Patents

Literature

1222results about "Magnetic circuit characterised by insulating materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

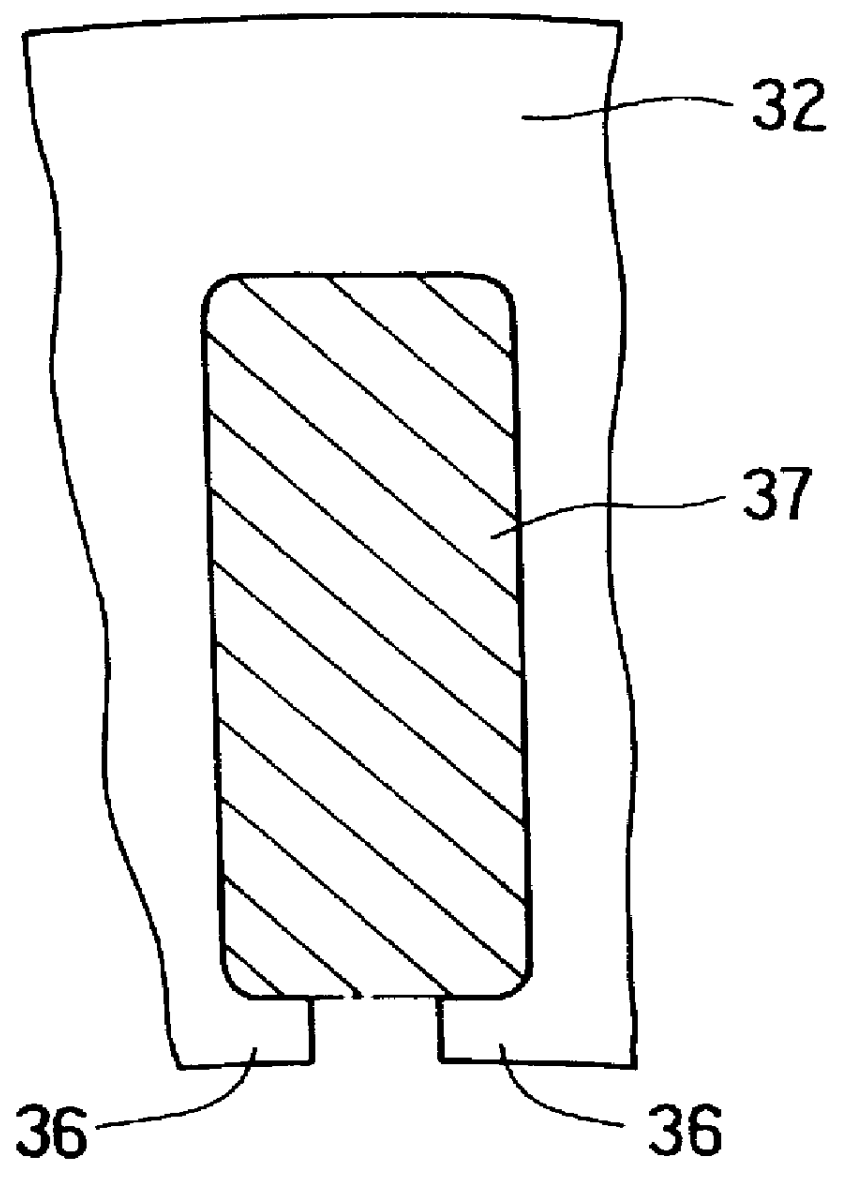

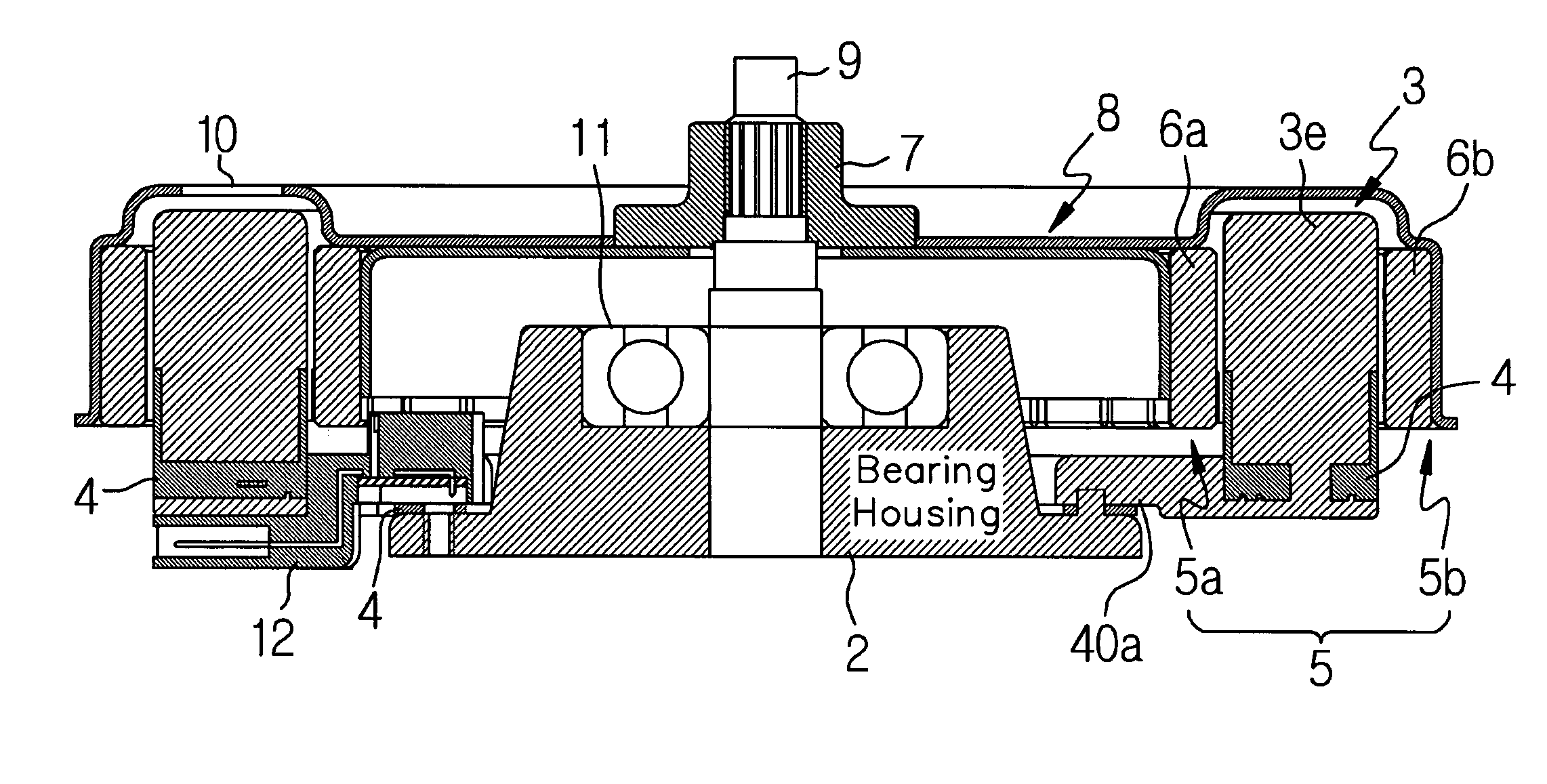

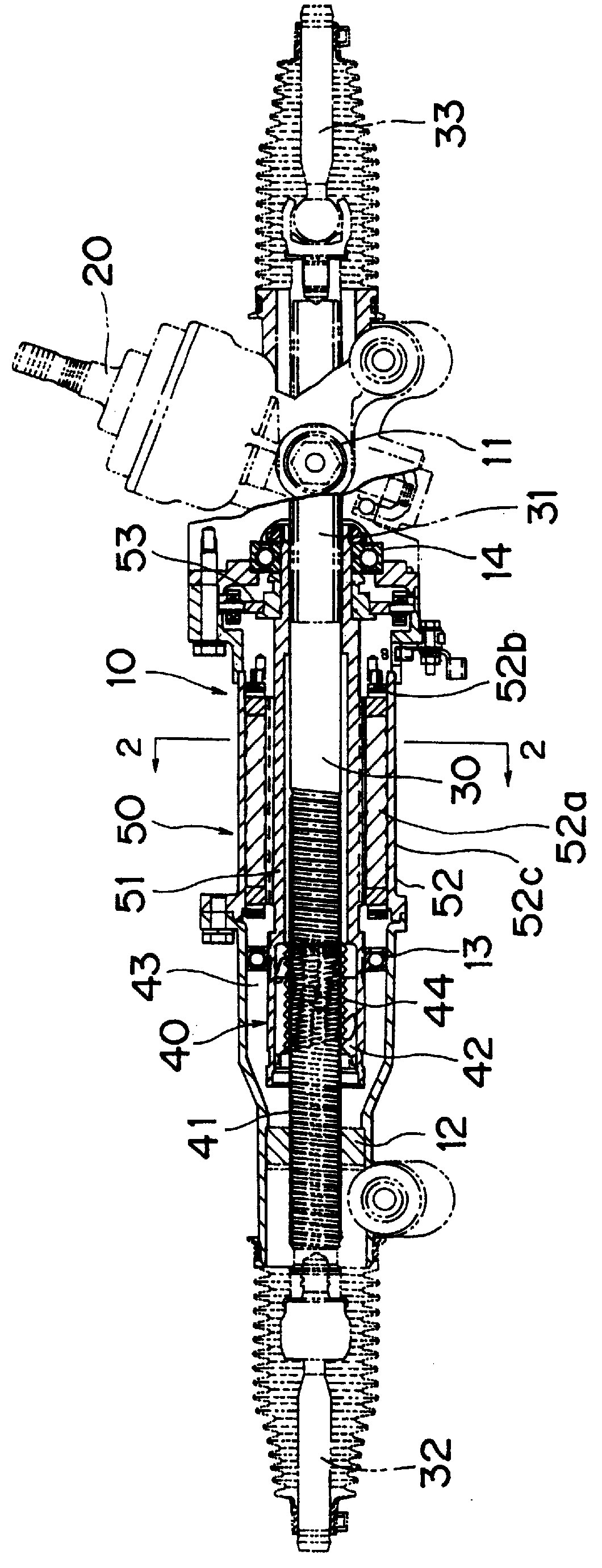

Motor mounted in a vehicle

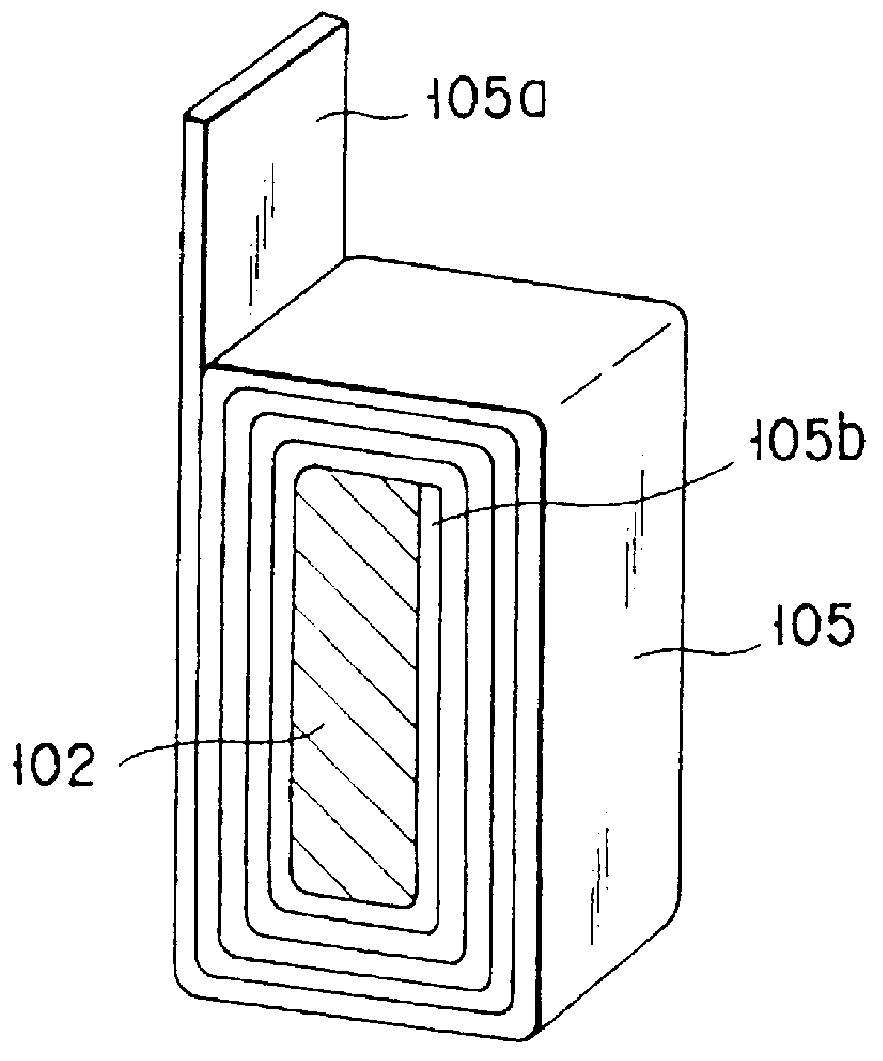

PCT No. PCT / JP96 / 02929 Sec. 371 Date Jun. 25, 1998 Sec. 102(e) Date Jun. 25, 1998 PCT Filed Oct. 9, 1996 PCT Pub. No. WO97 / 26700 PCT Pub. Date Jul. 24, 1997A motor mounted in a vehicle having a winding comprising a flat band-like copper wire is provided. The winding is wound on a projection that extends radially inward of a stator. The winding includes a first band-like section that is adapted to be wound on a radially inward portion of the projection of the stator. The winding also includes a connection section that is continuous with one longitudinal end of the first band-like section and extends radially outward along the radial direction of the projection of the stator. The winding further includes a second band-like section that is adapted to be wound on a radially outward portion of the projection of the stator. One longitudinal end of the second band-like section is continuous with the connection section. The first band-like section extends from a radially inward portion of the connection section and the second band-like section extends from a radially outward portion of the connection section. The first and second band-like sections extend from the connection section in opposite directions.

Owner:NIPPON DENSAN CORP

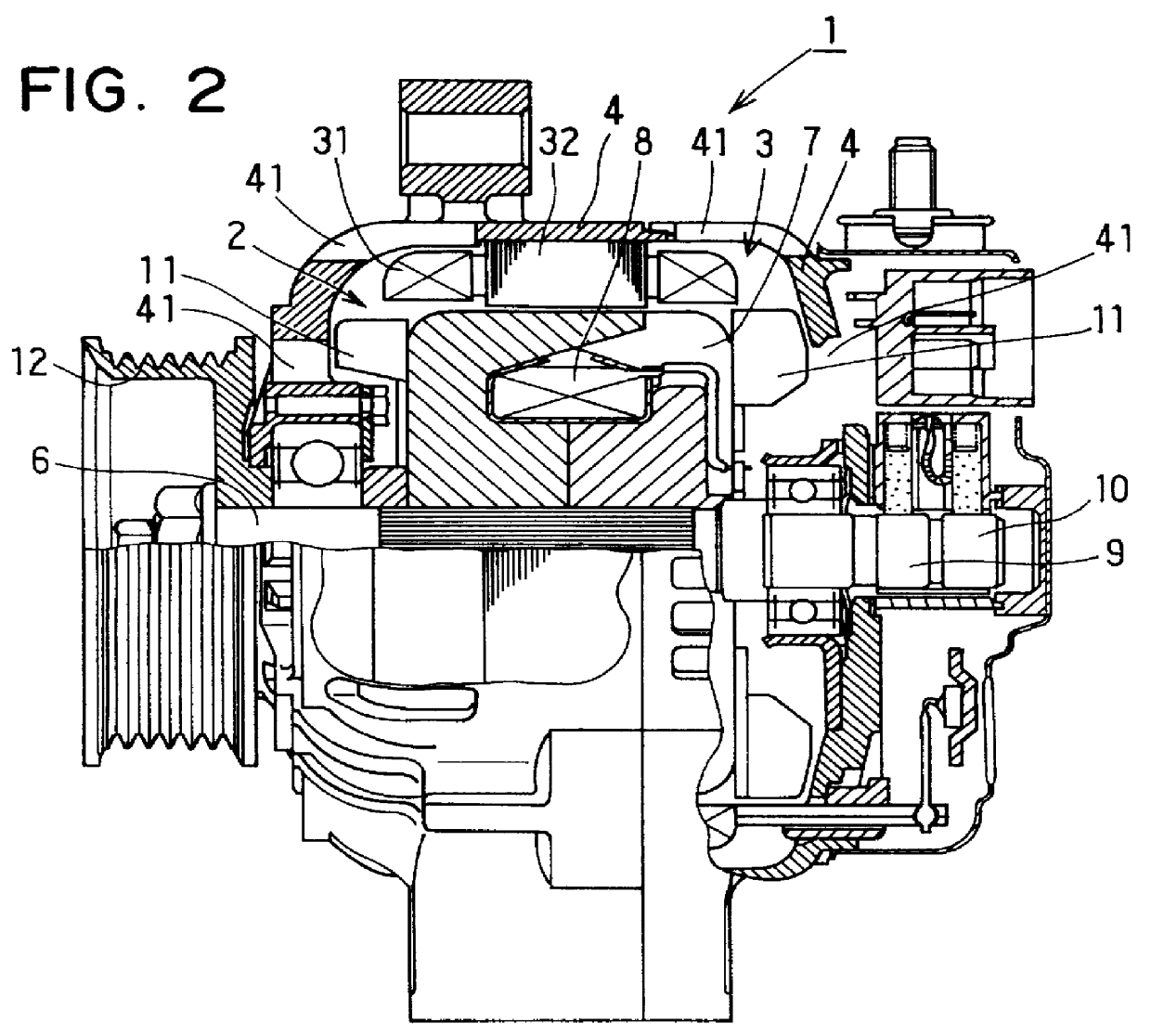

AC generator for vehicles

InactiveUS6137201ASynchronous generatorsMagnetic circuit rotating partsDynamoElectrical and Electronics engineering

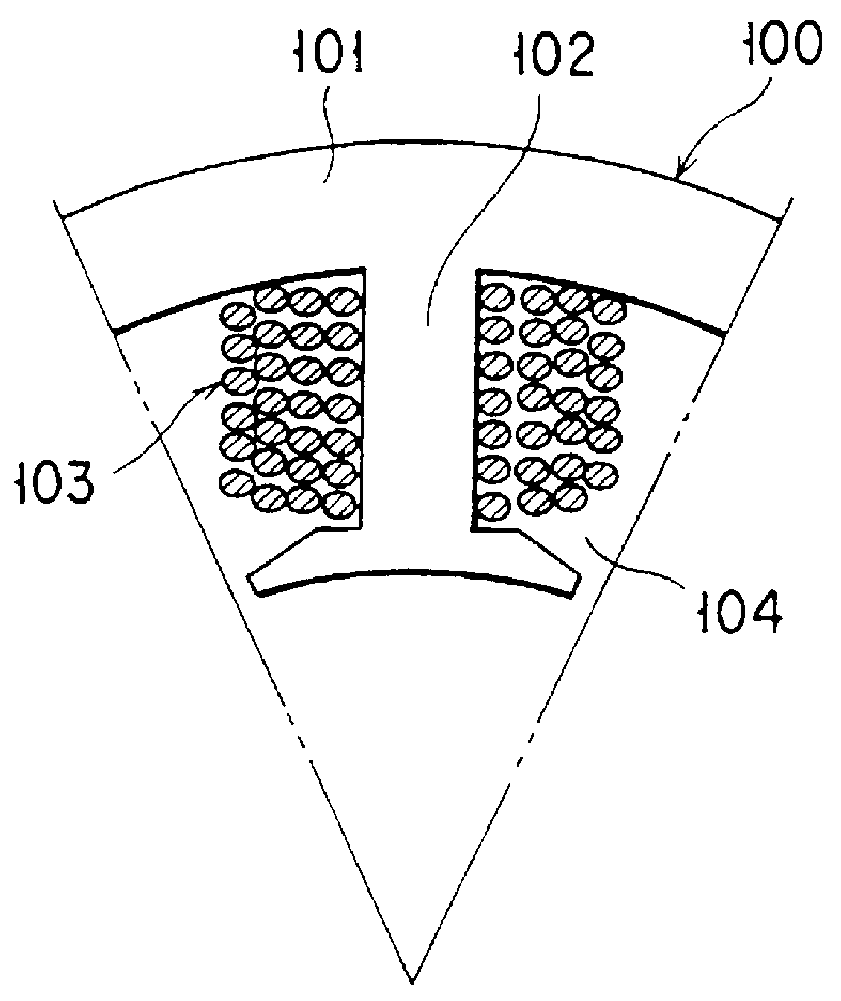

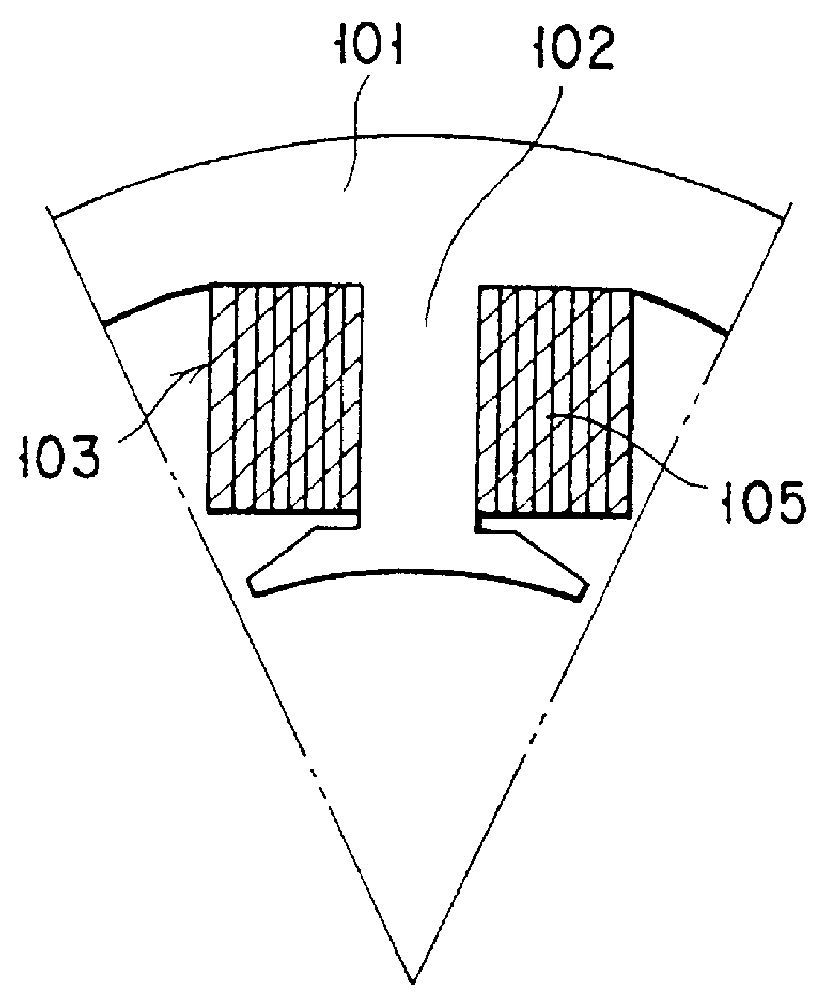

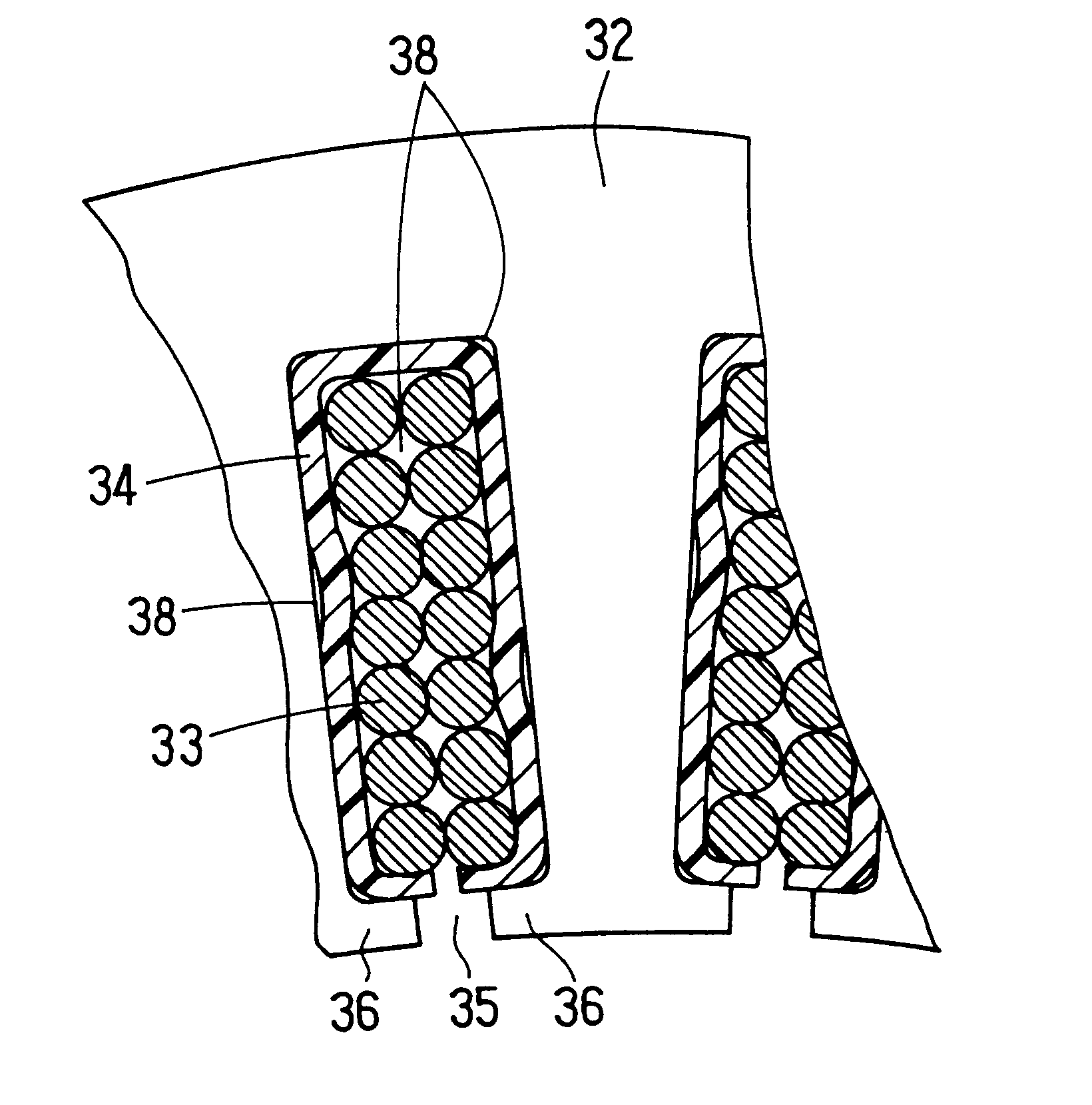

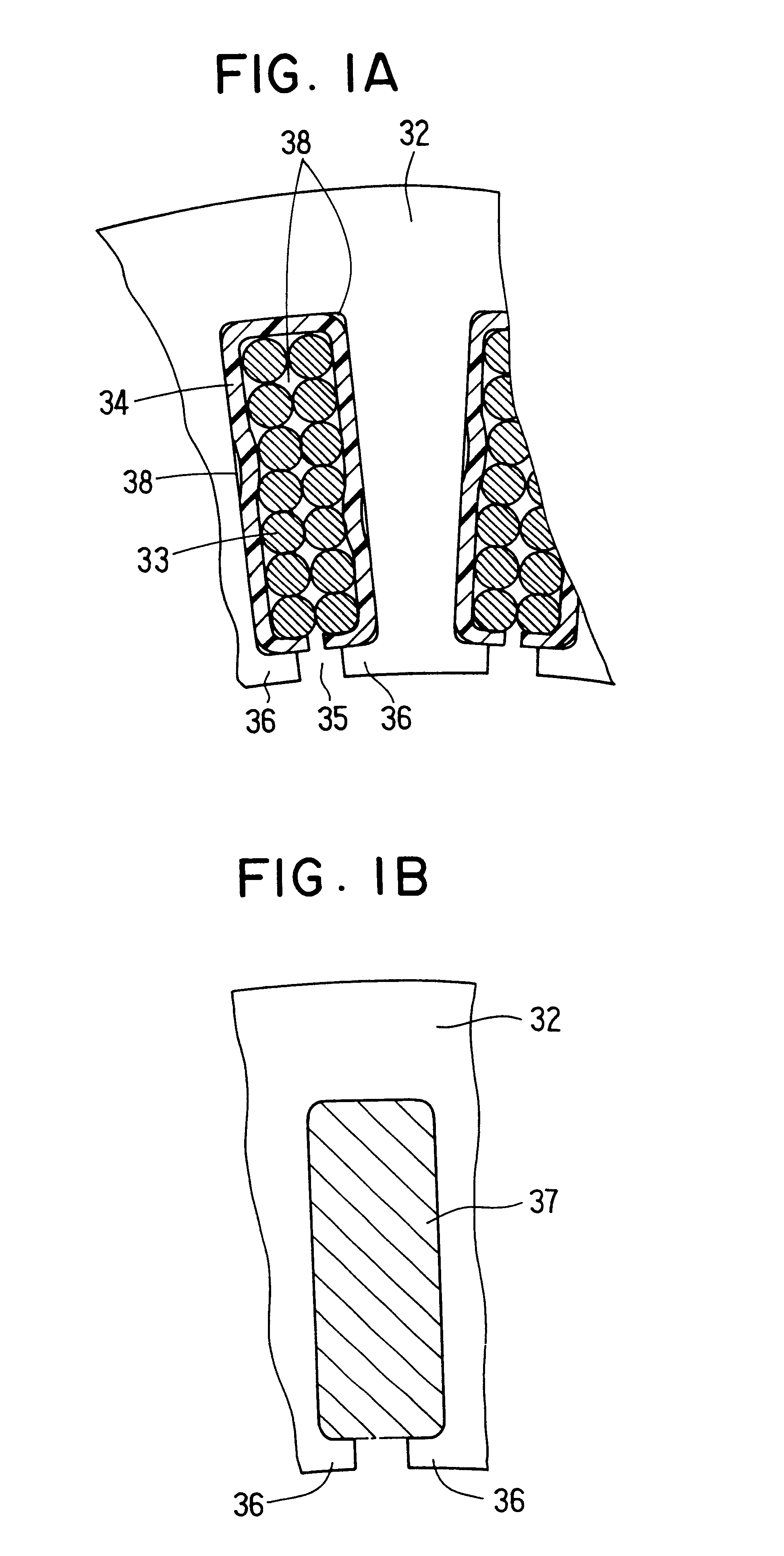

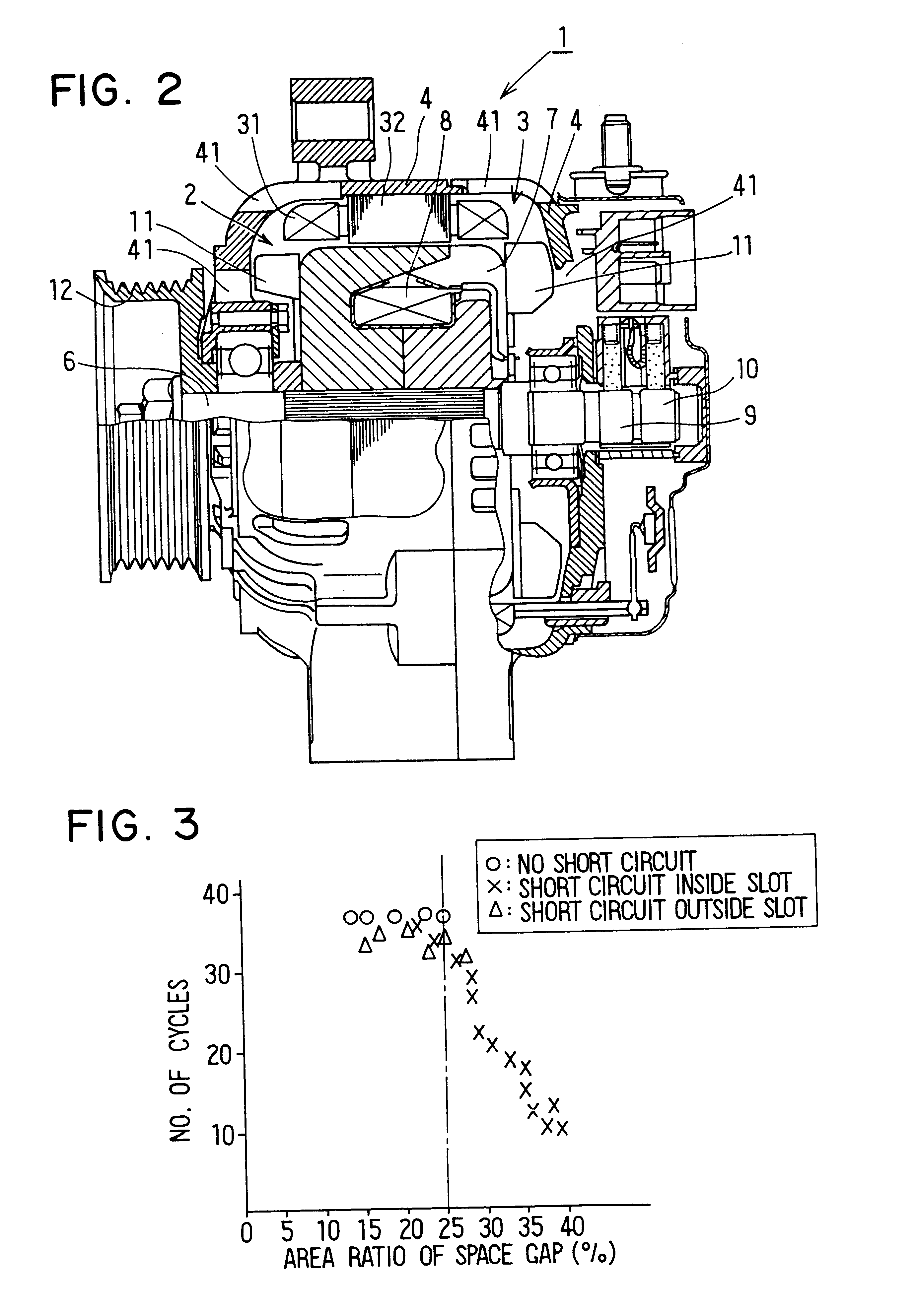

An AC generator for a vehicle including a rotor with a fan, a stator disposed around the outer periphery of the rotor, and a frame. The stator includes a laminated core having a plurality of slots, a plurality of electric conductors in the slots, and an insulator. There is a gap between the electric conductors and the insulator in a diametrical section of the slots, and an area ratio of the gap with respect to the sectional area of the slots is not more than 25%. A portion of the electric conductor positioned within the slot has a substantially rectangular shape along the shape of the slot.

Owner:DENSO CORP

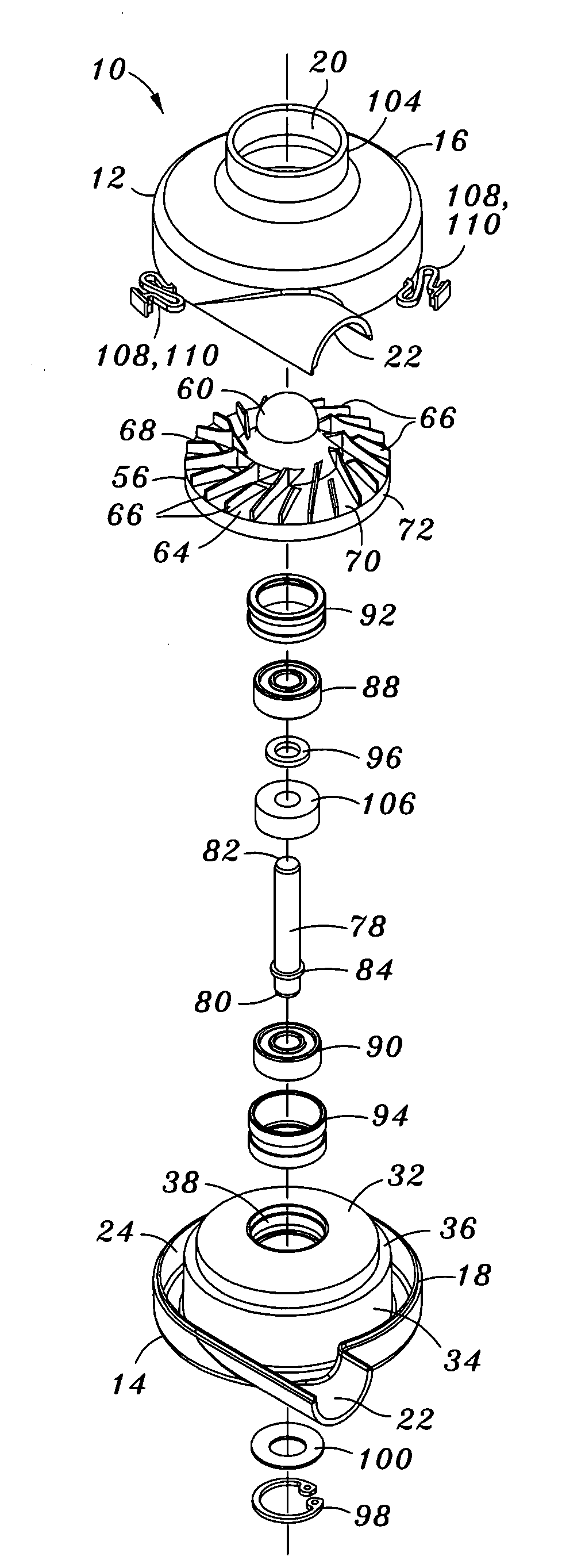

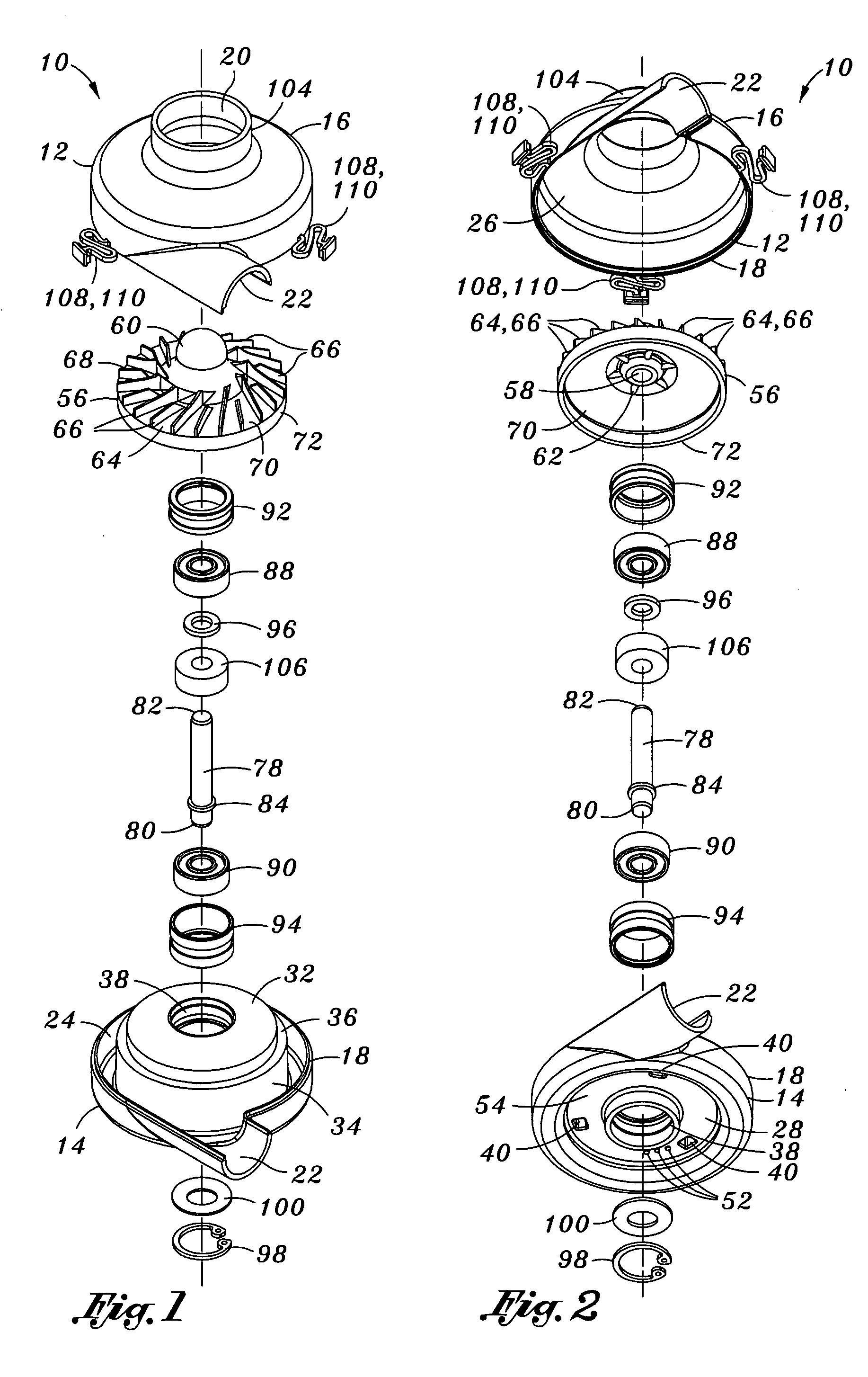

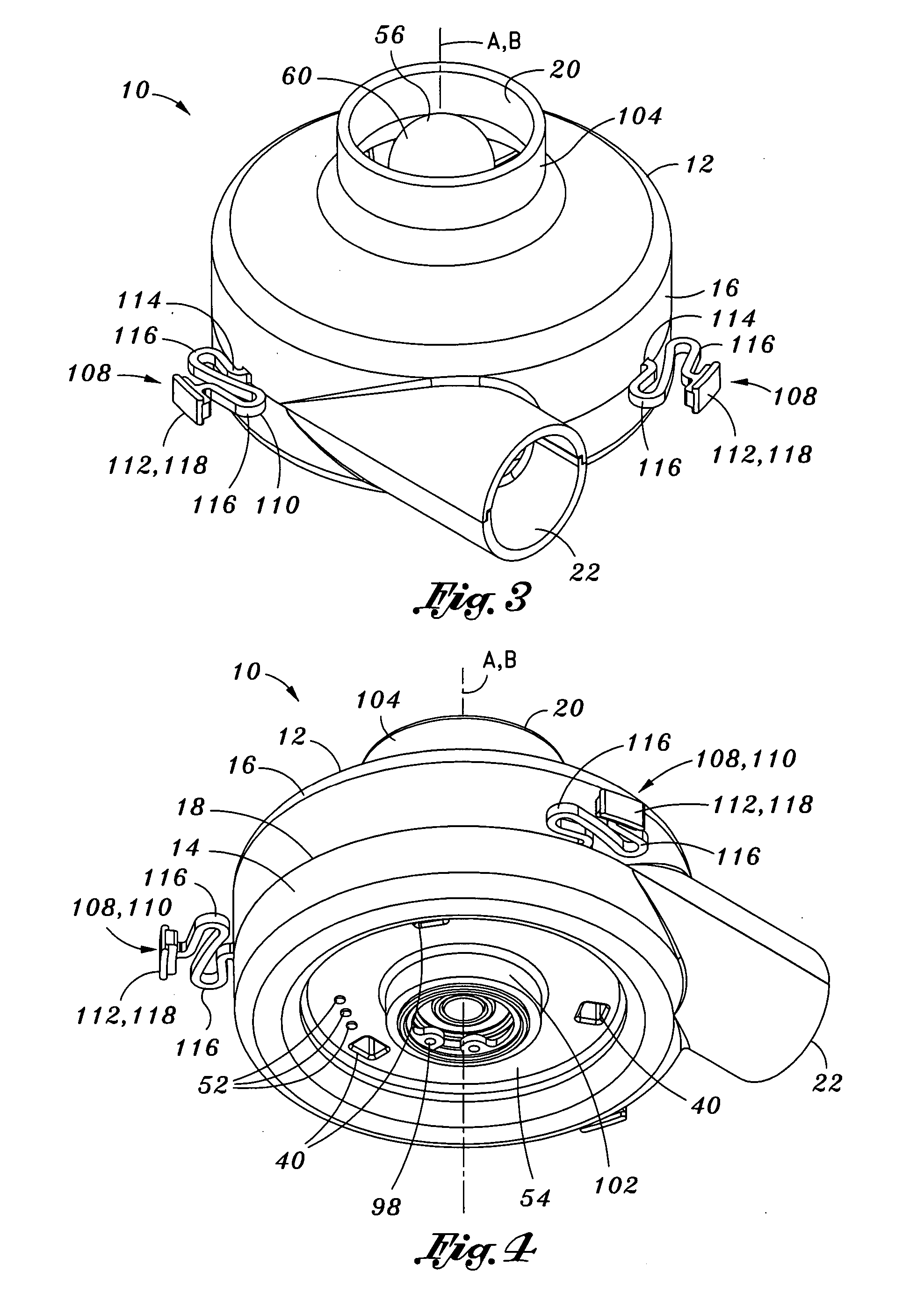

Motor blower unit

ActiveUS20070247009A1Improve compression efficiencyMinimizes vane-to-vane leakageRespiratorsPump componentsImpellerRotor magnets

A blower assembly comprises a blower housing having a stator assembly integrally formed therewith. The stator assembly includes a stator bore having a rotor magnet rotatable therewithin such that the motor assembly is configured as a brushless D.C. motor. An impeller is mounted on a motor shaft of the motor assembly and has a plurality of vanes extending upwardly therefrom. Each one of the vanes has a vane height which is optimized to minimize the formation of fluid eddy losses during compression of air by the impeller. A bearing assembly rotatably coupling the rotor magnet to the stator assembly is sized and configured to maintain an air gap of approximately 0.0002 inches between the vanes and a housing interior surface of the blower housing during rotation of the impeller.

Owner:VYAIRE MEDICAL 211 INC

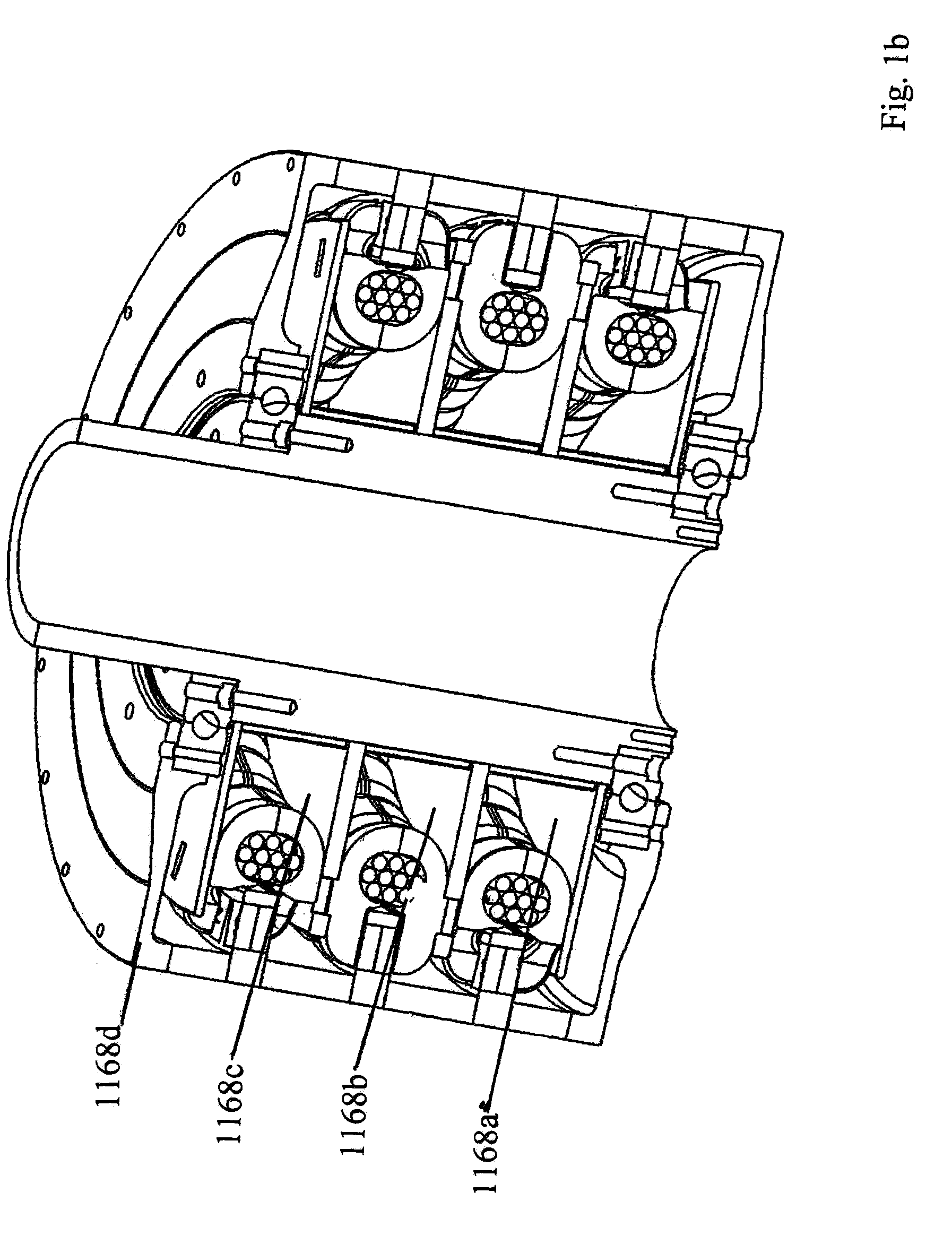

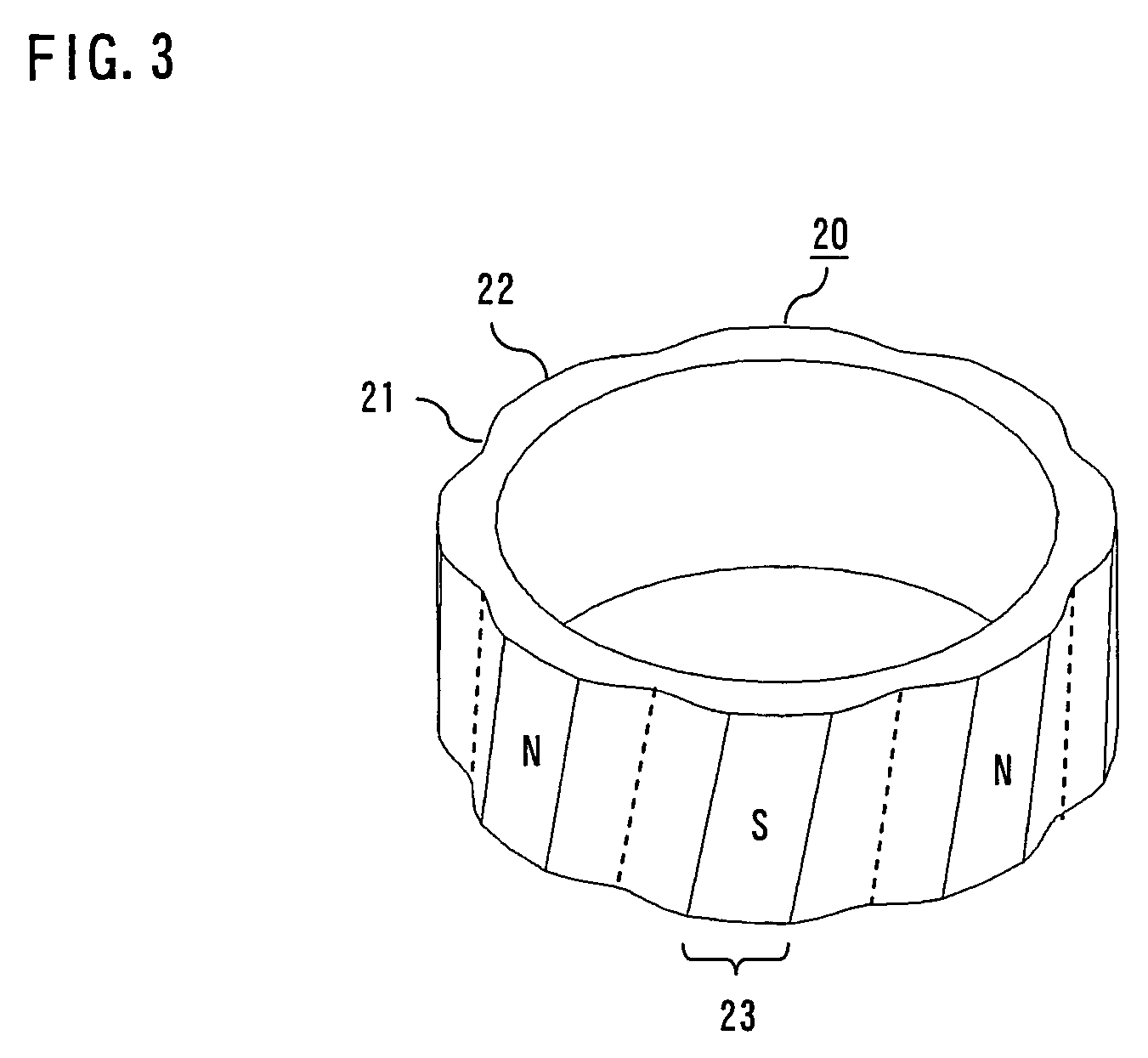

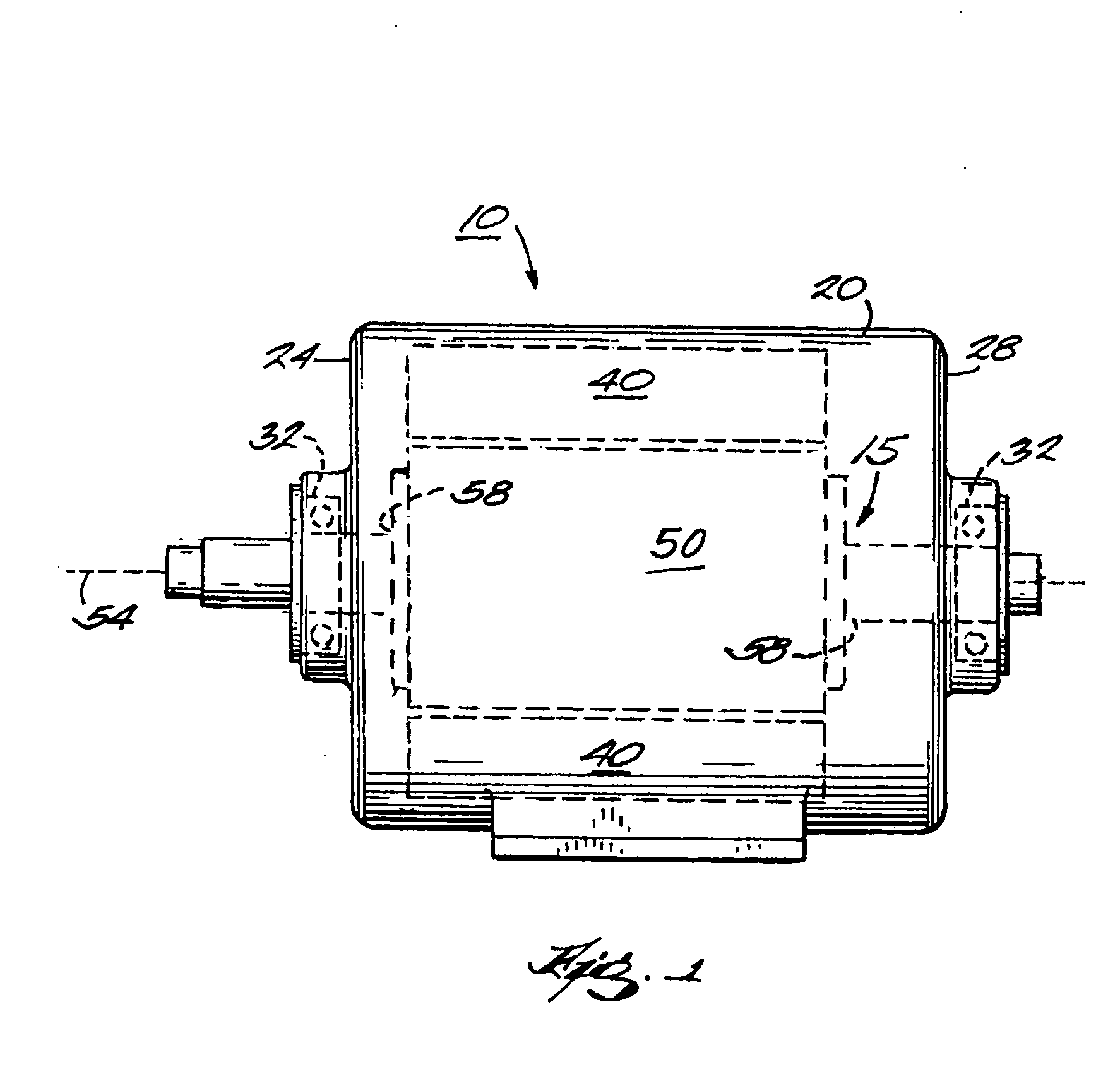

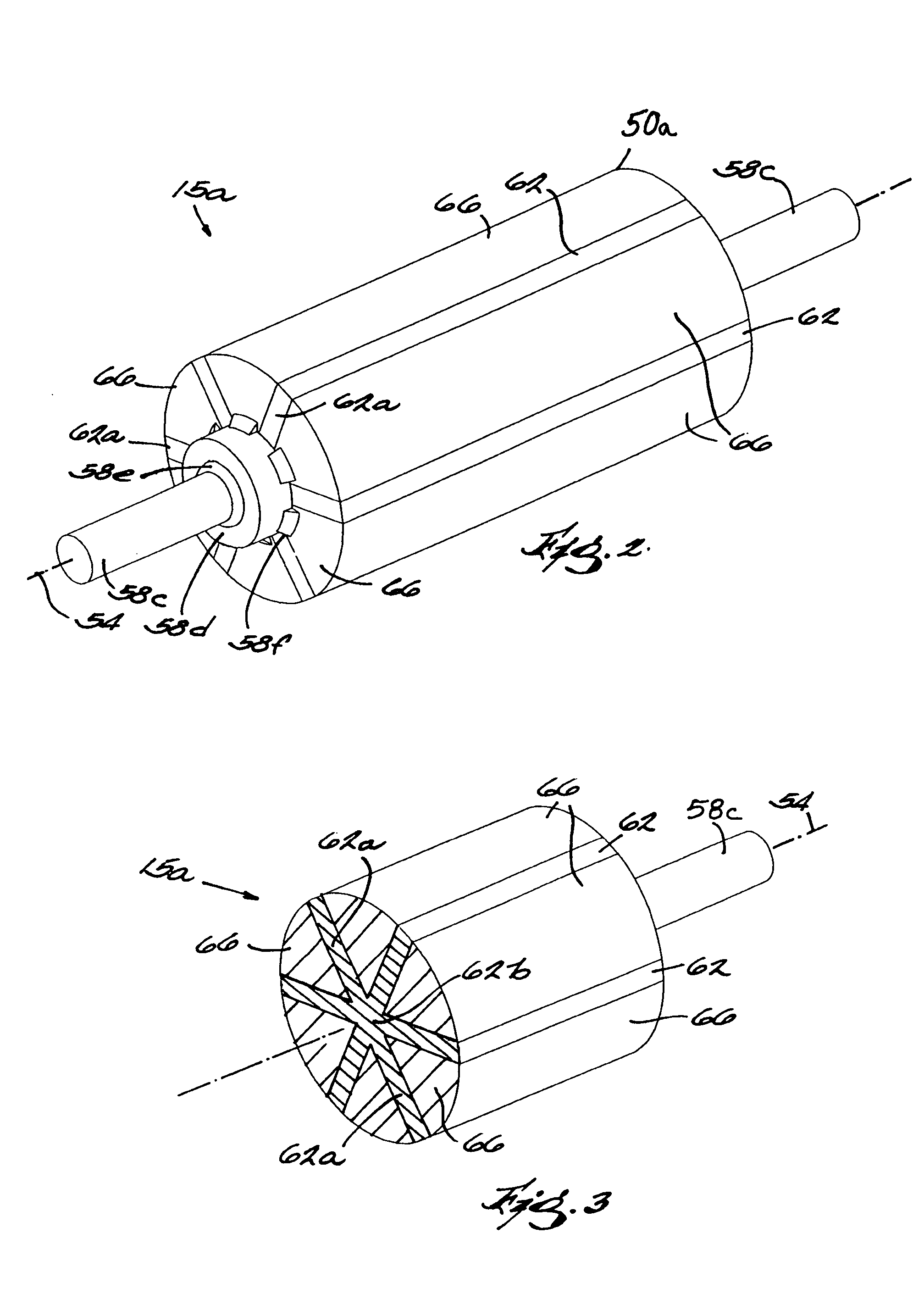

High-efficiency parallel-pole molded-magnetic flux channels transverse wound motor-dynamo

InactiveUS7579742B1Improve efficiencyTotal current dropMagnetic circuit stationary partsManufacturing dynamo-electric machinesDrive wheelDrive motor

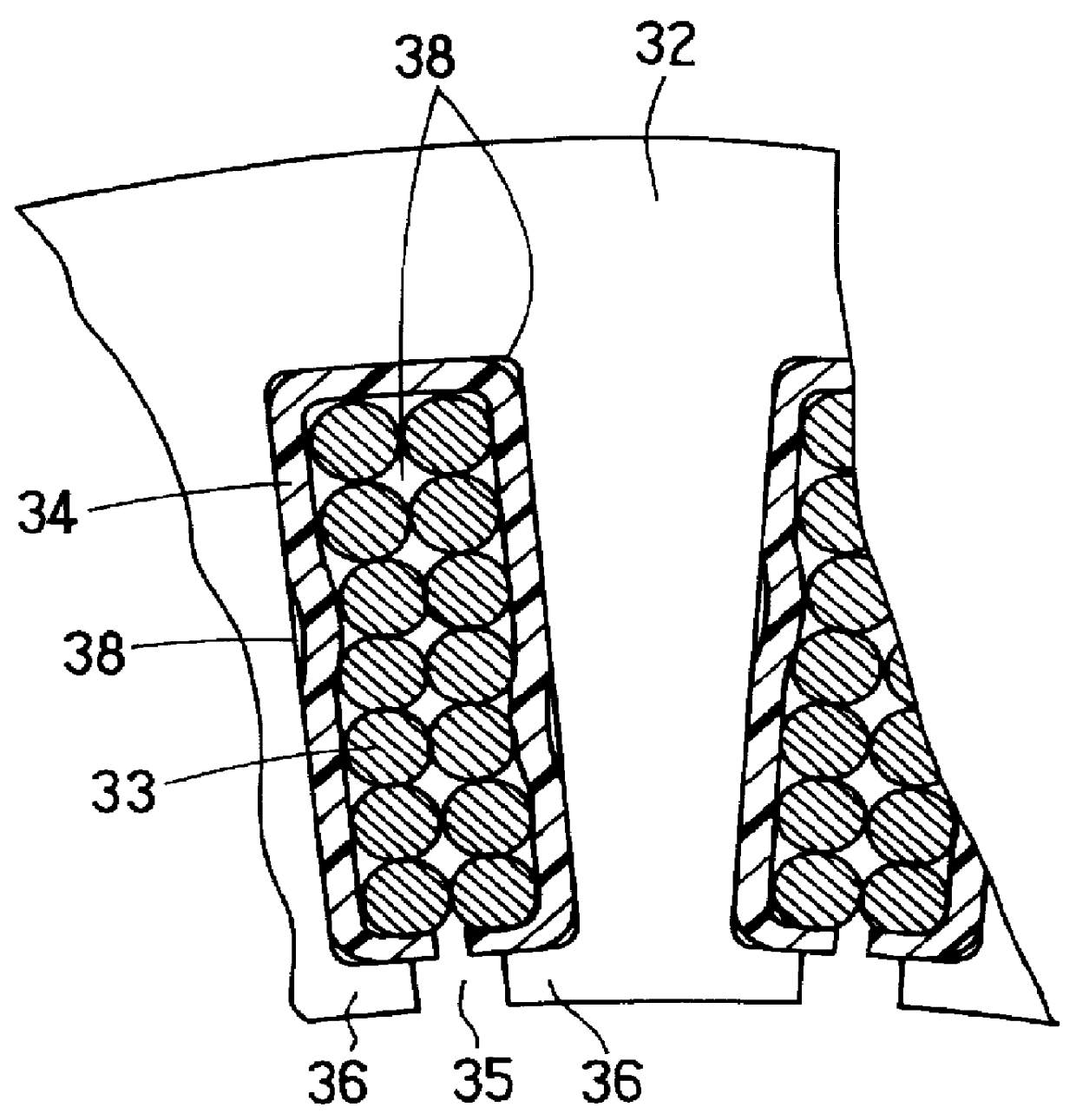

A motor / dynamo including a mounting shaft having a hollow channel and a bearing attached to each end, a non-rotating cylindrical hub having a hollow core for the mounting shaft, single or plural rows of plural parallel pole molded magnetic flux channels each having two halves and forming a hollow channel through which wire is transversely wound through fixedly attached on a surface of the cylindrical hub forming a high efficiency, high torque, direct drive motor / dynamo, utilizing Parallel Pole Molded Magnetic Flux Channels, low resistance and impedance transverse coil windings, and physically separate stators for electrical phases. The high torque, high efficiency motor capable of driving wheels, tracks, propellers, and other loads without a gearbox or other torque multiplying device. The high efficiency dynamo capable of being directly driven by wind turbines without a speed increasing gearbox or other speed multiplying device.

Owner:RITTENHOUSE NORMAN

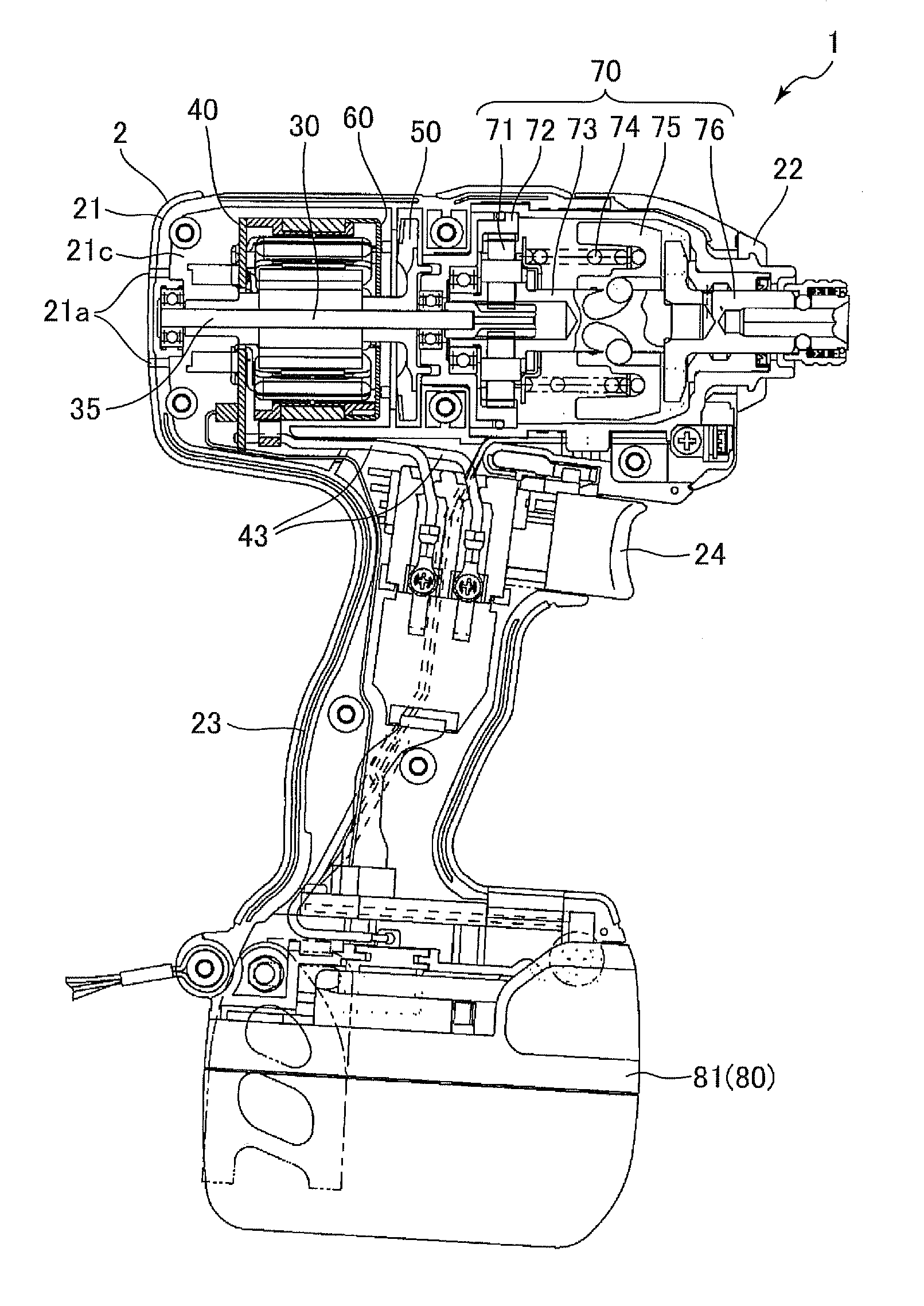

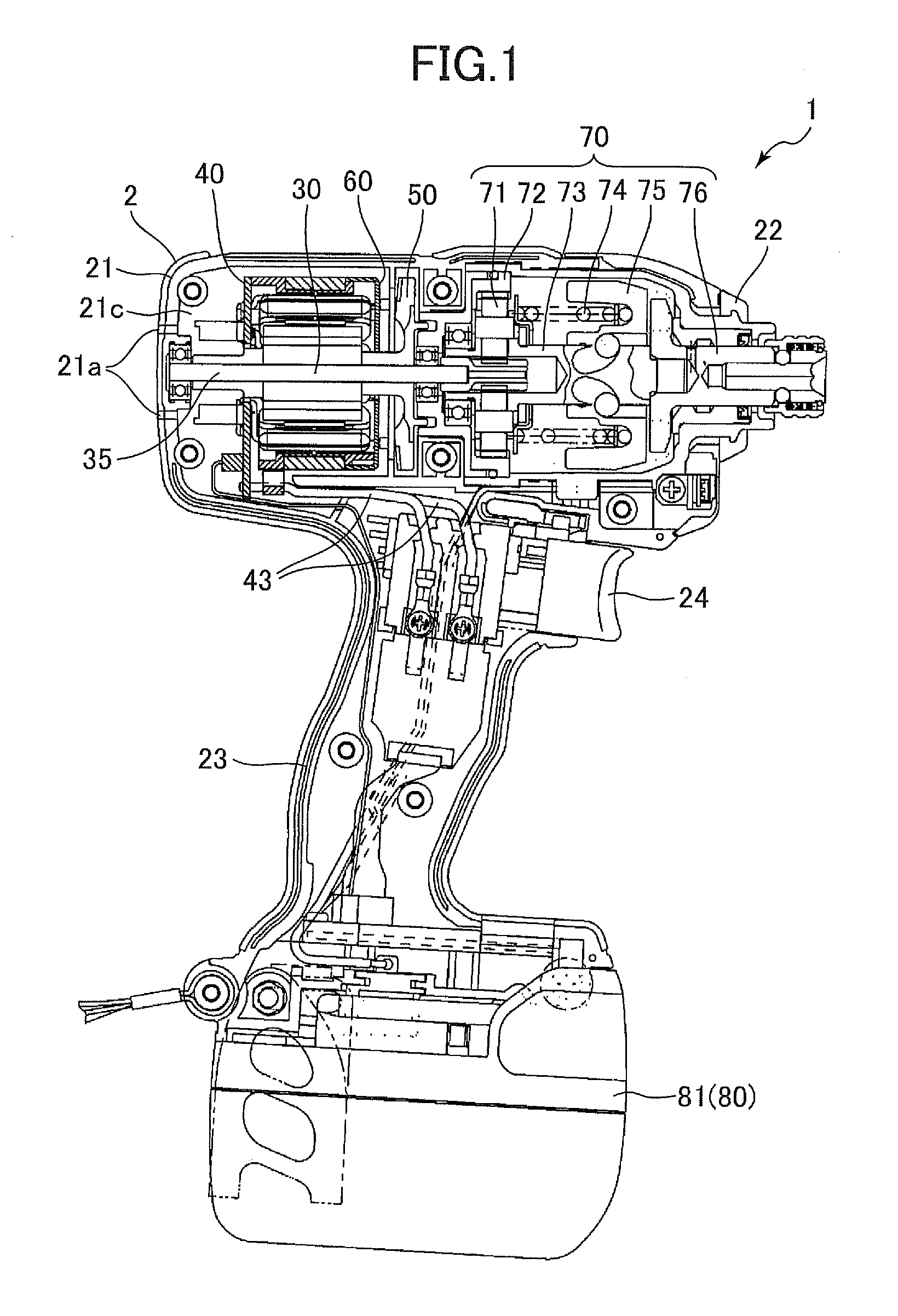

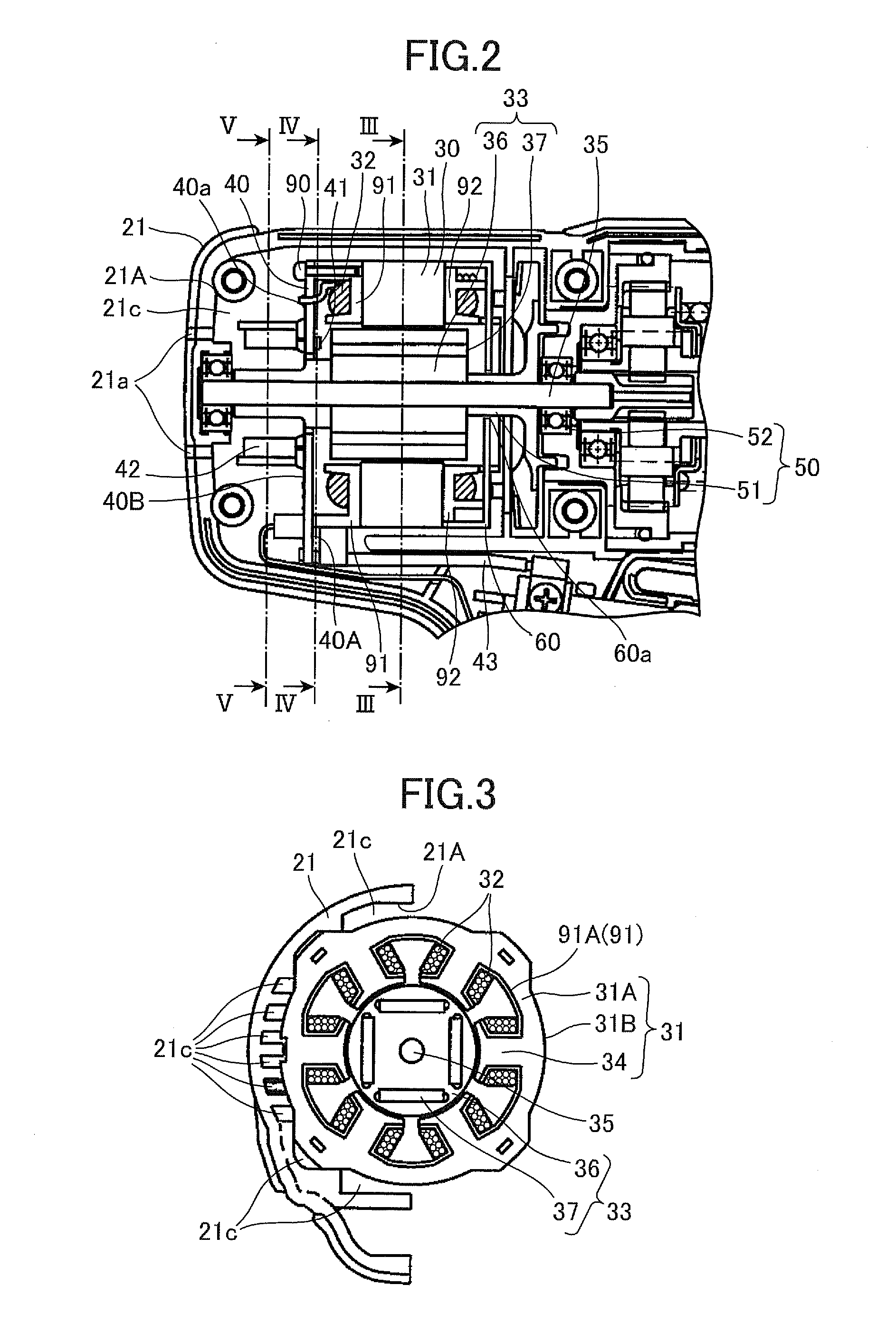

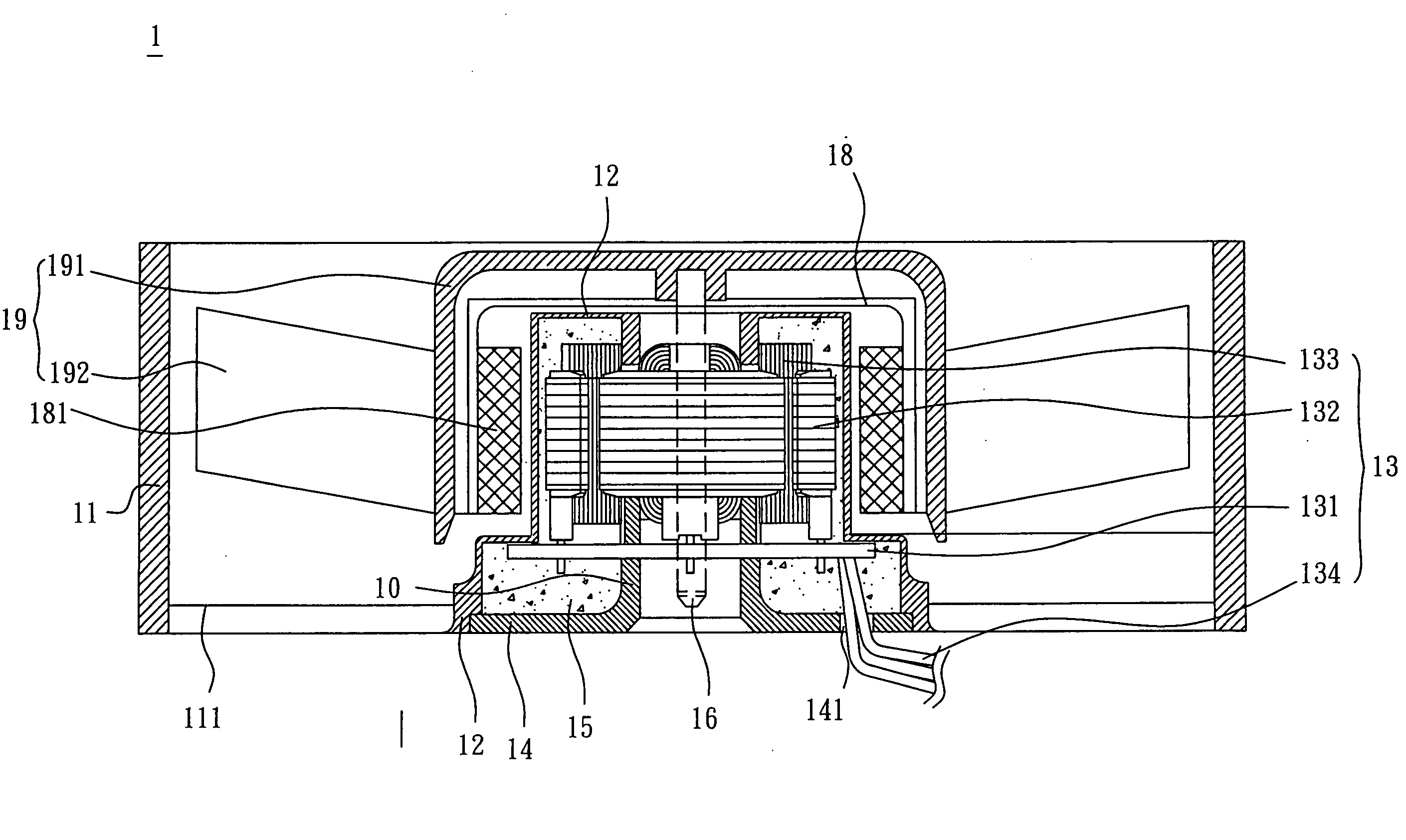

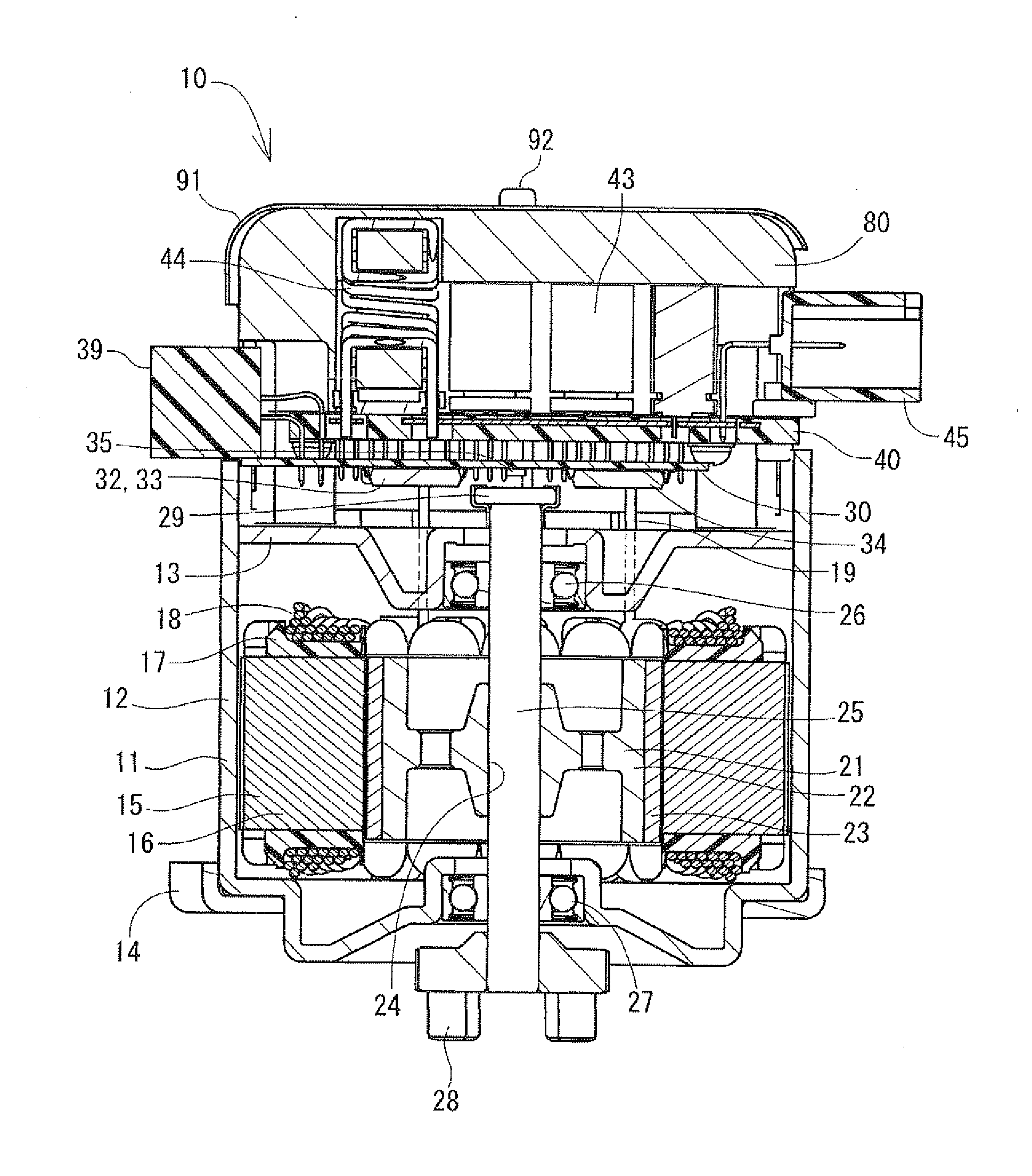

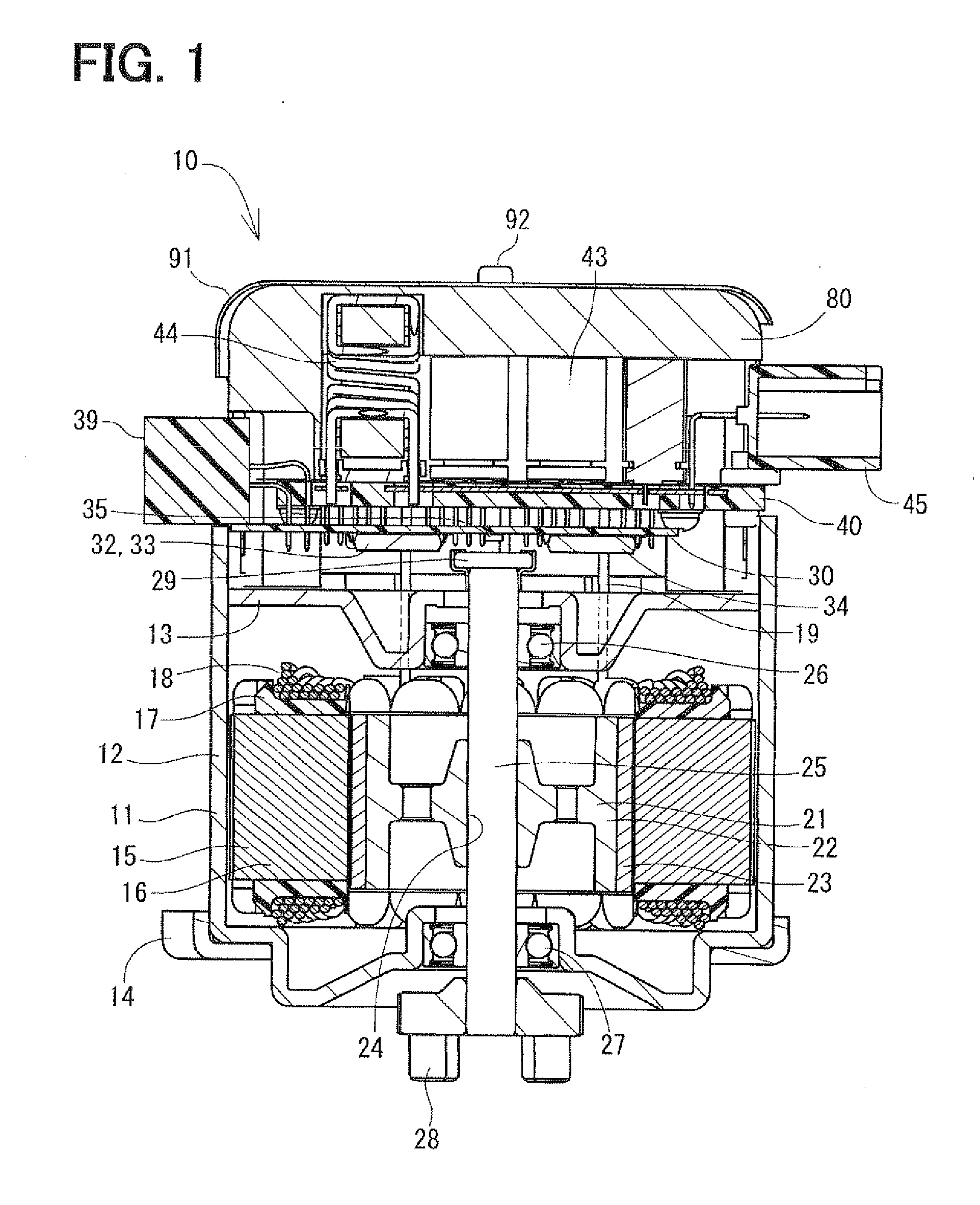

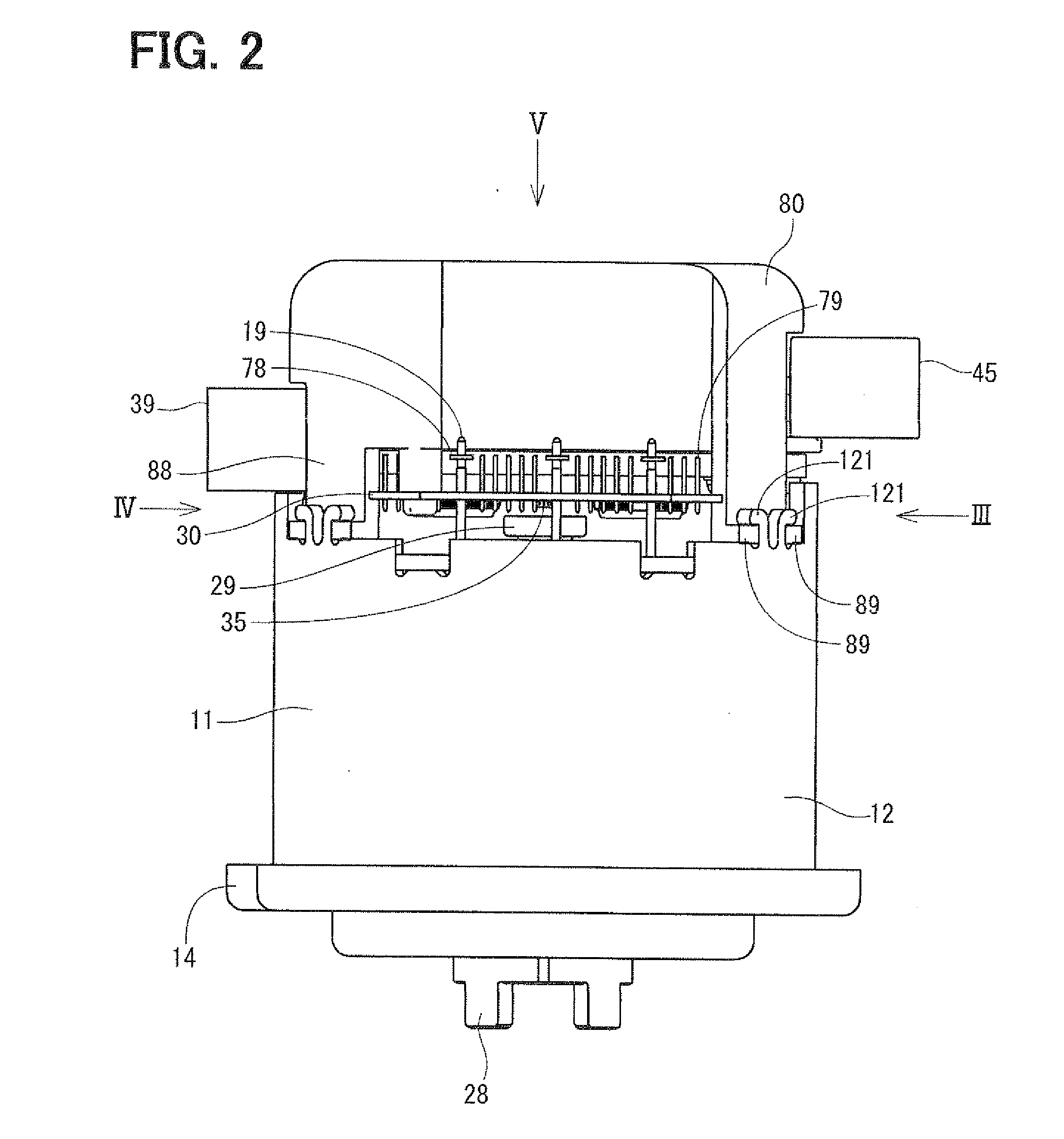

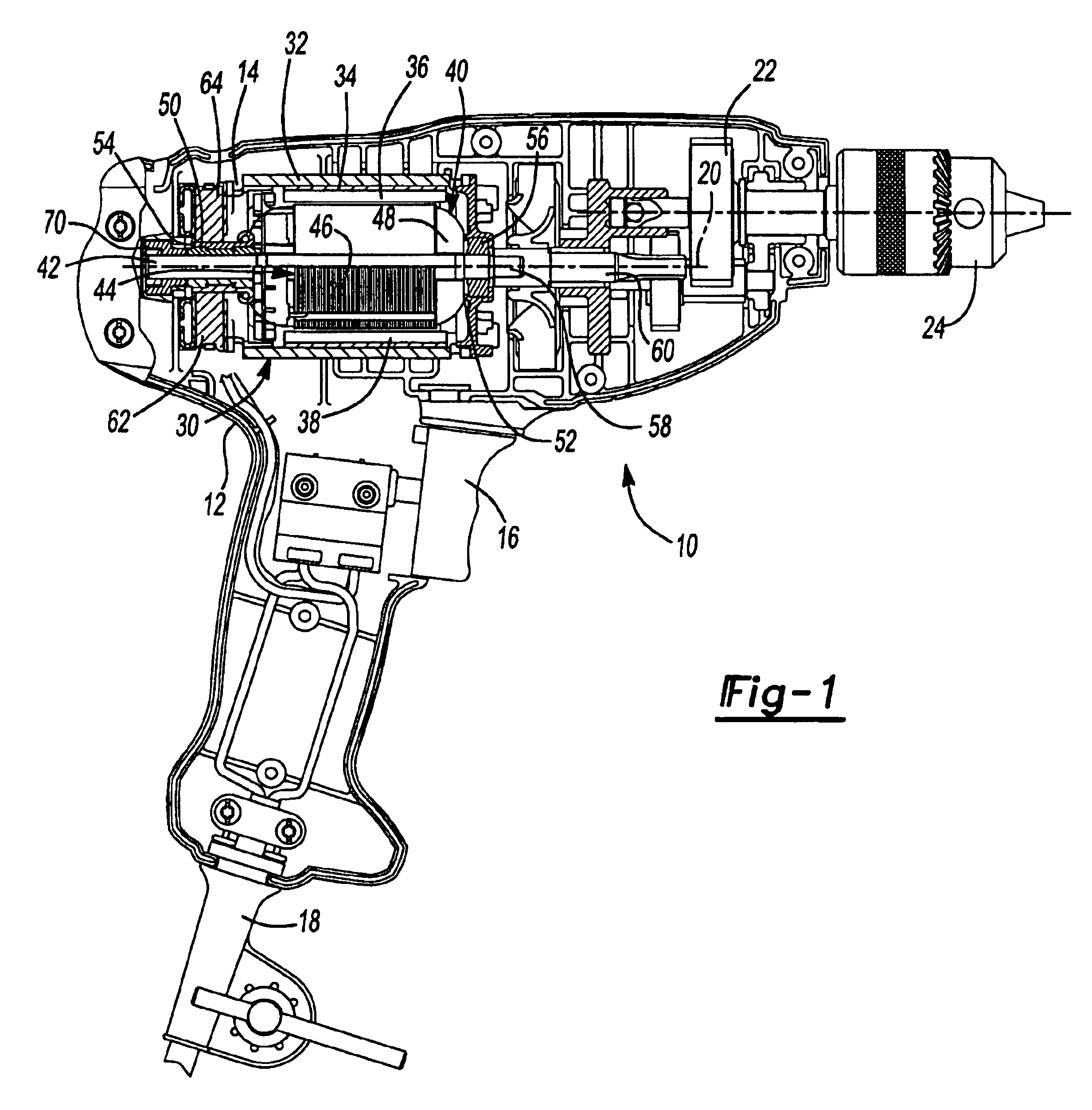

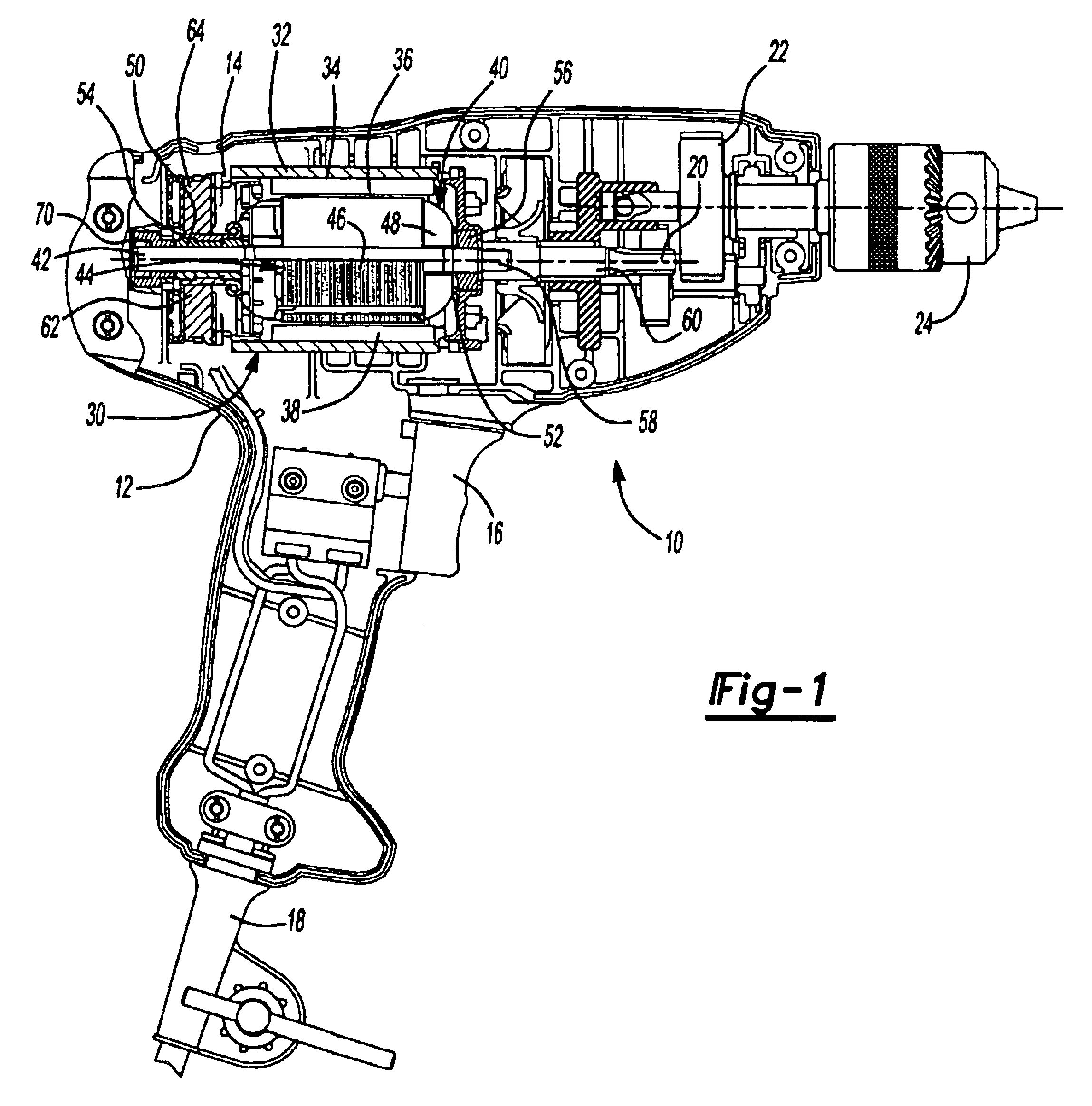

Power Tool

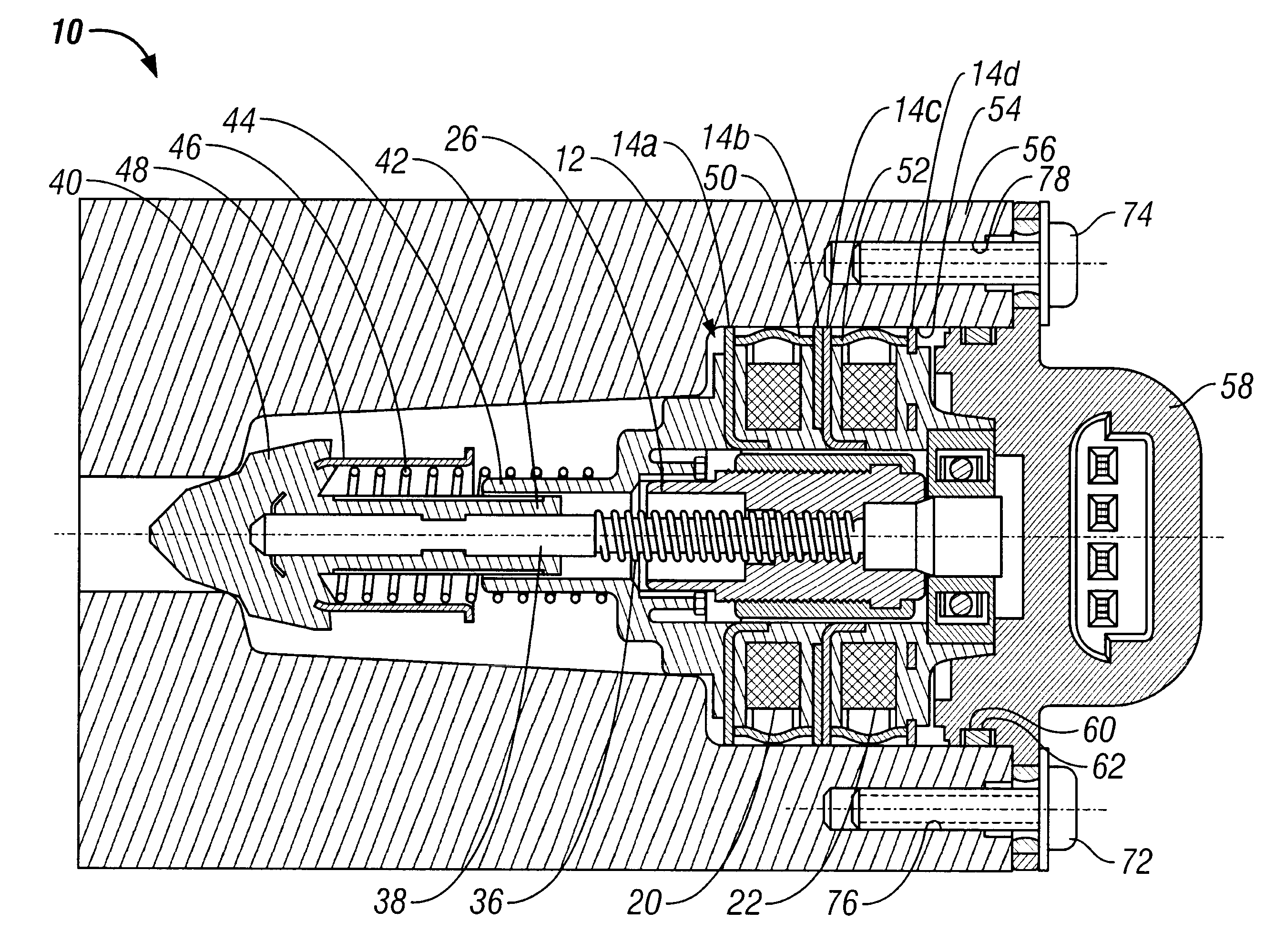

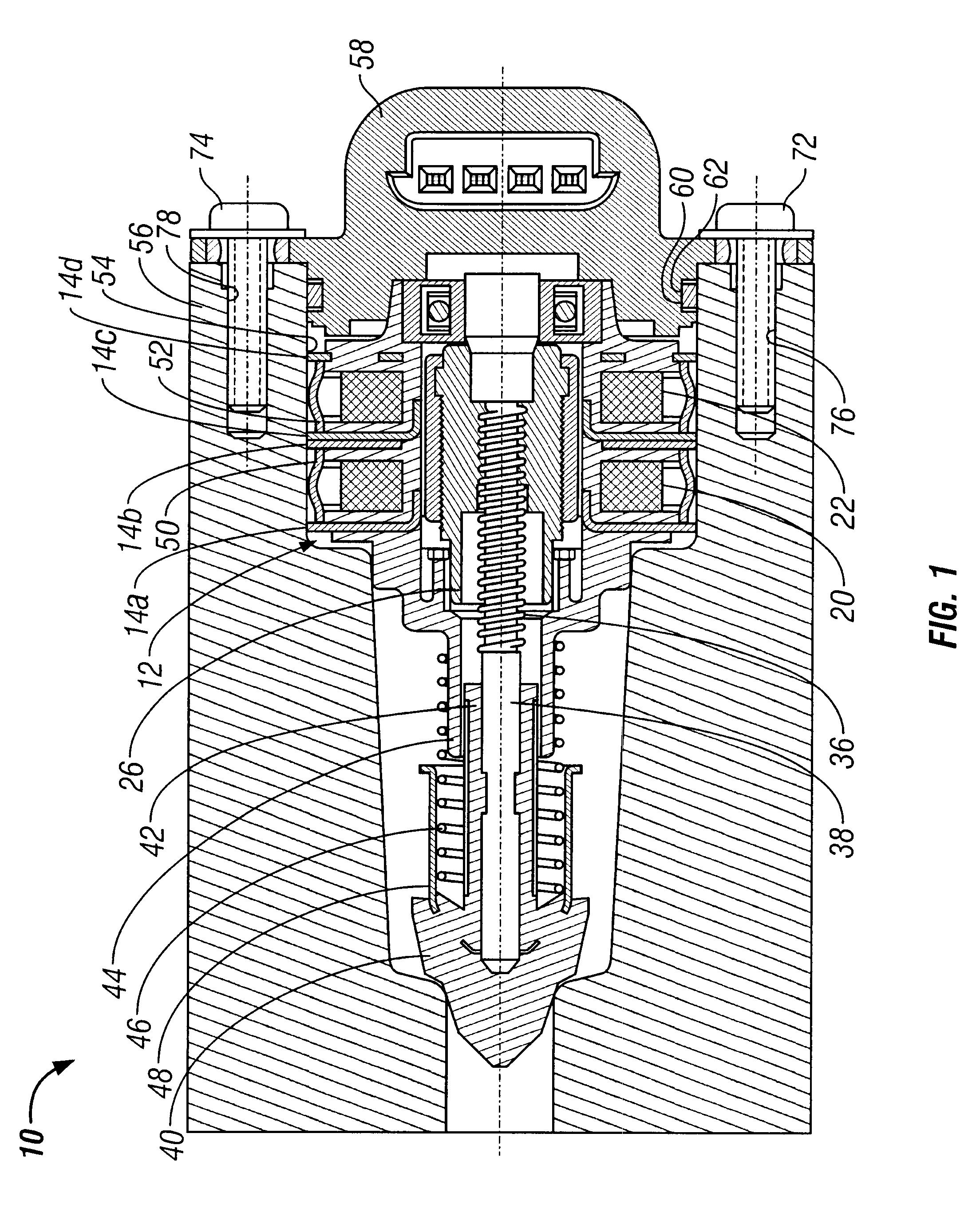

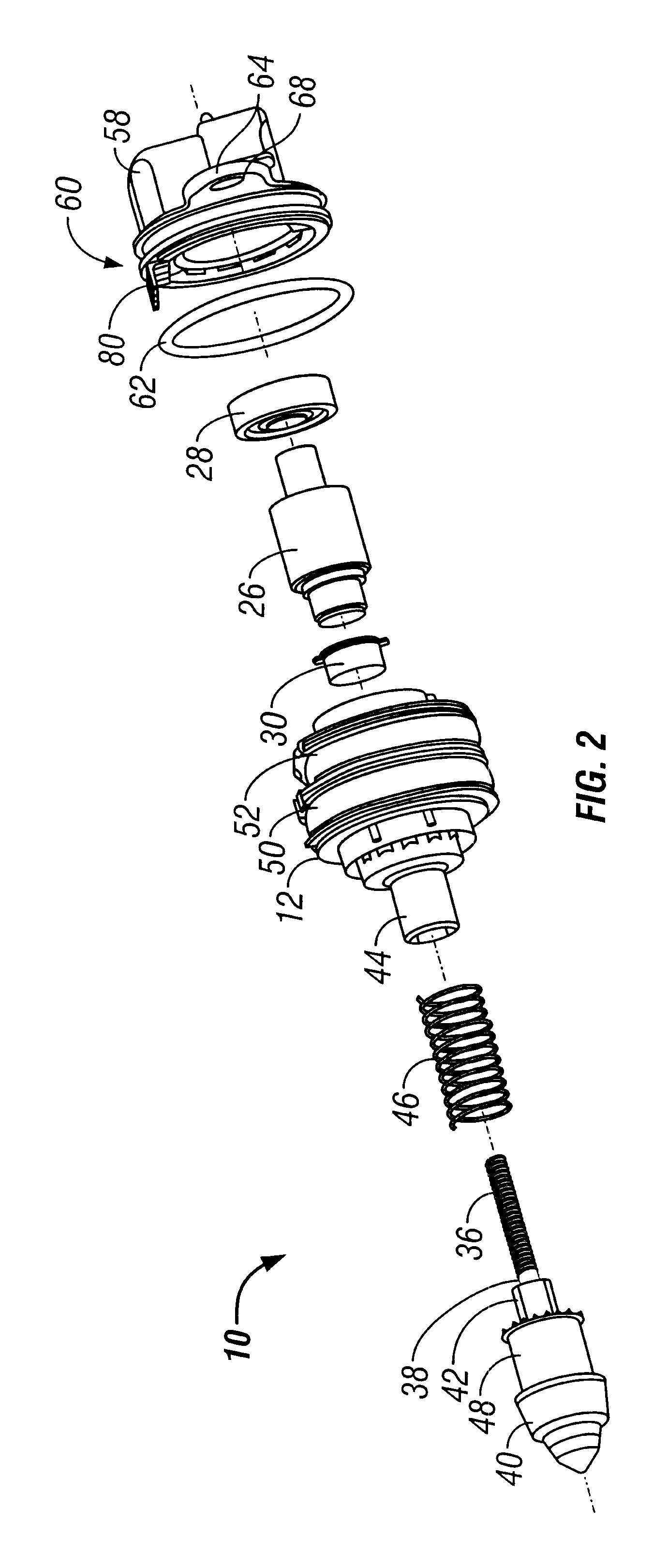

ActiveUS20080265695A1Portable power-driven toolsMagnetic circuit characterised by insulating materialsBrushless motorsEngineering

A power tool includes a housing, a brushless motor, and a cover member. The housing has an air intake hole and an air exhaust hole formed therein, the housing having an inner surface. The brushless motor has an outer surface disposed in the housing, a first endface near the air intake hole, and a second endface near the air exhaust hole. The cover member covers at least one of the first endface and the second endface for preventing dust from entering the brushless motor. The inner surface of the housing and outer surface of the brushless motor define a circulation path providing communication between the air intake hole and the air exhaust hole.

Owner:HITACHI KOKI CO LTD

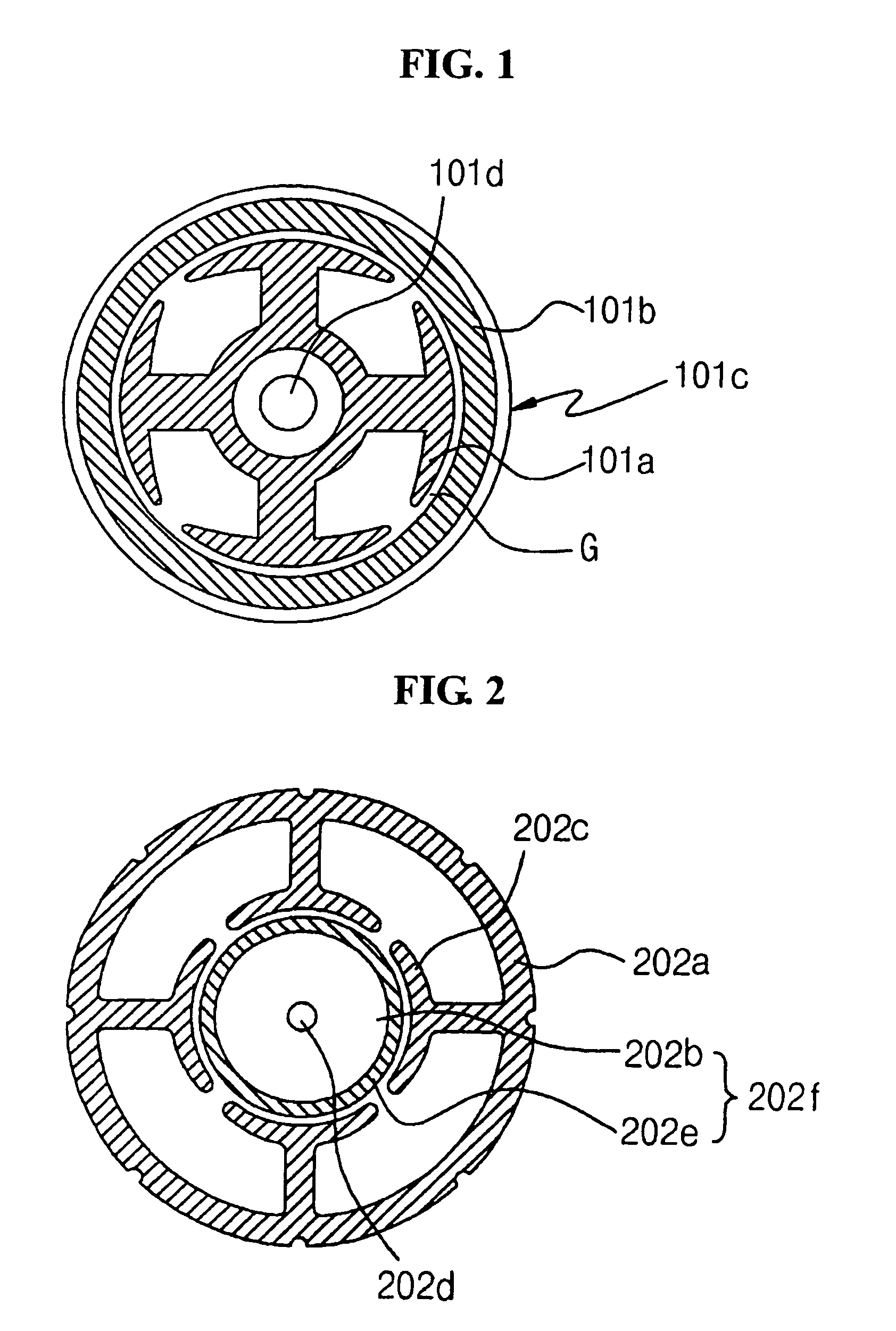

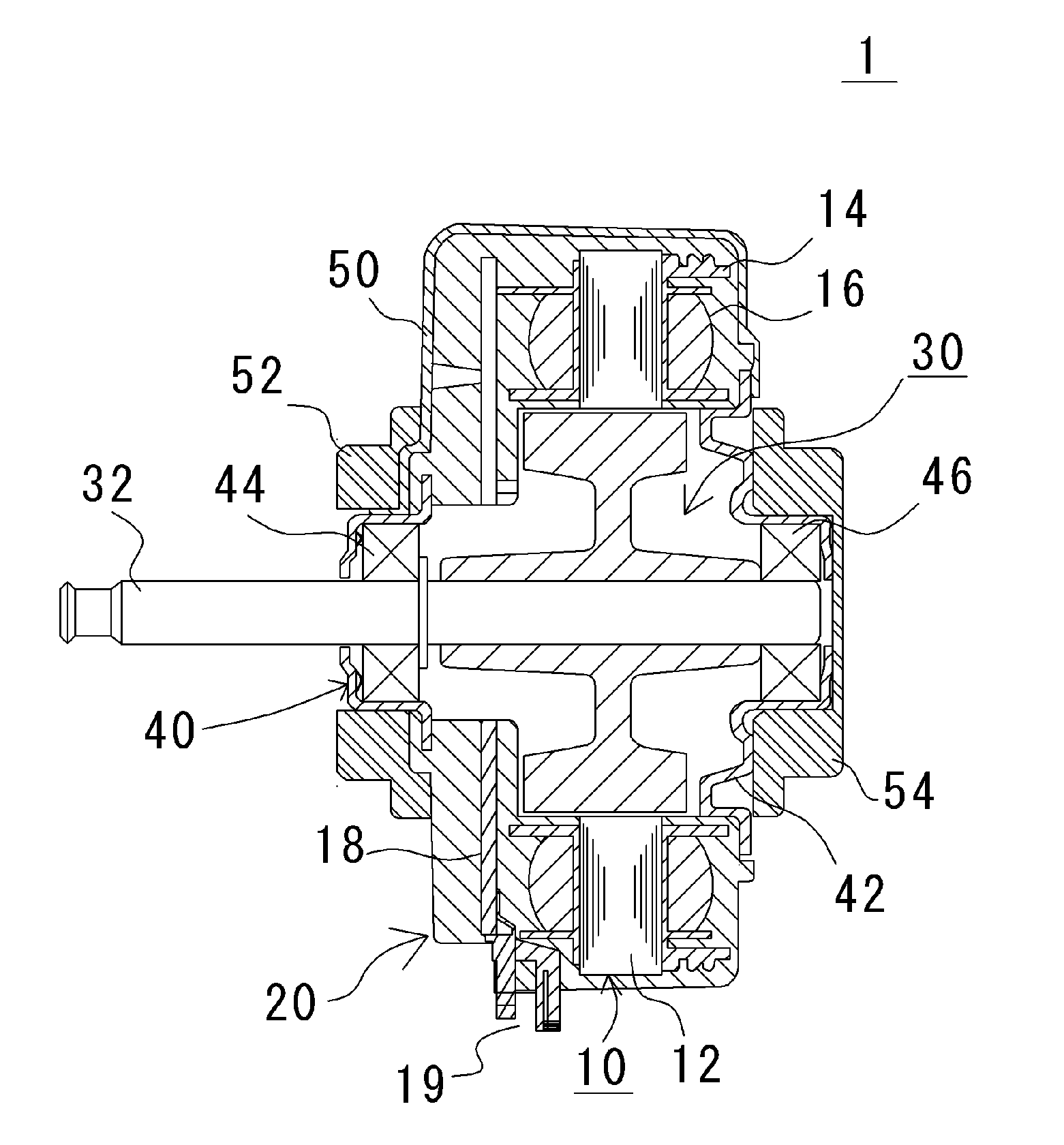

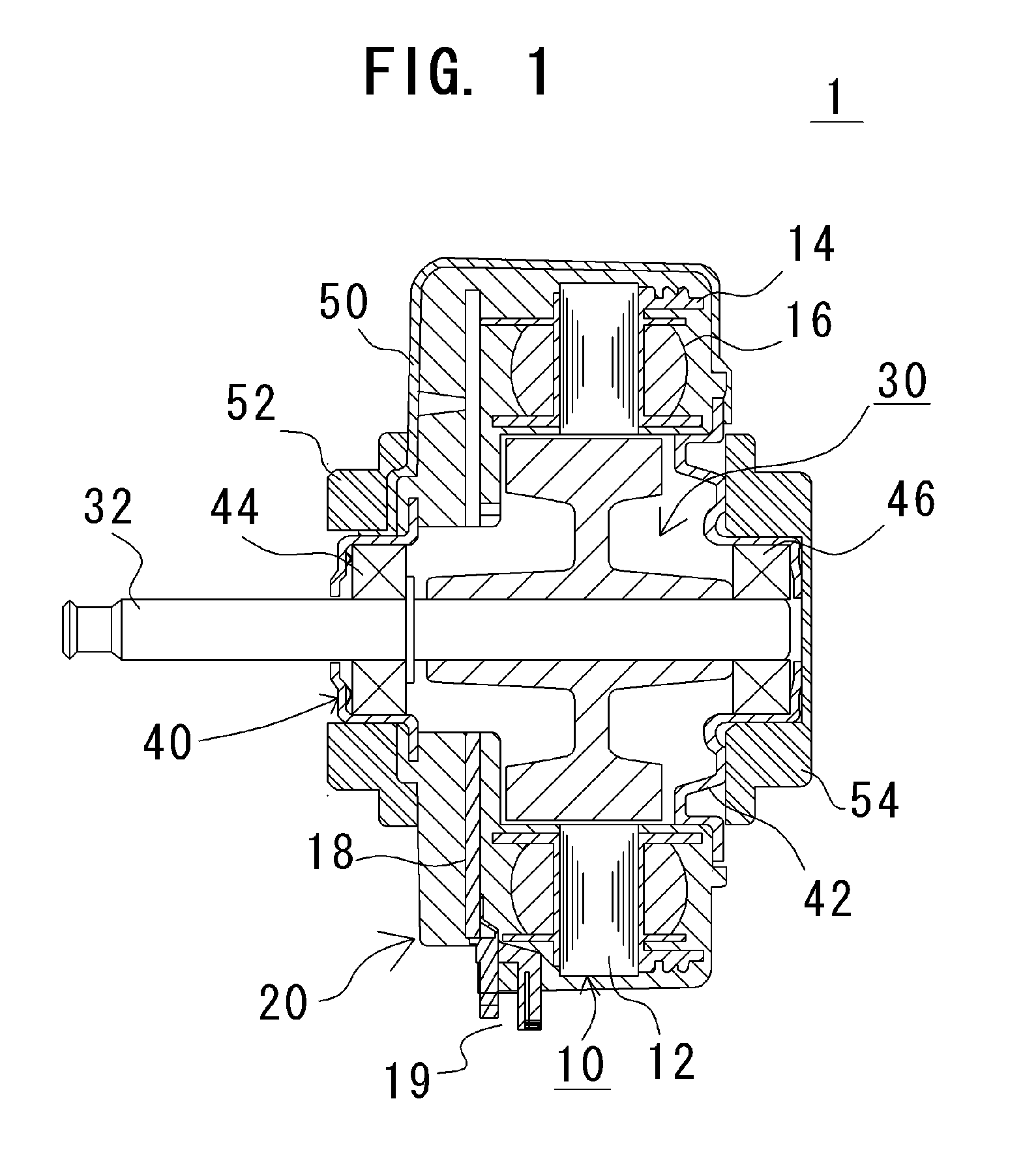

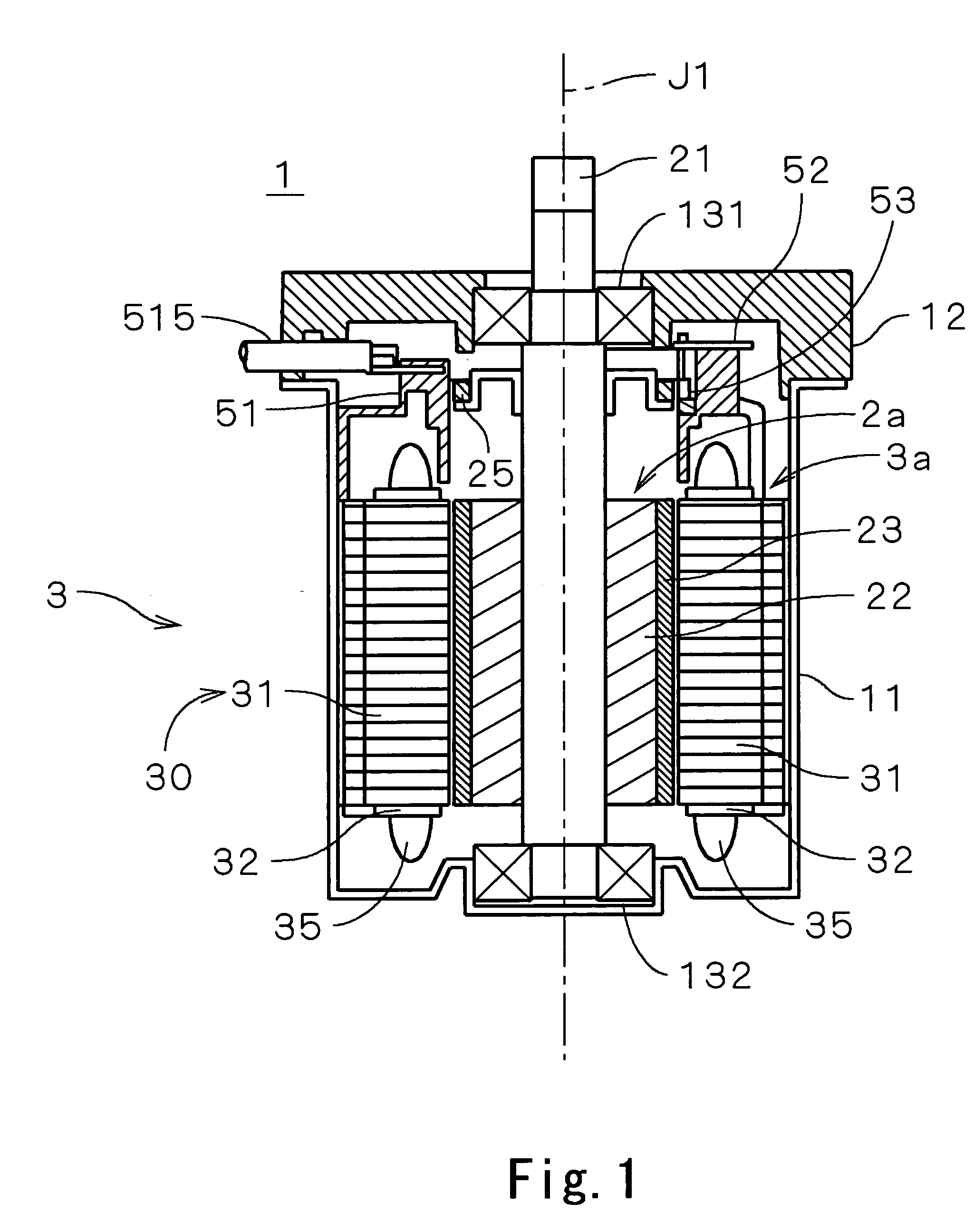

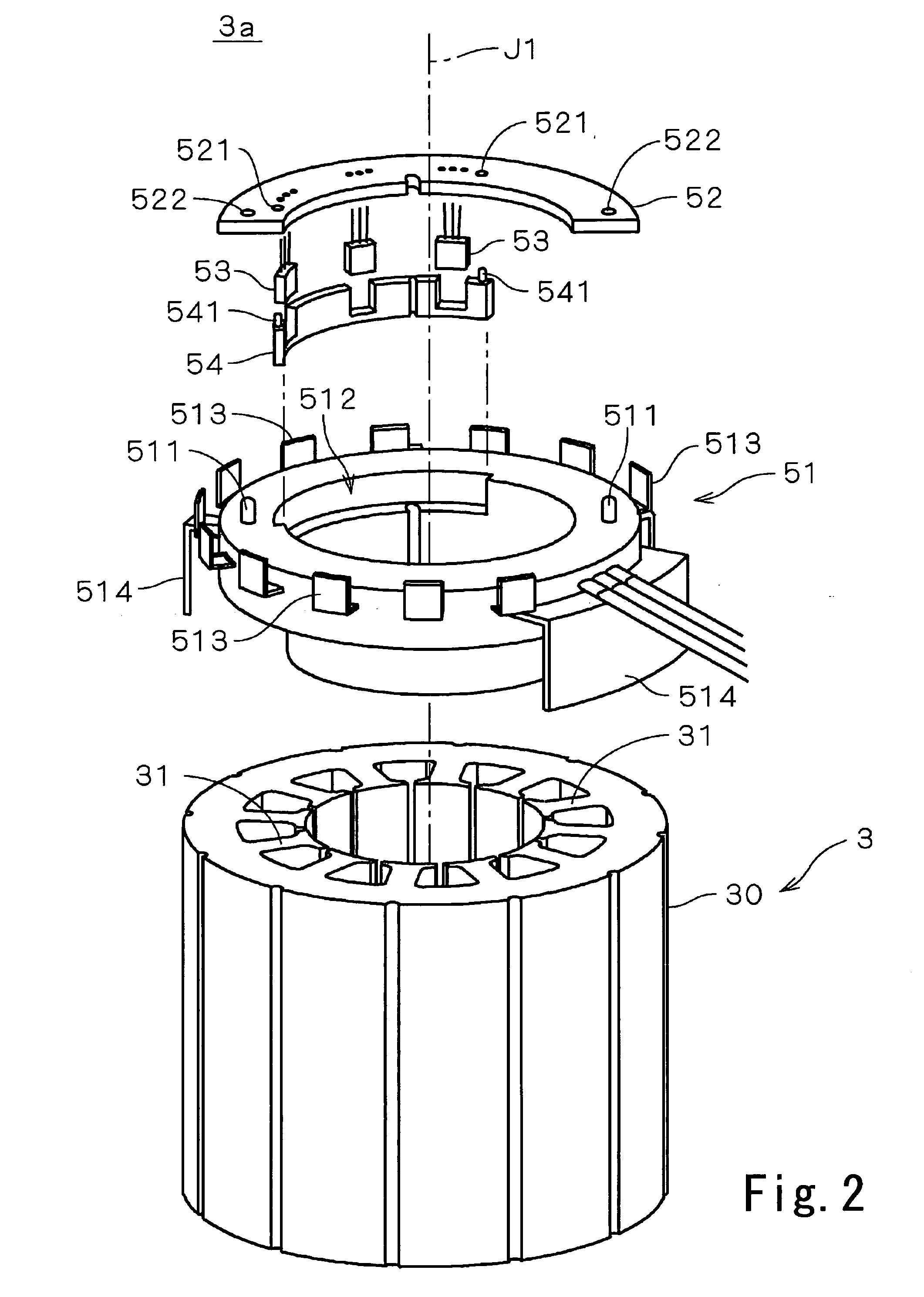

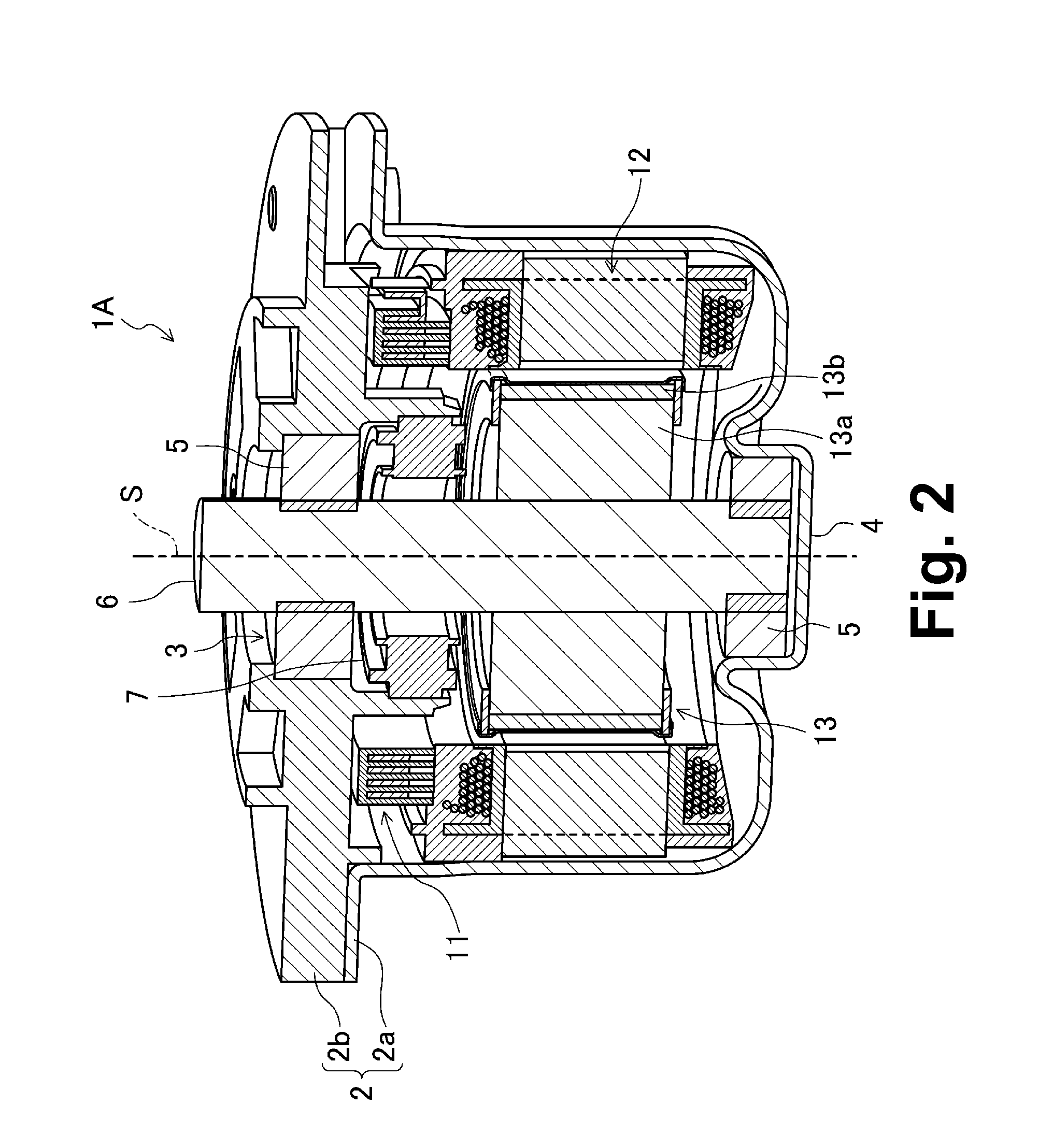

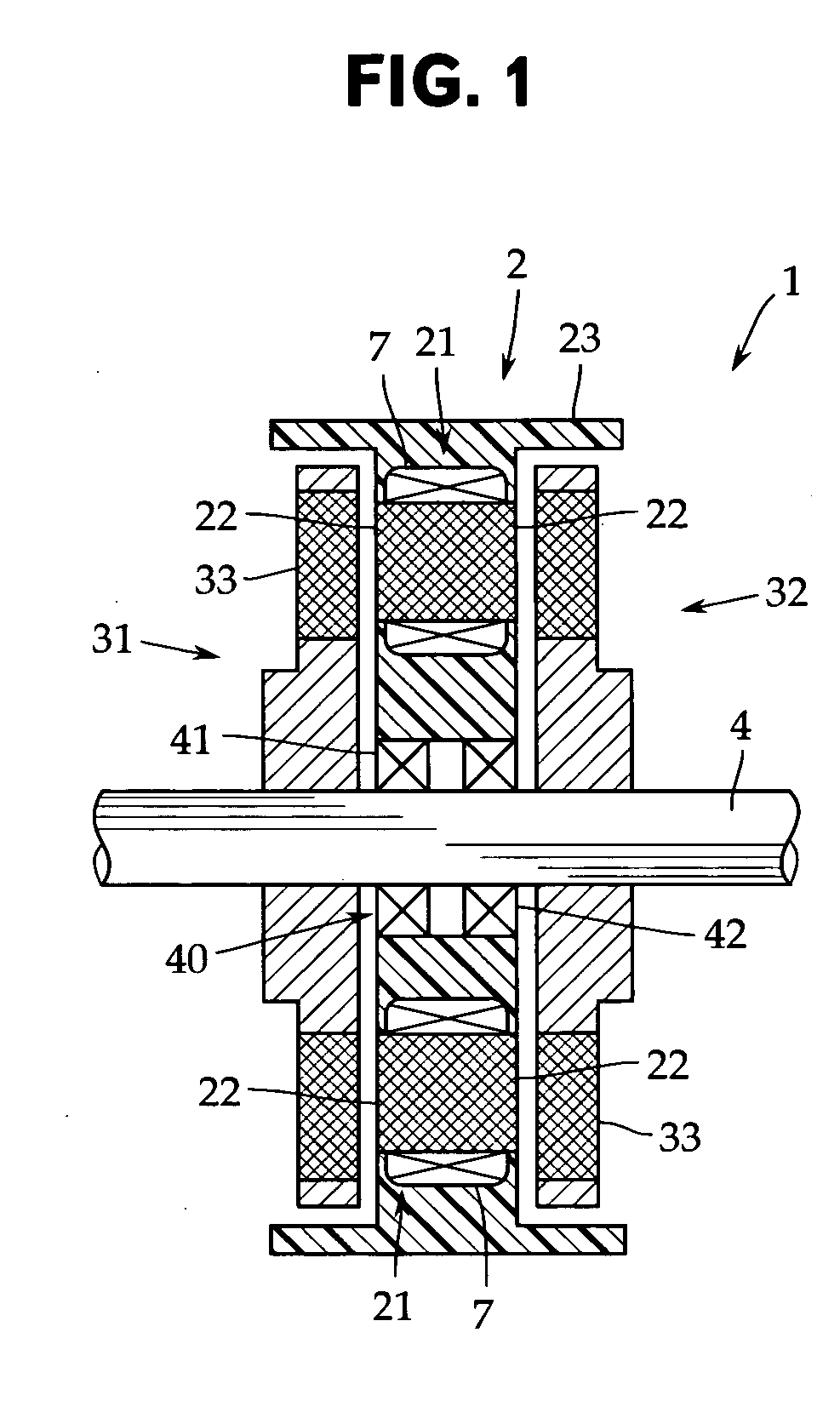

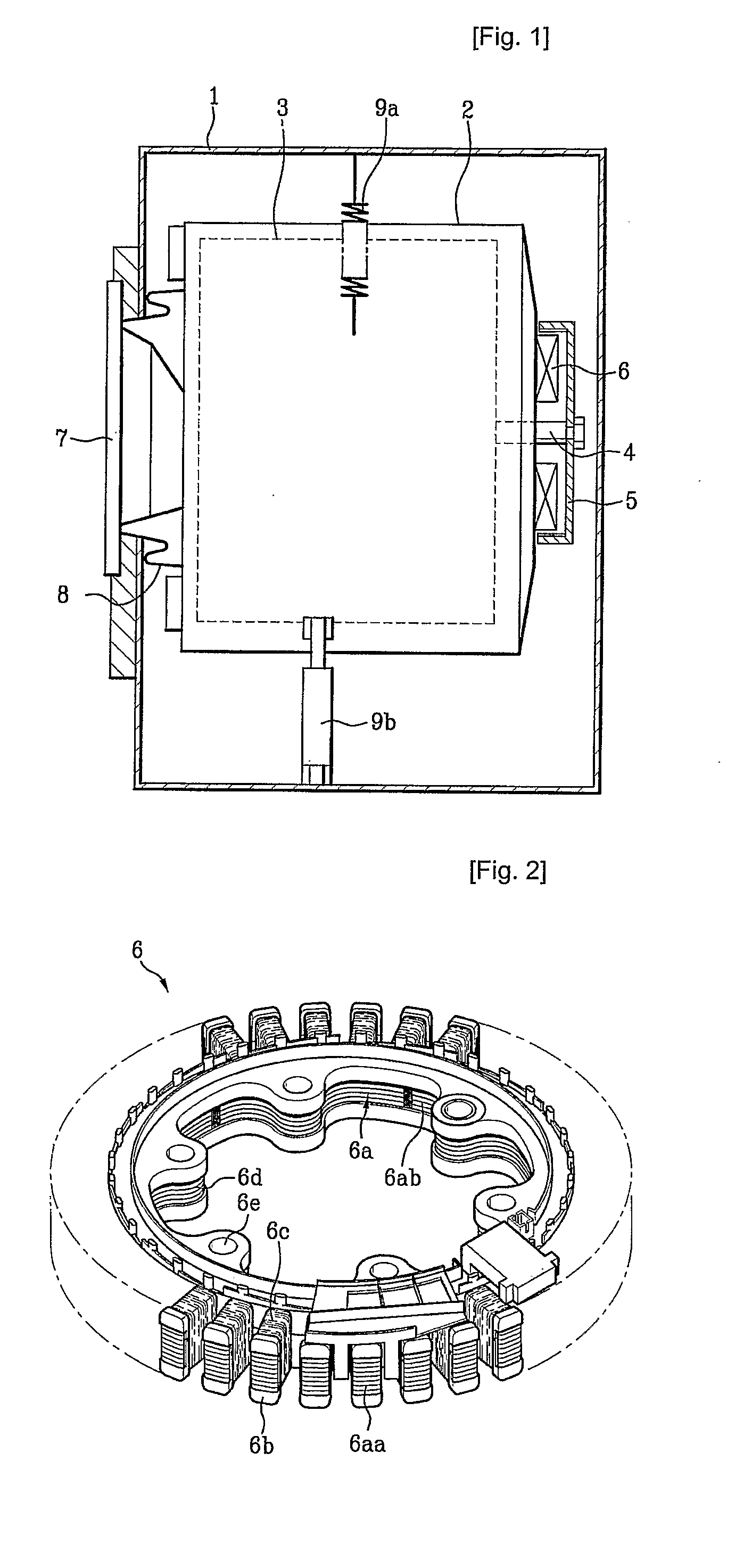

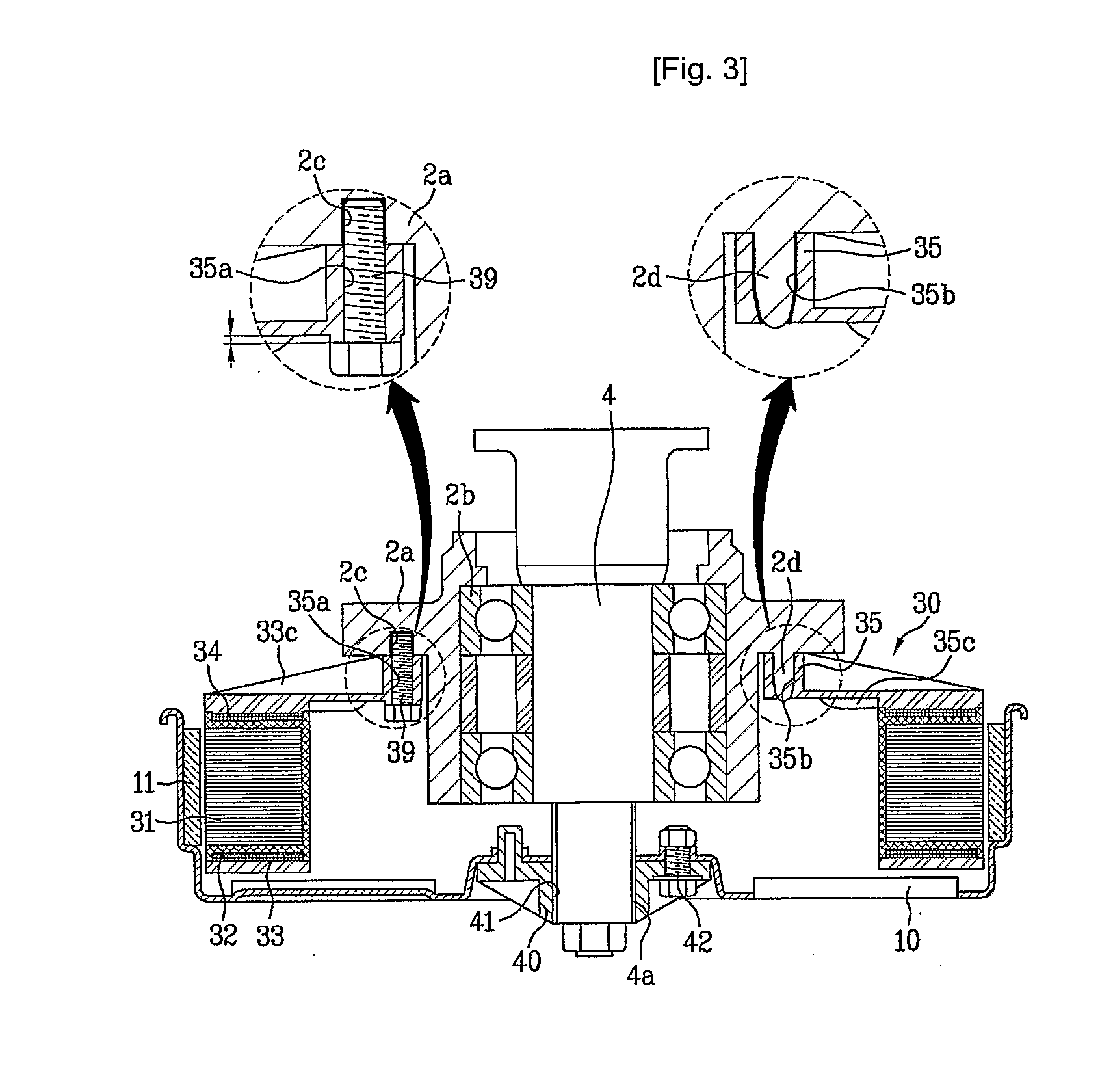

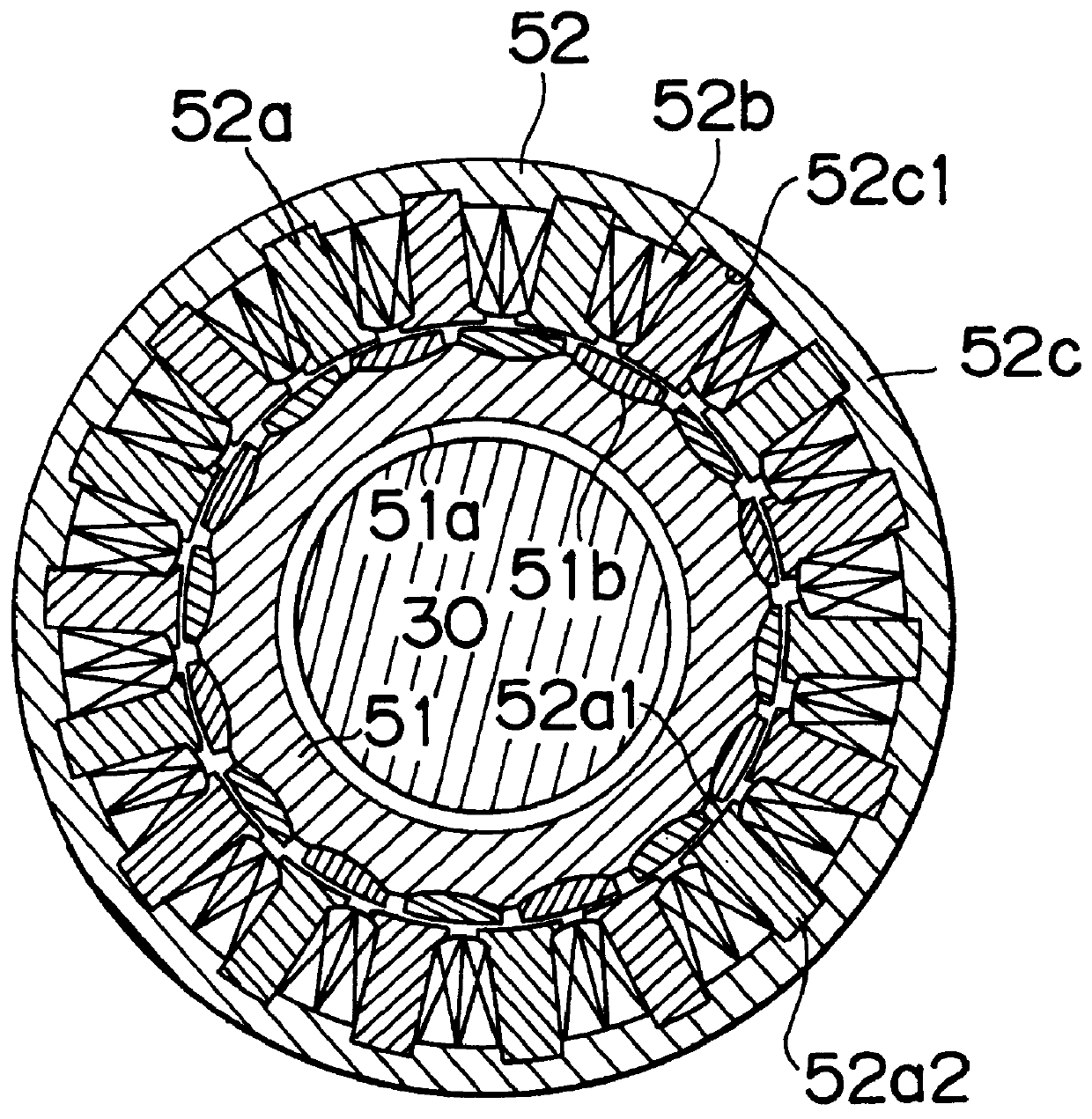

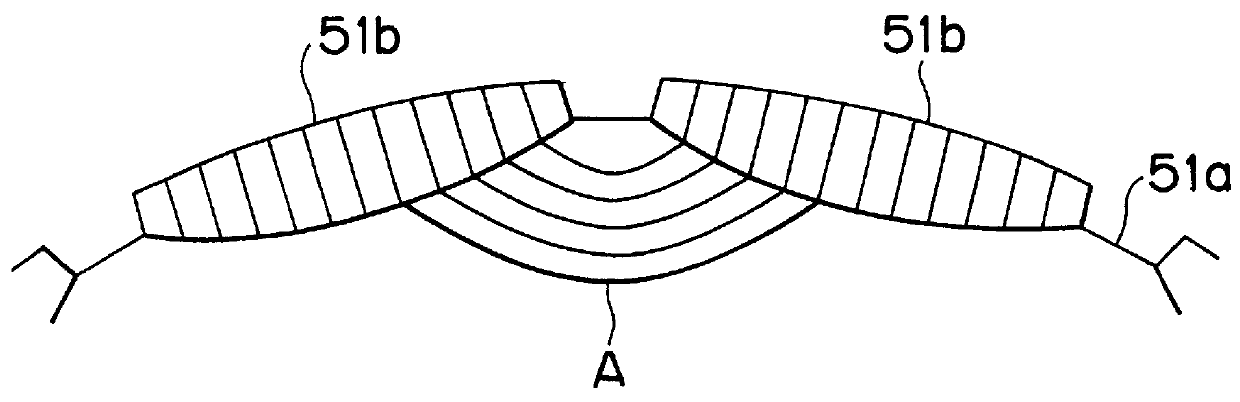

Brushless direct-current motor of radial core type having a structure of double rotors and method for making the same

InactiveUS6992419B2Improve productivityImprove shortcomingsWindingsMagnetic circuit rotating partsElectrical polarityEngineering

A radial core type double rotor brushless direct-current motor is provided in which a double rotor structure is employed with inner and outer rotors which are doubly disposed and thus a stator core is completely divided. The motor includes a rotational shaft which is rotatably mounted on a housing of an apparatus, cylindrical inner and outer yokes which are rotatably mounted on the center of the housing, inner and outer rotors including a number of magnets which are mounted with the opposing polarities on the outer surface of the inner yoke and the inner surface of the outer yoke, and a number of cores assemblies which are installed between the inner and outer rotors in which a number of coils are wound around a number of division type cores, respectively.

Owner:AMOTECH

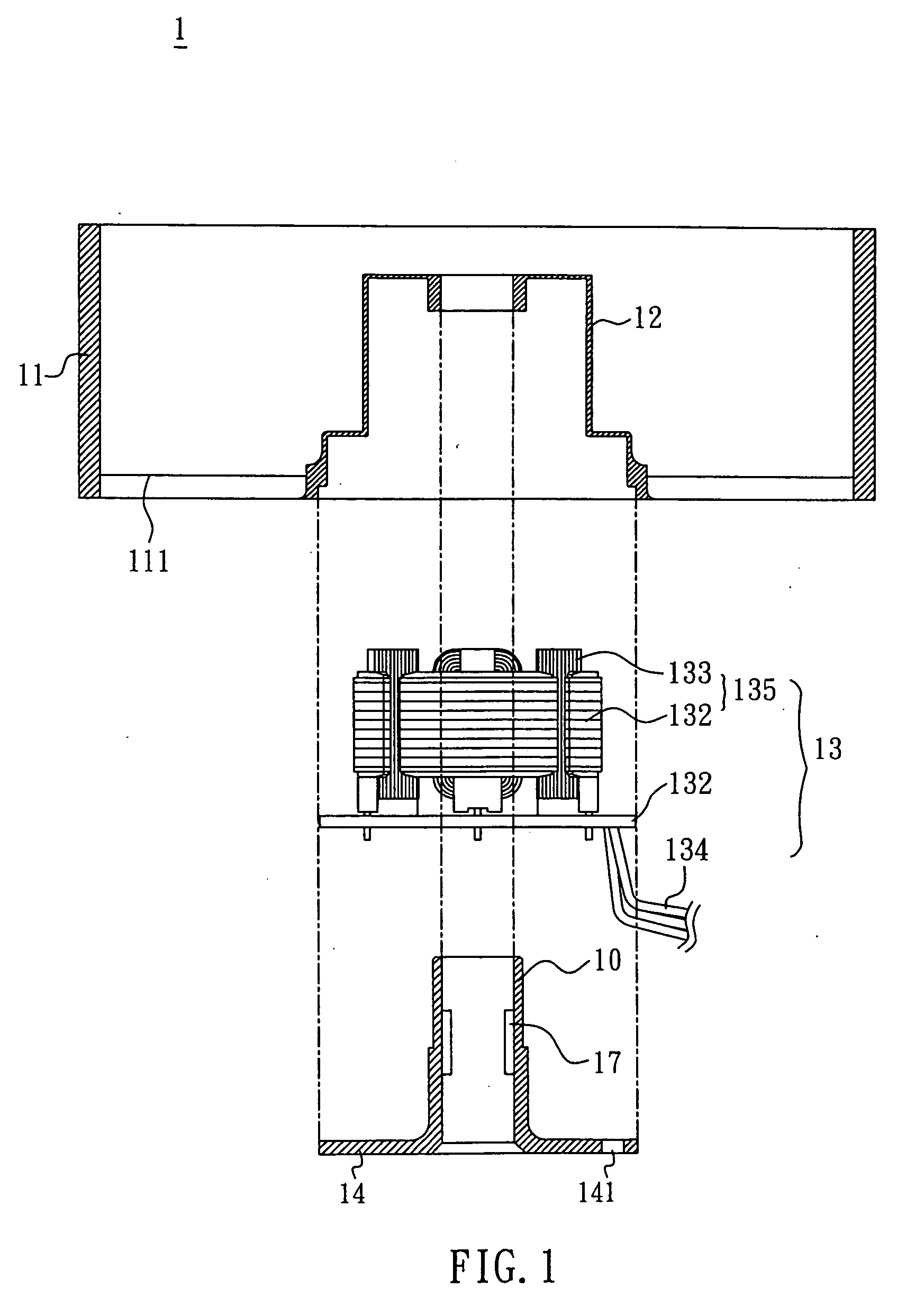

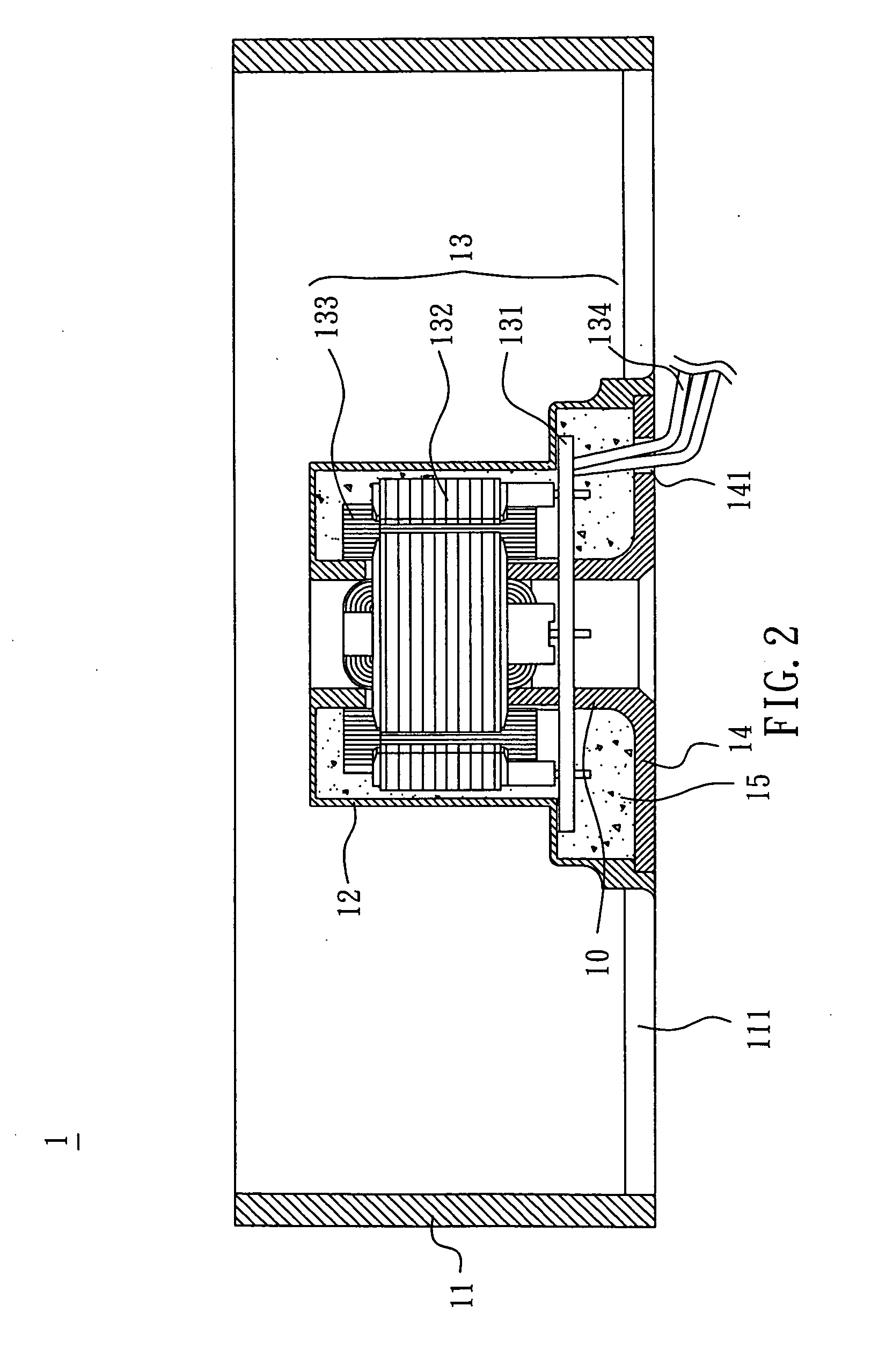

Fan and motor thereof

ActiveUS20070145842A1Low costImprove practicalityAssociation with control/drive circuitsPump componentsEngineeringElectric motor

Owner:DELTA ELECTRONICS INC

Molded motor

ActiveUS20080042499A1Hold steadyHigh strengthAssociation with grounding devicesMagnetic circuit characterised by insulating materialsEngineeringElectrically conductive

An inner rotor type molded motor controlled by pulse width modulation using an inverter circuit includes a pair of electrically conductive brackets attached to a load-side portion and an anti-load-side portion of a motor frame. An electrically conductive tape is attached on the outside of the motor frame to extend between the brackets, thereby short-circuiting the brackets to each other. In this manner, electrical erosion in the molded motor can be prevented.

Owner:NIDEC SHIBAURA CORP

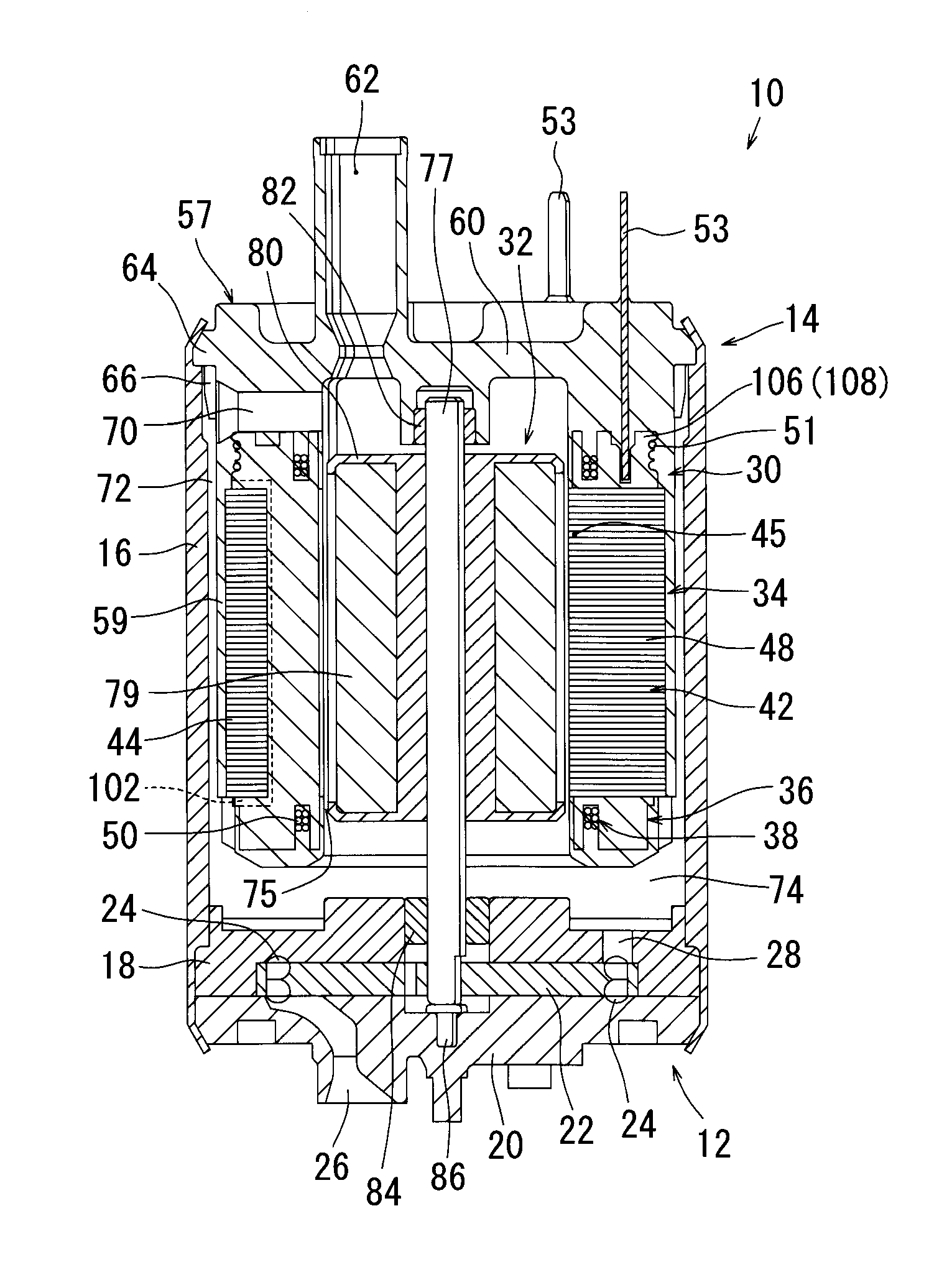

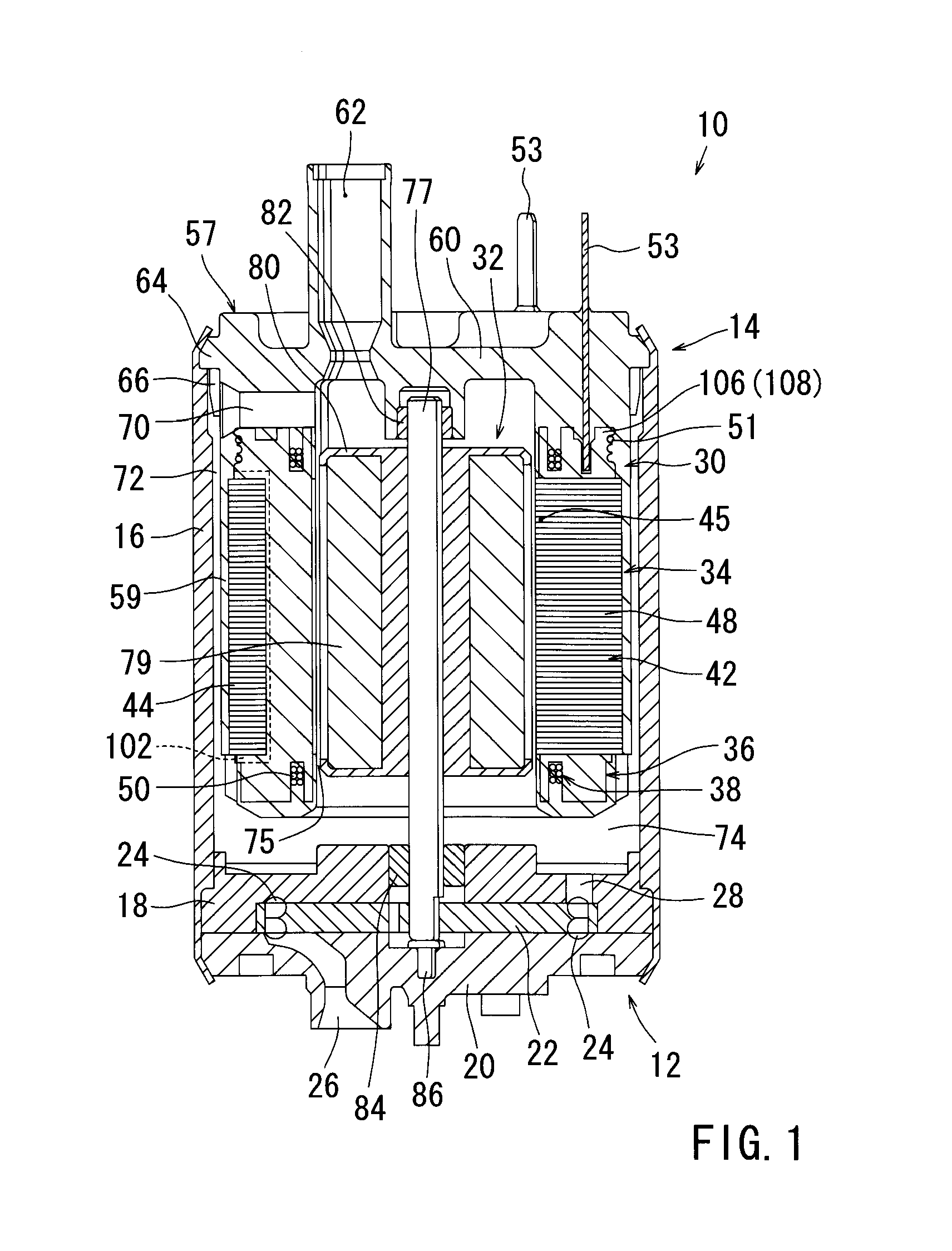

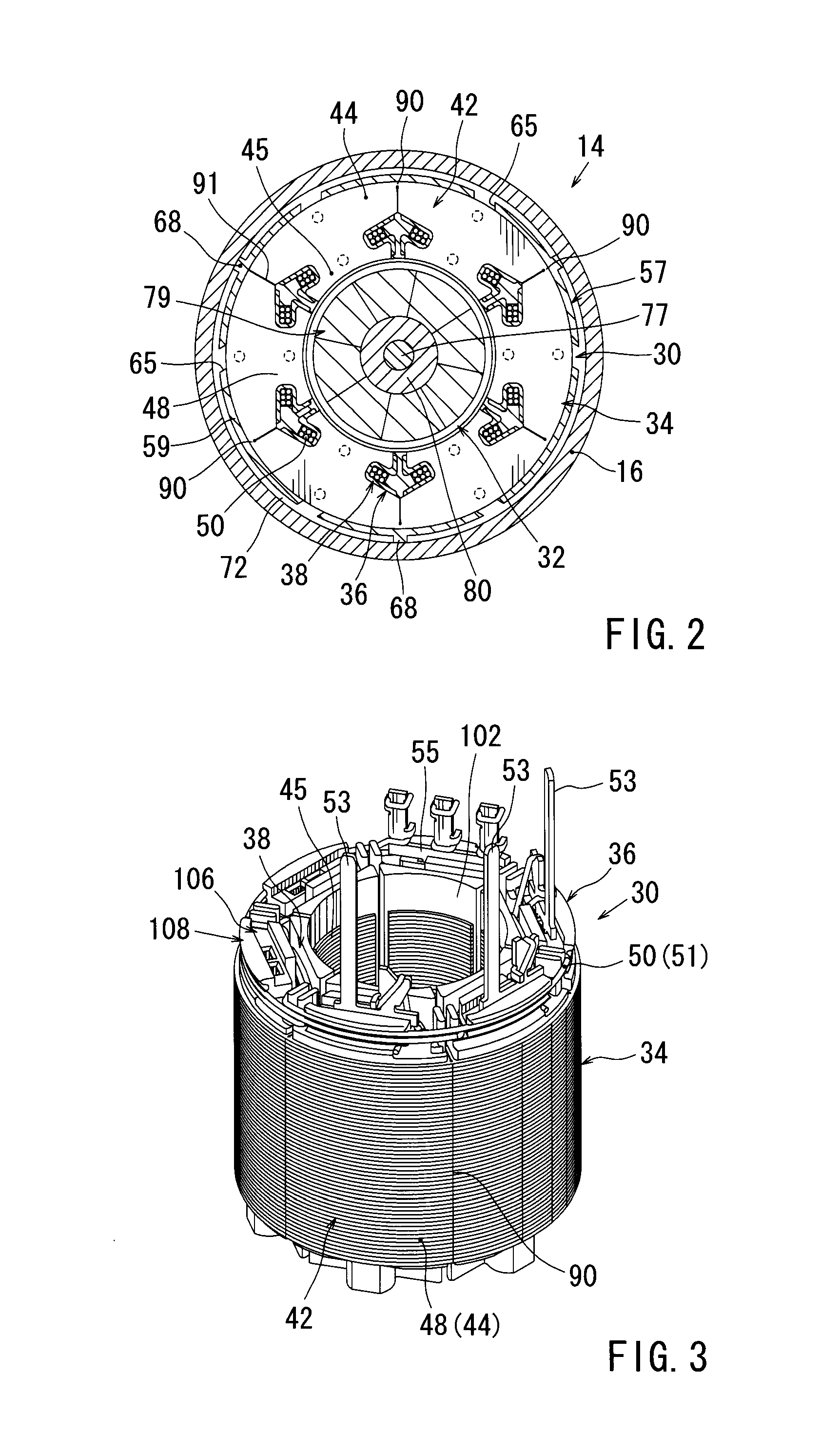

Rotating Electric Machine

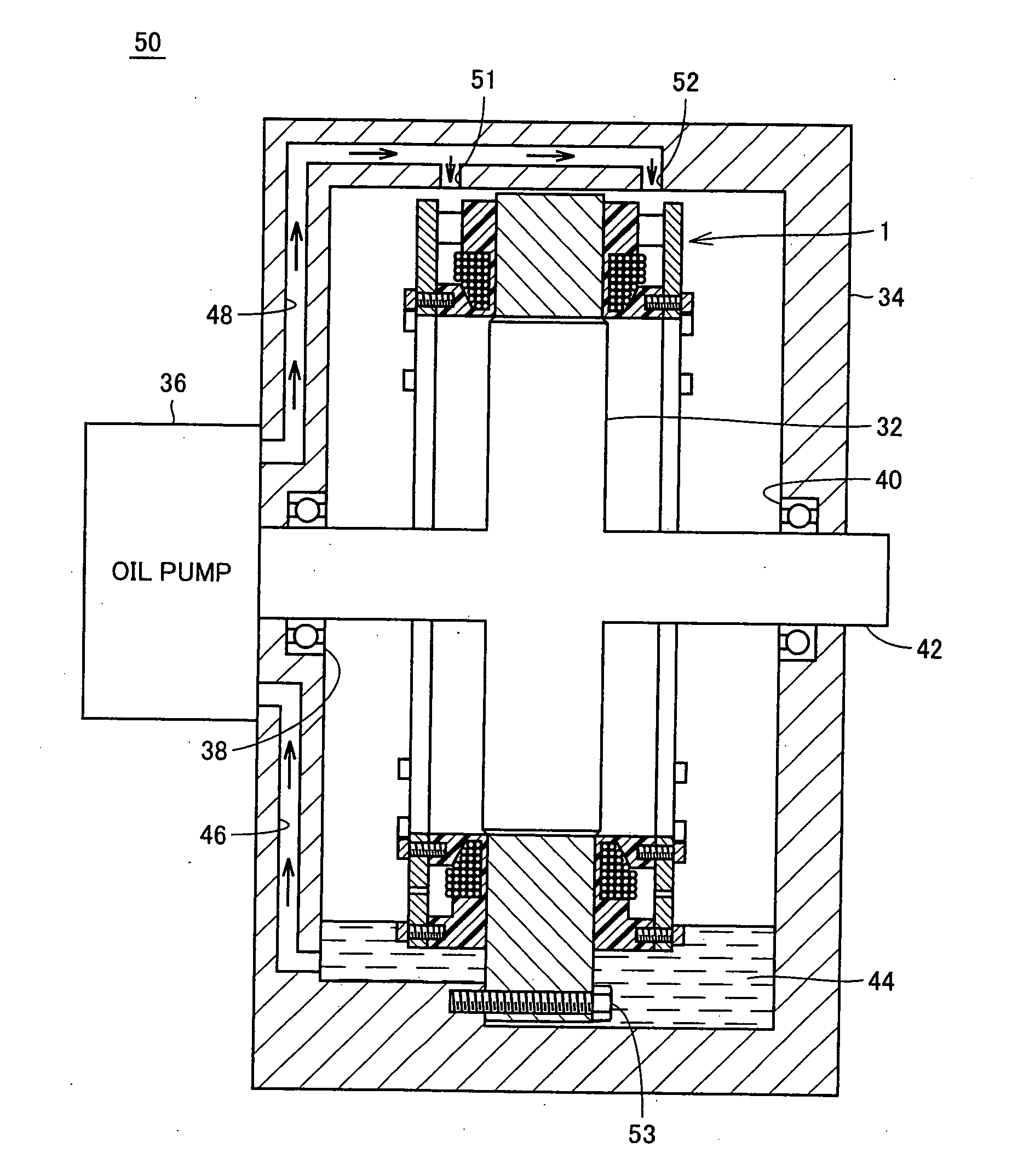

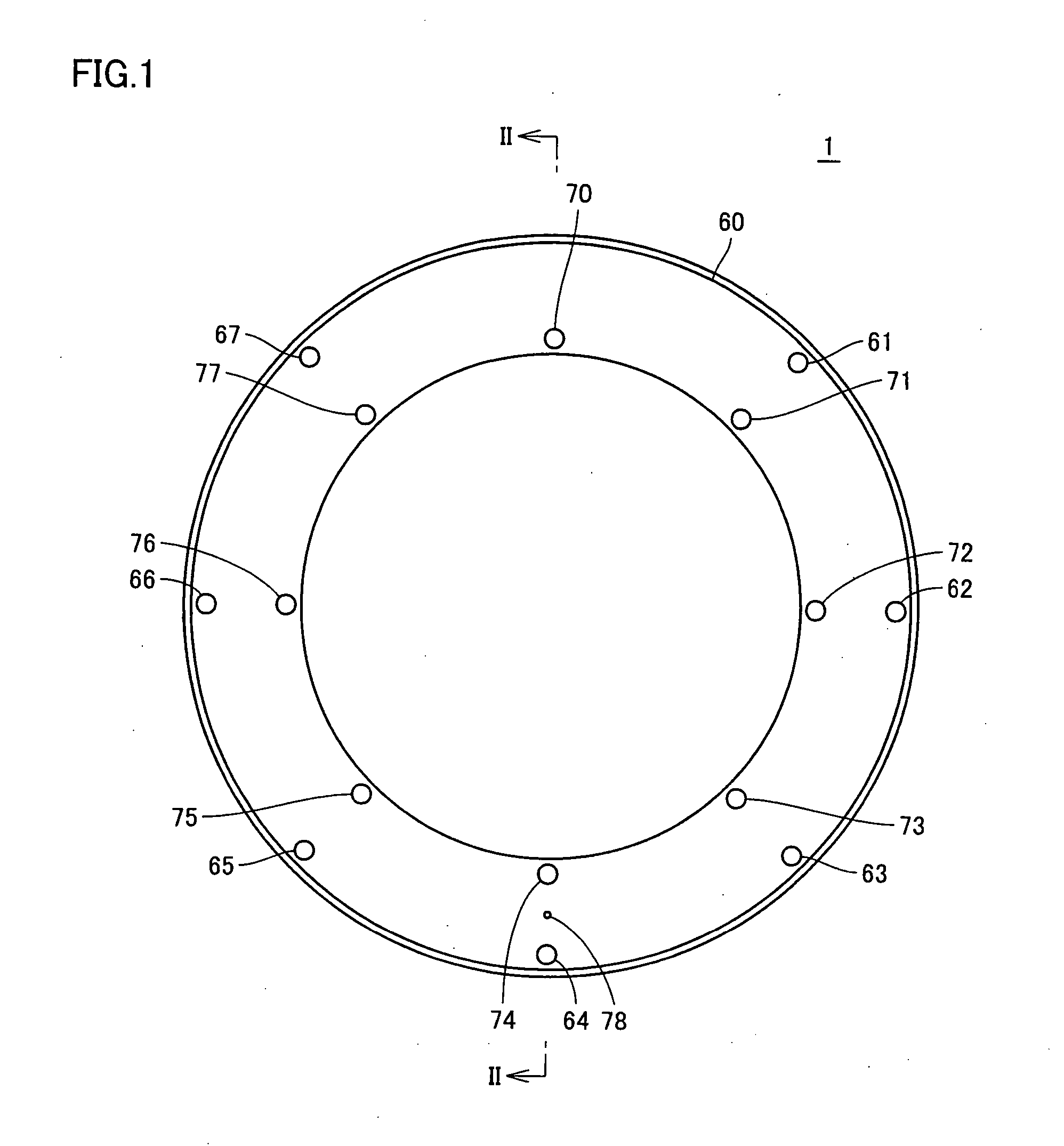

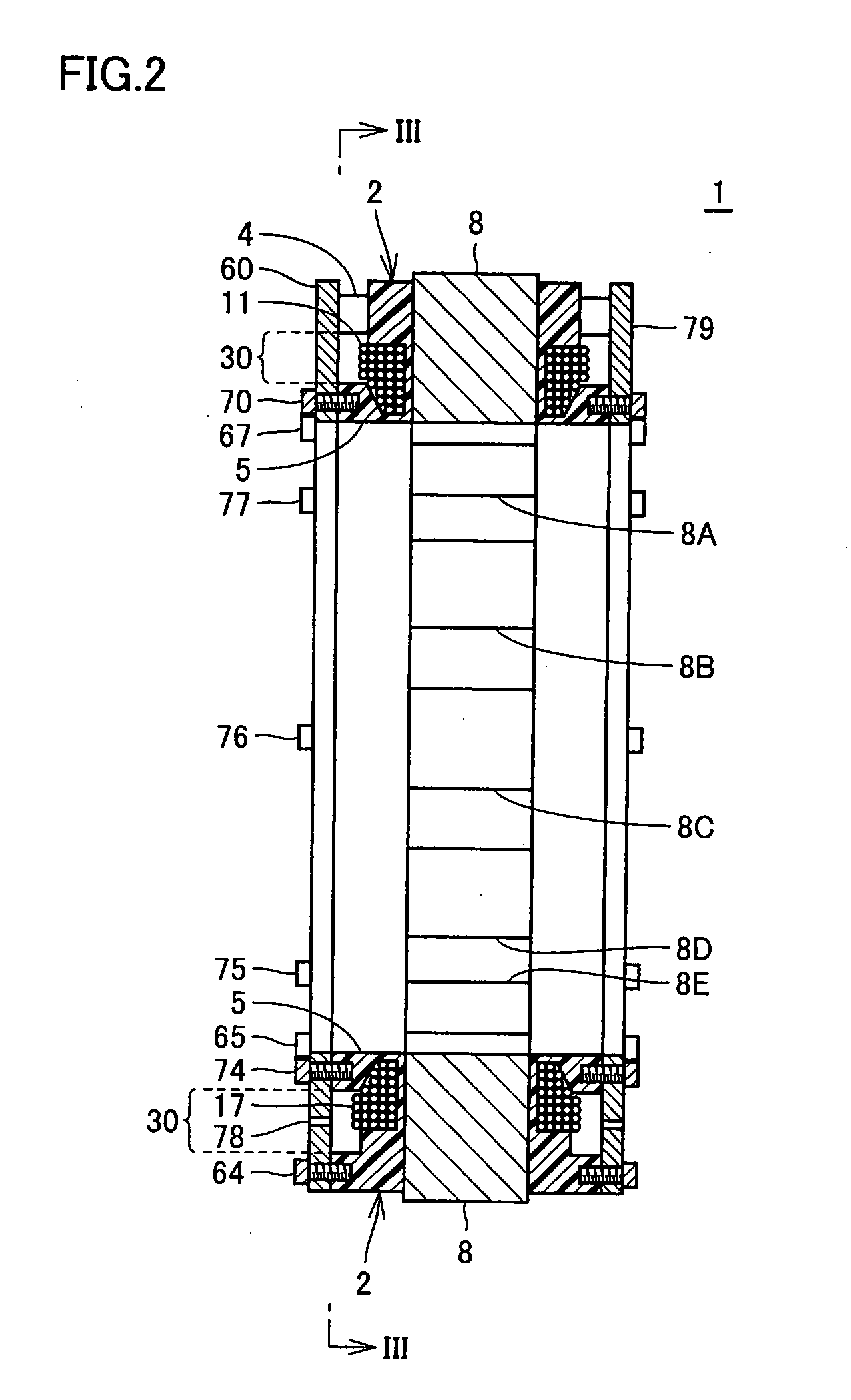

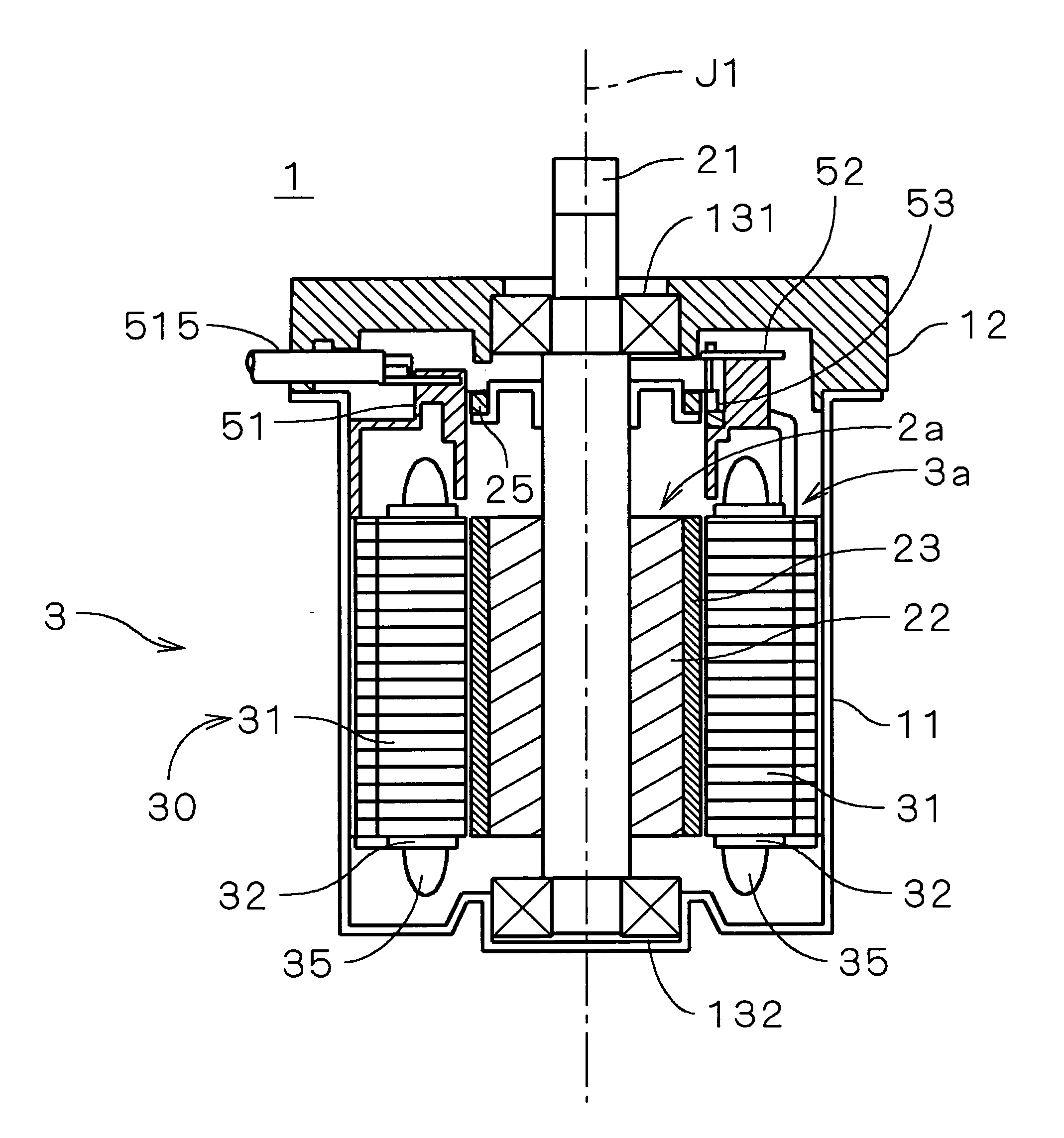

InactiveUS20070278869A1Improve cooling effectHeat resistantMagnetic circuit stationary partsMagnetic circuit characterised by insulating materialsElectric machineMechanical engineering

A rotating electric machine, comprising a stator, a rotor, a case storing the stator and the rotor, and an oil pump. Oil discharge ports are formed at the terminal part of an oil discharge passage of the case, and a cooling oil is supplied to the upper cutout parts of the stator. A groove part is covered by a cover to form a closed flow passage. Since the cooling oil is sufficiently applied to the portion of a coil exposed to the inside of the flow passage, a cooling efficiency is increased. Also the cooling oil is guided to an orifice on the lower side in the gravitational direction. Accordingly, since the cooling oil does not flow in an air gap between the rotor and the stator, a power loss can be prevented from occurring.

Owner:TOYOTA JIDOSHA KK

Motor and bus bar

ActiveUS20060068617A1Easy to fillWindingsManufacturing dynamo-electric machinesShell moldingEngineering

A bus bar secured to a stator in an electric motor in a preferred embodiment according to the invention includes four wiring boards, which are arranged perpendicularly to a center axis at intervals in a direction toward the center axis, and a resin portion for covering the surroundings of the four wiring boards by injection molding. Resin passing holes, through which a resin flows when the resin portion is molded, are formed at each of the wiring boards. When the bus bar is molded, the resin is injected into a resin molding die in a state in which the four wiring boards are supported by supporting pins disposed inside of the die. The resin flows to and fro between a space defined between the die and the wiring board and a space defined between the adjacent wiring boards.

Owner:NIDEC CORP

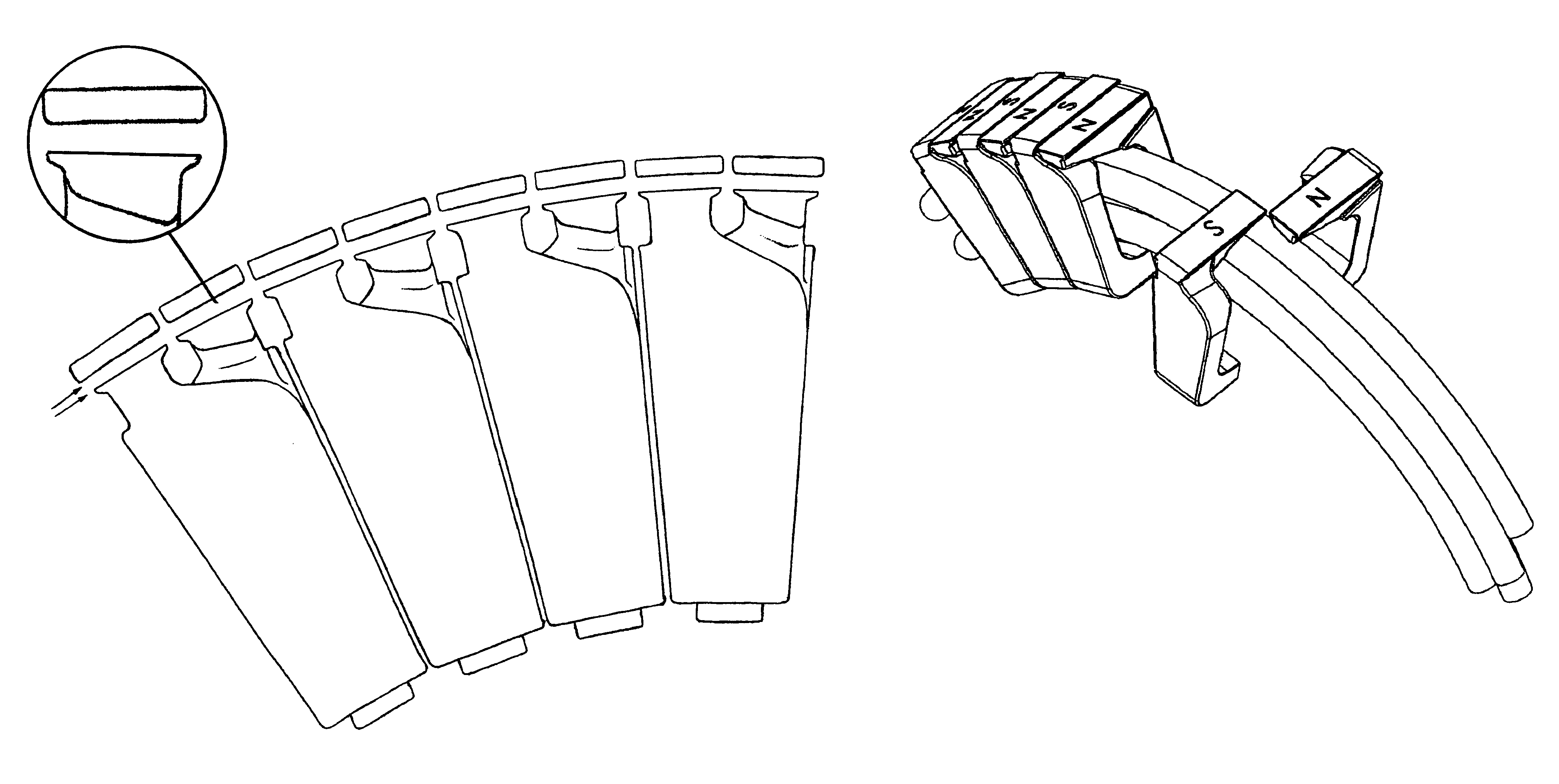

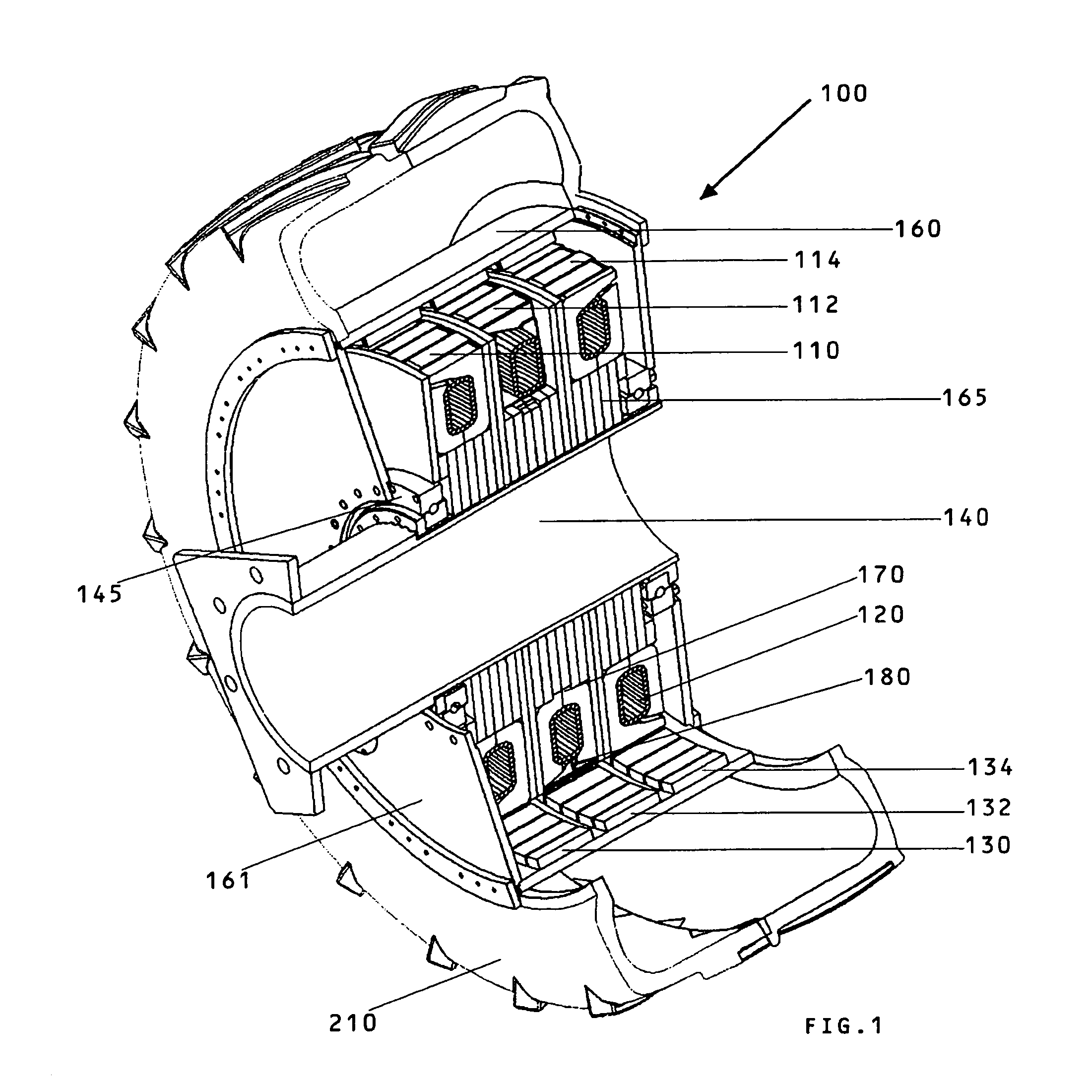

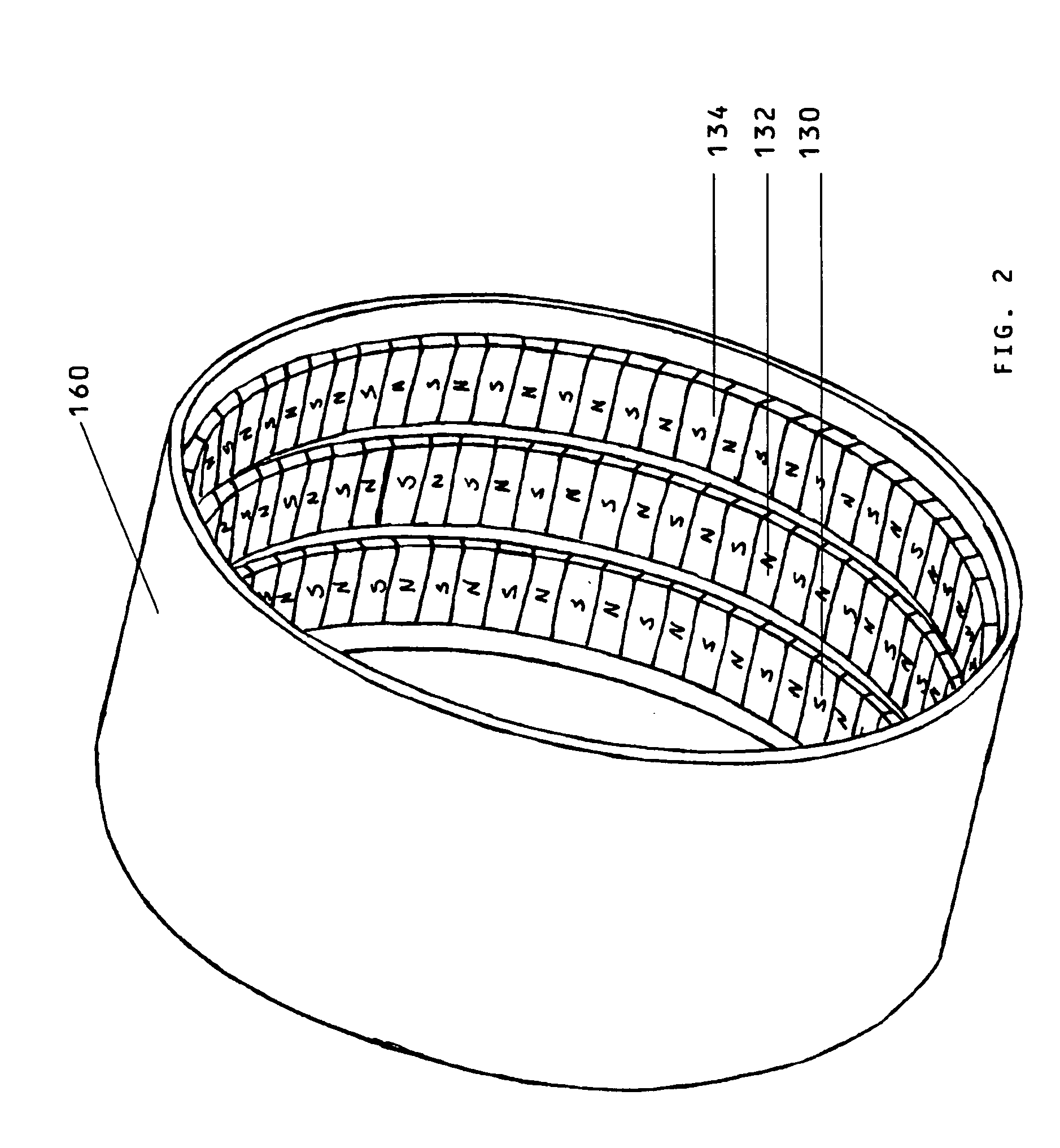

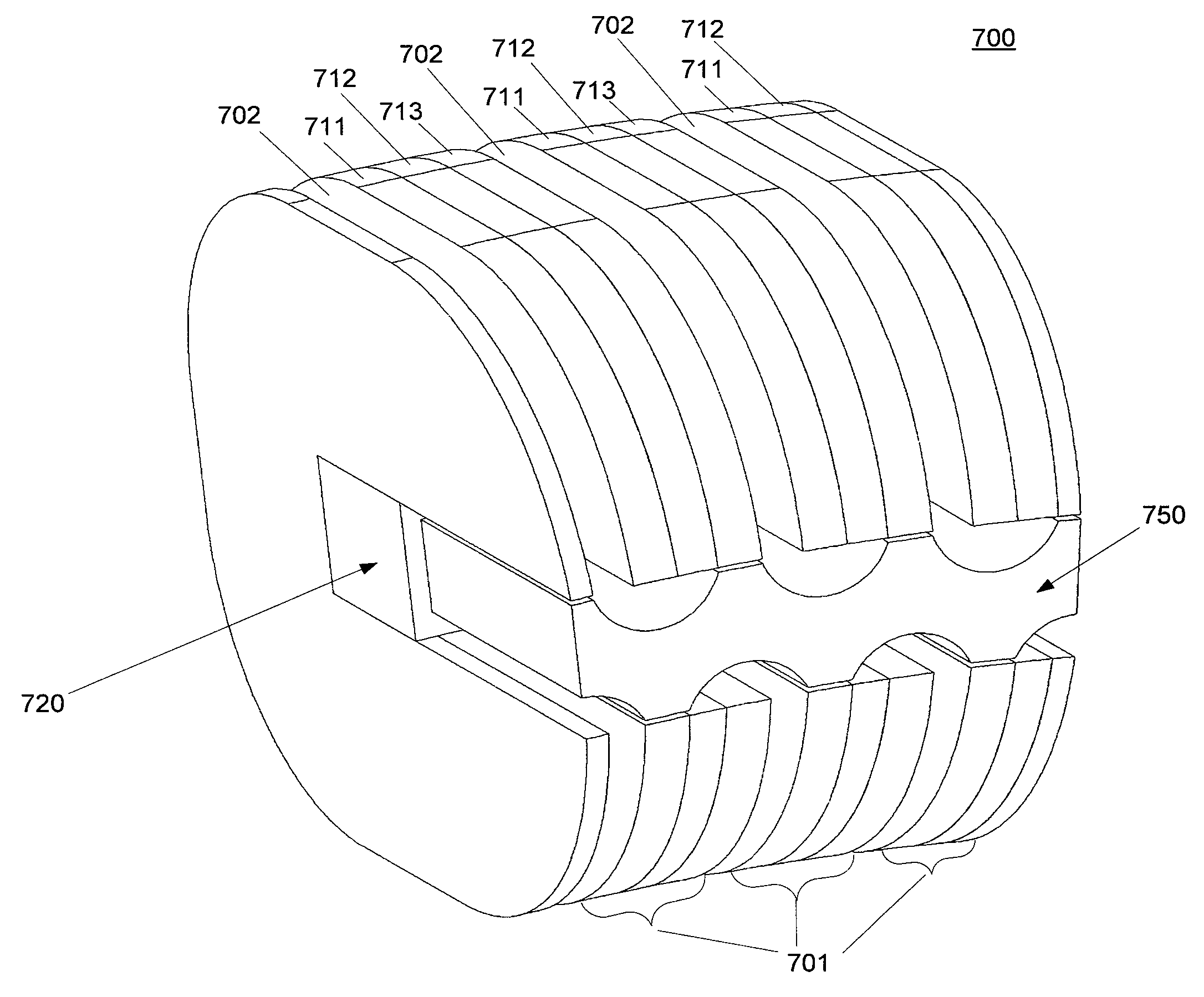

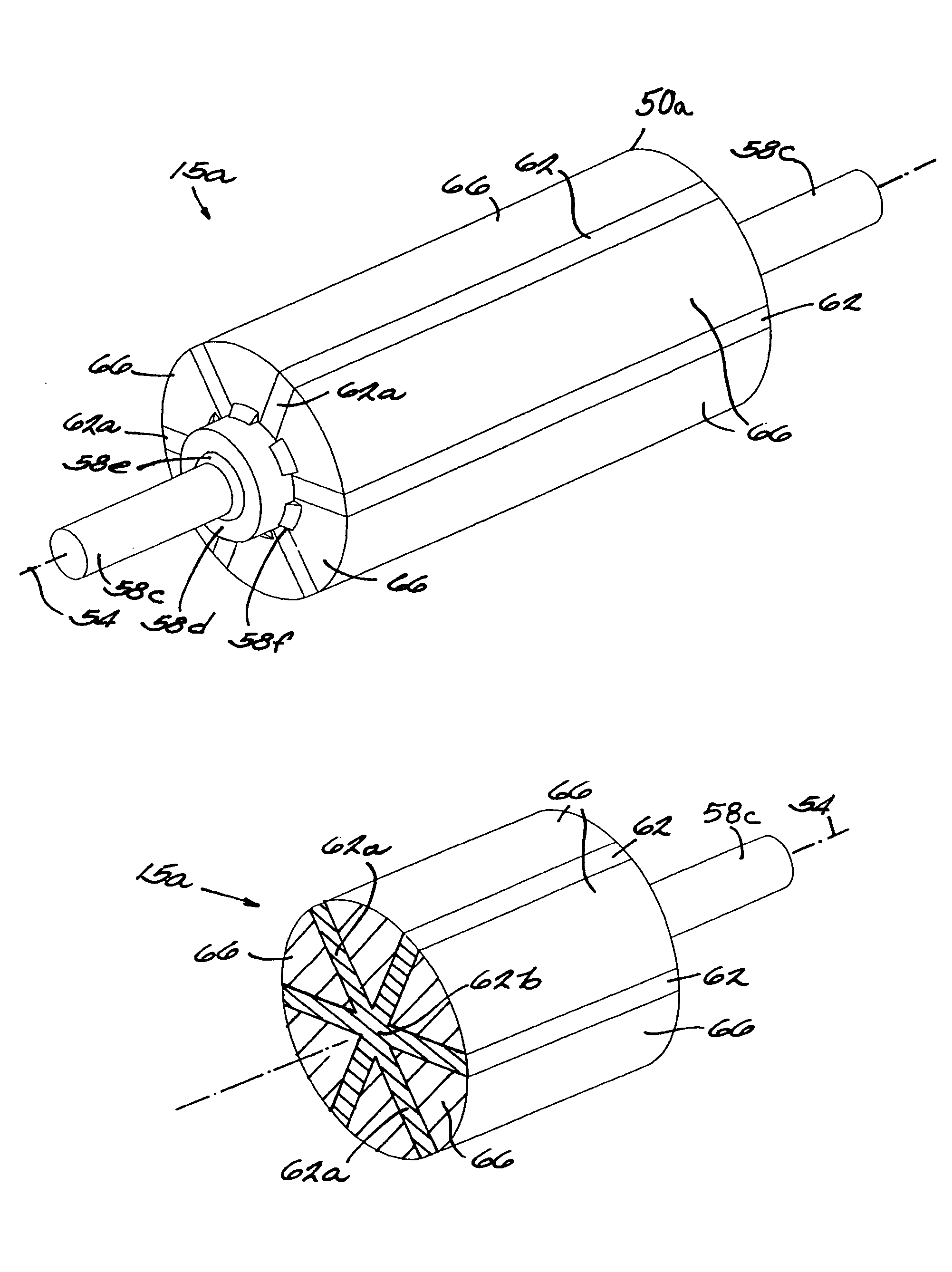

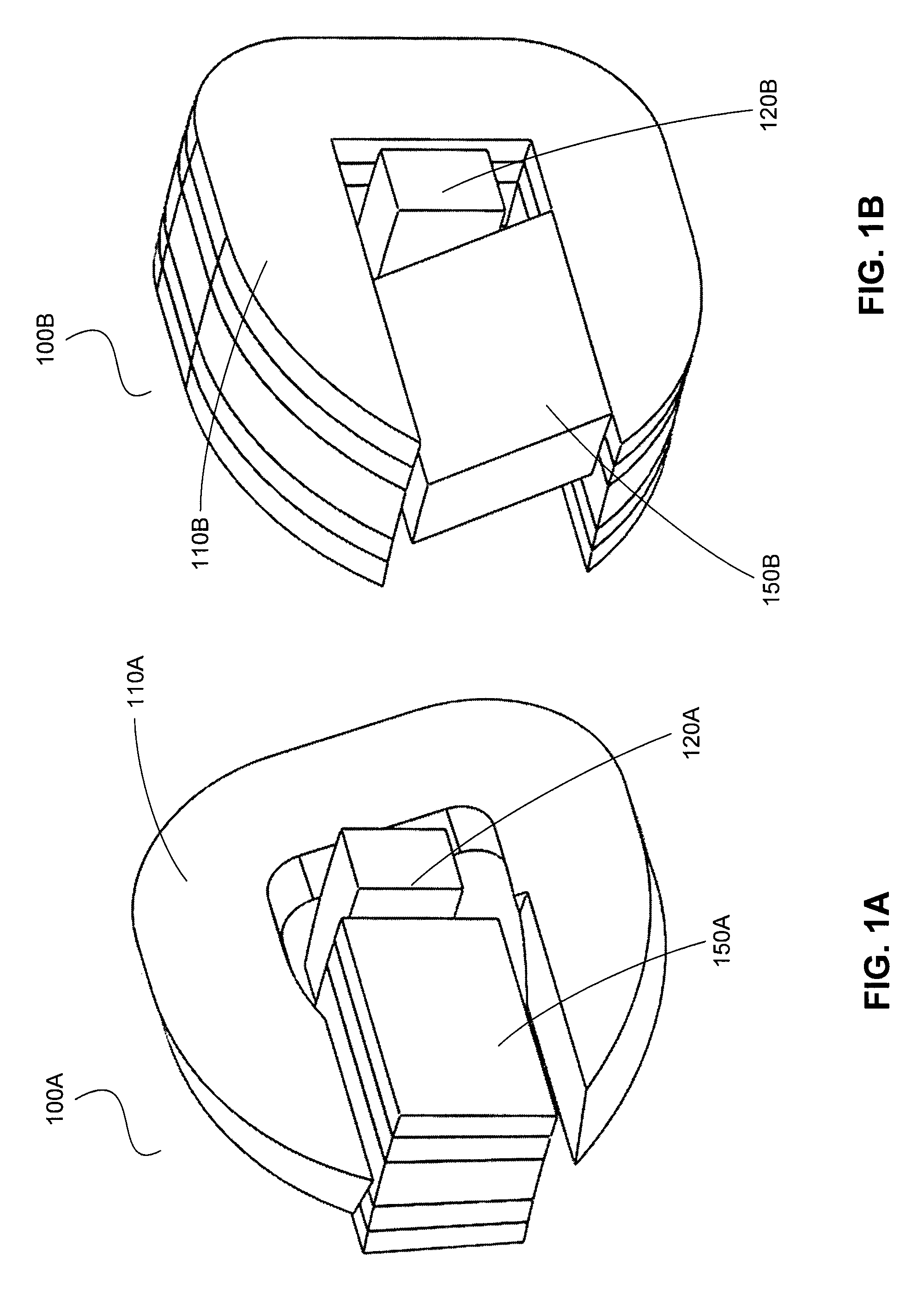

High-Efficiency Wheel-Motor Utilizing Molded Magnetic Flux Channels with Transverse-Flux Stator

InactiveUS20090322165A1Reducing hysteresis lossIncrease torqueMotor/generator/converter stoppersMotor control for very low speedsTransverse fluxEngineering

A motor including an outside rotor having a rotor disc with plural magnets alternating polarities flush mounted in the disc, an inside stator assembly with a ring of pole pieces forming a channel to house a transversely wound stator windings, and a controller coupled with feedback electronics for monitoring a timing, speed and direction and coupling a signal to a processing unit for adjusting the drive electronics driving the phase windings. A u-shaped gap above the channel to receive the rotor disc and focus the captured magnetic flux in the pole pieces toward the magnets. In an embodiment the molded magnetic flux channel pole pieces of the inside stator are sets of molded magnetic flux channel pole pieces, each set forming a channel and corresponding to one phase of the motor; and a section of each one of the transverse windings passing through one channel, the remaining section folding back outside the set in close proximity to the outer base of the set of molded magnetic flux channel pole pieces.

Owner:RITTENHOUSE NORMAN P

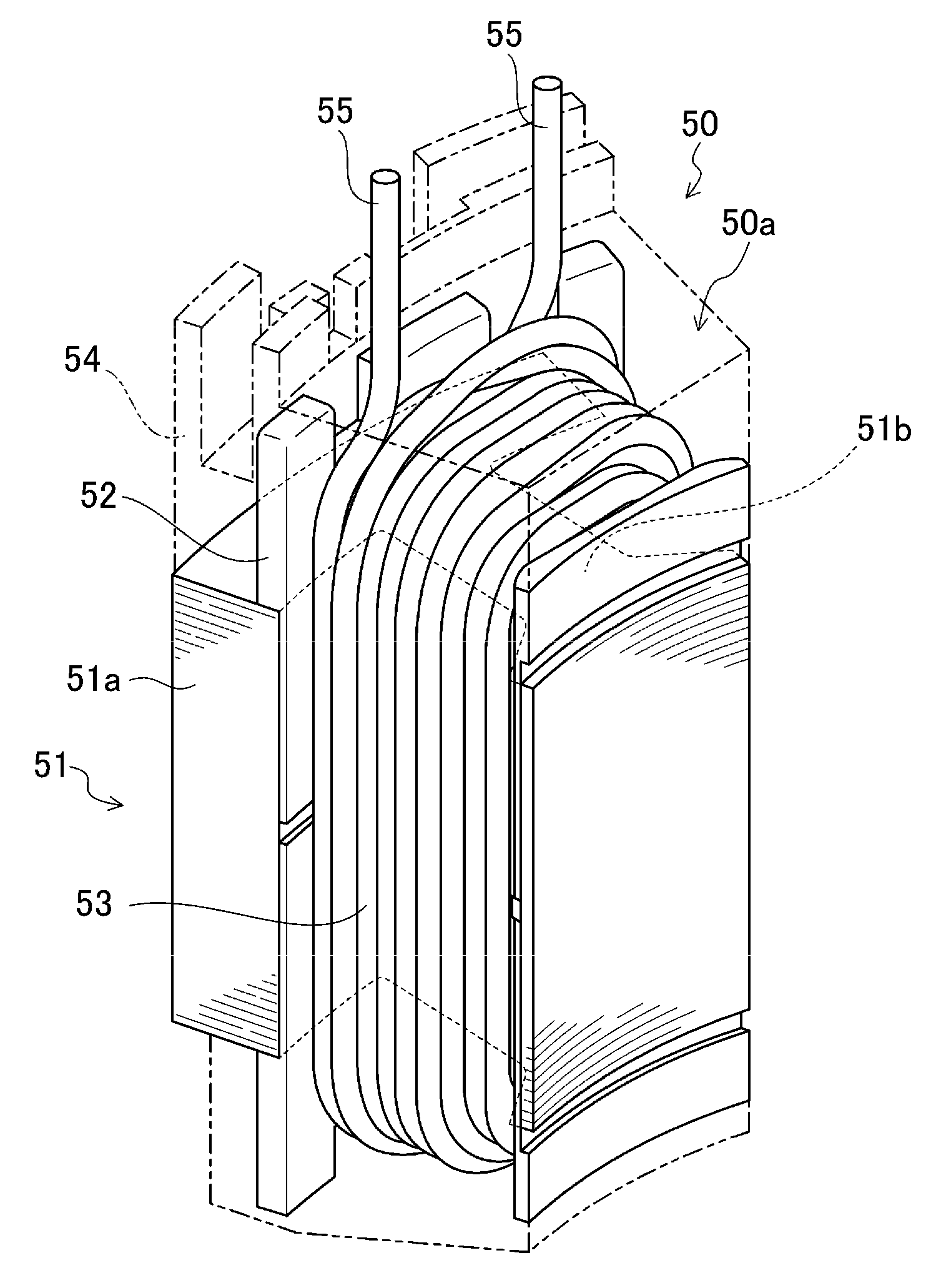

Stator and motor

InactiveUS20120286593A1Improve versatilityOverall small sizeWindings insulation shape/form/constructionManufacturing dynamo-electric machinesEngineeringElectrical and Electronics engineering

A stator is compatible with a variety of wiring configurations and possesses excellent versatility, while also preventing an increase in the size of a busbar unit. The stator includes a plurality of stator segments joined together to assume a cylindrical shape. Each stator segment includes a core segment including a core back portion and a tooth portion; a coil including a pair of coil wire terminals; an insulating layer arranged between the coil and the tooth portion; and a resin layer arranged to have the entire coil except for the coil wire terminals embedded therein. The resin layers of the stator segments include a supporting structure defined therein to allow a wiring member to be connected with any of the coil wire terminals to be attached to and removed from the stator.

Owner:NIPPON DENSAN CORP

AC generator for vehicles

An AC generator for a vehicle including a rotor with a fan, a stator disposed around the outer periphery of the rotor, and frame. The stator includes a laminated core having a plurality of slots, a plurality of electric conductors in the slots, and an insulator. There is a gap between the electric conductors and the insulator in a diametrical section of the slots, and an area ratio of the gap with respect to the sectional area of the slots is not more than 25%. A portion of the electric conductor positioned within the slot has a substantially rectangular shape along the shape of the slot.

Owner:DENSO CORP

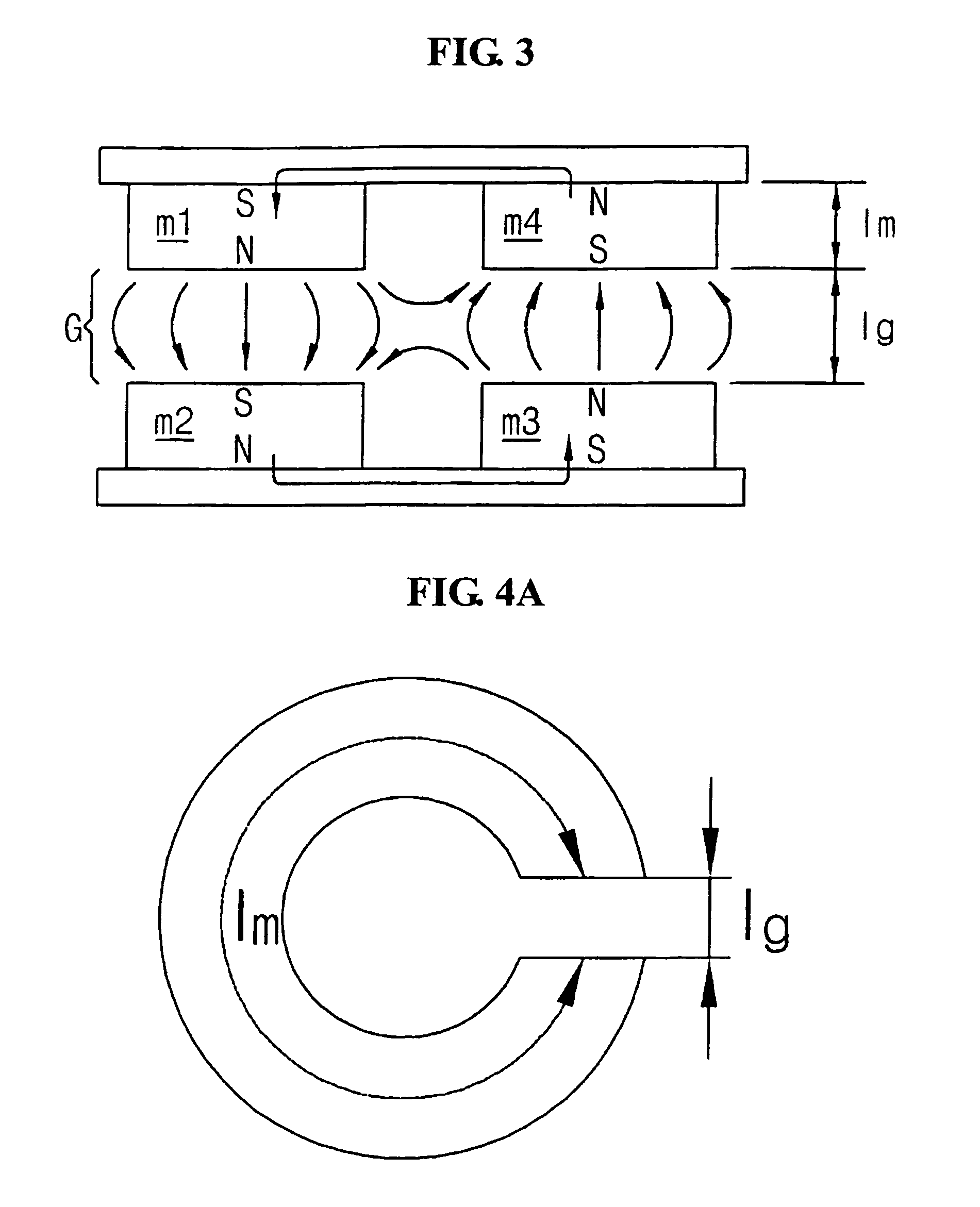

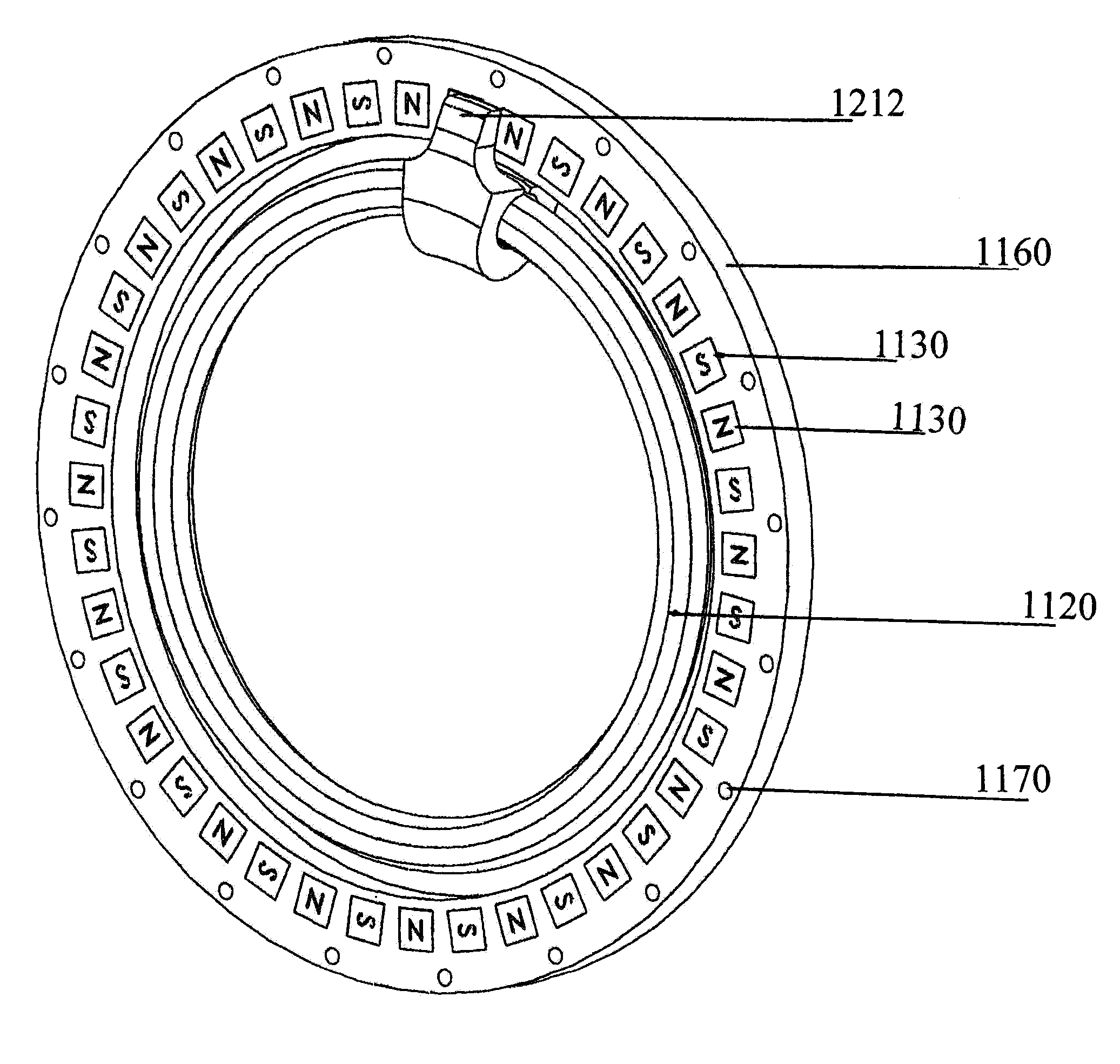

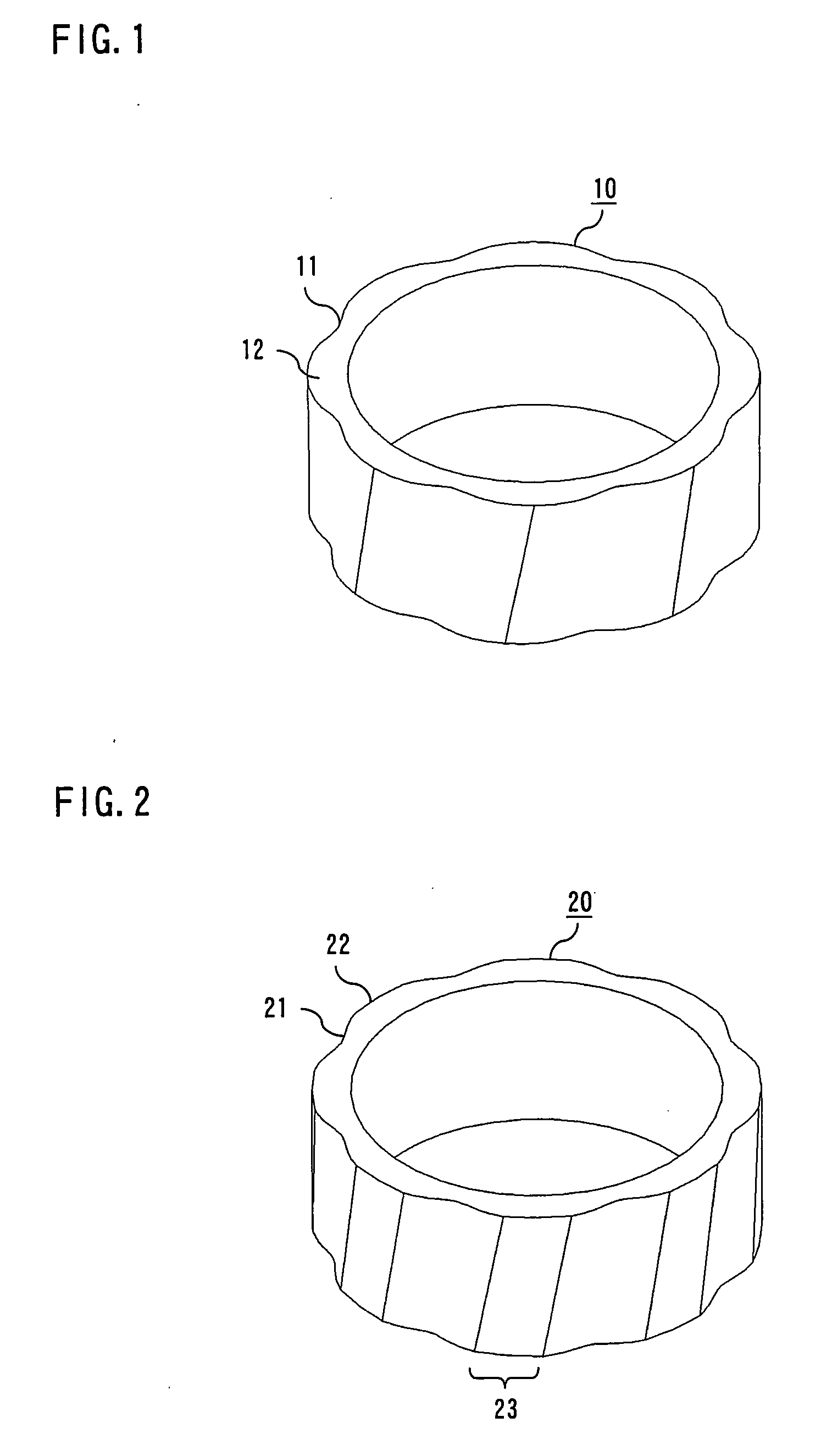

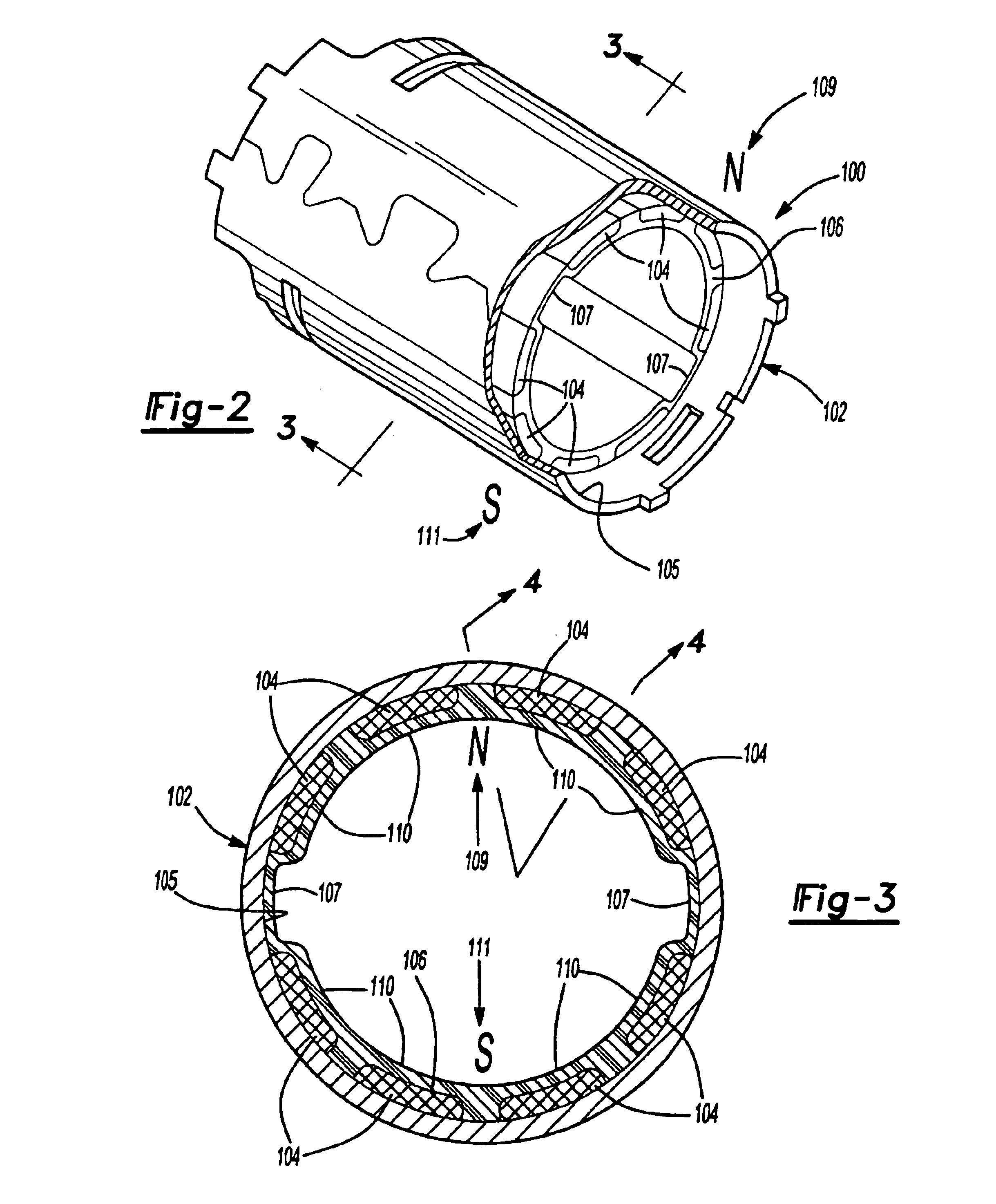

Sintered ring magnet

InactiveUS20060055266A1Reduce distortion problemsReducing cogging torqueMagnetic circuit rotating partsManufacturing dynamo-electric machinesMagnetic polesMaterials science

A sintered ring magnet (10) is produced through processes of magnetically orienting magnetic powder by applying a magnetic field, pressing the magnetic powder and sintering a ring-shaped powder compact (30) thus formed. The sintered ring magnet (10) has a generally cylindrical outer surface with surface corrugations formed by alternating hollows (11) and protrusions (12) at regular intervals around the sintered ring magnet (10) at least in part along an axial direction thereof, wherein the sintered ring magnet (10) varies in cross-sectional shape from one position to next along the axial direction, and magnetic poles are formed along the surface corrugations with boundaries of the magnetic poles located in the hollows (11). The hollows (11) and the protrusions (12) are skewed about a longitudinal axis of the sintered ring magnet (10). The surface corrugations are shaped into a wavy pattern expressed approximately by absolute values of a sine wave.

Owner:MITSUBISHI ELECTRIC CORP

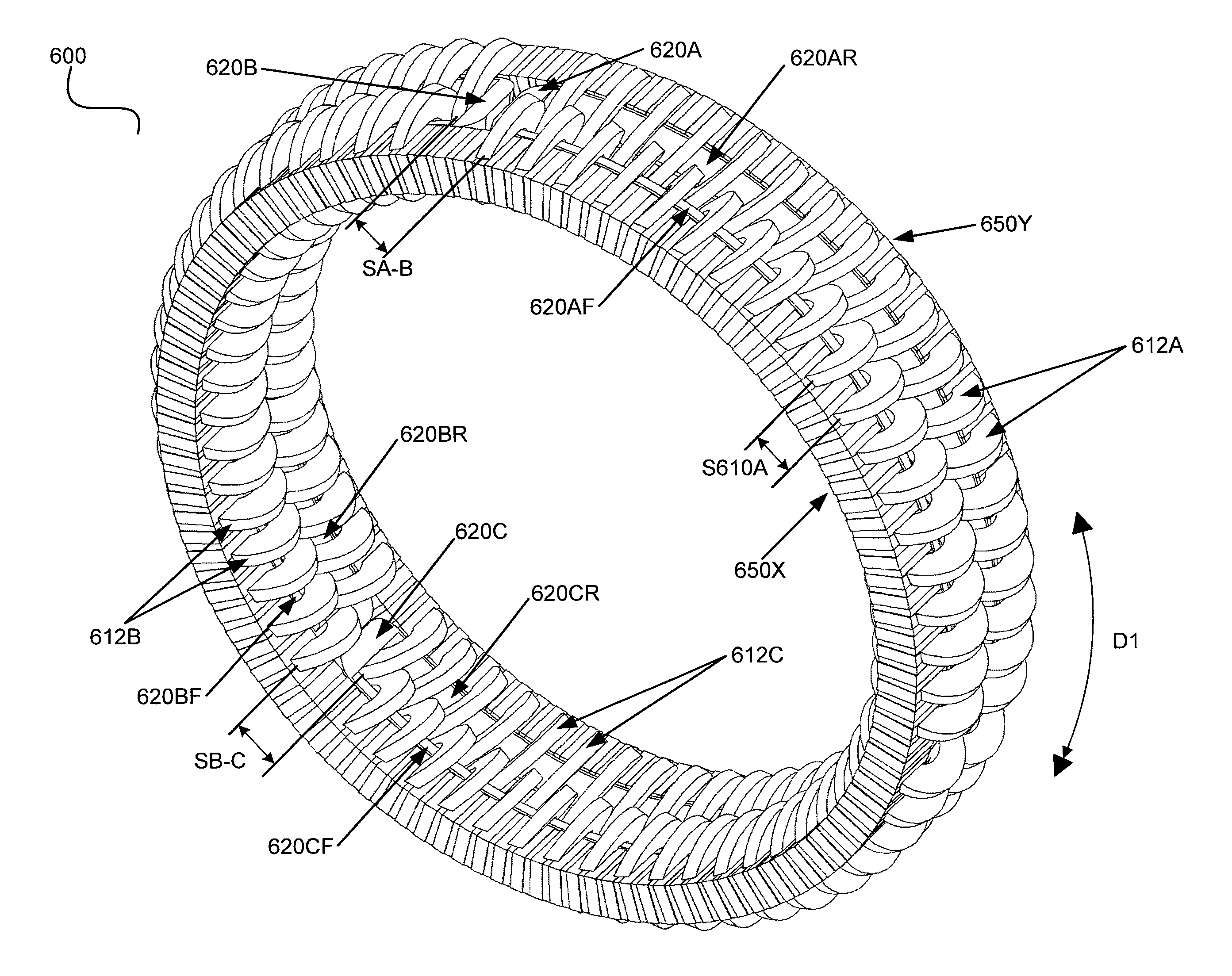

Transverse and/or commutated flux system stator concepts

Disclosed are transverse and / or commutated flux machines and components thereof, and methods of making and using the same. Certain exemplary stators for use in transverse and commutated flux machines may be configured with gaps therebetween, for example in order to counteract tolerance stackup. Other exemplary stators may be configured as partial stators having a limited number of magnets and / or flux concentrators thereon. Partial stators may facilitate ease of assembly and / or use with various rotors. Additionally, exemplary floating stators can allow a transverse and / or commutated flux machine to utilize an air gap independent of the diameter of a rotor. Via use of such exemplary stators, transverse and / or commutated flux machines can achieve improved performance, efficiency, and / or be sized or otherwise configured for various applications.

Owner:ELECTRIC TORQUE MASCH INC

Motorized equipment

ActiveUS20110254388A1Small body sizeCommonly usedAssociation with control/drive circuitsMagnetic circuit rotating partsDriving currentBody size

A power module, a control board and a heat sink are provided on one axial side of a shaft of an electric motor, which consists of a motor case, a stator, a rotor, the shaft and the like. The power module is electrically connected with extraction lines, which extend from a coil wound around the stator, and supplies a drive current to the coil. The control board for controlling switching of the power module is provided on a motor case side of the power module. The heat sink is provided on a side of the control board opposite to the motor case. Thus, when setting of an output of the electric motor is changed, a body size of the heat sink can be changed without changing a positional relationship between the control board and the electric motor and a positional relationship between the power module and the electric motor.

Owner:DENSO CORP

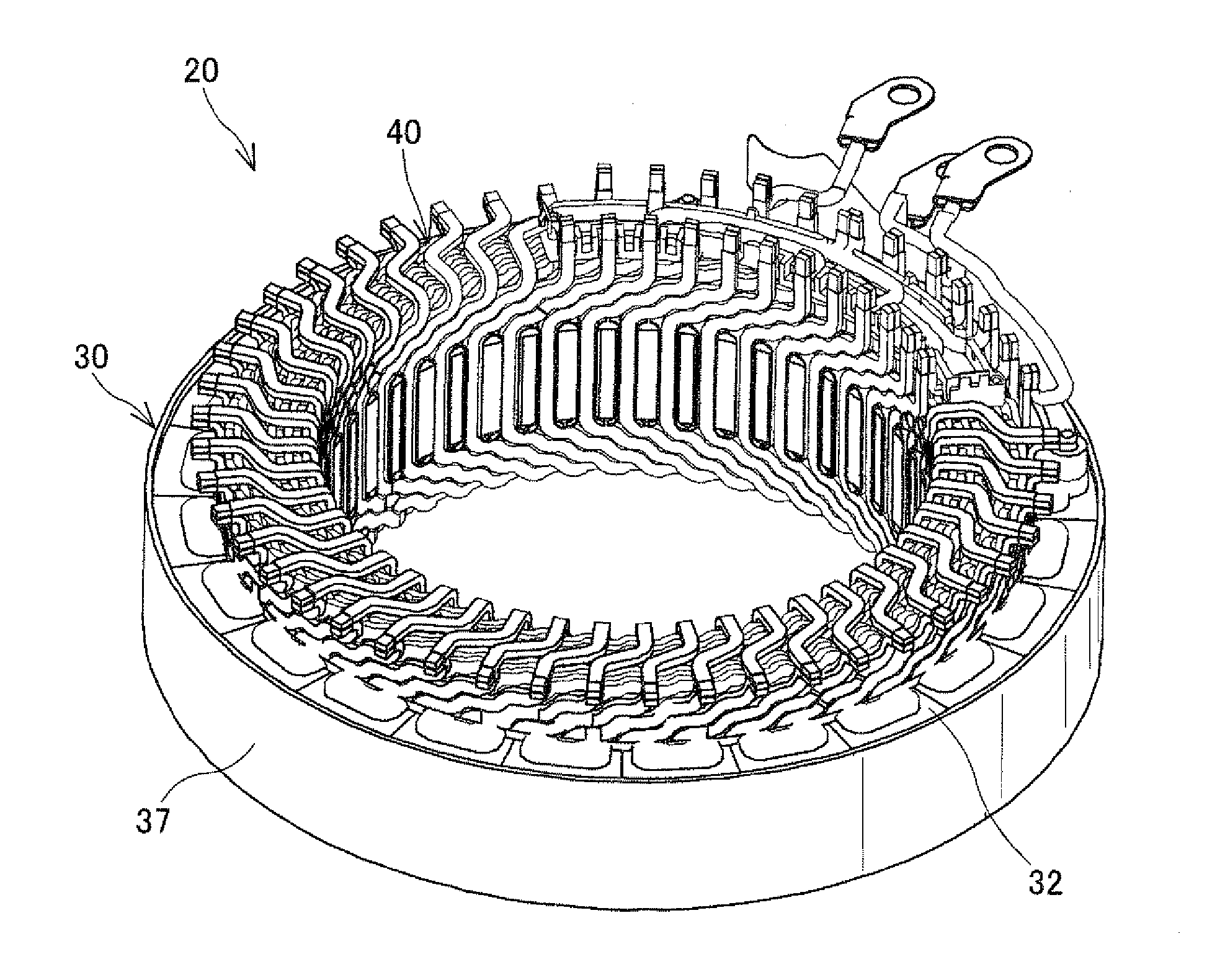

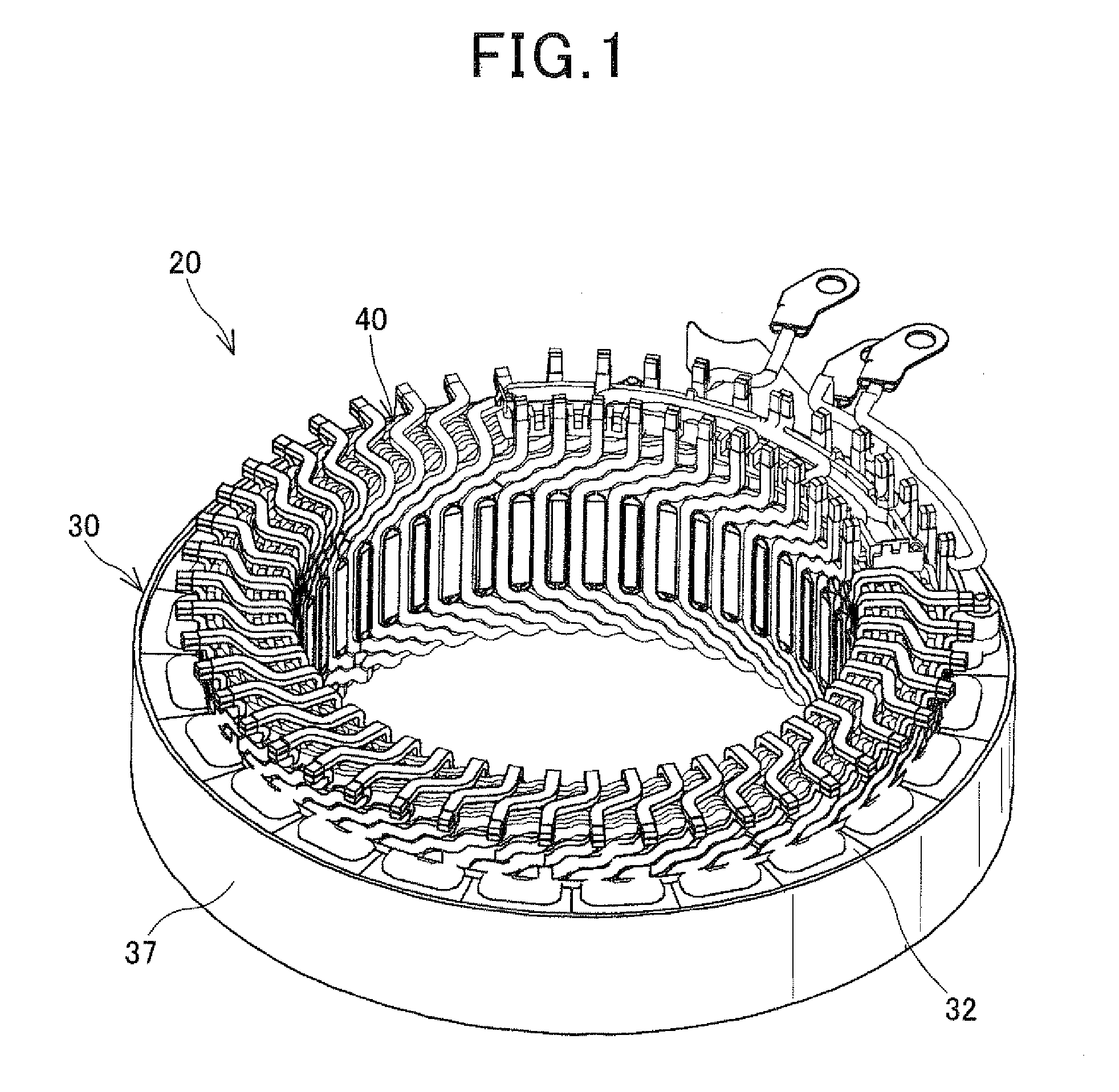

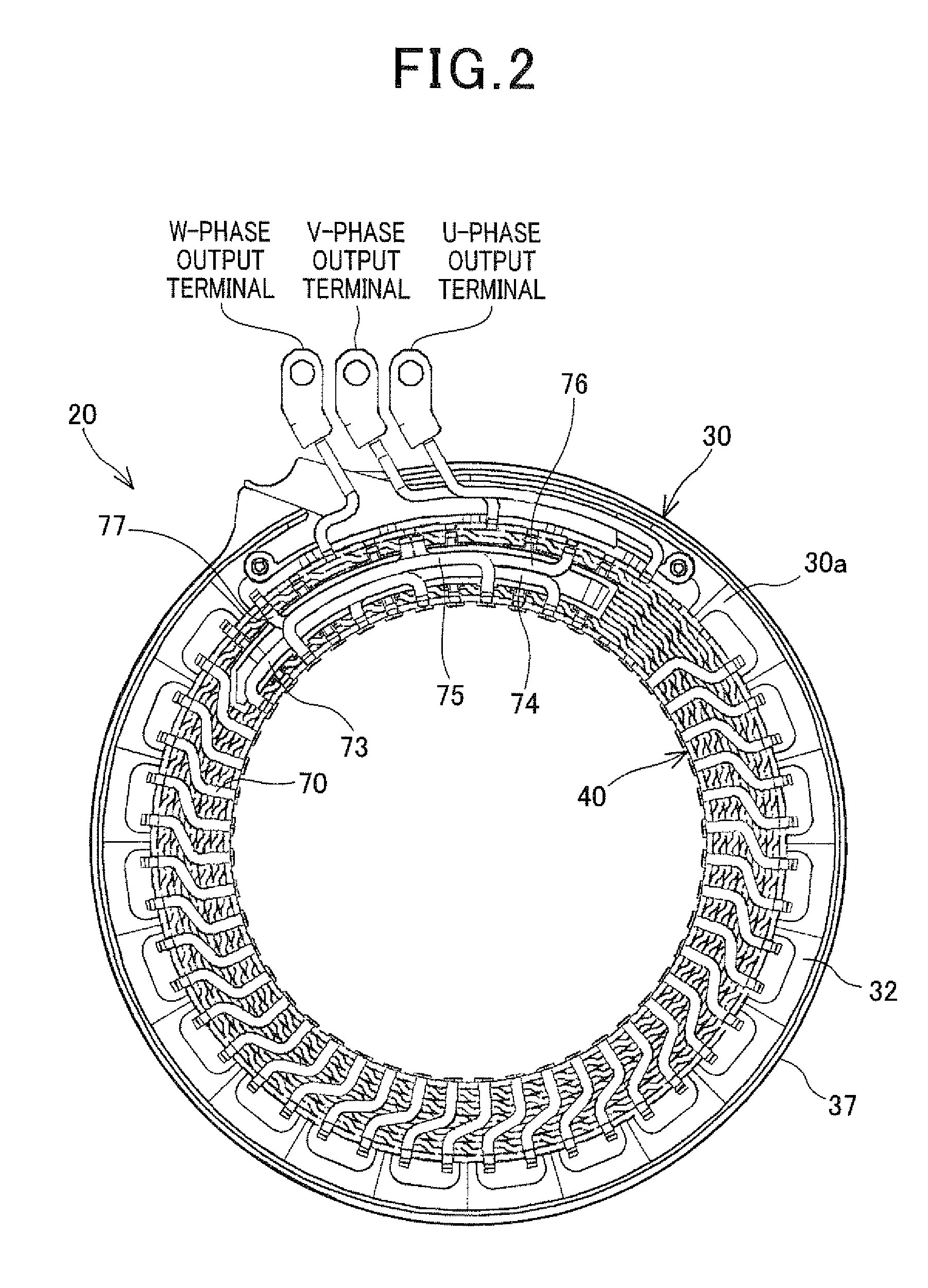

Stator for electric rotating machine

InactiveUS20120019081A1Avoid displacementImprove insulation performanceWindings insulation materialManufacturing dynamo-electric machinesElectric machineStator coil

A stator includes an annular stator core and a stator coil. The stator coil is formed of a plurality of electric wires mounted on the stator core. The stator coil has a coil end part that protrudes from an axial end face of the stator core so as to be located outside slots of the stator core. The electric wires forming the stator coil are grouped into a plurality of electric wire sets. Each of the electric wire sets consists of a predetermined number of the electric wires which are electrically connected to one another. The stator coil further includes a plurality of bridging wires. Each of the bridging wires extends, on an axially outer periphery of the coil end part of the stator coil, to electrically connect a corresponding pair of the electric wire sets. Further, at least two of the bridging wires are fixed to one another.

Owner:TOYOTA JIDOSHA KK

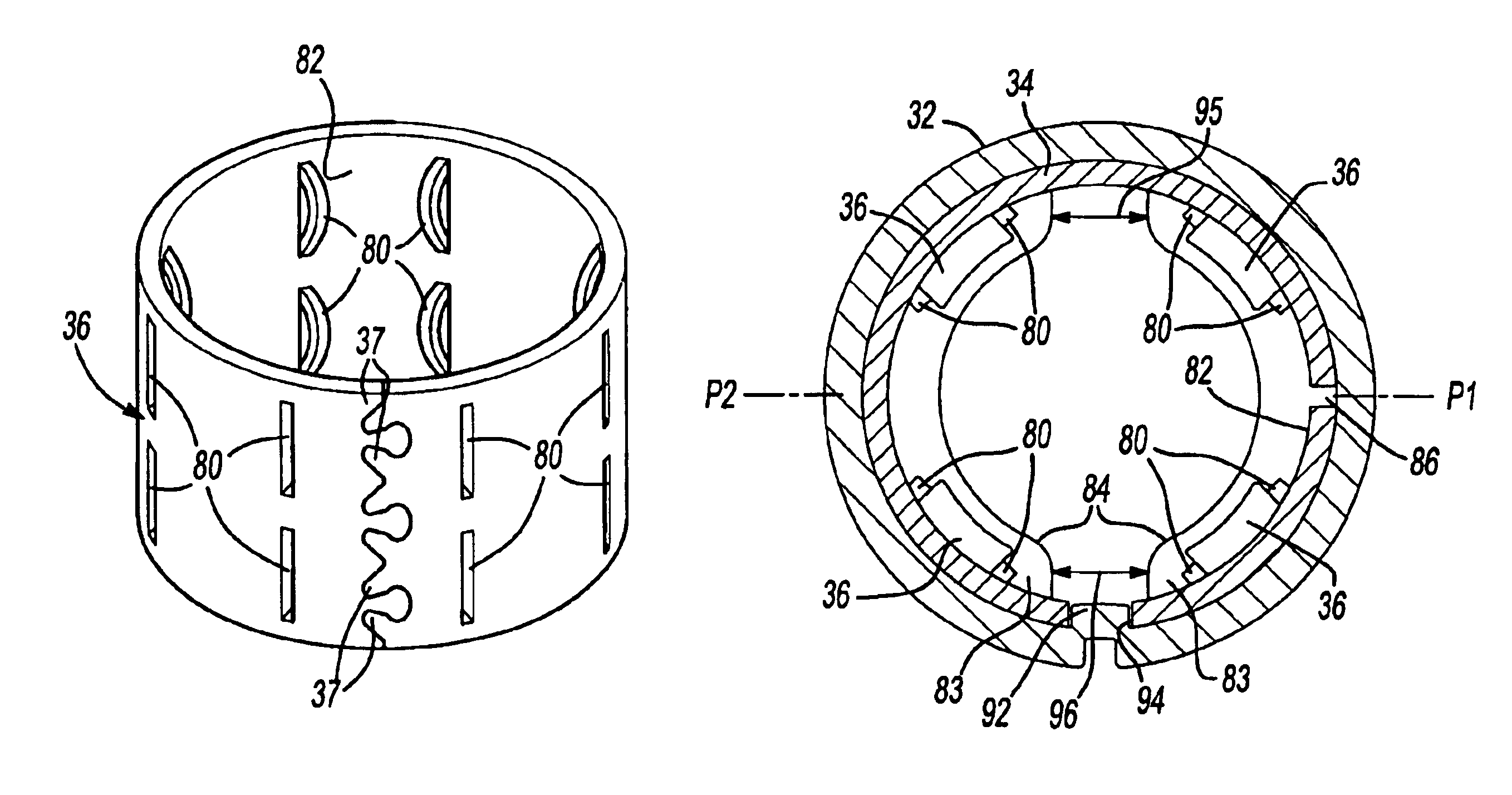

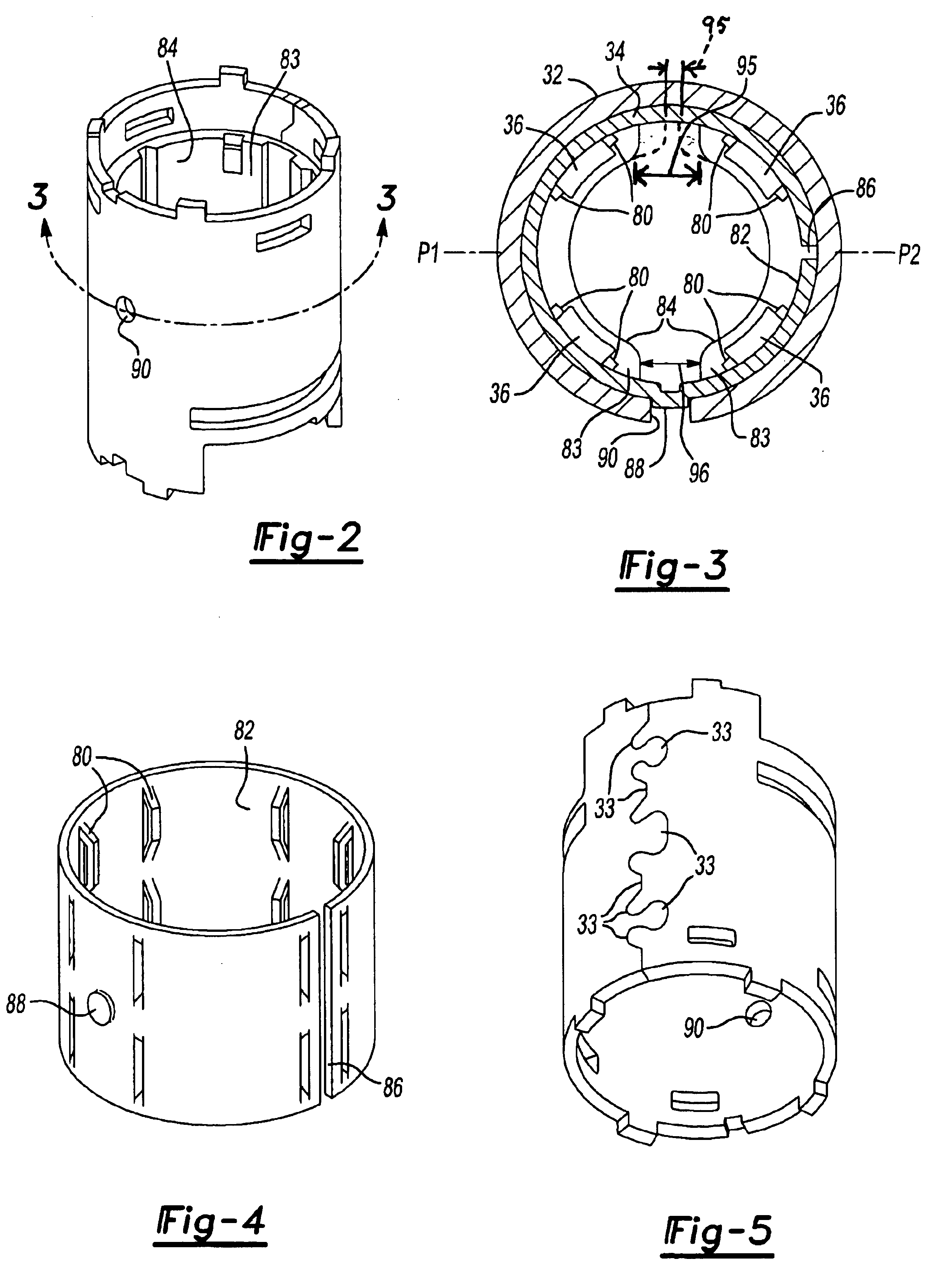

Stator assembly with an overmolding that secures magnets to a flux ring and the flux ring to a stator housing

InactiveUS6903475B2Prevent crashMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesInjection moulding

A stator assembly for an electric motor includes a stator housing, an expandable flux ring inserted into the stator housing and a plurality of magnets on an inner surface of the flux ring. Overmold material is molded around the magnets in the flux ring, such as by injection molding. The pressure of the overmold material as it is being molded expands the flux ring pressing the flux ring into engagement with the stator housing. The overmold material secures the magnets to the flux ring and the flux ring to the housing. One of the flux ring and stator housing has a dimple that engages a hole in the other of the flux ring and stator housing to align the flux ring and stator housing. In an aspect, the overmold material is molded to form at least one of a commutator end or rear bearing support, front bearing support and fan baffle. In an aspect, the overmold material is molded to form a keying feature. The keying feature can be slots of different widths between magnetic poles of the stator assembly. In an aspect, the flux ring and housing are preformed as a unit by stamping them from blanks and rolling them together. In a variation, the flux ring blank is rolled first to form the flux ring and the housing blank rolled around the flux ring with the flux ring acting as a rolling arbor.

Owner:BLACK & DECKER INC

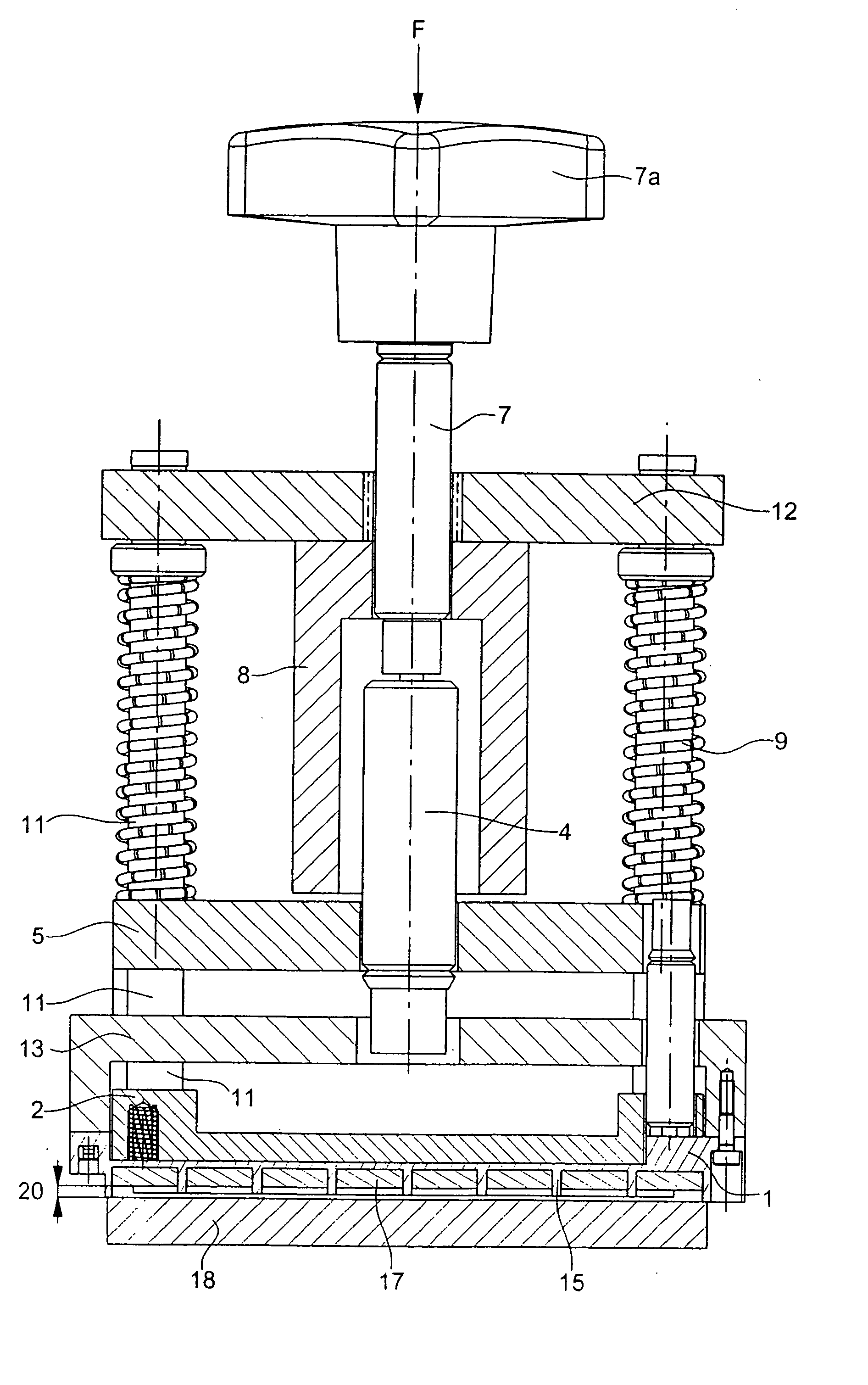

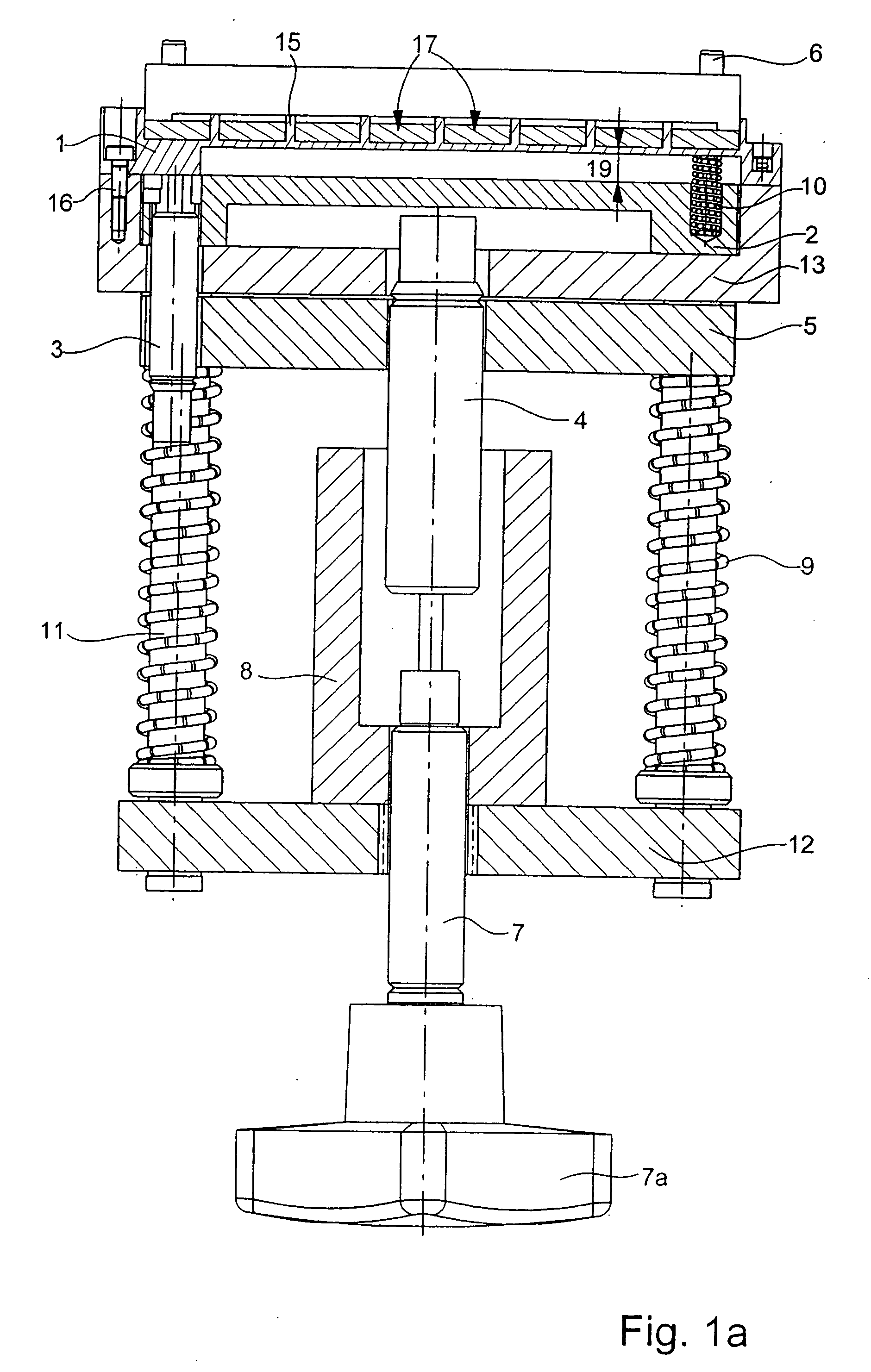

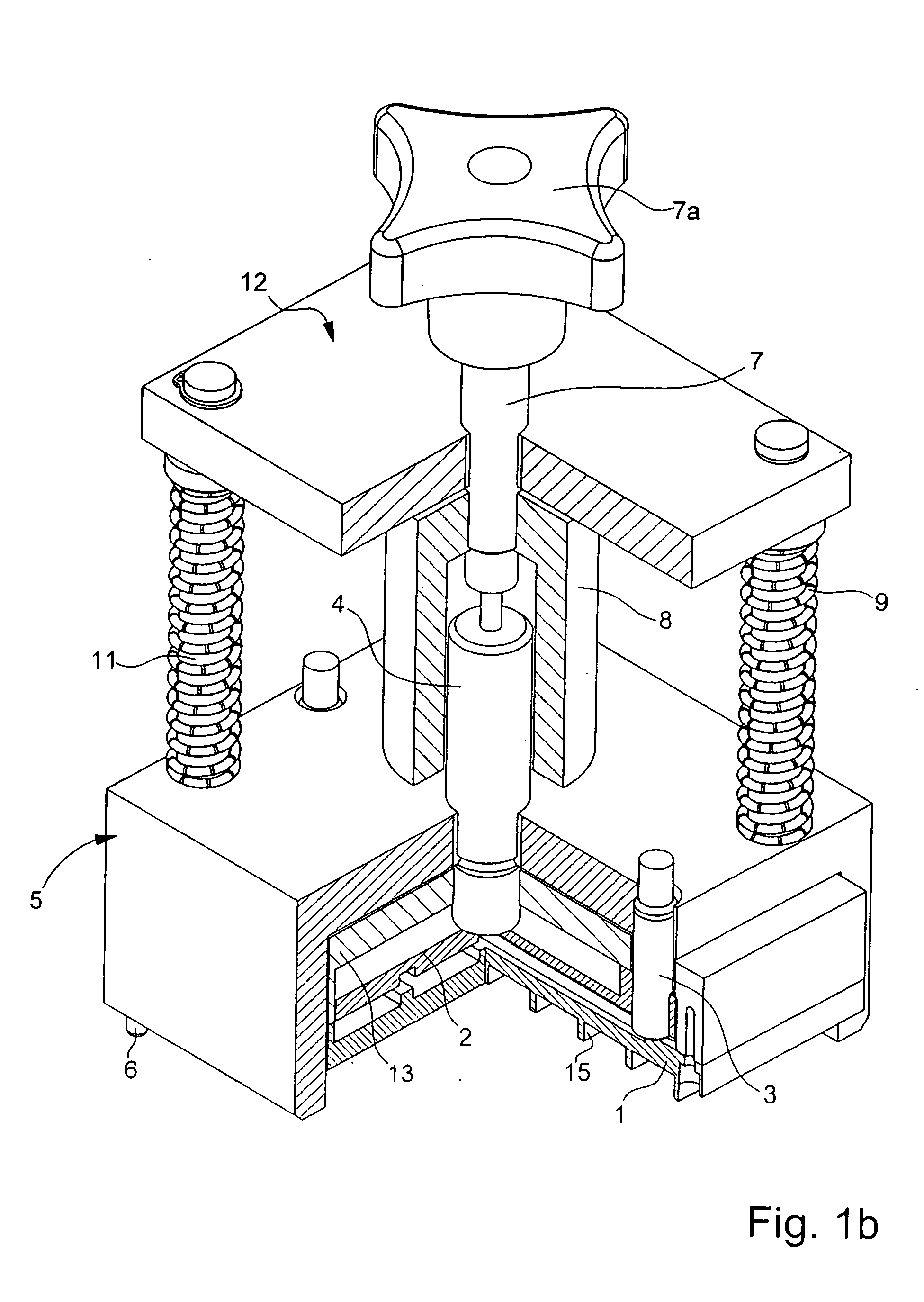

Method and device for positioning and affixing magnets on a magnetic yoke member of a motor

InactiveUS20050246886A1Not require complex toolingGood attractionWire articlesAssembly machinesLinear motorElectric motor

A method and a device are for positioning and affixing magnets on a magnetic yoke member of an electric motor. The device includes: a nonmagnetic support for receiving the magnets, this support having a shape complementary to that of the magnetic yoke member on which the magnets are to be affixed; a magnetic element for holding the magnets in position on the nonmagnetic support, this element being arranged on the other side of the nonmagnetic support with respect to the magnets, the attraction exerted by this element on the magnets being greater than that exerted by the magnetic yoke member during the positioning of the device with respect to the yoke; a device for varying the magnetic forces present, whereby the magnetic attraction of the magnetic yoke member and / or the magnetic element on the magnets may be varied such that the magnetic force of attraction exerted by the yoke on the magnets becomes greater than that exerted by the magnetic element on them, thus provoking the transfer of the magnets to the yoke. The yoke member forms the magnetic path of a linear motor.

Owner:ETEL SA

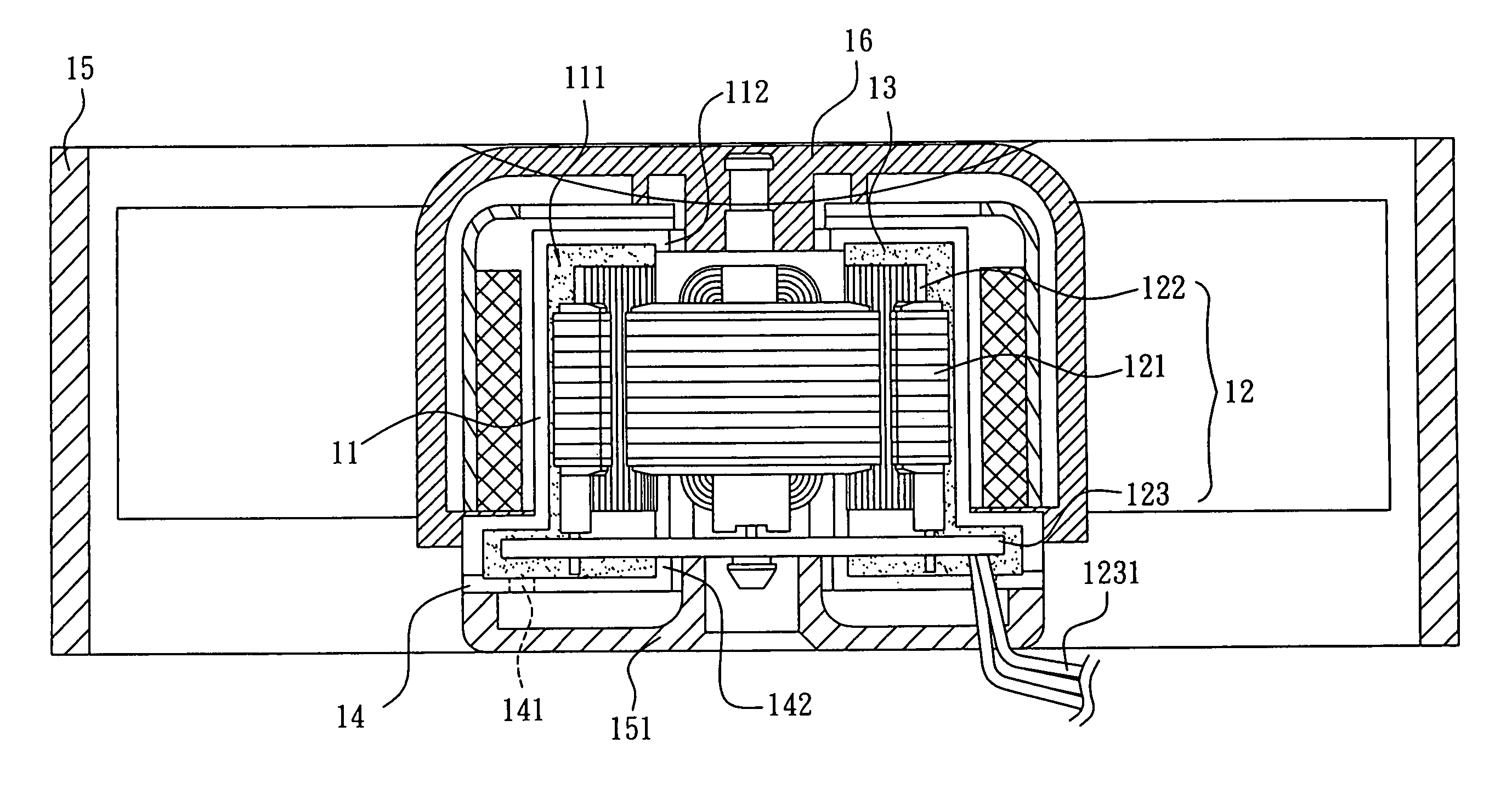

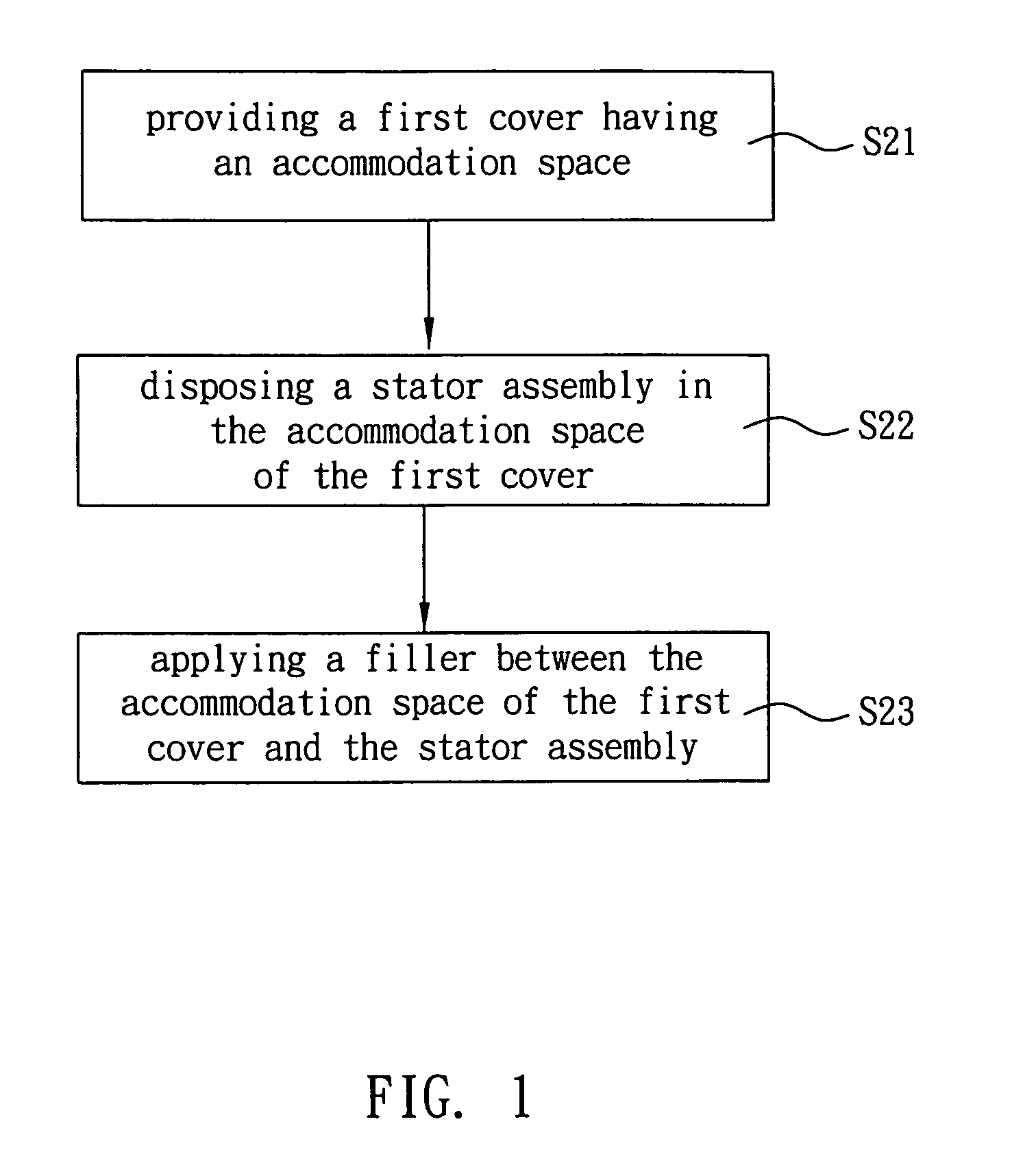

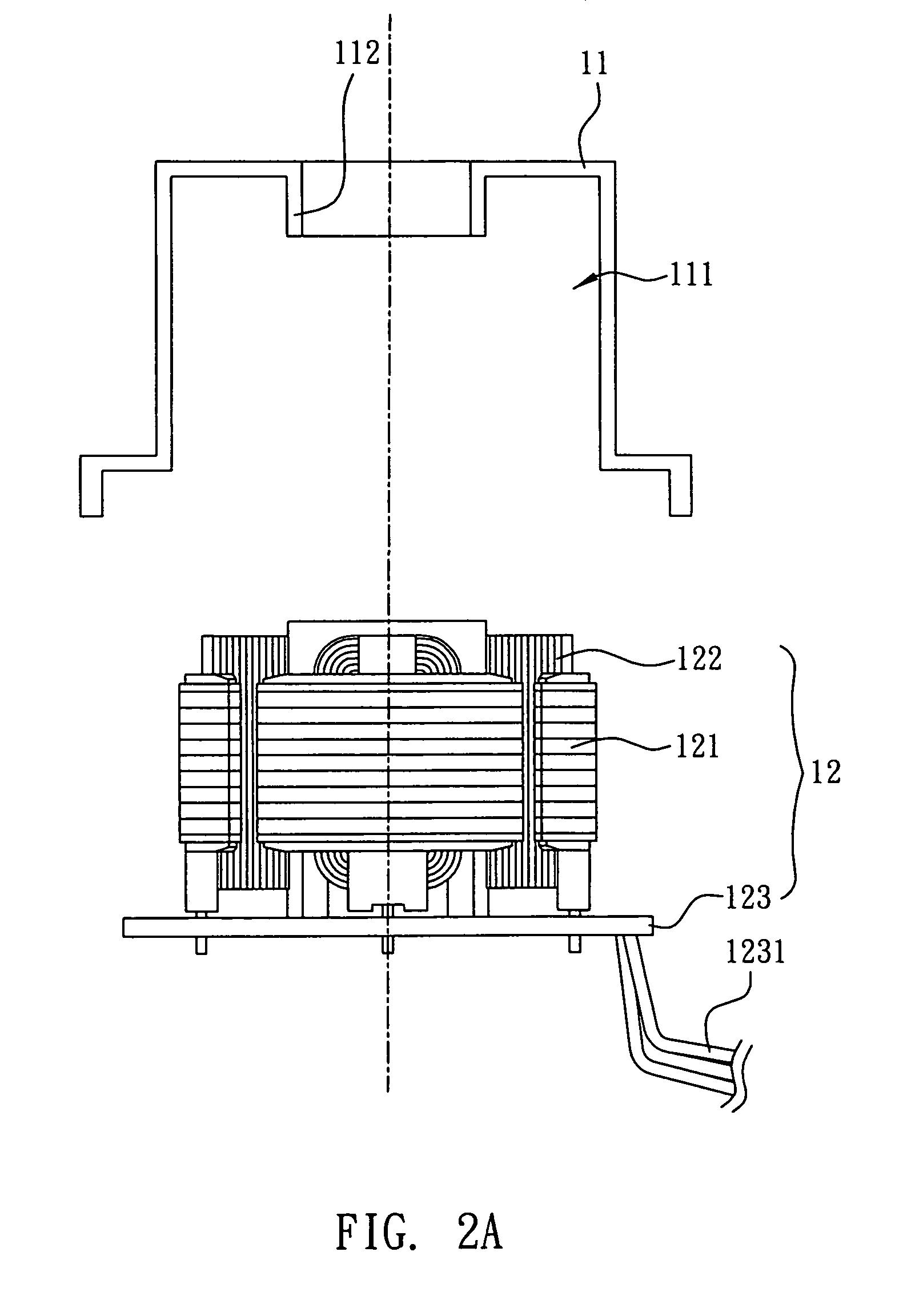

Stator structure and manufacturing method thereof

ActiveUS7667359B2Improve performanceAchieve effectManufacturing dynamo-electric machinesMagnetic circuit characterised by insulating materialsEngineeringElectrical and Electronics engineering

A stator structure includes a first cover, a stator assembly and a filler. The first cover has an accommodation space for accommodating the stator assembly therein. The filler is applied between the first cover and the stator assembly to surround the stator assembly. A manufacturing method of the stator structure is also disclosed.

Owner:DELTA ELECTRONICS INC

Stator of rotary electric motor and fuel pump

ActiveUS20110020154A1Convenient ArrangementWindings insulation shape/form/constructionManufacturing dynamo-electric machinesBobbinEngineering

A stator of a rotary electric motor has core segments. All or some of the core segments have terminal mounting members for mounting terminals to which coils are connected. The terminal mounting member and the bobbin for each of the core segments are molded by resin and integrated with the corresponding core segment.

Owner:AISAN IND CO LTD

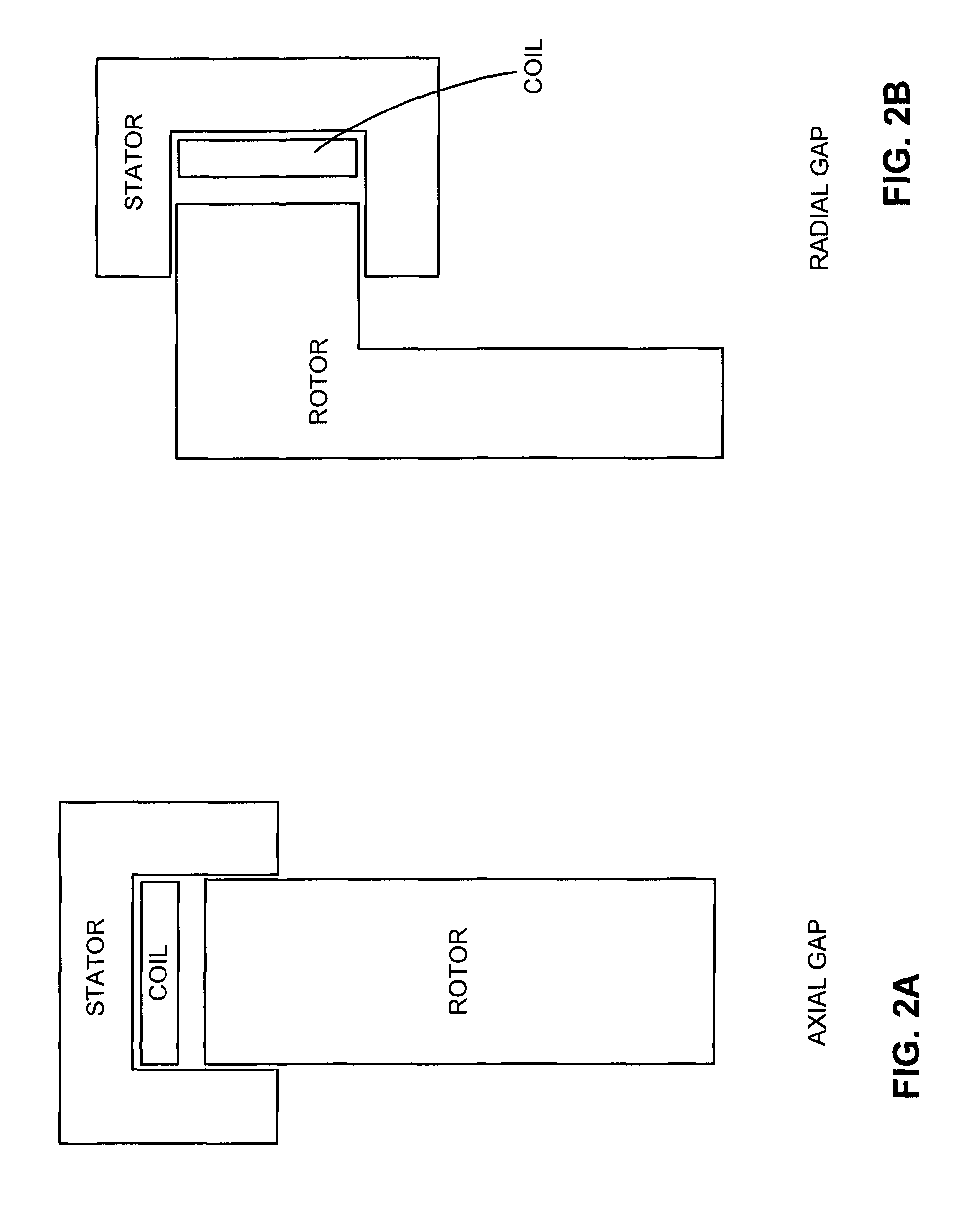

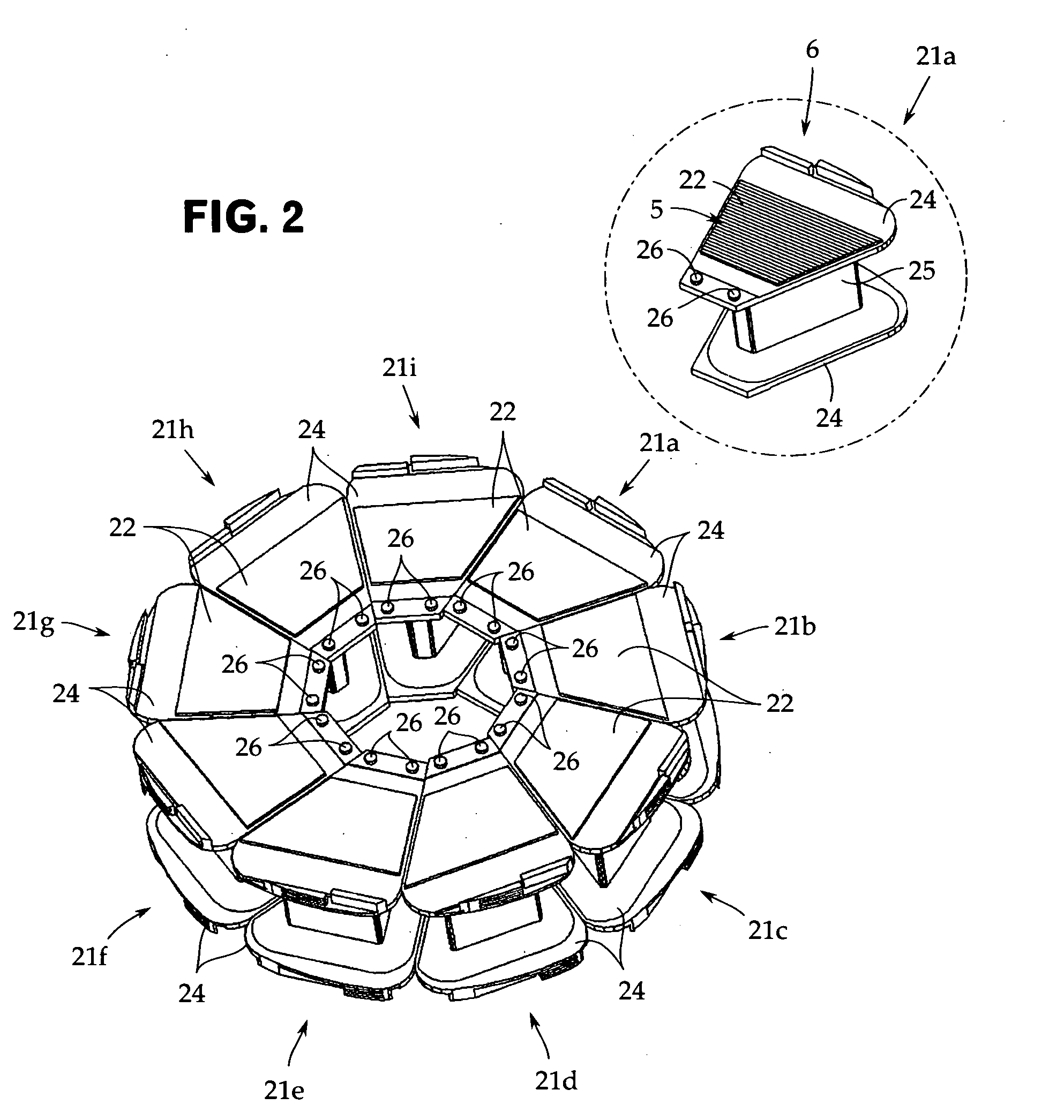

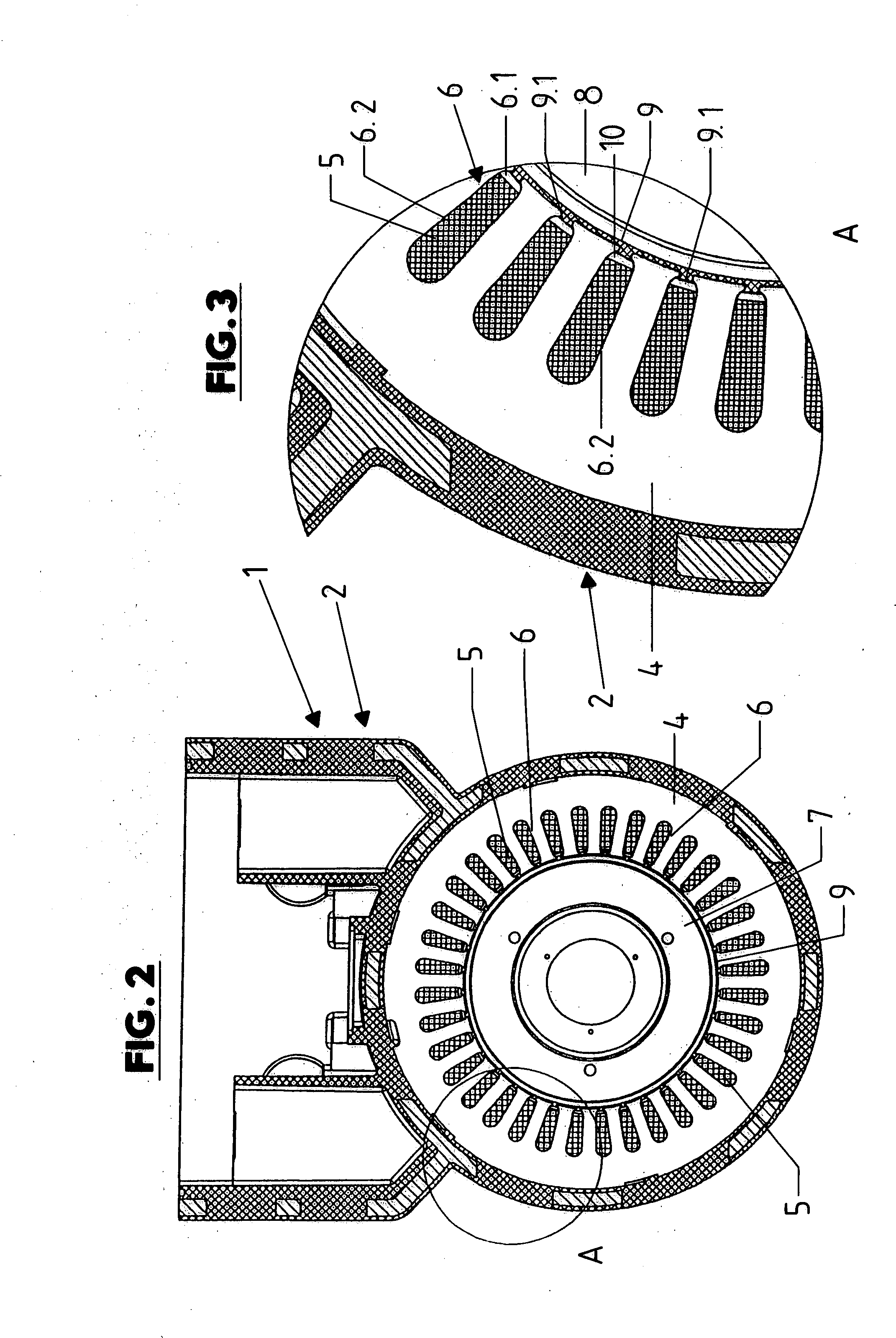

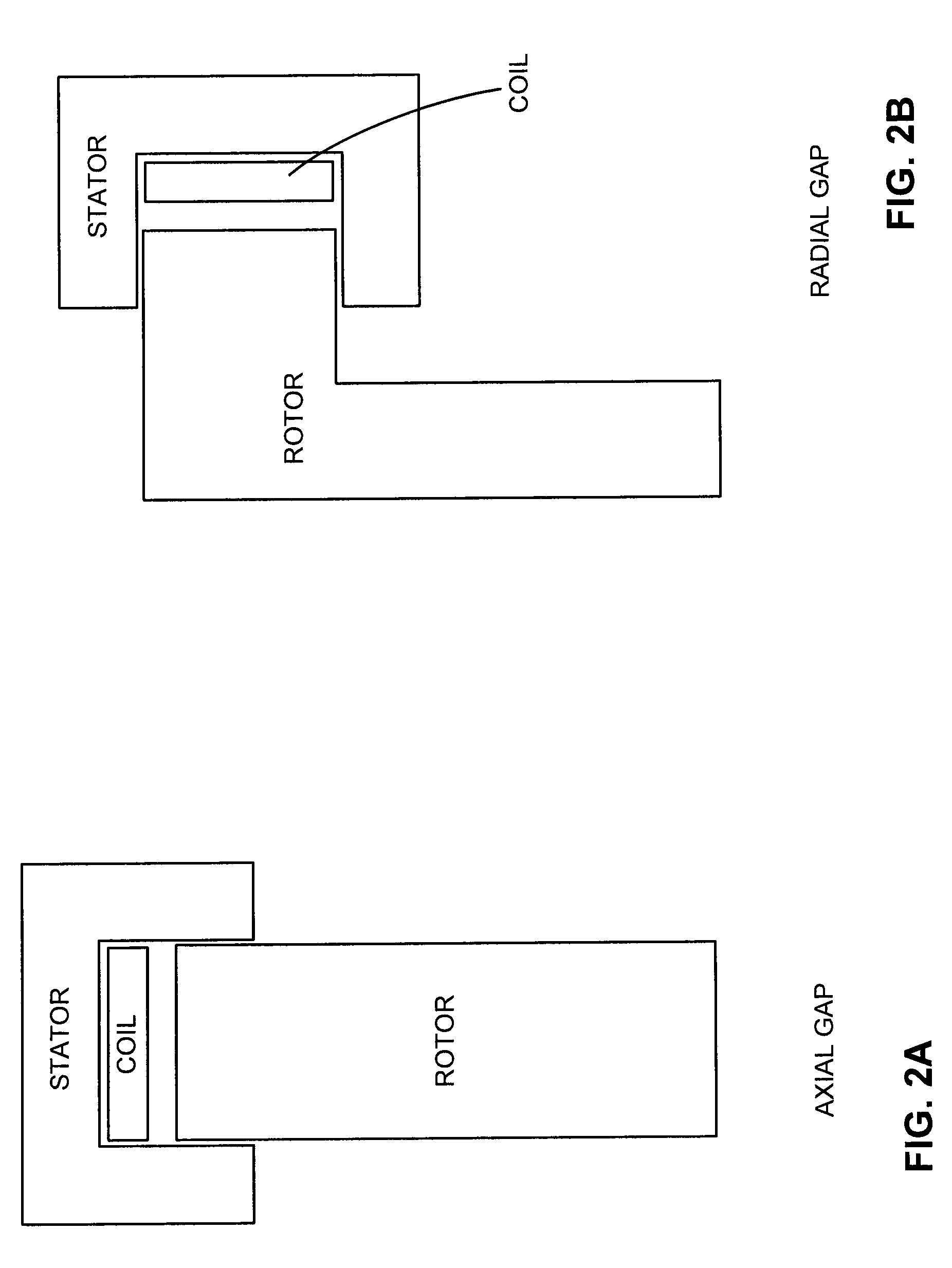

Axial air-gap electronic motor

ActiveUS20060043821A1Simple methodEfficient executionWindingsMagnetic circuit rotating partsFlangeElectric motor

There is provided an axial air-gap electronic motor in which work for assembling a stator can be performed efficiently. A locking protrusion 26 is provided on a flange portion 24 of core members 21a to 21i which are divided for each teeth 21 and are arranged in a ring form with the rotating shaft axis line being the center, and a connecting member 8 is fitted on the locking protrusion 26, by which the core members 21a to 21i are connected to each other in a ring form.

Owner:FUJITSU GENERAL LTD

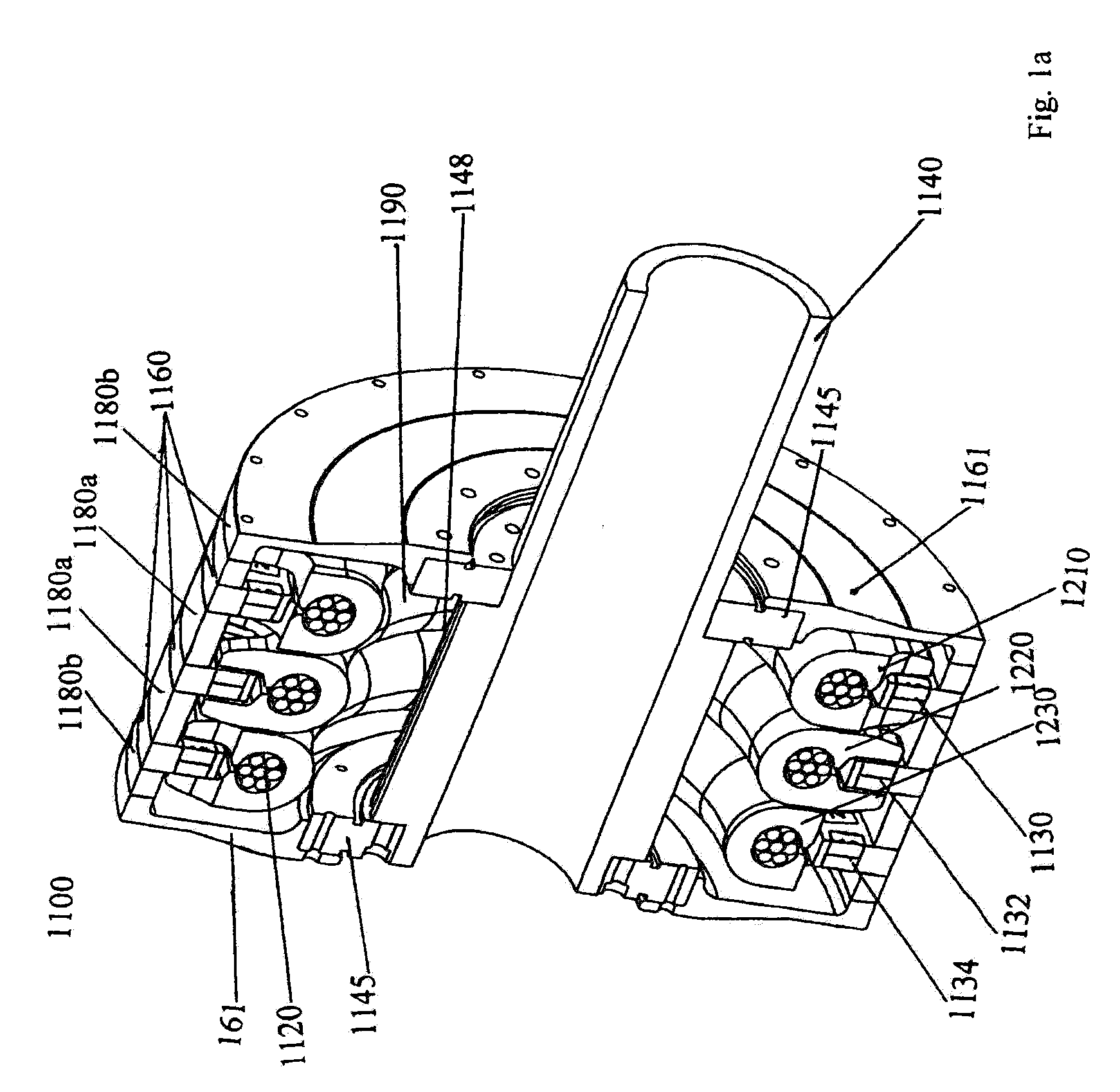

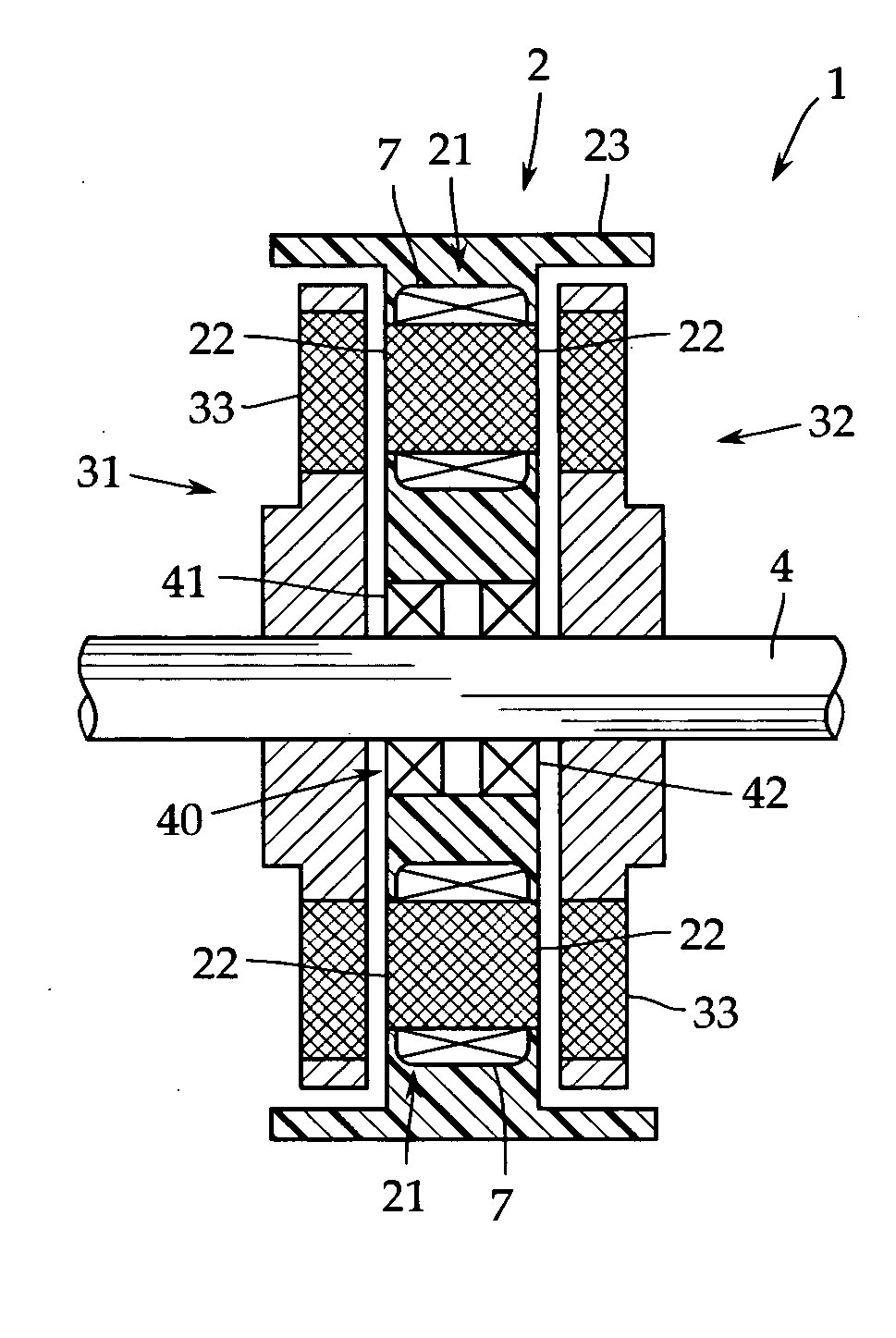

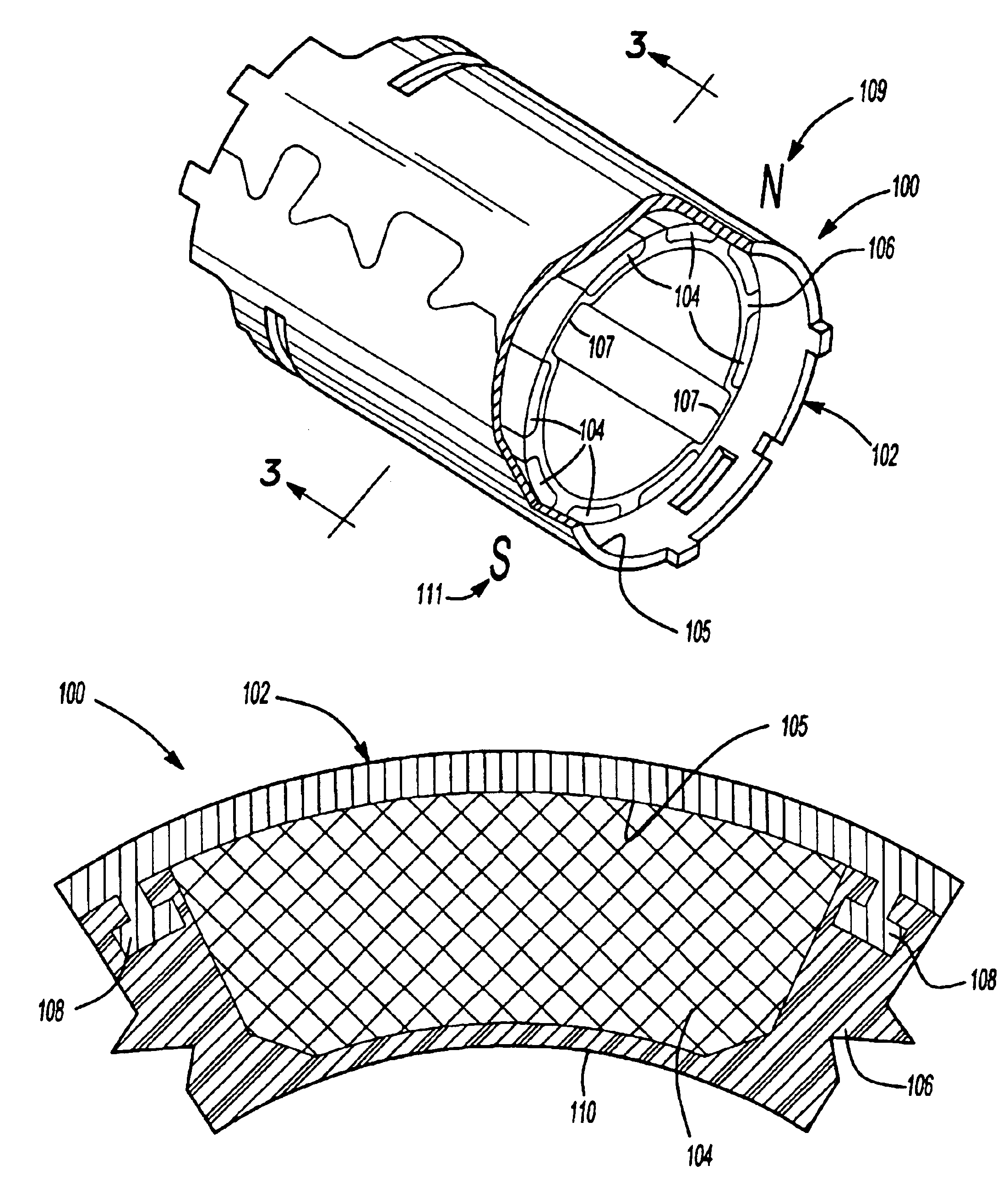

Field assembly for a motor and method of making same

InactiveUS7038343B2Prevent movementGood for scrollingMagnetic circuit rotating partsMagnetic circuit stationary partsPower toolRadial surface

A cylindrical magnet ring assembly having a cylinder magnet flux ring (102) formed with a plurality of inwardly projecting anchors (108); a plurality of permanent magnets (104), wherein the magnet can be formed with step portions (112) in the inner radial surface; a molded plastic member (106) being molded around the magnets and anchors to secure the magnets to a surface of the cylinder flux ring. There are several variations of the embodiments of the invention. Few embodiments are the following: in one aspect of the invention, magnets are inserted into magnet molded around an assembly ring (806) and the molded plastic secures the assembly ring to the flux ring; in another aspect, there are two assembly rings, a first assembly ring (is inserted into the one side of the cylinder flux ring then the second assembly ring is inserted into the other side of the cylinder flux ring and mated to the first assembly ring, after that the molded plastic secures the two assembly rings. The foregoing cylindrical magnet ring assembly is used in a stator of a motor which is used in a power tool.

Owner:BLACK & DECKER INC

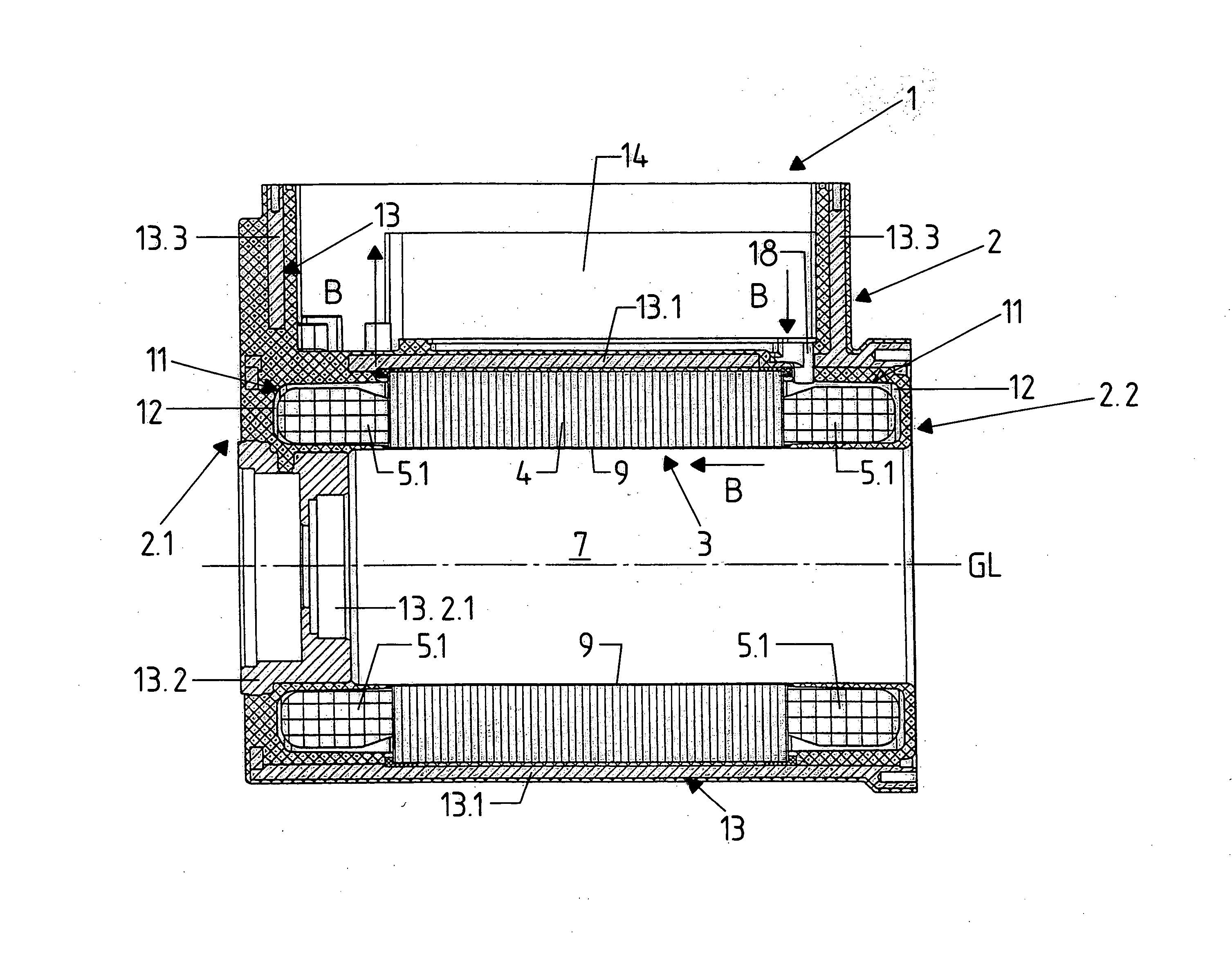

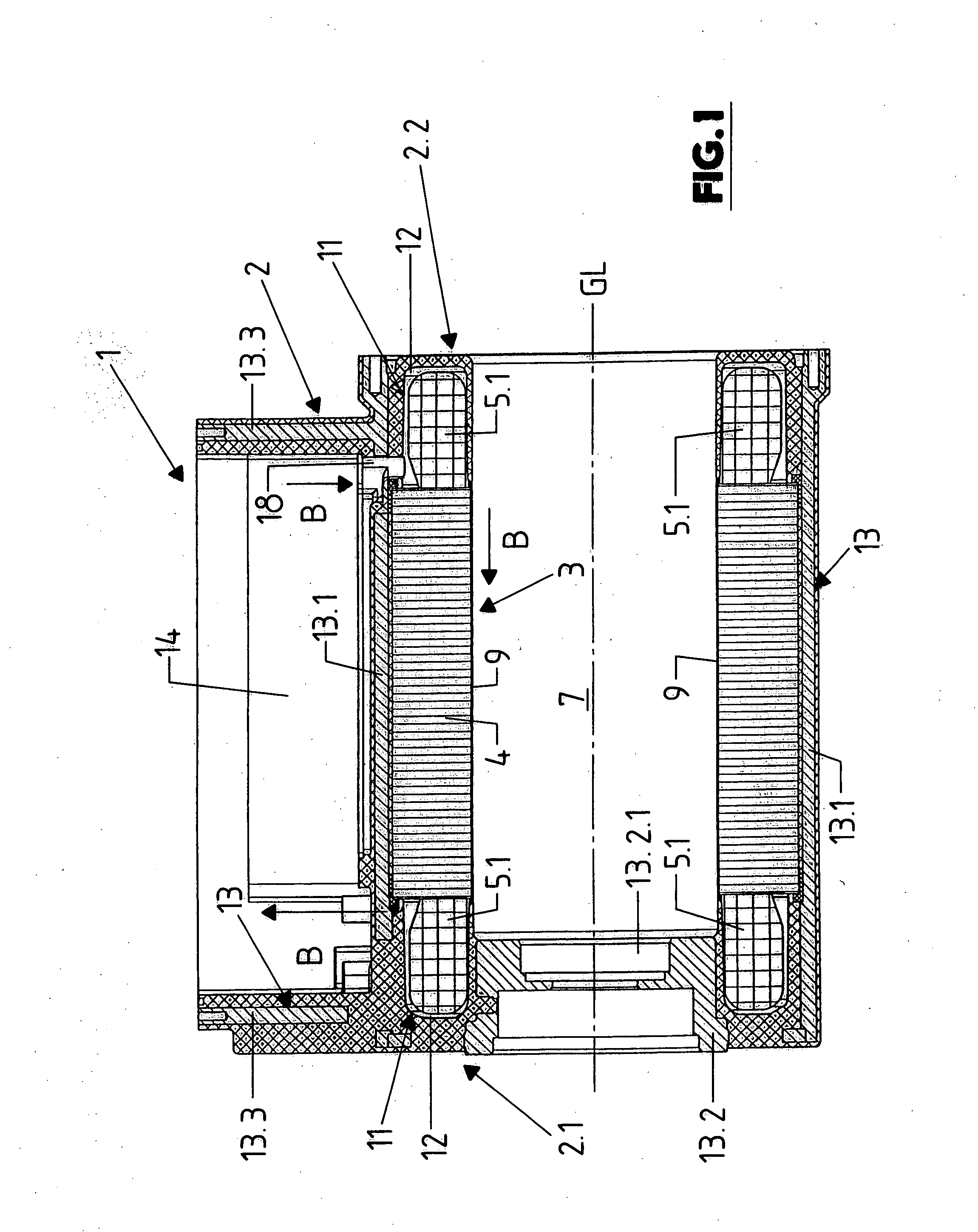

Method for manufacturing an electric machine and electric machine manufactured according to said method

InactiveUS20080042498A1High mechanical strengthImprove cooling effectMagnetic circuit stationary partsManufacturing stator/rotor bodiesElectrical conductorElectric machine

A method for manufacturing a machine element of an electric machine, with a plurality of magnetic poles distributed around a machine axis and with at least one coil, having several conductors distributed around the machine axis and each of which is located in a groove, wherein the machine element forms a gap surface enclosing the machine axis, on which (gap surface) when the machine is mounted it adjoins a second machine element via a machine gap and is made of a plastic, and wherein at least in the recesses for the conductors, channel sections are formed through which a coolant can circulate.

Owner:SALWIT AGRARENERGIE

Spoke permanent magnet rotors for electrical machines and methods of manufacturing same

ActiveUS20050088052A1Improve performanceLow costMagnetic circuit rotating partsManufacturing stator/rotor bodiesPermanent magnet rotorElectric machine

A rotor assembly for an electric motor includes a spoke permanent magnet rotor and a shaft connected thereto. The spoke permanent magnet rotor has an axis of rotation, permanent magnet material, and ferro-magnetic material. The permanent magnet material extends outwardly relative to the axis of rotation to form a plurality of outwardly extending spoke portions of permanent magnet material. The ferro-magnetic material is positioned adjacent to the outwardly extending spoke portions of permanent magnet material. The shaft supports the spoke permanent magnet rotor for rotation about the axis of rotation. The permanent magnet material may circumferentially surround the axis of rotation to form a center portion of permanent magnet material. Further, the axis of rotation may pass through the permanent magnet material. The spoke permanent magnet rotor may be formed using a compaction process and / or an injection molding process.

Owner:REGAL BELOIT AMERICA

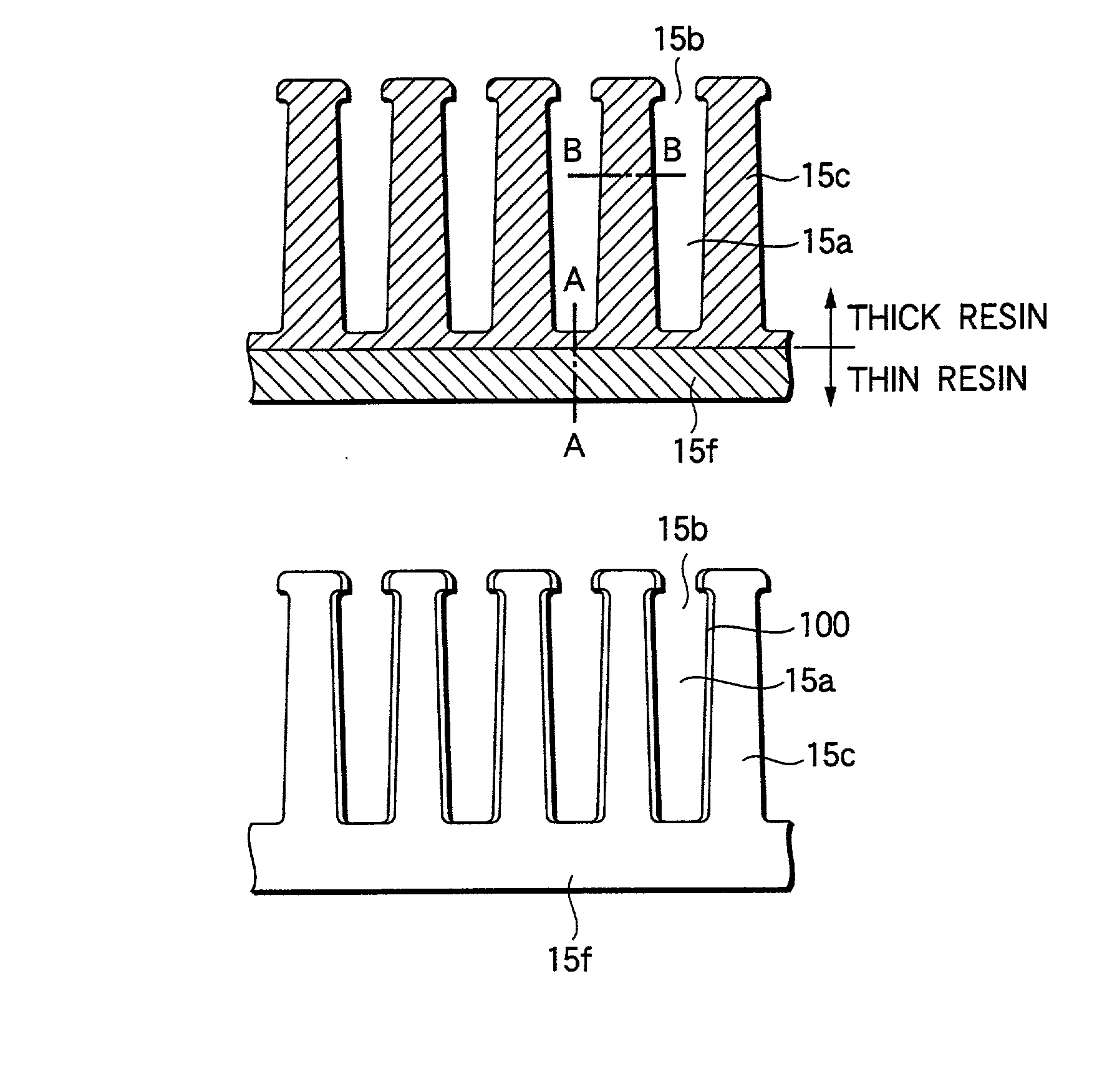

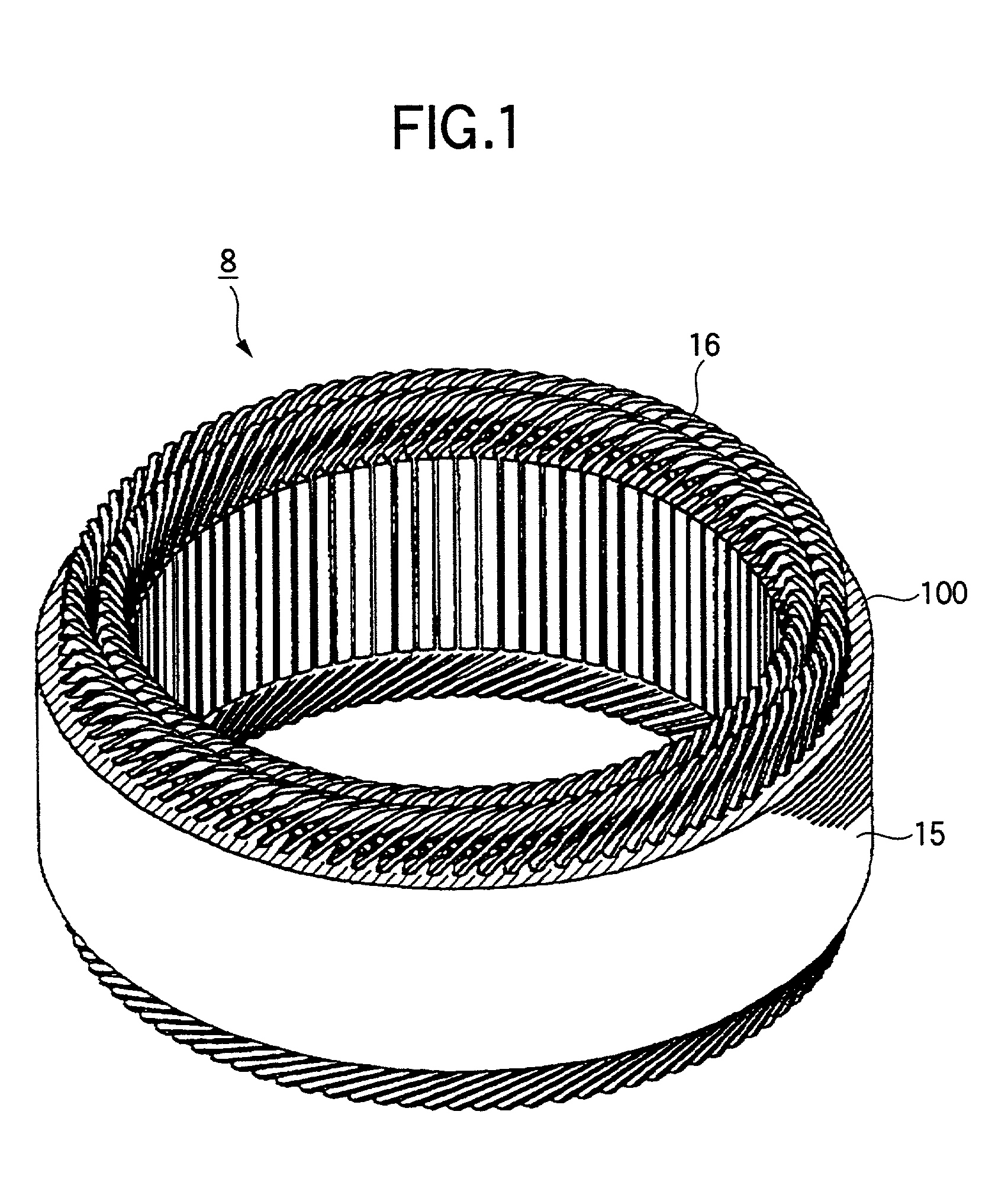

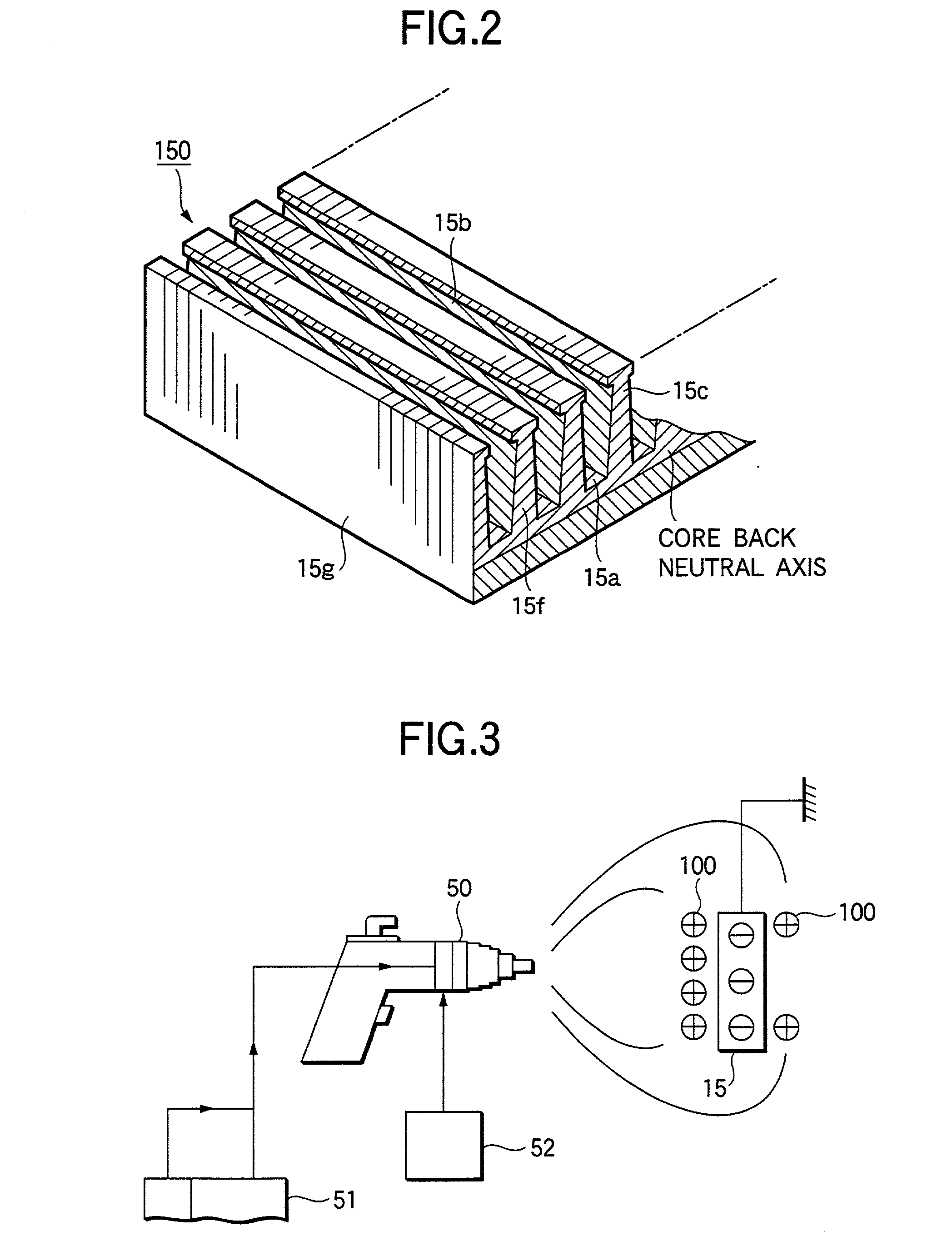

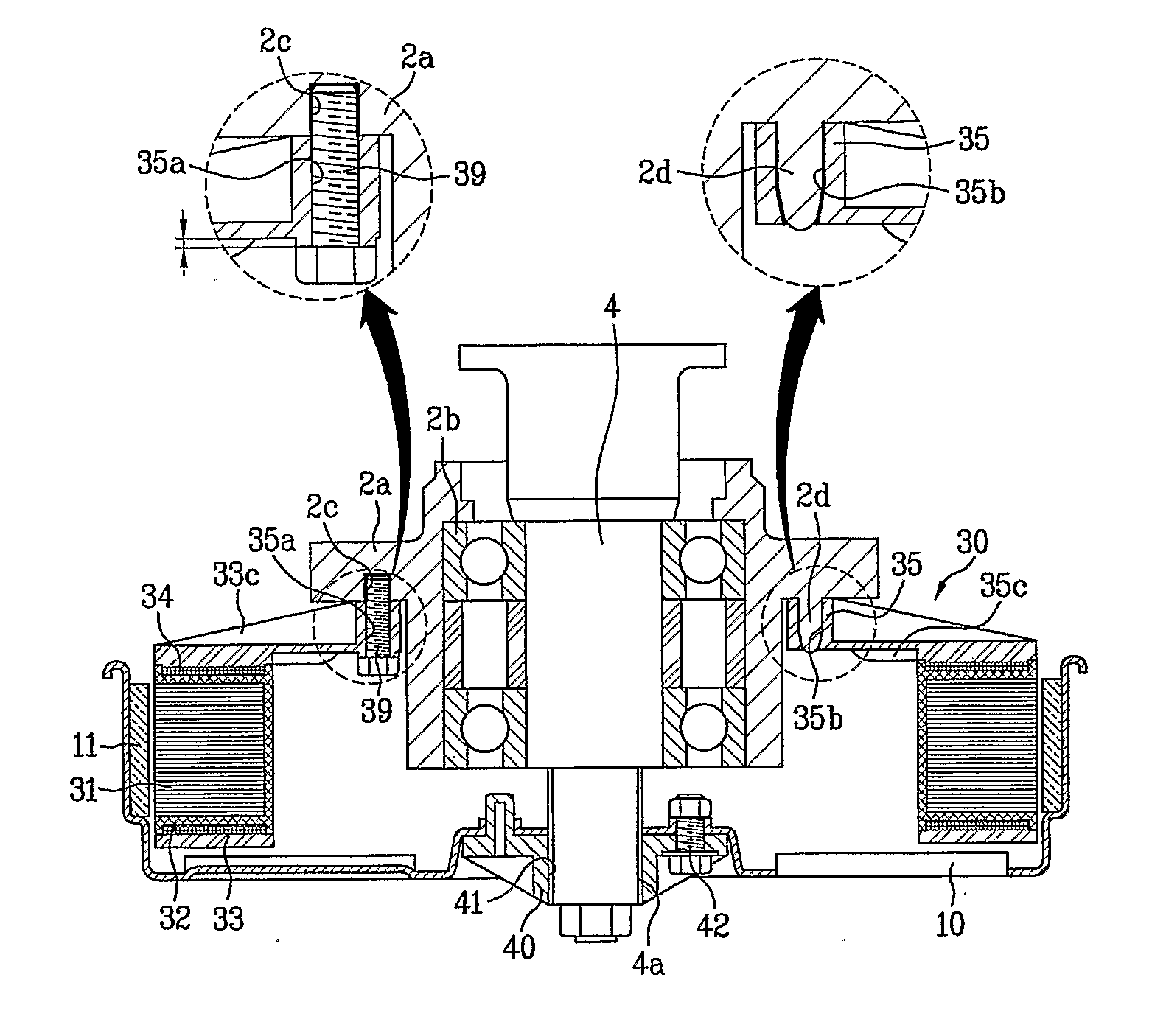

Stator for rotary machine and method of manufacturing the stator

InactiveUS20020130582A1Improve cooling effectHigh insulation performanceSynchronous generatorsWindings insulation shape/form/constructionStator coilMechanical engineering

A stator for a rotary machine includes a rotor 7 and a stator 8 having a stator iron core 15 disposed oppositely around the outer circumference of the rotor 7 and a stator coil 16 fitted around the iron core 15, wherein the iron core 15 has a laminated iron core 150 with plural axially extending slots 15a formed circumferentially at predetermined pitches, an insulating resin 100 is coated on an axial end face 15f of the iron core 15 and an inner wall face of a slot 15a in the laminated iron core 150 to provide insulation between the iron core 15 and the stator coil 16, and the iron core is cylindrically shaped by bringing both circumferential end portions 15g of the laminated iron core 150 into contact to bend the laminated iron core 150 so that an opening face 15b of the slot 15a is directed inside.

Owner:MITSUBISHI ELECTRIC CORP

Motor

InactiveUS20080122300A1Waterproofness can be improvedSimple structureWindings insulation shape/form/constructionManufacturing dynamo-electric machinesEngineeringMagnet

A motor adapted to rotate an element of an appliance, for example, a drum of a washing machine, is disclosed. The motor includes a rotating shaft which is rotatably mounted to a motor mounting member of an appliance, a rotor which includes magnets circumferentially arranged at a position radially spaced apart from a center of the rotating shaft by a predetermined distance such that N and S poles are alternately arranged, and a stator which includes a core made of metal, an insulator enclosing the core while allowing a surface of the core facing the magnets of the rotor to be outwardly exposed, the insulator being made of an insulating resin material, coils wound on the insulator, and a circular molded member formed in accordance with an insert molding method to enclose the insulator and the coils while allowing the surface of the core outwardly exposed through the insulator to be outwardly exposed.

Owner:LG ELECTRONICS INC

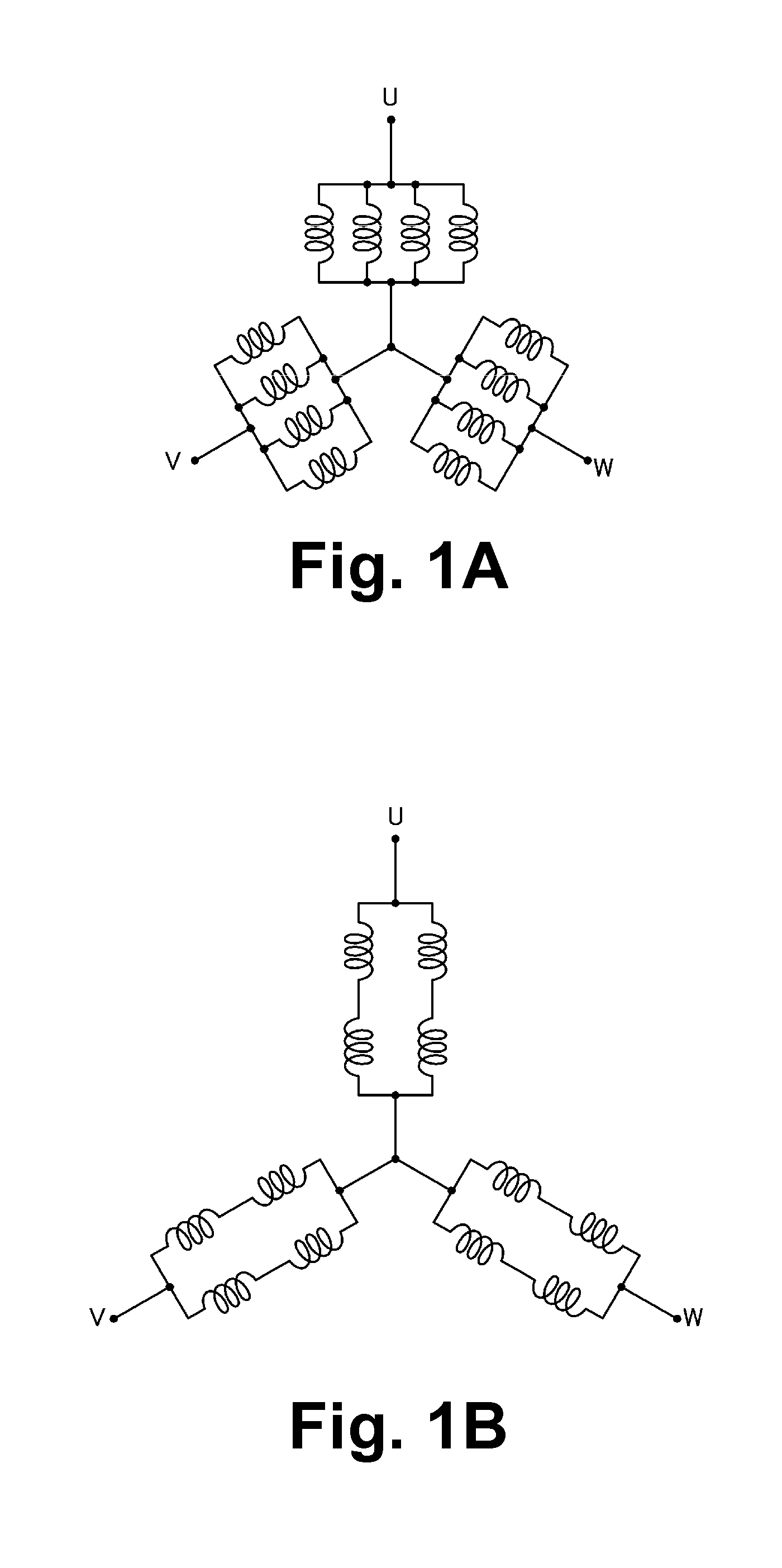

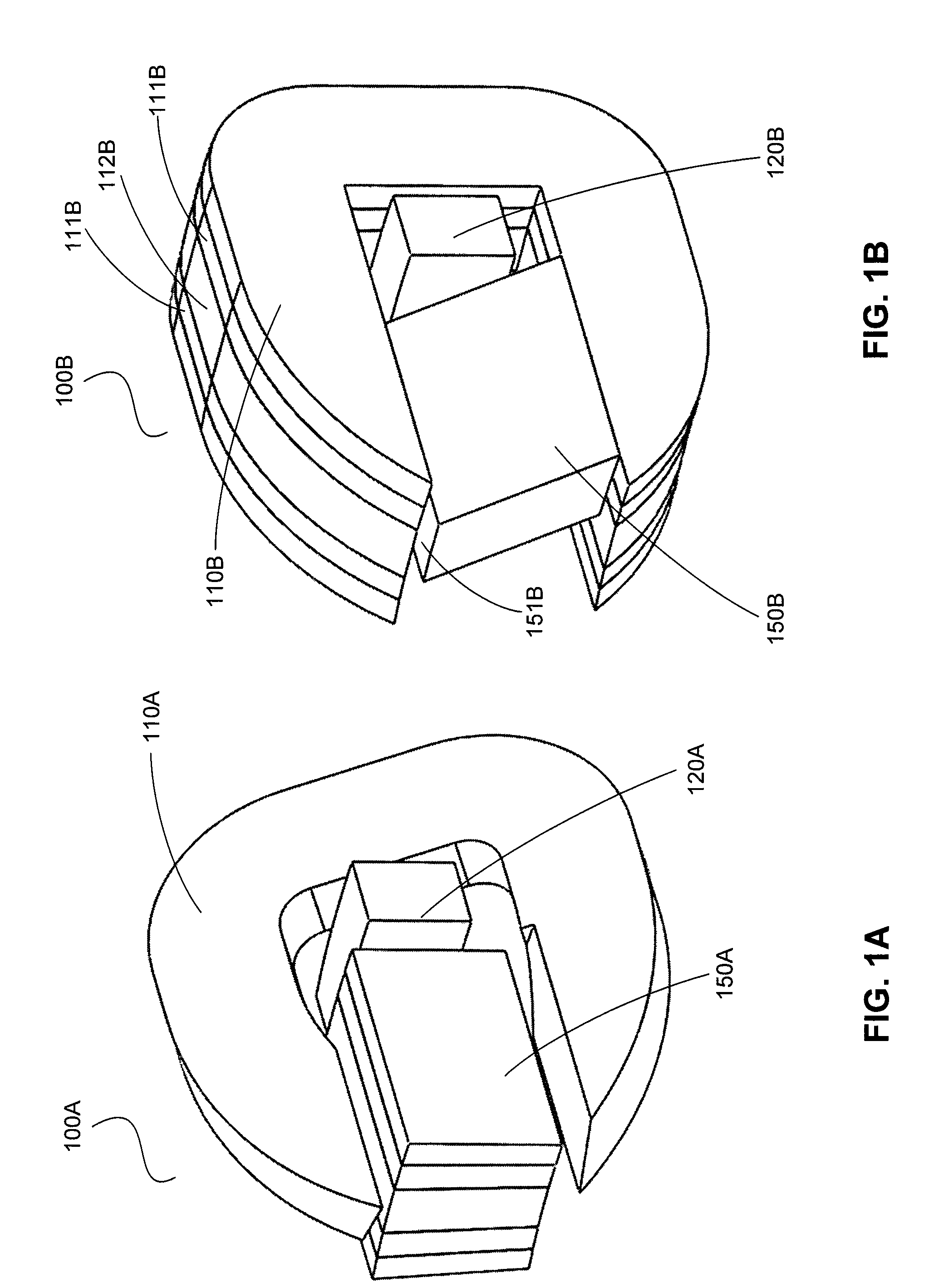

Polyphase transverse and/or commutated flux systems

Disclosed are single- and poly-phase transverse and / or commutated flux machines and components thereof, and methods of making and using the same. Exemplary devices, including polyphase devices, may variously be configured with an interior rotor and / or an interior stator. Other exemplary devices, including polyphase devices, may be configured in a slim, stacked, and / or nested configuration. Via use of such polyphase configurations, transverse and / or commutated flux machines can achieve improved performance, efficiency, and / or be sized or otherwise configured for various applications.

Owner:ELECTRIC TORQUE MASCH INC

Magnetic device with flux return strip

A magnetic device having a stator assembly having a magnetic flux return path comprising at least a pair of pole plates located a fixed distance apart from each other and at least one flux return strip pressed between each pair of spaced apart pole plates, and a rotor assembly having permanent magnetic material and being disposed for rotation relative to the stator assembly. Use of the flux return strip eliminates the need for a housing of ferrous material to complete the flux return path and facilitates flexible design of light-weight non-metallic housings and mounting systems or integral mounting to mating components.

Owner:MANNESMANN VDO AG

Electric motor and electric power steering apparatus employing the electric motor

InactiveUS6140728AMagnetic fluxIncrease contact areaWindings insulation shape/form/constructionMagnetic circuit rotating partsElectric power steeringEngineering

An electric motor has a rotor for rotation in a stator and a plurality of permanent magnets arranged on an outer peripheral surface of the rotor. A radially inner side surface of each permanent magnet is a curved to generally be convex in a radially inward direction. The outer peripheral surface of the rotor has curved recess surfaces, each of which contacts the radially inner side curved surface of a corresponding permanent magnet so that magnetic flux between adjacent permanent magnets is considerably prevented from locally concentrating within the rotor.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com