Industrial robot-based assembly method and device of piston, piston pin and connecting rod

An industrial robot and assembly device technology, applied in the field of piston pin and connecting rod assembly, and engine piston, can solve the problems of poor uniformity, low efficiency, high labor intensity, etc., to improve flexibility, improve reliability, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

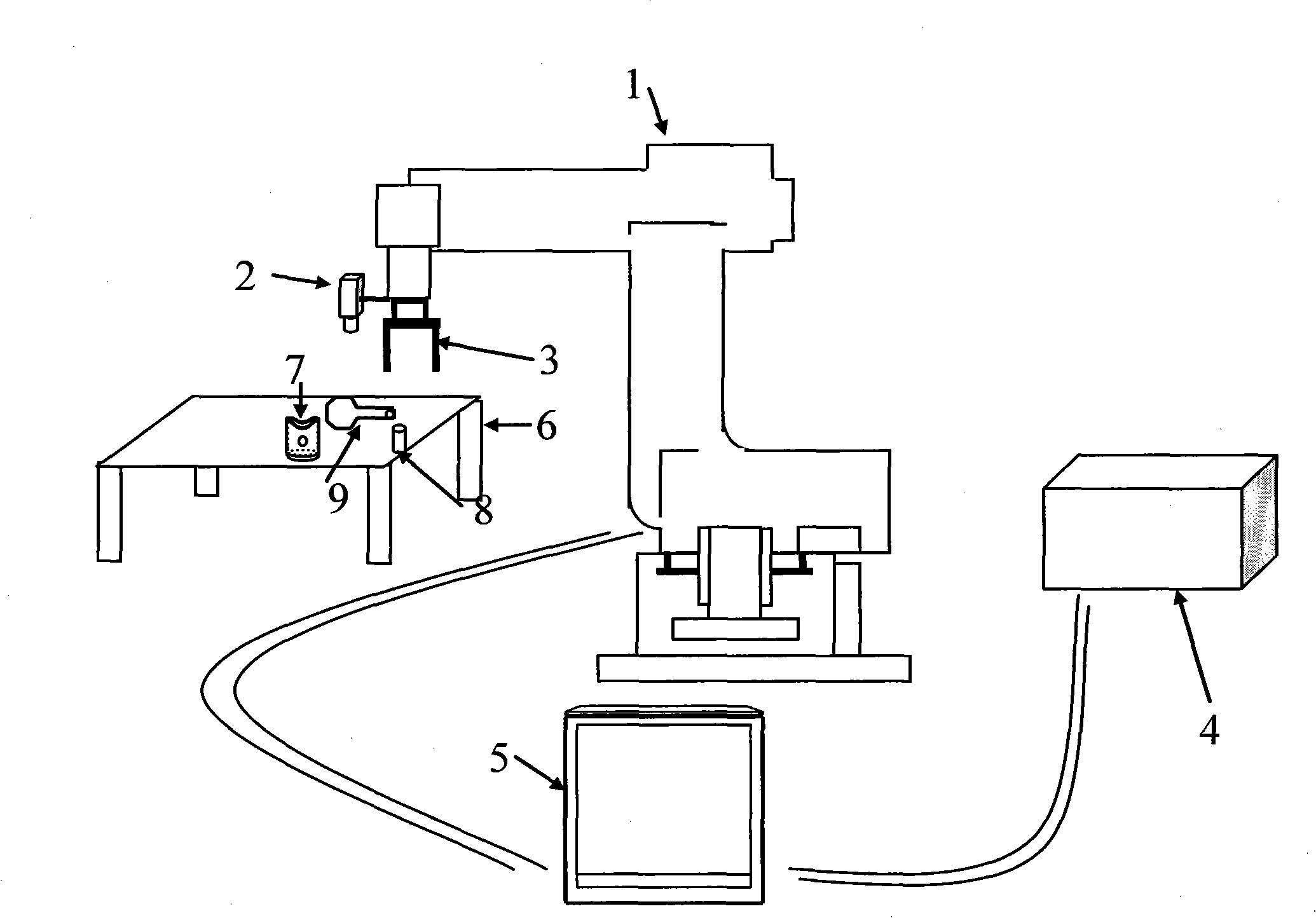

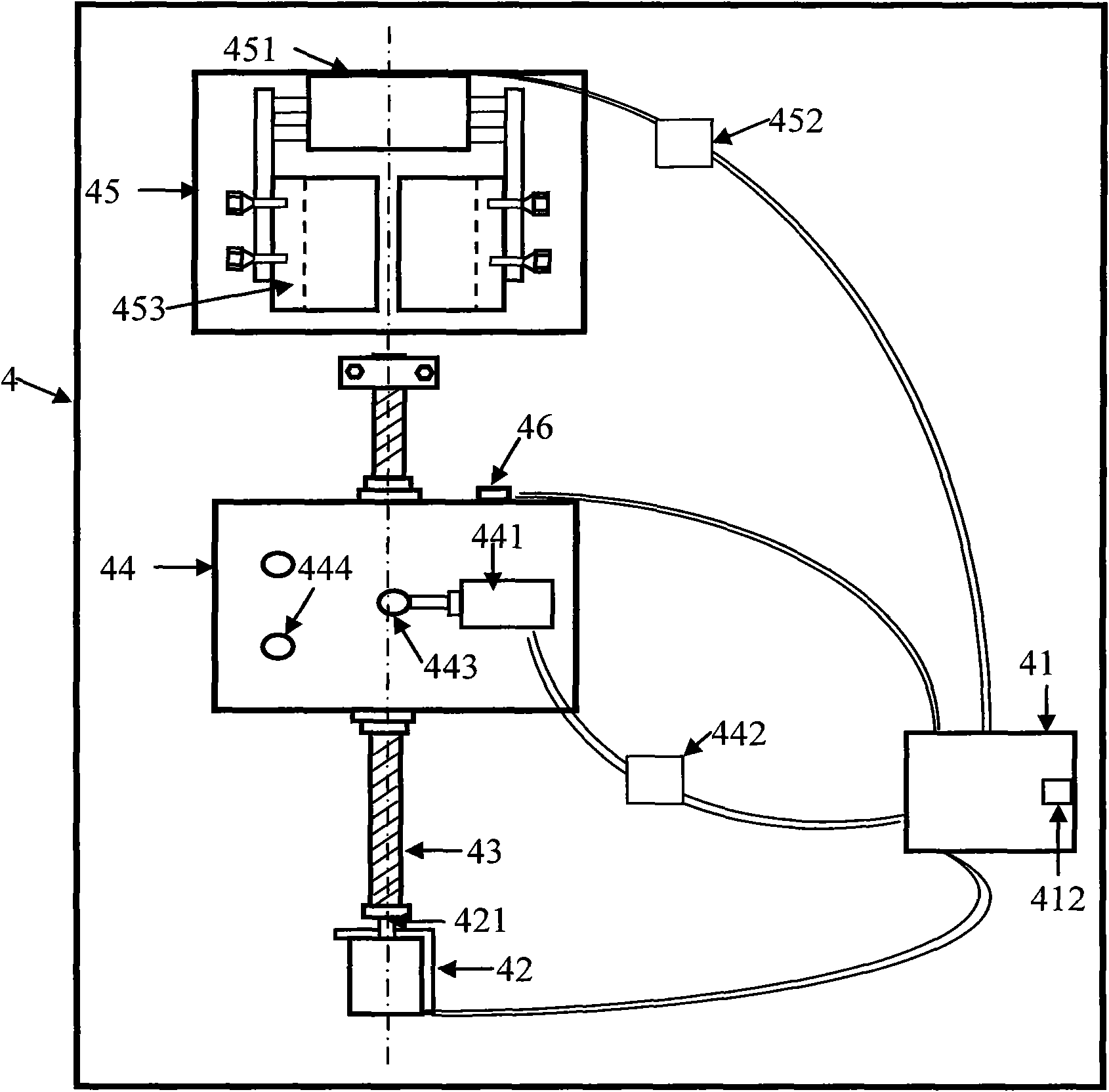

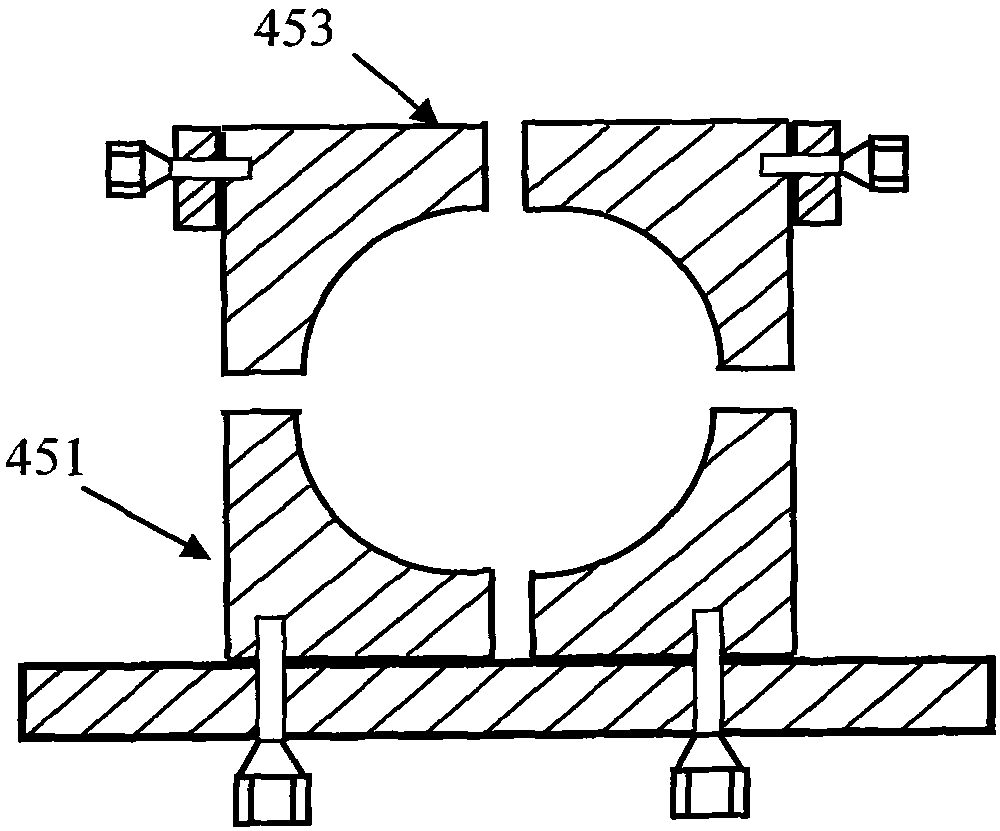

[0052] like figure 1 As shown, the automatic assembly device for engine pistons, piston pins and connecting rods based on industrial robots includes an industrial robot 1 , a visual camera 2 , a manipulator 3 , an intelligent assembly platform 4 , and a computer 5 . The visual camera 2 is installed on the industrial robot 1 and is used to collect images of the piston 7 , the piston pin 8 and the connecting rod 9 placed on the workbench 6 . The mechanical claw 3 is installed at the end of the industrial robot 1, and is used for grasping and assembling the piston 7, the piston pin 8, and the connecting rod 9. The data end of industrial robot 1 is connected with the data end of the data communication unit 54 of computer 5, and industrial robot 1 is used for carrying out data exchange between computer 5; The video signal line of visual camer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com