Patents

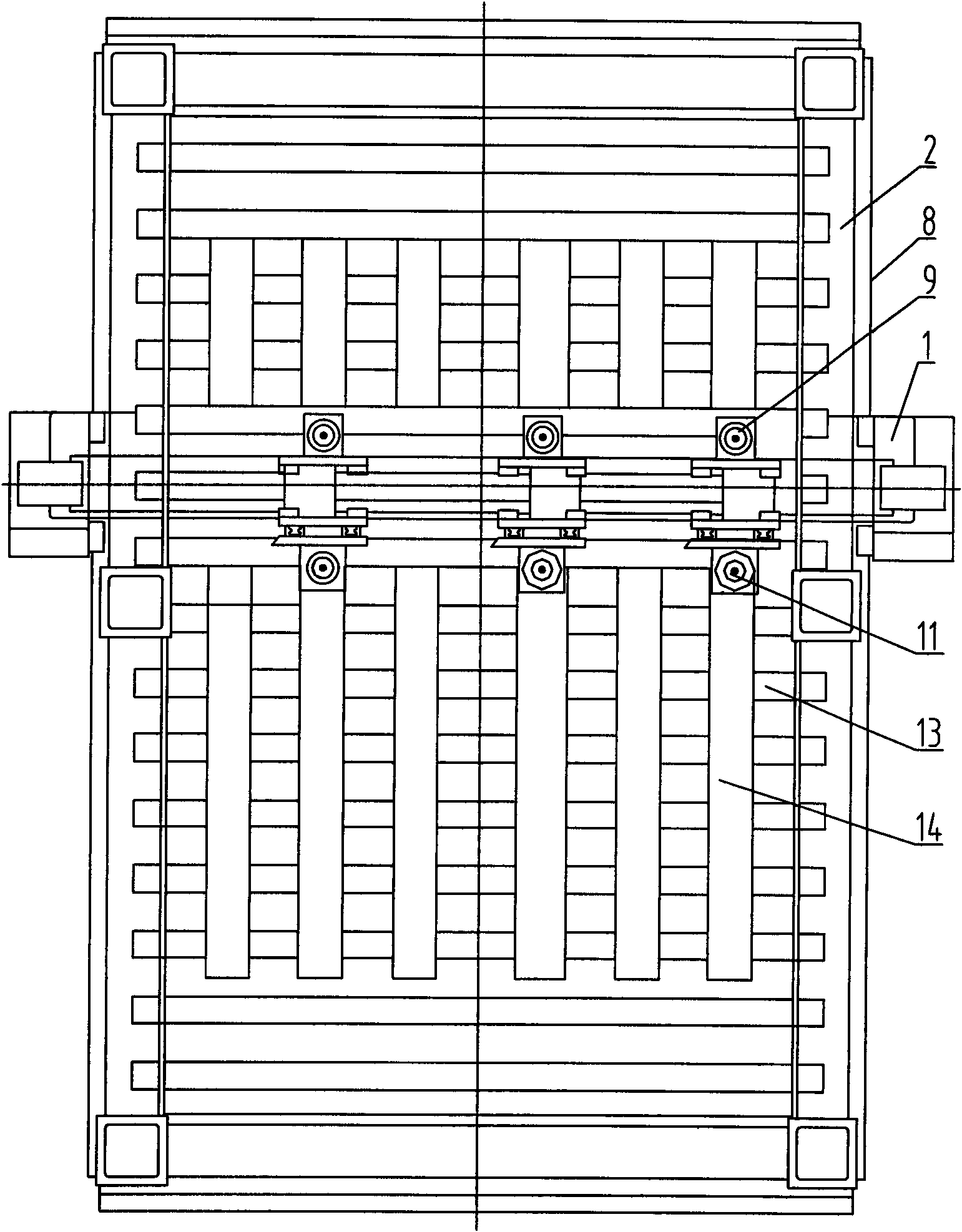

Literature

5570 results about "Portal frame" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Portal frame structures are designed to span between supports and rely on fixed joints with moment resisting capacity where vertical supports connect to horizontal beams or trusses. Portal frame structures can be constructed using a variety of materials and methods. These include steel, reinforced concrete and laminated timber such as glulam. The connections between the columns and the rafters are designed to be moment-resistant, i.e. they can carry bending forces. "They were first developed in the 1960s, and have now become the most common form of enclosure for spans of 20 to 60 m"

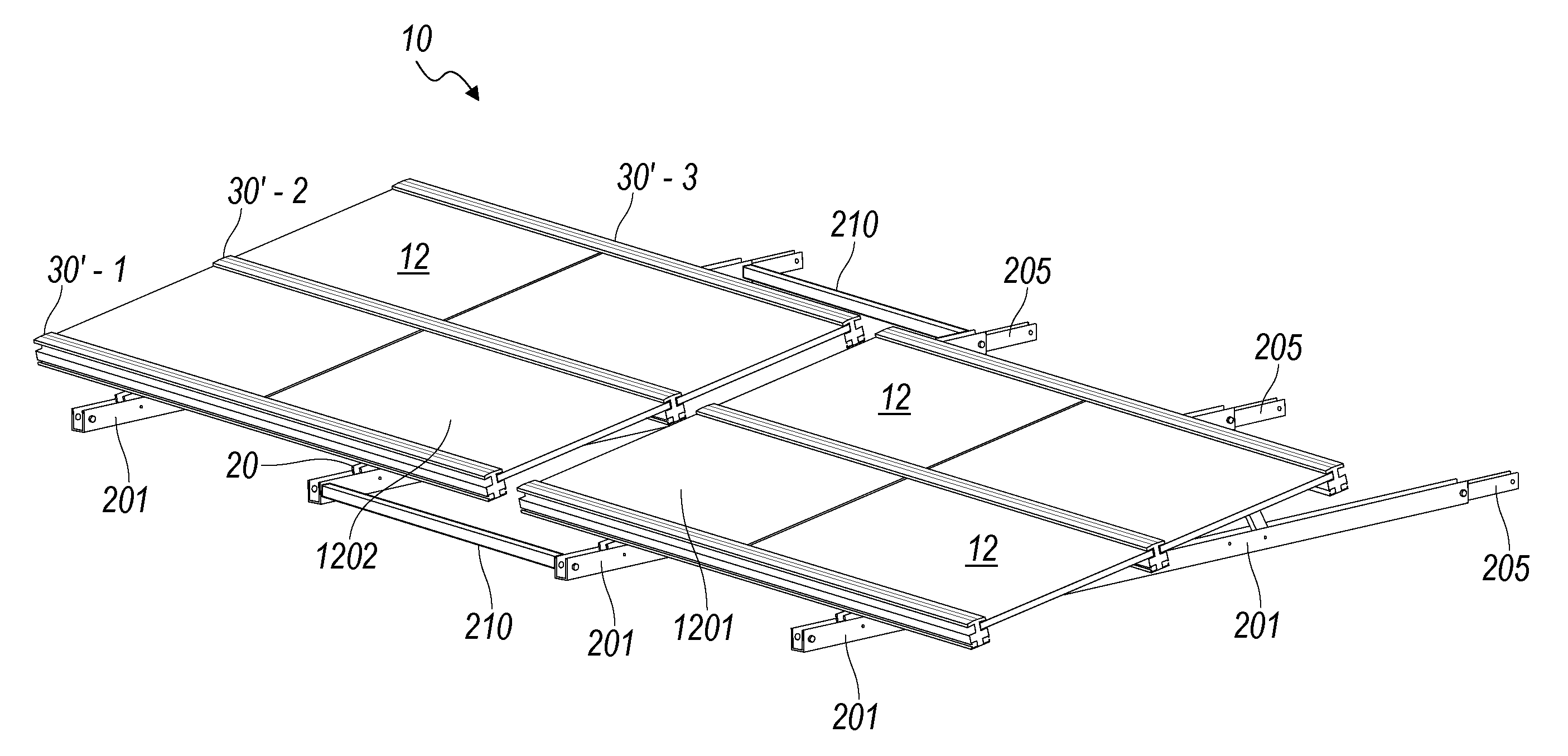

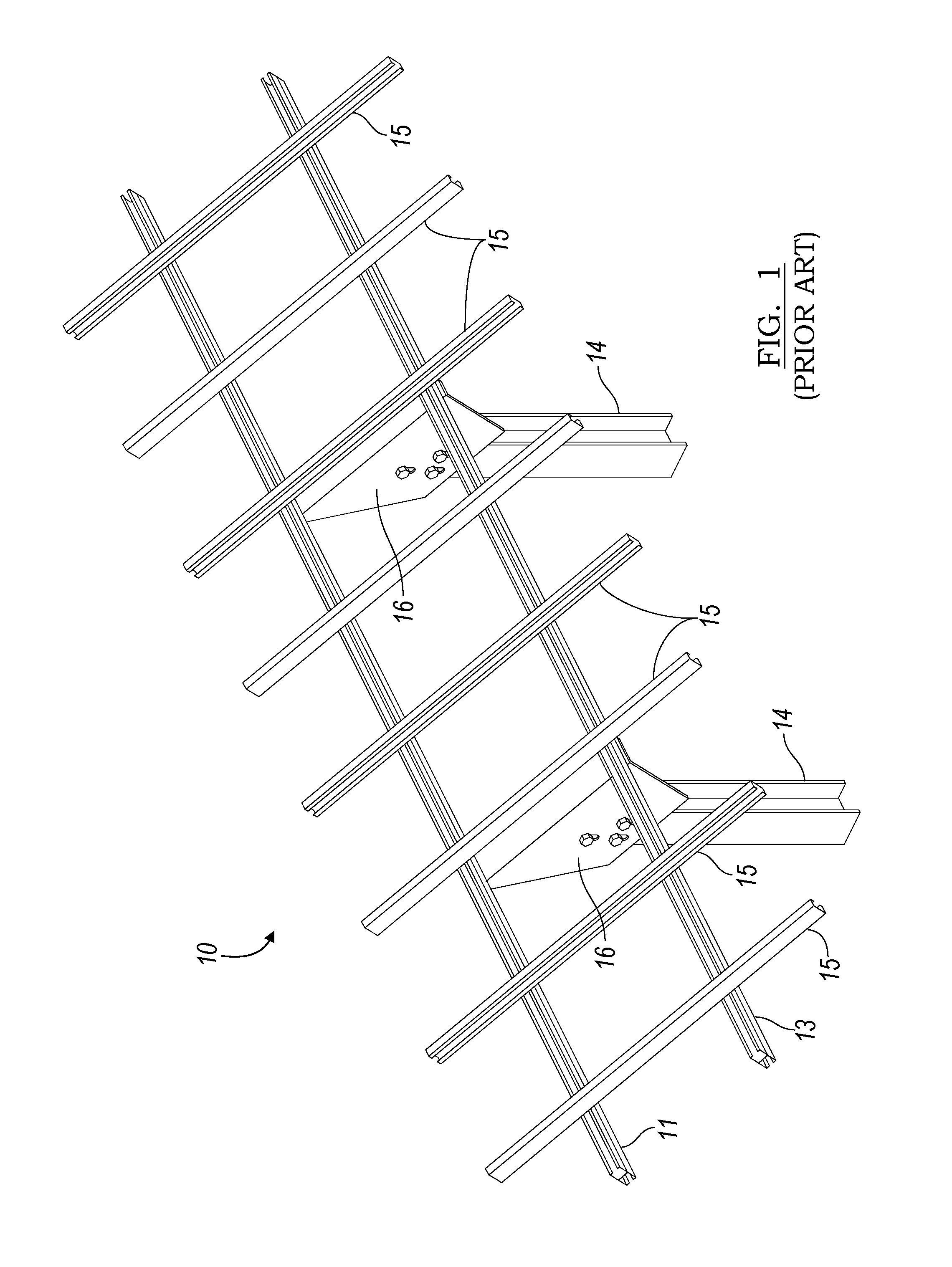

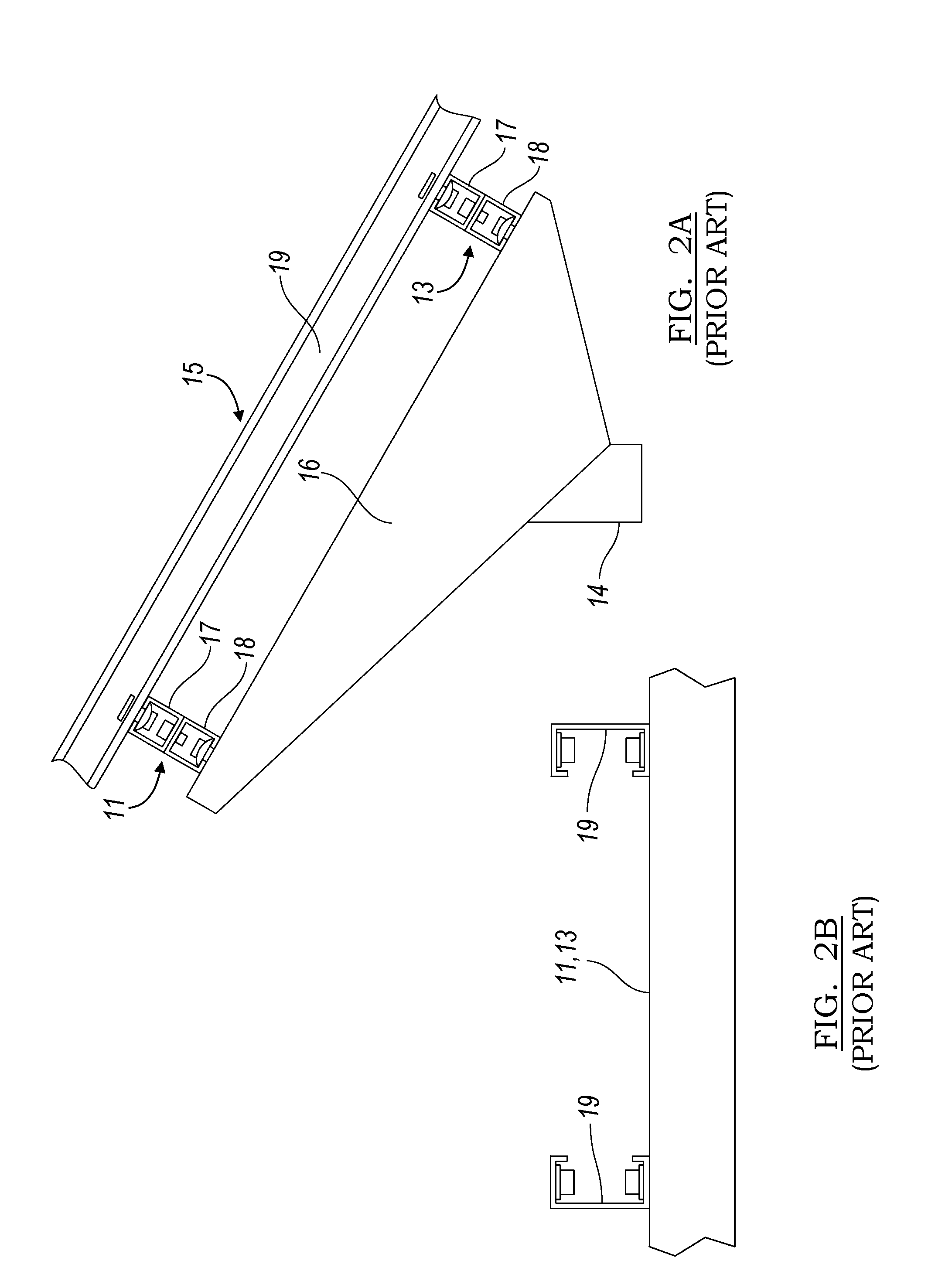

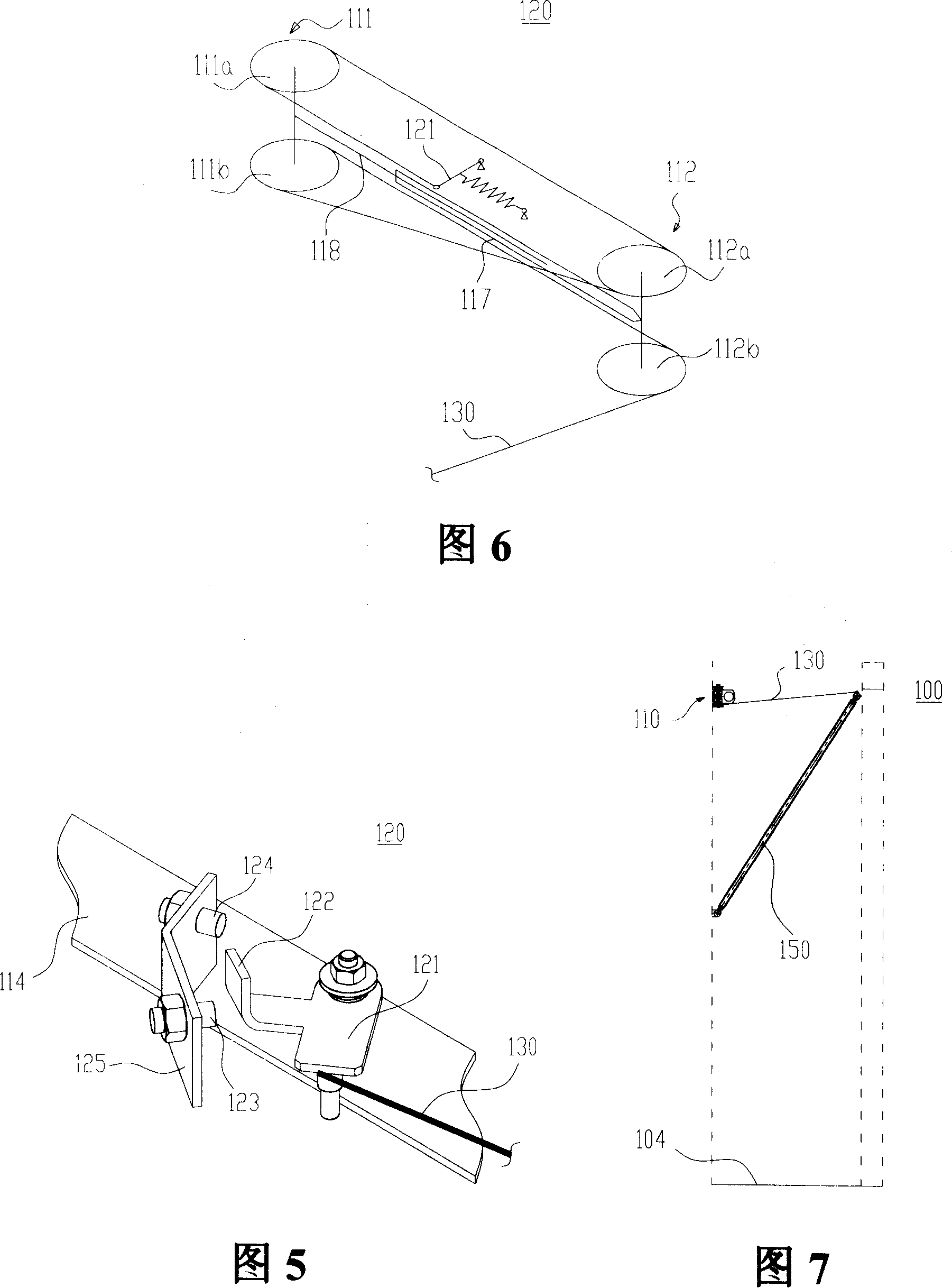

Support System for Solar Panels

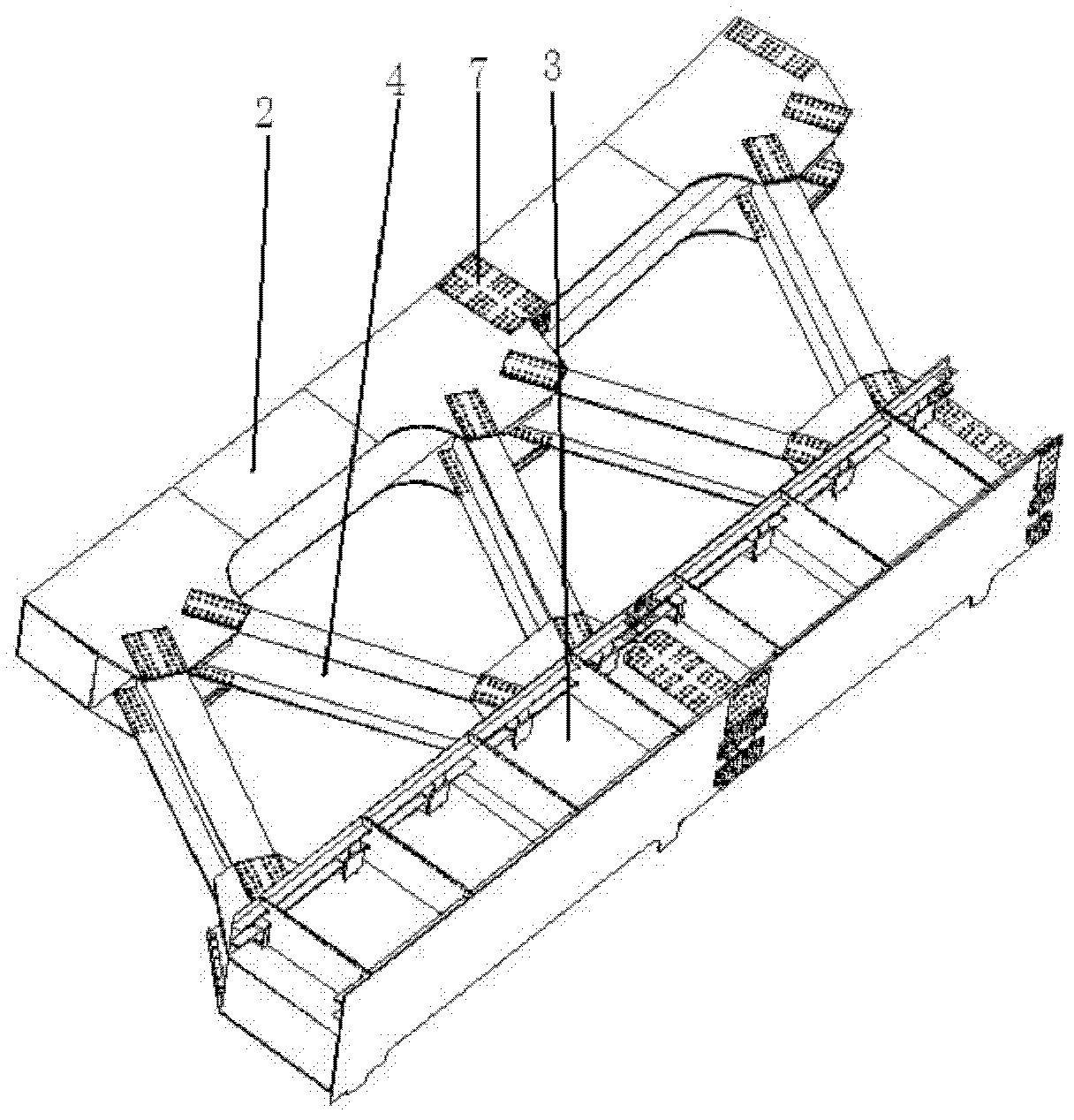

ActiveUS20100236183A1Easy to deployEasy to removePhotovoltaic supportsSolar heating energySupporting systemBraced frame

Precise parameters are maintained in a support system for solar panels or other panel-like structures through use of a collapsible folding, support frame which is preassembled to precise tolerances at a convenient staging site before being collapsed for shipment. Installation on flat roofs is also facilitated through the use of a roof interface frame which rotatably supports the panel support frame of the support system and folds along with it at the assembly, staging site.

Owner:NORTHERN STATES METALS

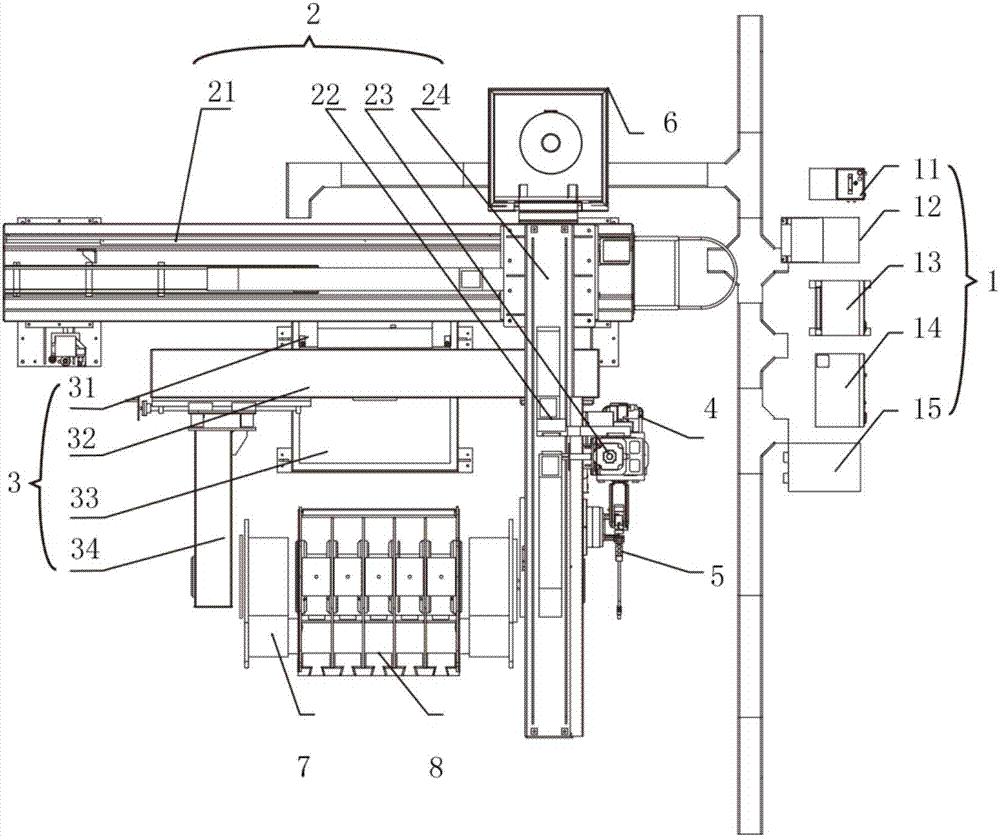

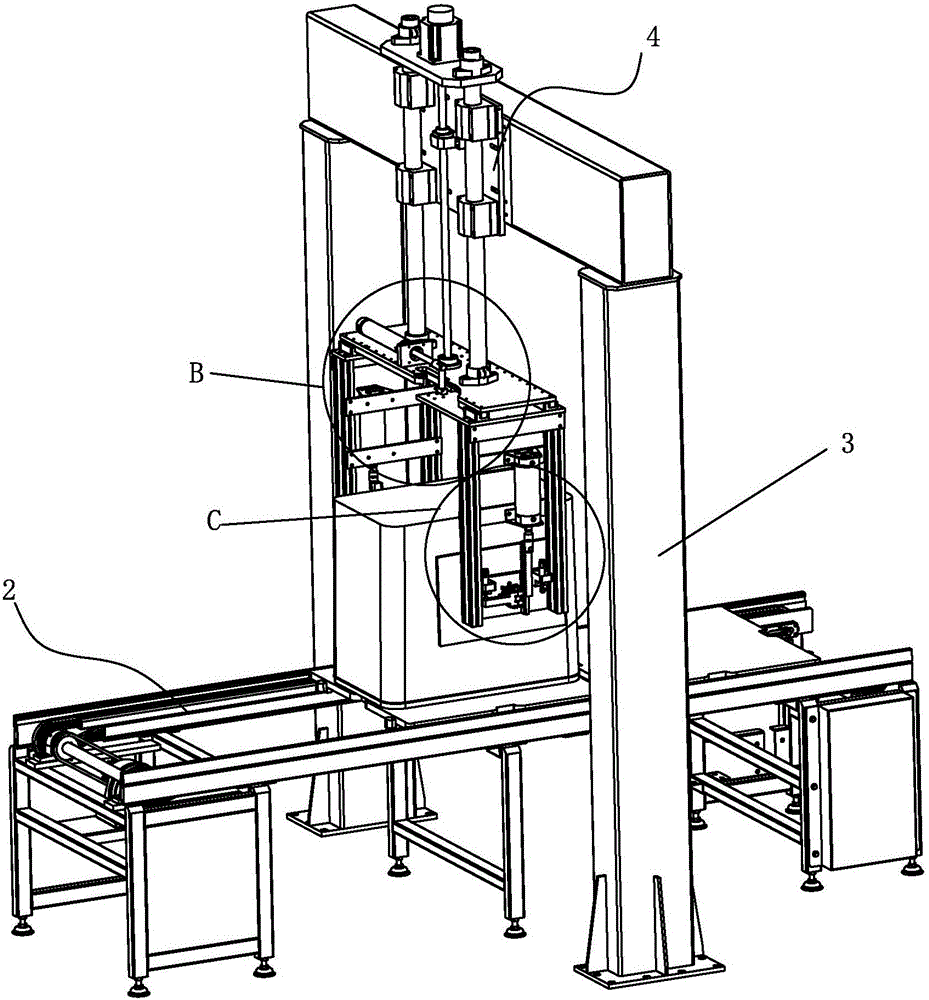

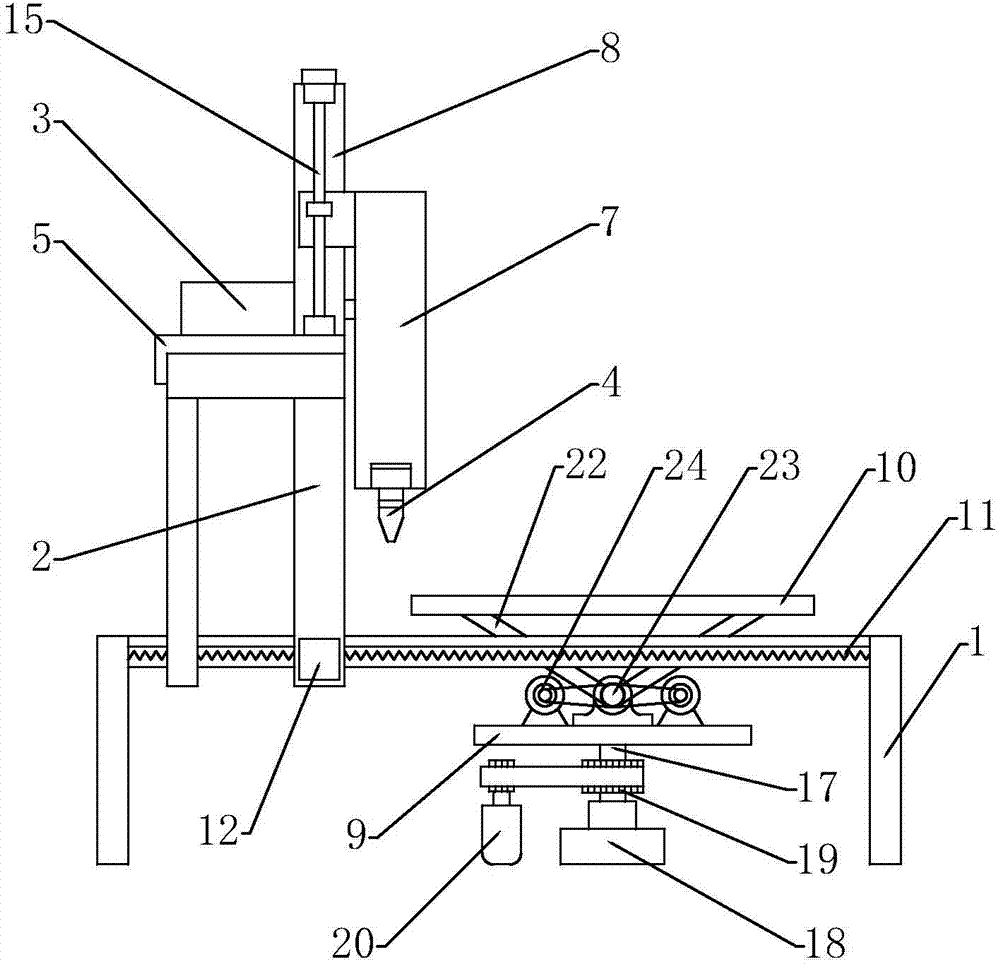

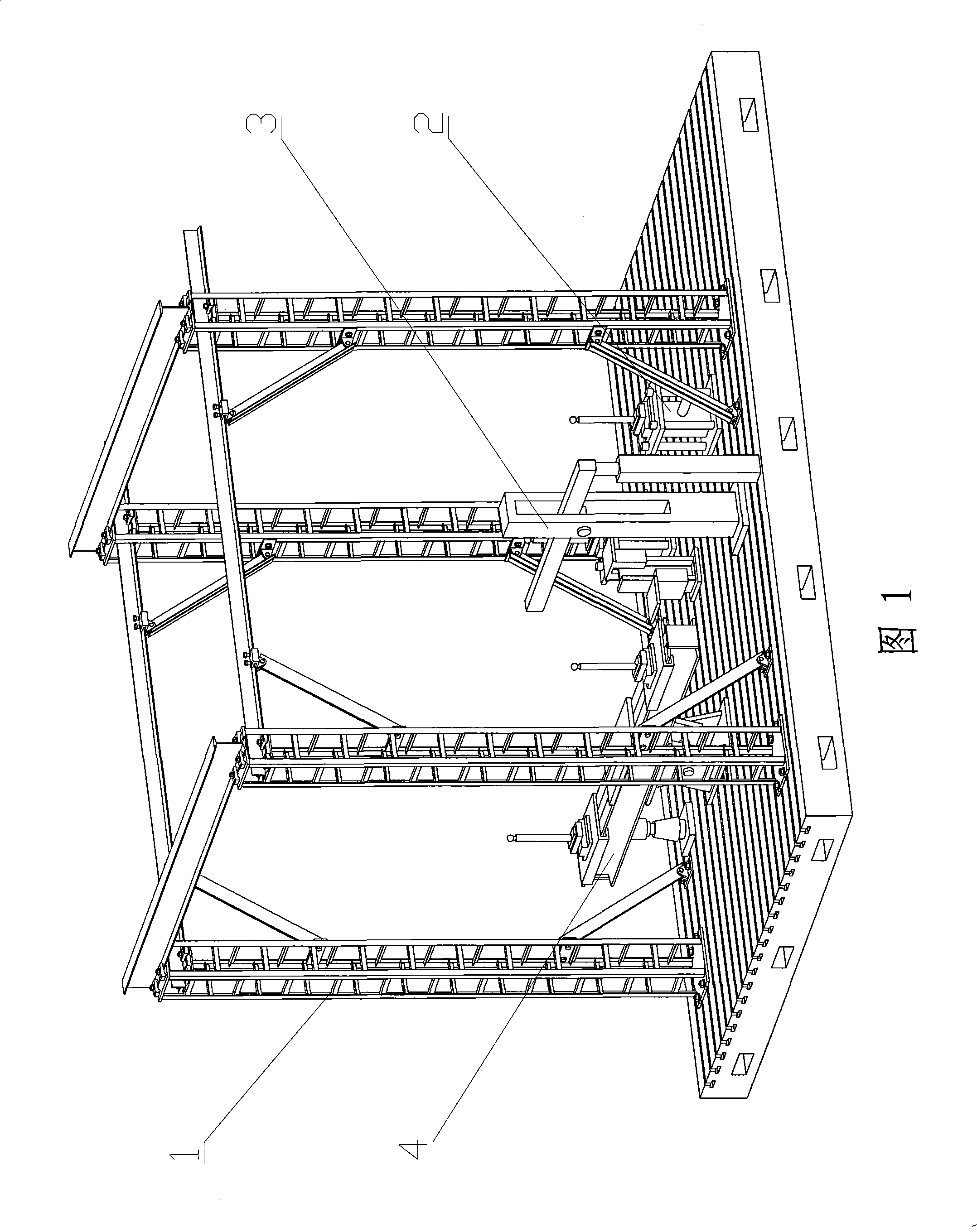

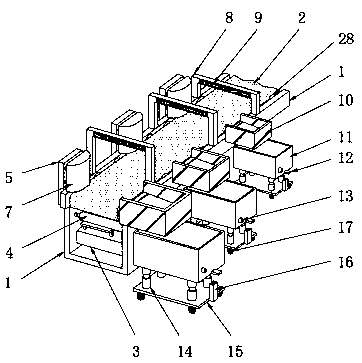

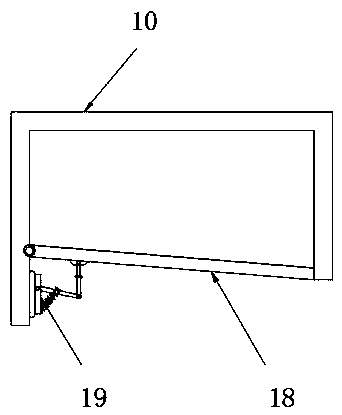

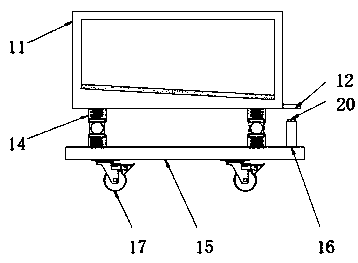

Welding robot device for welding of plunger pump power end shell

PendingCN107234358AGuarantee quality and efficiencyGuaranteed welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesFillet weldControl system

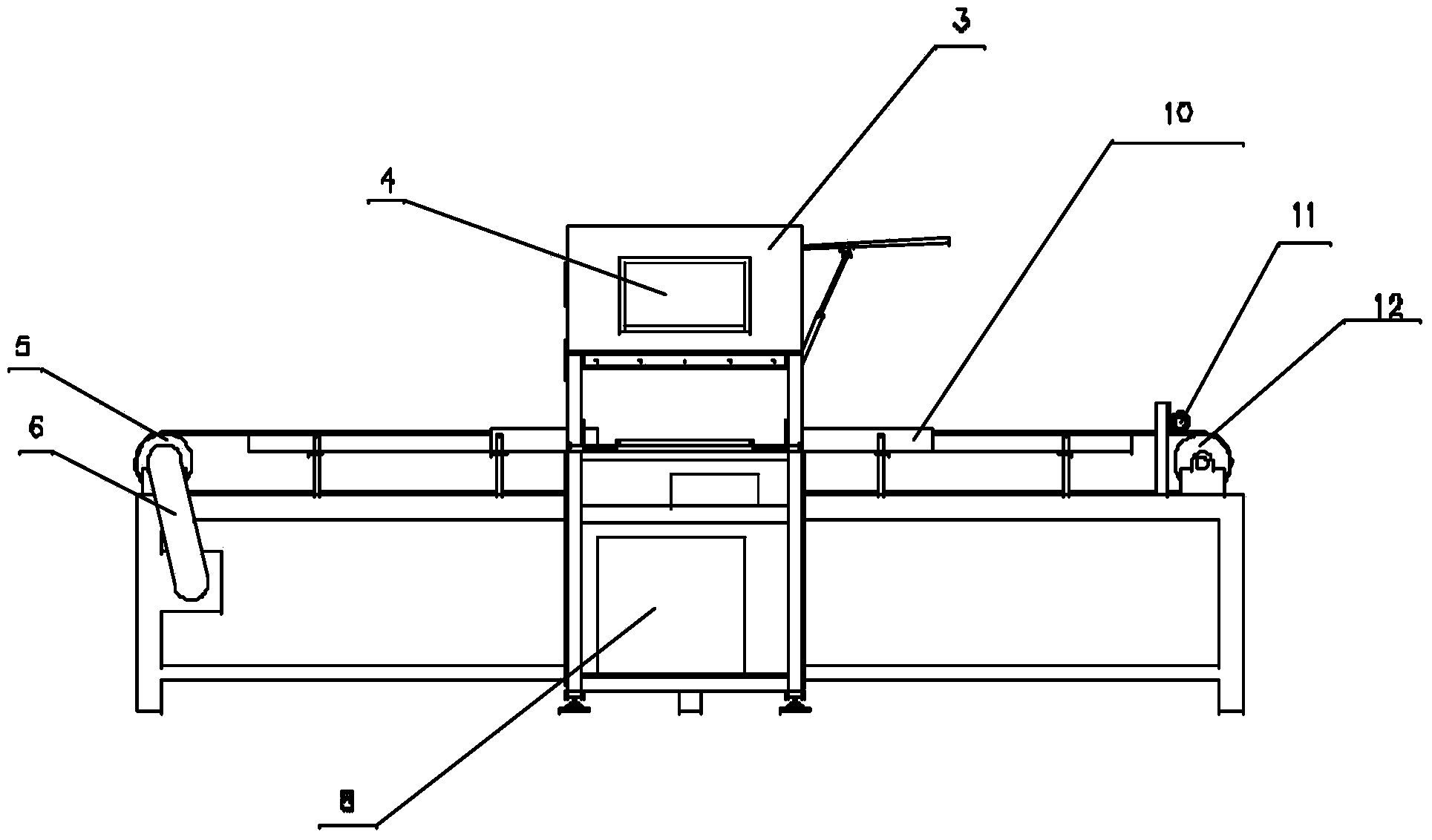

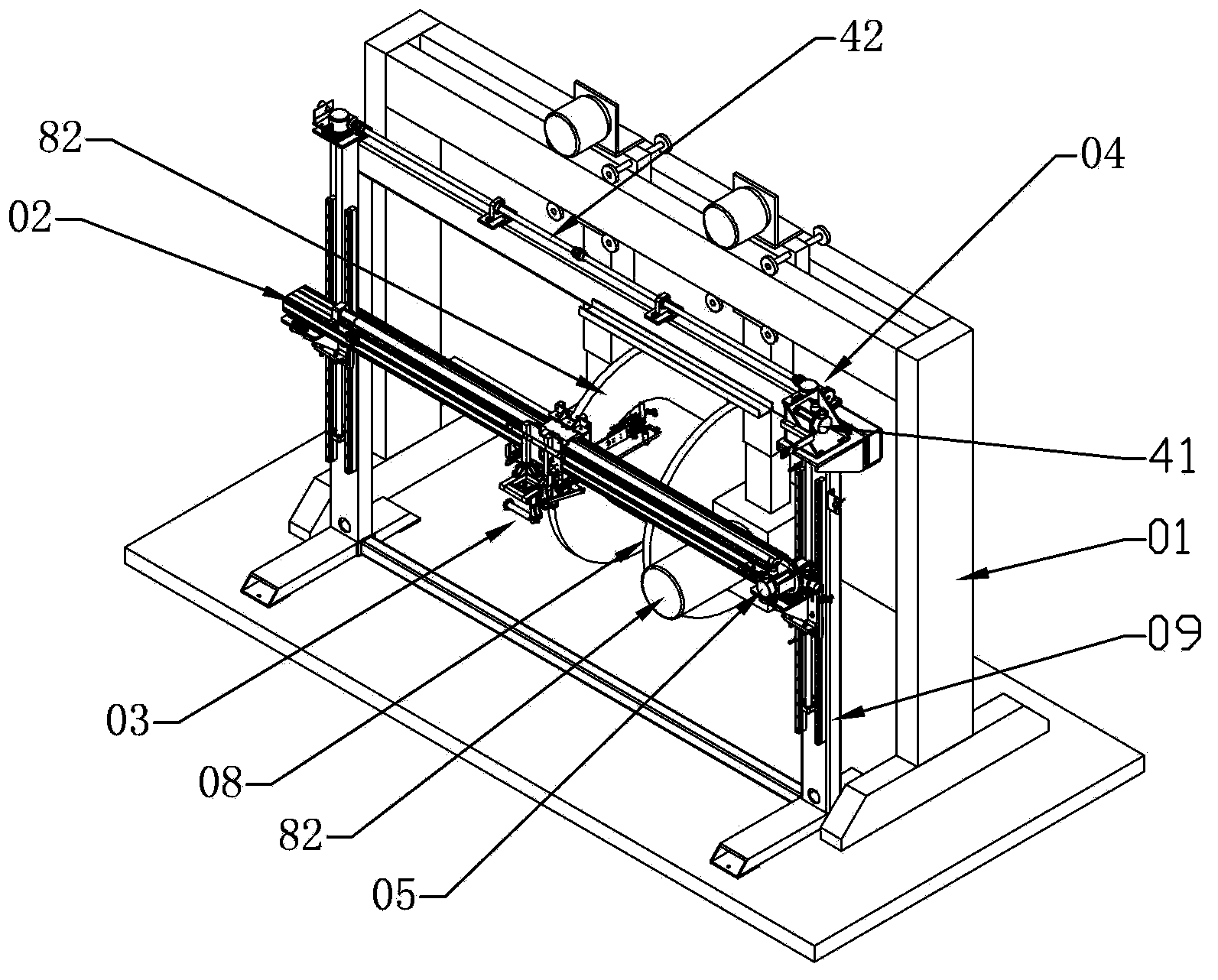

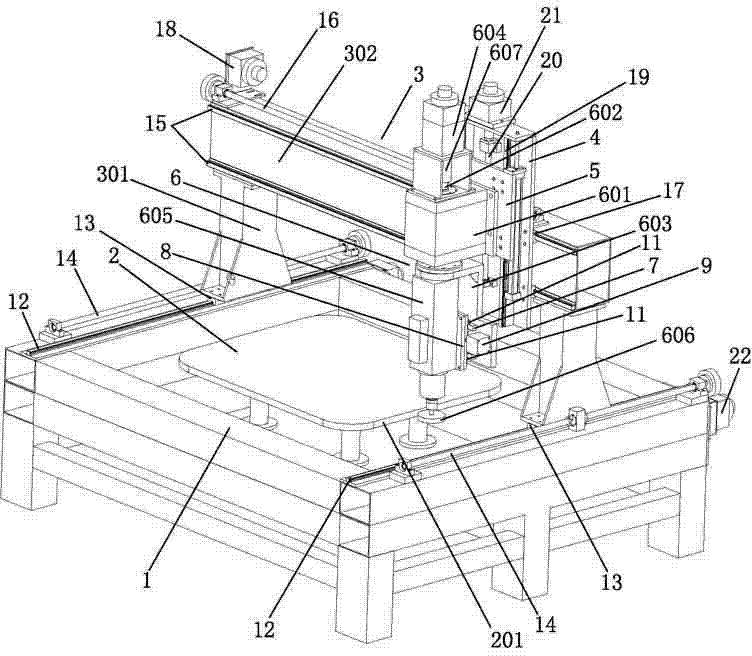

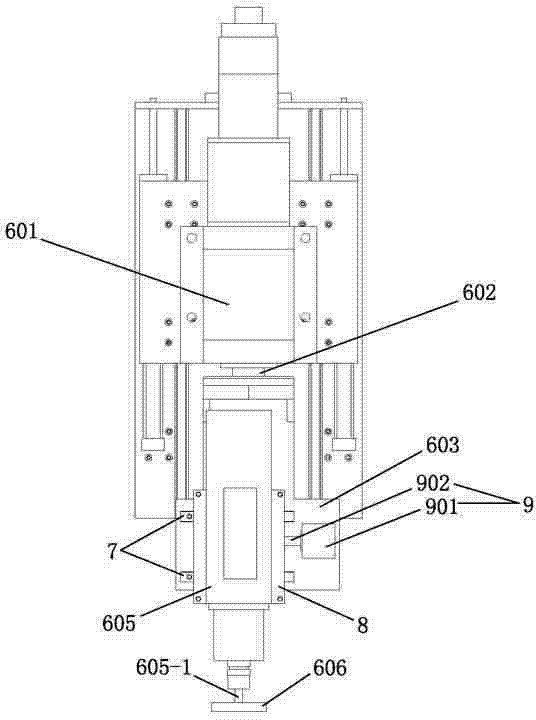

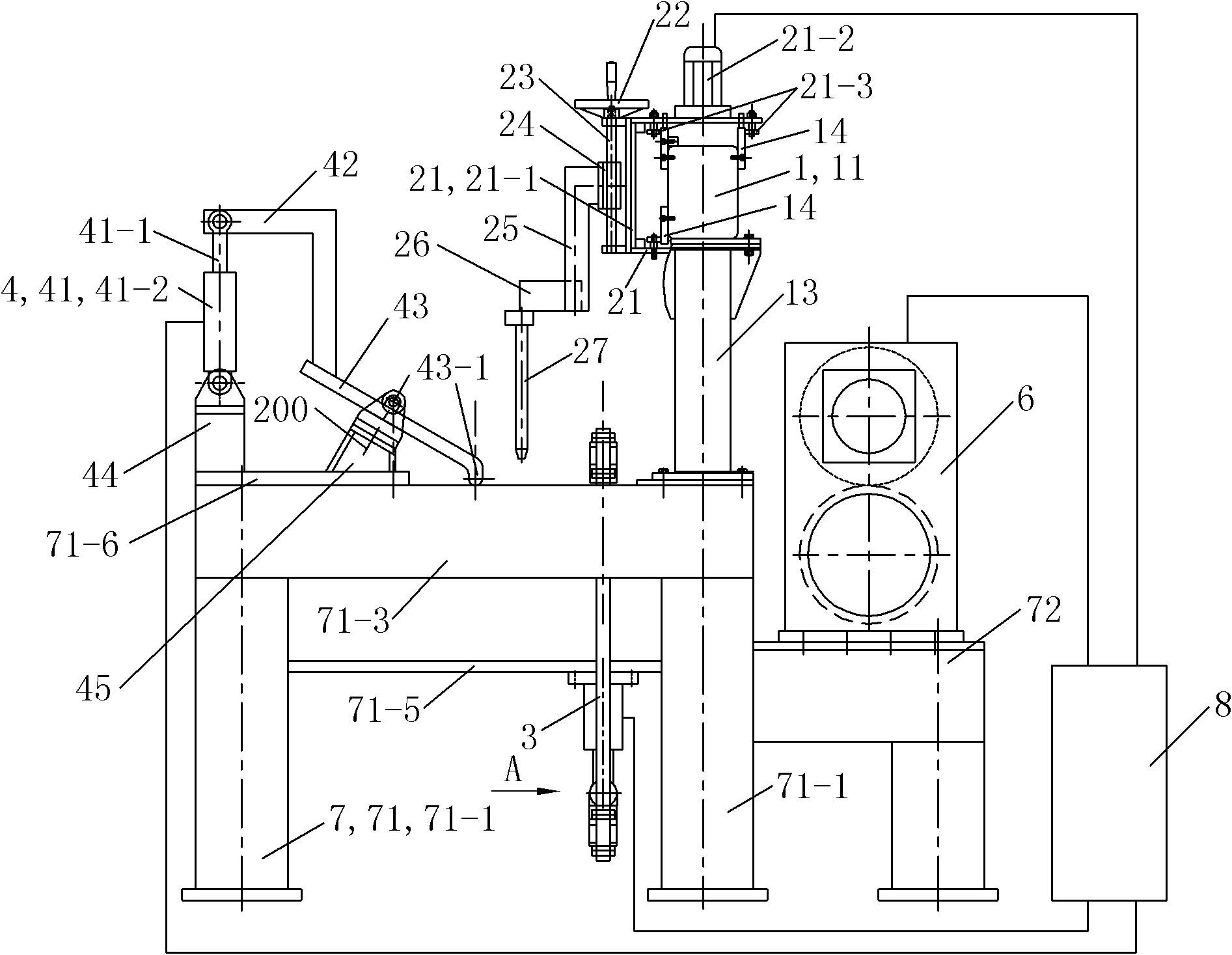

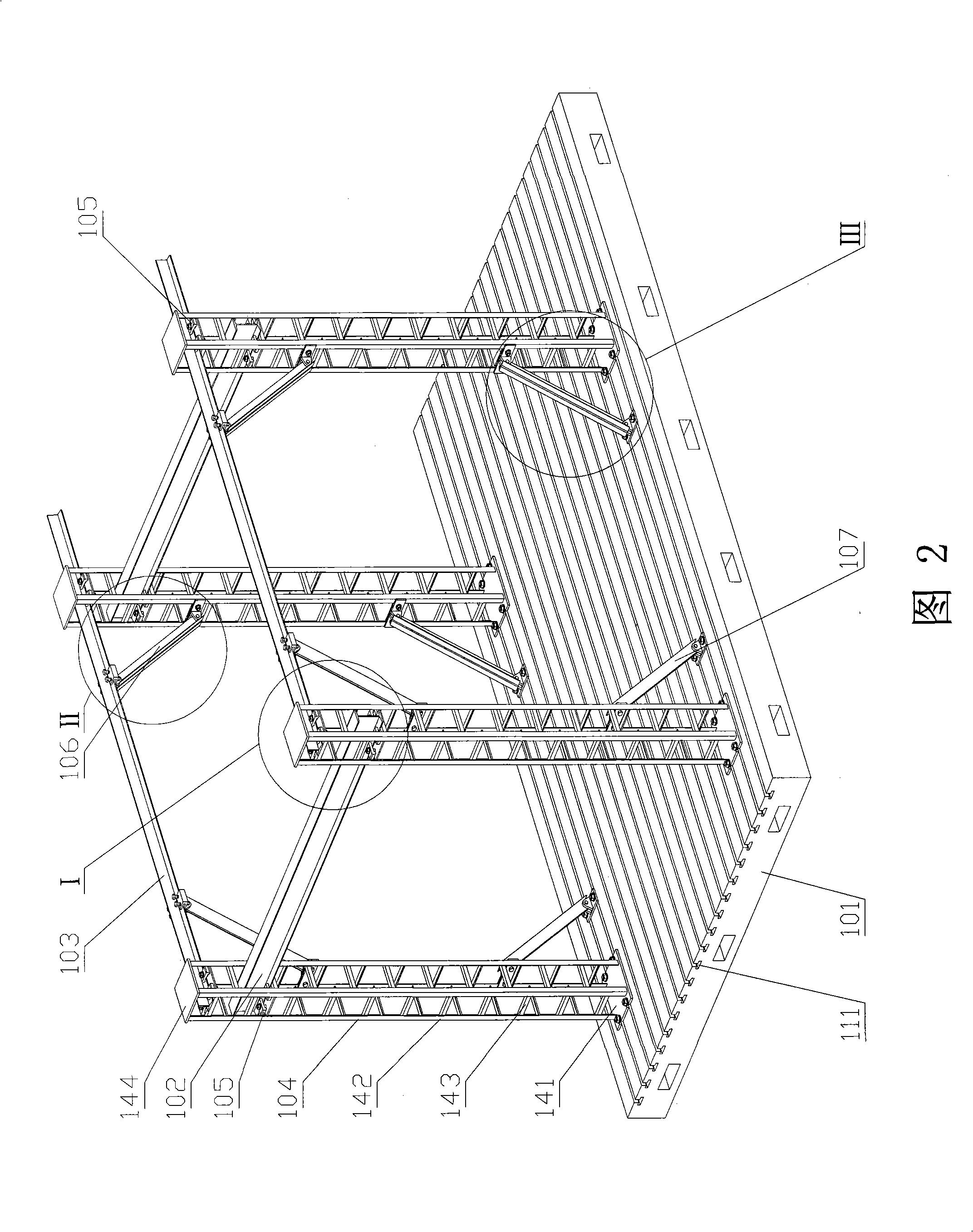

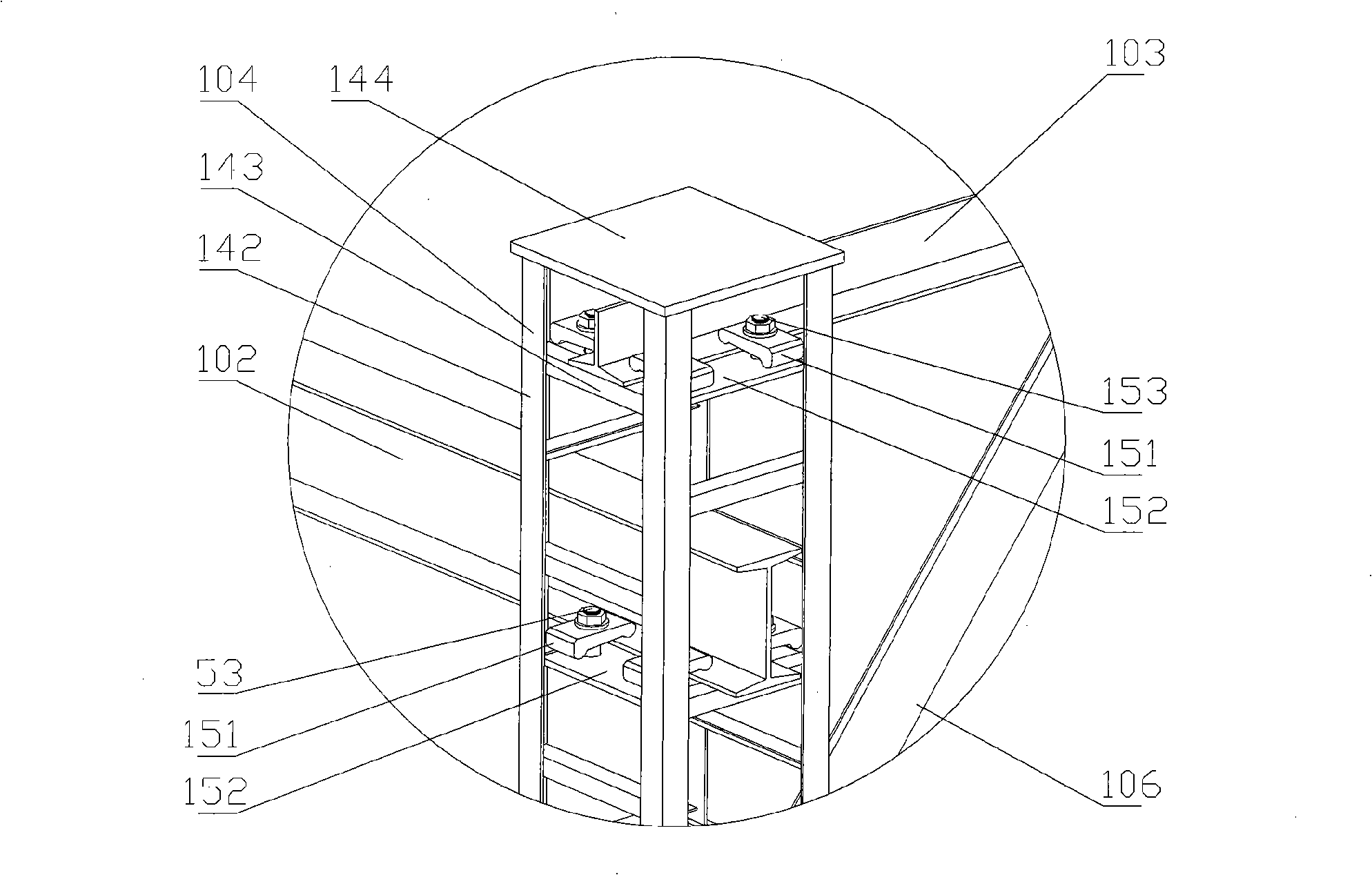

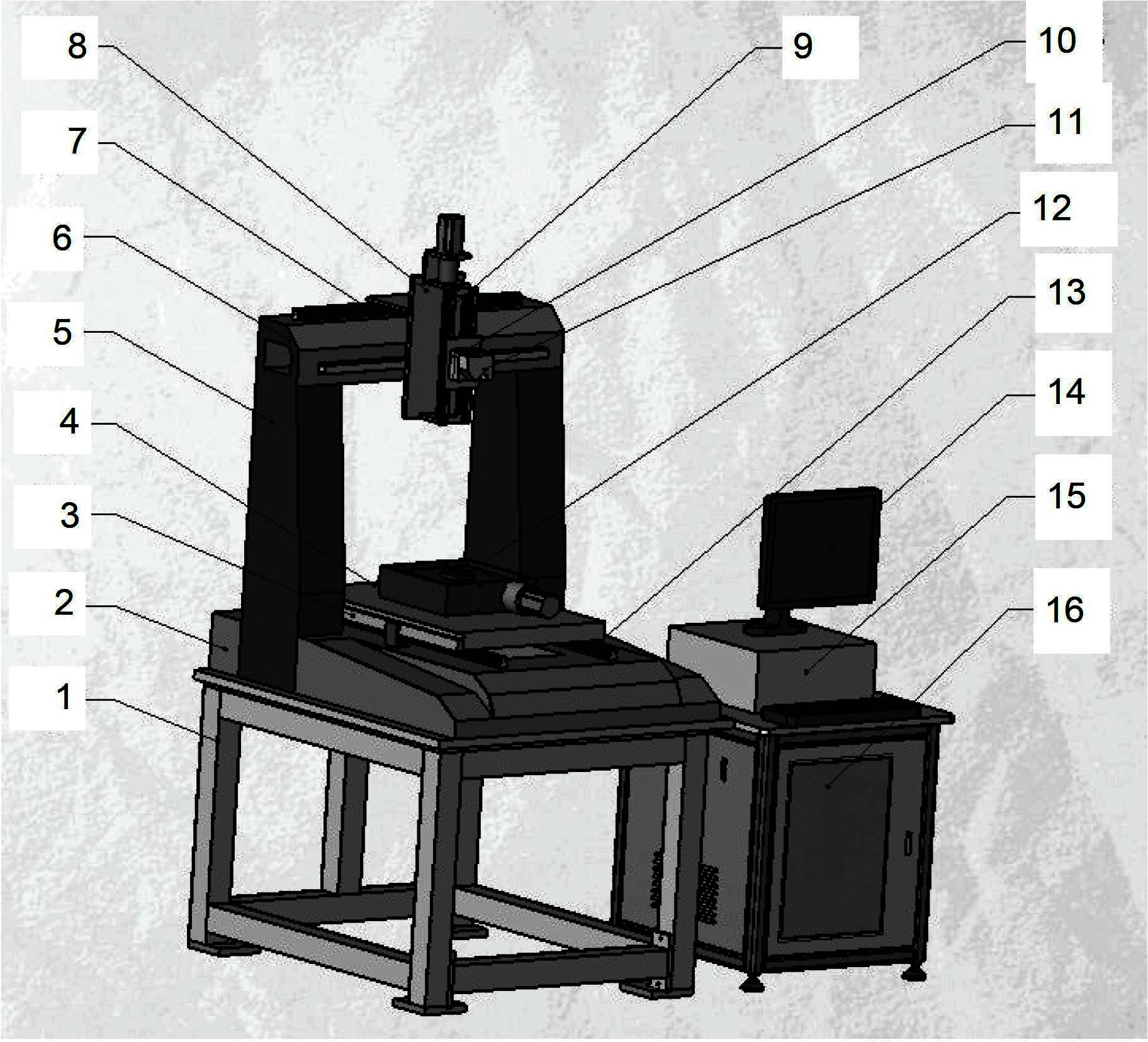

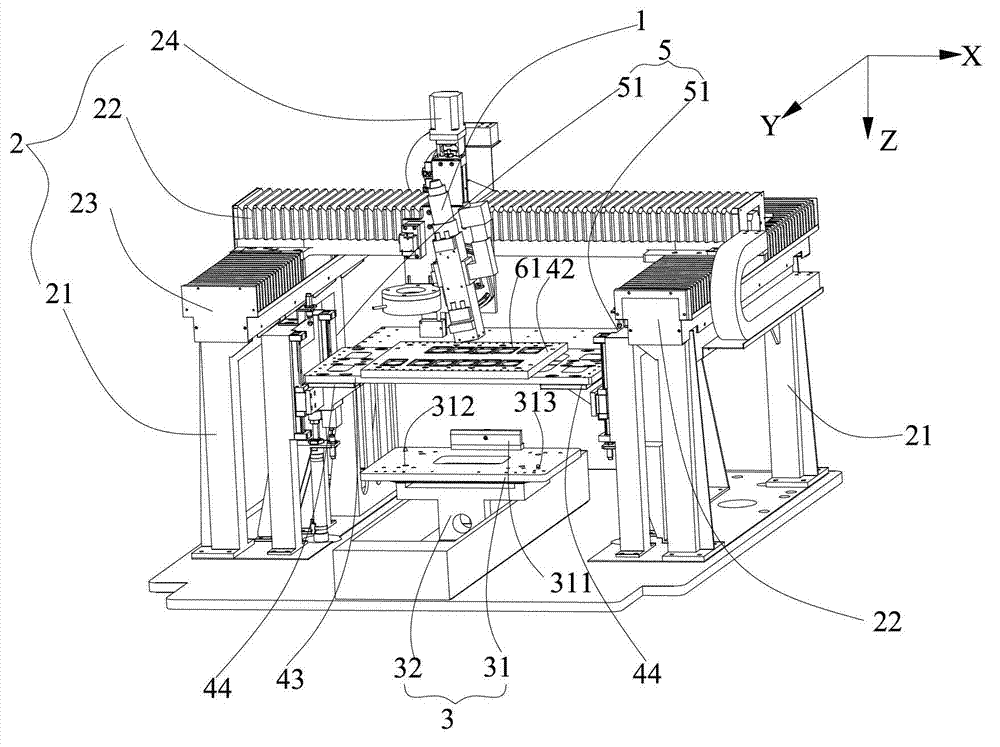

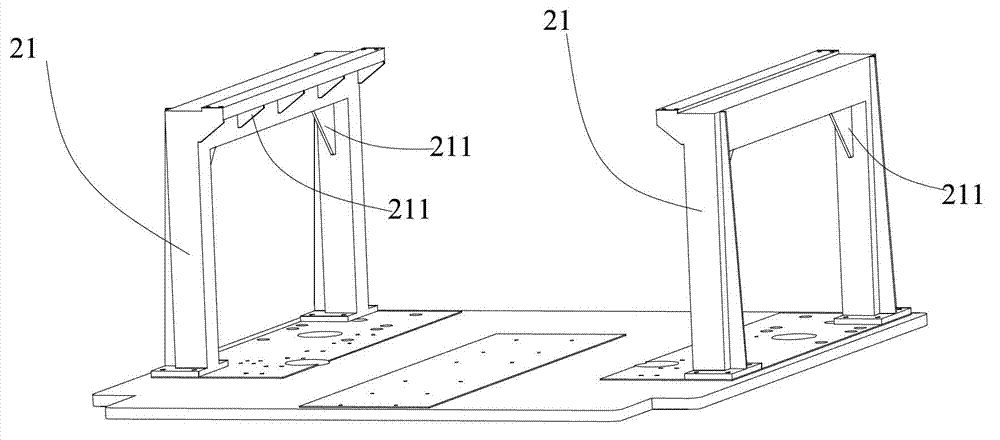

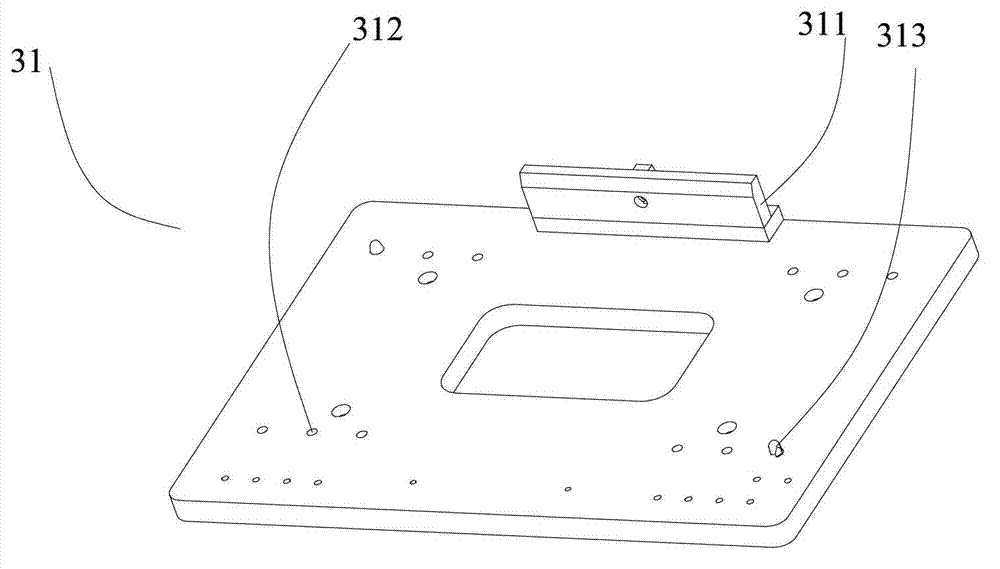

The invention provides a welding robot device for welding of a plunger pump power end shell. The welding robot device for welding of the plunger pump power end shell comprises a controlling system, a portal frame X-Y-Z coordinate system, a welding system, a space positioner and a tool clamp. The tool clamp is used for clamping the plunger pump power end shell, and a plunger pump shell can be one-time clamped; all welding joints of the plunger pump shell can be positionally changed to a flat welding position or a flat fillet welding position through the space positioner; a welding mechanical arm is connected with a coordinate Z-axis in the portal frame X-Y-Z coordinate system, and welding of welding joints in the different positions can be finished; and synchronized driving of the welding mechanical arm, a coordinate X-axis, a coordinate Y-axis, the coordinate Z-axis and the space positioner can be realized, so that continuity during the welding process is guaranteed, and welding quality and welding efficiency are ensured.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

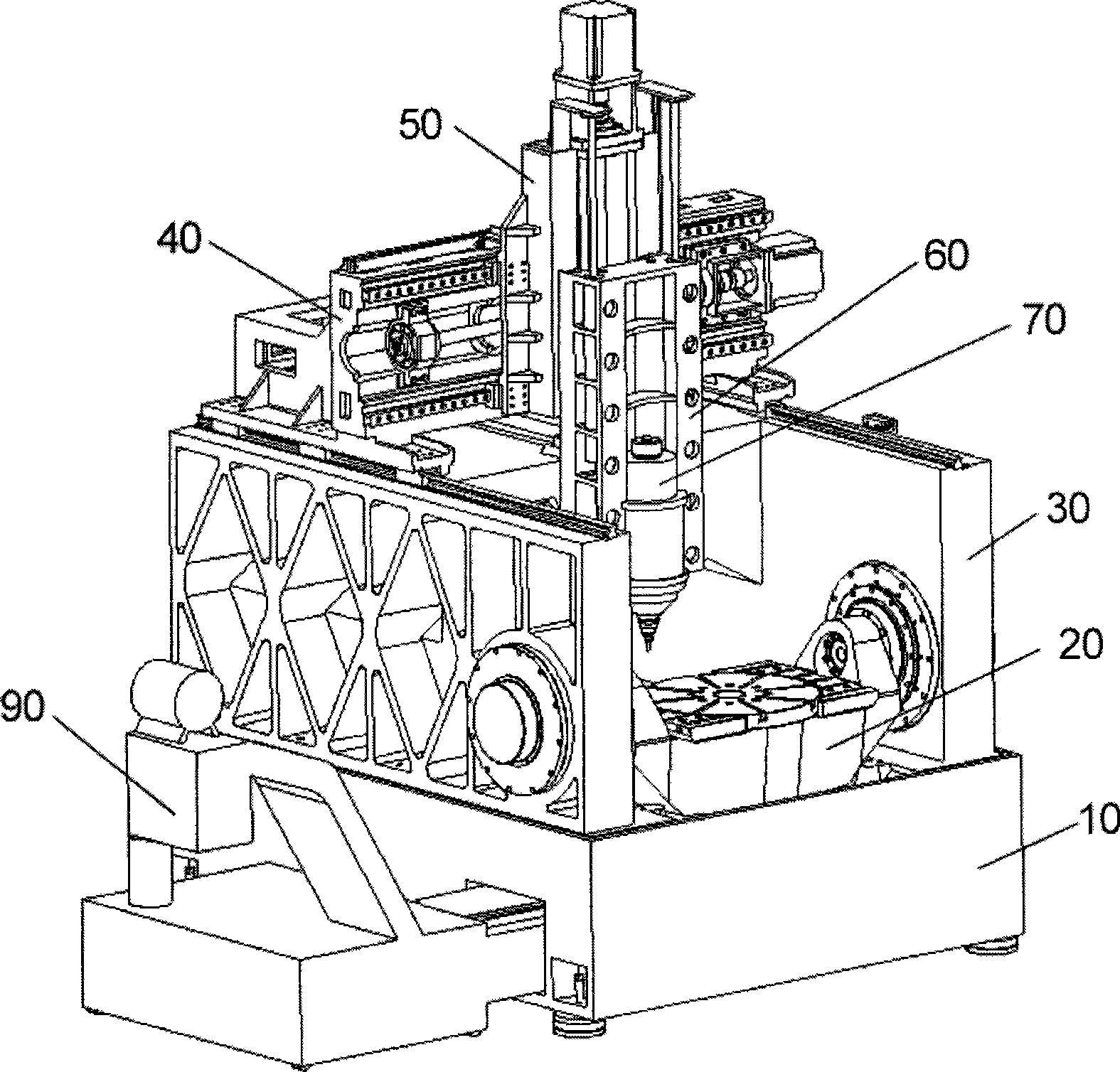

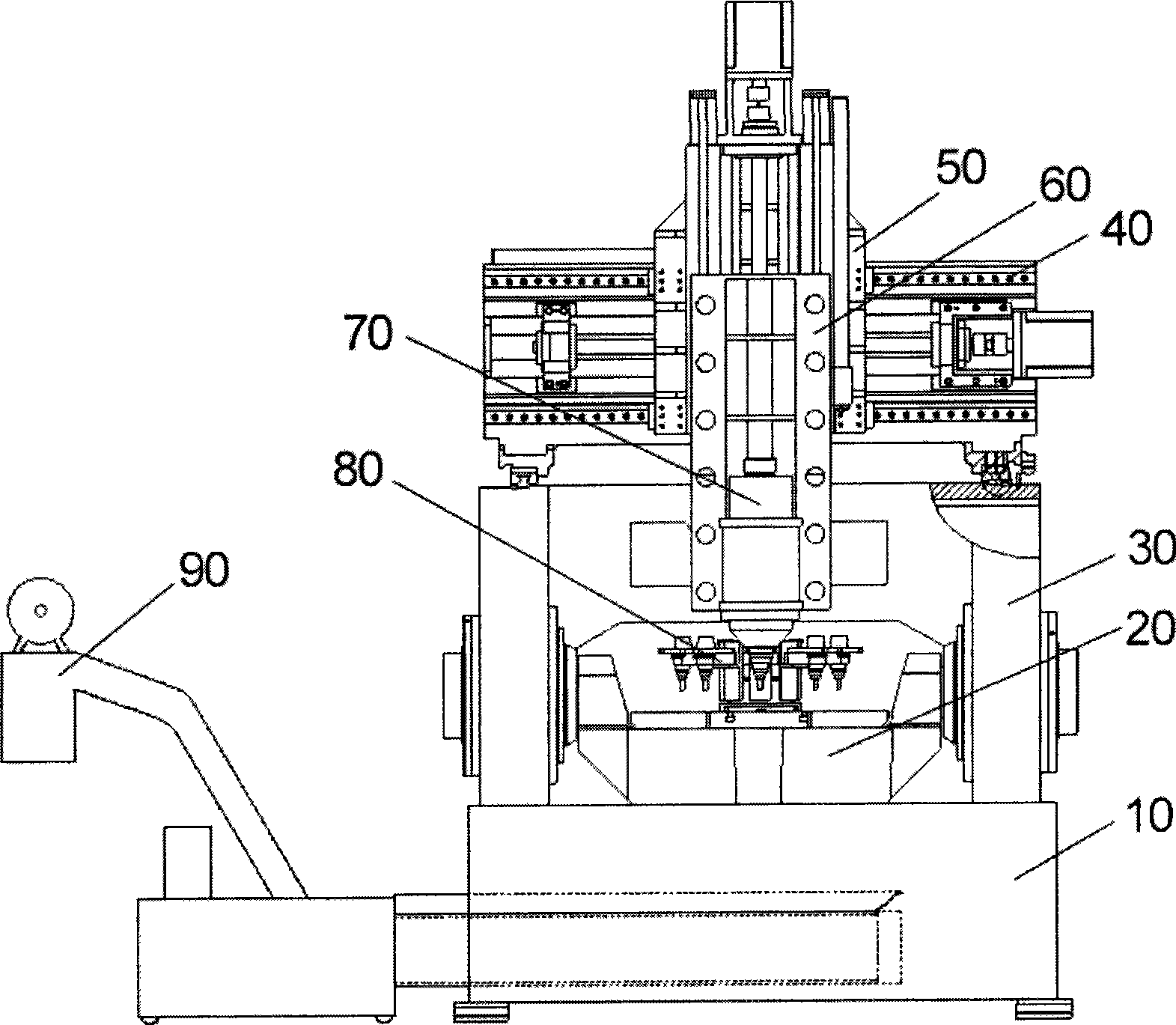

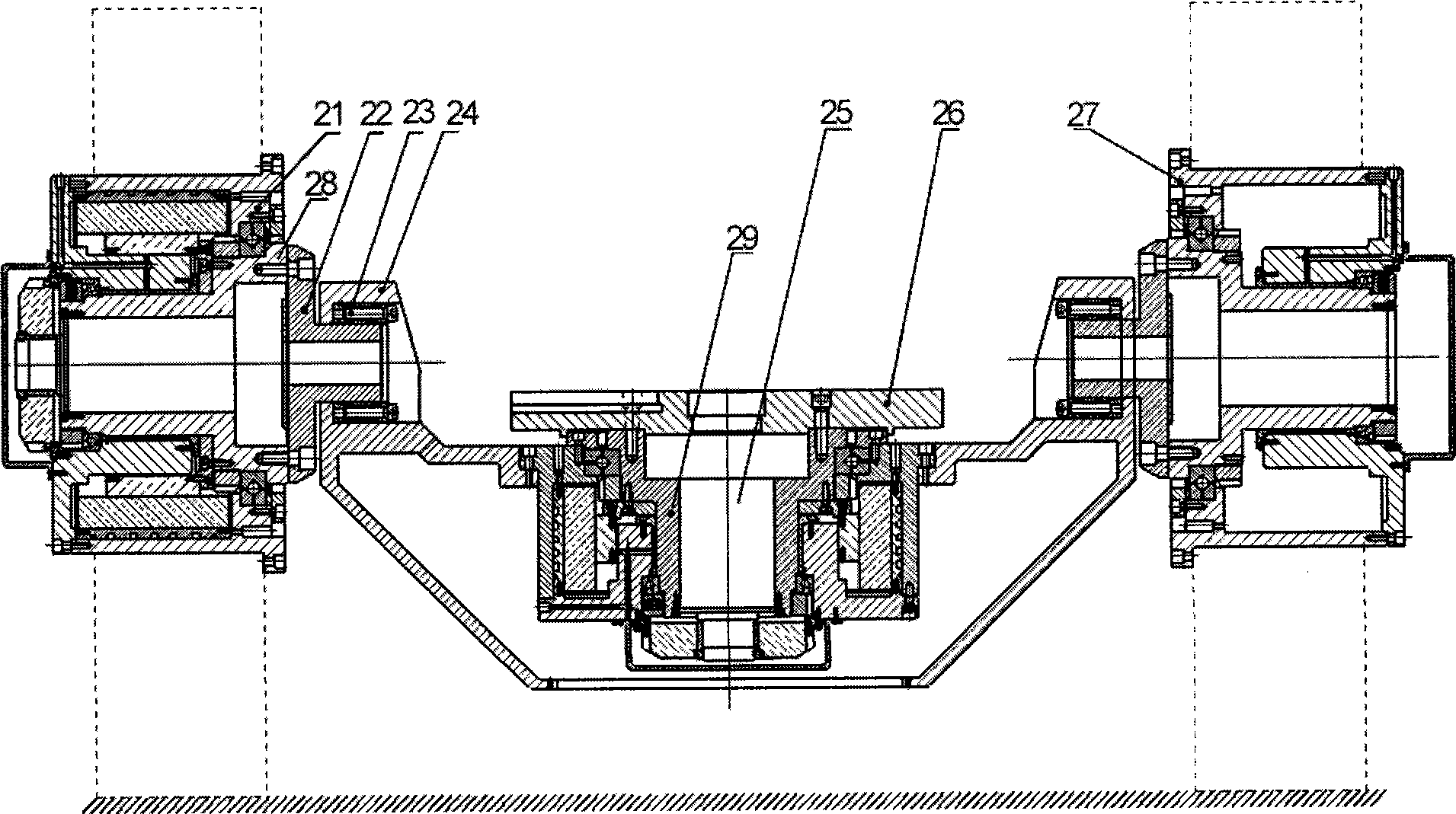

Five-shaft linkage numerical control machining center

InactiveCN101480777ANovel structureSmall footprintLarge fixed membersPositioning apparatusNumerical controlPortal frame

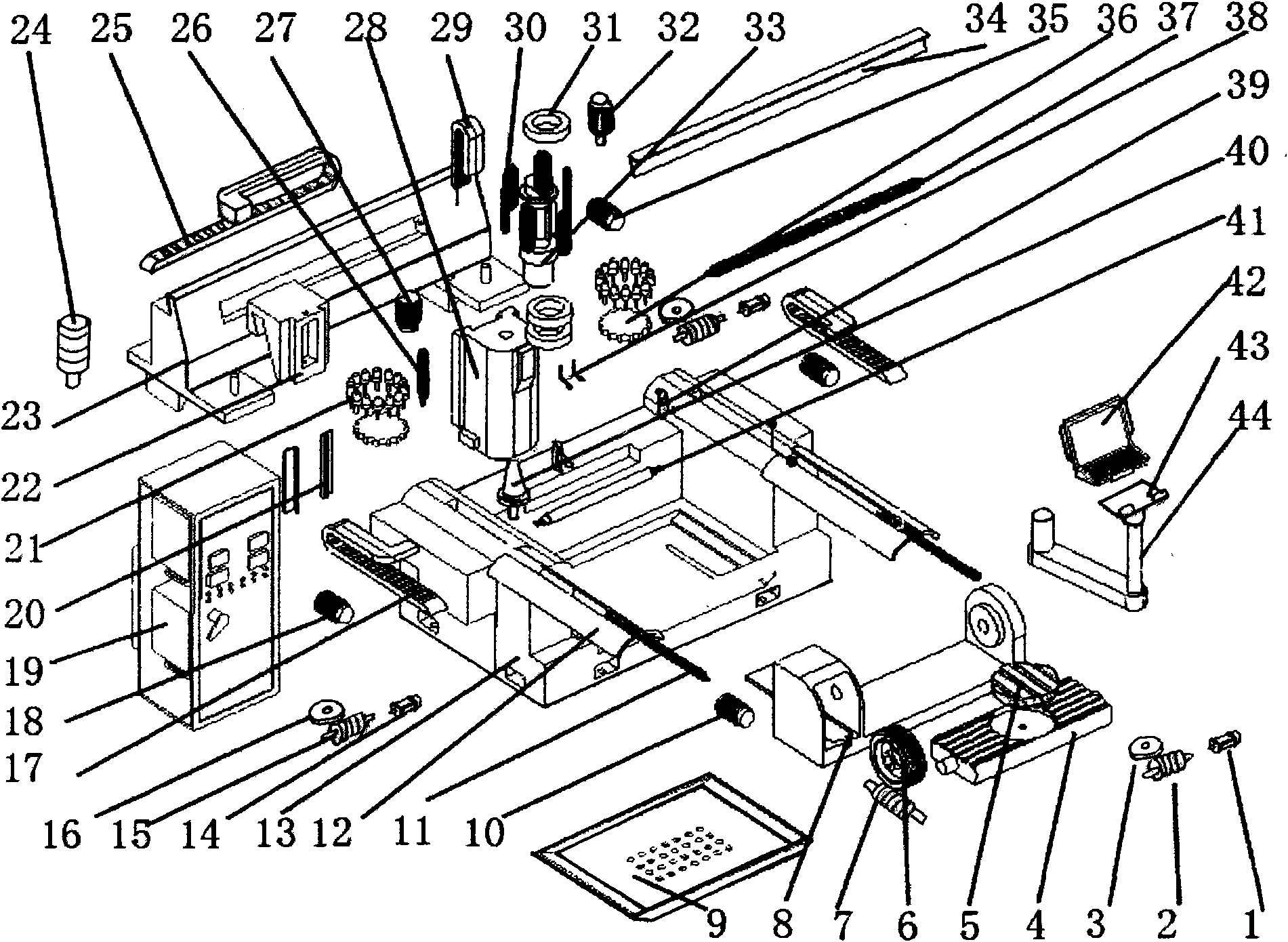

The invention discloses a five-axle linkage digital-control processing centre which comprises a lathe bed (10) and a portal frame (30), wherein the portal frame (30) comprises a left portal upright post (32), a right portal upright post (32) and a fixing portal crossbeam (35), and the front part of each portal upright post (32) is provided with a direct driving type double-shaft precise rotating table (20) which enables a working table (26) to simultaneously rotate round an A shaft and a C shaft. Furthermore, the portal frame (30) is provided with a crossbeam (40) which can move along the Y direction, the front part of the crossbeam (40) is provided with a slide carriage (50) which can move along the X direction, the front part of the slide carriage (50) is provided with a main shaft box (60) which can move along the Z direction, the main shaft box (60) is provided with a main shaft installing hole (66) used for installing a main shaft (70), and a tool magazine (80) is arranged in a cavity positioned between the lathe bed (10) and the portal frame (30). The invention has novel structure, small occupied area, space saving, low cost and stable operation and property. Besides, a motion shaft of a machine tool has high dynamic property, regulating property, positioning precision and repeated positioning precision.

Owner:三六零安全科技股份有限公司 +2

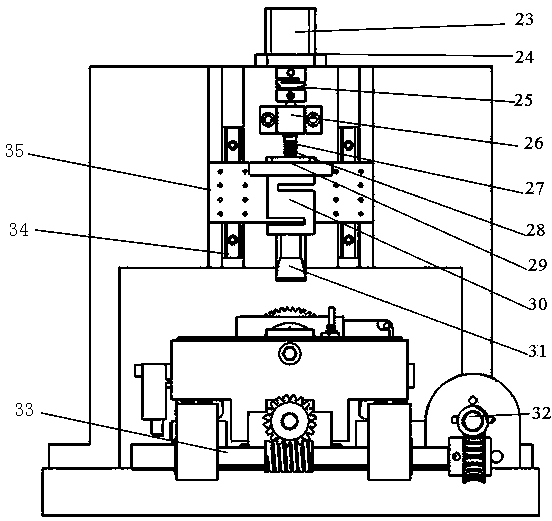

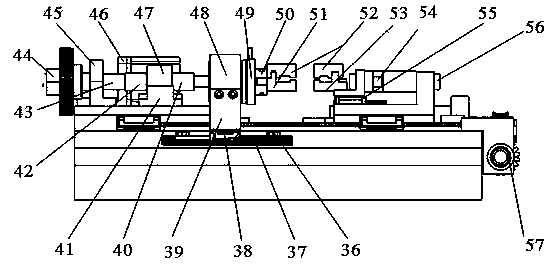

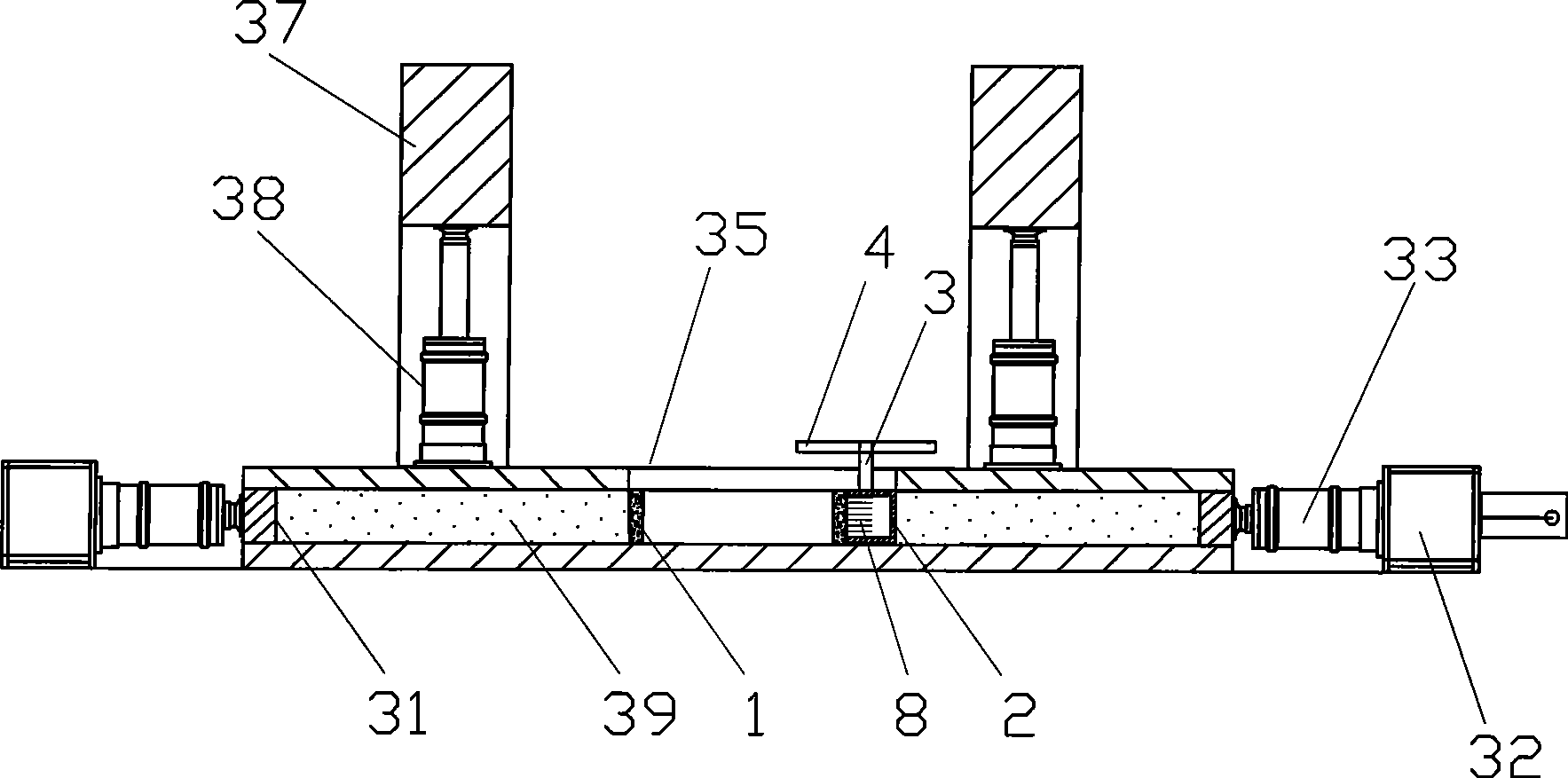

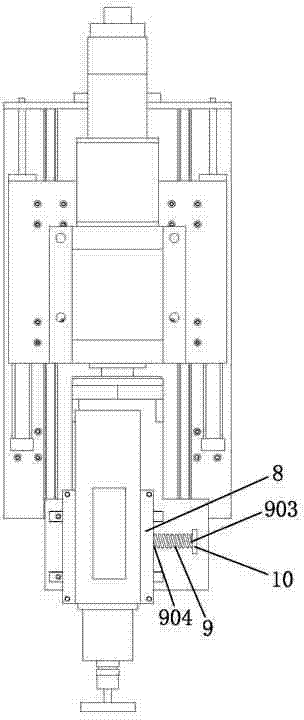

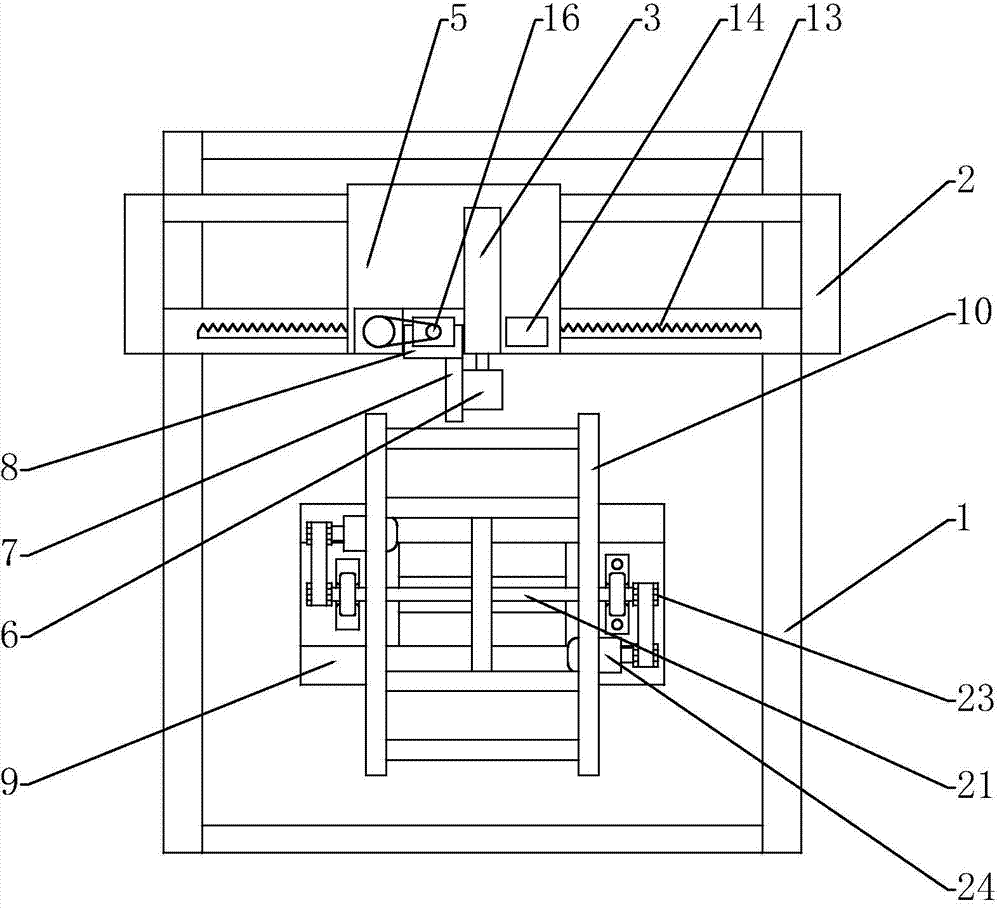

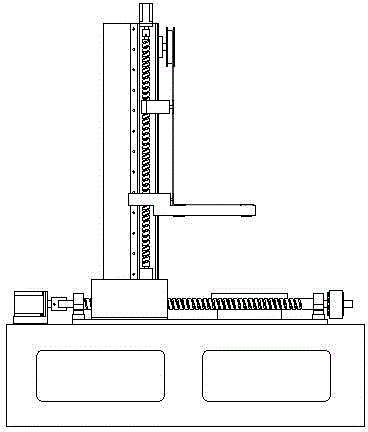

Micro material mechanical performance testing platform under stretching-bending-twisting multi-loads

ActiveCN103389243ANovel ideaCompact structureMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesElectromechanicsStress level

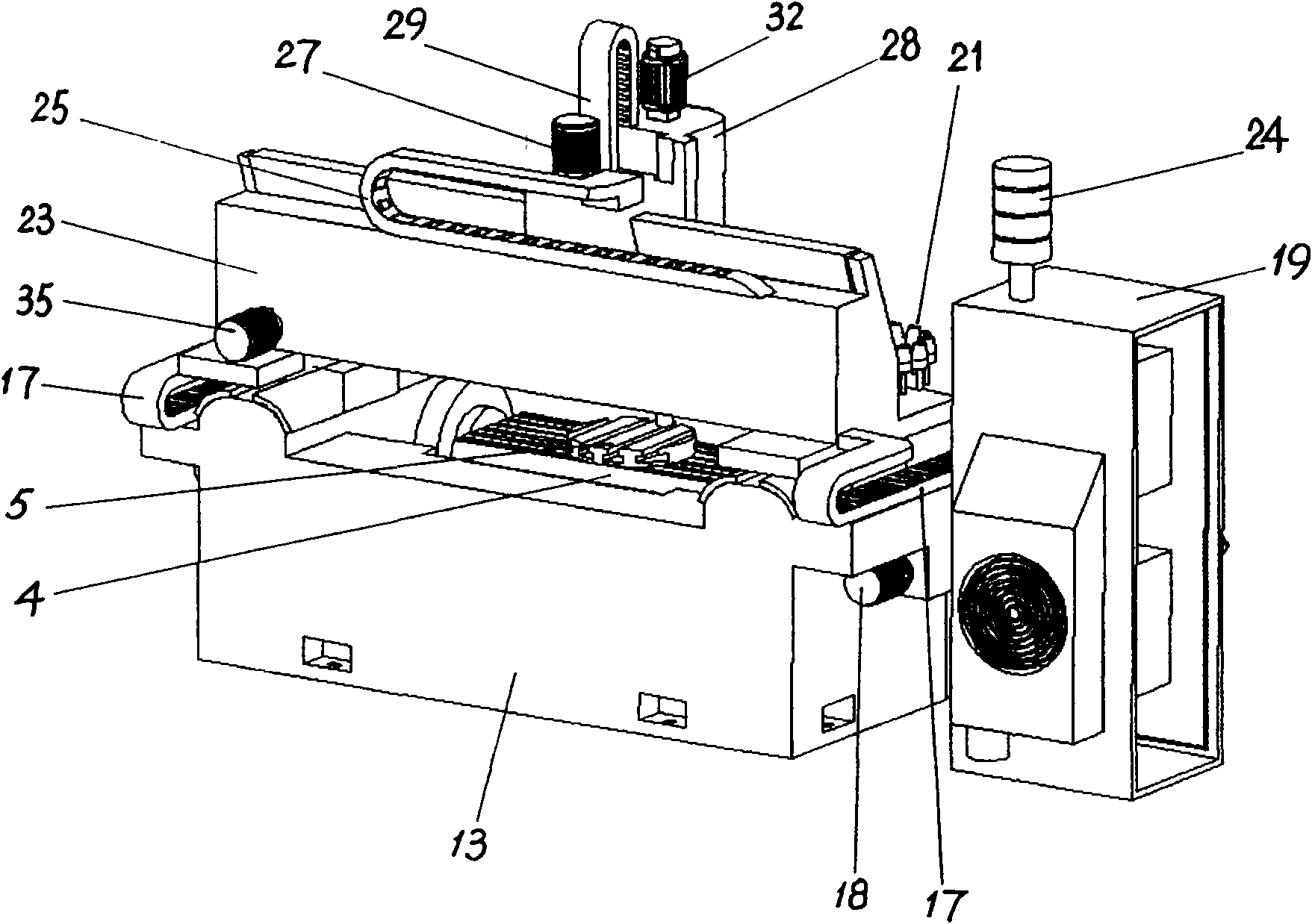

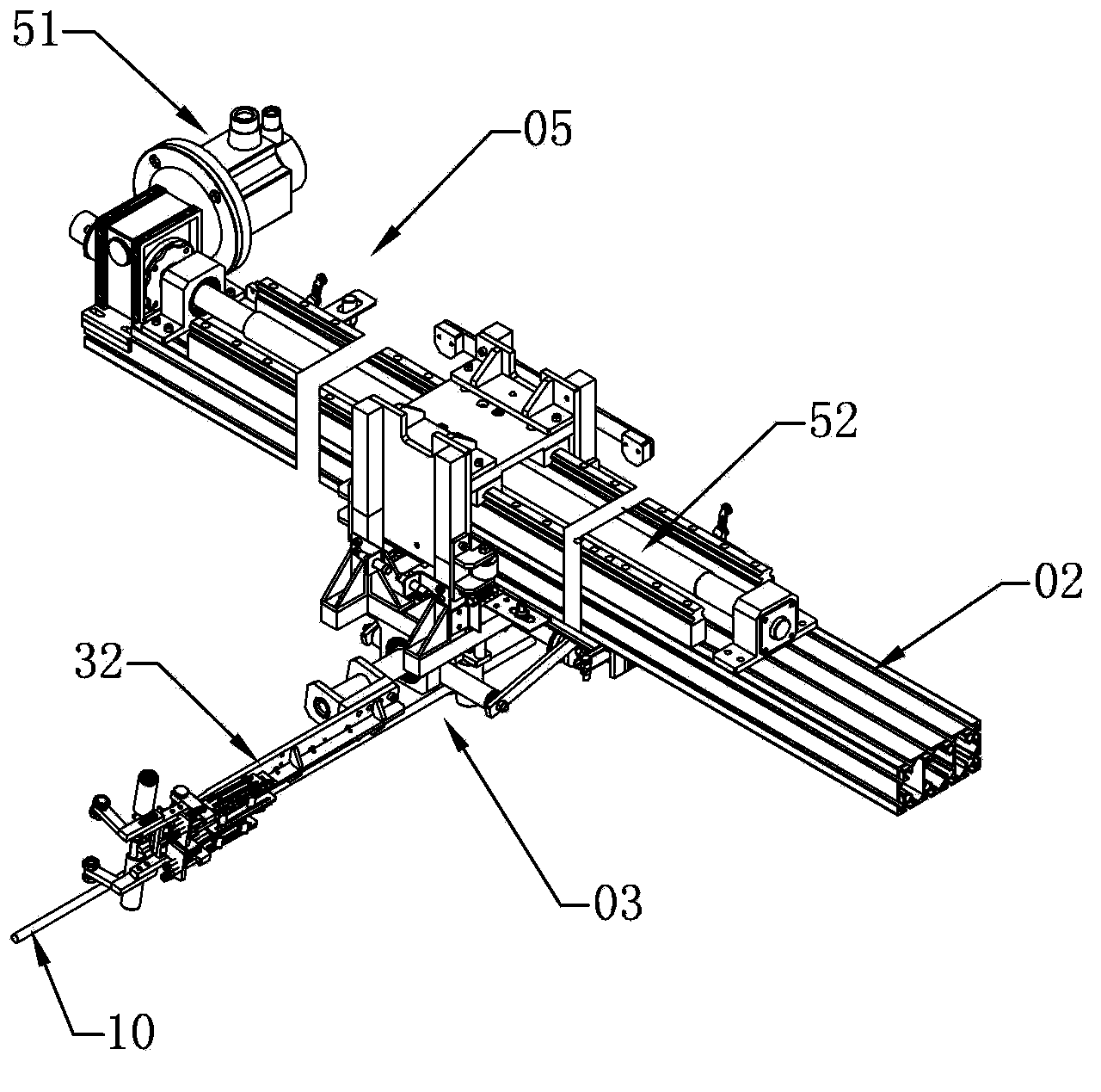

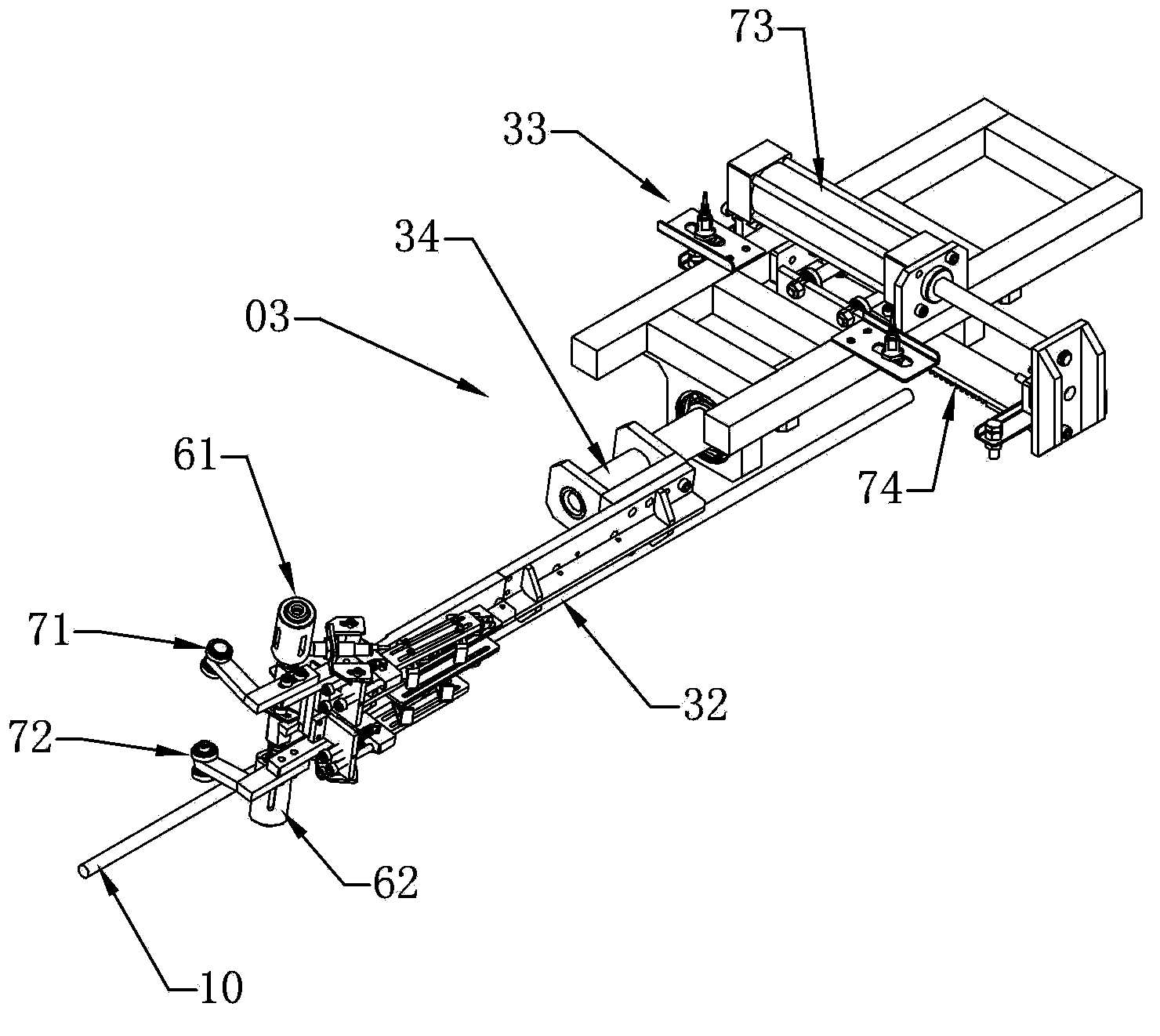

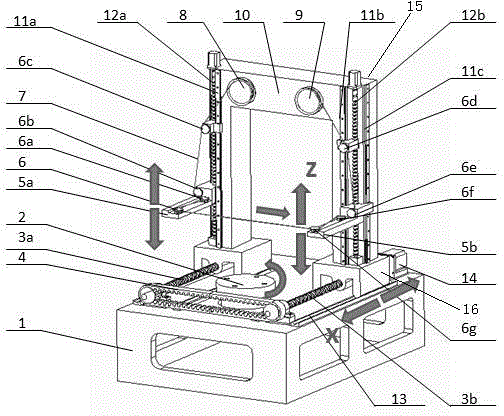

The invention relates to a micro material mechanical performance testing platform under stretching-bending-twisting multi-loads, and belongs to the field of electromechanics. The micro material mechanical performance testing platform comprises a tension and compression module, a bending module, a twisting module, a detection control module and a test-piece clamping module, wherein the testing platform takes the tension and compression module as a basic function module; the twisting module is arranged at one end of the tension and compression module; the test-piece clamping module is arranged on the tension and compression module; the bending module is independently arranged at one side of a portal frame. The micro material mechanical performance testing platform can be taken as a material mechanical performance test device with an independent stretching / compressing mode or an independent bending mode or independent twisting mode, namely a single load testing mode, and can be applied to a material mechanical performance test of a twisting load under the given stretching / compressing stress level or a material mechanical performance test of a bending load under the given stretching / compressing stress level, namely a composite load testing mode. The stress strain process of a material under the effect of a composite load can be detected by the collection of a load / displacement signal by using the detection control module.

Owner:JILIN UNIV

Nondestructive ceramic detection device and detection method thereof

InactiveCN104111260ASimple structureEasy maintenanceMaterial analysis by optical meansUsing optical meansDrive wheelEngineering

The invention discloses a nondestructive ceramic detection device and a detection method thereof. The detection device comprises a rack and an engine cover, wherein the engine cover stretches across the middle of the rack in a portal frame mode; a driving wheel and a driven wheel are respectively mounted at two ends of the rack; a motor is arranged on a framework on one side of the rack; the driving wheel is connected with the motor through a synchronous belt; a fan is mounted on one transverse side of the engine cover; a control cabinet is mounted on one vertical side of the engine cover; the lower half part of the control cabinet is of cabinet type; a detection host is arranged in the cabinet; a linear CCD (Charge Coupled Device) camera is arranged on a first cross beam in the engine cover; a linear light source is arranged under the linear CCD camera; a plurality of laser displacement sensors are arranged on a second cross beam of the engine cover. The detection device is simple in structure, convenient to maintain and capable of effectively avoiding artificial detection error; meanwhile, according to the detection method, the detection process is simple and quick, the detection result is accurate and the detection efficiency is high.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +1

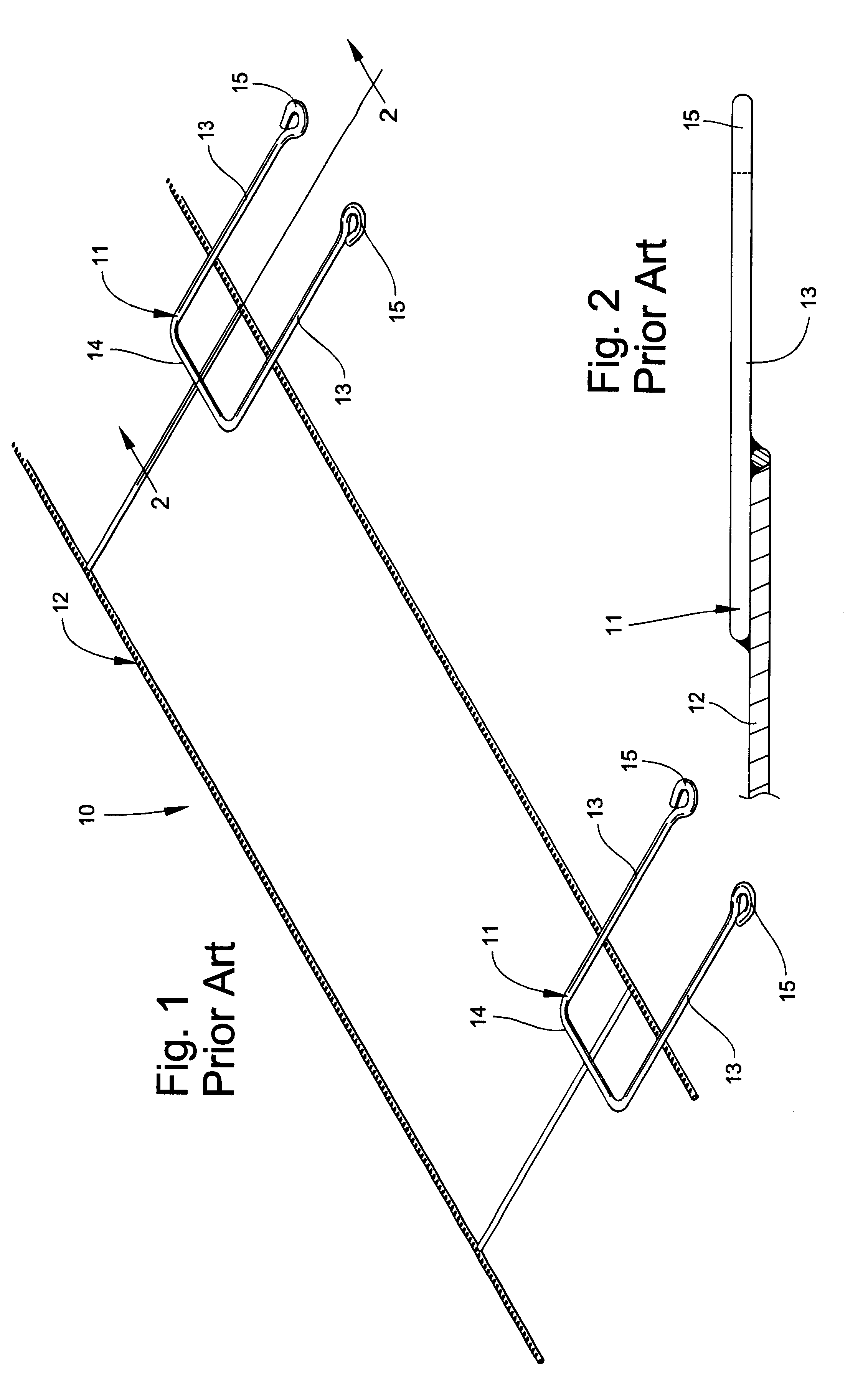

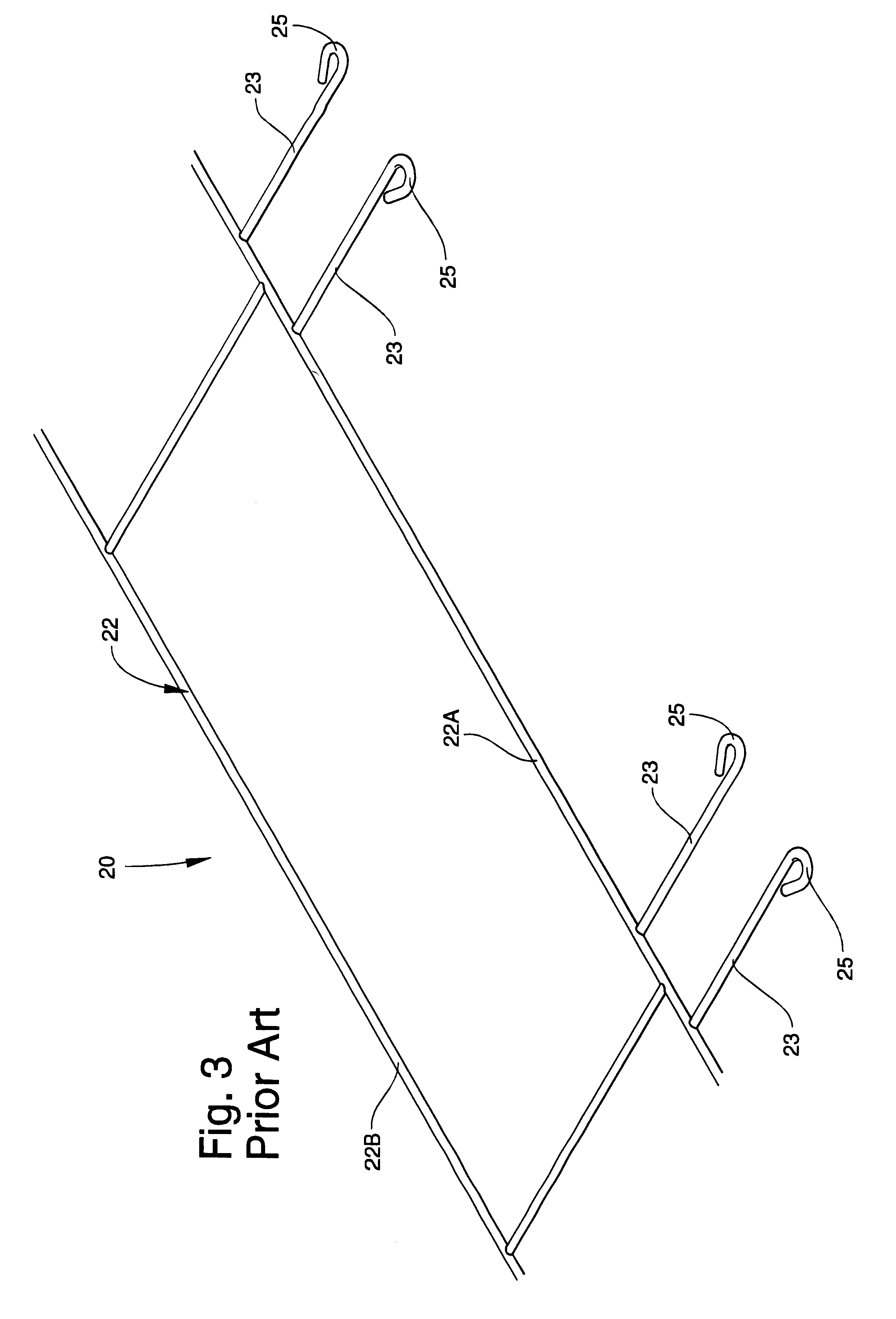

Masonry anchoring system

InactiveUS6735915B1Improve structural stabilityAvailable spaceConstruction materialStrutsBraced framePortal frame

Owner:MASONRY REINFORCING OF AMERICA

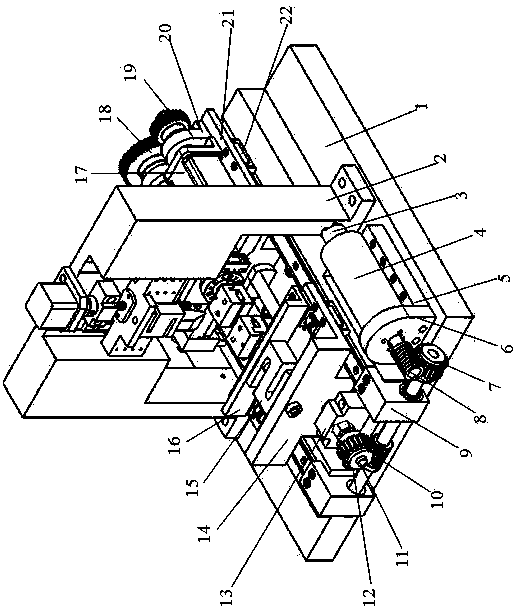

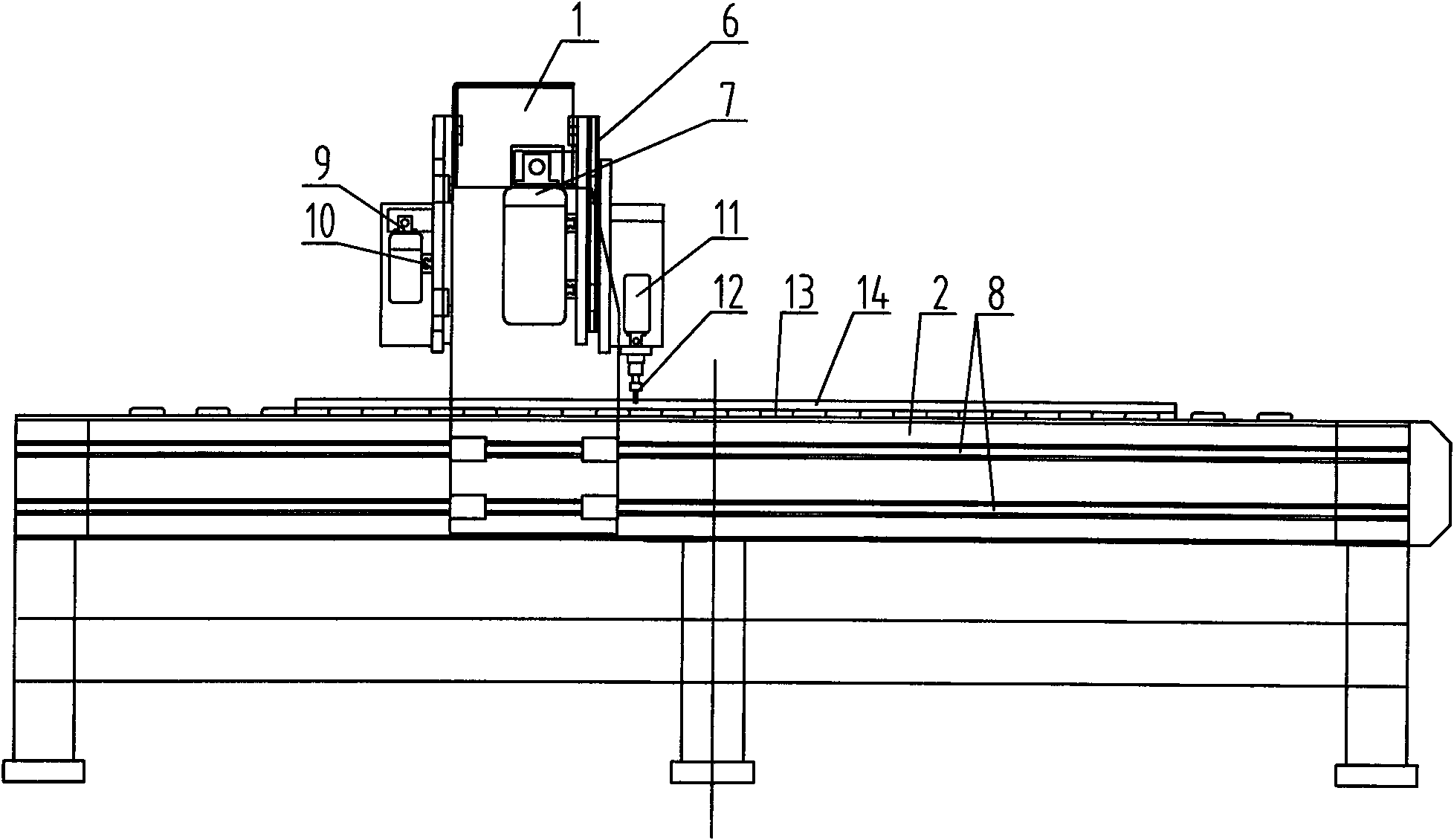

Vertical five axle interlocked gantry digital control milling machining center

ActiveCN101870063AReduce the number of clampingReduce machining errorsOther manufacturing equipments/toolsMilling cutterEngineering

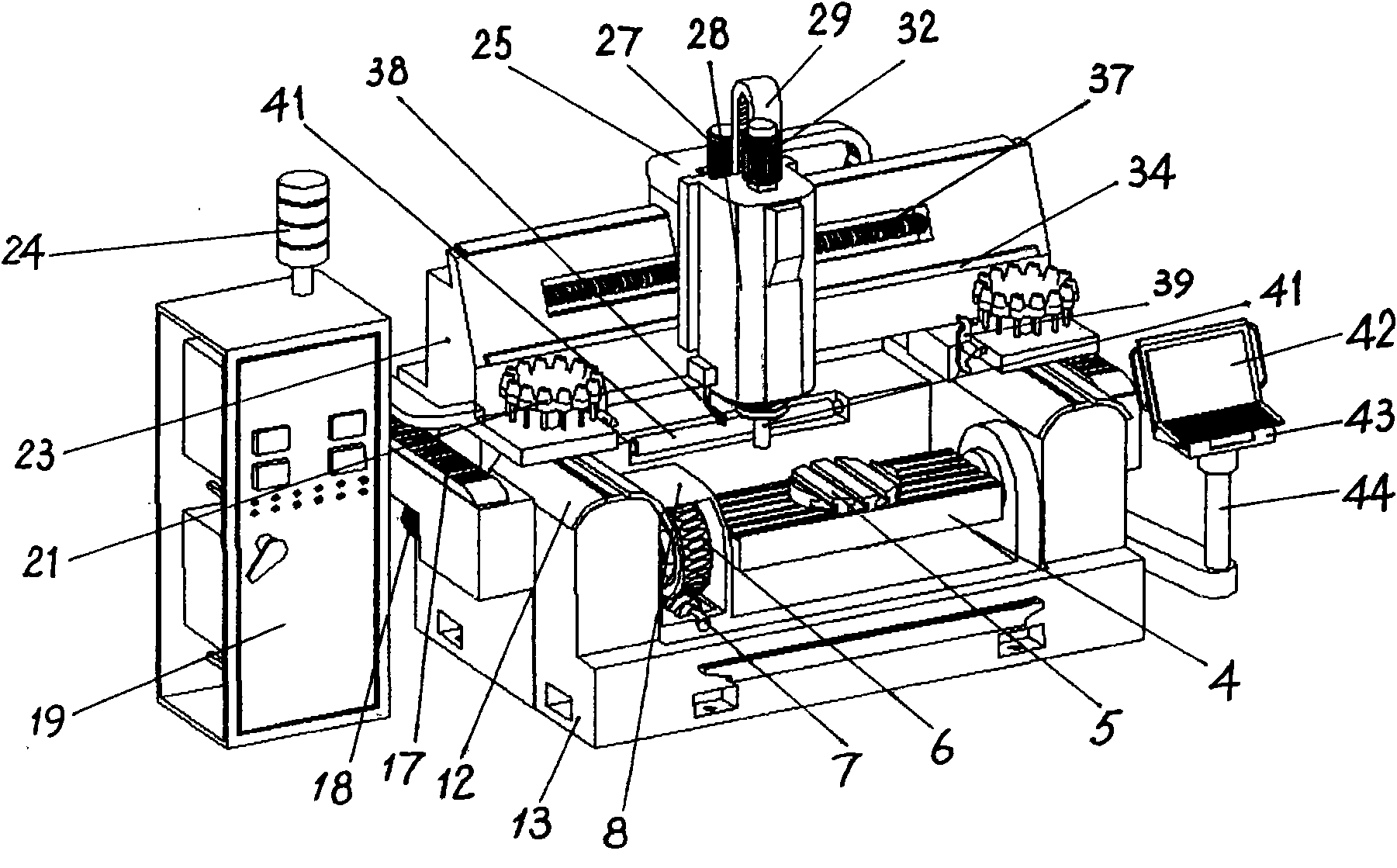

The invention provides a vertical five axle interlocked gantry digital control milling machining center, comprising a planer body, a portal frame, a rotary workbench stand, an electrical appliance control cabinet, a cutter, a main spindle box, an operation panel, a rotary workbench, X, Y and Z shaft driving screws and rotary tool changers, wherein the rotary workbench is formed by a large rotary workbench and a small rotary workbench which respectively rotate around an A shaft and a B shaft; the portal frame is arranged on the planer boxy and can move back and forth via the X shaft driving screws arranged at the two sides of the planer body, a Y-Z shaft connection block moves left and right via the Y shaft driving screw in the portal frame, and a main spindle in the main spindle box moves up and down via the Z shaft driving screw on the Y-Z connection block so as to form five axle interlocking; and the rotary tool changers arranged at the two sides of the portal frame are internally provided with 32 grinding cutters and milling cutters, and tool changing is realized by a tool changing manipulator. The invention has the positive effects of realizing multiply functions of one machine, and can process as many as five interfaces by primary clamping, thus reducing clamping times, saving labor, time and space, and having convenient equipment maintenance.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

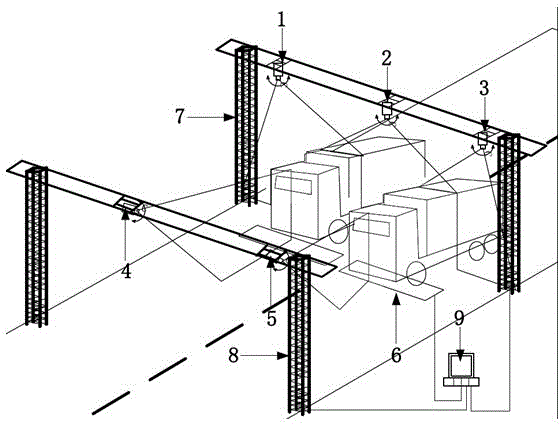

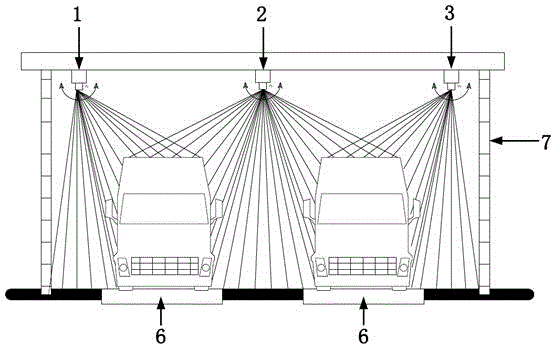

Vehicle information detecting and recognizing system under multilane condition

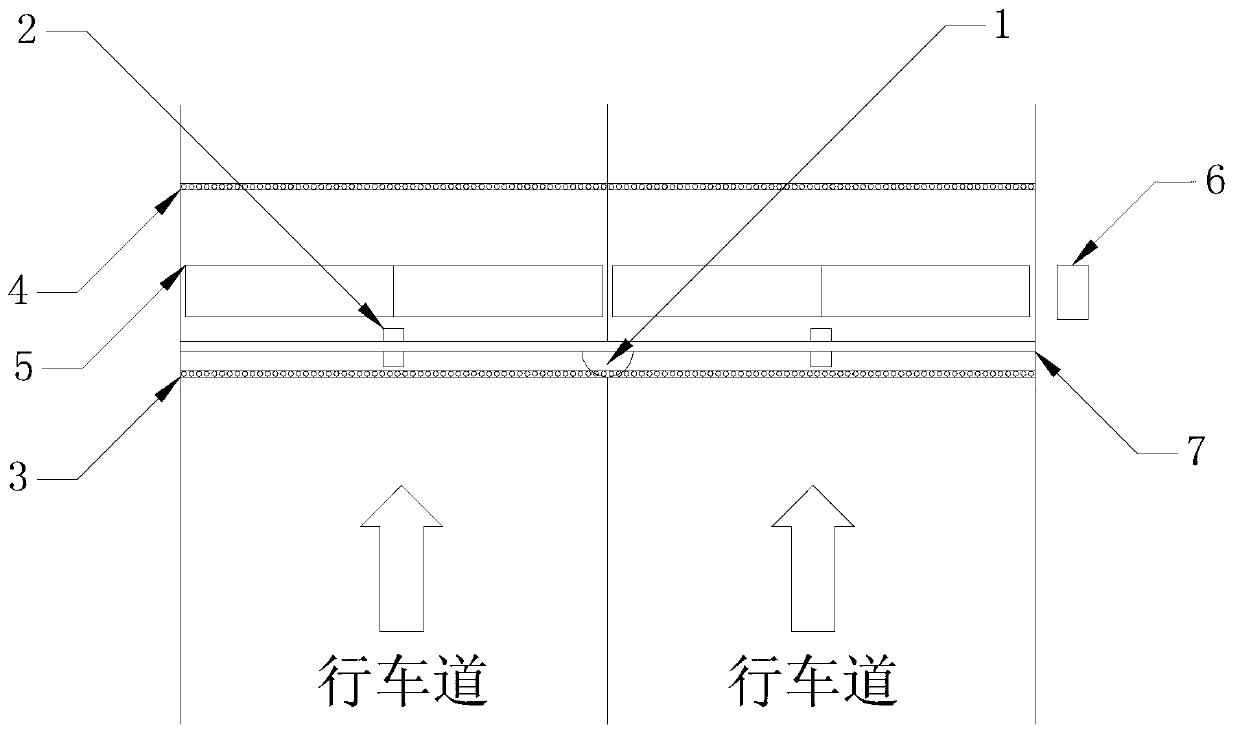

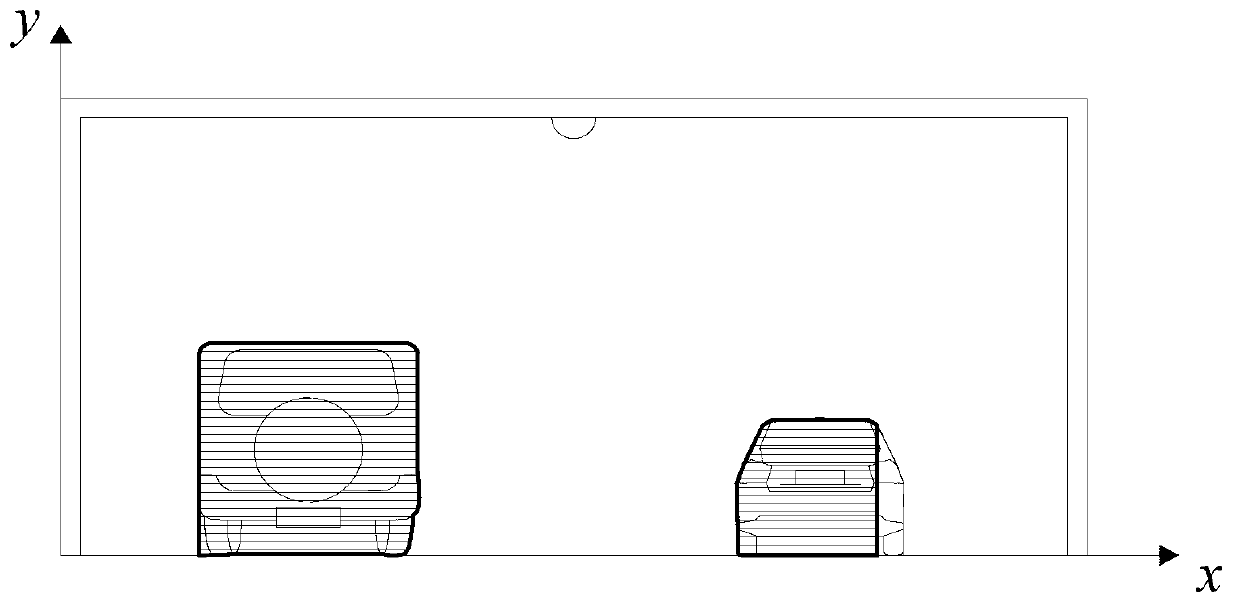

ActiveCN103279996AImprove detection accuracyEasy to identifyTicket-issuing apparatusRoad vehicles traffic controlDot matrixLaser scanning

The invention discloses a vehicle information detecting and recognizing system under the multilane condition. The vehicle information detecting and recognizing system comprises a computer system and a portal frame stretching over lanes, wherein a laser scanner and a high-definition license plate recognition device are arranged on the portal frame, a first dot matrix type wheel shaft sensor, a shaft weight sensor and a second dot matrix type wheel shaft sensor are sequentially arranged on the lane under the portal frame, and the laser scanner, the high-definition license plate recognition device, the first dot matrix type wheel shaft sensor, the shaft weight sensor and the second dot matrix type wheel shaft sensor are respectively connected with the computer system. The vehicle information detecting and recognizing system has the advantages that the two-dimension cross section size and the running position of a vehicle are detected through the laser scanner, and the vehicle three-dimension reconstitution and the vehicle separation are realized; the license plate information and the human face information are precisely collected through the license plate recognition device; the vehicle information such as the shaft distance, the shaft length, the shaft number, the shaft type, the wheel distance, the wheel width and the wheel number are measured according to signals output after a vehicle tyre presses the wheel shaft sensor; and the shaft weight and the total weight are measured through the shaft weight sensor.

Owner:广州顺如电子科技有限公司

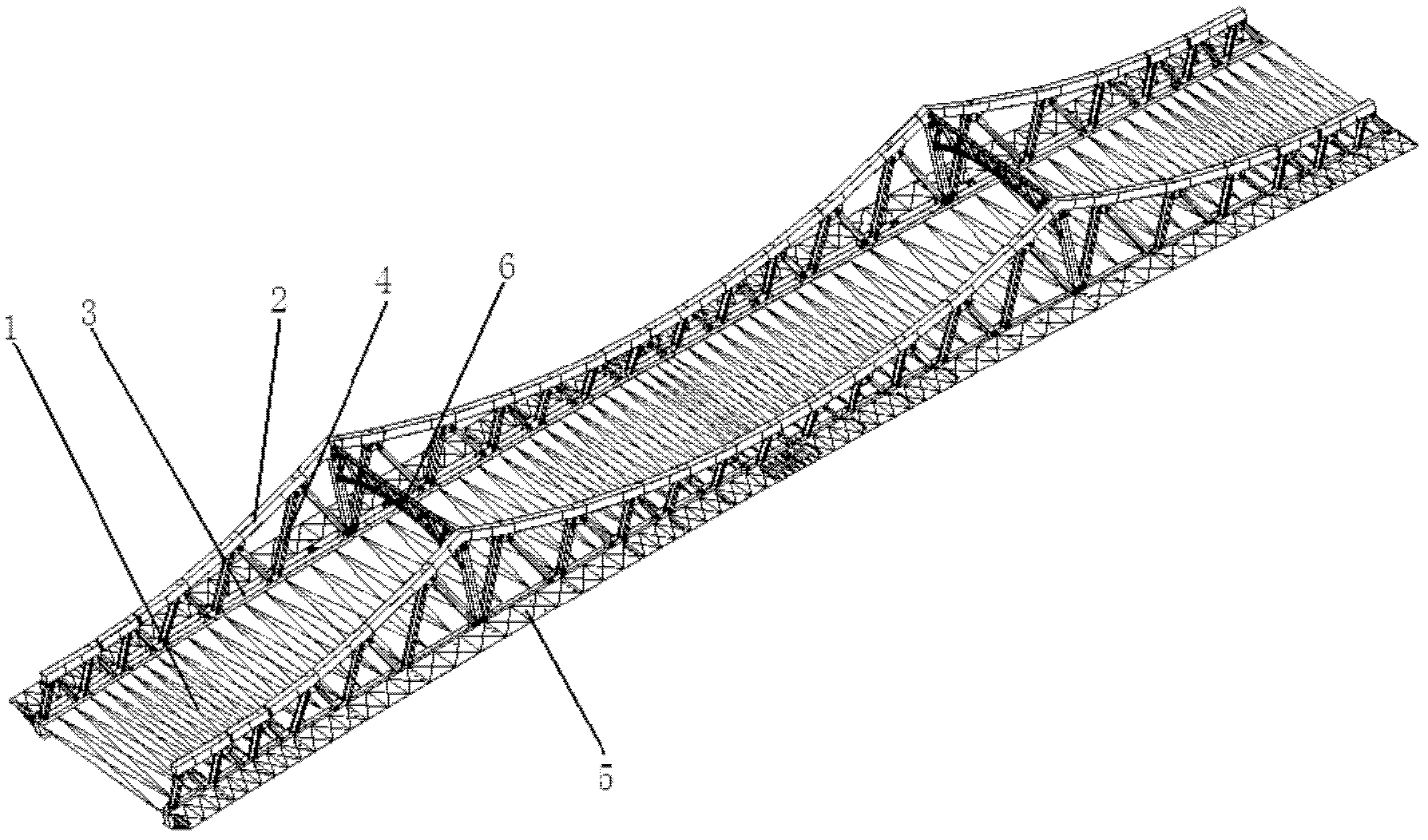

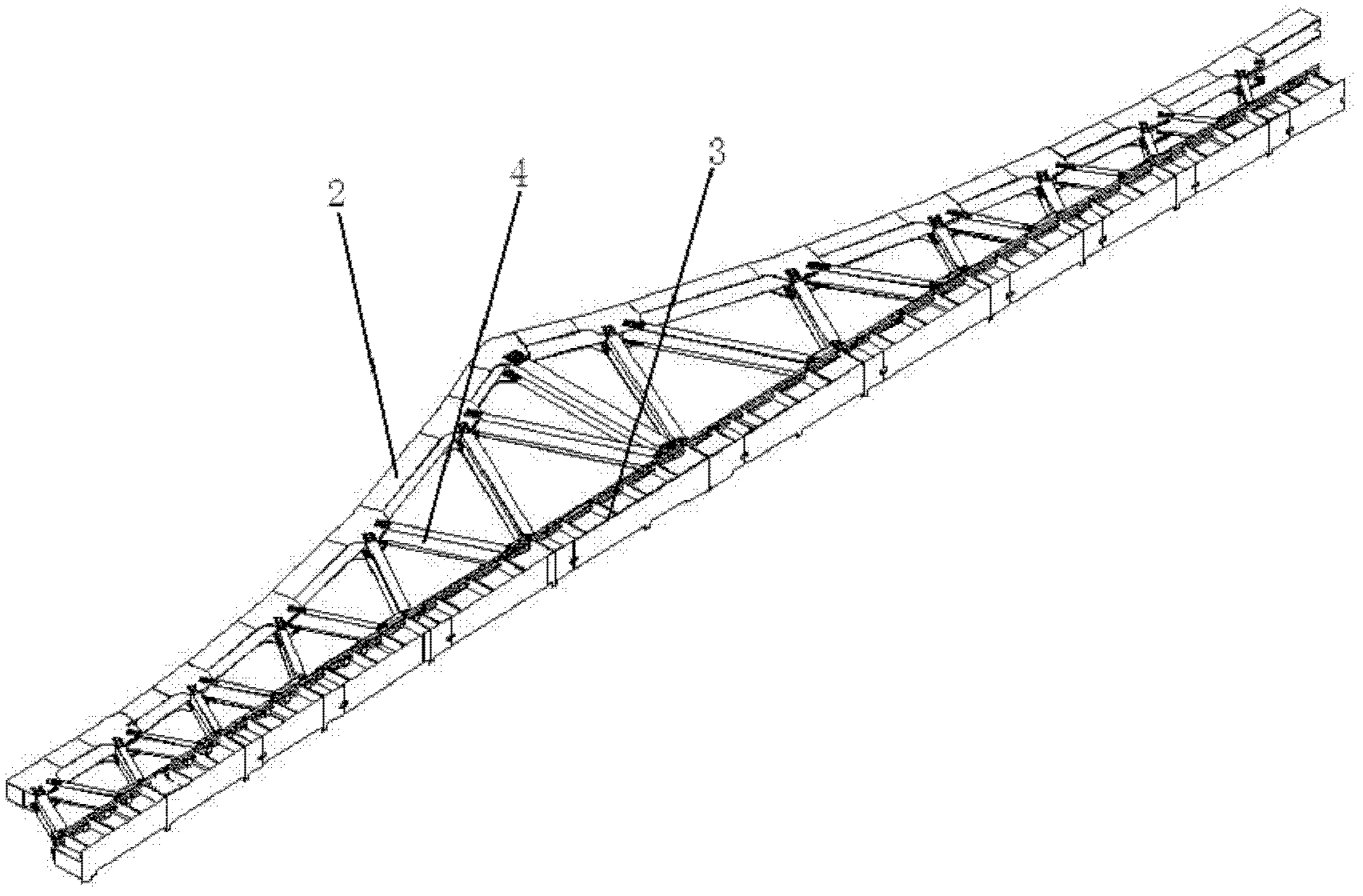

A kind of steel truss bridge and its manufacturing method

ActiveCN102277825AImprove stabilityImprove securityTruss-type bridgeBridge structural detailsBridge deckEngineering

The invention discloses a steel truss bridge and a method for fabricating the same. The steel truss bridge comprises a steel box girder bridge deck, a main truss composed of two steel trusses, and a steel portal frame. The steel truss comprises an upper chord member, a lower chord member, and a web member which is connected with the upper chord member and the lower chord member through bolts. A sidewalk bracket is arranged outside each steel truss. The lower chord member is connected to the steel box girder bridge deck and the sidewalk bracket, respectively. Besides, the two steel trusses are connected through the steel portal frame. During fabrication, all the sections of the steel trusses, the steel portal frame and the bridge deck are independently fabricated, respectively; all the sections of the upper and lower chord members of the steel truss are pre-assembled circularly with the corresponding web members, and all the sections of the steel box girder bridge deck are pre-assembled with the corresponding lower chord members by an orthotectonic method, respectively; and the steel portal frame is pre-assembled with the steel trusses. The steel truss bridge disclosed by the invention completely meets the design requirements so that the stability and safety factor of the bridge can be enhanced; and by employing the fabricating method, positioning is accurate so that the risks during the field assembling can be reduced; and the construction period can be shortened.

Owner:JIANGSU JINGHU HEAVY IND

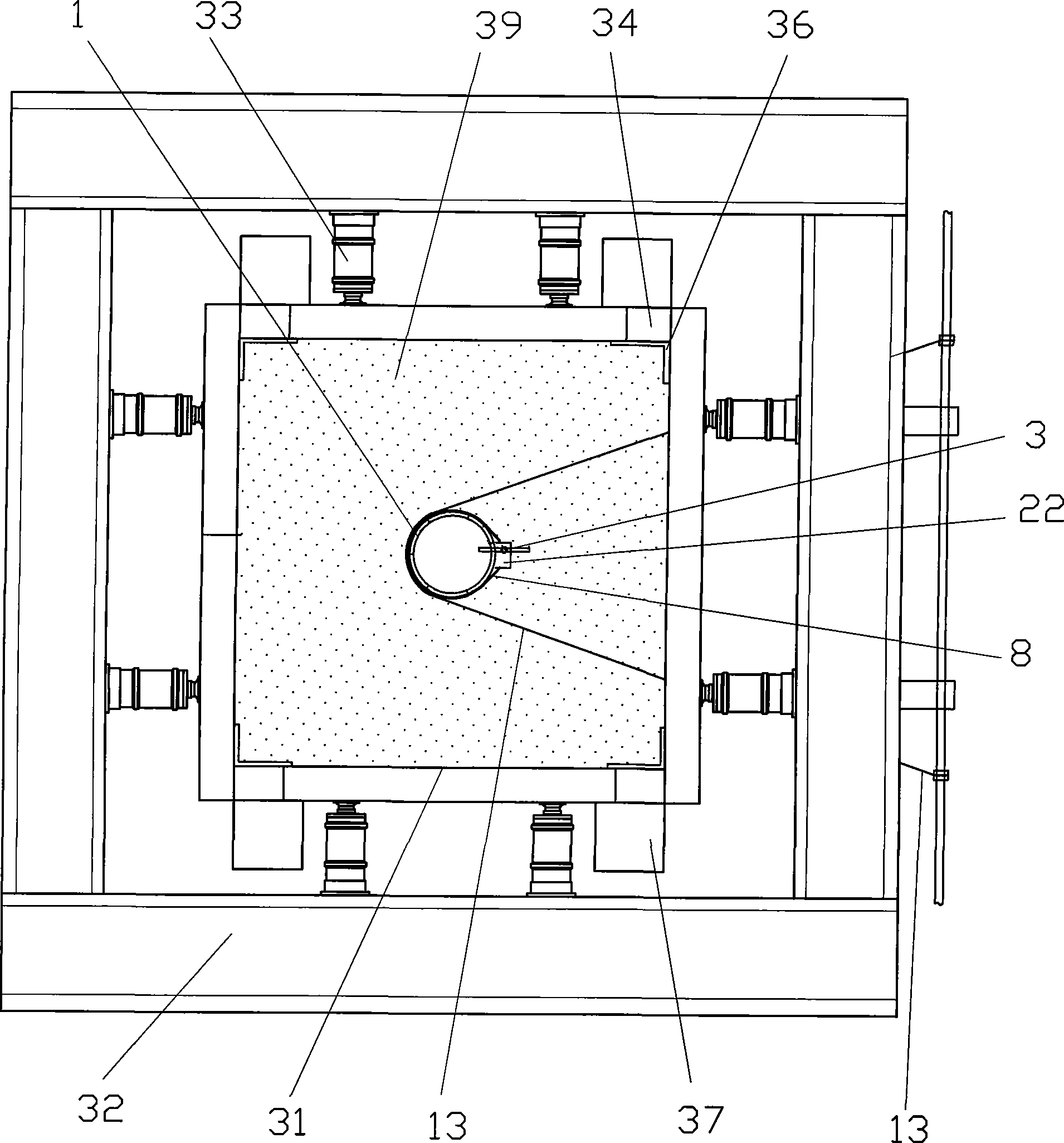

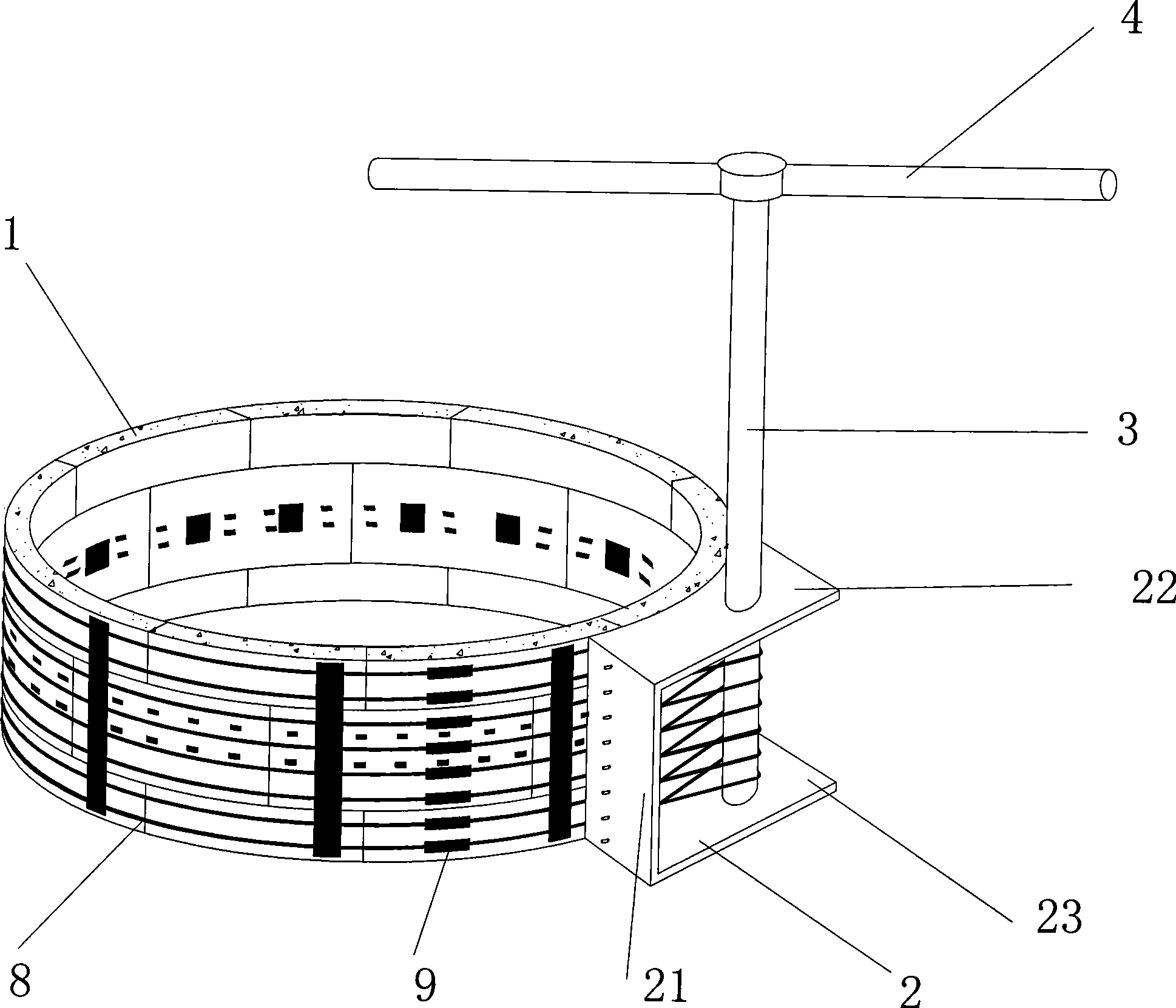

Comprehensive test system of shield tunnel construction model

InactiveCN101435746ARealistic simulation of formation pressureThe test data is accurateForce measurementStructural/machines measurementEngineeringShield tunnelling

The invention provides a comprehensive testing system for a shield tunnel structural model, which comprises a soil horizon simulating and soil pressure loading device and a tunnel structural model; the soil horizon simulating and soil pressure loading device is a simulated soil body cavity enclosed by steel plates; a horizontal reaction frame is arranged outside the soil body cavity; a horizontal soil pressure jack is connected between each edge of the reaction frame and the soil body cavity; the tunnel structural model is attached with a uniform water pressure loading device and a non-uniform water pressure loading device, and is axially and vertically arranged in the center of the soil body cavity; simulation testing soil is filled between the tunnel structural model and the soil body cavity; the upper part of the soil body cavity is covered by a steel cover board; a vertical reaction portal frame is arranged above the soil body cavity; and a vertical soil pressure jack is connected between the lower part of a girder of the vertical reaction portal frame and the steel cover board. The system can simulate interactions between tunnel structures in different forms of fractures with the stratum under different stratigraphic and hydrologic conditions, and more truly simulate the environment conditions of the tunnel structures with more accurate and reliable test data, thereby providing more reliable safeguard for shield tunnel constructions.

Owner:SOUTHWEST JIAOTONG UNIV

Automatic wire arranging device and method

ActiveCN103662967ASolve the problem of changing direction in timeSolve the flatnessFilament handlingManufacturing technologyEngineering

The invention discloses an automatic wire arranging device and belongs to the technical field of cable manufacturing. The existing wire arranging method is prone to notches, wire accumulation and wire jumping. The device comprises a portal frame, a transverse moving platform, a mechanical arm, a lifting mechanism, a horizontal moving mechanism, a dynamic complementing mechanism, an automatic reversing mechanism, a wire winding mechanism, a portal auxiliary frame, a controller and an encoder. Wire arranging is conducted according to a set pitch, in a wire arranging process, the wire arranging device can conduct position complementing control according to actual production conditions, a sheathed line and a designed mechanism structure are arranged in a set angle range, and the conditions of notches and wire jumping during wire arranging can not happen.

Owner:HANGZHOU FUTONG ELECTRIC WIRE & CABLE

Masonry anchoring system

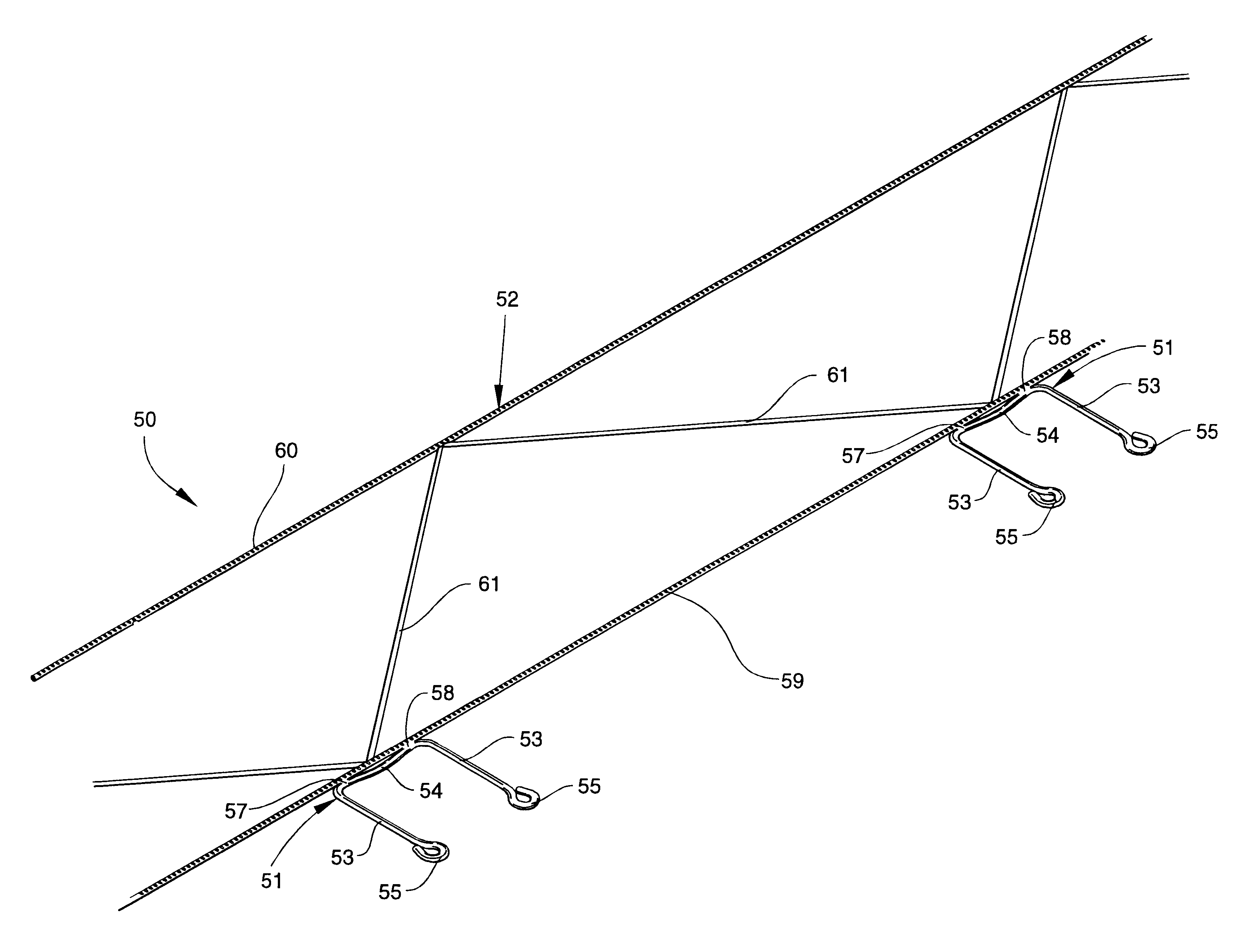

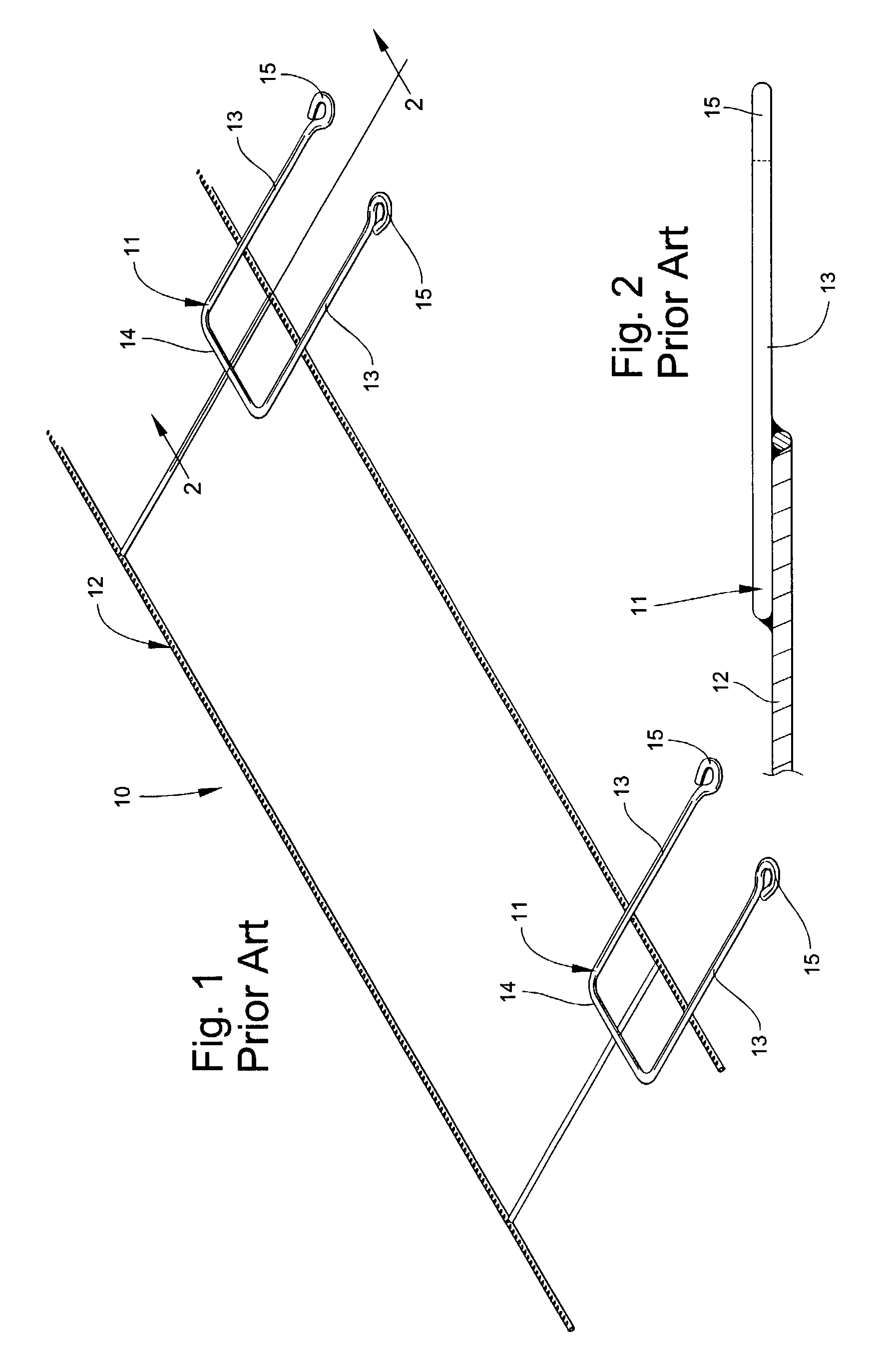

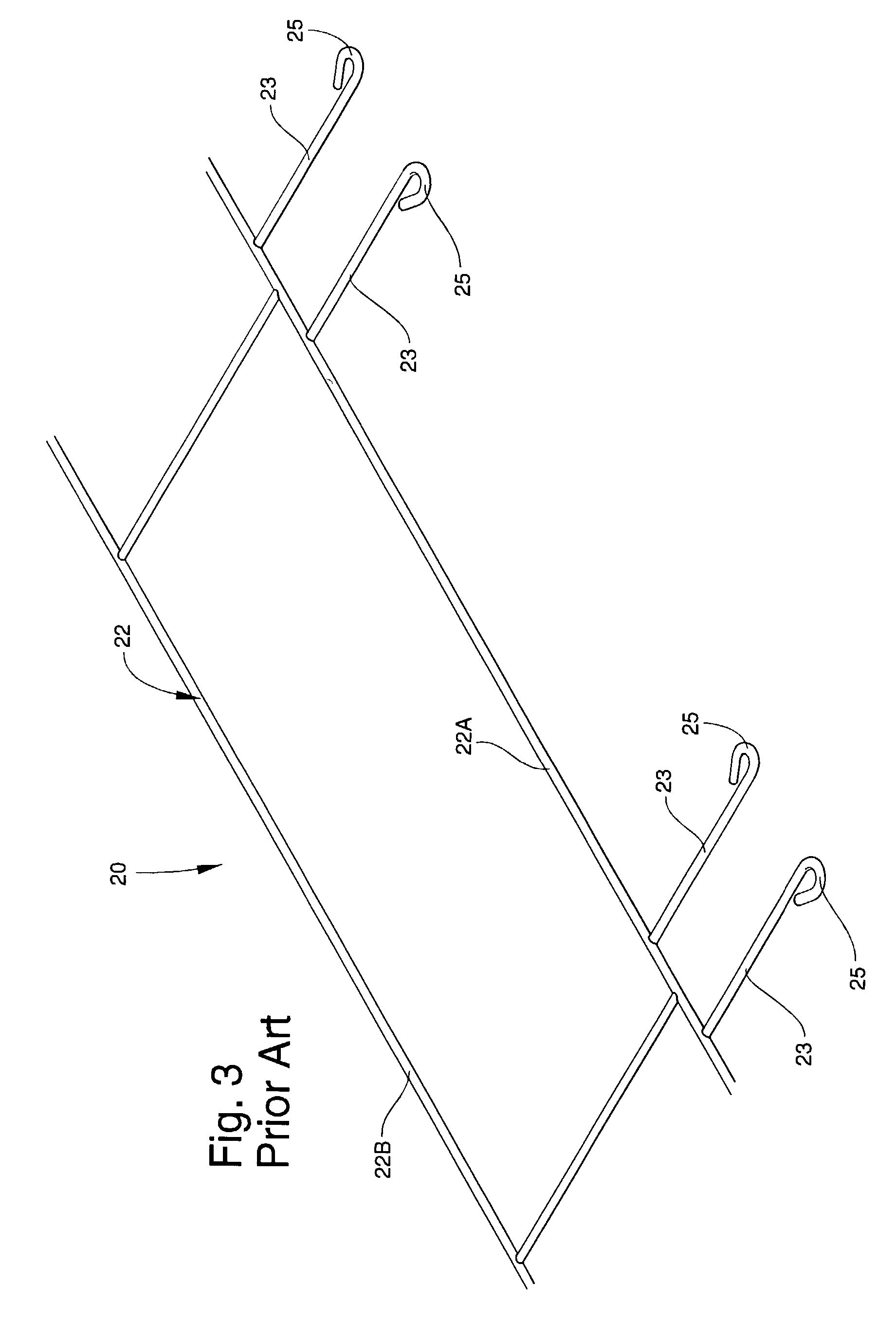

InactiveUS20040083667A1Stable structureExtension of timeConstruction materialStrutsBraced framePortal frame

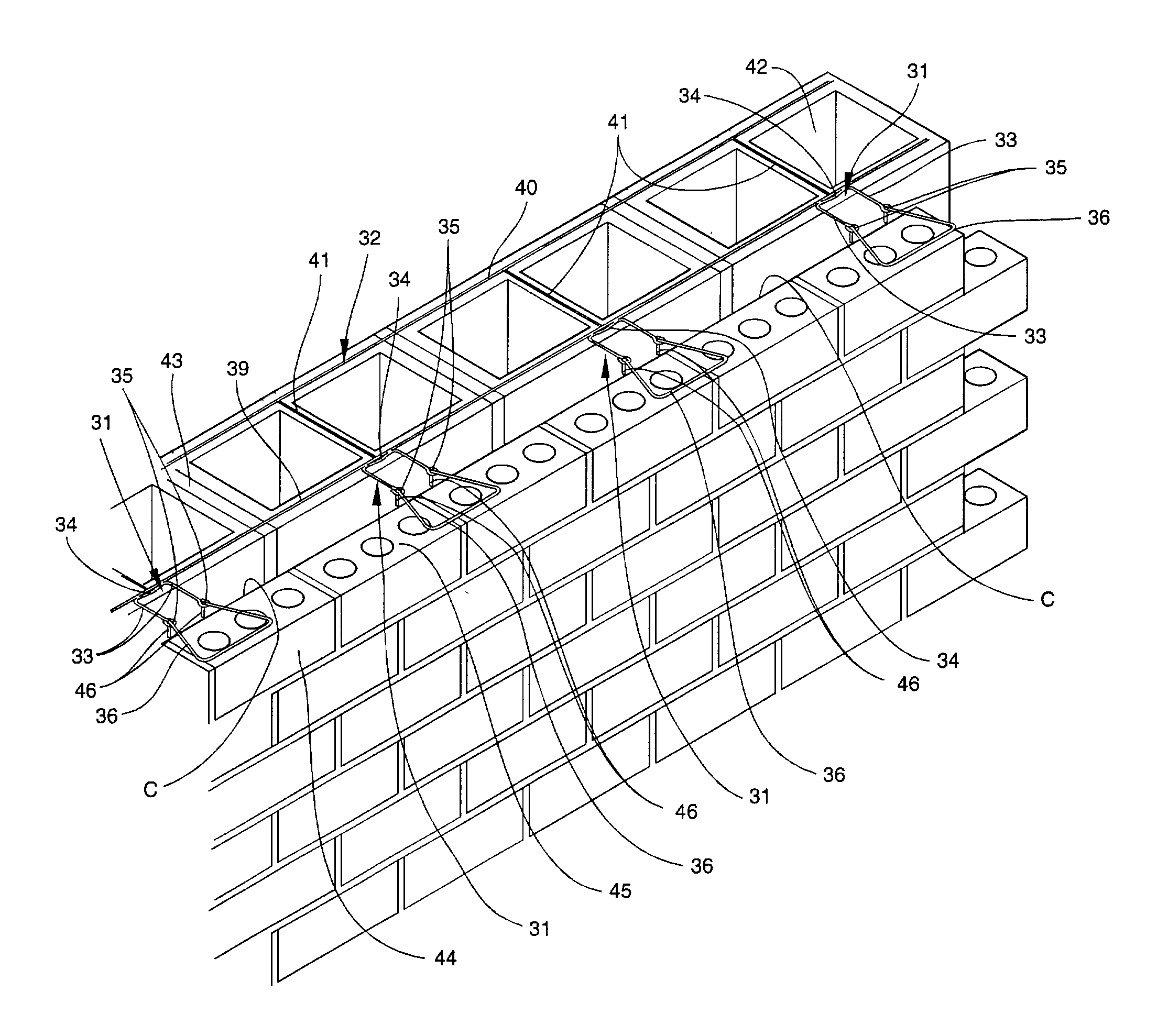

An masonry anchor is disclosed for anchoring two spaced apart masonry walls together to form a single wall structure. The masonry anchor includes a ladder or truss type support frame for positioning on top of a mortar joint in one wall, and a bracket having a pair of elongate arms connected by a cross-member affixed to the support frame. The cross-member is angled for providing two spaced apart points on the cross-member for contacting the support frame and affixing the cross-member thereto. The elongate arms extend transversely from the support frame and are sized to extend into the space between the two walls. Each of the arms have an eye portion formed at the end opposite the cross-member to receive a connecting member connected to the second wall. The support frame and the bracket reside in the same horizontal plane.

Owner:MASONRY REINFORCING OF AMERICA

Novel numerically controlled special-shaped glass edge grinding machine

InactiveCN104759962AEnsure consistencyBest force contact areaEdge grinding machinesGrinding machine componentsEngineeringSlide plate

The invention provides a novel numerically controlled special-shaped glass edge grinding machine. A glass workpiece is adsorbed on a frame; a portal frame sliding along the Y axis is mounted on the frame; an X-axis sliding plate sliding along the X axis is mounted on the portal frame; a Z-axis sliding plate sliding up and down along the Z axis is mounted on the X-axis sliding plate; a main shaft mechanism is mounted on the Z-axis sliding plate; a tilt-angle main shaft sleeve is fixed on the Z-axis sliding plate; a tilt-angle main shaft is mounted in the tilt-angle main shaft sleeve; one end of the tilt-angle main shaft is in driving connection with a tilt-angle servo motor, while the other end of the tilt-angle main shaft is connected with a tilt-angle rotating stand; a transversely sliding assembly is arranged on the tilt-angle rotating stand; a grinding head motor is connected to the transversely sliding assembly by use of a transversely sliding plate; an elastic compensation assembly for driving the transversely sliding plate to slide front and back is connected to one side of the transversely sliding plate; a cutting tool is mounted on the output shaft of the grinding head motor; an automatic grinding wheel compensation function can be realized, so that the cutting tool is always held down in contact with the glass workpiece in the grinding process; as a result, a consistent grinding effect can be achieved, and the glass workpiece can be consistent in smoothness after being ground.

Owner:刘忠文 +1

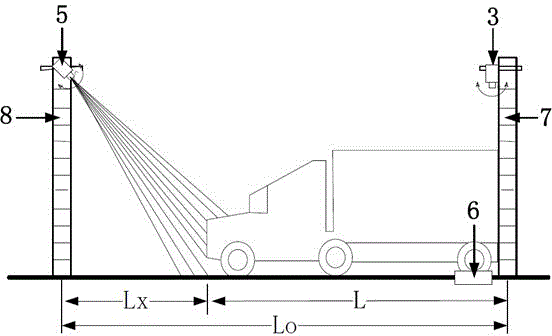

System and method for automatically measuring dimension and weight of road vehicle

InactiveCN104655249AAvoid forceReal-time measurementUsing optical meansSpecial purpose weighing apparatusRadarEngineering

The invention relates to a system and a method for automatically measuring dimension and weight of a road vehicle, in particular to an integrated system and an integrated method for rapidly and dynamically measuring the length, width, height and weight of a vehicle, and aims at effectively solving the problems in overloading detection work at present. According to the system, the dimension information of the vehicle is measured in a front and back portal frames manner; the width and height information of the vehicle in a single lane is measured by combination of two two-dimensional laser radars on the front portal frame, so that the measurement problem caused by vehicle deformation can be effectively avoided; and the length information of the vehicle in the single lane is indirectly measured by virtue of a single laser radar on the rear portal frame; and starting and stopping information of the single vehicle is provided for a shaft-type weighing scale by virtue of a laser radar separation vehicle on the front portal frame. The system has the advantages of high measurement speed and high accuracy, and normal running of the vehicle is not affected.

Owner:WUHAN UNIV

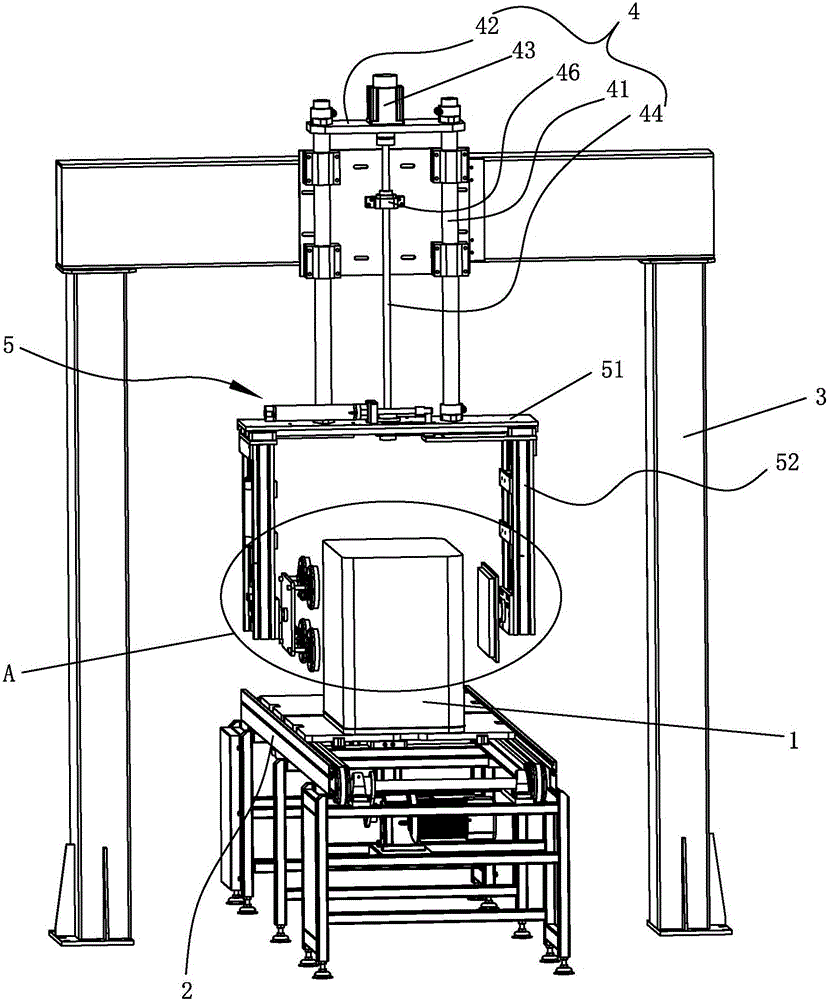

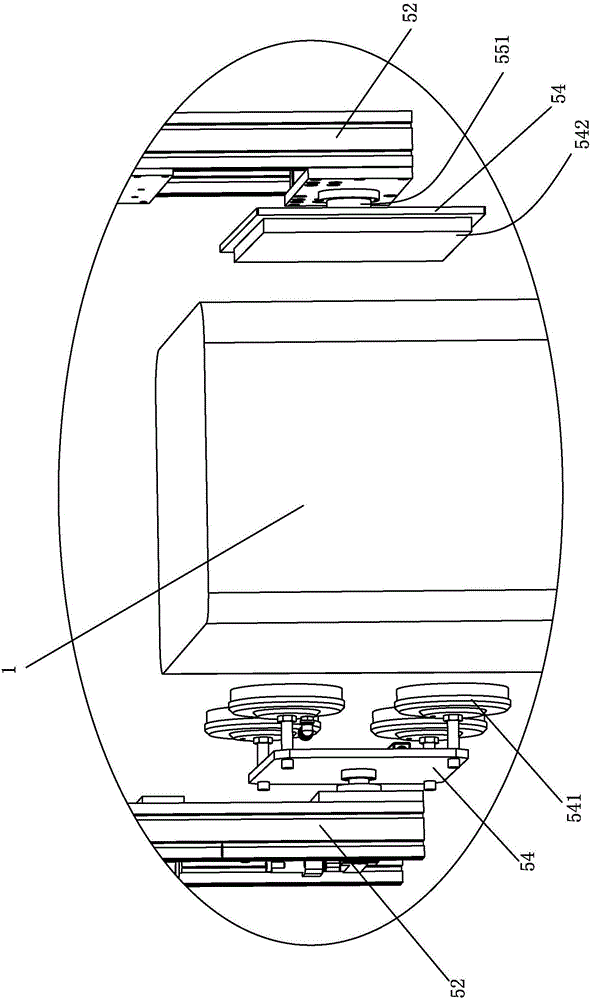

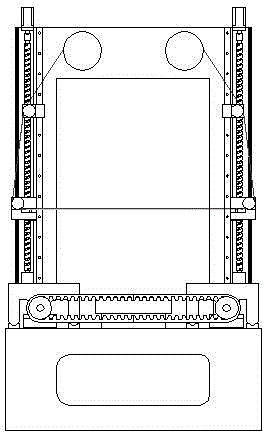

On-line automatic overturning equipment

InactiveCN106044140AReduce labor intensityImprove work efficiencyConveyorsConveyor partsEngineeringPortal frame

The invention discloses on-line automatic overturning equipment. The on-line automatic overturning equipment comprises a conveying line for conveying boxes and a portal frame arranged on the conveying line in a straddling manner; a lifting mechanism is arranged on the portal frame; the lower end of the lifting mechanism is connected with a clamping overturning mechanism; the clamping overturning mechanism comprises a clamping seat and two clamping arms; the clamping seat is connected to the lower end of the lifting mechanism; the two clamping arms are slidably connected onto the clamping seat; the clamping seat is provided with a clamping driving assembly which drives the two clamping arms to carry out clamping or releasing action; the lower ends of the two clamping arms are rotatably connected with clamping blocks for clamping the boxes respectively; an overturning driving assembly which is used for driving the corresponding clamping block to overturn so as to overturn the boxes is arranged between each clamping arm and the corresponding clamping block. Under collaborative operation of the lifting mechanism and the clamping overturning mechanism, the boxes from the conveying line are automatically overturned at an angle, by the clamping overturning mechanism, the boxes can be quickly and efficiently overturned at an angle, work efficiency is improved, labor intensity of workers is reduced, and production cost is reduced.

Owner:GUANGDONG HANDSOME INTELLIGENT EQUIP CO LTD

Three-dimensional laser cutting machine in five-axis linkage

ActiveCN104842067APromote sportsIncrease exerciseLaser beam welding apparatusHead movementsLight beam

The invention relates to a three-dimensional laser cutting machine in five-axis linkage. The three-dimensional laser cutting machine in five-axis linkage comprises a body, worktables, a portal frame and a laser cutting system. The worktables include an A-axis rotating worktable and a B-axis rotating worktable arranged above the A-axis rotating worktable. A laser device mounting seat is arranged at the top of the portal frame and moves at the top of the portal frame along the width direction of the body through an X-axis translation mechanism, a vertical column is arranged at the top of the laser mounting seat, and a laser conduction system mounting plate moves up and down along the vertical column through a Z-axis translation mechanism. The three-dimensional laser cutting machine in five-axis linkage has the advantages that five-axis machining of workpieces is achieved under cooperation between laser cutting head movement with worktable movement, so that special-shaped workpieces with complex spatial curved surfaces can be cut; since laser beams need no multi-time light path conversion, laser power loss is little and cutting efficiency is high; a laser cutting head is simple to move, convenient to control and program and high in controllability.

Owner:JINAN WEIER LASER EQUIP

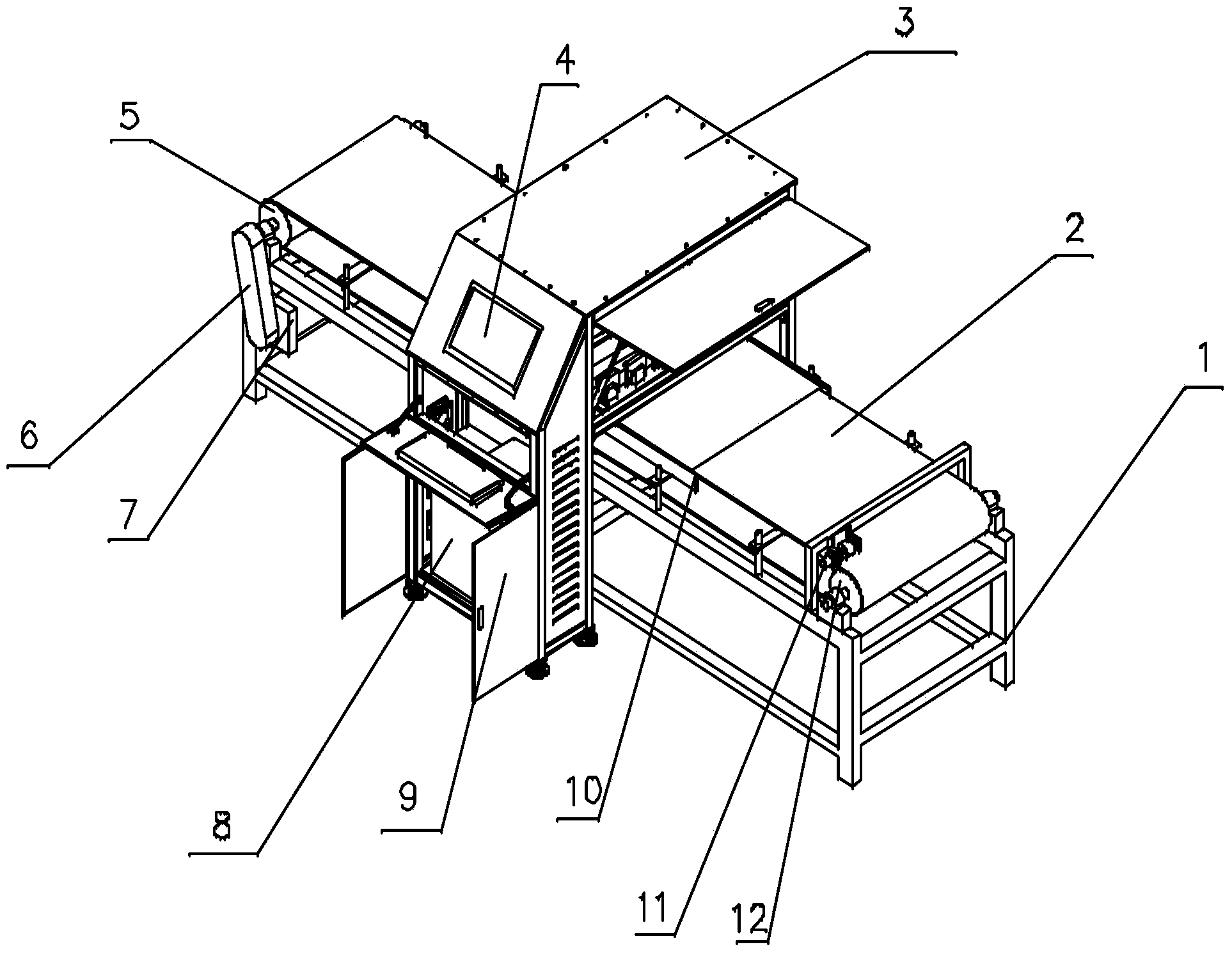

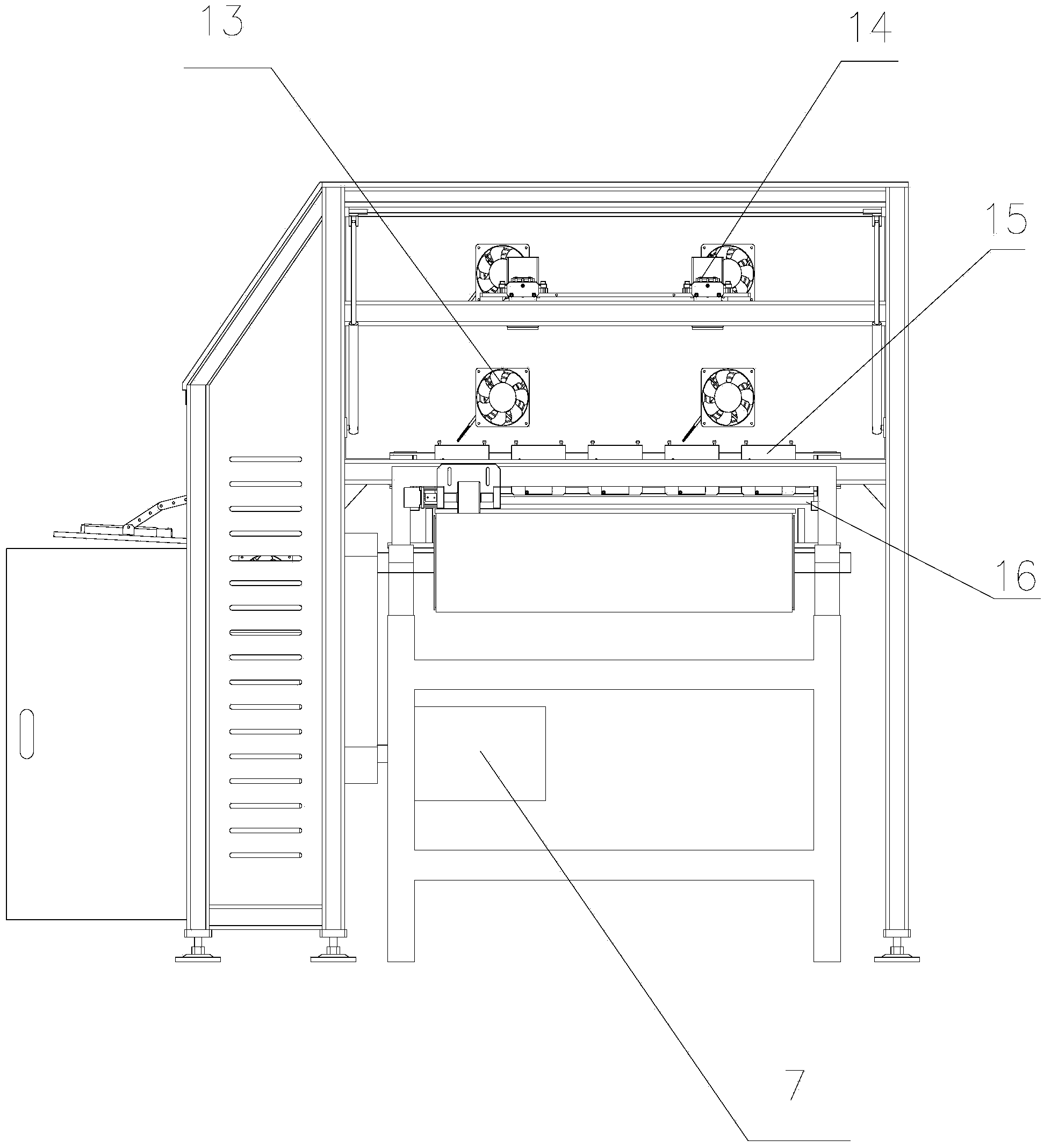

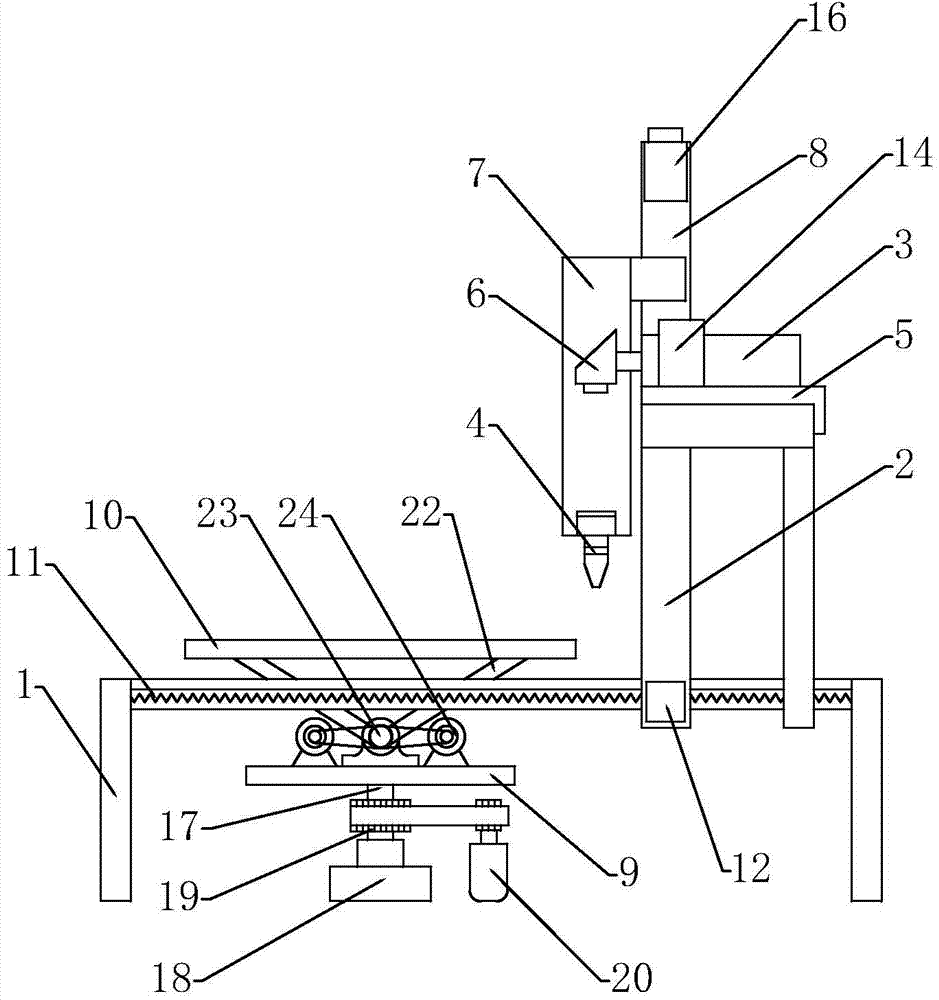

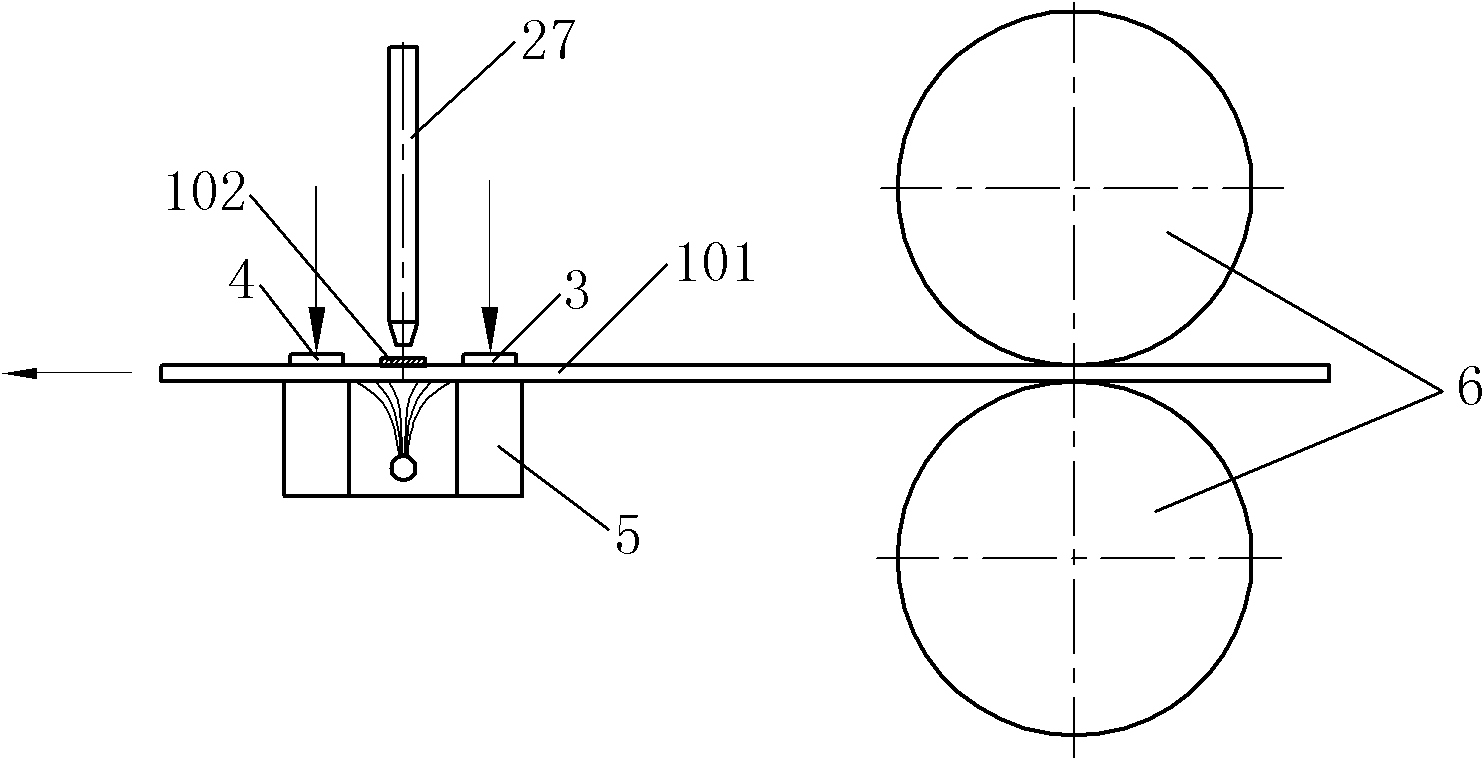

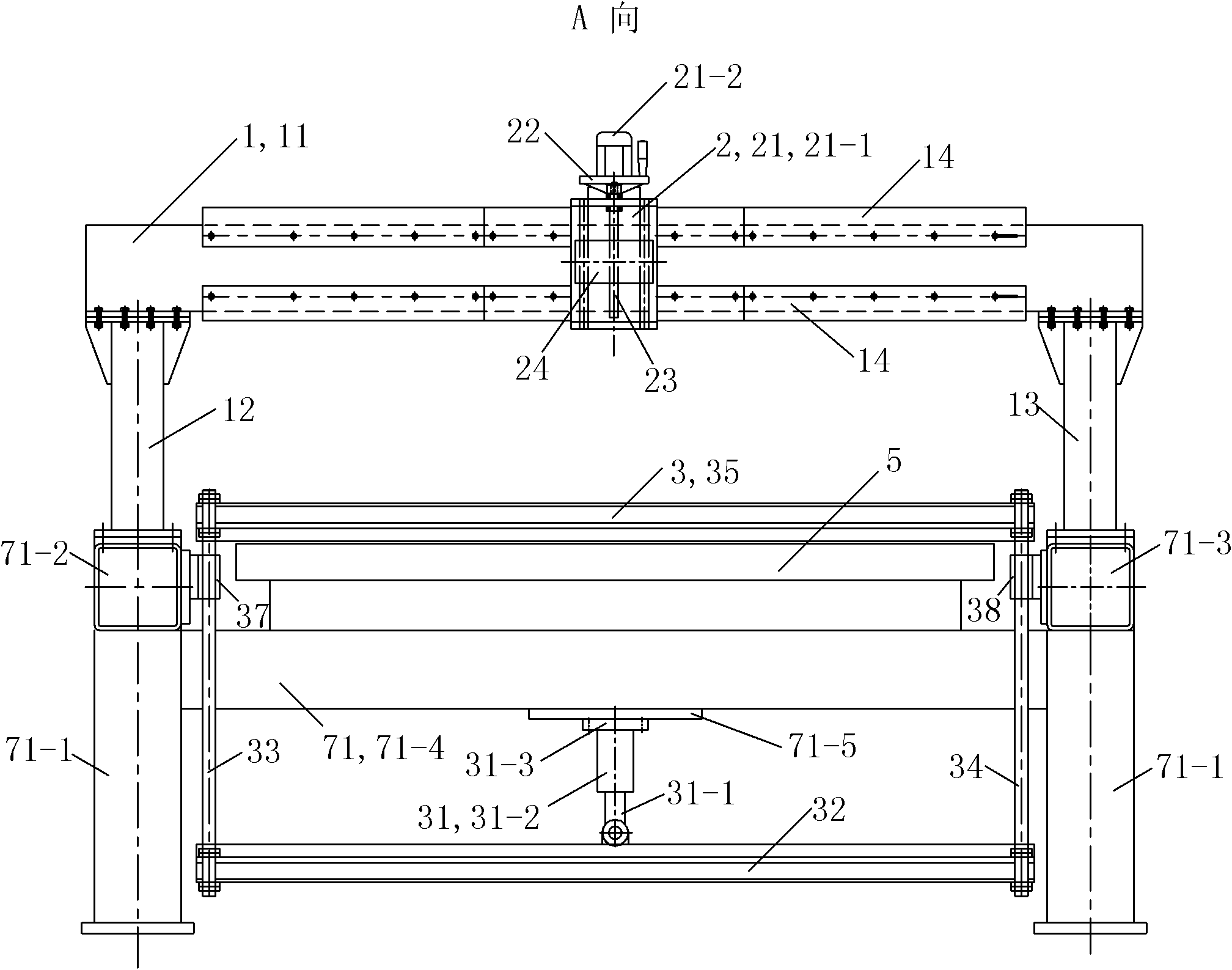

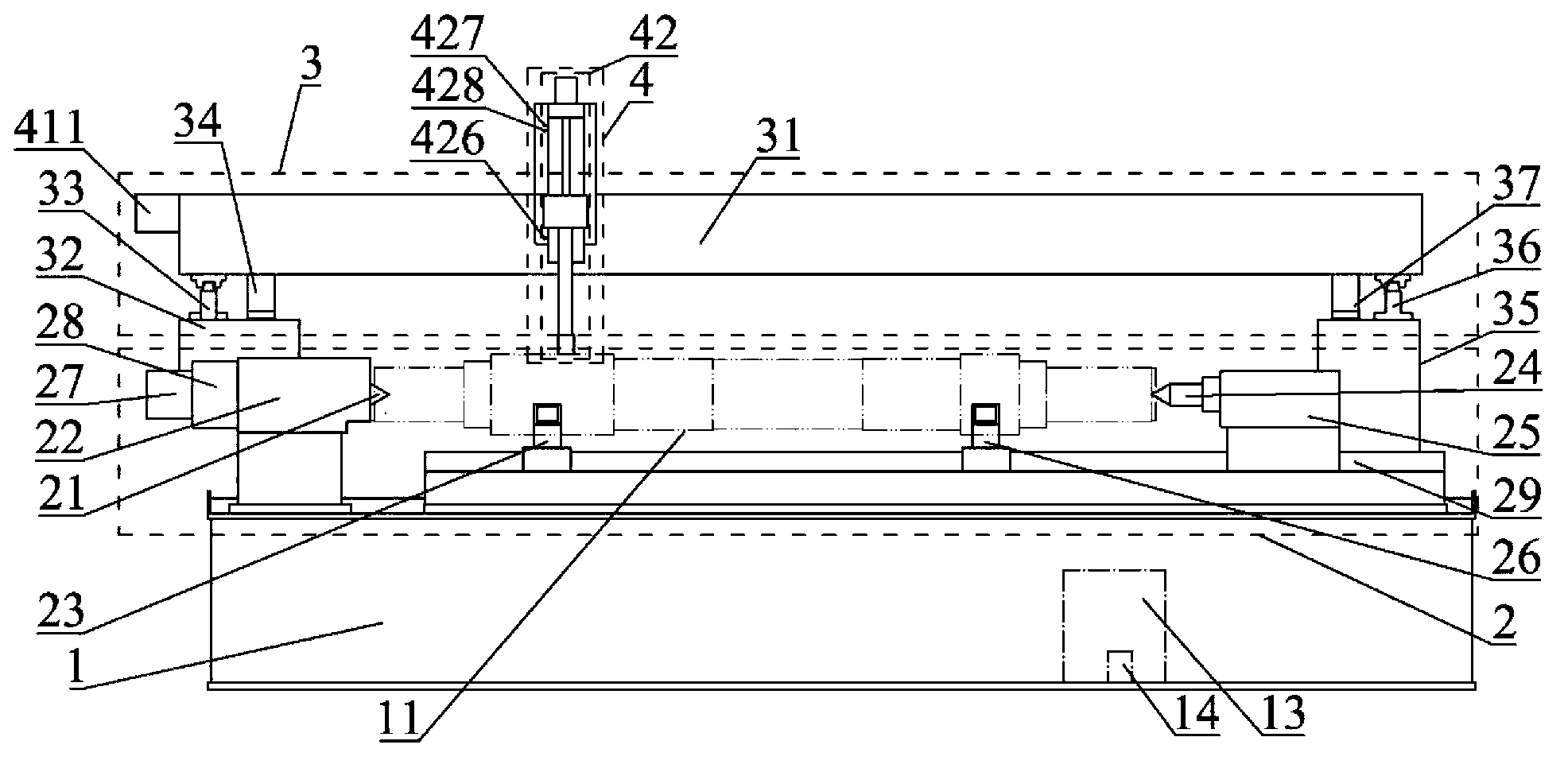

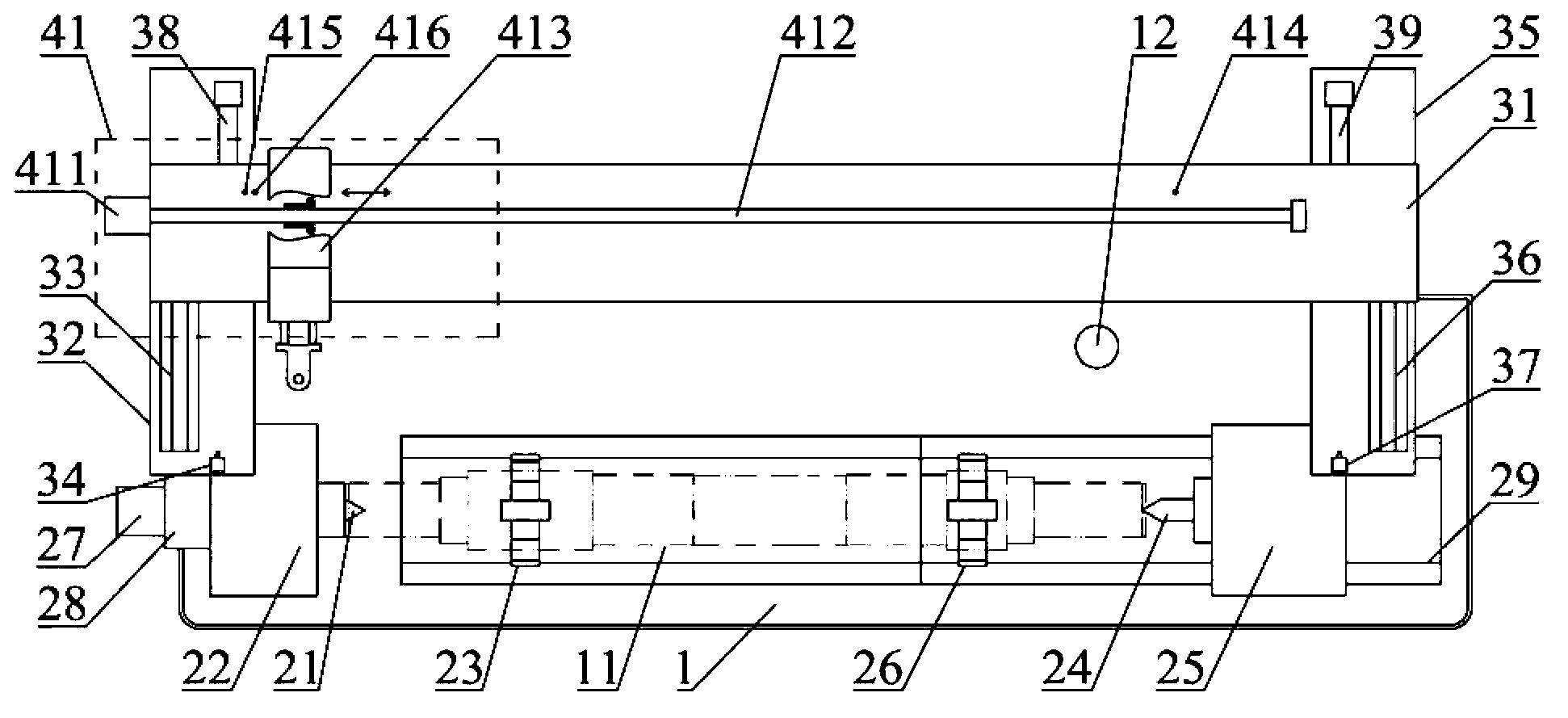

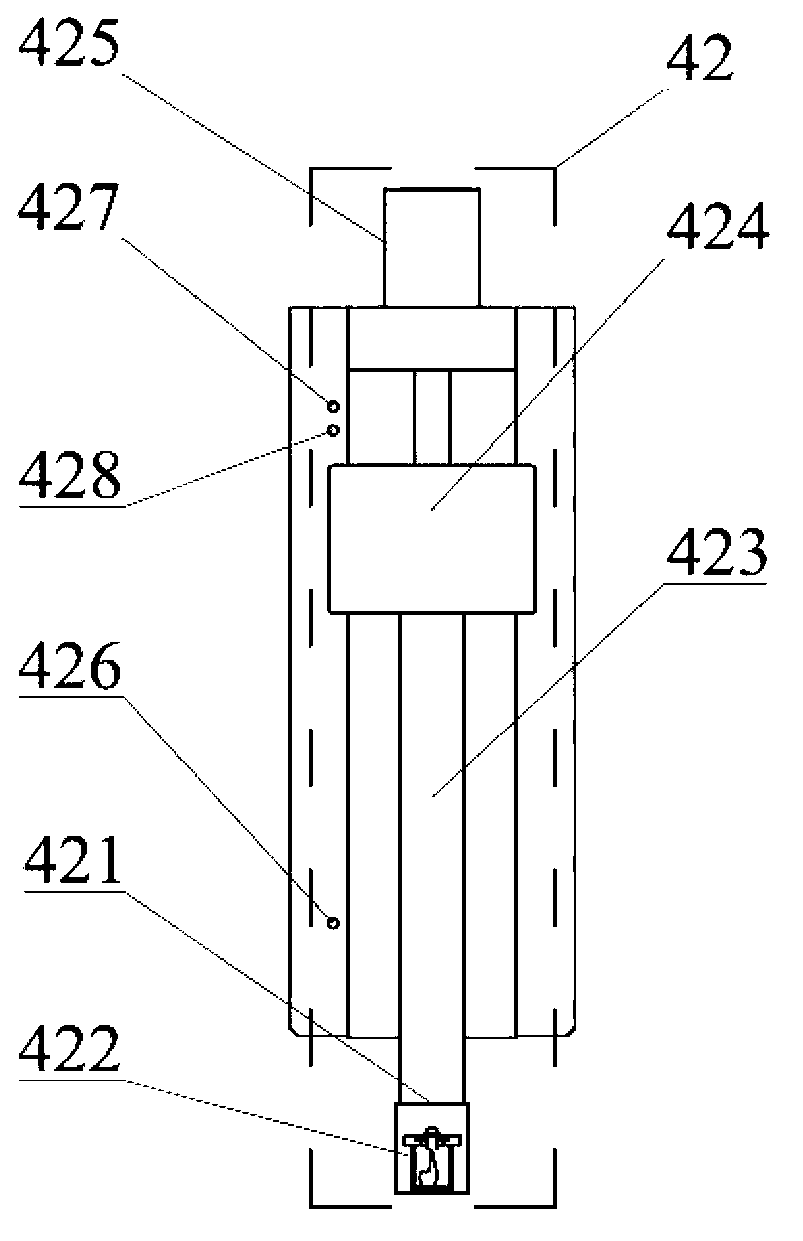

Method and equipment for manufacturing surfacing composite wear-resistant steel plate

ActiveCN102107315AImprove flatnessShrink flatWelding/cutting media/materialsSoldering mediaSheet steelWear resistant

The invention discloses a method for manufacturing a surfacing composite wear-resistant steel plate, which comprises the following steps of: tiling a steel base plate on a water-cooled platform, and compacting the steel base plate by employing front and rear side compaction devices respectively; after a weld pass is welded, opening the front and rear side compaction devices, and conveying the steel base plate for a certain distance forward through a pinch roll device; and repeating the steps for surfacing, until a flat surfacing composite wear-resistant steel plate with a high-chromium alloy wear-resistant layer is obtained on the whole steel base plate. A piece of equipment for manufacturing the surfacing composite wear-resistant steel plate applied to the method for manufacturing the surfacing composite wear-resistant steel plate comprises a portal frame, a welding device, a rear side compaction device, a front side compaction device, a water-cooled platform, a pinch roll device and a frame, wherein the rear side compaction device is arranged on the rear side of the welding device; and the front side compaction device is arranged on the front side of a welding gun of the welding device. The composite wear-resistant steel plate welded through the manufacturing method is small in deformation and high in welding quality and is not limited to specifications.

Owner:CHANGZHOU FUTONG WELDING

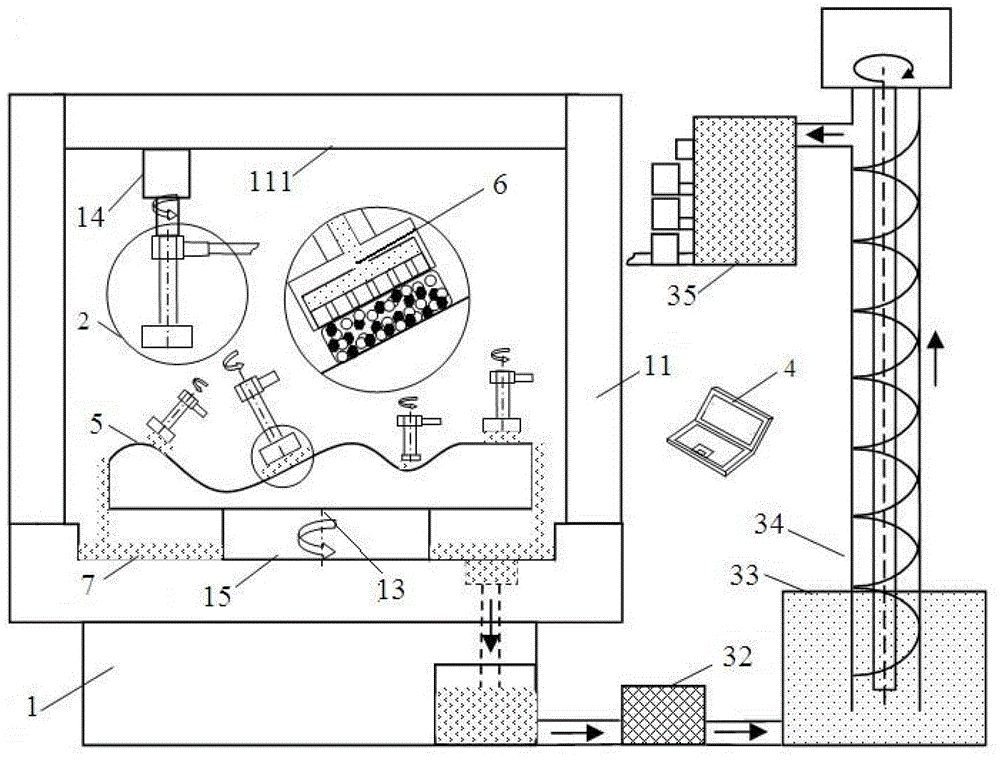

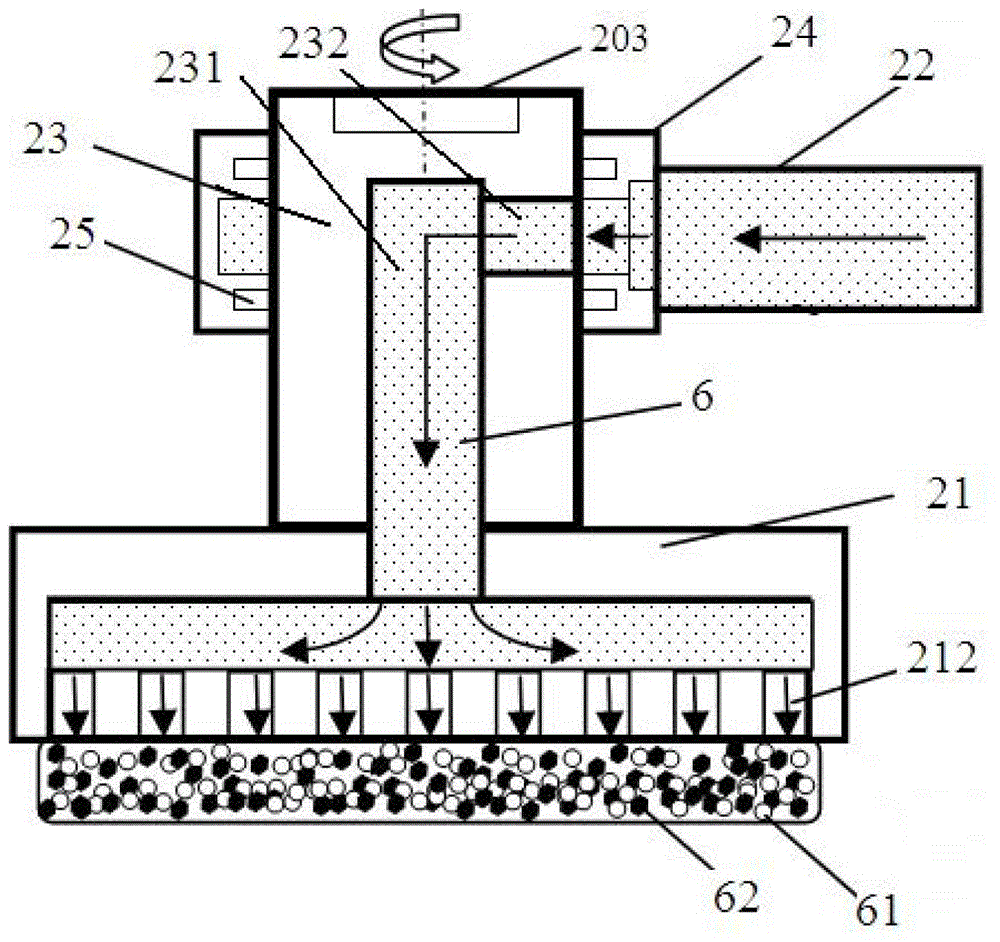

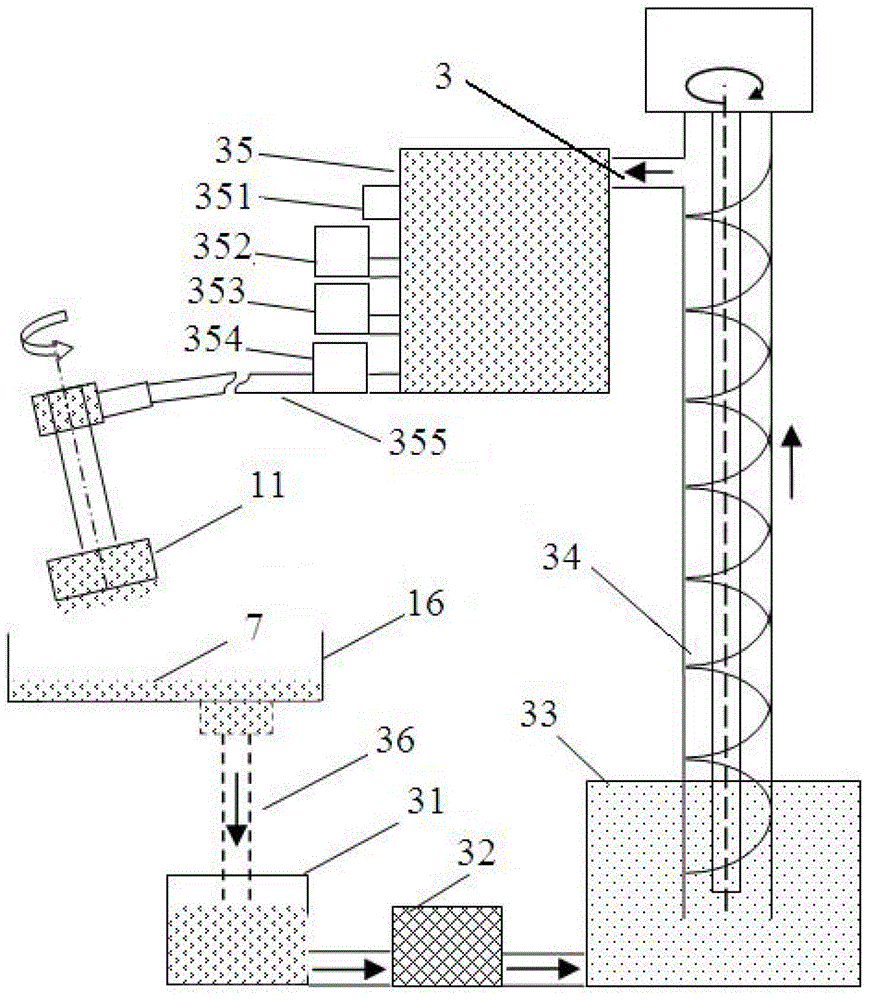

Machining device based on non-Newtonian fluid shear thickening mechanism polishing method

ActiveCN103331685ARealize multi-pose transformationRemovablePolishing machinesEngineeringPortal frame

A machining device based on a non-Newtonian fluid shear thickening mechanism polishing method comprises a workbench, a polishing tool system, an abrasive fluid circulation device and a computer control module, wherein the polishing tool system is installed on a portal frame of the workbench, an inlet of the abrasive fluid circulation device is communicated with an abrasive backflow opening in the workbench, and the workbench, the polishing tool system and the abrasive fluid circulation device are respectively connected with the computer control module. The machining device has the advantages that the application range is wide, the size of machined workpieces is not limited, the structure of the device is simple, the device is controlled easily, a computer controls the operation track of the device, the polishing process of non-Newtonian fluid abrasive fluid and the surfaces of the workpieces can be controlled effectively, a non-Newtonian fluid abrasive fluid circulation system is adopted, and the functions of removing abrasive dust, purifying, recycling, transporting and storing the abrasive fluid, and adjusting performance are achieved.

Owner:ZHEJIANG UNIV OF TECH

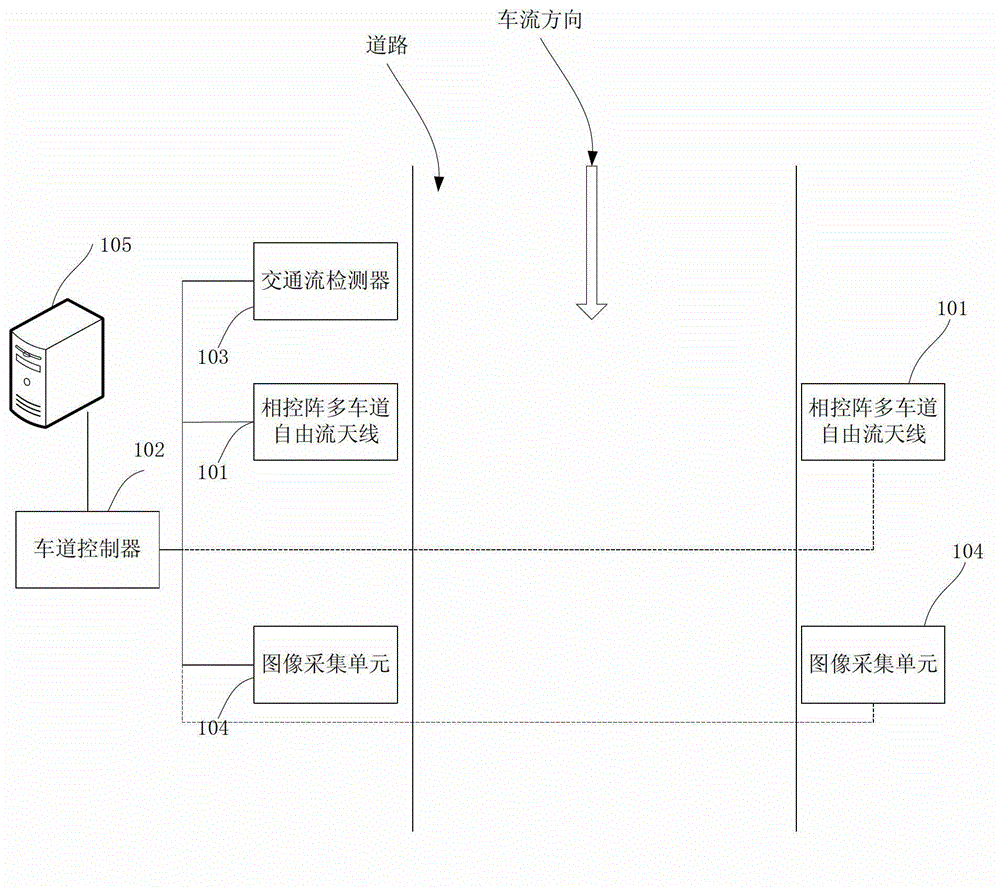

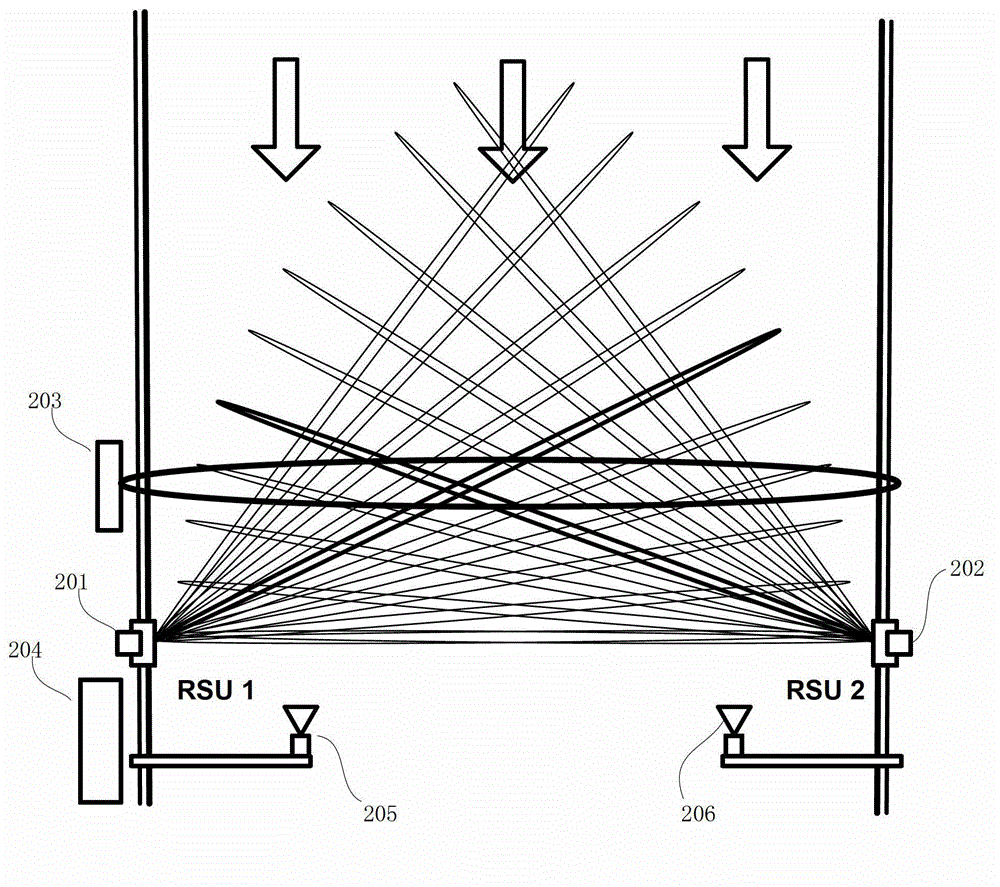

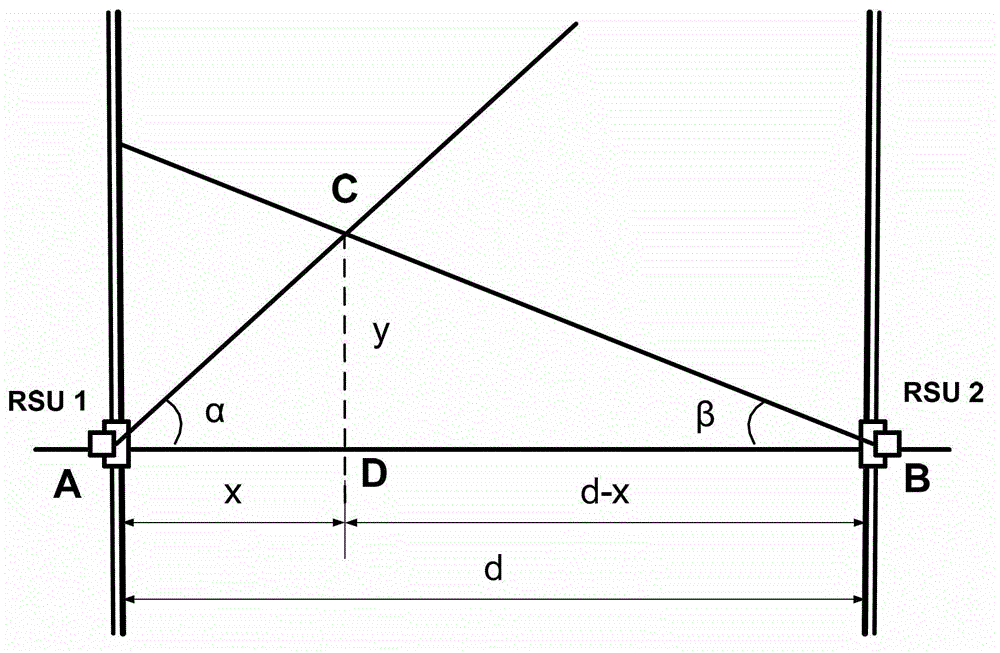

Multi-lane free flow electronic toll collection system arranged on side of road

InactiveCN103150772AReduce erection costSolve technical difficultiesTicket-issuing apparatusTime informationElectronic toll collection system

The invention relates to the field of an intelligent transportation system, in particular to a multi-lane free flow electronic toll collection system arranged on the side of a road. The multi-lane free flow electronic toll collection system comprises at least two phased array multilane free flow antennas arranged on the two sides of the road and used for measuring a vehicle electronic tag on a vehicle as well as angle information between the two phased array multilane free flow antennas respectively and transmitting the angle information as well as first time information during the measurement to a lane controller; and the lane controller is used for calculating according to the angle information between the two phased array multilane free flow antennas as well as self position information to obtain first position information of the vehicle, saving the first position information and the first time information of the vehicle and carrying out toll collection according to the first position information and the vehicle electronic tag of the vehicle. Through the system provided by the embodiment of the invention, the technical difficult problem that a transverse portal frame is erected above the wide road can be solved, so that the erection cost of the multi-lane free flow system is reduced.

Owner:北京速通科技有限公司

Combined type automobile white body dynamic and static state performance flexible integrated test system

InactiveCN101408470ACompact structureReasonable layoutVehicle testingElasticity measurementCombined testStatic performance

A flexible integrated test system of dynamic and static properties of a combination automotive body-in-white comprises a portal frame, a support restraint device, an adjustable concentrated force loading device, a torsion pendulum frame loading device and a measuring appliance assembly. The support restraint device for supporting the automotive body-in-white to be tested is fixed on the portal frame, the measuring appliance assembly is fixed on the portal frame by a support or directly fixed on the portal frame, the adjustable concentrated force loading device and the torsion pendulum frame loading device which loads stress on the automotive body-in-white to be tested are fixed on the portal frame or arranged on the peripheral side of the portal frame. The flexible integrated test system of dynamic and static properties of the combination automotive body-in-white has the advantages of simple and compact structure, reasonable layout, convenient operation, comprehensive function, wide application and good expansibility.

Owner:HUNAN UNIV

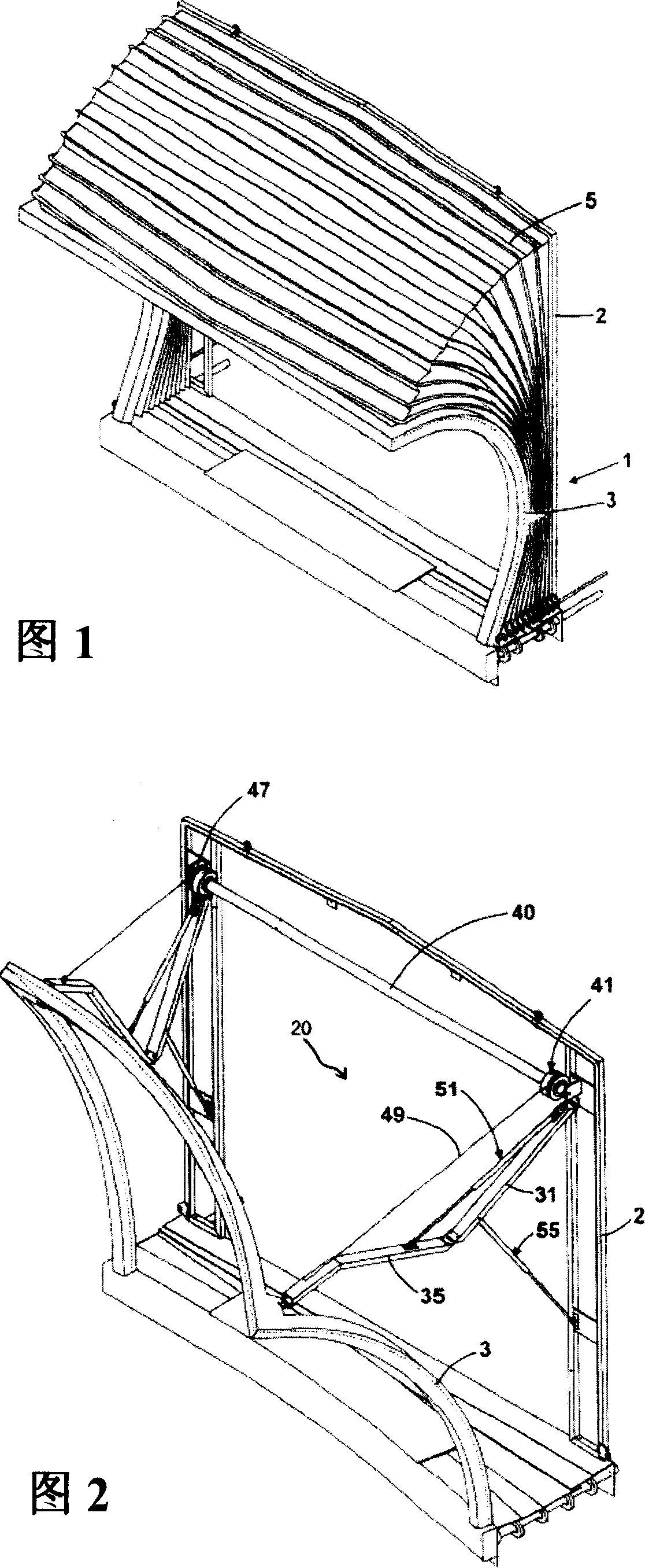

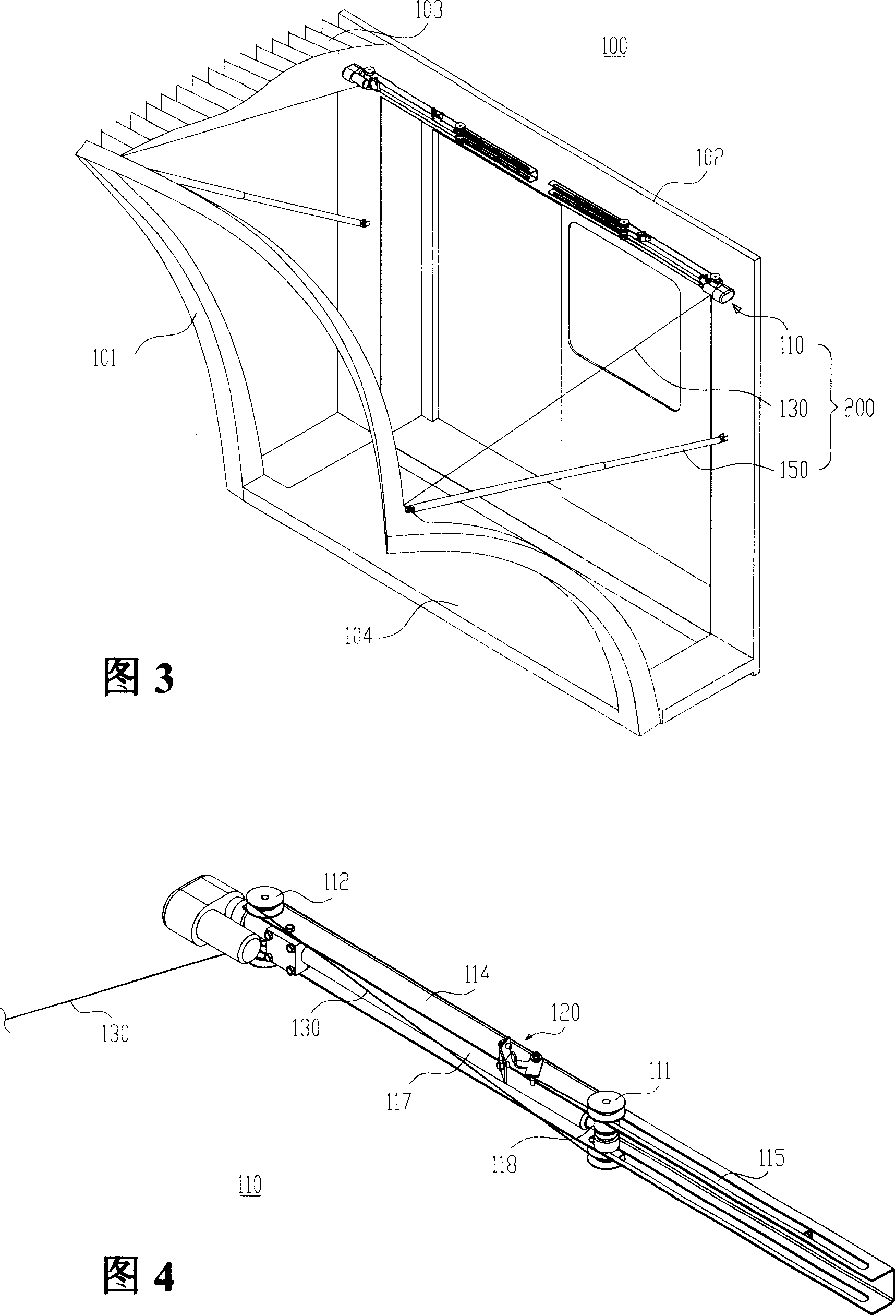

Awning device and its control method and embarking bridge with the awning device

The canopy apparatus for aerobridge includes one flexible frame capable of contacting the airplane covering, one portal frame connected to the aerobridge and one corrugated canopy connected between the flexible frame and the portal frame. The canopy apparatus includes also at least two independent operation mechanisms with one driving unit hinged between the portal frame and the flexible frame to push out the flexible frame each, one retracting mechanism installed onto the portal mechanism and one drawing rope with one end fixed onto the flexible frame and the other end fixed onto the control mechanisms. The retracting mechanism controls the retraction of the flexible frame through the drawing rope. The canopy apparatus of the present invention can well contact airplane covering hermetically.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

Sorting device convenient to classify express packages

ActiveCN108657800AEasy to classifyEasy to pack and transportConveyorsCleaningSurface mountingPortal frame

The invention discloses a sorting device convenient to classify express packages. The sorting device comprises a conveyor; a conveying belt is mounted on the upper surface of the conveyor; an arc block is fixedly mounted on the side, near the conveying belt, of the upper surface of the conveyor; an electrostatic generator is embedded in the conveyor; a cleaning roller is embedded in the upper side, near the electrostatic generator, in the conveyor; a fixed plate is fixedly mounted on one side of the conveyor; an express outlet box is fixedly mounted on the other side of the conveyor; and portal frames are fixedly mounted on the side, near the arc block, of the upper surface of the conveyor. Through the portal frames with different heights, the express packages can be classified and sortedaccording to the heights thereof, so that the express packages in the same regions can be conveniently transported; through a push plate and the arc block, the damage problem of the express packages caused by long-time friction with the conveyor can be prevented; and the electrostatic generator and the cleaning roller can clean the conveying belt during working of the conveyor.

Owner:磐安县天诚科技有限公司

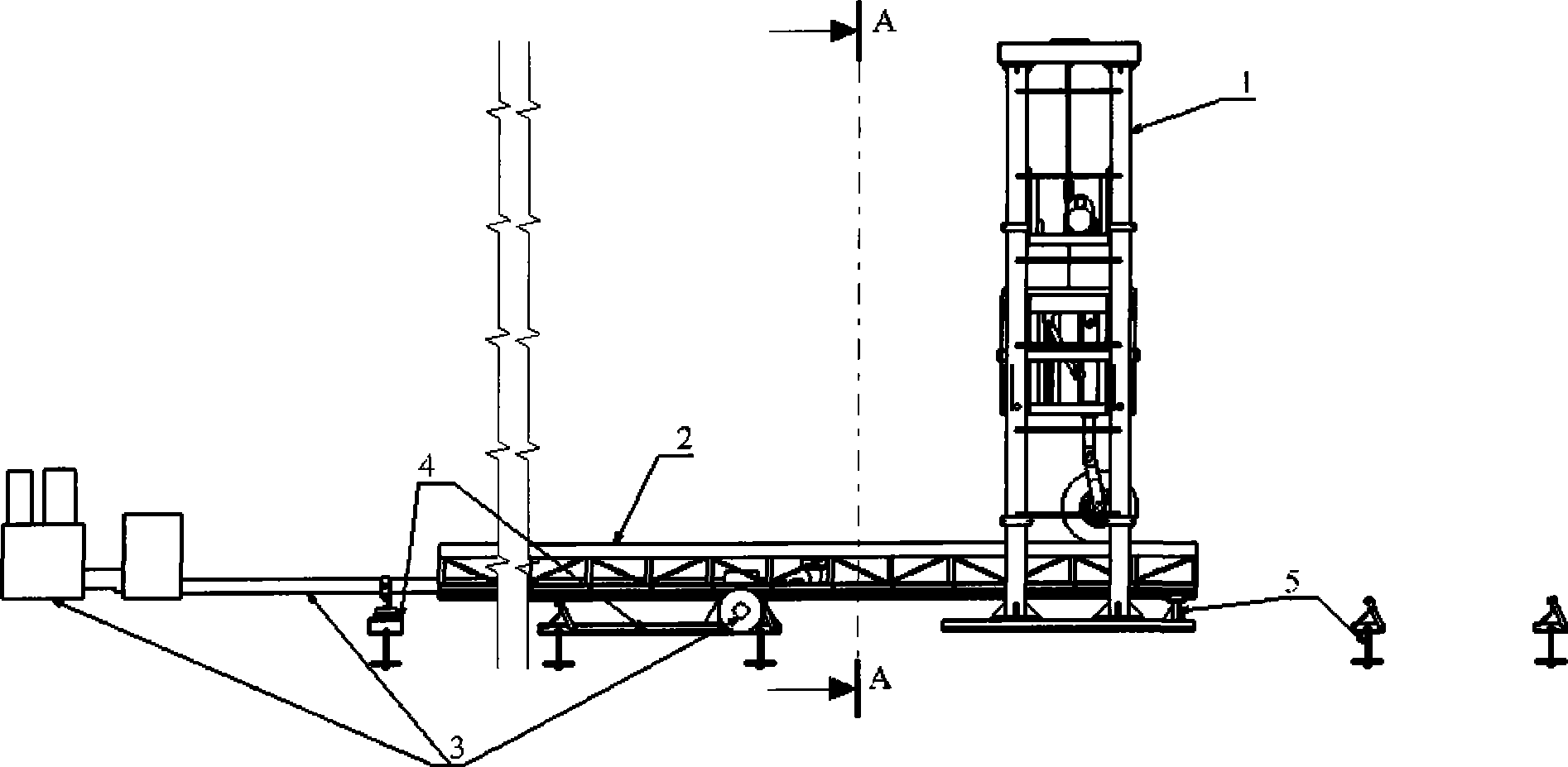

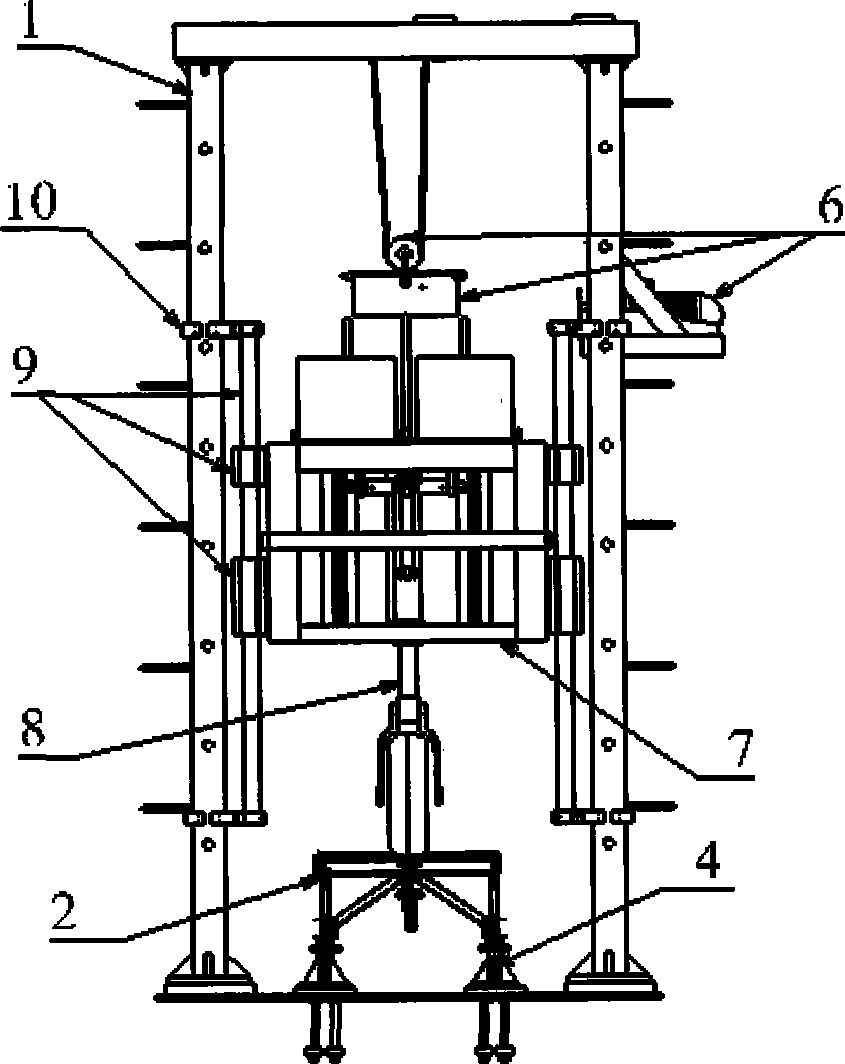

Drop test device for movable impact platform

A drop test device for a movable impact platform can be used in the fields of spin-up drop tests of an aircraft landing gear, rolling property tests, tire static property tests and tire dynamic property tests. The drop test device for the movable impact platform comprises a portal frame, a ground fixing mechanism, a retraction jack, a hanging basket, a landing gear, a hanging basket guide mechanism, a clearance regulation mechanism, a movable impact platform, a hydraulic driving system and a ground guide mechanism. The movable impact platform of the invention consists of a truss-frame structure and high-speed guide rails, wherein the high-speed guide rails are connected with the truss-frame structure by blots through guide rail mounting holes. The hydraulic driving system is a high-speed servo proportional hydraulic system and is fixed on the ground through the ground fixing mechanism. The ground guide mechanism is two rows of guide sliding blocks which pass through the portal frame and are arranged parallelly. The movable impact platform is connected with the hydraulic driving system and is placed on the ground guide mechanism. The drop test device for the movable impact platform provided by the invention has the advantages of compact and simple structure and high strength and rigidity.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

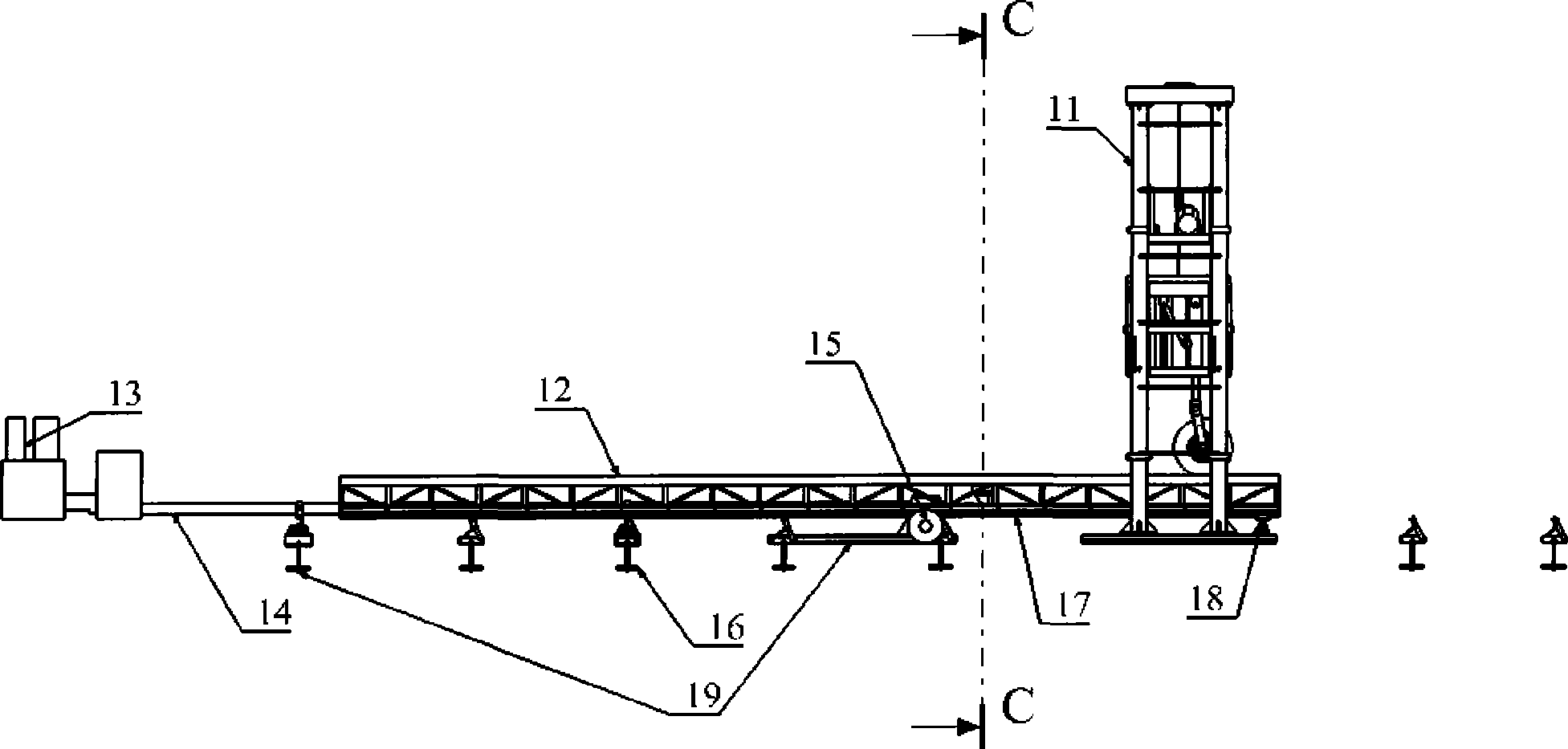

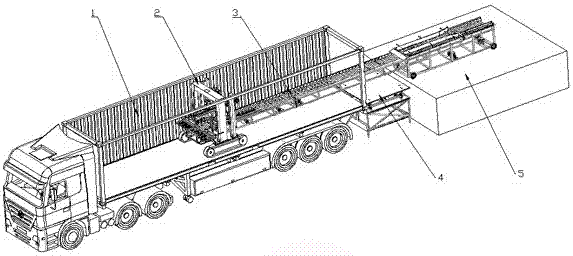

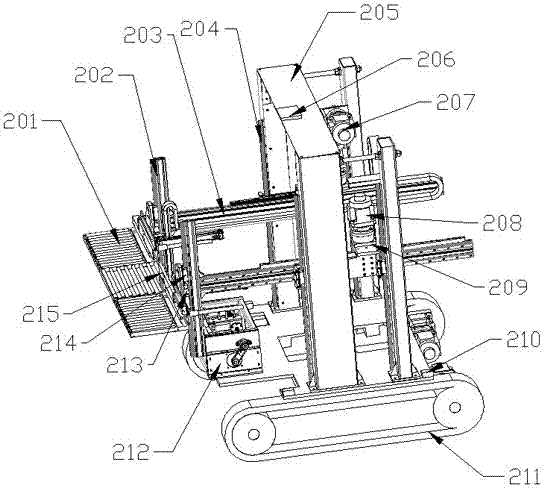

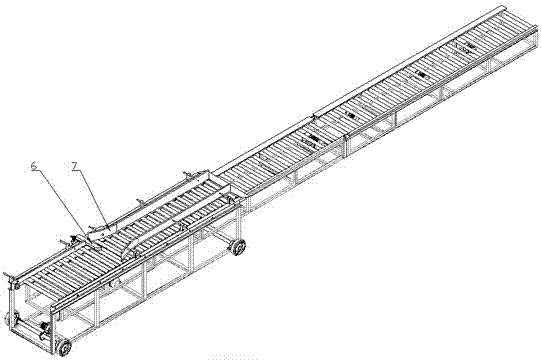

Automatic loading robot for packing boxes

The invention provides an automatic loading robot for packing boxes. The automatic loading robot comprises a PLC automatic control system, a packing stacking trolley and a transportation line, wherein the packing stacking trolley comprises a portal frame; a travelling device is arranged at the lower end of the portal frame; the front ends at the two sides of the portal frame are fixedly connected with a large Z axis; the large Z axis is connected with the X axis; the front end of the X axis is equipped with a small Z axis; a lifting device is arranged on the large Z axis; an X-axis servo motor is mounted on the X axis through a gear rack; the small Z axis is connected with a box drawing platform through a slide block and a guide rail brake; a box pushing device is arranged on the box drawing platform; a distributing device is arranged at the front end of the travelling device; and a reversing device and a normalizing device are arranged on the transportation line. The automatic loading robot can extend into a car to complete automatic stacking, and packing boxes do not need to be arranged into rows in advance, so that space is reduced, and loading stacking efficiency is improved; and a mechanical hand adopts a box pushing mode for the packing boxes, is free of damages on the packing boxes, can be operated in the car, and is limited by the car.

Owner:烟台海德智能装备有限公司

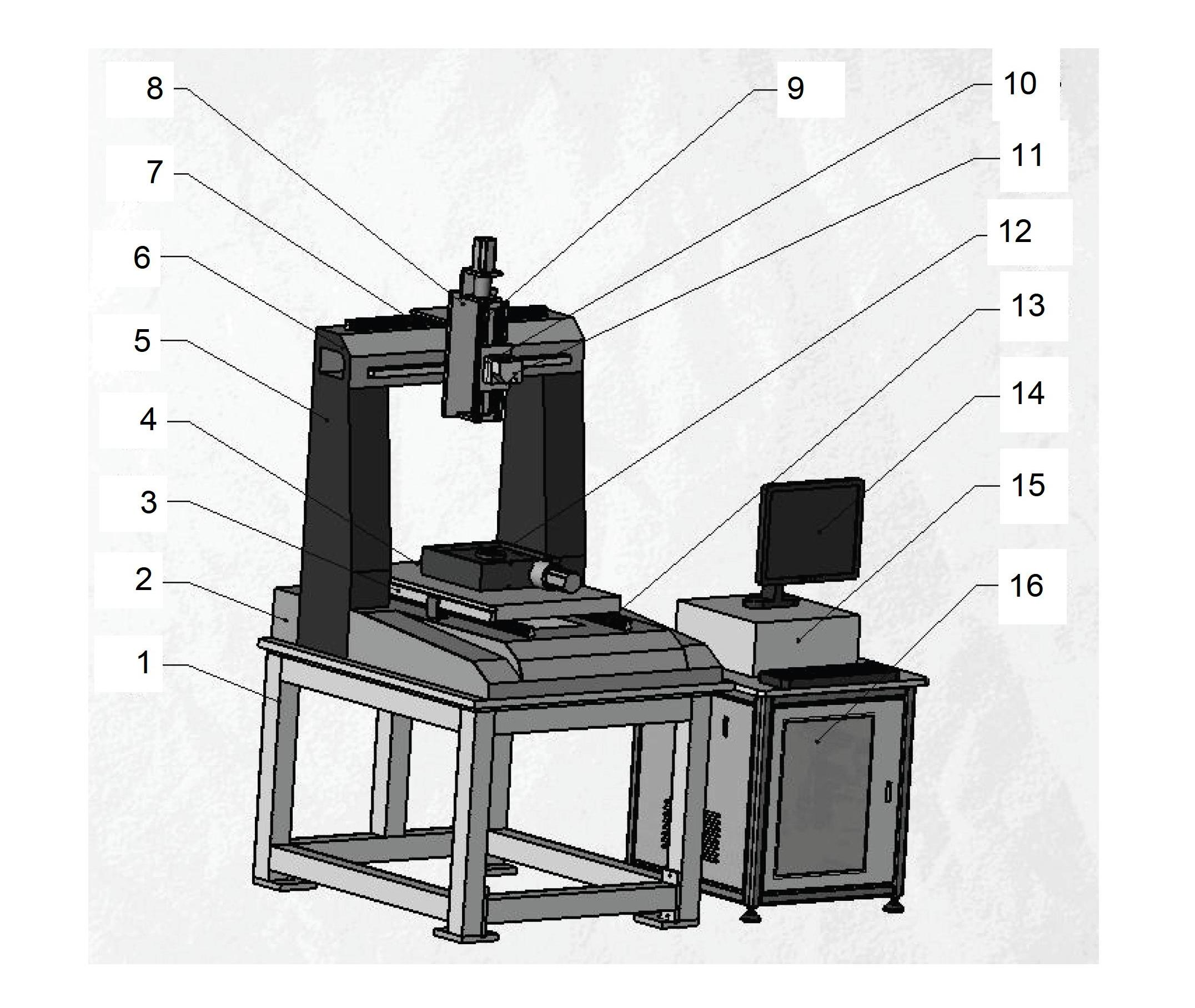

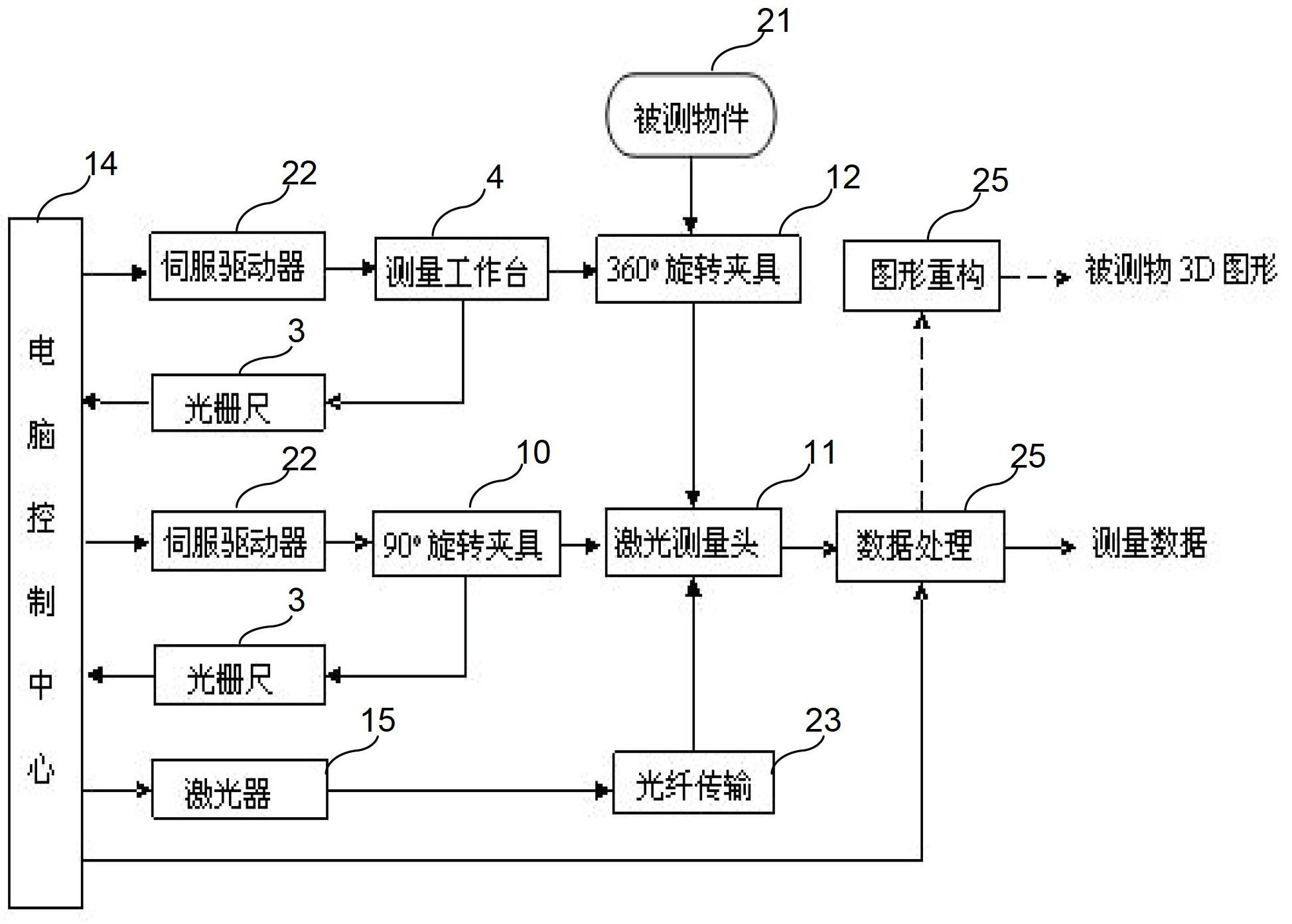

Six-axial numerical-control three-dimensional quick laser measurer

InactiveCN102661723AImprove efficiencyUsing optical meansNumerical controlThree dimensional measurement

The invention discloses a six-axial numerical-control three-dimensional quick laser measurer which comprises a measurer mechanical system. The measurer mechanical system comprises a measurement operating table, a base and a vertical column portal frame. The measurer is characterized in that the measurer mechanical system further comprises a guide rail system and two groups of rotatable precision positioning clamp devices. The guide rail system comprises an X-direction guide rail system, a Y-direction guide rail system and a Z-directional guide rail system in mutual orthogonality, wherein the X-direction guide rail system is mounted on the measurement operating table, the Y-direction guide rail system is disposed on a movable bridge crossbeam, and the Z-directional guide rail system is mounted in a central sliding frame. The rotatable precision positioning clamp devices are disposed on the measurement operating table and comprises 360-degree rotatable clamps and 90-degree rotatable clamps, wherein the 360-degree rotatable clamps are capable of rotating in a plane of the X and Y directions, and the 90-degree rotatable clamps are mounted in the Z direction and capable of rotating in a plane of the Y and Z directions or a plane of the Z and X directions.

Owner:SHANGHAI TROOP ELECTRONICS EQUIP +2

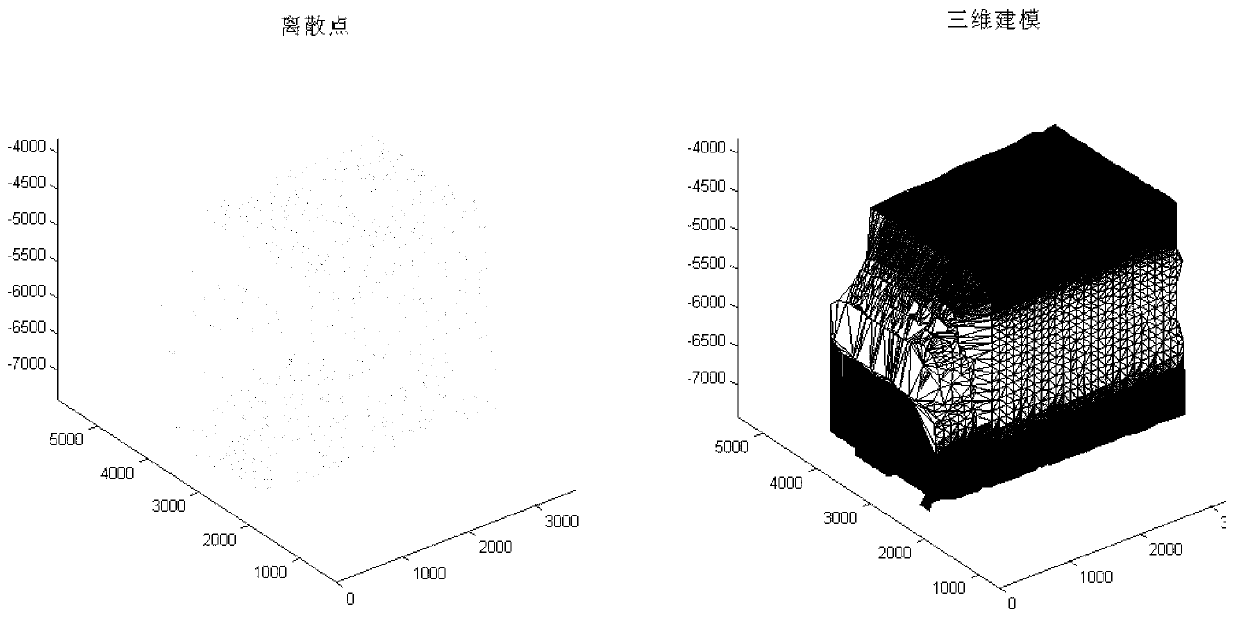

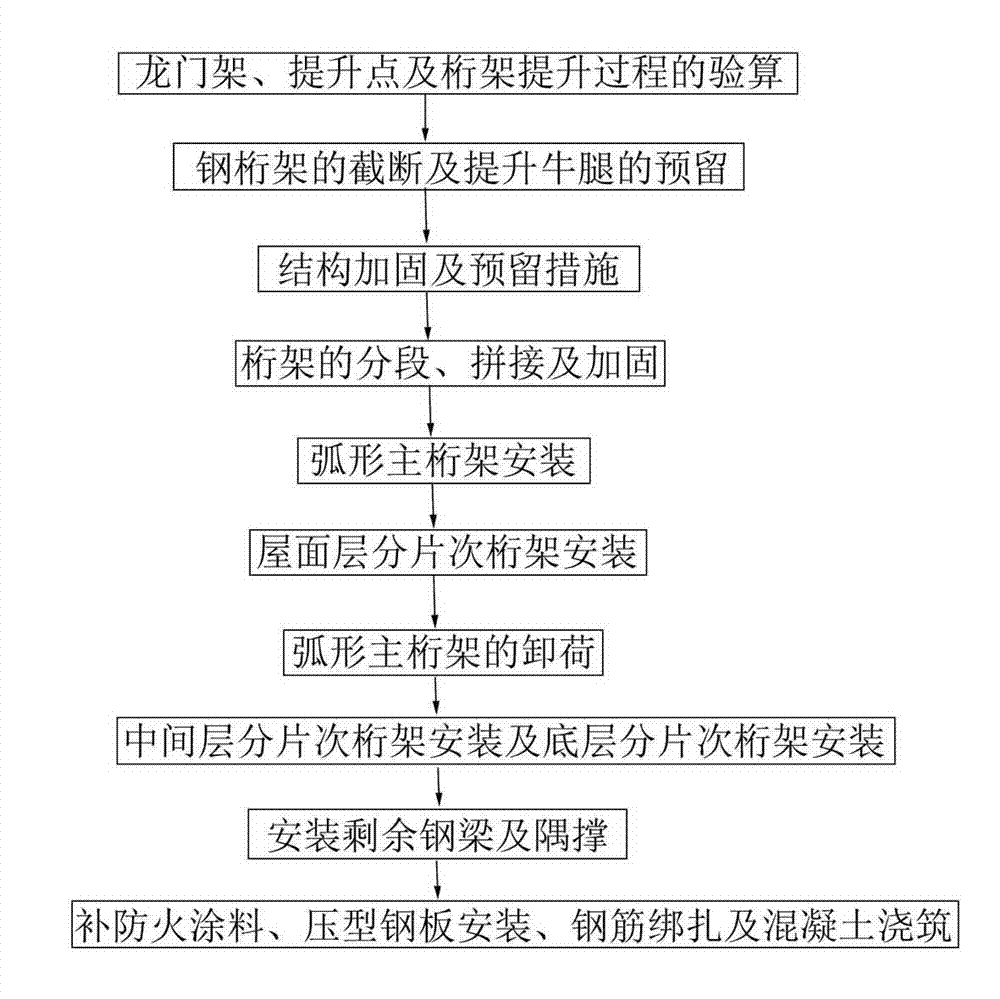

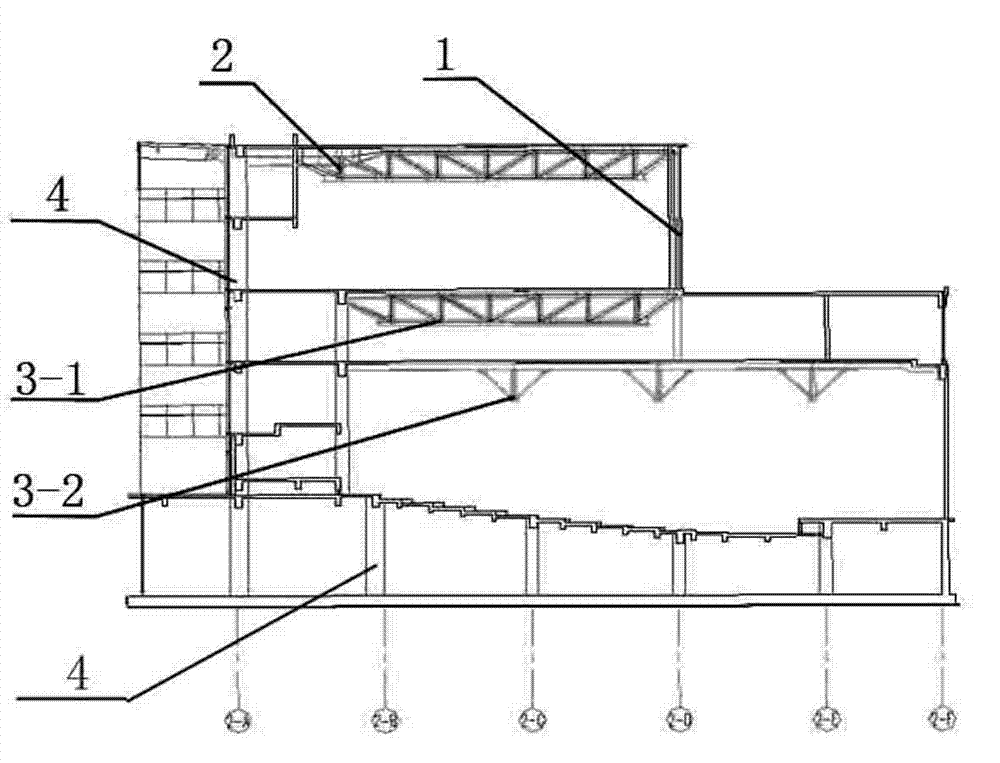

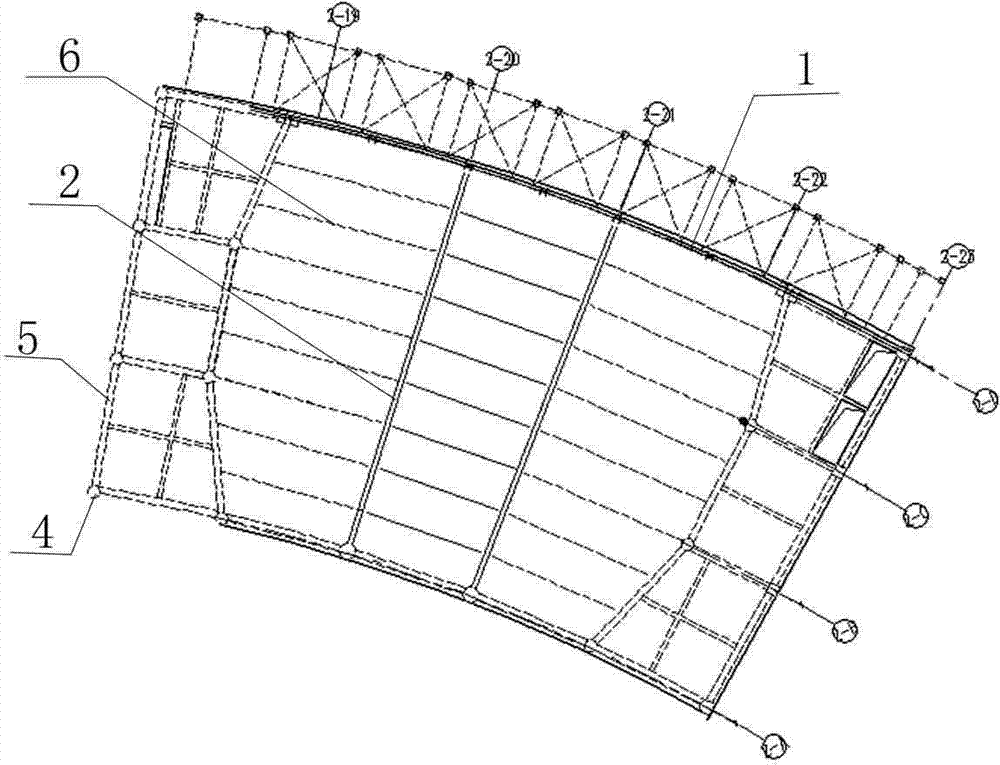

Multilayer steel truss fragmented reverse hoisting construction method in arc-shaped frame

ActiveCN103291076ASolve the problem of difficult control of lateral stabilityReduce high-altitude assemblyBuilding material handlingTower cranePortal frame

The invention relates to a steel truss hoisting construction method, in particular to a multilayer steel truss fragmented reverse hoisting construction method in an arc-shaped frame. The multilayer steel truss fragmented reverse hoisting construction method comprises the steps of firstly performing modeling and checking calculation to all of hoisting conditions, utilizing brackets at two ends and a portal frame in the middle as lifting points of an arc-shaped main truss, hoisting the arc-shaped main truss by combining a hydraulic synchronous hoisting technology, connecting sub trusses above two roof trusses and steel beams to form a trapezoid fragmented truss, utilizing the temporality-fixed main truss hoisted in position and the hydraulic synchronous hoisting technology to install roof layer fragmented trusses, dismounting the lifting point of the portal frame of the arc-shaped main truss after the arc-shaped main truss is stabilized, sequentially and inversely lifting multilayer fragmented sub trusses to a bottom layer downward, and then utilizing the main truss, the sub trusses, a truck-mounted crane, a tower crane and leading chains to install other members and finish hoisting of a multilayer steel structure of the arc-shaped frame. The multilayer steel truss fragmented reverse hoisting construction method in the arc-shaped frame has the advantages of achieving hoisting operation in a narrow field or on a building surface, ensuring quality and safety, saving expenses, shortening a construction period and being free of pollution and good in environmental-protection benefit.

Owner:JIANGSU NANTONG NO 6 CONSTR GRP

Full-automatic laser welder

ActiveCN103240527AGuaranteed compression effectSolving Automatic Laser Welding ProblemsLaser beam welding apparatusPortal frameLaser

The invention provides a full-automatic laser welder comprising a laser head, a laser head servo mechanism, a feeding and discharging device, a pressing mechanism and a transmission mechanism. The pressing mechanism comprises a plurality of pressing blocks and a pressing block support, wherein each pressing block is provided with a passage for laser emitted by the laser head to pass; and the pressing block support is elastically connected with each pressing block. The transmission mechanism is connected to the pressing block support to drive the pressing block support to move vertically so as to press or separate from corresponding connecting pieces. The laser head servo mechanism can further comprise two portal frames which are bilaterally and symmetrically arranged relative to the feeding and discharging mechanism along the X-direction, and each portable frame is provided with reinforcing ribs. The transmission mechanism can comprise a pair of transmission components which is bilaterally and symmetrically arranged relative to the feeding and discharging mechanism. The full-automatic laser welder can further comprise a gas cooling mechanism, a welding positioning unit and a controller. Therefore, pressing effects of welding spots of workpieces at different heights are guaranteed, welding temperature is lowered effectively, stability of a welding process is guaranteed, and welding optimal rate and efficiency are quite high.

Owner:CONTEMPORARY AMPEREX TECH CO

Horizontal diamond wire cutting machine tool

ActiveCN104890036AEasy clampingAvoid breakingMetal working apparatusStone-like material working toolsWire cuttingEngineering

Disclosed is a horizontal diamond wire cutting machine tool. The horizontal diamond wire cutting machine tool comprises a tool body (1), the tool body (1) is provided with a rotary worktable (2) for fixing workpieces, a portal frame (15), and a guide wheel group on the portal frame (15), wherein the portal frame (15) can be driven by an X-direction transmission mechanism on the tool body to move in an X direction. The horizontal diamond wire cutting machine tool is characterized in that the beam (10) of the portal frame (15) is provided with a pay-off drum (8) and a take-up drum (9), the stand columns on both sides of the portal frame (15) are respectively provided with an extending plate, and the cantilever end of each extending plate is provided with a cantilever end guide wheel; the extending plates on both sides are driven by the same or a separated Z-direction transmission mechanism to move up and down along the stand columns to control the height and accordingly to maintain a horizontal state so that a diamond wire on the cantilever end guide wheels on the cantilever ends can maintain a horizontal state and participate in cutting of the workpieces. The horizontal diamond wire cutting machine tool is convenient to fixe and high in machining efficiency and yield rate.

Owner:TAIZHOU CHEN HONG NC EQUIP MFG CO LTD +2

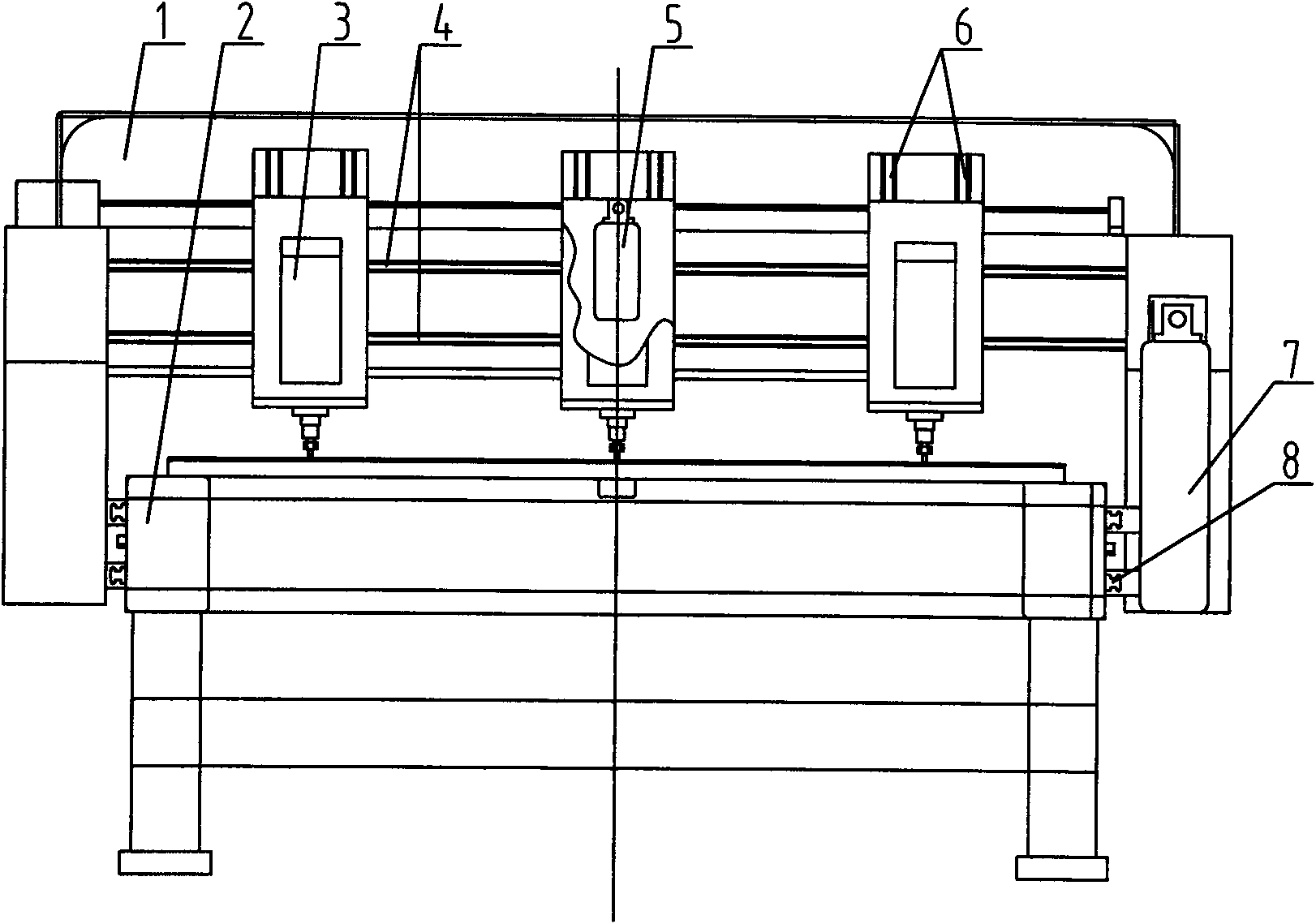

Multihead synchronous or asynchronous carving (drilling) milling numerical control processing equipment

InactiveCN102151883ASimple structureLow costMilling machinesLarge fixed membersNumerical controlControl system

The invention discloses multihead synchronous or asynchronous carving (drilling) milling numerical control processing equipment which comprises a portal frame, a lathe bed, a numerical control unit, a transmission system and x-axle, y-axle and z-axle guide rails, wherein the numerical control unit comprises an x-axle drive motor, a y-axle drive motor and a z-axle drive motor which are arranged on the portal frame. The multihead synchronous or asynchronous carving (drilling) milling numerical control processing equipment is characterized in that left and right sides of the portal frame are respectively provided with two y-axle guide rails, and the portal frame is also provided with 2-6 independent synchronous or asynchronous power heads and multiple sets of tools matched with the power heads, a lathe generates a three-dimensional processing figure by using a computer, the computer controls each power head respectively for processing after processing coordinates are input, a corresponding control system is provided with a servo motor or a stepping motor, the power heads move on the three guide rails along the x-axle direction, three points are fixed; and a screw or rack structure is adopted in the transmission system. The multihead synchronous or asynchronous carving (drilling) milling numerical control processing equipment has the advantages of simple structure, low cost, high processing accuracy, good stability, high processing efficiency, wide application range and the like.

Owner:ALNAN ALUMINIUM CO LTD

Axle radial ultrasonic automatic flaw detecting device and control method

ActiveCN103217477ARepeatableReduce labor intensityAnalysing solids using sonic/ultrasonic/infrasonic wavesRepeatabilityPortal frame

The invention discloses an axle radial ultrasonic automatic flaw detecting device and a control method, and belongs to the technical field of ultrasonic flaw detection for axle parts. The flaw detecting device comprises a lathe bed, an axle rotary supporting unit, a portal frame unit, at least one flaw detecting unit, an ultrasonic generating receiver, a motor driver unit, a control unit and an interactive operation unit. The adoption of the device and the control method comprehensively realizes the program controlled axle radial ultrasonic automatic flaw detection device for different axle types. The device and the control method improve the operating efficiency through the simultaneous operation of a plurality of groups of flaw detecting units, automatically identify flaw in real time in an on-line way through the control unit, and record detected flaw. Compared with the prior art, the device and the control method have the advantages that the flaw defection efficiency is high, the flaw defection result has repeatability, the labor intensity of workers can be reduced, and axle ultrasonic automatic flaw detection with high automation, high adaptability, low control difficulty and high reliability is realized. The device is applicable to the detection of internal flaws of solid axle parts.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com