Patents

Literature

9395 results about "Robot hand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surgical manipulator

InactiveUS6723106B1Reduce fatigueHigh dexterityProgramme-controlled manipulatorMicromanipulatorDegrees of freedomEngineering

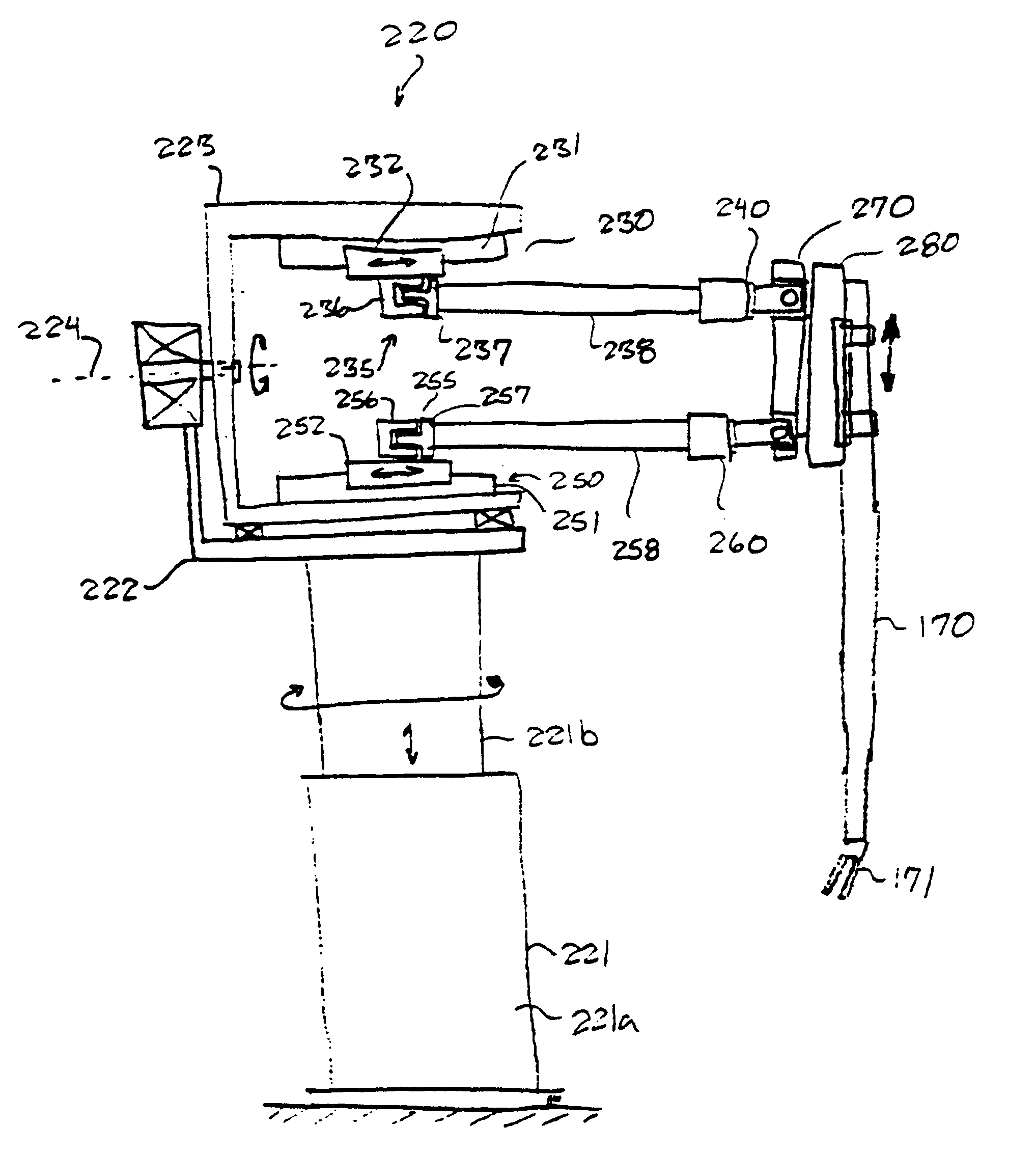

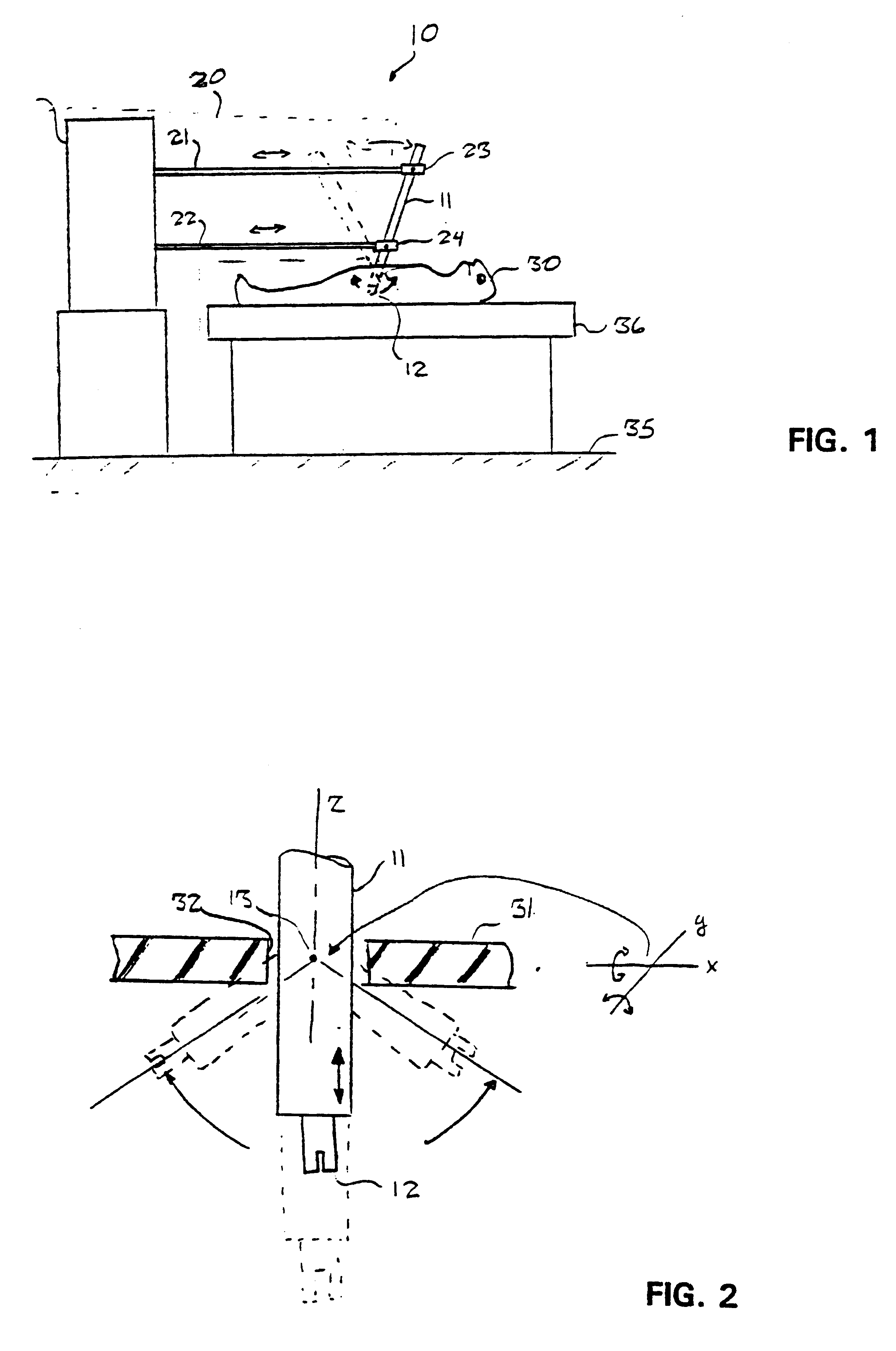

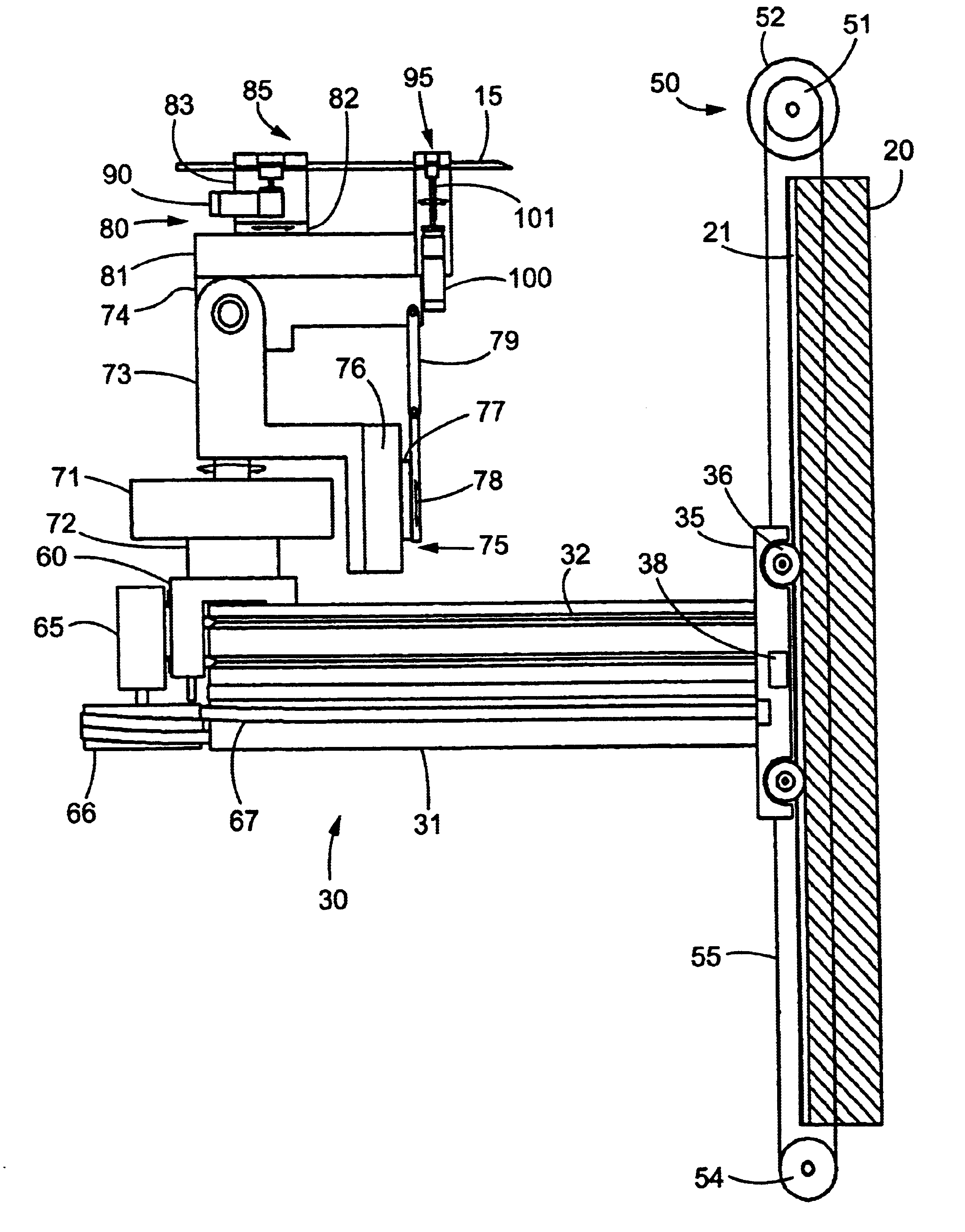

A surgical manipulator (10) can manipulate a medical tool (12) with one or more degrees of freedom. In preferred embodiments, the manipulator (10) is a parallel mechanism including a plurality of arms (21, 22) pivotally supporting a medical tool (12), with the orientation of the medical tool (12) being adjusted by varying the position of joints (23, 24) mounted on the arms (21, 22). The motions of the joints (23, 24) can be controlled such that the tool (12) is pivoted about a virtual pivot point located within the body wall of a patient (30). The manipulator (10) can enhance the dexterity of an operator and enable the operator to perform medical procedures more easily than by hand.

Owner:MICRODEXTERITY SYST

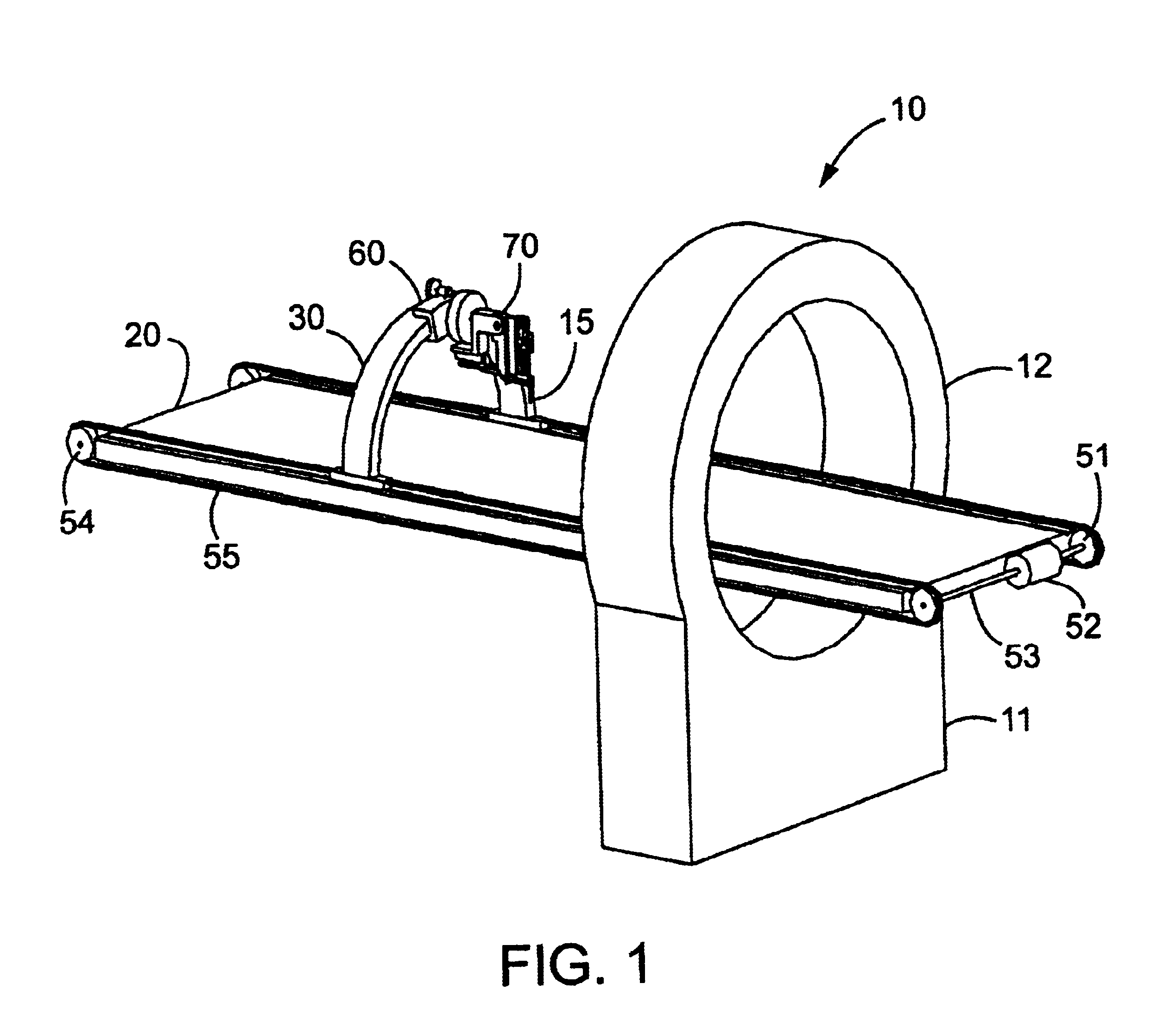

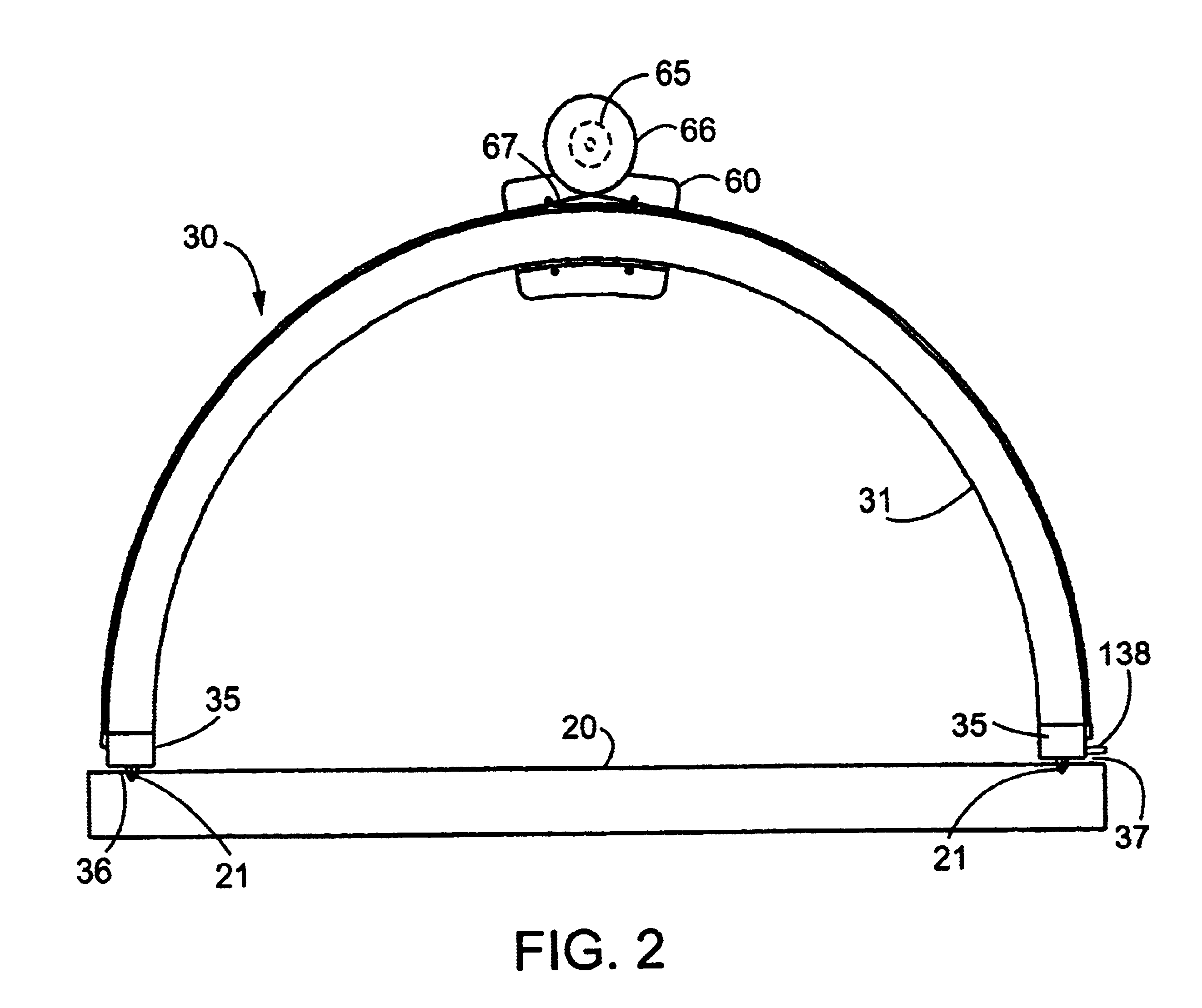

Medical manipulator for use with an imaging device

InactiveUS6665554B1Easy to insertLess stressSurgical needlesVaccination/ovulation diagnosticsDegrees of freedomEngineering

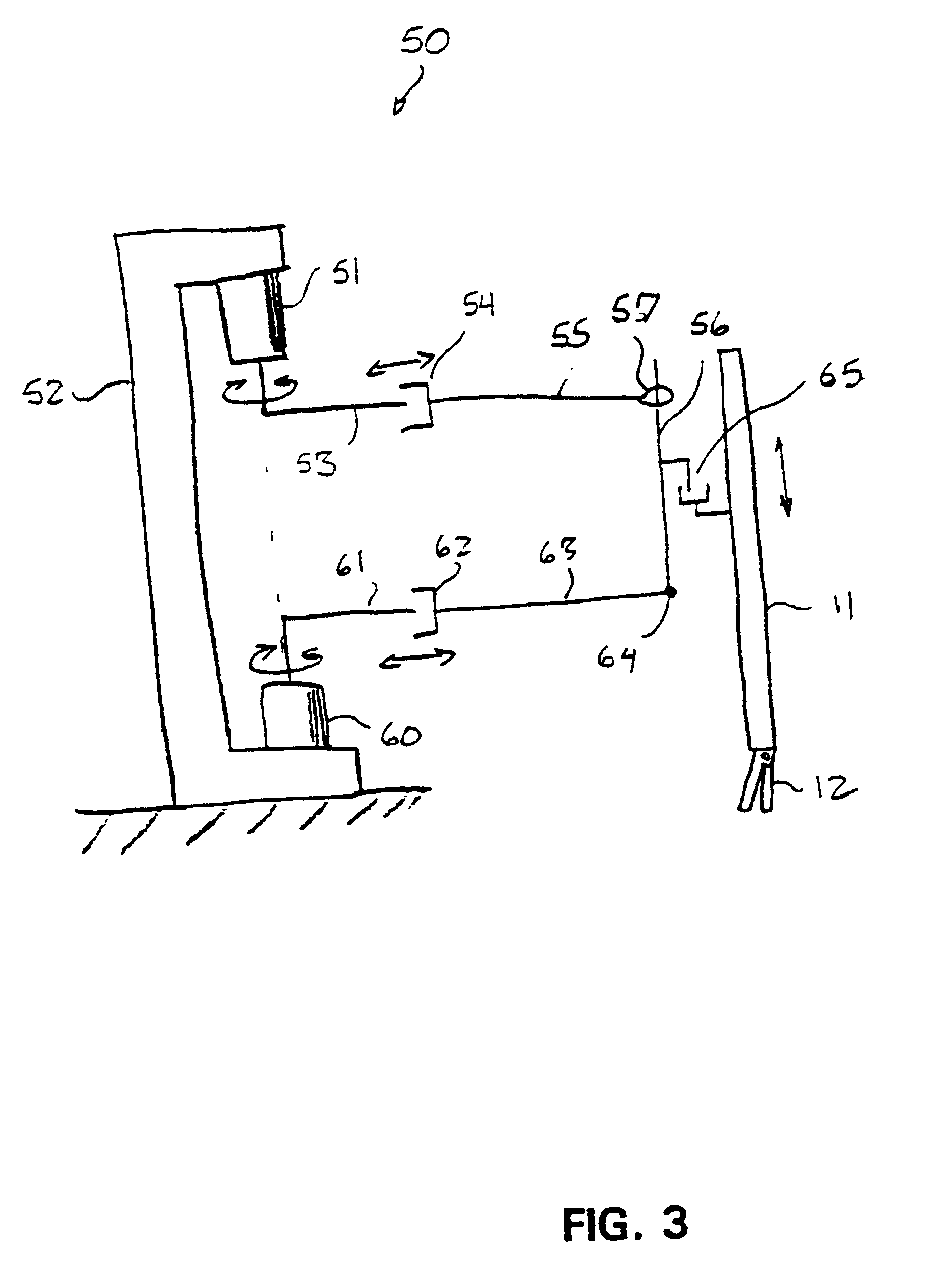

A manipulator for use in medical procedures can manipulate a medical tool with one or more degrees of freedom with respect to a patient. The manipulator is particularly useful for positioning a medical tool with respect to a patient disposed inside an imaging device such as a computer tomography machine.

Owner:MICRODEXTERITY SYST

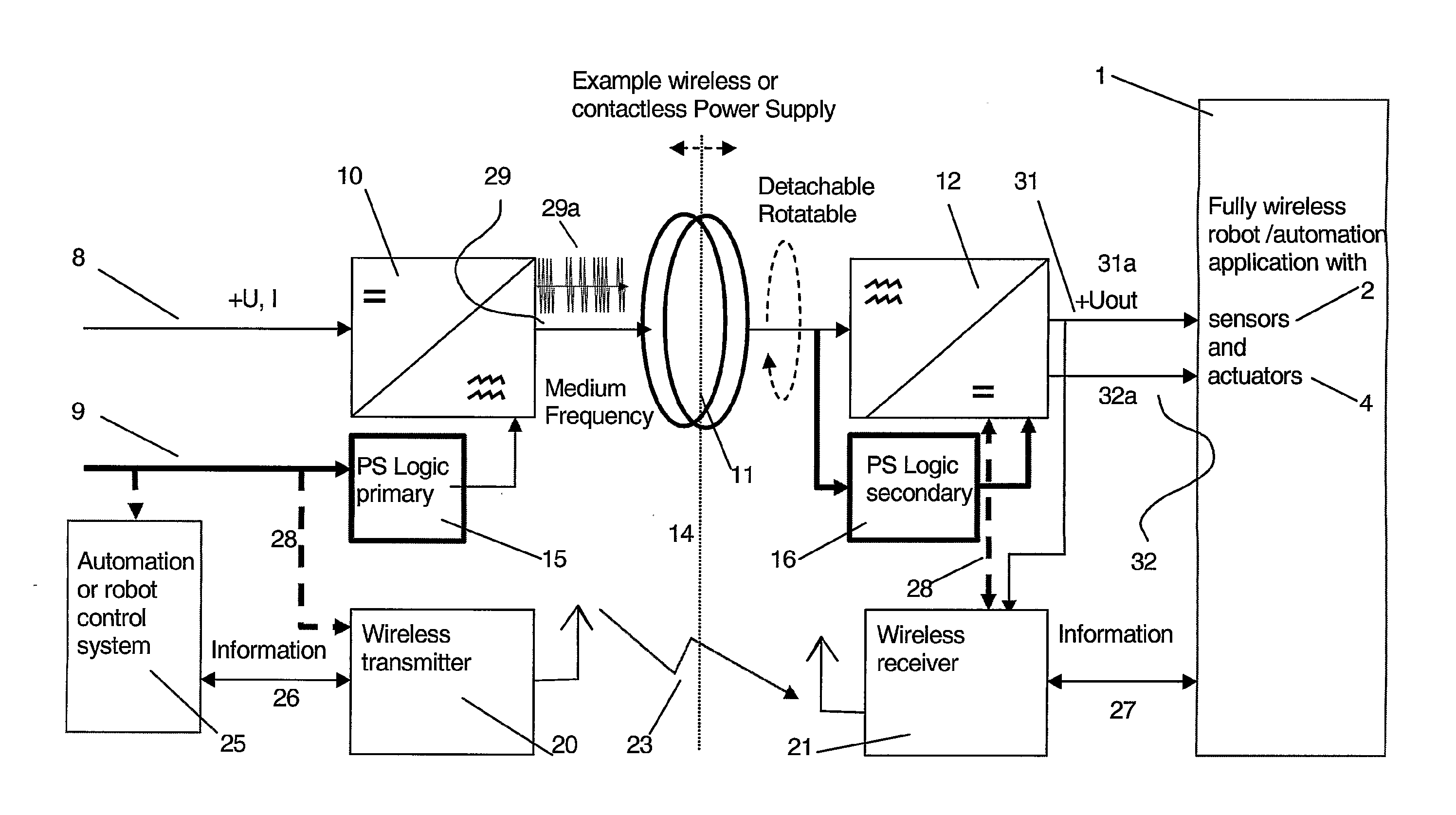

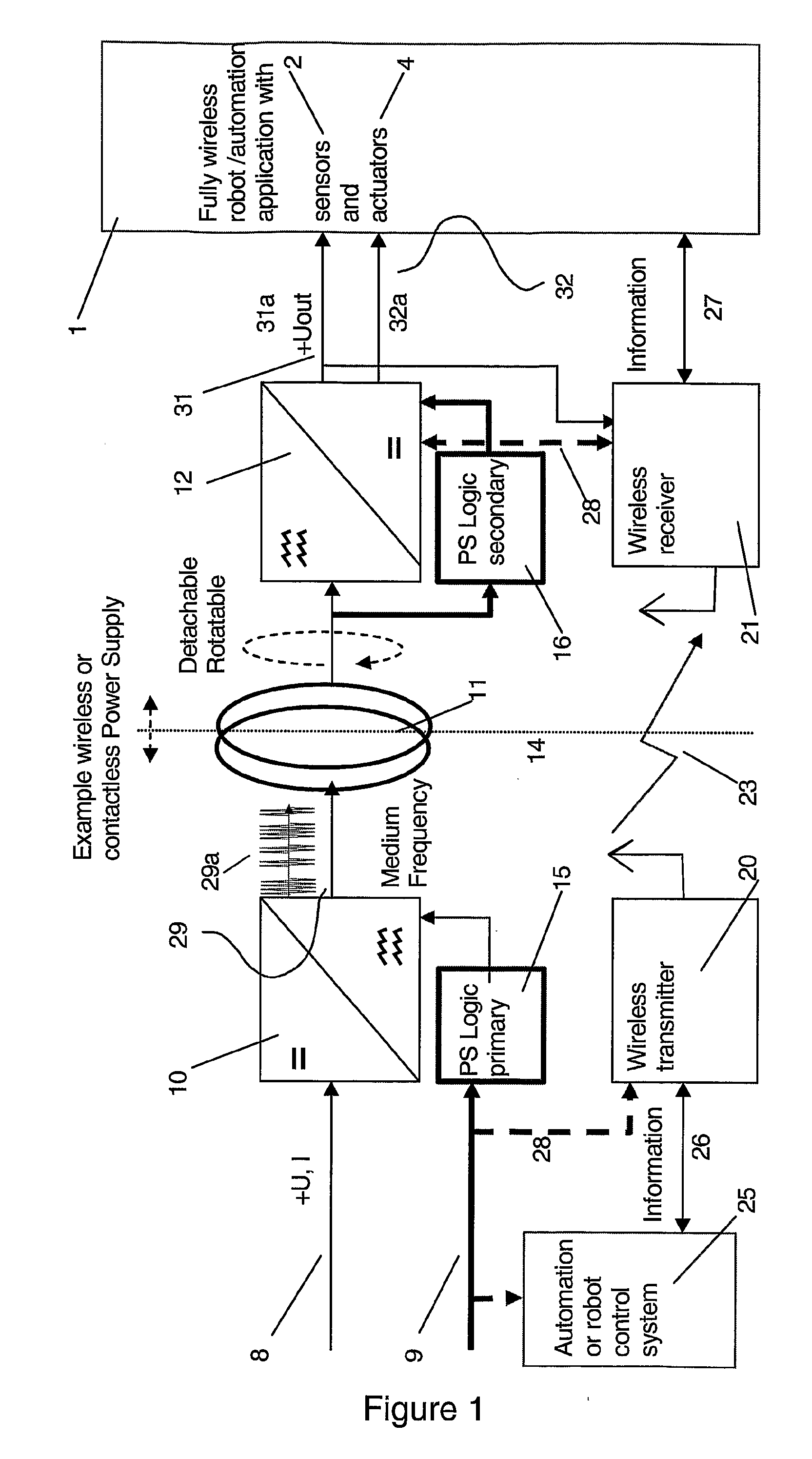

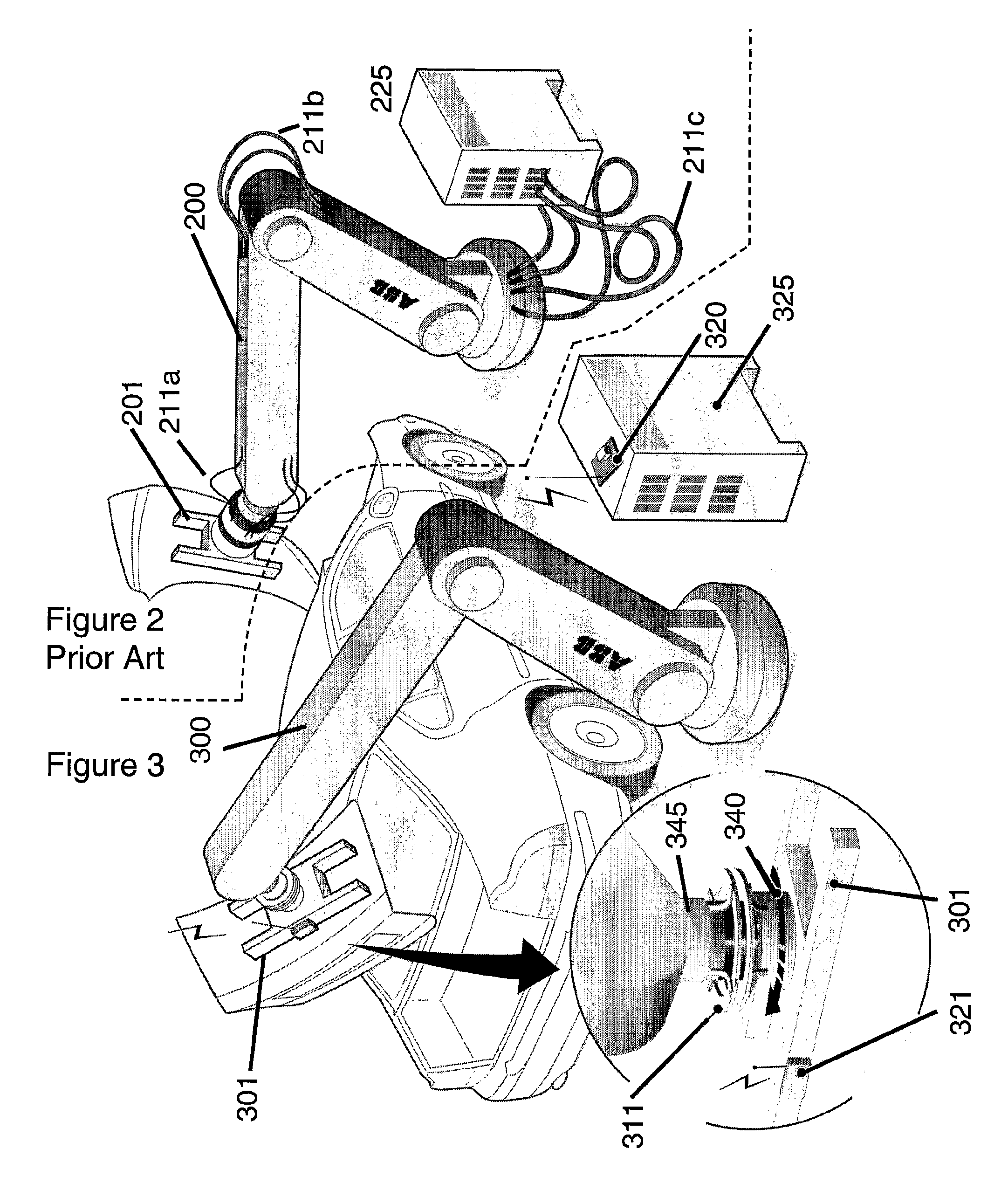

Tool for an Industrial Robot

InactiveUS20070276538A1Speeding up changeReduce downtimeSingle-phase induction motor startersProgramme-controlled manipulatorWireless controlIndustrial robotics

A robot or manipulator including a wireless power supply and a wireless communication device. One or more actuators on the robot tool may be wirelessly powered and wirelessly controlled. The robot tool may have one or more wireless communication members for transmission of data from sensors on the tool. The power supply includes a primary power supply member and secondary power supply member. Tool changes may be carried out automatically by the robot. In other aspects of the invention a method, a control system and a computer program for carrying out the method are described.

Owner:ABB RES LTD

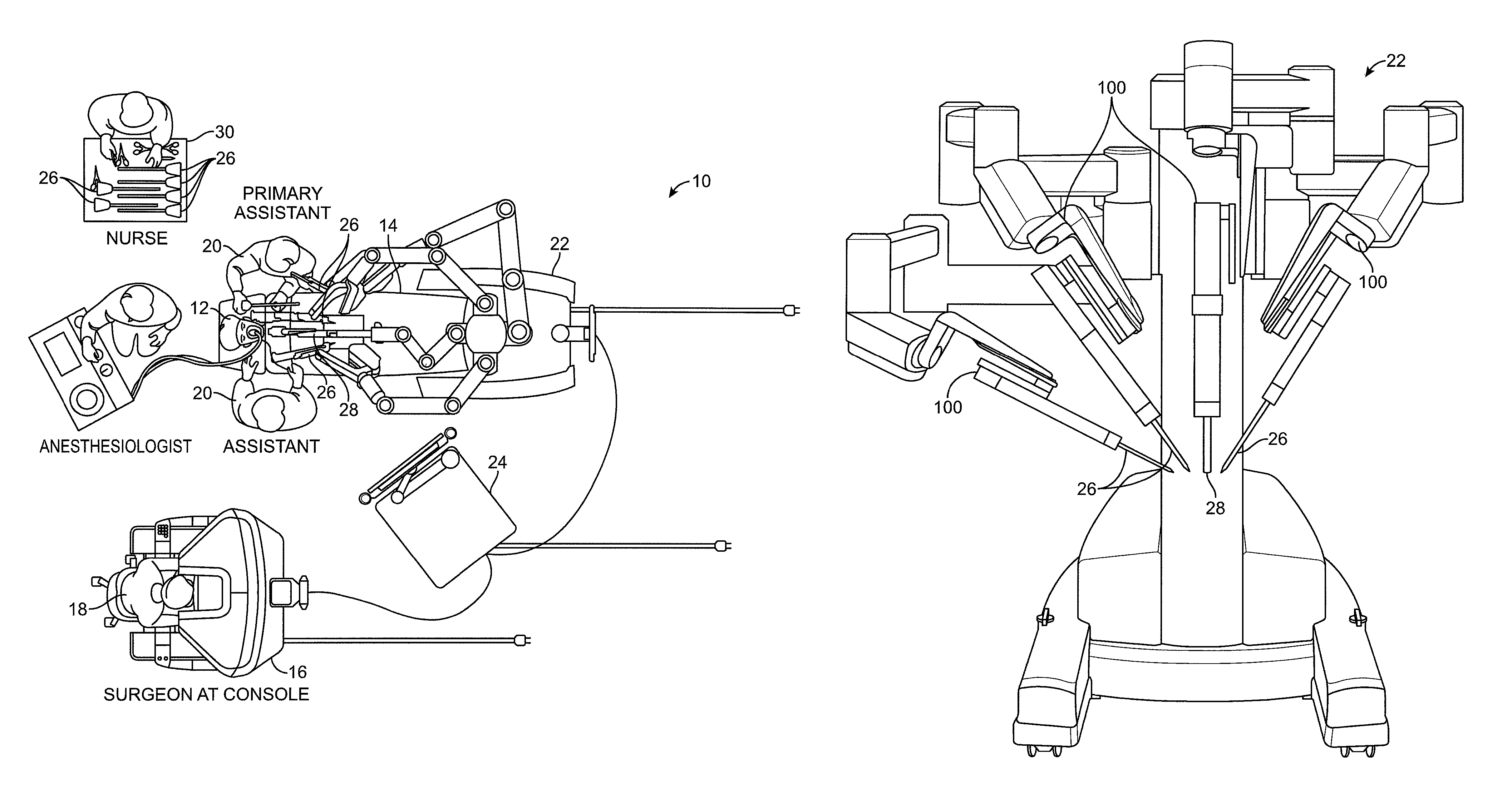

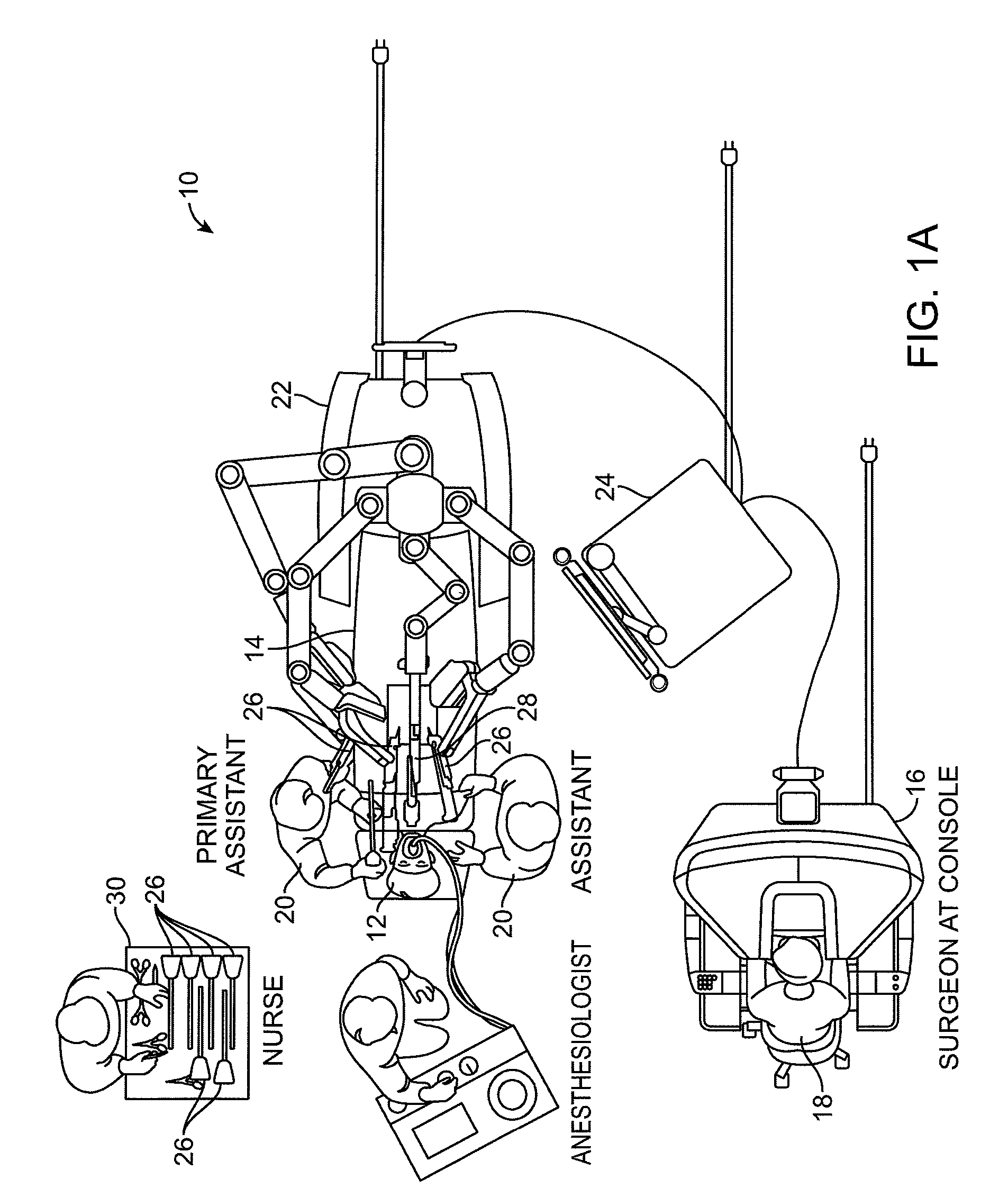

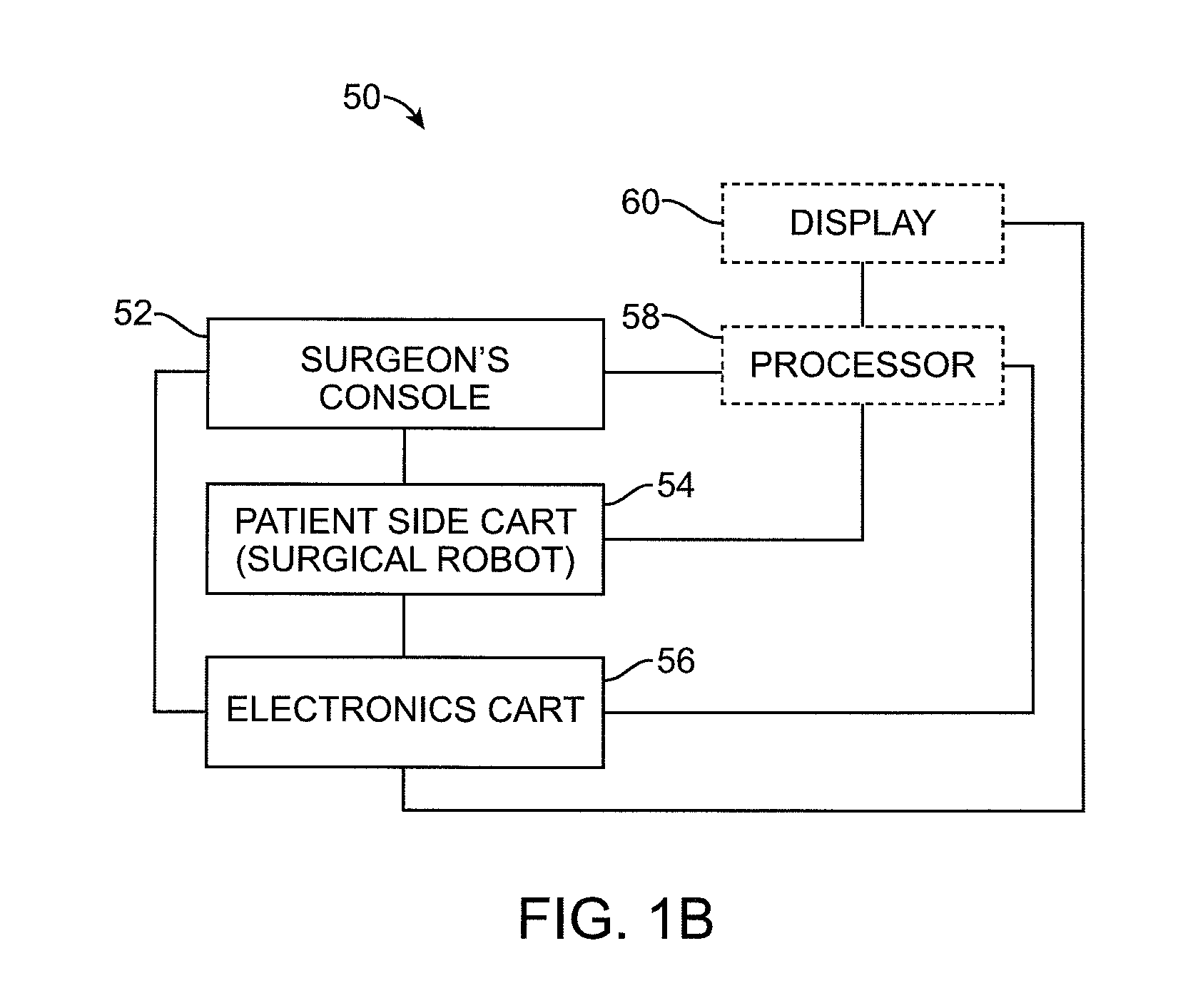

Manipulator arm-to-patient collision avoidance using a null-space

ActiveUS9492235B2Avoid collisionHighly configurable surgical robotic manipulatorsProgramme controlProgramme-controlled manipulatorEngineeringSacroiliac joint

Devices, systems, and methods for avoiding collisions between a manipulator arm and an outer patient surface by moving the manipulator within a null-space. In response to a determination that distance between an avoidance geometry and obstacle surface, corresponding to a manipulator-to-patient distance is less than desired, the system calculates movement of one or more joints or links of the manipulator within a null-space of the Jacobian to increase this distance. The joints are driven according to the reconfiguration command and calculated movement so as to maintain a desired state of the end effector. In one aspect, the joints are also driven according to a calculated end effector displacing movement within a null-perpendicular-space of the Jacobian to effect a desired movement of the end effector or remote center while concurrently avoiding arm-to-patient collisions by moving the joints within the null-space.

Owner:INTUITIVE SURGICAL OPERATIONS INC

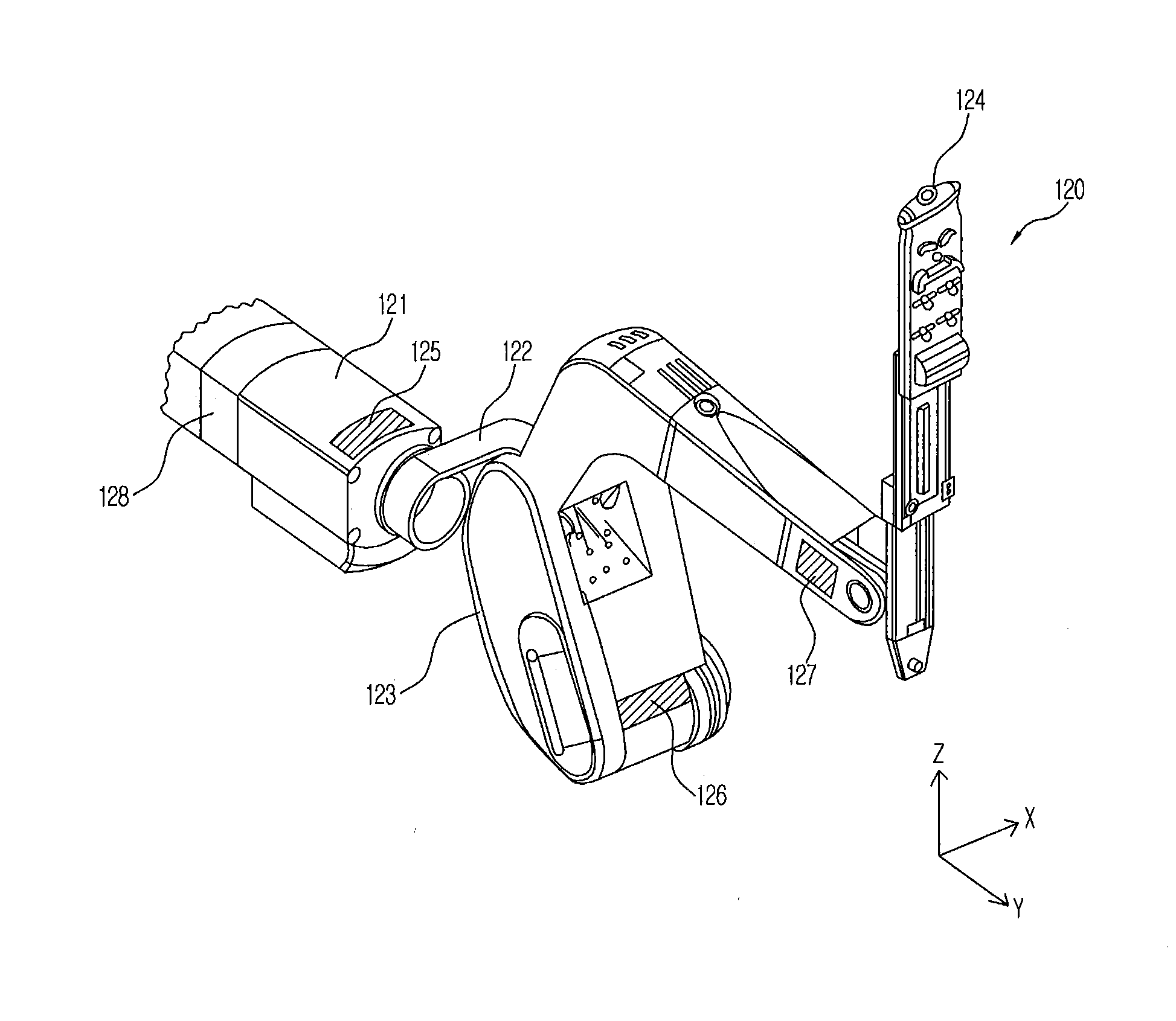

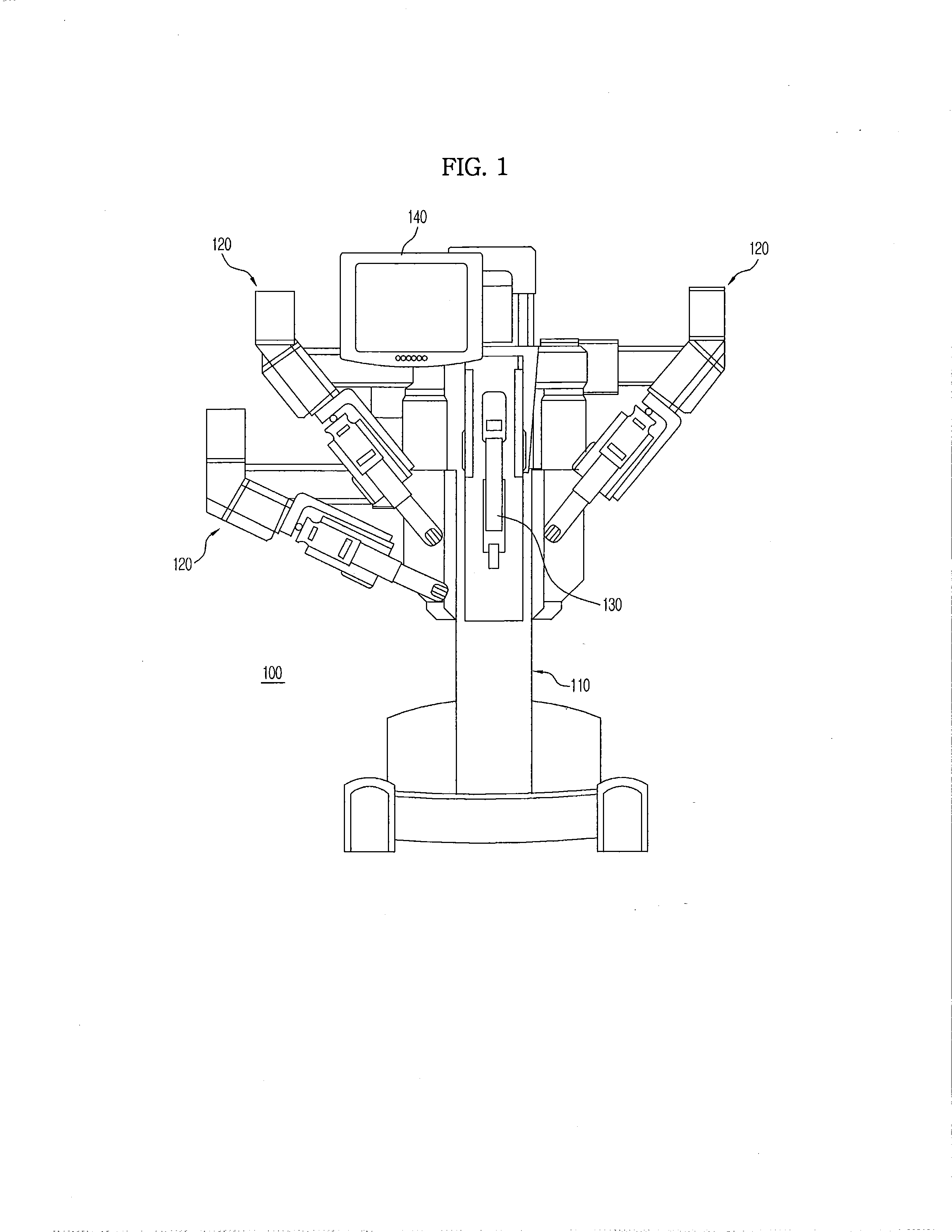

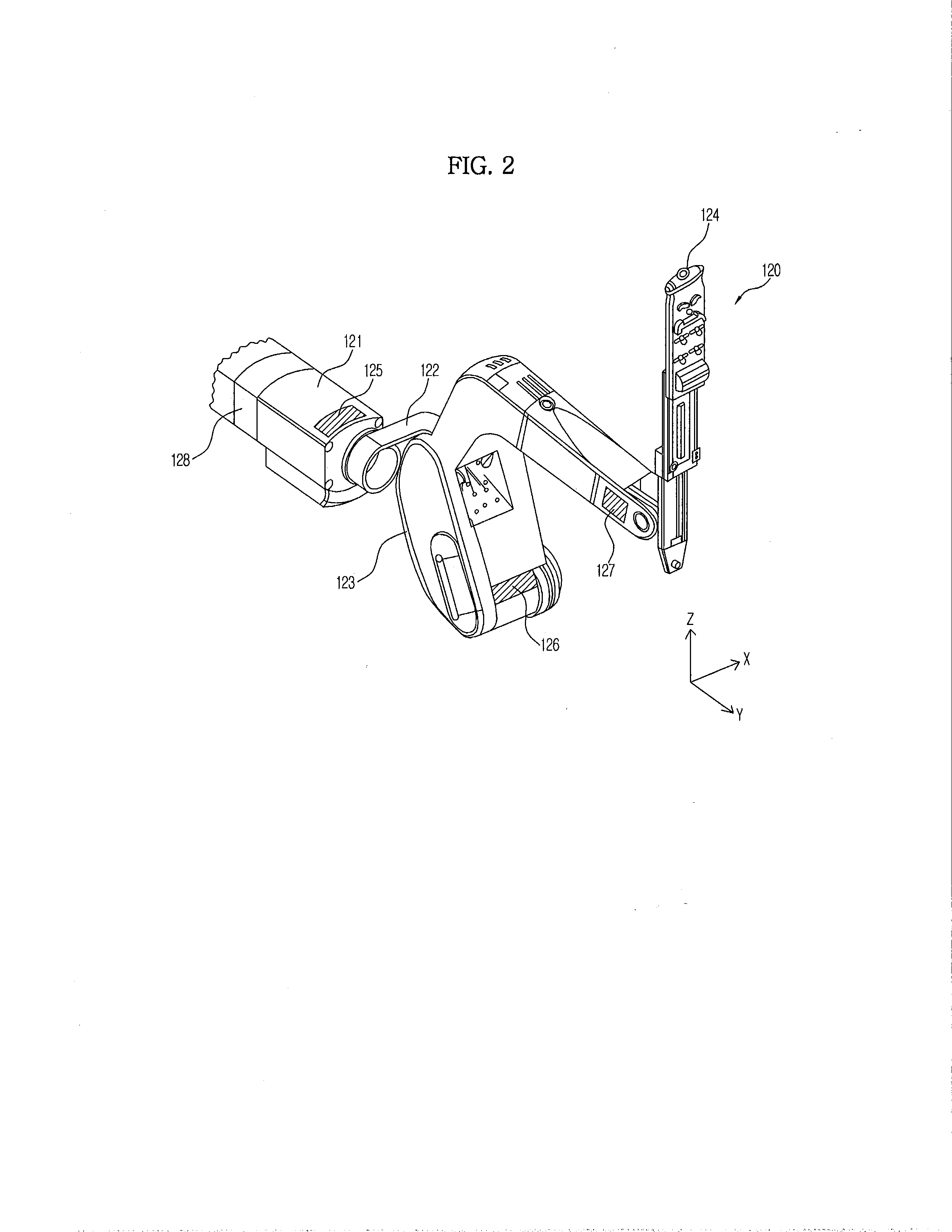

Surgical robot and method for controlling the same

InactiveUS20130178868A1Increasing stability and safetyInhibit posture changesDiagnosticsSurgical robotsPhysical medicine and rehabilitationRobot hand

A surgical robot includes a console and a manipulator assembly. The manipulator assembly includes at least one arm having a plurality of links and a motor provided between links adjacent to each other among the plurality of links, and a control unit configured to determine whether a mode is changed between a tele-operation mode and a manual mode. The control unit sets output data of the motor provided before the mode is changed as input data of the motor provided after the mode is changed, if it is determined that the mode is changed between the tele-operation mode and the manual mode, thereby preventing the vibration and the rapid change of the posture from occurring at the arm of the surgical robot during the change of the mode between the manual mode and the tele-operation mode, thereby increasing stability of the surgical robot.

Owner:SAMSUNG ELECTRONICS CO LTD

Intelligent early warning and fire extinguishing robot

InactiveCN104299351ATimely transmissionInstantly eliminate the initial fireFire rescueFire alarm electric actuationRobot handFire extinguisher

The invention discloses an intelligent early warning and fire extinguishing robot. The intelligent early warning and fire extinguishing robot is formed in the mode that a temperature sensor, a smoke sensor, a flame sensor, a pan-and-tilt camera, a two-freedom-degree mechanical arm, a fire extinguisher and a controller are installed on a wheel type vehicle, the two-freedom-degree mechanical arm is installed on the side of the fire extinguisher in a surrounding mode, and the temperature sensor, the smoke sensor, the flame sensor, the pan-and-tilt camera, the two-freedom-degree mechanical arm are connected with the controller in an electric loop mode. The intelligent early warning and fire extinguishing robot is high in anti-interference ability, good in space applicability, capable of monitoring fire flame videos of a tiny fire source at the beginning of a fire, high in fire early warning accurate and low in false alarm rate.

Owner:CHANGZHOU UNIV +1

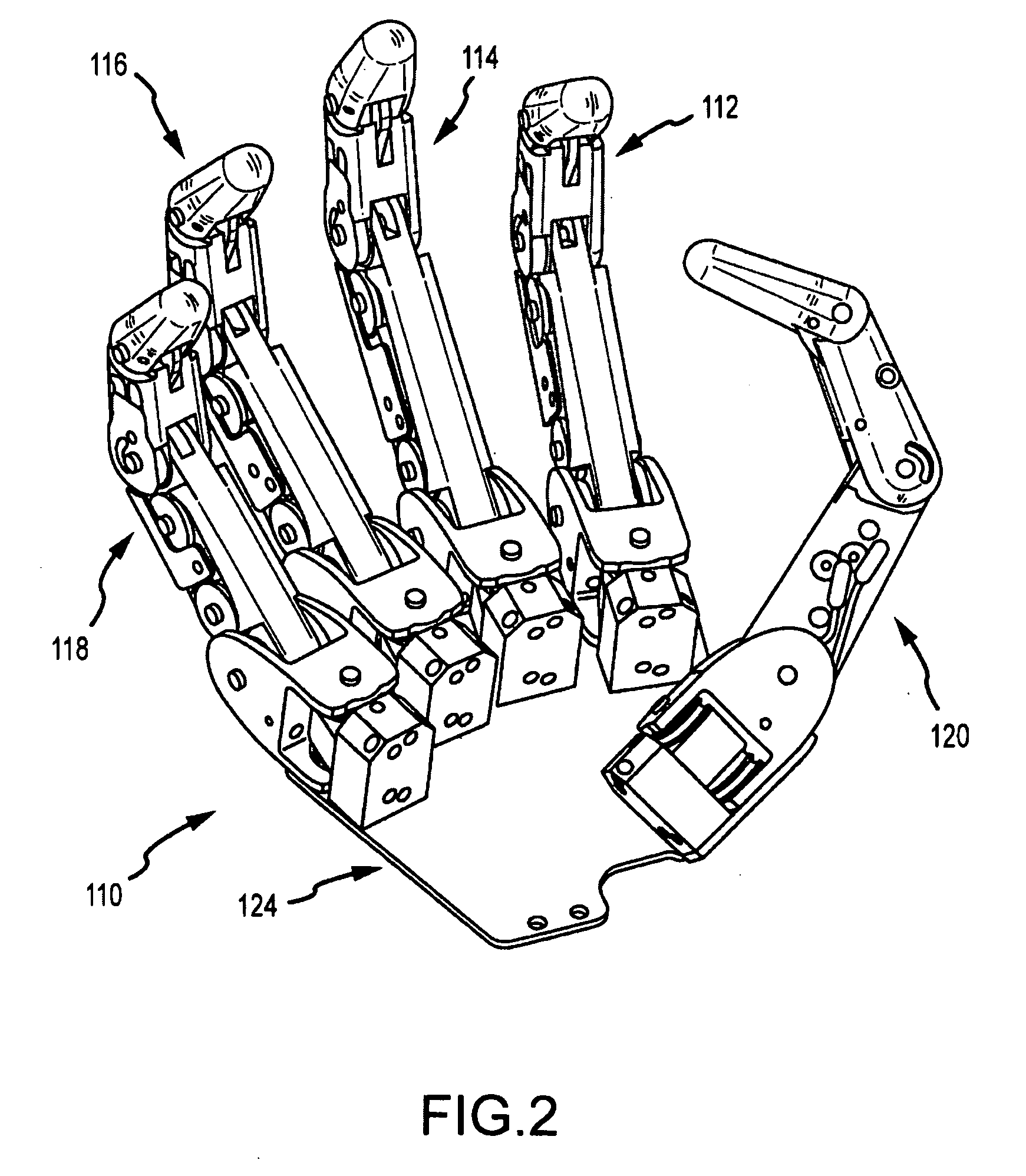

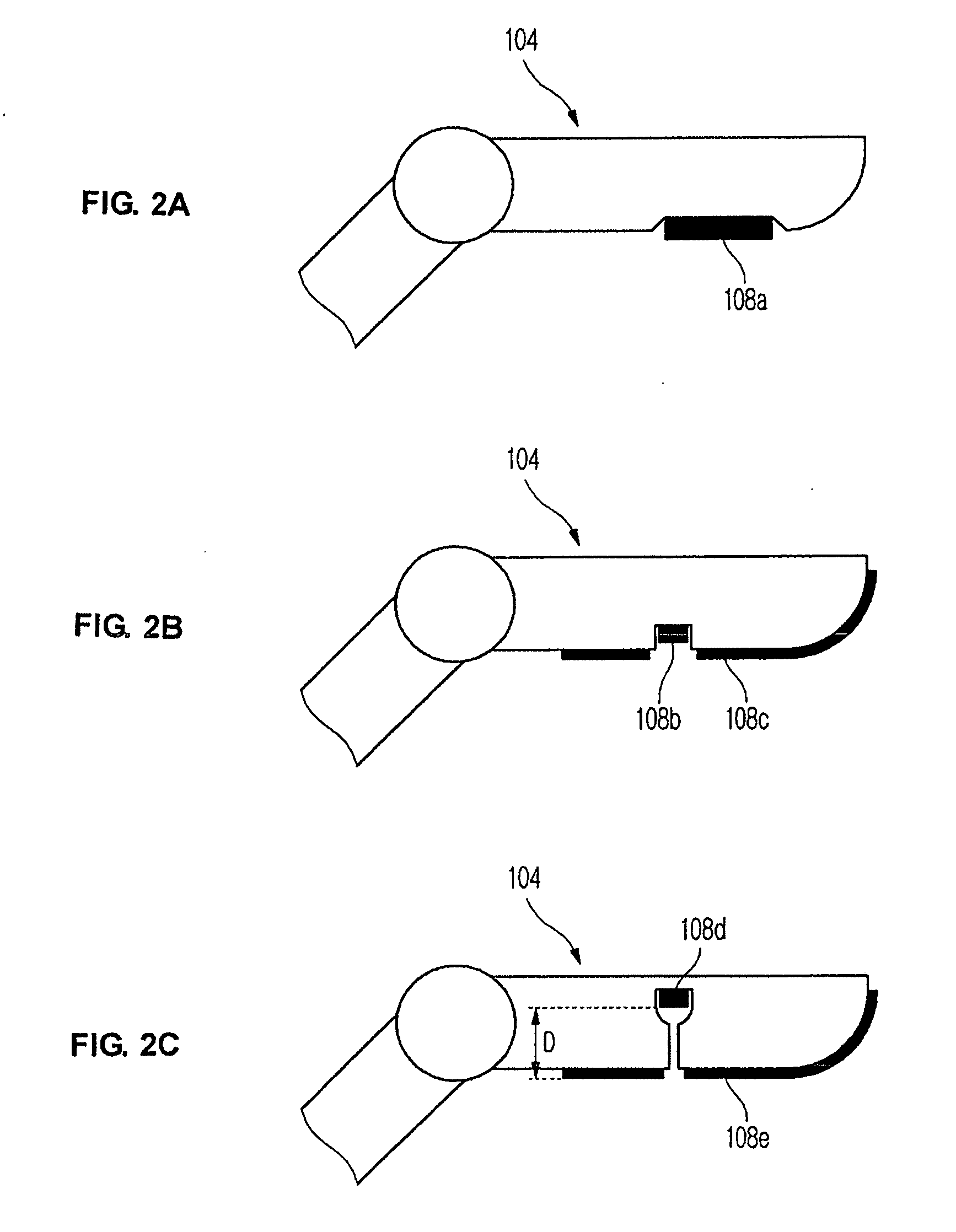

Robotic hand with extendable palm

A robotic hand comprises a base having fingers and a palm. The fingers define a working volume. The hand is able to grasp objects between the fingers and the palm by varying a distance from the palm to the working volume. Varying this distance can be achieved by either moving the palm towards the working volume or by moving the working volume towards the palm. Robotic hands that move the palm comprise an actuator that extends the palm from the base towards the working volume. Robotic hands that move the working volume relative to the palm have the fingers mounted to a common finger support unit that is configured to translate relative to the base.

Owner:STRIDER LABS

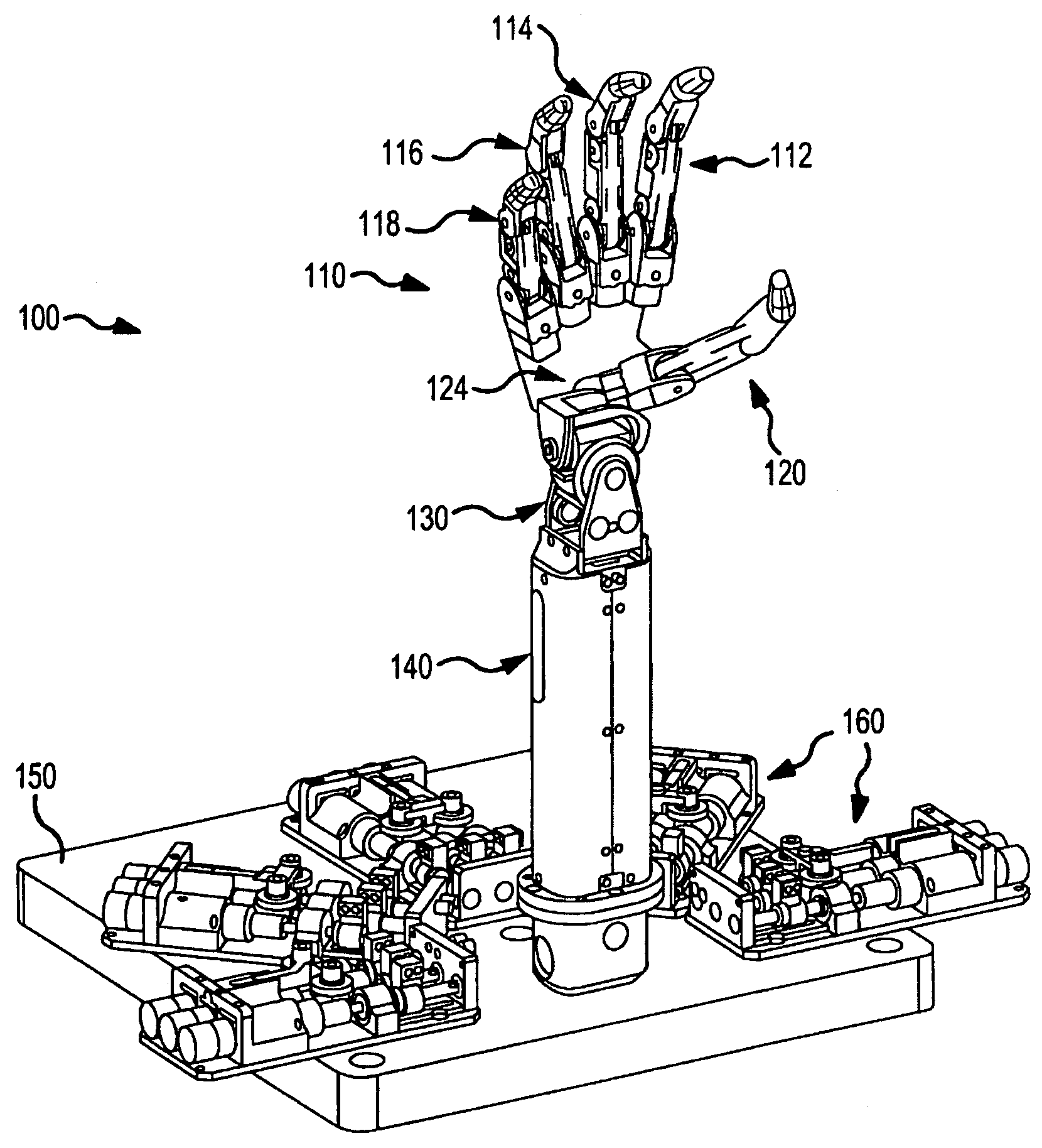

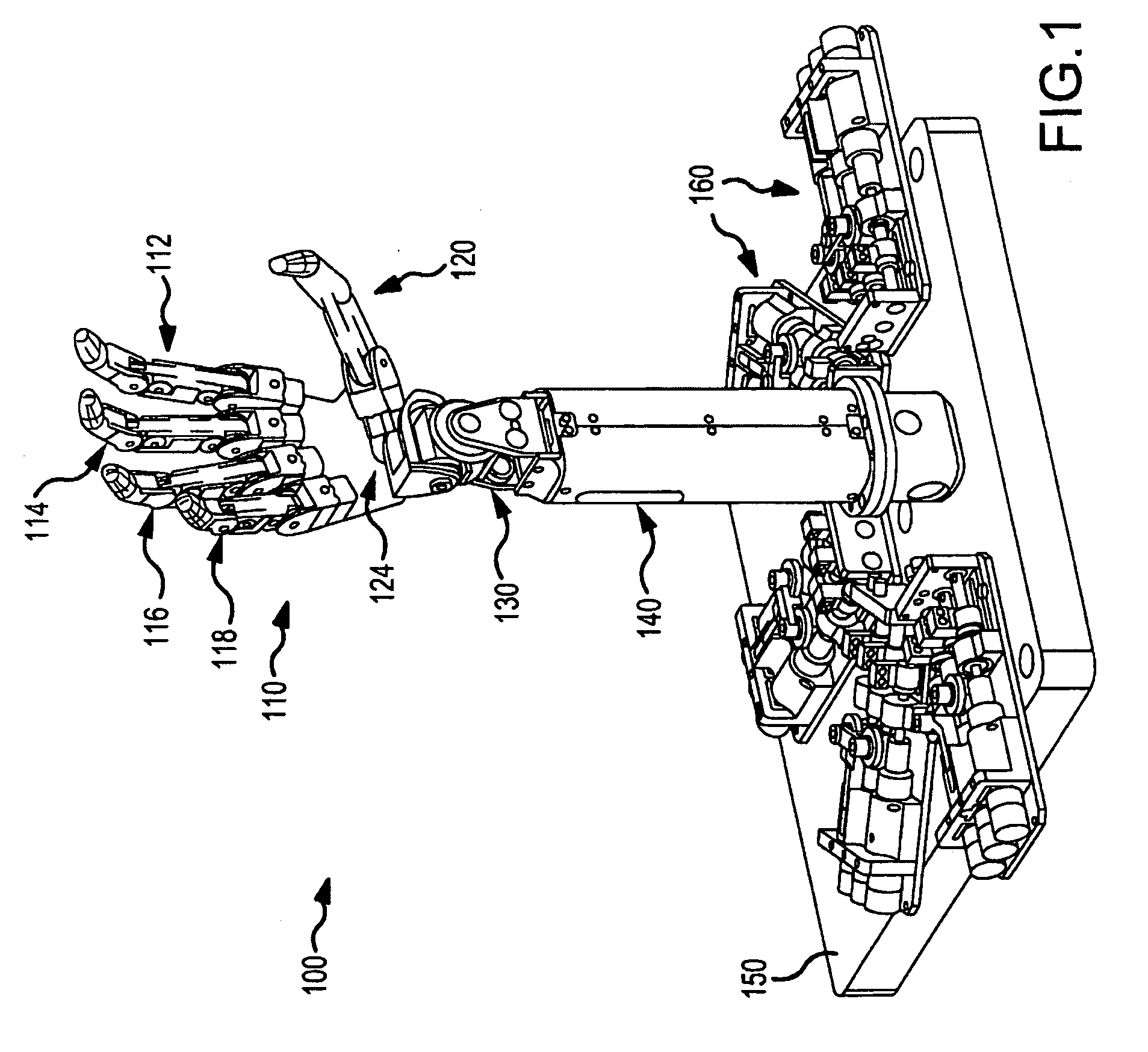

Robot hand with human-like fingers

ActiveUS20100259057A1Reduce tendonReduce cable frictionProgramme-controlled manipulatorGripping headsRobot handThree degrees of freedom

A robotic hand with finger assemblies to better simulate human hand form factors and gestures. For each finger assembly, the robotic hand includes a finger drive assembly that is operable to selectively apply tension to four elongated and flexible tension elements (e.g., steel cable). Each of the finger assemblies includes a set of links or link members that are actuated or moved by the selective tensioning / movement of the tension elements by the drive assembly. The links are interconnected with pivotal joints such that they have three degrees-of-freedom, and the finger assembly includes a set of pulleys that are supported on the links and that are arranged to provide support and to guide the tension elements through the finger assembly. The tension elements preferably extend only partially about any one of the pulleys, whereby the finger assembly utilizes “n+1” actuation with non-helical wrapping of the tension elements.

Owner:DISNEY ENTERPRISES INC

Object taking-out apparatus

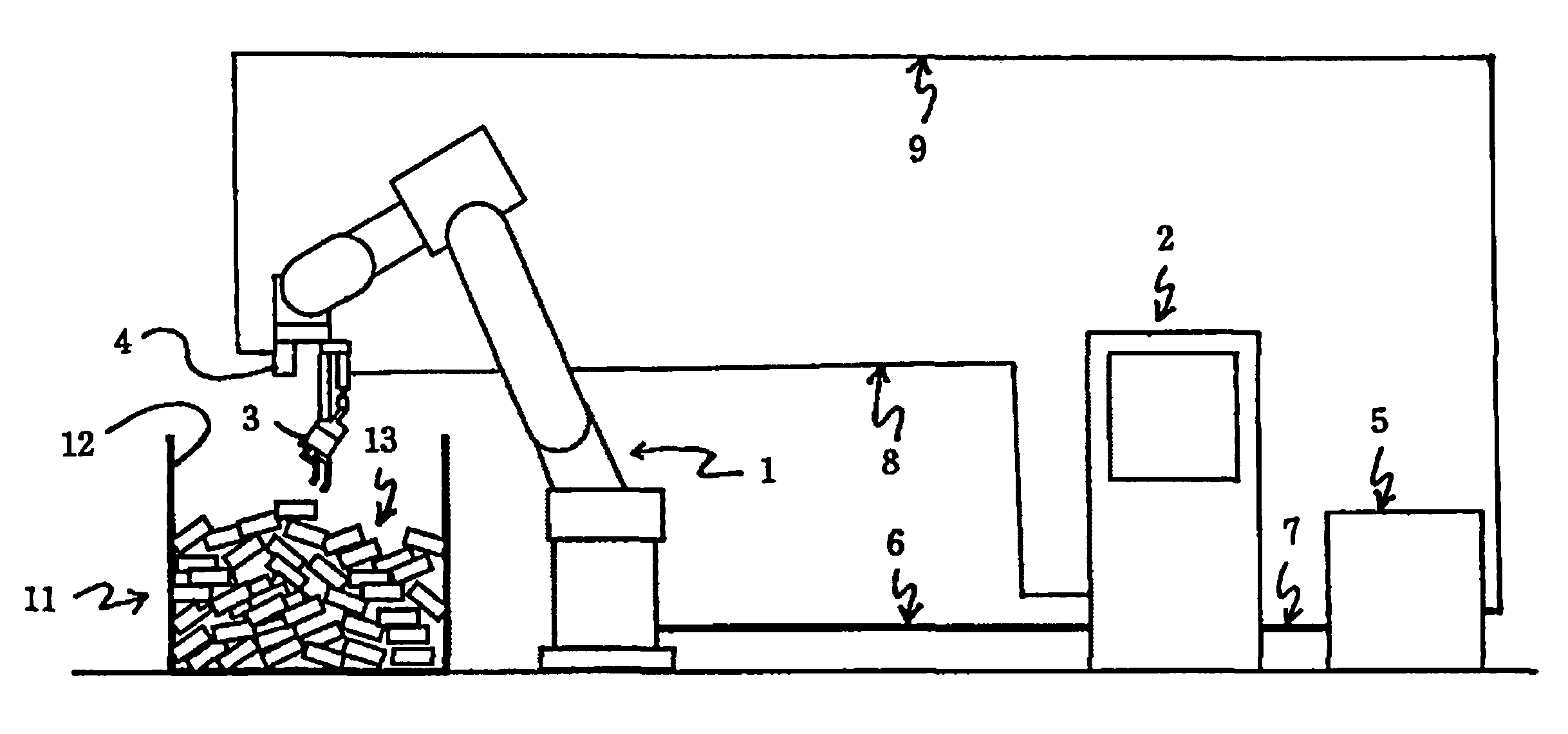

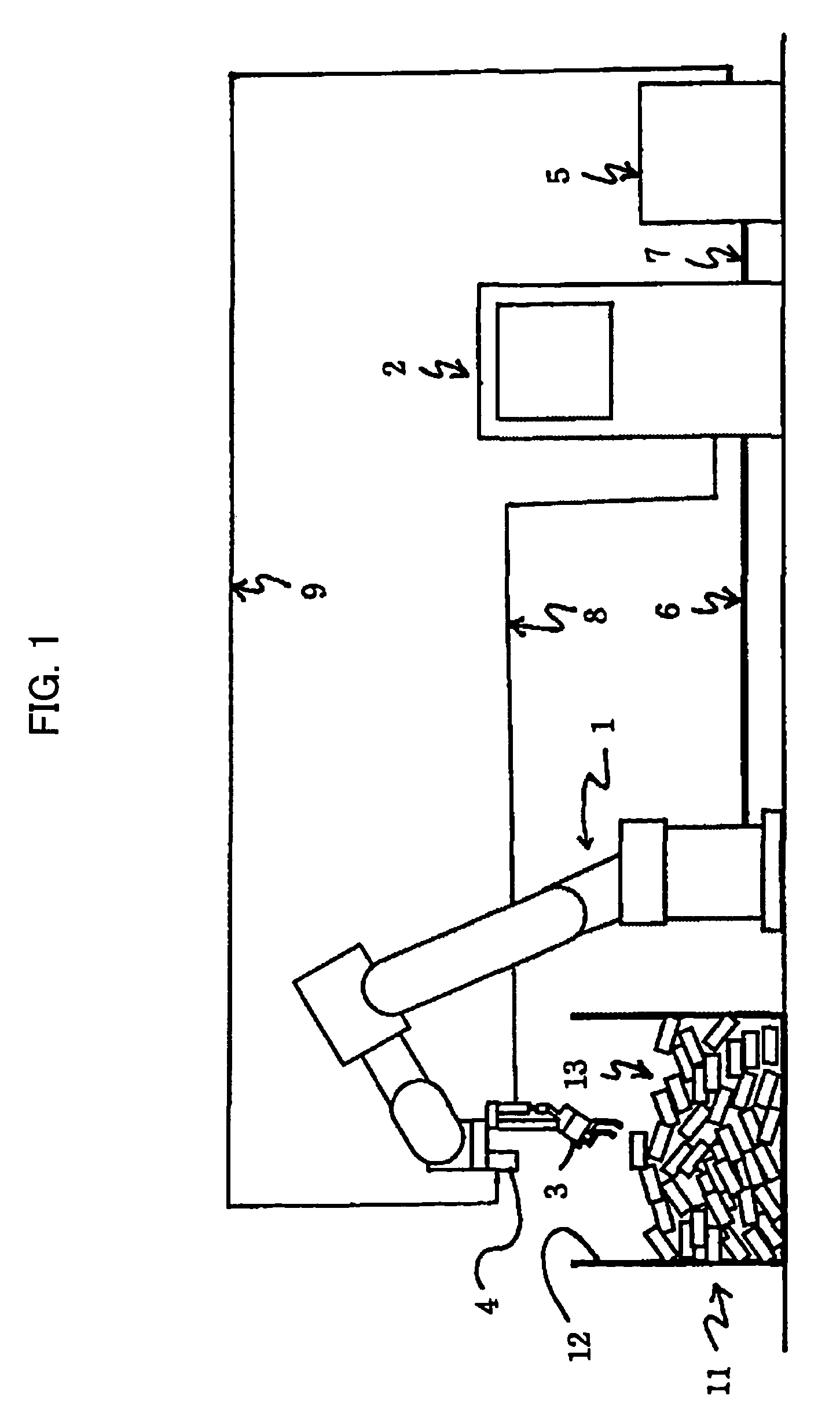

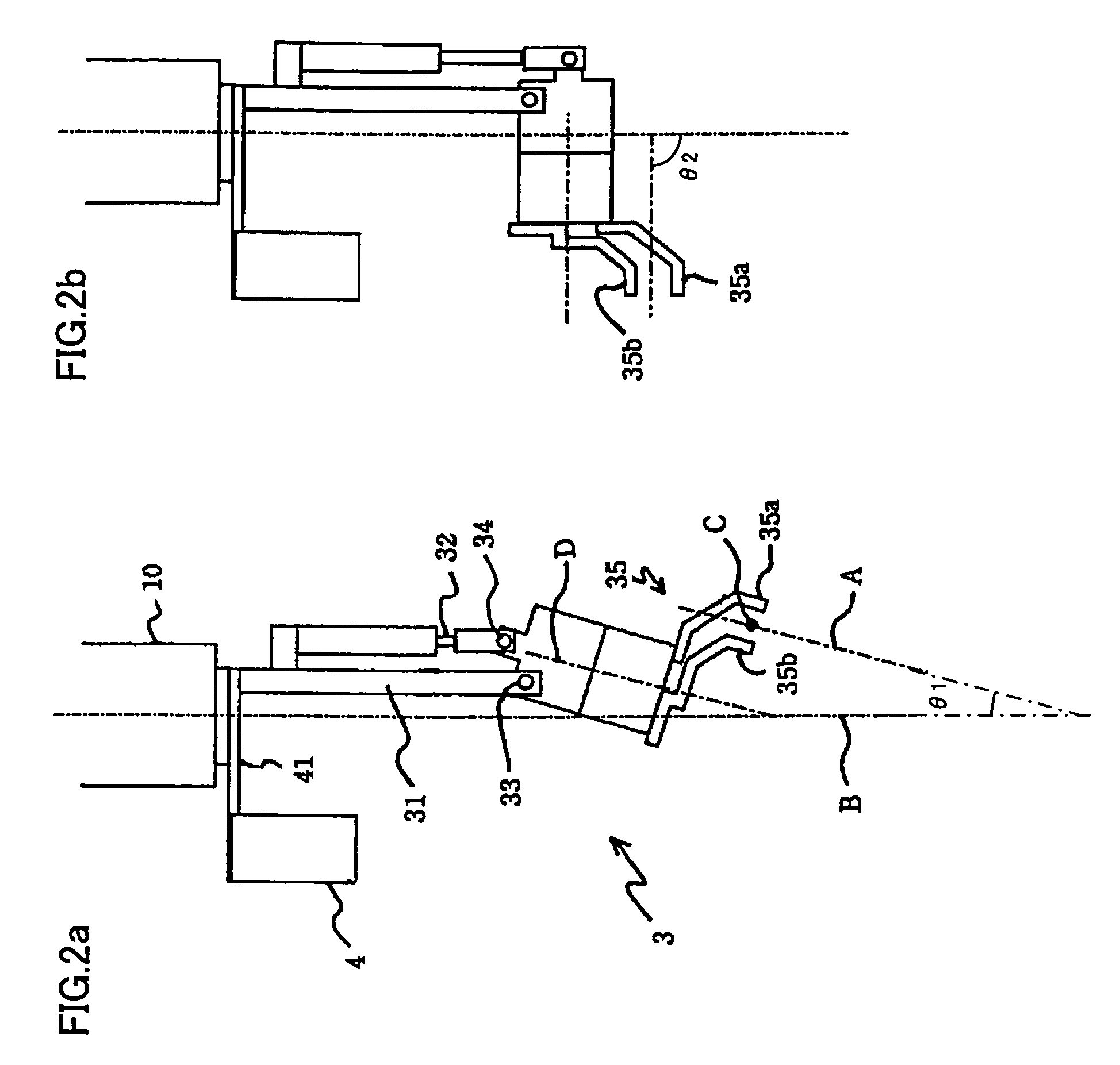

ActiveUS7474939B2Easy to useReduce interactionProgramme-controlled manipulatorJointsRobot handEngineering

An object taking-out apparatus for taking out objects randomly stacked in a container according to a condition of how each object is placed, which includes a robot hand having telescopic means and a coupling member whose one ends are connected to a robot arm end, and holding means coupled to their other ends. The telescopic means expands and contracts to cause the holding means to assume either a first orientation where a small angle is formed or a second orientation where a large angle is formed between a holding direction axis of the holding means and a rotary axis of the robot arm end, thereby taking out objects without causing interaction between the robot and the container.

Owner:FANUC LTD

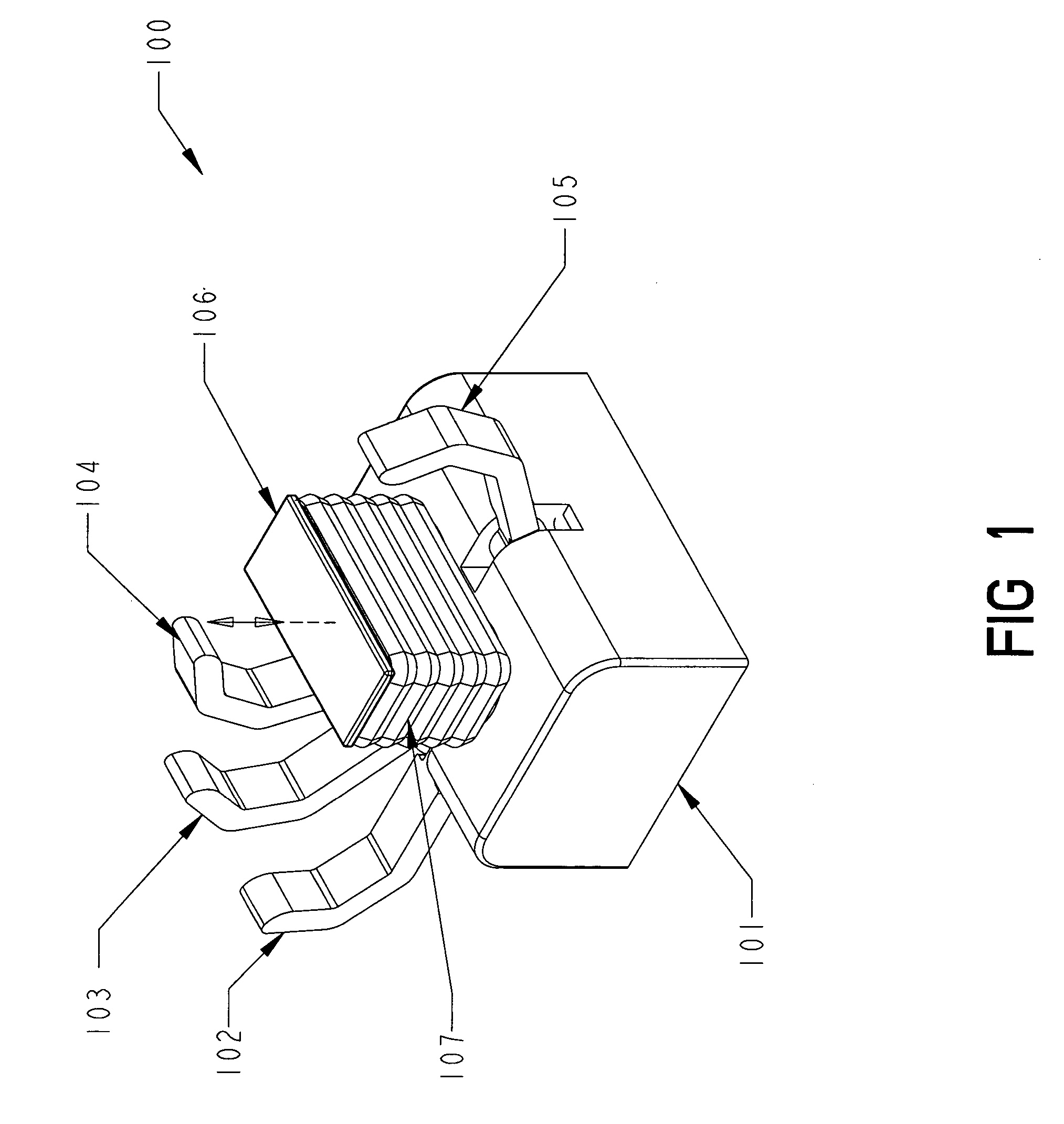

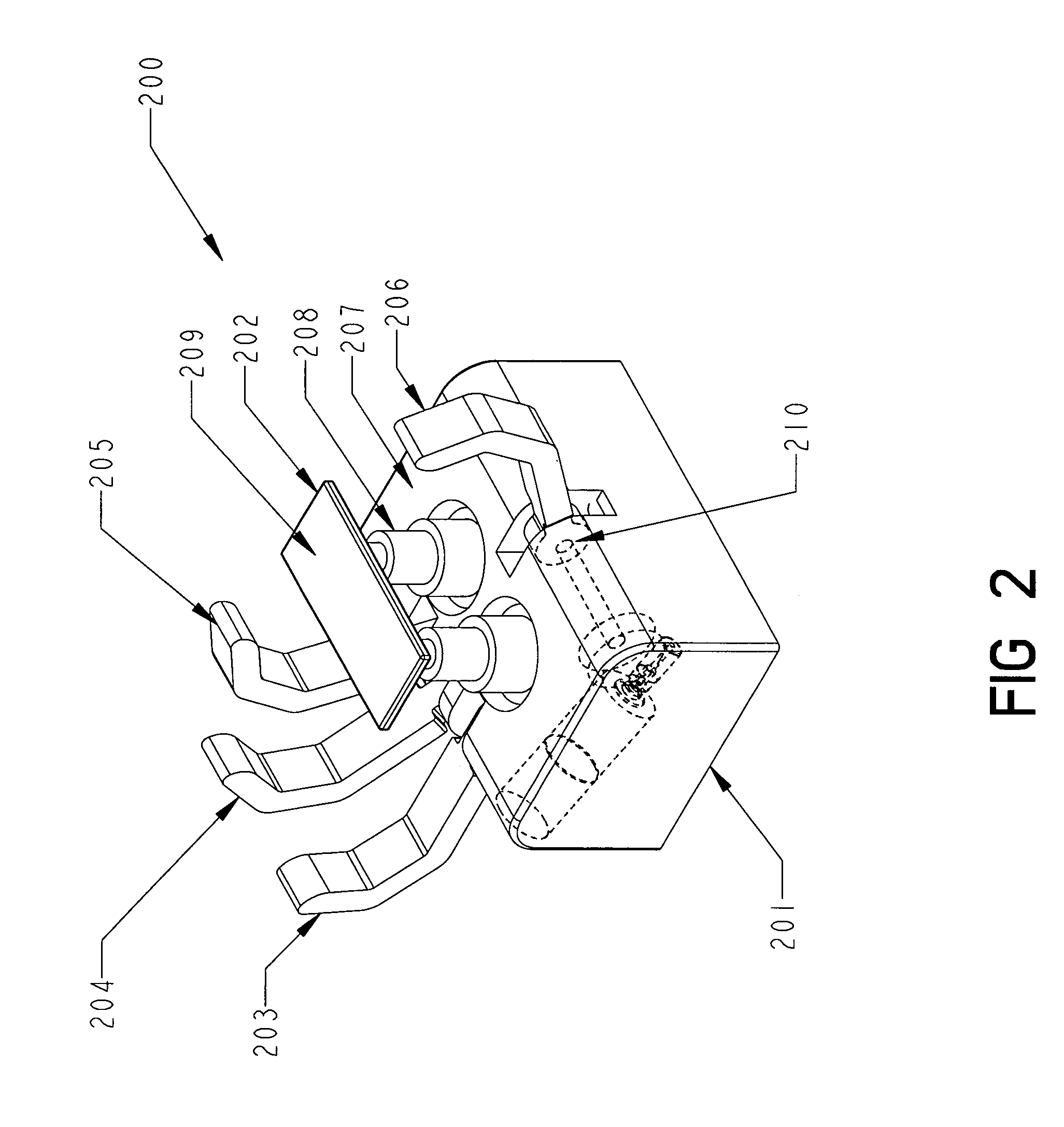

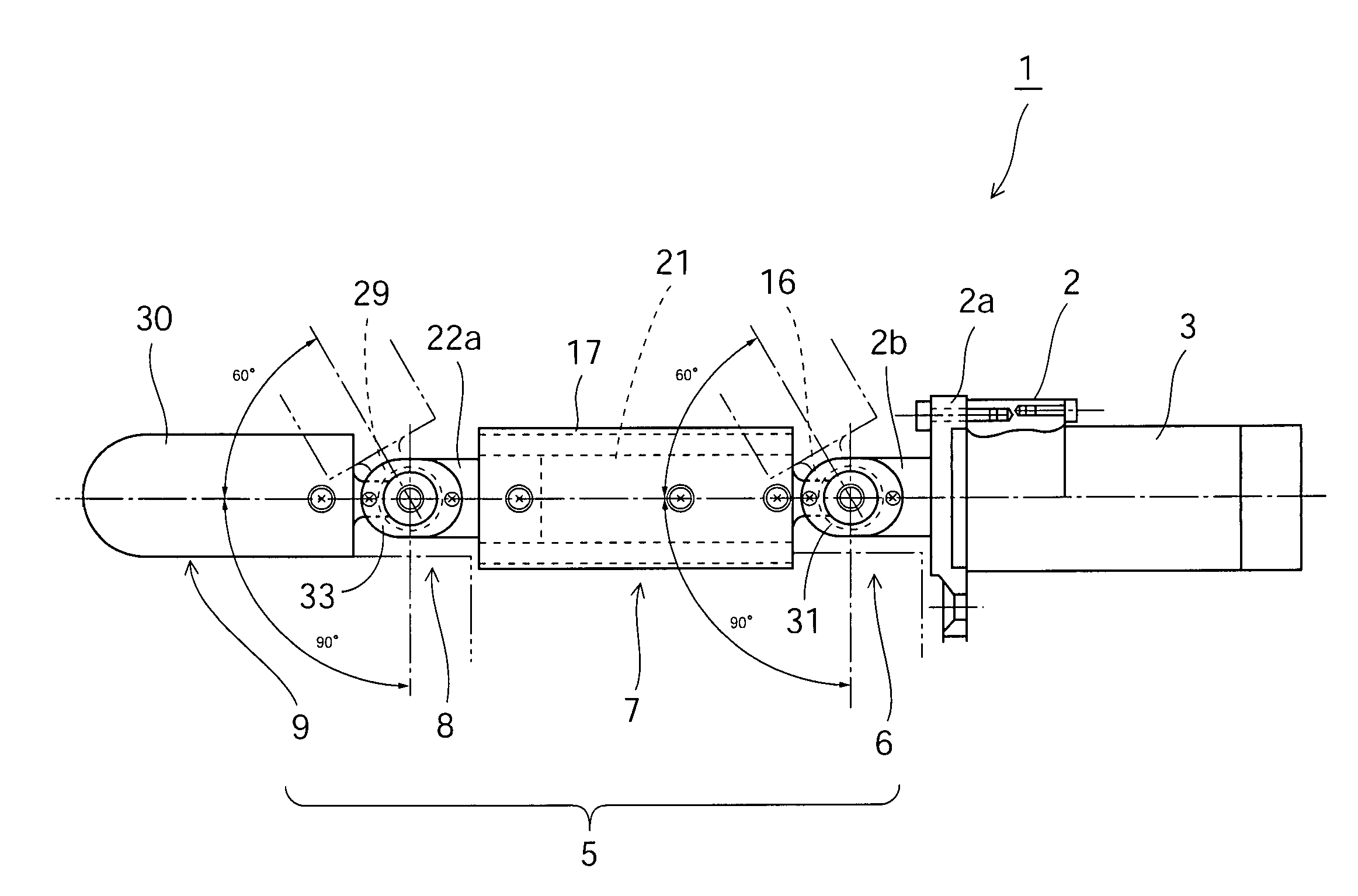

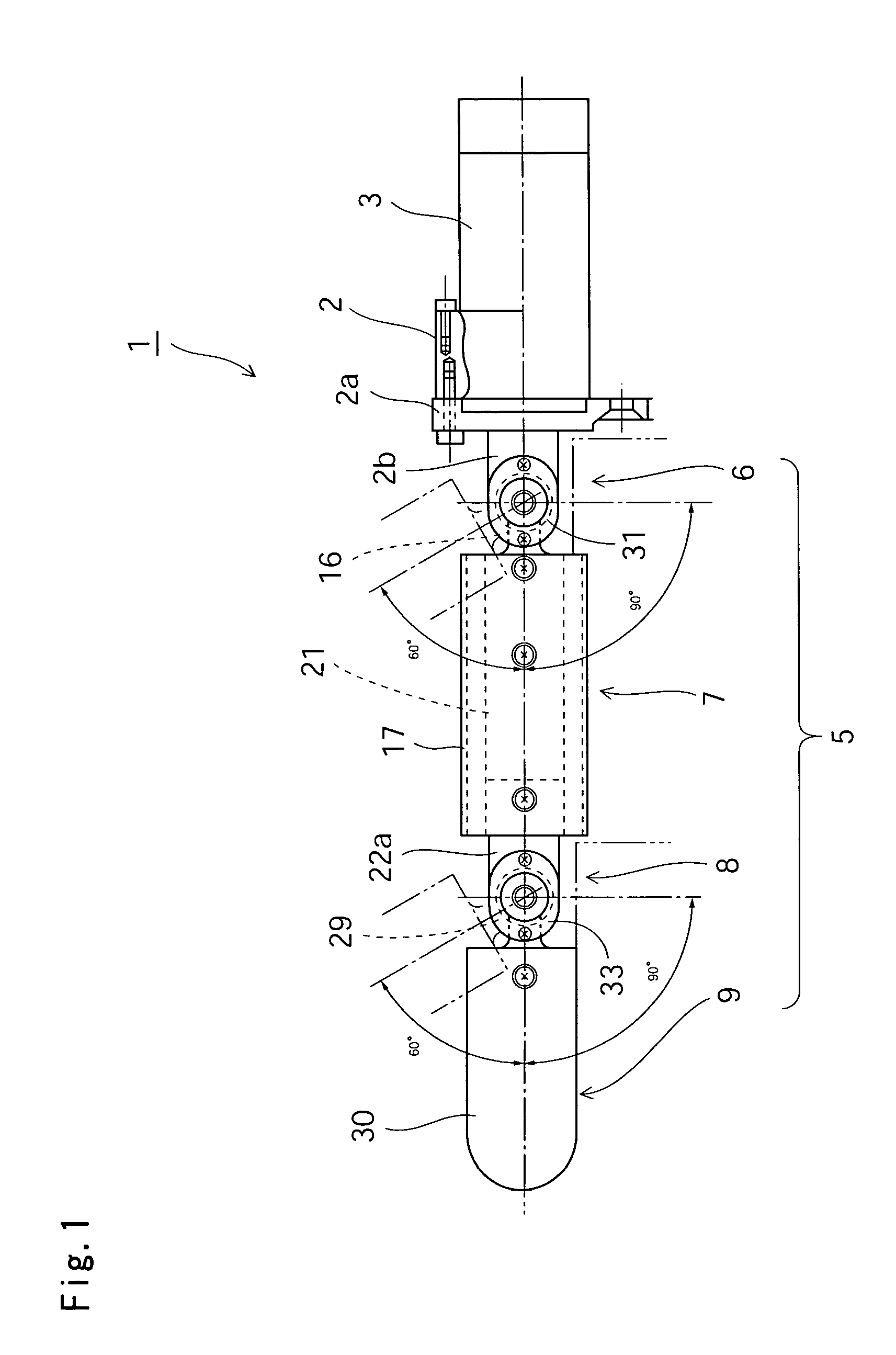

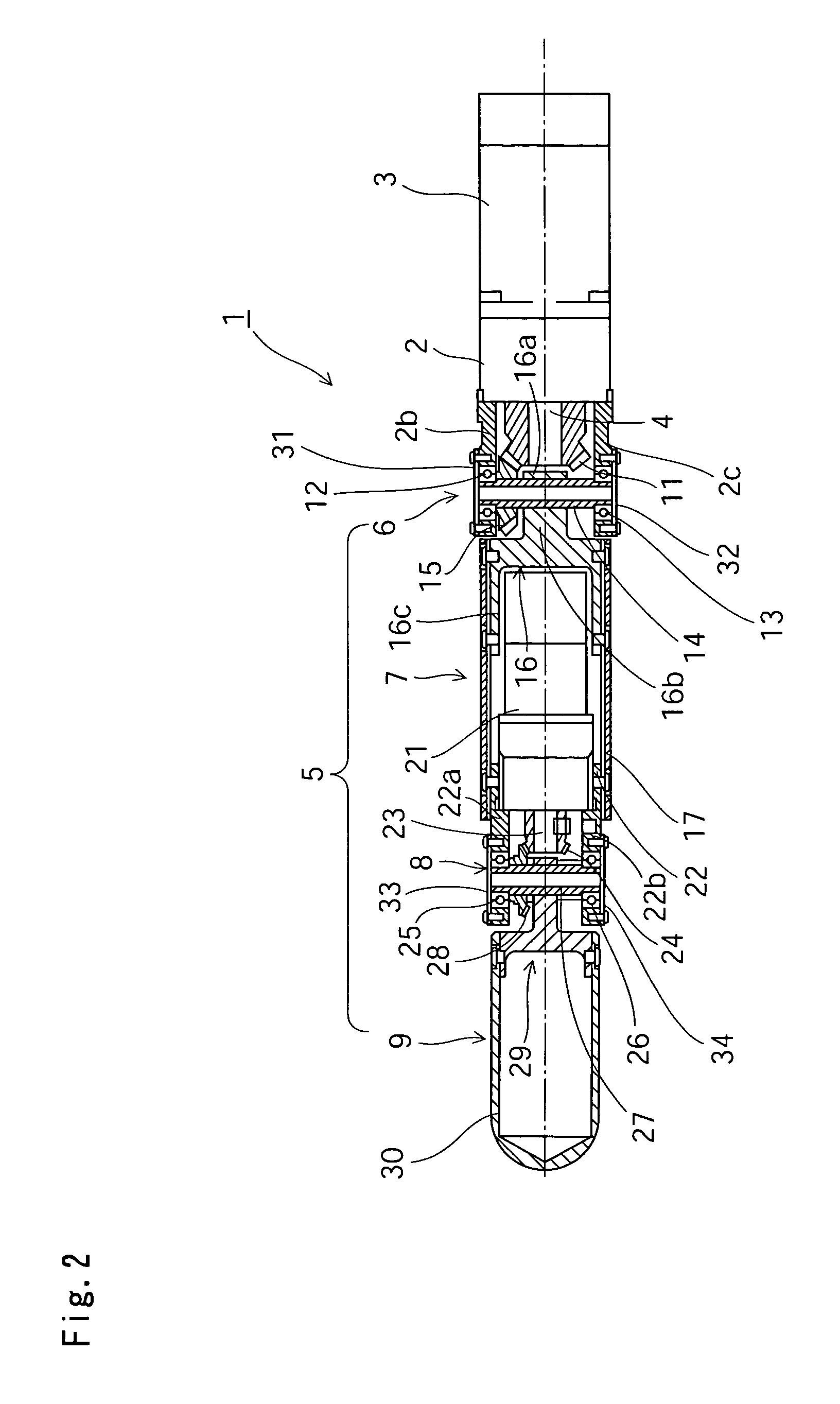

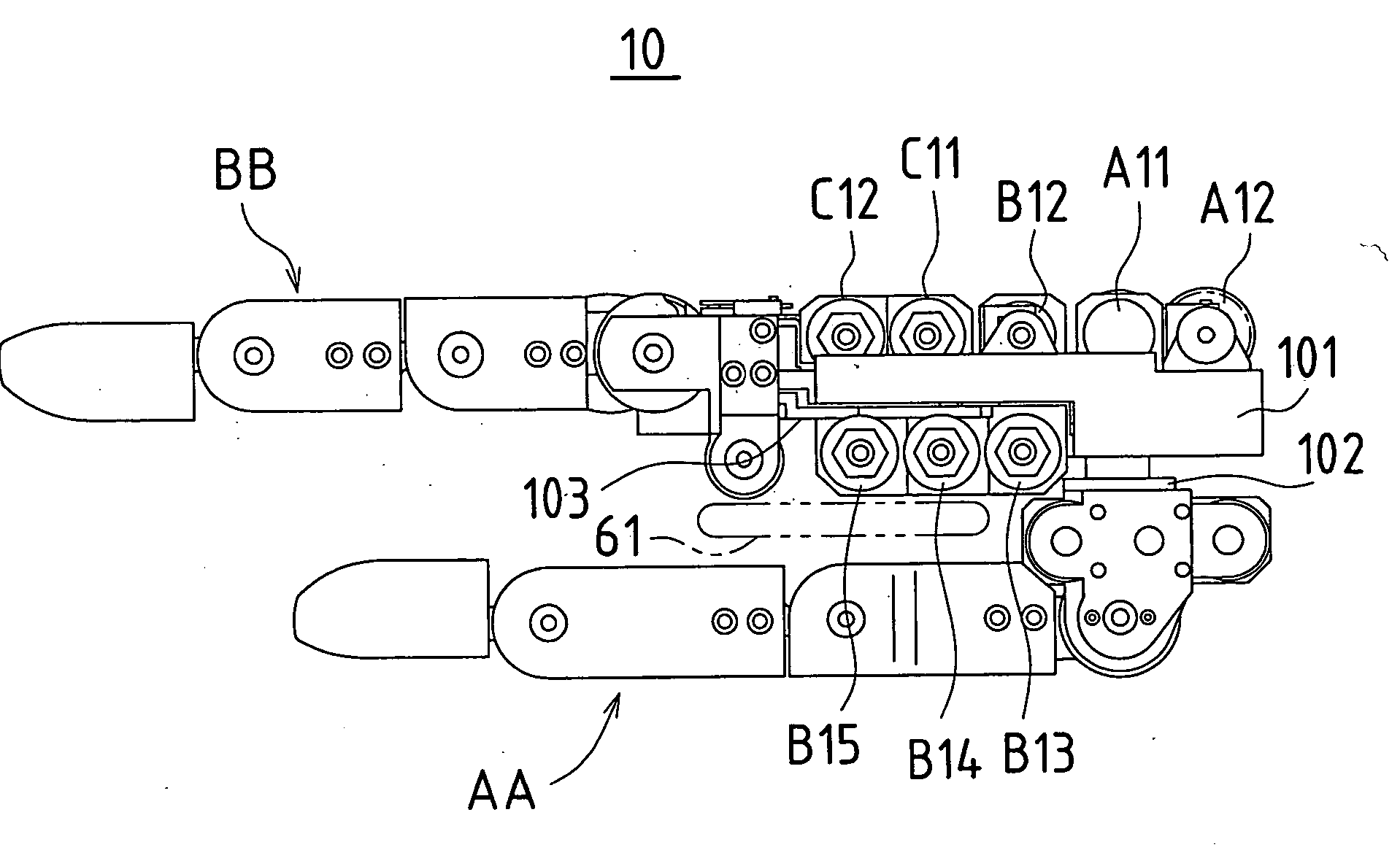

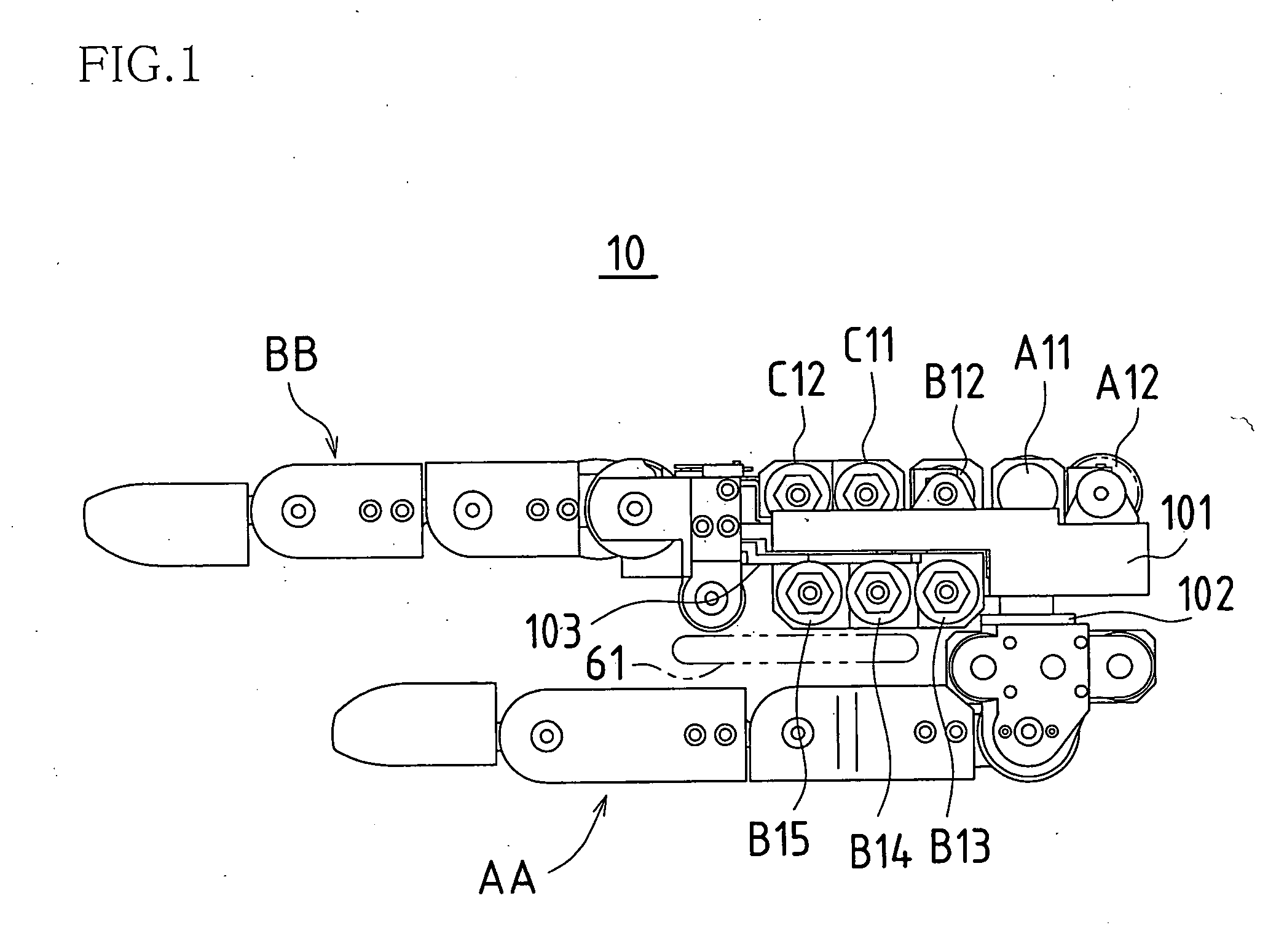

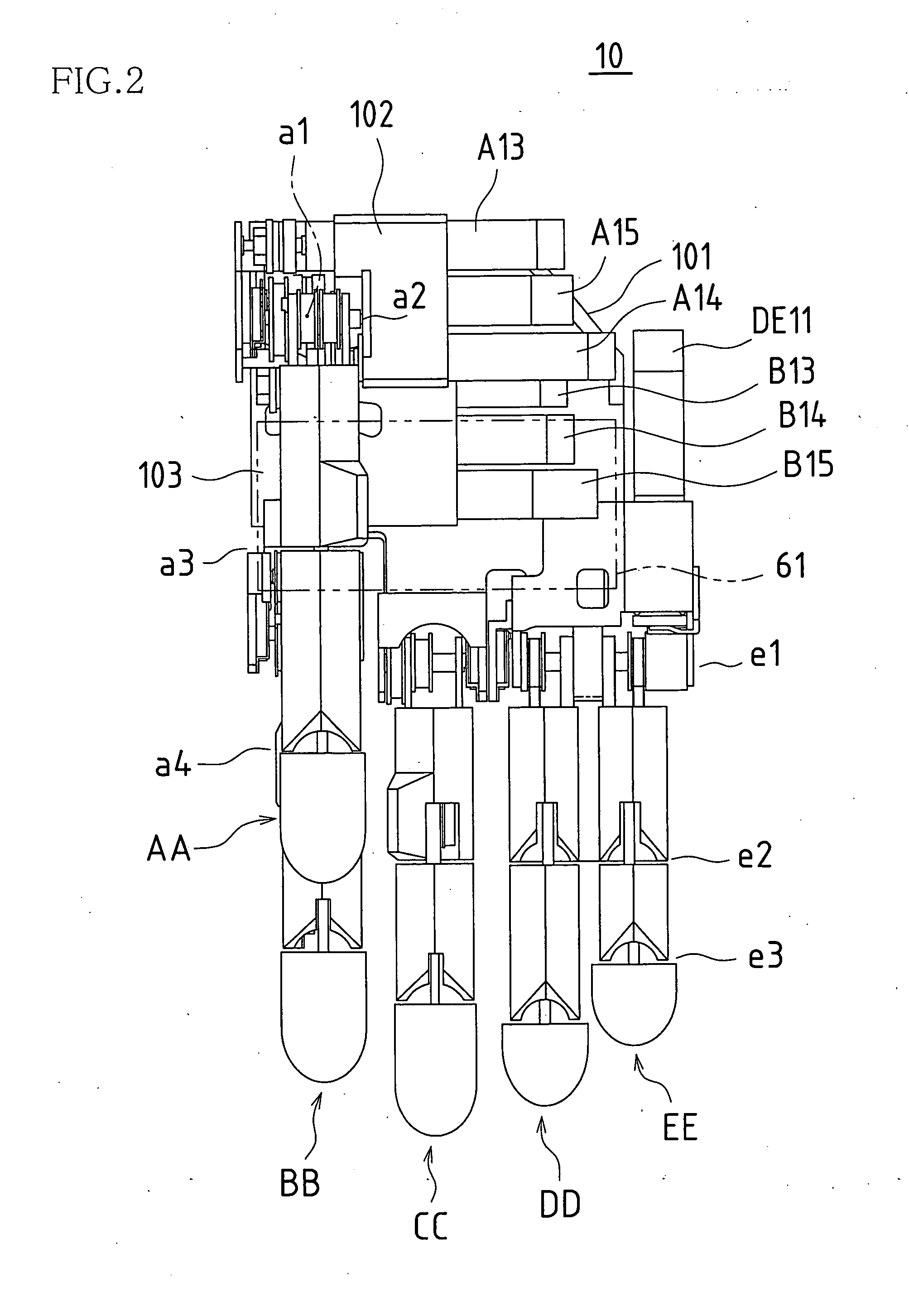

Finger unit for robot hand

An articulated finger unit has a two-jointed structure comprising a joint portion on a finger base side, a finger base portion, a joint portion on a fingertip side, and a fingertip portion; the joint portion on the finger base side has a drive-side bevel gear fixed to a rotational output shaft of an actuator, a driven-side bevel gear coaxially fixed to a joint portion that is perpendicular to the rotational output shaft, and a connecting member wherein an annular boss is fixed to the driven-side bevel gear and wherein a tip portion extends in a fork shape; and a cover on the finger base side is connected to the connecting member. A rotation of the rotational output shaft is converted to rotational movement of the joint shaft by way of a pair of bevel gears, and the connecting member fixed to the joint shaft turns right and left at an angle of 90° or more about the joint shaft. The finger unit suitable for use in a robot hand that moves at high speed and with precision can be realized.

Owner:HARMONIC DRIVE SYST IND CO LTD

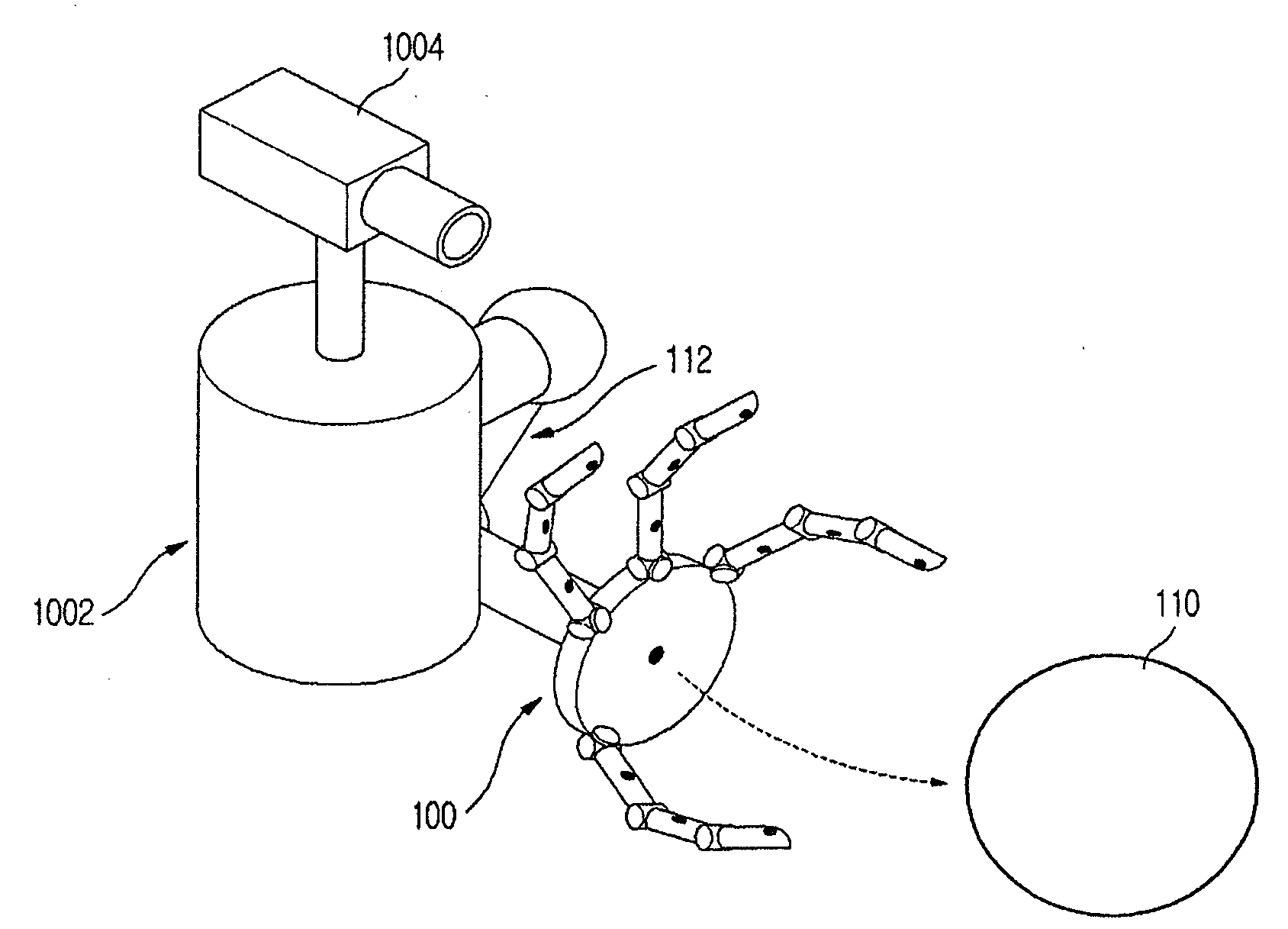

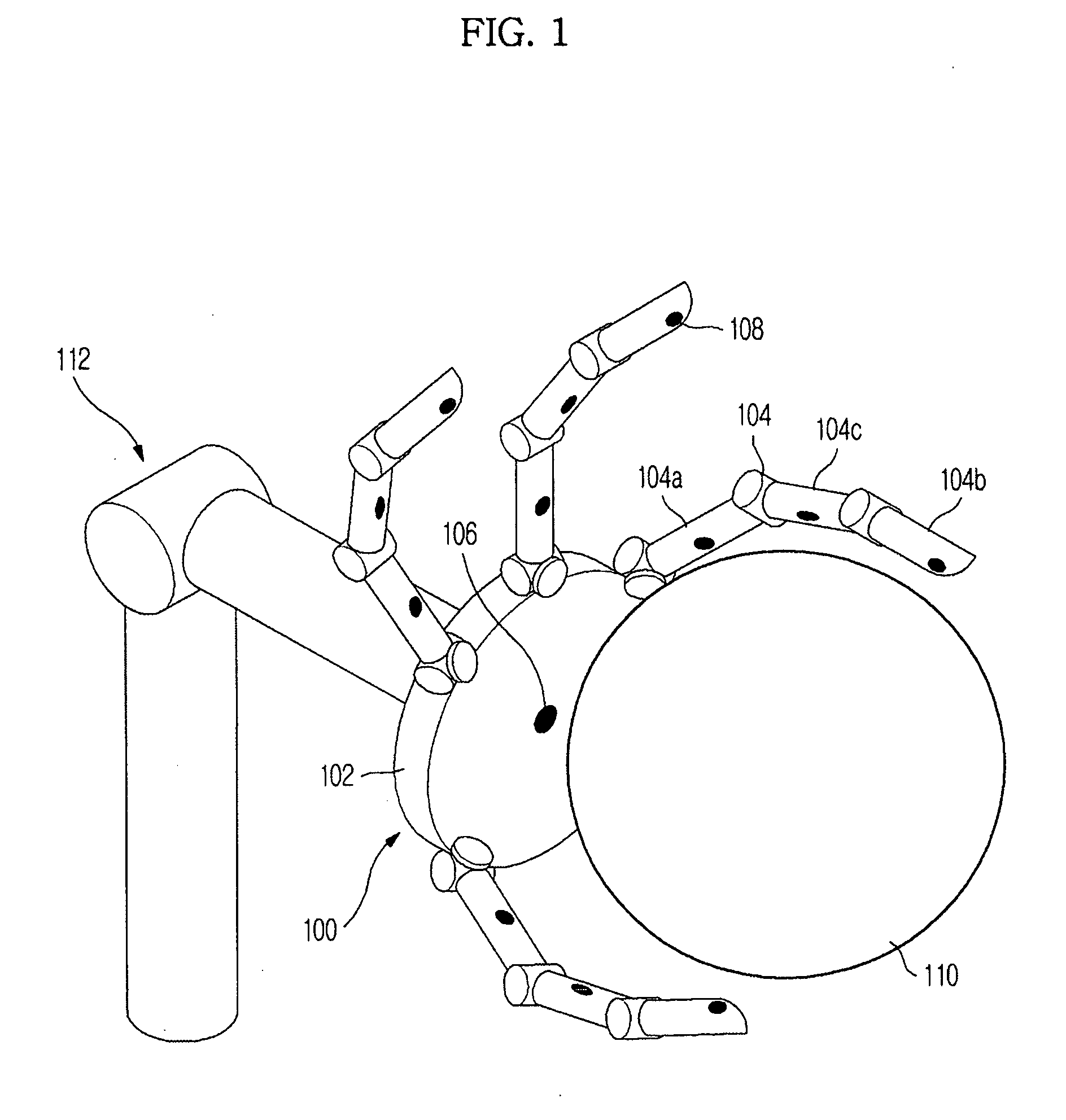

Robot, robot hand, and method of controlling robot hand

ActiveUS20090285664A1Safe gripAvoid interferenceProgramme-controlled manipulatorComputer controlRobot handDistance sensors

Disclosed are a robot, a robot hand, and a method of controlling the robot hand, in which the robot hand rapidly and correctly approaches an object to be gripped and safely grips the object regardless of the shape and material of the object. The method of controlling a robot hand, which has a palm, and a plurality of fingers, each having a plurality of segments, connected to the palm, includes causing the palm to approach an object using at least one first distance sensor installed on the palm; causing the plurality of fingers to approach the object using at least one second distance sensor installed on the plurality of fingers; and causing the palm and the plurality of fingers to come into contact the object to grip the object.

Owner:SAMSUNG ELECTRONICS CO LTD

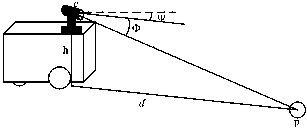

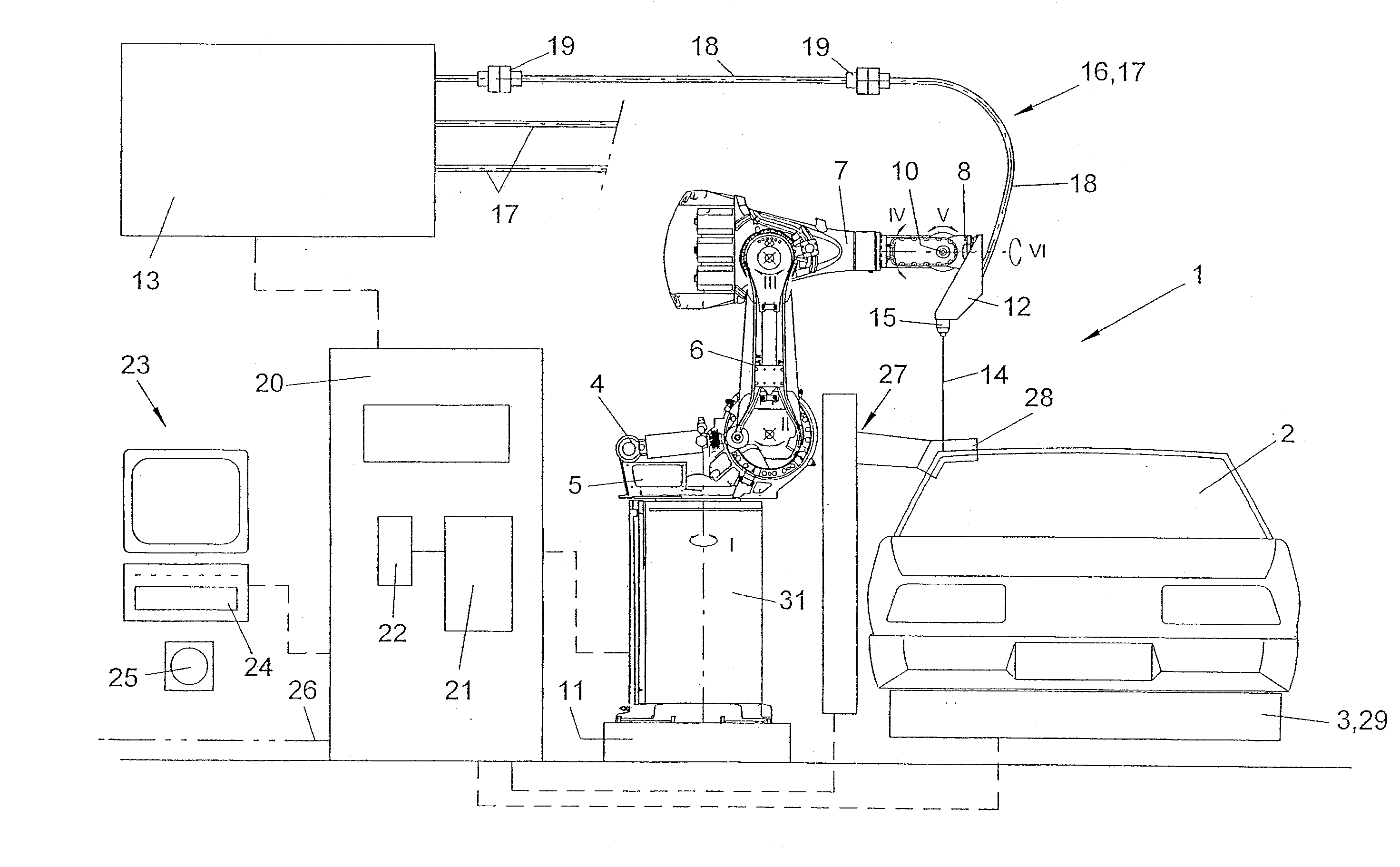

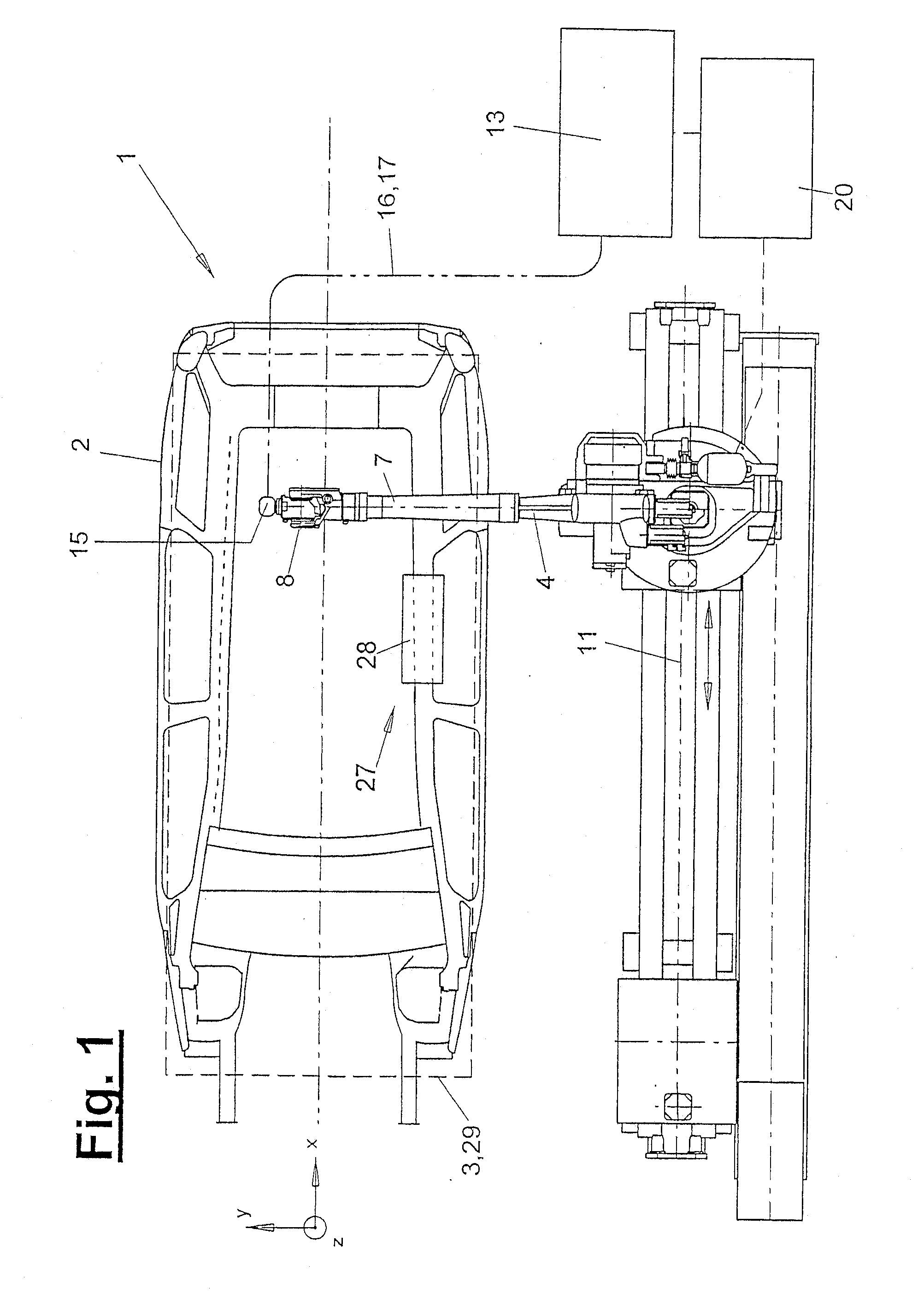

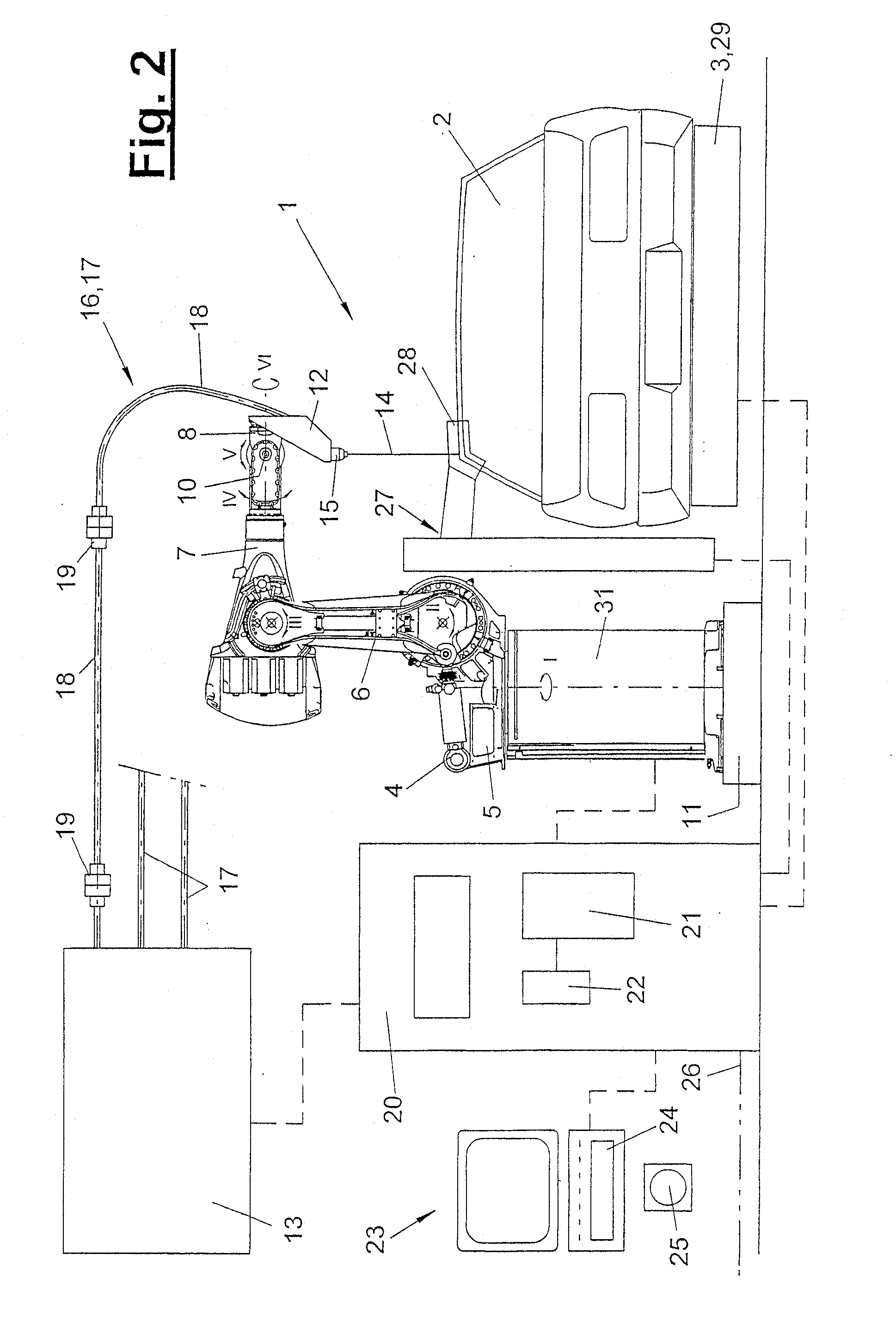

Method For Laser Machining And Laser Device With Laser Power Controlled As a Function Of The Laser Motion

InactiveUS20070199929A1Laser welding techniqueGood techniqueVehicle componentsMetal working apparatusContact freeRobot hand

A method and device (1) for laser machining vehicle bodies or body parts (2) uses a laser beam (14) that is guided from a laser source (13) to a remote laser tool (15) on a robot hand by a guiding device (16). The robot (4) maintains the laser tool (15) in a suspended manner over the tool (2), at a focal length (F) and at a contact free distance and guides it along a machining path (30). The laser beam (14) is deviated, by movement of the hand axis (IV, V, VI), about a variable deviation angle (α), and the laser source (13), whose power is variable, is controlled according to the movement of the laser beam. The beam deviation of the hand axis (IV, V, VI) can be superimposed on an offset movement of the robot (4).

Owner:KUKA SYSTEMS

Defective goods automatic sorting method and equipment for high-speed automated production line

InactiveCN1806940AHigh-speed grabbing and sorting processingHigh-speed sorting processProgramme-controlled manipulatorGripping headsProduction lineRobotic arm

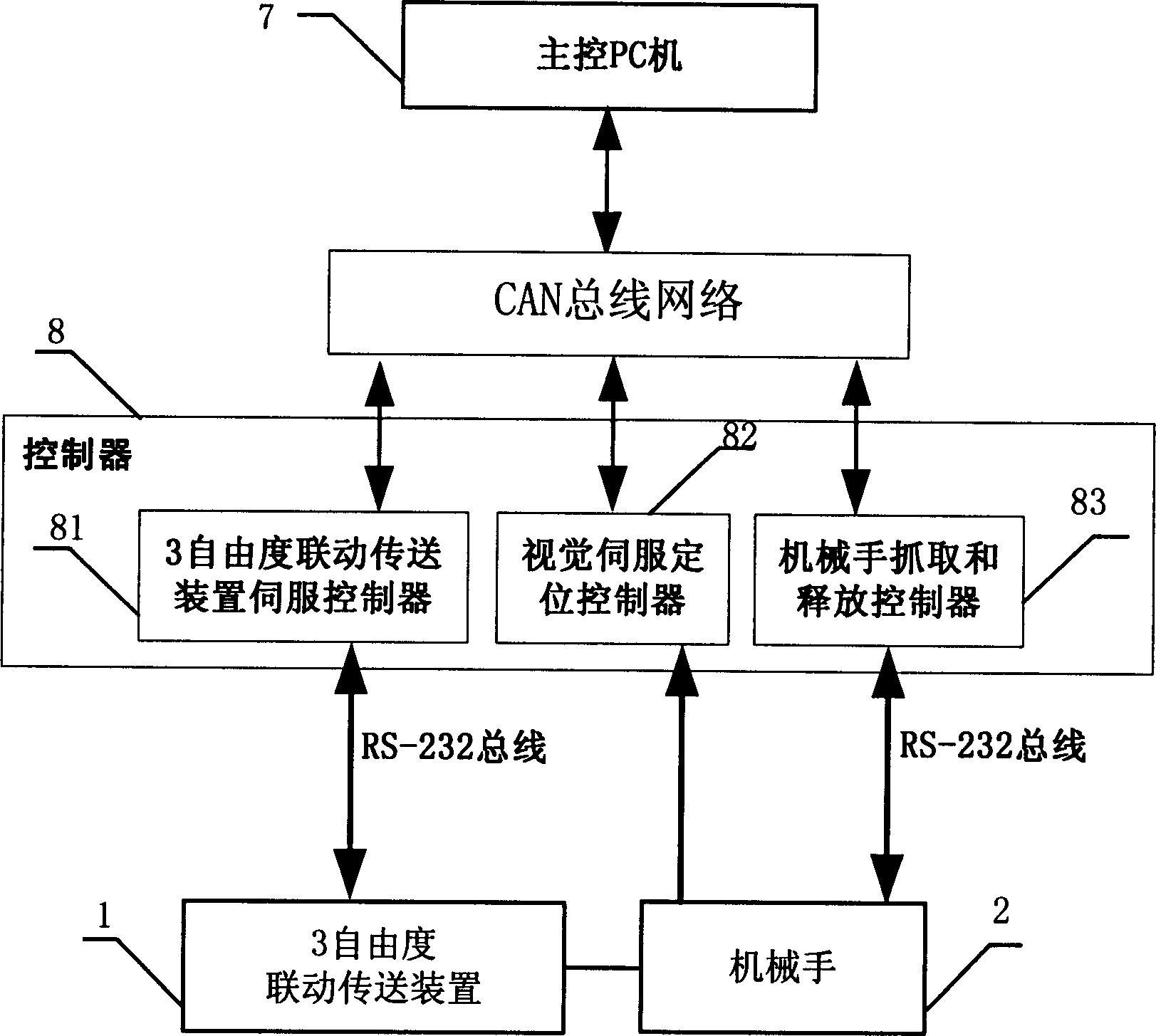

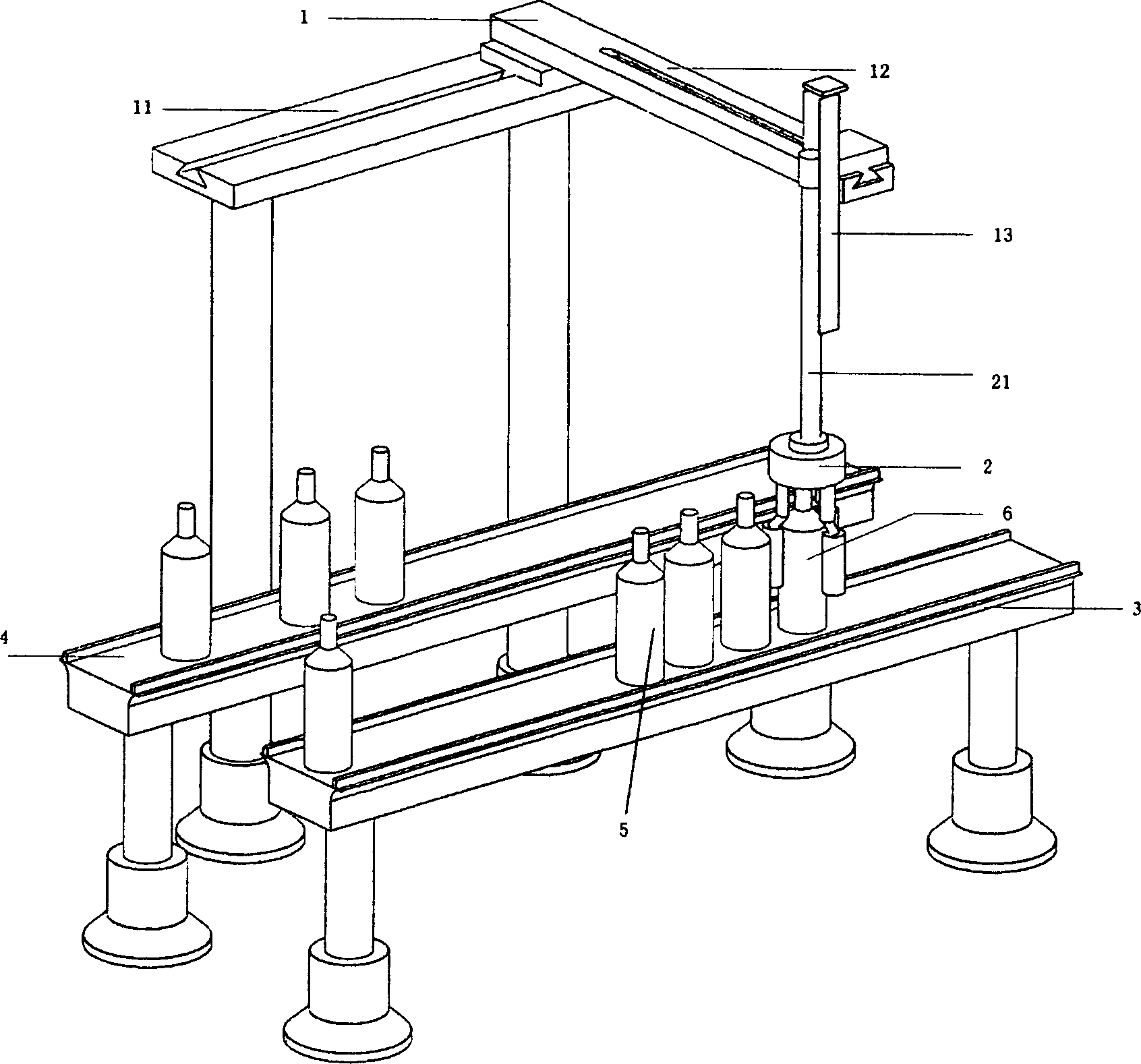

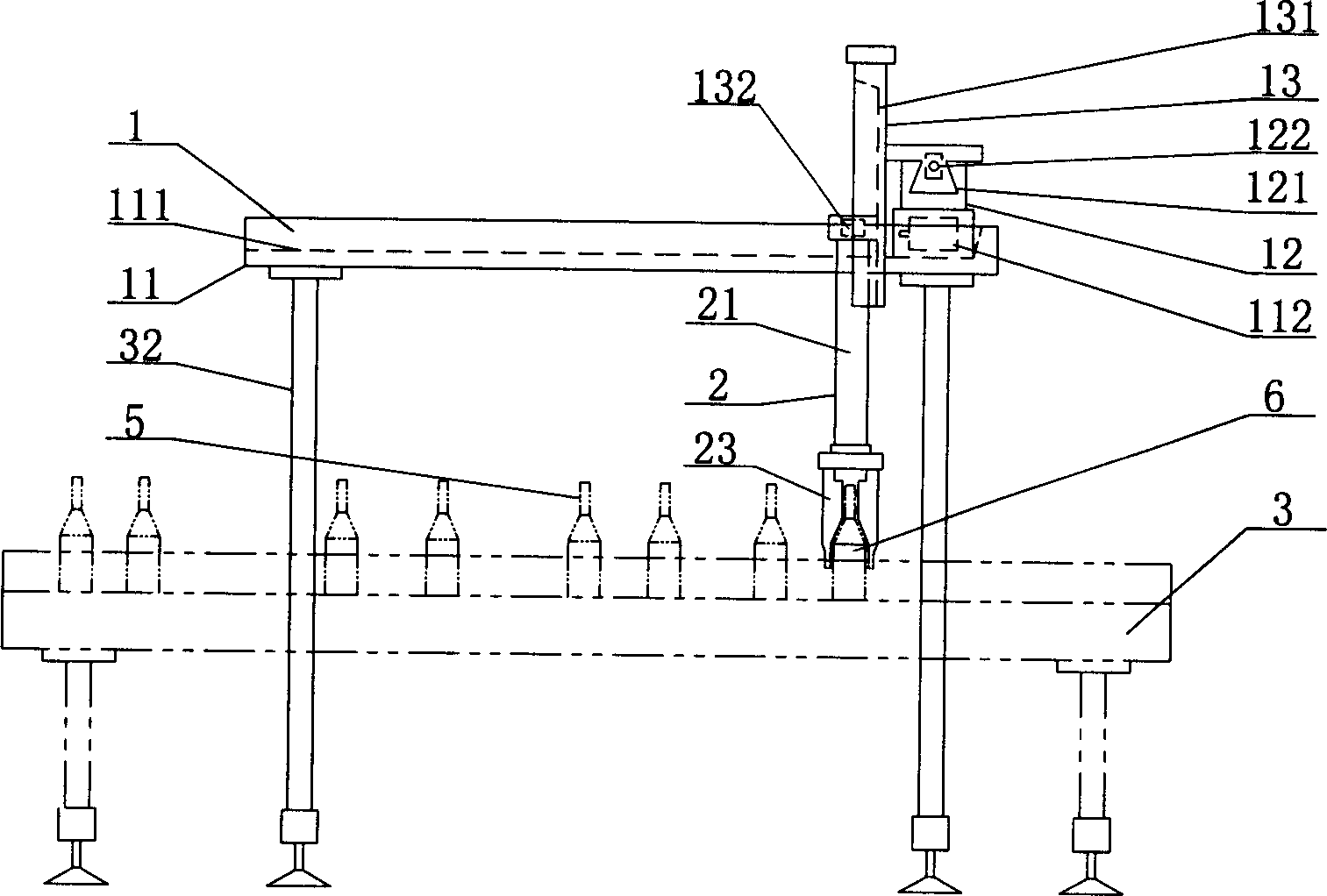

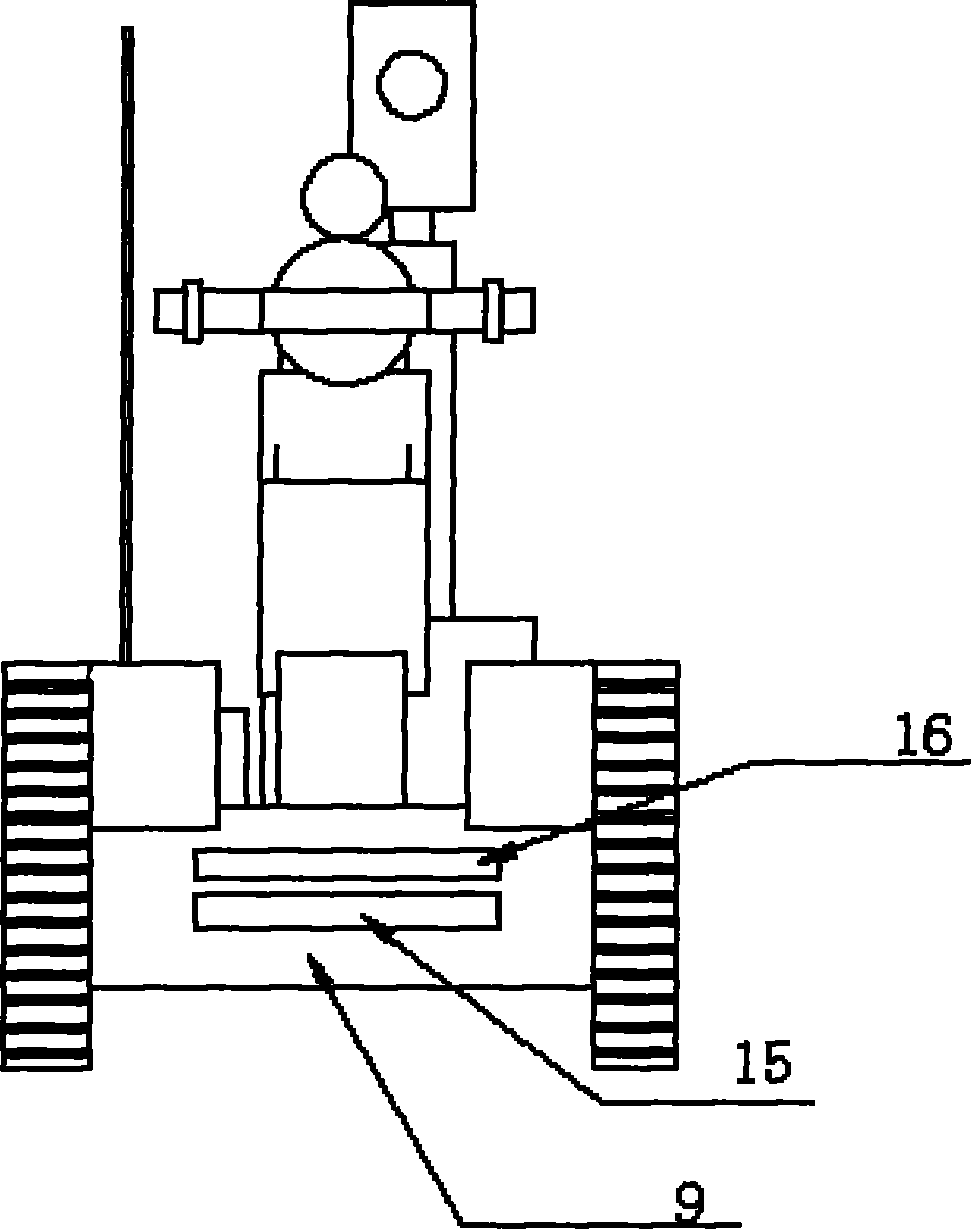

The invention relates the auto sorting faulty goods method on the high-speed automatic production line and unit. The method comprises the following steps: sorting faulty goods system receiving the sorting signal, starting the freedom degree linked conveying device 3, then positioning the mechanical arm connected with 3 on the faulty goods, the mechanical arm keeping the same speed with conveyer belt, gripping the faulty goods, lifting it and releasing it to appointed position. The unit comprises electrical control and mechanical part. The mechanical part comprises 3 and mechanical arm which comprises arm and hand. In the center of the mechanical hand there is camera, and the electrical control is connected with 3 and mechanical arm. The invention possesses high accuracy, low cost, good versatility, and no environmental pollution.

Owner:HUNAN UNIV

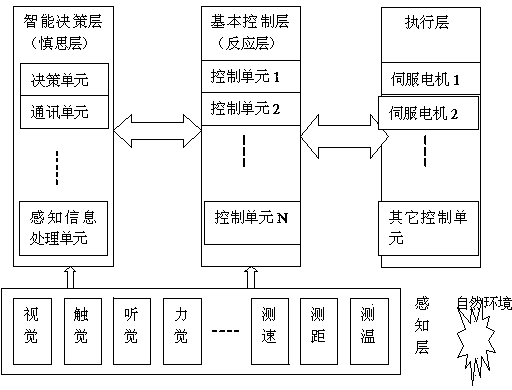

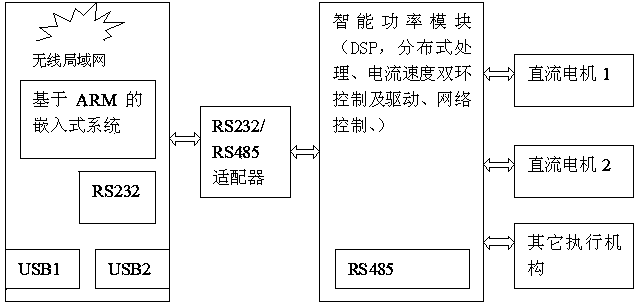

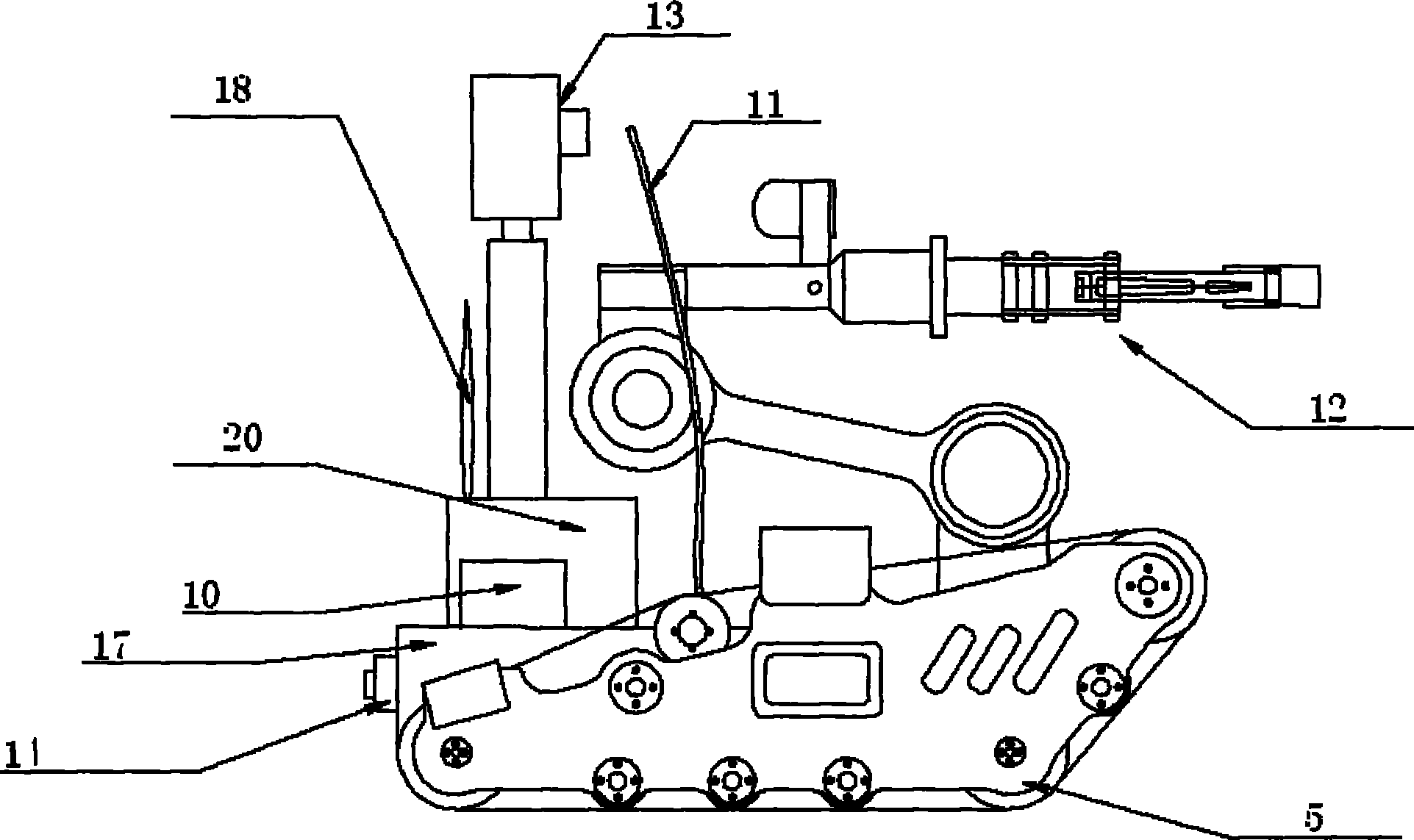

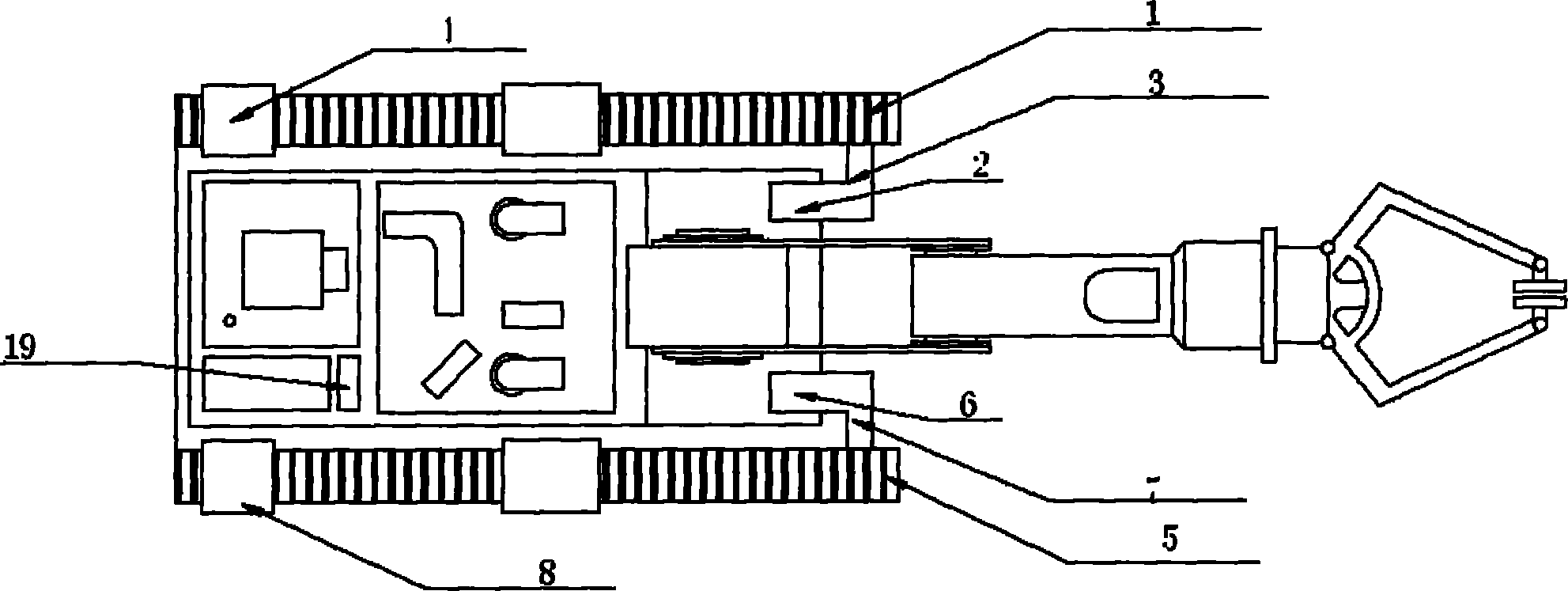

Nuclear power plant working robot and control system thereof

InactiveCN101774170ACapable of autonomous navigationRealize online monitoringEndless track vehiclesManipulatorTerrainOperational costs

The invention relates to a nuclear power plant working robot and a control system thereof, which belong to the fields of robots and automation equipment. The nuclear power plant working robot is a crawler-type mobile manipulator and is composed of a mobile platform driven by double crawlers and a four freedom degree manipulator carried on the mobile platform. The nuclear power plant working robot can move inside a nuclear power plant, has two control modes of manual remote control and autonomous control, and is remotely controlled by a wireless or wired mode. The control system of the nuclear power plant working robot includes a host monitoring and planning control system and a robot control system which are matched to control the operation of the robot. The robot operates autonomously, is safe and reliable, can complete certain dangerous tasks in high radioactivity environment; the robot has small size, stable performance, great maneuverability and low operation cost; a crawler-type chassis has strong gripping force as well as certain climbing and obstacle clearing ability, and is suitable to walking over complex terrains; and the robot has high intelligence degree and can realize autonomous control and manual remote control.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

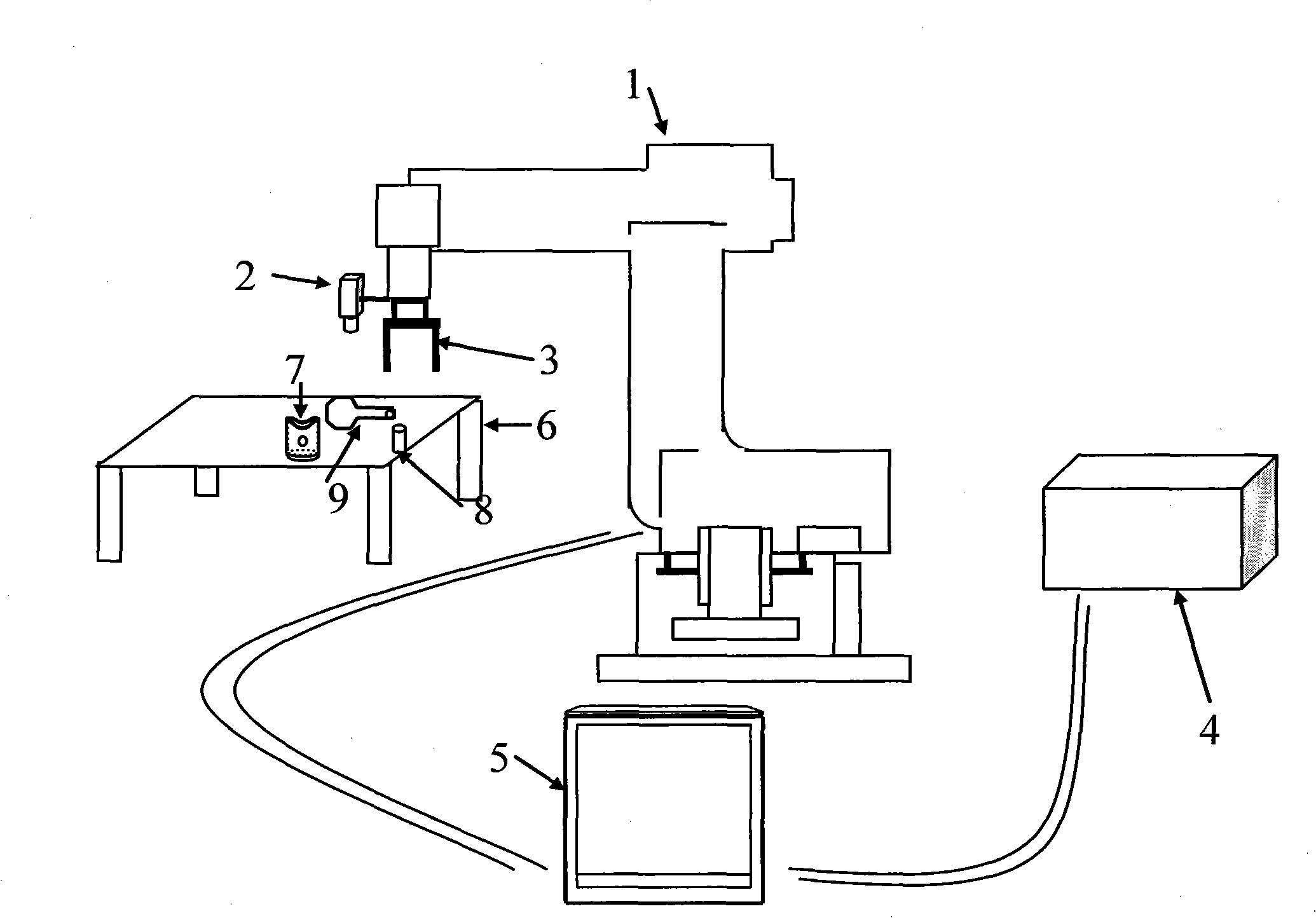

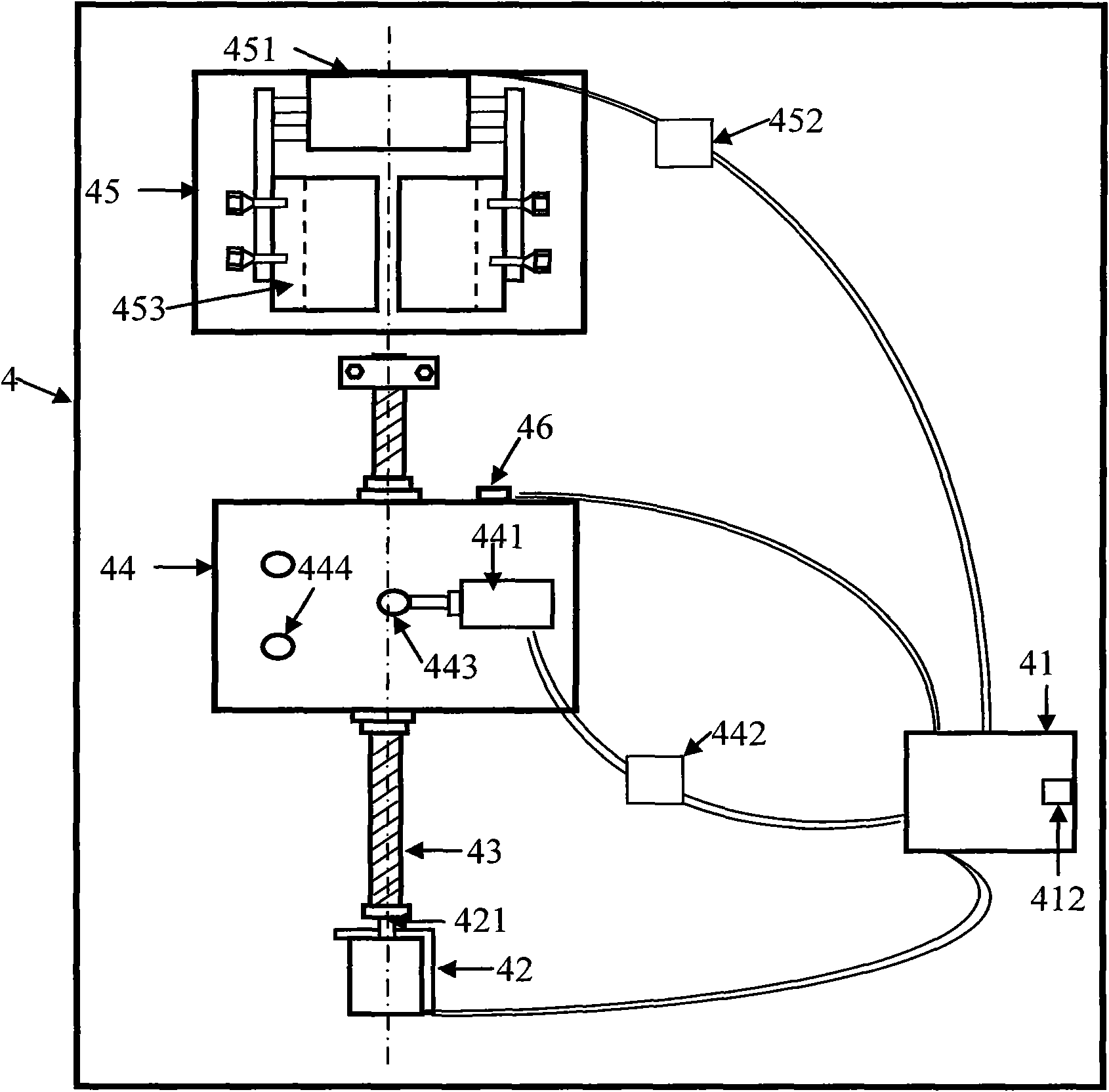

Industrial robot-based assembly method and device of piston, piston pin and connecting rod

ActiveCN101913076AImplement automatic assemblyImprove assembly efficiencyProgramme-controlled manipulatorAssembly machinesData terminalControl circuit

The invention relates to an industrial robot-based assembly method and device of a piston, a piston pin and a connecting rod. The method of the invention comprises the following steps: a vision camera is used to identify the positions and directions of the piston, piston pin and connecting rod, the grabing positions are calculated by a computer, a mechanical paw grabs the piston, the piston pin and the connecting rod to place on an intelligent assembly table; the connecting rod is inserted in the piston under the control of the intelligent assembly table; an industrial robot places the piston pin in a piston assembly hole; the vision camera in the device identifies and positions the piston, piston pin and connecting rod on a work platform; the data terminal of the industrial robot is connected with the data terminal of the computer; the vision camera is connected with the computer; the industrial robot controls the mechanical paw to grab the piston, piston pin and connecting rod and place on the intelligent assembly table; the serial signal line of the intelligent assembly table is connected with the computer, the control circuit board of the intelligent assembly table controls a connecting rod jig to insert the connecting rod in the piston; and the industrial robot assembles the piston pin in the piston assembly hole according to the sensorless assembly method.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

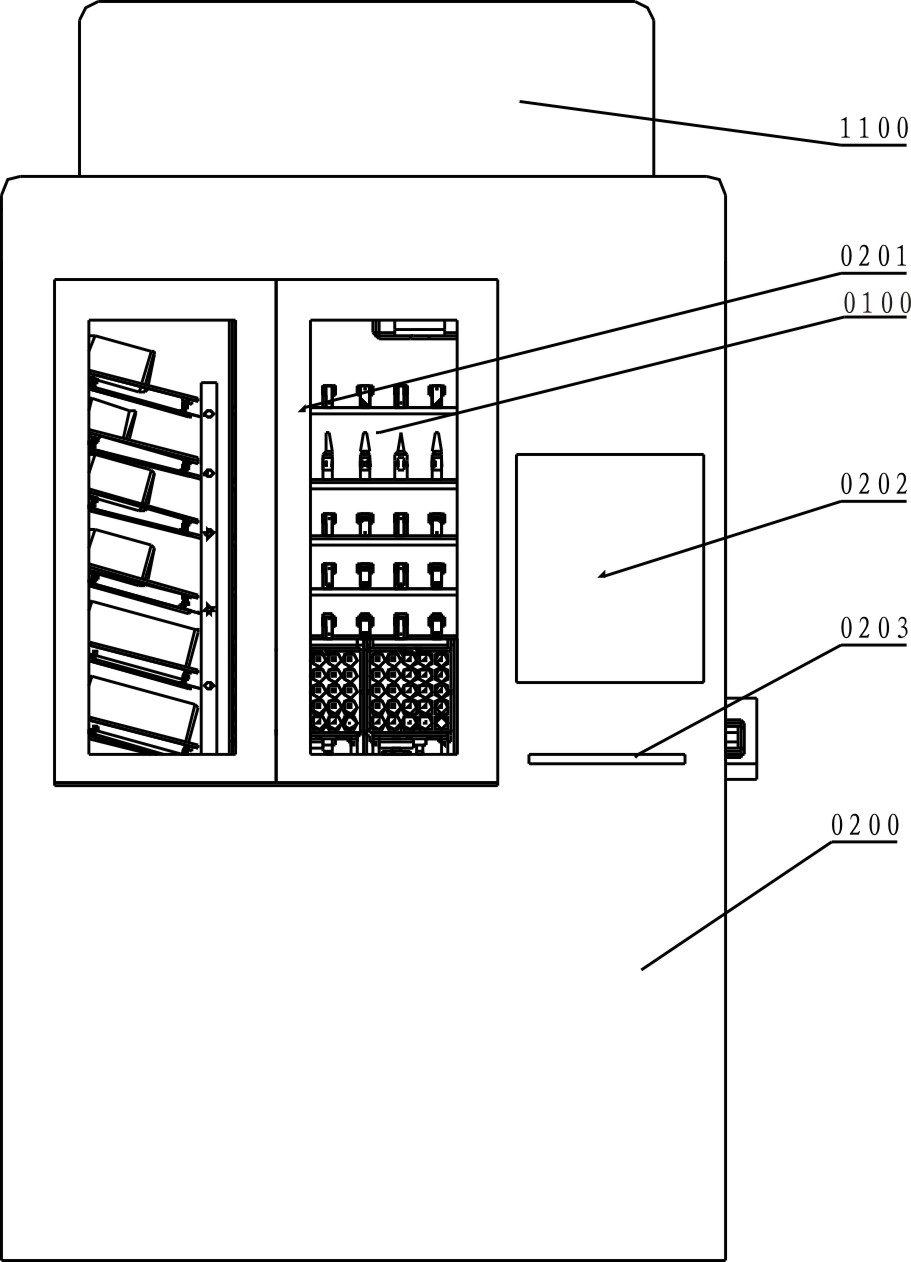

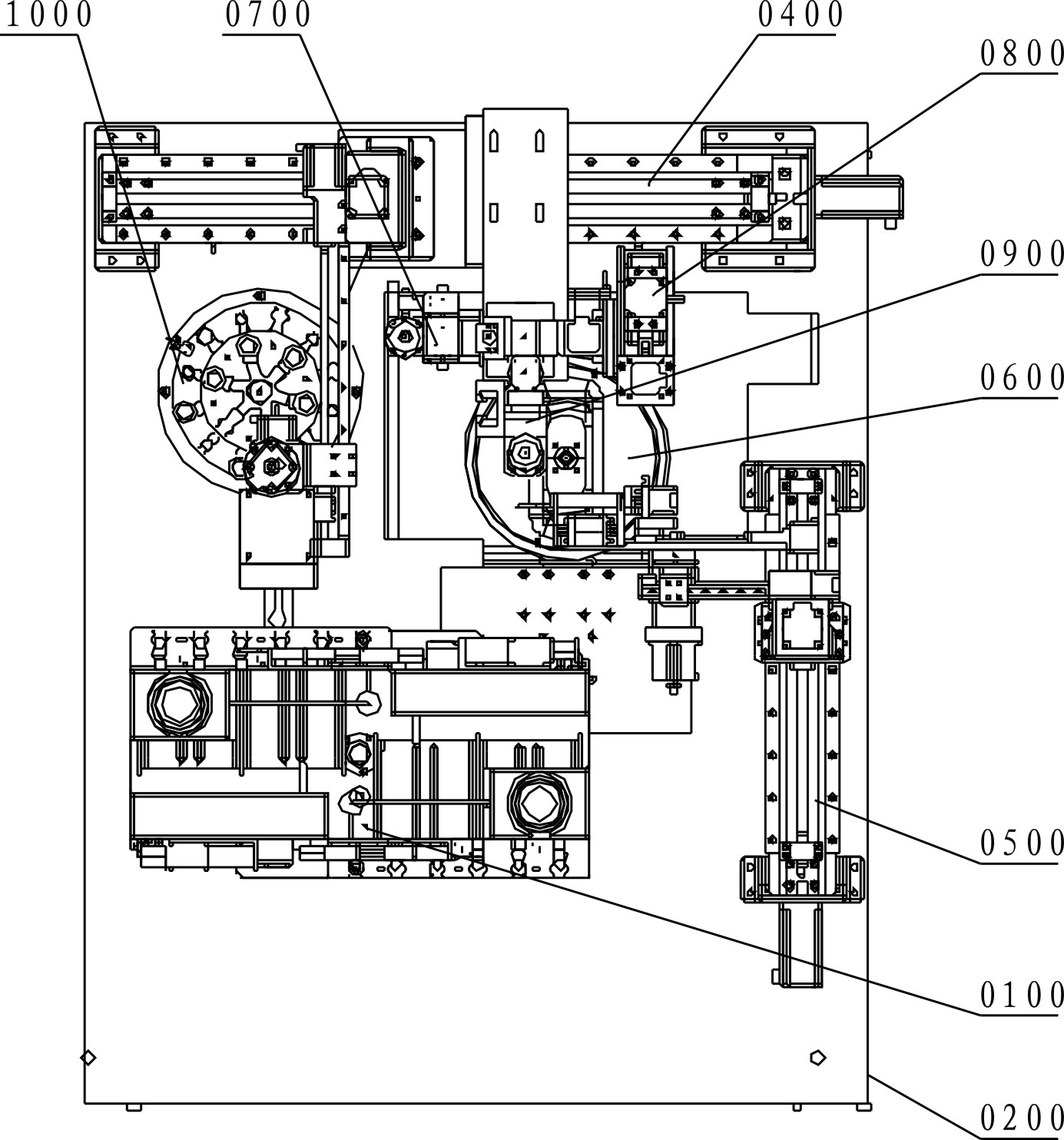

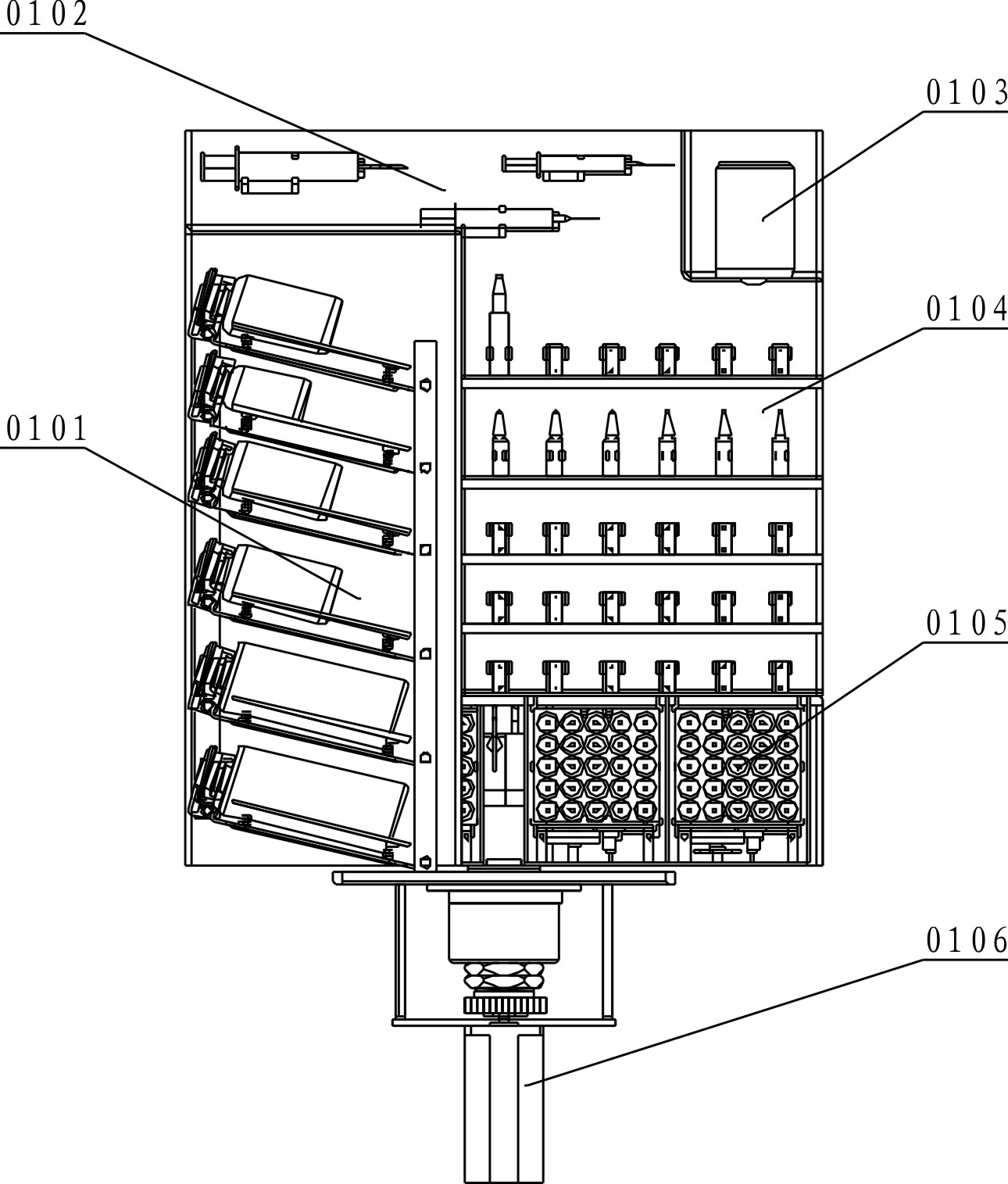

Full-function liquid medicine preparation intelligent robot and medicine preparation method thereof

ActiveCN102151228AChange configuration modePrevent leakagePharmaceutical containersPharmaceutical product form changeDispensing medicationsChemo therapy

The invention discloses a full-function liquid medicine preparation intelligent robot and a medicine preparation method thereof. The full-function liquid medicine preparation intelligent robot comprises a shell, a medicine rack, a bottle taking mechanical arm, a liquid pumping mechanical arm, a bottle clamping mechanism and a liquid medicine shaking device, and is characterized in that: the shellis provided with an operating door with a seal; the medicine rack is arranged in the shell and corresponds to the operating door; the medicine rack has a rotary structure with more than two side faces; and each side face of the medicine rack is provided with accommodating areas for different medicines, and an indoor constant temperature and disinfecting cotton ball accommodating area. The intelligent robot has the property of full functions of preparing medical liquid, nutrient solution and chemical therapy medicines, radically changes the traditional mode of preparing cytotoxic medicines andthe manual preparation environment, has the characteristics of accurate liquid preparation, sterile preparation process and no cross-infection, protects the health safety of medical workers, avoids the leakage of the cytotoxic medicines, is environment-friendly, and saves cost of hospital medication and labor cost.

Owner:衡阳桑谷医疗机器人有限责任公司

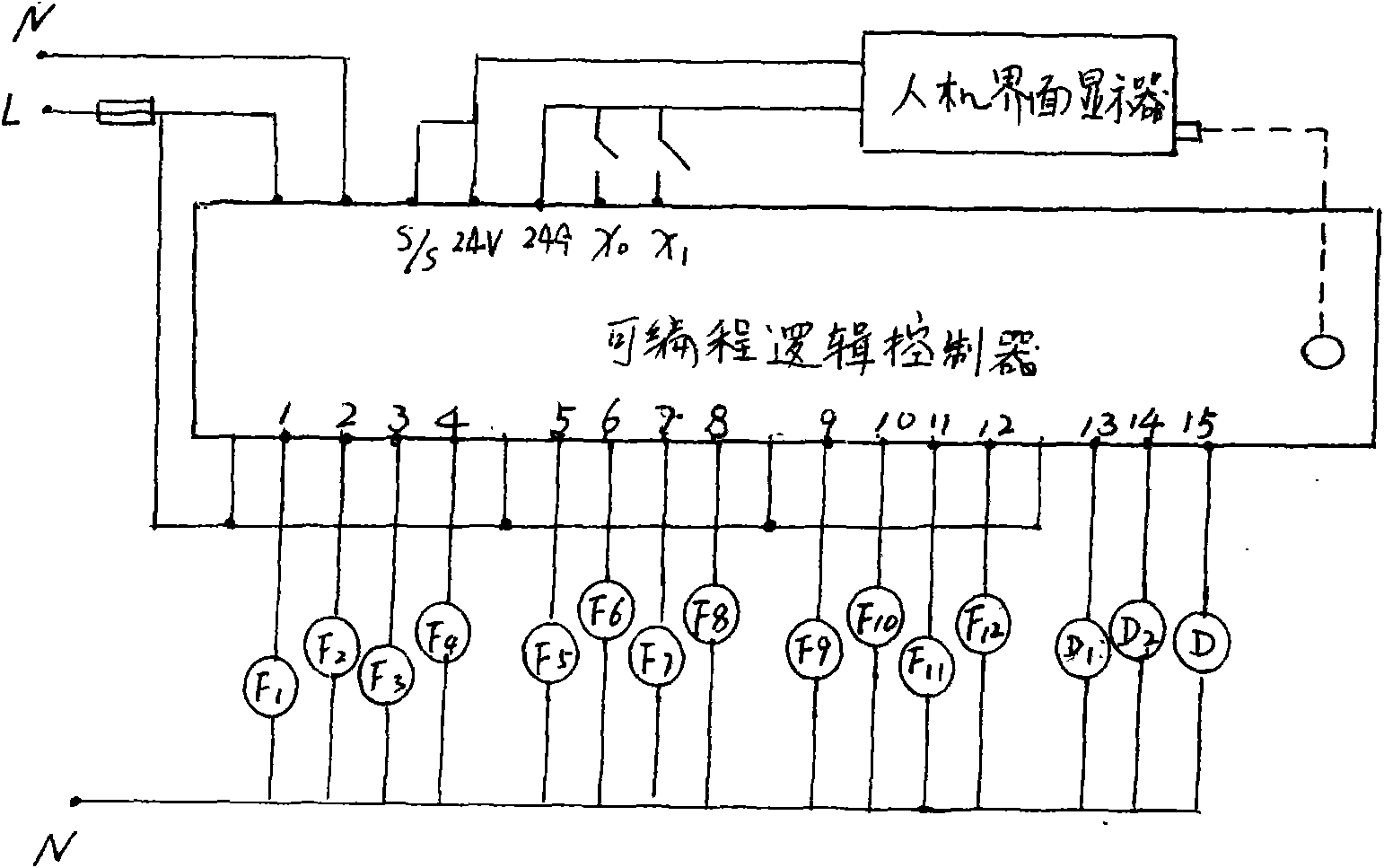

Intelligent fully automatic cooking robot

InactiveCN102273912AShorten the timeImprove qualityProgramme control in sequence/logic controllersWarming devicesAutomatic controlMicrowave oven

The intelligent fully automatic cooking robot involved in the present invention adopts the intelligent automatic control technology of mechanical and electrical integration, software and hardware combination, conducts intelligent automatic cooking based on microwave ovens and other stoves, and places multiple liquid and solid ingredient boxes and vegetable boxes on the panel , according to the prompts of the intelligent automatic cooking controller, after placing the prepared dishes, in the case of unattended, at any time according to the requirements of the person at the specified time for accurate and precise cooking, one intelligent automatic completion of one or more Cooking dishes, people can enjoy a delicious meal when they go home from work; the invention adopts the concept of a manipulator, which has a simple and efficient structure, small size, and is easy to use. Environmental protection requirements; used at home can save people a lot of time for cooking, so that people can live a higher quality of life or perform more creative work, and use it in commercial operations can reduce labor and save costs.

Owner:洪家平

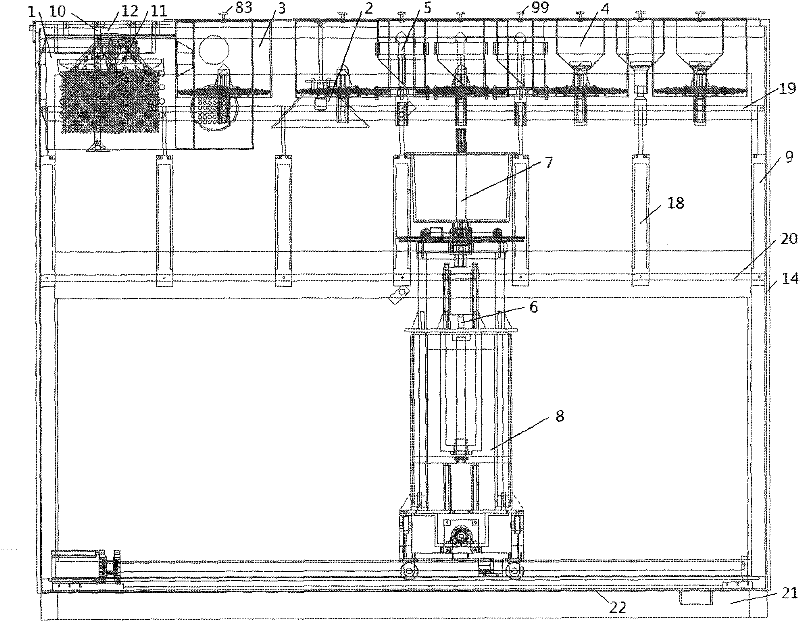

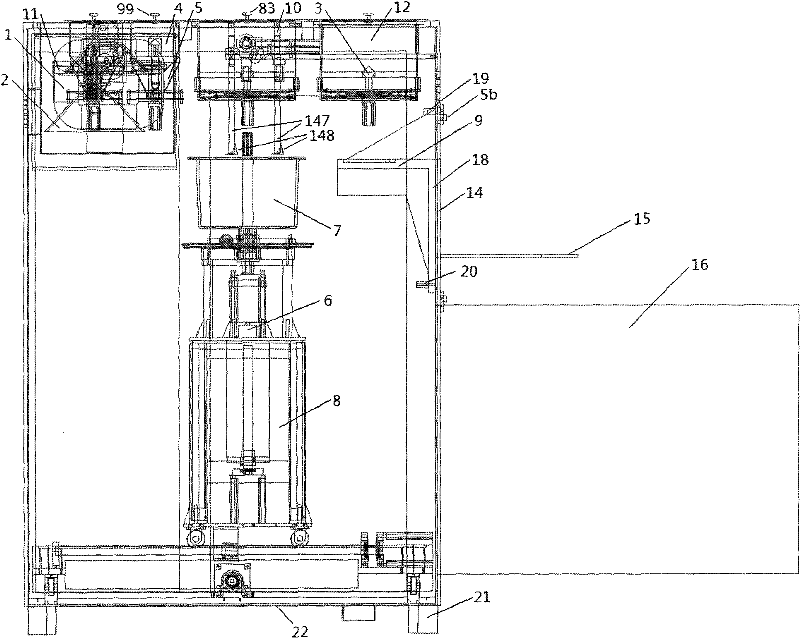

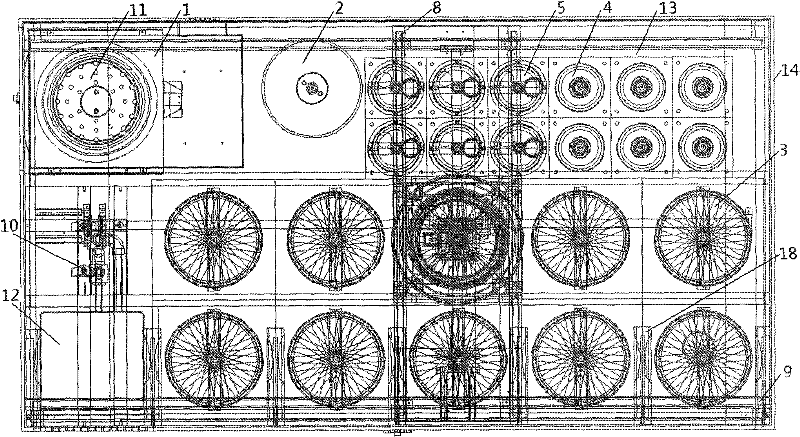

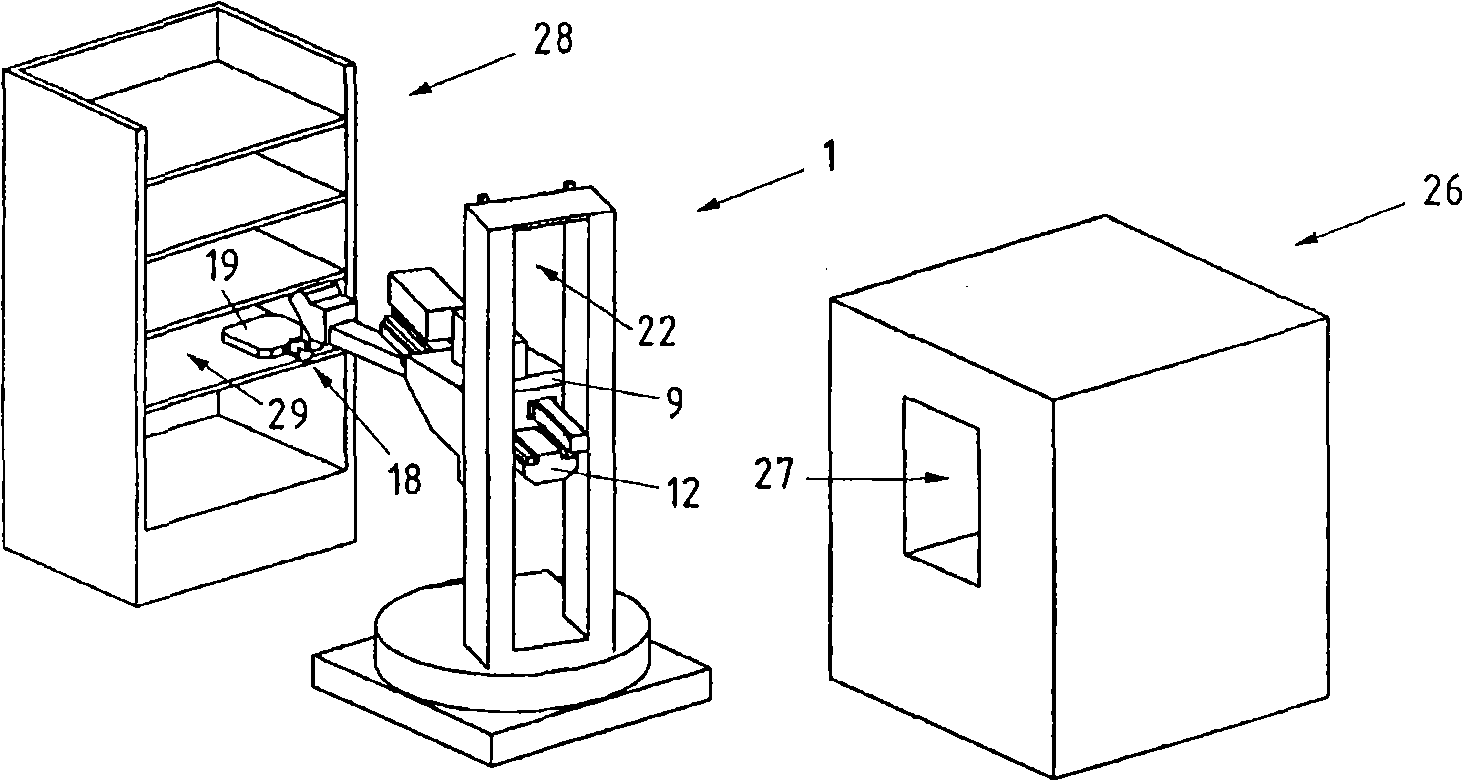

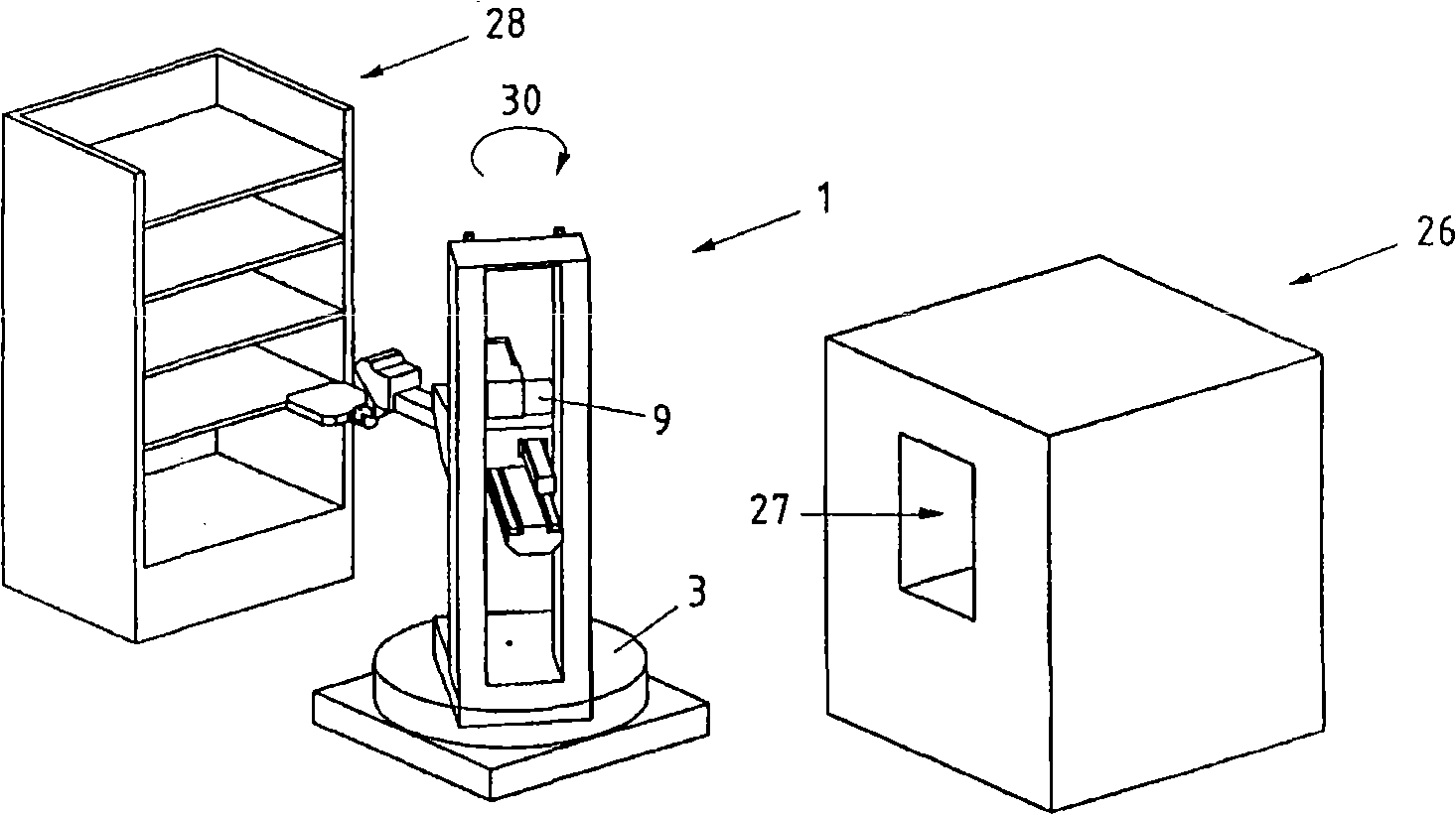

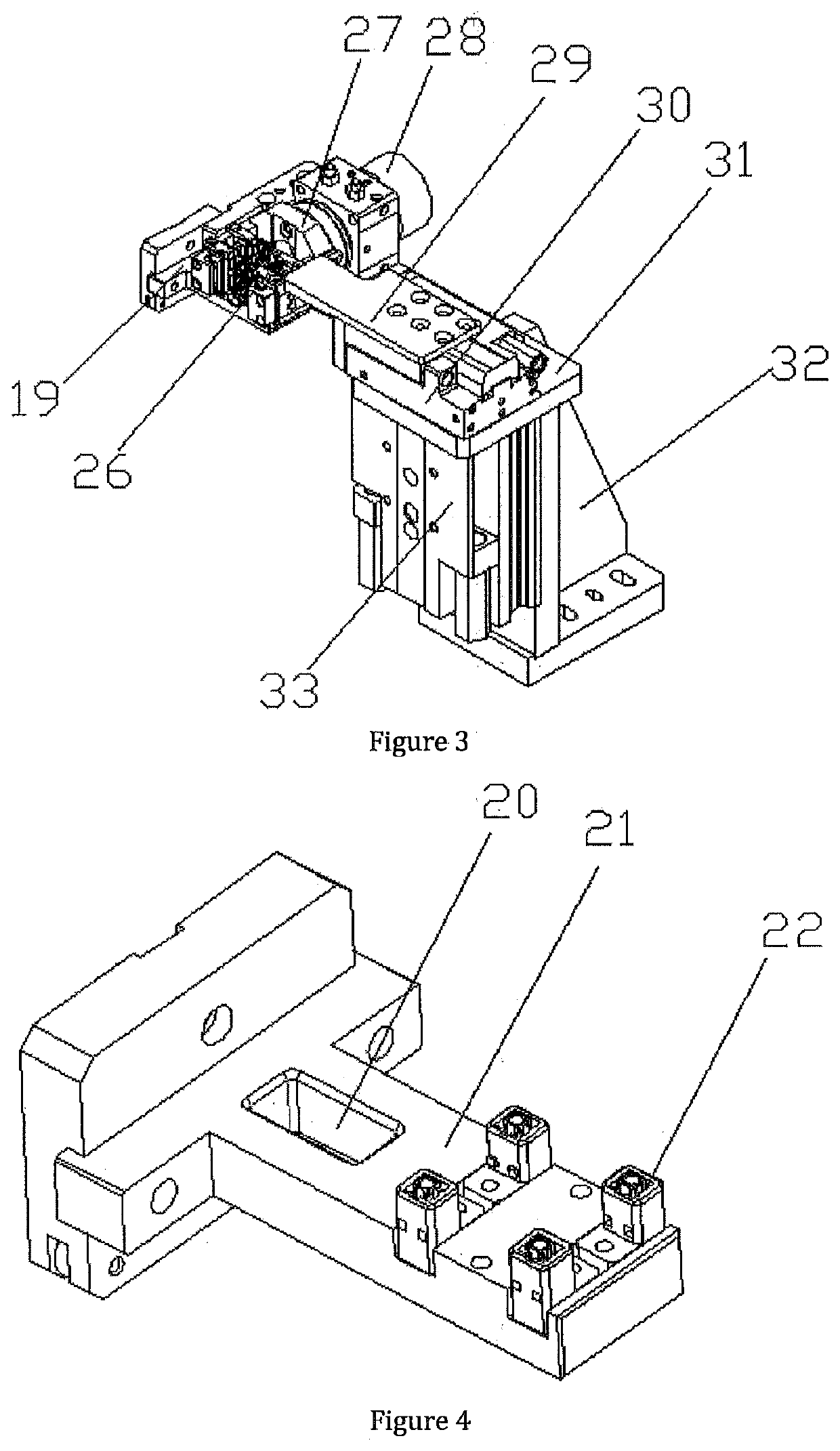

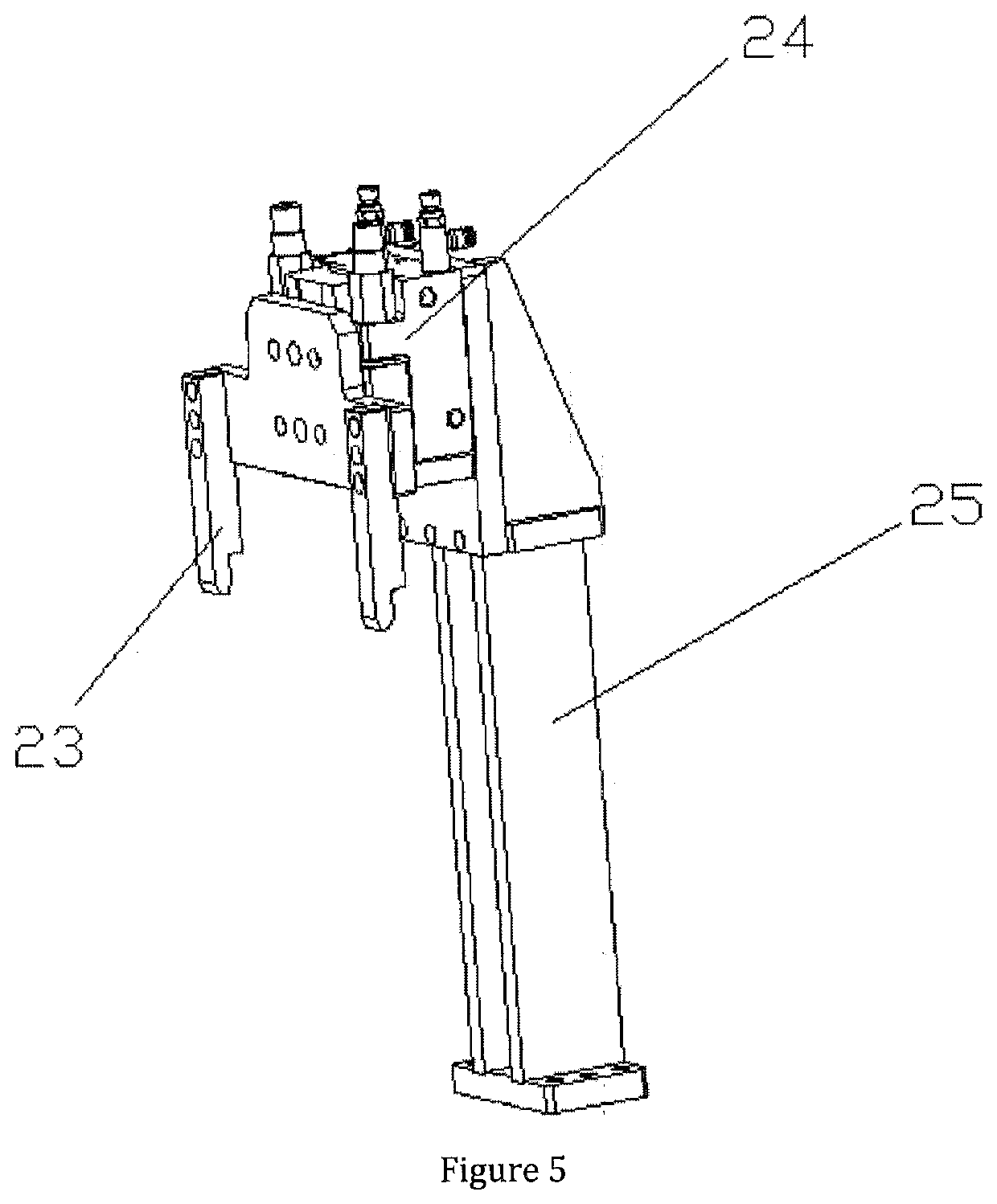

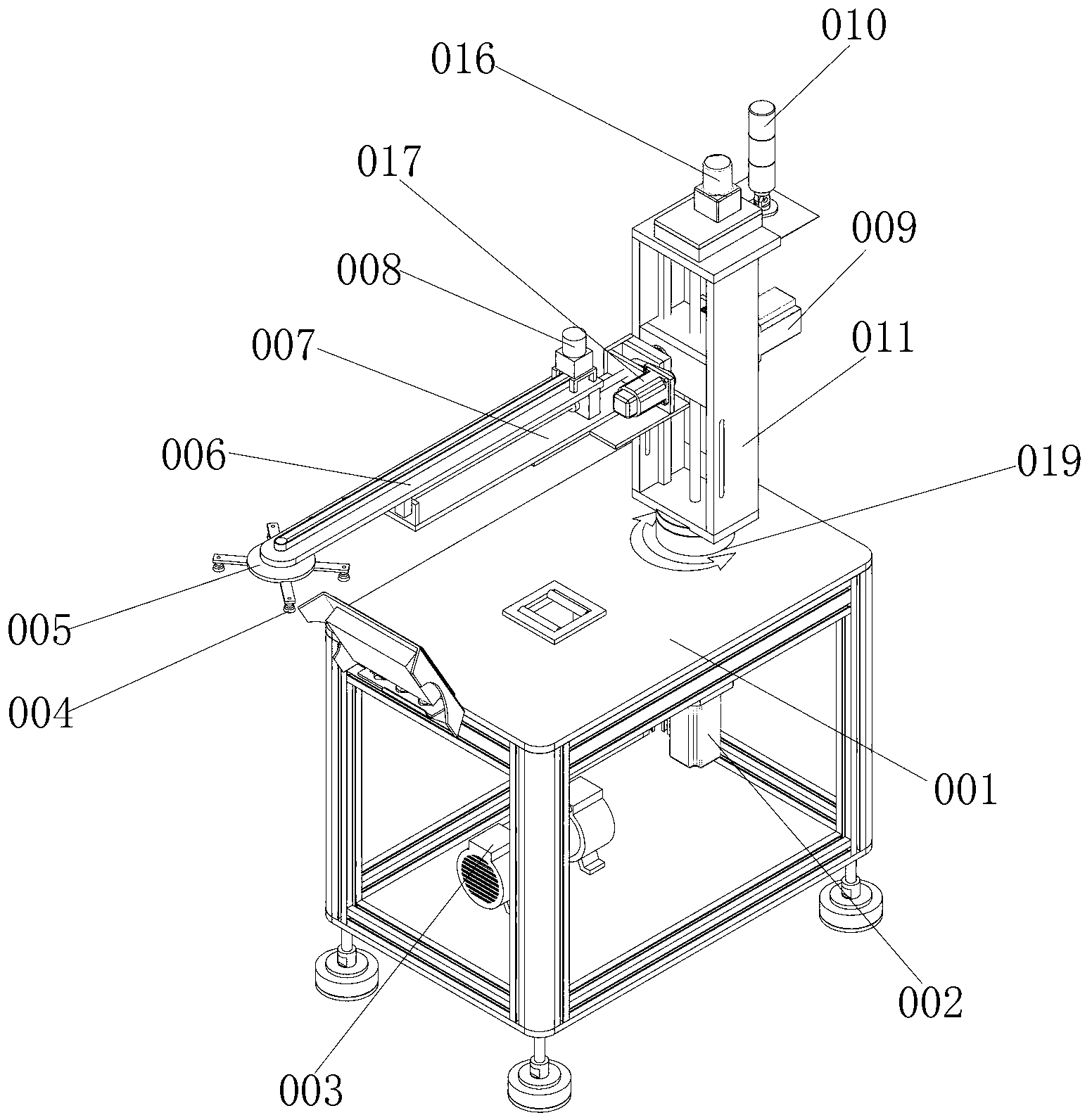

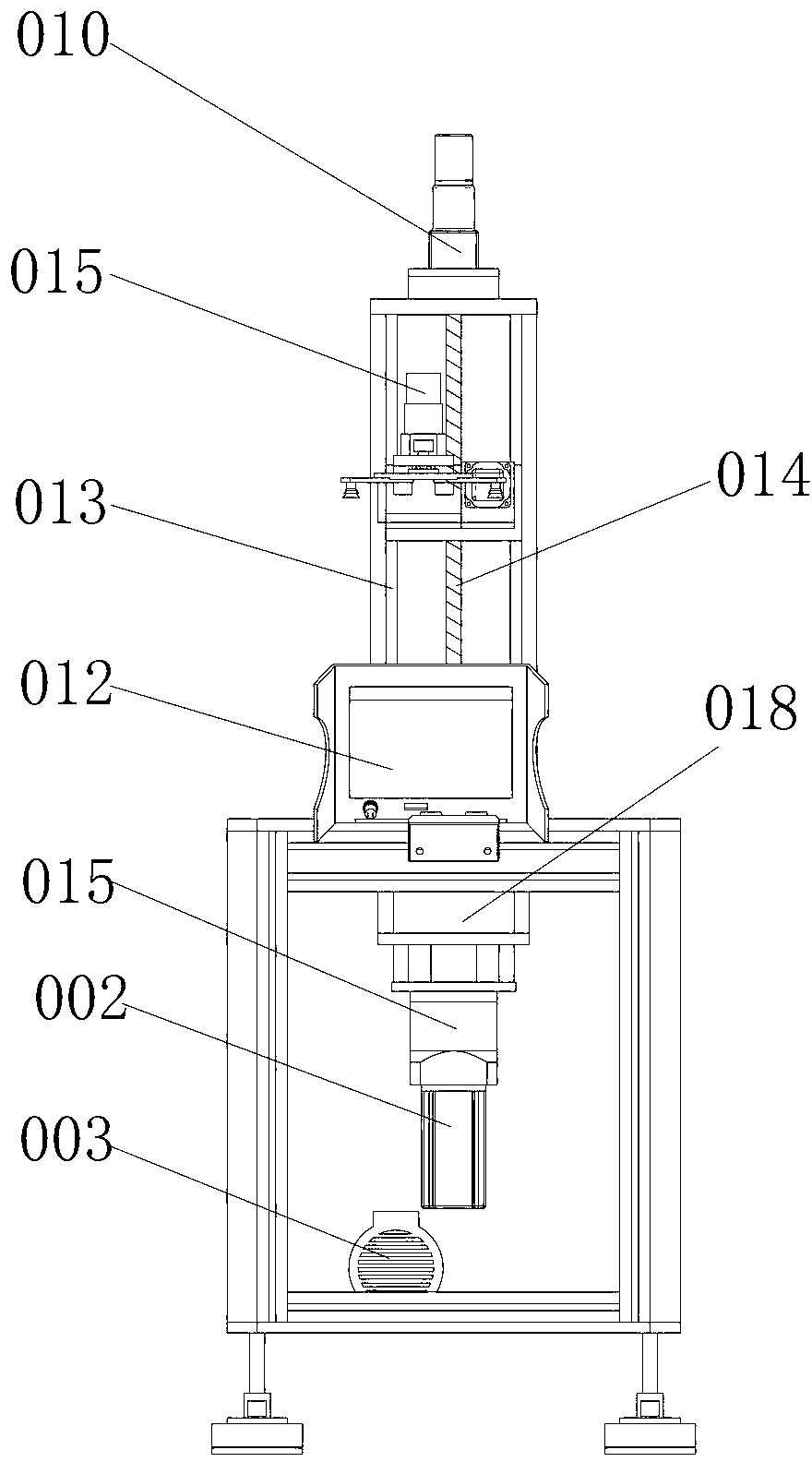

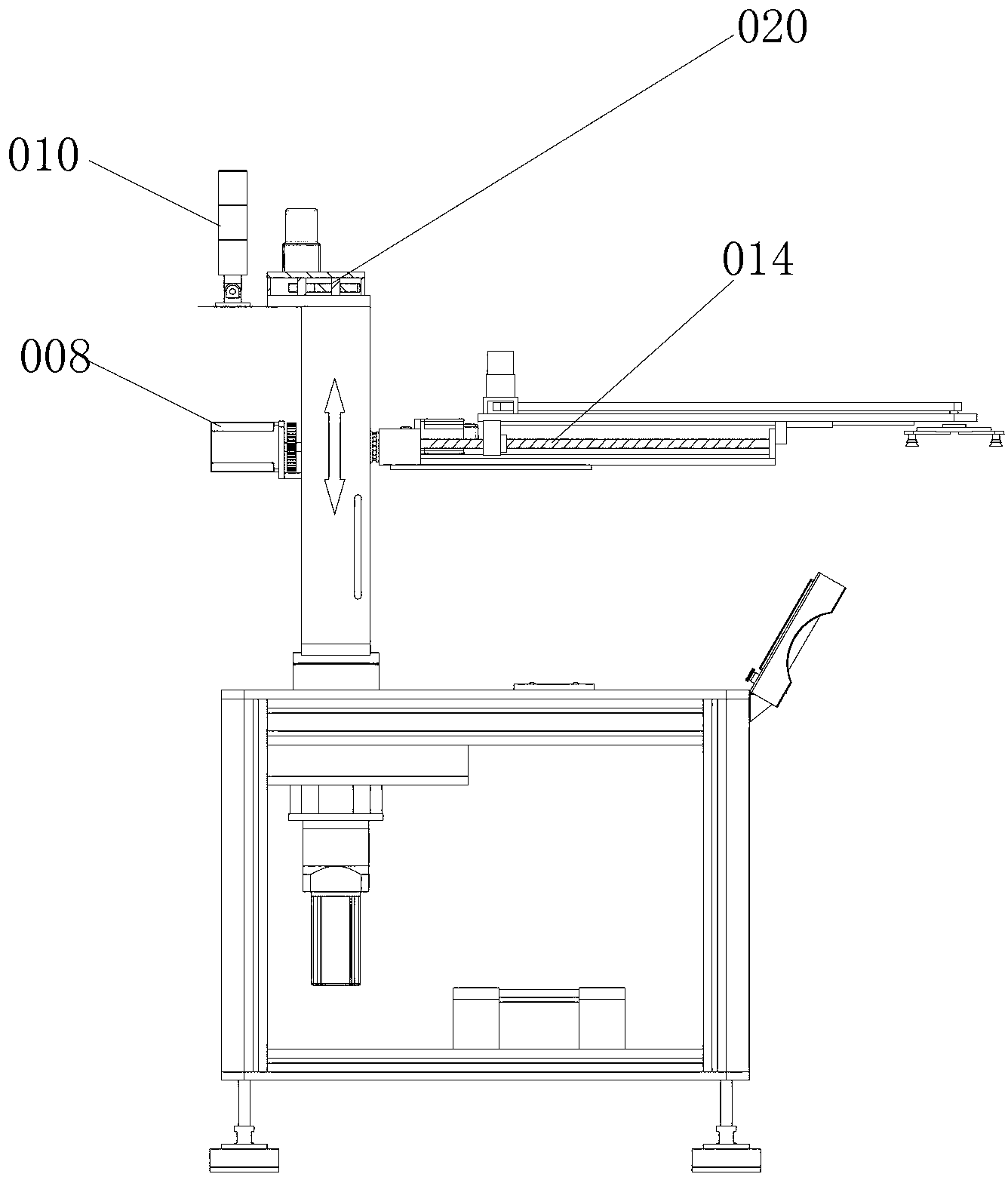

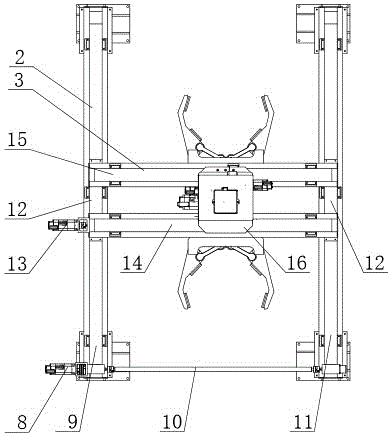

Handling manipulator assembly

InactiveCN101284379AHorizontal travel bigImprove mobilityProgramme-controlled manipulatorMechanical apparatusManipulatorEngineering

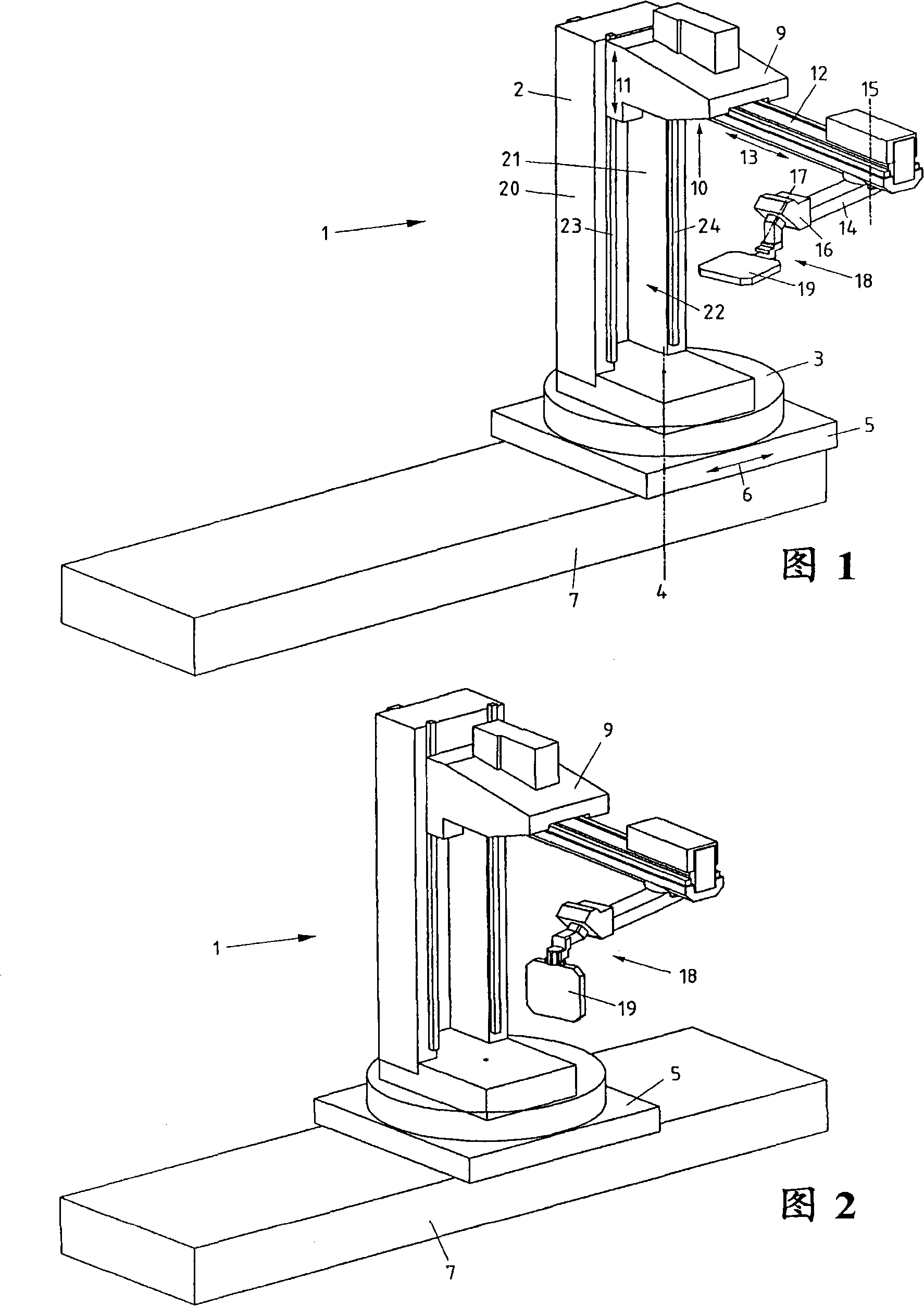

The assembly (1) has a vertically extending main support (2) rotatable about a vertical axis (4), and a horizontal extension arm (12) supported by a vertically traveling vertical carriage on the vertical main support. A manipulator gripper (18) is supported directly or indirectly on the horizontal extension arm, which is supported on the vertical carriage for horizontal travel by a linear guide. The horizontal extension arm is provided with an articulated arm (14) rotatable about a vertical axis (15), the manipulator gripper arranged at the end of the articulated arm. Independent claims are also included for the following: (1) a method for feeding / removing workpieces and / or tools to / from a machine tool (2) a machine tool assembly including a machine tool.

Owner:EROWA

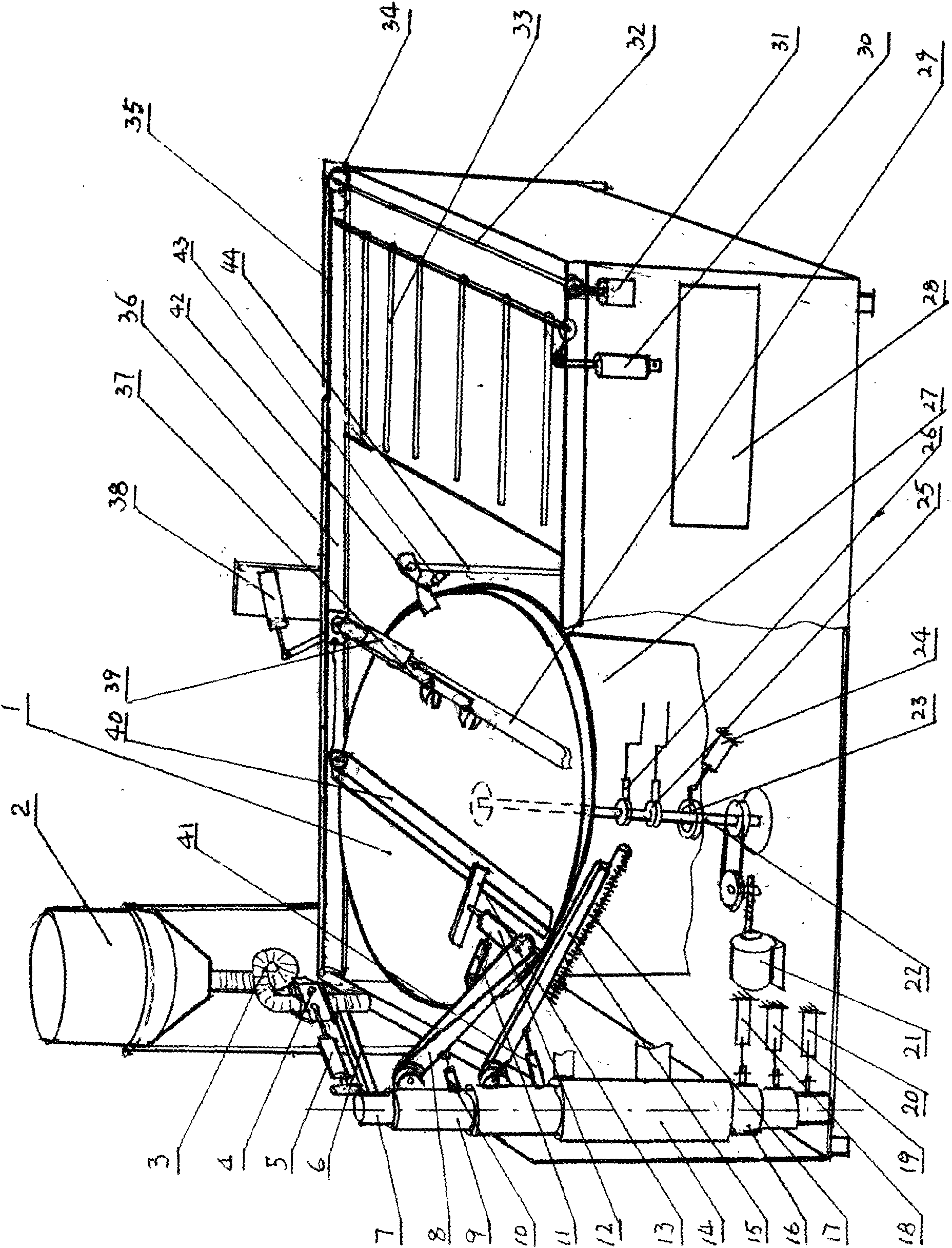

Full-automatic pancake machine

InactiveCN101584352AImprove processing efficiencyReduce labor intensityOil/fat bakingPancakes bakingRobot handElectric machinery

The invention discloses a full-automatic pancake machine, comprising a griddle heating and rotating under the drive of motor, an accumulator, a mechanical hand for polishing by simulating manual pancake making actions, a mechanical hand for feeding paste materials, a spreading mechanical hand, a raising mechanical hand, a pulling mechanical hand, a scraping mechanical hand, a turning-moving mechanical hand and an automatic controller. The automatic controller controls each mechanical hand to run according to program, thereby achieving the actions of simulating manual pancake making of the full-automatic pancake machine. All the manual operation procedures of pancake making in the invention are finished automatically, so that the pancake making is automatized, processing efficiency is improved, and labour intensity is reduced, besides, the made pancake still has the feeling of pancake made manually.

Owner:单传芹

Robot hand

InactiveUS20060158146A1More handleImprove survivabilityComputer controlSimulator controlRobot handEngineering

A robot hand has a plurality of fingers and is provided, at a location at which the robot hand touches an object, with a moving means for touching the object and moving the object. The moving means is provided to the palm side of the robot hand and / or the finger pad side of the robot hand.

Owner:SHARP KK

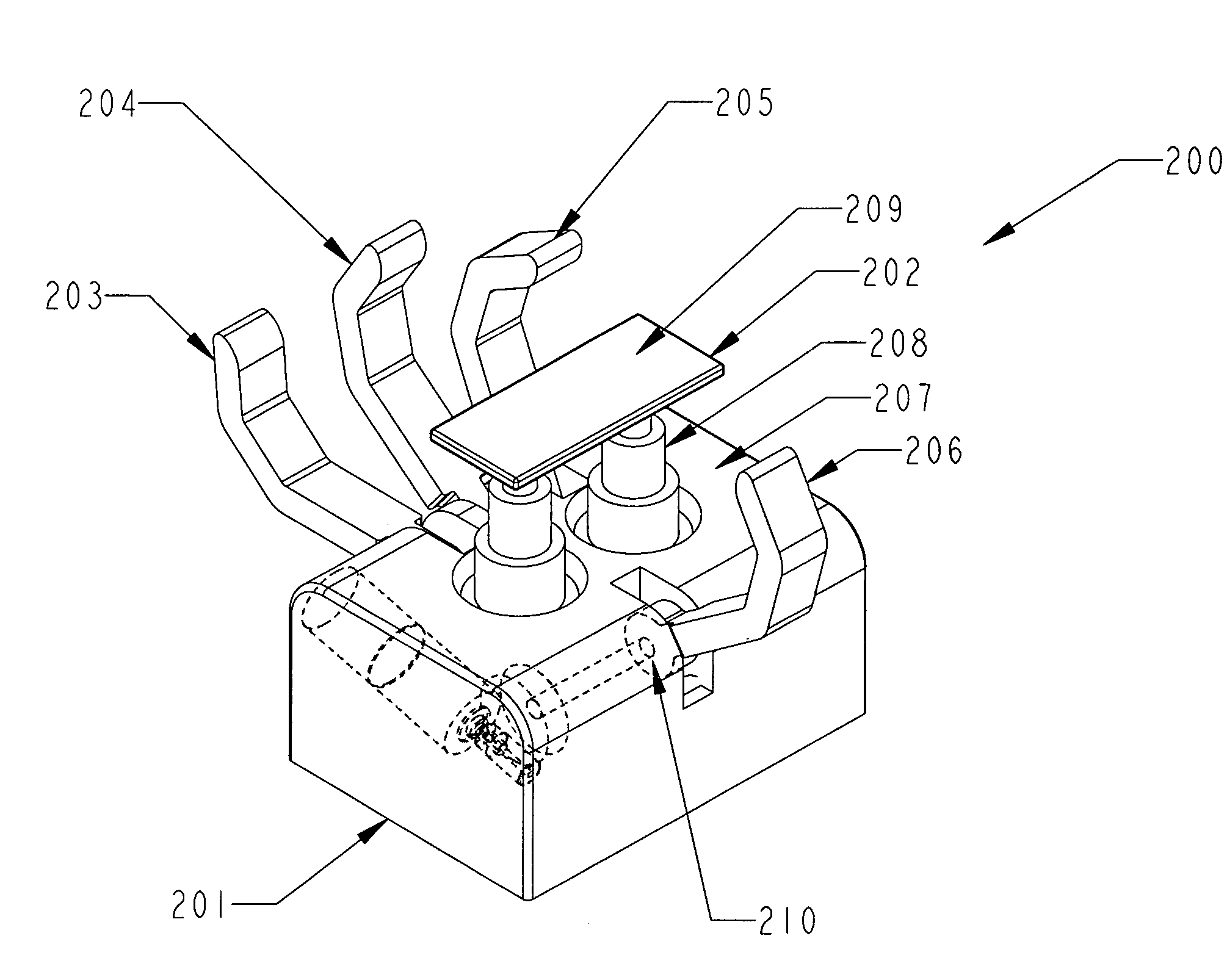

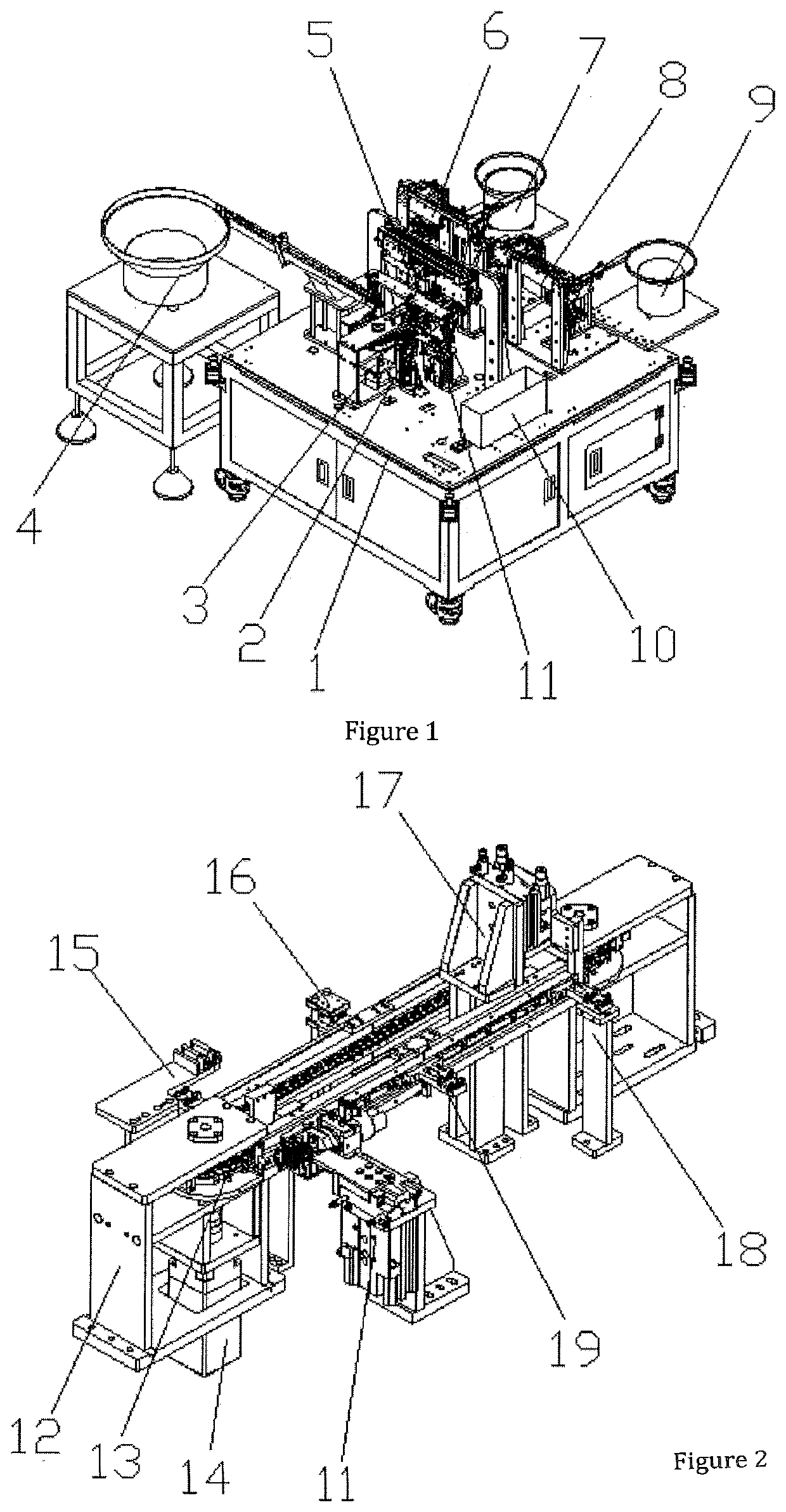

Automatic spring fastener assembly machine

ActiveUS20190337105A1Completed efficientlyCompleted fastContact member assembly/disassemblyAssembly machinesRobot handEngineering

The present invention relates to an automatic spring fastener assembly machine, including a rack and a power control box, and the rack is provided with a circulating conveying device, and a rubber casing feeding device, a fastener feeding device and a spring loading device which are in turn arranged around the circulating conveying device. The rubber casing feeding device includes a rubber casing vibration tray disposed to the left front side of the circulating conveying device, and the rubber casing feeding vibration tray is connected with a rubber casing distributing block through the rubber casing conveying track. The upper side of the circulating conveying device is provided with a rubber casing transportation manipulator, and the right front side thereof is provided with a rubber casing clamping device located below the rubber casing transportation manipulator, and a fastener pushing in device fitting the circulating conveying device is disposed under the rubber casing clamping device. In the present invention, material feeding and conveying is done by the circulating conveying device, and fasteners are fitted into corresponding holes on the rubber casings from a higher position with the fastener pushing in device, which can be completed fast and efficiently, is easy to operate, realize quick assembly of spring fasteners and improve working efficiency.

Owner:DONGGUAN UNIV OF TECH

Workpiece stamping intelligent control process and intelligent control manipulator

InactiveCN103252770AImprove work efficiencyImprove securityProgramme-controlled manipulatorMetal-working feeding devicesAutomatic controlMachining process

The invention discloses a workpiece stamping intelligent control process. The workpiece stamping intelligent control process controls automatically and satisfies all actions to be operated coherently to effectively improve working efficiency, no manual work is needed, safety is improved and cost is effectively saved. Product quality is guaranteed to enable products to meet market demands. The invention further provides an intelligent control manipulator implementing the process. Through an efficient, accurate, flexible, safe operation mode flexible in design, the intelligent control manipulator is convenient to operate, production efficiency is greatly improved, structural design is reasonable, design mode is flexible, effects are obvious, process persistence is high, raw materials are saved and energy consumption is quite low; a regulation and control type industrial control process satisfies different demands, the structural design enhances smoothness, swing precision is guaranteed, and machining process is guaranteed to be completed automatically, continuously and effectively; and conventional manual or semi-automatic machining modes are replaced, and resources are saved.

Owner:FOSHAN DINGFENG ROBOT

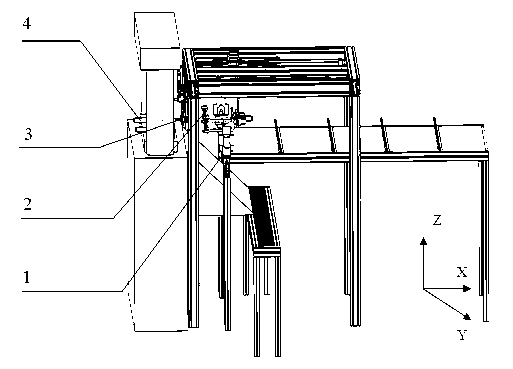

Loading and unloading manipulator

ActiveCN102699221AImprove processing qualityLabor savingMetal-working feeding devicesPositioning devicesTelescopic cylinderManipulator

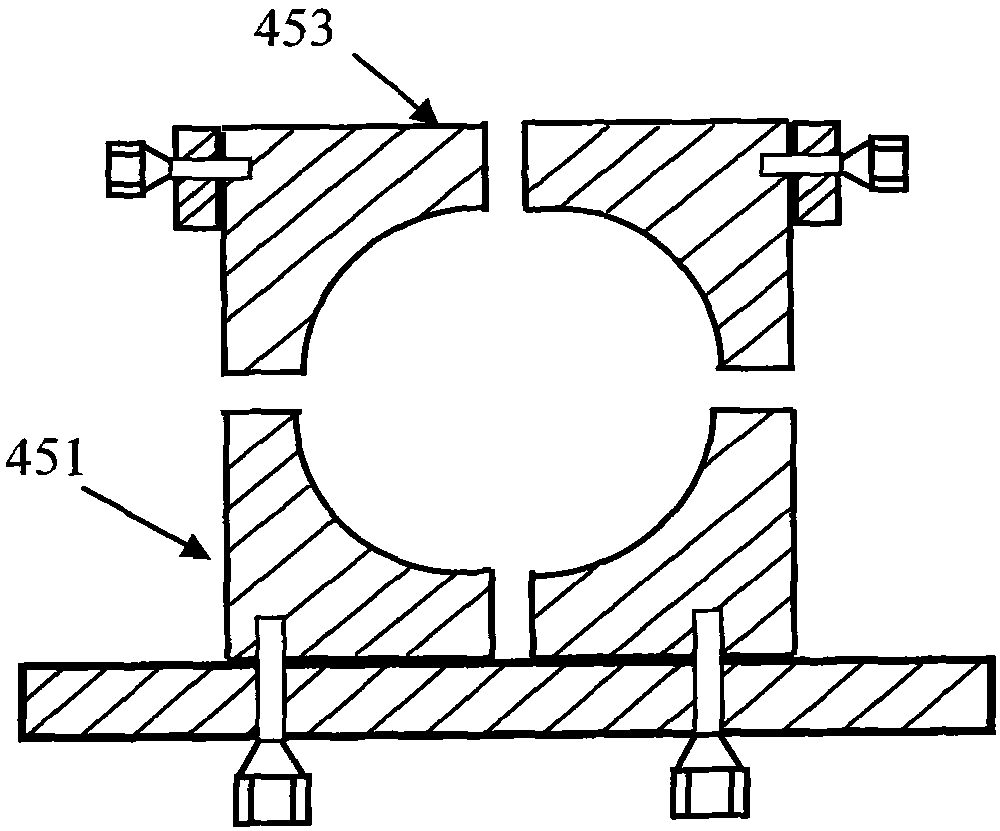

The invention discloses a loading and unloading manipulator which is characterized by comprising a rotary workpiece module, a loading module, a clamping module, an unloading module and a motion control system module, wherein the rotary workpiece module mainly comprises a bracket, a telescopic swinging cylinder, a connecting plate, a rotary motion device, a first linear slide rail and a rotary paw; the rotation of the telescopic swinging cylinder drives the rotary paw to rotate; the expansion and the contraction of the telescopic swinging cylinder drives the rotary paw to expand and contract along the first linear slide rail; the loading module mainly comprises a loading paw device, a tiny moving mechanism, a movable large cylinder and a second slide rail; the expansion and the contraction of the movable large cylinder drives the loading paw device to move forwards and backwards along an axis X under the driving of the tiny moving mechanism; the clamping module comprises two cylinders which are perpendicularly connected with each other; the vertical cylinder expands and contracts in an axis Z direction, and the horizontal cylinder expands and contracts in an axis Y direction, so as to clamp and release a workpiece; and the unloading module comprises an unloading pusher mechanism, an inclined plane delivery mechanism and an unloading conveyor belt.

Owner:HEBEI UNIV OF TECH

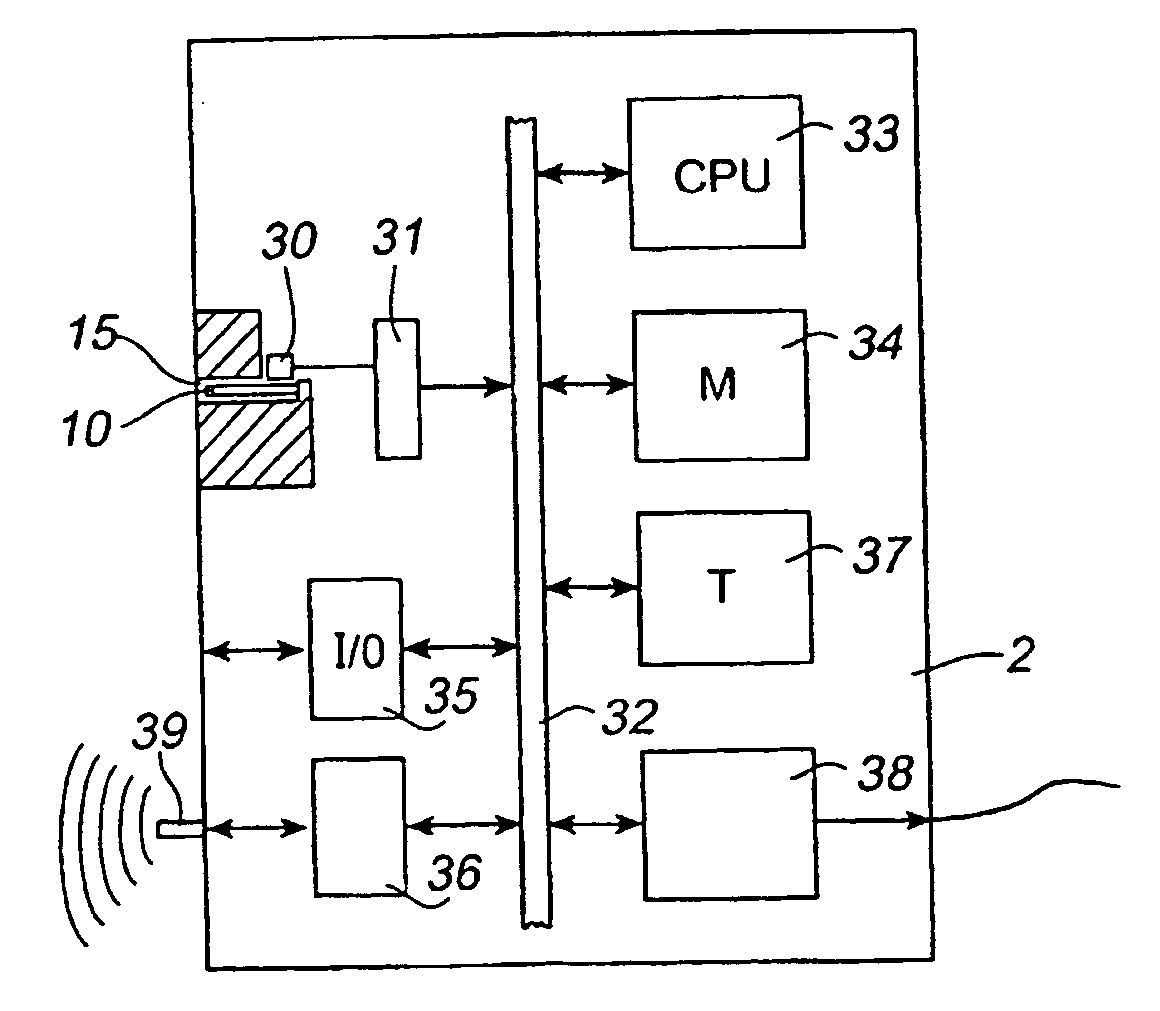

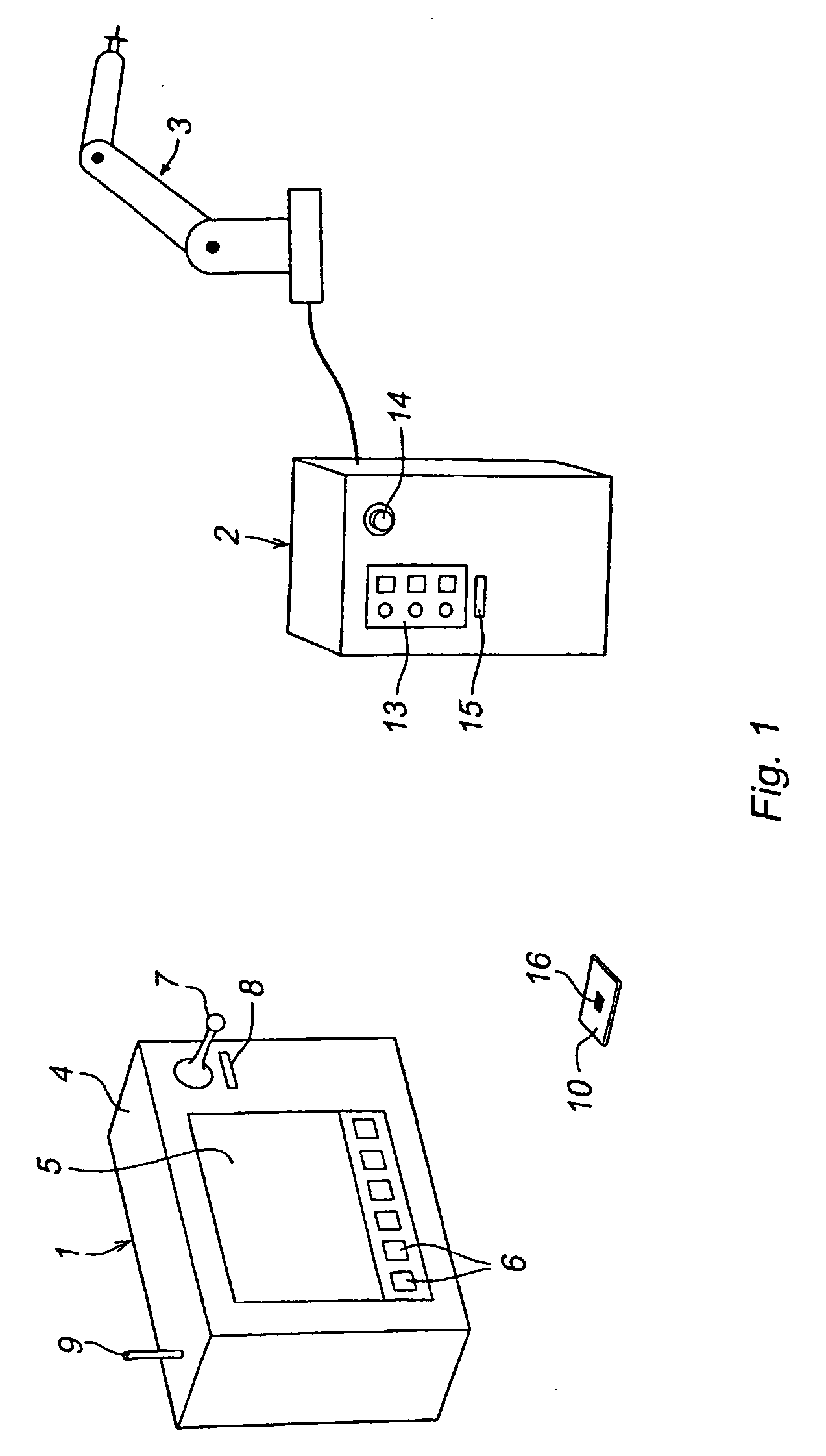

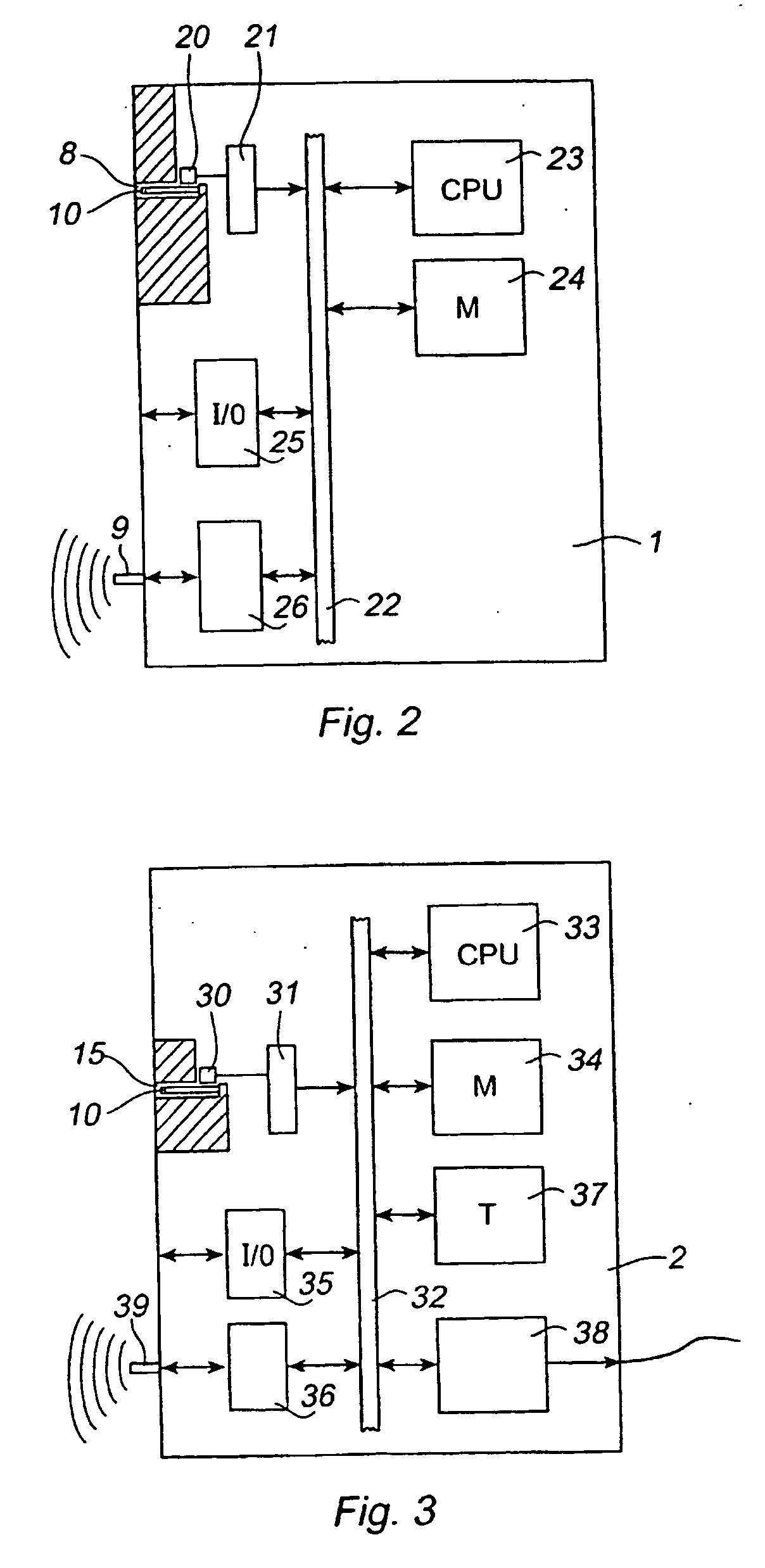

Industrial robot comprising a portable operating unit which a movable key device for identification of the robot

InactiveUS20040148058A1Mistakes due to the operator taking the wrong key device are preventedAvoid mistakesProgramme-controlled manipulatorComputer controlEmbedded systemManipulator

An industrial robot comprising a manipulator (3), a control unit (2) having means for automatically operating the manipulator, and a portable operating unit (1) having means for manually operating the manipulator. The robot further comprises a movable key device (10) carrying information about the identity of the robot and said portable operating unit (1) comprising a member (8) for receiving said movable key device and means for reading the robot identity from the key device.

Owner:ABB (SCHWEIZ) AG

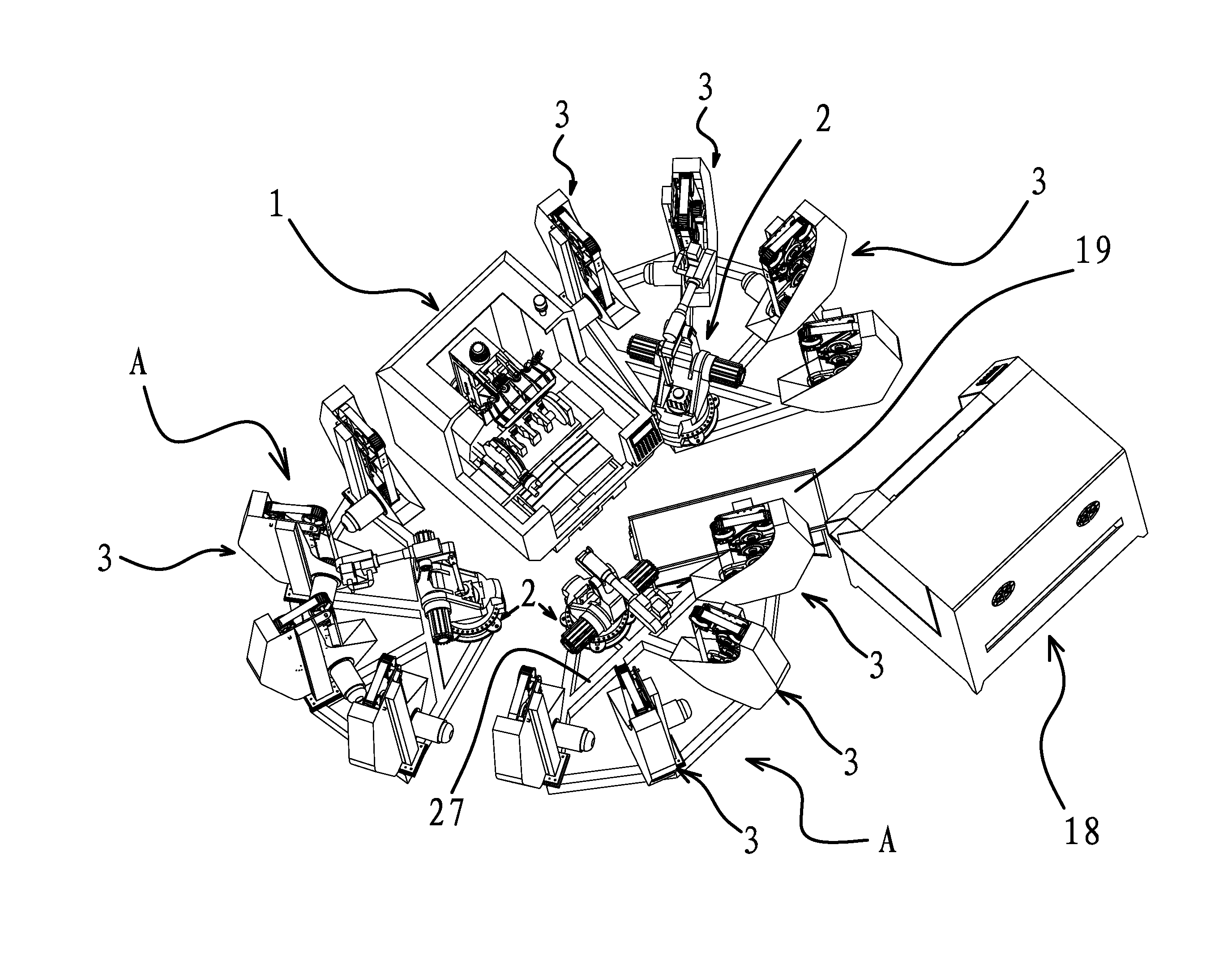

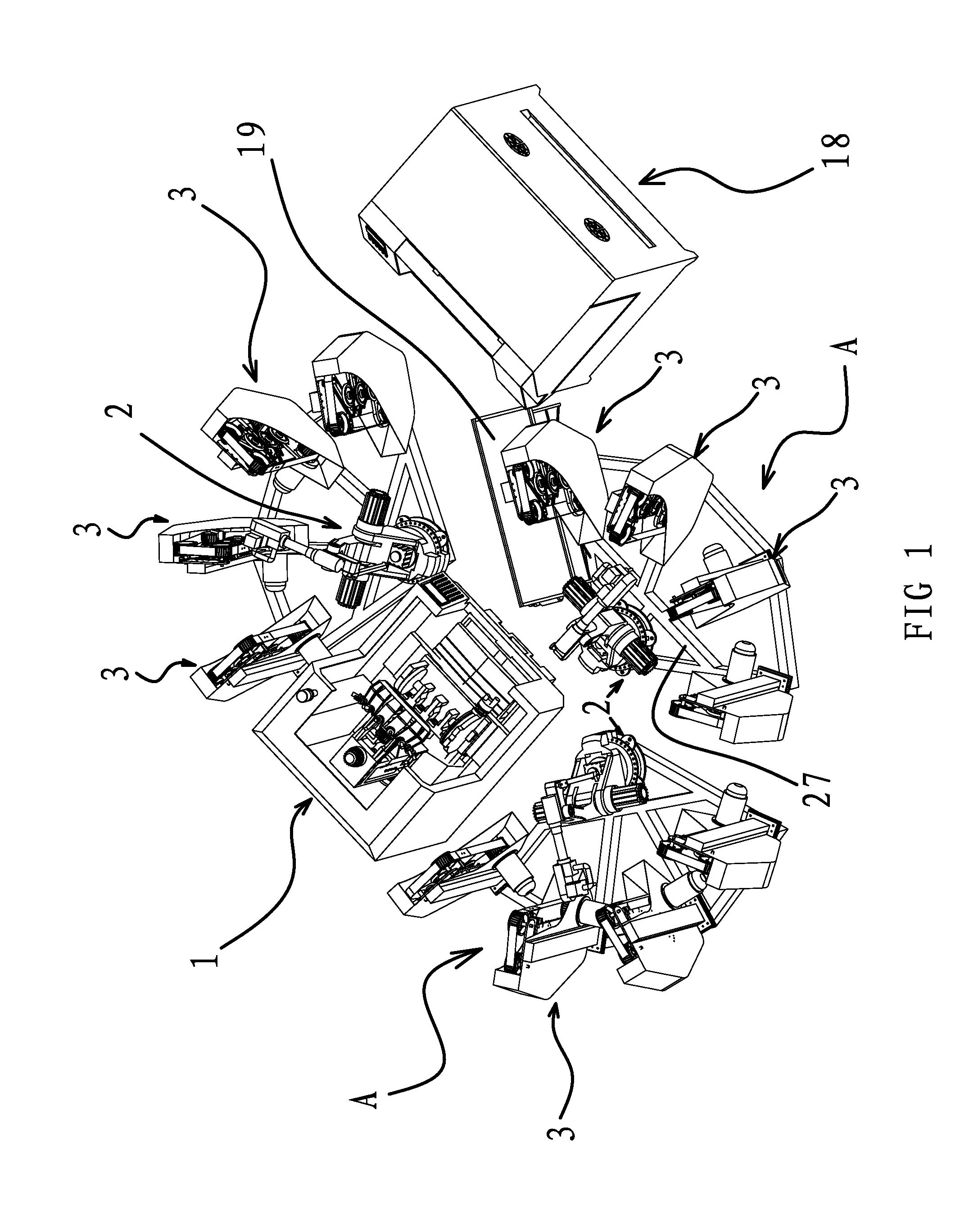

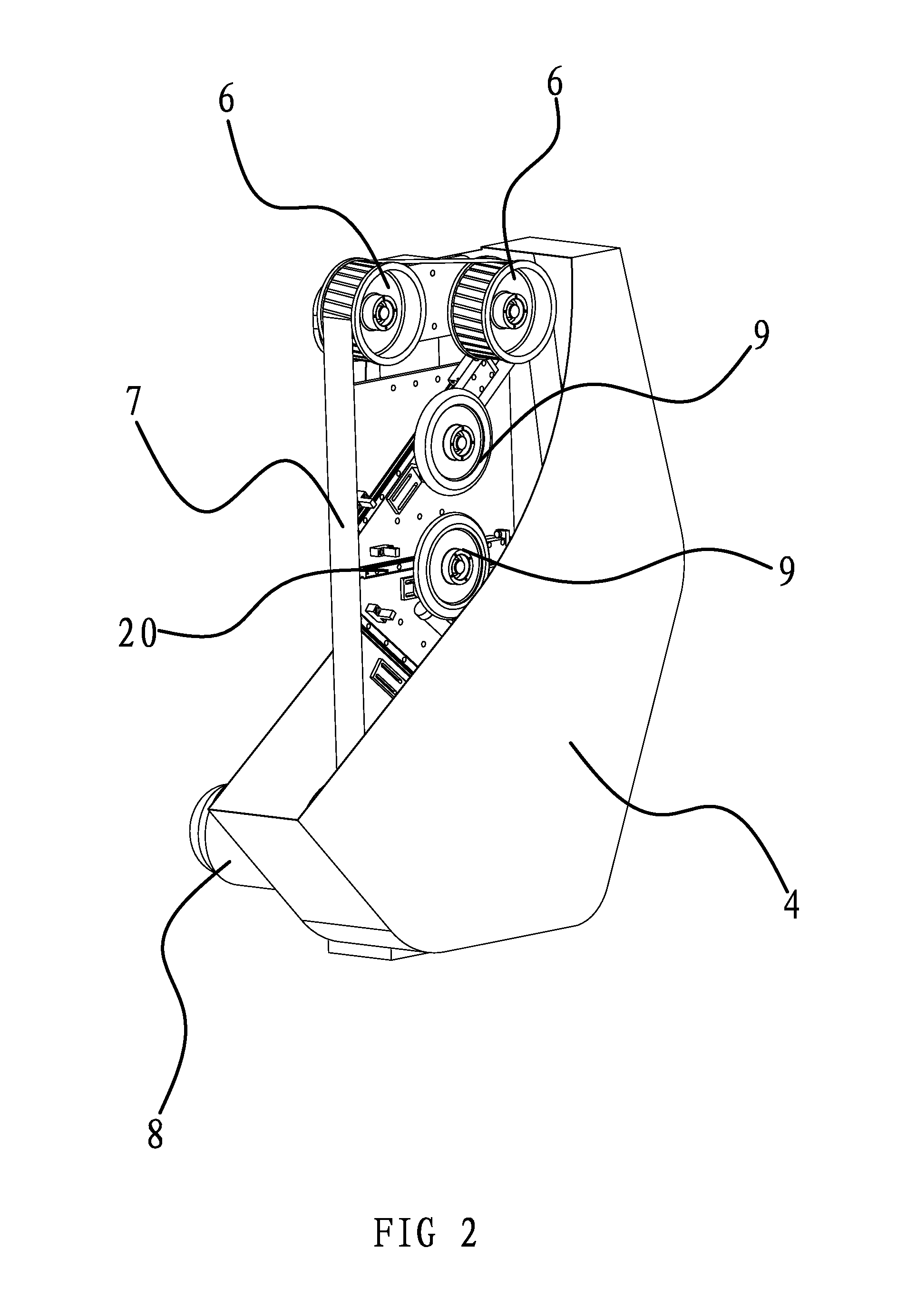

Surface Processing System for a Work Piece

InactiveUS20150044944A1Guaranteed to workImprove production efficiencyEdge grinding machinesBelt grinding machinesManipulatorMachining

The present invention provides a surface processing system for a work piece in the mechanical technical field. The system comprises at least one group of polishing units. A manipulator and several polishers with different polishing precisions are provided on the polishing units. The polishers are arranged around the manipulator in turn. The work piece could be moved by the manipulator between the processing center and the polishing units. The machined work piece is loaded by the manipulator for one time when the manipulator is located at the processing center. When the manipulator is located at the polishing units, the manipulator keeps holding the work piece and transfers the work piece in a preset sequence to each polisher corresponding to the polishing unit where the manipulator is located. The surface of work pieces having different wall thicknesses and complex surfaces could be processed in a large batch with a high efficiency.

Owner:TAIZHOU FEDERAL ROBOT TECH

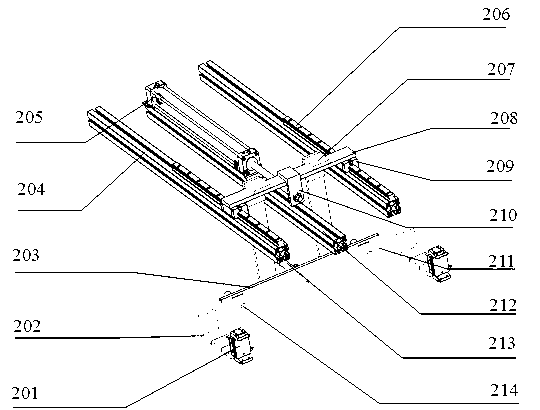

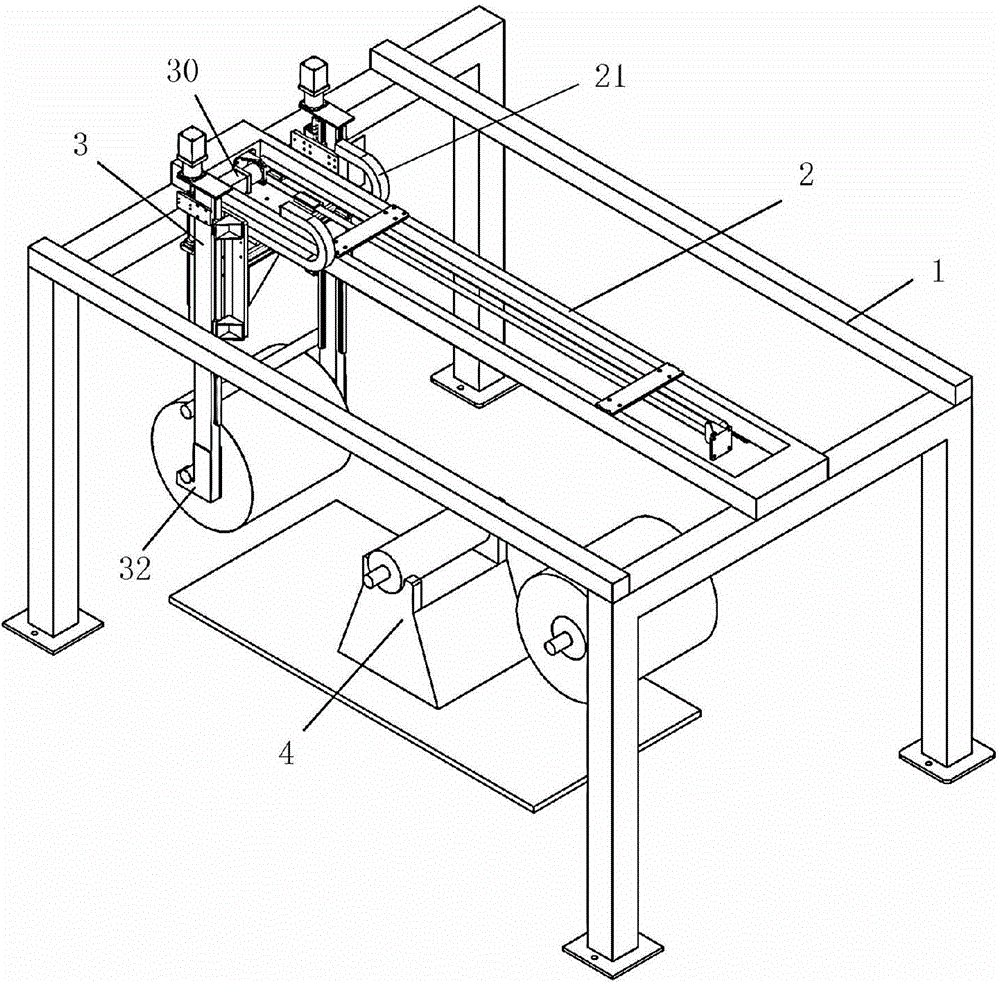

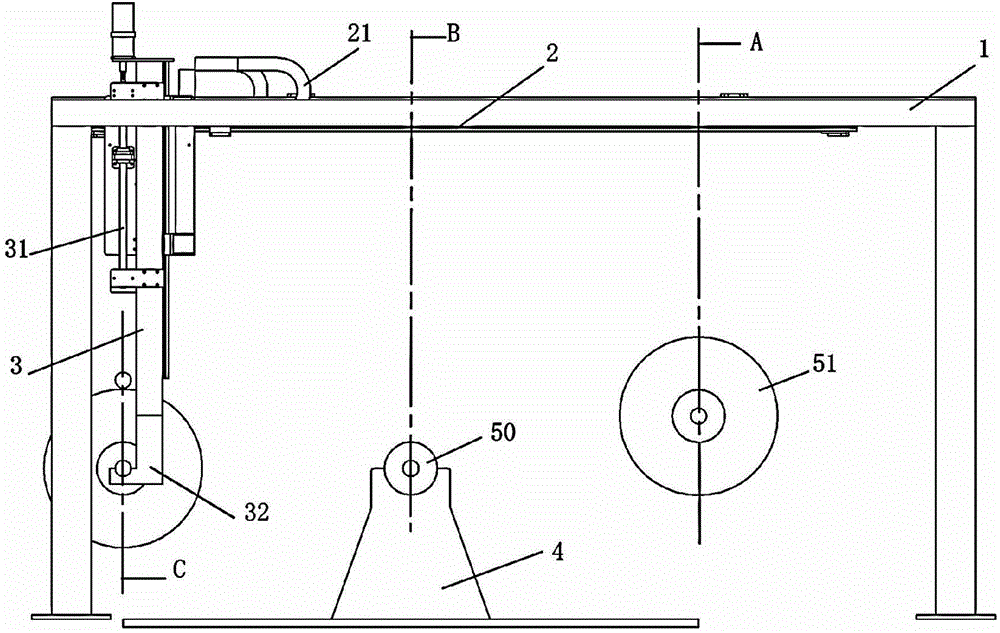

Transferring device and transferring method

ActiveCN104692113AImprove work efficiencyReduce processing costsConveyor partsRobot handControl engineering

The invention discloses a transferring device and a transferring method. The transferring device comprises a fixing rack, wherein the fixing rack is provided with a mechanical arm used for grabbing and placing material rollers, a horizontal driving device used for driving the guiding move of the mechanical arm in the horizontal direction and a vertical driving mechanism used for driving the mechanical arm to extend and retract in the vertical direction; the mechanical arm has a first station and a second station in the guiding move process in the horizontal direction; a third station used for temporarily storing idle material rollers is arranged between the first station and the second station on the fixing rack; a bracket used for supporting the idle material rollers is arranged at a part corresponding to the third station on the fixing rack. According to the transferring device, the third station is arranged between the first station and the second station; two material rollers can be operate at the same time; the working efficiency is improved; the processing cost is reduced.

Owner:CAMALUOYANGELECTROMECHANIC

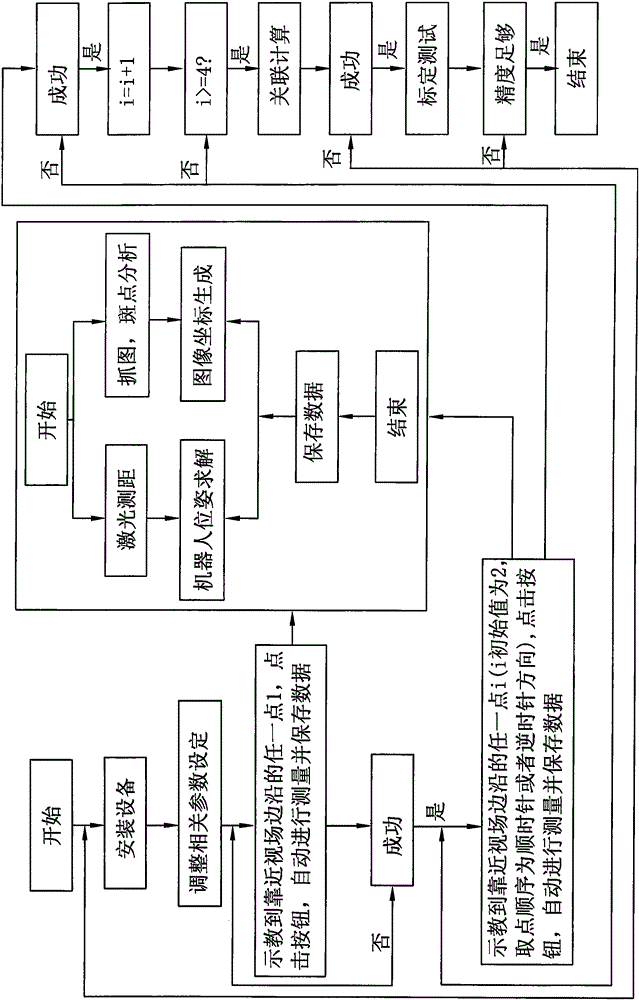

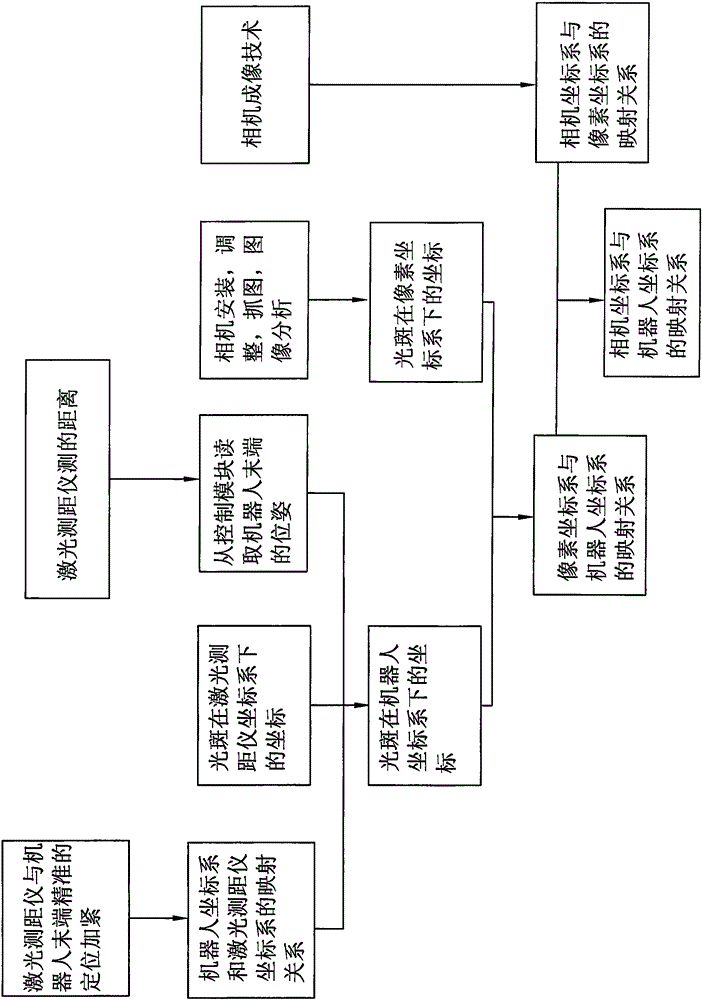

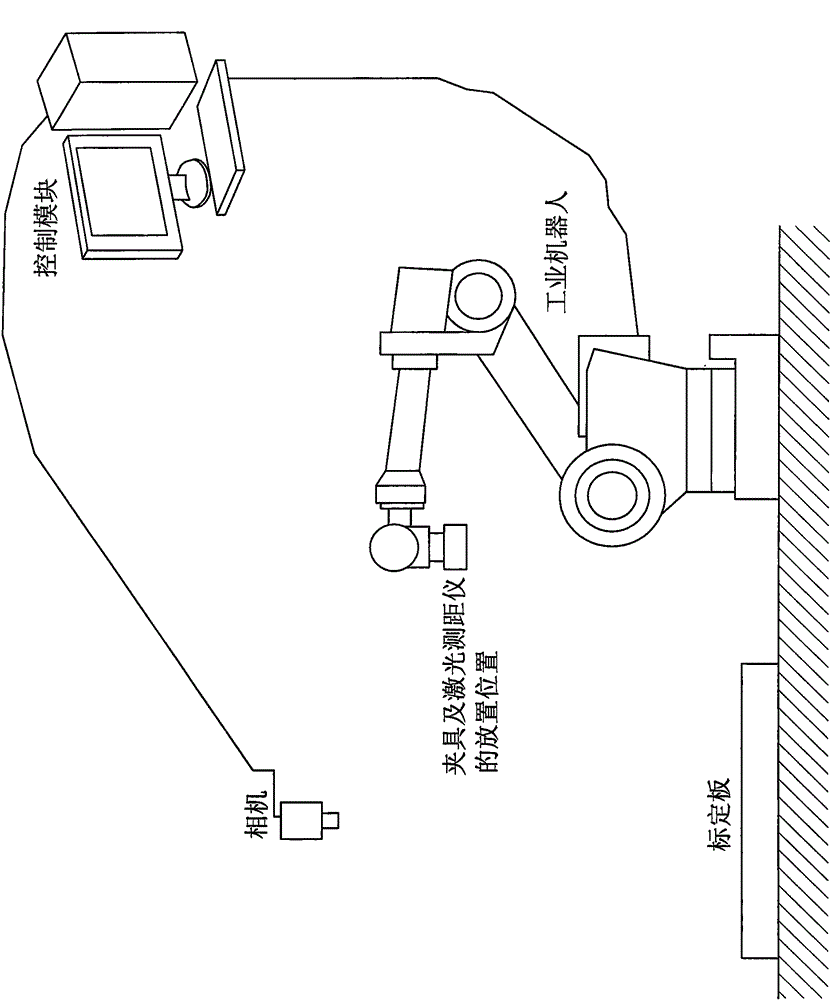

Robot hand-eye calibration method based on laser range finding

InactiveCN105014678AReduce operating errorsEasy to operateElectromagnetic wave reradiationManipulatorLaser rangingRobot hand

The invention discloses a robot hand-eye calibration method based on laser range finding. According to the method, by calculating the coordinates of laser spots under a laser range finder coordinate system, the coordinates of the laser spots under a robot coordinate system are calculated by means of the mapping relation between the laser range finder coordinate system and the robot coordinate system; by capturing pictures of the laser spots on a calibration board through a camera, the coordinates of the laser spots under a pixel coordinate system are calculated, and therefore the mapping relation between the pixel coordinate system and the robot coordinate system is calculated; the mapping relation between a camera coordinate system and the pixel coordinate system is obtained by means of parameters of the camera; and then the mapping relation between the camera coordinate system and the robot coordinate system is calculated according to the spatial switching relation. The method is carried out by emitting the laser spots to the surface of an object through a laser range finder, coordinate information of measurement points is obtained without the need of making contact with the object, in this way, operating errors are reduced, operation is easier, precision is high, manual participation is not needed in a calibration process, and automation and intellectualization are achieved.

Owner:LOTES SHENZHEN

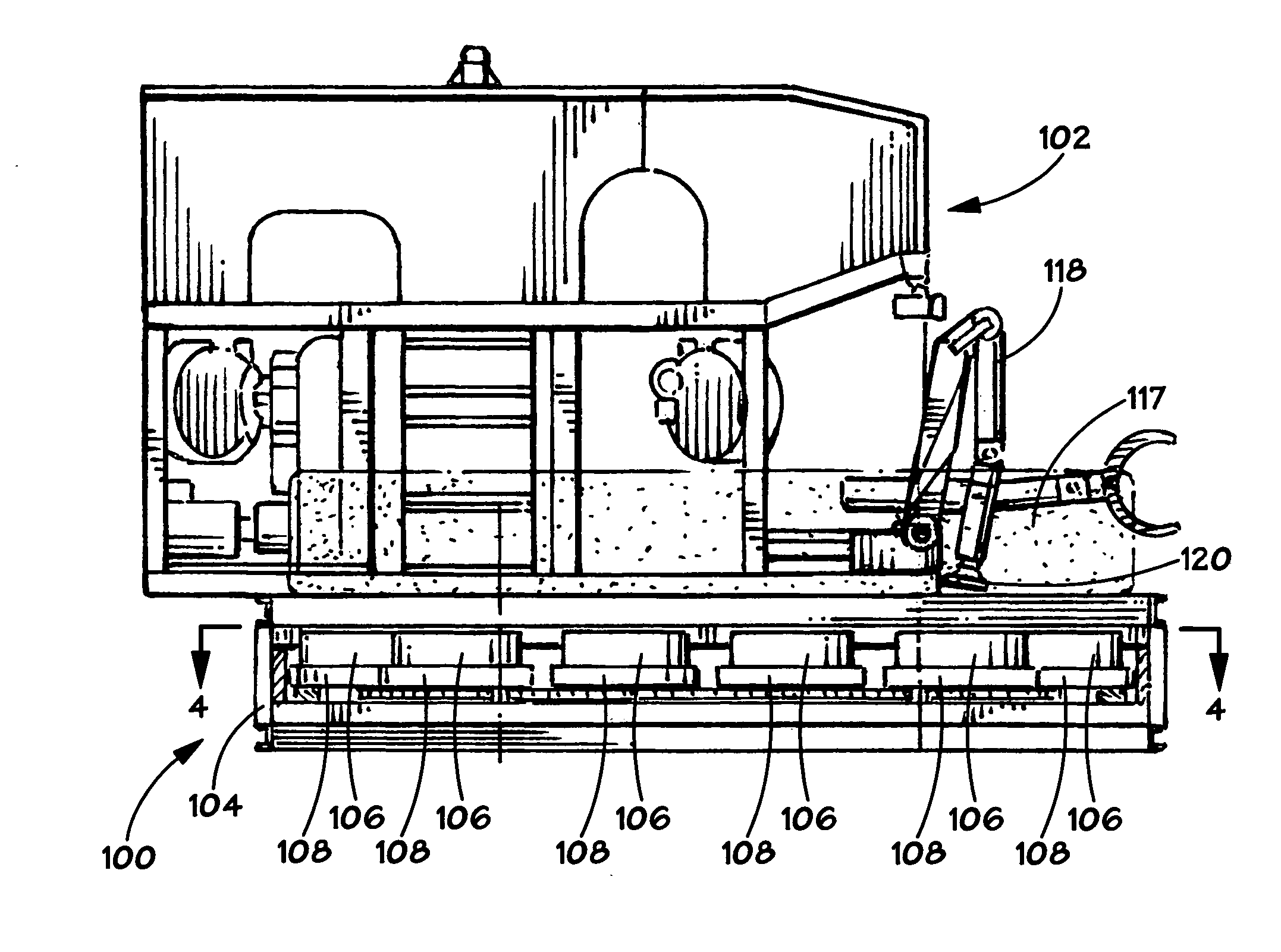

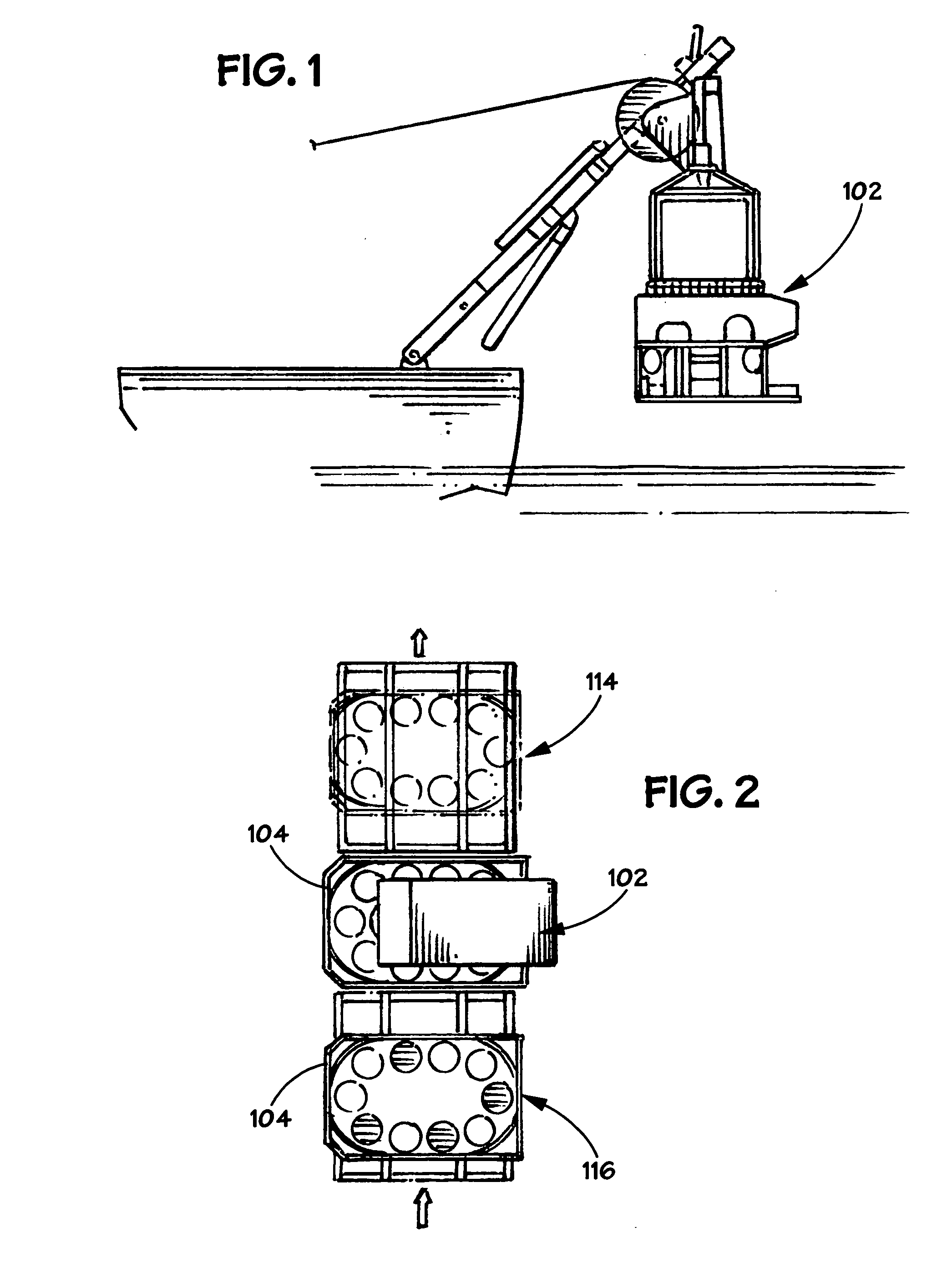

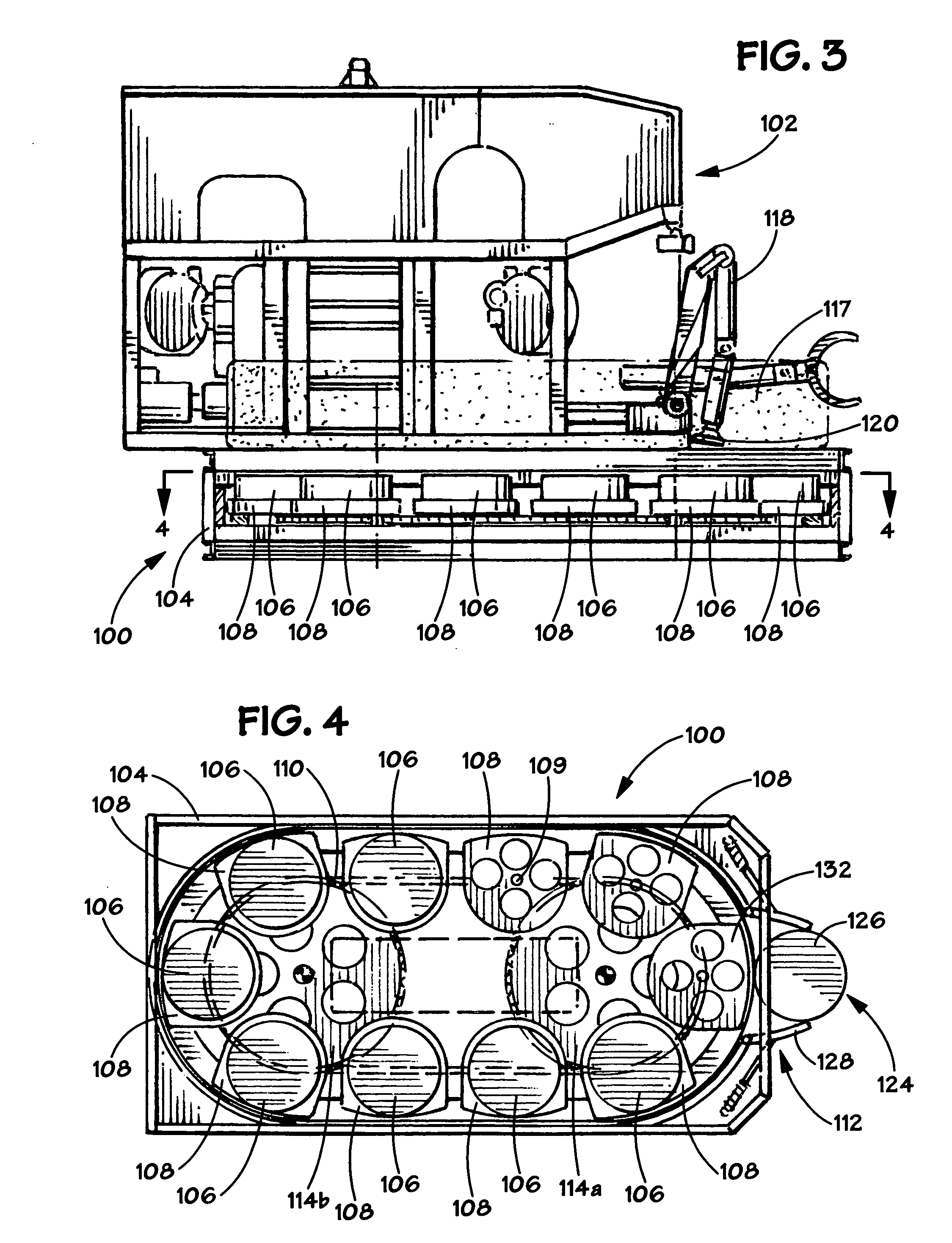

Method and apparatus for installing a sensor array

InactiveUS20050155814A1Sonic/ultrasonic/infrasonic transmissionSeismic energy generationSensor arrayActuator

An apparatus and method is provided for transporting, installing, retrieving, and replacing a sensor array of individual sensor pods at a geographically remote location, such as on the sea floor. The apparatus consists of a remotely operated vehicle (ROV), a carousel attached to the ROV, a pod ejector mechanism attached to the carousel, and a manipulator with a manipulator end effector attached to the ROV. The carousel contains a plurality of sensor pod holders, where each sensor pod holder is capable of holding a sensor pod. The pod ejector mechanism is capable of discharging a fresh sensor pod, while the manipulator end effector is capable of lifting a depleted sensor pod and placing the depleted sensor pod in an empty sensor pod holder in the carousel.

Owner:SAIPEM AMERICA

Device for robot-assisted surgery

Owner:AVATERAMEDICAL GMBH

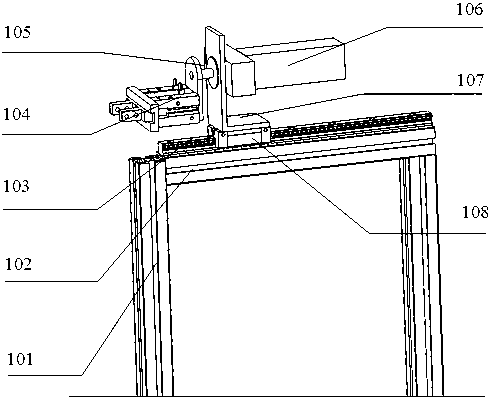

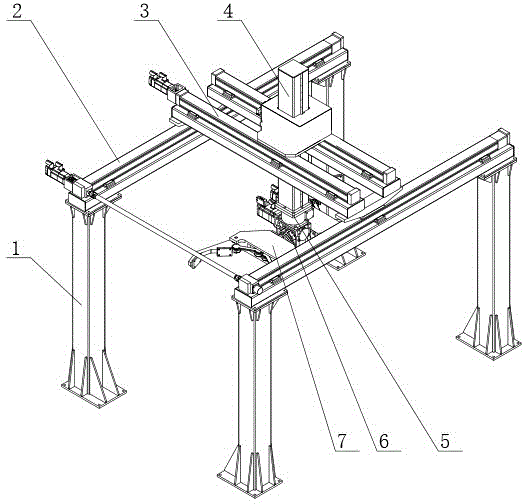

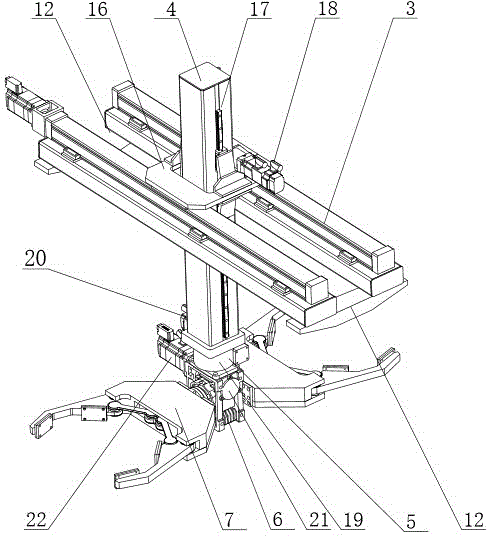

Five-axis hub transfer robot and clamping manipulator

ActiveCN104444360AFlexible handlingReduce material preparation waiting timeConveyor partsRobot handControl engineering

The invention discloses a five-axis hub transfer robot and a clamping manipulator. An X-axis drive system is mounted on a truss. A Y-axis drive system is mounted on the X-axis drive system in a crossing manner through an X-Y-axis connecting plate. A Z-axis drive system is vertically mounted on the Y-axis drive system through a Y-Z-axis connecting plate. The X-axis drive system, the Y-axis drive system and the Z-axis drive system are mutually orthogonal, and an X-Y-Z rectangular-coordinate robot is formed. A C-axis drive system and an A-axis drive system are disposed in order at the bottom of the Z-axis drive system. The C-axis drive system is connected with the A-axis drive system through a C-A-axis connecting flange. An output shaft of the A-axis drive system is connected with the clamping manipulator. The five-axis hub transfer robot and the clamping manipulator have the advantages that operations such as carrying, feeding, discharging, turning and interchanging among different production lines are automated for aluminum alloy hubs, labor intensity is greatly reduced, product quality is ensured, production efficiency is improved, and unattended automated production is achieved for different hub processing units on one hub production line.

Owner:HUST WUXI RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com