Patents

Literature

135results about How to "Reduce the number of operators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

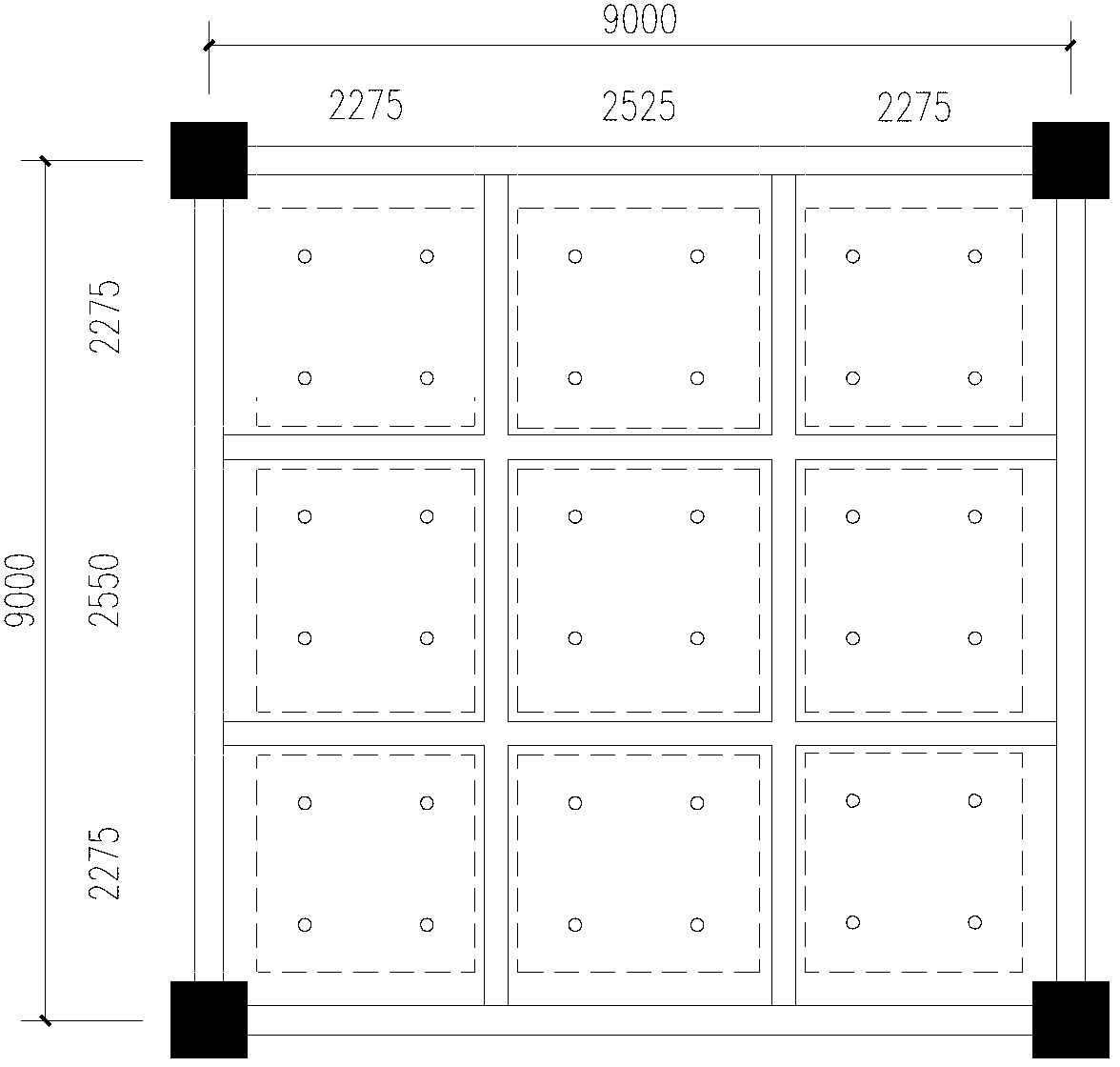

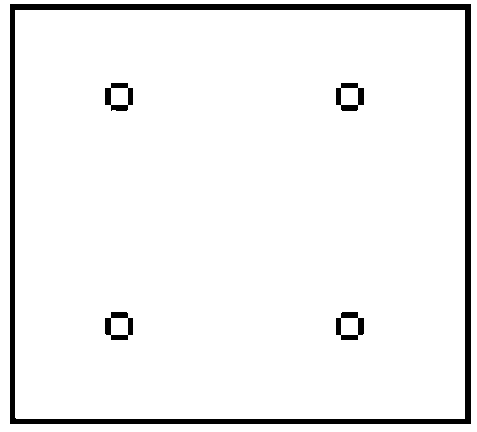

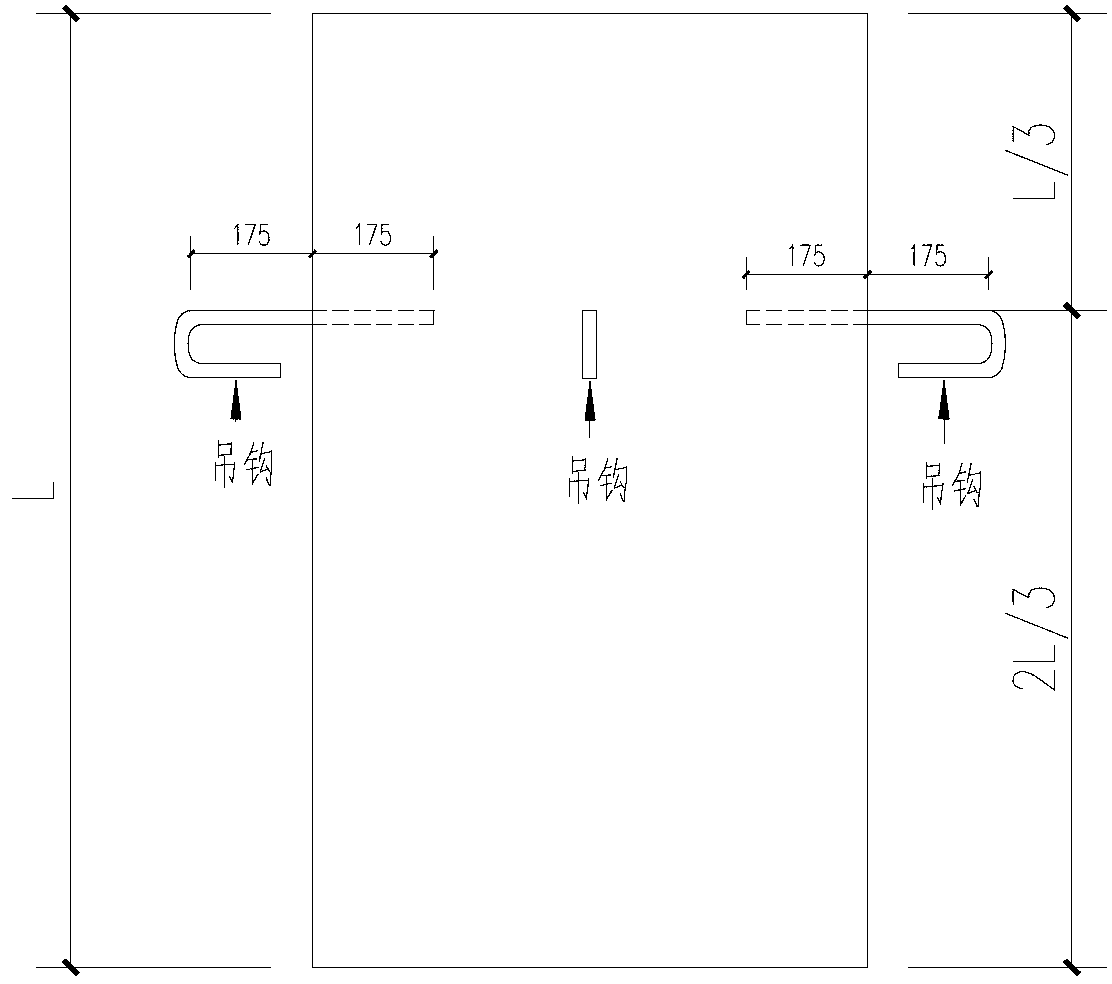

Concrete static force cutting dismantling construction method

InactiveCN103291085ANo vibration loadStructure has no effectBuilding repairsFalseworkReinforced concrete

The invention discloses a concrete static force cutting dismantling construction method which mainly comprises the steps of construction equipment selection, cutting unit division, supporting scaffold erection, hoisting auxiliary facility installation, cutting construction, component hoisting and site cleaning. The concrete static force cutting dismantling construction method has the obvious advantages that the effect on the surrounding structures is small in the process of constructing, the constructing speed, the constructing precision and the safety are high, and components which are cut through the static force are convenient to clean. The concrete static force cutting dismantling construction method is suitable for dismantling various reinforced concrete members, and especially for dismantling the part structures with the high demand for dismantling and with the small effect on an original structure. Time and production cost are greatly saved, and the construction period is effectively shortened.

Owner:恒中达建筑有限公司 +1

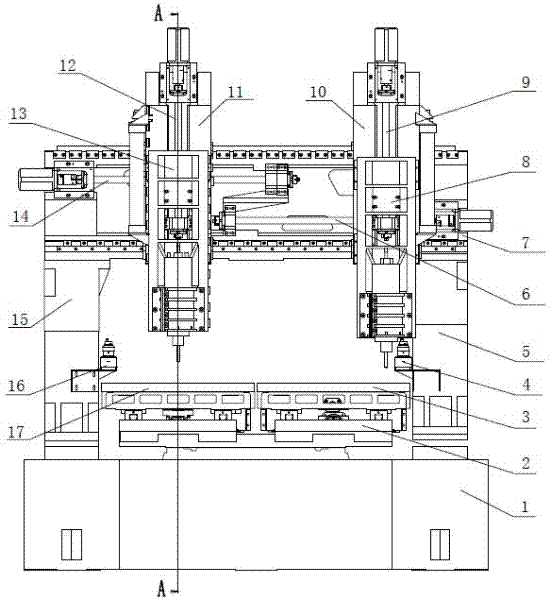

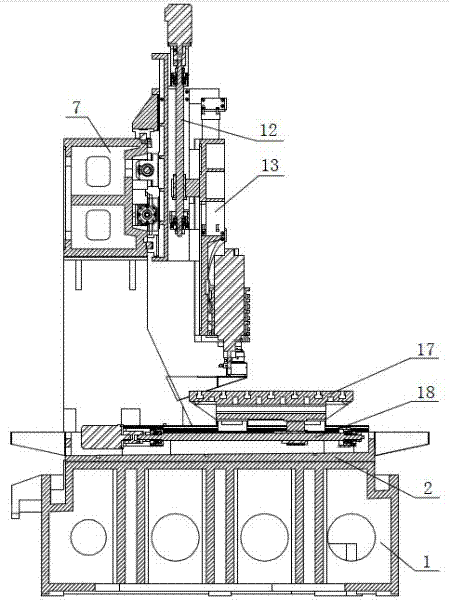

Numerical control double-station mould engraving and milling machine

InactiveCN102189288AIngenious structureSimple and fast operationMilling machinesLarge fixed membersNumerical controlBall screw

The invention relates to a machine tool, in particular to a numerical control double-station mould engraving and milling machine. A foundation, a left vertical shaft and a right vertical shaft are arranged on a frame body of the machine in a matched way; a beam is arranged above the left vertical shaft and the right vertical shaft in a matched way; the beam is connected with a left X-axle sliding table and a right X-axle sliding table through a left X-axle linear sliding block guide rail pair and a right X-axle linear sliding block guide rail pair in a matched way and the beam is in transmission fit with the left X-axle sliding table and the right X-axle sliding table through a left X-axle ball screw pair and a right X-axle ball screw pair; the foundation is connected with a left Y-axle sliding table and a right Y-axle sliding table through a left Y-axle linear sliding block guide rail pair and a right Y-axle linear sliding block guide rail pair in a matched way and the foundation is in transmission fit with the left Y-axle sliding table and the right Y-axle sliding table through a left Y-axle ball screw pair and a right Y-axle ball screw pair; and the left X-axle sliding table and the right X-axle sliding table are connected with a left Z-axle sliding table and a right Z-axle sliding table through a left Z-axle linear sliding block guide rail pair and a right Z-axle linear sliding block guide rail pair in a matched way and the left X-axle sliding table and the right X-axle sliding table are in transmission fit with the left Z-axle sliding table and the right Z-axle sliding table through a left Z-axle ball screw pair and a right Z-axle ball screw pair. The efficiency of the numerical control double-station mould engraving and milling machine is two times that of the conventional machine tool.

Owner:DOUBLE HEAD CNC

Method for recycling manganese ion in electrolytic manganese production tail end wastewater

InactiveCN101838064AImprove stabilityReduce the number of operatorsWater contaminantsWater/sewage treatment by ion-exchangeIonIon exchange

The invention provides a method for automatically recycling manganese ions in electrolytic manganese production tail end wastewater, which comprises the following steps of: pretreating stabilized production wastewater and carrying out ion exchange with cation exchange resin; adsorbing till the cation exchange resin is saturated and then adopting H2SO4 with the concentration of 0.5-1.5mol / L as a regenerant; and carrying out desorbing regeneration on the ion exchange resin adsorbed with Mn<2+>. The regenerated regenerating liquid forms MnSO4 with high concentration and meets the requirement of being recycled to the liquid preparation working section of electrolytic manganese production, and regenerating liquid with low concentration is recycled for regenerating operation in next batch. By utilizing the method, after the electrolytic manganese production tail end wastewater is processed, the discharge water is colorless and transparent and the manganese ion concentration approaches zero and is far lower than a discharge threshold value specified by the nation. Meanwhile, manganese ions in the wastewater can be separated and recycled, thereby realizing effective control of the wastewater and recycling of resources and having obvious environmental, economic and social benefits.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

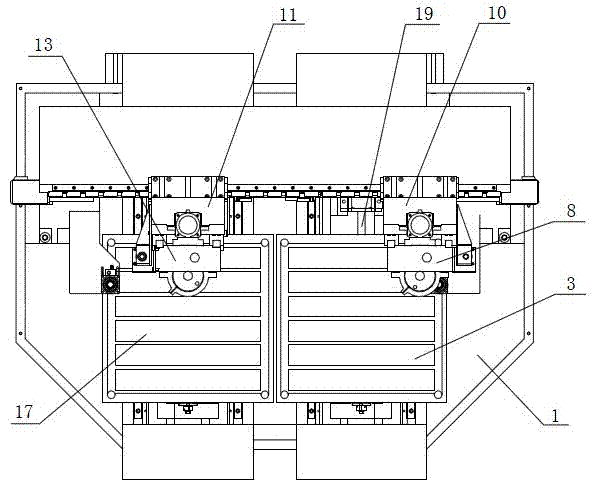

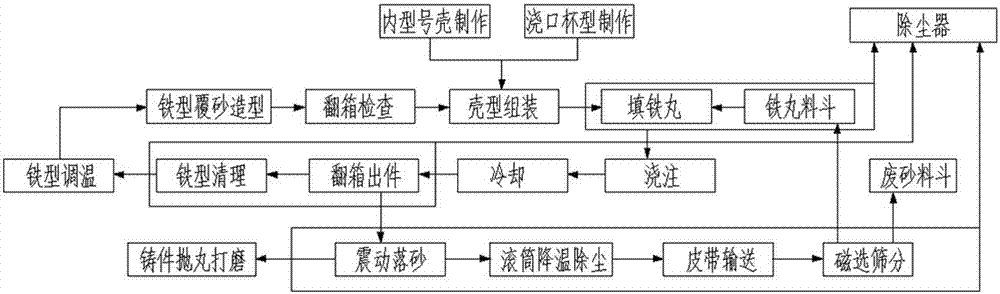

Novel casting technique of semitrailer brake drum

InactiveCN103286279AGuaranteed not to deformBack-off guaranteeCasting plantsFoundry mouldsBrakeDust control

The invention relates to a novel casting technique of a semitrailer brake drum. The novel casting technique of the semitrailer brake drum comprises the following steps of: manufacturing an inner mold shell and a pouring cup; regulating the temperature of an iron mold, covering with sands, and modeling; checking by turning over a mold; assembling a shell mold; filling iron shots; pouring and cooling; turning over the mold, discharging elements, assembling the elements, and recovering; carrying out magnetic separation, and screening; dedusting and cleaning. No deformation of the brake drum is ensured fully; the steel shots are filled in an internal mold sand shell; poured steel liquids generate pressure inward; firstly, because of the 'arch bridge principle', the internal mold sand shell has great support force; and then the steel shots also can block the pressure by steel liquids, and the internal mold sand shell cannot be cracked or deformed absolutely. Before cast elements are condensed and contracted, the internal mold sand shell is scattered, the filled steel shots are at the scattered state, the deformability of the cast elements in contraction is ensured fully, so that free contraction instead of hindered contraction is formed; a bottom-pouring-type pouring mode is adopted, air is discharged smoothly; the cracking possibility at the crossed part is reduced; air holes of the cast elements caused by dampness of a sand mold are prevented; the novel casting technique of the semitrailer brake drum is an environment-friendly casting technique.

Owner:FUDI PRECISION CASTING

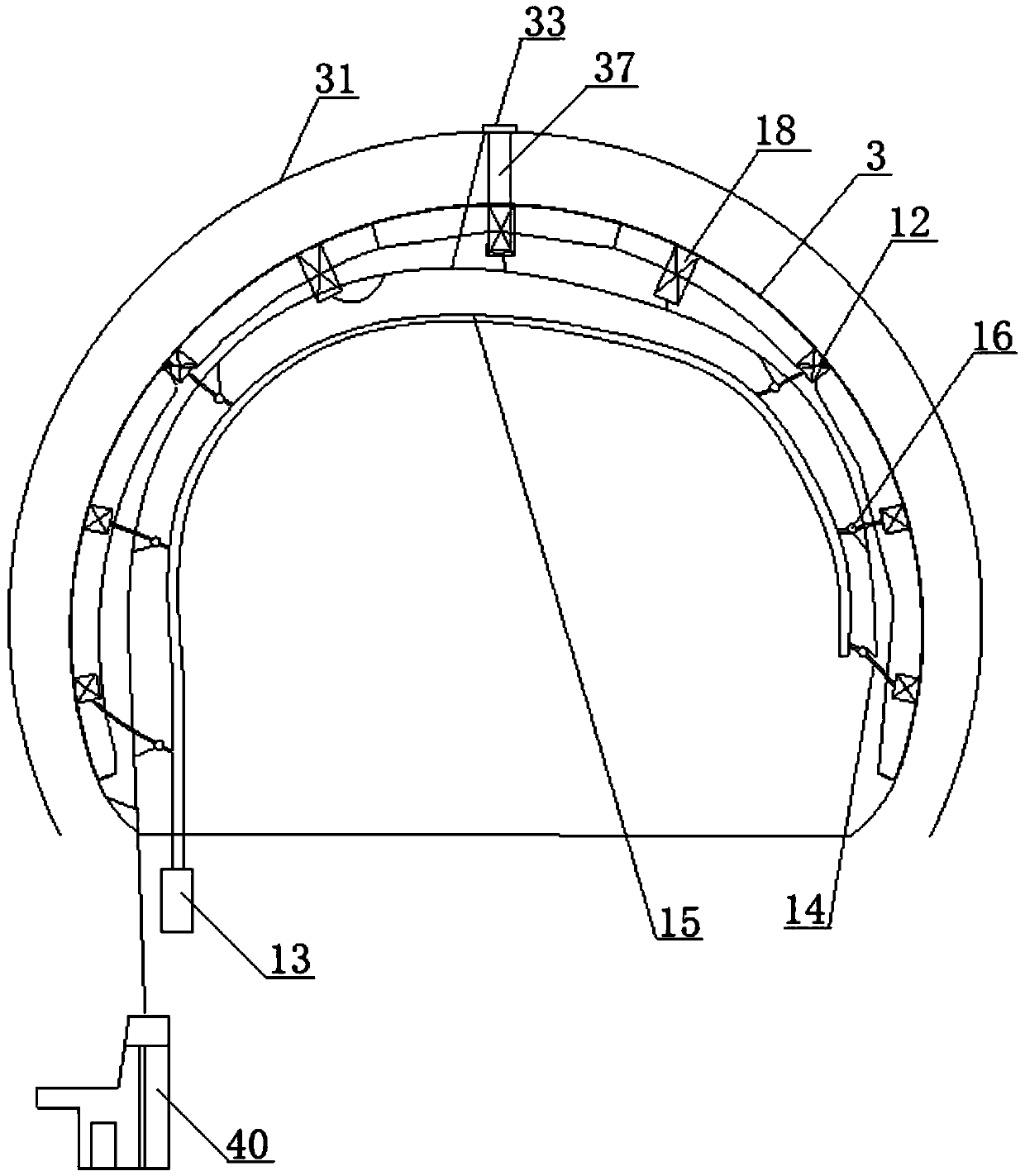

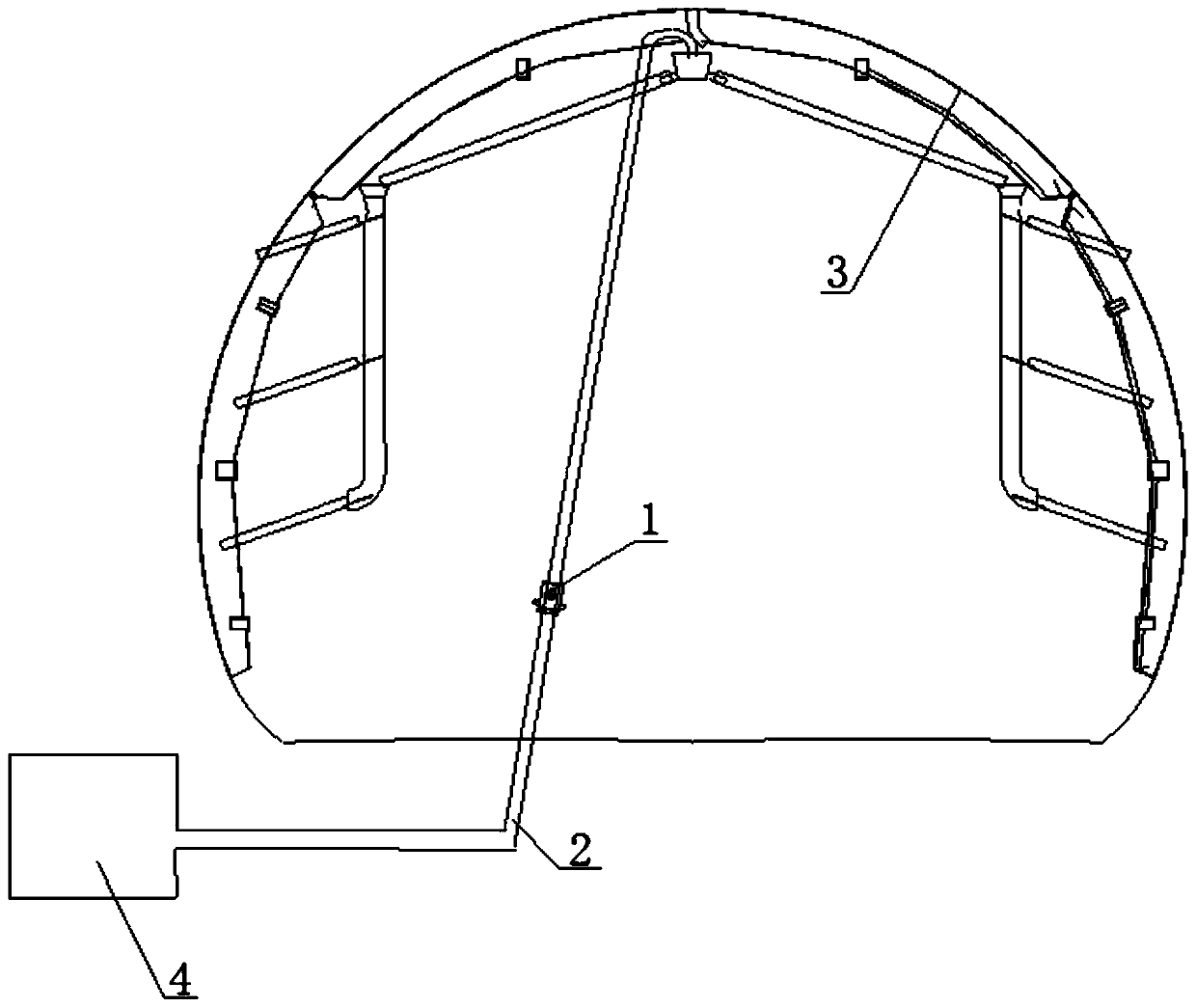

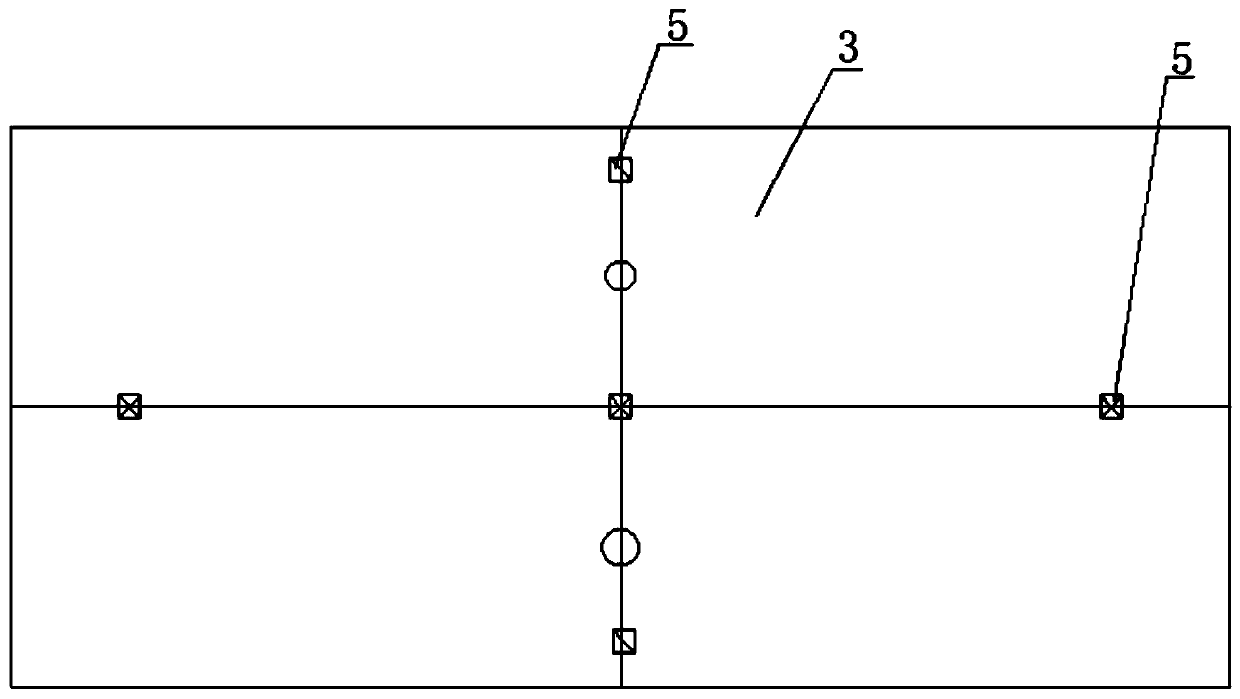

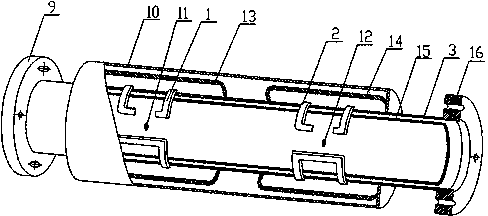

Construction method of tunnel two-lining concrete pouring system

ActiveCN109826649AWon't crackQuality assuranceUnderground chambersApparatus for force/torque/work measurementPressure senseEngineering

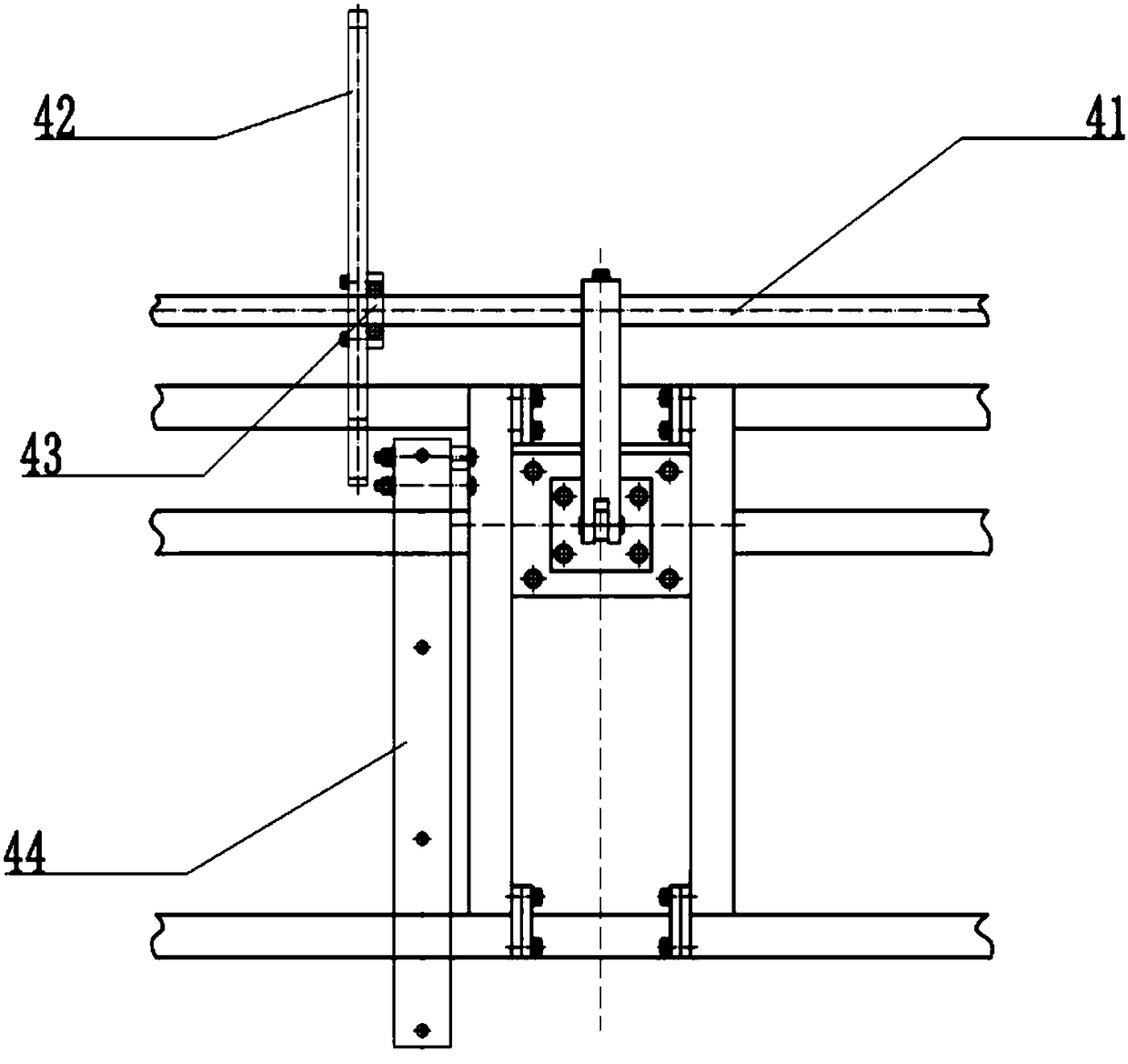

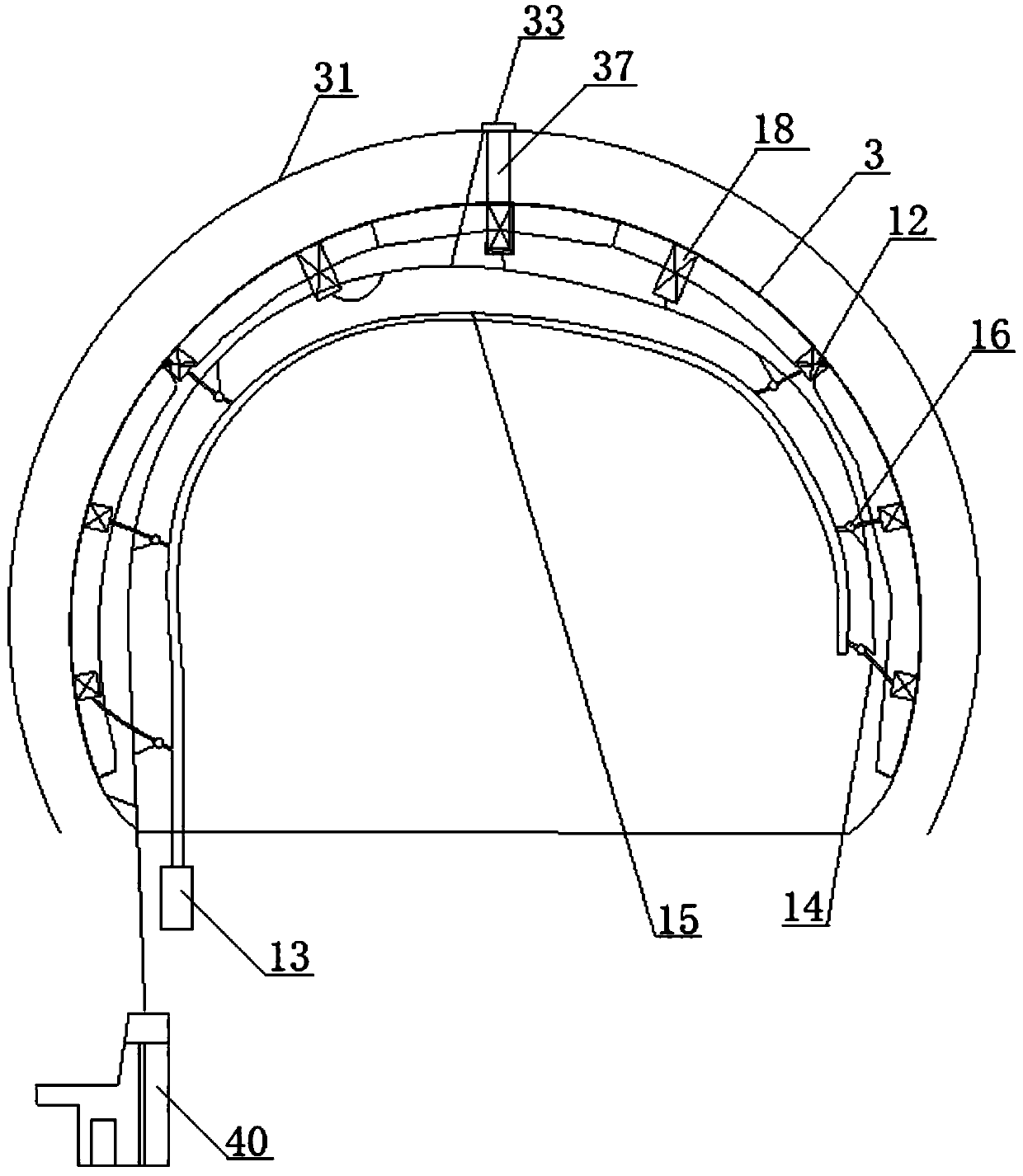

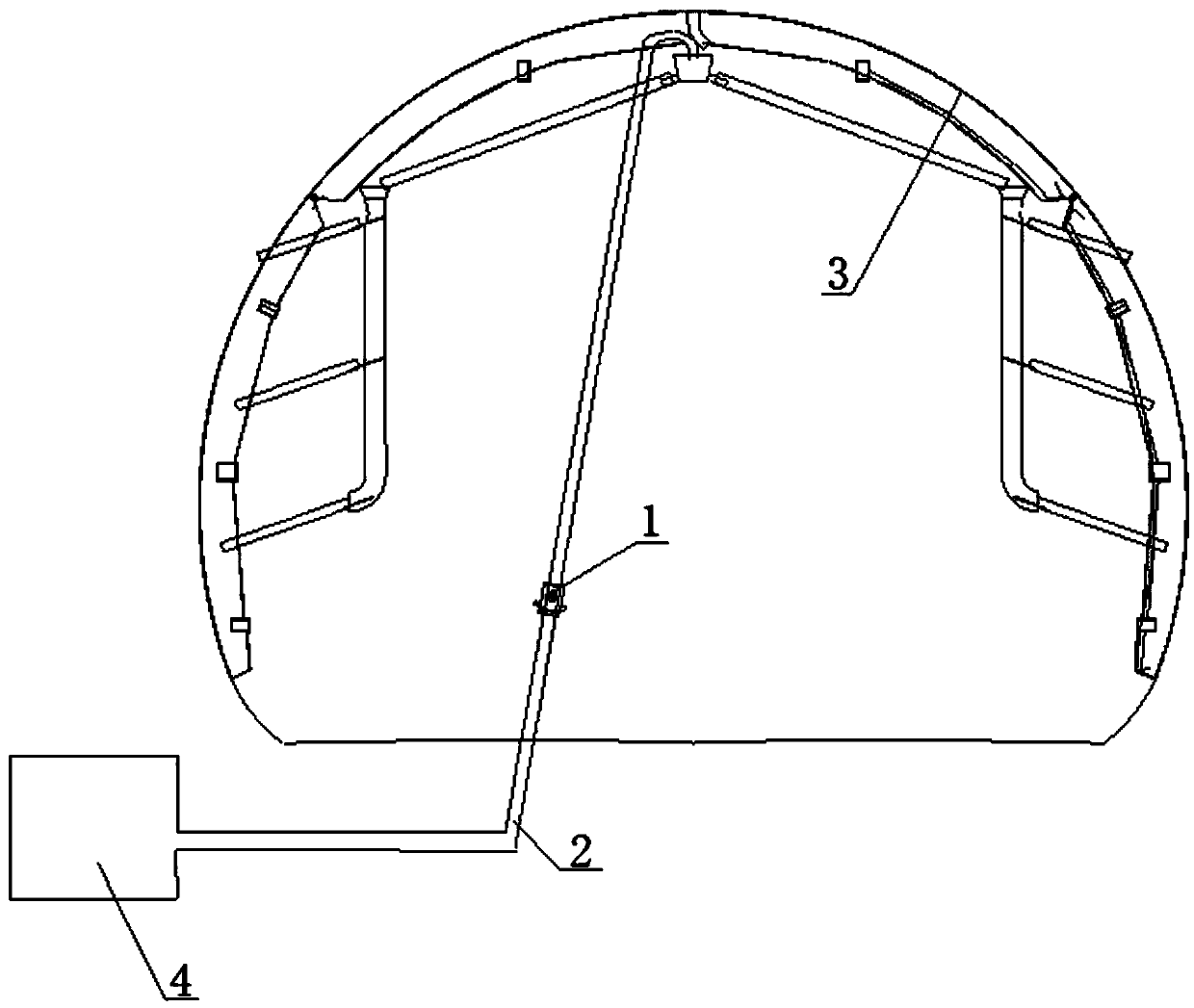

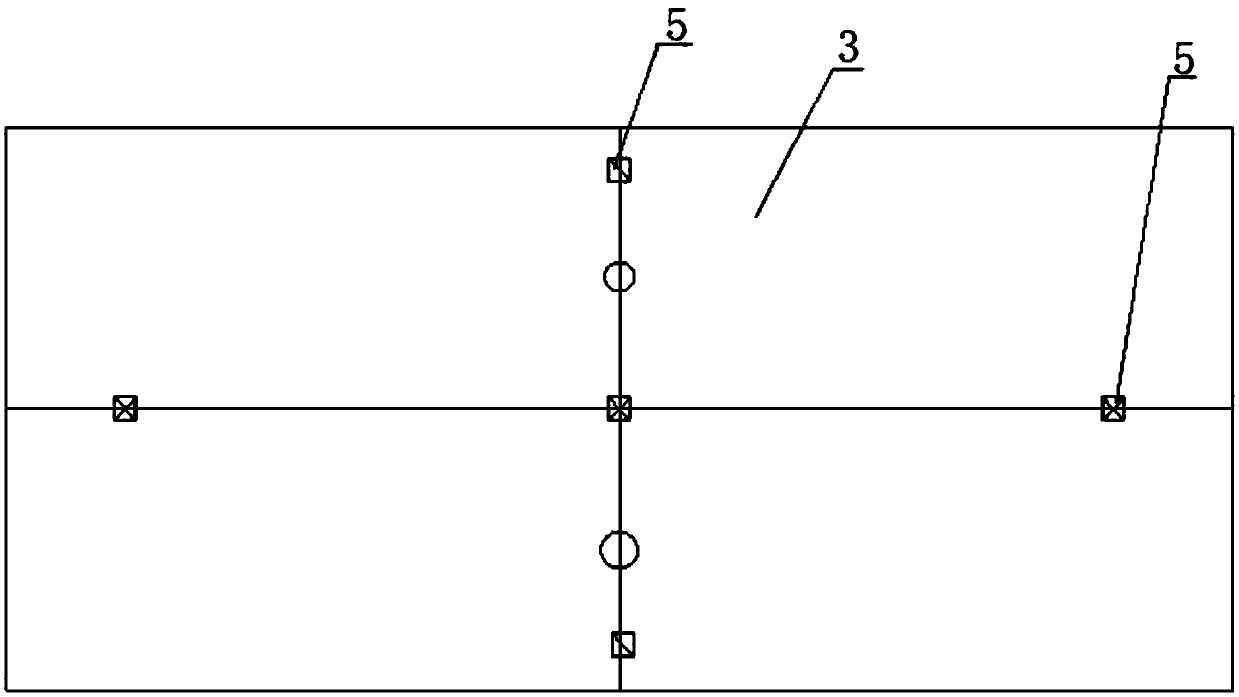

The invention relates to a construction method of a tunnel two-lining concrete pouring system, which comprises the following steps of: carrying out full-coverage scanning on a primary cross section byusing a three-dimensional laser scanner, calculating an estimated pouring two-liner concrete square quantity, and transmitting the estimated pouring two-liner concrete square quantity to an electriccabinet (40); installing a strip-shaped pressure sensing gasket (33) and a transparent pipe (30); installing a pressure sensing chip (9), a pressure sensing piece (32) and a temperature sensor (5); arranging a high-frequency pneumatic vibrator (12) and an automatic insertion type vibrator (18), and installing a flow sensor (1); stopping jacking when the pressure sensing value of the pressure sensing chip (9) is greater than the pressure resistance value of the upper plate two-lining concrete, installing a comprehensive pipe (3); pressing air, monitoring the square quantity of the concrete; carrying out pneumatic vibrating; carrying out insertion vibrating; judging that the concrete is full, and finishing pouring the concrete. The automation of the pouring of the two-lining concrete is achieved.

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY 11 BUREAU GRP +1

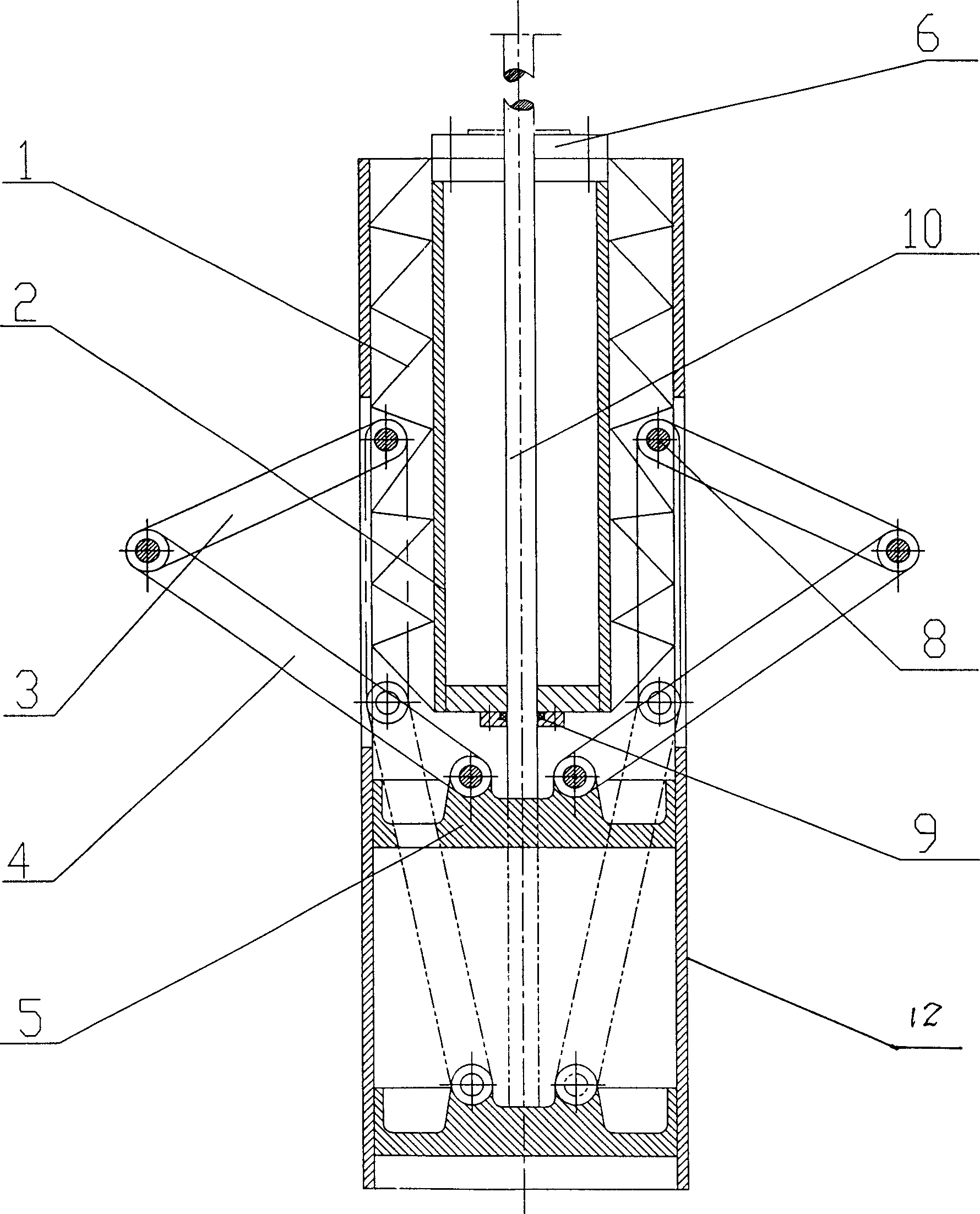

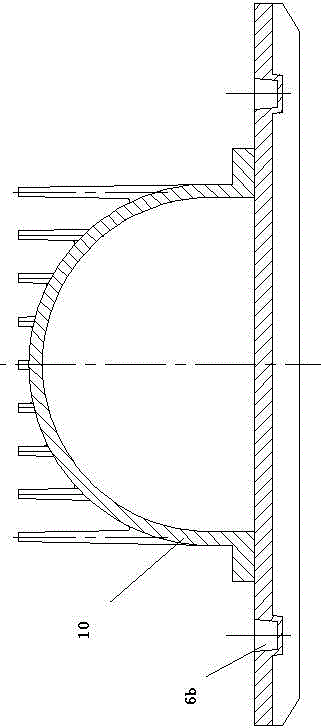

Reaming method for pile hole of building and reaming bit for screw drilling machine

InactiveCN1434190AMeet different needsFast molding speedDrill bitsBulkheads/pilesHelical bladeDrilling machines

The present invention relates to a reaming method for building pile hole and its special-purpose reaming drilling equipment of spiral drilling machine. It is characterized by that it makes the bowarmcutter progressively outward move to cut peripheral soil layer in the course of that the bowarm cutter is upwards and downwards moved with the lifting device so as to obtain the required pile form. Said special-purpose reaming drilling equipment has an internal pipe, said internal pipe is connected with drilling rod of spiral drilling machine, the periphery of the internal pipe is equipped with helical blade whose exterior has an external sleeve, and has a bowarm cutter which can be progressively outward movel under the action of lifting device. Its operation is simple and its accuracy is high.

Owner:萧守让

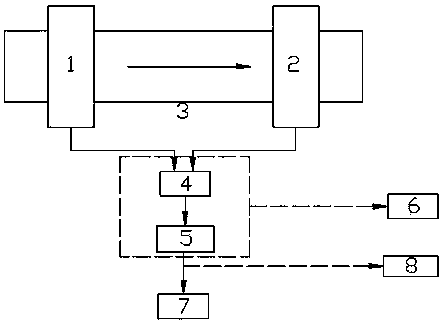

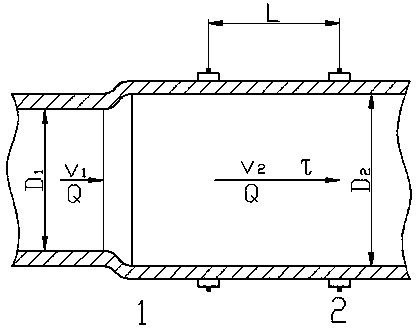

Method and device for measuring flow speed of dense paste based on electromagnetic signal cross correlation

InactiveCN103439528AWidely used valueSolve the small median particle sizeFluid speed measurementVolume/mass flow by electromagnetic flowmetersCross correlation analysisMeasurement device

The invention relates to a method and device for measuring the flow speed of a dense paste based on electromagnetic signal cross correlation. The device comprises a test tube section, a primary instrument and a secondary instrument. When the dense paste flows through a field coil 1 or 2 during pipeline conveyance, a current carrier of the dense paste performs movements of cutting magnetic induction lines in an applied magnetic field, and an electromotive force vertical to the flowing direction of the dense paste is formed; electromotive force signals in the two field coils are guided out by an electrode to be acquired, processed and analyzed; and the delay time of the two field coils is calculated by a cross correlation analysis method of two measuring points, and the quotient of the separation distance and the delay time of the two field coils is the flow speed of the dense paste. The method and the device solve the difficult problem that a special measuring device and a special measuring method for measuring the flow speed of the dense paste on a project site are not provided, and a condition for monitoring the condition of the project site and accurately controlling the flow of the dense paste is provided.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

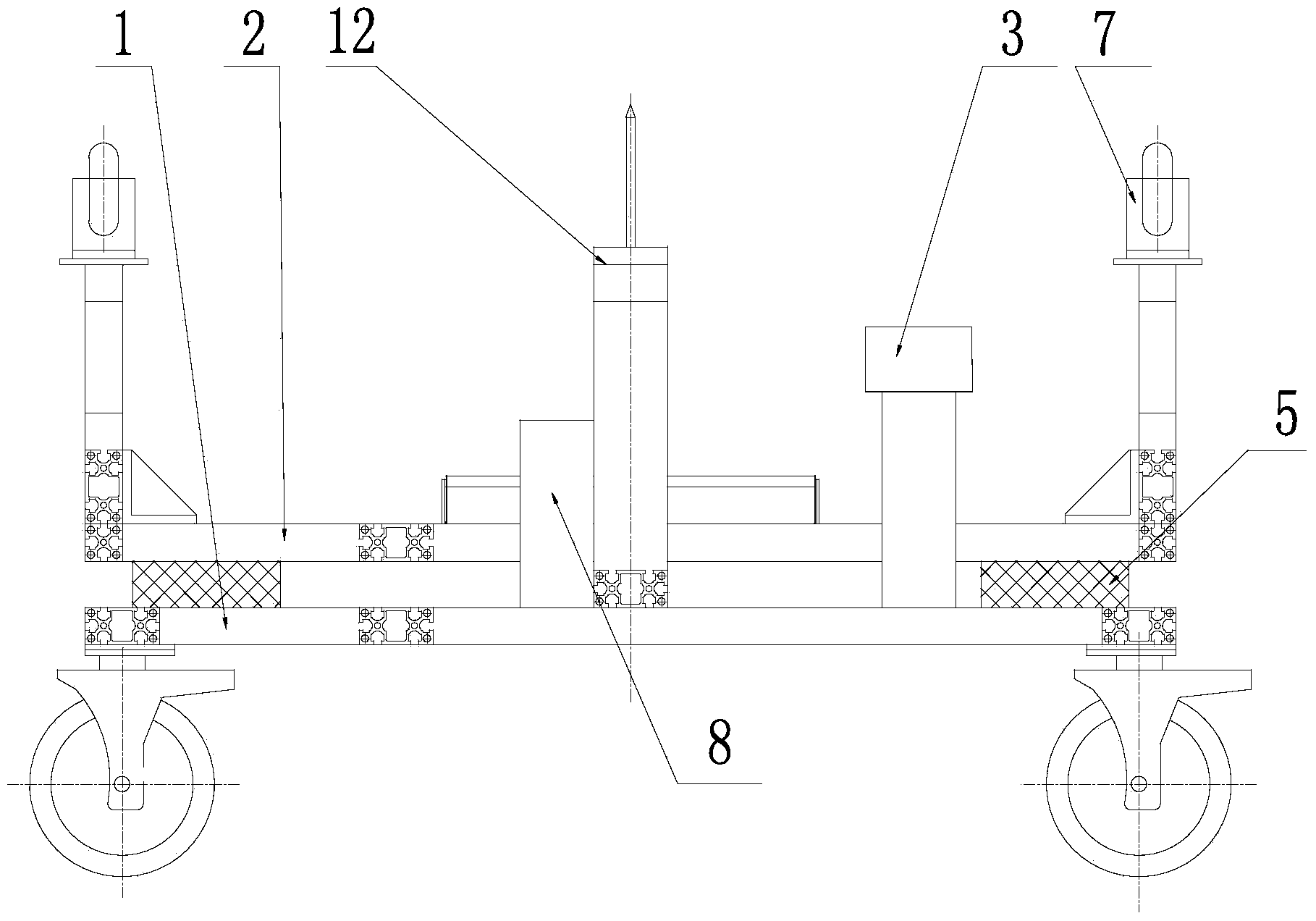

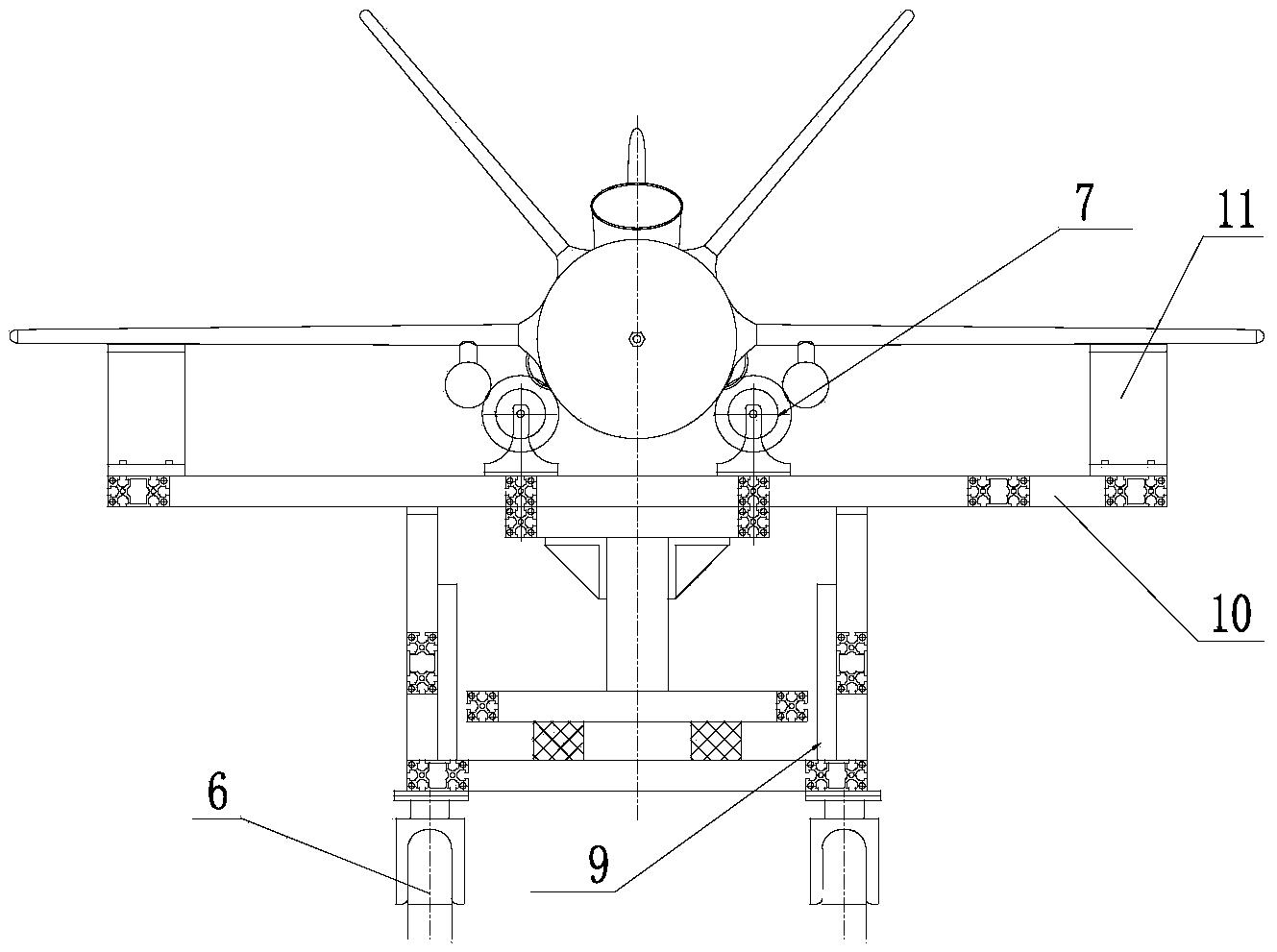

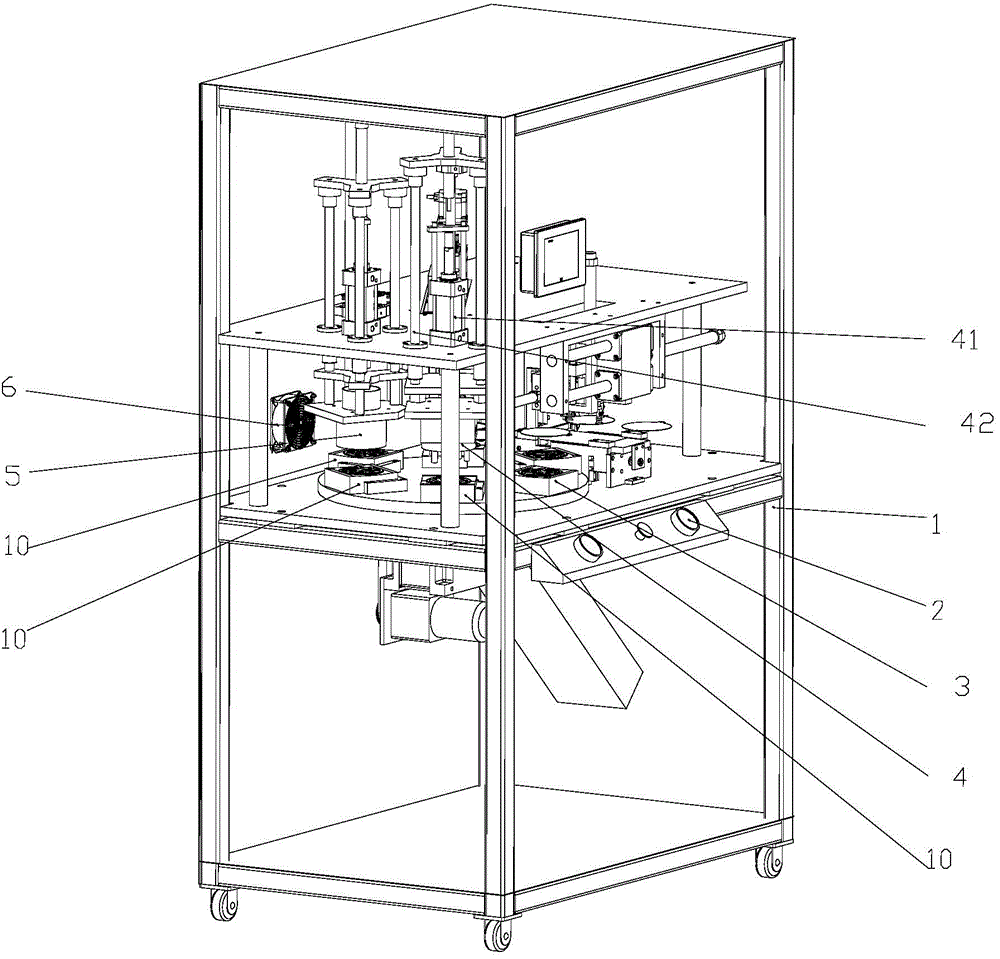

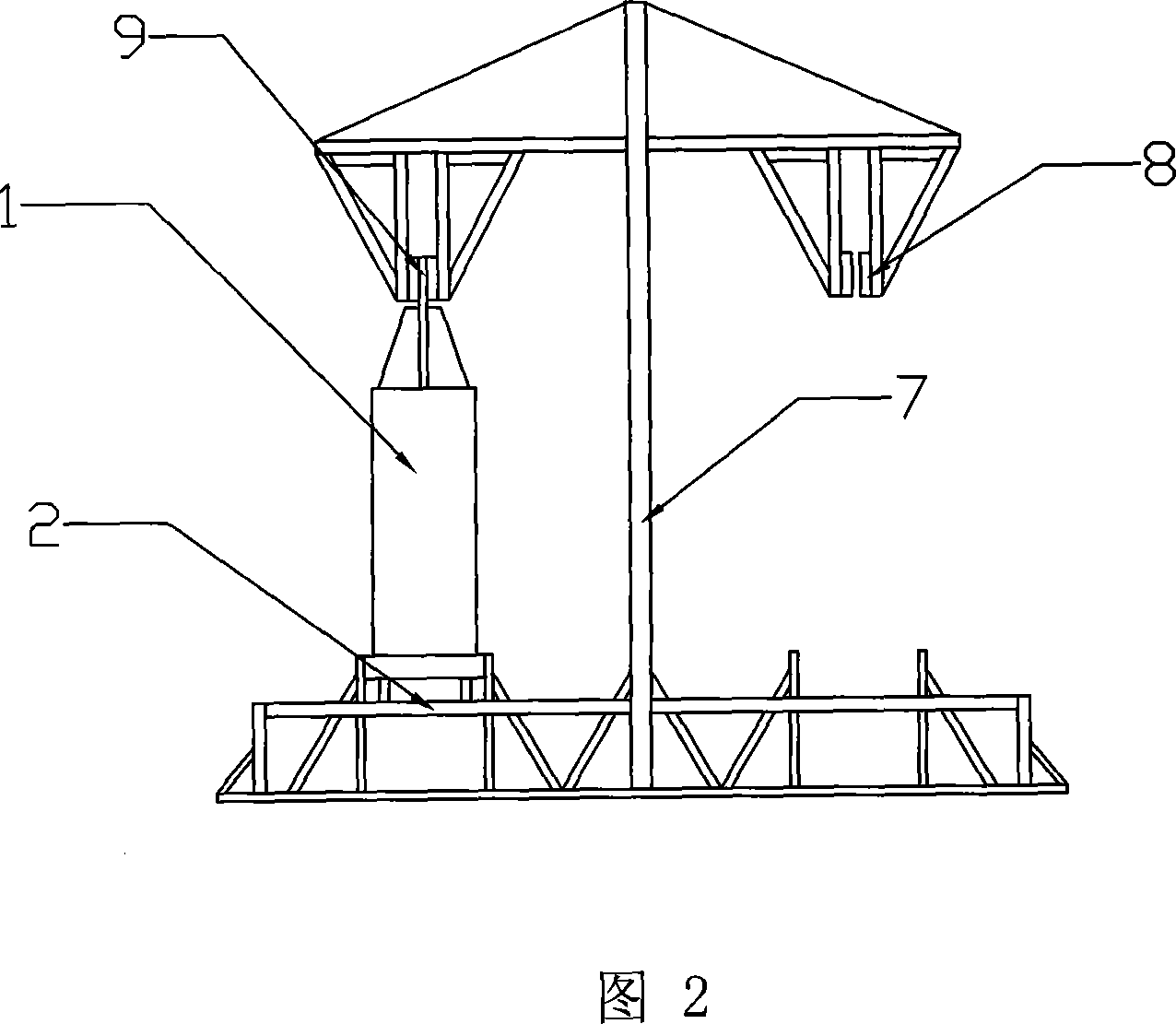

UAV (Unmanned Aerial Vehicle) assembling and debugging vehicle

ActiveCN103770951AEasy to operateImprove performanceAircraft assemblyAircraft components testingEngineeringPressure sensor

The invention relates to a UAV (Unmanned Aerial Vehicle) assembling and debugging vehicle which mainly comprises a chassis, a weighing disk, a balancing device, a display mechanism, support frames and lifting mechanisms. The weighing disk is arranged on the chassis; at least two pressure sensors are arranged between the chassis and the weighing disk; the T-shaped support frames are respectively arranged at the front and rear ends of the weighing disk; both sides of the upper parts of the support frames are provided with roller wheels; the chassis at both sides of the weighing disk is fixedly provided with the lifting mechanisms; each lifting mechanism is mainly formed by a motor, an electric push rod and a linear guide rail; the support frames arranged on the linear guide rails are pushed to ascend and descended by the electric push rods driven by the motors; the balancing device consists of balancing knife edges at both sides and a balancing cross bar; the balancing cross bar is fixedly arranged on supporting rods at both sides; and the balancing knife edges are symmetrically fixed at both sides of the balancing cross bar. The UAV assembling and debugging vehicle integrates each set of tool in each link of debugging, weighing, balancing and turnover of a UAV; the equipment is simple to operate, has reliable performance and is convenient to move; a work place is saved; and the UAV assembling and debugging vehicle can be suitable for the requirements for assembling and debugging of various types of UAVs.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA

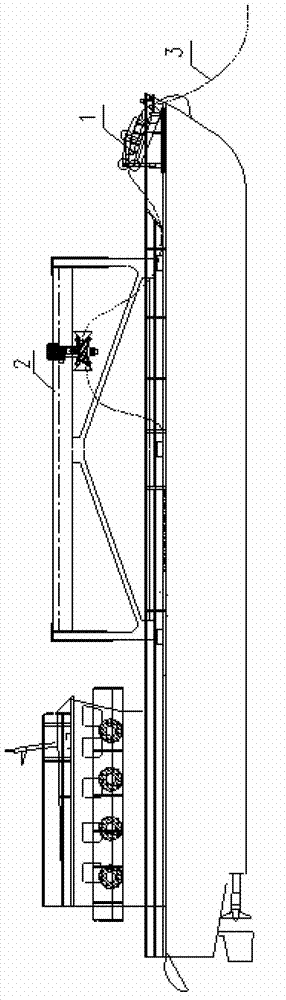

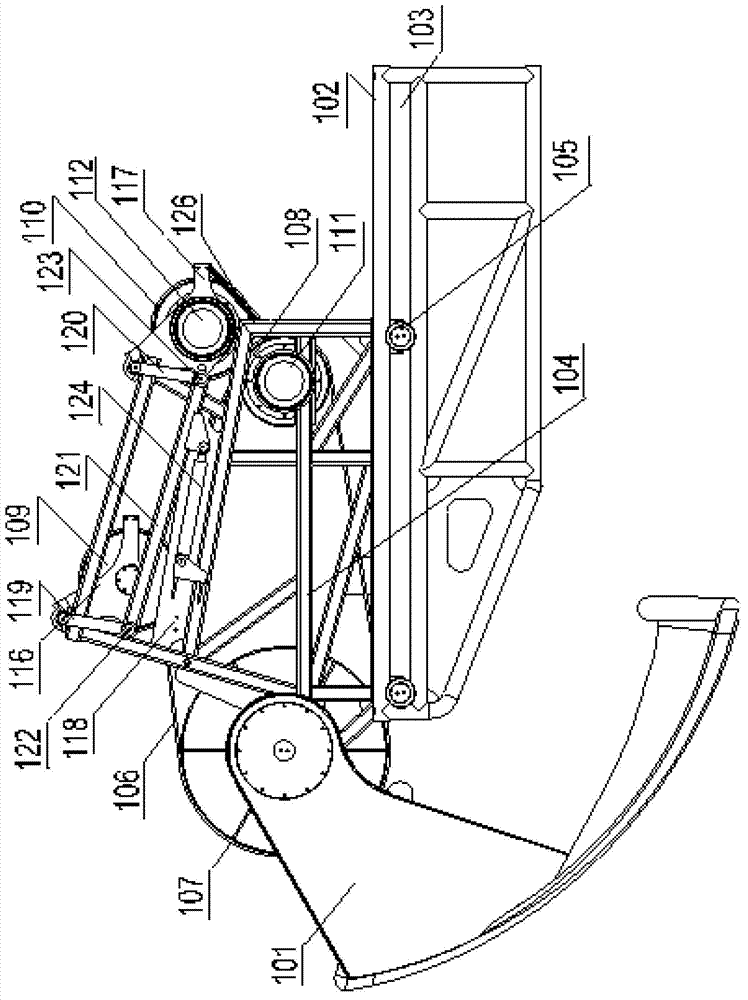

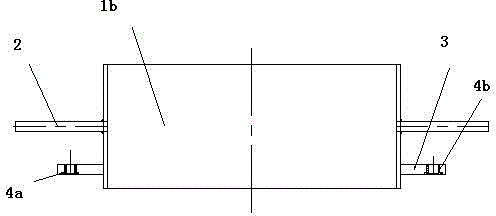

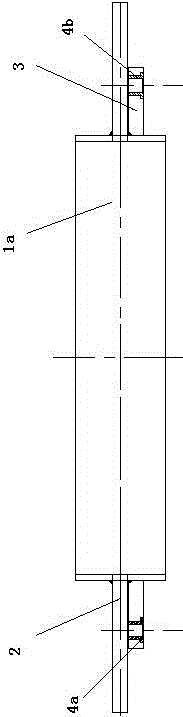

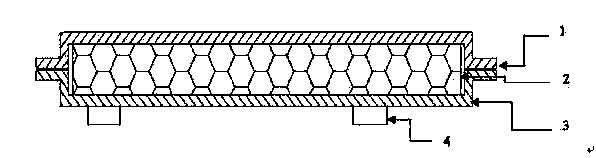

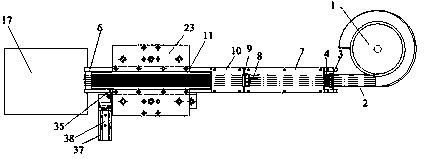

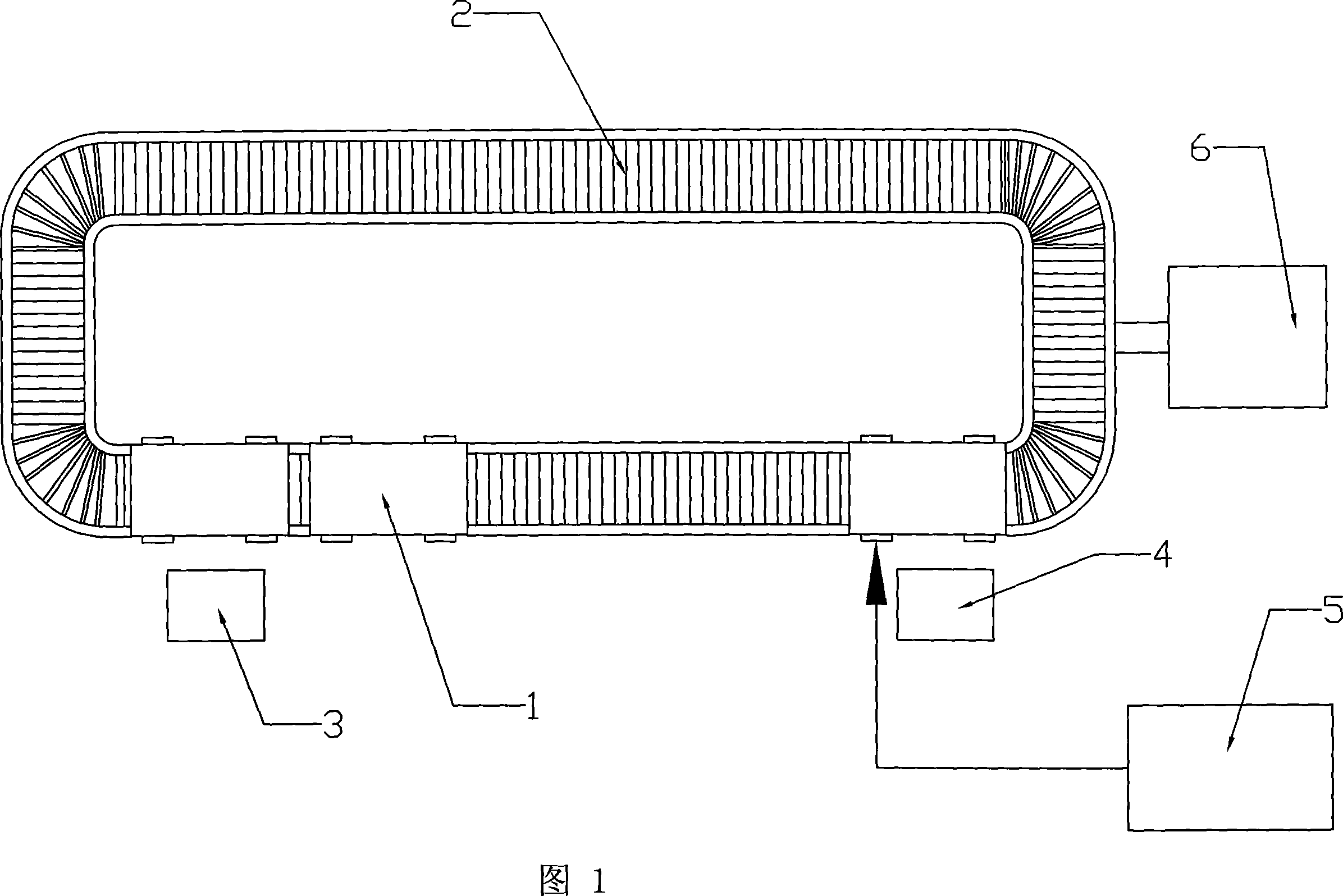

Seismic exploration submarine cable recycling and coiling device

The invention discloses a seismic exploration submarine cable recycling and coiling device, which is applied to collecting underwater cables after seism in areas such as lakes, rivers and oceans in oil seismic exploration. The seismic exploration submarine cable recycling and coiling device is characterized by mainly comprising a bow crawler-type cable collecting machine and a hoisting cable coiling device, wherein the bow crawler-type cable collecting machine is fixed to the deck of the bow of a cable boat; the hoisting cable coiling device is longitudinally fixed to the center of a working area of the cable boat; a submarine cable is inserted into the bow crawler-type cable collecting machine through a cable guide slot and is posited on a rubber track and between a driven pinch roller and a driving pinch roller; and then the submarine cable is inserted between a driven suspend roller and a driving suspend roller of the hoisting cable coiling device. The invention has the advantages that the seismic exploration submarine cable recycling and coiling device can normally recycle cables under the six-grade oceanic condition; the cables are recycled by machines under the assistance of staff, and the maximum 50-meter depth mechanical cable recycling operation is realized; 40 to 50 percent of the conventional cable recycling operators are saved, and the labor intensity of the cable recycling operators is reduced to the greatest extent; and the cables are prevented from being damaged and the damage rate of the cables is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

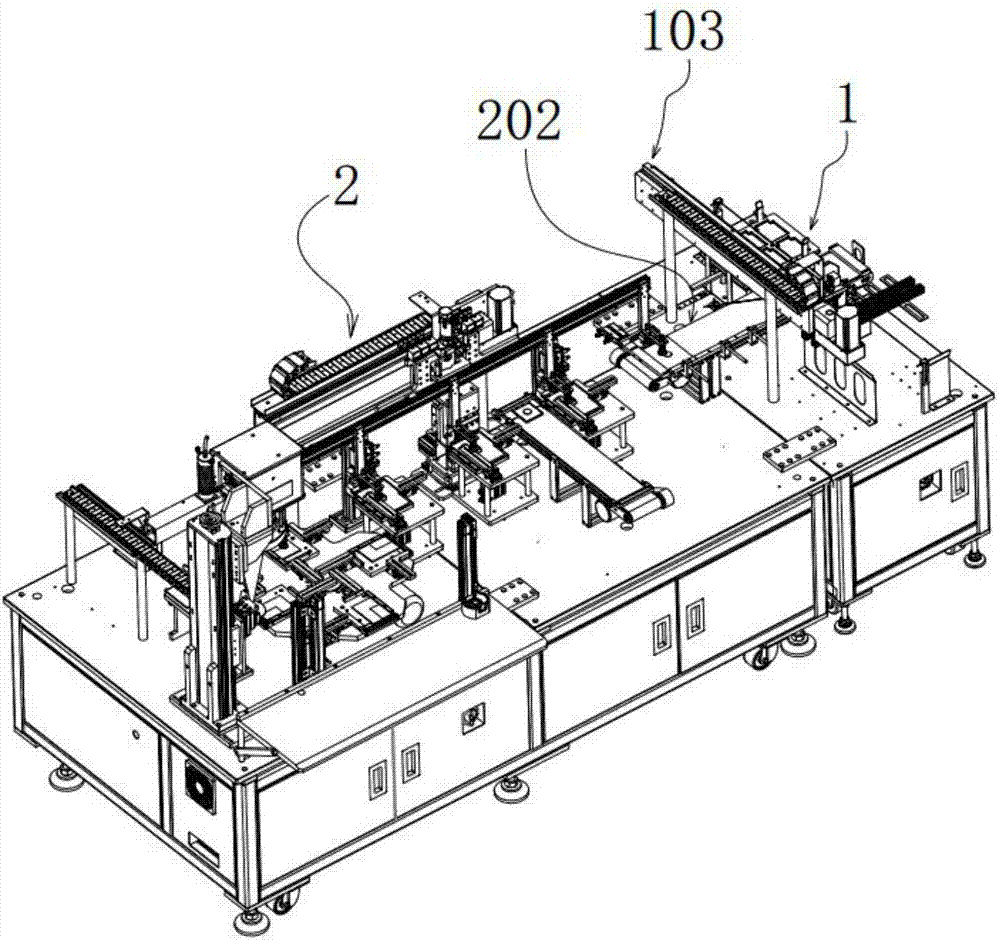

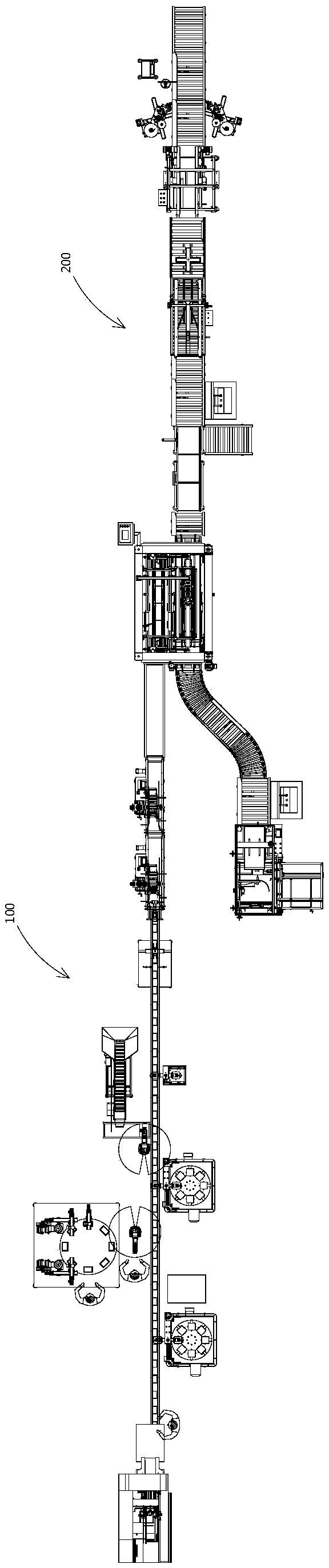

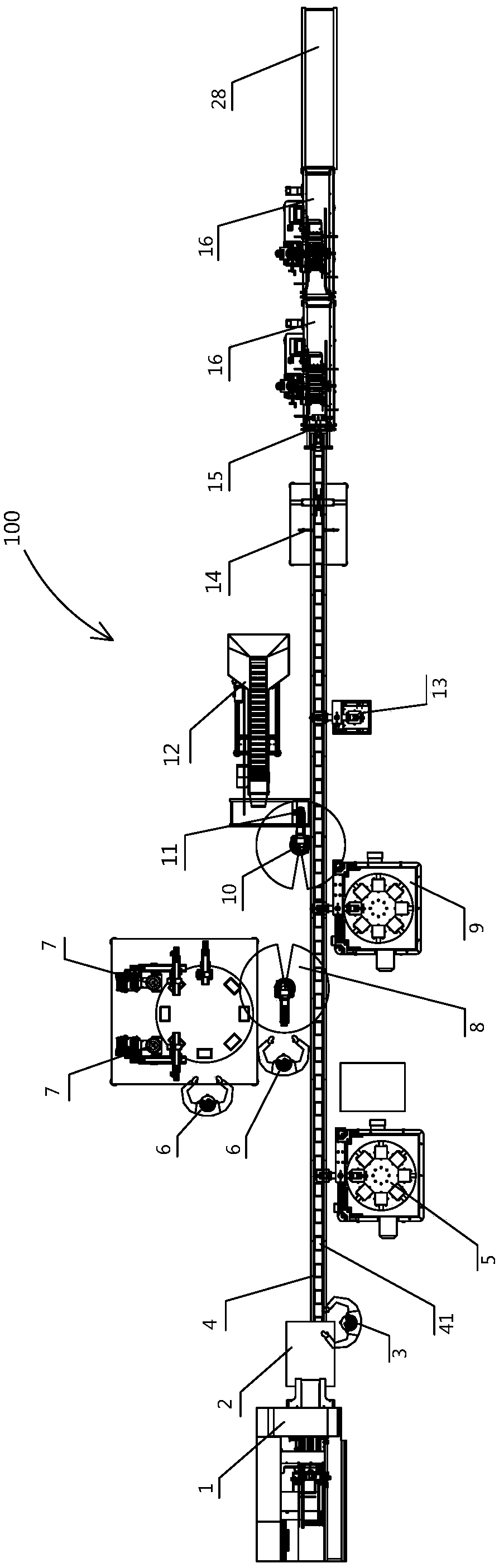

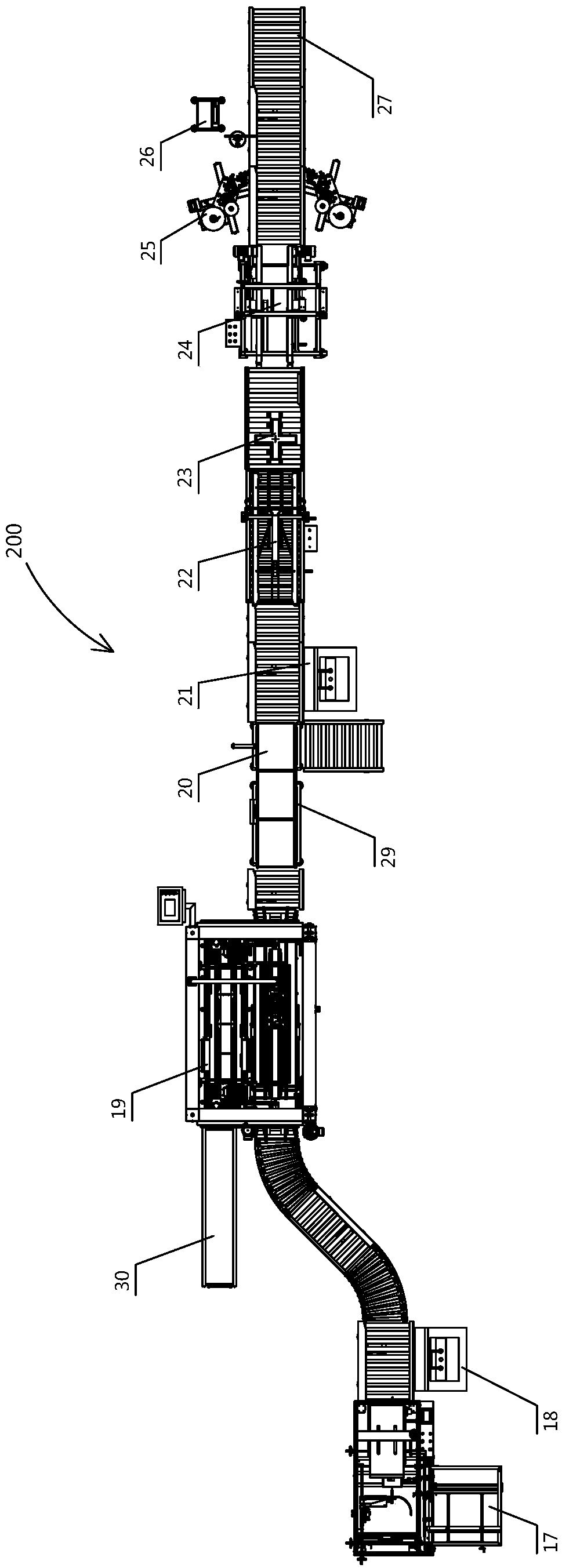

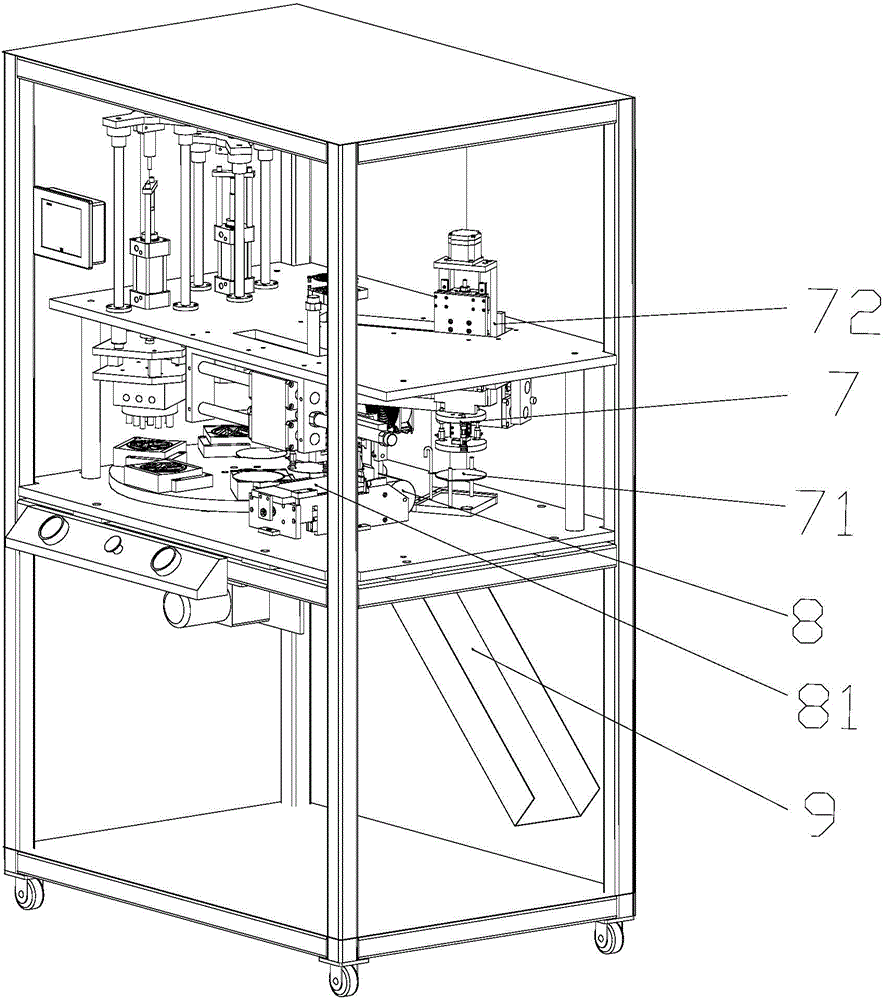

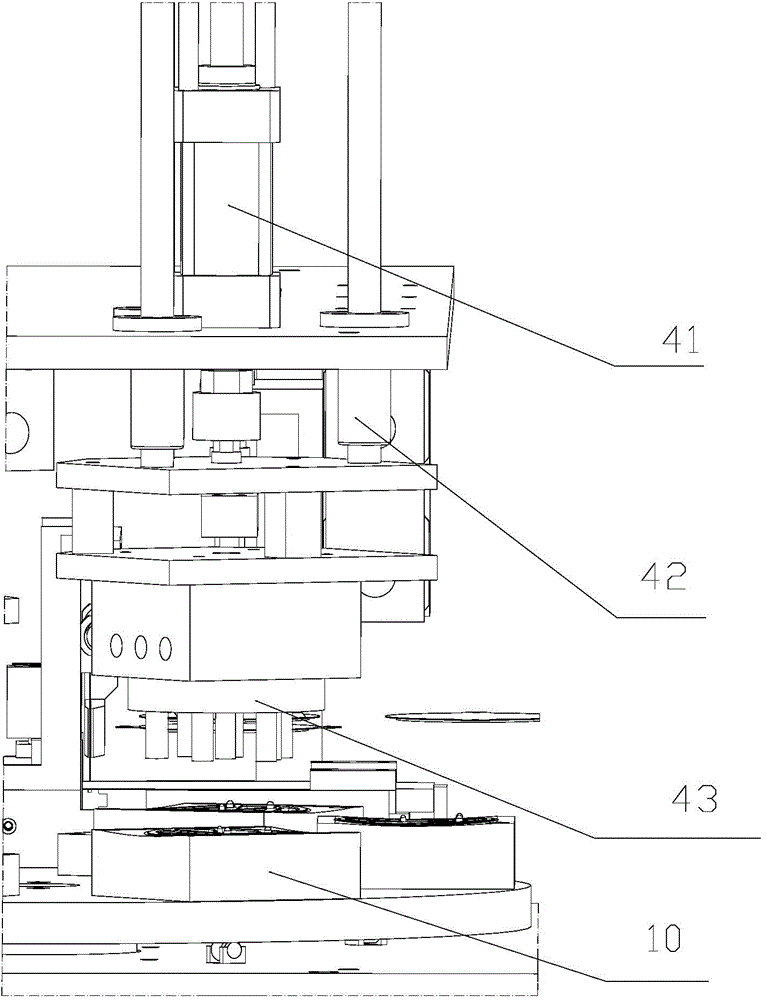

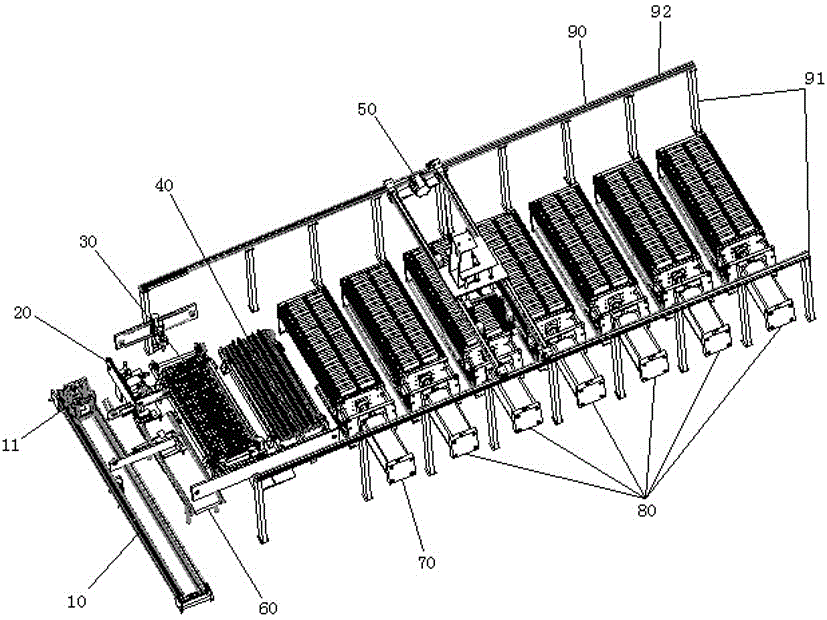

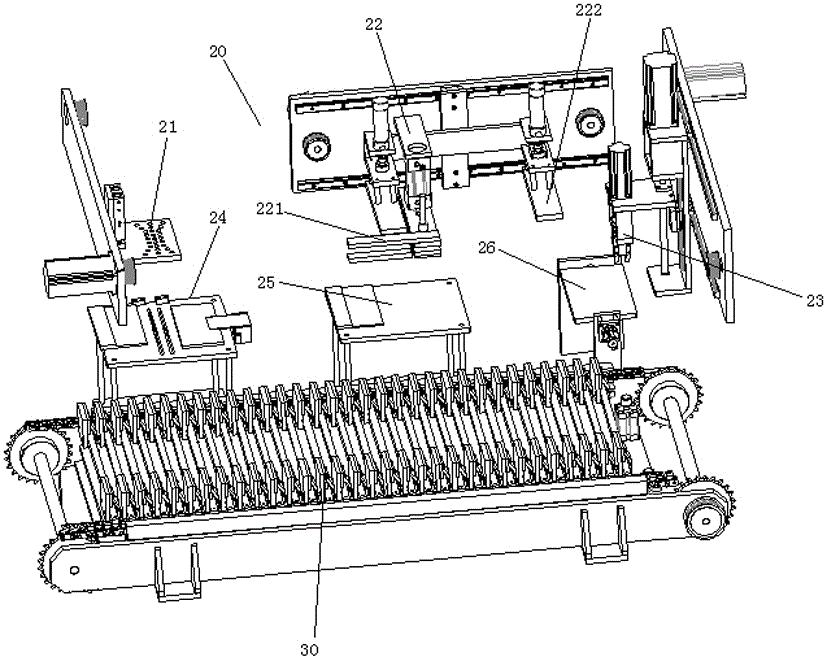

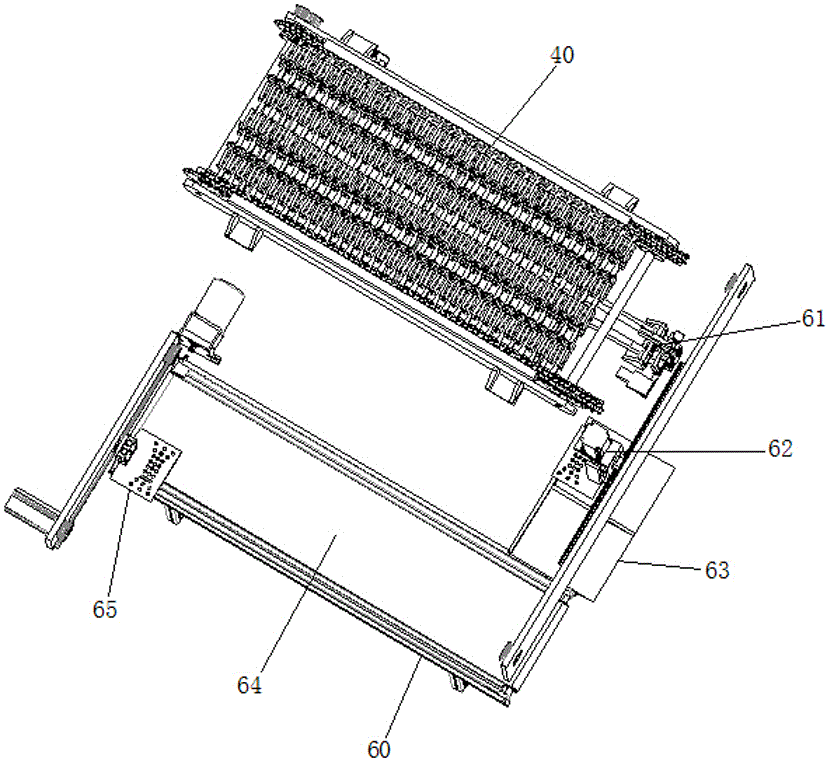

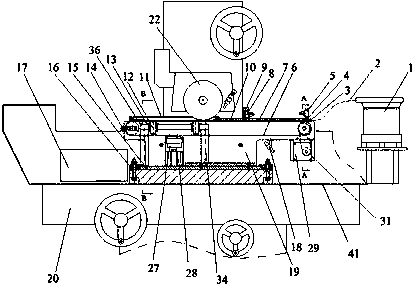

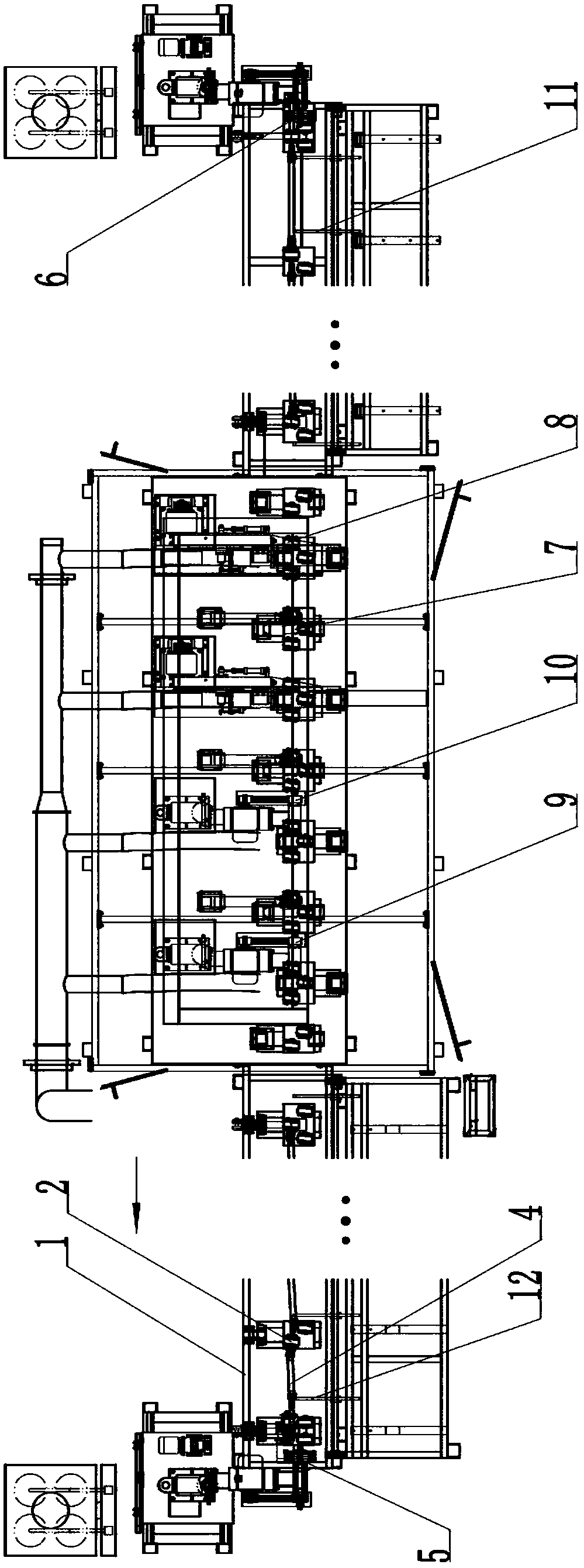

Automatic battery cell feeding, cutting, detecting and welding machine

PendingCN107052808AReduce the number of operatorsReduce manufacturing costPrimary cell manufactureElectrode manufacturing processesProduction lineElectrical battery

The invention relates to the field of automated equipment and particularly relates to an automatic battery cell feeding, cutting, detecting and welding machine applied to a battery production line. The automatic battery cell feeding, cutting, detecting and welding machine comprises automatic feeding equipment and automatic cutting equipment which are arranged in sequence and are connected through a cutting, feeding and transmission device. The automatic battery cell feeding, cutting, detecting and welding machine is simple in structure and convenient to assemble and feeds, cuts, detects and welds a battery cell and a production plate automatically, operation staff of battery production enterprises are reduced, the production cost of the battery production enterprises is lowered, and the production efficiency of the battery production enterprises is improved.

Owner:HUIZHOU DESAY AUTOMATION TECH

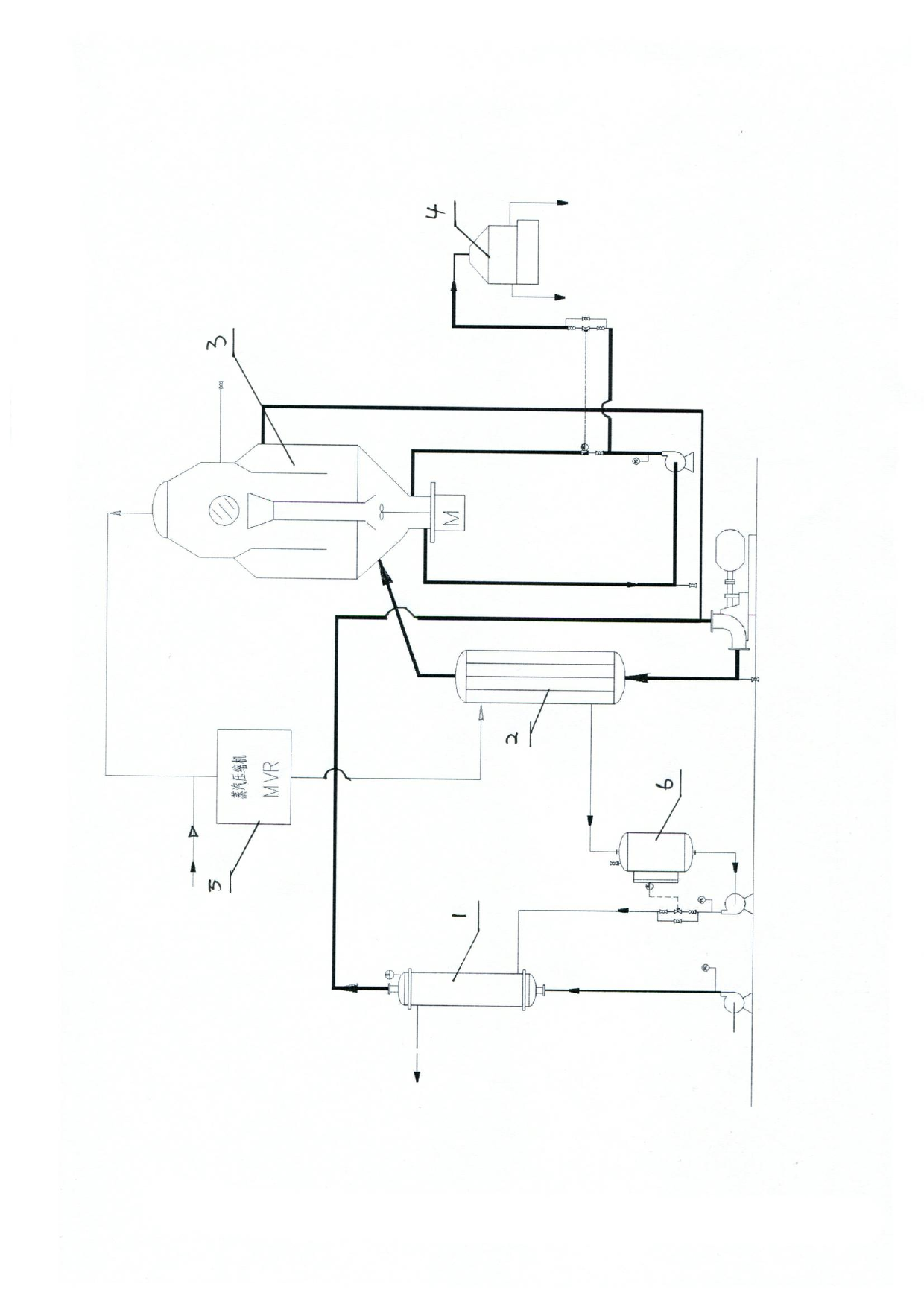

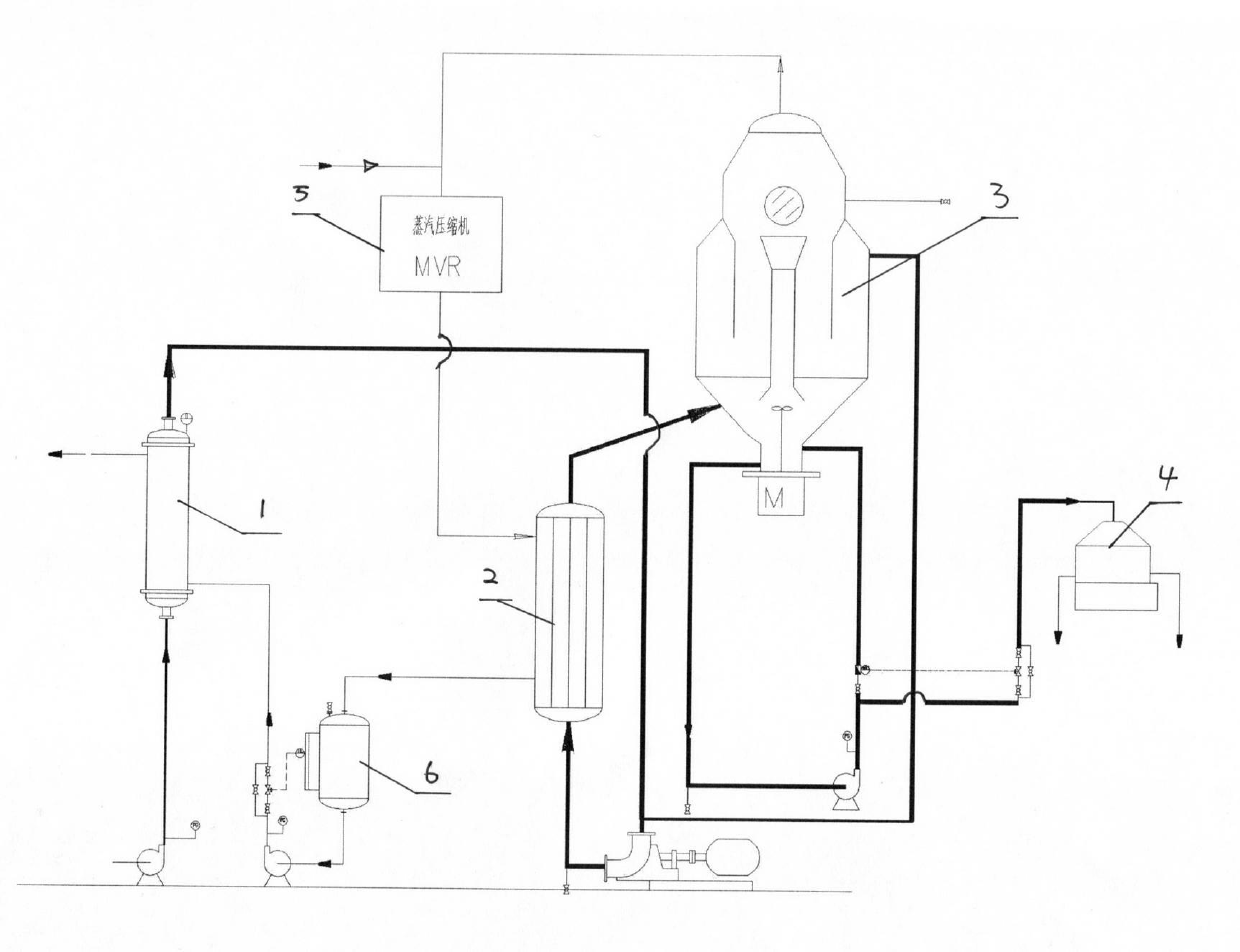

New energy-saving technology for producing edible potassium chloride

InactiveCN102167363AAccelerate evaporationEvenly distributedChemical industryAlkali metal halide purificationMagmaNew energy

The invention provides a new energy-saving technology for producing edible potassium chloride. The technology comprises the steps of: leading dissolved and decontaminated potassium chloride solution to enter a preheater for preheating; mixing mother liquor overflowed out of a DTB (draft tube) crystallizer with materials discharged out of the preheater, and transporting the mixture by a forced circulation pump to enter a heating evaporator; heating by the heating evaporator, and warming by absorbing the heat energy; and crystallizing in the DTB crystallizer; transporting magma to a centrifugal machine to separate by the transport of a magma pump so as to obtain a potassium chloride crystalloid; warming secondary vapor discharged out of the DTB crystallizer in a compressing way by a vapor compression machine, transporting the warmed secondary vapor into the heating evaporator to indirectly heat up the materials; and leading condensed water to enter a collector for preheating the preheater. The new energy-saving technology is stable and reliable in operation, large in crystallizing grain sizes, high in yield, and low in energy consumption.

Owner:LIANYUNGANG SHUREN KECHUANG FOOD ADDITIVE

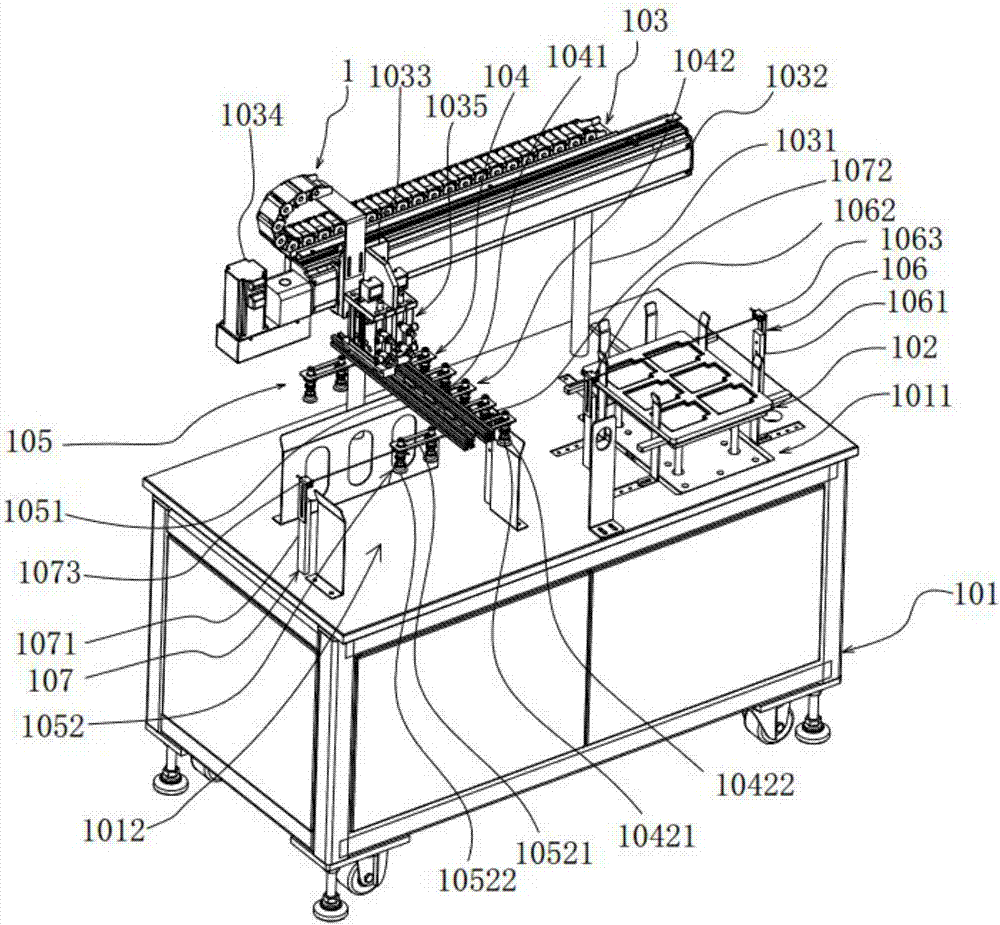

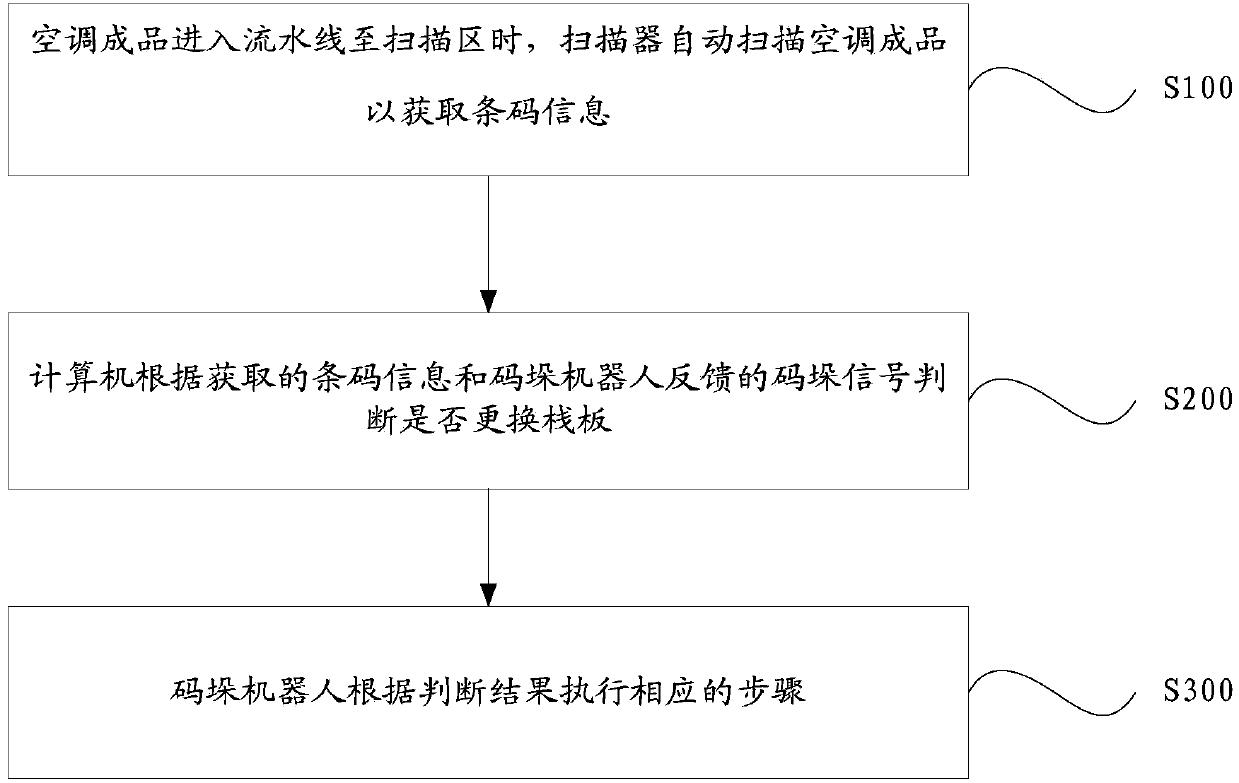

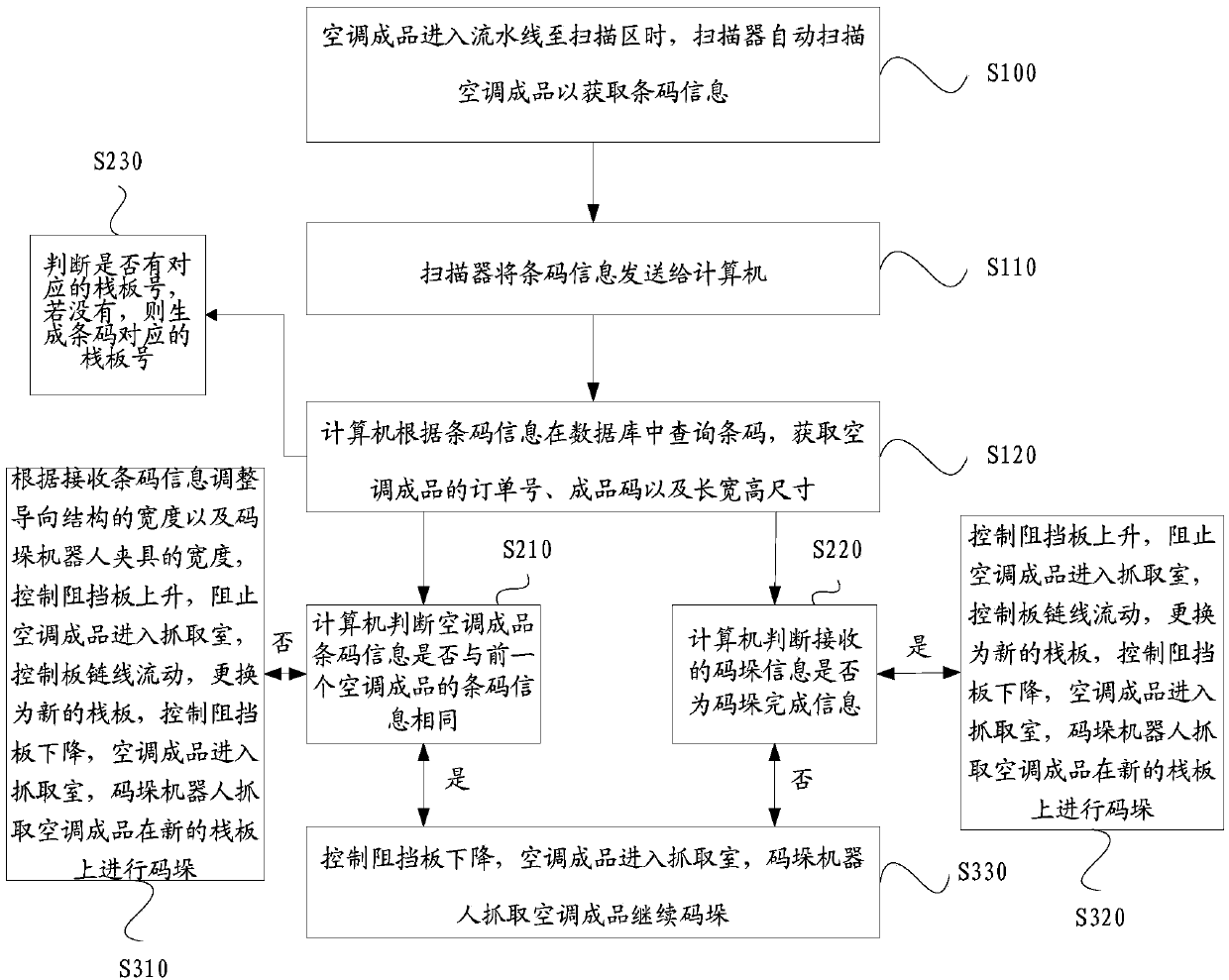

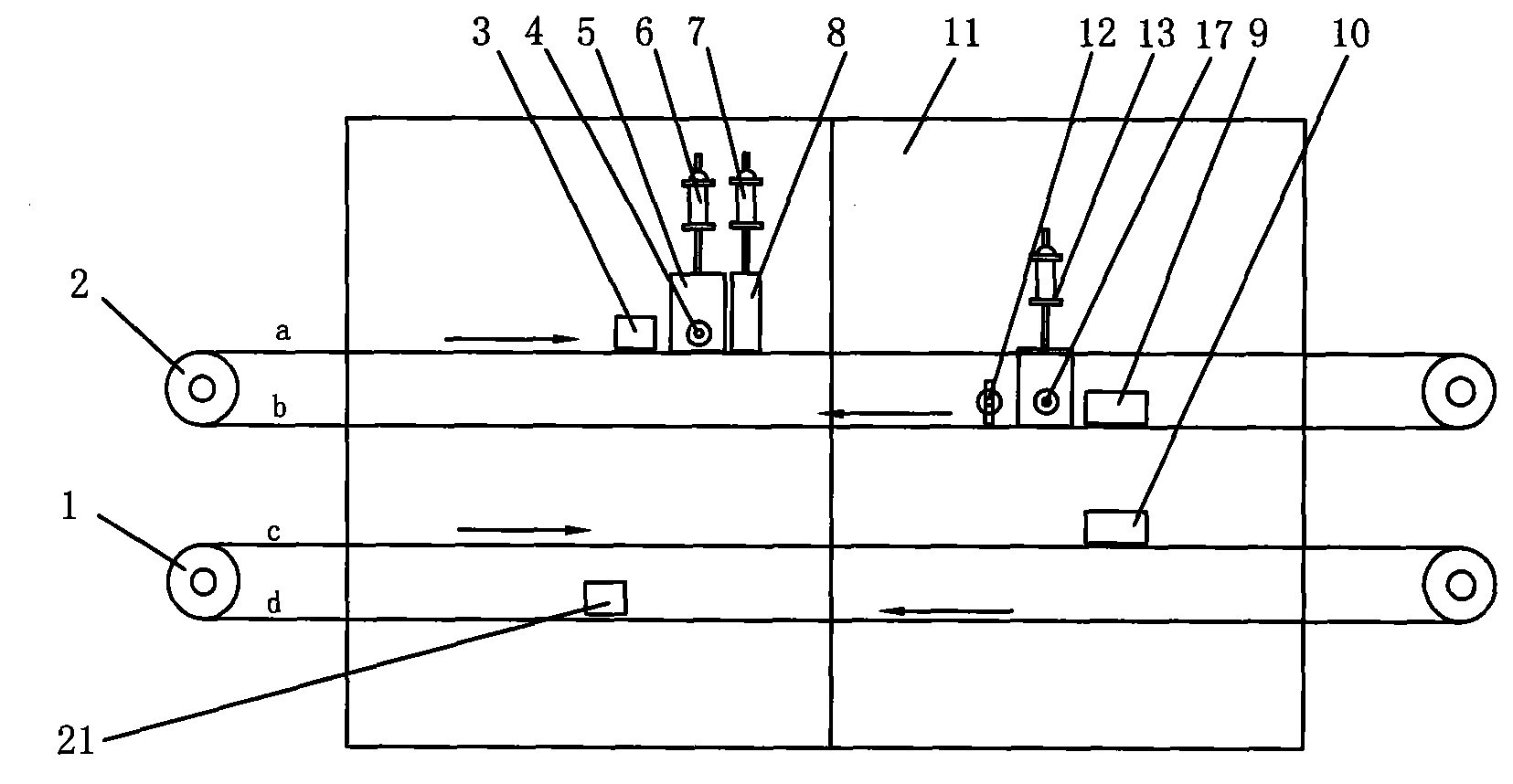

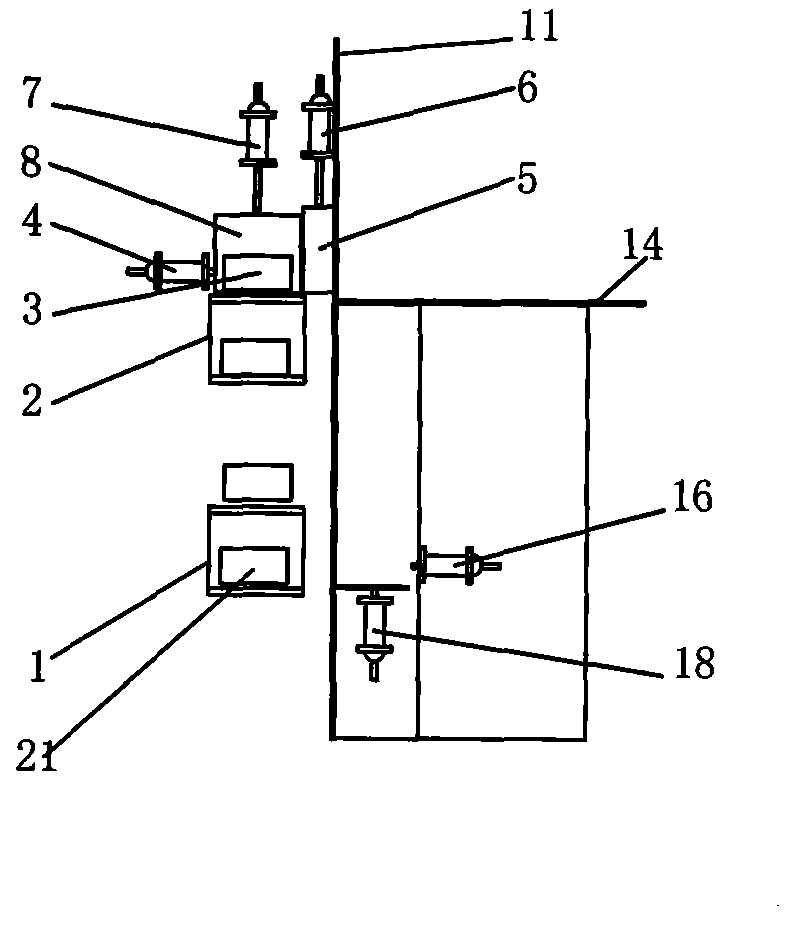

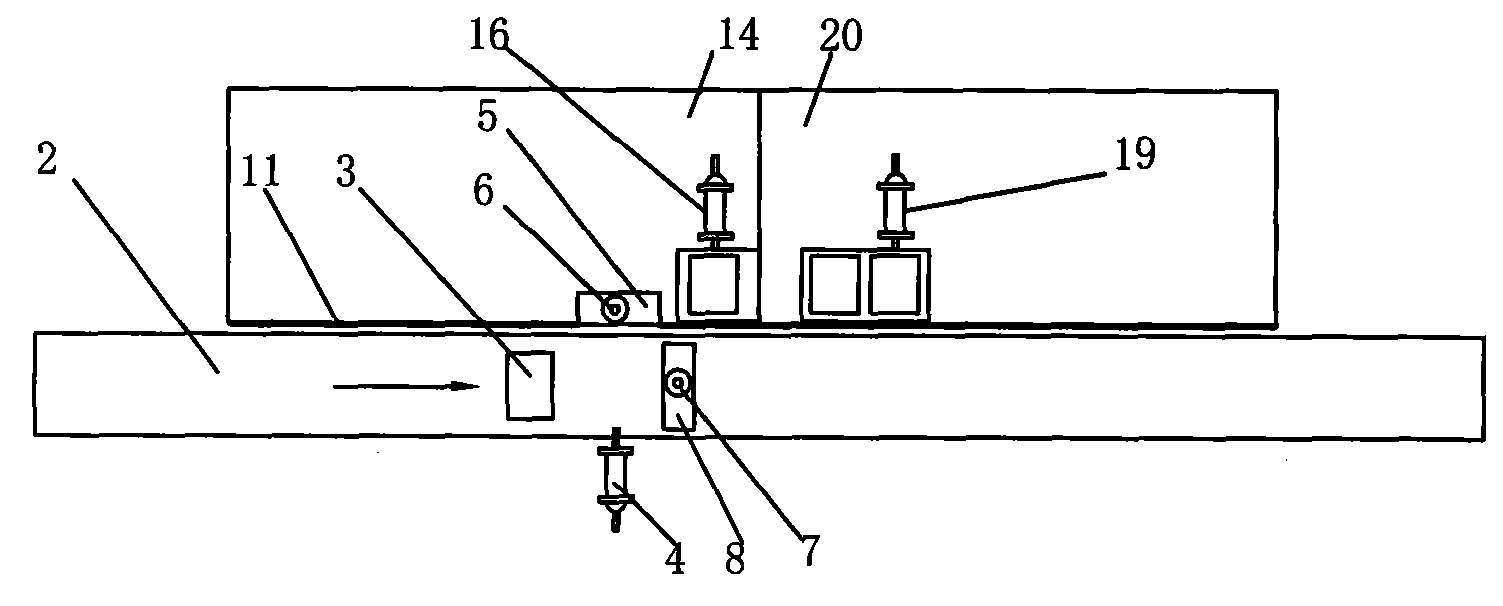

Full-automatic scanning stacking device and method thereof

ActiveCN104261032AReduce barcode scanning personnelReduce the number of operatorsStorage devicesElectricityEngineering

The invention provides a full-automatic scanning stacking device and a method thereof. The device comprises a stacking robot, a scanner, a stop plate, and a computer electrically connected with the scanner and the stacking robot, wherein the stop plate is arranged on a production line, is used for stopping an air conditioner finished product from entering a grabbing chamber, and is positioned between the scanner and the stacking robot; the grabbing chamber is positioned between the stop plate and the stacking robot; the stacking robot grabs the air conditioner finished product from the grabbing chamber; the scanner is used for scanning bar code information of the air conditioner finished product and sending to the electrically connected computer; and the stacking robot is used for stacking the air conditioner finished product grabbed from the grabbing chamber and returning generated stacking information to the computer. Compared with a traditional scanning stacking device, the full-automatic scanning stacking device has no need of manual operation to scan the bar code of the air conditioner finished product, and has no need of manual operation to operate the stacking robot, so that the manual cost is reduced, and the full automation of the scanning and stacking device is realized.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

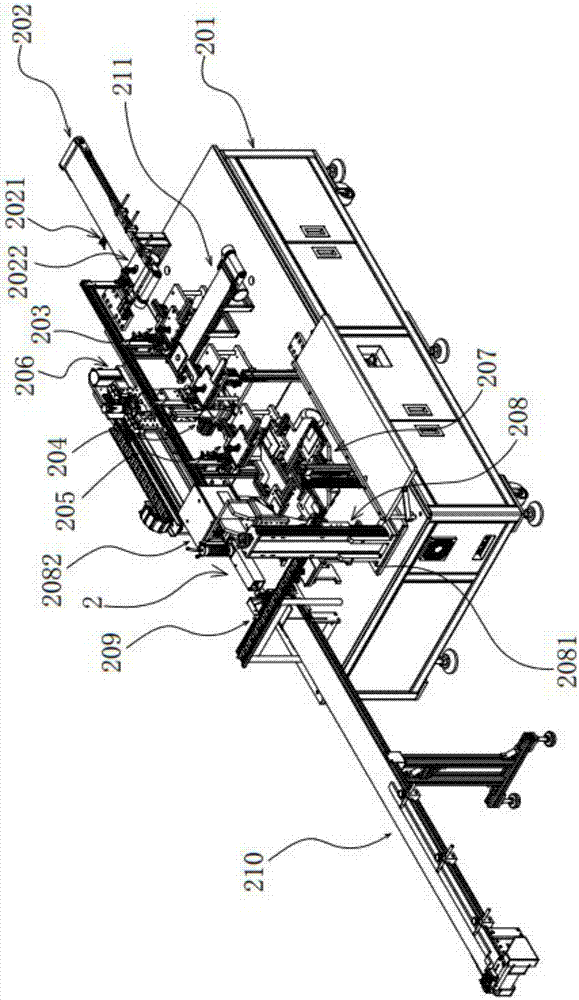

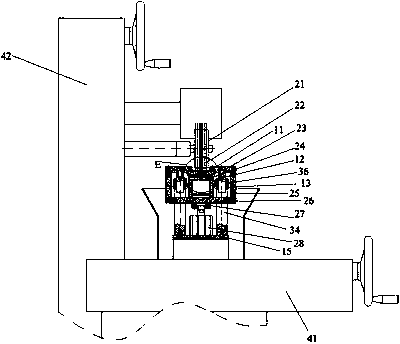

Coupling and middle chucking, conduction testing, encoding and die arraying device of detonator and automatic control method

InactiveCN103524280AIncrease productivityReduce the number of operatorsDetonatorsAutomatic controlEngineering

The invention provides a coupling and middle chucking, conduction testing, encoding and die arraying device of a detonator and an automatic control method and relates to the field of production of industrial explosive materials. According to the coupling and middle chucking, conduction testing, encoding and die arraying device, a protective board (11) is divided into a workpiece conveying mechanism and an operation station, wherein the workpiece conveying mechanism comprises a horizontal conveying device and a vertical conveying device; the operation station is a coupling and middle chucking station (14) and a conduction testing and die arraying station (20). The horizontal conveying device is provided with a coupling and middle chucking die splitting device and a conduction die splitting device; the coupling and middle chucking die splitting device is composed of a first port door (5), a cutting die plate (8) and a real die lateral pushing air cylinder (4); the conduction die splitting device is composed of a second port door (23), an empty encoding box die cutting air cylinder (22) and an empty encoding box lateral pushing air cylinder (12). The horizontal conveying device is used for automatically distributing and conveying a real die provided with the detonator and an empty encoding box on a belt conveyor to the operation station; the vertical conveying device is used for automatically conveying an empty die and a real encoding box back to the belt conveyor and intensive control is realized by a central processing unit; the coupling and middle chucking, conduction testing, encoding and die arraying device of the detonator has the positive effects of high efficiency, low cost and high safety guarantee coefficients.

Owner:王玉首

Positioning structure and positioning method for casting castings

InactiveCN104959552AAvoid typo problemsAvoid not in placeFoundry mouldsFoundry coresRisk strokeMaterials science

The invention discloses a positioning structure and a positioning method for casting castings, and belongs to the field of casting. Moulding flasks comprise an upper moulding flask and a lower moulding flask, wherein flask lugs are arranged on the moulding flasks; a pin bush or a positioning pin is arranged on each flask lug; dies comprise an upper die and a lower die; the upper die and the lower die are respectively arranged on base plates; positioning pins or pin bushes are arranged on the base plates of the dies; the pin bushes or positioning pins on the moulding flasks are matched with the corresponding positioning pins or pin bushes of the dies; long-stroke bolts are arranged on the moulding flasks; a positioning convex platform or positioning concave platform is arranged on each die. According to the positioning structure and the positioning method disclosed by the invention, the collision generated when the upper moulding flask and the lower moulding flask are closed, waste and defective products caused by shakeout and excessive metal, and the castings shift caused by flask deviation after the collision of the moulding flasks are avoided, the condition that the closing of the moulding flasks is influenced by flask packing of flask lumps is eliminated, the casting failure phenomenon caused by casting runout is avoided, the labor cost is reduced, and the rate of finished products is improved.

Owner:刘天平

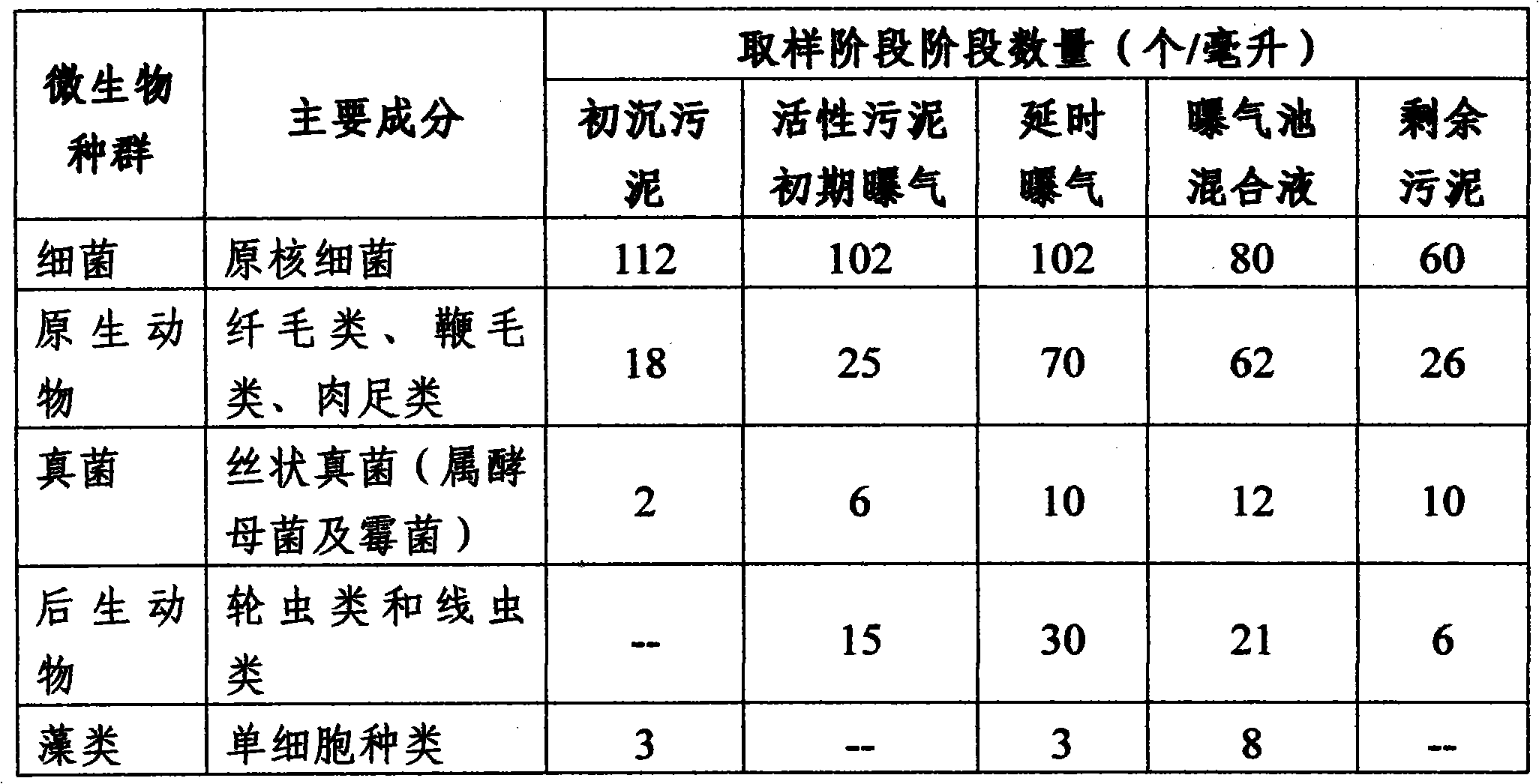

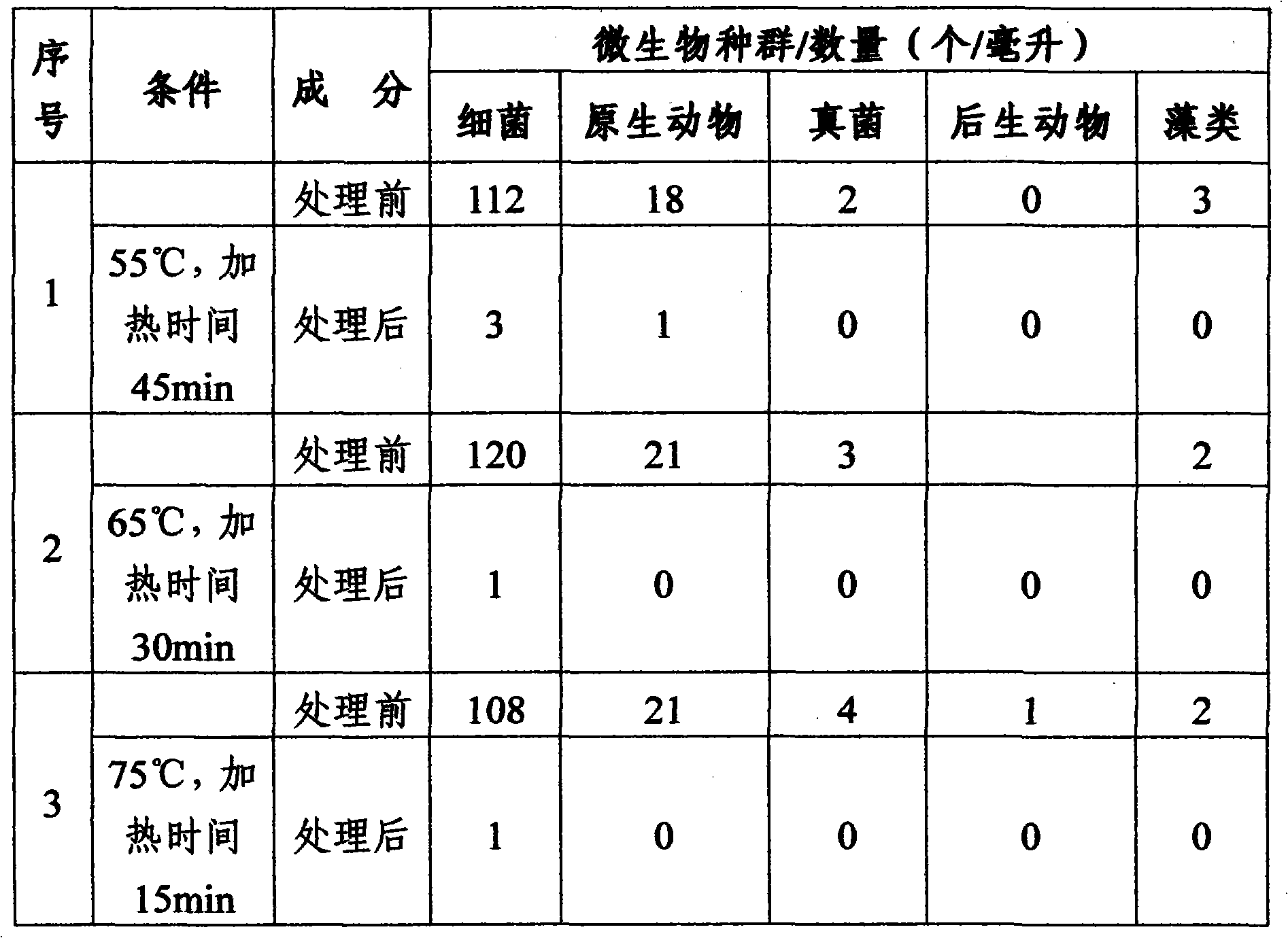

Method for effective sterilization and efficient hydration of primary sludge

InactiveCN101962255AEffective sterilizationEfficient dehydrationSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationMicrowaveFiltration

The invention discloses a method for effective sterilization and efficient hydration of primary sludge, which comprises the following steps of: (1) primary sludge acidifying treatment for preparing slurry; (2) microwave heating sterilization: heating the slurry to between 30 and 90 DEG C; (3) mechanical filtration: performing solid-liquid separation on the microwave heated slurry, and washing the solid by using water to obtain dry sludge residue and new slurry; and (4) adjusting pH value of the new slurry to be between 6.0 and 8.5 by using lime, wherein the new slurry can be used as circulating water for sludge acidification for preparing the slurry and separation and washing of the mechanical filtration, and the rest recycled partial new slurry can be returned to a sewage treatment system of a sewage treatment plant. The method realizes direct effective sterilization and efficient hydration of the primary sludge generated by the sewage treatment plant without the processes of secondary deposition, concentration, digestion and the like, and can save a large amount of operating cost.

Owner:CHANGSHA JIEXIANG ENVIRONMENTAL ENG

Boxed product automatic packaging device and boxed product automatic packaging production process

PendingCN109533487AReduce labor intensityReduce the number of operatorsWrapper twisting/gatheringPackaging automatic controlCartonManufacturing line

The invention provides a boxed product automatic packaging device. The device includes an automatic boxing packaging line and an automatic cartonning packing line. The automatic boxing packaging lineand the automatic cartonning packing line are connected to each other through a first conveyor belt. The automatic boxing packaging line includes a box opening machine, an object placement platform, afirst streamline, a tool tray, a boxing robot, a box sealing machine and a corner labeling machine. The automatic cartonning packing line includes a cartonning opening machine, a second streamline, acartonning machine, a packaging carton labeling machine and a code spraying machine. The invention also provides a boxed product automatic packaging production process. The process takes packaging boxes on the tool tray as the core, uses the machines to package products into the packaging boxes in order in the automatic boxing packaging line to complete a box sealing process, and enters the automatic cartonning packaging line to seal a plurality of boxed products into a transport packaging carton to complete the automatic packaging process. The boxed product automatic packaging device and theboxed product automatic packaging production process reduce the number of production line operators by means of automation and informatization and greatly improves the packaging efficiency.

Owner:SHENZHEN XINGDA ELECTRONICS

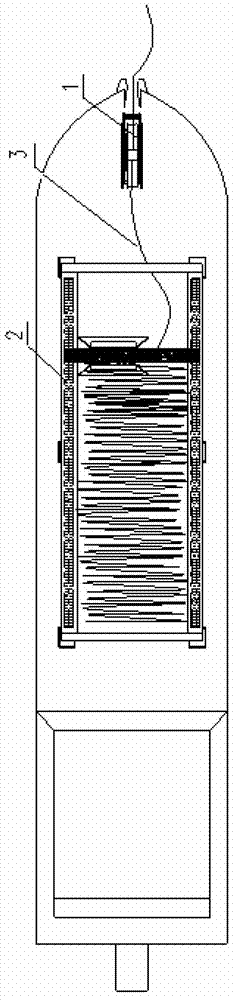

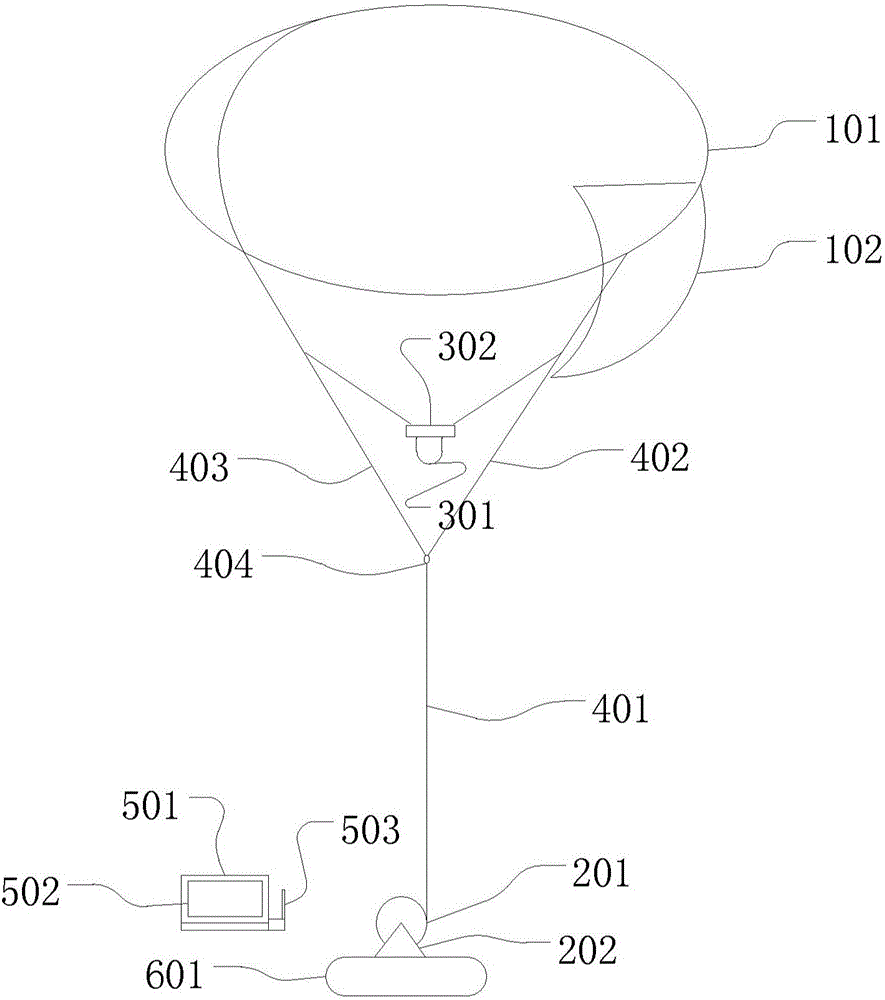

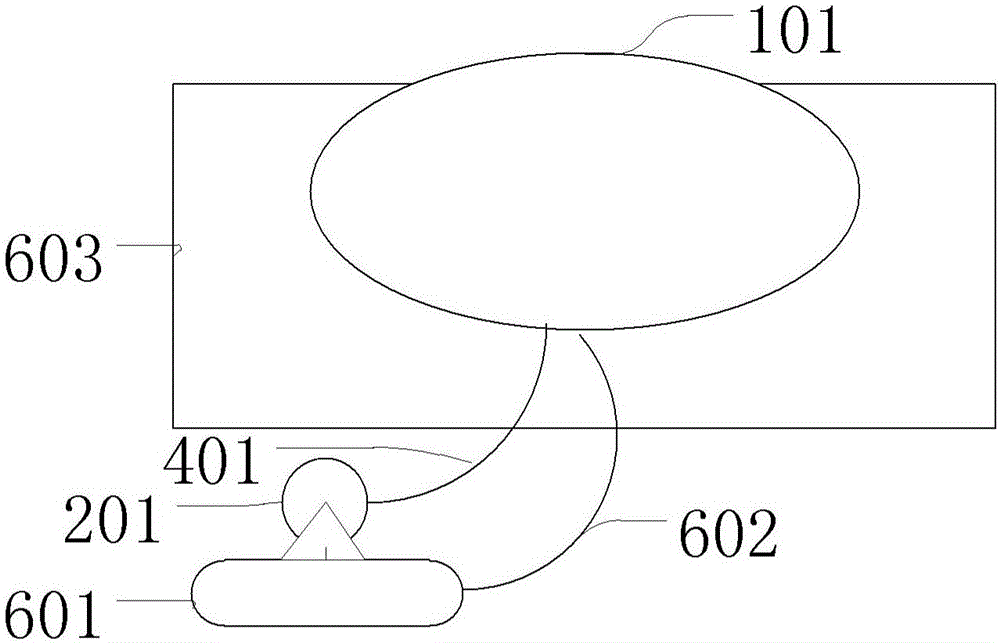

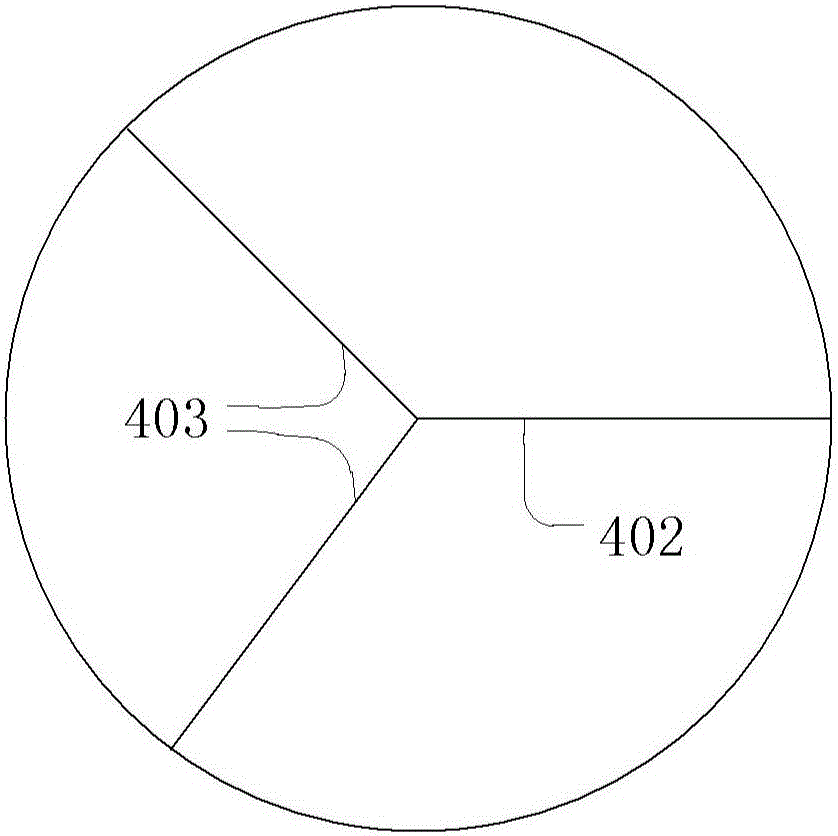

Subminiature tethered balloon system

ActiveCN106275363ASimple and efficient operationReduce the number of operatorsBalloon aircraftsGas-bag arrangementsBody systemMedicine

The invention discloses a subminiature tethered balloon system and relates to the field of tethered balloons. The system comprises a balloon body system, a winch system, an inflation system, a ground control and receiving system, a mooring rope system, a loading system and a containing and carrying system. A balloon body in the balloon body system is a flat round rotary balloon body, the wind-resistant effect is good, stability is good, winding and unwinding are convenient, and occupied space is small. A power system in the winch system is a winding and unwinding manual rocker or a winding and unwinding motor, and is convenient to carry. The subminiature tethered balloon system is easy and convenient to operate, the number of operators in need is small, quick deployment can be achieved, and the tethered balloon system is flexible. Requirements of sites are low, and the tethered balloon system can be unfolded and released in cities, countryside or remote areas.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

Double-flanged PP honeycomb plate luggage case spare cover plate and its production method

ActiveCN104385764AGuaranteed firmnessReduce the number of operatorsSynthetic resin layered productsLaminationFlangingWork in process

The invention discloses a double-flanged PP honeycomb plate luggage case spare cover plate and its production method. The spare cover plate is formed through compounding and flanging bonding of a skeleton layer (2), and a surface layer nonwoven fabric (1) and a back layer nonwoven fabric (3) which are compounded to the surfaces of the skeleton layer, the surface layer nonwoven fabric (1) and the back layer nonwoven fabric (3) are bonded in a double flanging compounding manner, the skeleton layer (2) is a PP honeycomb plate, and the surface layer nonwoven fabric (1) and the back layer nonwoven fabric (3) are nonwoven fabrics compounded with hot melt adhesive powder which can be easily bonded with a PP material respectively; and the back layer nonwoven fabric (3) at the back of the skeleton layer (2) is provided with a shock pad (4). The production method sequentially comprises the following steps: skeleton layer punching, heating compounding flanging, cooling fixing, semi-finished product punching and finished product production. The nonwoven fabric is compounded with back layer of the PP honeycomb plate and is bonded with the surface layer nonwoven fabric in a double flanging manner, so the strength and the rigidity of the cover plate are increased, the weight of the cover plate and the whole car noises are reduced, and the requirements of the car industry on light weight, environmental protection and beauty are met.

Owner:YANTAI ZHENGHAI HIGH TECH

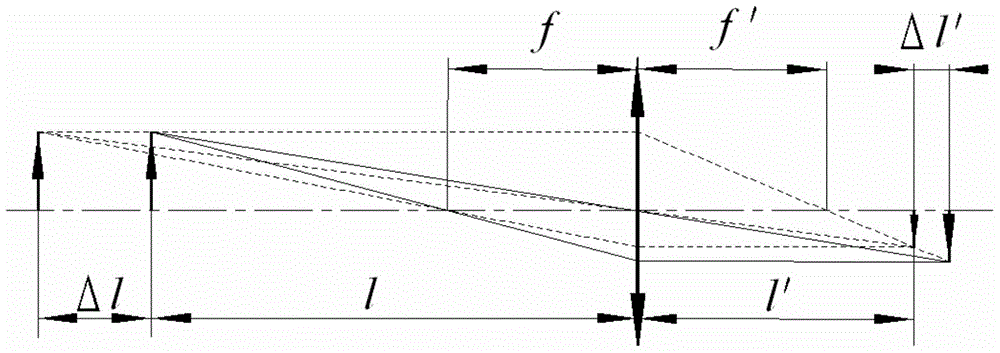

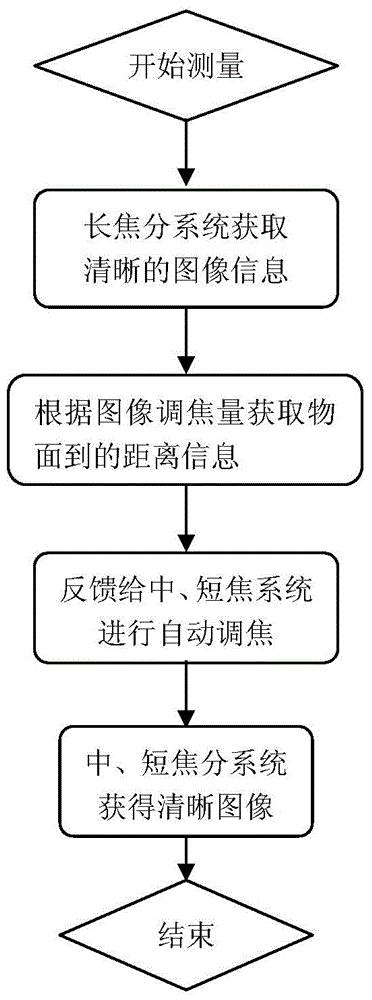

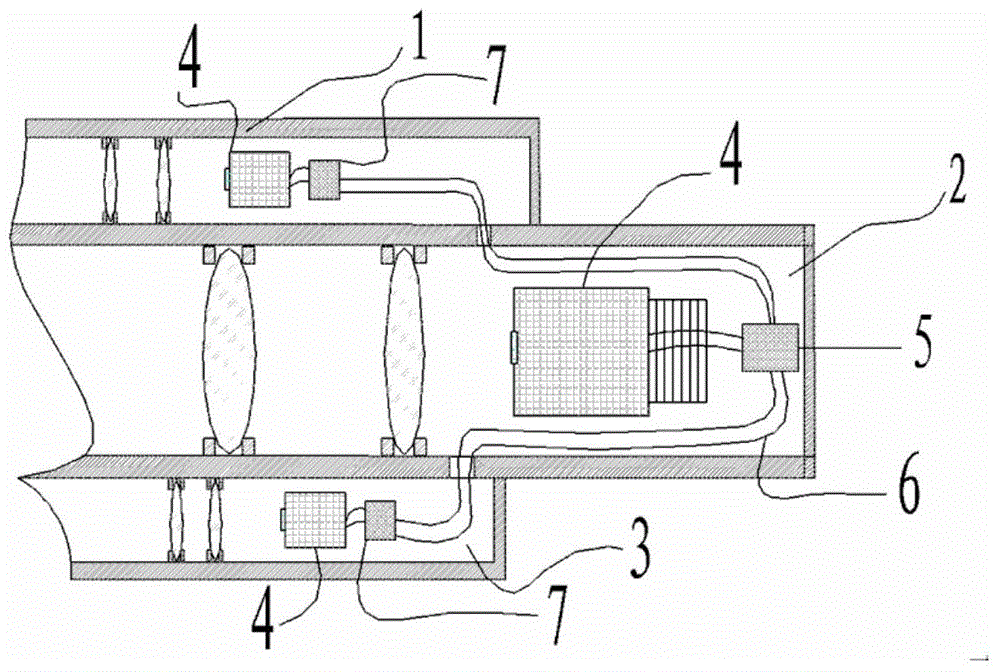

Multi-detector optical system linkage focusing mechanism and focusing method thereof

ActiveCN103605198ALow Error FocusingReduce the number of operatorsMountingsMaterial resourcesMulti detector

The invention provides a multi-detector optical system linkage focusing mechanism and a focusing method thereof. The multi-detector optical system linkage focusing mechanism comprises a medium focal length optical sub-system, a long focal length optical sub-system, a short focal length optical sub-system, detectors, an object plane distance calculating unit, a reactive circuit, position control units, a position measuring unit, a focusing unit and a detector mobile module, wherein there are three detectors which are respectively connected with the medium focal length optical sub-system, the long focal length optical sub-system and the short focal length optical sub-system; the object plane distance calculating unit is connected with the reactive circuit; and the object plane distance calculating unit is connected with the medium focal length optical sub-system, the long focal length optical sub-system and the short focal length optical sub-system. According to the invention, the multi-detector optical system linkage focusing mechanism has the advantages of simple control, high focusing precision, lightness, convenience, substantially reduced waste of labor and material resources, and the like.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Automatic welding and tape adhering integral machine for car plate

ActiveCN104924076AAchieve positioningAchieve sharingOther manufacturing equipments/toolsTectorial membraneEngineering

The invention discloses an automatic welding and tape adhering integral machine for a car plate. The machine comprises a rack, and an indexable assembling workbench arranged on the rack; a rotating plate connected with a stepping rotating mechanism is arranged on the workbench; a first station for feeding material, a second station for welding, a third station for coating a first coat, a fourth station for drying, a fifth station for adhering a tape, and a sixth station for adhering a protecting film and discharging finished products are sequentially arranged on the rotating plate; a positioning base for positioning the plate is arranged on each station, corresponding to the workbench; each station is controlled by a controller. The machine is simple in structural design, convenient to manufacture, and small in cost; the production efficiency and product quality are greatly increased; the market demand is adapted; the practicability is high; in addition, the unnecessary transfer is reduced, and thus the product can be prevented from being scratched due to transfer.

Owner:NINGBO ZHONGJUN SHANGYUAN AUTO PARTS

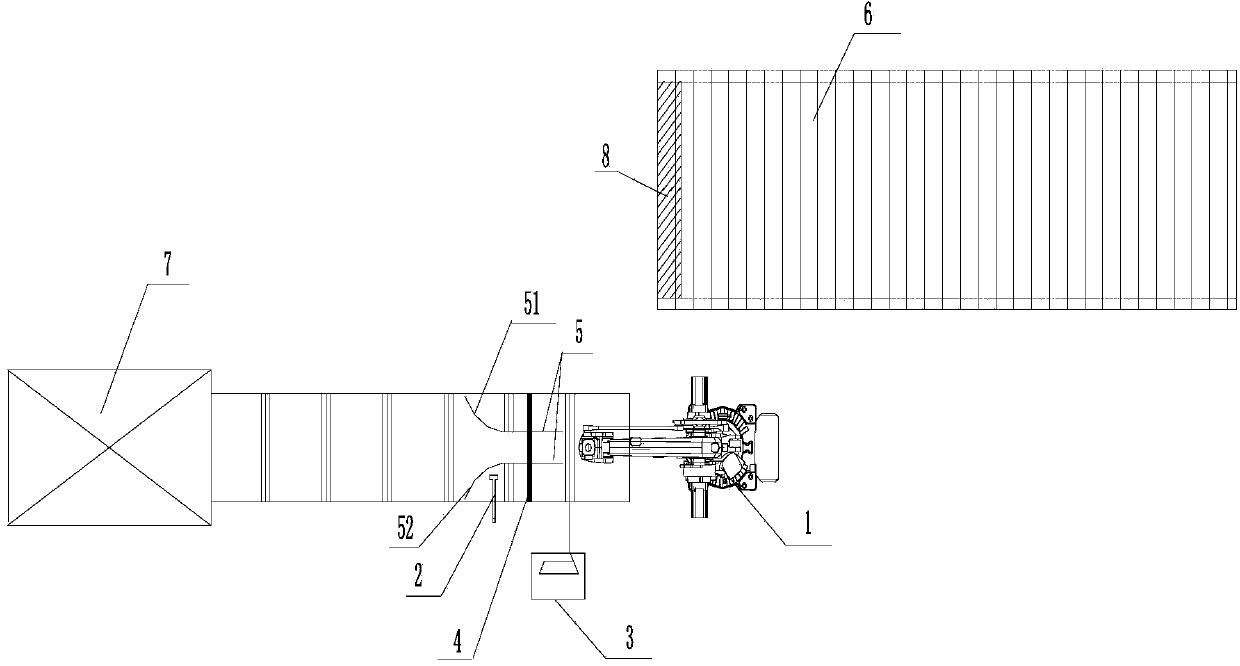

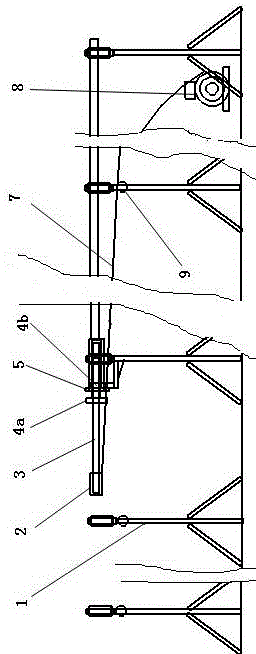

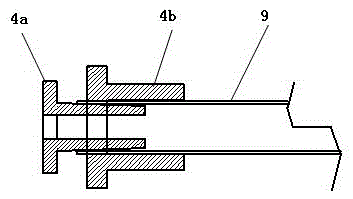

Sleeving equipment and sleeving method of profile steel and thermal shrinkage corrosion resisting jacket

ActiveCN105643254AGuaranteed packaging qualityEasy to fixMetal working apparatusMaterials scienceTractor

The invention discloses sleeving equipment and a sleeving method of profile steel and a thermal shrinkage corrosion resisting jacket, and belongs to the field of corrosion resistance. The sleeving equipment comprises inner and outer layers of clamping pipes for clamping and fixing a jacket opening of the thermal shrinkage corrosion resisting jacket, multiple Y-shaped brackets for supporting the profile steel or the thermal shrinkage corrosion resisting jacket, and a tractor for towing the profile steel to move; the tractor is used for pulling theprofile steel to insert in a pipe port of an inner-layer clamping pipe in the inner and outer layers of clamping pipes for clamping the thermal shrinkage corrosion resisting jacket; then, a heat source is used for heating the thermal shrinkage corrosion resisting jacket; and the thermal shrinkage corrosion resisting jacket tightly wraps the profile steel. According to the sleeving equipment,operators can be liberatedfrom highlabor intensity, the sleeving speed of the profile steel and the thermal shrinkage corrosion resisting jacketcan be accelerated, andthe sleeving quality of the thermal shrinkage corrosion resisting jacket and the production safety can be guaranteed.

Owner:ANYANG LONGTENG SPECIAL STEEL MFG

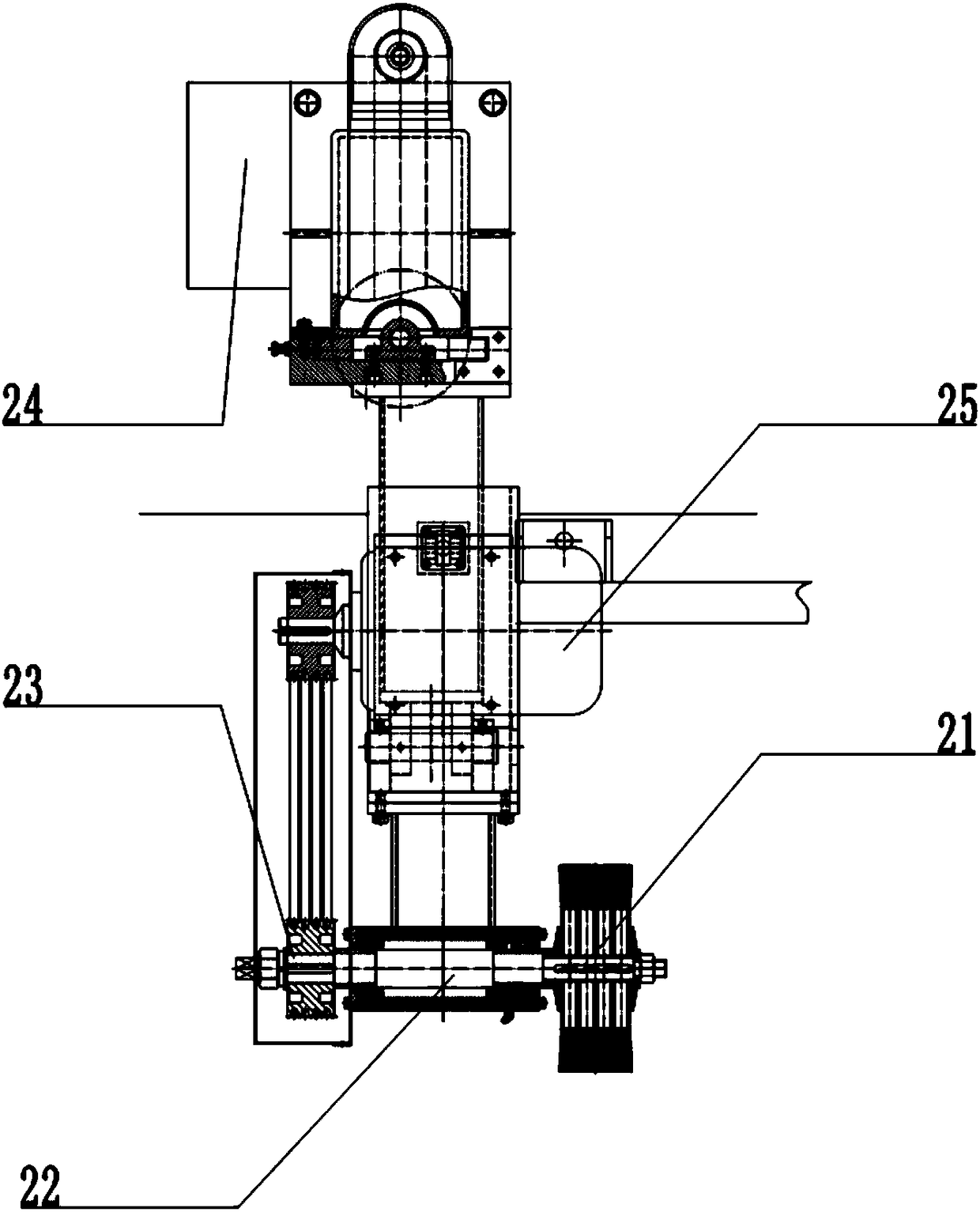

All-in-one machine for polymer lithium battery with functions of formation and capacity grading

PendingCN106129449AGood process continuityGood effectAssembling battery machinesFinal product manufactureCell assemblyManipulator

The invention discloses an all-in-one machine for a polymer lithium battery with functions of formation and capacity grading. The all-in-one machine comprises a cell assembly line, wherein a cell elastic clamp which is fully loaded with cells; a formation and capacity-grading apparatus is arranged on one side of the cell assembly line; the formation and capacity-grading apparatus comprises a material-feeding mechanical arm bracket and a material-discharging mechanical arm bracket; a material-feeding material-waiting frame, a material-discharging material-waiting frame, a group of formation clamps and multiple capacity-grading clamps are arranged in the material-feeding mechanical arm bracket and the material-discharging mechanical arm bracket; the material-feeding material-waiting frame, the material-discharging material-waiting frame, the group of formation clamps and the multiple capacity-grading clamps are arranged in sequence from one side to the other side; a material-feeding mechanism and a material-discharging mechanism are arranged between the material-feeding material-waiting frame and the cell assembly line; the material-feeding mechanism and the material-discharging mechanism are positioned on the front and back sides respectively; and material-moving mechanical arms are arranged on the material-feeding mechanical arm bracket and the material-discharging mechanical arm bracket. The all-in-one machine for the polymer lithium battery with the functions of formation and capacity grading has the advantages of high continuity of capacity-grading processes, high degree of automation, high efficiency, good formation effect, high product quality and the like.

Owner:东莞德方智能装备中心(有限合伙)

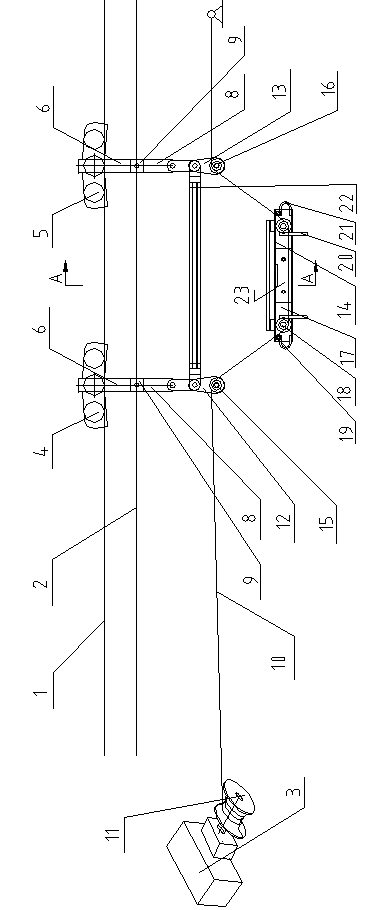

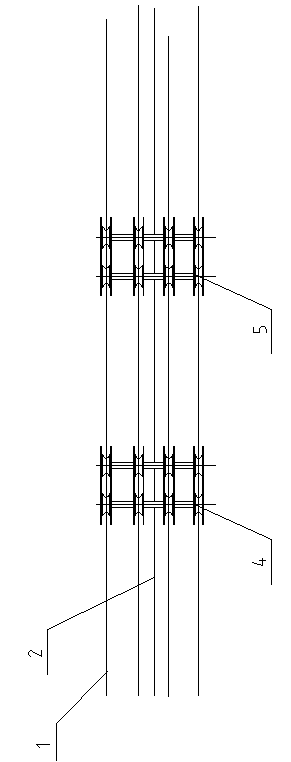

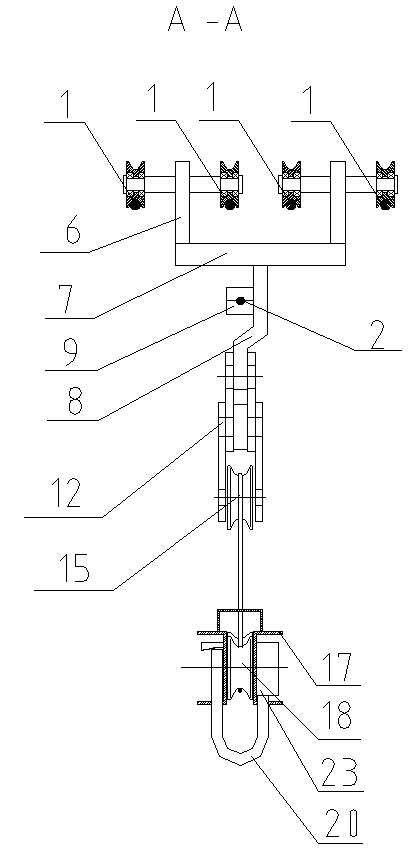

Self-lifting type cableway transporting device

ActiveCN103274310ARealize self-loading and unloadingReduce rental feeCable carsEngineeringCable transport

The invention relates to a self-lifting type cableway transporting device, and belongs to the field of conveying machinery. The self-lifting type cableway transporting device comprises a plurality of bearing steel cables arranged horizontally, a traction steel cable arranged below the bearing steel cables, traveling pulley blocks and a self-lifting device. According to the self-lifting type cableway transporting device, the self-lifting device is arranged, automatic loading and unloading during cableway transportation are achieved, the construction security and the working efficiency are improved, the number of operators is reduced, and lease charges of large scale equipment are decreased; and the transportation problem that large-scale high spare hoisting equipment cannot reach a cableway starting point is solved.

Owner:YANGZHOU ZHENDONG POWER DEVICES & TOOLS

Sleeve grooving machine and sleeve grooving method thereof

ActiveCN103862345AReduce manual labor intensityReduce the number of operatorsGrinding drivesGrinding machinesBatch productionEngineering

The invention discloses a sleeve grooving machine which comprises a cutting machine tool main body, a cutting supporting frame body, a feeding mechanism, a conveying belt driving mechanism, a conveying belt, a feeding distributing mechanism and a sleeve fixing mechanism. The cutting machine tool main body comprises a bed, a grinding wheel bracket and a working table; the grinding wheel bracket is provided with a grinding wheel and a grinding wheel driving mechanism; the conveying belt and the working table are arranged in parallel; the conveying belt driving mechanism is connected with the conveying belt; the feeding mechanism is connected to the initial end of the conveying belt; the feeding mechanism, the feeding distributing mechanism and the sleeve fixing mechanism are sequentially arranged along the conveying direction of the conveying belt; and the sleeve fixing mechanism is arranged below the grinding wheel and above the conveying belt. The invention also discloses a sleeve grooving method of the sleeve grooving machine. When the sleeve grooving machine and the sleeve grooving method thereof are adopted, manual operation does not need to be carried out, labor intensity of workers is reduced, and the number of operators can be reduced in the batch production; and moreover, automatic production can be implemented, production efficiency is improved and production cost is reduced.

Owner:CHAOZHOU THREE CIRCLE GRP +1

Red copper threading pipe connector producing method

A technology for manufacturing screwed red copper tube as jointer includes such steps as choosing high-purity (99%) thick-wall red copper tube, cutting short by 5-30 cm, cold die pressing to obtain semi-finished products, and machining. Its advantages are high quality and productivity, and low energy consumption and environmental pollution.

Owner:李康宁

Centerless excircle abrasive belt grinder integrated with slender rod containing stepped square shaft and multiple grinding heads

ActiveCN108356663ARealize automatic processingImprove consistencyRevolution surface grinding machinesBelt grinding machinesWorking environmentEngineering

The invention discloses a centerless excircle abrasive belt grinder integrated with a slender rod containing a stepped square shaft and multiple grinding heads. The centerless excircle abrasive belt grinder comprises an automatic feeding and discharging mechanism, the special centerless excircle abrasive belt grinding heads, a special excircle grinding wire brush and an automatic conveying mechanism. A grinding machine tool can realize the full automatic processing of the slender shaft containing steps, and the rough machining, semi-finish machining, finish machining and polishing processes ofworkpieces can be completed in the one-time processing process; and the surface quality of processing is good, the processing efficiency is higher than that of manual grinding, and the working environment of workers is effectively improved.

Owner:CHONGQING UNIV +1

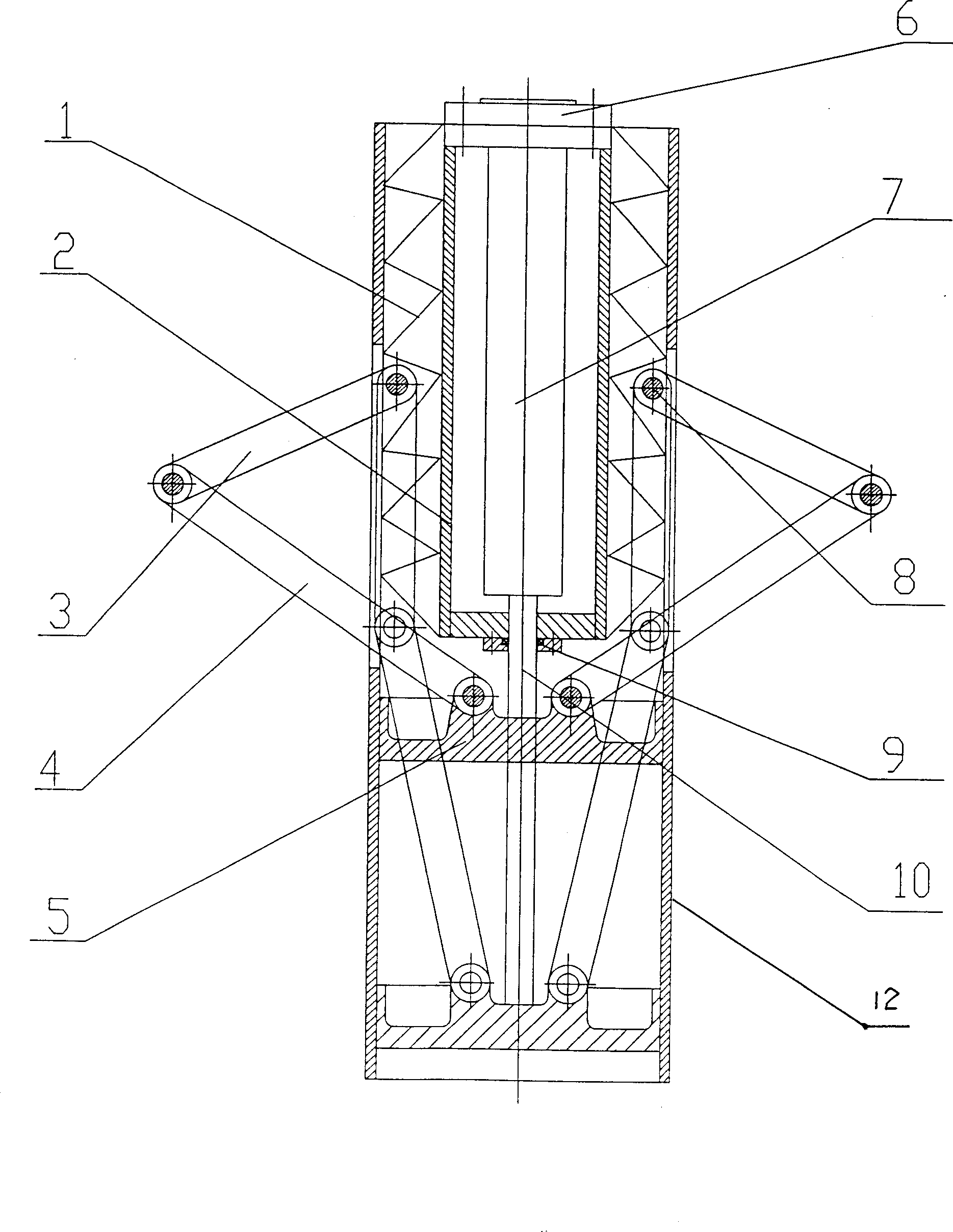

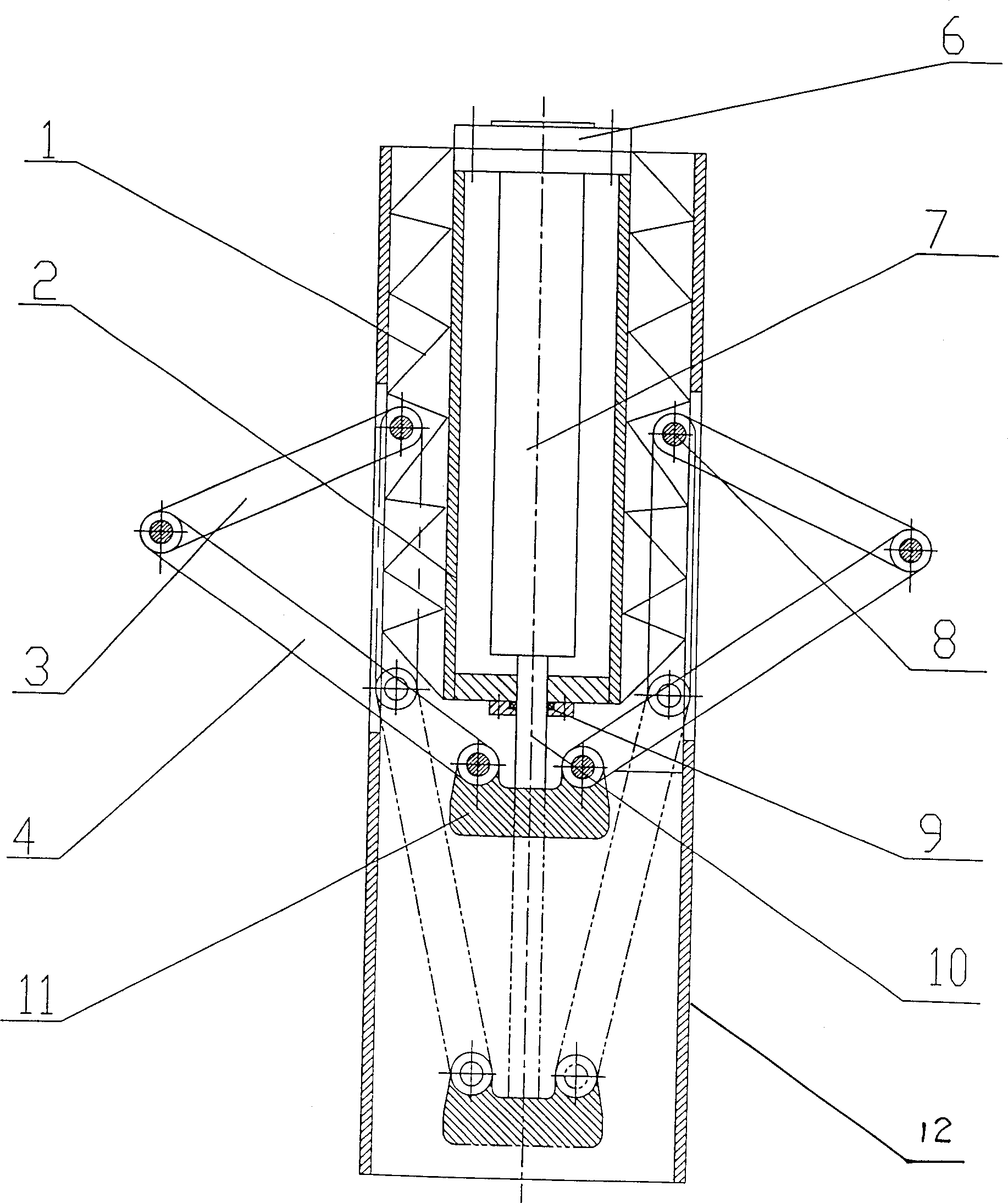

Tunnel two-lining concrete pouring system

PendingCN109630159AMeet construction needsSolve the lack of compactness of concreteUnderground chambersTunnel liningEngineeringElectromagnetic valve

The invention relates to a tunnel two-lining concrete pouring system which comprises a flow monitoring device, a molding temperature monitoring device, a pressure visualization soft lapping device, aplurality of high-frequency pneumatic vibrators (12), a gas compressor (13), and an electric cabinet (40), wherein a three-dimensional laser scanner of the flow monitoring device and a flow sensor (1)are all connected with the electric cabinet (40), a temperature sensor (5) of the molding temperature monitoring device is arranged on a back surface of a tunnel two-lining trolley steel molding plate (3), the temperature sensor (5) is connected with the electric cabinet (40), the pressure visualization soft lapping device comprises a rubber plate (6), the rubber plate (6) is additionally arranged at the bottom of a lapping plate (8), a pressure sensing chip (9) is arranged on the rubber plate (6), the pressure sensing chip (9) is connected with the electric cabinet (40), the high-frequency pneumatic vibrators (12) are arranged on the back surface of the two-lining trolley steel molding plate (3), a shunt pipe (14) is provided with a pneumatic switch electromagnetic valve (16), and the gas compressor (13) is connected with the electric cabinet (40). By the adoption of the tunnel two-lining concrete pouring system, automation of two-lining concrete pouring is achieved.

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY 11 BUREAU GRP +1

Movable charging battery chemical synthesizing method synthesizer

InactiveCN101030654AReduce the number of operatorsIncrease productivityFinal product manufactureSecondary cells manufactureEngineeringForming processes

The invention is concerned with moving forming process and equipment to rechargeable batteries. Move some equipment for filling or discharging on the scheduled orbit and set tasks for installation and selection of battery along the moving route. When the equipment for filling or discharging moves at the task for selection of battery, it will select and remove the battery then the equipment continue to move. So it needs a small quantity of people at task by setting tasks for installation and selection of battery along the moving route. It enhances the production efficiency and is fit for quality management to battery.

Owner:江门市朗达集团有限公司

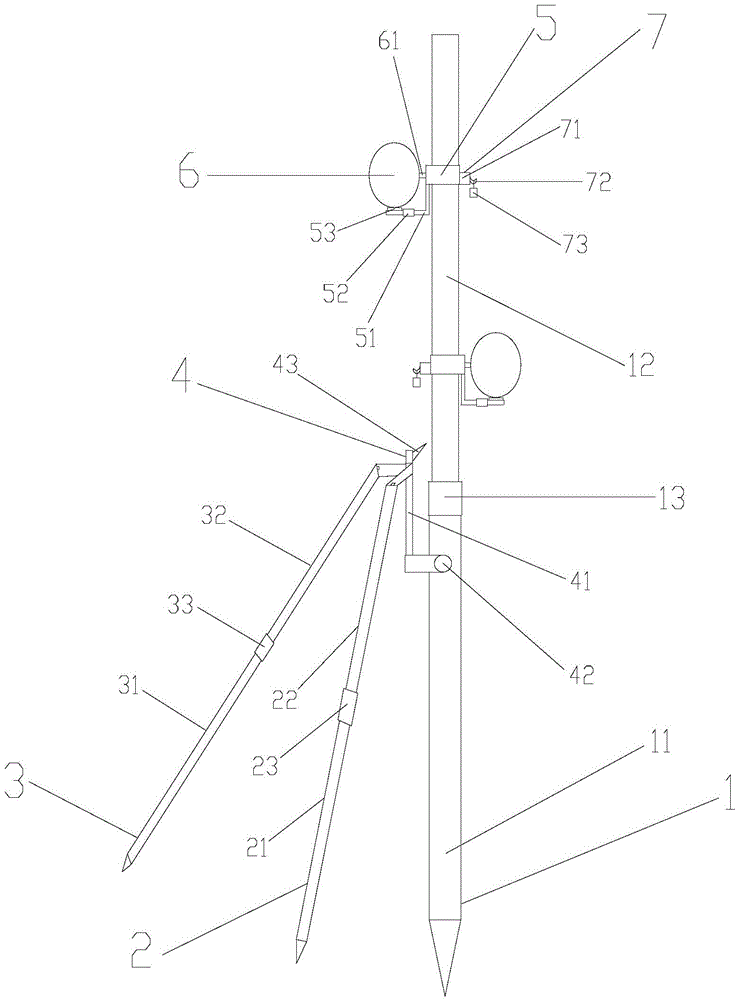

Prism centering rod

InactiveCN104061919AMultiple mapping resultsComprehensive surveying and mapping dataSurveying instrumentsPrismEngineering

The invention discloses a prism centering rod which comprises a centering rod and two support rods, wherein the centering rod and the support rod all comprise an outer tube and a telescopic inner tube which is inserted into the outer tube; the outer tube and the inner tube are fixed through handheld type locking pieces; the support rods are connected with the outer tube of the centering rod through a connecting component and have the function of supporting the centering rod; the inner tube of the centering rod is at least sleeved by one connecting sleeve; a support rack for supporting a prism detection piece is arranged at one end of the connecting sleeve; a balance counterweight component is arranged at the other end of the connecting sleeve. The prism centering rod disclosed by the invention has the advantages of simple structure, convenience in operation, high universality and solidness and reliability, not only is simultaneous plotting operation of multiple items of different heights at one same plotting point achieved, but also plotting on different adjacent plotting points of different heights in different directions within certain range that the centering rod is taken as the circle center can be achieved, the time and the labor are saved, the number of operators is reduced, the working efficiency is high, and the plotting result is precise and accurate.

Owner:SUZHOU HUALAI PHOTOELECTRIC INSTR

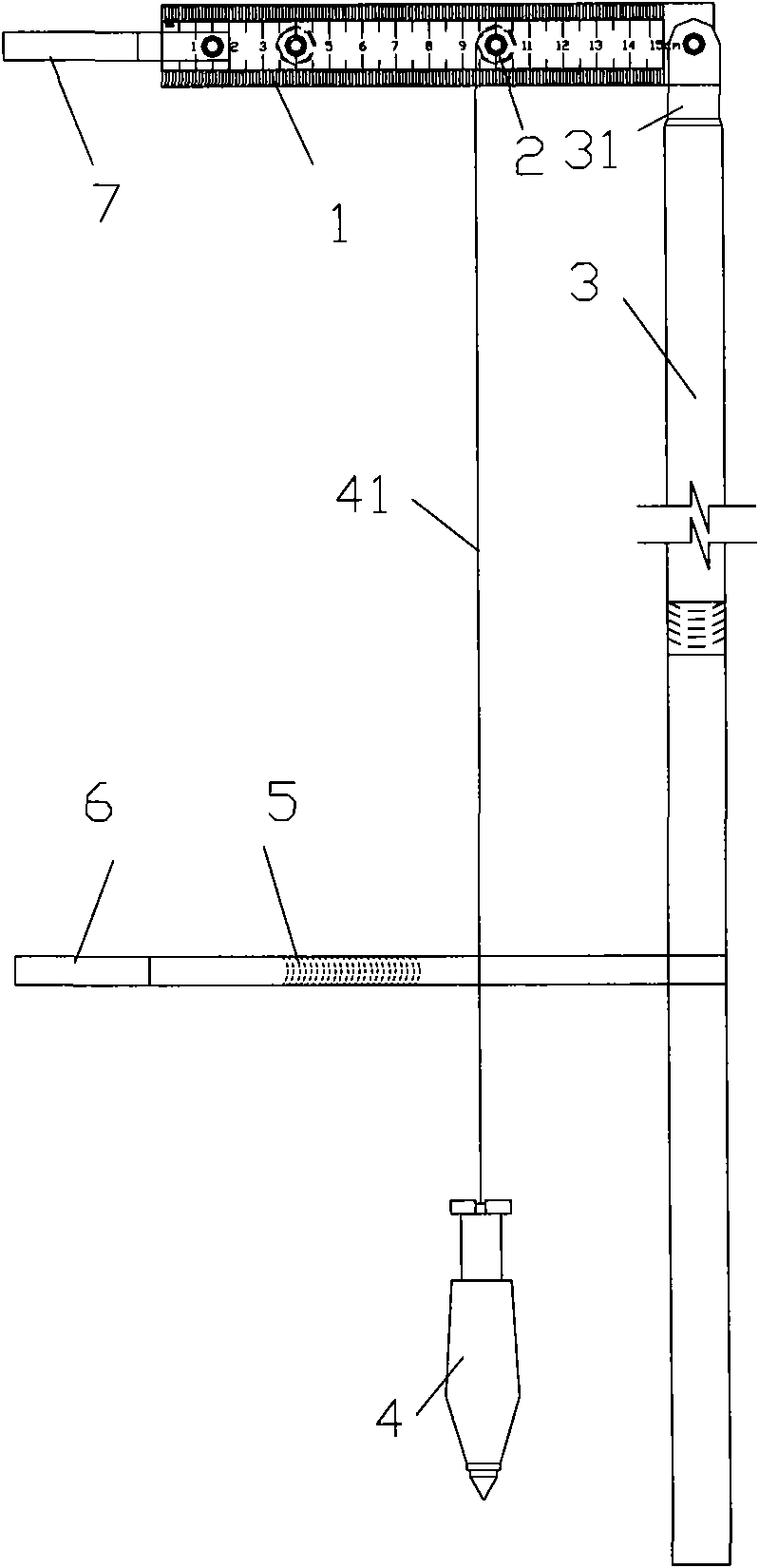

Column gradient measuring device and measuring method thereof

InactiveCN101586955AReduce field work timeReduce the number of operatorsIncline measurementPlumb bobScrew cap

The invention relates to a measuring tool, in particular to a column measuring tool. A column gradient measuring device comprises a straight steel ruler provided with scales, an upright post, two screw bolts, a telescopic sleeve tube and a tup, wherein the top of the upright post is provided with a joint fixedly connected with one end with large scales of the straight steel ruler; each screw bolt is provided with a screw cap and a spacing piece; the two screw bolts are fixedly connected and penetrates through the straight steel ruler, one screw bolt approaches the end with small scales of the straight steel ruler, and the other screw bolt is positioned on the middle section of the straight steel ruler; the telescopic sleeve tube is arranged in parallel with the straight steel ruler, and one end is fixedly connected with the lower section of the upright post; and the tup is hung on the screw bolt positioned on the middle section of the straight steel ruler through a hanging rope. The invention ensures that operators can fast, conveniently and accurately carry out column gradient measuring work in a complex environment in the field, shortens field work time, reduces the operators, and obviously enhances the efficiency of the measuring work.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com