Patents

Literature

672 results about "Bituminous materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term bituminous materials is generally used to denote substances in which bitumen is present or from which it can be derived. Bitumen is defined as an amorphous, black or dark-colored, (solid, semi-solid, or viscous) cementitious substance, composed principally of high molecular weight hydrocarbons, and soluble in carbon disulfide.

Thermosetting epoxy asphalt materials for pavement and bridge and process for preparing same

ActiveCN1837290AImprove performanceHigh strengthIn situ pavingsBuilding insulationsBituminous materialsTar

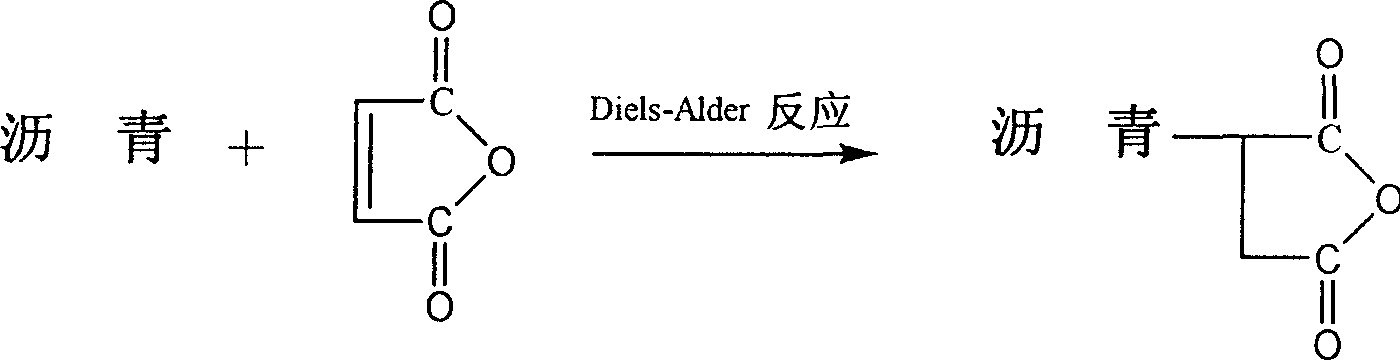

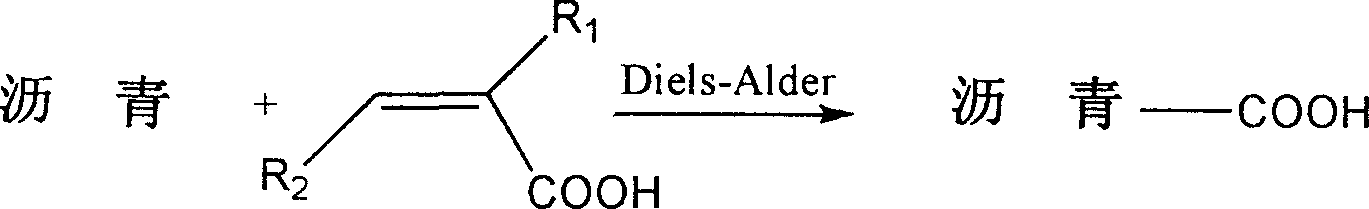

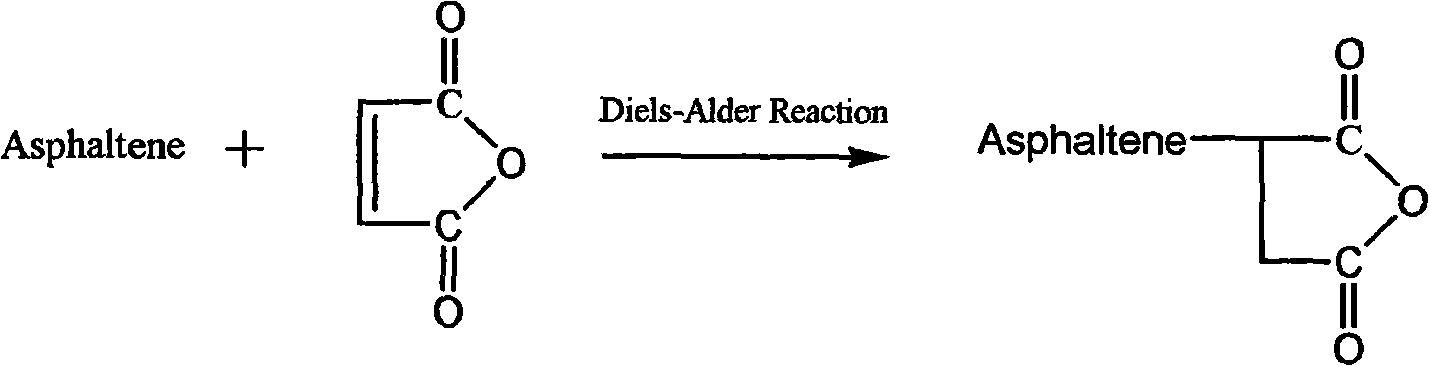

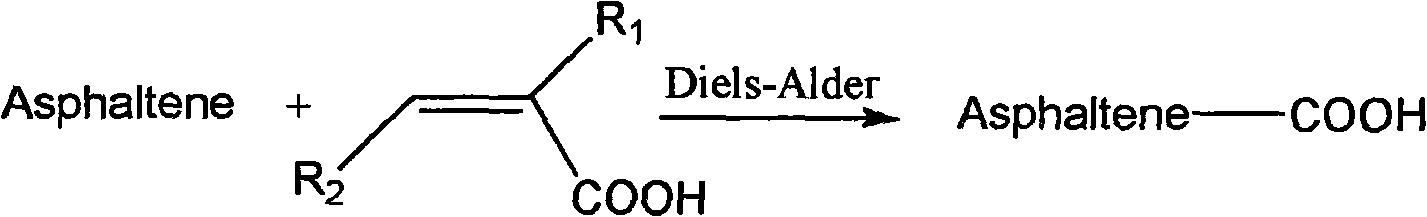

The invention discloses a bridge heat fixed epoxy tar material and preparing method, which consists of A and B, wherein A part quality component is 60-76 modified tar with carboxy group or acid anhydride, grease group diacid, 11-25 dimer acid or alkyd resin, 10-25 fatty acid and 0.05-0.65 solidifying celeratist; B is epoxy resin; the quality rate of A and B is 2:1-8:1. The invention possesses high strength and good flexibility, which is fit for higher occasion.

Owner:JURONG NINGWU SCI & TECH DEV

Epoxy asphalt material for road-bridge and environment-friendly preparation method thereof

The invention provides an epoxy asphalt material for bridge and green preparation method, comprising A part and B part, wherein the weight constitute of the A part is: modified asphaltum with carboxyl or anhydride group 60-76 parts, monohydric alcohol or polyhydric alcohol 2-20 parts, aliphatic diprotic acid, dimer acid or alkyd resin 11-25 parts, fatty acid anhydride 10-25 parts, solidified promoter 0.05-0.65 parts; and the constitute of the B part is epoxy resin. The mass ratio of A and B part is 2.2:1-10:1. The epoxy resin modified asphalt material has excellent property with high intensity and good flexibility; provides corresponding operation time according to different requirement and adjust the operation time to satisfy the different performance requirement at will with good storage stability. The corresponding epoxy asphalt concrete has excellent high, low temperature performance and fatigue endurance, and the environment is friendly, suitable for occasion with higher requirement such as autoroute and bridge, and arterial street, bus stop and airfield path. The invention also provides a preparation method thereof.

Owner:SOUTHEAST UNIV

Asphalt release agent

The present invention relates generally to the field of release agents commonly in uses in preventing asphalt and other sticky compounds such as rubbers from sticking to the transporting vehicles such as dump truck beds and processing tools, and equipment, and more particularly to a novel biodegradable release agent applied to metal surfaces prior to use for promoting free release of sticky hot-mix asphalt materials from the metal tools and equipment used in road construction applications.

Owner:ASHLAND LICENSING & INTPROP LLC

Moisture curable sealer and adhesive composition

ActiveUS7317051B2Low costMaintain good propertiesRoof covering using flexible materialsBituminous material adhesivesPolymer scienceCarcinogen

A low cost moisture curable sealer and adhesive composition containing a polymer having reactive silyl groups and a bituminous material and having many advantages over conventional moisture cure sealer compositions, including greater elastomeric properties, improved flexibility and pliability, lower durometer, faster and deeper cure, low temperature cure. The composition is also free of carcinogens such as coal tar, toxic isocyanates, and volatile solvents.

Owner:CHEMLINK

Anti-splitting paster and preparation method thereof

InactiveCN100999893AHigh viscoelasticityLow temperature flexiblePaving detailsRoads maintainencePolymer modifiedBituminous materials

The anticracking patch includes protecting film layer, upper coating layer, high strength base layer and lower coating layer arranged successively from the top to the bottom. Both the upper coating layer and the lower coating layer are made of polymer modified asphalt material comprising asphalt 48-58 wt%, SBS 5-10 wt%, tackifying resin 7-13 wt%, engine oil 4-8 wt%, rubber powder 9-11 wt%, tackifying petroleum resin 1-3 wt% and intensifier 3-13 wt%. The present invention is industrially produced and has excellent anticracking and waterproofing functions.

Owner:BAIHE INT HIGHWAY SCI & TECH HENAN

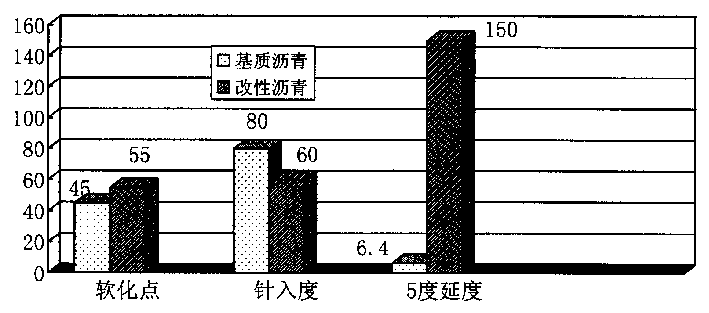

High performance SBS modified asphalt and its making method

InactiveCN1569964AHigh softening pointLow SBS contentBuilding insulationsBituminous materialsMaterials science

Owner:SHANGHAI QUNKANG ASPHALTUM TECH CO LTD

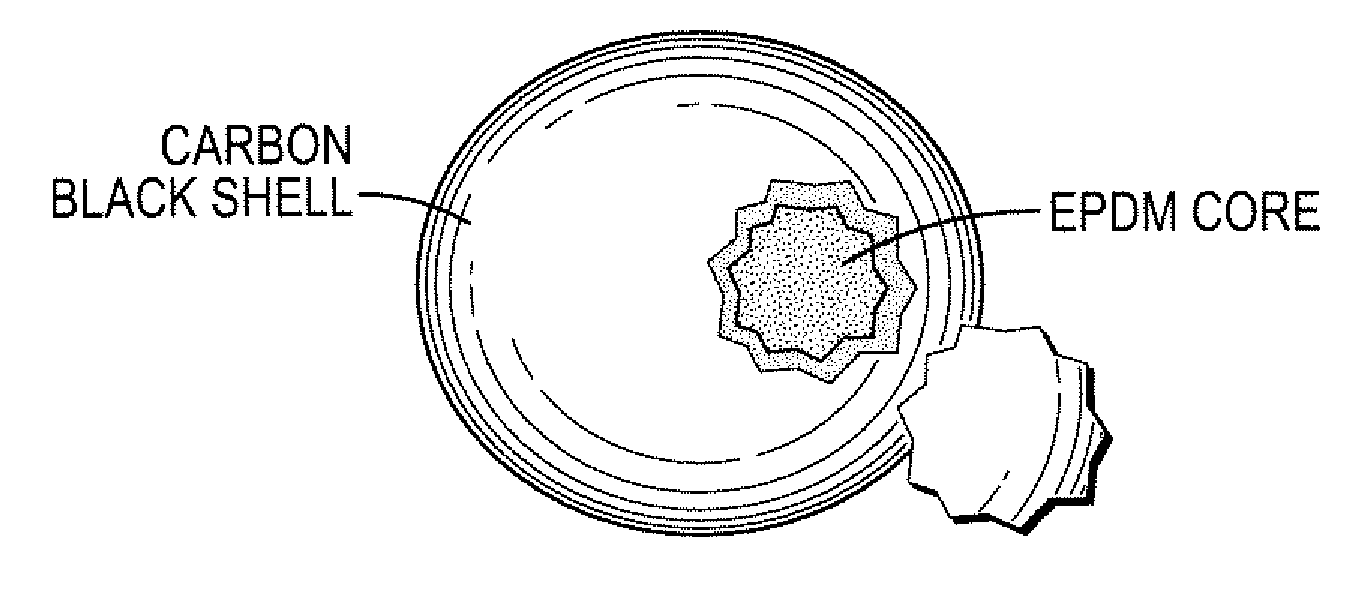

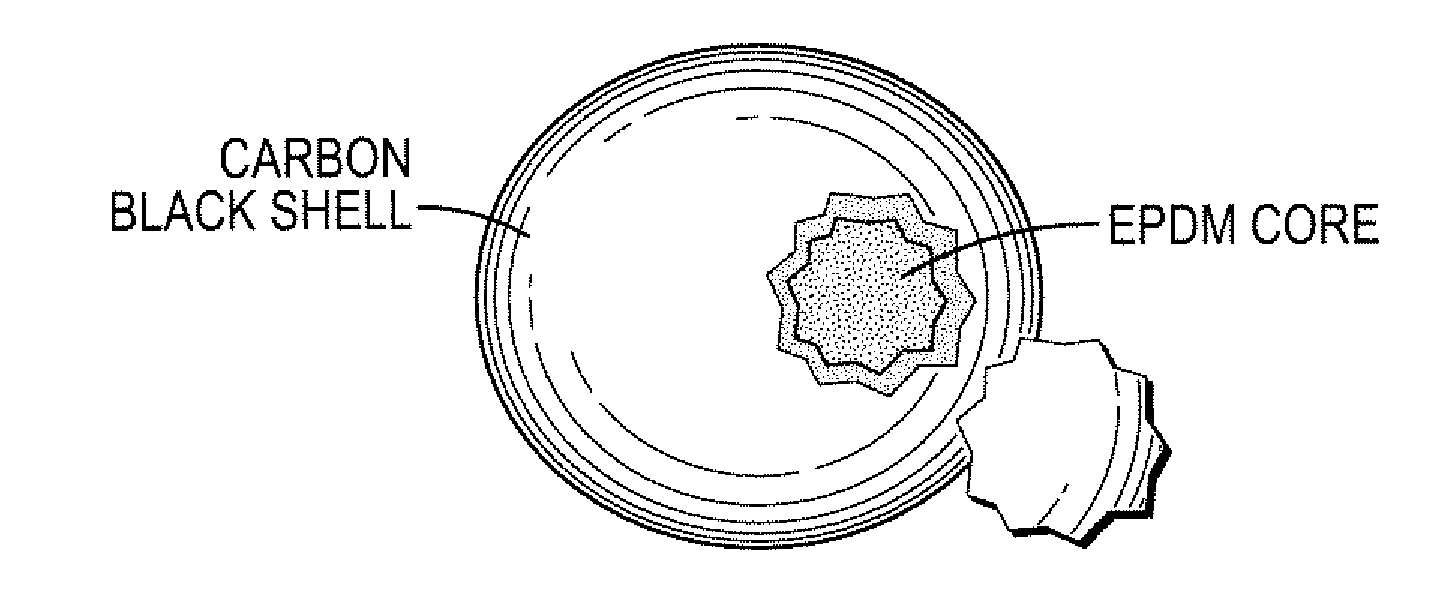

Bituminous compositions and methods of making and using same

InactiveUS20090061236A1Increase heatShorten the timeIn situ pavingsSingle unit pavingsBituminous materialsAlpha-olefin

This invention relates to bituminous compositions comprising an interpolymer and a bituminous material and methods of making and using same. The interpolymer may comprise ethylene, at least one alpha-olefin, and, optionally, at least one diene and the interpolymer is derived from polymer particles having a surface coating comprising a partitioning agent. Methods of making and using the bituminous compositions are also described.

Owner:DOW GLOBAL TECH LLC

Elastic plastics blended antioxidation modified bituminous water-proof coiled material

InactiveCN1354203AGood low temperature flexibilityImprove high temperature resistanceOther chemical processesBuilding insulationsBituminous waterproofingThermoplastic elastomer

The present invention relates to a modified water-proofing asphalt roll material (called SA roll material for short), and is characterized by that in the raw material formula of asphalt 4-15% of thermoplastic elastomer polystyrene-butadiene-styrene block copolymer (SBS), 3-12% of atactic polypropylene (APP), 1-8% of light shielding agent, 0.05-3% of antioxidant, 0.05-3% of light stabilizer and 0.05-3% of UV absorbing agent. Said water-proofing roll material possesses low-temp. resistance, high-temp. resistance. UV-resisting property and good ageing resistance.

Owner:CHONGQING CITY NEW TYPE WATER PROOFING MATERIAL

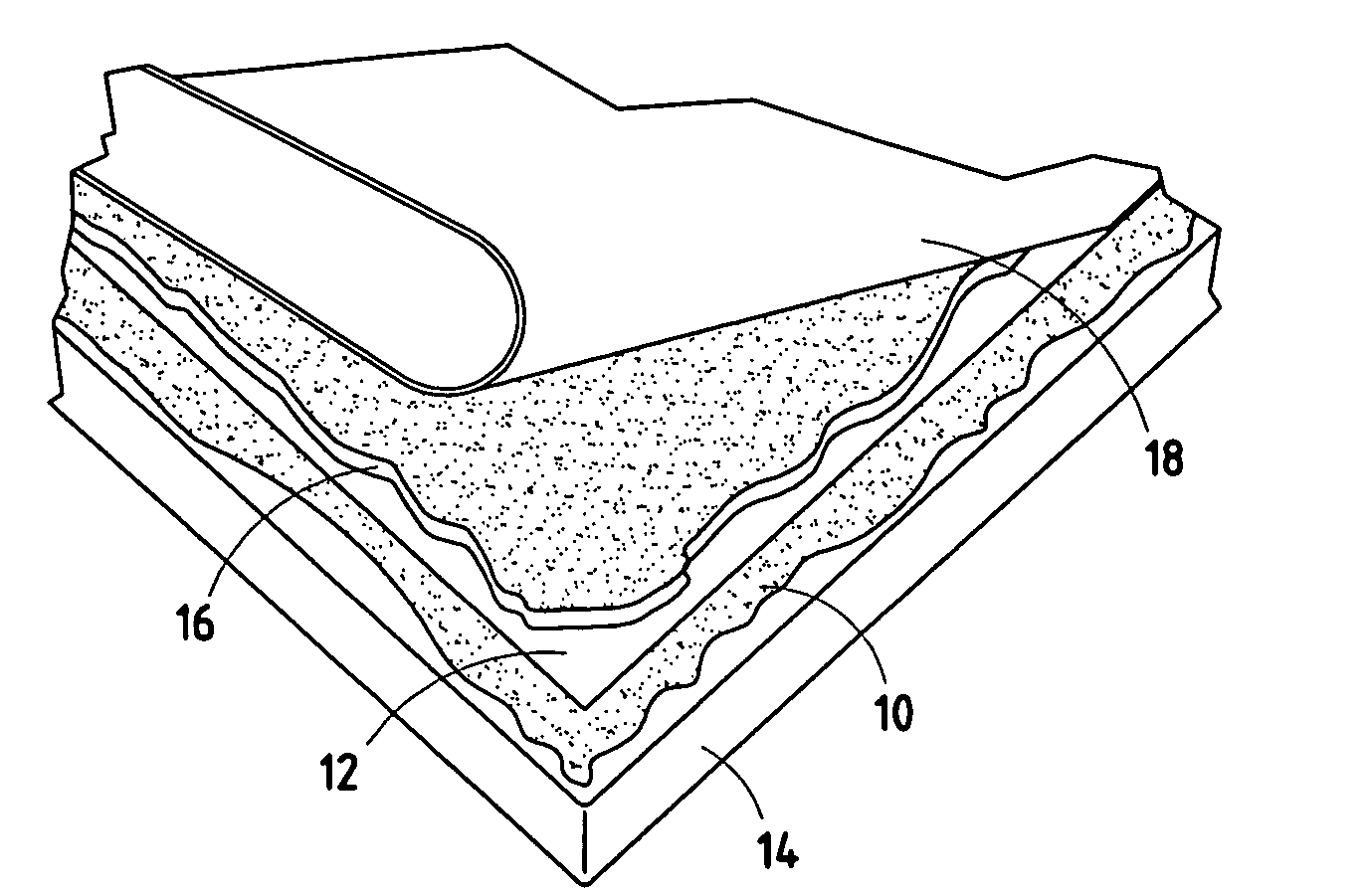

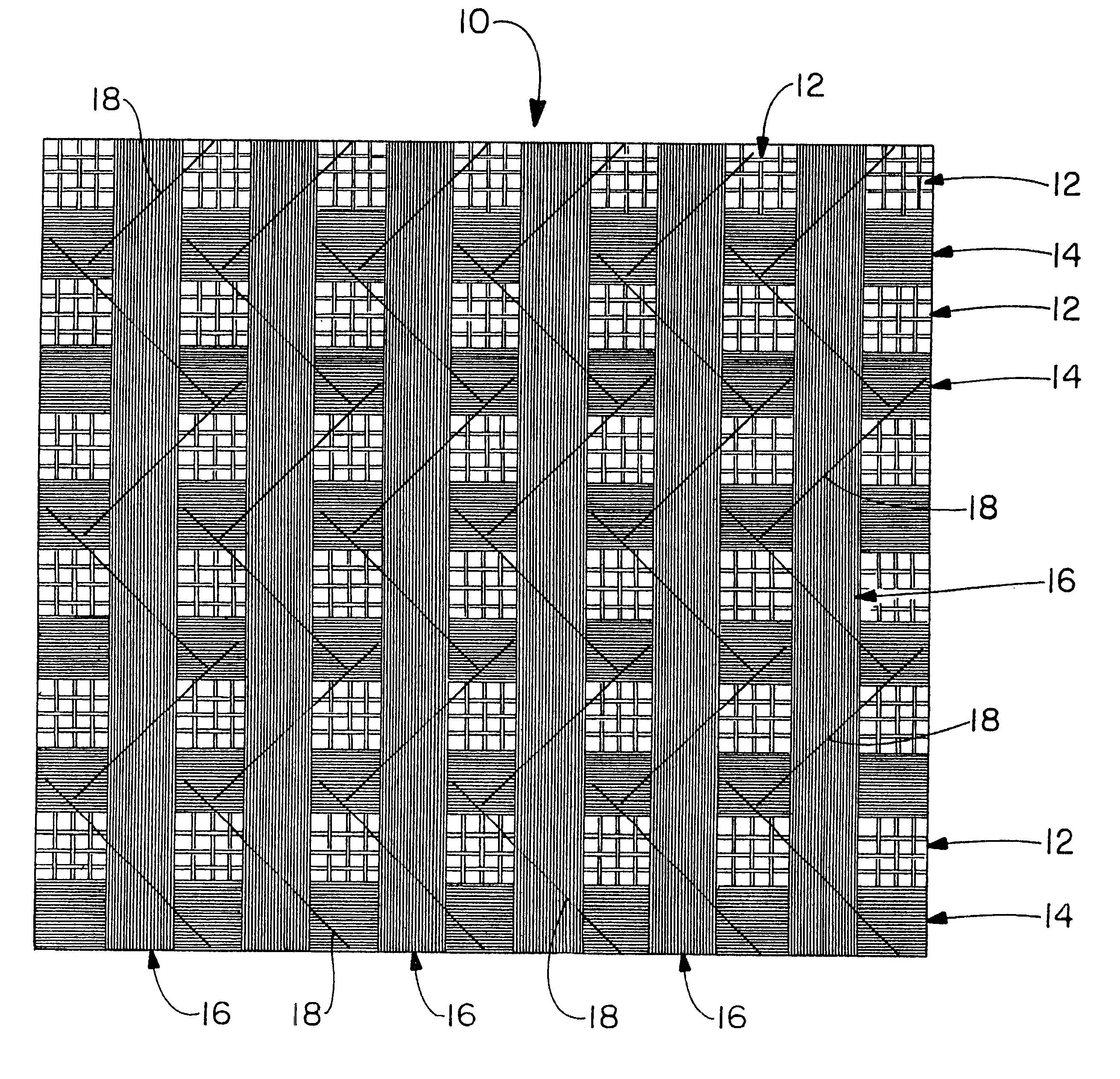

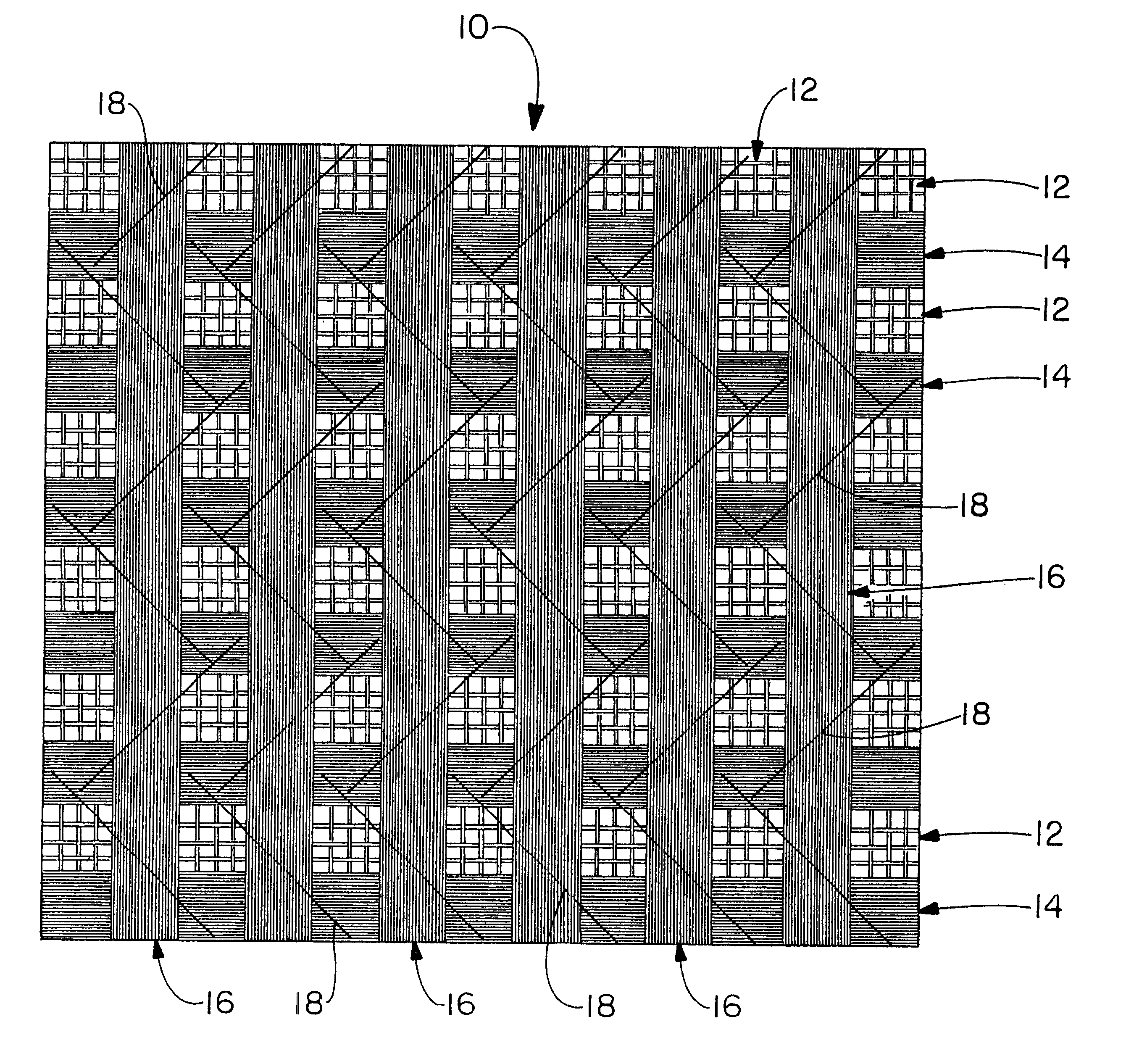

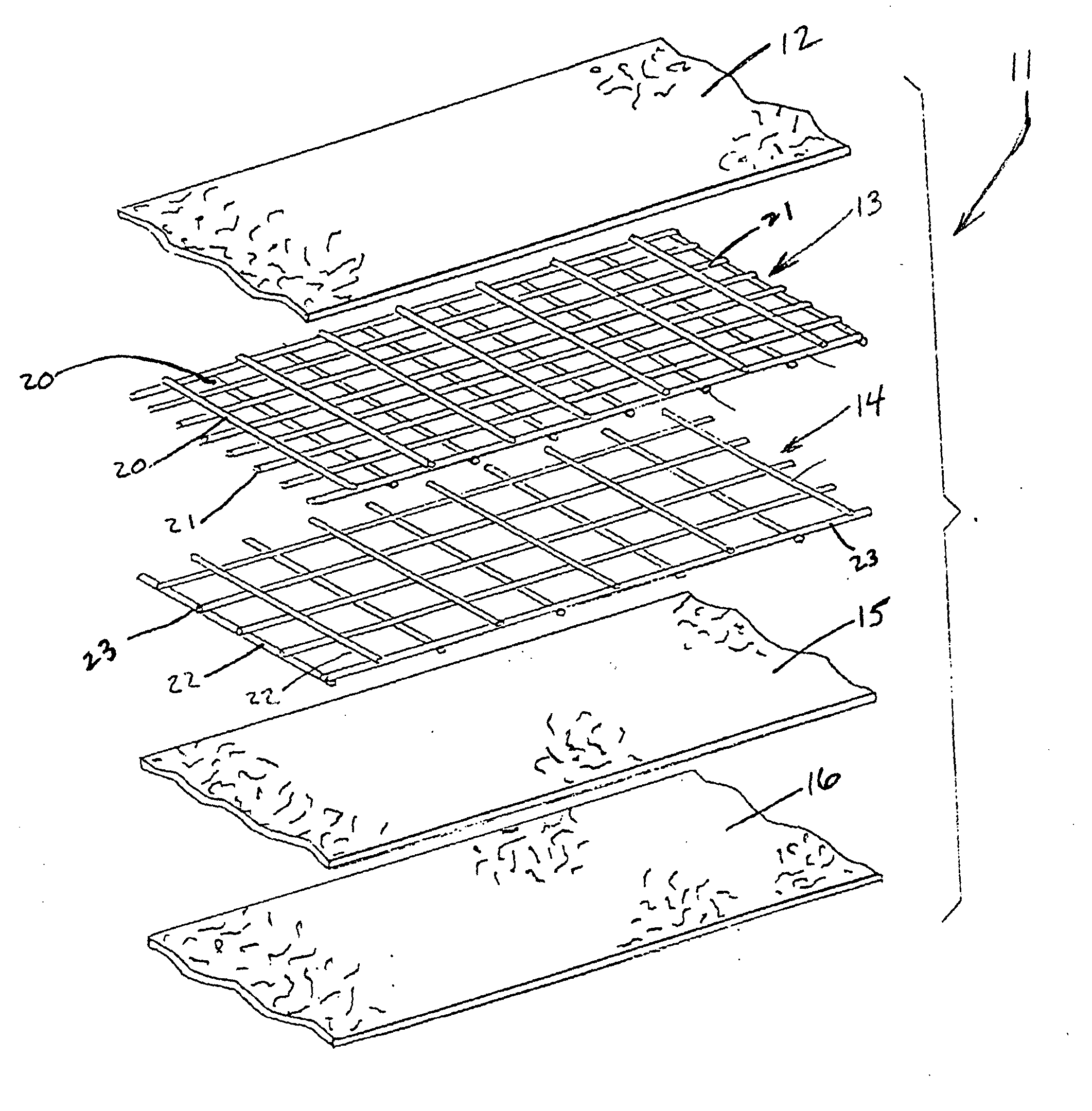

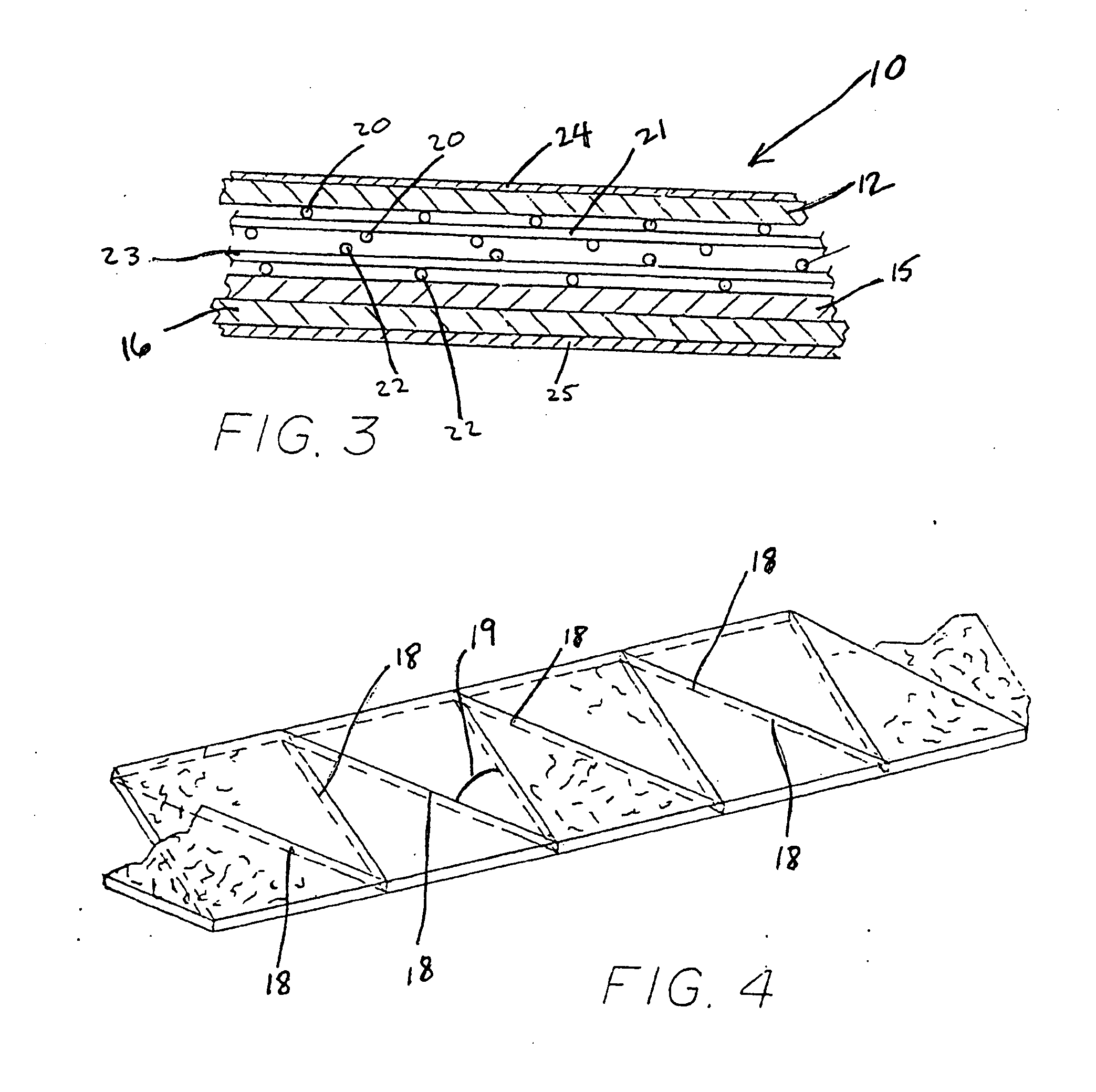

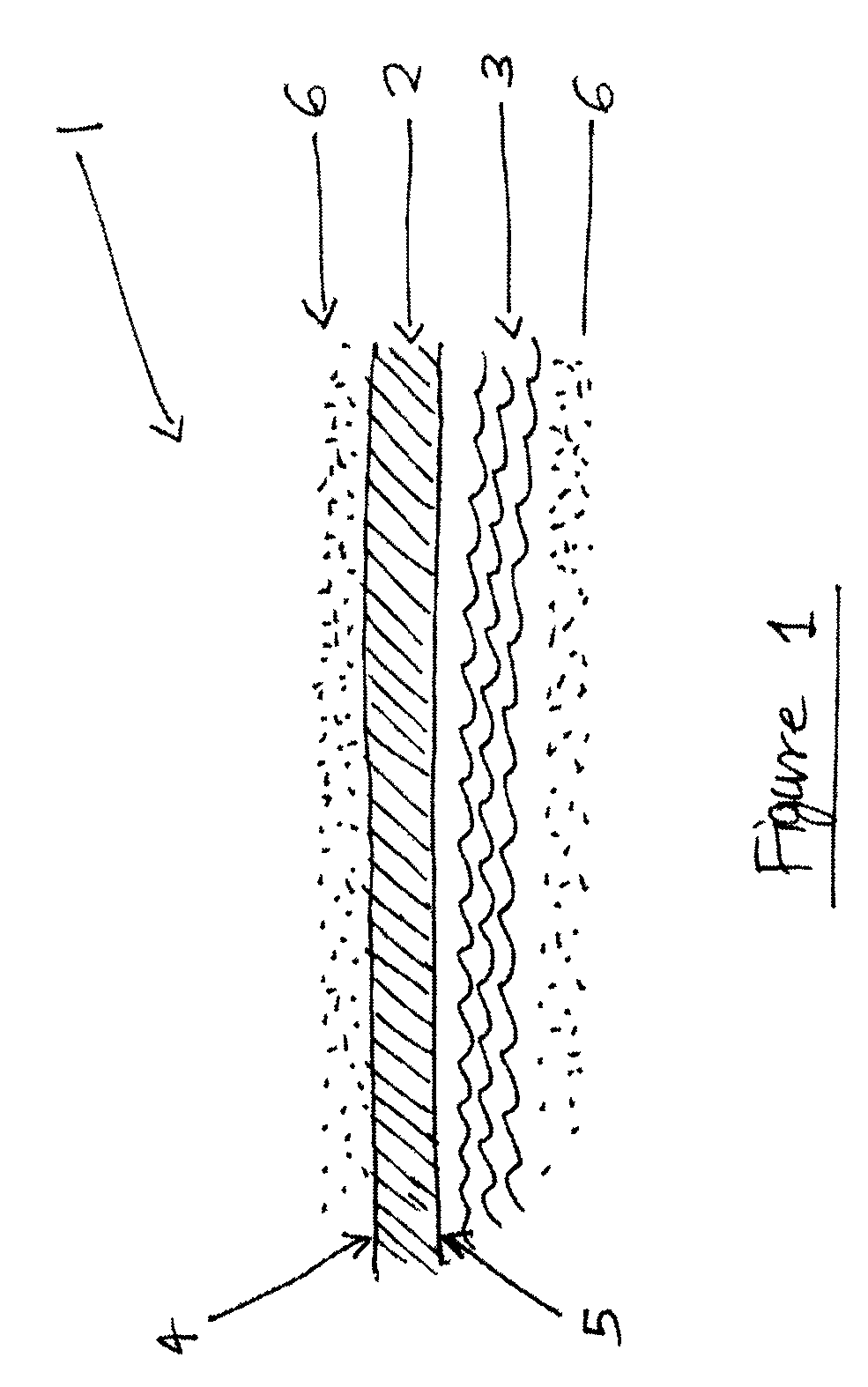

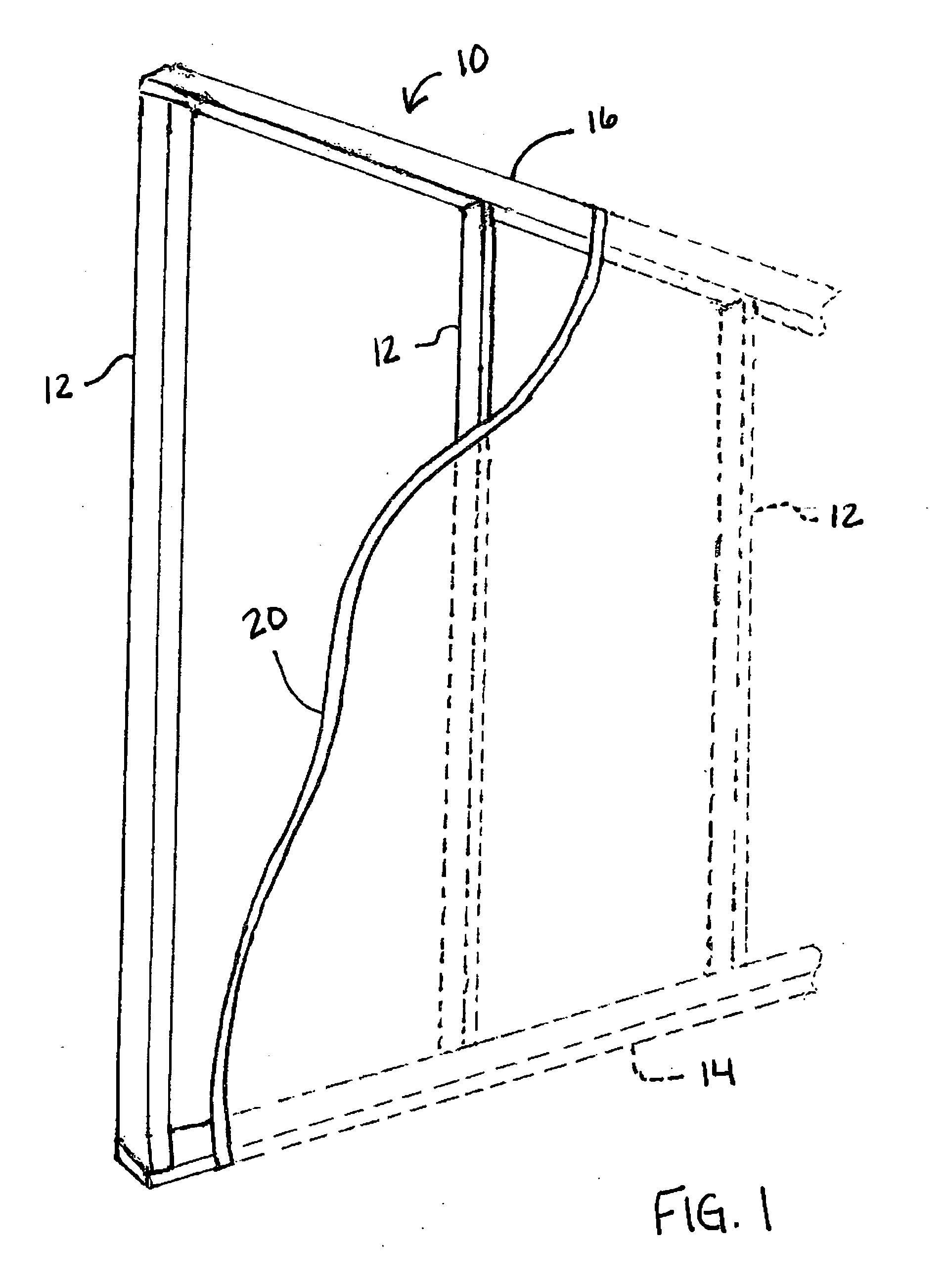

Roofing membranes using composite reinforcement constructions

A composite substrate (10) is prepared for reinforcing a bituminous roofing material by securing together a carrier web (12) with a first set (14) of fiberglass rovings bundles and a second set (16) of fiberglass rovings bundles. The carrier web will have a pair of opposed planar surfaces. The web will define a machine direction and a cross machine direction for the substrate, with the first and second sets of rovings bundles each positioned in parallel relationship, with the longitudinal axes defined by the individual rovings of the two sets being in non-parallel relationship to each other when viewed normal to the plane of the web. The bundle sets are maintained in the spaced apart parallel relationships and the non-parallel angular relationship by the adhesive, stitching or other conventional method of securing which holds the substrate together. If a stitching machine is used, the preferred yarn (18) would be a polyester yarn. The preferred web is a woven polyester mat and the preferred rovings bundles will be 1800 yield or heavier. After preparation, this substrate is dipped in molten bituminous material to provide a web of reinforced roofing material in which the substrate is embedded in a continuous matrix of the bitumen.

Owner:GARLAND CO THE +1

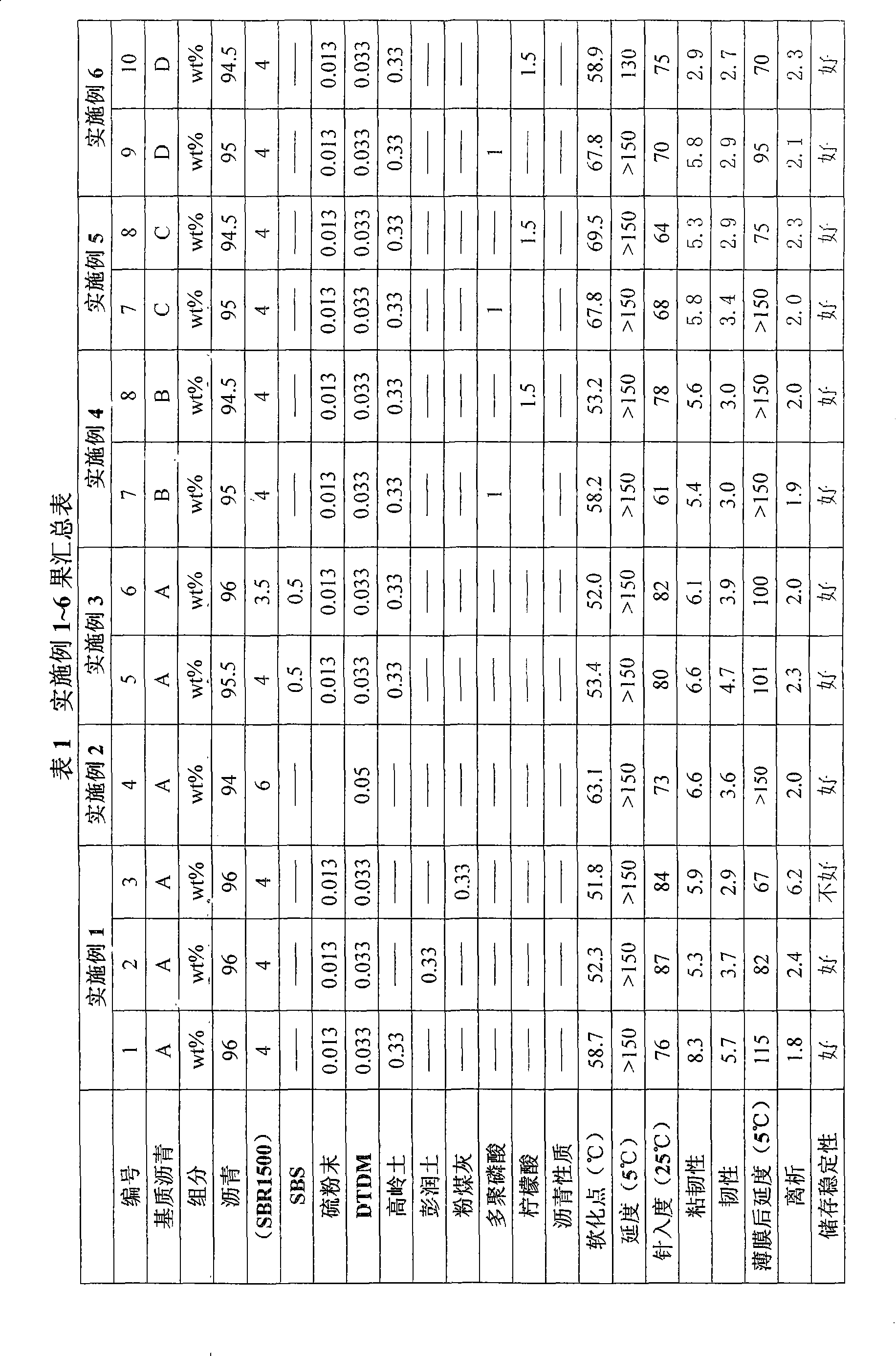

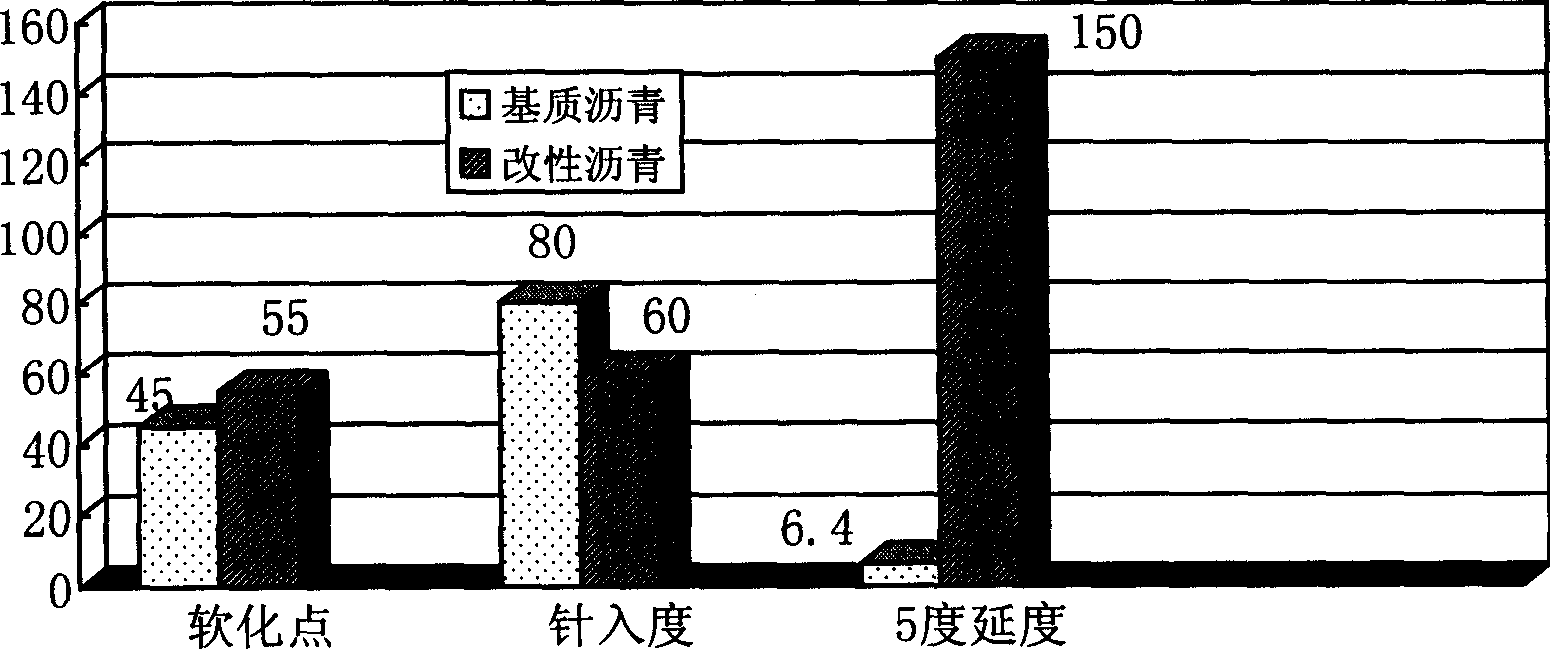

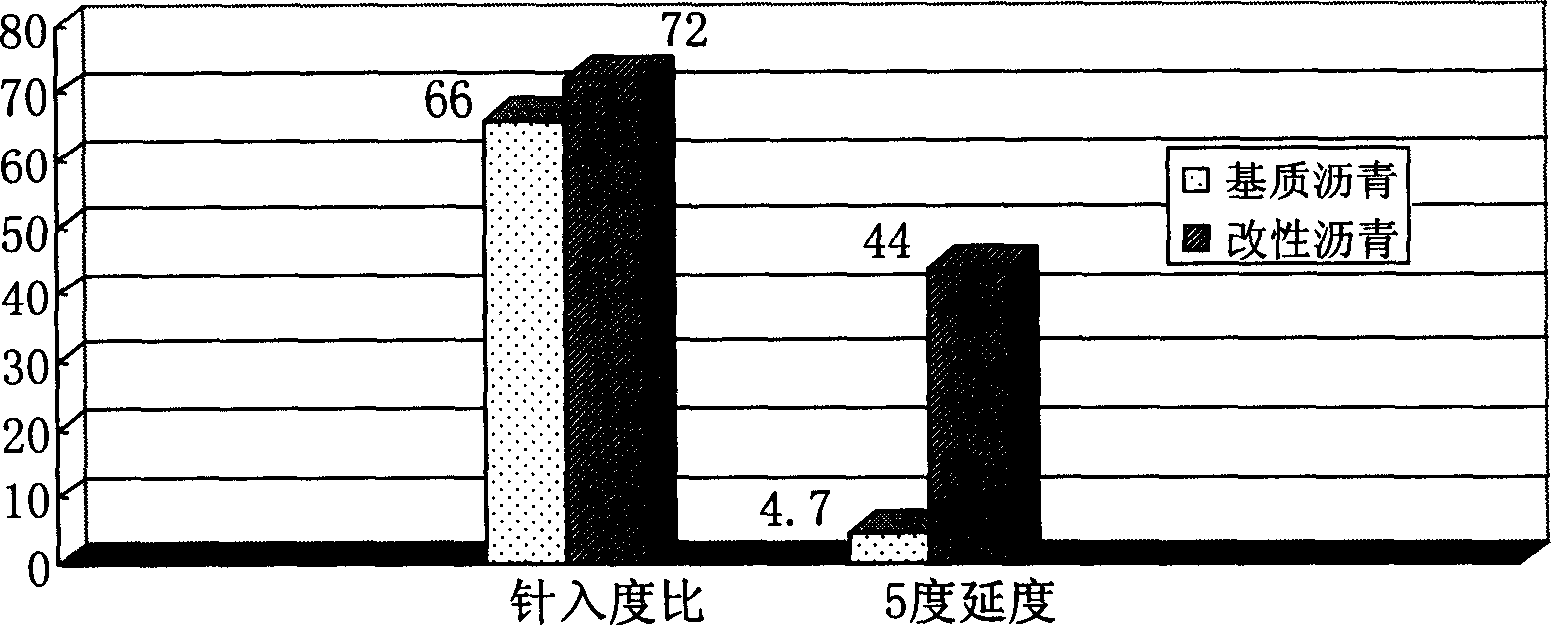

Polymer chemically-modified asphalt composition capable of being stably stored at high temperature and preparation method thereof

InactiveCN101613533AGood storage stability at high temperatureMeet usable requirementsBuilding insulationsElastomerViscous liquid

The invention relates to a high polymer chemically-modified asphalt composition and a preparation method thereof. The preparation method comprises the following steps: chemically modifying rubber, elastomer and base asphalt, and additionally matching stuffing and processing aids; premixing the materials by high polymer processing equipment to prepare the master batch of the modified asphalt; and fully dispersing the master batch into the asphalt by a high-speed shear mixer or by mechanical stirring. Or the modified asphalt material can be prepared by firstly pre-preparing a viscous liquid mixture of modified asphalt and then stirring and mixing the viscous liquid mixture of modified asphalt with the base asphalt. The modified asphalt material prepared by the invention has stable storage performance at high temperature, good performance at high temperature and low temperature, stable processing and preparation and simple and convenient method, and not only can be directly used in factory production but also can be used for road laying sites and in the construction of waterproofing materials.

Owner:NORTHWEST NORMAL UNIVERSITY

Uncured polyurethane waterproofing coating and preparation method thereof

ActiveCN103923565AGood adhesionGrowth Intermediate ConnectivityPolyurea/polyurethane coatingsBituminous coatingsElastomerPolymer science

The invention discloses an uncured polyurethane waterproofing coating and a preparation method thereof, belonging to the technical field of polyurethane waterproofing coatings. The uncured polyurethane waterproofing coating is prepared from the following raw materials in percentage by weight: 13-20% of prepolymer, 30-65% of asphalt, 1.0-1.5% of latent curing agent, 3-15% of compatilizer, 2-9% of thermoplastic elastomer and 0-3% of powder stuffing, wherein prepolymer is a substance synthesized by reaction between polyether and isocyanate. The uncured polyurethane waterproofing coating mainly aims to improve the material proportion and polymerization process of polyurethane, and the problem that a hot-melted asphalt material is needed to be heated by using a machine is solved; the uncured polyurethane waterproofing coating is convenient in construction and good in flowability; the viscosity of the constructed material can be automatically enhanced, so that the constructed material can become an elastic plastic body and a favorable waterproofing layer without internal stresses; in addition, the uncured polyurethane waterproofing coating can be well bonded with a coiled material and can be compounded to be waterproof so as to form a waterproofing layer capable of overcoming tension fracture caused by basement layer cracking and preventing puncturing; the uncured polyurethane waterproofing coating is simple and convenient in process, rapid in construction, free of maintenance, high in working efficiency and capable of becoming the development direction of building waterproofing in the further.

Owner:浙江鲁班建材科技股份有限公司

Preparation of active nano calcium carbonate composite modified asphalt material

InactiveCN101481504AReduce manufacturing costImprove high temperature performanceBuilding insulationsBituminous materialsNanometre

The invention discloses a method for preparing an active nano calcium carbonate compound modified asphalt material, which comprises the following steps in turn: heating base asphalt to be 120 to 190 DEG C till the base asphalt can fully flow, adding definite amount of SBS and active nano calcium carbonate into the base asphalt, stirring the mixture for 30 minutes at low speed, adding definite amount of stabilizing agent, emulsifying and shearing the mixture for 30 minutes. Based on the prior SBS modified asphalt, the method adds the definite amount of the active nano calcium carbonate as compound modifier. Because the surface of the active nano calcium carbonate is subjected to organic active treatment and has better oleophilic property, the active nano calcium carbonate has better compatibility and dispersion property in the asphalt. The high-temperature property and the dynamic stability of the asphalt can be remarkably improved by adding the definite amount of the active nano calcium carbonate into the modified asphalt; and simultaneously because the active nano calcium carbonate is already subjected to large-scale industrialized production, the cost is relatively low, and the active nano calcium carbonate after adding can lower the production cost of the modified asphalt remarkably.

Owner:山东海泽纳米材料有限公司

Packaging for bitumen

InactiveUS20070027235A1Little or no release of wastage into the environmentHigh densityMixingBuilding insulationsBituminous materialsPolymer chemistry

A consumable bitumen packaging compound including at least one packaging material / s, such as polymers, plastics and extenders and the like, used in combination with the bituminous material and a metal, either pure in powder form or in the form of salt or oxide, that is physically and / or chemically combined with the polymer material, so that the density of the packaging material is adjusted to prevent the material from floating to the surface of the molten material after melting. The components of the packaging are preferably selected such that they are compatible with the bitumen. After transport and storage, the packaging material can therefore be directly incorporated into the bitumen product for final use, such that the formation of a polymer skin accumulating at the surface of the molten material is largely avoided.

Owner:COSMIC ASPHALT TECH PTE

Modified asphalt material for road and its prepn

The present invention relates to one kind of modified asphalt material for road and its preparation. The modified asphalt material is prepared with asphalt with high wax content as base material and through adding powdered styrene-butadiene rubber, natural asphalite and organic metallic soap. The modified asphalt has the features of high temperature stability, low temperature crack resistance, fatigue resistance, peeling resistance, antiageing, etc. as well as improved comprehensive road use performance.

Owner:INST OF POLYMER NORTHWEST NORMAL UNIV

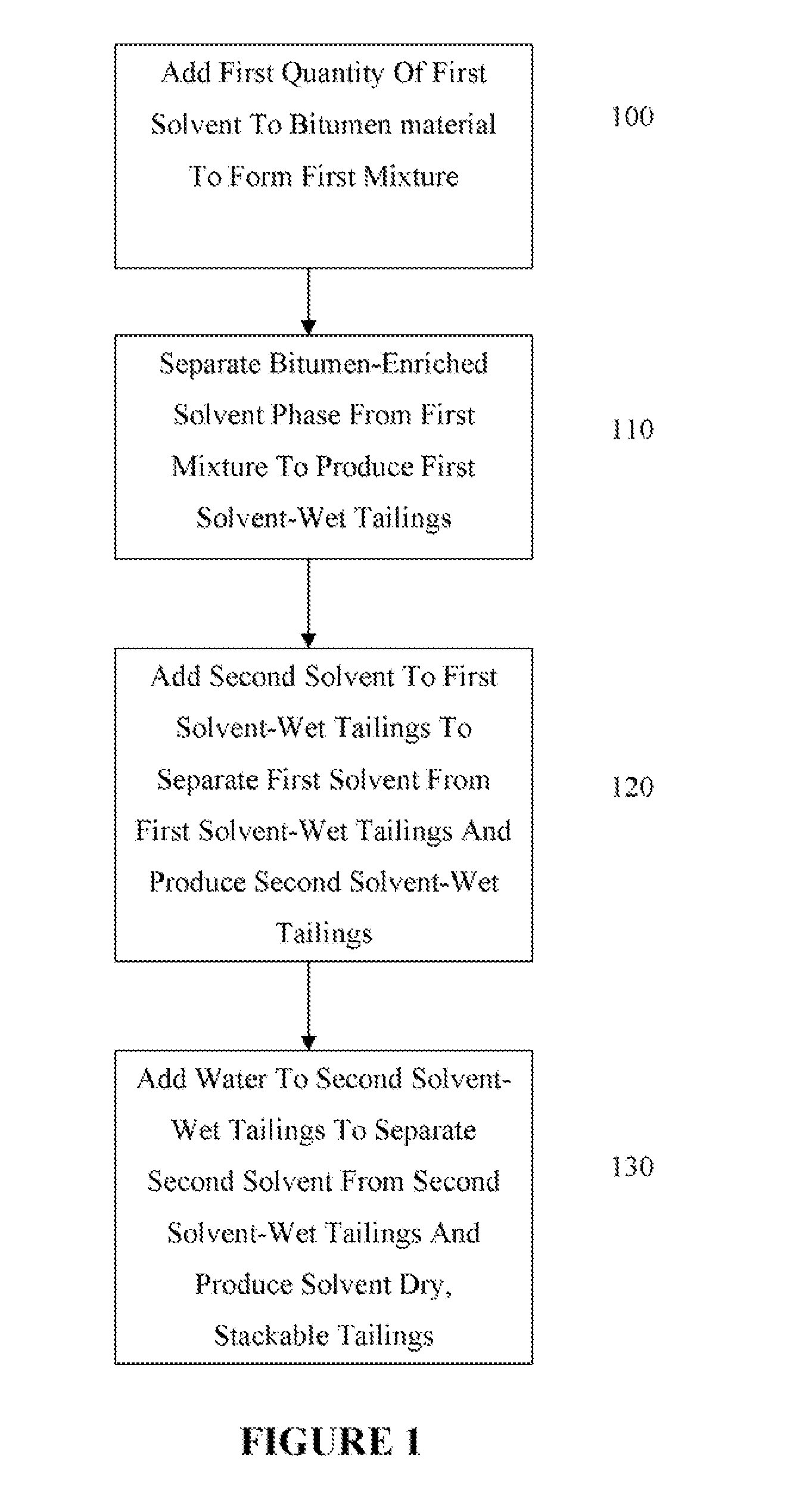

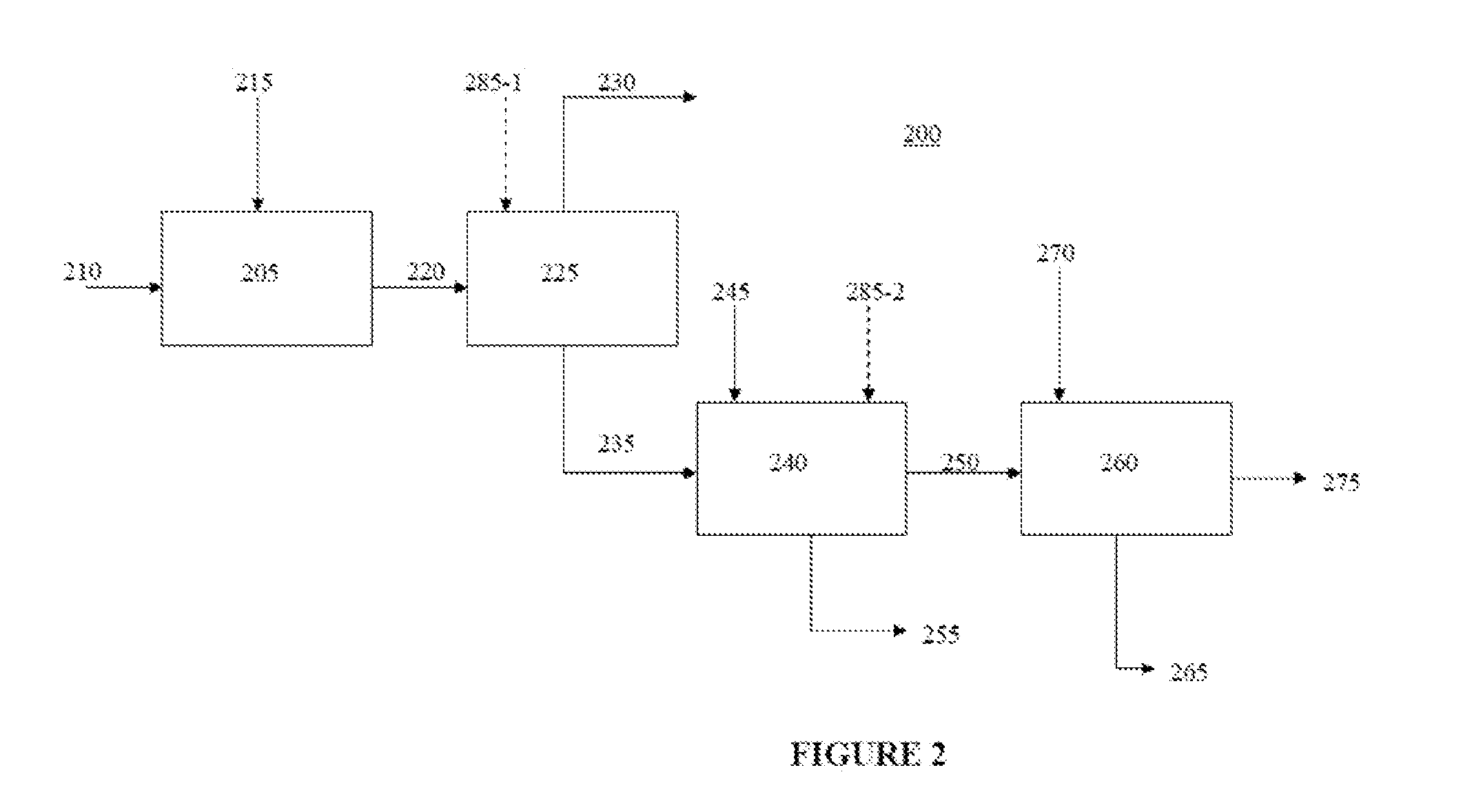

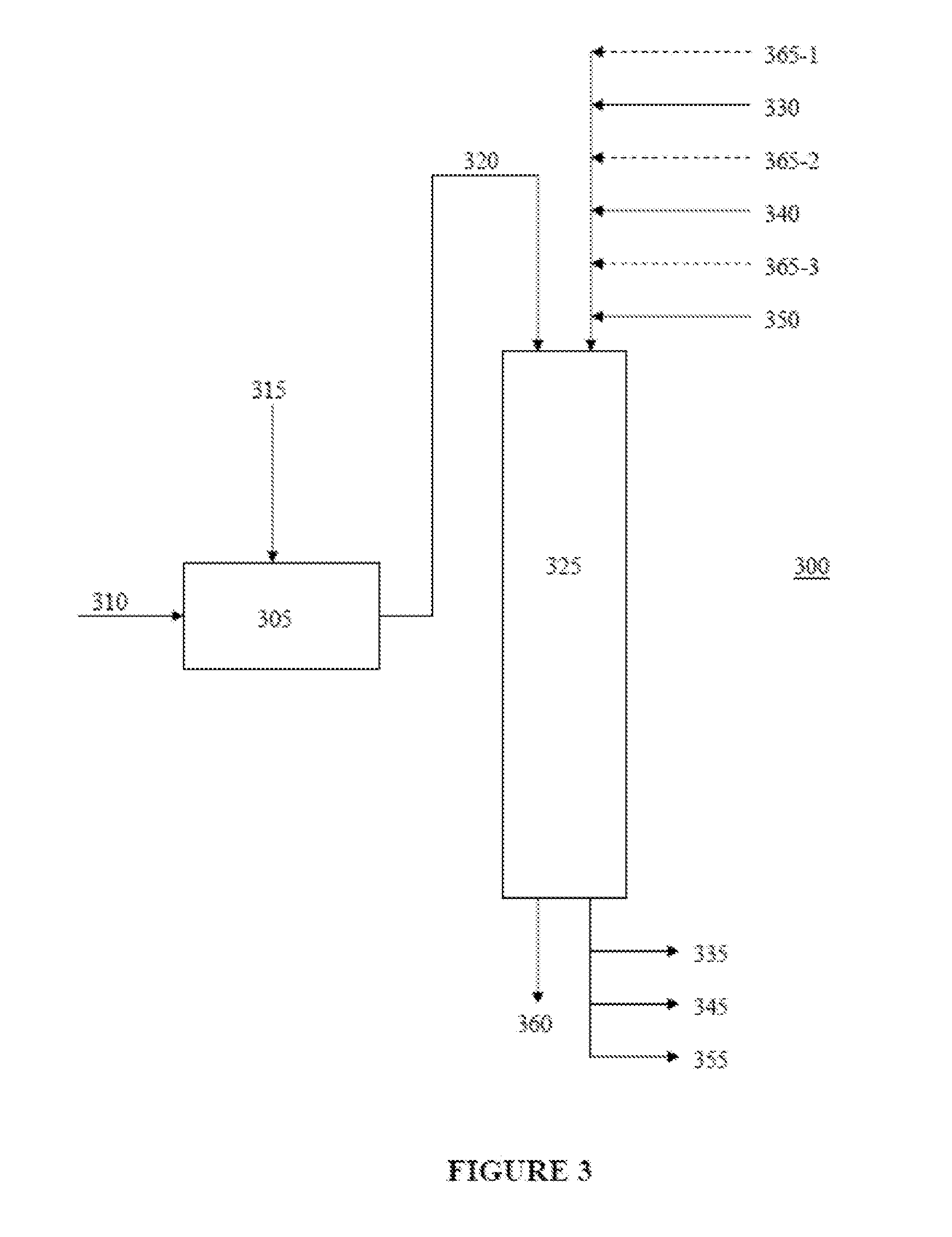

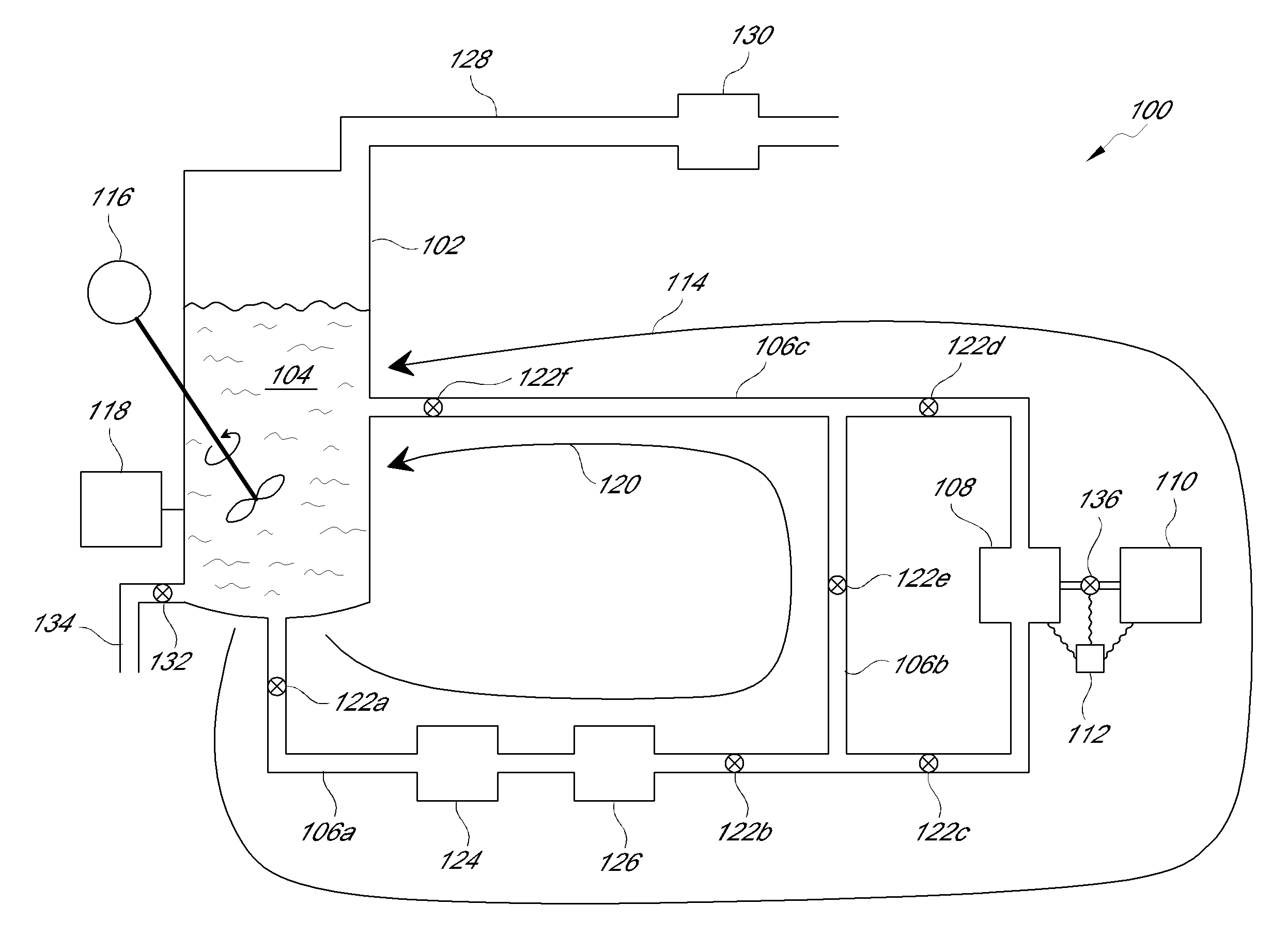

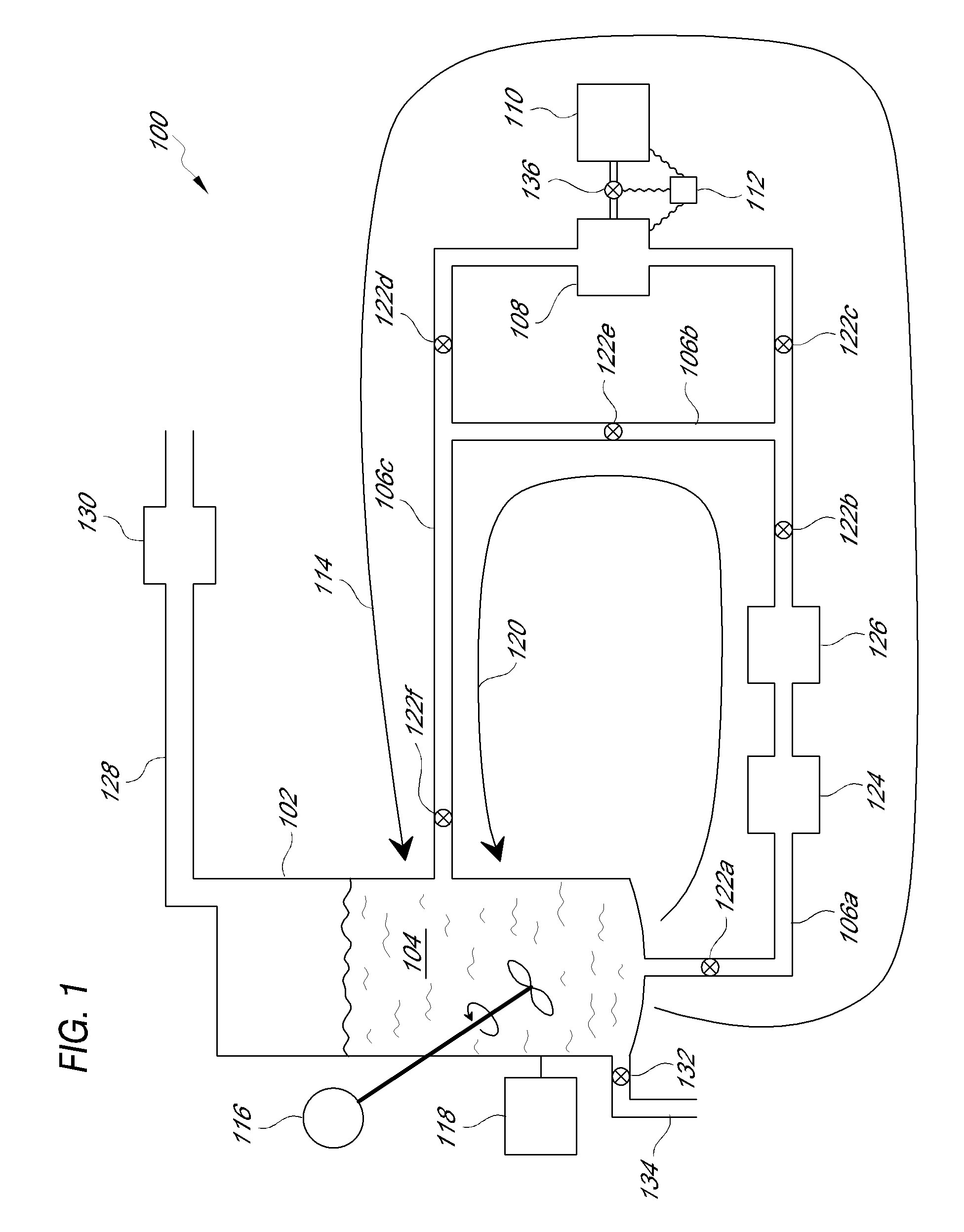

Methods for extracting bitumen from bituminous material

ActiveUS20110180459A1Efficient removalEasy disposalLiquid hydrocarbon mixture productionBituminous materialsSolvent

Methods for preparing solvent-dry, stackable tailings. The method can include the steps of adding a first quantity of first solvent to a bitumen material to form a first mixture, separating a first quantity of bitumen-enriched solvent from the first mixture and thereby creating first solvent-wet tailings, adding a quantity of second solvent to first solvent-wet tailings to separate a first quantity of first solvent component from the first solvent-wet tailings and thereby producing second solvent-wet tailings, and adding a quantity of water to the second solvent-wet tailings to separate a first quantity of second solvent component from the second solvent-wet tailings and thereby forming solvent-dry, stackable tailings.

Owner:CHEVRON CANADA +1

Waste alphalt regenerating agent and its preparing method

InactiveCN1580130ARaw materials are easy to getLow preparation equipment requirementsBuilding insulationsBituminous materialsEngineering

A kind of regenerant of wasted asphaltum belongs to the manufacturing field of asphaltum-processing accessory material, includes light oil, rosin, anti-aging agent, anti ultraviolet radiation auxiliary agent and so on and is featured by the following composition, in the amounts of weight: between 75% and 90% of light oil, between 10% and 25% of rosin, between 0.1% and 1% of anti-aging agent and between 0.1% and 1% of anti ultraviolet radiation. Aiming to the character of aged wasted asphaltum, the invention adds rosin, anti-aging agent and anti ultraviolet radiation auxiliary agent to light oil, selects and allocates the components reasonably. The invention have the advantage of finding the material easily, low requirement to the producing equipments, easy producing techniques, low cost, convenient use, obvious regeneration, taking action rapidly and long lasting active force. After practical use, the regenerant of wasted asphaltum in the invention can make the aged wasted asphaltum reach the technical indexes of the original asphaltum and the roads paved with it have almost the same life length as those paved with new asphaltum.

Owner:浙江兰亭高科控股有限公司

Cold-stirring cold-paving type epoxy modified asphalt material and preparation method thereof

InactiveCN106977966AImprove dispersion stabilityBreak the processBuilding insulationsBituminous materialsReactive diluent

The invention discloses a cold-stirring cold-paving type epoxy modified asphalt material and a preparation method thereof. The cold-stirring cold-paving type epoxy modified asphalt material is composed of a main ingredient A and a curing agent B; the main ingredient A comprises the following components in parts by weight: 0-50 parts of epoxy resin, 40-90 parts of flexibilizer, 5-15 parts of reactive diluent, 10-40 parts of asphalt, 10-40 parts of active bulking agent and 0-5 parts of coupling reagent; the curing agent B comprises the following components in parts by weight: 0-100 parts of flexible curing agent, 0-100 parts of alicyclic amine curing agent and 0-10 parts of accelerant; and the ratio of the main ingredient A to the curing agent B is (1-5):1. The invention utilizes a self-assembly behavior of the active bulking agent on the surface of asphalt particles to solve the problem of compatibility between weak polar asphalt and strong polar epoxy resin. A flexible chain segment is introduced into an epoxy asphalt three-dimensional structure network by the flexibilizer and the flexible curing agent, so that the fatigue toughness of the epoxy asphalt material is greatly promoted and the secondary cracking phenomenon caused by insufficient toughness is effectively restrained.

Owner:JIANGSU SINOROAD TRANSPORTATION SCI & TECH CO LTD

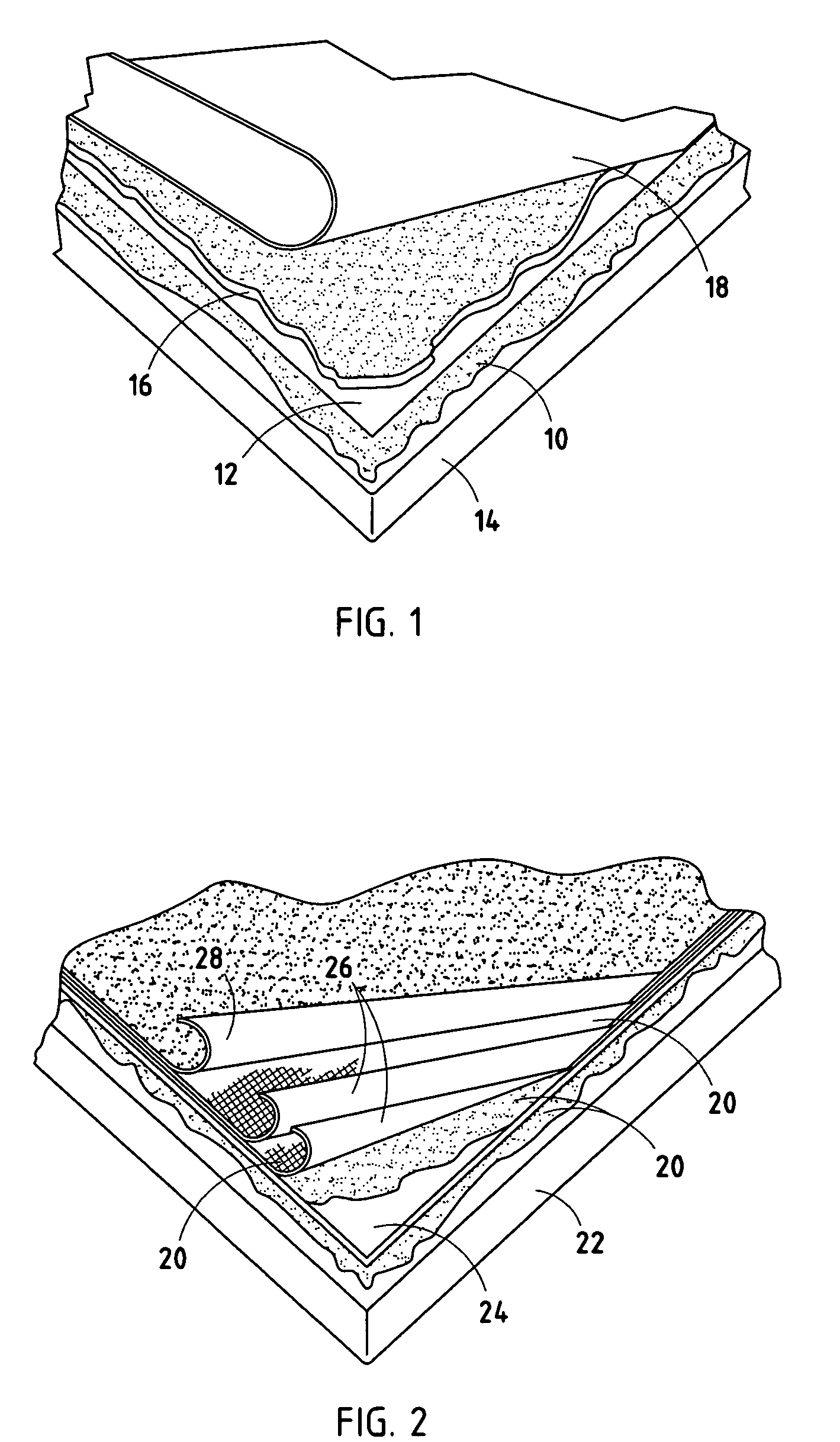

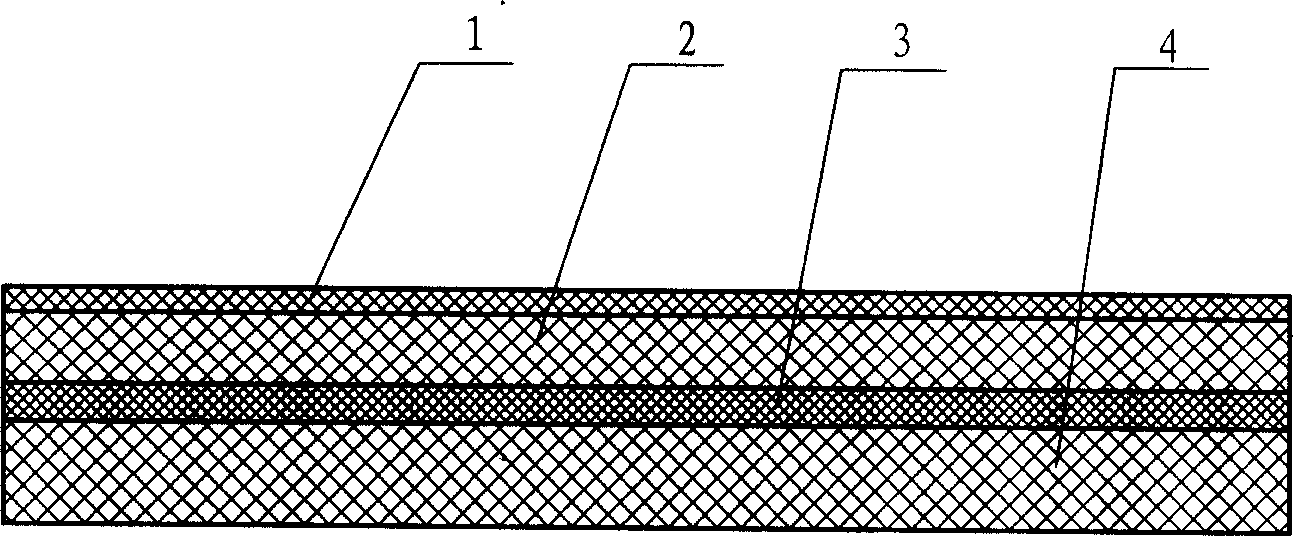

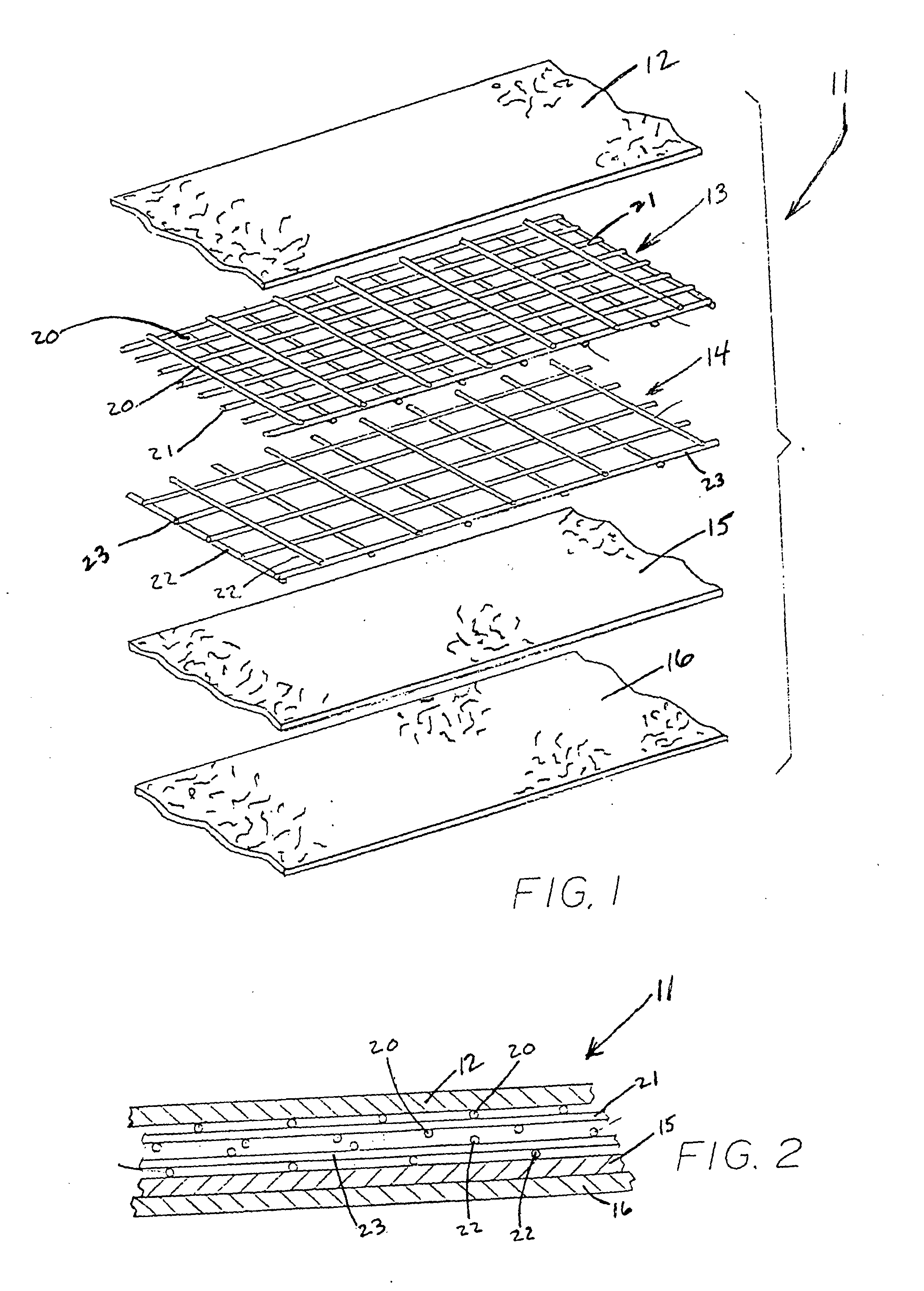

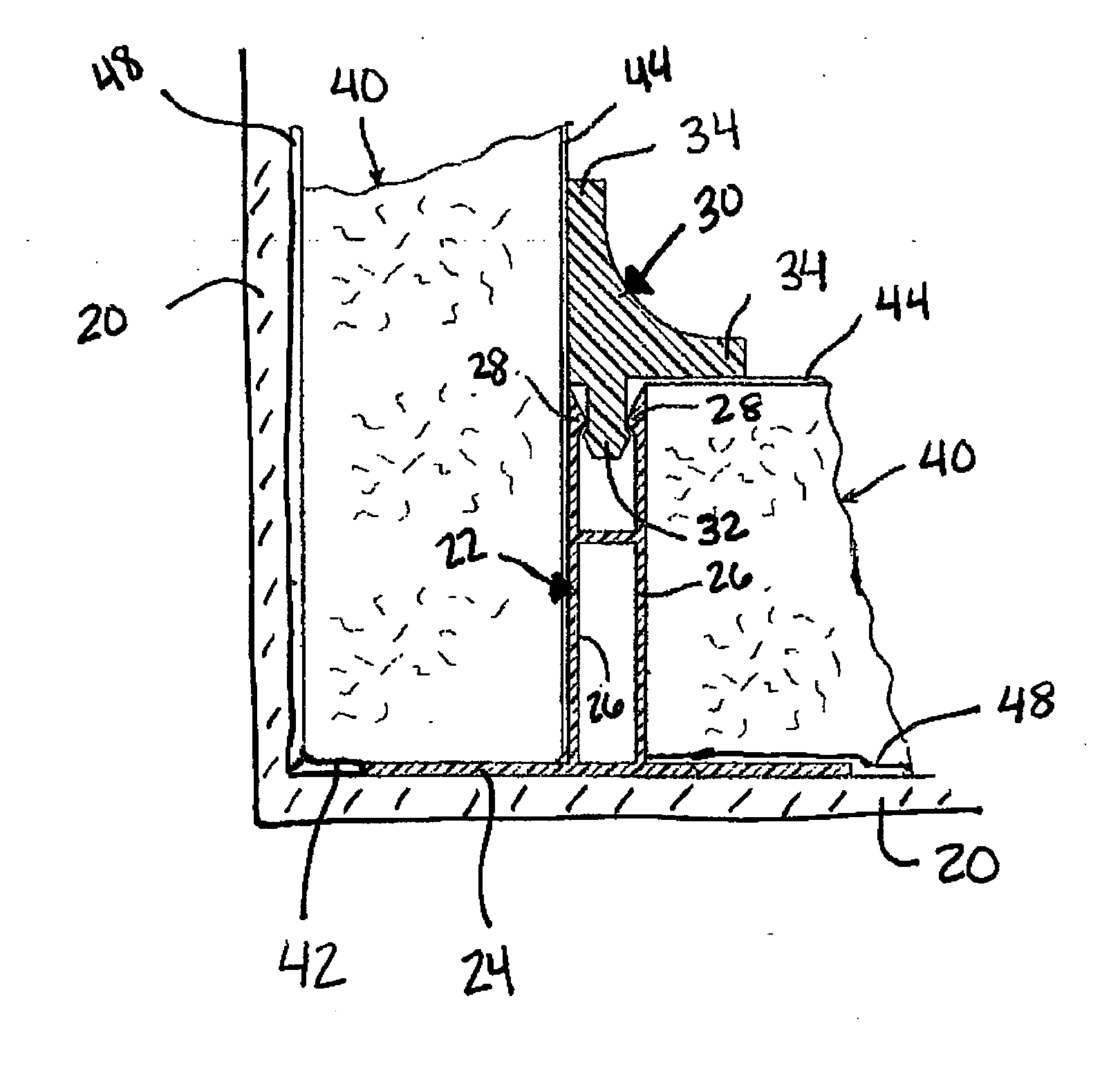

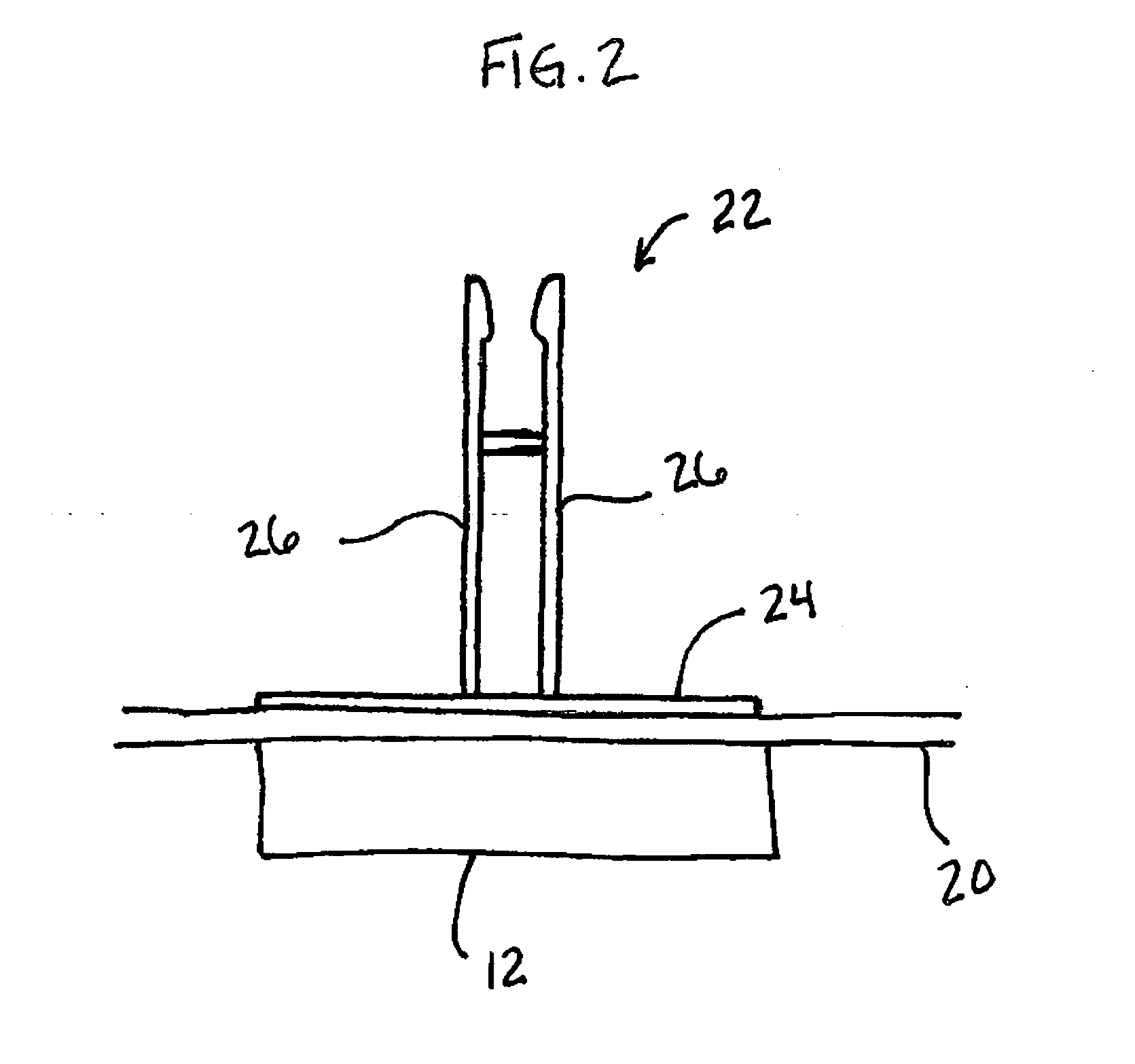

Reinforcement composite for a bituminous roofing membrane and method of making the composite

InactiveUS20050148250A1Roof covering using flexible materialsSynthetic resin layered productsPolyesterGlass fiber

A roofing membrane (10) is formed by impregnating and coating a composite material (11) with a bituminous material. The composite material (11) is formed with a first layer (12) made of a non-woven polyester mat. A second layer (13) is positioned adjacent to the first layer (12) and is formed as a non-woven fiberglass scrim. An optional third layer (14) is positioned adjacent to the second layer (13) and is formed of a non-woven polyester scrim. A fourth layer (15) is positioned adjacent to the third layer (14) and is made of a non-woven polyester mat. A fifth layer (16) is positioned adjacent to the fourth layer (15) and is also a non-woven polyester mat. The layers (12, 13, 14, 15, 16) may be attached by needle punching to form the composite material (11).

Owner:BFS DIVERSIFIED PRODS

Foaming modified asphalt composition and preparation method thereof

ActiveCN104448865AReduce production stepsReduce construction temperatureBuilding insulationsPolymer scienceEmulsion

The invention relates to a foaming modified asphalt composition. The foaming modified asphalt composition disclosed by the invention comprises 60-130 parts of matrix asphalt, 3-15 parts of waterborne emulsion, wherein the waterborne emulsion is formed by emulsifying 35-65wt% of asphalt modifier, 1-8wt% of emulsifier, 1-2wt% of foam stabilizer, 0.01-3wt% of coupling agent and 23-63% of water. The matrix asphalt and the waterborne emulsion containing the modifier are adopted, asphalt modification is realized when the matrix asphalt is foamed, the foamed modified asphalt has dual characteristics of a foam asphalt material and a modified asphalt material, the production step of modifying the asphalt is saved, the construction temperature of the asphalt mixture is reduced by 30-50 DEG C, and the asphalt mixture is prevented from aging, is superior to hot-mixed modified asphalt mixture and is obviously superior to common foamed asphalt in pavement performance. The modified asphalt equipment investment and production cost are saved, energy conservation and emission reduction are realized, and the process is easy and convenient.

Owner:SHANDONG DASHAN ROAD & BRIDGE ENG

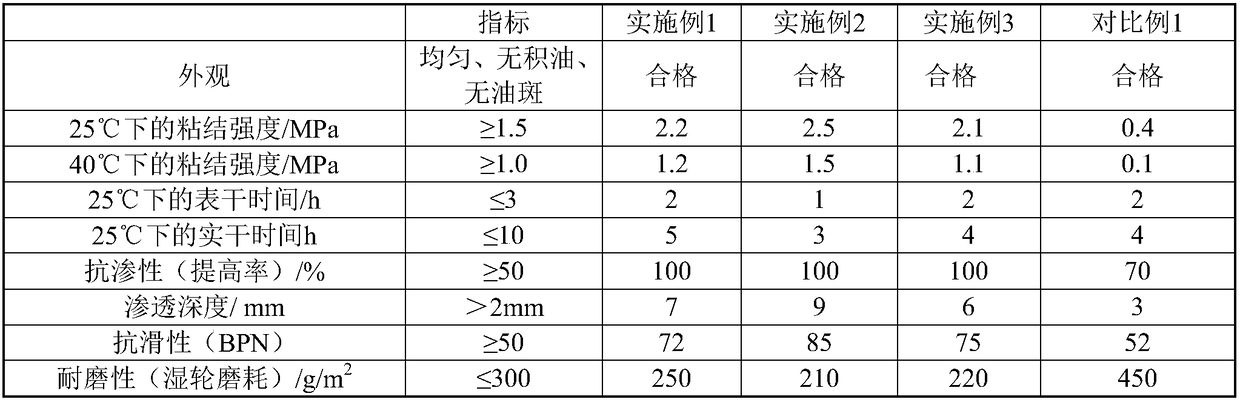

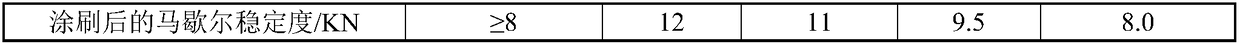

Epoxy modified emulsified asphalt sand-fog-containing sealing layer material and preparation method and application thereof

InactiveCN108070269AGood compatibilityNo premature demulsification and agglomerationIn situ pavingsBuilding insulationsEpoxyBituminous materials

The invention belongs to the technical field of compositions of asphalt materials, and particularly relates to an epoxy modified emulsified asphalt sand-fog-containing sealing layer material. The sand-fog-containing sealing layer material comprises the following main components: emulsified asphalt, epoxy resin and a water-soluble curing agent. The material is good in compatibility, a prepared sand-fog-containing sealing layer is uniform, and does not have accumulated oil or oil spots; the strength of the material is high; the anti-penetrability performance is good; the skid resistance is good;and the wear resistance is also good. The sand-fog-containing sealing layer prepared from the material has good inlaying effect on the original pavement. The preparation method is simple and speedy,convenient to operate and suitable for industrialized large-scale production.

Owner:重庆市智翔铺道技术工程有限公司

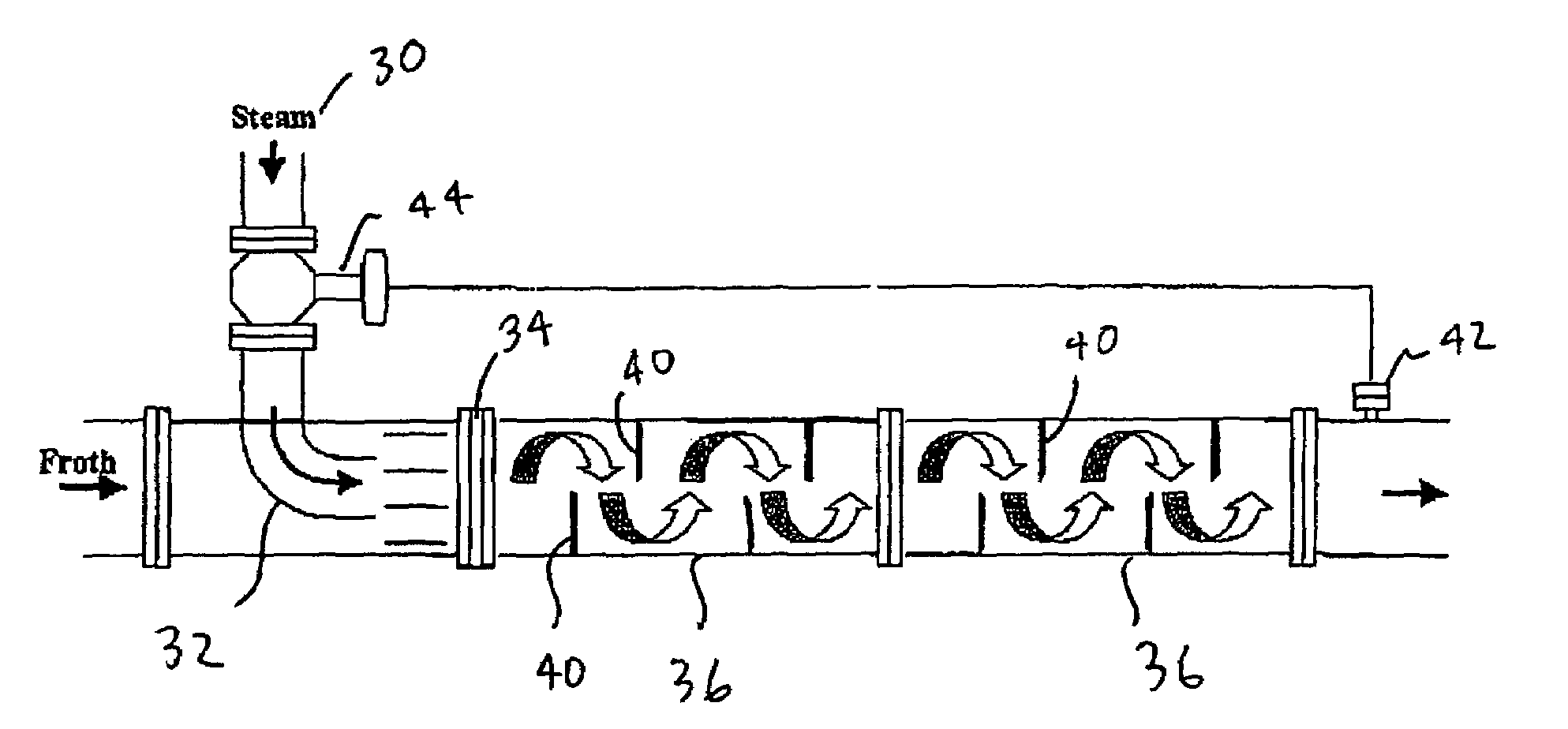

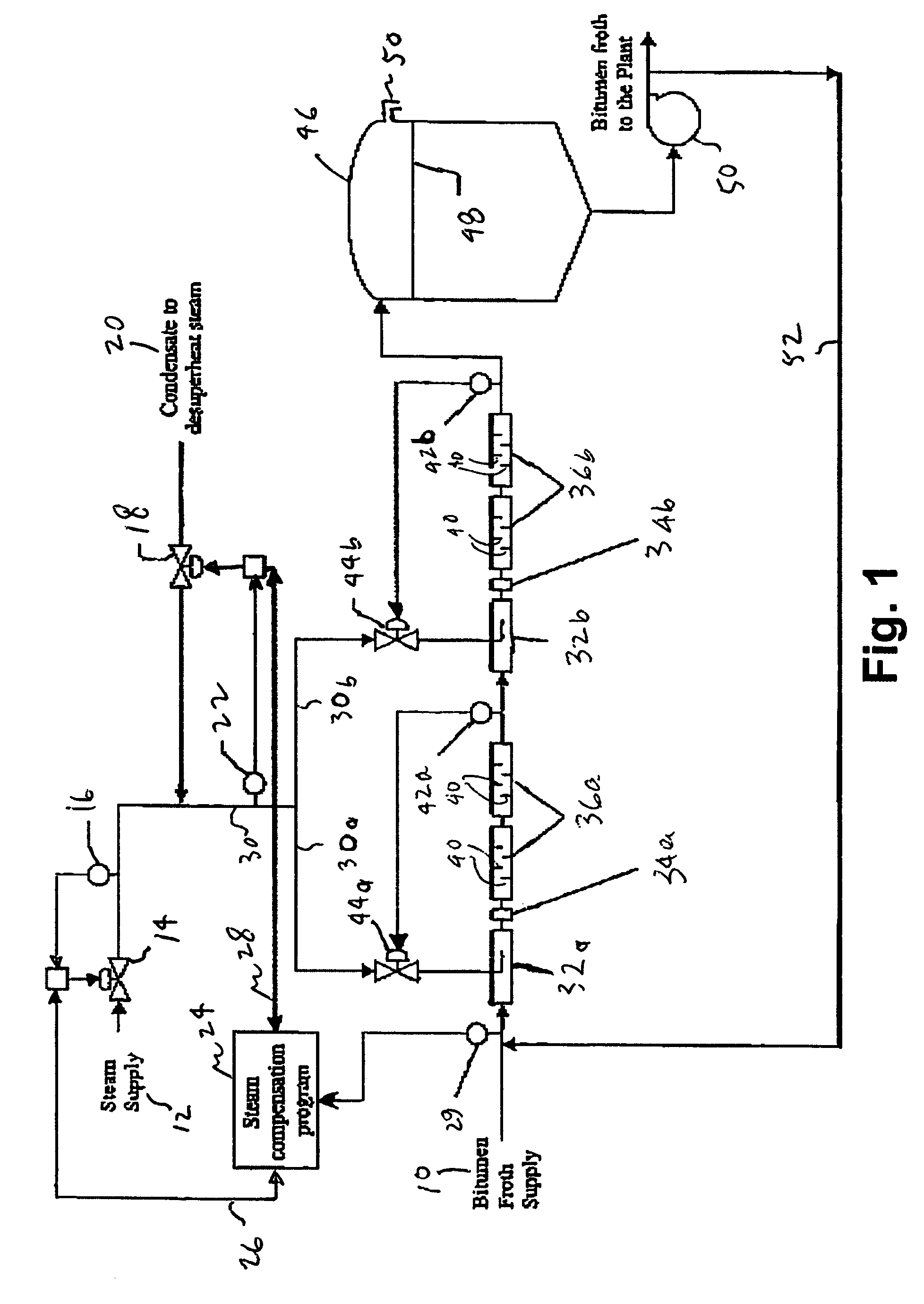

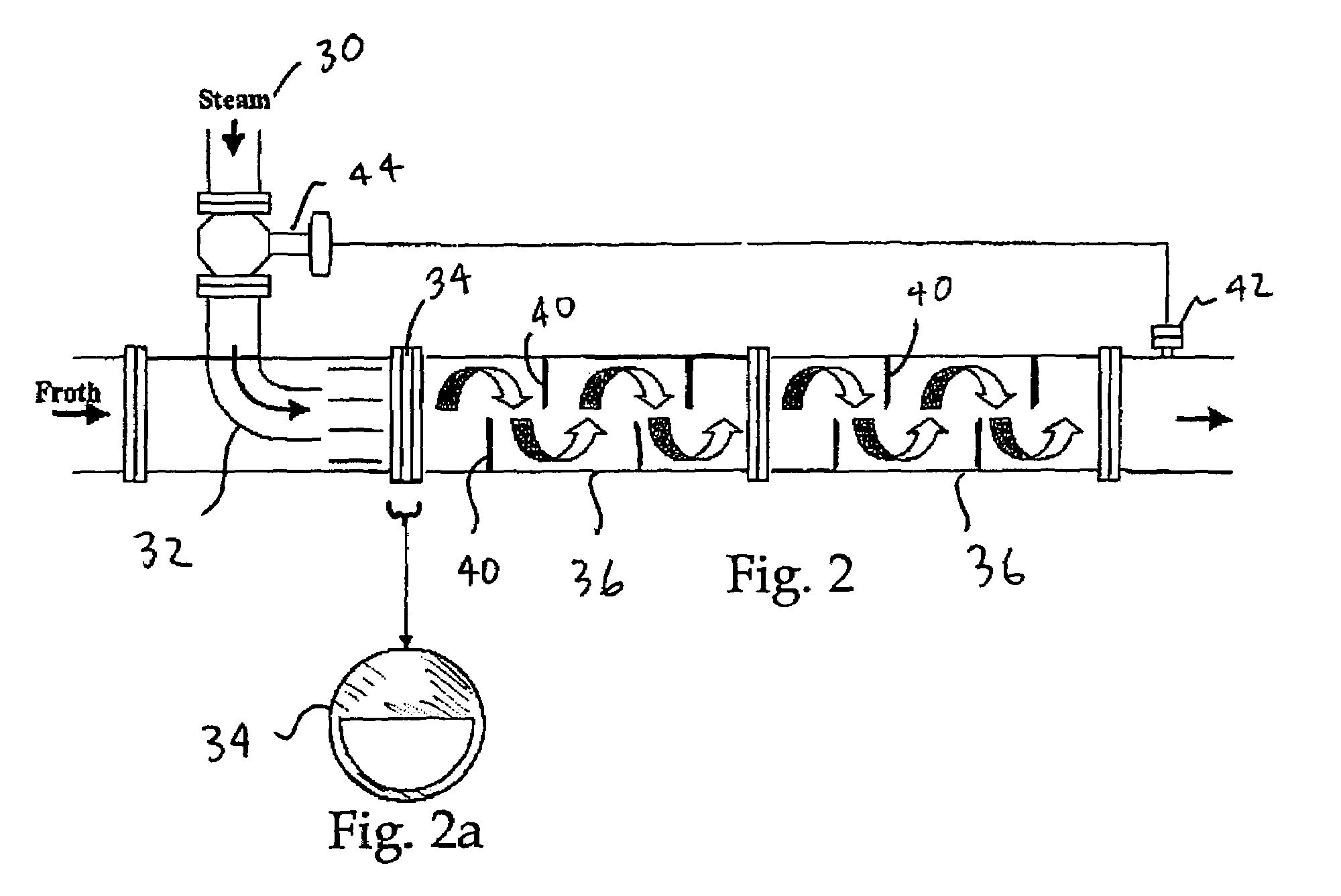

Bituminous froth inline steam injection processing

ActiveUS7556715B2Improve efficiencySuperior in friendlinessLiquid degasificationSolvent extractionDownstream processingBituminous materials

An inline bitumen froth steam heater system is comprised of steam injection and static mixing devices. The steam heater system heats and de-aerates an input bitumen froth without creating downstream processing problems with the bitumen froth such as emulsification or live steam entrainment. The inline bitumen froth steam heater is a multistage unit that injects and thoroughly mixes the steam with bitumen resulting in an output bitumen material having a homogenous temperature of about 190° F. The heating system conditions a superheated steam supply to obtain saturated steam at about 300° F. The saturated steam is contacted with a bitumen froth flow and mixed in a static mixer stage. The static mixers provide a surface area and rotating action that allows the injected steam to condense and transfer its heat to the bitumen froth. The mixing action and the increase in temperature of the bitumen froth results in reduction in bitumen viscosity and also allows the release of entrapped air from the bitumen froth.

Owner:SUNCOR ENERGY INC

Asphalt production from solvent deasphalting bottoms

ActiveUS20090301931A1Minimizing conventional waste handling demandEliminate wasteWorking-up pitch/asphalt/bitumen by selective extractionWorking-up tarEffective solutionDesorption

A cost-effective solution is provided for eliminating refinery process waste, including spent catalytic and non-catalytic adsorbent materials, as well as adsorbate process reject materials derived from desorption, while minimizing conventional waste handling demands. An asphalt composition includes asphalt and spent adsorbent material from a solvent deasphalting unit. The asphalt can comprise asphaltic material obtained from a solvent deasphalting unit, and spent adsorbent material in the asphalt composition was previously utilized in the solvent deasphalting unit. The asphalt composition can also include process reject materials.

Owner:SAUDI ARABIAN OIL CO

Methods and systems for manufacturing modified asphalts

InactiveUS20090312872A1Efficient preparationImprove the level ofFlow mixersRotary stirring mixersBituminous materialsShear rate

Methods and systems for efficiently manufacturing modified asphalt materials include agitating a base asphalt at a high shear rate using an in-line mixer equipped with a rotor-stator mixing tool while simultaneously exposing the asphalt to oxygen by blowing an oxygen-containing gas at a high gas flow rate through openings in the rotor-stator mixing tool and heating the asphalt at an elevated temperature.

Owner:FLEX PROD LLC

Rubber modified asphalt material for road and its preparing method

InactiveCN1364823AImprove dispersion stabilityGood effectBuilding insulationsPolymer scienceBituminous materials

The rubber modified asphalt material is produced through chemical mdofication with organic grafting material and / or crosslinking composition, the organic grafting material is organic unsaturated olefinic acid or its ester, acid anhydride or their mixture, and crosslinking composition is mixture of sulfurizing agent and sulfurizing assistant. One of the preparation process includes the first reaction of rubber solution and the added organic grafting material, mixing with asphalt and final additional of crosslinking composition; and the other one includes dispersing rubber into asphalt, and the subsequent addition of organic grafting material and crosslinking composition for reaction. The rubber modified asphalt has high performance or rubber consumption and stable dispersion of rubber in asphalt and may be used used in expressway and other important highway.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI +1

Bitumen recycling agent for improving high temperature stability of waste and old bitumen mixture

InactiveCN101177535AImprove high temperature stabilityLow costBuilding insulationsAntioxidantBituminous materials

The invention discloses an asphalt regenerator for improving the high temperature stability for mixing material of waste asphalt. According to the parts by weight, the components are as below: 70 to 95 of refinery waste rich in aromatic fraction and colloid; 5 to 25 of resin; 0.1 to 1 of antioxidant; 0.1 to 1 of anti-ultraviolet addition agent; 2 to 5 of stabilizing agent for high temperature. The invention also discloses the preparation method for the asphalt regenerator. Aiming at aged asphalt property in waste asphalt mixing material, the invention adds the resin, the antioxidant and the anti-ultraviolet addition agent in refinery waste rich in aromatic fraction and colloid and makes rational selection and matching for material of each material. The invention has the advantages of easy availability for raw material, low requirement for equipments, simple preparing art and convenient use. The invention obviously improves stability of high temperature for regenerated asphalt mixing material and other active results, lowers construction cost and is suitable for green ecological and sustainable development.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +1

Roofing underlayment and method of producing same

Owner:RATCLIFF STEVE A +1

Laminated nanometer clay/waste rubber power composite modified asphalt material and preparation method thereof

InactiveCN104212191ASimple internal structureImprove performanceBuilding insulationsWaste rubberBituminous materials

The invention relates to a laminated nanometer clay / waste rubber power composite modified asphalt material and a preparation method thereof. The composite modified asphalt material comprises the following components in percentage by mass: 100 parts of matrix asphalt, 1-7 parts of laminated nanometer clay, 5-20 parts of waste rubber power and 1-5 parts of furfural extract oil. The laminated nanometer clay and the waste rubber power are adopted as modifiers for the matrix asphalt, a shear emulsifying machine is adopted as a dispersing device and a melt blending method is adopted in the preparation method. The preparation method comprises the following specific steps: heating until raw materials are molten and carrying out shear mixing. The composite modified asphalt material prepared by the preparation method has the advantages of excellent anti-rutting property, excellent UV aging property and storage stability. The preparation method has the characteristics of cheap raw materials, simple process and the like and provides an economical and environment-friendly solution for subsequent processing of waste tires. The composite modified asphalt material can be used in the fields of pavement of high-grade road surface, such as bridge and airport, construction and the like.

Owner:SOUTH CHINA UNIV OF TECH

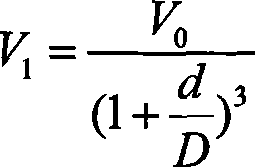

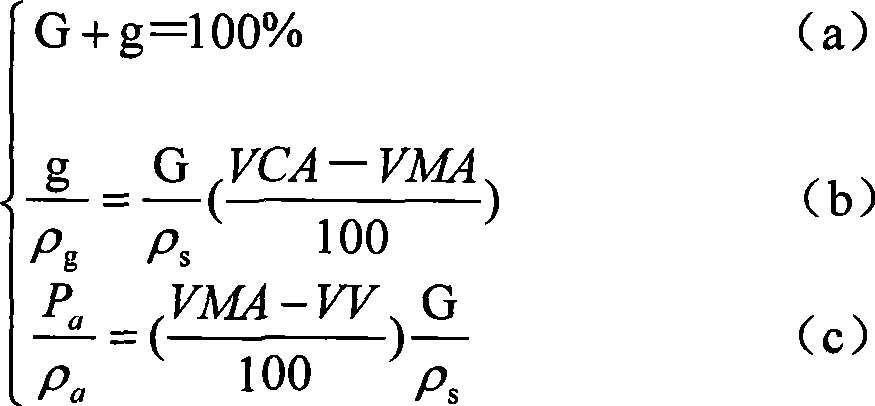

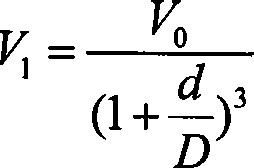

Design method of framework compact type asphalt mixture volume

InactiveCN101463584AUnified designImprove high temperature stabilityIn situ pavingsVoid ratioFilling rate

The invention provides a volume design method for asphalt mixture with skeleton dense structure, which is a method for mixture proportion design. The method comprises: step 1, according to the regulation of the current specifications, the densities of asphalt material and aggregates of various grades are determined; step 2, the void-filling rate V0, when the mixture is solely composed by the aggregate of the coarsest grade with the diameter of D0 in the asphalt material, is tested, and the theoretical gradation of the coarse aggregate is calculated; step 3, the theoretical densities and the integral density of the coarse aggregates and fine aggregates in the asphalt material are respectively confirmed; step 4, compact stacking density of the coarse aggregate and the void ratio VCA when the coarse aggregates are in a state of compact stacking are confirmed; step 5, the proper volume parameters and value of VMA and VV are chosen according to the maximum particle diameter of the asphalt material; step 6, the usage amount of the coarse aggregates, fine aggregates and asphalt in the asphalt material is determined according to the theoretical formula for asphalt mixture volume design so as to determine the mixture gradation. The completion of the volume design of the mixture is a key technical measure to improve the high-temperature property of the asphalt pavement.

Owner:SOUTHEAST UNIV

Fire-retardant modified asphalt material and preparing method

InactiveCN101024727AImprove flame retardant performanceGood high and low temperature performanceBuilding insulationsEmulsionCrack resistance

The invention relates to a inflaming retarding modification pitch material that includes ground substance pitch, rubber modification agent and inflaming retarding modification agent. It adopts high speed shear mixing emulsion machine to make inflaming retarding modification pitch material that includes the following steps: dehydrating for 30min at 110 degree centigrade, heating to 175 degree centigrade, adding SBS, cutting for 10min, and adding inflaming modification agent and cutting for 5min. The invention has the advantages of high temperature stability, low temperature crack resistance, good covering ability to stone, and good anti-aging and excellent inflaming retarding ability.

Owner:重庆市智翔铺道技术工程有限公司

Acoustic partition for removable panel finishing system

InactiveUS20070125011A1Easy to cutReduce echo timeWallsSound proofingGlass fiberBituminous materials

An acoustical absorbing membrane that may be used in removable panel finishing systems is provided. The acoustic membrane may be formed of any sound transmission loss material that possesses sound-absorbing or sound-deadening qualities. Examples of suitable materials include foil, a foil-faced asphalt material, elastomeric materials, composite laminates, a polymer film, a composite material formed of an organic bonding material and one or more types of reinforcement fibers, a cement board, a gypsum board, a gypsum / WUCS board, a dense WUCS mat, a film formed of a fiberglass reinforced resin, and / or any dense polymeric material. In at least one exemplary embodiment, the acoustic membrane may be a film formed of a loaded polymer or copolymer, such as a copolymer of ethylene-vinyl acetate loaded with barium or CaCO3. The acoustic membrane may have a density of approximately 1 lb / ft2-3 lbs / ft2 and preferably has a thickness from about 1 / 16-⅜ of an inch.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com