Patents

Literature

907results about How to "Strong hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

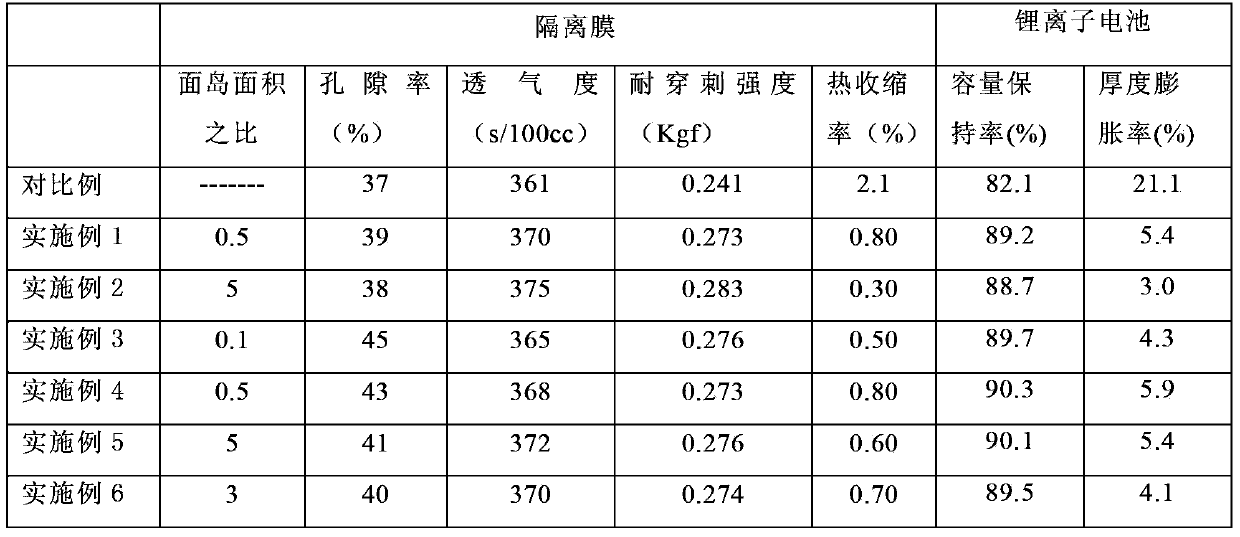

Organic/inorganic composite porous isolating membrane, preparation method thereof and electrochemical device

ActiveCN103441230AImprove breathabilityImprove conductivityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersPorous coatingInorganic particle

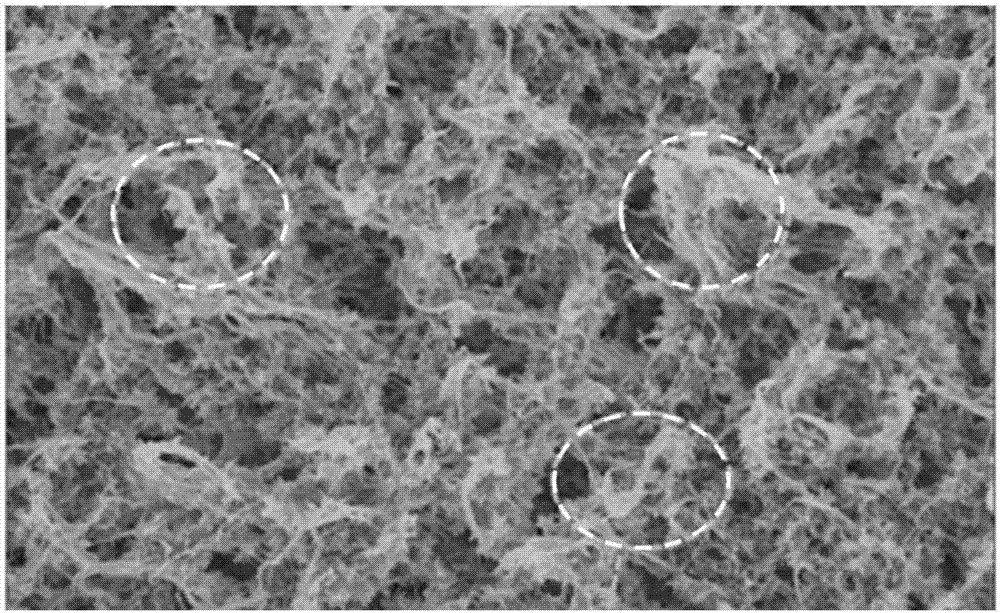

The invention provides an organic / inorganic composite porous isolating membrane, a preparation method thereof and an electrochemical device. According to the first aspect of the invention, the organic / inorganic composite porous isolating membrane comprises a porous base material and an organic / inorganic composite porous coating coated on at least one surface of the porous base material, wherein the organic / inorganic composite porous coating comprises inorganic particles, a binding agent and organic particles with at least two swelling degrees, and the organic particles are swelled by a plasticizer. The preparation method of the organic / inorganic composite porous isolating membrane is used for preparing the organic / inorganic composite porous isolating membrane described in the first aspect of the invention. According to the third aspect of the invention, the electrochemical device comprises the organic / inorganic composite porous isolating membrane described in the first aspect of the invention. Therefore, the organic / inorganic composite porous isolating membrane can form an excellent interface, so that a risk that the risk of blocking holes by the organic particles is reduced, breathability of the organic / inorganic composite porous isolating membrane is improved, and electrical conductivity of the organic / inorganic composite porous isolating membrane is improved.

Owner:DONGGUAN AMPEREX TECH +1

Chromium-free zinc aluminum anticorrosive paint and preparation method

InactiveCN101899254AReduce microcracksImprove adhesionAnti-corrosive paintsEpoxy resin coatingsChromium freeOrganic solvent

The invention relates to a chromium-free zinc aluminum anticorrosive paint and a preparation method. The invention adopts the technical scheme that the preparation method comprises the following steps of: stirring 5 to 25 weight percent of flake zinc powder and 5 to 15 weight percent of flake aluminum powder uniformly, adding 25 to 40 weight percent of organic solvent, 1.1 to 1.8 weight percent of dispersant, 3 to 8 weight percent of corrosion inhibitor and 3 to 10 weight percent of inorganic additive into the powder, and stirring the mixture for 20 to 40 minutes to form a base material; and then stirring 5 to 15 weight percent of modified resin, 1 to 3 weight percent of organic silane coupling agent and 25 to 30 weight percent of organic solvent uniformly, and adding the mixture into the base material; or stirring the mixture for 30 to 50 minutes to obtain the chromium-free zinc aluminum anticorrosive paint; or stirring the mixture for 30 to 50 minutes, adding 0.05 to 0.5 weight percent of hydroxyethyl cellulose into the mixture, and stirring the mixture for 20 to 50 minutes to obtain the chromium-free zinc aluminum anticorrosive paint. The preparation method has the characteristics of environment friendliness, low energy consumption and low cost; and a coating coated by the prepared chromium-free zinc aluminum anticorrosive paint has high impact strength, good corrosion resistance, strong bonding force and high hardness.

Owner:襄阳普士利工程器材有限公司 +1

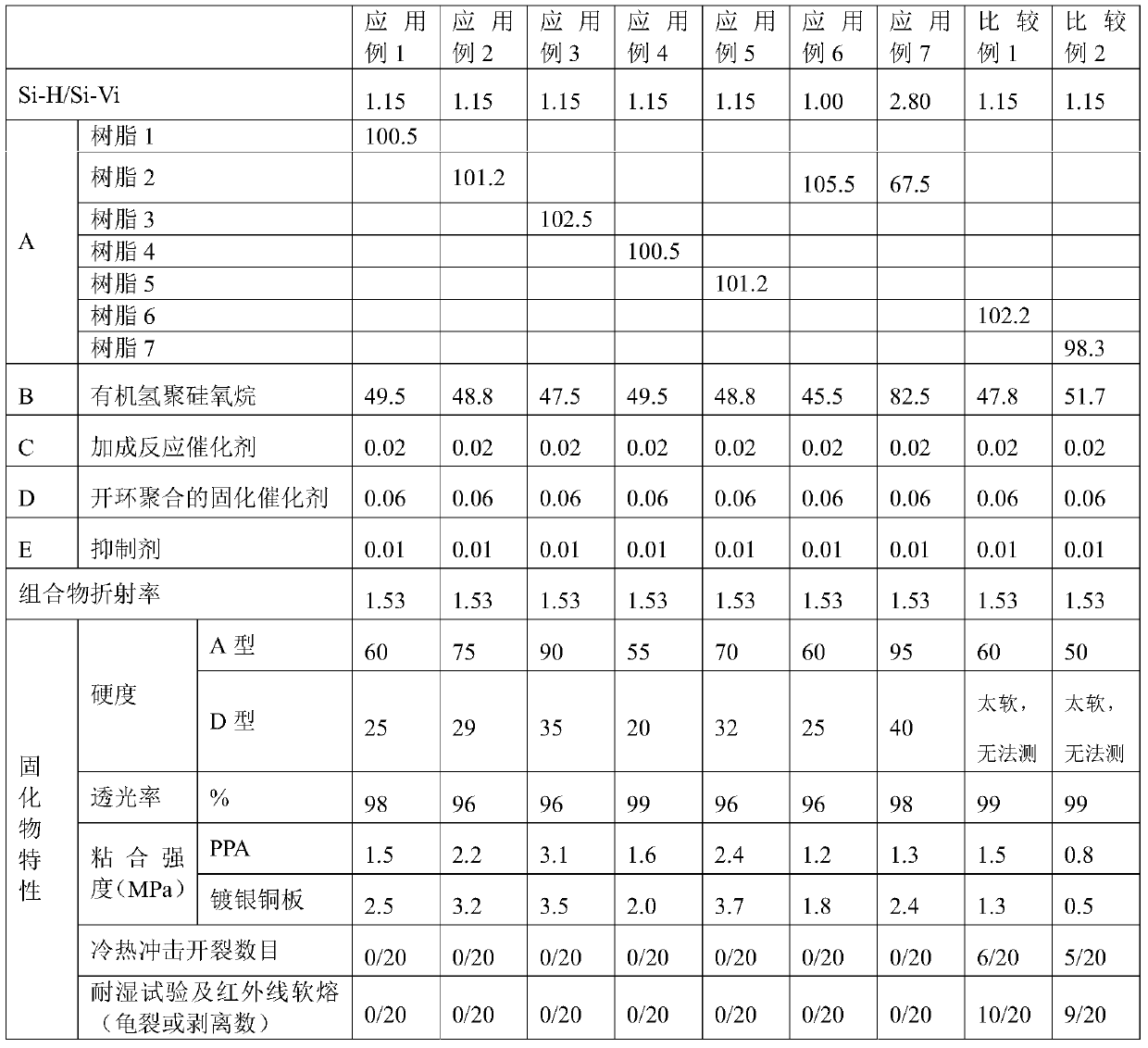

Organic silicone resin, curable organopolysiloxane composition and application

The invention discloses an organic silicone resin, a curable organopolysiloxane composition and an application. A structural formula of the organic silicone resin is shown as formula I. The curable organopolysiloxane composition is obtained by mixing the organic silicone resin with an organic silicone compound having at least two hydrogen atoms bonded with a silicone atom in one molecule. The curable organopolysiloxane composition can be applied on luminescent semiconductor package. The curable organopolysiloxane composition has the following advantages of excellent adhesive property, relatively strong hardness, excellent impact resistance, high transparency, little color change in a heat resistance test and high luminescent efficiency. Besides, the curable organopolysiloxane composition is not easy to peel off in a thermal shock test and presents excellent adhesive power in adhesive experiments with PPA and metal. The formula I is R1R22SiO(R3SiO3 / 2)a(SiO4 / 2)b(R42SiO)cOSiR22R1.

Owner:GUANGZHOU HUMAN CHEM

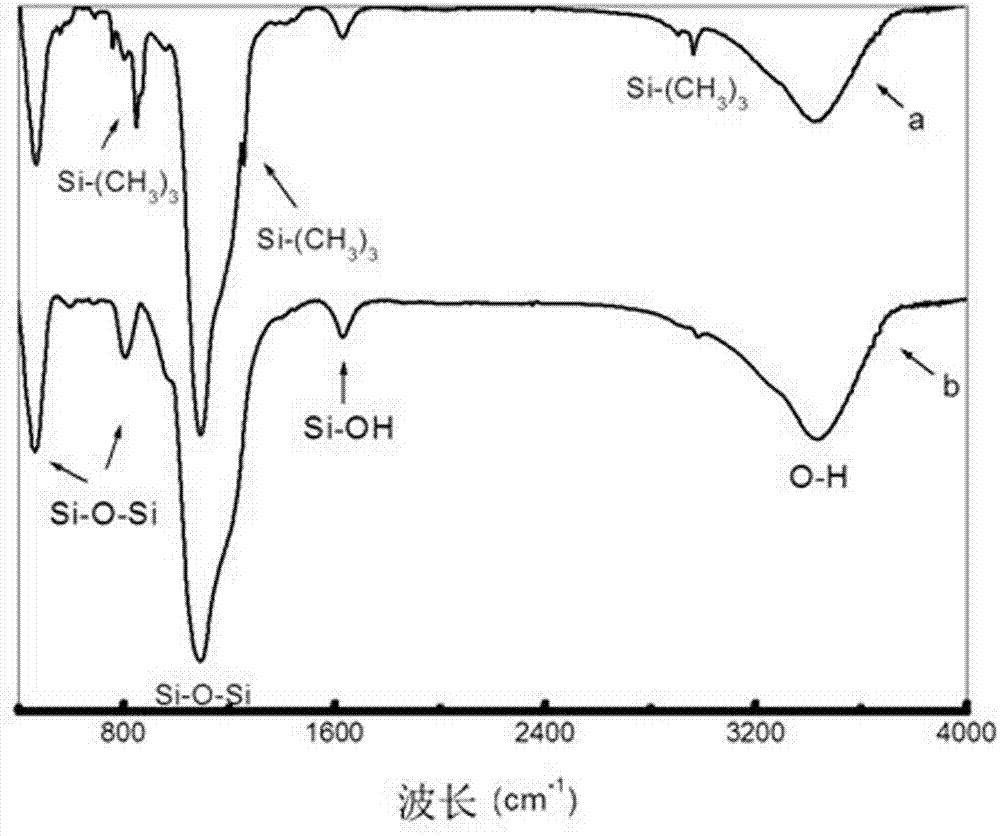

Heat-resisting silica aerogel material and preparation method thereof

The invention relates to a heat-resisting silica aerogel material and a preparation method thereof. SiO2 sol is prepared by adopting a sol-gel method, modified liquid is innovatively led to a supercritical drying process by ageing and solvent replacement through adopting a supercritical modification process, so as to obtain bulk aerogel which is high in mechanical strength and easy to process, and then the SiO2 aerogel of which linear contraction just is 5%, and the specific surface area can be up to 530m<2> / g after high-temperature treatment at 1000 DEG C can be obtained by high-temperature pretreatment at 800 DEG C and gas-phase modification of hexamethyldisilazane. By adopting the synthetic method, application of the SiO2 aerogel in high-temperature fields such as high-temperature catalysis, a catalyst carrier and high-temperature heat preservation and insulation is greatly facilitated.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

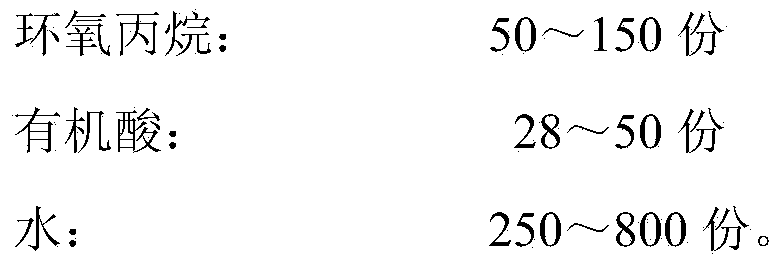

Water paint

ActiveCN102757710AFull play hardStrong hardnessAntifouling/underwater paintsPaints with biocidesEmulsionHardness

The invention discloses water paint. The water paint comprises following components in parts by weight: 70-150 parts of white cement, 5-15 parts of titanium dioxide, 30-70 parts of an urushiol-based emulsifier and 70-110 parts of urushiol formaldehyde condensation polymer emulsion. The water paint, disclosed by the invention, is added with raw lacquer, so that the advantages of the hard, bright, wear-resisting, heat-resisting and corrosion-resisting film formed by the raw lacquer are brought into full play; as the urushiol-based emulsifier is added in a matching manner to emulsify the raw lacquer, so that good compatibility of the raw lacquer can be guaranteed and formation of a compact and rigid interfacial film is facilitated; and as the urushiol-based emulsifier can participate in a film-forming reaction of the raw lacquer, adverse influences from a traditional emulsifier to film coating performances are avoided, and extremely strong hardness is obtained.

Owner:ANHUI JINDUN PAINT

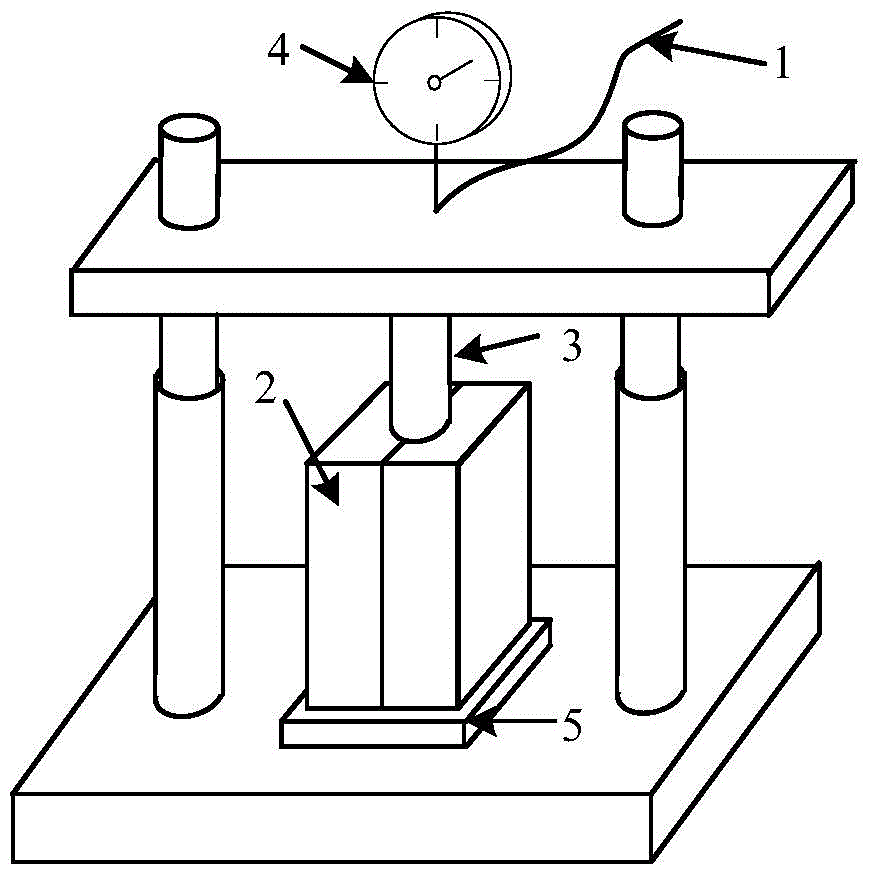

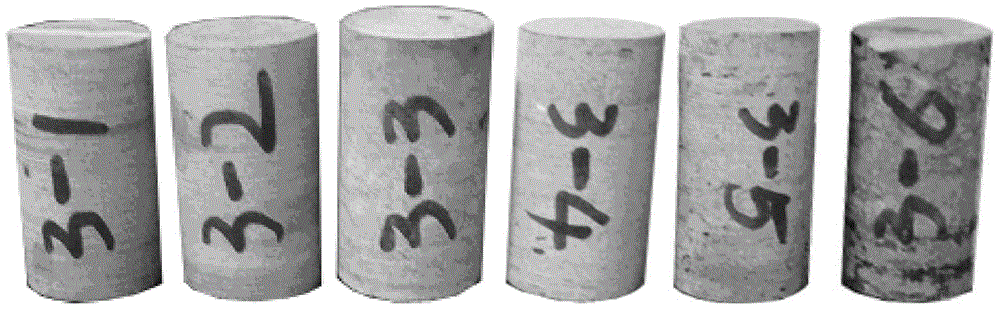

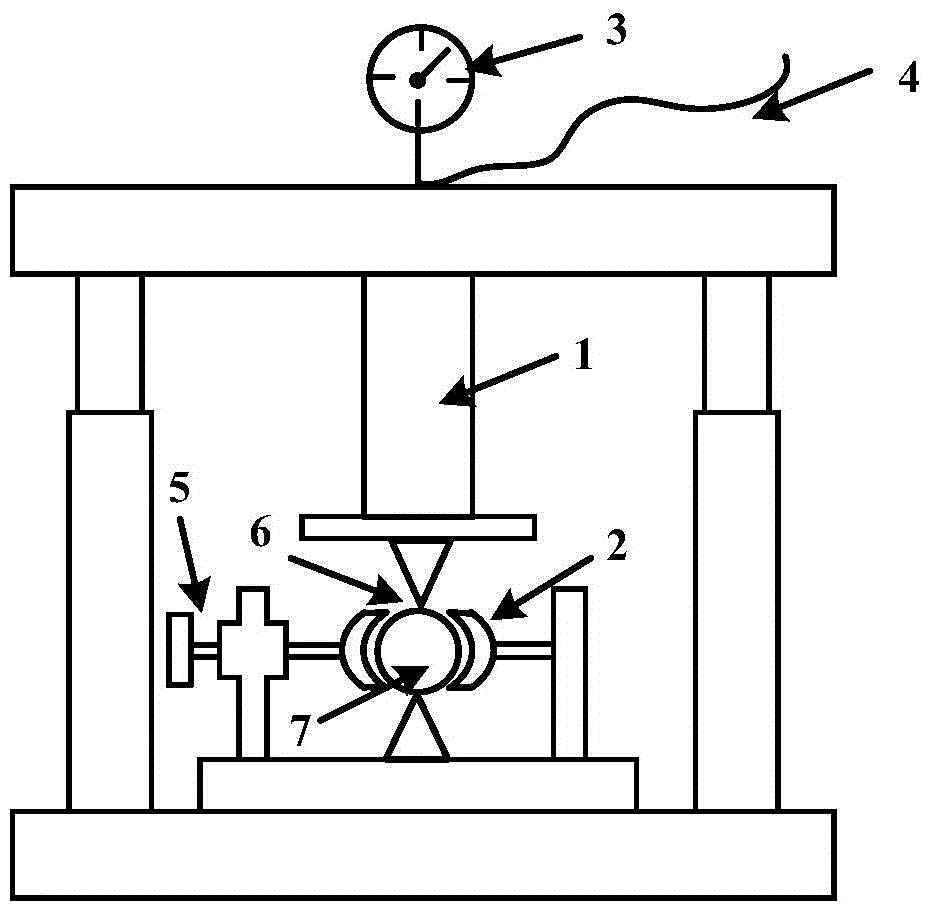

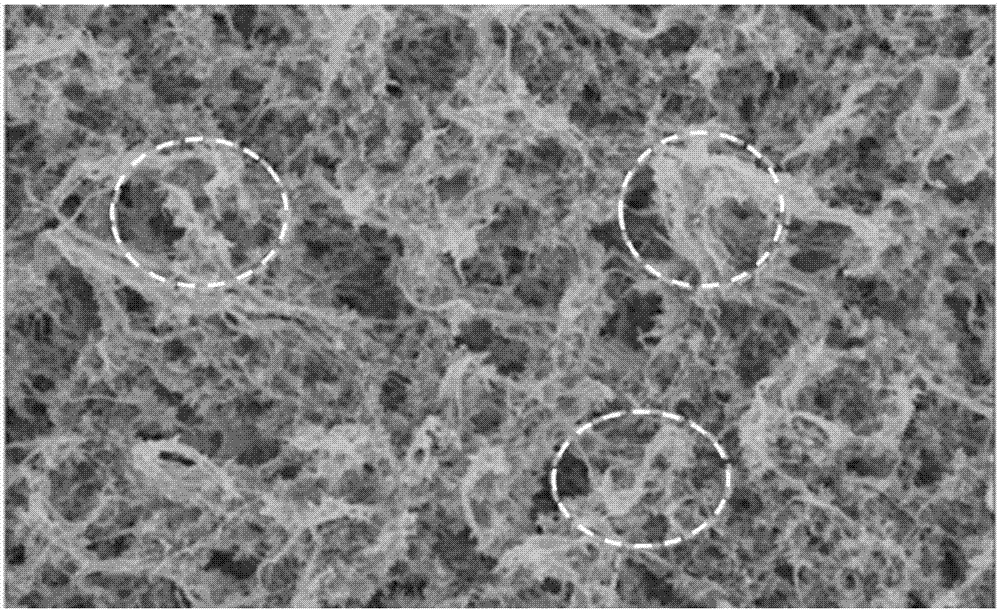

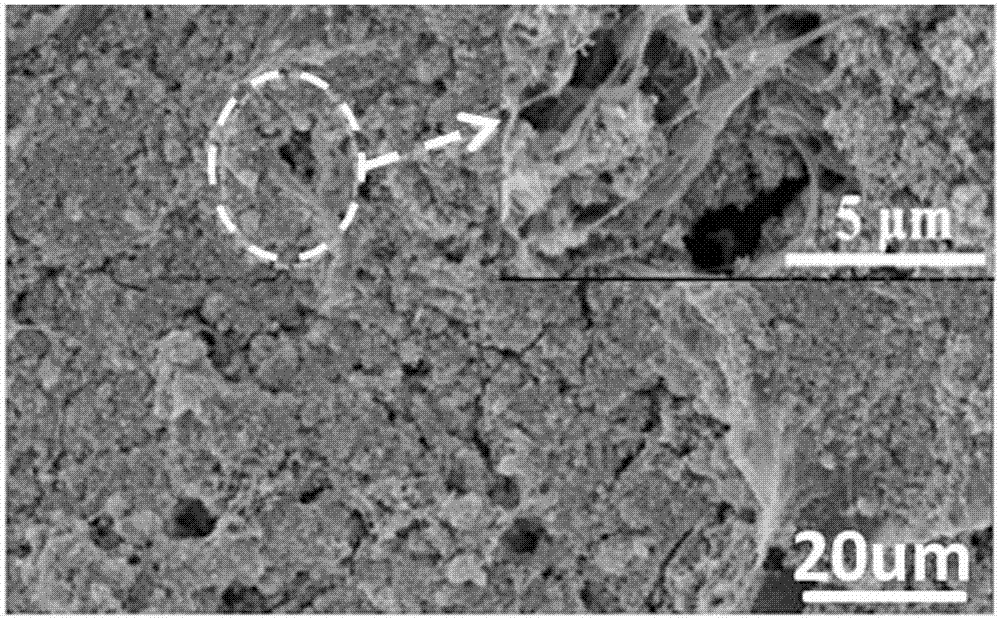

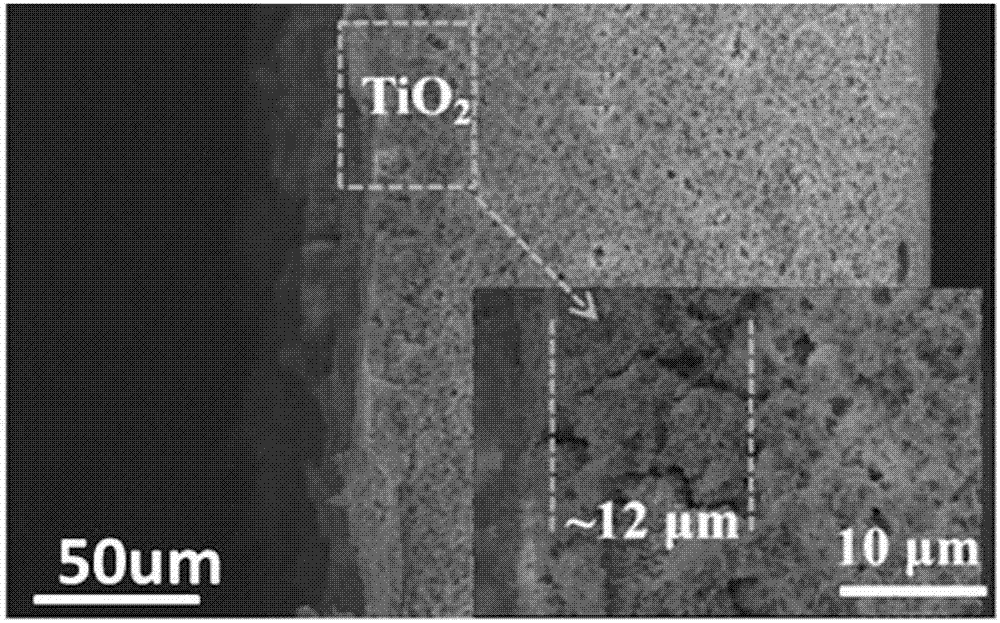

Method of performing stress sensitivity experiment with artificial fractured carbonate rock core

ActiveCN104977195AMeet the requirements of stress-sensitive experimentsStrong hardnessPreparing sample for investigationPermeability/surface area analysisCarbonate rockCalcium carbonate

The invention discloses a method of performing a stress sensitivity experiment with artificial fractured carbonate rock cores, which includes following steps: a) measuring the content of minerals in natural carbonate rock and performing proportion to obtain a mineral mixture; b) determining the use amount of a cement, mixing the cement with the mineral mixture to manufacture an artificial substrate rock body, and measuring the stress sensitivity characters of the substrate rock body; c) forming fractures on the artificial substrate rock body to obtain fractured rock cores; d) measuring the stress sensitivity characters of the fractured rock cores in a non-filled mode; e) with a crude quartz sand cement, filling the fractured rock cores to simulate a semi-filled fractured rock core, and measuring the stress sensitivity characters of the rock cores in the semi-filled mode; and f) with a calcium carbonate cement, filling the fractured rock cores to simulate a full-filled fractured rock core and measuring the stress sensitivity characters of the rock cores in the full-filled mode. The method can satisfy the requirement of the stress sensitivity experiment better.

Owner:CHINA PETROLEUM & CHEM CORP +1

Laser repair method for abraded centrifugal fan bearing block

ActiveCN102031519AReduce distortionStrong fusion rateMetallic material coating processesLaser beam welding apparatusEngineeringHardness

The invention relates to a laser repair method of the mechanical repair field, in particular to a laser repair method for an abraded centrifugal fan bearing block. The laser repair method comprises the following steps of: cleaning a workpiece, detecting the dimensions of each part and determining a damaged part and the abrasion loss thereof; carrying out circular runout and end face runout detection on the workpiece; carrying out failure analysis and service life evaluation on the workpiece; removing the fatigue layer of the damaged part of the centrifugal fan bearing block and washing clean; detecting the hardness and the component of the parent material of the centrifugal fan bearing block; according to a detection result, preparing cladding powder, regulating the operating data of a laser device, setting a laser cladding technical parameters and carrying out laser cladding on the damaged part of the centrifugal fan bearing block by adopting a synchronous powder feeding mode; carrying out mechanical processing according to the requirement; carrying out surface colouration flaw detection on the processed workpiece, and detecting the processing precision of the centrifugal fan bearing block; and checking the centrifugal fan bearing block. The method has the advantages of high abrasion resistance, high hardness, high fusing rate of a cladding layer and the parent material of the bearing block, small deformation of the bearing block and the like.

Owner:河北瑞兆激光再制造技术股份有限公司

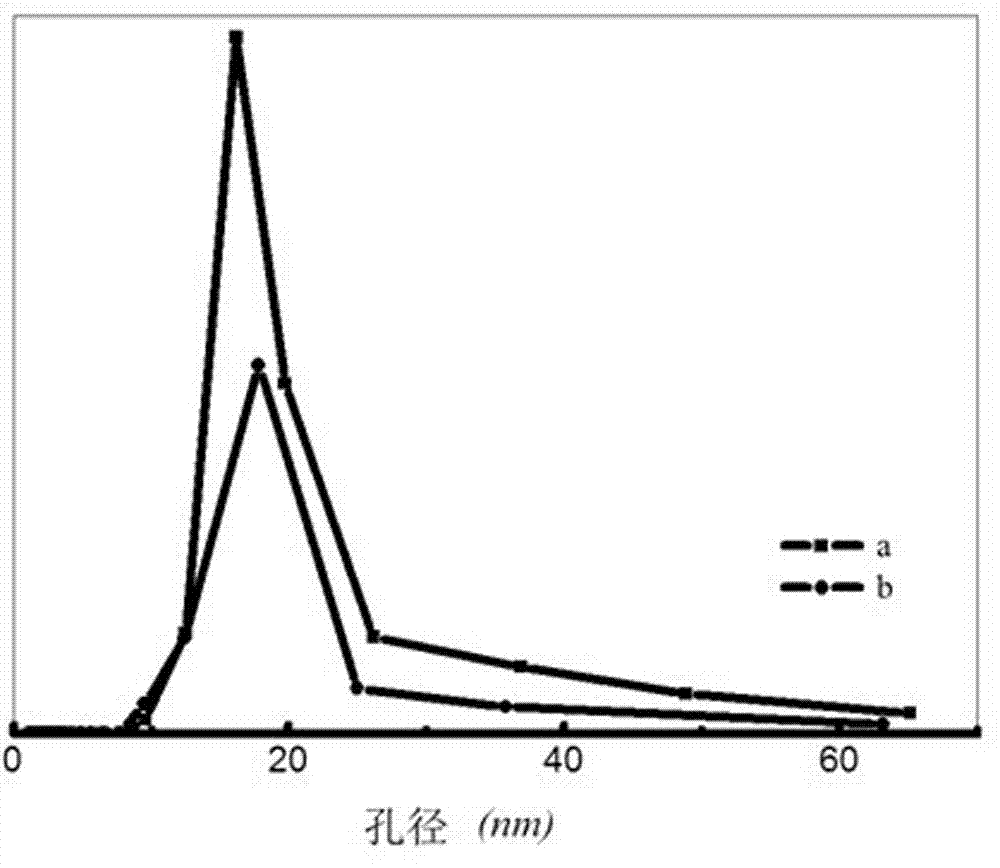

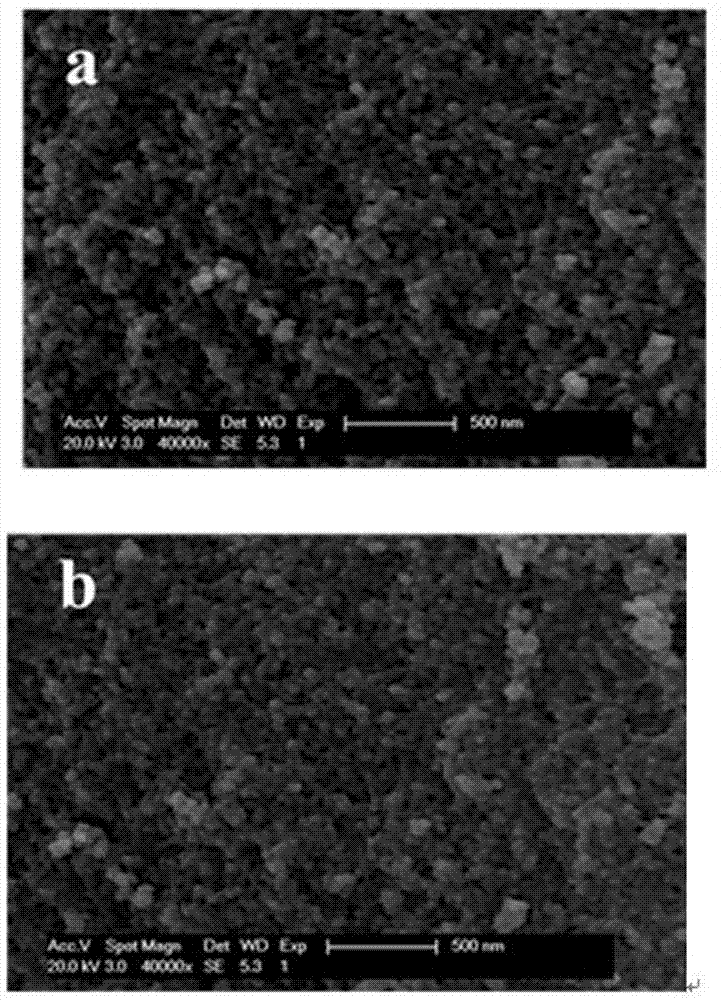

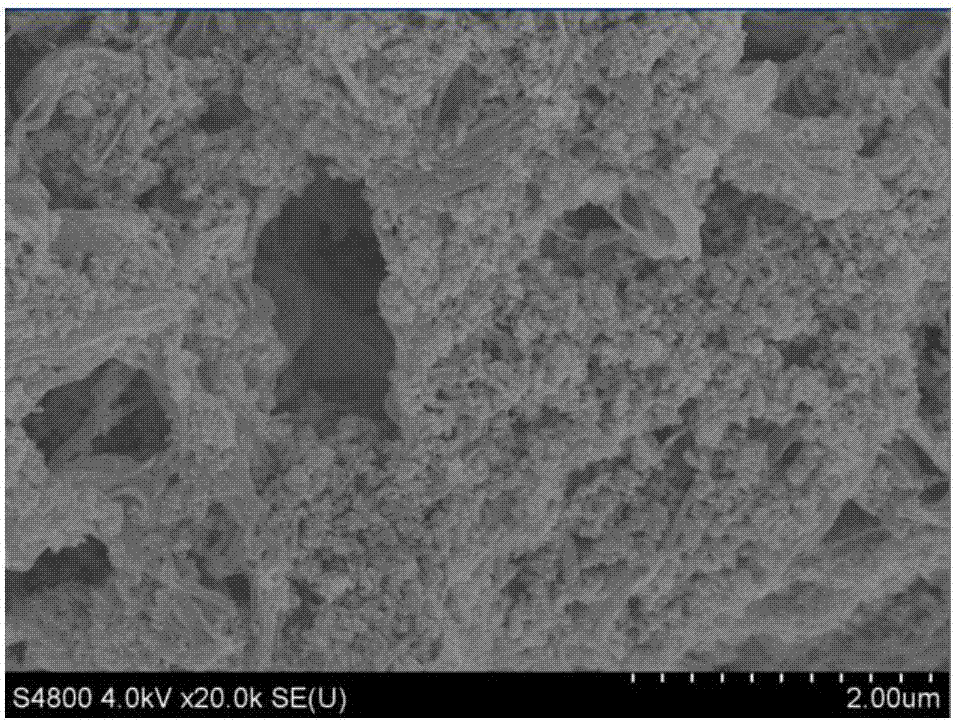

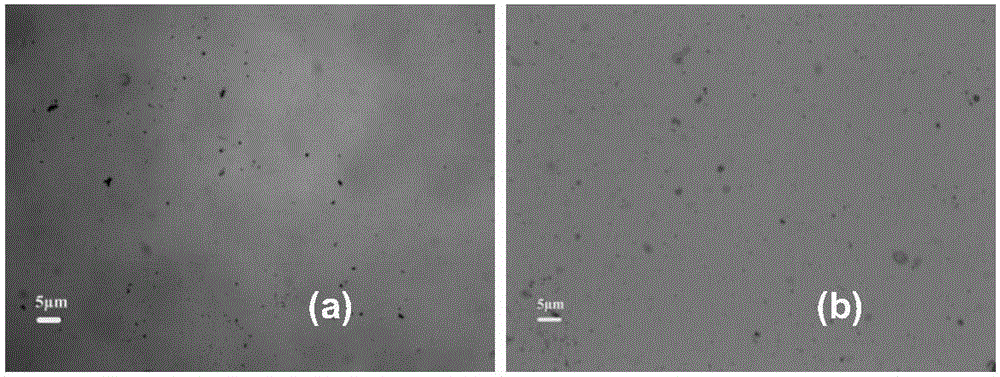

An ultra-hydrophobic polymer microporous membrane and a preparing method thereof

ActiveCN107349803ASurface performance is stableNo damage to physical and mechanical propertiesMembranesSemi-permeable membranesPolymer scienceSilanes

The invention relates to an ultra-hydrophobic polymer microporous membrane. The ultra-hydrophobic polymer microporous membrane includes a polymer microporous membrane and a hydrophobic coating attached to the surface of the polymer microporous membrane. The hydrophobic coating is a crosslinked layer comprising hydrophobic modified inorganic nanometer particles. The hydrophobic modified inorganic nanometer particles are prepared by subjecting inorganic nanometer particles to hydrophobic modification by utilizing multi-alkoxy silane end-capped with hydrophobic groups. The invention also relates to a preparing method of the ultra-hydrophobic polymer microporous membrane.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Ceramic part and production method thereof

PendingCN106977184AHigh densityImprove uniformityCeramic shaping apparatusInjection molding machineHigh heat

The invention relates to the technical field of powder metallurgy and particularly relates to a ceramic part and a production method thereof. The production method comprises (1) mixing granulation: putting ceramic powder into a mixer, heating the ceramic powder, adding a binder into the ceramic powder, carrying out mixing, and carrying out granulation through an extruder to obtain feed, (2) injection molding: placing the feed in an injection molding machine and carrying out injection molding to obtain an injected blank, (3) degreasing: placing the injected blank into an air furnace, carrying out hot degreasing, carrying out heating pre-sintering, carrying out furnace cooling and taking out a blank, and (4) sintering: putting the blank in a sintering furnace, carrying out sintering, and carrying out grinding and polishing to obtain a ceramic part. Through powder injection molding process and final degreasing and high temperature sintering, a fine ceramic part having a complex shape is obtained, the product has high compactness and good uniformity and is obtained by one step molding, the operation and control are simple, product quality is stable, production efficiency is high, a production cost is low and large-scale industrial production is realized.

Owner:深圳市星迪伟业科技有限公司

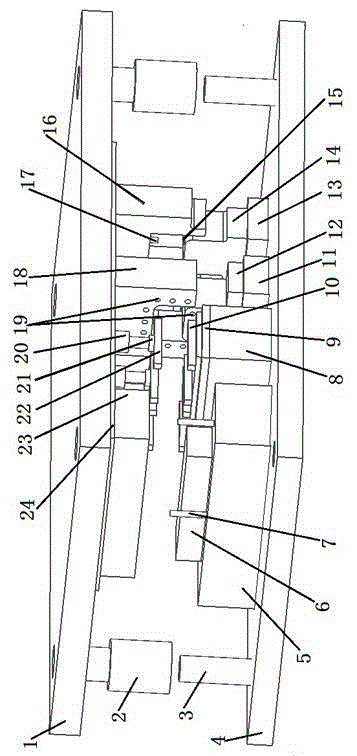

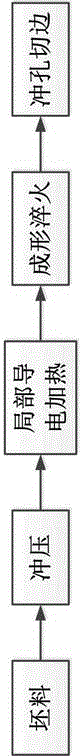

Multi-station hot forming device and hot forming method for high-strength parts

The invention relates to the technical field of hot stamping of high-strength parts, in particular to a multi-station hot forming device and a hot forming method for high-strength parts. The hot forming device comprises an upper die carrier, a lower die carrier, a forming female die and a forming male die. The upper die carrier is provided with a movable heating component, and the lower die carrier is provided with a fixed heating component. The hot forming method comprises the steps that firstly, machined blanks are conveyed to the fixed heating component for local heating, so that hot blanks are obtained; the forming male die and the forming female die mutually draw close to perform die assembly forming, so that the hot forming parts are obtained. Quick local conduction heating and forming quenching of the blanks are synchronously completed on a press machine, so that the heating time of the blanks is shortened, and heating efficiency is improved. Meanwhile, conveying equipment for heating furnaces and hot blanks and the conveying process in a traditional hot forming technology are omitted, heat loss of the hot blanks in the conveying process and oxidation of the surfaces of the hot blanks are avoided, and therefore the surface quality of the blanks and the quality of the final hot forming parts are guaranteed.

Owner:东莞市豪斯特热冲压技术有限公司 +1

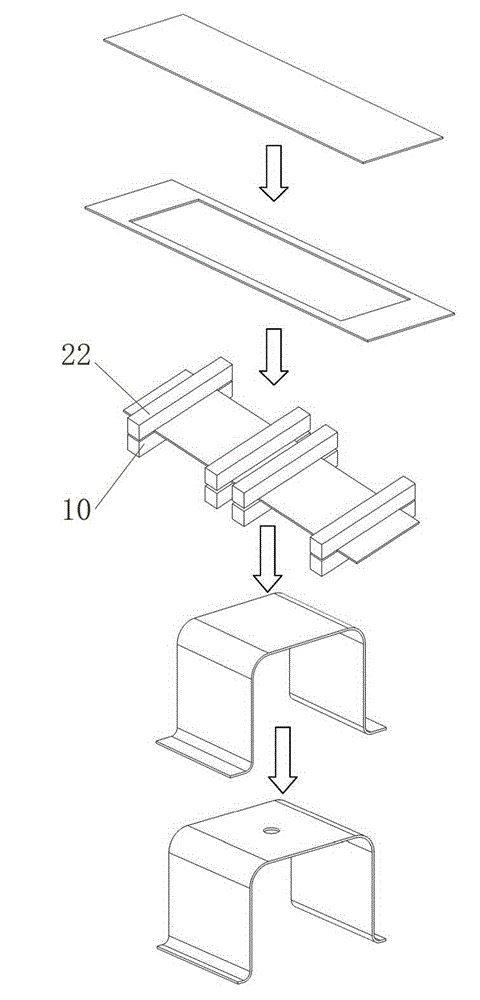

External wall heat insulation decorative board concealed anchor bolt and integral quick-mounting board for external wall heat insulation and decoration

The invention discloses an invisible anchor bolt of an external wall insulating decoration plate and an external wall insulating decoration integration packaged plate. The invisible anchor bolt comprises an inner tabletting with a column-shaped presser foot and a fastener, and the inner tabletting is embedded and inserted in a heat-insulating board, the pressure foot is an inner screw thread, one end of the fastener with an outer screw thread is connected with the pressure foot, and the outer wall of the other end is provided with a barb which is inserted in a mounting hole of the wall body, and the waist portion is provided with an outer tabletting which is vertical with the fastener, when the fastener is tightly screwed on the pressure foot, the outer tabletting is tightly clung on the surface of the packaged plate. The external wall insulating decoration integration packaged plate comprises a heated board whose inner surface is tightly clung on the wall body, and an alkali-fast break fiber web checked cloth layer and a decoration layer which are adhered on the outer surface of the plate one by one, the inner tabletting with the pressure foot are embedded into the heated board, and the surface of the pressure foot and the inner tabletting are all fell into the heated board, and the pressure foot is provided with an inner screw thread which is connected with the fastener. The invention has the advantages of simple structure, beauty and firmness, convenient transporting, and fast assemblage, which achieves a possibility of the industrialized production of external wall insulating decoration packaged plate.

Owner:合肥乐千年涂料有限公司

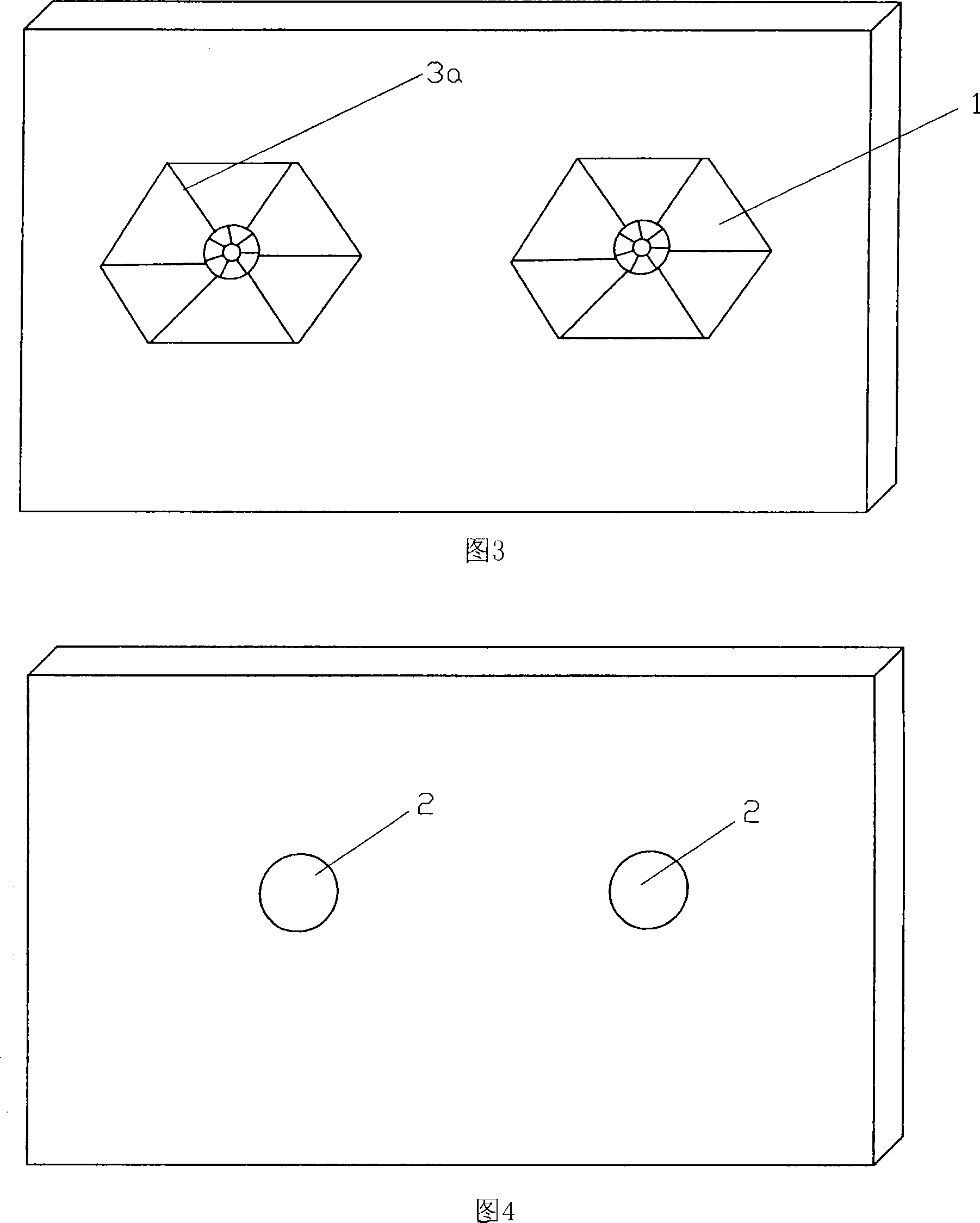

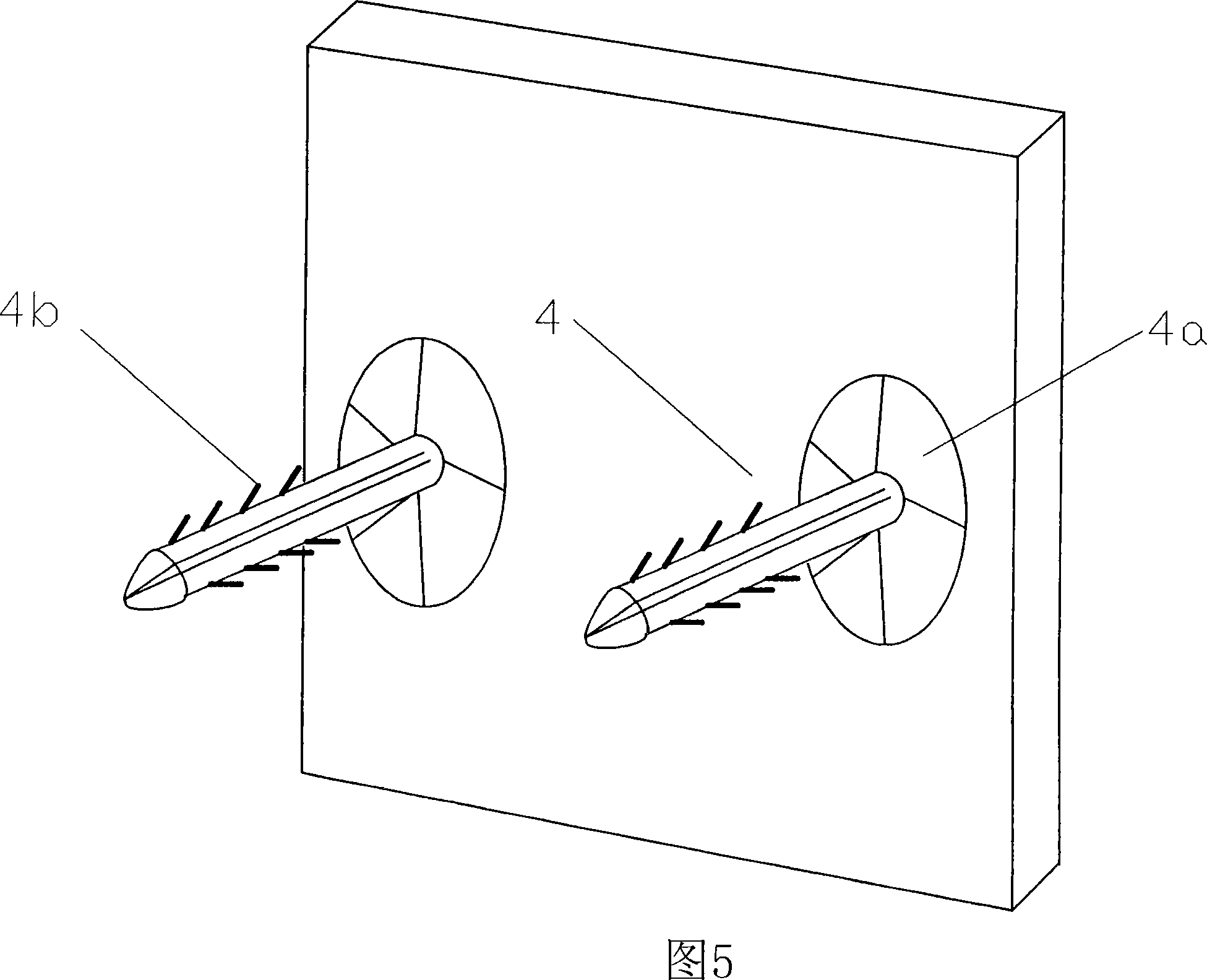

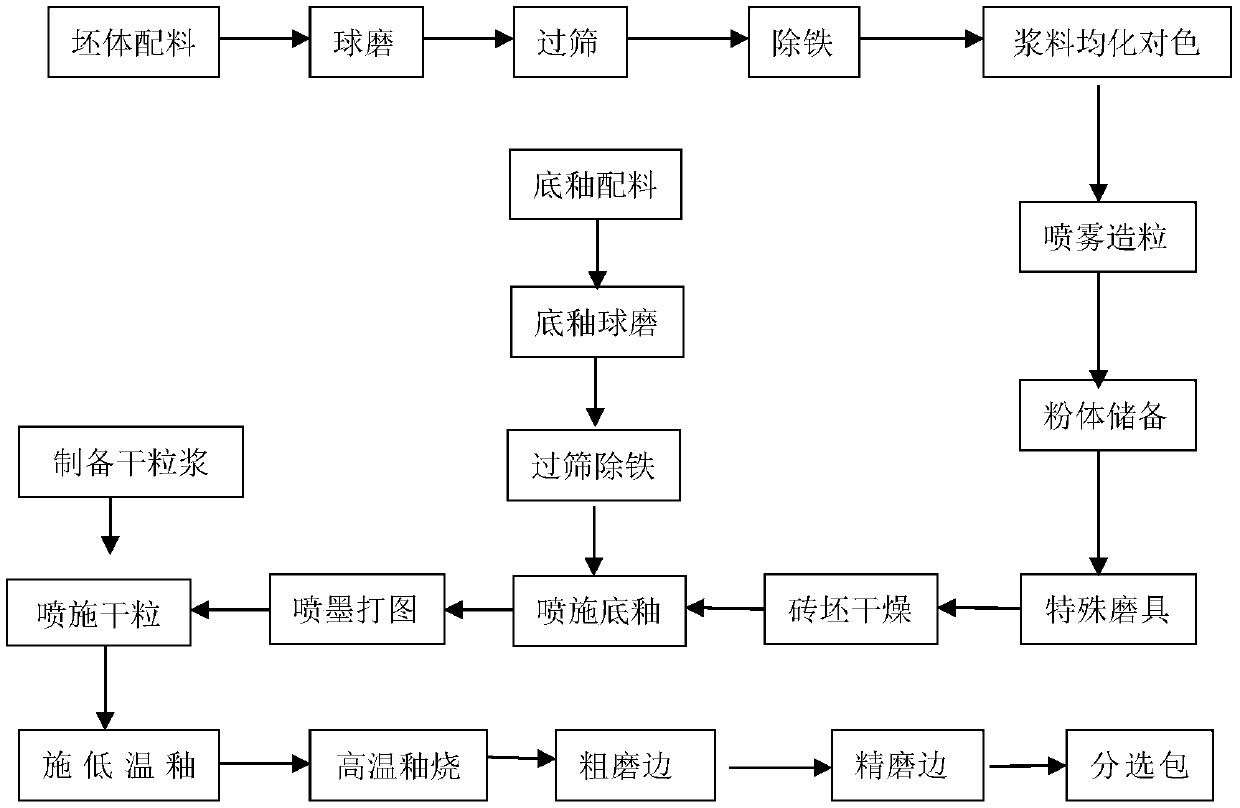

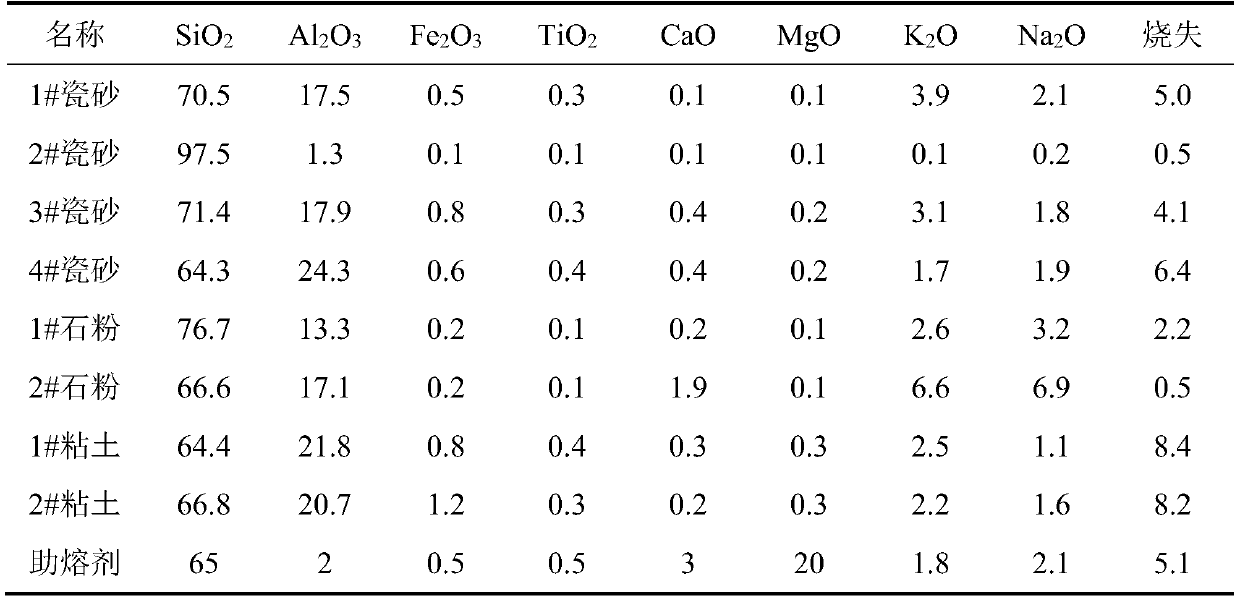

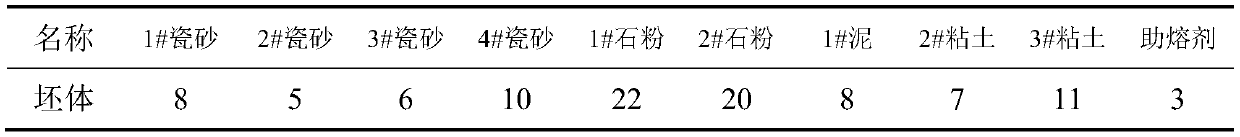

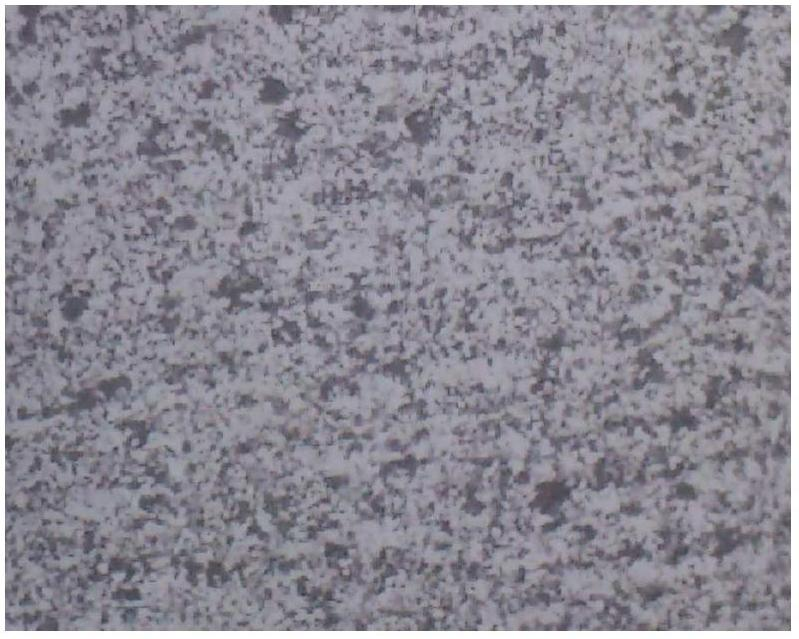

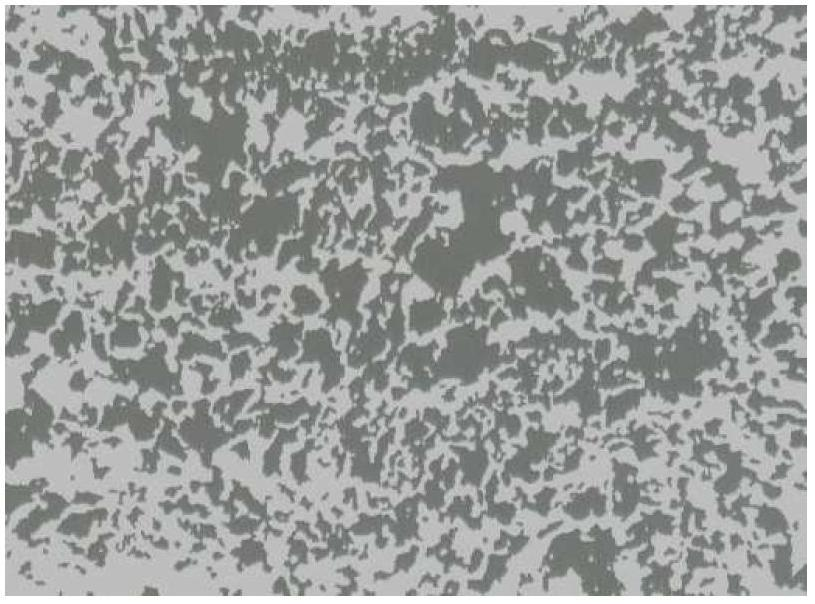

Granite texture ceramic tile and preparation method thereof

The invention discloses a granite texture ceramic tile and a preparation method thereof. A green body of the granite texture ceramic tile is prepared from the following chemical components in percentage by mass: 68 to 70 percent of SiO2, 18 to 19 percent of Al2O3, small than 1.0 percent of Fe2O3, small than 0.3 percent of TiO2, small than 0.5 percent of CaO, small than 1.5 percent of MgO, 2.5 to 2.8 percent of K2O, 2.0 to 2.5 percent of Na2O and small than 4.5 percent of ignition lost; a ground coat of the granite texture ceramic tile is prepared from the following raw materials in percentageby weight: 35 to 40 percent of potash feldspar, 8 to 10 percent of zirconium silicate, 10 to 15 percent of calcined kaoline, 7 to 10 percent of zinc oxide, 5 to 8 percent of barium carbonate, 13 to 17percent of barium carbonate and the balance of additives; overglaze raw materials of the granite texture ceramic tile are high temperature matte dry grains with mesh numbers of 10 to 120; the firingtemperature of the granite texture ceramic tile is 1210 to 1240 DEG C and the firing period of the granite texture ceramic tile is 150 to 160 minutes. By adjusting and optimizing a green body preparation process and a ground coat formula of the ceramic tile, the prepared ceramic tile has the advantages of natural and smooth texture, stronger stereoscopic effect in vision and sandstone particle hand feel of natural stones; the texture and color patterns of granite texture ceramic tile are exactly the same as those of natural granite materials, so that the needs of consumers are met.

Owner:GUANGDONG HOMEWAY CERAMICS IND

Production method of nano crystal-sand floor

ActiveCN101337366AStrong hardnessAnti-wear strengthPolishing machinesPretreated surfacesFloor slabWear resistant

The invention discloses a method for producing nanometer crystal sand surface floor slabs. The production method comprises the steps of slicing timber, selecting slabs and grooving according to conventional techniques, and further comprises the steps of conducting the polishing treatment for floor slab base materials, including seventeen-layer multiple permeation paint application technique, that is, applying two layers of water environmental protection primer, three layers of wear-resistant primer, nine layers of elastic primer, and three layers scraping-resistant finishing coat. The production method adopts the seventeen-layer multiple mutual-type permeation technique, that is, three plus two plus nine plus three, and utilizes the interactive permeation technique of nano-titanium paint molecules, so as to enable paint molecule layers to permeate into wood molecules. Through a plurality of layers of wear-resistant primer and hardening primer, and through leveling and a plurality of curing and sanding layers, the floor slab has high performance of super strong hardness, wear resistance, scraping resistance, oxidation and yellowing resistance. The paint surface adhesive force, the flexibility, and the scraping resistance of the floor slab greatly exceed those of the ordinary technical floor slab.

Owner:浙江永吉木业有限公司

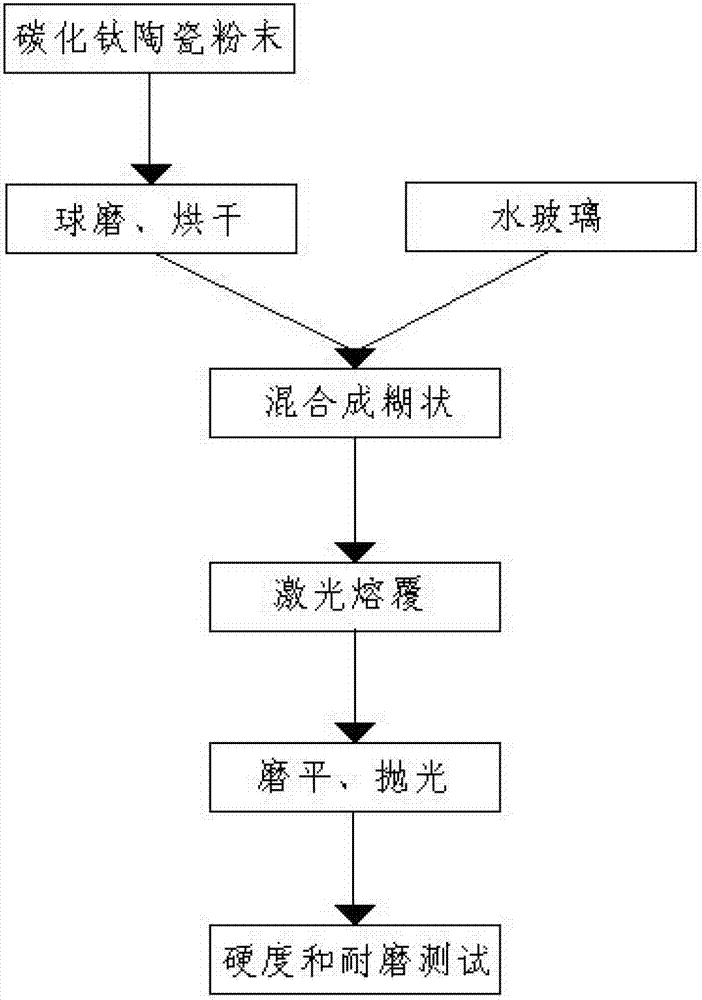

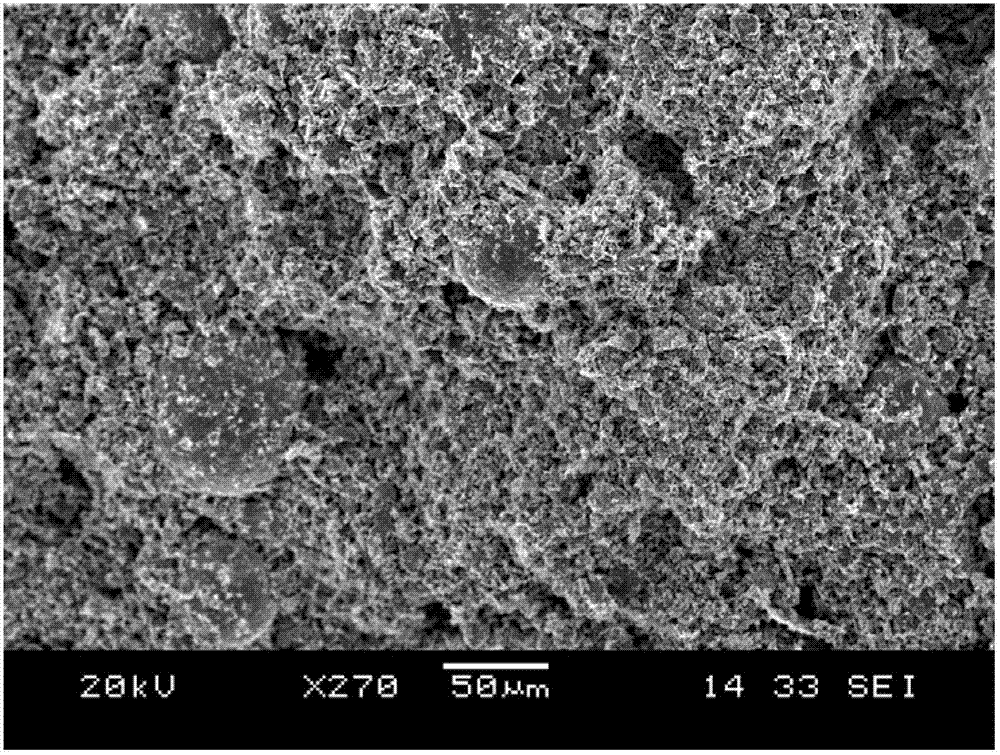

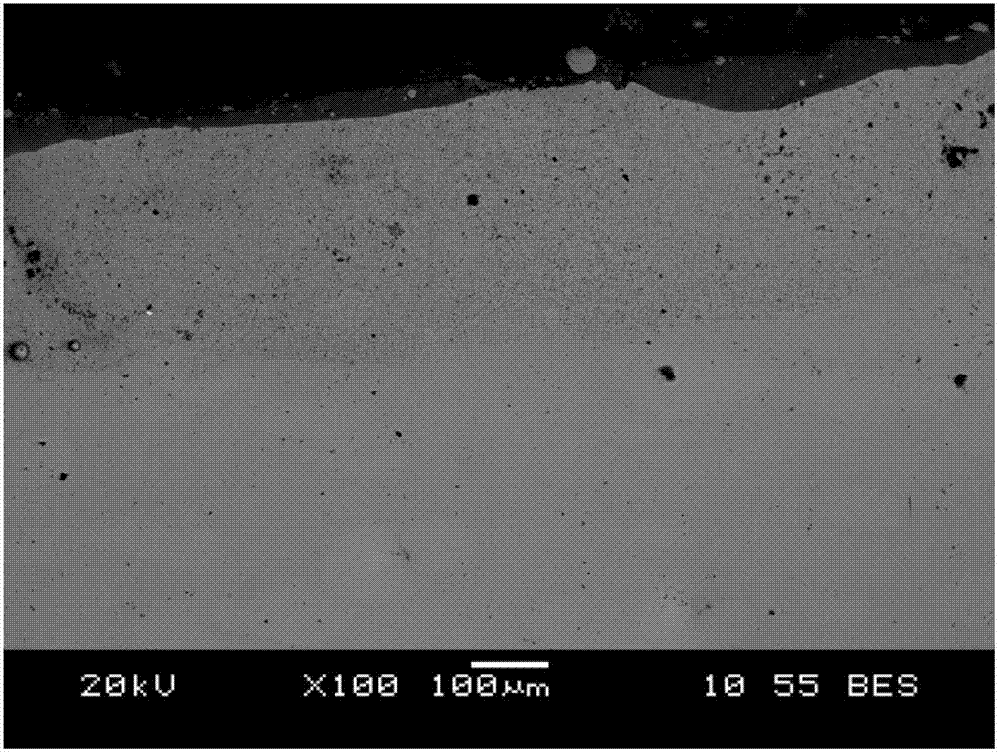

Titanium carbide metal ceramic powder and method for laser cladding of powder

InactiveCN102962447AImprove wear resistanceHigh hardnessMetallic material coating processesHardnessTitanium carbide

The invention relates to the technical field of metal surface treatment, and specifically discloses a titanium carbide metal ceramic powder and a method for laser cladding of the powder. The titanium carbide metal ceramic powder consists of titanium carbide, lanthanum oxide and nickel 60. The method comprises the following steps of: putting the titanium carbide ceramic powder in a ball mill to be ball-milled for 15 hours to 20 hours, and drying the ball-milled powder; mixing the dried powder and water glass into a paste powder; coating the paste powder onto the surface of a test block to be clad to be flatly pressed, and drying naturally; cladding the dried paste powder on the test block by using a pulsed laser machine; flatly grinding the clad test block, carrying out the polishing treatment of the clad surface, and then cleaning with anhydrous ethanol; and carrying out the hardness test and the wear test of the test block. The cladding layer obtained from the invention has the advantages of strong high temperature resistance, strong wear resistance, high hardness, compact and uniform structure, uniform thickness, grain refinement, few pores and cracks, good surface quality and the like.

Owner:SHANTOU UNIV

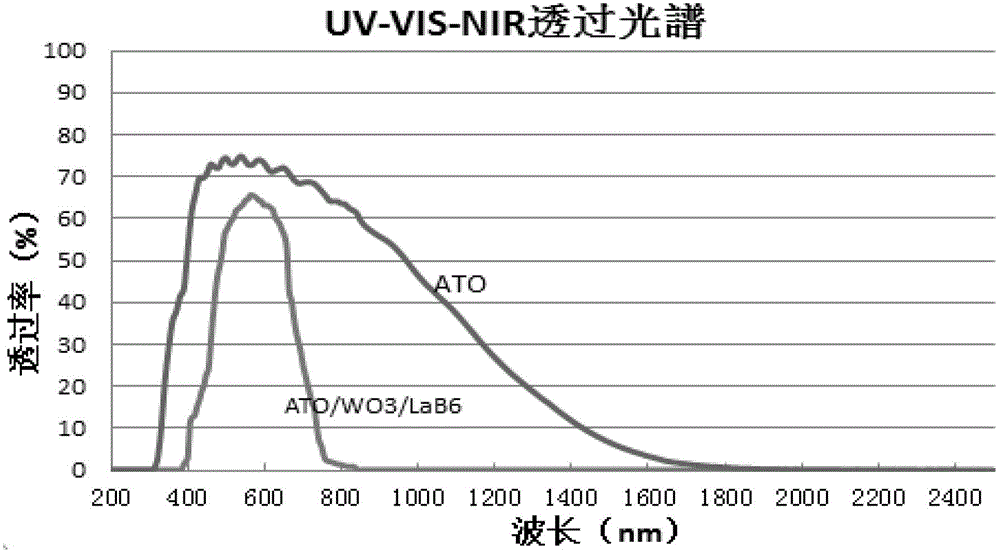

Full-shielded infrared and ultraviolet polyurethane nanometer transparent heat insulating coating

InactiveCN102746781AStrong hardnessHardness can reach 5H level, strong adhesionPolyurea/polyurethane coatingsRadiation-absorbing paintsInfraredArchitectural glass

The invention relates to a full-shielded infrared and ultraviolet polyurethane nanometer transparent heat insulating coating and a preparation method. The coating comprises 40 to 80% of polyurethane resin, 5 to 30% of nanometer ATO dispersions, 1 to 10% of nanometer LaB6 dispersions, 1 to 15% of nanometer WO3 dispersions, 0.5 to 3% of auxiliary, and 5 to 20% of solvent. The preparation method comprises the steps of sequentially dropwise adding the nanometer ATO dispersions, the nanometer LaB6 dispersions an the nanometer WO3 dispersions into the a polystyrene resin component A in proportion by weight based on a formula, and agitating to disperse for 15 to 30 minutes, and then adding a flatting agent, a defoamer, an adhesion promoter, a solvent and a firming agent B based on the ratio of the formula, and agitating to obtain a full-shielded nanometer transparent heat insulating coating. The coating is applied to the glass of a building, the glass of a vehicle and a cement surface for heat insulating; the coating is economic and practical, and can shield all the ultraviolet rays and infrared rays; and the full-shielded infrared and ultraviolet polyurethane nanometer transparent heat insulating coating has obvious performance on heat insulating.

Owner:惠州市彩田化工实业有限公司

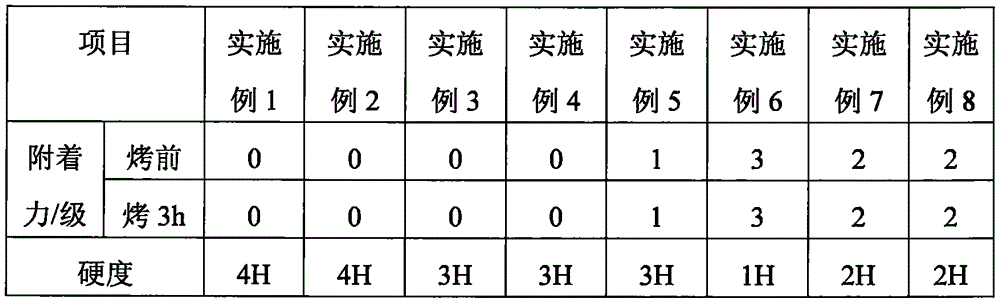

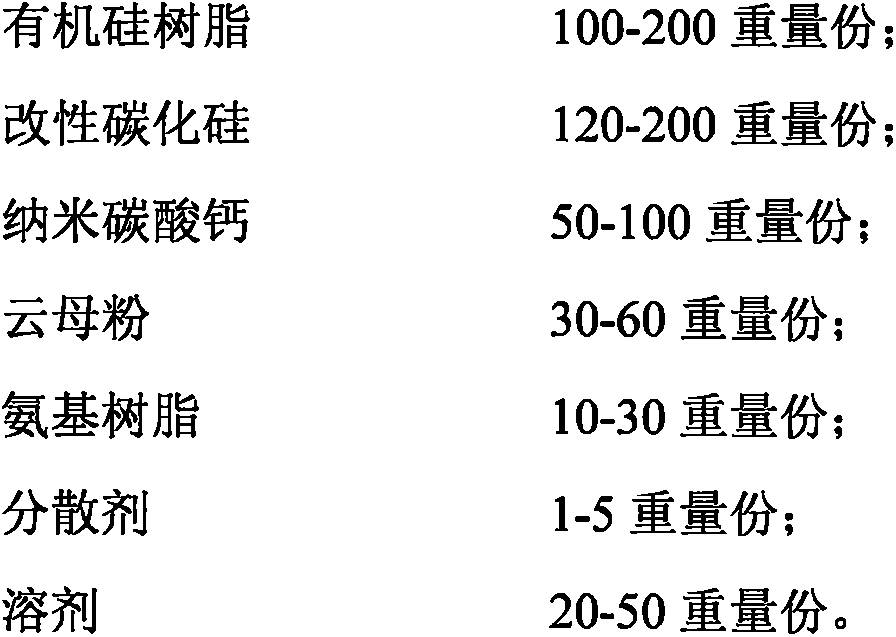

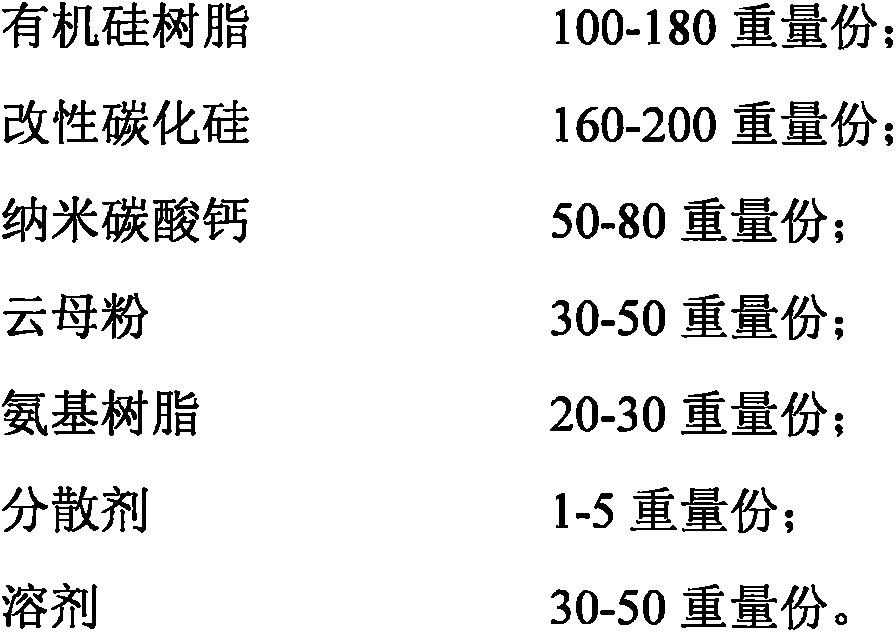

Nonstick pan coating layer, and production method and nonstick pan thereof

ActiveCN105925176AHigh hardnessImprove heat resistanceCooking-vessel materialsAnti-corrosive paintsPorositySolvent

The invention provides a nonstick pan coating layer, and a production method and a nonstick pan thereof. The production method comprises the following steps: mixing organosilicone resin, modified silicon carbide, nanometer calcium carbonate, mica powder, amino resin, a dispersant and a solvent, grinding the obtained mixture, dispersing the ground mixture, and filtering the dispersed mixture to obtain a coating; and spraying the coating on the surface of a metal pan matrix, and baking the sprayed metal pan matrix at 200-300DEG C for 10-30min to obtain the nonstick pan coating layer. The organosilicone resin, saturated modified silicon carbide and the nanometer calcium carbonate are simultaneously applied to the nonstick pan coating layer in order to form the coating layer with excellent performances of above three components. The modified silicon carbide has good thermal stability, corrosion resistance and thermal conduction performance, and guarantees the thermal distribution uniformity of the coating layer; the nanometer calcium carbonate makes the microscopic surface of the organosilicone coating layer be tight and have zero porosity, protects the matrix, and enhances the nonstick effect of the coating layer, and the nanometer calcium carbonate and the modified silicon carbide have synergism, and enhance the hardness and the heat resistance of the nonstick pan coating layer.

Owner:宁波贝得厨具有限公司

Special insulating material for electrical equipment and preparation method for special insulating material

InactiveCN105348739AGood compatibilityGood dispersionPlastic/resin/waxes insulatorsEpoxyPower equipment

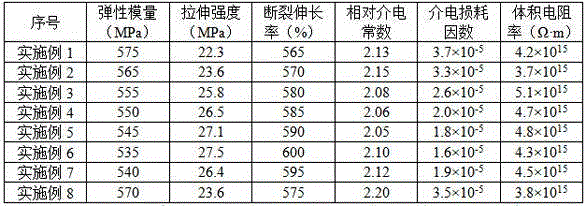

The invention discloses a special insulating material for electrical equipment and a preparation method for the special insulating material. The special insulating material for the electrical equipment comprises the following components in parts by weight: 90-100 parts of epoxy resin, 15-25 parts of methyl vinyl silicone rubber, 20-25 parts of fluorosilicon resin, 15-20 parts of polytetrafluoroethylene, 10-15 parts of glass fiber, 15-20 parts of nano inorganic powders, 0.2-1 part of butyl titanate, 20-40 parts of distilled water, 1-6 parts of a compatilizer, 1-5 parts of a flame retardant, 0.3-1.2 parts of an antioxidant and 1-10 parts of a crosslinking agent. The special insulating material for the electrical equipment prepared by the invention can inhibit the space charge accumulation in the cable insulating material, improve the anti-aging property, the anti-flashover property and the anti-acidic and alkaline water-resistent property of the material, has good mechanical properties, electrical property and thermal property, and is excellent in comprehensive properties.

Owner:国网河南唐河县供电公司

Corrosion proof impregnating varnish used for water-based metal components and manufacturing method thereof

ActiveCN101560351ALong-lasting colorHigh hardnessAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses a corrosion proof impregnating varnish used for water-based metal components and a manufacturing method thereof. The corrosion proof impregnating varnish is made of de-ionized water, propanediol, dispersant, antifoaming agent, wetting agent, carbon black, iron oxide black, water borne acroid resin, water borne epoxy resin, dipropylene glycol butyl ether, propylene glycol ether and polyaniline water solution, polyaniline carrier particles or polyaniline emulsion. The manufacturing method comprises: the propanediol and the de-ionized water are mixed and stirred, and then added with the dispersant, the antifoaming agent, the wetting agent and the polyaniline water solution or the water solution of emulsion or carrier particles to be evenly mixed together; the carbon black and the iron oxide black are added in to the mixed solution to form uniform pigment paste which is then put into a blending tank after being ground to be evenly stirred; the obtained mixture is added with the water borne acroid resin, the water borne epoxy resin, the dipropylene glycol butyl ether and the propylene glycol ether to be stirred; finally, the stirred mixture is added with the de-ionized water to be diluted and ground. The invention has the advantages of high coating efficiency, stable coating quality, uniform paint film of dip coating, flat and smooth paint film, good hardness, strong adhesive attraction, good corrosion proof performance, excellent painting performance at edges and corners, no leaking painting, good salt mist resistance, environmental protection, low cost, etc.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

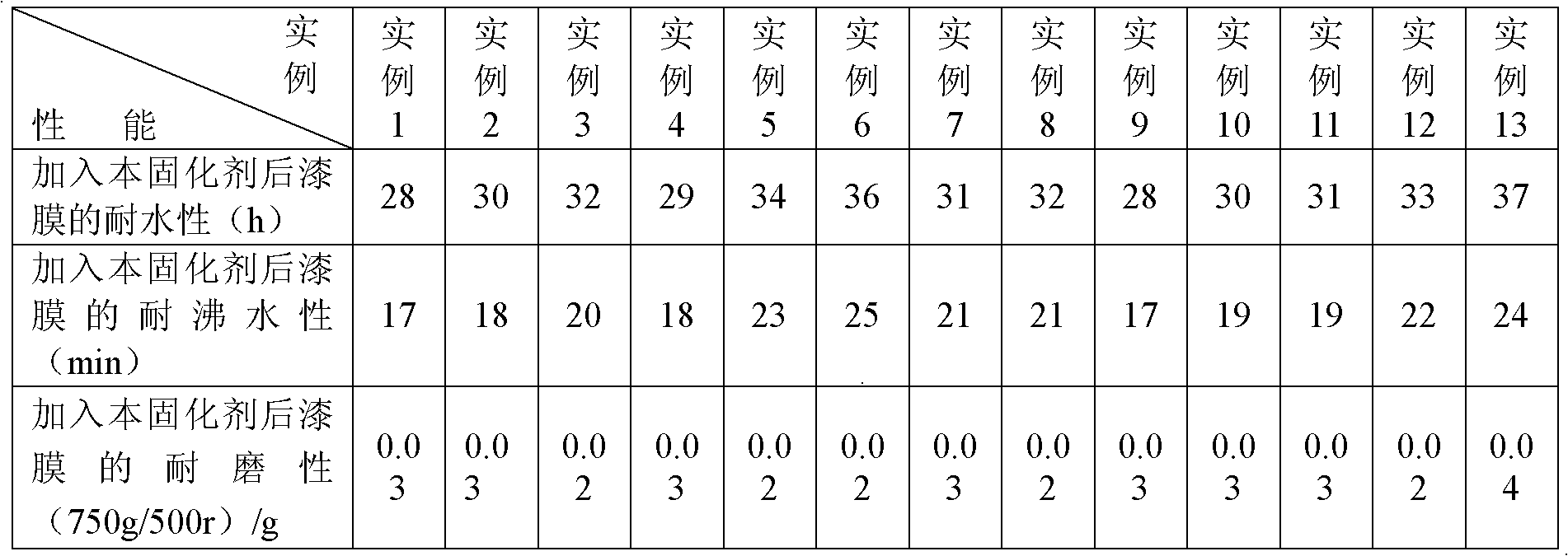

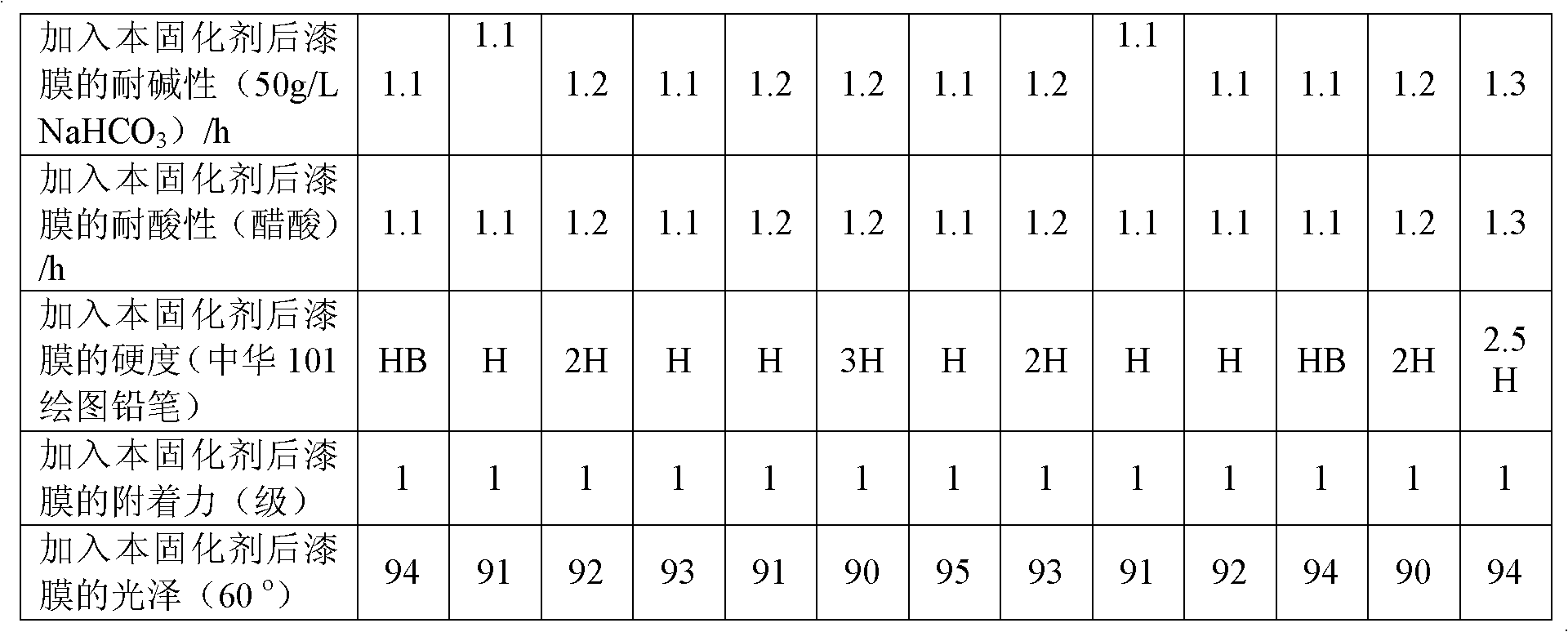

Water-soluble polyurethane curing agent and preparation method thereof

InactiveCN102050935ASimple reaction conditionsSuitable for industrial applicationsPolyurea/polyurethane coatingsAcrylic resinToluene diisocyanate

The invention discloses a water-soluble polyurethane curing agent and a preparation method thereof. The curing agent comprises toluene diisocyanate, trimethylolpropane, polyethylene glycol, polycarbonate diols, acetic ether and a catalyst. The preparation method comprises the following steps: adding 18-25% of toluene diisocyanate, 20.01-80% of acetic ether and 0.01-40% of polycarbonate diols, adding 1-5% of trimethylopropane for reaction in three batches, adding 0.01-40% of polyethylene glycol for reaction in two batches, and then keeping the temperature at 58-63 DEG C for 3 hours; and adding 0.1-0.5% of catalyst, reacting for 2.5-4 hours while the temperature is kept at 50-60 DEG C, cooling until the temperature is reduced to 20-30 DEG C, and discharging. According to the invention, the preparation method is simple, and the curing agent prepared by utilizing the method can react with water-soluble acrylic resins or water-soluble alkyd resins to form a film when being mixed with the water-soluble acrylic resins and water-soluble alkyd resins. Thus, the curing agent is not only applicable to curing at normal temperature but also applicable to preparation of high temperature curing paints.

Owner:肇庆千江高新材料科技股份公司

An ultra-hydrophilic polymer microporous membrane and a preparing method thereof

ActiveCN107349797ASurface performance is stableNo damage to physical and mechanical propertiesMembranesSemi-permeable membranesHydrophilic coatingHydrophilic polymers

The invention relates to an ultra-hydrophilic polymer microporous membrane. The ultra-hydrophilic polymer microporous membrane includes a polymer microporous membrane and a hydrophilic coating attached to the surface of the polymer microporous membrane. The hydrophilic coating is a crosslinked layer comprising hydrophilic modified inorganic nanometer particles. The hydrophilic modified inorganic nanometer particles are prepared by subjecting inorganic nanometer particles to hydrophilic modification by utilizing multi-alkoxy silane end-capped with hydrophilic groups. The invention also relates to a preparing method of the ultra-hydrophilic polymer microporous membrane.

Owner:NINGBO SHUIYI FILM TECH DEV CO LTD +1

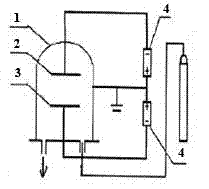

Gamma-TiAl alloy surface high temperature oxidation resistance and wear resistance coat, and preparation method thereof

ActiveCN102732833AImprove high temperature oxidation resistanceImprove wear resistanceVacuum evaporation coatingSputtering coatingCoated surfaceGlow plasma

The invention relates to a gamma-TiAl alloy surface high temperature oxidation resistance and wear resistance coat. According to the coat, the surface of the coat is an oxide film layer comprising Cr2O3 and NiO2, wherein the thickness is 2-3 mum; the middle of the coat is a Cr-Ni alloy layer, wherein the thickness is 2-4 mum; and a Cr-Ni-Ti-Al interdiffusion layer is arranged between the coat and a substrate to achieve metallurgical collection, wherein the thickness of the Cr-Ni-Ti-Al interdiffusion layer is 4-6 mum. According to the present invention, the Cr2O3 and NiO2 oxide film on the surface of the coat has characteristics of compact structure and strong antioxidant capacity; the Cr-Ni alloy layer in the middle of the coat has characteristics of uniform structure and high hardness so as to greatly improve wear resistance of the gamma-TiAl alloy; the metallurgical collection of the coat and the substrate is achieved through the Cr-Ni-Ti-Al interdiffusion layer, and the combination strength is high; and a double glow plasma surface metallurgy technology and a plasma oxygen permeation technology are firstly combined in the coat preparation process of the present invention, special plasma oxygen permeation equipment is not required, the coat can be directly prepared in 5 hours by adopting double glow plasma surface metallurgy equipment, the process is simple, and the efficiency is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for producing wood floors of blue and white porcelain technology

ActiveCN101632982AHigh hardnessStrong hardnessPretreated surfacesWood working apparatusWear resistantInfrared

The invention discloses a method for producing wood floors of blue and white porcelain technology, which comprises the following production steps: (a) brushing an aqueous adhesive, drying with infrared rays, coating a sealing primer, and scraping elastic hardening putty; (b) coating the sealing primer, brushing the elastic hardening primer, and sanding; (c) spraying the primer, leveling, collecting plates and tenoning; (d) brushing the first line of wear-resistant primer, and then, brushing the second line of the wear-resistant primer after UV semi-solid preparation; (e) brushing the elastic hardening primer, and sanding; (f) spraying the primer, and leveling; and (g) coating the first line of elastic hardening finish, and then, coating the second line of the elastic hardening finish after UV semi-solid preparation. The floor produced by adopting the method of the invention forms a layer of hard and clear enamel on the paint surface, shows natural three-dimension effect and tactile sensation similar to the blue and white porcelain, has clear, bright and beautiful texture on the surface, has high hardness, good wear resistance and good scraping resistance of the paint film, has harmonious light colors which achieve perfect integral paving effect, can resist ultraviolet rays and can not fade easily.

Owner:ZHEJIANG BIYORK WOODEN

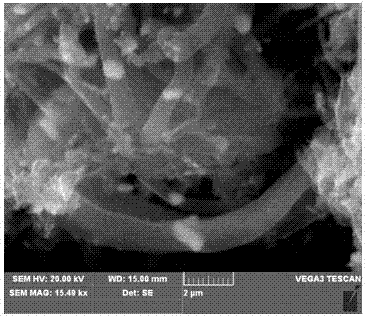

Application and preparation method of helical carbon nano tube

InactiveCN102766286ASimple processLow costMaterial nanotechnologyCarbon compoundsCarbon nanotubeSolid matter

The invention discloses application and a preparation method of a helical carbon nano tube. The helical carbon nano tube serving as a reinforcing material is used for reinforcing rubber. The preparation method includes: placing nickel oxide of the nanometer size into a quartz tube through a carrier; leading nitrogen, then hydrogen and finally acetylene, and conducting reduction to obtain primary products of the helical carbon nano tube; ultrasonic separating the primary product to obtain a deionized solution of the primary product; centrifugal separating the deionized solution to obtain a solid matter and drying; preparing mixed acid of concentrated nitric acid and concentrated sulfuric acid, adding the dried solid matter into the mixed acid, then heating to 90 DEG C and keeping the temperature for 6 hours; and separating the solid matter, washing to neutral and drying to obtain the helical carbon nano tube. The helical carbon nano tube is simple in process, low in cost and easy to achieve and is used for reinforcing the rubber. The rubber reinforced by using the helical carbon nano tube is improved on the aspects of 300% and 500% stress at definite elongation, elongation at break, hardness and abrasion compared with standard rubber reinforced by using carbon black.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

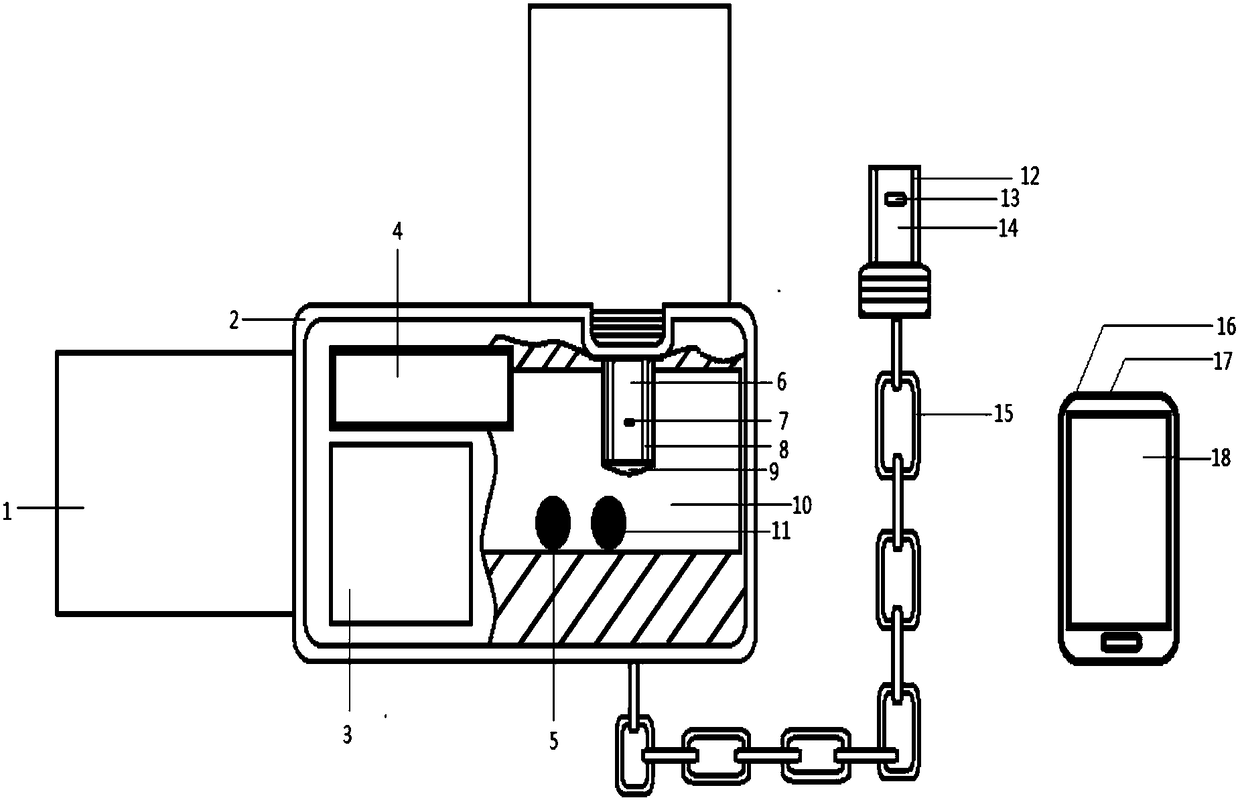

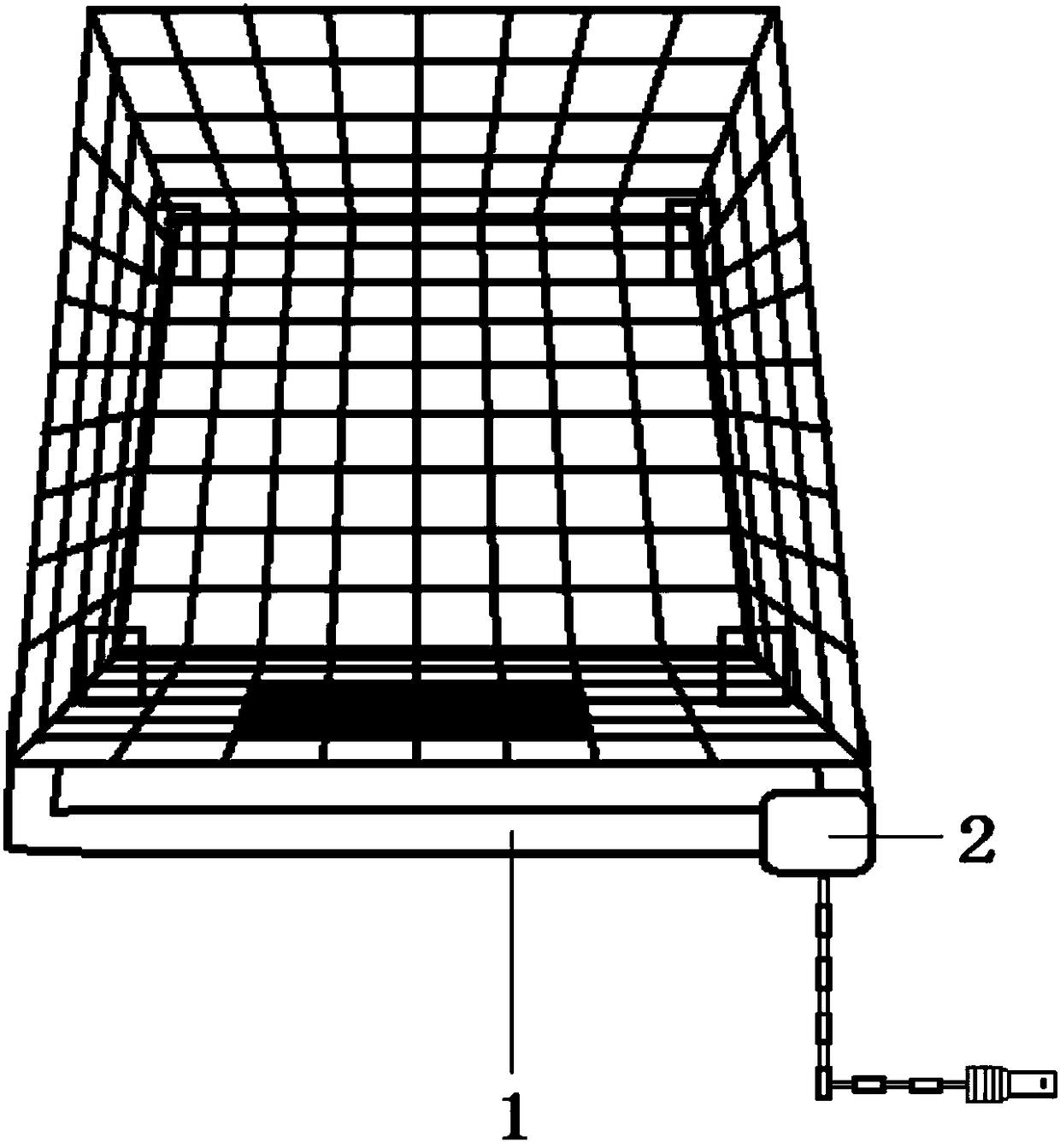

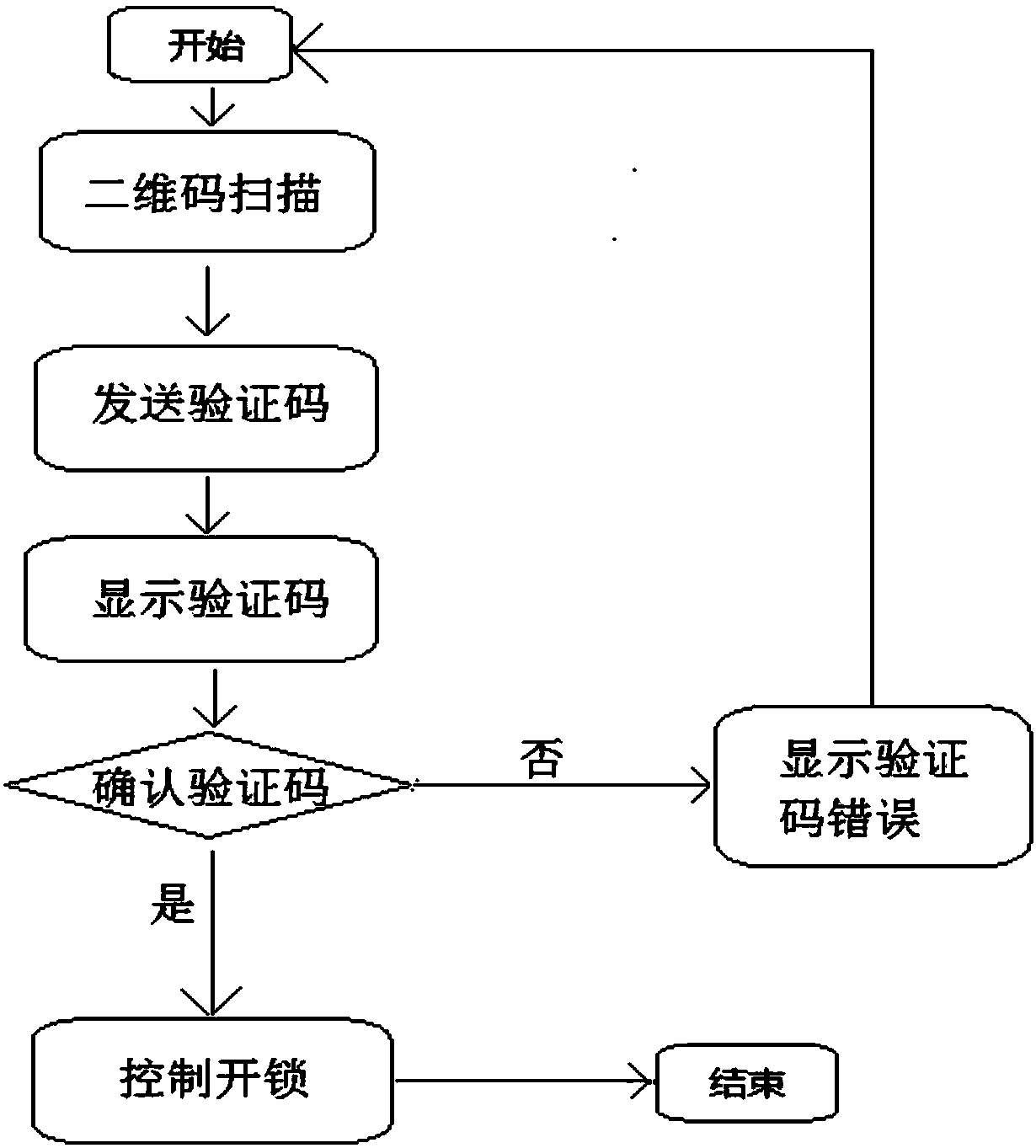

Intelligent supermarket shopping trolley lock and control system thereof

PendingCN108364408AStrong hardnessWear-resistantAcutation objectsNon-mechanical controlsInformation transmissionControl system

The invention belongs to the technical field of shopping trolley lock equipment, and particularly provides an intelligent supermarket shopping trolley lock and a control system thereof. The lock mainly comprises an electronic lock shell, a shopping trolley lock two-dimensional code, a display screen, a chain lock insertion hole, a control chip, an insertion head, a chain, a mobile phone supermarket shopping APP and the like; information transmission between the mobile phone supermarket shopping APP and the control chip are achieved through wireless connection, so that the opening and closing of the shopping trolley lock can be controlled; and the intelligent supermarket shopping trolley lock controlled by using the mobile phone supermarket shopping APP comprises a code scanning verification module, a verification success unlocking shopping trolley module, a shopping completed locking shopping trolley module and a supermarket shopping credit record and a value-added service module. Theintelligent supermarket shopping trolley lock and the control system thereof have the advantages that the lock body is reasonable in structure, the principle is reliable, it is convenient and fast that the shopping trolley can be unlocked through the mobile phone APP, and the mobile phone supermarket shopping APP is provided with the functions of providing a series of services such as a supermarket map, goods positions, supermarket discounted goods, supermarket free shuttle bus situations and the like, thereby greatly satisfying the shopping needs of customers.

Owner:QINGDAO UNIV

Enhanced polyurethane wood-imitation material and manufacturing method thereof

The invention relates to a manufacturing method of an enhanced polyurethane wood-imitation material. The material comprises components of nano cellulose, polyisocyanate, polyether polyol and additives. The components are mixed according to a certain proportion and synthesized into the enhanced polyurethane wood-imitation material through a one-step forming method. The invention adopts the nano cellulose prepared from wood machining residues to mix with polyisocyanate, polyether polyol and additives, and the mixture is synthesized into the enhanced polyurethane wood-imitation material through a one-step forming method; so the polyurethane wood-imitation material has high strength, good heat resistance, good molding ability and high strength-to-weight ratio, and is a novel engineering material. Compared with an existing polyurethane wood-imitation material, the polyurethane wood-imitation material of the invention has advantages of greatly enhanced mechanical properties and heat resistance, good size stability, high hardness, good aging resistance, effectively expanded application range, simple manufacturing process, easiness for application and low comprehensive cost.

Owner:GUANGDONG YIHUA TIMBER IND +1

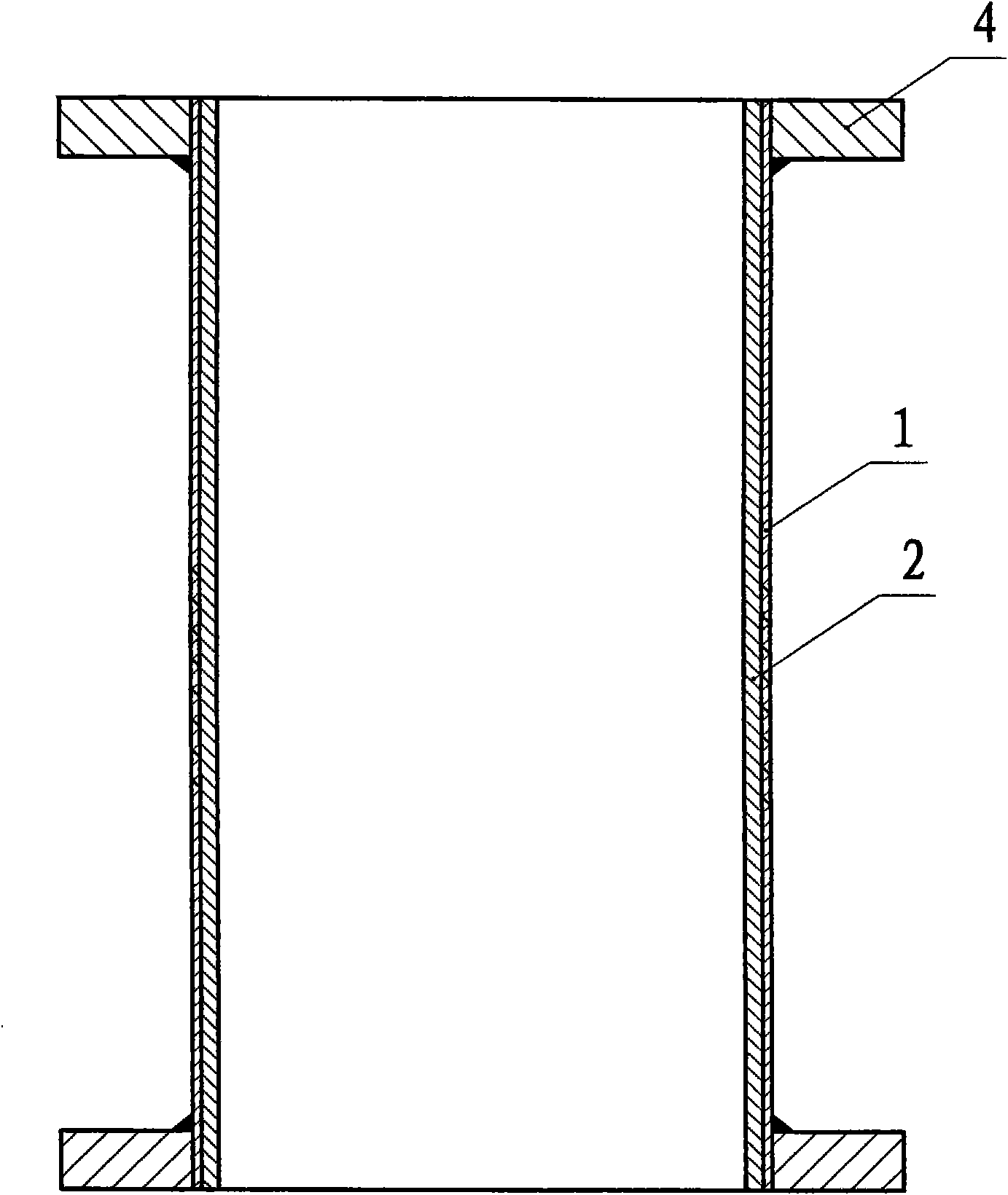

Hardening and tempering technology of alloy-steel tube

ActiveCN102676780AStress reliefUniform internal organizationFurnace typesHeat treatment furnacesHydraulic cylinderFree cooling

The invention discloses a hardening and tempering technology of an alloy-steel tube, and through the technology, the hardened and tempered alloy-steel tube is high in intensity and hardness, has good abrasion resistance and high plasticity, bears great pressure, and has small deformation and less decarburization. The technology comprises the following steps of: (1) annealing treatment: warming to 870-880 DEG C at the speed of 20-25 DEG C / minute, keeping the temperature for 35-40 minutes, and then cooling to 500 DEG C below; (2) quenching treatment: warming to 930-935 DEG C at the speed of 5-10 DEG C / minute, keeping the temperature for 50-60 minutes, then cooling rapidly at the speed of 190-200 DEG C / second to 320-325 DEG C, and cooling naturally to 30-40 DEG C; and (3) tempering treatment: warming to 500-510 DEG C at the speed of 5-10 DEG C / minute, then keeping the temperature for 230-240 minutes, and then cooling naturally to room temperature, thus the hardened and tempered alloy-steel tube is high in intensity and hardness, has good abrasion resistance and high plasticity, bears great pressure, and has small deformation and less decarburization. The hardening and tempering technology of the alloy-steel tube provided by the invention is mainly applied to the hardening and tempering of the alloy-steel tube for a hydraulic cylinder barrel.

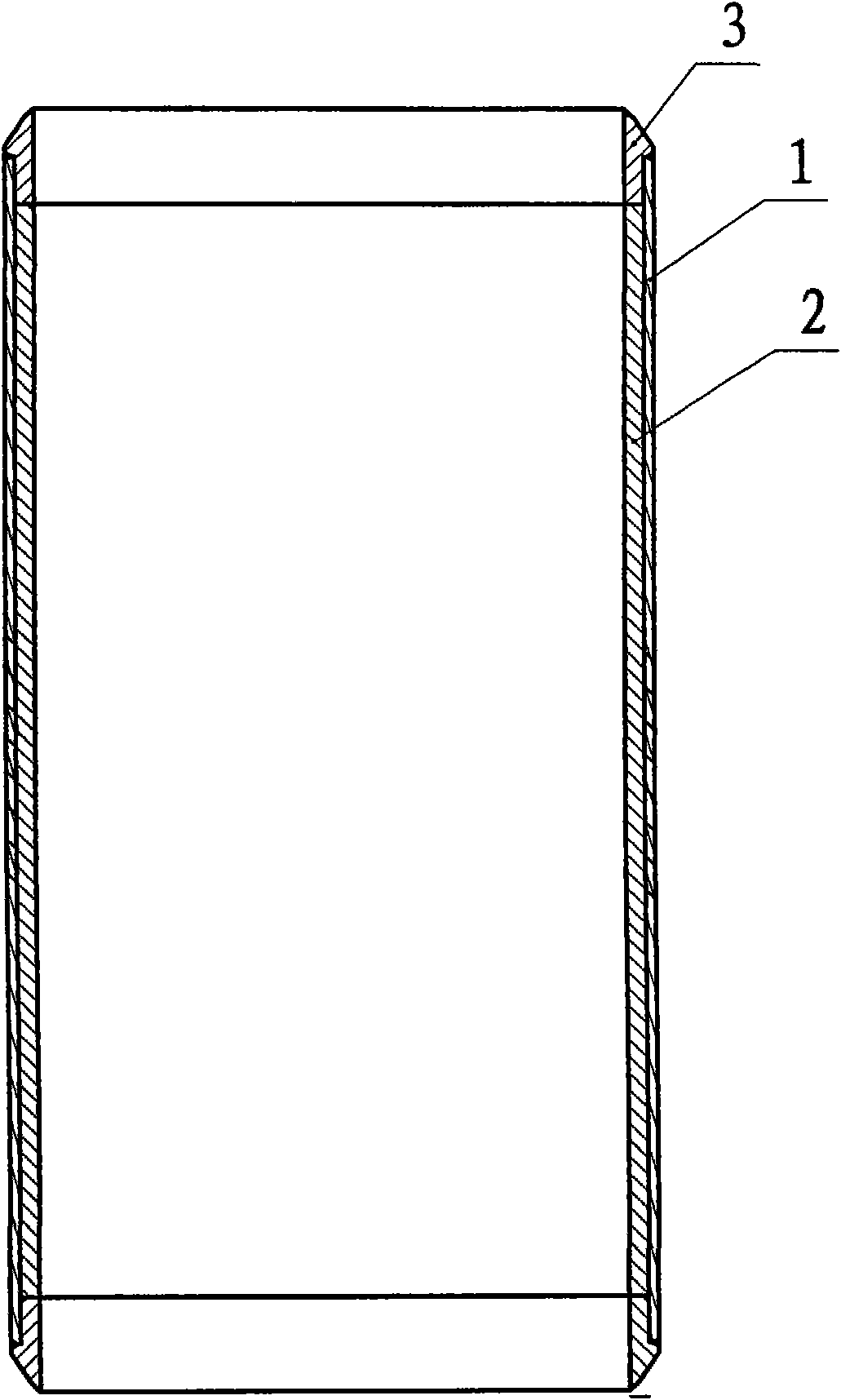

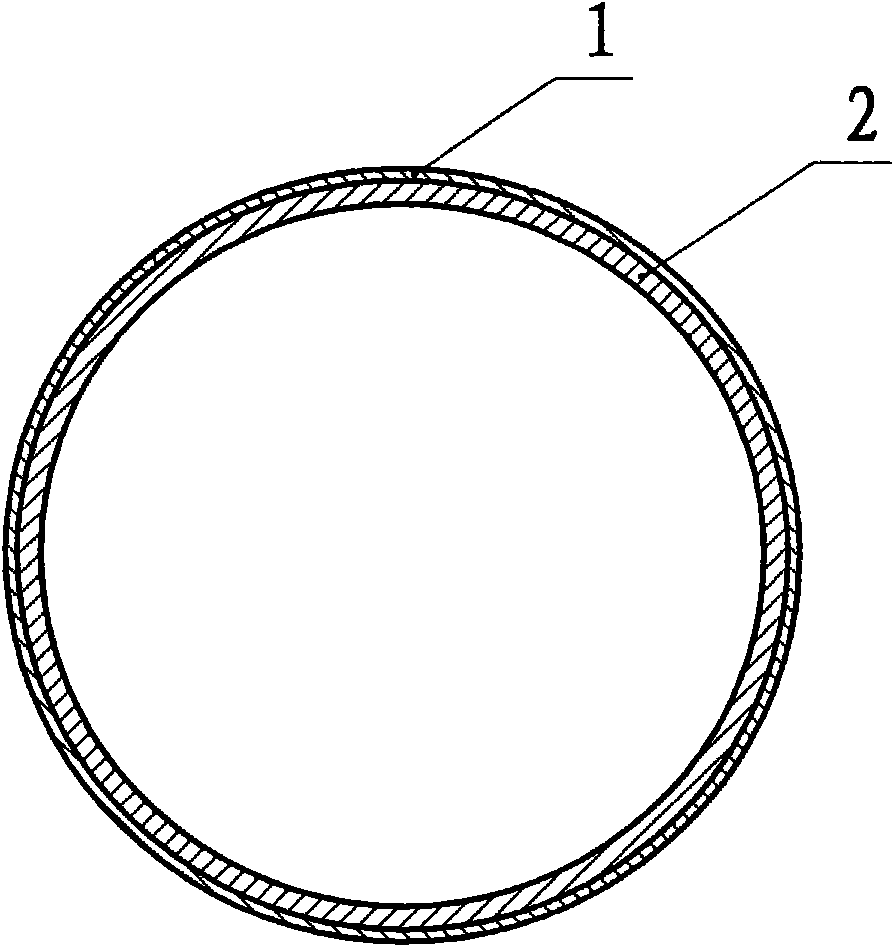

Bimetal wear resistant composite tube

InactiveCN101592265AImproved impact resistance and abrasion resistanceIncrease production speedBranching pipesRigid pipesCarbon steelChromium

The invention provides a bimetal wear resistance composite tube, which comprises a carbon steel layer in an outer layer and a wear resistant high-chromium cast iron layer in an inner layer; the carbon steel layer is made of one of three materials of ZG15, ZG25 and ZG35; and the wear resistant layer is made of one of three materials of KMTBCr26G, KMTBCr20MoG and KMTBCr15MoG. The composite tube is one of a straight tube, an elbow tube, a tee tube, a four-way tube and a special tube. The composite tube has the advantages of jointly utilizing the characteristics of the carbon steel and the high-chromium cast iron, solving the problems of wear resistance and toughness, having low cost, and also solving the unsolvable contradiction of weldability and wear resistance existing in the composite tube adopting the single material, along with long service life and convenient transportation, assembly and use.

Owner:郑州神牛铸造有限公司

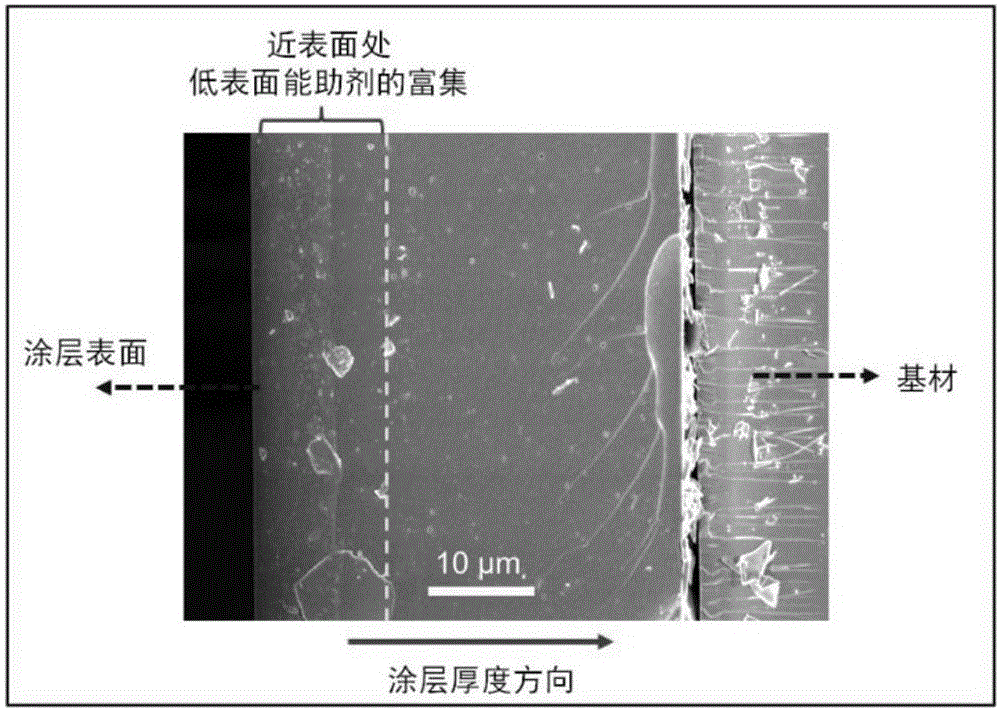

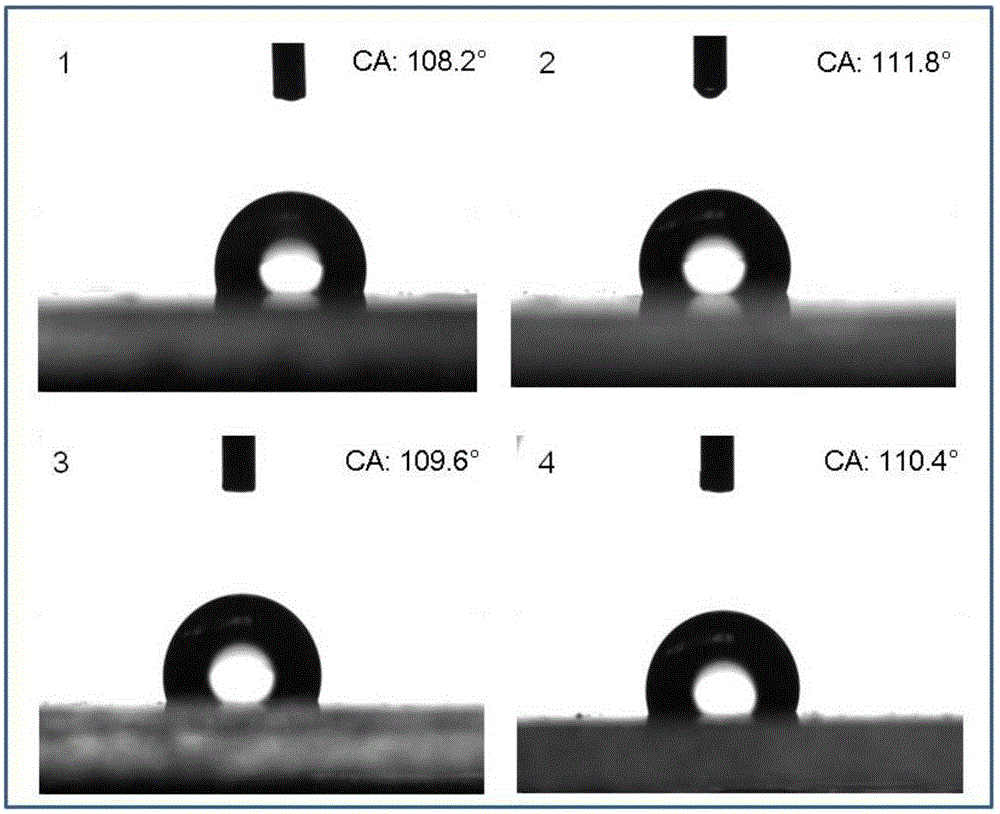

Ice-coating-resistant coating and preparation method and application thereof

ActiveCN105315870AStrong anti-icing durabilityIncreased durabilityPolyurea/polyurethane coatingsAcrylic resinDiluent

The invention is applicable to the field of coatings and provides an ice-coating-resistant coating and a preparation method and application thereof. The ice-coating-resistant coating comprises a component A and a component B, wherein the component A comprises hydroxy acrylic resin, a silane coupling agent, low-surface energy auxiliaries containing silicon, surface modification auxiliaries, diluents and other auxiliaries, and the component B is fatty acids isocyanate. The ice-coating-resistant coating is good in ice-coating-resistant durability, the water contact angle of the coating is large, the adhesive force between the coating and a substrate is good, mechanical performance is excellent, and the process is simple.

Owner:安徽足迹新材料科技有限公司

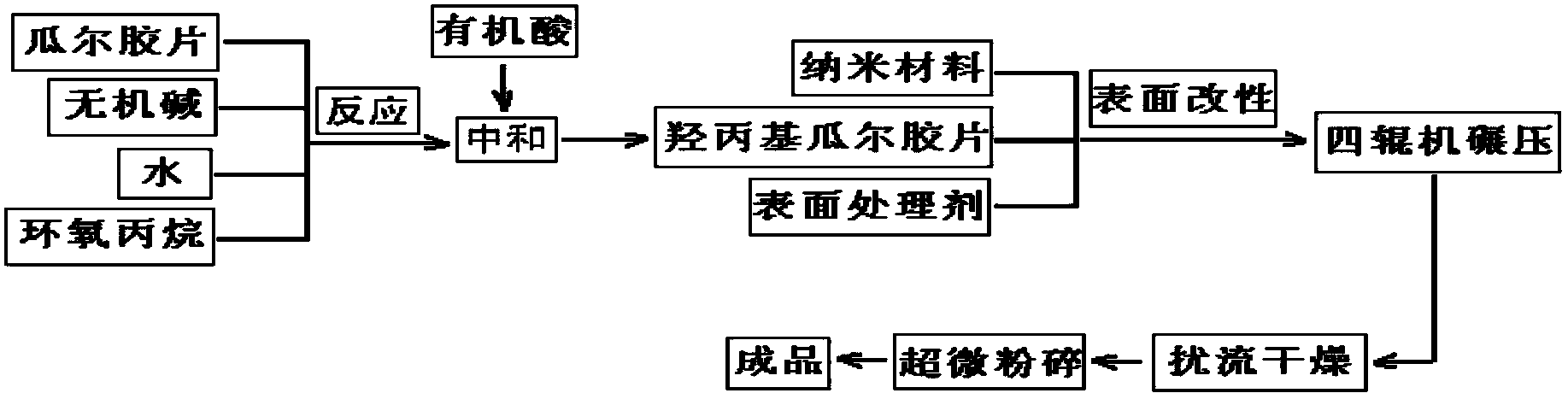

Method for preparing instant guar gum applicable to continuous blending under low temperature condition

ActiveCN103641927ARapid dispersion and thickeningFast dissolutionDrilling compositionSolubilityEnvironmental resistance

The invention relates to a method for preparing instant guar gum applicable to continuous blending under a low temperature condition. The method comprises the following steps: performing chemical modification and neutral reaction on guar gum pieces in a kneading machine so as to prepare hydroxypropyl guar gum pieces, adding a nano material and a surfactant to perform surface modification so as to obtain a surface modification material, subsequently performing a grinding technique based on a four-roller machine, a succeeding stretch and tackifying technique, a turbulent flow drying technique and an airflow vortex micro powder crushing and separation technique on the surface modification material so as to obtain the instant guar gum applicable to continuous blending under the low temperature condition. By adopting the method, the difficult problem of construction in winter and autumn in northern areas can be solved, the complex separation and purification processes of washing in alcohol and water are omitted, and the method has the characteristics of freedom of wastewater and waste gas discharge in the reaction process, safety, environment friendliness, simple process, low cost, high reaction efficiency and good guar gum instant solubility.

Owner:山东金明新材料有限公司 +1

Composite adhesive specially for heat insulating polystyrene outer-wall board

InactiveCN1403522AImprove adhesionImprove aging resistanceHydrocarbon polymer adhesivesPolymer scienceAdhesive

The composite adhesive is prepared with styrene and acrylic acid copolymer emulsion, which is inorganic silica gel and organosilicon modified and has low vitrification point and high adhesion, as main adhesive component and through adding quartzite, asbestos and other reinforcing material and some assistants. The composite adhesive has high adhesion effect, high adhesion strength, good antiaging performance, high hardness and high water resistance.

Owner:上海丰慧节能环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com