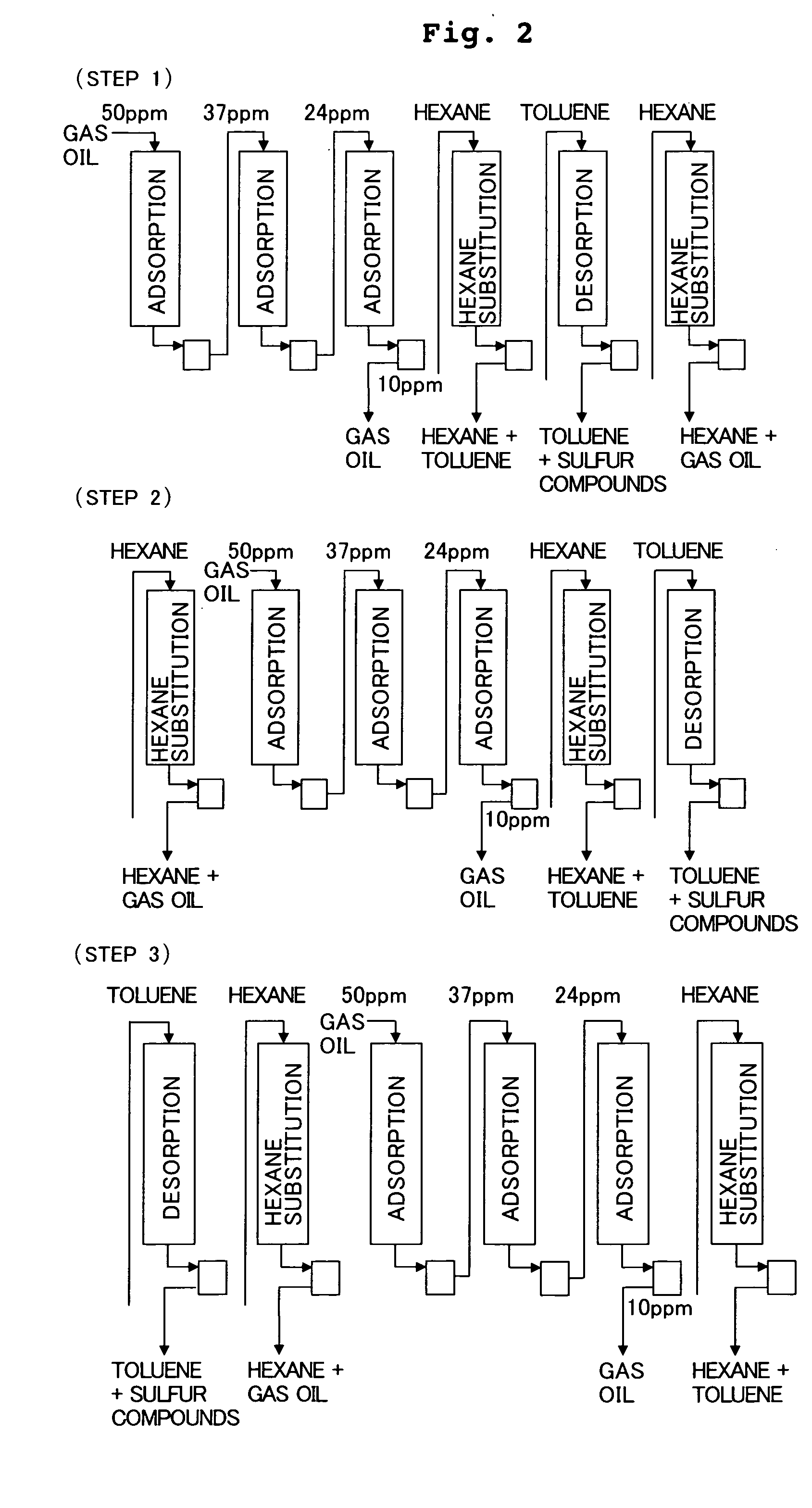

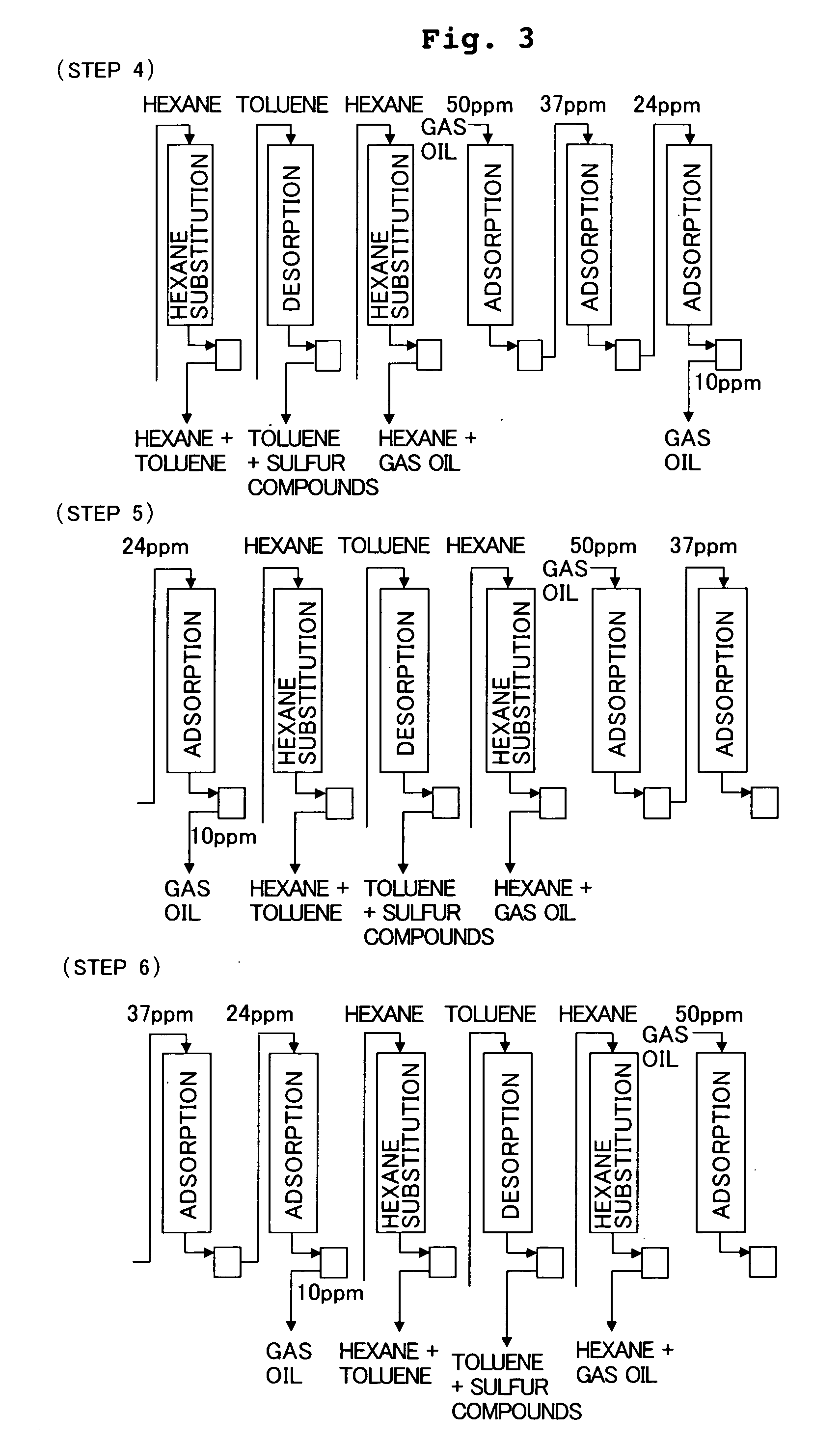

Adsorption desulfurization agent for desulfurizing petroleum fraction and desulfurization method using the same

InactiveUS20050173297A1Reduce equipment costsLow running costOther chemical processesLiquid organic insulatorsDesorptionTower

A desulfurization method for a gas oil which includes a step of removing sulfur compounds contained in a gas oil distillate product by the adsorption with an adsorptive desulfurization agent formed of a fibrous active carbon and provided in an adsorption tower (1), and a desorption regeneration step of washing the used adsorptive desulfurization agent with an aromatic solvent to regenerate the desulfurization agent. The method allows the production of gas oil being satisfactorily freed of sulfur content at relatively low equipment and operation costs over a long period of time, and in the method, difficult-to-remove sulfur compounds, such as 4,6-DMDBT, and polycyclic aromatic compounds having two or more rings are selectively removed.

Owner:JAPAN ENERGY CORP

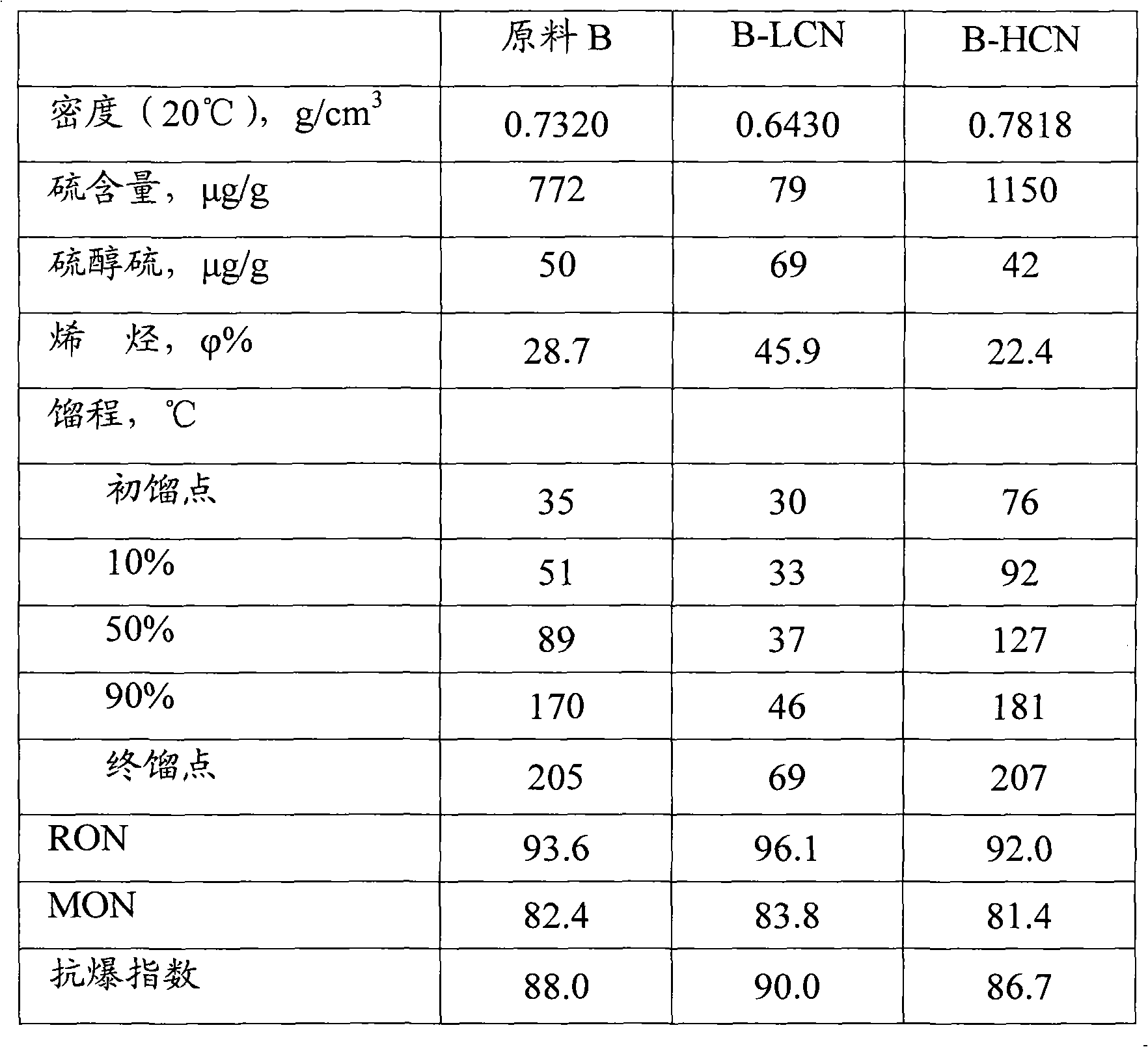

Gasoline hydrodesulfurization method

ActiveCN101787307ASmall mercaptan sulfur contentReduce lossesTreatment with hydrotreatment processesHydrodesulfurizationGasoline

The invention relates to a gasoline hydrodesulfurization method, which comprises the following steps that: gasoline raw materials are fractionated into light fraction gasoline and heavy fraction gasoline, wherein the light fraction gasoline is removed mercaptan sulfer through caustic washing refining, the heavy fraction gasoline carries out a hydrogenation diene-removal reaction, a selective hydrodesulfurization reaction and a selective hydrogenation mercaptan sulfer-removal reaction respectively through two hydrogenation reactors, and the obtained hydrogenation heavy fraction gasoline and the refined light fraction gasoline are mixed to obtain full fraction gasoline with ultra-low sulfur. According to the method provided by the invention, under the condition that the desulfurization degree reaches a target, the full fraction gasoline product have small mercaptan sulfur content, less olefin saturation and small octane value loss. The mercaptan sulfur content of the obtained dull fraction gasoline product is less than 10Mug / g, the total sulfur content is reduced under 50Mug / g, and the octane value RON loss is less than 1.0 unit, particularly, the total sulfur content of the full fraction gasoline product is reduced under 10 Mug / g, and the octane value RON loss is less than 1.5 units.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sorbent for reducing sulfur content in hydrocarbon oils

ActiveCN101433821AHigh desulfurization activityEvenly distributedOther chemical processesHydrocarbon oils refiningSorbentRare earth

The invention relates to a sorbent for reducing sulfer content in hydrocarbon oil, which comprises 1 to 30 weight percent of rare earth faujasite, 5 to 40 weight percent of active metal oxide and 30 to 94 weight percent of carrier, wherein the carrier comprises alumina and zinc oxide. The mixture of the rare earth faujasite and the carrier is preformed into porous heat-resistant solid particles which are introduced with the metal active ingredient to prepare the sorbent; sulfer-containing light hydrocarbon oil raw material and hydrogen donors enter a reactor filled with the sorbent for separating reaction; materials and products after the separating reaction are sent to a subsequent separation system for product separation; sorbent to be regenerated after the reaction is burnt to be regenerated after steam stripping; and the regenerated sorbent is reduced by the hydrogen donors and returned to the reactor for recycling. The sorbent realizes deep removal of sulfer in the light hydrocarbon oil; meanwhile, the product gasoline has high octane number, low benzene content and high strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

Very low sulfur gas feeds for sulfur sensitive syngas and hydrocarbon synthesis processes

Very low sulfur content hydrocarbon gas is achieved by sequentially contacting the gas first with zinc oxide and then with nickel metal. This has reduced the total sulfur content of natural gas feed for a fluid bed syngas generator to less than 0.1 ppm and has resulted in greater syngas productivity. A zinc oxide guard bed downstream of the syngas generator reduces the total sulfur content of the syngas to less than 10 vppb and preferably less than 5 vppb. This very low sulfur content syngas is used for sulfur sensitive processes, such as hydrocarbon synthesis. The process is especially useful for natural gas which contains H2S, COS, mercaptans and other sulfur bearing compounds.

Owner:EXXON RES & ENG CO

Blending for density specifications using Fischer-Tropsch diesel fuel

ActiveUS20050288537A1Low densitySolid fuelsLiquid carbonaceous fuelsEngineeringVolumetric Mass Density

The present invention includes a method for adjusting a fluid density. In one embodiment, a method for upgrading a petroleum-derived hydrocarbonaceous fraction comprises providing a synthetically-derived hydrocarbonaceous fraction, wherein the synthetically-derived hydrocarbonaceous fraction is derived from synthesis gas, and further wherein the synthetically-derived hydrocarbonaceous fraction and the petroleum-derived hydrocarbonaceous fraction have a difference in density at 15° C. of at least about 60 kg / m3; and blending both fractions so as to form a blend suitable for use as a diesel or diesel blendstock, wherein the blend has a density at 15° C. equal to or more than about 800 kg / m3; alternatively or additionally, equal to or less than about 860 kg / m3. The blending is also effective in reducing the sulfur content of the petroleum-derived hydrocarbonaceous fraction. In preferred embodiments, the synthetically-derived hydrocarbonaceous fraction is a Fischer-Tropsch diesel.

Owner:PHILLIPS 66 CO

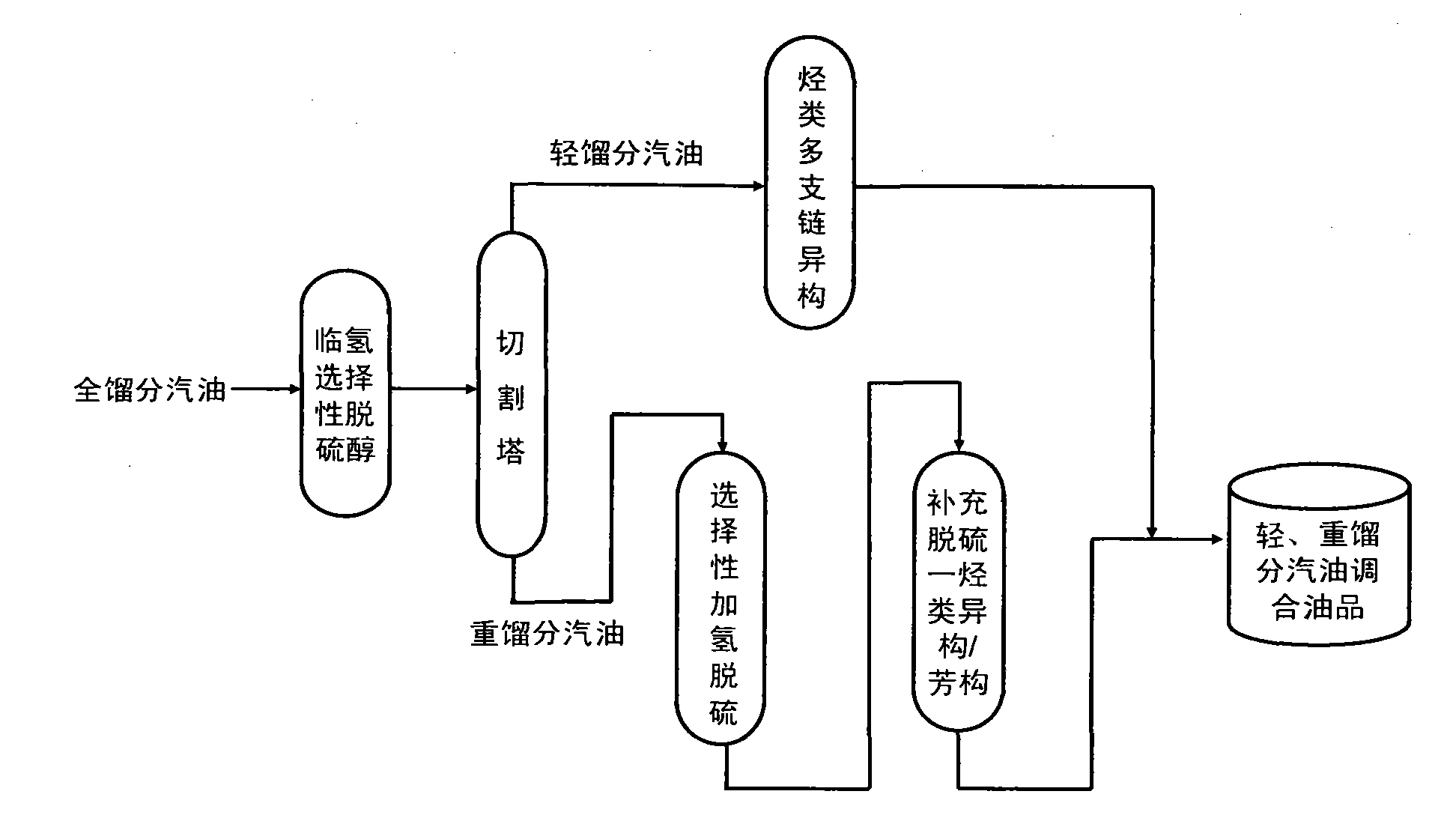

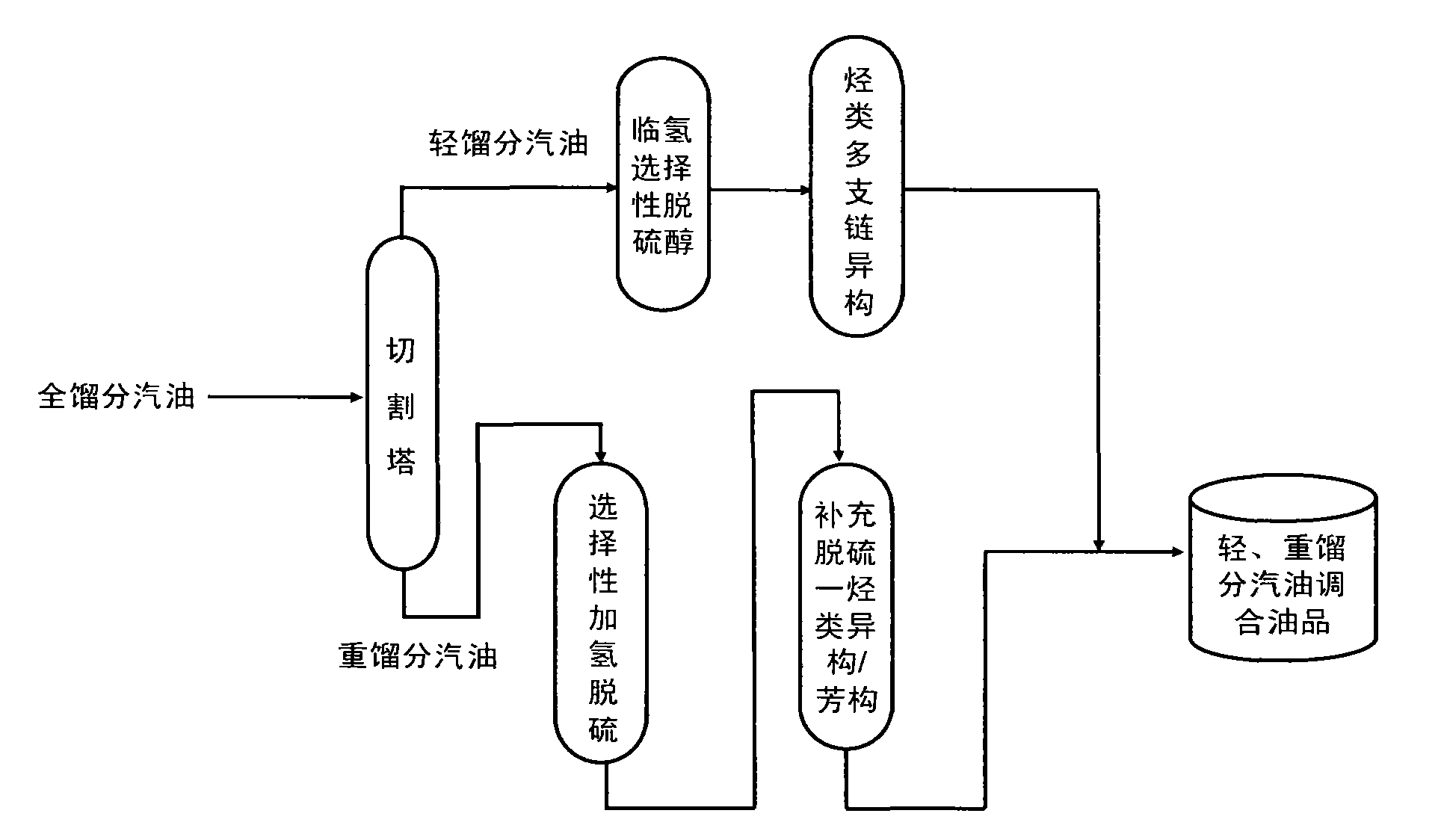

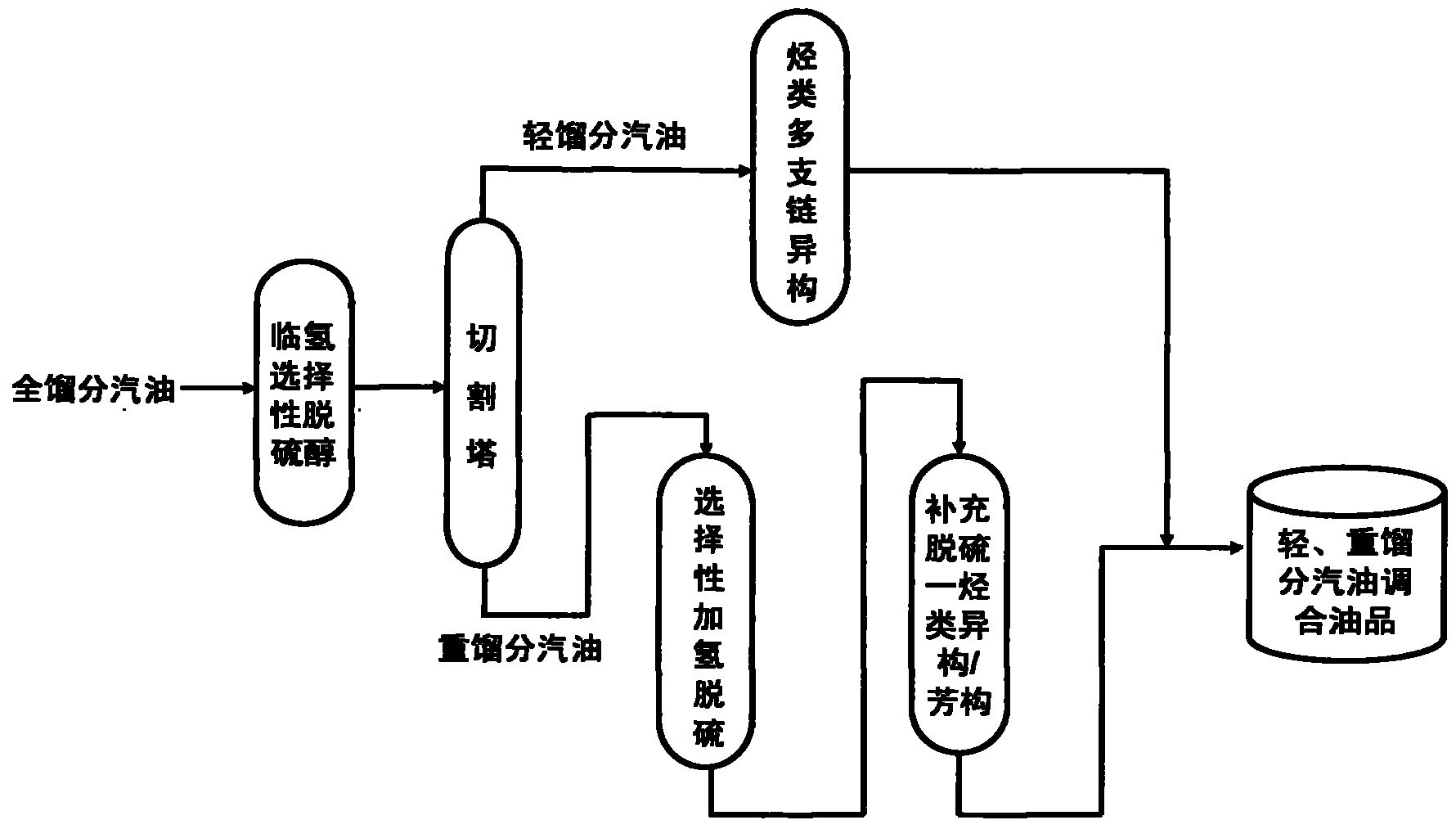

Efficient coupling hydro-upgrading method for producing gasoline with ultra-low sulfur and high octane number

ActiveCN101885983AImprove octaneOctane recoveryTreatment with hydrotreatment processesIsomerizationAlcohol

The invention relates to an efficient coupling hydro-upgrading method for producing gasoline with ultra-low sulfur and a high octane number. The method comprises the following steps of: distilling inferior full cut gasoline at 50-90 DEG C to obtain light cut gasoline and heavy cut gasoline; making the light cut gasoline contact with a hydrocarbon multi-branched isomerization catalyst; making the heavy cut gasoline contact with a selective hydrogenation desulfurization catalyst and a complement desulfurization isomerization / aromatization catalyst sequentially; and finally, mixing the treated light cut gasoline with the treated heavy cut gasoline to obtain the gasoline with the ultra-low sulfur and the high octane number. The method further comprises the step of: before the distillation, making the inferior full cut gasoline contact with a hydro-selective desulfurization alcohol catalyst, or, before making the light cut gasoline contact with a hydrocarbon multi-branched isomerization catalyst, making the light cut gasoline contact with the hydro-selective desulfurization alcohol catalyst. The efficient coupling hydro-upgrading method is suitable for the hydro-upgrading treatment of inferior gasoline with ultrahigh sulfur and high olefin, reduces the sulfur content after the upgrading treatment to below 5mu g / g (no sulfur substantially) and can maintain the octane number and higher yield of products.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

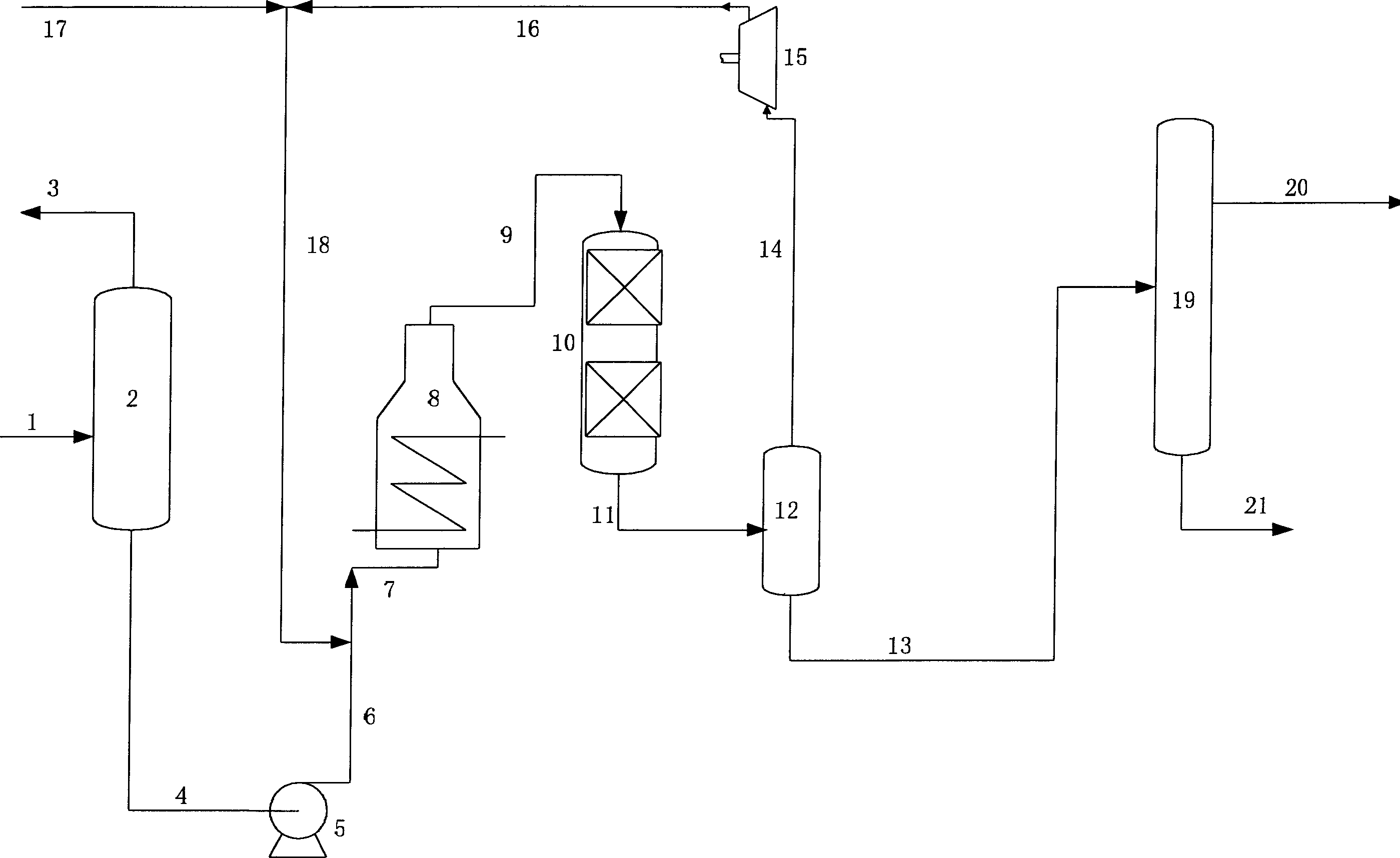

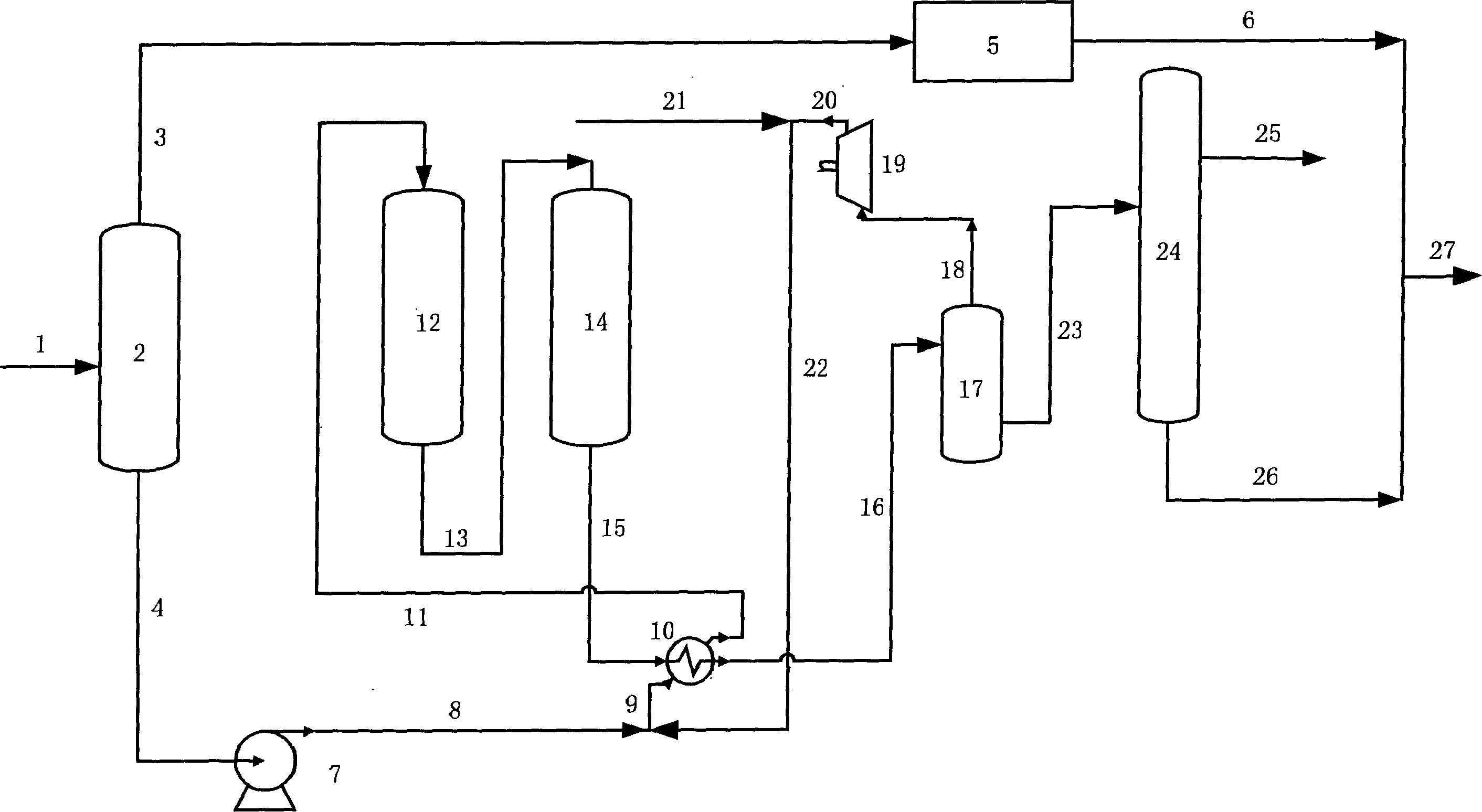

Process and installation for conversion of heavy petroleum fractions in a fixed bed with integrated production of middle distillates with a very low sulfur content

InactiveUS20080093262A1Low investment costEasy to useHydrocarbons from unsaturated hydrocarbon additionHydrocarbon oil crackingDistillates petroleumNaphtha

This invention relates to a process and an installation for treatment of a heavy petroleum feedstock, of which at least 80% by weight has a boiling point of greater than 340° C., whereby the process comprises the following stages:(a) Hydroconversion in a fixed-bed reactor operating with an upward flow of liquid and gas, whereby the net conversion in products boiling below 360° C. is from 10 to 99% by weight;(b) Separation of the effluent obtained from stage (a) into a gas containing hydrogen and H2S, a fraction comprising the gas oil, and optionally a fraction that is heavier than the gas oil and a naphtha fraction;c) Hydrotreatment by contact with at least one catalyst of at least the fraction comprising the gas oil obtained in stage (b);d) Separation of the effluent obtained at the end of stage (c) into a gas containing hydrogen and at least one gas oil fraction having a sulfur content of less than 50 ppm, preferably less than 20 ppm, and more preferably still less than 10 ppm,the hydroconversion stage (a) being conducted at a pressure P1 and the hydrotreatment stage (c) being conducted at a pressure P2, the difference ΔP=P1−P2 being at least 2 MPa, the hydrogen supply for the hydroconversion (a) and hydrotreatment (c) stages being ensured by a single compression system with n stages.

Owner:INST FR DU PETROLE

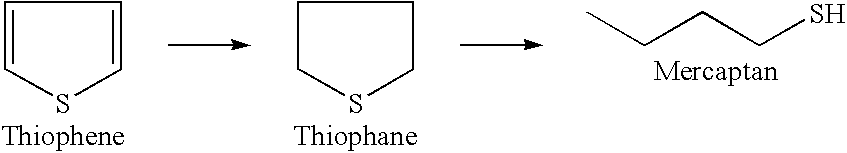

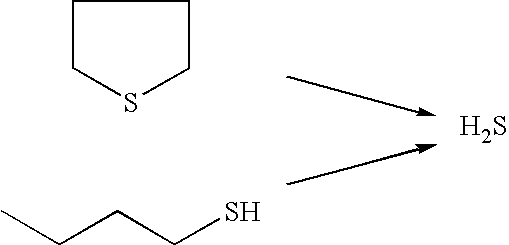

Selective naphtha hydrodesulfurization with high temperature mercaptan decomposition

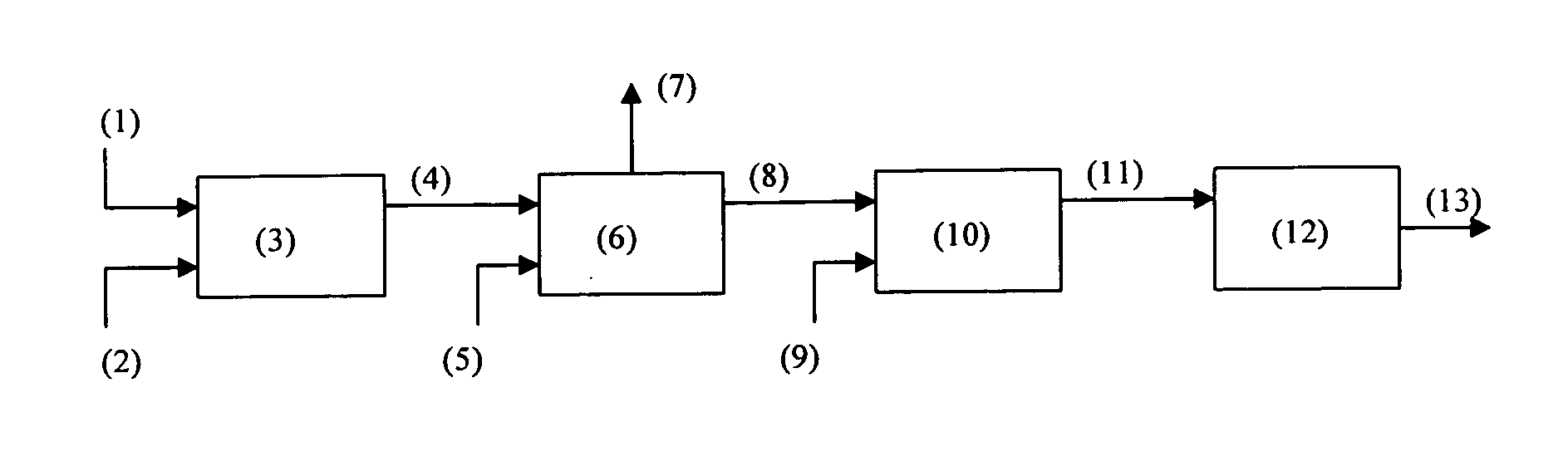

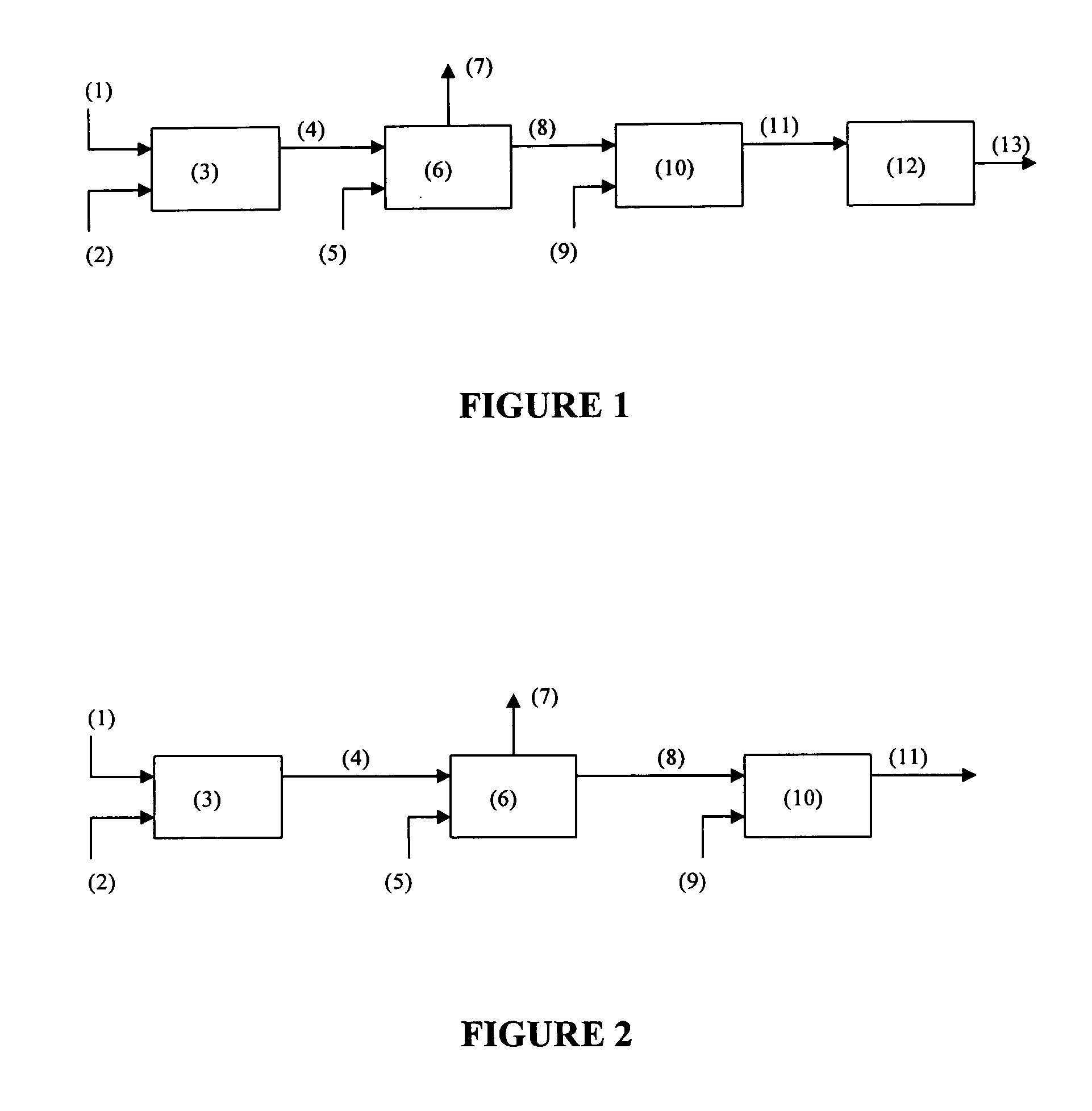

A process for the selective hydrodesulfurization of olefinic naphtha streams containing a substantial amount of organically bound sulfur and olefins. The olefinic naphtha stream is selectively desulfurized in a first hydrodesulfurization reaction stage. This effluent stream is then contacted with a stripping agent in a H2S removal zone, such as steam or an amine solution, to remove H2S from the effluent stream, thereby reducing the H2S partial pressure of the process stream. The process stream is then subjected to a second desulfurization reaction stage followed by a mercaptan decomposition stage to reduce the content of mercaptan sulfur in the final product stream. In a second embodiment, the effluent stream from the first hydrodesulfurization reaction stage, after being subjected to the H2S removal zone, is fed directly to the mercaptan decomposition stage where total sulfur content and mercaptan sulfur content are reduced in the final product stream.

Owner:EXXON RES & ENG CO

Method of heavily desulfurating and reducing olefinic hydrocarbon for gasoline

InactiveCN1465666ALess octane lossMeet sulfur content standardsHydrocarbon oils treatmentRefining to eliminate hetero atomsHydrogenGasoline

The method for further desulfurization and reducing olefine content in the gasoline includes the following steps: cutting the gasoline raw material into light fraction and heavy fraction, making the light fraction undergo the processes of alkali refinement treatment and removing mercaptans, and making the heavy fraction and hydrogen gas successively contact with hydrogenation refining catalyst and octane value restoring agent, then mixing the above-mentioned desulfurized light fraction and heavy fraction so as to obtain the invented gasoline product in which the sulfur content is less than 200 ppm and olefine content is less than 20 V%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for deep desulfurization olefin hydrocarbon reduction of inferior gasoline

ActiveCN101492608AStructuring reaction does not affectReduce olefin contentRefining to eliminate hetero atomsCatalytic pyrolysisHydrogen

The invention discloses a gasoline deep desulphurization and olefin reduction method, comprising that the gasoline raw material and hydrogen are contacted with hydrogenation absorption desulphurization and olefin aromatization difunctional catalyst to remove sulfur in the gasoline and reduce the olefin content in the gasoline product. The method of the invention can produce gasoline product with the sulfur content lower than 50 micrograms per gram, and can further produce gasoline product with the sulfur content lower than 10 micrograms per gram while the olefin content is lower than 20v%, and meanwhile the antiknock quality index loss is low. The method of the invention can be applied to deep desulphurization and olefin reduction process of FCC gasoline, catalytic pyrolysis gasoline, coker gasoline, pyrolysis gasoline and pressure gasoline or the mixed gasoline raw material thereof.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com