Patents

Literature

2219results about How to "Reduce brittleness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SiCOH dielectric

InactiveUS20070173071A1Improve cohesive strengthReduce brittlenessSemiconductor/solid-state device detailsSolid-state devicesDielectricDevice material

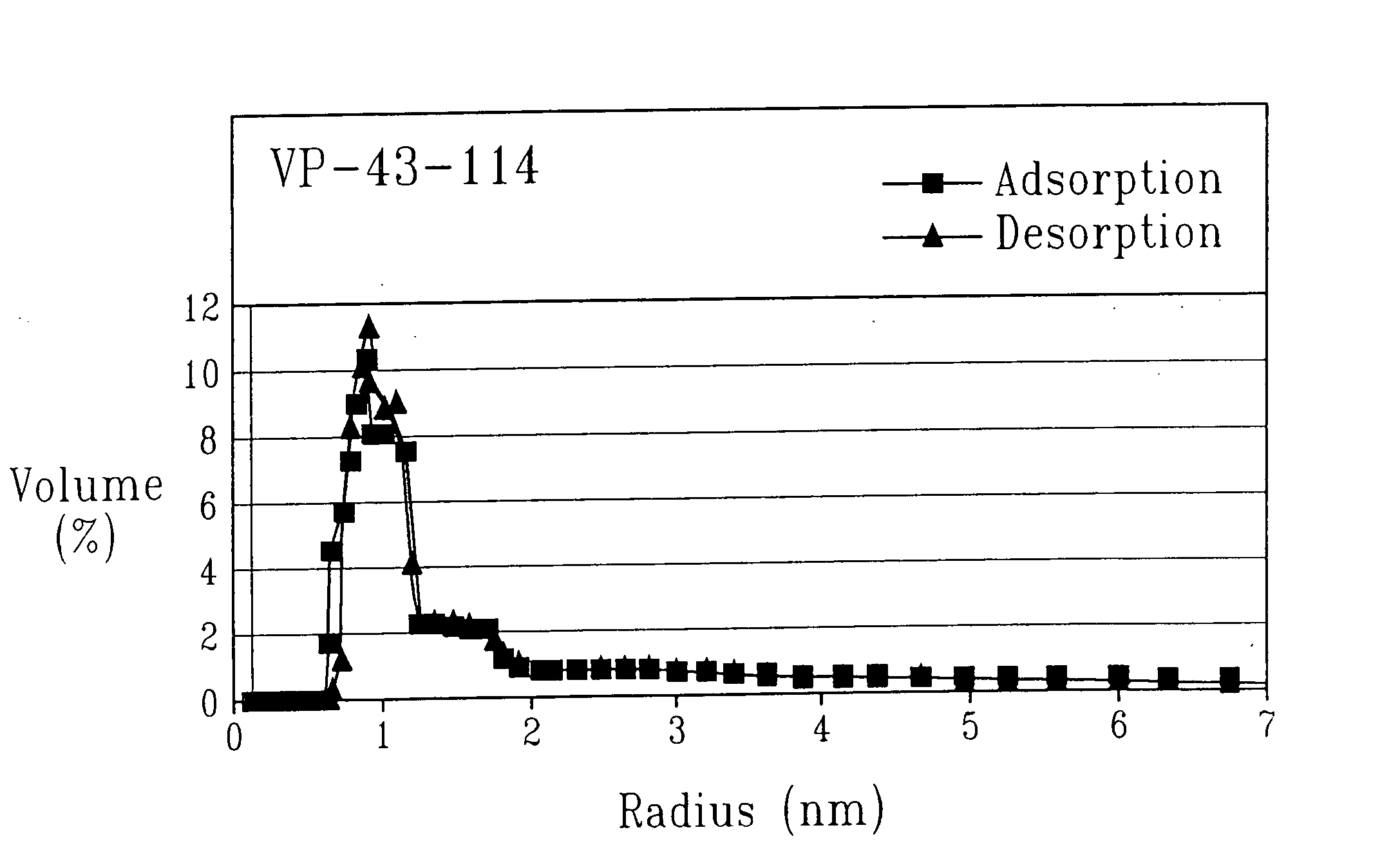

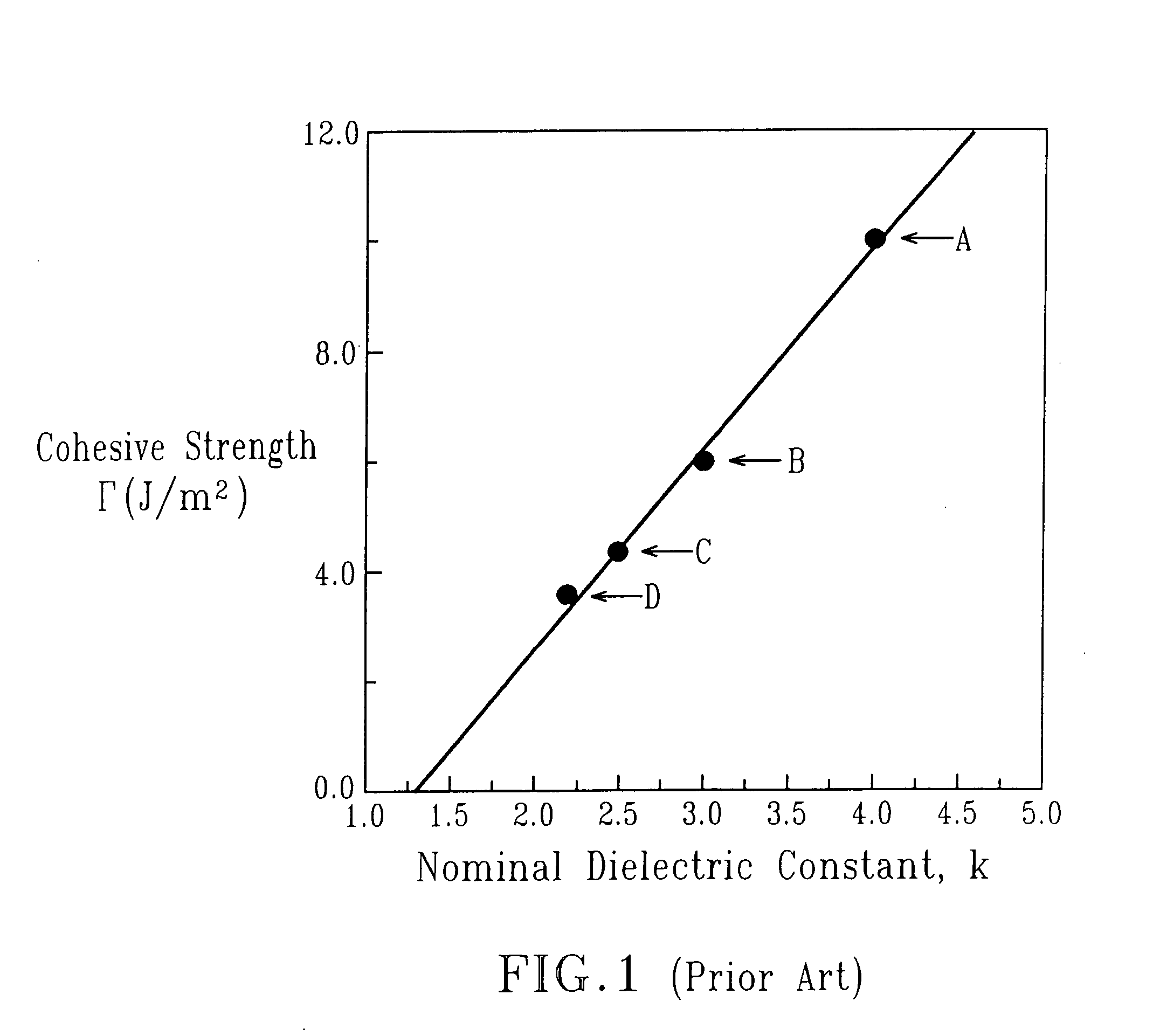

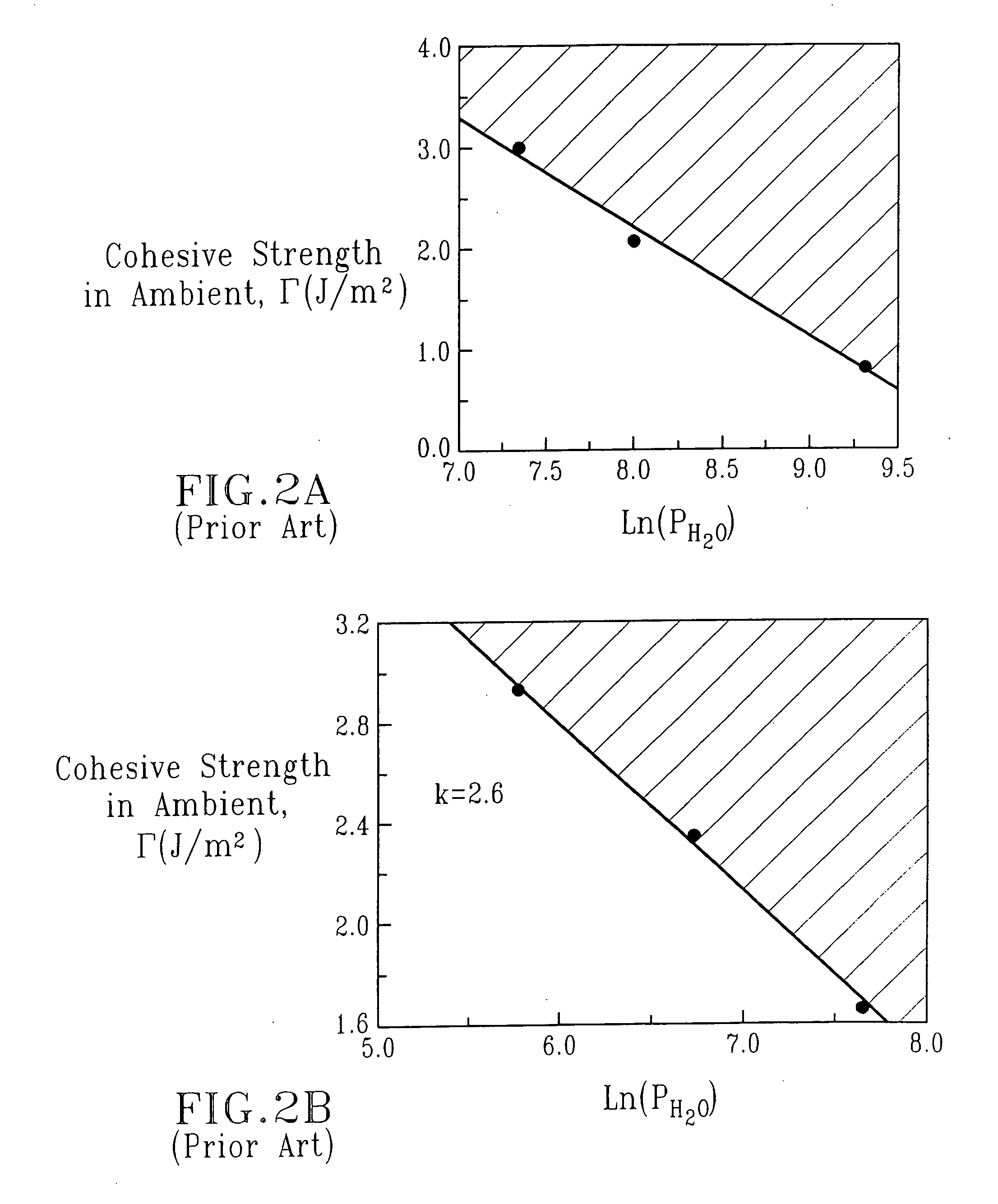

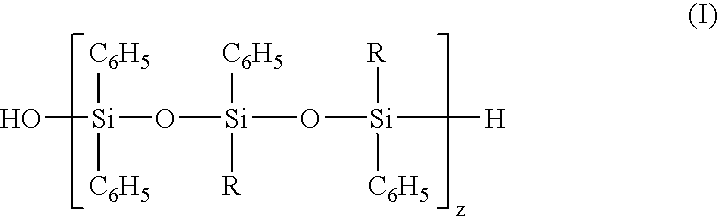

A porous composite material useful in semiconductor device manufacturing, in which the diameter (or characteristic dimension) of the pores and the pore size distribution (PSD) is controlled in a nanoscale manner and which exhibits improved cohesive strength (or equivalently, improved fracture toughness or reduced brittleness), and increased resistance to water degradation of properties such as stress-corrosion cracking, Cu ingress, and other critical properties is provided. The porous composite material is fabricating utilizing at least one bifunctional organic porogen as a precursor compound

Owner:INTEL CORP

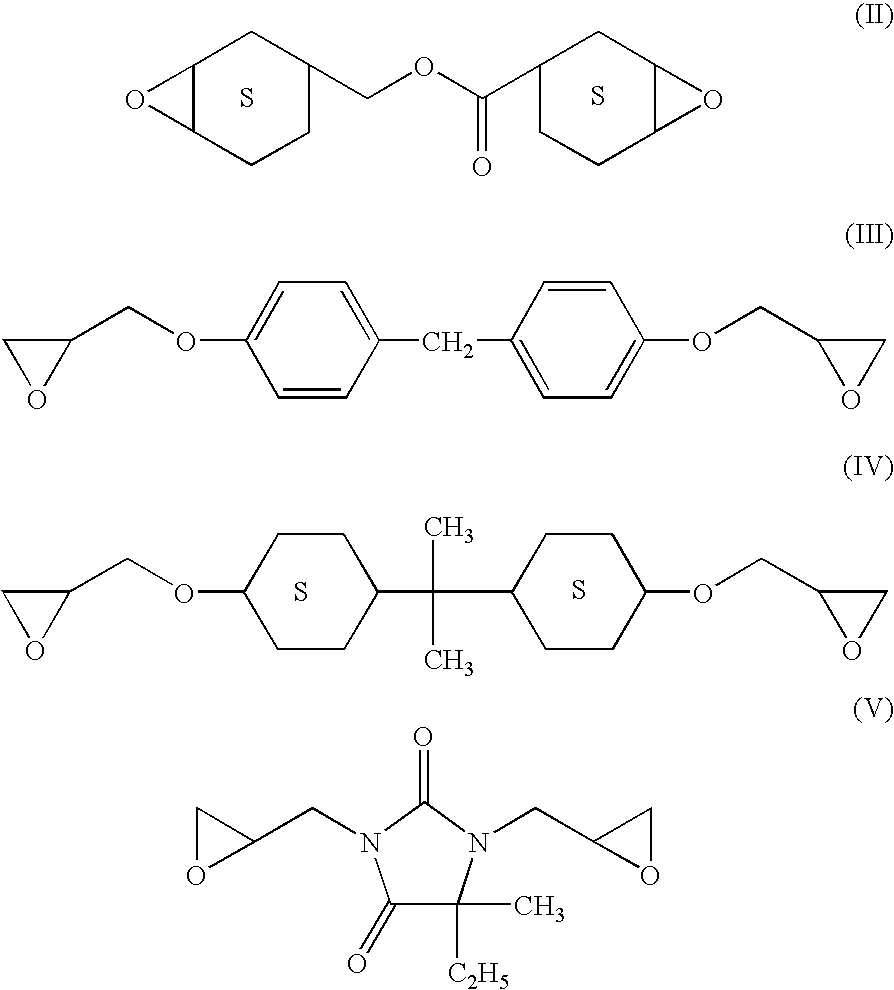

Epoxy resin compositions, solid state devices encapsulated therewith and method

InactiveUS6800373B2Reduce discolorationReduce brittlenessSemiconductor/solid-state device detailsSynthetic resin layered productsEpoxySealant

Owner:GENERAL ELECTRIC CO

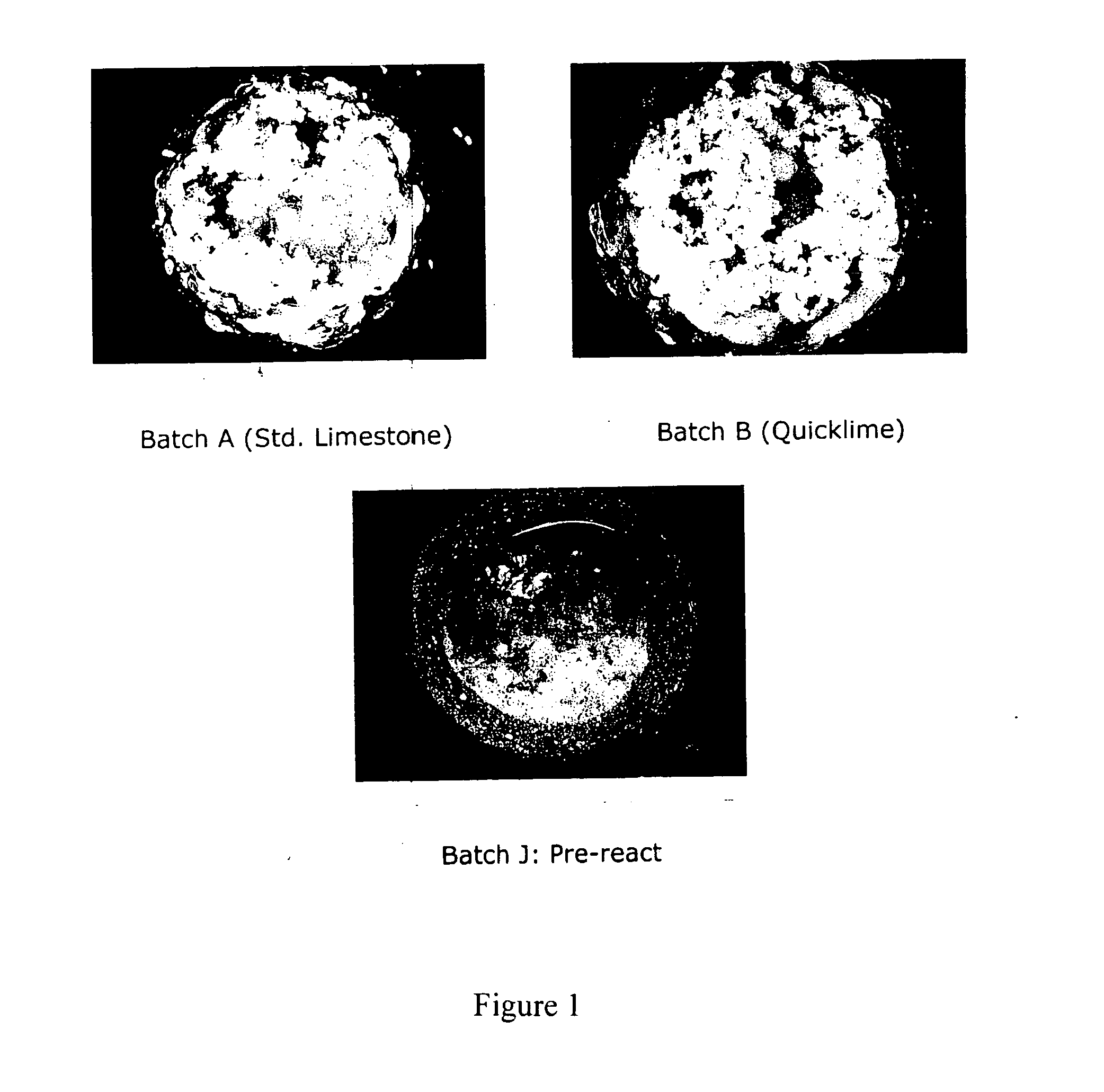

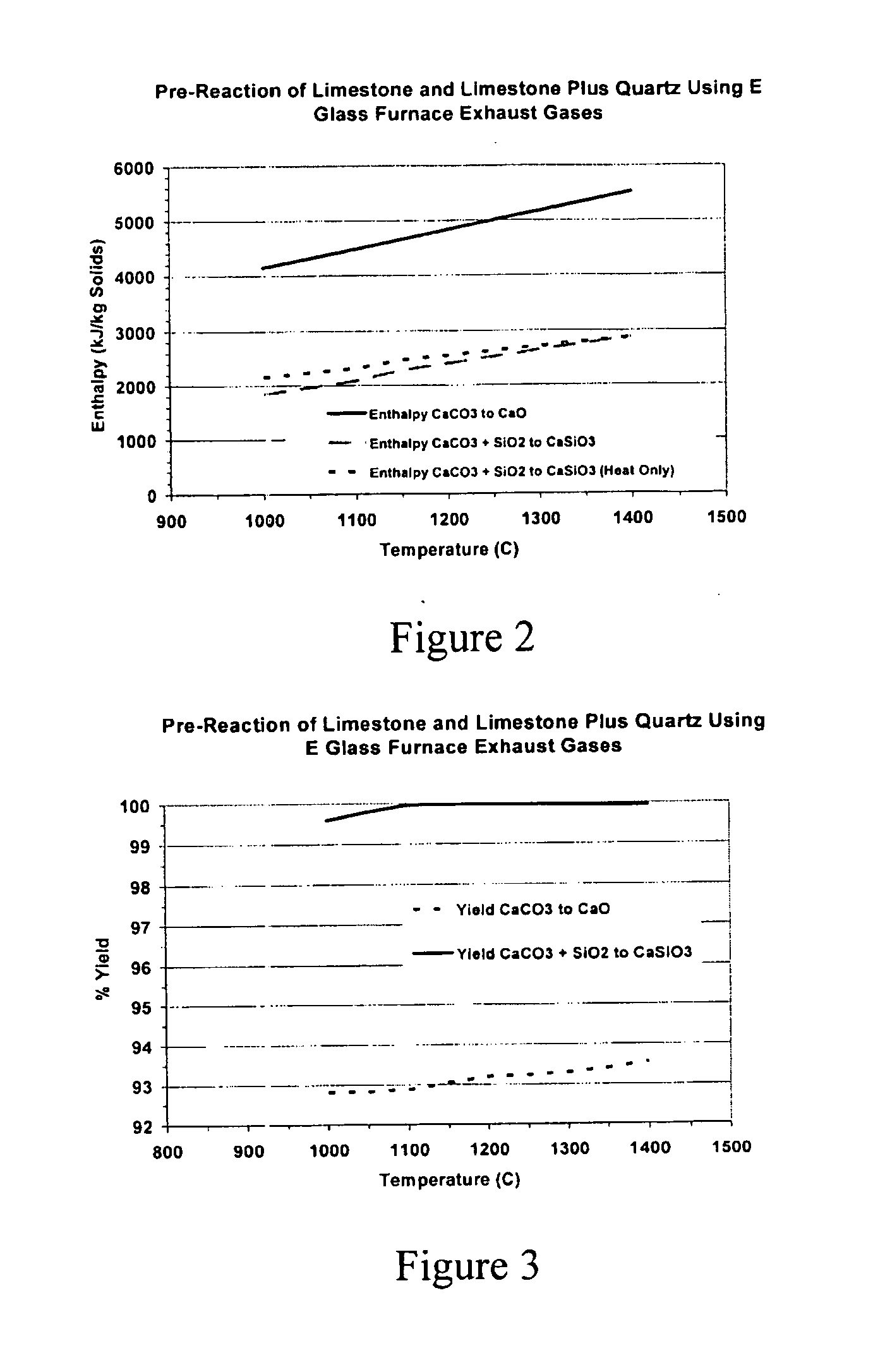

Method for making glass fibers

InactiveUS20070220922A1Significant energy savingReduce brittlenessGlass making apparatusGlass fiberImproved method

The invention is an improved method for manufacturing fiberglass. In the method of the invention, quartz is replaced in whole or in part by silica containing raw materials. The use of silica containing raw materials as a replacement for quartz results in significant energy savings and a reduction in defect producing components in the glass.

Owner:JOHNS MANVILLE CORP

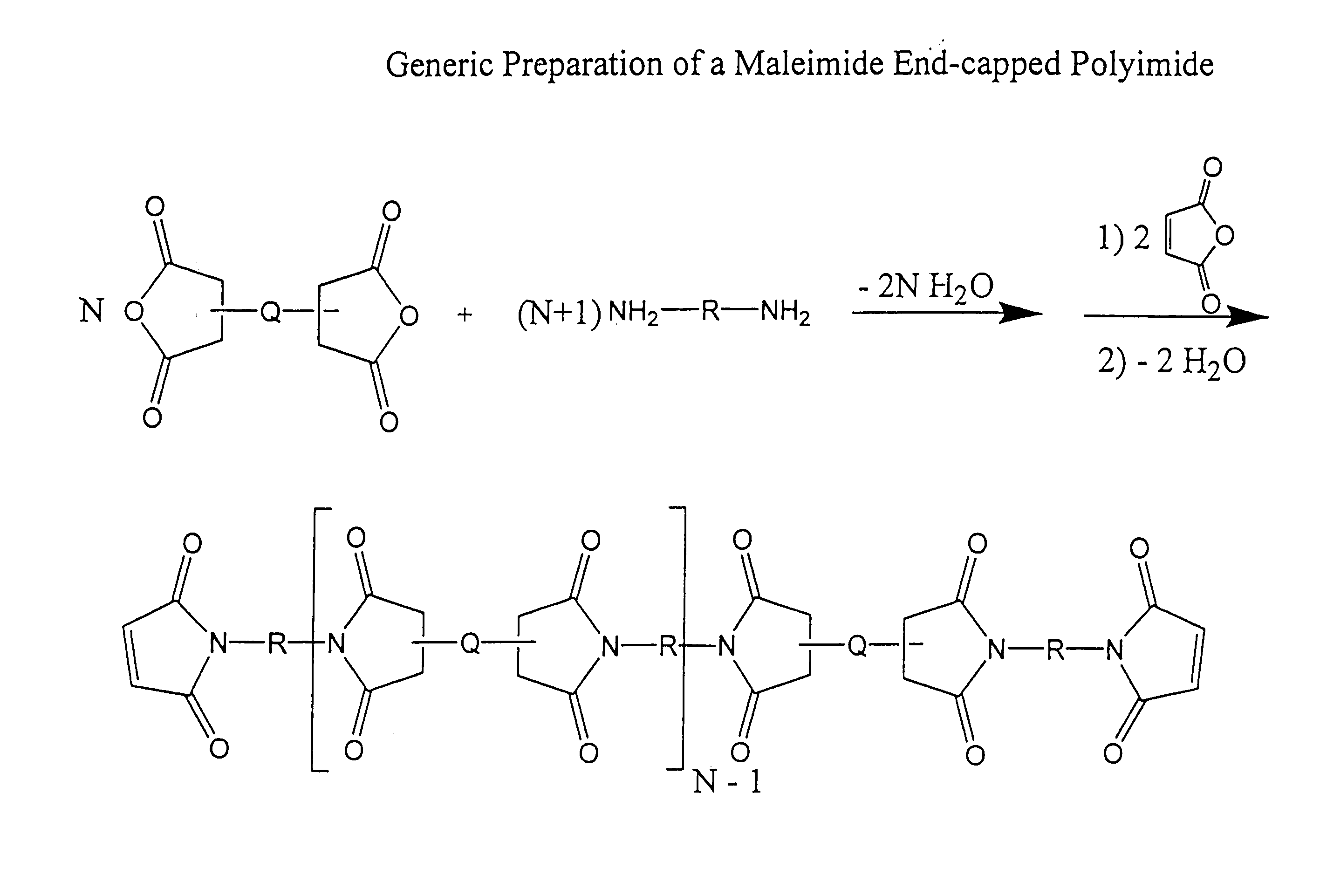

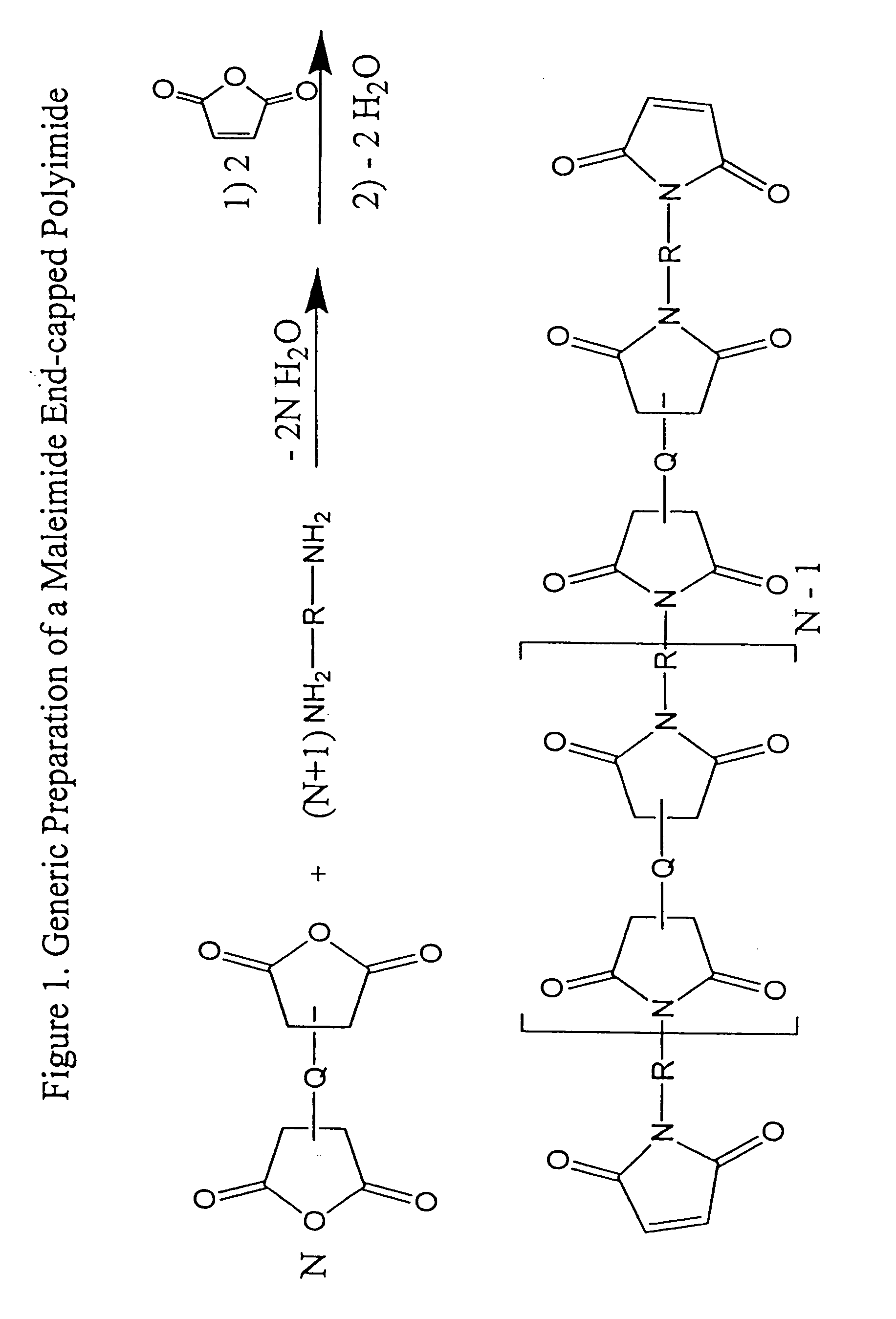

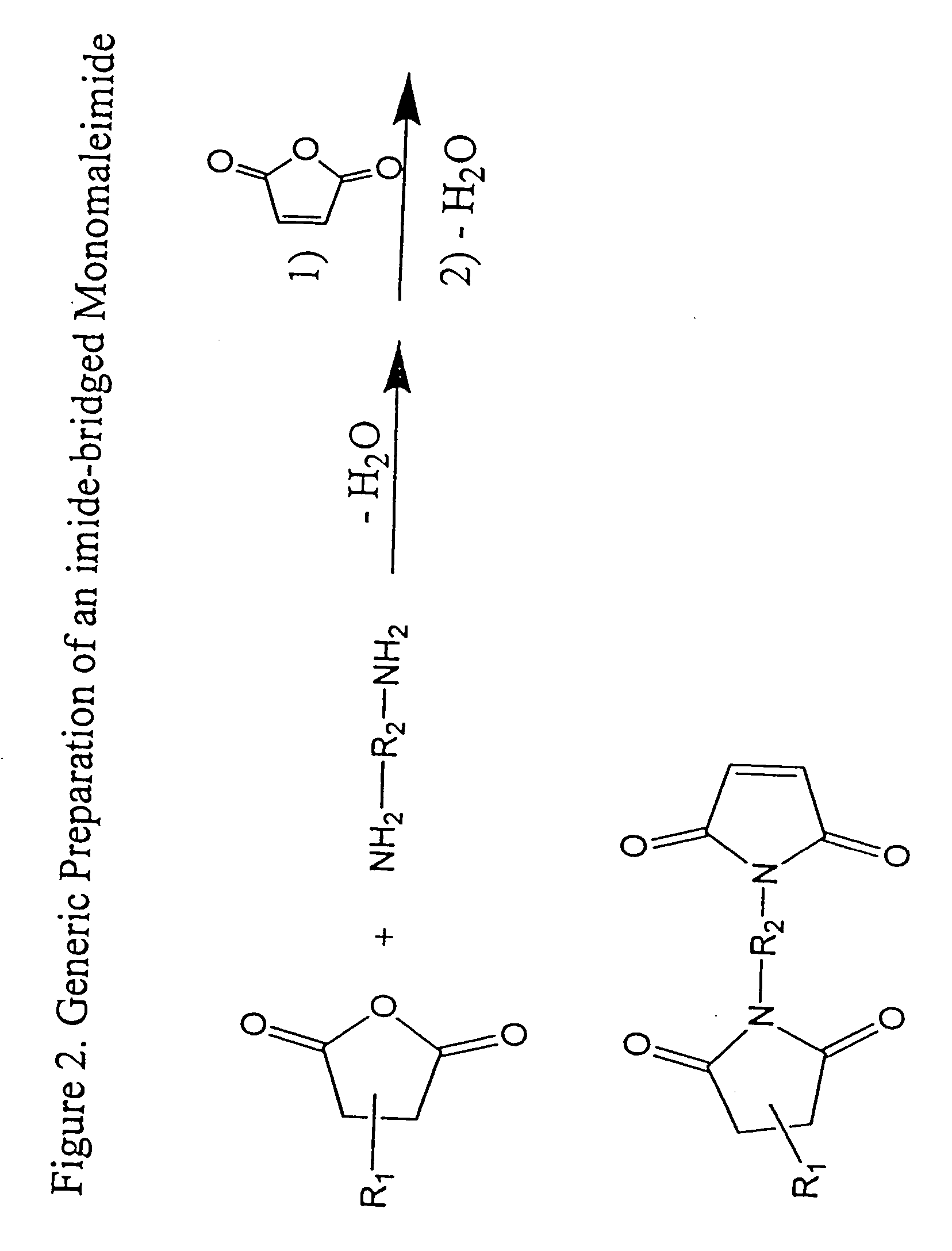

Imide-linked maleimide and polymaleimide compounds

ActiveUS7208566B2Improve toughnessNot sacrificing thermal stabilityOrganic chemistryAdhesivesPolyamine CompoundImide

The invention is based on the discovery that a remarkable improvement in the performance of maleimide thermosets can be achieved through the incorporation of imide-extended mono-, bis-, or polymaleimide compounds. These imide-extended maleimide compounds are readily prepared by the condensation of appropriate anhydrides with appropriate diamines to give amine terminated compounds. These compounds are then condensed with excess maleic anhydride to yield imide-extended maleimide compounds.

Owner:DESIGNER MOLECULES

Method for injection moulding moulded bodies consisting of (meth) acrylate copolymers

InactiveUS20040104501A1Reduce contentLittle reabsorptionPharmaceutical non-active ingredientsEndocrine system disorderPolymer scienceMeth-

The invention relates to a process for producing mouldings by injection moulding the steps in the process being a) melting and mixing of a (meth)acrylate copolymer composed of from 85 to 98% by weight of C1-C4-alkyl (meth)acrylates capable of free-radical polymerization and from 15 to 2% by weight of (meth)acrylate monomers having a quaternary ammonium group in the alkyl radical, with from 10 to 25% by weight of a plasticizer, and also from 10 to 50% by weight of a dryers [sic] and / or from 0.1 to 3% by weight of a release agent, and, where appropriate, with other conventional pharmaceutical additives or auxiliaries and / or with an active pharmaceutical ingredient, b) devolatilizing the mixture at temperatures of at least 120° C., thus reducing the content of the low-boiling constituents with a vapour pressure of at least 1.9 bar at 120° C. to not more than 0.5% by weight, and c) injecting the devolatilized mixture at a temperature of from 80 to 160° C. into the mould of an injection moulding system and removing the resultant moulding from the mould.

Owner:ROEHM GMBH & CO KG +1

Rapidly disintegrable tablets

InactiveUS7282217B1Reduce brittlenessHigh porosityDispersion deliveryPill deliveryAdditive ingredientWater insoluble

The invention provides a rapidly disintegrating tablet comprising an active ingredient, a water soluble, directly compressible carbohydrate, and a water soluble, directly compressible filler. Also provided is a method of producing a rapidly disintegrating tablet, which method comprises wet granulating a mixture comprising a directly compressible, water soluble carbohydrate, a directly compressible, water insoluble filler, a beneficial ingredient, and a solvent, and compressing the granulate to produce the tablet.

Owner:AMAG PHARMA USA INC

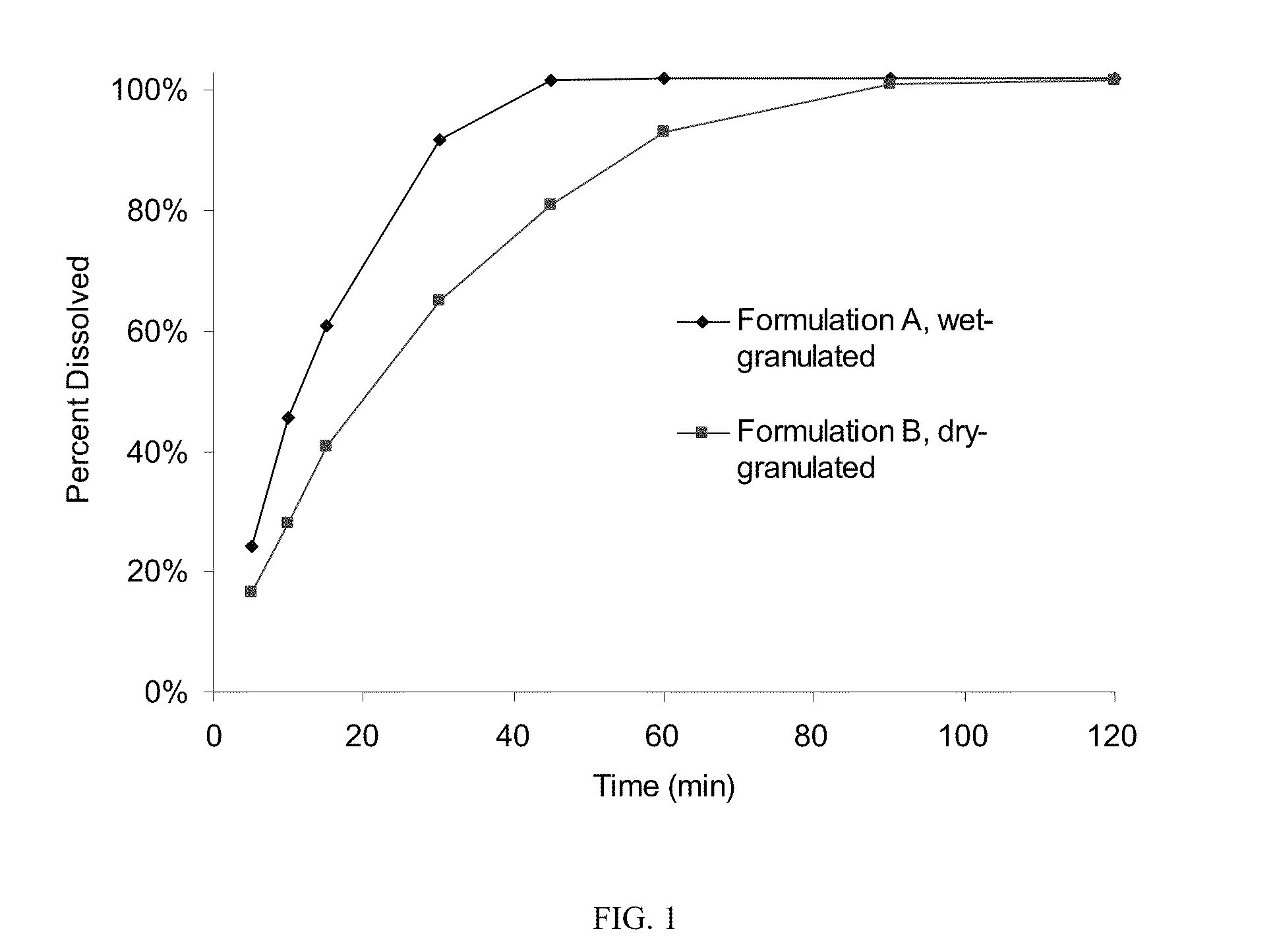

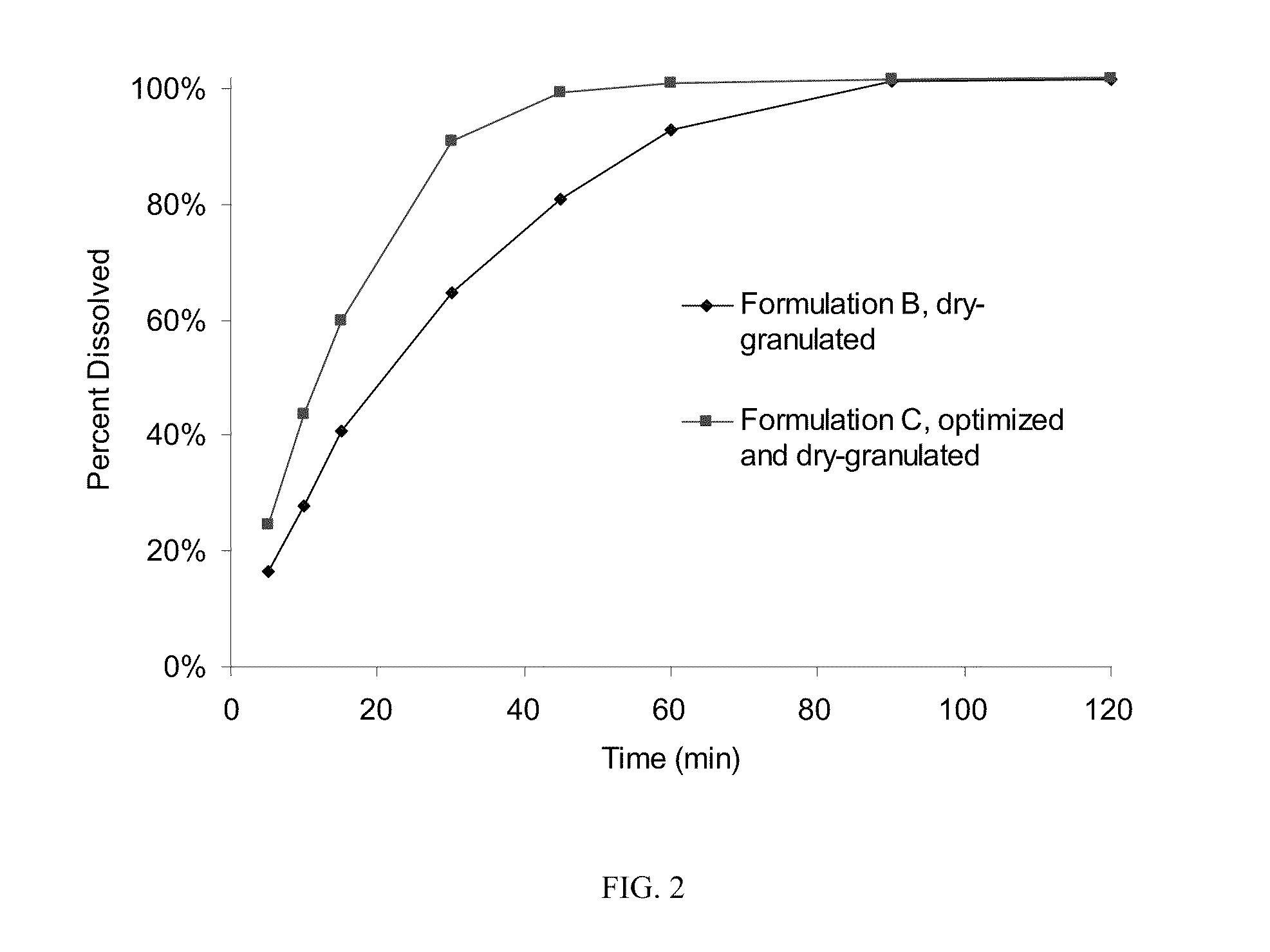

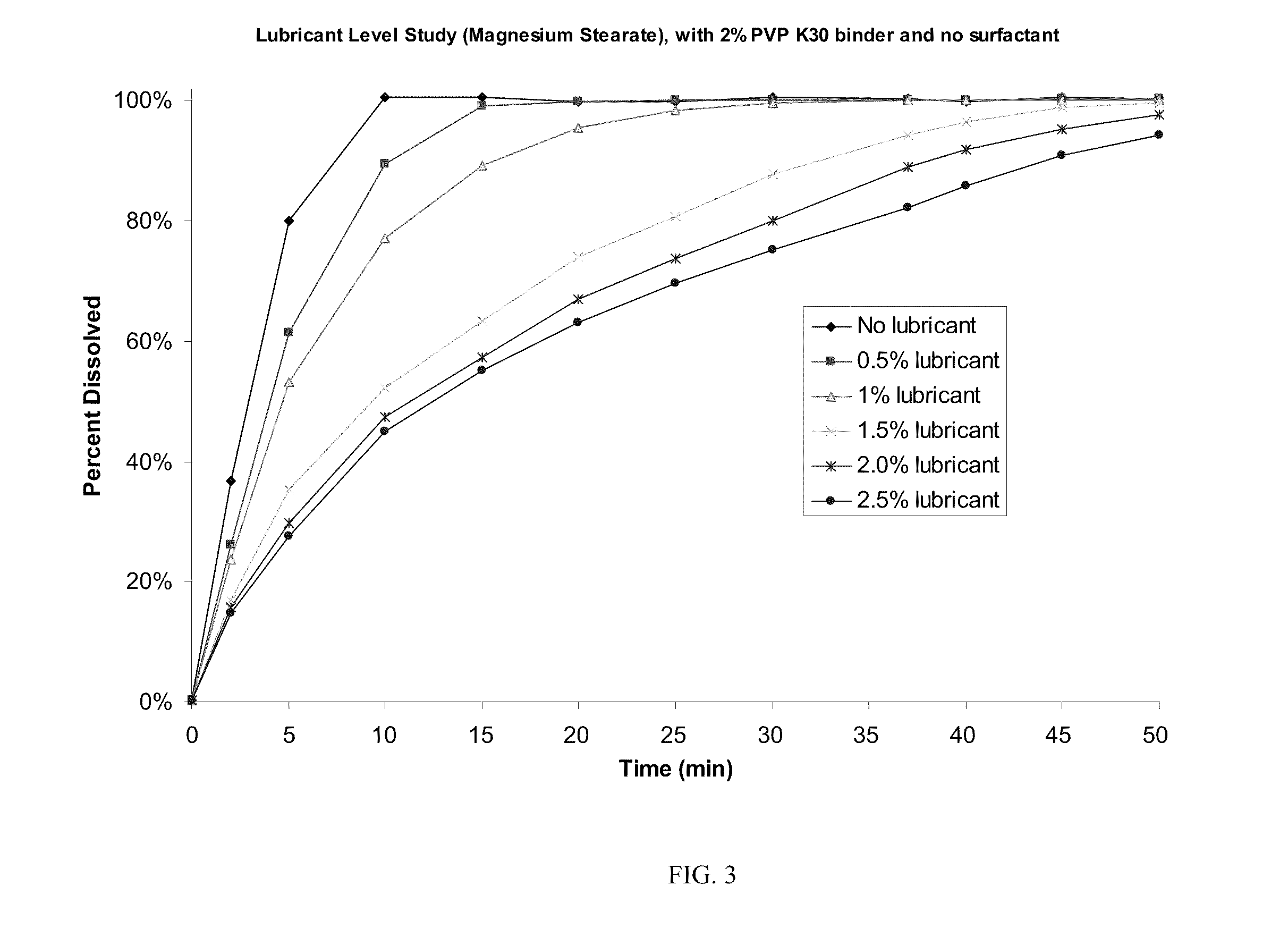

Immediate release formulations and dosage forms of gamma-hydroxybutyrate

ActiveUS20110111027A1Reduce brittlenessDissolve fastBiocideNervous disorderOral medicationHigh weight

The present invention provides a solid immediate release dosage form adapted for oral administration of GHB. The solid immediate release dosage form includes an immediate release formulation comprising a relatively high weight-percentage of GHB with a bioavailability similar to that of a liquid GHB dosage form.

Owner:JAZZ PHARMA

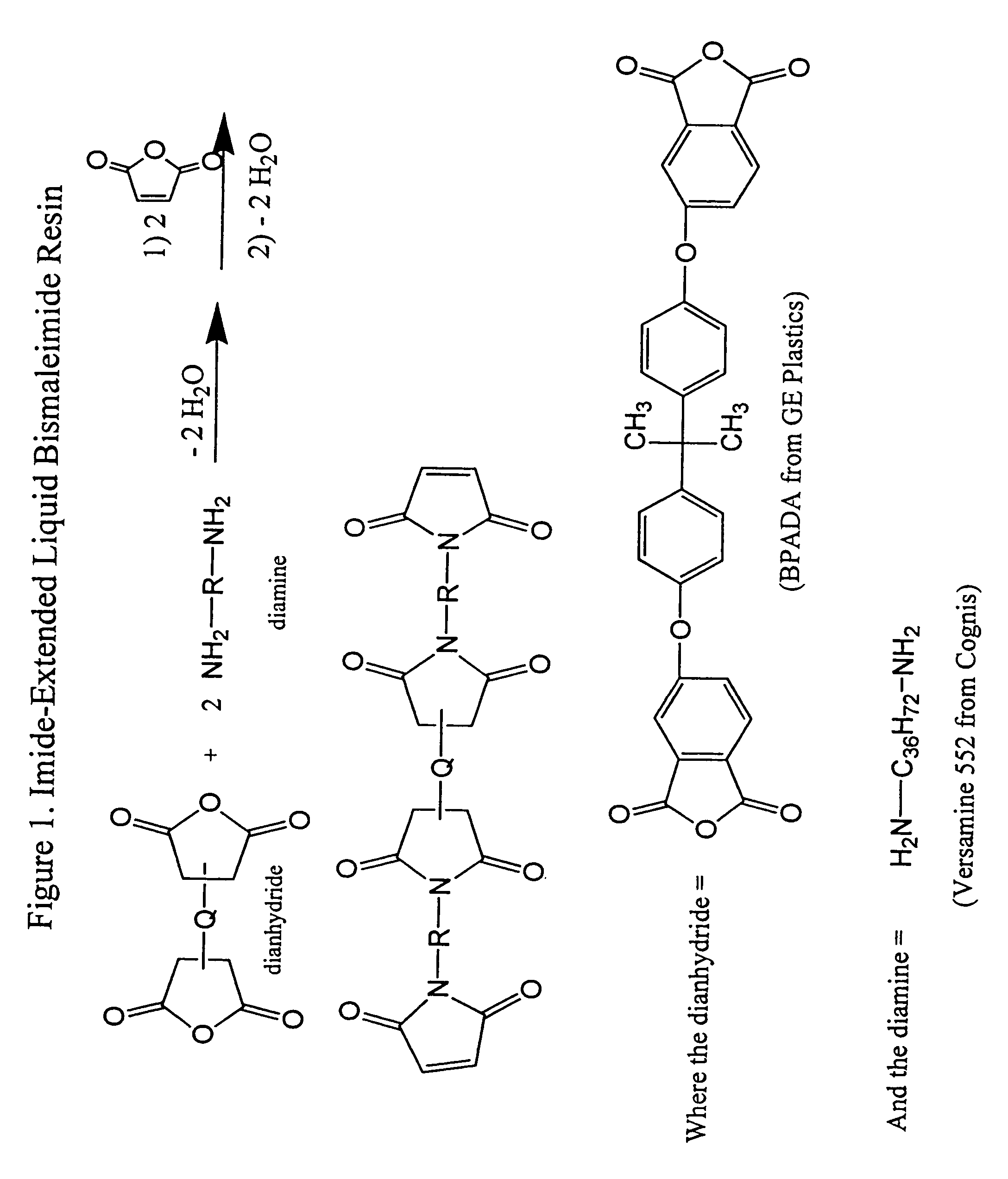

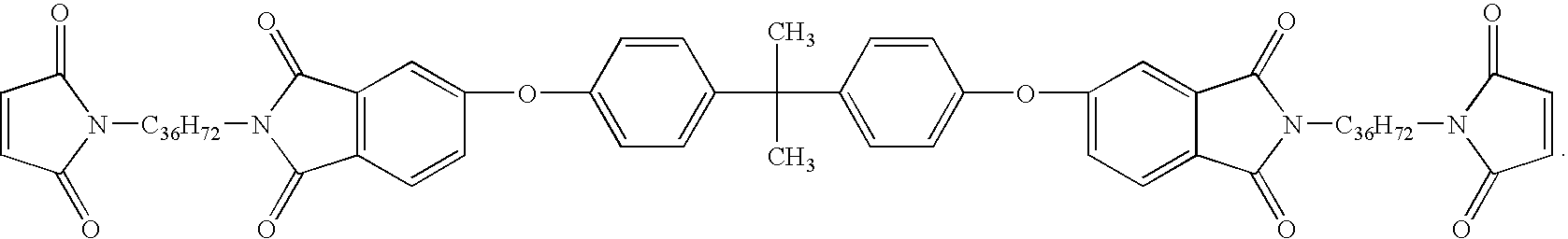

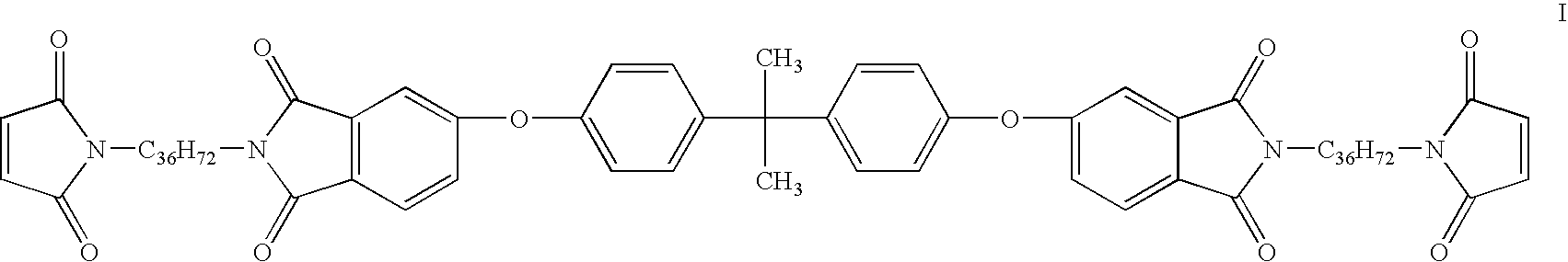

Imide-extended liquid bismaleimide resin

ActiveUS7157587B2Improve toughnessNot sacrificing thermal stabilityOrganic chemistrySynthetic resin layered productsImideDiamine

The invention is based on the discovery that a remarkable improvement in the performance of bismaleimide thermosets can be achieved through the incorporation of an imide-extended liquid bismaleimide monomer. This imide-extended liquid bismaleimide monomer is readily prepared by the condensation of an appropriate dianhydride with two equivalents of an appropriate diamine to give an amine terminated compound. This compound is then condensed with an excess of maleic anhydride to yield an imide-extended liquid bismaleimide monomer.

Owner:DESIGNER MOLECULES

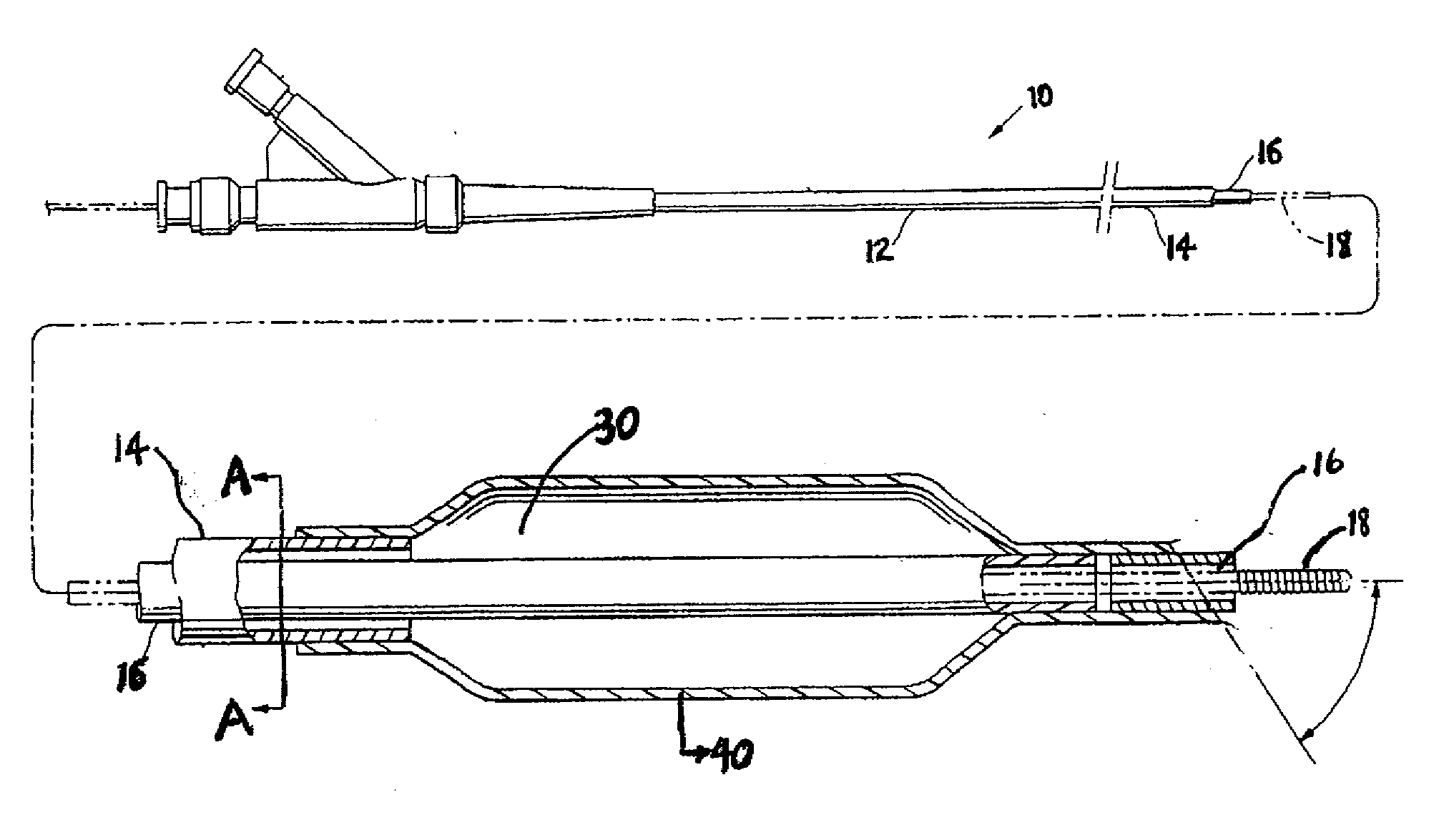

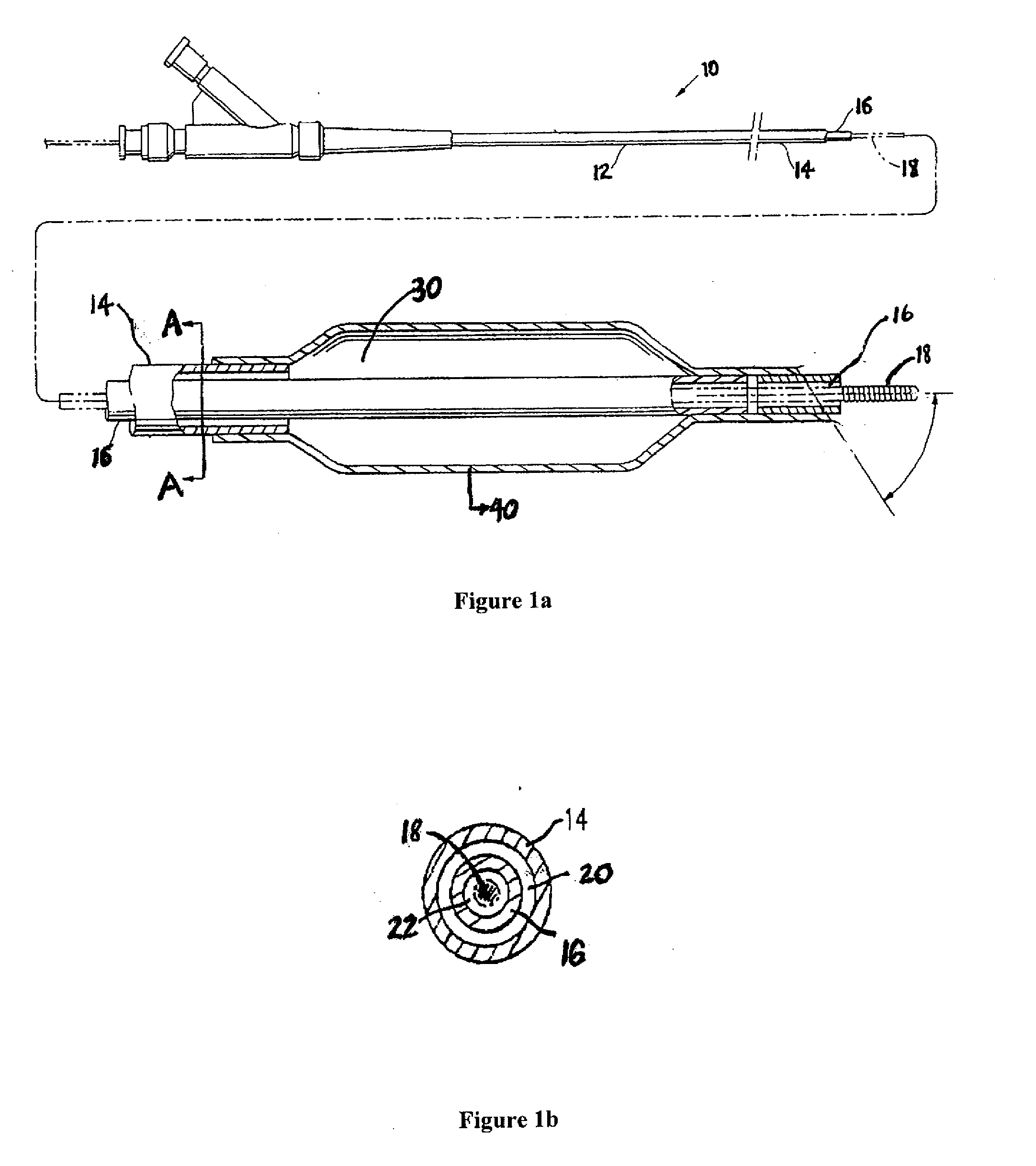

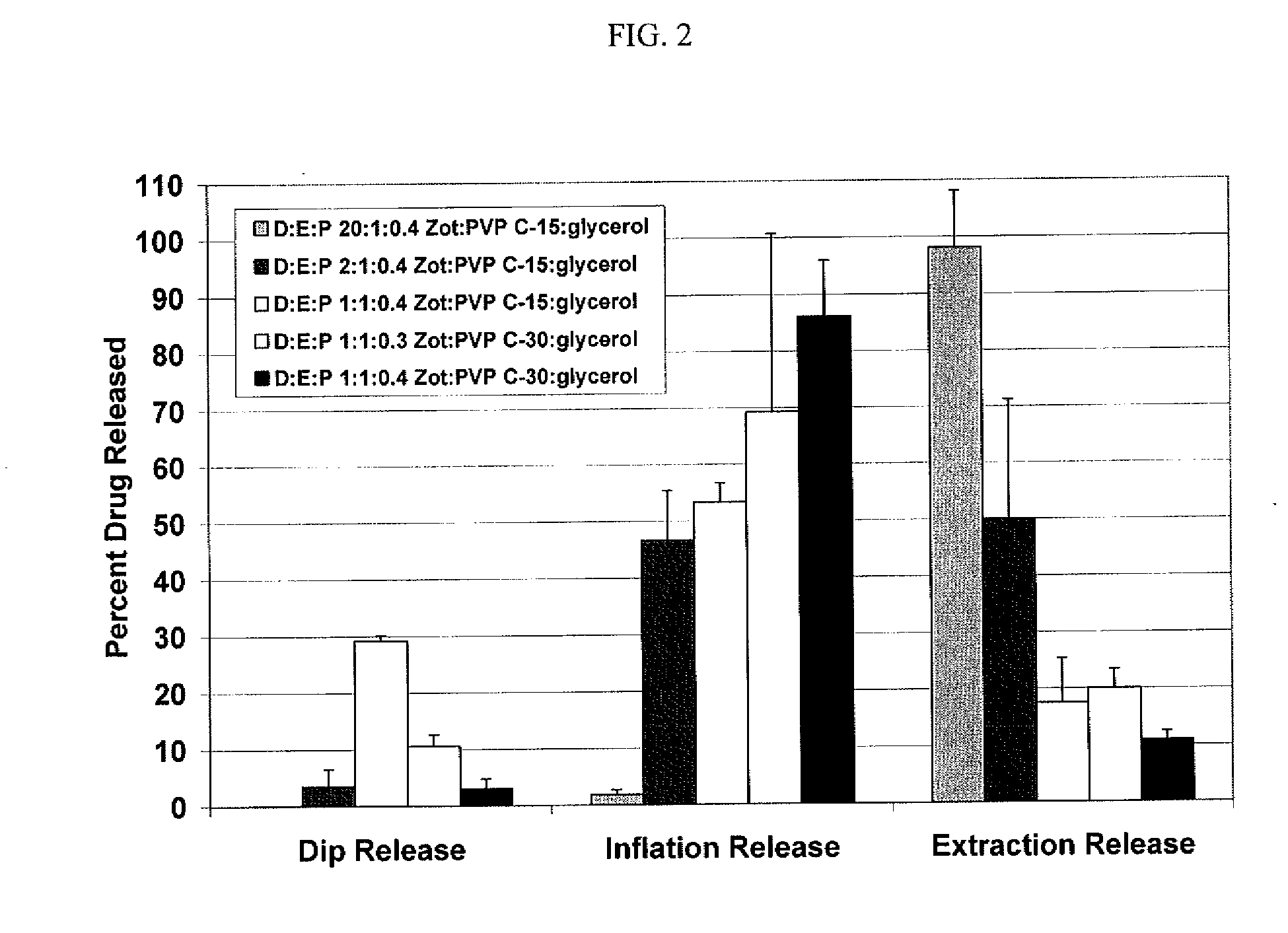

Hydrophilic coatings with tunable composition for drug coated balloon

InactiveUS20110144577A1Minimized drug lossImproved drug recoveryBiocideSurgeryHydrophilic coatingPlasticizer

A tunable coating formulation is described for a drug delivery balloon comprising a therapeutic agent, an excipient and a plasticizer. The tunable coating includes a first therapeutic agent and a first excipient, and can have a second therapeutic agent and a second excipient. The first and second therapeutic agents have different dissolution rates during balloon inflation and therefore provide a coating that is tunable. The plasticizer in the formulation has a weigh ratio of excipient to plasticizer below 1:0.1.

Owner:ABBOTT CARDIOVASCULAR

Tough composition for food applications

Heterophasic polypropylene composition comprising:—a polypropylene matrix (M) and—an elastomeric copolymer (E) being dispersed in the matrix (M), wherein the elastomeric copolymer (E) comprises units derived from—propylene and—ethylene and / or C4 to C20 α-olefin, and wherein further,—the intrinsic viscosity of the xylene cold soluble fraction (XCS) of the heterophasic polypropylene composition is above 2.1 dl / g measured according to ISO 1628-1 (at 135° C. in decaline) and / or—Mz / Mw of the xylene cold soluble fraction (XCS) of the heterophasic polypropylene composition is more than 2.6, preferably 2.7, wherein the Mz is the z-average molecular weight measured according to ISO 16014-4:2003 and Mw is the weight average molecular weight measured according to ISO 16014-4:2003.

Owner:BOREALIS AG

Coated substrate, a process for production of a coated substrate, a package and a dispersion coating

InactiveUS20130017349A1High strengthEasy to recycleMaterial nanotechnologyStarch dervative coatingsFiberCellulose

The present invention relates to a coated fiber based substrate comprising a dispersion coating wherein said dispersion coating comprises microfibrillated cellulose and colloidal particles of a polymer. The invention further relates to a package formed from said substrate, a dispersion coating and process for the production of mentioned substrate.

Owner:STORA ENSO OYJ

Method to obtain microparticles

InactiveUS6753014B1Reduce brittlenessEasily controllable density and strengthPowder deliveryDrying solid materials without heatMicroparticleFreeze Technique

Method of obtaining microparticles.A method for the preparation of homogeneous microparticles containing a pharmaceutically active substance by a spray freezing technique wherein the medium to be atomized into droplets has a high dry content and comprises besides the active substance a polymer and a liquid (in which the polymer may be soluble) in which the active substance and polymer are suspended, dissolved or emulsified.

Owner:ASTRAZENECA AB

Polymer compositions and films and method of making

InactiveUS20070092744A1Maintain good propertiesHigh glossSynthetic resin layered productsThin material handlingNylon materialPolymer science

Polymer compositions, single layer films and multiple layer films, where the composition and / or a layer of a film has base polymer of either amorphous nylon or EVOH, and a modifying semi-crystalline nylon component. Where the base polymer is amorphous nylon, the modifying nylon composition includes a first relatively lower melting temperature nylon, and typically a second relatively higher melting temperature nylon. Where the base polymer is EVOH, the modifying semi-crystalline nylon composition can optionally be defined completely by the relatively lower melting temperature nylon, which has a melting temperature less than 170 degrees C. Blends of disclosed amounts of amorphous nylon or EVOH with the semi-crystalline nylon component can be used to produce films which can be uniaxially oriented or biaxially oriented to provide shrink capacities of at least 28 percent, and up to about 57 percent or more.

Owner:PLASTICOS DISE

Biodegradable resin composites

InactiveUS20110229698A1More rigidityMore strengthAdhesive processesDecorative surface effectsPolymer scienceResin composite

Owner:E2E MATERIALS

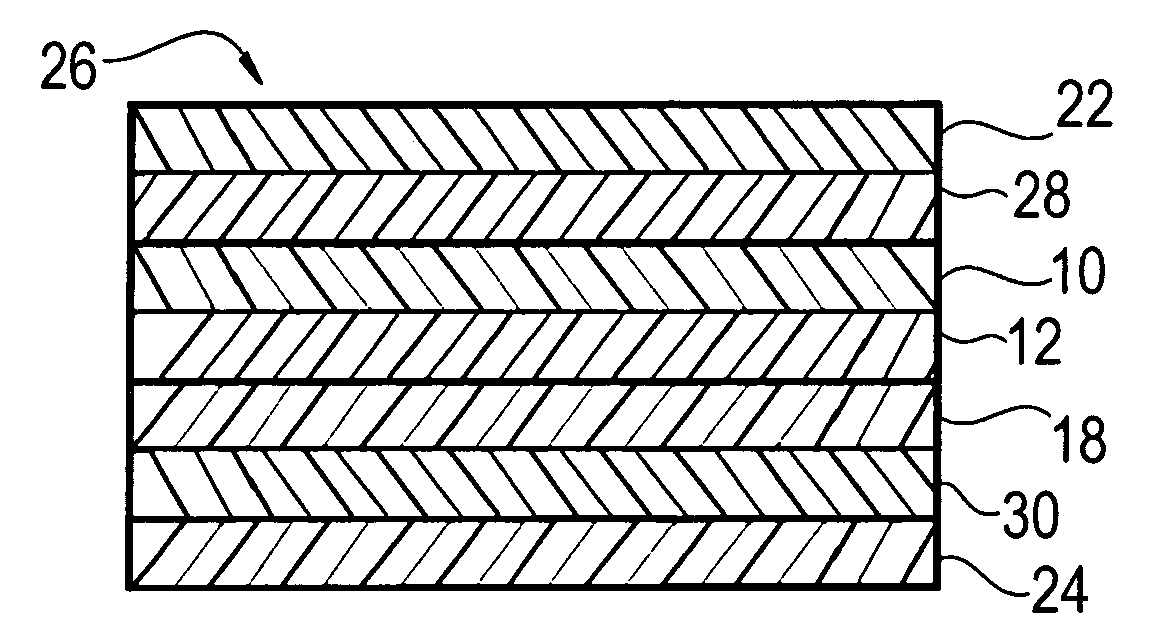

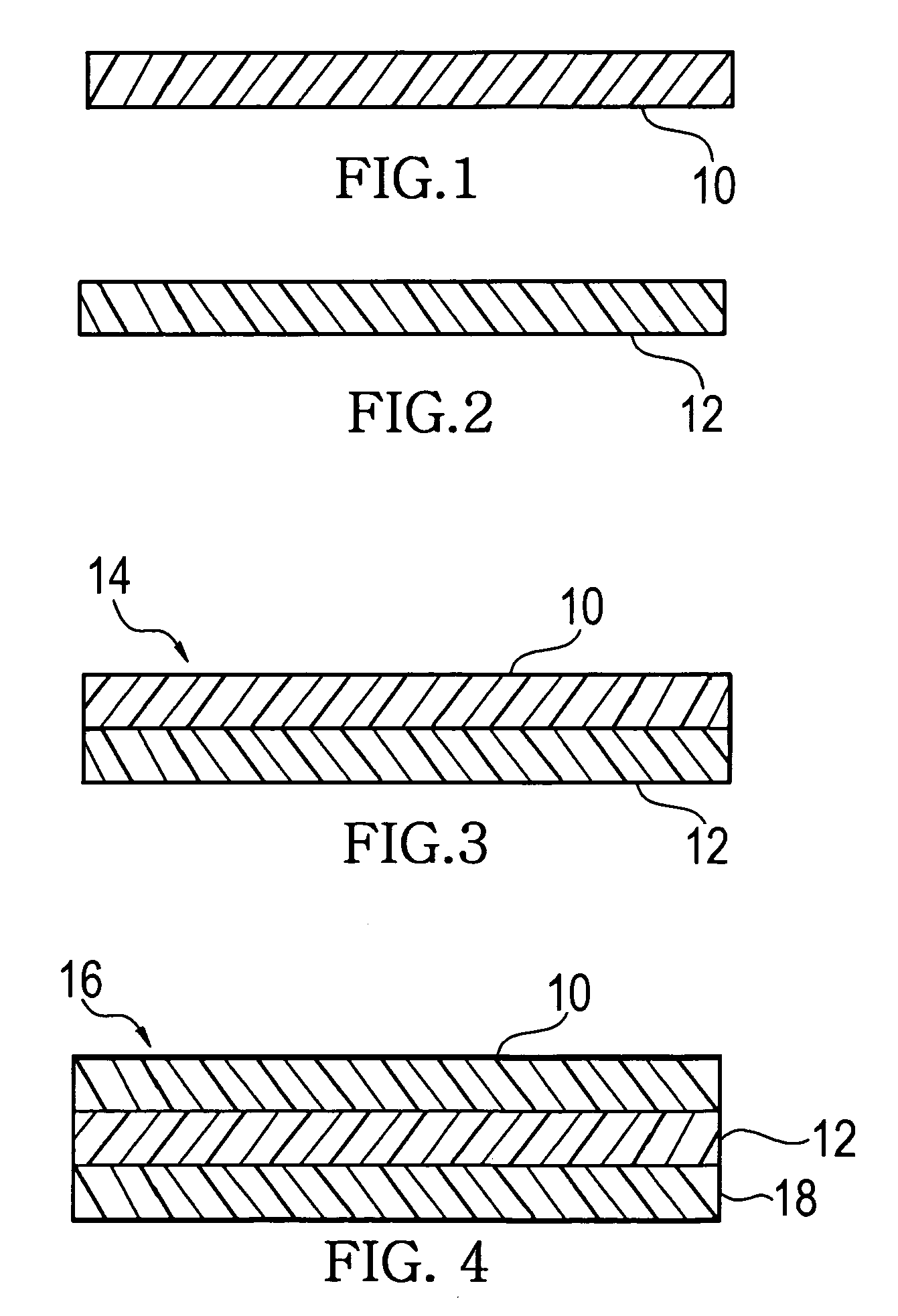

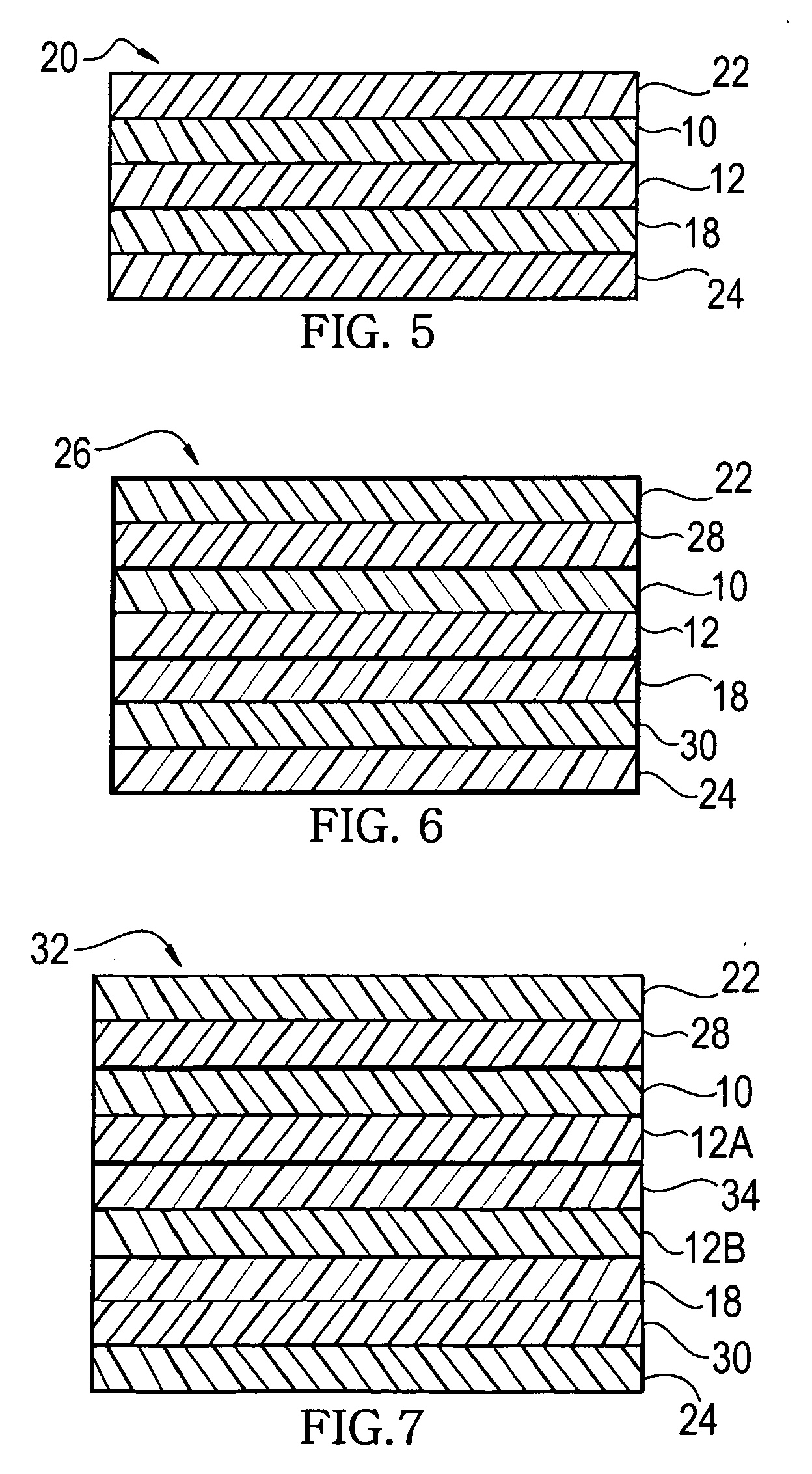

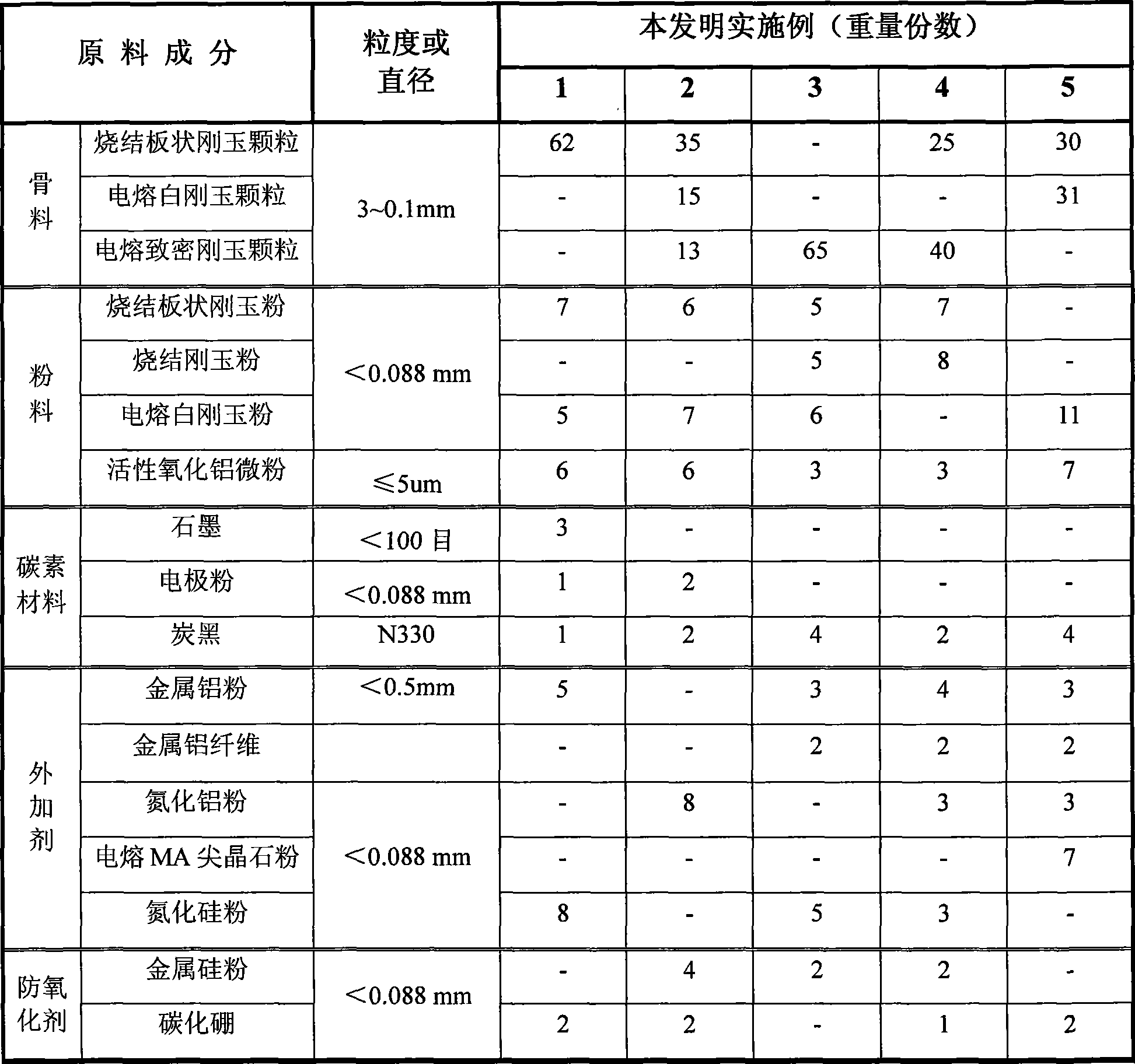

Aluminum-carbon sliding tile and method of producing the same

The invention provides an aluminum-carbon sliding brick, which comprises the following compositions: 60 to 75 percent of aggregate, 15 to 30 percent of powder, 1 to 6 percent of carbon element materials, 2 to 7 percent of antioxidant and 3 to 20 percent of additive. The production method for the aluminum-carbon sliding brick comprises the following steps: firstly, the powder in the raw materials is premixed and prepared into mixed powder for standby; secondly, mixing is performed according to the feeding order of granular materials, a binder and the mixed powder; thirdly, the mixture is discharged and subjected to mechanical pressing; and fourthly, a green brick is dried and prepared into the aluminum-carbon sliding plate brick by an unfired technology or a light burning technology. The method adds nitride and spinel materials in the sliding brick to substantially improve the thermal shock stability of the sliding brick, so as to achieve the level of the aluminum-zirconium-carbon sliding brick; and because the addition of Al metals is adequately increased, air holes can be filled, and the method reduces the brittleness of materials, is favorable for green brick formation, and improves the volume density, the normal temperature strength and the high temperature strength, so as to improve the oxidation resistance of the sliding brick. The aluminum-carbon sliding brick produced by the method not only has good product quality and high strength but also has simple procedure and saves the sintering cost.

Owner:鞍山钢铁集团耐火材料有限公司

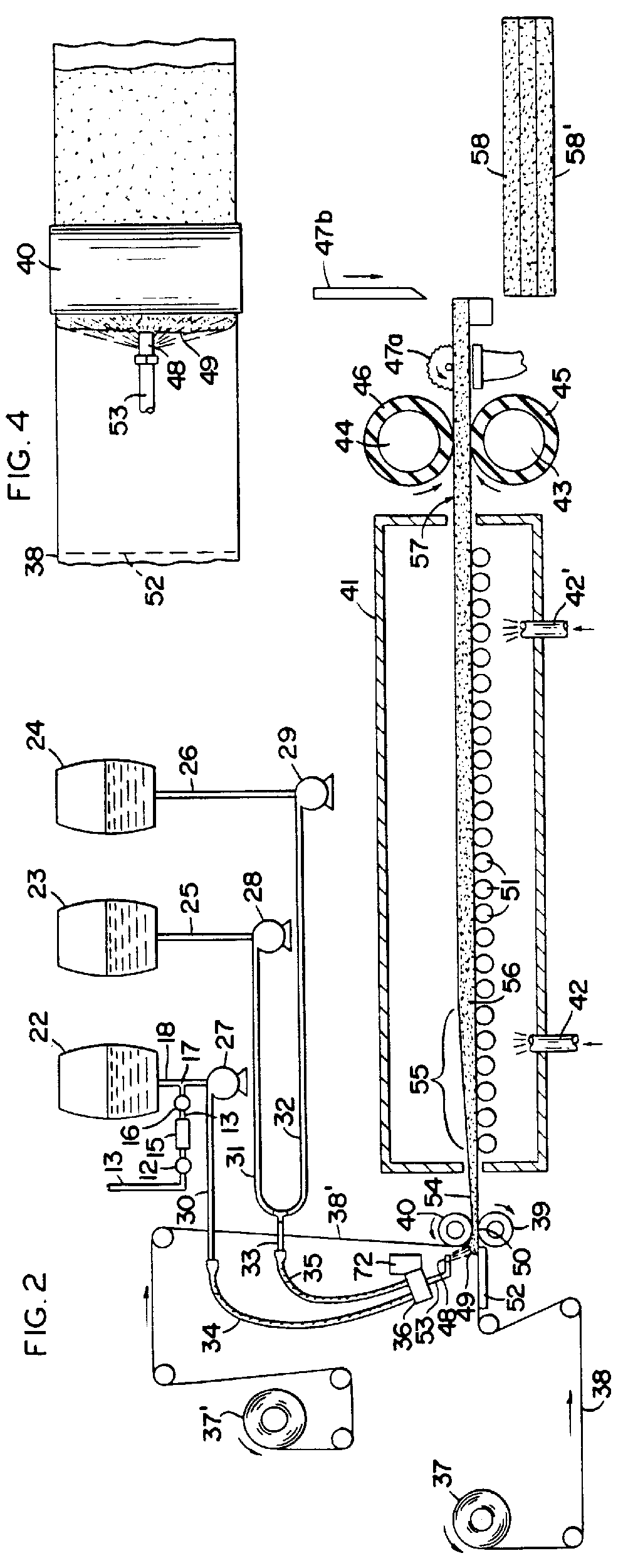

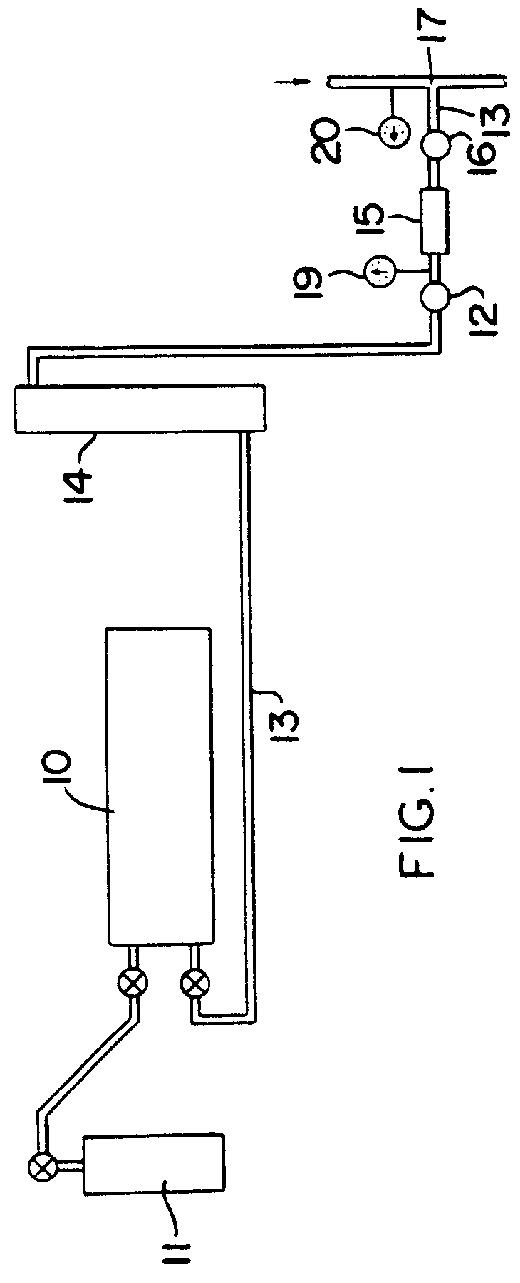

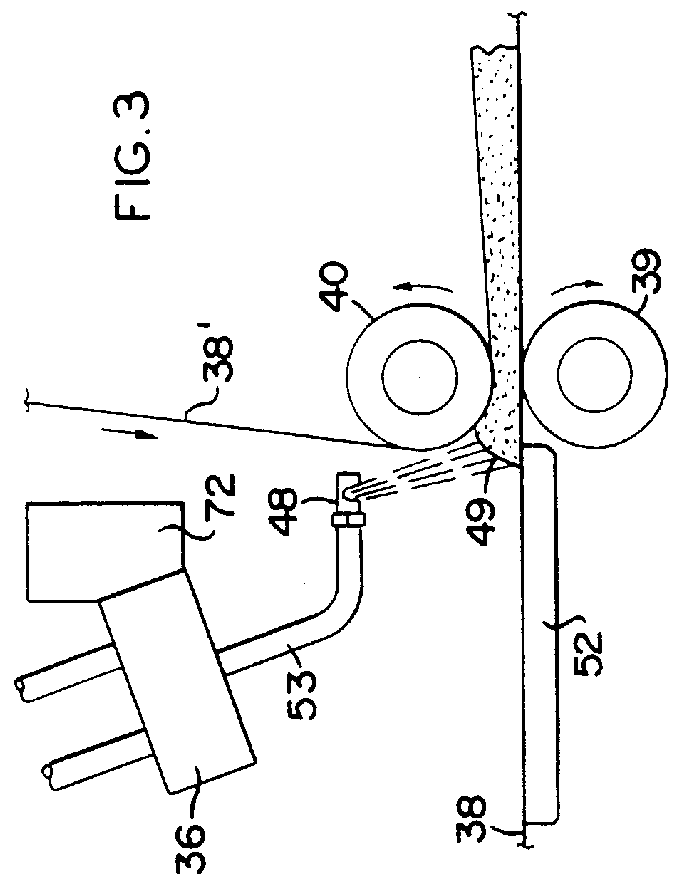

Faced foam insulation board and froth-foaming method for making same

InactiveUSRE36674E1Big lossSimple and economical mannerConfectionerySweetmeatsProduction lineEngineering

A method for continuously producing an insulation board comprising a rigid plastic foam core having two major surfaces and a facing material on one or both of the major surfaces, the method including conveying a facing material along a production line, depositing a partially expanded froth foam of a plastic mixture, which contains at least one frothing agent, on the facing material, and further expanding and curing the froth foam in contact wiht the facing material to form the insulation board. The board is particularly useful as roof insulation.

Owner:THE DOW CHEM CO

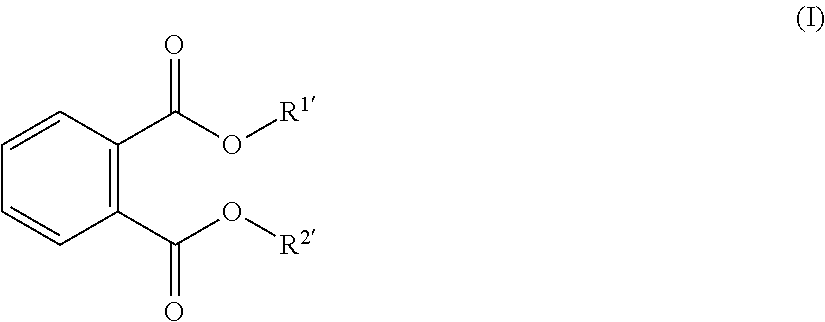

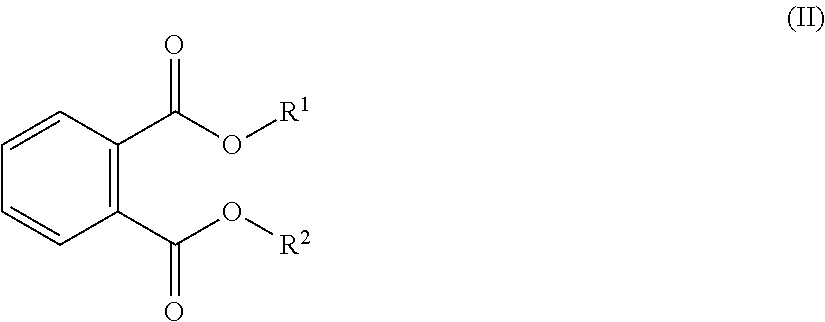

Anticorrossion antiwear ceramic paint

InactiveCN1325931AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyGlass fiber

An anticorrosion and antiwear ceramic paint is prepared from epoxy resin (28.5-35 wt.portions), dibutyl phthalate (3.75-6), mixed solvent of xyrene and n-butyl ester (20-24), gas-phase SiO2 (0.5-1) and ceramic powder (38-45) which contains TiO2 (3-6.3), Al2O3 (11.7-20) and Si3N4 (16-20.45). The weight ratio of main component to slidifying agent is (14.5-17):1. It can be directly applied to the surfaces of metal, glass fibre, plastic, or concrete with the advantages of high antiwear performance and adhesion, and thin and compact coated layer.

Owner:BEIJING UNIV OF CHEM TECH

Utility tool device and related methods and systems

ActiveUS20140143958A1Facilitate additional protrusionImprove portabilityOpening closed containersBottle/container closureEmbedded system

Owner:CAFFEINATE LABS

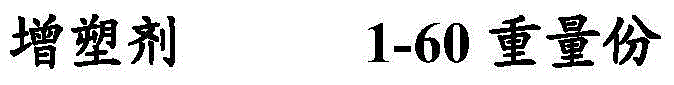

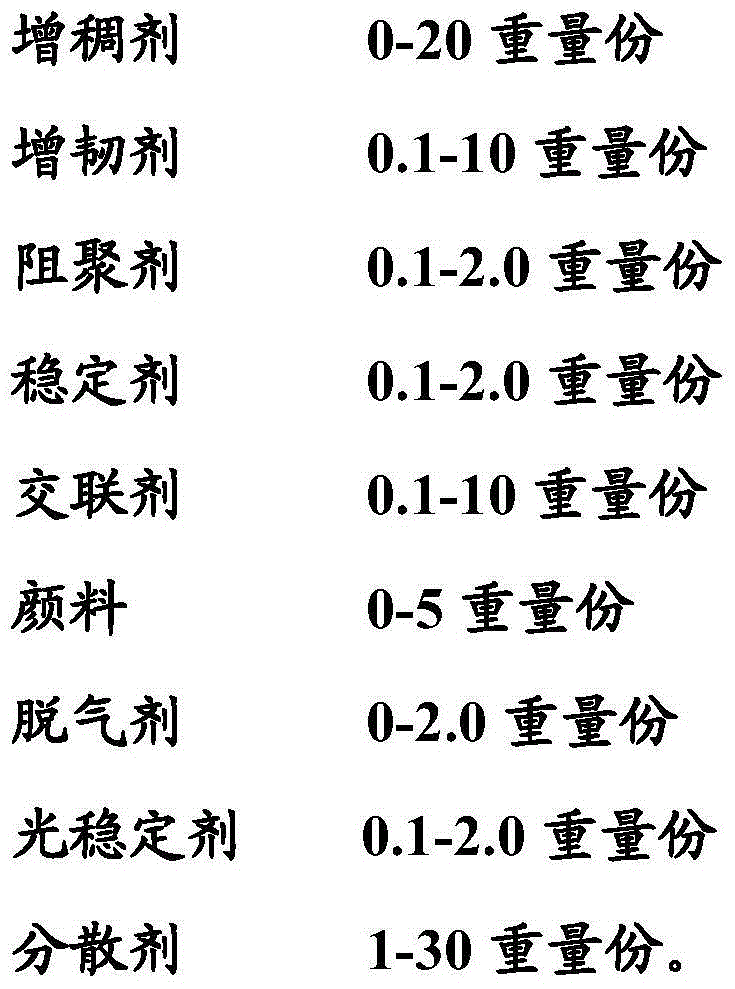

3D printing composition, preparation and application methods and product thereof

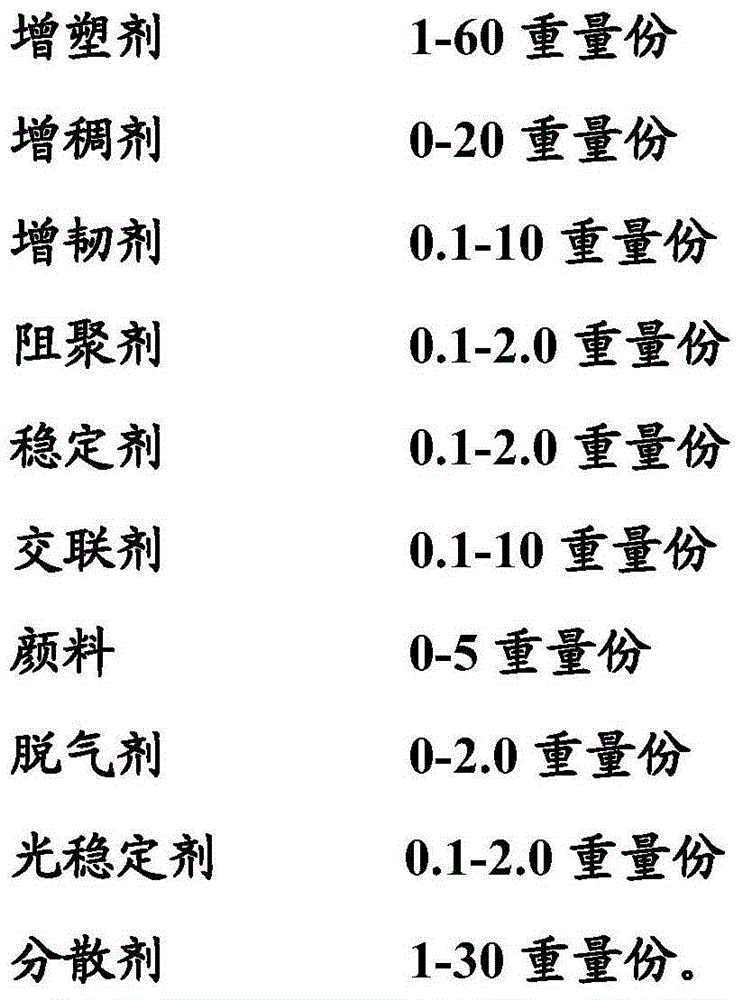

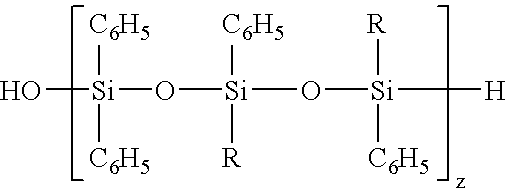

The invention discloses a 3D printing composition, its preparation and application methods and a product thereof. According to the material, cyanoacrylate and a powder material are used as main bodies; a solvent is added to adjust fluidity of the material; and simultaneously, certain amounts of a plasticizer, a thickener, a flexibilizer, a stabilizer, a cross-linking agent, a pigment, a degassing agent and the like are contained to raise stability of the material and mechanical property of a printing product. As the material is a liquid and solidification process of the material is controlled by controlling conditions such as environment humidity, temperature and the like during printing, an ink-jet printing head which has been developed comparatively mature at present can be used for printing. The composition provided by the invention has characteristics of high printing precision, fast forming speed and low cost. Meanwhile, a printing product has high mechanical strength. The composition is a novel green 3D printing material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Rapidly dissolving tablets comprising low surface area calcium phosphates

InactiveUS20070196477A1Effective quick dissolving resultReduce brittlenessCosmetic preparationsToilet preparationsCalcium biphosphateMedicine

This invention pertains to the ability to provide rapidly disintegrating tablets through the inclusion of a calcium phosphate material in combination with other common tablet components. Such a calcium phosphate material must exhibit a sufficiently low surface area in order to boost the ability of the table to separate quickly when introduced into a user's mouth cavity. Such a tablet is dimensionally stable prior to use (low friability) and, when immersed in water the tablet disintegrates therein in less than about 60 seconds.

Owner:WITHIAM MICHAEL C +2

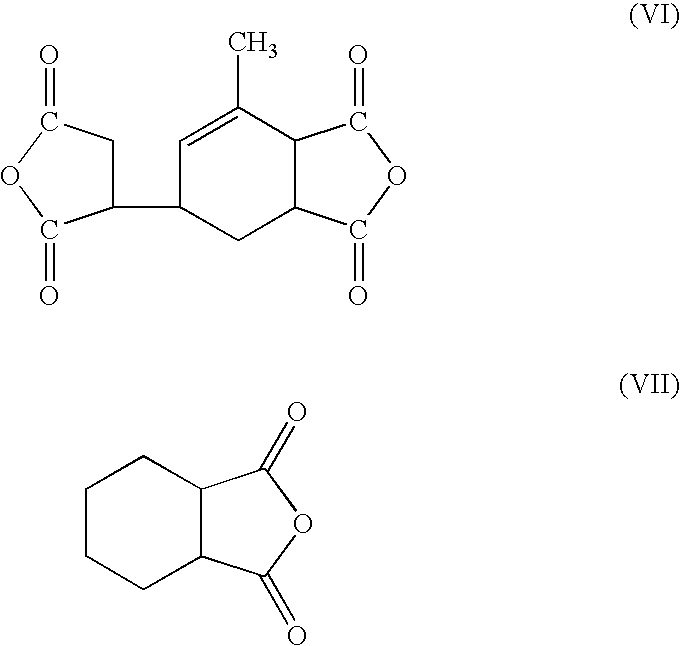

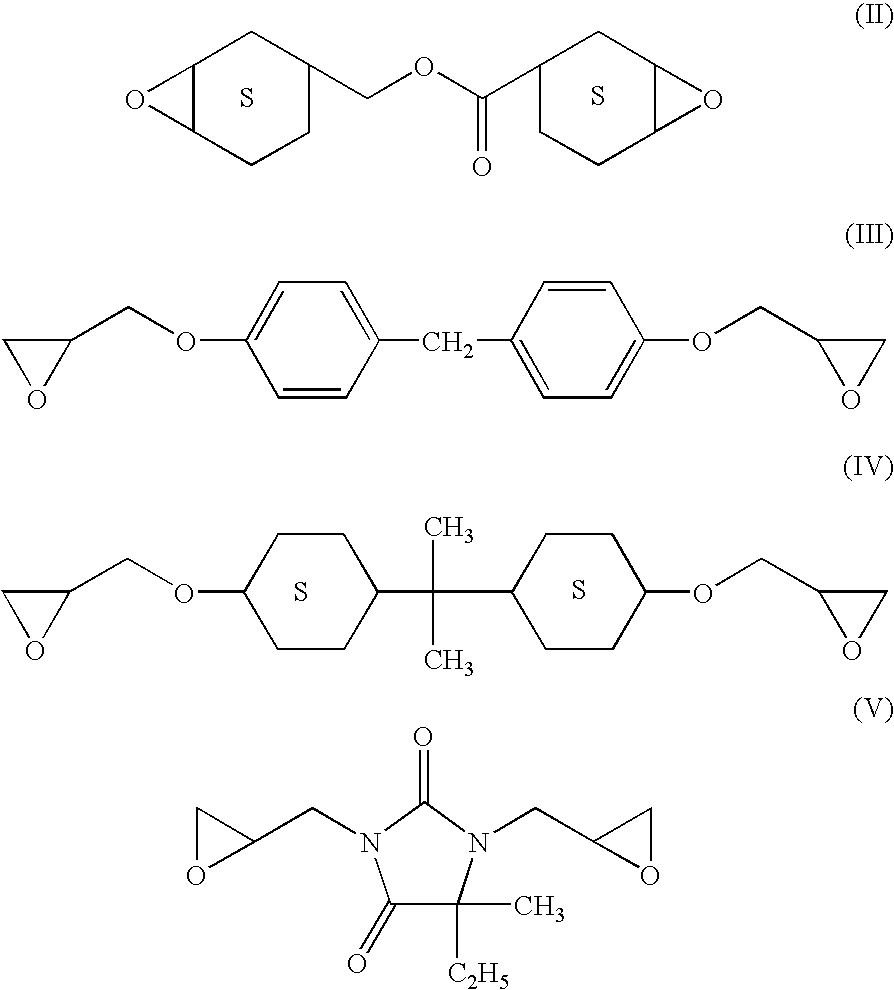

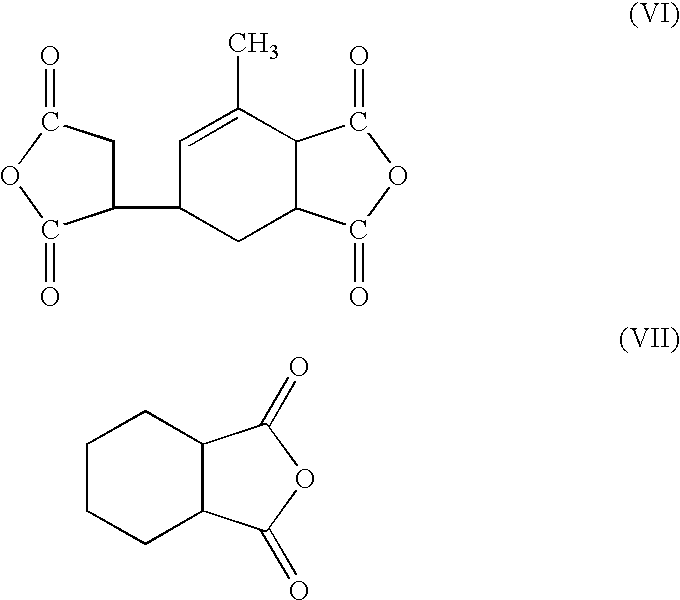

Epoxy resin compositions, solid state devices encapsulated therewith and method

InactiveUS20040067366A1Reduce discolorationReduce brittlenessSemiconductor/solid-state device detailsSynthetic resin layered productsSilicone resinSolid-state

Epoxy resin compositions are disclosed which comprise (A) at least one silicone resin, (B) at least one epoxy resin, (C) at least one anhydride curing agent, (D) at least one siloxane surfactant, and (E) at least one ancillary curing catalyst. Also disclosed are a packaged solid state devices comprising a package, a chip, and an encapsulant comprising a composition of the invention. A method of encapsulating a solid state device is also provided.

Owner:GENERAL ELECTRIC CO

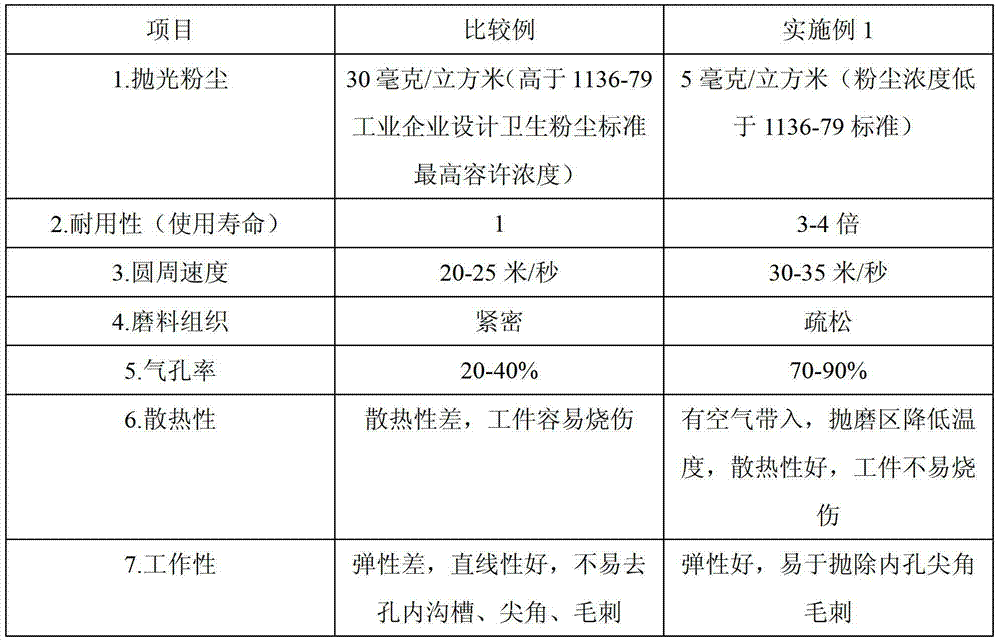

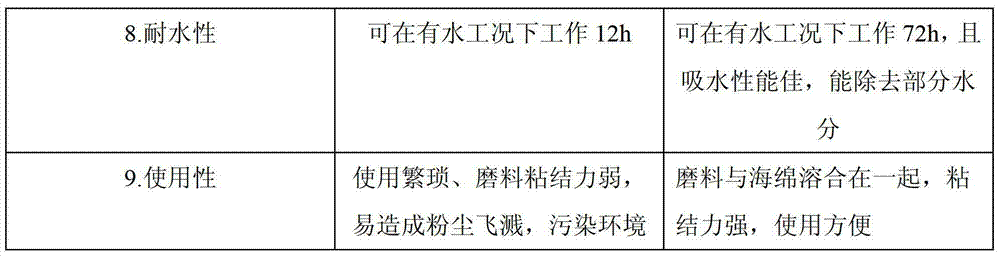

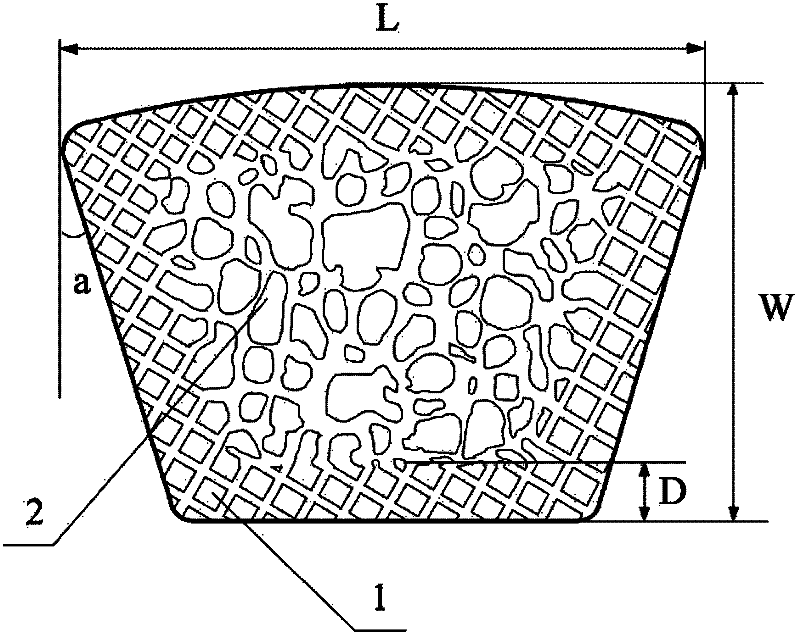

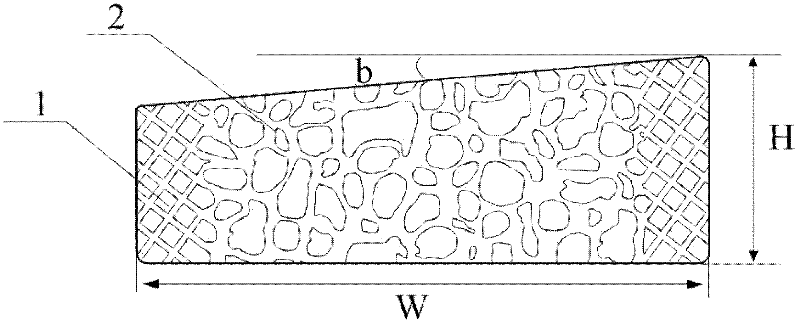

Polyvinyl alcohol-polyurethane elastic buffing wheel and preparation method thereof

InactiveCN103395011AUniform cellsNo stuffingAbrasion apparatusGrinding devicesWater bathsDistilled water

The invention discloses a polyvinyl alcohol-polyurethane elastic buffing wheel and a preparation method of the polyvinyl alcohol-polyurethane elastic buffing wheel. The preparation method comprises the steps that firstly, polyvinyl alcohol is mixed with distilled water, and the mixture is dissolved for 20-30 minutes under the condition of 50-95 DEG C water bath and at the rotation speed of 400-600r / min to obtain a polyvinyl alcohol aqueous solution; then, the polyvinyl alcohol aqueous solution is heated up to 30-100 DEG C, grinding materials are firstly added into the polyvinyl alcohol aqueous solution, after the mixture of the grinding materials and the polyvinyl alcohol aqueous solution is stirred and mixed evenly at the rotation speed of 400-600r / min, polyurethane pre-polymers, catalysts and air hole generating agents are added, and all the components are stirred and mixed evenly at the rotation speed of 400-600r / min and react for 5-10min; solidification is conducted for 2-4h under the condition of 30-100 DEG C, and then the buffing wheel which is good in elasticity, good in water resistance, good in heat-dissipating performance and high in mechanical strength is obtained. The elastic buffing wheel is even in foam hole, good in abrasion resistance and grinding force, not prone to deforming or curling in humid environment and applicable to long-time grinding work.

Owner:SOUTH CHINA UNIV OF TECH

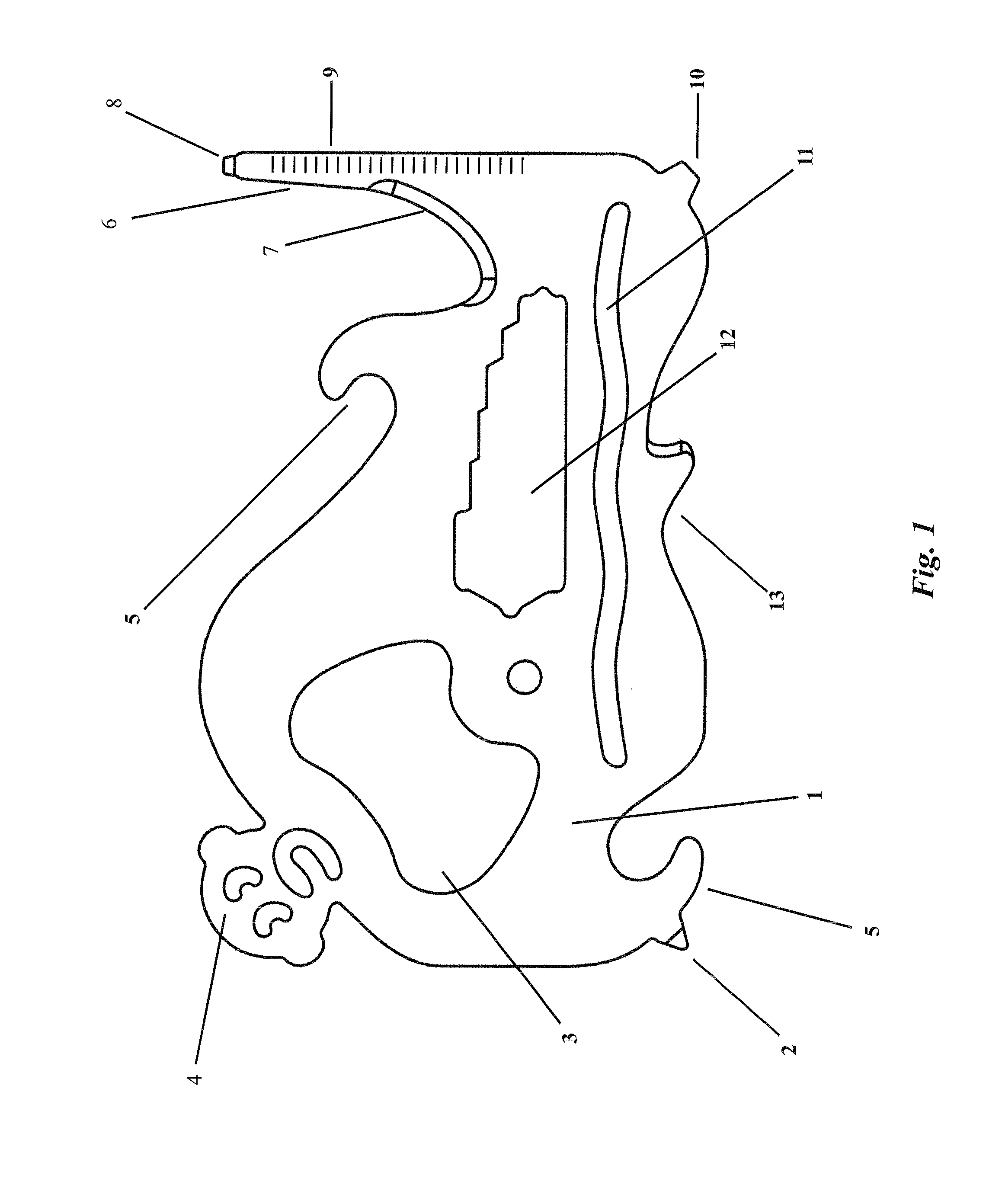

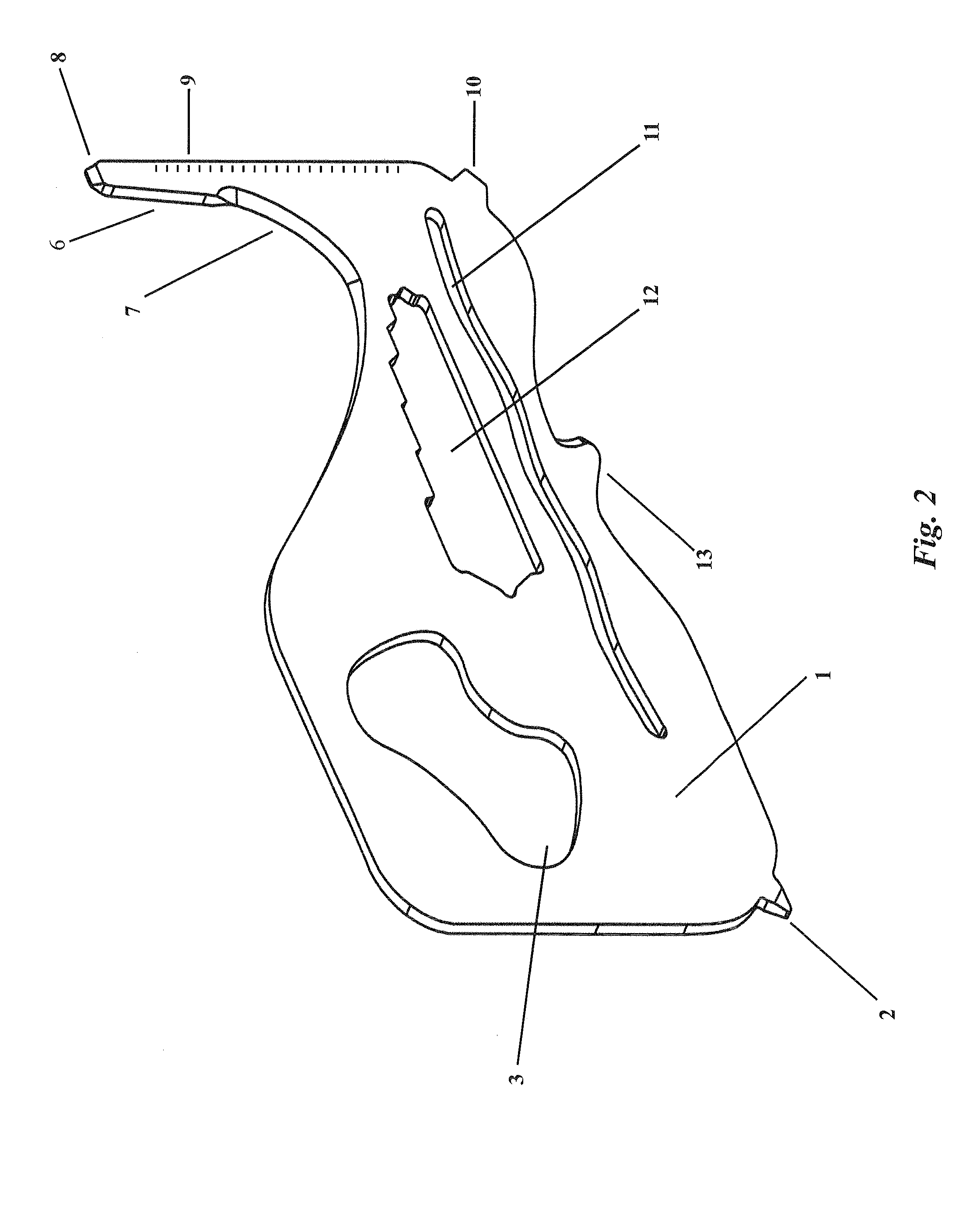

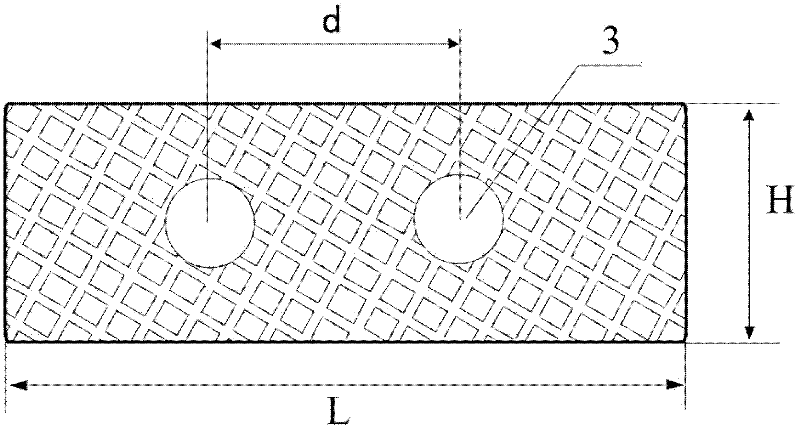

A bioactive porous titanium alloy human cervical intervertebral fusion device and its preparation method

ActiveCN102293693AEven by forceSolve the interface binding problemInternal osteosythesisMedical devicesMetallurgyDrug biological activity

The invention provides a porous titanium alloy human cervical interbody fusion cage with bioactivity and a preparation method thereof. The method comprises the following steps: firstly, inputting model data into electron beam melting equipment according to a design requirement to prepare a porous titanium alloy human cervical interbody fusion cage; secondly, preparing gelatin microspheres; and immersing gelatin microsphere dry powder in an rhBMP-2 solution for gelatin coating modification, preparing a gelatin solution A in double distilled water, immersing the porous titanium alloy human cervical interbody fusion cage in the gelatin solution A, mixing the rhBMP-2 gelatin microspheres and absolute ethanol to obtain suspension B, and immersing the gelatin-coating-modified porous titanium alloy human cervical interbody fusion cage in the suspension B to prepare the porous titanium alloy human cervical interbody fusion cage internally containing an rhBMP-2 sustained-release system. The cervical interbody fusion cage prepared with the method has modulus of elasticity close to that of natural bone tissues, and the porous structure and the bioactivity factor sustained-release system inside the cervical interbody fusion cage can induce growth of new bone tissues, so that the binding problem of bone-material interfaces is solved. Therefore, the cervical interbody fusion cage has bettermechanical compatibility and bone integration capability than those of a compact material.

Owner:维度(西安)生物医疗科技有限公司

Transparent solid oil cosmetics

ActiveUS20060280763A1High transparencyLarge transmittanceCosmetic preparationsHair removalWaxDiisostearyl malate

A solid cosmetic comprising components (A), (B), (C), and (D) below: (A) a polyamide resin; (B) diisostearyl malate; (C) a polyglyceryl isostearate; and (D) a liquid oil; and not containing a wax when the component (A) comprises only an ester-terminated polyamide resin.

Owner:KOKYU ALCOHOL KOGYO

No-shrinkage grouting filler with adjustable performance

The present invention belongs to the field of building material, and is especially one kind of no-shrinkage grouting filler with adjustable performance. The no-shrinkage grouting filler is hydraulic mixture comprising Portland cement and fly ash or silica fume as cementing material, quartzite, water reducing agent, expanding agent, water loss reducing agent, early settling preventing agent and early contract preventing agent. It has high flowability, no settling, no weeping, micro plastic expansion, no shrinkage, no cracking, adjustable performance, and no plastic settling and other excellent performance, and may be applied widely in installing large precise equipment, large area leveling, emergency repair engineering, etc.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Solid dust suppressant

InactiveCN104817997AHigh bonding strengthGuaranteed moisture contentOther chemical processesBursting strengthMoisture absorption

A solid dust suppressant is prepared by mixing 40-90% of a water-soluble high molecular polymer, 5-40% of water-soluble high molecular glue, 0-25% of a moisture absorption humectant, 0.5-5% of a flexibilizer, 1-5% of an antiseptic and 3-10% of an osmotic agent, and has the characteristics of high film forming strength, low brightness and moderate viscosity. The viscosity (at 25DEG C), the pH value, the wind loss rate (under 30mm / s wind speed 5mins, %), the cured layer thickness, the film tensile strength, the film elongation at break and the material bursting strength of the solid dust suppressant are not lower than 8.0mPa.s, 6.0-7.0, not greater than 0.40, not lower than 11.25mm, greater than 11mpa, greater than 13% and greater than 0.05mpa respectively, and the solid dust suppressant realizes difficult brittle rupture after film formation, has a long effective dust suppression time and an ideal dust suppression effect.

Owner:INNER MONGOLIA BORAN TECH CO LTD

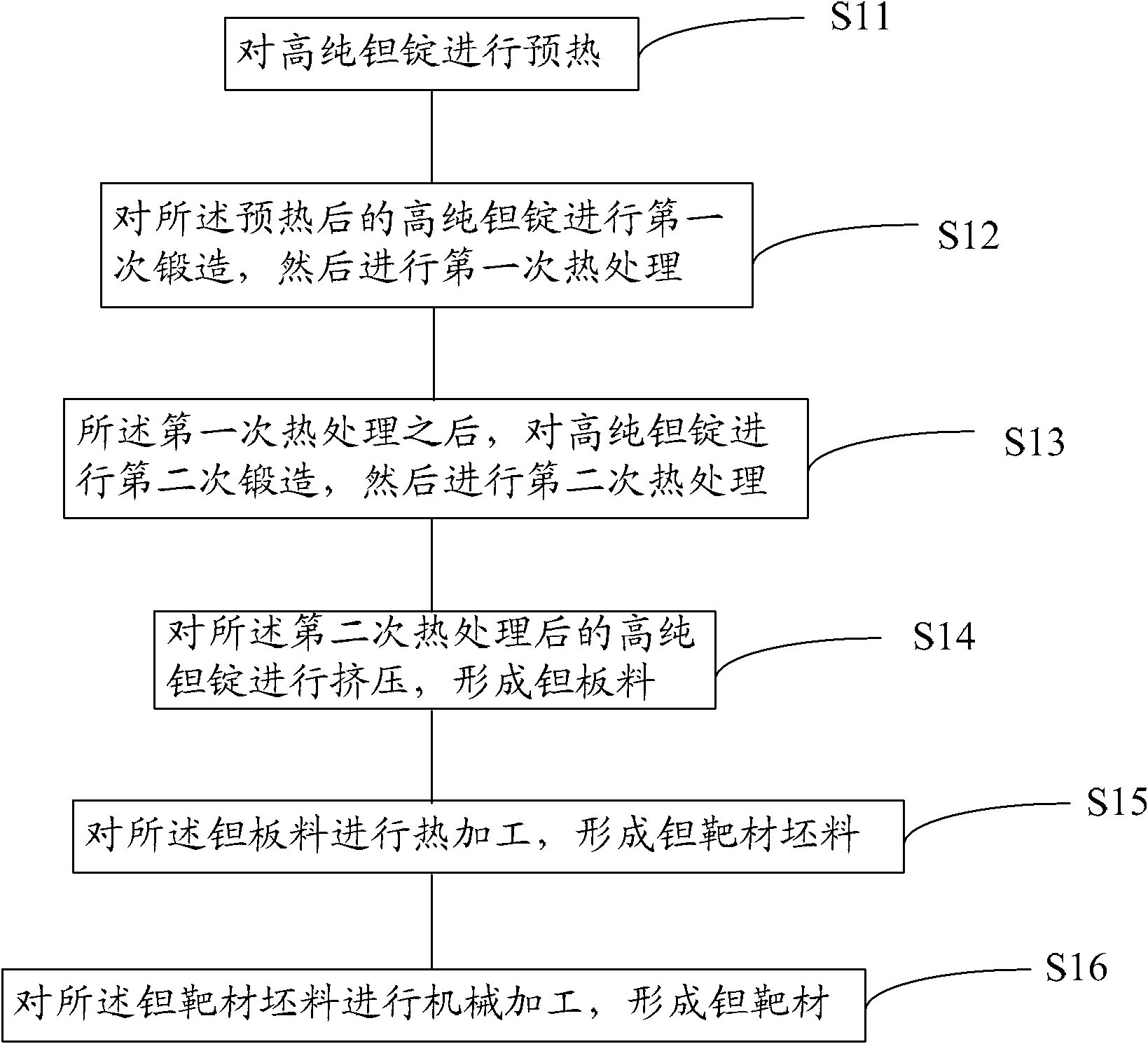

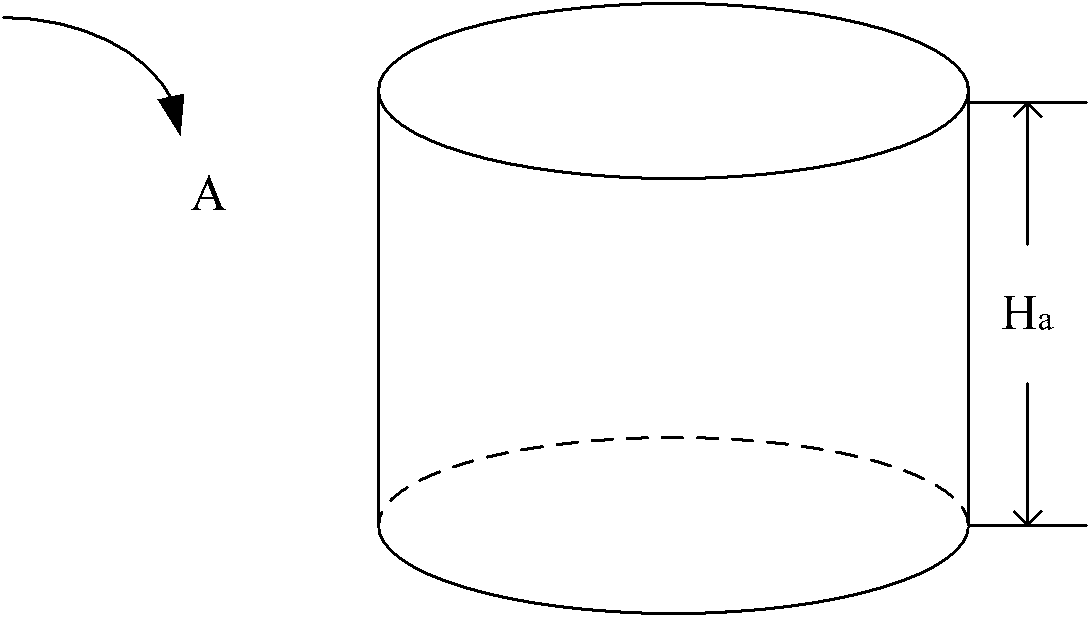

Method for preparing high-purity tantalum target

ActiveCN102517531ADense tissue structureFine and uniform grainVacuum evaporation coatingSputtering coatingSputteringCrystal orientation

A method for preparing a high-purity tantalum target comprises the following steps: preheating high-purity tantalum ingots; forging the preheated high-purity tantalum ingots by at least two times, wherein the high-purity tantalum ingots are heated after being forged each time; extruding the high-purity tantalum ingots after the high-purity tantalum ingots are heated for the last time, so as to obtain a tantalum board; heating the tantalum board to obtain a tantalum target blank; and machining the tantalum target blank to obtain the tantalum target. According to the process for preparing the tantalum target, the uniformity and the compactability of the tantalum target can be better, so as to meet the crystal particle requirements and the crystal orientation requirements of the tantalum target for semi-conductor sputtering.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

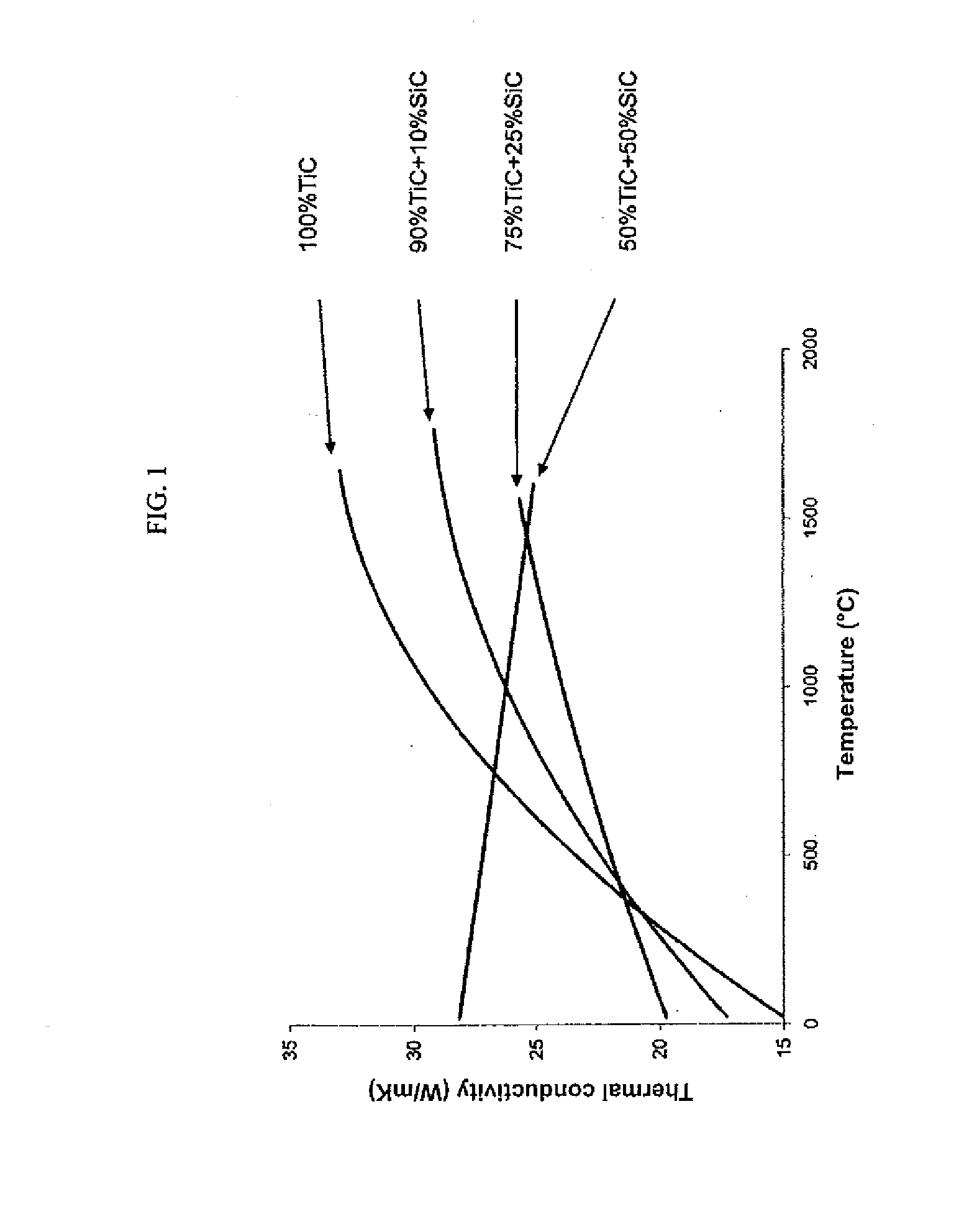

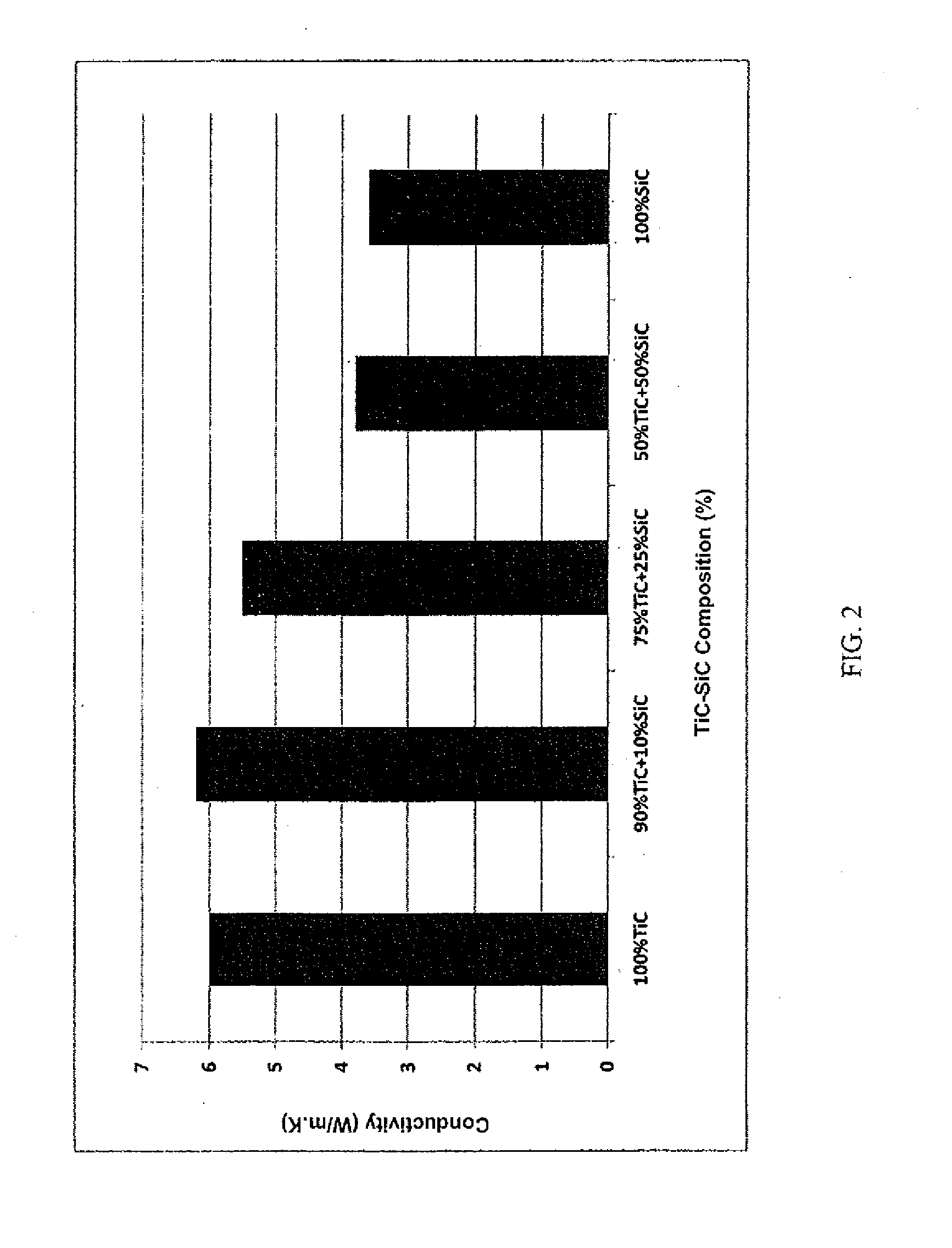

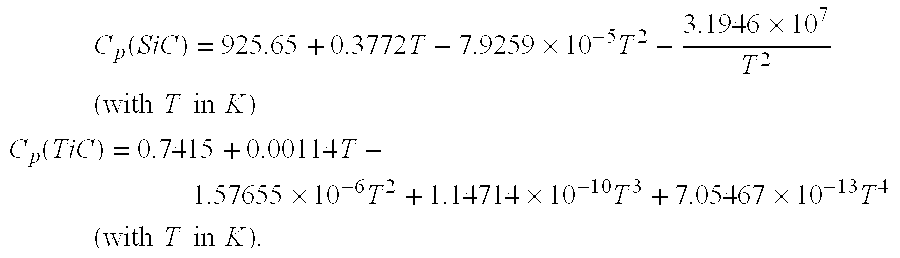

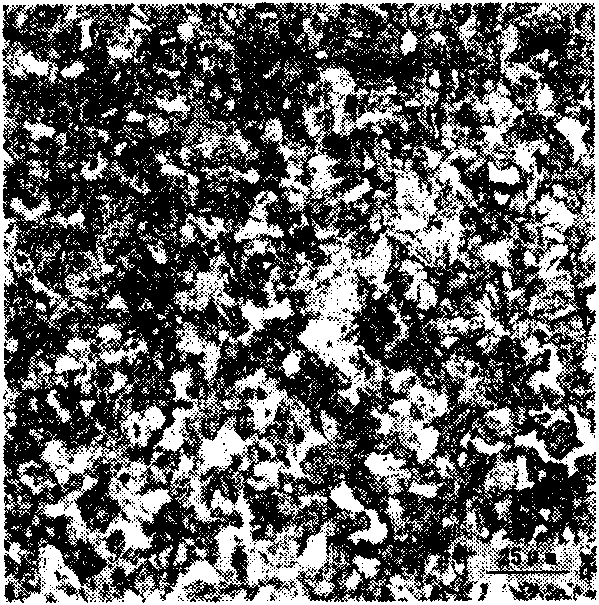

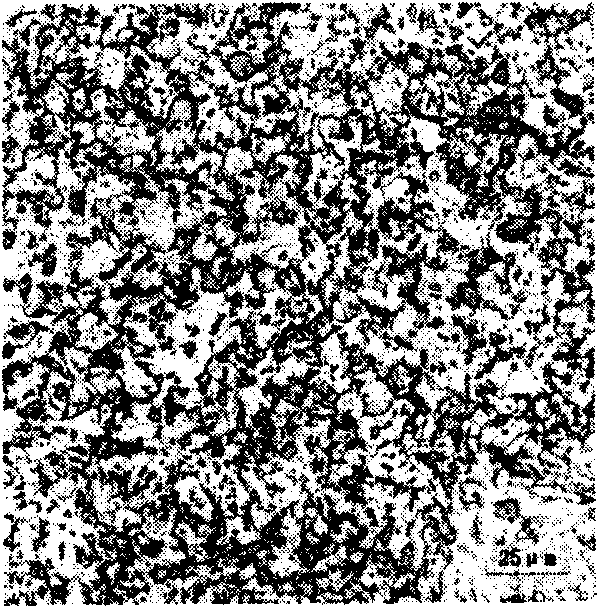

Nuclear fuel cladding with high heat conductivity and method for making same

ActiveUS20110170653A1Optimal transfer of thermal energyEasy transferFuel elementsNuclear energy generationThermal energyFiber

The invention relates to a nuclear fuel cladding totally or partially made of a composite material with a ceramic matrix containing silicon carbide (SiC) fibers as a matrix reinforcement and an interphase layer provided between said matrix and said fibers, the matrix including at least one carbide selected from titanium carbide (TiC), zirconium carbide (ZrC), or ternary titanium silicon carbide (Ti3SiC2).When irradiated and at temperatures of between 800° C. and 1200° C., said cladding can mechanically maintain the nuclear fuel within the cladding while enabling optimal thermal-energy transfer towards the coolant.The invention also relates to a method for making the nuclear fuel cladding.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Method for improving low-temperature impact toughness of high strength thick steel plate

InactiveCN101876001AHigh strengthImprove toughnessTemperature control deviceSheet steelChemical composition

The invention discloses a production method for improving the low-temperature impact toughness of a high strength thick steel plate, and belongs to the technical field of medium and thick steel plate production. The steel comprises the following chemical compositions: 0.05 to 0.15 percent of C, 0.15 to 0.40 percent of Si, 0.90 to 1.60 percent of Mn, less than 0.01 percent of P, less than 0.01 percent of S, 0.10 to 0.80 percent of Ni, 0.1 to 0.5 percent of Mo, 0.0008 to 0.0015 percent of B, 0.01 to 0.06 percent of microalloy element Nb, 0.01 to 0.07 percent of V, 0.01 to 0.03 percent of Ti and the balance of Fe; the thick steel plate is produced by soft reduction technology in a continuous casting process under the condition that a compression ratio is less than 4.0; and by a heat treatment process which comprises the steps of quenching, quenching and tempering, the texture of the steel plate after double quenching is controlled to be a hybrid texture with a hard phase and a soft phase, and the requirements on steel plate strength and low-temperature toughness are met at the same time. Under a small compression ratio, the thick steel plate has the performance equivalent to that of a thin steel plate by the combination of the heat treatment process and texture control; and compared with the methods such as die casting, forging and the like, the method is simple and feasible, and has high yield and low production cost.

Owner:SHOUGANG CORPORATION

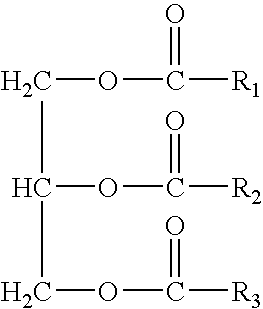

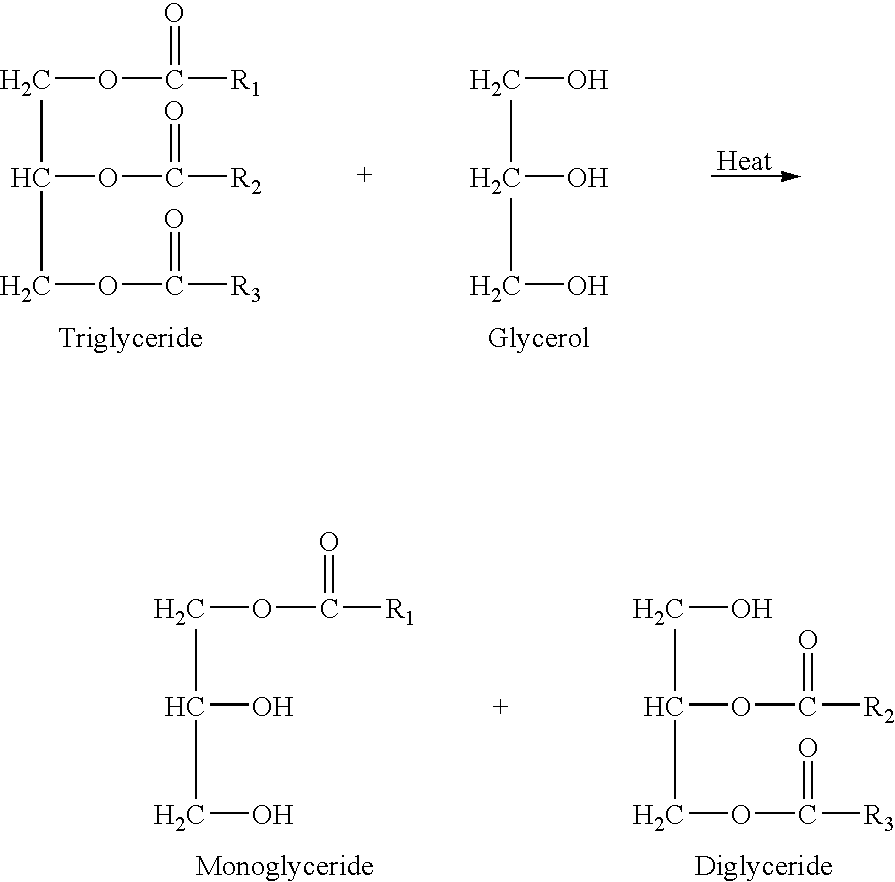

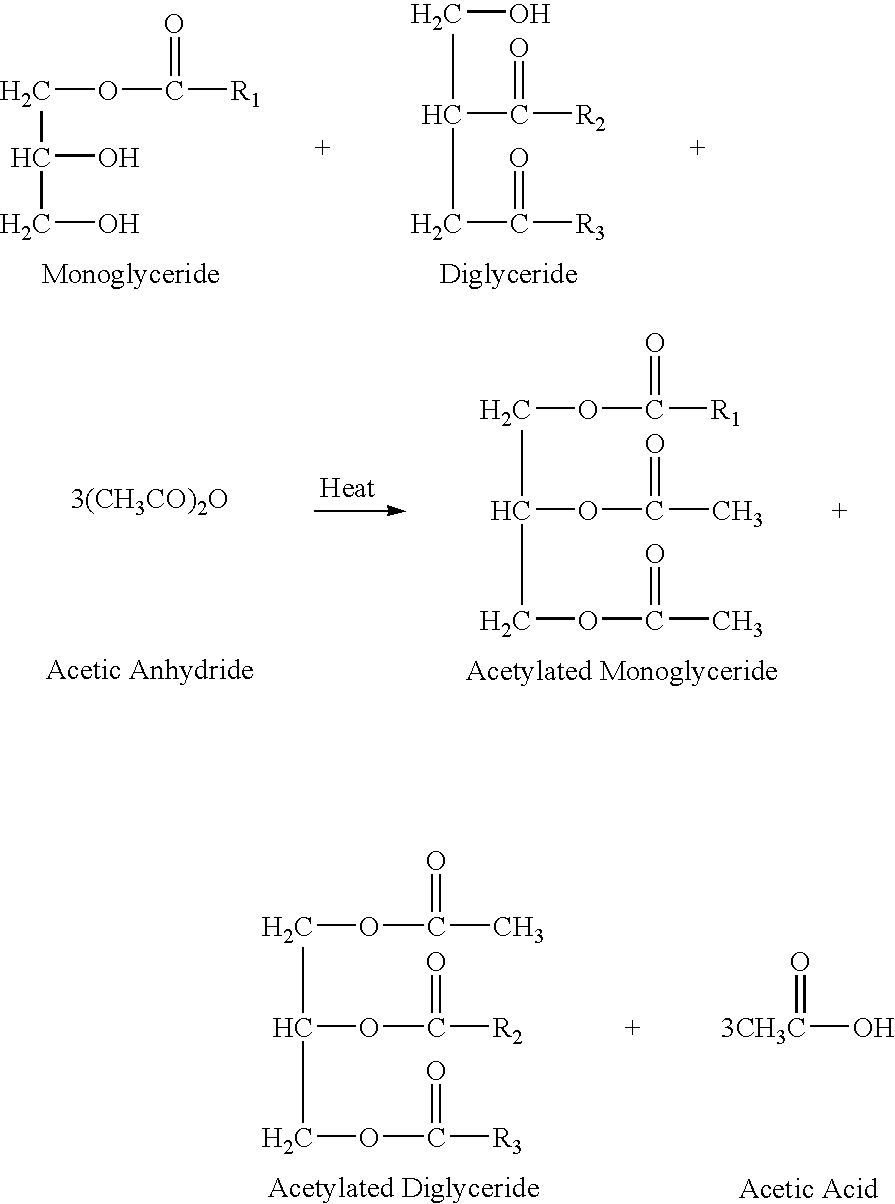

Acetylated wax compositions and articles containing them

InactiveUS7510584B2Increase flexibilityGood chemical stabilityCosmetic preparationsOrganic chemistryWaxDental flossing

A wax composition is provided having high melt temperature, flexibility, pliability and chemical stability. The wax composition includes an acetylated wax including an acetylated glyceride and, optionally, a plant-based wax. The wax composition is useful for candle wicks, dental floss, candle bodies and other articles where these properties are advantageous.

Owner:CAP DANIEL S

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com