Patents

Literature

3579 results about "Guar gum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

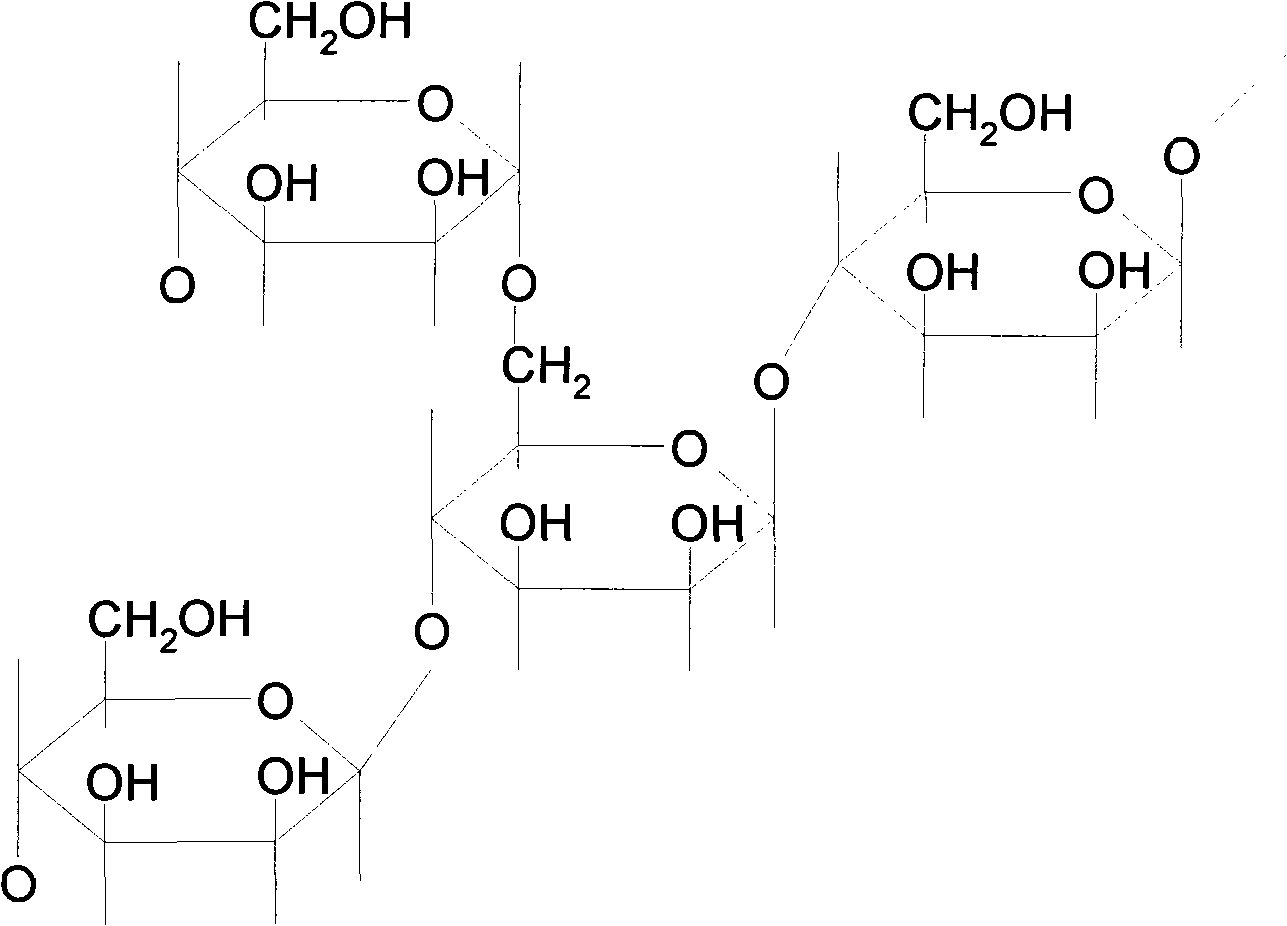

Guar gum, also called guaran, is a galactomannan polysaccharide extracted from guar beans that has thickening and stabilizing properties useful in the food, feed and industrial applications. The guar seeds are mechanically dehusked, hydrated, milled and screened according to application. It is typically produced as a free-flowing, off-white powder.

Well treating compositions containing water superabsorbent material and method of using the same

A well treating composition containing a polysaccharide-based water-superabsorbent material has particularly applicability as a thermal insulating, fracturing or acid stimulation fluid. The water-superabsorbent material is capable of absorbing, at a minimum, its own weight. Particularly effective are biodegradable materials containing guar gum and carrageenan. The composition may further contain a crosslinking agent, brine and / or a viscosifying polymer or a gelling agent. As an oil-based fluid, the crosslinking agent is absorbed onto the water-superabsorbent material and serves to effectively delay crosslinking.

Owner:BAKER HUGHES INC

Nutritional compostions comprising a soluble viscous fiber in a solid crisp matrix

InactiveUS20060078593A1Great tasteReduced slimy feelingBiocidePharmaceutical non-active ingredientsVolumetric Mass DensityGuar gum

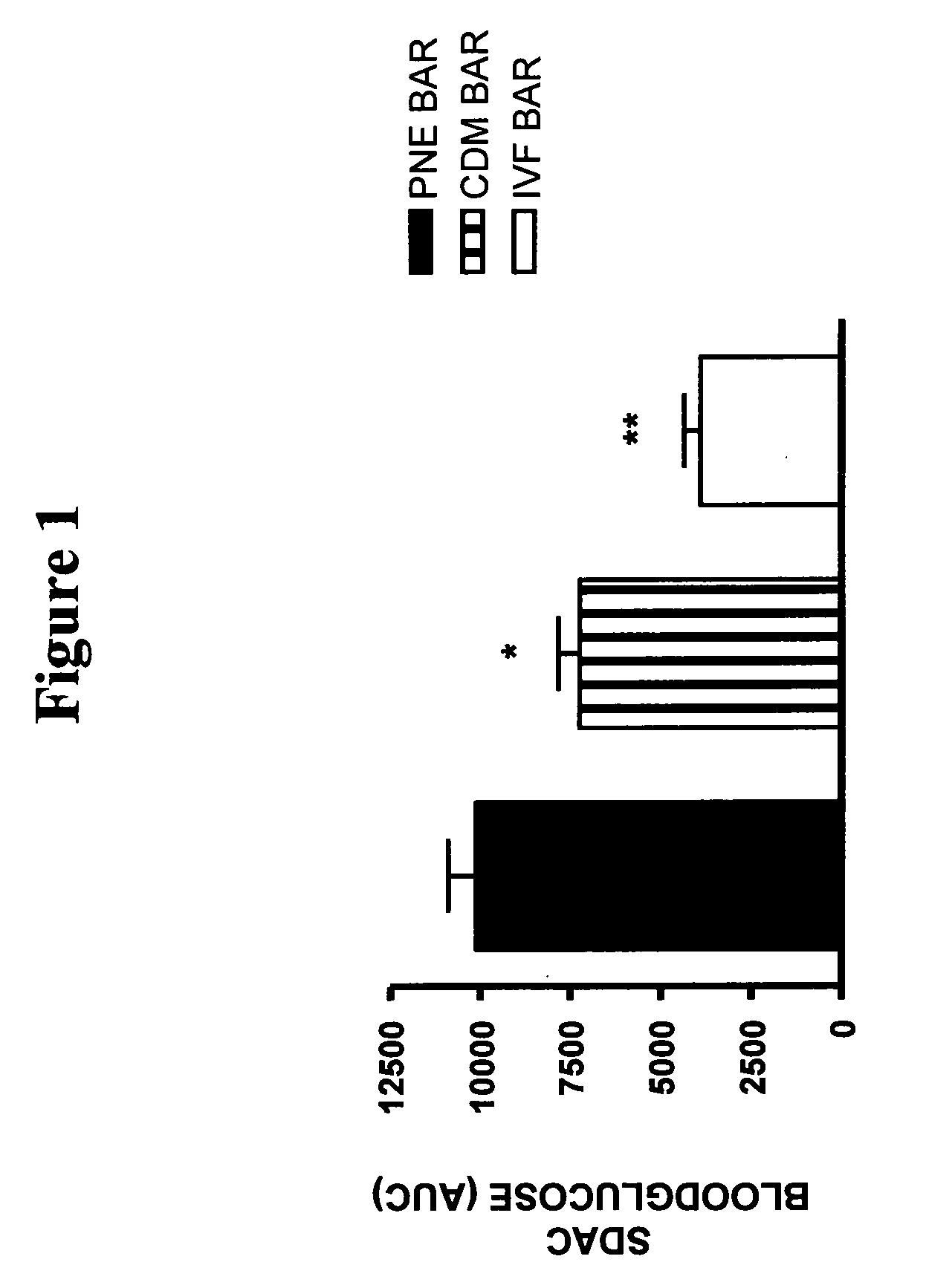

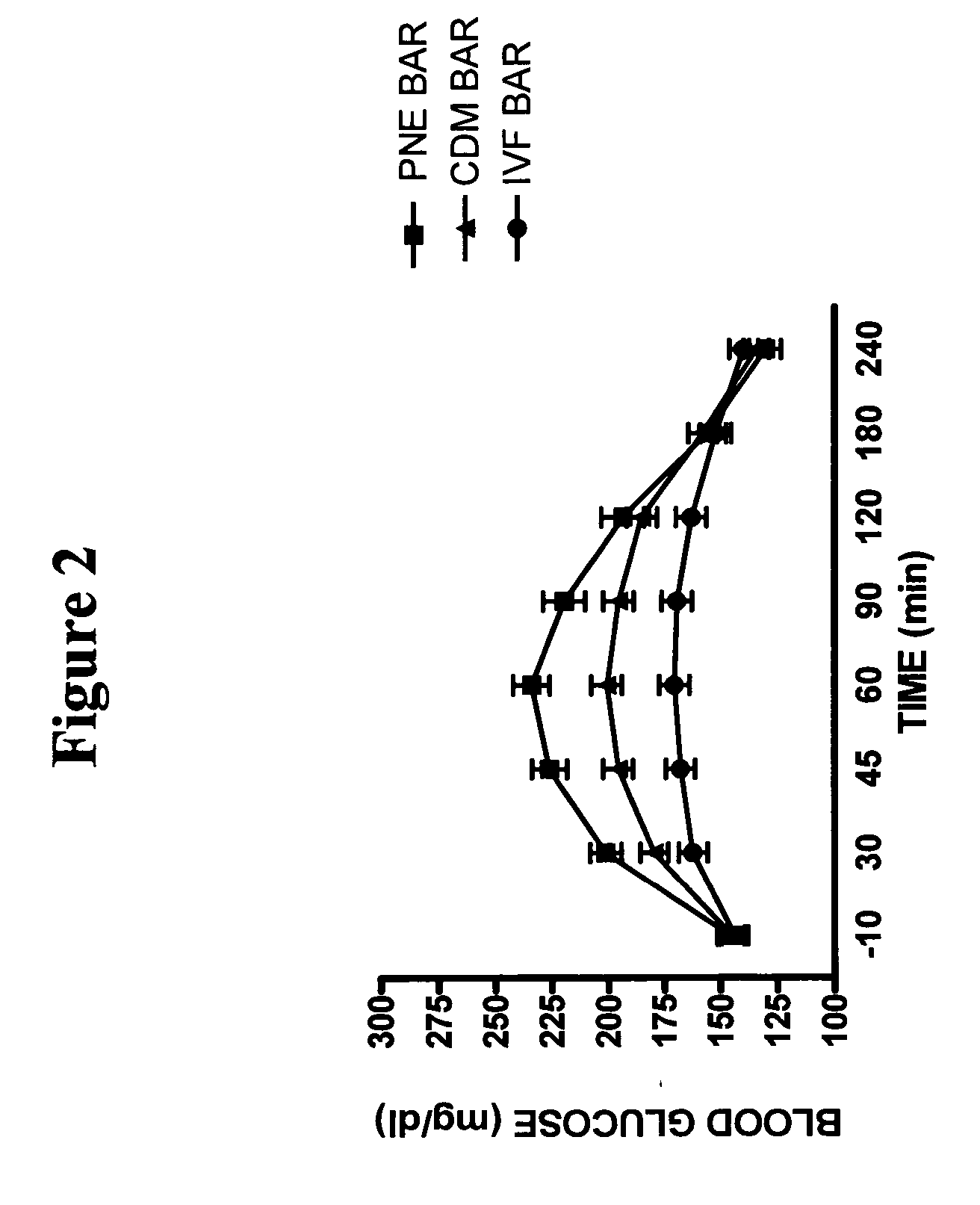

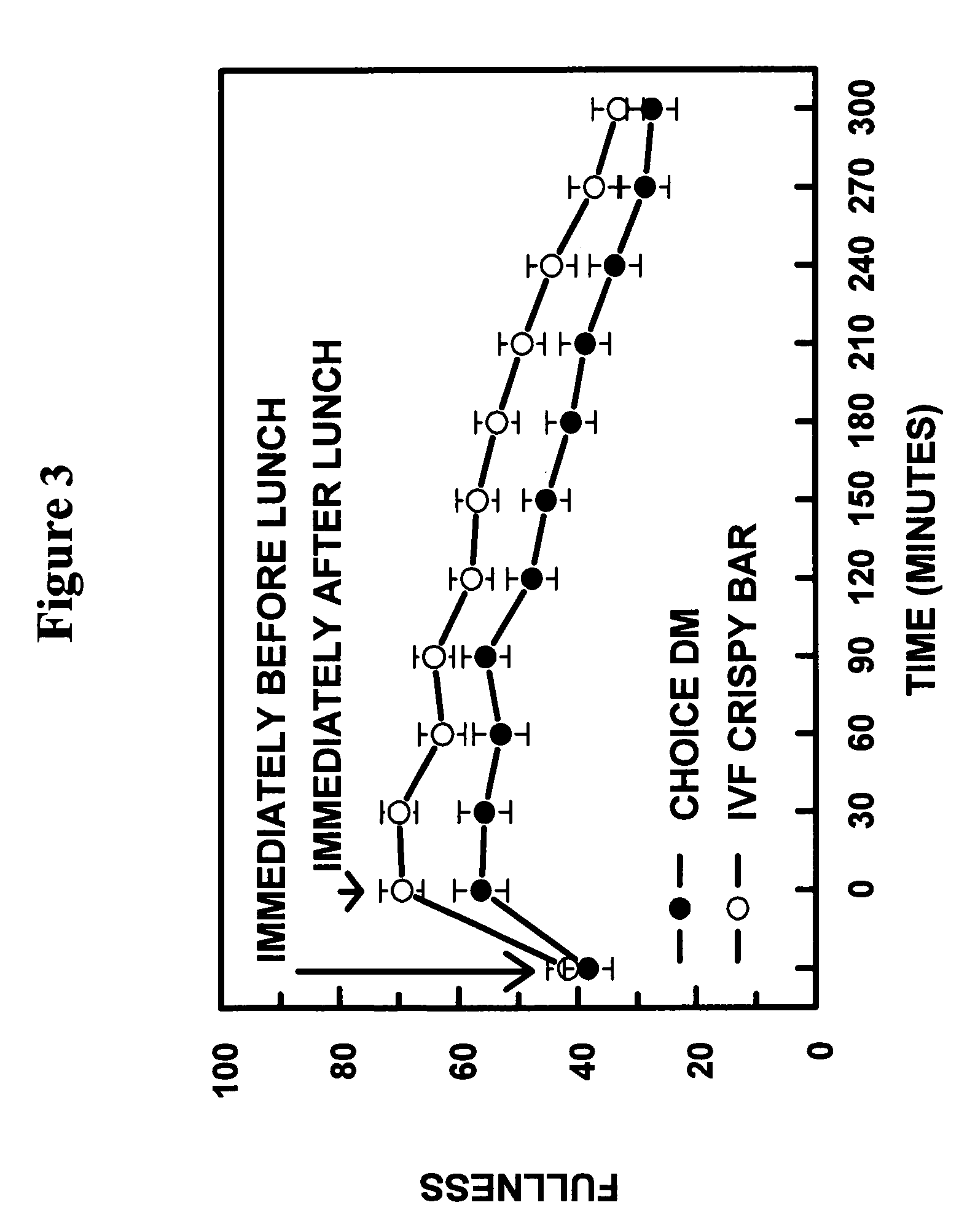

Disclosed are nutritional compositions having a solid crisp matrix, or a flour derived from the solid crisp matrix, said matrix comprising (A) from about 10% to about 50% by weight of a soluble viscous fiber, preferably guar; (B) from about 10% to about 99% by weight of a carbohydrate other than and in addition to the soluble viscous fiber; and (C) from about 1% to about 49% by weight of protein, wherein the matrix has a bulk density of less than about 0.4 g / cc. It has been found that soluble viscous fiber sources such as guar gum can be formulated into a solid crisp matrix, which then minimizes several limitations commonly associated with the formulation of such fiber sources into a conventional nutrition bar, e.g. slimy mouthfeel, tooth packing. These compositions are especially effective when formulated with gelled inclusions, including those containing or associated with acidulants, sour flavorants, or both. The nutritional compositions are especially useful as satiety agents, weight reduction agents, and / or for blunting the postprandial glycemic response in diabetics or other individuals in whom such a response would be beneficial.

Owner:ABBOTT LAB INC

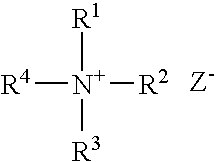

Azetidinium-functional polysaccharides and uses thereof

The present invention relates to polysaccharides that have been modified by providing azetidinium functionality thereto. Such functionality can be provided by crosslinking a polysaccharide with a resin having azetidinium functional groups. In one or more aspects, the polysaccharide can comprise one or more of starch, guar gum, alginate or derivatives thereof. Polysaccharides having azetidinium functionality according to the present invention are suitable for multiple uses. Such uses include, but are not limited to, removal of one or more solid materials from a liquid, beneficiation of an ore, removal of metallic ions from a liquid; providing oil from bitumen; and removal of mercury from synthetic gypsum. Other uses of the functionalized polysaccharides of the present invention include hydroseeding, dust control and corosion control.

Owner:GEORGIA PACIFIC CHEM LLC

Hair conditioning composition containing a non-guar galactomannan polymer derivative

A hair conditioning composition comprising:a) from about 0.01 wt. % to about 10 wt. % of a non-guar galactomannan polymer derivative having a mannose to galactose ratio of greater than 2:1 on a monomer to monomer basis, said non-guar galactomannan polymer derivative selected from the group consisting of a cationic non-guar galactomannan polymer derivative and an amphoteric non-guar galactomannan polymer derivative having a net positive charge;i. wherein said non-guar galactomannan polymer derivative has a molecular weight from about 1,000 to about 10,000,000; andii. wherein said non-guar galactomannan polymer derivative has a cationic charge density from about 0.7 meq / g to about 7 meq / g;b) a conditioning agent selected from the group consisting of cationic surfactants, cationic polymers, nonvolatile silicones, nonvolatile hydrocarbons, saturated C14 to C22 straight chain fatty alcohols, nonvolatile hydrocarbon esters, and mixtures thereof; andc) wherein said hair conditioning composition is substantially free of an anionic surfactant.

Owner:THE PROCTER & GAMBLE COMPANY

Method for preparing bacillus subtilis lipopeptid biosurfactant

InactiveCN101838621AThe fermentation process is simple to operateEfficient productionBacteriaMicroorganism based processesBacterial strainGuar gum

The invention relates to a method for preparing a bacillus subtilis lipopeptid biosurfactant, which is characterized in that the adopted bacterial strain is efficient lipopeptid producing strain bacillus subtilis BIT09S1,BIT09S2 and BIT09A2, and the lipopeptid biosurfactant is prepared by taking cheap molasses, pulse flour, konjac gum finemeal, guar gum and gum breaking liquid of modified guar gum as carbon sources for the culture medium; adding other nitrogen sources, phosphorus sources, inorganic salt components and nutrient elements into the culture medium; and carrying out fermentation, separation and purification. The raw materials used for producing lipopeptid by the method are easily obtained and can be enormously purchased. The crude extract of the obtained lipopeptid biosurfactant Surfactin can be used in various drilling and production processes such as oil-gas field fracturing, acidizing, de-plugging, controlling and water shut-off, oily water treatment, environment renovation and the like, and the biosurfactant has wide prospect.

Owner:DALIAN BITEOMICS INC

Single compartment unit dose fabric treatment product comprising pouched compositions with cationic fabric softener actives

InactiveUS20040142840A1Good flexibilityCationic surface-active compoundsDetergent materialsWater solubleGuar gum

Owner:THE PROCTER & GAMBLE COMPANY

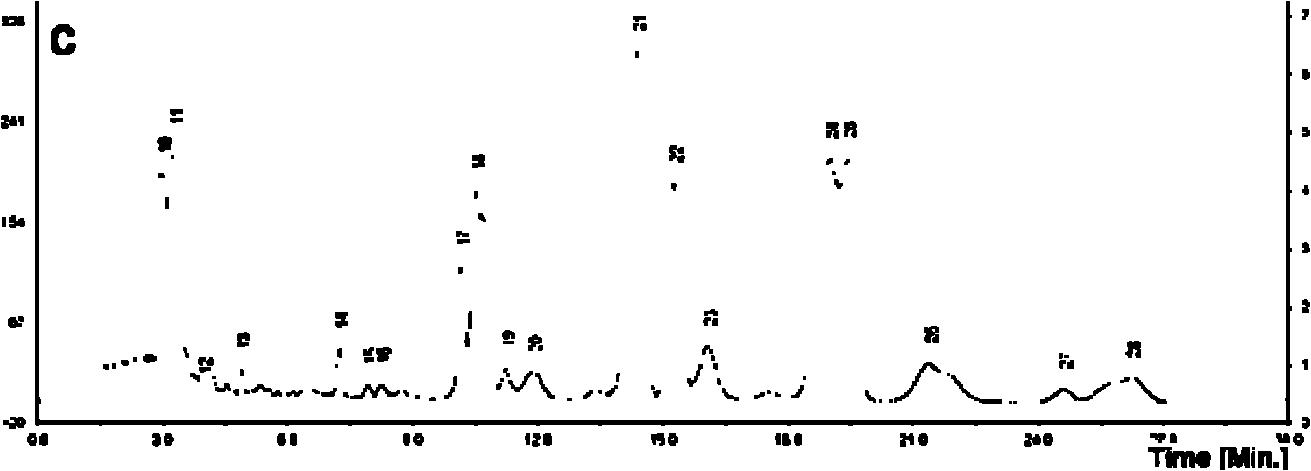

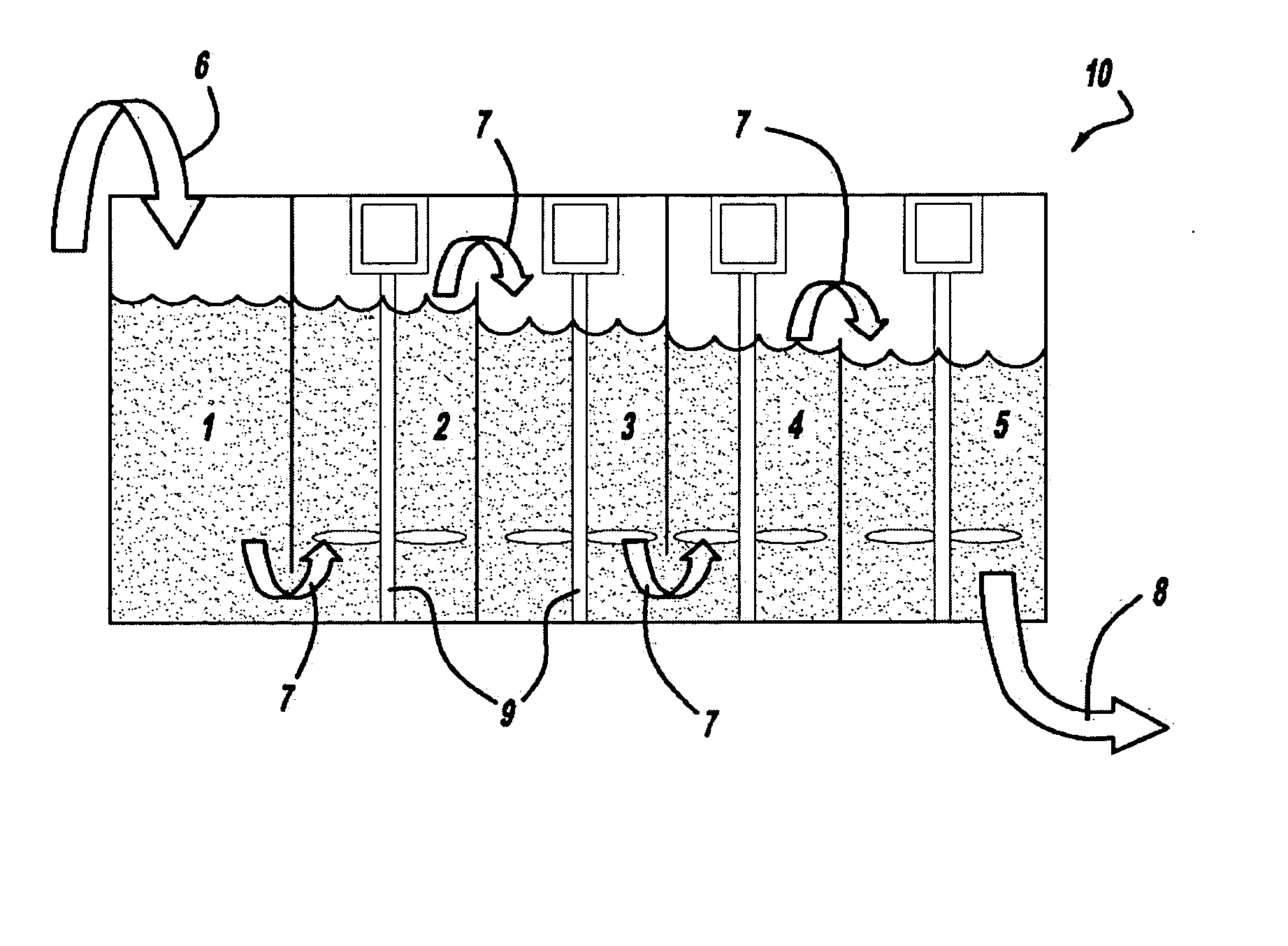

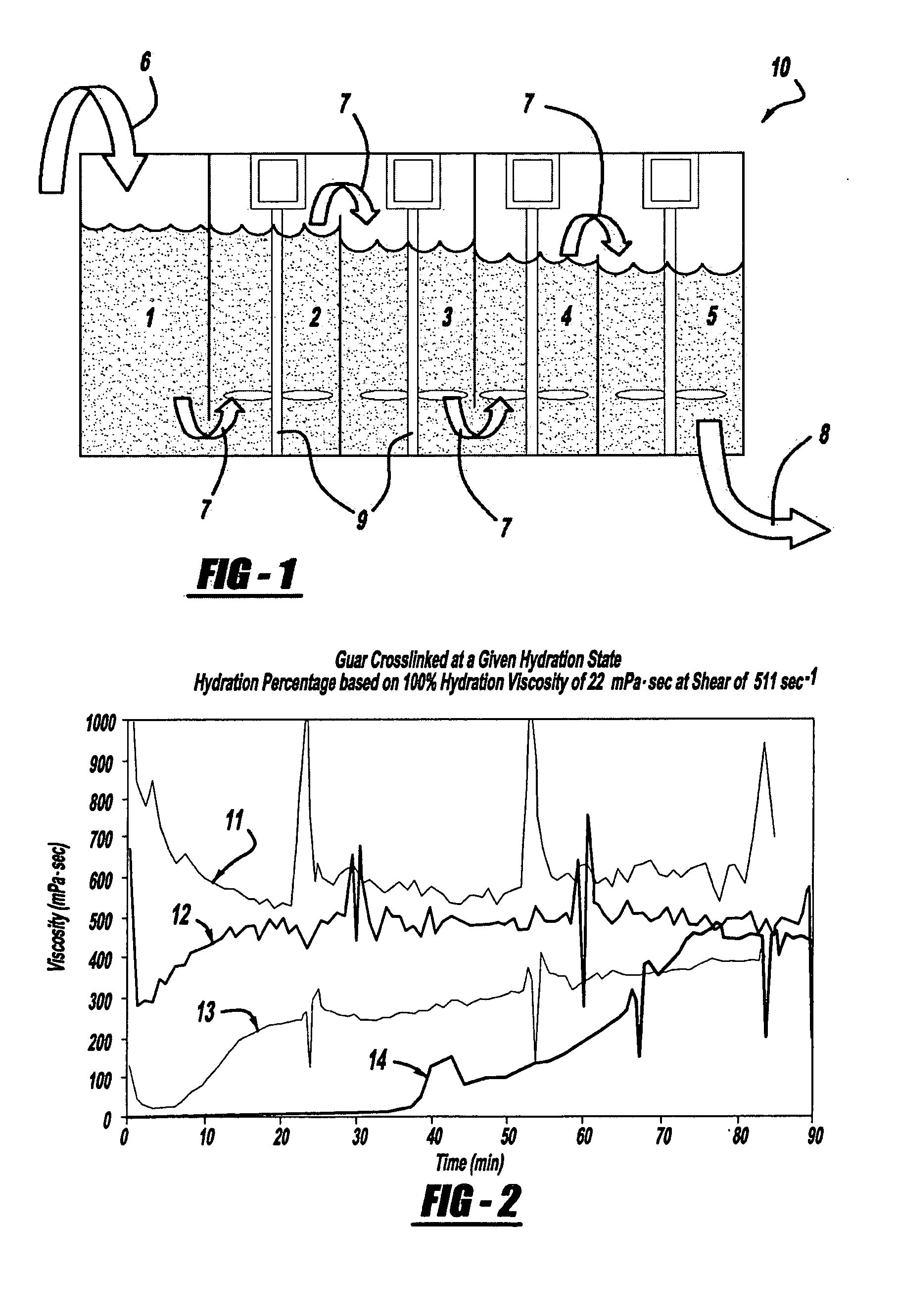

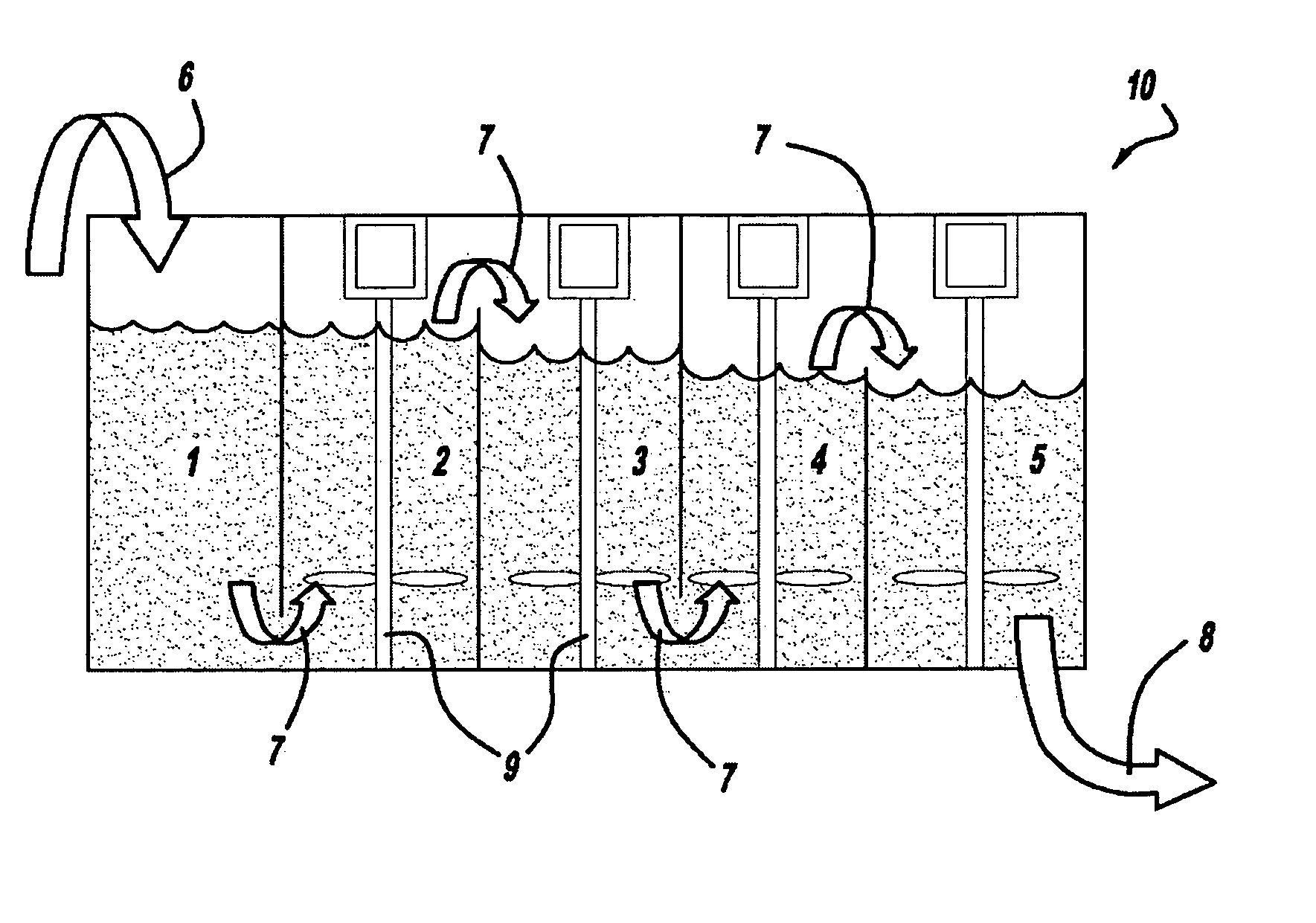

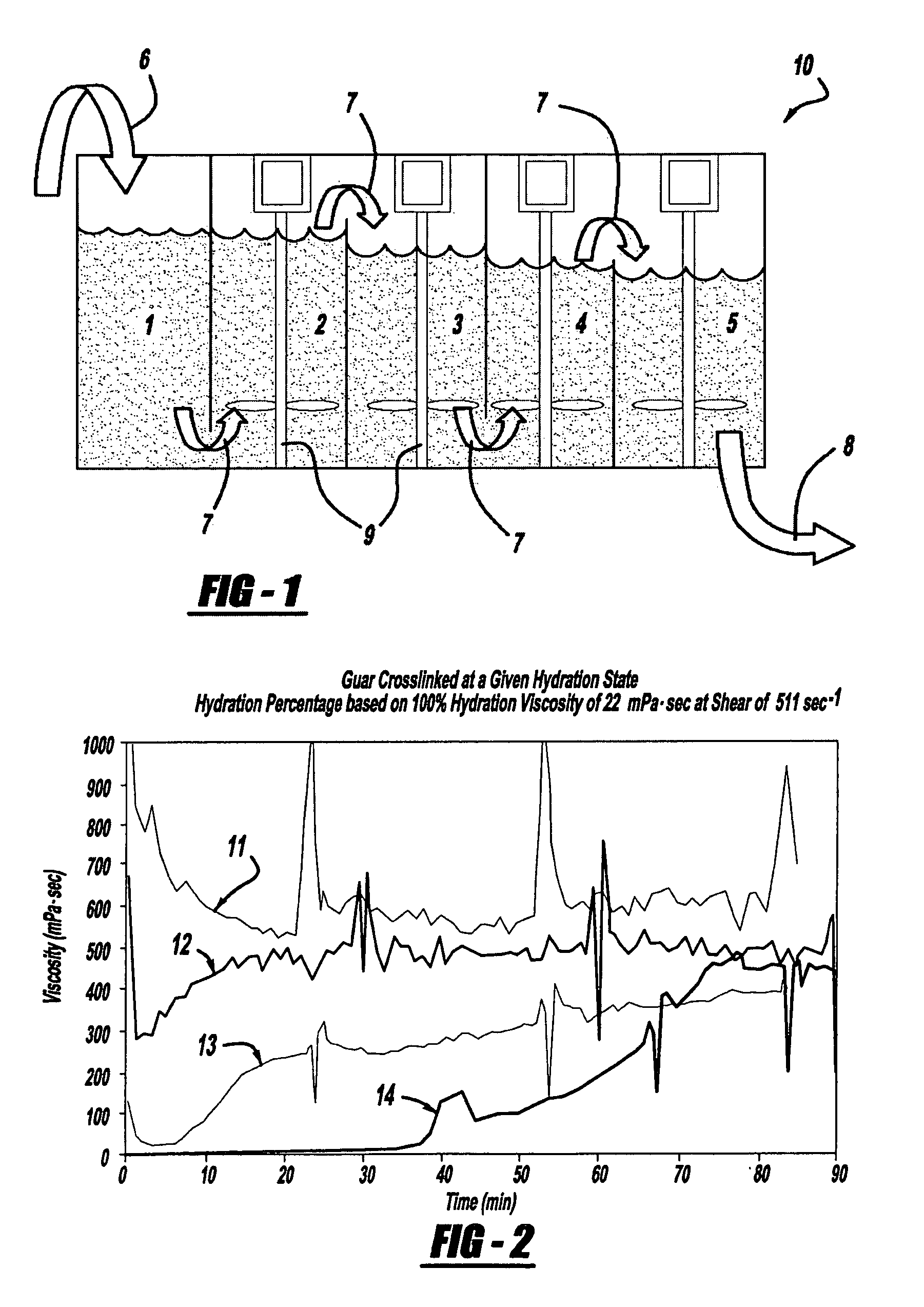

Method and composition of preparing polymeric fracturing fluids

InactiveUS20070114035A1Reduce device sizeStimulating oil productionDrilling rodsFluid removalPolyolSized small

In the presence of certain polyols, a guar gum or similar polysaccharide thickener solution is boron crosslinked before achievement of complete hydration of the thickener, without compromising the viscosity level achieved in a fracturing fluid by the time it is pumped into the wellbore and fractures the subterranean formation adjacent the wellbore. Methods continuously involve hydrating a polysaccharide thickener to an extent of 10% to 75%, but less than full hydration. Before 75% hydration is exceeded, a boron crosslinker is added. Upon addition of the boron crosslinker, the fluid is injected into the wellbore to stimulate hydrocarbon production. Because less time is needed for hydration, well site mixing equipment is down-sized smaller to achieve better efficiency and cost savings.

Owner:SCHLUMBERGER TECH CORP

Galactomannan based well treating fluids

ActiveUS20050272612A1Low polymer contentHigh molecular weightFluid removalFlushingPolymer scienceFracturing fluid

A well fracturing fluid is shown which includes an aqueous base fluid, a hydratable polymer, such as a guar gum, and a suitable crosslinking agent for crosslinking the hydratable polymer to form a polymer gel. The hydratable polymer has a higher molecular weight which is achieved by improvements in the processing of the guar split. The higher molecular weight polymer provides improved performance in well fracturing operations.

Owner:BAKER HUGHES INC

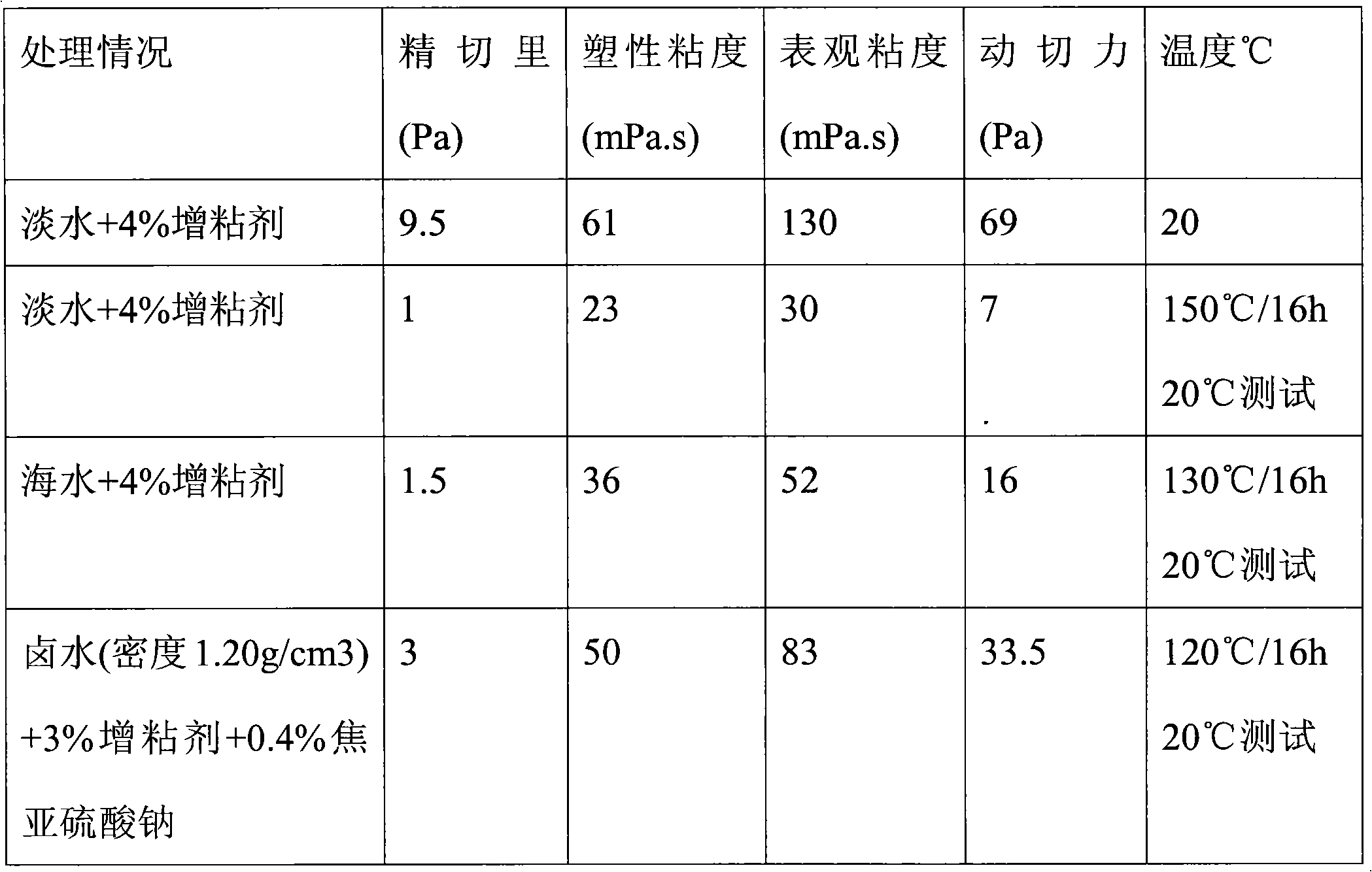

High-temperature resistance tackifier for drilling fluid and preparation method thereof

ActiveCN102127401AGood resistance to salt and viscosity increaseImprove temperature resistanceDrilling compositionTemperature resistanceSolvent

The invention relates to a petroleum drilling fluid, in particular to a high-temperature resistance tackifier for a drilling fluid and a preparation method thereof. The high-temperature resistance tackifier for the drilling fluid comprises the following components in parts by mass: 1 part of starch, 0.05-5 parts of guar gum, 0.01-2 parts of alkaline hydroxides, 0.02-6 parts of epoxide and 0-9 parts of alcohol solvent. The preparation method of the high-temperature resistance tackifier for the drilling fluid comprises the following steps of: adding the starch and the guar gum to a vessel, thenadding the epoxide and the alcohol solvent and stirring for 10-30min, then adding a water solution of alkaline hydroxides, continuously stirring and reacting for 20min-3h at 0-120 DEG C, discharging,drying and crushing to obtain a finished product. The tackifier prepared by adopting the preparation method disclosed by the invention achieves the purpose of improving the temperature resistance of a solid-free drilling fluid for a deep well and the viscosity and the shearing force of the drilling fluid.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

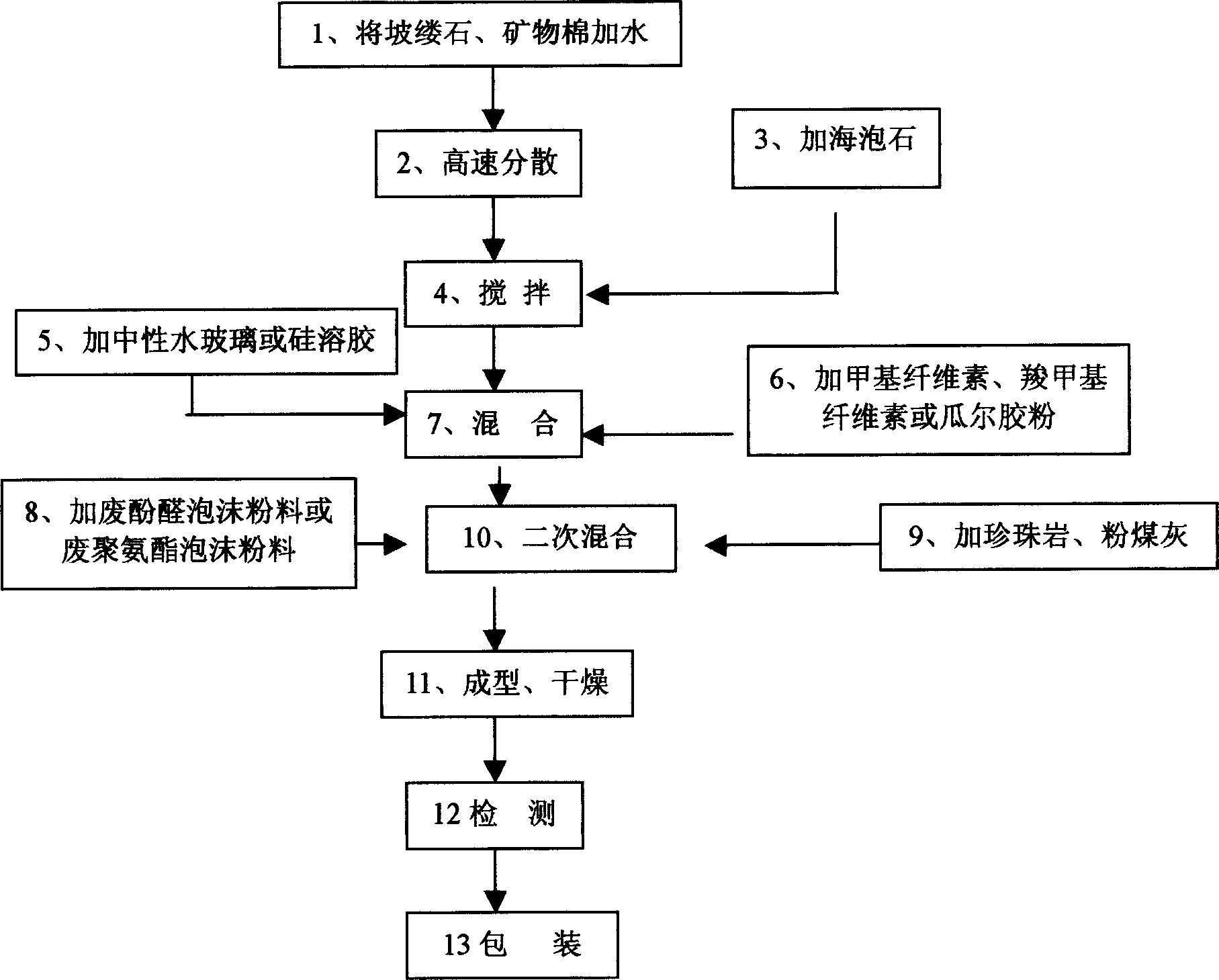

Composite material thermal insulation plate

InactiveCN1511808ANo pollution in the processStrong self-breathing functionThermal insulationSolid waste managementAdhesiveHeat conducting

The thermal insulating plate of composite material is produced with waste foamed phenolic plastic powder as basic heat insulating material, flyash as stuffing, expanded perlite as aggregate, mineral wool, glass wool, sepiolite and palygorskite as reinforcing material, neutral water glass or silica sol as inorganic adhesive and guar gum, methylcellulose or CMC as organic adhesive, and through high speed dispersion, stirring, mixing, molding, forming and drying. The thermal insulating plate has low heat conducting coefficient, is non-inflammable, smell-less, non-toxic, long in service life and wide in application range. The production process adopts industrial waste as main components and produces no waste, and used plate may be reused, so that the present invention is significant in environment protection.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

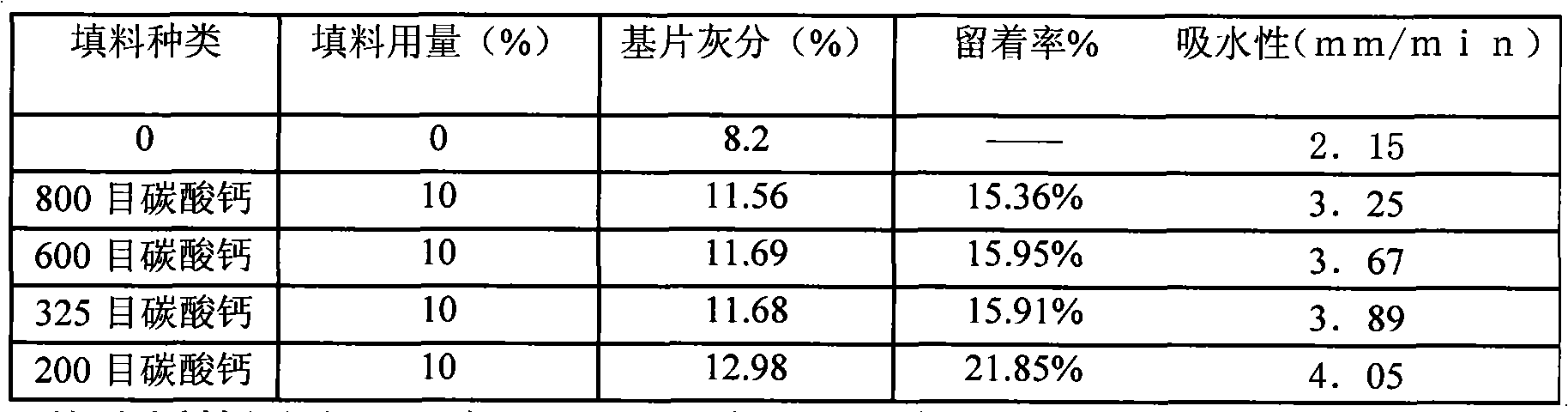

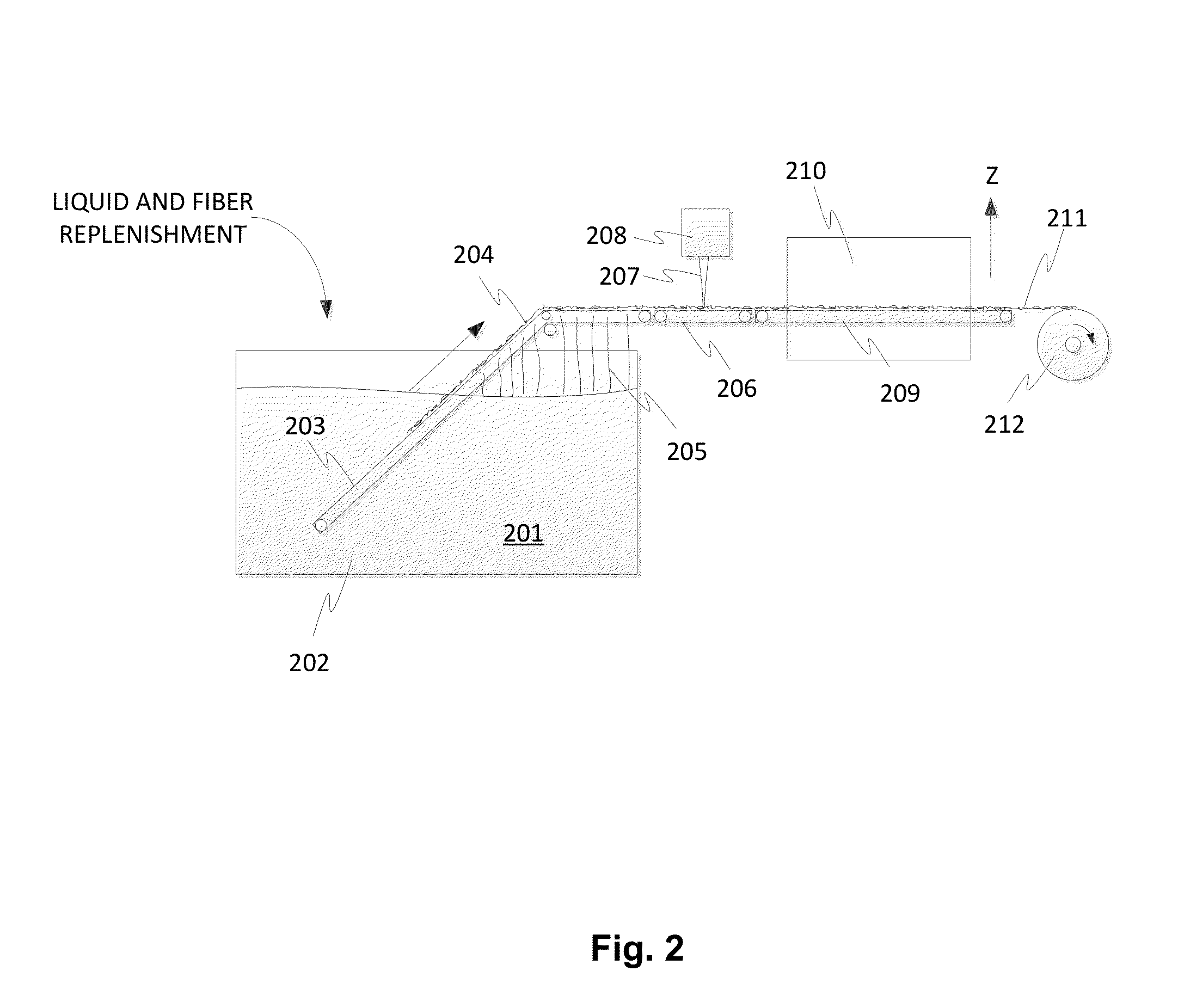

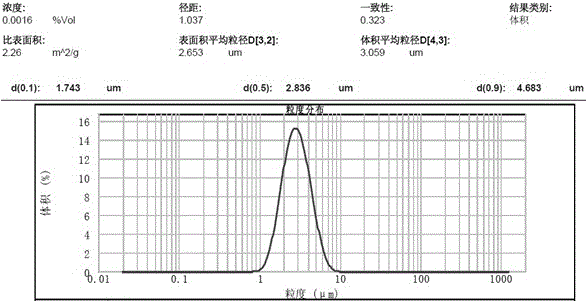

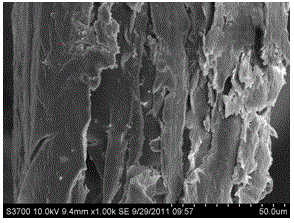

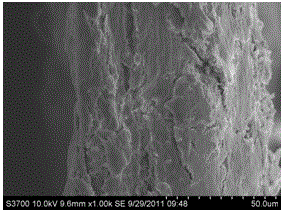

Method for improving sheet quality by increasing retention of filler calcium carbonate in sheet

InactiveCN101683180AImprove retentionQuality improvementTobacco preparationGranularityElectron microscope

The invention discloses a method for improving sheet quality by increasing retention of a filler calcium carbonate in a sheet, belonging to the technical field of tobacco sheets. The method adopts thefollowing technical measures: (1) selecting nonsphericity as the grain shape of the calcium carbonate through an electron microscope; (2) controlling the granularity between 125 meshes and 400 meshes; (3) ensuring the addition of the filler calcium carbonate to be 7-12% of the total weight of mixed slurry; (4) adding guar gum accounting for 0.04-0.2% of the total weight of the mixed slurry into the slurry to serve as a retention aid; and (5) adding an anion catcher accounting for 0.1-0.8% of the total weight of the mixed slurry into the slurry. The method features effective measures and obvious generated technical effects, solves the technical problems and can improve the retention of the filler calcium carbonate in the sheet and the sheet quality.

Owner:HUBEI CHINA TOBACCO IND +1

Highland barley noodle

ActiveCN1969666AHigh nutritional valueImprove immunityDough treatmentMetabolism disorderManihotCholesterol

The invention discloses a barley noodle, which comprises the following parts: one or more component from barley noodle, wheat flour, maize starch, manihot starch, sweet potato starch, potato starch and glutelin powder, one or more of glutamine transaminase, xylanase and cellulose enzyme, one or more of guar gum, xanthan gum, sodium polyacrylate, sodium alginate and konjaku flour, one or more of monosodium calcium lactate stearate, diacetyl tartaric acid monoester, soya phosphatide and monoaliphatic acid glyceride, water, salt and egg.

Owner:青海大垚生态农业科技发展有限公司

Well treating compositions containing water superabsorbent material and method of using the same

InactiveUS7316275B2Improve the level ofFacilitate cross-linkingDrilling rodsInsulationCarrageenanAbsorbent material

A well treating composition containing a polysaccharide-based water-superabsorbent material has particularly applicability as a thermal insulating, fracturing or acid stimulation fluid. The water-superabsorbent material is capable of absorbing, at a minimum, its own weight. Particularly effective are biodegradable materials containing guar gum and carrageenan. The composition may further contain a crosslinking agent, brine and / or a viscosifying polymer or a gelling agent. As an oil-based fluid, the crosslinking agent is absorbed onto the water-superabsorbent material and serves to effectively delay crosslinking.

Owner:BAKER HUGHES INC

Viscosity modified formaldehyde-free binder compositions

ActiveUS20140134909A1High viscosityLaminate strength deterioratesNon-fibrous pulp additionNon-macromolecular adhesive additivesGuar gumHydroxyethyl cellulose

Viscosity-modified carbohydrate binder compositions are described. The binder compositions may include a carbohydrate, a nitrogen-containing compound, and a thickening agent. The binder compositions may have a Brookfield viscosity of 7 to 50 centipoise at 20° C. The thickening agents may include modified celluloses such as hydroxyethyl cellulose (HEC) and carboxymethyl cellulose (CMC), and polysaccharides such as xanthan gum, guar gum, and starches.

Owner:JOHNS MANVILLE CORP

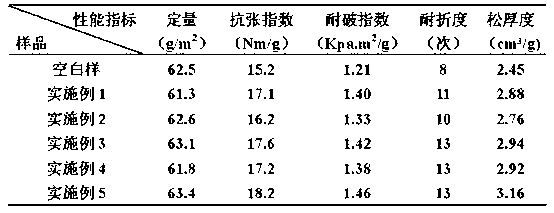

Method for improving reconstituted tobacco paper-base quality through adding calcium carbonate and reconstituted tobacco paper-base

ActiveCN102715642APlay the role of reducing focus and harmImprove surface propertiesTobacco preparationTobacco treatmentPaper basedGuar gum

The invention discloses a method for improving the reconstituted tobacco paper-base quality through adding calcium carbonate and a reconstituted tobacco paper-base, belonging to the technical field of cigarette production. The method for improving the reconstituted tobacco paper-base quality through adding calcium carbonate comprises the steps of soaking and extracting tobacco stems and tobacco powder, grinding, pulping, sheet making, squeezing and drying, wherein in the sheet making step, the calcium carbonate and guar gum which respectively occupies 10-70% and 0.05-0.5% of the mass percent of the tobacco raw pulp are added into the tobacco raw pulp. Researches show that after the calcium carbonate and the guar gum are added according to an appropriate proportion, the tensile index, tear index and air permeability of the produced reconstituted tobacco paper-base are obviously improved, the whole water-absorption performance of the reconstituted tobacco paper-base is also improved, the tar yield, CO content and total particle matter content of the sheet paper-base are obviously decreased, so that the tar and harm reduction function of the reconstituted tobacco is better played, the combination property of the tobacco sheet is effectively improved, and the operation performance and effectiveness of a reconstituted tobacco production line are improved.

Owner:CHINA TOBACCO GUANGDONG IND +1

Method of using immunoglobulin and fiber-containing compositions for human health

InactiveUS6180099B1Restore gastrointestinal healthMaintain gastrointestinal healthBiocideDispersion deliveryFiberGluconic acid

A composition for restoring and maintaining gastrointestinal health comprises 40-60% by weight of an immunoglobulin composition comprising concentrated immunologically active immunoglobulins and 40-60% by weight of soluble dietary fiber selected from inulin, fructo-oligosaccharides, pectin, guar gum, and mixtures thereof. The immunoglobulin and fiber-containing composition can optionally contain one or more of a beneficial human intestinal microorganism, components of a non-immune natural defense system, an iron-sequestering molecule, and gluconic acid. Preferred beneficial human intestinal microorganisms include lactobacilli and bifidobacteria. The immunologically active immunoglobulins are preferably purified from bovine milk, milk products, or whey. Methods of use are also described.

Owner:METAGENICS INC

Preparation method and application of hydrophobic modified guar gum

InactiveCN102827300ANot easy to degradePreserve macromolecular quality propertiesWater-repelling agents additionCelluloseOrganic acid

The invention discloses a preparation method and an application of hydrophobic modified guar gum. The method comprises the following steps of: suspending guar gum in an ionic liquid, adding a basic catalyst, and alkalifying at the temperature of 10-40 DEG C; gradually heating under the protection of nitrogen, dropwise adding a modifying agent slowly, and heating to 30-80 DEG C for performing a modification reaction; and after the reaction, adding organic acid for adjusting the pH to 5-7, soaking and washing with ethanol, filtering, and drying a filter cake in vacuum to obtain the hydrophobic modified guar gum. A hydrophobic alkyl long chain is introduced into guar gum hydroxyl, and a terminal group is a carboxylic acid group, so that the water dissolving speed of the guar gum is increased, the macromolecular quality characteristic of the guar gum is protected to the maximum extent, and the guar gum is endowed with hydrophobic performance. Compared with other modified guar gum, the hydrophobic guar gum has the advantages of high molecular weight, high compatibility with cellulose, increase in the molecular bonding force of cellulose-guar gum, improvement on the paper strength and applicability to a paper-making wet part chemical process as a reinforcing agent and a surface sizing agent.

Owner:SOUTH CHINA UNIV OF TECH

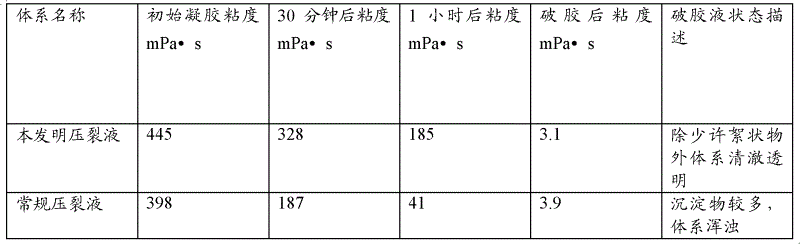

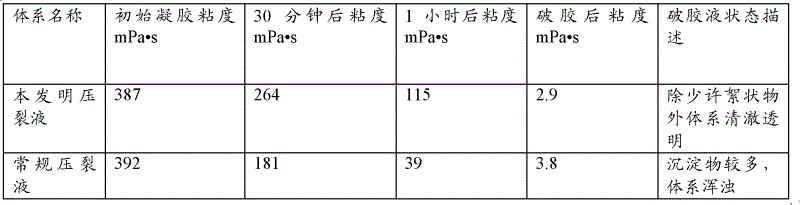

Seawater base fracturing fluid and preparation method thereof

The invention relates to seawater base fracturing fluid, which is obtained by the steps of mixing 97-99 weight parts of seawater, 0.3-0.7 weight part of a thickening agent, 0.5-0.8 weight part of a surfactant, 0.05-0.2 weight part of a potential of hydrogen (pH) adjusting agent and 0.01-0.05 weight part of a gel breaker, and then performing cross-linking reaction with 0.3-0.7 weight part of a cross-linking agent. The thickening agent is a guar gum derivative formed by modifying hydroxyalkyl, carboxyl alkyl and sulfonic acid groups. The invention further relates to a preparation method of the seawater base fracturing fluid.

Owner:CHINA NAT OFFSHORE OIL CORP +1

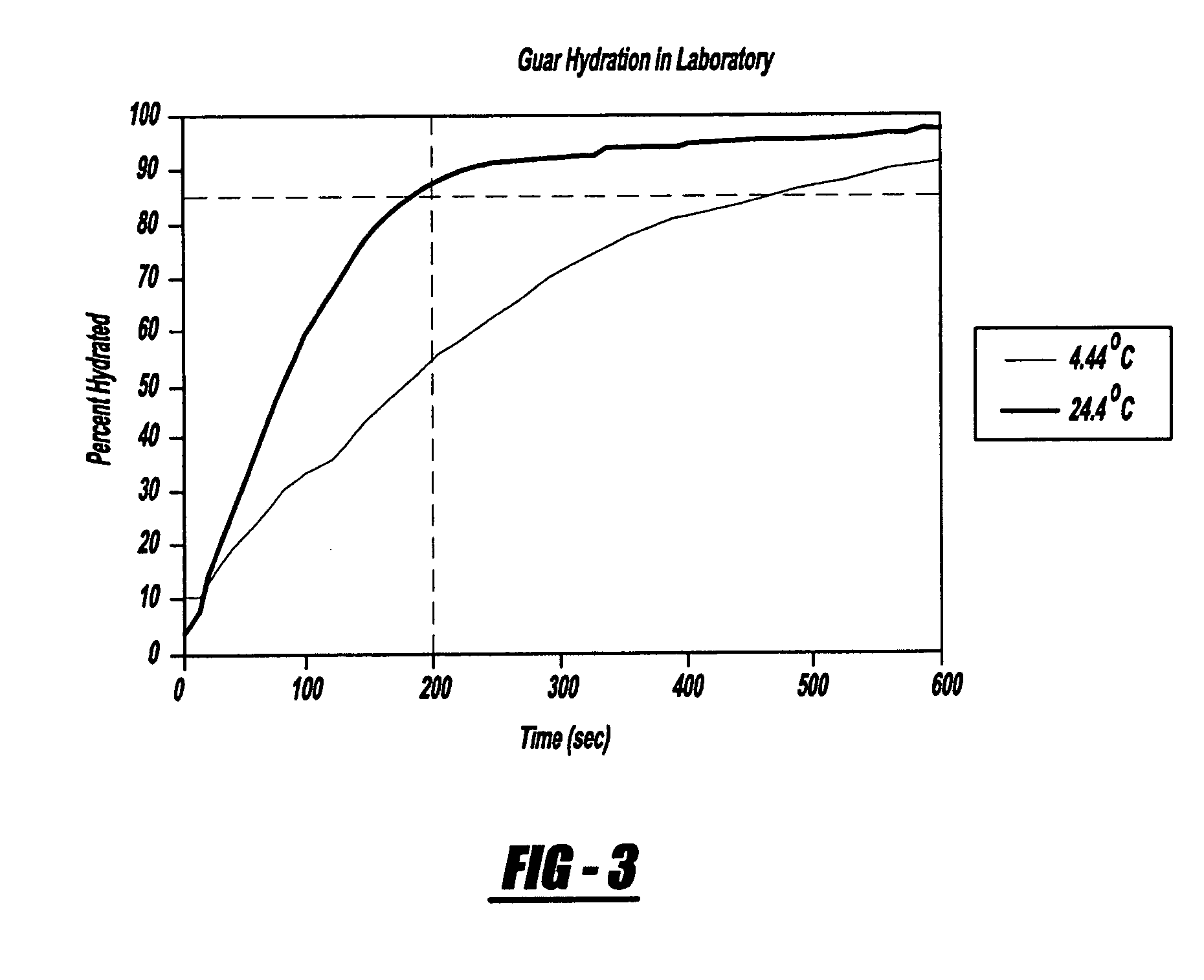

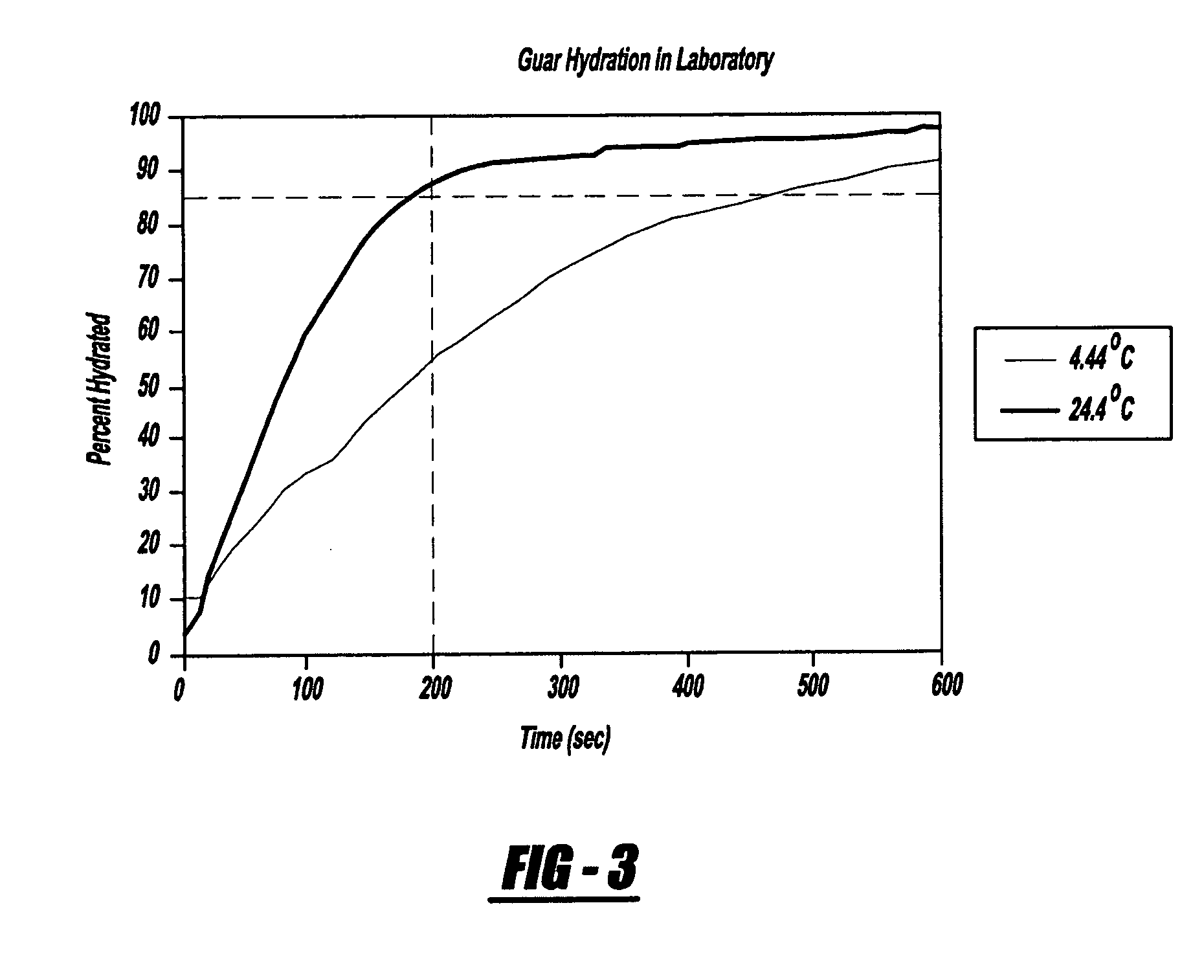

Methods and compositions for enhancing guar hydration rates and performing guar derivitization reactions

One embodiment of the present invention provides a method of treating guar splits comprising exposing guar splits to a treatment chemical to create treated guar splits; and then, without first washing the treated guar splits, grinding the treated guar splits; and, then drying the ground, treated guar splits. Another embodiment of the present invention provides a method of treating a portion of a subterranean formation comprising providing a treatment fluid comprising a viscosifying agent wherein the viscosifying agent comprises ground, treated guar splits made by the following method: exposing guar splits to a treatment chemical to create treated guar splits; and then, without first washing the treated guar splits, grinding the treated guar splits; and, then drying the ground, treated guar splits; placing the treatment fluid into a portion of a subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

Coarse cereal noodles and preparation method thereof

The invention provides coarse cereal noodles with abundant nutriments and smooth mouthfeel and a preparation method thereof. The coarse cereal noodles comprise the following components in percentage by weight: 88.8 percent of flour, 0.5 percent of mung beans, 0.5 percent of red beans, 1.5 percent of kidney beans, 2.5 percent of black beans, 0.5 percent of oats, 2.5 percent of buckwheat, 0.5 percent of corn meal, 0.5 percent of sorghum, 0.2 percent of guar gum and 2 percent of iodized salt, wherein water is added in an amount which is 35 percent based on the total weight of the components in the process of kneading dough. The preparation method comprises the following steps of: sifting raw materials; adding the water into 0.2 weight percent of guar gum and 2 weight percent of iodized salt,pouring the mixture into a dough kneading pot, and stirring; making the aged dough into dough belts through a compound machine; cutting calendered dough sheets into strips and cutting the strips off;and cutting dried noodles into noodles with the standard length meeting packaging requirements. The coarse cereal noodles keep the nutrition components of coarse cereals, and replenish multiple nutrient substances such as amino acids, vitamins, proteins, mineral substances and the like for human bodies.

Owner:BEIDAHUANG FENGYUAN GRP +1

Method and composition of preparing polymeric fracturing fluids

InactiveUS7497263B2Reduce device sizePromote productionFluid removalDrilling compositionPolyolSized small

In the presence of certain polyols, a guar gum or similar polysaccharide thickener solution is boron crosslinked before achievement of complete hydration of the thickener, without compromising the viscosity level achieved in a fracturing fluid by the time it is pumped into the wellbore and fractures the subterranean formation adjacent the wellbore. Methods continuously involve hydrating a polysaccharide thickener to an extent of 10% to 75%, but less than full hydration. Before 75% hydration is exceeded, a boron crosslinker is added. Upon addition of the boron crosslinker, the fluid is injected into the wellbore to stimulate hydrocarbon production. Because less time is needed for hydration, well site mixing equipment is down-sized smaller to achieve better efficiency and cost savings.

Owner:SCHLUMBERGER TECH CORP

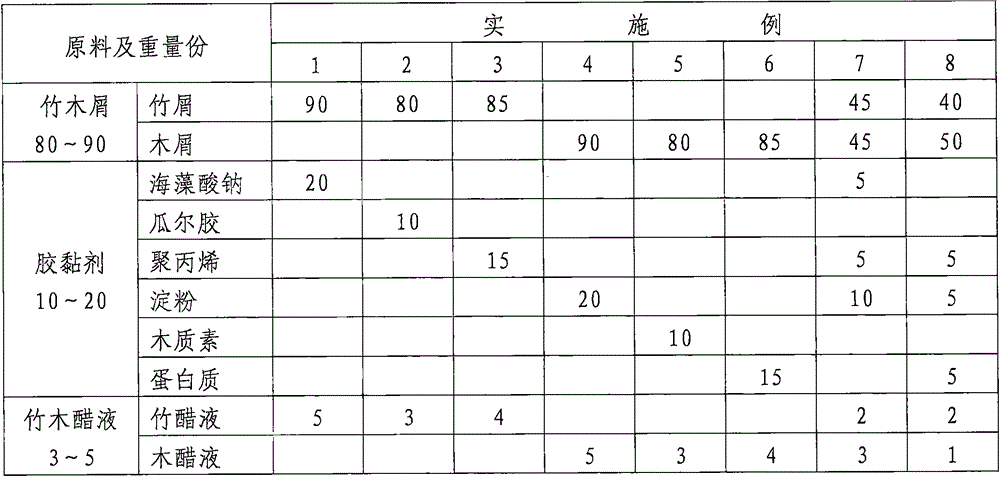

Bamboo-wood sawdust pet clustering padding material and preparation method thereof

The invention relates to a bamboo-wood sawdust pet clustering padding material. The bamboo-wood sawdust pet clustering padding material is prepared from, by weight, 80-90 parts of bamboo sawdust or wood sawdust, 10-20 parts of an adhesive, 3-5 parts of bamboo vinegar or wood vinegar and 50-100 parts of water, the formed particle padding material is light yellow or yellow or brown yellow, and the particle size is 1-8 mm. Aromatic wood sawdust of pine wood, Chinese fir wood and camphorwood is adopted as the wood sawdust. The particle size of the bamboo sawdust or wood sawdust is 60-80 mesh. At least one of sodium alginate, guar gum, food-grade polypropylene, starch, a lignin adhesive and a protein adhesive is adopted as the adhesive, and the adhesive is solid and needs to be ground into 100-120-mesh powder. The bamboo vinegar or wood vinegar is a scorched flavor removing type. According to the bamboo-wood sawdust pet clustering padding material, the adopted bamboo sawdust or wood sawdust are both waste obtained after natural wood processing, the adhesive is in a food grade, the padding material can serve as organic fertilizer to be completely and naturally biodegraded after being used, and therefore the padding material can be directly flushed into a sewer without blocking the sewer; the padding material is green and environmentally friendly.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Aqueous film-forming foam extinguishing agent special for fire extinguishing bullet and throwing type fire extinguisher

InactiveCN104117176AImprove fire extinguishing effectPrevent re-ignitionFire extinguisherDiethylene glycol diethyl etherAmmonium dodecyl sulfate

The invention provides an aqueous film-forming foam extinguishing agent special for a fire extinguishing bullet and a throwing type fire extinguisher. The aqueous film-forming foam extinguishing agent has the advantages of being small in additive amount, rapid in fire extinguishing, good in recrudescence resisting effect, environmentally friendly, efficient and the like. The aqueous film-forming foam extinguishing agent comprises, by weight, 8 percent to 12 percent of main foaming agents, 8 percent to 20 percent of auxiliary foaming agents, two percent to 10 percent of antifreeze agents, 12 percent to 22 percent of cosolvents, 0.1 percent to one percent of stabilizers, 8 percent to 20 percent of fire retardants, two percent to five percent of burning-resistance agents and the balance water. The main foaming agents are selected from F1157N, F1203 and F1460, the auxiliary foaming agents are selected from lauryl sodium sulfate, ammonium lauryl sulfate, alkyl glycoside, dodecyl dimethyl betaine and cocamidopropyl betaine. The antifreeze agents are selected from ethylene glycol, glycerol and the like. The cosolvents are selected from dodecanol, n-butyl alcohol and diethylene glycol diethyl ether. The stabilizing agents are selected from xanthan gum, Arabic gum, guar gum and sodium alginate tech grade. The fire retardants are selected from ammonium polyphosphate and ammonium dihydrogen phosphate.

Owner:ANHUI TIANYUAN FIRE PROTECTION TECH

Quick-frozen fish tofu and processing method thereof

The invention discloses quick-frozen fish tofu and a processing method thereof. The quick-frozen fish tofu comprises a meat material part and a soybean part; the meat material part comprises the following components in part by weight: 600-800 parts of minced fish meat, 300-500 parts of chicken breast meat, 200-500 parts of pork fat, 50-150 parts of cassawa starch, 100-200 parts of maize meal, 100-300 parts of monoacetate starch, 200-300 parts of water, 100-150 parts of egg white, 40-60 parts of edible salt, 40-60 parts of white granulated sugar, 10-30 parts of glucose, 10-30 parts of gourmet powder, 10-30 parts of cooking wine, 1-2 parts of freshener, 1-2 parts of fish essence, 4-5 parts of moisture retention agent, 3-4 parts of xylitol, 0.1-0.3 part of ethyl maltol, 1-2 parts of sorbitol, and 1-3 parts of guar gum; and the soybean part comprises the following components in part by weight: 200-300 parts of isolated soy protein, 1000-1500 parts of ice water, 4-6 parts of transglutaminase, 1-2 parts of Beta-cyclodextrine, and 2-4 parts of gourmet powder. The quick-frozen fish tofu has the advantages of mellow outline, golden color, pure flavor, dense scent, elasticity and crisp, and is oily but not greasy.

Owner:NANJING DADI REFRIGERATION FOOD

Water-soluble thick oil viscosity reducer

InactiveCN101906295ALow viscosityReduce dosageDewatering/demulsification with chemical meansDrilling compositionPolyvinyl alcoholActive agent

The invention discloses a water-soluble thick oil viscosity reducer belonging to the technical field of emulsified viscosity reducers of viscous crude oil. The water-soluble thick oil viscosity reducer is prepared from the following components in parts by weight: 0.01-1.0 part of surface active agent, 0.01-1.0 part of dispersant and 0.01-0.6 part of demulsifier, wherein the surface active agent is a nonionic surface active agent selected from OP-10, TX100, Span80 and Tween80, the dispersant is a water-soluble polymer material selected from polyacrylamide, polyvinyl alcohol, guar gum and cellulose, and the demulsifier is a polyoxyethylene-polyoxypropylene segmented copolymer. The invention has good emulsifying and viscosity-reducing effects, the emulsified crude oil can be automatically demulsified to reach a dehydration rate over 95 percent, and the viscosity reducer has little consumption and low cost by adopting low-price materials.

Owner:SICHUAN HAIDUN PETROLEUM NEW TECH DEV

Panada composition for flour-coating meat food capable of being frozen and pre-fried by microwave and products produced by the composition

The invention relates to a panada composition used for pre-fried flour-coated meat ware and the pre-fried flour-coated meat ware made of the panada composition, which comprises flour, soybean protein, soybean lecithin, maltodextrin, and guar gum. The pre-fried flour-coated meat ware made of the panada composition and the preparation method in the invention can still retain great crispness after refrigeration and freezing and then reheating by microwave; therefore, the processing of the pre-fried flour-coated meat ware is simplified and facilitated, is conducive to expanding the market occupation, and generate tremendous economic gains.

Owner:FUJIAN ANJOY FOODS CO LTD +4

Fresh-keeping method for fresh wet noodle

The invention relates to a method for keeping raw wet noodle fresh, which includes the steps that: (1) before dough making, ultraviolet lamp is switched on to irradiate the dough for 30min to 1.5h; (2)during the dough making, purified water or sterile water with an amount controlled between 25 to 32 percent is added to the dough and at least one of the three antistaling agents, salt, sodium dehydroacetate and calcium propionate in proportions respectively of 2 to 7 percent, 0.02 to 0.05 percent and 0.1 to 0.3 percent, is added to the water; additionally, 0.1 to 0.3 percent of phosphate, 0.1 to 0.3 percent of sucrose ester, 0 to 0.3 percent of guar gum and 0 to 0.3 percent of edible alkali as well as 5 to 10 percent of wheat gluten powder are added; (3) sterilization treatment is applied to cooking equipment, strip press and the like and noodle strip after pressing is thermally insulated and cooked; (4) asepsis treatment is applied to wet noodle strip and the moisture of the product is controlled between 18 to 28 percent; (5) sterilization is applied to the product before packaging. The method of the invention does not affect the flavor and color of products and the raw wet noodle is characterized by bright appearance, cream white color and strong tenacity and has a shelf life of two months at normal temperature and as long as six months at the temperature below 10 DEG C (cold storage).

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

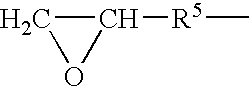

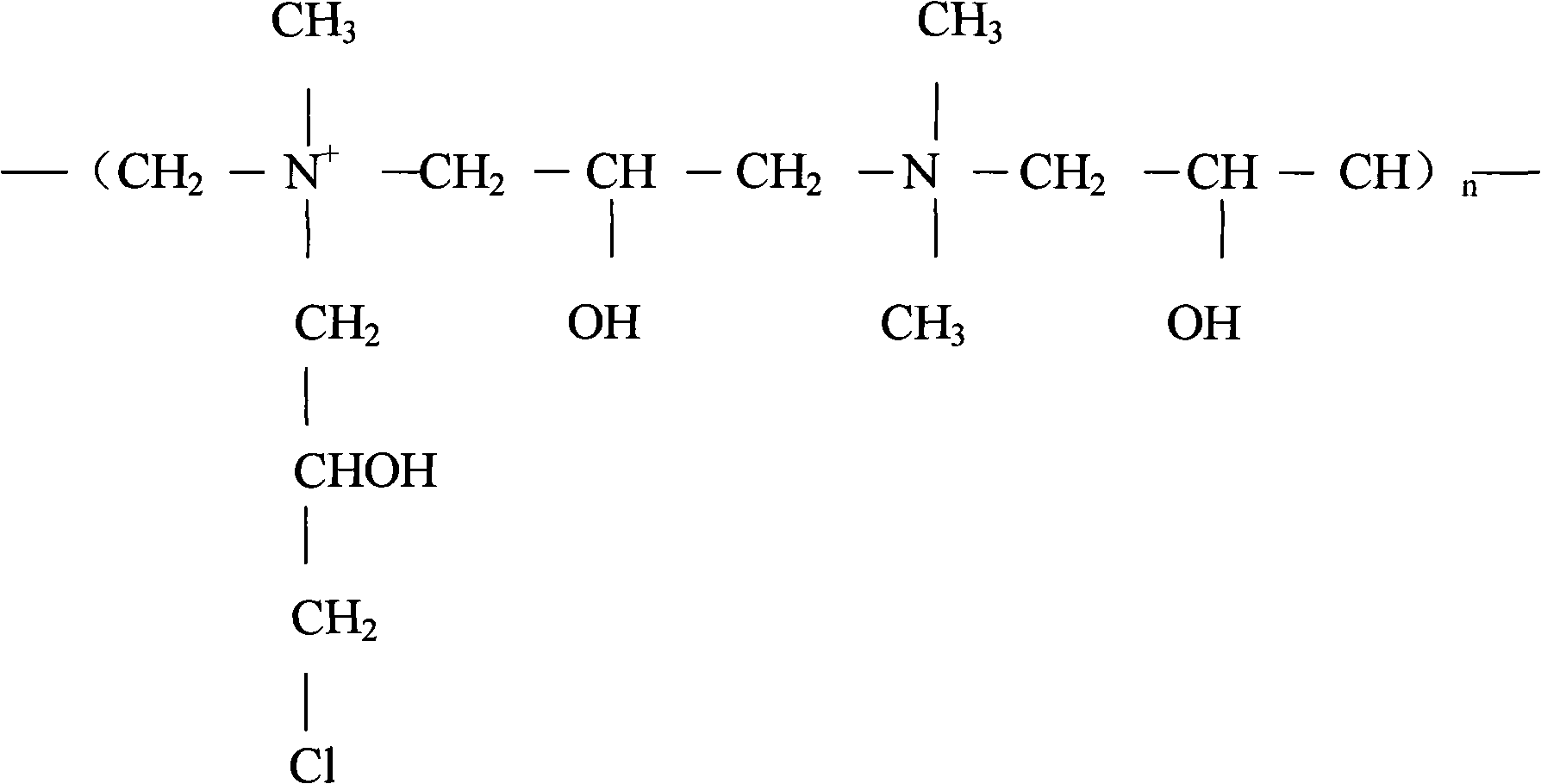

Hydroxyalkyl cationic guar gum and its preparation method and application

InactiveCN1757827ASolve forming problemsImprove adsorption capacityPaper/cardboardRetention agents additionAlcoholGraft reaction

A process for preparing the cationic hydroxyalkyl guar gum includes such steps as dispersing the raw powder of guar gum in the aqueous solution of low-carbon alcohol, adding high-alkaline catalyst, immersing, adding cationic etherifying agent, cationic graft reaction, adding phase-transfer catalyst and alkoxy etherifying agent, hydro-xyalkylating reaction, neutralizing and filtering. It can be used as the retention aid or filter aid of paper pulp.

Owner:SOUTH CHINA UNIV OF TECH

Porous tobacco material for heating non-combustion type cigarettes and preparation method of porous tobacco material

The present invention discloses a porous tobacco material for heating non-combustion type cigarettes and a preparation method of the porous tobacco material. The preparation method comprises the following steps of: firstly adding tobacco powder, guar gum and fire retardant into a mixer, atomizing and spraying dry distillated flavor to the stirred and lifted materials, continuing to stir the materials to obtain a primarily-mixed material of the tobacco material after spraying is completed, then sending the primarily-mixed material into a single screw extruder for continuous mixing, simultaneously injecting CO2 for foaming extrusion molding, cutting the extrudate into shreds after the extrudate is dried, and obtaining the tobacco material for the heating non-combustion type cigarettes. The tobacco material is uniformly heated under the heating non-combustion state due to porosity of the tobacco material, smoke release is easier, and smoke amount is more sufficient; sensory quality of the smoke is largely improved through adding the dry distillated flavor; and the tobacco material has better flame-retardant performance due to the fact that the fire retardant is cooperatively used.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Rice ball modifier and preparation method thereof

The invention discloses a rice ball modifier comprising the following raw materials in proportions by weight: 1-3 parts of sodium polyacrylate, 2-5 parts of sodium carboxy methyl cellulose, 3-7 parts of xanthan gum, 80-87 parts of guar gum and 7-10 parts of glycerin monostearate. Through the rice ball modifier provided by the invention, the problem that the strength of water-milled glutinous riceflour which is used for making wrappers of the rice balls is insufficient can be solved.

Owner:ZHENGZHOU SYNEAR FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com