Epoxy modified emulsified asphalt sand-fog-containing sealing layer material and preparation method and application thereof

A technology of fog seal layer material and emulsified asphalt, which is applied in the direction of building insulation materials, on-site coagulation pavement, building components, etc., and can solve the problem of difficult to meet the preventive maintenance requirements of asphalt pavement and the bond strength between cement and base surface Low, emulsified asphalt demulsification and agglomeration problems, to achieve the effect suitable for industrial scale production, good embedding effect, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

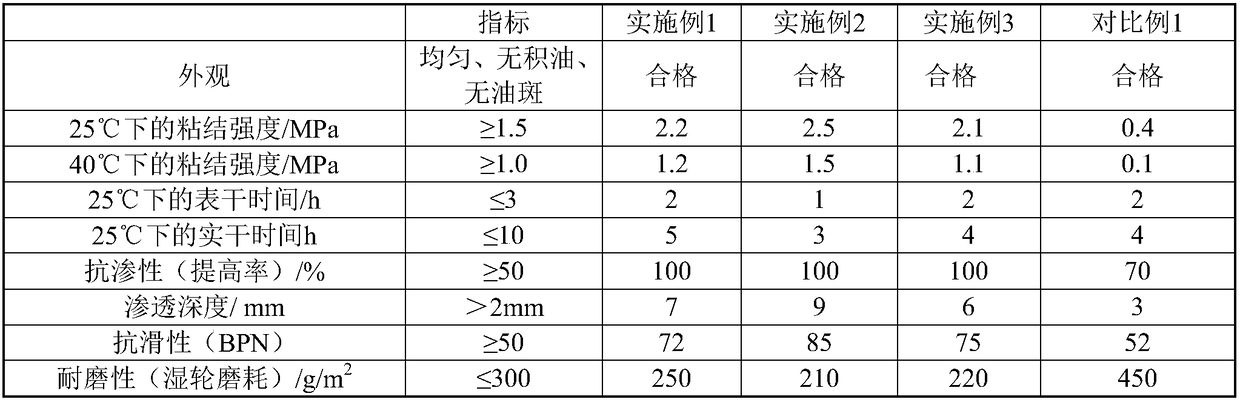

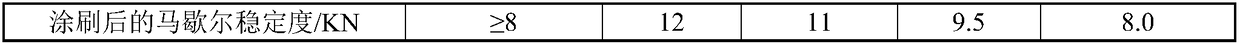

Examples

Embodiment 1

[0042] Epoxy modified emulsified asphalt containing sand mist sealing layer material, its composition is: 32.5 ordinary Portland cement 10 parts, 70# emulsified asphalt, SBS modified 70# emulsified asphalt 80 parts, E51 epoxy resin 30 parts, aliphatic 30 parts of polyamine curing agent, 3 parts of silicone waterproof penetrating agent, 2 parts of polyether modified silicon defoamer, 2 parts of sodium polyacrylate dispersant, 10 parts of alkylphenol polyoxyethylene ether TX-10, granules 30 parts of quartz sand with a diameter of 40-120 mesh and 10 parts of silicon dioxide; all in parts by mass.

[0043] The preparation method of the sand mist-containing sealing layer material, its specific steps are:

[0044] A: Heat the emulsified asphalt and epoxy resin to 40°C respectively, then shear at a shear rate of 600 rpm, then add surfactant to the emulsified asphalt, after shearing for 3 minutes, add epoxy to the emulsified asphalt Resin and filler, then shear 45min at a shear rate ...

Embodiment 2

[0049] Epoxy modified emulsified asphalt containing sand mist sealing layer material, its composition is: 20 parts of 32.5 ordinary Portland cement, 100 parts of SBR latex modified 70# emulsified asphalt, 15 parts of E40 epoxy resin, aromatic polyamine 15 parts of curing agent, 10 parts of silicone waterproof penetrating agent, 5 parts of polyether modified silicon defoamer, 5 parts of sodium polyacrylate dispersant, NP-1020 parts of alkylphenol polyoxyethylene ether, the particle size is 20 parts of 40-120 mesh carborundum and 5 parts of bentonite 60 parts; all in parts by mass.

[0050] The preparation method of the sand mist-containing sealing layer material, its specific steps are:

[0051] A: Heat the emulsified asphalt and epoxy resin to 60°C, then shear at a shear rate of 500 rpm, then add surfactant to the emulsified asphalt, after shearing for 5 minutes, add epoxy to the emulsified asphalt Resin and filler, then shear 30min at a shear rate of 8000 rpm / min to obtain com...

Embodiment 3

[0056] Epoxy modified emulsified asphalt containing sand mist sealing layer material, its composition is: 10 parts of 32.5 ordinary Portland cement, 120 parts of 70# emulsified asphalt, 15 parts of E20 epoxy resin, 20 parts of aliphatic polyamine curing agent , 2 parts of silicone waterproof penetrating agent, 3 parts of polyether modified silicon defoamer, 4 parts of sodium polyacrylate dispersant, 15 parts of fatty alcohol polyoxyethylene ether AEO-9, emery with a particle size of 40-120 mesh 25 parts and 8 parts of kaolin; all in parts by mass.

[0057] The preparation method of the sand mist-containing sealing layer material, its specific steps are:

[0058] A: Heat the emulsified asphalt and epoxy resin to 45°C respectively, then shear at a shear rate of 600 rpm, then add surfactant to the emulsified asphalt, after shearing for 4 minutes, add epoxy to the emulsified asphalt Resin and filler, then shear 40min at a shear rate of 6000 rpm / min to obtain component A of epoxy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com