Patents

Literature

26741 results about "Wire rope" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wire rope is several strands of metal wire twisted into a helix forming a composite "rope", in a pattern known as "laid rope". Larger diameter wire rope consists of multiple strands of such laid rope in a pattern known as "cable laid".

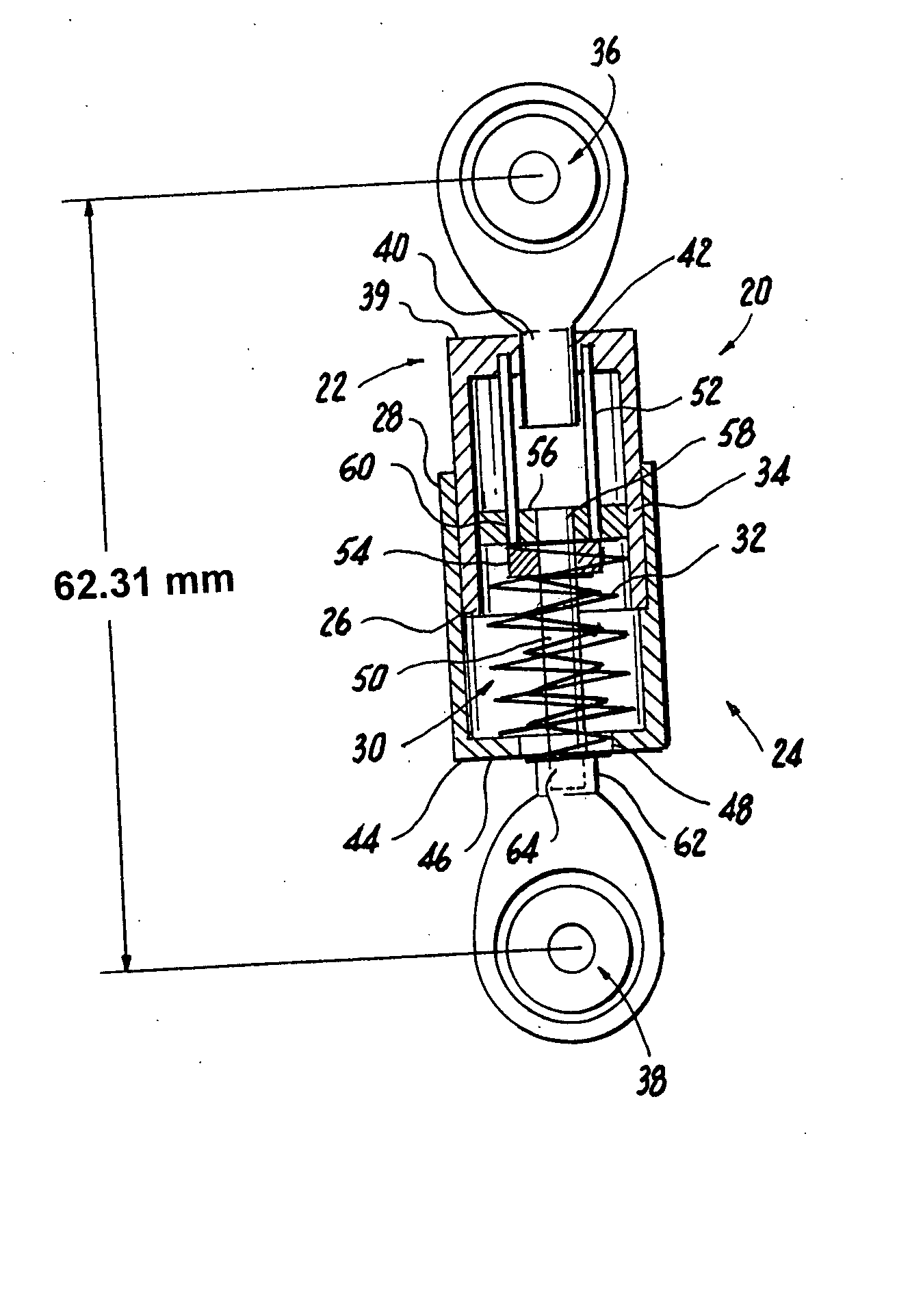

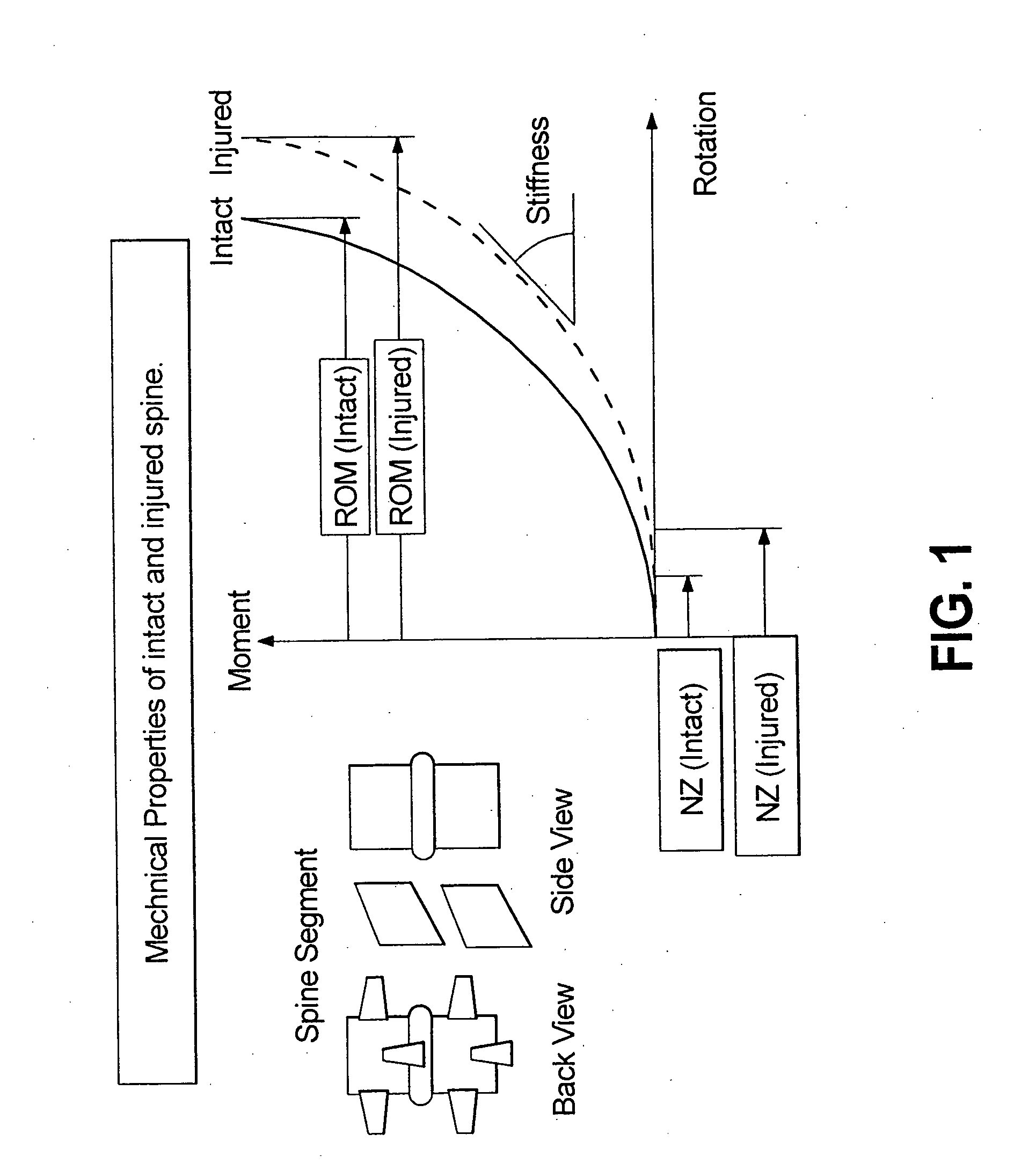

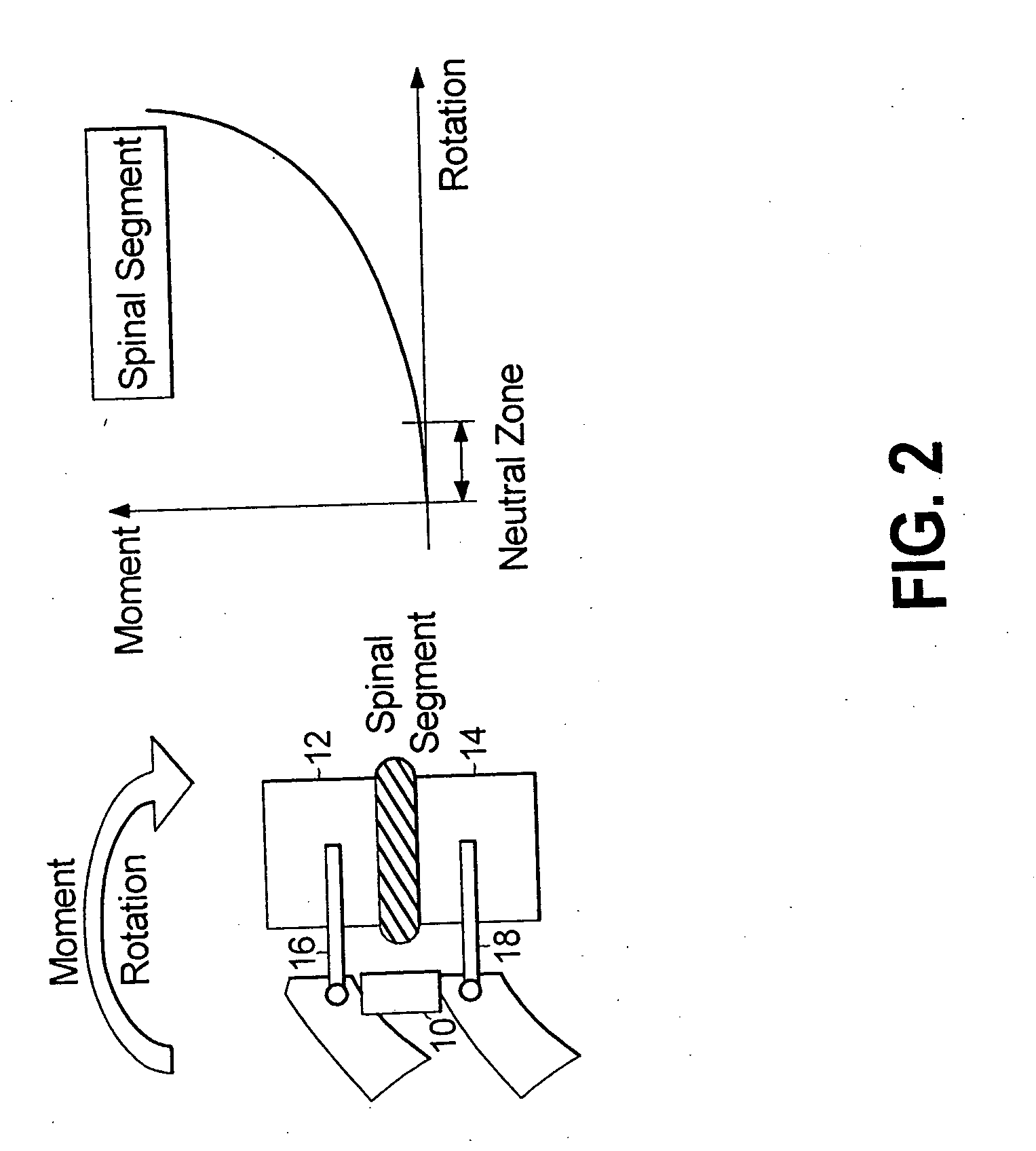

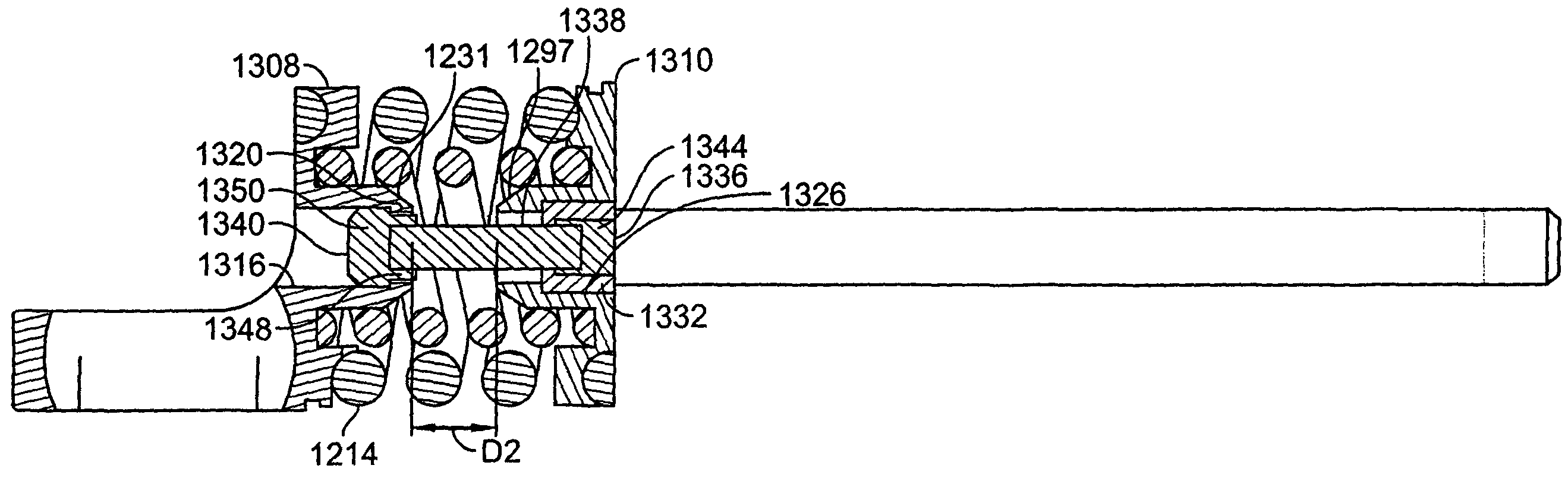

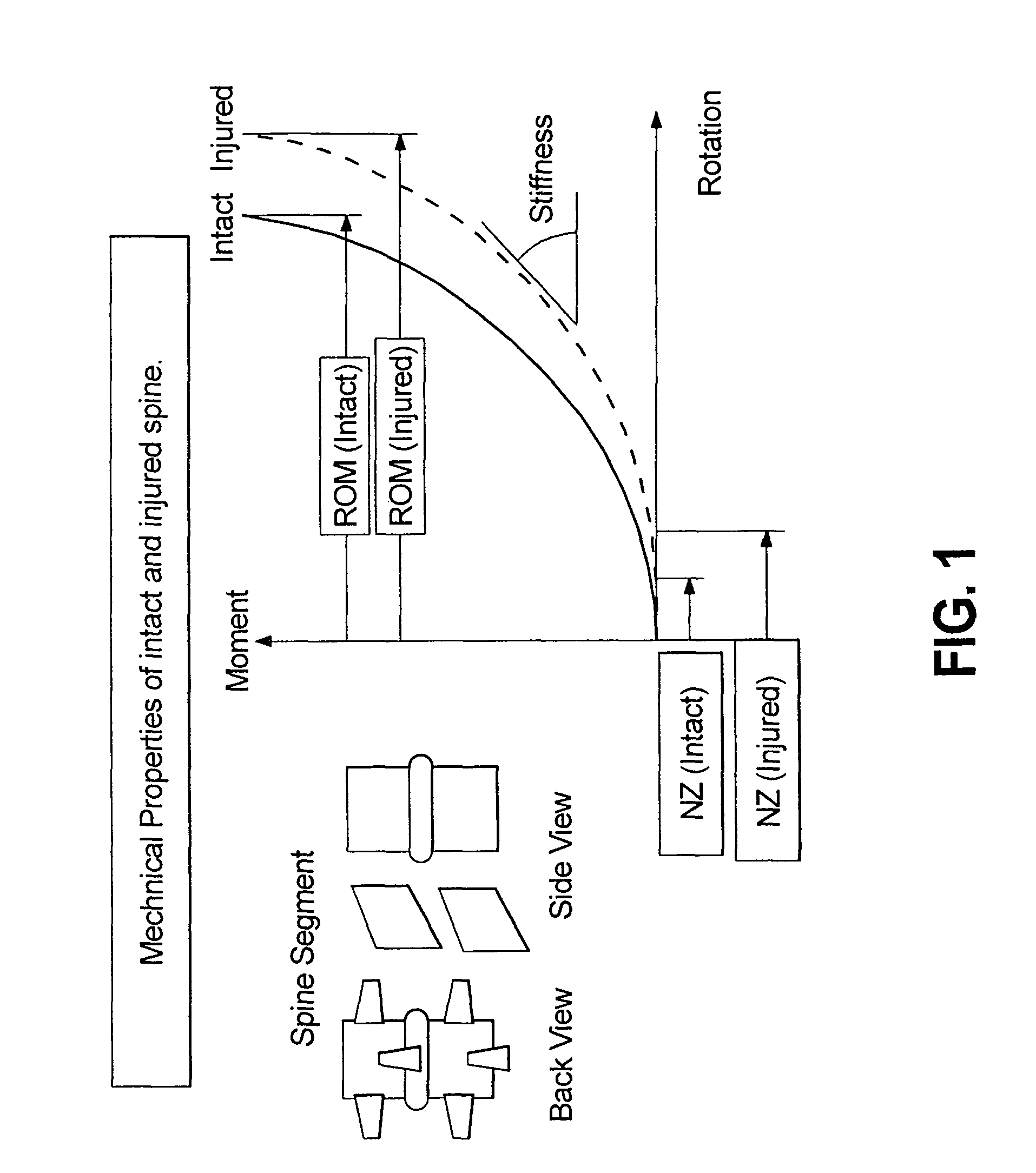

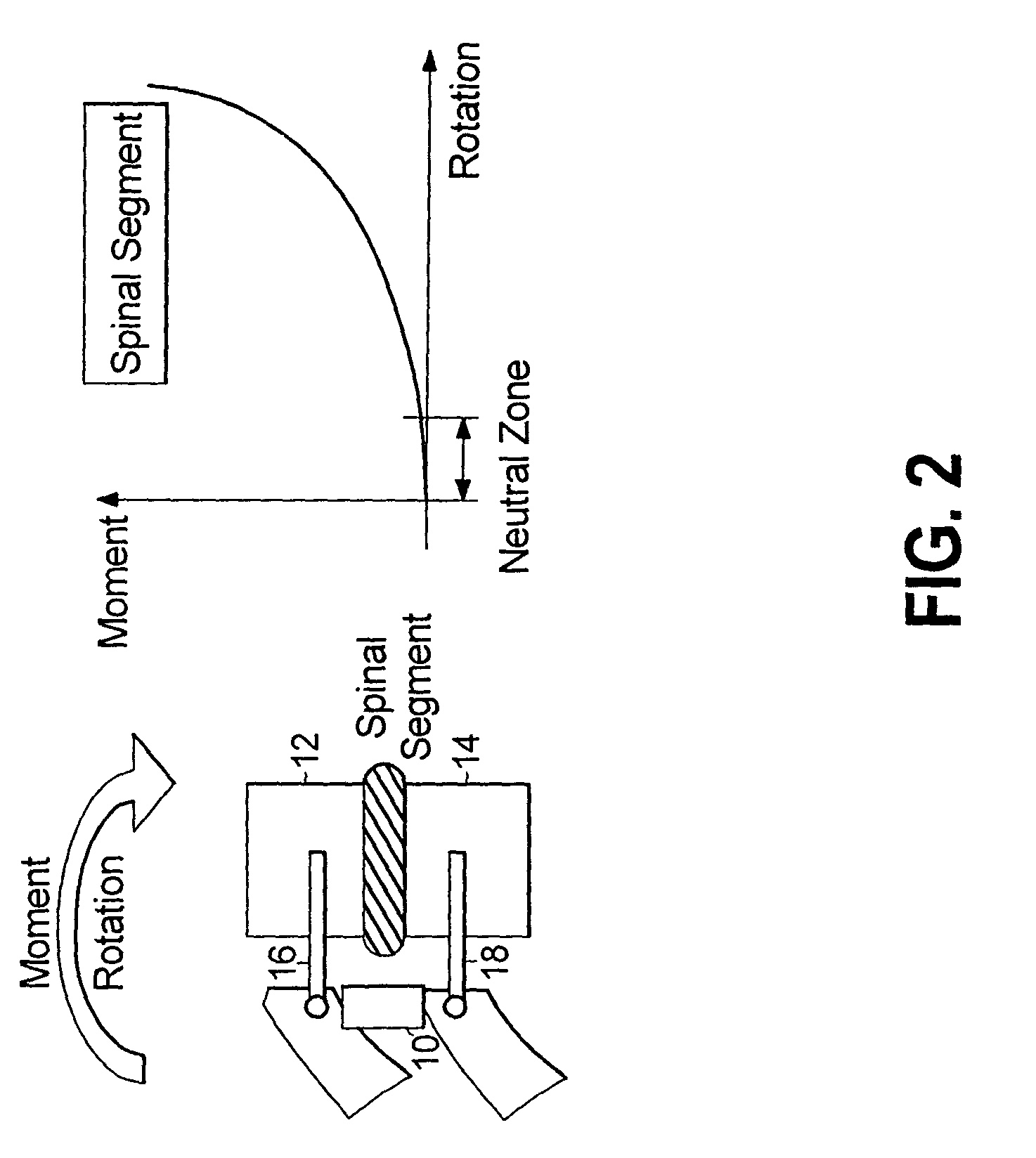

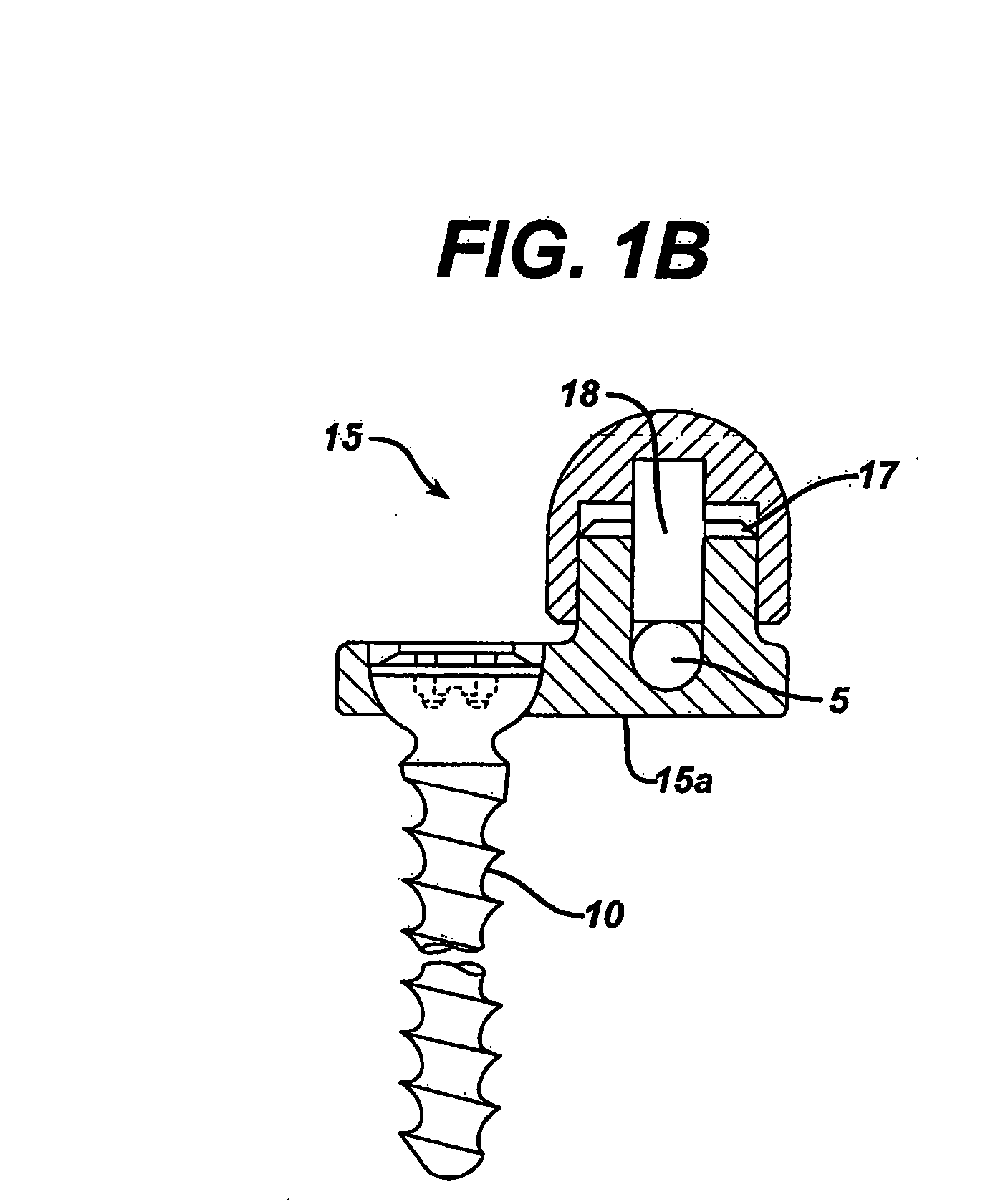

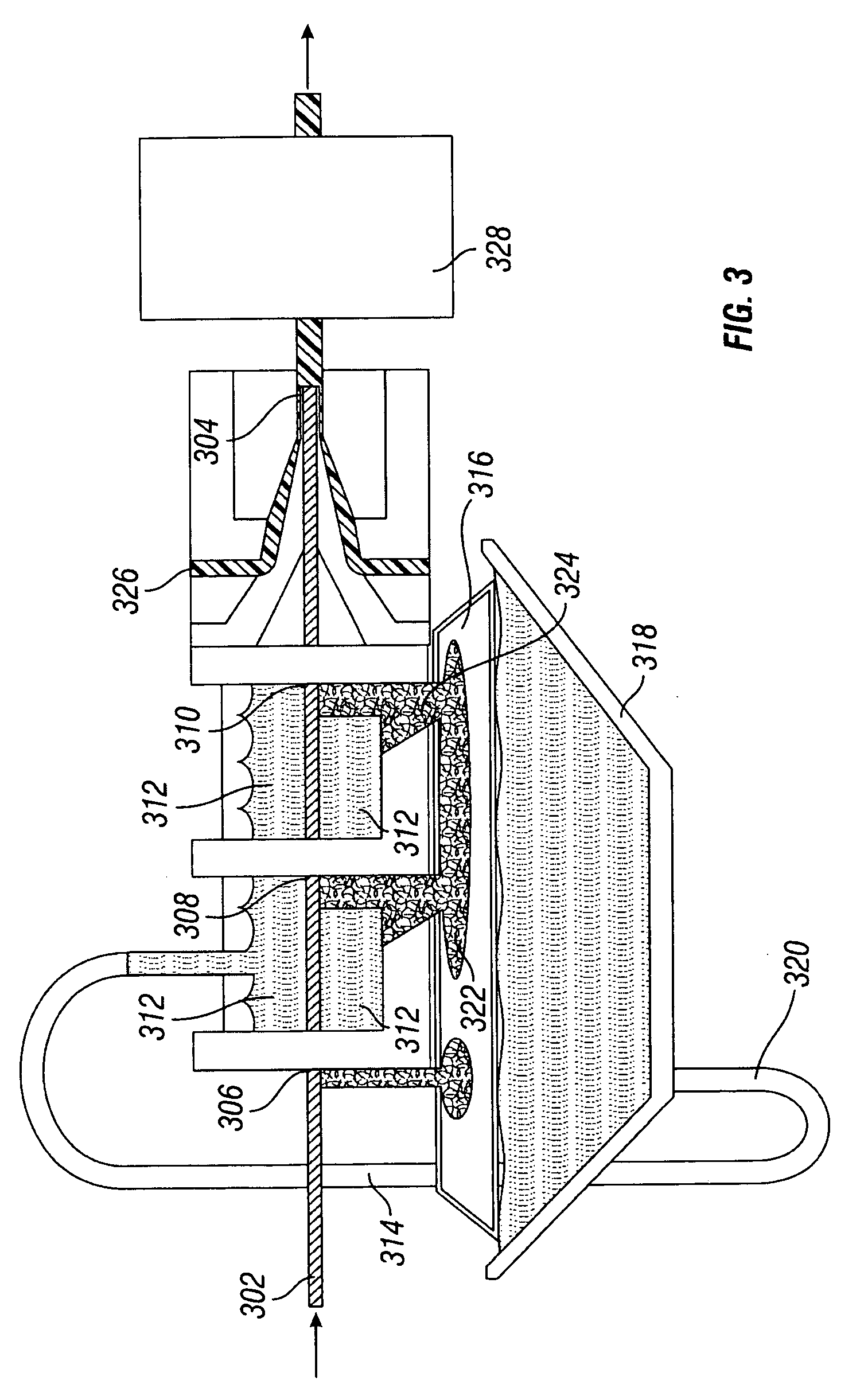

Dynamic spine stabilization device with travel-limiting functionality

InactiveUS20070043356A1Enhance alignment and durabilityLimit distanceInternal osteosythesisJoint implantsSpinal columnClassical mechanics

Spinal stabilization devices, systems and methods are provided that include a stabilization member including a first structural member that mounts to a pedicle screw, a second structural member adjacent the first structural member and that can move away therefrom, a resilient element mounted between the structural members and that elongates to accommodate relative movement therebetween, and a travel-limiting structure mounted between the structural members and that defines and imposes upon the stabilization member a maximum distance by which the first and second structural members may be separated. The travel-limiting structure can include an axially inextensible, laterally flexible elongate element, e.g., wire-rope cable, disposed between the structural members. The resilient element extends between respective first ends of the structural members, while the travel-limiting structure can include terminations at opposite ends of the elongate element and mounted to respective second ends of the structural members opposite the first ends thereof.

Owner:RACHIOTEK

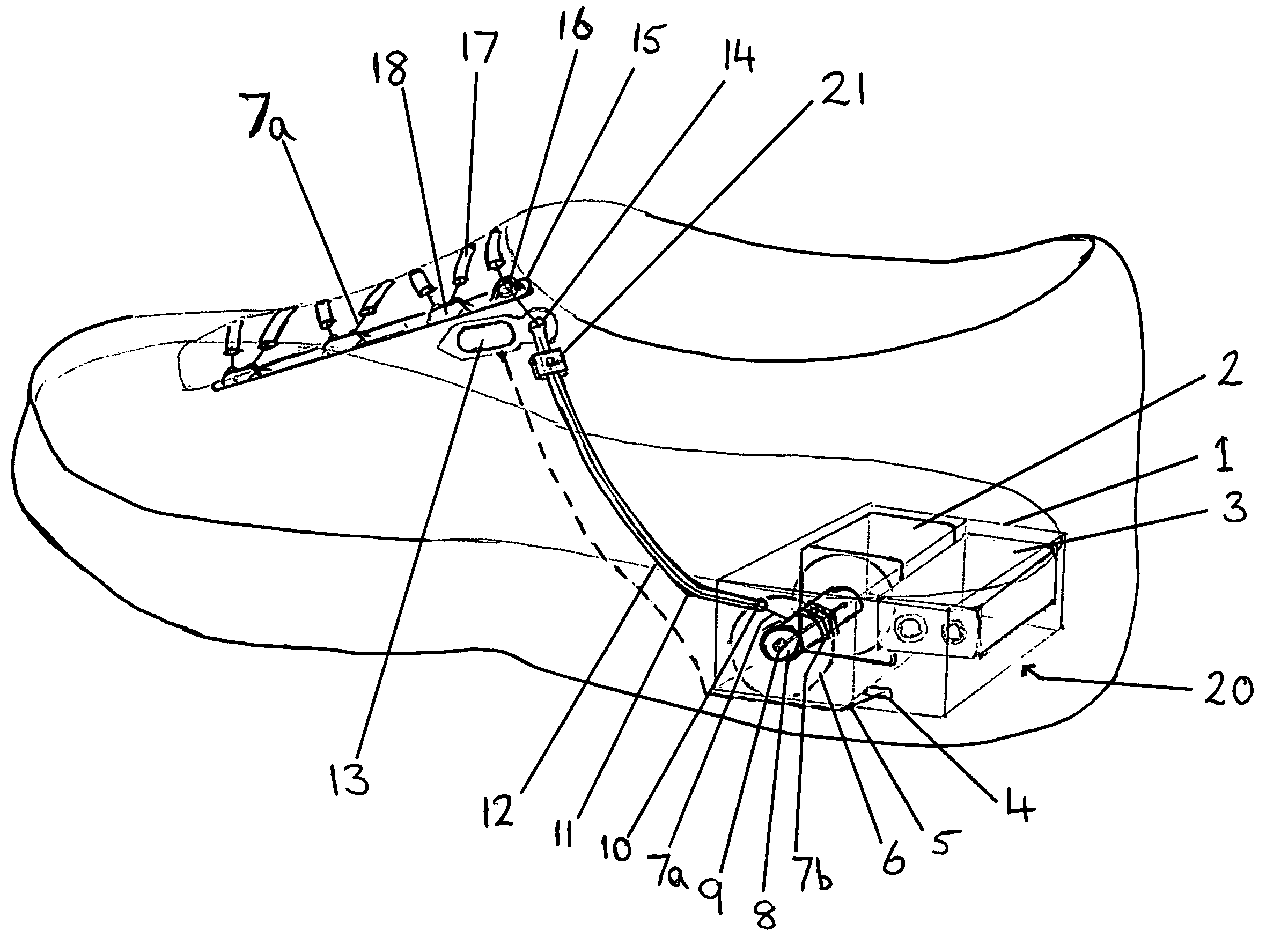

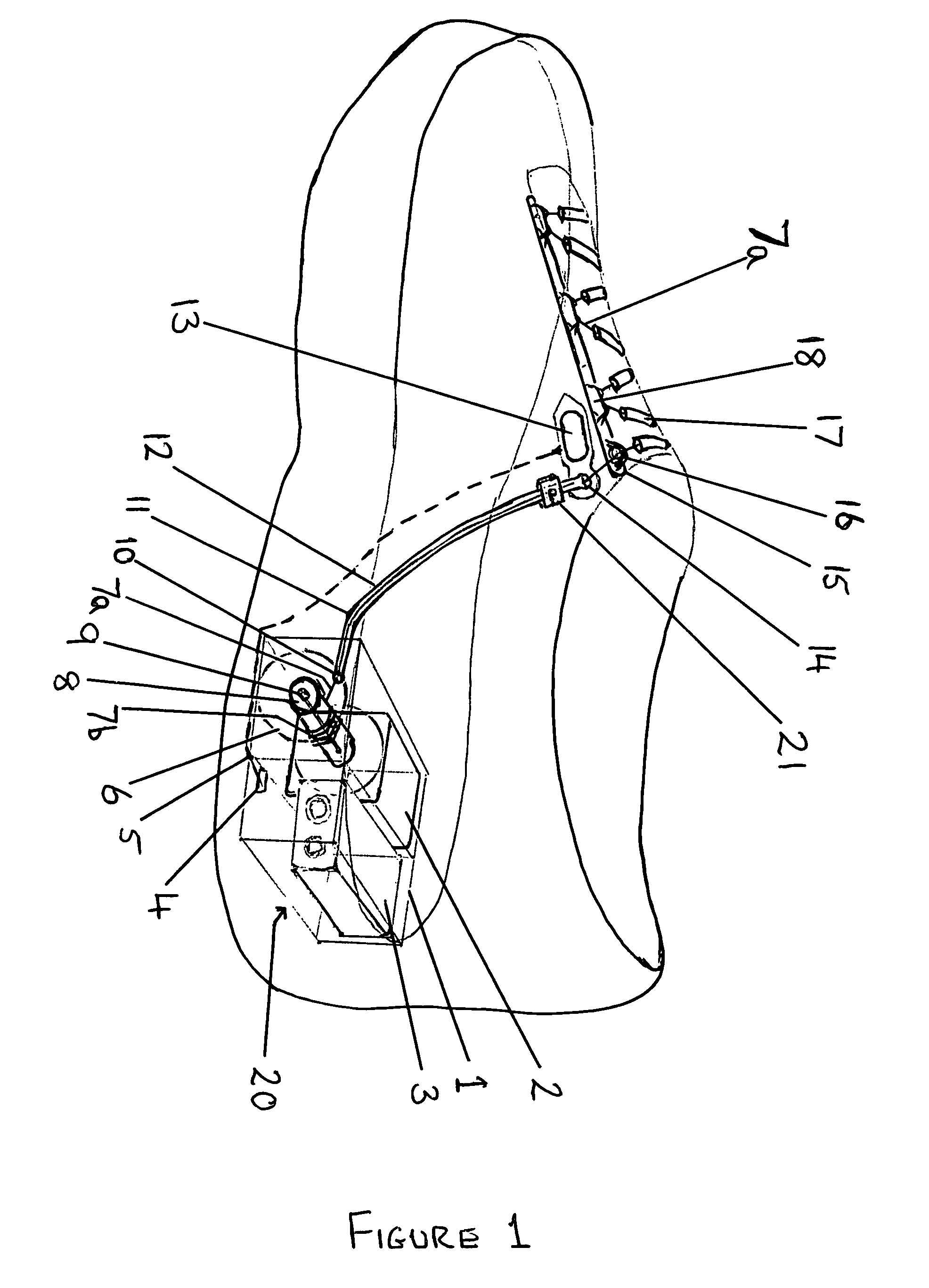

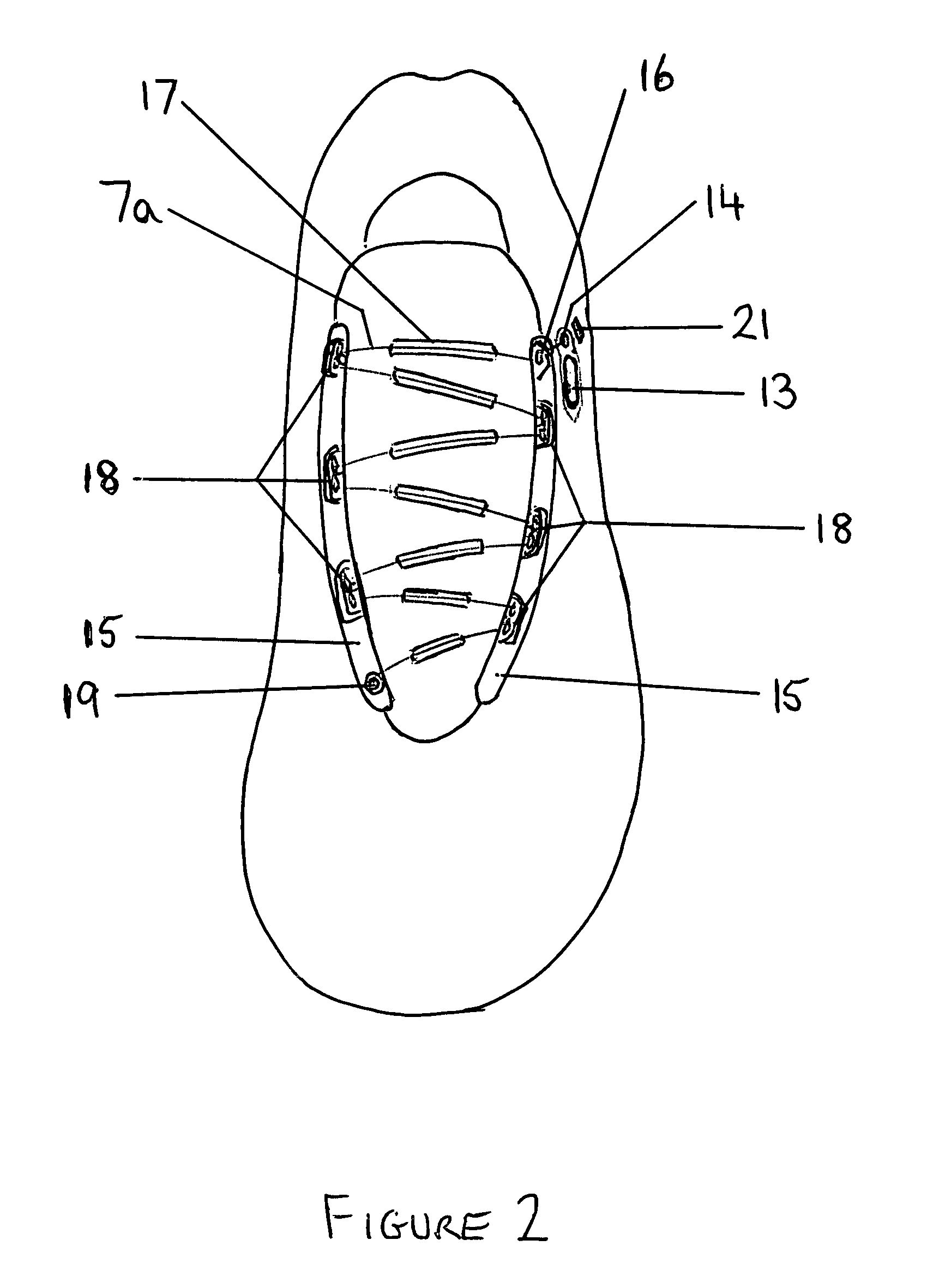

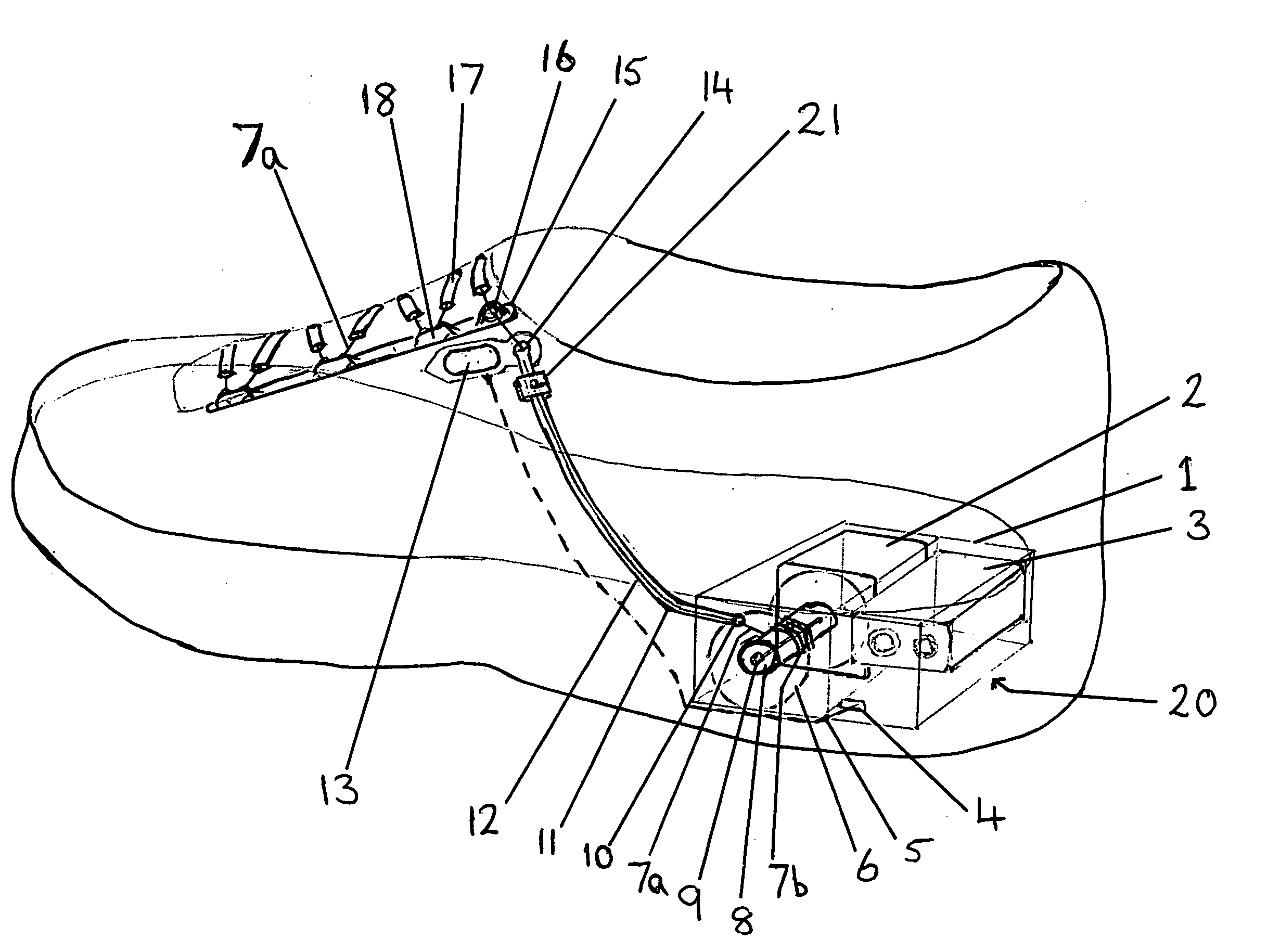

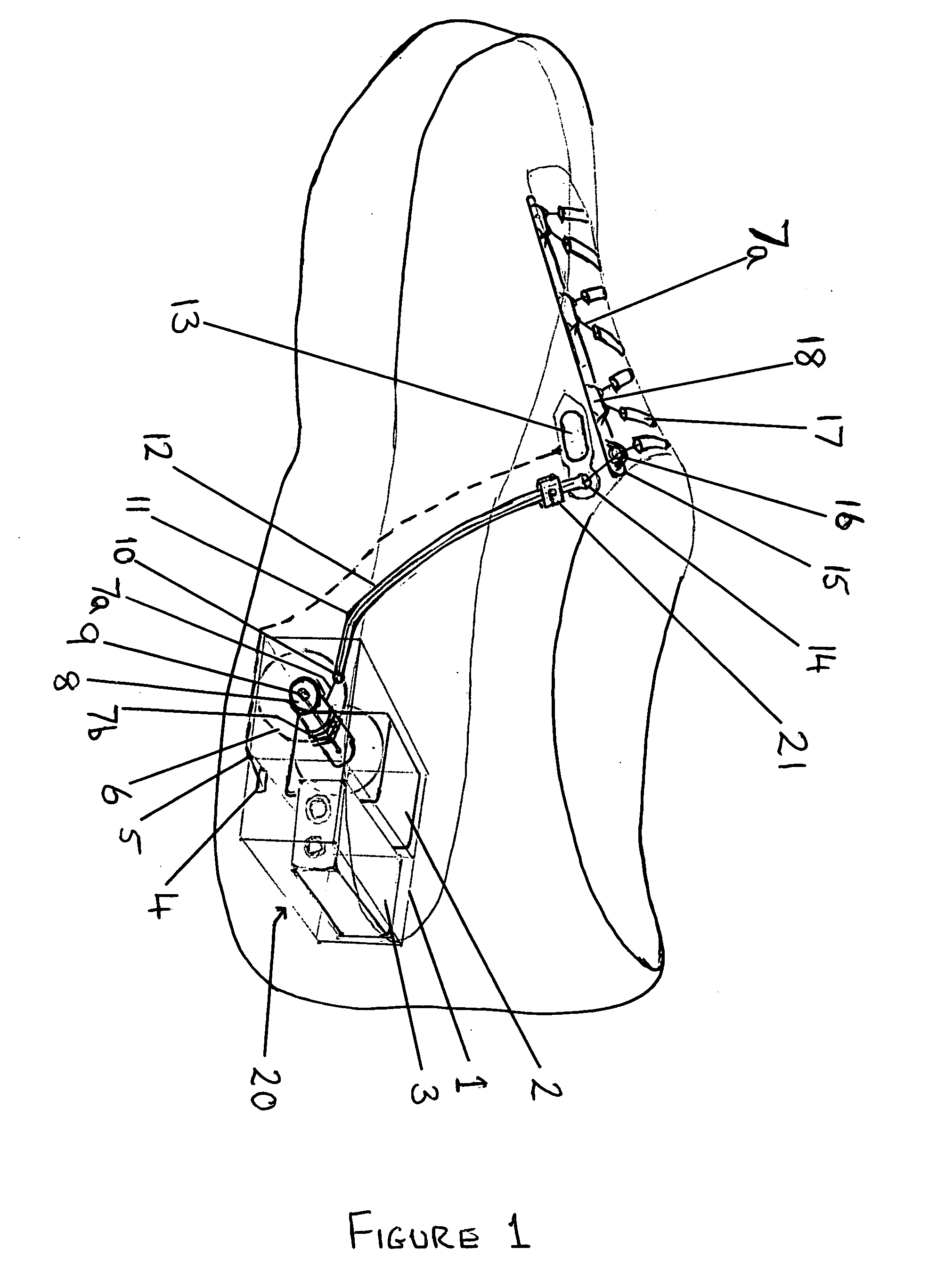

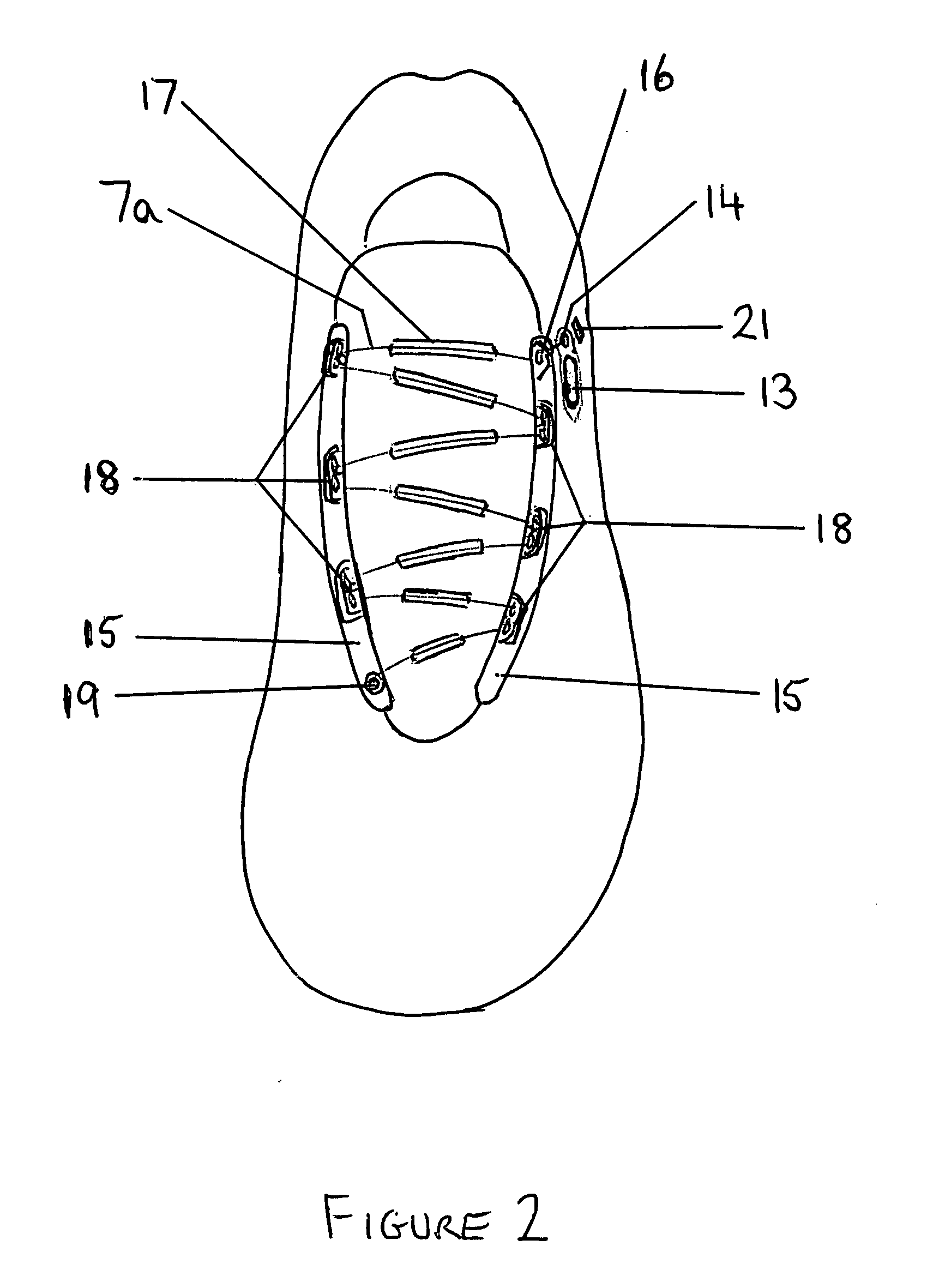

Powered shoe tightening with lace cord guiding system

The automatic shoe lace tightening system or power lace has a switch on the shoe upper to activate a small battery powered slow speed motor fixed into a recess in the heel which winds in onto the winder spool the smooth plastic or wire lacing cord passing through guiding tubes positioned across the shoe tongue and down the side of the shoe through to the motor housing upon which the tightening cord draws together the lace loop plates fixed either side of the shoe's upper adjacent to the tongue by passing in a zig-zag through cord loops fixed to and along the lace plates with the end of the cord attached to the bottom of one of the plates and the desired tension of the cord and shoe fit is automatically held in place as the cord passes through a sprung loaded clamp which can then be manually released to loosen the shoe.

Owner:USSHER TIM JAMES

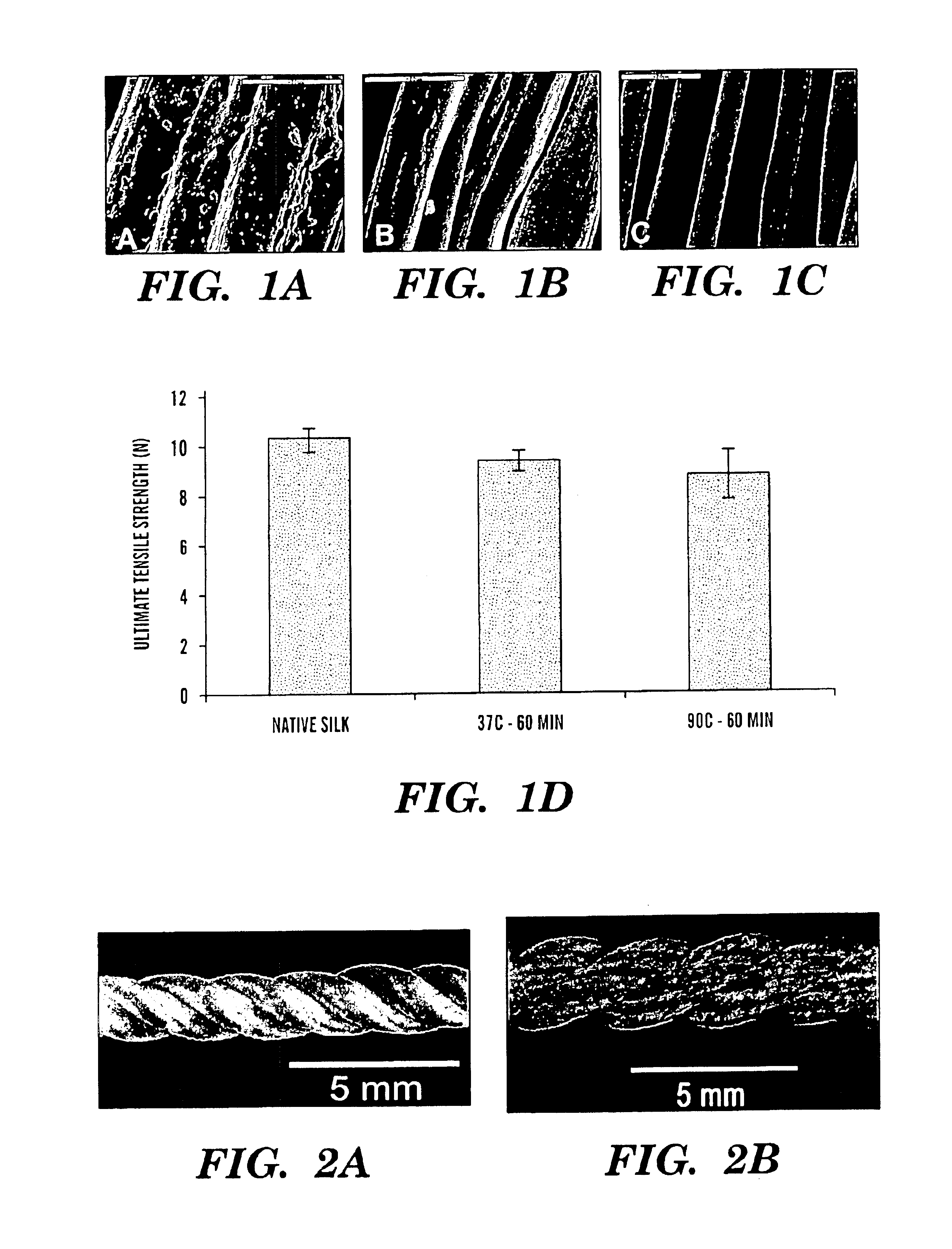

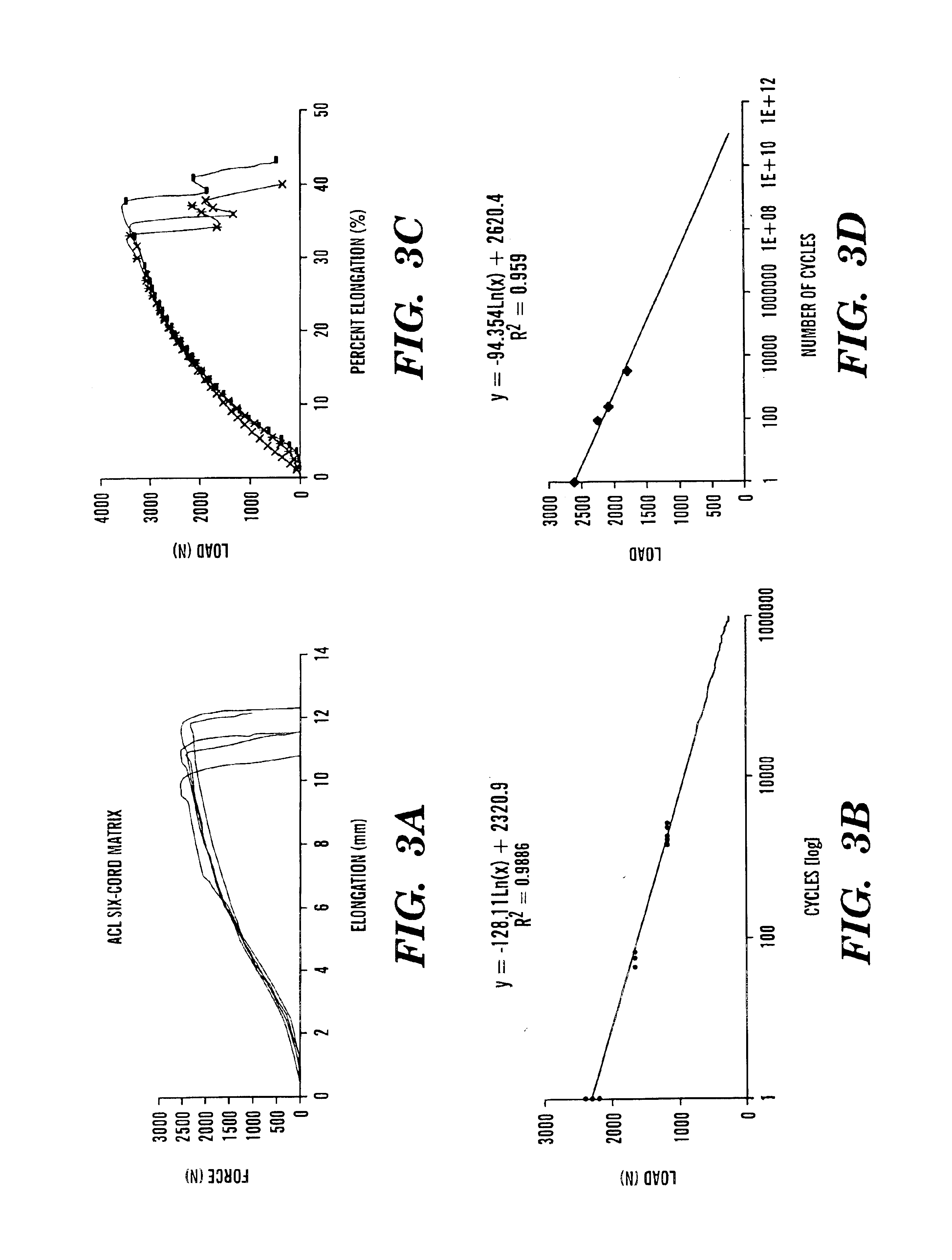

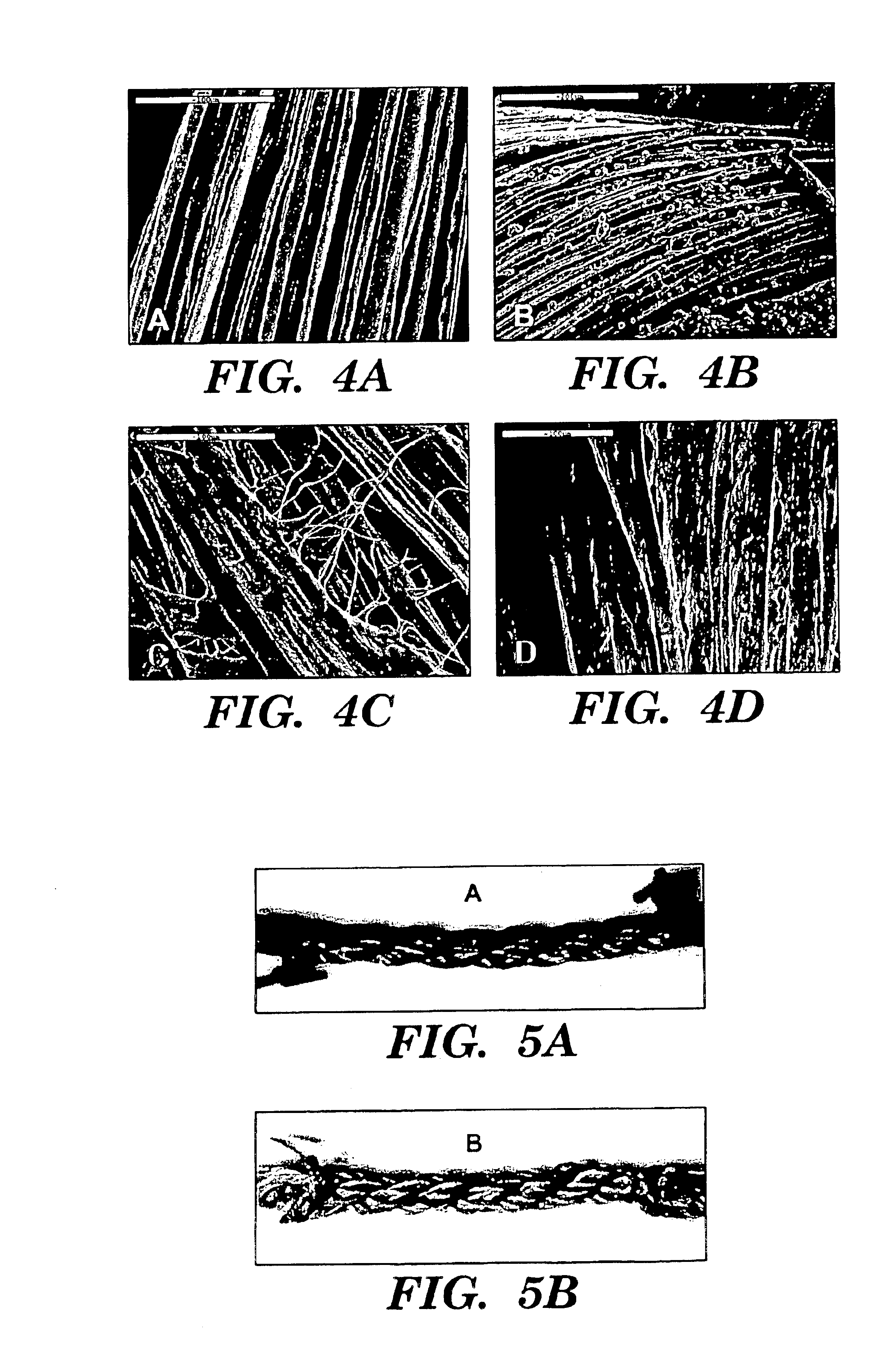

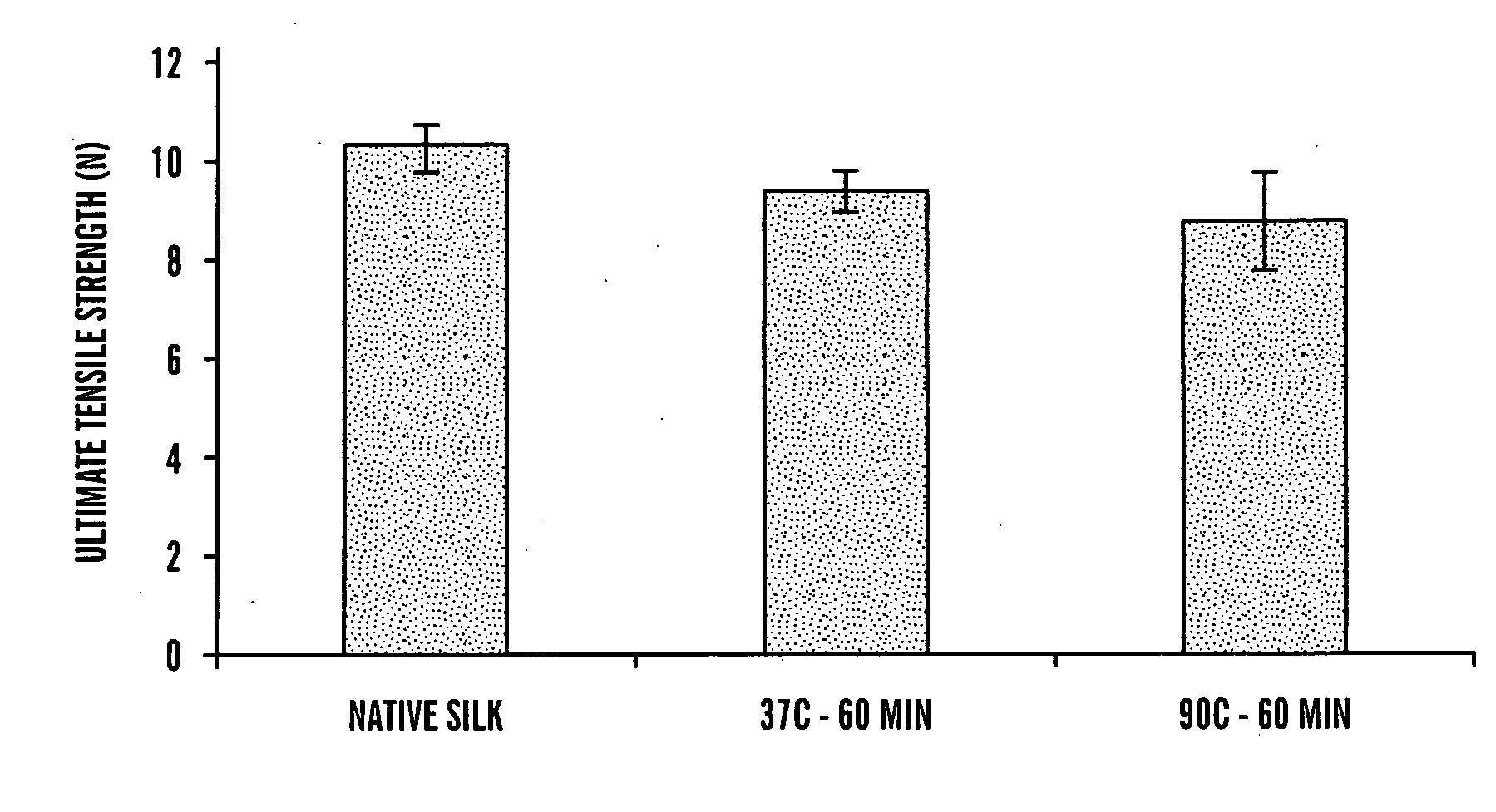

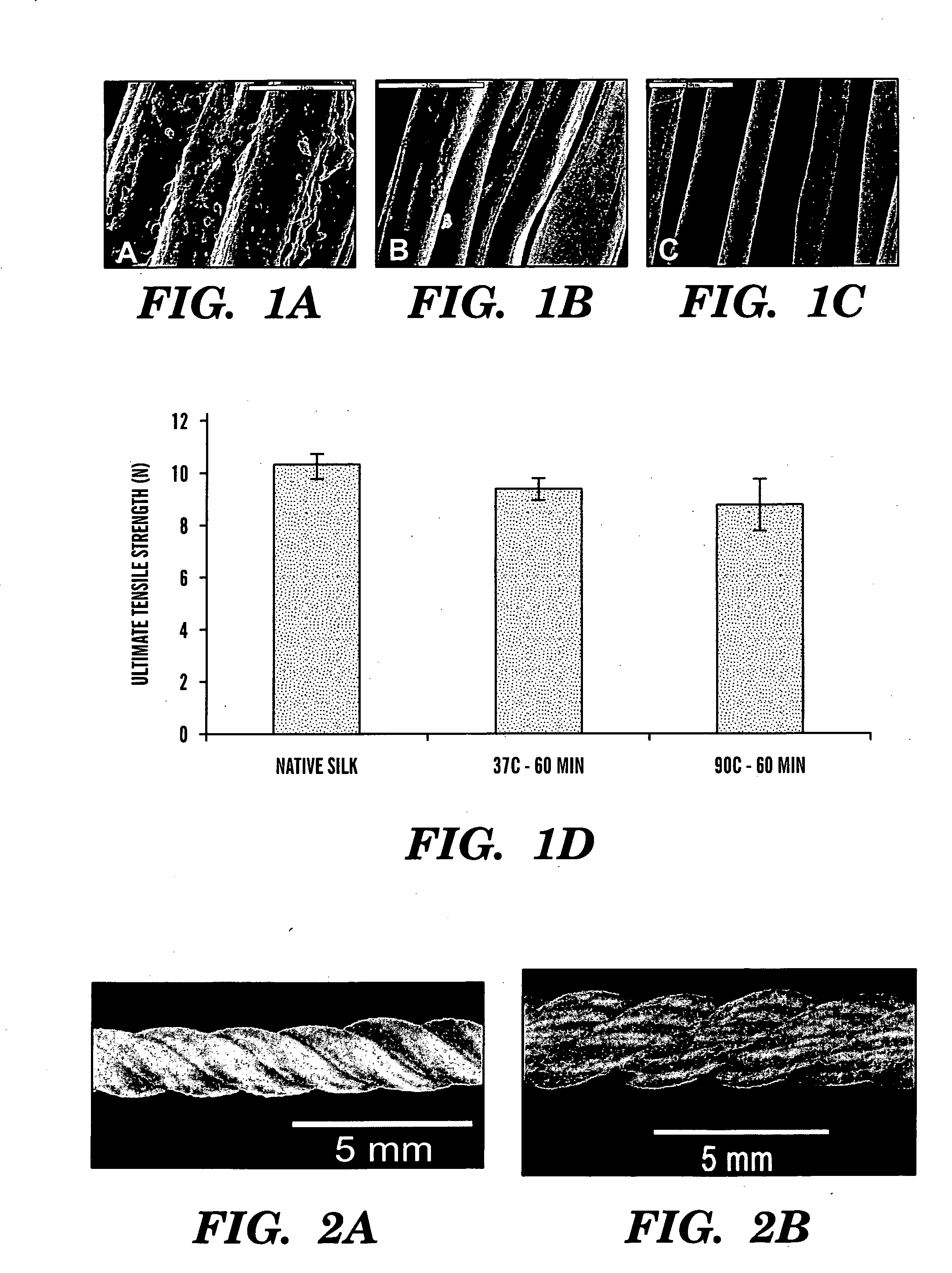

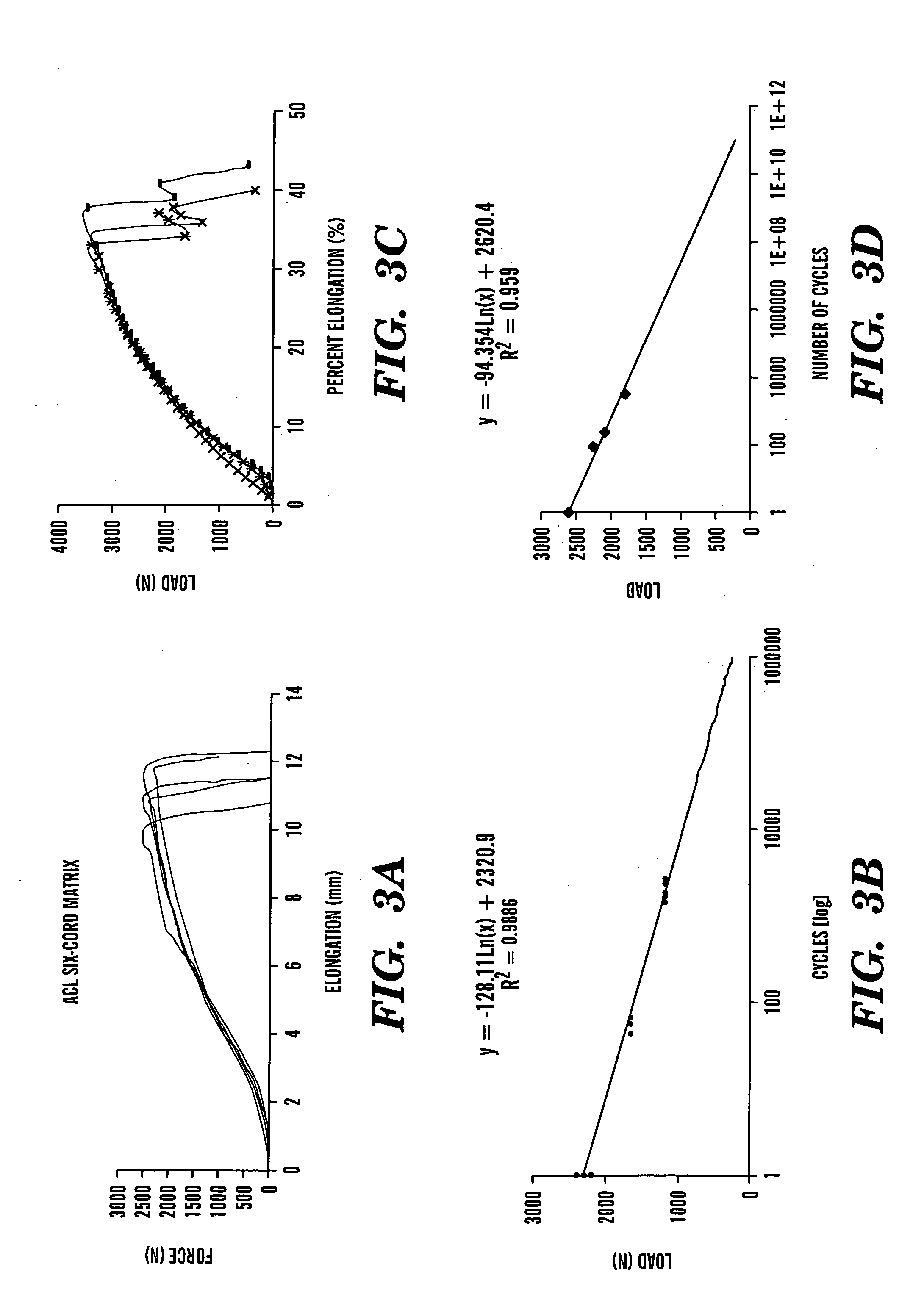

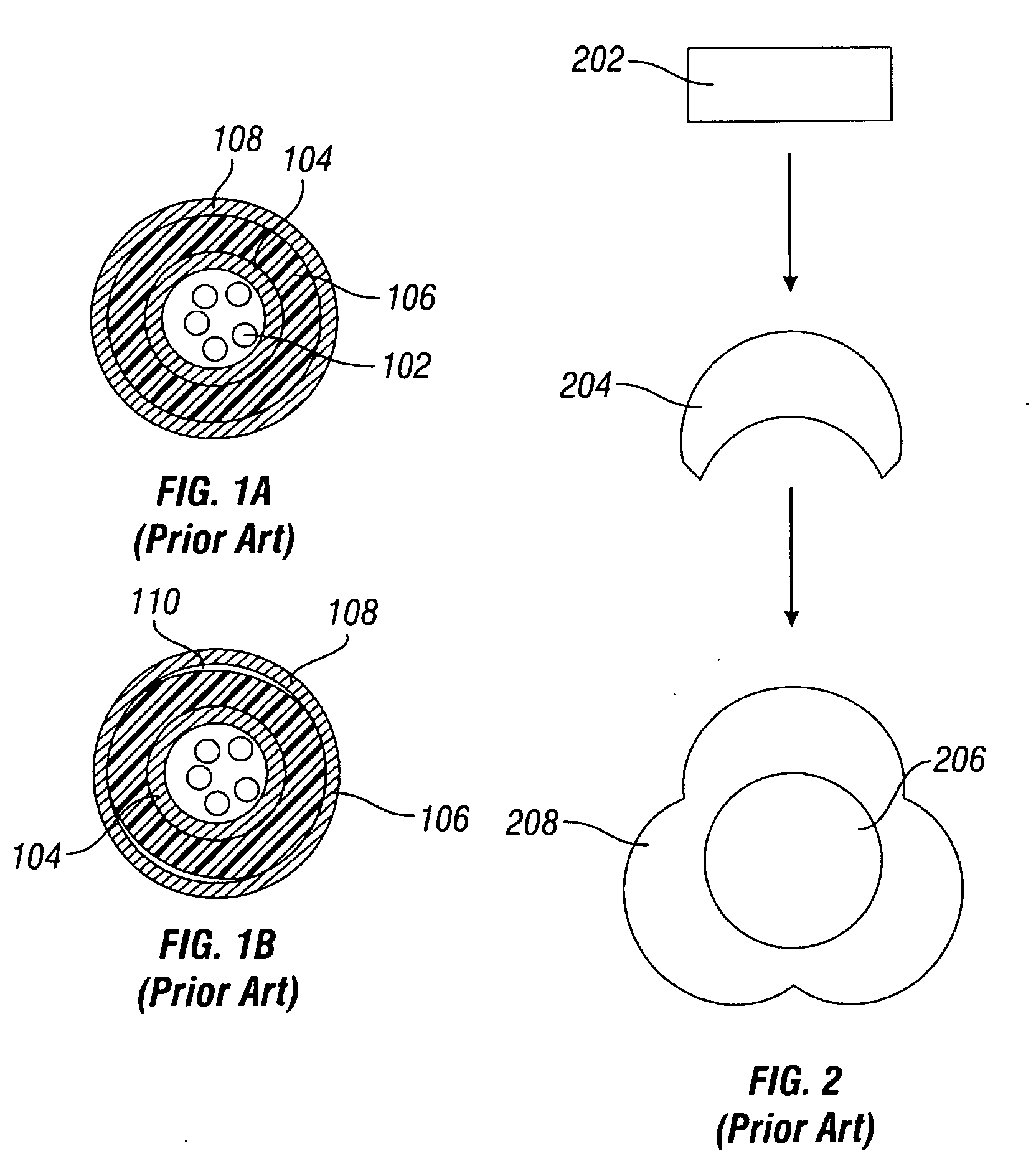

Helically organized silk fibroin fiber bundles for matrices in tissue engineering

InactiveUS6902932B2Immobilised enzymesBioreactor/fermenter combinationsFiber bundleLigament structure

The present invention provides a novel silk-fiber-based matrix having a wire-rope geometry for use in producing a ligament or tendon, particularly an anterior cruciate ligament, ex vivo for implantation into a recipient in need thereof. The invention further provides the novel silk-fiber-based matrix which is seeded with pluripotent cells that proliferate and differentiate on the matrix to form a ligament or tendon ex vivo. Also disclosed is a bioengineered ligament comprising the silk-fiber-based matrix seeded with pluripotent cells that proliferate and differentiate on the matrix to form the ligament or tendon. A method for producing a ligament or tendon ex vivo comprising the novel silk-fiber-based matrix is also disclosed.

Owner:ALLERGAN INC +1

Powered shoe tightening with lace cord guiding system

InactiveUS20080301919A1Fast and convenient methodShoe lace fasteningsHaberdasheryShoe lacesEngineering

The automatic shoe lace tightening system or power lace has a switch on the shoe upper to activate a small battery powered slow speed motor fixed into a recess in the heel which winds in onto the winder spool the smooth plastic or wire lacing cord passing through guiding tubes positioned across the shoe tongue and down the side of the shoe through to the motor housing upon which the tightening cord draws together the lace loop plates fixed either side of the shoe's upper adjacent to the tongue by passing in a zig-zag through cord loops fixed to and along the lace plates with the end of the cord attached to the bottom of one of the plates and the desired tension of the cord and shoe fit is automatically held in place as the cord passes through a sprung loaded clamp which can then be manually released to loosen the shoe.

Owner:USSHER TIM JAMES

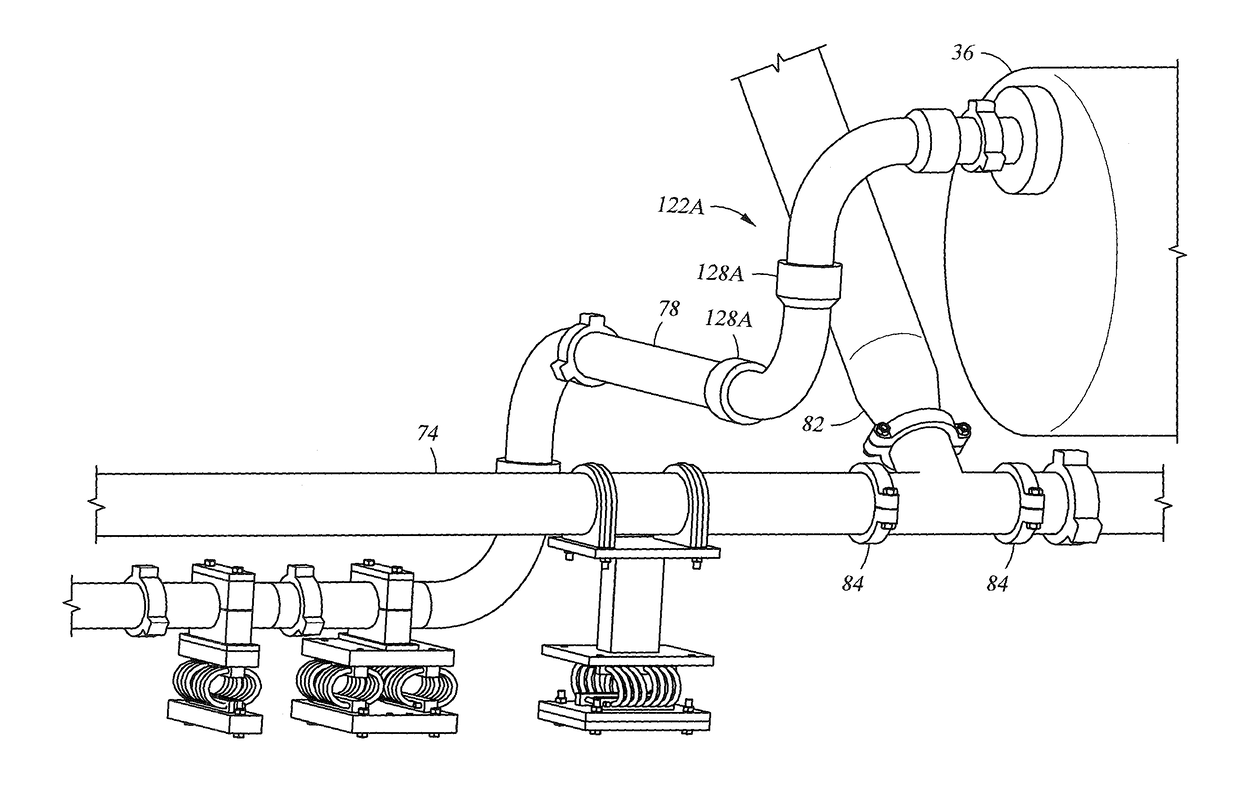

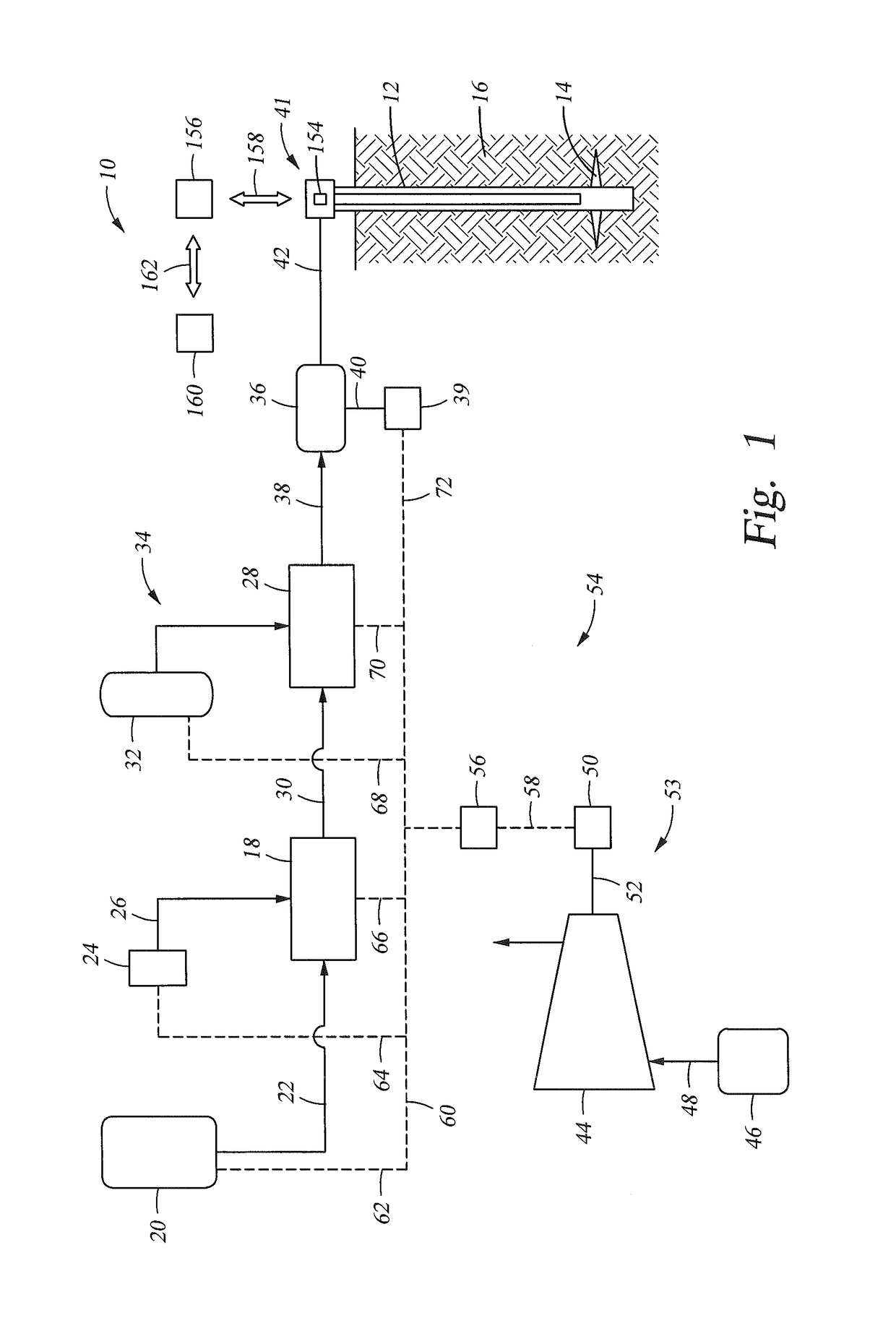

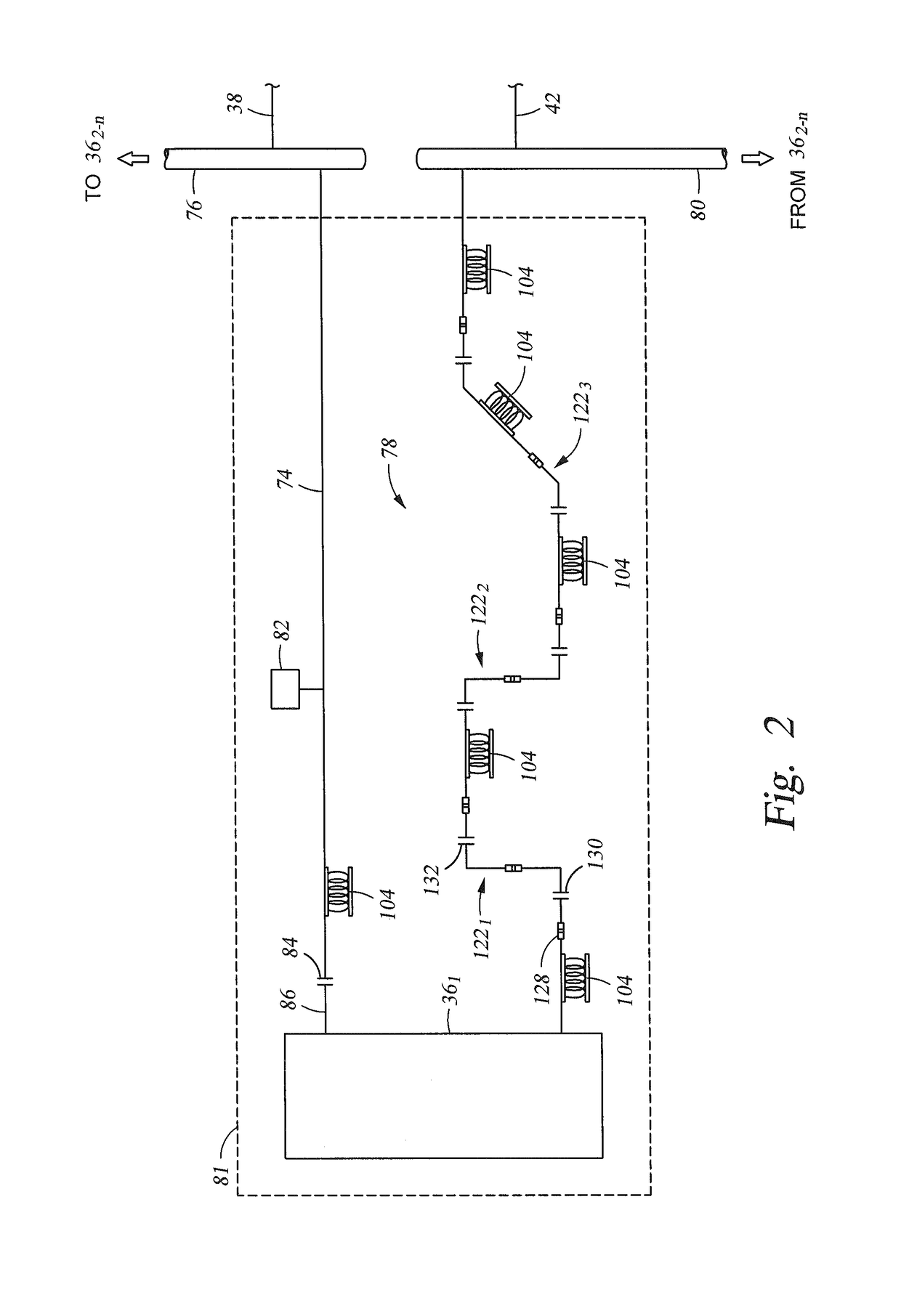

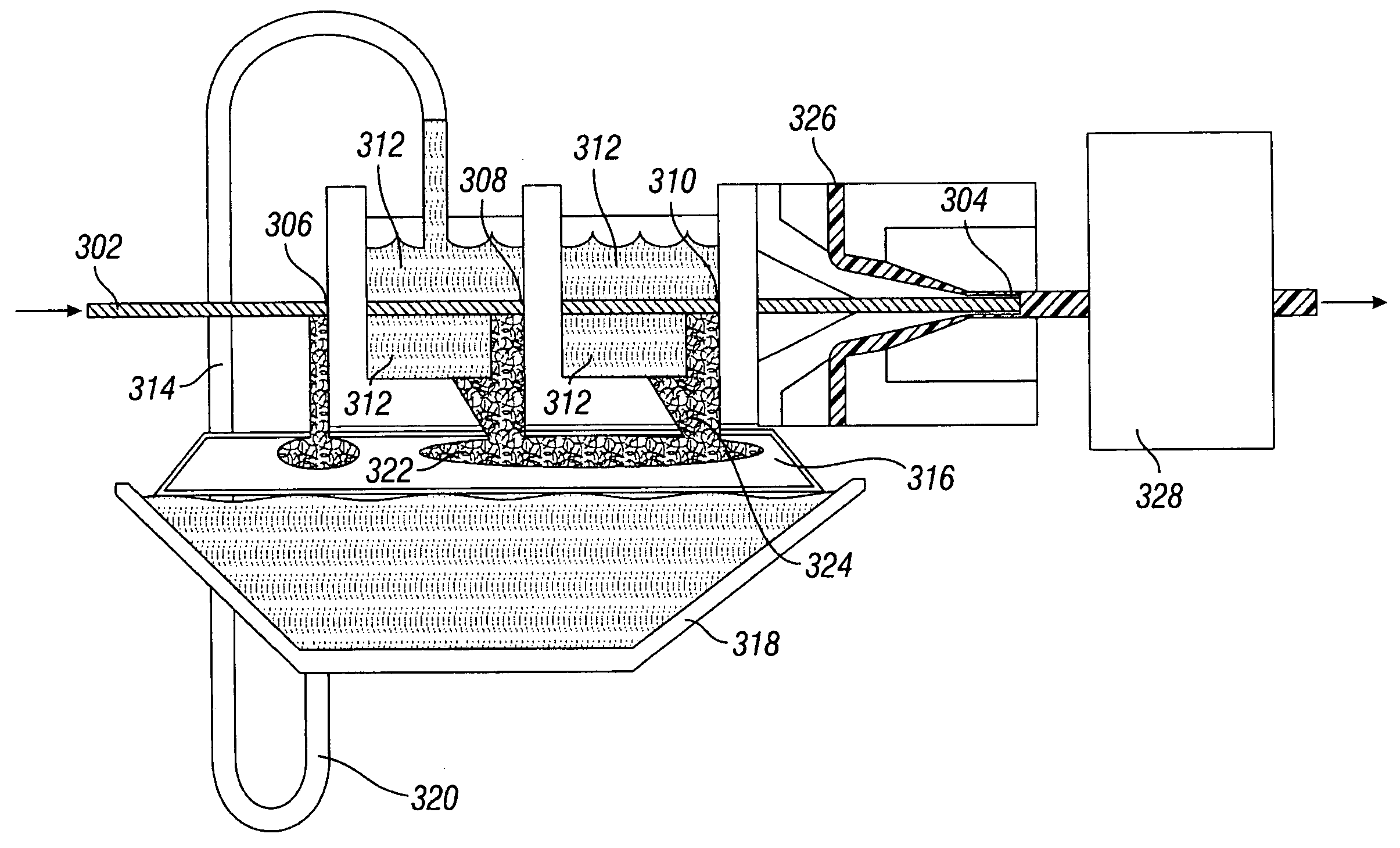

System for reducing vibrations in a pressure pumping fleet

ActiveUS10119381B2Vibration highReduce turbulenceAC motor controlPositive displacement pump componentsFracturing fluidHelical coil

An electrically powered hydraulic fracturing system having pumps for pressurizing fracturing fluid, piping for carrying fracturing fluid, and vibration reducing equipment for use with the piping. The vibration reducing equipment includes helical coils that support the piping. The coils are made of a wire rope made of strands of steel cable twisted together. Grooved fittings are provided on some piping connections, and which allow pivoting between adjacent fluid conveyance members. Swivel joints are strategically located in the piping which allow rotational flexing between adjacent sections of the piping; thereby attenuating vibration in the piping but without stressing the piping.

Owner:US WELL SERVICS LLC

Dynamic spine stabilization device with travel-limiting functionality

InactiveUS7811309B2Enhance alignment and durabilityLimit distanceInternal osteosythesisJoint implantsSpinal columnClassical mechanics

Owner:RACHIOTEK

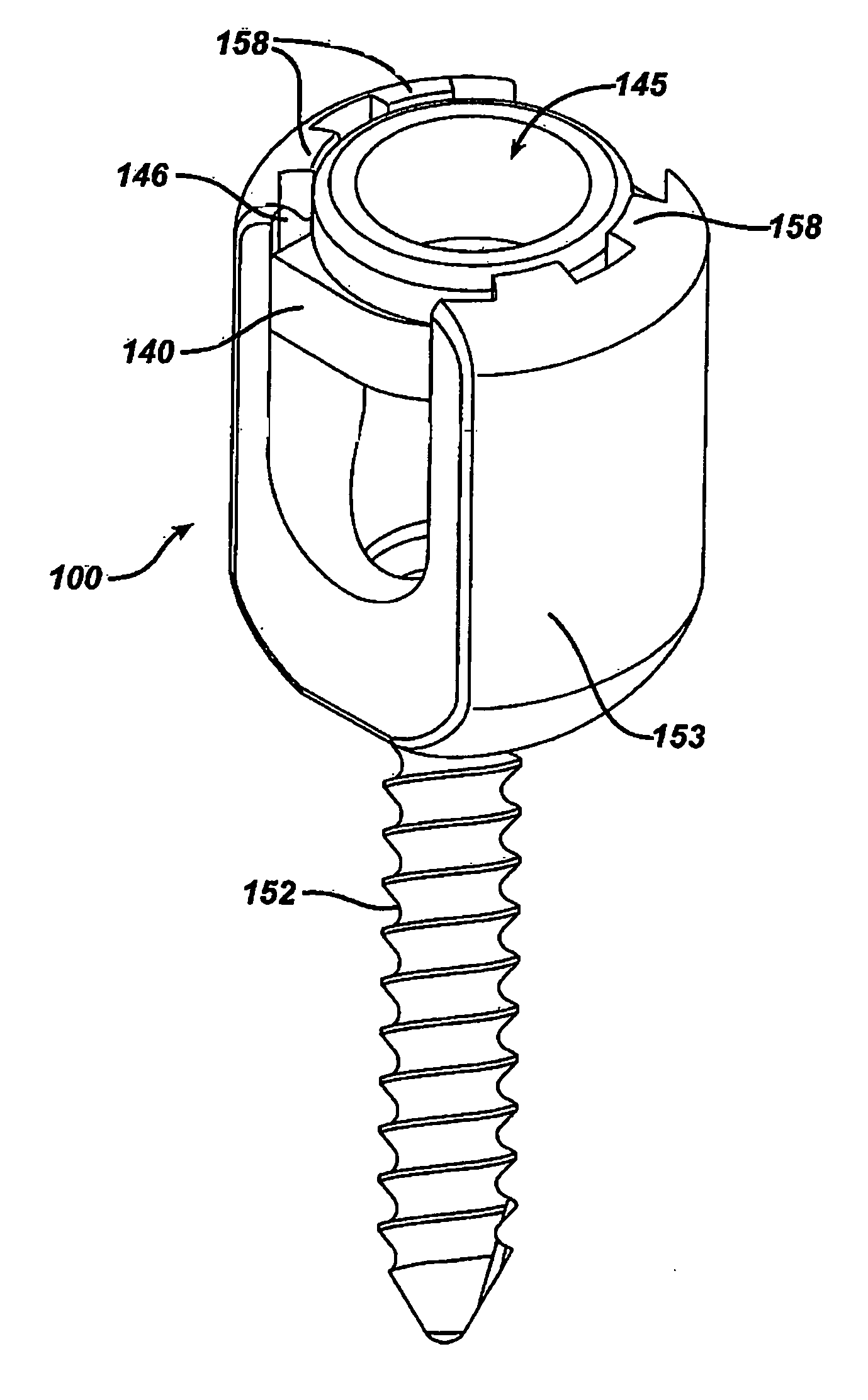

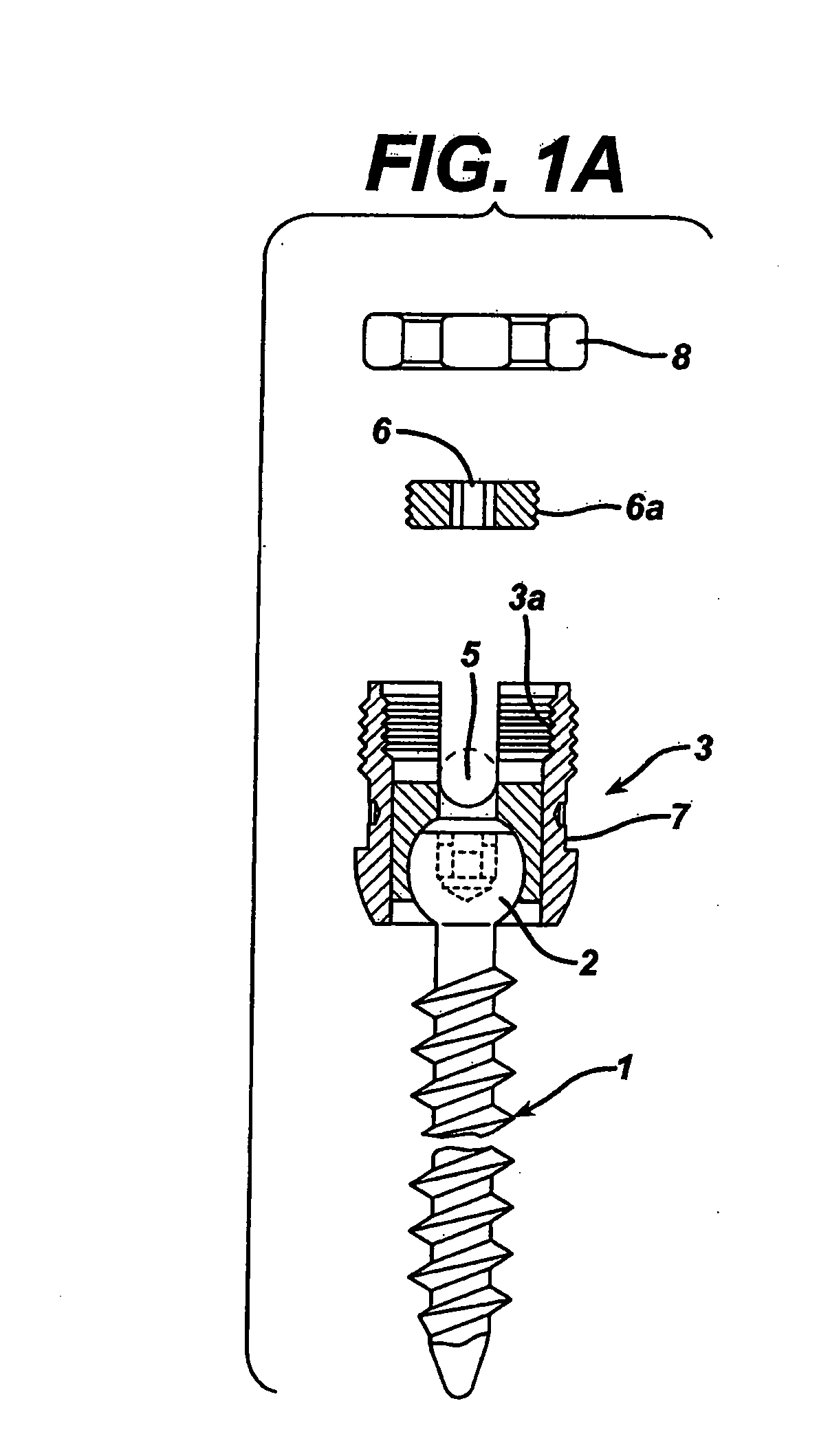

Locking cap assembly for spinal fixation instrumentation

InactiveUS20050033296A1Prevent rotationSuture equipmentsInternal osteosythesisWire ropeLinkage concept

Owner:DEPUY ACROMED INC

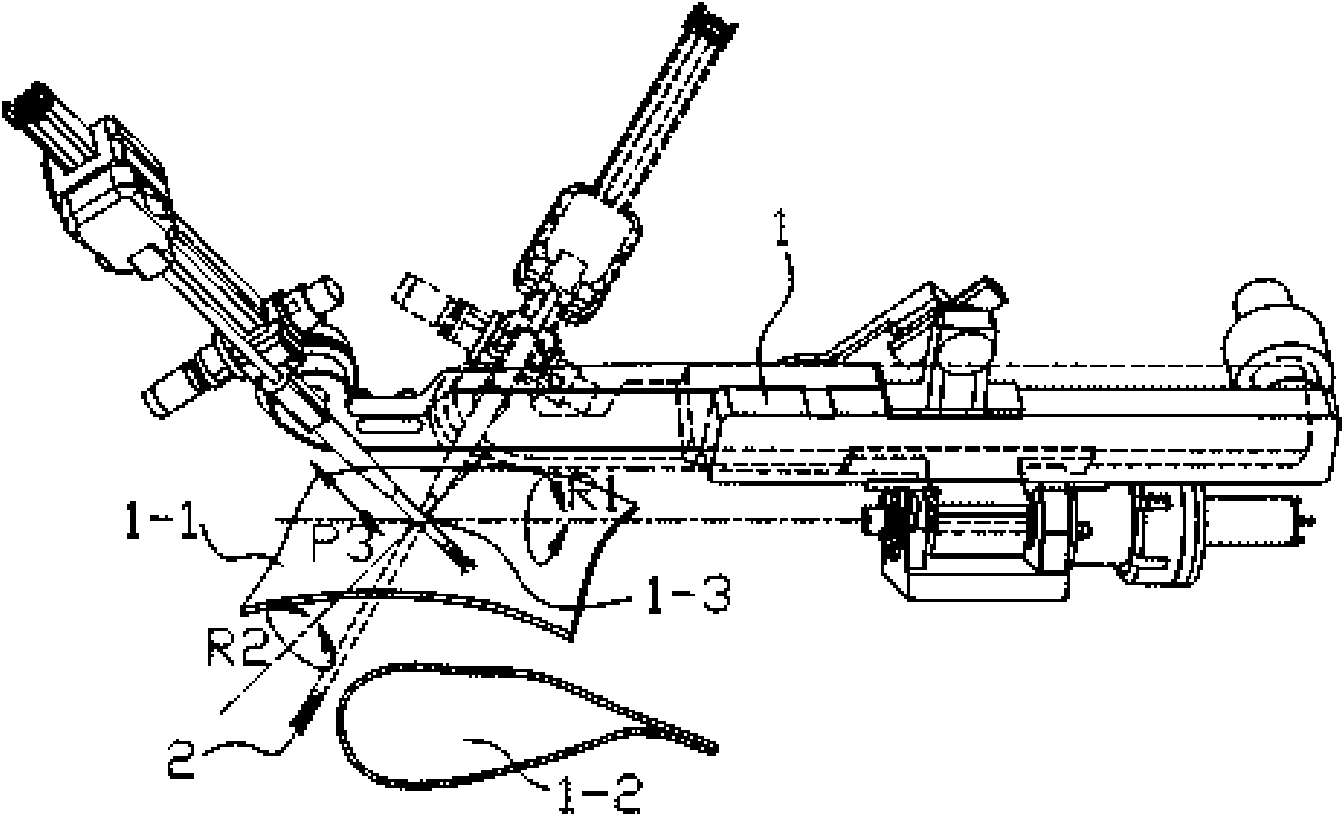

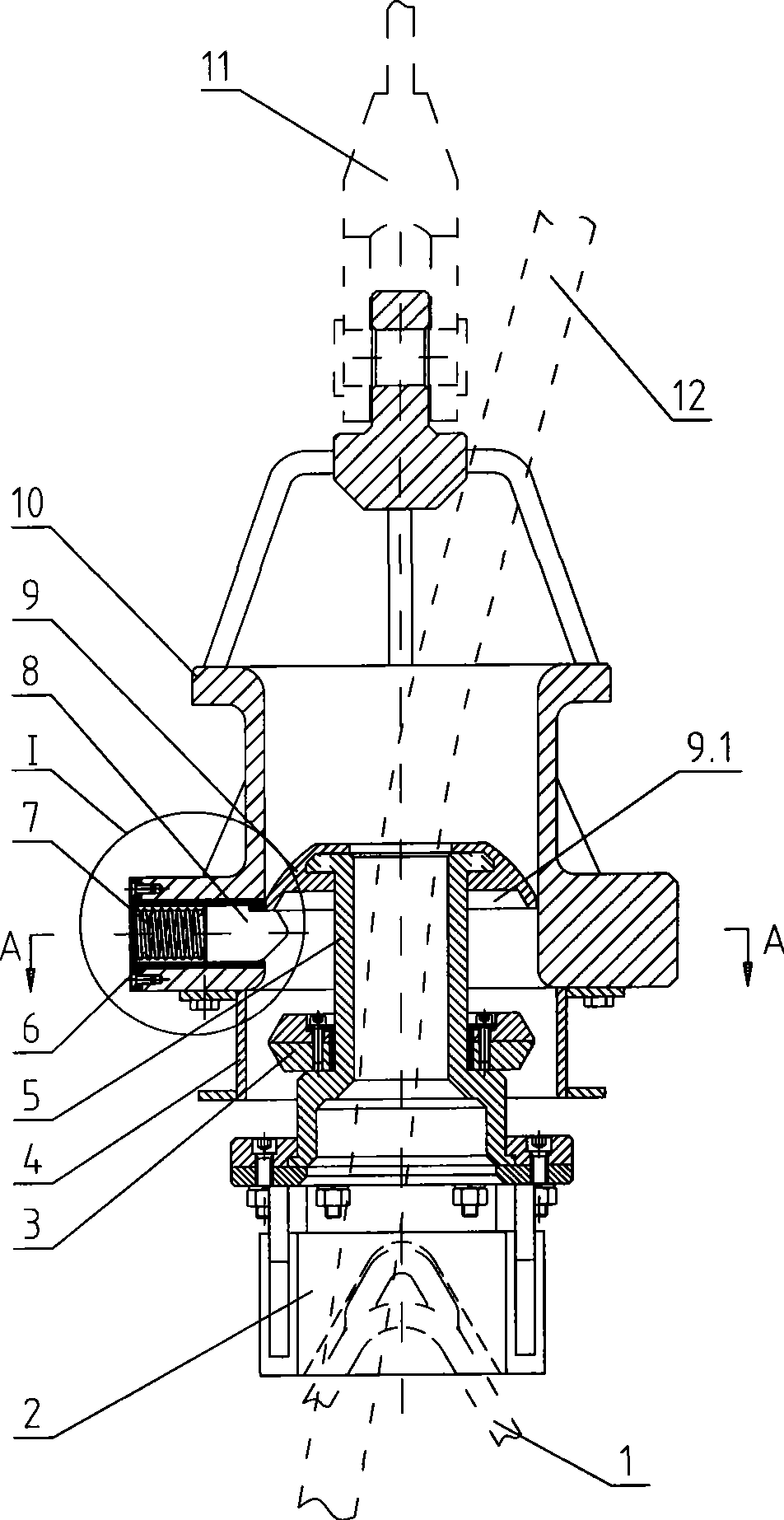

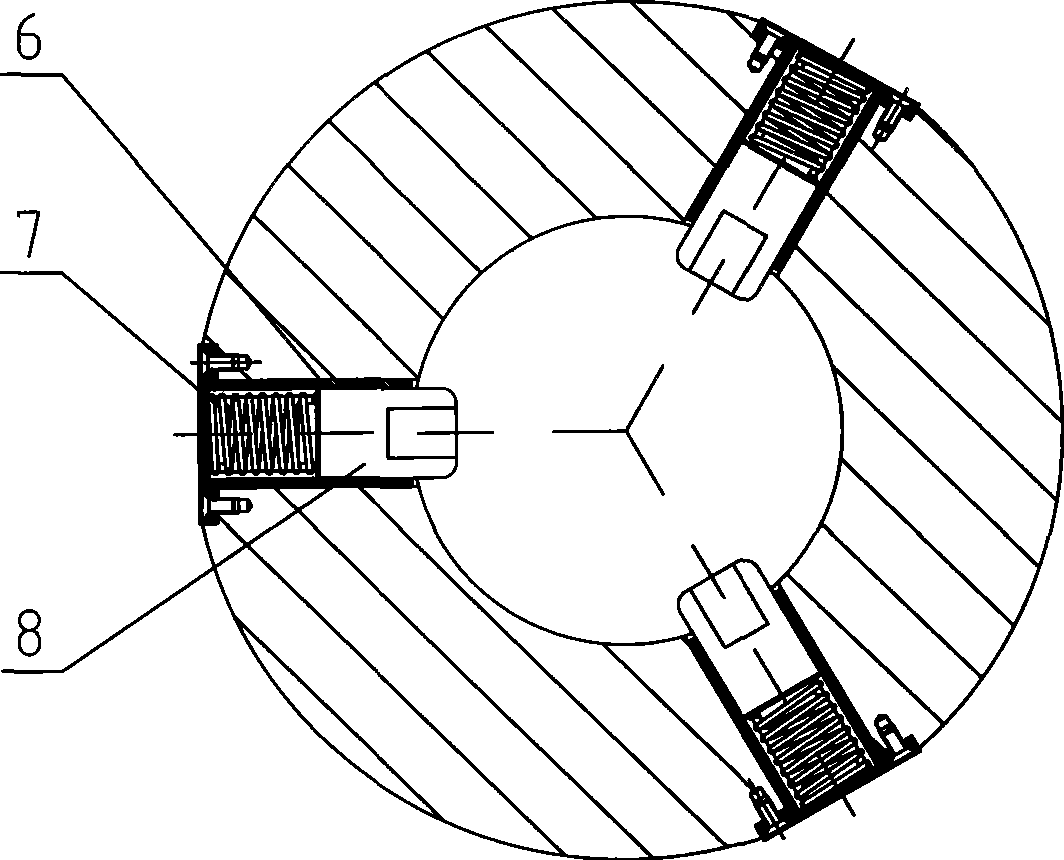

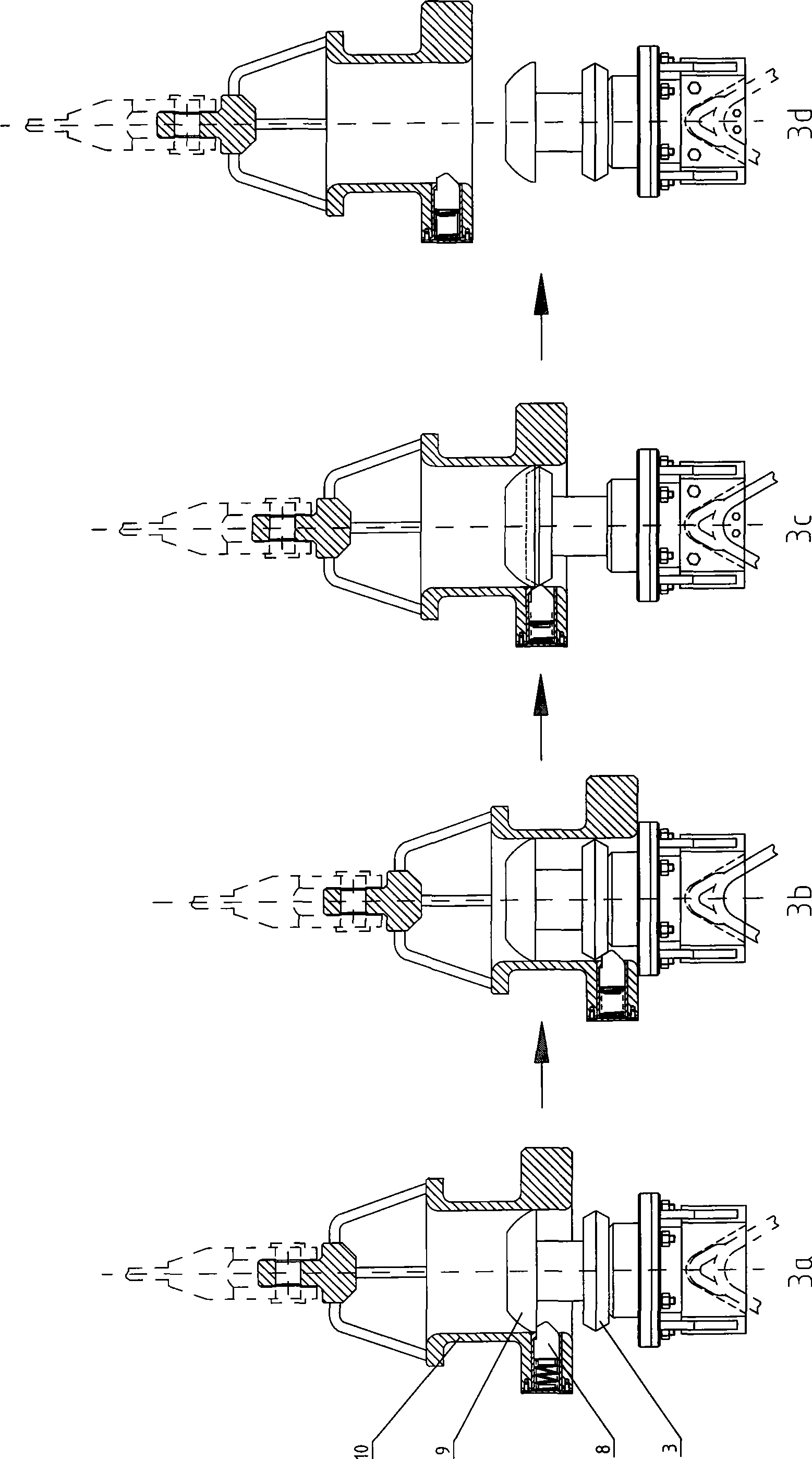

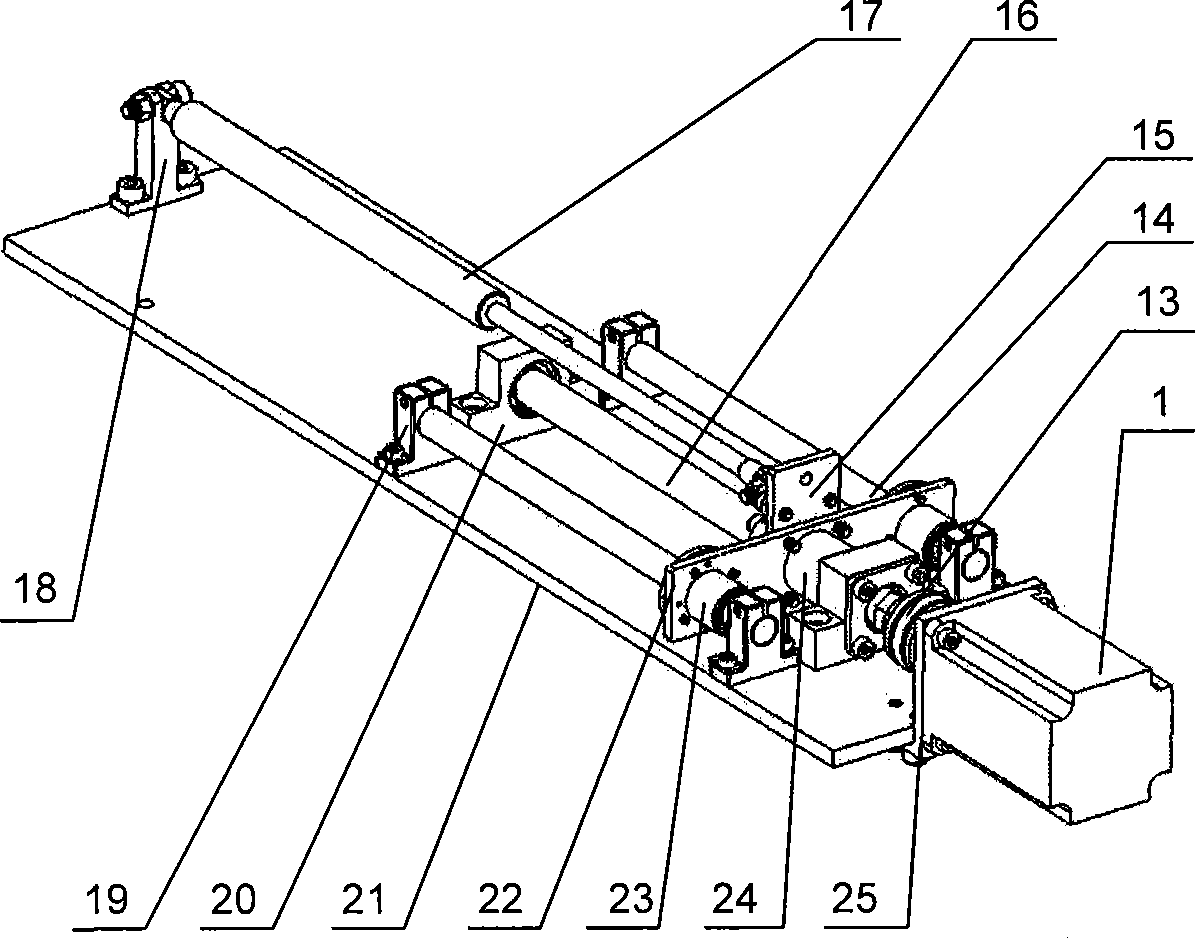

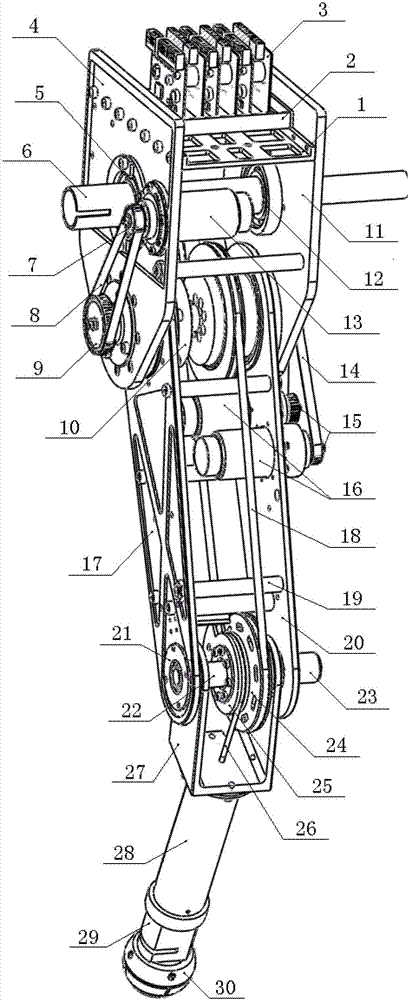

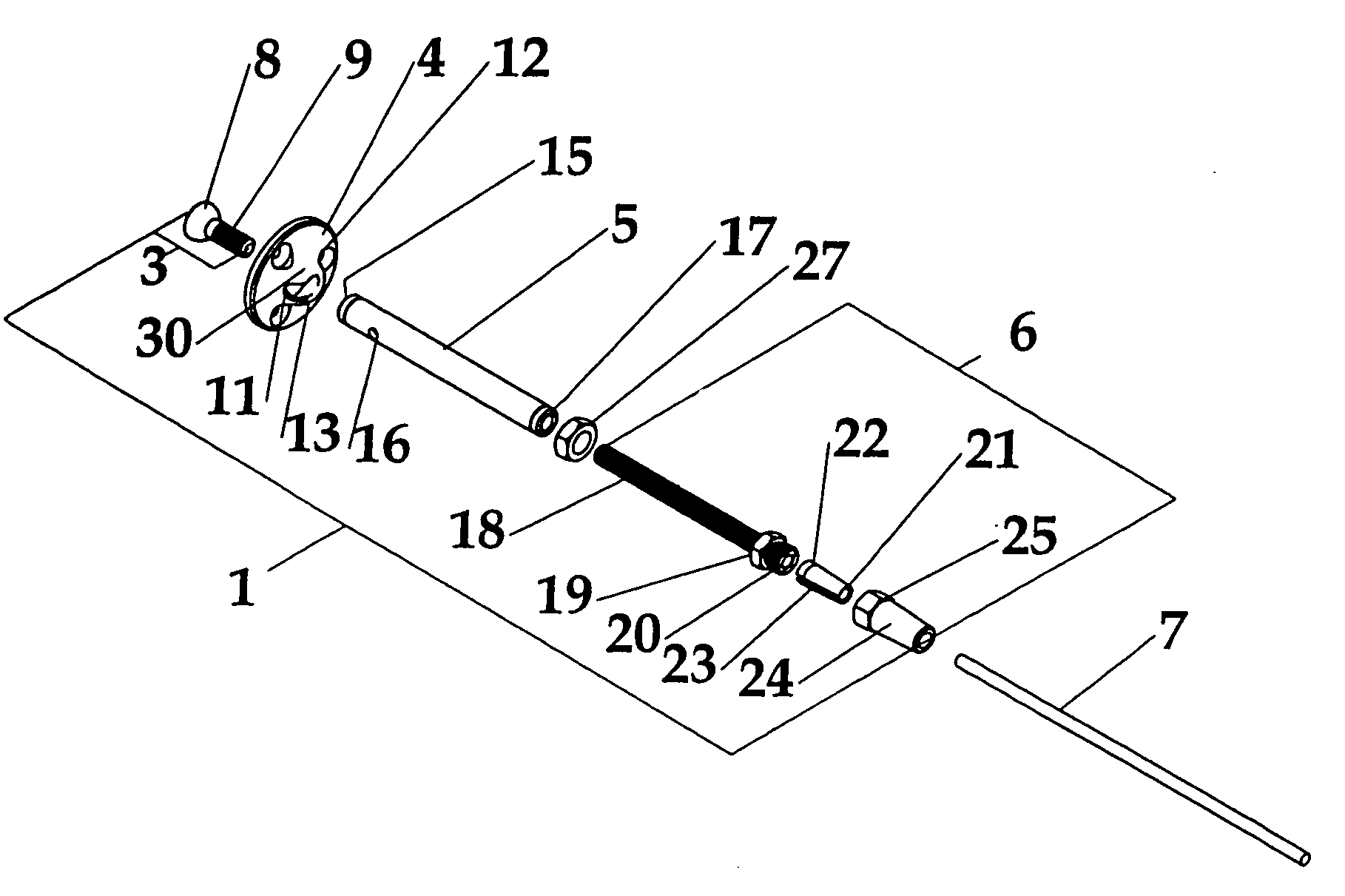

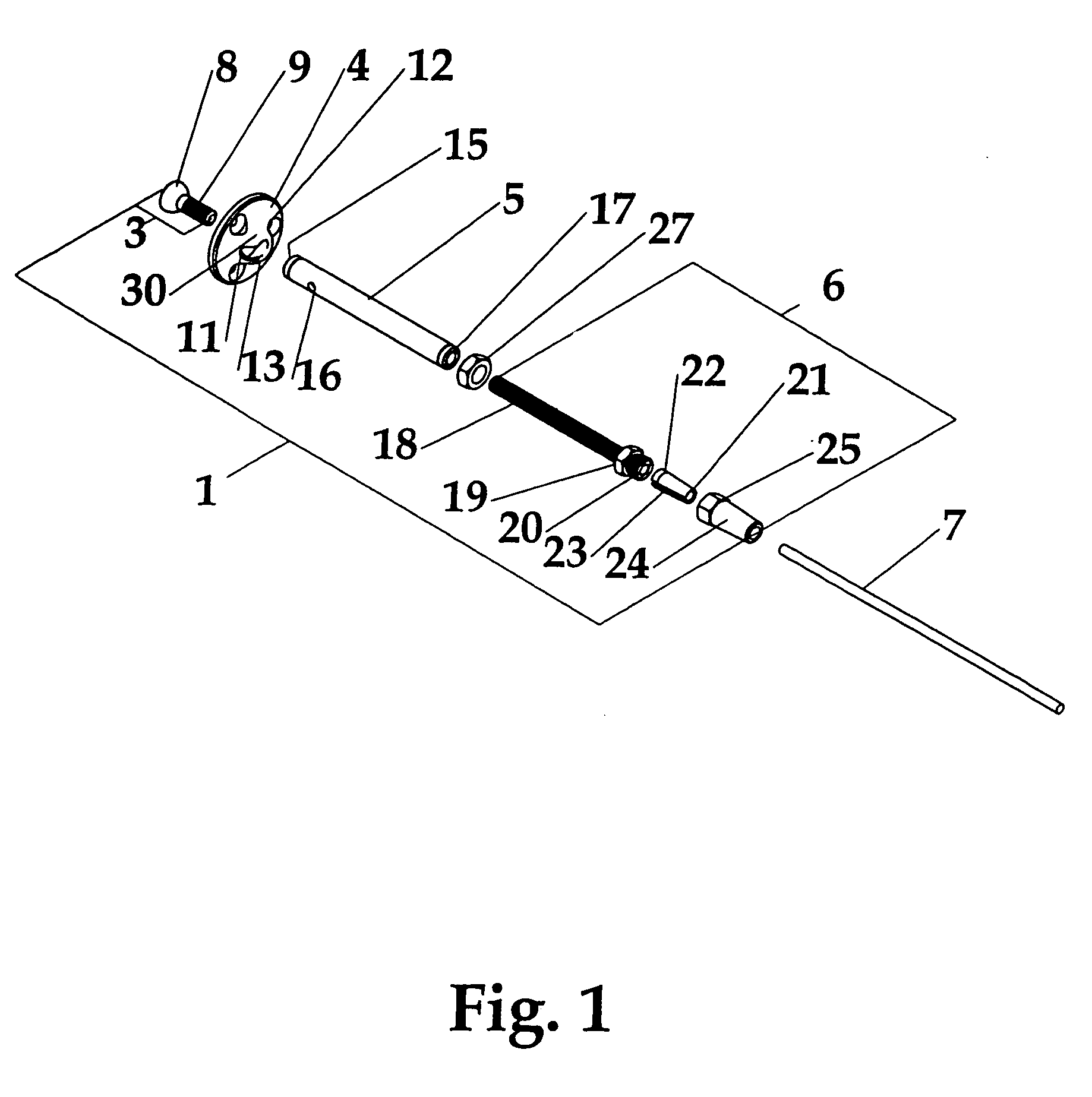

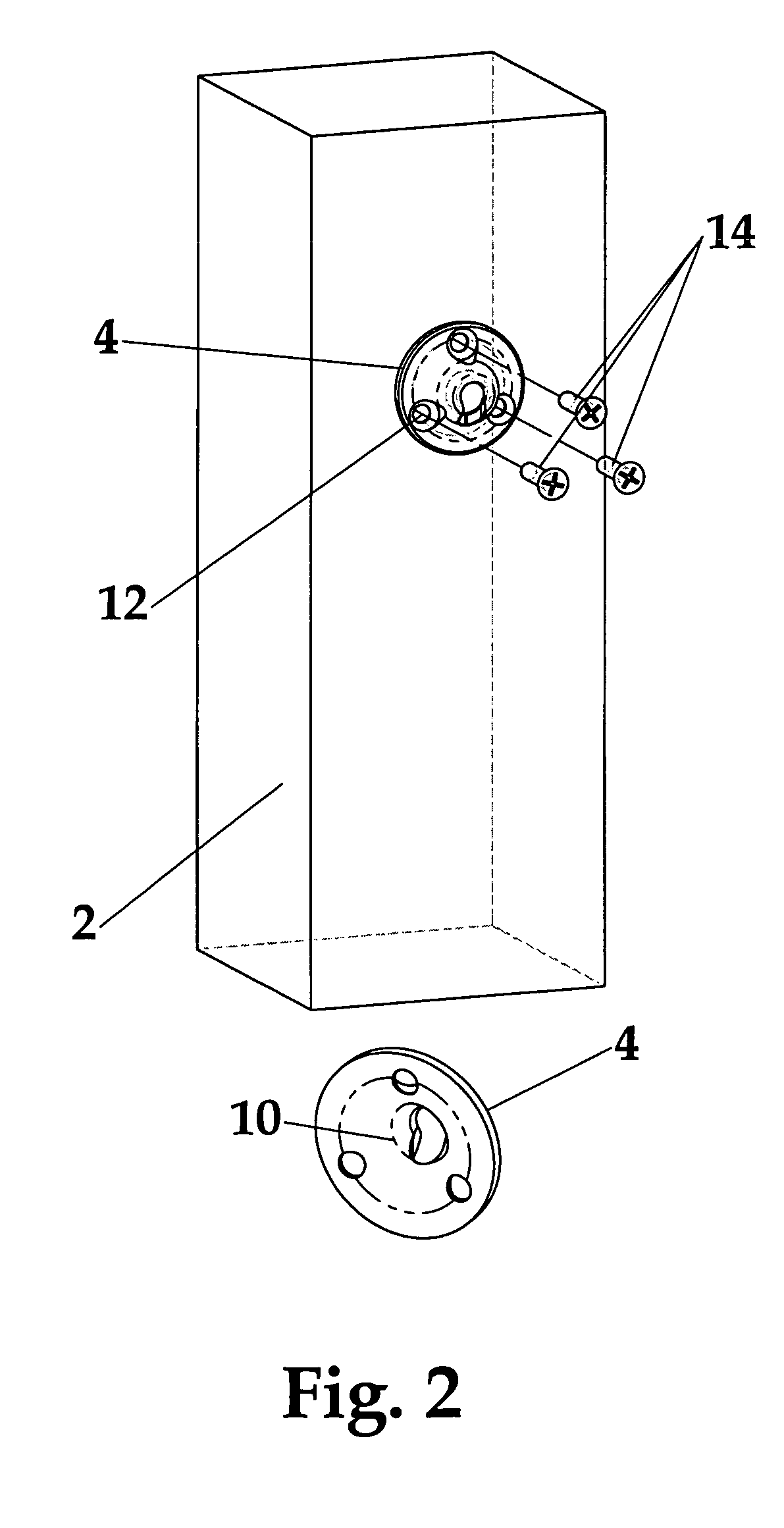

Minimally invasive surgical wire driving and four-freedom surgical tool

ActiveCN101637402ARealize long-distance transmissionEliminate hysteresisSuture equipmentsInternal osteosythesisDrive wheelEngineering

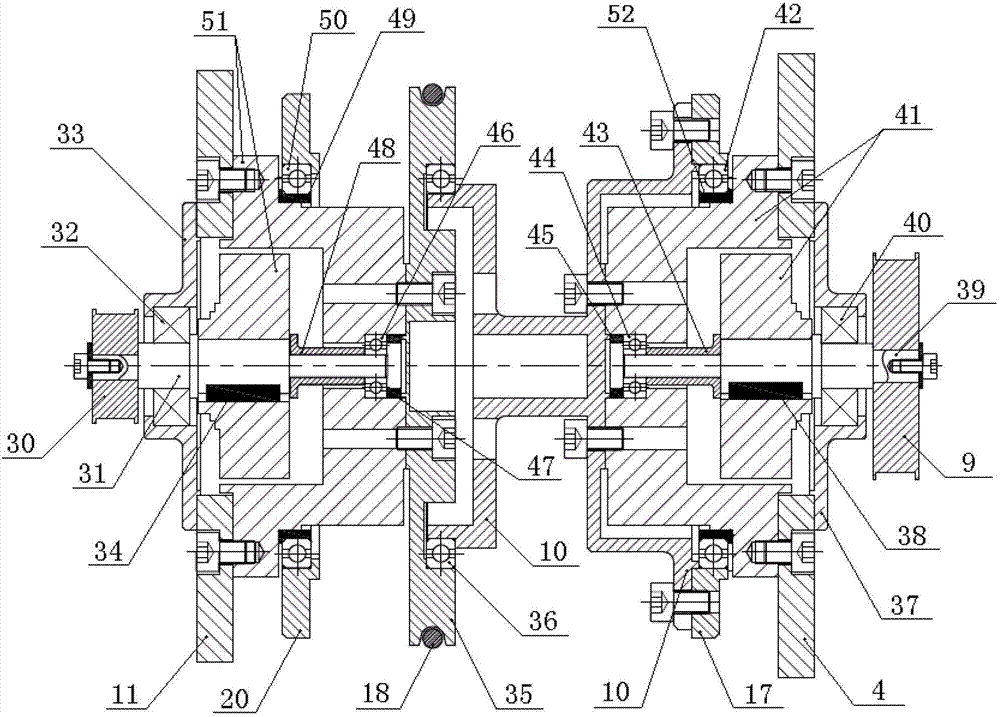

The invention discloses a minimally invasive surgical wire driving and four-freedom surgical tool which comprises a tool connecting rod, wherein one end of the tool connecting rod is connected with the tail end of the tool, and the tail end of the tool comprises a main tool body; the rear end of the main tool body is connected with a main body driving wheel; the front end of the tool connecting rod is provided with a rear shaft pin; both sides of the rear shaft pin are respectively provided with two rear driving wheels which are connected with the main tool body of the tail end of the tool through the main body driving wheel in the middle of the two rear driving wheels; the middle part of the main tool body is provided with two middle driving shafts with middle driving wheels; the front end of the main tool body is provided with a front shaft pin which is connected with a tool pliers body through two pliers body driving wheels arranged on the tool pliers body; each pliers body drivingwheel is fixedly connected with one end of a front wire rope and divides the front wire rope into two parts, and one part is turned for one time, while the other part is turned for two time through the middle wheels. The tool realizes long-distance driving by adopting the wire rope, thereby eliminating return differences and guaranteeing reliable driving.

Owner:SHANDONG WEIGAO SURGICAL ROBOT CO LTD

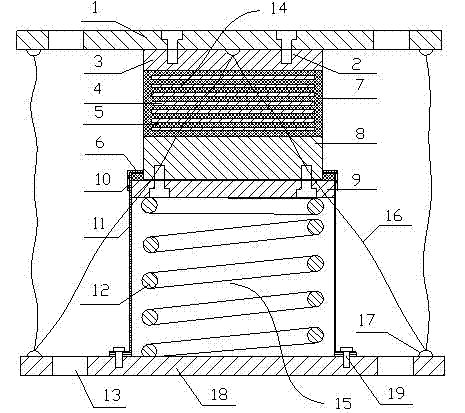

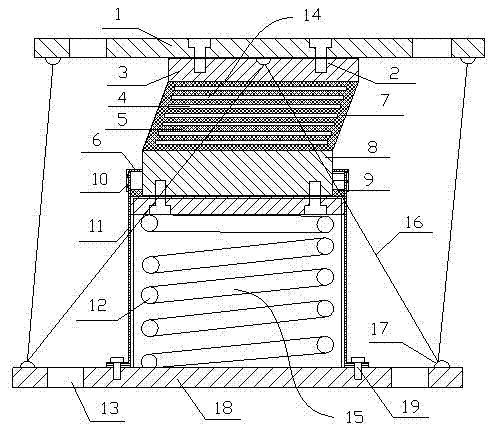

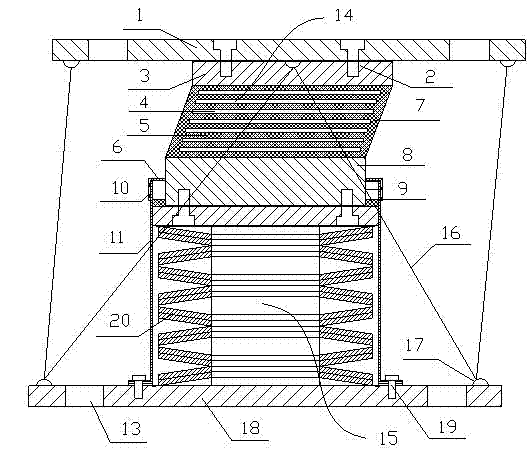

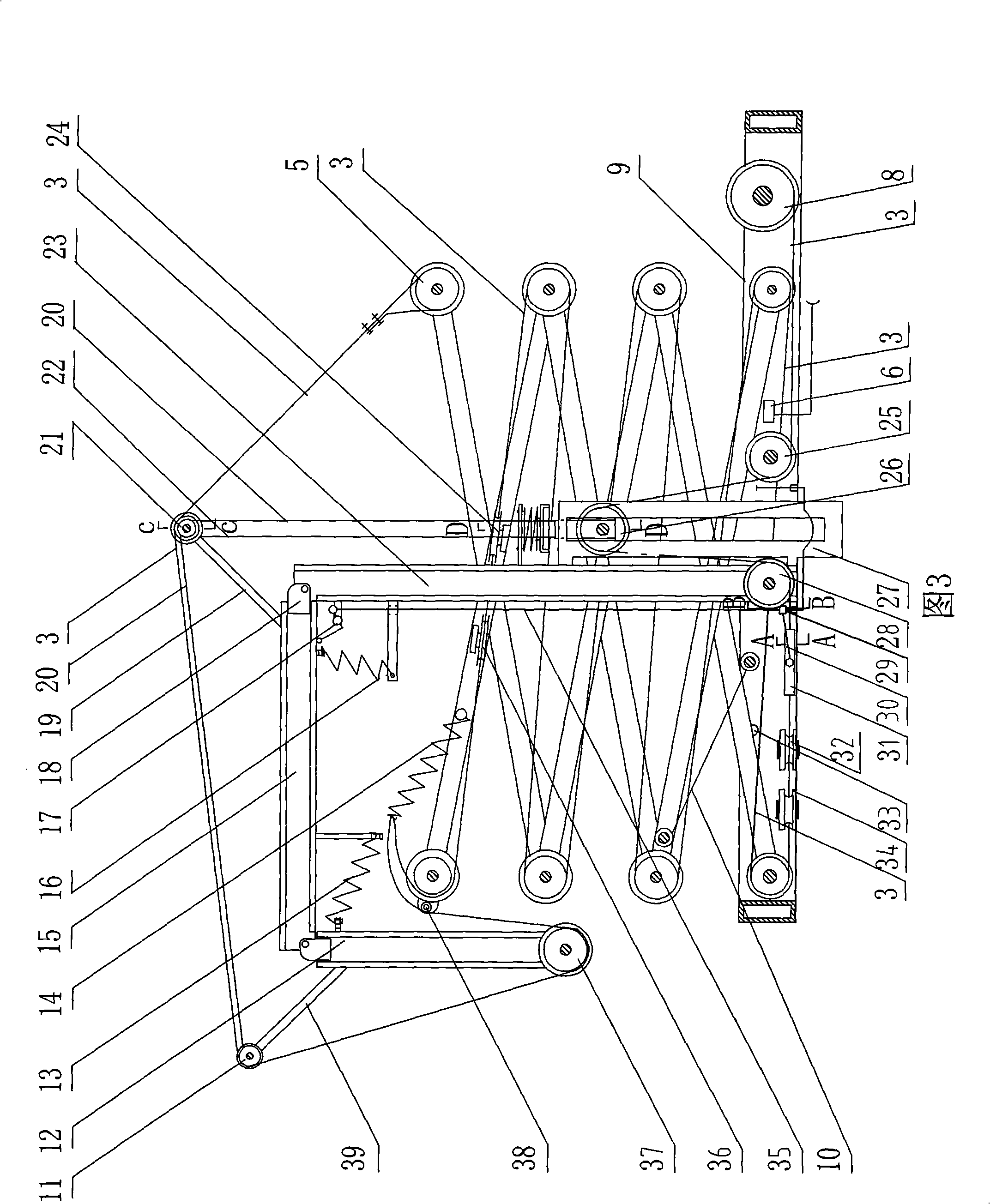

Structural three-dimensional shock isolation and anti-overturning device

The invention relates to a structural three-dimensional shock isolation and anti-overturning device. The main body mechanism of the device is formed by connecting a laminated rubber shock isolation support and a spring shock isolation support in series, and an upper connecting plate and a lower connecting plate are respectively arranged on the upper and lower sides of the main body mechanism. The device is characterized in that: a tensile steel wire rope uniformly distributed on four sides of the main body mechanism is arranged between the upper connecting plate and the lower connecting plate, and the limit deformation of the tensile steel wire rope in the horizontal direction is greater than the horizontal shearing elastic deformation of the main body mechanism. Through the device, the tensile strength of a common three-dimensional shock isolation device is improved, and swing of a high-rise building in an earthquake and even huge tension generated by overturning are resisted; meanwhile, because external tensile steel wire ropes are adopted, the device is convenient to mount and replace and has lower replacing expense.

Owner:FUZHOU UNIV

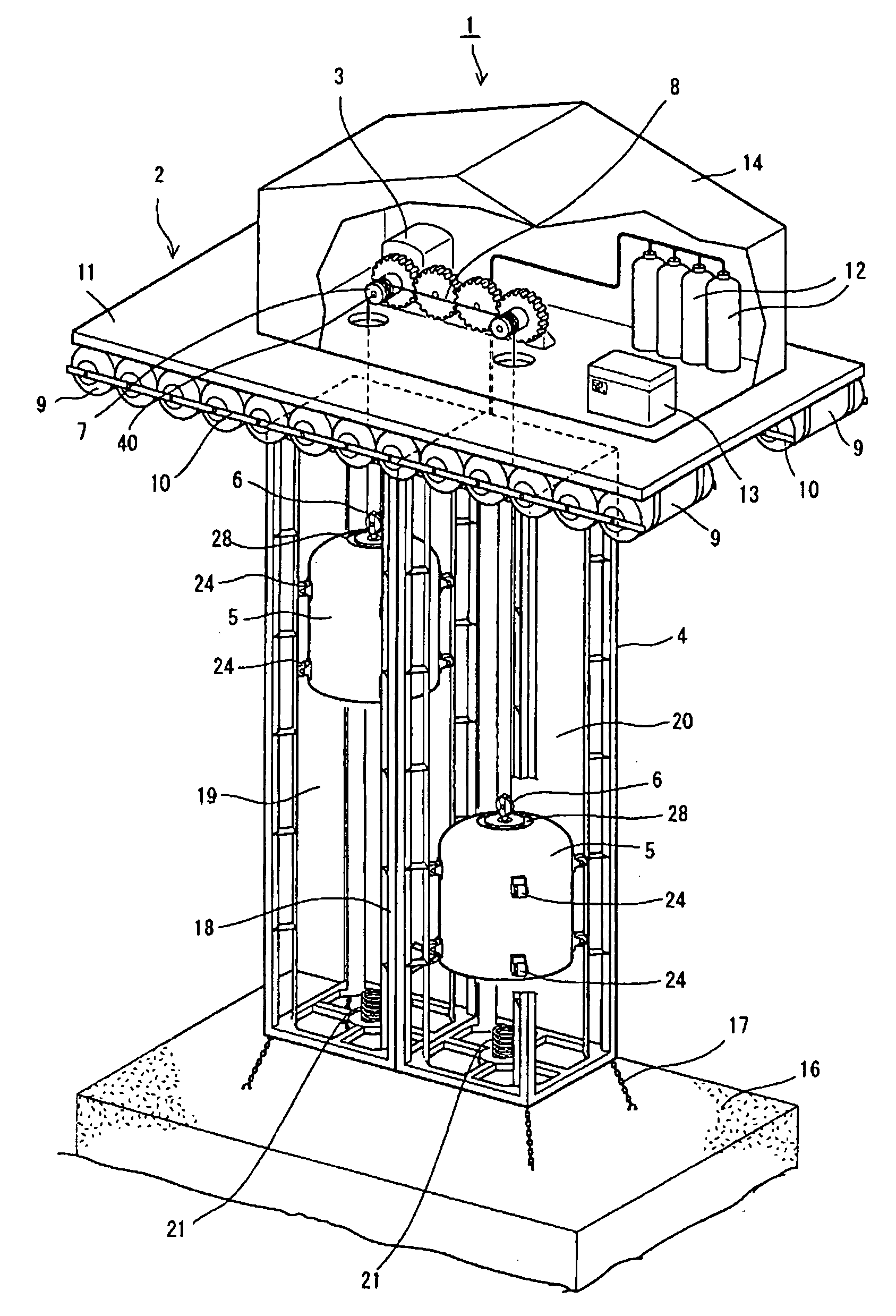

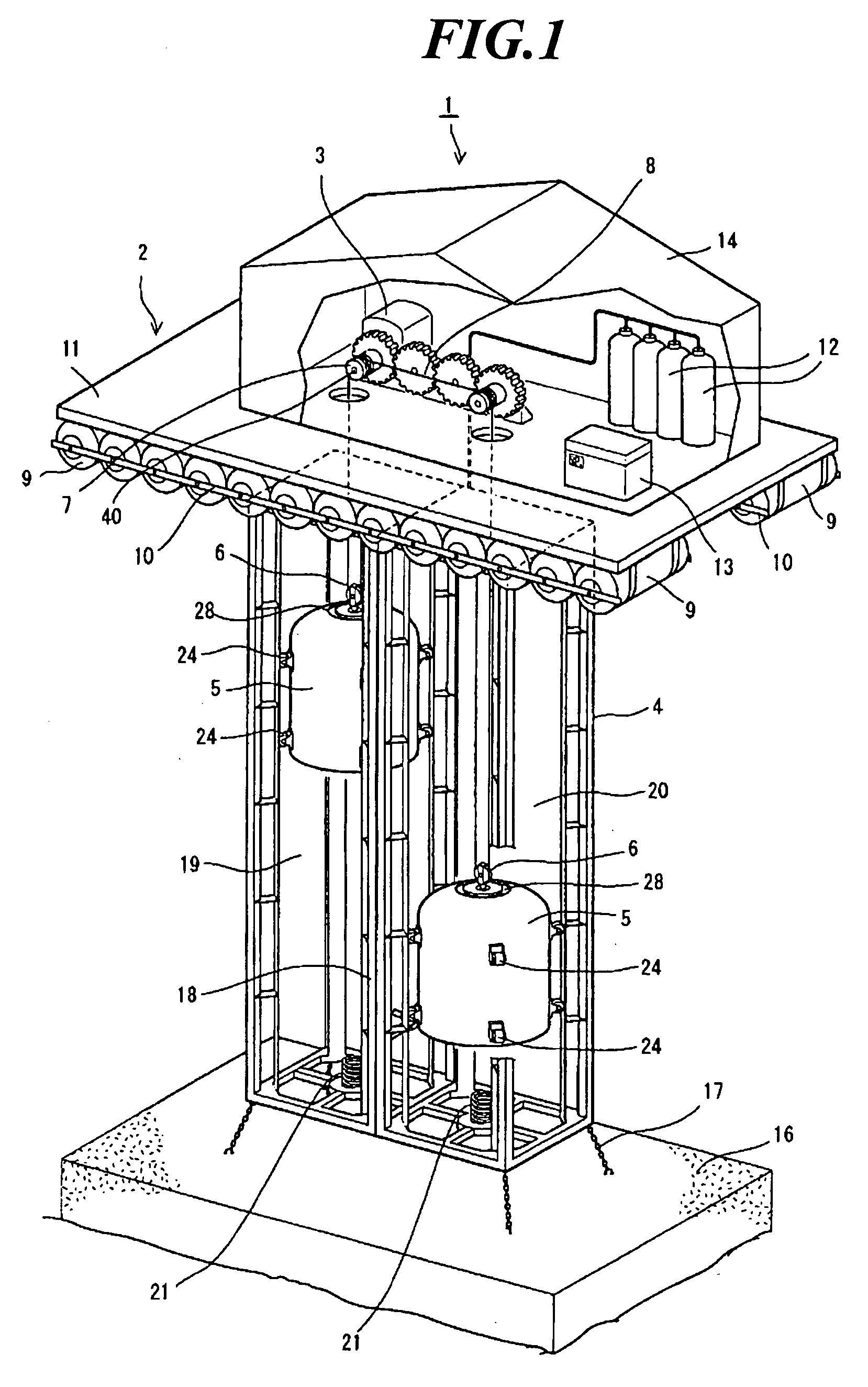

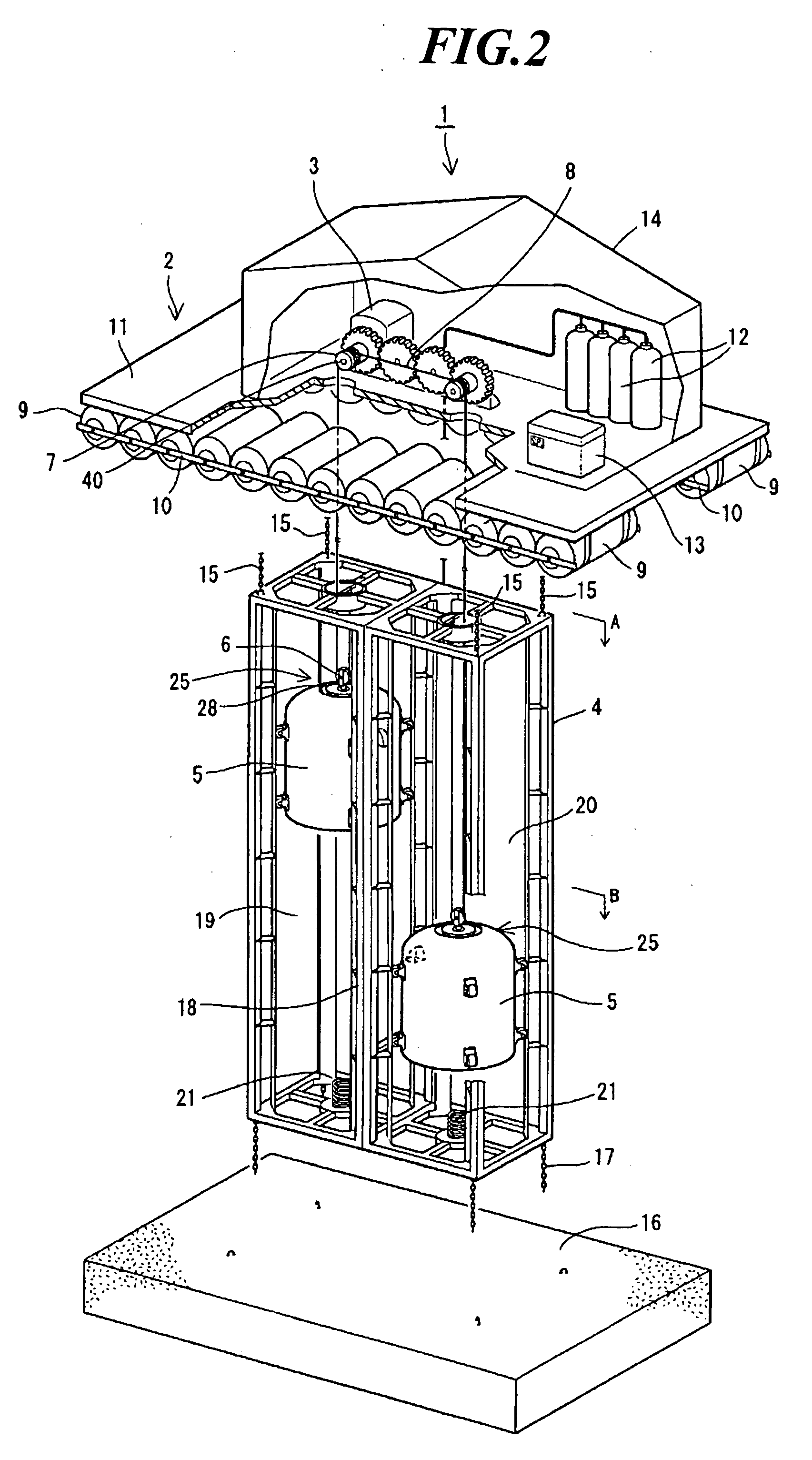

Electric power generator equipment

InactiveUS20060017292A1Generate efficientlyLow costGas turbine plantsWater-power plantsWater bathsBody positions

In order to obtain an electric power generator equipment capable of efficiently generating electric power and capable of reducing cost, without a water bath and constructive maximum height, the electric power generator equipment comprises a floating member for floating on a water surface, a power generator installed on an upper surface of the floating member, a cage suspended from a lower end of the floating member and held to a water bottom, a pair of floating bodies positioned in the cage which is separated, a wire rope whose both ends are fixed to the cage, and an air filling-up apparatus for filling up air to each of the floating bodies. The wire rope is winded to a pulley installed an end portion of each floating body and is winded to a pulley installed on the power generator.

Owner:MATSUBARA TADAHIRO

Silk fibroin fiber bundles for matrices in tissue engineering

InactiveUS20050089552A1Increase differentiationEnhance tissue development processBioreactor/fermenter combinationsPeptide/protein ingredientsFiber bundleLigament structure

The present invention provides a novel silk-fiber-based matrix having a wire-rope geometry for use in producing a ligament or tendon, particularly an anterior cruciate ligament, ex vivo for implantation into a recipient in need thereof. The invention further provides the novel silk-fiber-based matrix which is seeded with pluripotent cells that proliferate and differentiate on the matrix to form a ligament or tendon ex vivo. Also disclosed is a bioengineered ligament comprising the silk-fiber-based matrix seeded with pluripotent cells that proliferate and differentiate on the matrix to form the ligament or tendon. A method for producing a ligament or tendon ex vivo comprising the novel silk-fiber-based matrix is also disclosed.

Owner:ALLERGAN INC

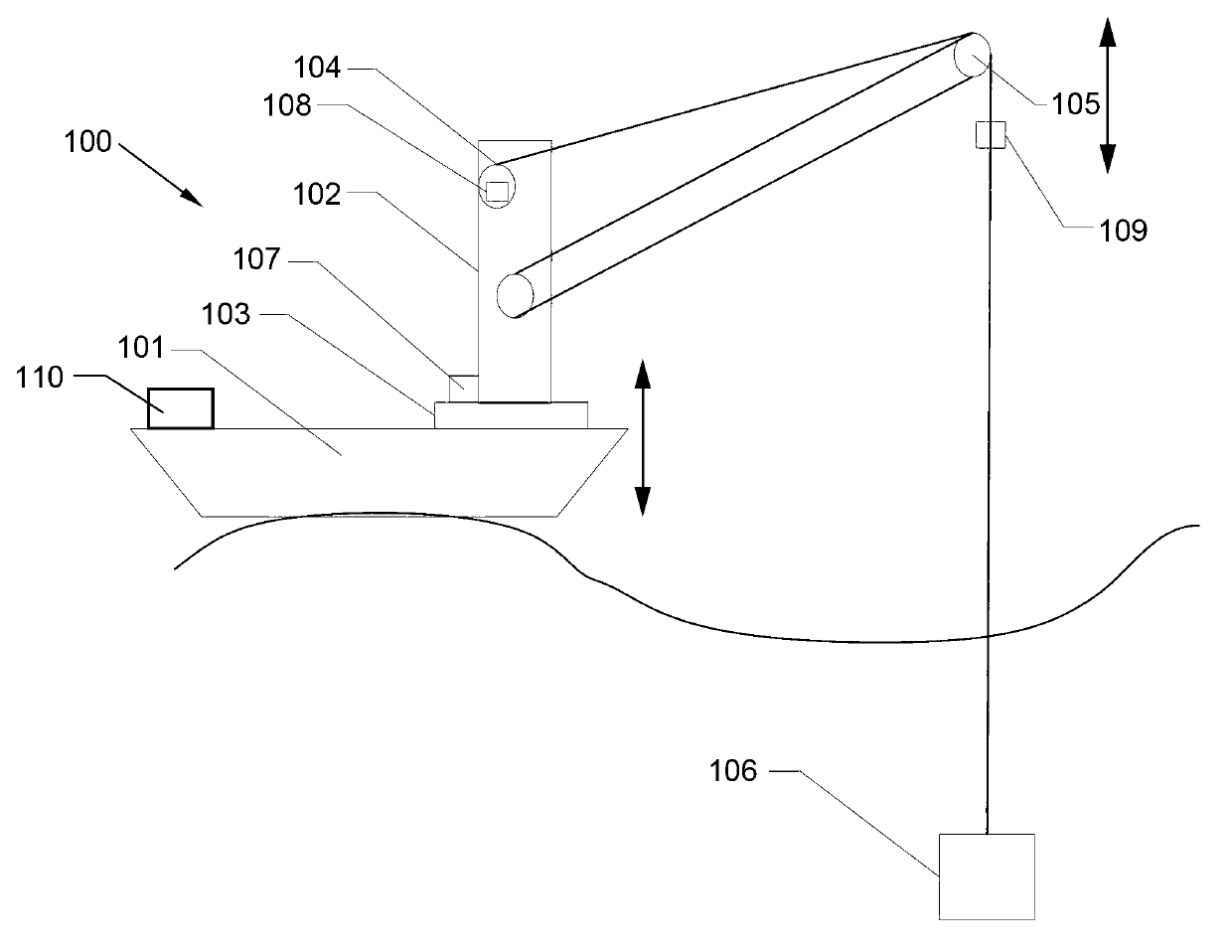

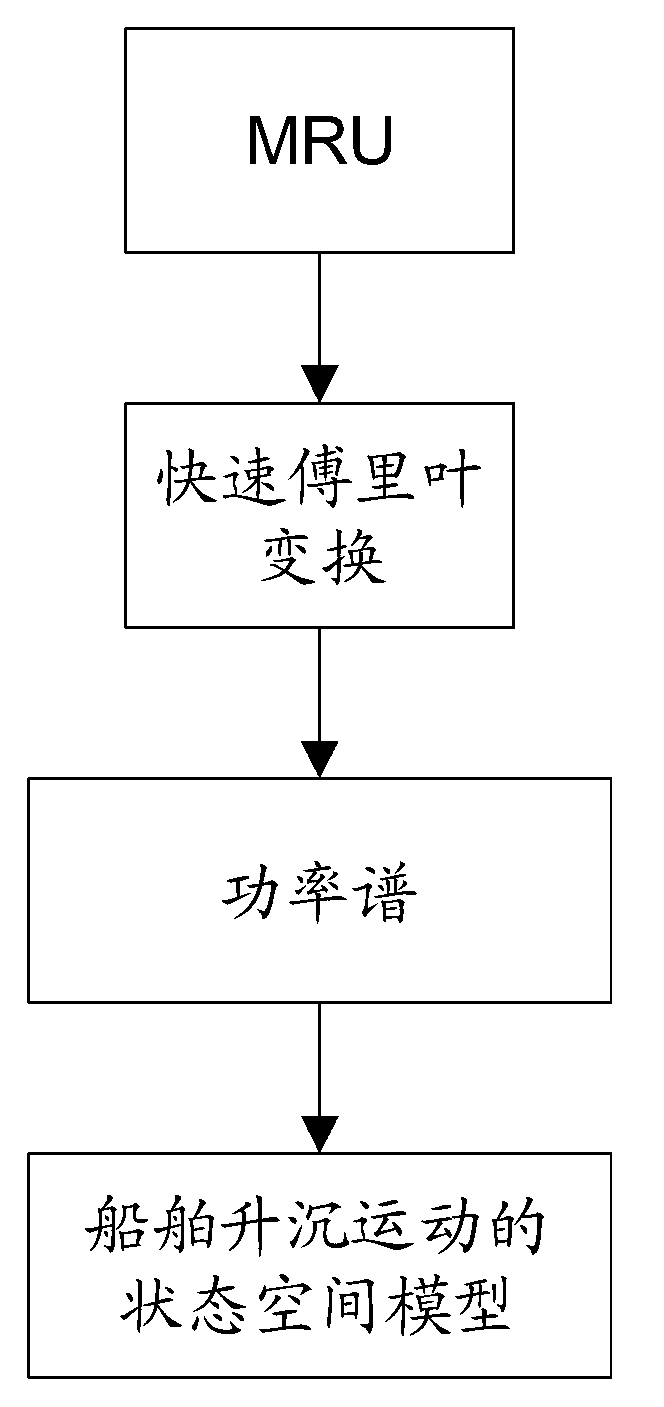

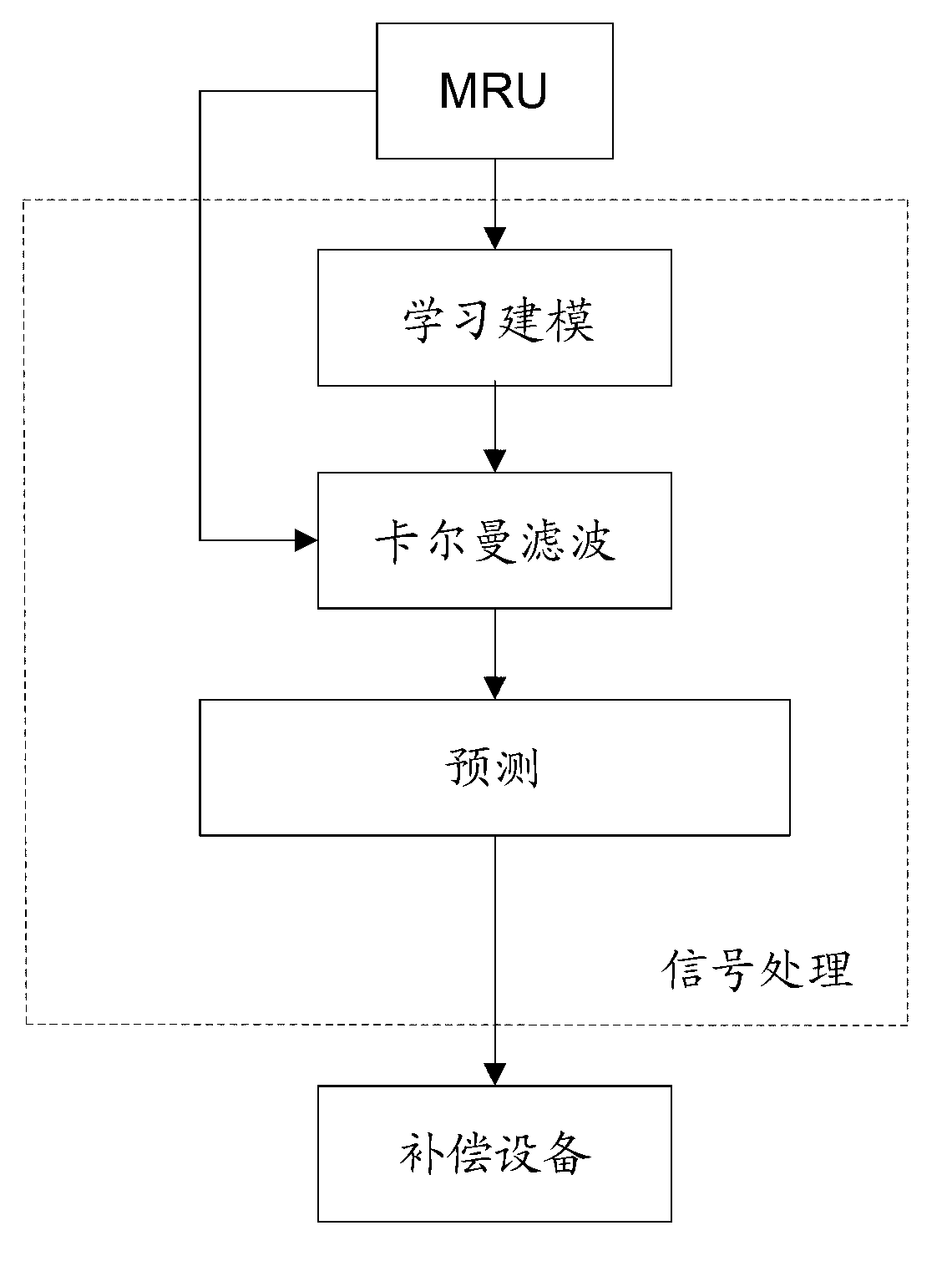

Active heave compensation control system and control method thereof

ActiveCN103318776ARealization of active heave compensationCranesReal-time dataActive heave compensation

The invention discloses an active heave compensation control system comprising a lifting reel, a ship attitude motion sensor, an absolute value encoder, a tension sensor and a compensation unit. The lifting reel is arranged on an offshore crane, a load is suspended by a wire rope which stretches from the lifting reel and goes across a suspension fulcrum at the front end of a support arm, and the load in immersed in water. Real-time detection of heave movement of the ship is performed by the ship attitude motion sensor. Real-time detection of movement of the lifting reel is performed by the absolute value encoder. Real-time detection of dynamic tension of the wire rope is performed by the tension sensor. The compensation unit is connected to the ship attitude motion sensor, the absolute value encoder and the tension sensor. Predictive parameters are calculated by the compensation unit based on historical data and real-time data of the heave moment of the ship, the movement of the lifting reel and the dynamic tension of the wire rope; and compensation voltage is provided for the lifting reel based on the predictive parameters. The invention also discloses an active heave compensation control method.

Owner:SHANGHAI ZHENHUA HEAVY IND

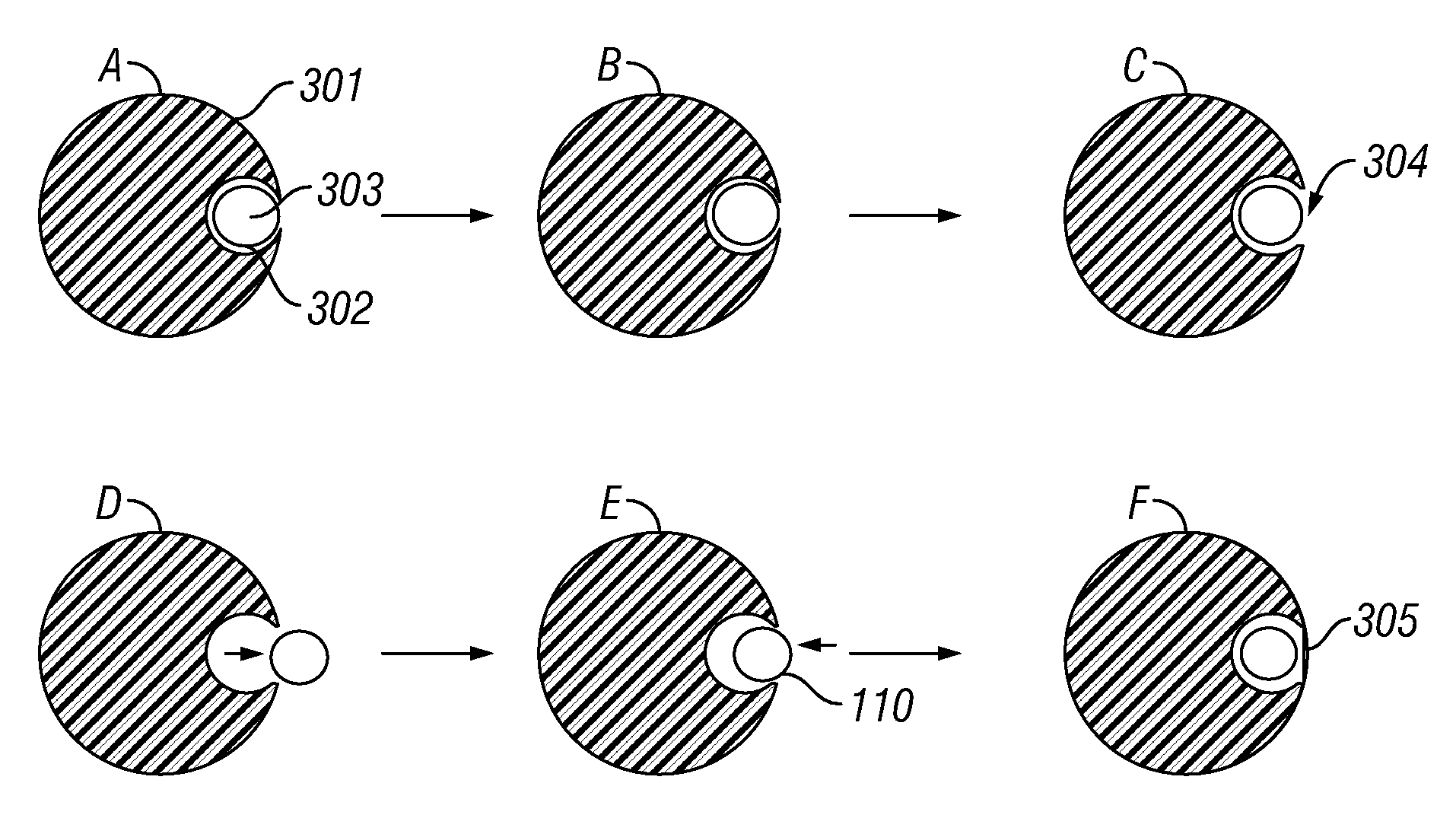

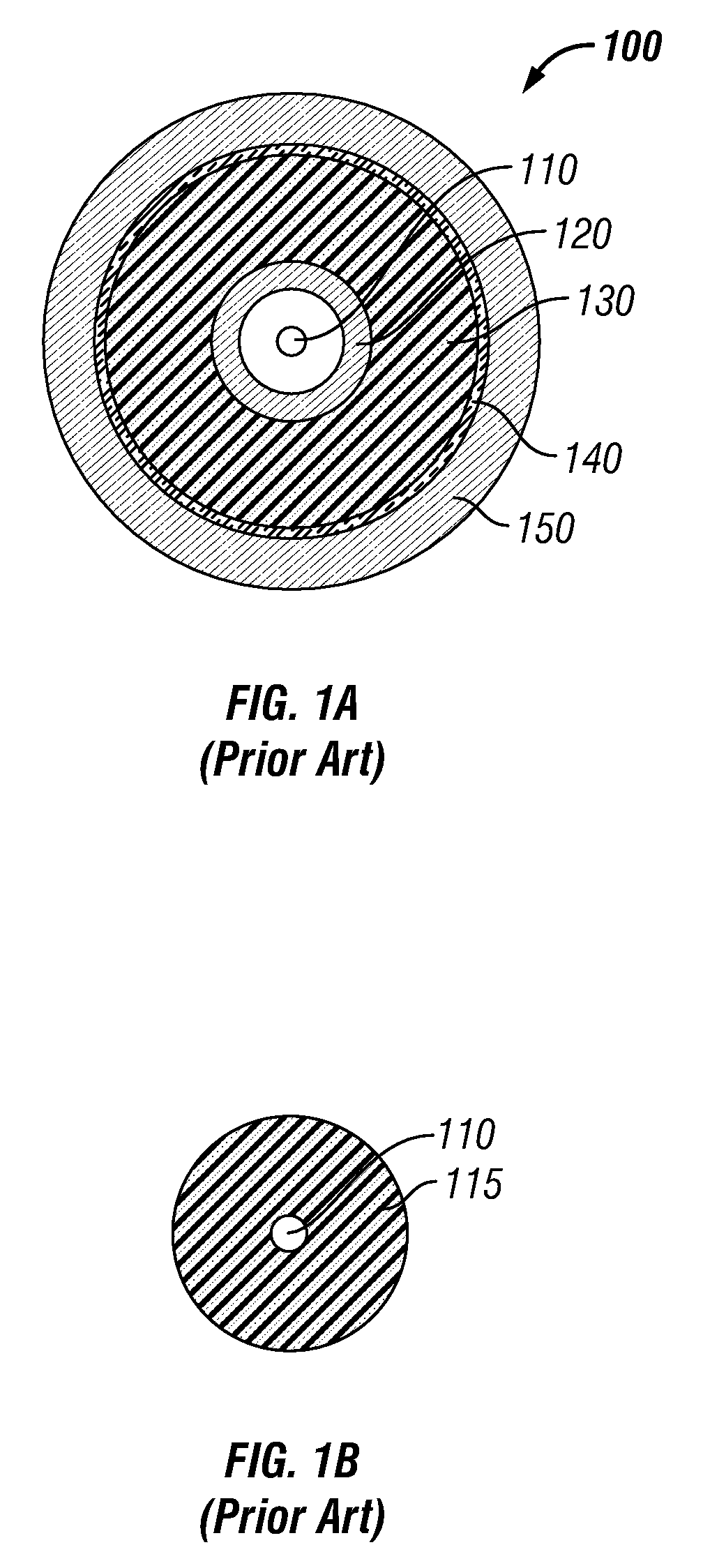

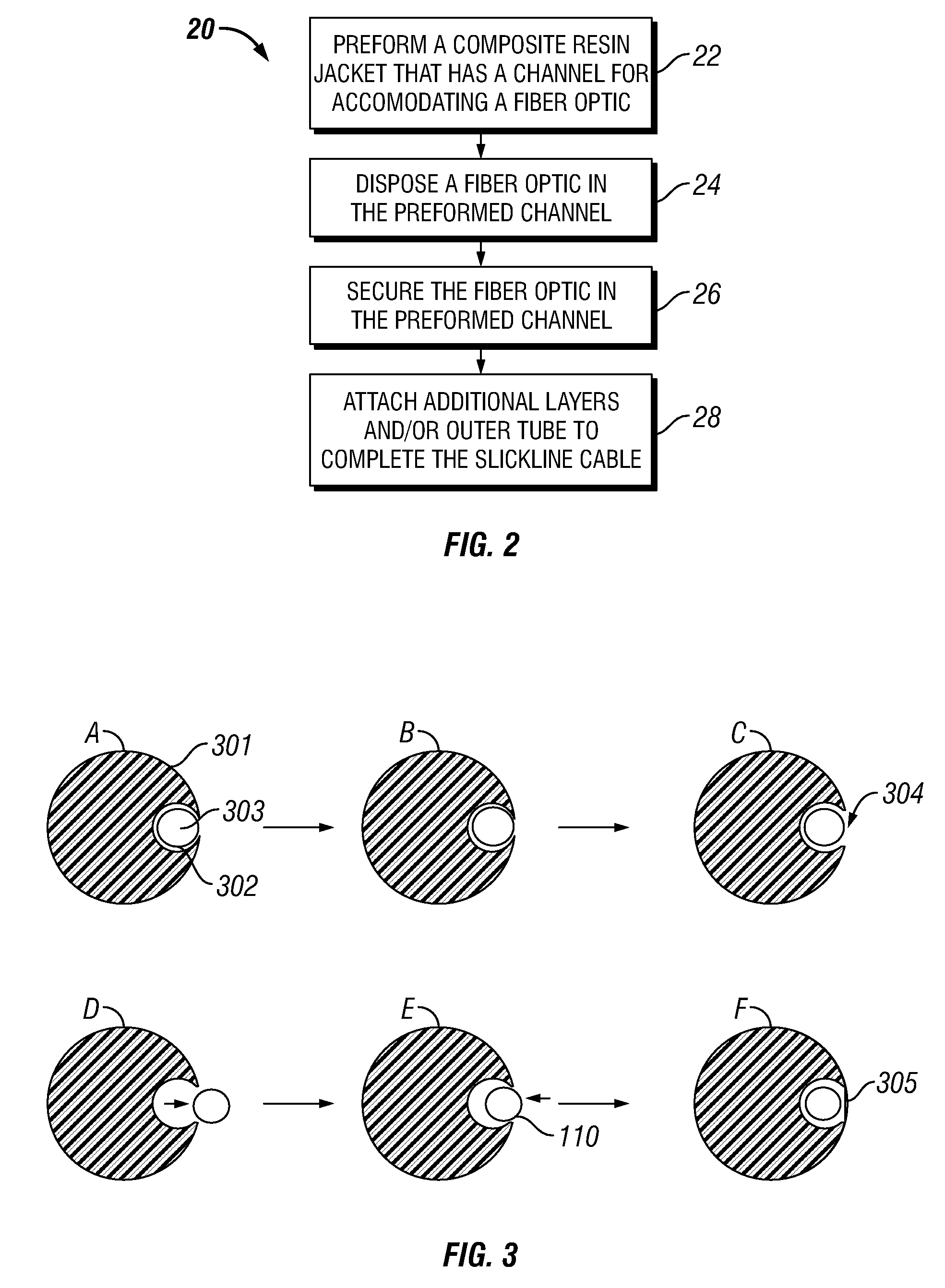

High strength-to-weight-ratio slickline and multiline cables

Slickline cables and methods for preparing such cables are disclosed. A slickline cable includes a pre-manufactured polymer composite rod having a channel therein; an optical fiber disposed in the channel; a fastener securing the optical fiber in the channel, wherein the fastener is selected from the group comprising a polymer tape, a polymer layer, and a combination thereof, and an outer tube disposed outside the polymer composite rod having the optical fiber therein. A method for manufacturing a slickline cable includes preparing a polymer composite rod having at least one channel therein; placing at least one optical fiber in the at least one channel in the polymer composite rod; securing the at least one optical fiber in the at least one channel using a polymer tape, a polymer layer, or a combination of a polymer tape and a polymer layer; disposing an outer tube over the polymer composite rod.

Owner:SCHLUMBERGER TECH CORP

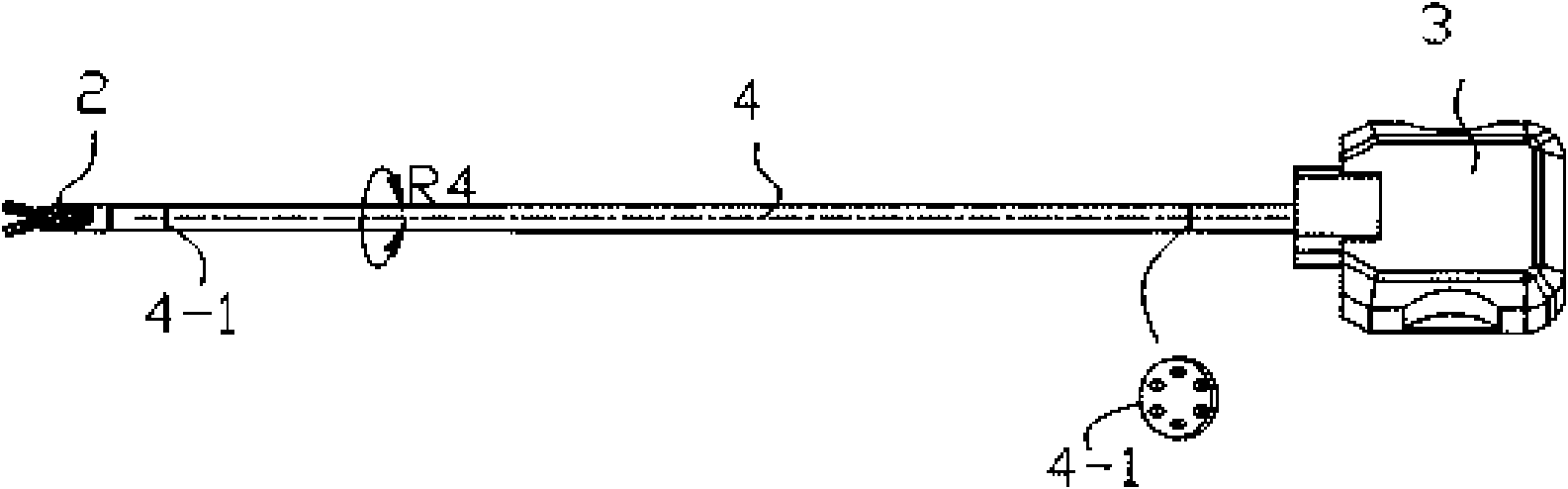

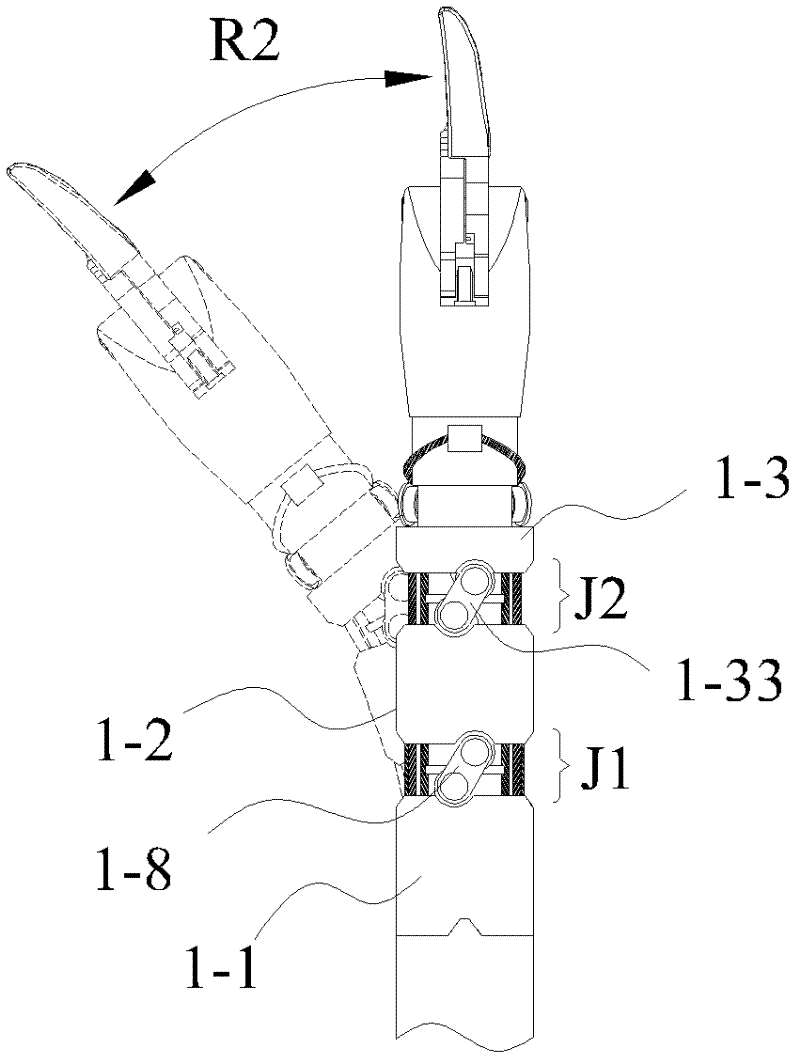

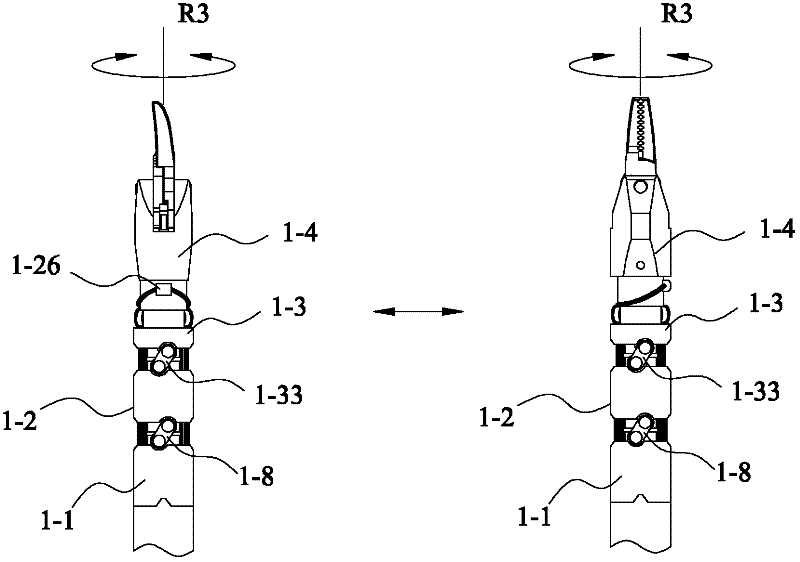

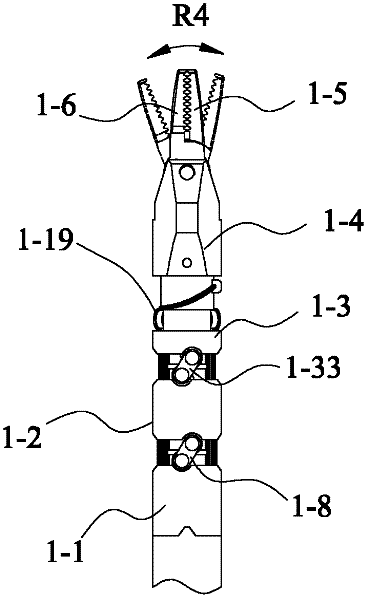

Micro instrument terminal based on module joint and used for minimally invasive surgery robot

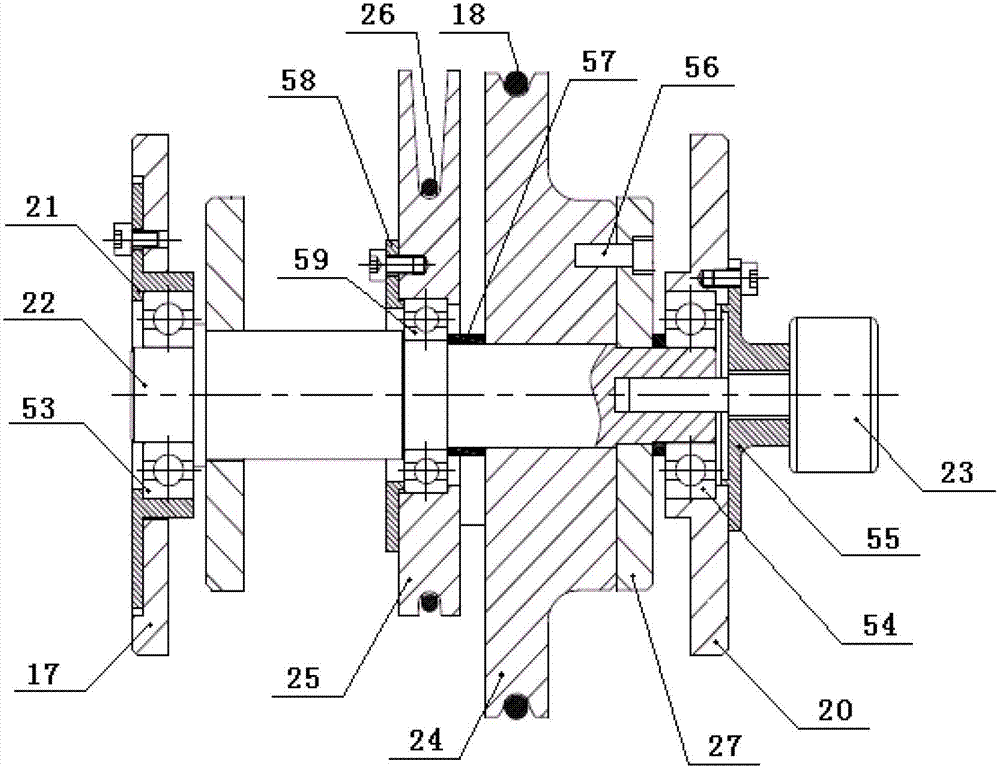

ActiveCN102488554AFlexible to completeThe total length of the closed-loop transmission remains unchangedDiagnosticsSurgical robotsSurgical departmentTarsal Joint

The invention discloses a micro instrument terminal based on module joints and used for a minimally invasive surgery robot. The micro instrument terminal comprises a rotary module of a first four-bar mechanism consisting of a module top end part, a module bottom end part, a lower support and first left and right connection pieces, and a rotary module of a second four-bar mechanism consisting of amodule top end part, a rotary connection shaft, an upper support and second left and right connection pieces; two ends of a first steel wire rope are connected with the top surfaces of the module topend parts, and the other two ends of the first steel wire rope are sequentially connected with a first rotary actuating device through the module bottom end part; two ends of a second steel wire ropeare connected with a rotary connecting shaft, and the other two ends of the second steel wire rope are sequentially connected with the first rotary actuating device through the module top end parts and the module bottom end part; and the upper part of the rotary connecting shaft is inserted into the central hole of a rotary rod and is in clearance and running fit with the rotary rod, and the rotary rod is connected with a surgery apparatus. Complex surgery can be more flexibly completed by adopting the device.

Owner:SHANDONG WEIGAO SURGICAL ROBOT CO LTD

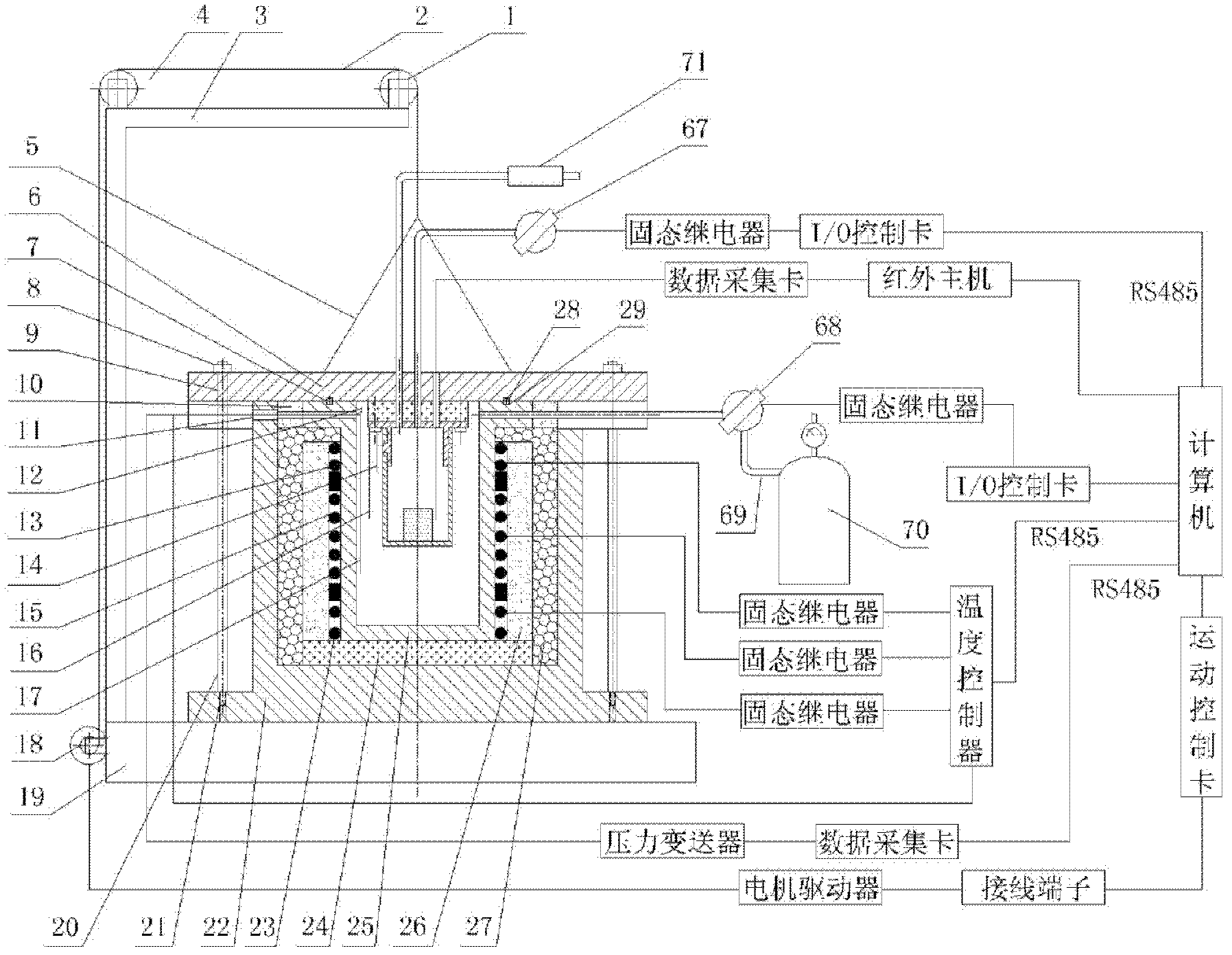

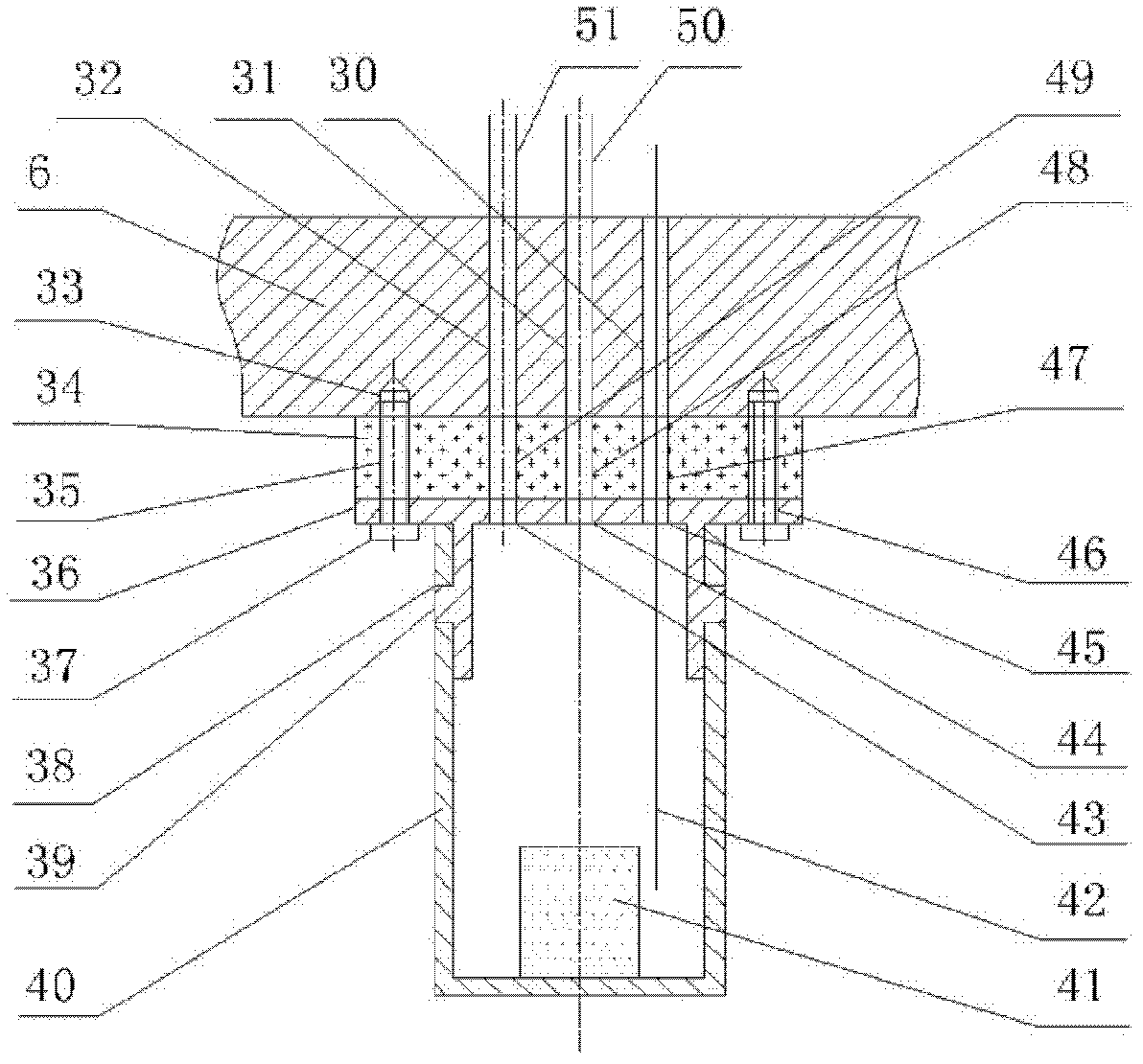

Testing system for critical pressure during thermal explosion of explosives

InactiveCN102608160ARealize multi-point temperature controlImprove uniformityMaterial exposibilityData acquisitionData treatment

The invention discloses a testing system for critical pressure during thermal explosion of explosives. The testing system comprises a pressure-resistance heating unit, a pressure control unit, a sample loader unit, a decomposed product detection unit and a computer; the pressure-resistance heating unit comprises a single-cavity heating furnace body, wherein a temperature sensor which is connected with the computer is arranged in a furnace cavity, and temperature, temperature rise speed and pressure of the single-cavity heating furnace body are controlled by the computer; the pressure control unit comprises a high-pressure gas cylinder, a pressurizing gas channel pipe, a pressurizing electromagnetic valve, a heat conduction layer extension edge pressurizing pipe, a pressure-releasing gas channel pipe, a pressure-releasing electromagnetic valve, a safety valve gas channel pipe, a safety valve and a pressure sensor; the sample loader unit comprises an L-shaped bracket, a stepping motor, two fixed pulleys, a steel wire rope, a furnace cover, a sample reservoir bracket and a sample reservoir; the decomposed product detection unit comprises an infrared sensor which is arranged in the sample reservoir; and the computer is provided with a data acquisition card, a graphic display control and a data processing unit and can be used for identifying the critical state of thermal decomposition to combustion or explosion and acquiring a critical pressure parameter.

Owner:XIAN MODERN CHEM RES INST

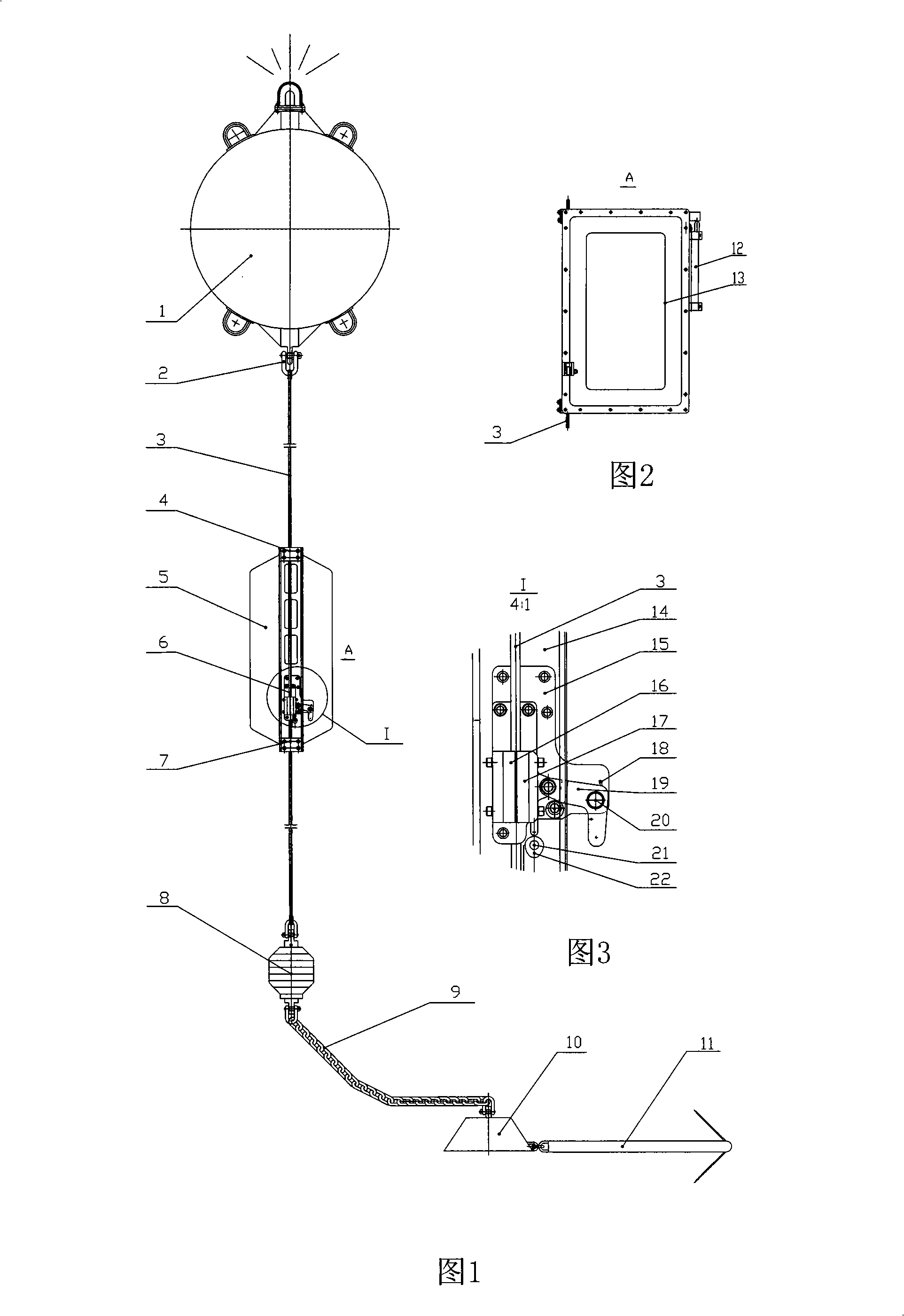

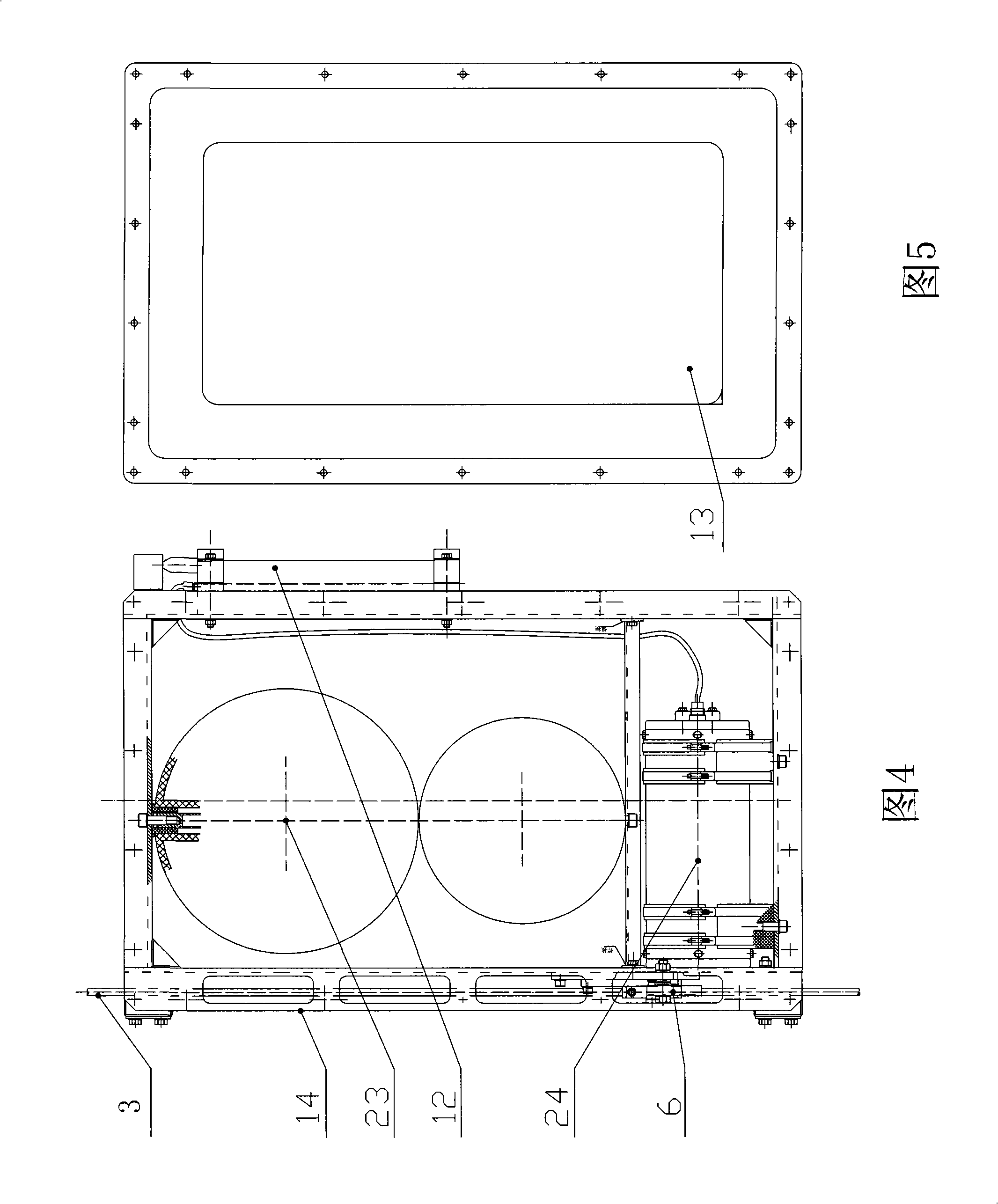

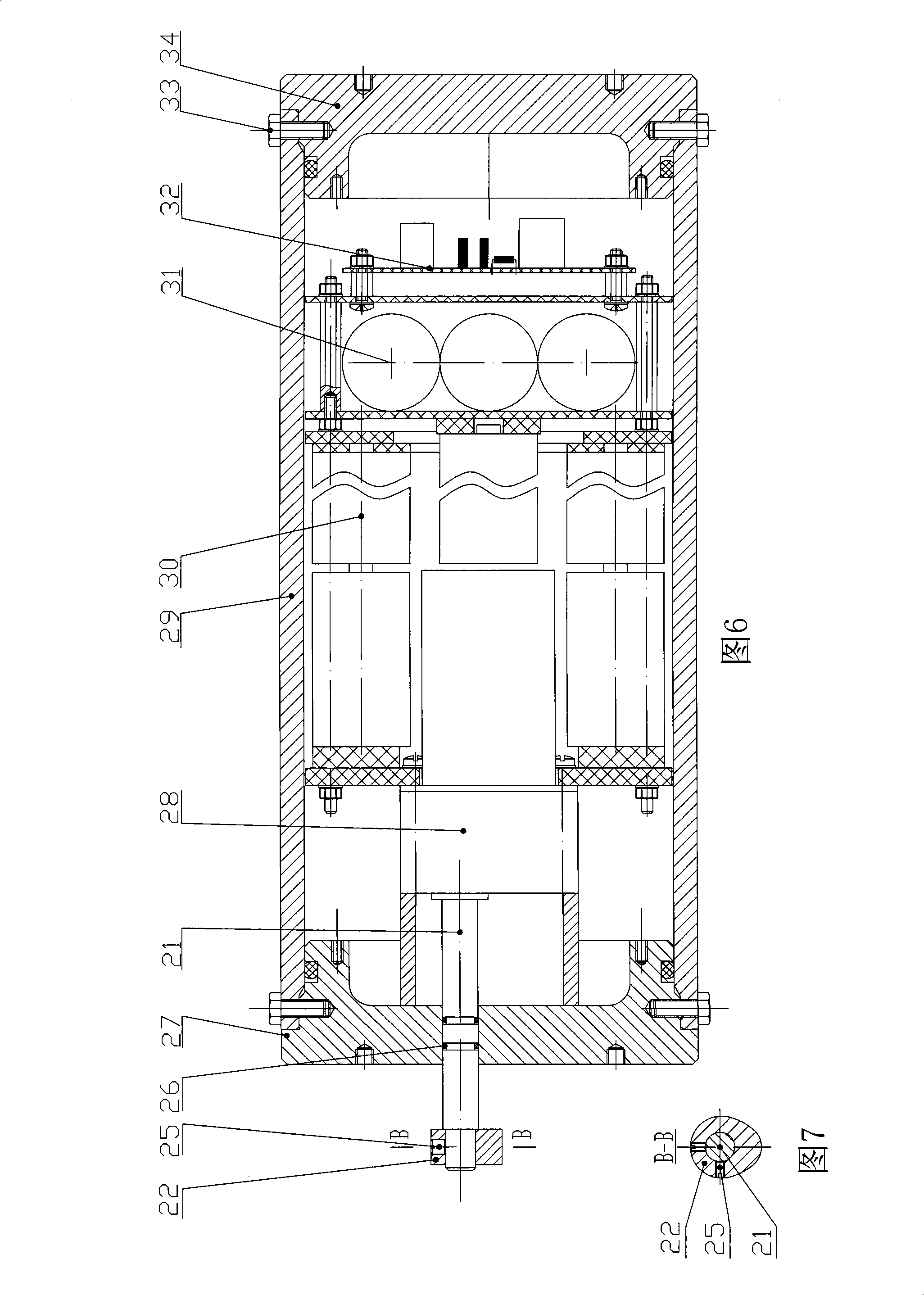

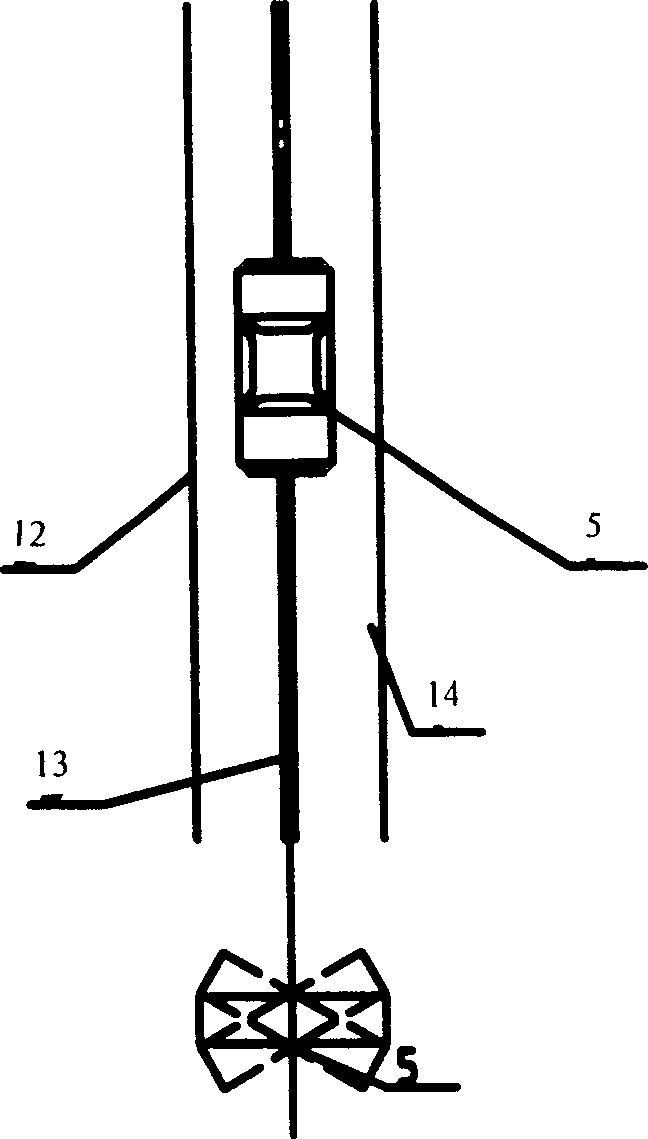

Self-holding marine environmental monitoring system

InactiveCN101318541AEnables continuous vertical profile measurementsReduce in quantityWaterborne vesselsBuoysMarine engineeringMonitoring system

The invention relates to a self-sustaining marine environment monitoring system used in an offshore area. The system comprises a jellyfish, a measuring platform and an anchoring system; wherein, the anchoring system consists of an anchoring injection wire rope, a tension hammer, a storage chain, a heavy anchor block and a high holding power anchor. The measuring platform comprises a platform frame body, a buoyancy floating ball, a motor battery tank, a thermohaline depth sensor, a pawl mechanism, etc. The lower end of the jellyfish is connected with the upper end of the anchoring injection wire rope; the anchoring injection wire rope overhangs from the surface to the bottom of the offshore; the tension hammer, the storage chain, the heavy anchor block and the high holding power anchor are hung at the lower end of the anchoring injection wire rope. The measuring platform is spanned on the anchoring injection wire rope by the special transmission pawl mechanism; the measuring platform dives from the surface to the bottom of the offshore along the anchoring injection wire rope under the driving of the waves, can also float upward by the self positive buoyancy and carry out measuring and storing on the water body parameters by a sensor carried by the measuring platform during the upward floating process. The self-sustaining marine environment monitoring system has the characteristics of high efficiency, energy saving, low cost and high anti-biological adhesive ability.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

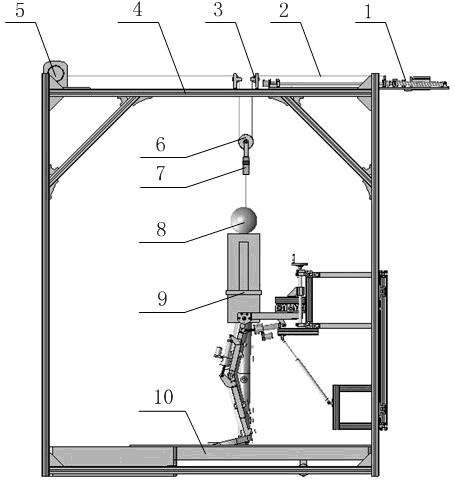

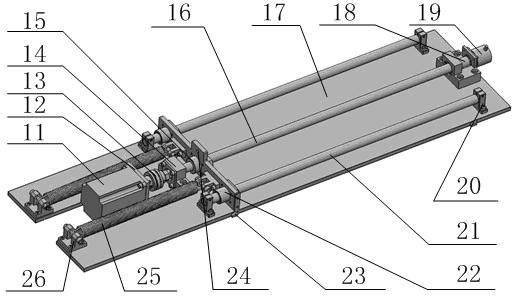

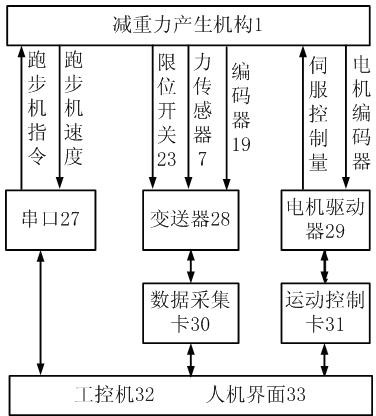

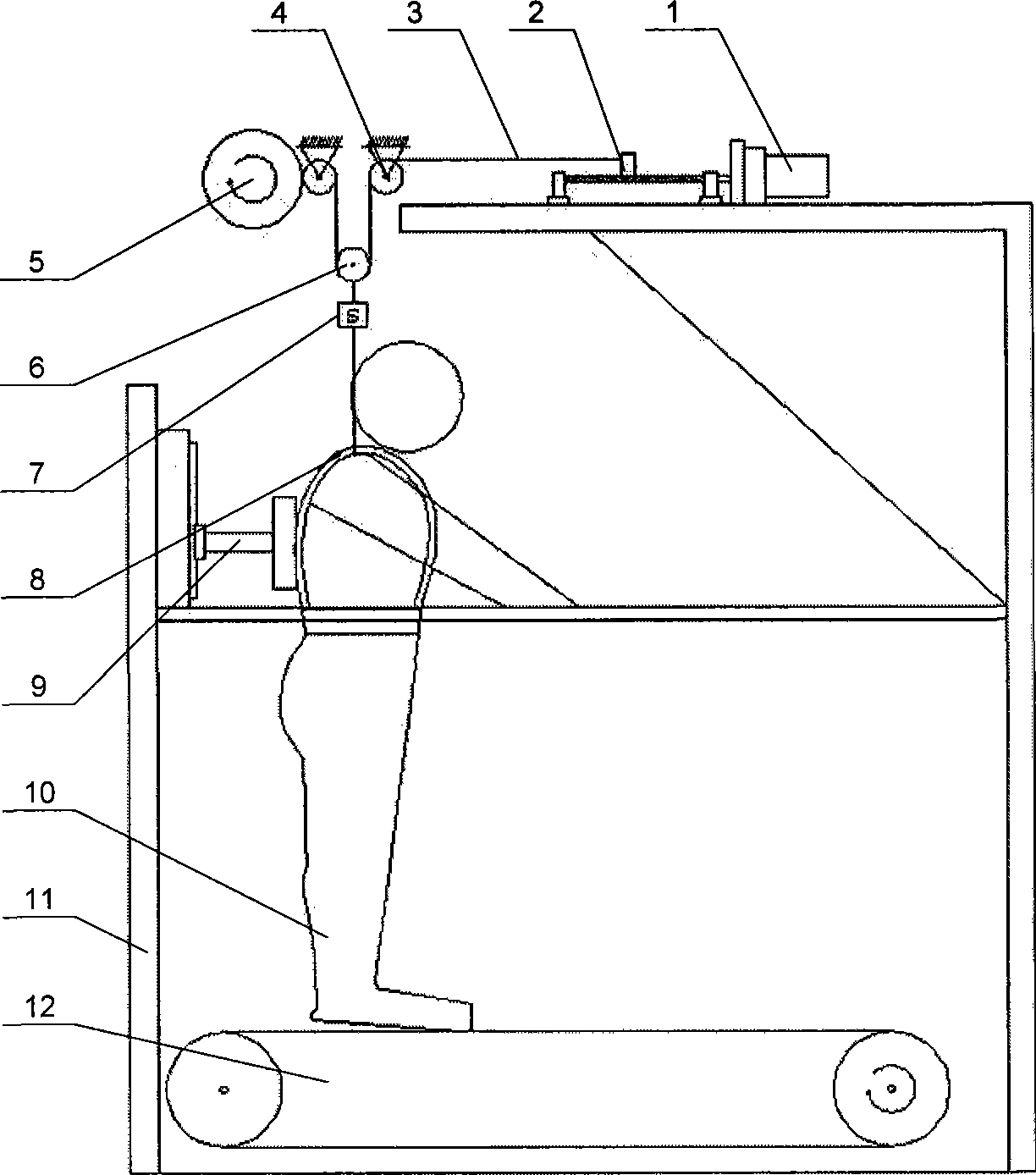

Mass balancing device and method for lower limb rehabilitation training patient

InactiveCN102526947AReduce fearEasy to standChiropractic devicesMovement coordination devicesDiseaseGravity center

The invention relates to a mass balancing device and method for a lower limb rehabilitation training patient. The balancing device comprises a reduced gravity generating mechanism, a bracket, an electric winch, a steel wire rope, a pulley wheel, a force sensor, a suspender, a running machine and a control system. When a reduced gravity walking training is carried out, the patient wears the suspender to stand on the running machine; the suspender is connected to the steel wire rope through the pulley wheel and two ends of the steel wire rope are respectively mounted on the reduced gravity generating mechanism and the electric winch; and the size of the actual reduced gravity detected by the force sensor is fed back to the control system to realize closed-ring control. Aiming to the patient of lower limb motor dysfunction caused by central nervous system diseases including spinal injuries, brain stroke and the like, a load to lower limbs of the patient which is caused by the self-gravity of the patient and the dynamic load in the walking process can be simultaneously relieved when the reduced gravity walking training is carried out, so as to realize constant-mass gravity reduction. According to the rehabilitation conditions of the patient or the training requirements, a weight reducing device provided by the invention can conveniently adjust a gravity reducing ratio. The suspender of the weight reducing device can be moved along the gravity center of the patient in real time and is good for the rehabilitation of normal physiological gaits of the patient.

Owner:SHANGHAI UNIV

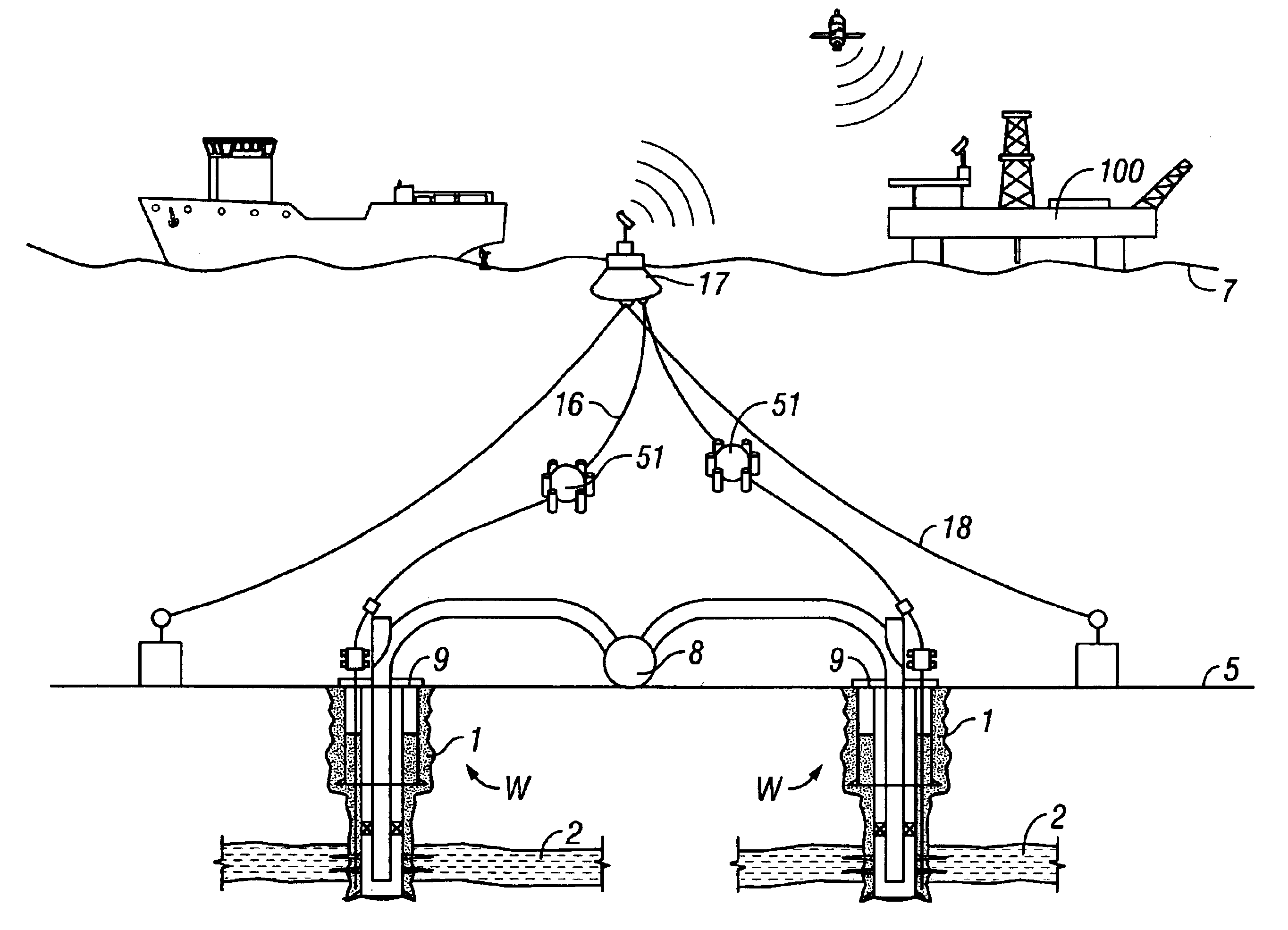

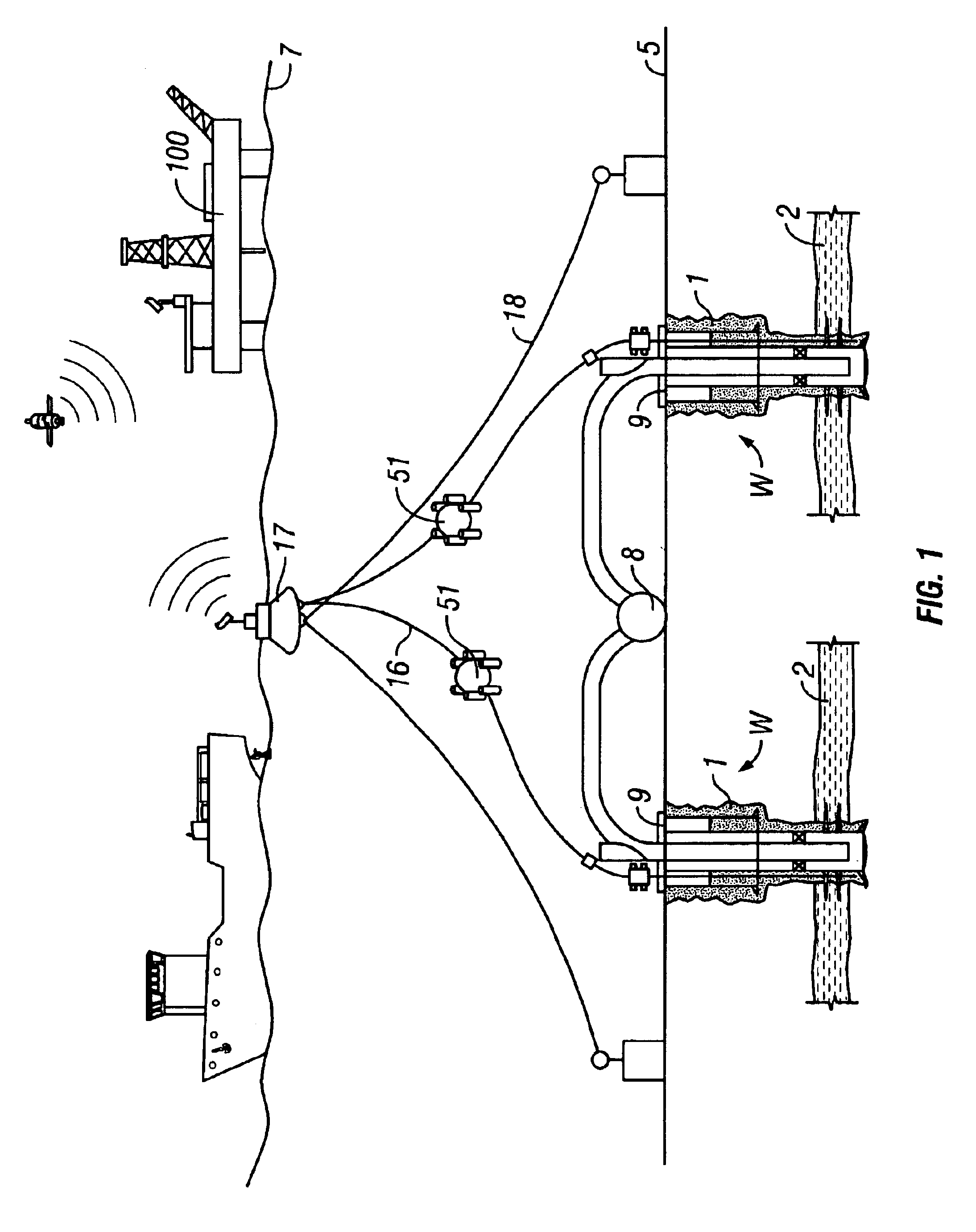

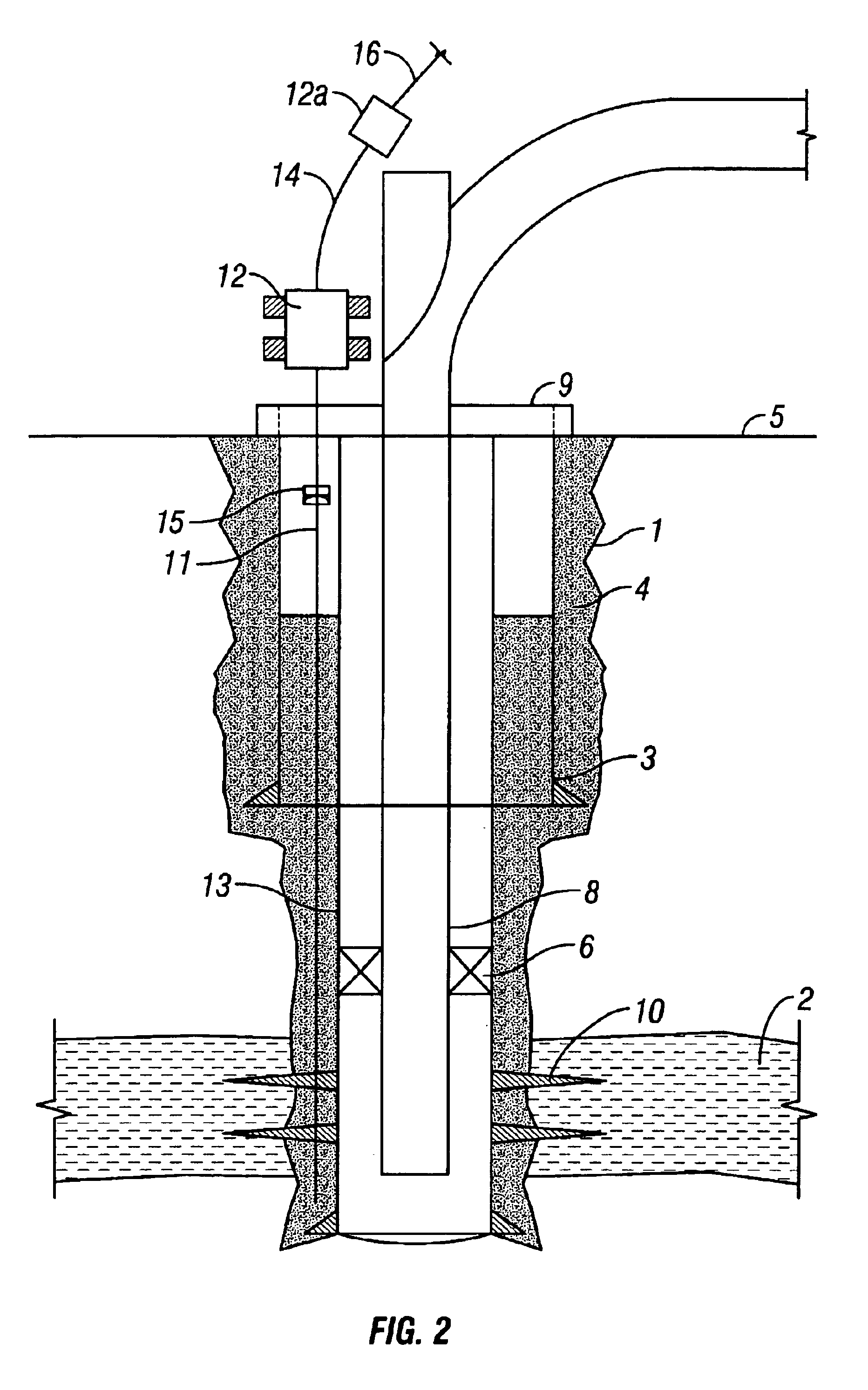

Method and apparatus to monitor, control and log subsea oil and gas wells

A method and apparatus for logging, controlling, or monitoring a subsea well or group of wells through a path not within production tubing. Preferred embodiments allow logging tools, wire rope, optic fibers, electrical cables, monitoring and measuring instruments and other items known to those skilled in the art of oil and gas production to be disposed into the well without interfering with the flow path through the production string. A further preferred embodiment includes the mooring or tethering of an instrument pod over the subsea well. The instrument pod is designed to provide on-board data storage, data processing, data receiving, and data transmission equipment, such that data from the well can be transmitted back to a receiving network where the data may be stored and processed into useful information for reservoir operators.

Owner:SENSOR HIGHWAY LTD

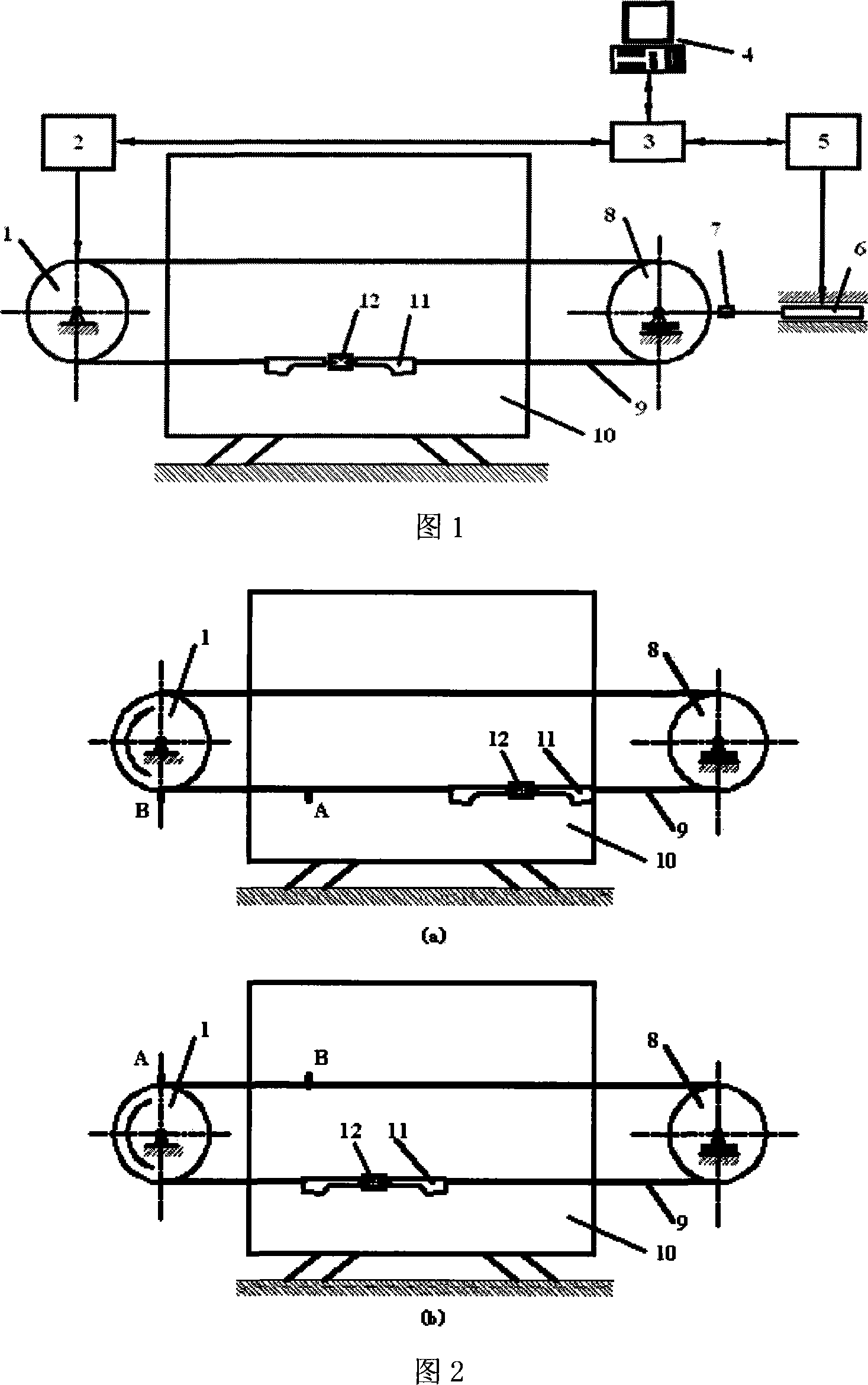

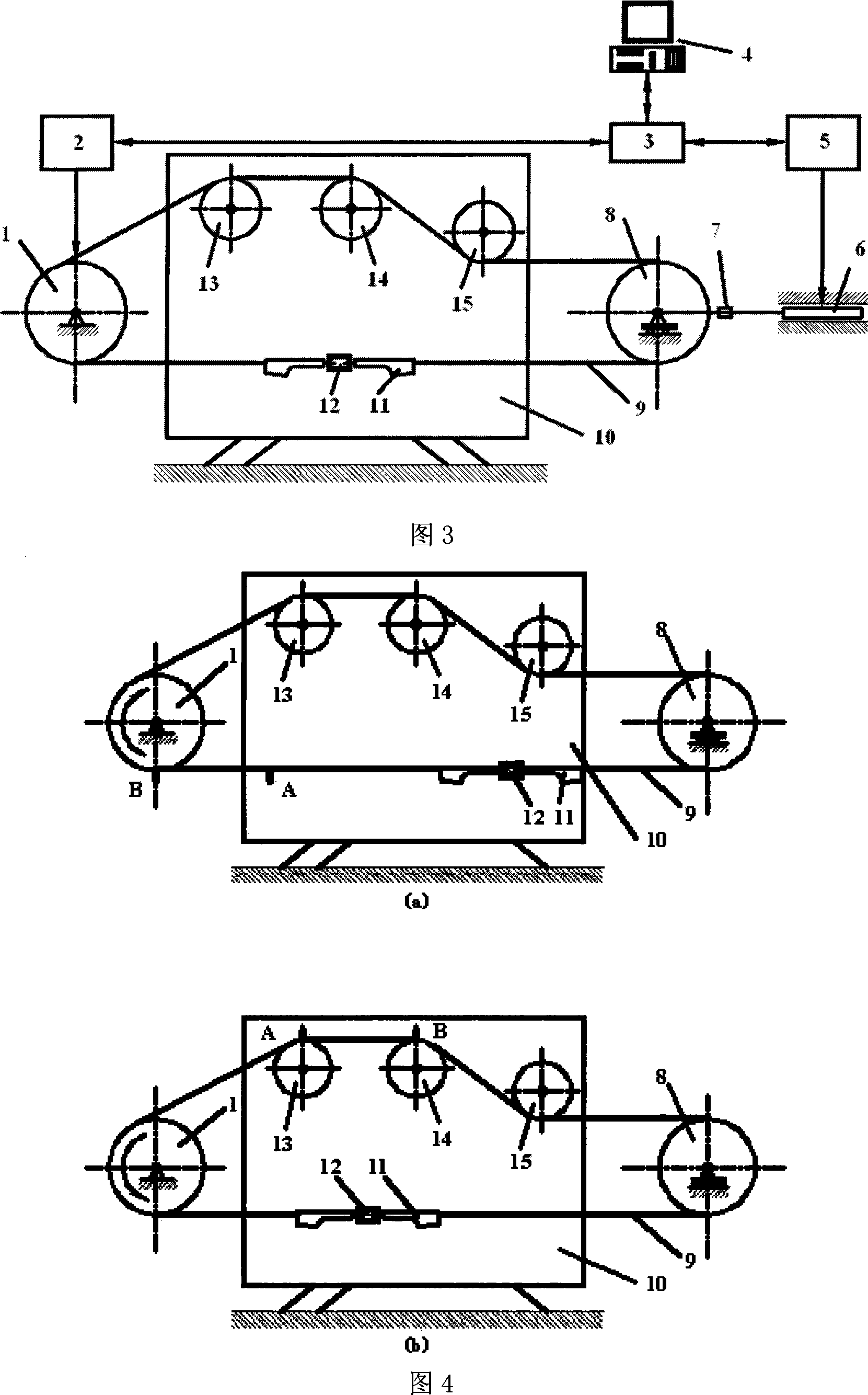

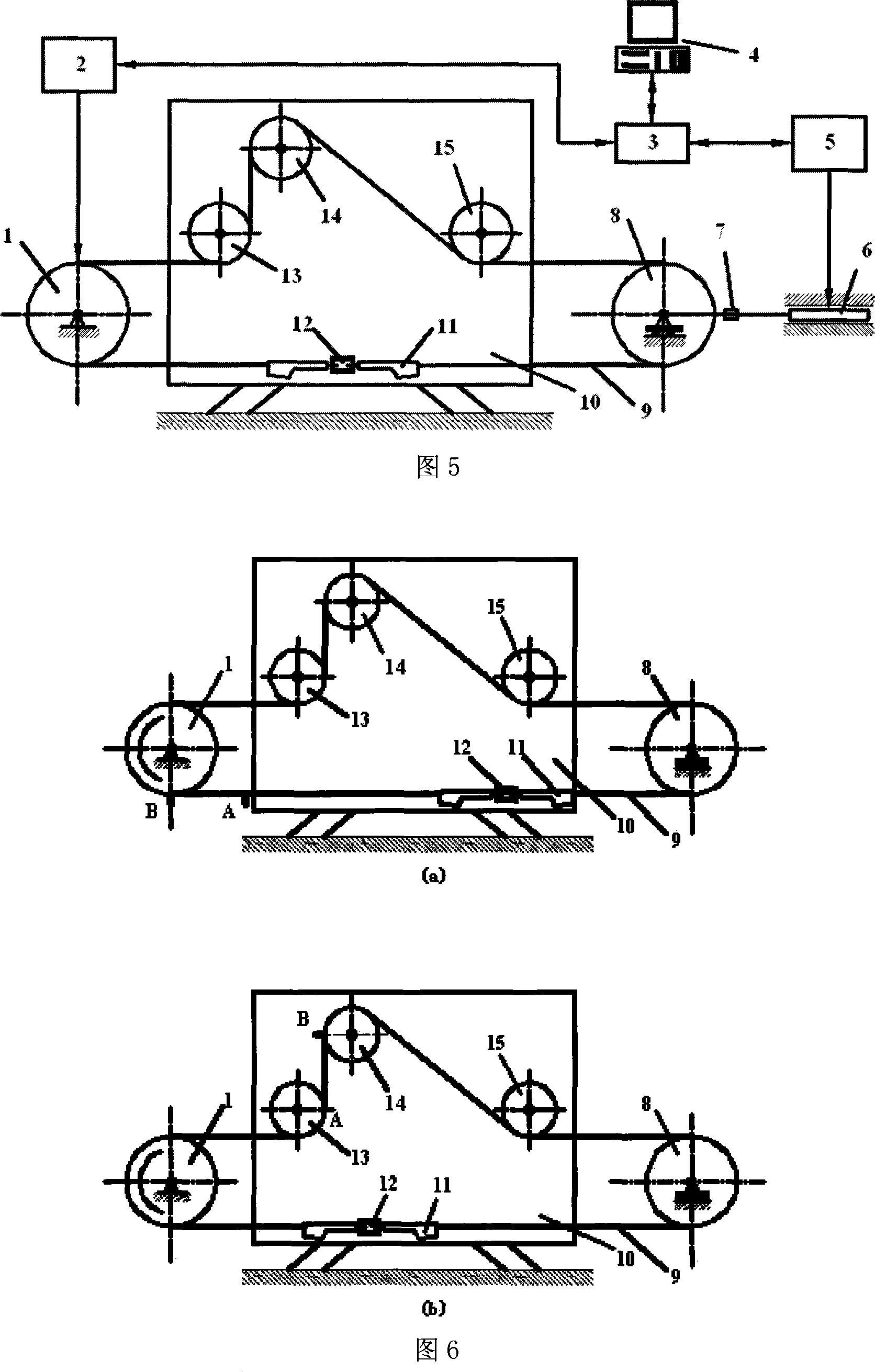

Elevator armored rope bending fatigue state experimental bench

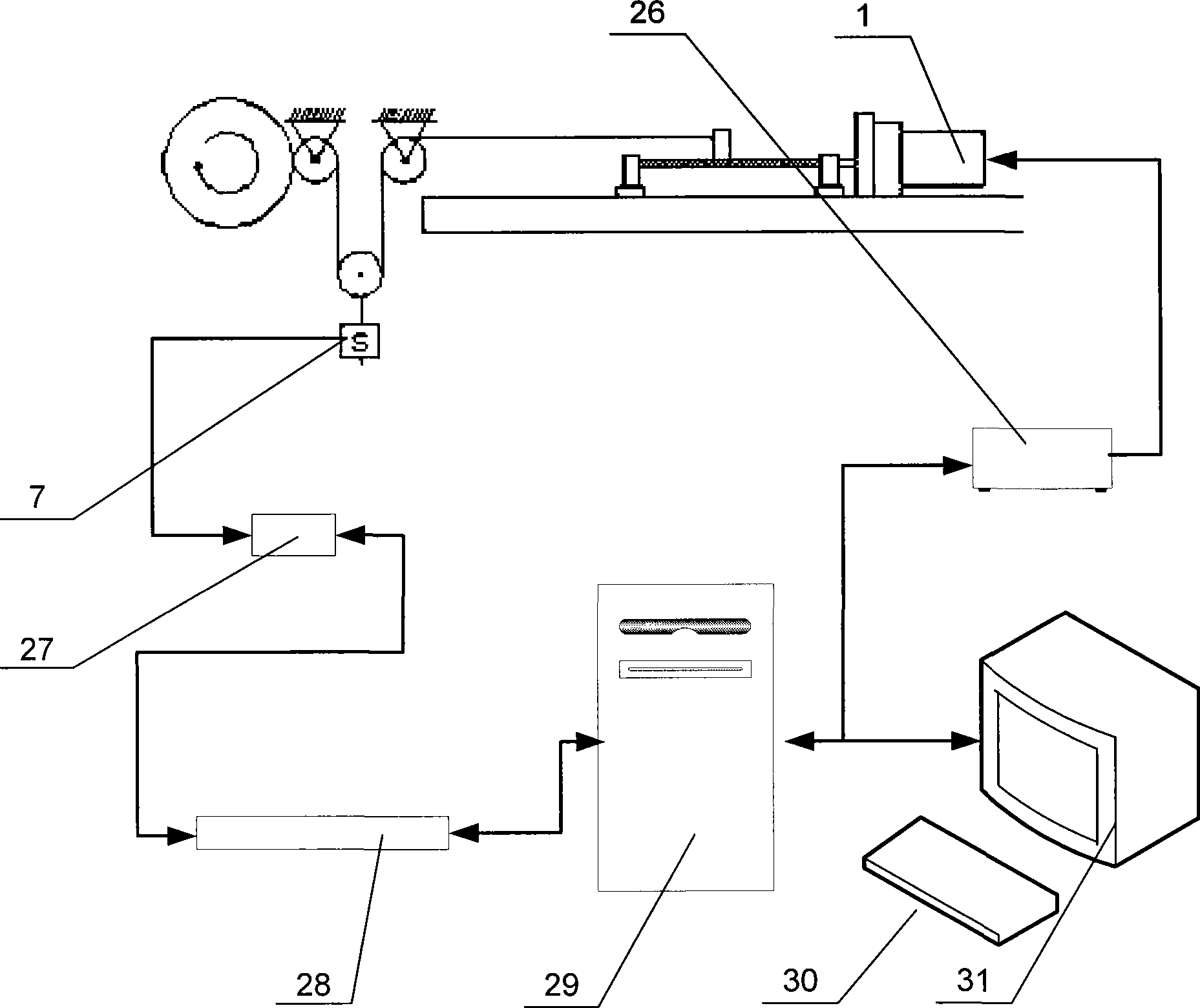

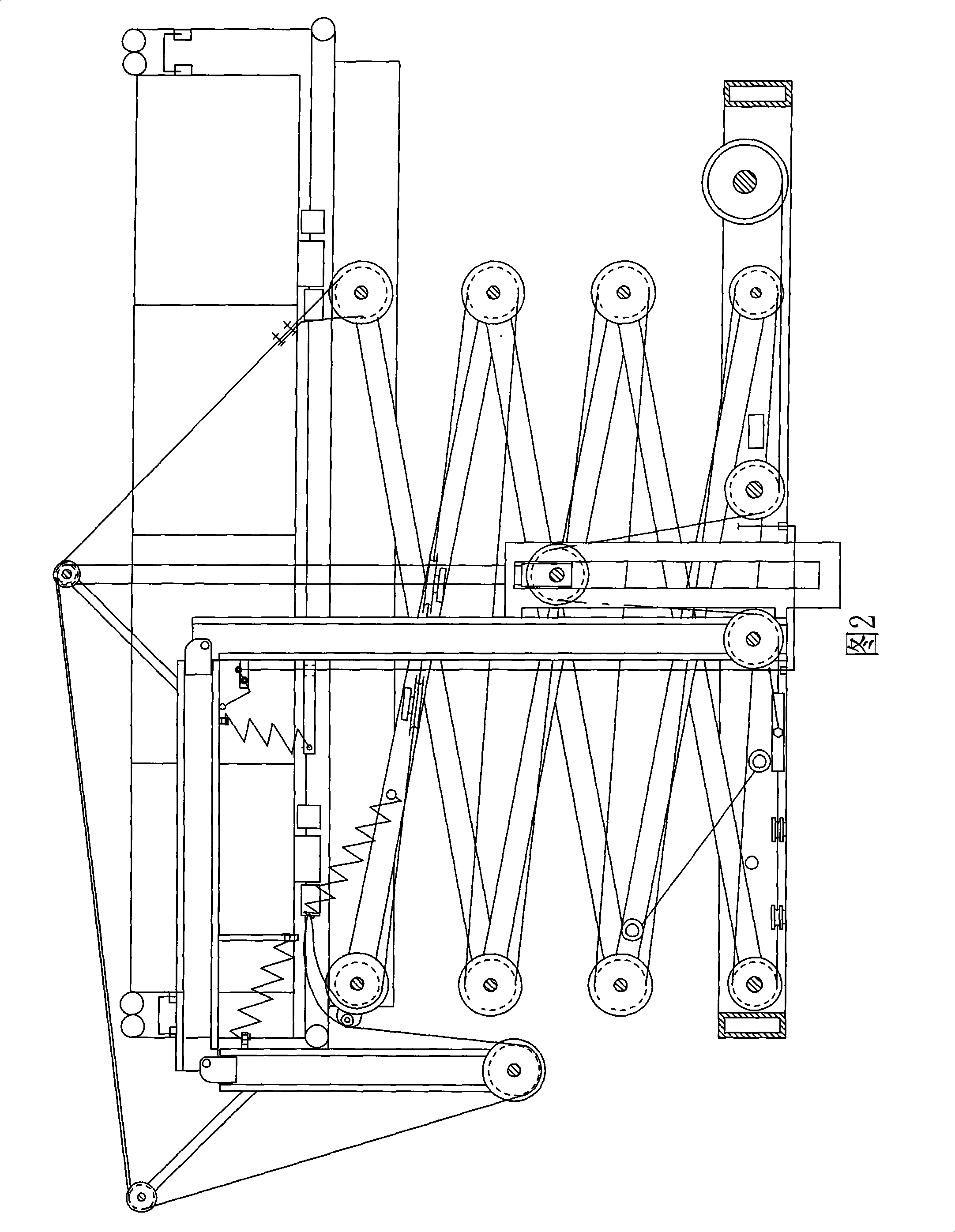

InactiveCN101216397AAvoid heavy operationsCompact structureMaterial strength using repeated/pulsating forcesHydraulic cylinderPull force

A bending fatigue test platform of wire rope for an elevator in the field of mechanical technology comprises a traction wheel, a frequency-variable motor, a data collecting and control device, a host computer platform, a hydraulic pump, a hydraulic cylinder, a tension sensor, a tension pulley, a wire rope, a rope head device, a connection terminal and a guide support, wherein the traction wheel and the tension wheel are positioned on both ends of the test platform; the guide support is positioned between the traction wheel and the tension pulley; the wire rope is wound in the grooves of the traction wheel, the guide wheel of the guide support and the tension pulley; the shaft of the tension wheel is connected with the tension sensor; the tension sensor is connected with the hydraulic cylinder; the hydraulic cylinder is connected with a hydraulic pump; the frequency-variable motor, the hydraulic pump and the tension sensor are connected with the data collecting and control device; and the data collecting and control device is connected with the host computer platform, which is in charge of monitoring, recording and control. The invention can adjust the wrap angle, the bending state, the tension and the travel of the bending fatigue test of wire rope more flexibly.

Owner:SHANGHAI JIAO TONG UNIV

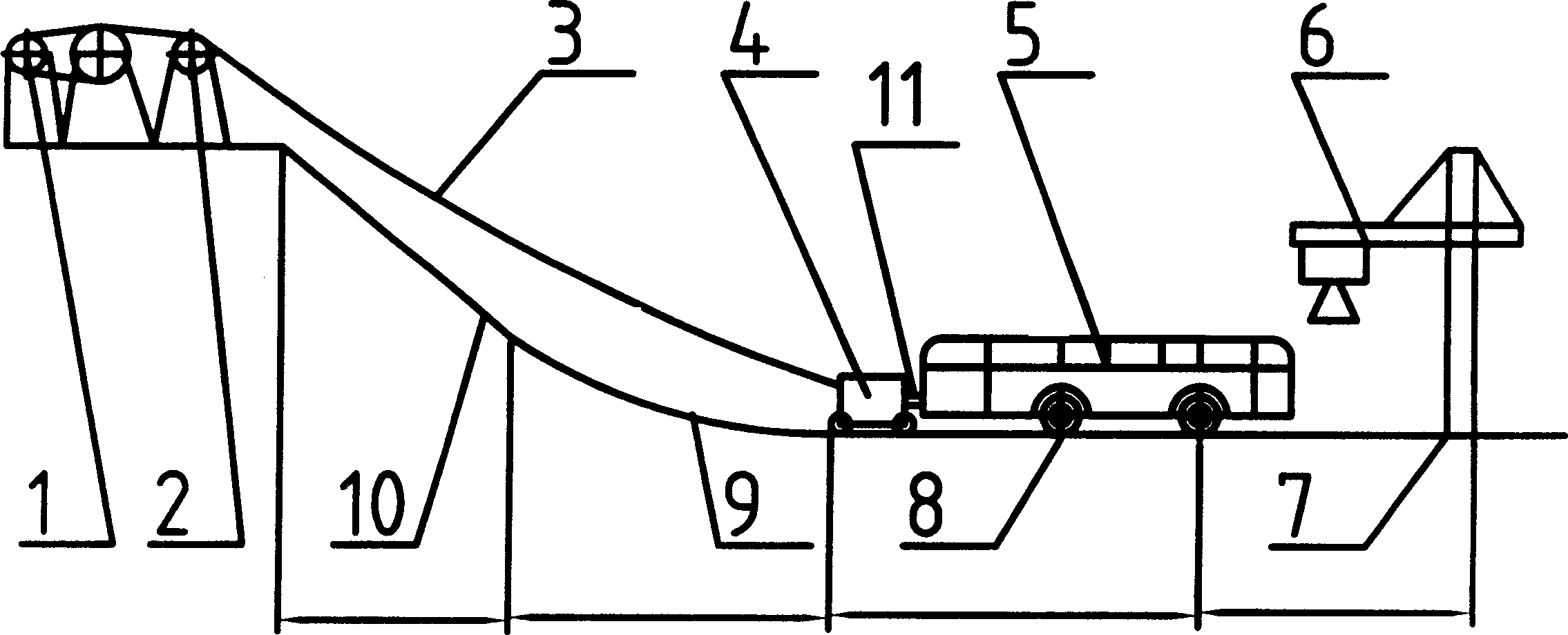

Ramp automobile collision experiment system and method

InactiveCN1420036ALow powerSmooth connectionVehicle fittingsSpeed/accelaration controlWinding machineEngineering

A ramp-type collision experiment system and method for car is disclosed. Said system is composed of a drawing-guiding unit consisting of supporting frames at high end of ramp, steel cable, winding machine and supporting roller, a ramp consisting of horizontal transition segment, curved transition segment and straight acceleration segment, a experiment segment, an observing tower with test equipment, and acceleration tester in experimental car.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

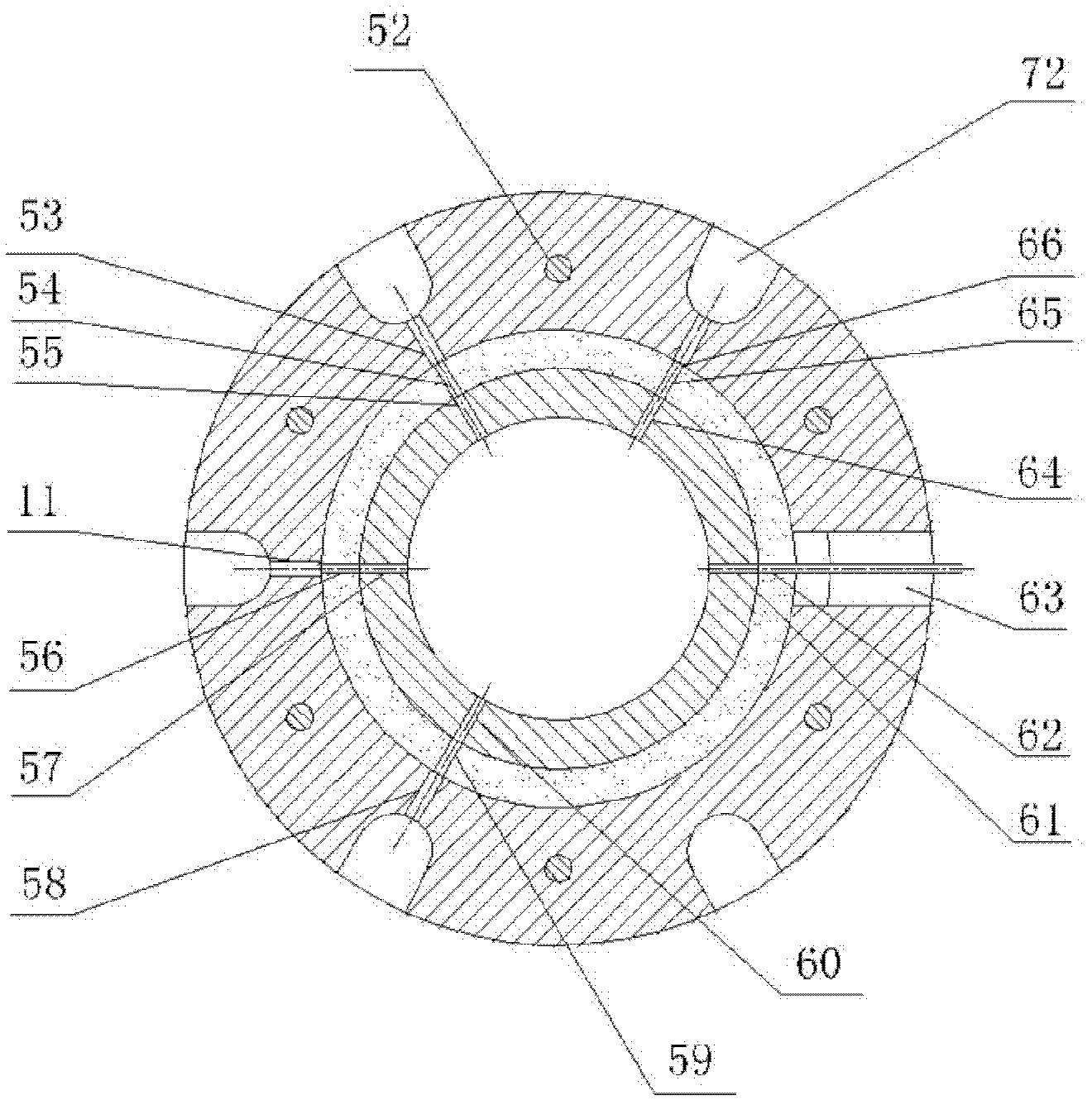

Mechanical automatic butt-joint releasing device

InactiveCN101508333ARealize automatic dockingAchieve releaseUnderwater equipmentButt jointEngineering

The invention relates to a mechanical automatic butting and releasing device, which comprises a drop hanger part and a hanger rod part. The drop hanger part comprises a cylindrical drop hanger body of which an upper end flange is connected with a lifting wire rope through a wire rope joint, and the interior of a lower end flange is provided with at least two shaft pin sliding bushes on the same axial cross section along the radial direction. A spring shaft pin which can flex under the action of a compression spring is arranged in each of the shaft pin sliding bushes; and the hanger rod part comprises a step cylindrical hanger rod body of which the top end is provided with a hanger rod head capable of sliding along the inner wall of the drop hanger body and matching the front end of the spring shaft pin in a blocking mode. A releasing sliding ring which can slide axially along the hanger rod body is arranged between the hanger rod head and steps of the hanger rod body. The upper ring surface and the lower ring surface of the releasing sliding ring are matched with the shapes of the front ends of the spring shaft pins so that the releasing sliding ring can press the spring shaft pins into the shaft pin sliding bushes when the releasing sliding ring passes through the spring shaft pins. The bottom end of the hanger rod body is provided with a clamping device for connecting a hung device. The mechanical automatic butting and releasing device uses a pure mechanical structure to effectively realize the automatic butting and releasing of an underwater operating device.

Owner:WUHAN HAIWANG MECHANICAL & ELECTRICAL ENGTECH

Methods of manufacturing composite slickline cables

ActiveUS20060260739A1Minimizing variation in diameterUniform circular cross-sectional shapeLamination ancillary operationsLaminationComposite strengthElectrical conductor

Disclosed are wellbore electric cables, and methods of manufacturing such cables, and in one aspect, methods of manufacturing wireline composite slickline cables. Some embodiments are methods which include preparing a slickline cable by providing an inner metallic tube containing at least one conductor (such as an optical fiber), disposing an epoxy / fiber composite strength layer substantially upon the outer periphery of the inner metallic tube, and exposing the combination of the inner metallic tube and composite strength layer to at least one technique for minimizing the variation in diameter and providing a substantially uniform circular cross-sectional shape of the combination. Further, an outer metallic tube is draw around the combination of the composite strength member and the inner metallic tube, to form a wellbore slickline. Cables prepared using such methods are also disclosed.

Owner:SCHLUMBERGER TECH CORP

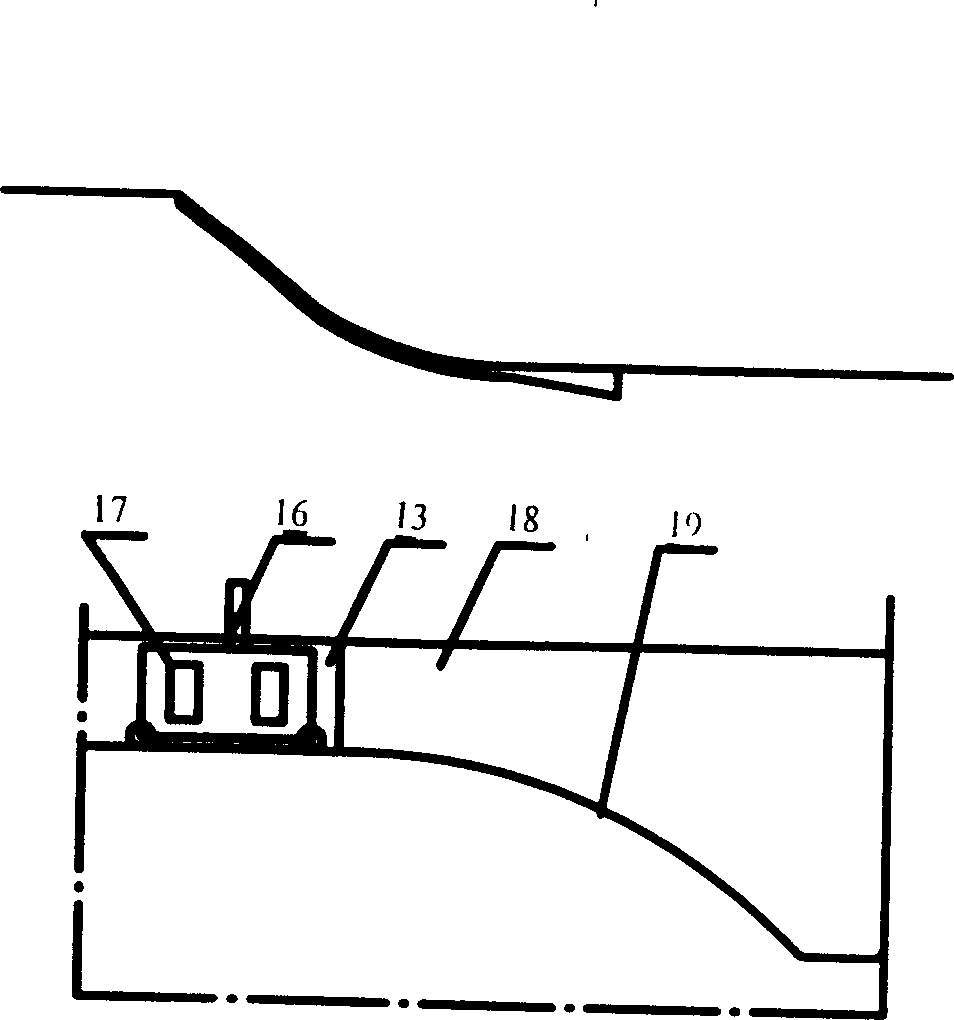

Active partial body weight support treadmill training device and active partial body weight support treadmill training method

InactiveCN101518490AReduce mistakesImproving the Effects of Weight Loss Walking TrainingChiropractic devicesMovement coordination devicesClosed loopEngineering

The invention relates to an active partial body weight support treadmill training device and an active partial body weight support treadmill training method. The device comprises a force sensor, a support, a treadmill, and a partial body weight support mechanism. During the training, a patient is positioned on the treadmill and is connected to a steel wire rope through a sling, one end of the steel wire rope is provided with a winch which can adjust the length of the steel wire rope according to the height of the patient, while the other end is connected to the partial body weight support mechanism which is used for providing a partial body weight support force, and the partial body weight support force can be given according to the requirement of a doctor. During the whole training process, the force sensor is used to detect the actual partial body weight support force and feed back the actual partial body weight support force to a virtual instrument to realize closed-loop control, so that the constancy of the partial body weight support force is ensured. The active partial body weight support method can effectively improve the effect of partial body weight support treadmill training, has simple operation, and is suitable for rehabilitation training in hospitals and families.

Owner:SHANGHAI UNIV

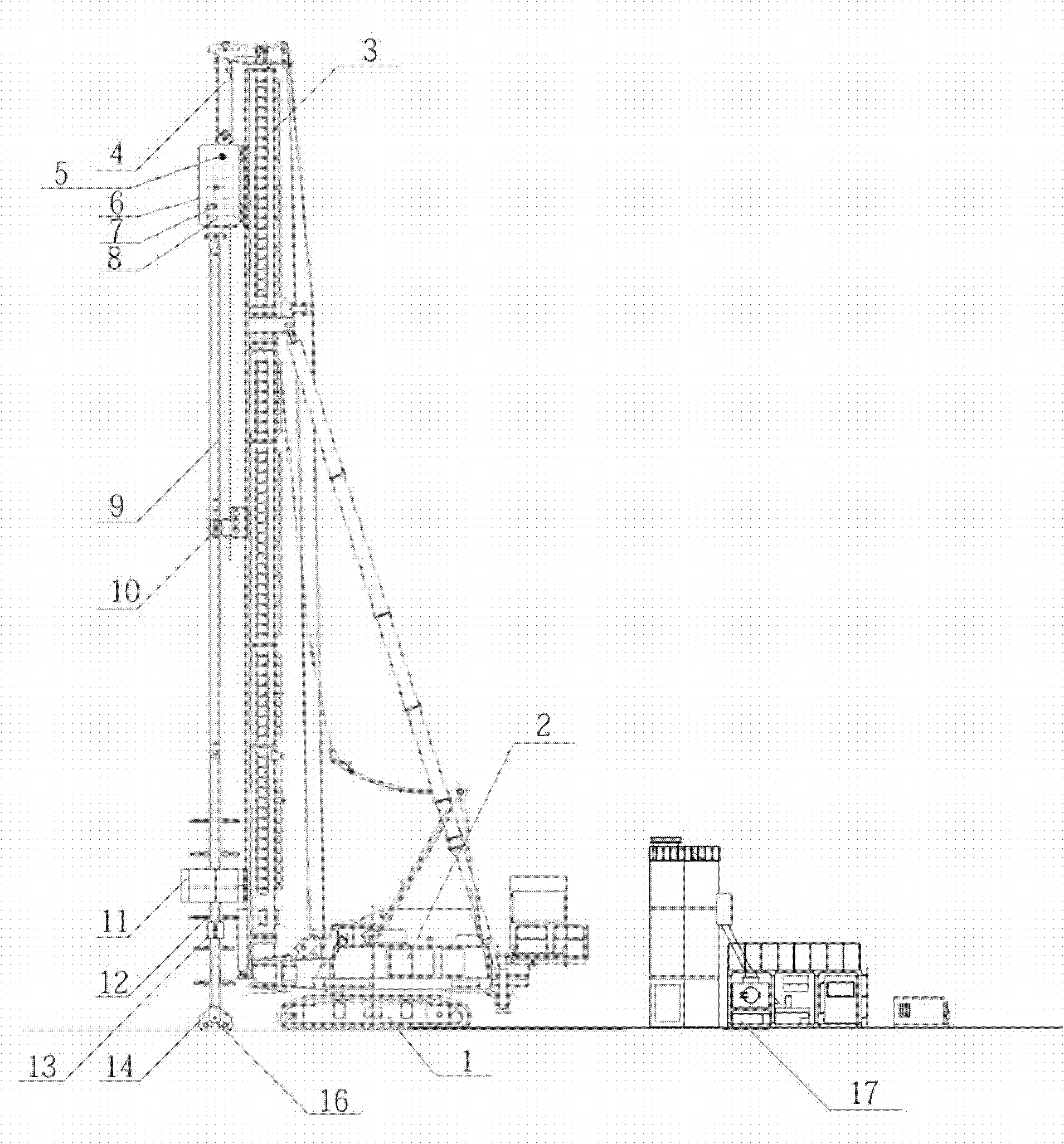

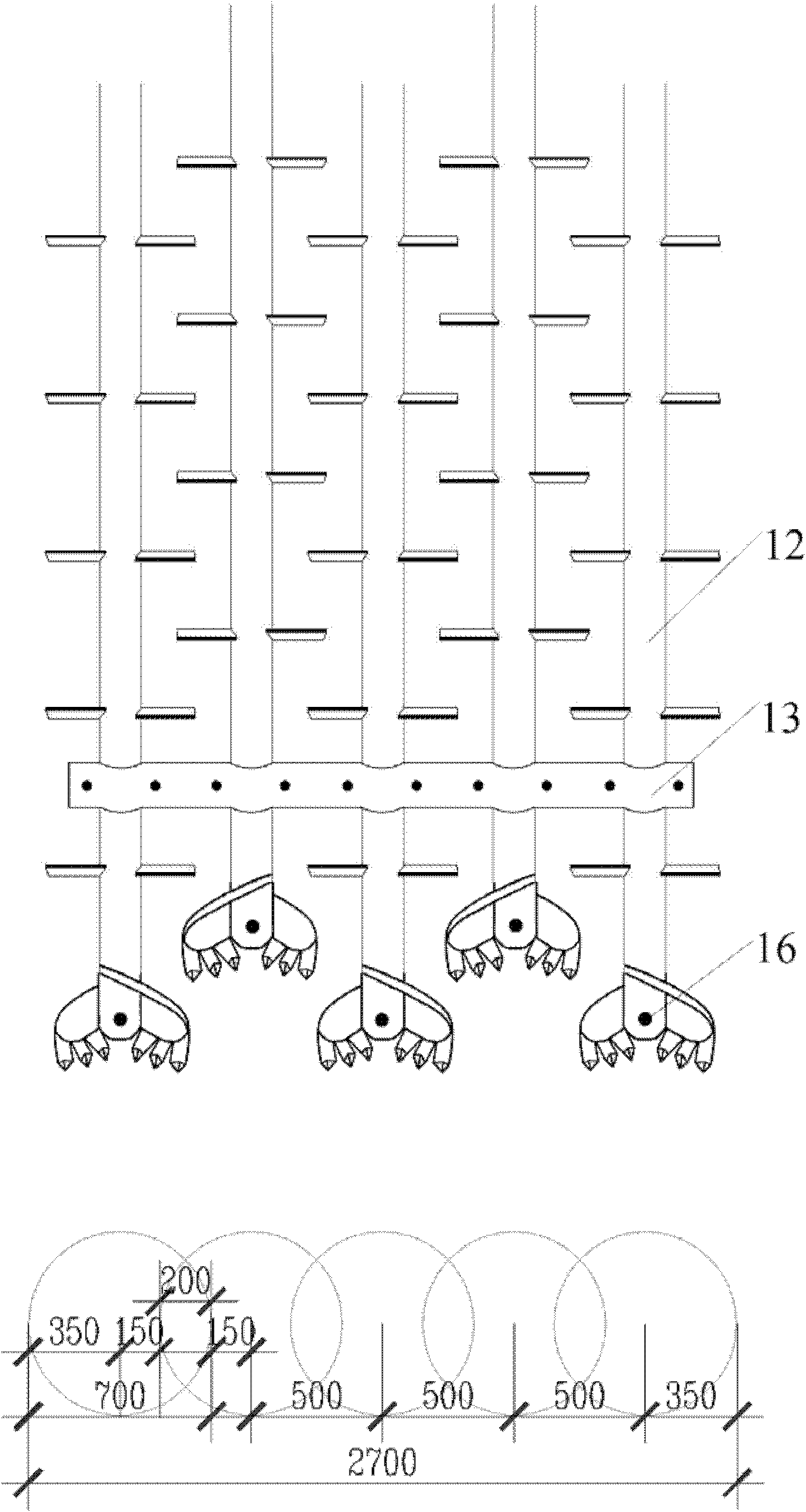

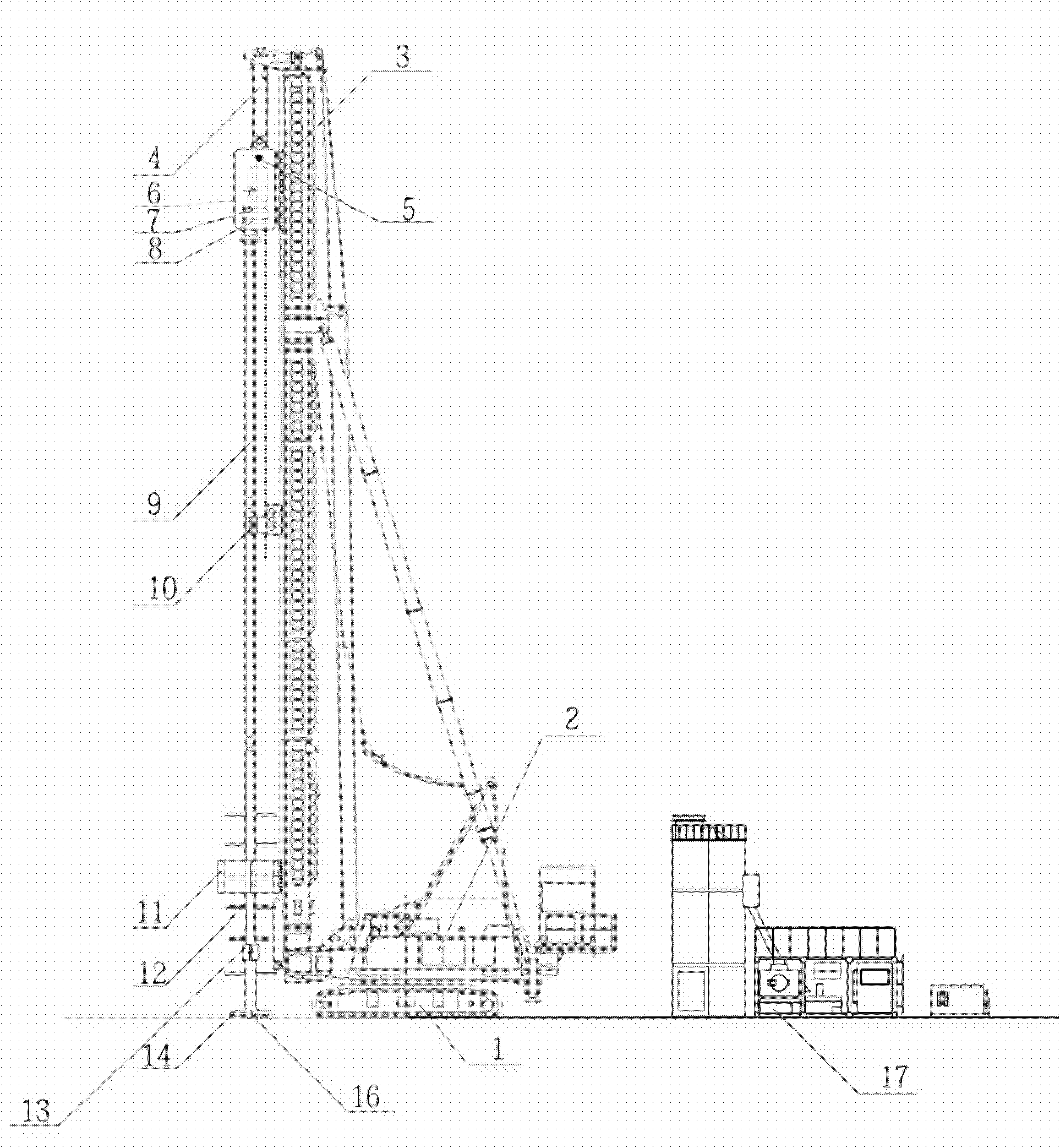

Five-axis cement-soil mixing pile device and construction method

The invention relates to a five-axis cement-soil mixing pile device and a construction method. The device comprises a walking-type and crawler-type host machine, a winding machine, a guide rod, a steel wire rope, a slurry inlet, a power head, a speed change box, a speed reducer, drill stems, a middle support frame, a lower support frame, drill stems with wings, hoops, a multifunctional drill head, a slurry spraying opening and a background cement slurry mixing system, wherein the winding machine and the guide rod are fixed on the host machine; the power head is connected with a pulley on the top of the guide rod through the steel wire rope; the steel wire rope drives the power head to rise and fall in a vertical direction; the power head is connected with five drill stems sequentially through the speed change box and the speed reducer; the middle support frame is arranged on the middle parts of the five drill stems, and the lower support frame is arranged on the lower parts of the five drill stems; the drill stems with wings are connected to the lower ends of the drill stems; the hoops are arranged on the drill stems with the wings; the lower ends of the drill stems with the wings are connected with the multifunctional drill head; and the slurry spraying opening is formed in the multifunctional drill head. Compared with the prior art, the five-axis cement-soil mixing pile device has the advantages of guaranteeing the safety and the quality, reducing the cost, shortening the work period and the like along with no noise, no vibration and high efficiency.

Owner:SHANGHAI CHENGDI CONSTR

Production process of contact net anchorage steel wire rope

InactiveCN102517941AHigh breaking forceGood non-rotationRope making machinesExtrusion cleaning devicesIndustrial engineeringHeat treating

The invention discloses a production process of a contact net anchorage steel wire rope. The production process comprises the following steps: carrying out surface acid cleaning and phosphating; drawing; carrying out lead bath heat treatment; galvanizing; drawing; detecting; entwisting; stranding; forging; and greasing. The production process has the advantages of convenience in operation and time-saving and labor-saving properties; and the produced contact net anchorage steel wire rope has the advantages of high breaking force, long fatigue service life, good abrasion resistance and good corrosion resistance.

Owner:NANTONG GUANGMING STEEL WIRE PROD

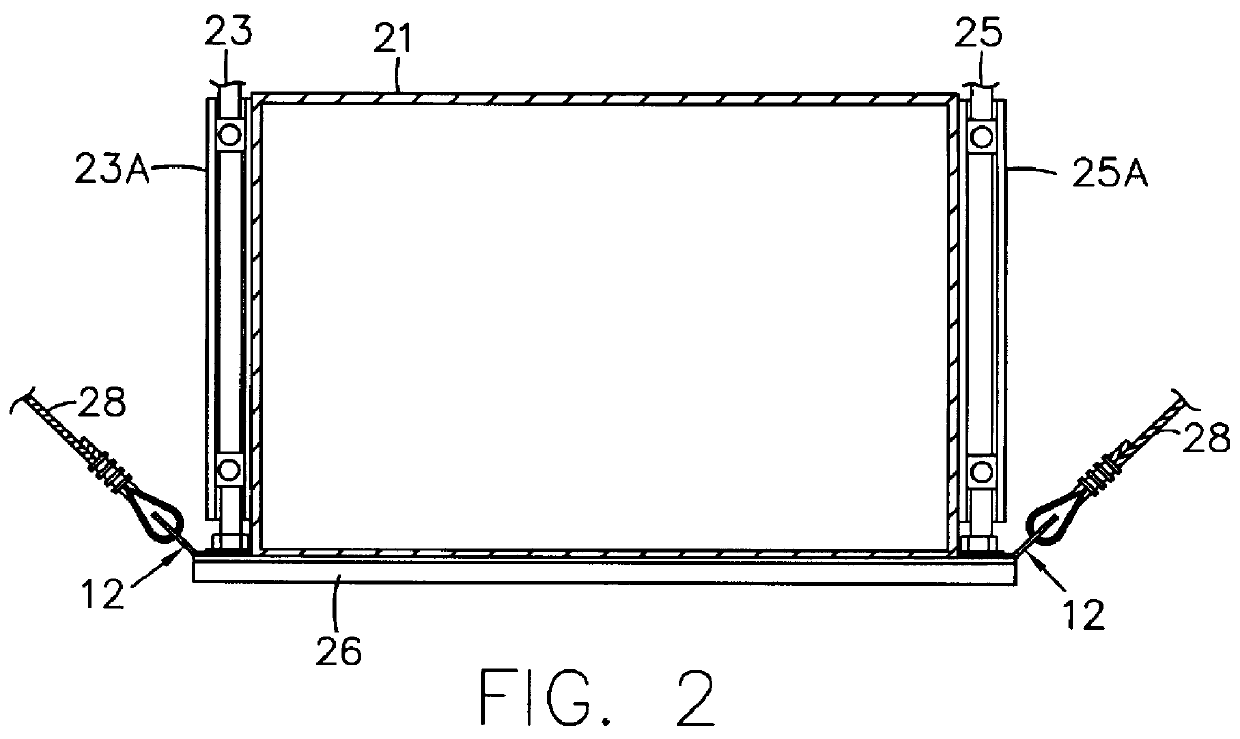

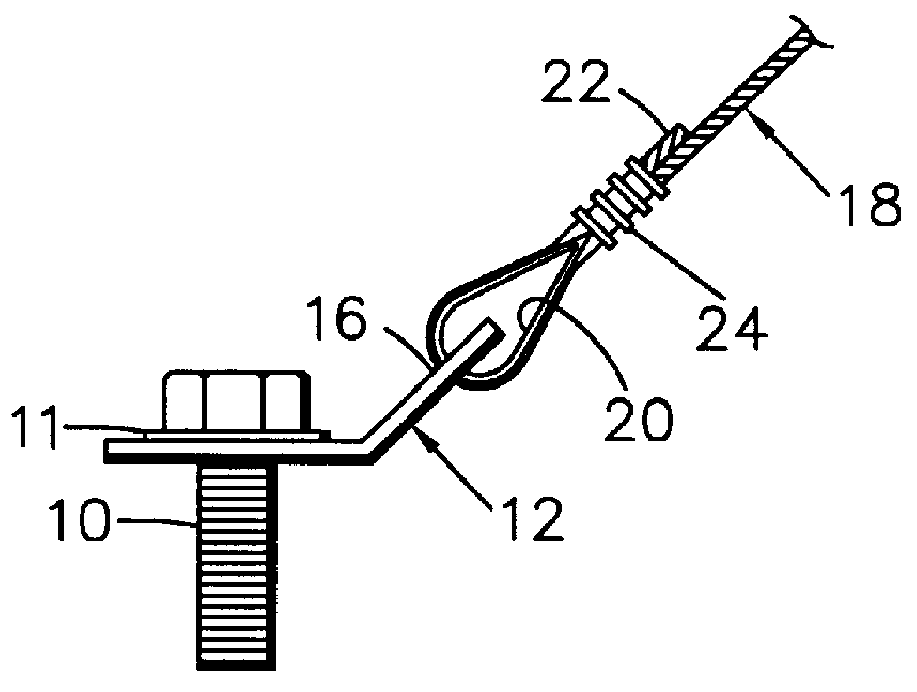

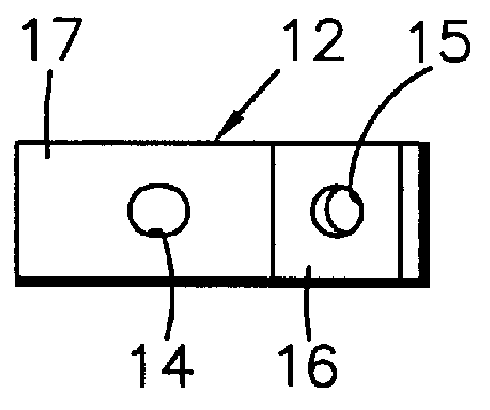

Universal restraint clip fitting

A universal one piece restraint bracket particularly suited for use with wire rope or cable for transverse, longitudinal and combined transverse and longitudinal seismic bracing systems for supporting an object. The bracket is generally L shaped to define a flattened apertured central portion with two wing portions generally at right angles to each other, apertured at their free ends and joined to the flattened central portion, each wing being elevated or upwardly bent away from the plane of the central portion. Aircraft type cables or wire rope connect the bracket to an adjacent support structure with the central portion of the bracket being secured to an object to be supported, whereby the bracing system acts in tension only so as to dampen earthquake loads and forces and thus is not subject to compression loads. A single bracket accommodates a wide variety of seismic bracing, and the bracket is configured for stacking with another bracket where necessary.

Owner:DUGGAN WERNER INC

Hopping robot mechanism

The invention discloses a hopping robot mechanism which comprises a body, a thigh and a shank which are connected through a hip joint and a knee joint respectively. First harmonic reducers and second harmonic reducers of the hip joint and the knee joint are all mounted on the hip, and driving motors are mounted at a position close to the hip, so that a robot is close to an ideal inverted pendulum model to reduce controlling difficulty; the knee joint drives through a thigh steel wire rope which adopts an inclined plane mechanism and a slider adjusting mechanism to realize adjustment of tensioning degree of the steel wire rope; and the knee joint when bent compresses a spring, so that force of gravity is transformed into potential energy of the spring to accumulate energy for stretching. A force sensor is mounted on the pelma of the hopping robot and used for sensing grounding information, and a pelma rubber pad buffers grounding impact. By rationally distributing force of gravity and serially connecting spring energy storage mechanism, improvement of flexibility, compliance and effectiveness of motion of the robot is facilitated.

Owner:ZHEJIANG UNIV

Mobile hoistable platform and labor-saving apparatus

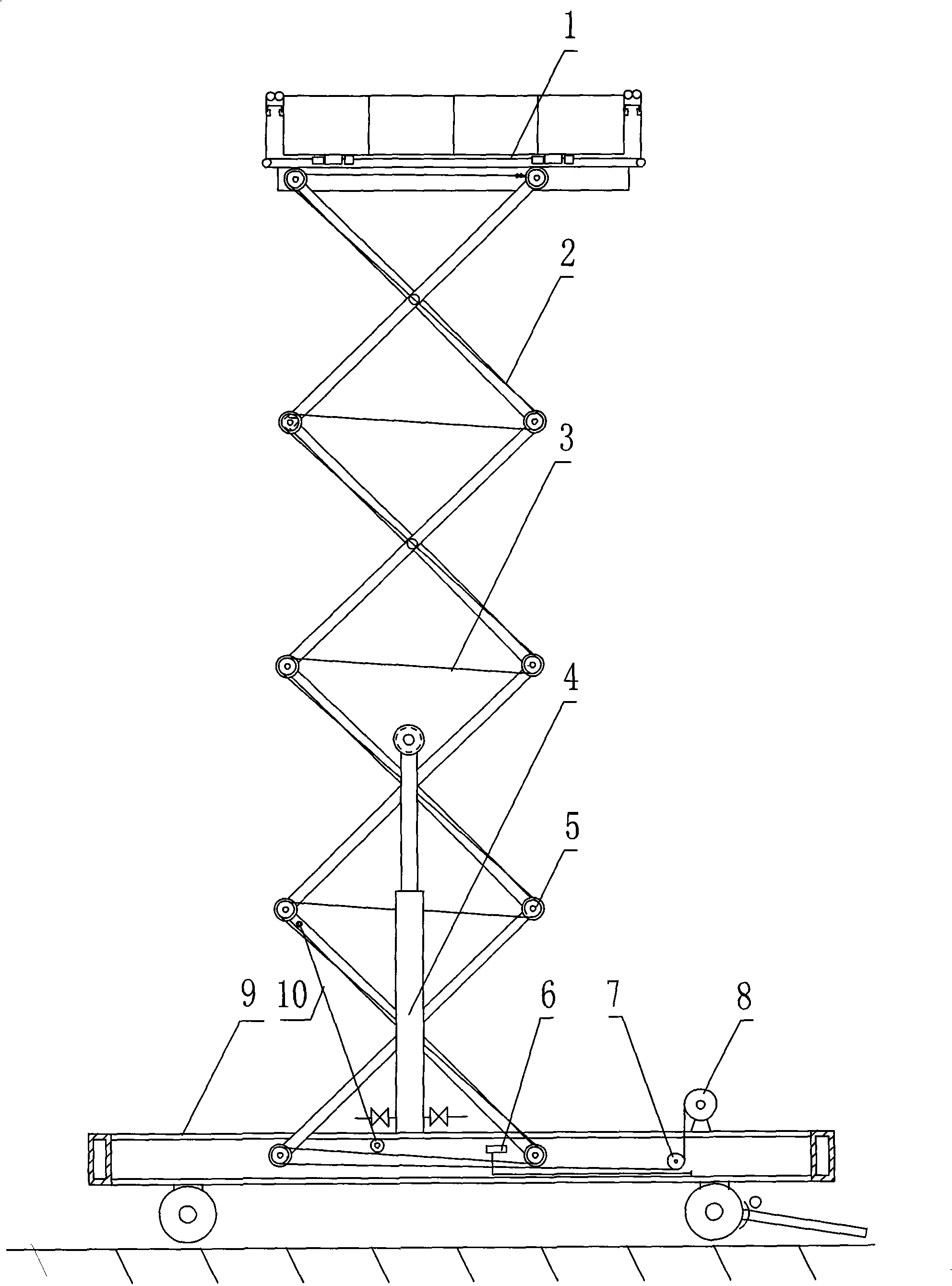

InactiveCN101402440AImprove the unfavorable situationRelief of very unfavorable conditionsLifting devicesHydraulic cylinderEngineering

The invention discloses a mobile lifting platform labor-saving device, which consists of a chassis, a platform, a shearing fork rod, a pulley, a wire rope, and a wire rope loop cylinder, and is characterized in that the chassis of a vehicle is provided with the labor-saving device; when the mobile lifting platform is lifted initially, the labor-saving device is lifted firstly, and lifts the shearing fork rod through the wire rope with small force on an advantageous position, or pushes the shearing fork rod to lift through a hydraulic cylinder to increase the included angle on the ends of the shearing fork rod and reduce the stress of the shearing fork rod; and then the shearing fork rod gets rid of contacting the labor-saving device and is stressed in full load to lift. The various labor-saving devices improve the factor that the prior device is stressed adversely in initial lifting, and greatly reduce the stress of the shearing fork rod in the initial lifting. When the mobile lifting platform has the same load as the prior mobile lifting platform, the stress applied on the shearing fork rod in the initial lifting is about one fifteenth of that of the prior platform in the initial lifting, and the self weight of equipment can be reduced more then twice; and the labor-saving device has the advantages of simple operation and time conservation.

Owner:白天海

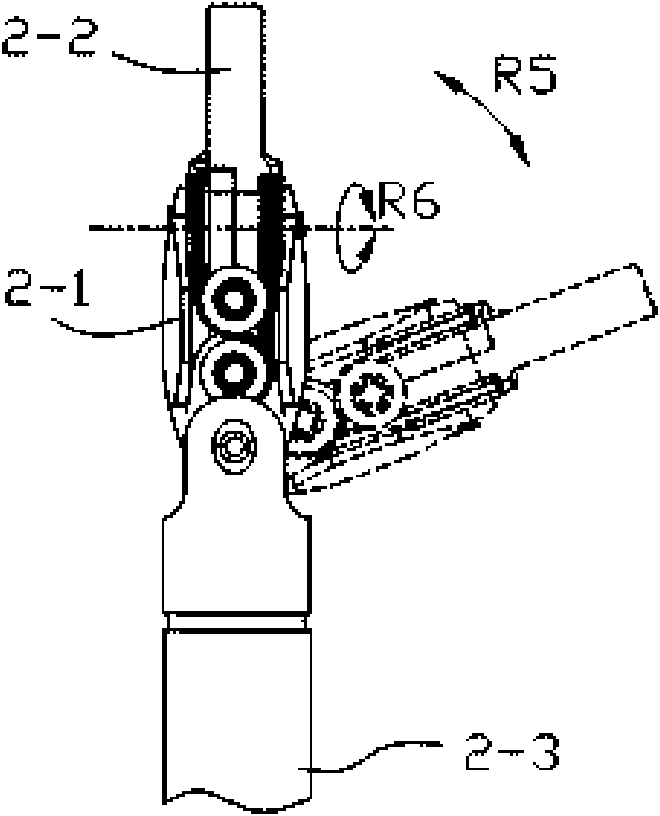

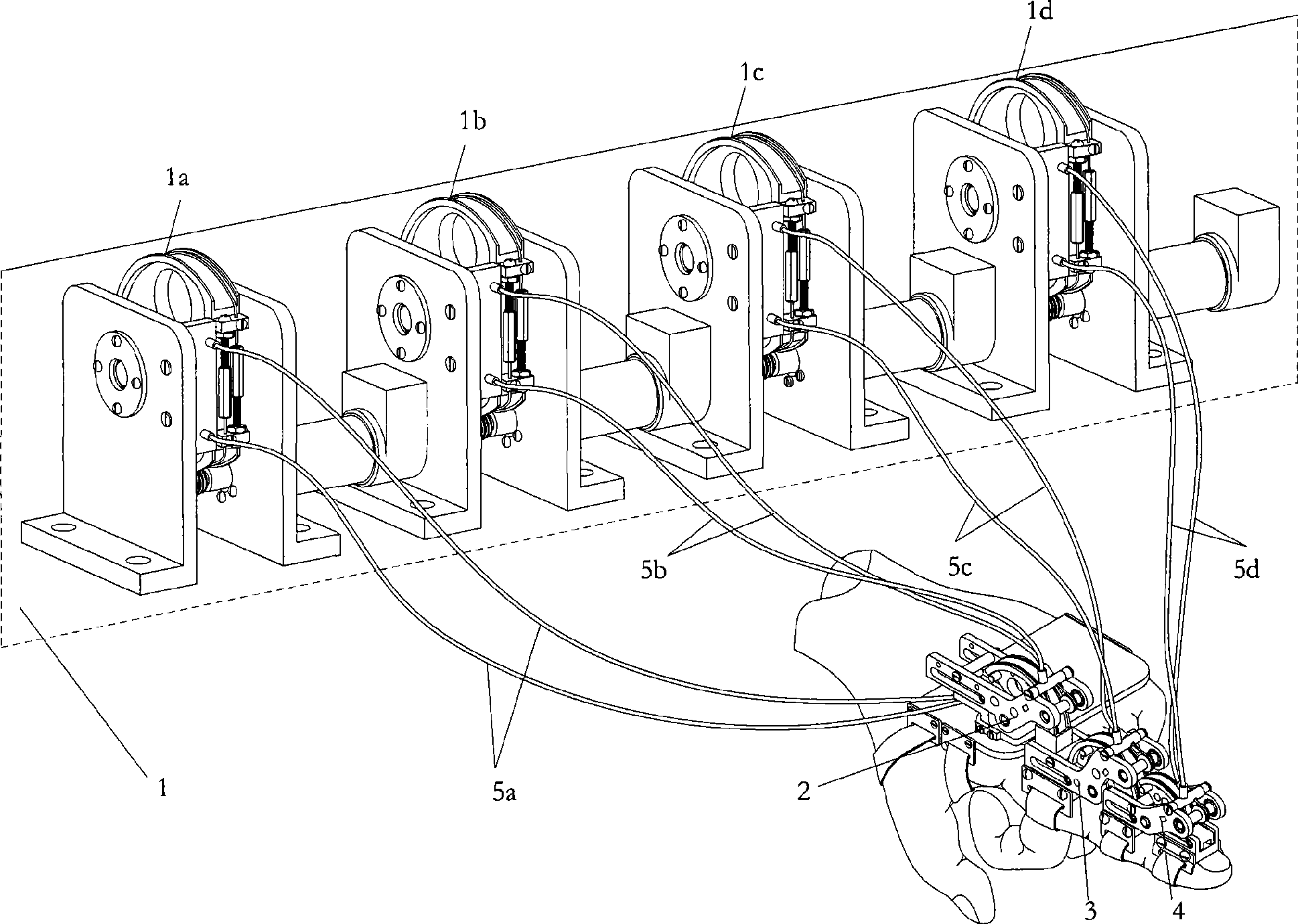

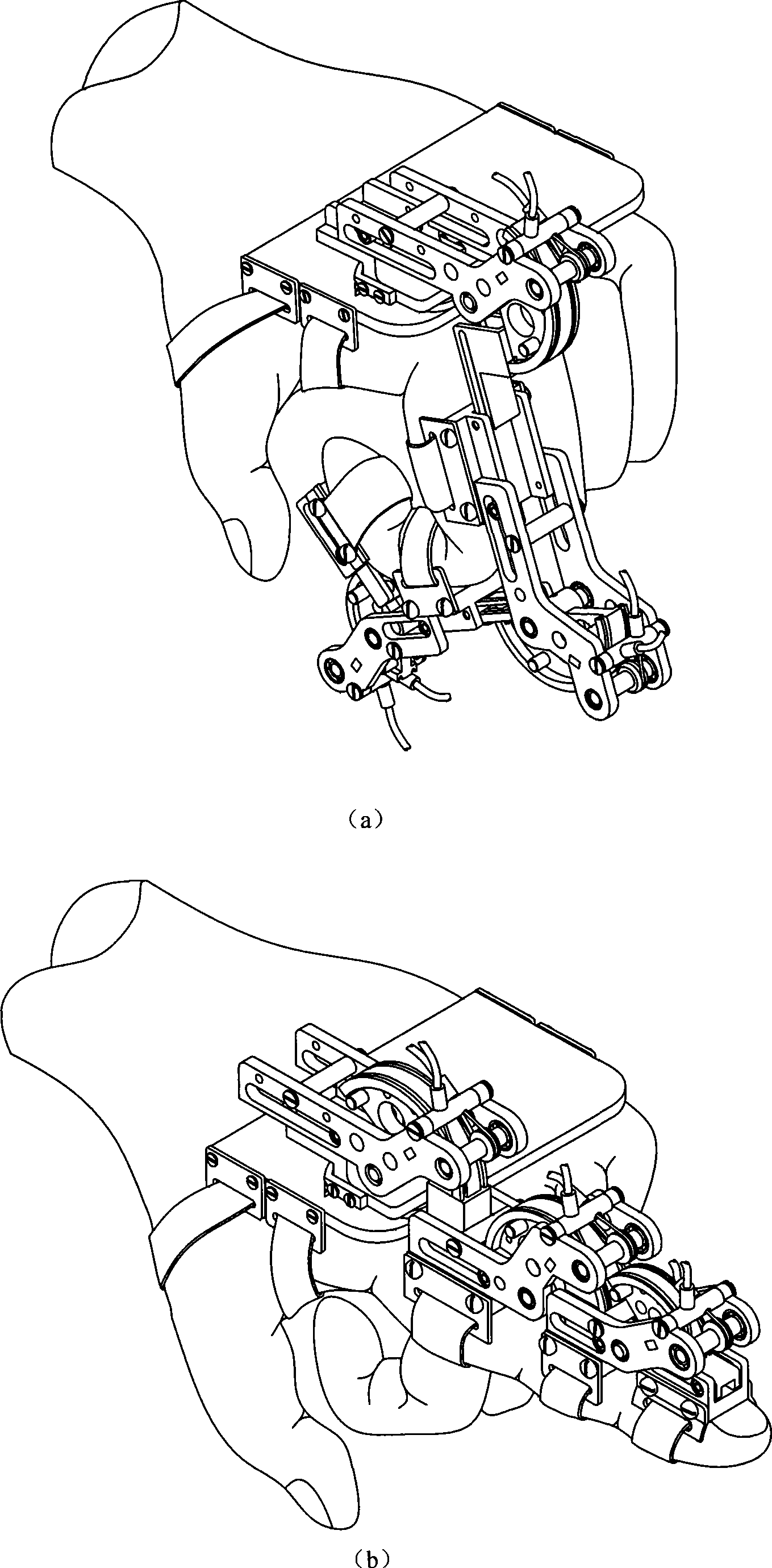

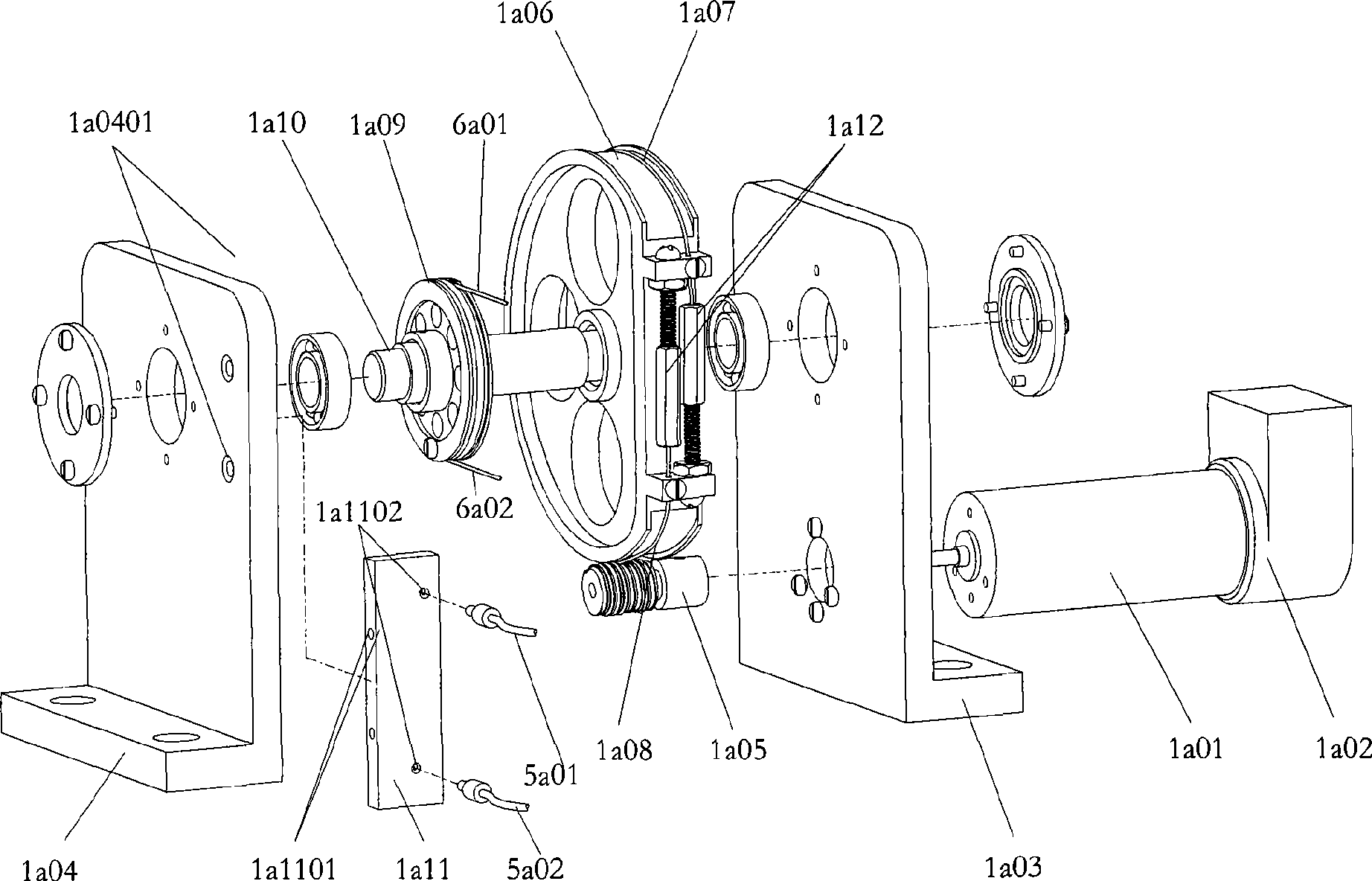

Finger motor function rehabilitation robot

InactiveCN101518491AMeet the needs of different range of motionGymnastic exercisingChiropractic devicesFar distanceRange of motion

The invention relates to a finger motor function rehabilitation robot comprising an executing part and a driving part which are connected by steel wire rope outer sleeves (5a, 5b, 5c and 5d), wherein the executing part is divided into a palm bone joint module (2), a near-end joint module (3) and a far-end joint module (4); and the driving part is divided into four independent driving modules (1a, 1b, 1c and 1d) to drive the executing part. Because the whole system realizes far distance and variable distance transmission though steel wire ropes, the hands of people can arbitrarily move in a certain range in a rehabilitation process. The invention has the advantages that each joint of fingers is singly driven in a bidirectional mode; the robot has mechanical position-limiting function and can regulate the maximal rotating range of each finger joint to satisfy the requirement of different motion ranges of a patient in different rehabilitation periods; and the robot is suitable for hands with different sizes to wear in a certain range, and the hands can arbitrarily move in a certain range.

Owner:BEIHANG UNIV

Wire rope connectors and tensioners for deck railing systems

ActiveUS7198253B2Good adhesionReduce wasteBalustradesRopes and cables for vehicles/pulleyWire tensionWire rope

Owner:SUNCOR STAINLESS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com