Patents

Literature

11987 results about "Oxide zinc" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

ZINC oxide is a mild astringent and topical protectant with some antiseptic action. It is also used in bandages, pastes, ointments, dental cements, and as a sunblock. Zinc oxide is an inorganic compound with the formula ZnO.

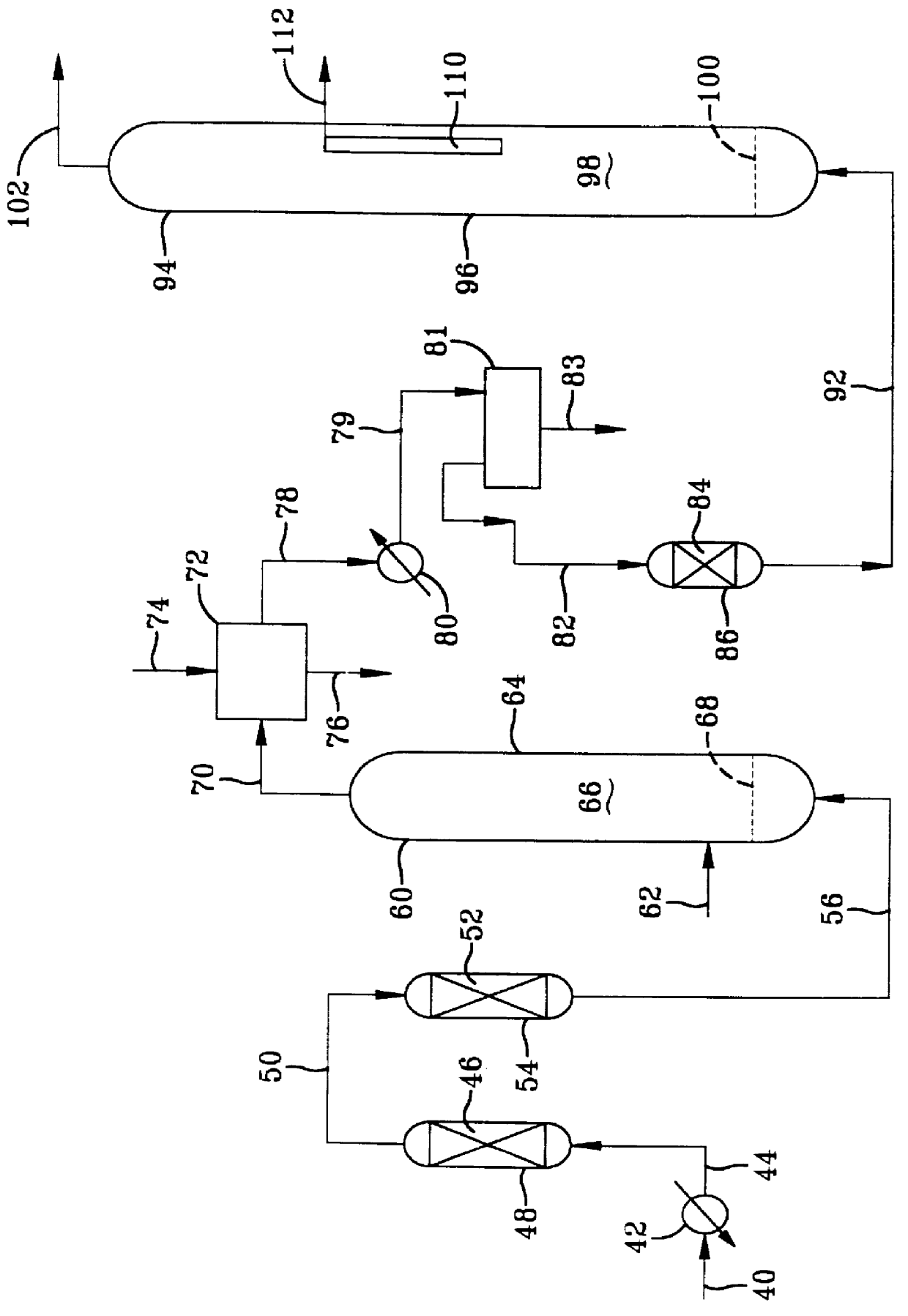

Sorbent composition, process for producing same and use in desulfurization

Particulate sorbent compositions comprising a mixture of zinc oxide, silica, alumina and a substantially reduced valence nickel are provided for the desulfurization of a feedstream of cracked-gasoline or diesel fuels in a desulfurization zone by a process which comprises the contacting of such feedstreams in a desulfurization zone followed by separation of the resulting low sulfur-containing stream and sulfurized-sorbent and thereafter regenerating and activating the separated sorbent before recycle of same to the desulfurization zone.

Owner:CHINA PETROLEUM & CHEM CORP

Sorbent composition, process for producing same and use in desulfurization

A particulate adsorbent composition comprising a mixture of zinc oxide, silica, alumina and substantially reduced valence cobalt for use in desulfurizing a cracked gasoline or diesel fuel feed stream in a desulfurization zone by: The desulfurization zone contacts the feed stream, then separates the resulting low sulfur content stream and the sulfurized adsorbent, regenerates and activates the separated adsorbent, and then returns to the desulfurization zone.

Owner:CHINA PETROLEUM & CHEM CORP

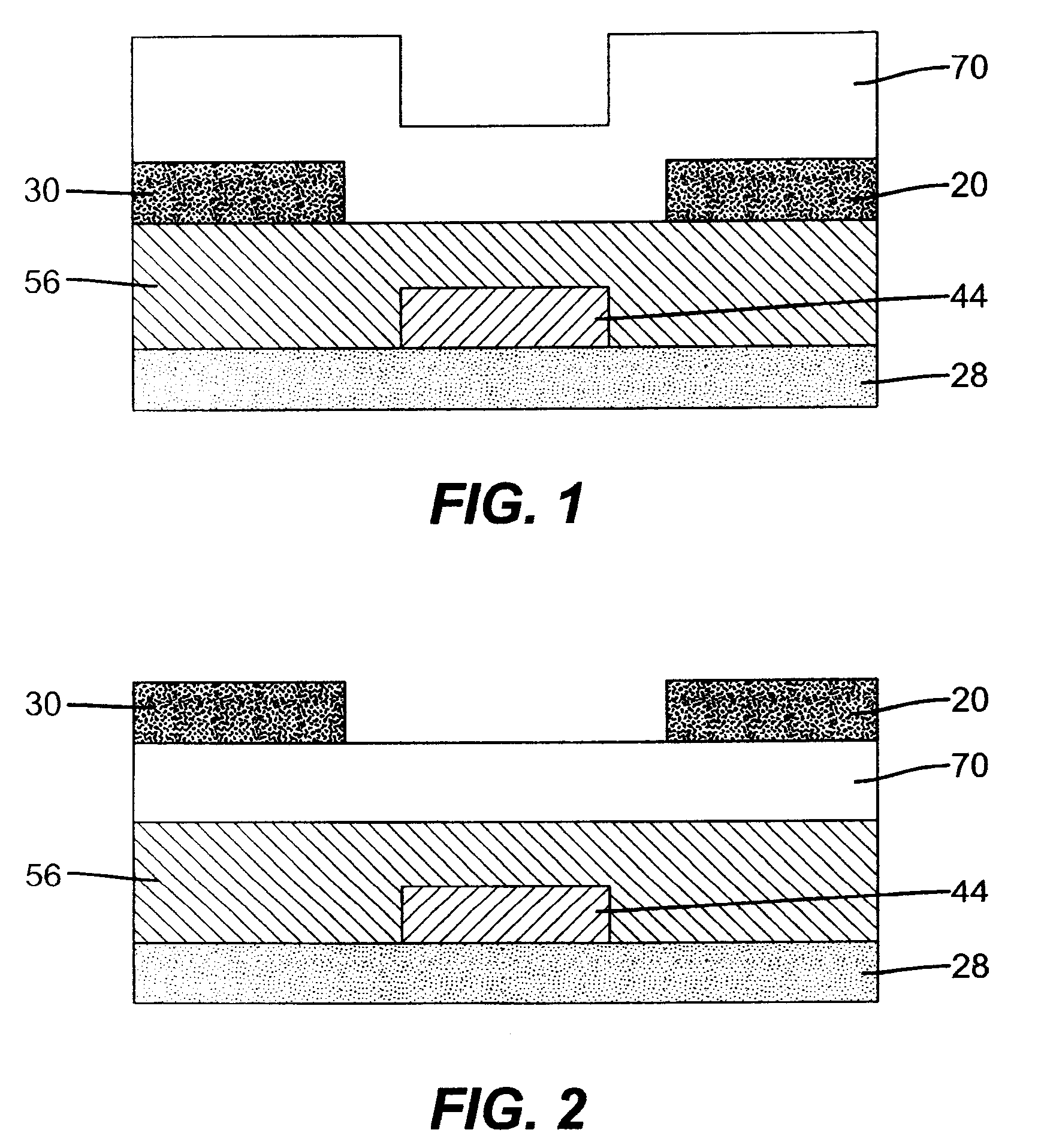

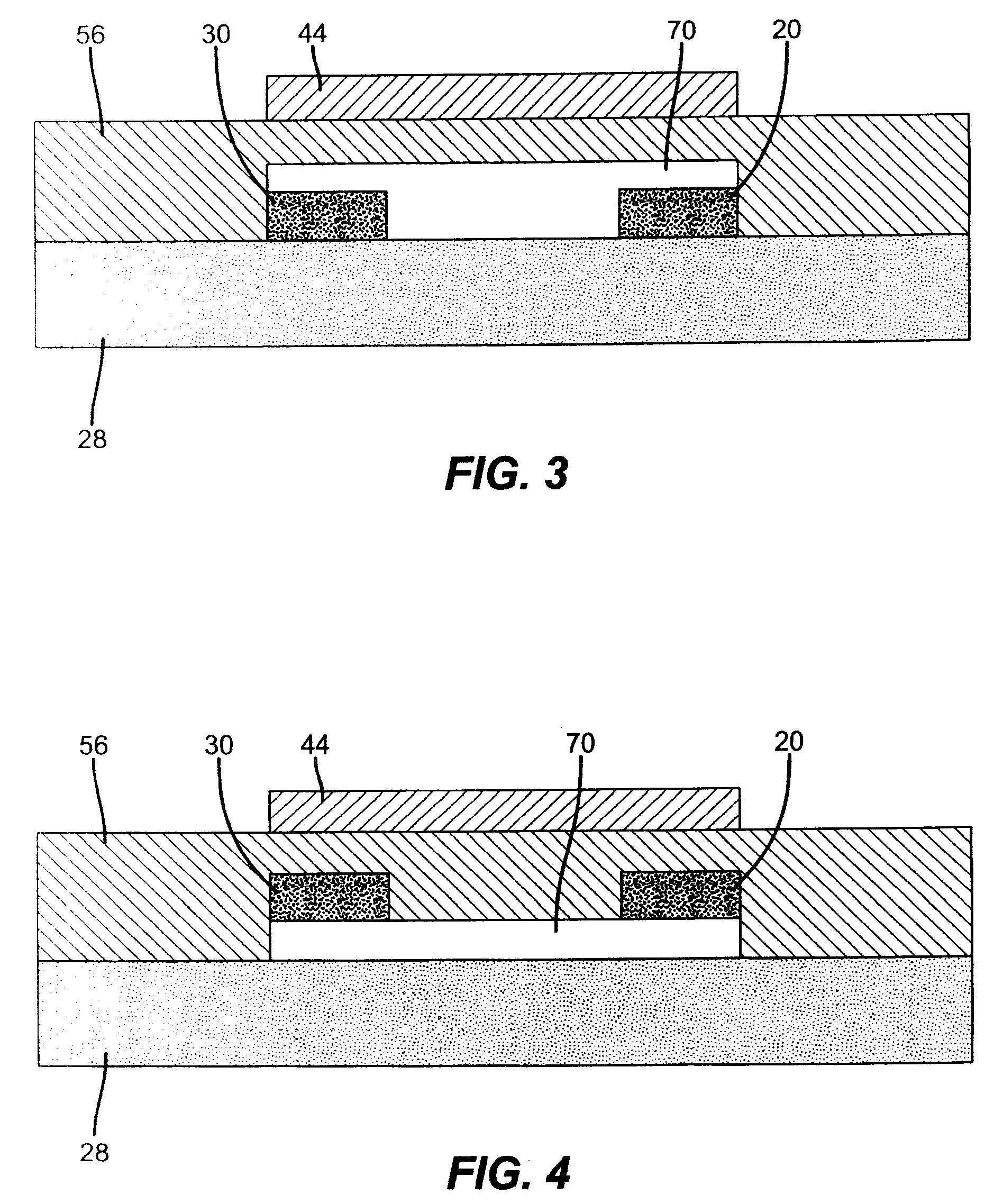

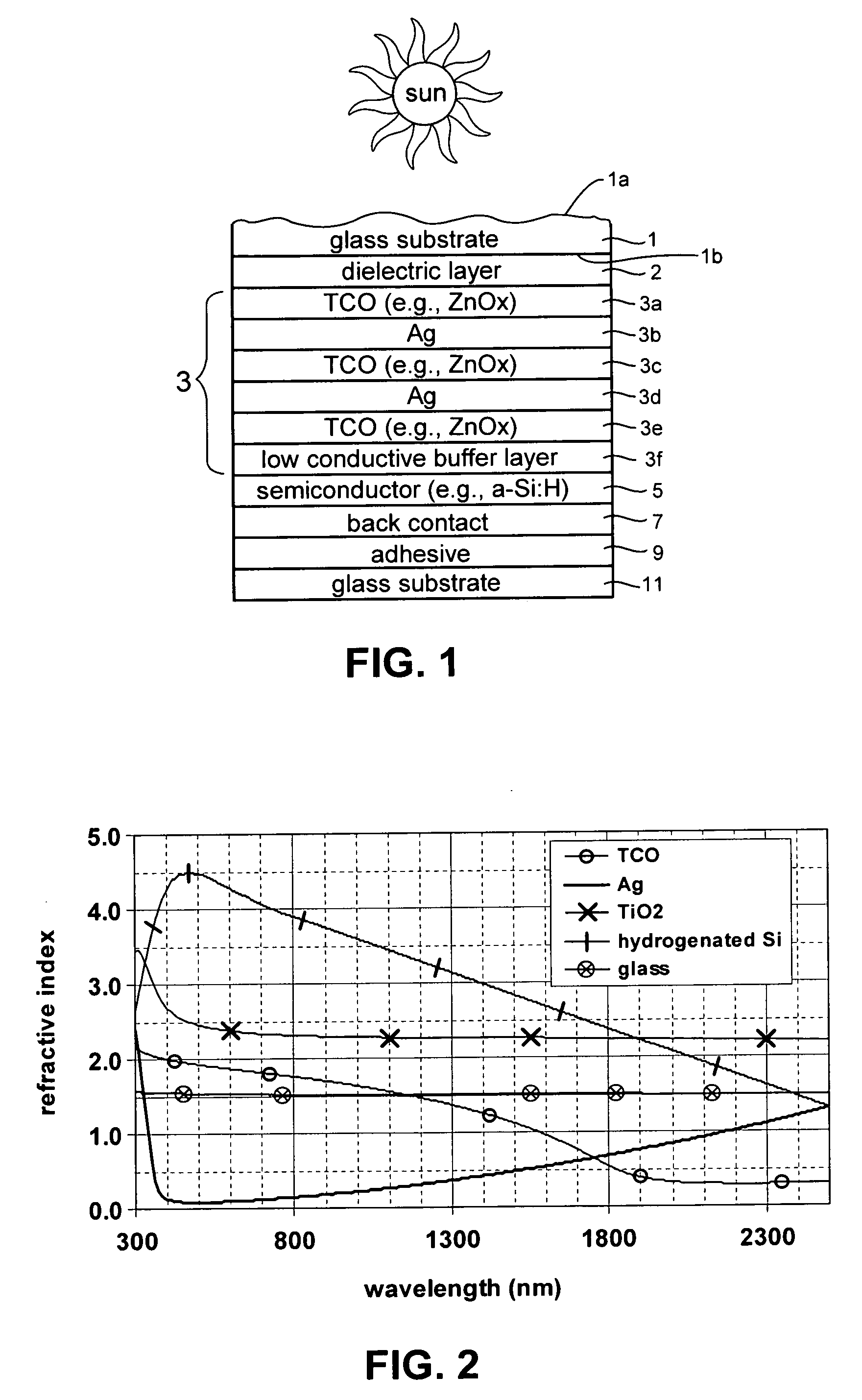

Front electrode for use in photovoltaic device and method of making same

ActiveUS20090084438A1Reduce reflection lossPromote absorptionPhotovoltaic energy generationSemiconductor devicesIr reflectionLight reflection

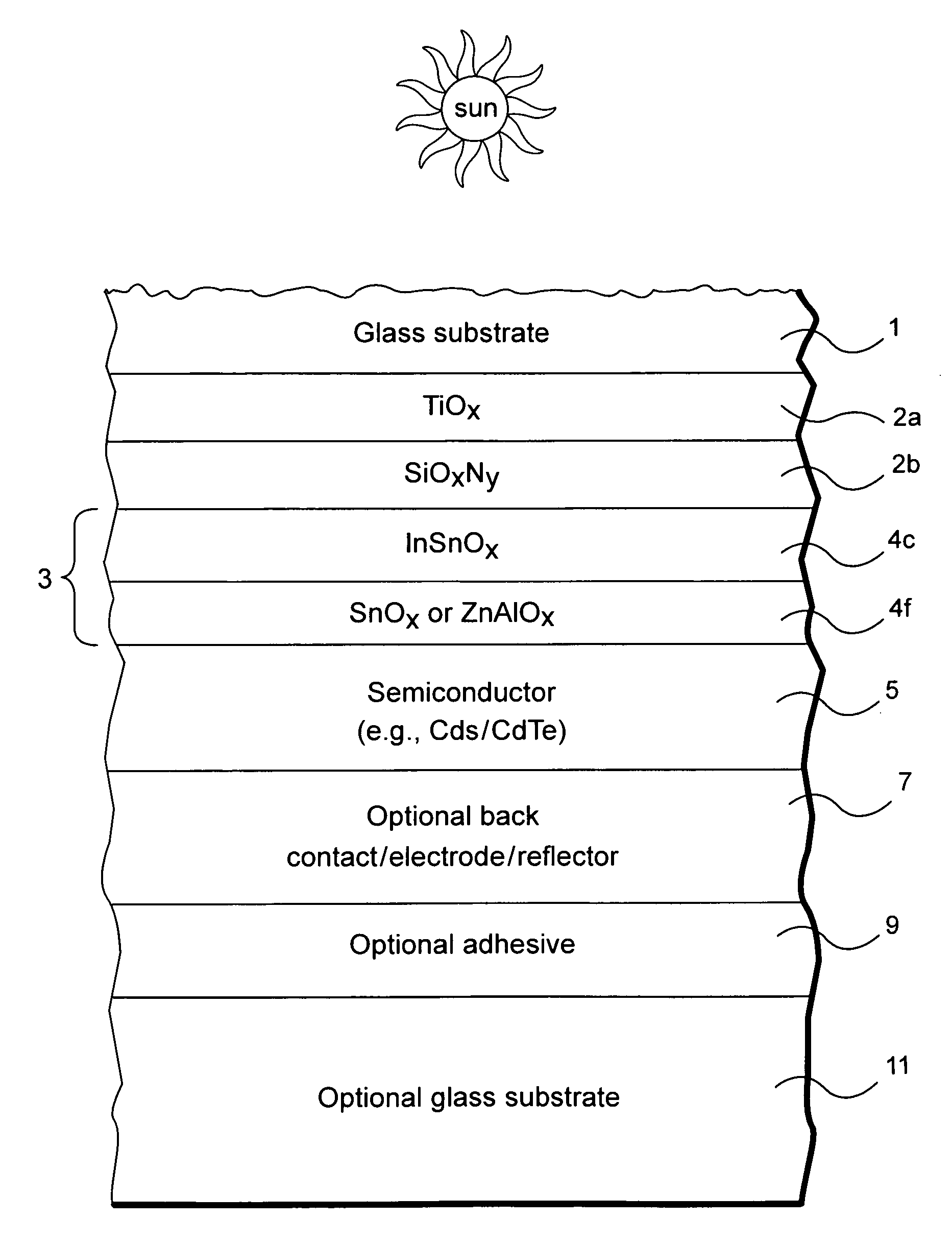

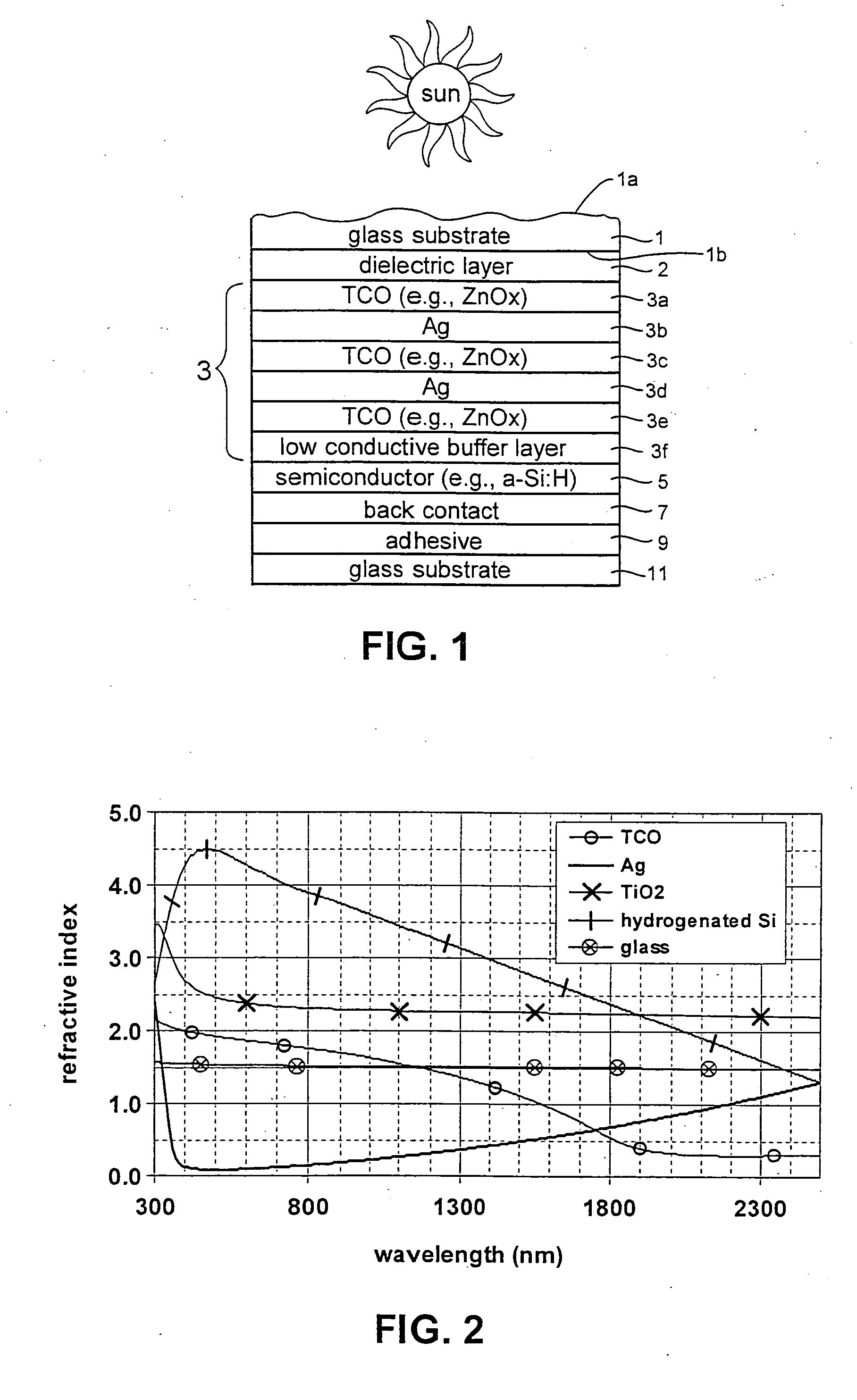

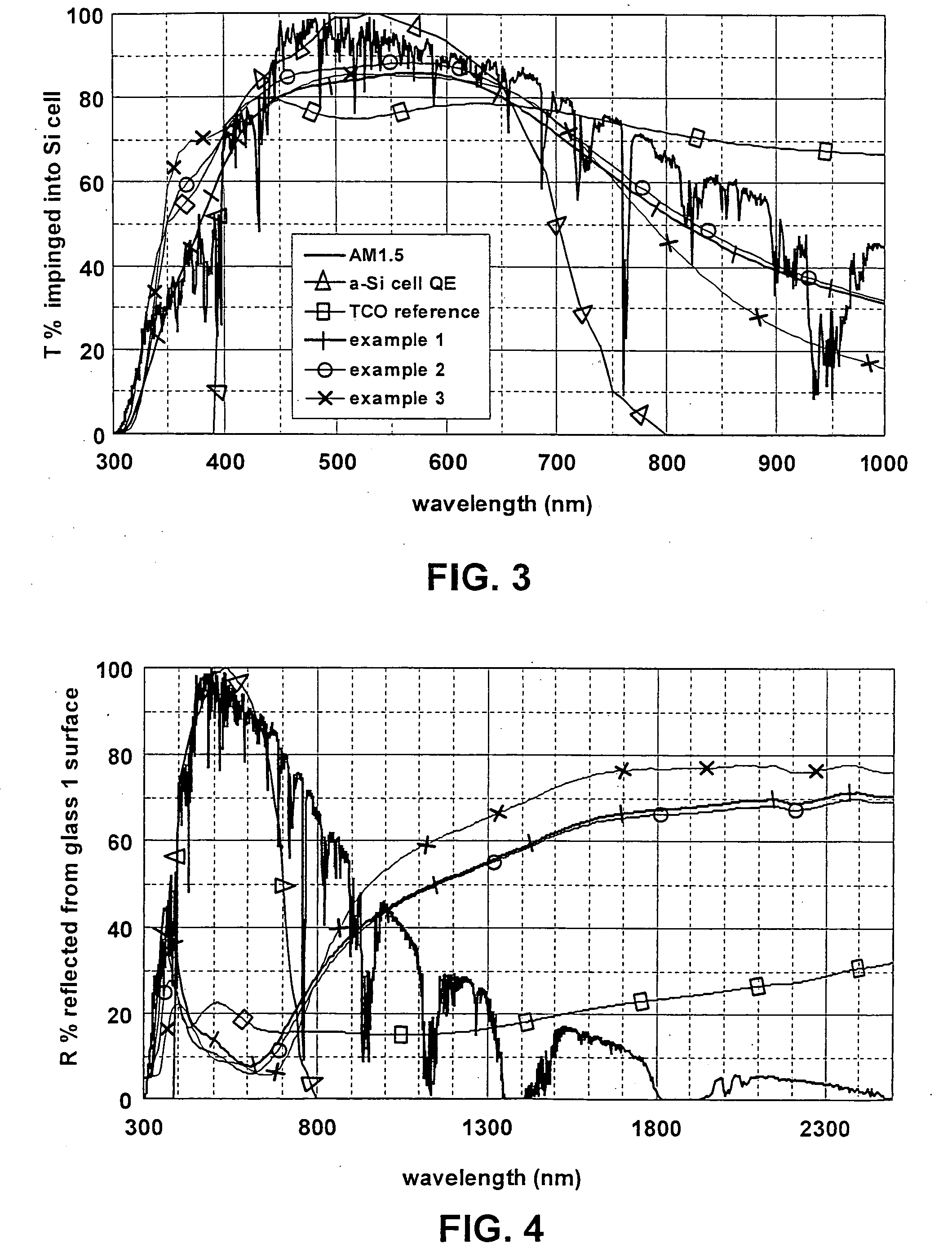

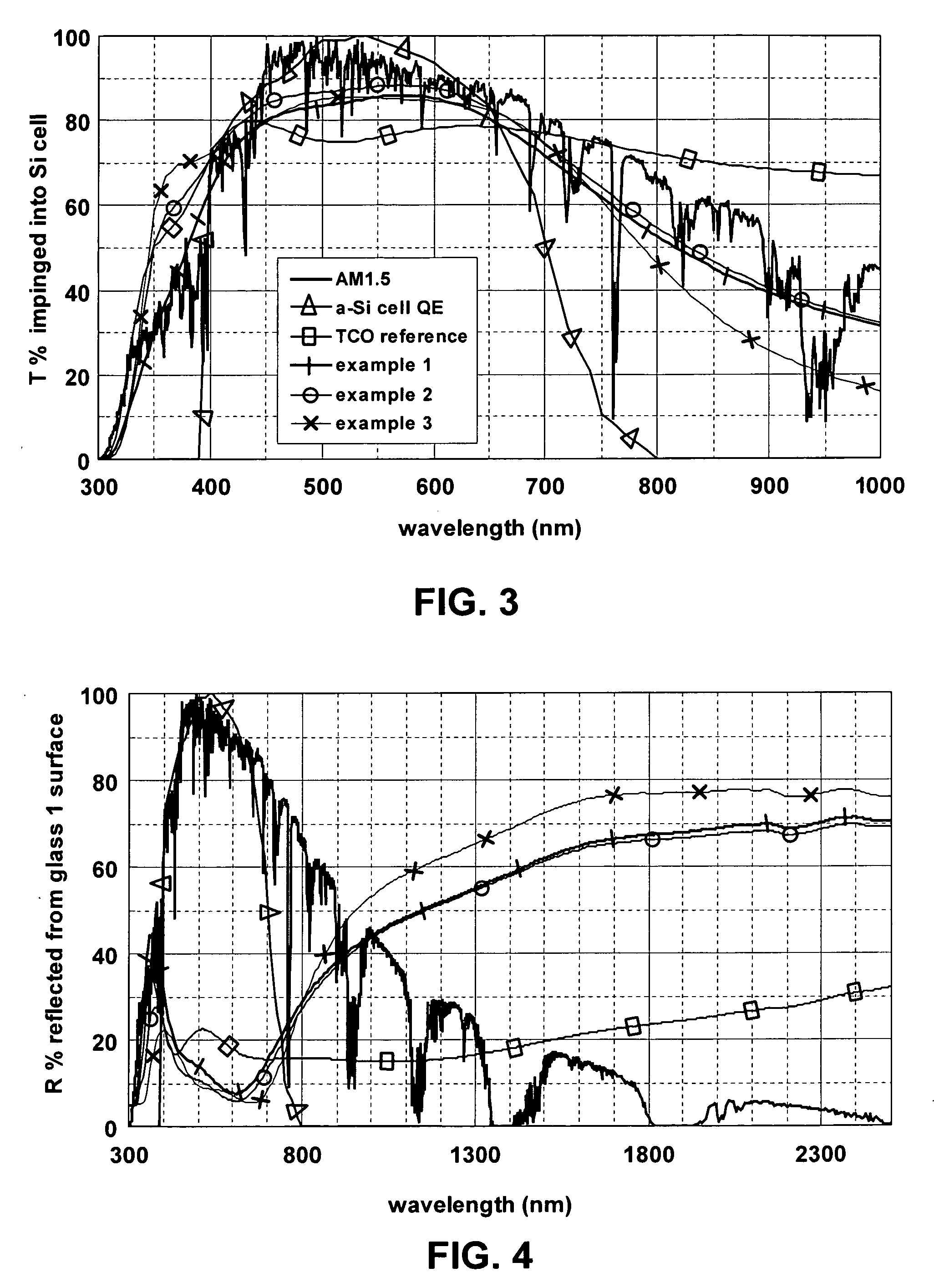

This invention relates to a front electrode / contact for use in an electronic device such as a photovoltaic device. In certain example embodiments, the front electrode of a photovoltaic device or the like includes a multilayer coating including at least one transparent conductive oxide (TCO) layer (e.g., of or including a material such as tin oxide, ITO, zinc oxide, or the like) and / or at least one conductive substantially metallic IR reflecting layer (e.g., based on silver, gold, or the like). In certain example instances, the multilayer front electrode coating may include one or more conductive metal(s) oxide layer(s) and / or one or more conductive substantially metallic IR reflecting layer(s) in order to provide for reduced visible light reflection, increased conductivity, cheaper manufacturability, and / or increased infrared (IR) reflection capability.

Owner:GUARDIAN GLASS LLC

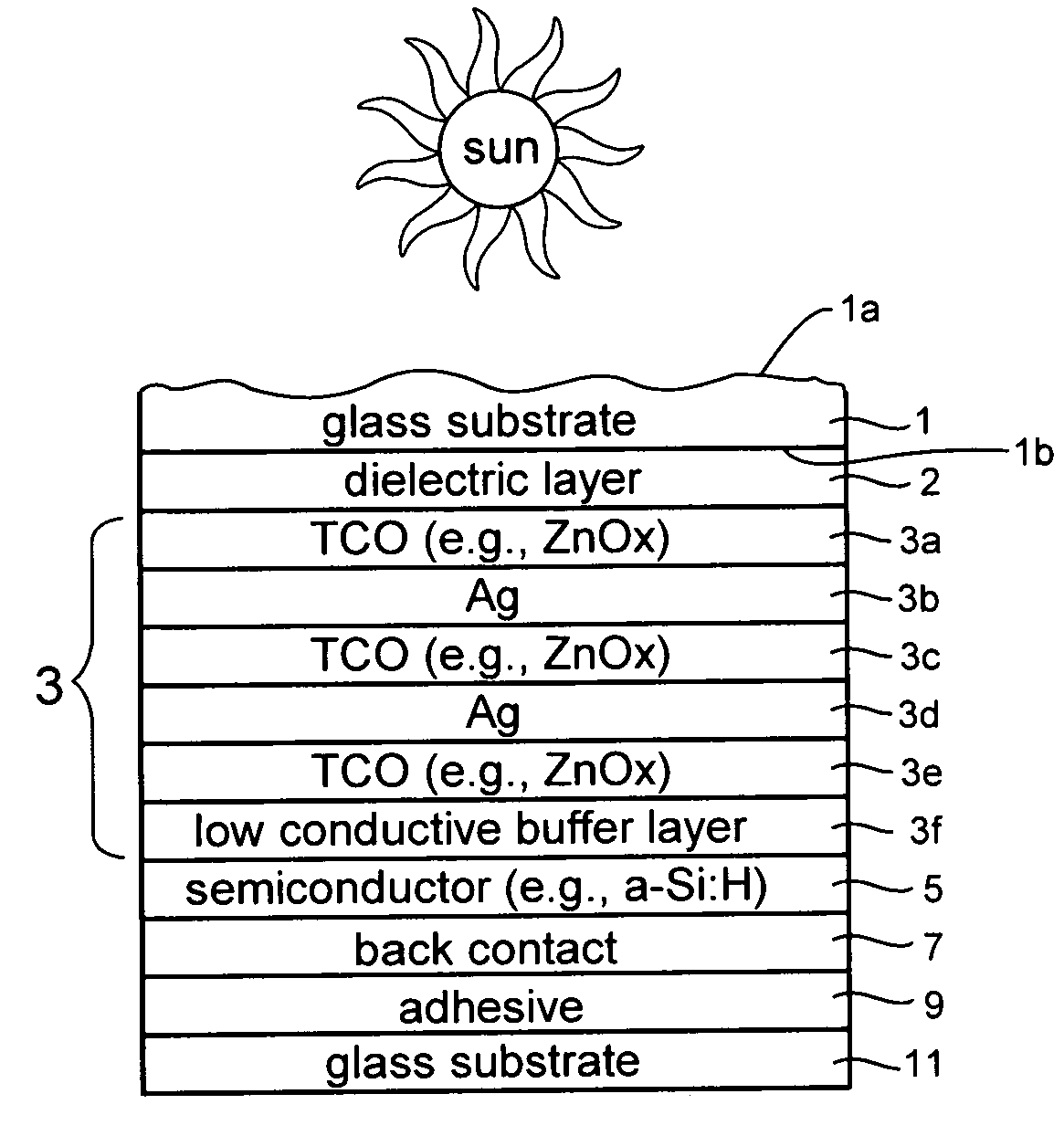

Method of making thin film transistors comprising zinc-oxide-based semiconductor materials

InactiveUS20080296567A1Threshold Voltage StabilityExcellent field-effect electron mobilityFinal product manufactureSolid-state devicesSemiconductor materialsZinc

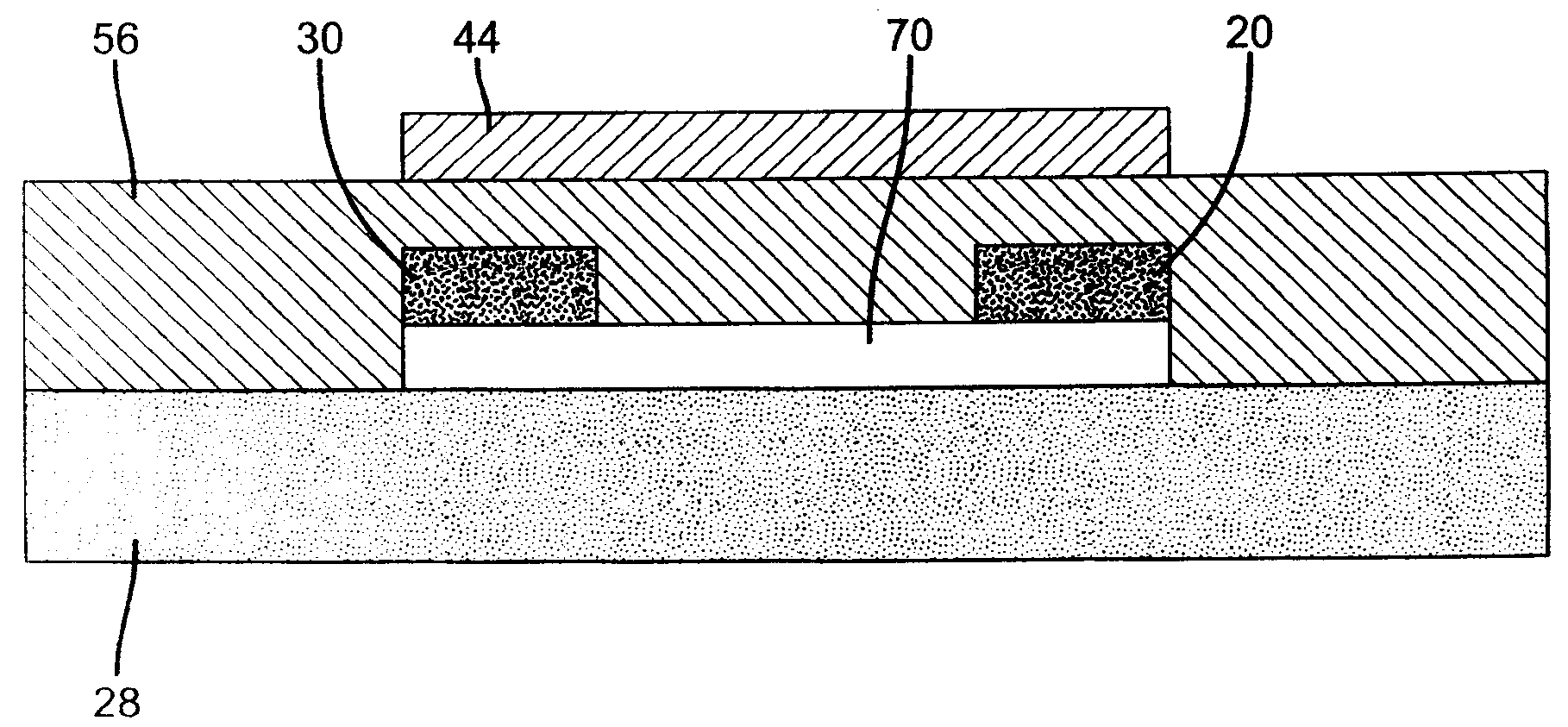

A method of making a thin film transistor comprising a zinc-oxide-containing semiconductor material and spaced apart first and second electrodes in contact with the material. The co-generation of high quality zinc oxide semiconductor films and contact electrodes is obtained, at low temperatures, using non-vacuum conditions, silver nanoparticles are deposited to form the source and drain and, upon heating, converted to conducting metal. Such an in-situ formation of the silver metal / zinc oxide interface provides superior transistor activity compared to evaporated silver.

Owner:EASTMAN KODAK CO

Nanometer doped zinc oxide and its prepn and application in photocatalysis to degrade organic matter and kill bacteria

InactiveCN1772375AImprove photocatalytic activityImprove performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsFiberRare earth

The present invention relates to Ag and RE doped nanometer zinc oxide and its preparation process and application in photocatalysis to degrade organic matter and killing bacteria. Ag, RE metals La, Ce, Pr, Nd, Sm, etc. are doped into nanometer zinc oxide to raise its photocatalytic activity in degrading harmful chemical matter and resisting bacteria. Under lighting, the doped nanometer zinc oxide has higher photocatalytic activity and higher antibacterial capacity; and in case of no lighting, it has relatively high antibacterial effect owing to the antibacterial effect one Ag, Zn, RE and other antibacterial ions. The preparation process may be an organic matter complexing process or a sprying pyrolysis process. The doped nanometer zinc oxide may be used through mixing with other material, or used as additive added into plastic, ceramic, fiber, timber, rubber, glass, cement, metal and other material to form various kinds of photocatalytic antibacterial material and product.

Owner:NANJING UNIV

Front electrode for use in photovoltaic device and method of making same

InactiveUS20080308151A1Reduce reflection lossPromote absorptionFinal product manufacturePhotovoltaic energy generationHigh energyLight reflection

This invention relates to a front electrode / contact for use in an electronic device such as a photovoltaic device. In certain example embodiments, the front electrode of a photovoltaic device or the like includes a multilayer coating including at least one transparent conductive oxide (TCO) layer (e.g., of or including a material such as tin oxide, ITO, zinc oxide, or the like) and / or at least one conductive substantially metallic IR reflecting layer (e.g., based on silver, gold, or the like). In certain example instances, the multilayer front electrode coating may include one or more conductive metal(s) oxide layer(s) and one or more conductive substantially metallic IR reflecting layer(s) in order to provide for reduced visible light reflection, increased conductivity, cheaper manufacturability, and / or increased infrared (IR) reflection capability. In certain example embodiments, the front electrode acts as not only a transparent conductive front contact / electrode but also a short pass filter that allows an increased amount of photons having high energy (such as in visible and near infra-red regions of the spectrum) into the active region or absorber of the photovoltaic device.

Owner:GUARDIAN GLASS LLC

Powder comprising silica-coated zinc oxide, organic polymer composition containing the powder and shaped article thereof

InactiveUS20060167138A1Help shapeSufficient UV shielding abilityPigmenting treatmentMaterial nanotechnologyMicroparticleSilicon dioxide

A powder comprising silica-coated zinc oxide fine particles in which the surface of each particle is coated with silica, wherein large particles of 5 μm or more account for 0.1 mass % or less. A powder comprising surface-hydrophobicized silica-coated zinc oxide fine particles in which the silica-coated zinc oxide fine particles whose surfaces have been coated with silica are further treated with a hydrophobicity-imparting agent, wherein large particles of 5 μm or more account for 0.1 mass % or less.

Owner:SHOWA DENKO KK

Surface-modified zinc oxide for the production of nanoparticulate dispersions

InactiveUS20050048010A1Laborious grinding process can be avoidedEasy to separateCosmetic preparationsBiocideLiquid mediumPolyethylene glycol

The present invention relates to a surface-modified nanoscale zinc oxide, where the surface modification involves coating with an oligo- or polyethylene glycol acid. This surface-modified zinc oxide is characterized in that it forms stable dispersions in a liquid medium. In addition, the present invention relates to a process for the production of surface-modified zinc oxide, and also to a process for the production of nanoscale zinc oxide dispersions.

Owner:HENKEL KGAA

Preparation method of large-area and continuous graphen/zinc oxide composite structure

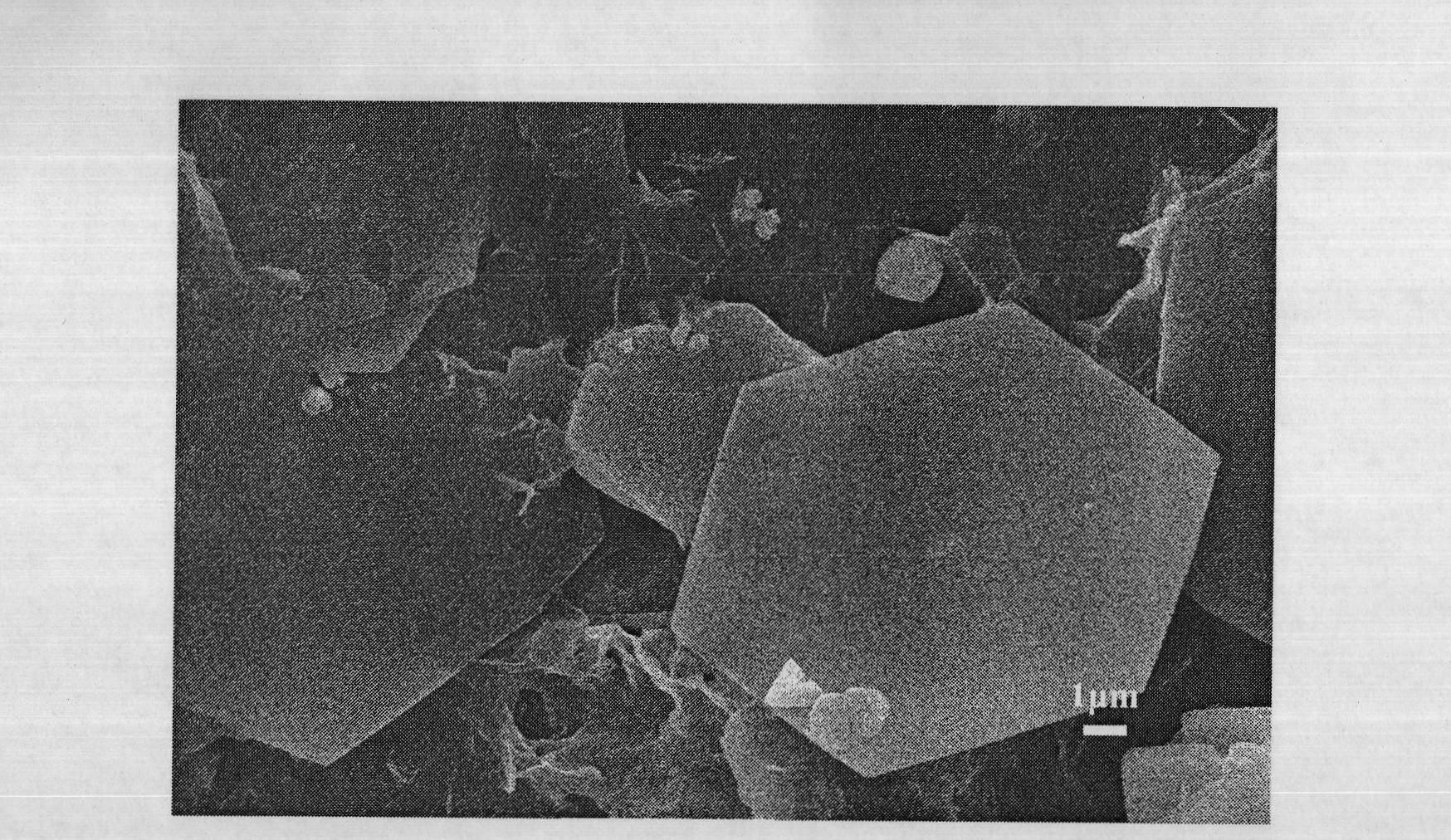

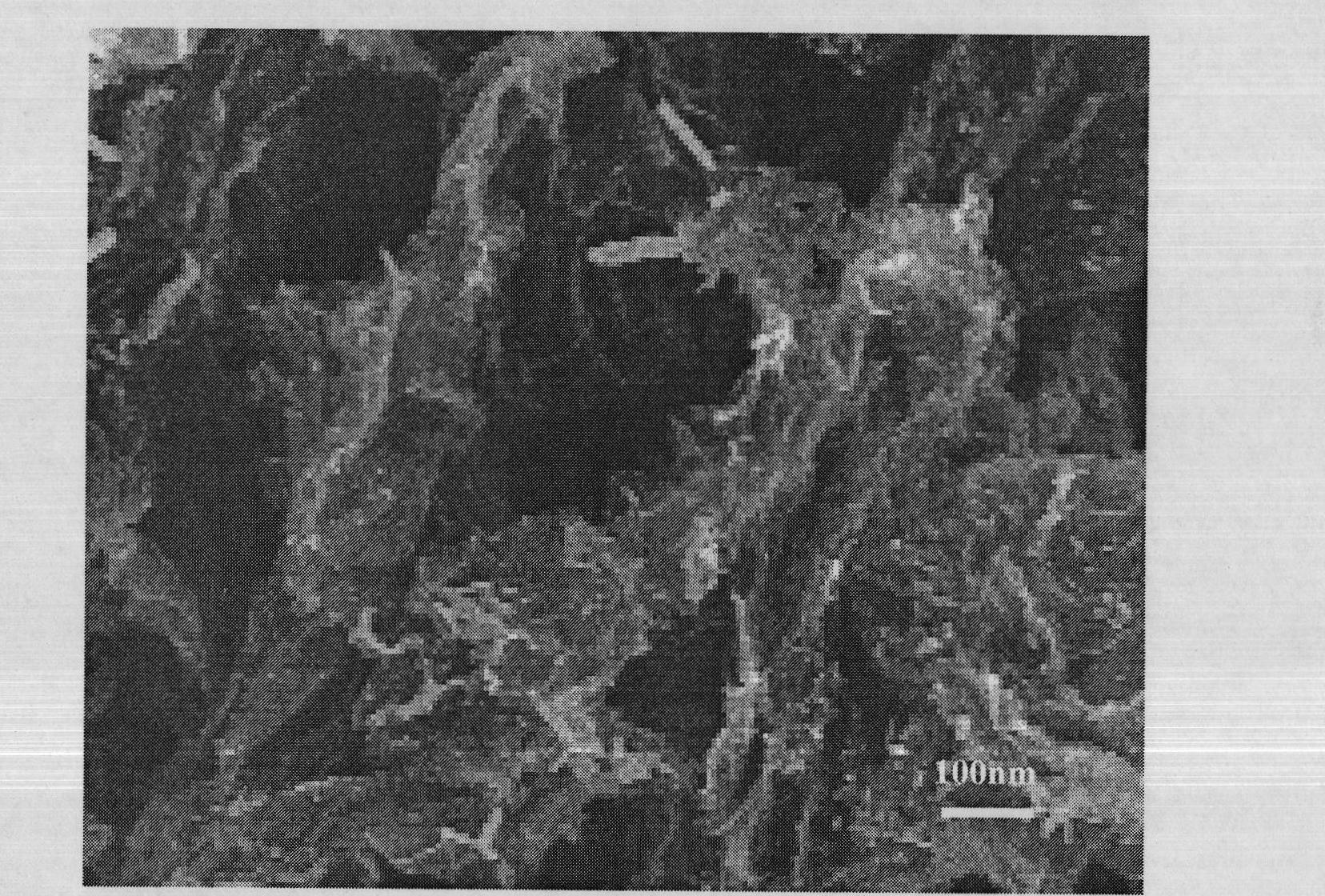

ActiveCN101857222AThickness is easy to controlSimple processZinc oxides/hydroxidesNanoparticleThree-dimensional space

The invention relates to a method for preparing continuous graphen / zinc oxide composite structure in large area, which belongs to the preparation field of the novel nanometer material, and is applicable to the fields such as sensor, solar panel, novel nanometer part and the like. The method comprises the following three steps that: first step: uniformly dispersing graphen or graphene oxide in liquid phase; second step: utilizing a hydrothermal process to ensure the zinc oxide nanometer structure and the graphen two-dimensional sheet to form a continuous structure in a three-dimensional space; third step: transferring the prepared composite structure onto a substrate to be dried. The method has simple process and low device requirement since the composite structure is synthesized in the solution; the process repeatability is strong, and the process parameter can be well controlled; the prepared graphen / zinc oxide composite structure has large area and is continuous, the generated zinc oxide nanometer sheet layer, nanometer particle and nanometer line are connected with each other and intersected with each other under the effect of the graphen so as to form a continuous porous structure in the three-dimensional space.

Owner:如东文园投资开发有限公司

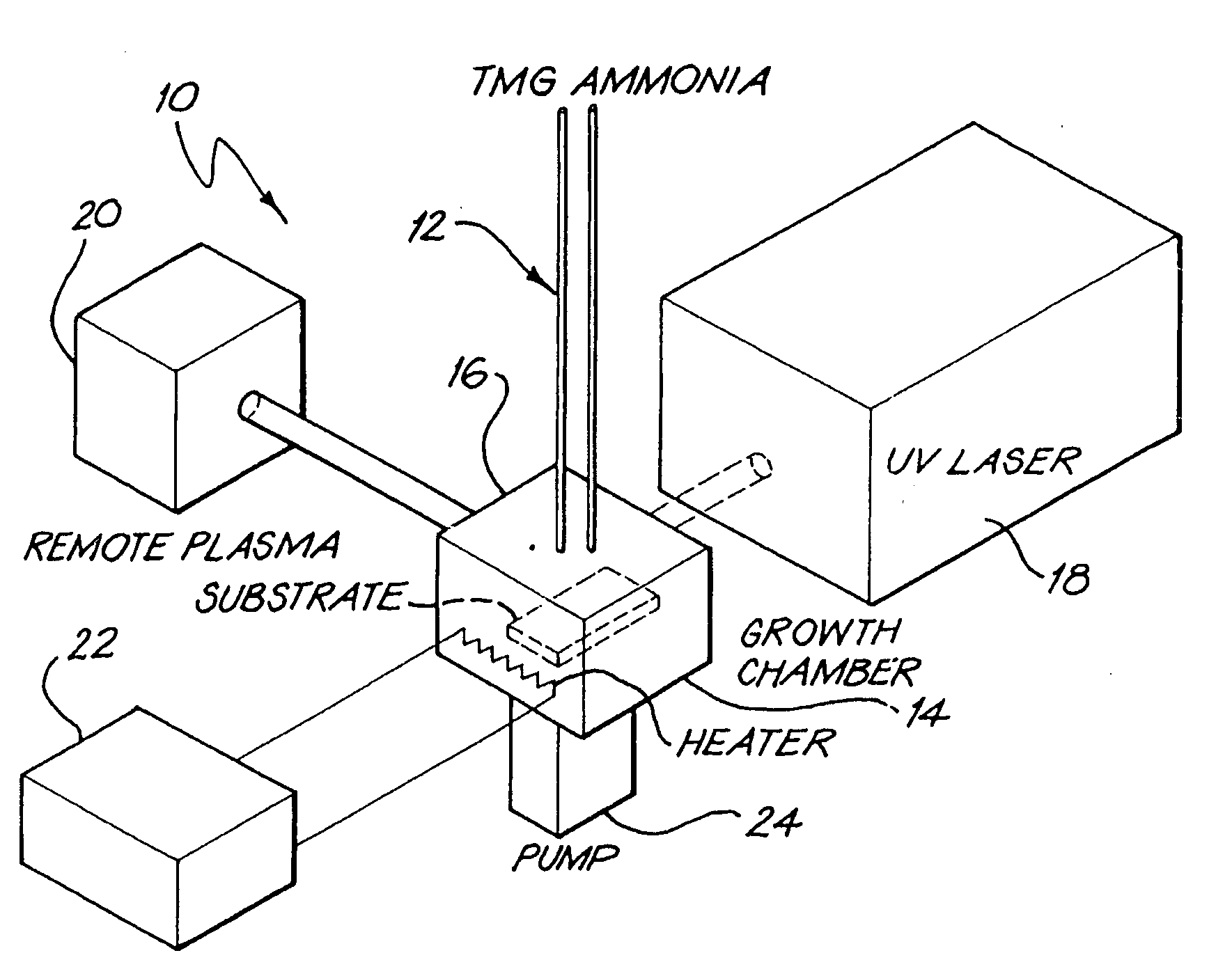

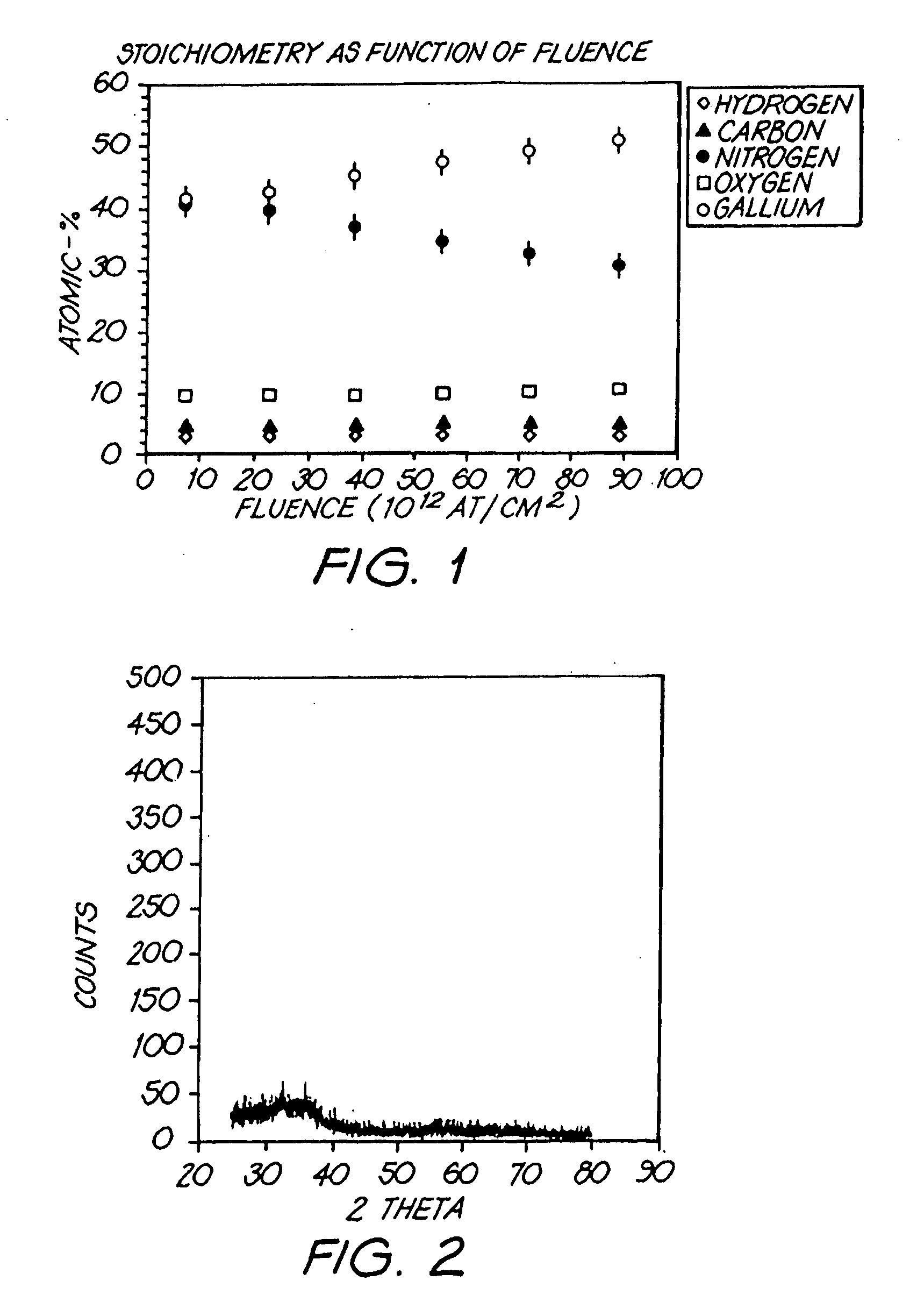

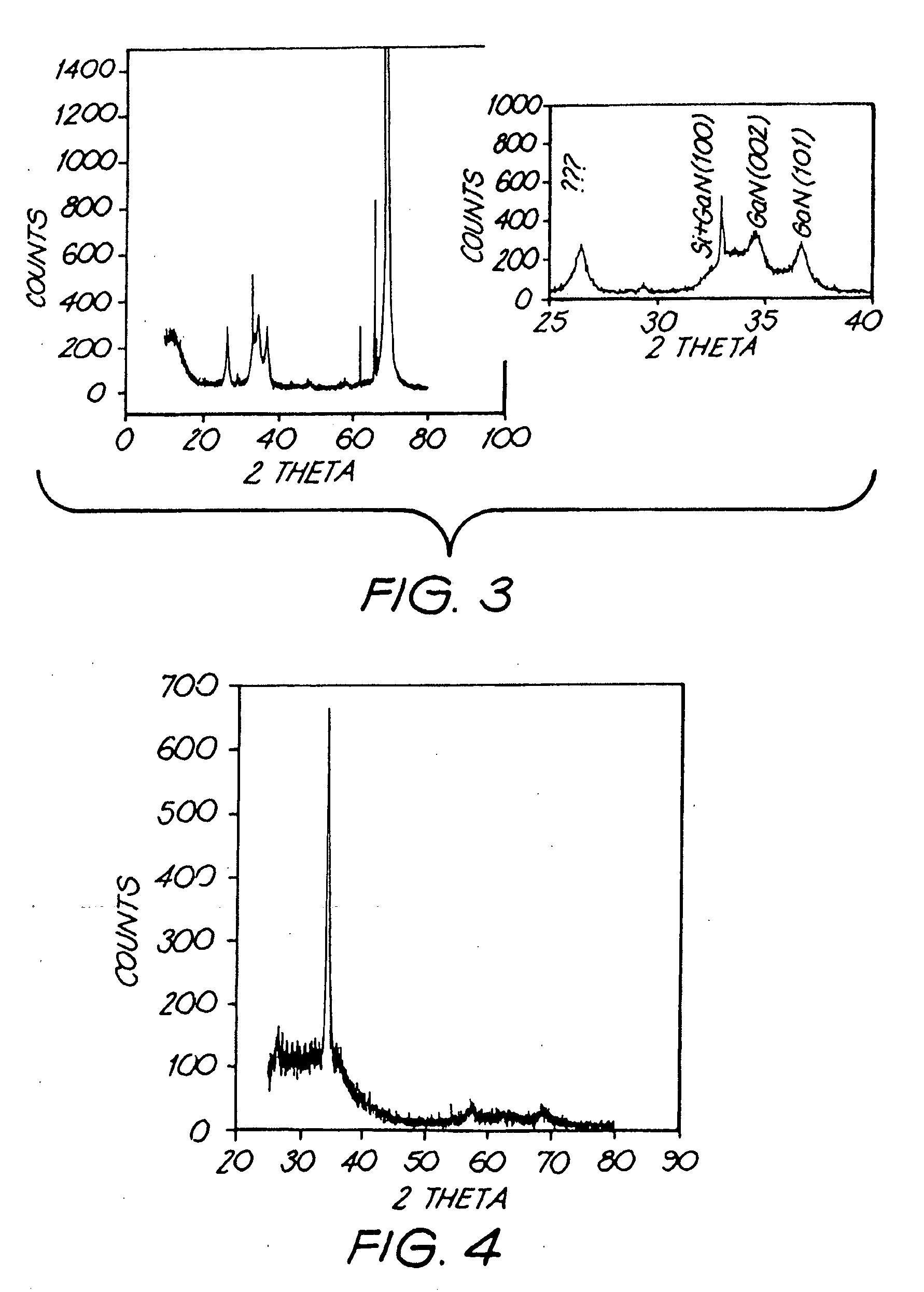

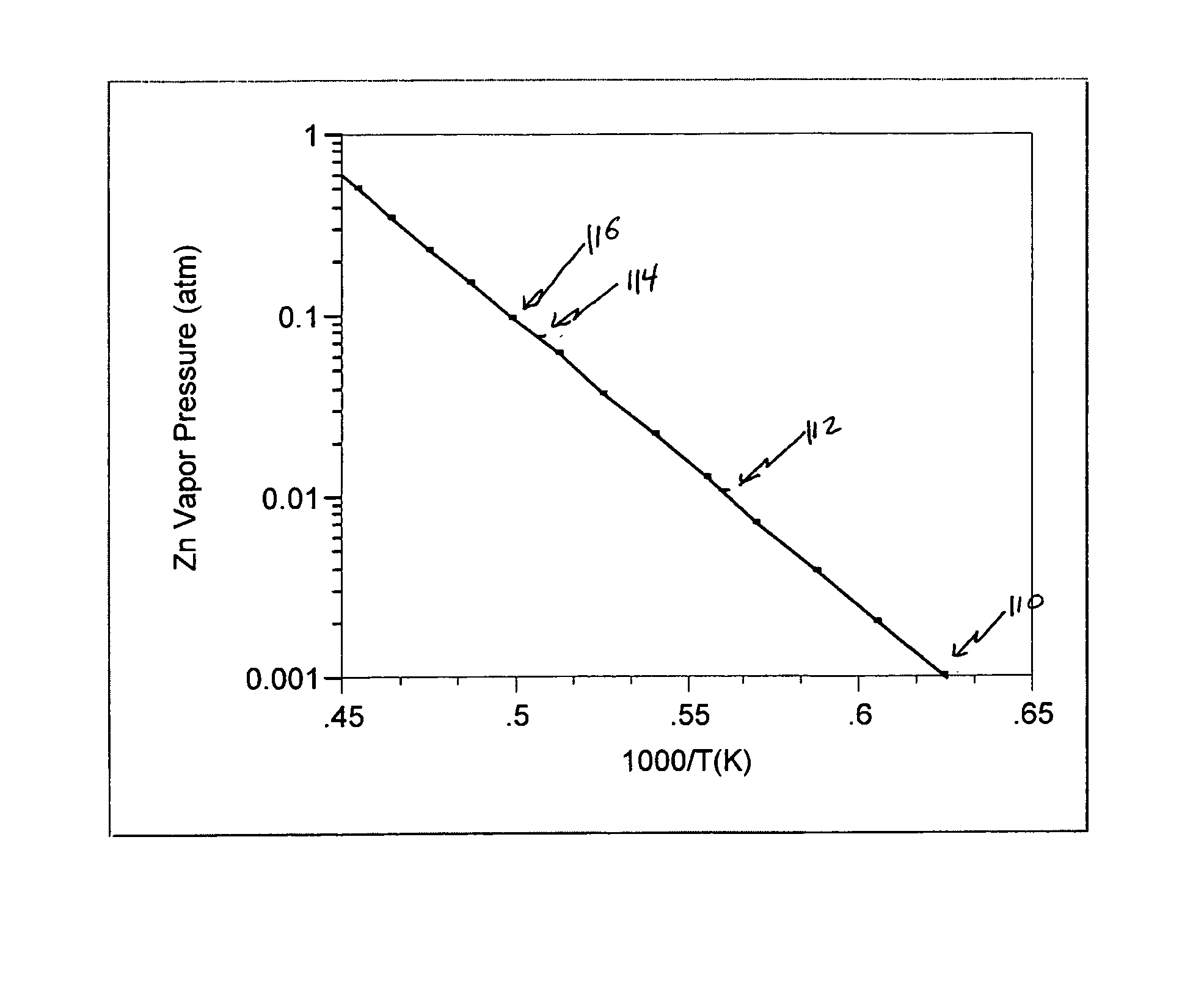

Process For Manufacturing A Gallium Rich Gallium Nitride Film

InactiveUS20080282978A1Improve conductivityLow resistivityPolycrystalline material growthAfter-treatment detailsGalliumGallium nitride

A process for the manufacture of a gallium rich gallium nitride film is described. The process comprises (a) preparing a reaction mixture containing a gallium species and a nitrogen species, the gallium species and the nitrogen species being selected such that, when they react with each other, gallium nitride is formed; and (b) growing the gallium rich gallium nitride film from the reaction mixture, by allowing the gallium species to react with the nitrogen species and to deposit gallium nitride on a substrate selected from the group consisting of silicon, glass, sapphire, quartz and crystalline materials having a lattice constant closely matched to gallium nitride, including zinc oxide, optionally with a zinc oxide buffer layer, at a temperature of from about 480° C. to about 900° C. and in the presence of a gaseous environment in which the partial pressure of oxygen is less than 10−4 Torr, wherein the ratio of gallium atoms to nitrogen atoms in the gallium rich gallium nitride film is from 1.01 to 1.20. The invention also provides the option of annealing the gallium rich gallium nitride film at a temperature of from about 20° C. to about 650° C. and for a time sufficient to decrease the resistivity of the film so that it becomes electrically conductive, for instance to a resistivity below 100 ohm.cm.

Owner:BUTCHER KENNETH SCOTT ALEXANDER +2

Special-purpose energy-saving environment-friendly type nano coating for aluminum alloy sections (door and window) and preparing method thereof

InactiveCN101012350AStrong UV resistanceImprove insulation efficiencyLiquid surface applicatorsEpoxy resin coatingsEpoxyPolyvinyl butyral

The invention discloses a specific nanometer paint of energy-saving environment-protective typed aluminium alloy section bar (door and window), which comprises the following parts: 90-100% filming agent, 0.1-10% hardener, 0.5-8% levelling agent, 0.5-10% nanometer material, 20-50% fill and 10% hollow microball, wherein the filming agent is one or more of epoxy resin, polyester resin, acrylic acid resin, amino resin, phenol resin or alkide resin; the hardener is one or more of dicyandiamide, imidazole, dihydrazide, polybasic carboxylic acid, beta-hydroxyalkyl amide or triglycidol isocyanuric ester hardener; the levelling agent is one or more of polyacrylic resin, siliceous acryl resin, polyvinyl butyral, benzoin, hydrocastor oil, cellulose acetate butyrate or epoxy soy oil; the nanometer material is nanometer zinc oxide; the hollow micro-ball is hollow ceramic microball.

Owner:苏州裕丰装饰门窗有限公司

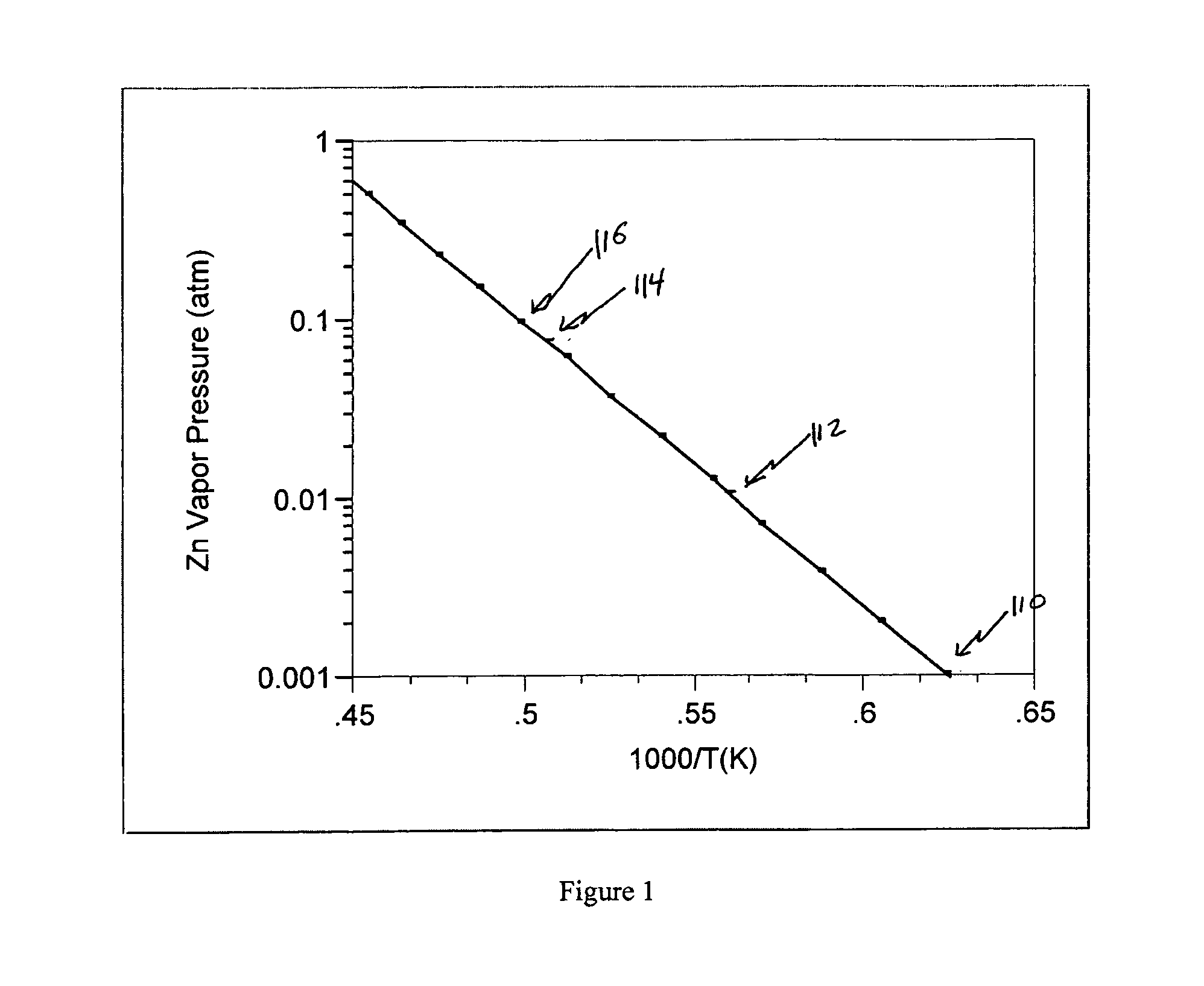

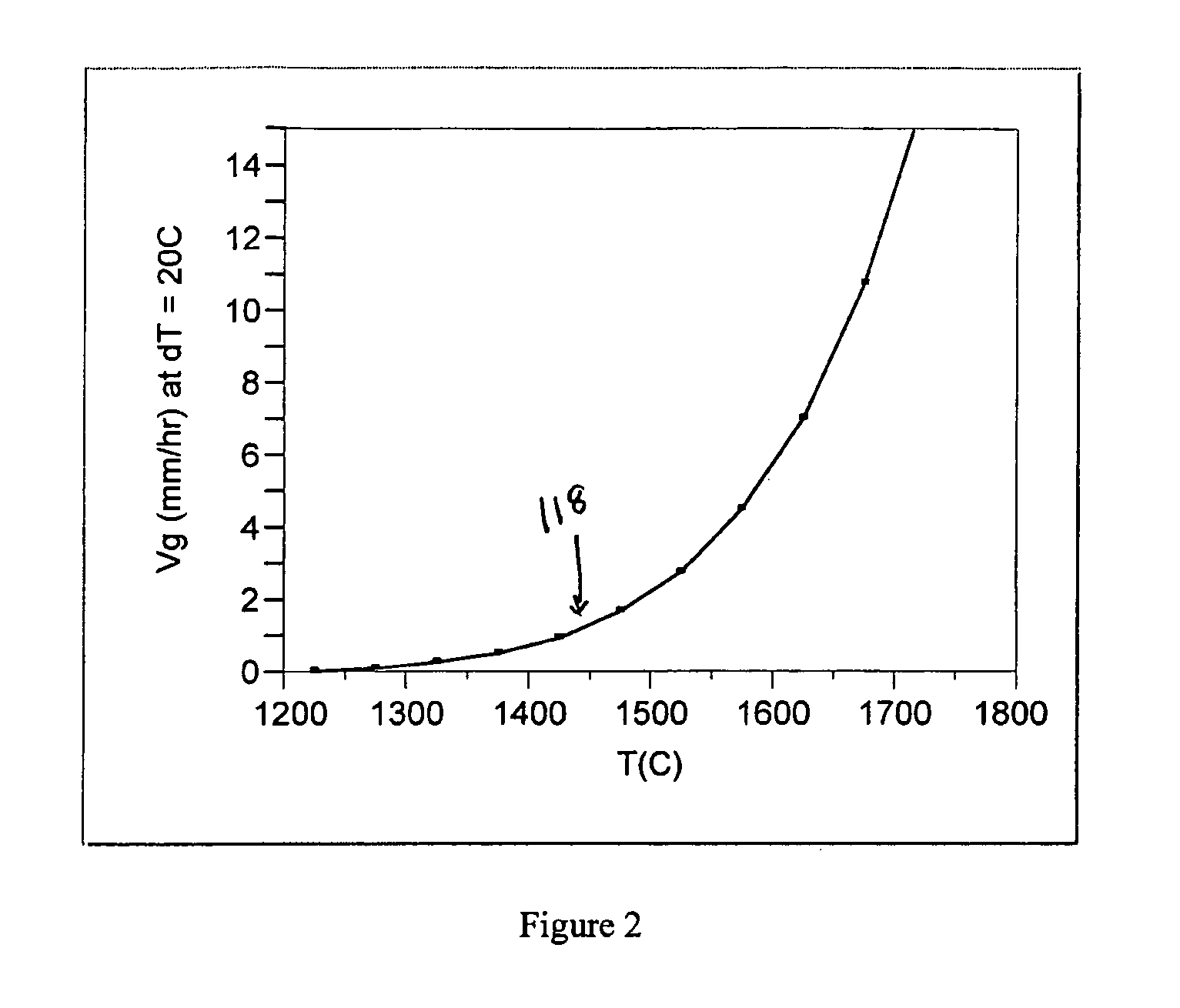

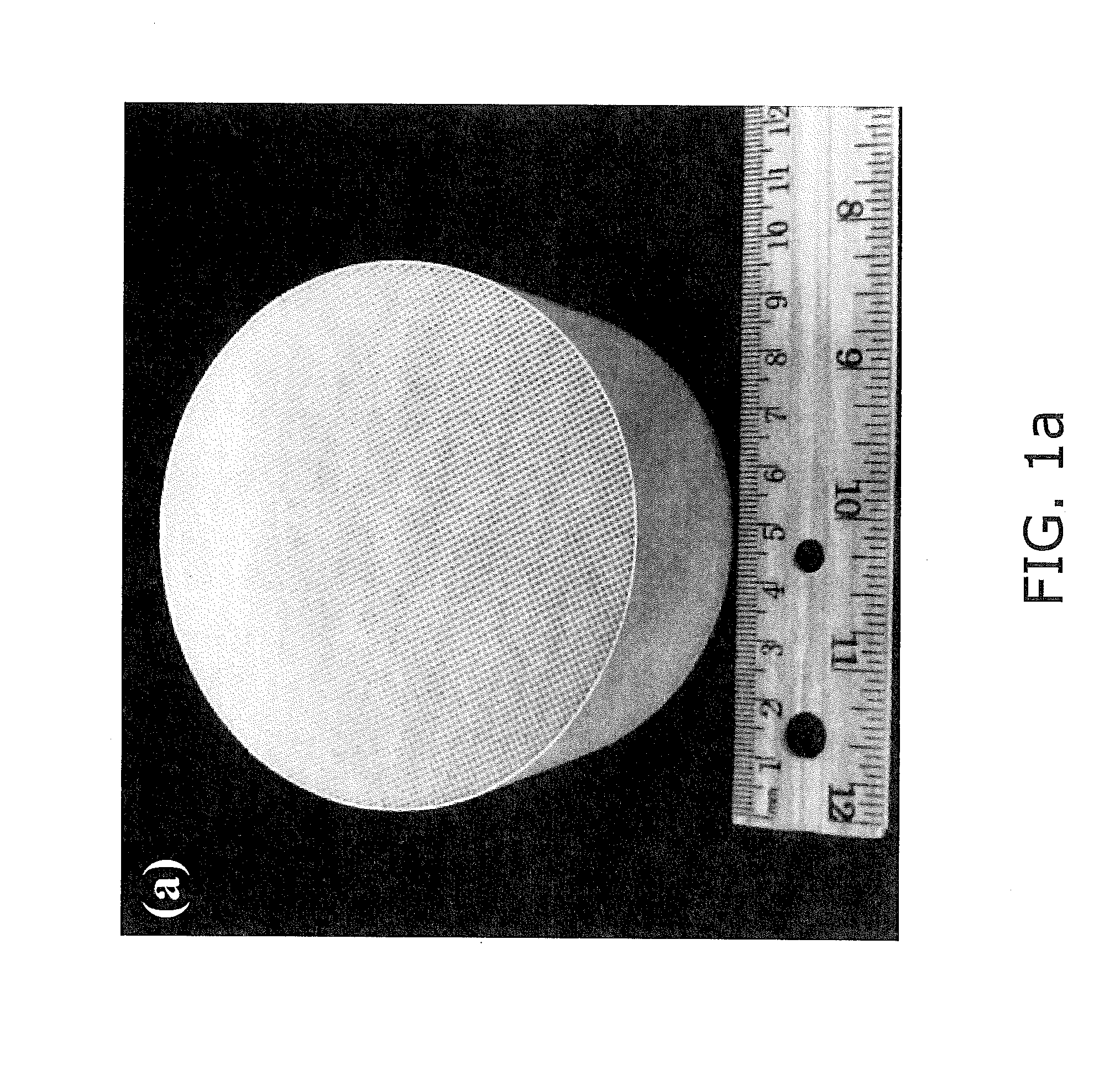

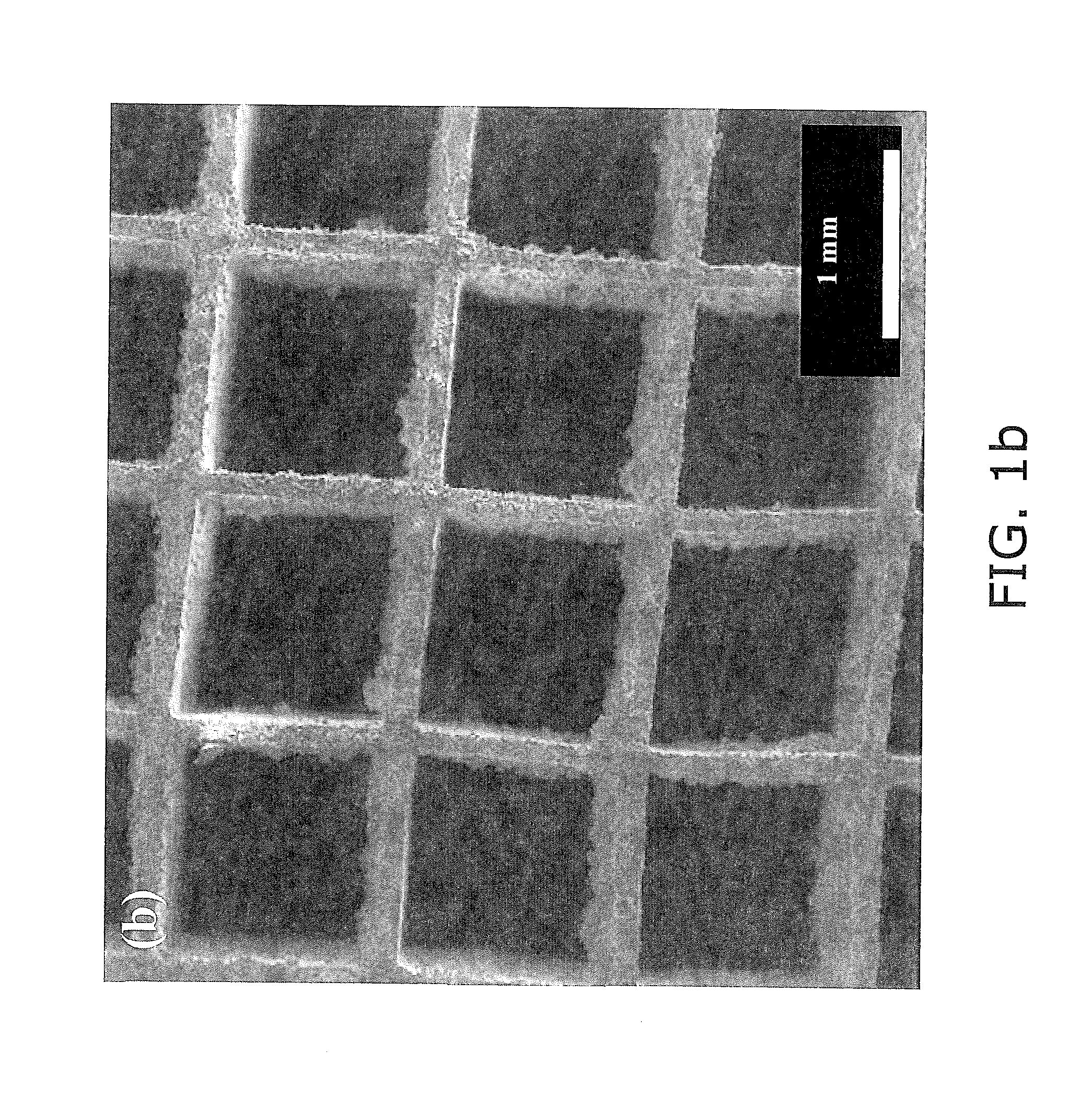

Method and apparatus for zinc oxide single crystal boule growth

ActiveUS7279040B1After-treatment apparatusPolycrystalline material growthSeed crystalSource material

There is provided a method for growing one or more single crystal ZnO boules within a physical vapor transport furnace system. This method includes the steps of: (a.) placing a source material at a first end of an interior crucible enclosure and placing one or more seed crystals at an opposing second end of the interior crucible enclosure with the seed crystal and the source material separated by a predetermined distance; (b.) heating the crucible, the one or more seed crystals and the source material to predetermined temperatures in such way that the temperature of the source material is higher than the temperature of the seed crystal; (c.) maintaining a pressure within the interior crucible enclosure through flowing a gas mixture; and (d) maintaining a temperature distribution within the crucible enclosure thereby causing a ZnO boule growth on each one of the one or more seed crystals. The ZnO may be doped with desired additional elements. In alternative embodiments, that other boules, both doped and un-doped, such as ZnSe and ZnS may also be formed.

Owner:FAIRFIELD CRYSTAL TECH

Silicone rubber for composite insulator and preparation method thereof

The invention discloses a silicone rubber for a composite insulator, wherein the silicone rubber comprises the following raw materials in parts by weight: 30-50 parts of methyl vinyl silicone rubber A, 50-70 parts of methyl vinyl silicone rubber B, 25-50 parts of fumed silica, 100-130 parts of aluminium hydroxide, 1-6 parts of silane coupling agent, 0.2-2 parts of ultraviolet absorber, 2-6 parts of zinc oxide, 0.5-3 parts of triethanolamine, 0.2-1 parts of stearic acid, 0.5-2 parts of hydrogen-containing silicone oil, 0.2-1 parts of vinyl silicone oil, 0.5-3 parts of color masterbatch rubber, 2-6 parts of hydroxyl silicone oil and 0.5-1 parts of vulcanizing agent. The silicone rubber provided by the invention can achieve the following performances: the tensile strength is larger than 4 MPa; the breaking elongation is larger than 350%; the peel strength is larger than or equal to 12 KN.m<-1>; the shore hardness is 60+ / -5 degrees; the thermal aging tensile strength retention is larger than or equal to 90%; the anti-creep track passes a grade of 1A4.5; the flame retardance reaches a grade of FV-0; the average static contact angle is larger than 105 degrees; the electrical surface resistivity is larger than 2*10<15> omega; the dielectric constant is smaller than 3.8; and the dielectric loss angle tangent is smaller than 0.01.

Owner:PINGGAO GRP +2

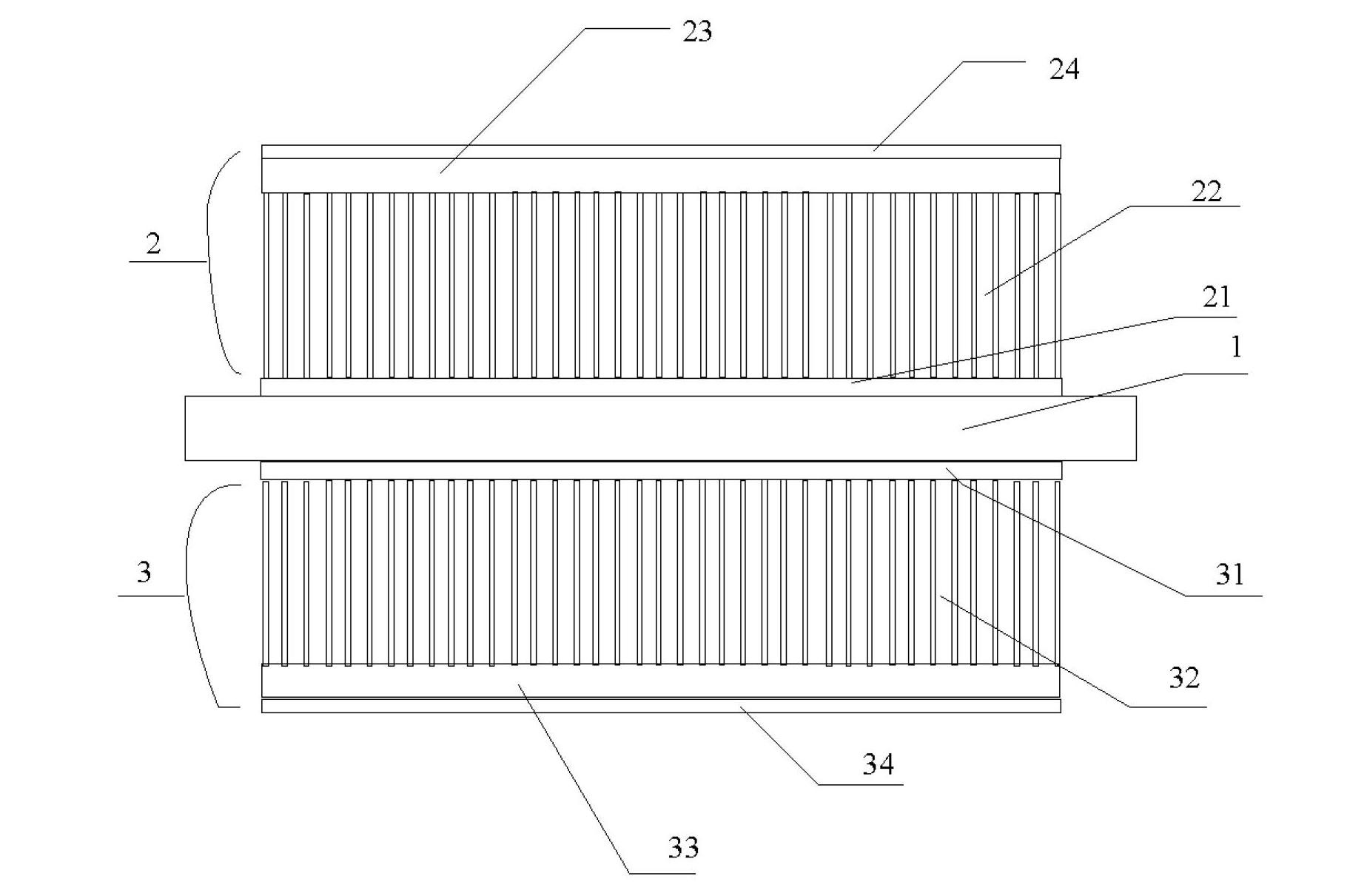

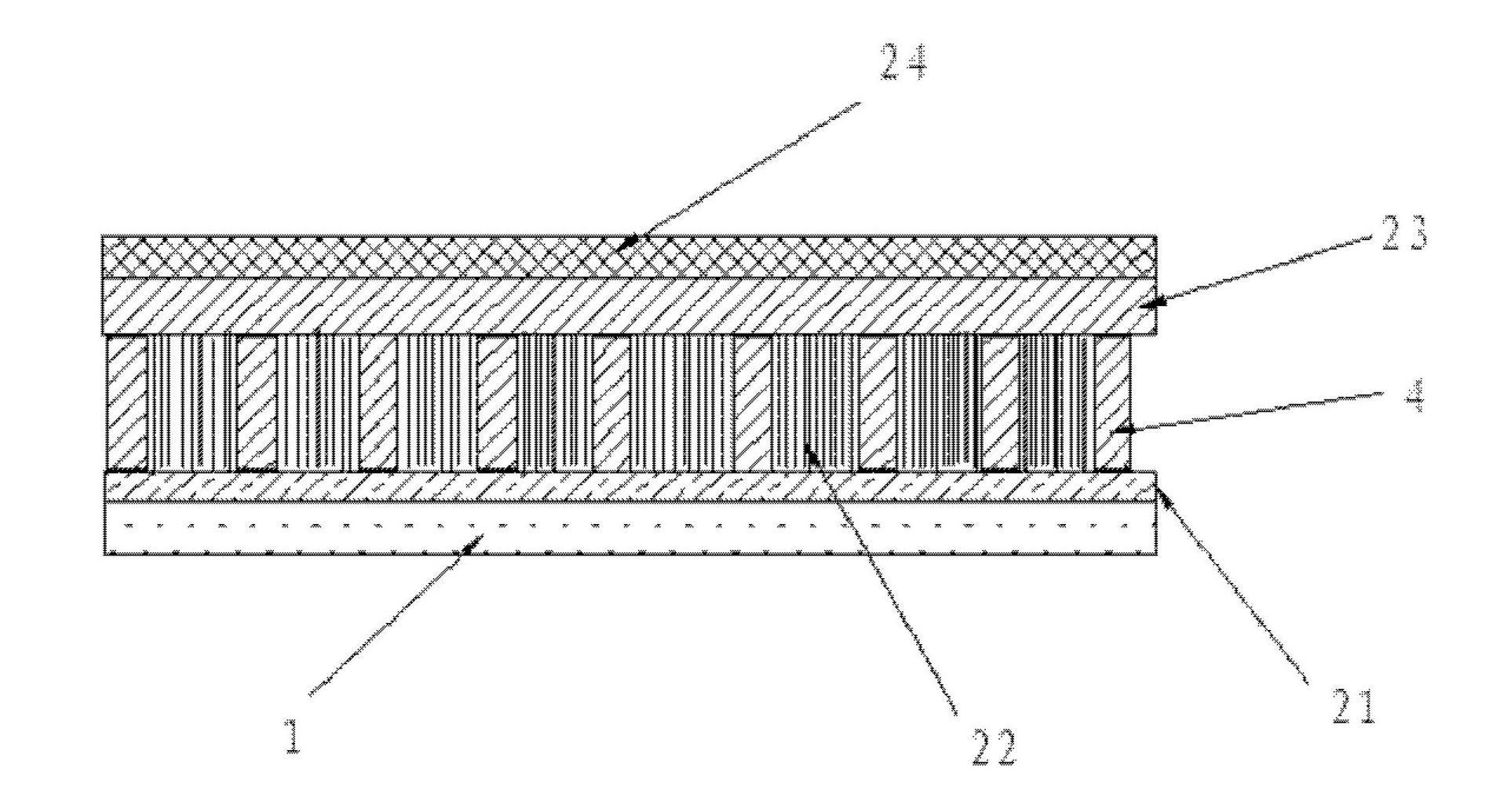

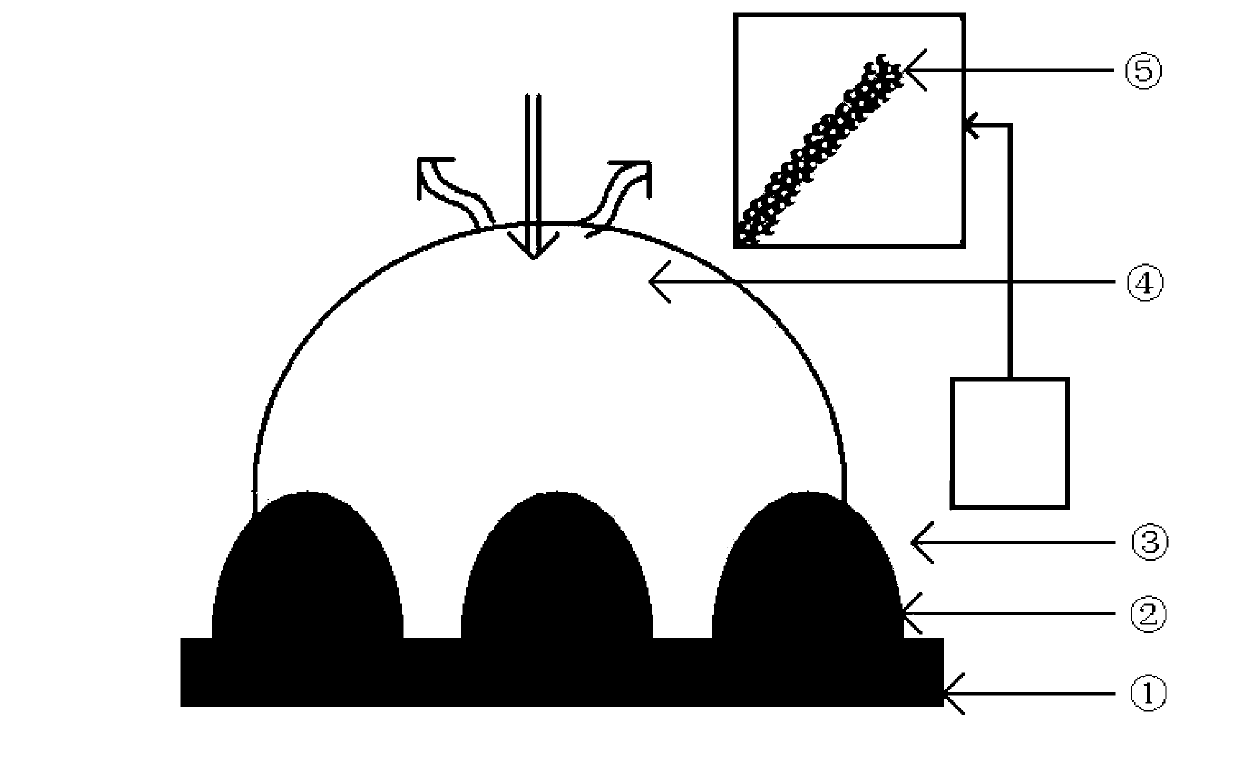

Nano generator, nano generator set and self-powered system comprising nano generator or nano generator set

InactiveCN102683573AImprove efficiencyImprove stabilityPiezoelectric/electrostriction/magnetostriction machinesNanotechnologyNanogeneratorPower flow

The invention provides a nano generator, a nano generator set and a self-powered system comprising the nano generator or the nano generator set. The nano generator comprises a supporting substrate, and upper and lower electrodes which are arranged at two sides of upper and lower surfaces of the supporting substrate by glue, wherein each electrode respectively comprises a zinc oxide nanowire array layer, a macromolecular insulating layer and a conductive thin film; the zinc oxide nanowire array layers vertically grow on the supporting substrate; the macromolecular insulating layers are coated on the zinc oxide nanowire array layers; the conductive thin films are arranged on the macromolecular insulating layers; and the conductive thin films form output electrodes of voltage and current of the nano generator. The self-powered system can obtain energy from very small force in an environment through utilizing the nano generator and can store most of the energy when a sensor is at a standby mode; the collected energy is used for triggering the sensor under an active mode to rapidly process and transmit data; and therefore, the self-powered system has huge potentials of application on the aspects of radio biological sensing, environment / infrastructure monitoring, sensor networks, individual electronic products, even national security.

Owner:NEWNAGY TANGSHAN

Desulfurization process and novel bimetallic sorbent systems for same

Novel sorbent systems for the desulfurization of cracked-gasoline and diesel fuels are provided which are comprised of a bimetallic promotor on a particulate support such as that formed of zinc oxide and an inorganic or organic carrier. Such bimetallic promotors are formed of at least two metals of the group consisting of nickel, cobalt, iron, manganese, copper, zinc, molybdenum, tungsten, silver, tin, antimony and vanadium with the valence of same being reduced, preferably to zero. Processes for the production of such sorbents are provided wherein the sorbent is prepared from impregnated particulate supports or admixed to the support composite prior to particulation, drying, and calcination. Further disclosed is the use of such novel sorbents in the desulfurization of cracked-gasoline and diesel fuels whereby there is achieved not only removal of sulfur but also an increase in the olefin retention in the desulfurized product. Such sorbents can also be utilized for the treatment of other sulfur-containing streams such as diesel fuels.

Owner:CHINA PETROCHEMICAL CORP

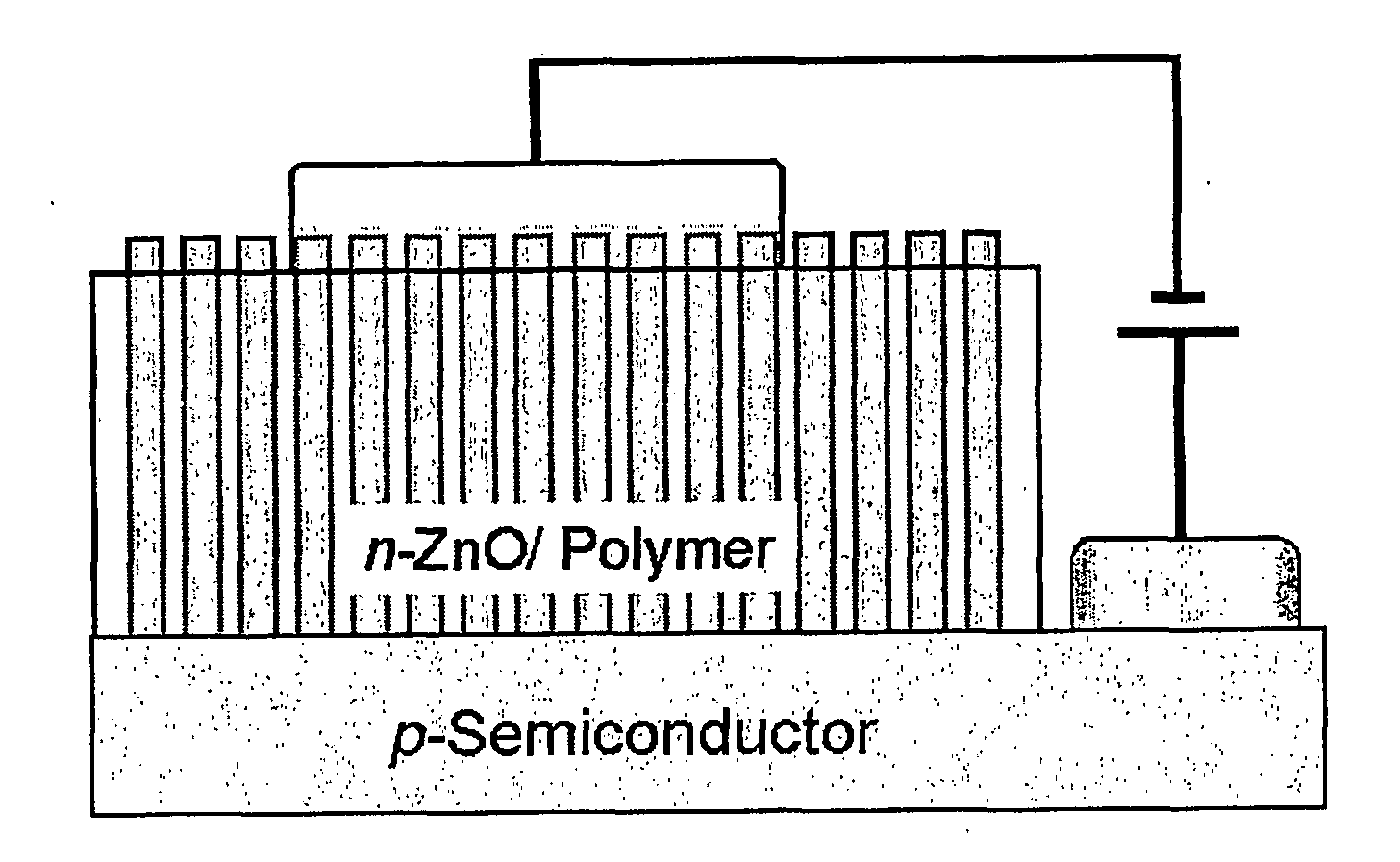

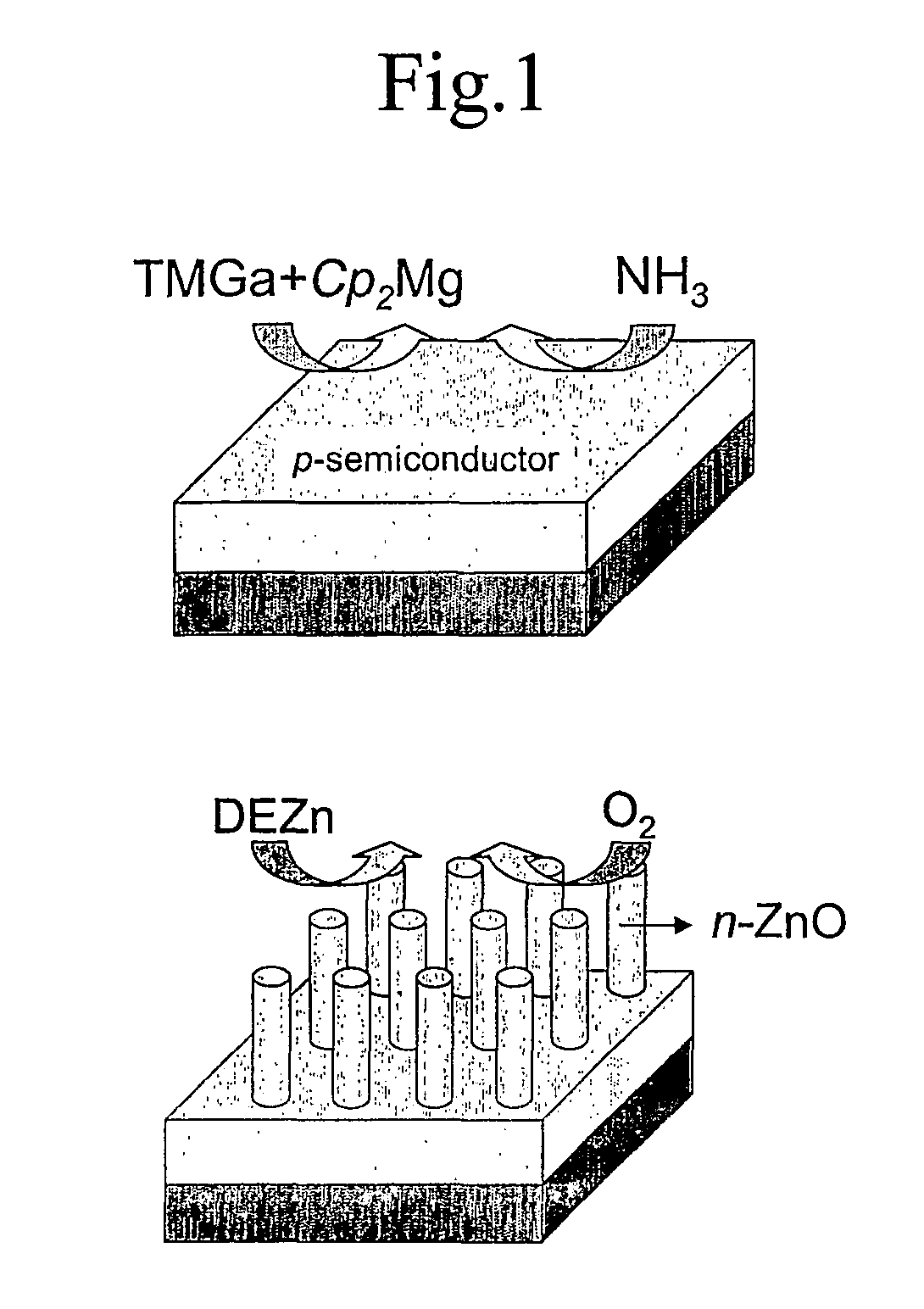

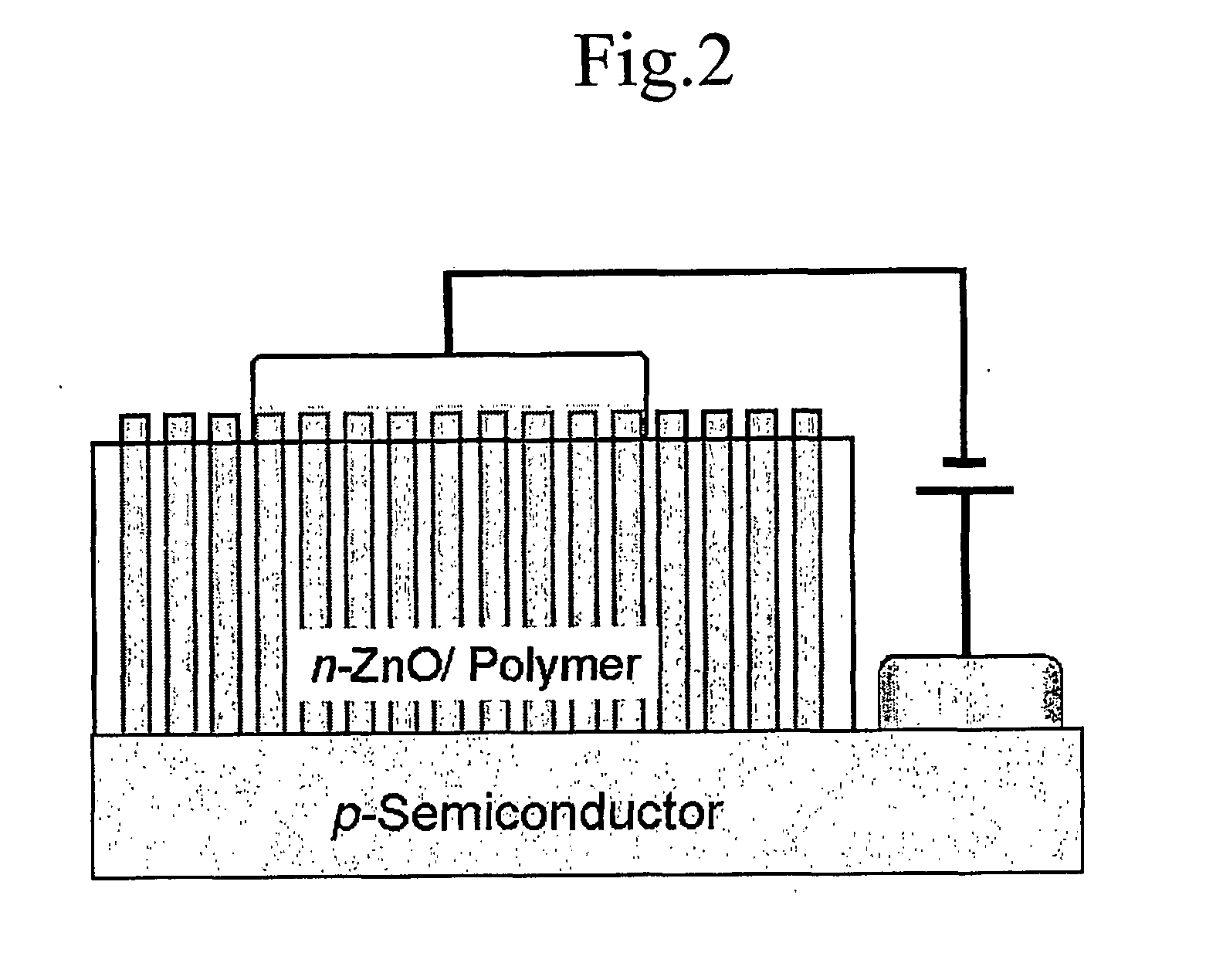

P-n heterojuction structure of zinc oxide-based nanorod and semiconductor thin film, preparation thereof, and nano-device comprising same

ActiveUS20060189018A1Conducive to useEasy to useMaterial nanotechnologyPolycrystalline material growthOxideSemiconductor

A heterojunction structure composed of a p-type semiconductor thin film and n-type ZnO-based nanorods epitaxially grown thereon exhibits high luminescence efficiency property due to facilitated tunneling of electrons through the nano-sized junction and the use of ZnO having high exciton energy as a light emitting material, and thus it can be advantageously used in nano-devices such as LED, field effect transistor, photodetector, sensor, etc.

Owner:LG DISPLAY CO LTD

Production method of once-fired super-spar ceramic tile and ceramic tile

The invention relates to a production method of once-fired super-spar ceramic tile and the ceramic tile. The production method of the once-fired super-spar ceramic tile comprises the following steps: preparing green body powder; pressing a tile body; cleaning the green body; pouring ground glaze; printing; pouring overglaze; firing a glaze body at a high temperature; polishing; performing surface treatment; performing edge polishing; and packaging to obtain a finished product, wherein the overglaze comprises the following components in parts by weight: 5 to 13 parts of quartz powder, 3 to 20 parts of potassium feldspar, 20 to 28 parts of soda feldspar, 12 to 18 parts of dolomite, 3 to 6 parts of fired talc, 3 to 8 parts of kaolin, 14 to 22 parts of calcined kaolin, 3 to 8 parts of zinc oxide, 7 to 14 parts of barium carbonate and 3 to 6 parts of grammite. According to the invention, the problems that microlite has low wear resistance and is difficult to process in the prior art are solved, and the defect of water ripples caused by the situations that fully-polished glaze absorbs dirt, bottom is easy to expose and the tile surface is uneven is also solved. The super-spar product produced with the method has the advantages that the microlite is transparent, bright and smooth like a mirror and does not absorb dirt completely; and the fully-polished glaze is light, thin and wear-resistant.

Owner:周予

Shippable heat-treatable sputter coated article and zinc cathode sputtering target containing low amounts of tin

InactiveUS6899953B1Improve chemical durabilityReduced hazeVacuum evaporation coatingSputtering coatingMetal PrimerLow emissivity

Tin is added to a zinc cathode target to enhance the sputter efficiency of the target. Films deposited using the cathode, e.g., greater than zero but less than 10 weight percent tin and greater than 90 but less than 100 weight percent zinc improve the chemical durability of a high transmittance, low emissivity coating stack over coating stacks having zinc oxides without tin oxide. High transmittance, low emissivity coating stacks are heated with the heated coating having reduced haze by selecting the thickness of metal primer layer between an infrared reflective film, e.g. a silver film and a dielectric film, e.g., a 52-48 zinc stannate, zinc oxide, tin oxide film or a zinc oxide film. Also disclosed are enhancing films that lower the resistivity of silver films deposited thereon and improve chemical durability of the coating stack.

Owner:VITRO FLAT GLASS LLC

Very low sulfur gas feeds for sulfur sensitive syngas and hydrocarbon synthesis processes

Very low sulfur content hydrocarbon gas is achieved by sequentially contacting the gas first with zinc oxide and then with nickel metal. This has reduced the total sulfur content of natural gas feed for a fluid bed syngas generator to less than 0.1 ppm and has resulted in greater syngas productivity. A zinc oxide guard bed downstream of the syngas generator reduces the total sulfur content of the syngas to less than 10 vppb and preferably less than 5 vppb. This very low sulfur content syngas is used for sulfur sensitive processes, such as hydrocarbon synthesis. The process is especially useful for natural gas which contains H2S, COS, mercaptans and other sulfur bearing compounds.

Owner:EXXON RES & ENG CO

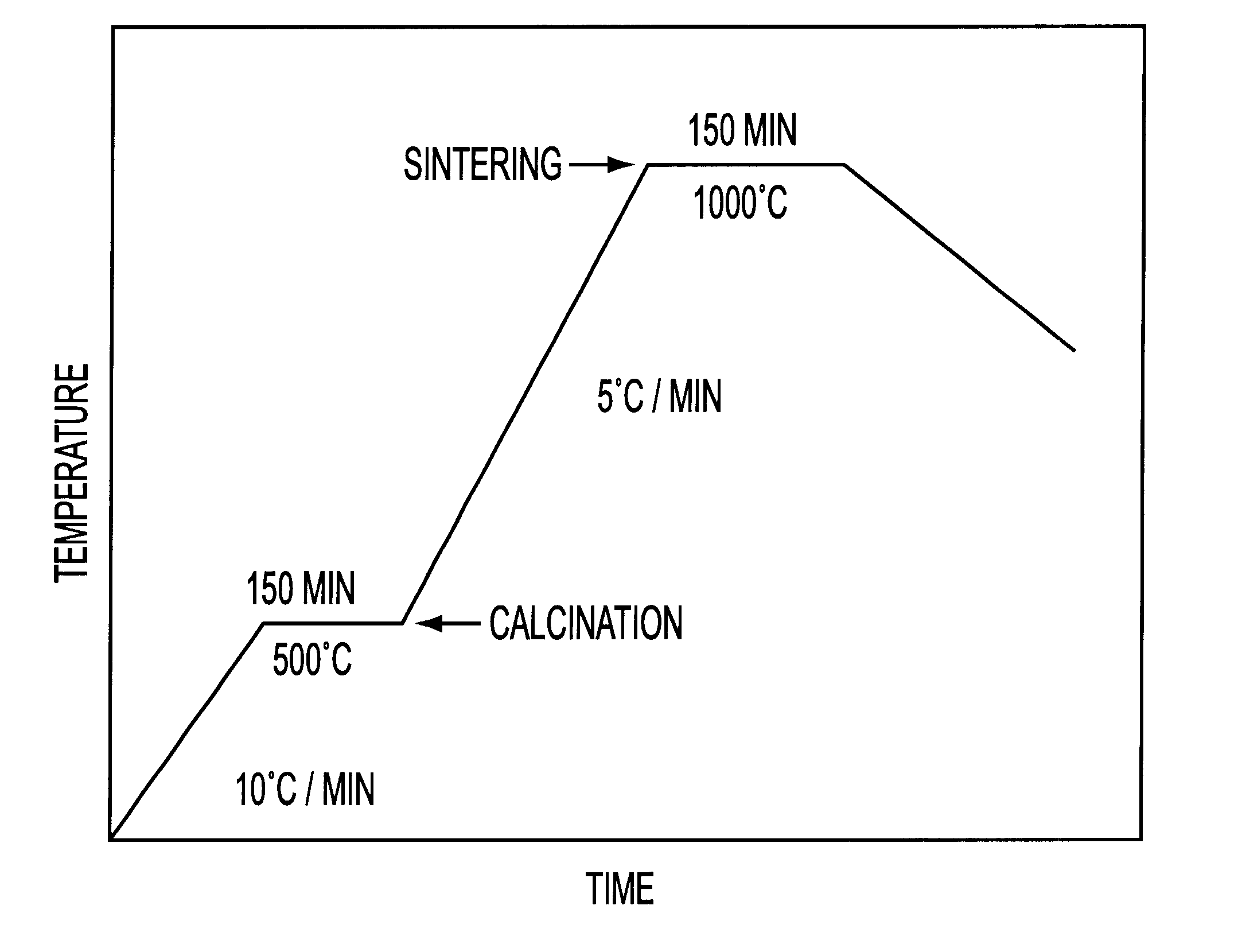

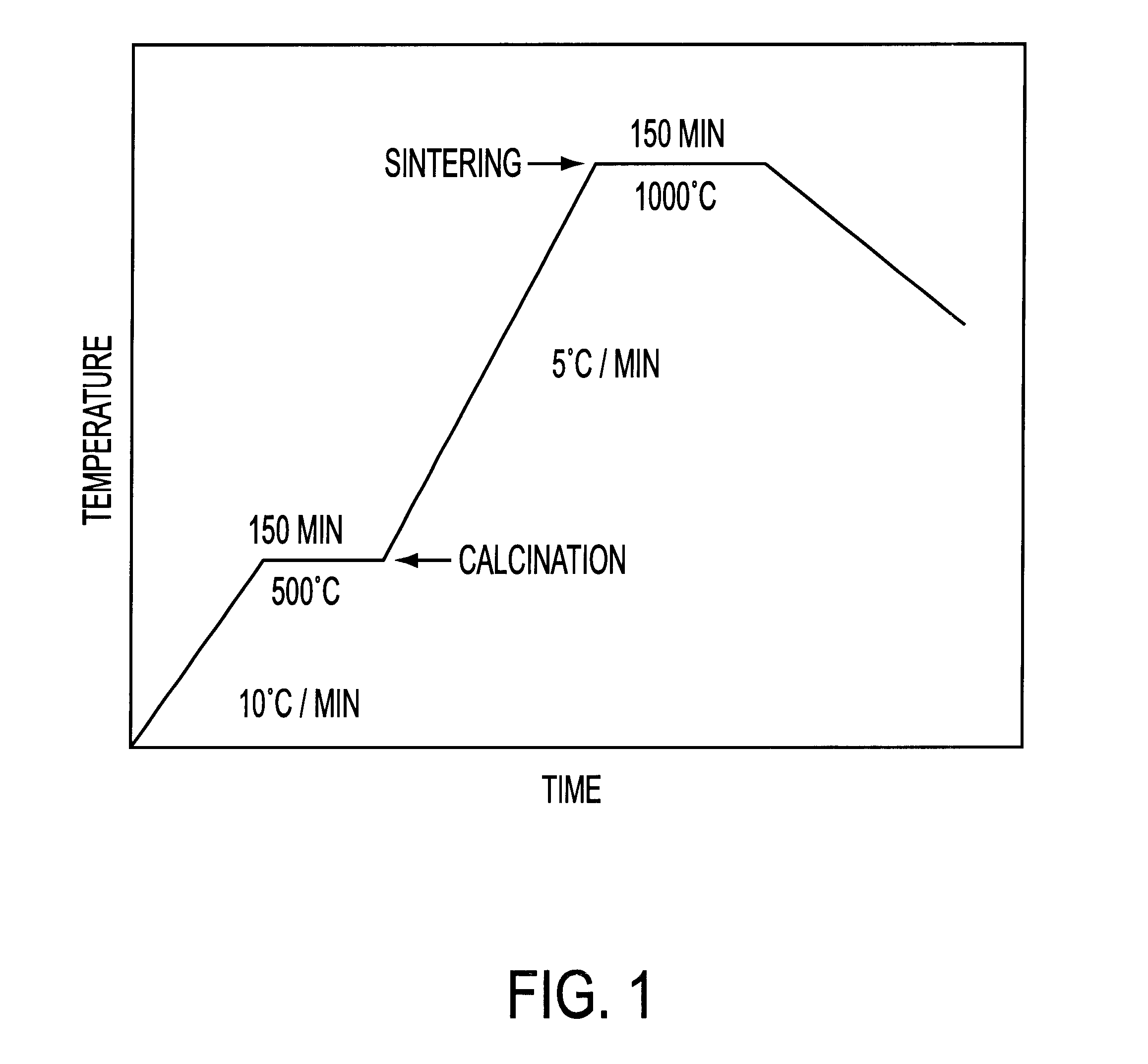

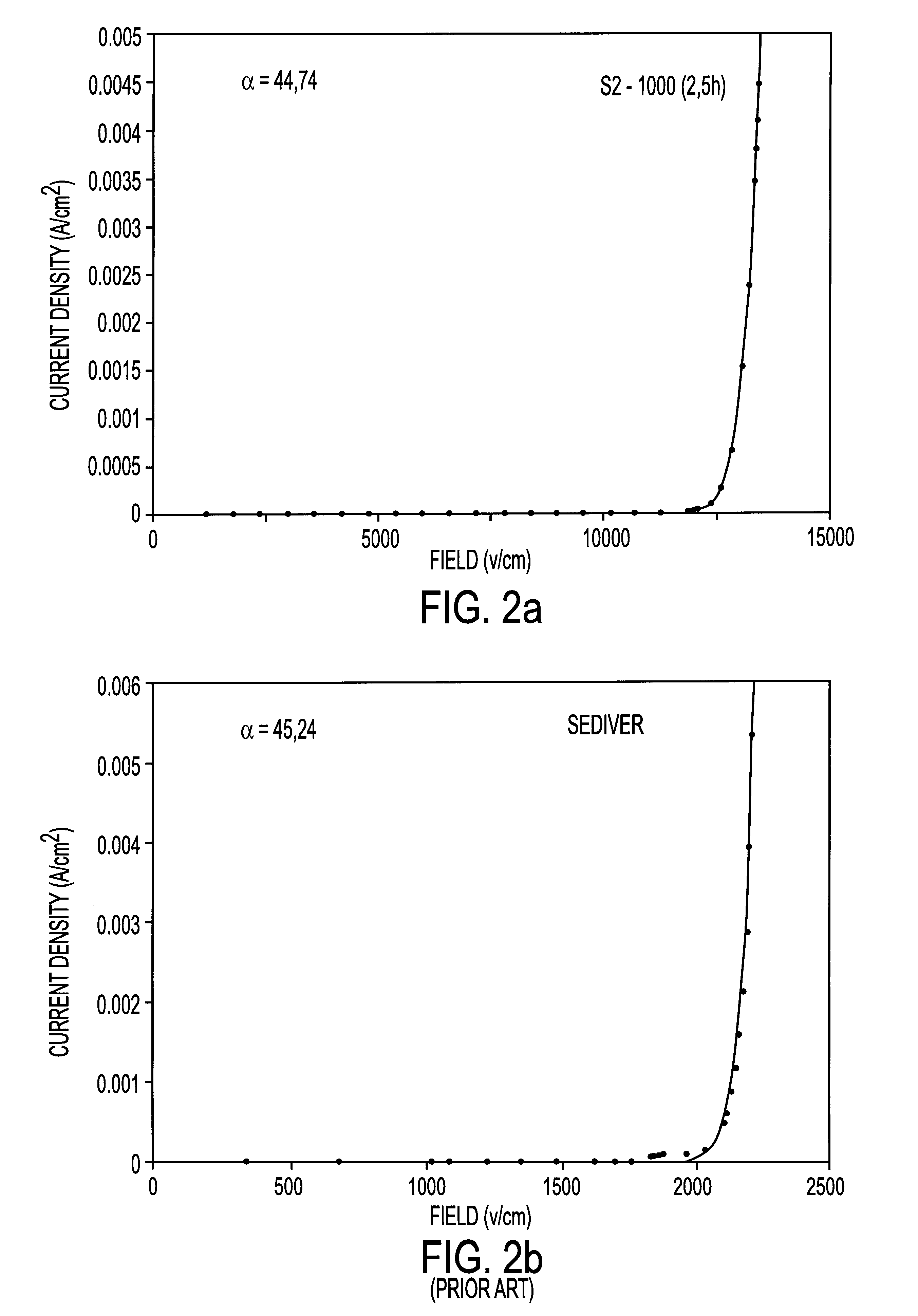

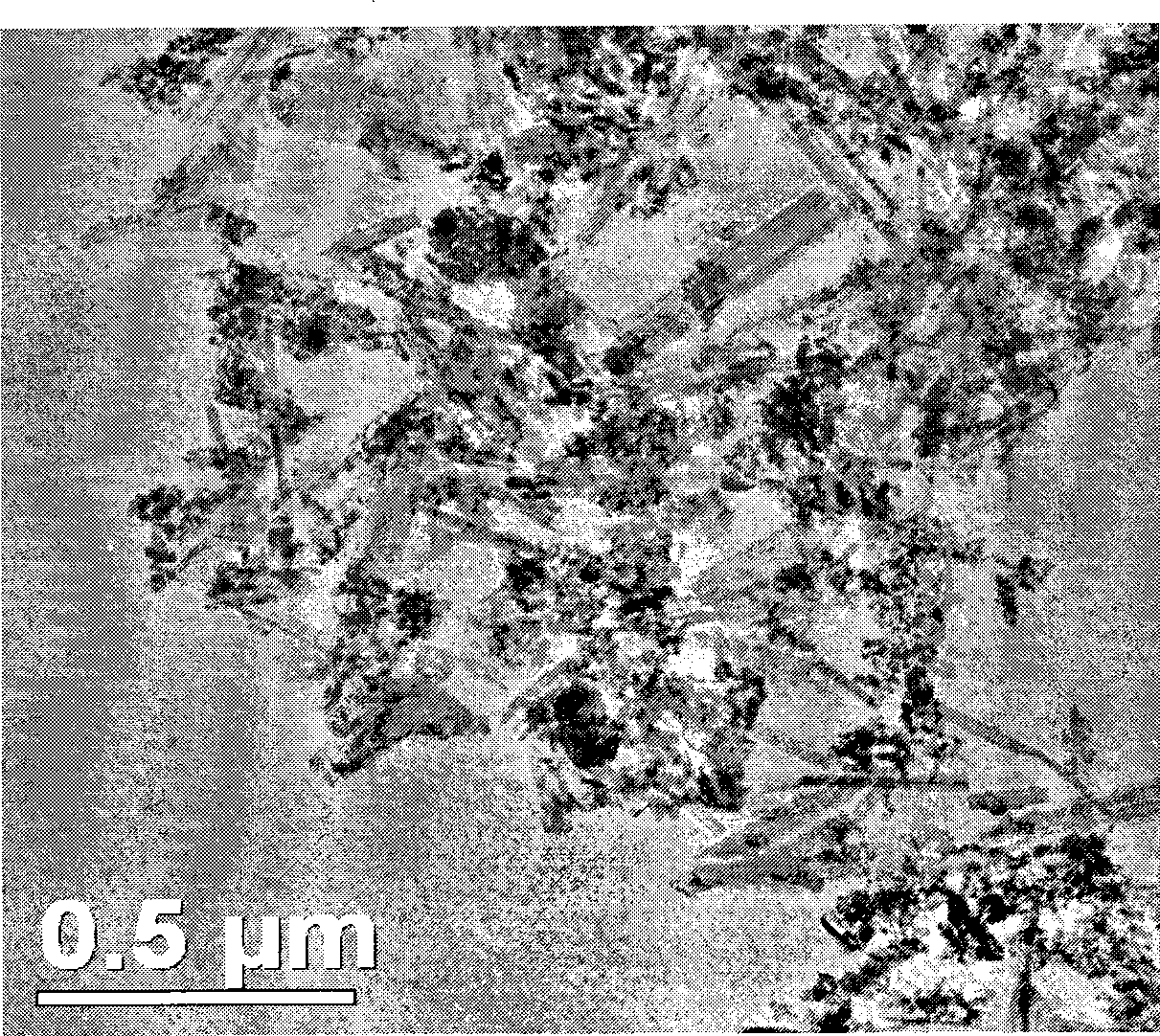

Varistors based on nanocrystalline powders produced by mechanical grinding

InactiveUS6620346B1Lower breakdown voltageImprove breakdown voltageMaterial nanotechnologyConductive materialGrain boundaryBreakdown voltage

The invention concerns novel varistors based on zinc oxide and a method for making same, which consists in using as base products nanocrystalline powders obtained by high-intensity mechanical grinding and in subjecting the mixture resulting from said nanocrystalline powders a consolidating treatment such as sintering, in suitably selected temperature and time conditions so as to retain the smallest possible grain size of ZnO. The resulting varistors have a very fine homogeneous microstructure and an average grain size characteristically not more than 3pm, i.e. five times smaller than standard materials. Said novel varistors have a larger number of grain boundaries per unit length unit and therefore a much higher breakdown voltage. Said voltage is characteristically higher than 10 kV / cm and can reach 17 kV / cm which is almost one order of magnitude above the breakdown voltage of standard varistors. The non-linearity coefficient of the current-voltage curve is also improved, and is greater than 20 and can reach values as high as 60. Moreover, the leakage currents below the breakdown voltage of said varistors, are much lower.

Owner:HYDRO QUEBEC CORP

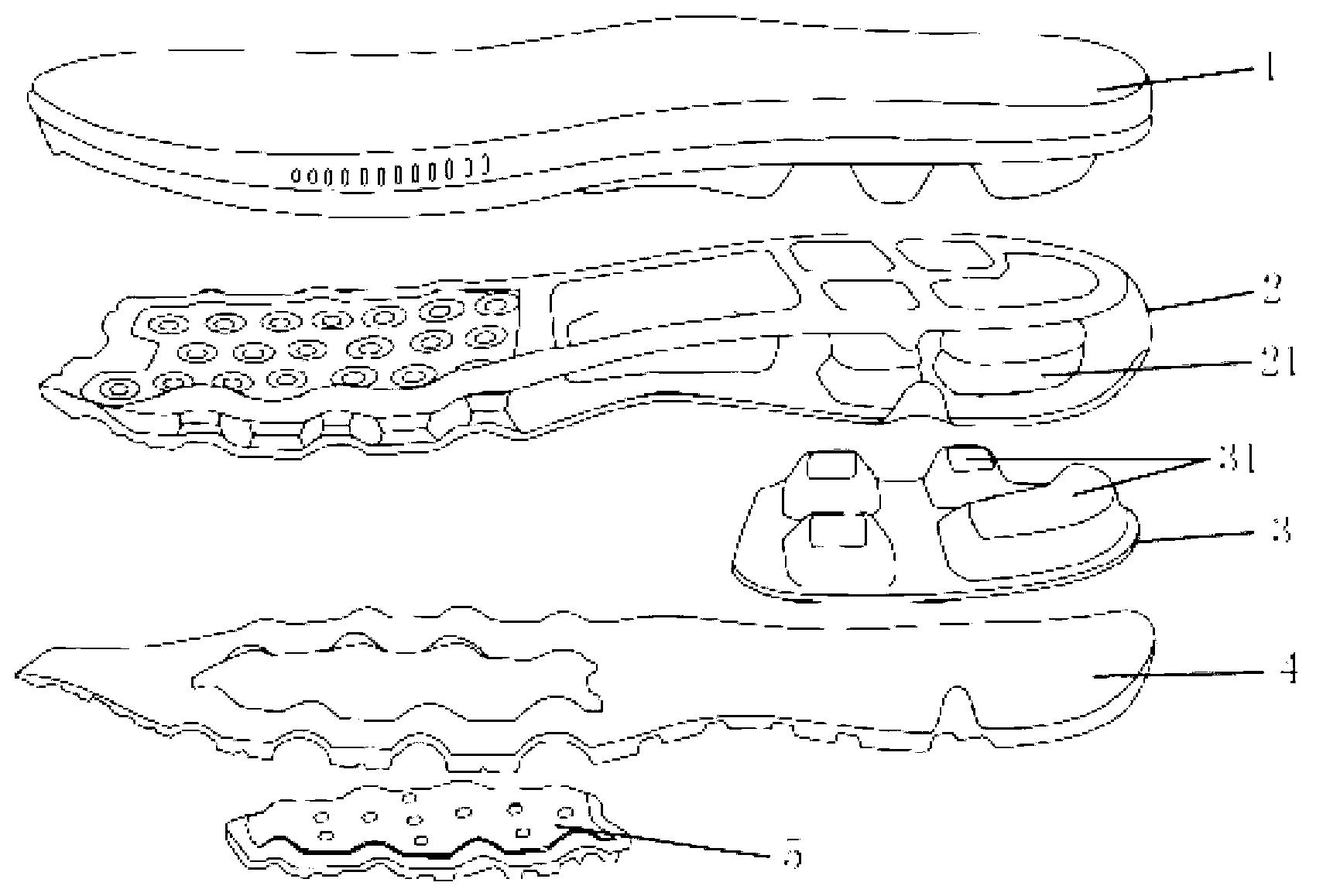

High-elasticity sneaker air cushion sole and production method thereof

The invention provides a high-elasticity sneaker air cushion sole and a production method thereof and researches a sneaker sole with high elasticity, high wear resistance and low hardness. The high-elasticity sneaker air cushion sole comprises a phylon (MD) midsole, an air cushion and a large sole which are sequentially and fixedly connected with one another from top to bottom, wherein an ethylene-vinyl acetate copolymer (EVA) cushion piece is assembled on a heel part of the air cushion; and the material formula of the MD midsole comprises the following components in parts by weight: 40-60 parts of EVA, 0-20 parts of ethylene propylene ternary gel, 0-30 parts of polyolefin elastomer (POE), 0-10 parts of talcum powder, 2.0-4.0 parts of a foaming agent, 0.6-1.0 part of a bridging agent, 1.0-2.0 part of a zinc oxide desulfurizing agent, 0.6-1.2 parts of stearic acid, 0.5-1.0 part of zinc stearate, 0.8-1.5 parts of a flow promotor and 0.3-0.8 part of a bridging addition agent.

Owner:新侨伟(福建)鞋服有限公司

Method and composition for preventing tooth hypersensitivity when using passive bleaching agents

InactiveUS20060013778A1Avoid allergiesLonger contact/coating periodCosmetic preparationsGum massageZinc peroxidePotassium nitrate

Dental bleaching compositions, for example in the form of liquids, gels, creams, pastes and ointments, comprising a peroxide releasing compound and from 1% to 35% by weight of a potassium-containing compound such as potassium nitrate, wherein the potassium nitrate is present in a safe and effective amount to prevent tooth hypersensitivity in the patient during the bleaching process. The potassium nitrate contemplated by the invention is compatible with peroxide yielding bleaching compounds such as peroxide, carbamide peroxide, calcium peroxide, zinc peroxide, magnesium peroxide and sodium perborate. Potassium nitrate is complimentary and synergistic with the peroxide bleaching agents contemplated by the invention and enhances the release of oxygen to the tooth enamel. Also contemplated are methods of bleaching teeth comprising application of the dental bleaching compositions of the invention.

Owner:HODOSH MILTON

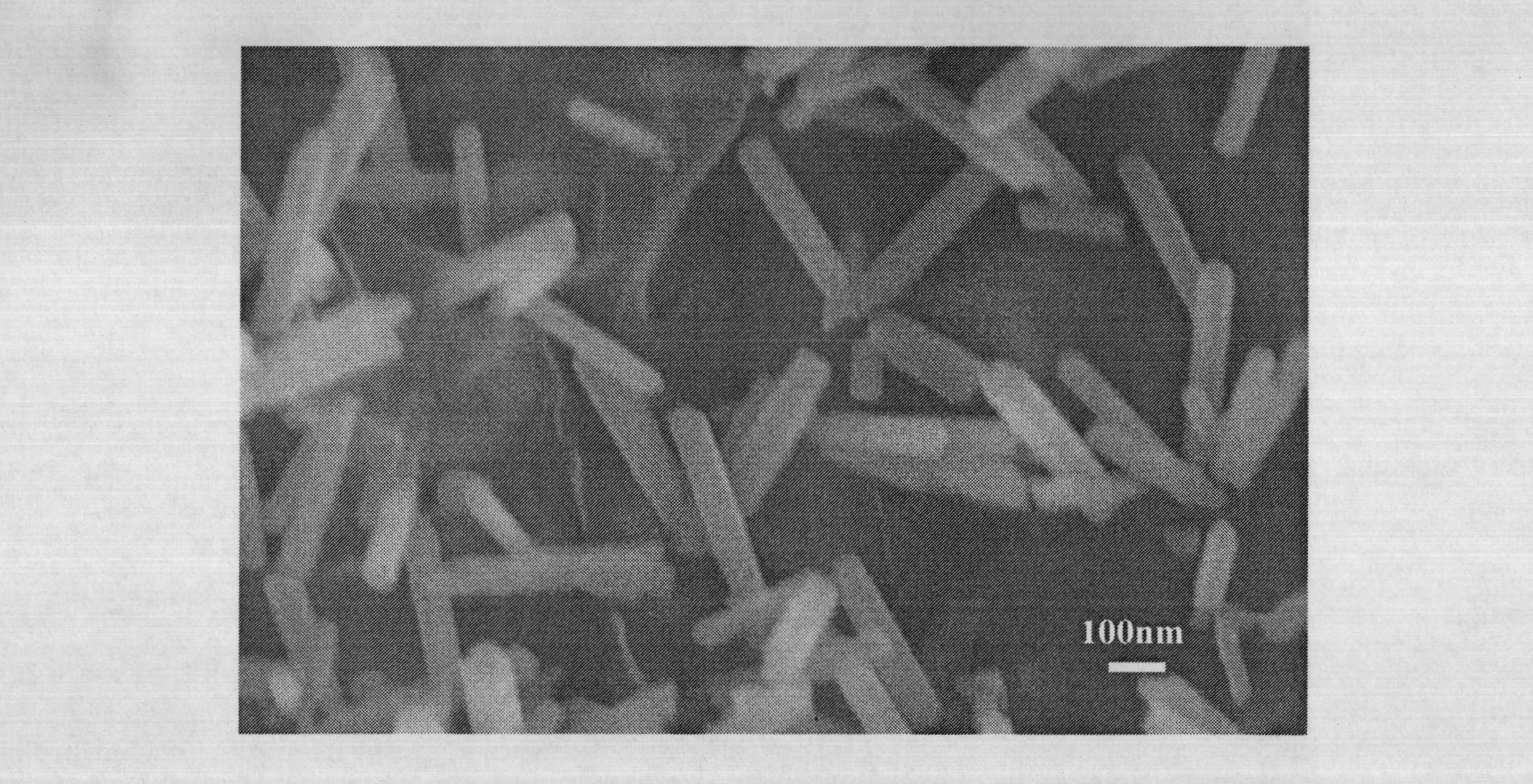

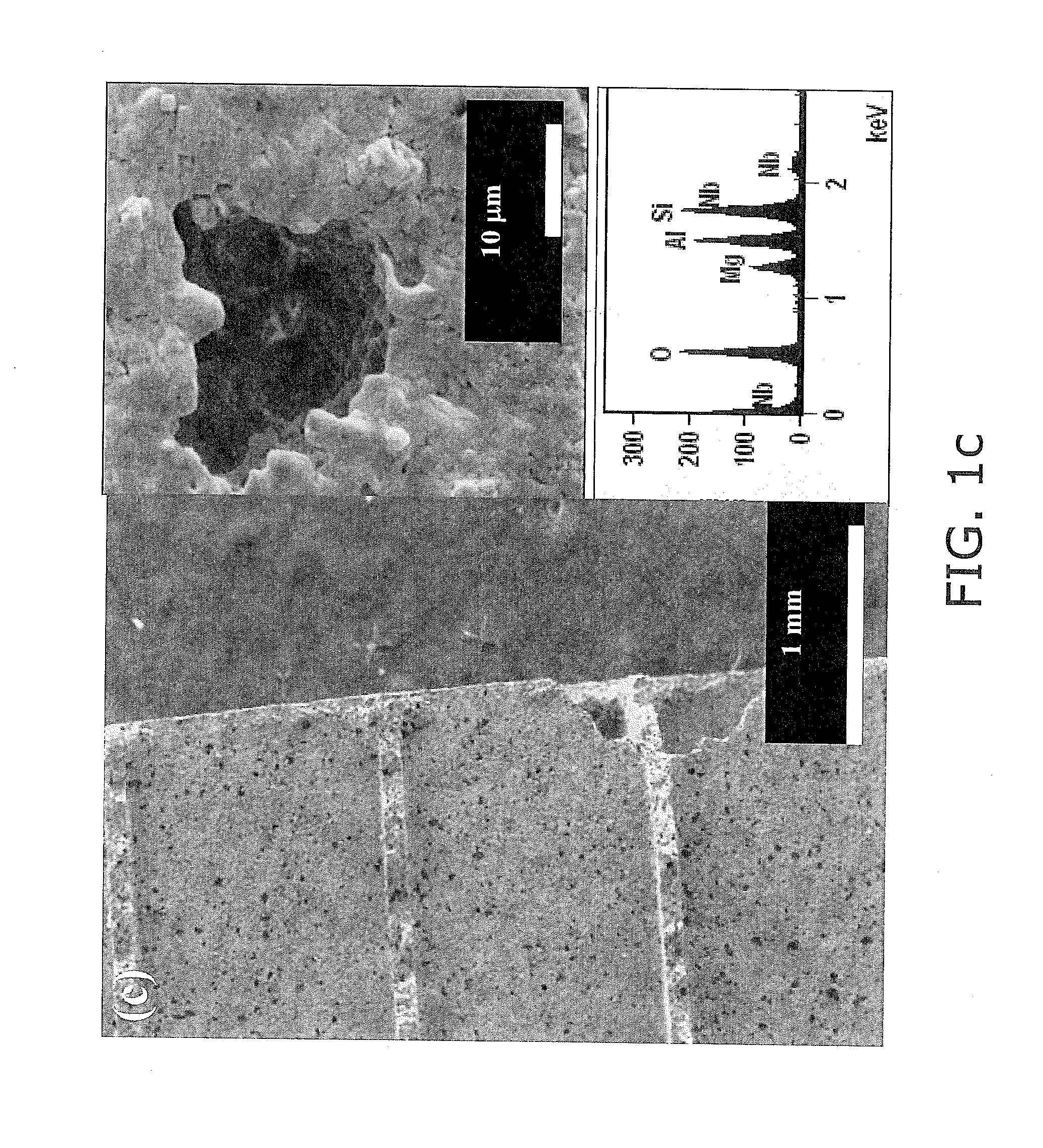

Metal oxide nanorod arrays on monolithic substrates

ActiveUS20140256534A1Improve thermal stabilitySulfur poisoningMolecular sieve catalystsLayered productsCerium(IV) oxideMetal particle

A metal oxide nanorod array structure according to embodiments disclosed herein includes a monolithic substrate having a surface and multiple channels, an interface layer bonded to the surface of the substrate, and a metal oxide nanorod array coupled to the substrate surface via the interface layer. The metal oxide can include ceria, zinc oxide, tin oxide, alumina, zirconia, cobalt oxide, and gallium oxide. The substrate can include a glass substrate, a plastic substrate, a silicon substrate, a ceramic monolith, and a stainless steel monolith. The ceramic can include cordierite, alumina, tin oxide, and titania. The nanorod array structure can include a perovskite shell, such as a lanthanum-based transition metal oxide, or a metal oxide shell, such as ceria, zinc oxide, tin oxide, alumina, zirconia, cobalt oxide, and gallium oxide, or a coating of metal particles, such as platinum, gold, palladium, rhodium, and ruthenium, over each metal oxide nanorod. Structures can be bonded to the surface of a substrate and resist erosion if exposed to high velocity flow rates.

Owner:UNIV OF CONNECTICUT

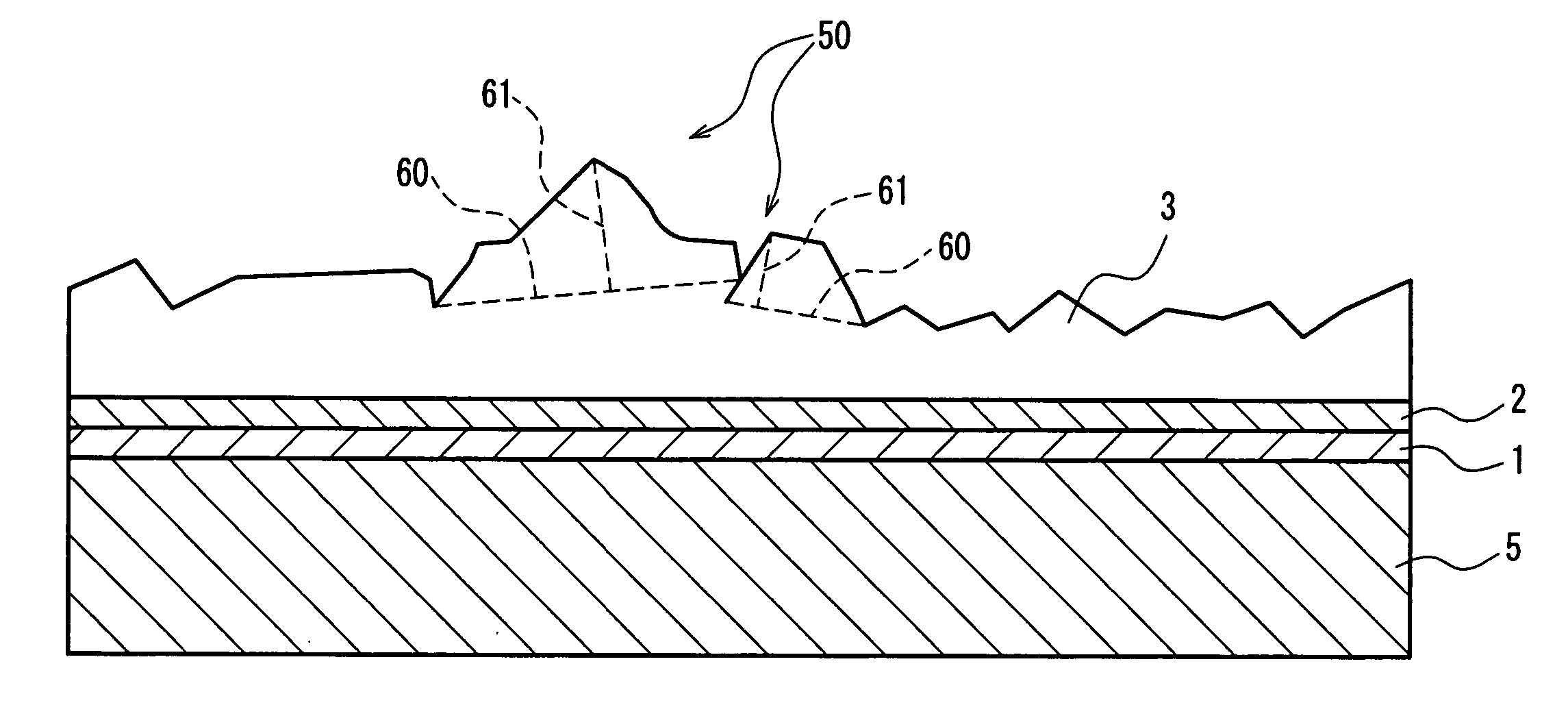

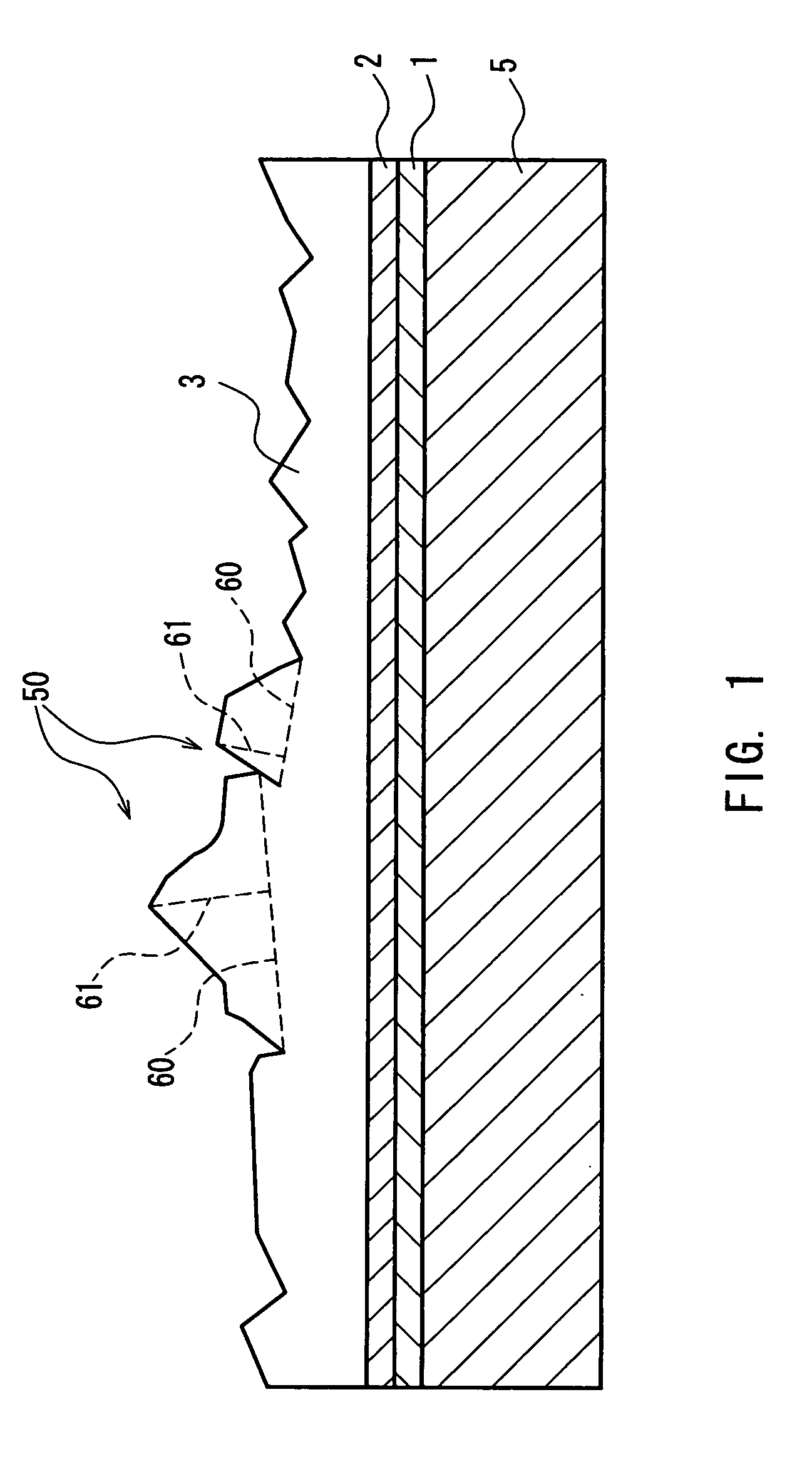

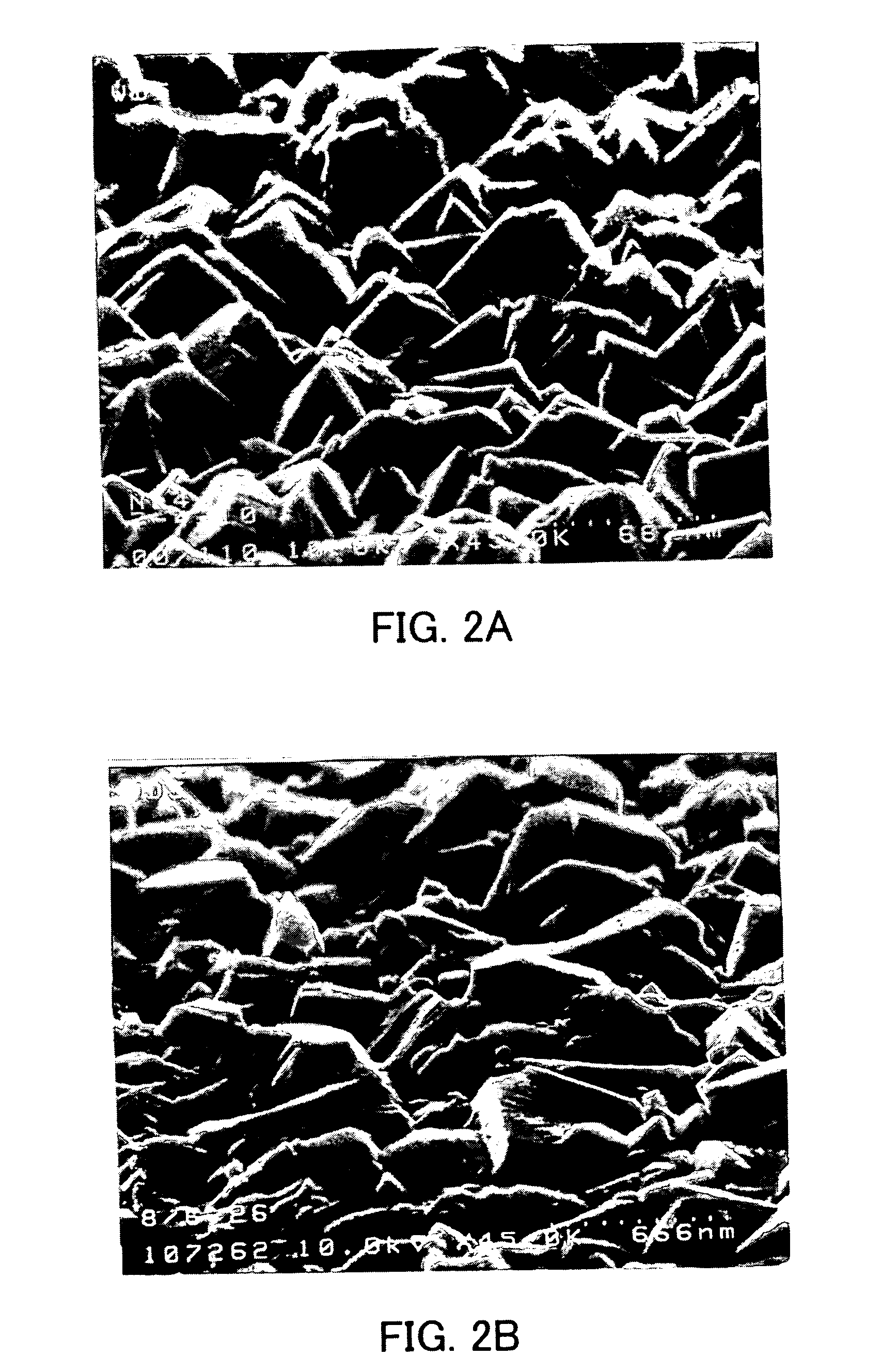

Conductive film, production method therefor, substrate provided with it and photo-electric conversion device

InactiveUS20040038051A1Conductive layers on insulating-supportsRecord information storageIndiumGas phase

A conductive film which is formed on a substrate, wherein a total of areas of the base surfaces of protrusions at least 250 nm in height is at least 5% of the area of a surface on which this conductive film is formed. The conductive film mainly contains at least one kind of compound out of tin oxide, titanium oxide, indium oxide and zinc oxide, and is formed on a transparent substrate by a chemical vapor deposition using an oxygen atom-containing material as vapor. A photoelectric conversion device is formed by a conductive film-carrying substrate and at least one photoelectric conversion layer disposed on the substrate and containing a crystalline silicon thin film 1-5 mum in thickness.

Owner:FUJISAWA AKIRA +3

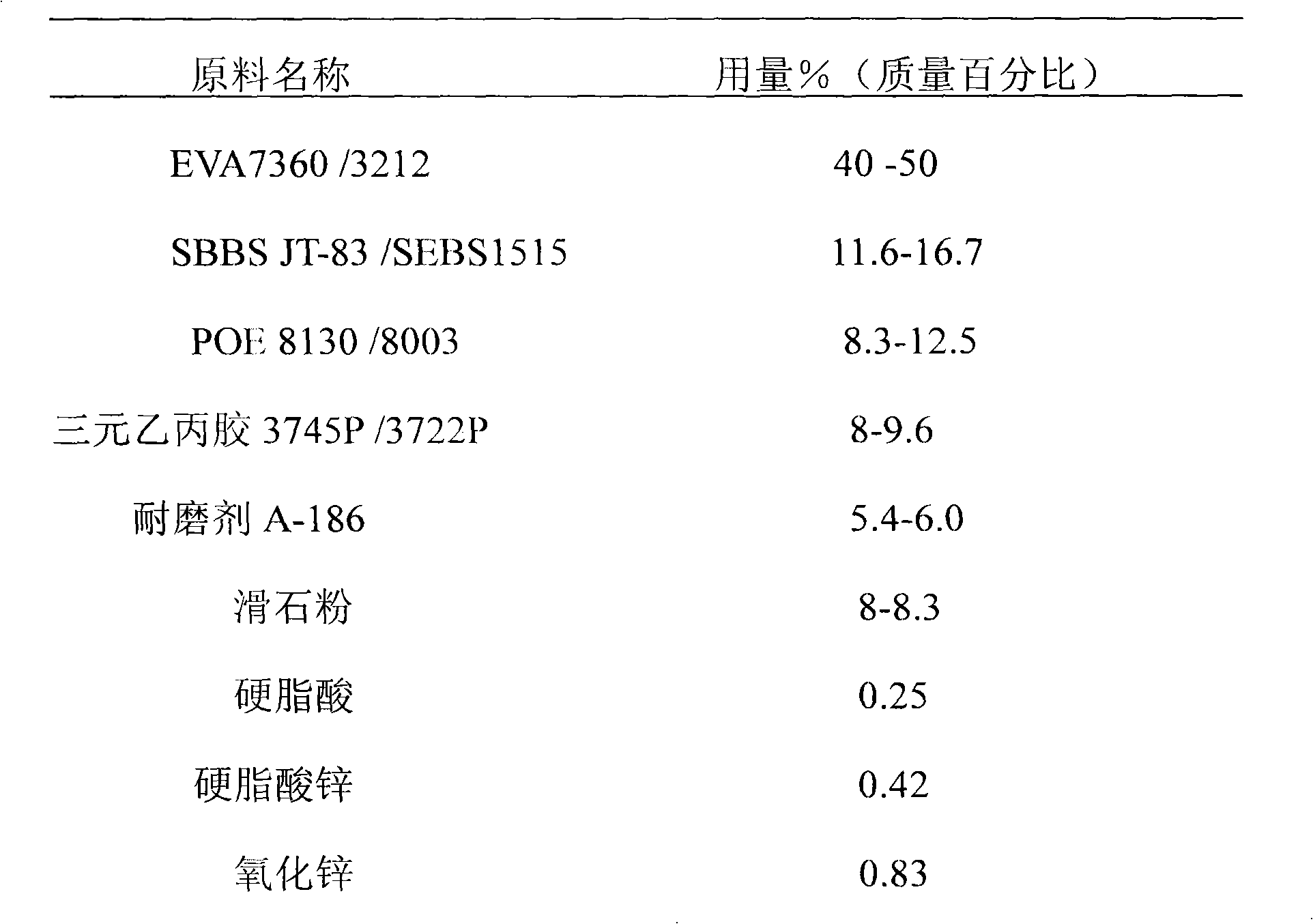

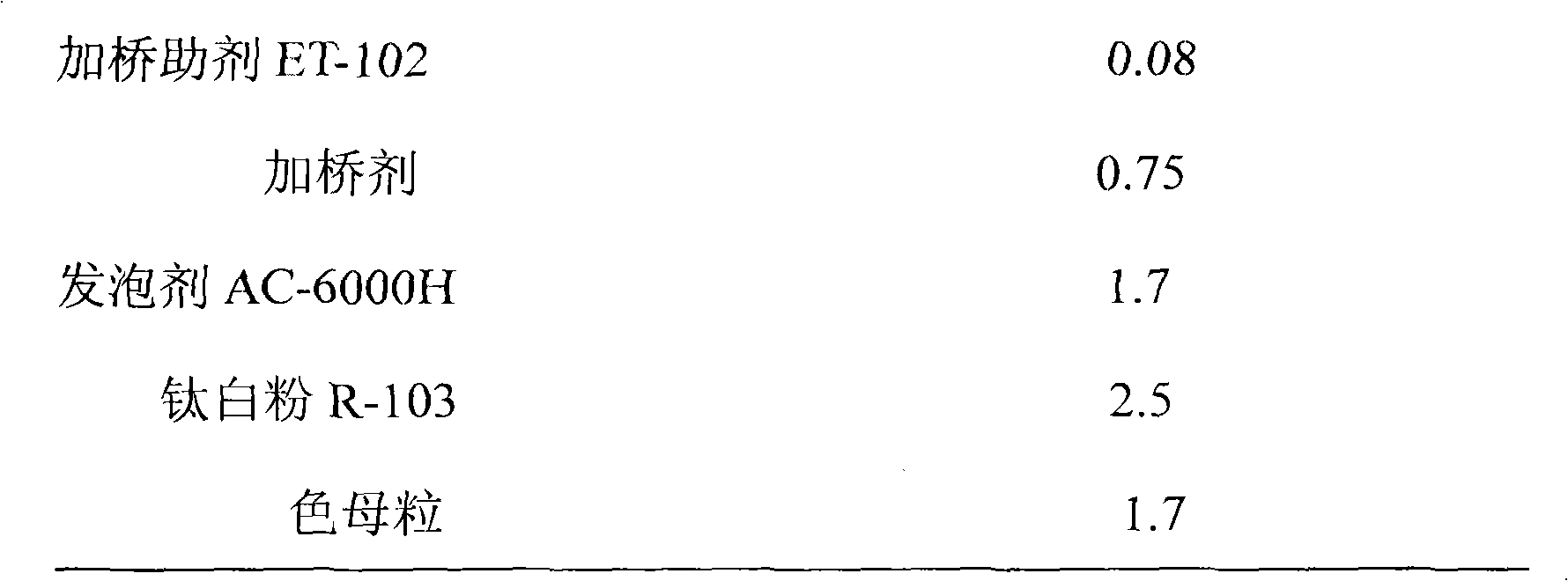

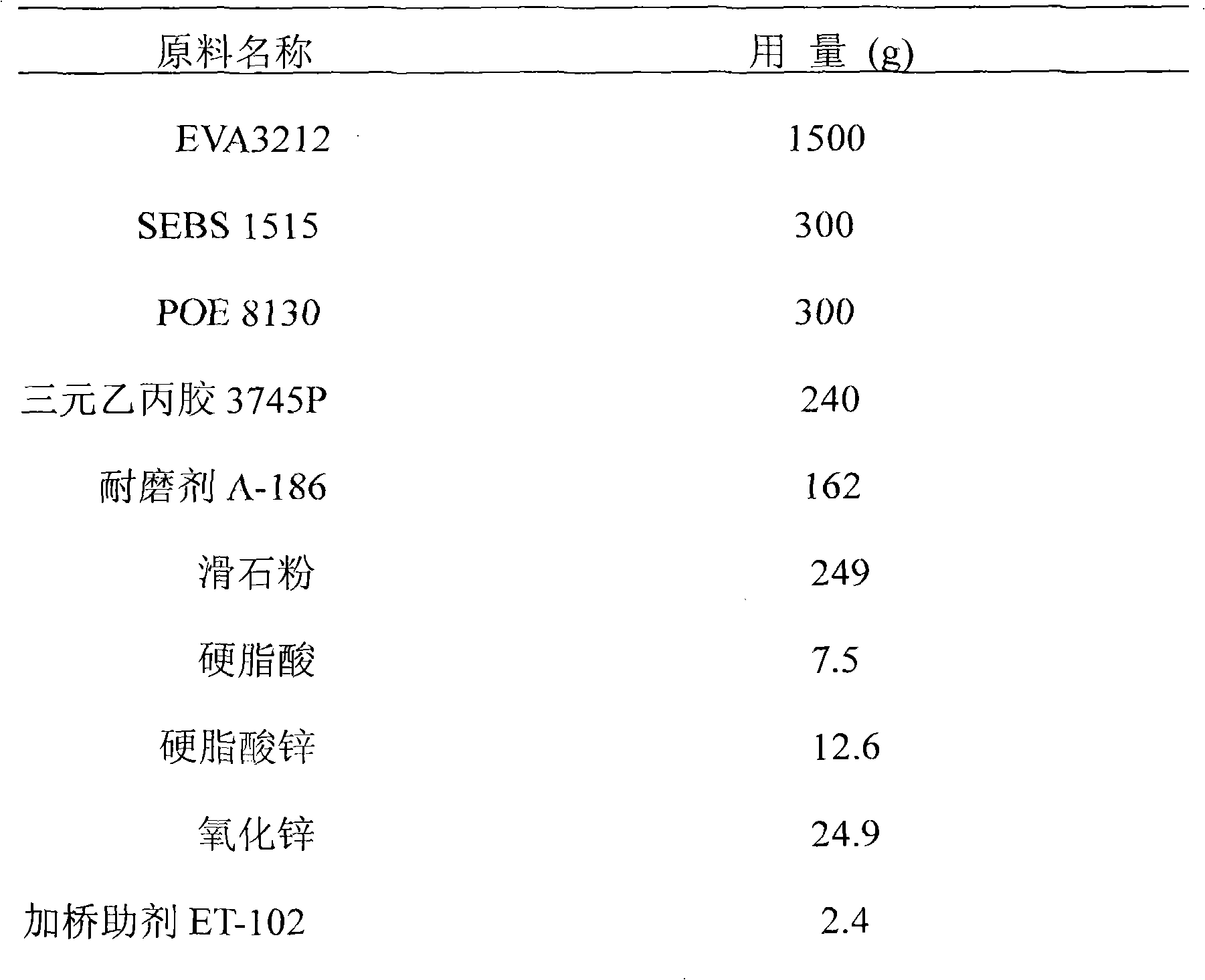

Formula of soles of PU-simulated foaming sneakers through injection and manufacturing method

The invention relates to a formula of soles of PU-simulated foaming sneakers through injection, which comprises the following raw materials in percentage by mass: 40 percent of 21 percent ethylene-vinyl acetate copolymer (EVA 7360), 16.7 percent of styrene butadiene copolymer SBBSJT-83, 12.5 percent of ethylene octylene copolymer POE8130, 8.3 percent of ethylene-propylene-diene copolymer 3745P, 65.9 percent of wear-resisting agent A-18, 8.3 percent of talcpowder, 0.25 percent of stearic acid, 0.42 percent of zinc stearate, 0.9 percent of zinc oxide, 0.08 percent of bridging auxiliary agent ET-102, 0.75 percent of bridging agent DCP, 1.7 percent of high-temperature foaming agent AC-6000H, 2.5 percent of titanium white powder R-103 and 1.7 percent of master batch. The preparation method comprises the steps of banburying, mixing, granulation, injection molding, physical property tests and the like. Thus, in the research and development and application, the PU-simulated foaming soles not only have the physical and chemical properties of no crease marks, high elasticity, low compression and wear resistance of PU soles, and but also have the advantages of low production cost, light specific gravity, good limited-slip properties, no hydrolysis and long service life.

Owner:泰亚投资集团有限公司

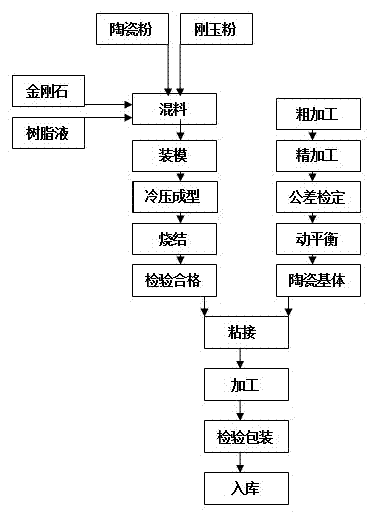

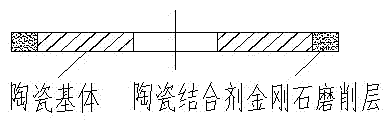

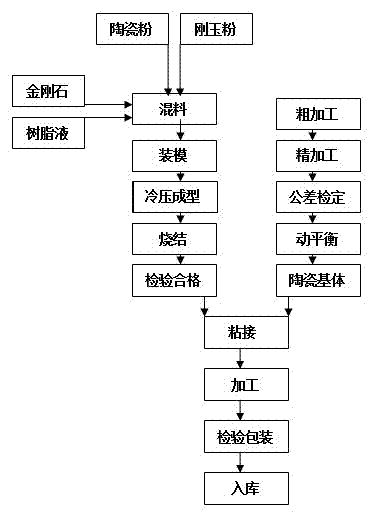

Special ceramic bond diamond grinding wheel for grinding diamond

InactiveCN102229122AHigh strengthSmall expansion coefficientAbrasion apparatusGrinding devicesDiamond grindingCeramic

The invention belongs to the field of diamond grinding wheels, and particularly relates to a ceramic bond and a method for manufacturing a ceramic bond diamond grinding wheel for grinding a diamond by adopting the ceramic bond. The ceramic bond is prepared from the following raw materials in percentage by weight: silicon dioxide, borax, lithium hydroxide, zinc oxide, calcium oxide and aluminum oxide; and the ceramic bond is obtained through the steps of: mixing the raw materials, then smelting at the high temperature of 1300+ / -5 DEG C, cooling, then performing ball milling to prepare ceramic powder, and sieving through a standard sieve of 180 meshes. The ceramic bond provided by the invention has high intensity and a low coefficient of expansion, so that the ceramic bond can be perfectly matched with the adopted ceramic grinding wheel basal body. The diamond grinding wheel manufactured by adopting the ceramic bond has good heat conductivity and heat resistance; and compared with the traditional resin bond diamond grinding wheel, the ceramic bond diamond grinding wheel not only ensures that the diamond is excellently sintered at the temperature of not being carbonized, but also ensures that grinding grains are always at an excellent holding state without falling off when grinding is carried out. The special ceramic bond diamond grinding wheel has the grinding efficiency and service life far higher / longer than that of the traditional grinding wheel, and has a comprehensive benefit which is increased by over 50%.

Owner:SUZHOU SAILI PRECISION TOOLS

Preparation method of active radical with surface-enhanced Raman scattering (SERS) effect

InactiveCN102759520AQuick checkIncrease surface areaRaman scatteringChemical vapor depositionCadmium Cation

The invention provides a preparation method of an active radical with a surface-enhanced Raman scattering (SERS) effect, belongs to the technical field of spectrum detection, and relates to the preparation technology of the SERS active radical, which is rapid, has high sensitivity and performs a low trace detection function. The preparation method is characterized in that firstly, a nano porous silicon columnar array with a large specific surface area is prepared by utilizing a hydrothermal etching technology; afterwards, a nanowire structure of an II-VI group compound semiconductor (such as zinc oxide, titanium dioxide, cadmium sulfide, cadmium selenide, cadmium telluride, and the like) by utilizing a chemical vapor deposition method; and finally, nano particles of precious metal (such as gold, silver, copper and the like) are finally prepared on the nanowire structure by using a chemical reduction method, so as to obtain an active radical material. The preparation method has a wide application prospect in the aspects of clinical biomolecular fast recognition, trace chemical substance detection, biological sample analysis, and the like. The preparation method has the advantages that the preparation process of each material is simple, the condition is mild and the repetition rate reaches 100 percent.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing concavo-convex rod soil/zinc oxide nanometer composite material

The invention discloses a method for preparing concavo-convex rod soil / zinc oxide nanometer composite materials, which comprises the following steps: purifying and dispersing the concavo-convex rod soil in water to prepare concavo-convex rod soil dispersion liquid; then adjusting the temperature of the concavo-convex rod soil dispersion liquid to 30 to 100 DEG C; agitating the concavo-convex rod soil dispersion liquid dispersion liquid and while adding zinc salt aqueous solution with the concentration of 0.3 to 3 mol.L<-1> and carbonate aqueous solution with the concentration of 0.3 to 2 mol.L<-1> to the concavo-convex rod soil dispersion liquid dispersion liquid; and keeping the pH value of mixed liquid within the range of 6.0 to 8.0. The prepared mixed serous fluid comprising the prepared nanometer concavo-convex rod soil and basic zinc carbonate is filtered; and a filter cake is washed by deionized water; when the electrical conductivity of filtrate is less than 300 MuS.cm<-1>, the washing is finished; and the filter bake obtained is dried at the temperature of below 100 DEG C, then baked for 1 to 10 hours at the temperature of 300 to 600 DEG C, and finally crushed. The invention is simple and has the advantages of low energy consumption and high safety; the load of the adsorbing material prepared is uniform and has good dispersibility, strong adsorbability and remarkable photo-catalyzed degradation property.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

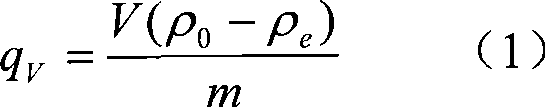

High-temperature gas composite oxide desulfurizer and production thereof

InactiveCN1712500AHigh mechanical strengthHigh wear resistanceGas purification by catalytic conversionActive componentFluidized bed

A high-temperature gas composite oxide desulfurizer and its production are disclosed. The desulfurizer consists of active component zinc oxide 33í½50% and multiple additives 31í½51% which comprises titanium dioxide, active stabilizer, surface modifier, strength reinforcer, regenerative improver and composite binder. The process is carried out by mixing active component with additives, grinding, kneading, forming, laying aside, drying, particle rectifying, calcining at 850í½1060íÒC in high-temperature furnace, and obtaining desulfurizer. It achieves better reactivity and efficiency, good abrasion resistance and regeneration. It can be used for fixed bed, fluidized bed and desulfurizing reactor of flowing bed.

Owner:CHINA COAL RES INST

High-temperature (800 DEG C) wear-resistant paint and preparation method thereof

The invention discloses high-temperature (800 DEG C) wear-resistant paint and a preparation method thereof. The high-temperature wear-resistant paint comprises a component 1 and a component 2, wherein the component 1 is prepared by mixing a component A and a component B; the component A in the component 1 comprises the following components: black silicon carbide, fine-grain aluminum oxide, dispersing agent, zinc oxide, modified epoxy resin, flatting agent and an auxiliary material; the component B in the component 1 comprises the following components: organic silicon modified epoxy resin, a filler, antimony trioxide, film-forming assistant and thickener; and the component 2 is curing agent and coupling agent. The high-temperature (800 DEG C) wear-resistant paint is prepared by the following steps: mixing the component A and the component B in the component 1, and curing the component 1 with the component 2. The high-temperature wear-resistant paint is prepared by compounding the double components, has excellent high temperature resistance and wear resistance, and also has the fine properties of favorable hardness, high heat stability, ductility, workability and the like. The invention also designs the method for preparing the high-temperature wear-resistant paint. The preparation method is simple and low in cost.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com