Patents

Literature

417results about How to "Reduce the number of clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

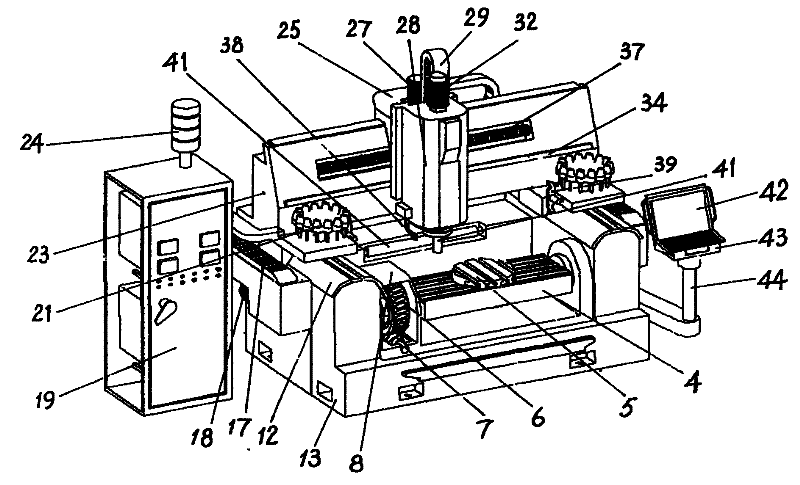

Vertical five axle interlocked gantry digital control milling machining center

ActiveCN101870063AReduce the number of clampingReduce machining errorsOther manufacturing equipments/toolsMilling cutterEngineering

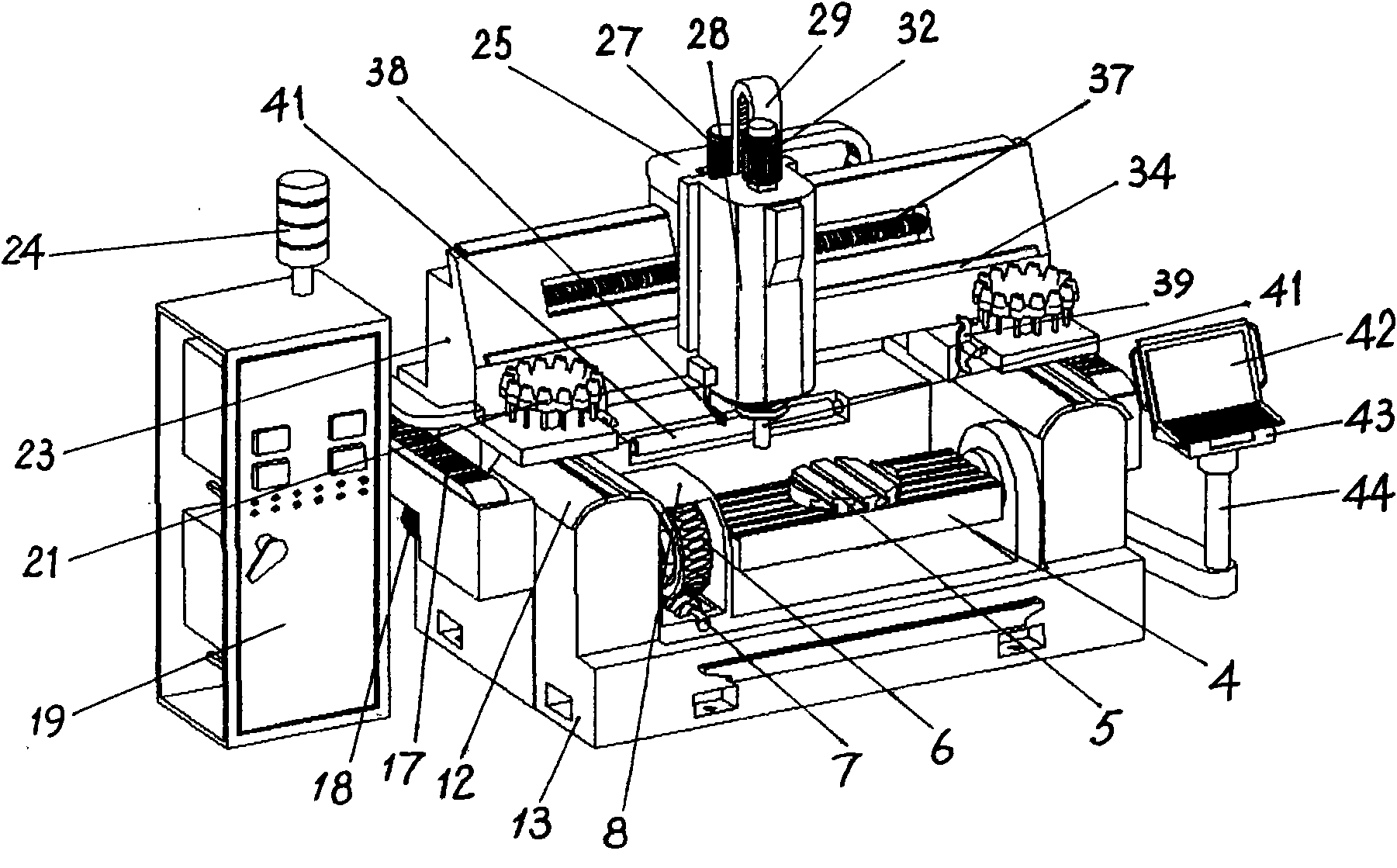

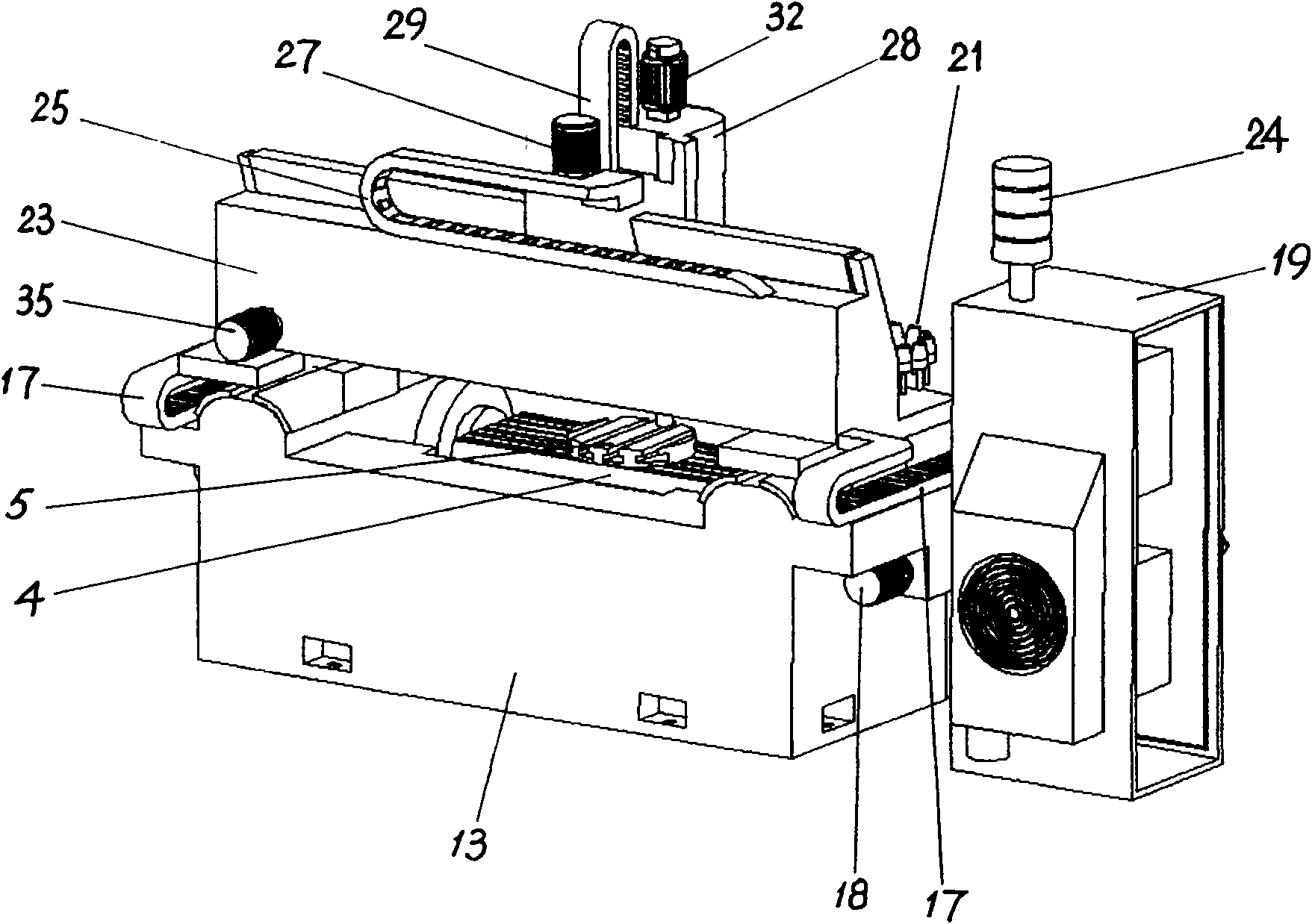

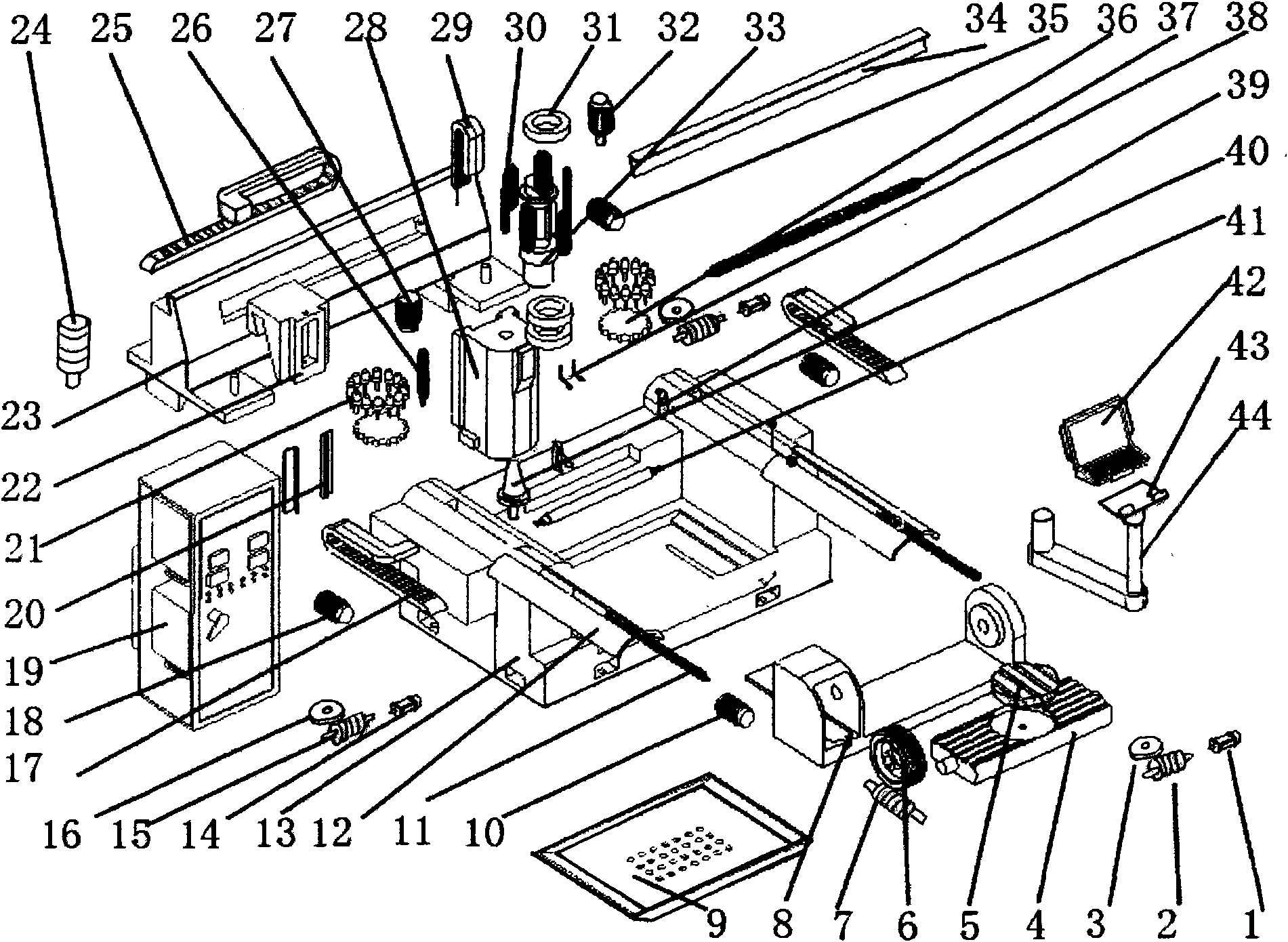

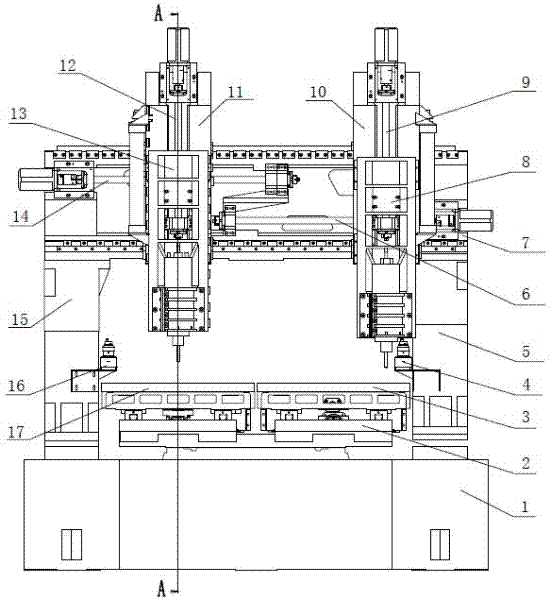

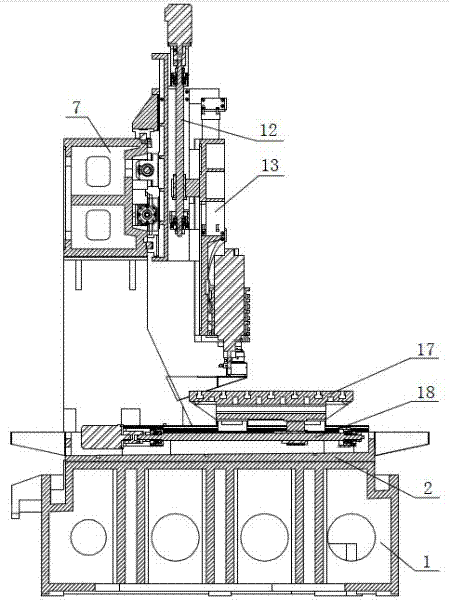

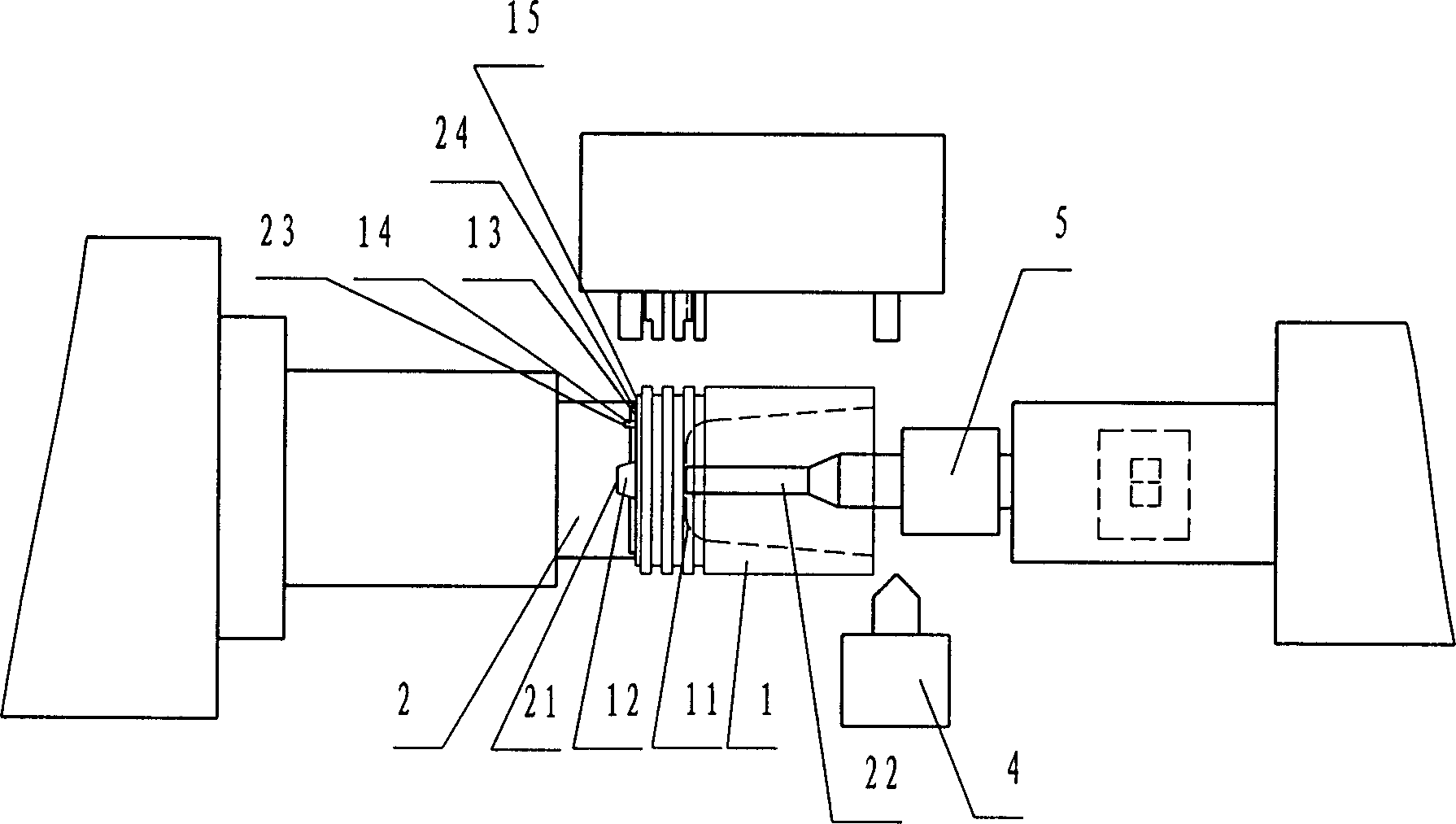

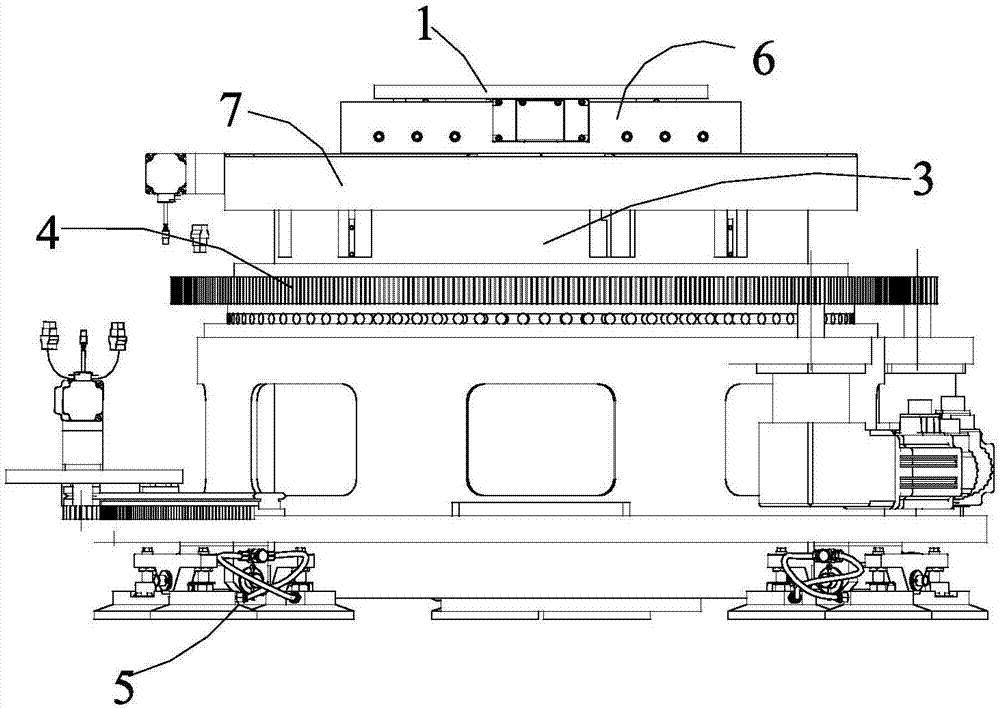

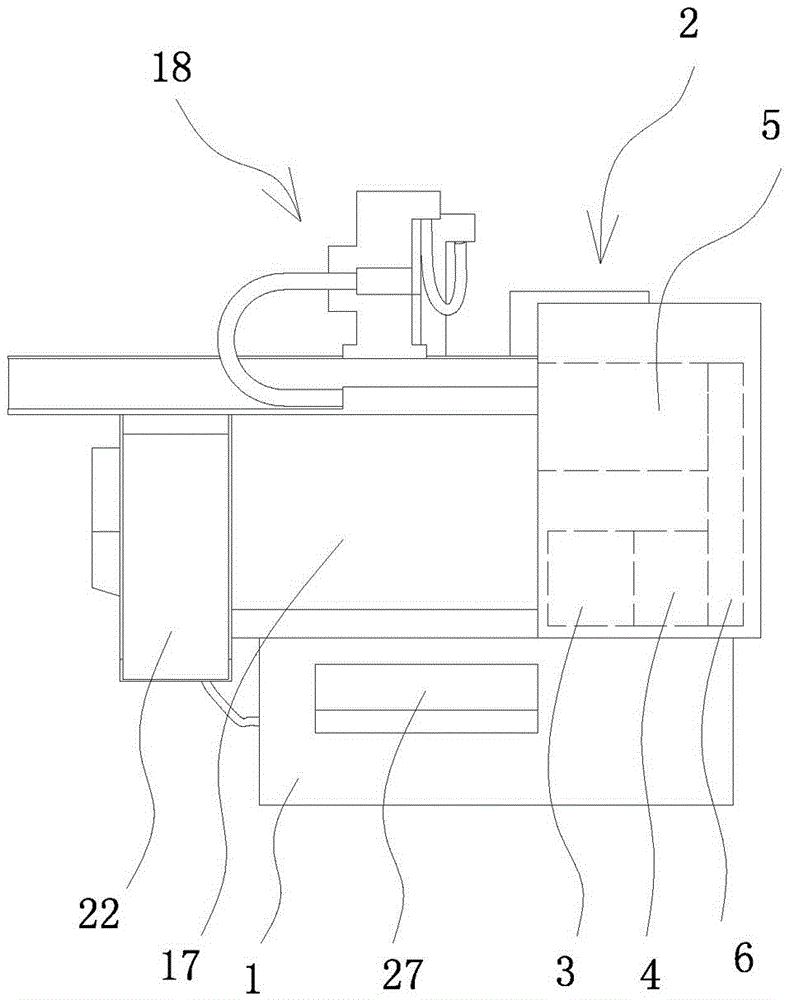

The invention provides a vertical five axle interlocked gantry digital control milling machining center, comprising a planer body, a portal frame, a rotary workbench stand, an electrical appliance control cabinet, a cutter, a main spindle box, an operation panel, a rotary workbench, X, Y and Z shaft driving screws and rotary tool changers, wherein the rotary workbench is formed by a large rotary workbench and a small rotary workbench which respectively rotate around an A shaft and a B shaft; the portal frame is arranged on the planer boxy and can move back and forth via the X shaft driving screws arranged at the two sides of the planer body, a Y-Z shaft connection block moves left and right via the Y shaft driving screw in the portal frame, and a main spindle in the main spindle box moves up and down via the Z shaft driving screw on the Y-Z connection block so as to form five axle interlocking; and the rotary tool changers arranged at the two sides of the portal frame are internally provided with 32 grinding cutters and milling cutters, and tool changing is realized by a tool changing manipulator. The invention has the positive effects of realizing multiply functions of one machine, and can process as many as five interfaces by primary clamping, thus reducing clamping times, saving labor, time and space, and having convenient equipment maintenance.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

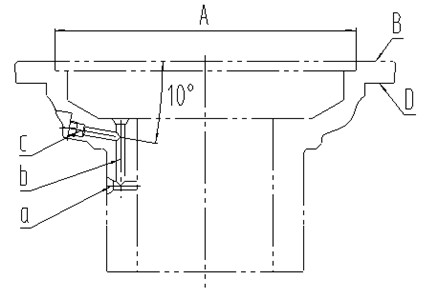

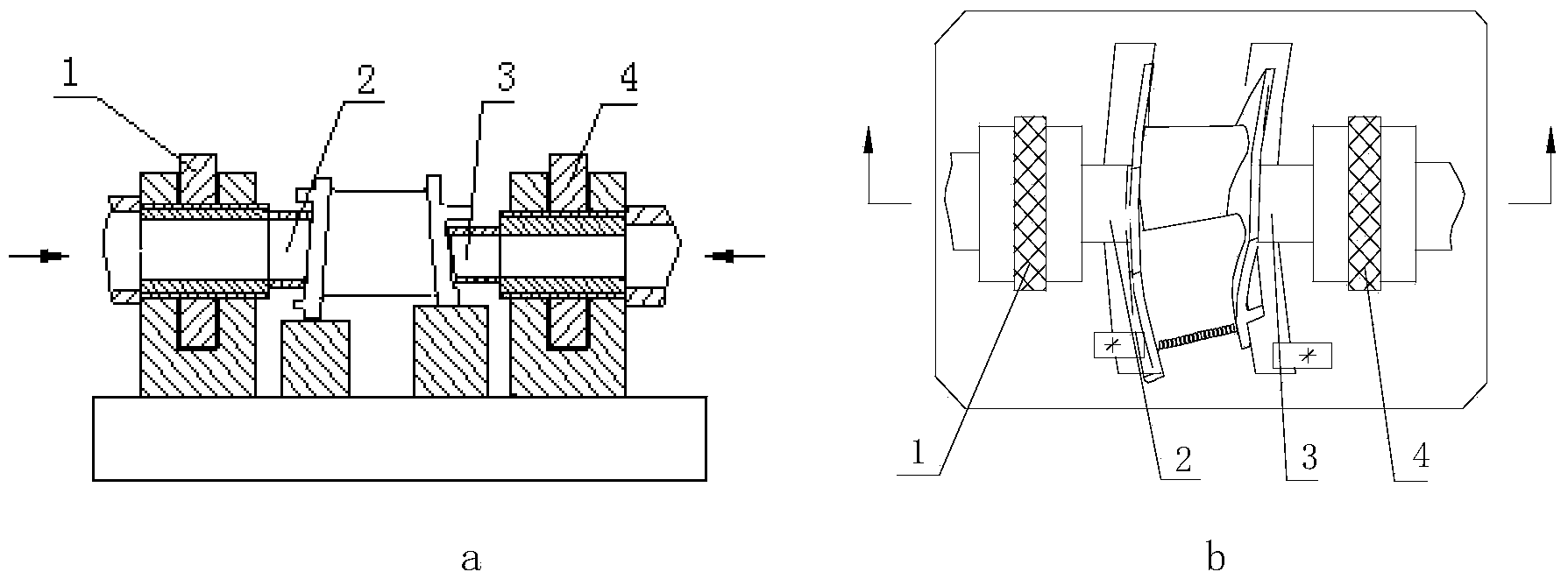

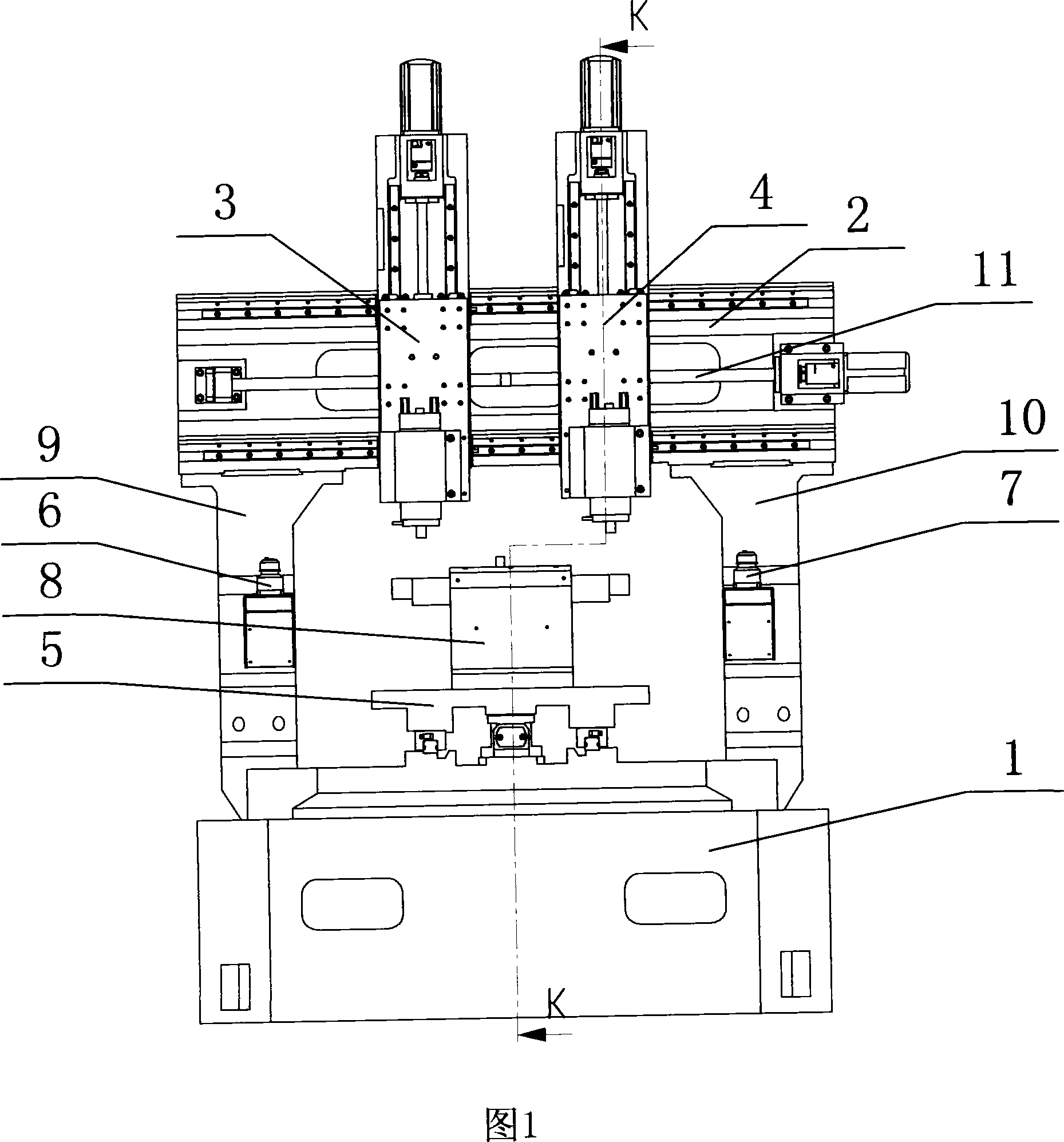

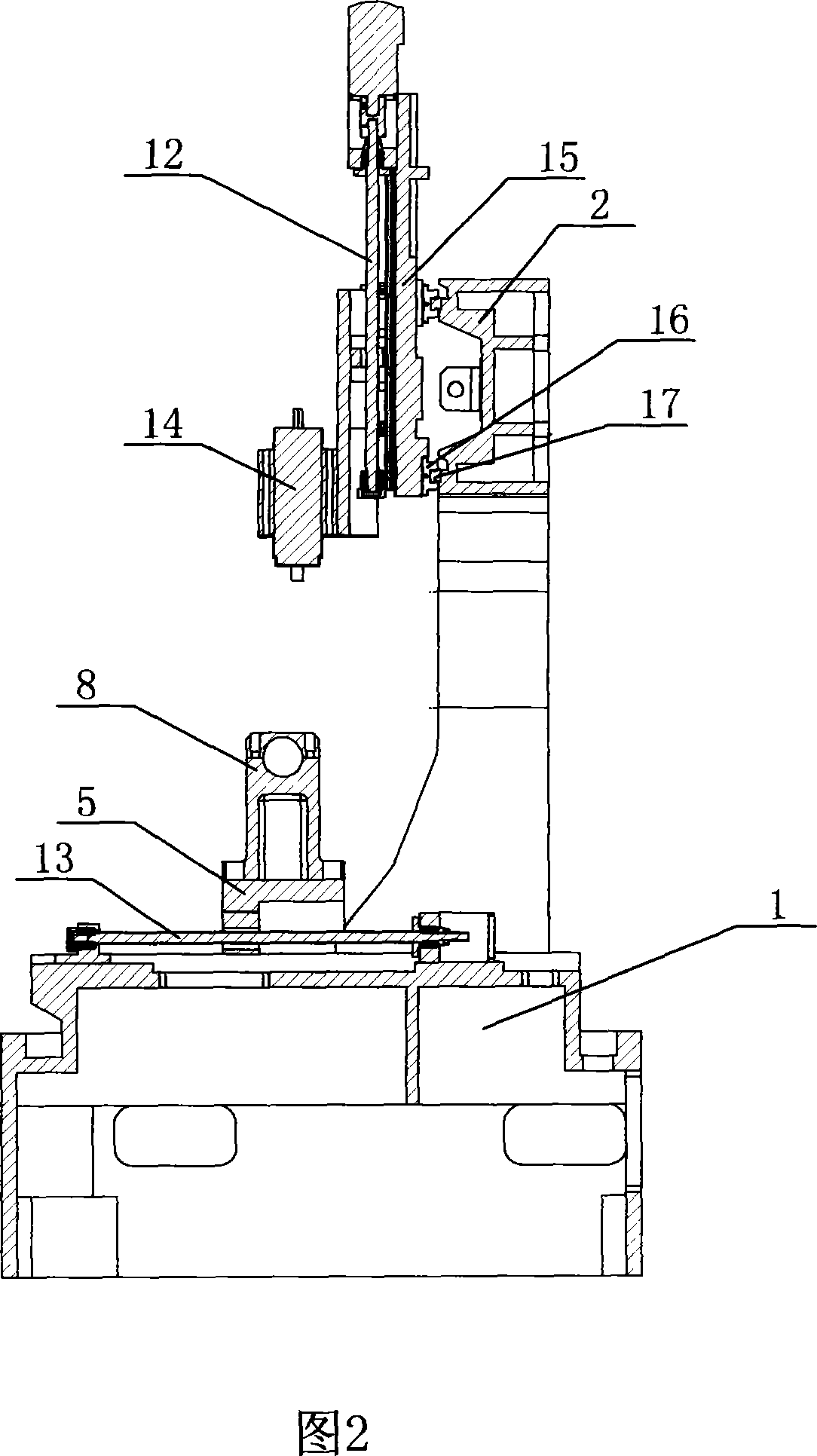

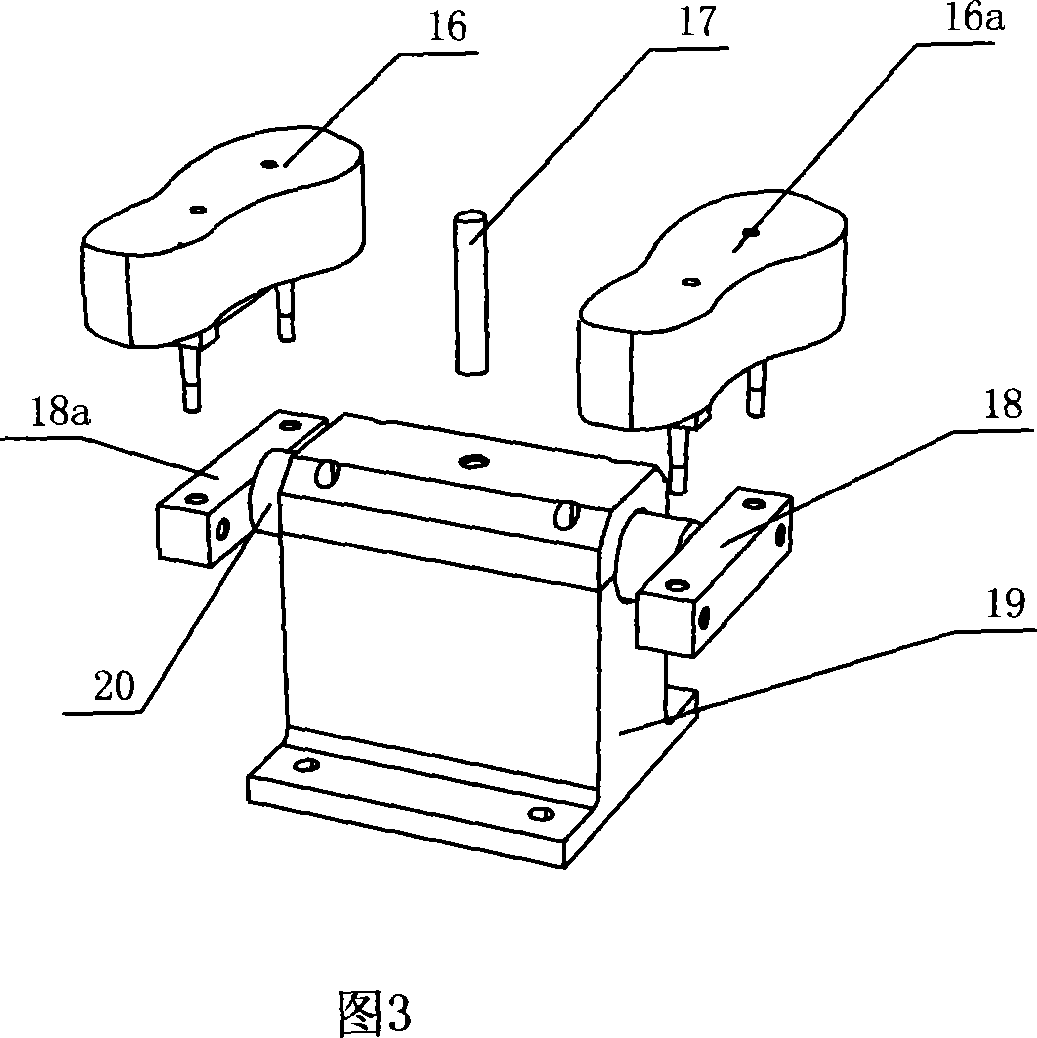

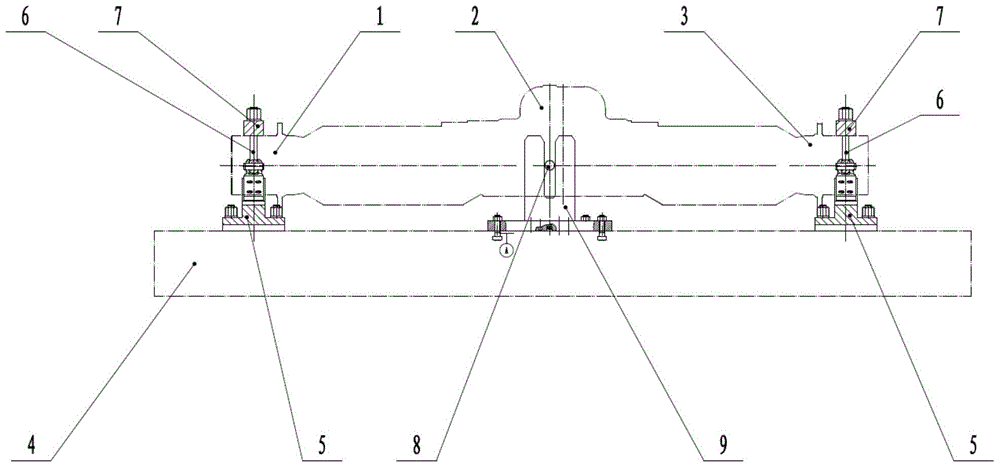

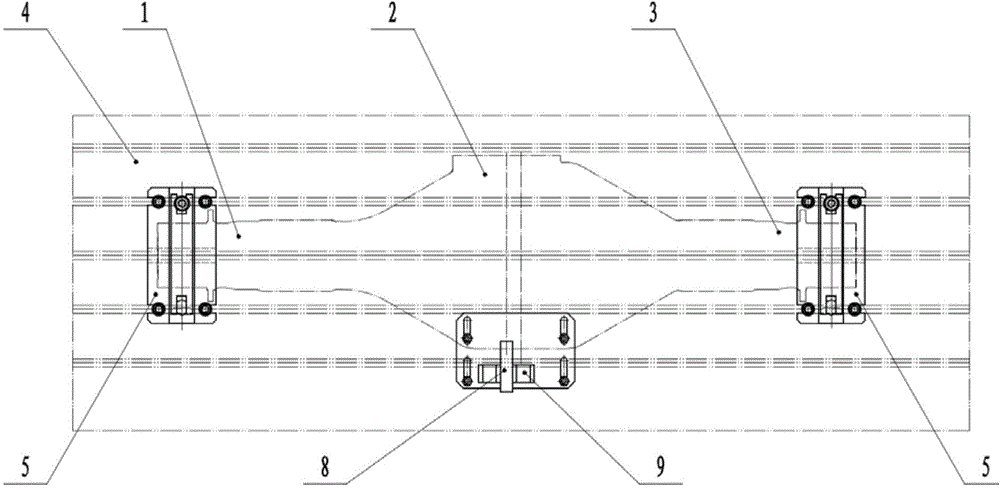

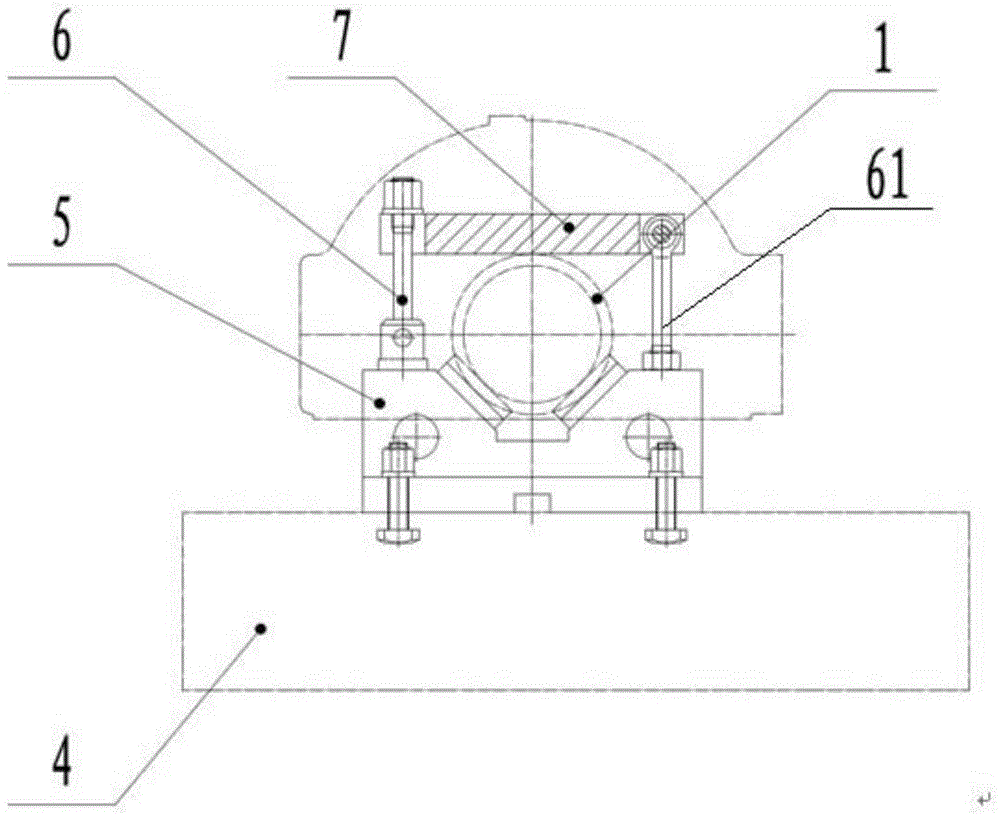

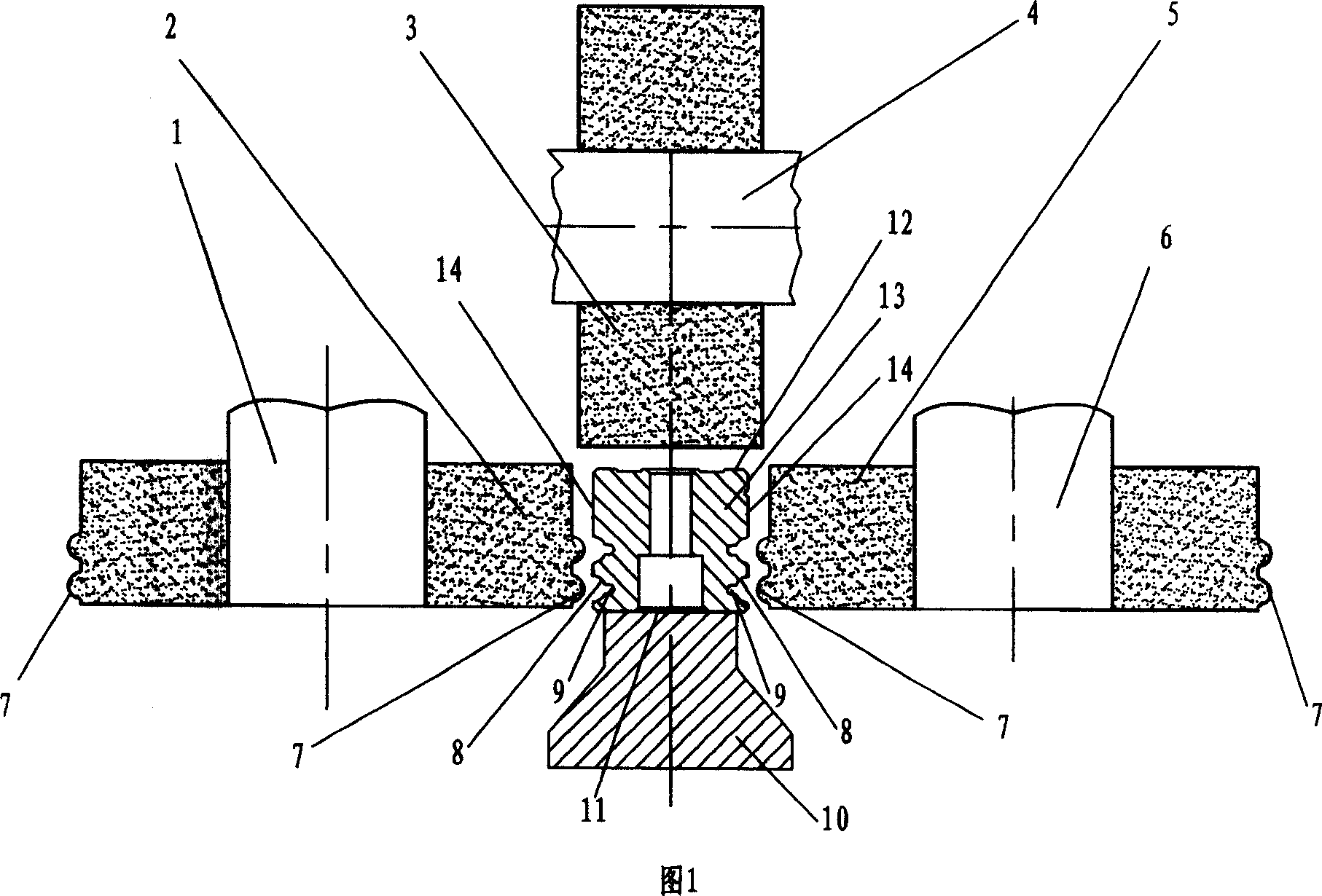

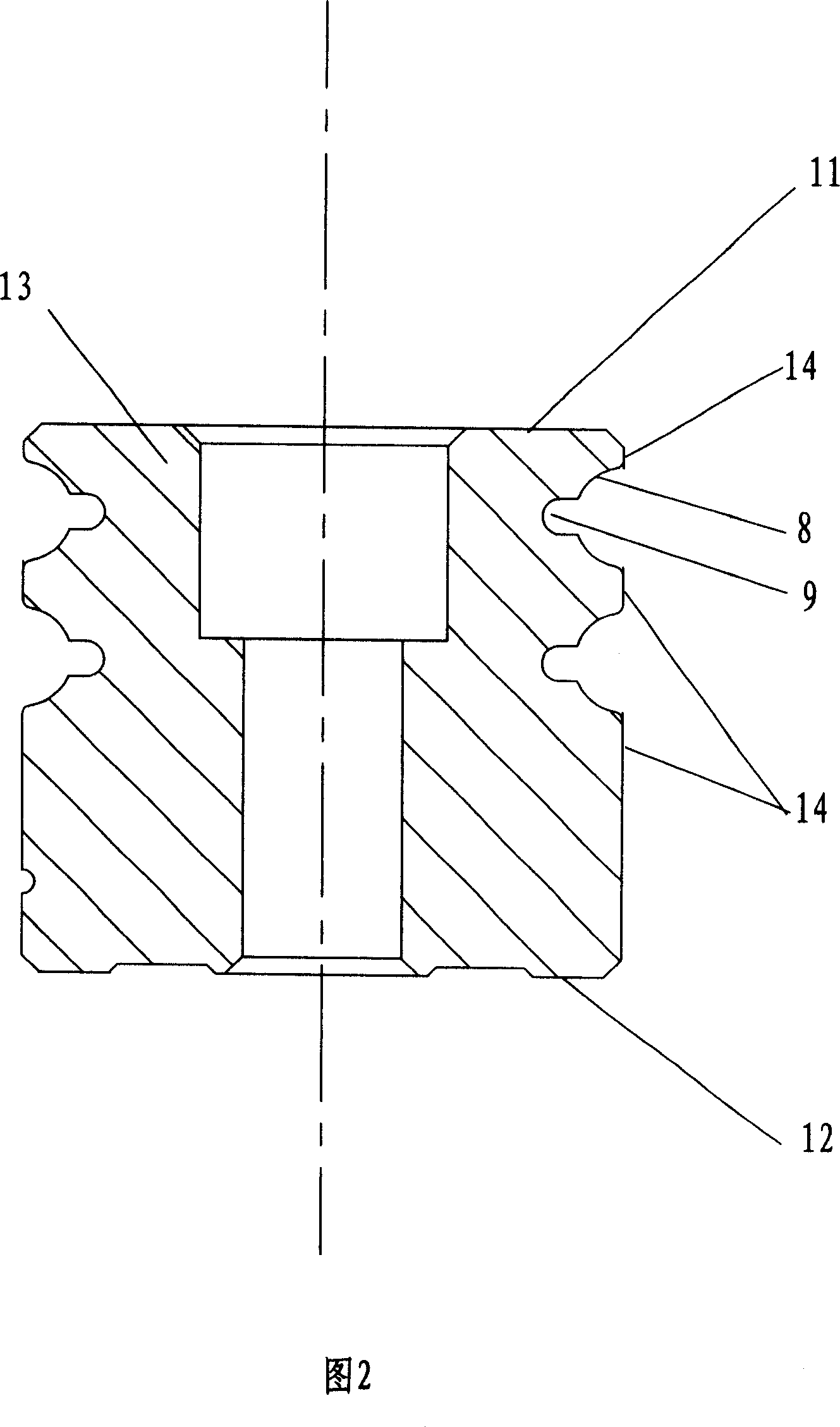

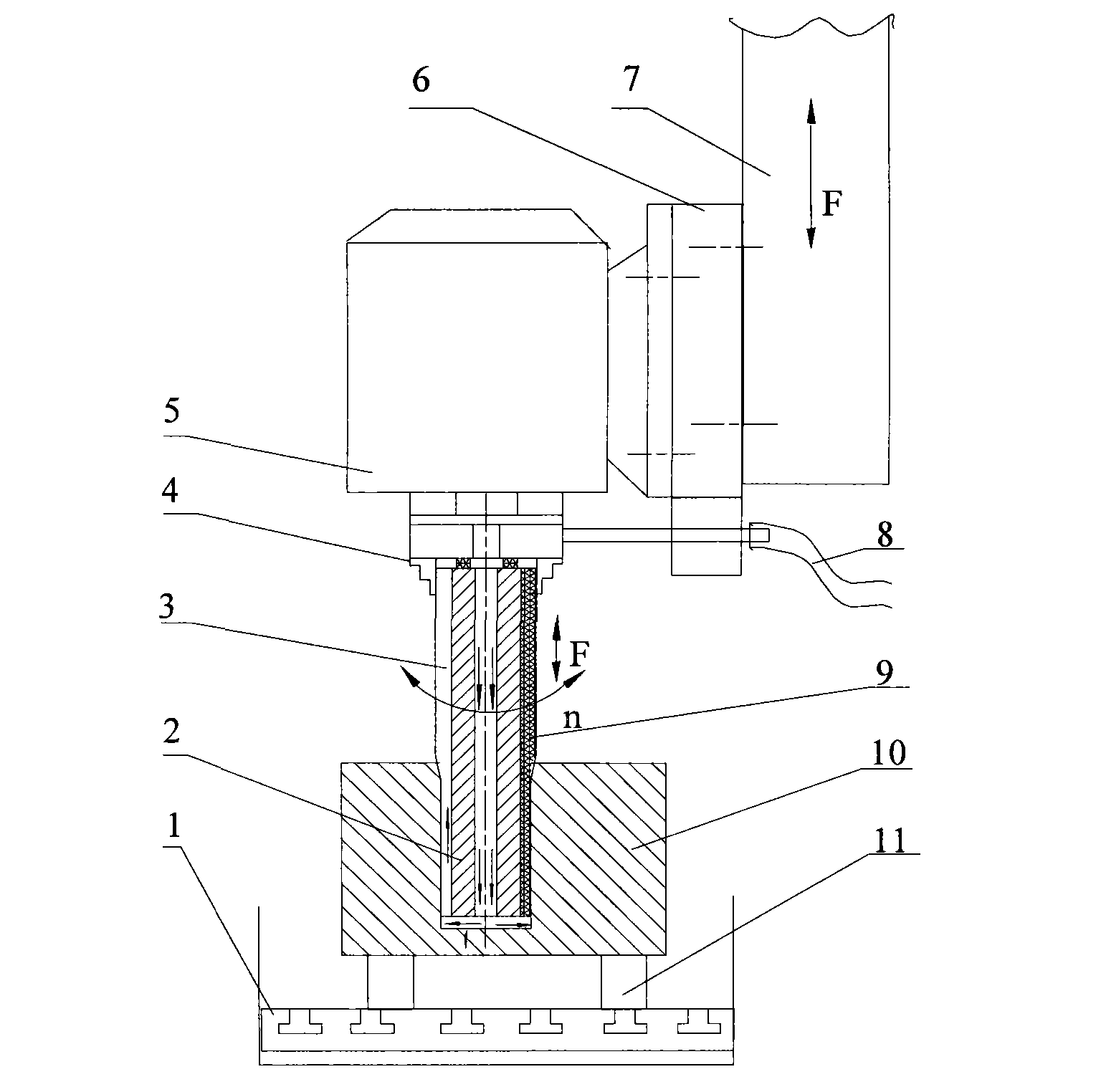

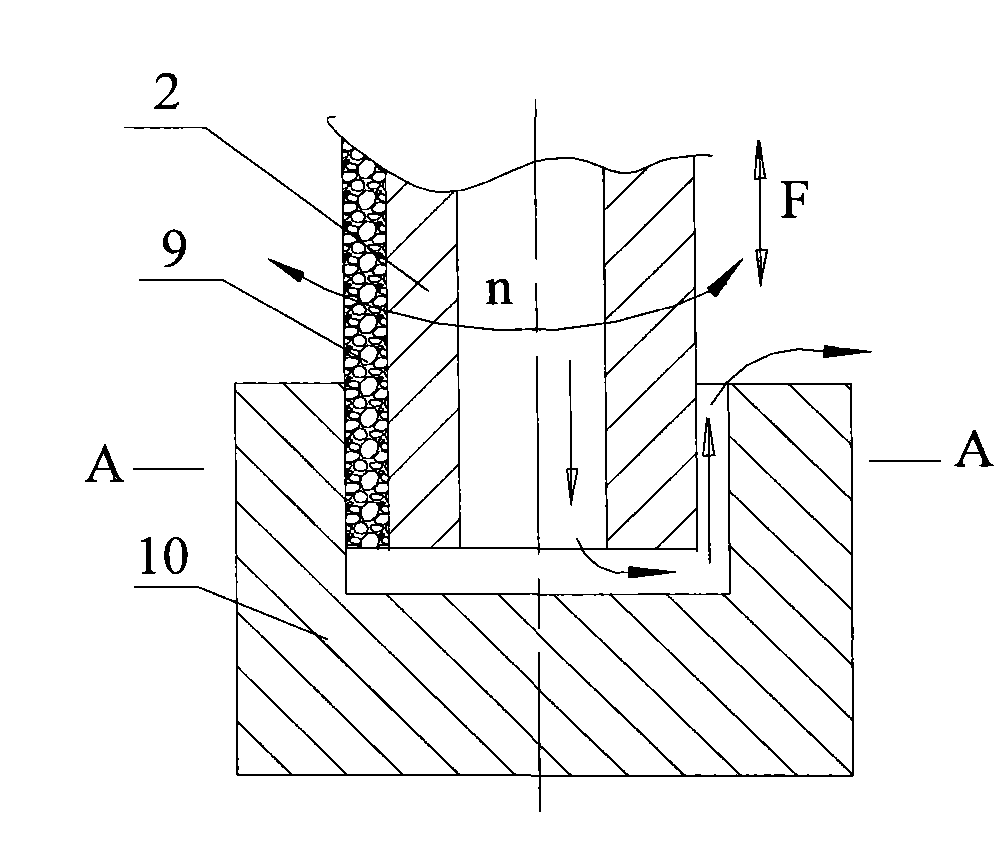

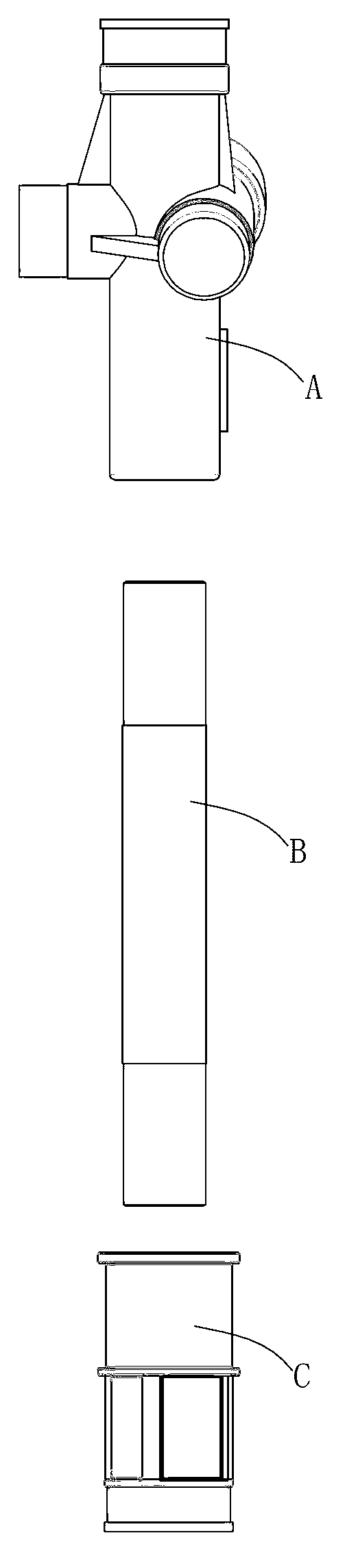

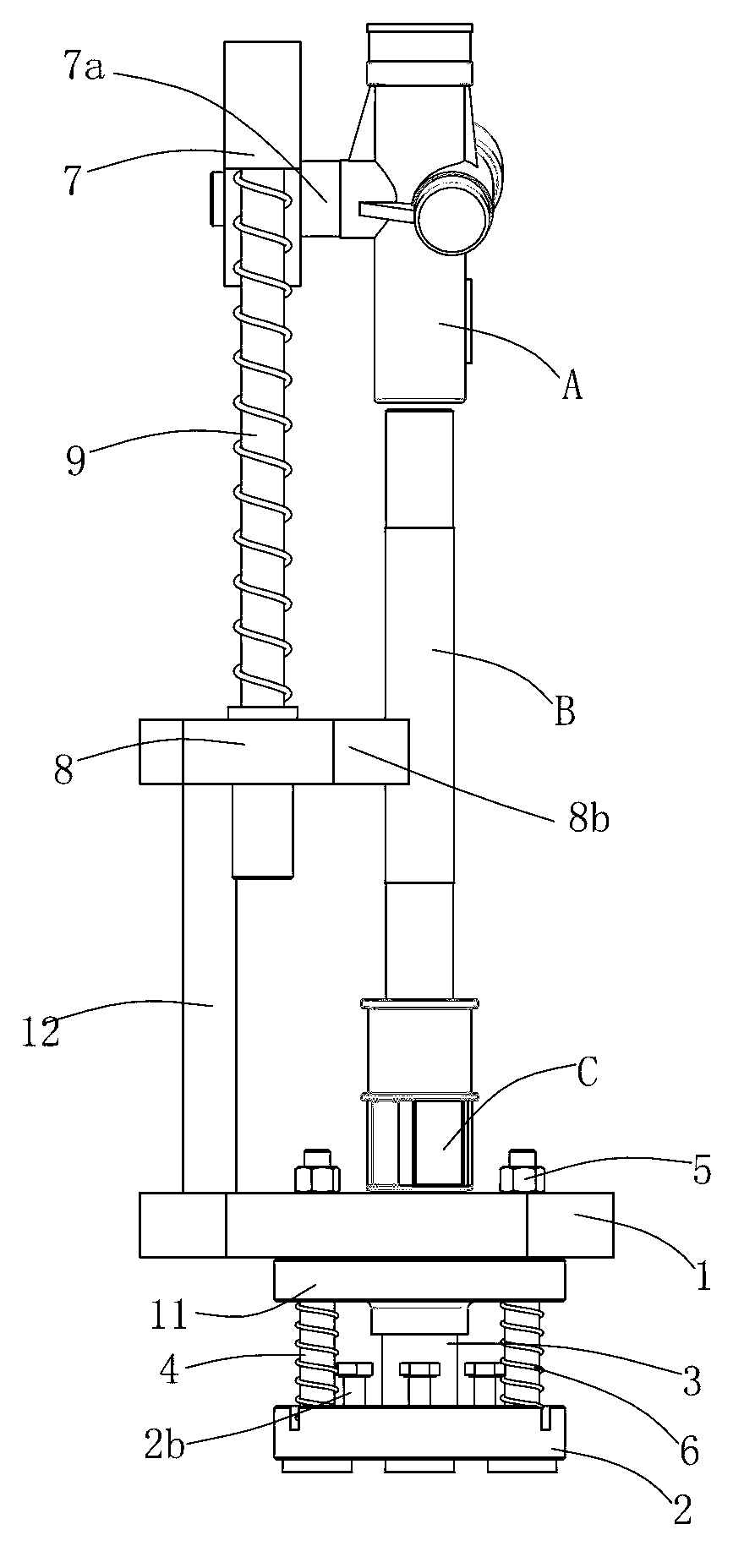

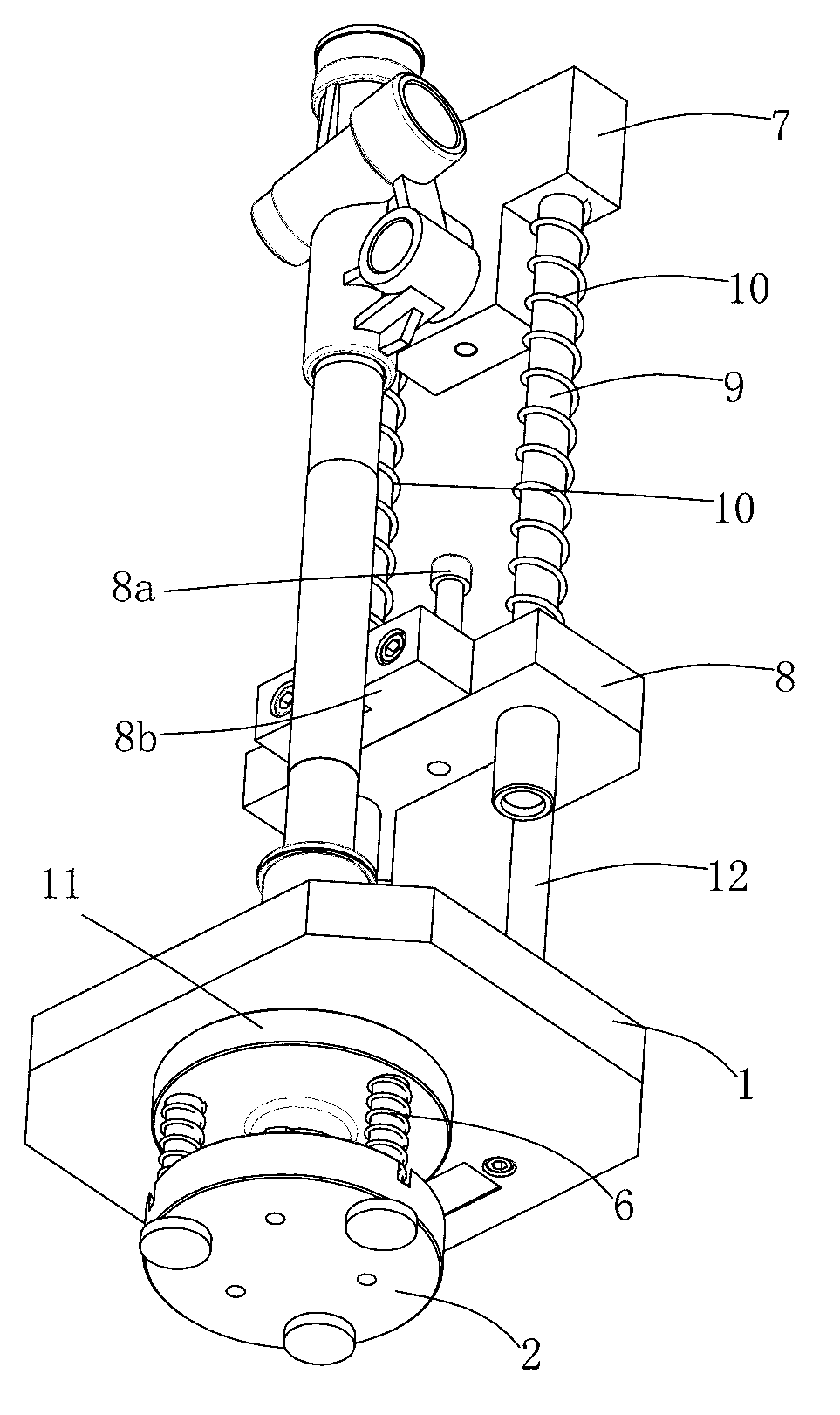

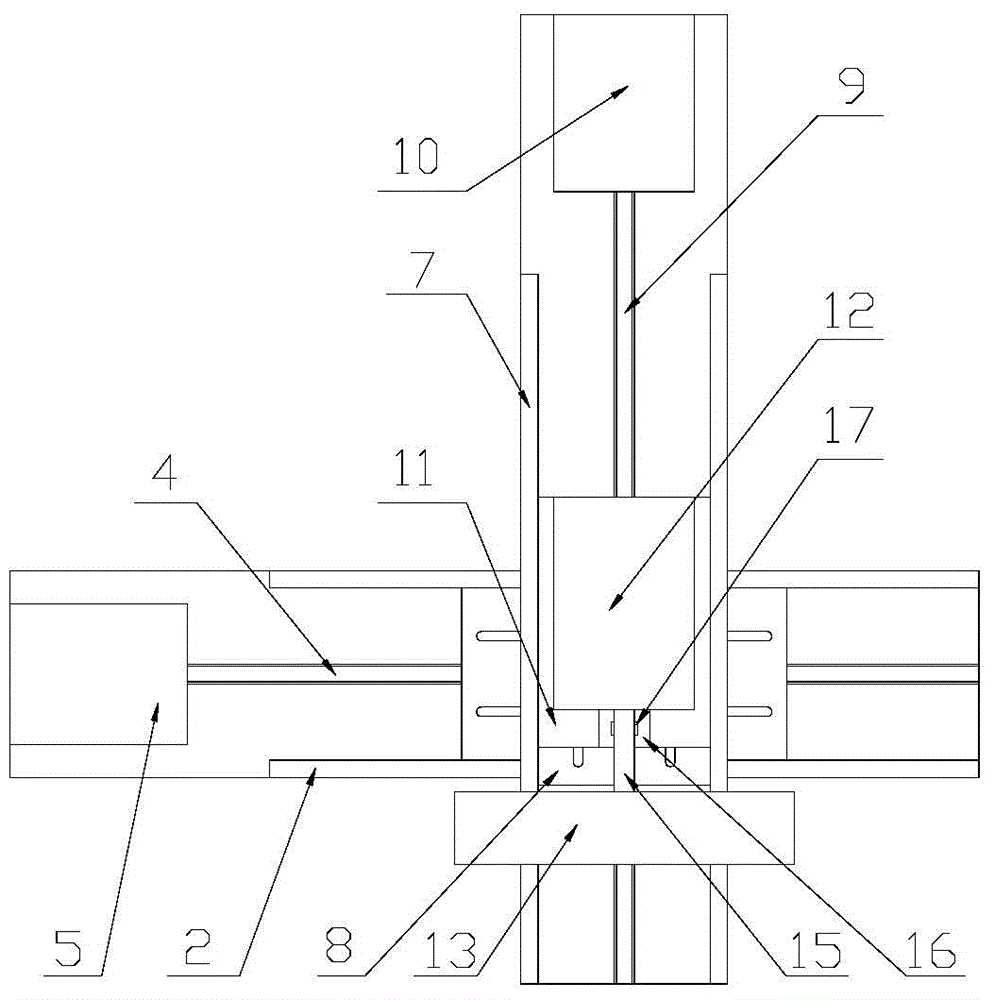

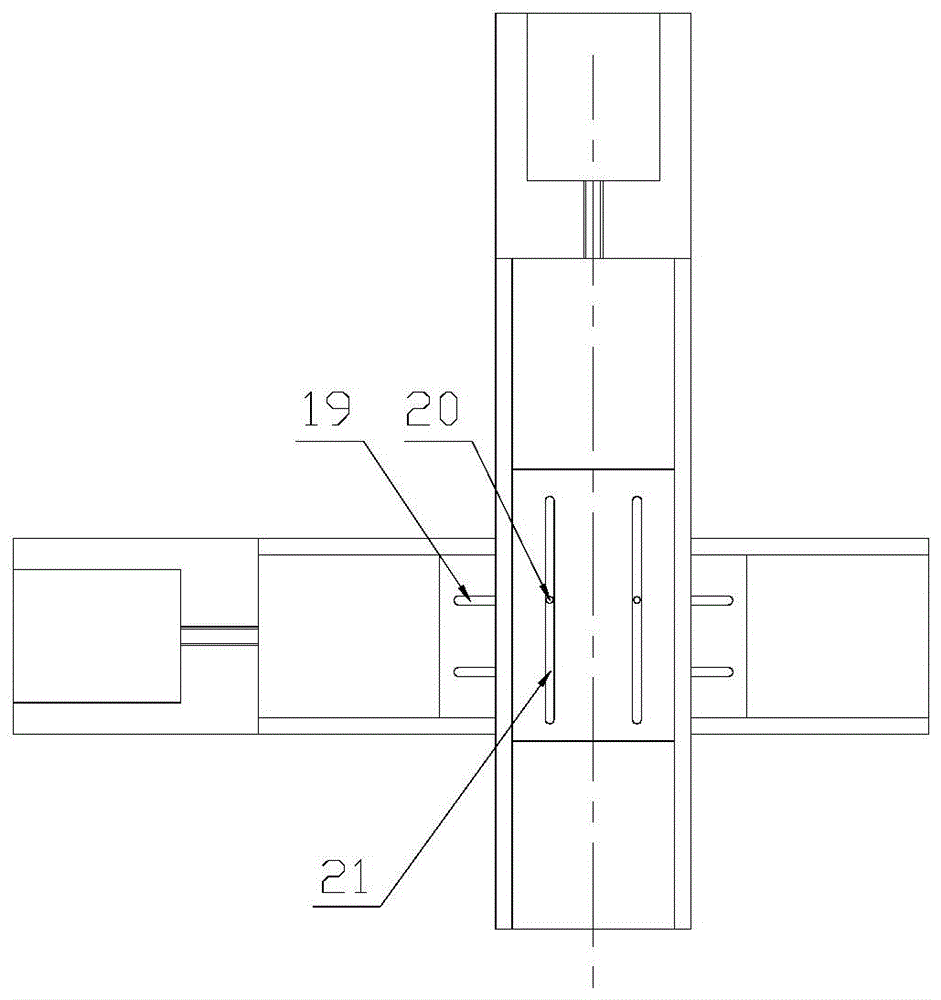

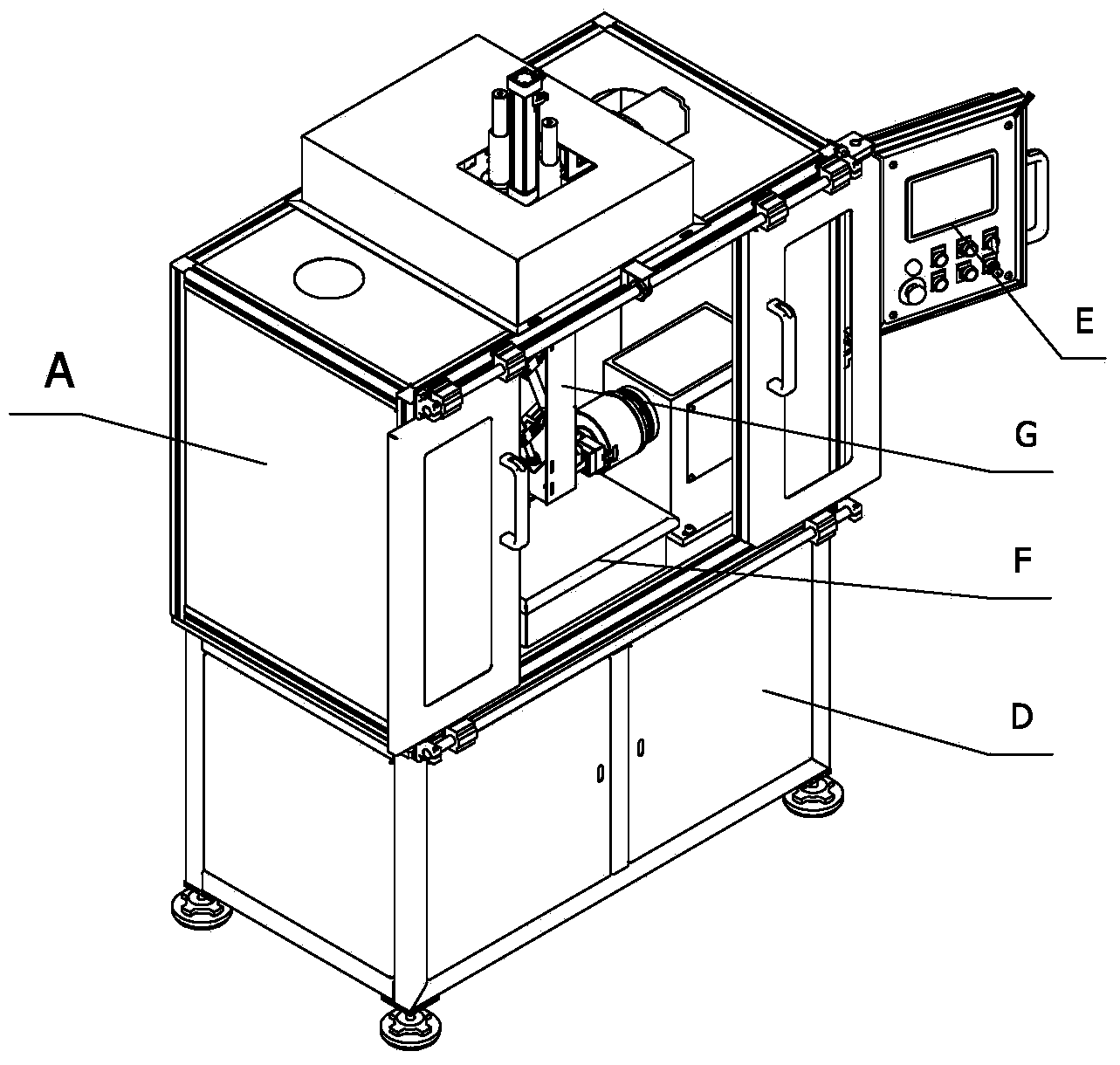

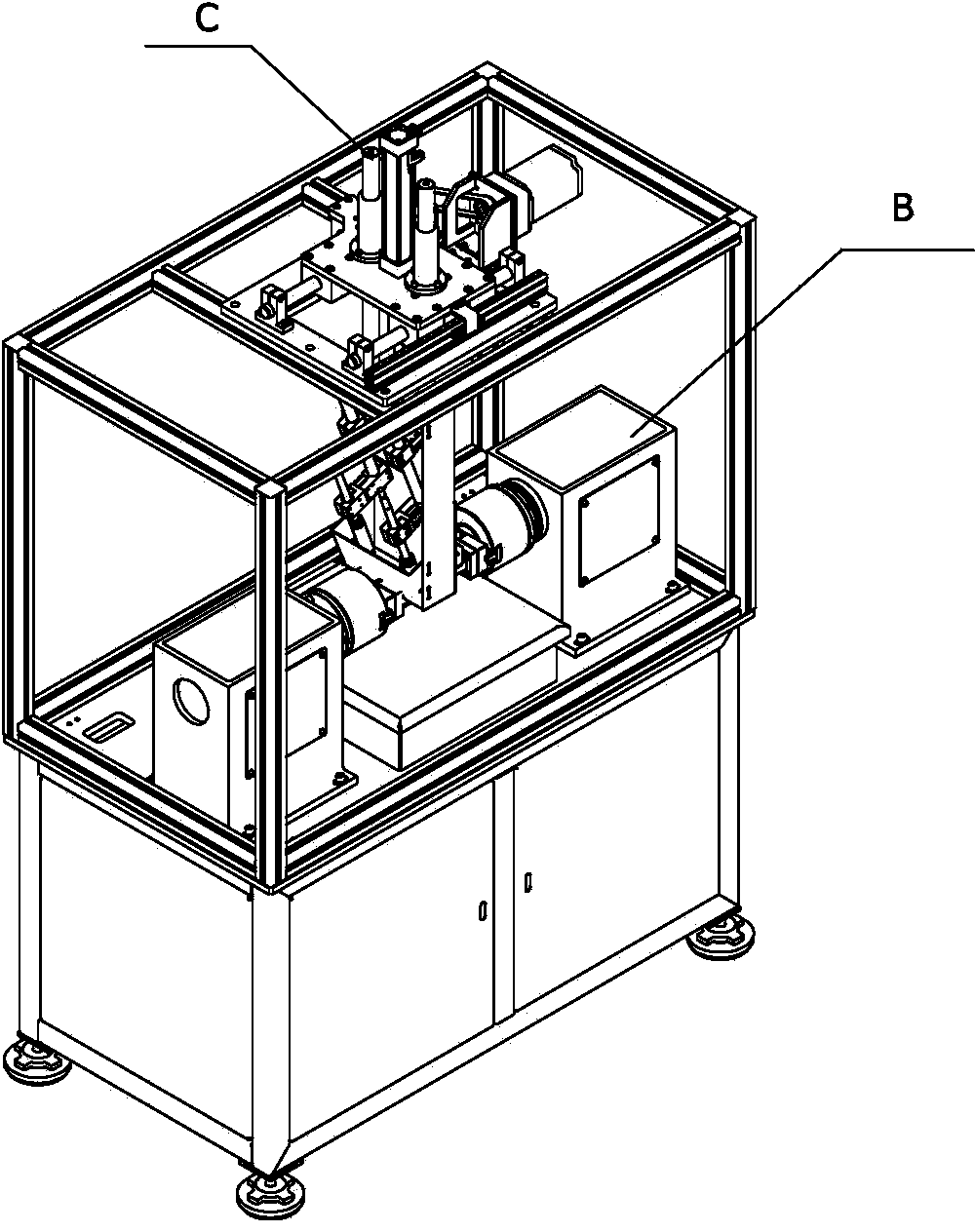

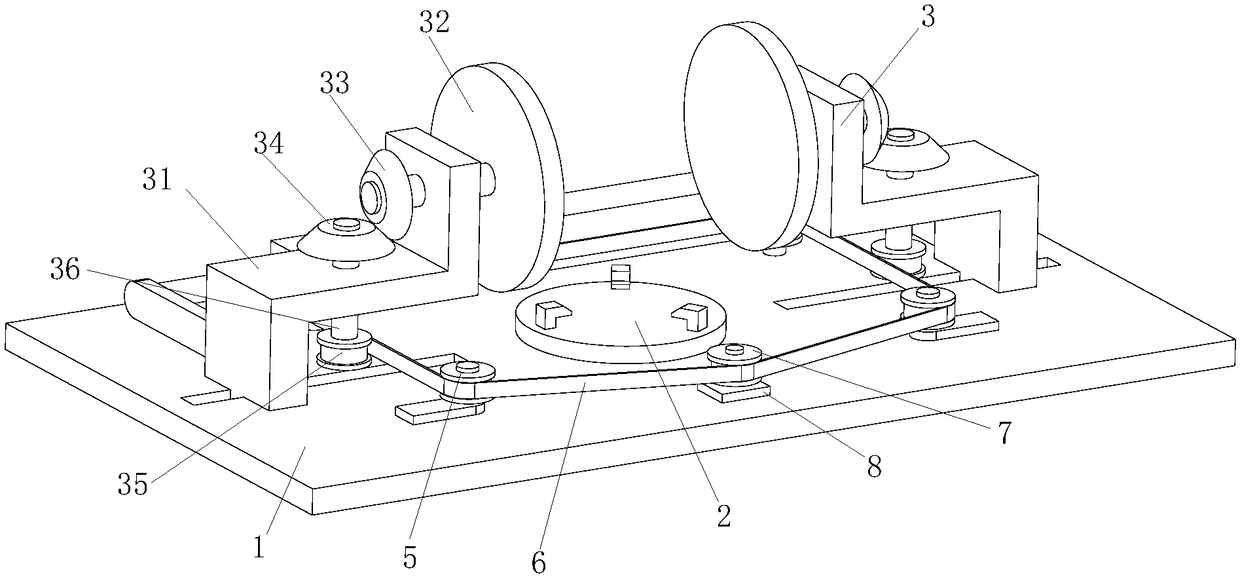

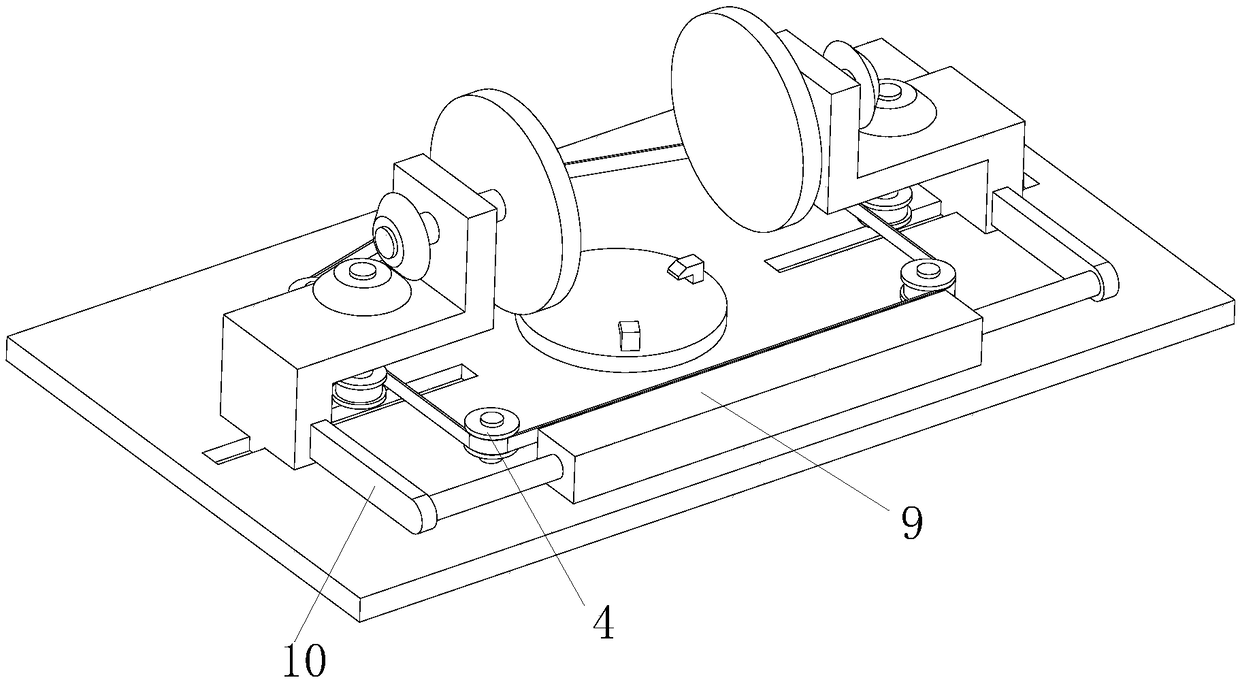

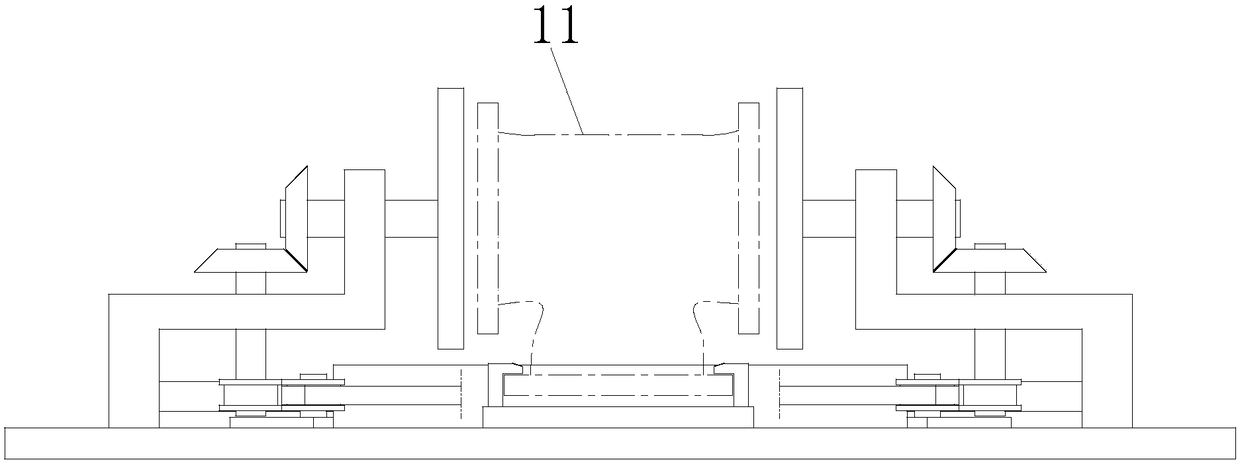

Machining method for valve body, clamping clamp and machining equipment

ActiveCN102528538AReduce the number of clampingReduce human resource investmentMetal working apparatusPositioning apparatusMachine partsEngineering

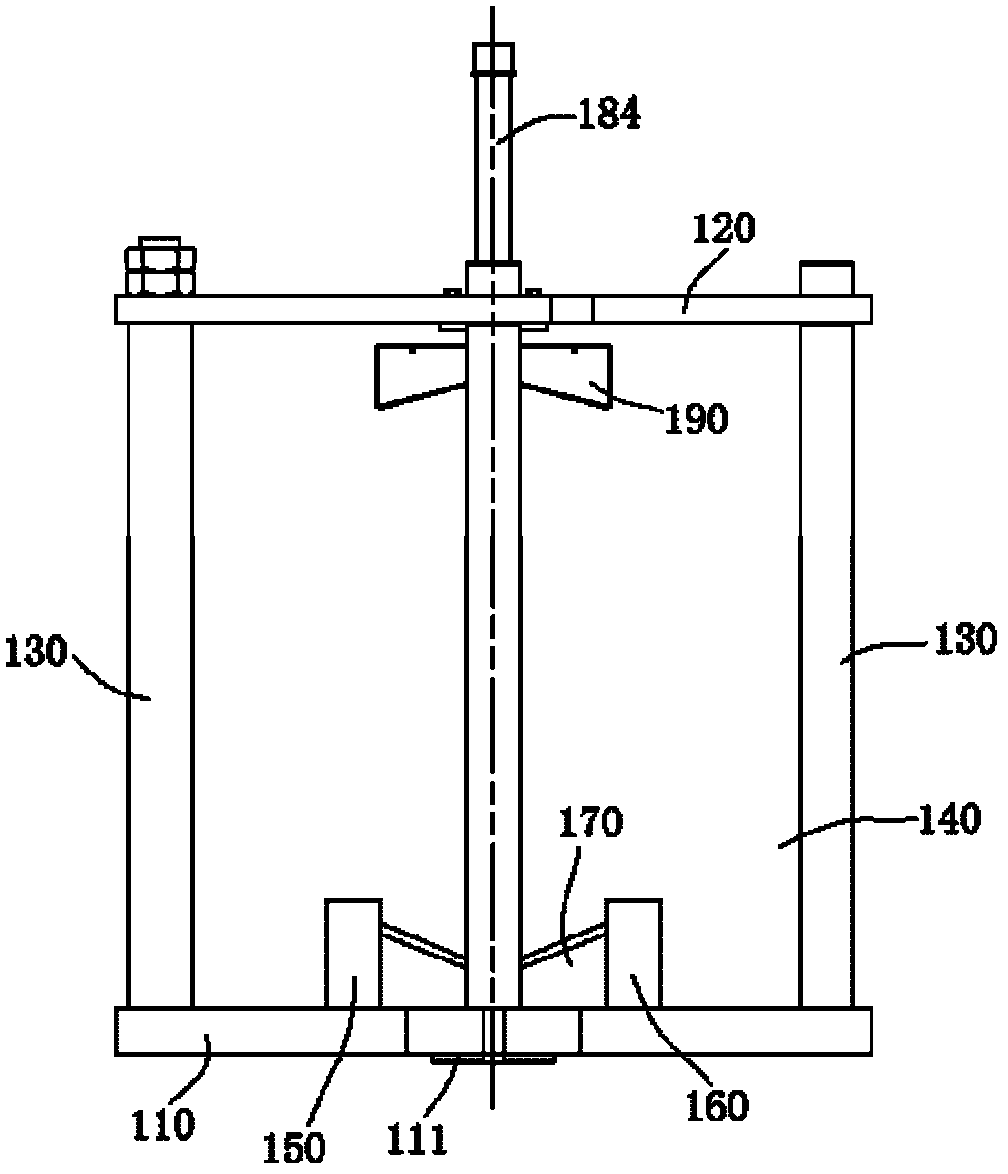

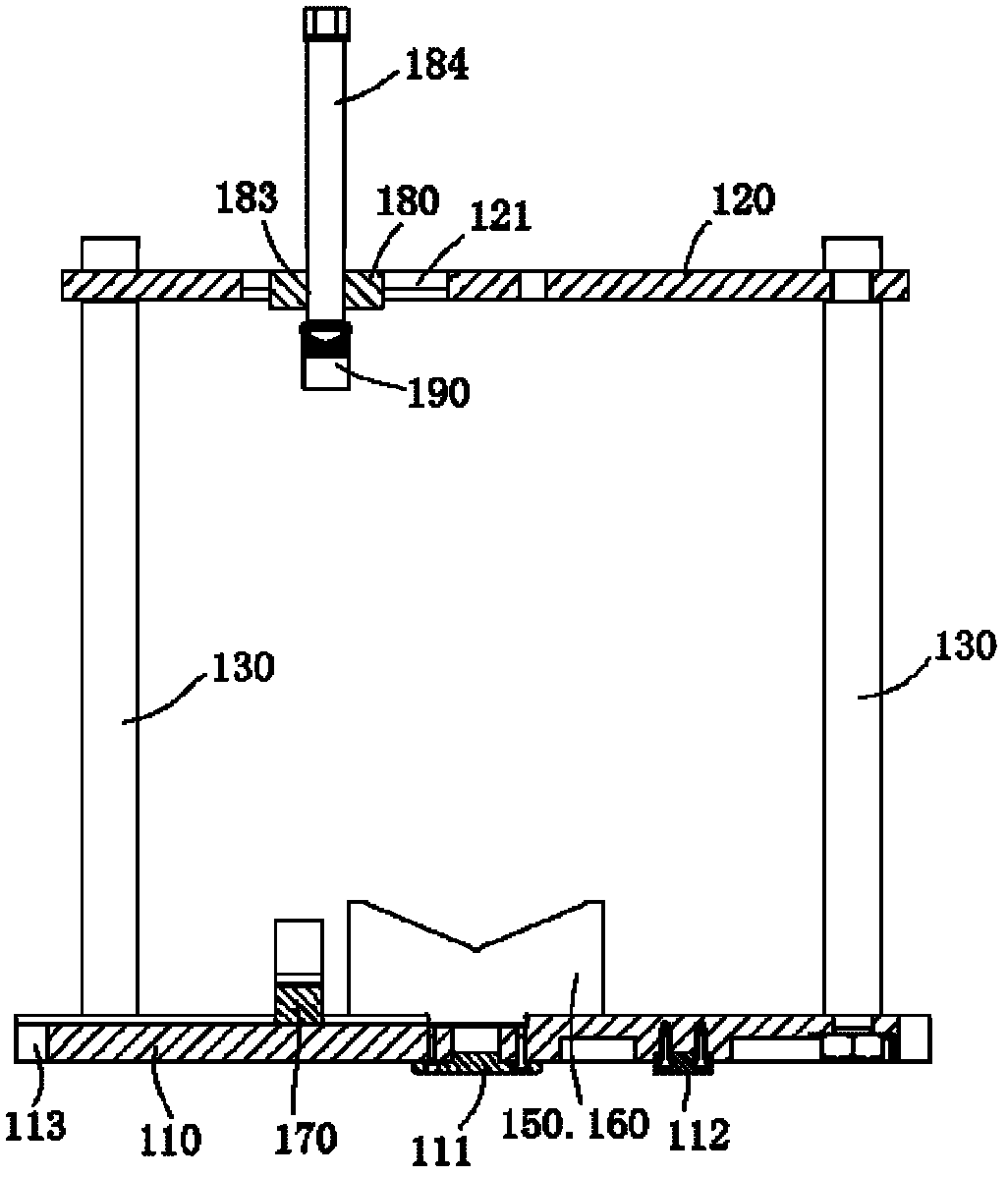

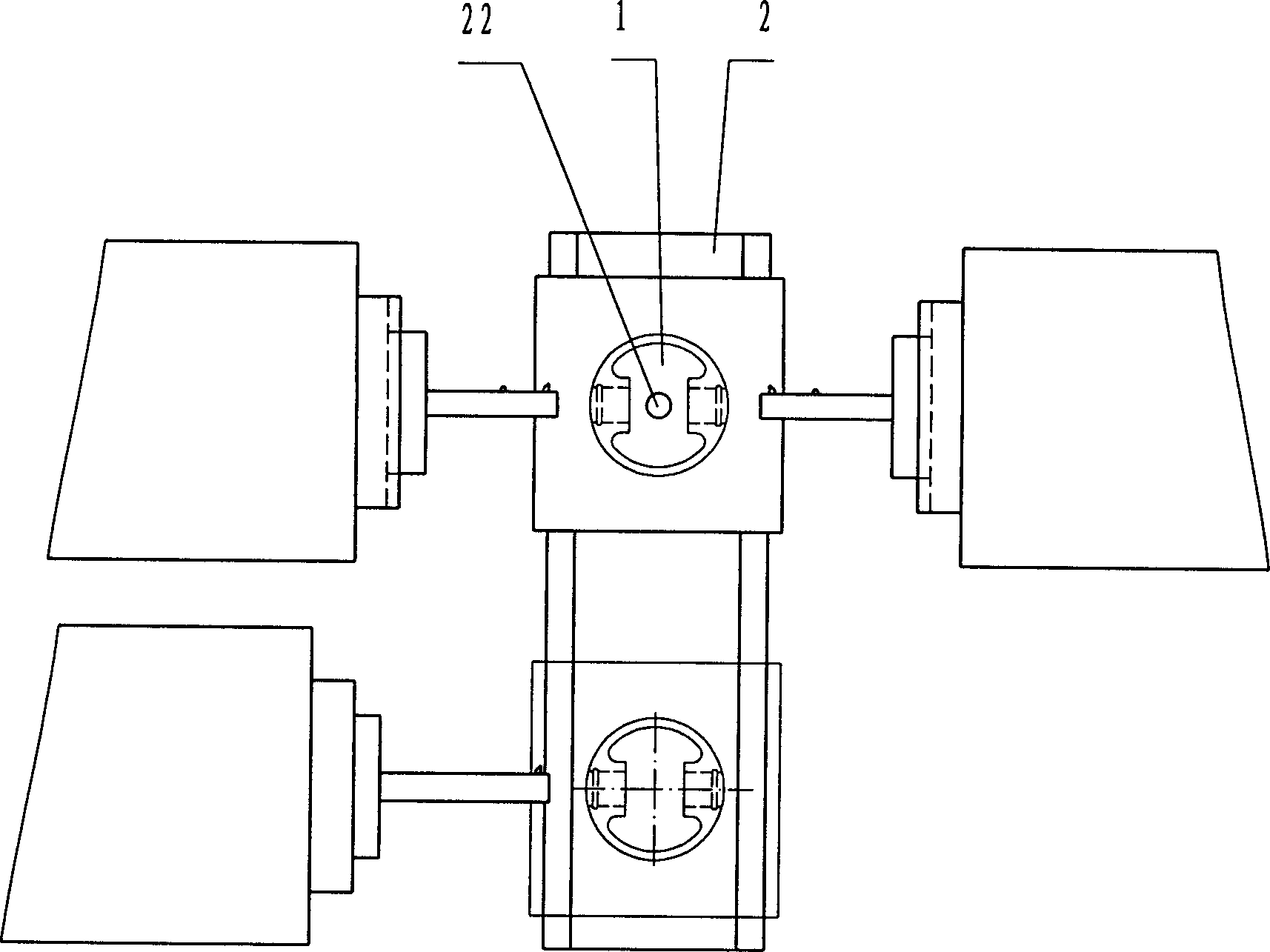

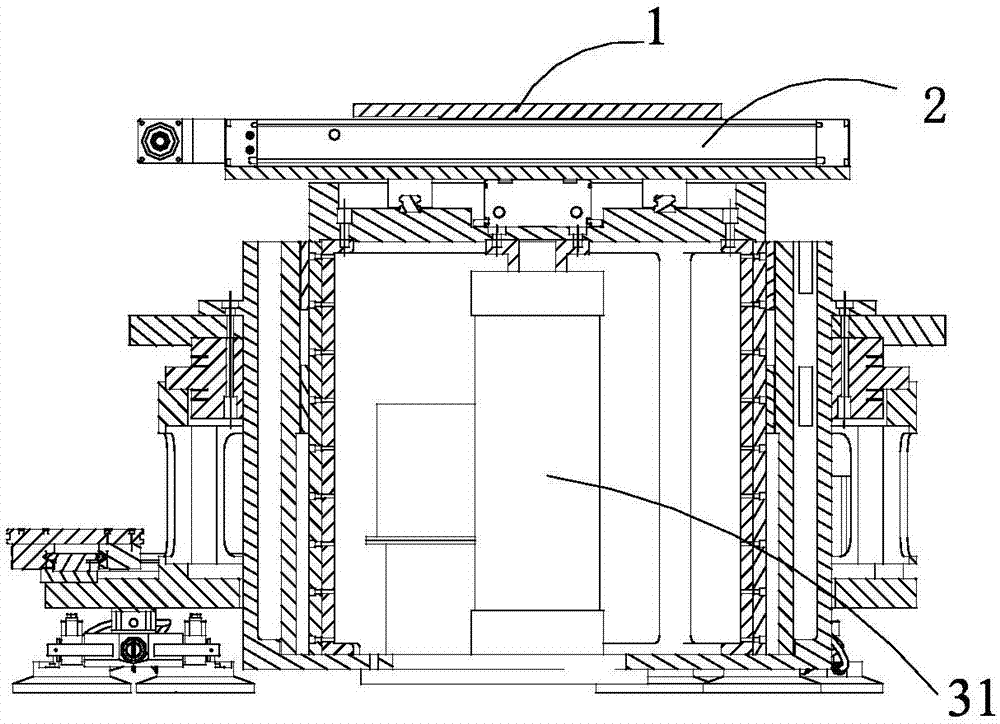

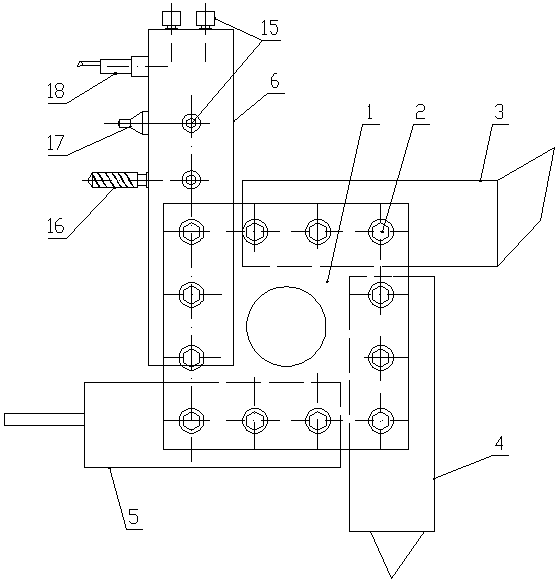

The invention discloses a machining method for a valve body. The valve body to be machined is horizontally clamped on a workpiece revolving platform of machining equipment by using a clamping clamp, and a plane to be machined of the valve body is adjusted to be perpendicular to the workpiece revolving platform of the machining equipment, so that an intersection point of a central axis of the plane to be machined of the valve body is overlapped with a revolving center of the workpiece revolving platform, and the machining method requires that an extension line of a central axis of a cutter revolving body of the machining equipment is intersected with that of the revolving central axis of the workpiece revolving platform; and after a machining part is machined, a next machining part can be machined every time when the workpiece revolving platform is turned for an angle. The invention also discloses the clamping clamp and the machining equipment for realizing the machining method. According to the machining method, the clamping clamp and the machining equipment, all machining can be finished with one person and one machine, so that the aims of reducing the clamping frequency, increasing the machining efficiency, reducing investment in human resources and reducing manufacturing cost of a product are fulfilled. The machining method can also be used for machining a part with a plurality of machining surface perpendicular to the same reference planes, and has broad universality.

Owner:SHANGHAI HONGGONG MASCH TECH CO LTD

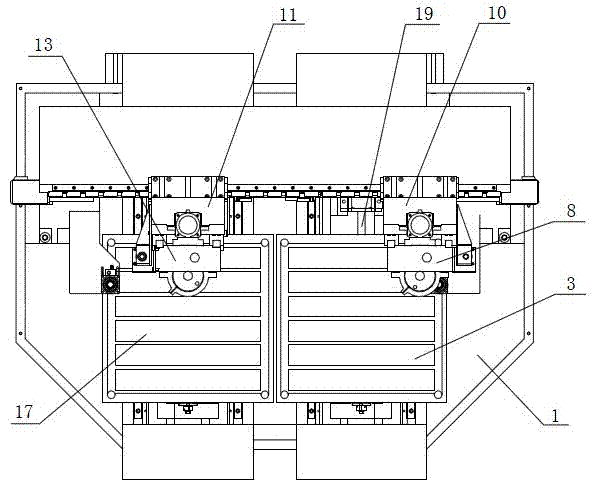

Numerical control double-station mould engraving and milling machine

InactiveCN102189288AIngenious structureSimple and fast operationMilling machinesLarge fixed membersNumerical controlBall screw

The invention relates to a machine tool, in particular to a numerical control double-station mould engraving and milling machine. A foundation, a left vertical shaft and a right vertical shaft are arranged on a frame body of the machine in a matched way; a beam is arranged above the left vertical shaft and the right vertical shaft in a matched way; the beam is connected with a left X-axle sliding table and a right X-axle sliding table through a left X-axle linear sliding block guide rail pair and a right X-axle linear sliding block guide rail pair in a matched way and the beam is in transmission fit with the left X-axle sliding table and the right X-axle sliding table through a left X-axle ball screw pair and a right X-axle ball screw pair; the foundation is connected with a left Y-axle sliding table and a right Y-axle sliding table through a left Y-axle linear sliding block guide rail pair and a right Y-axle linear sliding block guide rail pair in a matched way and the foundation is in transmission fit with the left Y-axle sliding table and the right Y-axle sliding table through a left Y-axle ball screw pair and a right Y-axle ball screw pair; and the left X-axle sliding table and the right X-axle sliding table are connected with a left Z-axle sliding table and a right Z-axle sliding table through a left Z-axle linear sliding block guide rail pair and a right Z-axle linear sliding block guide rail pair in a matched way and the left X-axle sliding table and the right X-axle sliding table are in transmission fit with the left Z-axle sliding table and the right Z-axle sliding table through a left Z-axle ball screw pair and a right Z-axle ball screw pair. The efficiency of the numerical control double-station mould engraving and milling machine is two times that of the conventional machine tool.

Owner:DOUBLE HEAD CNC

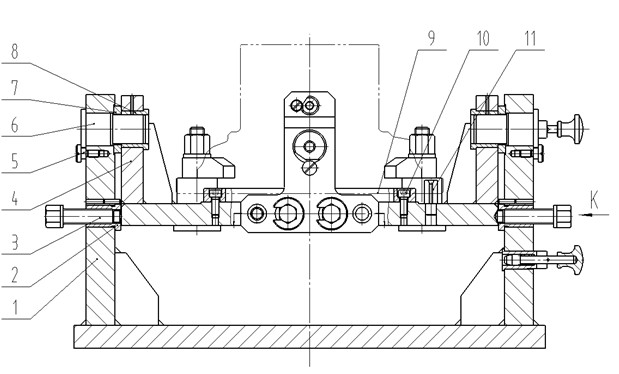

Fixture for drilling inflating and discharging holes in hub

ActiveCN102069401AReduce the number of clampingImprove labor efficiencyPositioning apparatusBoring/drilling componentsEngineeringMechanical engineering

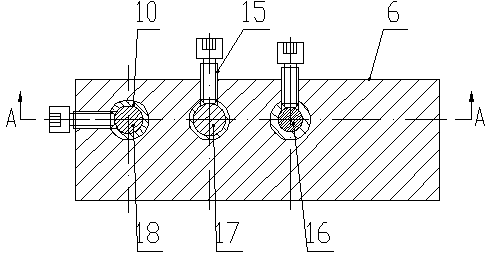

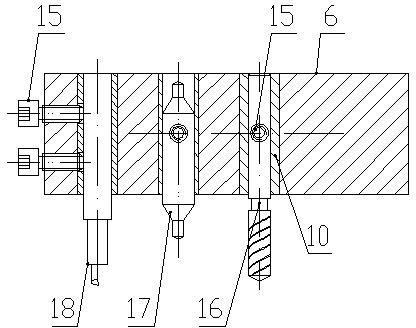

The invention relates to a fixture for drilling inflating and discharging holes in a hub, which comprises a body, a revolution body, a rotating shaft, housing screws, a locating ring, a locating pin, a drilling template, a b-type drilling template, a hook clamp plate and a localizer. The revolution body is a U-shaped frame body, and both sides of the revolution body are connected with the body through the rotating shaft and an adjusting washer. The housing screws are symmetrically arranged on both sides of the body with three screws on each side, wherein two screws in each side are distributed in a horizontal position and the third screw is vertical to the horizontal plane. By adopting a rotation design, three working procedures are merged into one working procedure, and three holes are processed with a set of fixture and a drilling machine, thus reducing fixturing frequency, saving time and labor, and improving labor efficiency.

Owner:重庆大江车桥有限责任公司

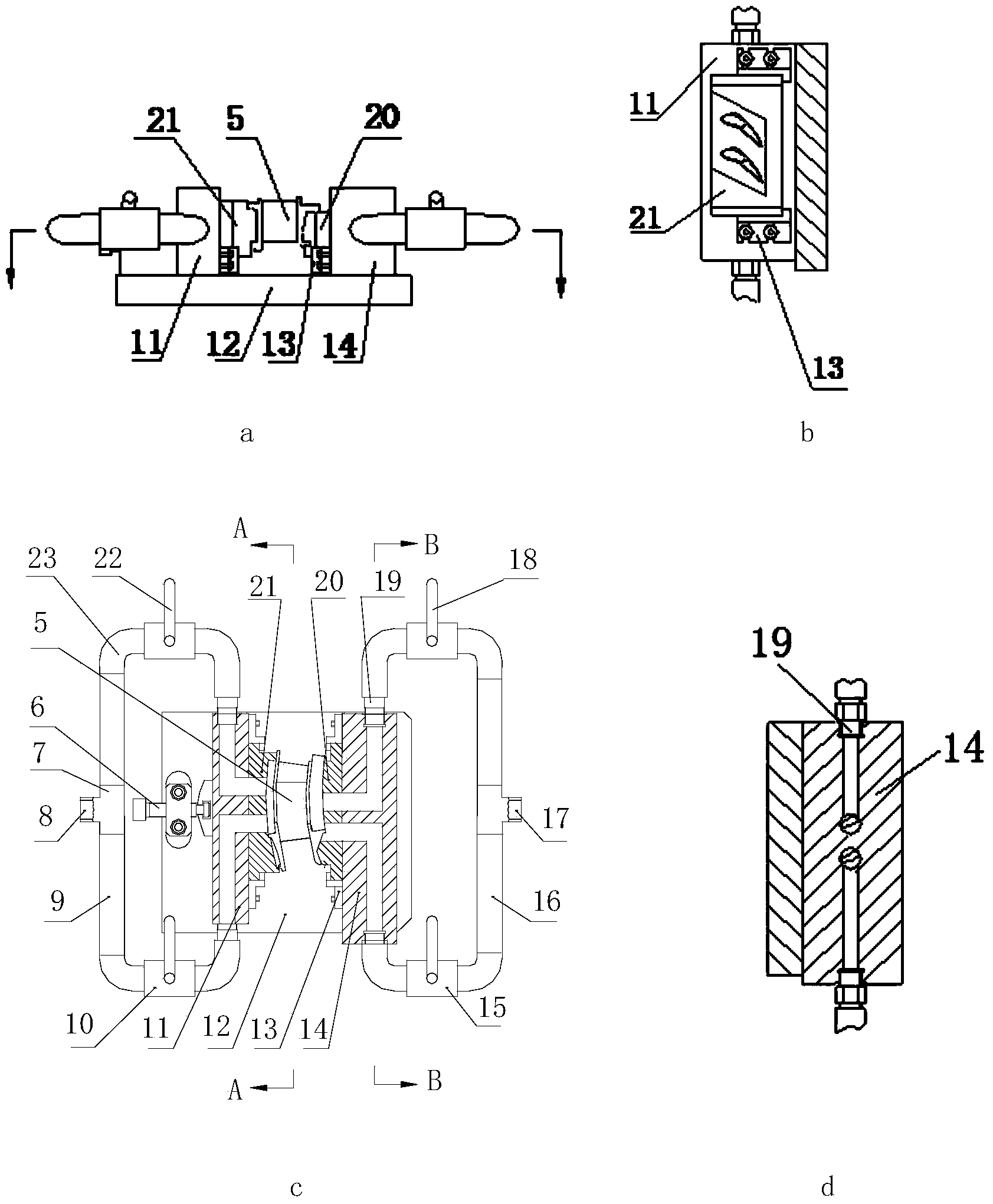

Guide blade water flow measuring clamp and guide blade water flow measuring method

ActiveCN103481219AReduce the number of clampingReduce mistakesMachine part testingWork holdersWater flowEngineering

The invention discloses a guide blade water flow measuring clamp and a guide blade water flow measuring method. Improvements on aspects of a sealing pad, a clamp passage structure and a water inlet waterway control are made. The sealing pad is changed into a mode that a blade is integrally contained and sealed and cavity passage docking is reserved, so that effective sealing is realized and the objective of multi-passage measuring is realized; four corresponding water incoming passages are designed for a clamp corresponding to the blade according to the position of a hole of the blade to be suitable for water incoming systems of four cavities of the blade. By the guide blade water flow measuring clamp and the guide blade water flow measuring method, the four cavities of the blade can be communicated with the four water incoming passages of a measuring system simultaneously only by clamping and mounting the blade for one time, and when measuring any cavity of the blade, water flow value of the cavity can be acquired only by opening a control valve. The guide blade water flow measuring method is simple and convenient to operate and stable in data, and the guide blade water flow measuring clamp is timesaving, laborsaving and good in sealability.

Owner:AECC AVIATION POWER CO LTD

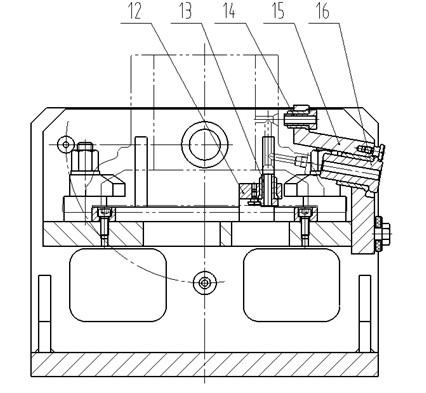

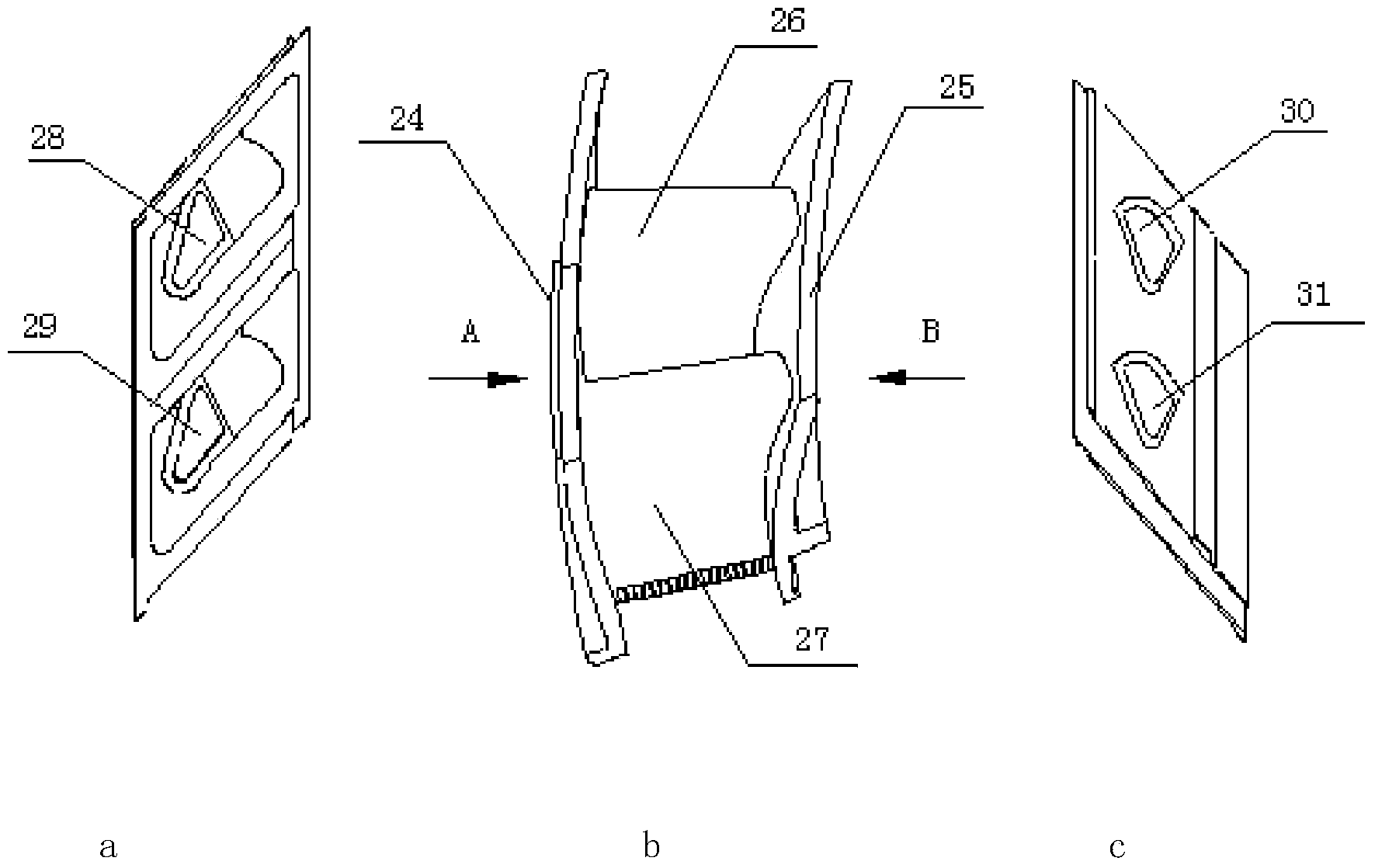

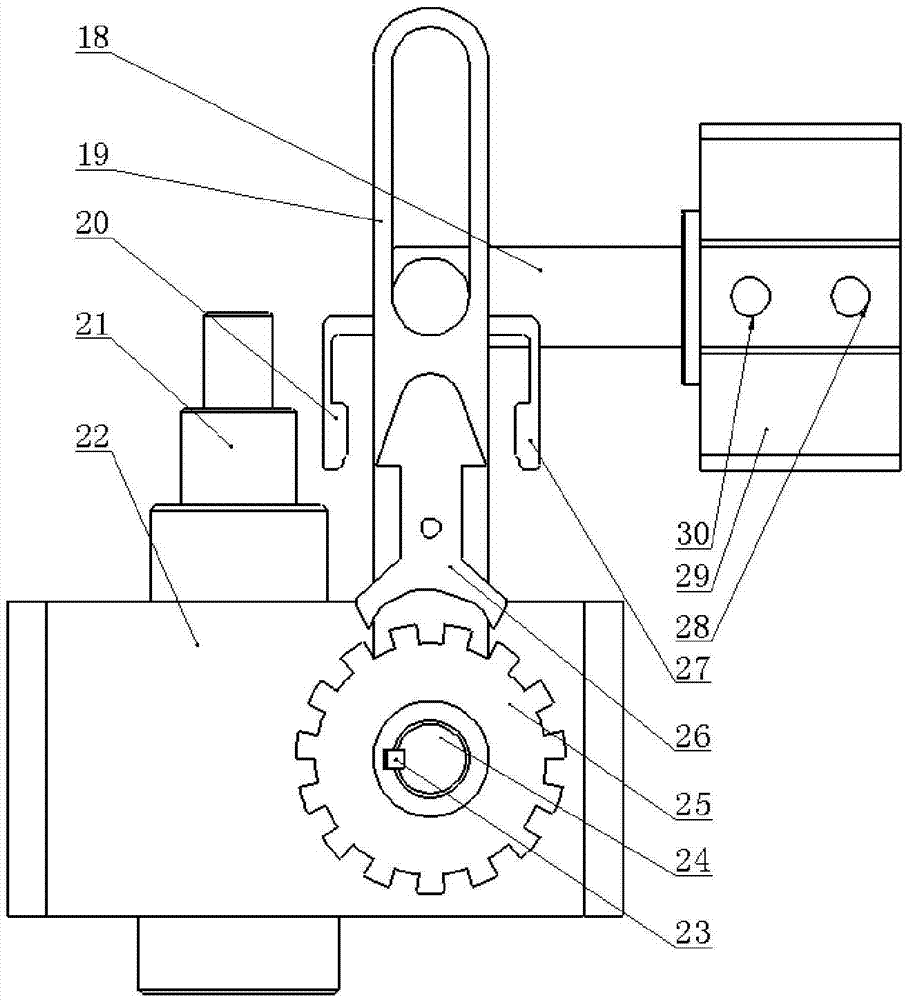

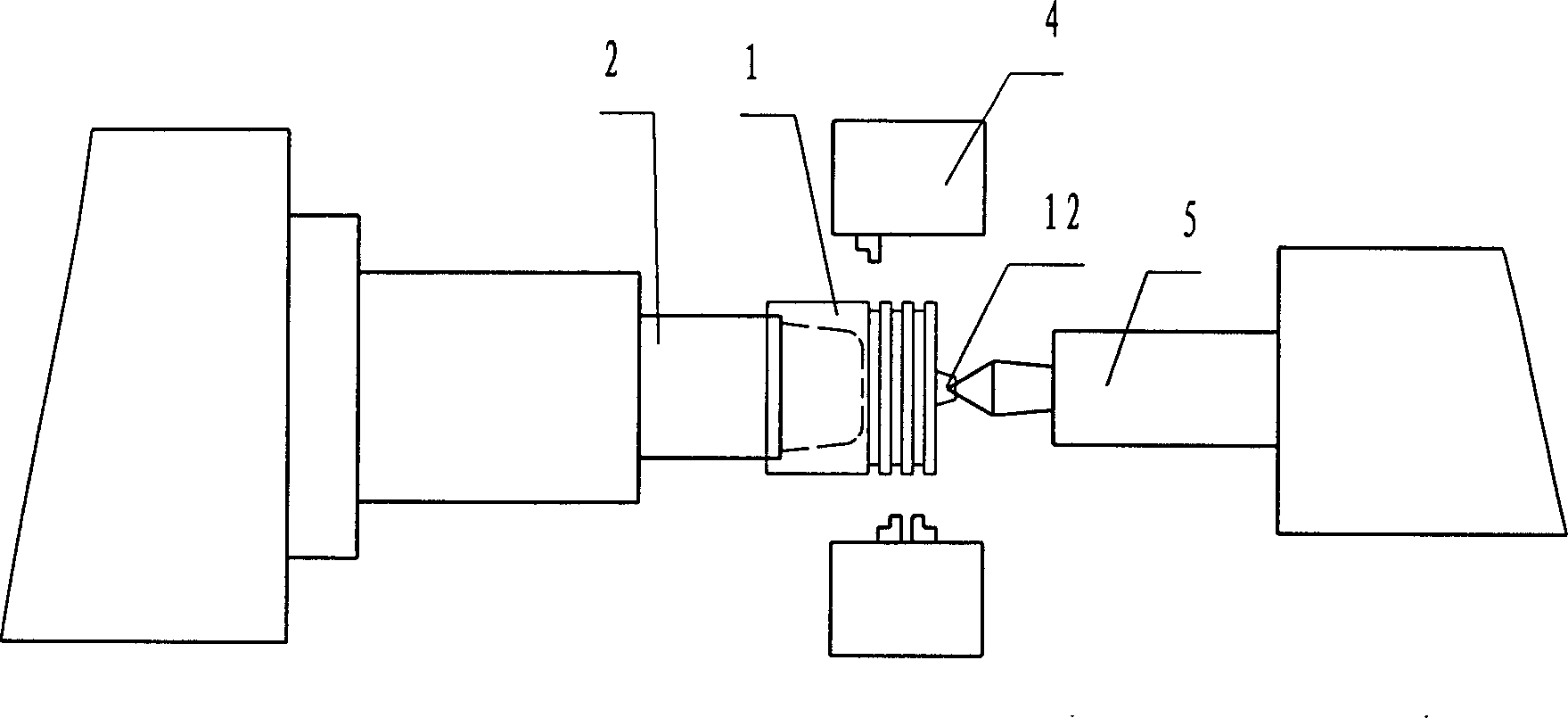

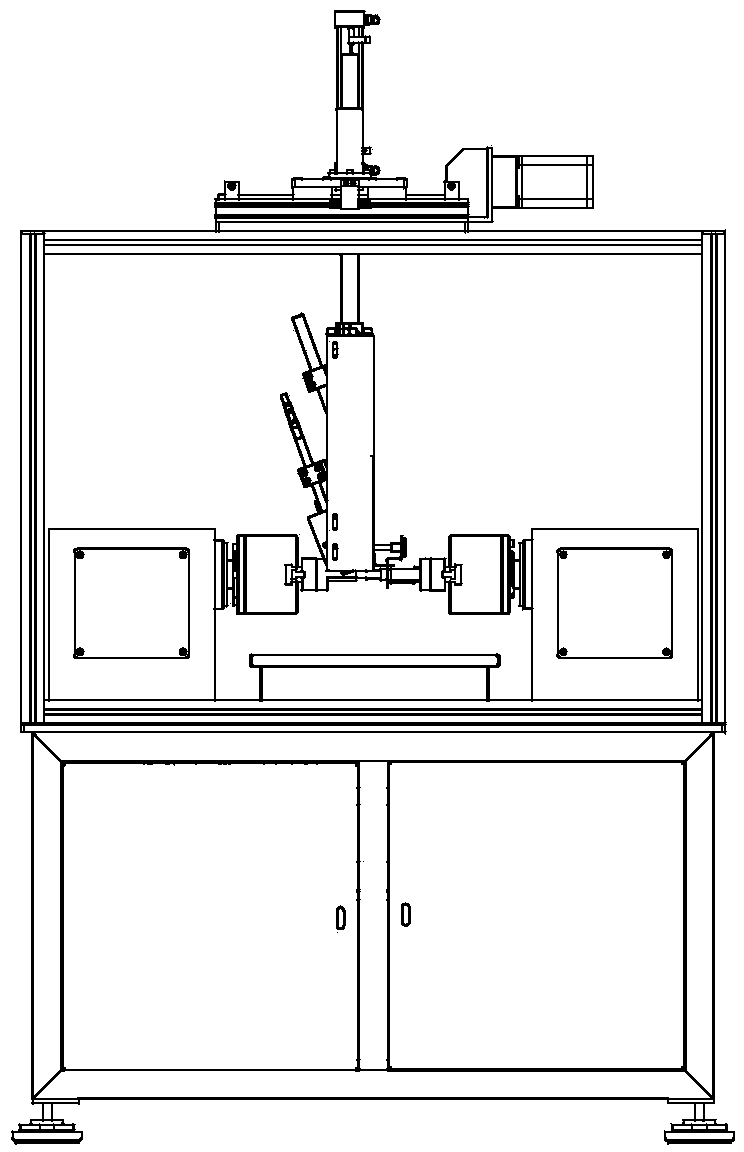

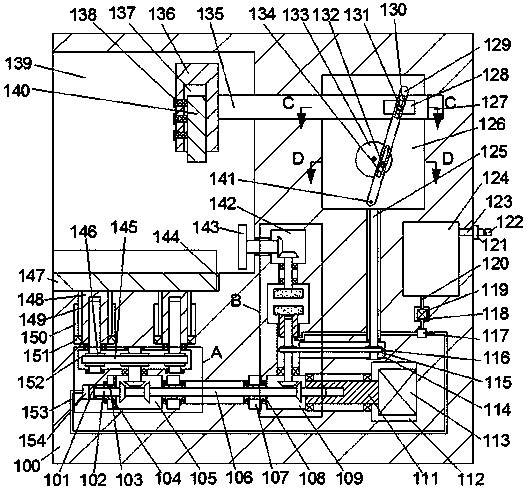

Static index testing platform and method for industrial robot joint decelerator

InactiveCN105445023ACompact structureSimple structureMachine gearing/transmission testingReduction driveEngineering

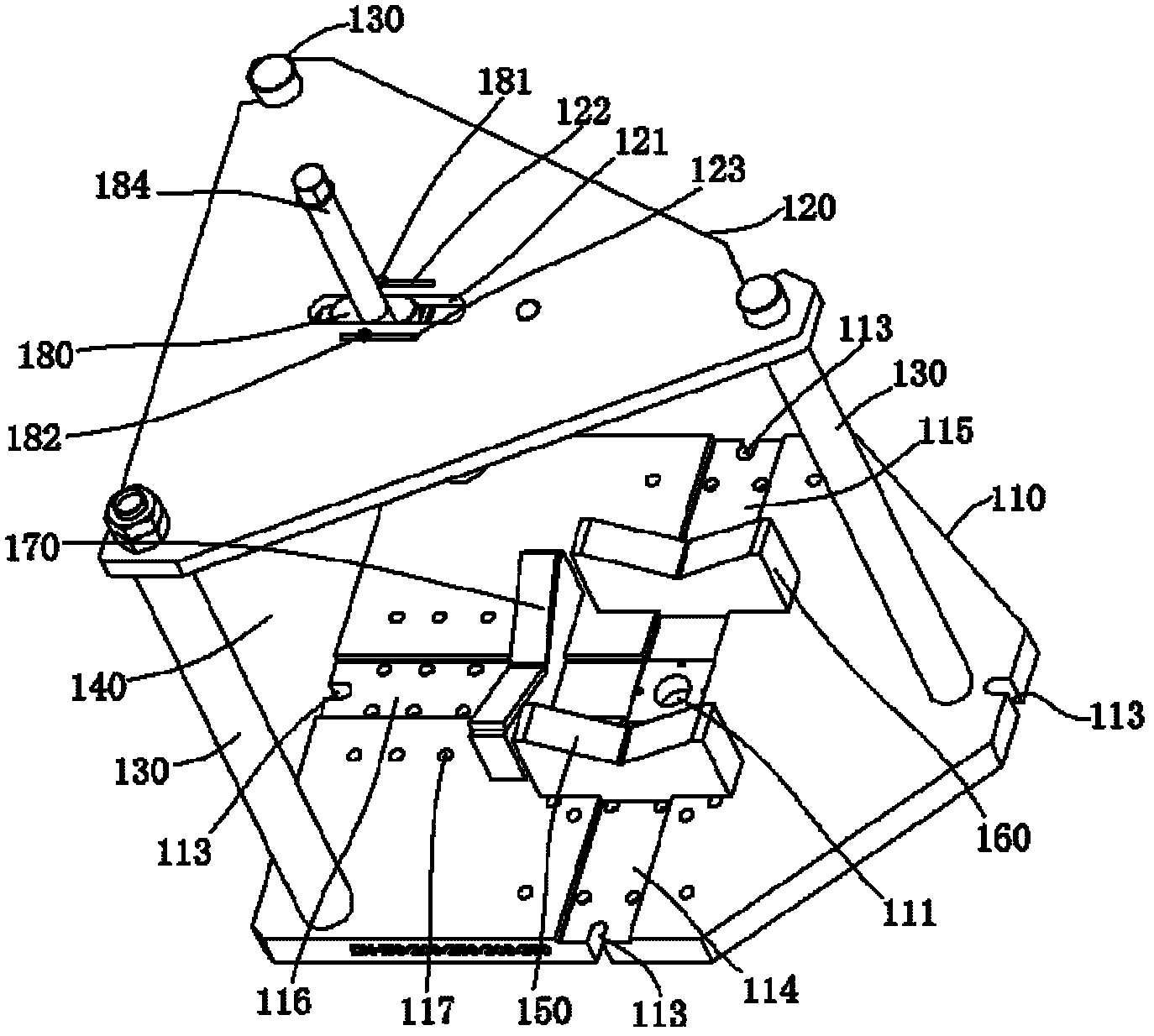

The invention discloses a static index testing platform and method for an industrial robot joint decelerator, and the platform comprises a first automatic loading device which comprises an output shaft. One end of a first tension and pressure sensor is connected with the output shaft of the first automatic loading device, and the other end of the first tension and pressure sensor is connected with one end of a first connecting shaft. One end of the first connecting shaft is connected with one end of a force arm, and one end of the force arm is connected with a second connecting shaft. The other end of the force arm is provided with a first displacement sensor and a second displacement sensor, which are used for measuring the displacement of the force arm. According to the invention, the first automatic loading device employs the large transmission ratio of a spiral lifting machine, can achieve a large pushing force, and is compact in structure. The platform is simple and compact in overall structure, is small in size, and can achieve automatic testing. The method can achieve the testing of bending moment rigidity, torsional rigidity, tooth spaces and return difference through the platform, and is high in precision of testing results.

Owner:XI AN JIAOTONG UNIV

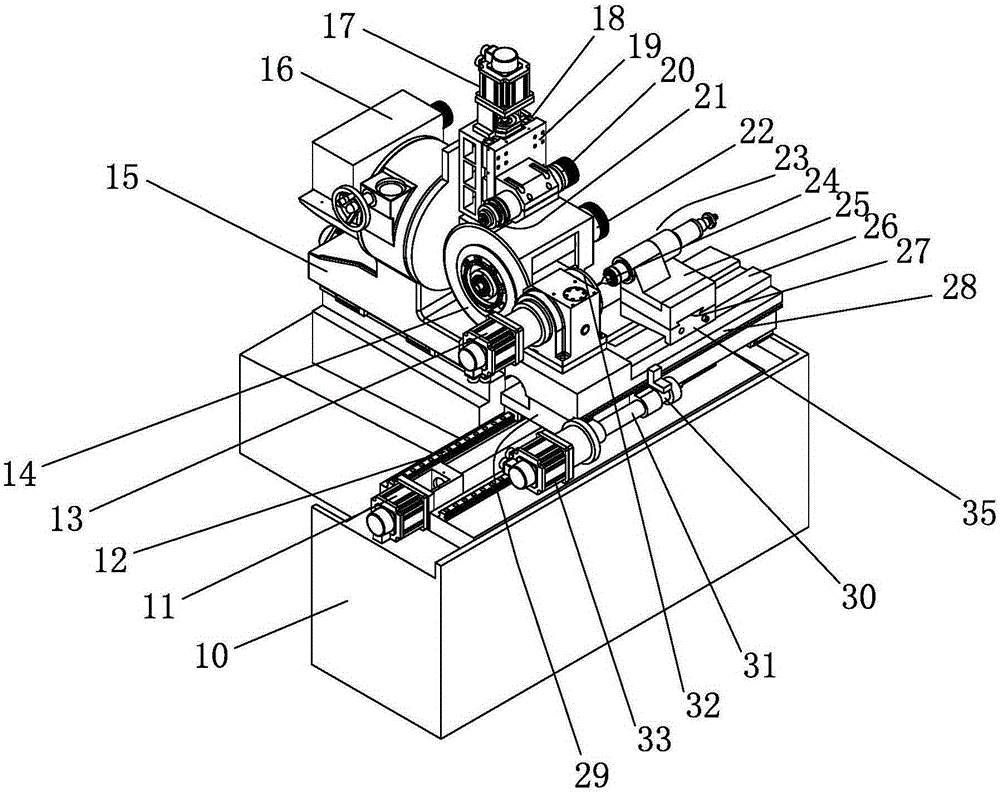

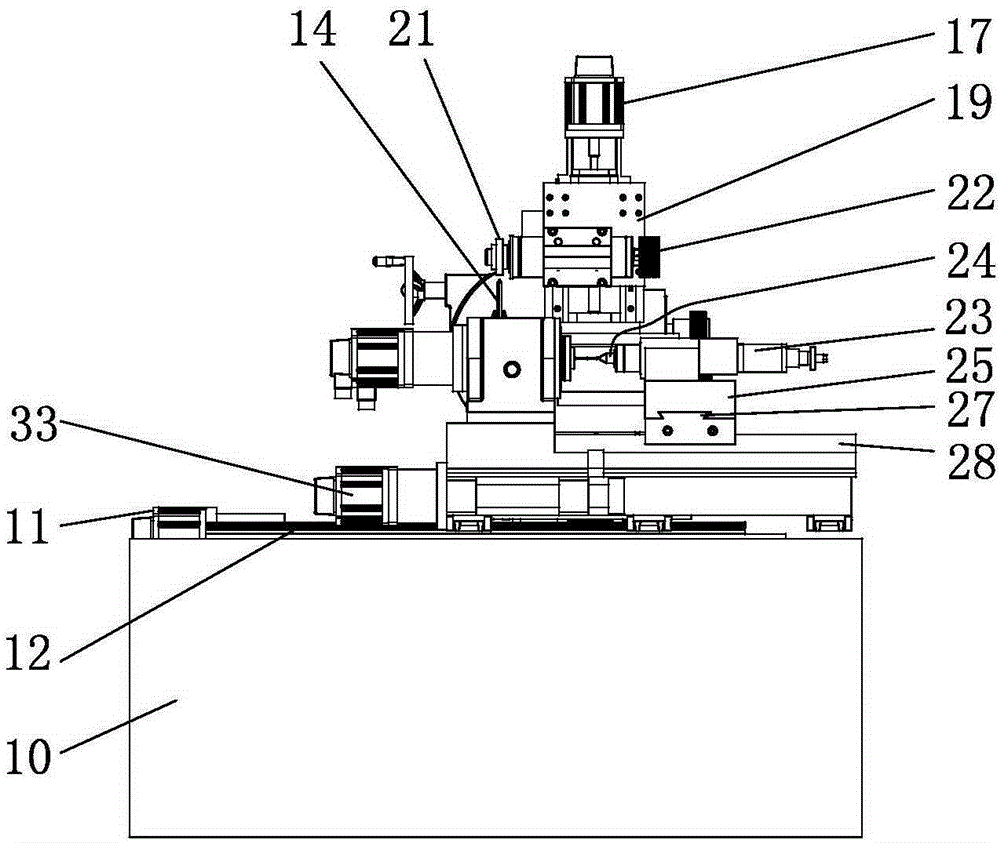

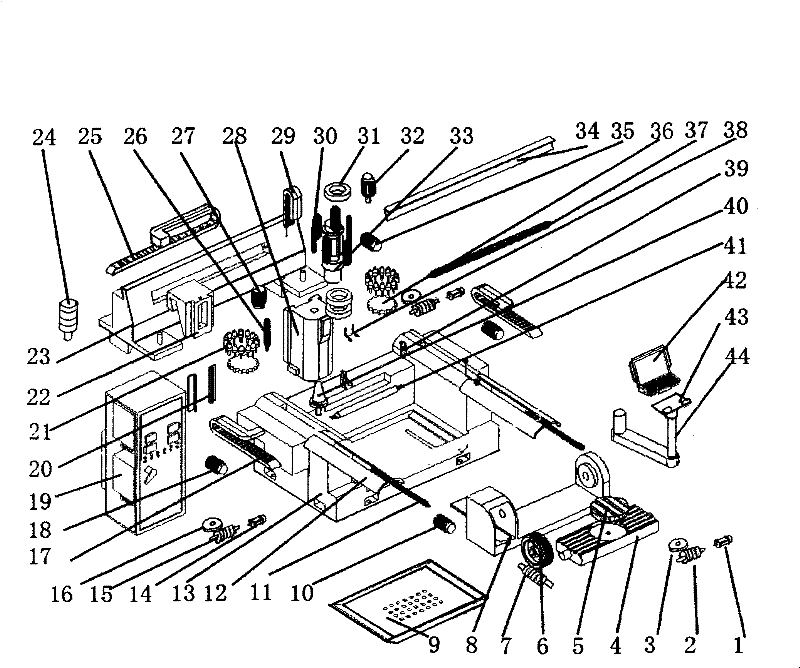

Full-automatic numerical control screw tap thread grinder

InactiveCN105196117AOutstanding and Beneficial Technical EffectsImproved relief grinding structureGrinding drivesAbrasive surface conditioning devicesNumerical controlEngineering

The invention belongs to the technical field of grinders, and relates to a full-automatic numerical control screw tap thread grinder. A rear support plate moving along a longitudinal slide rail is arranged at the rear side of a work table of a grinder base, a grinding wheel spindle is arranged at the front side of the rear support plate, driven by a power device to rotate and provided with a screw tap relief-grind grinding wheel, a sliding block moving along a vertical slide rail is arranged on the portion, located at the rear side of the grinding wheel spindle, of the rear support plate, and a diamond wheel is installed on a diamond rotating shaft arranged on the sliding block; a front support plate moving transversely is arranged at the front side of the work table, a swing tray is hinged to the front support plate, an indexing workpiece clamp is arranged at one side of the swing tray, a tailstock centre moving along a transverse slide rail is arranged at the other side of the swing tray, a swing shaft driven by the power device to rotate and a cam installed on the swing shaft are hinged to the front side of the front support plate, and actions of the power device are controlled by a controller program. The full-automatic numerical control taped thread grinder has the advantages that the screw tap relief-grind grinding wheel is high in finishing accuracy, clamping frequency is reduced, the accuracy and efficiency of screw tap machining are improved, and the grinder is applicable to the field of full-automatic numerical control screw tap thread grinders.

Owner:ZHEJIANG WEIKE MACHINERY TECH

Computerized numerical controlled engraving and milling machine with symmetrical double station of shoe modules

InactiveCN101032765AIngenious structureSimple and fast operationMilling machinesLarge fixed membersNumerical controlEngraving

The symmetrical numerically controlled double site shoe mold carving and milling machine includes one machine pedestal, one right upright and one left upright with upper ends connected to the crossbeam, one right Z axis power mechanism and one left Z axis power mechanism slide fitting the crossbeam via the Z axis slide plate, one right X axis ball screw pair and one left X axis ball screw pair with opposite rotation direction for stroke control, one Z axis power head slide fitting the Z axis slide plate and transmission fitting to the Z axis ball screw pair, one Y axis bench slide fitting the machine pedestal and transmission fitting to the Y axis ball screw pair, and shoe mold fixture on the Y axis bench. The present invention has smart structure, simple operation and small size, and can machine one pair of shoe molds through once machining, resulting in doubled machining efficiency.

Owner:郭云飞

Method of processing impeller on five-axis machining center

InactiveCN104827113ASmall thermal deformationImprove surface roughnessMilling equipment detailsImpellerSurface roughness

The invention provides a method of processing impellers on a five-axis machining center and relates to the field of machining, and particularly relates to the method of processing the impellers on the five-axis machining center. The method comprises following steps: (1) clamping positioning with a mandrel: processing a key groove on a workblank for assistant positioning and performing the clamping positioning being suitable for the mandrel; and (2) alignment of a workpiece with a dial indicator: calculating the coordinate system of the workpiece, installing a mounting rod of the dial indicator on a cutter handle and moving a workbench to move the central line of a main shaft approximately to the center of the workpiece. By mean of the method, clamping times can be reduced and positioning precision is ensured, and meanwhile the surface roughness of the impellers can be increased. By means of high-speed milling, the cutting force and the cutting zone temperature are effectively reduced, thereby reducing thermo-deformation of the impellers. The method can not only increase processing efficiency but also increasing processing quality and precision, and can enhance the strength and the rigidity of the impellers.

Owner:王晓冬

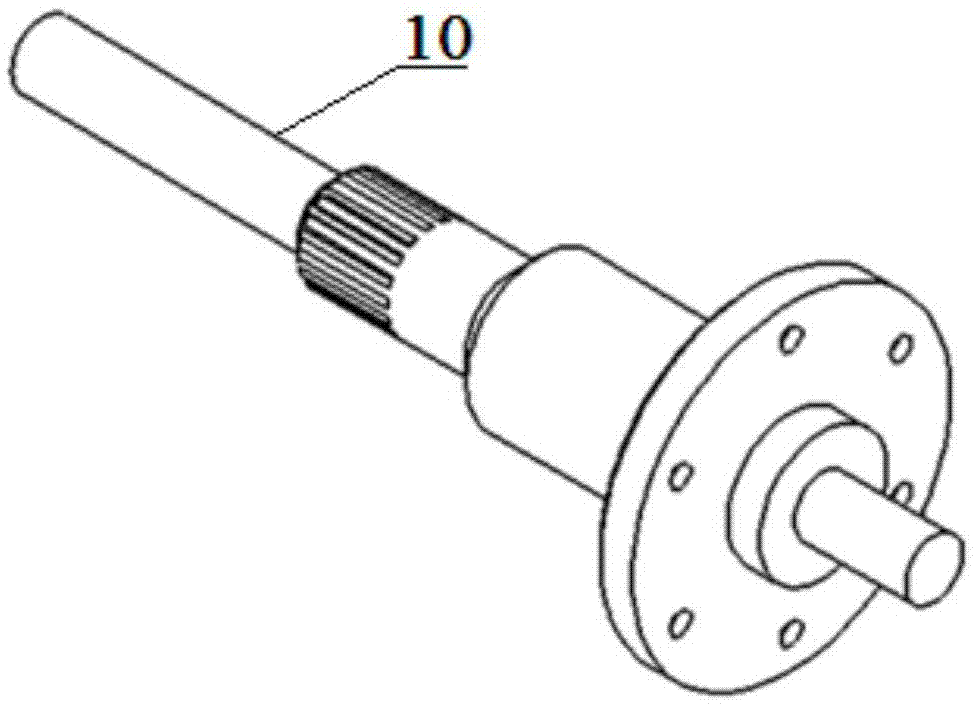

Fixture and method for processing half-shaft casing holes at both ends of rear axle housing in vehicle

InactiveCN104476258AReduce processing difficultyReduce the number of clampingPositioning apparatusMetal-working holdersIn vehicleEngineering

The invention relates to a fixture for processing half-shaft casing holes at both ends of a rear axle housing in a vehicle. The fixture comprises a working table and is characterized in that both ends of the working table are respectively provided with V-shaped seats; a first upright is arranged at one side of each V-shaped seat; the upper ends of the first uprights are provided with screw threads and are matched with nuts; a second upright is arranged at the other side of each V-shaped seat; the upper ends of the second uprights are hinged to one ends of working pressure plates; transverse rabbets are formed at the other ends of the working pressure plates; the transverse rabbets are correspondingly matched with the upper parts of the first uprights; a limiting seat is arranged at the middle part of the working table; the limiting seat is provided with a vertical rabbet; the fixture can ensure processing accuracy of the half-shaft casing holes at both the ends of the rear axle housing in the vehicle and production efficiency can be improved. The invention also relates to a method for processing the half-shaft casing holes at both the ends of the rear axle housing in the vehicle. By the method, size accuracy and coaxiality of the half-shaft casing holes are improved and design and manufacturing cost of a tool is reduced.

Owner:CHONGQING DAJIANG IND

Positioning and clamping method for processing piston and processing technique

A locating and clamping method for machining piston includes providing machine-tool, cutter and fixture, using the top of the inner cavity of the piston to be machined as the point to be clamped, and using the external end face and locating boss of the piston as the locating surface. Its advantages are no deformation caused by clamping, high locating precision, and high productivity and quality.

Owner:薛玉田

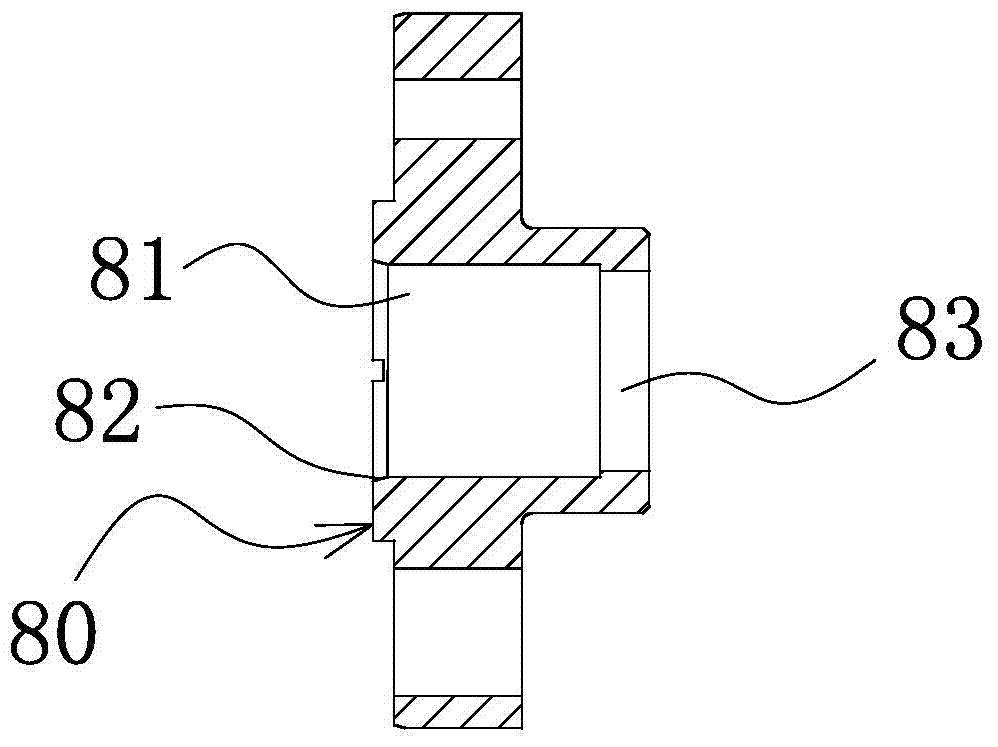

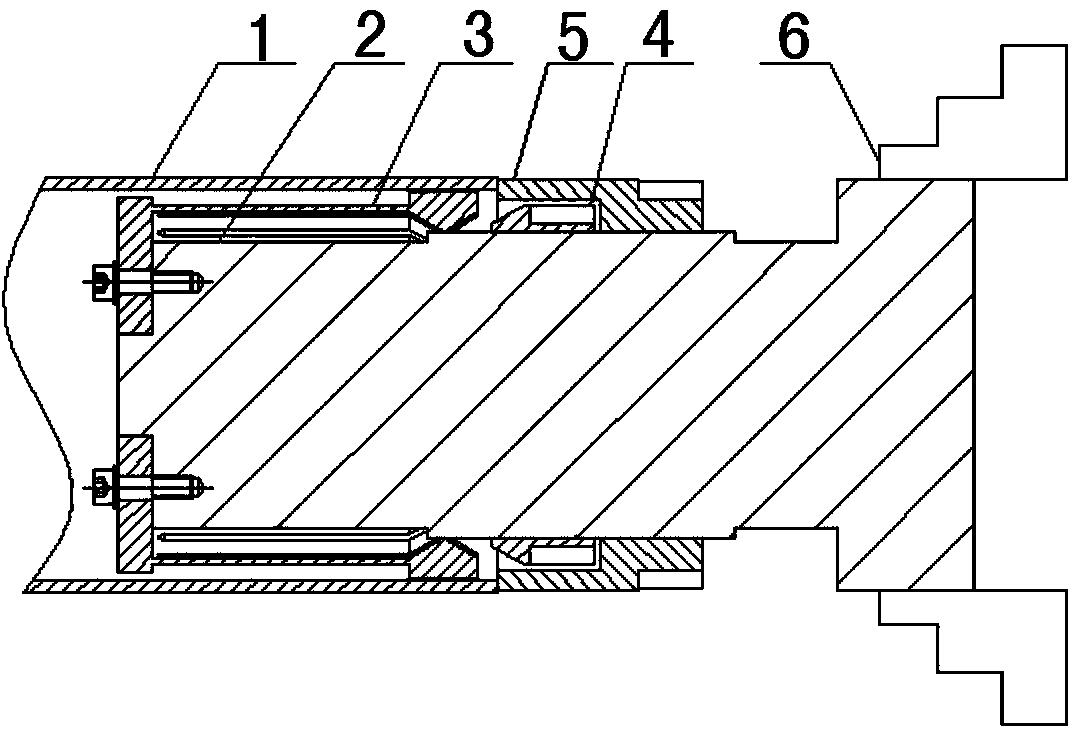

Novel proportion electromagnet

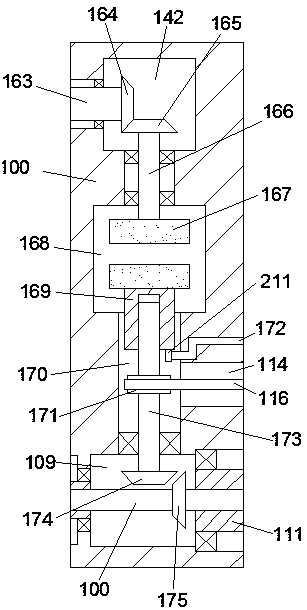

ActiveCN103700464AReduce scrap rateReduce fit sizeElectromagnets with armaturesEngineeringMechanical engineering

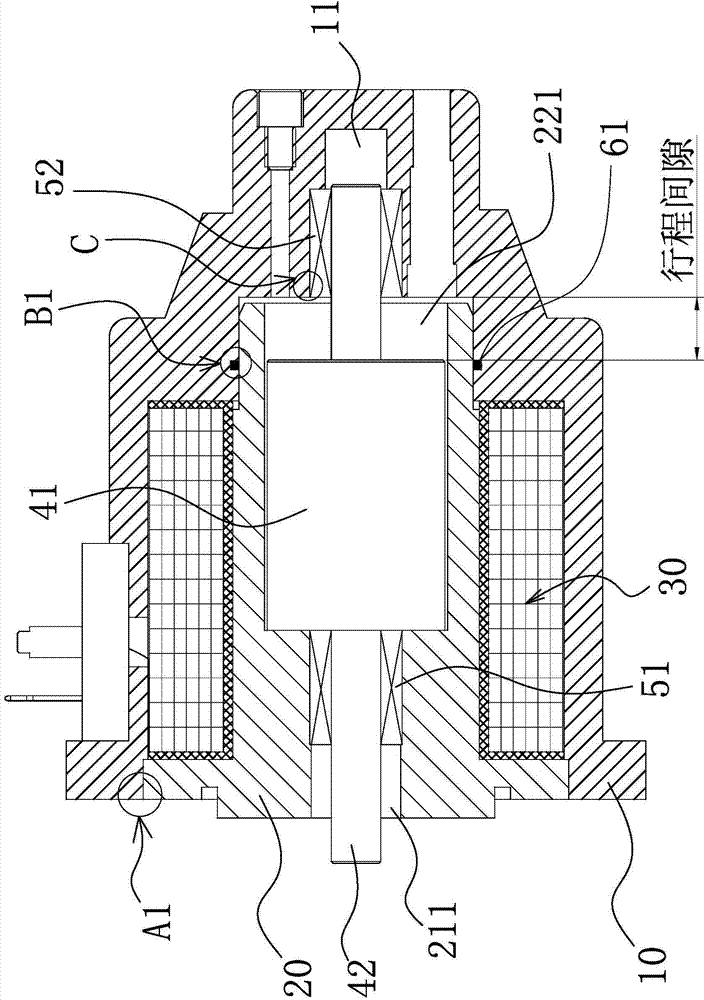

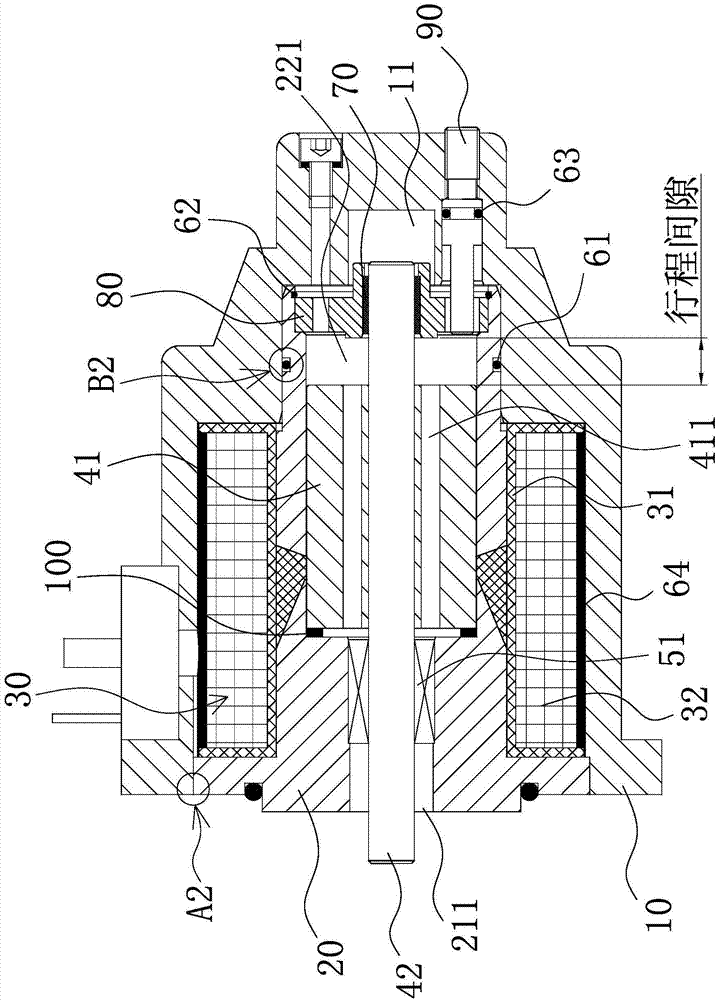

The invention provides a novel proportion electromagnet and belongs to the technical field of electromagnets. The electromagnet solves the problem that the existing proportion electromagnet is unreasonable in design and cannot ensure concentricity of two bearings arranged at two ends of a push rod. The novel proportion electromagnet comprises a casing with a first inner cavity and a second inner cavity. A magnetic core pipe, a coil assembly and a first sealing ring are arranged in the first inner cavity, an output through hole and a containing cavity are formed in the magnetic core pipe, an armature assembly formed by an armature and a push rod is installed in the containing cavity, a first bearing is sleeved at one end of the push rod, a self-lubricating bearing coaxial with the push rod is sleeved at the other end, a bearing seat for installing the self-lubricating bearing is connected onto one end of the containing cavity close to the second inner cavity in a sealing mode, and the push rod sequentially penetrates the first bearing, the armature and the self-lubricating bearing and partially stretches into the second inner cavity. The proportion electromagnet has the advantages of being reasonable in design, reducing matched size between parts and being capable of ensuring the concentricity of the two bearings arranged at two ends of the push rod.

Owner:NINGBO HOYEA MACHINERY MFG

Machining method for aero-engine high-temperature alloy counterweight blade

The invention discloses a machining method for an aero-engine high-temperature alloy counterweight blade. The machining method includes the following steps that (1) a blade root mortise is cut in a wire cutting mode, specifically, most of the margin of a mortise part of a counterweight blade blank is removed through a wire cutting method; (2) the blade root and the blade form are milled, specifically, the blade root of the blank with the mortise margin removed in a wire cutting mode is upwards vertically clamped on a two-rotary-table five-shaft linkage machining center, then the end surface, the inner arc radial surface, the back arc radial surface, the steam inlet lateral surface and the steam outlet lateral surface of the blade root are machined through a face mill cutter in a rough and fine mode, a profile modeling milling cutter is used for machining a mortise in the steam inlet side and a mortise in the steam outlet side, and finally the adaptation surface of the blade root and the blade form and a blade form surface are machined in a rough, semi-fine and fine mode; and (3) the blade crown is cut in a wire cutting mode. According to the machining method for the aero-engine high-temperature alloy counterweight blade, the clamping frequency, the tool number and the varieties of tools are reduced. Meanwhile, the machining procedure is reasonably planned, reliability of machining is guaranteed, the machining accuracy is guaranteed, the machining efficiency is improved, and the production cost is reduced.

Owner:JIANGSU JITRI HUST INTELLIGENT EQUIP TECH CO LTD

Rolling linear track grinding process

InactiveCN101020296AReduce the number of clampingReduce mistakesPlane surface grinding machinesEngineeringGrinding wheel

The grinding process of rolling linear track includes the following steps: 1. grinding the top of linear track with a surface grinding machine; 2. inverting the linear track and fixing magnetically on the magnetic work bench of a three-axis grinder; 3. correcting the work surfaces of the right grinding wheel and the left grinding wheel and the work surface of the middle grinding wheel with corresponding correcting devices; and 4. grinding the side surfaces, the roller track surface and the bottom of the linear track simultaneously with grinding wheels. The present invention has high machining precision, high machining efficiency and other advantages.

Owner:大连高金数控集团有限公司

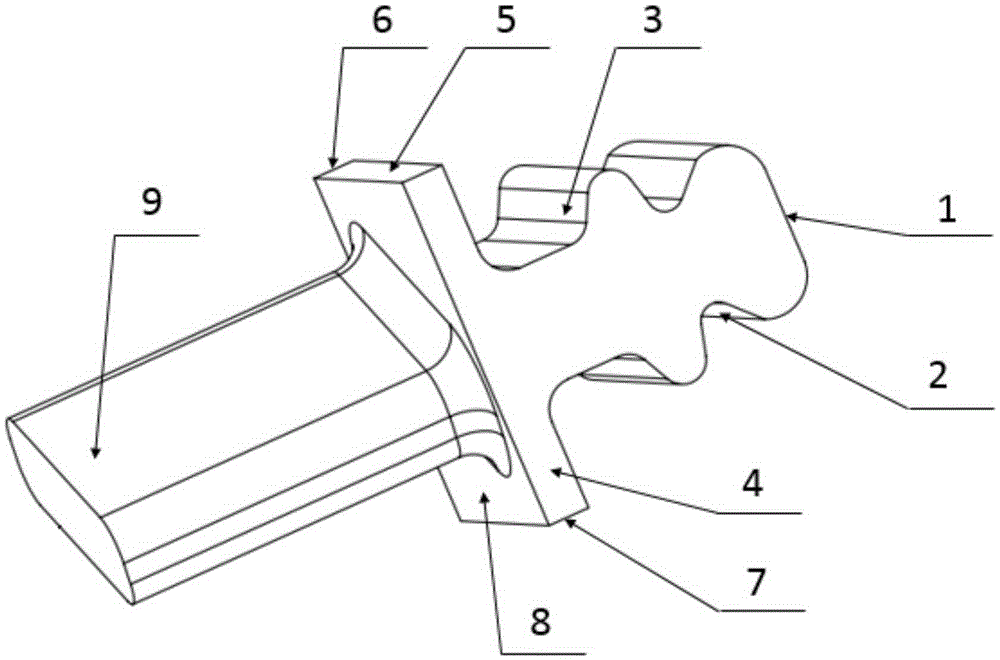

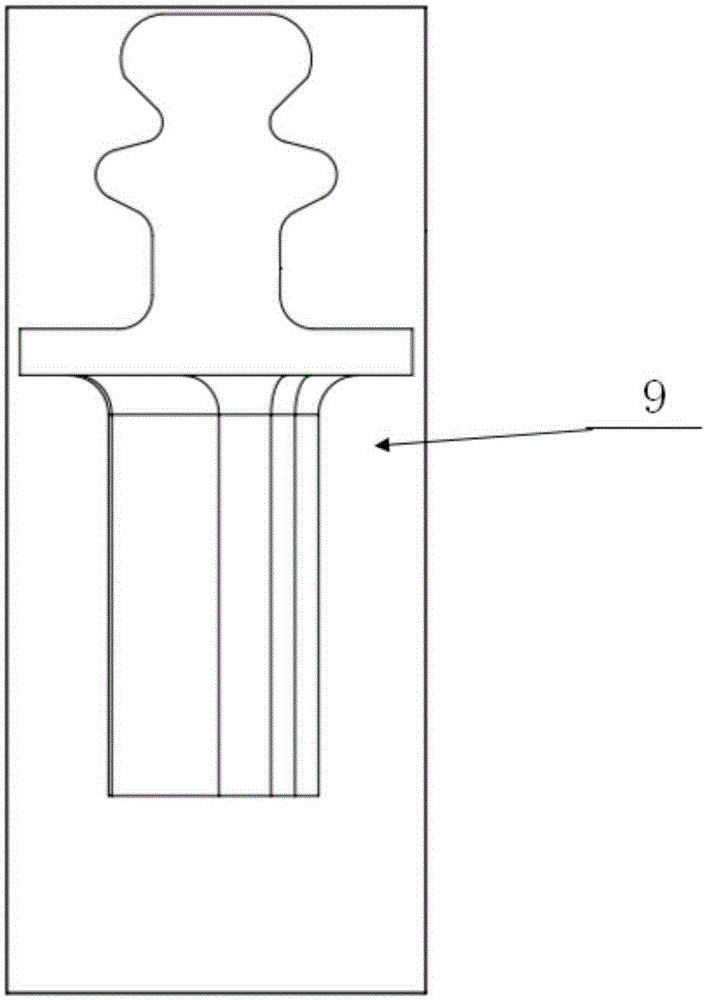

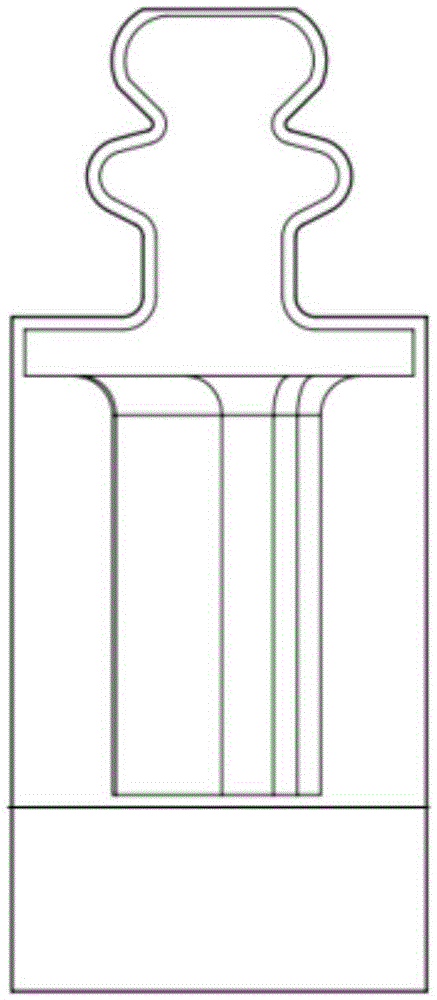

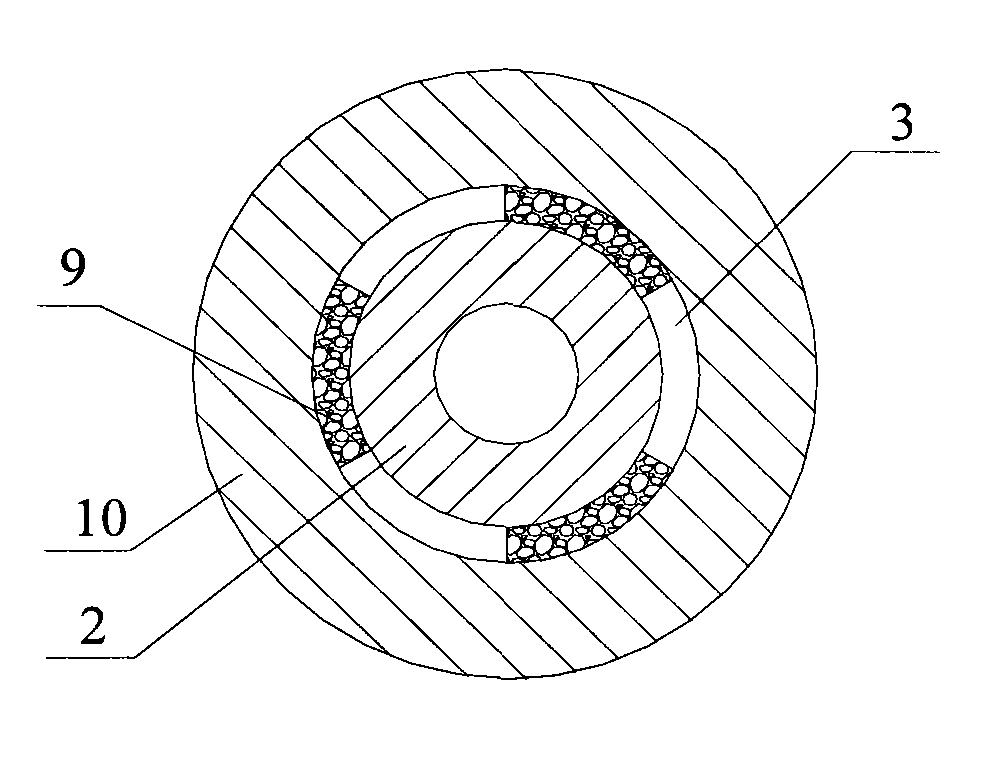

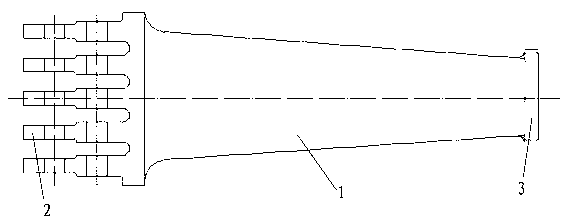

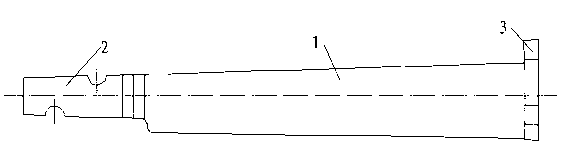

Electrode and machine tool dedicated for combined machining of electric spark shaping of inner round bore and elastic honing

InactiveCN102059417AImprove processing efficiencyImprove machining accuracyMetallic materialsEngineering

The invention discloses a electrode dedicated for combined machining of electric spark shaping of an inner round bore and elastic honing, comprising a tool electrode (2) of metal material, wherein the tool electrode is axially provided with an inner bore of electric spark operating fluid; the end surface of the tool electrode forms an electric spark discharging zone; and the outer side surface of the tool electrode (2) is covered with an elastic material grinding layer (9) provided with an outlet path (3) for the electric spark operating fluid. On the basis, the invention also discloses a machine tool for combined machining of electric spark shaping of an inner round bore and elastic honing, which is used for integrally and synchronously carrying out rough machining for the electric spark shaping of the inner round bore and fine machining for the elastic honing, and is favorable for improving the machining efficiency and the machining precision of a workpiece.

Owner:GUANGDONG IND TECHN COLLEGE

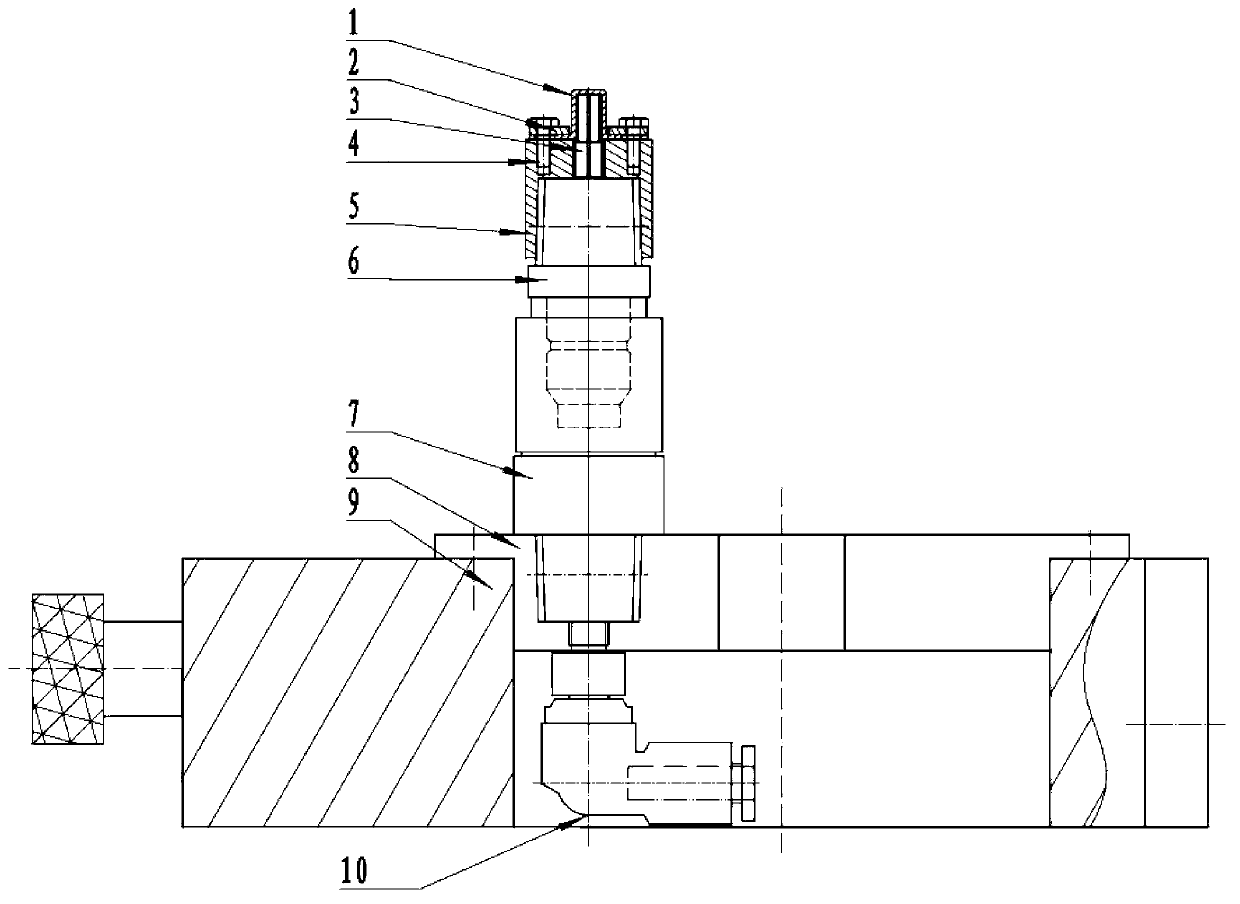

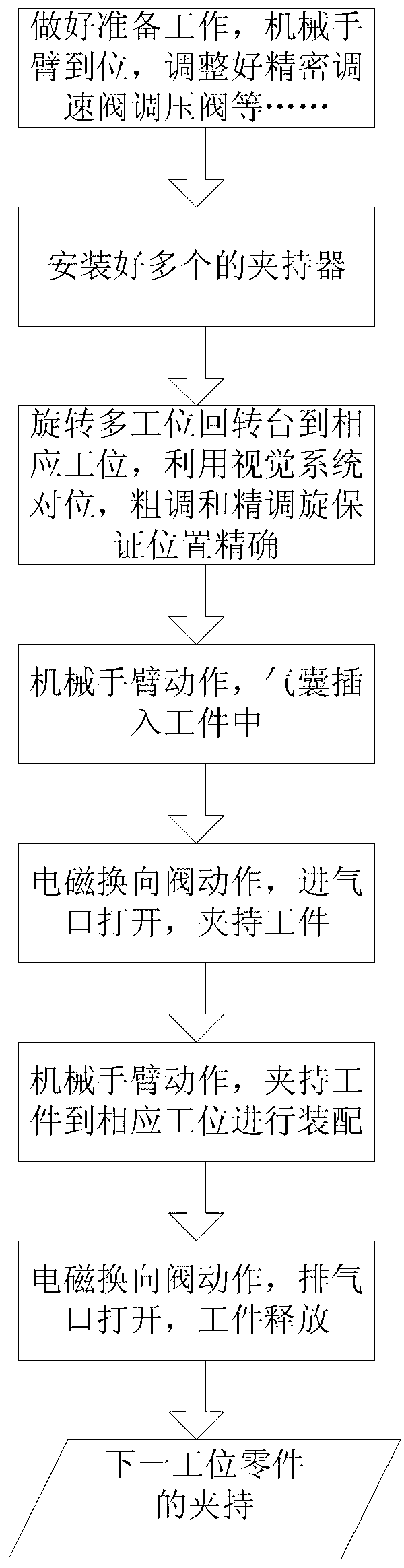

Multi-station silica gel air bag clamping device for clamping ultrathin wall deep cylinder part

ActiveCN103341861ARealize flexible clampingImprove clamping efficiencyGripping headsMetal working apparatusMagnetic exchangeEngineering

The invention relates to a multi-station silica gel air bag clamping device for clamping an ultrathin wall deep cylinder part and belongs to the field of microoperation and the micro electromechanical technology. The multi-station silica gel air bag clamping device for clamping the ultrathin wall deep cylinder part particularly comprises an air bag clamping head, a conical surface quick-insertion connector, a multi-station rotary table and a gas circuit system. The air bag clamping head comprises an air bag, a center retainer, a ring fastening gasket and a connection transition part. The conical surface quick-insertion connector comprises a quick-change connector plug and a quick-change connector socket. The multi-station rotary table comprises a 360-degree manual rotary table and a pinboard. The gas circuit system comprises a gas source, a filter, a pressure regulating valve, a speed controlling valve, a magnetic exchange valve and a gas pipe connector. The multi-station silica gel air bag clamping device for clamping the ultrathin wall deep cylinder part solves the problems that clamping of thin-wall parts is small in strength, poor in intensity, and deformation, invalidation and even damage are prone happening. Use of the quick-change connector and the multi-station rotary table can effectively achieve quick and flexible clamping and assembling of parts of different sizes and the same kind, facilitate operation and improve assembling precision and assembling efficiency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Flange end plate all-in-one machine with drilling, tapping and groove milling functions

ActiveCN105537943AReduce labor intensityReduce the number of clampingFeeding apparatusOther manufacturing equipments/toolsMilling cutterFlange

The invention discloses a flange end plate all-in-one machine with drilling, tapping and groove milling functions. The flange end plate all-in-one machine comprises a base. A clamping mechanism is arranged on the base, drilling mechanisms are arranged on the two sides of the clamping mechanism, and movable platforms are further arranged on the two sides of the clamping mechanism. The drilling mechanisms are arranged on the movable platforms, and the movable platforms are further provided with tapping mechanisms and groove milling mechanisms which can move towards the clamping mechanism along the movable platforms and further provided with longitudinal slide rails. The drilling mechanisms, the tapping mechanisms and the groove milling mechanisms can move longitudinally along the longitudinal slide rails. Each groove milling mechanism comprises a groove milling base, and groove milling power heads capable of rotating relative to the groove milling bases are arranged on the groove milling bases. A plurality of milling cutters are arranged on the groove milling power heads in the circumferential direction. The groove milling bases are provided with driving devices used for driving the milling cutters to rotate and further provided with pulling devices used for pulling the groove milling power heads to rotate when the milling cutters rotate so as to ensure that strip-shaped grooves are milled in a flange end plate through the milling cutters. According to the flange end plate all-in-one machine with the drilling, tapping and groove milling functions, the structure is simple, the production efficiency is high, the size precision of a product is high, and the production cost is low.

Owner:汤嘉铸锻(江苏)有限公司

Fixture

InactiveCN102357818ASimple structureEasy to operatePositioning apparatusMetal-working holdersEngineeringMechanical engineering

Owner:崔伶玲

Tool for processing cylindrical workpiece

ActiveCN104043851AAvoid spending timeReduced clamping times and auxiliary timeExpansion mandrelsThin walledBatch production

A tool for processing a cylindrical workpiece comprises a mandrel, a snap spring, a pressure ring and a plug, wherein the snap spring sleeves the outer circumference surface of one end of the mandrel, and is fixedly connected with the mandrel through a fixing hole in the end surface of a small-diameter end of the mandrel. The plug is sleeved in the middle of the mandrel, and a large-aperture end of the plug is adjacent to the snap spring. The snap spring sleeves the outer circumference surface of the mandrel, and is located in an inner hole in one end of the snap spring. When the tool is used to process a cylindrical slender thin-walled workpiece, the clamping for cylindrical turning and radial facing can be finished at one step, the time for injecting gypsum is reduced, the clamping frequency and the assisting time are reduced, the processing efficiency is improved, and the tool meets the requirements of batch production. Meanwhile, the tool is light in structural weight, one person can finish the mounting of the tool, operation personnel are reduced, and the production cost is reduced.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

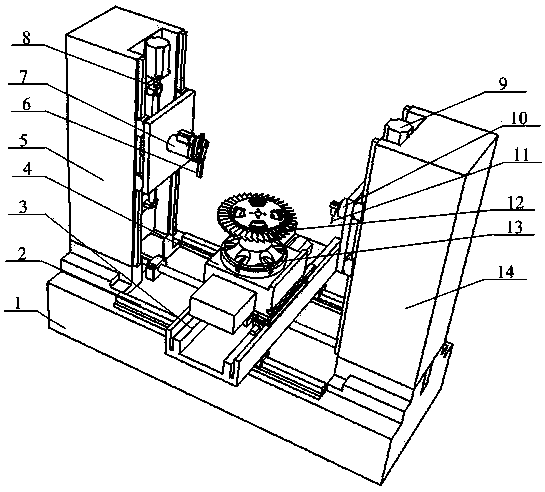

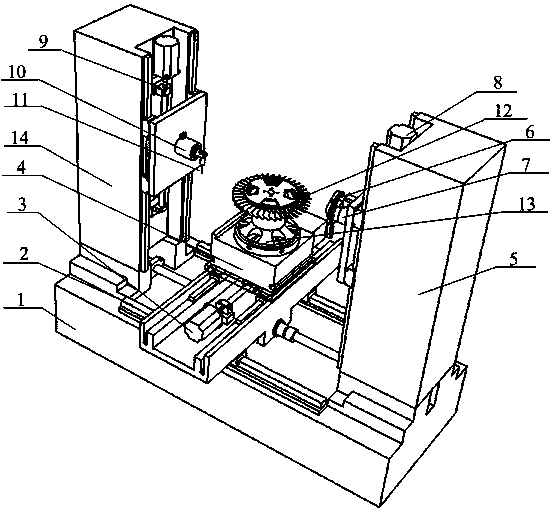

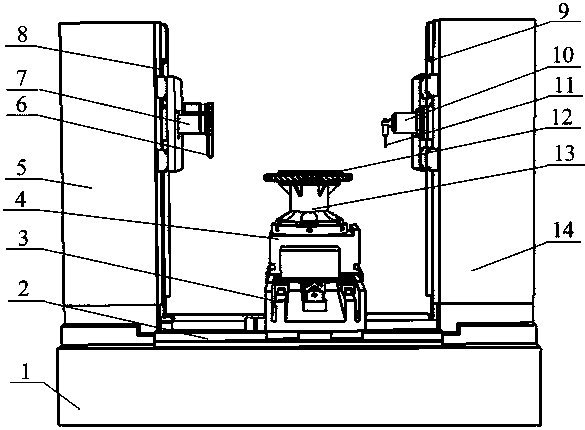

Integral leaf disk grinding and polishing processing and measuring integration device

InactiveCN103447920ANovel structureReduce positioningGrinding feed controlGrinding machinesMeasurement deviceEngineering

The invention provides an integral leaf disk grinding and polishing processing and measuring integration device, which belongs to the machine manufacture field. Two stand columns are respectively provided with a grinding and polishing tool, a measuring device, a Z-shaft servo drive unit and a B-shaft servo drive unit, wherein the Z-shaft servo drive unit and the B-shaft servo drive unit are used for driving the grinding and polishing tool and the measuring device and can respectively enable the grinding and polishing tool and the measuring device to rotate along the Z shaft and around the B shaft; a lathe bed is provided with a Y-shaft servo drive unit; the Y-shaft servo drive unit is provided with an X-shaft servo drive unit; the X-shaft servo drive unit is provided with a C-shaft rotary driving unit; the integral leaf disk is positioned and clamped on the C-shaft servo drive unit by a fixture to realize a purpose that the integral leaf disk moves along the X shaft and the Y shaft and rotates around the C shaft. The positioning and clamping time can be reduced by one-time clamping, errors generated by multi-time positioning and clamping are eliminated, the grinding and polishing processing and measuring integration of the integral leaf disk can be realized, and the integral leaf disk processing quality and efficiency can be improved.

Owner:JILIN UNIV

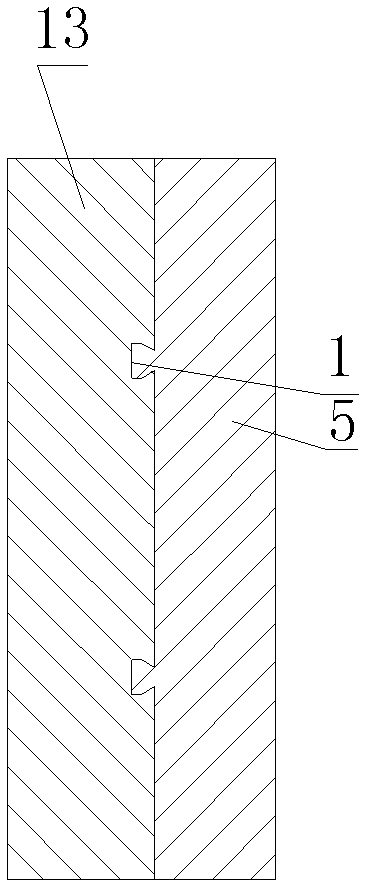

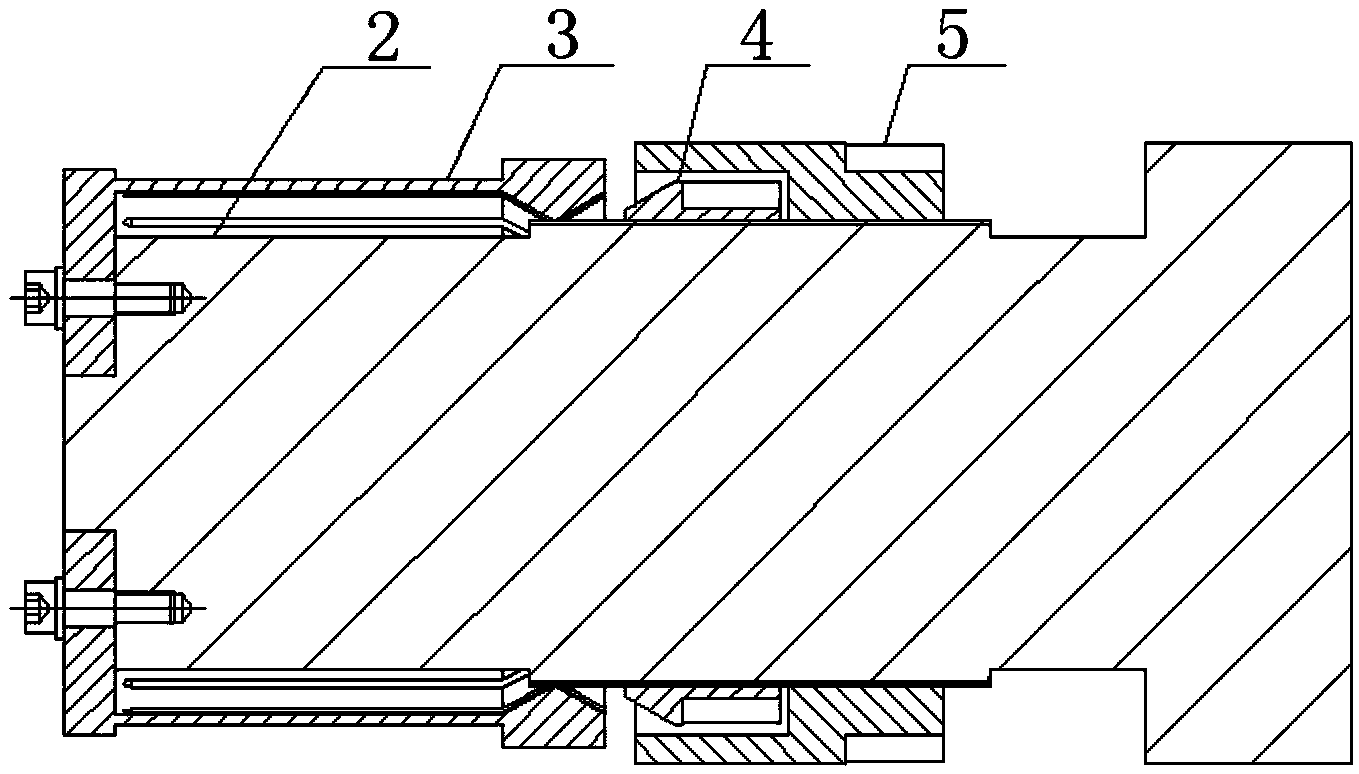

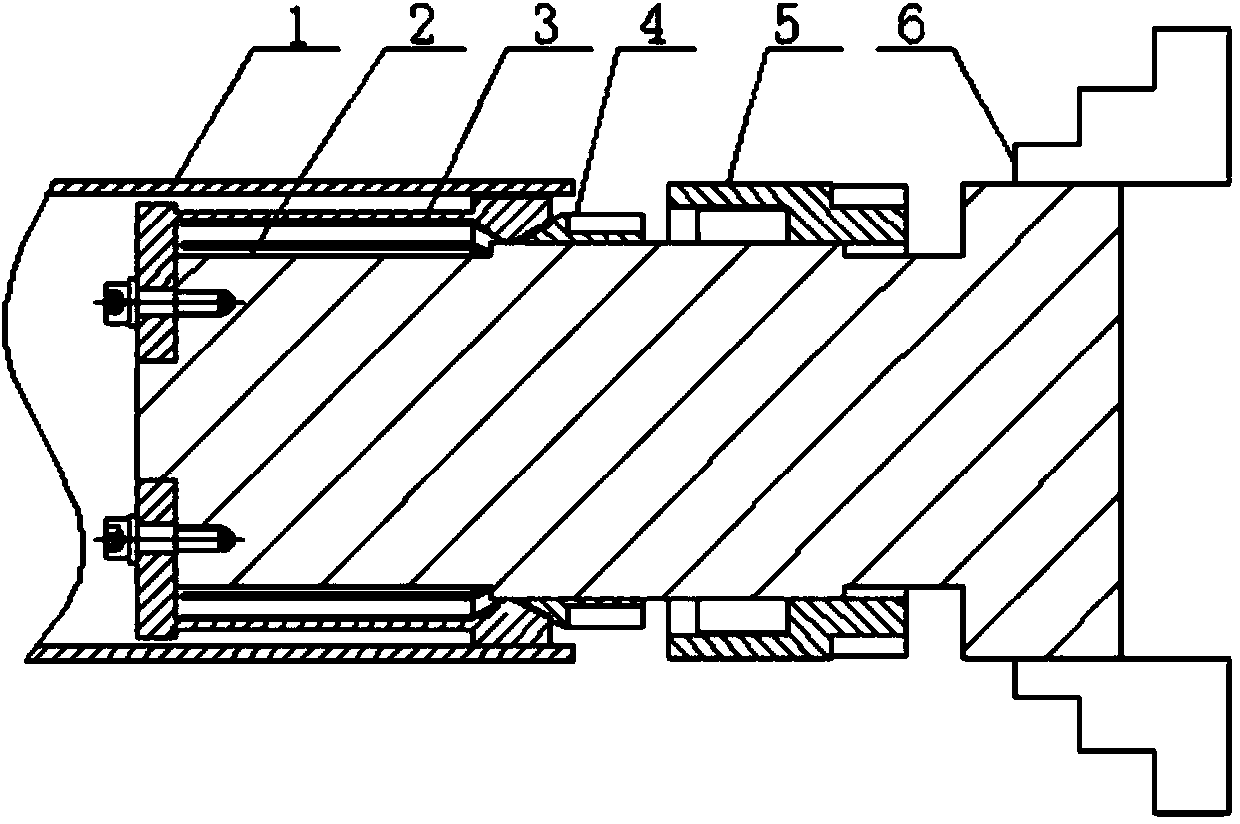

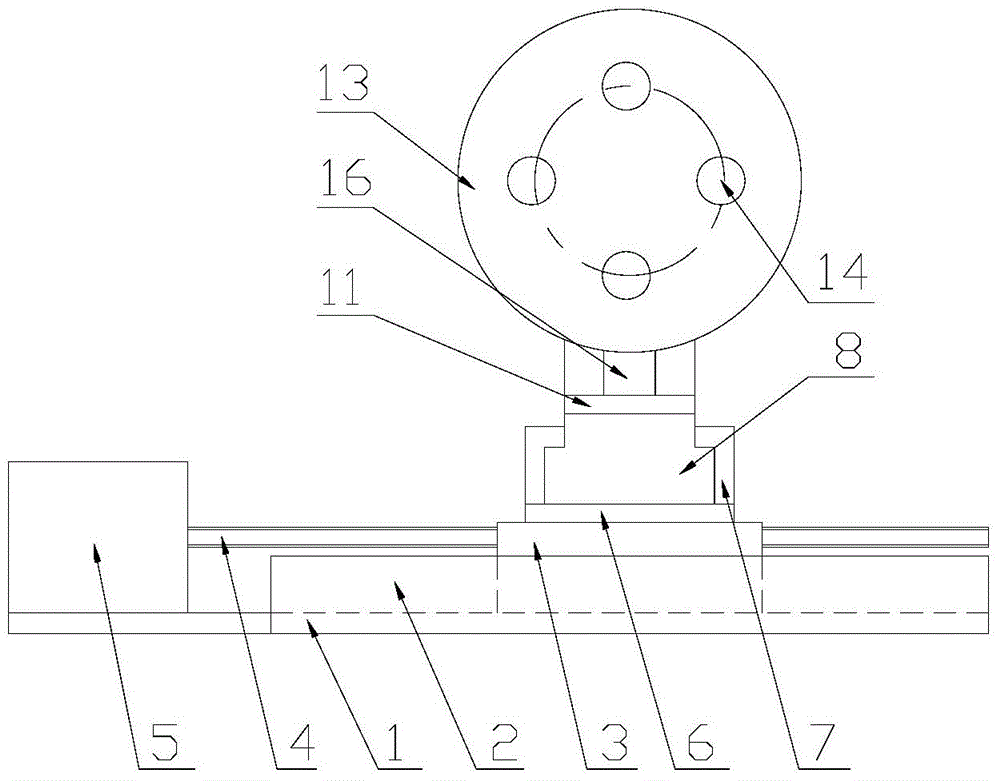

Steering gear shell body pressing clamp

InactiveCN102837179AAvoid deformationSimple structureMetal working apparatusMechanical engineeringEngineering

The invention discloses a steering gear shell body pressing clamp comprising a base, and a first pressing mechanism and a second pressing mechanism which are arranged on the base; the base comprises an upper bedplate (1), a lower bedplate (2), a guide rod (3), a screw rod (4) and a nut (5); the first pressing mechanism comprises an upper pressure block (7), a lower pressure block (8), a connecting rod (9), a first compression spring (10) and a support rod (12); and the second pressing mechanism comprises a movable plate (11) and a second compression spring (6). According to the structure, twice of the pressing of a steering gear shell body can be completed at one time; after the one-time clamping is realized, the pressing of two shell bodies and a connecting shaft is completed at the same time, so that a plurality of times of clamping is not needed, the clamping times are reduced, the assembly efficiency is improved, and the shell body deformation caused by secondary pressing is prevented.

Owner:CHONGQING LONGRUN AUTOMOBILE STEERING GEARS

Clamping device of numerical control machine tool

InactiveCN105773211APrevent affecting processing qualityImprove clamping effectPrecision positioning equipmentExpansion mandrelsNumerical controlElectric machinery

The invention discloses a clamping device of a numerical control machine tool. The clamping device is wider in moving range, capable of clamping a plurality of workpieces at a time and conducting machining in turn and higher in working efficiency. The clamping device comprises a first base, wherein the first base is in sliding fit with a first moving plate, and a first screw rod is in internal thread fit with the first moving plate and is connected with a first driving motor arranged on the first base; the first moving plate is fixedly provided with a second base which is in sliding fit with a second moving plate, and a second screw rod is in internal thread fit the second moving plate and is connected with a second driving motor arranged on the second base; the second moving plate is provided with a mounting base, and the longitudinal direction of the mounting base is parallel to a second guide rail; the mounting base is provided with a third driving motor; a rotating shaft of the third driving motor is fixedly provided with a turntable on which four fixtures are arranged; the four fixtures form a square; and the intersection point of diagonals of the square is located on the axis of the first driving motor.

Owner:重庆丰德数控机床有限公司

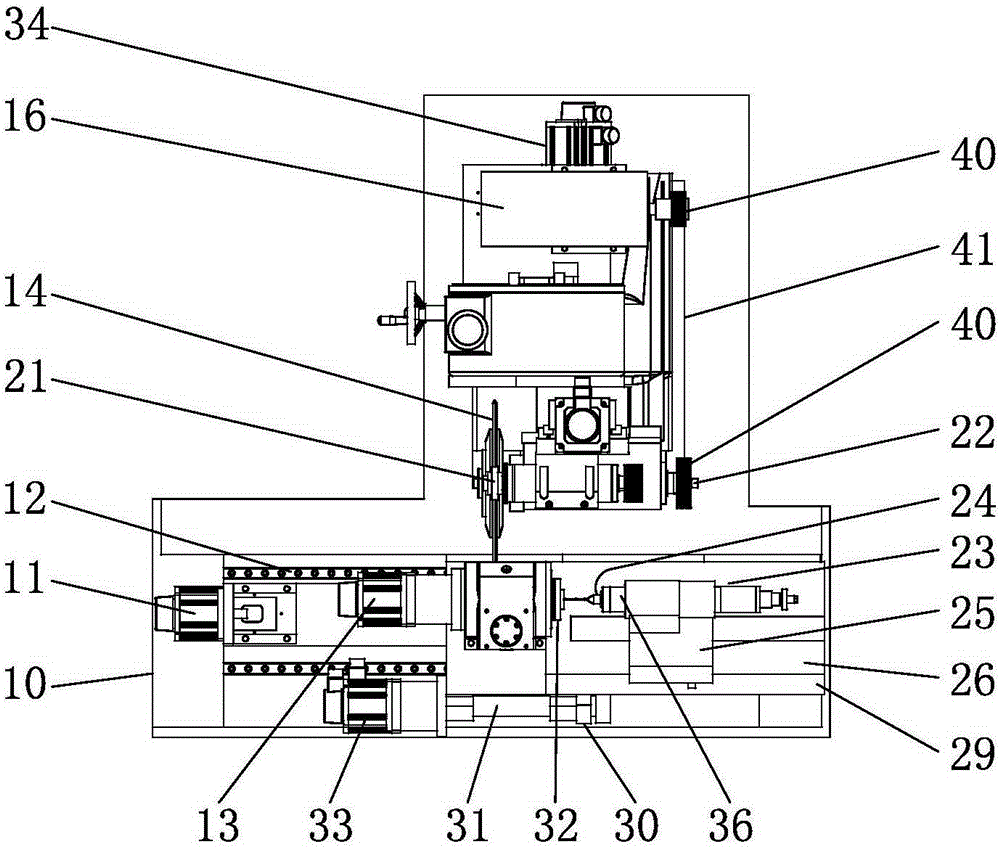

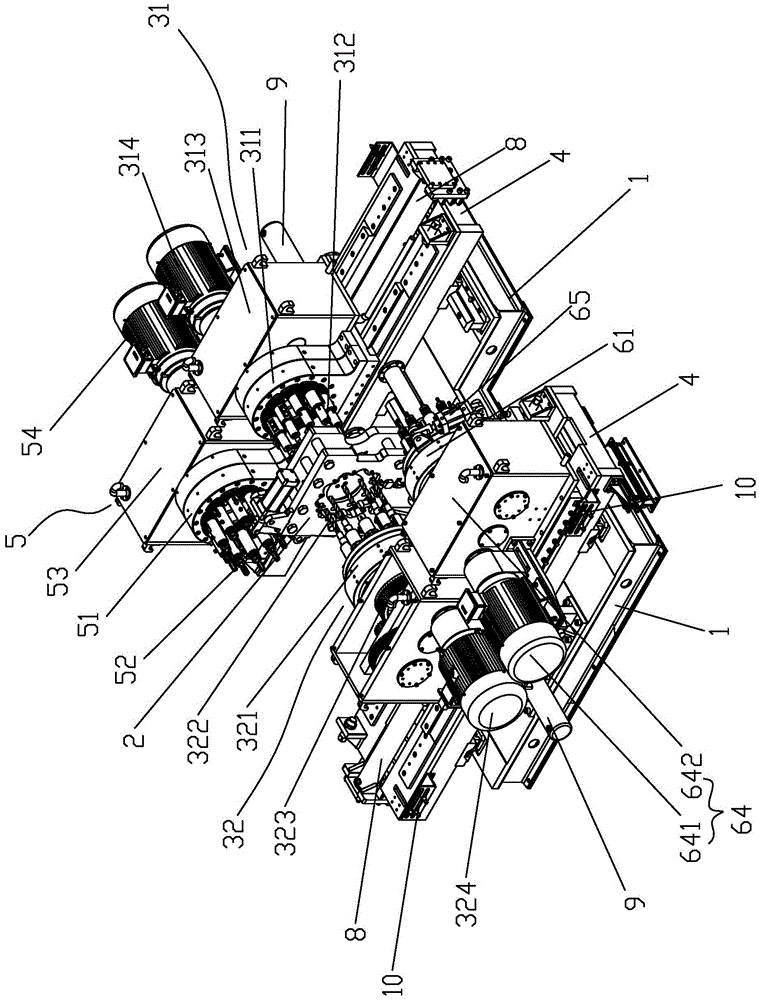

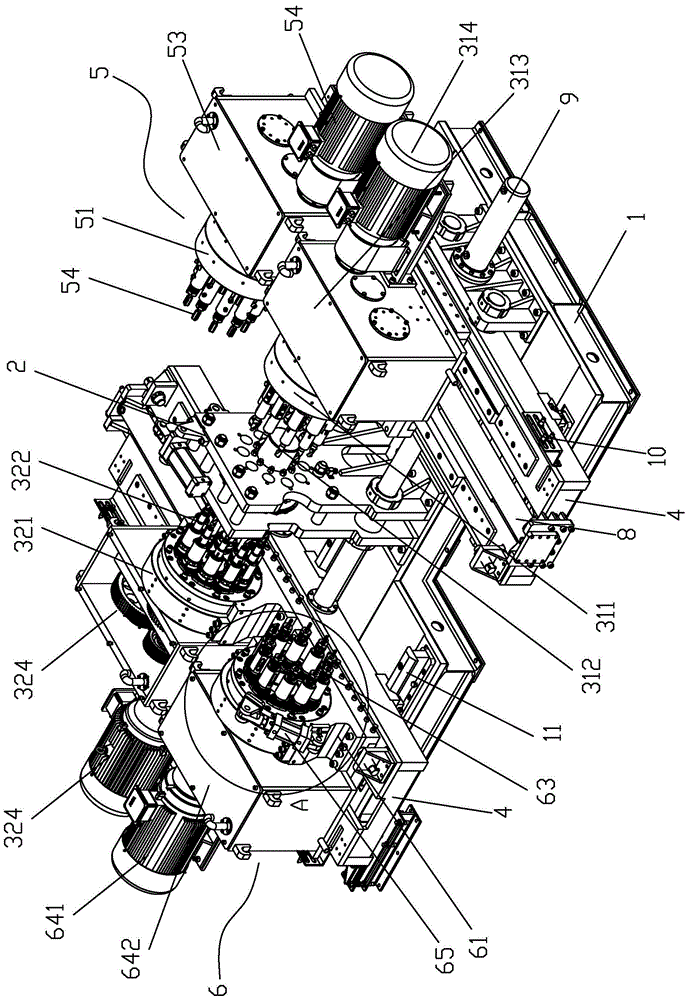

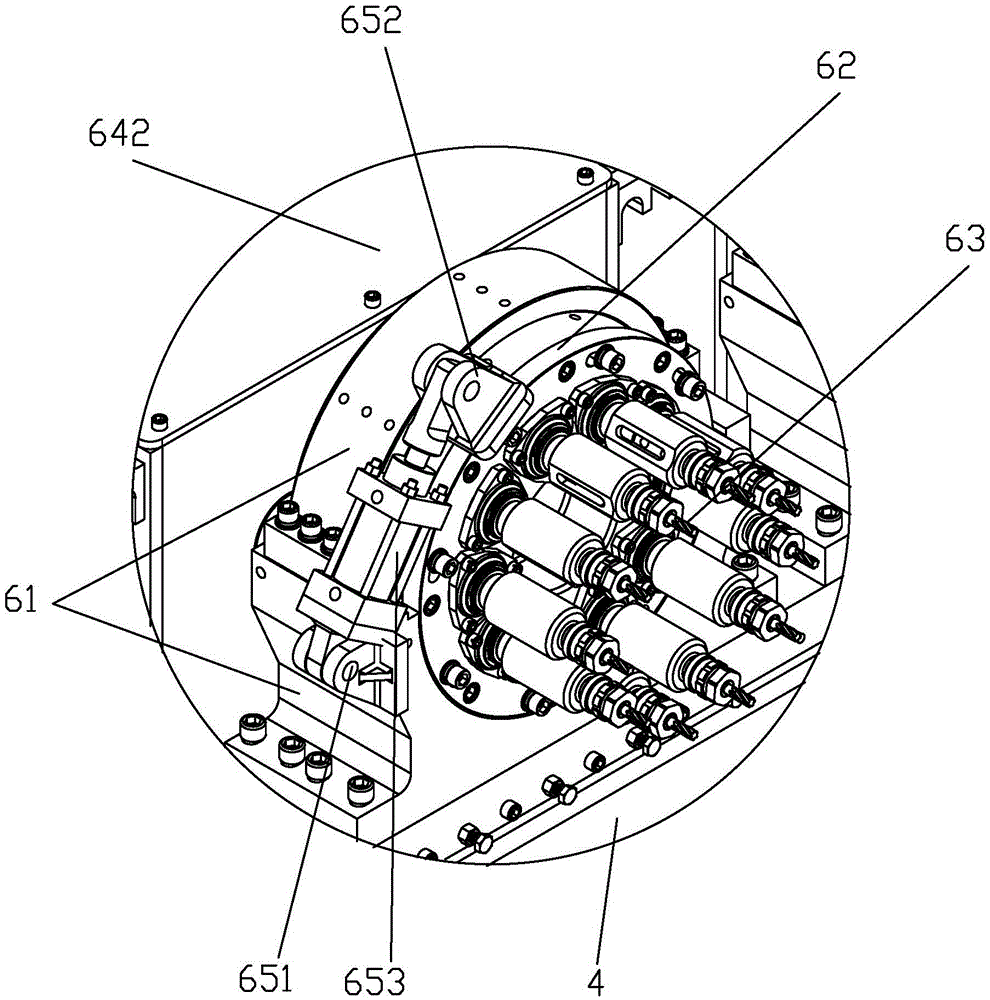

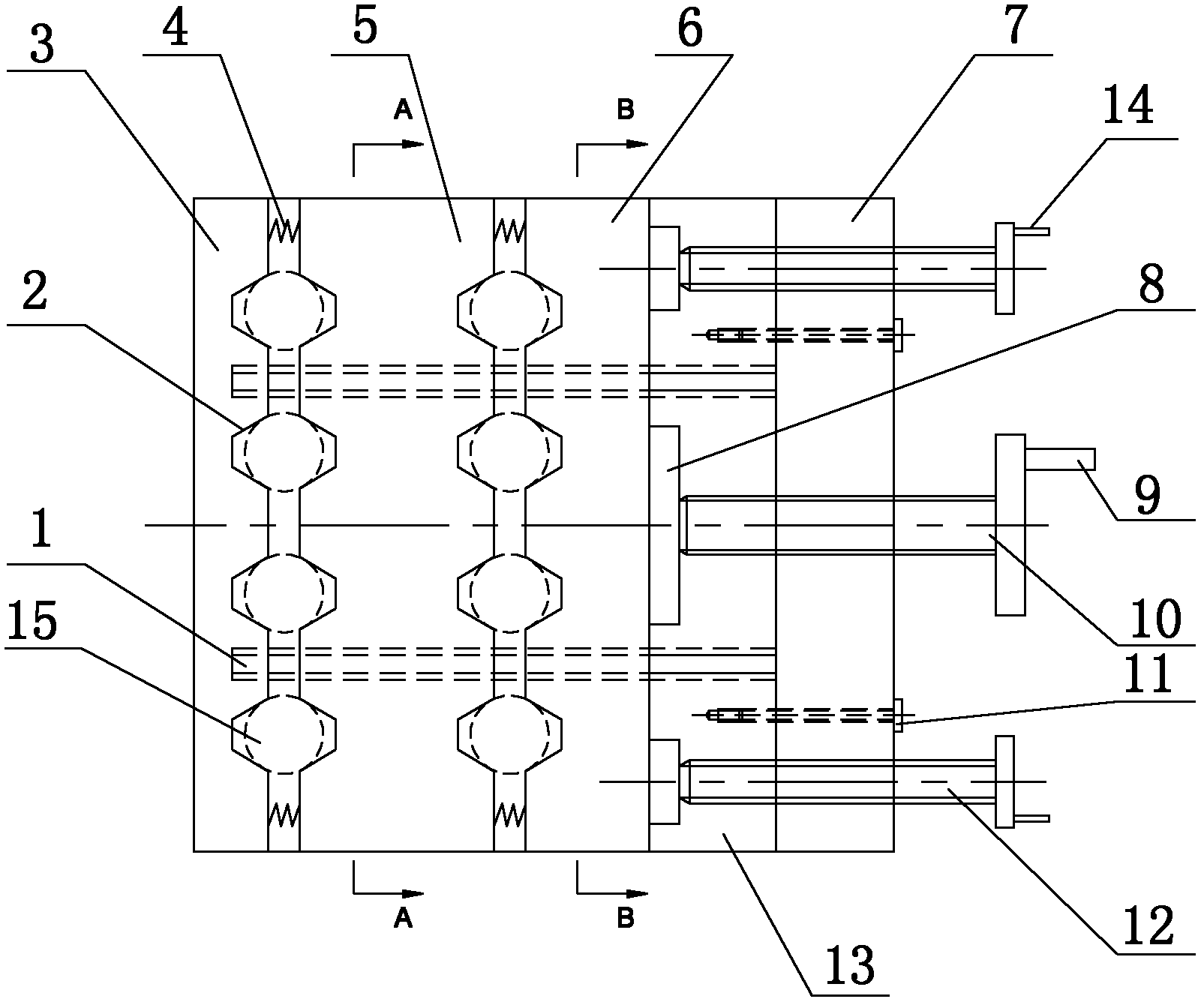

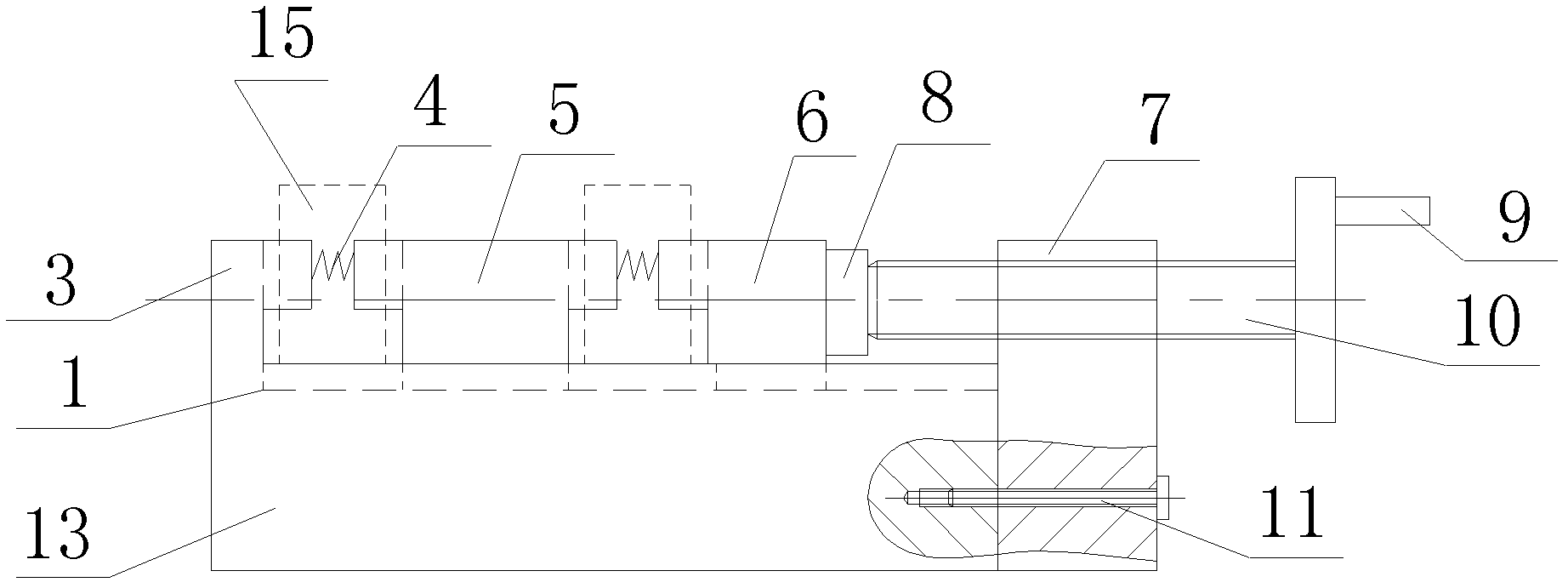

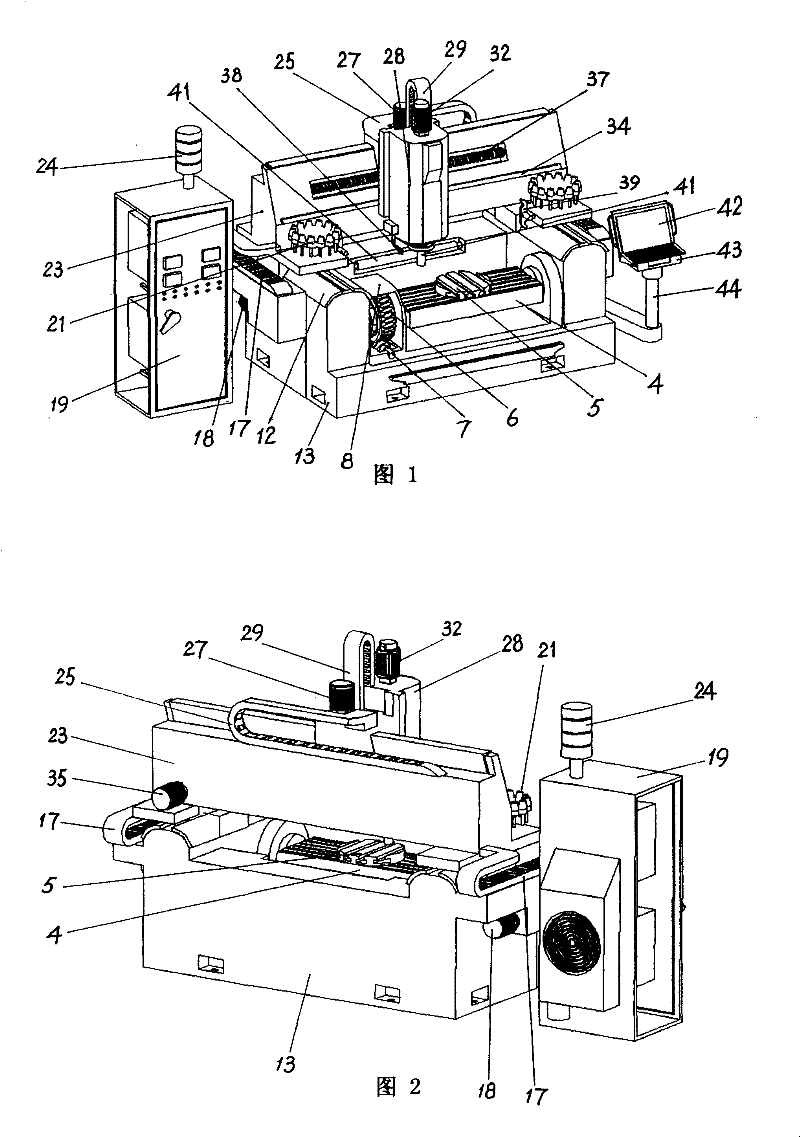

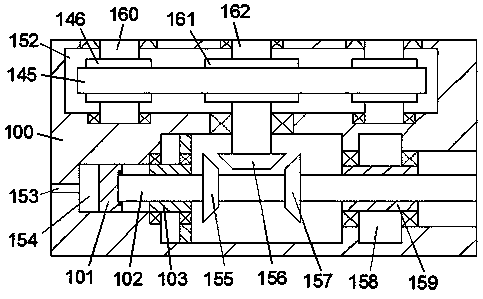

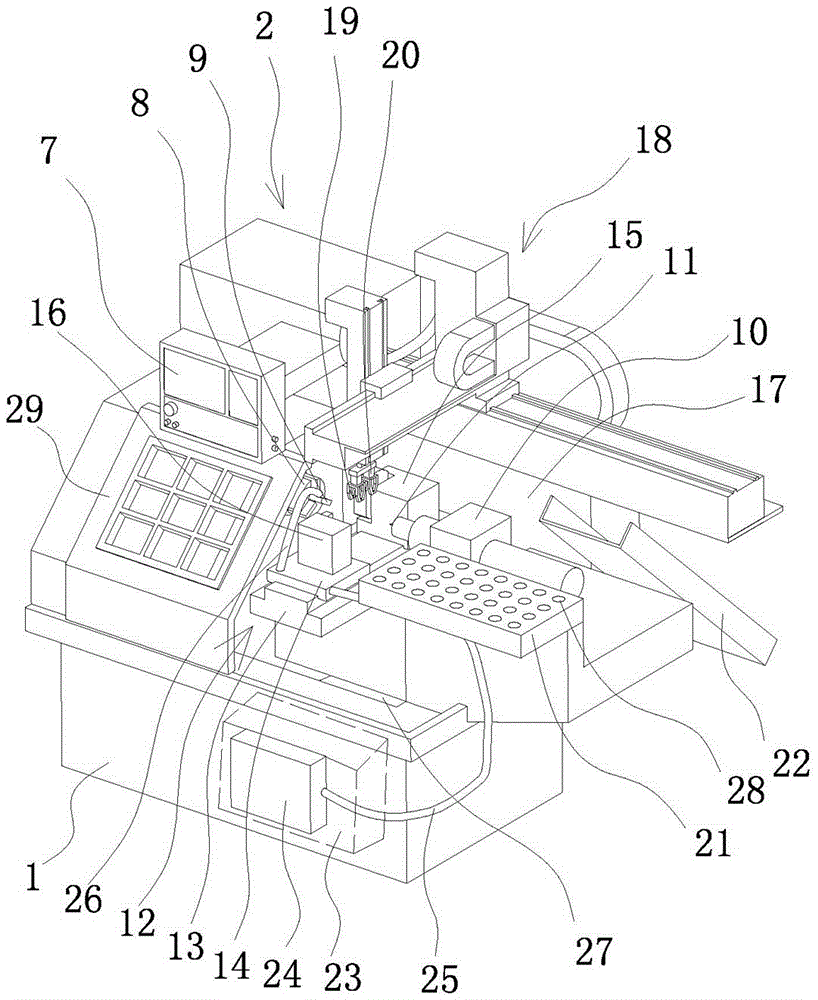

Vertical five axle interlocked gantry digital control milling machining center

ActiveCN101870063BRealize functionReduce the number of clampingOther manufacturing equipments/toolsMilling cutterEngineering

The invention provides a vertical five axle interlocked gantry digital control milling machining center, comprising a planer body, a portal frame, a rotary workbench stand, an electrical appliance control cabinet, a cutter, a main spindle box, an operation panel, a rotary workbench, X, Y and Z shaft driving screws and rotary tool changers, wherein the rotary workbench is formed by a large rotary workbench and a small rotary workbench which respectively rotate around an A shaft and a B shaft; the portal frame is arranged on the planer boxy and can move back and forth via the X shaft driving screws arranged at the two sides of the planer body, a Y-Z shaft connection block moves left and right via the Y shaft driving screw in the portal frame, and a main spindle in the main spindle box movesup and down via the Z shaft driving screw on the Y-Z connection block so as to form five axle interlocking; and the rotary tool changers arranged at the two sides of the portal frame are internally provided with 32 grinding cutters and milling cutters, and tool changing is realized by a tool changing manipulator. The invention has the positive effects of realizing multiply functions of one machine, and can process as many as five interfaces by primary clamping, thus reducing clamping times, saving labor, time and space, and having convenient equipment maintenance.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Automatic tow hook welding equipment

ActiveCN104289833AReduce the number of clampingIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesMotor driveEngineering

The invention discloses automatic tow hook welding equipment. The automatic tow hook welding equipment comprises a case cover, an overturn clamp assembly and a welding head assembly, wherein the overturn clamp assembly and the welding head assembly are arranged inside the case cover. The welding head assembly is arranged right in the middle of the position over the overturn clamp assembly. In the overturn clamp assembly, a first air cylinder drives a gear rack to move front and back along a gear rack sliding guide rail, the gear rack drives a transmission shaft and driving synchronous pulleys to rotate together through a gear, each driving synchronous pulley drives a driven synchronous pulley, a claw chuck and a parallel pneumatic claw on the same side as the driving synchronous pulley to rotate through a synchronous belt perpendicularly penetrating through a work platen, and therefore workpieces on the parallel pneumatic claws can be overturned automatically. In the welding head assembly, a second air cylinder drives welding nozzle assemblies to move upwards and downwards, a motor drives the welding head assemblies to move leftwards and rightwards, the welding nozzle assemblies are hinged to an air cylinder lower ejector plate, and the welding nozzle assemblies are good in operation flexibility.

Owner:CHONGQING LANGZHENG TECH

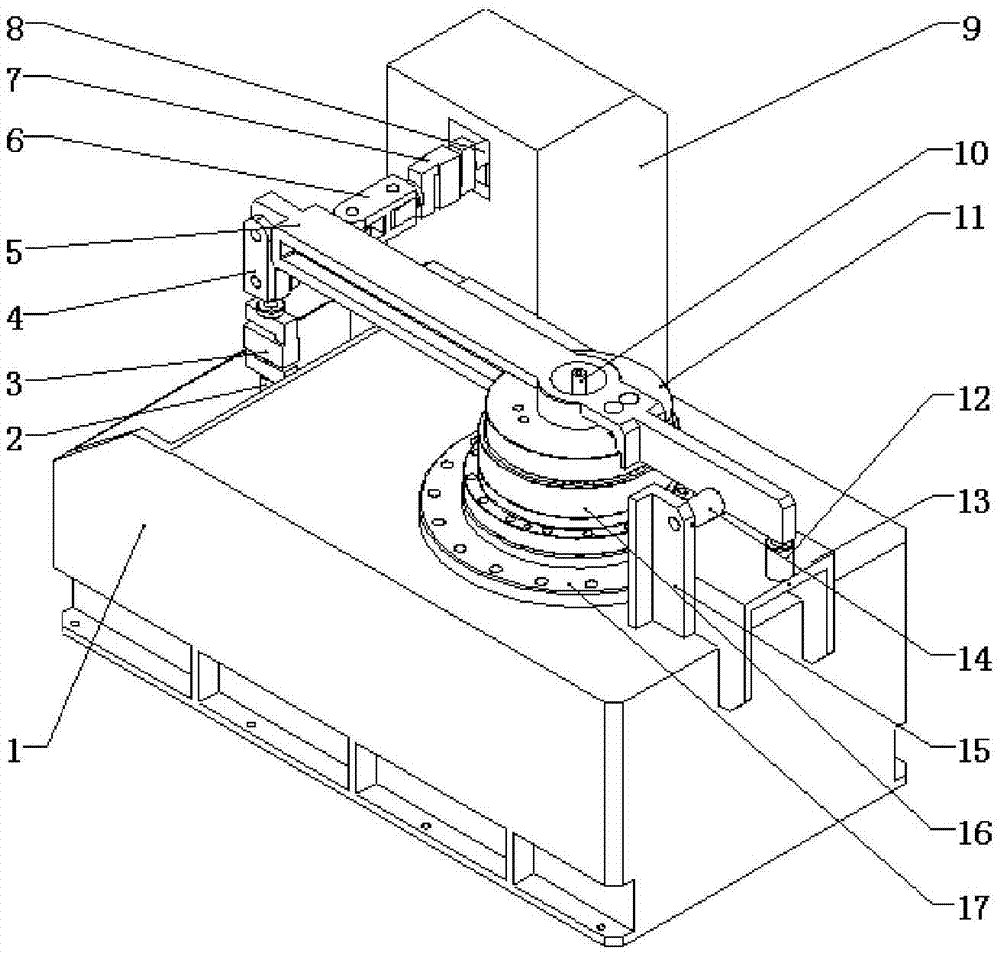

A sample table of a neutron diffraction stress spectrometer

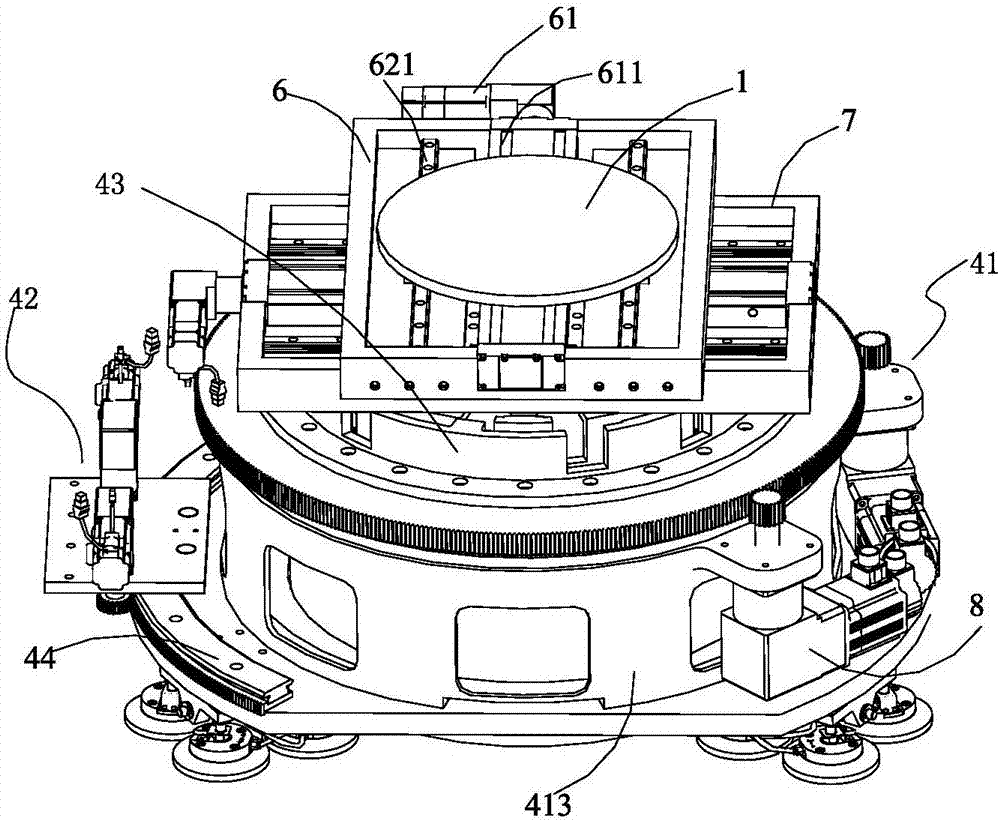

InactiveCN107490590AGuaranteed uptimeReduce the number of clampingMaterial analysis using radiation diffractionSupporting systemMovement system

A sample table of a neutron diffraction stress spectrometer is provided. The sample table includes a sample mounting plate, a horizontal movement system controlling horizontal movement of the sample mounting plate, a vertical lifting and descending system controlling vertical movement of the sample mounting plate, and a rotation movement system controlling rotation of the sample mounting plate, a neutron diffraction stress spectrometer detector and a capturer. The sample mounting plate is disposed on the horizontal movement system. The lower part of the horizontal movement system is connected to the vertical lifting and descending system. The vertical lifting and descending system is connected to the rotation movement system. The bottom of the rotation movement system is connected to a floating supporting system. The rotation movement system includes a sample table autorotation part, a sample table supporting mechanism and a swing and connecting part. The sample table autorotation part is used for controlling the sample mounting plate to rotate around the center axis. The swing and connecting part is mounted to the sample table supporting mechanism through a circular-arc guide rail, and is used for connecting the detector and the capturer, and moves along the circular-arc guide rail.

Owner:CENT SOUTH UNIV

Planer for wood processing

InactiveCN109849113AReduce the number of clampingReduce machining errorsFlat surfacing machinesWood machiningEngineering

The invention discloses a planer for wood processing. The planer comprises a fixed machine body; the upper side of the left end surface of the fixed machine body is internally provided with a workingspace; the lower end wall of the working space is provided with a placement cavity in a communicating manner; the placement cavity is internally provided with a working device; the working device comprises a fixed block; the fixed block is internally provided with a power mechanism; the upper side of the power mechanism is provided with a sliding assembly; and the lower side of the power mechanismis provided with a rotating component. By adopting the planer, the number of times of clamping during wood processing is reduced, the processing error caused by clamping for multiple times is lowered, and the processing quality is improved; meanwhile, planing and sawdust removal are performed at the same time, so that the processing efficiency is improved, and the service life of equipment is prolonged; and by adopting double motors and double hydraulic machines, an operation load of the equipment is lowered, and safety hidden dangers caused by superloads are avoided.

Owner:杭州红凌服饰有限公司

Processing method of five-fork blade-root moving blades with own shrouds

ActiveCN103203490AAvoid deformationLess effective cuttingMilling equipment detailsProcess engineeringMachine tool

The invention discloses a processing method of five-fork blade-root moving blades with own shrouds, belonging to the technical field of blade processing. The processing method comprises: step 1, clamping blades, step 2, roughing, step 3, semi-refining, step 4, refining, step 5, positioning a steam-out side of a shoulder of the blade root, a steam-out side of a shroud and a back radial surface of the blade root, selecting a cutter with cutting edges matching with five-fork blade root lines, with a rotating speed being 25-30 r / min, a feeding speed being 12.5 mm / min, a feed amount being 0.5-0.8 mm, and performing fine milling for the five-fork blade root lines of the blade along a linear direction. According characteristics of the five-fork blade-root moving blades with own shrouds, positioning reference surface during processing is unified, a one-time clamping is used to complete processing of each part, thereby effectively preventing accumulative errors, increasing processing precision, optimizing integration processing, shortening processing periods of products, reducing required amount of machine tool, and reducing production cost.

Owner:SICHUAN MIANZHU XINKUN MACHINERY MAKING

Valve body grinding device with multi-surface machining function

InactiveCN108527038AEasy to grindImprove production taktPlane surface grinding machinesDrive shaftDrive motor

The invention relates to valve body grinding device with a multi-surface machining function. The device comprises a bottom plate, a clamping tool and grinding mechanisms, wherein the clamping tool isfixed in the middle of the bottom plate, and grinding mechanisms are horizontally arranged on the left side and the right side of the bottom plate; each grinding mechanism comprises a movable table, agrinding wheel, a first bevel gear, a second bevel gear, a first belt wheel and a transmission shaft; second belt wheels are installed on the left rear side and the right rear side of the bottom plate respectively, tensioning wheels are installed the left front side and the right front side of the bottom plate respectively, a belt is jointly installed on the left rear side and the right rear sidesecond belt wheels and the left front side and the right front side tensioning wheels, a driving belt wheel is matched with the belt, and the driving belt wheel is connected to a driving motor; and adouble-head air cylinder is fixed on the rear side of the bottom plate, the two output ends of the double-head air cylinder are connected to a driving plate respectively, wherein the driving plates are fixedly connected to a left-side moving table and a right-side moving table. According to the valve body grinding device with the multi-surface machining function, the positioning precision is high, the two end surfaces on the valve body can be ground simultaneously during the one-time clamping process, the clamping frequency and time are reduced, the labor intensity of workers is relieved, andthe working efficiency is improved.

Owner:WUHU JIENUO TECH

Screw tap lathe

ActiveCN106424764AReduce the number of clampingSimplify processing stepsTurning machinesMetal working apparatusControl powerEngineering

The invention provides a screw tap lathe, belongs to the technical field of machining equipment, and solves such problems as multiple clamping times and low machining precision in a traditional screw tap lathe. The screw tap lathe comprises a base and a machine tool body; a control power supply, a motor, a main shaft box and a transmission device are arranged in the machine tool body; the front part of the machine tool body is connected with a control panel; a rotating cutter frame is fixed on the right side outer wall of the machine tool body; a chuck is mounted on the rotating cutter frame; a tail frame is arranged on the right side of the top surface of the base; a thimble is mounted on the tail frame; a cutting device is arranged between the machine tool body and the tail frame; the bottom of the cutting device includes a lower slide table, and an upper slide table capable of sliding front and back on the lower slide table; a square head turning tool is mounted on the back side of the top surface of the upper slide table; a handle part turning tool is mounted on the front side of the top surface of the upper slide table; a protective cover is fixed on the back side of the top surface of the base; a manipulator is mounted on the top surface of the protective cover; and a tray is arranged on the front side of the tail base. The screw tap lathe has such advantages as few clamping times and high machining precision.

Owner:WENLING HONGTAI IND MEASURE CO LTD

Numerical control lathe multi-cutter-position device

ActiveCN104368831AReduce the number of clampingIncrease profitTool holdersNumerical control systemEngineering

The invention relates to a numerical control lathe multi-cutter-position device. The numerical control lathe multi-cutter-position device comprises a power-driven square cutter rest with four clamping positions, three clamping positions of the power-driven square cutter rest are provided with outer circular turning tool, a threaded turning tool and cutoff groove cutting turning tool in a clamped mode through compression bolts, and the fourth clamping position of the power-driven square cutter rest is provided with a common type cutter installation structure. By means of the numerical control lathe multi-cutter-position device, the time of number of camping of parts is decreased, the auxiliary time for clamping, aligning and the like is shortened, efficiency and the machining accuracy are improved, and the production effect, the practicing effect and the application effect are good. After cutters are additionally arranged, cutter compensation numbers for uniquely identifying the additionally-arranged cutters can be obtained through compensation, calling can be conveniently carried out in the procedure at any time, and the using rate of a numerical control system is increased.

Owner:河南华中星科技电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com