Patents

Literature

6716 results about "Portland cement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and non-specialty grout. It was developed from other types of hydraulic lime in England in the mid 19th century, and usually originates from limestone. It is a fine powder, produced by heating limestone and clay minerals in a kiln to form clinker, grinding the clinker, and adding 2 to 3 percent of gypsum. Several types of Portland cement are available. The most common, called ordinary Portland cement (OPC), is grey, but white Portland cement is also available. Its name is derived from its similarity to Portland stone which was quarried on the Isle of Portland in Dorset, England. It was named by Joseph Aspdin who obtained a patent for it in 1824. However, his son William Aspdin is regarded as the inventor of "modern" Portland cement due to his developments in the 1840s.

Lightweight cementitious compositions and building products and methods for making same

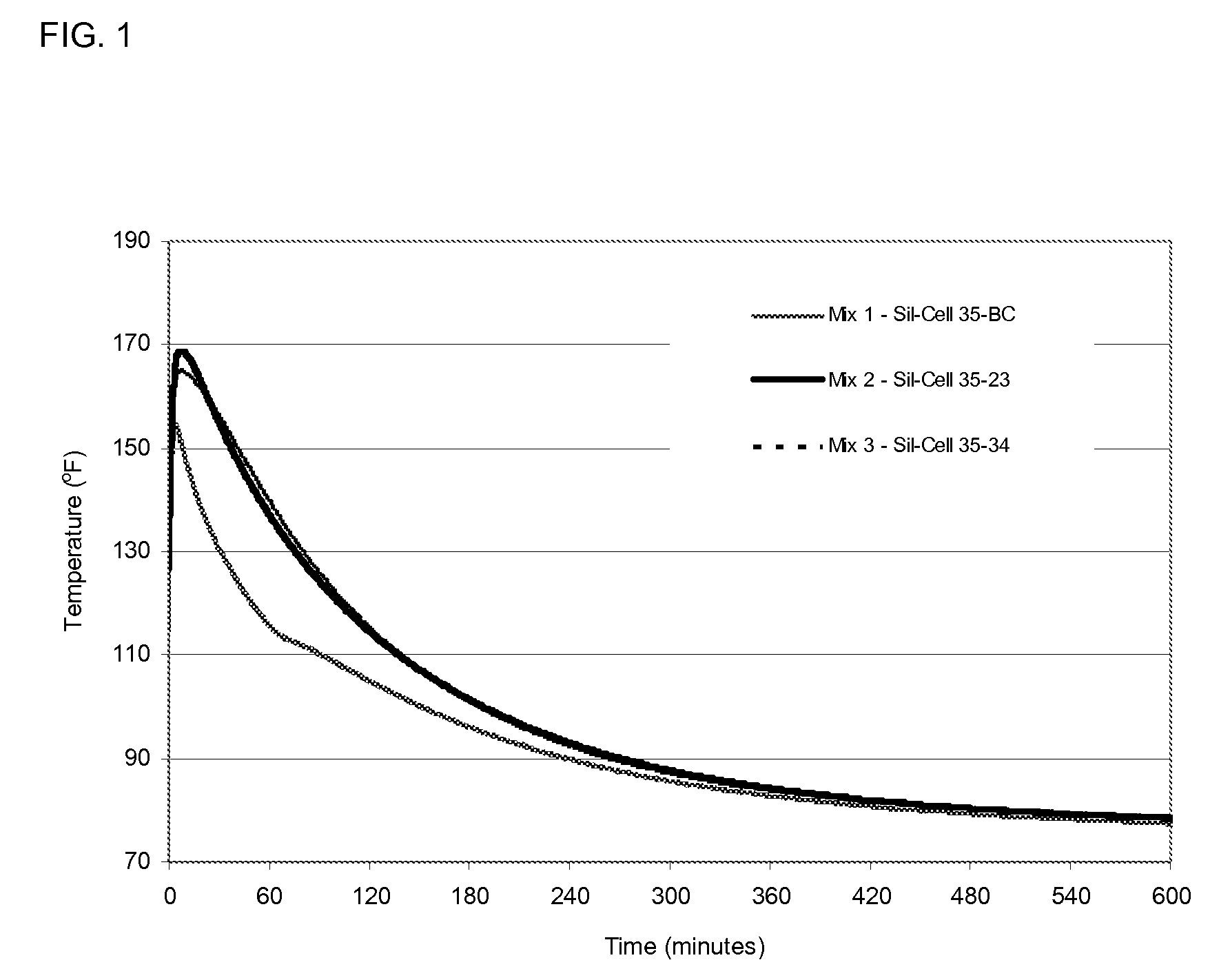

Cementitious compositions and methods for making same, in which the cementitious compositions include 35-60 wt. % cementitious reactive powder (also termed Portland cement-based binder), 2-10 wt. % expanded and chemically coated perlite filler, 20-40 wt. % water, entrained air, and optional additives such as water reducing agents, chemical set-accelerators, and chemical set-retarders. In addition, the lightweight cementitious compositions may contain 0-25 wt. % on a wet basis secondary fillers such as expanded clay, shale aggregate, and pumice.

Owner:UNITED STATES GYPSUM CO

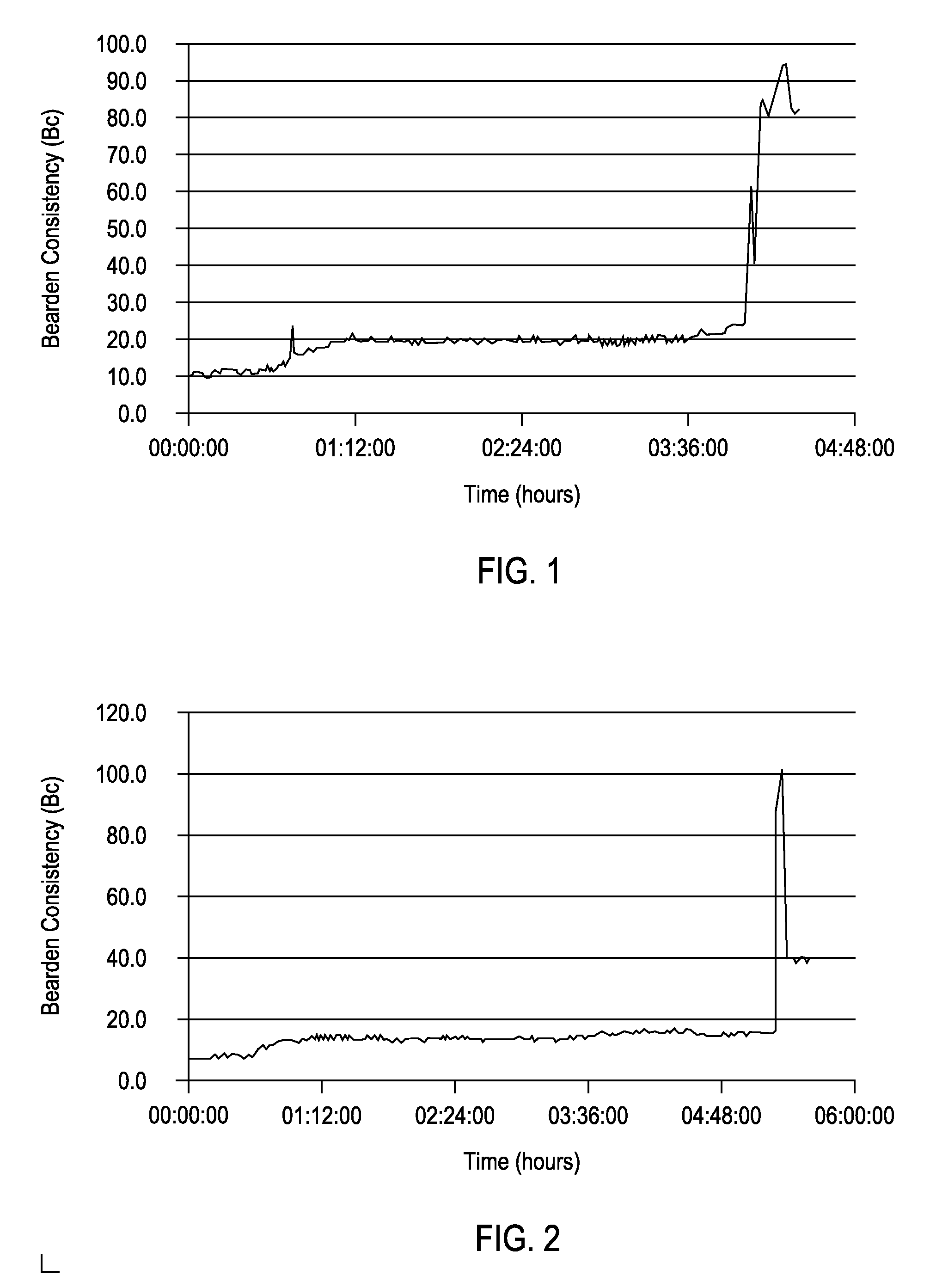

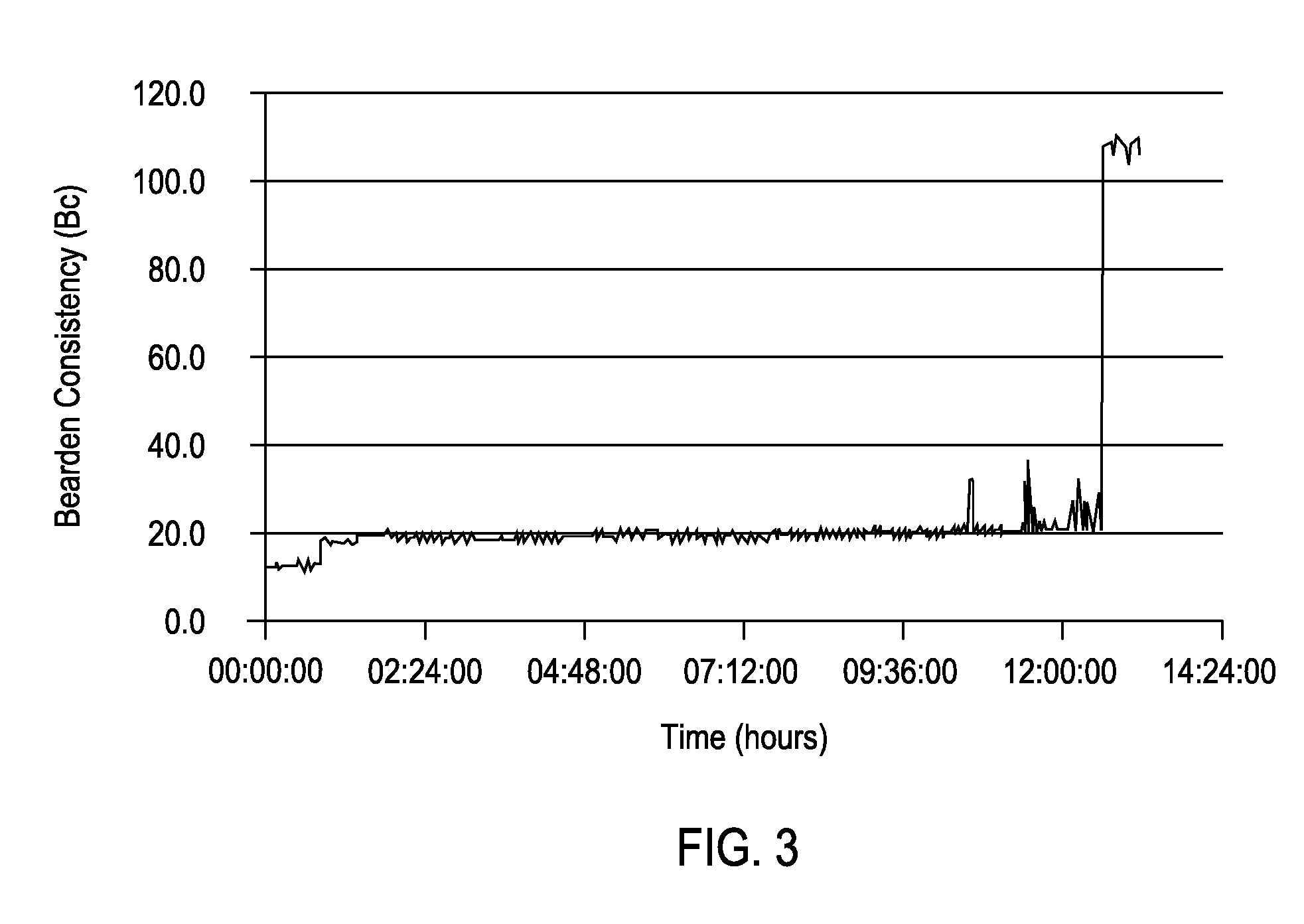

Cementing compositions and application of such compositions to cementing oil wells or the like

InactiveUS6874578B1Improve mechanical propertiesReduce penetrationFluid removalDrilling compositionPolymer sciencePortland cement

Method of well cementing with a foamed slurry having a very low water content. When based on ordinary cement, the solid fraction of the slurry includes (by volume) 20-35% Portland cement, 35-65% particles ranging from 200 μm to 600 μm, and 5% to 25% of fine particles in the range 0.5 μm to 5 μm and the water content is less than 50% by volume. When based on micro-cement, the solid fraction includes (by volume) 50-75% micro-cement, 15-40% fine particles in the range 0.5 μm to 5 μm, and 0-20% particles in the rang 3 nanometers to 60 nanometers and the water content is less than 72% by volume.

Owner:SCHLUMBERGER TECH CORP

Methods of cementing in subterranean formations using cement kiln dust in compositions having reduced Portland cement content

The present invention includes methods of cementing in subterranean formations using cement kiln dust in compositions having reduced Portland cement content. An embodiment of a method comprises placing a sealant composition that comprises cement kiln dust and is essentially free of Portland cement in a subterranean formation; and allowing the sealant composition to set.

Owner:HALLIBURTON ENERGY SERVICES INC

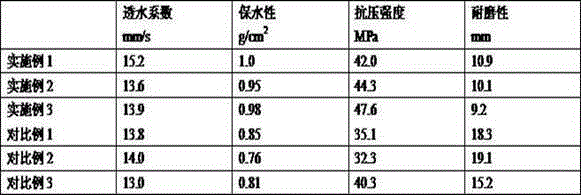

Corrosion resistant water permeable brick

ActiveCN105016765AHigh permeability coefficientHigh compressive strengthCeramicwareCompressive resistanceBrick

The present invention relates to a corrosion resistant water permeable brick, and belongs to the technical field of building materials. The corrosion corrosion resistant water permeable brick comprises 20-25wt% of Portland cement, 1.0-1.2wt% of anhydrite powder, 15.0-20.0wt% of slag pellets, 10-12wt % of cenospheres, 1.5-2.1wt% of admixtures, and the balance of quartz sand. Under the premise that the porosity and water permeability coefficient of the corrosion resistant water permeable brick are significantly higher than that of a water permeable brick, the compressive strength of the corrosion resistant water permeable brick is still higher than that of the conventional water permeable brick, the corrosion resistant water permeable brick has good corrosion resistance, and service life is significantly increased.

Owner:江苏溧阳建设集团有限公司

Composition of materials for use in cellular lightweight concrete and methods thereof

InactiveUS6488762B1Economical and stableImprove mechanical propertiesSolid waste managementCeramicwarePortland cementMaterials science

A more economical and light-color cellular concrete is provided by the replacement of Portland cement with ground glass powder in a cellular lightweight concrete mixture and the resulting method to make cellular concrete products. The use of ground glass also increases the stability of the cellular lightweight concrete mixture during the foaming or aeration process. The products are suitable for use in structural applications, insulation, and as a lightweight aggregate.

Owner:ADVANCED MATERIALS TECHNOLOGIES

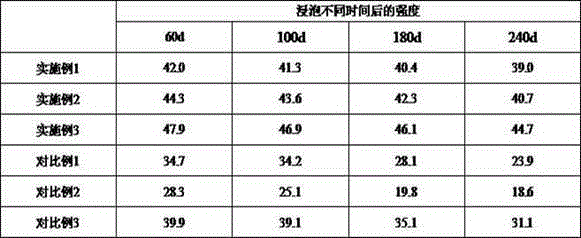

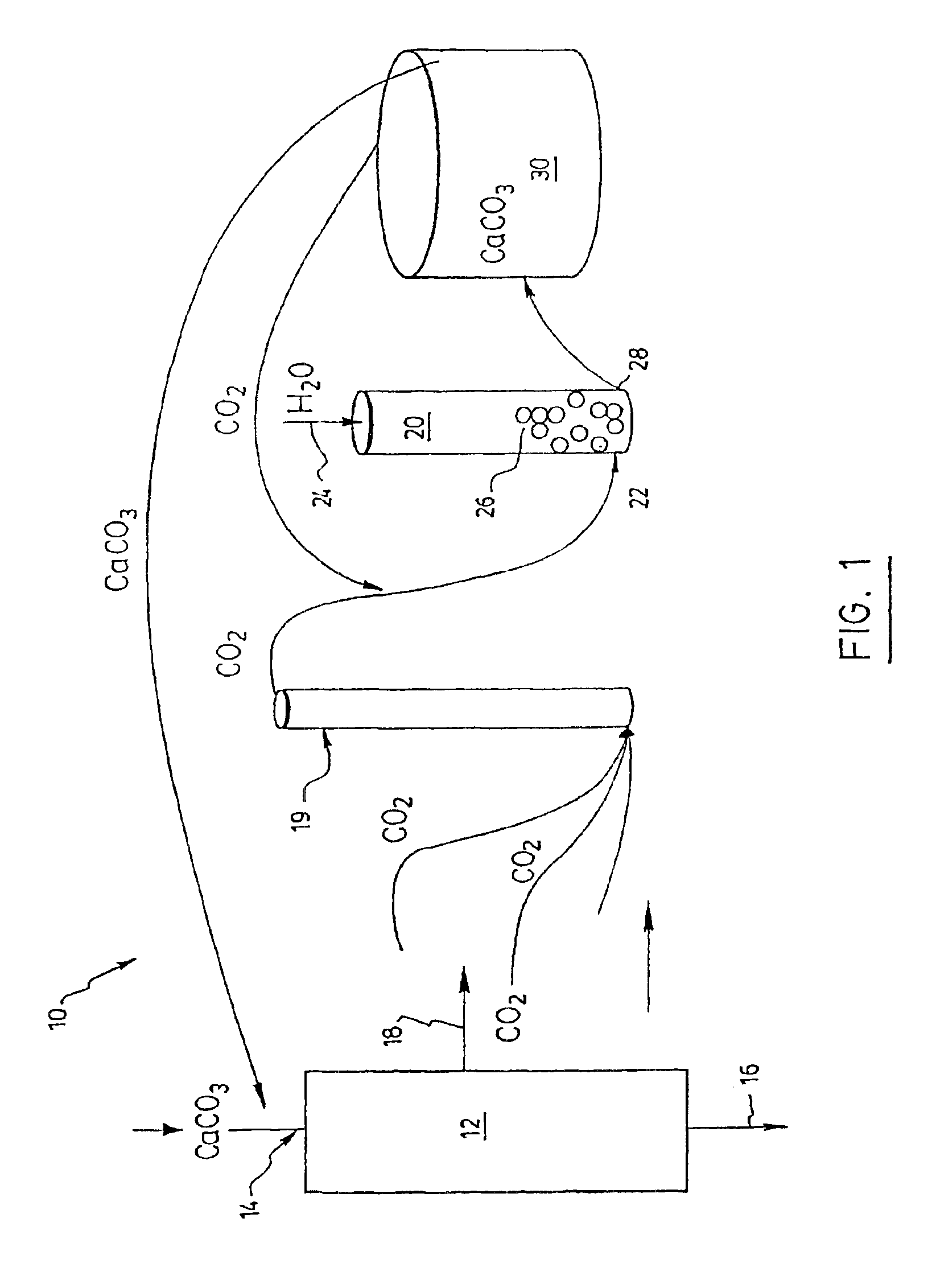

Process and a plant for the production of Portland cement clinker

InactiveUS6908507B2Emission reductionReduce carbon dioxide emissionsGas treatmentDispersed particle separationCalcium in biologyHydrogen

A process is disclosed for producing cement clinker, comprising the steps of: a) providing a mixture of ground calcareous materials and ground argillaceous materials; b) heating the mixture of step a) to a temperature sufficient to calcine and fuse the ground materials to form the cement clinker, and thereby producing an exhaust gas containing CO2; c) catalysing the hydration of at least a portion of the CO2 contained in the exhaust gas and producing a solution containing bicarbonate ions and hydrogen ions; and d) adding to the solution obtained in step c) metal ions, and adjusting the pH of the solution to precipitate a carbonate or said metal. Preferably, the metal ions are Ca++ obtained from the dissolution of a material selected from the group consisting of CaCl2, cement kiln dust and sea salts and the carbonate is CaCO3 which is advantageously recycled into the process by adding the CaCO3 to the mixture of step a). A cement plant for performing this process is also disclosed.

Owner:CO2 SOLUTION

Zeolite colored coating powder having air-purifying function

InactiveCN105272114ASolving difficult-to-disperse reunionsImprove the bactericidal effectPorosityPyrophosphate

The invention discloses zeolite colored coating powder having an air-purifying function. According to the technical scheme, the zeolite colored coating powder having the air-purifying function is characterized in that ingredients include attapulgite pottery clay powder having the air-purifying function, acidified zeolite particles, colored portland cement, Paris plaster, white carbon black, calcium chloride, aerosil, expanded perlite, nanometer silver-loaded antibacterial powder, nanometer titanium dioxide, sodium pyrophosphate and powder defoaming agents. The ingredients of the zeolite colored coating powder having the air-purifying function are input three times into a stirring machine to be stirred evenly and packaged into the finished product. By the adoption of the colored coating, in indoor wall decoration, an artistic emboss effect of various embossed three-dimensional colored patterns can be achieved through spraying and manufacturing, after spraying, a coating is hard, the porosity is high, the specific surface area is large, adhesion is strong, indoor formaldehyde, ammonia nitrogen, benzene and other harmful substances can be adsorbed and decomposed, and the functions of automatic humidification, mould prevention, sterilization, deodorization and air purification are achieved.

Owner:蒋文兰

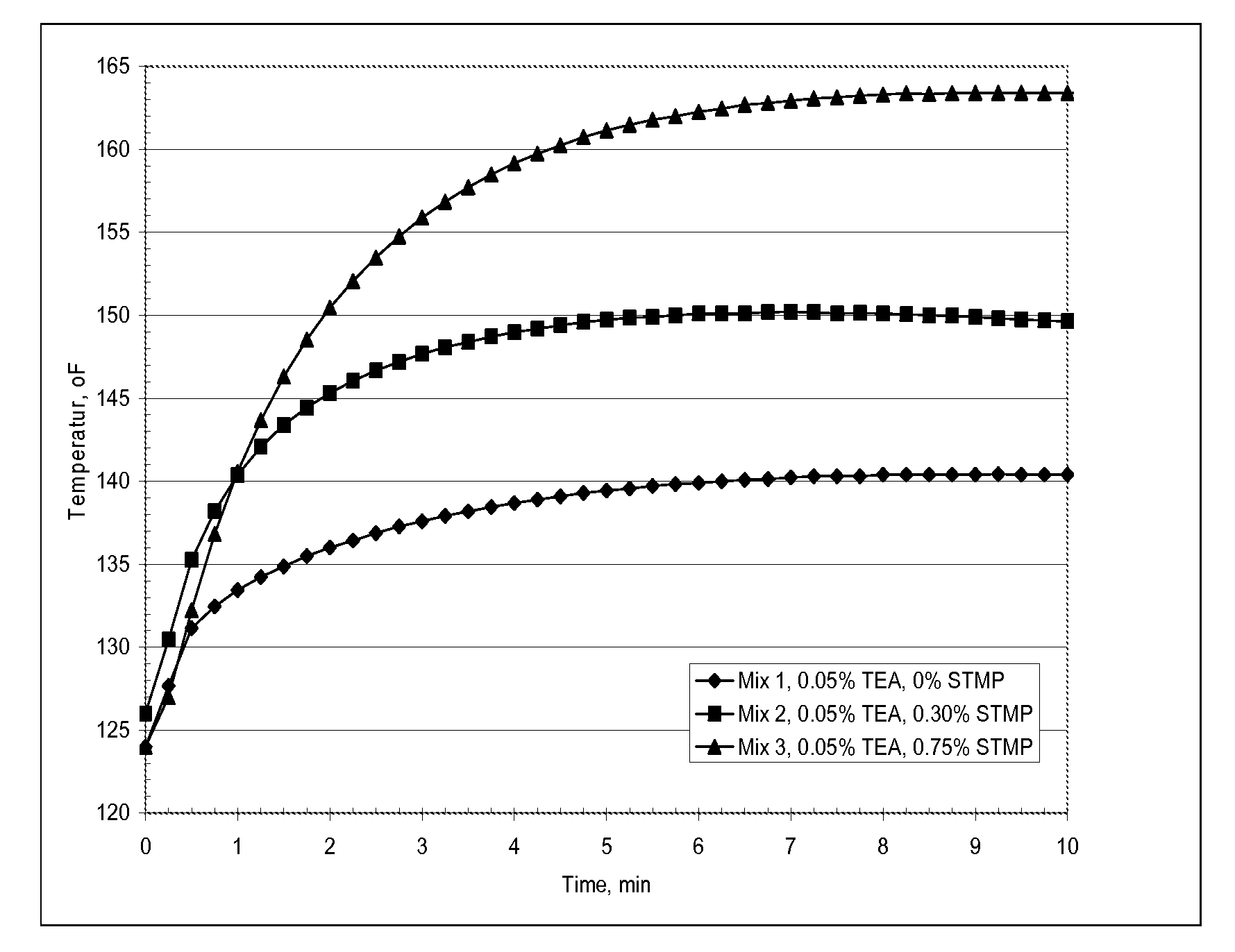

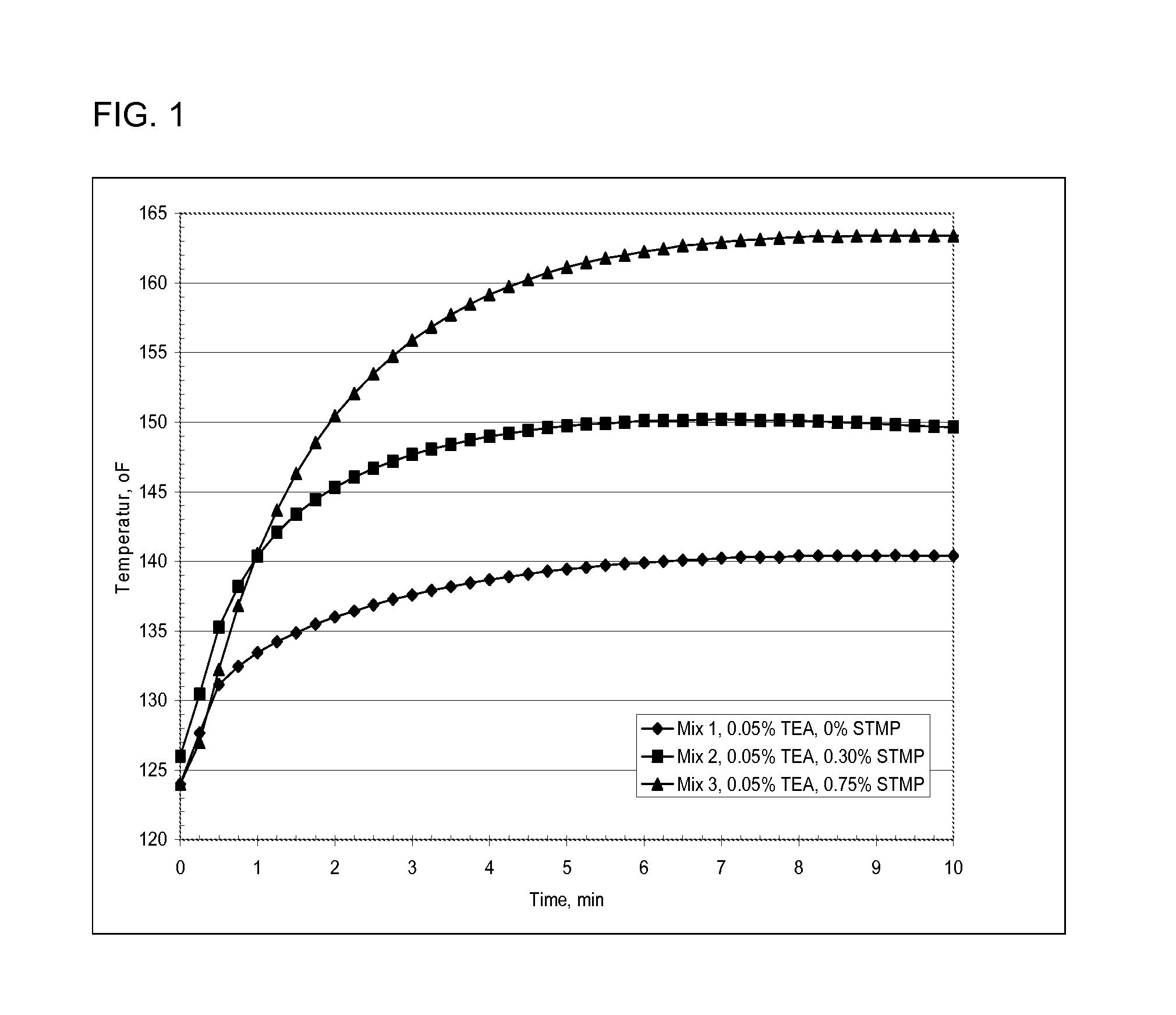

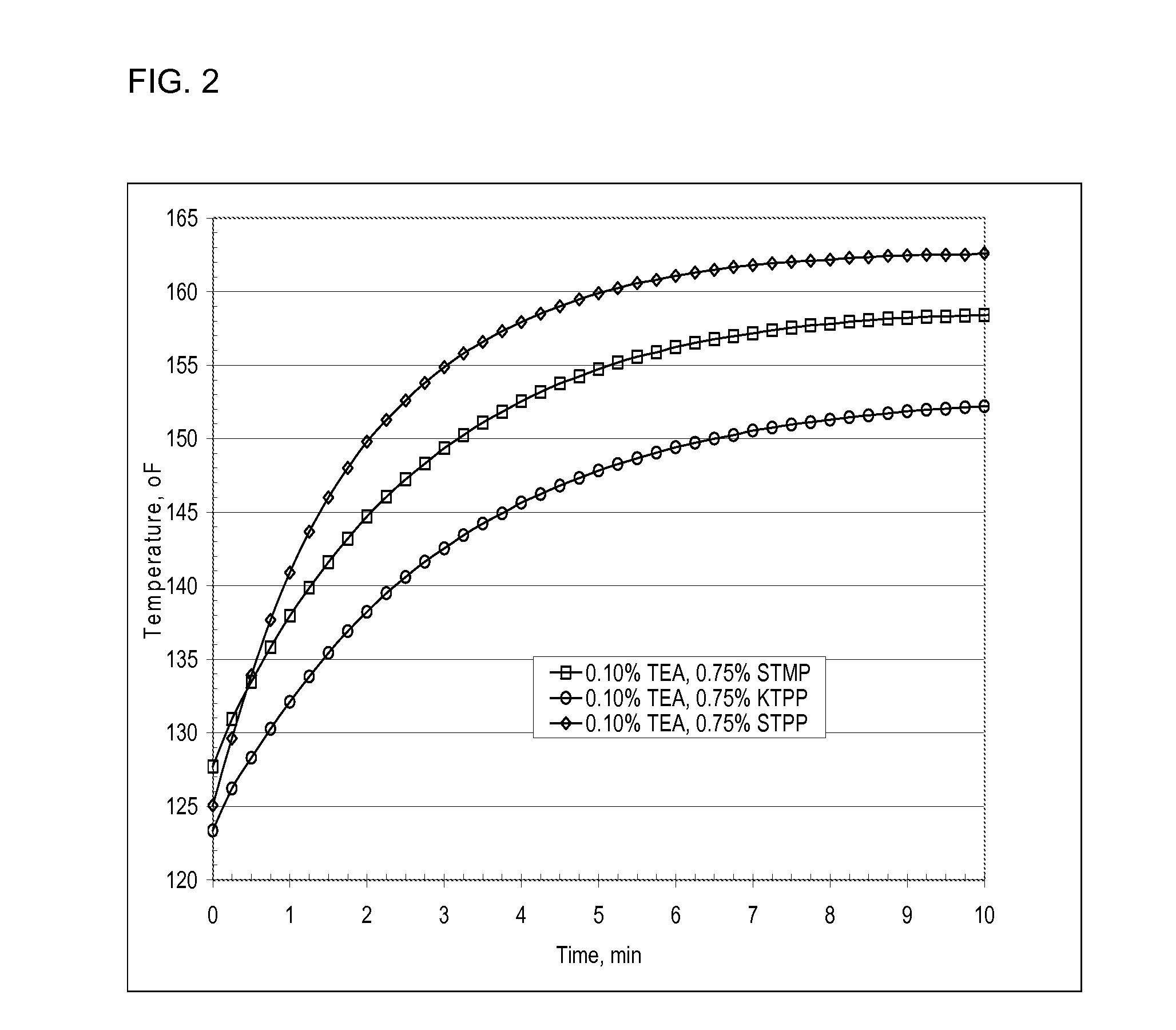

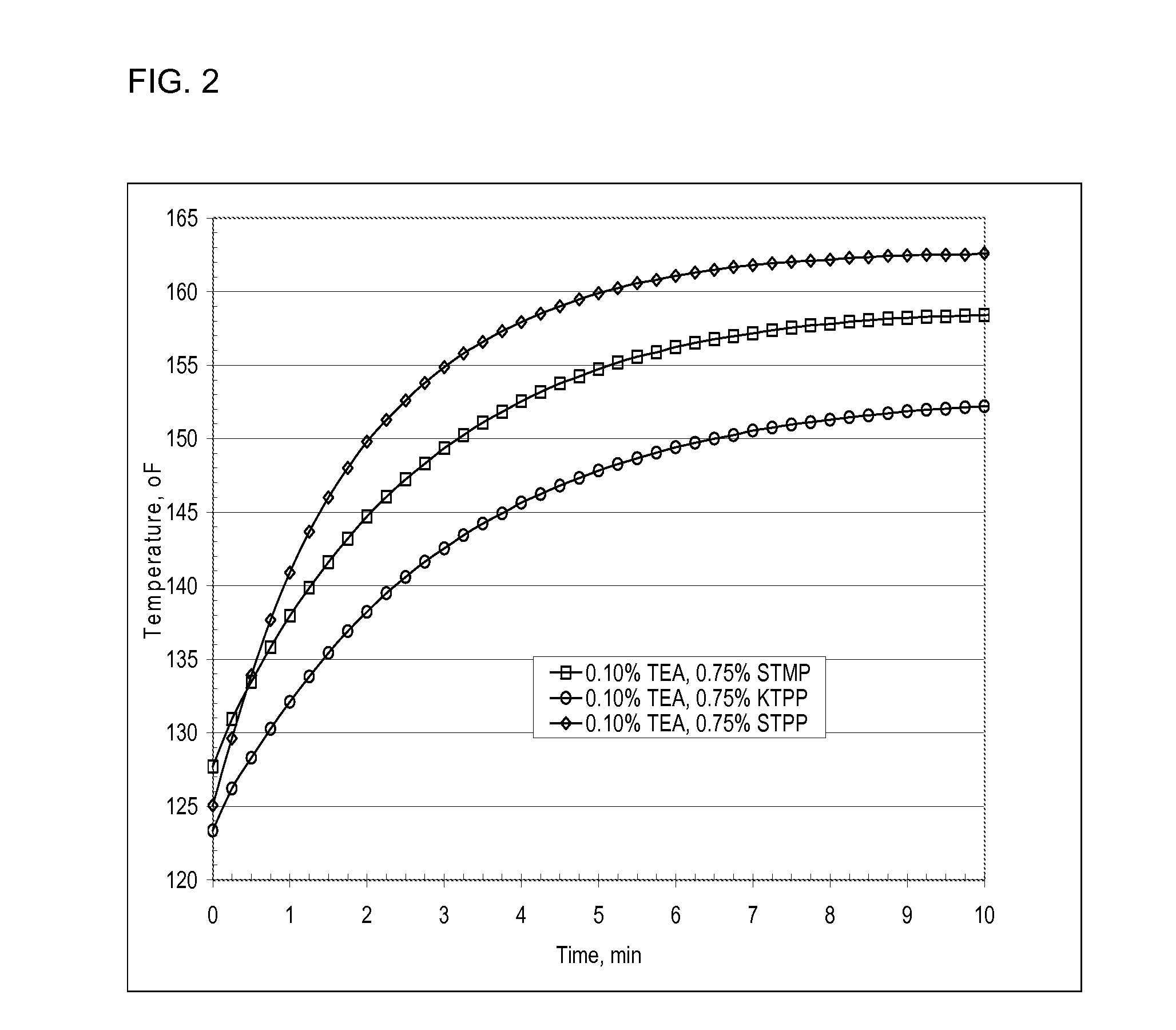

Very fast setting cementitious composition with high early-age compressive strength

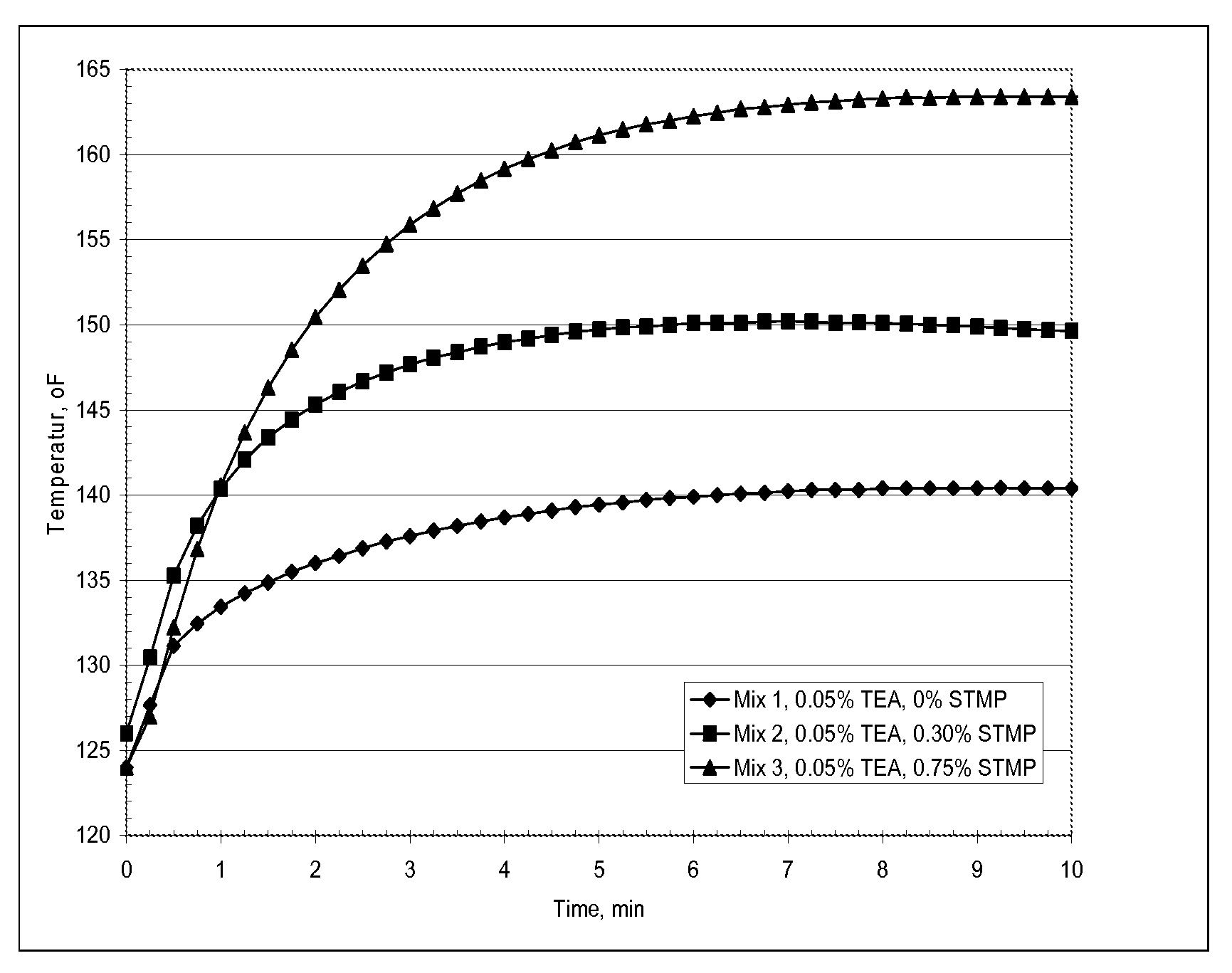

ActiveUS7670427B2Addressing slow performanceHigh compressive strengthSolid waste managementPortland cementCement board

A method of making a rapid setting composition for cement boards is disclosed. Compositions including portland cement, fly ash, gypsum, alkanolamine and phosphate are disclosed. A synergistic interaction between the alkanolamine and phosphate increases the effectiveness of accelerating reactions thus allowing for quick setting and increased early-age compressive strength compositions.

Owner:UNITED STATES GYPSUM CO

Cementitious Veneer and Laminate Material Incorporating Reinforcing Fibers

A cementitious veneer and laminate composition is provided. The cementitious laminate composition includes a substrate, a primer layer applied to the substrate, the primer layer comprising a mixture of polyvinyl alcohol catalyst, Portland cement, and sand; and a cementitious veneer layer applied to the primer layer, the cementitious veneer layer comprising a mixture of magnesium sulfate, filler, magnesium oxide, gypsum cement or bassanite, cellulose ethers, and polyvinyl alcohol catalyst. The polyvinyl alcohol catalyst comprises a mixture of polyvinyl alcohol fibers dissolved in water and mixed with butylene carbonate. The veneer layer is applied to the substrate and primer layer by means including spraying and manual spreading, and can be ornamentally manipulated either before or after curing of the veneer layer. The veneer composition can be formed into laminated tiles or panels for use in building applications.

Owner:ECOMELD CORP

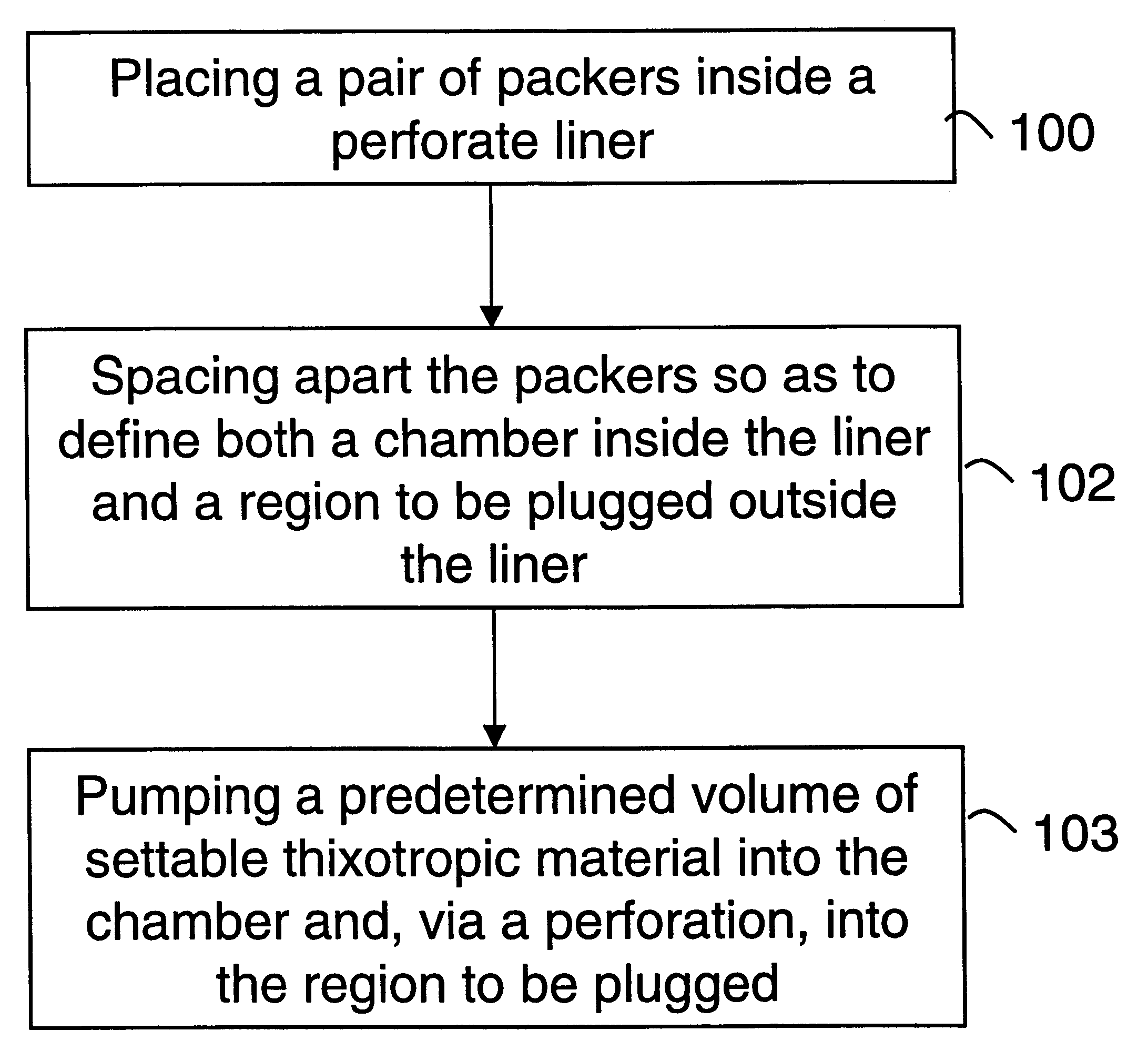

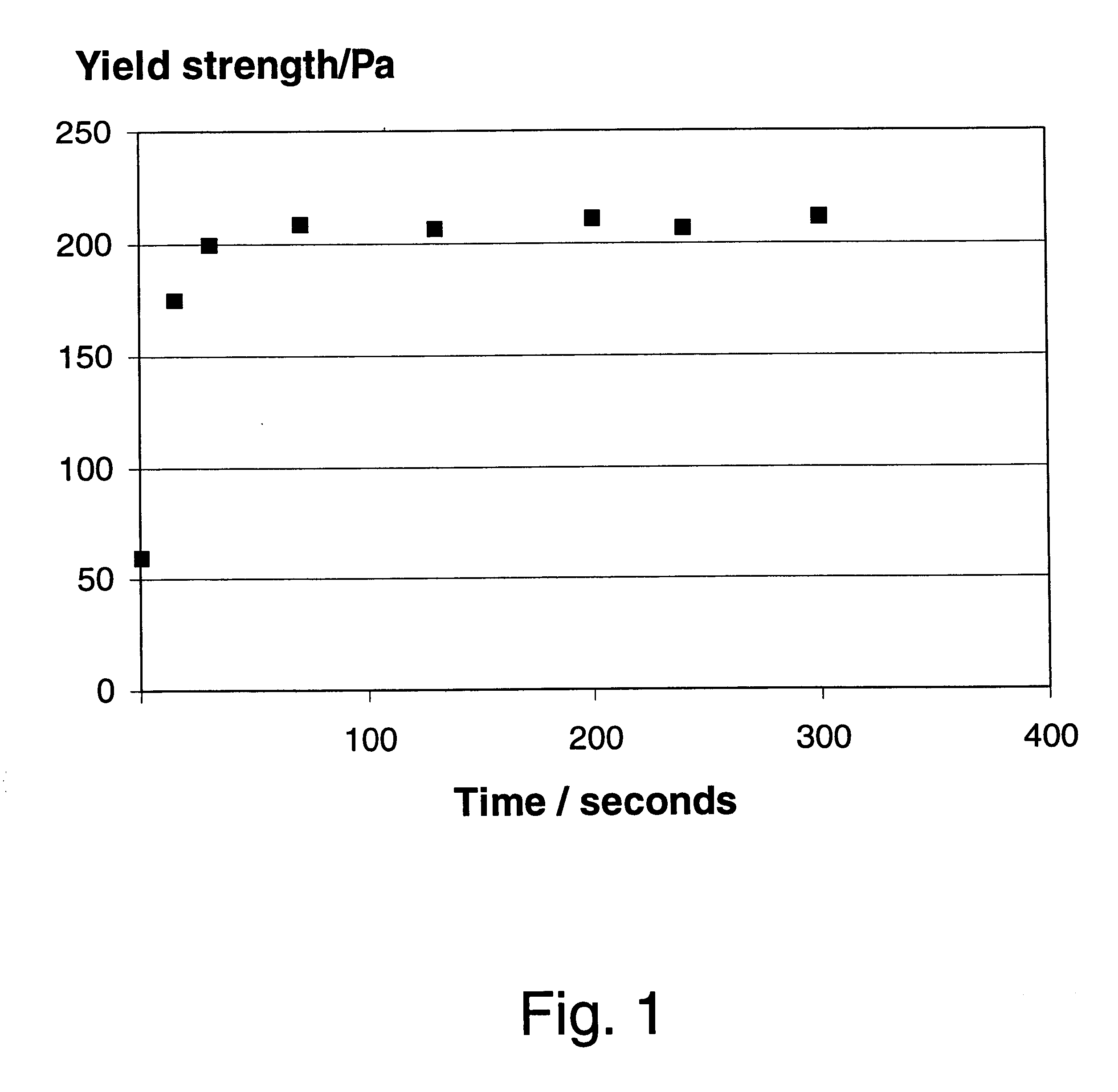

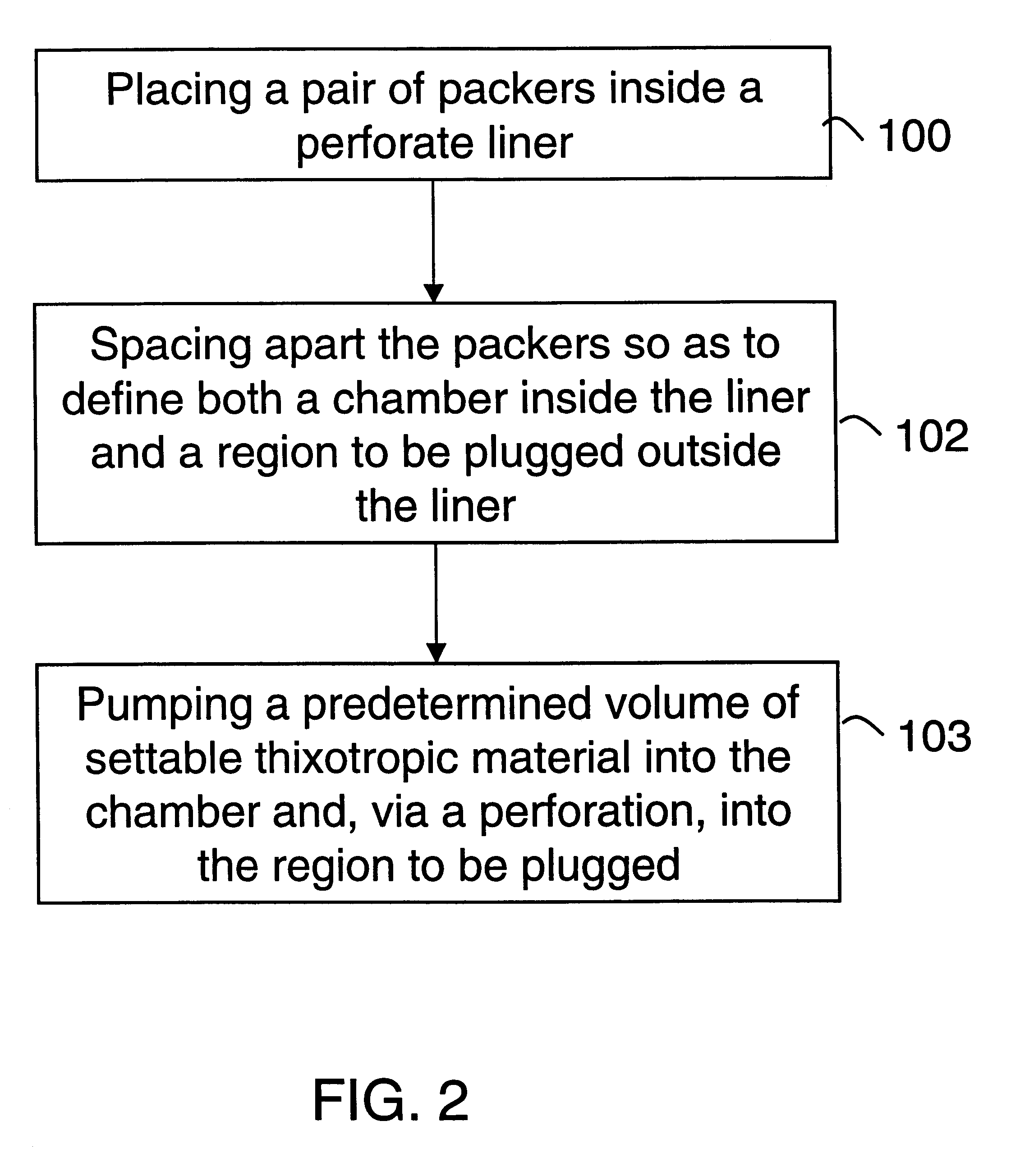

Thixotropic materials

A settable thixotropic material comprises a thixotrope and a settable substance, the material being capable of gelling reversibly in a gelling time of less than 60 seconds. The thixotrope conveniently comprises a fine grained clay, especially smectite clays, e.g. hectorites. It is preferred to use synthetic smectite type clay colloids, and goods results have been obtained with the synthetic clay known as Laponite RDS. The settable material conveniently comprises cement, particularly Portland cement. The thixotropic material finds use generally in oilwell applications, e.g. to plug lost circulation zones, to repair damaged or corroded casing, as grouts, and to limit annular gas migration. The material also finds particular application in techniques for completion of horizontal wells completed with slotted or pre-drilled liners.

Owner:SCHLUMBERGER TECH CORP

Cement Compositions and Methods of Using the Same

The present invention relates to cement compositions and their use in cementing operations. The cements comprise an aluminosilicate; a sodium aluminate, a calcium aluminate, a potassium aluminate, or a combination thereof; and water. In some cases the cement does not include Portland cement. The cement may be used in a subterranean formation having corrosive components therein, wherein the set cement sheath is resistant to degradation from the corrosive components within the subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

Low cost active powder concrete and preparation thereof

InactiveCN101486554ALow raw material costReduce maintenance costsSolid waste managementMixing operation control apparatusFiberSlag

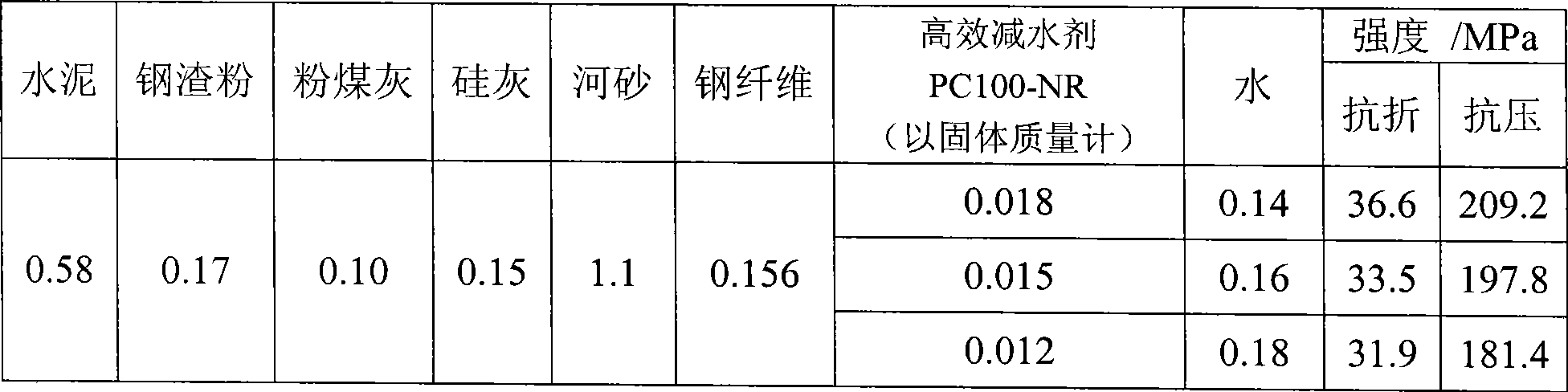

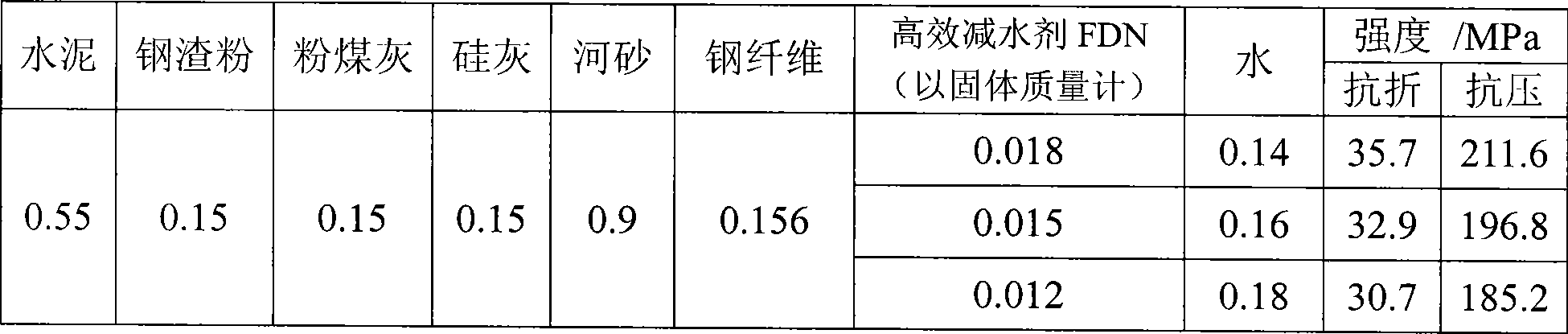

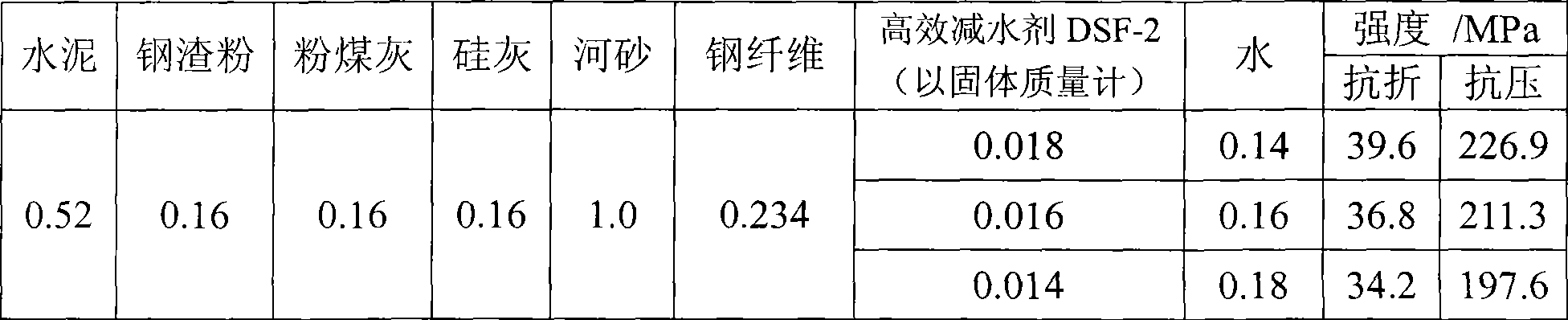

The invention discloses active powder concrete which is prepared by Portland cement, steel slag powder, fly ash, silicon ash, effective water reducing agent, river sand, mixing water and steel fiber with the mass ratios of 0.52 to 0.58 : 0.16 to 0.18 : 0.10 to 0.16 : 0.13 to 0.16 : 0.012 to 0.018 : 0.9 to 1.1 : 0.14 to 0.18 : 0.156 to 0.234. The preparation method thereof is as follows: each component is sequentially added into a stirring machine for being uniformly stirred and shaped; then after the components are maintained, the temperature is raised to 80 to 90 DEG C at the temperature rising speed of 15 to 20 DEG C / h and then constant temperature maintaining is carried out for 72 to 96h; then, the components are cooled to room temperature at the cooling speed of not more than 20 DEG C / h to obtain the active powder concrete product. The invention employs the industrial wastes like steel slag powder and fly ash to replace quartz powder, partial cement and silicon ash, and employs thin river sand to replace quartz sand to prepare the active powder concrete of 200 grade under the maintaining conditions of normal pressure below 100 DEG C, thus not only being capable of remarkably reducing the material cost and the shaping maintaining cost, but also playing important roles on saving resources and energies, protecting the environment and promoting sustainable development as a large amount of industrial waste slag is used.

Owner:WUHAN UNIV OF TECH

Ultrahigh-strength active powder concrete and preparation method thereof

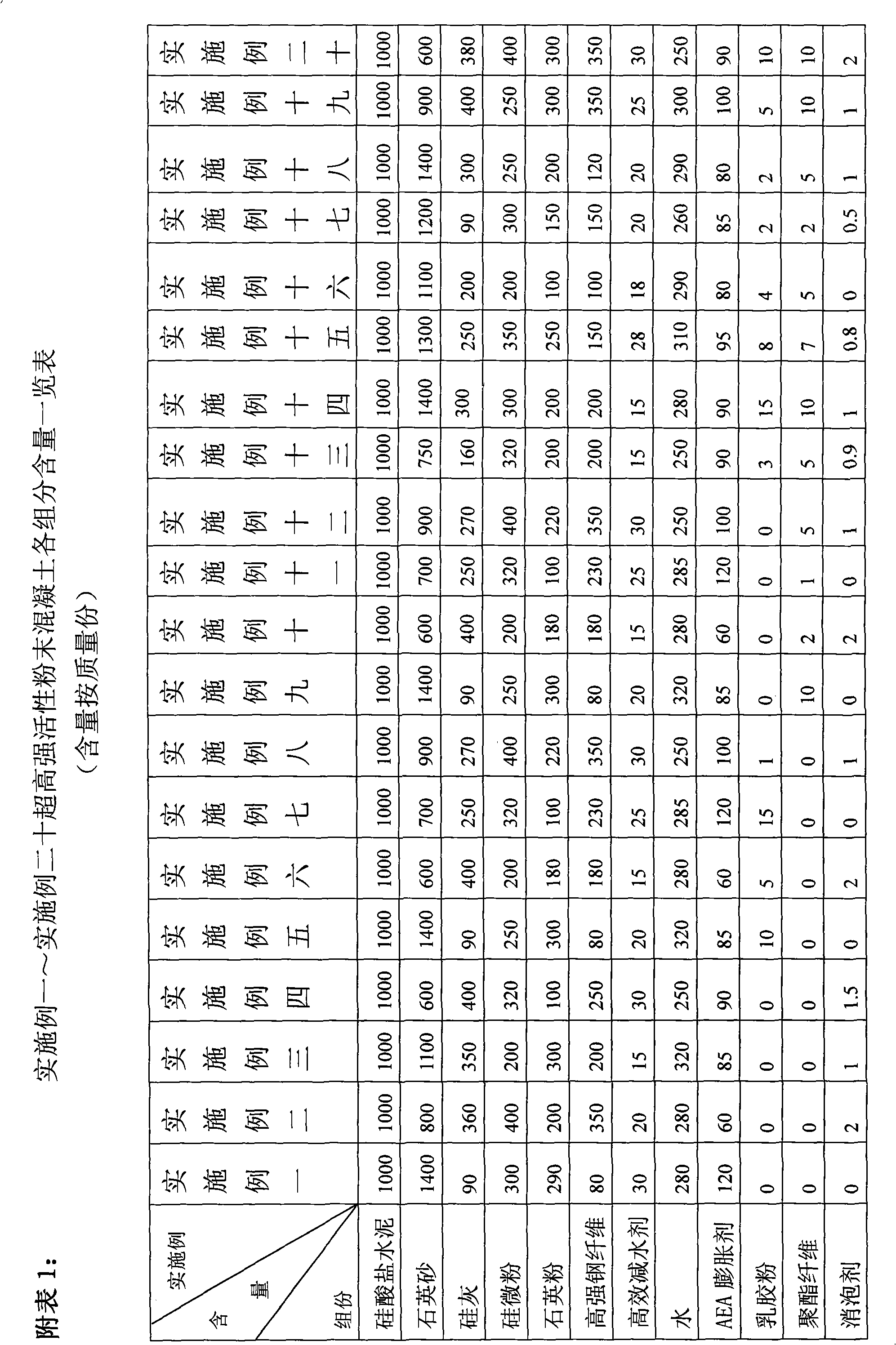

An ultrahigh-strength active powder concrete is a mixture prepared by mixing the following materials according to weight portion: 1000 portions of Portland cement, 600-1400 portions of quartz sand, 90-400 portions of siliceous dust, 200-400 portions of silicon powder, 100-300 portions of quartz powder, 80-350 portions of high-strength steel fiber, 15-30 portions of high-efficiency water reducing agent, 250-320 portions of water, 60-120 portions of AEA expanding agents, 0-15 portions of latex powder, 0-10 portions of polyester fiber and 0-2 portions of antifoam agents. The preparation method comprises the following steps: preparing the materials according to the weight proportion, firstly mixing water, cement, quartz sand, siliceous dust, silicon powder, quartz powder, AEA expanding agents, high-efficiency water reducing agent, latex powder, polyester fiber, and antifoam agents into pasty state; then adding high-strength steel fiber, and mixing for 4-6 minutes. The prepared active powder concrete has super-high compressive and bending strengths, high mechanical property and high durability.

Owner:LIUZHOU OVM MASCH CO LTD

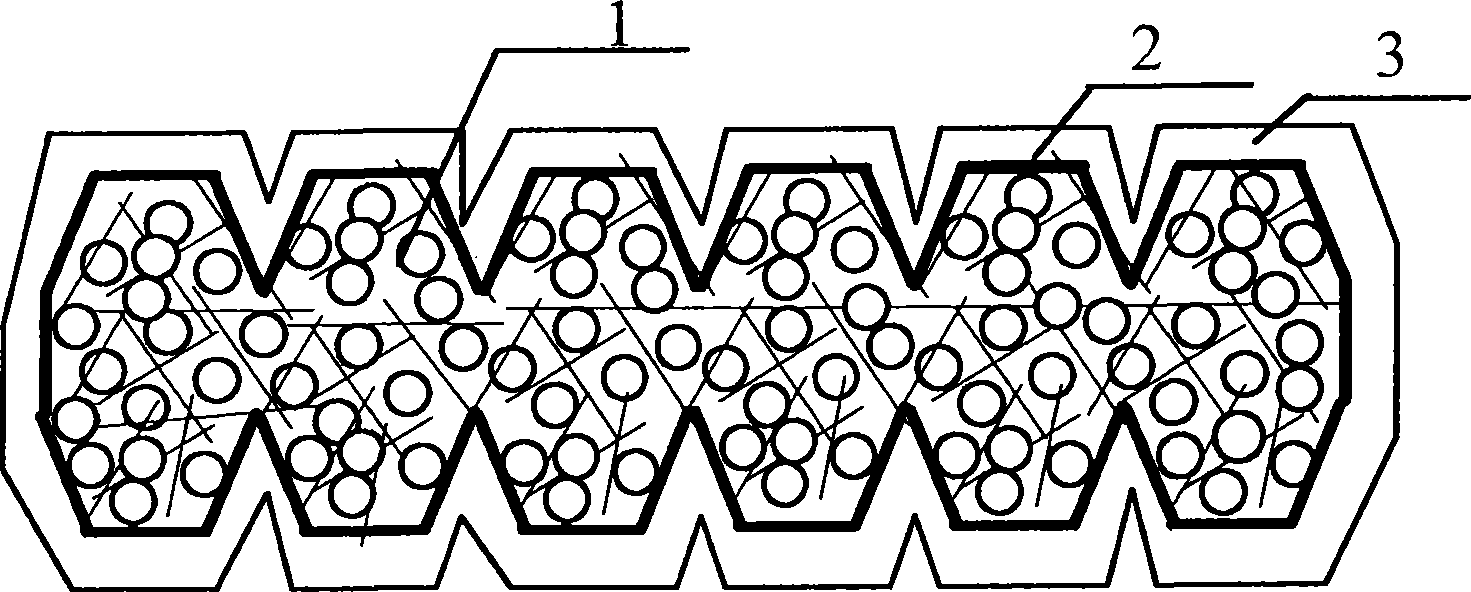

Concrete base sound absorption material for road sound screen and method of manufacturing the same

The invention relates to a cement-matrix sound-absorption material used in road noise barriers and a preparation method thereof; the sound-absorption material is a noise barrier material which can be used in airports, high-speed railways, expressways, urban viaducts, subways and light rails; the components and weight ratios are as follows: 15.4 to 62.3 percent of Portland cement, 0.1 to 15.7 percent of mineral admixture, 18.9 to 79.9 percent of lightweight porous aggregate, 0.013 to 0.078 percent of foaming agents, 0.1 to 0.7 percent of water reducing agent and 0.4 to 2.6 percent of fiber. The sound-absorption material and the preparation method thereof have the advantages of large sound absorption coefficient, high strength, good anti-impact performance, excellent durability, fire resistance, moisture resistance, anti-corrosion and self-clean function; at the same time, the sound-absorption material is wide in sources of raw materials, convenient in preparation and processing, suitable for large-scale production, low in cost, environment-friendly and good in decorativeness.

Owner:SOUTHEAST UNIV +1

Expanding material for cast-in-situ hollow building roof component

InactiveCN101456716AReduce dosageCorrosion resistanceSolid waste managementCeramicwareAluminateCrack resistance

The invention relates to an expansion material for a cast-in-situ hollow floor member, which comprises 4 to 15 percent of sulphoaluminate cement or ferro-aluminate cement, 50 to 65 percent of Portland cement, 18 to 35 percent of fly ash, and 2 to 10 percent of modifying agent (weight percentage). The invention adopts the sulphoaluminate cement or the ferro-aluminate cement to be mixed with the Portland cement to ensure that the expansion material has good performances of light mass, high strength, corrosion resistance, thermal insulation and so on, and then is matched with other modifying agents to ensure that the expansion material can save the using amount of the cement and ensure that a floor system has the advantages of high strength, permeation resistance, freezing resistance, cracking resistance, friction resistance, ultraviolet irradiation resistance, tensile resistance, compression resistance, shock resistance, and good sound insulation effect when reducing the weight of the floor system.

Owner:HUNAN BDF ENERGY SAVING TECH

Very fast setting cementitious composition with high early-age compressive strength

ActiveUS20080302276A1Addressing slow performanceHigh compressive strengthSolid waste managementPortland cementCement board

A method of making a rapid setting composition for cement boards is disclosed. Compositions including portland cement, fly ash, gypsum, alkanolamine and phosphate are disclosed. A synergistic interaction between the alkanolamine and phosphate increases the effectiveness of accelerating reactions thus allowing for quick setting and increased early-age compressive strength compositions.

Owner:UNITED STATES GYPSUM CO

Cement-base dual-liquid slip-casting material

The invention relates to a kind of pair-slurry affusing material prepared with cement as basic raw material. It is comprised of two kinds of dry powdery mixed materials A and B of affusing slurry pair-liquid formed after adding water. Their weight percents are respectively: mixed material A: sulfur aluminate cement 30% - 98.1%, retarder citric acid 0.1% - 0.5%, flocculant polyacrylamide 0% - 0.8%, water-reducing agent FDN 0.6% - 1.5% and inorganic padding pulverized coal ash 0% - 69.1%; mixed material B: Portland cement 20% - 88%, land plaster 6% - 15%, flocculant UWN 0% - 0.7%, accelerator lithium carbonate 0.4% - 1.0%, water-reducing agent FDN 0.5% - 1.3%, calcareousness 2.0% - 5.0% and inorganic padding pulverized coal ash 0% - 70.8%.

Owner:张振秋

Manufacturing method of aerated concrete

ActiveCN101823864AIncreased durabilityExcellent mechanical propertiesSolid waste managementCeramicwareCalcium hydroxideFoaming agent

The invention discloses a manufacturing method of aerated concrete, which comprises the following steps of: preparing liquid feed liquid; precuring; mixing an amorphous silicon material and water to prepare amorphous silicon material slurry; then mixing the amorphous silicon material slurry, the liquid feed liquid, a crystalline silicon material, one of calcined lime or calcium hydroxide or lime milk, dihydrate gypsum or semi-hydrated gypsum, ordinary portland cement, feldspar materials, strength intensifier, calcined lime digestion regulator, bubble regulator, lubrication tackifier, water repellent, a foaming agent and water; stirring the mixture at the speed of between 800 and 1,500rpm for 3 to 7 minutes to prepare foam slurry; and performing standing curing and still kettle curing to prepare the aerated concrete. The product obtained by the manufacturing method has the characteristics of light weight, high strength, flame retardance, heat preservation, heat insulation, hydrophobic property, long service life, impact resistance, small shrinkage, and the like; moreover, the material sources are wide, and the products are simple and convenient to process and manufacture.

Owner:吴智深 +2

Cementing compositions containing substantially spherical zeolite

ActiveUS20050133222A1Improve flexural strengthReduce brittlenessDrilling compositionSealing/packingPortland cementNatrolite

A cementitious composition for cementing an oil or gas well and which exhibits, when cured, increased flexural strength and a flexural strength to compressive strength ratio between from about 0.29 to about 0.80, contains a hydraulically-active cementitious material, such as Portland cement, and substantially spherical zeolite. Representative zeolites include natrolite, heulandite, analcime, chabazite, stilbite, and clinoptilolite. The weight percent of zeolite in the cement composition is generally less than or equal to 15 percent. In practice, a well bore may be cemented by pumping the activated slurry and pumping it within the well bore to a pre-selected location and allowing it to solidify.

Owner:BAKER HUGHES INC

Lost circulation composition for fracture sealing

ActiveUS8739872B1Avoid loopsQuickly de-fluidizeSolid waste managementFluid removalSuspended particlesPortland cement

A lost circulation material and method for well treatment employing the material that is effective at sealing or plugging fractured zones and has utility over a wide range of temperatures, including high temperatures. The lost circulation material includes particulate material to quickly de-fluidize the fluid formulation, fibrous material to suspend particles in the slurrified form of the composition and increase the shear strength of the resultant seal, and non-Portland cement material for increasing the compressive strength.

Owner:HALLIBURTON ENERGY SERVICES INC

Rapid hardening hydraulic cement from subbituminous fly ash and products thereof

A rapid hardening hydraulic cement is provided that is made substantially exclusively from a subbituminous fly ash with no portland cement or other strengthening aid.

Owner:CEMEX

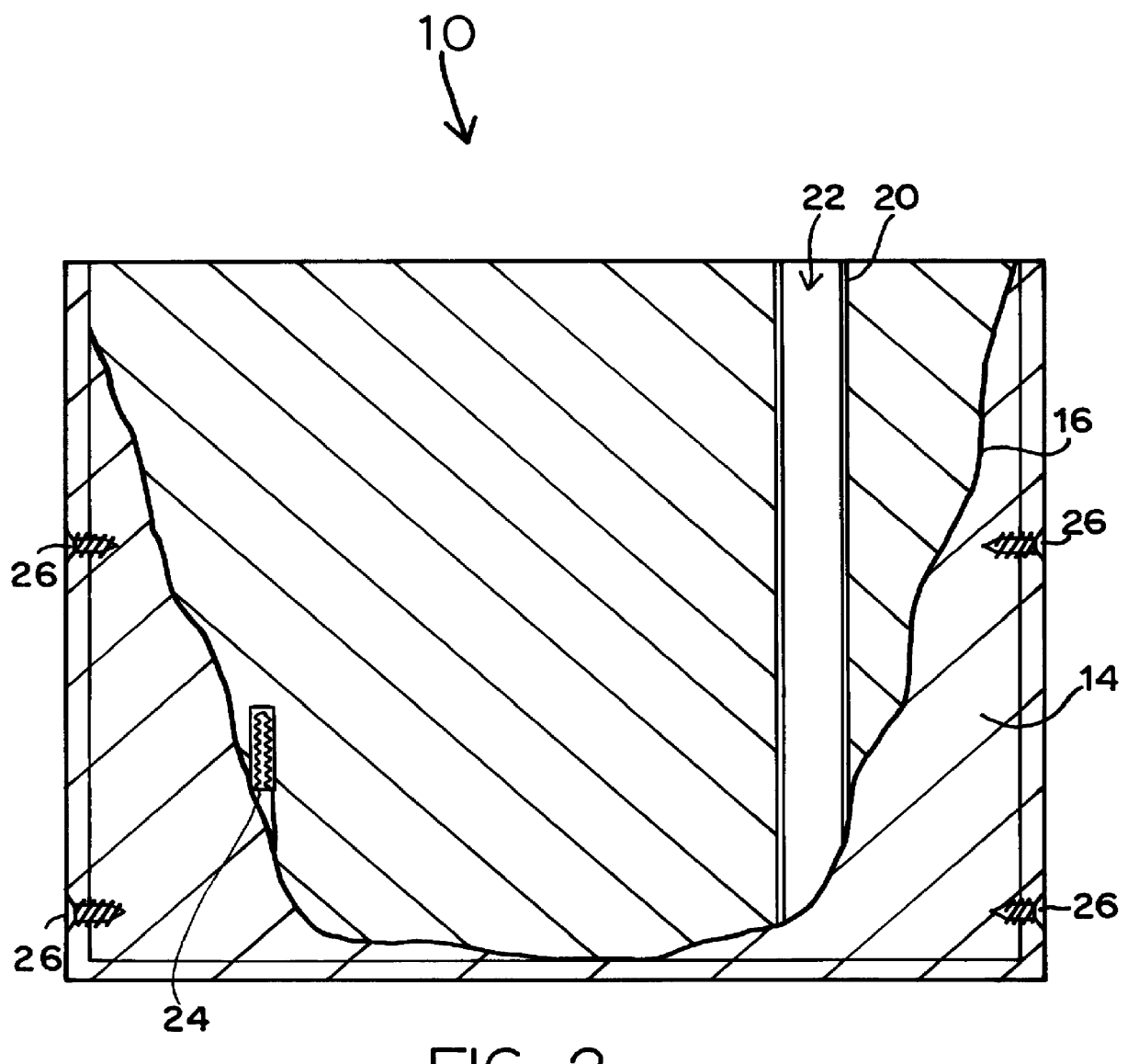

Simulated rock and method of making same

A simulated rock and a method of producing it, using Portland Cement, Bentonite or lime, polystyrene, and water. Ground polystyrene is mixed with cement, Bentonite or lime, and water, to form a settable cement formulation which is poured into removable forms. Reinforcing members are included in the mold, and a lifting hook is provided for later lifting and transporting of the resultant simulated rock. One or more base coats can be applied using a different formula, and a color coat can be applied. The method is use for making landscaping rocks, rock fountains, stone barbecues, light pillars, planters, room dividers, artificial masonry panels, and any structure which uses rocks or masonry.

Owner:CALLAHAN HARVEY J

Cement composition

A cement composition of an environmental impact reducing type, used in the field of civil engineering and construction, which provides initial strength-development equal to that of ordinary Portland cement and which can reduce the clinker calcination amount, is provided. A cement composition containing Portland cement having a 3CaO.SiO2 content of at least 60% and a slowly cooled blast furnace slag powder, wherein the content of the slowly cooled blast furnace slag powder is from 10 to 50 parts per 100 parts of the cement composition.

Owner:DENKA CO LTD

Insulating dry powder mortar

InactiveCN101525226ALoose bulk densityLow thermal conductivitySolid waste managementFiberCrack resistance

The invention discloses insulating dry powder mortar which is made from portland cement, pulverized fuel ash and / or slag powder, organic polymer emulsion powder, flame-retardant polystyrene foam particles, thermal insulating aggregate, composite fiber, water resisting agent and admixture. The insulating dry powder mortar has the advantages of light volume weight, low thermal conductivity, comprehensive utilization of waste material, environmental protection, resource saving, cracking resistance, ageing resistance, strong cohesive force, favorable workability and construction performance, convenient use, waterproofness, permeation resistance, high compression strength, convenient storage and transportation, no environmental pollution, and the like and can be widely used for preserving heat in the internal wall and the external wall of a building and other special engineering.

Owner:CHANGSHA YUANPENG CHEM TECH

Lightweight cementitious compositions and building products and methods for making same

Cementitious compositions and methods for making same, in which the cementitious compositions include 35-60 wt. % cementitious reactive powder (also termed Portland cement-based binder), 2-10 wt. % expanded and chemically coated perlite filler, 20-40 wt. % water, entrained air, and optional additives such as water reducing agents, chemical set-accelerators, and chemical set-retarders. In addition, the lightweight cementitious compositions may contain 0-25 wt. % on a wet basis secondary fillers such as expanded clay, shale aggregate, and pumice.

Owner:UNITED STATES GYPSUM CO

Cement-based lightweight porous heat insulating material and preparation method thereof

The invention relates to a cement-based lightweight porous heat insulating material and a preparation method thereof. The material is prepared from portland cement or ordinary portland cement, water reducing agent, foam stabilizer, early strength agent, fiber, emulsion powder, water repellent, foaming agent and water according to a certain ratio. The weight ratio of cement, water reducing agent, foam stabilizer, early strength agent, fiber, emulsion powder, water repellent and foaming agent is 100:0.2-2.4:(0.1-3.)0:(1.0-4.0):(0.3-1.5):(0.1-5.0):(0.1-6.0):(3.0-8.0); and the water cement ratio is 0.45-0.55. The dry density of the LWFC material is 250-300kg / m<3>, the compressive strength is 0.5-1.0MPa, the heat conduction coefficient is 0.05-0.08W / m.k, the water absorption rate is 4-8%; the material can not deform and crack, is used as an inorganic incombustible lightweight heat insulating material and can replace the organic combustible heat insulating material represented by polystyrene foam; and the material can be used in the external wall exterior insulation construction of the building energy-efficient project and can also be used in the roof insulation project, the floor heating project or the occasions for preparing the composite heat insulating board and the like.

Owner:NANJING UNIV OF TECH

High-performance powder concrete for 3D (three-dimensional) printing

The invention relates to high-performance powder concrete for 3D (three-dimensional) printing. The concrete is prepared from the following raw materials in parts by weight: 500-900 parts of ordinary Portland cement, 250-350 parts of active mineral admixture, 800-1,300 parts of inert filler, 10-20 parts of composite efficient water reducing agent powder, 2-5 parts of thickener, 4-10 parts of self-curing agent, 2-10 parts of fast setting time regulator, 145-230 parts of water, 3 parts of organic fiber and 40-200 parts of copper plated fiber. The concrete material for 3D printing has the characteristics of ultrahigh strength and toughness, good durability, long full life cycle, high curing rate, good flowing property and easiness in pumping and lifting and is suitable for constructing 3D-printed building structural materials in all kinds of engineering.

Owner:黄贺明

Foam concrete block manufactured by chemical foaming and manufacture method thereof

The invention belongs to the field of application of building materials, and particularly discloses a foam concrete block manufactured by chemical foaming and a manufacture method thereof. The manufacture method comprises the following steps of: with ordinary portland cement, coal ash, superfine slag powder, silica fume, a composite additive, an accelerator, a reinforcing agent, a stabilizer, a water reducing agent, polypropylene fibers, a foaming agent and water serving as the raw materials; mixing all the raw materials, except the foaming agent; stirring at the first grade and the second grade to obtain uniform size; adding the foaming agent to the uniform size and stirring at the third grade quickly; quickly placing the material subjected to third grade stirring into a die; and naturally curing under a condition that the outside temperature is not less than zero. The foam concrete block is free of shrinkage and sinking, collapsing and deforming in the whole process from pouring to solidifying, can realize low density and low heat conductivity coefficient, is large, uniform and relatively independent in bubble, and has a good heat insulating effect.

Owner:菏泽景行电子材料有限公司

Thermal insulation building mortar and preparation process thereof

InactiveCN101759416AWith thermal insulationWith phase change energy storageCement mixing apparatusSodium BentoniteThermal insulation

The invention discloses a thermal insulation building mortar. The thermal insulation building mortar is prepared by the mixing portland cement, pulverized fuel ash, calcium bentonite, re-scattering glue powder, hypromellose, polyacrylamide powder, polypropylene fibre, wood fiber, permeating crystal waterproof agent, air entraining agent, vitrified micro-bead, sizing phase-change material and hollow glass bead. A preparation process thereof comprises the steps of: a) preparing the sizing phase-change material, b) preparing the permeating crystal waterproof agent and c) preparing the thermal insulation building mortar. The mortar of the invention is characterized by the functions of thermal insulation, phase-change energy storage, temperature control, water resistance and energy saving, the wide application scope and low cost. The mortar is widely applied in thermal insulation work inside or outside the buildings and has a broad prospect.

Owner:唐山市思远涂料有限公司

Heat resistant and fire retardant materials and methods for preparing same

InactiveUS8172938B2Increased durabilityHigh strengthFireproof paintsSolid waste managementWater basedFluoropolymer

A silica cement blend having an insulating, fire retarding and high temperature characteristic capable of withstanding temperatures ranging from ambient to greater than 40000 F without degradation of the concrete structure. In addition to its high temperature capabilities the blend can be produced as ultra light weight to heavy weight concrete. The silica based mixture when added to cementitious materials such as Portland cement, Class C Fly Ash, silica fume and other cementitious materials. Presented also are methods for reducing fire damage by coating interior / exterior walls, ceiling, and roofs of a building with a water based latex coating containing a fire retardant material and low heat conductivity silicas. Methods for painting internal / external walls, ceilings, and roof are also presented. This coating retains thermal blocking properties comprised of processed, expanded and / or finely milled, pyrogenic silicas and micro spheres in combination of but not limited to, one, two or more component water based polymer / copolymer latex binders and a water born fluoropolymer emulsion. The combined properties of these elements create a coating similar to paint with a high level of thermatic resistance which slows the composition break-down from fire, extreme temperatures, and restricts the thermal conductivity which helps to preserve the integrity of the substructure or underlying materials. The properties of this coating reduce or slow the potential of catastrophic fire by retarding flashover and protecting the under structure; which in turn assist fire fighters and rescue personnel by helping to retard the potential of a catastrophic fire.

Owner:SPECIALTY CONCRETE DESIGN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com