Hydraulic fracturing pump system

a pump system and hydraulic technology, applied in the direction of fluid removal, earth-moving drilling, borehole/well accessories, etc., can solve the problems of bulky and heavy pumps and associated engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]It is to be understood that the following disclosure provides many different embodiments, or examples, for implementing different features of various embodiments. Specific examples of components and arrangements are described below to simplify the present disclosure. These are, of course, merely examples and are not intended to be limiting. In addition, the present disclosure may repeat reference numerals and / or letters in the various examples. This repetition is for the purpose of simplicity and clarity and does not in itself dictate a relationship between the various embodiments and / or configurations discussed.

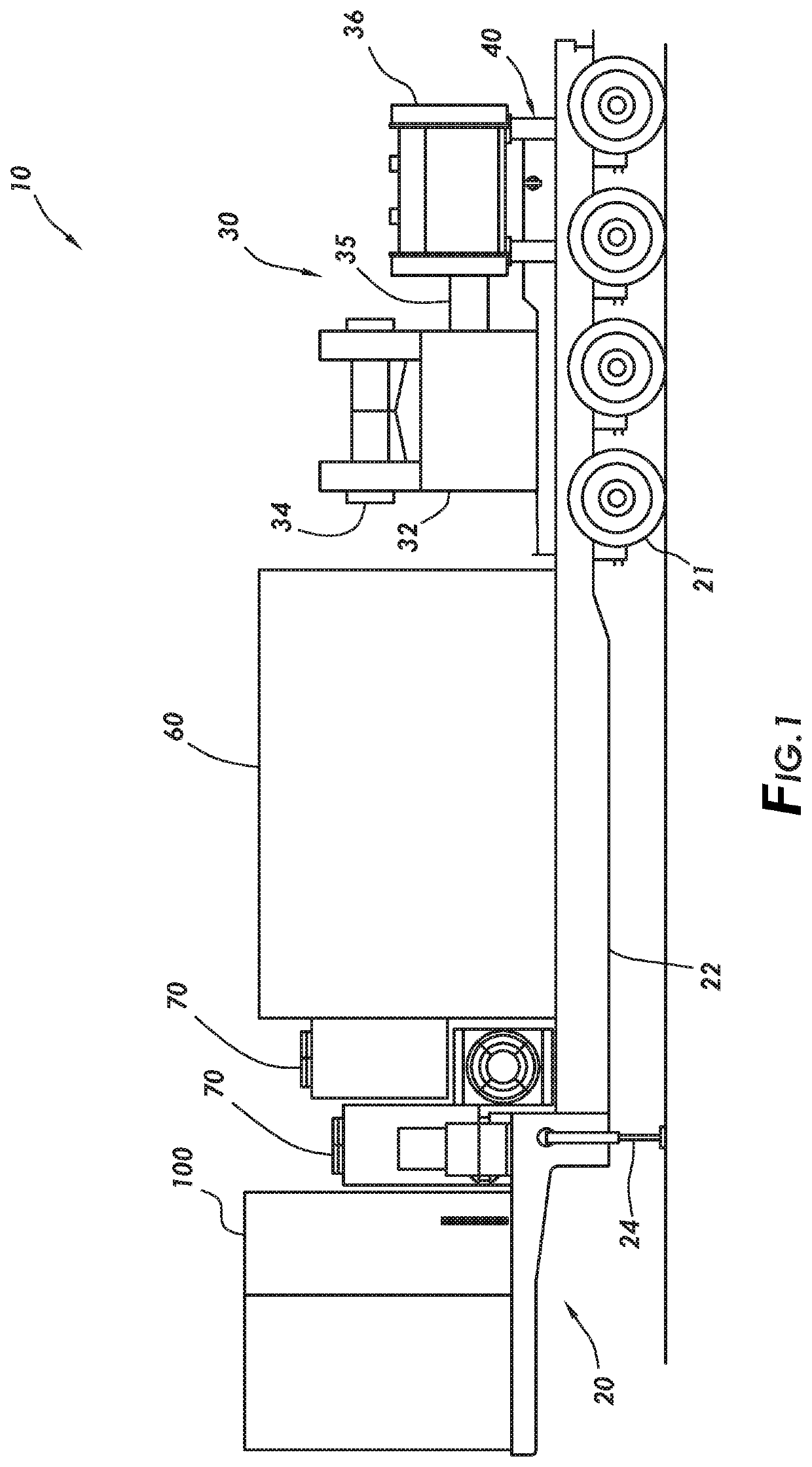

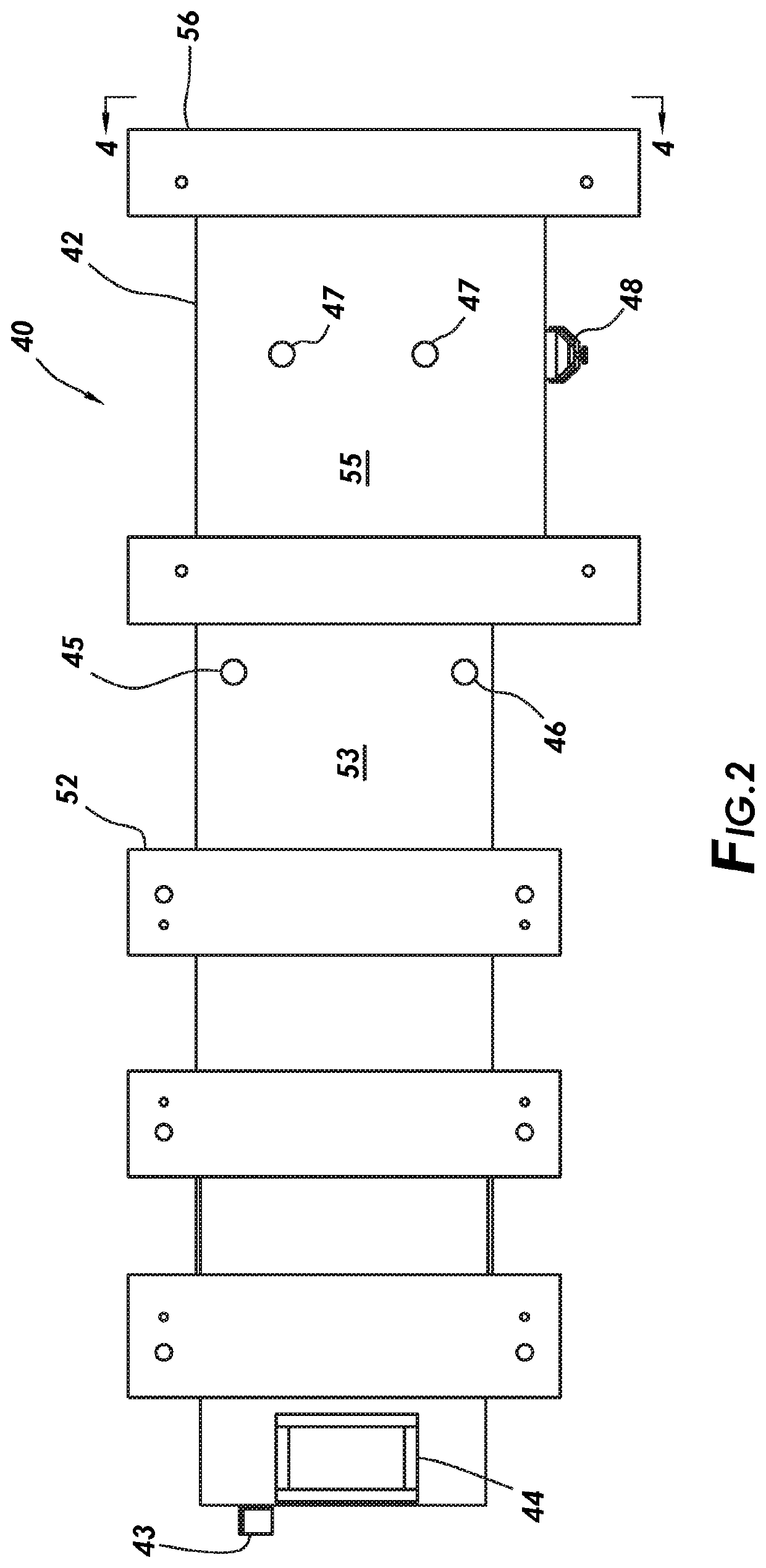

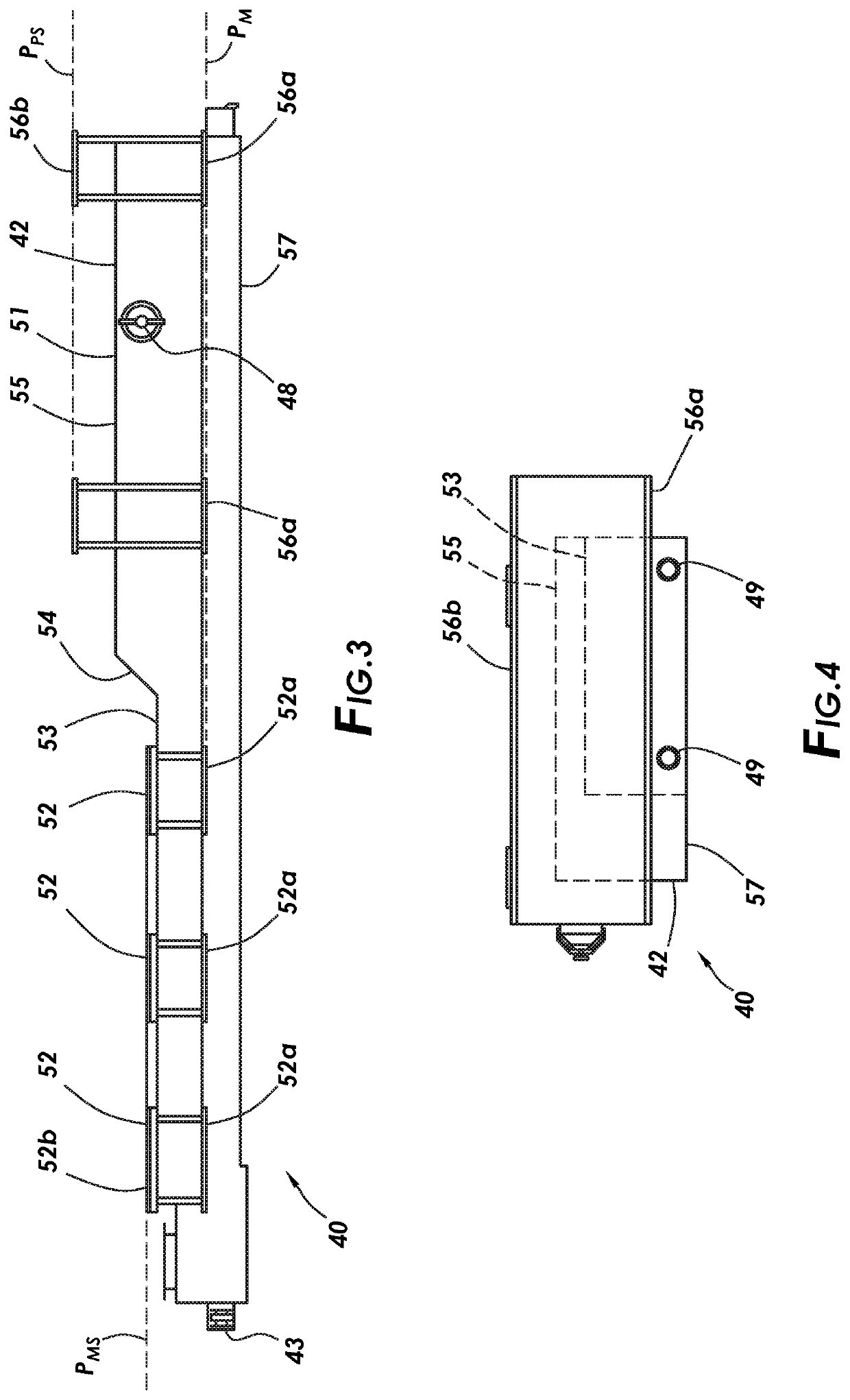

[0019]Referring initially to FIG. 1, transportable hydraulic fracturing system 10 in accordance with some embodiments may comprise several components including but not limited to: transport unit 20, pump unit 30, tank and beam assembly 40, variable frequency drive (VFD) house 60, condensers 70 and control valve system 100. Transport unit 20 may comprise a trailer confi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com