Patents

Literature

58 results about "Microlite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microlite was once known as a pale-yellow, reddish-brown, or black isometric mineral composed of sodium calcium tantalum oxide with a small amount of fluorine (Na,Ca)₂Ta₂O₆(O,OH,F). Today it is a name of a group of oxide minerals of a similar stoichiometry having tantalum prevailing over titanium and niobium. The microlite group belongs to a large pyrochlore supergroup that occurs in pegmatites and constitutes an ore of tantalum. It has a Mohs hardness of 5.5 and a variable specific gravity of 4.2 to 6.4. It occurs as disseminated microscopic subtranslucent to opaque octahedral crystals with a refractive index of 2.0 to 2.2. Microlite is also called djalmaite, but both names are now obsolete.

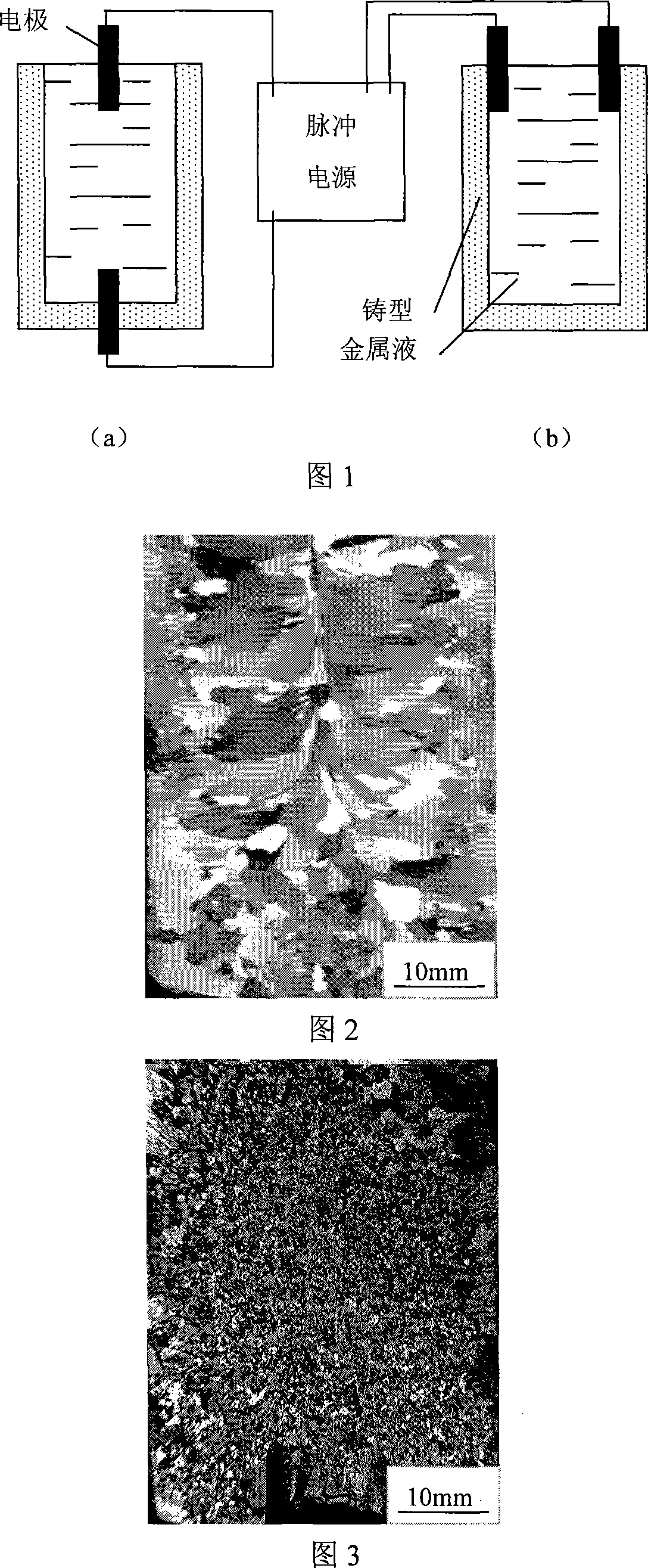

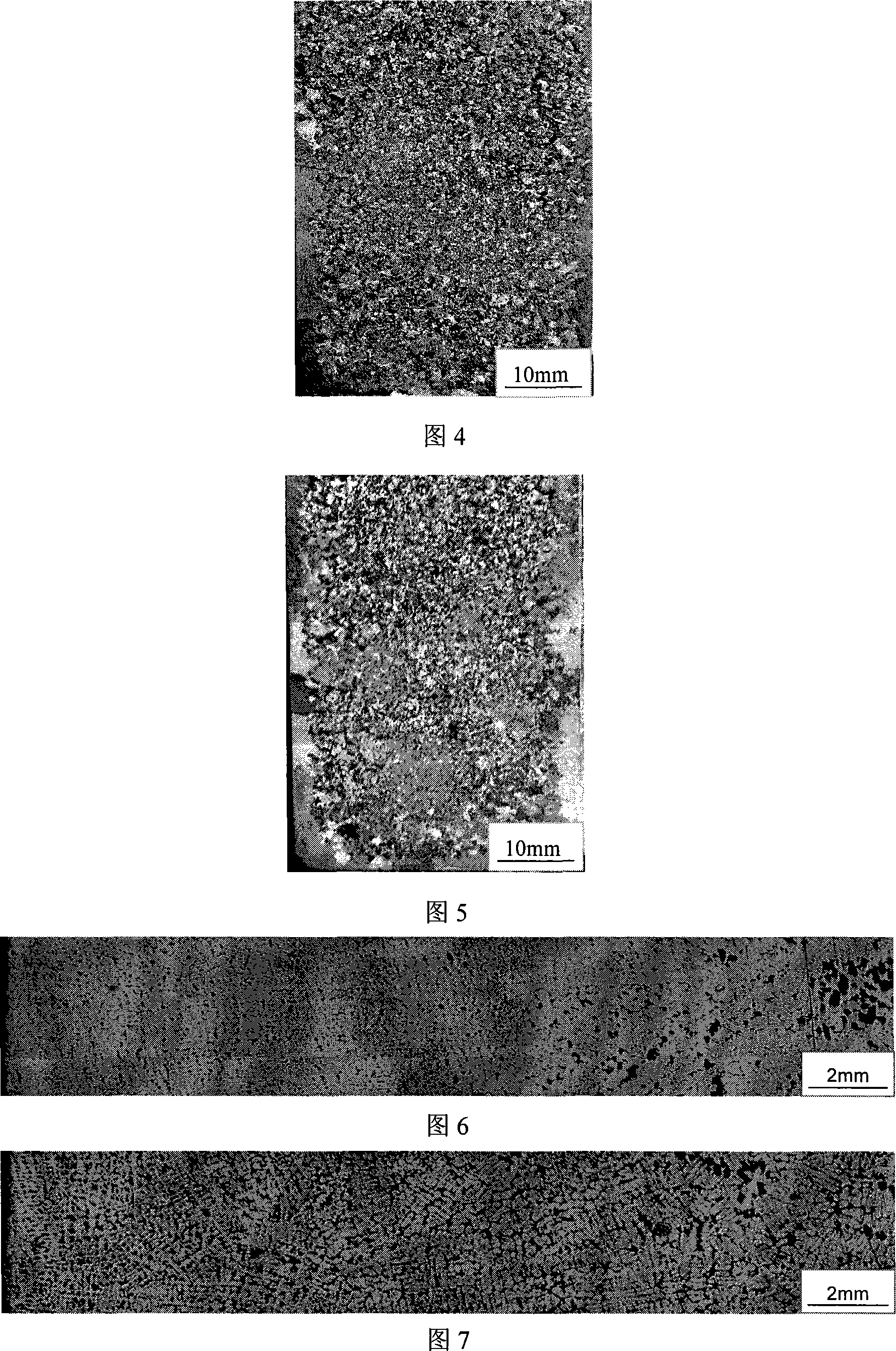

Method for solidifying microlite by impulse current liquid surface disturbance

A process for fine crystallization of metal liquid by electric current pulses is carried out by: smelting metal and over-heating, casting, inserting two parallel electrodes from above into molten metal, and disturbing metal liquid by 1000-4000A impulse electric current at 100-1000Hz to obtain fine-crystallized cast ingots. The disturbance is divided into both periods of core forming and solidifying. It can be used mold casting or continuous casting various metals.

Owner:SHANGHAI UNIV

Cubic boron nitride superhard cutter

The invention discloses a superhard cutter with high hardness and good abrasive resistance and heat resistance. The cutter comprises the following components in percentage by weight: 75-85 percent of cubic boron nitride micro powder with the granularity of 1-10 mum, 0.5-3 percent of microlite powdered boron with the purity above 99.5 percent, 5-10 percent of microlite powdered aluminum with the purity above 99.5 percent, and 6-15 percent of carbon with a diamond structure. Because the invention is prepared by adopting the cubic boron nitride as a main raw material and adding the high-purity microlite powdered aluminum and the high-purity microlite powdered boron as well as the carbon with the diamond structure under super-high pressure and high temperature, the high hardness, the abrasive resistance and the heat resistance are obviously improved; and the superhard cutter is used for high-hardness alloy materials with turning HRC within 48-53, and has better effect particularly on chromel alloy materials.

Owner:刘书锋

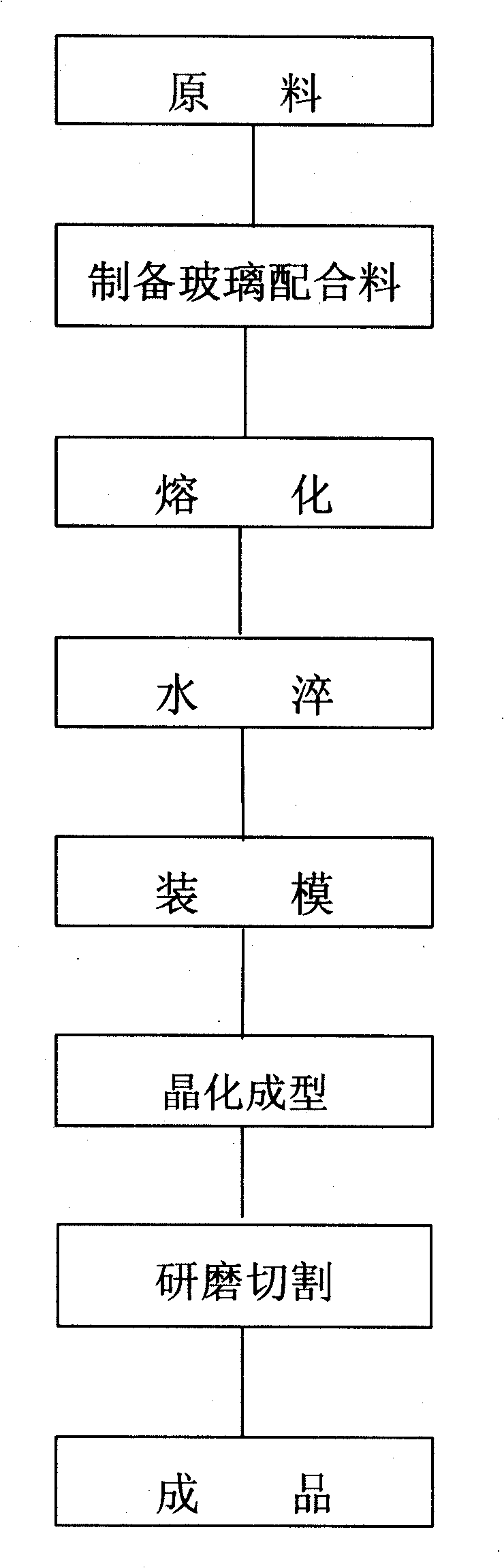

Method for manufacturing microlite by using high-silicon iron tailings

The invention discloses a method for manufacturing microcrystalline glass plates by using iron tailings, which comprises the steps of adding 30 to 70 percents of iron tailings in a glass batch, wherein quartz sand, aluminum oxide, sodium carbonate, calcium carbonate and other raw materials can be partially replaced by the iron tailings; melting the glass batch for four hours in a crucible or an electric box furnace, wherein the melting temperature is 1480-1500 DEG; introducing the molten glass liquid into water directly to form glass particles after the melting process; laying the glass particles in a refractory mould to carry out crystallization heat treatment in a tunnel kiln, a shuttle kiln or an electric box furnace with the crystallization temperature to be 1020-1050 DEG. The invention utilizes castoff microcrystalline glass, thereby not only reducing the stockpiling amount of tailings and relieving the environmental pollution, but also improving the product performance. Meanwhile, the production cost is reduced. Thus, the method for manufacturing microcrystalline glass plates by using iron tailings has good social benefit and economic benefit.

Owner:BEIJING QING MAI HUA QING HLDG GRP CO LTD

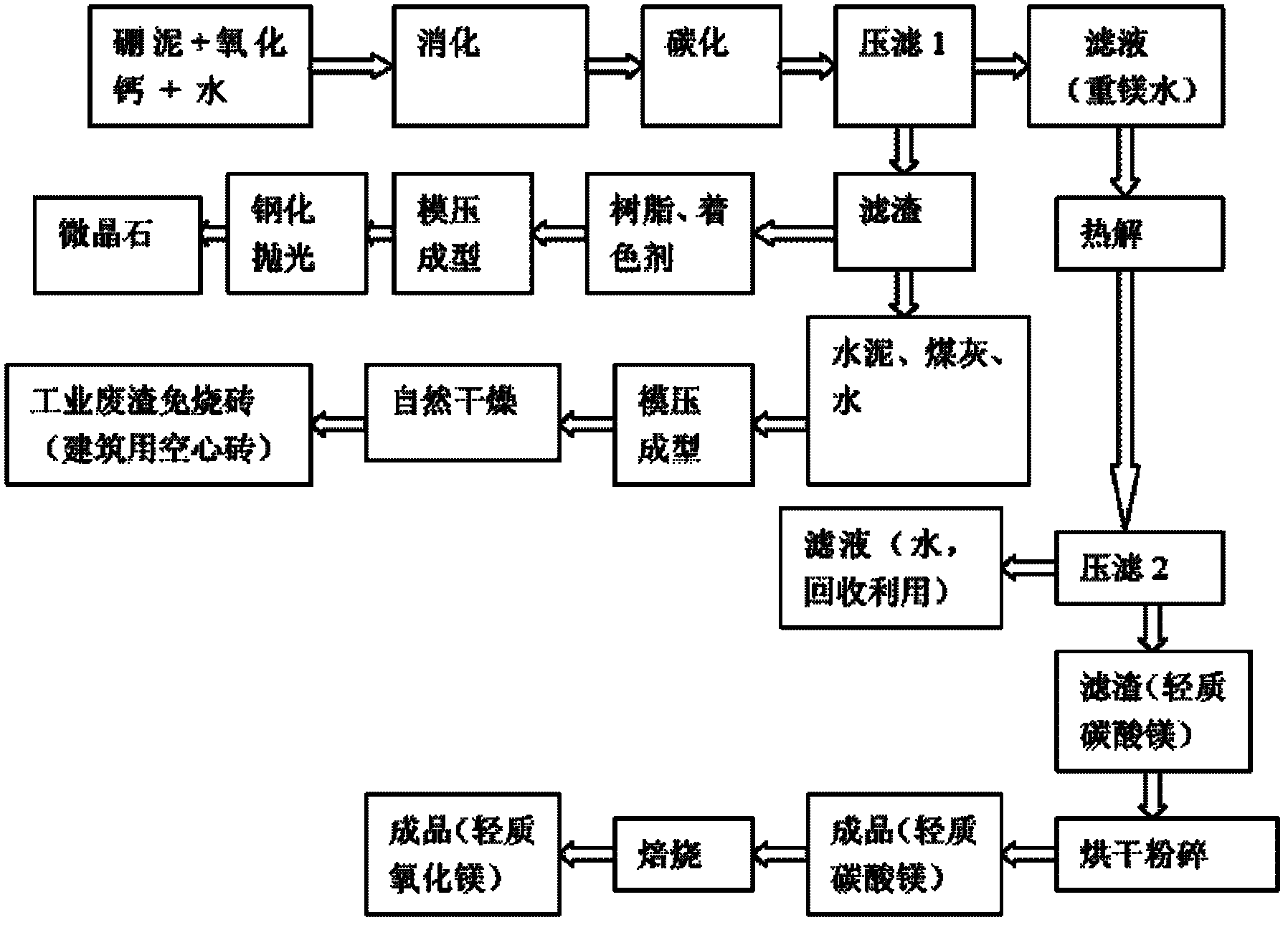

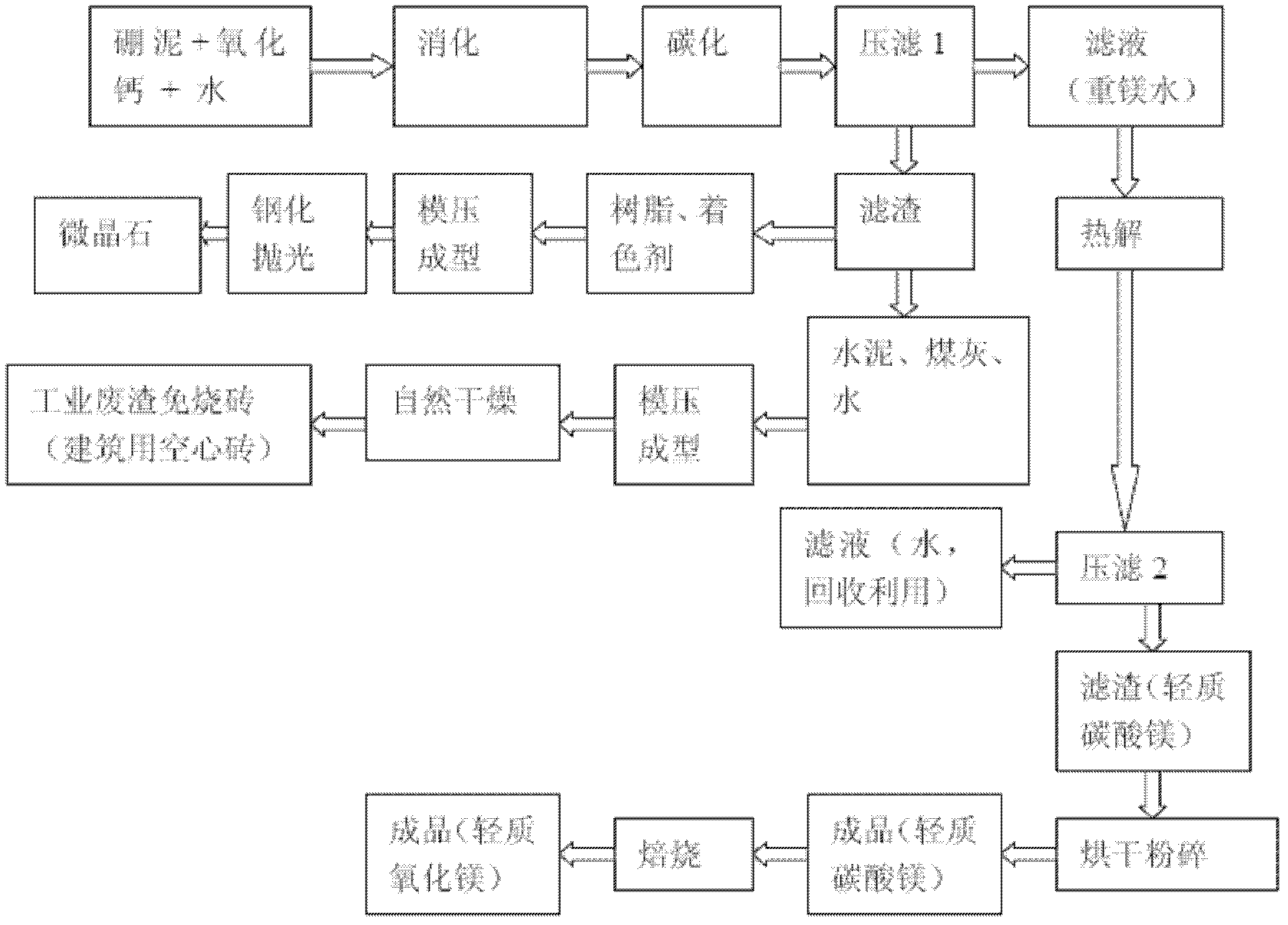

Comprehensive utilization method of boric sludge

The invention provides a comprehensive utilization method of boric sludge. Comprising a digestion step and a carbonization step in order, the method is characterized in that the digestion step consists of: with boric sludge taken in magnesium oxide terms, mixing boric sludge, calcium oxide and water in a weight ratio of 1:0.5-2:6-10, conducting digestion at a temperature of 85-100DEG C for 2-3.5h. The comprehensive utilization method of boric sludge in the invention has low energy consumption and high magnesium yield. Besides, the waste residue from magnesium compound extraction can be converted into microlites and / or hollow bricks completely, thus realizing high unification of ecological benefits, environmental benefits, economic benefits, and social benefits. And the microlites and hollow bricks prepared by the filter residue from magnesium compound extraction have the advantages of uneasy deformation, uneasy cracking, high strength and hardness, water and frost resistance, etc.

Owner:SHENZHEN XINNUOTAI INVESTMENT MANAGEMENT

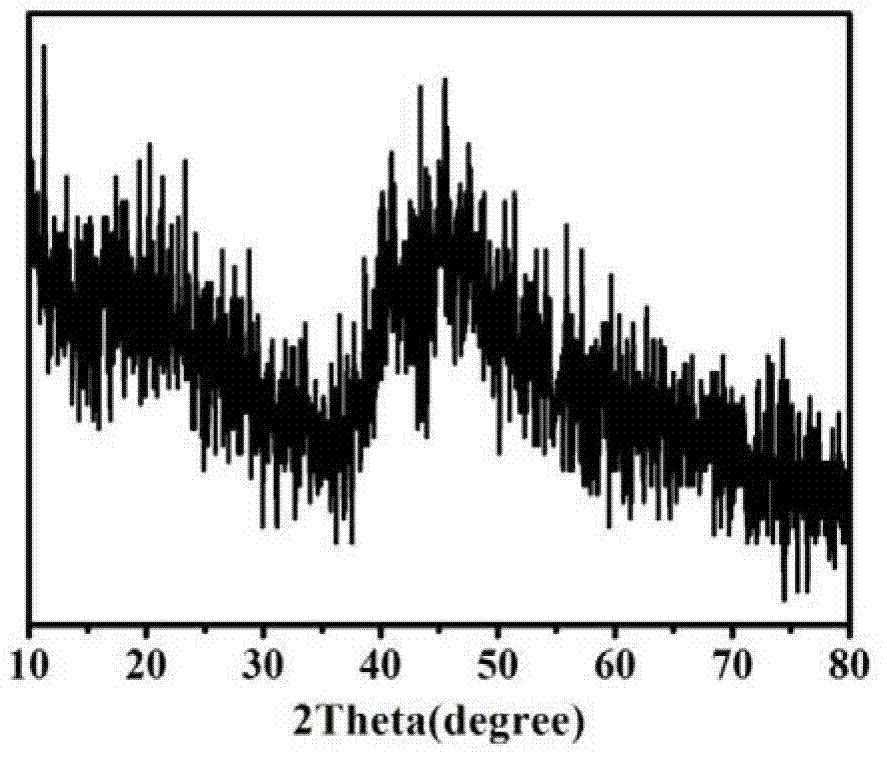

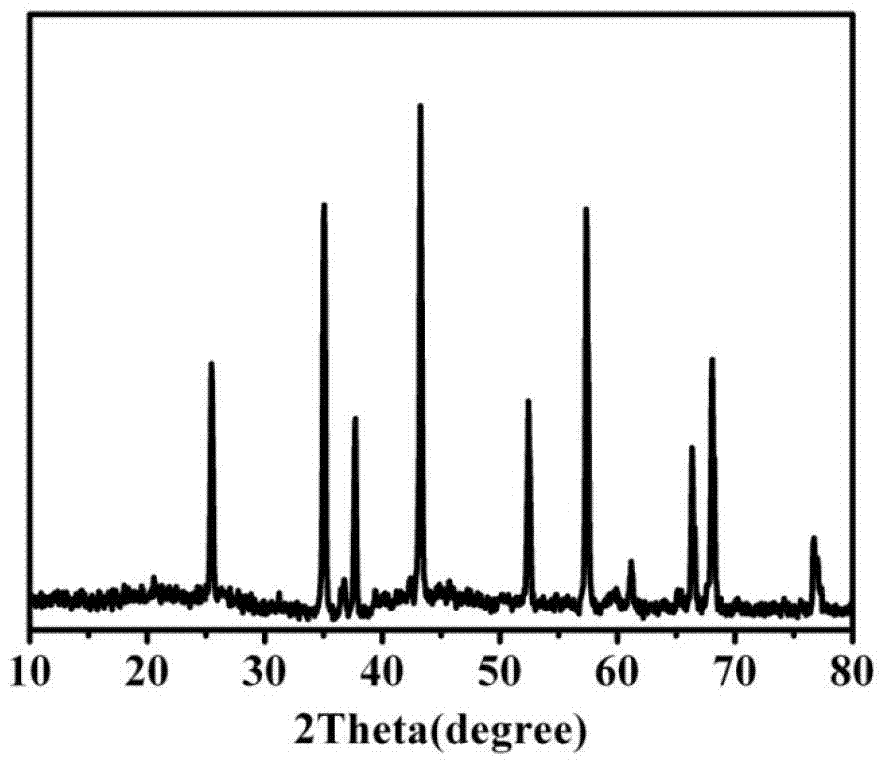

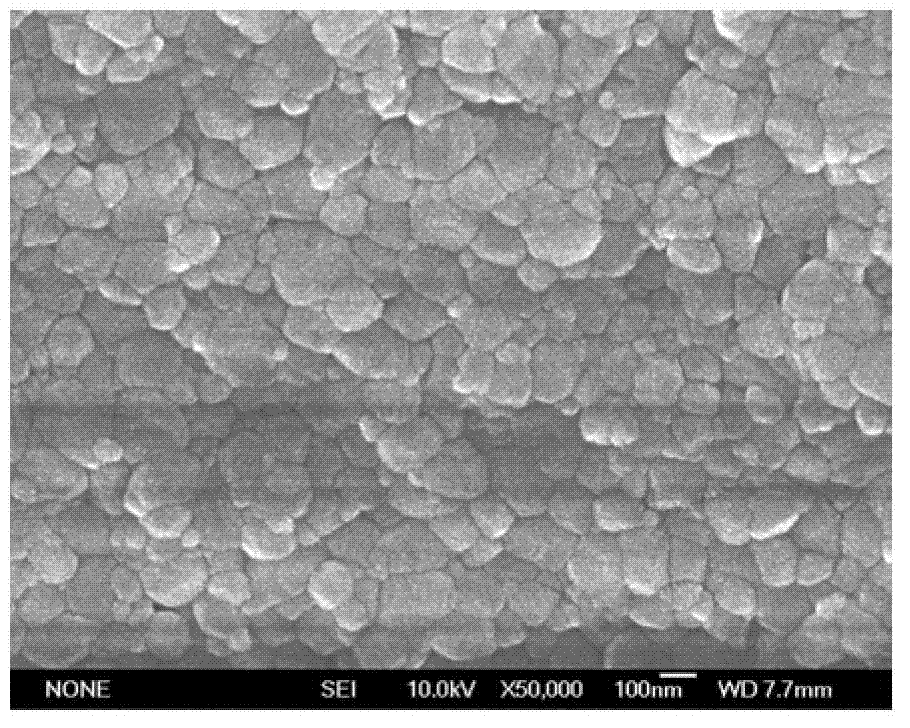

Preparation method of aluminum hydroxide gel and microlite alpha-Al2O3 aggregate

ActiveCN102807243ASmall grainReduce grain sizeAmmonium nitratesAluminium oxide/hydroxide preparationAluminium hydroxideDevice material

The invention relates to an aluminum hydroxide gel. The preparation method includes performing reaction of aluminum nitrate hydrate and ammonia water to obtain aluminum hydroxide, adding additive to suspension after ball-milling to obtain aluminum hydroxide gel, and drying to obtain aluminum hydroxide dried gel; and grinding and calcining the aluminum hydroxide dried gel to prepare microlite alpha-Al2O3 aggregate. The preparation method is suitable for large-scale production of the microlite alpha-Al2O3 aggregate, conditions of process are easy to control, grain size of primary grain of the prepared microlite alpha-Al2O3 aggregate is 50-400nm, particle size of secondary aggregate particle of the prepared microlite alpha-Al2O3 aggregate is 75-600um, the prepared microlite alpha-Al2O3 aggregate is compact in structure, density is 3.90-3.98g / cm<3>, and hardness is 19-24GPa. The prepared microlite alpha-Al2O3 aggregate can be used for abrasive, high-temperature-resistant material, electronic device material, high-frequency insulation material, aerospace material, information material and the like.

Owner:SHANDONG UNIV

Automobile interior trim material capable of removing formaldehyde

InactiveCN105504717AImprove interface compatibilityGood acid and alkali resistanceBiochemical fibre treatmentHeat resistant fibresFiberPolyvinyl alcohol

The invention discloses an automobile interior trim material capable of removing formaldehyde. The automobile interior trim material is prepared from, by weight, 30-35 parts of bamboo fiber, 2-3 parts of antimonous oxide, 5-7 parts of shell powder, 10-12 parts of waterborne polyurethane, 0.2-0.4 part of a silane coupling agent kh570, 1-2 parts of polyethylene wax, 10-13 parts of polyvinyl alcohol, 100-105 parts of polylactic acid, 60-68 parts of dimethylacetamide, 30-35 parts of dimethyl sulfoxide, 9.6-10.7 parts of carbonized scindapsus aureus, 9.5-10.5 parts of microlite powder, 6-7 parts of poly(butylene succinate), 10-12 parts of acrylic emulsion and an appropriate amount of deionized water. According to the automobile interior trim material, operation is easy, the raw material sources are wide, the biodegradability is good, toxic substances such as formaldehyde in an automobile can be removed, air can be purified, and a healthy and comfortable environment can be built.

Owner:芜湖跃飞新型吸音材料股份有限公司

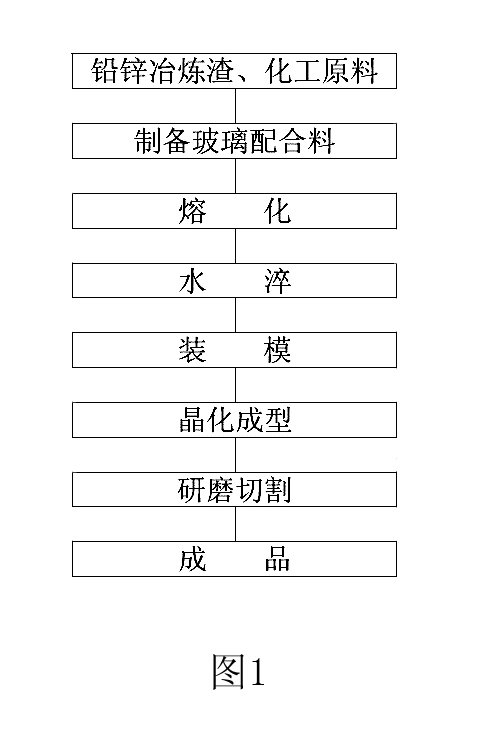

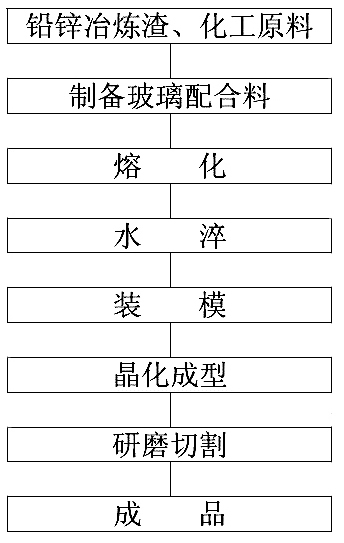

Black microlite manufactured by using lead and zinc smelting dreg and manufacturing method thereof

The invention relates to a black microlite manufactured by using lead and zinc smelting dreg and a manufacturing method thereof. The glass raw material of the black microlite comprises the following components in parts by weight: 40-60 parts of lead and zinc smelting dreg, 21-35 parts of quartz, 20-27 parts of limestone, 3.5-4 parts of soda ash, 2-3.5 parts of zinc oxide, 3-5 parts of barium carbonate, 2-5.2 parts of ferric oxide, 0-0.5 part of manganese dioxide, 0-0.2 part of nickel oxide and 0-0.05 part of cobalt oxide. The invention has the same performance as that of common glass ceramics produced completely by using industrial materials, and can utilize waste, thereby reducing the environment pollution, reducing the production cost and the melting temperature of glass, improving the melting speed and the melting furnace efficiency of glass and reducing the energy consumption. The invention can be widely applied to architectural ornament materials, in particular applied to various building decoration projects such as inner and outer walls, floors, aisle columns, table-boards and the like.

Owner:FENGXIAN SANLIAN BUILDING MATERIALS

Preparation method for microlite tile

ActiveCN106495493AImprove wear resistanceLow water absorptionCoatingsPolymer scienceWear coefficient

The invention relates to a preparation method for a microlite tile and belongs to the technical field of tile preparation. The method comprises the following steps: firstly, stirring, mixing and milling the materials, including aedelforsite, quartz powder and the like, thereby obtaining glaze slip; mixing the glaze slip with sodium dodecyl benzene sulfonate and a coupling reagent, thereby obtaining the modified glaze slip; mixing with the materials, including glass-ceramic powder, albite, ball clay and the like, thereby obtaining the mixed powder; ball-milling, pressing and drying the mixed powder, thereby obtaining a green body; soaking the green body into the modified glaze slip; taking out and sintering, thereby obtaining the microlite tile. The microlite tile prepared according to the method provided by the invention has high abrasion resistance with the wearing coefficient of 0.2-0.3, low water absorption below 0.32% and difficulty in cracking.

Owner:邯郸市永年区金缔陶瓷有限公司

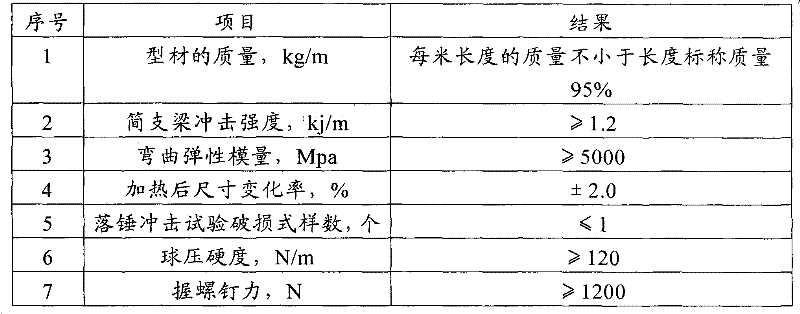

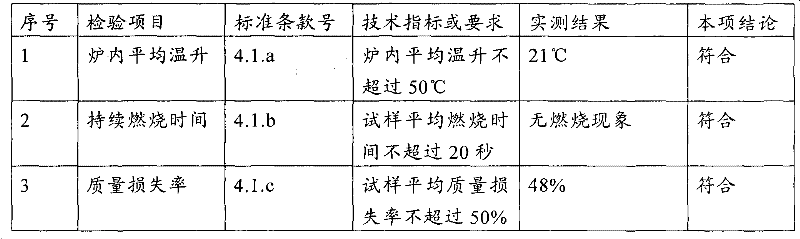

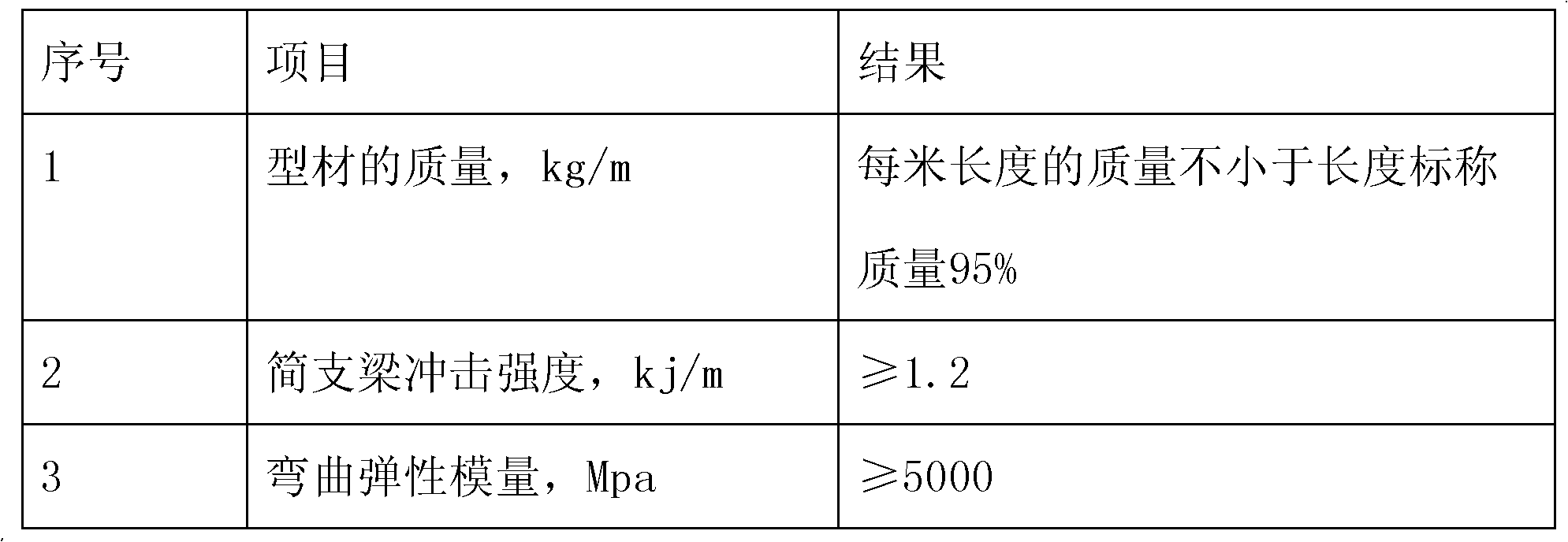

Microlite fireproof section

The invention provides a fireproof section. The main ingredients of the microlite fireproof section comprise heavy calcium carbonate powder and polyvinyl chloride (PVC) resin. Other chemical assistants which may be one or more of alumina, hard lead, chlorinated poly ethylene (CPE), a dibutyl ester and a compound stabilizer. The fireproof section comprises 50 to 70 weight parts of heavy calcium carbonate powder, 20 to 40 weight parts of PVC resin and 5 to 25 weight parts of other chemical assistants. The fireproof section disclosed by the invention does not contain radioactive harmful matters, has high fireproof performance, can protect the safety of state property and people's life and property, and fills the blank of firefighting and fireproof sections in China.

Owner:深圳必图新型材料科技有限公司

Micron fine-grained titanium-nickel-copper alloy block constant-diameter corner extrusion preparation method

The invention is an equant bending-angle extrusion preparing method of micron microlite Ti, Ni-Cu alloy block, vacuum-melting Ti, Ni and Cu, where their atomic percents are 48-55%, 35-47% and 5-10% in turn, to make the Ti, Ni-Cu alloy cast ingot, cutting the alloy block into blanks, polishing and coating glass lubricant, adopting the equant bending-angle extrusion mould whose extrusion channel angle is 90-120 degrees and whose molding cavity surface is coated with graphitic lubricant, heating the blanks and the mould and preserving heat, at the same time taking out the blanks and the mould from the heating furnace for equant bending-angle extrusion and finally obtaining good -intensity and -plasticity Ti, Ni-Cu alloy block.

Owner:SHANGHAI JIAO TONG UNIV

Method for manufacturing microlite from high-temperature ferronickel alloy waste slag

The invention relates to a method for manufacturing microlite from high-temperature ferronickel alloy waste slag, belonging to the technical field of reutilization of alloy waste slag. The technical process mainly comprises the steps of preparation and preheating of an admixture, hot mix melting, water quenching and cooling, grinding, and crystallization. The method comprises the following steps: by using kaolin with the particle size of 0.5mm as kaolin, weighing an alloy waste slag solution and the admixture in a mass ratio of (85-90):(10-15), and heating the admixture to 1300-1400 DEG C; keeping the mix melting temperature at 1450-1500 DEG C for 30-45 minutes while stirring; cooling the molten slag by water quenching; and adding the water quenching slag into a ball mill, milling, filling the slag powder into a mold, sending into a crystallizing kiln or crystallizing tunnel, heating to 950-1000 DEG C, keeping the temperature to perform crystallizing treatment for 120-180 minutes, carrying out furnace cooling or slow cooling at the rate of 5-8 DEG C / minute, and finally, demolding to obtain the microlite finished product. By effectively utilizing the high-temperature ferronickel alloy waste slag for producing microlite, the method reduces the environmental pollution, conforms to the requirements for national clean production, and has the advantages of lower investment cost, reliable technology and obvious economic benefit of production.

Owner:商都中建金马冶金化工有限公司

Environmental protection type nano composite microlite

InactiveCN102021987AWith agate stone effectImprove the decorative effectCovering/liningsFlooringNanometreMaterials science

The invention relates to environmental protection type nano composite microlite which is provided with a base plate layer. A microlite decorating layer is compounded on the base plate layer; a reinforced pattern plate is arranged in the base plate layer; a plurality of combining holes and a plurality of convex nails are uniformly distributed on the reinforced pattern plate; the periphery of the composite microlite plate is provided with a metal frame; the base plate layer is a cement and expanded perlite composite layer; and the microlite decorating layer comprises resin, aluminum hydroxide rough powder, aluminum hydroxide fine powder, glass fine grains, pigment and fine stone powder. The invention has the agate effect on appearance, prevents water, resists acid and alkali and can be used for the decoration of walls, ceilings, floors and furniture.

Owner:北京新丰海顺科技发展有限公司

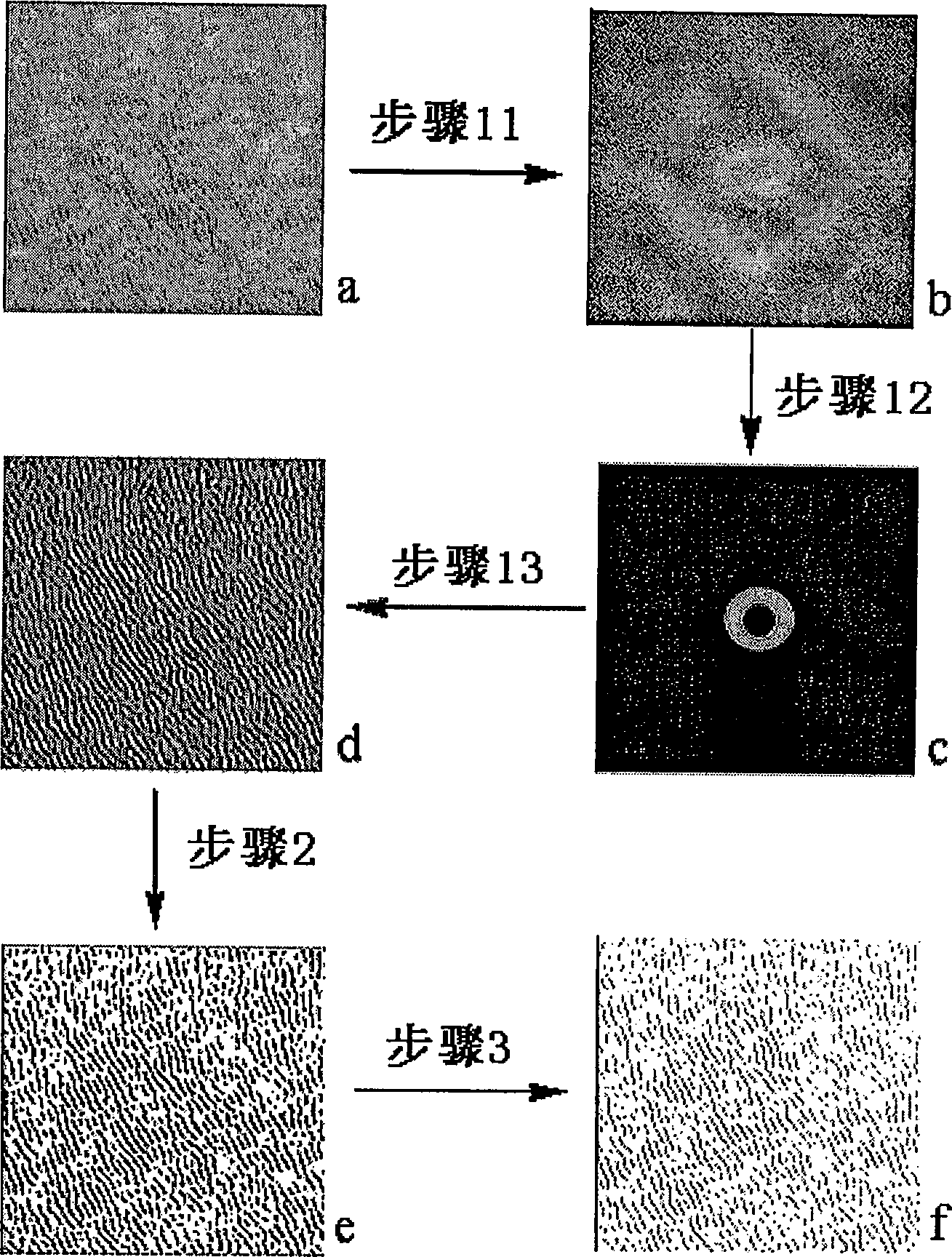

Method for processing images of transmissive electron microscope in high resolution for crystallite of coke

InactiveCN1873659AEasy to calculate lengthEasy to calculate the spacing of stripesCharacter and pattern recognitionElectricityFiltration

The invention discloses a method of dealing with coke microlite distinguish transmission electricity glass image, including the steps of: 1.imaging filtration, making two-dimensional fast Fourier to the primitive coke HRTEM picture, filtering frequency chart in range of certain frequency, again carrying on anti-fast Fourier to transform for the substantive chart; 2. imaging division, in 0-255 definite values, and filtering division substantive chart for the black and white two values chart. 3. Striping skeleton: Transforming stripe the in black and white two values chart into the single picture element stripe. This invention provides a method of processing the coke microlite high distinguishes the radio mirror picture, its may obtain the primitive coke HRTEM picture transformation the clear graphite microlite stripe chart, and may be directly used to calculate graphite microlite size and slice space parameter, and so on.

Owner:BAOSHAN IRON & STEEL CO LTD +1

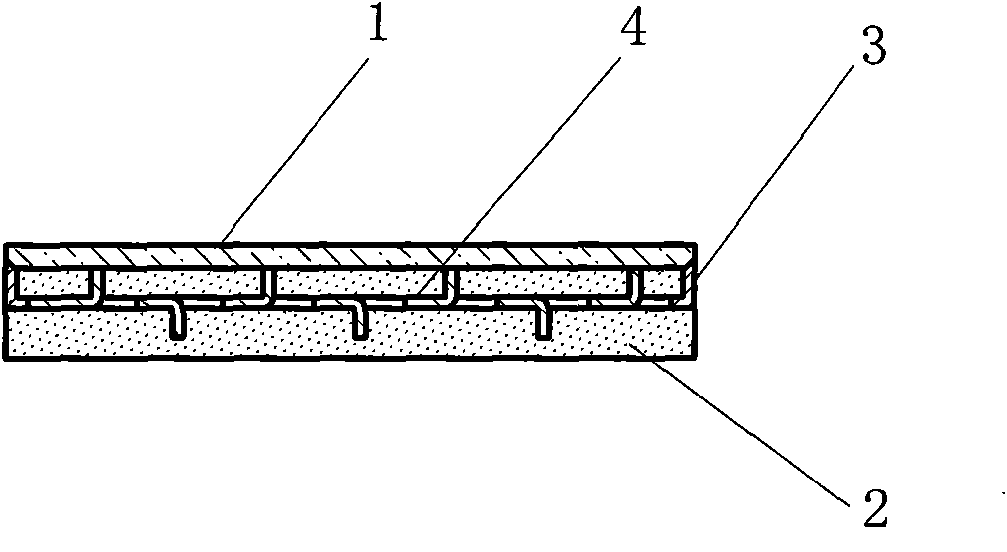

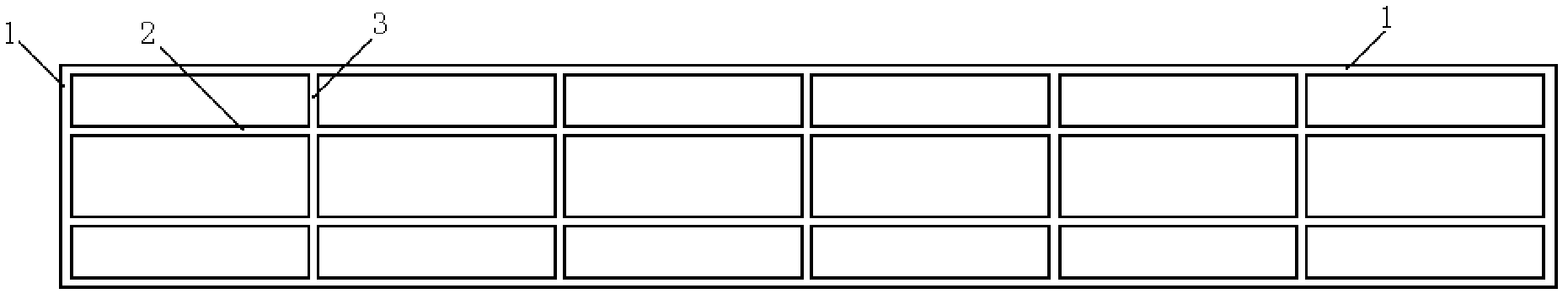

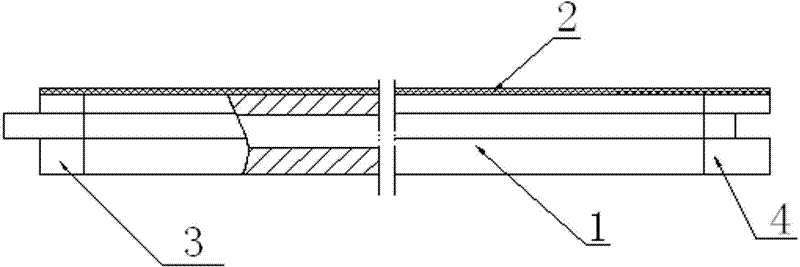

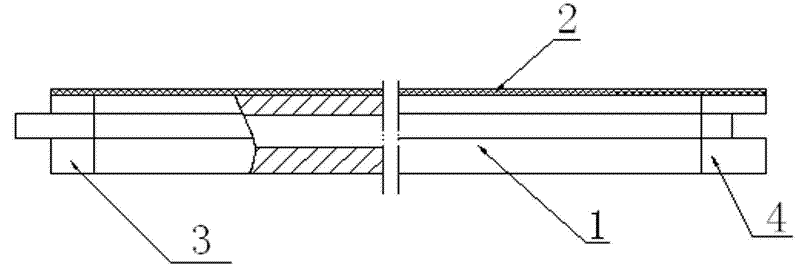

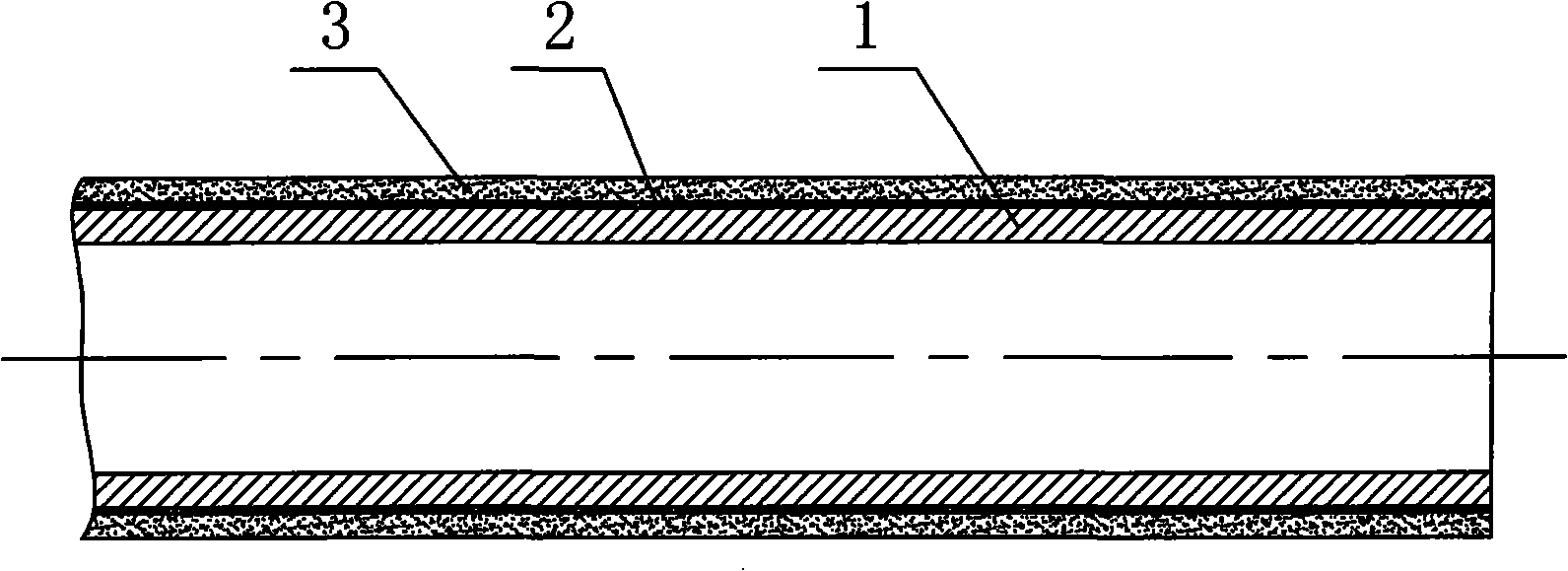

Microlite external wall fire-prevention and heat-preservation integral plate and microlite materials thereof

ActiveCN102628312AGuaranteed various advantagesSave resourcesCovering/liningsThermal insulationMicrolite

Disclosed are a microlite external wall fire-prevention and heat-preservation integral plate and microlite materials thereof. The plate is composed of outer ribs and inner ribs, wherein the outer ribs are four ribs surrounding four sides of the plate to form a rectangular section plate, the inner ribs are mounted inside the plate and comprise transverse ribs and at least five vertical ribs; the plate has a simple structure, convenient usage, a standard that reaches the state standard of fire-preventing and heat-preserving performances of external wall, and is a triune plate that can achieve decorating effect. As a high-tech product of comprehensive utilization of new technology and energy-saving resources of new materials, the integral plate serves as a new material possessing the properties of highly efficient flame retardance, safety, heat-preservation and thermal insulation, and is a revolution material in external wall decorating materials, and a creation material of accelerating the renovation and upgrade of traditional base material industry, and constructing regeneration and recycling of sources. The integral plate further has the advantages of convenient installation and maintenance, small occupied area, better environment-friendly effect, is easy to clean, and does not contain radioactive harmful substances.

Owner:深圳必图新型材料科技有限公司

Waterproof and fire-retardant floor and manufacturing method thereof

The invention provides a waterproof and fire-retardant floor and a manufacturing method thereof. The technical scheme is as follows: the waterproof and fire-retardant floor comprises a base plate and a surface layer compounded on the base plate, wherein the surface layer is an ultraviolet curing paint coating; and two ends of a base body with a hollow hole in a length direction are plugged by plugs to obtain the base plate. The base body is formed by compounding the following components in percentage by weight: 25-30% of PVC (Polyvinyl Chloride), 30-35% of wood meal, 30-35% of microlite powder and 3-6% of industrial chemicals; and the industrial chemicals is prepared by dioctyl-phthalate, stearic acid, paraffin wax, chlorinated polyethylene and dust-free compound lead salt stabilizer. The manufacturing method of the waterproof and fire-retardant floor comprises the following steps of: mixing the components; and hot-pressing, extruding and forming the mixture to obtain the base body; and then plugging the two ends of the base body along the length direction by the plugs to obtain the base plate; and finally, coating the ultraviolet curing paint on the upper surface of the base plate to obtain the waterproof and fire-retardant floor. The waterproof and fire-retardant floor and the manufacturing method thereof provided by the invention has the advantages of waterproof and fire-retardant effect and anti-skid performance.

Owner:SHIYAN FANGXIAN CHANGCHENG WOOD IND

Environment-friendly microlite building decoration plate and processing technology thereof

InactiveCN109129852ASolve the problem of not preventing insectsSolve the problem of mothproofCeramic shaping apparatusElectricitySizing

The invention discloses a processing technology of an environment-friendly microlite building decoration plate. The processing technology includes the following steps that firstly, a base material selecting process is conducted, wherein a high-fidelity fireproof base material is selected, performance detection is conducted, and a base material conforming to the decoration plate GB8624-2006 standard is selected; secondly, a base material preprocessing process is conducted, wherein the selected base material is preprocessed, and the surface of the base material is flat, smooth and compact; thirdly, a priming paint roll painting or spraying process is conducted, priming paint roll painting or spraying is conducted on the surface of the preprocessed base material, a transition layer is formed,and a linking effect between the base material and finish paint is achieved; fourthly, a transfer printing or printing process is conducted, the transfer printing or printing process is conducted onthe base material obtained after priming paint rolling painting or spraying, transfer printing or printing of simulation designs is conducted on the base material, and curing sizing is conducted; andfifthly, a postprocessing process is conducted, showering coating and laminating treatment are conducted on the base material, and the whole environment-friendly microlite building decoration plate processing technology process is completed. By means of the processing technology, a series of good characteristics of being light in body, soft in texture, porous, capable of insulating sound, resistant to heat, resistant to acid, large in specific area, stable in chemical property and the like of kieselguhr are utilized, a produced kieselguhr composite decoration plate has the beneficial effects that conductivity to sounds, heat and electricity is low, no formaldehyde exists, and water resistance and flame retardance are achieved; and meanwhile, the processing characteristics that nailing, sawing and planing can be conducted are achieved, and the processing technology can be widely used for household indoor and outdoor decoration.

Owner:高玉涛

Kyanite base composite paint and preparation method thereof

ActiveCN108746483AImprove fire resistanceHas low temperature plastic deformation propertiesFoundry mouldsFoundry coresCoesiteSillimanite

The invention belongs to the field of paint preparation, and in particular, relates to kyanite base composite paint and a preparation method thereof. The kyanite base composite paint comprises the rawmaterials of bauxite, kaolin, kyanite, andalusite, chromite, zircon sand, hematite, microlite and sillimanite. The preparation method of the kyanite base composite paint comprises the following steps: all the raw materials are crushed, are weighed in proportion to load into a bucket elevator, and are unloaded into a planet sand mixer for mixing, discharge and packing to obtain the kyanite base composite paint. The prepared paint is excellent in thixotropy and leveling property, and is free of gaps in coating layers.

Owner:李保珍

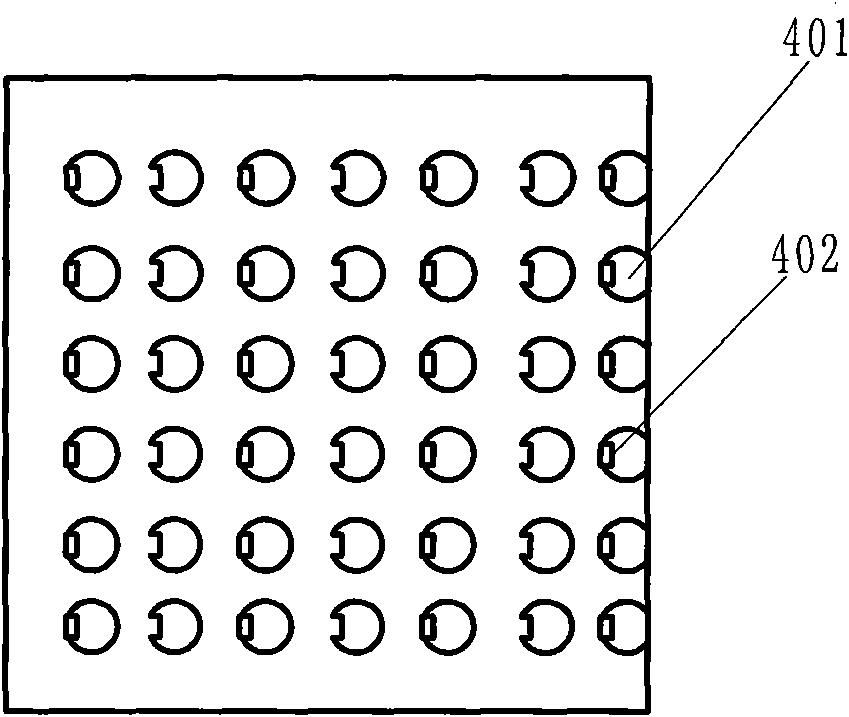

PVC (polyvinyl chloride) microlite foamed floor

The invention relates to the technical field of a chemical building material and particularly provides a PVC (polyvinyl chloride) microlite foamed floor. The PVC microlite foamed floor is formed by the following components by weight percent: 49.5% of PVC, 39.6% of microlite, 3.4% of stabilizing agent, 3.4% of foaming modifying agent, 0.7% of foaming agent, 0.6% of lubricating agent and 3.9% of a copolymer of styrene, acrylonitrile and methacrylic acid. The PVC microlite foamed floor has the beneficial effects that 1, a glue type binding agent cannot be used, no formaldehyde exists and fungus does not grow; 2, the water absorbing capacity is low, the floor is not deformed when being immersed in water for long time, the wear resistance is good and worms cannot grow, a solid wood floor is not waterproof, a sintered floor and a floor brick are not damp-proof and the solid wood floor is easily damaged by worms; 3, the floor does not contain heavy metals and can be recycled and reutilized, while the sintered floor, the solid wood floor and the floor brick basically cannot be recycled and reutilized; and 4, textures are beautiful, the elasticity is good, the floor is comfortable and wear-resisting and the density is moderate and is 0.8-1.0, while the density of the sintered floor, the floor brick, a stoned molded floor and the like is about 1.5-2.0, so that the weight of a high-rising building can be reduced and the transportation cost is reduced.

Owner:崔海明

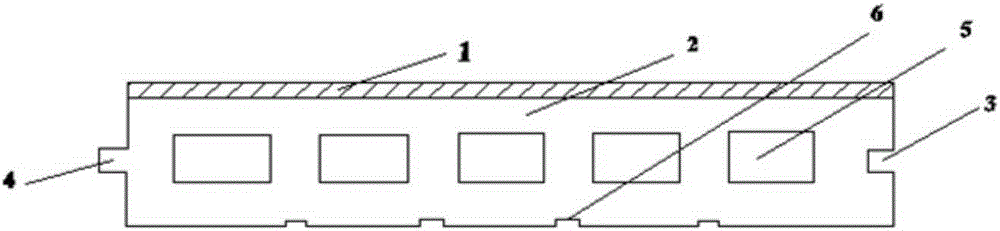

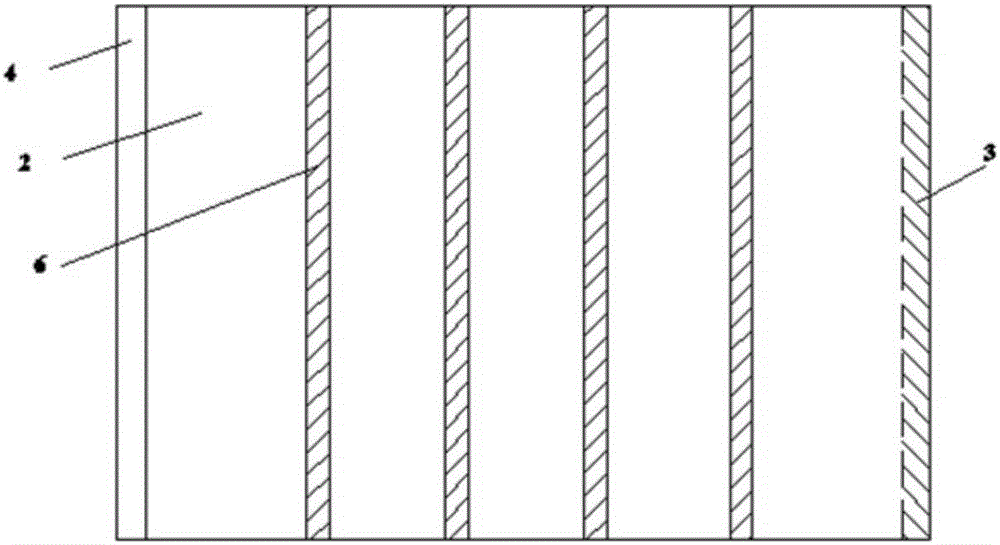

Microlite environment-friendly base material and multifunctional plate

ActiveCN105174815AWide variety of sourcesImprove anti-staticFlooringThermal insulationAntimony trioxide

The invention relates to a microlite environment-friendly base material and a multifunctional plate. The microlite environment-friendly base material is composed of the following components in percentage by weight: 30 to 60% of microlite powder, 8 to 20% of PVC resin, 4 to 10% of composite stabilizing agent, 1 to 10% of CPE, 1 to 10% of kaolin, 1 to 10% of fly ash, 1 to 5% of alumina, 1 to 10% of magnesium hydroxide, 1 to 5% of antimony (III) trioxide, 1 to 8% of stearic acid, 4 to 6% of DOP, 1 to 10% of antistatic powder, and 1 to 10% of aluminium triphosphate. The multifunctional plate comprises a base material layer containing the microlite environment-friendly base material. The microlite environment-friendly base material and multifunctional plate have the advantages of good antistatic effect and low apparent density. The multifunctional plate contains hollow channels, thus the multifunctional plate is beneficial for ventilation, moreover, the dampproof function and thermal insulation function of the multifunctional plate are good, the thermal conductivity coefficient is low, the heat transfer effect is good, the multifunctional plate also has the characteristics of antistatic function, dampproof function, corrosion resistance, ant resistance, good thermal insulation effect, and weathering resistance, and the product can be recovered and reutilized and has a wide application range.

Owner:深圳必图新型材料科技有限公司

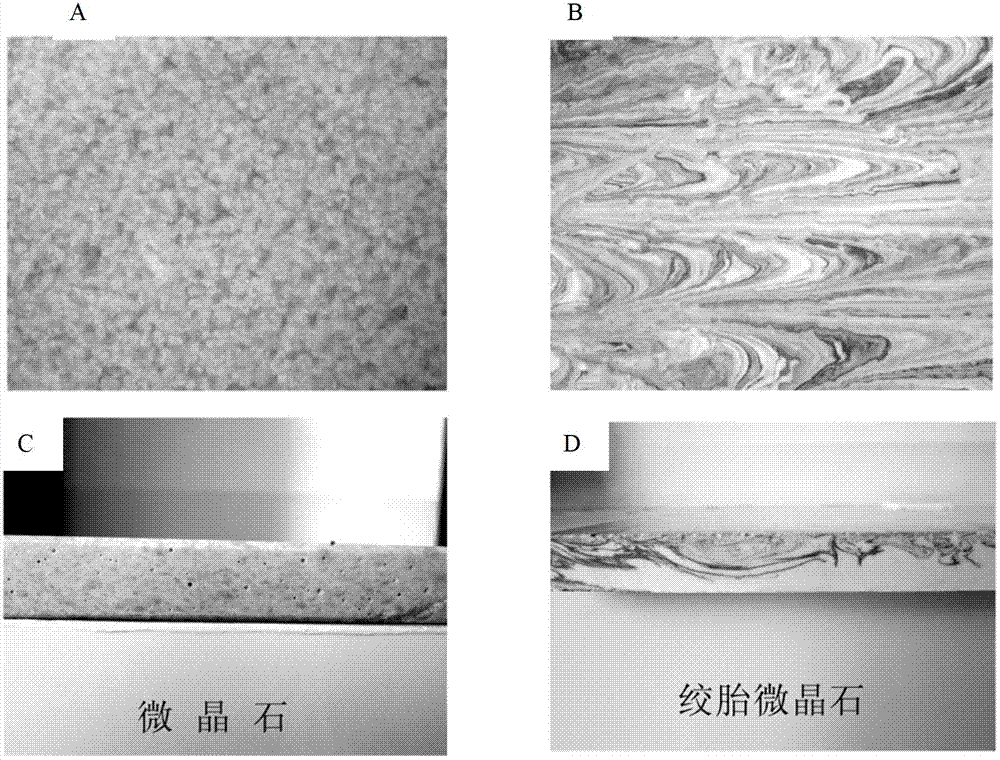

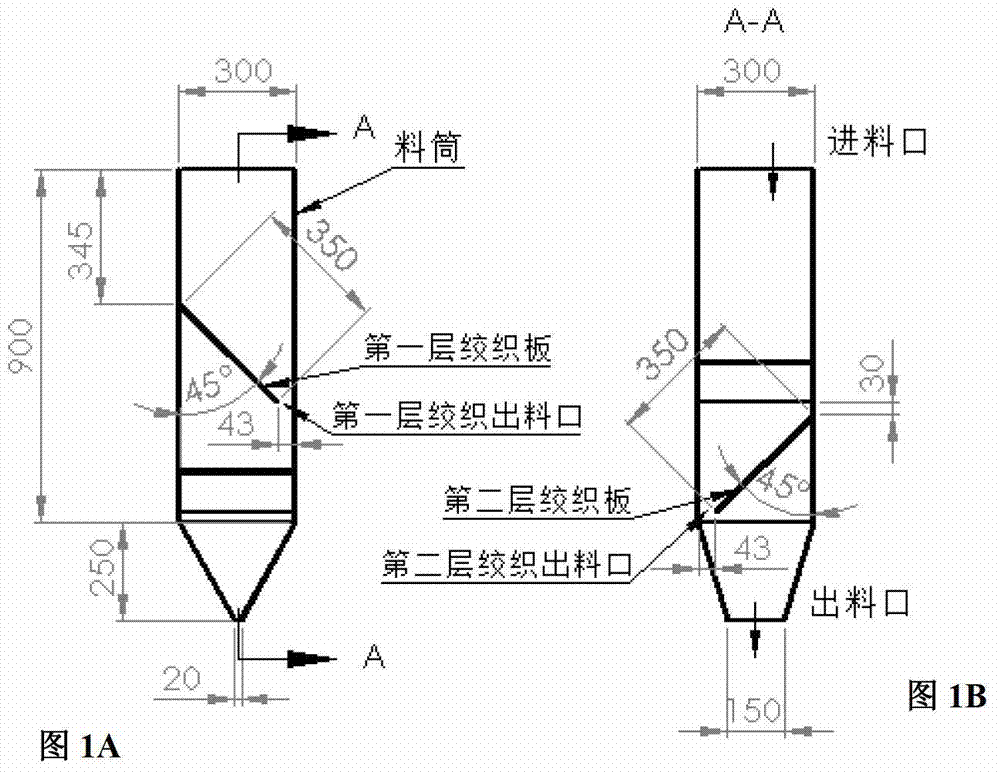

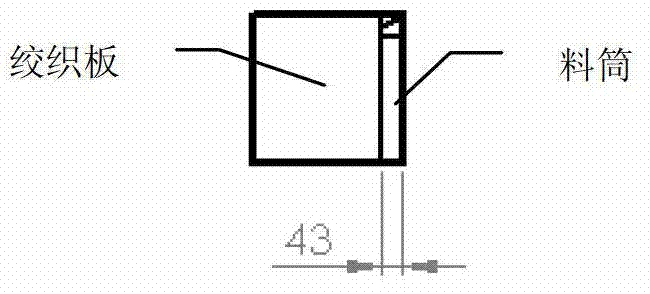

Microlite with twistable glaze, and production method and special-purpose equipment

ActiveCN103588418AExcellent physical and chemical propertiesImprove textureCeramic shaping apparatusAdvanced materialsMaterials science

The invention discloses microlite with twistable glaze, and a production method and special-purpose equipment, and belongs to the field of building ceramic materials. The new product microlite with twistable glaze is formed by combing Tang-dynasty twistable glaze idea and microlite by a special technology. The provided microlite with twistable glaze not only possesses through texture, and unique natural pattern and creative pattern which possess same outside and inside, but also keeps the original advantages of microlite, also pores on the surface of conventional microlite products and in the products are eliminated, so that the quality of microlite is substantially improved. The provided microlite product with twistable glaze not only can be used as a microlite sheet material with twistable glaze for walls, grounds, building and decoration, but also can become microlite board drawings as handicrafts, and further becomes a genuine advanced material in building decoration industry.

Owner:张桂兰 +1

Wear-resistant microlite ceramic tile

The invention discloses a wear-resistant microlite ceramic tile, which relates to the technical field of building material processing. A sheet material comprises the following ingredients by weight part: 55-65 parts of silicon dioxide, 8-10 parts of calcium oxide, 5-8 parts of zinc oxide, 6-8 parts of alumina, 4-5 parts of ferric oxide, 8-10 parts of calcium carbonate, 3-4 parts of barium carbonate, 2-3 parts of sodium hydroxide, and 0.8-1.2 parts of titanium dioxide; a layer of membrane is arranged on the sheet material, and the membrane raw material comprises 90-95% of poly tetrachloroethylene. Compared with prior art, problem of poor wear resistance of the surface of the current microlite can be solved.

Owner:LIUZHOU PUYA TRADE

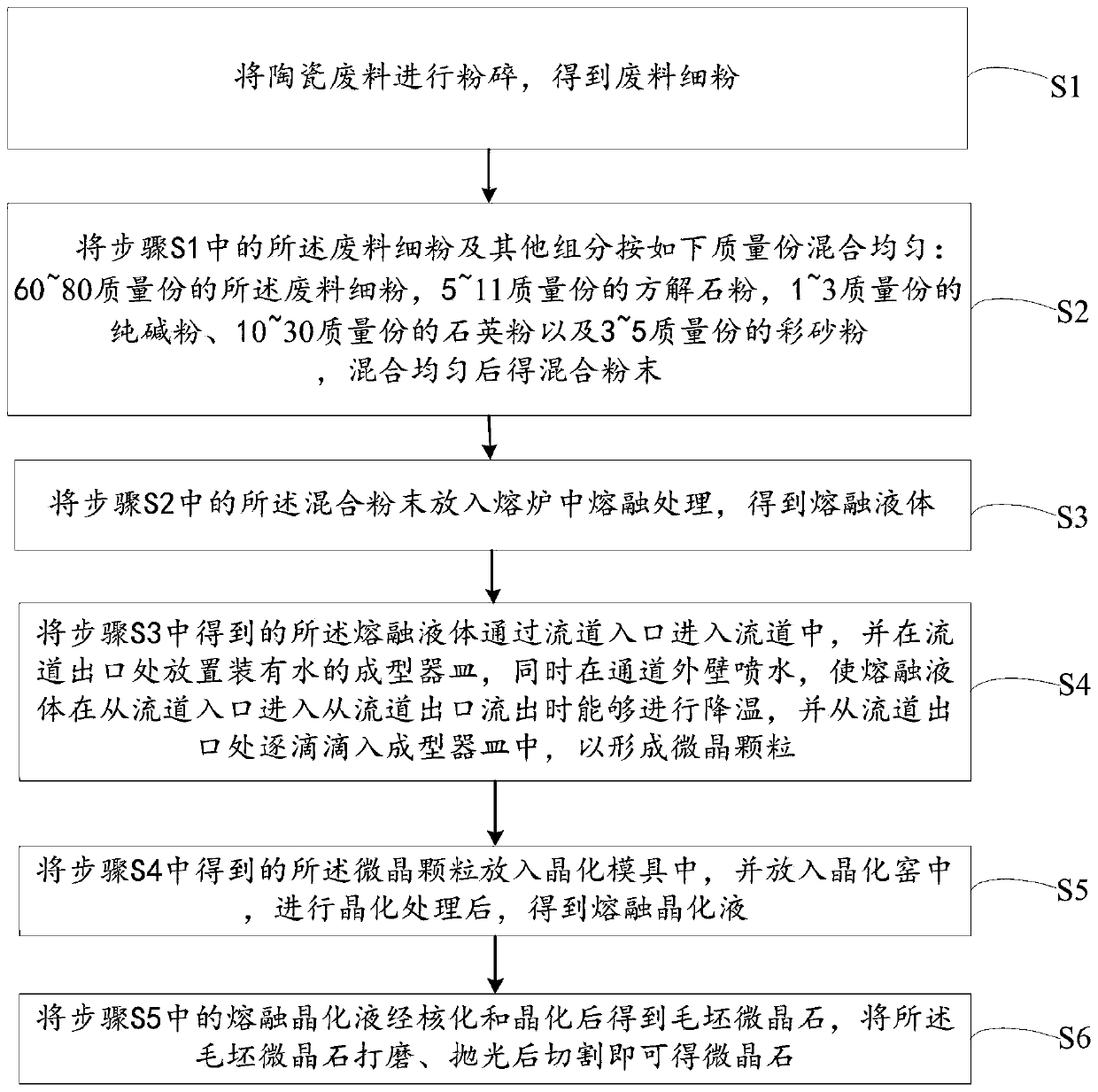

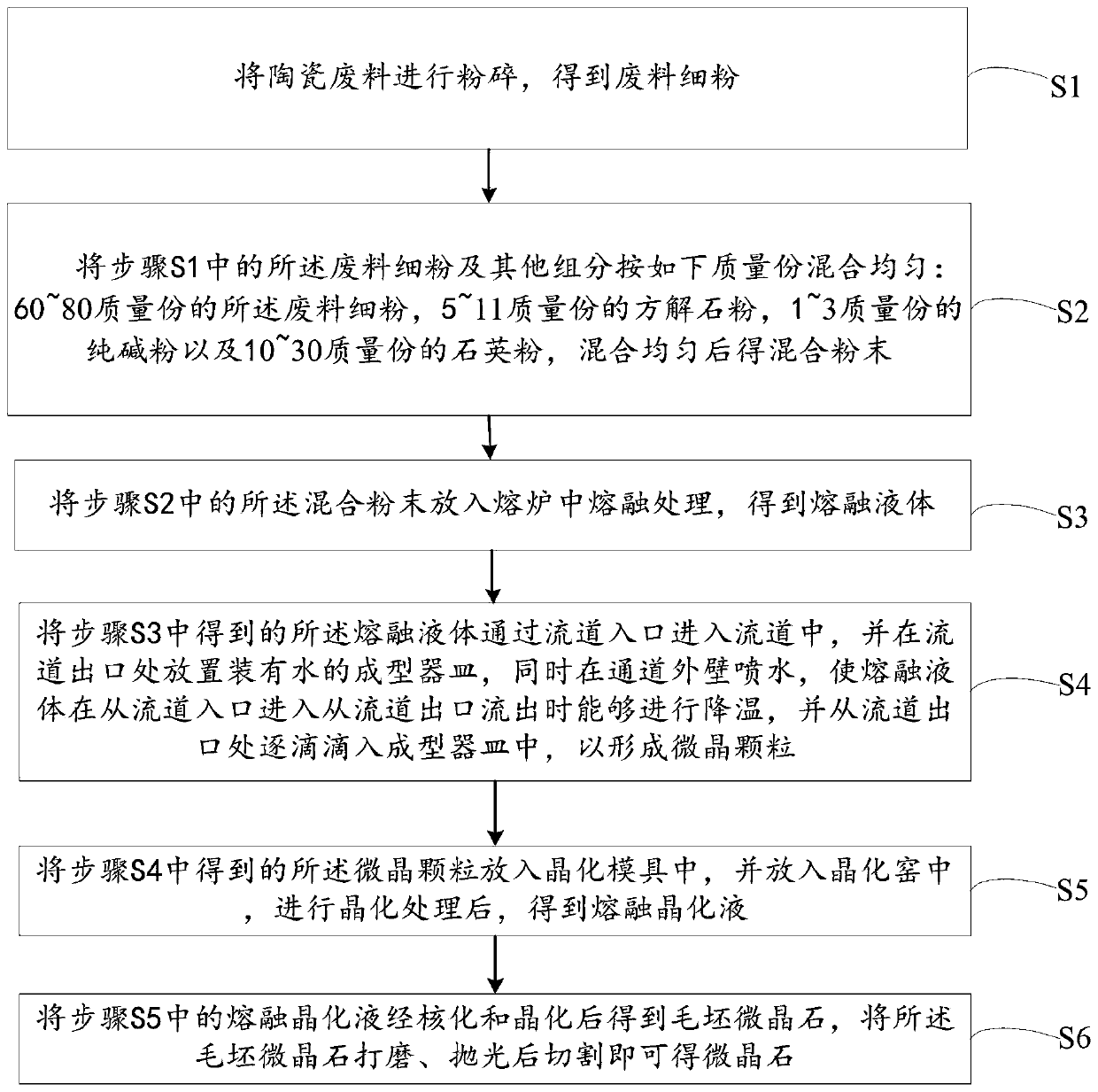

Method for preparing microlite from ceramic waste and microlite

The invention discloses a method for preparing microlite from ceramic waste and the microlite, which comprises the following steps: pulverizing the ceramic waste to obtain waste fine powder; uniformlymixing the waste fine powder and other components in parts by mass as follows: 60-80 parts of the waste fine powder, 5-11 parts of calcite powder, 1-3 parts of soda ash powder, 10-30 parts of quartzpowder and 3-5 parts of colored sand powder to obtain mixed powder. According to the microlite provided by the invention, the ceramic tailings, calcite, soda ash and quartz powder are adopted to prepare the microlite; according to the method, the potassium element, the calcium element, the aluminum element and the silicon element in the ceramic tailings can be utilized to prepare the microlite, the ceramic tailings can be recycled, the environment is protected while the waste is utilized, and the microlite prepared by adopting the method is high in whiteness and planeness.

Owner:江西飞宇新能源科技有限公司

Environment-friendly wood-plastic composite floorboard

The invention relates to an environment-friendly wood-plastic composite floorboard which is prepared from the following raw materials in parts by weight: 22-36 parts of regenerated PP, 12-18 parts of microlite, 1.2-2 parts of lubricant, 2-3 parts of antioxidant, 6-9 parts of isooctyl tin dimethyldithioglycolate, 4-8 parts of paraffin, 30-40 parts of polyvinyl chloride resin, 7-12 parts of paraffin, 35-56 parts of waste plant fiber, 0.4-0.7 part of acrylate copolymer 2-3.6 parts of acrylate foaming regulator, 0.3-0.6 part of modifier, 4-12 parts of heat-conducting filler, 3-7 parts of color paste and 4-6 parts of barium stearate. The environment-friendly wood-plastic composite floorboard has the advantages of favorable ultraviolet stability, favorable stainability, high environment friendliness and no pollution, can not be easily eaten by worms, and can be recycled.

Owner:青岛特澳能源检测有限公司

Microlite alumina ceramic belt roller barrel and processing method therefor

InactiveCN101274705AImprove wear resistanceImprove vibration resistanceRollersAdhesiveFlexural strength

The invention relates to a fine alumina ceramic belt supporting roller cylinder and a processing method thereof. The fine alumina ceramic belt supporting roller cylinder comprises a steel tube which is externally and fixedly sheathed with a fine alumina ceramic tube, the steel tube and the ceramic tube are installed coaxially and the clearance between the steel tube and the ceramic tube is 1 to 1.6mm and is filled with an adhesive fixing layer. The thickness of the ceramic tube is 5 to 8mm, and the clearance between the steel tube and the ceramic tube is 1.5mm, namely, the thickness of the adhesive layer is 1.5mm. The processing method of the cylinder comprises the steps that firstly the outer surface of the steel tube is coated with a special adhesive and then the ceramic tube is sheathed on the steel tube, and the steel tube and the ceramic tube are adjusted to be basically coaxial and finally cured naturally. The technical proposal of the fine alumina ceramic belt supporting roller cylinder with high wear resistance, good vibration resistance, high bending strength and long service life adopts the perfect combination of the steel tube and the ceramic tube, thus effectively overcoming the defects and the deficiency of the existing single steel tube and ceramic tube and having simple processing method and easy execution and operation.

Owner:ZOUPING COUNTY HUAXING HEAT ENERGY ENVIRONMENT PROTECTION EQUIP

Method for preparing microlite from ceramic waste and microlite

The invention discloses a method for preparing microlite from ceramic waste and the microlite, and the method comprises the following steps: pulverizing the ceramic waste to obtain waste fine powder;and uniformly mixing the waste fine powder and other components in parts by mass: 60-80 parts of the waste fine powder, 5-11 parts of calcite powder, 1-3 parts of soda ash powder and 10-30 parts of quartz powder to obtain mixed powder. According to the microlite provided by the invention, the ceramic tailings, calcite, soda ash and quartz powder are adopted to prepare the microlite; according to the method, the potassium element, the calcium element, the aluminum element and the silicon element in ceramic tailings can be utilized to prepare the microlite, the ceramic tailings can be recycled,the environment is protected while the waste is utilized, and the microlite prepared by adopting the method is high in whiteness and planeness.

Owner:江西飞宇新能源科技有限公司

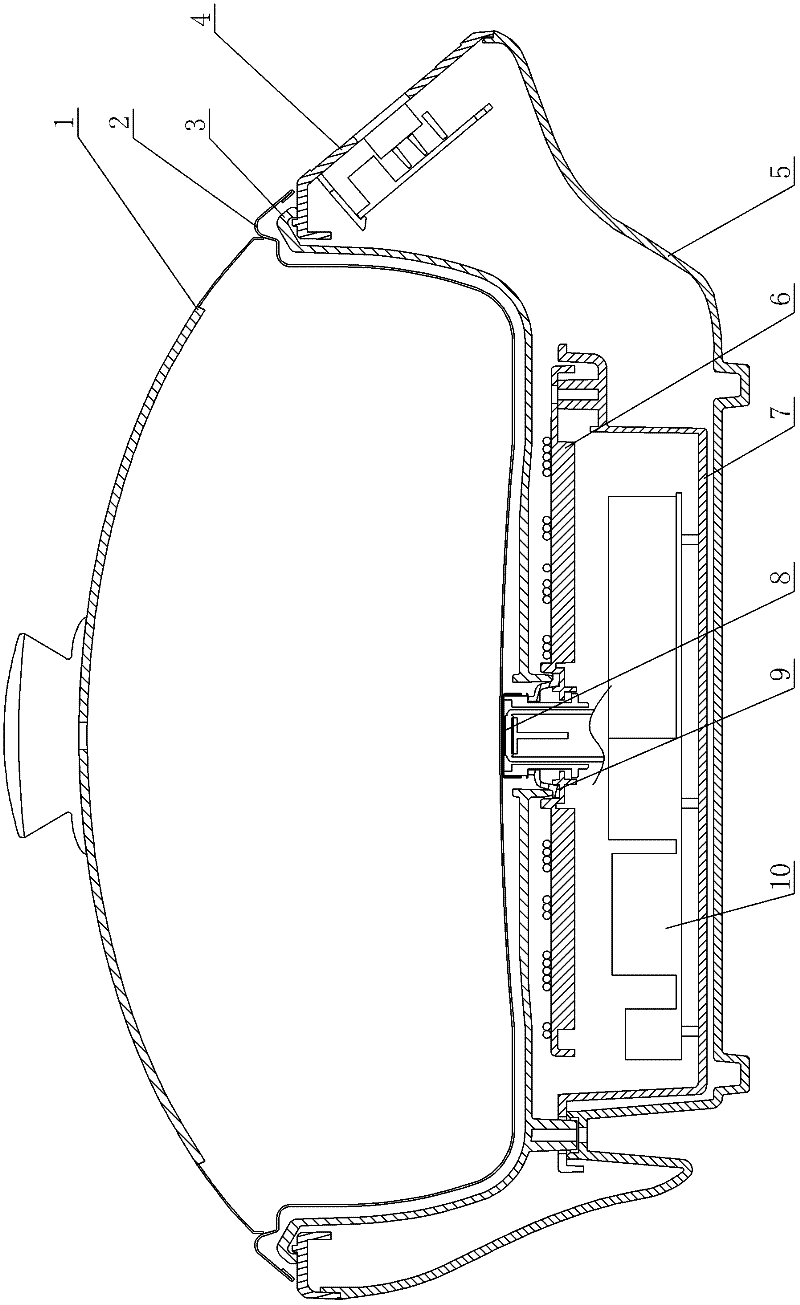

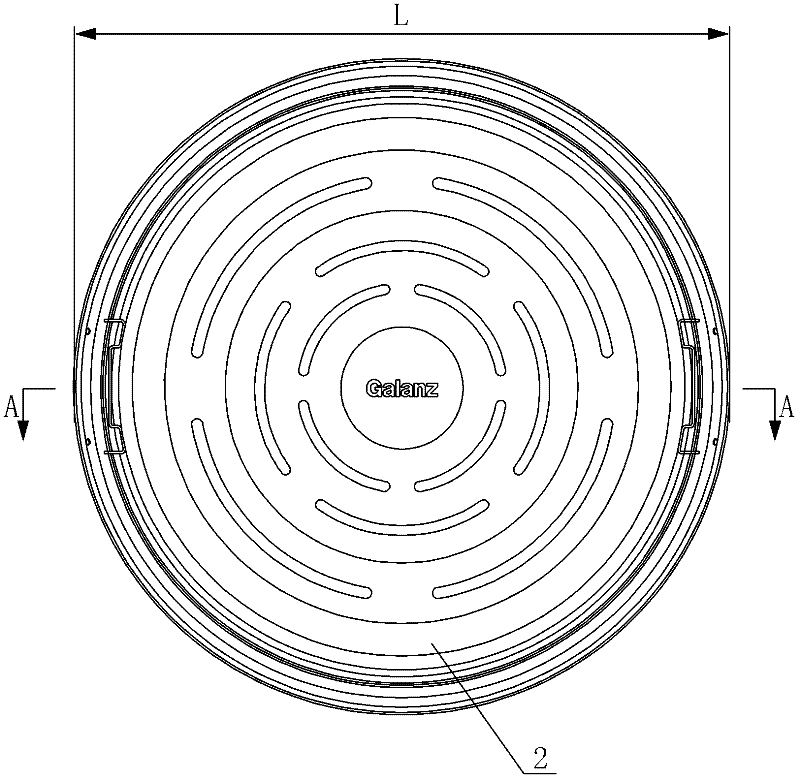

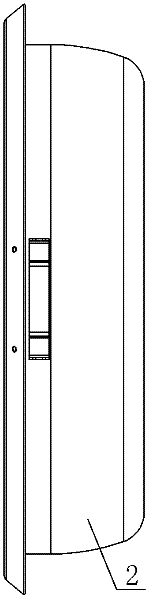

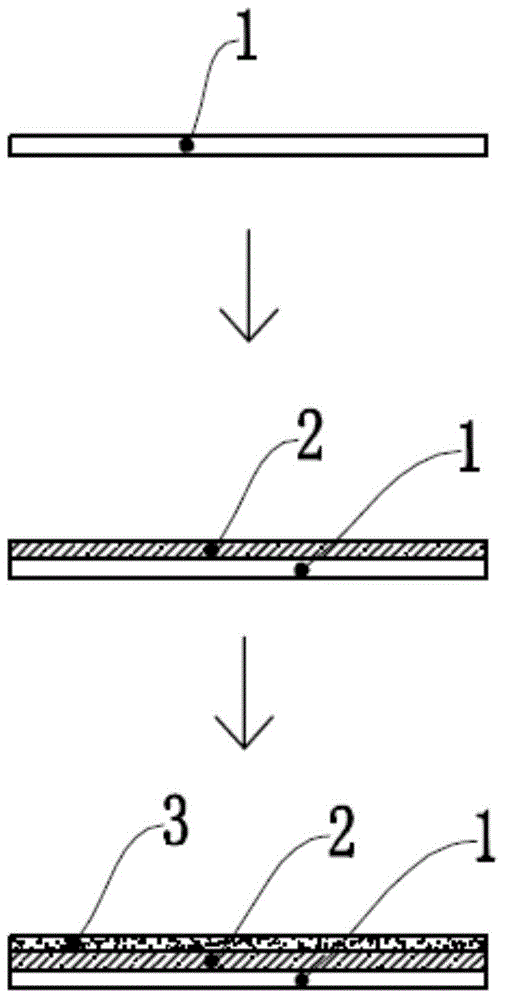

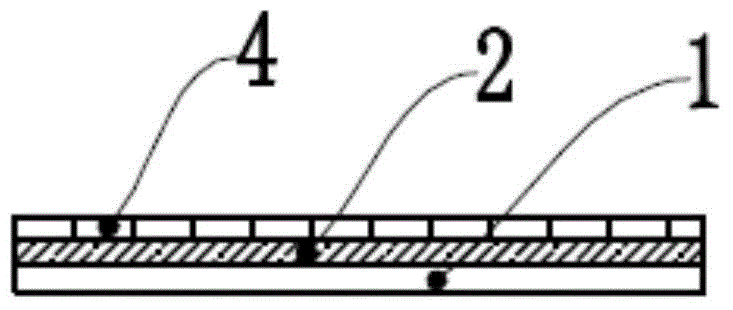

Electromagnetic oven without microlite board

InactiveCN102410563ATo keep warmPositioningDomestic stoves or rangesLighting and heating apparatusTemperature controlThermal insulation

The invention relates to an electromagnetic oven without a microlite board. The electromagnetic oven comprises a base and a control panel, wherein a thermal-insulation cover is arranged on the base, and a certain distance is reserved between the thermal-insulation cover and the base, thereby together forming an electrical apparatus assembly cavity; a pan lining assembly is arranged at the concave of the thermal-insulation cover; and the pan lining assembly is hung at the outer edge of the thermal-insulation cover. Compared with the prior art, the electromagnetic oven provided by the invention has the following beneficial effects: 1) the thermal-insulation cover is additionally arranged on the base and used for replacing the microlite board, so as to reduce the cost, and the thermal-insulation cover can play roles in thermal insulation and effective positioning of the pan lining assembly, thereby solving the problems that the electromagnetic oven in the prior art has a poor cooking effect, the pan lining assembly is easily moved during operation, and the like; and 2) by means of a spring, a sensor penetrates through the central hole of the thermal-insulation cover, abuts against the lower part of a pan lining, and directly induces the internal temperature of the pan lining, thus accurate temperature control is realized, and the competitiveness of the product in the market is realized, and the electromagnetic oven without the microlite board has the characteristics of simple and reasonable structure, high heat utilization efficiency, long service life and convenience for processing and manufacturing.

Owner:GUANGDONG GALANZ GRP CO LTD

A kind of adobe fired into a glass-ceramic composite board at one time

ActiveCN104250116BSolve the problem of being easily sucked awayColor effects do not existBrickAdhesive

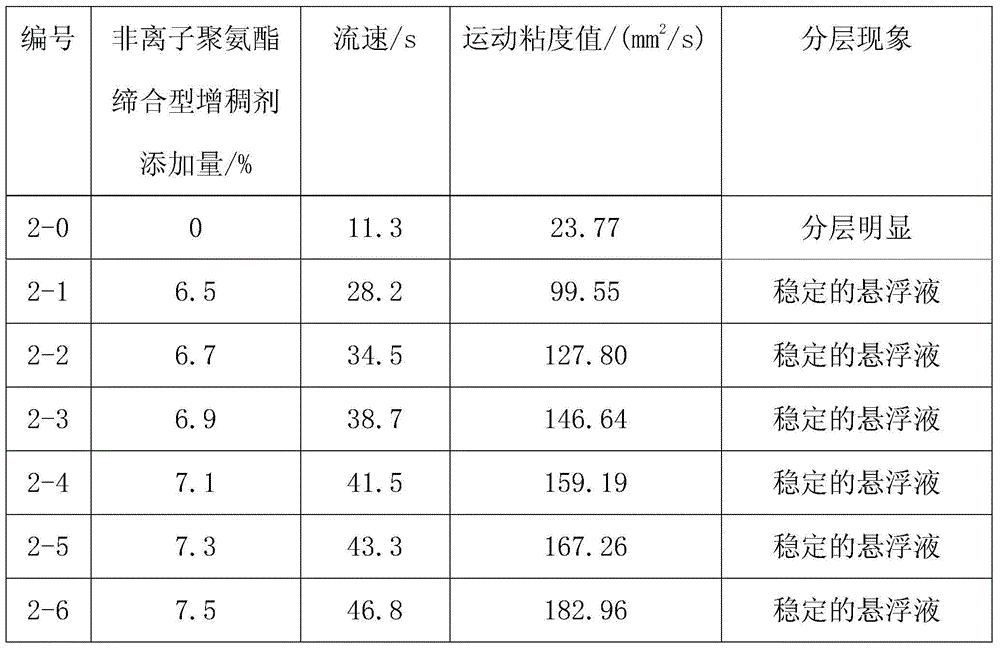

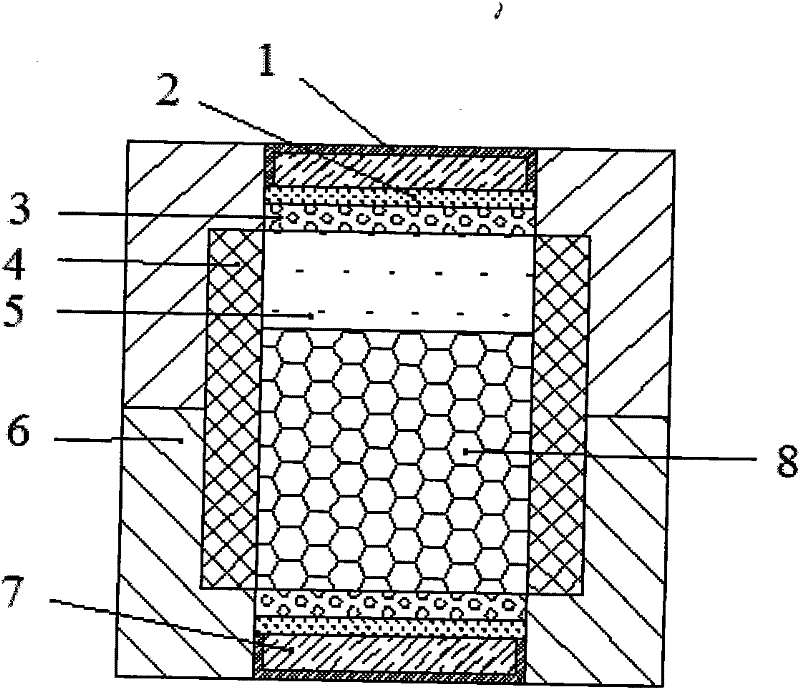

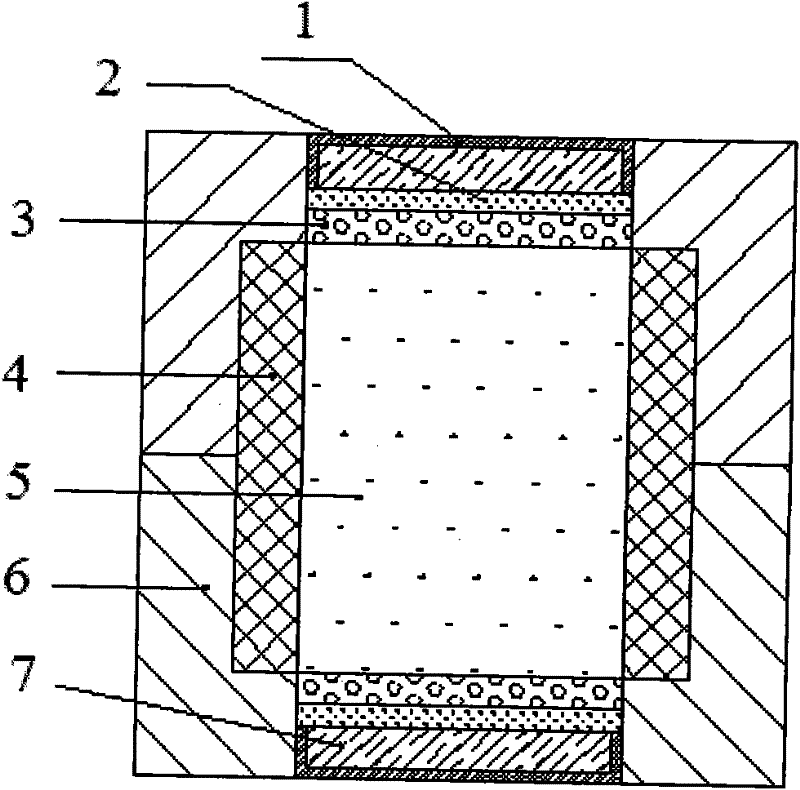

The invention relates to a green brick of a monofired glass ceramic composite plate. The green brick comprises a green body layer, a ground glaze layer and a glass ceramic frit layer from bottom to top, wherein the glass ceramic frit layer is formed in the way that microlite frit particle suspension liquid formed by mixing the glass ceramic frit particles and a frit particle adhesive is applied to the surface of the ground glaze layer; the frit particle adhesive comprises the following components by mass percent: 6.5-7.5 percent of a nonionic polyurethane associative thickener, 3.2-4.4 percent of silica, 1-1.5 percent of a defoamer, 0.3-1.3 percent of a dispersant and the balance of a solvent. The glass ceramic frit particles of the surface of the green brick structure are not taken away by a blower at a preheating zone during firing, so that waste is avoided and the defect rate of the glass ceramic composite plate product is reduced.

Owner:张家港和智珅知识产权有限公司

Cubic boron nitride/ titanium carbide compound sintered cutter material and preparation method thereof

The invention relates to a cubic boron nitride / titanium carbide compound sintered cutter material. The cutter material is mainly prepared by sintering the following raw materials in part by weight: 40 to 70 parts of cubic boron nitride microlite with the granularity between 1 and 20 mu m, 30 to 50 parts of titanium carbide microlite with the granularity between 1 and 4 mu m, 0.05 to 0.5 part of silicon powder with the granularity between 1 and 3 mu m, 0.05 to 0.5 part of carbon powder with the granularity of 300 meshes, 0.1 to 2 parts of tungsten carbide powder with the granularity between 1and 3 mu m, and 1 to 10 parts of aluminum powder with the granularity between 2 and 10 mu m. The hardness of the cutter material is HV 5,500 to 6,500, and the bending strength is 1,000 to 1,500 Mpa. Cutters made of the cutter material are applied to machining gears after quenching, and can be used under the condition that the on-line velocity is 300m, the machining efficiency of the cutters is more than 1.5 times that of the conventional cutters, and the service life is more than 2 times that of the conventional cutters.

Owner:ZHENGZHOU BERLT HARD MATERIALS

A kind of wet blasting material for pump body casting processing doped with nano crystallite

The invention discloses a nanometer microlite doped wet blasting sand material for pump body casting processing, and relates to the technical field of wet blasting processing. The nanometer microlite doped wet blasting sand material is prepared from, by weight, 90-100 parts of quartz sand, 15-20 parts of bentonite, 5-8 parts of nanometer microlite powder, 12-15 parts of river sand, 8-11 parts of alumdum, 5-8 parts of putty powder, 3-5 parts of cement, 1-2 parts of aminohexadecane, 0.5-1 part of water glass, 0.2-0.5 parts of zinc carbonate, 25-30 parts of ethanol and 280-300 parts of water. Bentonite is modified by the nanometer microlite, so improvement of comprehensive performances of the sand material is benefited; and the prepared sand material can be directly used in wet blasting treatment of a pump body casting, so the roughness of the casting surface is reduced, scales, rusts, oil stains and other impurities on the surface are removed, and subsequent coating spraying and pump assembling are benefited.

Owner:SANLIAN PUMP IND CO LTD

Metal wire microlite tile

The invention discloses a metal wire microcrystalline stone tile, which comprises a layer of microcrystalline stone tile body, and the raw materials of the microcrystalline stone tile body include the following components in parts by weight: 60-70 parts of silicon dioxide, carbonic acid 16 to 20 parts of calcium, 6 to 10 parts of calcium oxide, 3 to 4 parts of zinc oxide, 2 to 3 parts of barium carbonate, 2 to 3 parts of boron oxide, and 0.04 parts of silver wire; Apparently, there is at least one silver wire in the microcrystalline stone tile body. Compared with the prior art, the present invention can solve the problems that the existing microcrystalline stone tiles have single pattern, no sense of metal wire, and not three-dimensional enough.

Owner:王桂生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com