Patents

Literature

6427 results about "Oil pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The oil pump in an internal combustion engine circulates engine oil under pressure to the rotating bearings, the sliding pistons and the camshaft of the engine. This lubricates the bearings, allows the use of higher-capacity fluid bearings and also assists in cooling the engine.

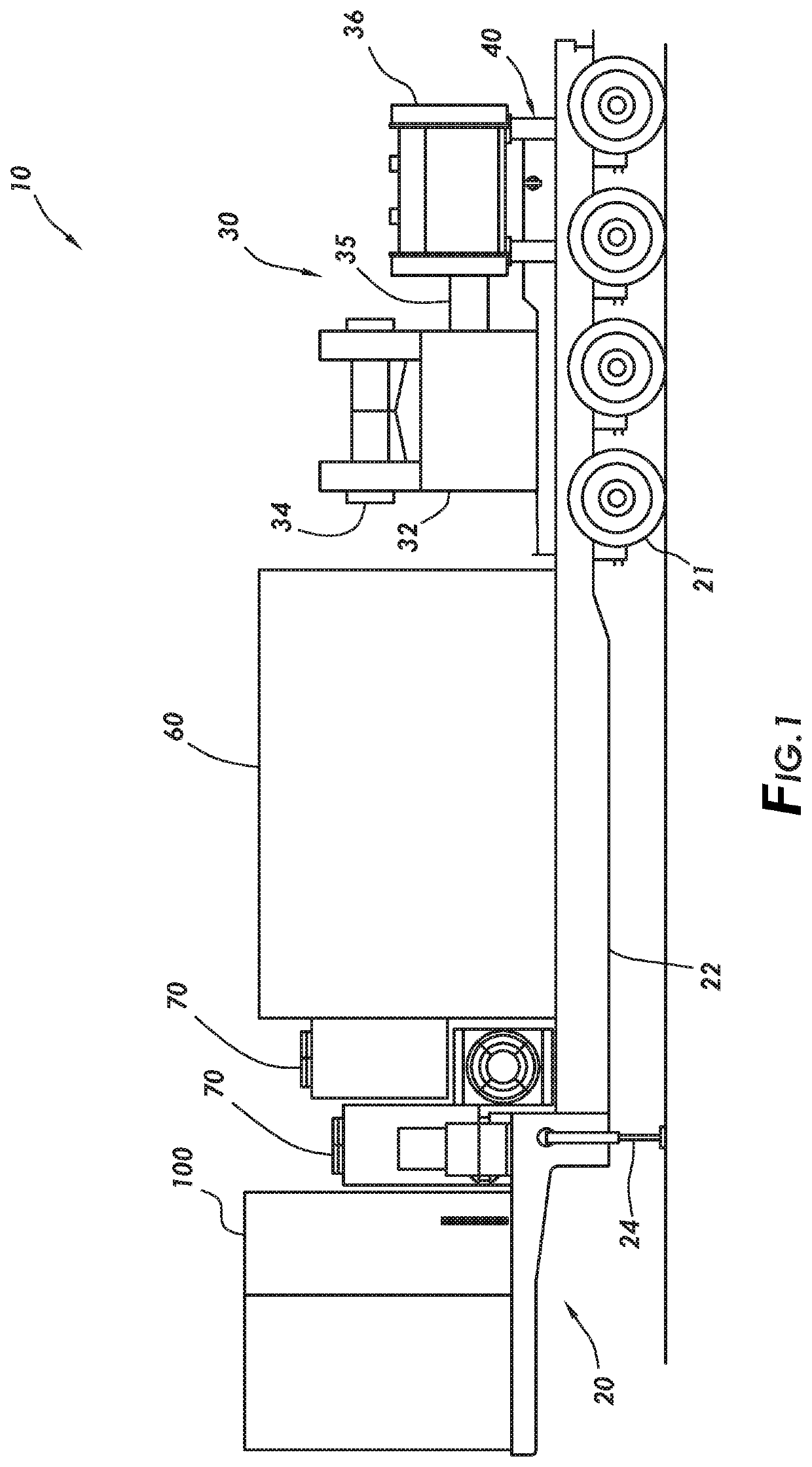

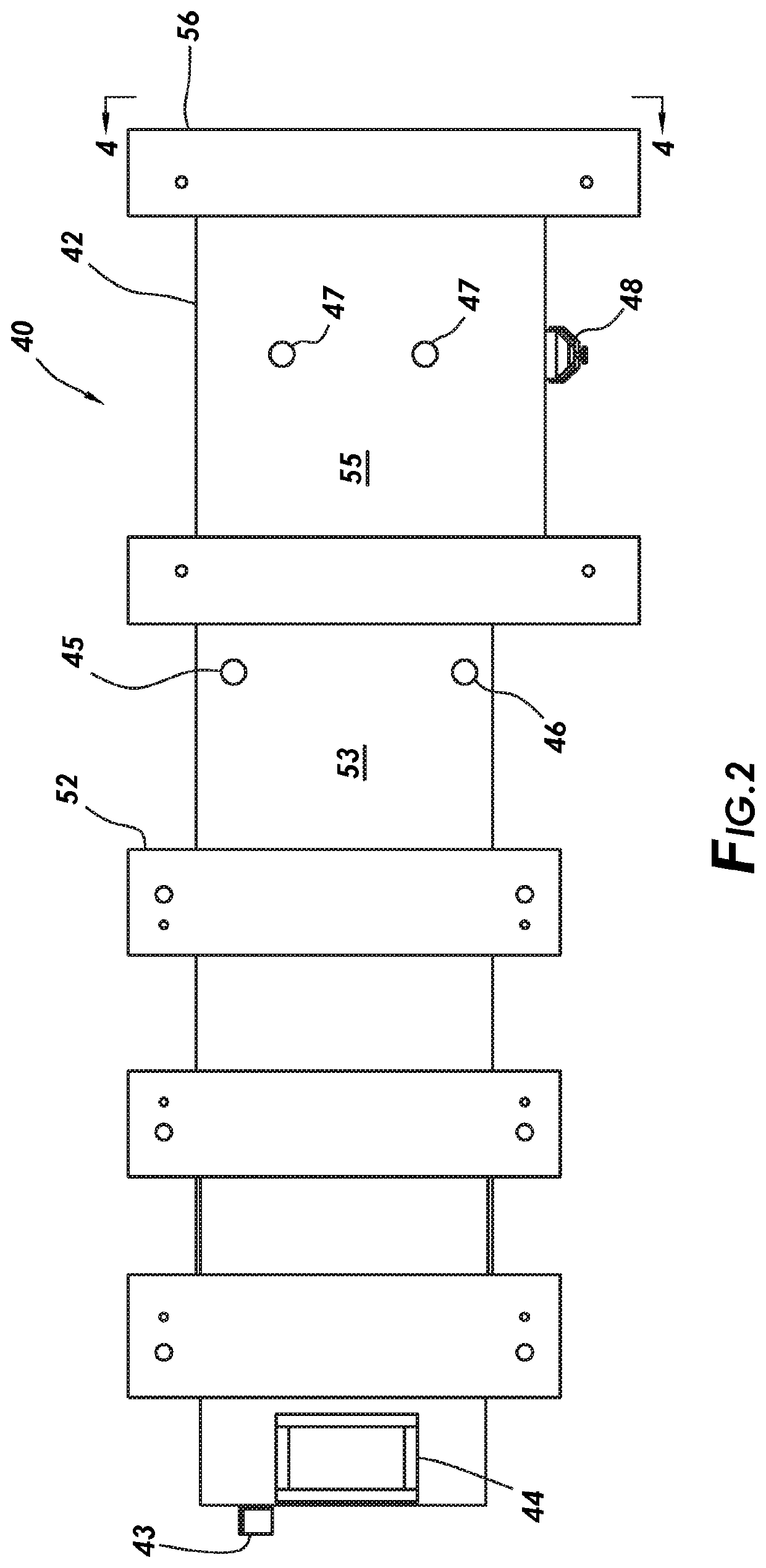

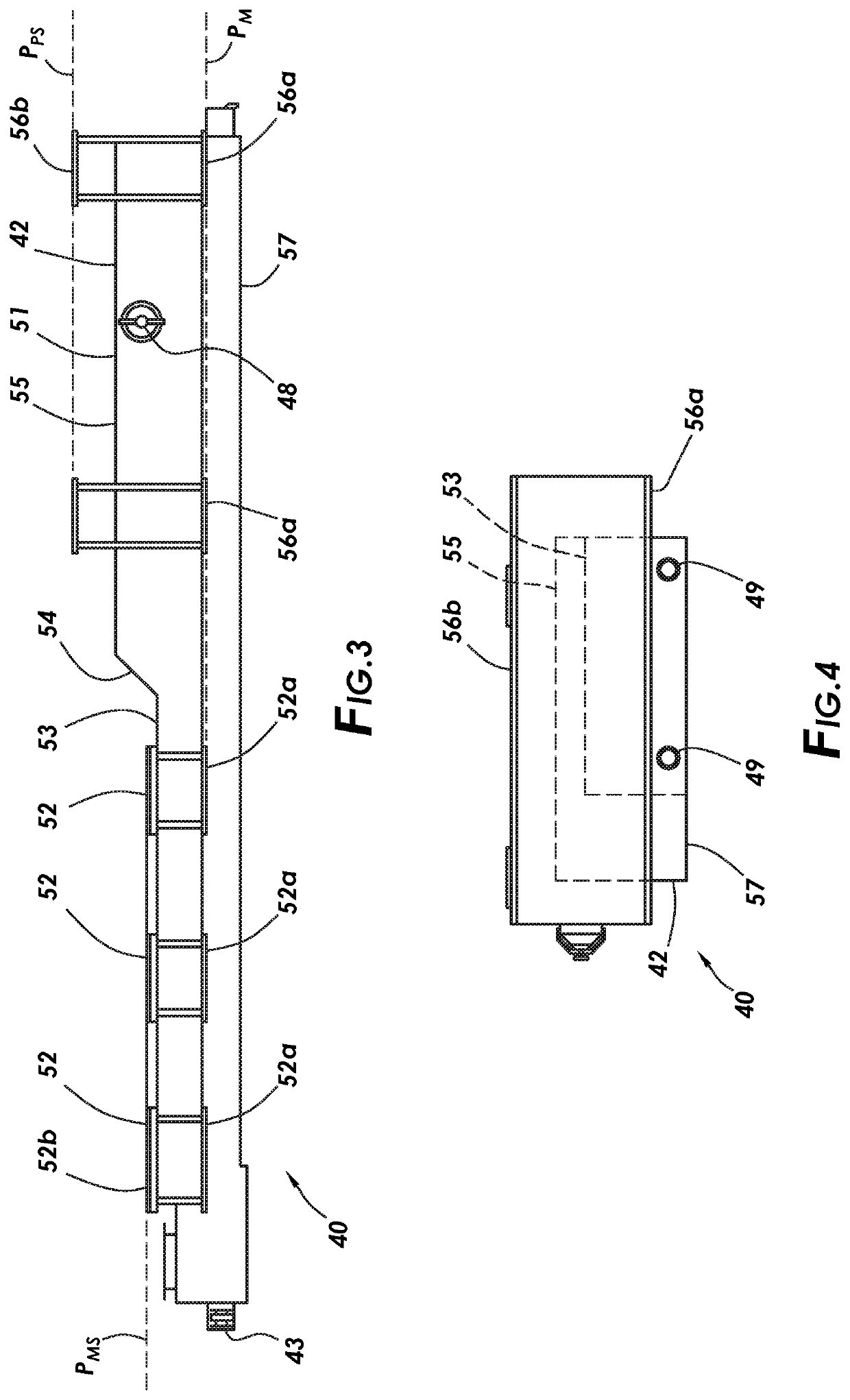

Hydraulic fracturing pump system

A system for fracturing a subsurface formation may comprise a transport unit with hydraulic legs, an electric motor mounted on the transport unit, a fracking pump mounted on the transport unit and configured to be powered by the electric motor, and an oil tank mounted on the transport unit such that the motor and the fracking pump are above the oil tank. The oil tank may have a first tank height under the pump and a second tank height under the motor and the first tank height may be greater than the second tank height. The oil tank, motor support beam, and pump support beam may form a single structural unit. The system may also include an oil pump for pumping lubricating oil through the fracking pump, an electric motor configured to drive the oil pump, a variable frequency drive configured to control the electric motor.

Owner:THE MODERN GROUP

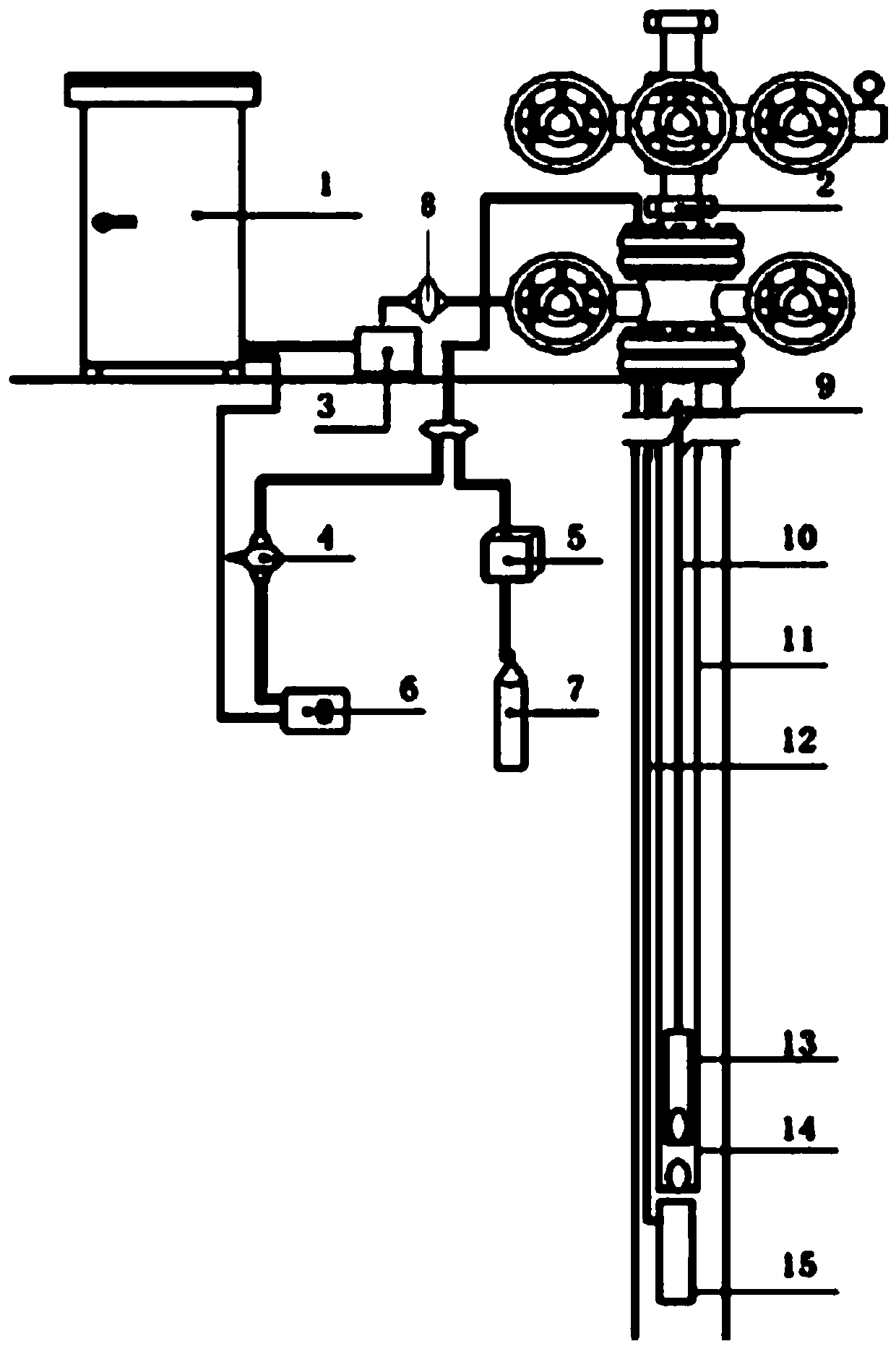

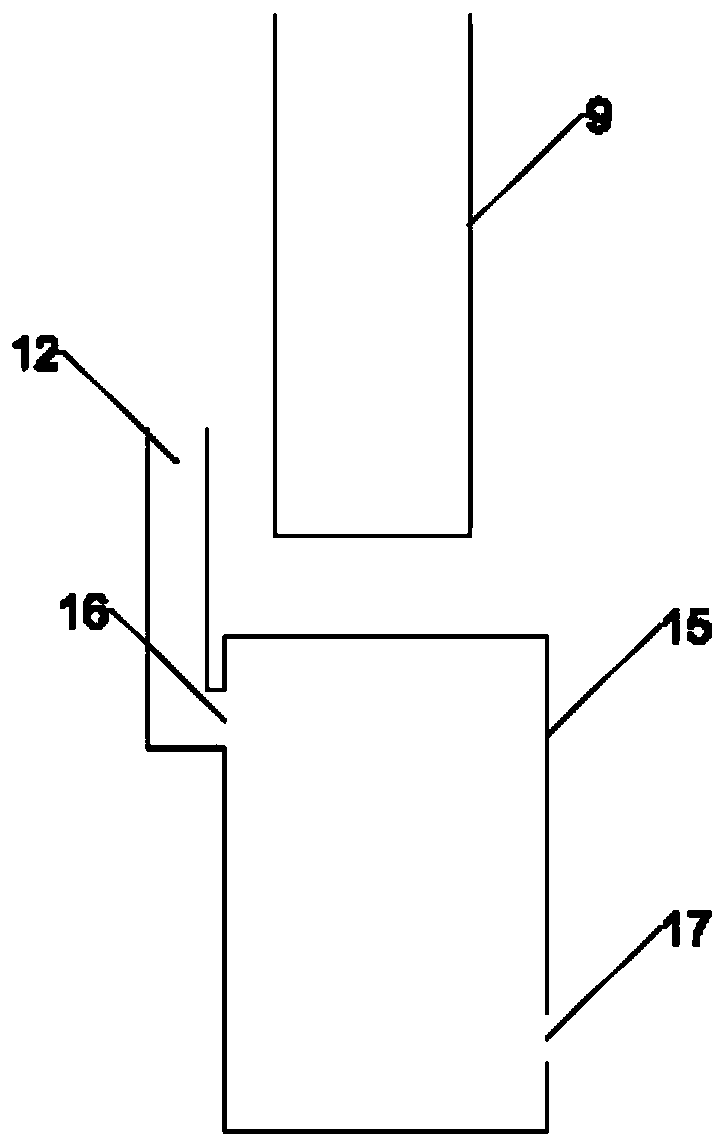

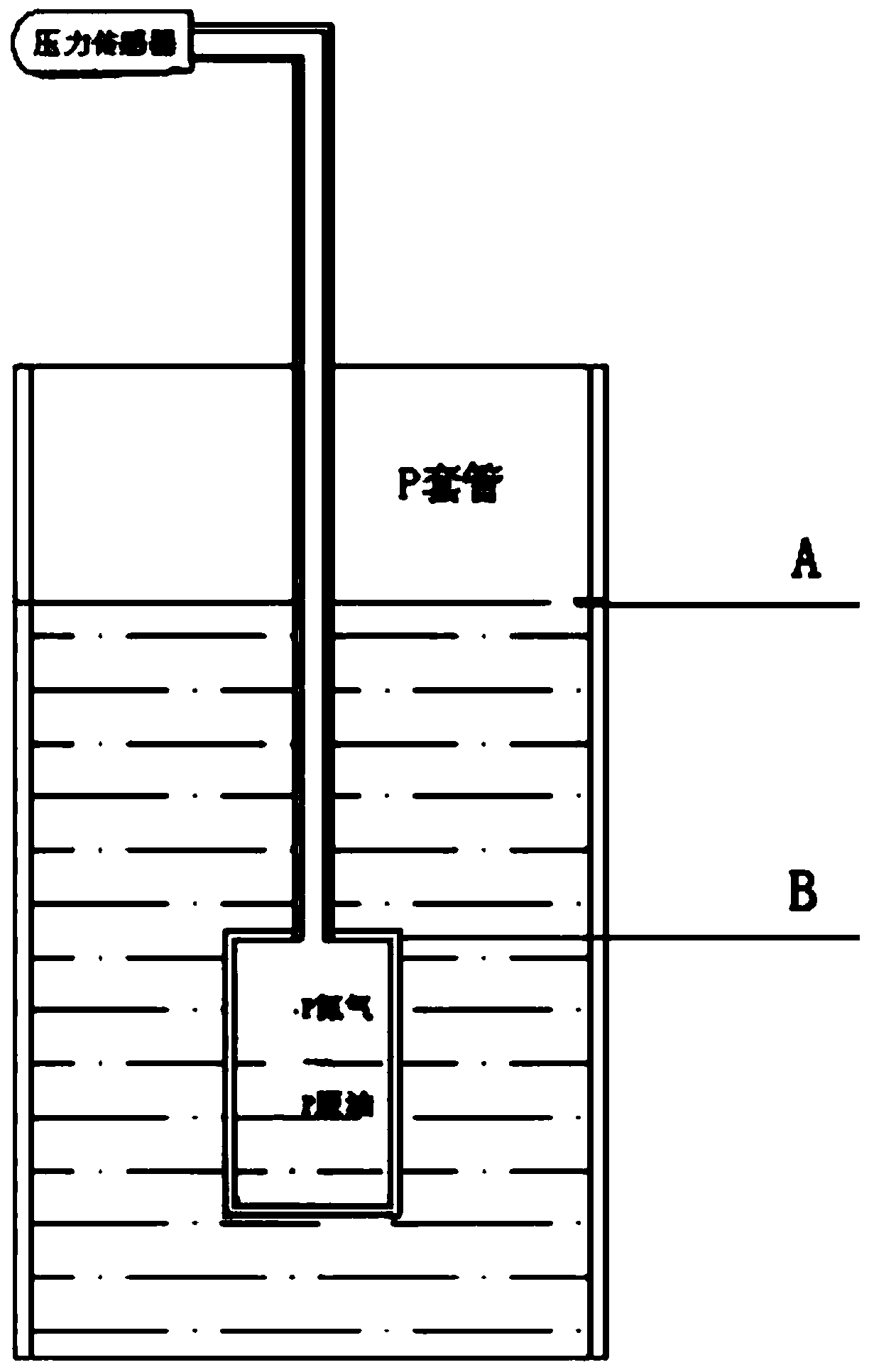

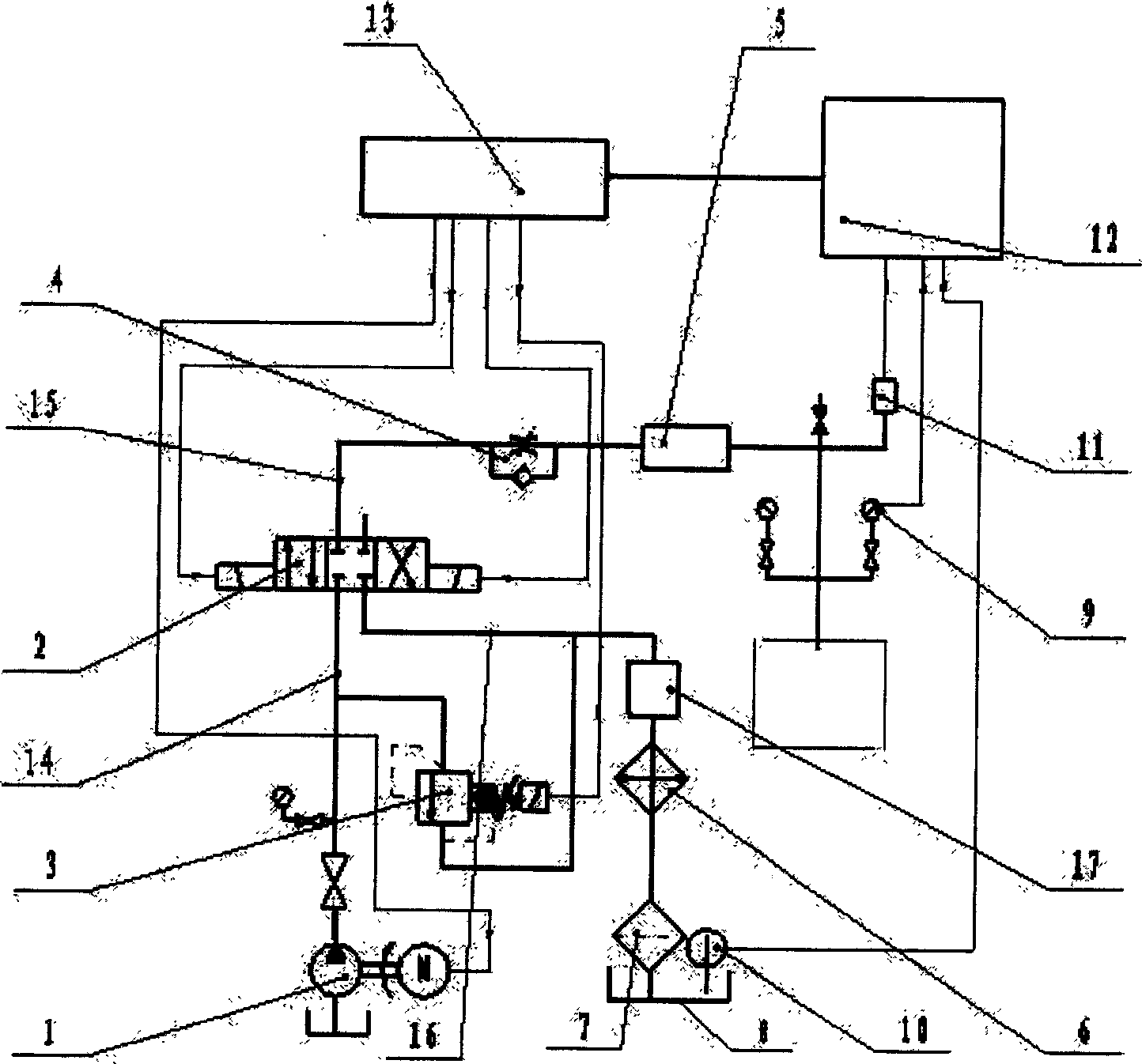

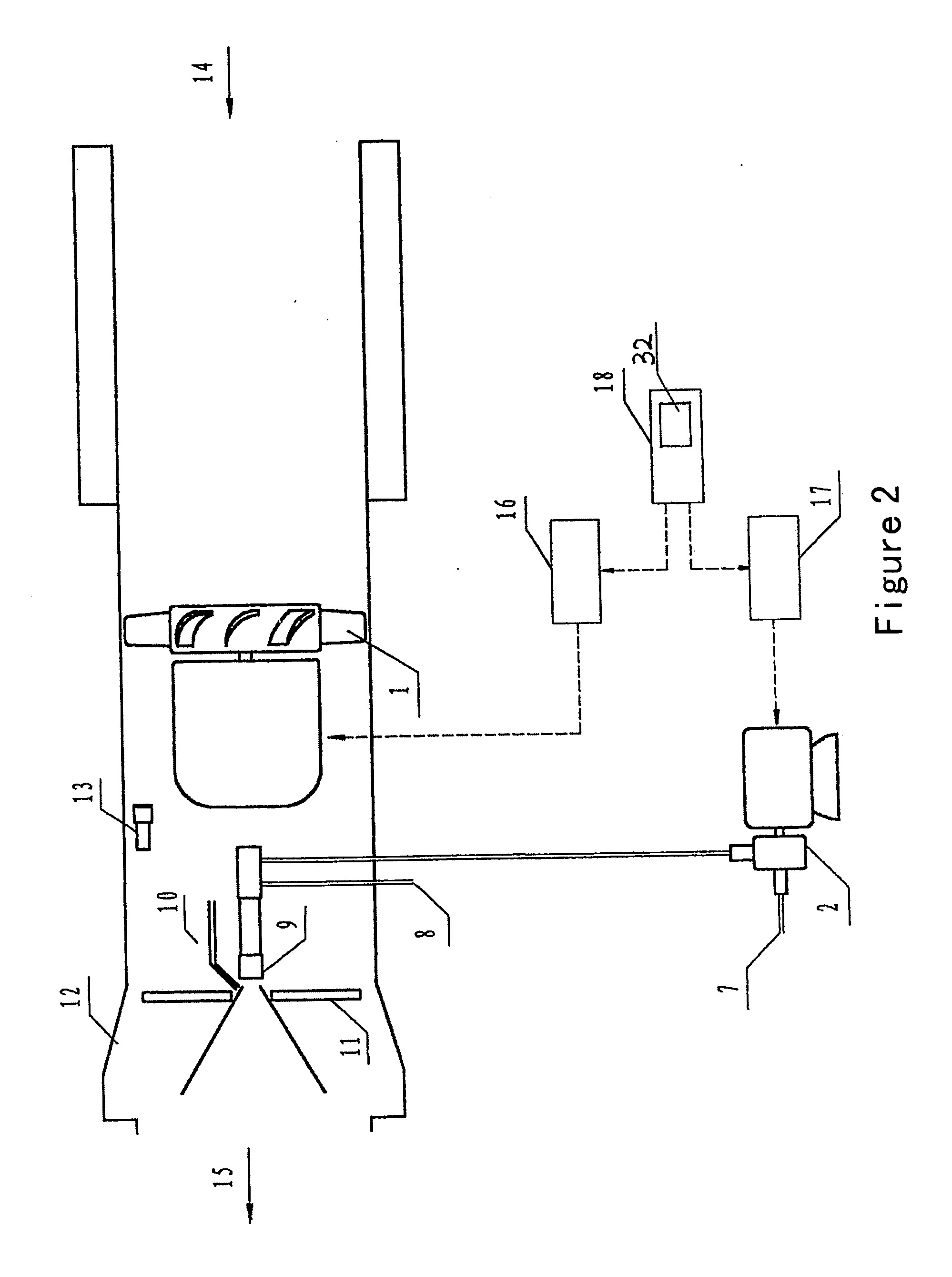

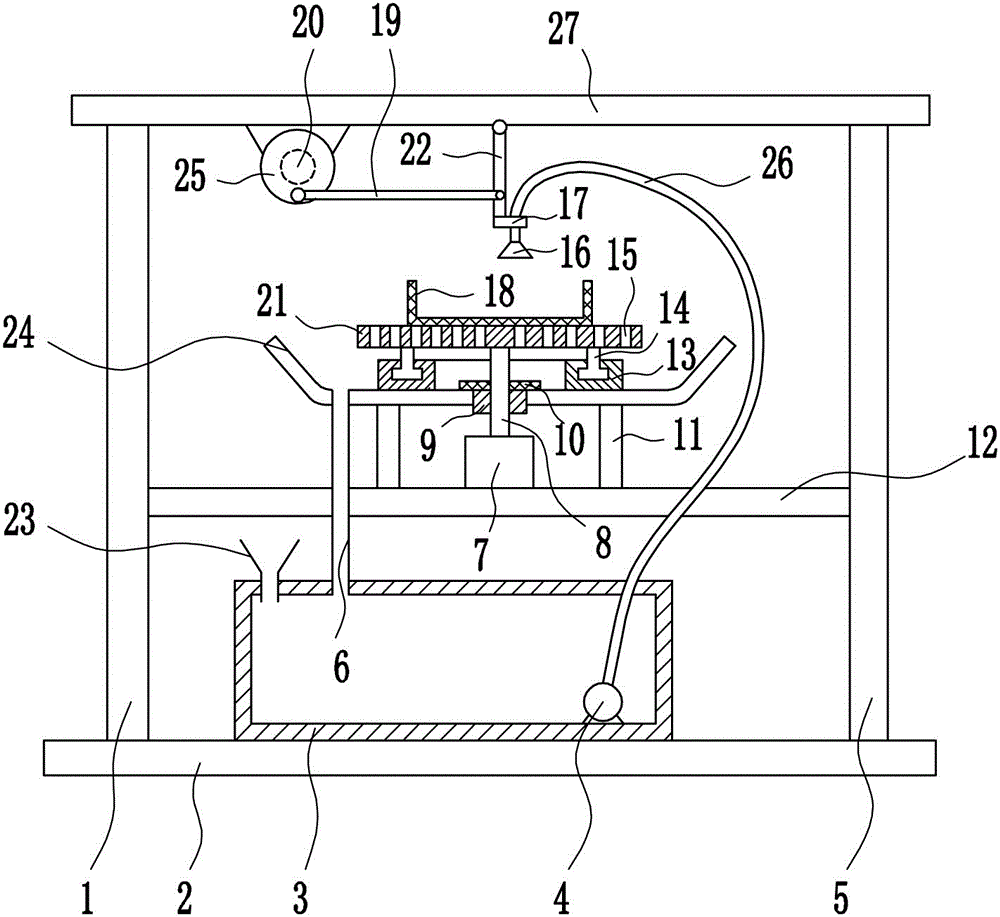

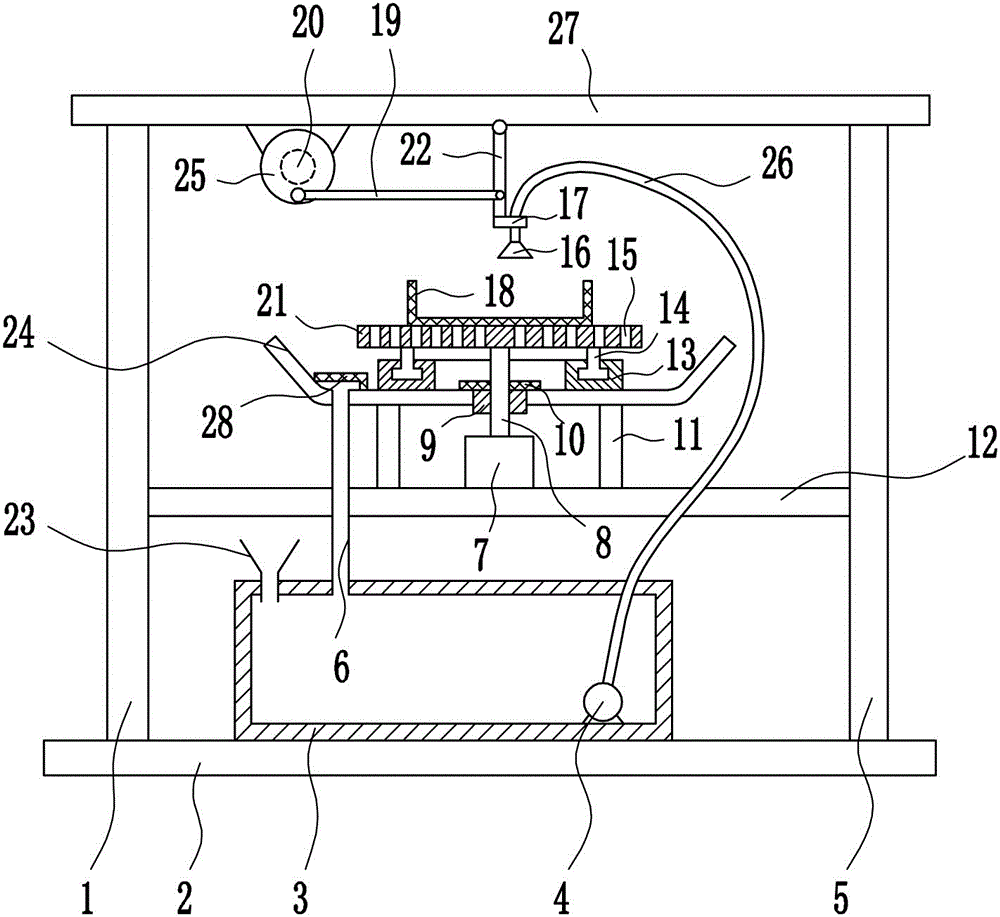

Gas-conducting pressure measuring intermittent producing oil exploitation device

The invention discloses a gas-conducting pressure measuring intermittent producing oil exploitation device. The gas-conducting pressure measuring intermittent producing oil exploitation device makes contact with well liquid during working, the gas-conducting pressure measuring intermittent producing oil exploitation device comprises gas conducting and pressure measuring equipment used for measuring the hydrostatic fluid column pressure, controlling equipment used for receiving data of the gas conducting and pressure measuring equipment so as to control oil pumping equipment to realize intermittent oil production, and the oil pumping equipment making direct contact with the well liquid, wherein the gas conducting and pressure measuring equipment comprises tubular billet pressure measuring equipment and sleeving pressure measuring equipment, the tubular billet pressure measuring device comprises a nitrogen cylinder, a nitrogen booster pump, a capillary steel pipe used for conducting nitrogen, a pressure transmitting cylinder used for bearing the nitrogen and tubular billet pressure sensors connected to an outlet of the nitrogen booster pump and an inlet of the capillary steel pipe which are sequentially connected, and the sleeving pressure measuring device comprises a sleeving pressure sensor connected with the oil pumping equipment. Controller equipment receives data of a data collector to control the working frequency of oil extraction equipment or start and stop of the oil extraction equipment, so that the intermittent production is realized to achieve the effect of reducing the production cost.

Owner:JEREH ENERGY SERVICES

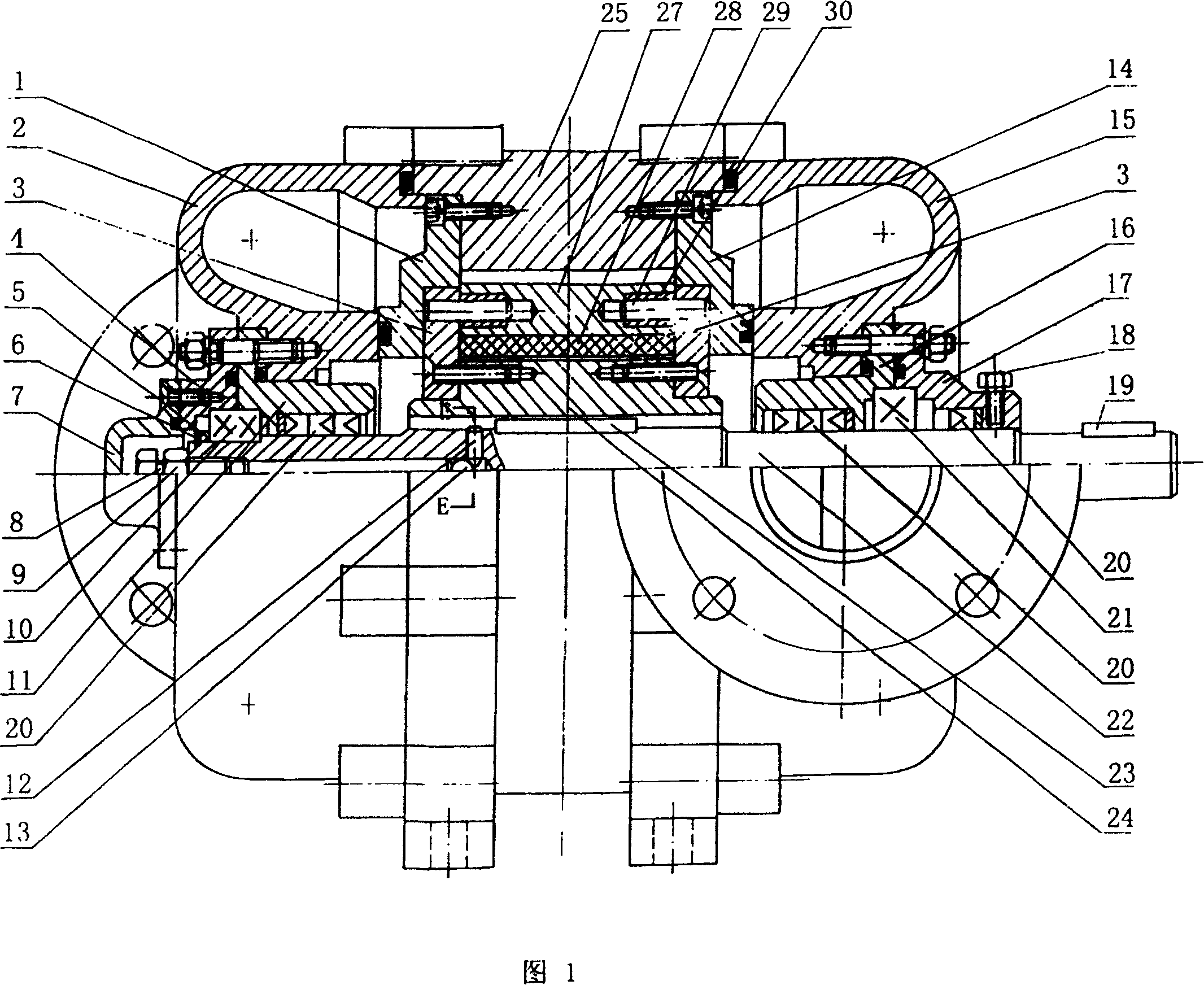

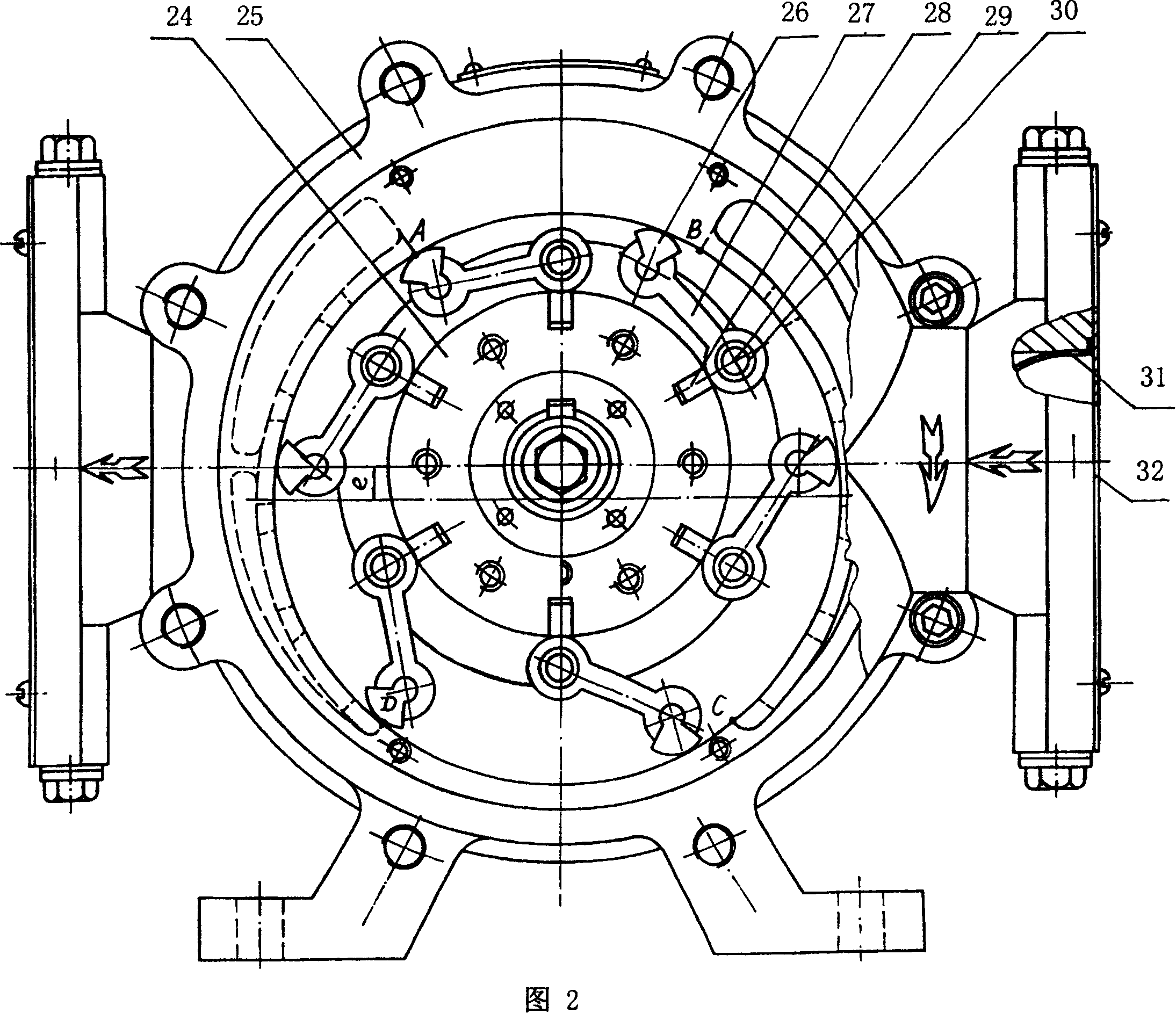

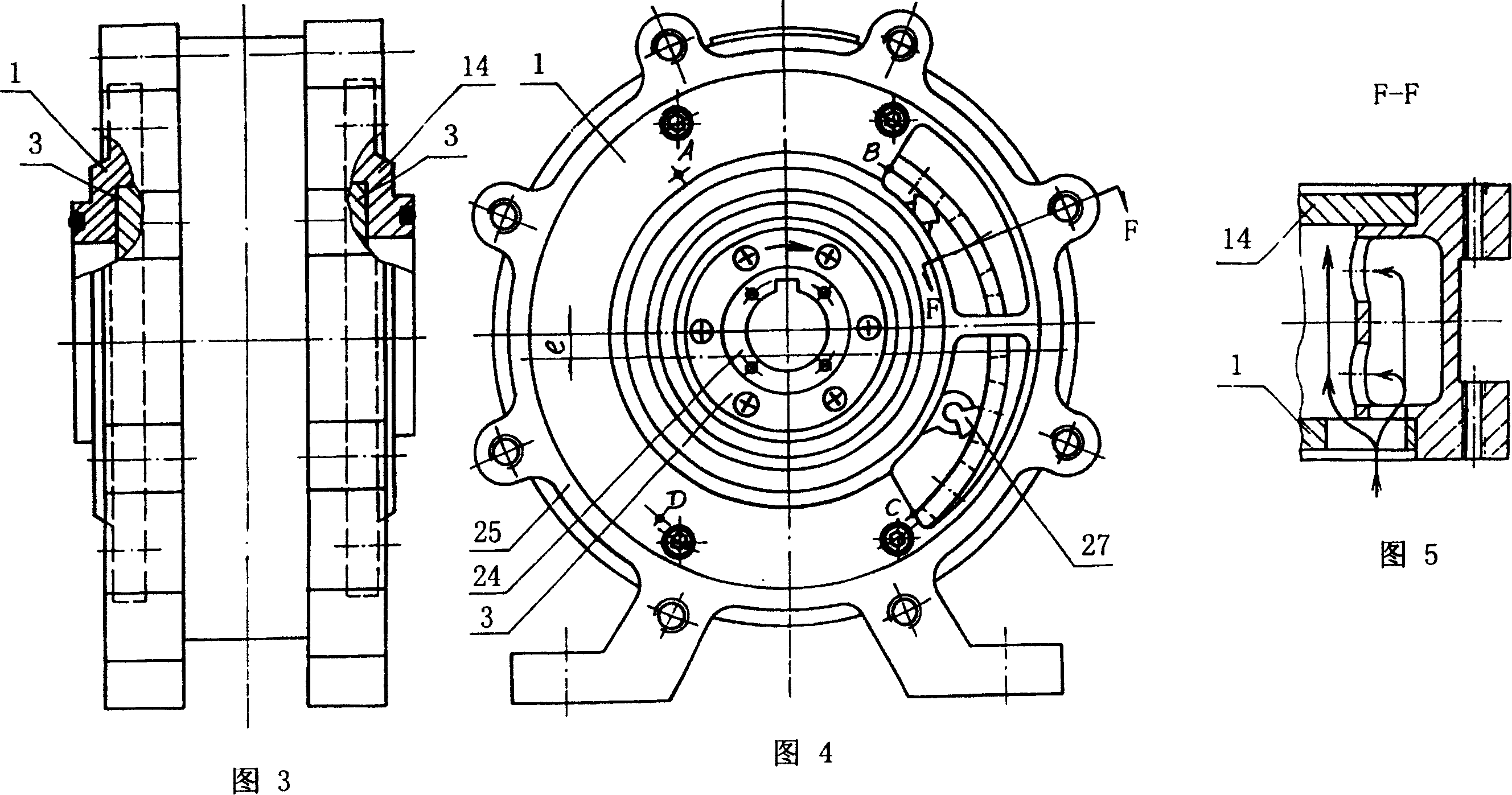

Rotary blade pump

InactiveCN100374725CReduce line speedEliminate cavitationRotary piston pumpsRotary piston liquid enginesClassical mechanicsEngineering

In the invention, an inlet-outlet oil flow plate is fixed at two ends of a pump case stator. A radial inlet-outlet runner is built-up on the pump case stator to realize axial and radial inlet and outlet oil at the same time. A rotor is mounted in the internal cavity of the pump case stator and there is an offsetting e between the rotor and the ID of the pump case stator. Rotary vanes are mounted on a rotating board fixed on the two end faces of the rotor. The rotor is mounted on the pump spindle via a rotor key. A rotor locking device is assembled on the front part of the pump spindle. The inlet-outlet oil pump covers are fixed at two ends of the pump stator separately. A ring inlet-outlet oil passageway is disposed in inlet-outlet oil pump. A bearing support and sealing device is assembled on the central of the inlet-outlet oil pump cover.

Owner:王振忠 +1

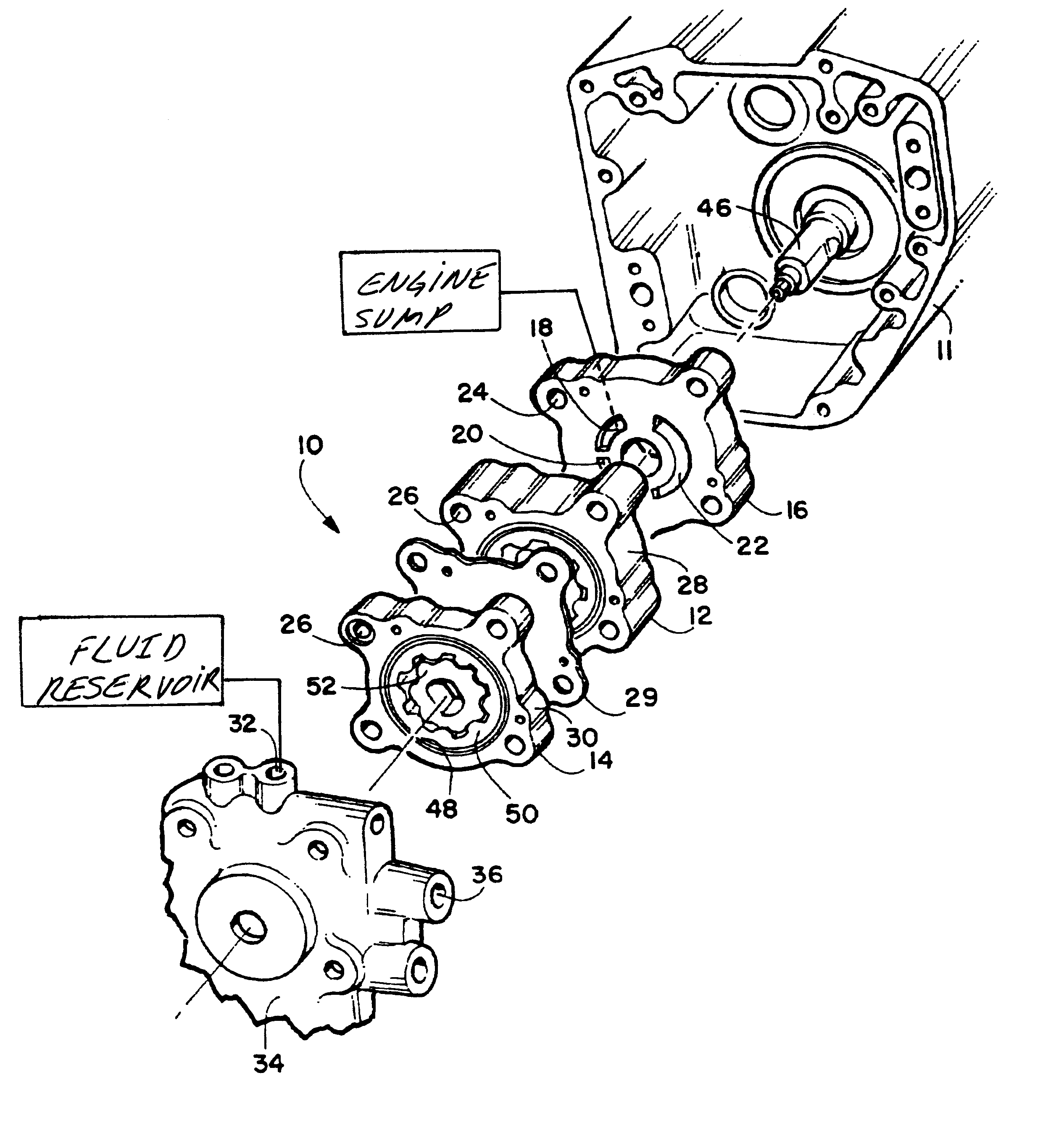

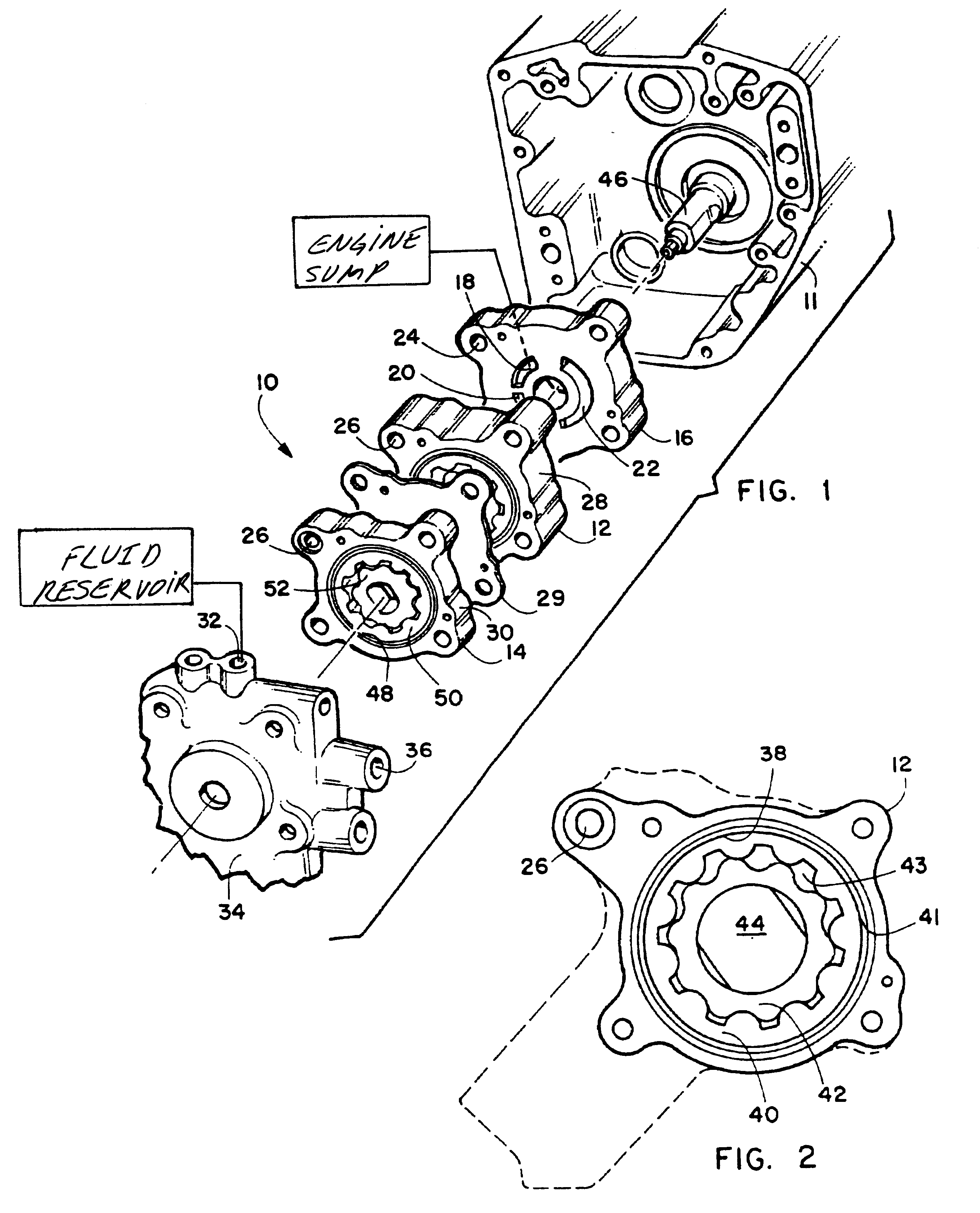

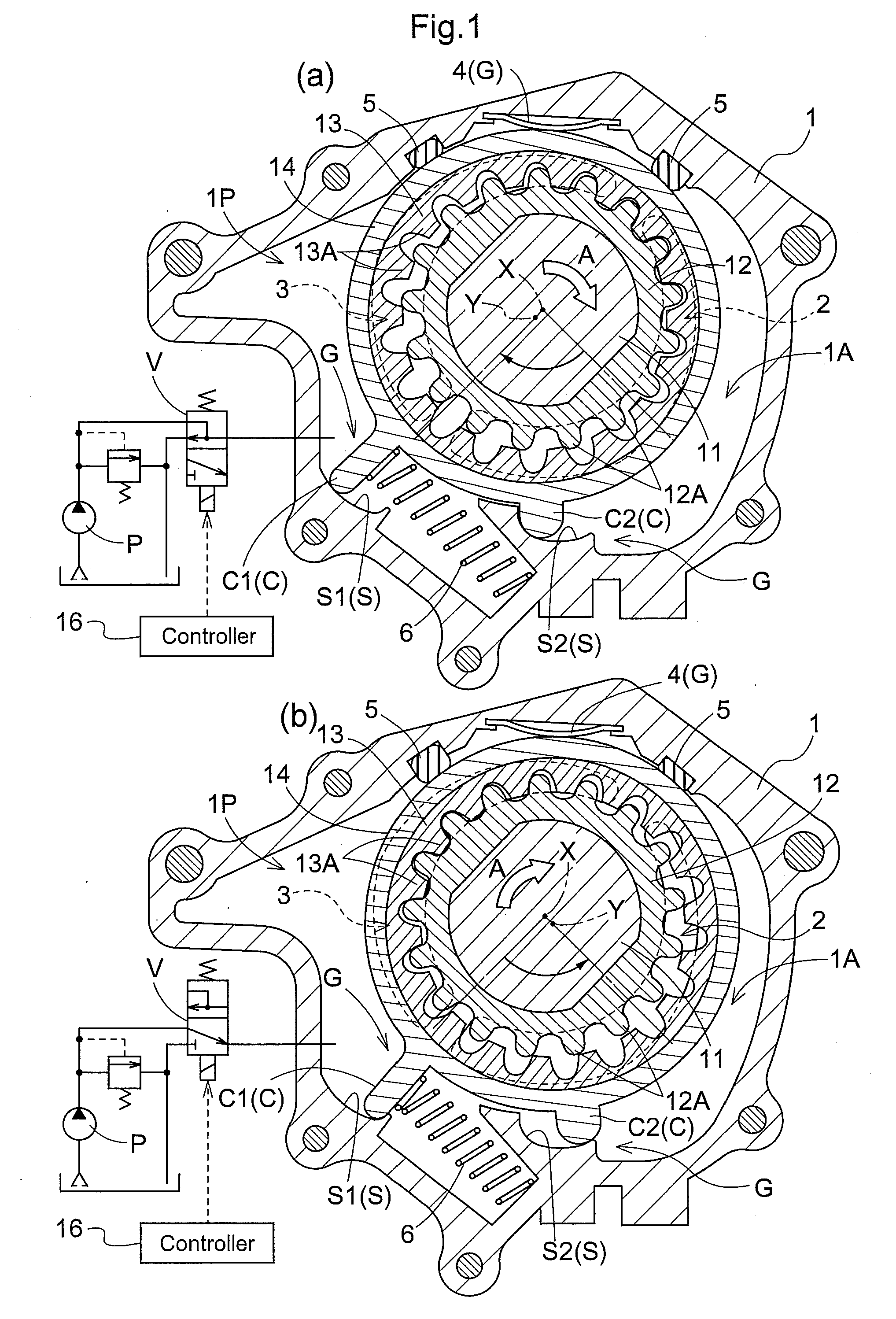

Oil pump

InactiveUS6679692B1Easy to replacePromote repairRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesFuel tankEngineering

A modular oil pump for use in combination with an internal combustion engine having a dry sump lubrication system. The device features a first gerotor pump having an intake port engageable in communication with at least one engine sump and having an discharge port engageable in sealed communication with a fluid reservoir for the dry sump system. A second gerotor pump, engageable in sealed communication with the fluid reservoir has a discharge port fluidly engageable with the engine lubrication system oil supply conduit. Both the first pump and second pump are assembled from separate housings, and cooperatively engaged inner and outer gears sized for rotation and in line mounting on the engine crankshaft inside a cavity in the housings. The volume pumping capacity of the first pump at a ratio to efficiently drain fluid and gas from the engine sumps and supply the reservoir with a constant supply of lubrication fluid. The device may be assembled from a kit having a plurality of different sized components to adjust the ratio of the pumping volume of the first pump to the second pump.

Owner:FEULING JAMES J

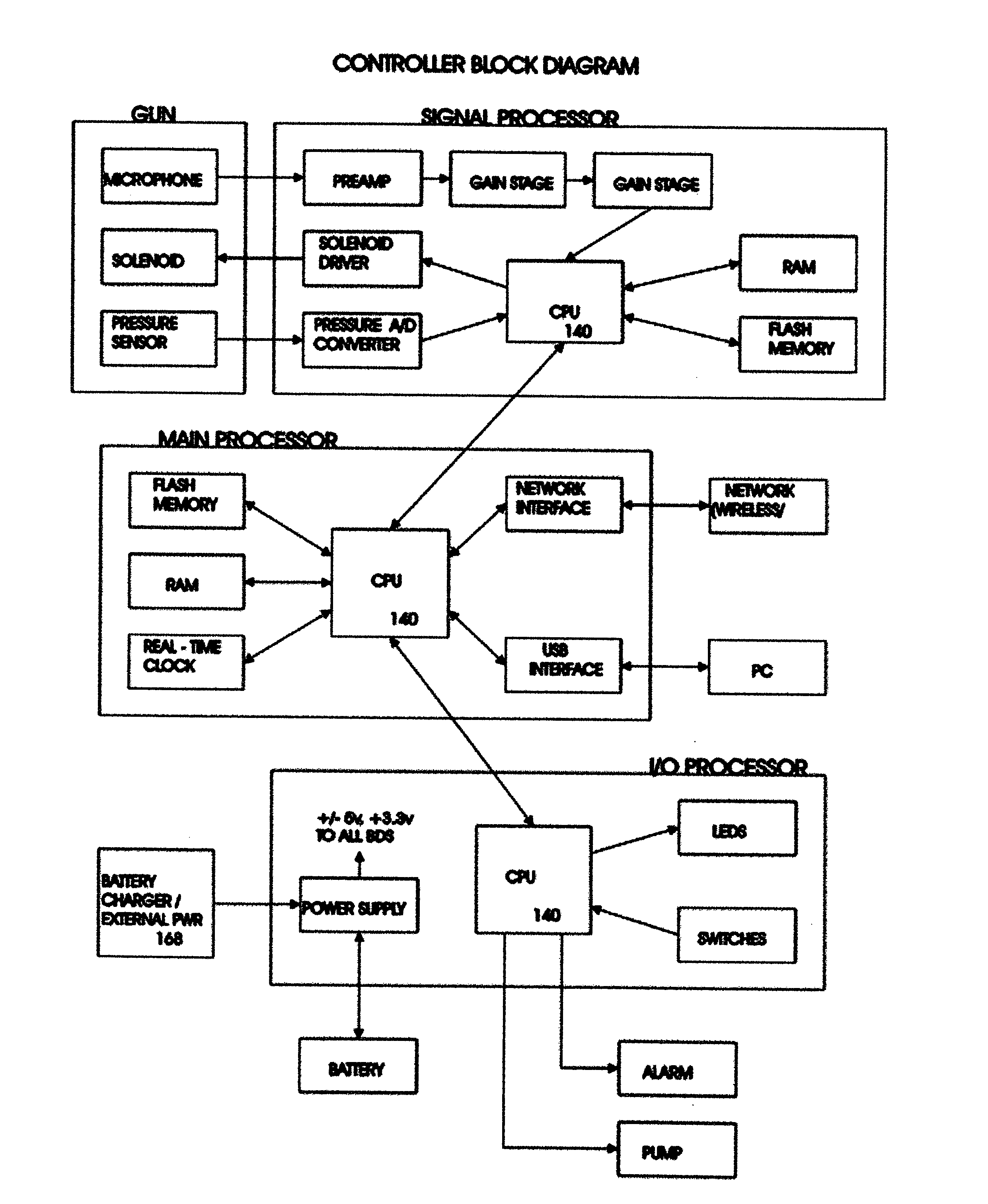

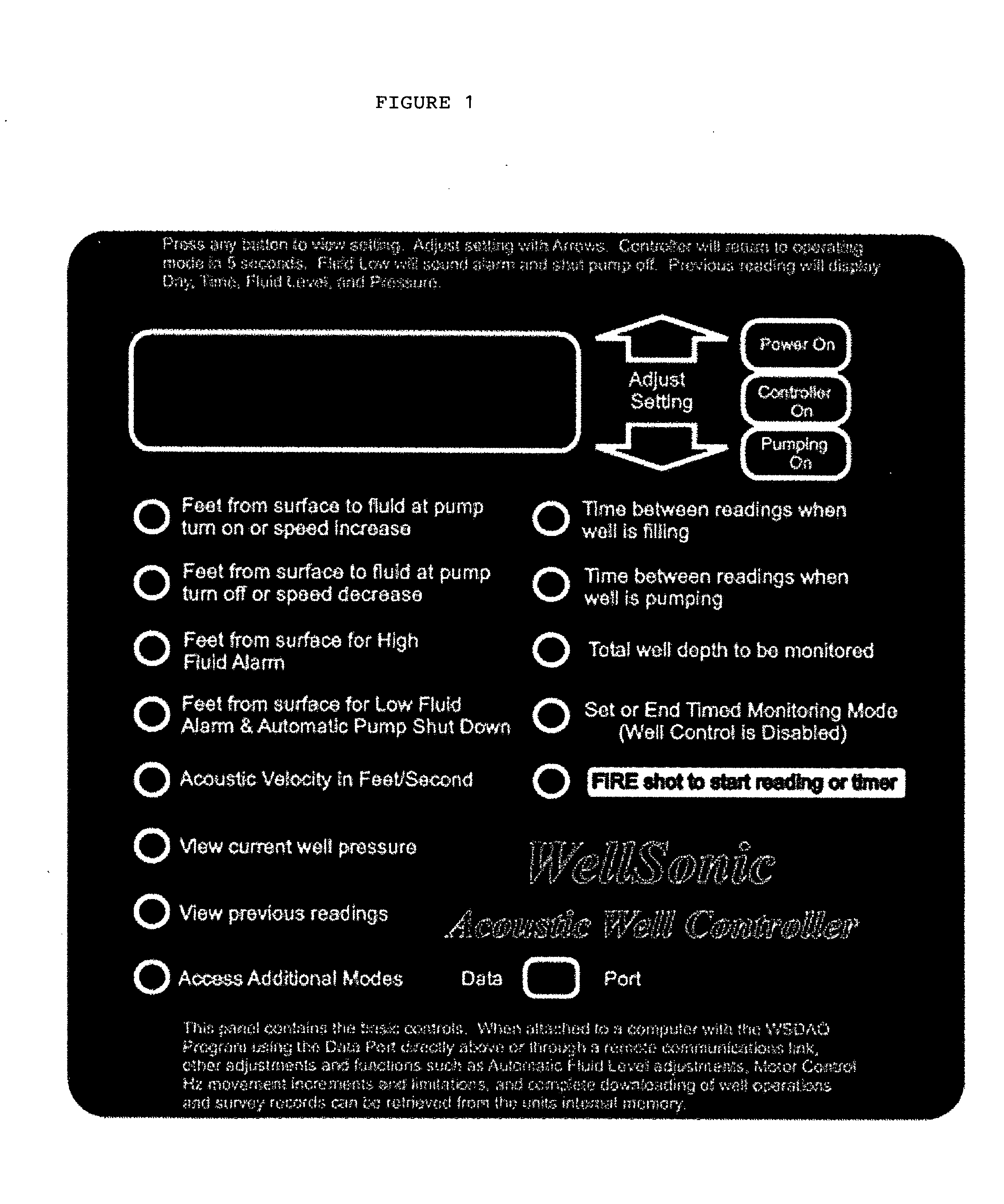

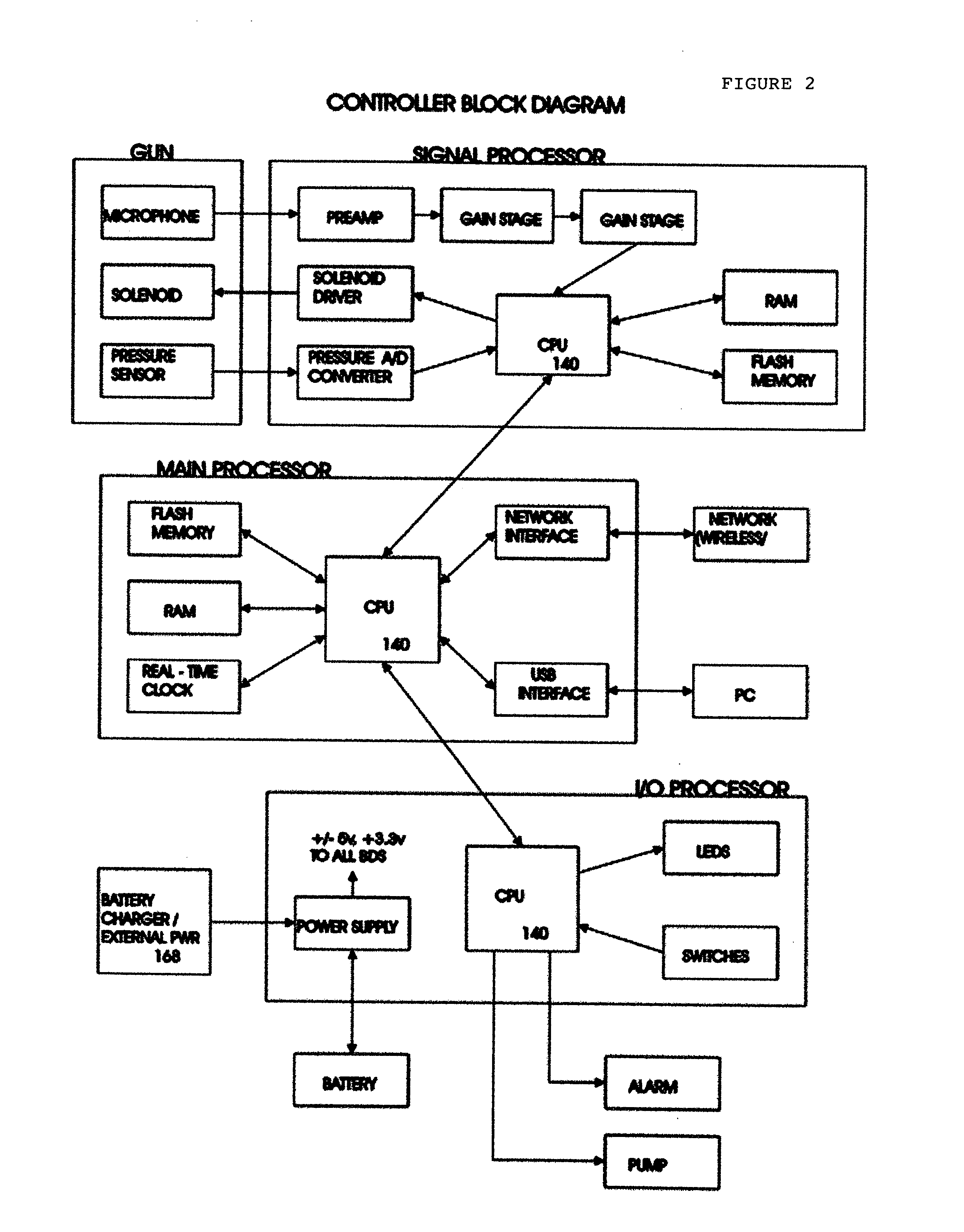

Well Pump Controller Unit

InactiveUS20060235573A1Optimizing oil productionOil production operating costSurveyFlexible member pumpsOil productionMeasurement device

In the oil production industry one objective of the field operator is to streamline their oil pumping operations for the more efficient production. The current invention is a controller device used to continuously control and optimize oil production from a well. The current invention is used in conjunction with a precise well measuring device, i.e. a device that can precisely measure characteristics of a well at a moment in time, for generating real-time information to be used by the controller device to optimize the rate of oil production.

Owner:GUION WALTER FRANKLIN

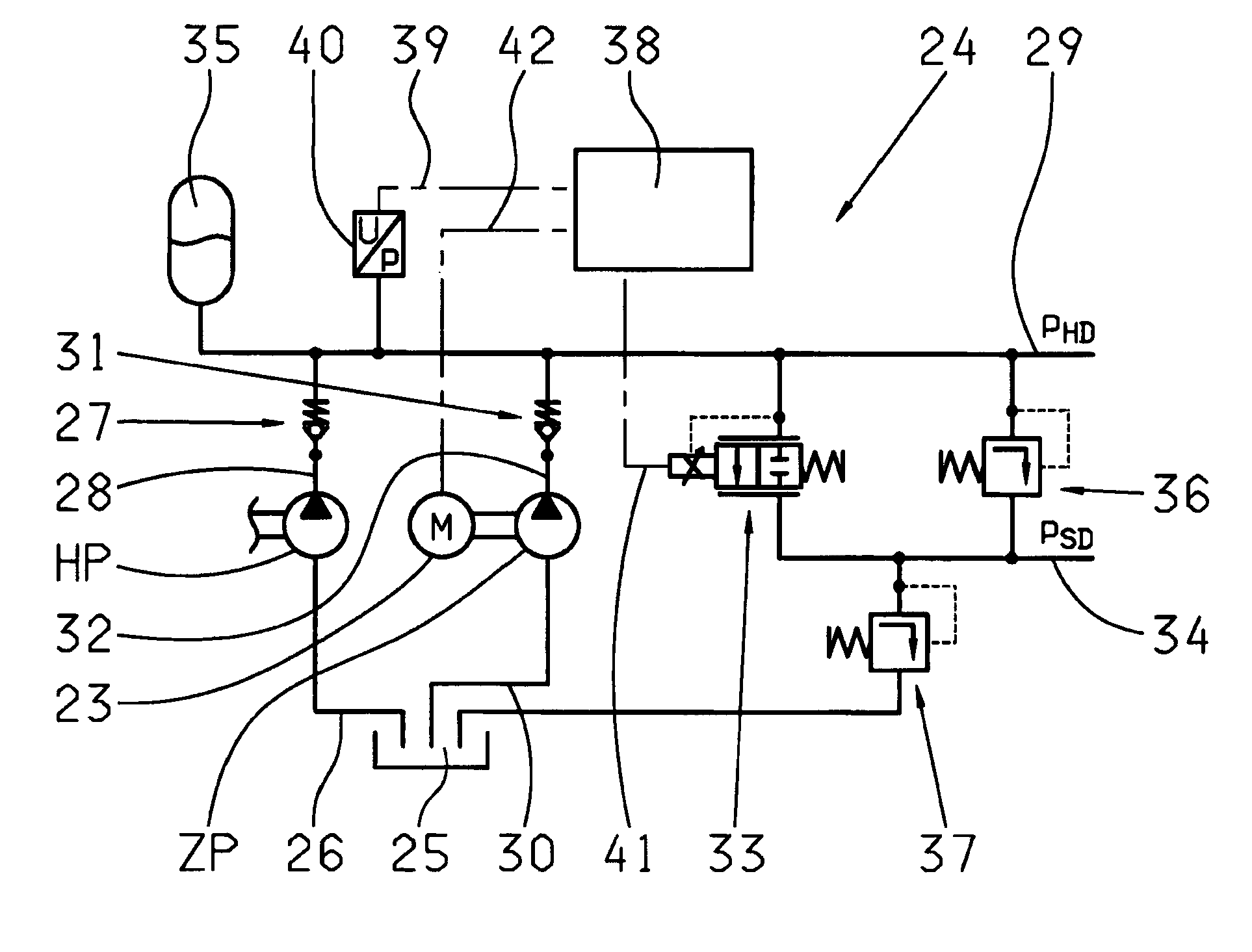

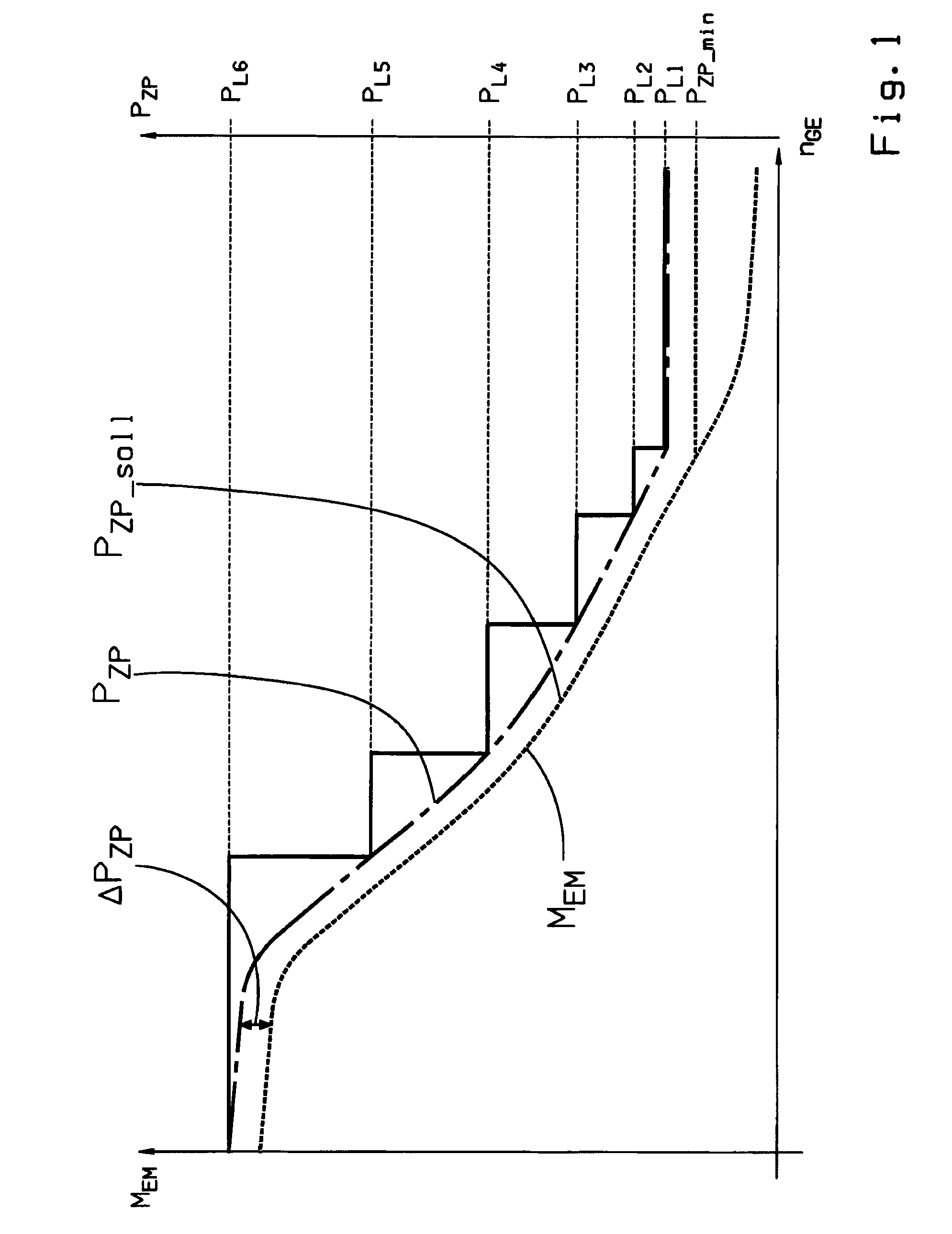

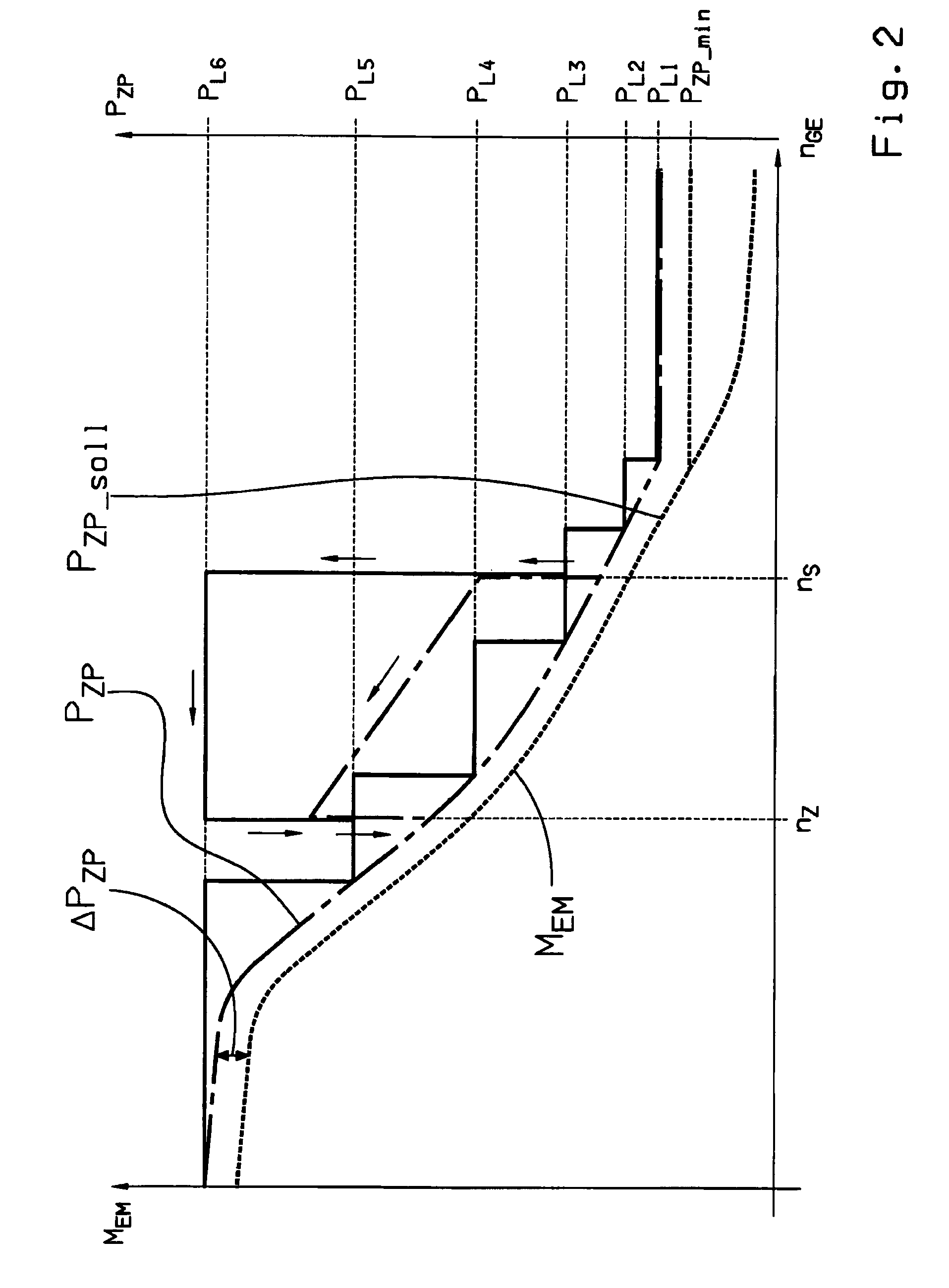

Method for controlling the oil supply of an automatic planetary transmission

InactiveUS20100018808A1Improve accessibilityIncrease installation spaceElectric propulsion mountingGear lubrication/coolingEngineeringInternal combustion engine

The invention relates to a method for controlling the oil supply device of an automatic planetary transmission, comprising a main oil pump (HP), which is mechanically drivably connected to the drive shaft of an internal combustion engine (VM), and an auxiliary oil pump (ZP) that may be driven via a controllable electric motor, the automatic transmission (ATG) being part of a parallel hybrid powertrain of a motor vehicle having an input shaft (5), which may be connected via a separating clutch (K) to the drive shaft (2) of the internal combustion engine (VM) and is permanently drivably connected to the rotor (4) of an electric machine (EM).In order to achieve an oil supply to the automatic transmission (ATG) as and when needed, it is provided that the current oil requirement (PHD<sub2>—< / sub2>soll) of the automatic transmission is determined as a function of at least one currently captured operating parameter, and that the delivery rate (PZP) of the auxiliary oil pump (ZP) is set, by a correspondingly actuation of the associated electric motor, in the combustion and combined driving mode below a minimum input speed of the main oil pump (HP) and in the electric driving mode to at least the total oil requirement, and at least in the combined driving mode above the minimum input speed of the main oil pump (HP) is set to at least the residual oil requirement exceeding the delivery rate (PHP) of the main oil pump.

Owner:ZF FRIEDRICHSHAFEN AG

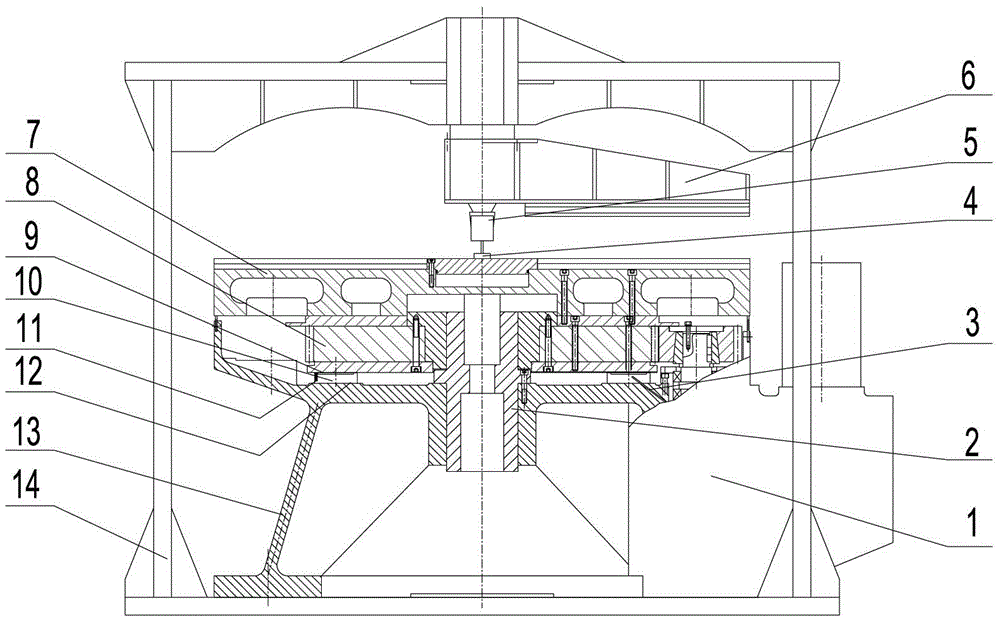

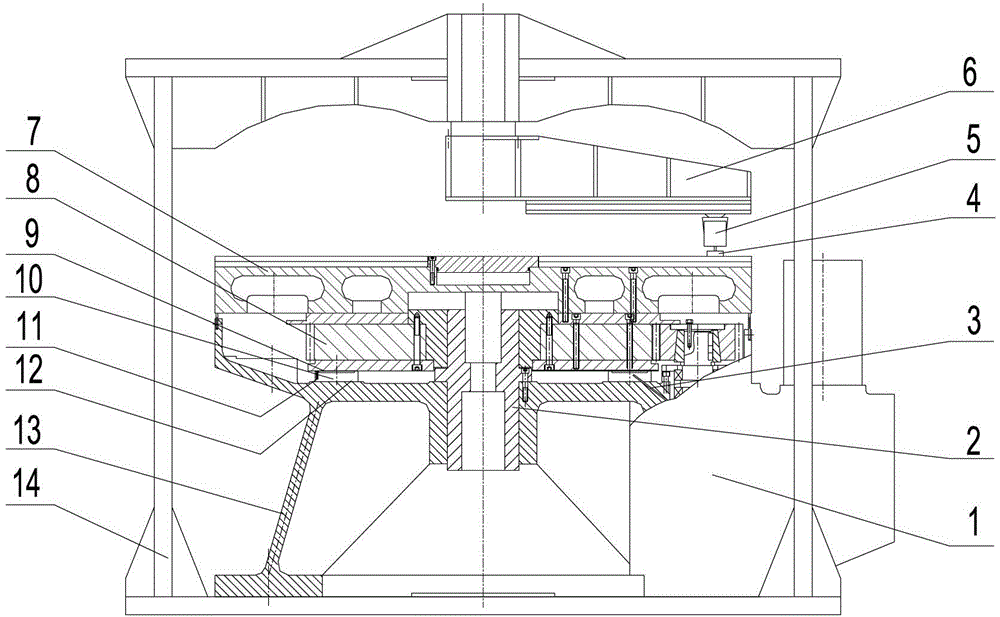

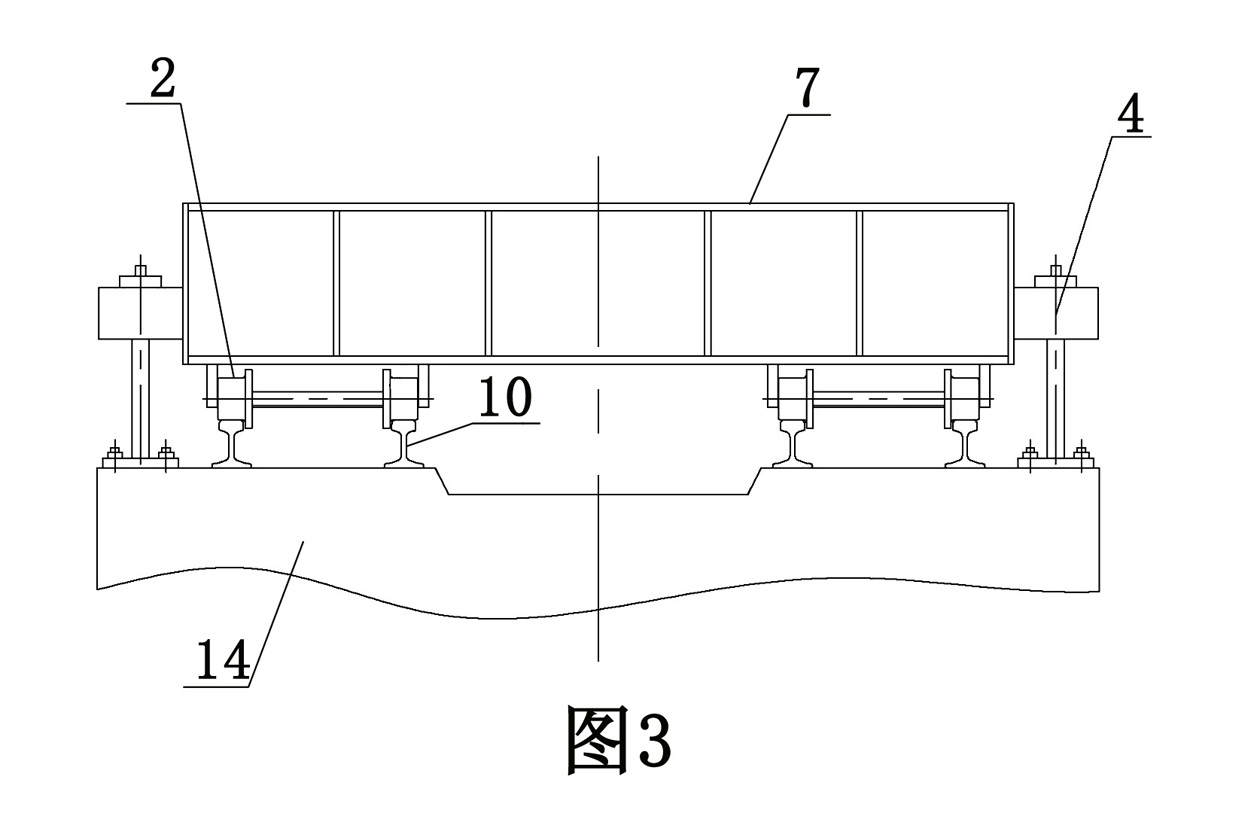

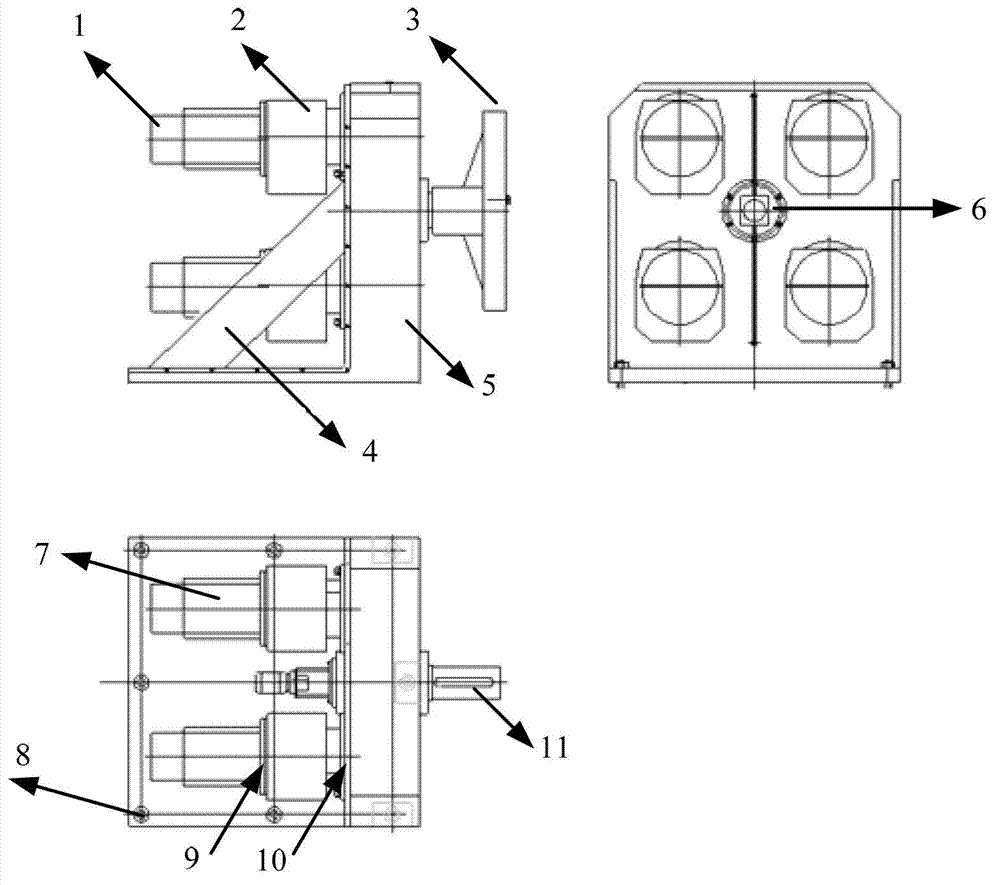

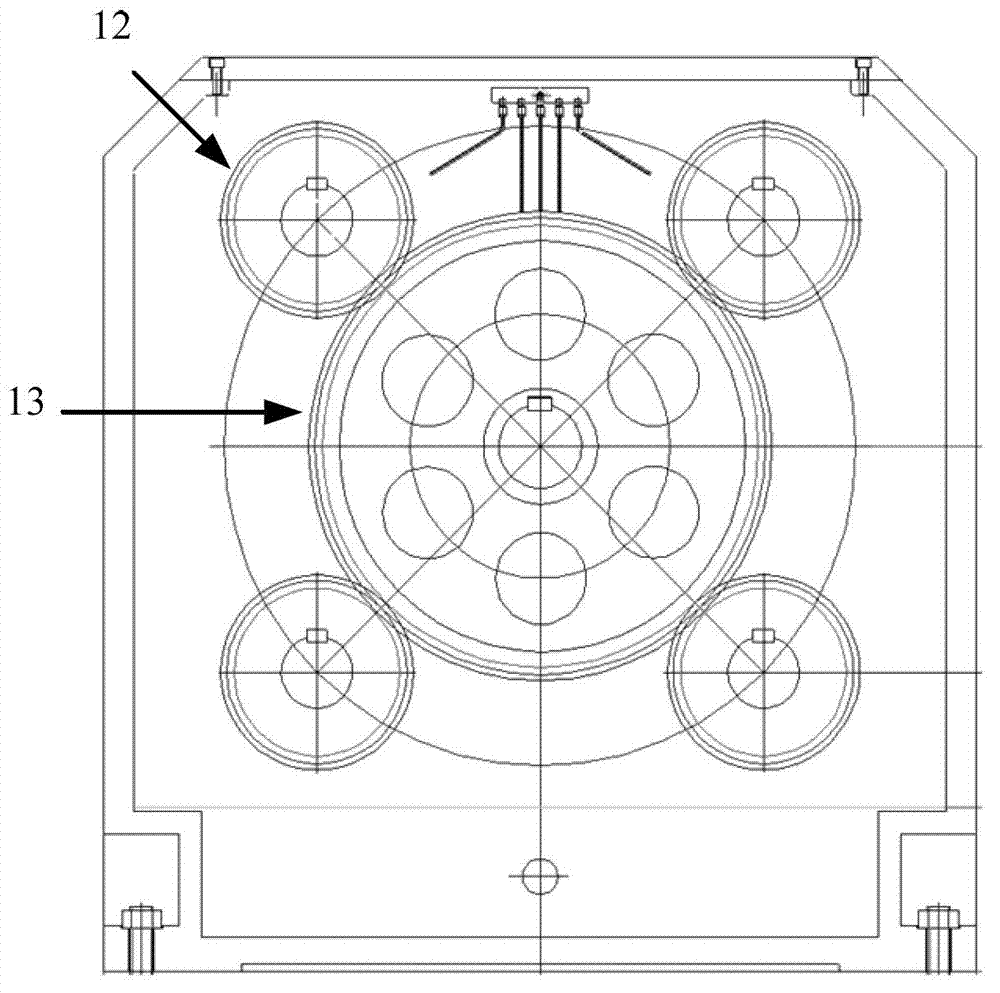

Quantitive type experimental device for dynamic and static performances of static-pressure rotary table

ActiveCN102980755AStructural parameter optimizationImprove machining accuracyMachine part testingElectricityEddy current

The invention provides a quantitive type experimental device for dynamic and static performances of a static-pressure rotary table, and belongs to the field of machinery design and manufacture. According to the experimental device, a loading device (5) and a loading arm (6) are used for changing magnitude of loads or changing oil supply pressure to control the distance between a static-pressure oil cushion (10) and a rotary table disc chuck (7), a pressure sensor (12) is used for measuring pressure in an oil cavity, an eddy current displacement sensor (11) is used for measuring the thickness of an oil film, a thermocouple temperature sensor (3) is used for measuring oil temperature, a force sensor (4) is used for obtaining magnitude of loading force, a pressure gauge a (15) on a multi-head pump at an oil inlet in the oil cavity is used for measuring pressure of the oil inlet of the oil cavity, and a pressure gauge b (16) arranged between an oil pump and the multi-head pump is used for measuring the oil supply pressure of the static-pressure rotary table. By means of the experimental device, a test of the dynamic and static performances of the static-pressure rotary table is carried out under the condition that temperature is between minus 10 DEG C and 60 DEG C and pressure is not more than 100 MPa, and the experimental device provides guarantee for solving problems in engineering, optimizing structural parameters of the rotary table, and improving machining precision of the rotary table.

Owner:BEIJING UNIV OF TECH

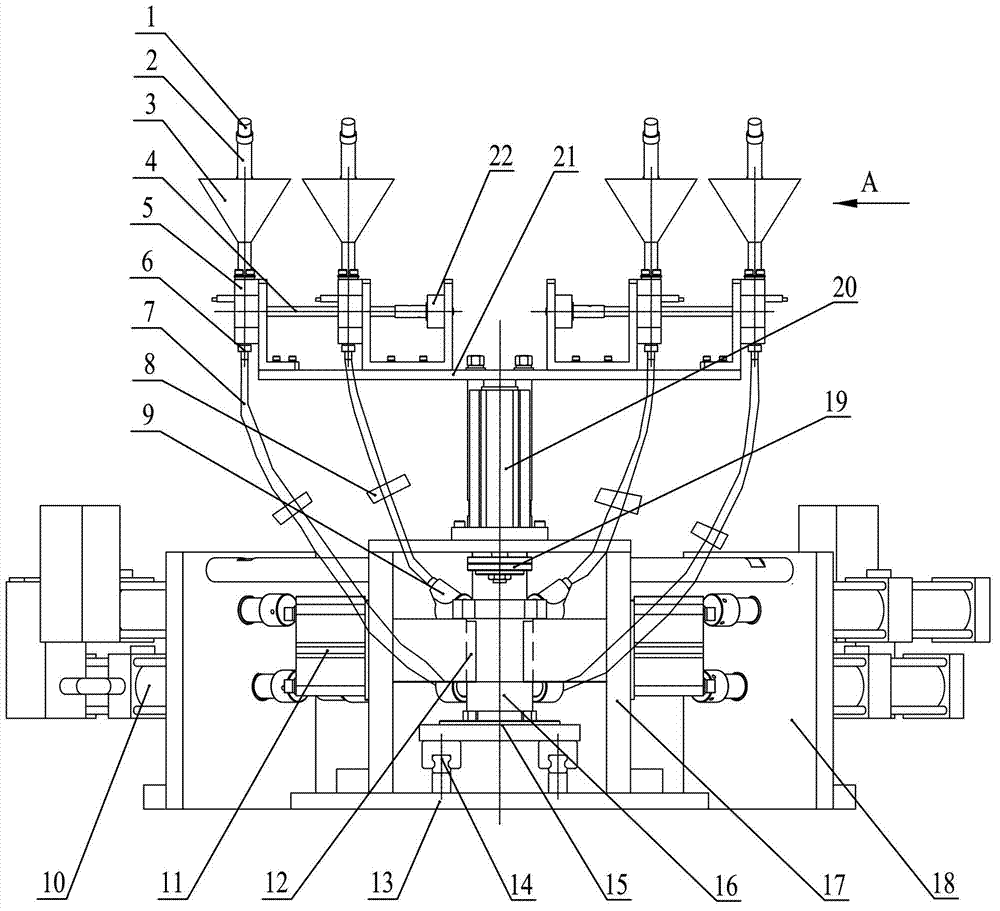

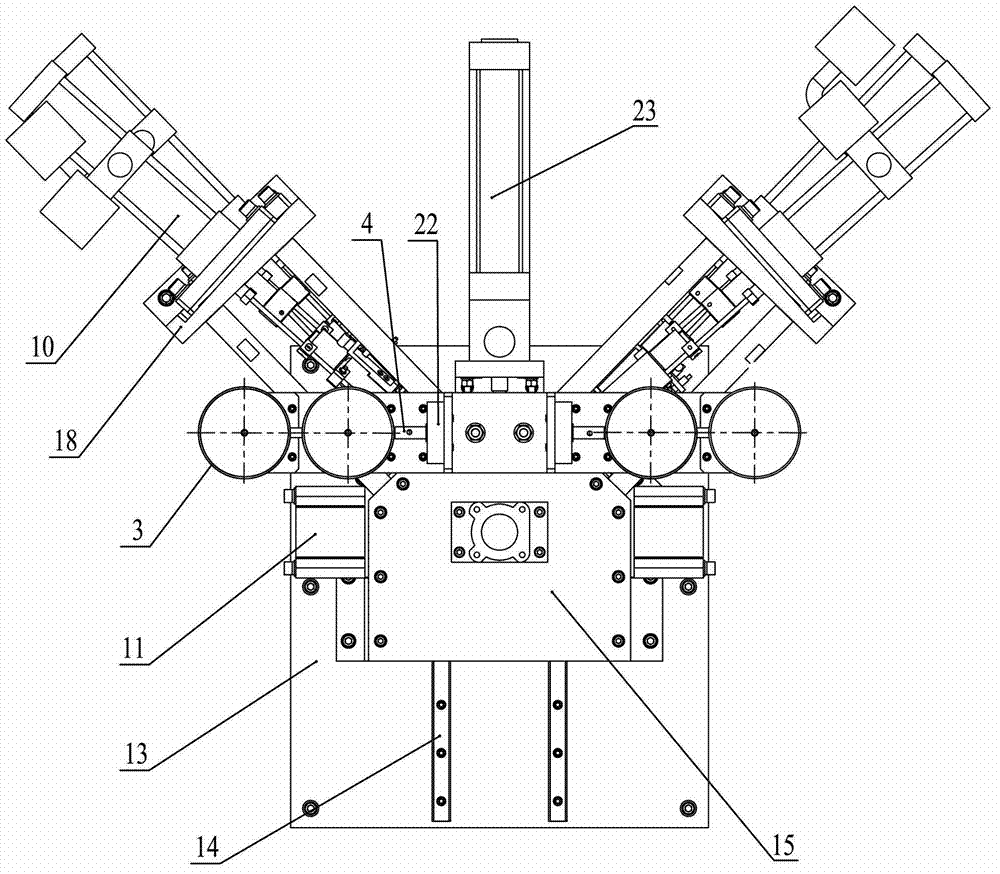

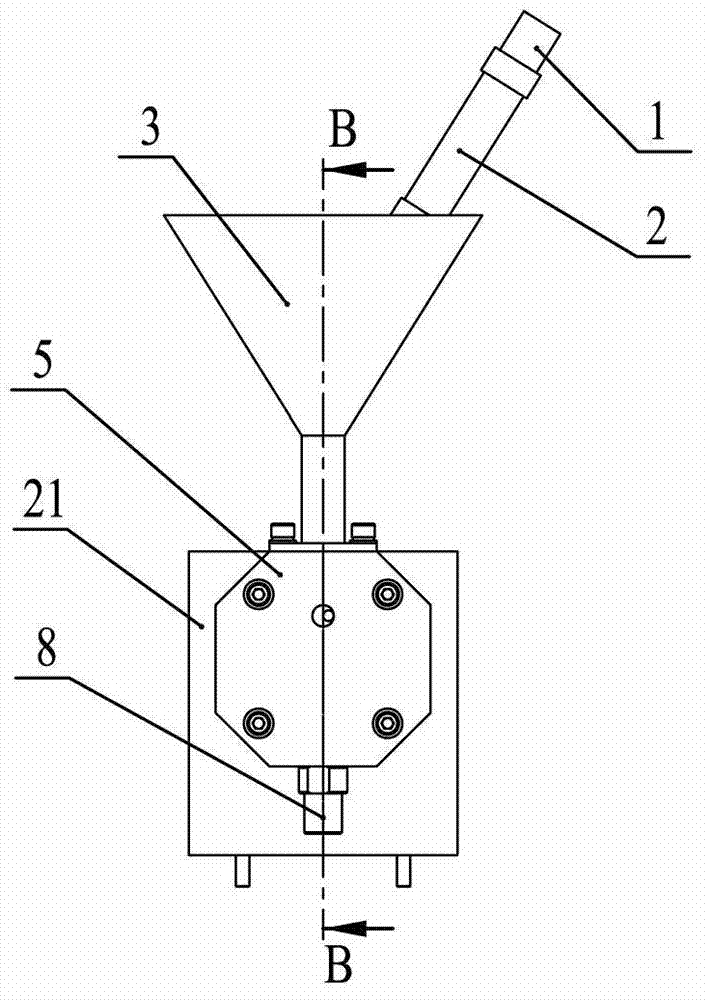

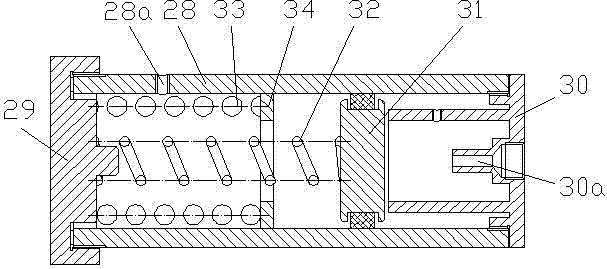

Automatic pressing-filling device for steel balls

ActiveCN102729035AImprove quality stabilityReduce work intensityAssembly machinesMetal working apparatusEngineeringSteel ball

The invention relates to an automatic pressing-filling device for steel balls. The automatic pressing-filling device is characterized by comprising a base and a support, wherein a workpiece conveying mechanism is installed on the base, and a workpiece clamping mechanism, a steel ball sorting and conveying mechanism and a steel ball pressing-in mechanism are installed on the support; the workpiece conveying mechanism is used for loading and conveying a workpiece, the workpiece clamping mechanism is used for fixing the workpiece which is conveyed in place, the steel ball sorting and conveying mechanism is used for conveying the steel balls to the workpiece, and the steel ball pressing-in mechanism is used for pressing the steel balls in the workpiece. The automatic pressing-filling device for steel balls disclosed by the invention is ingenious, compact and reasonable in structure, accurate in pressing-fitting and positioning, convenient in installation and maintenance, capable of automatically conveying the steel balls and accurately pressing-filling the steel balls in the workpiece of an oil pump shell, thus improving the quality stability of a positioning and pressing-filling process for the steel balls in the oil pump shell, lightening the working intensity of operating personnel, and improving the labour production efficiency; therefore, the quality of pressing-filling for the steel balls of the oil pump shell meets the requirements of a process assembly standard.

Owner:WUXI YAZHONG PNEUMATIC HYDRAULIC

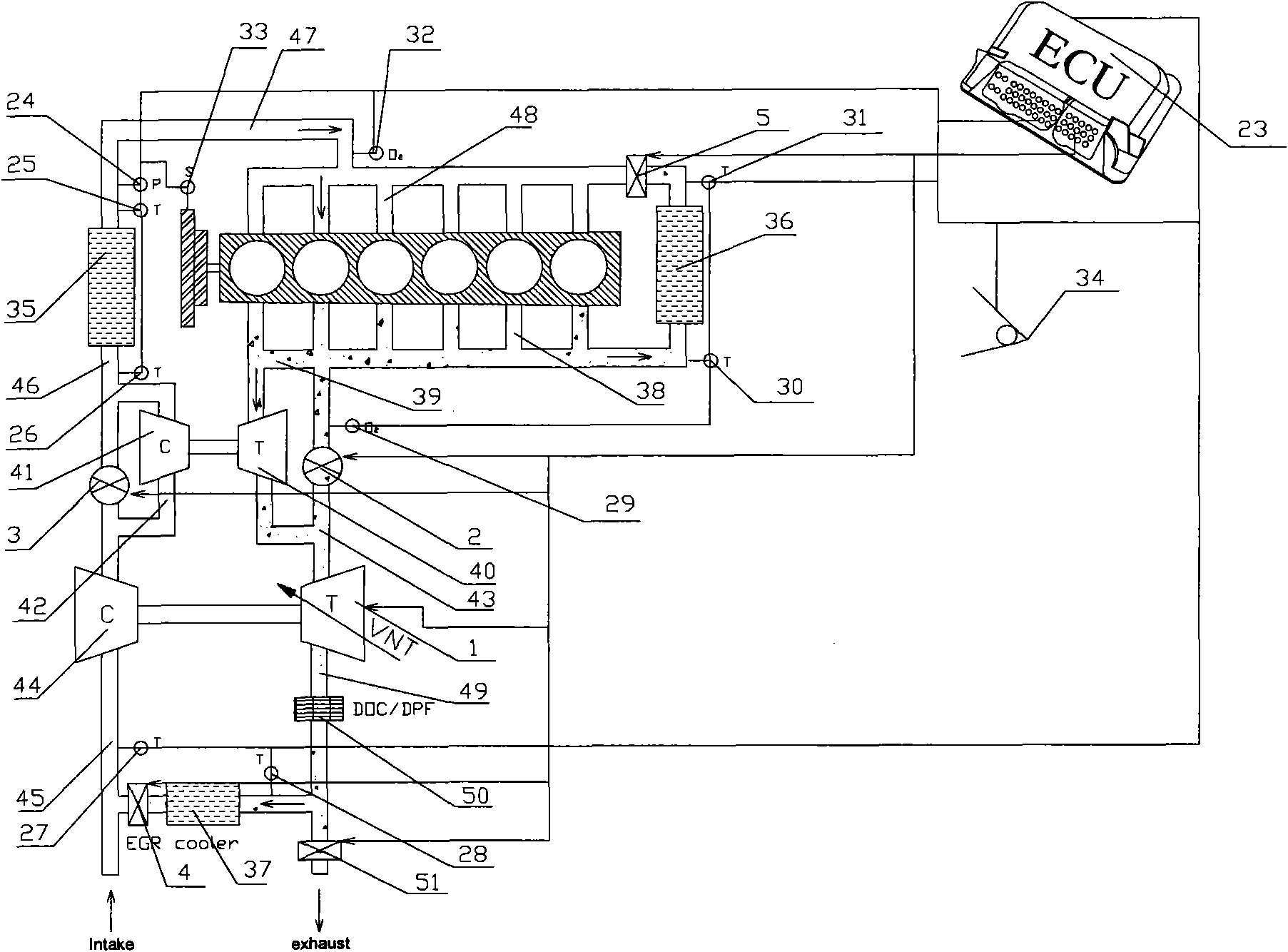

Electronic control method of variable gas inlet and exhaust system of compression ignition engine

InactiveCN101526042AImprove performanceImprove reliabilityElectrical controlMachines/enginesTurbochargerControl system

The invention relates to an electronic control method of a variable gas inlet and exhaust system of a compression ignition engine, comprising a pressurization system, a waste gas recycle system, a gas intake valve late-closing mechanism and an electronic control system. The pressurization system adopts a two-level turbocharger; the waste gas recycle system comprises a high-pressure part and a low-pressure part; the gas intake late-closing mechanism is a gas intake valve push rod which is capable of adjusting the telescopic length in a self-adapting hydraulic control mode based on self motion position, and the gas intake late-closing mechanism consists of a hydraulic push rod assembly and a hydraulic auxiliary mechanism, wherein the hydraulic push rod assembly is fixed at the upper end of an internal-combustion engine cylinder head; a hydraulic oil pump is fixed on an internal-combustion engine body; an electronic control system is controlled by an electronic control unit; and the electronic control unit judges and controls the density of intake gas in real time through a pressure sensor, a temperature sensor, a rotate speed sensor, and the like in the system. The invention can control the density of intake gas in real time, improves the performance of the internal-combustion engine, greatly reduces discharged harmful product and enhances the reliability.

Owner:TIANJIN UNIV

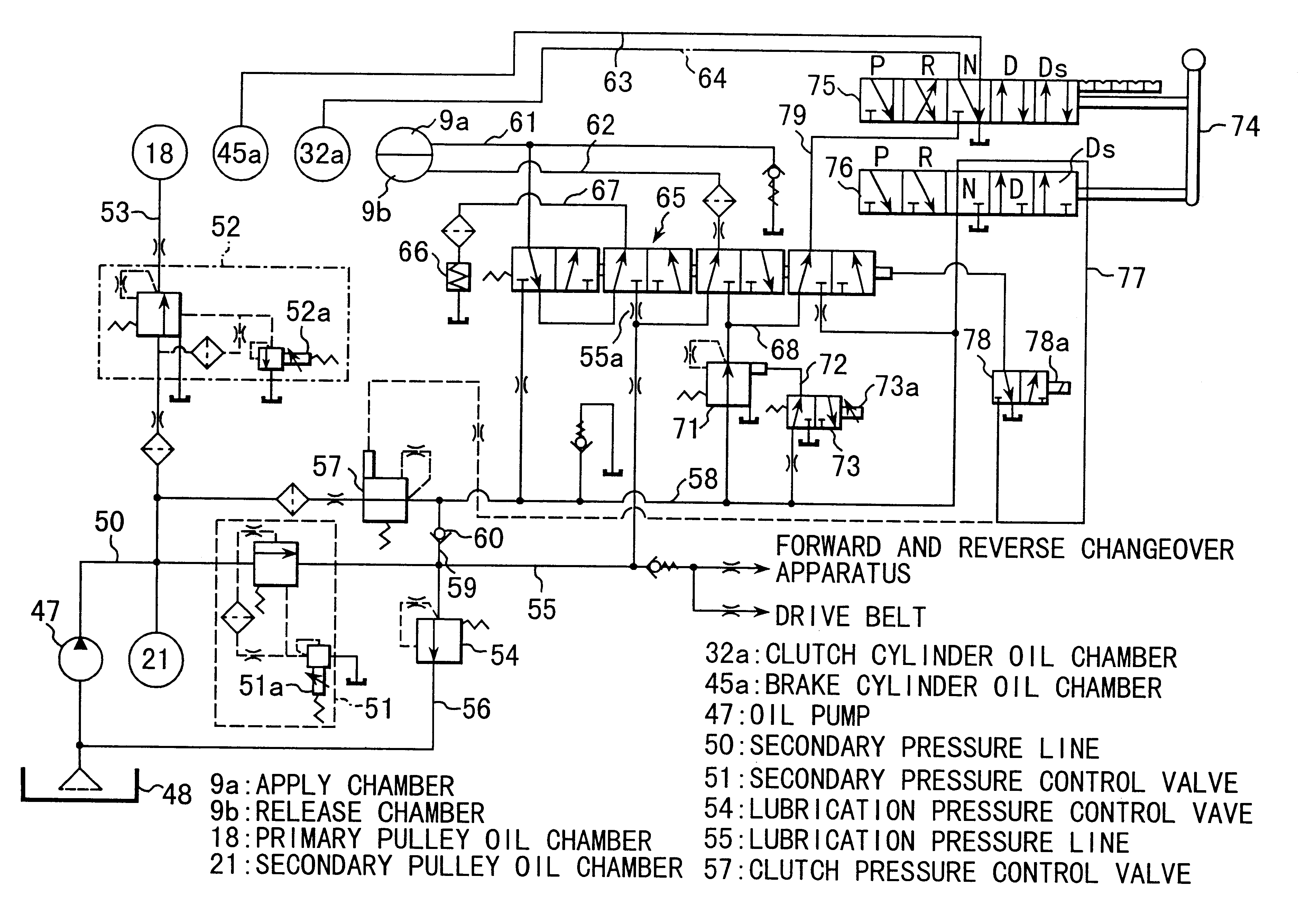

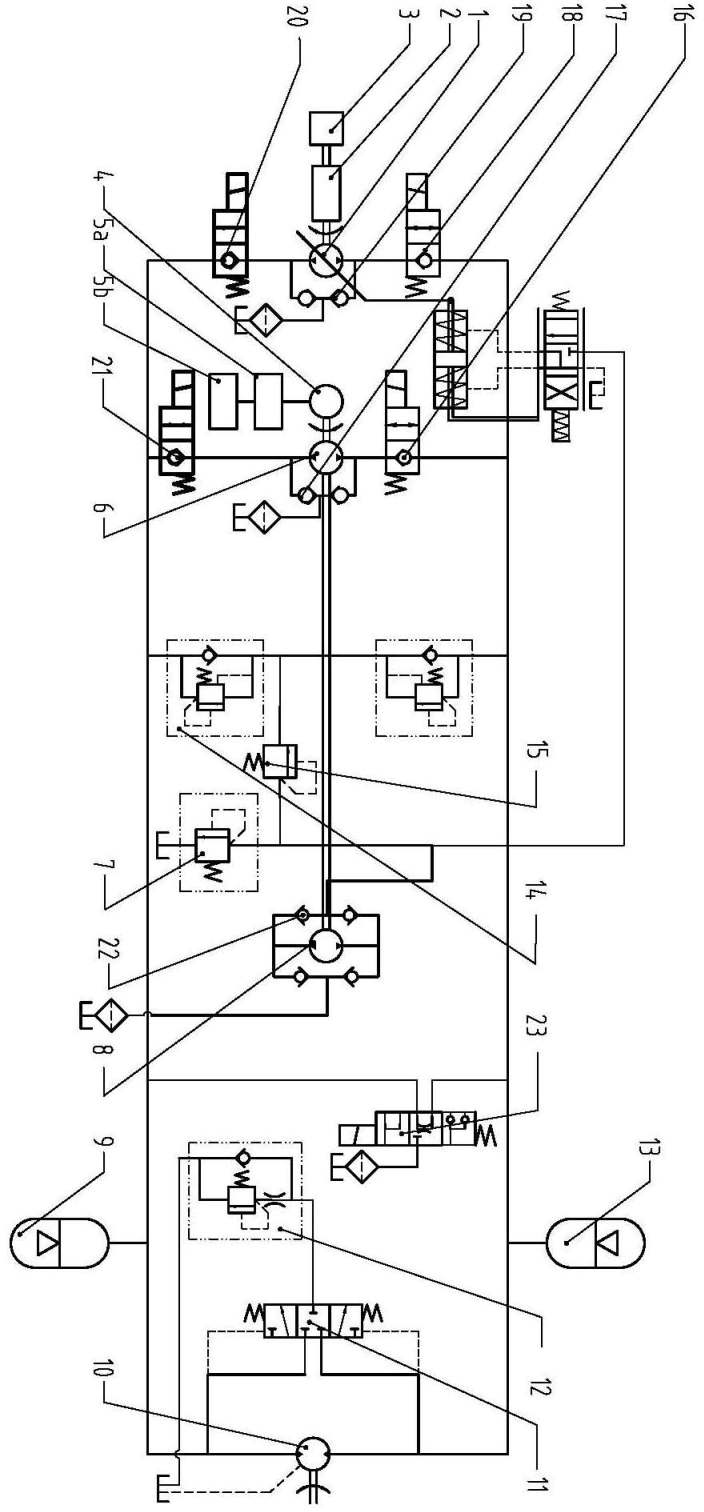

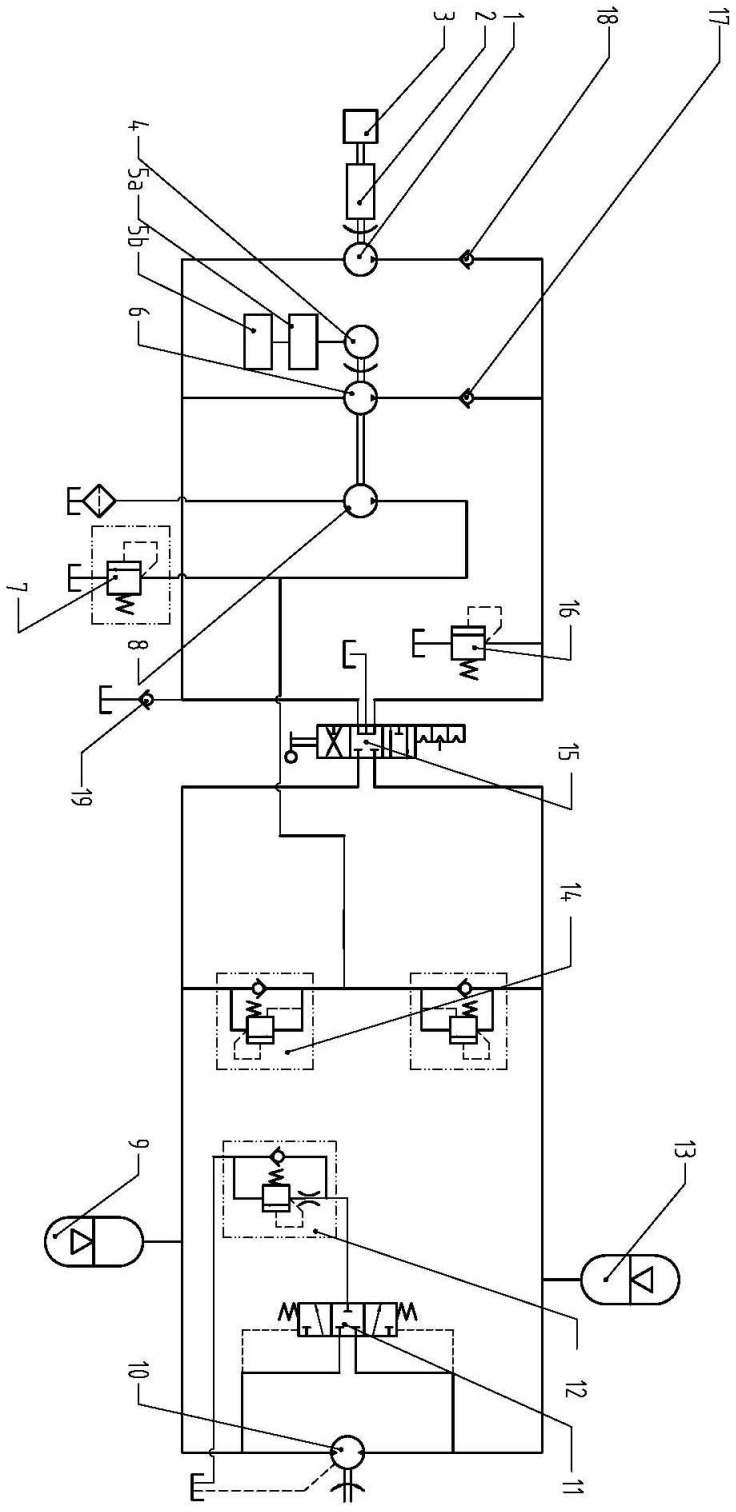

Hydraulic control system for continuously variable transmission

InactiveUS6306061B1Small sizeSolve insufficient capacityGearing controlEngine controllersEngineeringActuator

Hydraulic pressure generated by an oil pump driven by an engine is regulated to a secondary pressure by means of a secondary pressure control valve. The secondary pressure is employed for controlling a secondary pulley and a primary pulley. On the other hand, the secondary pressure is reduced to a clutch pressure by means of a clutch pressure control valve. The communication between an apply chamber and a release chamber of a torque converter, oil chambers of actuators for a forward clutch and a reverse brake of a forward and reverse changeover apparatus and a clutch pressure line and a lubrication pressure line are controlled by means a switching valve. The clutch pressure is regulated to a high clutch pressure and to a low clutch pressure, respectively by controlling reverse signal pressures supplied to these outer pilot chambers. Thus, respective hydraulic controls for the pulleys, the lockup clutch and the forward and reverse changeover apparatus can be performed independently by use of a single hydraulic pressure source.

Owner:SUBARU CORP

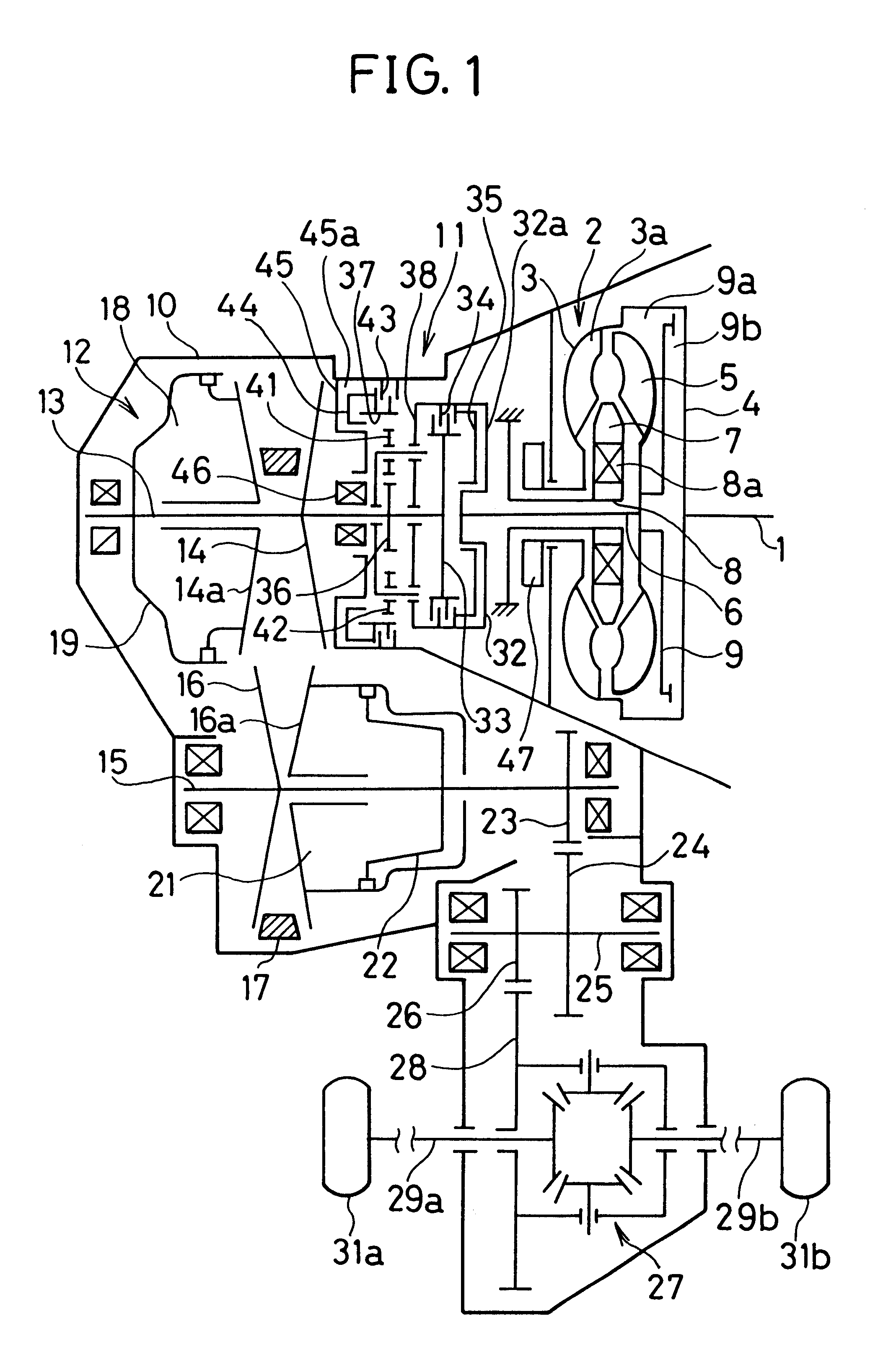

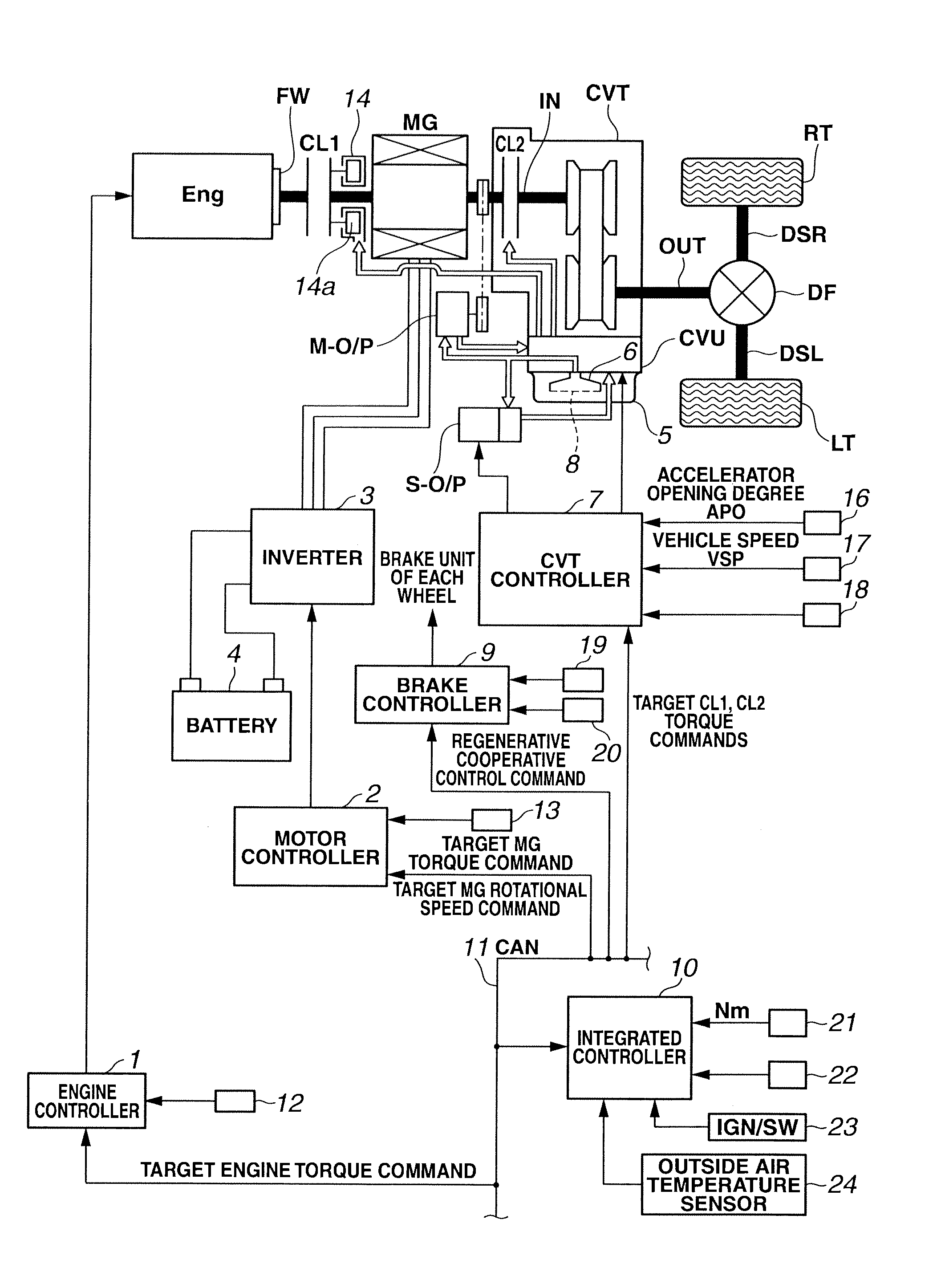

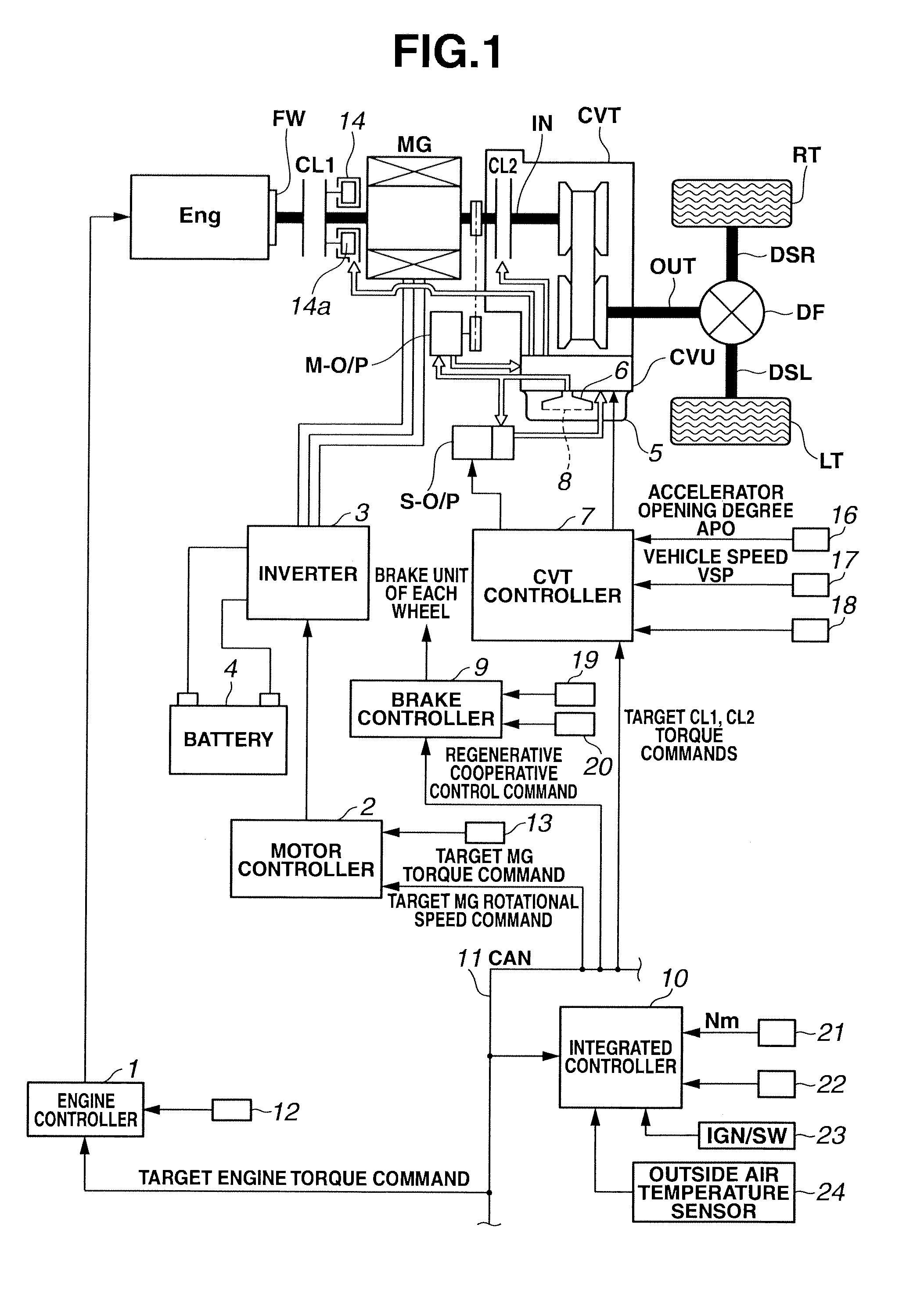

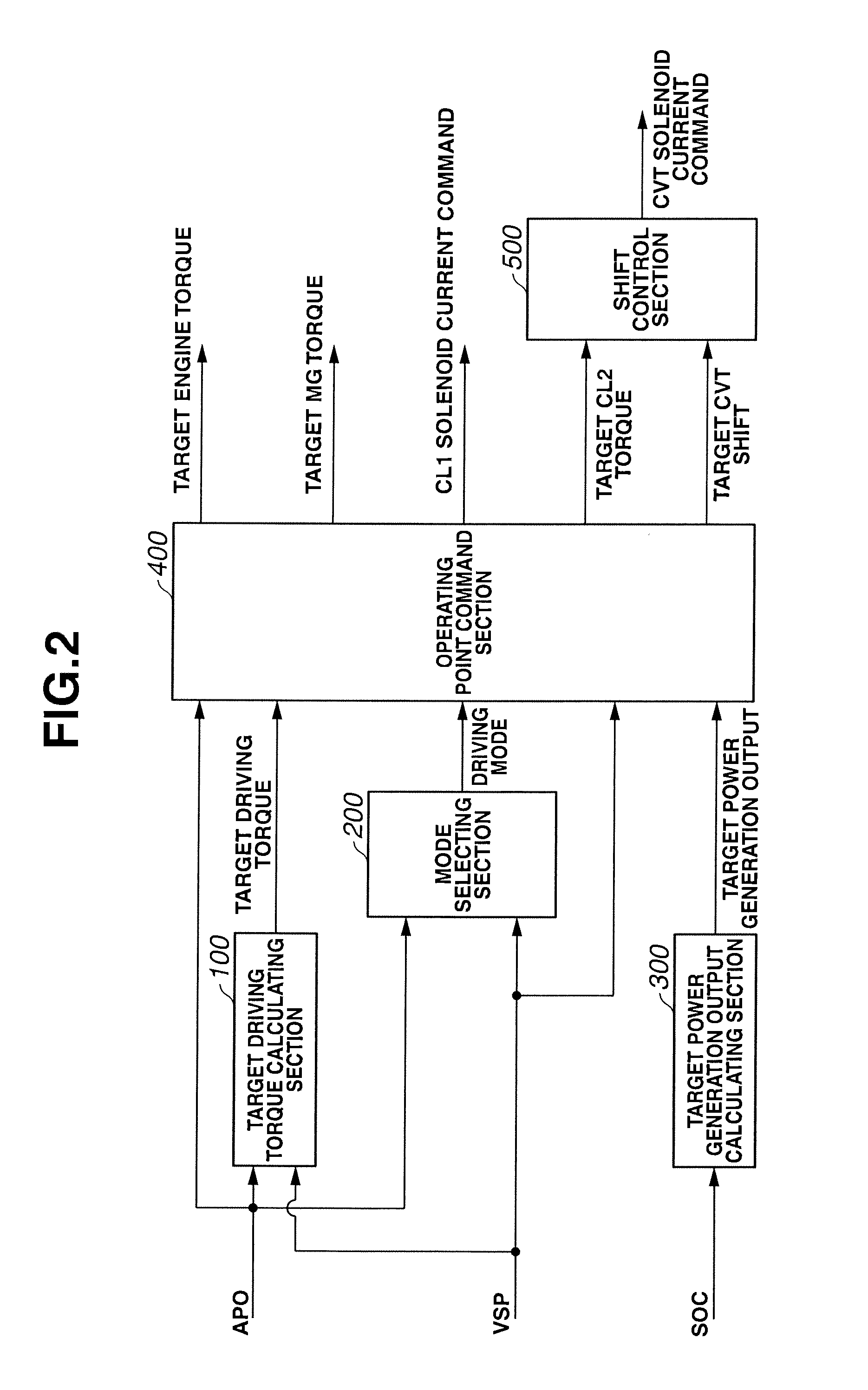

Engine start control apparatus for hybrid vehicle

ActiveUS20130191012A1Increase frictionBattery voltage is lowHybrid vehiclesAnalogue computers for vehiclesClutchHybrid vehicle

An engine start control apparatus for a hybrid vehicle includes: an engine start control section configured to crank the engine by using the motor as a starter motor while the hydraulic clutch is slip-engaged when the discharge pressure from the oil pump is ensured by driving the motor, when the engine is started after an ignition switch is switched to an ON state, the engine start control section being configured to drive the oil pump by the motor at a no load during a predetermined time period after the engine is stopped when the ignition switch is in an OFF state.

Owner:JATCO LTD

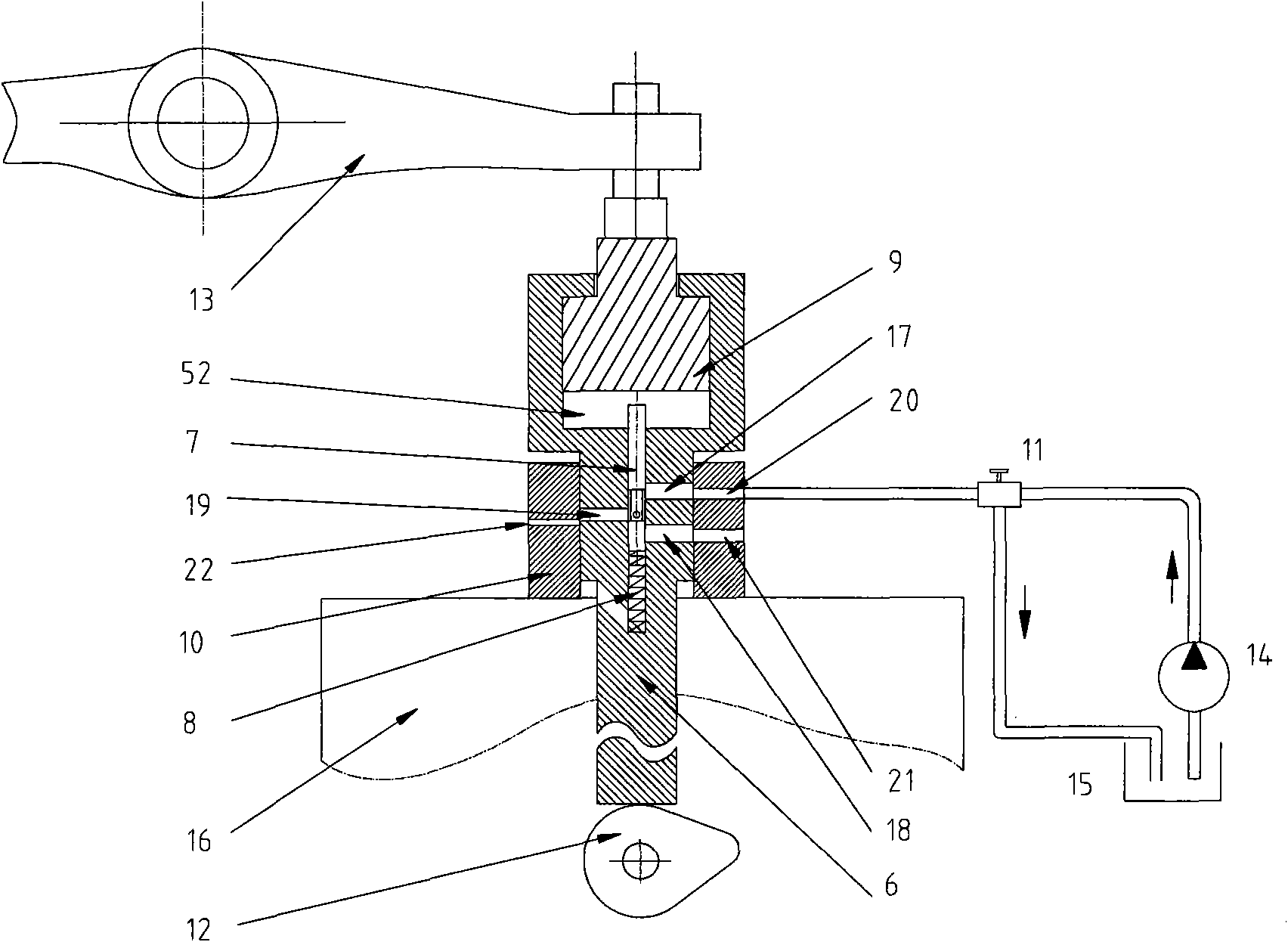

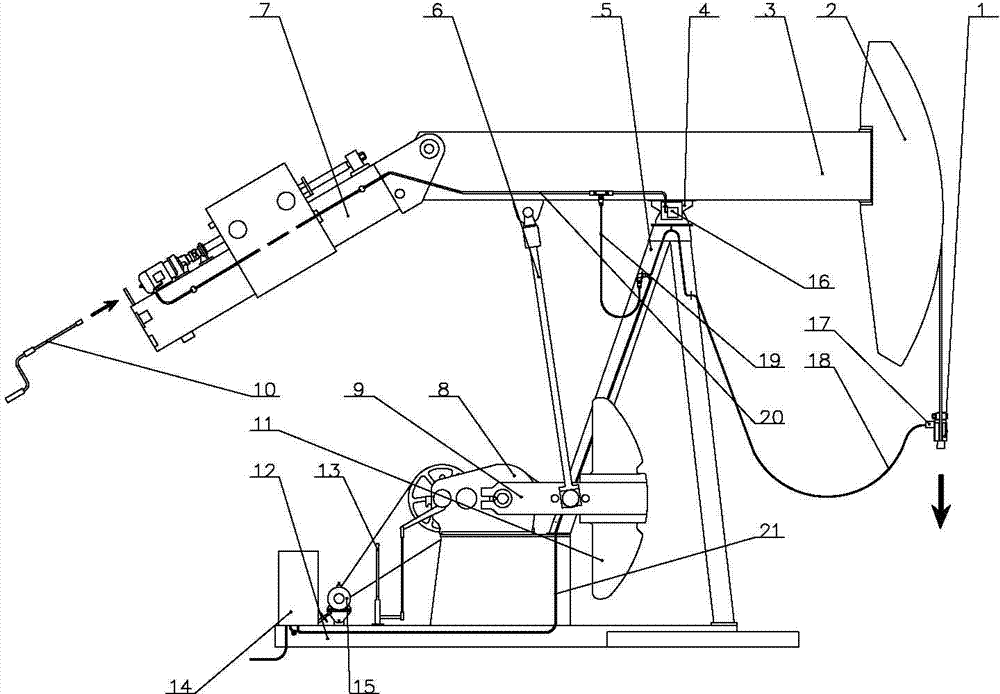

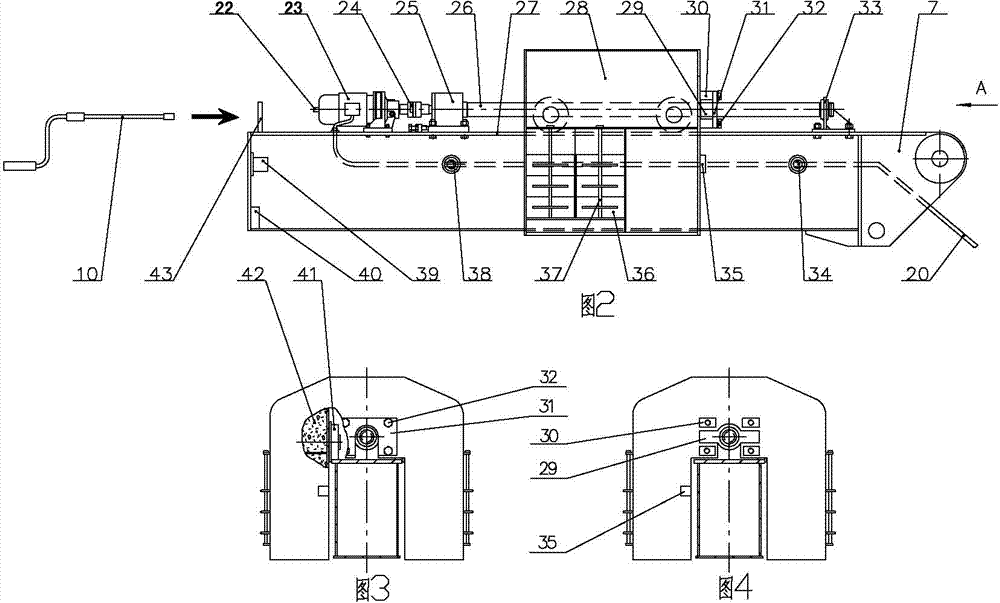

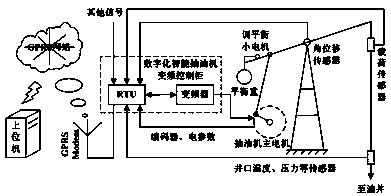

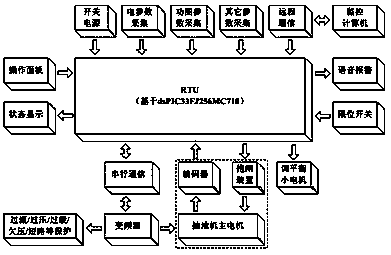

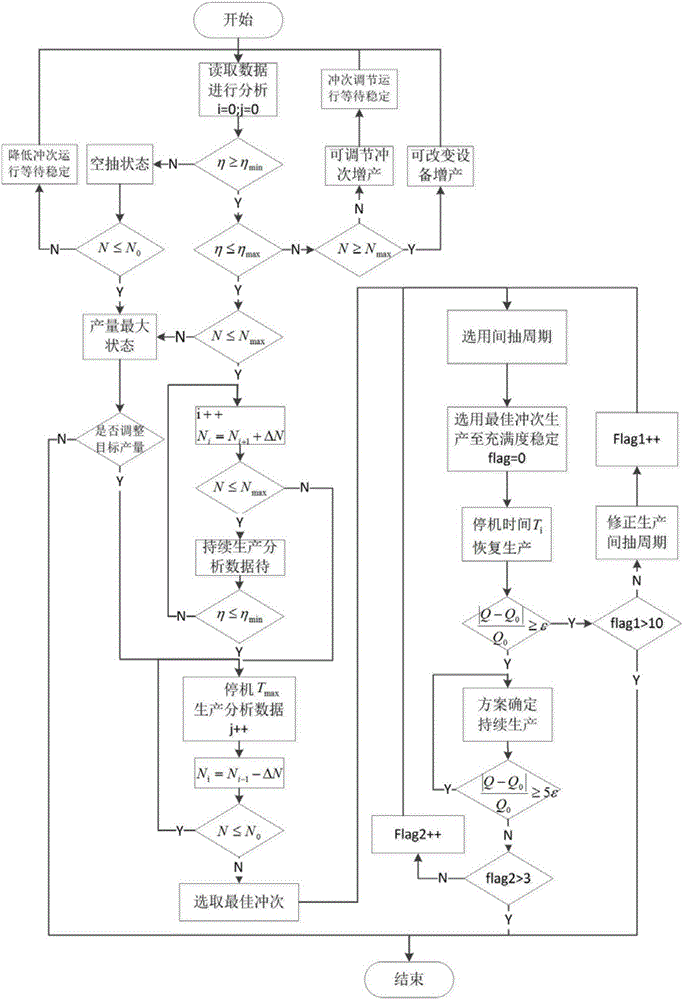

Intelligent oil pumping control method and intelligent oil pumping unit

ActiveCN104775792AMaximize outputCompact and reasonable structureFlexible member pumpsFluid removalReduction driveNetworked system

The invention relates to the technical field of beam-pumping units, in particular to an intelligent oil pumping control method and an intelligent oil pumping unit. The intelligent oil pumping unit comprises a main motor, a speed reducer, a crank, a connecting rod, a walking beam, a balance lifting arm, a bracket, a horse head, a base, a brake device, a beam hanger, a load sensor, a strole process measurer, a safety limiting device and a digital control cabinet, has the characteristics of safety and reliability, realizes the intelligent optimization and adjustment of stroke times and balance of the oil pumping unit, fully exerts the well yield, improves the oil pumping unit well system efficiency, is in seamless joint with an oil field computer network system to realize the data remote transmission and the remote switch well control, simplifies the operation, is convenient and fast, saves the labor, saves the energy, reduces the emission, and improves the economic benefit.

Owner:XINJIANG UYGUR AUTONOMOUS REGION NO 3 MACHINE TOOL WORKS

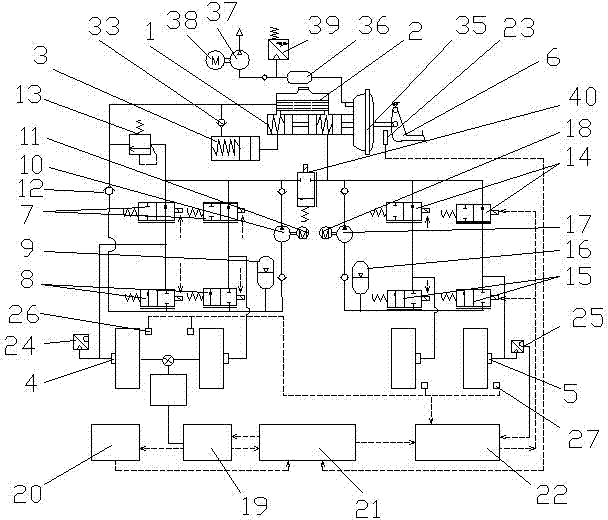

Hydraulic fatigue test system for pressure container

InactiveCN1587972ALow costEasy to implementMaterial strength using repeated/pulsating forcesPress ramSolenoid valveFiltration

A pressure vessel fatigue test system belongs to pressure vessel test technical field, comprising oil circuit pressure device, pressurizer, weight relieving motion, and measuring and control system. The oil circuit pressure device, pressurizer, weight relieving motion consists of pump linked by pipeline and oil pump driven by electric machinery, solenoid valve, overflow valve, water cooled oil cooler, back oil filtration device, oil tank and pipelines linked with them, the measuring and control system is consisted of electric contact pressure gauge, temperature sensor, pressure sensor, computer, controller for measurement and control temperature of pressure vessel, hydraulic oil, one-way throttle valve and high pressure filtration device are fitted with pipeline linked with solenoid valve and the container, stabilization tank is fitted with oil return pipe linked to solenoid valve and oil tank. The invention is suitable for fatigue test of pressure vessel containing impurity within and fairly high pressure needed and reconstruction to present pressure vessel fatigue test device.

Owner:DALIAN UNIV OF TECH

Fuel injection rule measuring device of diesel engine and measuring method thereof

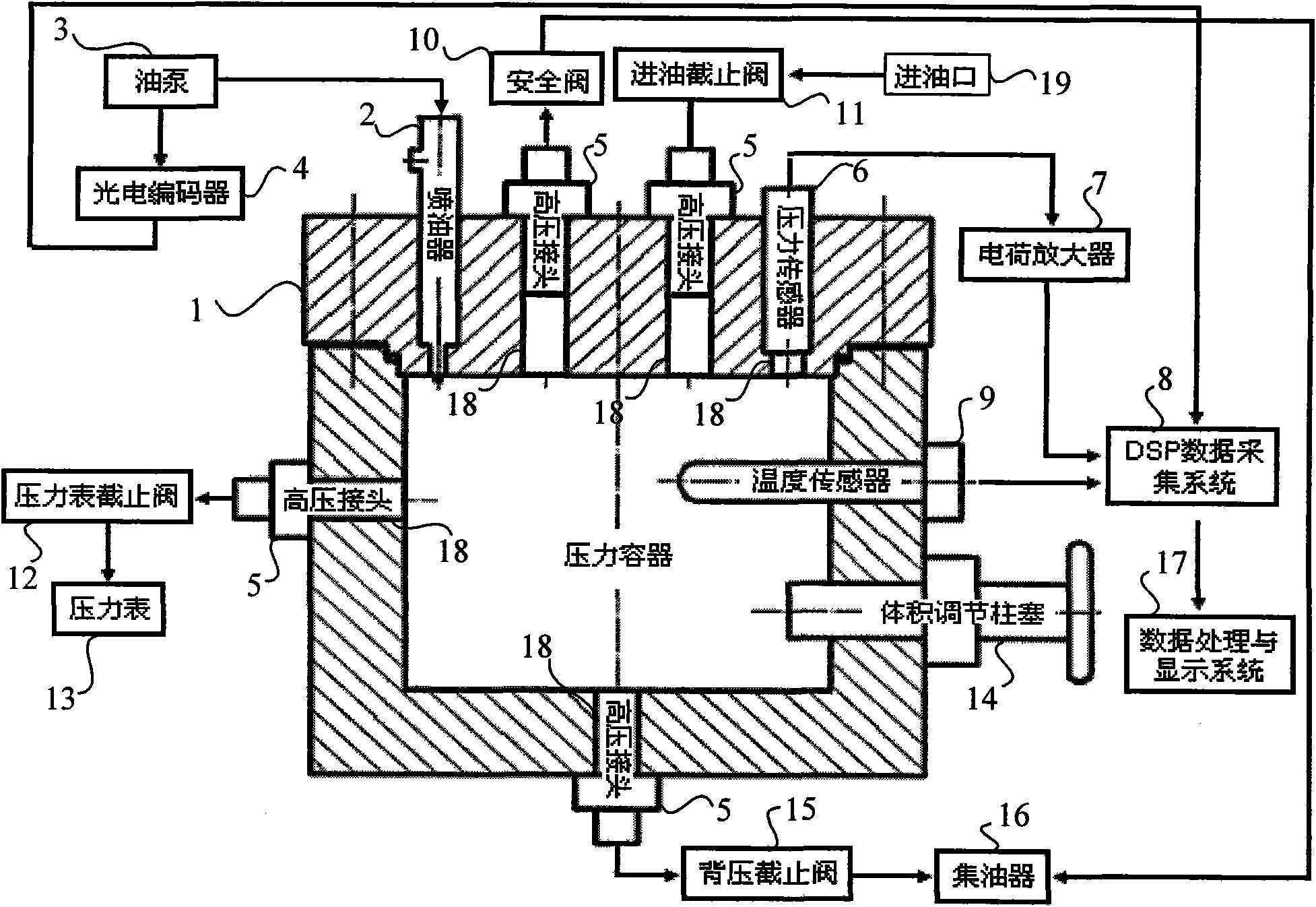

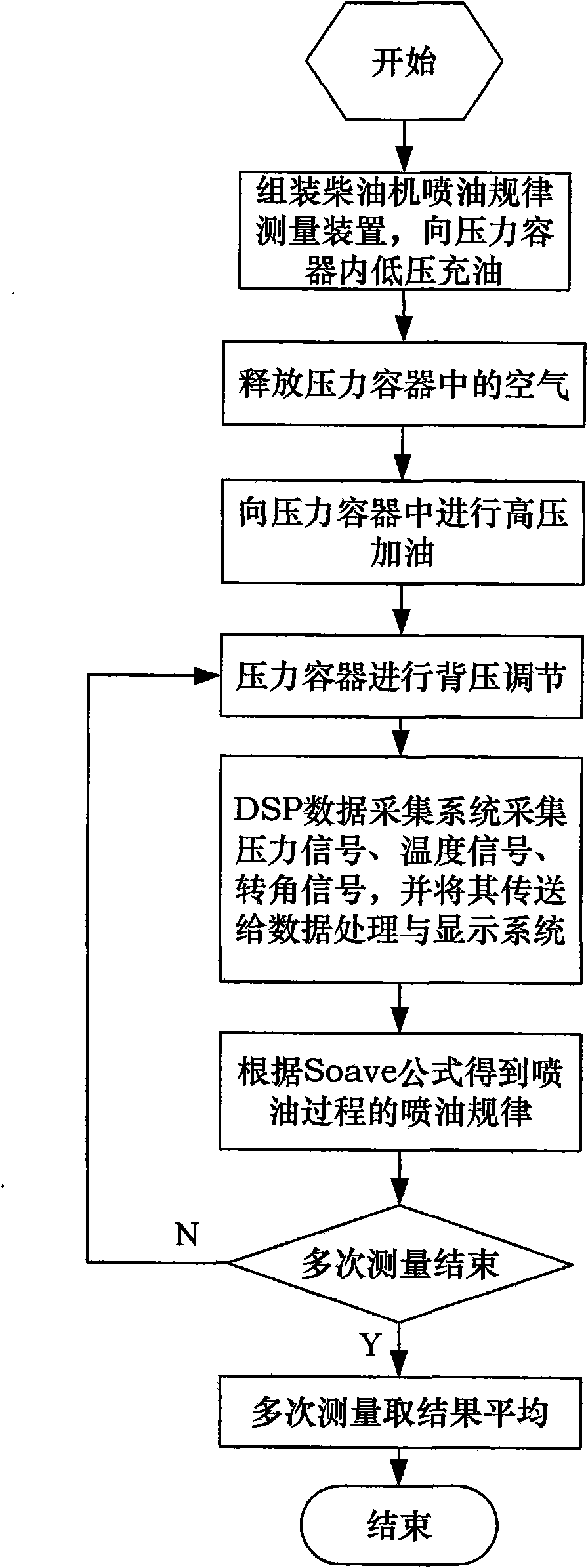

InactiveCN101571090APrecise control of initial pressureEliminate measurement interferenceEngine testingFuel injection apparatusMeasurement deviceData processing

The invention discloses a fuel injection rule measuring device of a diesel engine and a measuring method thereof. The device comprises a pressure vessel, an oil atomizer, an oil pump, a photoelectric encoder, a high pressure connector, a pressure sensor, a charge amplifier, a DSP data acquisition system, a temperature sensor, a safety valve, a feeding disconnecting valve, a pressure meter disconnecting valve, a pressure meter, a volume regulating plunger, a back pressure disconnecting valve, an oil collector and a data processing and display system. The method includes that a measuring rule is obtained by utilizing Soave formula by acquiring the temperature and pressure of the pressure vessel and the angle signal of the oil pump. In the invention, the back pressure disconnecting valve is used for back pressure adjustment, the initial pressure in the pressure vessel is accurately controlled, environment back pressure injected by the oil atomizer is accurately simulated, and the volume adjusting plunger can adjust the volume of the pressure vessel. The invention eliminates that measuring interference between two adjacent injections in one injecting process which probably appears in plunger displacement method and ensures fuel injection rule measuring accuracy.

Owner:BEIHANG UNIV

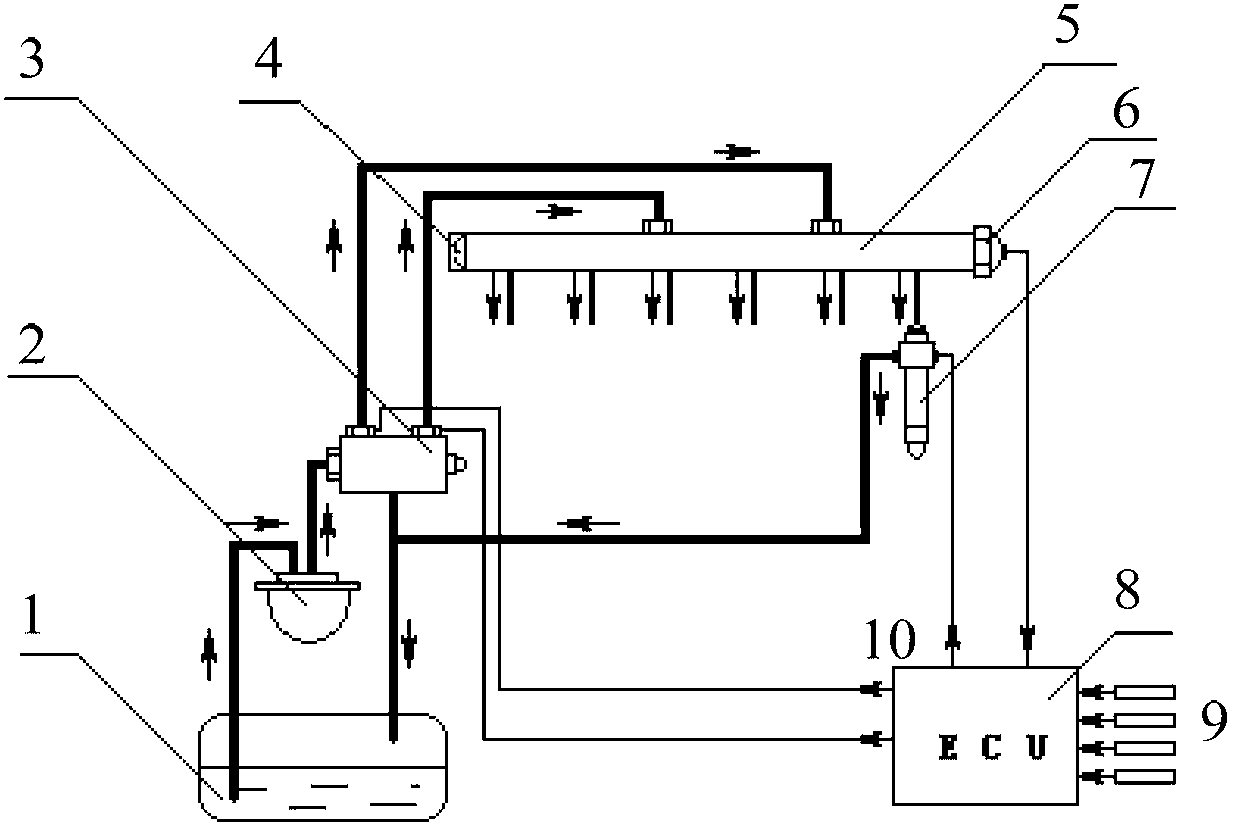

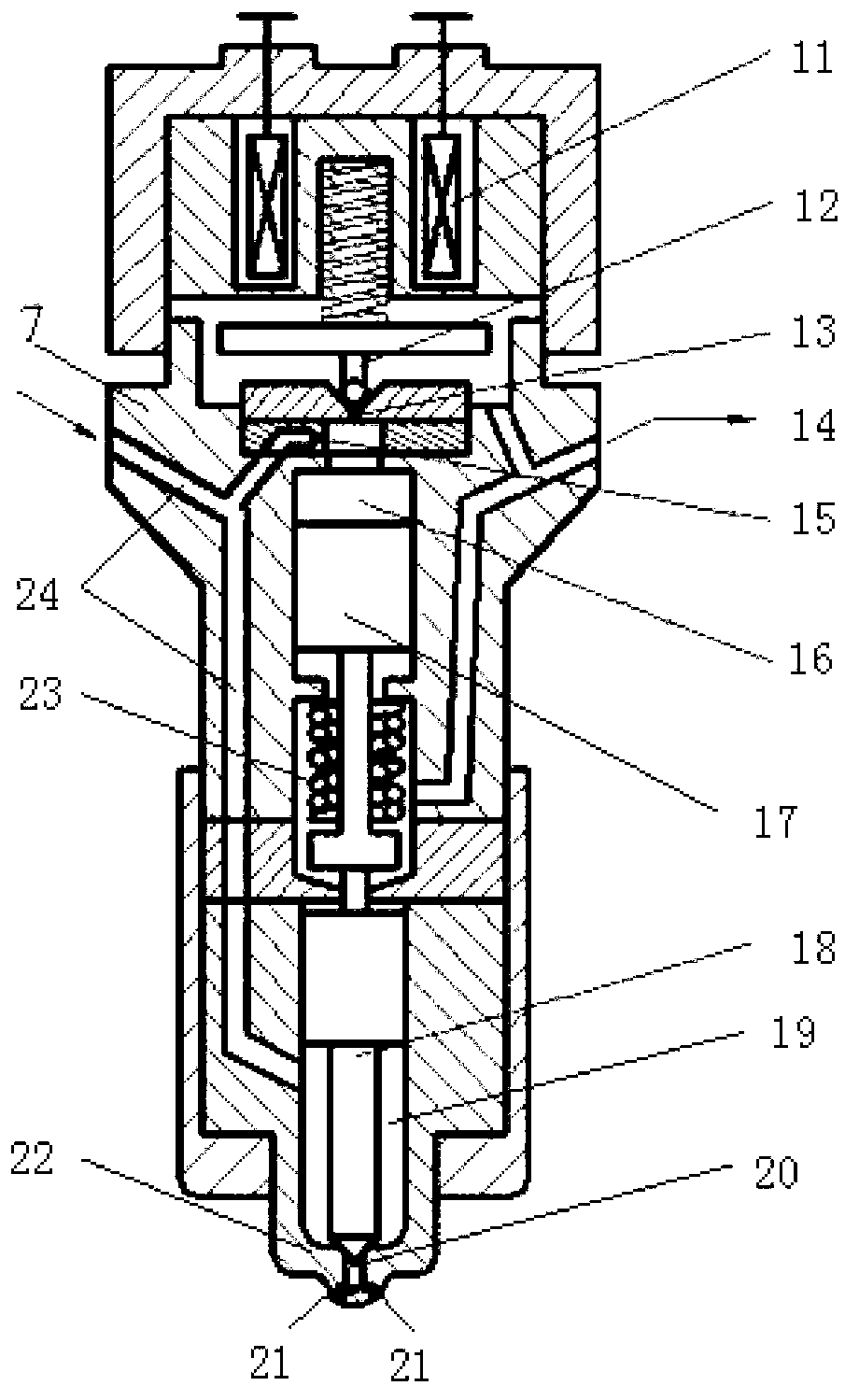

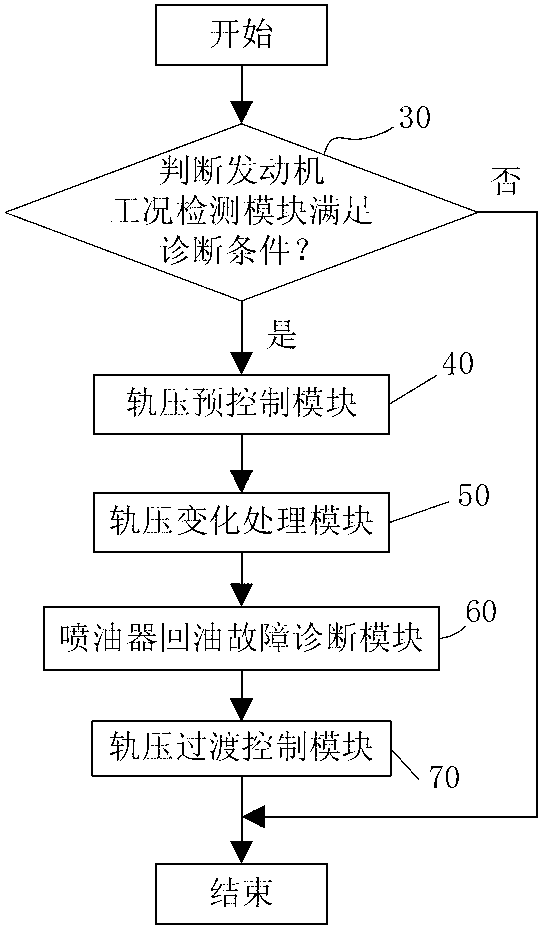

Method and system for diagnosing oil return failure of electronic control common rail oil sprayer

ActiveCN102996311ARealize online diagnosisReliable non-disintegration fault diagnosisEngine testingFuel injection apparatusRail pressureSprayer

The invention relates to a method and system for diagnosing an oil return failure of an electronic control common rail oil sprayer. The method comprises the following steps of: a, when the oil sprayer is in a non-spraying state and the rail pressure in a common rail pipe is more than a first preset threshold, diagnosing the oil return failure of the oil sprayer, otherwise, ending a diagnosis program; b, controlling a high-pressure oil pump to ensure that the rail pressure in the common rail pipe is a target pressure value PFin1, when the rail pressure in the common rail pipe is the target pressure value PFin1, stopping the working state of the high-pressure oil pump; c, calculating the variable required in the common rail pipe; d, comparing the variable with a preset reference value, judging whether the oil sprayer generates the oil return failure according to the relationship between the variable and the preset reference; and e, when the rail pressure in the common rail pipe is reduced to the preset pressure limit value, starting the high-pressure oil pump to ensure that the rail pressure in the common rail pipe is a target pressure value PFin2 under the current working condition. The method can be used for realizing online detection on the oil return failure of the oil sprayer and has the advantages of high automation degree and wide application range.

Owner:CHINA FIRST AUTOMOBILE

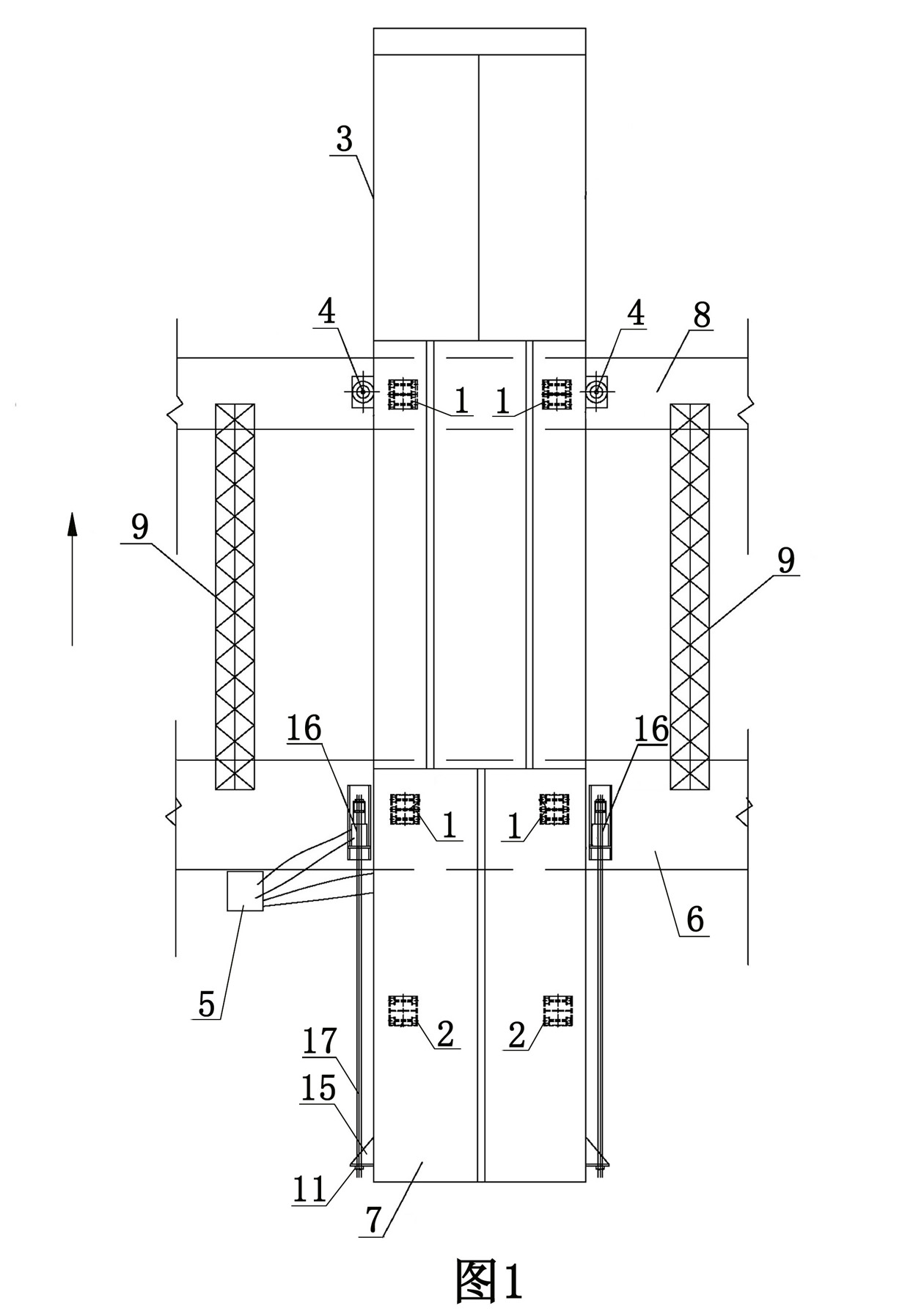

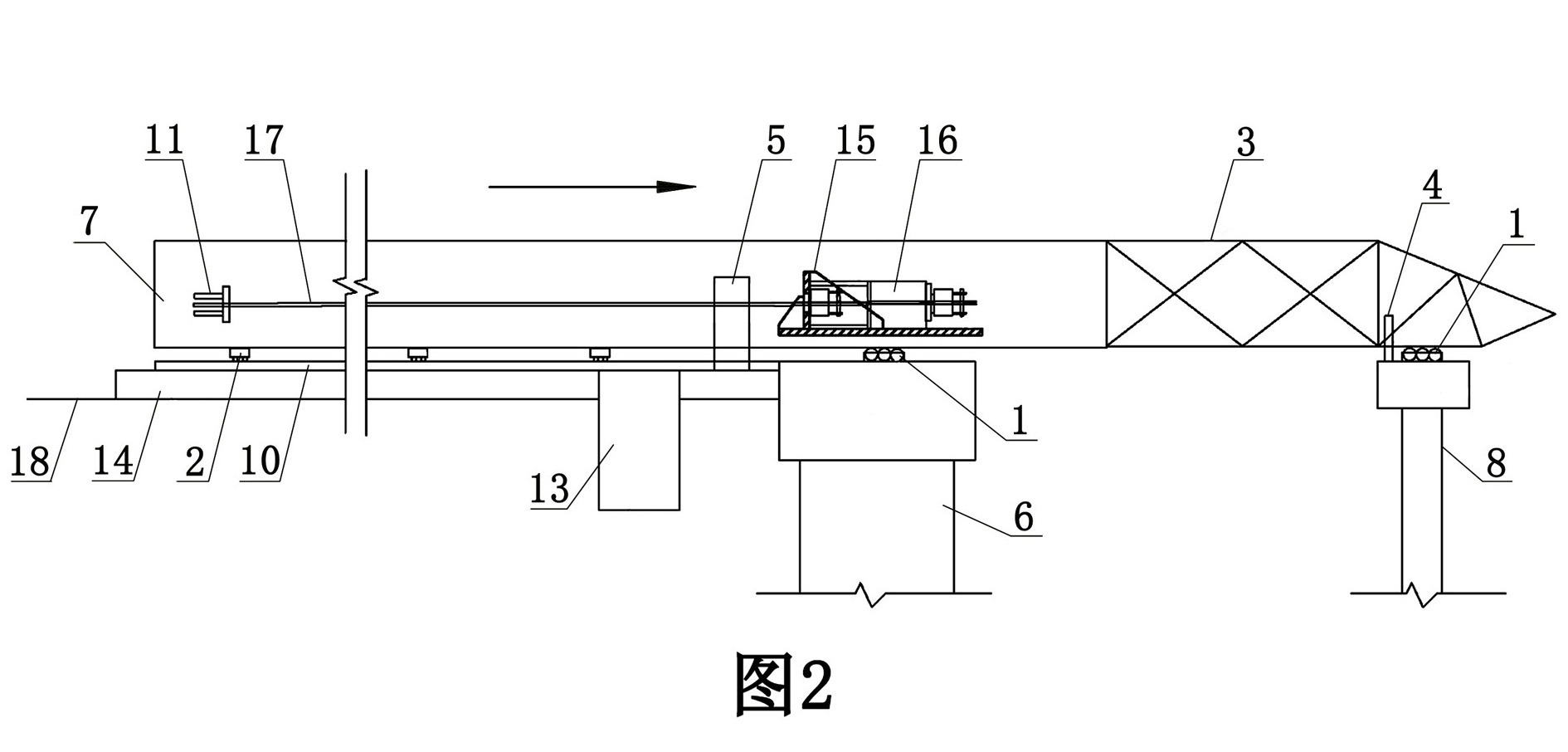

Device for performing incremental launching construction on bridge by using multi-roller sliding ways and construction method thereof

ActiveCN101818481AMeet the needs of climbingReduced longitudinal stiffness requirementsBridge erection/assemblyEngineeringSteel box girder

The invention discloses a device for performing incremental launching construction on a bridge by using multi-roller sliding ways and a construction method thereof. The device comprises a drawing part and a sliding part, wherein the drawing part comprises jack reaction supports, centre hole jacks, steel stranded wires, fixed end clampers, steel box girder reaction seats and an oil pump; the jack reaction supports are fixed on two sides at a predetermined position of a steel box girder of a structural pier; the centre hole jacks are arranged on the jack reaction supports; one end of each steel stranded wire is fixed with corresponding centre hole jack, while the other end is fixed on the corresponding steel box girder reaction seat through the corresponding fixed end clamper; and the sliding part comprises the multi-roller sliding ways fixed on the structural pier and a temporary pier in pairs, and further comprises a railway foundation and a steel guide way which are paved on a platform foundation, and a girder-transporting track run on the steel guide way. The device utilizes the mechanical characteristics of a roller structure so as to reduce requirements on the longitudinal rigidity of the temporary pier, satisfying needs on the climbing of vertical curves in the incremental launching process and greatly accelerating the incremental launching construction process.

Owner:BEIJING URBAN CONSTR ROAD & BRIDGE GROUP +1

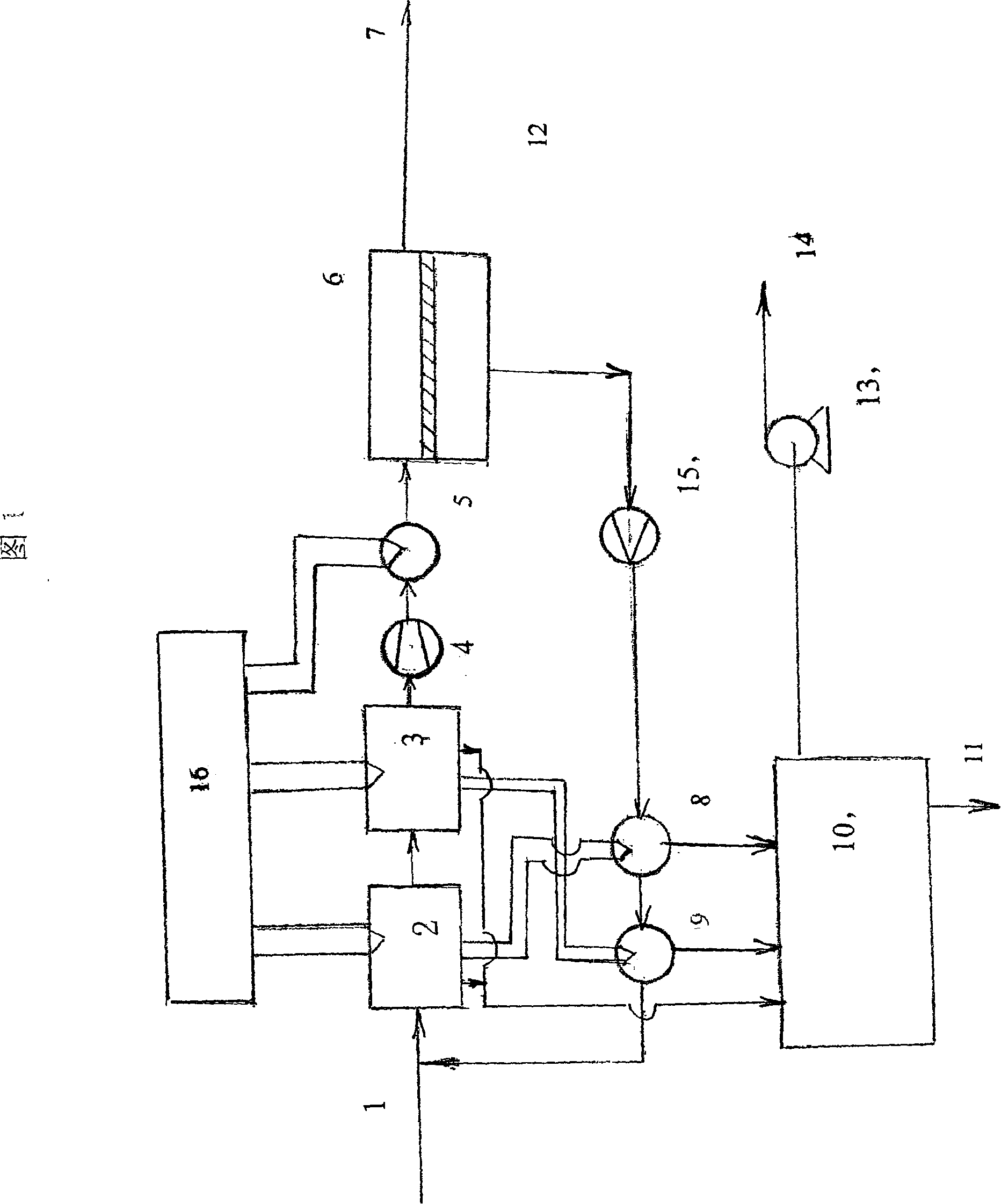

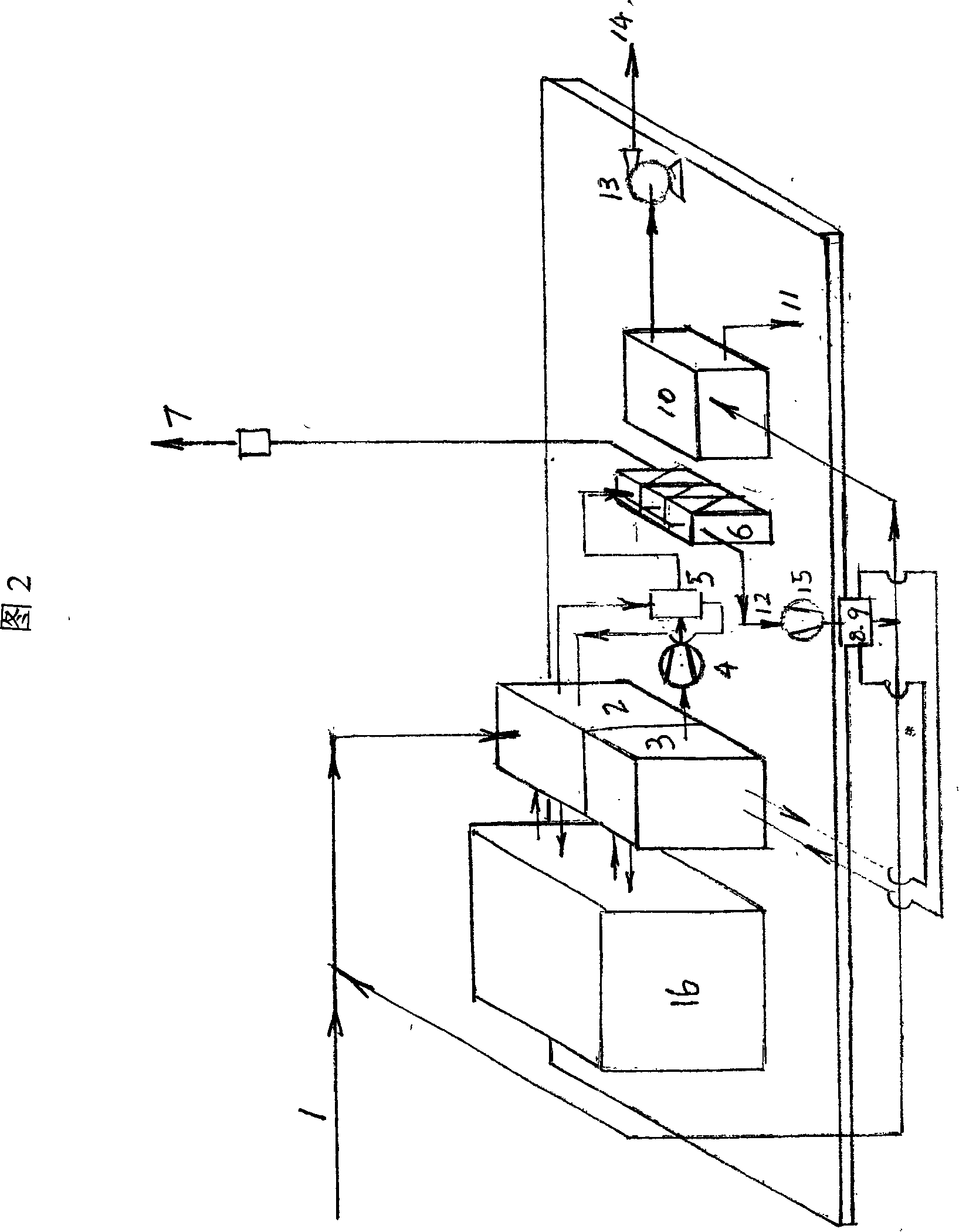

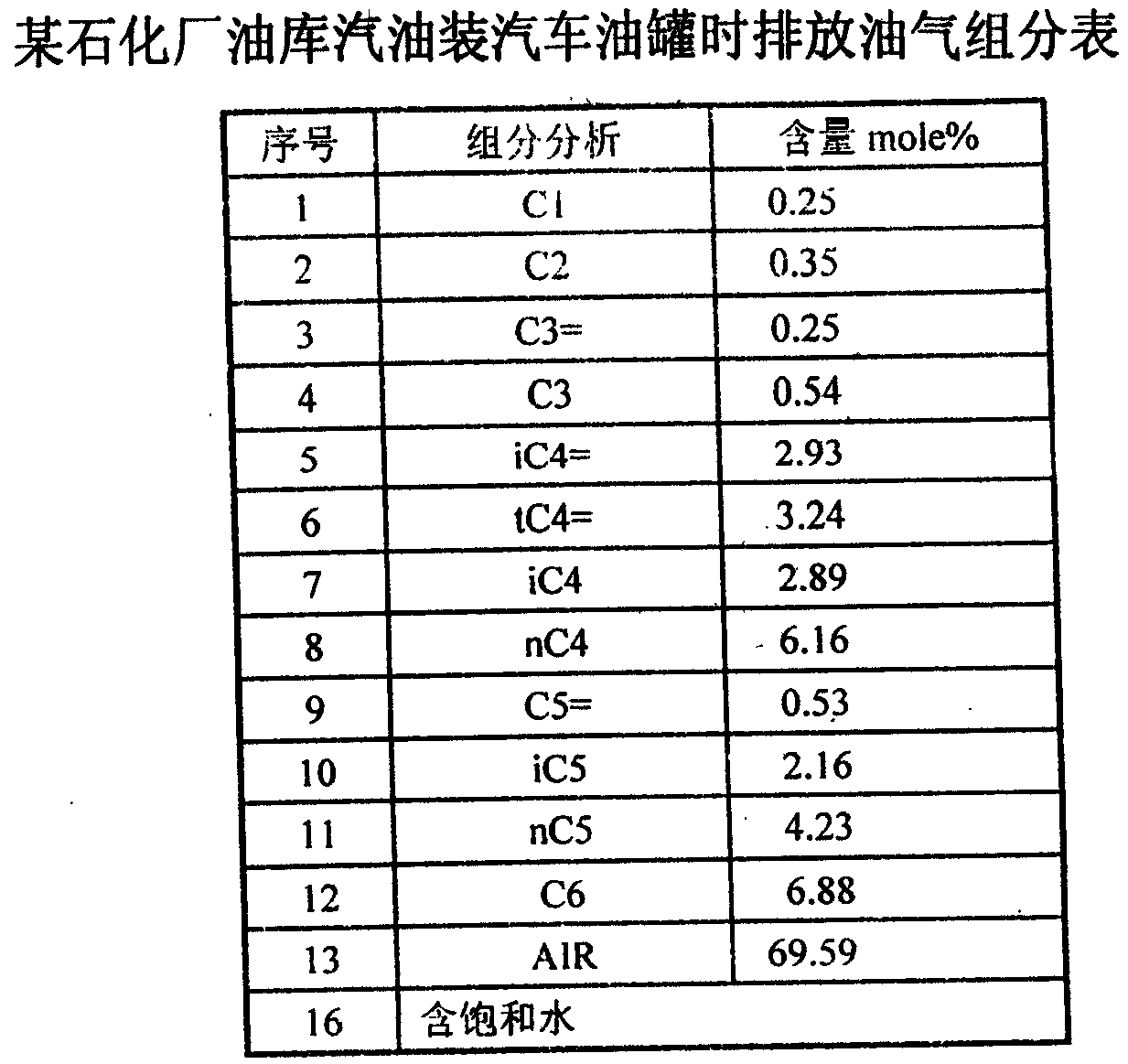

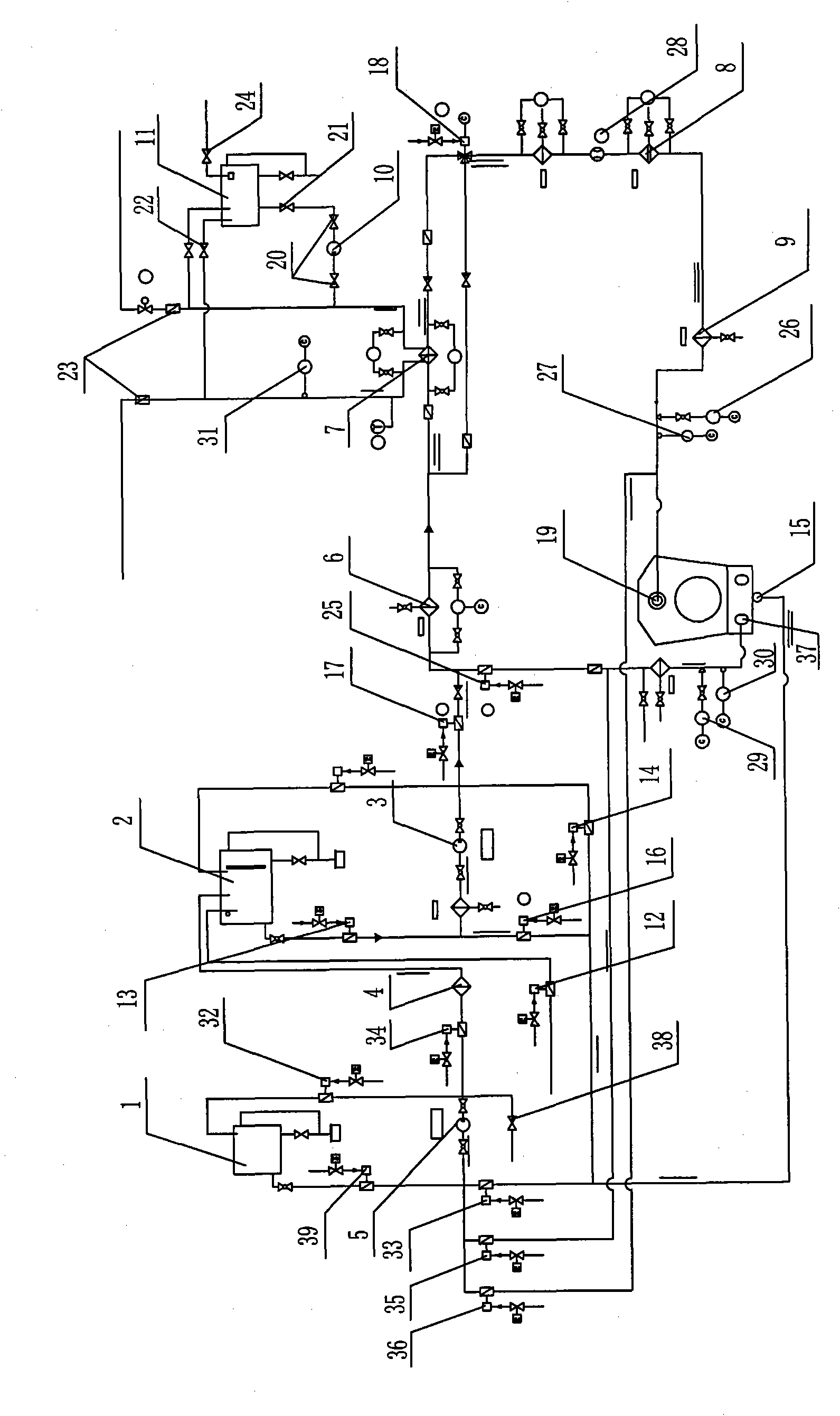

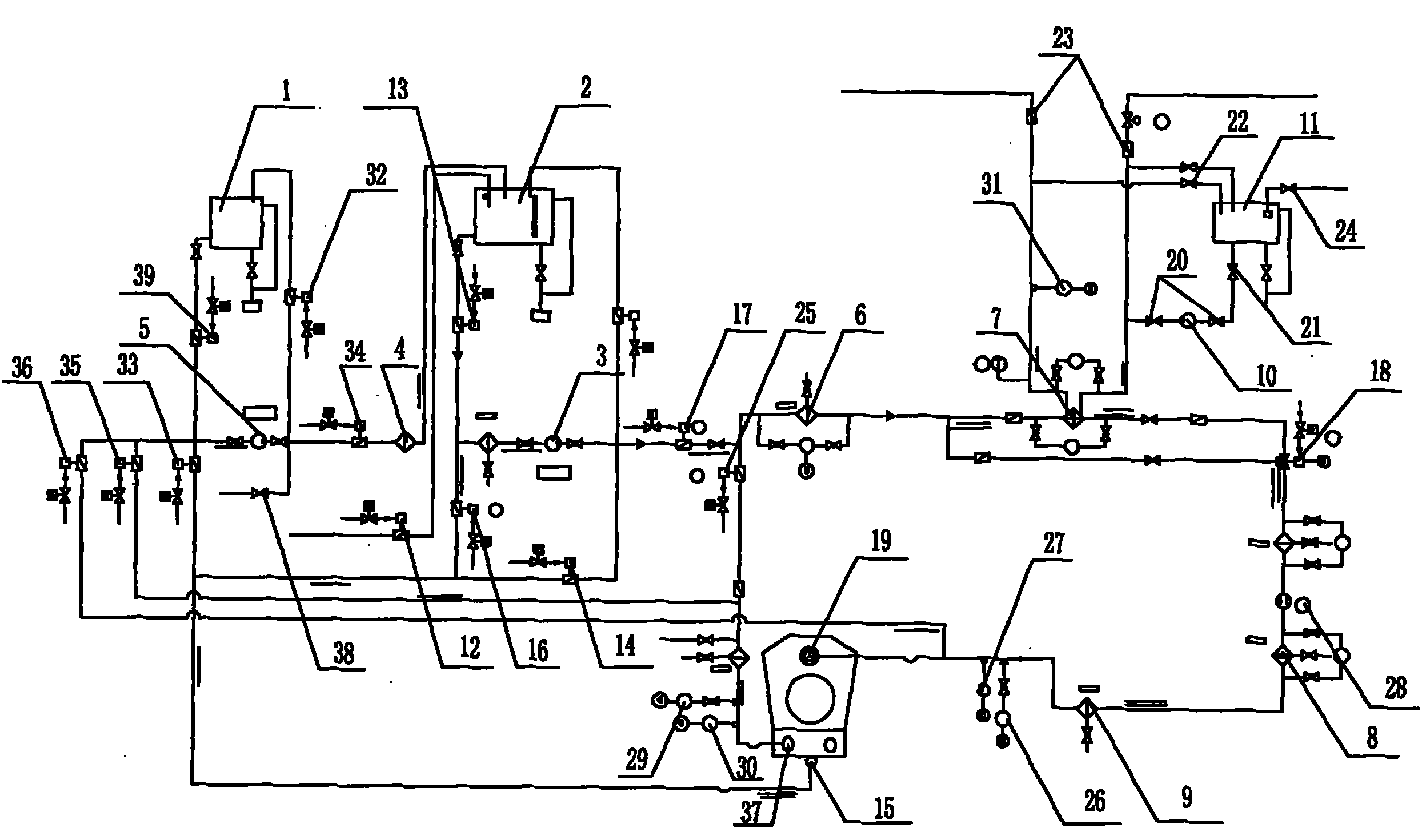

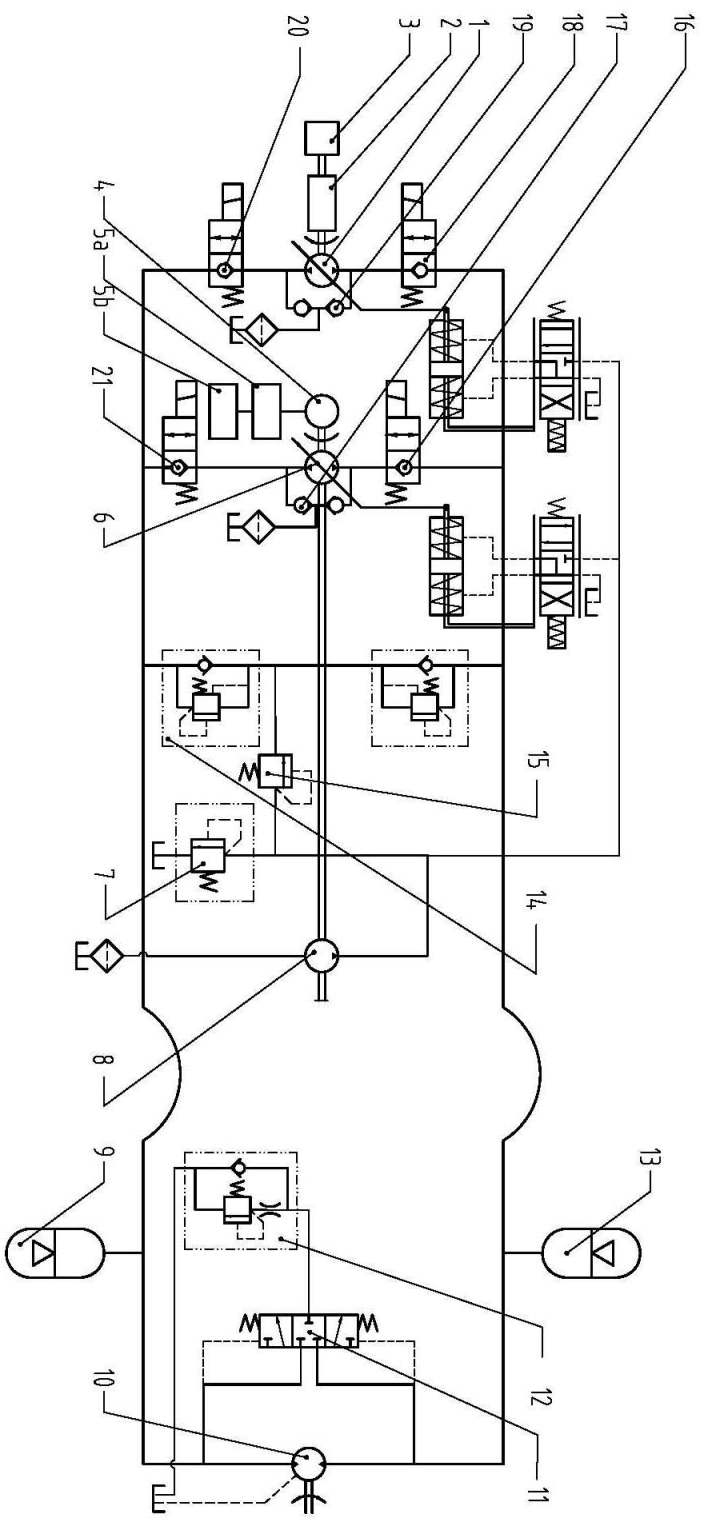

Condensing and membrane separation combined type oil gas reclaiming technical technology

InactiveCN101161590ALiquid hydrocarbon mixture recoveryVapor condensationSeparation technologyCombined method

The invention relates to a condensation and film separation combination type oil gas recycling art technique which is an improvement of condensation type oil gas art technique. The invention adopts the combined method of condensation technique and film separating technique to reach discharging standards. The problem that the temperature of single condensation type oil gas recycling reaches lowers than 95 DEG C below zero is overcome. The invention belongs to the oil gas recycling technical field, and is mainly used for the oil gas recycling of oil house, city transfer oil house, gasoline and light weight oil loading and unloading process. The invention consists of a refrigeration machine set 16, a pre-cooling box 2, a middle cooling box 3, a liquid ring type compressor 4, a switch 5, a membrane module 6, a vacuum pump 15, a switch 8, a switch 9, an oil water separator 10 and an oil pump 13. According to the art flow sequence in the attached drawing 1, the refrigeration machine set 16, the pre-cooling box 2, the middle cooling box 3, the liquid ring type compressor 4, the switch 5, the membrane module 6, the vacuum pump 15, the switch 8, the switch 9, the oil water separator 10 and the oil pump 13 are connected together and are arranged on a base crowing. The construction is shown in the attached drawing 2. The three-dimensional graph of the modular structure is shown in the attached drawing 2.

Owner:王建基 +1

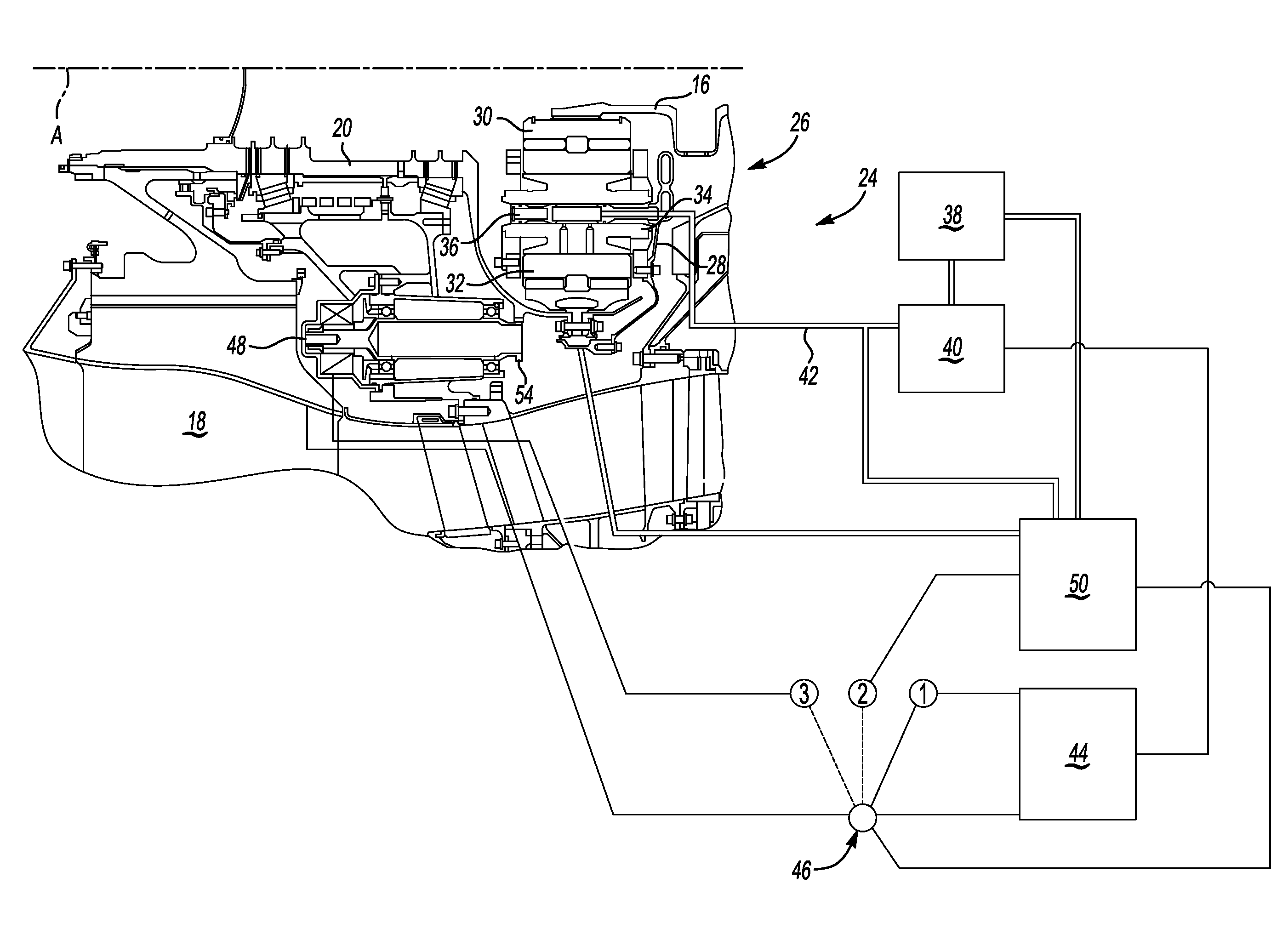

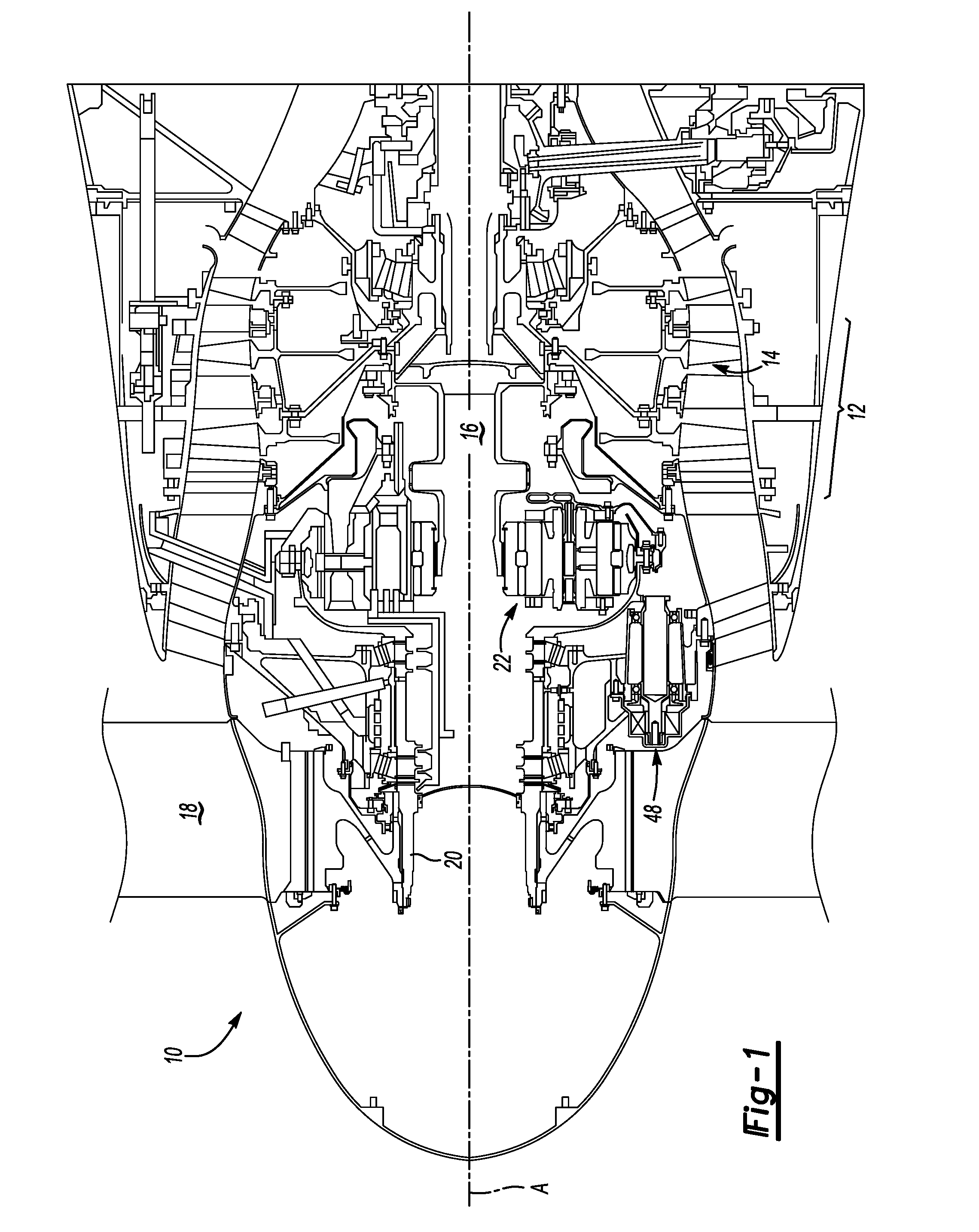

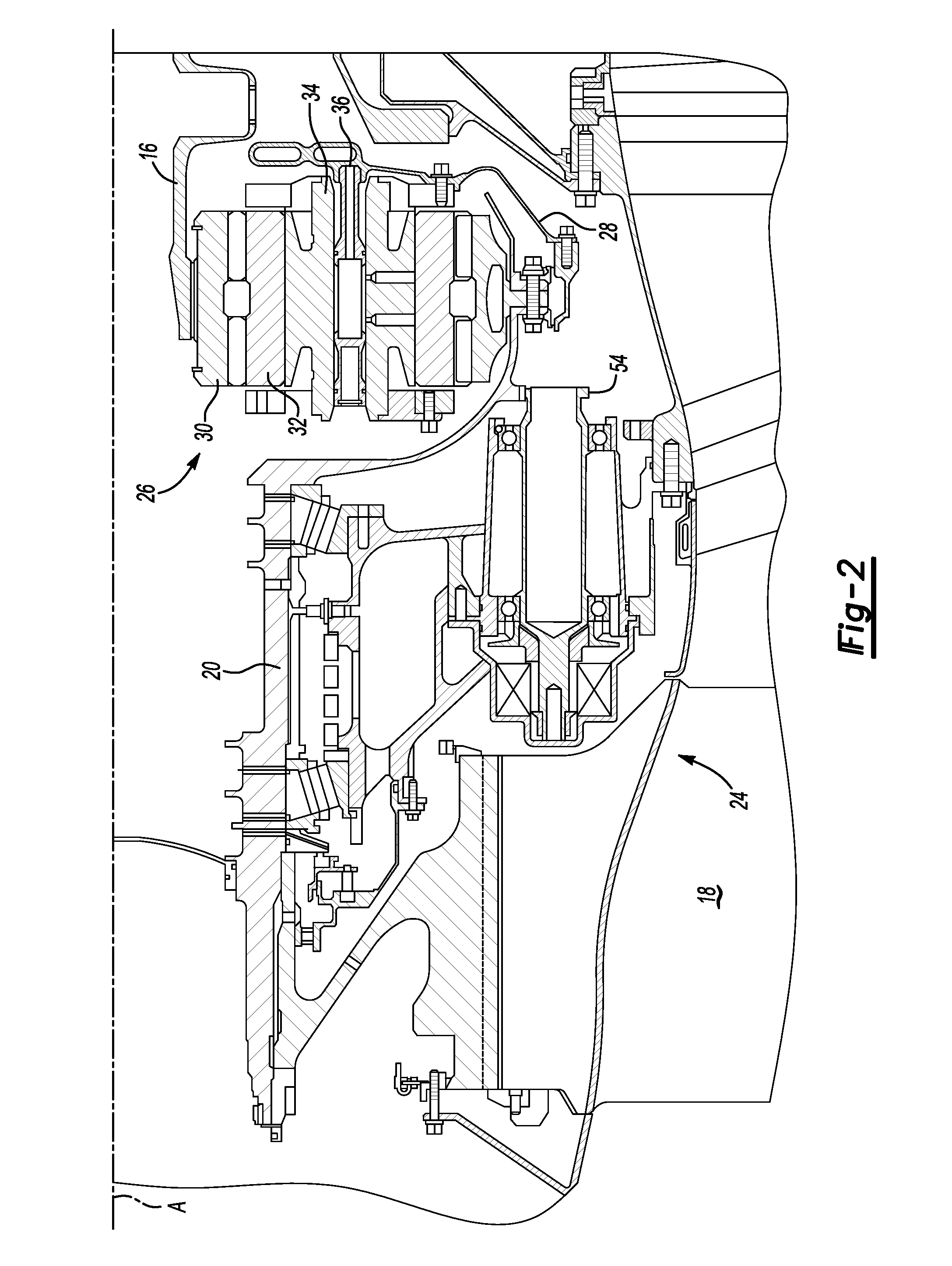

Rotor brake and windmilling lubrication system for geared turbofan engine

ActiveUS20080098712A1Preventing undesired rotationRolling contact bearingsEngine fuctionsTurbofanLubrication

A journal bearing provides lubrication to planetary gears during windmilling operation of a fan section. A primary oil pump provides oil from an oil supply during driven operation of the fan and a secondary oil pump driven by a generator provides oil during windmilling operation of the fan. The generator acts as a dynamic brake when the aircraft is grounded to prevent windmilling. A switch selects between the primary and secondary oil pump and controls the brake application.

Owner:RTX CORP

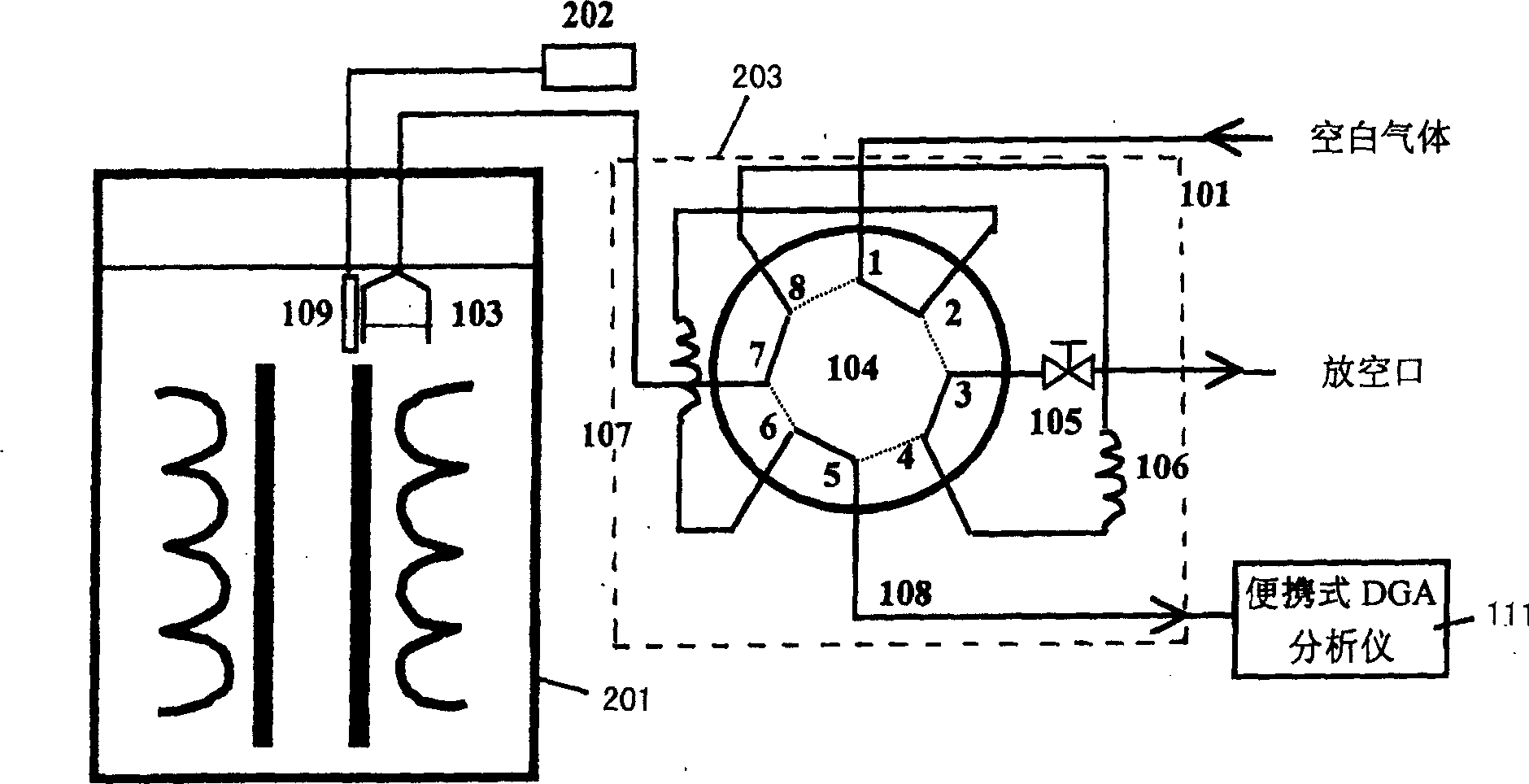

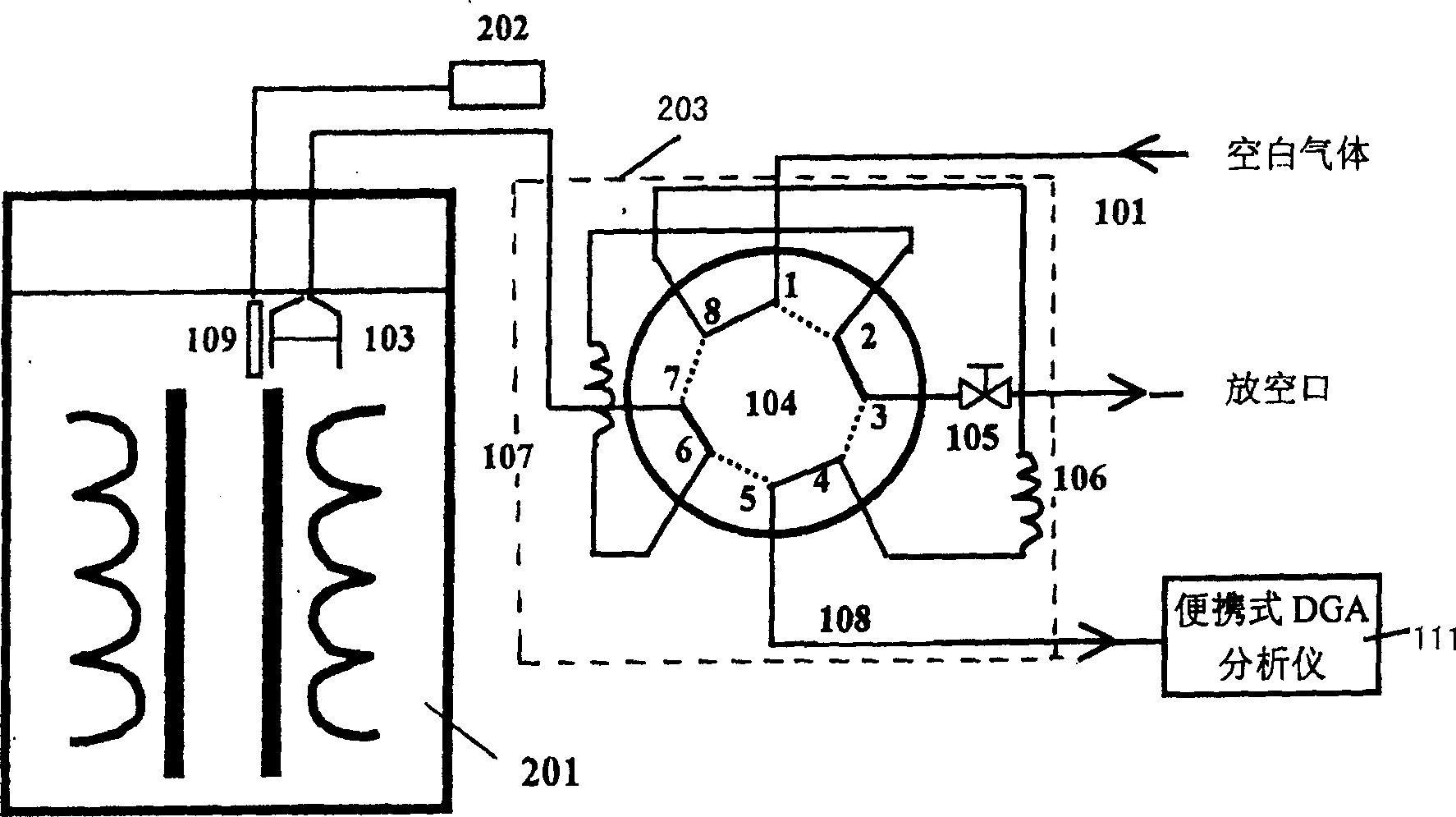

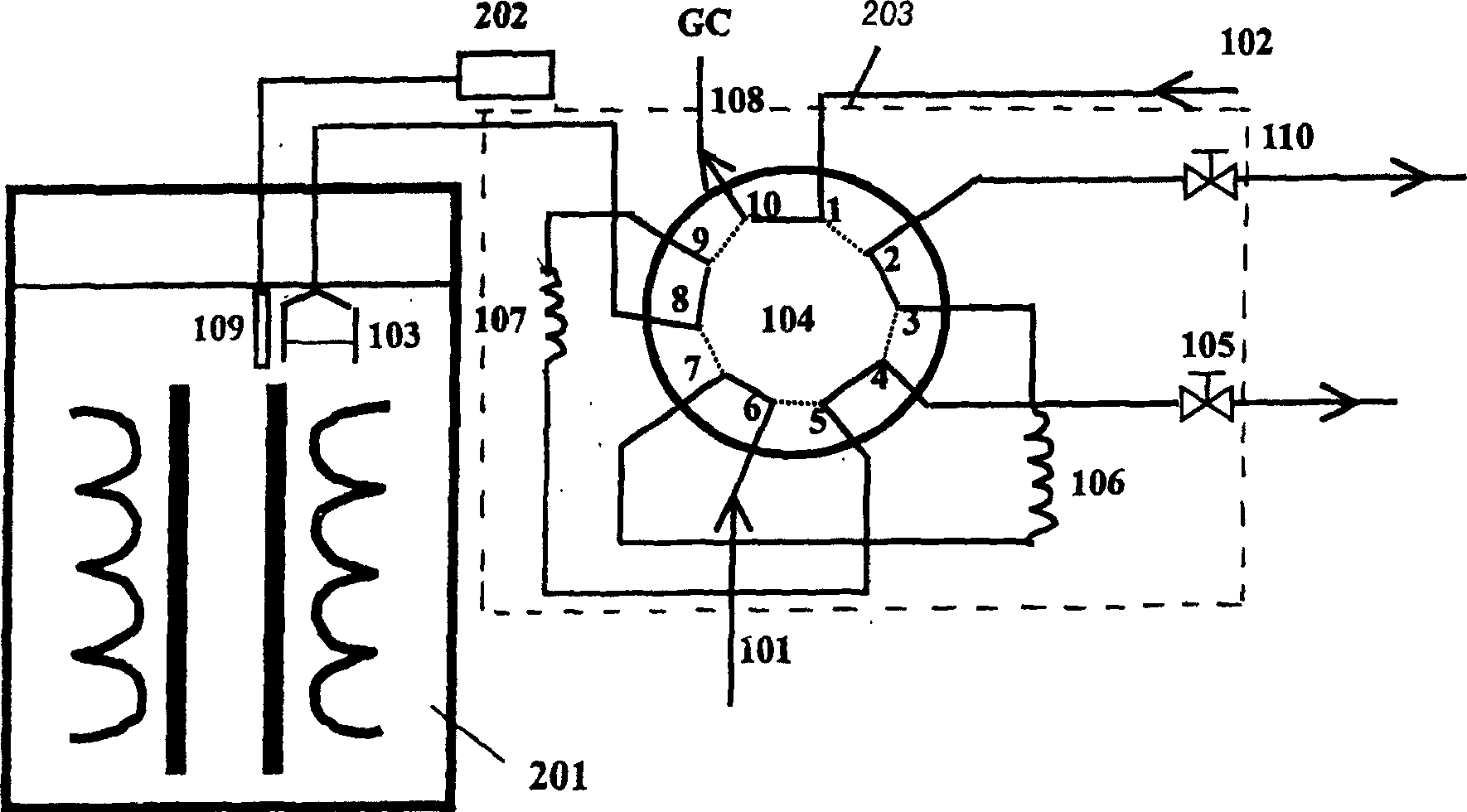

Dissolved gas sampling apparatus and method used in transformer oil gas-chromatography on-line analysis

ActiveCN1721835AGuaranteed volumeGuaranteed repeatabilityWithdrawing sample devicesPreparing sample for investigationGas liquid chromatographicProduct gas

The invention relates to a sampling device and method of gas chromatographic online analysis transformer dissolved gas, which comprises sampling probe, temperature sensor, multi-ported valve, sample quantitative pipe, marginal gas quantitative pipe, cutoff valve and marginal gas regulating system. The method directly inserts sampling probe into transformer oil and presses marginal gas into sampling probe by switching of multi-ported valve; the transformer oil is circulated by oil pump so that the dissolved gas of transformer oil can spill into marginal gas and then it achieves gas-liquid equilibrium in probe.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Diesel engine oil test bed system

ActiveCN102012318AMeet the test requirementsEasy to useInternal-combustion engine testingTest requirementsDiesel engine

The invention relates to a diesel engine test system, in particular to a diesel engine oil test bed system, which comprises a return oil filter tank, a cleaning oil tank, a cleaning oil pump, a first engine oil filter, a lubricating feedback pump, an engine oil filter, a heat exchanger, a secondary engine oil filter, a first engine oil inlet / outlet filter, a heating water pump, a diesel engine oil bottom shell and an engine oil preheating water tank. The diesel engine oil test bed system has favorable use effect, safety and reliability, is simple and convenient for operation and can meet the test requirement of the diesel engine, and the advancement of the automatic regulation property and the control technology, of the system, is worth of popularization and adoption.

Owner:CRRC QISHUYAN CO LTD

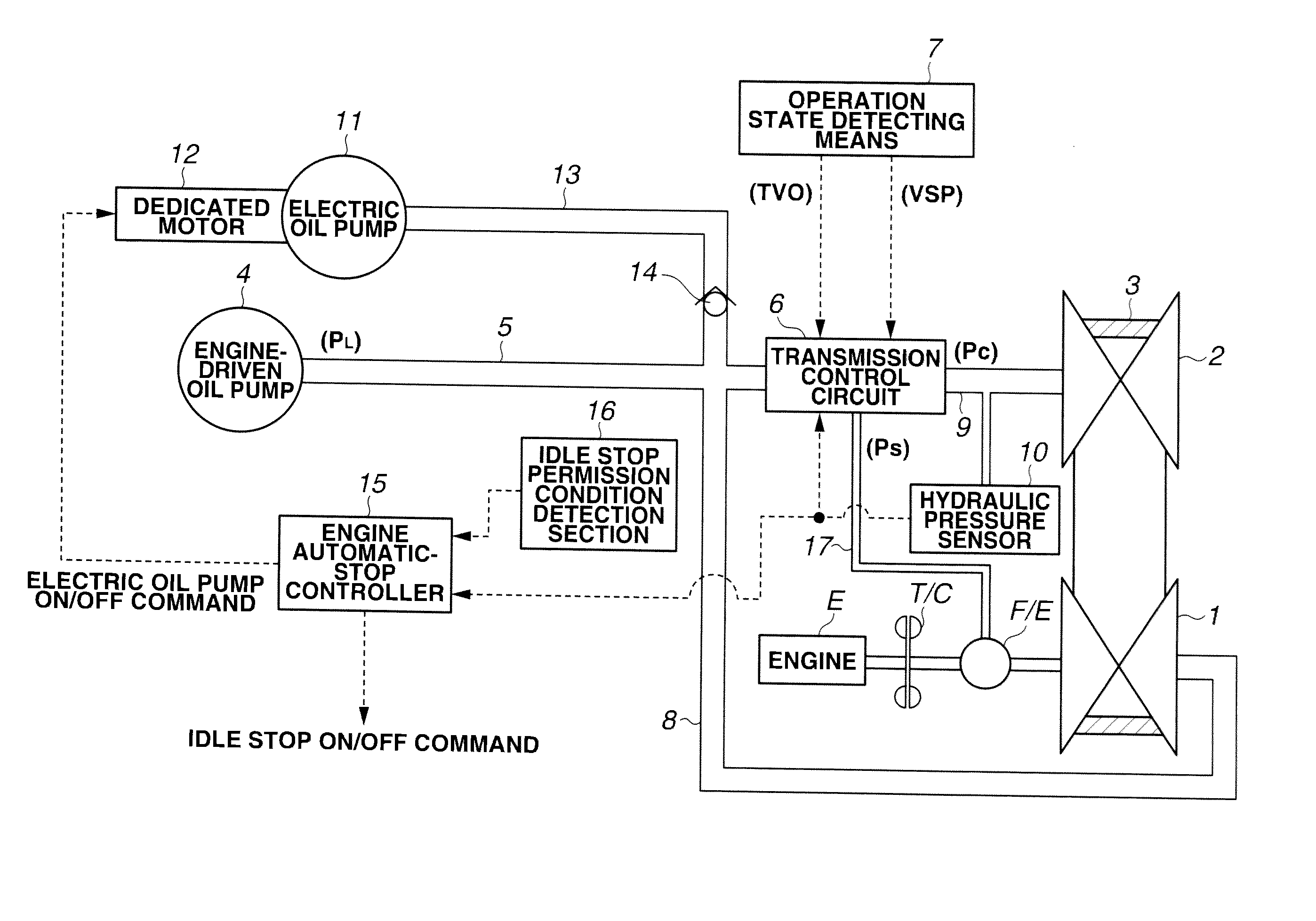

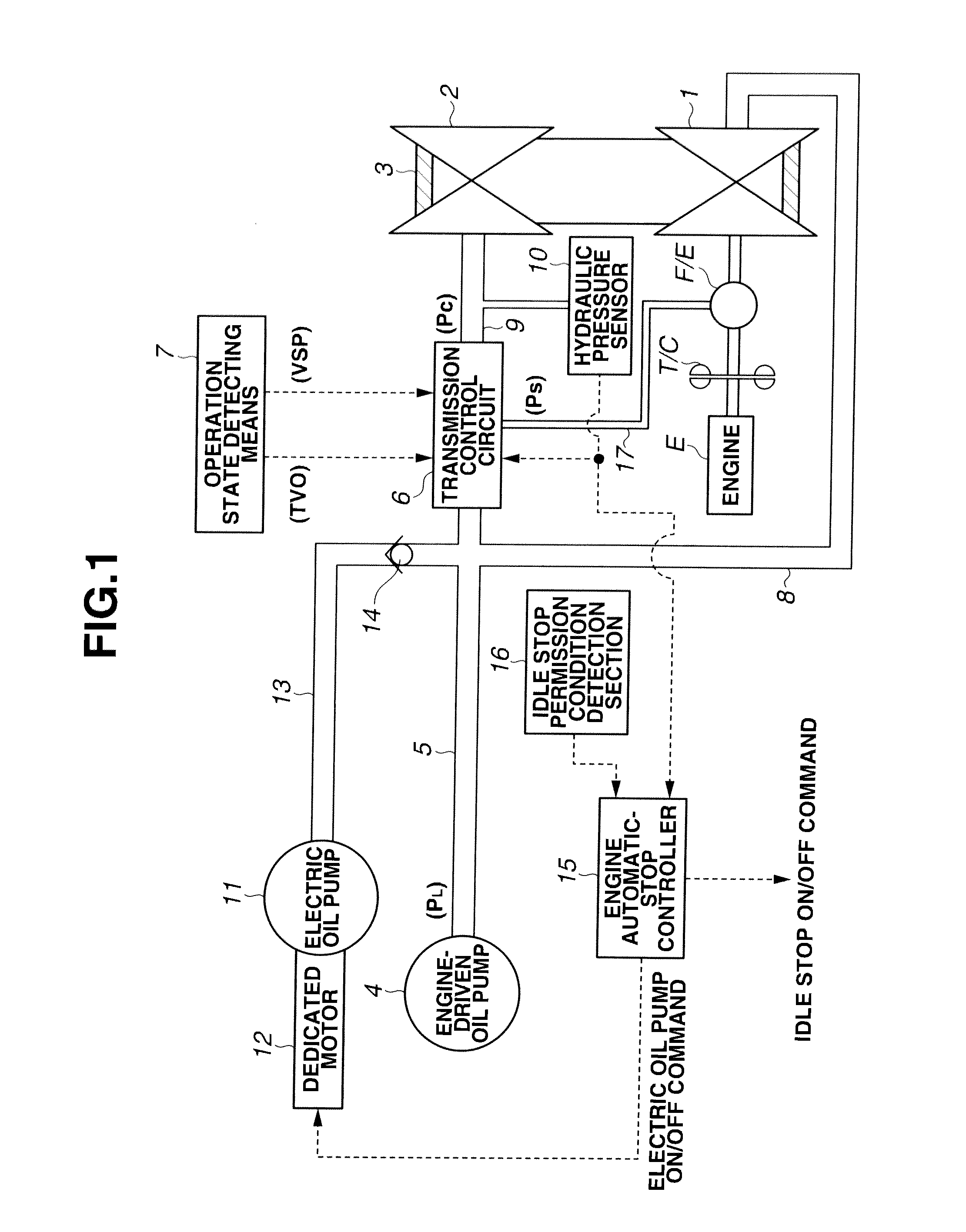

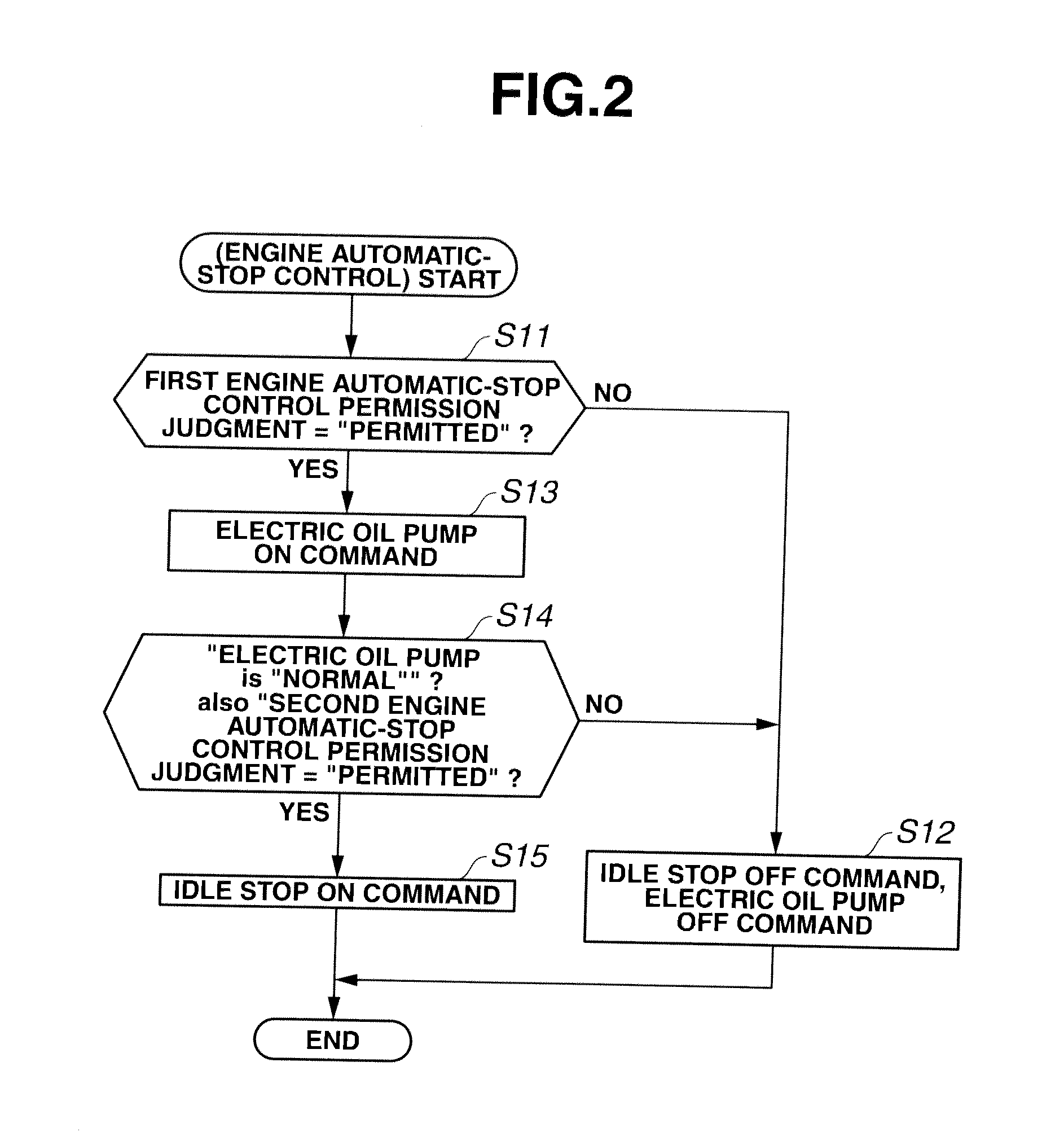

Trouble-deciding device for electric oil pump to be used in transmission of vehicle having engine automatic-stop control device

At vehicle stop judgment time t1, a first engine automatic-stop control permission judgment, based on idle stop permission conditions by which an instant permission judgment can be possible, is carried out. If a result of the first engine automatic-stop control permission judgment at time t1 is “permitted”, the second engine automatic-stop control permission judgment, based on an idle stop permission condition which requires a certain time for the judgment, is initiated, and an electric oil pump ON (drive) command (the test drive command) is issued. At time t2 at which an actual drive of the electric oil pump in response to the test drive command is detected, it is judged that a failure of an electric system of the electric oil pump and a foreign matter-biting failure of the electric oil pump do not occur, then a failure judgment of the electric oil pump becomes “normal”. This judgment is completed before time t3 at which the second engine automatic-stop control permission judgment ends, and both of “permitted” of a result of the second engine automatic-stop control permission judgment and “normal” of the failure judgment of the electric oil pump, an idle stop ON command is not outputted.

Owner:NISSAN MOTOR CO LTD

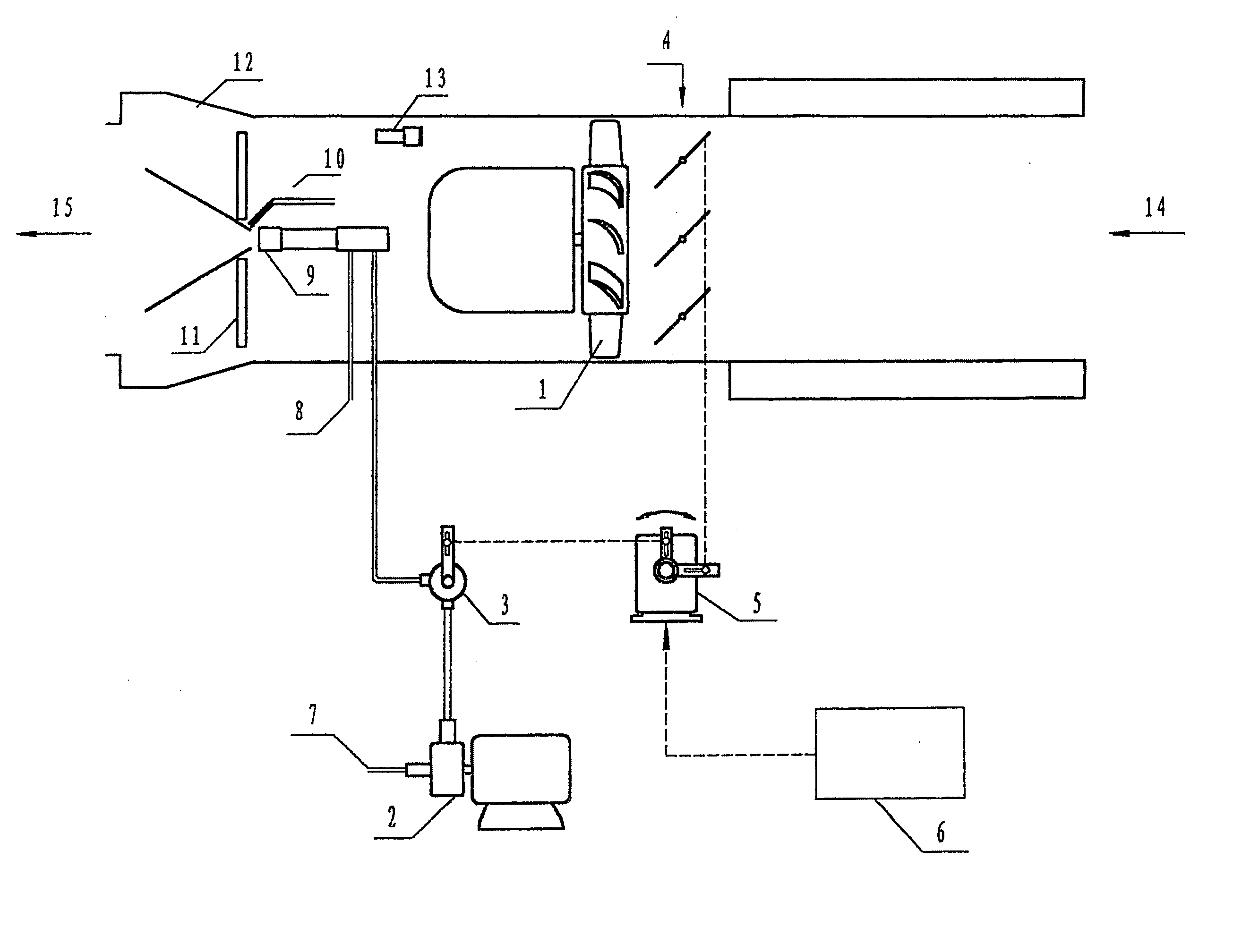

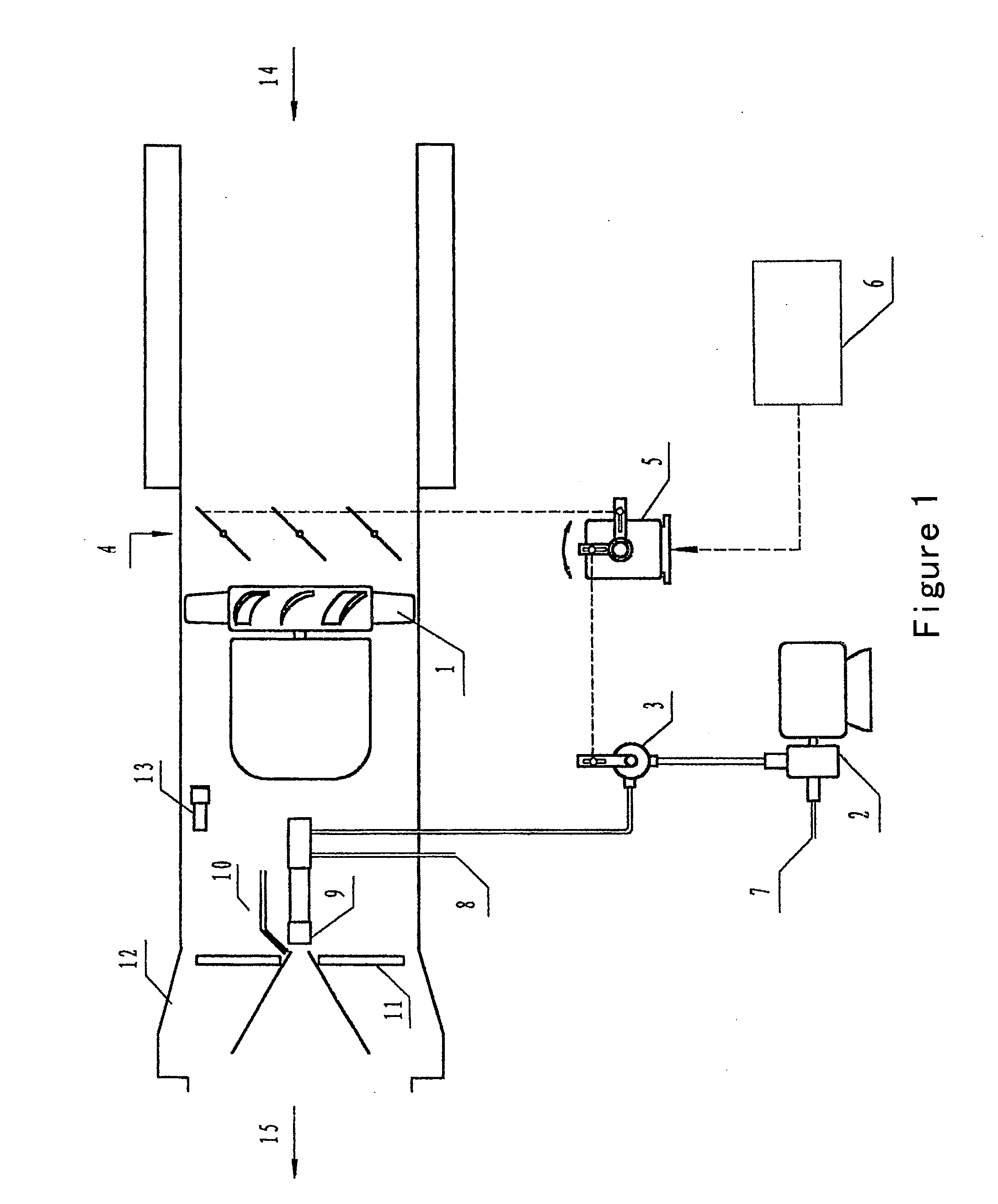

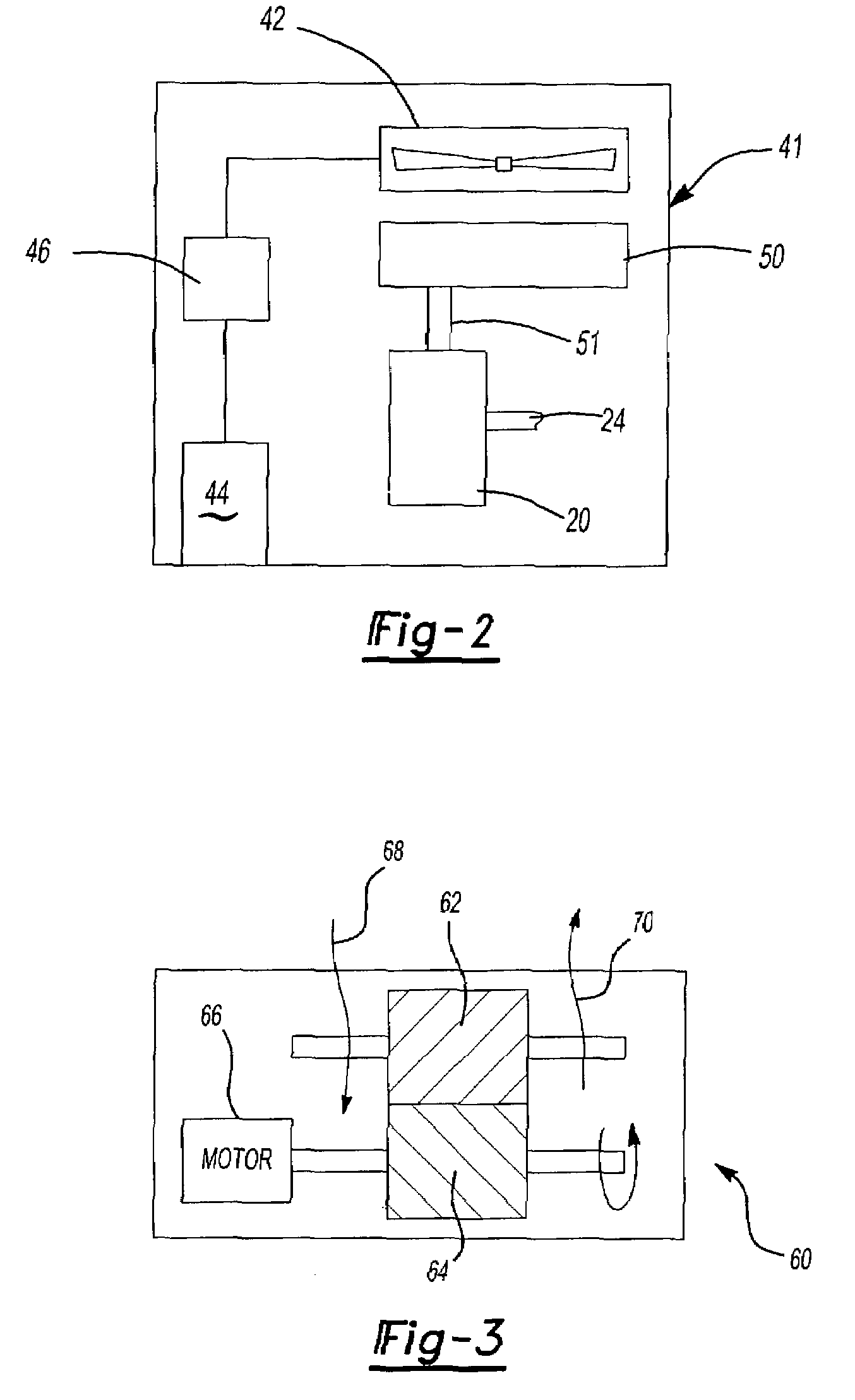

Autocontrol burner and a combustion control method

InactiveUS20060068347A1Improve efficiencyReduce energy consumptionBurnersFuel supply regulationMotor speedCombustor

A combustion control method for a burner comprises: the fuel supplying means outputs a given amount of fuel oil to the fuel oil atomizing means; the fuel atomizing means sprays fuel atomized gas; said gas is ignited by the igniter; the amount of air is sent to facilitate burning by the air blowing means; the outputting flow rate of fuel oil and the flow rate of air are adjusted automatically, simultaneously and proportionally by controlling the rotating speed of the electric motors of the fuel supplying means and the air blowing means. An autocontrol burner comprises a main body, an oil pump (2), a blower fan (1), a spray gun (9) and an ignition gun (10), and further comprises a programmable control unit (18), motor speed controller (16,17) and a signal acquisition assembly. The output port of the signal acquisition assembly is connected with the input port of the programmable control unit (18). The oil pump (2) and the blower fan (1) are connected with the programmable control unit (18) by the motor speed controller (16, 17).

Owner:LI YANXIN

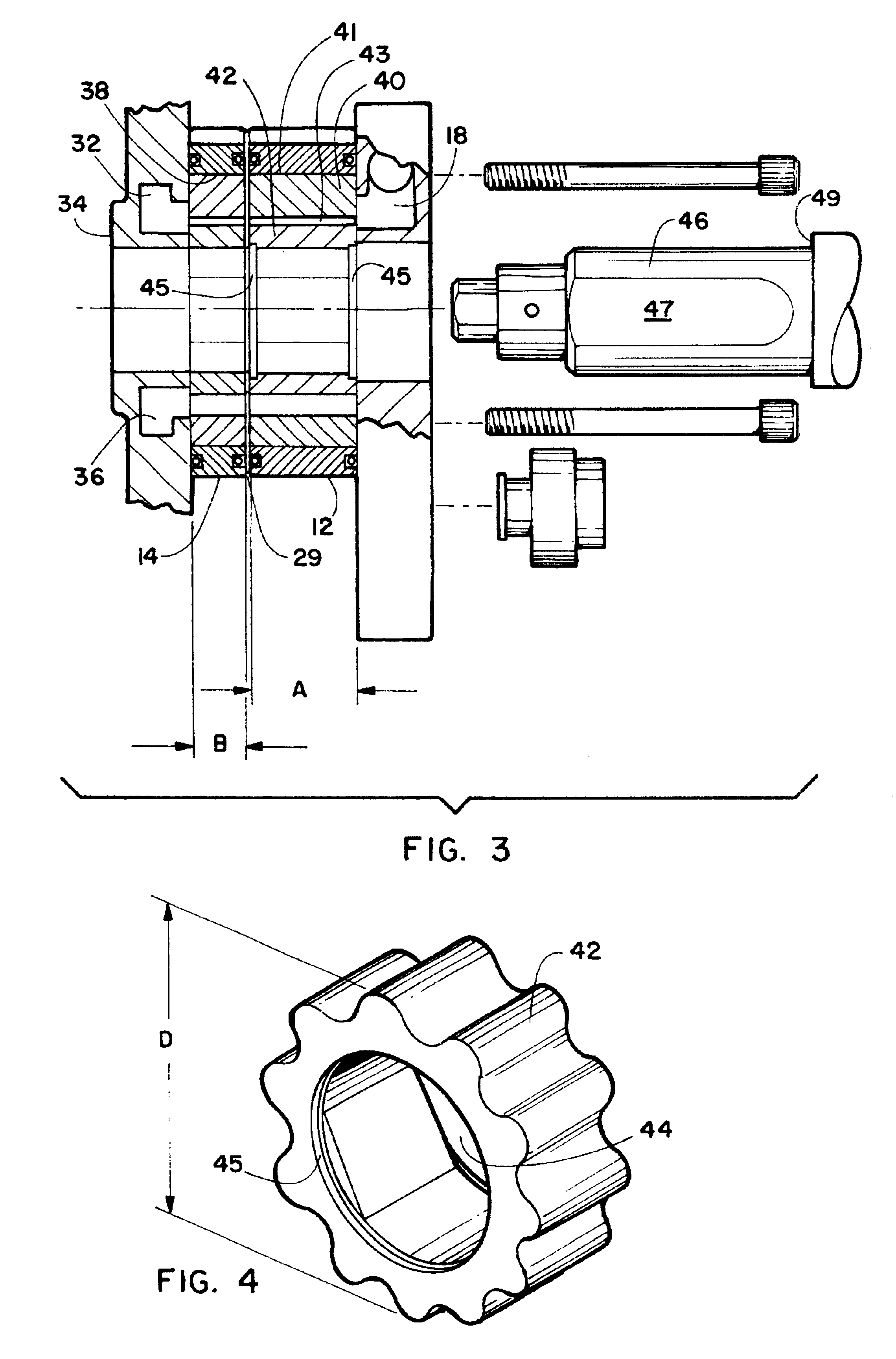

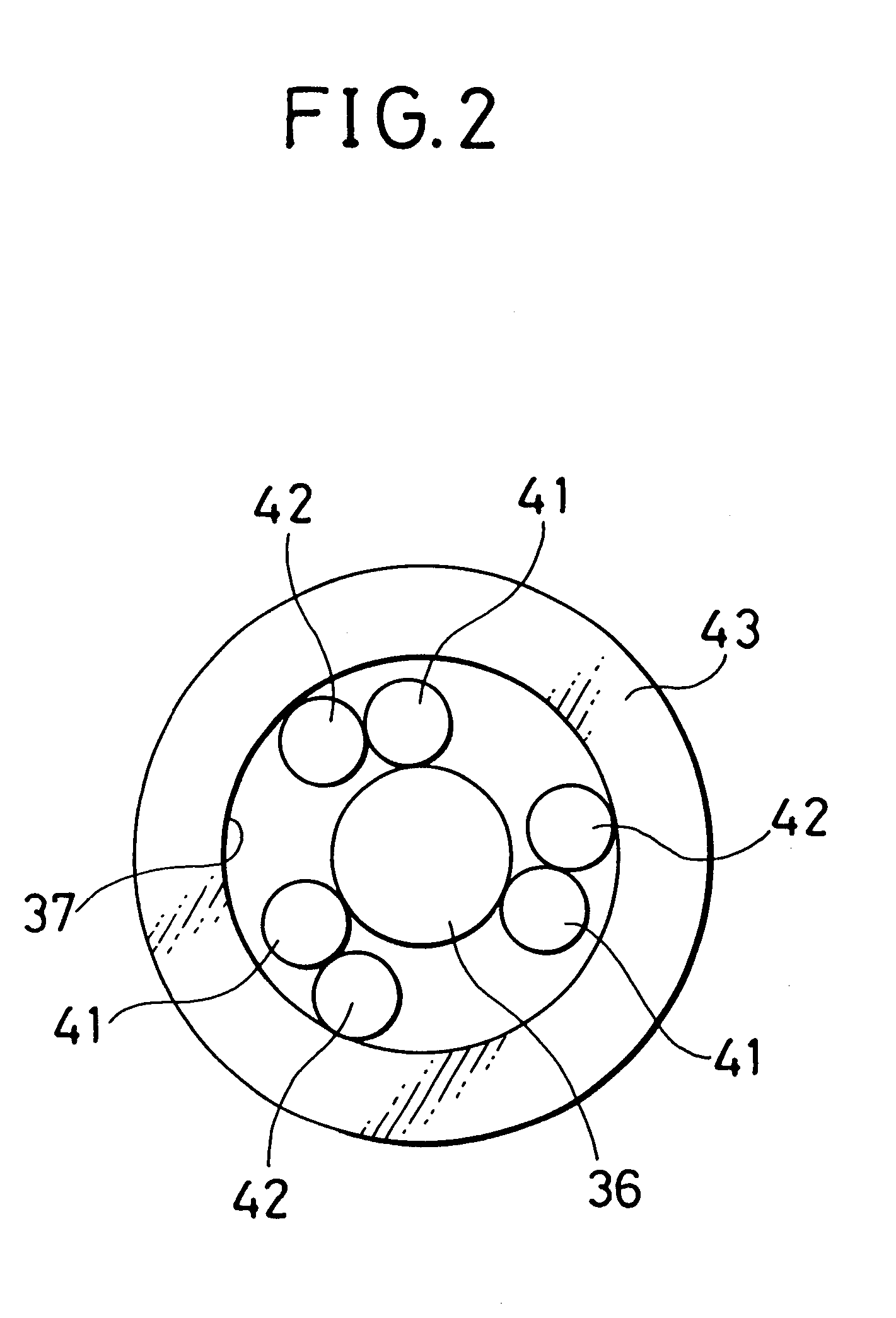

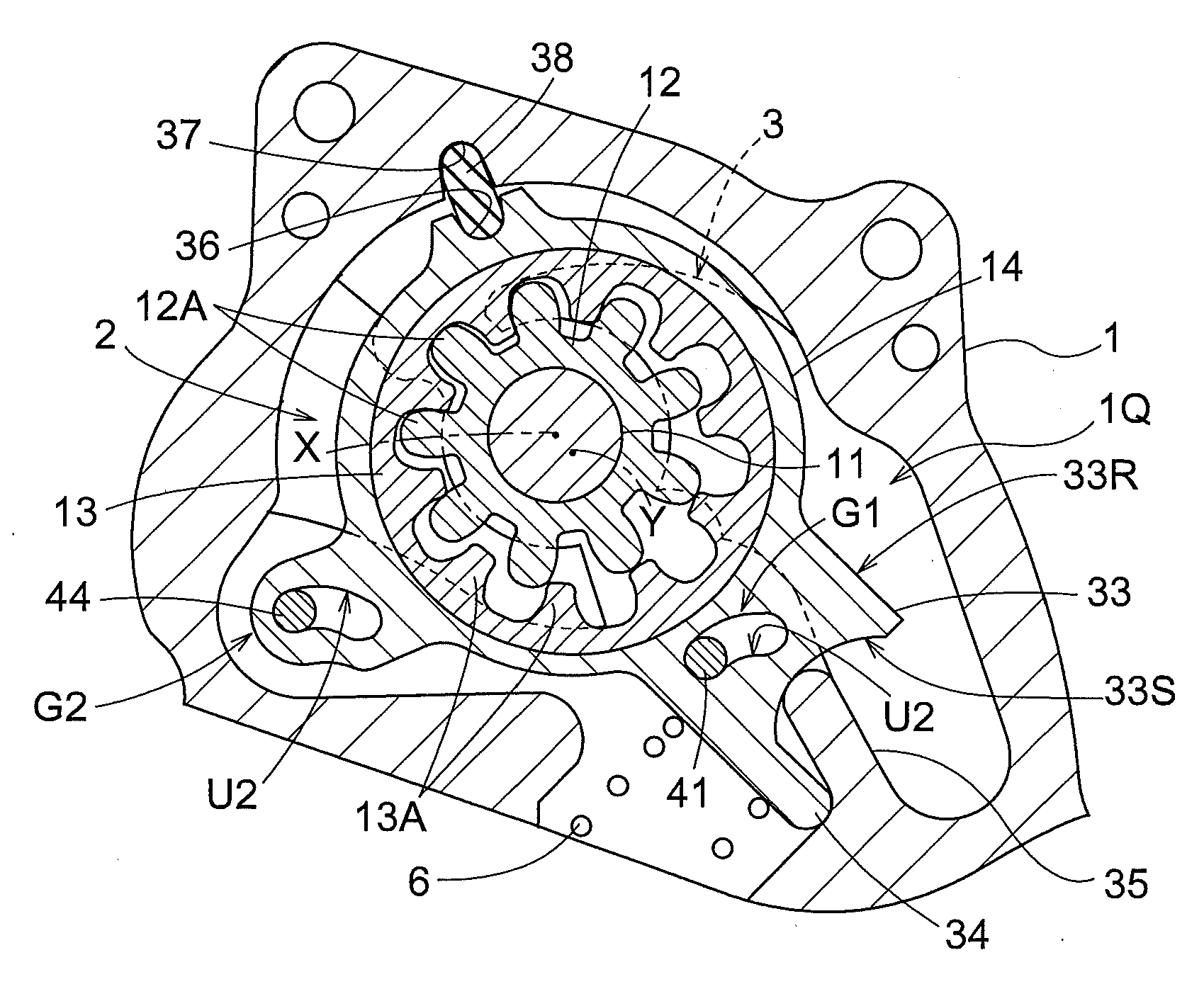

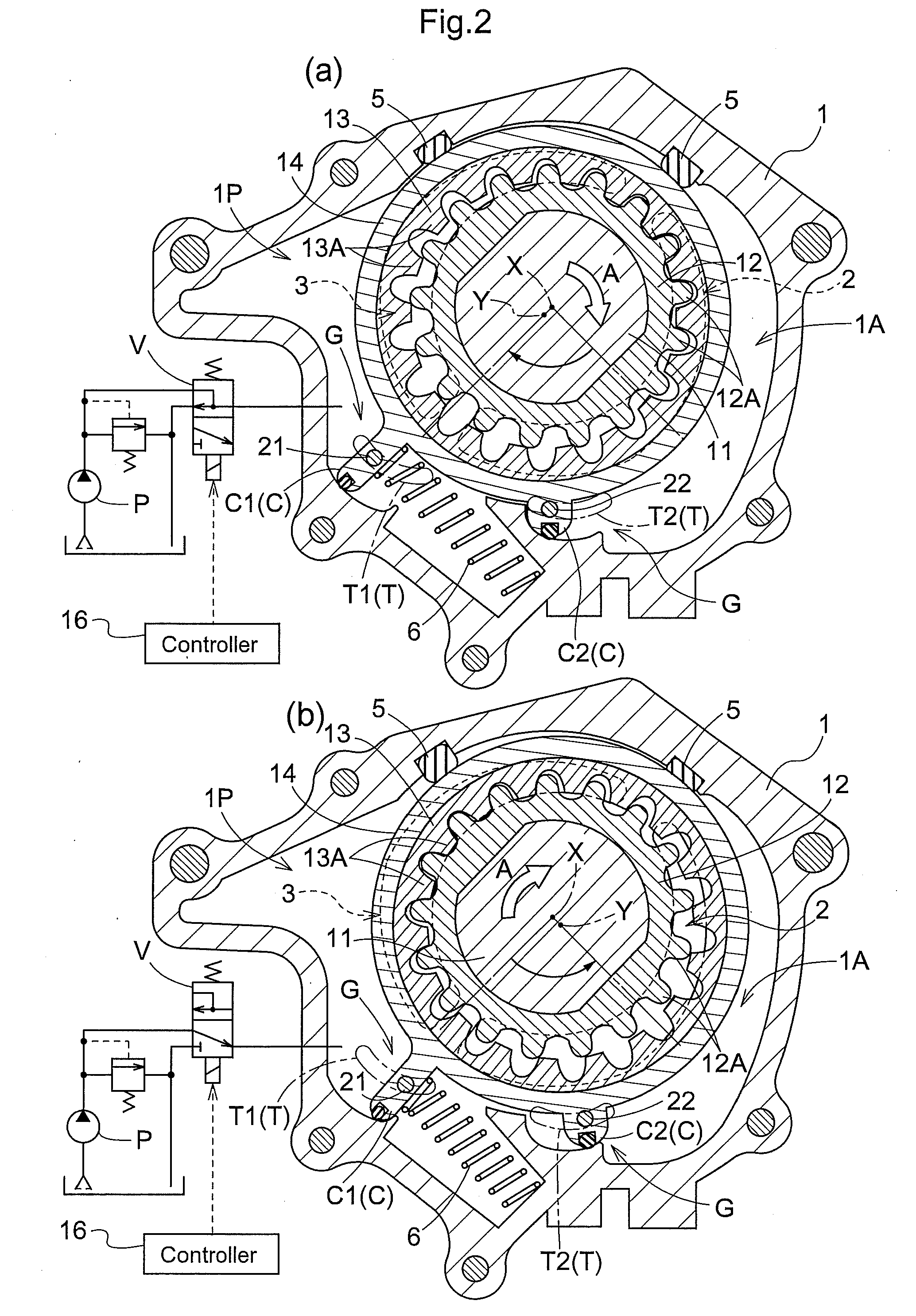

Oil pump

ActiveUS20110014078A1Reducing teeth numberEasy dischargeOscillating piston enginesEngine of intermeshing engagement typeRotational axisDrive shaft

An oil pump includes: an inner rotor rotatable with a drive shaft in a unified manner on a drive-rotation axis; an outer rotor which has inner teeth configured to engage with outer teeth of the inner rotor and is rotatable about a driven axis eccentric to the drive-rotation axis; and an adjustment ring for rotatably supporting the outer rotor. A guide means which allows the adjustment ring to rotate about the driven axis, while allowing the driven axis to revolve about the drive-rotation axis, is formed of: first and second arm portions provided on the adjustment ring; and first and second guide faces with which the first and second arm portions are brought into slidable contact.

Owner:AISIN SEIKI KK

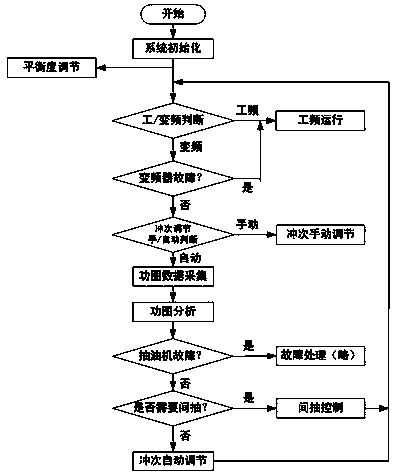

Efficient method for frequency conversion and energy saving of oil pumping unit

ActiveCN103984300AReduce peak currentProtect the reducerFluid removalTotal factory controlFrequency changerHigh energy

The invention discloses an efficient method for frequency conversion and energy saving of an oil pumping unit. The efficient method comprises the following steps that after a device is started, a system is initialized and the balance degree of the oil pumping unit is adjusted; whether the oil pumping unit is in a power frequency operation mode or in a frequency conversion operation mode is judged; in the frequency conversion operation mode, whether a frequency converter breaks down or not is judged, and if not, a stroke frequency adjustment mode of the oil pumping unit is judged; in an automatic stroke frequency adjusting mode, indicator diagram data are collected and whether the oil pumping unit breaks down or not is judged according to an indicator diagram; if the oil pumping unit does not break down, whether the oil pumping unit needs interval pumping control or not is judged; if the oil pumping unit does not need the interval pumping control, the stroke frequency of the oil pumping unit is automatically adjusted. The method for frequency conversion and energy saving of the oil pumping unit has the advantages that the adjustment of the balance degree, the optimal operation stroke frequency and the optimal interval pumping mode is conducted according to the working conditions of the oil pumping unit, the states of high efficiency and low energy consumption of the oil pumping unit can be kept, and the problems of high energy consumption and low efficiency in the operation process of the oil pumping unit can be solved.

Owner:ANHUI DORJE ELECTRIC

A new type of rotating drive system for mixing drum of concrete mixer truck

InactiveCN102275223AReduced power ratingImprove work efficiencyCement mixing apparatusPrime moverHydraulic motor

The invention relates to a novel rotation driving system for a mixing drum of a concrete mixing transport vehicle. In the system, two prime movers, two hydraulic main pumps, an oil supply pump and a hydraulic motor form a hydraulic closed loop together with a hydraulic valve block with the functions of relatively completing oil supply, cooling and safe buffering; the delivery volumes of the two hydraulic main pumps are different; and the low-delivery volume hydraulic main pump is used for separately realizing slow and constant mixing action of the mixing drum, and the high-delivery volume hydraulic main pump is used for rotating the mixing drum along positive and negative directions at a high speed during feeding and discharging when separately operated or combined with the low-delivery volume hydraulic main pump. The system aims to solve the problems of the influence on the concrete uniformity and the influence on the driving dynamic performance and driving safety performance which are caused by driving a roller to rotate by separately using a chassis engine under different working conditions and different road conditions in the mixing drum, fuel waste caused by the long-term operation of the high-power chassis engine at low-efficiency points and the hydraulic shock generated during the switching of the mixing drum under different working conditions.

Owner:SICHUAN UNIV

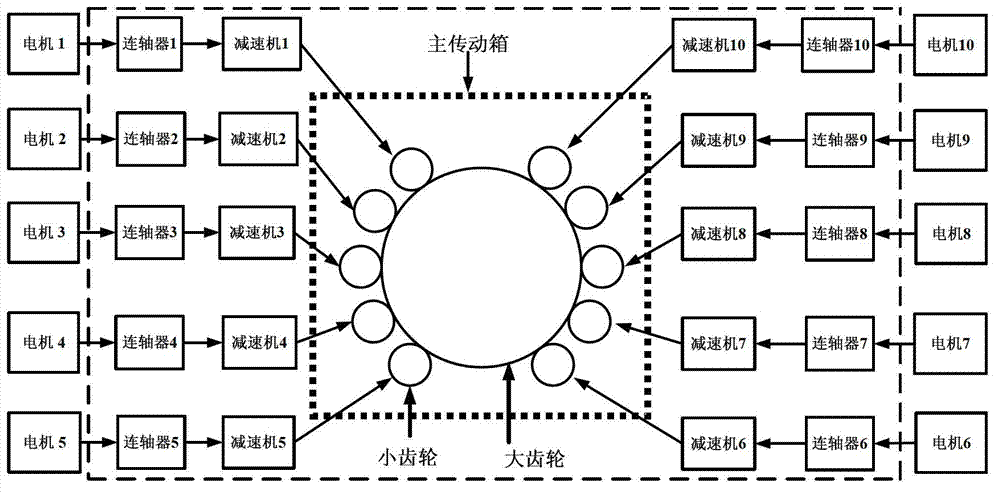

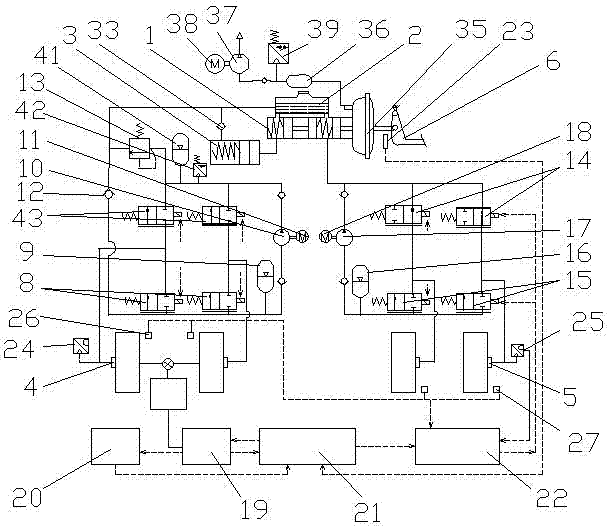

Cutter head driving device for shield tunneling machine and synchronous control method thereof

InactiveCN103016014ASolve fundamental problemsSolve the important technical problems of synchronous output operationMultiple dynamo-electric motors speed regulationTunnelsProportion integration differentiationLoop control

The invention relates to a cutter head driving device for a shield tunneling machine and a control method thereof. The driving device comprises a plurality of driving motors, a plurality of speed reducers, a main transmission box, a circular cutter head and a circulating oil pump. The synchronous control method for a cutter head of the shield tunneling machine comprises the following steps of: performing synchronous and parallel PID (Proportion Integration Differentiation) closed-loop control on the driving motors; keeping the reference input signals of the driving motors the same; computing the compensation signal of the output signal of each driving motor by adopting a synchronous error compensation method, and feeding back to the input end of a corresponding driving motor; and adding the compensation signals with a control signal output by an optimal PID controller, and inputting into a corresponding driving motor. Due to the adoption of the cutter head driving device and the synchronous control method, the technical problem of synchronous running of a plurality of motors of the cutter head of the shield tunneling machine is solved; the running synchronous performance and tracking performance of a cutter head driving system of the shield tunneling machine are improved; and the motors of the cutter head are enabled to have the same stable torque or speed, and dynamic performances among the driving motors of the cutter head of the shield tunneling machine can be kept the same.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Hybrid electrical vehicle (HEV)/electrical vehicle (EV) regeneration brake pressure coordinate control system based on antilock brake system (ABS) hardware

ActiveCN102303597AGood braking feelAccurate braking forceBraking action transmissionElectrodynamic brake systemsDrive motorWheel cylinder

The invention discloses a hybrid electrical vehicle (HEV) / electrical vehicle (EV) regeneration brake pressure coordinate control system based on antilock brake system (ABS) hardware. The system comprises a hydraulic brake subsystem, a motor regeneration subsystem and a control system for controlling the hydraulic brake subsystem and the motor regeneration brake subsystem; and the hydraulic brake subsystem comprises a vacuum assistance system, a brake main cylinder, an oil storage tank, a travel simulator, a front wheel ABS pressure regulation system, a front wheel brake wheel cylinder, a rearwheel ABS pressure regulation system and a rear wheel brake wheel cylinder, and a working cavity I of the brake main cylinder is communicated with the travel stimulator. In the HEV / EV system regeneration brake pressure coordinate control system based on the ABS hardware, the working modes such as pure motor brake, electrohydraulic combined brake, pure hydraulic brake, antilock brake and the like can be flexibly selected according to specific conditions, and accurate brake force is provided; when a brake pedal is trampled, the travel simulator can produce good retardation brake feeling; and during pressurization, an overflow valve and a solenoid directional valve can protect an oil pump I driving motor to ensure that a system can work stably.

Owner:CHONGQING UNIV

Rolling bearing high-efficiency anti-rust oil spraying device

InactiveCN105880080AEasy to operateSpray evenlySpraying apparatusRolling-element bearingElectric machine

The invention relates to a spraying device, in particular to a rolling bearing high-efficiency anti-rust oil spraying device. The technical problem to be solved in the invention is to provide a rolling bearing high-efficiency anti-rust oil spraying device with the advantages of simplicity in operation, uniformity in spraying and high spraying speed. In order to solve the technical problem, the rolling bearing high-efficiency anti-rust oil spraying device provided by the invention comprises a left rack, a bottom plate, an oil tank, an oil pump, a right rack, an oil return pipe, a motor I, a rotating shaft, a bearing base, a sealing ring, supporting rods, a fixing plate, a circular sliding rail, slide blocks, a nozzle, a fastening sleeve, a meshed frame, a connecting rod, a motor II, a spraying adapter plate, a swing rod, an oil inlet hopper, a spraying disc, a rotating disc, a hose and a top plate, wherein the left rack, the oil tank and the right rack are arranged at the top of the bottom plate sequentially from the left to right; the oil pump is arranged on the right side at the bottom in the oil tank; the hose is arranged on the oil pump; the hose penetrates through the top of the oil tank. According to the invention, the effects of being simple in operation, uniform in spraying and high in spraying speed are achieved.

Owner:刘焕雄

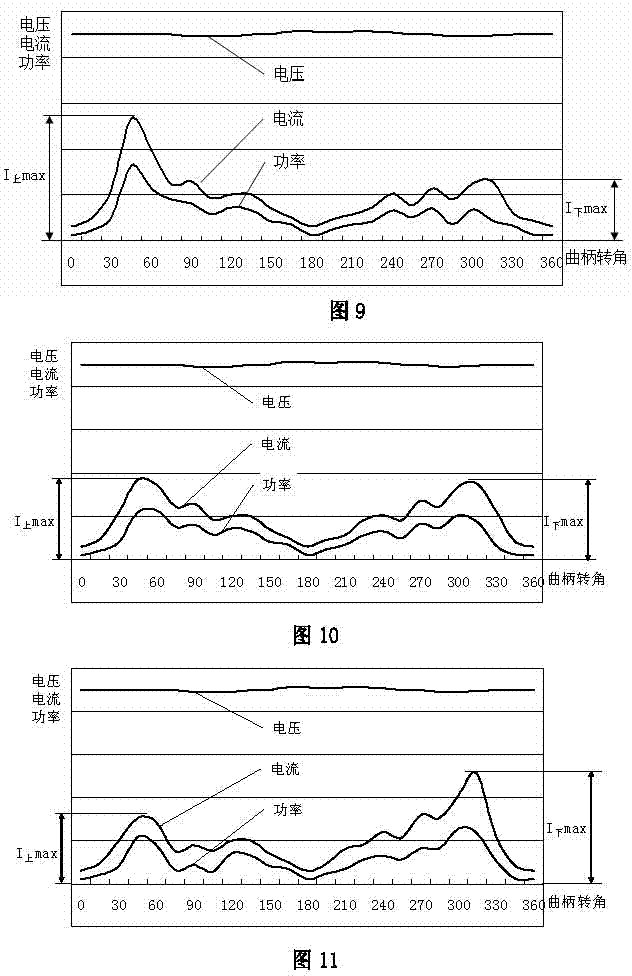

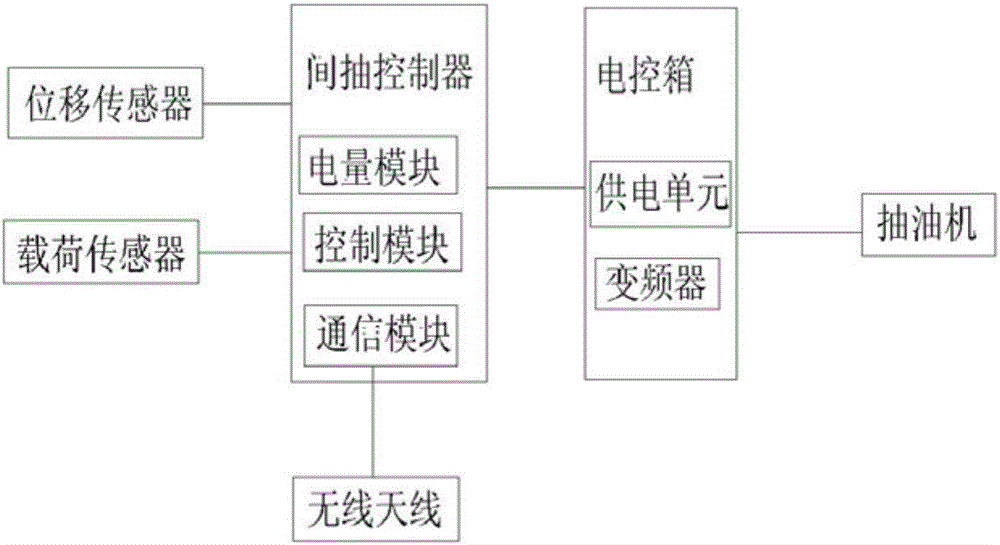

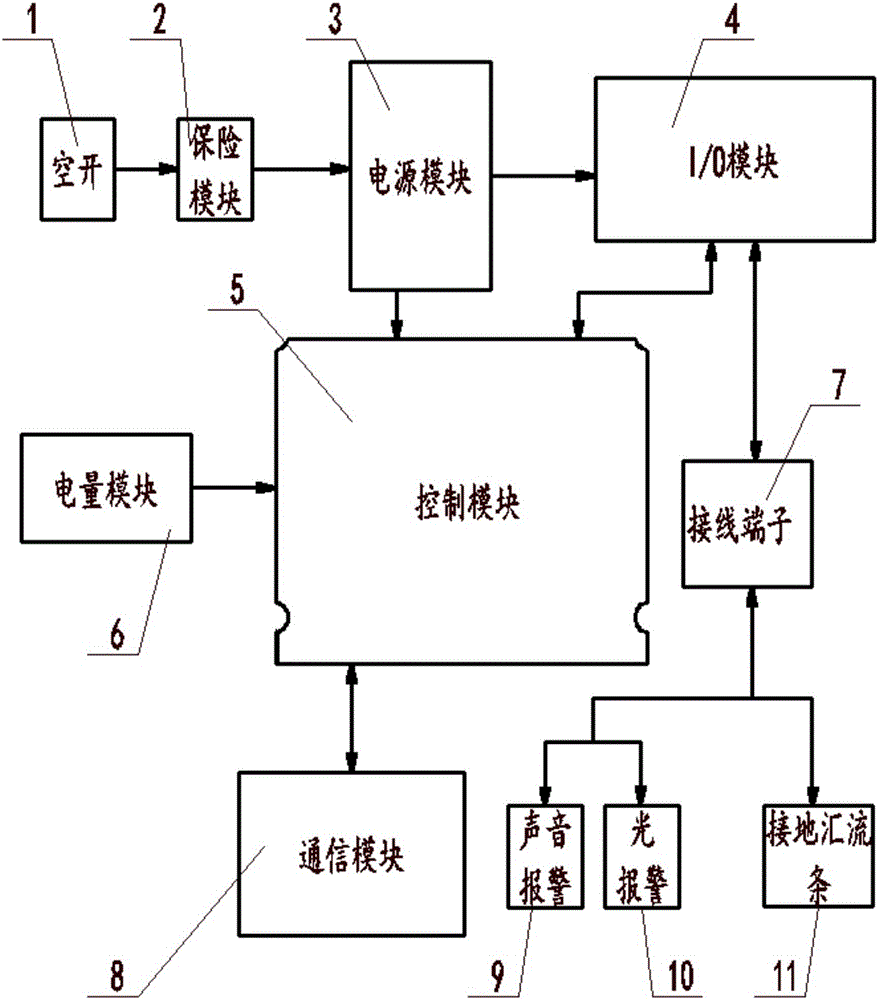

Intelligent intermittent pumping control device for oil pumping machine and control method of intelligent intermittent pumping control device

The invention discloses an intelligent intermittent pumping control device for an oil pumping machine. The intermittent pumping control device for the oil pumping machine comprises an intermittent pumping controller, an electric control box, a displacement sensor, a load sensor and a wireless antenna; the displacement sensor measures displacement at a polished rod of the oil pumping machine and is connected to the intermittent pumping controller; the load sensor measures a load at the polished rod of the oil pumping machine and is connected to the intermittent pumping controller; the intermittent pumping controller is connected with the electric control box, and comprises a power supply module, a communication module, a control module and an electric quantity module; the electric quantity module acquires the current, the voltage and the power of the oil pumping machine in a working process, and transmitting the current, the voltage and the power of the oil pumping machine to the control module; the communication module is connected with the wireless antenna; the control module acquires start-stop information of the oil pumping machine according to the load and the displacement at the polished rod of the oil pumping machine, and transmits a start-stop command to the electric control box; the electric control box comprises a power supply unit and a frequency converter, and realizes the start-stop of the oil pumping machine and the adjustment of jig frequency according to the command of the intermittent pumping controller. The invention also discloses a control method of the intermittent pumping control device for the oil pumping machine.

Owner:陕西安控科技有限公司

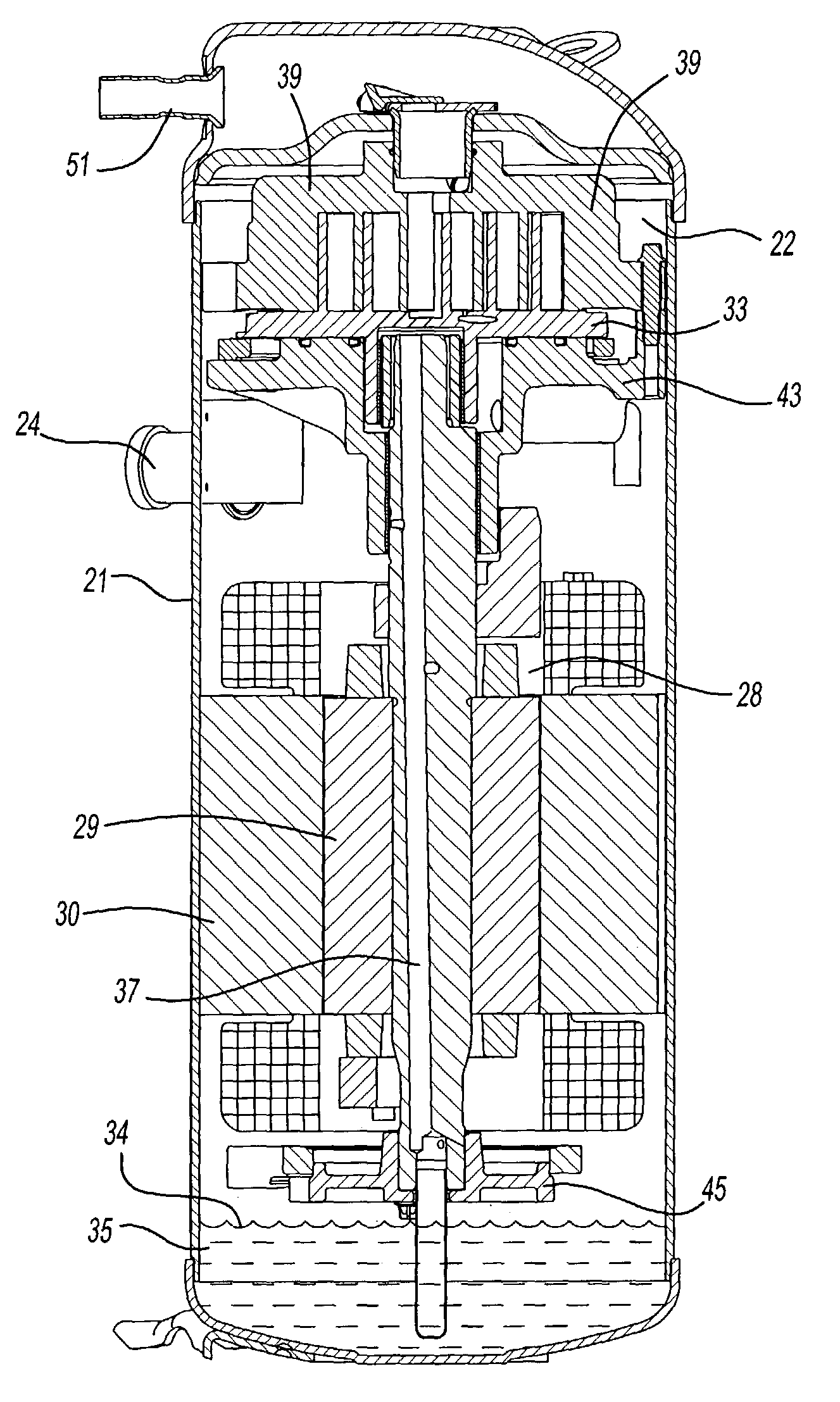

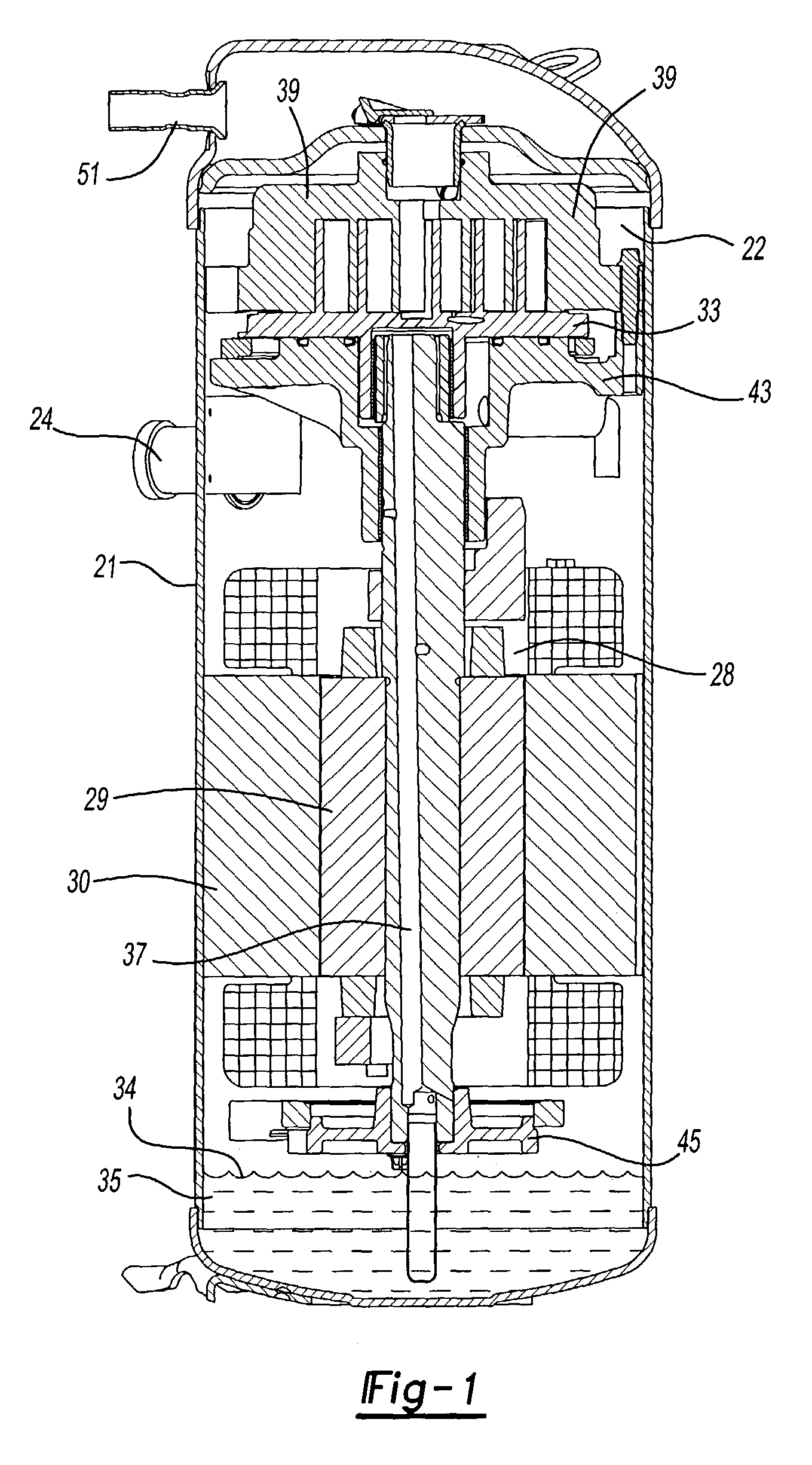

Short reverse rotation of compressor at startup

InactiveUS7290990B2Rotary/oscillating piston combinations for elastic fluidsFlexible member pumpsEngineeringBrief periods

In a method of operating a scroll or screw compressor at startup, the compressor is rotated in reverse for a brief period of time. The compressor is of a type that does not compress liquid when rotated in reverse. The purpose is to boil off the liquid refrigerant from the oil by heating and agitating the mixture of oil and refrigerant in the oil sump. This results in much more benign forward start as no refrigerant is drawn into the scroll compressor pump and the amount of oil pumped out of the compressor on start up is minimized. Also, the viscosity of oil is increased and lubrication of the bearings is improved. After a short period of time reverse rotation is stopped and the compressor can begin to be driven in the forward direction.

Owner:CARRIER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com