Patents

Literature

4160 results about "Engineering plastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Engineering plastics are a group of plastic materials that have better mechanical and/or thermal properties than the more widely used commodity plastics (such as polystyrene, PVC, polypropylene and polyethylene).

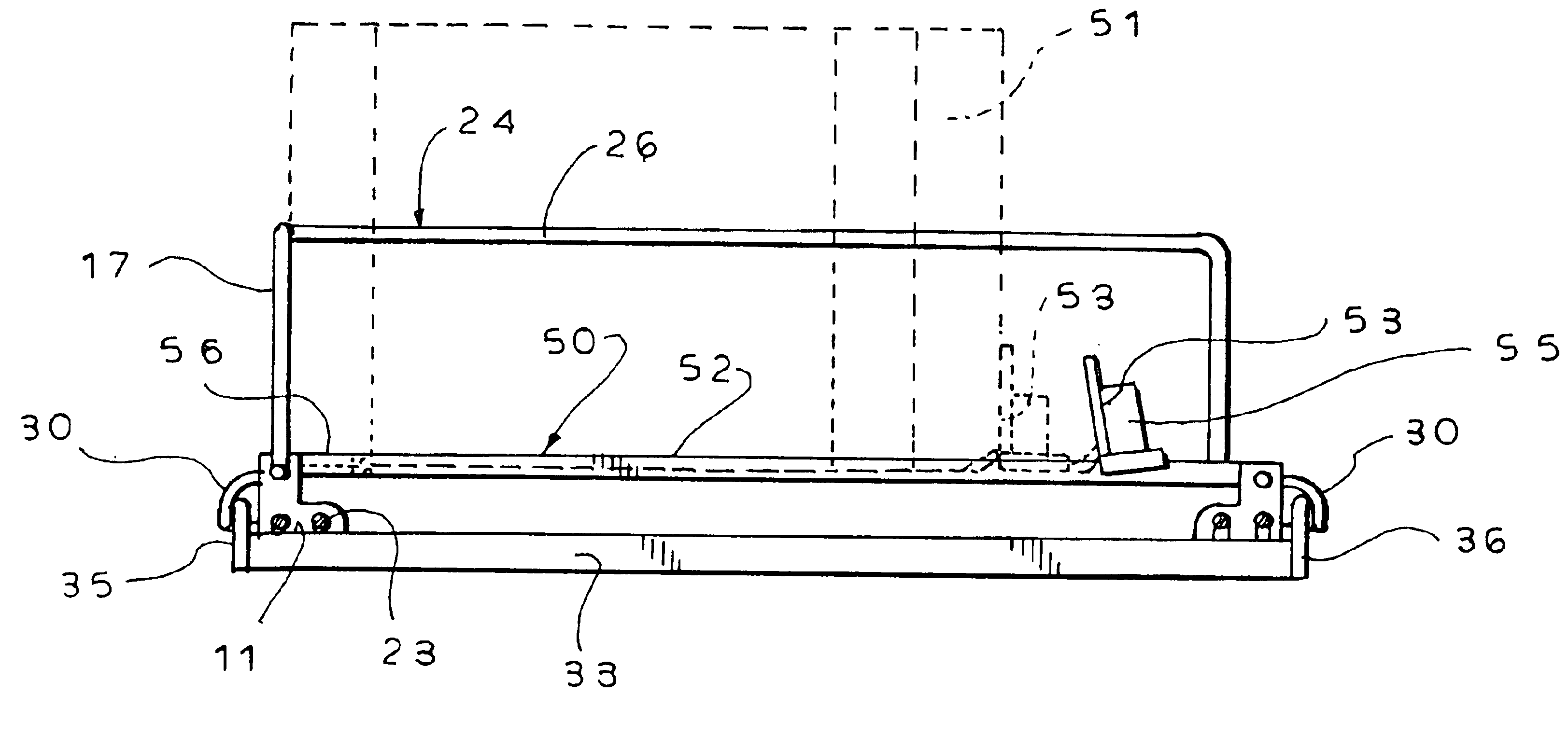

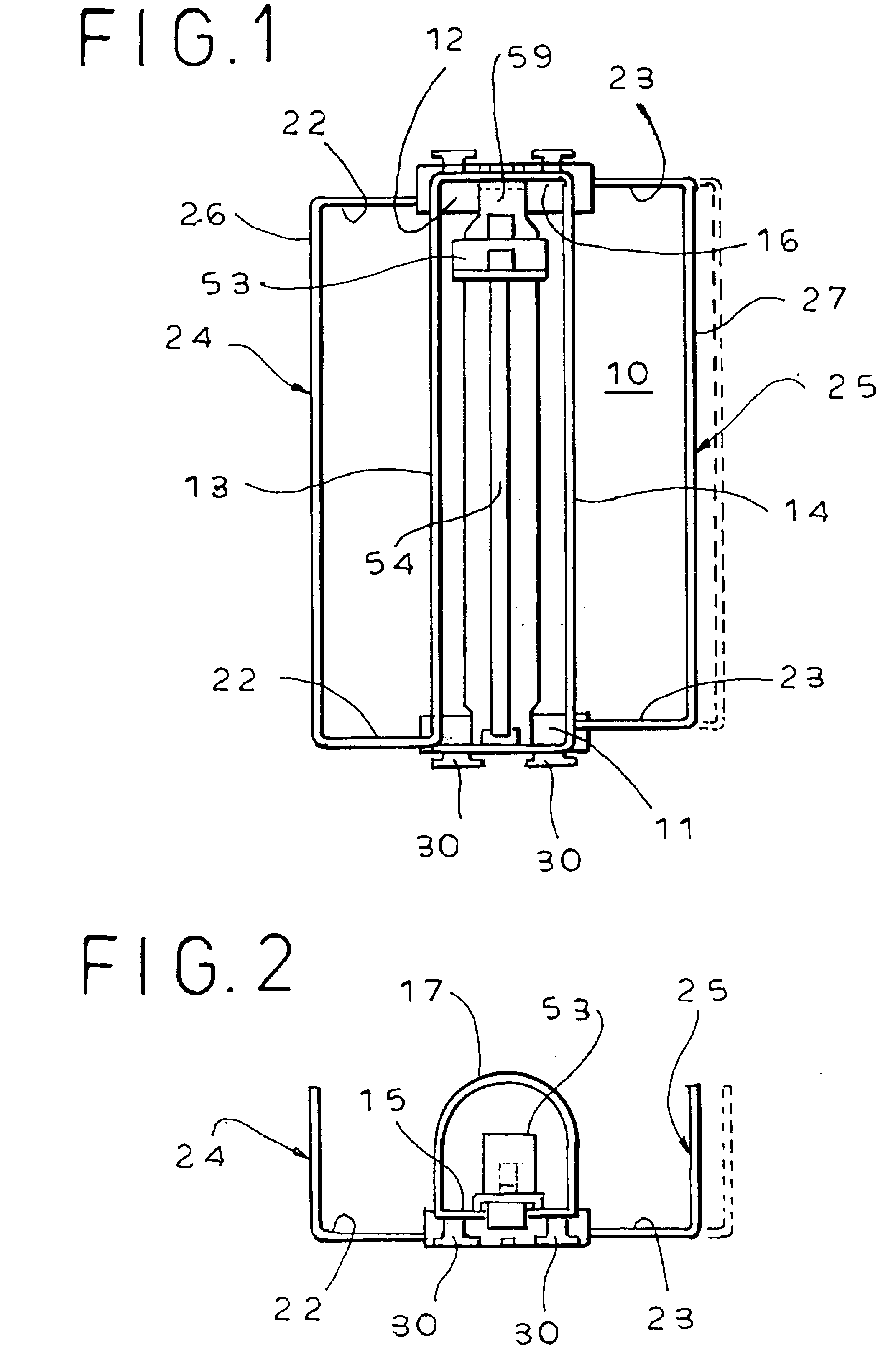

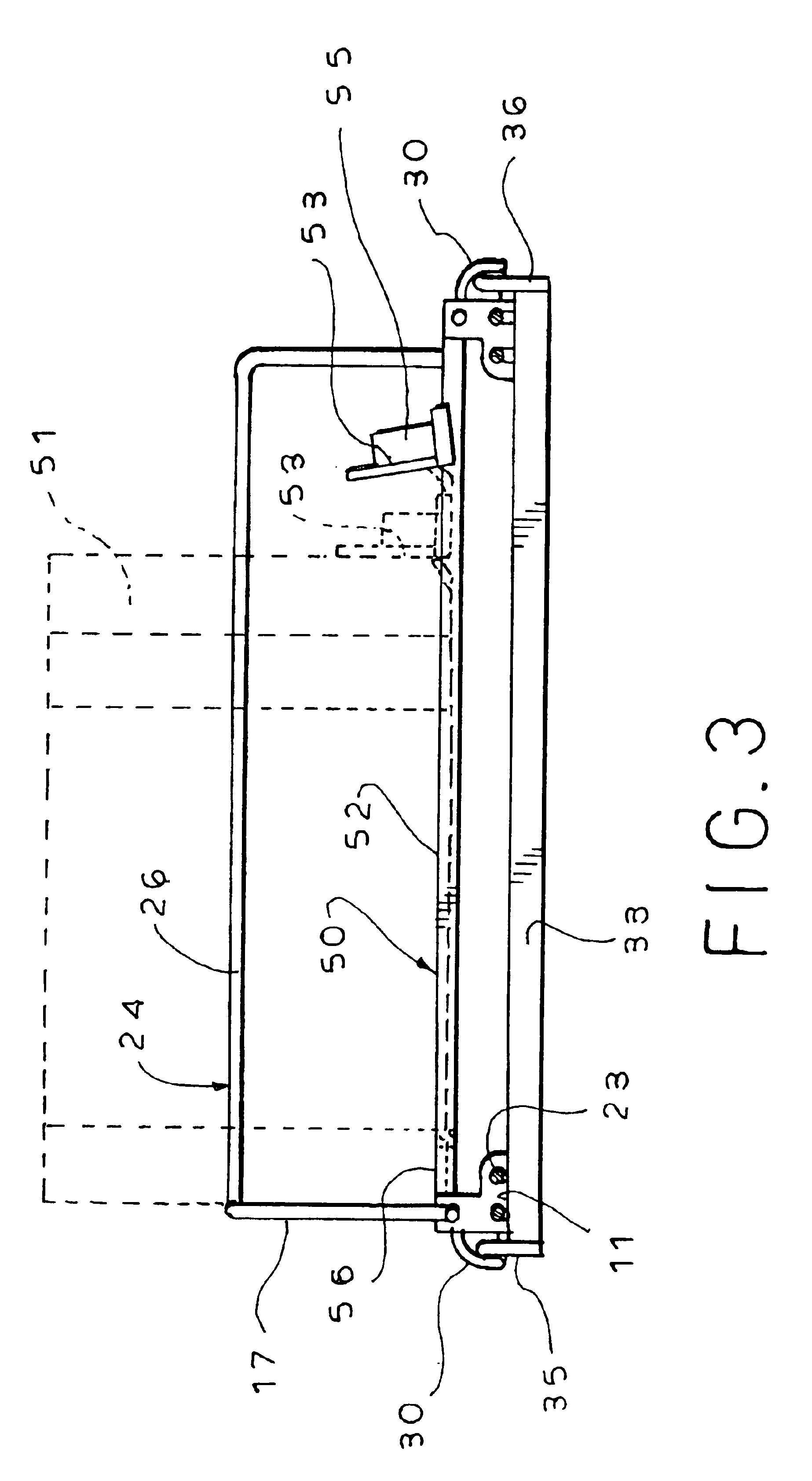

Adjustable width product display system

InactiveUS6866156B2Adjustable widthEasy to processRacksFolding cabinetsPlastic materialsDisplay device

An adjustable width product display system which includes spaced-apart front and back display supports formed of an engineering plastic material, suitable for food freezer environments. Formed wire side elements, provided with transversely extending mounting portions, are slideably received in transversely disposed recesses in the plastic display supports. Each display support includes a pair of closely adjacent, parallel recesses for receiving the mounting portions in overlapping relation, providing a wide range of width adjustment to accommodate packages of different size. A wire frame, comprising a pair of elongated wire elements extending from front to back of the display system joins the two display supports in spaced relation. These wire elements also function as an underneath support for product packages confined between the side elements. Laterally adjacent elements can be connected in series by intermediate wire side supports provided with transverse mounting elements extending in opposite directions and engagable in plastic display supports on both sides. Product pusher means are easily incorporated into the product display system either in the form of a preassembled pusher device, or the use of a spring-driven pusher sled mounted on the wire elements connecting the front and back display supports. The system, is ideally suited for food freezer environment, because plastic materials are minimally present in the structure and thus can be of a suitable engineering grade material. Additionally, the open wire structure accommodates free circulation of air in a freezer compartment to help maintain the desired environment throughout the compartment.

Owner:TRION IND

Highly heat-conducting insulation engineering plastic and preparation method thereof

InactiveCN102174254AIncrease China UnicomImprove thermal conductivityPlastic/resin/waxes insulatorsHeat-exchange elementsFiberAntioxidant

The invention discloses highly heat-conducting insulation engineering plastic, which consists of the following components in part by weight: 100 parts of plastic substrate, 100 to 900 parts of heat-conducting filler, 1 to 45 parts of compatibilizer, 1 to 90 parts of toughening agent, 1 to 45 parts of reinforcing agent, 1 to 36 parts of lubricating agent and 0.3 to 5.4 parts of antioxidant. The invention also discloses a preparation method of the engineering plastic, which comprises the following steps of: drying the plastic substrate and the heat-conducting filler in a 60 to 100 DEG C air dry oven for 4 to 8 hours; putting the components into a high-speed mixer and mixing for 3 to 5 minutes; performing internal mixing on the mixture in an internal mixer for 10 to 30 minutes; and uniformly grinding the mixture in a grinder, transferring to a charging hopper of a double-screw extruder, feeding fiber fillers through a fiber inlet of the double-screw extruder, melting, mixing, extruding, cooling, drying, and pelletizing. The prepared material has high heat-conducting property and mechanical property, and is easily subjected to injection molding.

Owner:GUANGDONG JANUS SMART GRP CO LTD

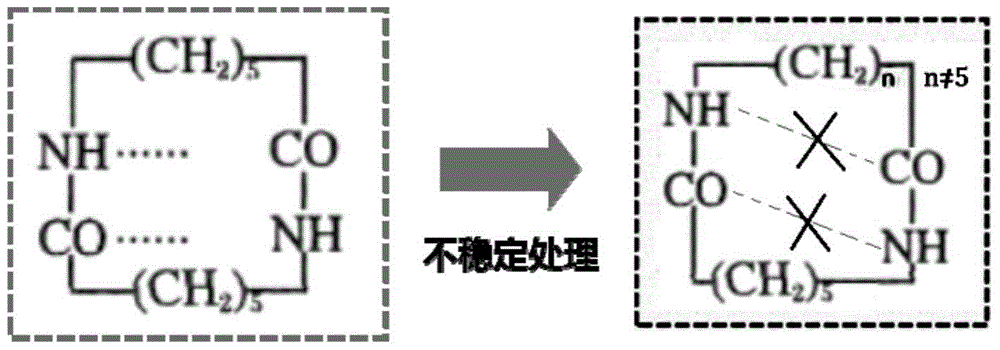

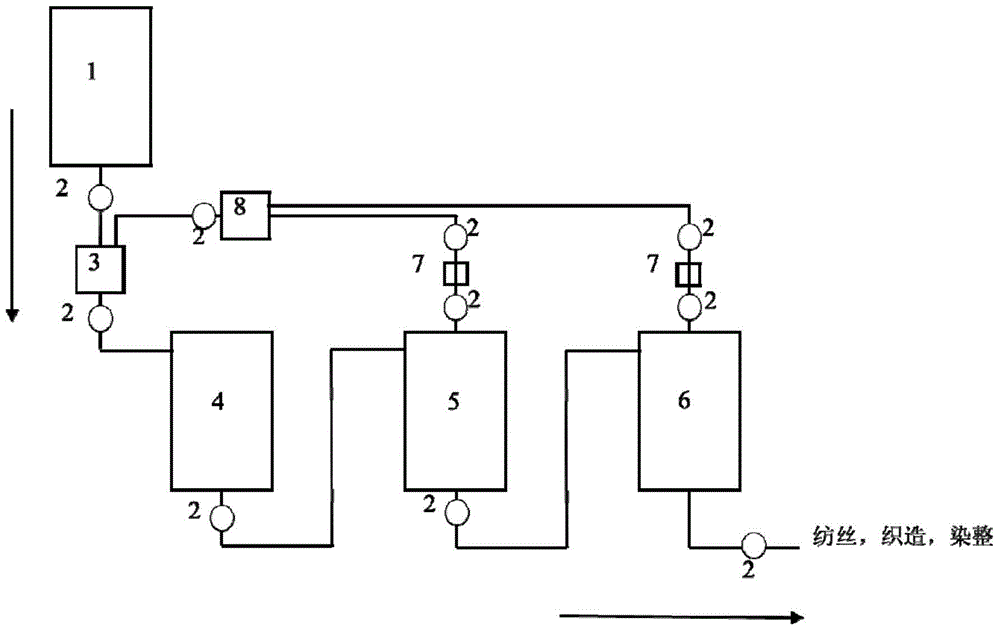

Nylon 6 polymerization method and direct spinning method of melt of polymer obtained with nylon 6 polymerization method

ActiveCN105669969AIncrease profitReduce manufacturing costFlame-proof filament manufactureHollow filament manufacturePolymer sciencePolyamide

The invention relates a nylon 6 polymerization method and a direct spinning method of a melt of a polymer obtained with the nylon 6 polymerization method. A polyamide 6 prepolymer is prepared at the low temperature, the content of oligomers in the melt is controlled in advance, polymerization is completed before a large quantity of cyclic oligomers are generated with a condensation polymerization dynamic strengthening method, a nylon 6 polymer melt with certain molecular weight is acquired, the content of extracts in the product is smaller than or equal to 1.5 wt%, and the content of cyclic dipolymers is smaller than or equal to 0.2wt%; then, direct melt spinning forming is performed after condensation polymerization dynamic strengthening ends. The process is simple, energy consumption is further reduced while the utilization rate of caprolactam is increased, the obtained melt can be directly used for melt spinning, high-capacity large-scale production is easy to realize, a modifier can be added in the polymerization process, flexible production of nylon 6 is realized, and the nylon 6 can be applied to fibers for clothes, industrial filaments, engineering plastics and other fields.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

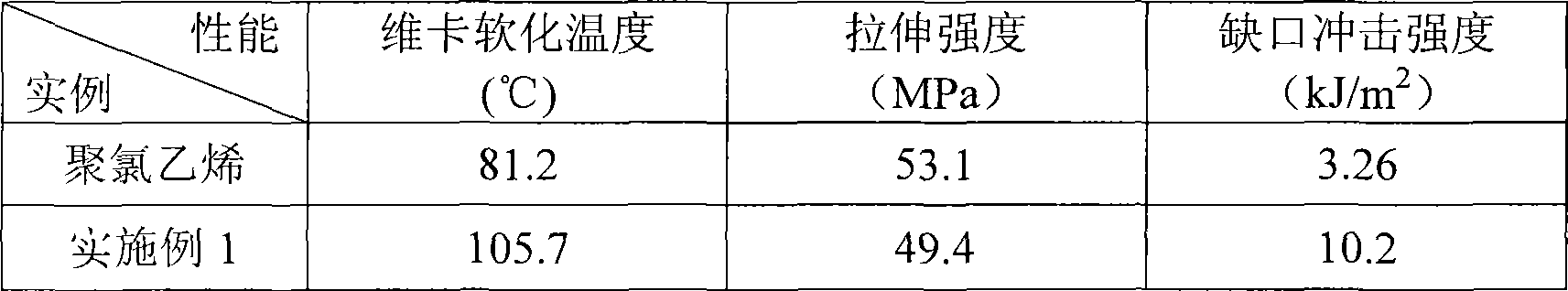

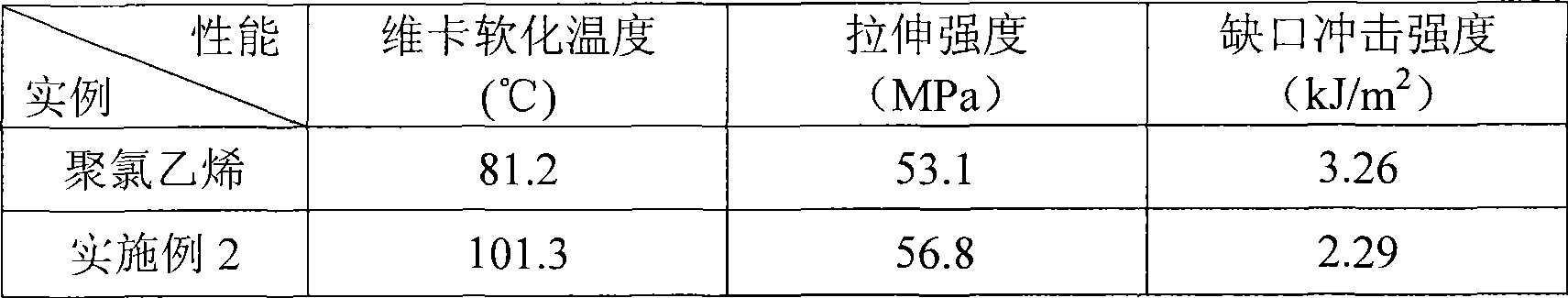

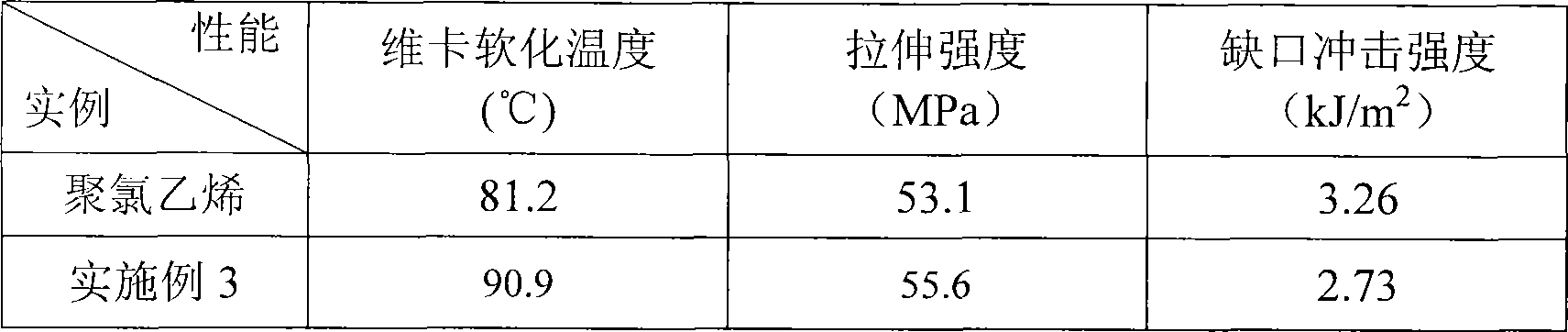

Preparation method of super-strong high temperature-resistant chlorinated polyvinyl chloride tubes

ActiveCN102134360ADoes not show brittlenessExcellent low temperature toughnessRigid pipesPolymer scienceChlorinated polyvinyl chloride

The invention discloses a preparation method of super-strong high temperature-resistant chlorinated polyvinyl chloride tubes, which is characterized in that the tubes are made by the following steps: 75 to 100 portions of chlorinated polyvinyl chloride resin, 0 to 25 portions of vinyl chloride resin, 3 to 10 portions of ABS, 1 to 8 portions of acrylic acid resin, 3 to 8 portions of bismaleimides, 1 to 5 portions of plasticizing accelerator, 1 to 5 portions of compatibilizer, 10 to 25 portions of engineering plastics, 1 to 3 portions of lubricant, 1 to 5 portions of nanometer materials, 4 to 8 portions of stabilizing agent, 2 to 15 portions of filler, 0 to 1 portion of cross-linking agent, 1 to 5 portions of processing modifier and 3 to 10 portions of impact modifier are mixed and blended according to weight proportion, and then extruded by a mould. Compared with the prior art, the super-strong high temperature-resistant chlorinated polyvinyl chloride tubes has the advantages of being high in vicat softening point, being capable of meeting the high-temperature requirement of more than 120 DEG C, and having good anti-aging performance, antiflaming and insulation performance, and compression resistance, and long service life.

Owner:SHANGHAI YUANZHOU PIPE

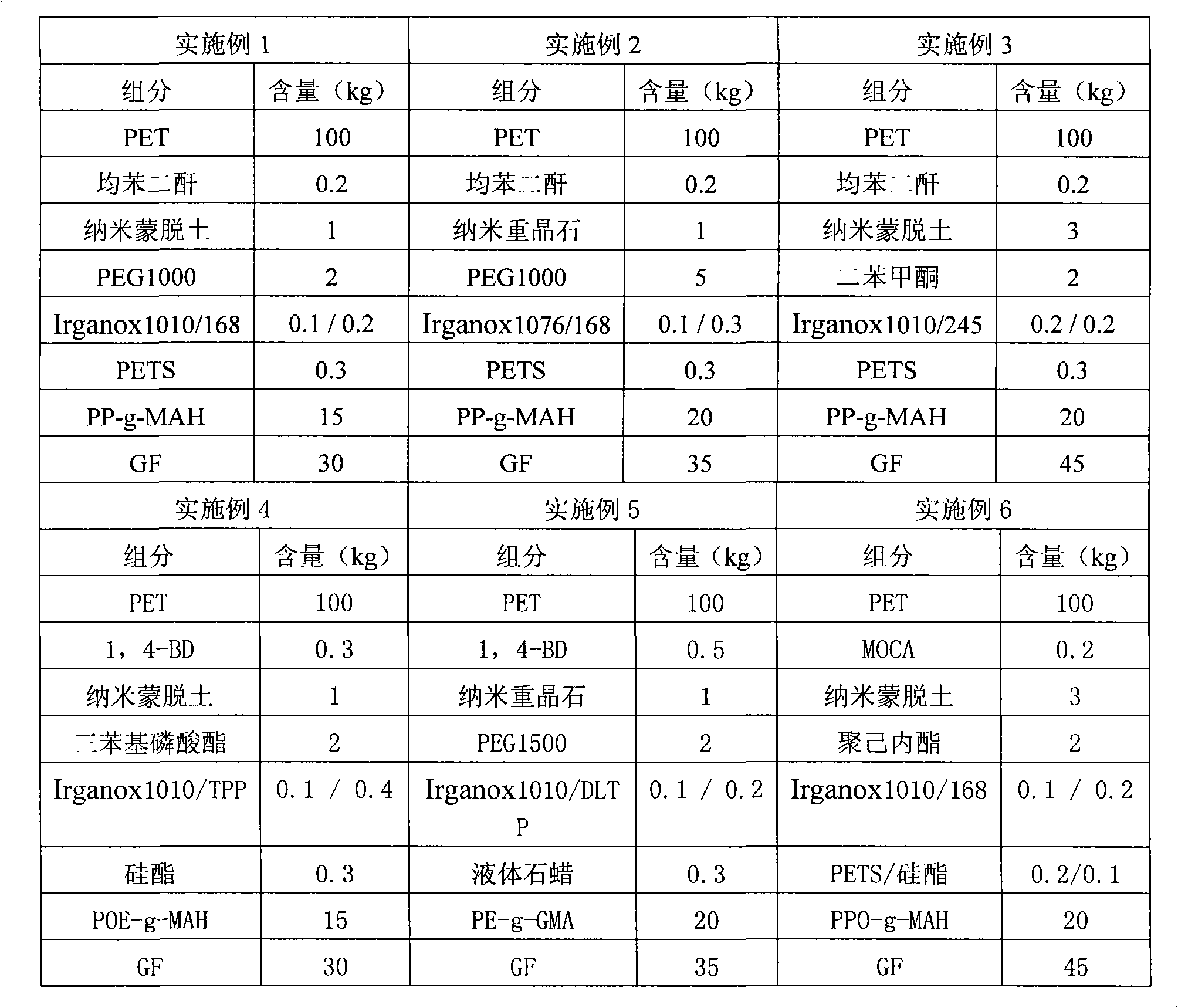

Glass fiber reinforced polyethylene glycol terephthalate composite material and preparation thereof

The invention relates to a PET glass fiber reinforced composite material, which has the following components based on weight proportion: 100 portions of PET, 10-45 portions of alkali-free glass fibers, 5.0-25 portions of toughener, 0.1-10 portions of crystallization promoter, 0.1-1.0 portion of chain extender, 0.5-5.0 portions of nucleating agent, 0.1-0.5 portion of antioxidant and 0.3-0.5 portion of lubricant. The preparation method is that the components are evenly mixed on a high-speed mixer and melted and blended by a twin-screw extruder to prepare the composite material. The composite material has the advantages of good mobility, high tensile strength and high impact strength, which aims to realize low-cost and high-quality PET engineering plastic scale production to effectively substitute for high-grade plastics and expensive imported special materials.

Owner:SHANGHAI UNIV +1

Polyethylene corrugated pipe and preparation method thereof

InactiveCN103937075AThe preparation method is simple and convenientLow costAntioxidantEngineering plastic

The invention relates to a polyethylene corrugated pipe and a preparation method thereof, belonging to the technical field of non-metal building materials. The invention aims to provide a high-strength aging-resistant polyethylene corrugated pipe which is prepared through the following steps: preliminarily mixing the following raw materials in parts by weight: 75-100 parts of polyethylene, 5-25 parts of polypropylene, 0.5-15 parts of compatibilizer, 0.5-25 parts of rigid master batch, 0.05-1.5 parts of antioxidant, 0.02-1.5 parts of light stabilizer, 0.05-5 parts of light screening agent and 0.5-10 parts of nano material, uniformly stirring, and then granulating to obtain a preliminarily mixed granulation material; adding 2-15 parts by weight of engineering plastic, blending with the preliminarily mixed granulation material, uniformly stirring, and then granulating to obtain a blended granulation material; and then extruding the blended granulation material through an extruder, sizing with a mold, cooling, pulling, and cutting.

Owner:KANGTAI PLASTIC SCI & TECH GRP

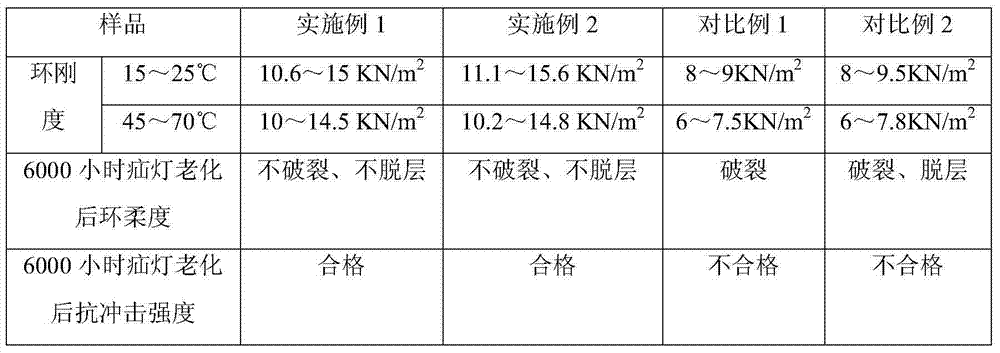

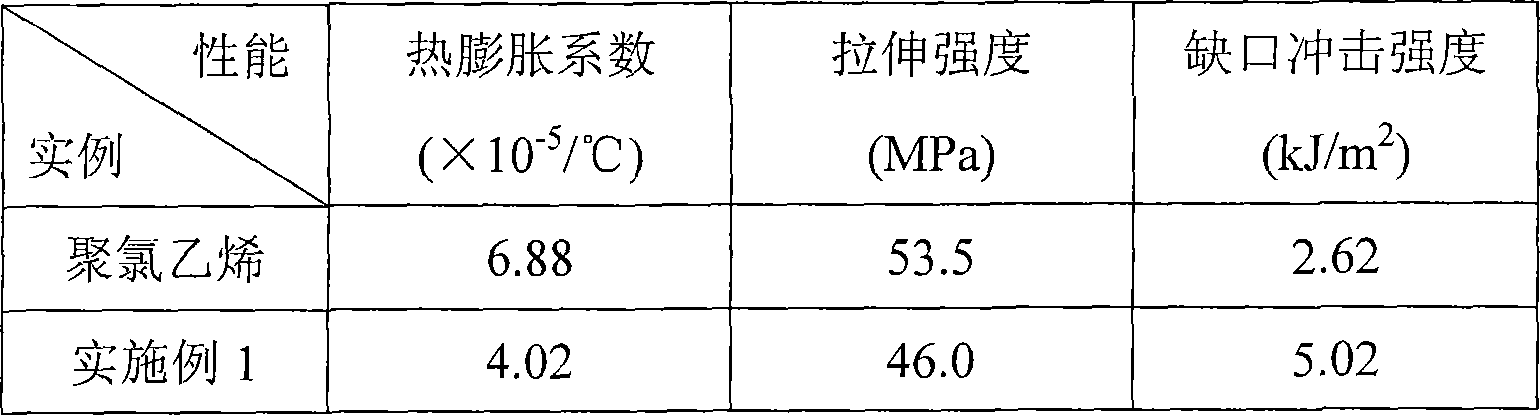

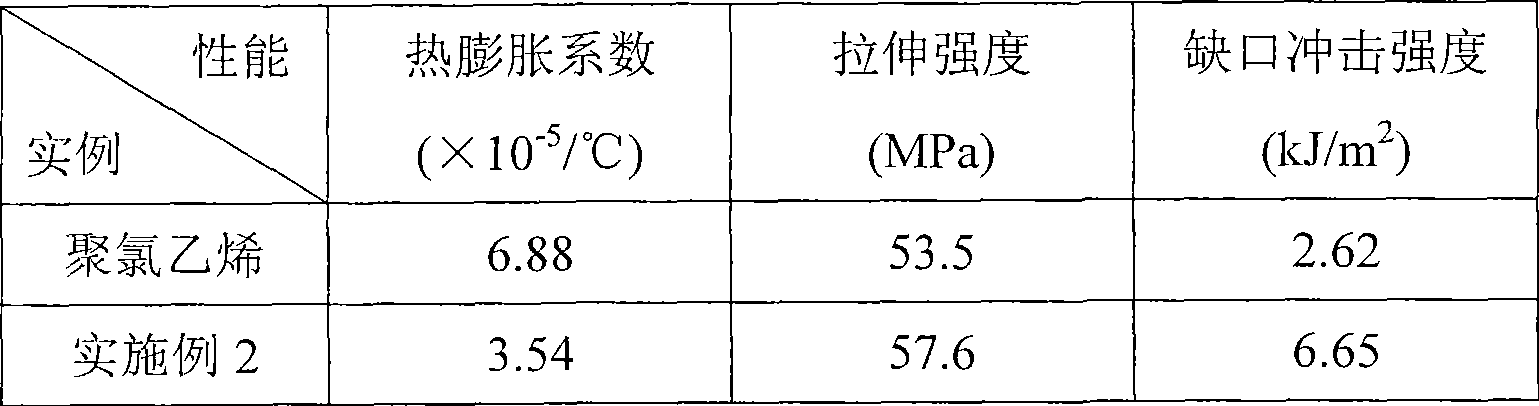

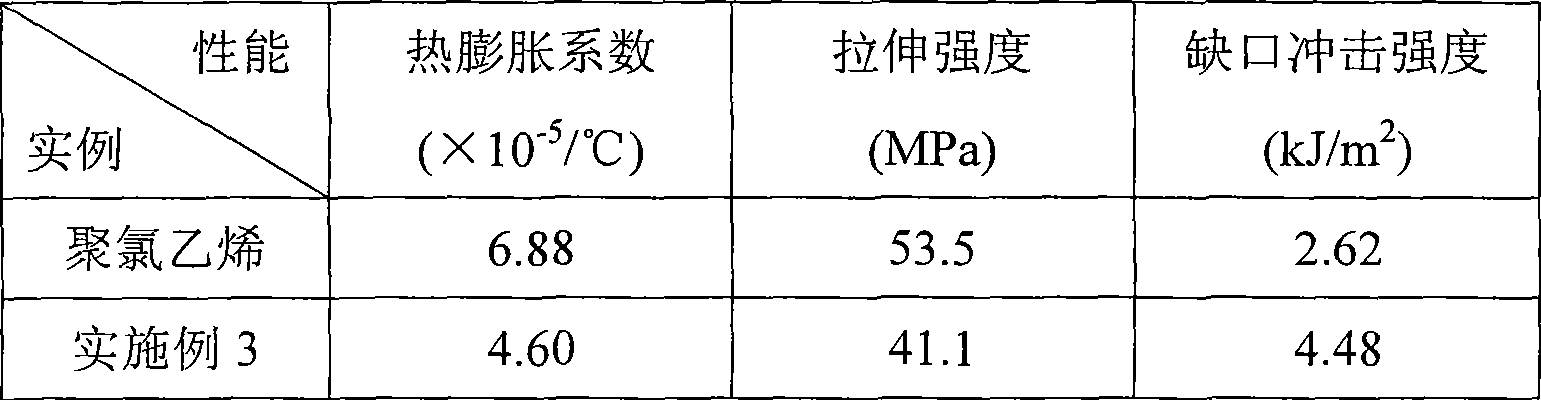

Low-expansion coefficient polyvinyl chloride alloy material and manufacturing method thereof

The invention provides a low-expansion coefficient polyvinyl chloride alloy material and a manufacturing method thereof. The ingredients of raw materials of the alloy material comprise a polyvinyl chloride substrate, a heat-resistant modifier, a heat stabilizer, a lubricator, a filler and a processing agent, and the alloy material is manufactured by a melt blending technique. The processing agent and the filler in the ingredients of the raw materials of the invention are the processing agent that is subjected to modification by a new method and the filler that is subjected to organic treatment, and by means of a mechanochemical reaction, self-plastification, toughening and reinforcement of the PVC can be combined organically to improve compatibility and dispersity of the polyvinyl chloride, the filler and heat-resistant resin, thus settling the problem about the contraction between the improvement of heat expansion performance and heat resistance of the PVC, and processing performance, strength and toughness of the PVC; the polyvinyl chloride engineering plastic with low expansion coefficient, high heat resistance, high strength, high toughness, excellent aging resistance and outstanding processing performance is manufactured; the invention has extensive industrial market prospect and the manufacturing method thereof is simple in technology, convenient in operation and control, stable in quality and high in production efficiency.

Owner:SICHUAN UNIV

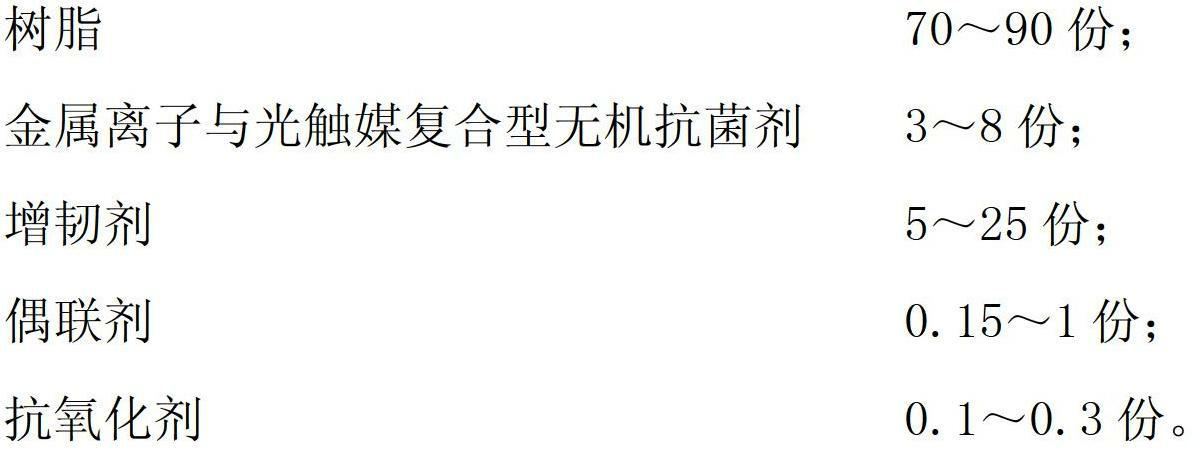

Metal-like engineering plastic composite material and preparation method thereof

The invention discloses a metal-like engineering plastic composite material and a preparation method thereof, and relates to a polymer composite material. The invention provides the metal-like engineering plastic composite material which combines plastic with metal and simultaneously keeps the advantages of the two and the preparation method thereof. The composite material comprises thermoplastic engineering plastic, high-density packing, mineral powder, glass fiber, toughener, coupling agent, lubricant and antioxidant. The metal-like engineering plastic composite material has high density, high mechanical properties, excellent thermal deformation temperature and good injection molding property. The preparation method adopts the method of being combined with the coupling agent and the optimized granulation conditions, the process is simple and easy to operate, extrusion and granulation can be carried out by adopting an ordinary twin-screw granulator, and injection molding can be carried out by adopting an ordinary injection machine.

Owner:XIAMEN RUNNER IND CORP

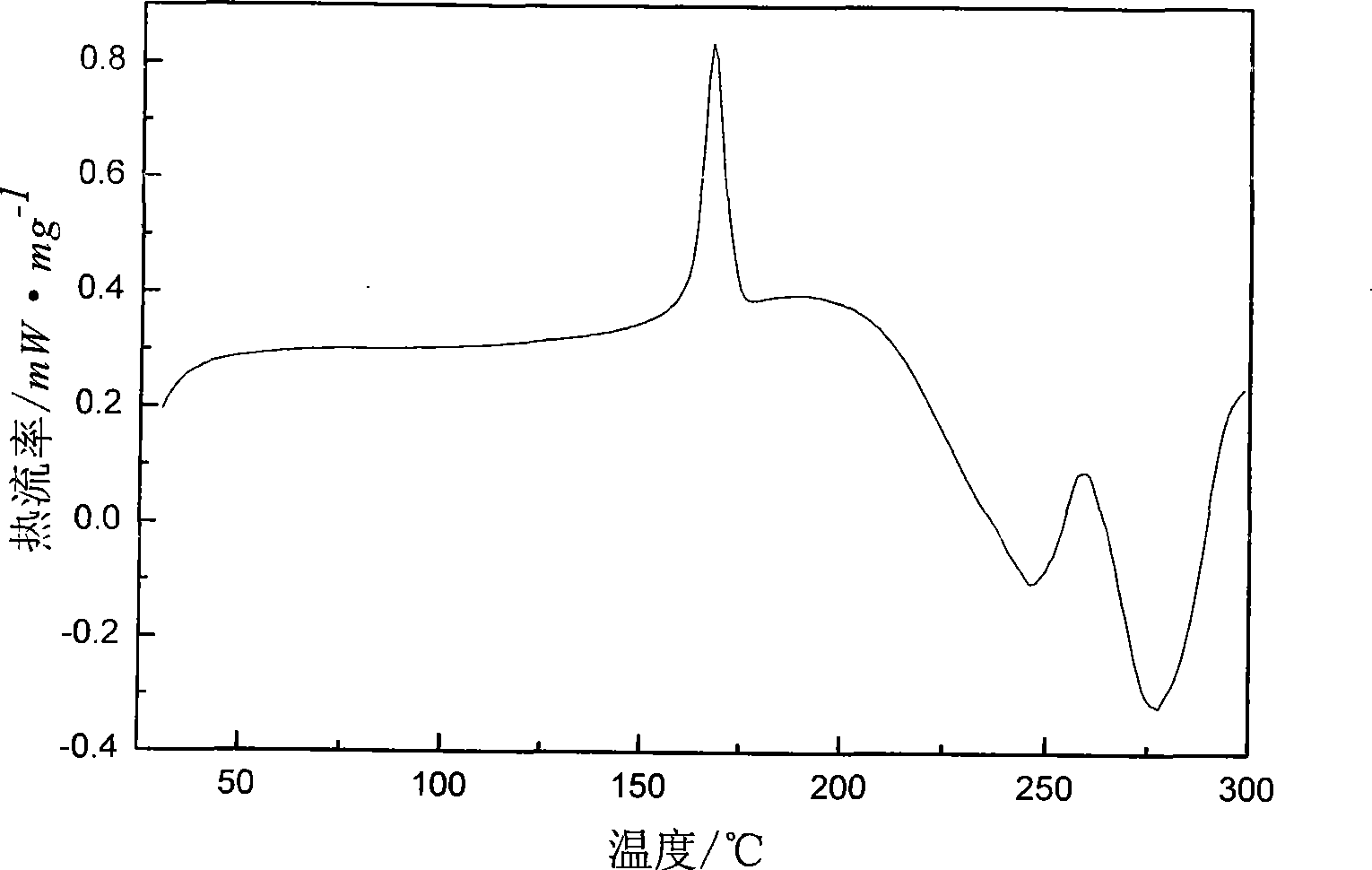

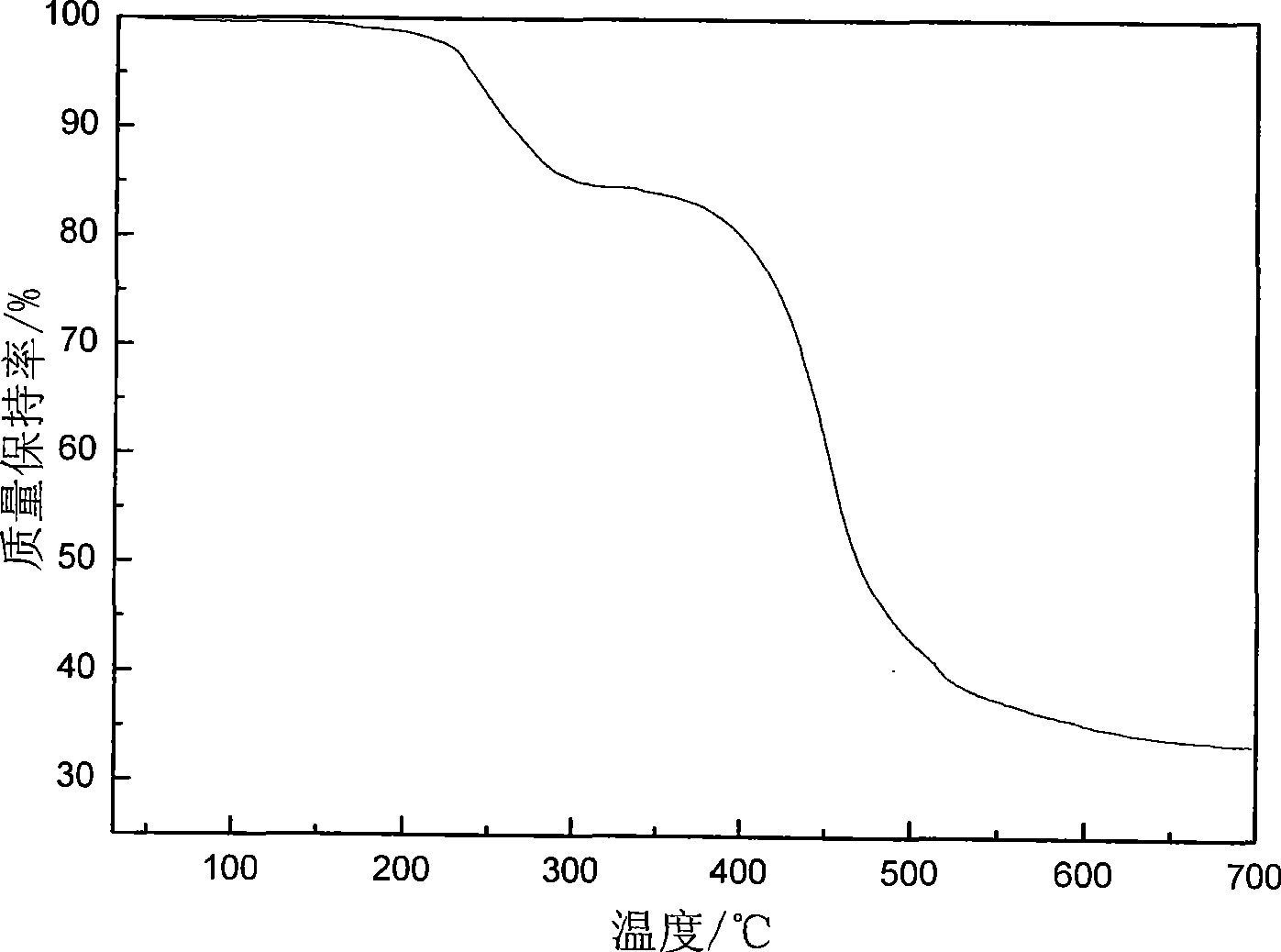

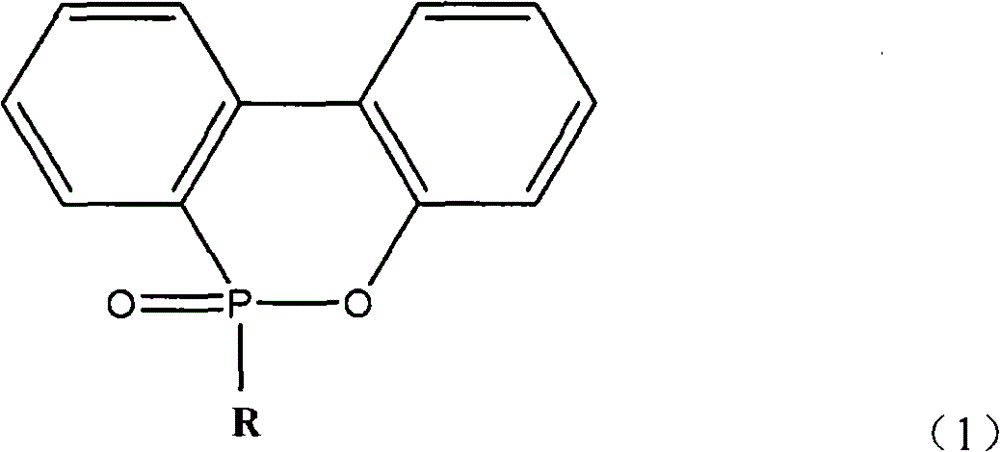

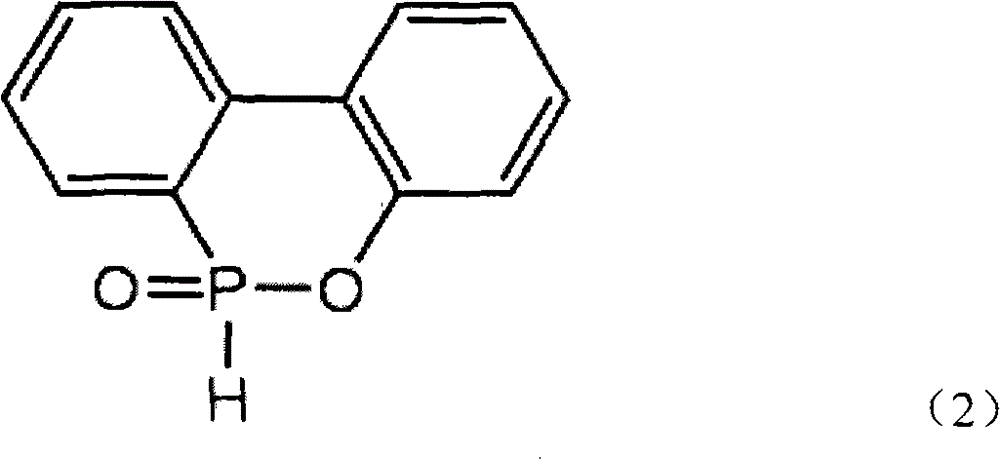

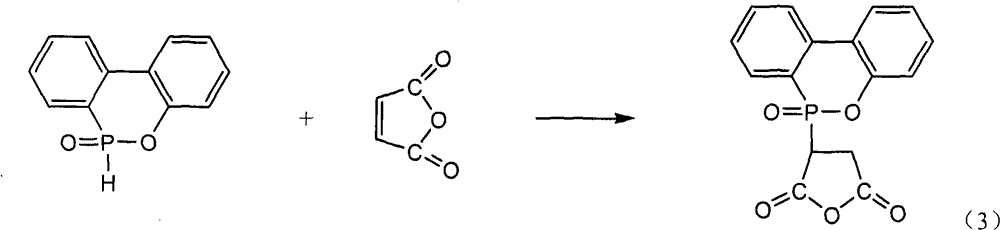

Phosphaphenanthrene flame-retardant compound containing s-triazine structure, and preparation and use thereof

ActiveCN101376665AReduce energy consumptionEasy to operateGroup 5/15 element organic compoundsEpoxyPolymer science

The invention discloses an oxa-phosphaphenanthrene flame retardant compound containing the sym-triazine structure and a preparation method thereof. The method is characterized in that an intermediate is synthesized from 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide(DOPO) and p-hydroxybenzaldehyde as raw material by the solution method, and then reacts with cyanuric chloride in the presence of phase transfer catalyst to obtain a 2,4,6-tri(4-(10-methenyl hydroxy-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide)phenoxy)-1,3,5-triazine product. The compound is white crystal, and has a melting point of 166 to 169 DEG C, good thermal stability and high flame retardation efficiency, and can be adopted as a reactive flame retardant for the flame retardation of thermosetting resins such as epoxy resin, polyurethane and the like, and also as an additive flame retardant for the flame retardation of engineering plastics such as ABS, nylon and the like.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

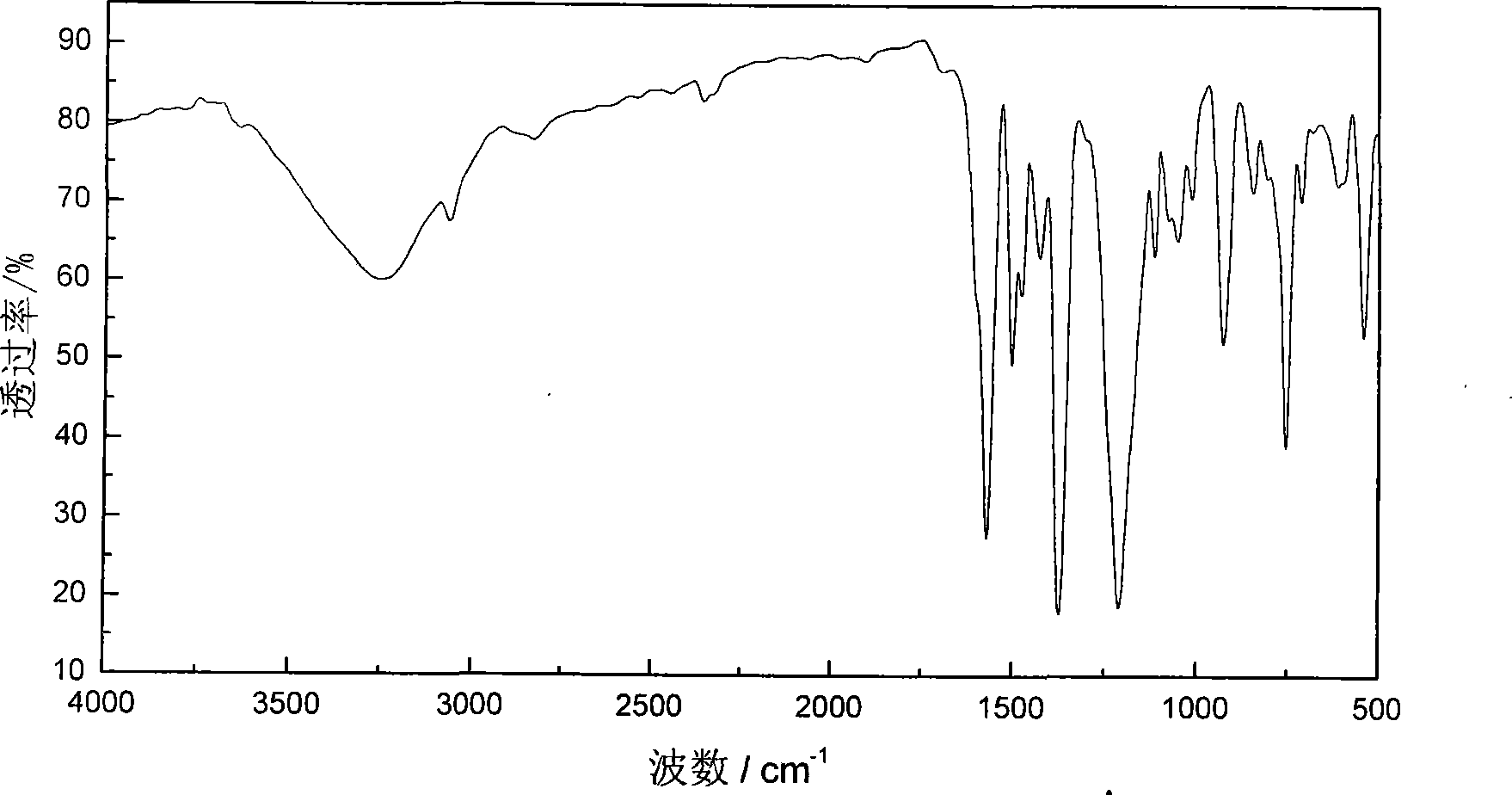

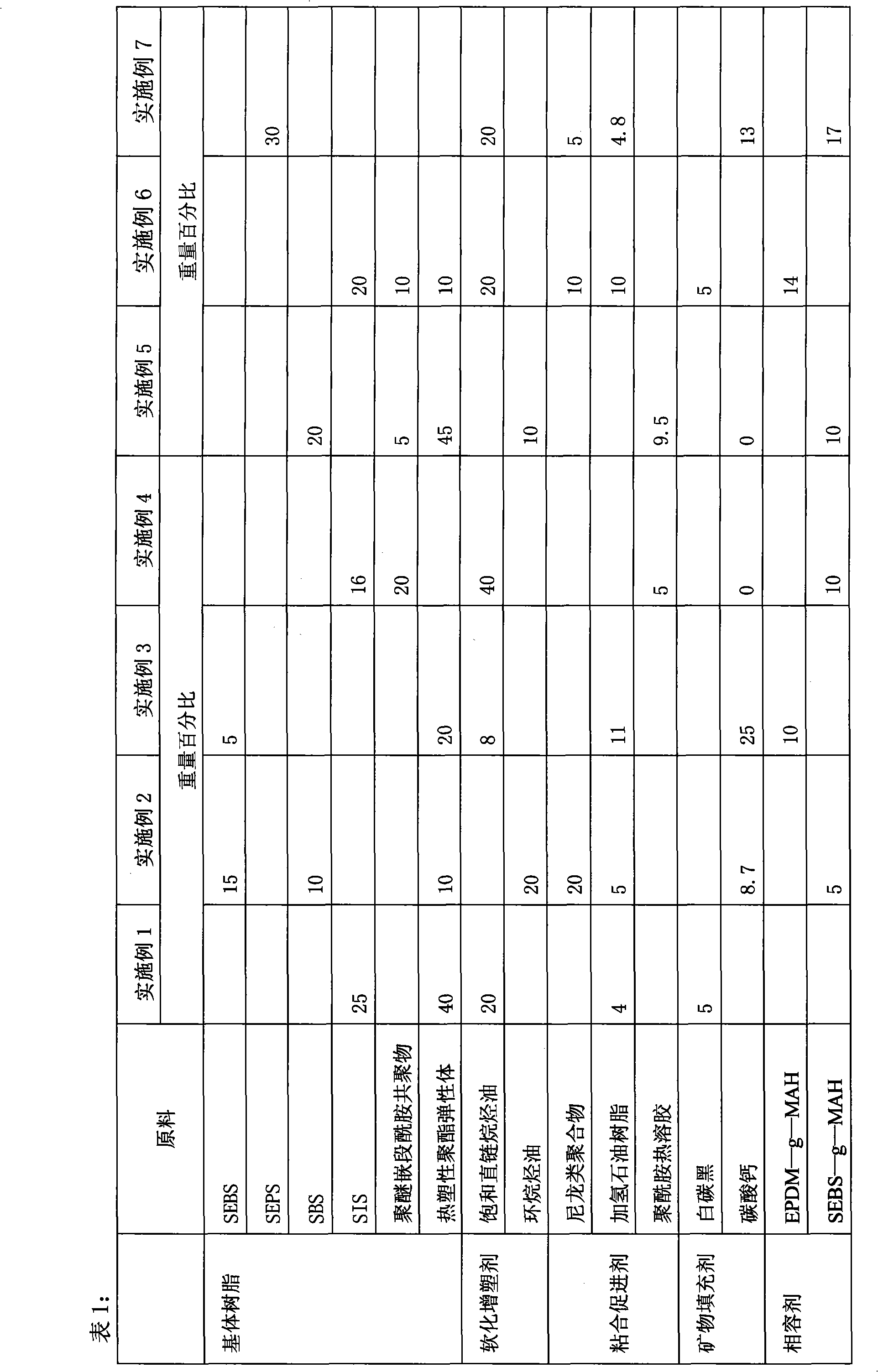

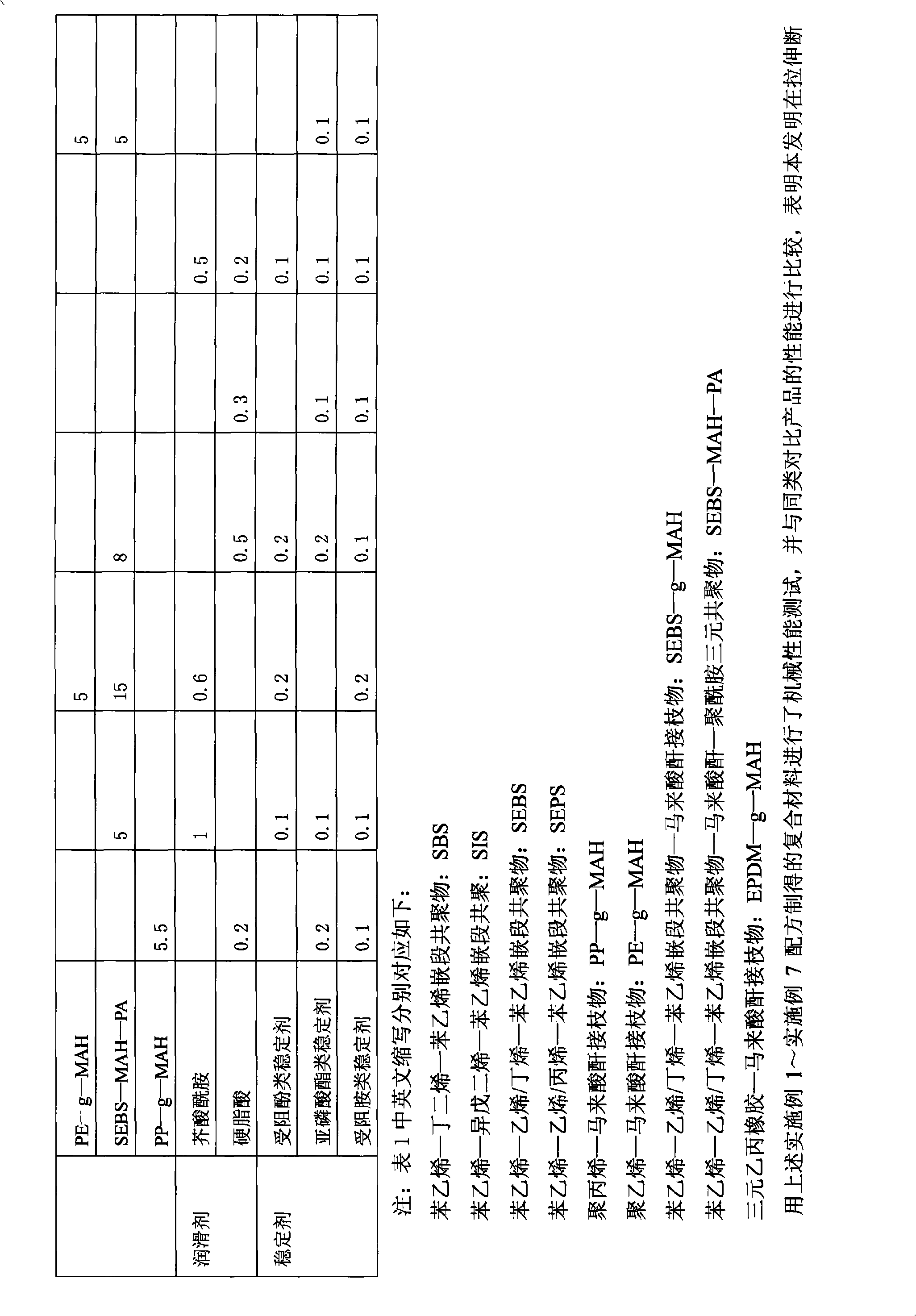

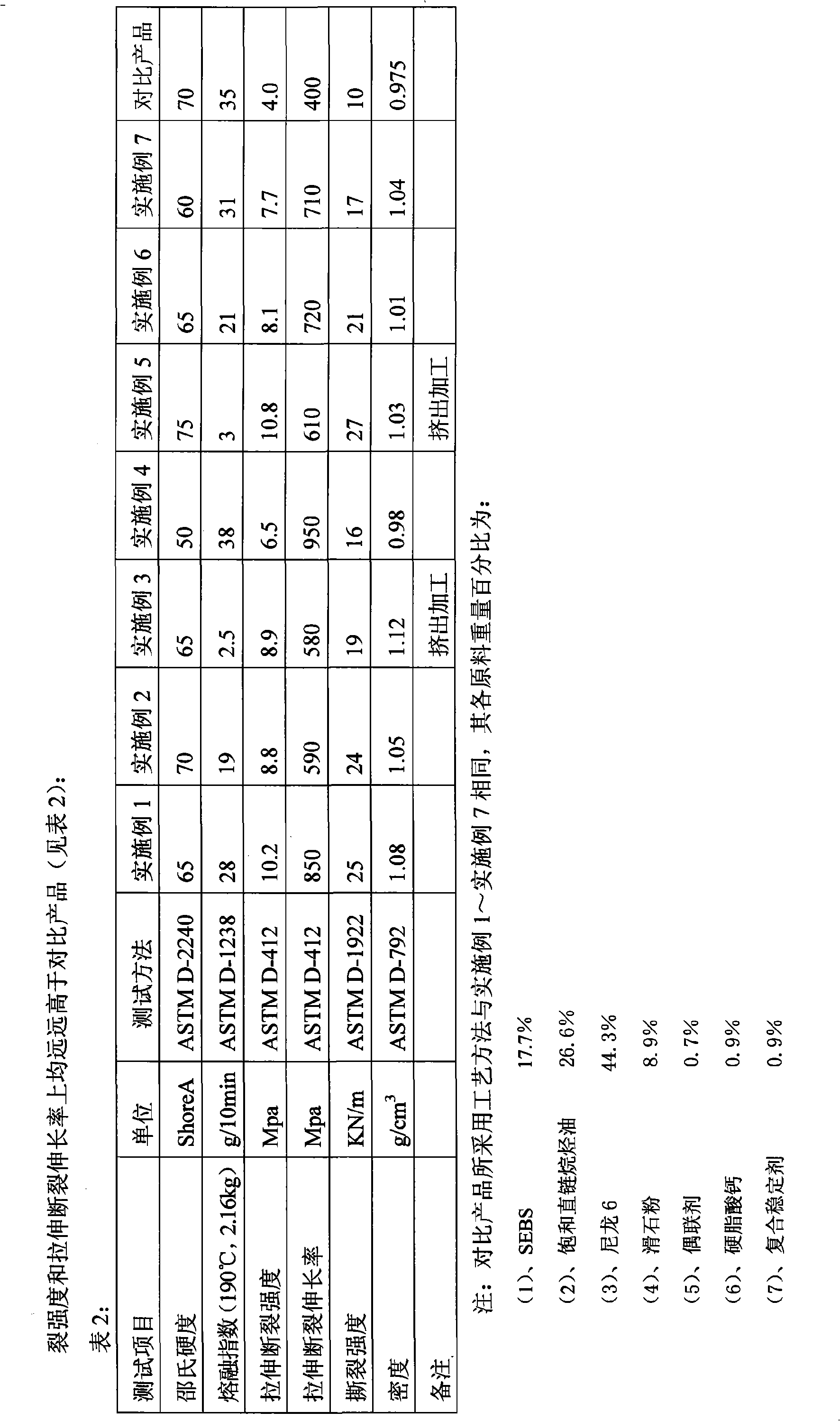

Thermoplastic elastomer capable of coating and bonding with nylon

The invention provides a thermoplastic elastomer coated and bonded by nylon, comprising matrix resin, softened plasticizer, adhesion promotor, mineral filler, lubricant and stabilizer, wherein the weight percentage of the material is as follow: resin 20-75%, softened plasticizer 5-45%, adhesion promoter1-30%, mineral filler 0-3%, compatiblizing agent 5-35%, lubricant 0-2%, stabilizer 0-2%. The matrix resin also comprises: thermoplasticity polyurethane elastomer or polymerized silica block amide copolymer, which makes the thermoplastic elastomer with good physical property, in addition a great variety of compatiblizing agents are used, therefore each component fully and mutually dissolves with each other to reduce the occurence of delamination, and the solubility of the composite material to the other engineering plastics, so that the thermoplastic elastomer is firmly adhesive on the surface of the nylon material without any bonding agent by twice injection of plastic jetting-moulding machine or extruder, and coating adhesive on the material such as ABC, PC. The market prospect is increased.

Owner:NINGBO SHIP PLASTIC CO LTD

Method for preparing high-strength heat-resistant and cold-resistant modified polypropylene pipe

ActiveCN102966801AImprove toughnessGood strength performanceRigid pipesMasterbatchEngineering plastic

The invention discloses a method for preparing a high-strength heat-resistant and cold-resistant modified polypropylene pipe. The pipe is formed by the following steps of: extruding an outer layer, a middle transition layer and an inner wall layer onto the same one mold through three extruders, fusing and compounding. The outer layer of the pipe consists of modified polypropylene, an impact-resistant modifying agent, an antibacterial agent, a light stabilizer, an antioxygen, a compatibilizer, nanometer materials, a tackifier and a color masterbatch in parts by weight; the middle transition layer of the pipe consists of engineering plastics, the modified polypropylene, the compatibilizer, the a tackifier and the color masterbatch in parts by weight; and the inner wall layer of the pipe consists of the engineering plastics, the modified polypropylene, the compatibilizer, a fortifier, a filler, the nanometer materials and the color masterbatch in parts by weight. Compared with traditional similar pipes, the operating temperature of the pipe prepared by the method disclosed by the invention is improved by 30-70 DEG C; the cold-resistant temperature is lowered by minus 15-minus 30 DEG C; the pressure-resistant property is improved by 30-50 percent; the creep resistance is improved by 100-200 percent; the service life is prolonged by 10-20 years; and the wall thickness of the pipe is reduced by 20-50 percent.

Owner:HONGYUE PLASTIC GROUP

Thermoplastic resin composition and engineering plastic composition

InactiveUS20050159533A1Improve liquidityImprove melt fluiditySpecial tyresEngineering plasticTape recorder

Owner:MITSUBISHI CHEM CORP

Thermoplastic polyester composition and preparation method thereof

The invention belongs to the technical field of engineering plastic modification, and discloses a thermoplastic polyester composition and a preparation method thereof. The thermoplastic polyester composition is prepared from the following components by weight: 37-95 parts of thermoplastic polyester, 5-25 parts of a flexibilizer, 0-35 parts of an organic filler, 0-1 part of a coupling agent, 0-1 part of a lubricant, and 0-1 part of an antioxidant, wherein the thermoplastic polyester is selected from one or more than one of thermoplastic polyester resin or thermoplastic polyester reclaimed materials; the flexibilizer is selected from a flexibilizer 1 or a flexibilizer 2; when thermoplastic polyester is selected as the thermoplastic polyester, the flexibilizer is selected from one or more than one of flexibilizer 1 or a mixture of flexibilizer 1 and flexibilizer 2; when thermoplastic polyester reclaimed materials or a mixture of reclaimed materials and resin are selected as the thermoplastic polyester, the flexibilizer is selected from one or more than one of flexibilizer 1, flexibilizer 2, or a mixture of flexibilizer 1 and flexibilizer 2. The product of the invention maintains excellent comprehensive performance, and has very high cost performance.

Owner:HEFEI GENIUS NEW MATERIALS

Heat-resistant polyvinyl chloride alloy material and preparation method thereof

The invention provides a heat-resistant polyvinyl chloride alloy material and a preparation method thereof. The alloy material mainly comprises the components of a polyvinyl chloride matrix, a heat-resistant modifying agent, a thermal stabilizer, a lubricating agent, a filler, a shock-resistant modifying agent and a processing agent. The components of the processing agent and the filler in the invention are the processing agent modified by a new method and the organically processed filler, and self plasticisation, toughening and reinforcement of PVC are organically combined by a mechanical chemical reaction, so as to improve the compatibility between the polyvinyl chloride and a heat-resistant resin, to solve the conflict among the increment of heat-resistant quality, the working quality, the strength and the ductility of the polyvinyl chloride, to overcome the problems that the polyvinyl chloride has a low heat-resistant temperature and the working quality of the polyvinyl chloride is poor even though the heat-resistant temperature of the polyvinyl chloride is high, and to prepare the polyvinyl chloride engineering plastic with high heat resistance, high strength, high ductility and excellent working quality. The preparation method of the heat-resistant polyvinyl chloride alloy material in the invention has simple technology, stable quality and high production efficiency, and is easily operated and controlled.

Owner:SICHUAN UNIV

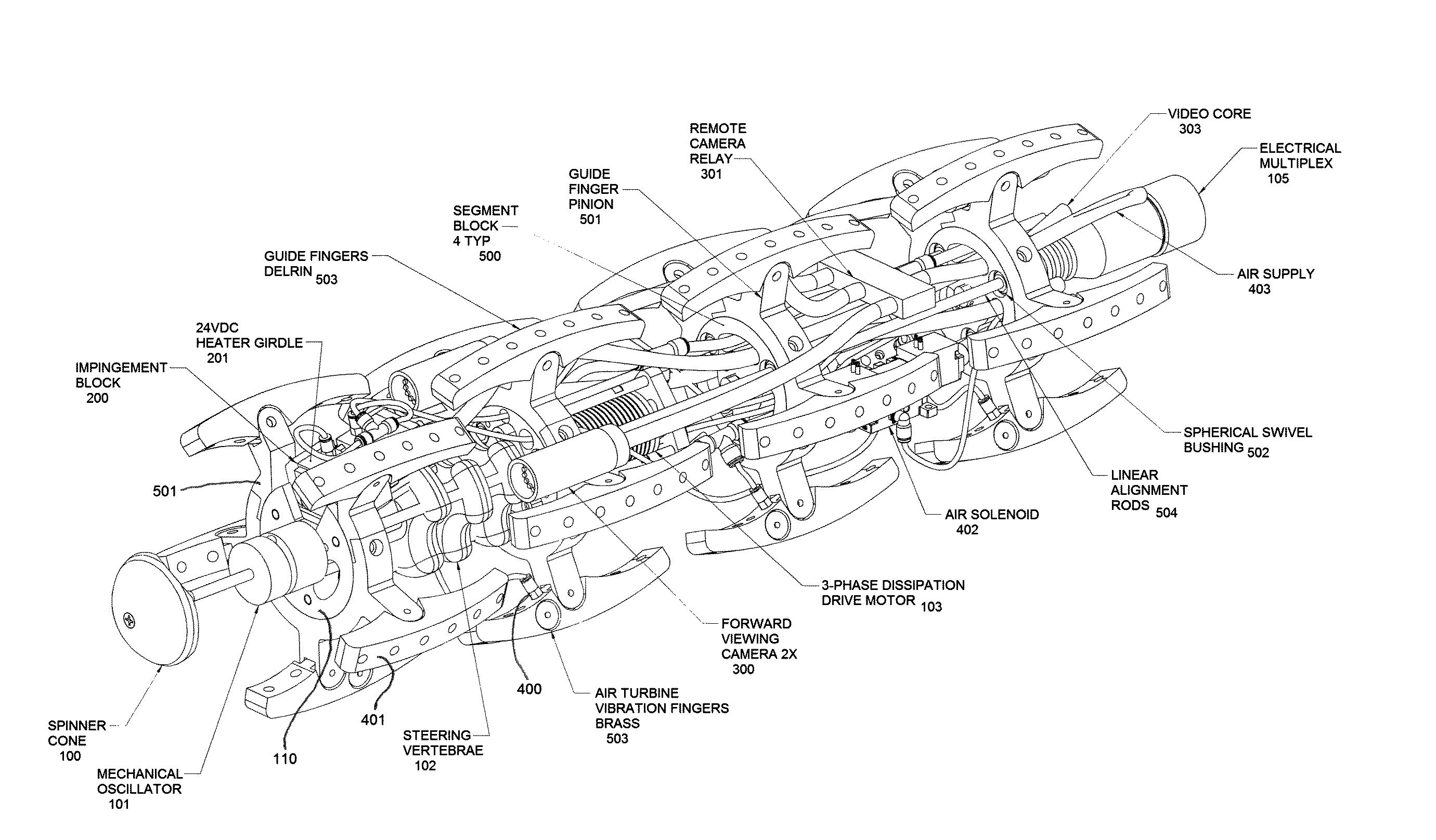

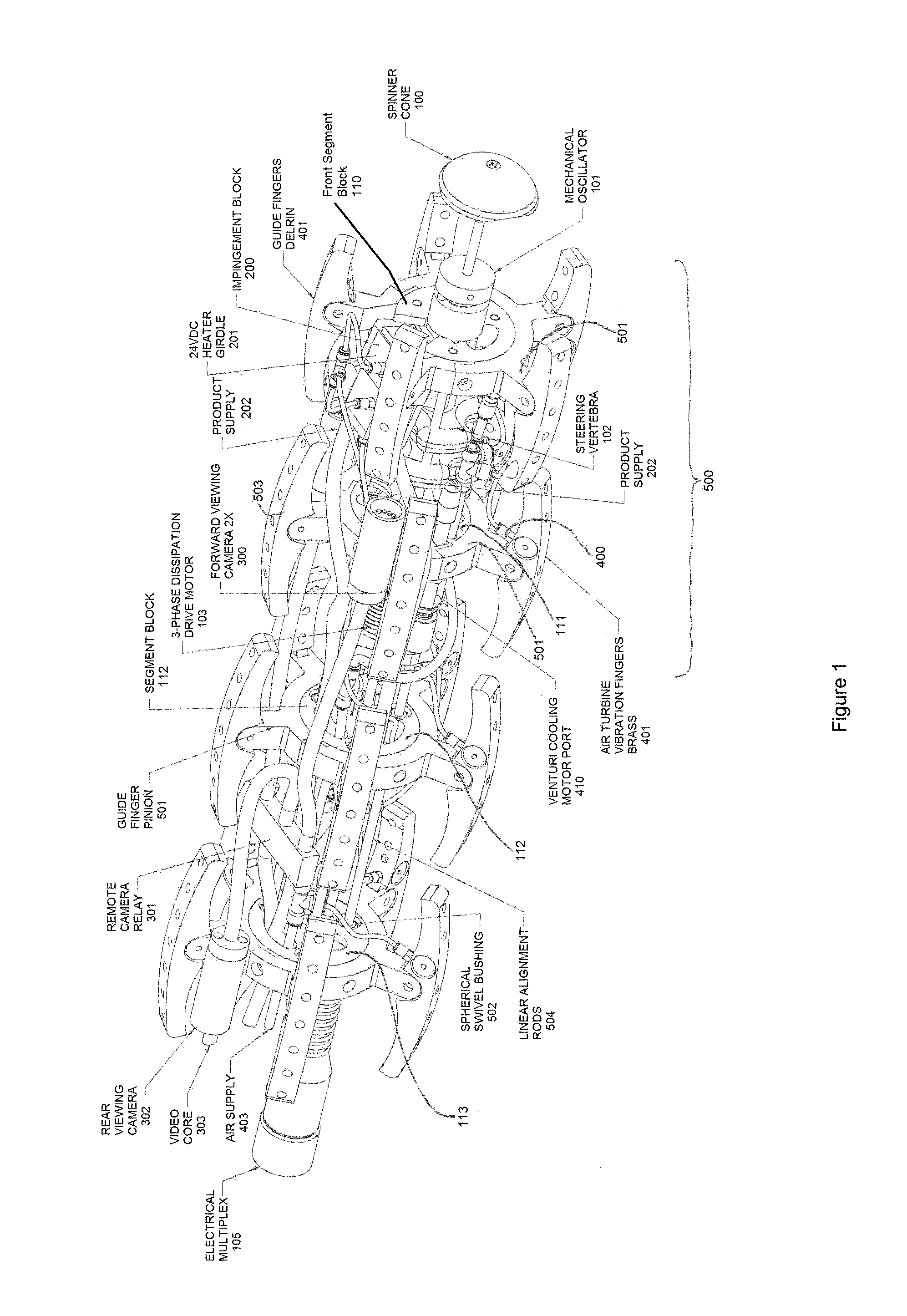

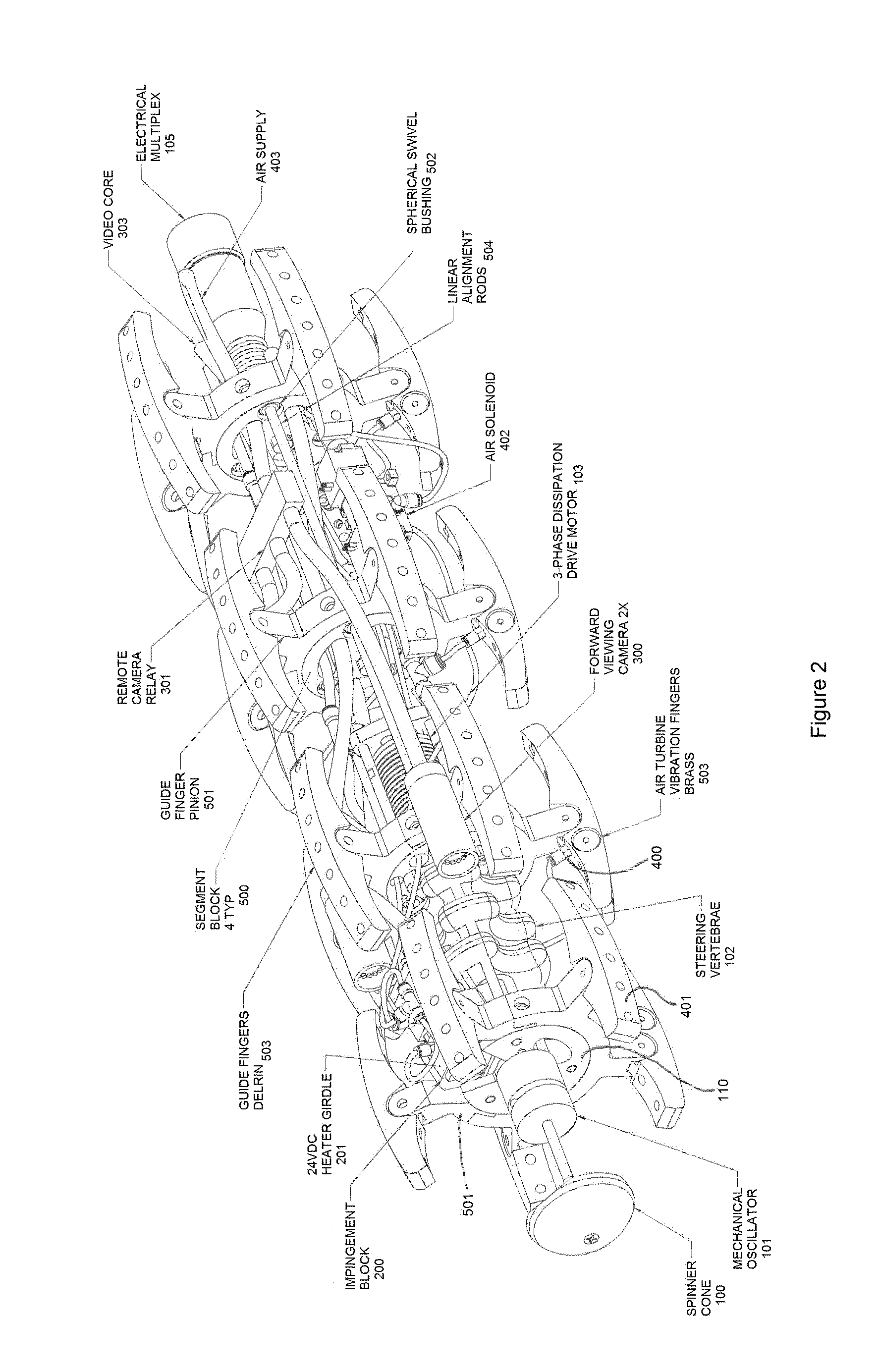

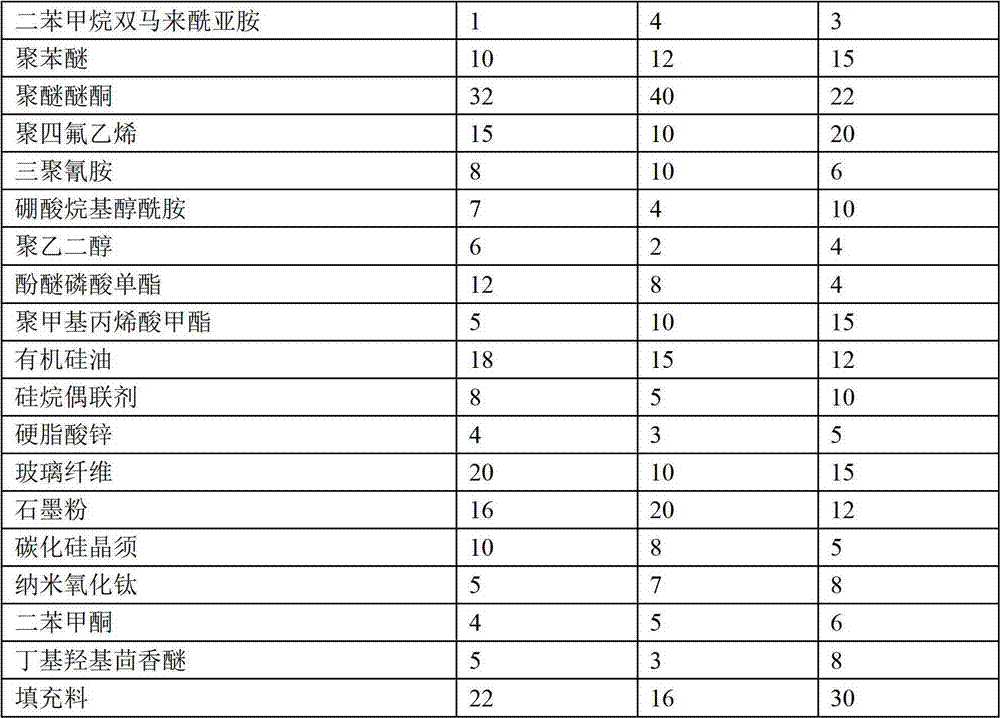

Multi-segmented apparatus for lining pipe with multiple convoluted bends and varied orientations with a structural membrane

ActiveUS8402911B1Rapid responseFast curingRailway tunnelsRailway componentsTeleoperated robotEngineering plastic

The invention provides an improved method and robotic apparatus for applying a structural membrane lining in conduits. The remotely controlled robot comprises a series of segment blocks maintained in alignment by flexible linear rods supported in spherical swivel bushings. The rods allow for articulation as the robot negotiates bends. Segment blocks include radial guide finger pinions and guide fingers for concentric positioning. Fingers are of engineered plastics and brass to provide ballast weight for perpendicular alignment and contain high frequency air turbine vibrators. Steering vertebrae are included to maintain concentricity of the lining dissipation cup through bends. Also included are electric servo motors controlling cables and take up wheels controlling the angle of the segment blocks.

Owner:QUEST INSPAR

In-situ modified halogen-free flame retardant thermoplastic resin composition and preparation method thereof

InactiveCN102875982AImprove flame retardant performanceImprove mechanical propertiesPolyesterPolymer science

The invention discloses a halogen-free flame retardant thermoplastic engineering plastic composition prepared by in-situ modification, and a preparation method for the halogen-free flame retardant thermoplastic engineering plastic composition. According to the composition, polyester or polyamide is used as a base material, and reactive type halogen-free flame retardant, namely a 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) composition is added, so that the halogen-free and flame retardant aims are fulfilled. The invention also discloses the preparation method for the halogen-free flame retardant engineering plastic composition. According to the method, the reactive type flame retardant and end groups or other functional groups of molecular chains of thermoplastic polymer are reacted in the melt blending process, so that the dispersibility and the compatibility between the flame retardant and a material are improved, the using amount of the flame retardant is reduced, the material is excellent in flame retardant property and high in heat resistance, and a large amount of toxic gas and fume can be prevented from being released in the combustion process.

Owner:NINGBO ECOT SCI & TECH

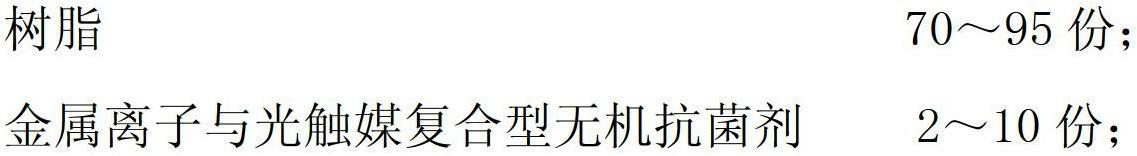

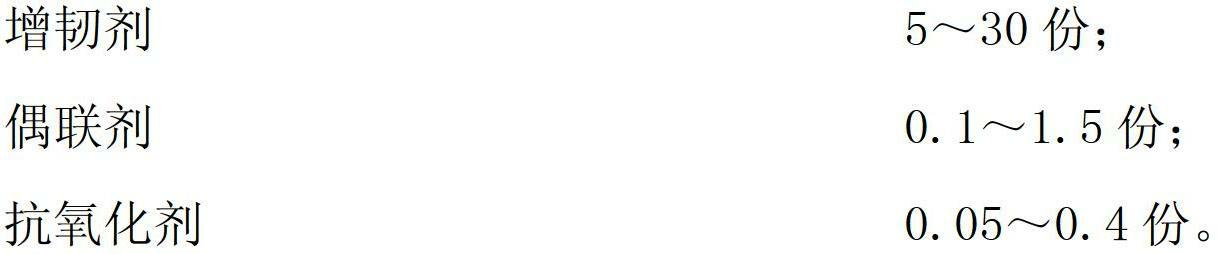

Antibacterial plastic for household appliances and preparation method thereof

The invention discloses an antibacterial plastic used for household appliances and being good in antibacterial effect and a preparation method thereof, and belongs to the technical field of macromolecular engineering plastics. The antibacterial plastic used for the household appliances is made by mainly blending 70-95 parts of resin, 2-10 parts of metal ion and photocatalyst mixed type inorganic antibacterial agents, 5-30 parts of flexibilizers, 0.1-1.5 parts of coupling agents and 0.05-0.4 part of antioxidants. The preparation method of the antibacterial plastic comprises evenly mixing various raw materials, and obtaining the antibacterial plastic used for the household appliances by blending at a temperature range of 170-240 DEG C. The antibacterial performance of the antibacterial plastic can meet the national newly-issued standard GB21551.2-2010 and can be widely applied to refrigerators, washing machines, air conditioners, televisions, cell phones and computer products.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Natural fibre reinforced polylactic acid composite material and method for making same

The present invention belongs to the macromolecular material technical field and concretely relates to natural fibre enhanced polylactic acid composite material and a preparation method thereof. The composite material consists of graft modified polylactic acid and the natural fibre. A concrete preparation step is that a polylactic acid matrix is processed for the graft modification, so as to improve the interface combined degree of the natural fibre and the polylactic acid matrix. Firstly, the polylactic acid is processed for the graft reaction with maleic anhydride under the action of an initiator to prepare the graft modified polylactic acid matrix; then the modified polylactic acid and the natural fibre are compounded to obtain biological full-degraded natural fibre enhanced polylactic acid composite material. Compared with pure polylactic acid, the mechanical performance and the thermal performance of the composite material are all improved, and the composite material can be used for preparing the project plastic with rigorous condition requirement. The composite material of the present invention can be degraded completely in the natural environment after being used and wasted and belongs to environmental friendly material.

Owner:TONGJI UNIV

Nylon engineering plastic for high-speed railway rail fastening and method for manufacturing same

InactiveCN101250322AHigh anti-climbing resistanceHigh precisionRail fastenersEngineering plasticNylon 66

Polyamide engineering plastic for rail fasteners of high speed railway and a preparation process are disclosed. The plastic belongs to organic material, which is characterized in that the plastic is formed through conducting mixture extrusion pelleting for the following components: material substrate material with 48-88% percentage by weight, wherein the substrate material is polyamide 6 resin, or is polyamide 66 resin, or is the mixture of polyamide 6 resin and polyamide 66 resin, addition agent with 0-15% percentage by weight, wherein the addition agent is toughening agent and compatilizer, intensifier with 10-50% percentage by weight, wherein the surface of intensifier is treated with silane coupling agent with 0.2-5% percentage by weight relative to additive matters. Polyamide engineering plastic provides raw material for producing first-grade railway rail fasteners. The fastener which is produced by the plastic has the advantages of light weight, high strength and high impact, large loading, easy machine shaping and dyeing and reasonable cost.

Owner:NANJING JULONG SCI&TECH CO LTD

Nylon engineering plastics for high-speed transit railway track and manufacture method thereof

The invention relates to nylon engineering plastics and a manufacture method thereof, in particular to nylon engineering plastics for high-speed transit railway tracks and a manufacture method thereof. The nylon engineering plastics comprise the following components in percentage by weight: 35 to 60 percent of nylon resin, 20 to 35 percent of glass fibre, 0 to 10 percent of inorganic mineral, 16 to 30 percent of compatilizer, 0.3 to 0.5 percent of light stabilizer, 0.1 to 0.3 percent of coupling agent, 0.1 to 0.5 percent of antioxygen and 0.4 to 1 percent of lubricant, wherein the compatilizer is one kind of or a mixture of two kinds of Maleic anhydride grafted EPDM (Ethylene Propylene Diene Monomer) rubber and maleic anhydride grafted POE (Polyolefin Elastomer), and the melt flow rate of the compatilizer is 0.5 to 1.5g / 10min. The manufacture method comprises the steps of: adding the compatilizer into an extruder in a lateral feeding addition method under the condition that the melt temperature is 220 to 280 DEG C and the mixing time is 1-5min; and controlling the rotate speed of a screw between 300 and 450rpm. According to the invention, the tensile strength, the impact toughness and the size stability can all meet the requirements for the operation of high-speed trains with running speed more than 300km / h.

Owner:NANJING JULONG SCI&TECH CO LTD

Method for the production of block copolycarbonate/phosphonates and compositions therefrom

Disclosed is a new method and compositions from the method consisting of block copolycarbonate / phosphonates that exhibit an excellent combination of flame resistance, hydrolytic stability, high Tg, low melt viscosity, low color and high toughness. Also disclosed are polymer mixtures or blends comprised of these block copolycarbonate / phosphonate compositions and commodity and engineering plastics and articles produced therefrom. Further disclosed are articles of manufacture produced from these materials, such as fibers, films, coated substrates, moldings, foams, adhesives and fiber-reinforced articles, or any combination thereof.

Owner:FRX POLYMERS LLC

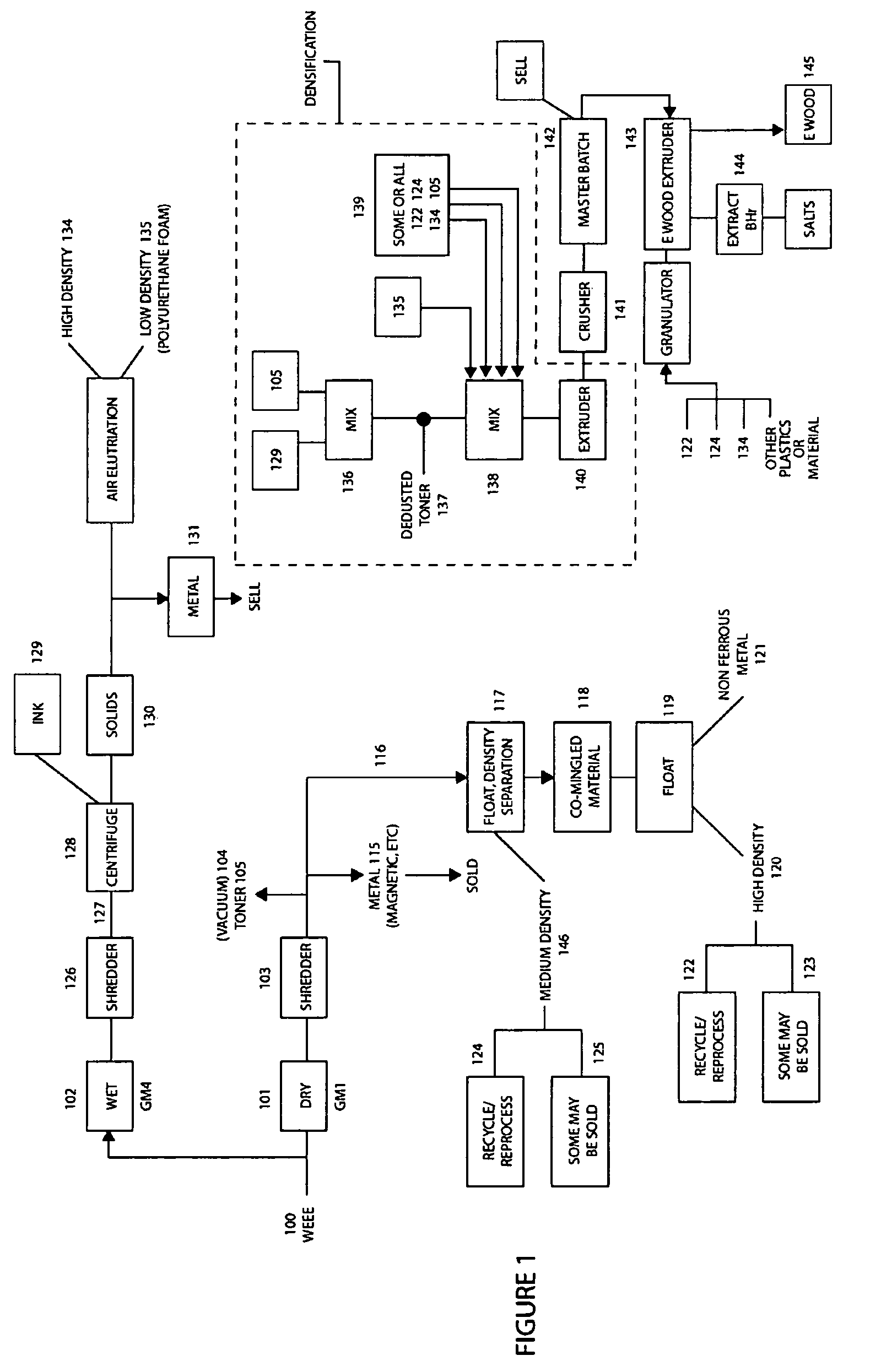

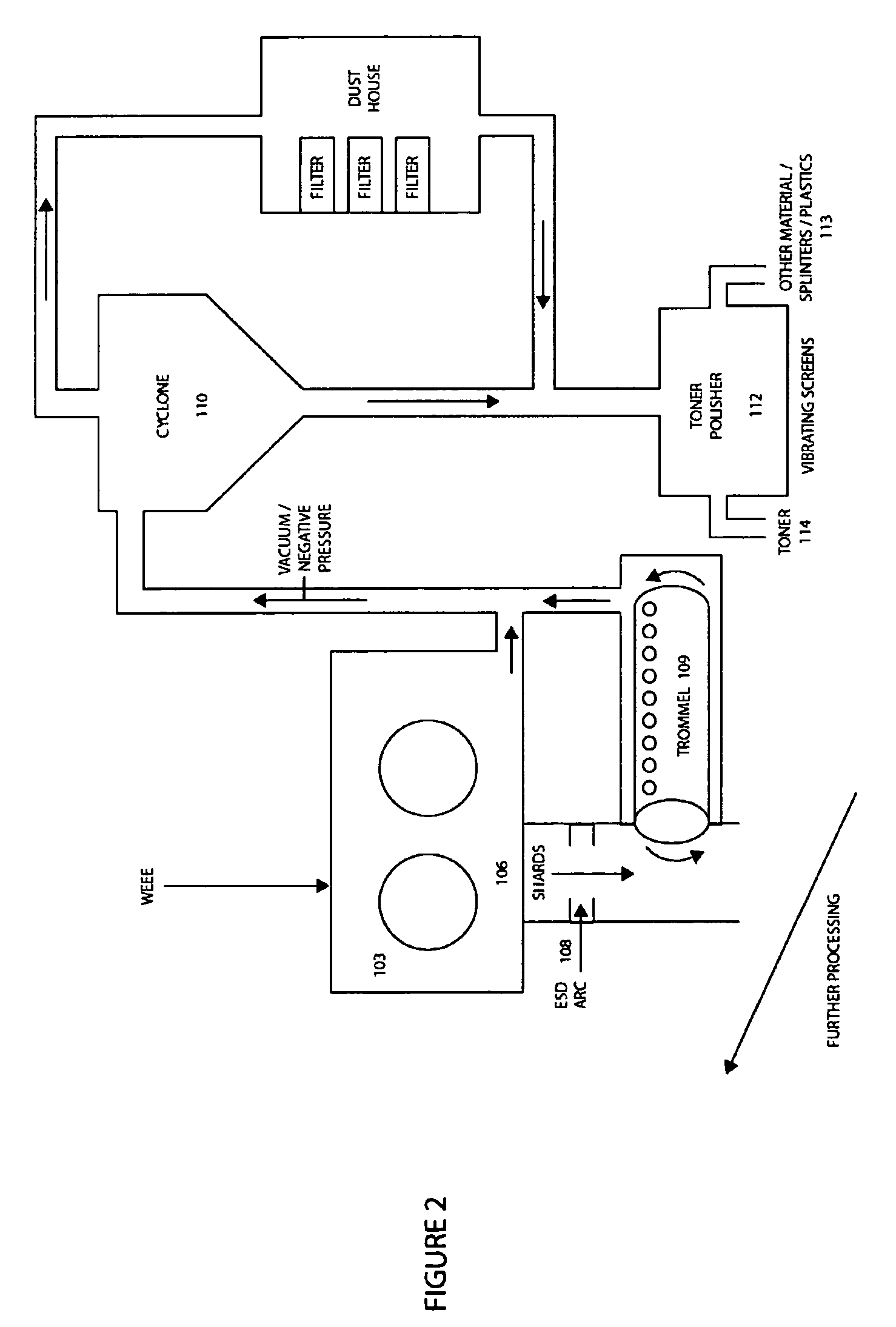

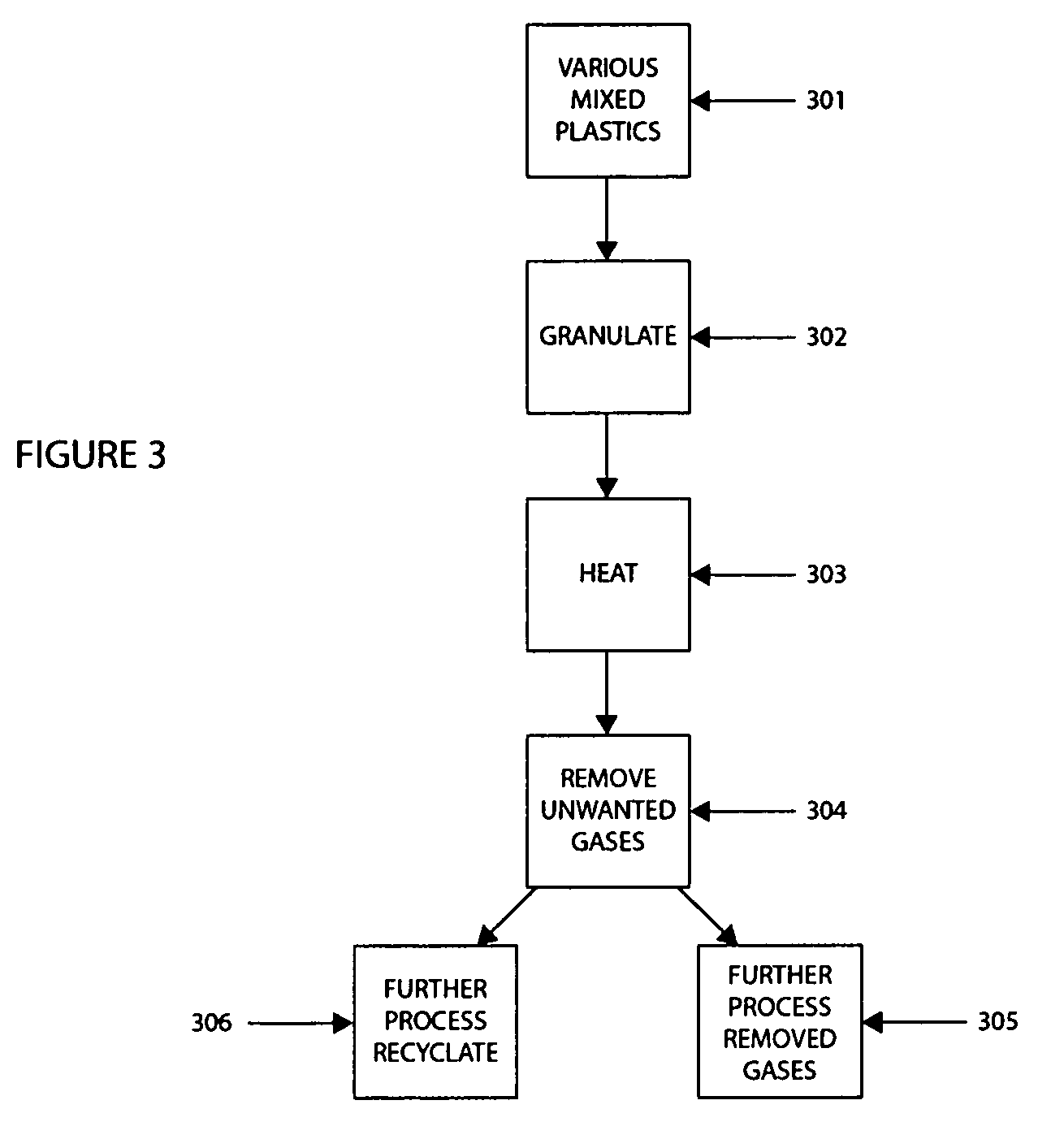

Method of recycling mixed streams of ewaste (WEEE)

The present invention relates to the recycling of waste electrical and electronic equipment (WEEE). Preferably, the present invention relates to the substantial recycling of all material forming the WEEE, thus providing substantially zero landfill. In yet another form, the invention relates to an additive and / or method of providing an additive. In still another form, the invention relates to recycling ink, toner, and / or PU foam from imaging consumables, forming part of the WEEE. In another form, the invention relates to the recycling of plastic materials containing flame retardants, including the recycling of plastics materials, such as plastics materials containing brominated flame retardants generally based on styrenics (e.g. PS, HIPS, ABS, PPO / PS, PPE / PS, ABS / PC) and polyamides (Nylon 6, nylon 6,6, nylon 12) and other engineering plastics such as polyacetal, polycarbonate, PET, PBT, liquid crystal polymers.

Owner:CLOSE THE LOOP TECH

Polyamide composition and preparation method thereof

The invention belongs to the technical field of engineering plastic modification, and discloses a polyamide composition and a preparation method thereof. The polyamide composition comprises the following components by weight: 27-95 parts of polyamide, 5-35 parts of a toughening agent, 0-35 parts of an inorganic filler, 0-1 part of a coupling agent, 0-1 part of a lubricant, and 0-1 part of an antioxidant. The polyamide composition prepared by the method provided by the invention has a very low product cost and high price performance while keeping good comprehensive performance, and consumes a large amount of waste polyamide and rubber waste to solve the problem of waste reutilization; therefore, the method is as well a resource reuse engineering with both economic and environmental benefits, and promotes the development of circular economy. The product has strong competitiveness in the market, and can be widely used in the fields of machinery, electronics, automobile, electrical appliances and consumer goods.

Owner:HEFEI GENIUS NEW MATERIALS

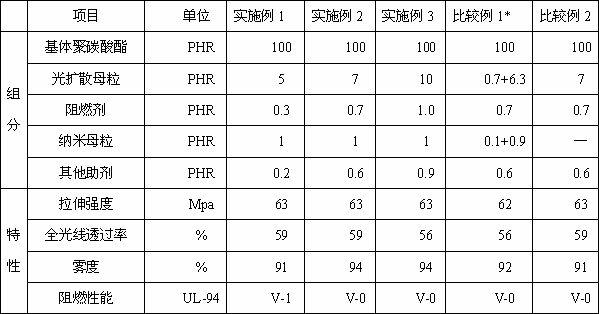

Polycarbonate composite material suitable for LED (light-emitting diode) lamp cover and preparation method thereof

ActiveCN102532857AGood light diffusion effectEvenly dispersedPoint-like light sourceGlobesLight guideEngineering plastic

The invention discloses a polycarbonate composite material suitable for an LED (light-emitting diode) lamp cover and a preparation method thereof. Based on the 100 weight parts PHR (parts per hundreds of rubber or resin) of a substrate polycarbonate material, the composition of the composite comprises the following components in PHR: 100PHR of polycarbonate, 5-15PHR of light scattering master batch, 0.2-1.0PHR of flame retardant, 1-3PHR of nano master batch and 0.2-1.0PHR of other additives. In the method, engineering plastic polycarbonate is used as a main body; and the light scattering master batch and the nano additive master batch are firstly prepared through an internal mixer and then smashed at high speed, and finally, the light scattering master batch and other raw materials are subjected to blending, extruding and granulating by adopting a side feeding method. By using the method, the problem that the dispersion of a light dispersing agent and other additives is not uniform issolved, and the obtained light dispersing material has high transmissivity and haze. The polycarbonate composite material disclosed by the invention can be used for preparation of related products inthe optical field, is environment-friendly, high in safety and excellent in various physical and mechanical properties, and is suitable for preparing the LED lamp covers and other light guiding materials.

Owner:SHANGHAI UNIV

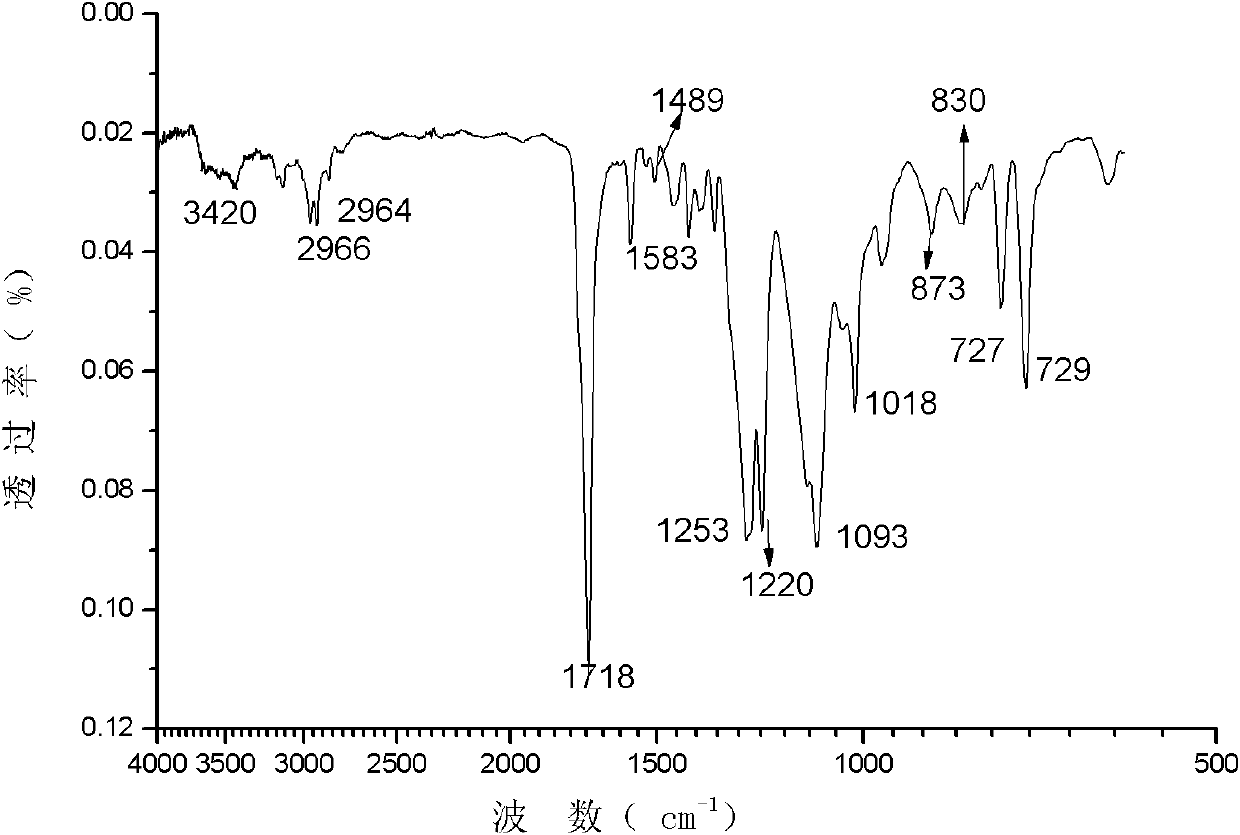

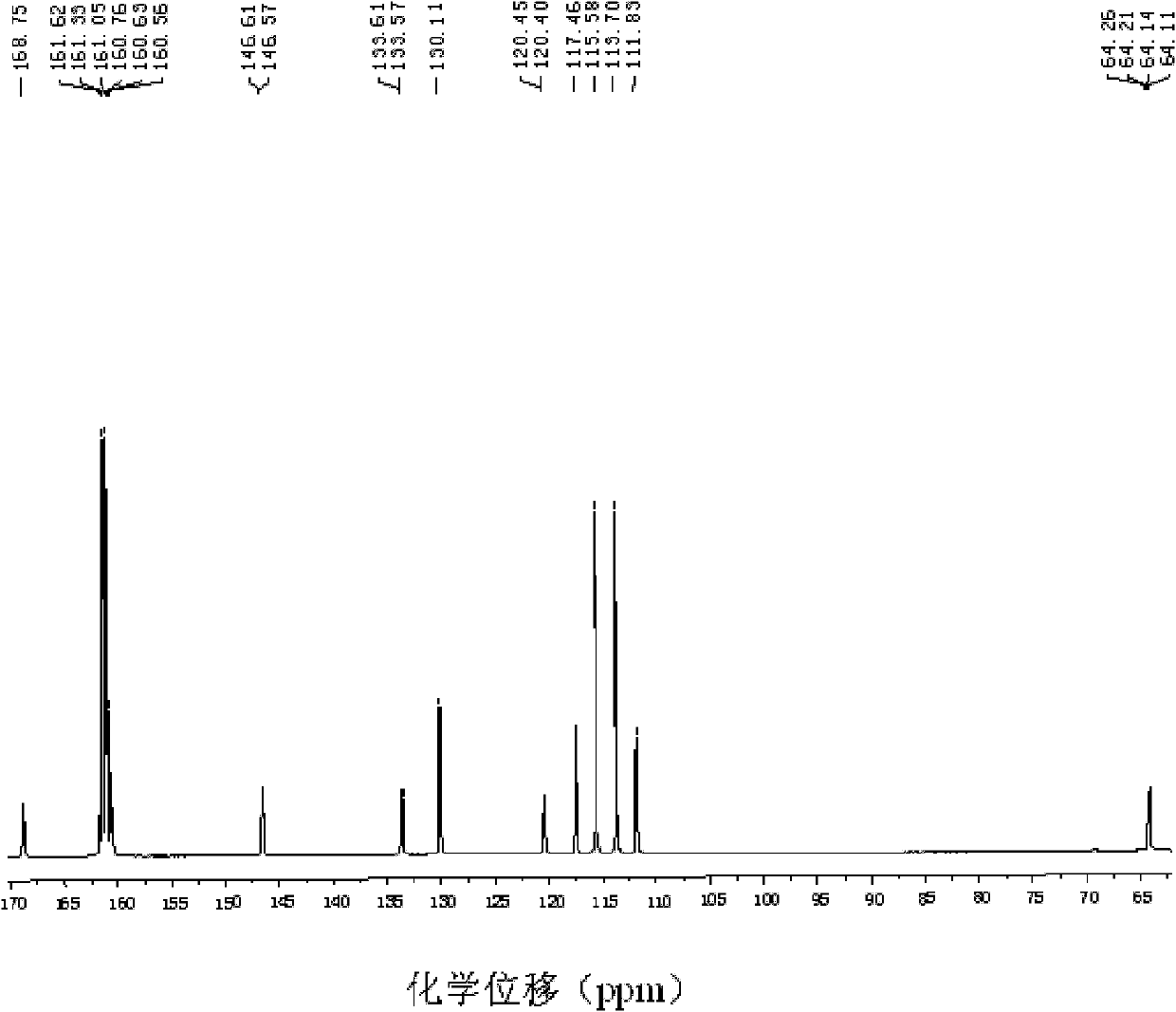

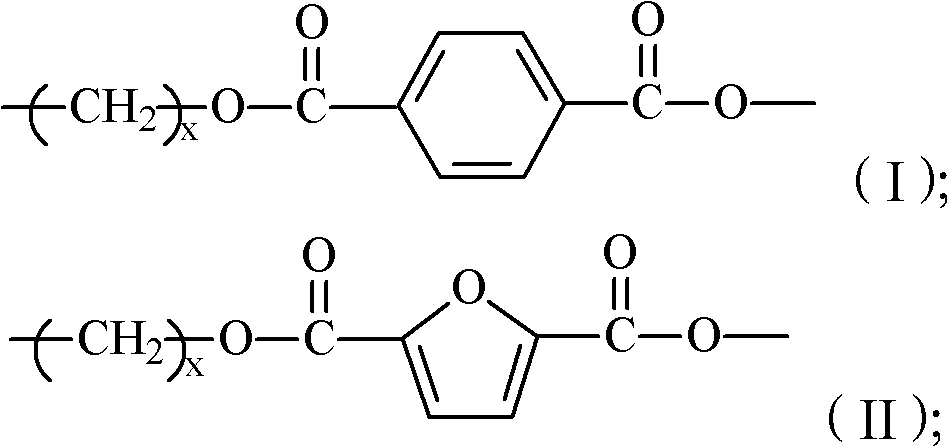

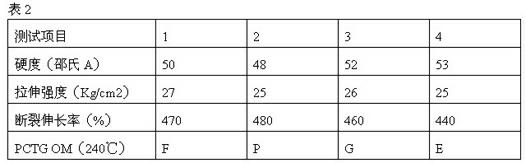

2,5-furandicarboxylic-terephthalic-aliphatic copolyester and preparation method thereof

ActiveCN102432847ANot affected by resource depletionImprove performancePolymer scienceEngineering plastic

The invention provides 2,5-furandicarboxylic-terephthalic-aliphatic copolyester and a preparation method thereof. 2,5-furandicarboxylic-terephthalic-aliphatic copolyester has a first repetitive unit represented by a formula (I) and a second repetitive unit represented by a formula (II), wherein x=2 to 8. The molar ratio of the first repetitive unit to the second repetitive unit is 1:1000-1000:1. 2,5-furandicarboxylic-terephthalic-aliphatic copolyester provided by the invention has a structure and even a good performance similar to that of diol polyterephthalate. 2,5-furandicarboxylic-terephthalic-aliphatic copolyester can be used for preparing materials such as engineering plastics and membranes. As one of the raw materials, 2,5-furandicarboxylic acid can be obtained based on renewable resources, such that the resource is wide, and is not influenced by increasingly exhausted petroleum resources. The invention also provides a preparation method of 2,5-furandicarboxylic-terephthalic-aliphatic copolyester.

Owner:芜湖万隆新材料有限公司

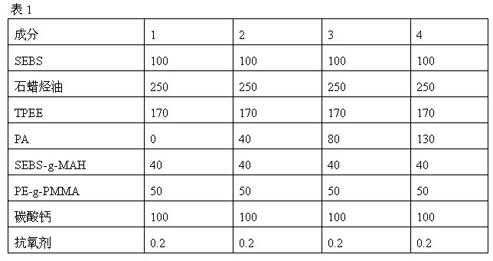

Preparation method of thermoplastic elastomer (TPE) alloy material for polyethylene terephthalate (PBT) bonding encapsulation

InactiveCN102181169AHigh strengthHigh modulusPolyethylene terephthalate glycolPolyethylene terephthalate

The invention discloses a thermoplastic elastomer (TPE) alloy material for polyethylene terephthalate (PBT) bonding encapsulation and a preparation method thereof. The TPE alloy material is characterized by comprising the following components in part by weight: 30 to 40 parts of TPE, 10 to 30 parts of plasticizer, 15 to 30 parts of engineering plastic, 10 to 15 parts of compatilizer, 10 to 15 parts of filler and 0.02 to 0.1 part of auxiliary agent. The invention provides the TPE alloy material which has specific bonding property to PBT, is simple and convenient to process, is energy-saving and environment-friendly and can be widely applied to food contact and skin contact.

Owner:深圳市塑源实业有限公司

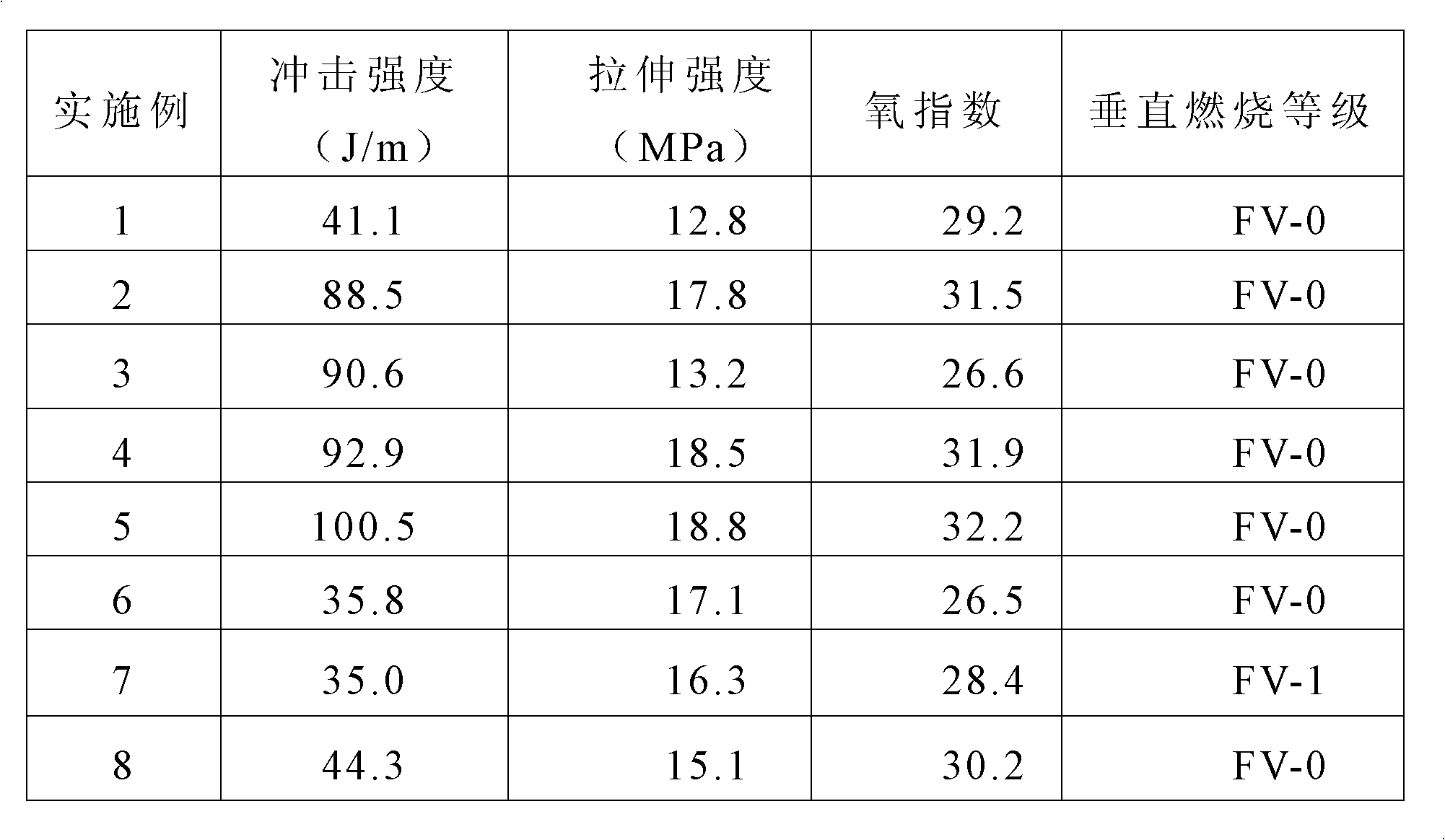

Magnesium hydroxide composite flame retardant material and preparation method thereof

The invention discloses a magnesium hydroxide flame-retardant composite material and a preparation method thereof. The flame-retardant material comprises the following components in parts by weight: 20-100 parts of high polymer, 40-80 parts of magnesium hydroxide and 5-20 parts of toughening agent, wherein the high polymer is one or more of polyethylene, polyvinyl chloride, polypropylene, polystyrene, polyamide, polyformaldehyde, rubber or nylon; and the toughening agent is one or more of dioctyl phthalate, poly(ethylene-octene) elastomer, tricresyl phosphate, styrene-butadiene-styrene block copolymer, hydrogenated styrene-butadiene-styrene block copolymer or styrene-isoprene-styrene block copolymer. Practice proves that the magnesium hydroxide flame-retardant composite material has the advantages of strong shock resistance, high tensile strength and high oxygen index. The preparation method of the composite material is simple in operation, has low cost and high production efficiency,and can be widely used in the field of engineering plastics.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

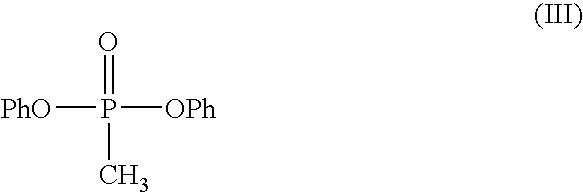

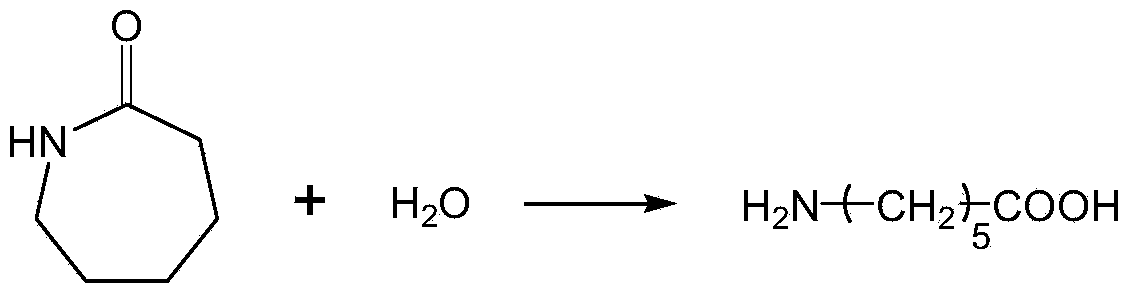

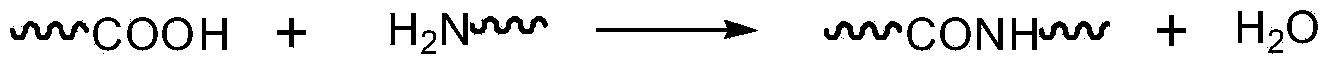

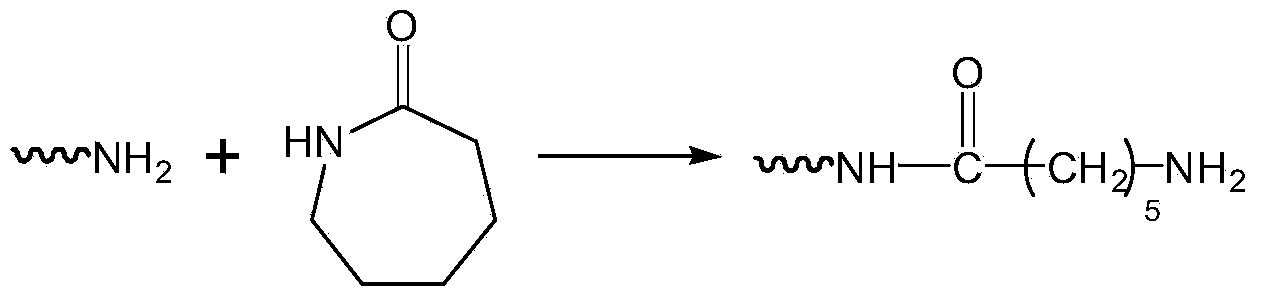

Preparation method for organic phosphorus copolymerized antiflaming polyamide material

ActiveCN104231262AImprove flame retardant performanceReaction is easy to controlEngineering plasticPolyamide

The invention relates to the field of antiflaming materials and particularly relates to a preparation method for an organic phosphorus copolymerized antiflaming polyamide material used for textile, engineering plastics and thin films. The preparation method of the organic phosphorus copolymerized antiflaming polyamide material specifically comprises the following steps: (1) enabling a fire retardant and a diamine monomer to react in advance to prepare a prepolymer; (2) adding a polymerized monomer, a catalyst and the prepolymer into a reaction kettle to prepare the organic phosphorus copolymerized antiflaming polyamide material. According to the organic phosphorus copolymerized antiflaming polyamide material provided by the invention, a small amount of the reaction fire retardant needs to be added, no synergic fire retardant is needed, the viscosity is controllable in the preparation process, the use property of the polymer finally obtained in the reaction is excellent, and the organic phosphorus copolymerized antiflaming polyamide material can be used in various fields of textile, engineering plastics, thin films and the like. Meanwhile, the use amount of raw materials is small, the process is simple, the cost is low, the actionability is high, and the flame retardant property of the prepared product is high.

Owner:JIANGSU RUIMEIFU IND

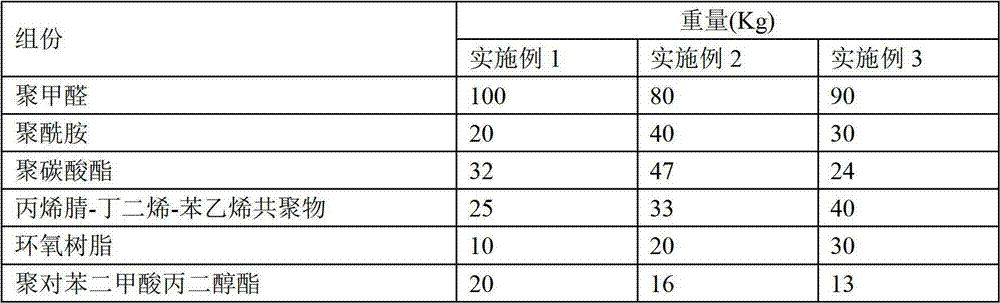

Engineering plastic with high wearing resistance

InactiveCN102875956AGood mechanical propertiesReduce wear ratePolyethylene glycolPolymethyl methacrylate

The invention provides an engineering plastic with high wearing resistance. The engineering plastic is made from the following raw materials by weight: 80-100 parts of polyformaldehyde, 20-40 parts of polyamide, 20-50 parts of polycarbonate, 25-40 parts of acrylonitrile-butadiene-styrene copolymer, 10-30 parts of epoxy resin, 12-20 parts of polytrimethylene terephthalate, 1-5 parts of diphenylmethane bismaleimide, 10-15 parts of polyphenyl ether, 20-40 parts of polyether-ether-ketone, 10-20 parts of polytetrafluoroethylene, 5-10 parts of melamine, 4-12 parts of boric acid alkanolamide, 2-6 parts of polyethylene glycol, 4-12 parts of phenolic ether phosphomonoester, 5-15 parts of polymethyl methacrylate, 10-20 parts of organic silicone oil, 5-10 parts of silane coupling agent, 3-5 parts of zinc stearate, 10-20 parts of glass fibre, 12-20 parts of graphite, 5-10 parts of silicon carbide whisker, 5-8 parts of nanometre titanium oxide, 4-6 parts of diphenyl ketone, 3-8 parts of butylated hydroxyanisole and 15-30 parts of filler. The engineering plastic provided by the invention has a good wear-resisting property.

Owner:SUZHOU YUNYUAN NETWORK TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com