Patents

Literature

484 results about "Continuous mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microemulsion process and composition

ActiveUS20060057168A1Quality improvementCosmetic preparationsOrganic active ingredientsVegetable oilSilanes

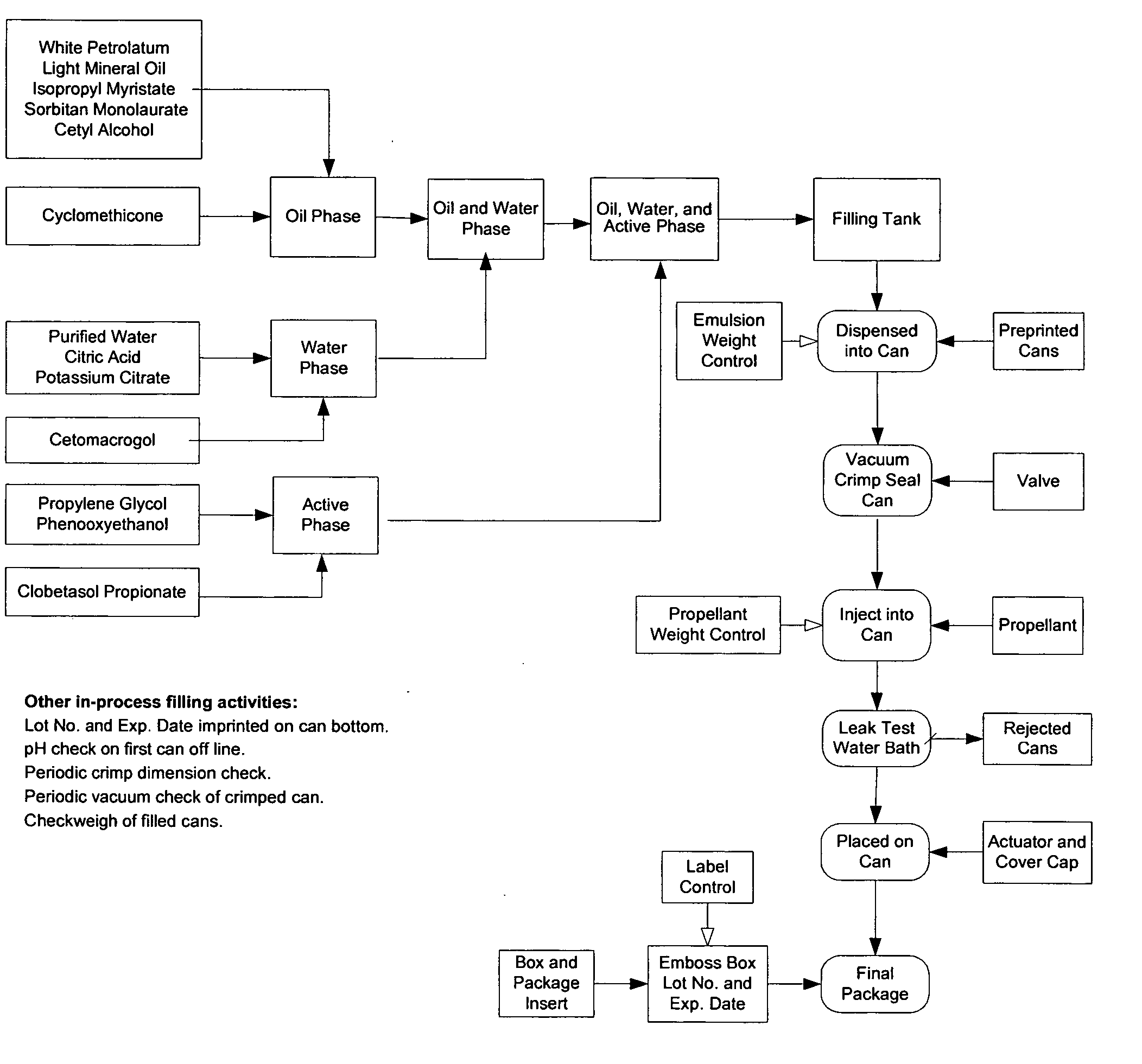

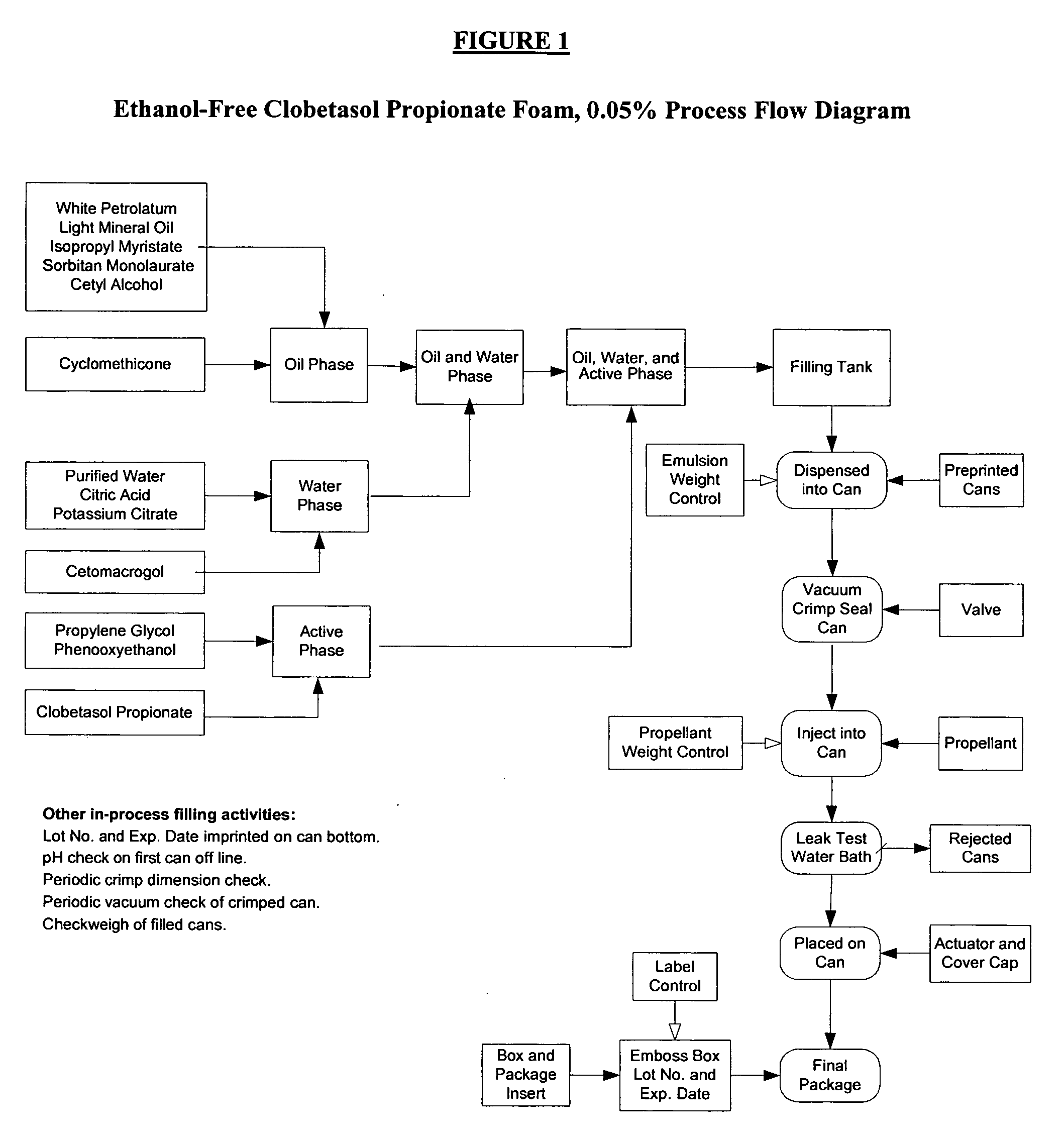

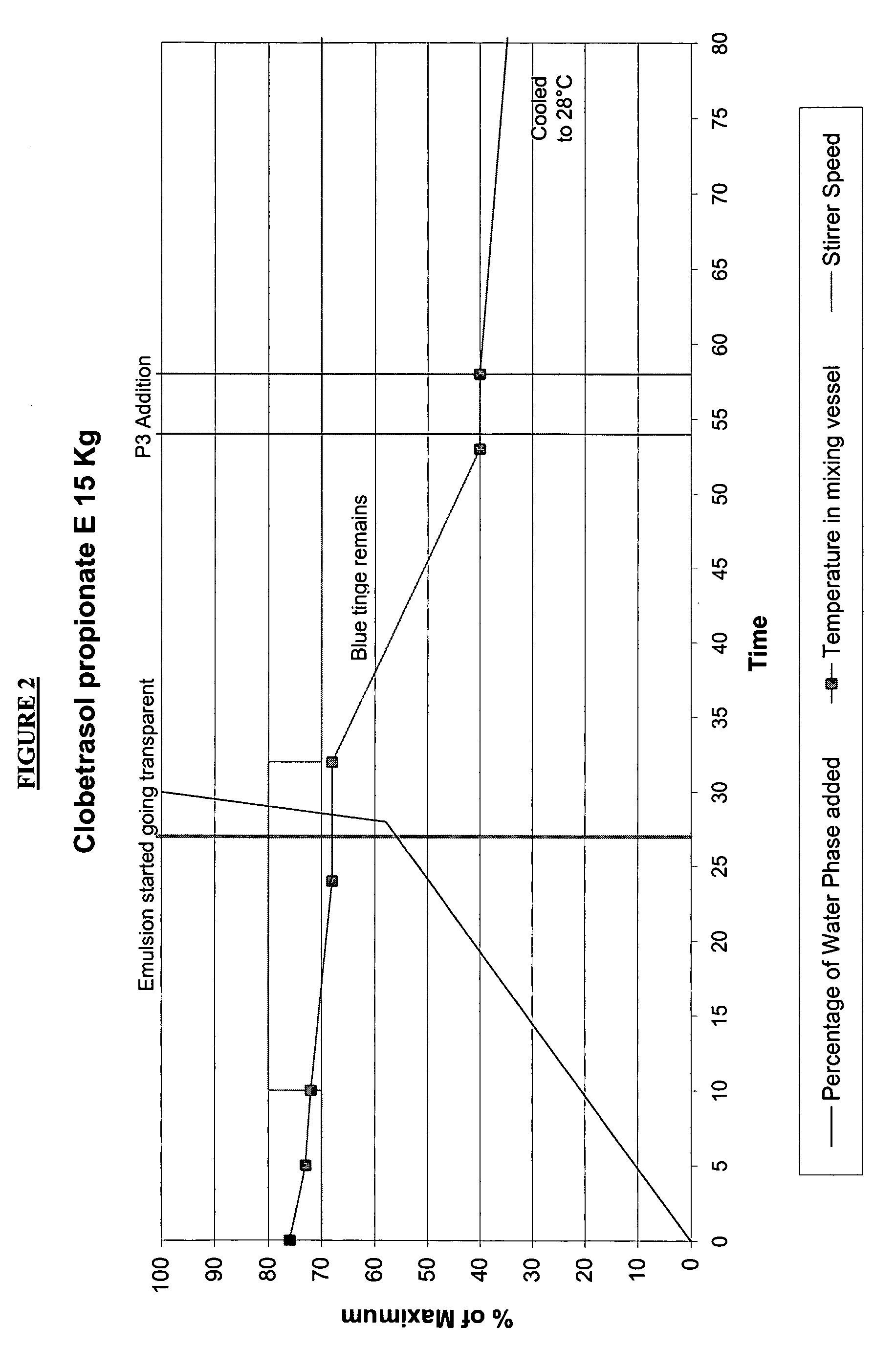

There is provided a process for the preparation of an oil in water (O / W) microemulsion or sub-micron emulsion composition for dermal delivery of at least one pharmaceutically active ingredient, the method including the steps of a) Admixing a first part including at least one of the group consisting of animal, mineral or vegetable oils, silanes, siloxanes, esters, fatty acids, fats, halogen compounds or alkoxylated alcohols; and one or more lipophilic surfactants, and a second part including water and at least one hydrophilic surfactant to achieve homogeneity, b) heating the mix of step a) to a phase assembly temperature in the range of 40-99° C., preferably 45-95° C., more preferably 65-85° C. with continuous mixing to obtain a microemulsion or sub-micron emulsion, c) allowing said microemulsion or sub-micron emulsion to cool, and d) adding a third part to said microemulsion or sub-micron emulsion at a temperature between 2° C. and said phase assembly temperature, said third part if necessary being premixed and heated until the components are dissolved and including at least one component selected from the group consisting of non-surfactant amphiphilic type compound, surfactant and water with the proviso that when the third part includes water it also includes a non-surfactant amphiphilic type compound and / or surfactant. The phase assembly temperature can be determined visually by the achievement of translucence in the composition or by measures such as conductivity which peaks and then is maintained at a plateau whilst phase assembly occurs. It has been found that whilst if a non-surfactant amphiphilic type compound such as the polyol is added together with the second part as would conventionally be the case, a microemulsion or sub-micron emulsion is not formed, by adding the so called third part, phase assembly occurs at a lower temperature than would be expected and moreover, this phase appears to assist in maintaining the microemulsion or sub-micron emulsion characteristics of the formulation during storage at normal temperatures.

Owner:STIEFEL WEST COAST

Continuous mixing feeder

The invention is for mixing at least one kind of an additive with a powdery or granular main material homogeneously so as to continuously supply the same quantitatively. A barrel comprises a front side cylindrical part, a trough part, and a rear side cylindrical part from the upstream side. A quantitative extruding zone comprises the front side cylindrical part and a quantitative extruding part having a full flight provided on the peripheral surface of the axis part of a screw, for quantitatively transporting a main material to the downstream side. A mixing zone comprises the trough part and a mixing part having an agitating blade formed zigzag on the axis part of the screw and a ribbon screw having a distance with respect to the peripheral surface of the axis part, for homogeneously dispersing additives added from additive supply openings in the main material. The scraping out zone comprises the rear side cylindrical part and a scraping out part having forward paddles and backward paddles formed alternately on the peripheral surface of the axis part of the screw, for discharging the mixture from a discharge opening.

Owner:JAPAN STEEL WORKS LTD

Continuous dispensing system for liquids

InactiveUS6010032ALower Level RequirementsOpening closed containersBottle/container closureEngineeringDip-coating

The present invention relates to the continuous production of coated, dyed, printed, or painted materials by dip coating, spraying or printing in which a plurality of flowable materials including a liquid color concentrate are fed to a continuous mixing chamber with a substantially continuous input and output. The liquid color concentrate is dispensed by a dispensing apparatus including at least a first substantially vertical hollow chamber; a controllable pump device having an inlet fluidly connected to an outlet of said first hollow chamber for pumping the liquid color concentrate to the mixing chamber; a sensor for outputting substantially continuously a signal dependent upon a height of a liquid in the first hollow chamber; and a control device suitable for controlling at least one flow rate determining characteristic of the controllable pump in response to the output signal of the sensor so as to maintain the flow rate of the liquid to be dispensed through the pump device at a predetermined value. The method and apparatus are particularly useful in the manufacture of printed carpets.

Owner:E M E NV +1

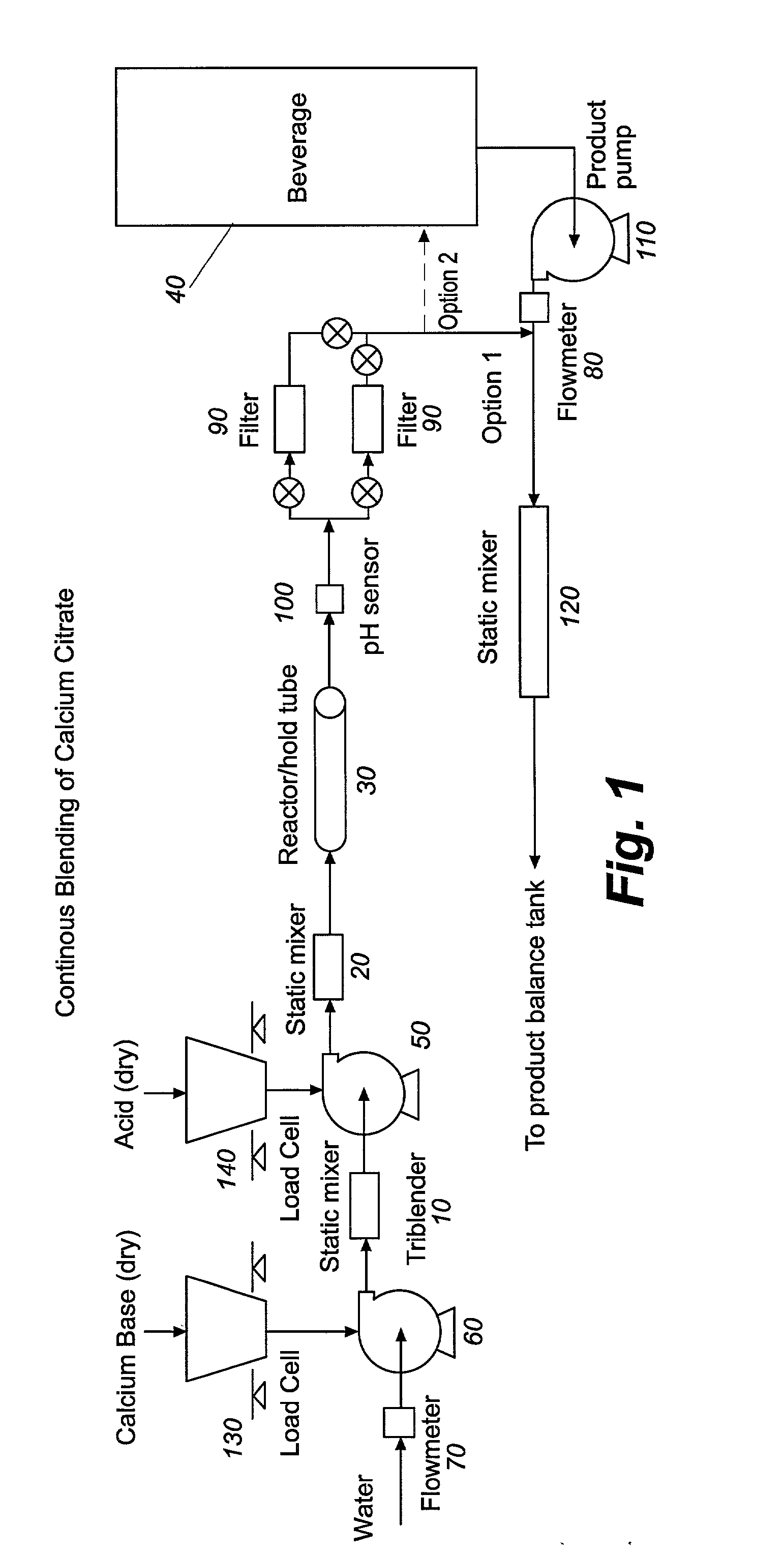

Process apparatus, and composition for calcium fortification of beverages

InactiveUS20020122866A1Inhibit productionReduce presenceFood ingredientsFood preparationCalcium hydroxideSufficient time

Process, apparatus and composition for calcium fortification of beverages are provided. The methods comprise continuously blending in water a calcium source, preferably calcium hydroxide, and an acid source for a time sufficient to produce soluble calcium salts, but with minimal precipitation. The acid source is preferably citric acid. The calcium salt solution remains in an in-line retaining reaction hold tube for the necessary period to produce calcium salt in solution without significant precipitation, and is then continuously and immediately added to a non-dairy beverage, such as orange juice, to calcium fortify the beverage. The pH of the calcium salt solution can be monitored to optimize the amount of soluble salt and minimize the amount of precipitate.

Owner:THE COCA-COLA CO

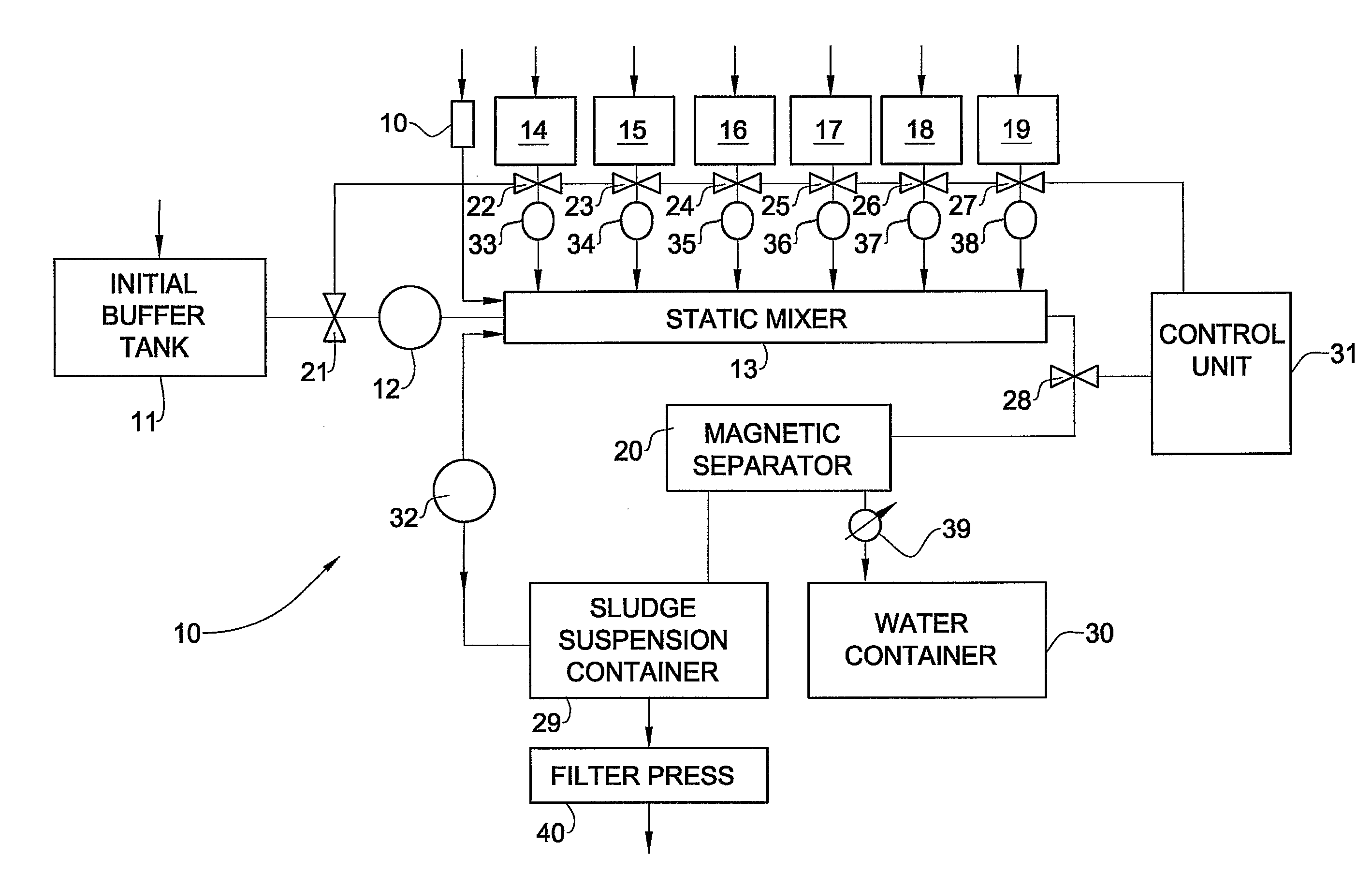

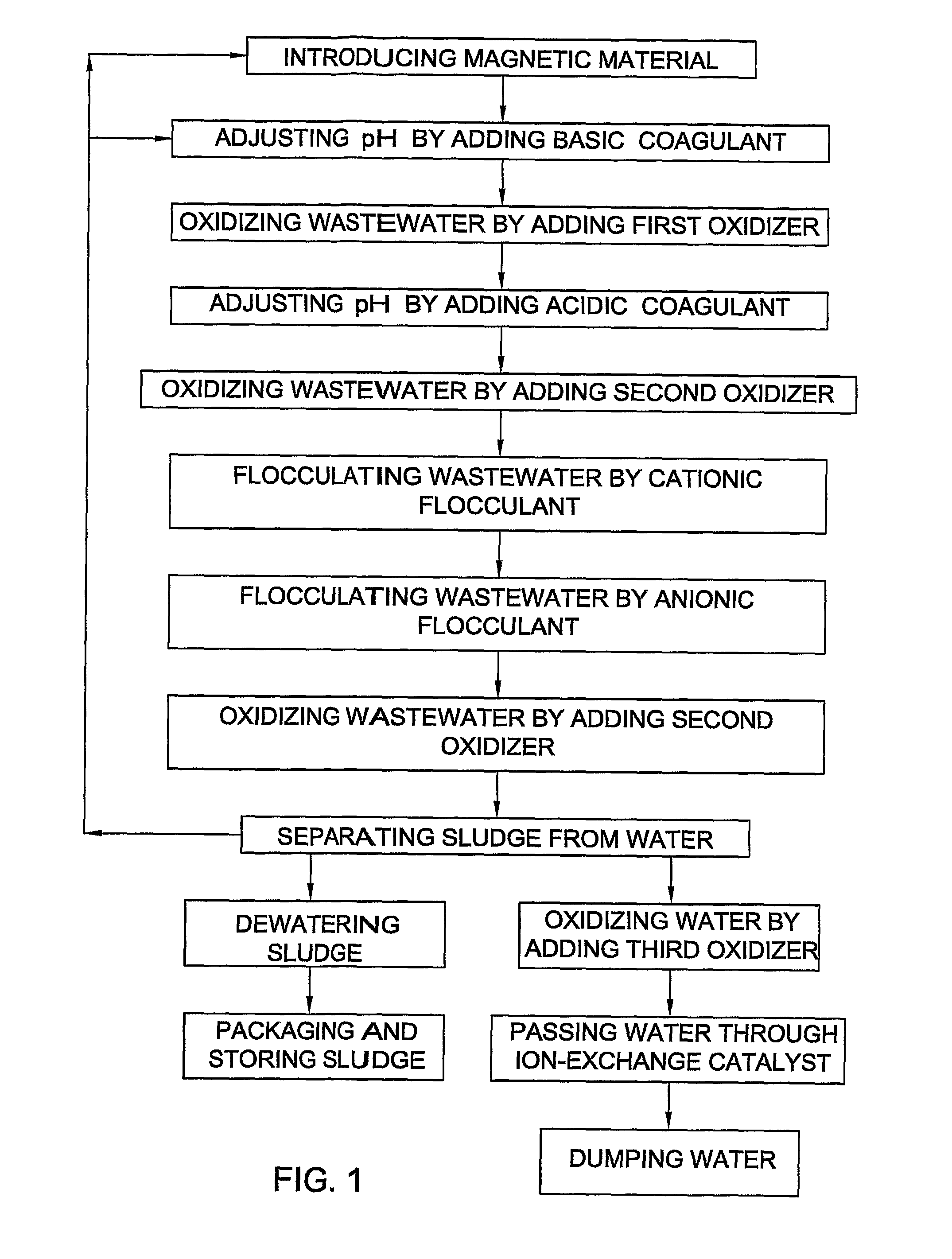

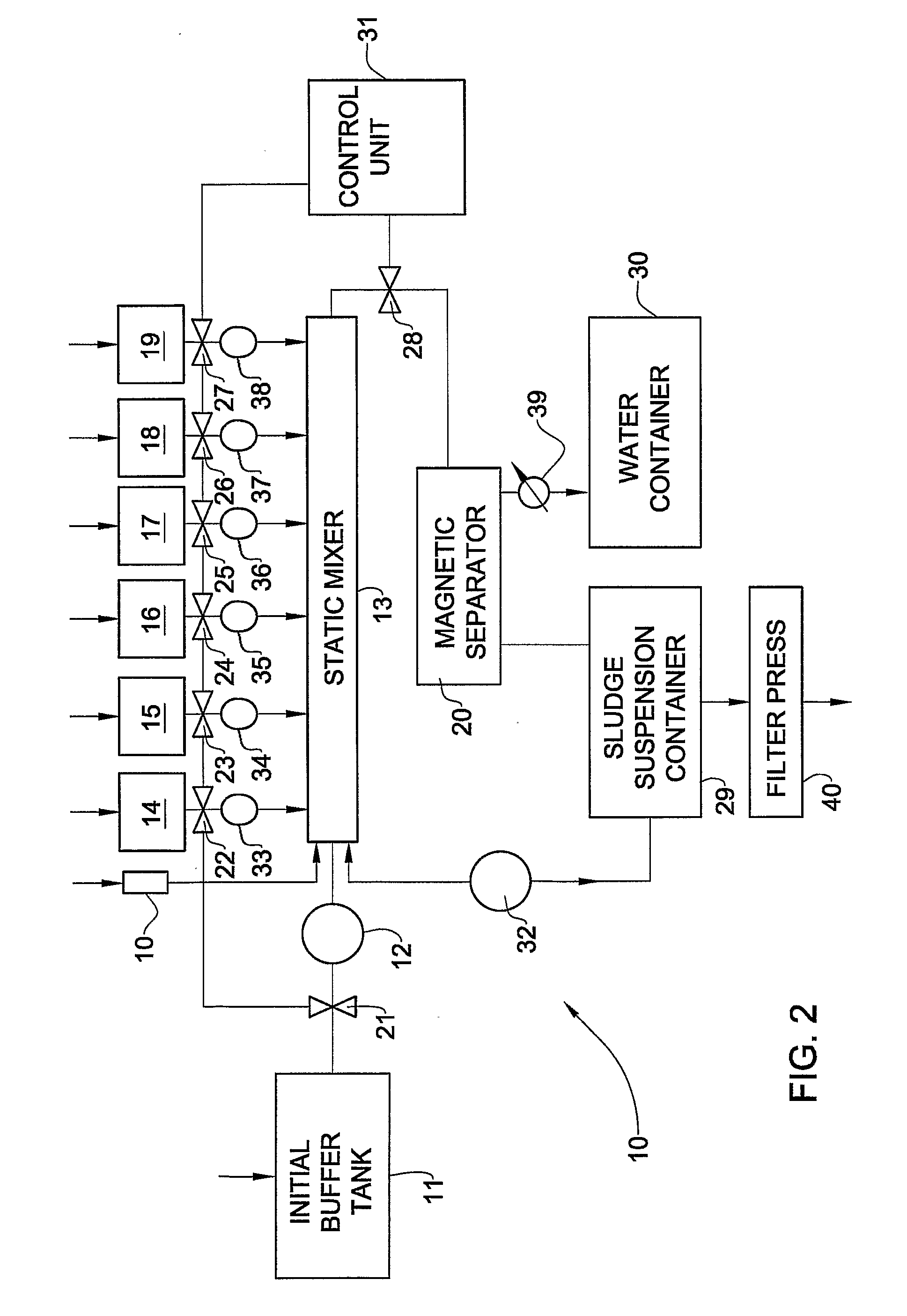

System and Method for Treatment of Industrial Wastewater

InactiveUS20080035577A1Improve efficiencyImprove standardsSolid sorbent liquid separationWaste water treatment from metallurgical processPHENOL LIQUIDSludge

Owner:UNIQKLEEN WASTEWATER TREATMENT

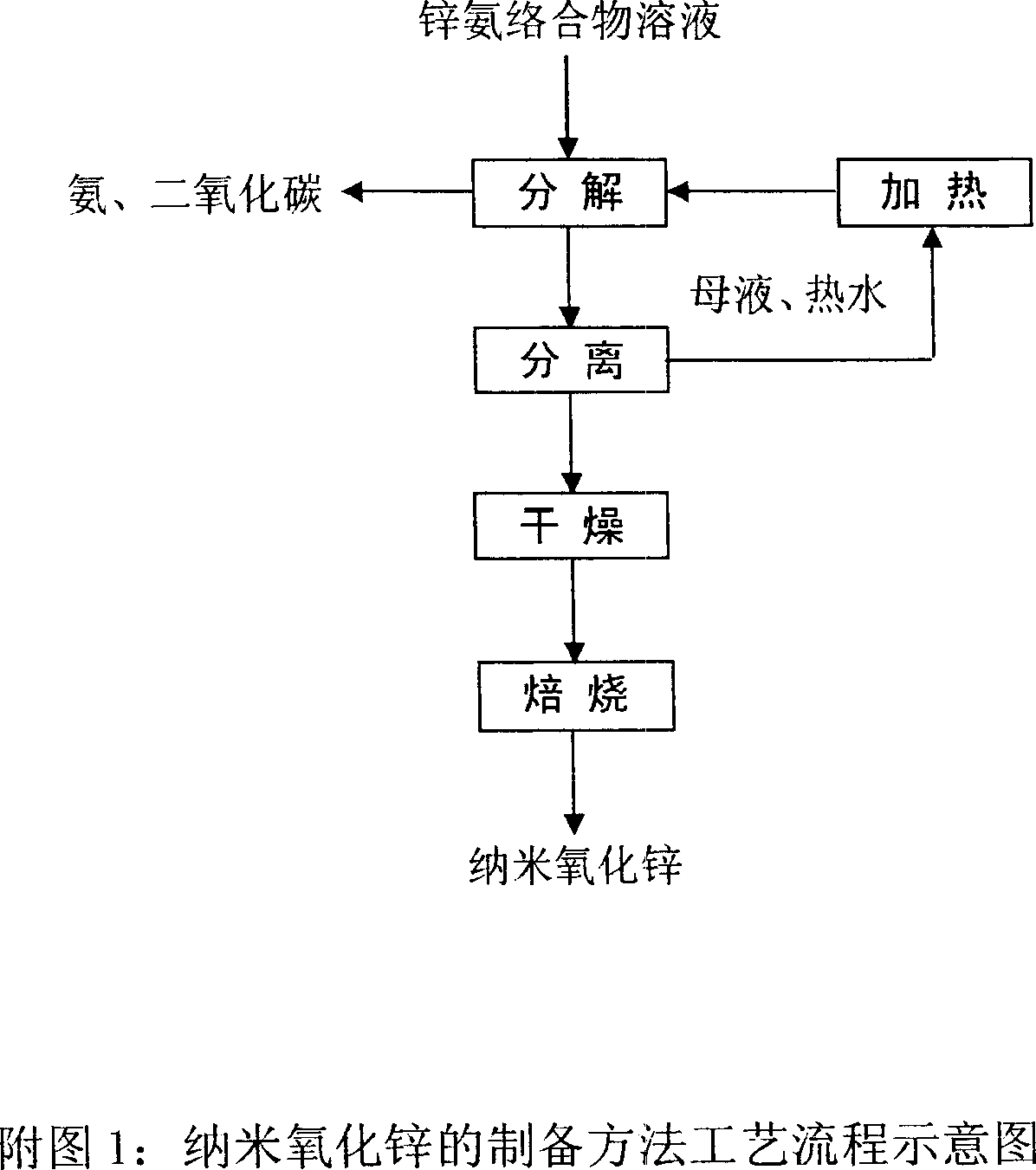

Preparing process of nano zinc oxide

InactiveCN1986421AUniform particle sizeUniform sizeNanostructure manufactureZinc oxides/hydroxidesDecompositionManganese

The process of preparing nanometer zinc oxide with low grade zinc oxide containing material includes the following steps: leaching the material with the mixed solution of ammonium bicarbonate and ammonia, separating to eliminate insoluble impurity, redox to eliminate Fe, Mn, Pb and other metal impurity to obtain zinc-ammonia complex solution; heating the zinc-ammonia complex solution to 90-100 deg.c through continuous mixing with hot circular mother liquid or hot water for fast continuous decomposition of zinc-ammonia complex; controlling the flow rate ratio between the circular mother liquid and the zinc-ammonia complex solution in 2-20, separating the basic zinc carbonate crystal continuously from the decomposed solution; drying and roasting at 400-600 deg.c for 1-4 hr to obtain the nanometer zinc oxide product of homogeneous size 10-50 nm.

Owner:CHINA NAT OFFSHORE OIL CORP +1

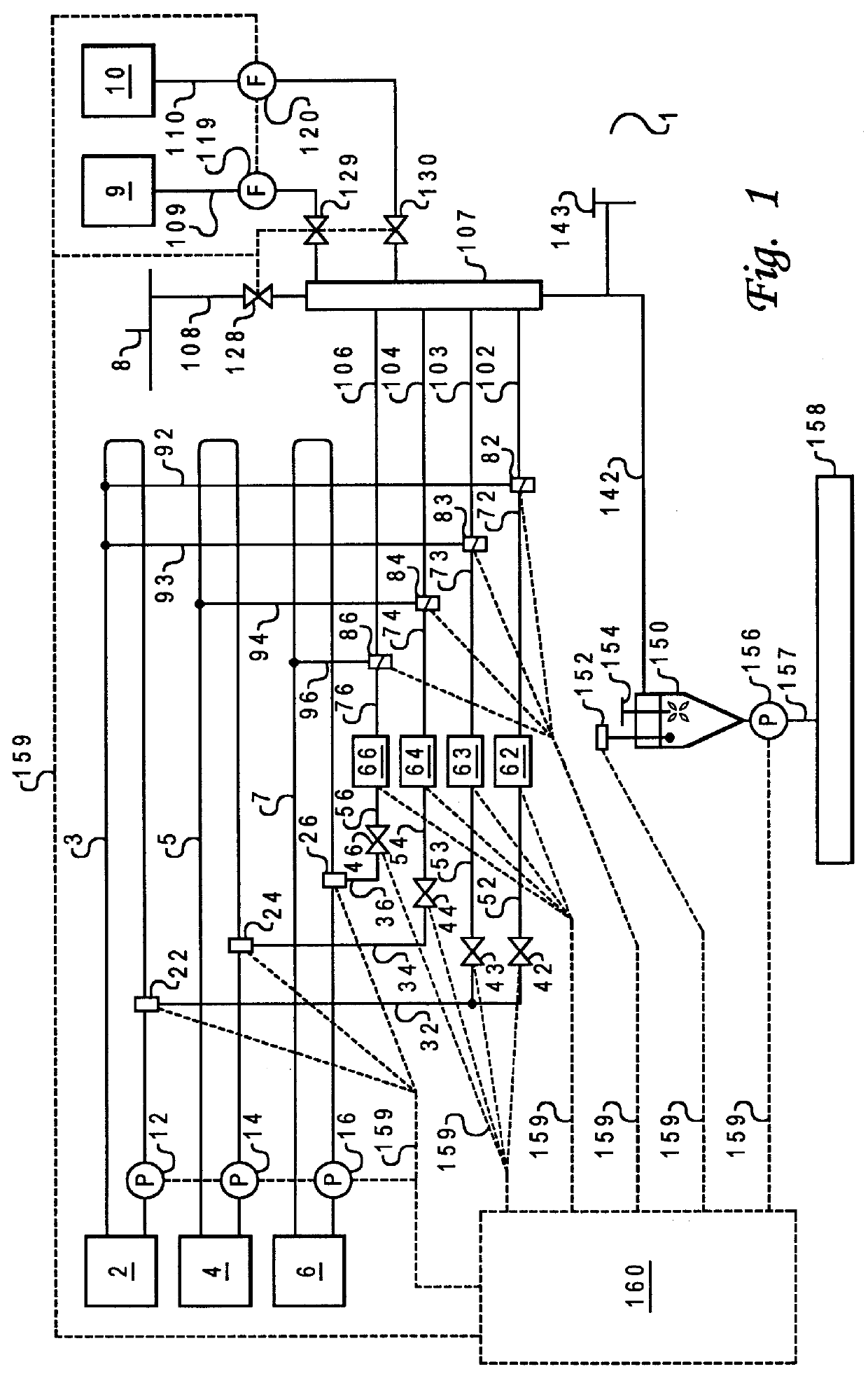

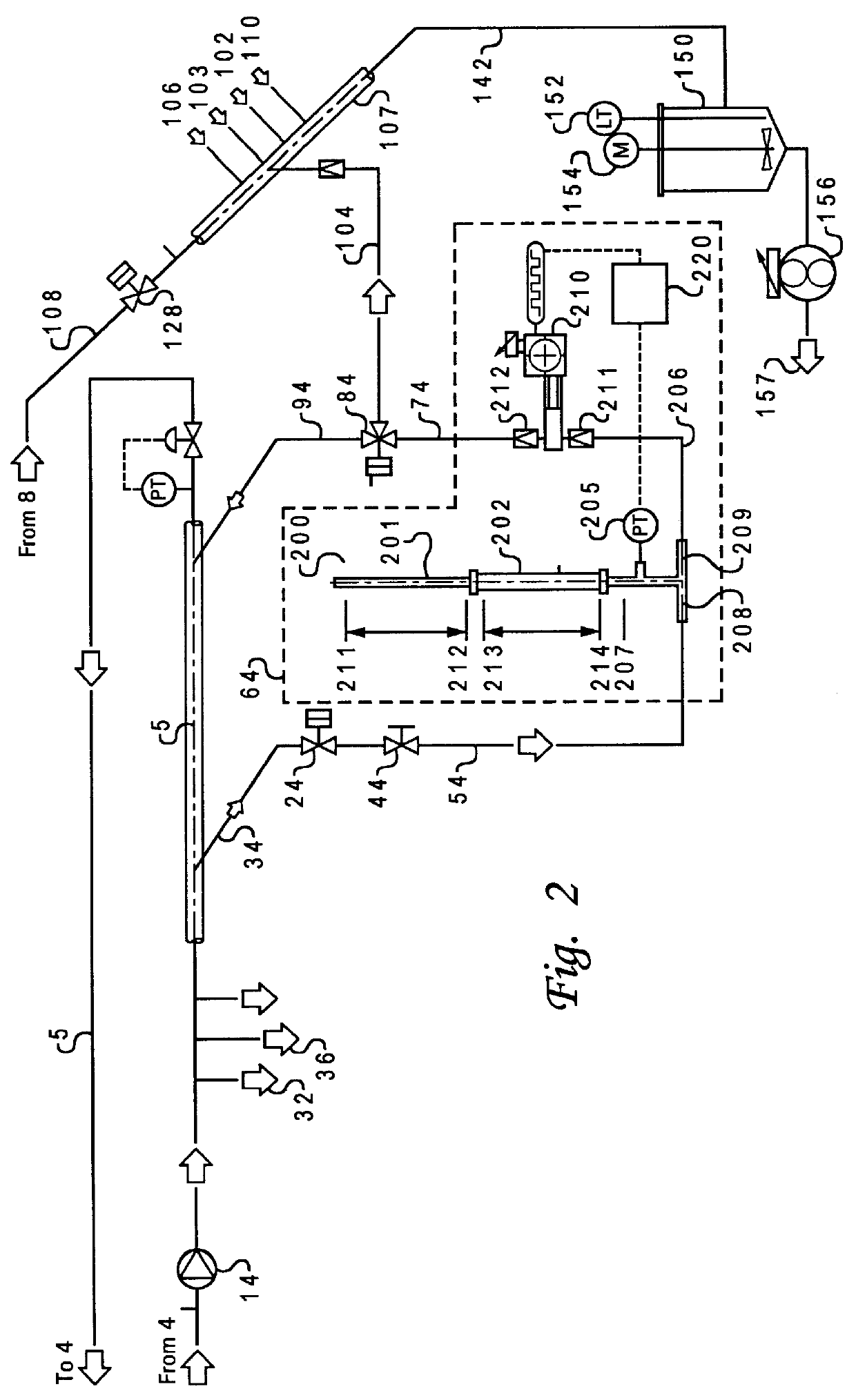

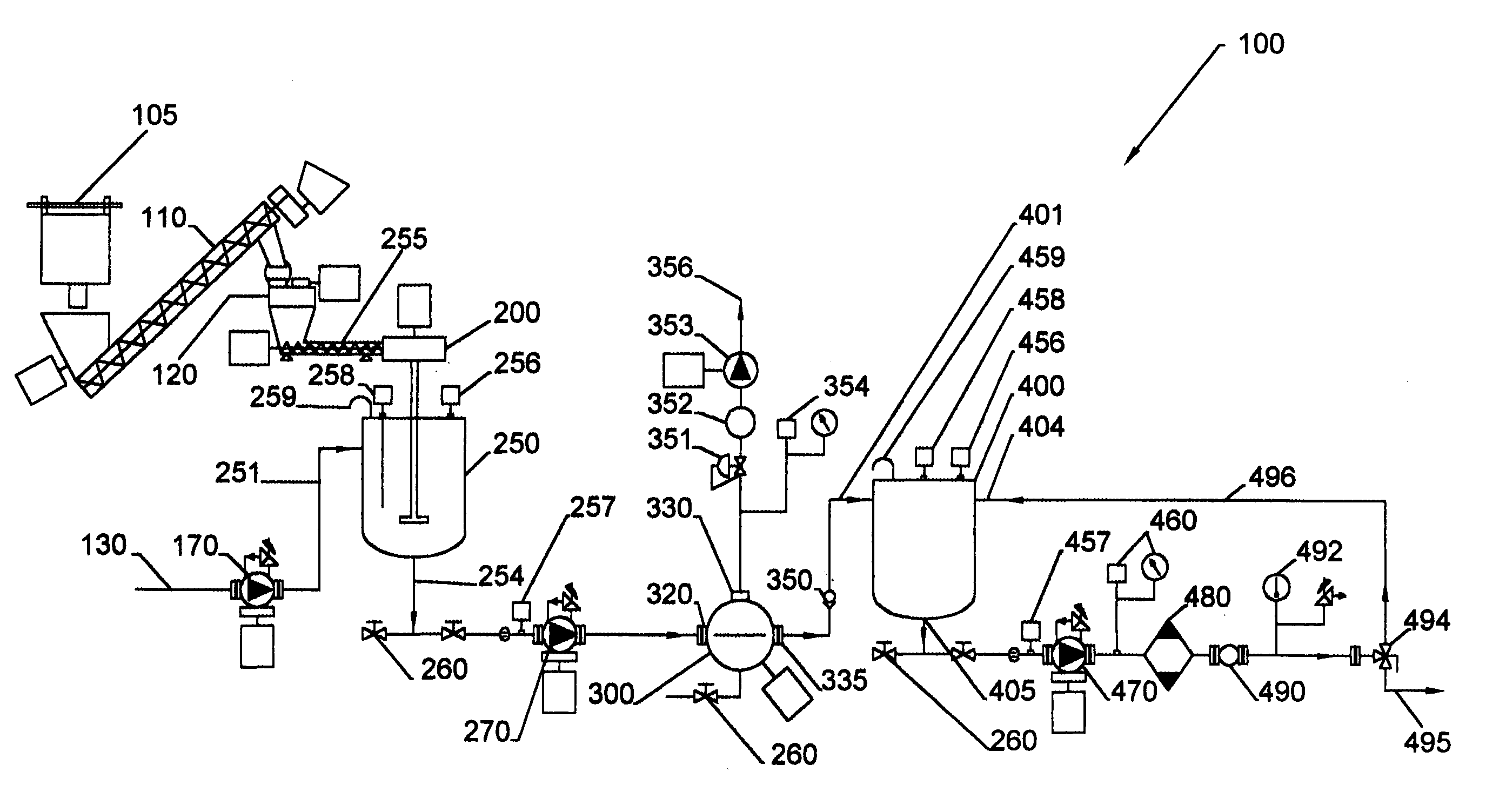

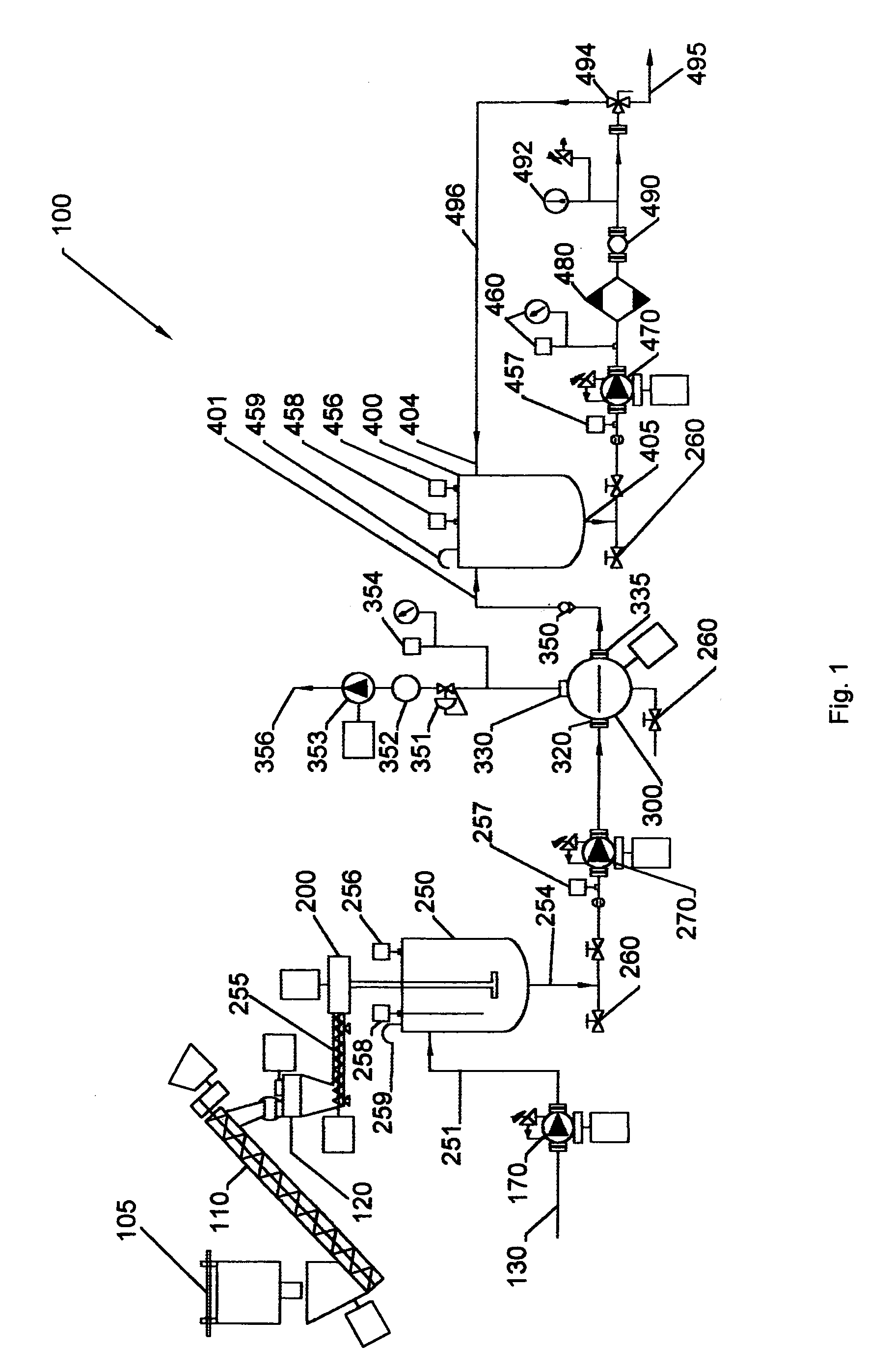

Control system and method for continuous mixing of slurry with removal of entrained bubbles

InactiveUS6994464B2Easy to controlControlling ratio of multiple fluid flowsRotary stirring mixersSurge tankControl system

The present invention comprises a control system and method for the continuous mixing of slurry while removing entrained bubbles. The control system for continuous mixing of slurry with removal of entrained bubbles comprises a power and fluid rate control, wherein the powder and fluid rate control is coupled to a mixer through a powder feeder and a liquid pump. A fluid level control is coupled to the mixer and a surge tank, and a flow rate is coupled to the surge tank. The present invention also comprises a method for controlling the continuous mixing of slurry while removing entrained bubbles comprising providing a powder and fluid rate control, wherein the powder feeder and fluid rate control is coupled to a mixer through a powder feeder and a liquid pump. A fluid level coniol is coupled to the mixer and a surge tank and flow rate control is coupled to the surge tank.

Owner:MOBIUS TECH

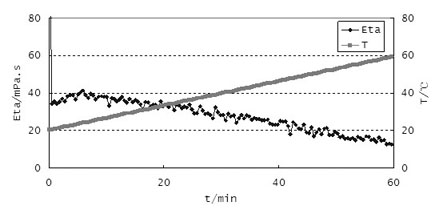

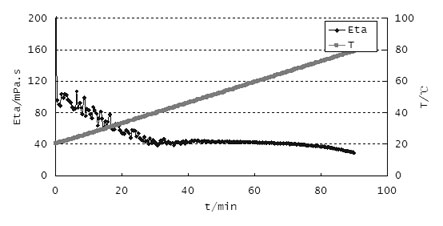

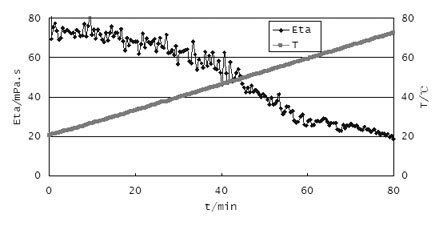

Preparation method and fracturing construction method of locally and continuously mixed clean fracturing fluid additive

ActiveCN102031102AGood sand carryingEasy to getFluid removalDrilling compositionFracturing fluidProcess engineering

The invention discloses a preparation method and a fracturing construction method of a locally and continuously mixed clean fracturing fluid additive. The invention is characterized in that the preparation of the locally and continuously mixed clean fracturing fluid additive comprises four steps, and the purposes of local and continuous mixing and continuous construction of the prepared clean fracturing fluid additive can be realized without preparation in a fluid preparation station or a well filed in advance. Thus, both the preparation method and the fracturing construction method of the locally and continuously mixed clean fracturing fluid additive are very simple and convenient.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

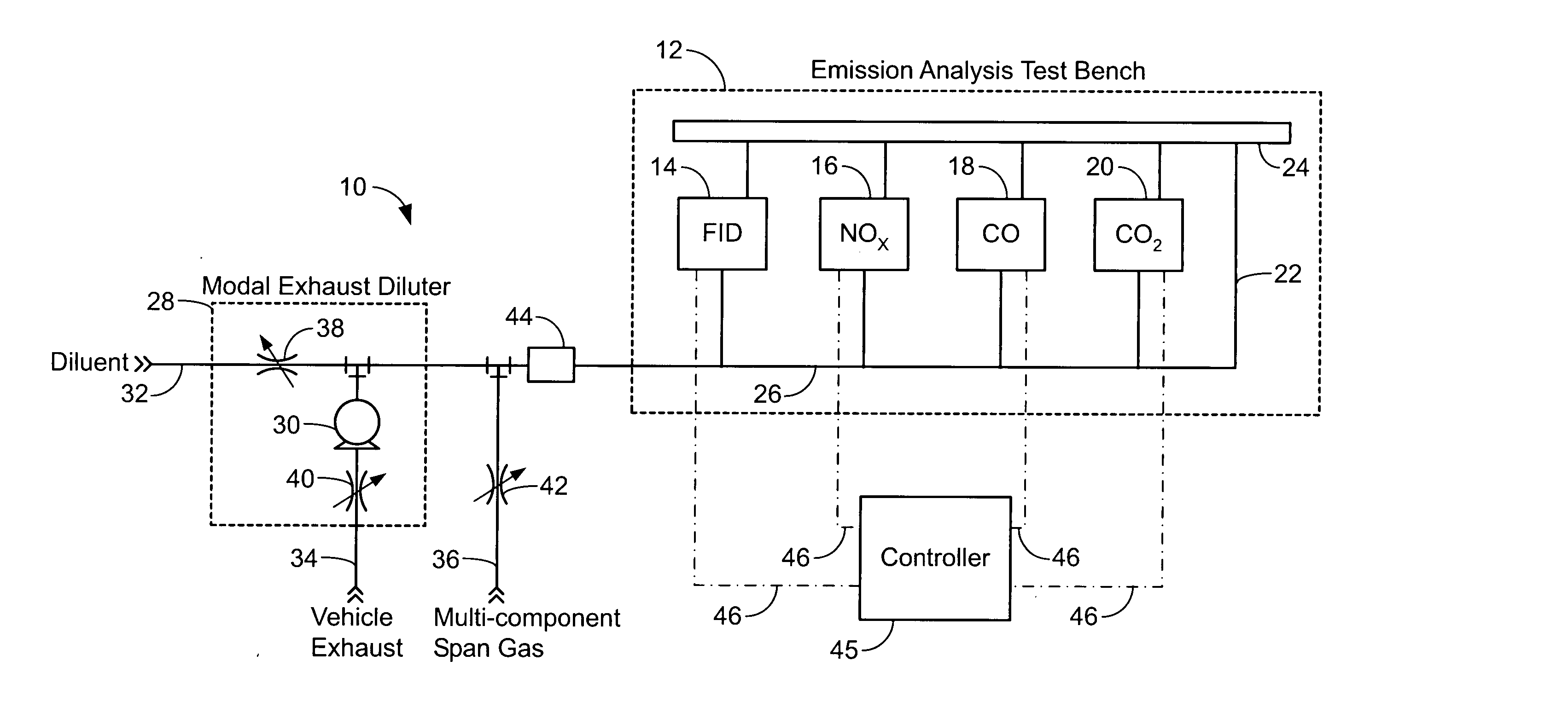

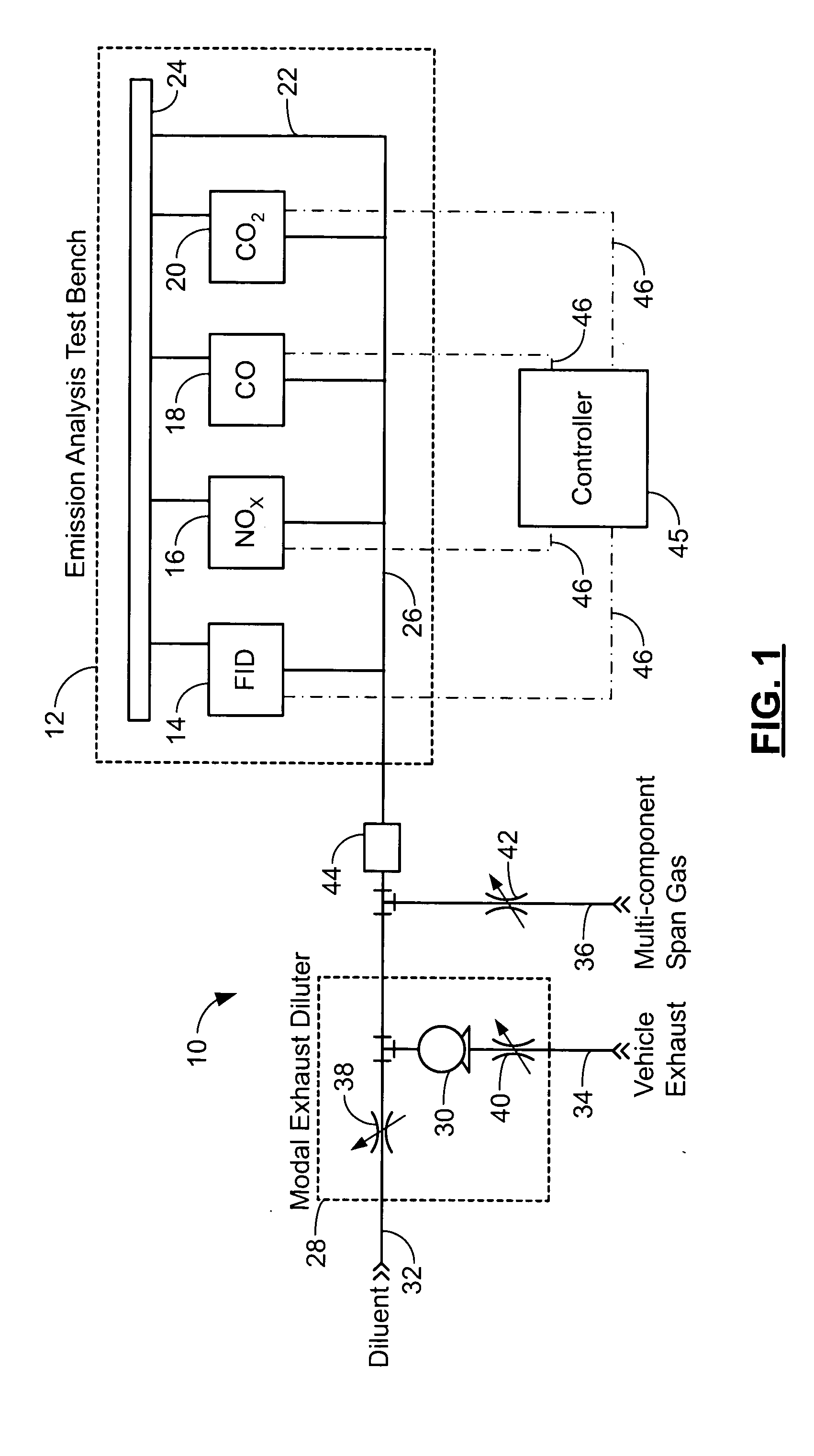

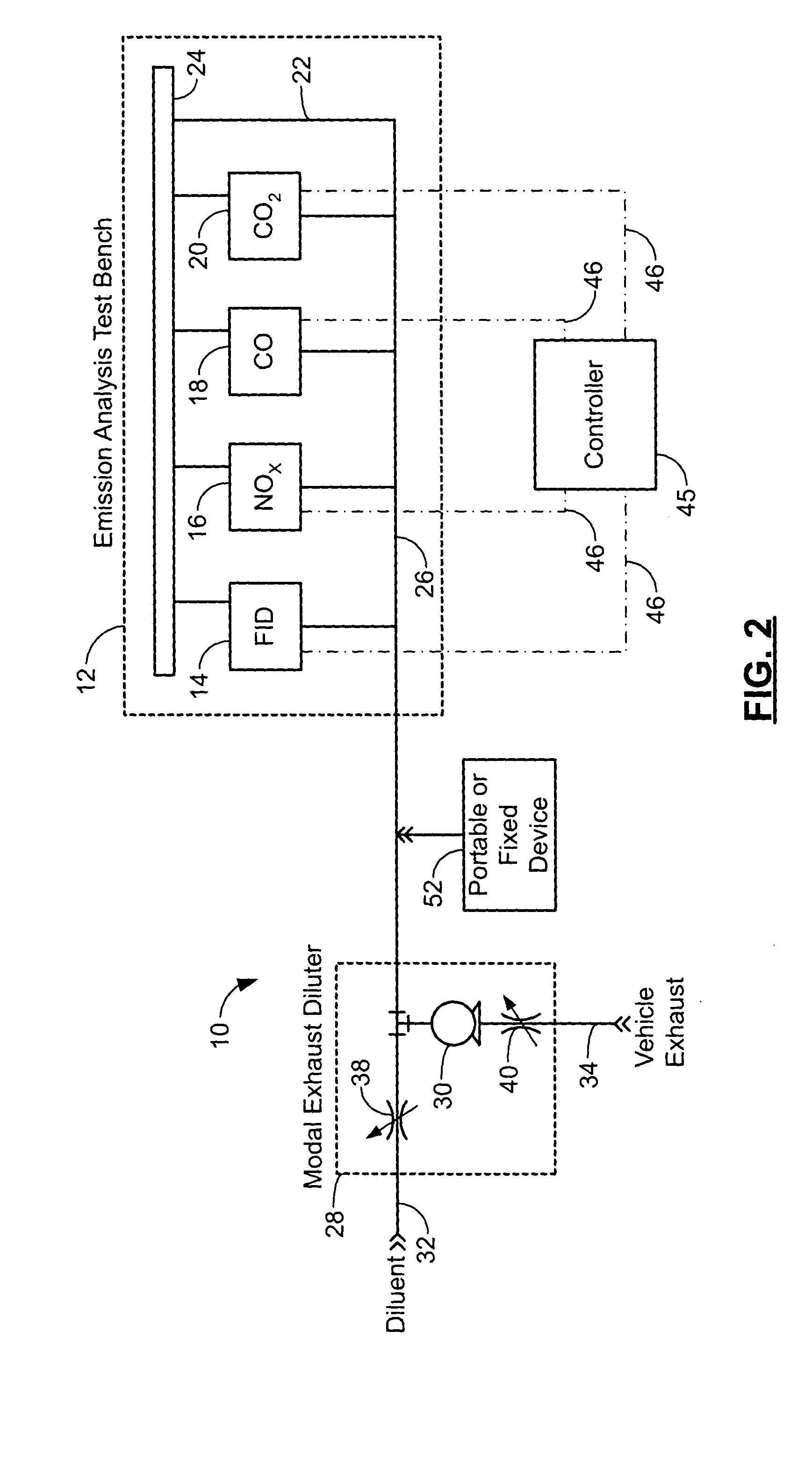

Continuous blending for gas analyzer calibration

InactiveUS20050056079A1Material analysis by electric/magnetic meansMaterial analysis by optical meansArray data structureEngineering

A method for calibrating a plurality of gas analyzers includes providing gas analyzers that measure the concentrations of gases. A span gas includes a mixture of the gases. A calibration mixture is supplied to the gas analyzers that includes the span gas and a non-reactive zero gas. At least one of a concentration of the non-reactive zero gas and a concentration of the span gas is varied in the calibration mixture as a function of time. The gas analyzers generate sets of readings of the concentrations of the gases. A controller generates response functions of the gas analyzers based on the sets of readings. The controller determines exact concentrations of the gases in the calibration mixture based on a set of readings from a gas analyzer with a predetermined response to a gas. The controller calibrates the gas analyzers based on the response functions and the exact concentrations.

Owner:GM GLOBAL TECH OPERATIONS LLC

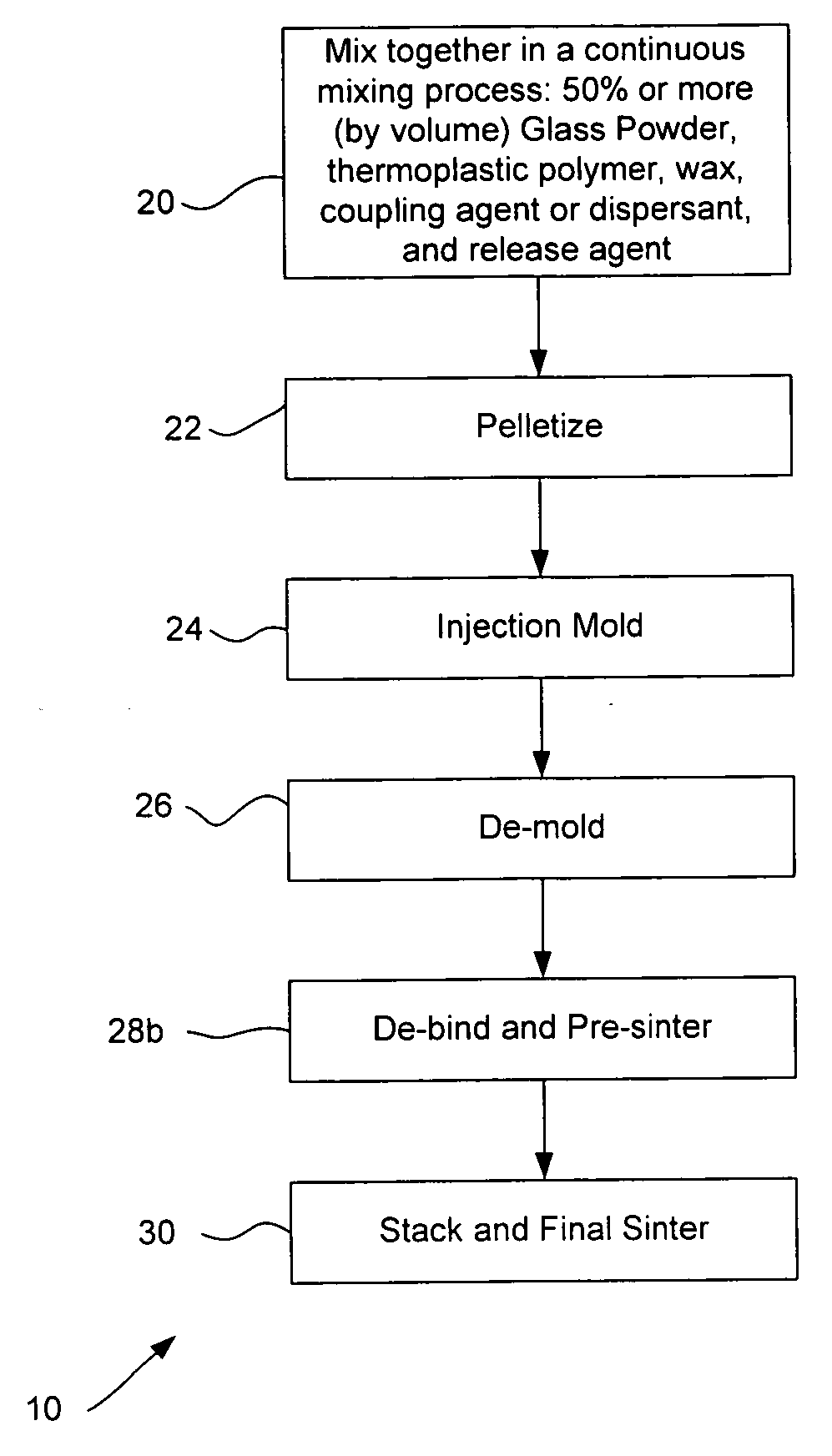

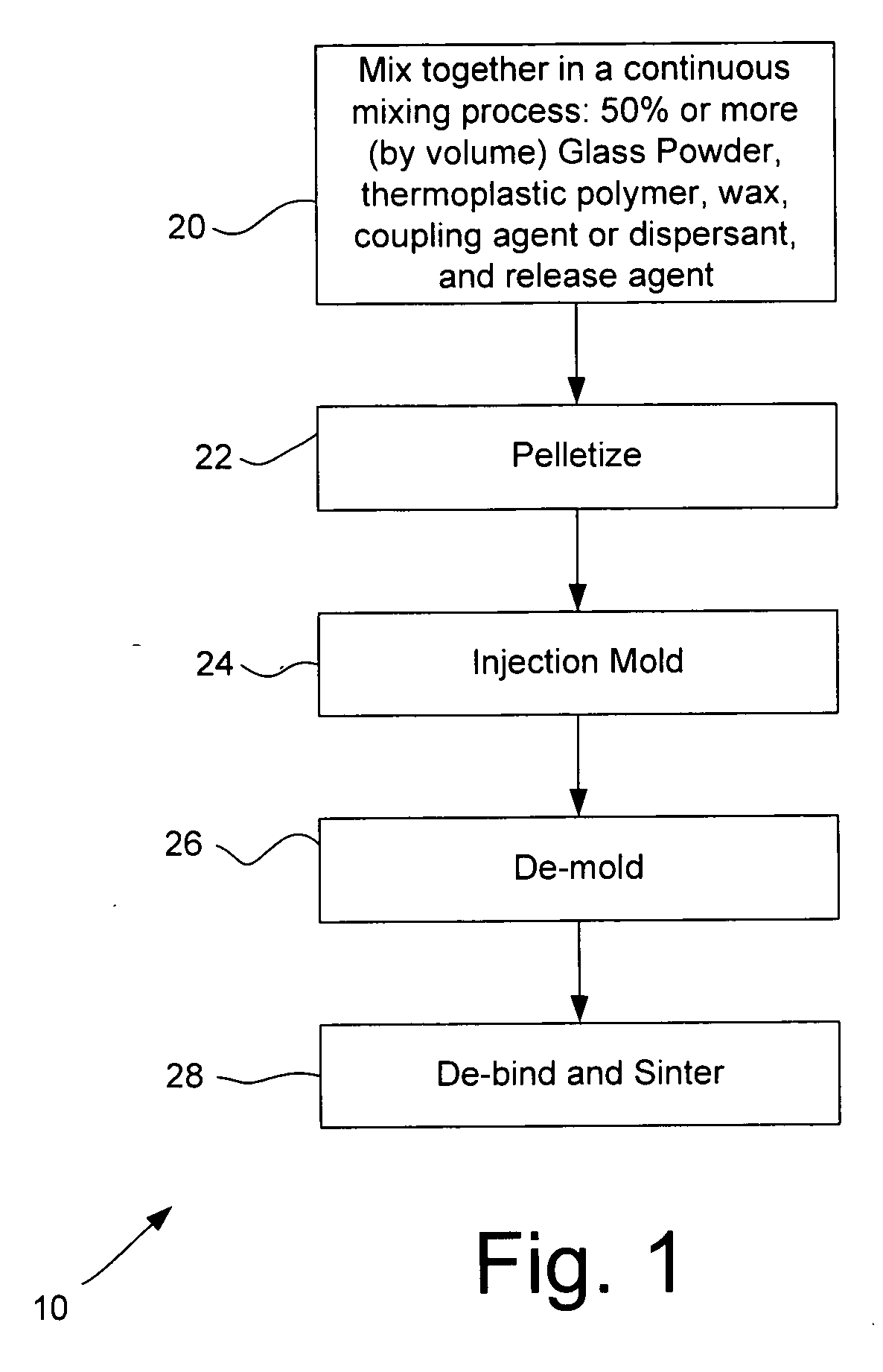

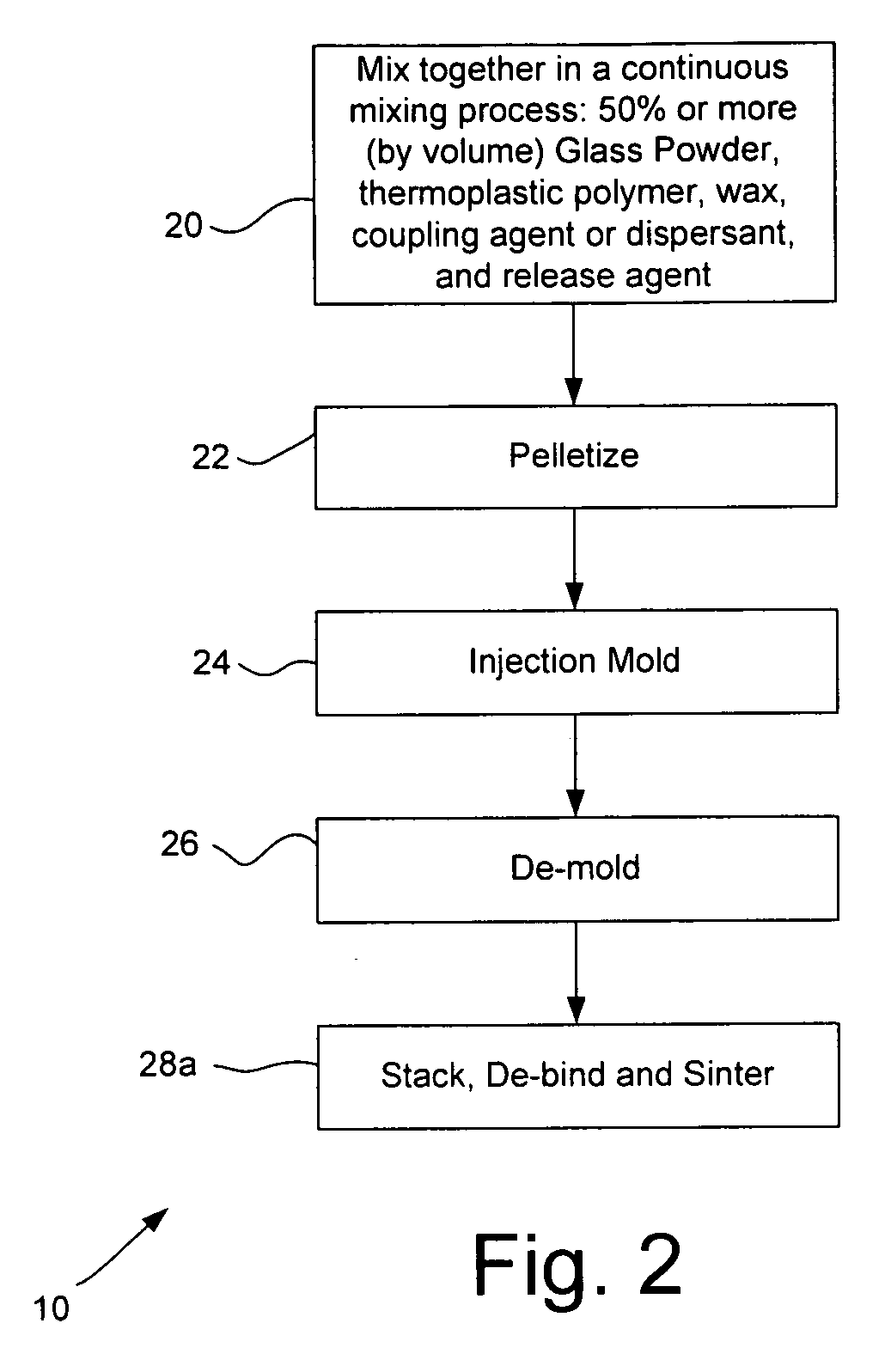

Powder injection molding of glass and glass-ceramics

InactiveUS20070154666A1Good shape retentionImprove surface propertiesLayered productsGlass shaping apparatusMetallurgyAdditive ingredient

A method for producing glass or glass ceramic articles by powder injection molding of glass powder includes mixing together, in a continuous mixing process, ingredients to form a mixture comprising a glass powder and a binder, where the ingredients include a glass powder in a relative amount sufficient to equal at least 50% by volume of the resulting mixture and a binder comprising a thermoplastic polymer, desirably a thermoplastic elastomer, and a wax; forming the mixture into a formed structure; and de-binding and sintering the formed structure. The method desirably involves mixing via a high intensity mixing process, desirably by mixing in a twin-screw extruder. The forming process may include pelletizing the mixture and injection molding the pelletized mixture to form the formed structure. The ingredients of the mixture desirably comprise a glass powder in a relative amount sufficient to equal at least 70% by volume of the resulting mixture. The glass powder desirably includes at least some glass particles having irregular shapes.

Owner:CORNING INC

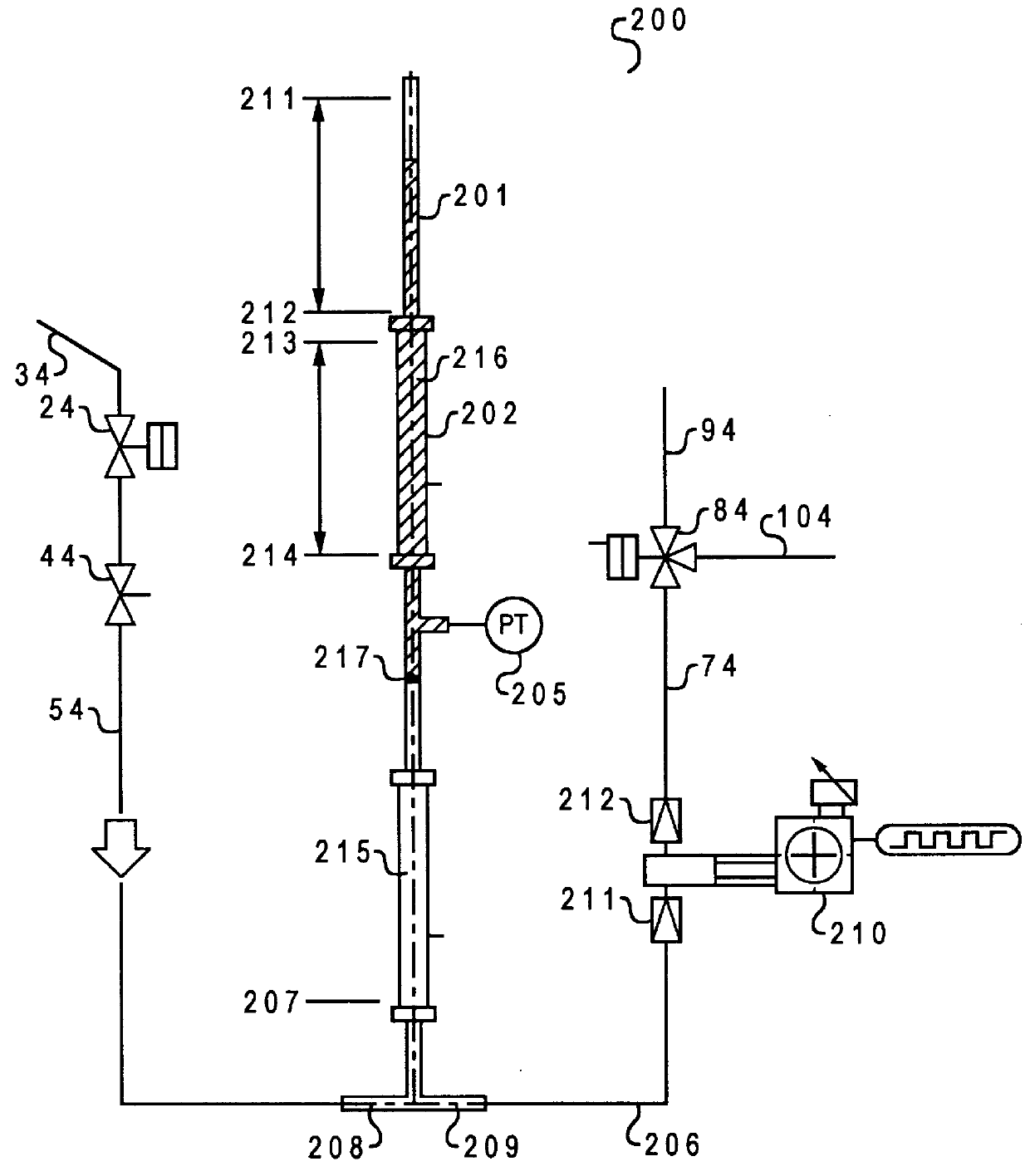

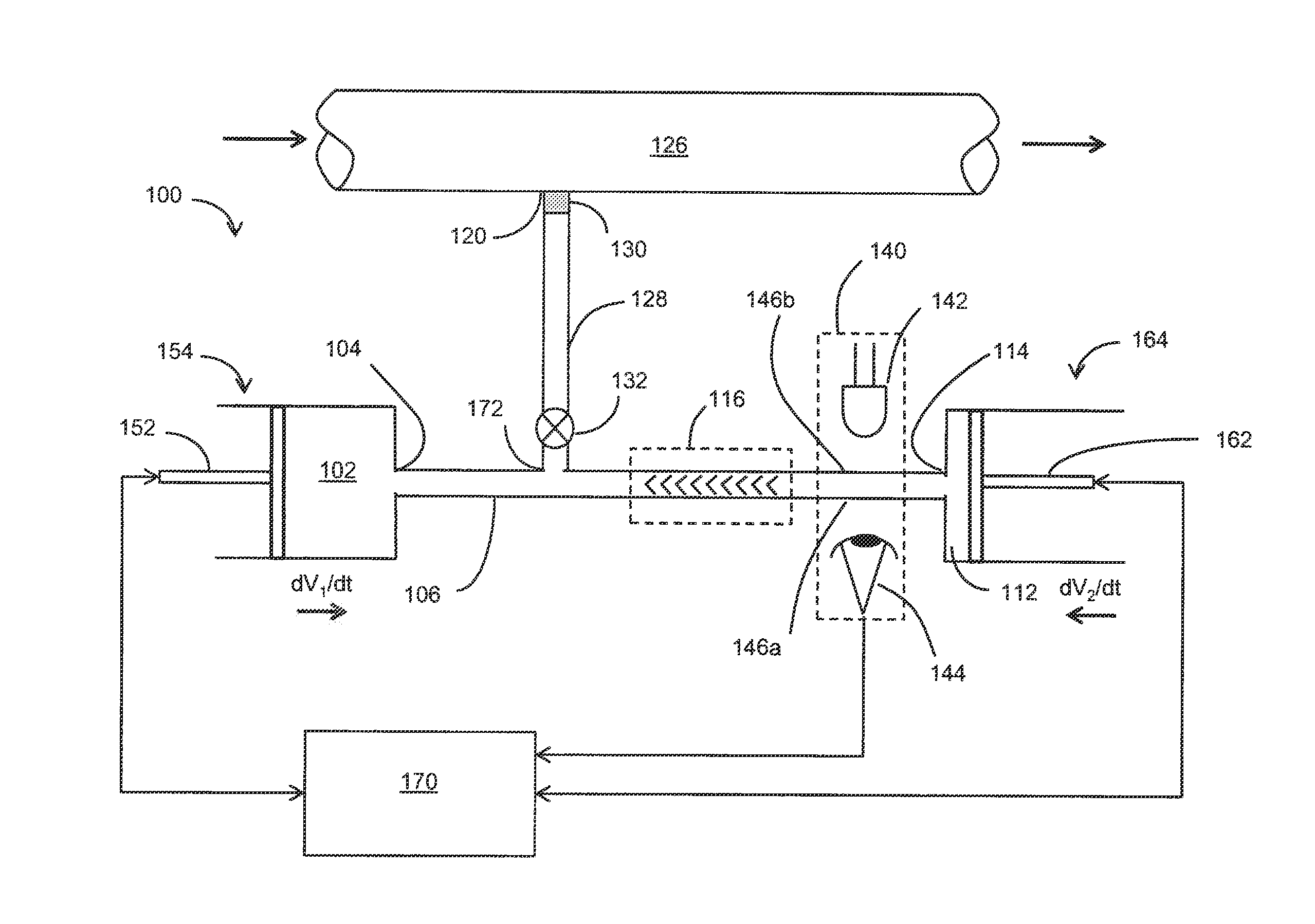

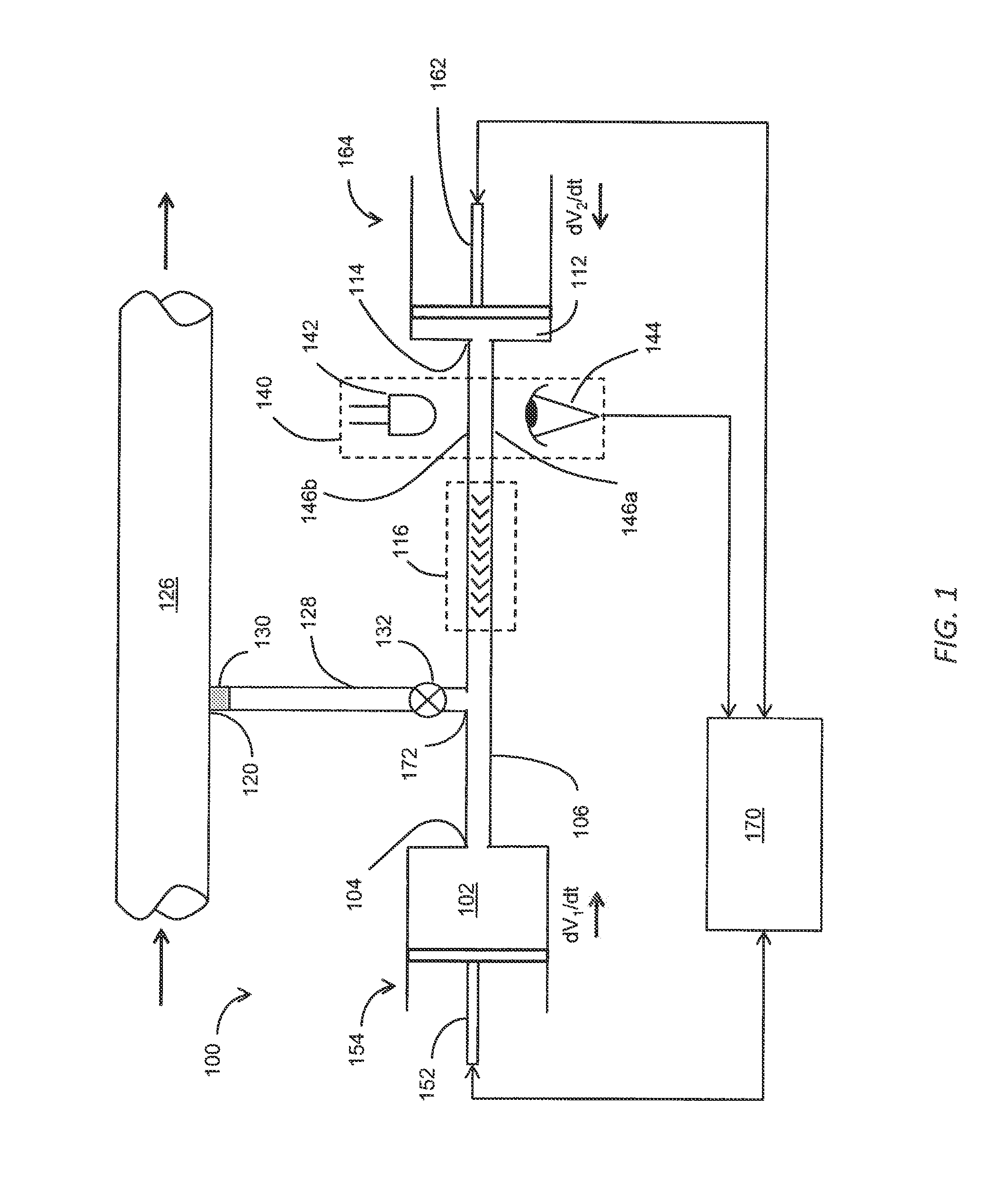

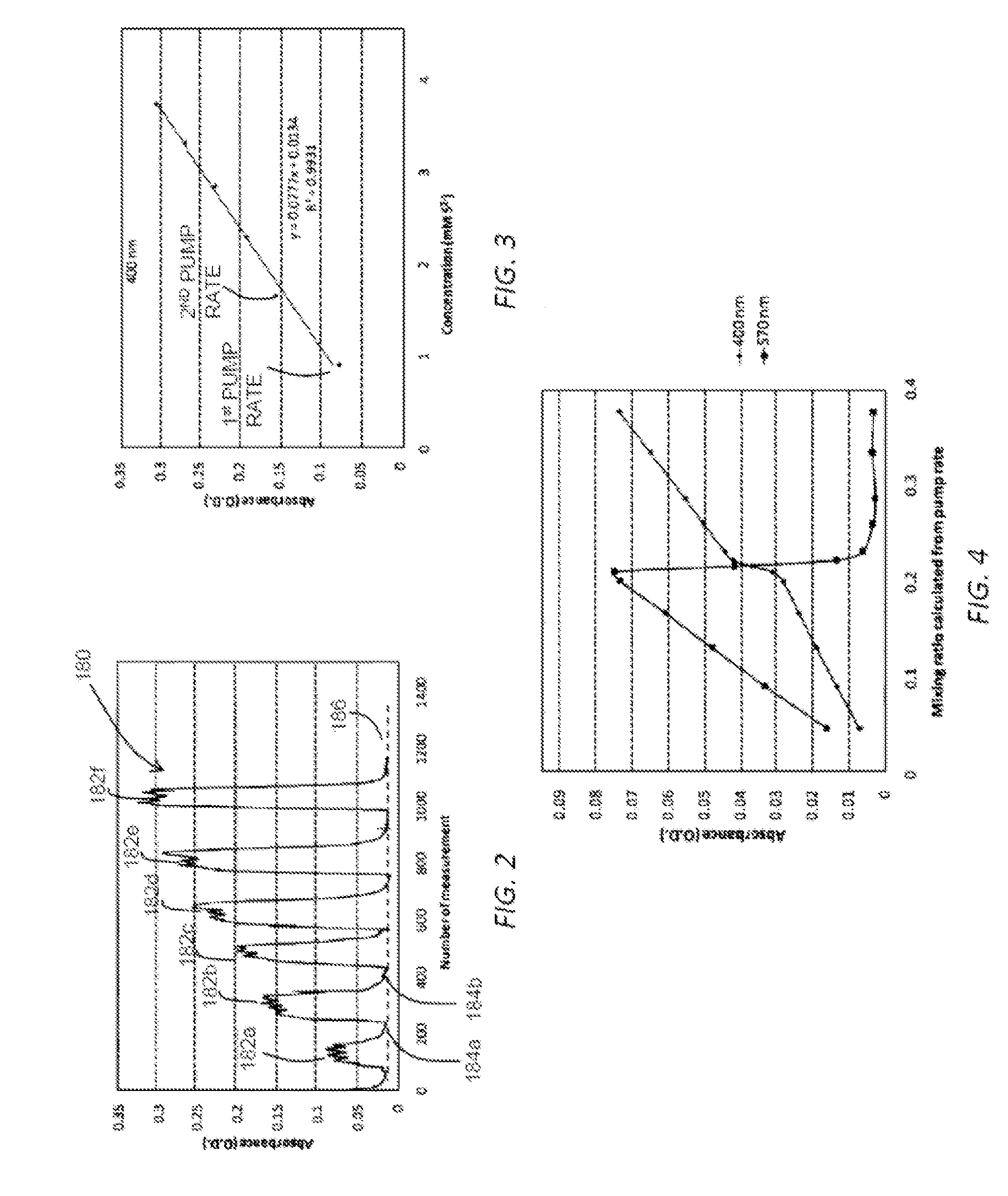

System and method for fluid processing with variable delivery for downhole fluid analysis

Described herein are variable-volume reservoir (e.g., syringe pump) based processes and systems usable to characterize samples of reservoir fluids, without having to first transport the fluids to the surface. Variable-volume reservoirs are used, for example, for one or more of storing reactants, controlling mixing ratios and storing used chemicals. The processes and systems can be used in various modes, such as continuous mixing mode, flow injection analysis, and titrations. A fluid interrogator, such as a spectrometer, can be used to detect a change in a physical property of the mixture, which is indicative of an analyte within the mixture. In at least some embodiments, a concentration of the analyte solution can be determined from the detected physical property.

Owner:SCHLUMBERGER TECH CORP

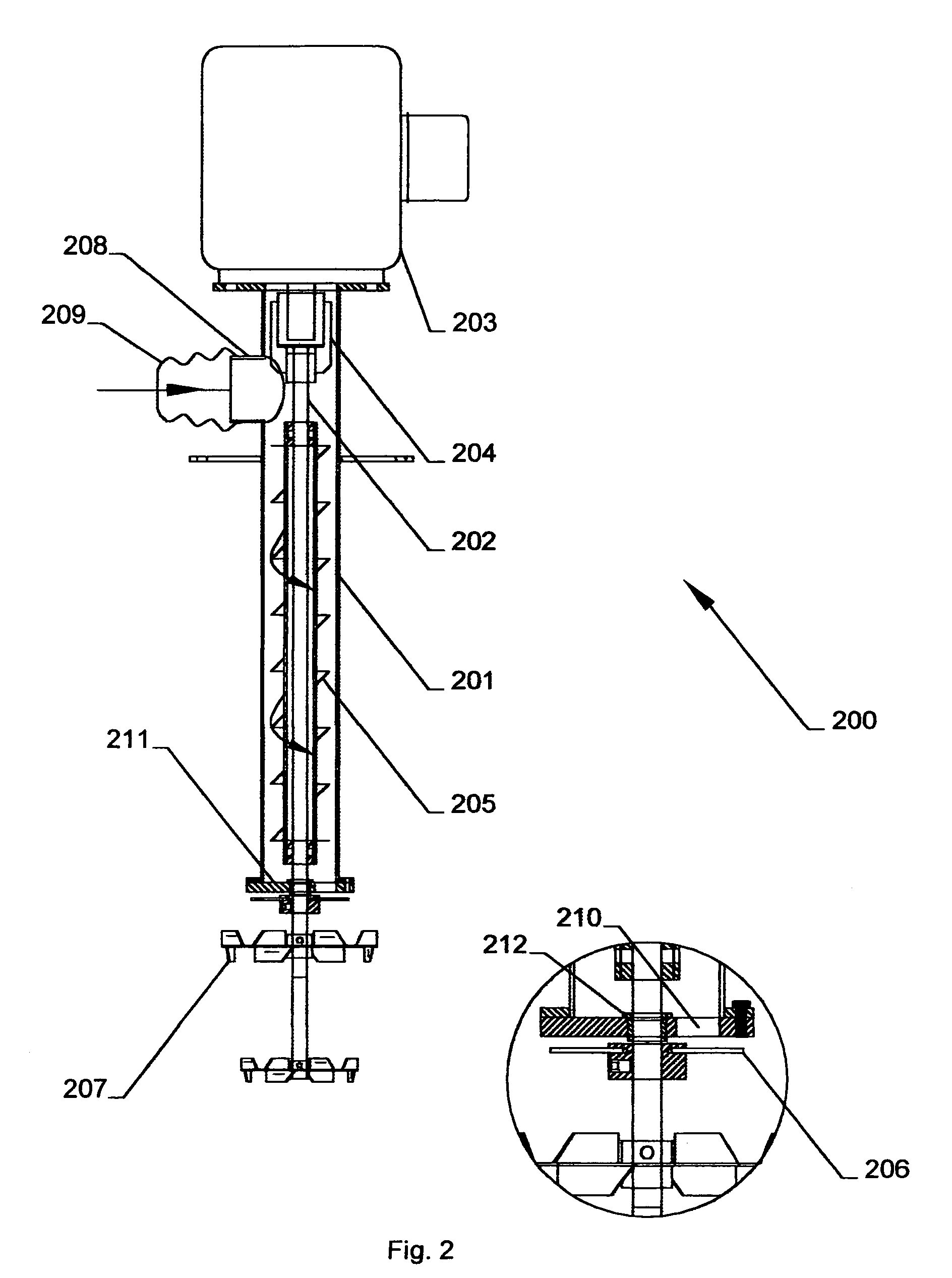

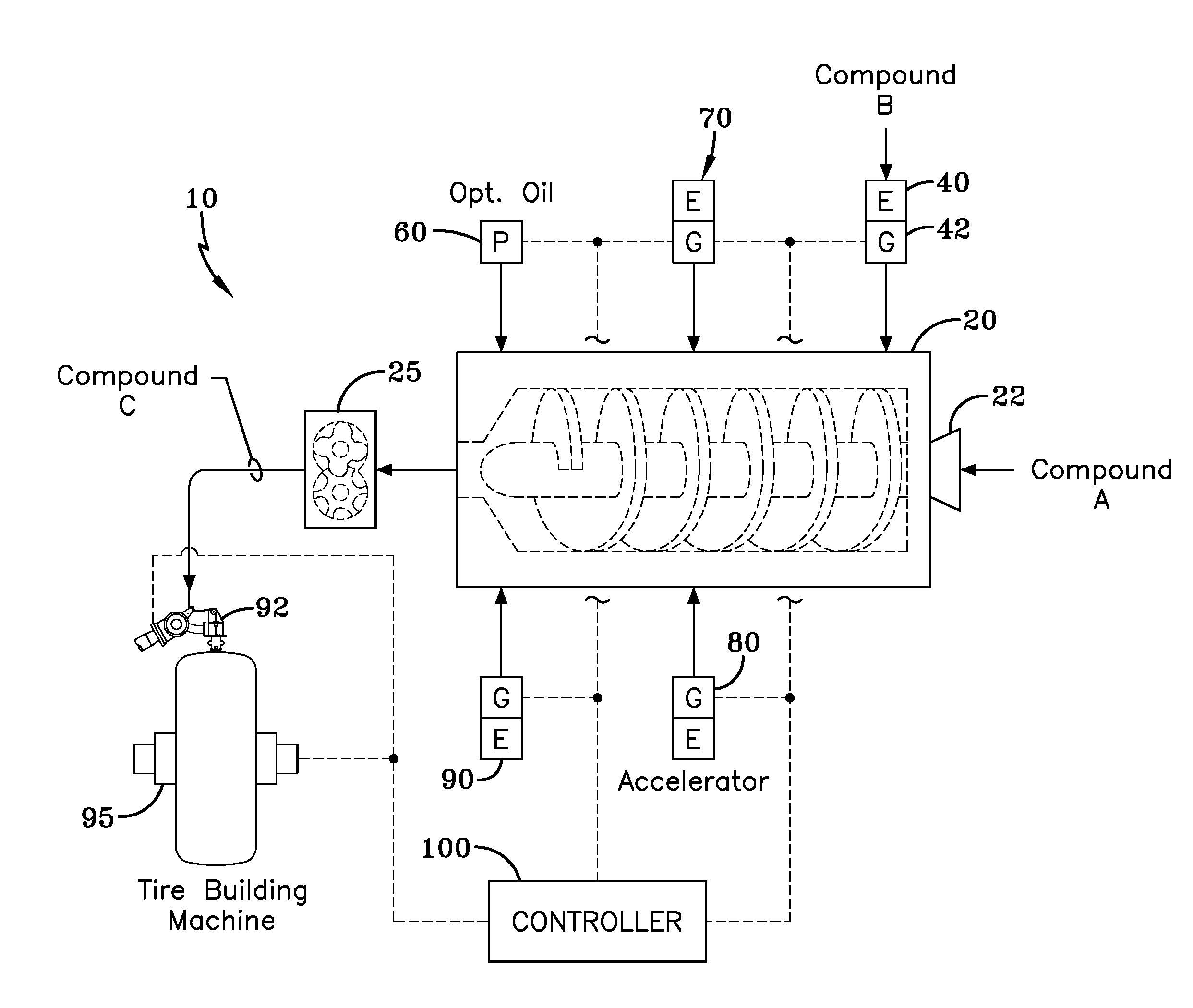

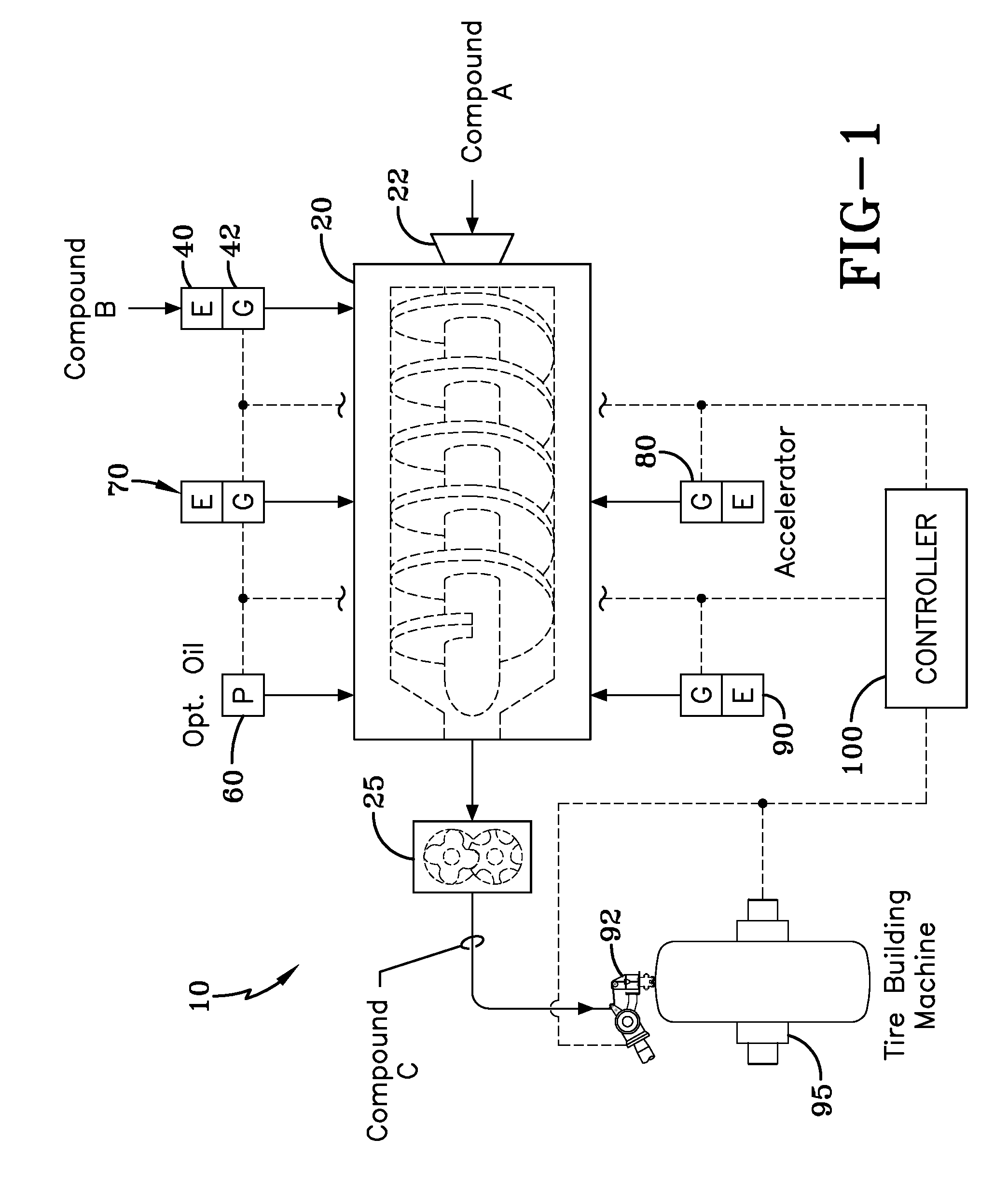

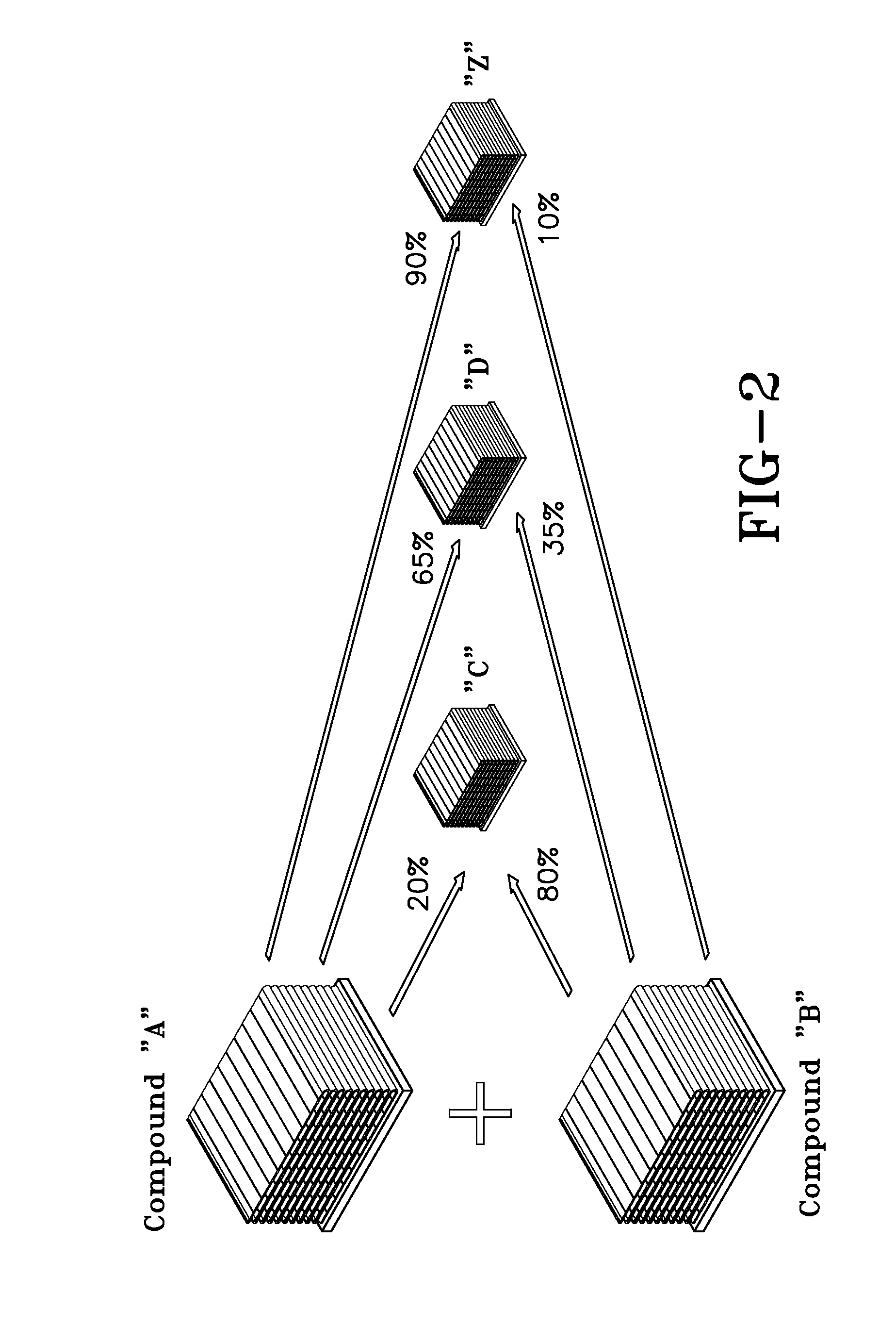

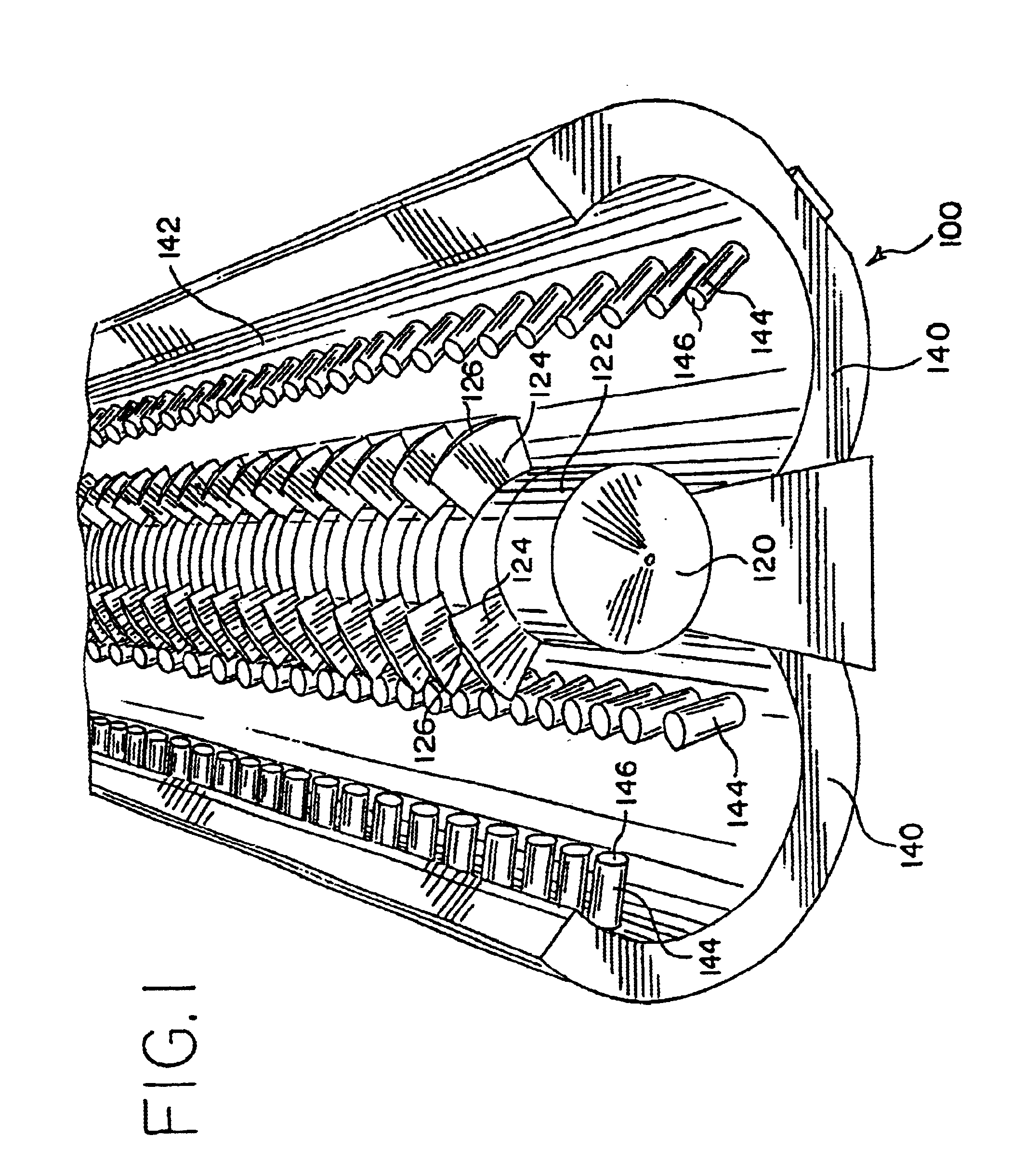

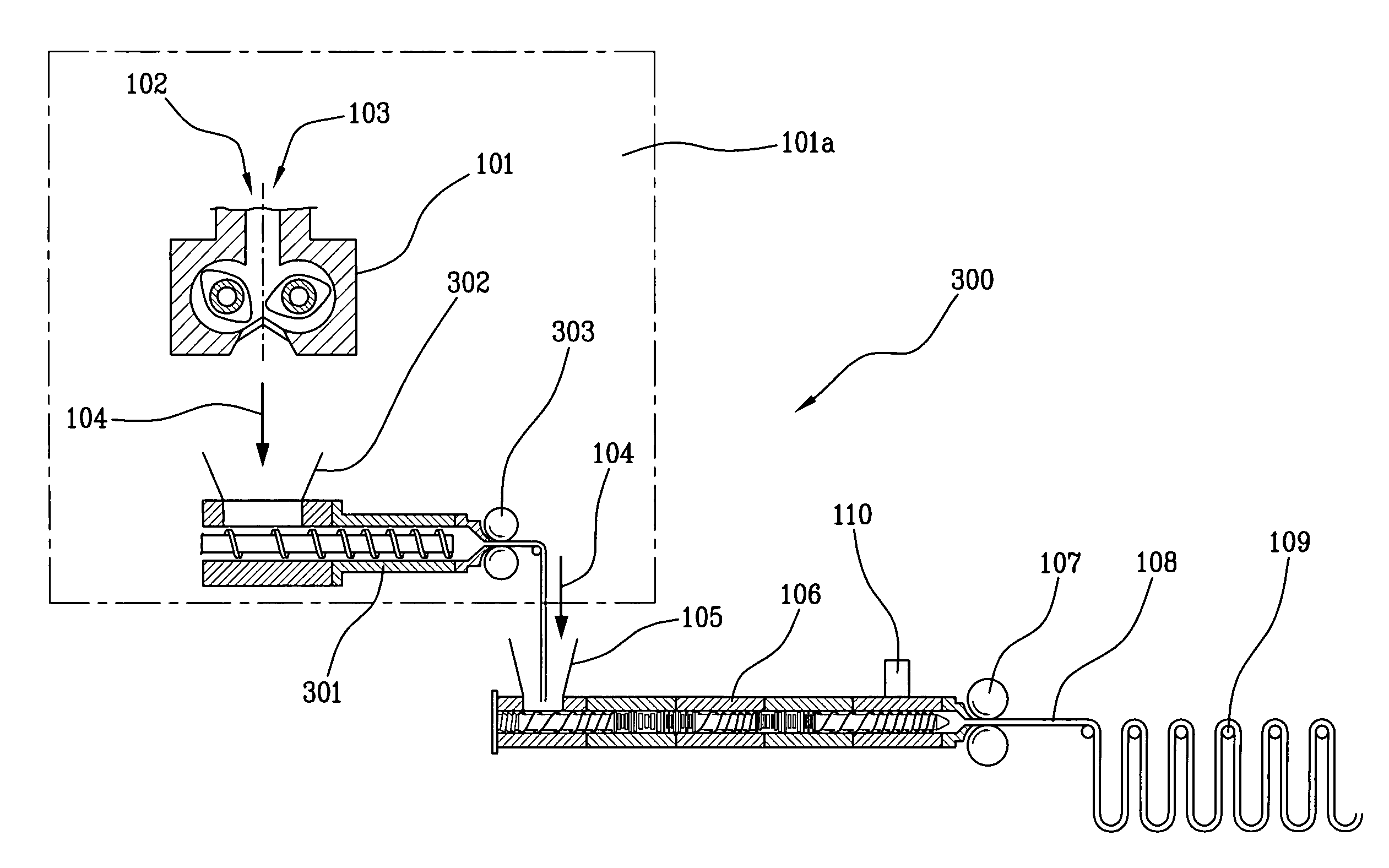

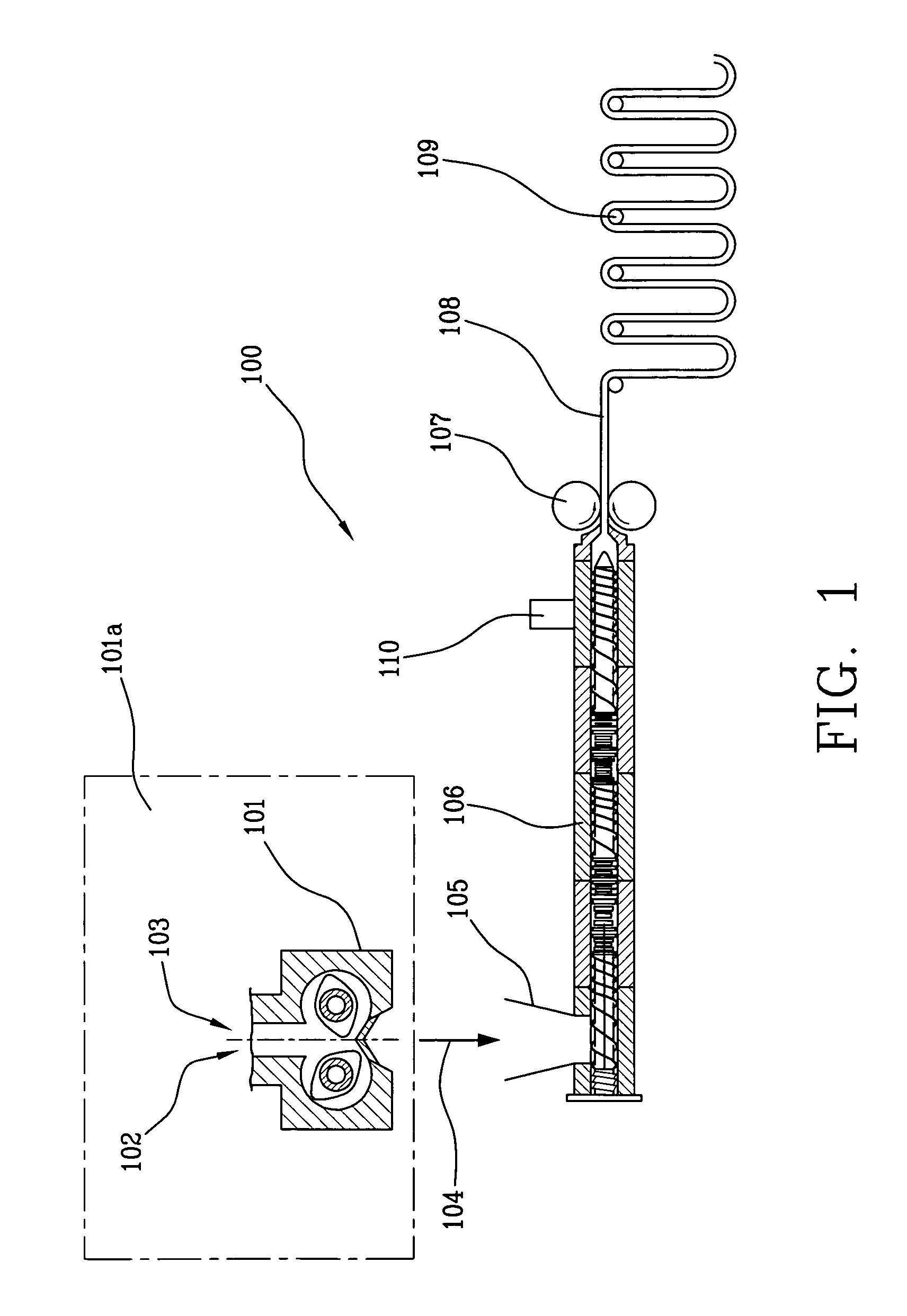

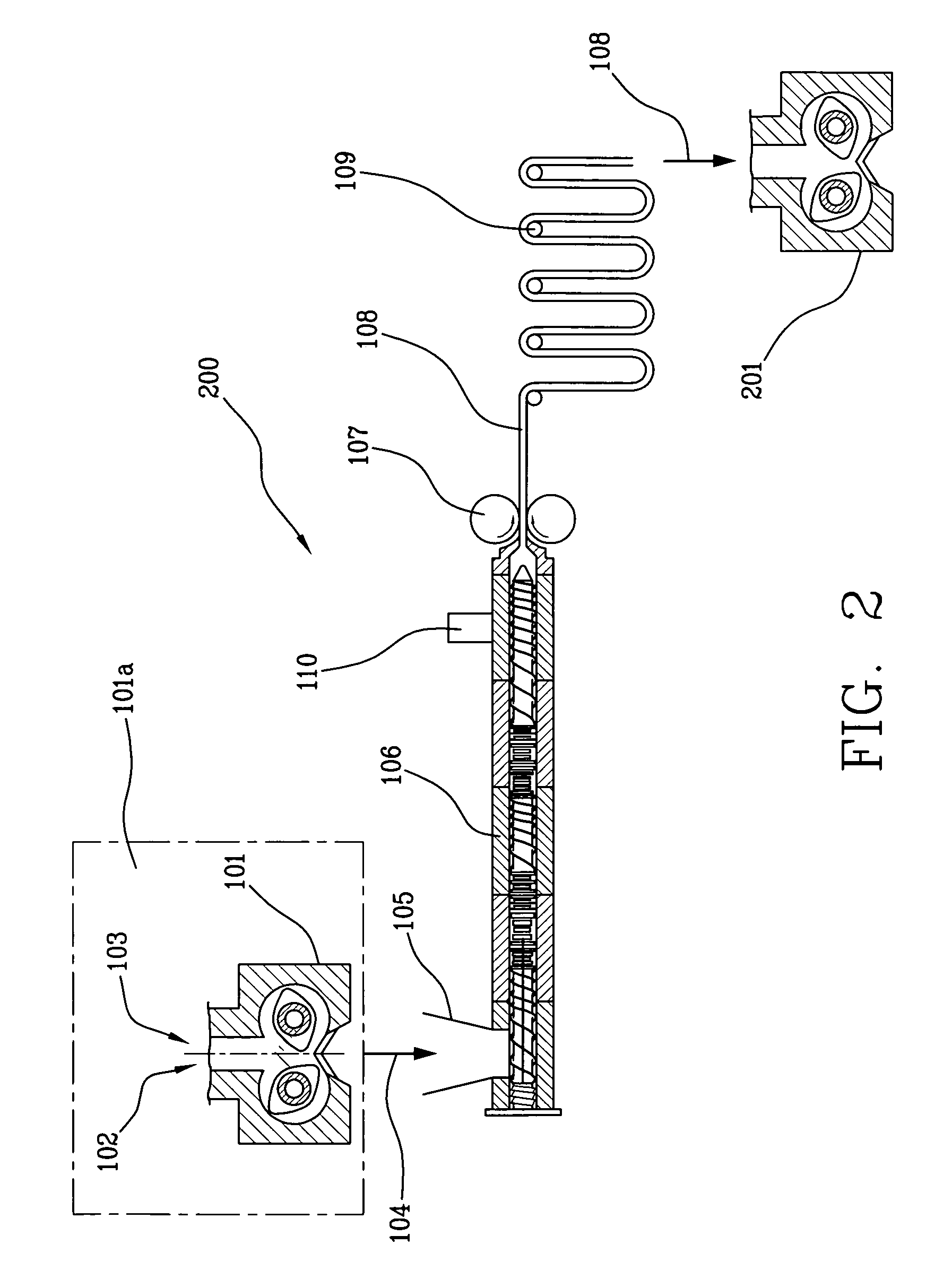

Continuous mixing system and apparatus

A method and apparatus for applying a blended rubber composition directly onto a tire building drum or core is described. A first extruder and a first gear pump for a first compound is provided. A second extruder and a second gear pump for a second compound is provided. The output of the second gear pump is fed into the main extruder. A third gear pump is provided for adding an accelerator mixture; mixing together said first compound and said second compound and said accelerator mixture.

Owner:BURG GARY ROBERT +1

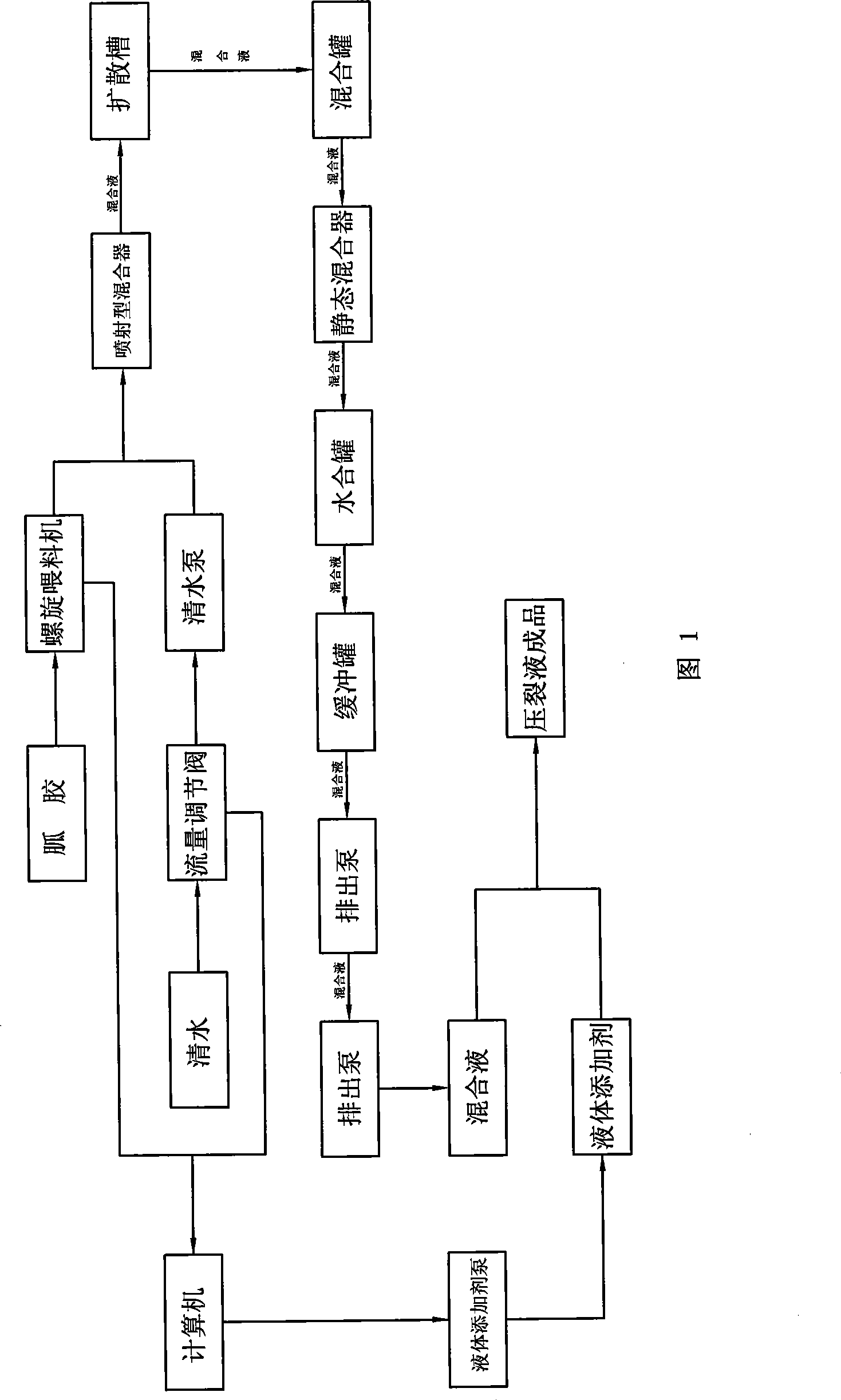

Continuous compounding method for fracturing fluid

The invention discloses a fracturing fluid continuous mixing method, comprising the steps as follows: guar gum is input into an injection-typed mixer which can automatically adjust the flux by a precise spiral feeding machine; the feeding quantity of the guar gum is adjusted by the rotation speed of the precise spiral feeding machine; the blanking quantity of the spiral feeding machine is controlled by a computer which can continuously read the difference value of an electronic balance within unit time, adjusts the rotation speed of the spiral feeding machine according to the flux and proportion of the external clean water and keeps the given liquid mixing ratio; the method is applicable to continuous mixing in-situ, the mixed fracturing fluid has good quality, the hydration speed of the liquid is fast, the labor intensity of workers is reduced, the cost payout is saved and the environmental pollution is reduced.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

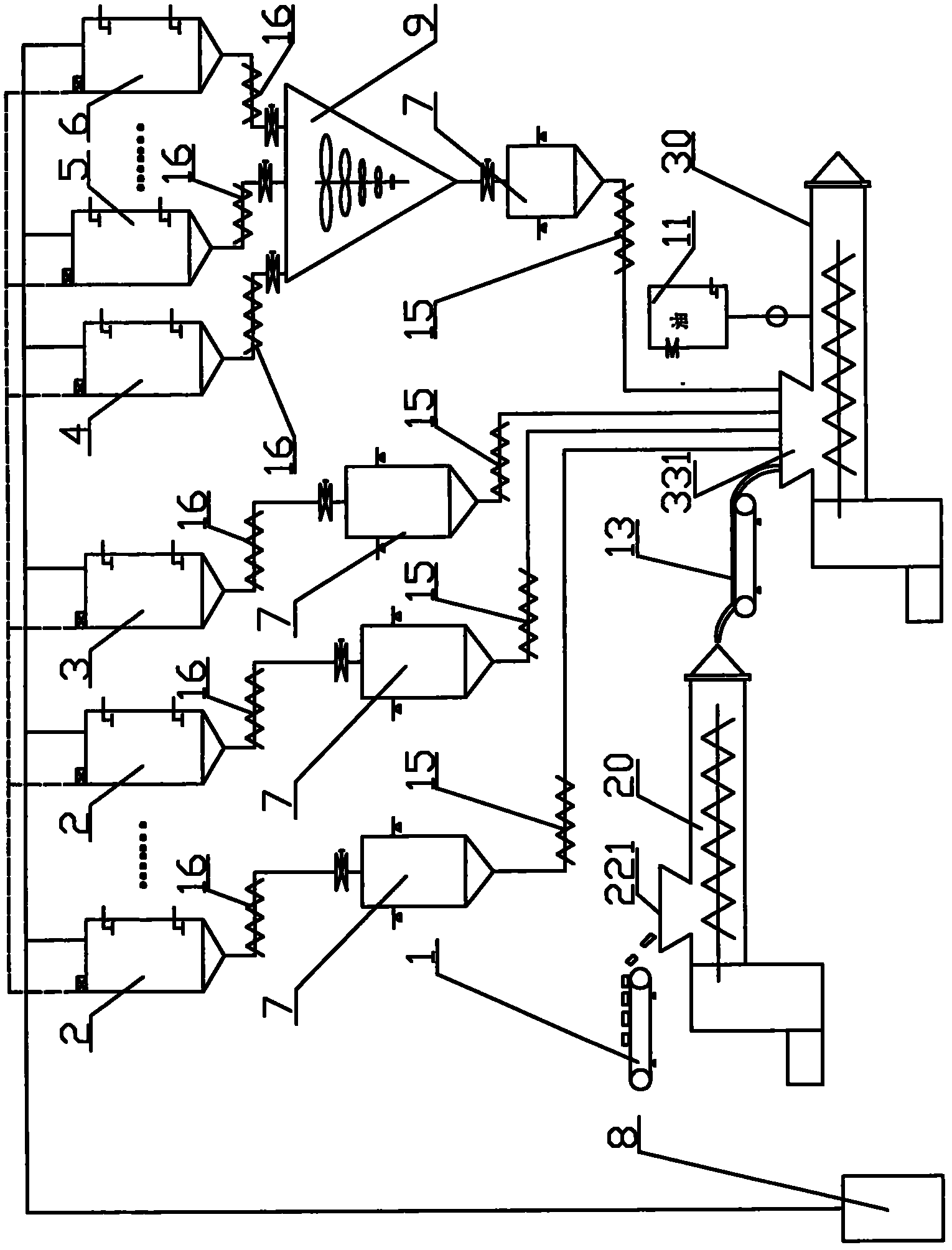

Blocky rubber continuous mixing method and device

The invention discloses a blocky rubber continuous mixing method and device. A crude rubber conveying device is used for feeding a blocky rubber raw material into a rubber continuous plastifying device and conveying a solid compounding agent and an extruded plastifying rubber sheet into the rubber continuous mixing device; a rubber feeding controlling device and a compounding agent feeding controlling device are connected with an equipment control system; and the blocky rubber raw material is directly put into the blocky rubber continuous plastifying device to be continuously plastified without prophase treatment, plastified rubber is mixed through the rubber continuous mixing device, and continuous production of continuous feeding, discharging, continuous plastifying and continuous mixing is realized. The blocky rubber continuous mixing device has the advantages of less quantity of auxiliary devices, little investment of production devices, low energy consumption, high efficiency, and high mixing quality because stable device parameters and process conditions can be realized due to strong controllability.

Owner:QINGDAO UNIV OF SCI & TECH

Rice and chicken lobster continuous mixing planting and breeding method capable of stabilizing grain income and increasing fishery income

InactiveCN106386302AReduce pests and diseasesImprove qualityClimate change adaptationPisciculture and aquariaPotamogeton maackianusPrawn

The invention discloses a rice and chicken lobster continuous mixing planting and breeding method capable of stabilizing the grain income and increasing the fishery income. The method includes: digging circular furrows in a rice field, increasing the height and the width of ridges, reinforcing the ridges, and additionally arranging escape-proof facilities; transplanting Ceratophyllum demersum and Alternanthera philoxeroides in the circular furrows after water in the rice field is disinfected; transplanting Hydrilla verticillata, Potamogeton maackianus and Potamogeton wrightii in the rice field outside the circular furrows; performing a rice and chicken lobster continuous cultivation mode, breeding chicken lobsters from the last ten days of September or the first ten days of October to the first ten days of June of the secnd year after the rice is harvested; raising rice seedlings in a special field from May to the first ten days of June, and planting the rice from the middle ten days of June to the last ten days of September; using a ground cage to catch the chicken lobsters from May to the first ten days of June, and leaving a part of the chicken lobsters to be cultivated with the rice; putting parent chicken lobsters into the circular furrows of the rice field from the middle ten days of August to the first ten days of September; applying a fermentative organic fertilizer and putting Bellamya quadrata from the last ten days of February and the last ten days of May; putting Elodea nuttallii from March to June; feeding the chicken lobsters with a compound fodder at 18 p.m. to 19 p.m. every day; controlling the water level all through the year; controlling diseases of the chicken lobsters; catching the chicken lobsters; and planting the rice.

Owner:陈冬林

Preparation and application of MOF-derived porous carbon/graphene composite electrode material

ActiveCN108328706AFully evenly dispersedEvenly dispersedDispersed particle separationWater/sewage treatmentPorous carbonFreeze-drying

The invention discloses preparation and an application of an MOF-derived porous carbon / graphene composite electrode material. The preparation method comprises the steps as follows: (1) a clean container is taken, a graphene or graphene oxide dispersion liquid is added, then, MOFs crystal powder is added, the container is placed on a vortex mixer for continuous mixing after being sealed, the rotating speed is adjusted repeatedly from zero to the highest rotating speed, so that a sample is fully oscillated in the vertical direction, formation of a graphene sheet or graphene oxide sheet self-assembly three-dimensional structure and full and uniform dispersion of MOFs crystals in the three-dimensional frame structure are promoted, and finally, graphene / MOF porous aerogel is obtained through freeze drying; (2) the aerogel is subjected to high-temperature roasting in the N2 atmosphere and a carbonized product is obtained; (3) the carbonized product is subjected to acid treatment and the MOF-derived porous carbon / graphene composite electrode material is obtained. The MOF-derived porous carbon / graphene composite electrode material is applied in CDI or MCDI desalination and has good effects.

Owner:ZHEJIANG UNIV OF TECH

Chewing gum manufacture using high efficiency continuous mixer

InactiveUS6858237B1Improve throughputLess equipmentContainers for annular articlesConfectioneryEngineeringContinuous mixing

A method is provided for the total manufacture of chewing gum on a continuous basis. The method uses a continuous high efficiency mixer which includes at least one conveyor element that is not located under a feed port.

Owner:WM WRIGLEY JR CO

Method for producing vegetarian ham sausages through twin-screw extrusion

InactiveCN103190525AFine surface structureSmooth surface structureProteins working-up by texturisingVegetable proteins working-upSmall footprintContinuous mixing

The invention discloses a method for producing vegetarian ham sausages through twin-screw extrusion. The vegetarian ham sausages are produced by performing pretreatment on vegetable protein powder, isolated soy protein and vital wheat gluten as raw materials through, and then mixing and stirring the pre-treated raw materials by adopting a twin-screw extruder and a twin-screw extrusion technology for completing the processes such as extrusion curing, denaturation and texturization forming for one time. The method completely takes the vegetable protein powder as the raw material without adding any additives or auxiliary materials, so that the vegetarian ham sausages are good in texturization structure, high in protein content, similar to meat taste in taste, smooth in appearance, compact in structure and stable in quality, the moisture content of final products can be up to 50%, and the vegetarian ham sausages can be eaten as leisure food and staple food. By utilizing the twin-screw extruder for production, the method is a continuous mixing, melting and forming process, and as a high-temperature instantaneous biochemical reactor, the twin-screw extruder has the outstanding advantages of high efficiency and energy, low cost, energy consumption and the like, and also has the characteristics of high volume of the production, continuous production process, realization of the large-scale industrialized production, stable product quality, high degree of automation, small occupying area for the production and the like.

Owner:湖南富马科食品工程技术有限公司

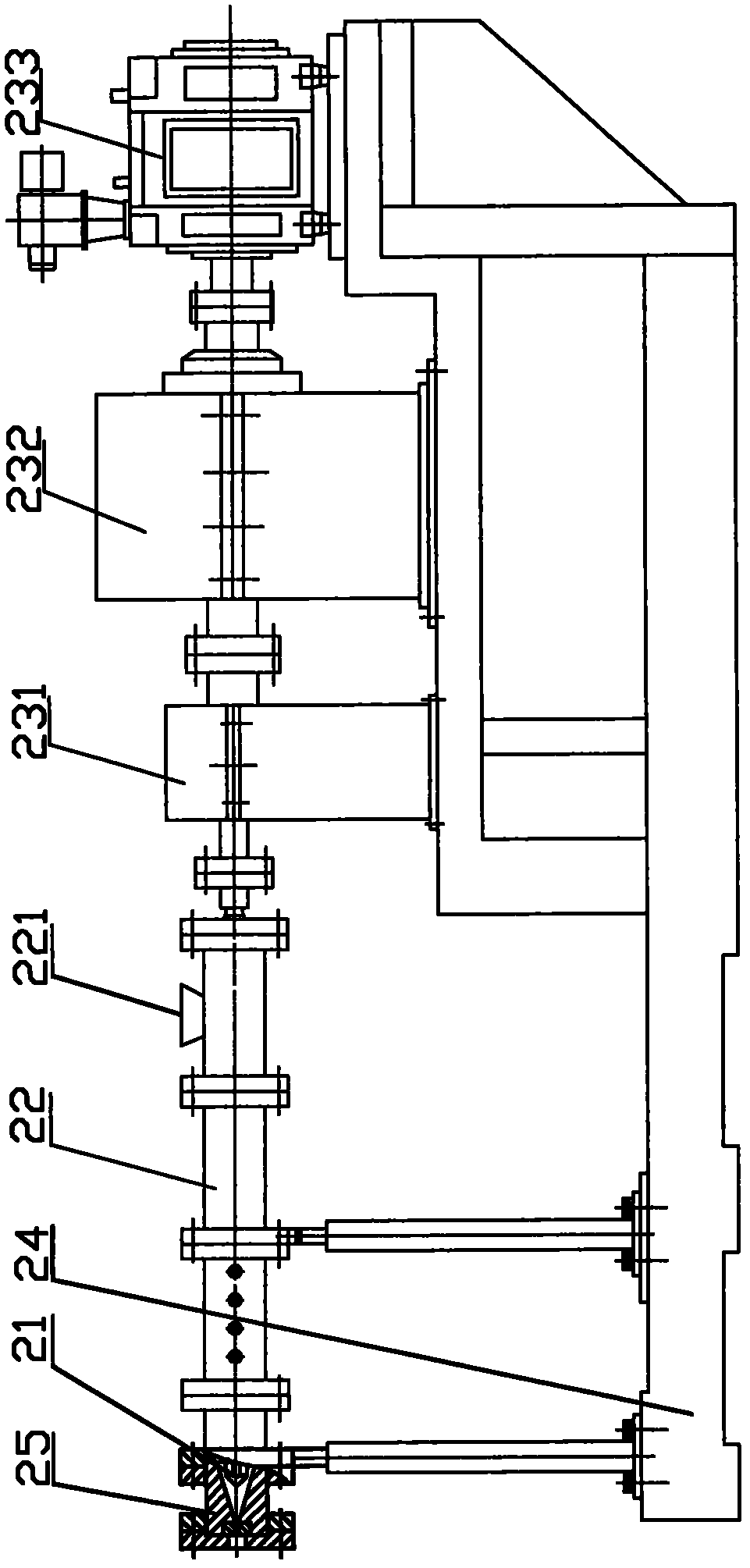

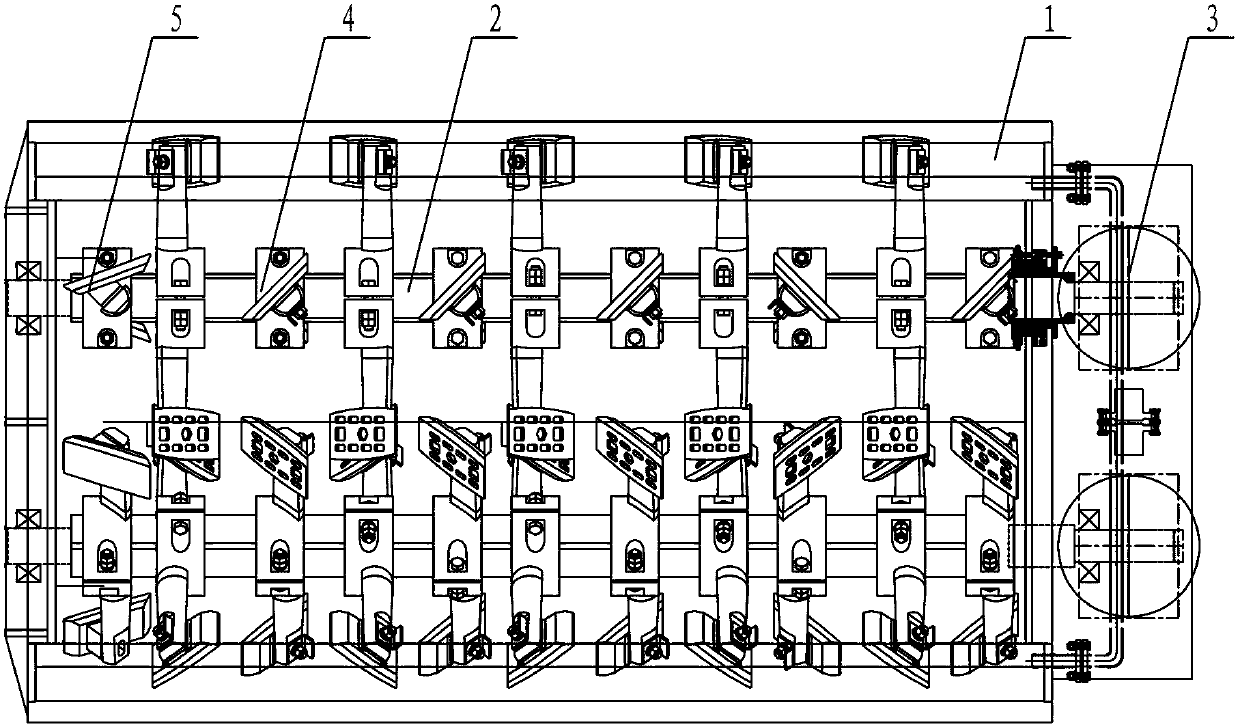

Continuous double-horizontal-shaft forced mixer for asphalt and concrete

ActiveCN103128854AYield easily achievedImprove transmission efficiencyDischarging apparatusMixing operation control apparatusContinuous mixingMechanical engineering

The invention belongs to the technical field of asphalt and concrete mixing, and particularly relates to a continuous double-horizontal-shaft forced mixer for asphalt and concrete. The continuous double-horizontal-shaft forced mixer for the asphalt and the concrete comprises a mixing tank provided with a feeding port and a discharging port, two mixing shafts which are arranged in the mixing tank in a parallel mode, a driving device which drives the mixing shafts to rotate synchronously and reversely, a plurality of groups of mixing units and a material scraping unit. Each mixing unit comprises mixing arms and blades, wherein the mixing arms are mounted on the mixing shafts in an opposite mode, the blades are mounted on the mixing arms and comprise a feeding blade and a returning blade, and the feeding blade and the returning blade are the same in structure and size and opposite in mounting direction. The material scraping unit comprises a group of mixing arms which are arranged in an opposite mode, and material scraping blades which are connected on the mixing arms, wherein an acute included angle is formed between each material scraping blade and a side plate of the mixing tank. According to the bituminous mixture mixer, namely the continuous double-horizontal-shaft forced mixer for the asphalt and the concrete, the methods of continuous grading feeding, continuous mixing and continuous discharging are used, and the output of the bituminous mixture mixer can reach 100-1,000 tons per hour.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

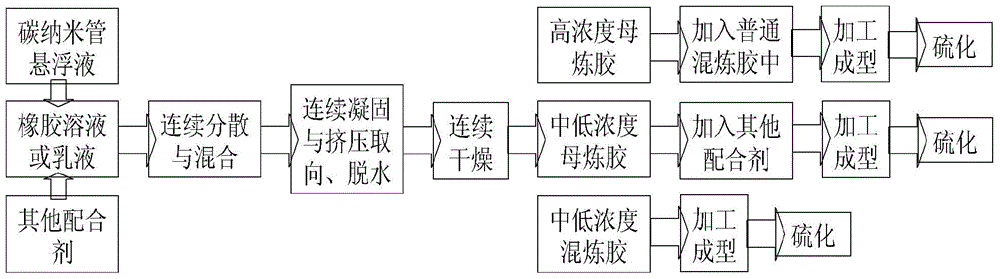

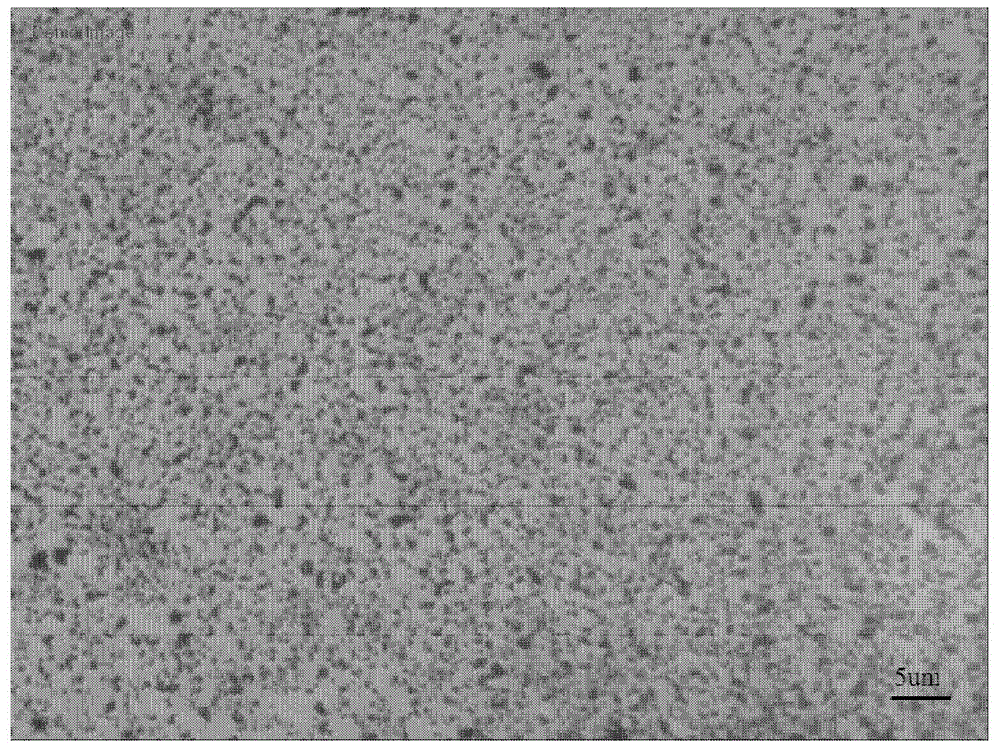

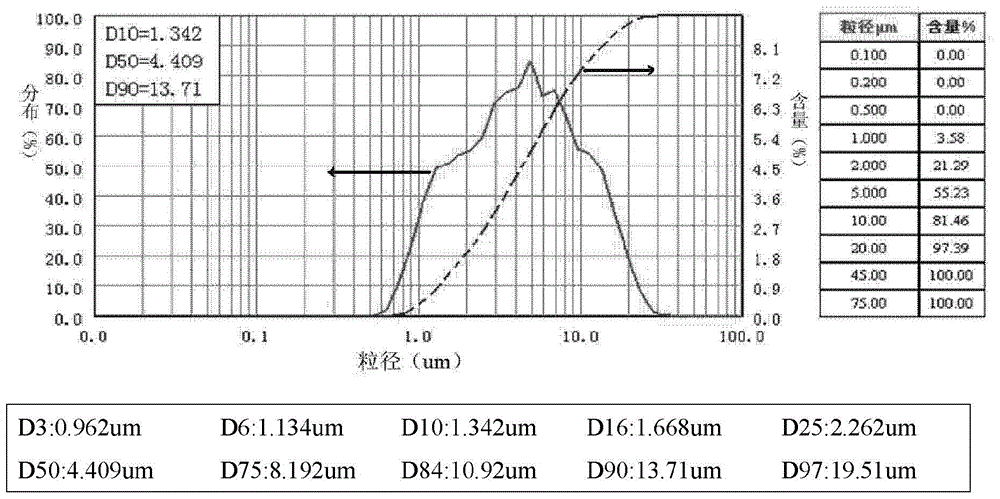

Liquid phase continuous mixing process of high dispersion carbon nanotube masterbatch and rubber product thereof

The invention discloses a liquid phase continuous preparation method of a carbon nanotube masterbatch. The method includes: preparing a carbon nanotube suspension; concinuously dispersing and mixing the carbon nanotube suspension with a rubber solution / emulsion and an optional rubber compounding ingredient solution / suspension to obtain a carbon nanotube / rubber / solvent mixture; carrying out solidification and continuous extrusion on the carbon nanotube / rubber / solvent mixture simultaneously to realize carbon nanotube orientation, and removing water or the solvent to obtain the carbon nanotube / rubber mixture; and continuously drying the carbon nanotube / rubber mixture to obtain the carbon nanotube masterbatch. The invention also includes the carbon nanotube masterbatch obtained by the liquid phase continuous preparation method and the rubber product prepared from the carbon nanotube masterbatch.

Owner:SHANDONG DAZHAN NANO MATERIALS

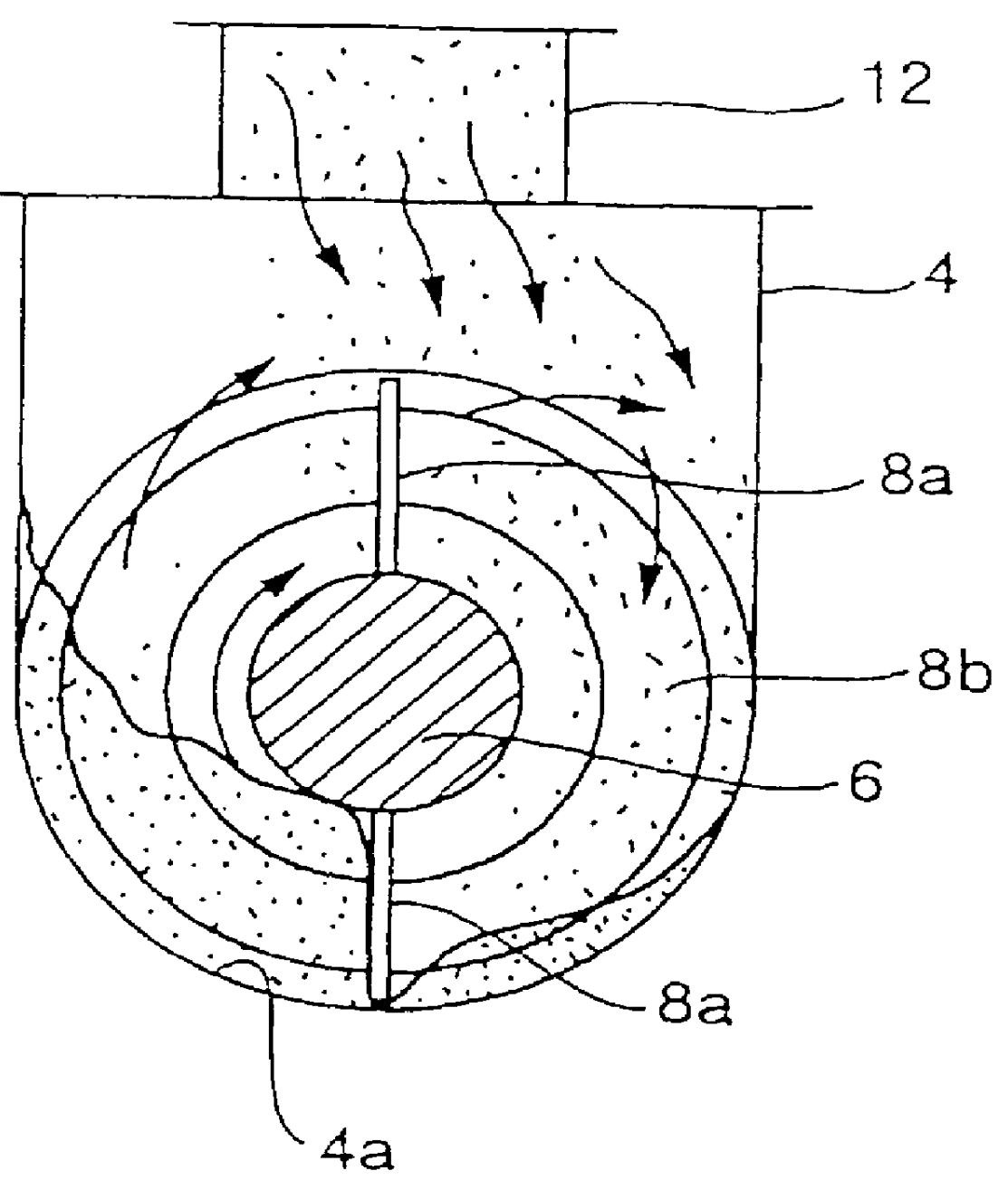

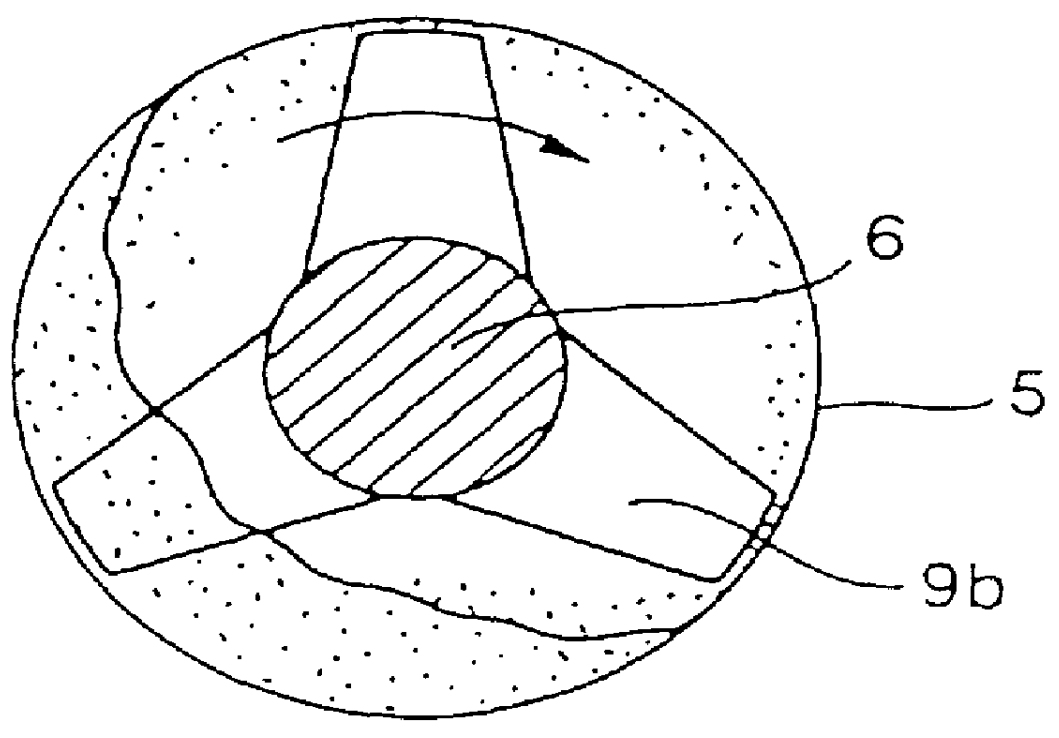

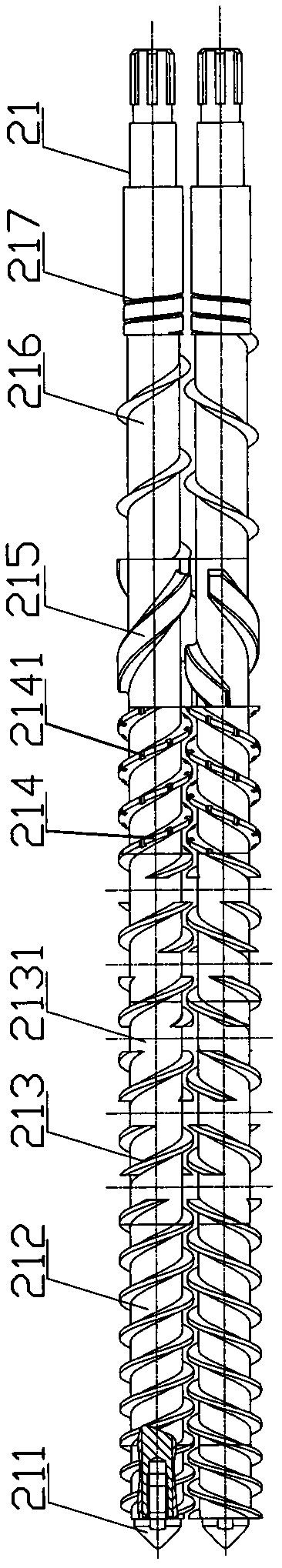

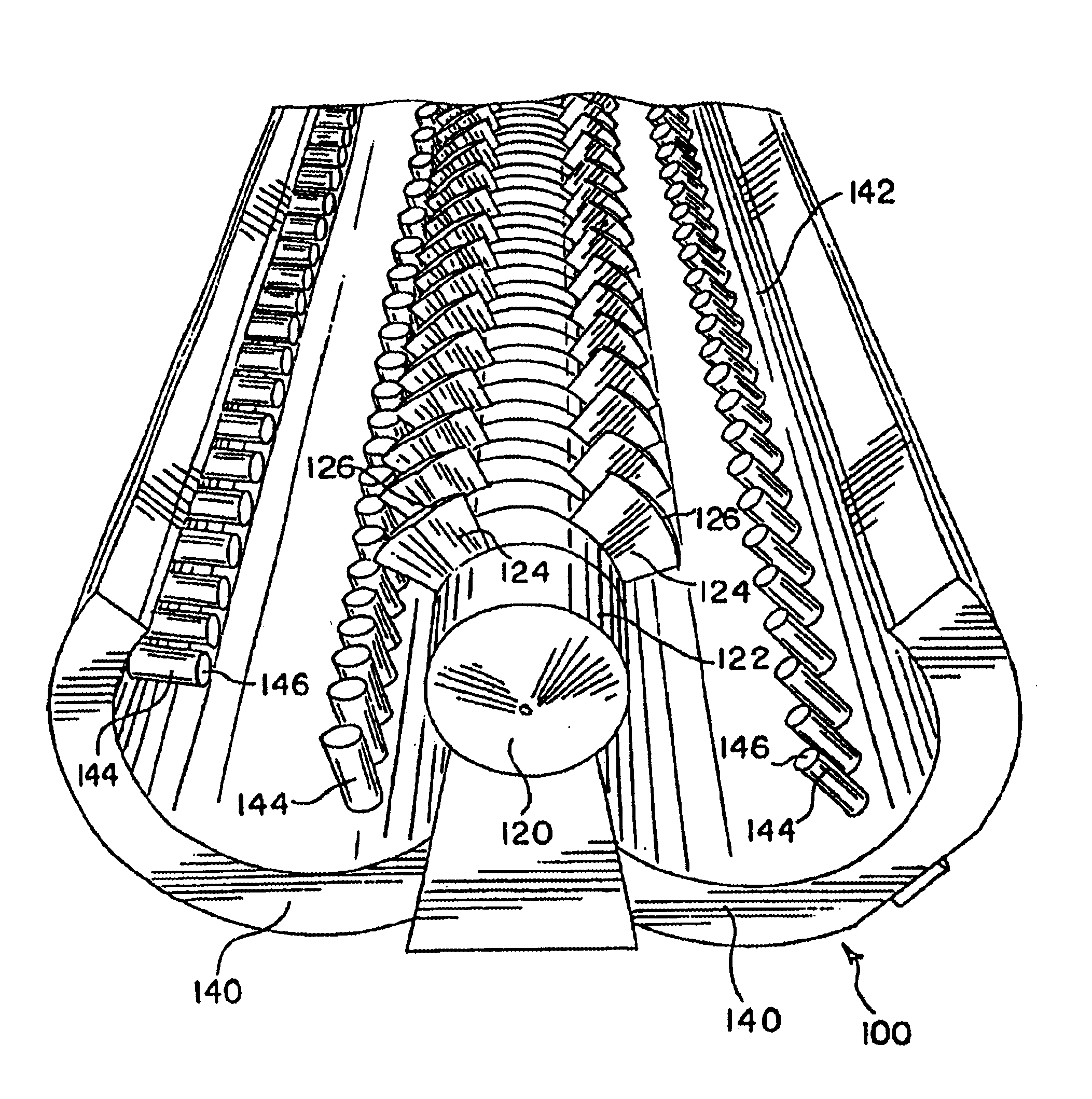

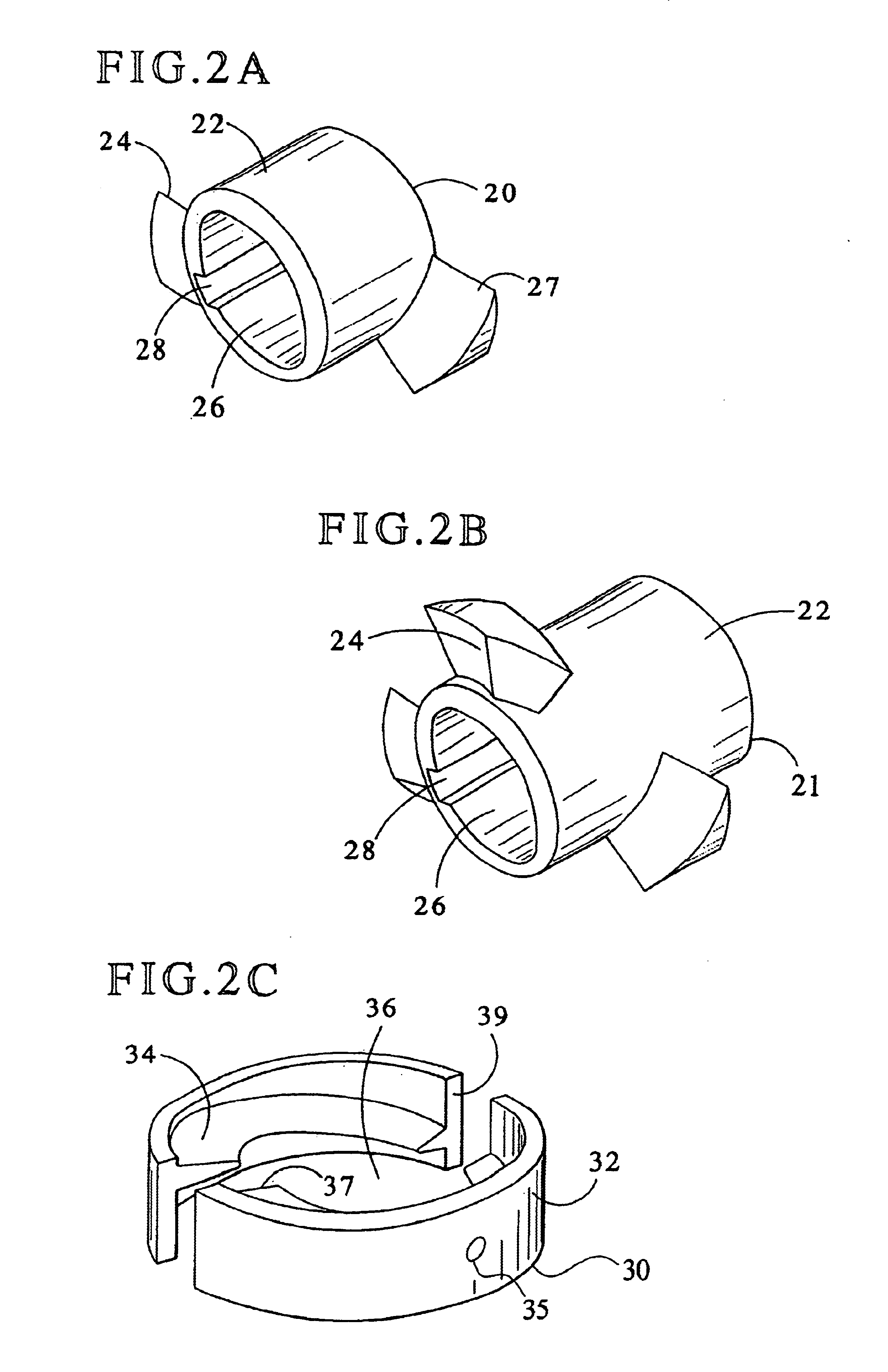

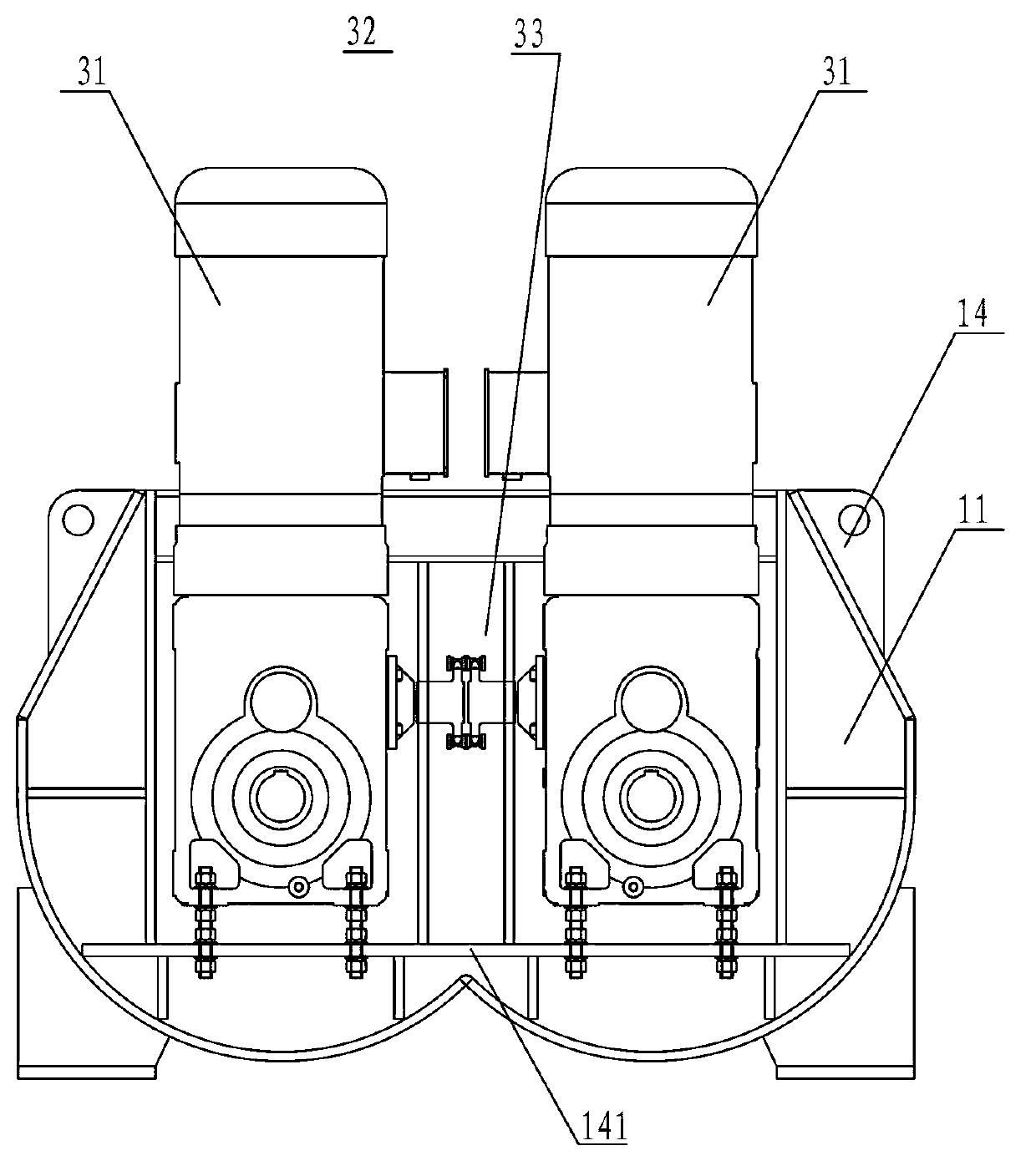

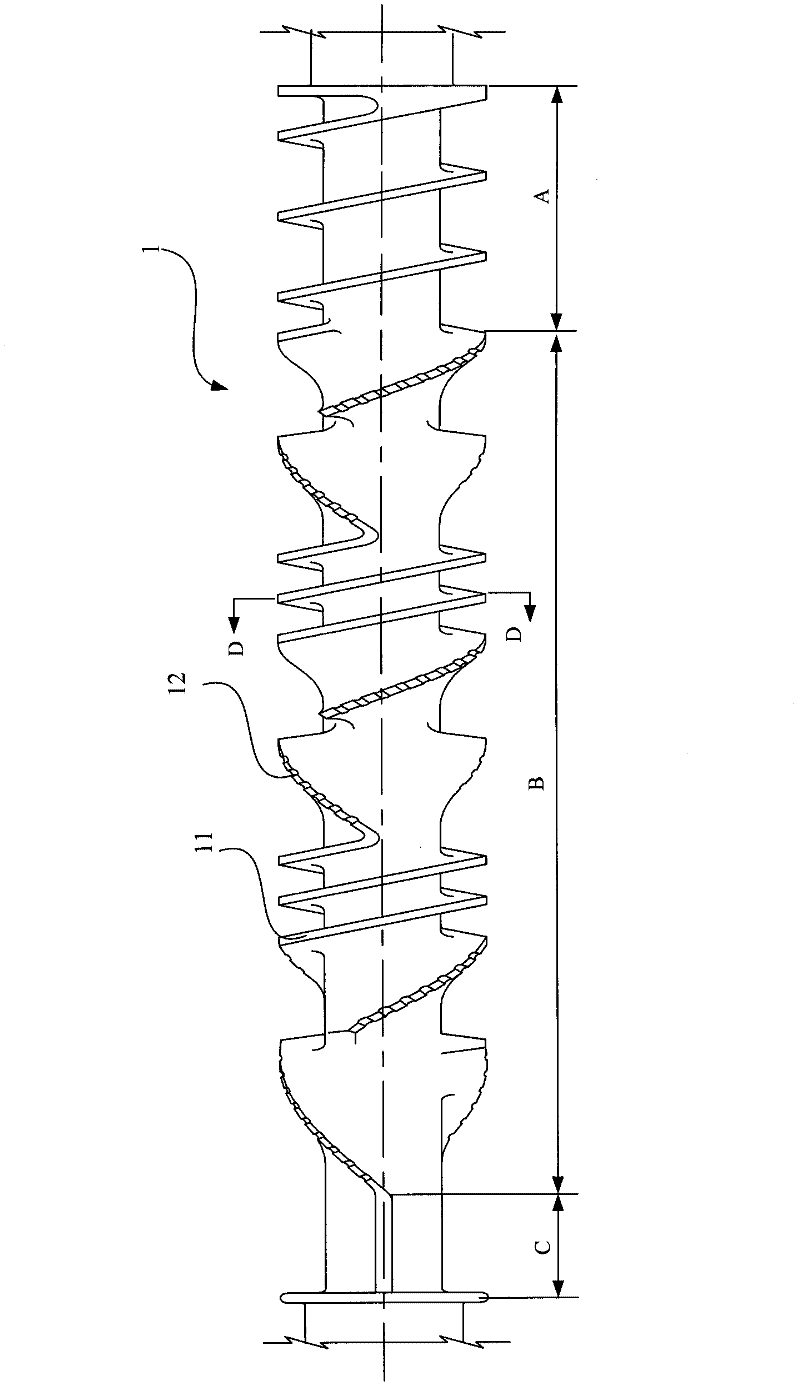

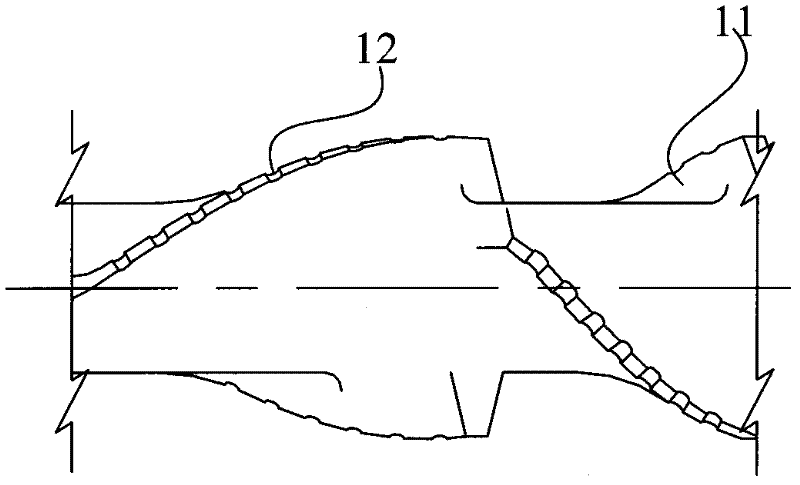

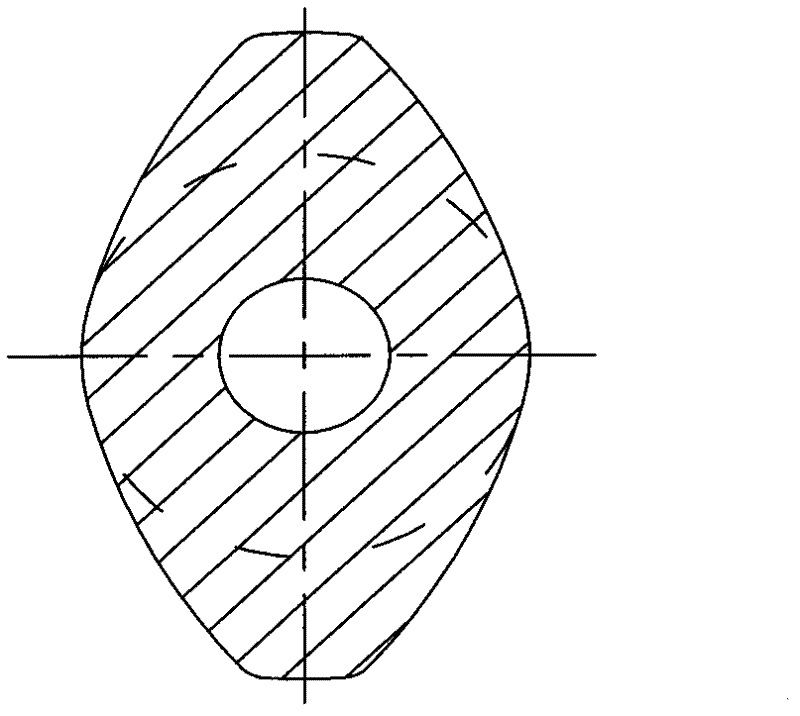

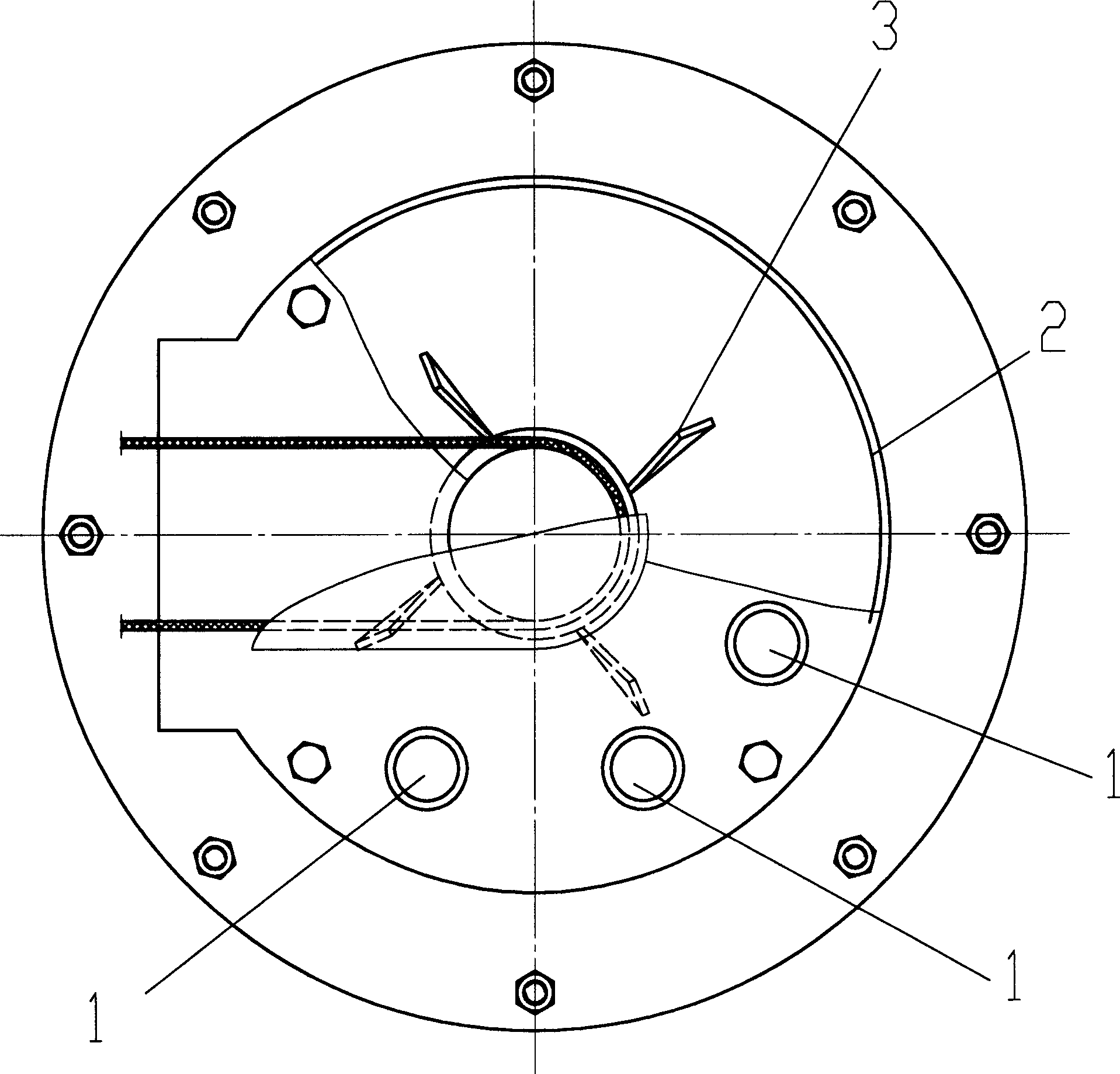

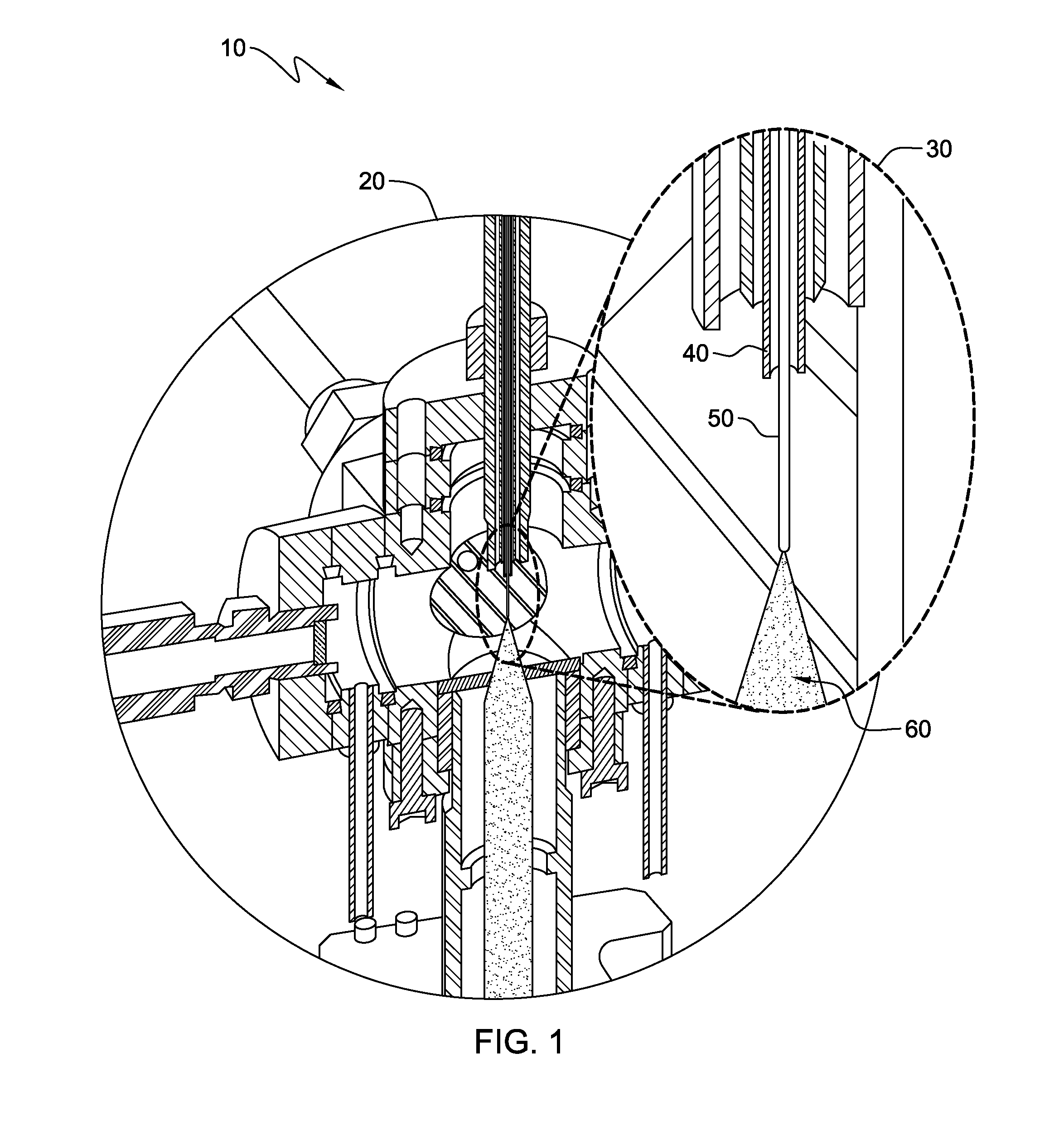

Rotor used for double-rotor continuous mixing mill and mixing mill with same

The invention discloses a rotor used for a double-rotor continuous mixing mill. The rotor comprises a whorled charging section, at least three mixing sections and a discharging section along axial direction in sequence from right to left, wherein each mixing section is provided with at least one pair of discontinuous thread edges which have opposite directions and different spiral angles. The discontinuous thread edges are unengaged or tangent to each other. The invention also discloses a double-rotor continuous mixing mill with the roller. More than two mixing sections are arranged in the roller, thereby prolonging the retention time of material in a mixing chamber. By controlling the temperature, the non-molten solid phase of the material unspecific mixing chambers is pre-covered and mixed. The structure of the rotor with unengaged or tangent thread edges is adopted, thereby efficiently preventing materials from accumulating and stagnating and promoting the distributing mixing capability of the rotor.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for continuous production of modified bituminous materials

InactiveUS6380284B1In situ pavingsWorking-up pitch/asphalt/bitumen by chemical meansPolymer modifiedBituminous materials

The invention concerns the continuous production of asphalts modified by the addition of polymers and reacted with sulfur. The binders produced by said methods can contain very high amounts of polymers, also combined with secondary materials such as: rubber, various plastics, and waste lubricants. This type of binder, which cannot be obtained by discontinuous batch technology, is produced by the continuous mixing of several asphalt components through a static mixer. Said binders provide very high-performance asphalts and agents for regenerating old asphalts contained in waste road materials, in the process of hot recycling of coated materials. They are also used for producing novel emulsions of highly modified binders, with multiple applications and in particular for cold recycling. This novel method, by regenerating old asphalt contained in waste coated materials, represents a means for waste conversion and for limiting the use of asphalt and road-surfacing aggregates.

Owner:FENIXFALT

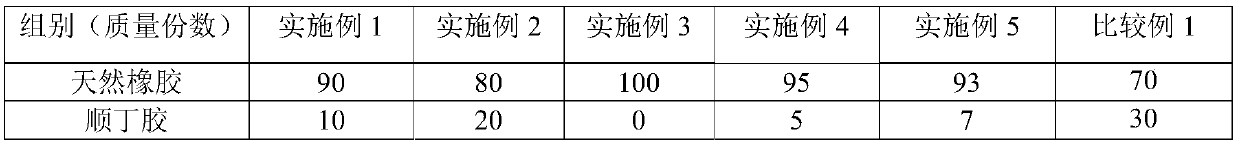

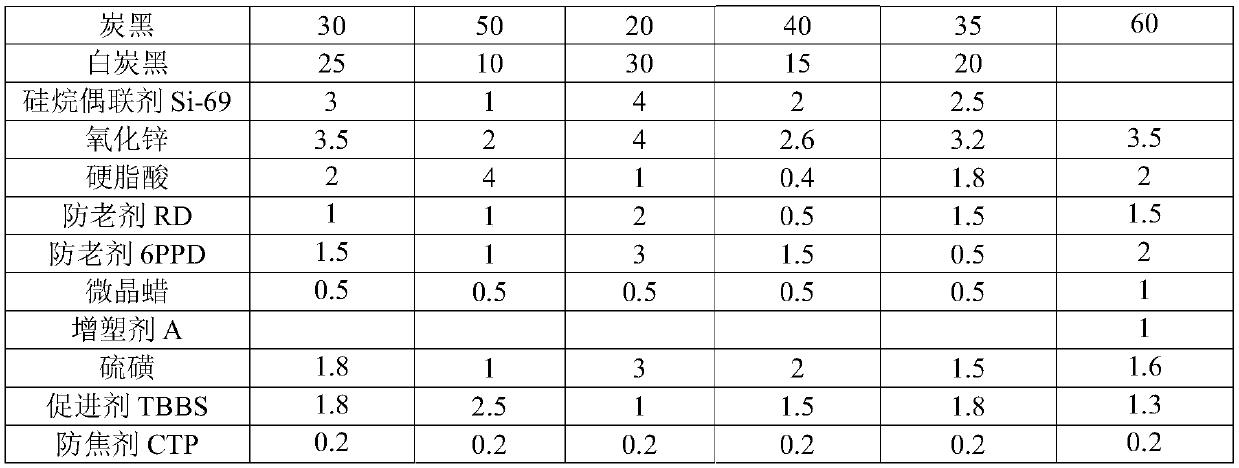

Tread rubber material of low-rolling-resistance all-steel radial tire and preparation method thereof

InactiveCN109627509ALower rolling resistance coefficientReduce fuel consumptionRolling resistance optimizationSpecial tyresRubber materialRolling resistance

The invention provides a tread rubber material of a low-rolling resistance all-steel radial tire and a preparation method thereof. The tread rubber material is mainly prepared by mixing, by mass, 80-100 parts of natural rubber, 0-20 parts of butadiene rubber, 20-50 parts of carbon black, 10-30 parts of white carbon black, and 1-4 parts of a silane coupling agent, the preparation comprises the following steps of: adding the white carbon black and the silane coupling agent after the natural rubber and the butadiene rubber are pressed into a plug to be mixed to obtain master batch, standing for8-24 hours, and adding carbon black for continuous mixing. According to the tread rubber material of the all-steel radial tire, a low-lag matched rubber material system is adopted, and the componentsare matched with each other, so that the produced rubber material has excellent performances in all aspects, the resilience and the wear resistance are good, especially the rolling resistance performance is more remarkable, the tan delta value of the produced rubber is in the range of 0.04-0.06 at the temperature of 60 DEG C, and the rolling resistance coefficient of the produced tire reaches grade B.

Owner:GUIZHOU TIRE

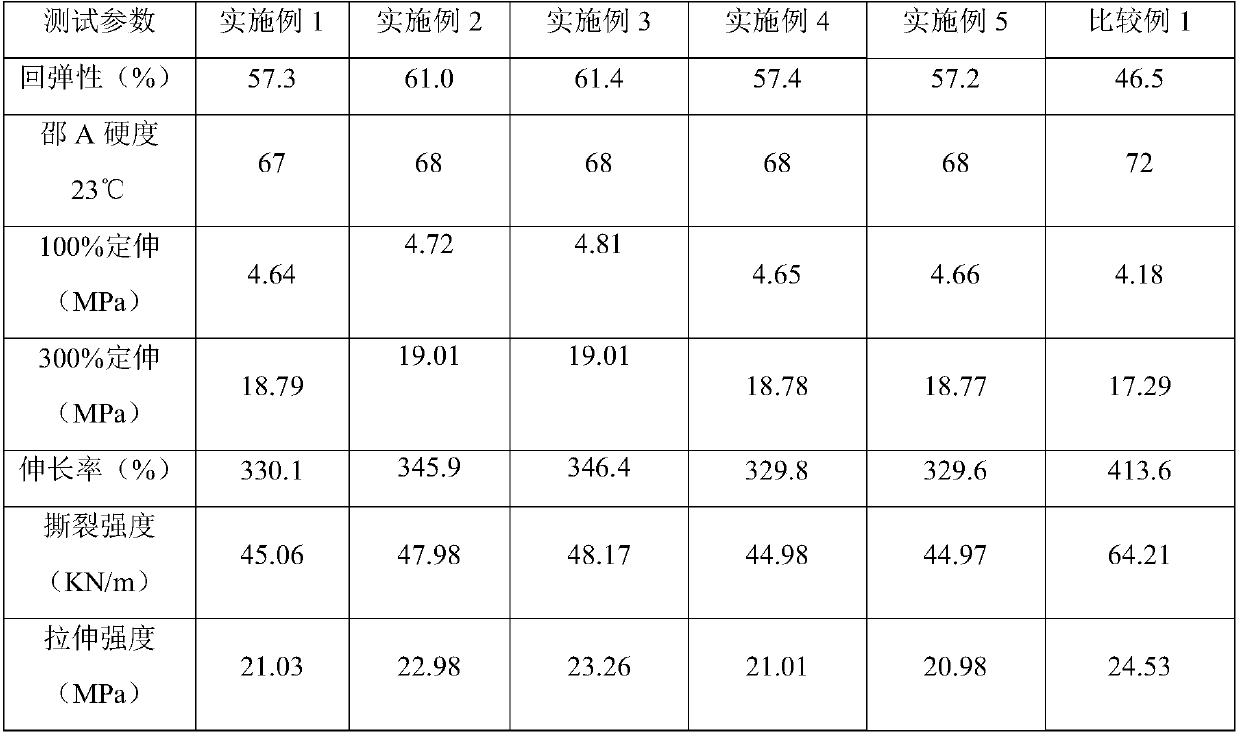

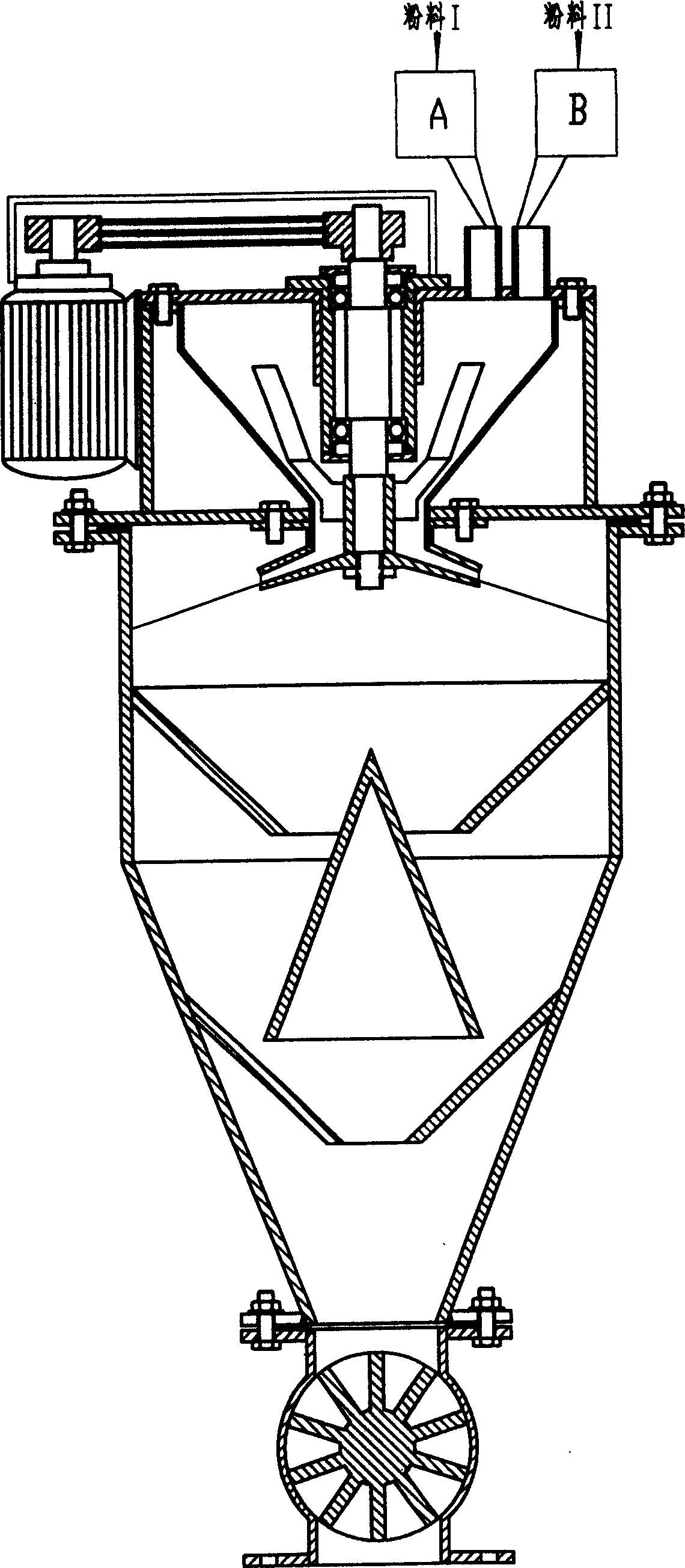

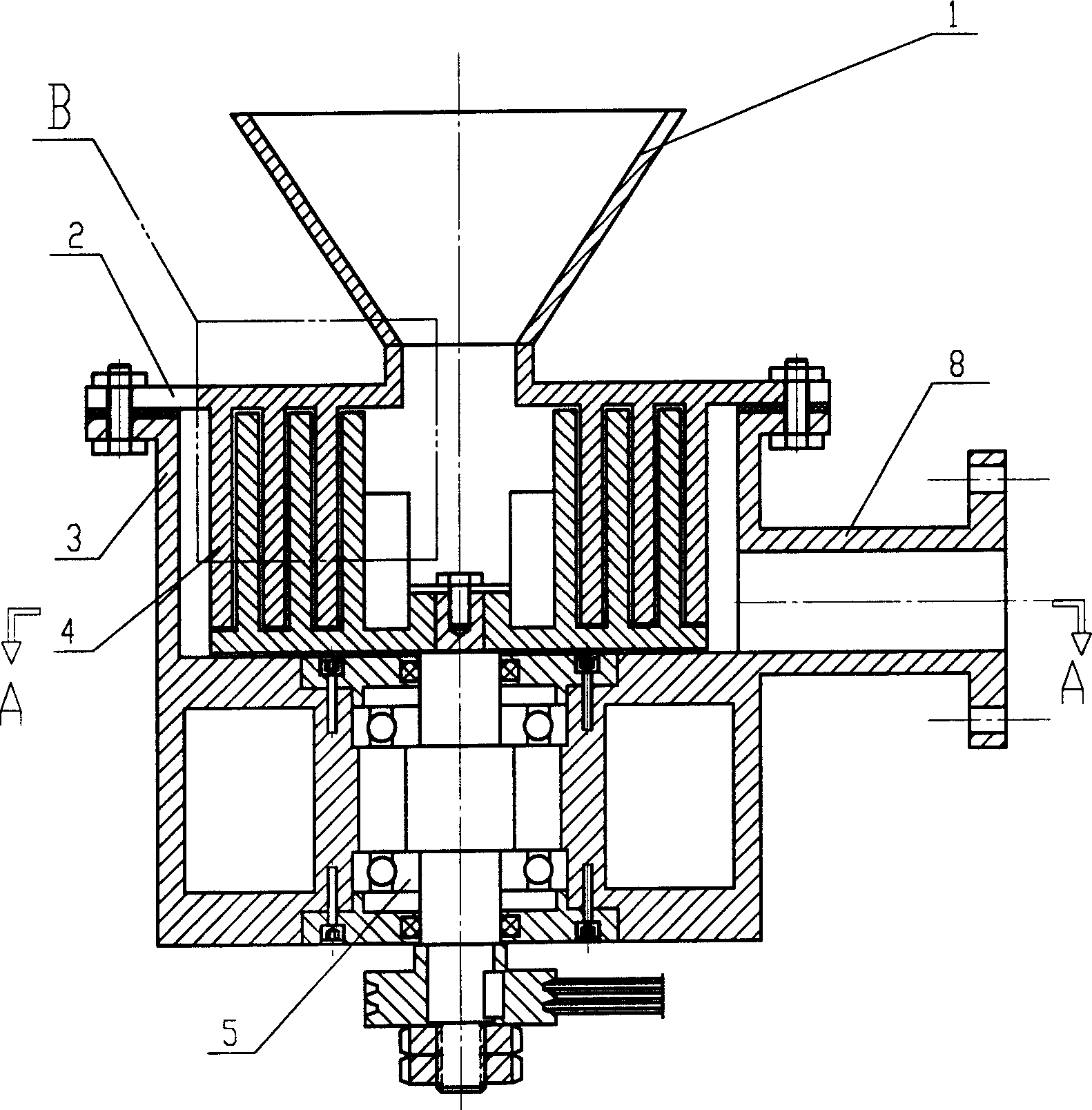

Solid powder continuous mixing machine

InactiveCN1579607AUniform and stable contentImprove mixing uniformityFlow mixersTransportation and packagingContinuous mixingMechanical engineering

The invention relates to a blending machine for solid fine material. It includes: feed inlet, premixing chamber, premixing palm, sprinkling pan, collector, baffle and discharge lip. Premixing chamber, sprinkling pan and collector are placed in gravity direction. Premixing palm and sprinkling pan are installed in same axis. The blending machine has a simple and novel construction and flexible operation. It can realize fine material blending continually and automatically.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process and plant for producing an elastomeric compound

A process for producing an elastomeric compound, includes: feeding at least one elastomeric polymer and at least one reinforcing filler to a mixing apparatus including at least one batch mixing device; mixing and dispersing, in the at least one mixing apparatus, the at least one reinforcing filler into the at least one elastomeric polymer, so as to obtain a first elastomeric compound; discharging the first elastomeric compound from the at least one mixing apparatus; feeding the first elastomeric compound to at least one continuous mixing device, said continuous mixing device including at least two rotating screws; mixing the first elastomeric compound in the at least one continuous mixing device, so as to obtain a second elastomeric compound; and discharging said second elastomeric compound from said at least one continuous mixing device.

Owner:PIRELLI TYRE SPA

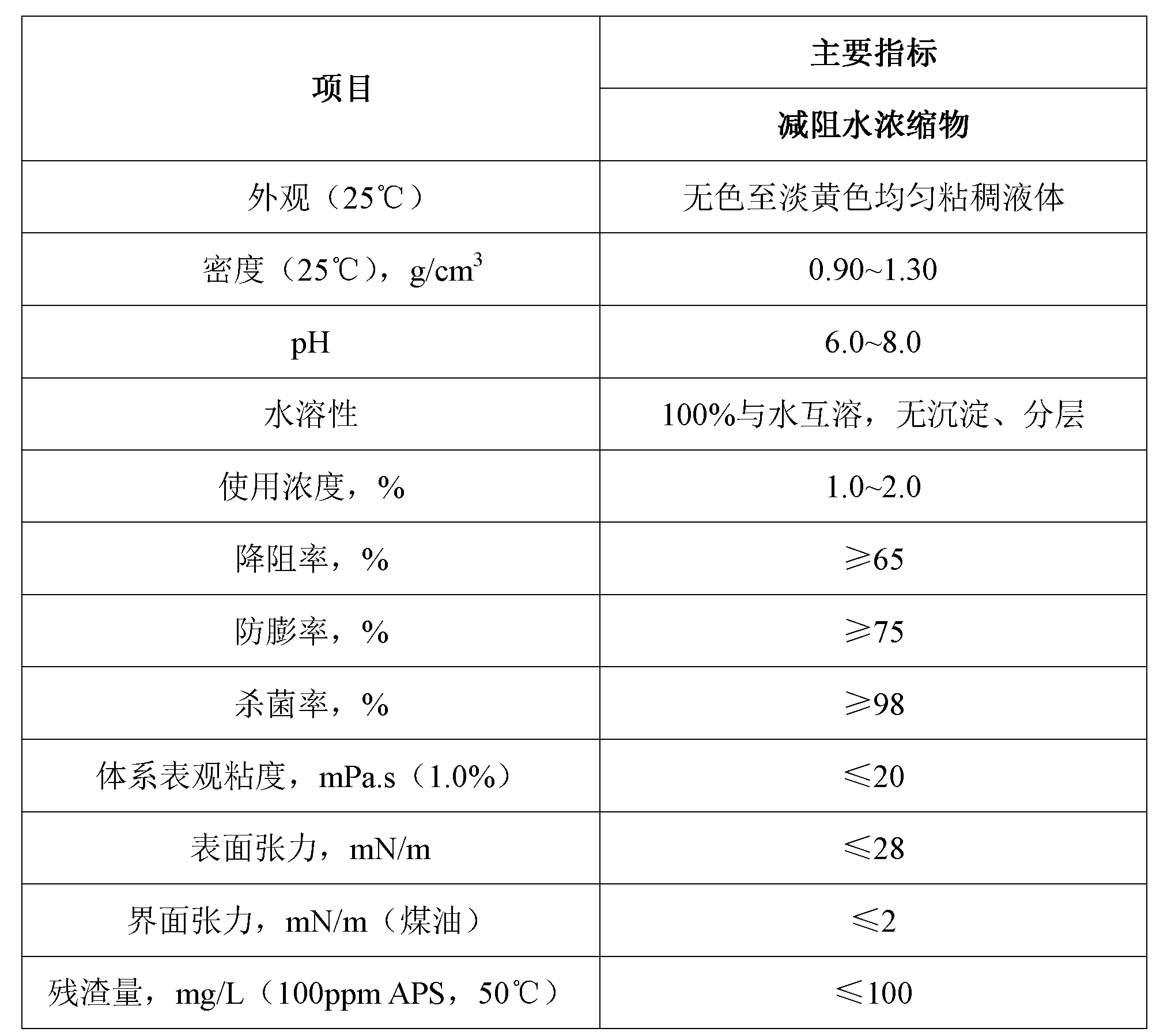

Anti-drag aqueous fracturing fluid preparation

InactiveCN103254887AGuarantee the demand for large displacement pumping in constructionMeet the needs of efficient developmentDrilling compositionSolubilityPolyethylene glycol

The invention aims at providing an anti-drag aqueous fracturing fluid preparation, and provides a single-dosage anti-drag aqueous fracturing fluid preparation in order to overcome defects during preparation of anti-drag aqueous fracturing fluid and construction. The preparation can be compounded with water in any proportions, is good in solubility, meets the requirement on continuous mixing during on-site construction of shale gas, and has an important application value in shale gas exploration. The anti-drag aqueous fracturing fluid preparation comprises the following components by weight percentage: 4-6% of anti-drag agent, 8-12% of clay stabilizing agent, 1-3% of cleanup additive, and the balance of water, wherein the anti-drag agent is a bipolymer of acrylamide and polyethylene glycol oxide ether acrylate; the clay stabilizing agent is polydimethyl propylenediene ammonium chloride; and the cleanup additive comprises the following components by mass percentage: 9-11% of perfluorooctanoyl ethylene amino methyl diethyl ammonium iodide, 20-30% of polyoxyethylene 2,5-dimethyl stearyl alcohol ether, and 20-30% of isopropanol.

Owner:郑建立

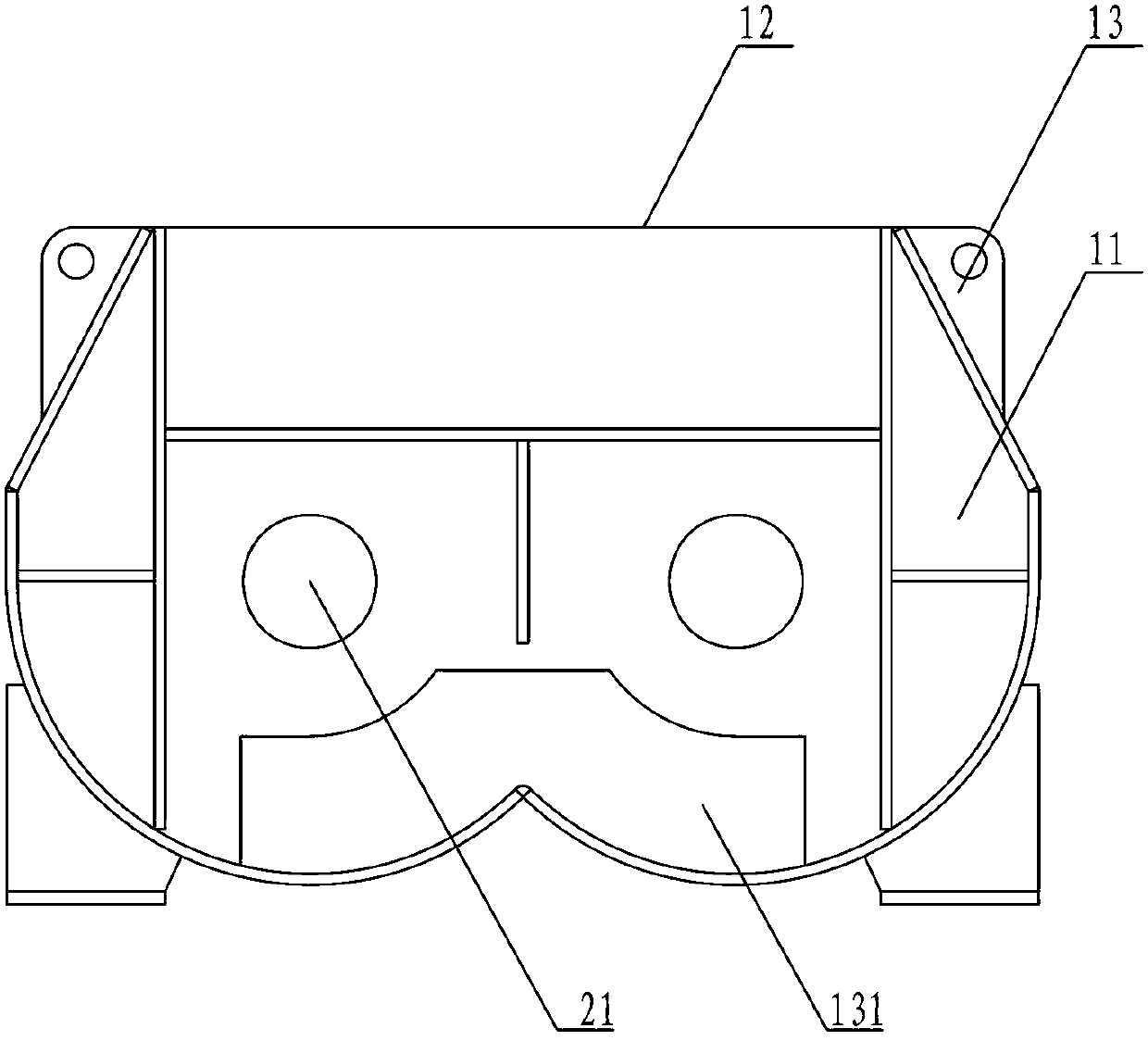

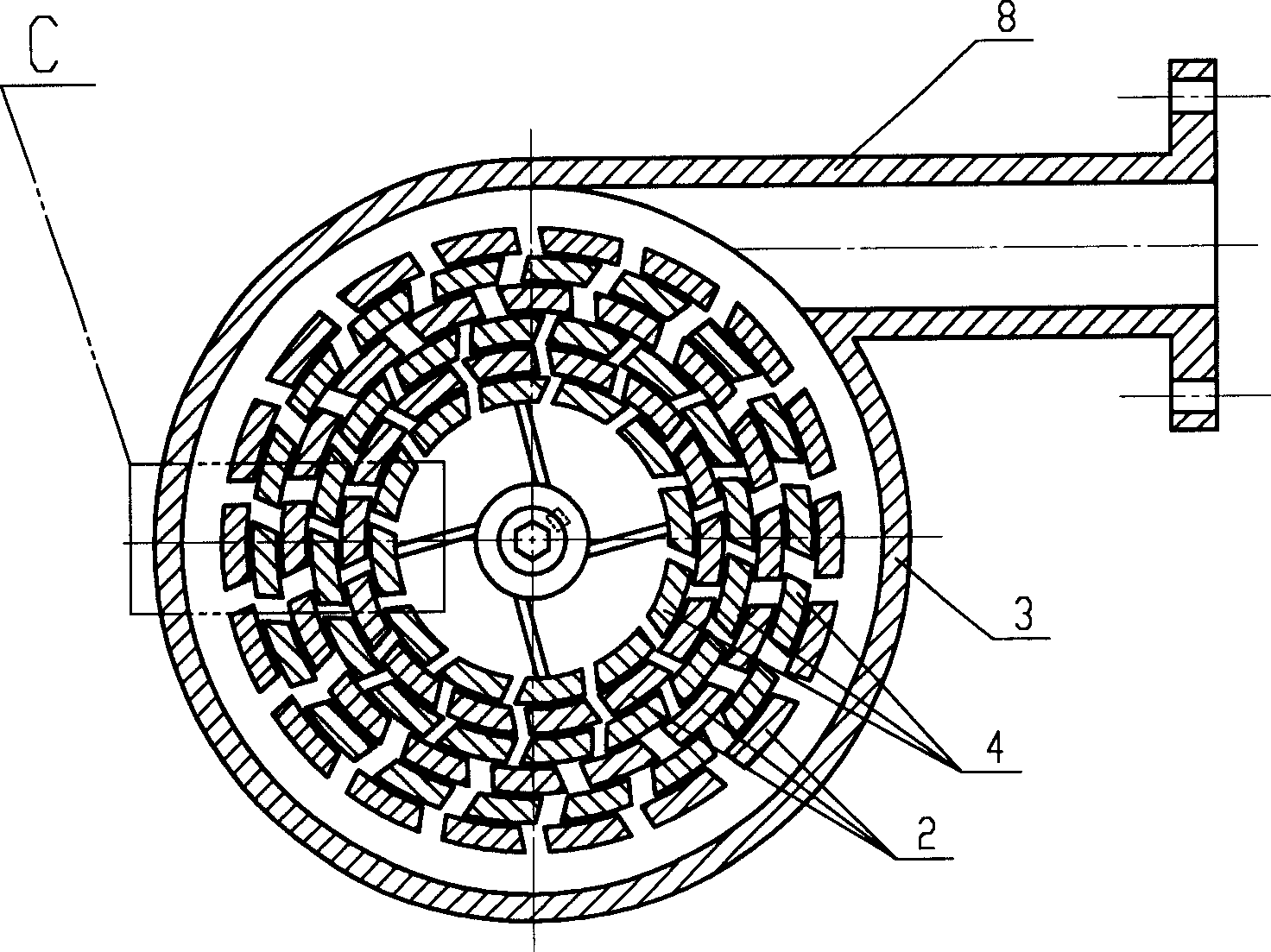

Continuous-blending muller

ActiveCN101204675AHigh solid contentShort processFlow mixersTransportation and packagingColloidEngineering

The invention provides a continuous mixing-grinding machine including a mixing device and a grinding device. The mixing device includes a feed inlet, a mixing stator, a mixing rotor, a mixing chamber and a material discharge space. The grinding device includes a grinding stator, a grinding rotor, a grinding chamber, an accumulating chamber and a colloid discharge opening; among which, the mixing device and the grinding device are coaxially arranged up and down and the material discharge space is communicated with the grinding chamber. The bottom of the mixing rotor is provided with a material scraping machine used for scraping the colloid on an inner wall of the mixing device and forcing the colloid to be discharged from the material discharge space and then enter the grinding chamber; and the bottom of the grinding rotor is provided with a material extrusion apparatus used for forcing the colloid to be discharged from the colloid discharge opening. The mixing-grinding machine provided by the invention can continuously manufacture the colloid with high solid content on line.

Owner:CHINA PETROLEUM & CHEM CORP +1

Drag-reduction water system, preparation method and application

The invention discloses a drag-reduction water system, a preparation method and application. The drag-reduction water system includes the following components according to weight percentages: 0.02 to 0.1 percent of a drag reducer JC-J10, 0.08 to 0.5 percent of a compound synergist JC-ZP2, 0.1 to 1.0 percent of a compound anti-swelling agent JC-FC03, and the balance of water. The preparation method includes the following steps: the drag reducer with the mentioned percentage is added into water, the mixture is stirred for dissolution, the compound anti-swelling agent and the compound synergist with the mentioned percentages are then added in sequence, and the mixture is stirred uniformly, so as to obtain the drag-reduction water system. The drag-reduction water system provided by the invention has the characteristics of no residues, good fast-dissolving property, high drag reduction rate (larger than 70 percent) and good anti-swelling performance, and can satisfy the requirement for continuous mixing of large liquid volumes under a complex mountainous environment; moreover, the formation of network cracks is facilitated, so as to greatly enlarge the crack volume and improve the fracturing effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

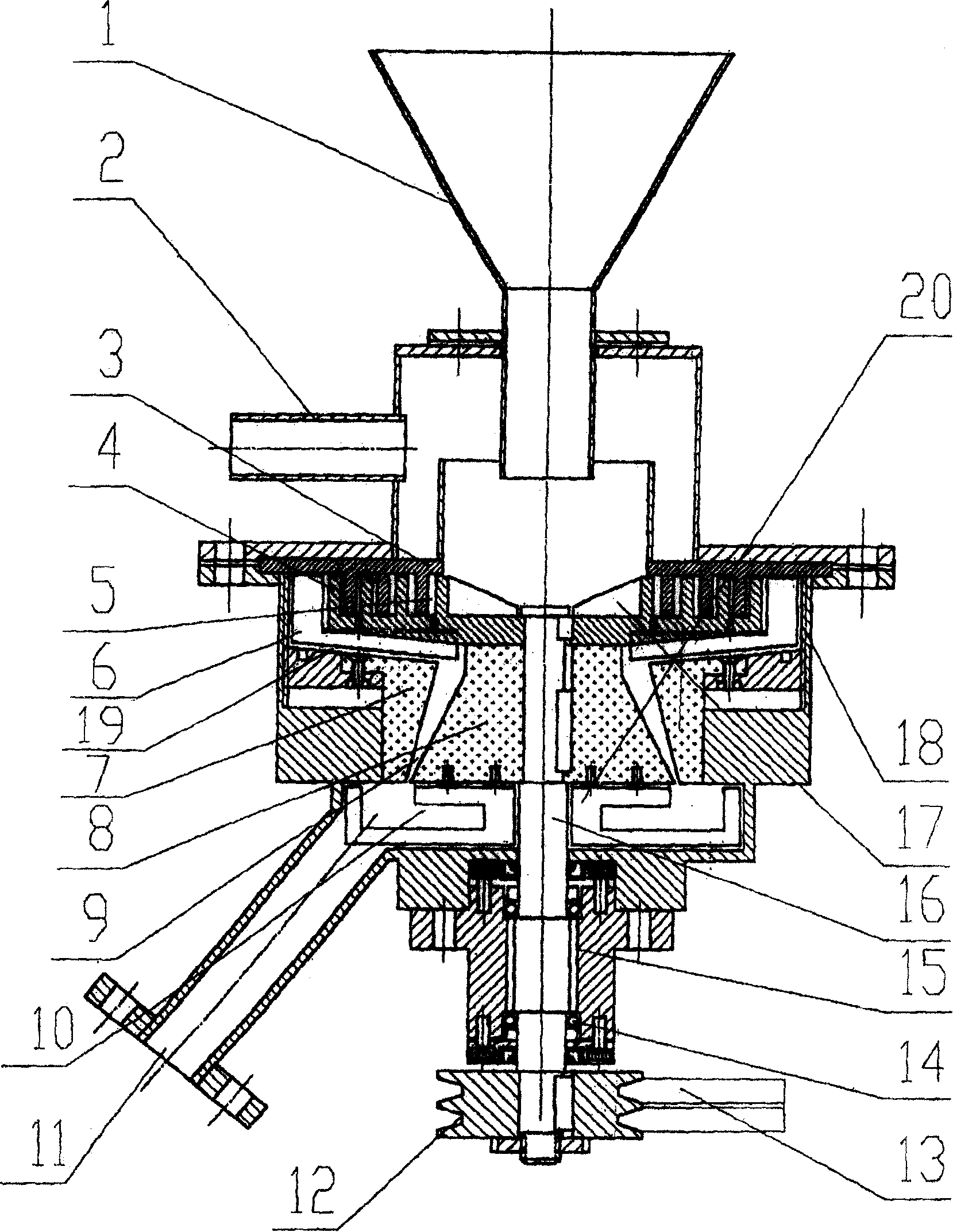

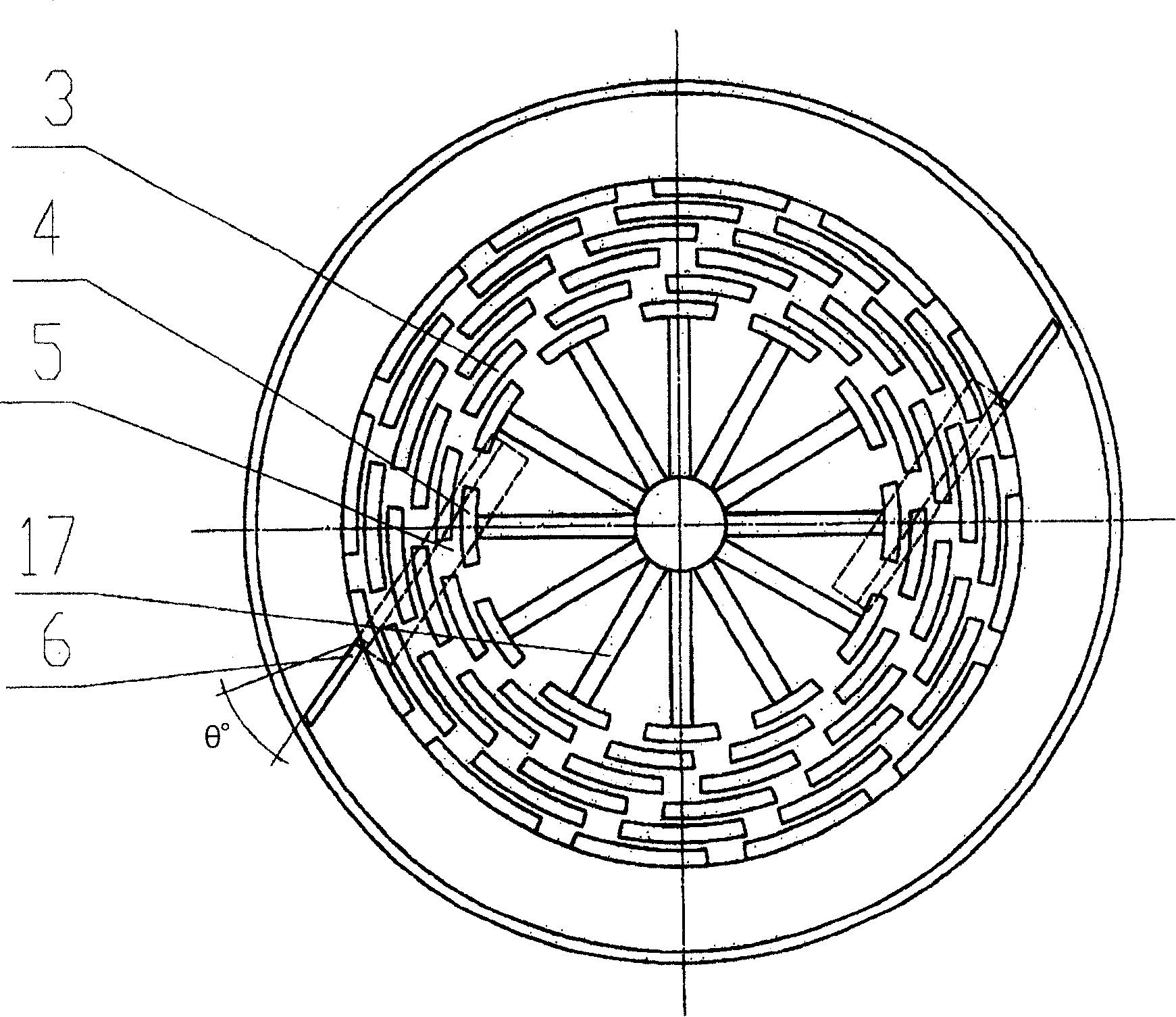

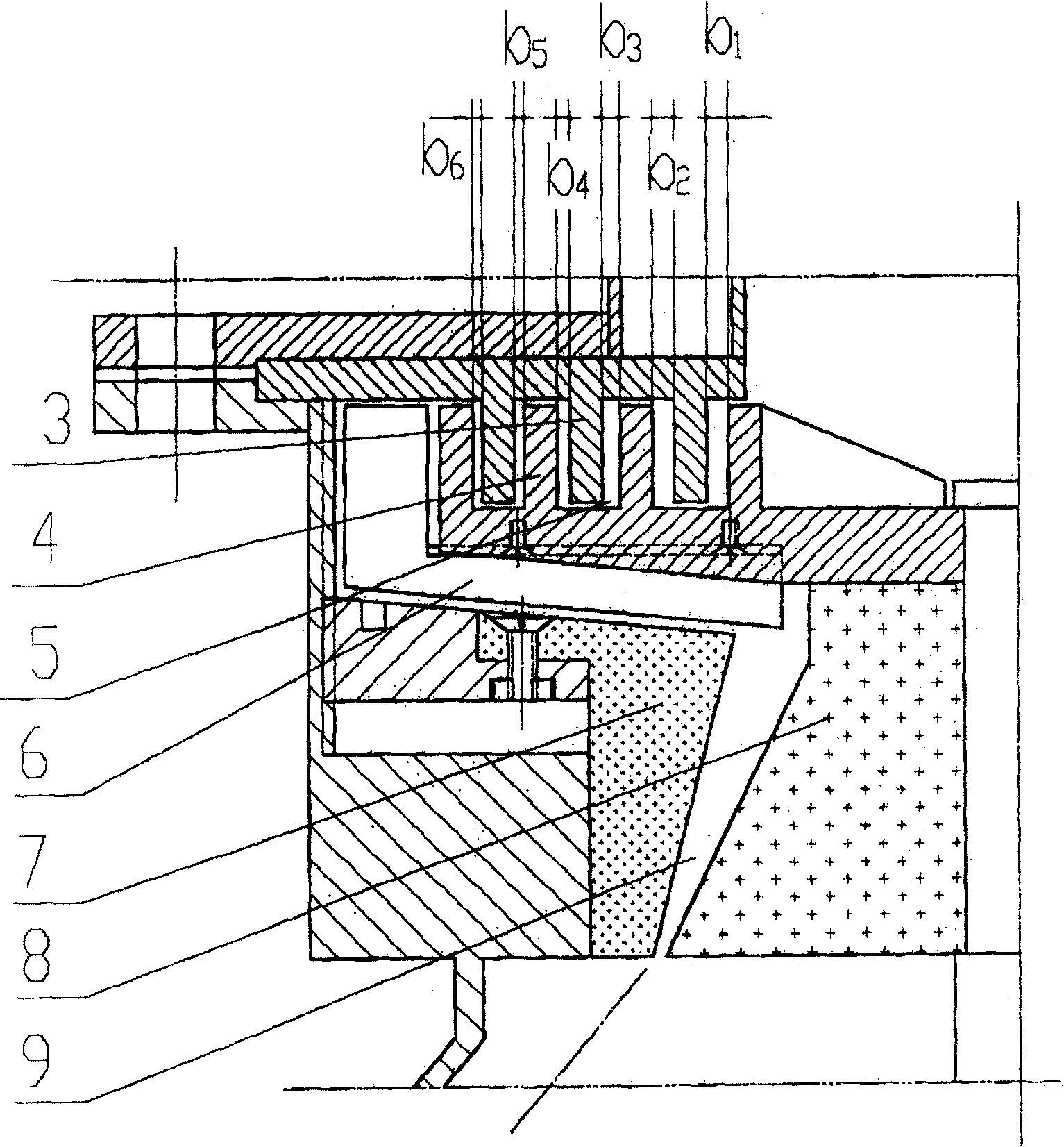

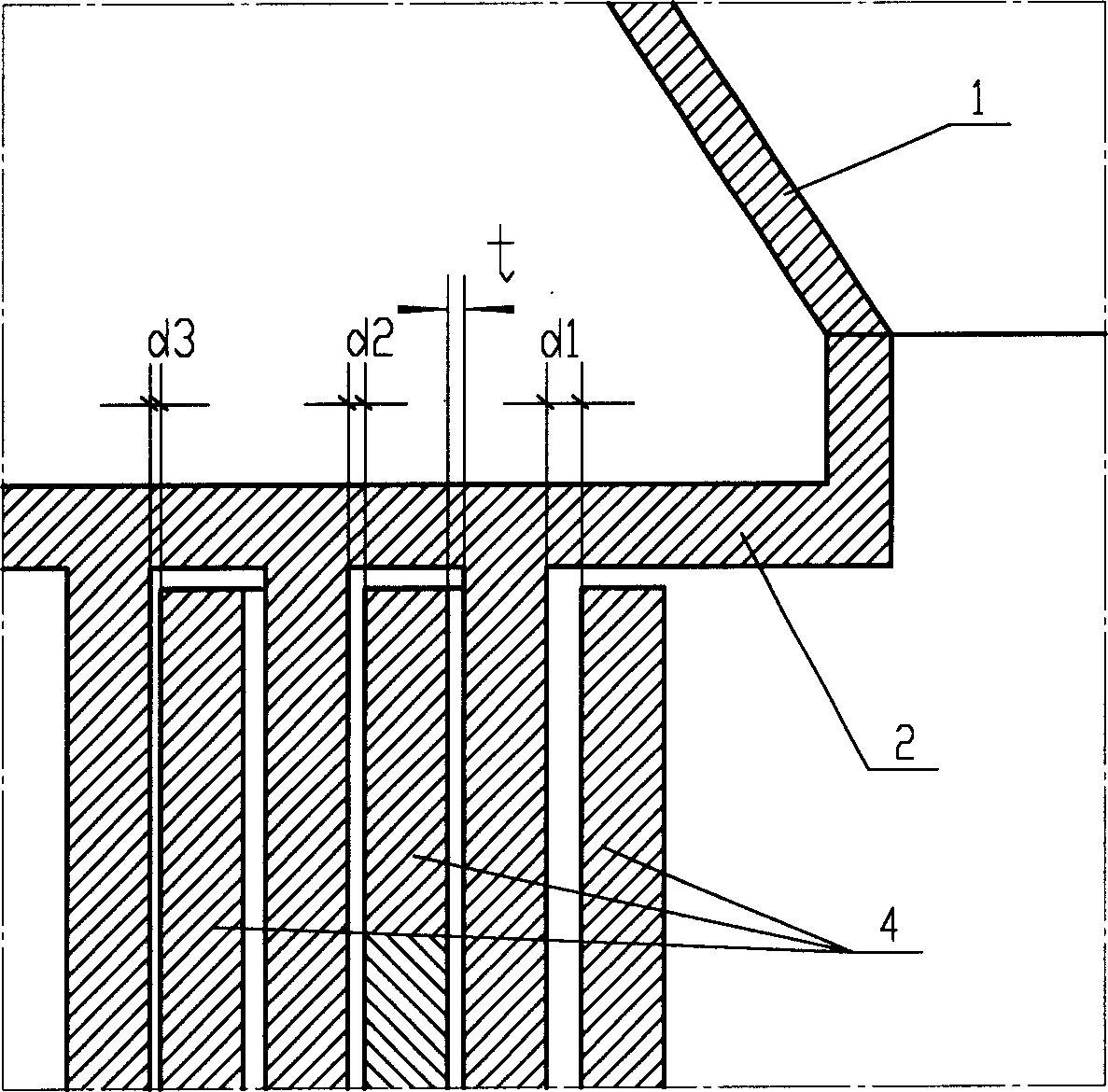

Fluid continuous mixing device

The continuous fluid mixer includes the following members: inlet pipe, stator, casing, mixing rotor, driver and material outlet, and its stator, casing and mixing rotor are set coaxially. Each of the stator and the mixing rotor includes 2-20 layers of teeth in different diameters crossly arranged radially, and each of stator layers and rotor layers has 6-40 teeth. The angle between adjacent rotor teeth and stator teeth decreases gradually with the increasing stator layer and rotor layer diameters. The mixer can on-line mix continuously in high mixing efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

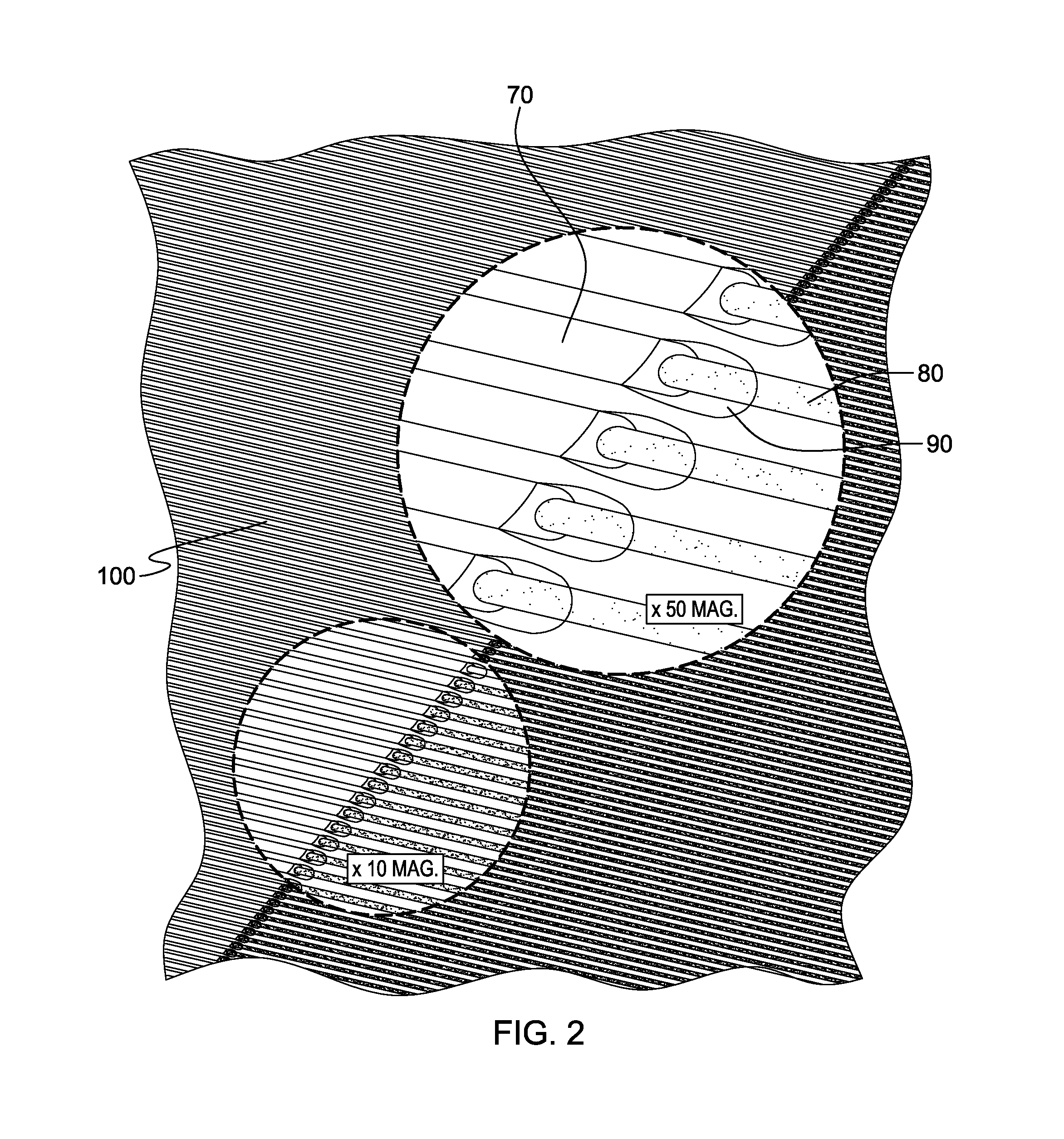

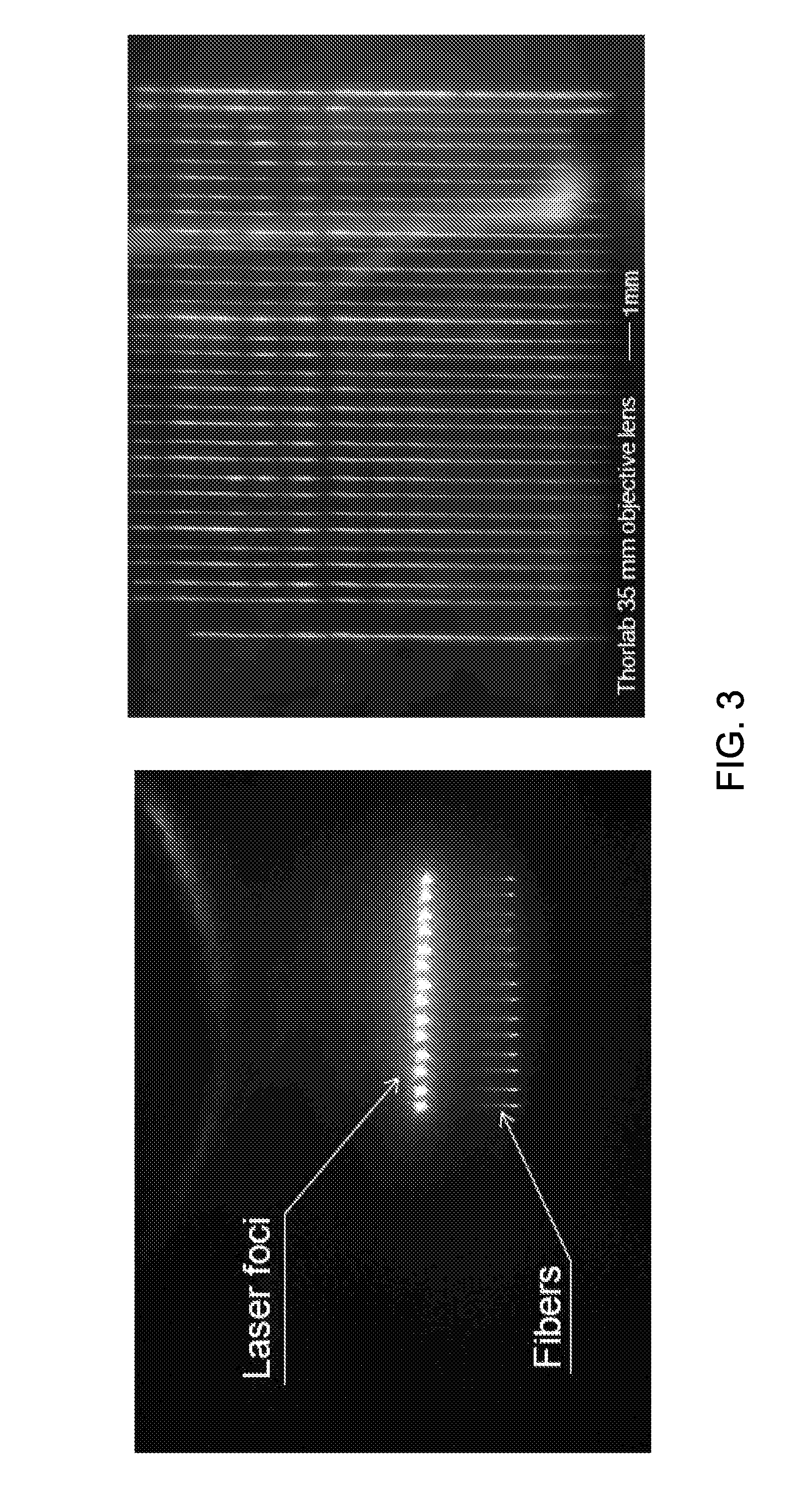

Contiguously blended nano-scaled multi-phase fibers

ActiveUS20160347672A1Inorganic material artificial filamentsConjugated artificial filamentsFiberCompound (substance)

A multi-component or ‘composite’ inorganic fiber comprising a nano-scale contiguous collection of a plurality of packed unique phases of material randomly interspersed throughout the fiber body, without unwanted impurities, and a method for producing same. Said phases include three or more foundational chemical elements from the Periodic Table mixed together during fiber production, producing distinct material phases interspersed throughout the fiber volume.

Owner:FREE FORM FIBERS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com