Patents

Literature

1291 results about "Nylon material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nylon is a generic designation for a family of synthetic polymers, based on aliphatic or semi-aromatic polyamides. Nylon is a thermoplastic silky material that can be melt-processed into fibers, films or shapes.

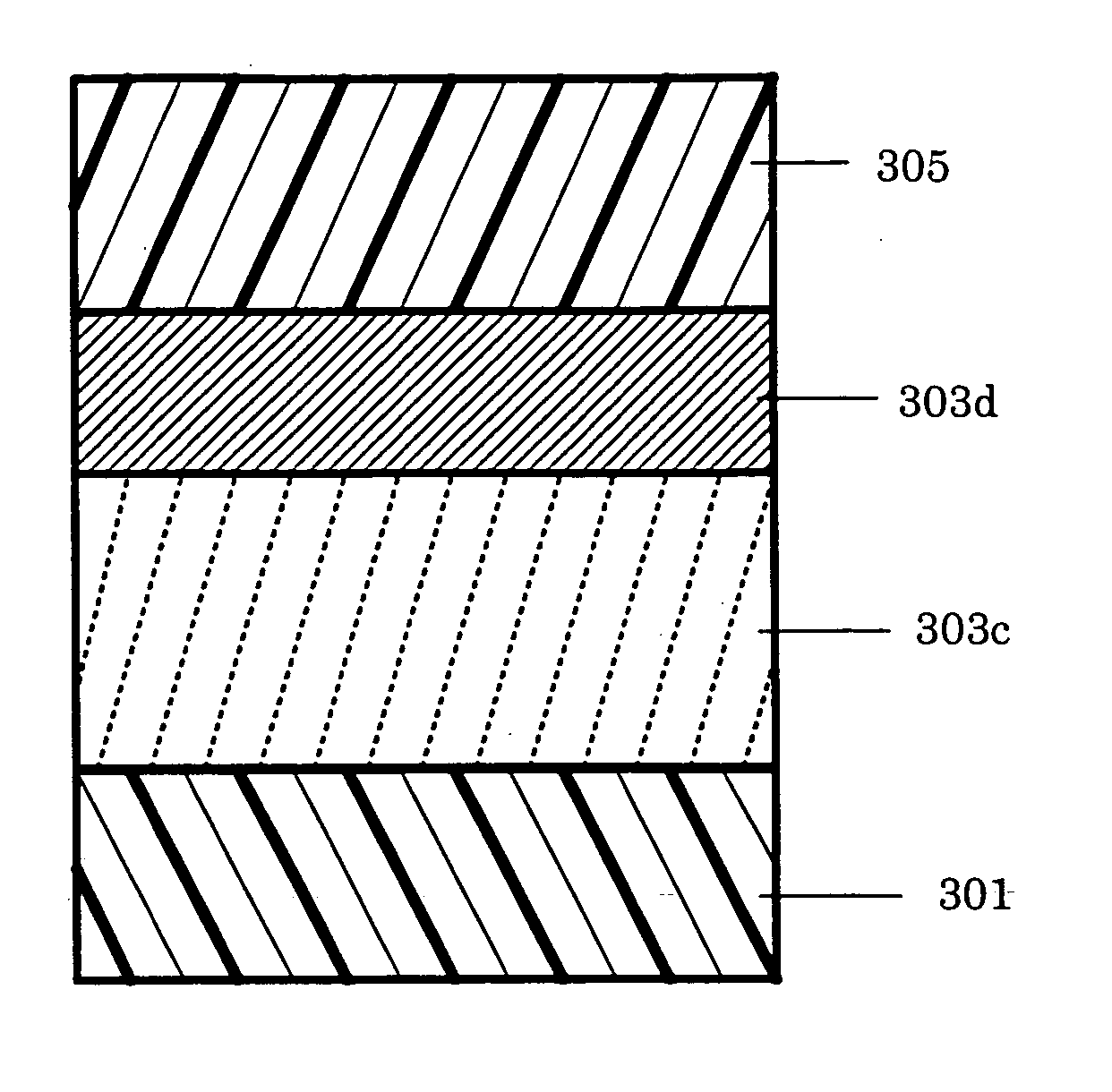

Coating liquid for intermediate layer in electrophotographic photoconductor, electrophotographic photoconductor utilizing the same, image forming apparatus and process cartridge for image forming apparatus

ActiveUS20060057479A1Prevent gelationAvoid viscosity increaseElectrographic process apparatusCoatingsNylon materialElectrical conductor

A coating liquid for an intermediate layer of an electrophotographic photoconductor comprises at least one of alcohol solvents; and N-methoxymethylated nylon, in which the N-methoxymethylated nylon has solution viscosity within a range from 43 mPa·s to 50 mPa·s when dissolving into methanol at 30° C. in a concentration of 20% by mass.

Owner:RICOH KK

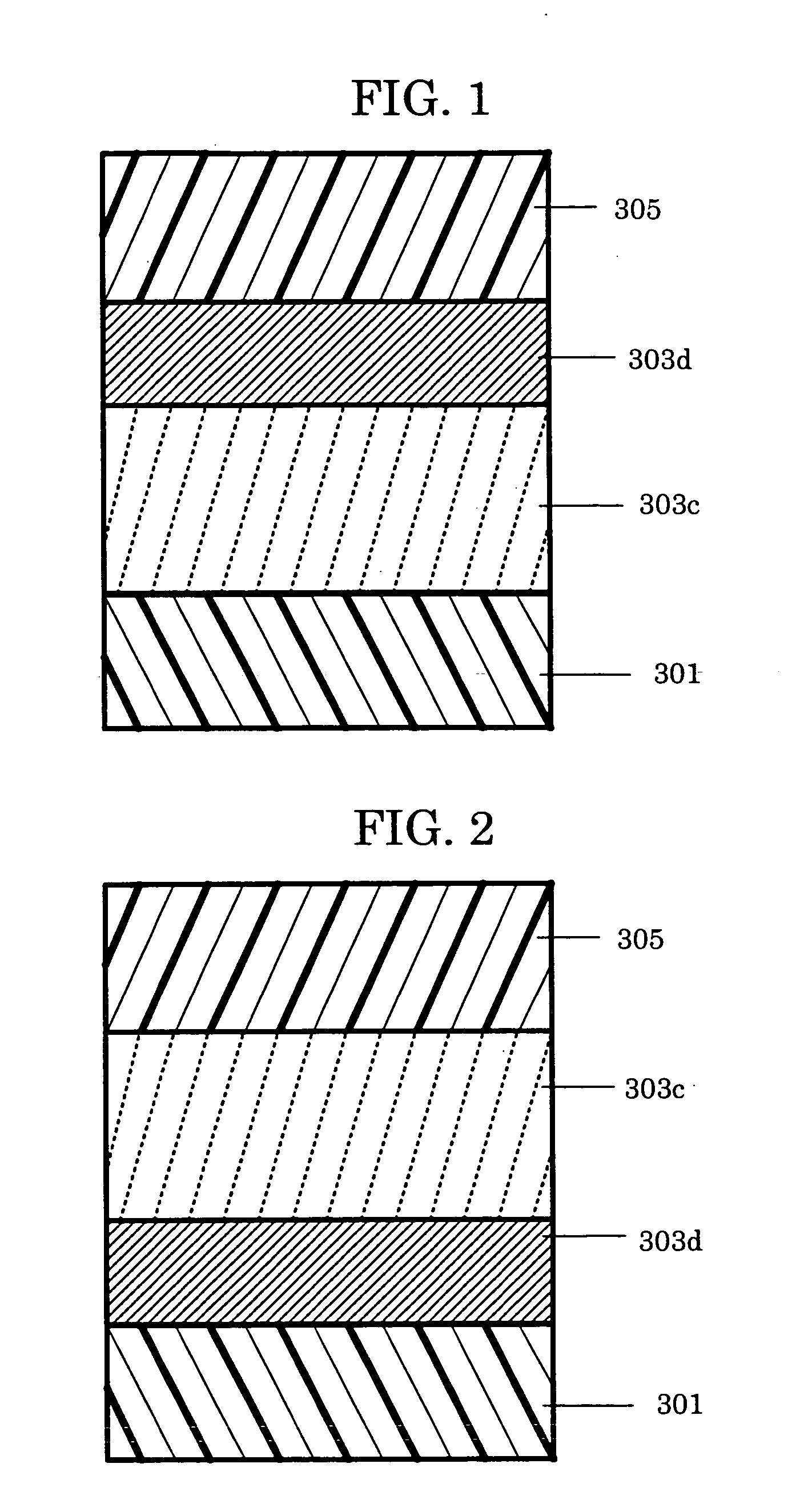

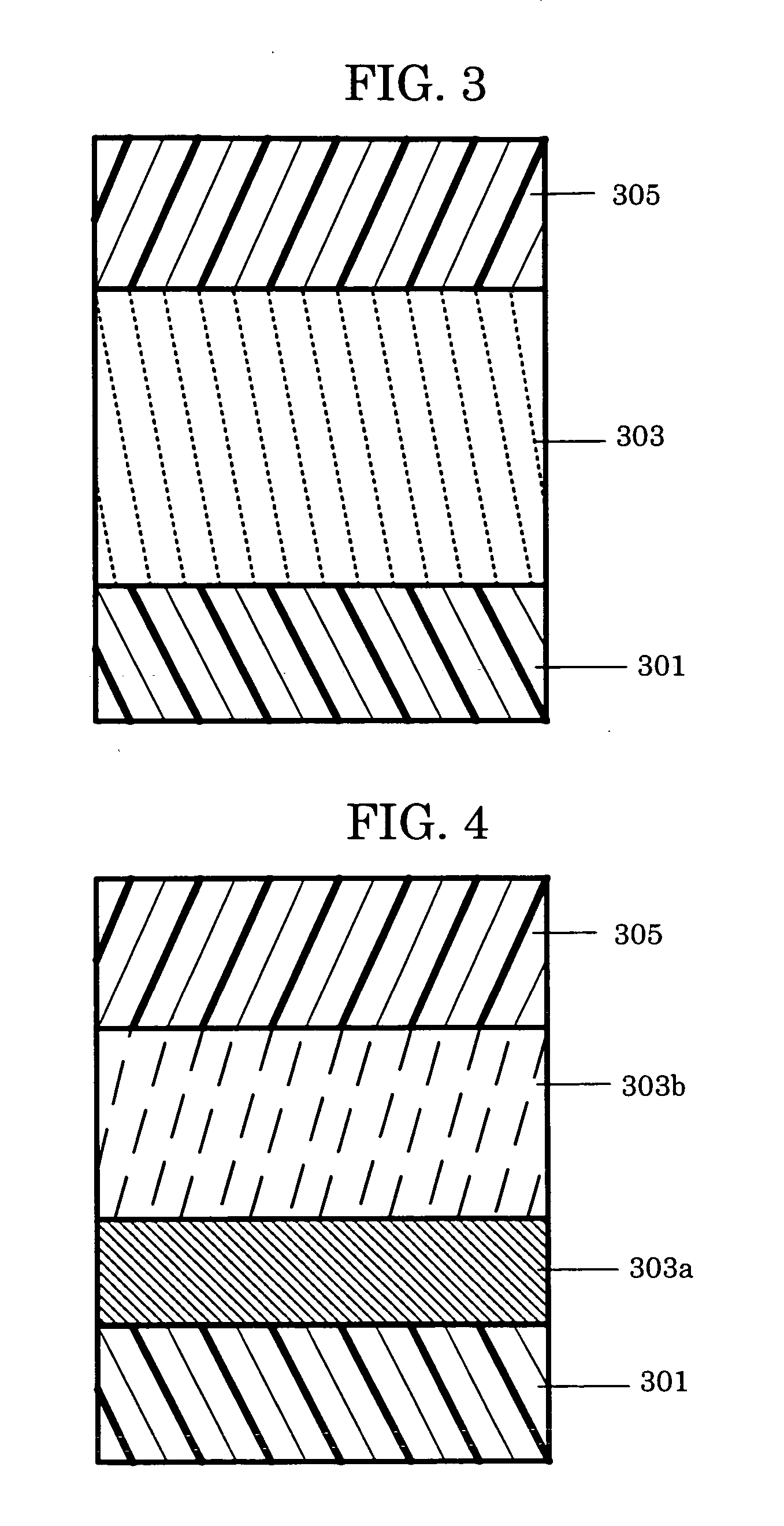

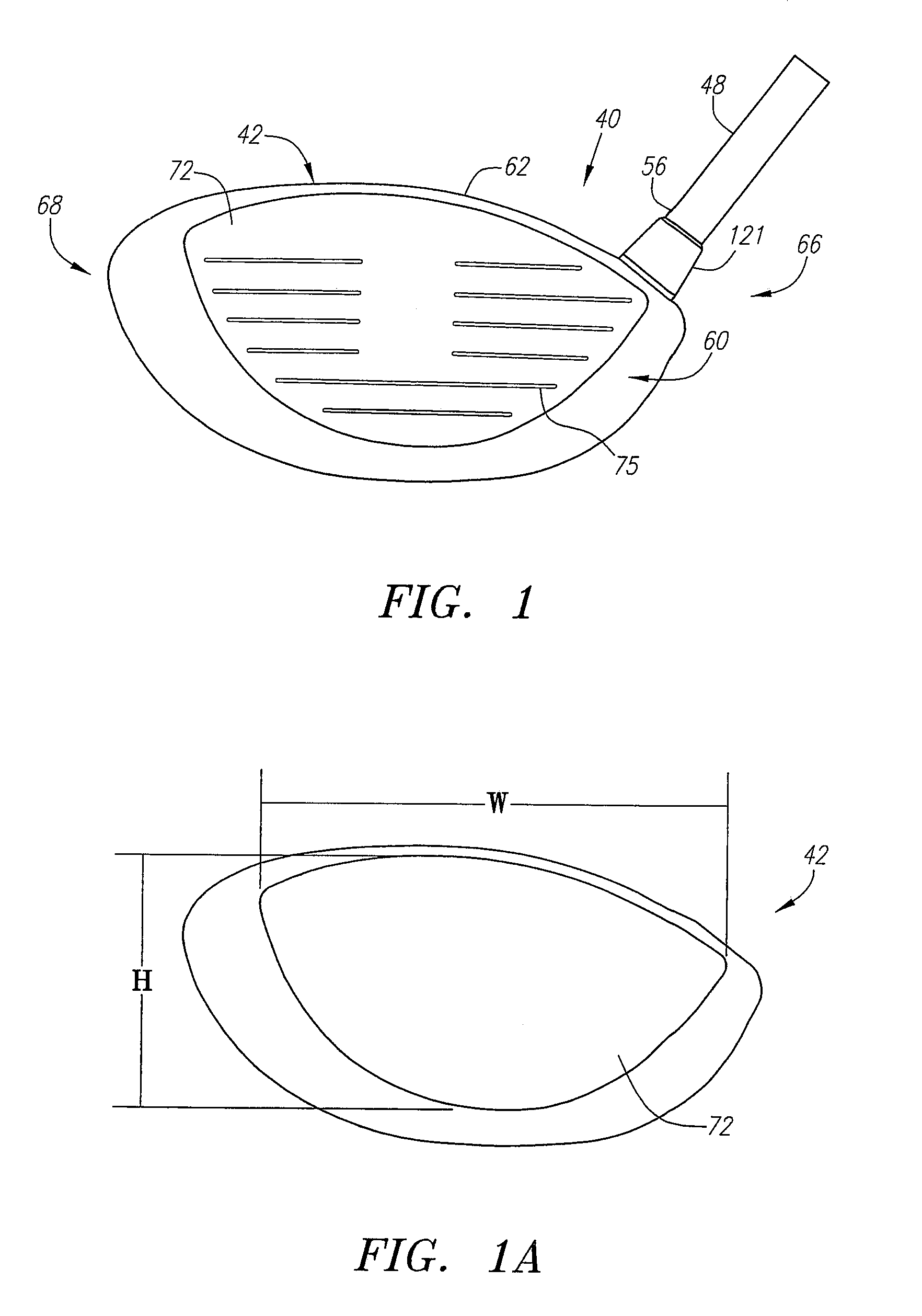

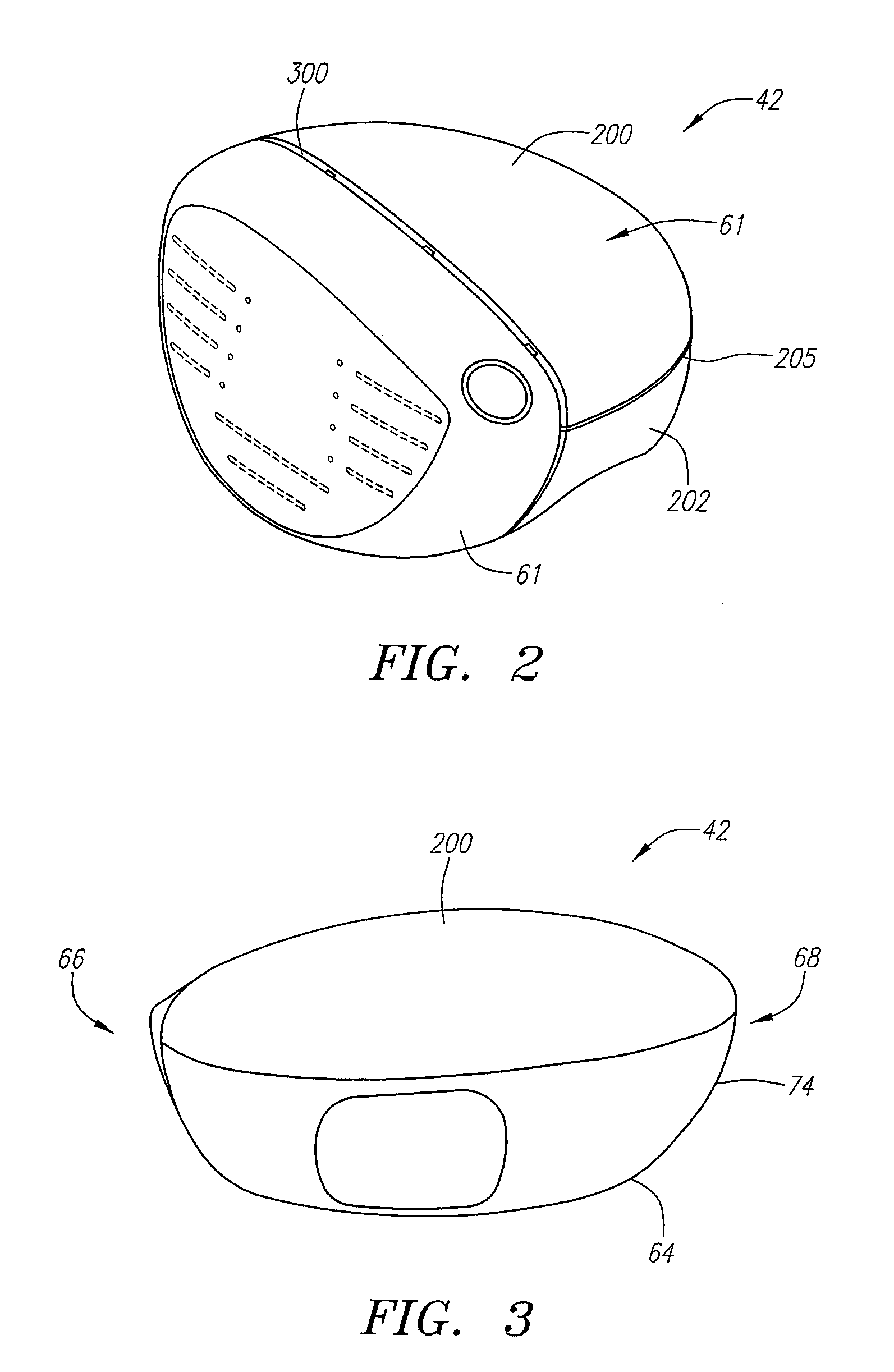

Nanocrystalline plated golf club head

A golf club (40) having a club head (42) with a face component (60) and an aft body (61) is disclosed herein. The face component (60) has a striking plate portion (72) and a return portion (74). The aft-body (61) is composed of a crown portion (62), a sole portion (64) and optionally a ribbon section (90). The face component (60) is composed of a metal material, and the aft-body (61) is composed of an injectable polymer material such as a nylon. A plating layer (300) is disposed on at least a portion of the aft-body (61). The plating layer (300) preferably comprises a nanocrystalline material. The club head (42) preferably has a volume in the range of 290 cubic centimeters to 600 cubic centimeters.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Polyester films and methods for making the same

The present invention is directed to blended monolayer films and multilayer films having odor barrier properties, methods of making such films, and bags made from such films. Blended monolayer films include blends of non-elastic polyesters and blends of non-elastic polyesters, polyester thermoplastic elastomers, polyolefins, or combinations thereof. Multilayer thermoplastic films include a plurality of layers of film. The plurality of layers of film includes at least one non-elastic polyester layer of film and at least one additional layer of film. The one additional layers of film can be polyester thermoplastic elastomer layers, polyolefin layers, nylon layers, and combinations thereof. Blended monolayer films and multilayer films are a substantial odor barrier for at least 3 days and have a gauge thickness of from about 0.00015 to about 0.01 inches.

Owner:M & Q PLASTIC PROD

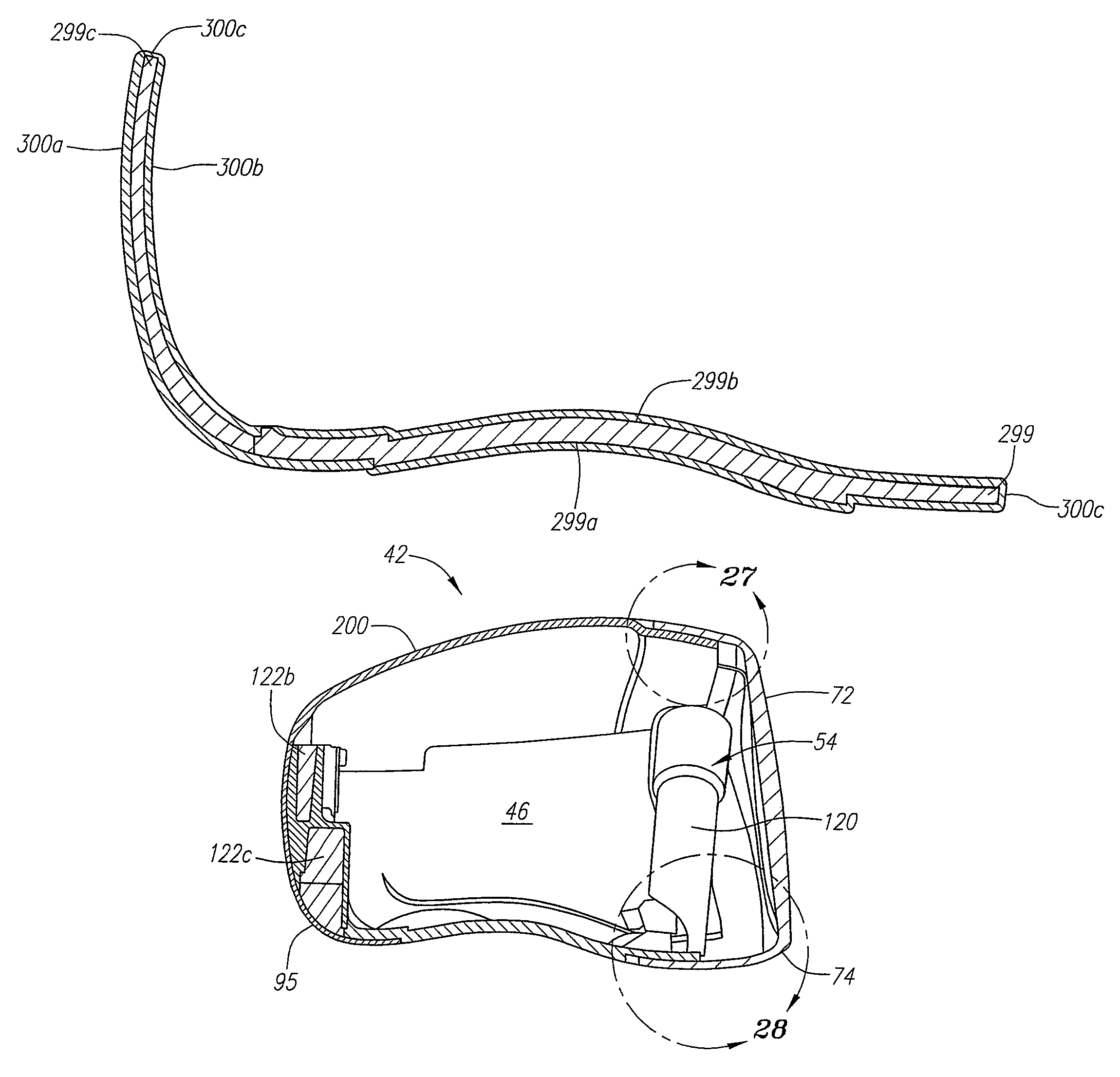

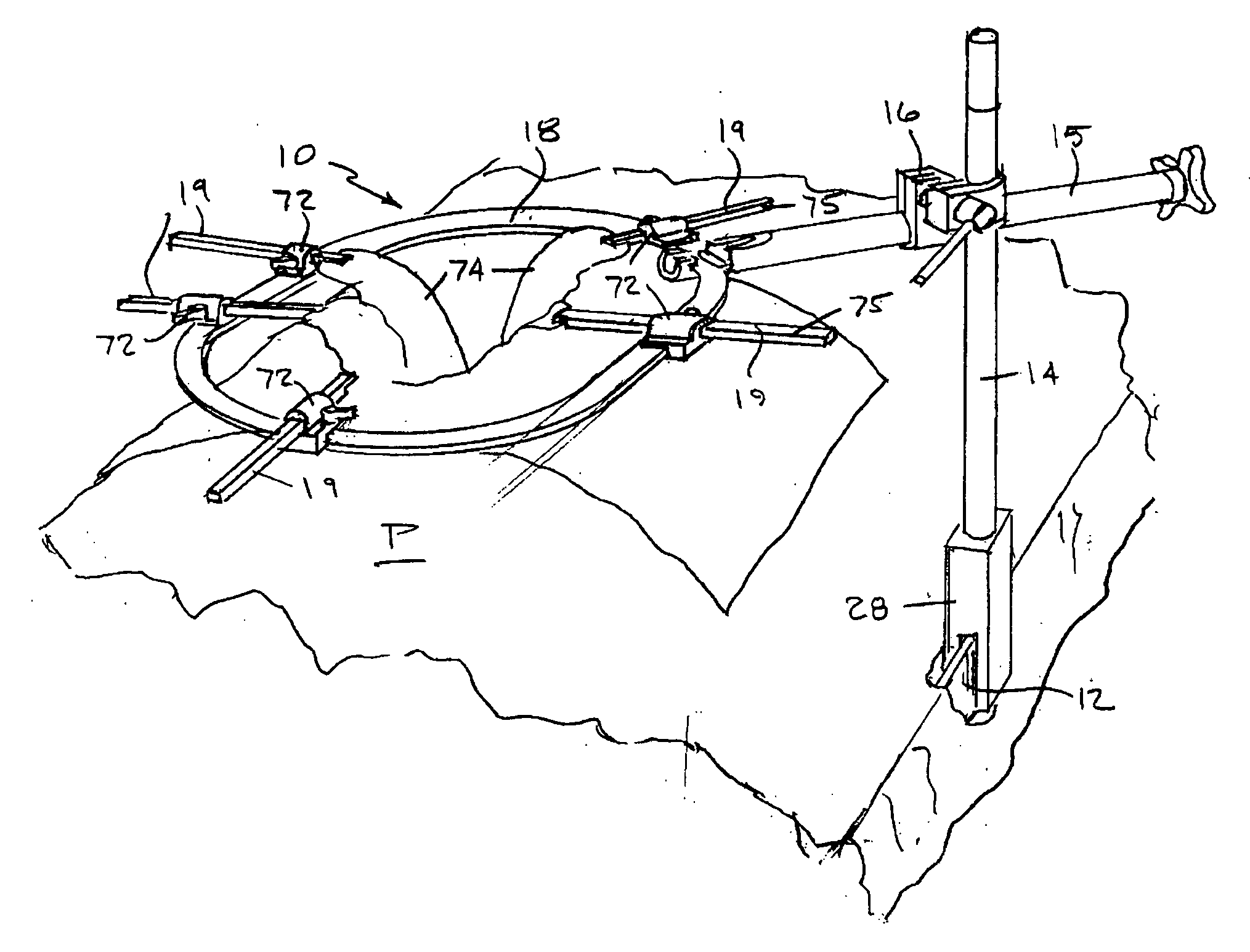

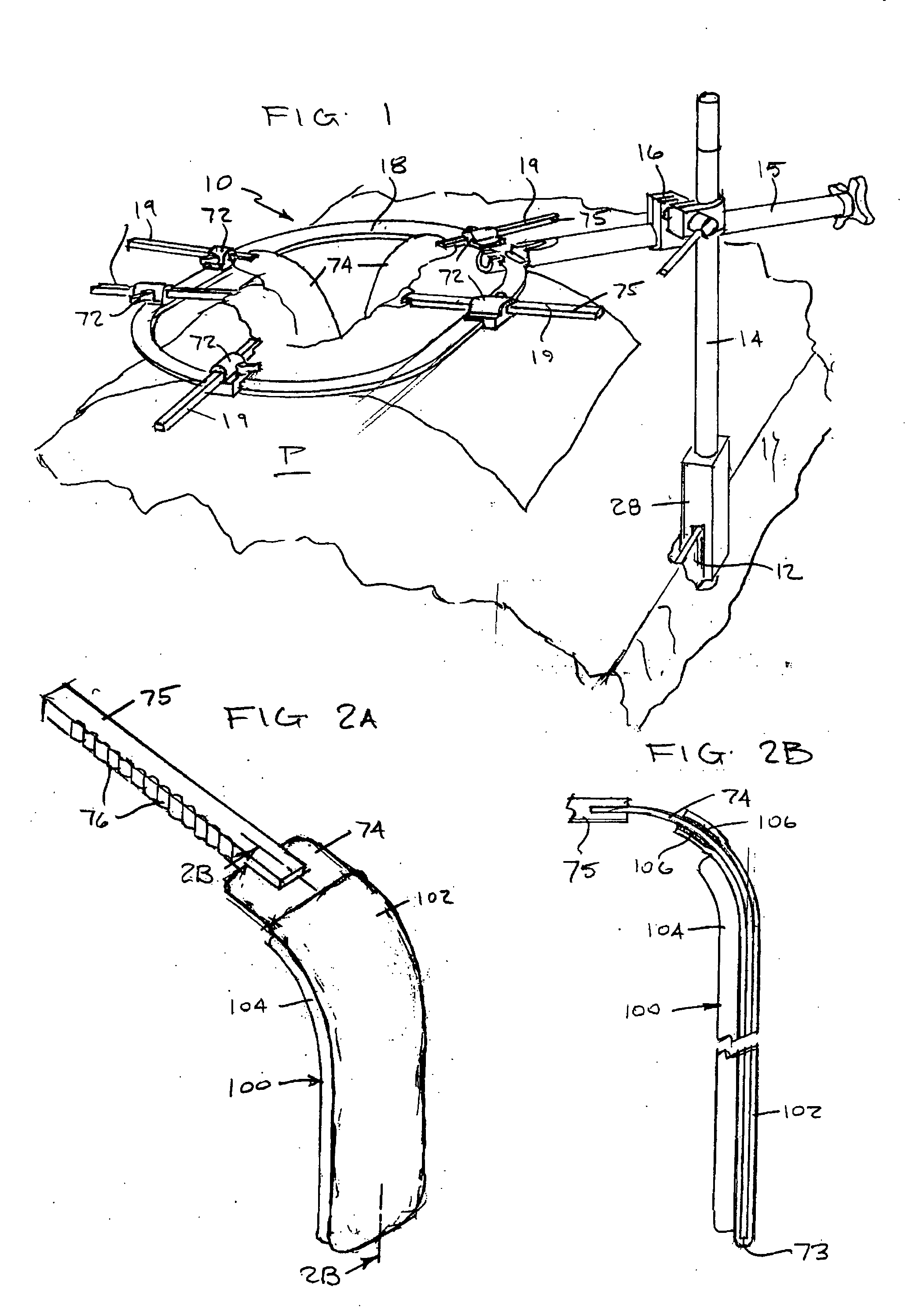

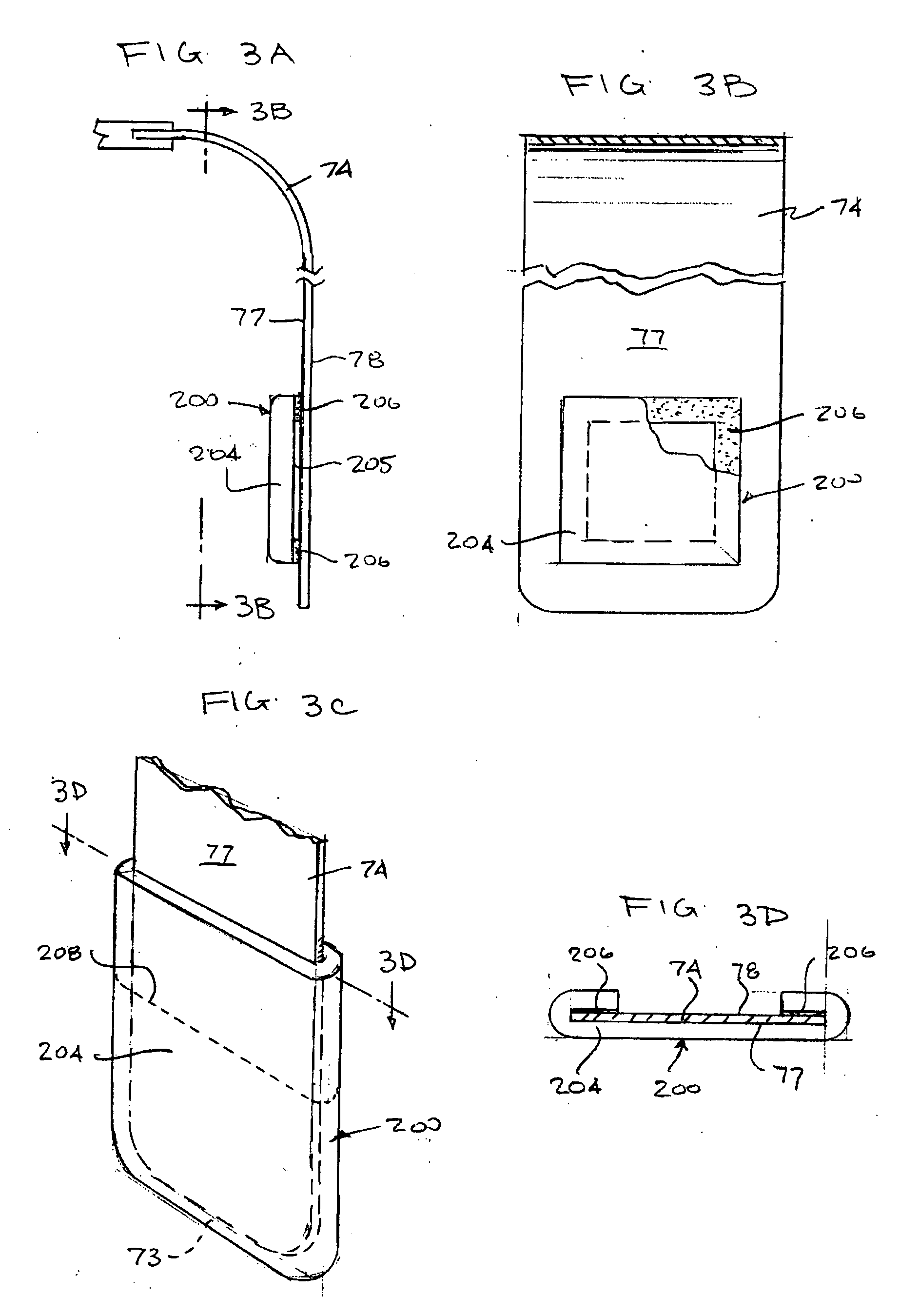

Disposable padding for a self-retaining retraction device

InactiveUS20060084843A1Easy to disassembleGood removal effectDiagnosticsSurgical drapesNylon materialBand shape

A disposable cover for a retractor of a self-retaining retractor system has an elastic sheath that can be easily placed and removed by elastically engaging the blade and a disposable pad attached on the elastic sheath. The elastic sheath can be an open cylinder (band shaped) or closed at one end (sock shaped) and is sized to cover a majority of the different size and shaped retractor blades. The elastic sheath retains the disposable pad on the blade by elastic compressive force. A single elastic sheath must be elastic enough to accommodate multiple sized blades and retain them in a fixed position while the blade is approximately vertically disposed within patient. The elastic sheath can be made from latex, nylon or any other surgical grade elastic or elastic type product.

Owner:CODMAN & SHURTLEFF INC

Glass fiber reinforced polyamide/polyester alloy and preparation method thereof

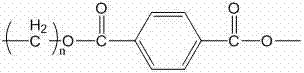

The invention discloses a glass fiber reinforced polyamide / polyester alloy and a preparation method thereof. The glass fiber reinforced polyamide / polyester alloy consists of the following components in percentage by weight: (A) 99-30 percent of resin component and (B) 70-1 percent of glass fiber, wherein the resin component (A) consists of the following components in percentage by weight: (1) 97-1 percent of polyamide of which the intrinsic viscosity is 1.8-3.0 dL / g, (2) 97-1 percent of polyester of which the intrinsic viscosity is 0.6-0.9 dL / g, (3) 1-20 percent of compatilizer and (4) 1 percent of other aids. The preparation method comprises the following steps of: weighing the materials with an electronic metering scale; feeding the materials into a dual-screw extruder respectively; and melting and mixing together to obtain a high-strength and high-toughness glass fiber reinforced polyamide / polyester alloy. The method is simple, and the performance of the obtained polyamide / polyester alloy is higher than that of a glass fiber reinforced nylon material.

Owner:KINGFA SCI & TECH CO LTD +1

Nylon modified plastic

The invention discloses a nylon modified plastic which comprises the following raw materials in parts by weight: (1) 20-80 parts of nylon resin; and (2) one or more of 15-45 parts of reinforcer, 5-20 parts of toughener or 9-15 parts of compound flame retardant, wherein the nylon resin is prepared from pentamethylene diamine and aliphatic dibasic acid used as raw materials, and at least one of the pentamethylene diamine and the aliphatic dibasic acid is prepared through a biological method. The nylon modified particle prepared by the invention has excellent properties of reinforcing, toughening, flame retardance and the like, can be further used in the fields of automobile industry, electronic / electric apparatus industry, mechanical equipment and the like, and has wide industrial application prospects.

Owner:CATHAY R&D CENT CO LTD +1

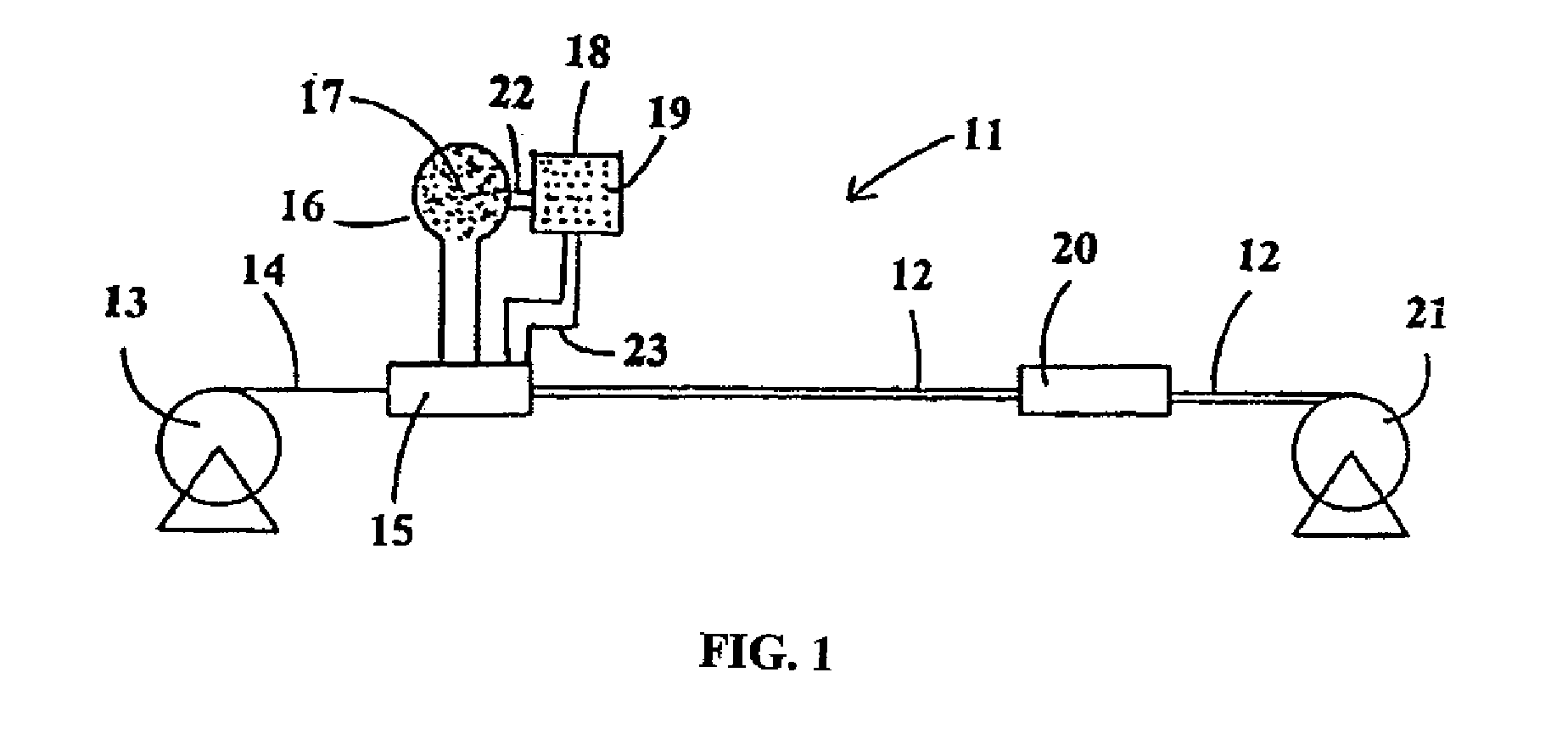

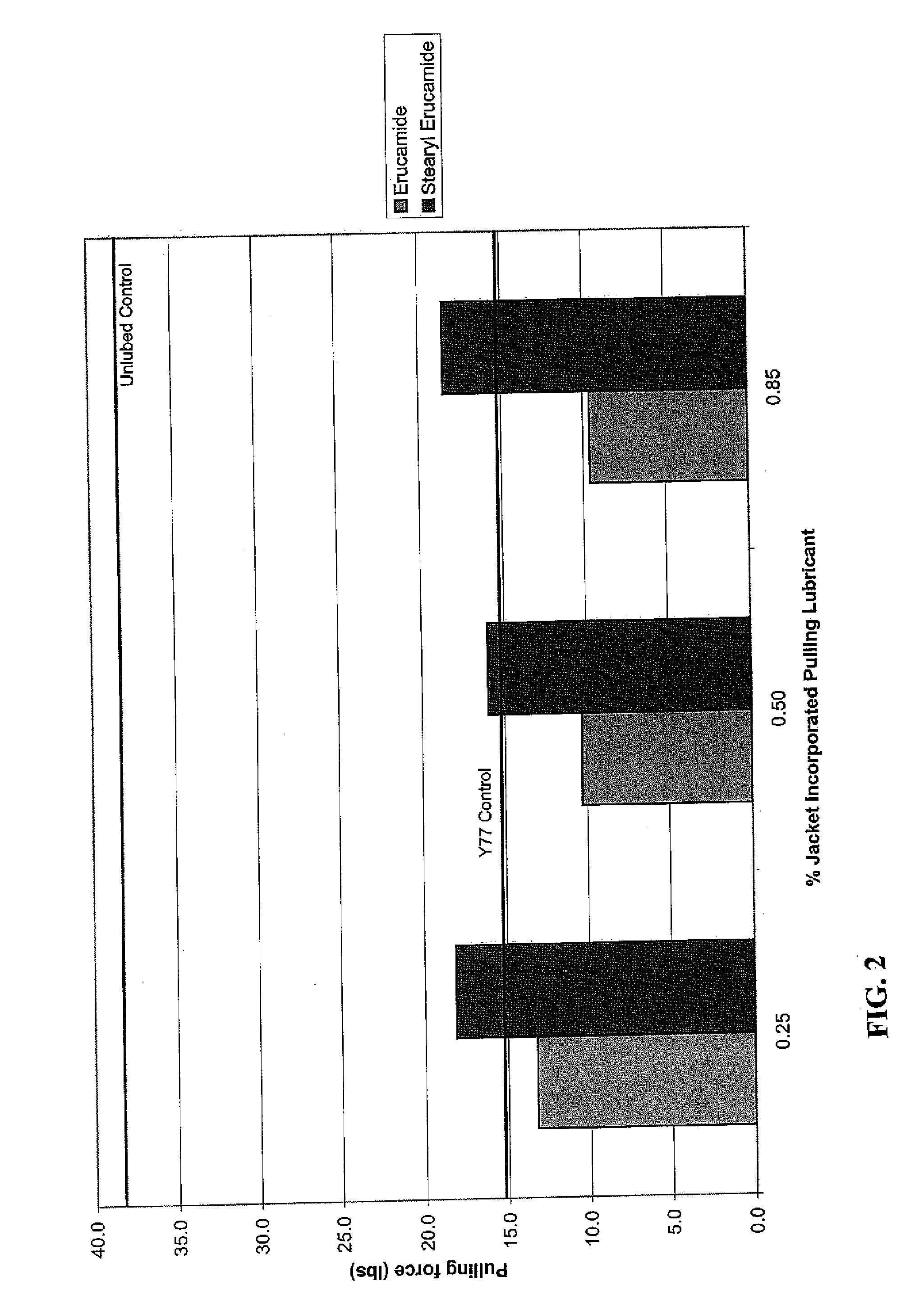

Method of manufacturing electrical cable, and resulting product, with reduced required installation pulling force

ActiveUS20100230134A1Reduce coefficient of frictionLower surfaceLine/current collector detailsLiquid organic insulatorsNylon materialElectrical conductor

Disclosed is type THHN cable having a reduced surface coefficient of friction, and the method of manufacture thereof, in which the central conductor core and insulating layer are surrounded by a nylon sheath. A high viscosity, high molecular weight silicone based pulling lubricant for THHN cable, or alternatively, erucamide or stearyl erucamide for small THHN gauge wire, is incorporated, by alternate methods, with the nylon material from which the outer sheath is extruded, and is effective to reduce the required pulling force on the cable during installation.

Owner:SOUTHWIRE CO LLC

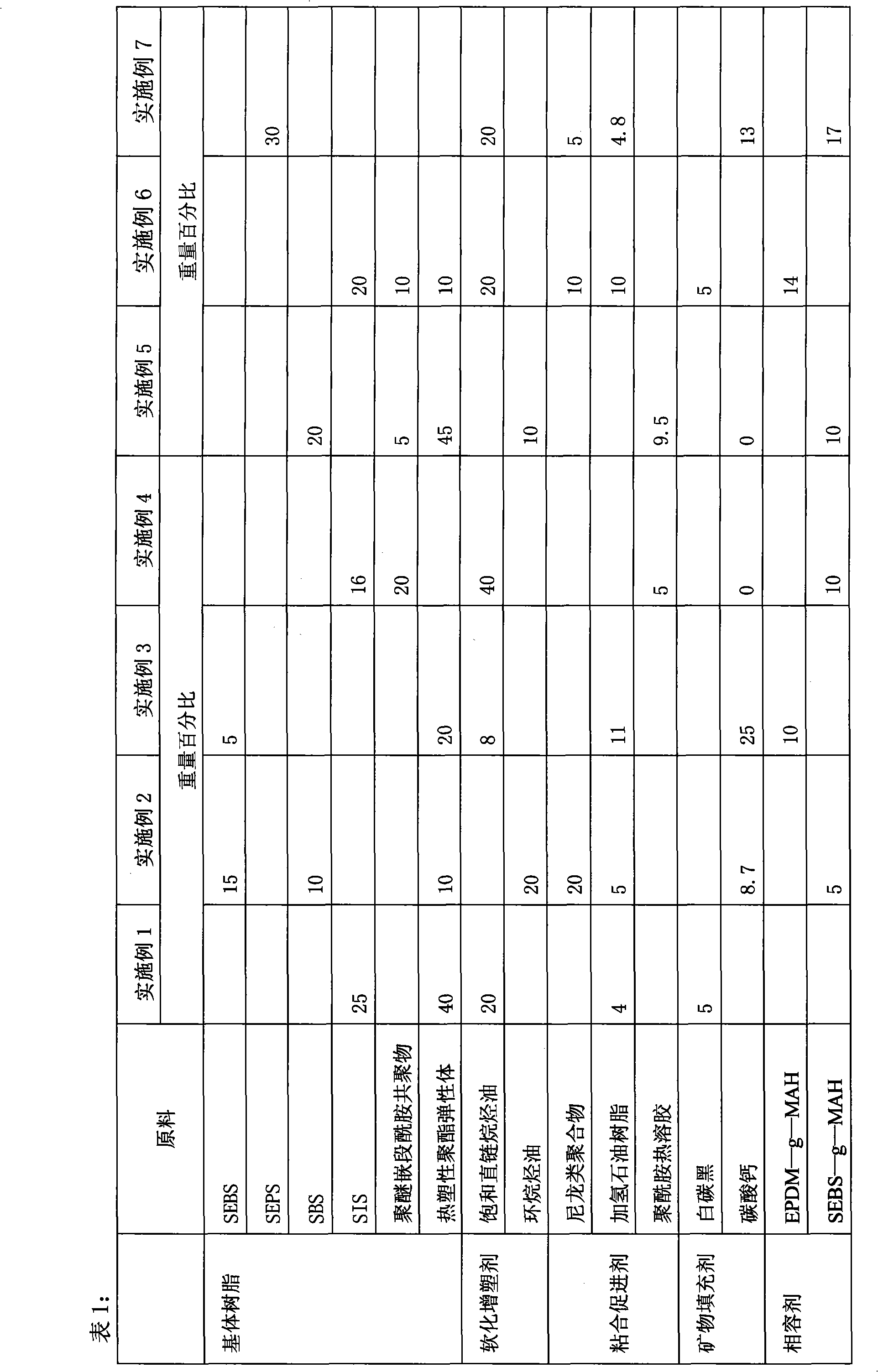

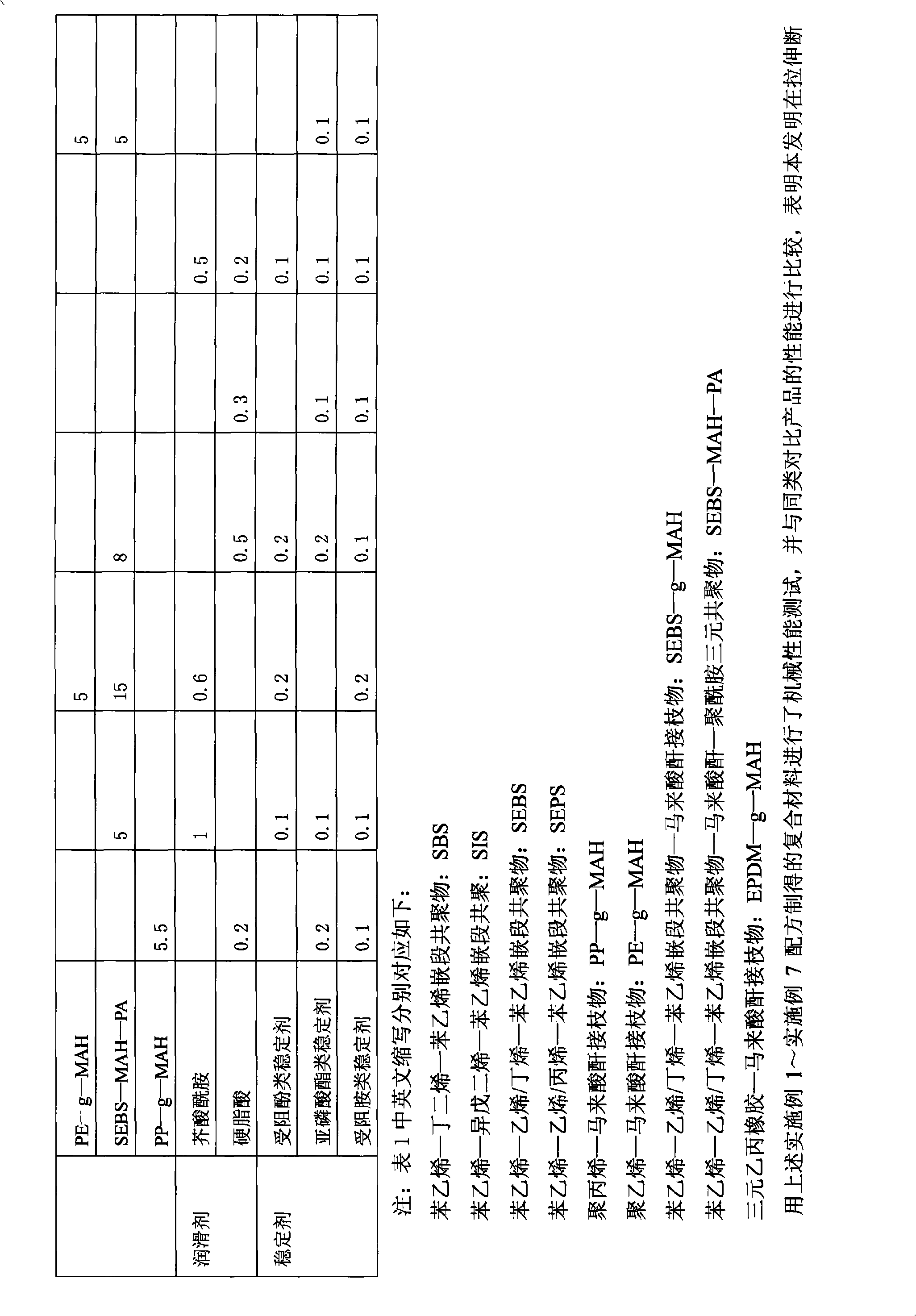

Thermoplastic elastomer capable of coating and bonding with nylon

The invention provides a thermoplastic elastomer coated and bonded by nylon, comprising matrix resin, softened plasticizer, adhesion promotor, mineral filler, lubricant and stabilizer, wherein the weight percentage of the material is as follow: resin 20-75%, softened plasticizer 5-45%, adhesion promoter1-30%, mineral filler 0-3%, compatiblizing agent 5-35%, lubricant 0-2%, stabilizer 0-2%. The matrix resin also comprises: thermoplasticity polyurethane elastomer or polymerized silica block amide copolymer, which makes the thermoplastic elastomer with good physical property, in addition a great variety of compatiblizing agents are used, therefore each component fully and mutually dissolves with each other to reduce the occurence of delamination, and the solubility of the composite material to the other engineering plastics, so that the thermoplastic elastomer is firmly adhesive on the surface of the nylon material without any bonding agent by twice injection of plastic jetting-moulding machine or extruder, and coating adhesive on the material such as ABC, PC. The market prospect is increased.

Owner:NINGBO SHIP PLASTIC CO LTD

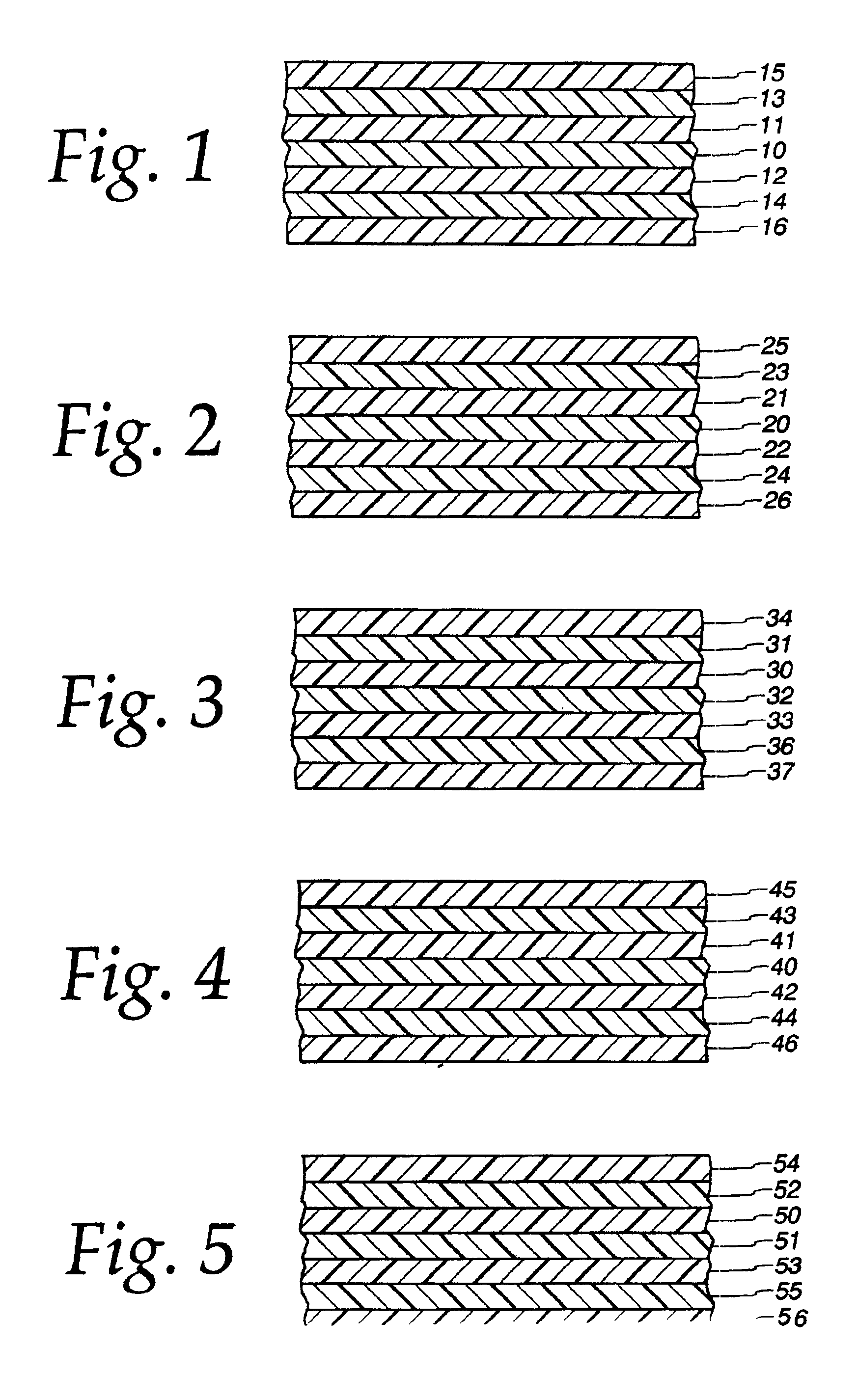

Polymer compositions and films and method of making

InactiveUS20070092744A1Maintain good propertiesHigh glossSynthetic resin layered productsThin material handlingNylon materialPolymer science

Polymer compositions, single layer films and multiple layer films, where the composition and / or a layer of a film has base polymer of either amorphous nylon or EVOH, and a modifying semi-crystalline nylon component. Where the base polymer is amorphous nylon, the modifying nylon composition includes a first relatively lower melting temperature nylon, and typically a second relatively higher melting temperature nylon. Where the base polymer is EVOH, the modifying semi-crystalline nylon composition can optionally be defined completely by the relatively lower melting temperature nylon, which has a melting temperature less than 170 degrees C. Blends of disclosed amounts of amorphous nylon or EVOH with the semi-crystalline nylon component can be used to produce films which can be uniaxially oriented or biaxially oriented to provide shrink capacities of at least 28 percent, and up to about 57 percent or more.

Owner:PLASTICOS DISE

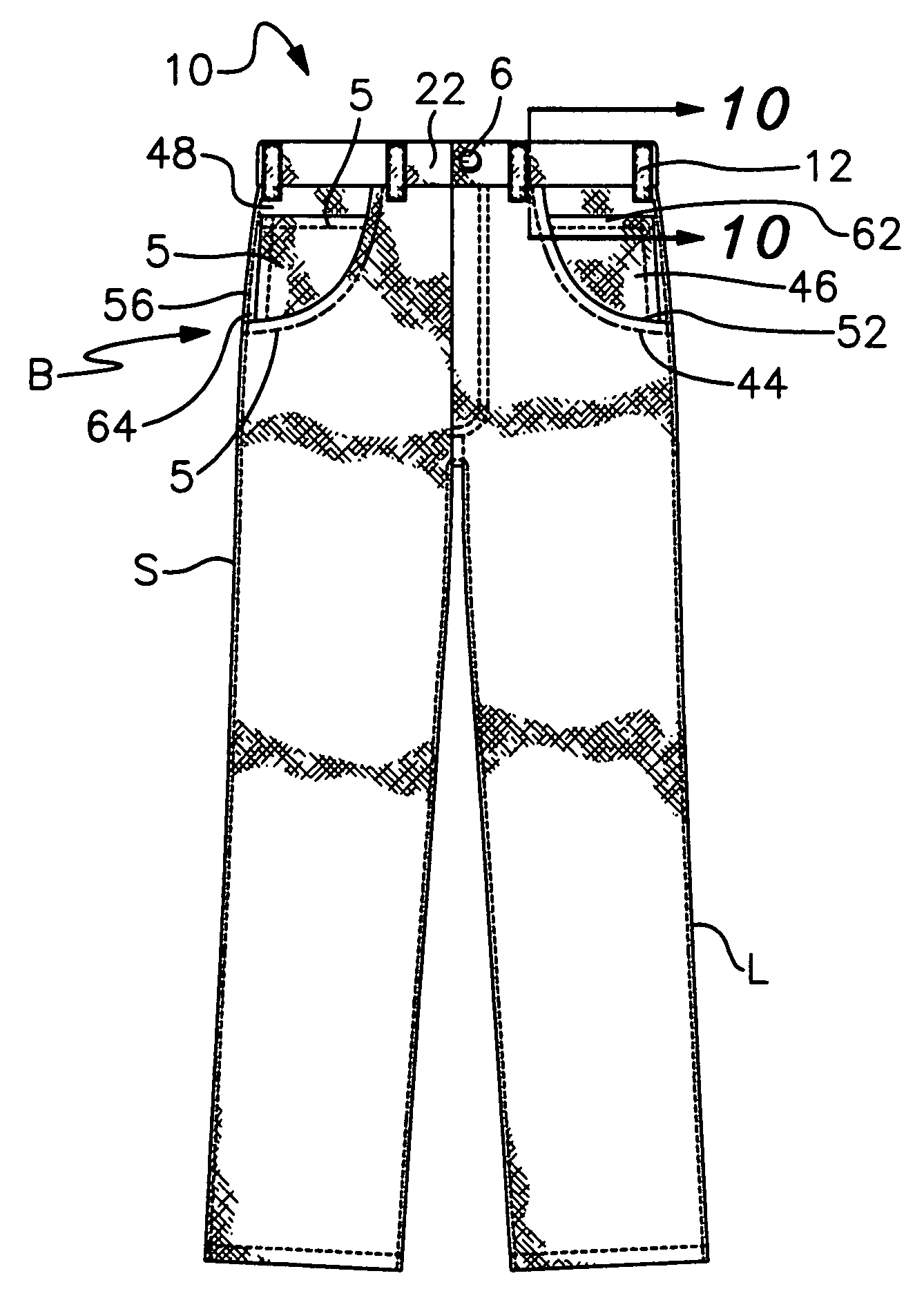

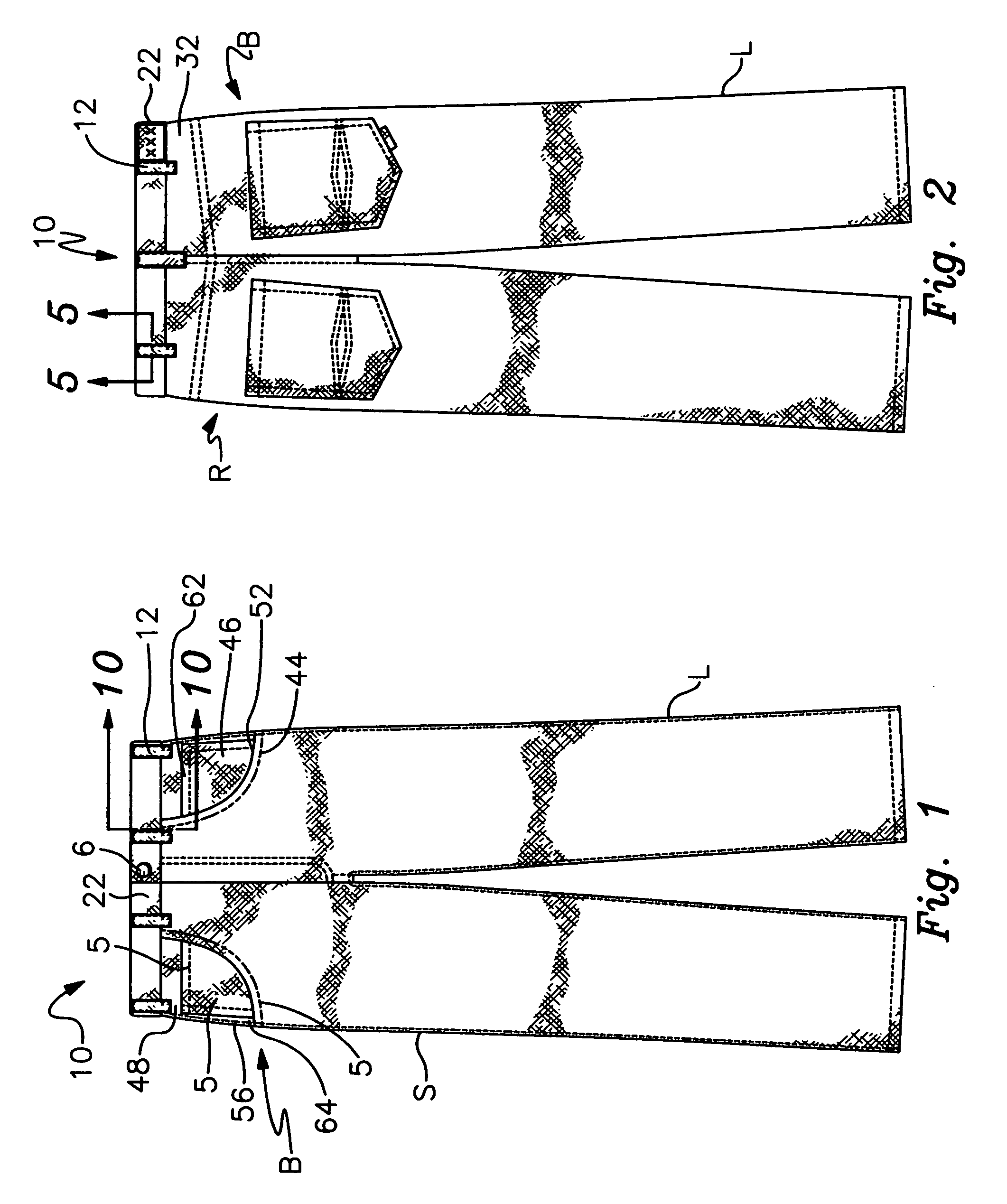

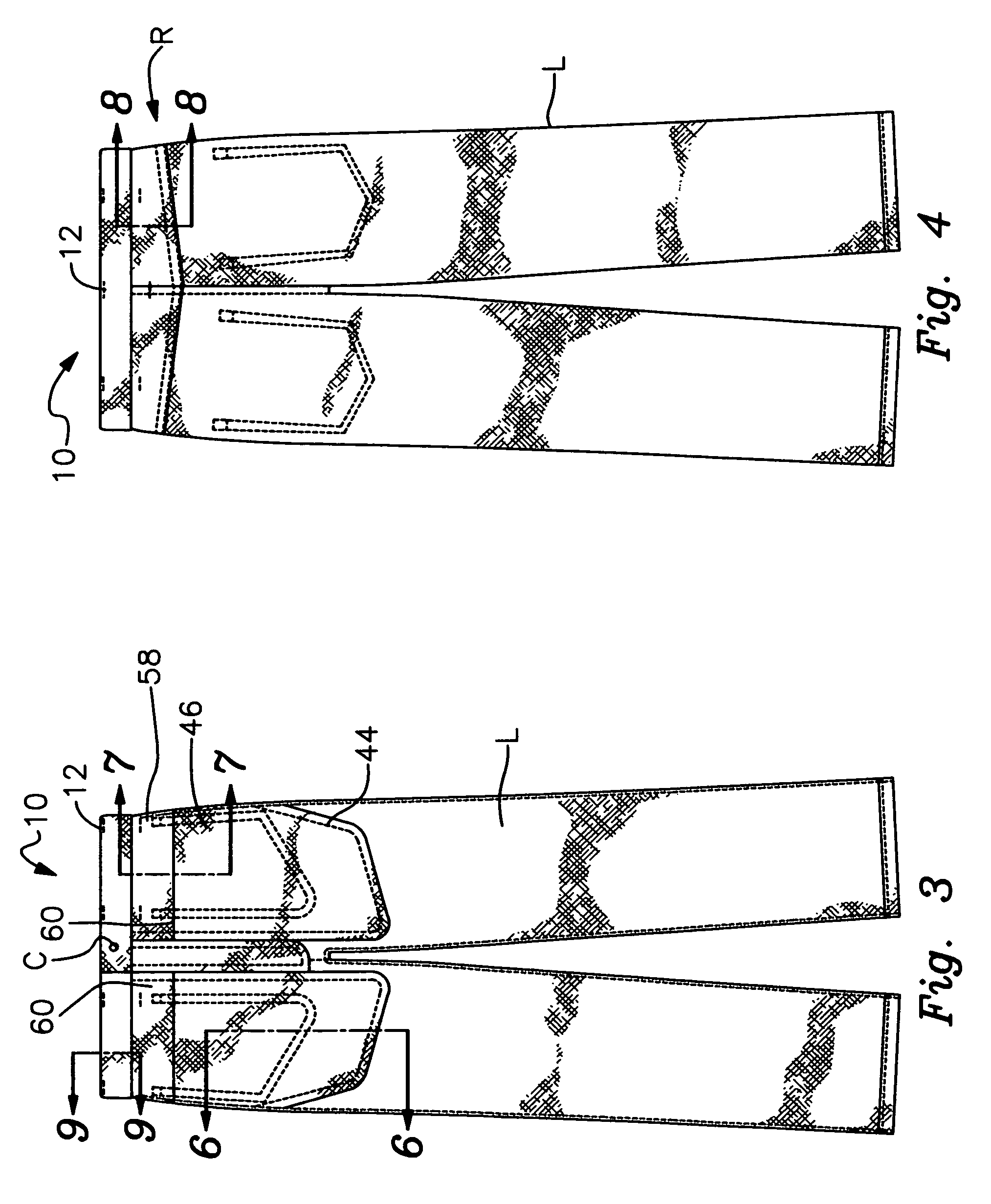

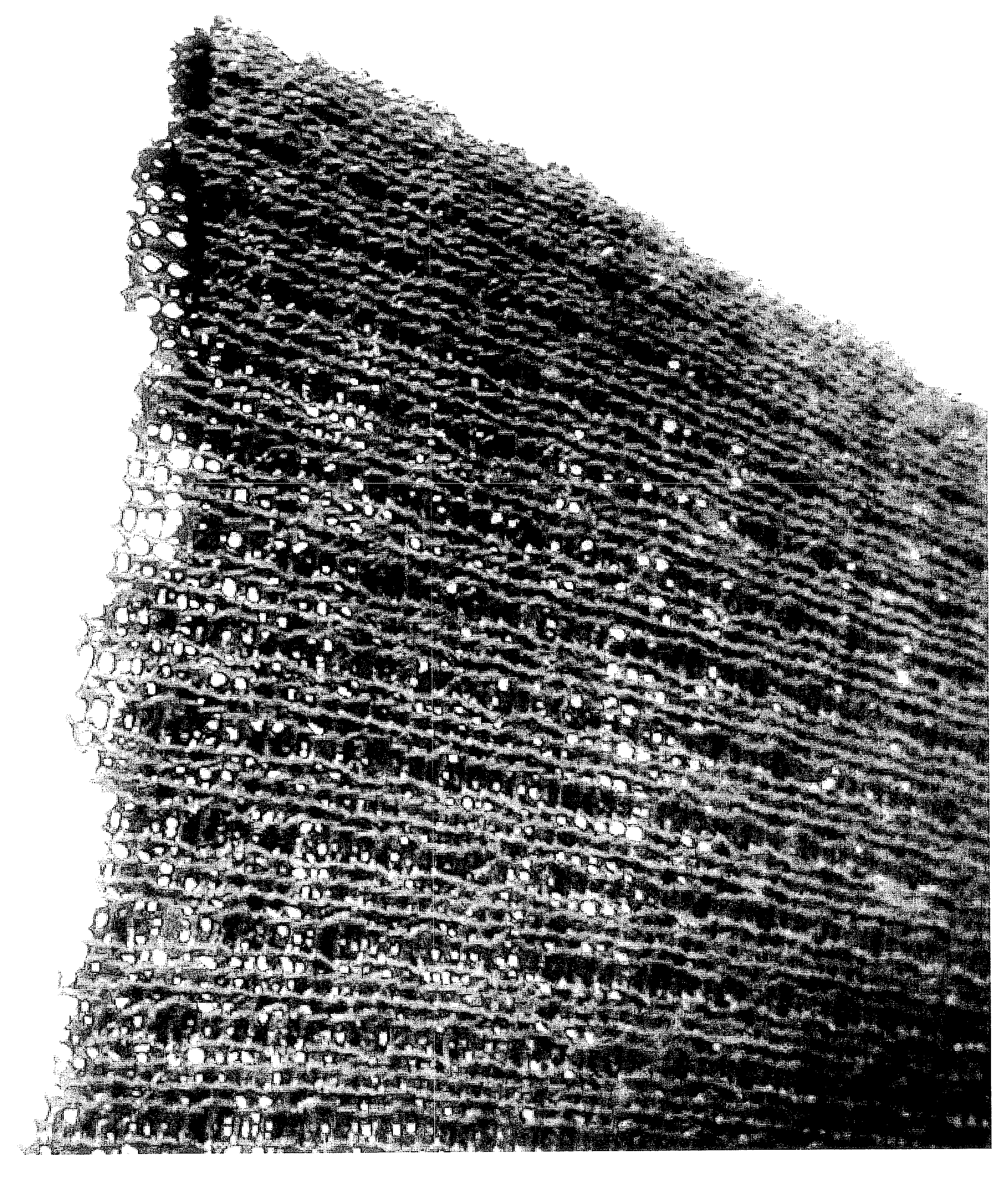

Reinforced denim garment construction

InactiveUS20070136930A1Strong and durableEasy constructionTrousersProtective garmentNylon materialHigh stress

The pair of denim pants, particularly jeans, designed for added durability in areas of high stress. The areas of high stress include the waistband, the belt loops, pockets and yoke on a pair of denim. These areas of high stress are lined and reinforced with a nylon material. The denim material will encase the nylon material increasing the strength of pants when stitched in the final form.

Owner:DIPIETRO STEPHEN B

Glass reinforced nylon blend with improved knitline strength

The present invention provides a polymer alloy including from about 40% to about 75% by weight of at least one polyamide, from about 10% to about 50% by weight polypropylene, from about 0.01% to about 1.0% by weight of at least one block copolymer including a vinyl aromatic monomer and a conjugated diene, and also includes an unsaturated dicarboxylic reagent, from about 0.1% to about 5.0% by weight of at least one block copolymer or terpolymer, wherein the terpolymer may have an unsaturated dicarboxylic reagent grafted thereto, from about 0.01% to about 7.5% of a compatibilizing agent, and from about 5% to about 50% by weight of a filler. The alloy of the present invention exhibits improved knitline strength and improved drop impact results compared with prior art fiberglass-reinforced nylon blends.

Owner:LYONDELLBASELL ADVANCED POLYMERS INC

Knit fabrics and base layer garments made therefrom with improved thermal protective properties

ActiveUS20090019624A1Effective thermal protective characteristicHigh tensile strengthChemical protectionHeat protectionFiberYarn

Knit fabrics and military apparel such as T-shirts made therefrom are disclosed. The fabrics are constructed from blended yarns made from an intimate combination of nylon and cotton staple fibers. Such fabrics comprise a weight ratio of cotton to nylon which ranges from about 55:45 to about 85:15, and these fabrics also have a weight ranging from about 3 to about 8 oz / yd2. Knit fabrics of this type possess a desirable combination of good thermal protective properties, provided the specified high level of staple fiber blend uniformity is achieved, along with very useful abrasion resistance, bursting strength and drying time characteristics.

Owner:INV PERFORMANCE MATERIALS LLC

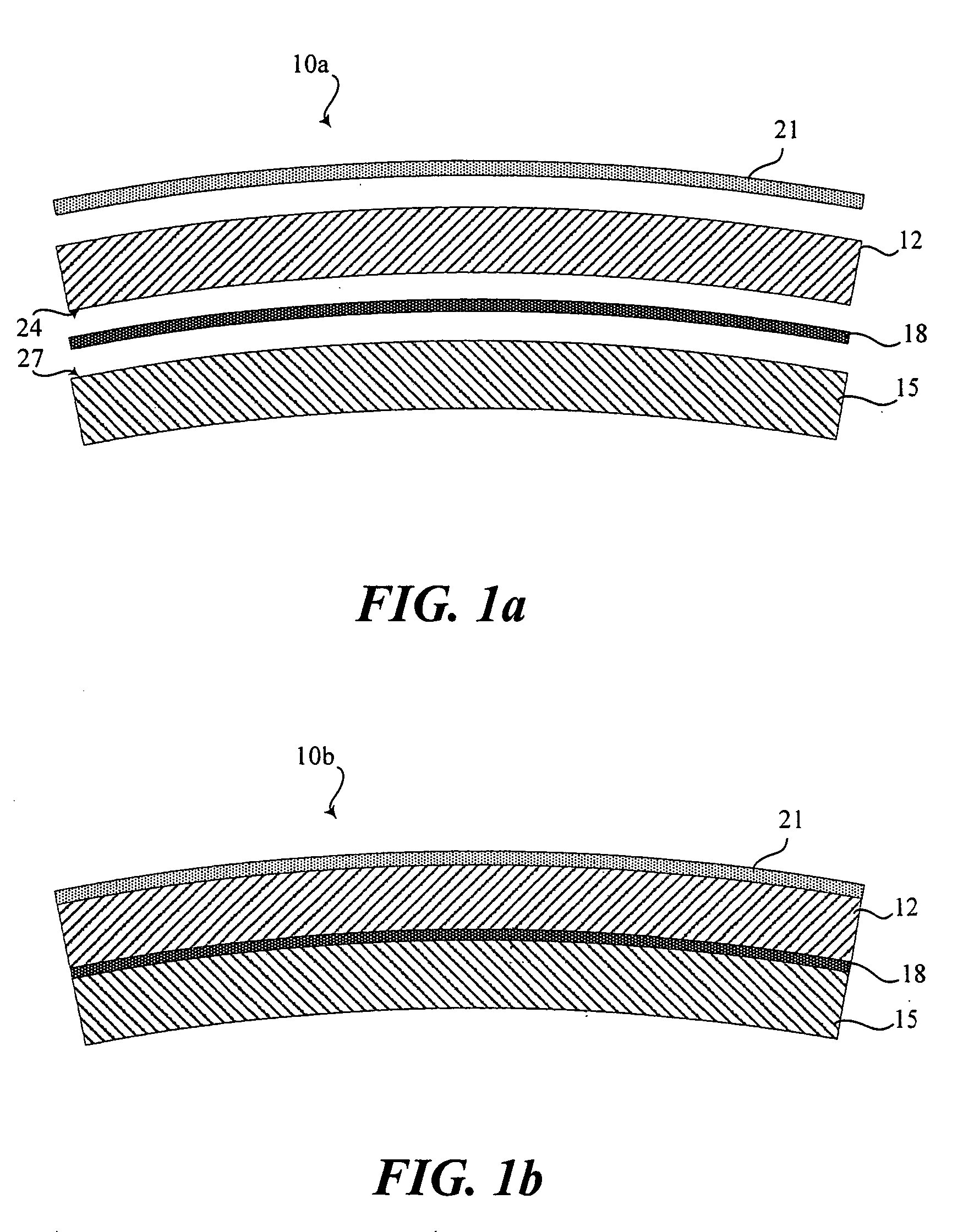

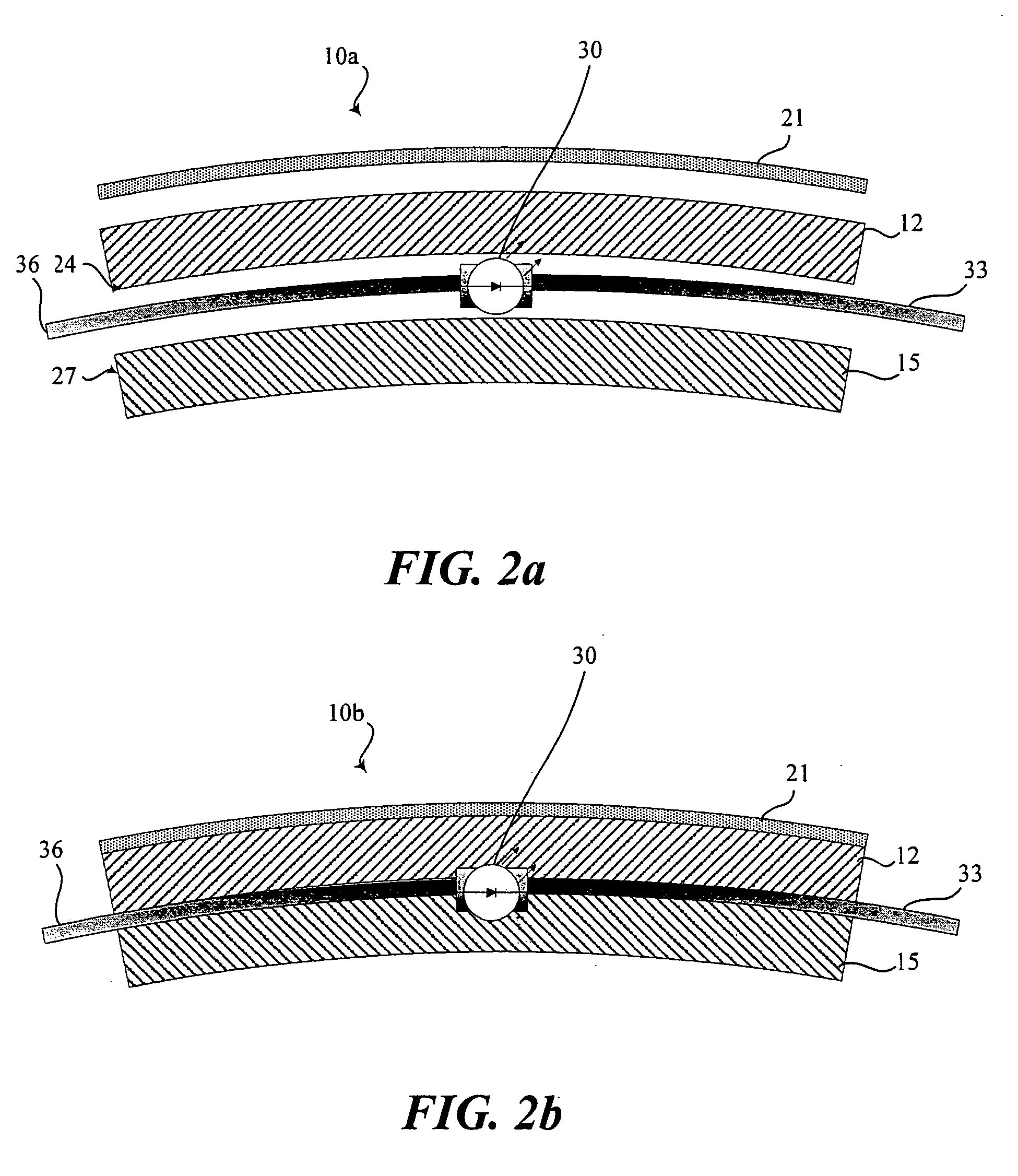

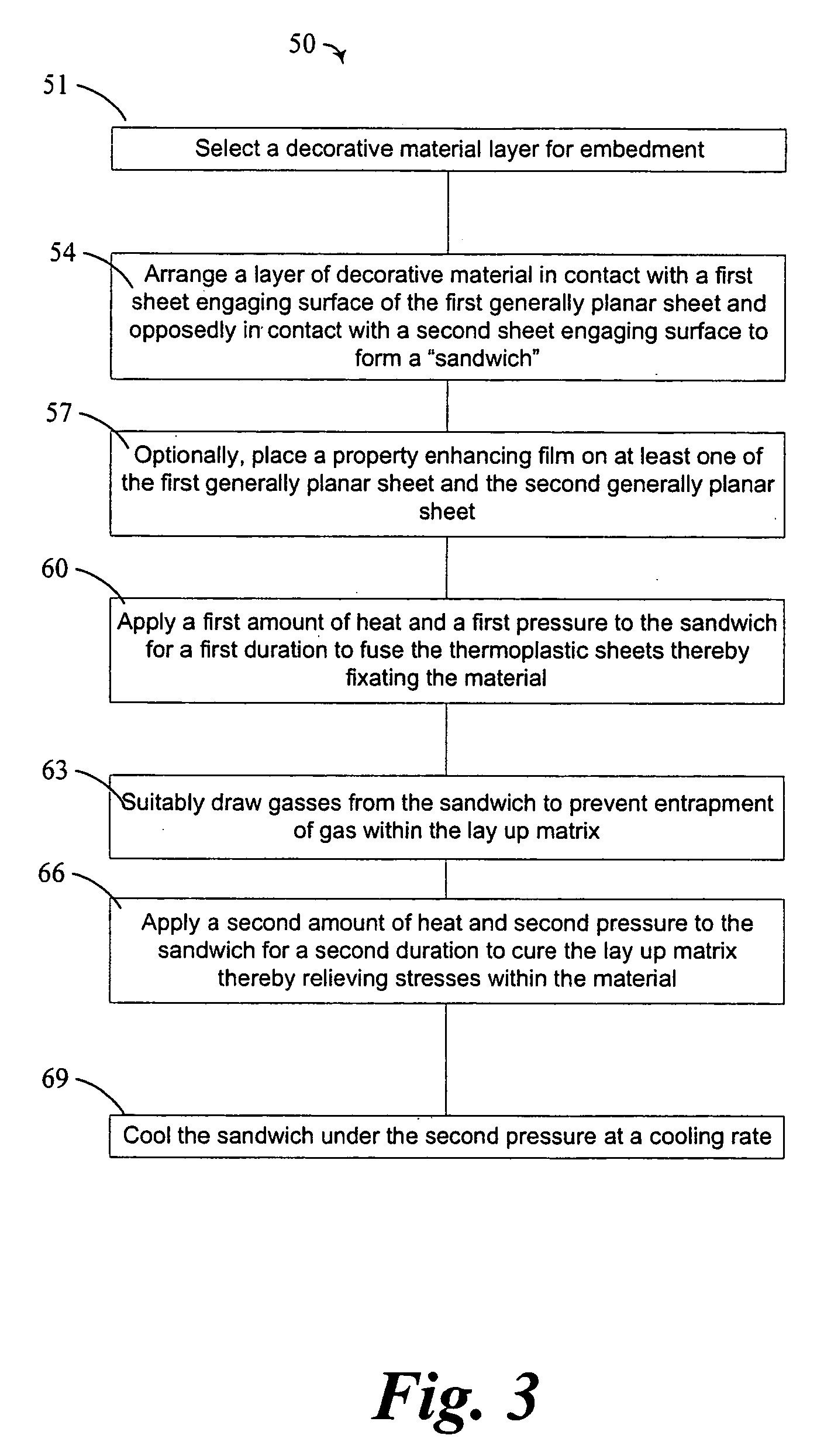

Solid surface products

A bullet resistant, non-porous unitary solid surface structure. The structure includes a first non-porous unitary material, a decorative material, and a second non-porous unitary material. The second non-porous unitary material is fused to the first non-porous unitary material in opposed relation relative to the decorative material. The fused materials produce a bullet resistant structure. The first and second non-porous unitary materials include at least one of acrylic, cross-linked acrylic, polymethyl methacrylate, polycarbonate, polyvinyl chloride, polyethylene, polypropylene, polyester, nylon, polyurethane, polystyrene, fluoropolymers, acrylonitrile-butadiene-styrene, polylactic acid, and cellulosics.

Owner:LUMICOR

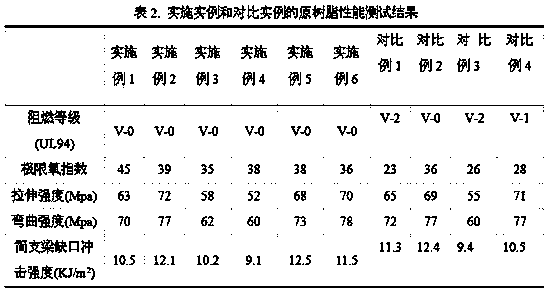

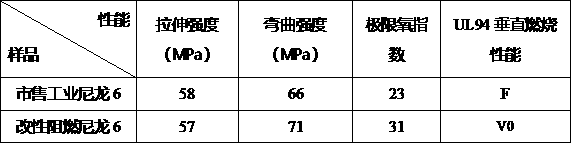

Heat and flame resistant nylon composite

InactiveCN101735601AImprove flame retardant performanceImprove mechanical propertiesNylon materialNitrogen

The invention relates to heat and flame resistant nylon composite belonging to the filed of the electrical and electronic material. The heat and flame resistant nylon composite is characterized by comprising phosphorus flame retardant, nitrogen flame retardant, inorganic synergist, filler and auxiliary agent facilitating the processing and stabilizing. Due to the synergistic effect of the phosphorus flame retardant, the nitrogen flame retardant and the inorganic synergist, the nylon has the flame resistance, mains the mechanical performance, the thermal performance and the electrical insulating performance and can pass the test of the glow wire at 850 DEG C, and the problems that the defect of the nylon product is increased and the mechanical performance and the electrical insulating performance of the nylon produce are decreased due to the large consumption of the phosphorus flame retardant are solved. The heat and flame resistant nylon composite has good flame resistance, mechanical performance, thermal performance and electrical insulating performance and is mainly applied to the electrical and electronic industry.

Owner:SINOPLAST NEW MATERIAL

Process for producing high-density nylon fabric

ActiveCN103147304AImprove dye uptakeImproves UV resistanceFibre typesDyeing processCross-linkNylon material

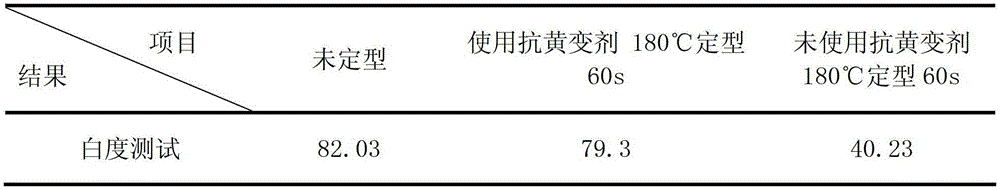

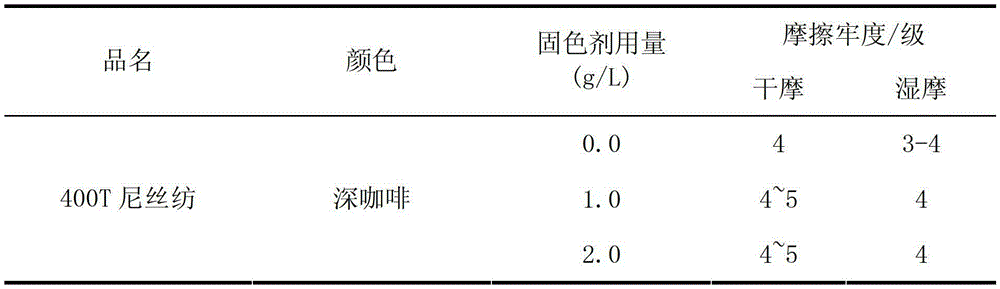

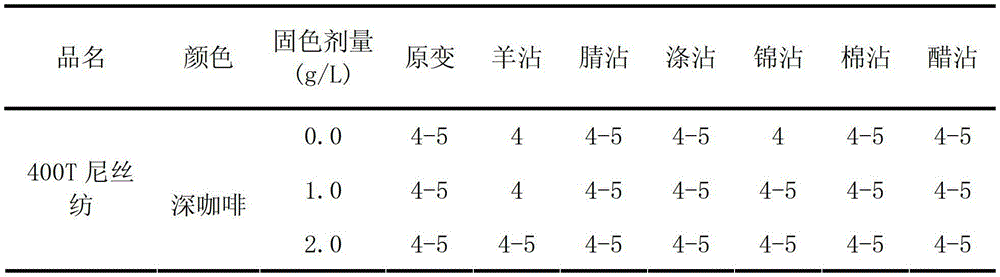

The invention discloses a process for producing a high-density nylon fabric. The process comprises the following steps of: unwinding and sewing; treating before desizing; presetting; dyeing; fixing color; dewatering; scutching; after-finishing; calendaring; detecting, folding and packaging. The process is characterized in that the phenomenon that the fabric gets yellow at high temperature can be reduced and the dyeing rate of the fabric can be improved because a yellowing resisting agent is used in the process of presetting, the ultraviolet resisting capacity of the fabric can be well improved because an ultraviolet absorbing agent is used in the process of dyeing, the tearing strength of the fabric can be improved because a right amount of a cross-linking agent and a tearing-fastness improving agent are added into a setting and finishing solution, and the excellent down penetration effect of the fabric can be achieved without using a chemical additive coating because the process of calender finishing is adopted.

Owner:SHENGHONG GRP CO LTD

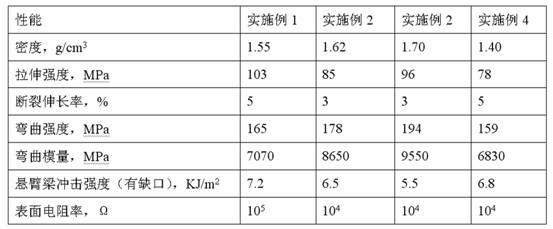

High-wearing high-rigidity reinforced nylon 66 complexes and method for making same

ActiveCN101182388ALow surface energy activitySpherulite refinementStatic friction coefficientGlass fiber

The invention relates to a highly wear-resistant and high-rigidity reinforced nylon 66 compound. The invention is characterized in that the compound consists of materials of the following weight portions: 66 portions to 100 portions of nylon, 0.1 portions to 15 portions of nucleater, 5 portions to 30 portions of wear-resistant agent, 0.5 portion to 3 portions of heat stabilizer and processing aid, and 15 portions to 105 portions of glass fiber. The invention has the advantage that each index all reaches or surpasses the scheduled requirements; the bending modulus of the material reach above 11000MPa; the hardness reaches to 135 N / mm2. Under the condition of no lubrication, surface pressure of 1.5 kg / m2, speed of 29 m / min and a temperature of 23 DEG C, the maximum static friction coefficient is 0.11; the maximum dynamic friction coefficient is 0.07. Under the condition of no lubrication, surface pressure of 100kg / cm<2> and speed of 23m / min, the PV value reaches above 2270kg / cm<2> question mark m / min.

Owner:SHANGHAI KINGFA SCI & TECH +1

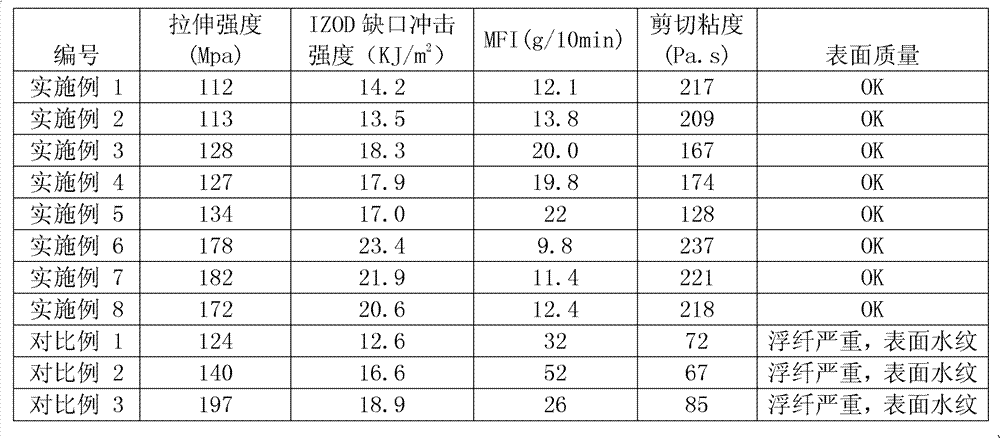

High-gloss, low-smell, reinforced nylon composite material and preparation method thereof

The invention relates to a high-gloss and low-odor reinforced nylon composite material and the preparation method thereof. The composite material is characterized in that the composite material contains, by weight percentage, PA66 resin, PA6 resin, glass fiber, inorganic minerals, micro-beads, compatibilizer, antioxidant, lubricant, etc. The preparation method comprises the following steps: mixing the above materials in a high-speed mixer; discharging, and extruding and granulating the mixed material in a screw extruder. Compared with common fiber glass reinforced PA and mineral reinforced PA, the PA composite material prepared by the method has the advantages of high gloss, high strength, low odor, etc., and can be widely used for exterior trimming parts such as electric tool housing and motor housing and for interior parts.

Owner:SHANGHAI SUNNY

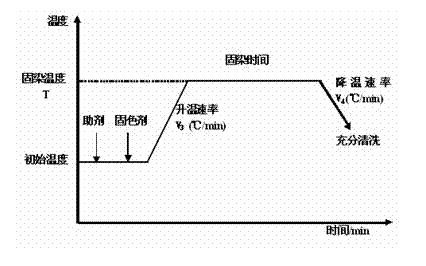

Method for dyeing ultrafine-denier porous nylon fabric

InactiveCN102251415AOvercome the difficulty of dyeingOvercome the shortcomings of YisehuaDyeing processNylon materialEngineering

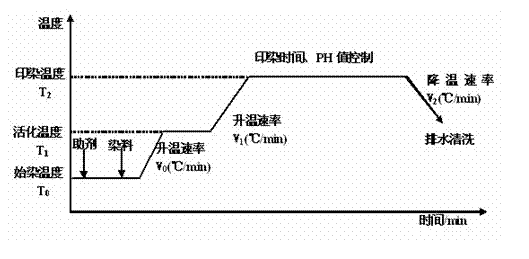

The invention relates to a method for dyeing an ultrafine-denier porous nylon fabric, which aims to solve the technical problems of difficult control on dyeing, probably caused uneven dye, color difference and the like in the dyeing process. The method is applicable to a fabric formed by weaving ultrafine-denier nylon filaments of 22dtex / 35f and 44dtex / 72f. The method is characterized by selecting optimized parameters for each step, especially the progressive heating-dyeing step. In the progressive heating-dyeing step, the heating rate is controlled at 1.0 DEG C / min when the temperature is below 55 DEG C, and the heating rate is controlled at 0.5 DEG C / min when the temperature is above 55 DEG C; and the dyeing temperature is controlled to range between 95 DEG C and 99 DEG C, the dyeing time is controlled to be 45 minutes, and the pH value is controlled to range between 4 and 6. Thus, the dyeing evenness can be ensured.

Owner:HANGZHOU NORMAL UNIVERSITY

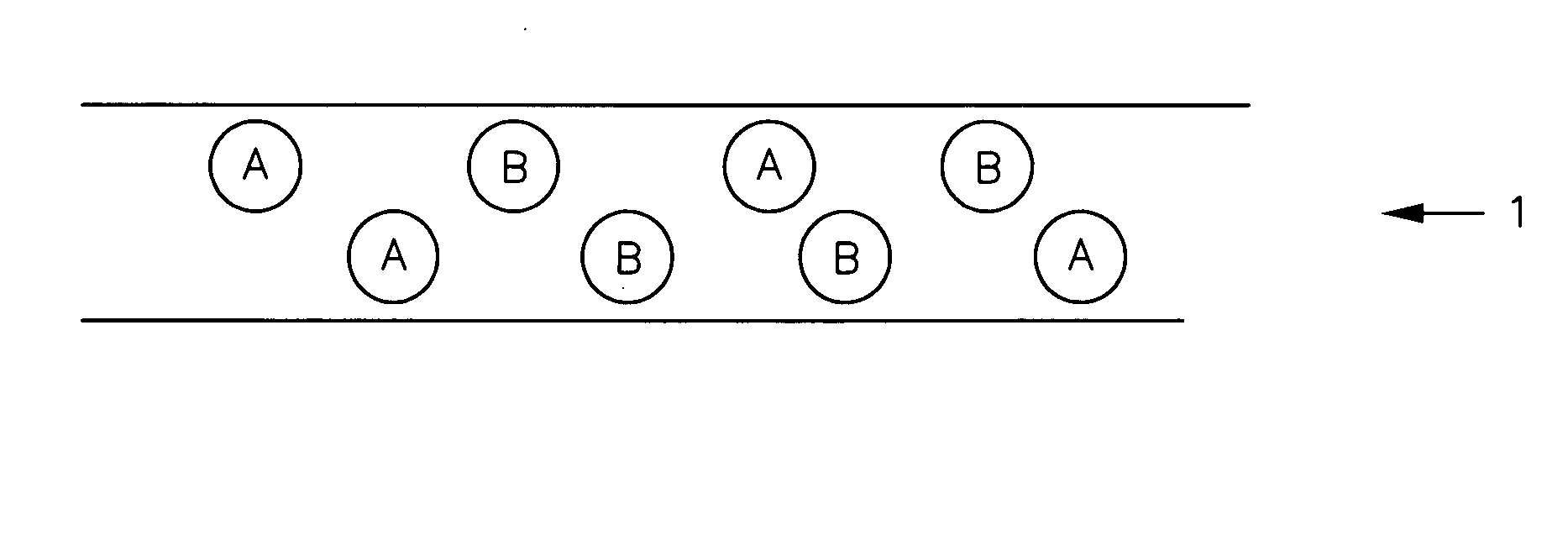

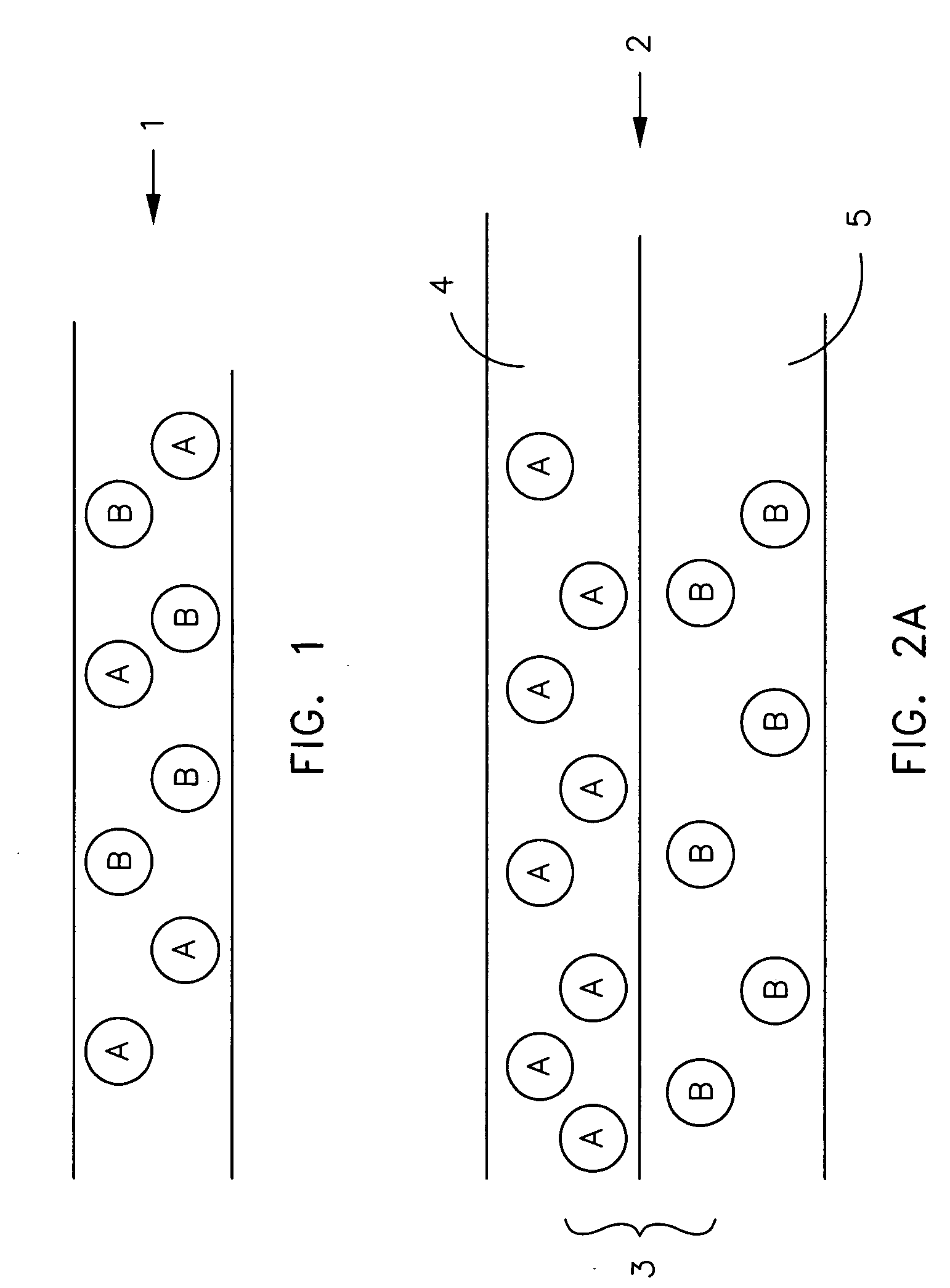

High performance fiber reinforced nylon composite material and preparation thereof

The invention discloses a high-performance fiber-reinforced nylon composite material and a preparation method thereof. The components in weight portion of the high-performance fiber-reinforced nylon composite material are: 30 to 80 portions of nylon resin, 10 to 50 portions of fibrous long fiber A, 10 to 30 portions of fibrous long fiber B, 0 to 10 portions of toughening agent, 0.1 to 1 portion of antioxidant and 0.2 to 1.5 portions of processing aid. The preparation method comprises the following steps of mixing, stirring, extruding, granulating, cooling and drying a certain proportion of aforementioned substances. The high-performance fiber-reinforced nylon composite material prepared in the invention has the characteristics of high strength, high modulus and little creep deformation. In contrast, the properties of the composite material are higher than pure glass fiber-reinforced nylon, but the price of the composite material is lower than carbon fiber-reinforced nylon. In addition, the preparation method has the advantage of simple operation, and is suitable for industrial production and application.

Owner:GUANGDONG HIGH & NEW ENG PLASTICS

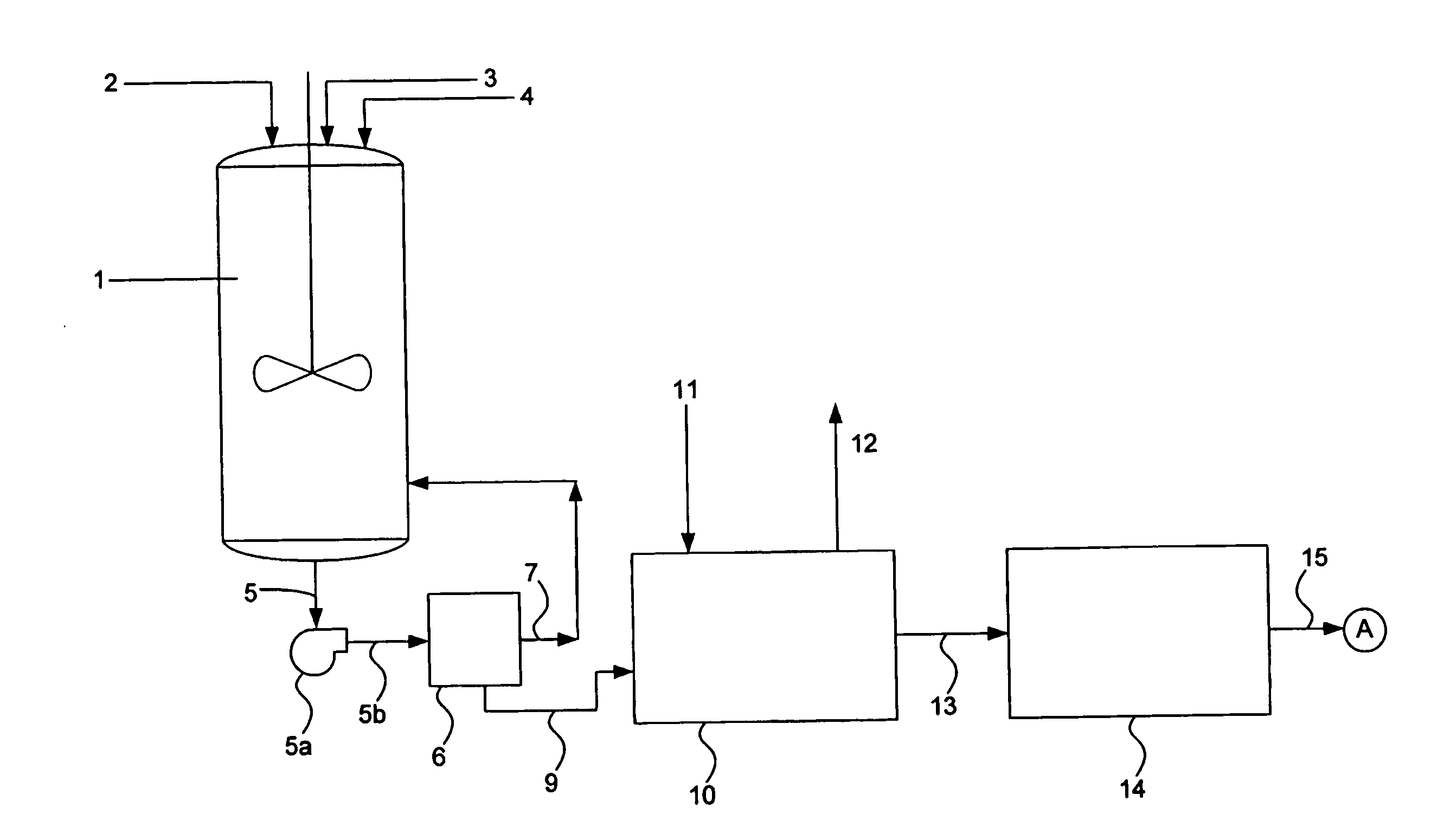

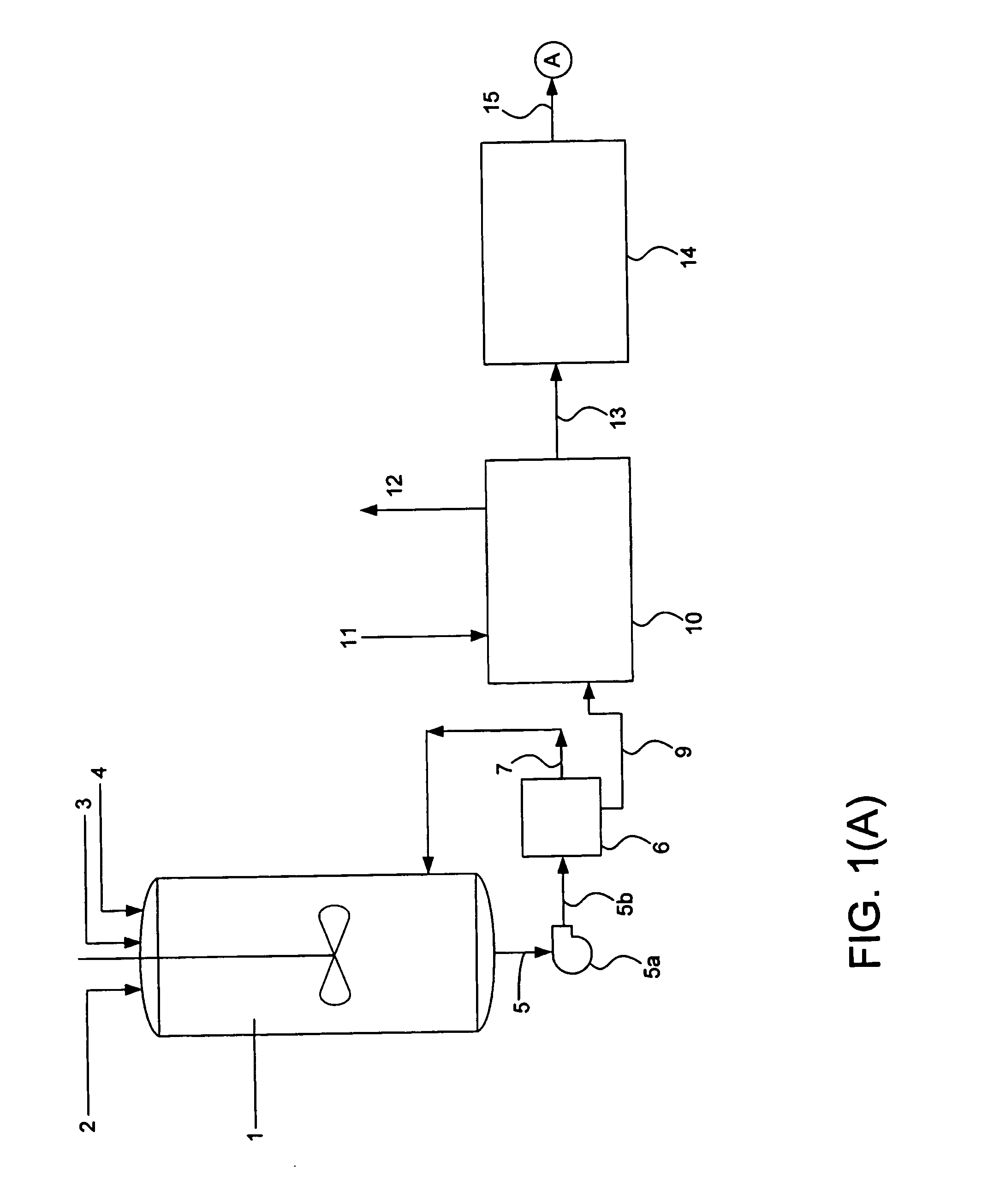

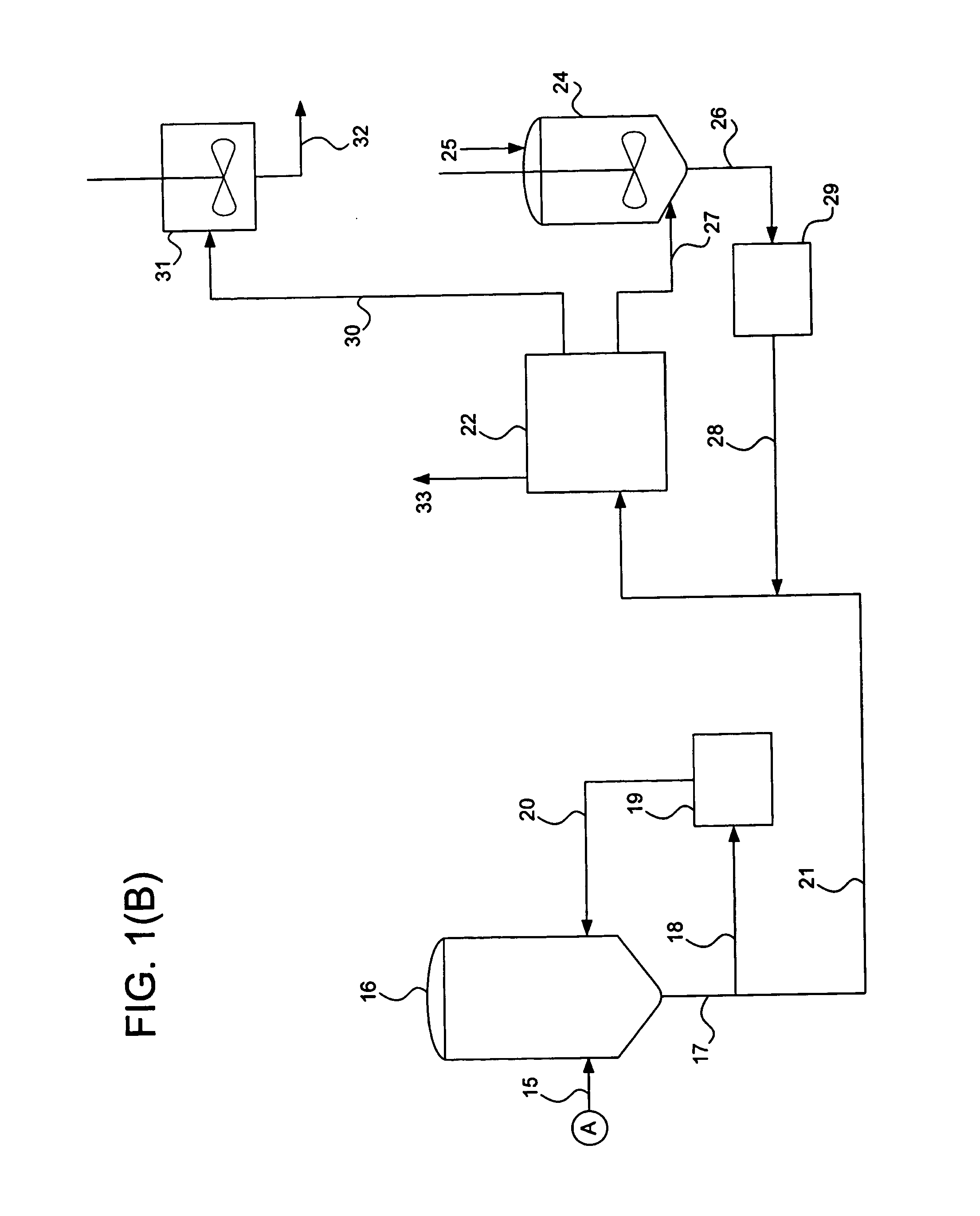

Method for extracting nylon from waste materials

InactiveUS20060031997A1Shorten the dissolution timeReduce the temperaturePlastic recyclingRotary piston pumpsNylon materialSolvent

The invention relates to a method for recovering nylon from a nylon-containing material by contacting the nylon-containing material with an alkanol-containing solvent at elevated temperature and at a pressure higher than the equilibrium pressure of the alkanol-containing solvent at the elevated temperature, thereby dissolving the nylon in the alkanol-containing solvent, removing the alkanol-containing solvent containing dissolved nylon from any undissolved solids, and decreasing the temperature of the alkanol-containing solvent containing dissolved nylon to precipitate the dissolved nylon.

Owner:INTERFACE INC

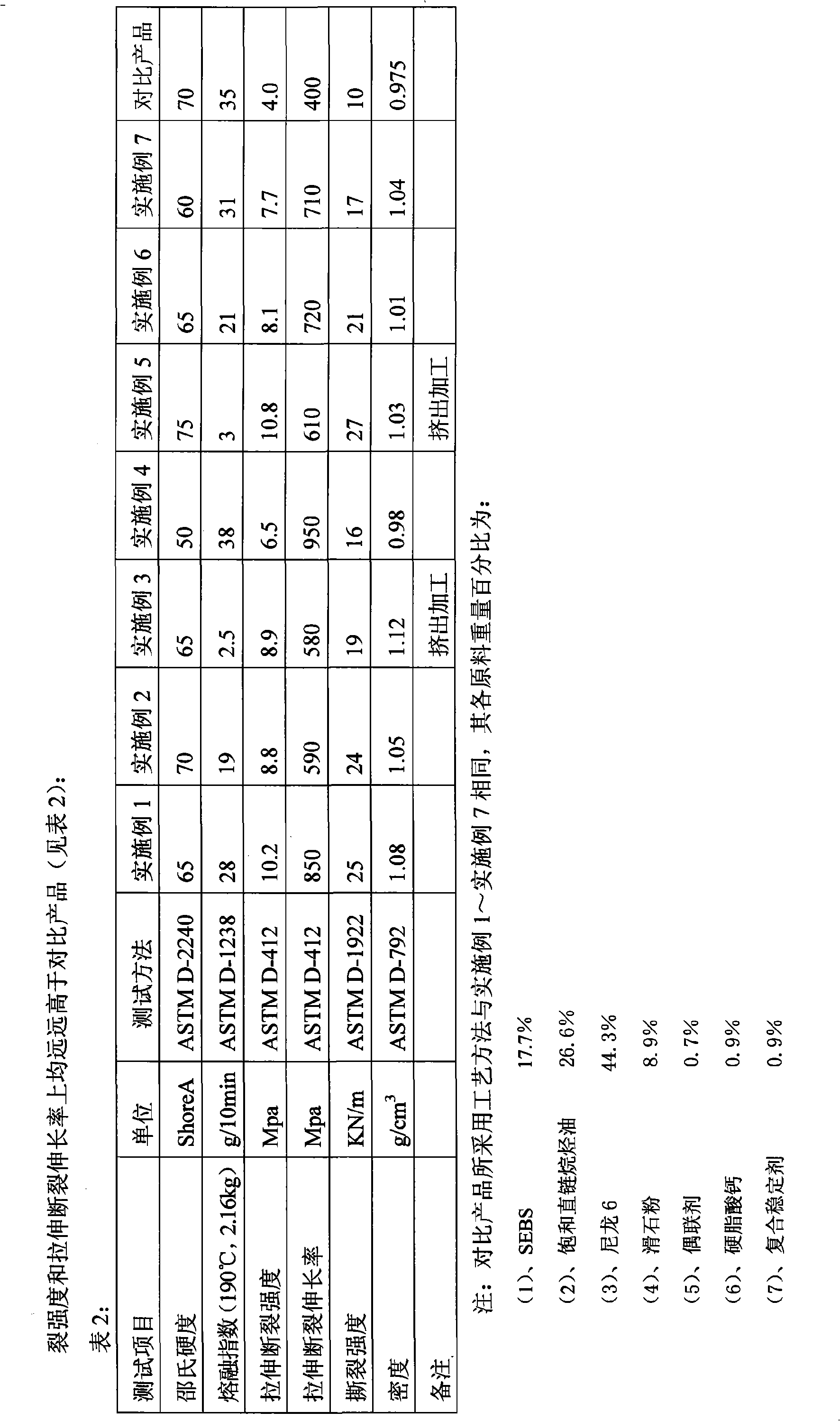

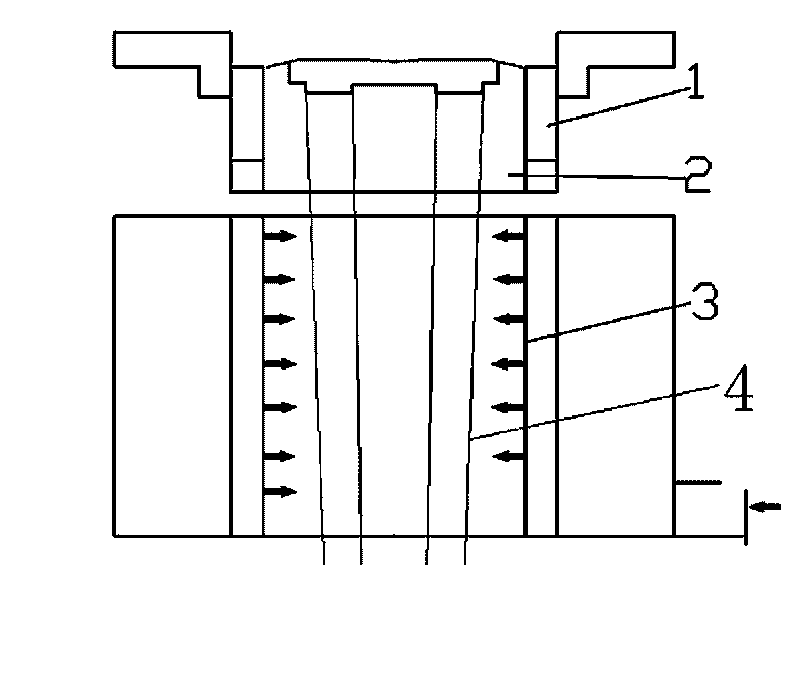

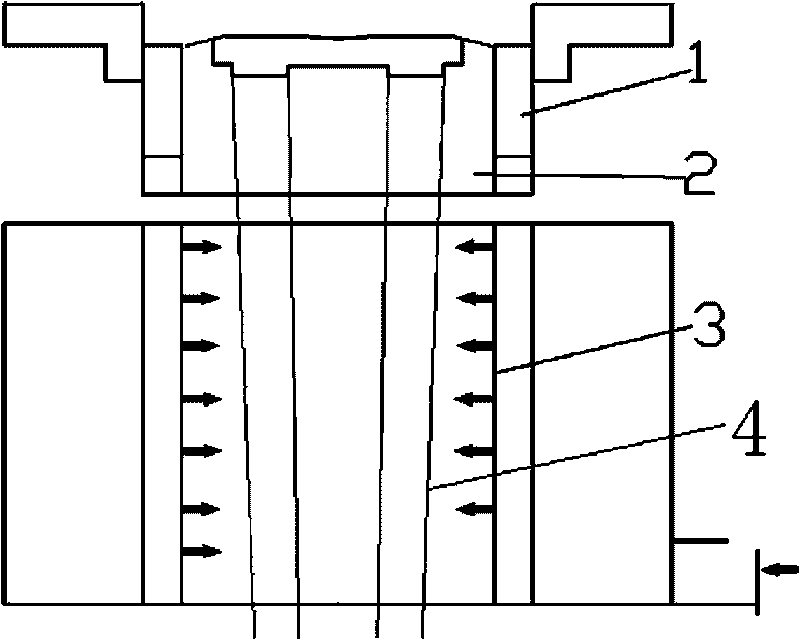

Glass fiber reinforced nylon material used for extrusion molding, preparation method and application

The invention discloses a glass fiber reinforced nylon material used for extrusion molding, a preparation method and an application thereof. The glass fiber reinforced nylon material is prepared by 30-75 parts of a nylon resin, 10-50 parts of glass fibers, 1-10 parts of a toughening agent, 0.1-10.0 parts of a surface quality-improving agent, 0.1-5.0 parts of a chain extender and 0.1-1.5 parts of a processing aid, wherein the surface quality-improving agent is polyethylene or a copolymer of ethylene and other olefins. The melt strength of the nylon material is increased, allowing the glass fiber reinforced nylon material to meet the requirements of injection molding and a product to have excellent appearance.

Owner:KINGFA SCI & TECH CO LTD +1

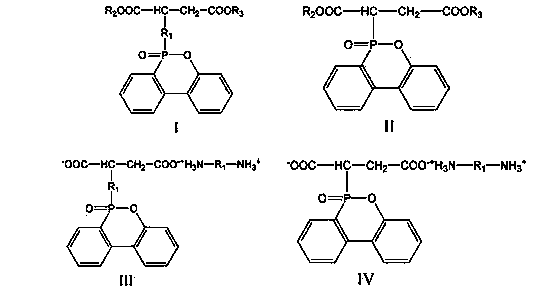

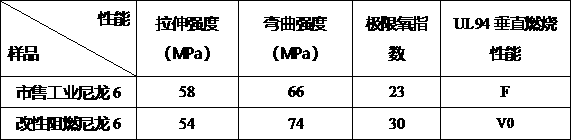

High flame retardant nylon resin and its preparation method

The invention discloses high flame retardant nylon resin and its preparation method. The preparation method comprises the following steps: reacting a polymerization monomer with a catalyst, a reactive flame retardant agent, a synergistic flame retardant agent, a carbon forming agent and a charring promoter according to a certain ratio at a specified temperature to obtain the flame retardant nylon resin, the reactive flame retardant agent can reacts with the polymerization monomer for polycondensation, and the synergistic flame retardant agent does not participate in the reaction, and is distributed in a polymer product to play a flame retardant function. The mechanical properties of the prepared flame-retardant nylon resin are good, the flame retardancy is long-lasting, the flame retardant efficiency is high, the flame retardant grade can reach UL94 standard V-0, and the flame-retardant nylon resin is suitable for injection of electronic equipment, household electrical appliances and automotive parts with environmental protection and flame retardant requirements, and is also suitable for military industry, aerospace and rail traffic fields with high flame retardant grade requirements.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

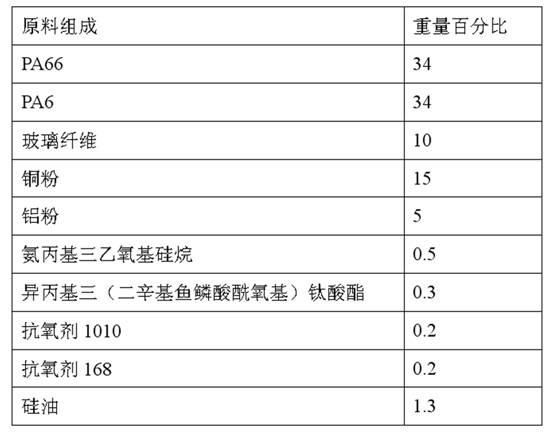

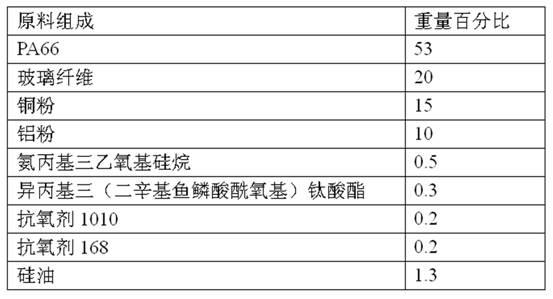

Enhanced conductive nylon material and preparation method thereof

InactiveCN101955653AGood dispersionEvenly dispersedNon-conductive material with dispersed conductive materialGlass fiberNylon material

The invention relates to an enhanced conductive nylon material and a preparation method thereof. The enhanced conductive nylon material comprises the following raw materials in percentage by weight: 40 to 70 percent of nylon, 10 to 40 percent of glass fibers, 10 to 40 percent of metal powder, 0.1 to 5 percent of coupling agent, 0.1 to 0.5 percent of antioxidant and 0.5 to 5 percent of silicone oil. The invention provides a method for thermoplastic conductive plastics by attaching the metal powder to the glass fibers twice and mixing the glass fibers, the metal powder and plastics for pelleting by utilizing the characteristics of easy machining and dispersion of the glass fibers in the plastics, and the prepared thermoplastic conductive plastics have the characteristics of simple and convenient production process, uniform dispersion of the metal powder, small addition amount, controlled conductivity and smooth surfaces of products.

Owner:NANJING HONGRUI PLASTIC PROD

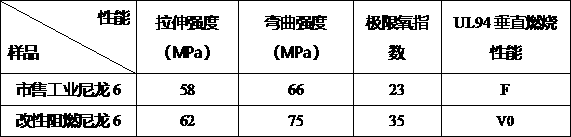

Preparation method of composite material for inorganic modified melamine chlorinated isocyanurate flame-retardant nylon 6

The invention discloses a preparation method of a composite material for inorganic modified melamine chlorinated isocyanurate flame-retardant nylon 6. The preparation method is characterized in that melted caprolactam is taken as a reaction medium; melamine and cyanuric acid react under the conditions of certain temperature and certain pH value; during the reaction process, water, an inorganic modified component and / or a precursor for generating the inorganic modified component, and other blending agents are added to prepare inorganic modified melamine chlorinated isocyanurate compound flame retardant; and then the composite material for the inorganic modified melamine chlorinated isocyanurate flame-retardant nylon 6 is prepared through in-situ polymerization under the conditions of certain temperature and certain pressure. During the whole preparation process, melted caprolactam not only serves as a resolvent for preparation of inorganic modified melamine chlorinated isocyanurate, but also serves as a polymerization monomer of the nylon 6; and synthesis and modification of modified melamine chlorinated isocyanurate and polymerization of the nylon 6 are accomplished at one step. The composite material for the flame-retardant nylon 6 has the characteristics of small additive amount of flame retardant, excellent overall performance of the composite material, and the like.

Owner:HUNAN UNIV OF TECH

Nylon-reinforced fishing net

InactiveCN103724769AHigh tensile strengthImprove toughnessMonocomponent polyolefin artificial filamentArtifical filament manufactureNylon materialWeather resistance

Owner:CHAOHU ASIANEPS FISHING NET MFG

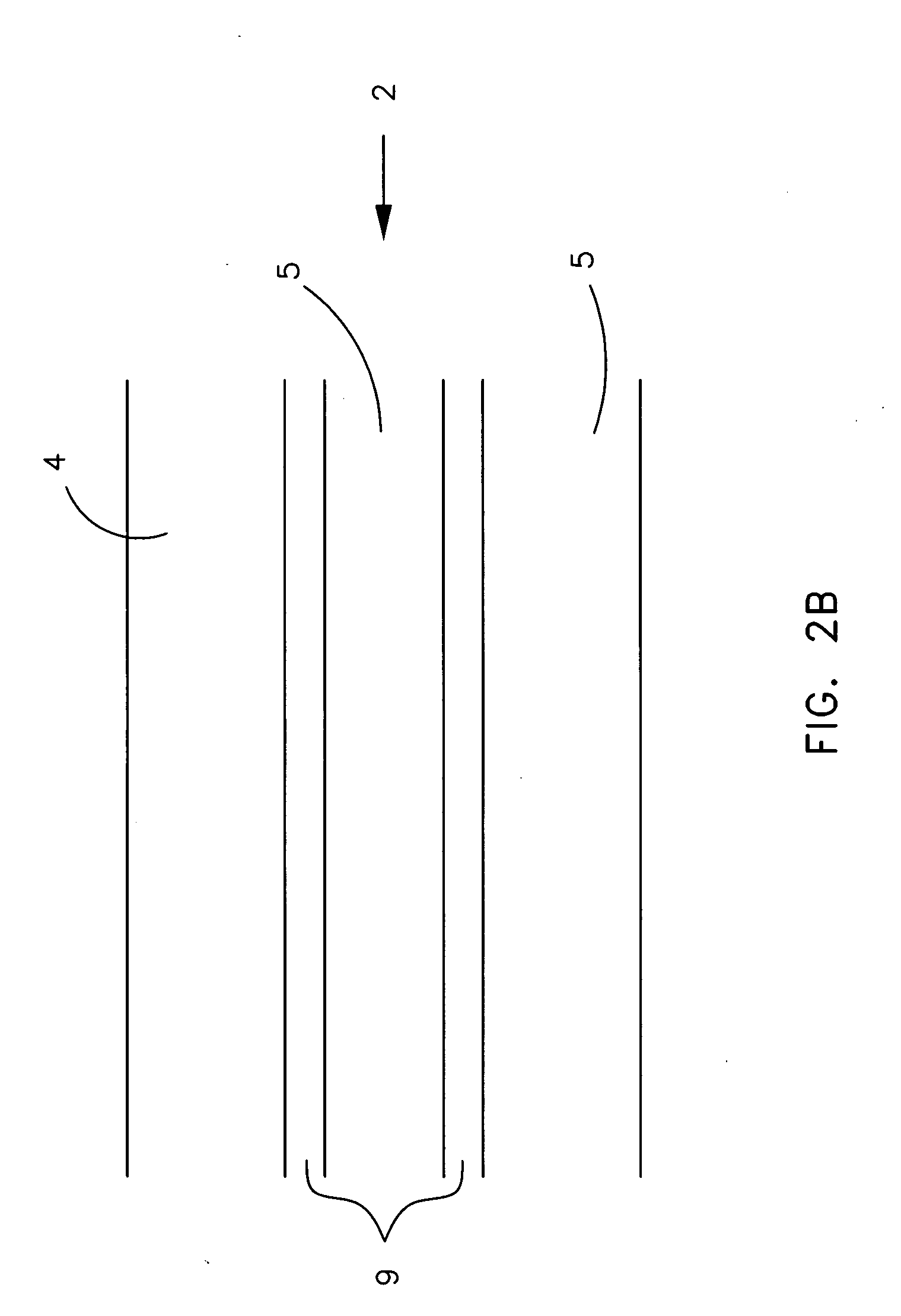

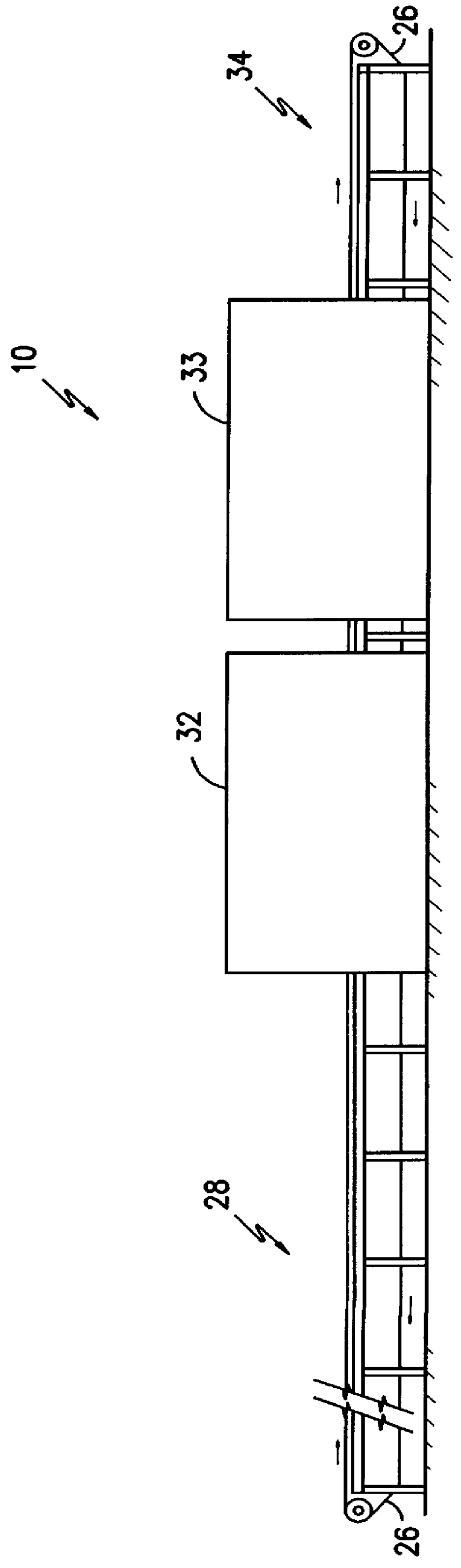

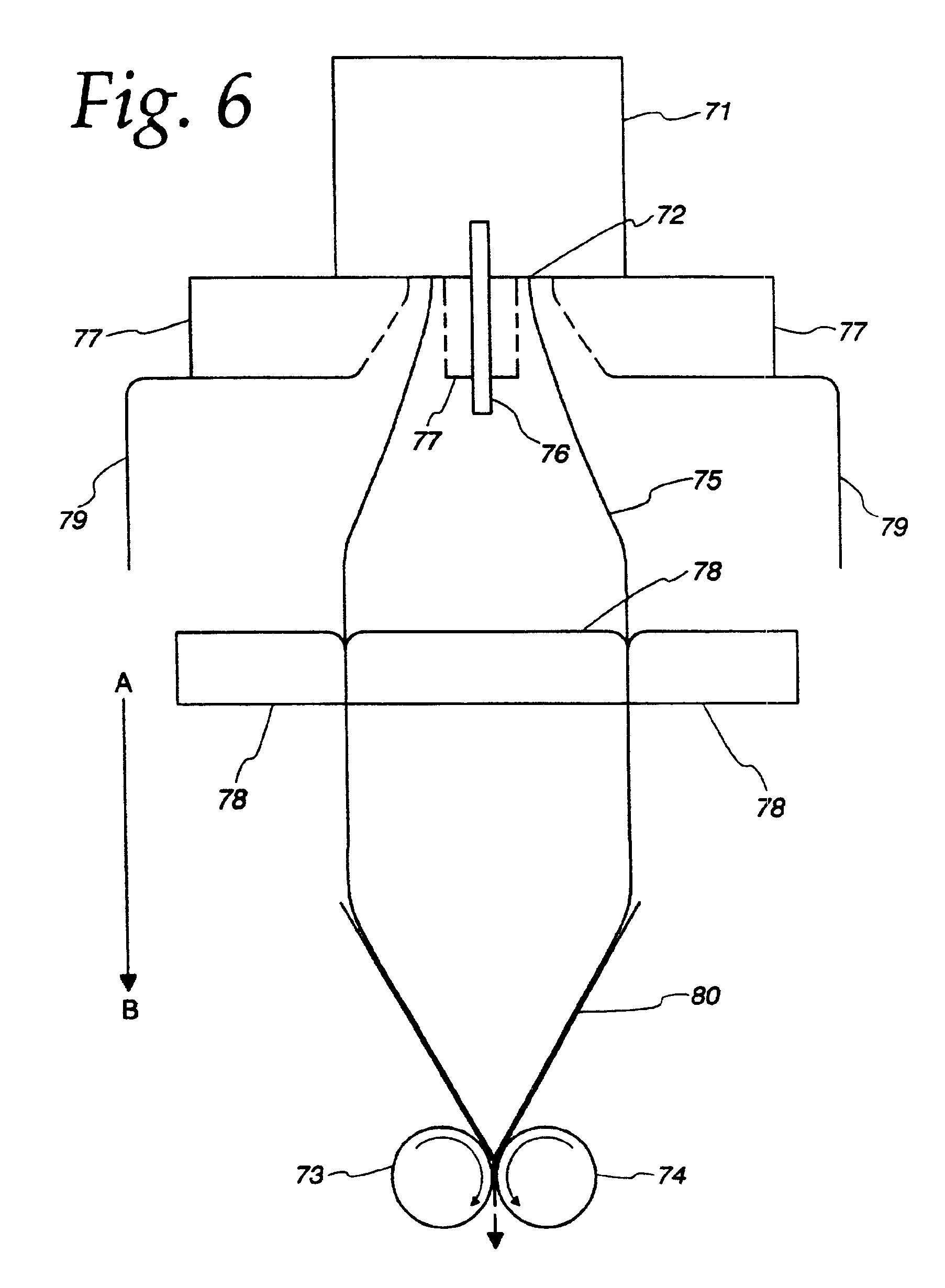

Method for producing fine denier nylon FDY filament with aromatic function

InactiveCN101736433AHas aroma functionSimple production processFilament/thread formingFilament-forming treatmentMasterbatchFiber

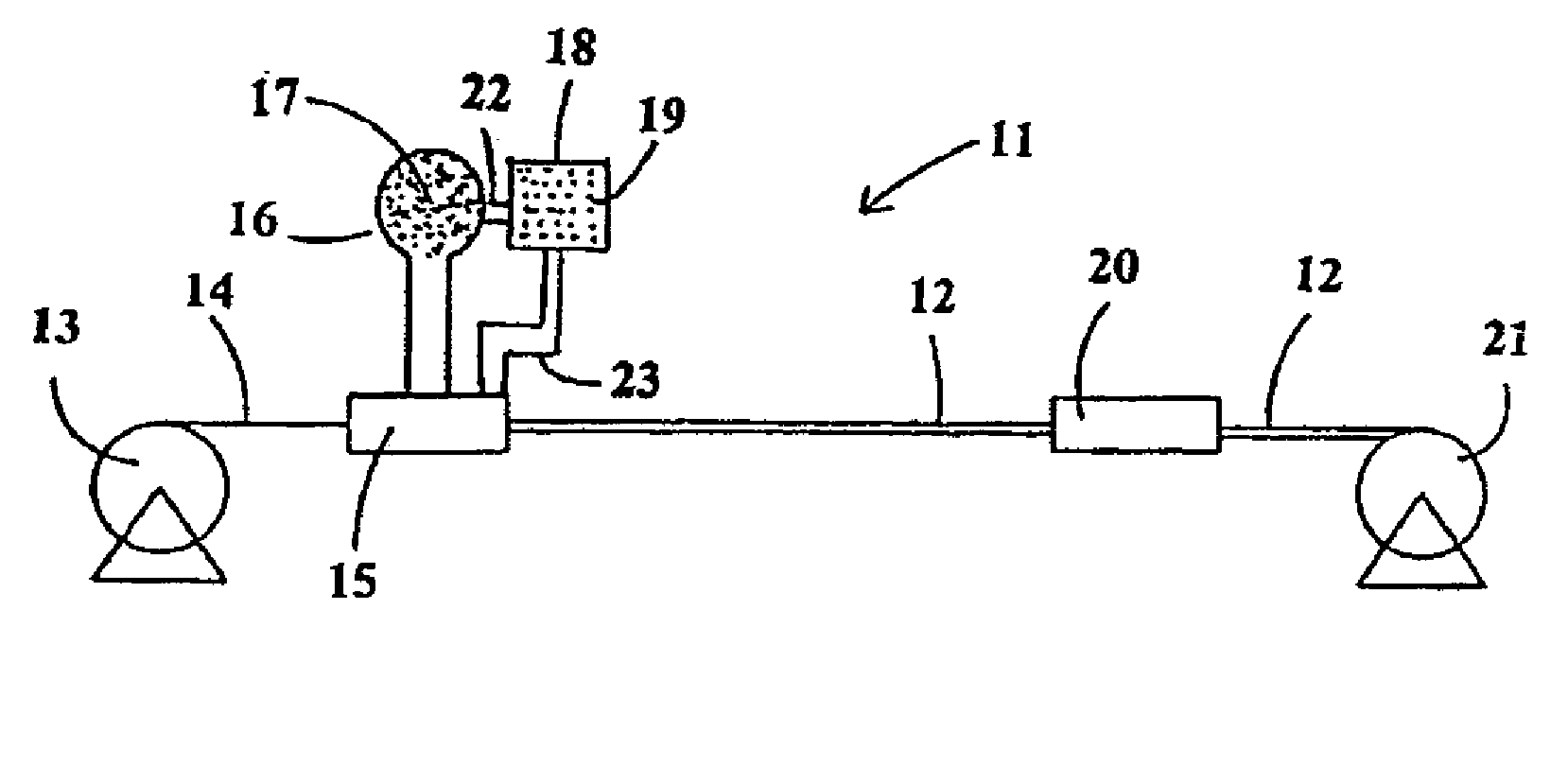

The invention relates to a method for producing a fine denier nylon FDY filament with aromatic function. The technical problem to be solved is to produce a filament that the filament number is between 0.5 and 1.0dtex, and the aroma retention time is long. In the production method, the weight ratio of three raw materials, namely nylon chips to fine denier nylon masterbatch to aromatic microcapsules is 1:5-20 percent: 0.5-10 percent. The process comprises the following steps of: 1) keeping steady pressure in a spinning component; 2) adopting 40-100-mesh metal sand for filtration; 3) adopting a spinneret plate, wherein the aperture of the spinneret plate is between 0.1 and 0.3mm, and the slenderness ratio is 2-4; 4) arranging an annealing device (1) behind the spinning component, and forming a windless region (2) with the height of between 20 and 40cm between the annealing device (1) and cross air blow (3); 5) ensuring that the position of a beam concentration point is 600 to 1,000mm away from the spinneret plate; and 6) ensuring that the spinning winding speed is between 3,000 and 5,000m / min.

Owner:HANGZHOU NORMAL UNIVERSITY

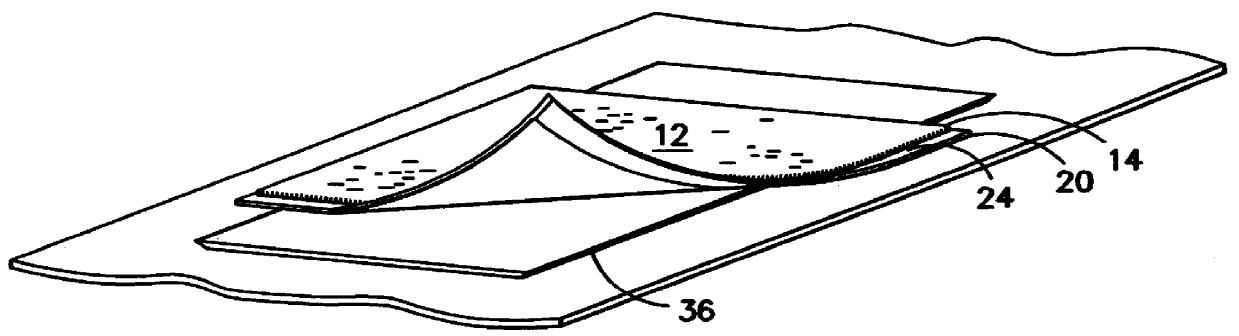

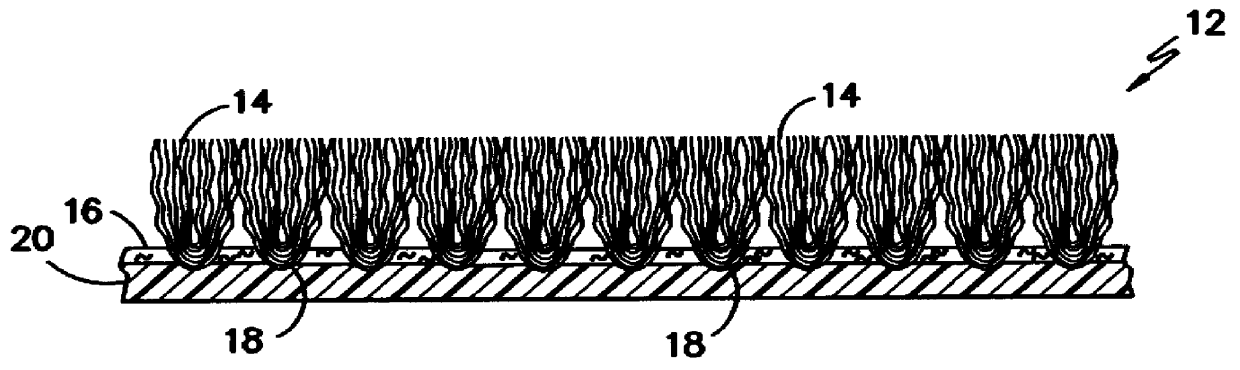

Floor mat solely comprised of monofilament nylon fiber and having an ozone resistant, non-staining rubber backing sheet

This invention relates to a floor mat primarily for use in an outdoor environment wherein the mat includes a tufted carpet solely comprised of nylon monofilament fibers. Furthermore, this mat comprises a foam rubber backing which possesses a high level of ozone resistance and simultaneously will not appreciably stain a handler's skin or a floor's surface with carbon particles. The utilization of all monofilament nylon fibers provides for the extreme effective removal of moisture, dirt, and debris from the footwear of pedestrians and also permits easy cleaning and effective drying of the overall article. The utilization of a foam rubber backing also allows for heavy duty industrial-scale laundering in such standard washing machines without appreciably damaging either the washing machines or inventive floor mats themselves.

Owner:MILLIKEN & CO

Flame retardant reinforced nylon material with high glow wire ignition temperature and preparation method thereof

The invention relates to the technical field of high-molecular material, and more specifically relates to a flame retardant reinforced nylon material with a high glow wire ignition temperature and a preparation method thereof. The flame retardant reinforced nylon material with a high glow wire ignition temperature of the invention comprises nylon 6 resin, brominated flame retardant system, anti-oxidant alkali-free glass fibre and processing auxiliary agent. The material of the invention has an increased glow wire ignition temperature of 850 DEG C compared with 750 DEG C specified in European Union IEC60695 standard, so as to expand usage scope of an unwatched electric appliance; the flame retardant reinforced nylon material has advantages of high strength, high toughness, rapid moulding and good cost performance, and can satisfy requirements of electron electric appliances and household electrical appliances, such as microswitch, socket connector and fuse.

Owner:GUANGDONG WAYLAM ENG PLASTICS

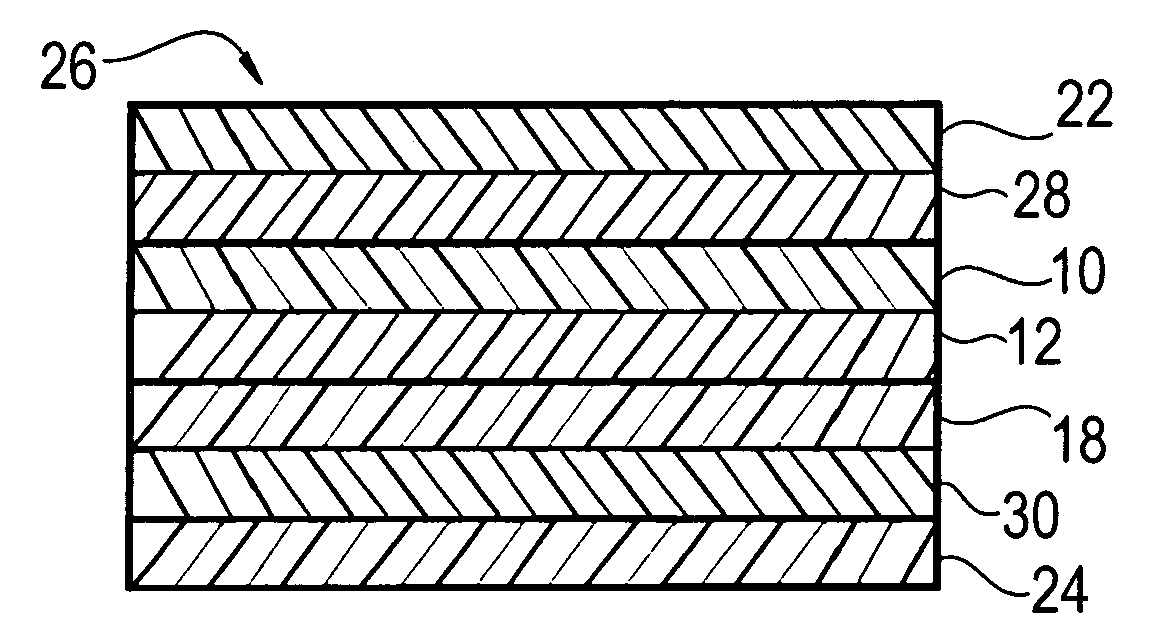

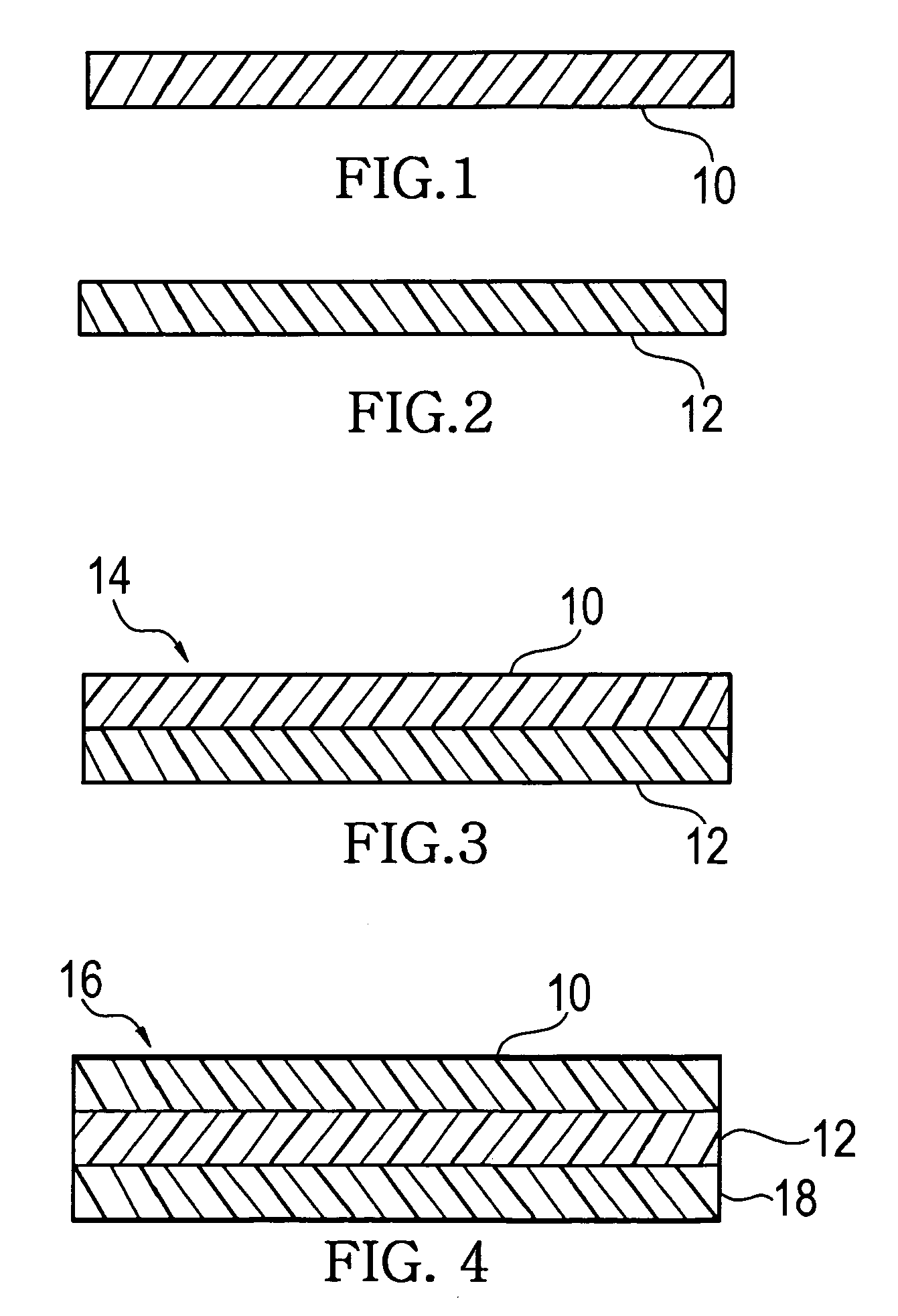

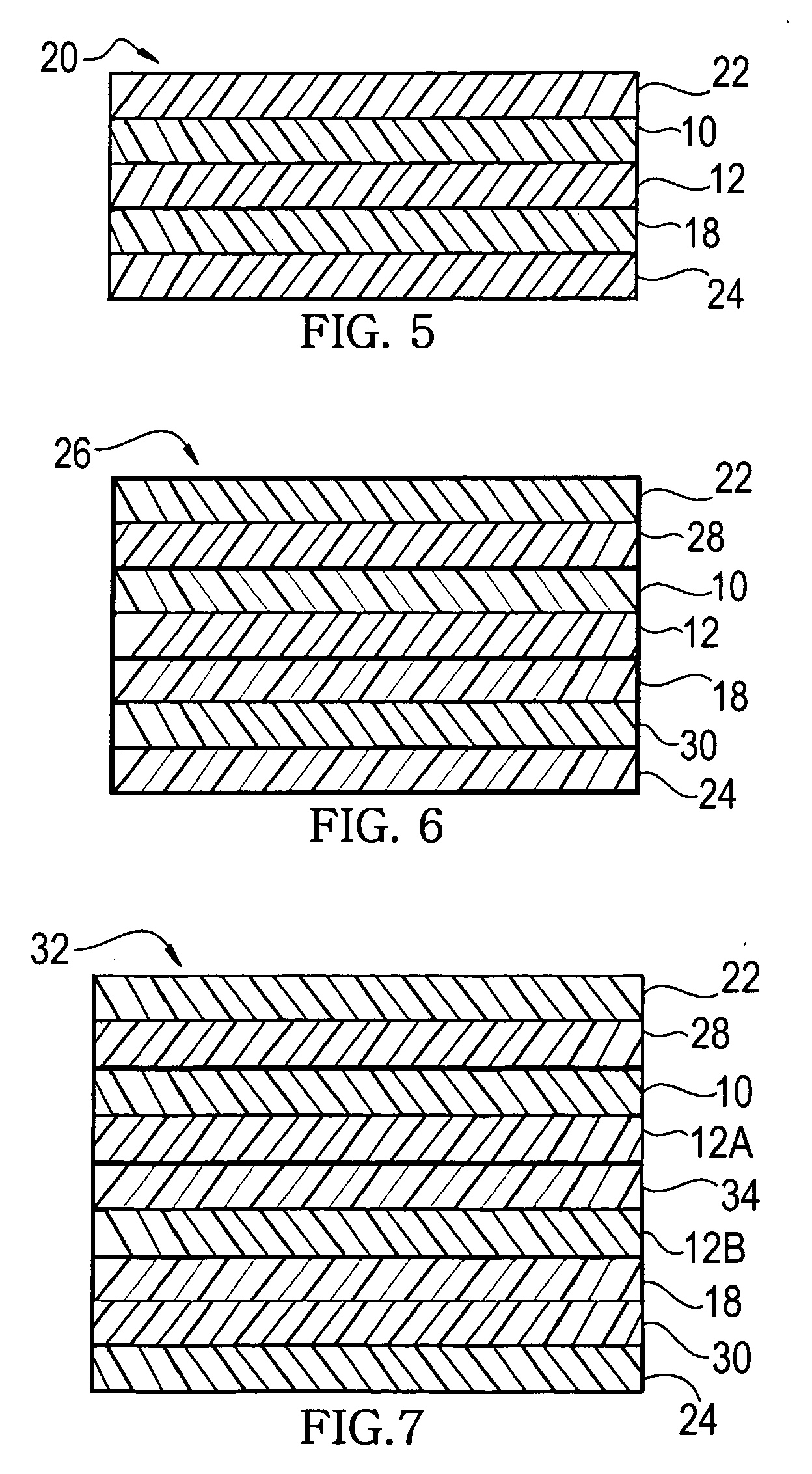

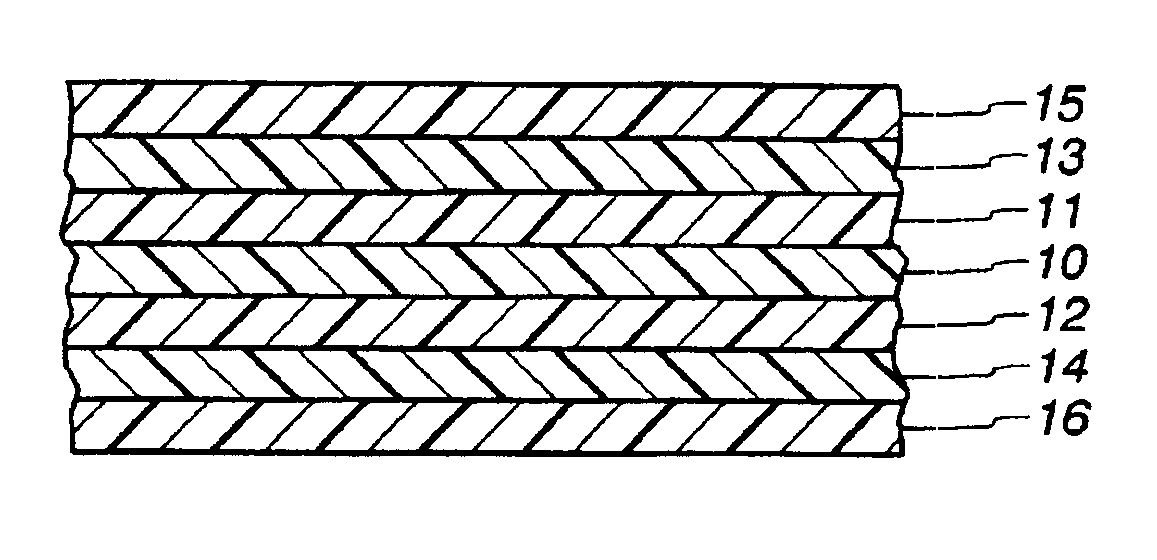

Thermoformable multilayer polymeric film

InactiveUS6942927B2Packed tightlyGood physical propertiesLayered product treatmentSynthetic resin layered productsNylon materialCLARITY

A clear, multilayer polymeric film that is desirable for thermoforming applications. The film in its various embodiments include two inner layers of nylon and / or a core layer of ethylene vinyl alcohol or ethylene vinyl alcohol copolymer sandwiched between the two inner nylon layers. The film also has an outer layer of a heat sealable polymer and may also have an outer layer of nylon. The film is coextruded, blown into a tubular shape, oriented, and cooled by the method of tubular water quenching. The film has various improved physical properties over the prior art, including properties of “memory”, clarity, gloss and low haze.

Owner:EXOPACK

Dyeing technology of nylon-imitating high-elastic polyester yarn

InactiveCN103498350AImprove featuresEnsure stabilityFibre typesHeating/cooling textile fabricsTextile printerPolyester

The invention relates to the technical field of textile printing and dyeing, and provides a dyeing technology of a nylon-imitating high-elastic polyester yarn. According to the dyeing technology, by combining of low-elastic polyester and twisting into high-elastic polyester, the nylon yarn dyeing problem can be solved and an elastic hand feeling effect of the nylon yarn can be achieved, and the dyeing technology comprises a polyester yarn dyeing preprocessing process, a yarn reeling process, high temperature preforming, a dyeing process, a reduction cleaning process, a finishing process and a dehydration drying process.

Owner:福建锦丰印染有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com