Self-lifting type cableway transporting device

A transportation device and self-elevating technology, which is applied in the direction of transportation and packaging, cable cranes, cranes, etc., can solve the problems that tower materials are installed on cableway transportation devices, lifting equipment cannot be reached, and the starting point of transport trolleys is high, so as to reduce the rent cost, improve safety, and reduce the number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

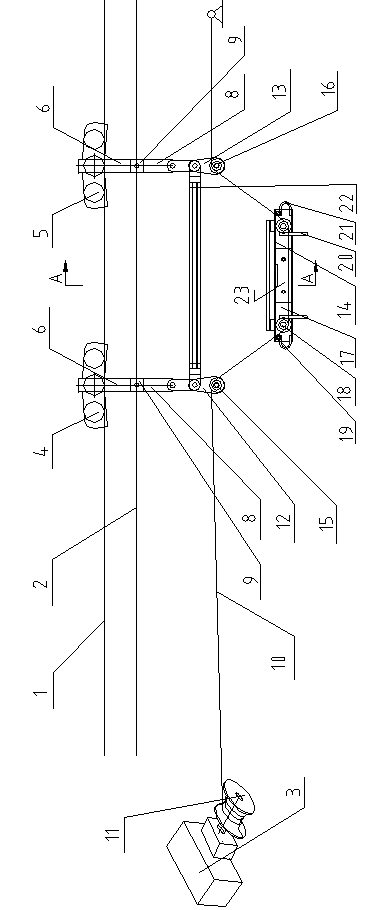

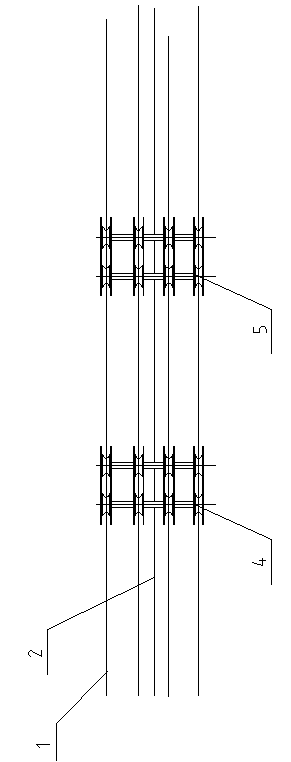

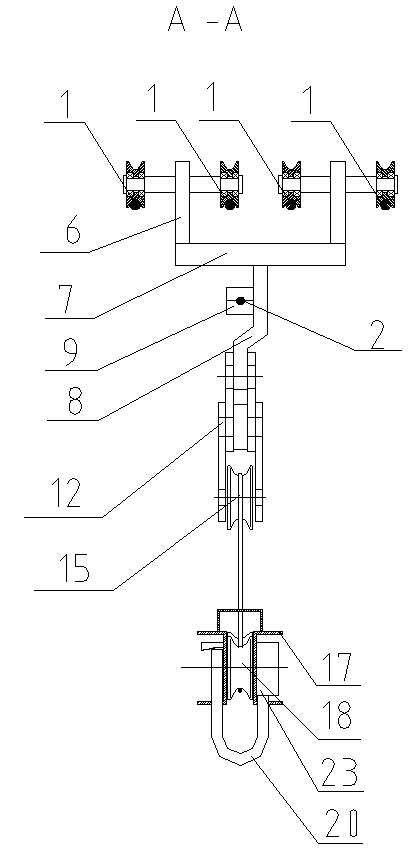

[0021] The present invention comprises four load-bearing steel cables 1 arranged transversely, a traction steel cable 2 arranged below the load-bearing steel cables 1 and a self-elevating device 3;

[0022] Two rows of longitudinally arranged traveling pulley blocks 4,5 are arranged on the four load-carrying steel cables 1, and the lower ends of the two rows of longitudinally arranged traveling pulley blocks 4,5 are respectively connected with vertically arranged connecting plates 6, and the connecting plates at the lower ends of the traveling pulley blocks 4,5 are The plates 6 are respectively connected as a whole by a connecting rod 7 arranged horizontally; the center positions of the lower ends of the connecting rods 7 of the walking pulley blocks 4 and 5 are respectively provided with a transition connecting plate 8, and the positions corresponding to the transition connecting plate 8 on the traction cable 2 are respectively A gripping device 9 is provided, and the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com