Patents

Literature

9862 results about "Winding machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A winding machine or winder is a machine for wrapping string, twine, cord, thread, yarn, rope, wire, ribbon, tape, etc. onto a spool, bobbin, reel, etc.

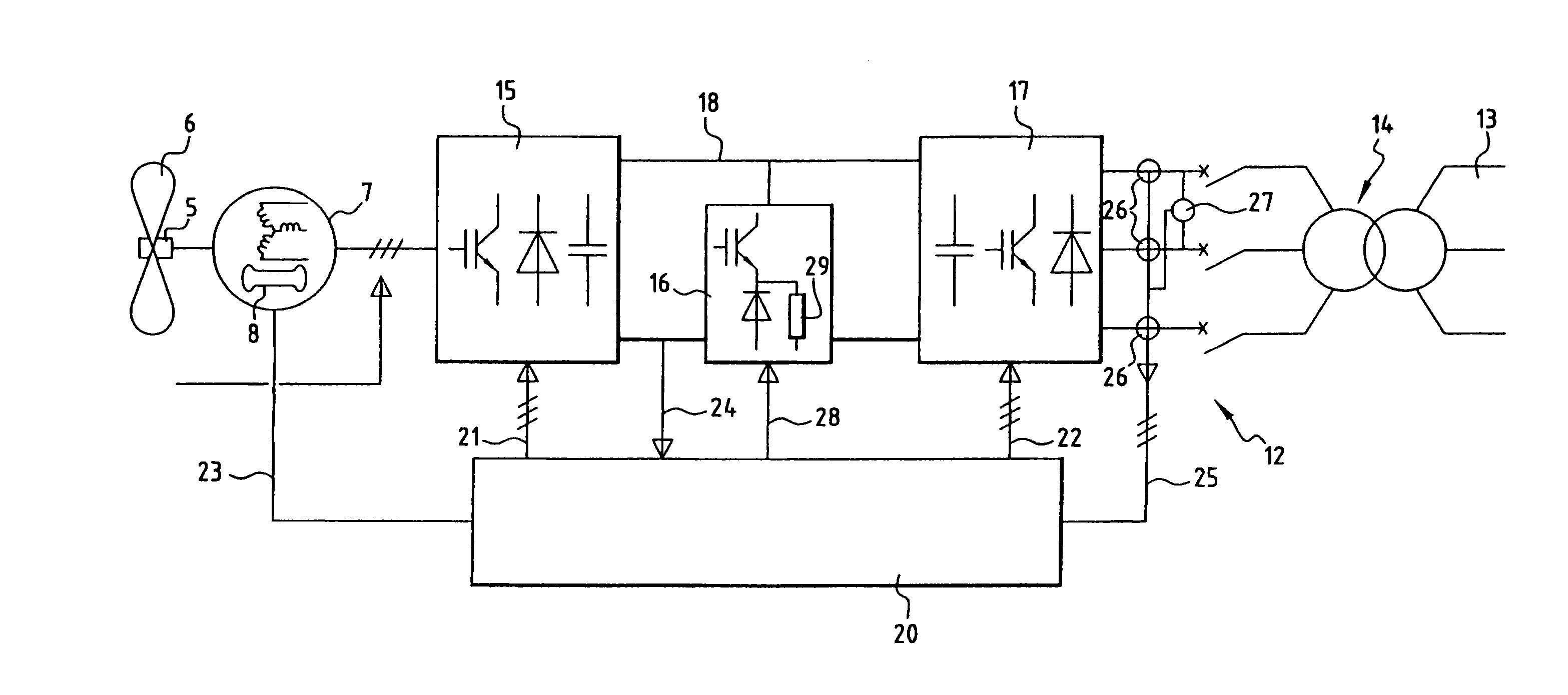

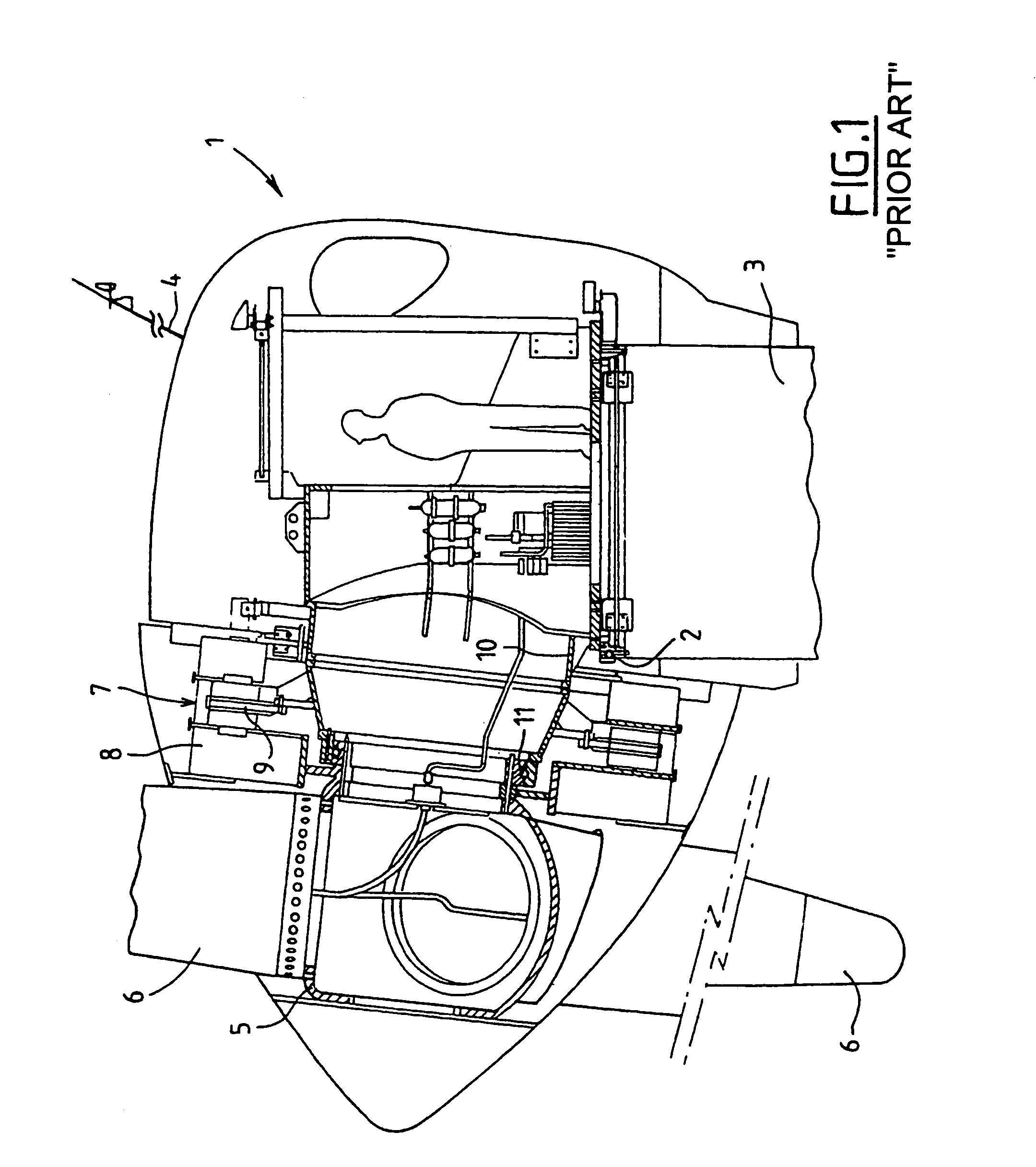

Method and device for regulating a wind machine

A method and corresponding apparatus for regulating a system that produces electric power, the system including an electric alternator having a rotor integral with a rotating part of a wind machine to form a rotary assembly, and a power electronics module, the method including the steps of: producing an alternating current at output terminals of the alternator; converting the alternating current produced by the alternator into modulated pulses of direct current. Alternating electric current produced by the alternator is regulated by controlling the speed of rotation of the rotary assembly by resisting torque imposed by the alternator in response to modulating the pulses of continuous current produced by the converted the alternating current.

Owner:JEUMONT

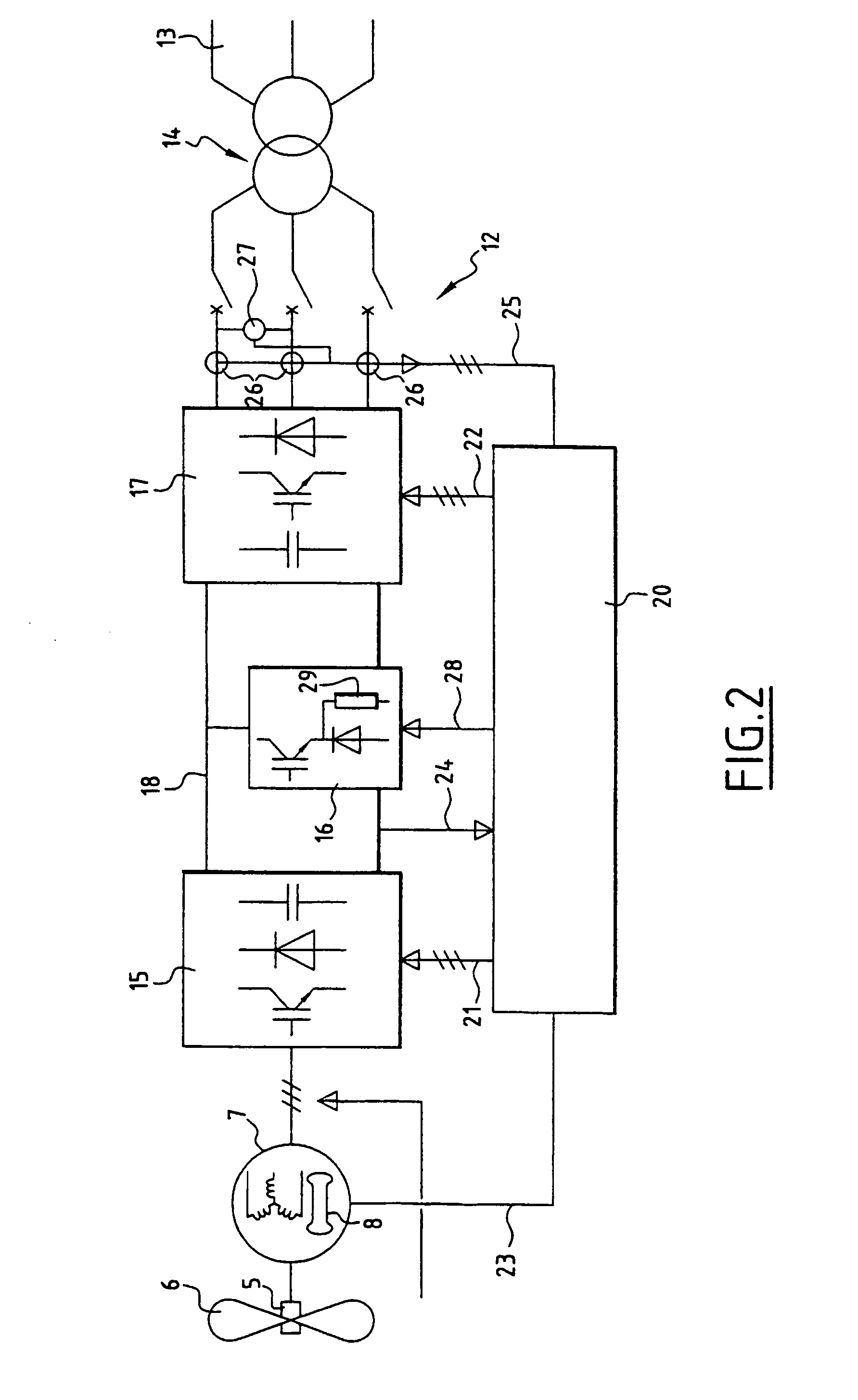

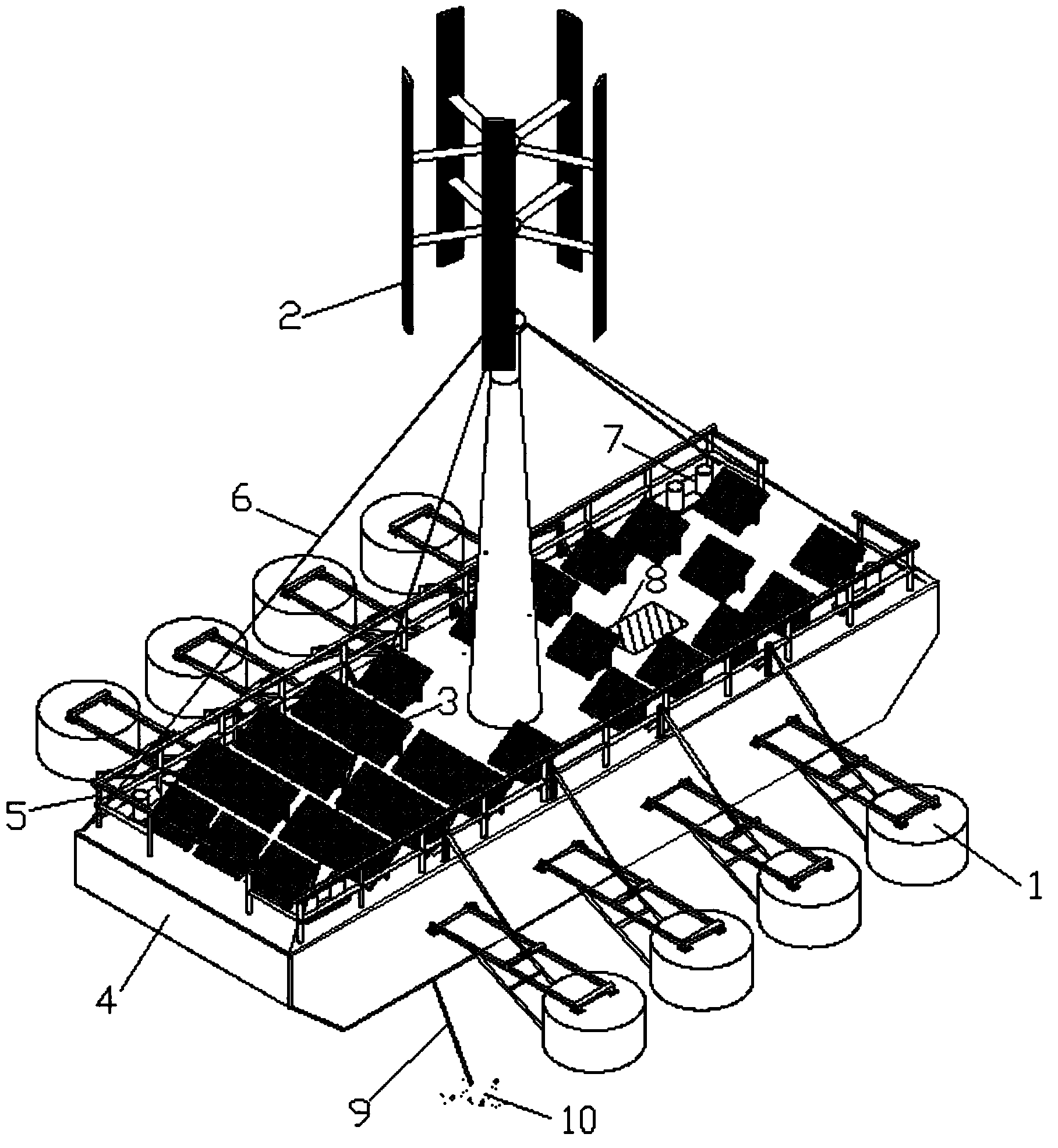

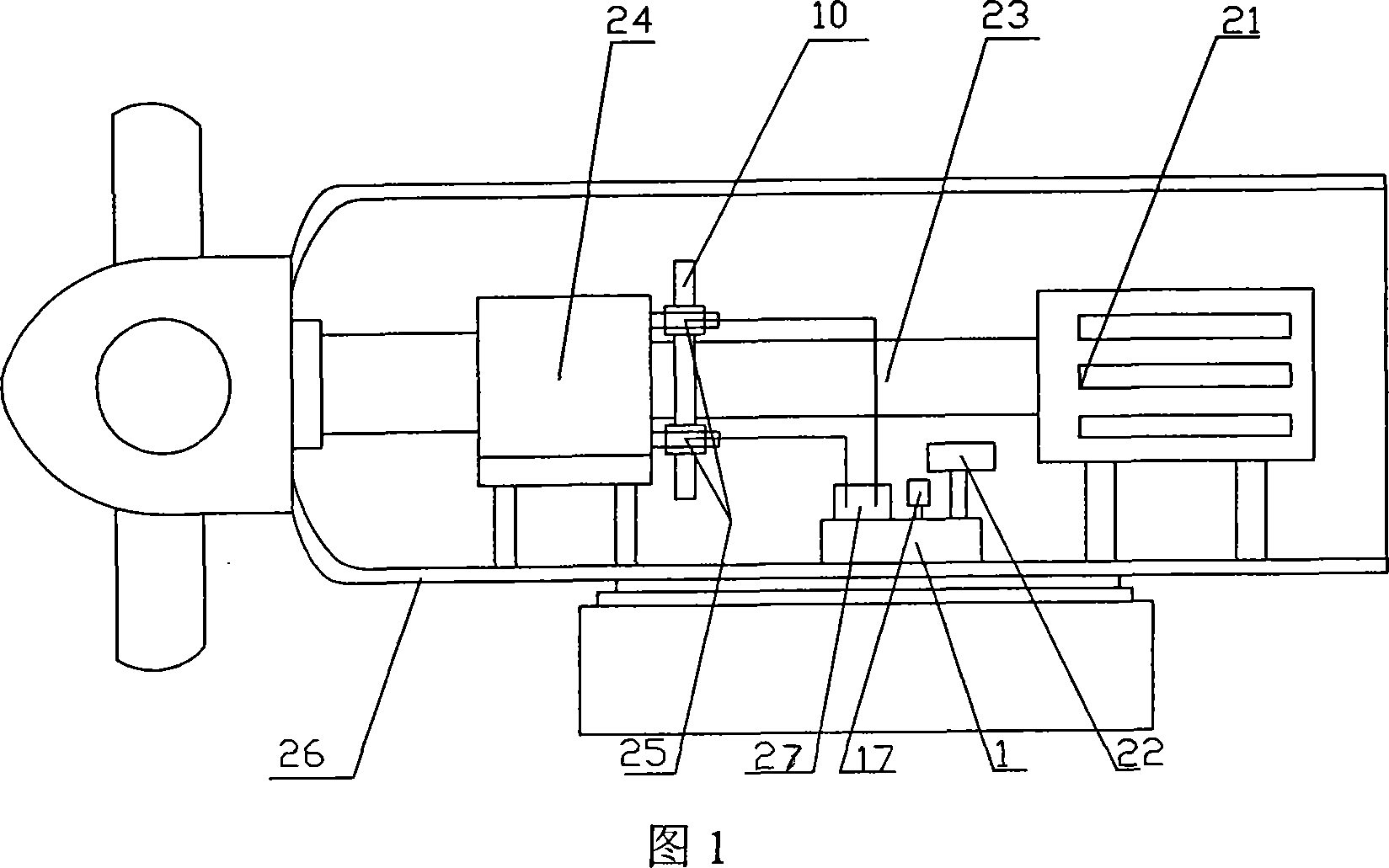

Wave, wind and light comprehensive electricity generation ship on sea

ActiveCN103523181AImprove stability and securityAvoid direct erosionWaterborne vesselsEnergy industryMechanical energyEngineering

The invention discloses a wave, wind and light comprehensive electricity generation ship on the sea in the technical field of development and utilization of ocean renewable energy sources. Floaters are installed on the two sides of a hull respectively, the floaters vibrate up and down under the action of waves, and wave energy is firstly translated into mechanical energy and then translated into high-pressure energy of hydraulic oil through a hydraulic transition system; a perpendicular shaft wind machine is installed on a deck of the hull, wind rotors rotate under the action of blown wind, and wind energy is firstly translated into mechanical energy and then translated into high-pressure energy of the hydraulic oil through the hydraulic transition system; the hydraulic oil carrying the high-pressure energy works through impacting a hydraulic motor and drives a direct driven electric generator to generate electricity; a photovoltaic cell square matrix is installed on the deck of the hull to absorb solar energy and translate the solar energy into electric energy. The wave, wind and light comprehensive electricity generation ship solves the problems that electricity generation with ocean energy resources is high in unit cost, poor in stability and the like, and greatly improves competitive power of the development and utilization of the ocean renewable energy sources due to the high flexibility of a system.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

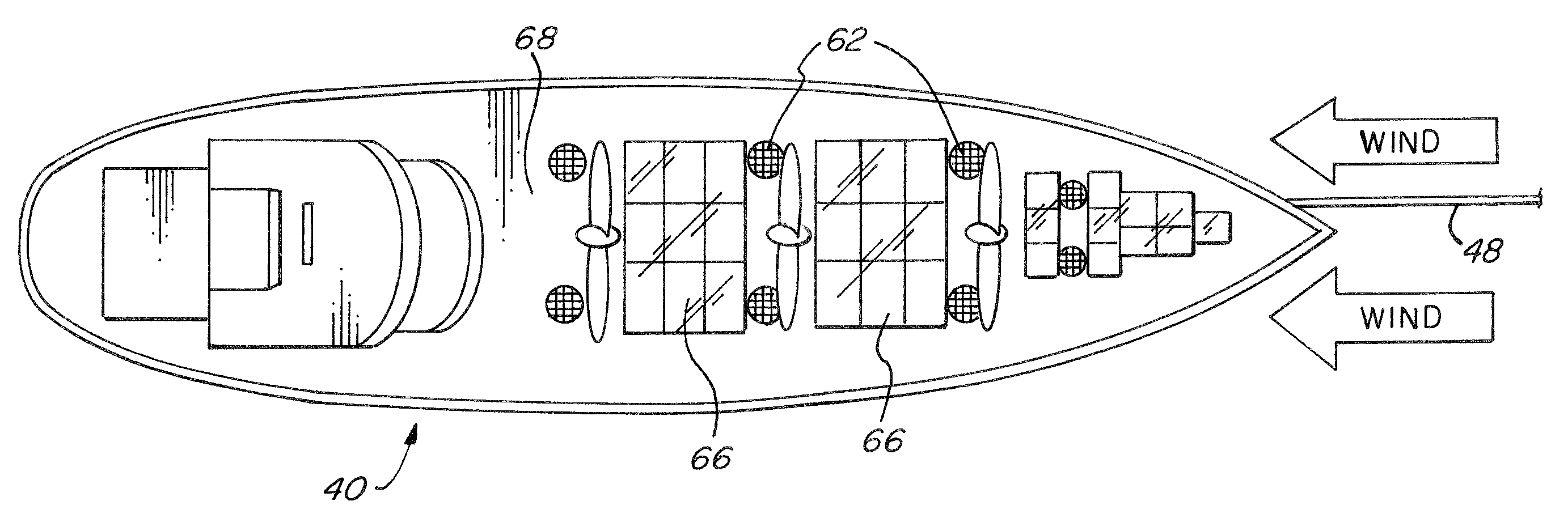

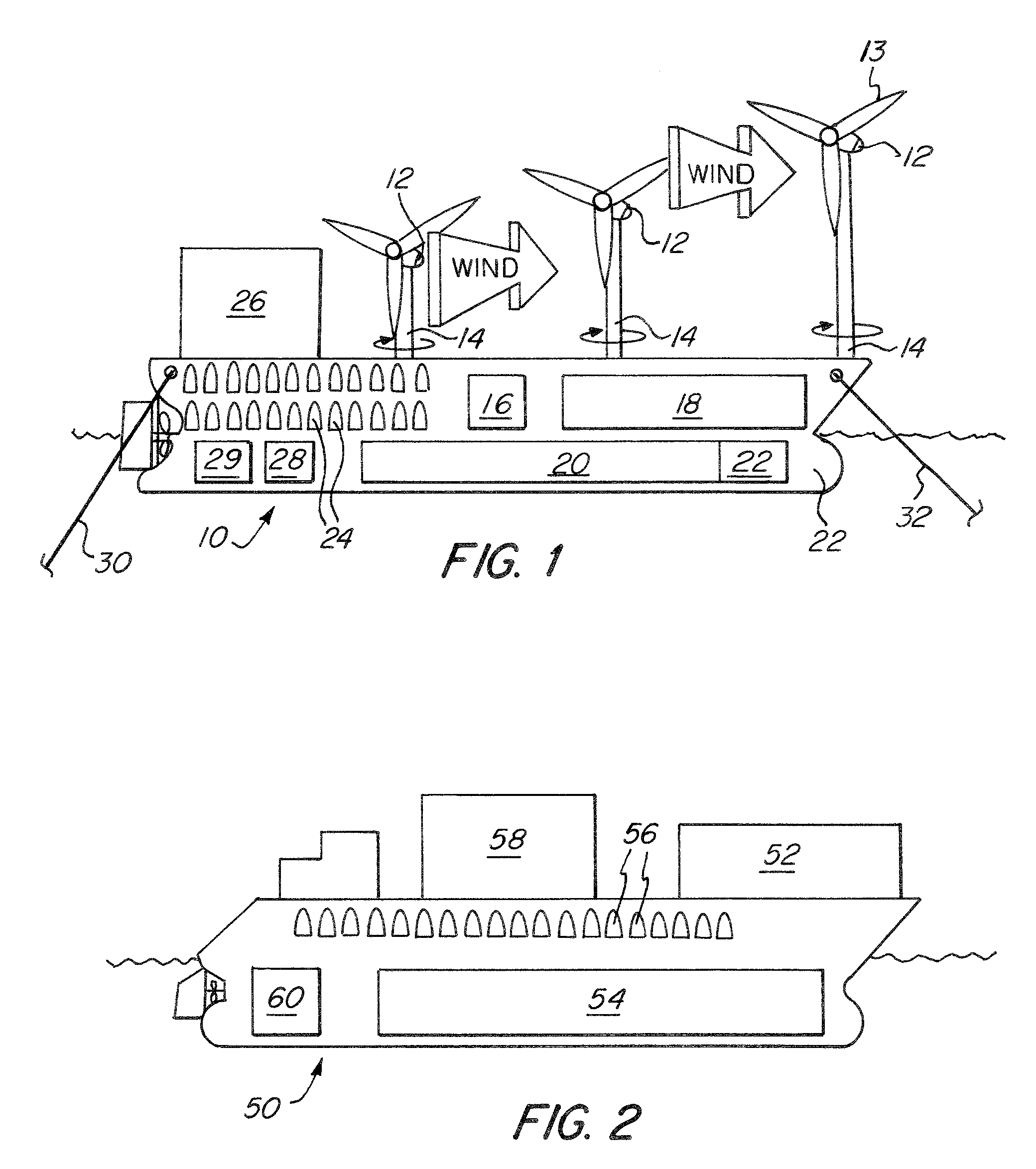

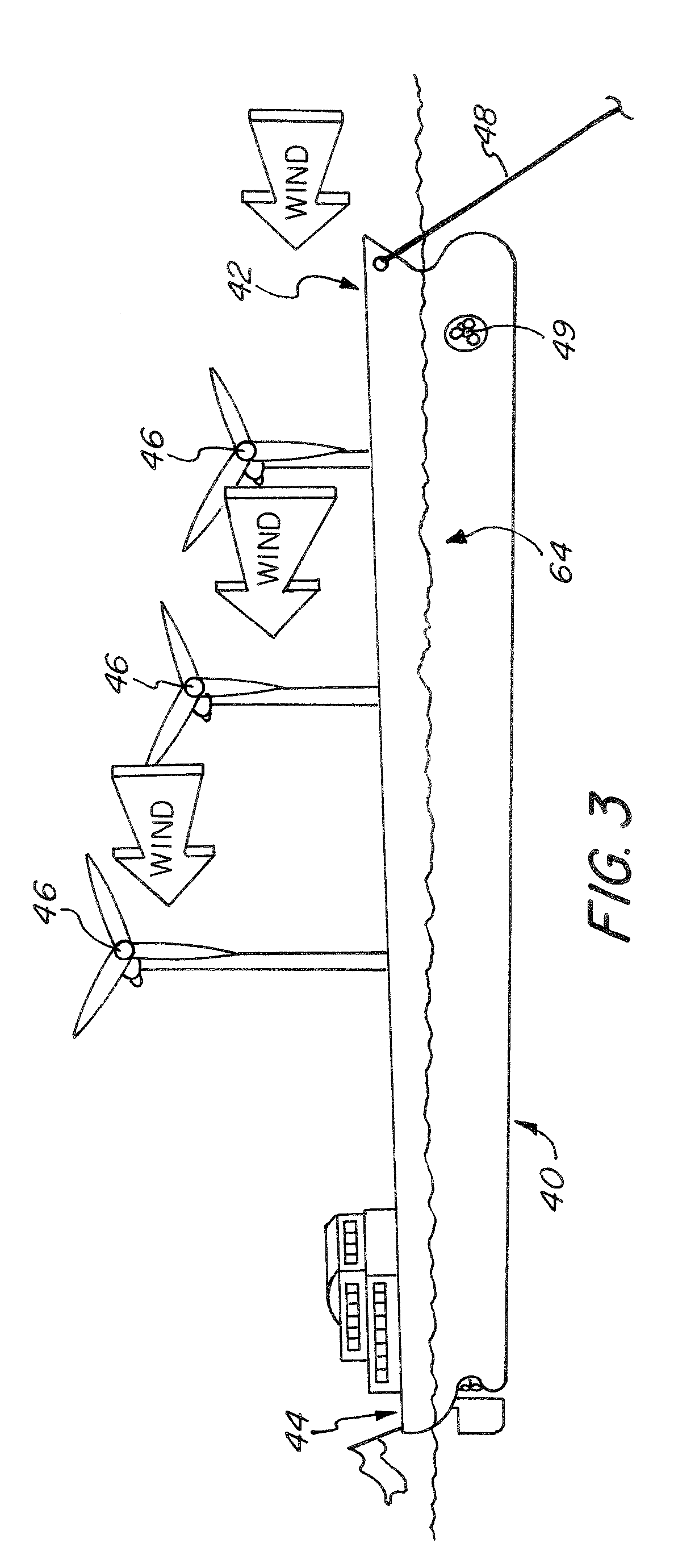

Wind Power System

A system for capturing and converting and / or storing wind energy includes a vessel adapted to receive at least one wind machine for capturing wind and a device for converting wind energy to storable energy. A method of adapting a vessel, such as a surplus cargo ship or an oil tanker, for use as a offshore power generating system comprises equipping a vessel with devices for capturing a renewable energy source, positioning the vessel at sea to capture the renewable energy source, converting the renewable energy to a storable energy source, and storing the converted energy, and repositioning the vessel to capture further renewable energy or transport the stored, converted energy.

Owner:POLESTAR LTD LLC

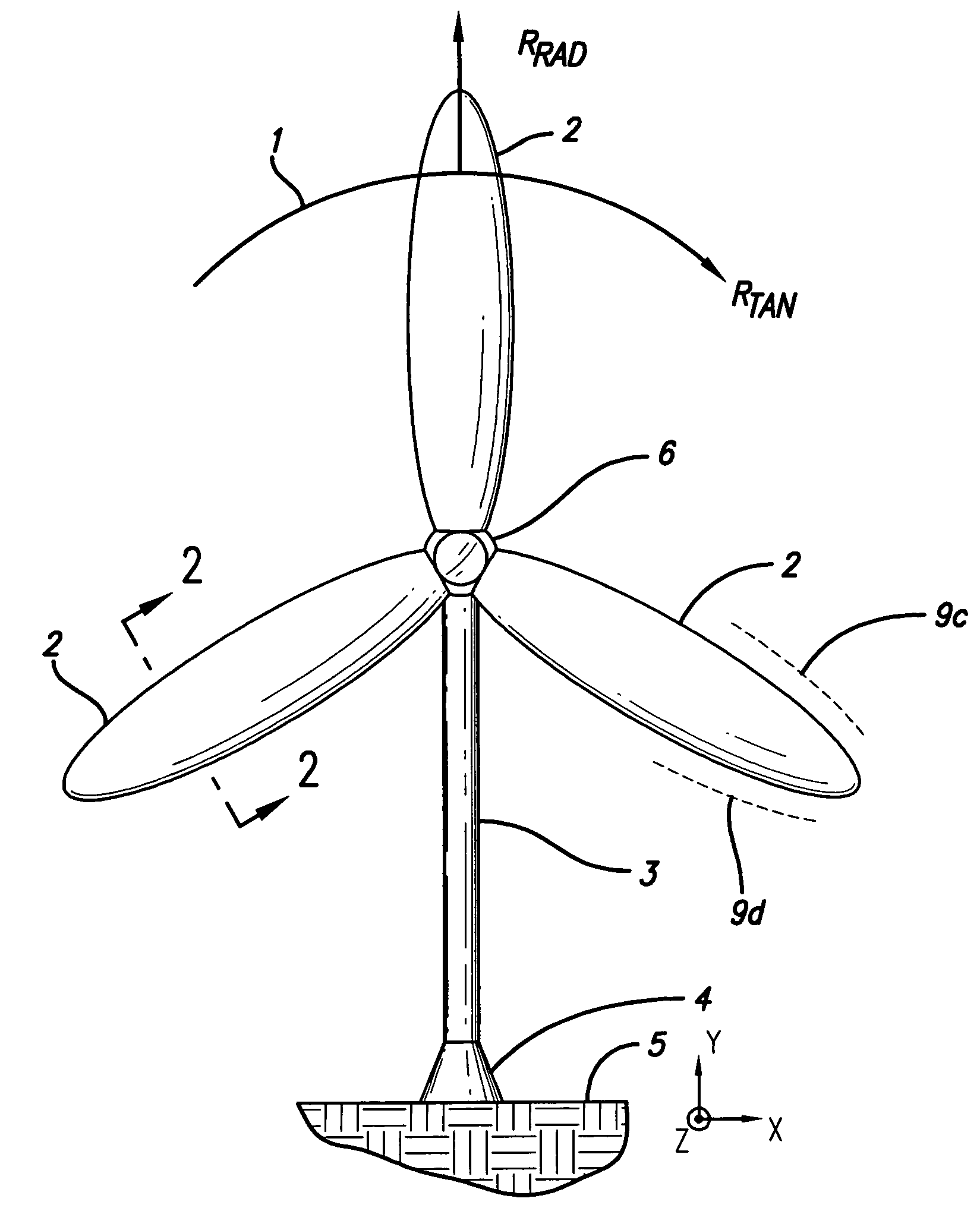

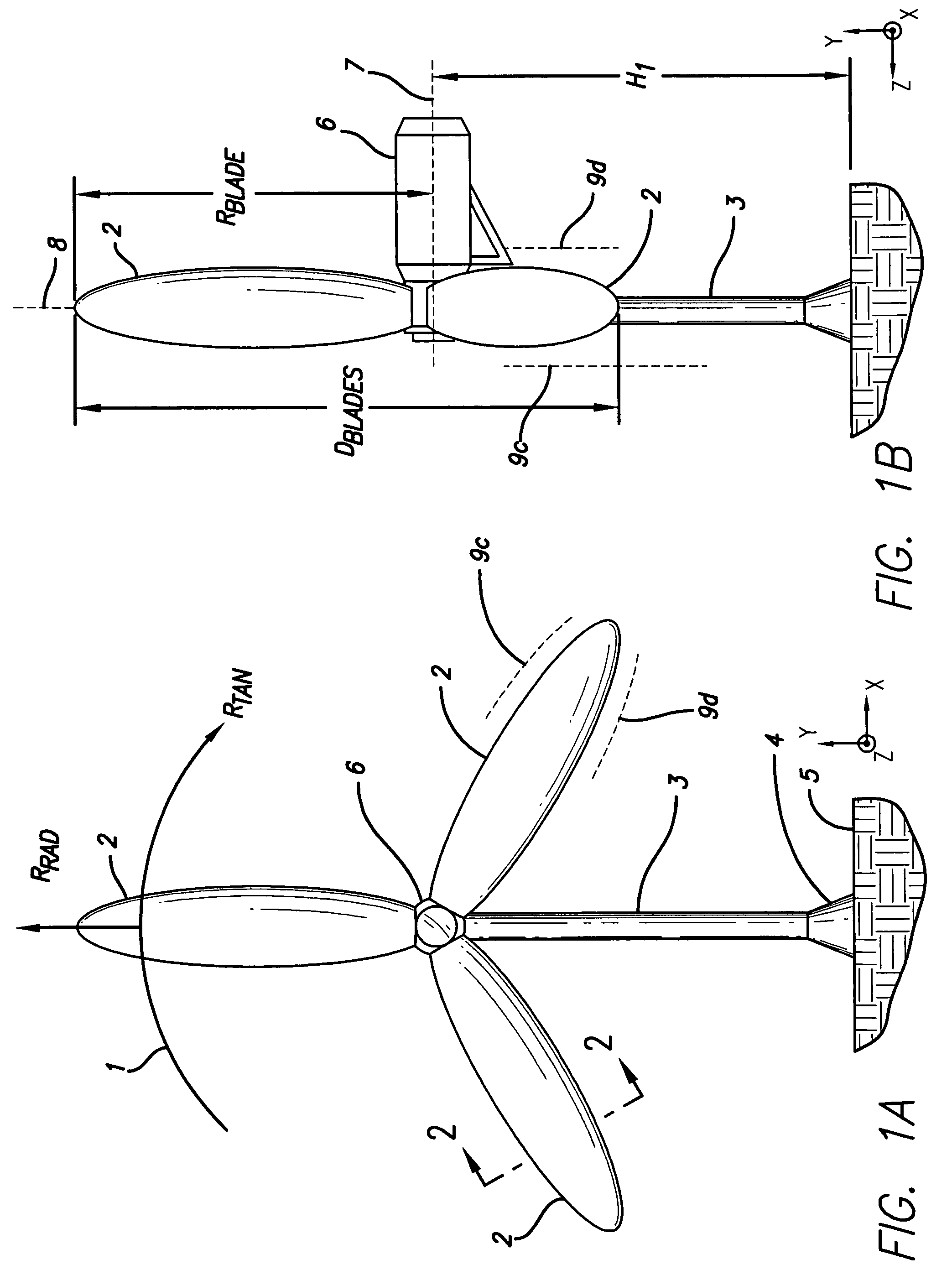

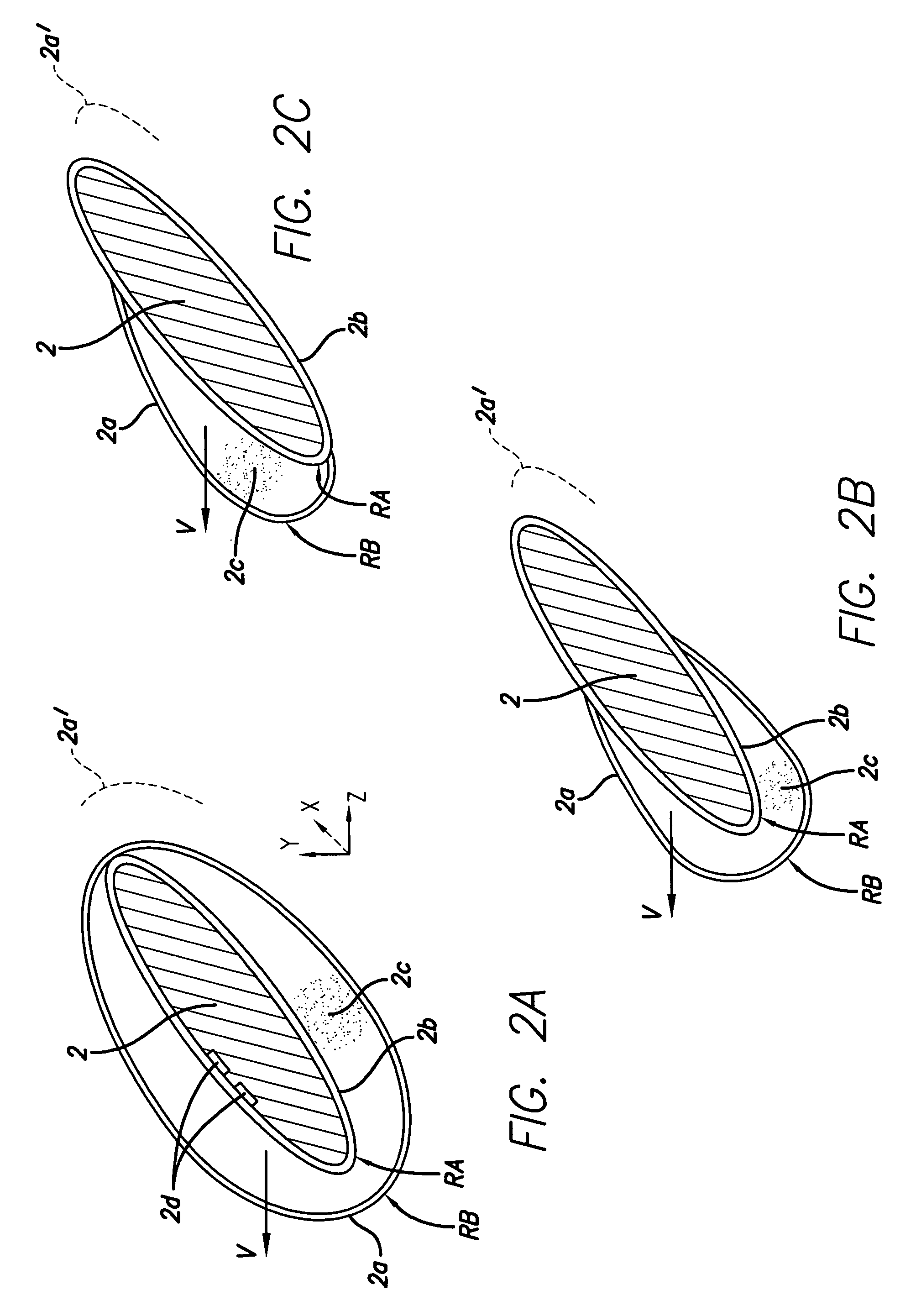

Method and apparatus for reducing bird and fish injuries and deaths at wind and water-turbine power-generation sites

A simple system is provided to dramatically reduce the number of bird fatalities and injuries, as these are bird-kills that man should be able to do something about. Essentially, the inventive apparatus comprises one or more instantaneously inflatable mini-airbags on turbine blade leading edges which, in the “stowed position” are tightly conformally elastically wrapped around or juxtaposed to the turbine blade surface(s) and / or edges(s) thereby not affecting the blade's aerodynamic efficiency. The airbag(s) can be activated and restowed or recollapsed very rapidly, thereby not significantly negatively impacting the operational efficiency of the wind machine. In a similar manner, fish-kills or injuries taking place in the turbine impellers of hydroelectric power-generator facilities may be avoided (as opposed to ameliorated) using another inventive system and method taught herein, this one being primarily a collision avoidance system which does not require the problematic alteration of the turbine blades themselves.

Owner:I P FOUNDRY

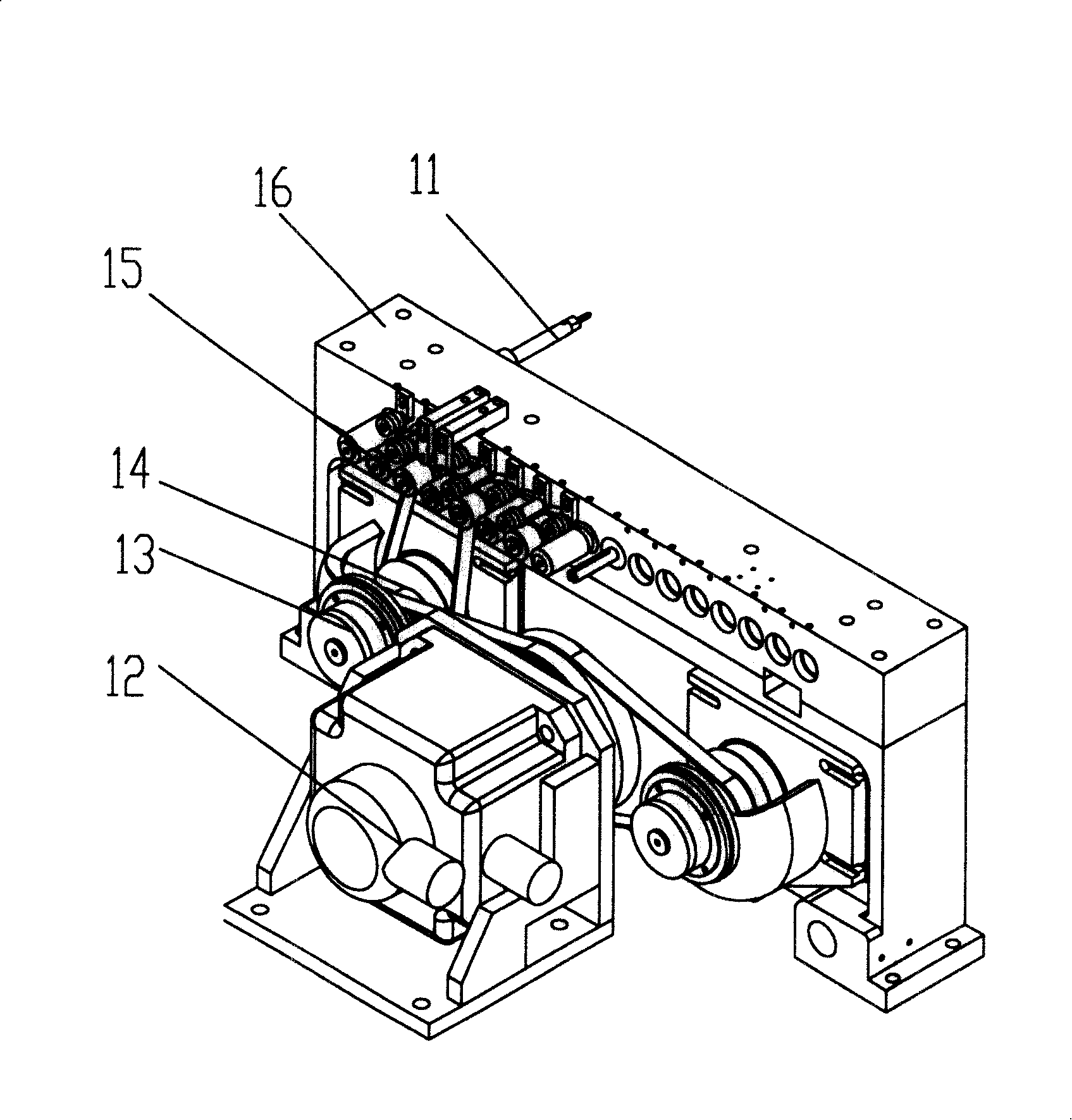

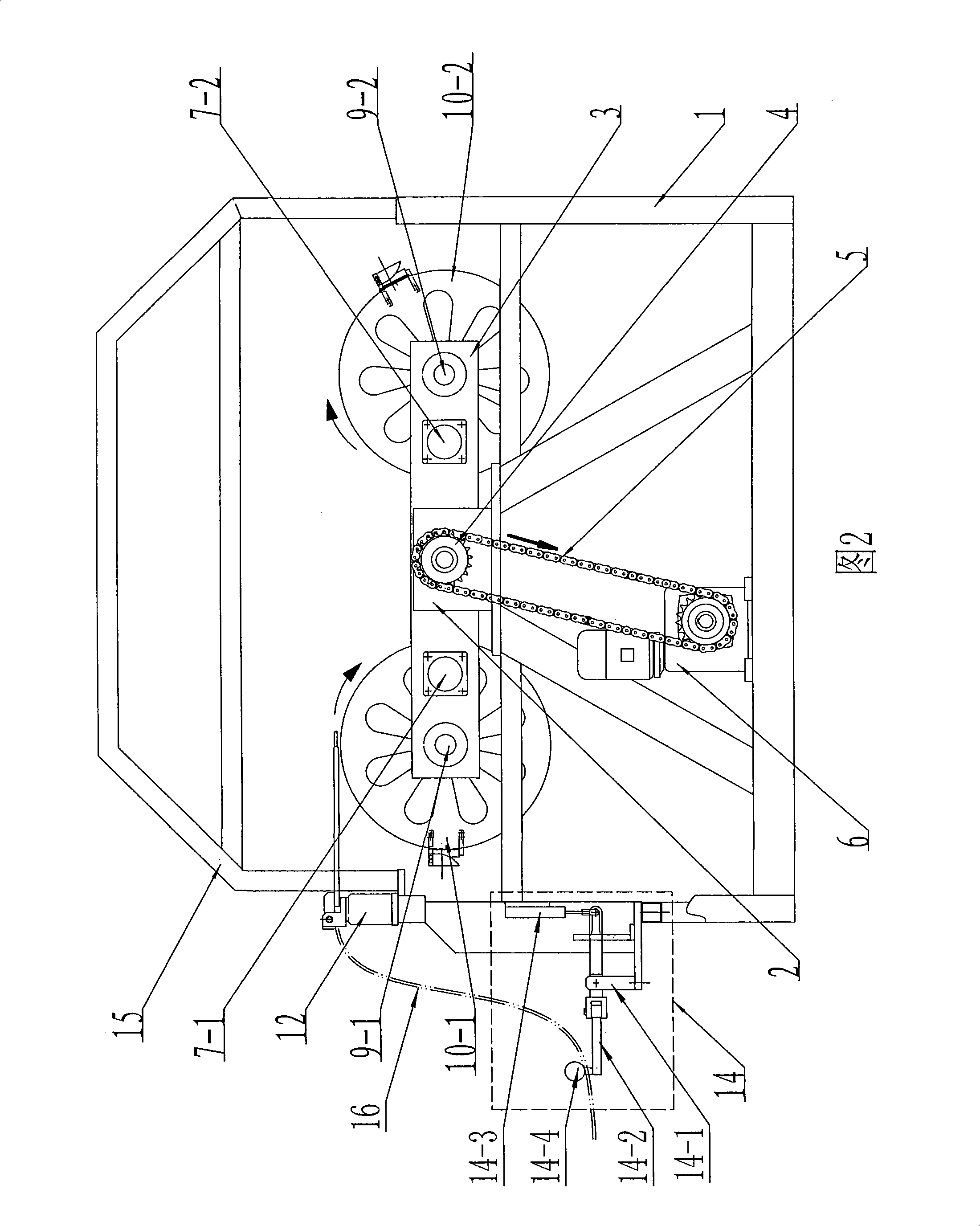

Biax full-automatic coiling machine

InactiveCN101441935AIncrease profitReduce production processCoils manufactureWinding machineEngineering

The present invention discloses a dual spindle full-automatic winding machine which is set on the base and characterized in that, it mainly comprises a feeding mechanisms, a mobile mechanism, a pick-and-place mechanism, a tension control mechanism, a thread drawing mechanism, a wire winding and arranging mechanism, a curing mechanism, and a discharging mechanism who are interactive with each other for coordination under PLC control; the above mechanisms coordinate with each other from imputing to magnetic core in the shape of 'I' to final product outputted according to requirement of winding process. The invention is full-automatic, practical, can improve production efficiency and has good promotion value.

Owner:广东昭信平洲电子有限公司

Aluminum strip continuous anodic oxidation automatic production line

InactiveCN101676439AContinuous production saves time and laborAnodisationWinding machineProduction line

Owner:浙江聚力文化发展股份有限公司

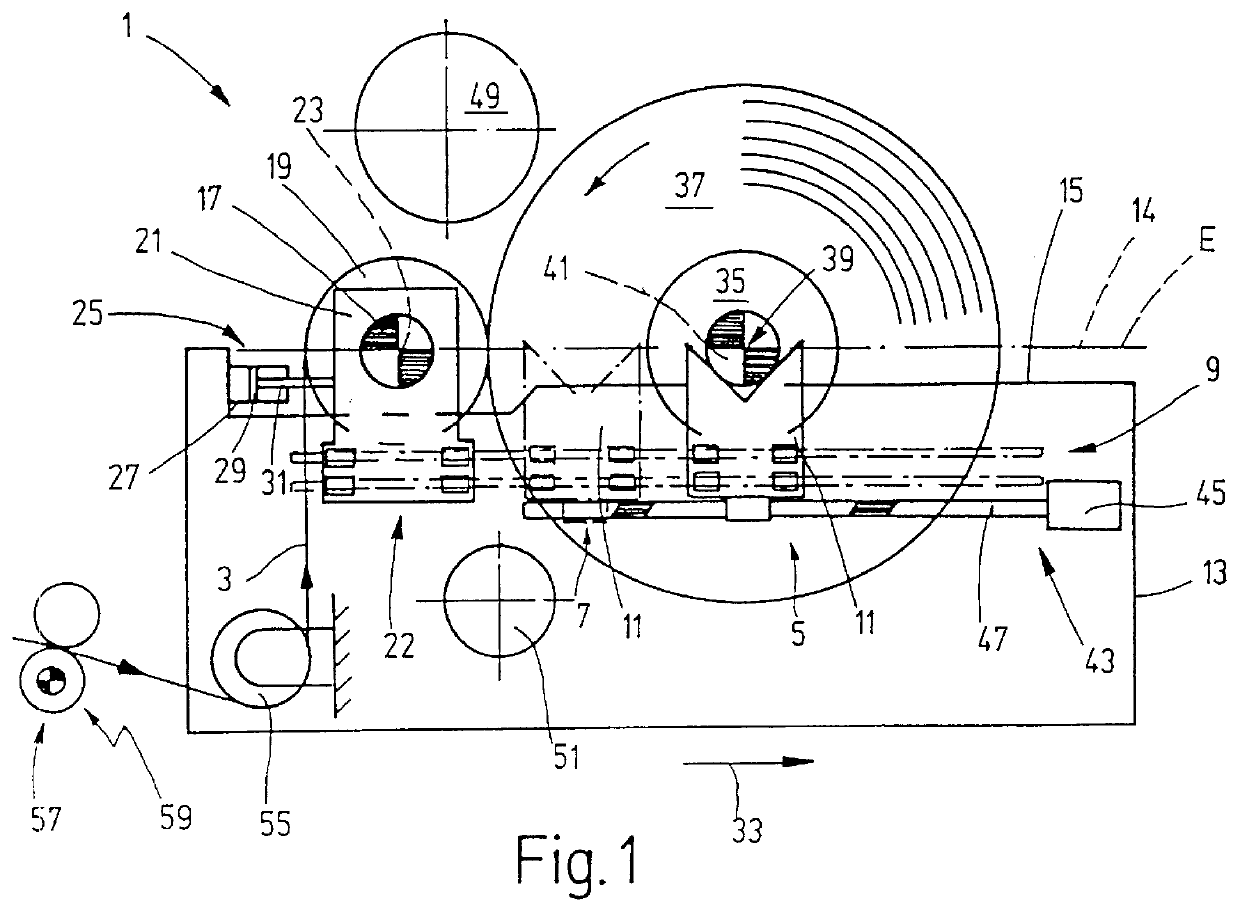

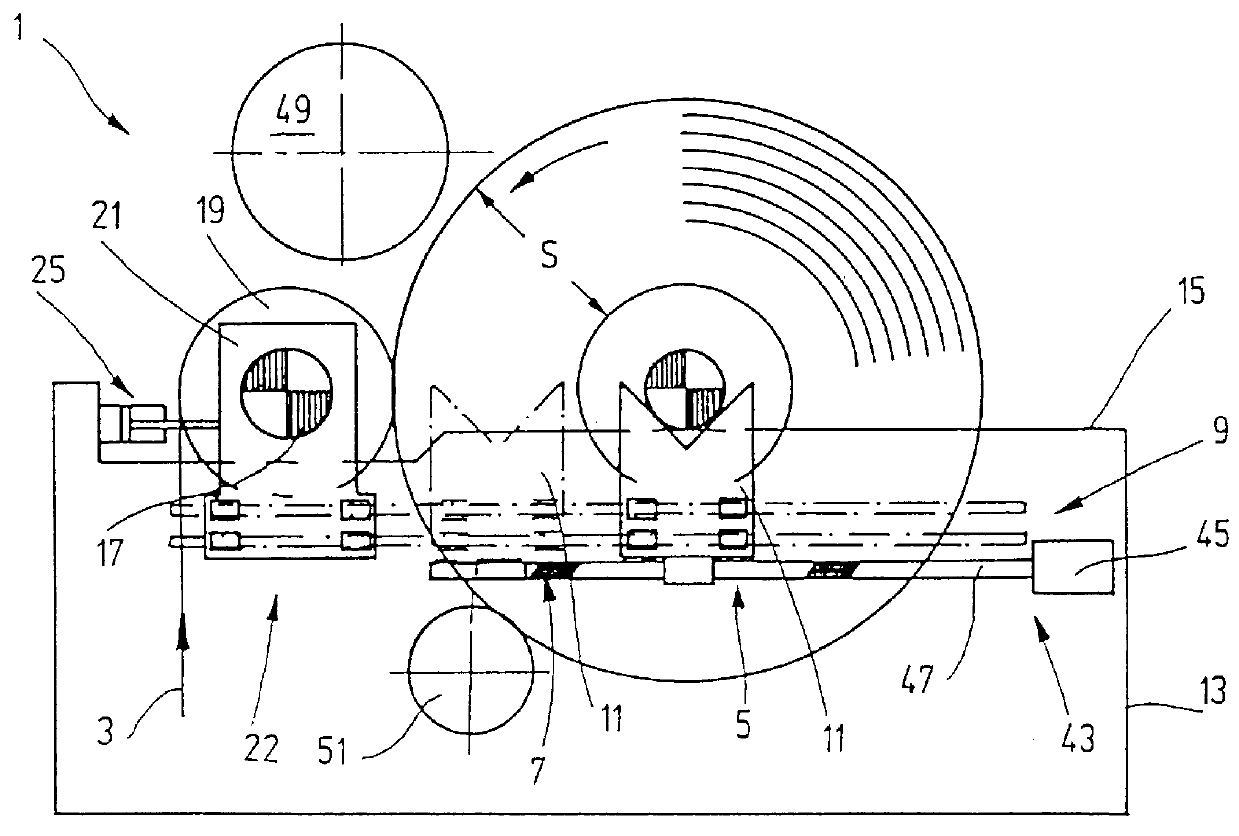

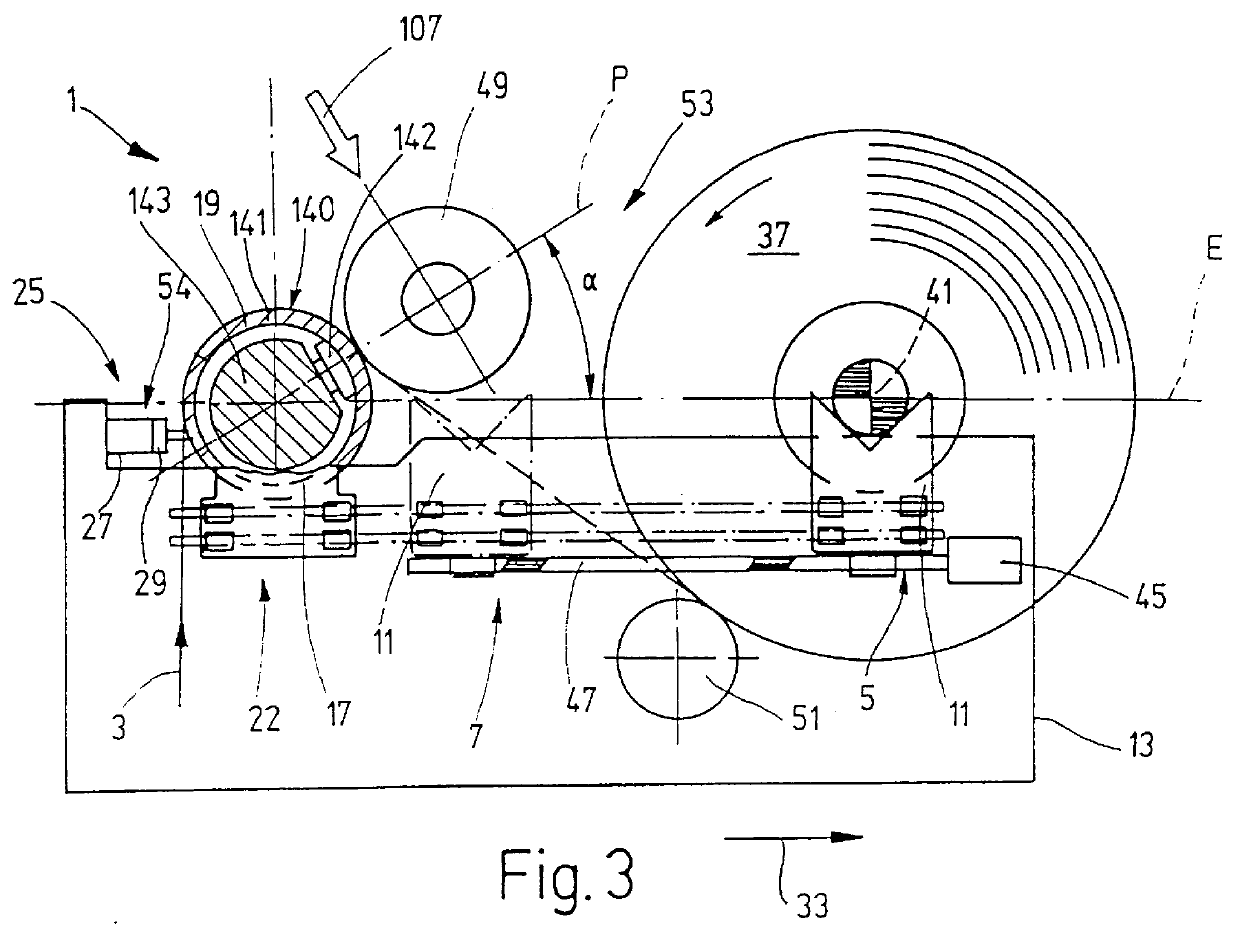

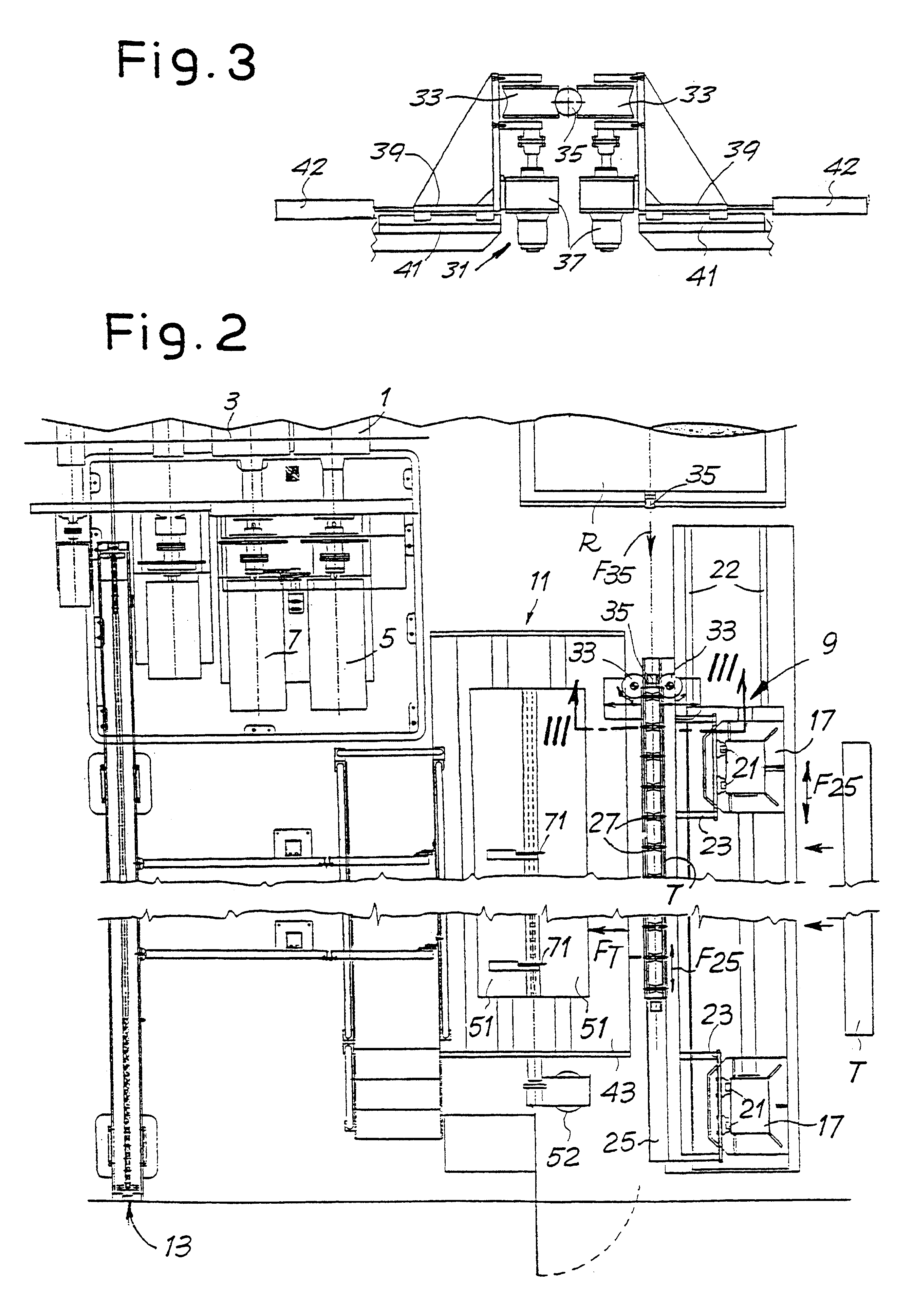

Process and winding machine for continuous winding of a material web

PCT No. PCT / EP98 / 02867 Sec. 371 Date Nov. 18, 1998 Sec. 102(e) Date Nov. 18, 1998 PCT Filed May 15, 1998 PCT Pub. No. WO98 / 52858 PCT Pub. Date Nov. 26, 1998Winding machine for continuous winding of a material web, in particular a paper or cardboard web, onto a reel into a winding roll, having a movable pressing drum, which forms a winding gap with the winding roll, having at least one primary transport device by means of which the reel can be moved along a first guide track, and at least one secondary transport device that guides the reel along a second guide track. To prepare for a reel change, the new reel can be shifted by the primary transport device into a reel-changing position in which a new winding gap is formed between the new reel and the pressing drum. In the reel-changing position, the material web is guided over a circumference region of the new reel.

Owner:VOITH PATENT GMBH

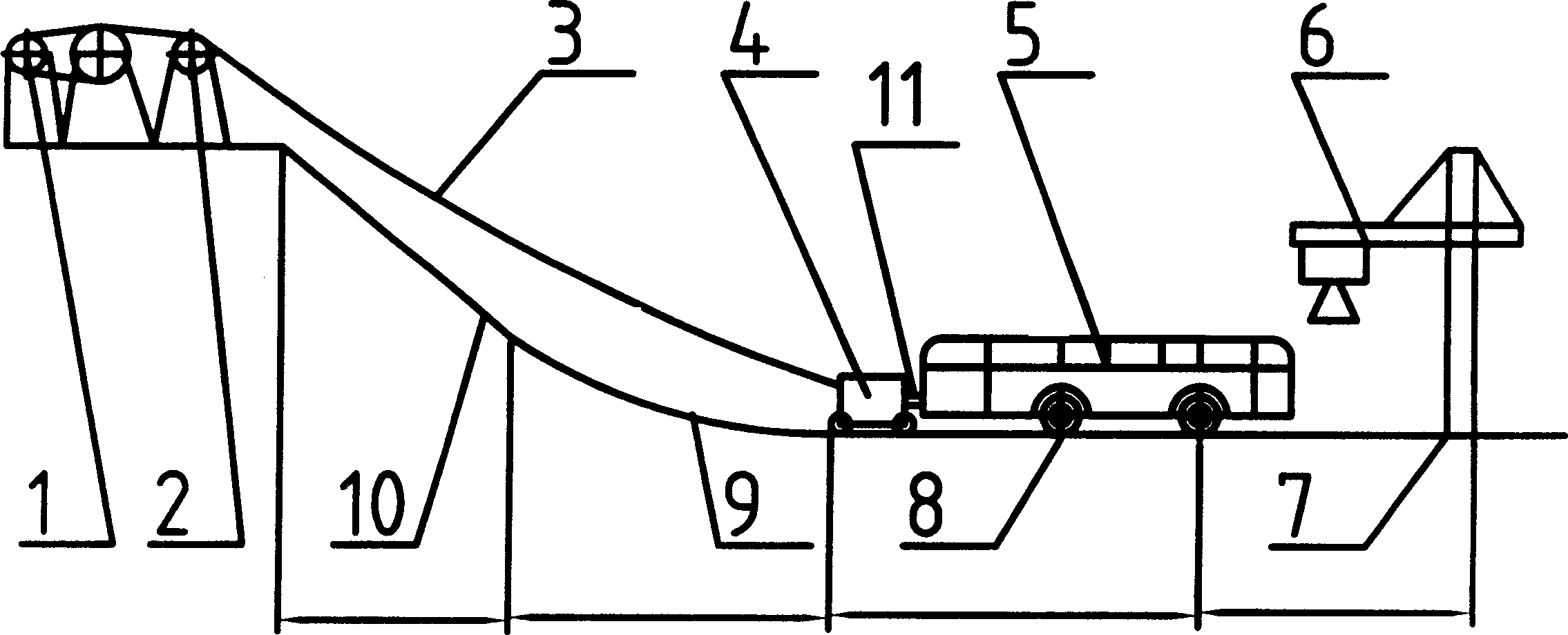

Ramp automobile collision experiment system and method

InactiveCN1420036ALow powerSmooth connectionVehicle fittingsSpeed/accelaration controlWinding machineEngineering

A ramp-type collision experiment system and method for car is disclosed. Said system is composed of a drawing-guiding unit consisting of supporting frames at high end of ramp, steel cable, winding machine and supporting roller, a ramp consisting of horizontal transition segment, curved transition segment and straight acceleration segment, a experiment segment, an observing tower with test equipment, and acceleration tester in experimental car.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

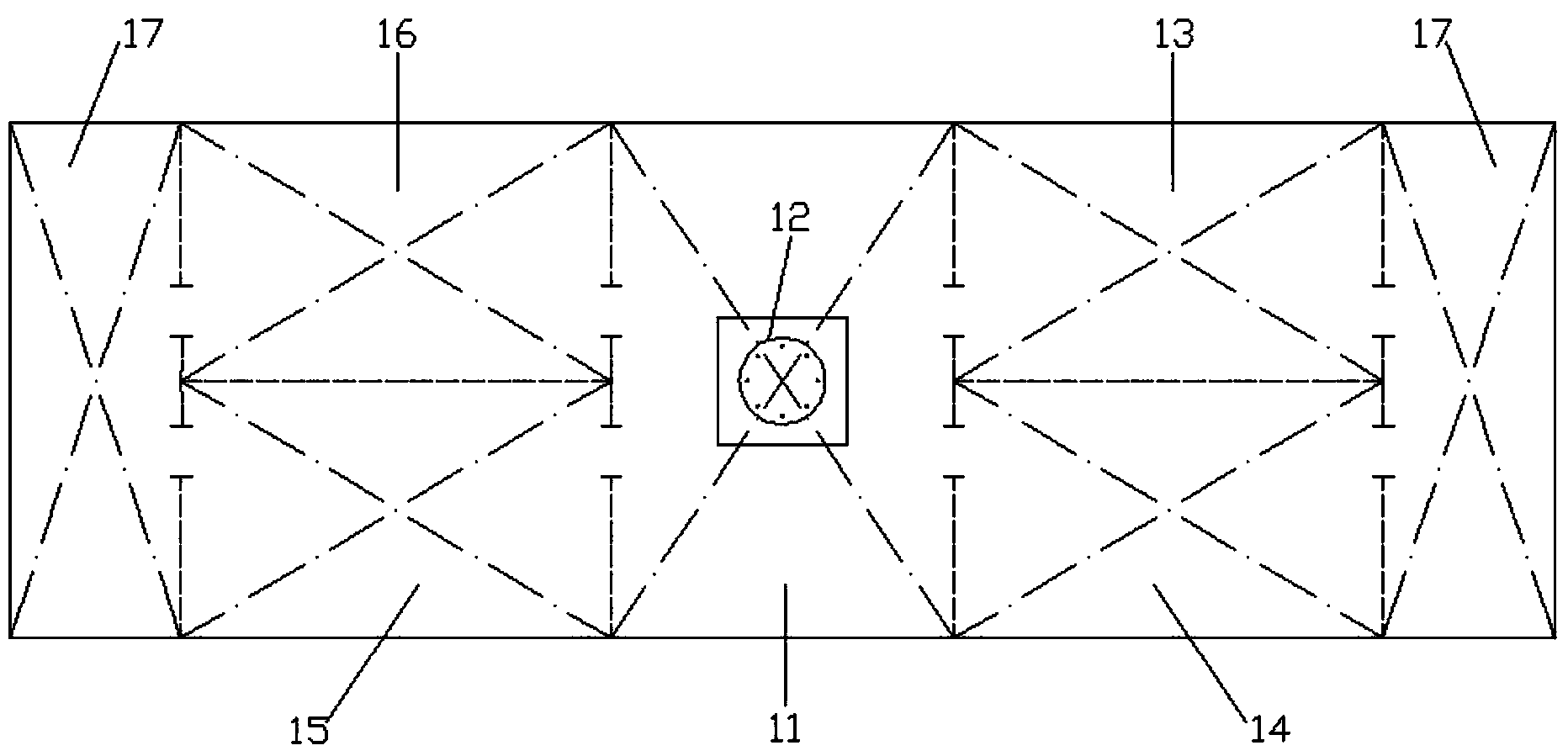

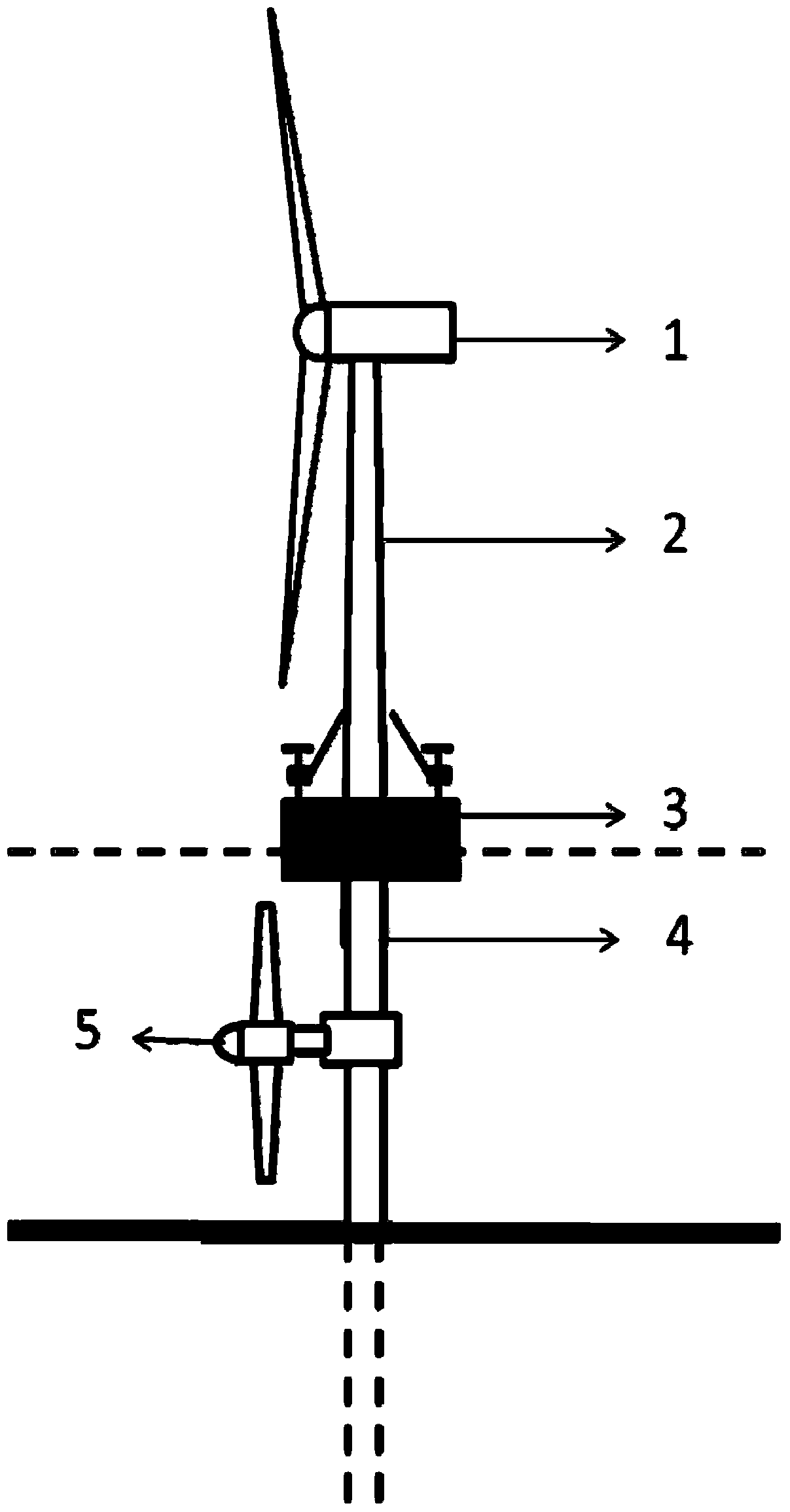

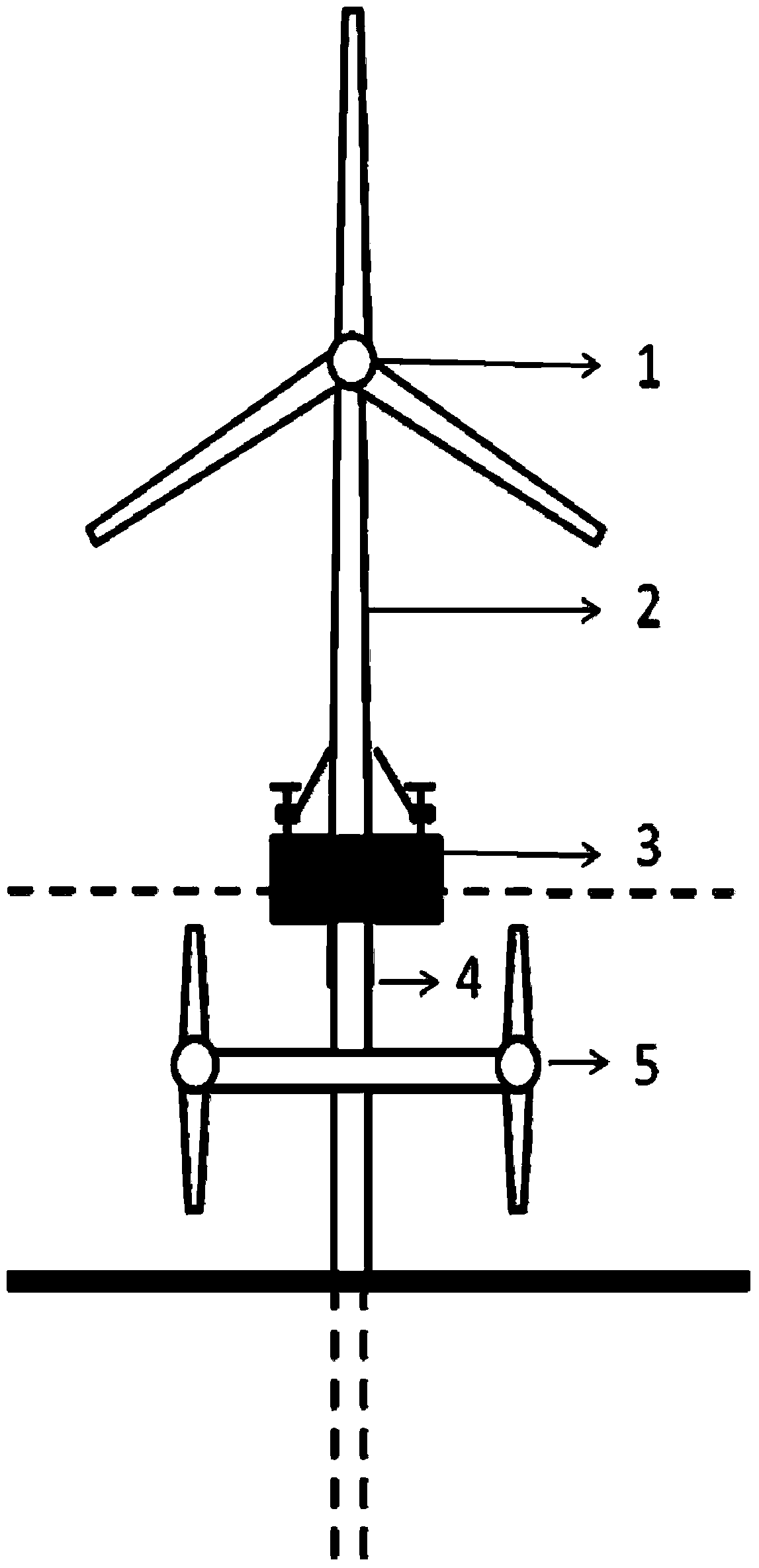

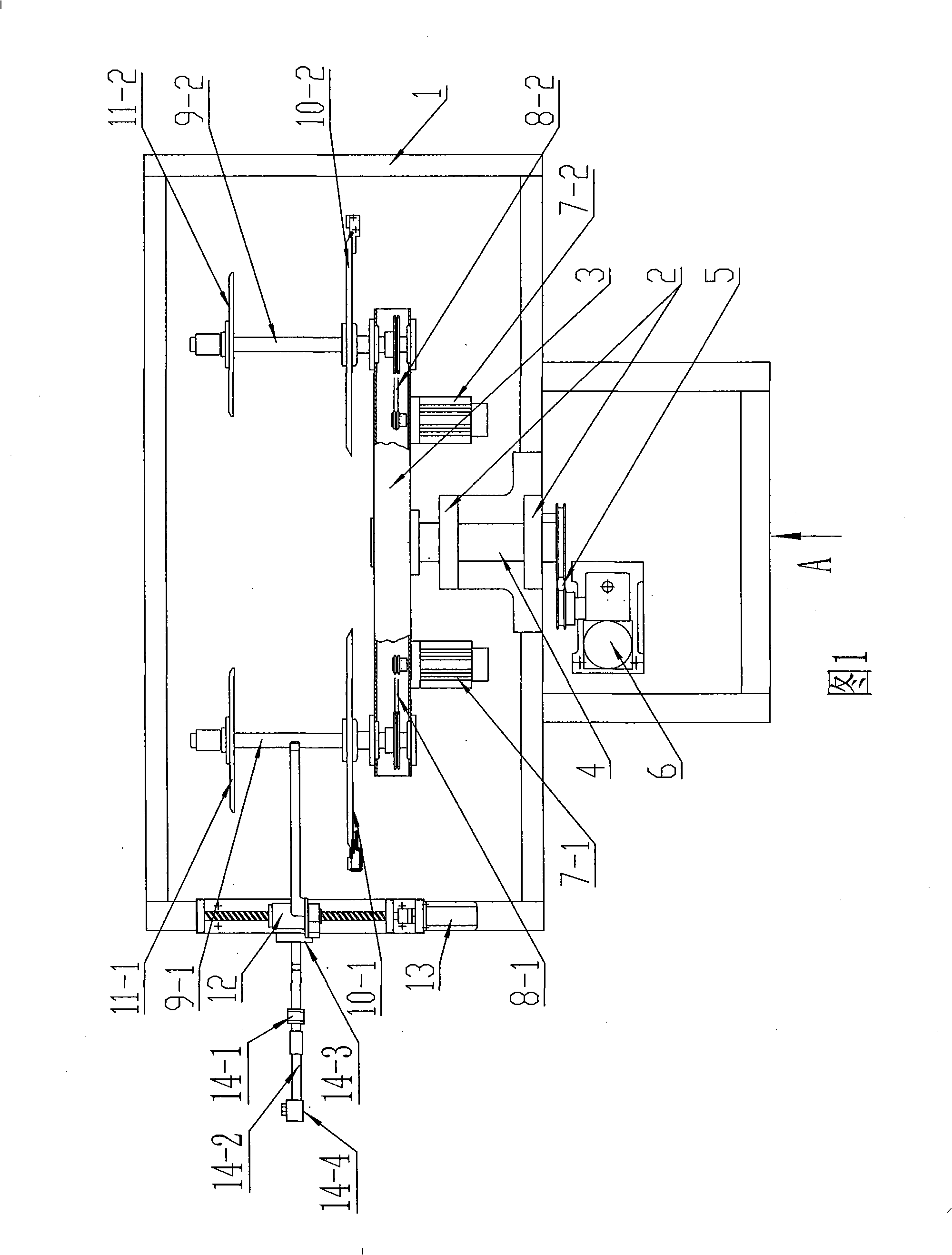

Wind energy-wave energy-tidal current energy integrated power generation structure based on single pile platform

InactiveCN103967714AEasy structure constructionReduce construction costsWind motor combinationsMachines/enginesElectric power transmissionWinding machine

A wind energy-wave energy-tidal current energy integrated power generation structure based on a single pile platform comprises a single pile platform wind power generation structure, a wave energy power generation device and a tidal current energy power generation device, the single pile platform wind power generation structure comprises a wind machine, a tower frame structure, a single pile supporting structure and a matched power transmission system, the wave energy power generation device is arranged on the water surface of the tower frame structure, and the tidal current energy power generation device is arranged on an underwater single pile supporting structure. The wind energy-wave energy-tidal current energy integrated power generation structure has the advantages that the single pile platform structure is convenient to construct, low in construction cost and wide in application range, the wind power generation structure, the wave energy power generation device and the tidal current energy power generation device share the single pile supporting structure and the power transmission system, the unit power generation cost can be effectively reduced, the structural design is reasonable and stable, the construction scheme is mature in technology, existing commercial products can be selected by a wind power generator and a tidal current power generator, modeling is simple and convenient to achieve, and performance optimizing design can be performed on a wave energy power generator by combining wave statistical features of a site selecting place.

Owner:DALIAN UNIV OF TECH

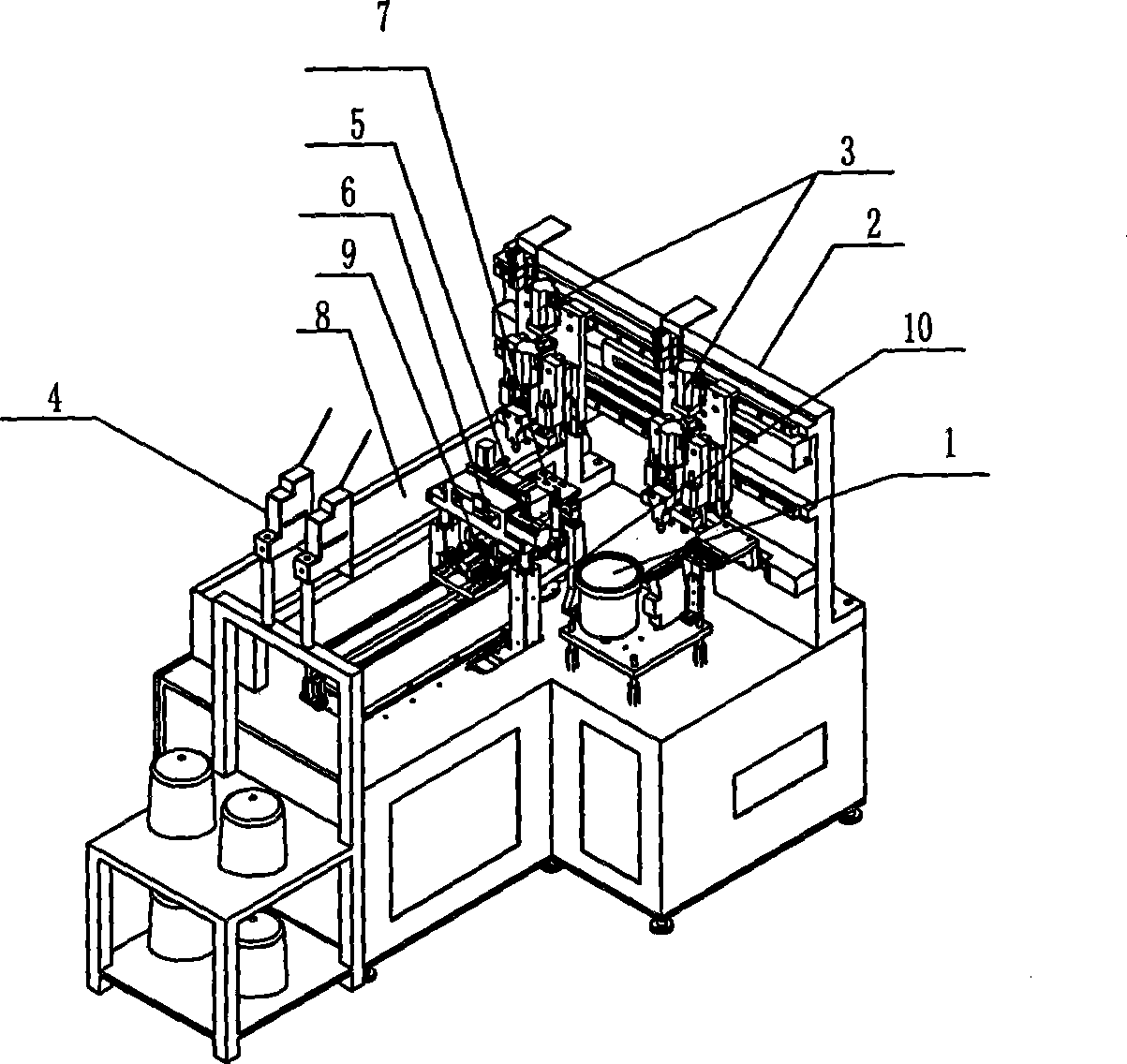

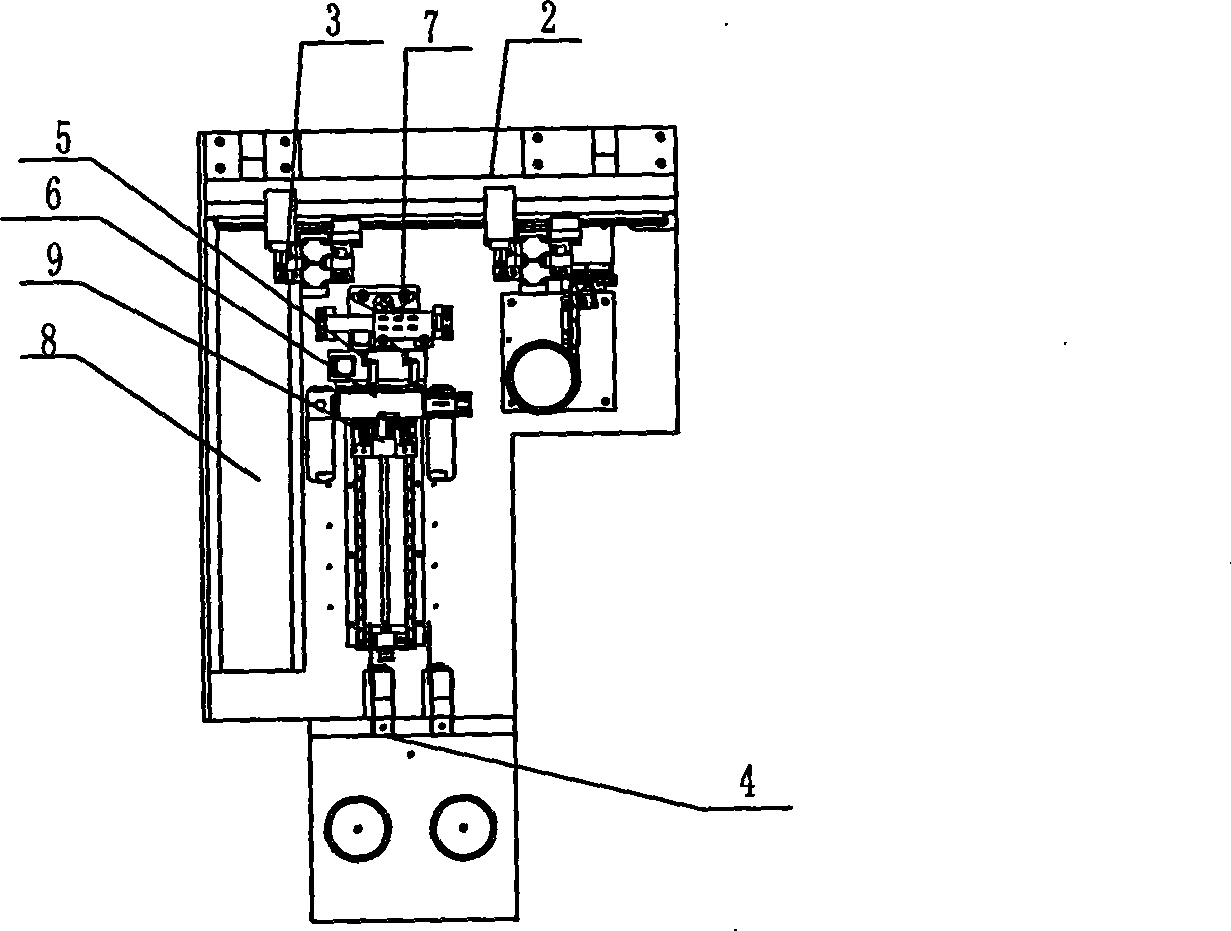

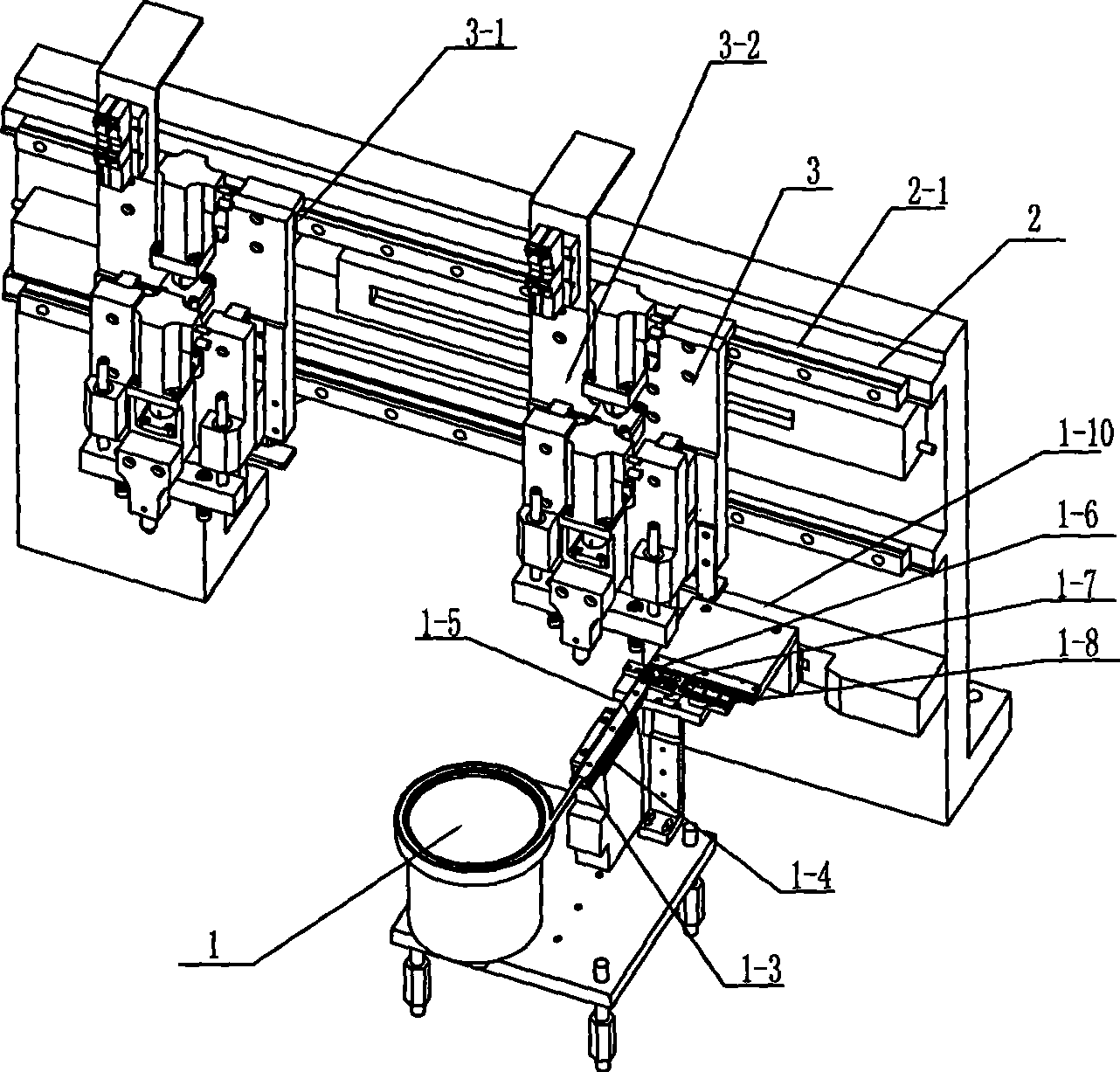

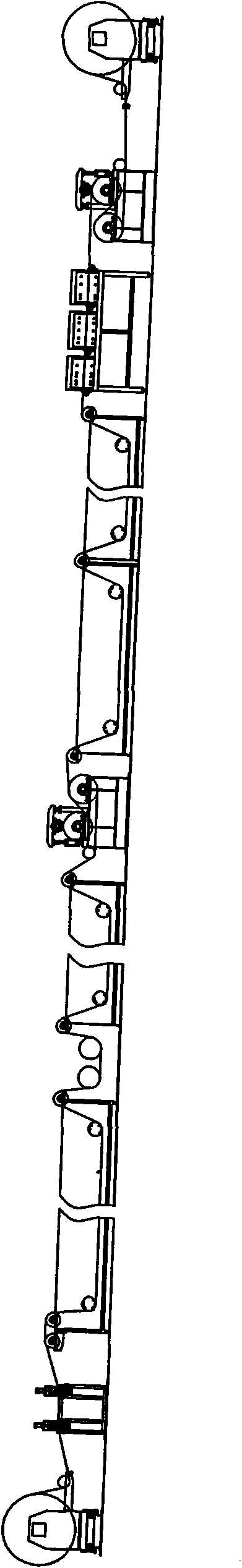

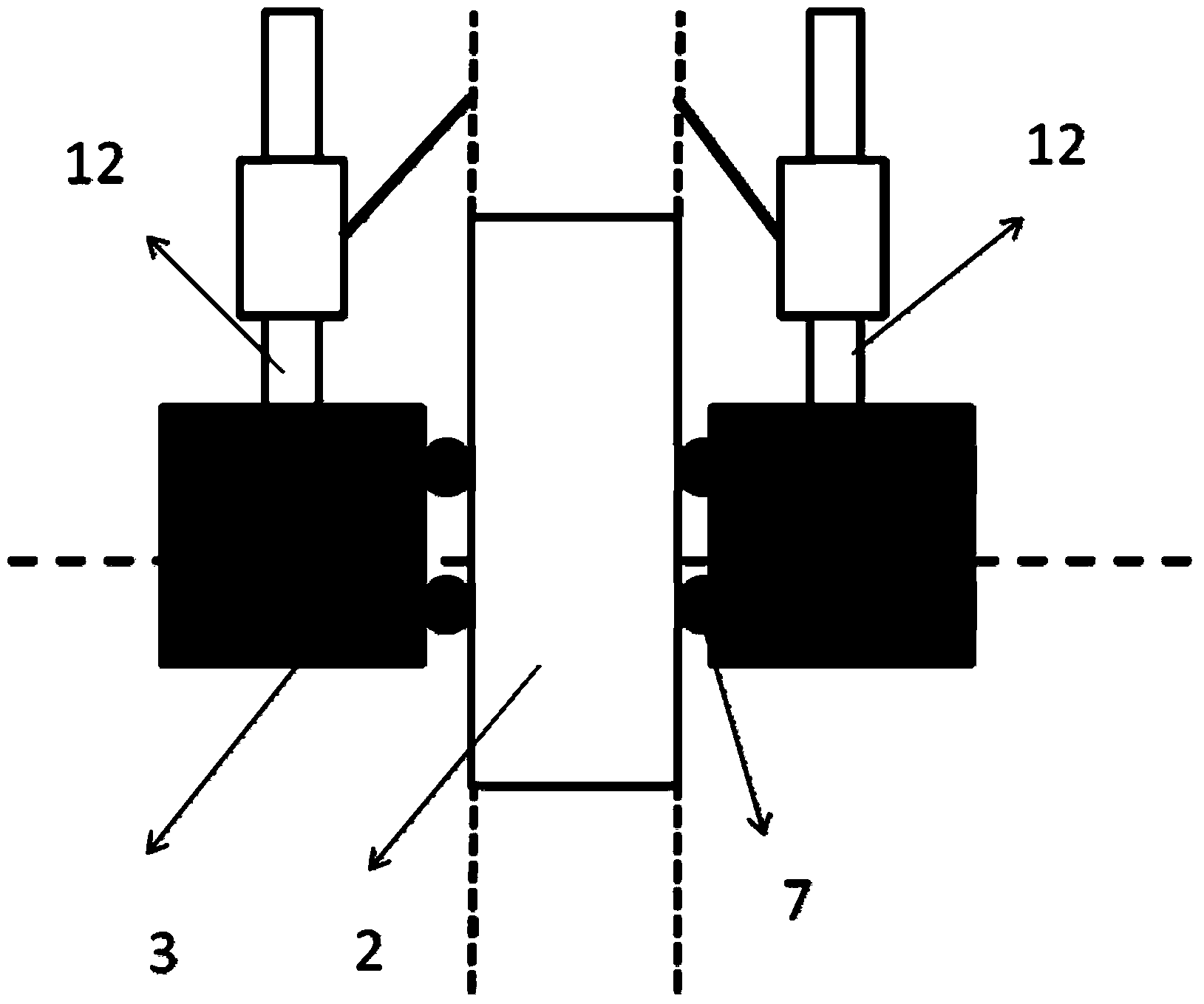

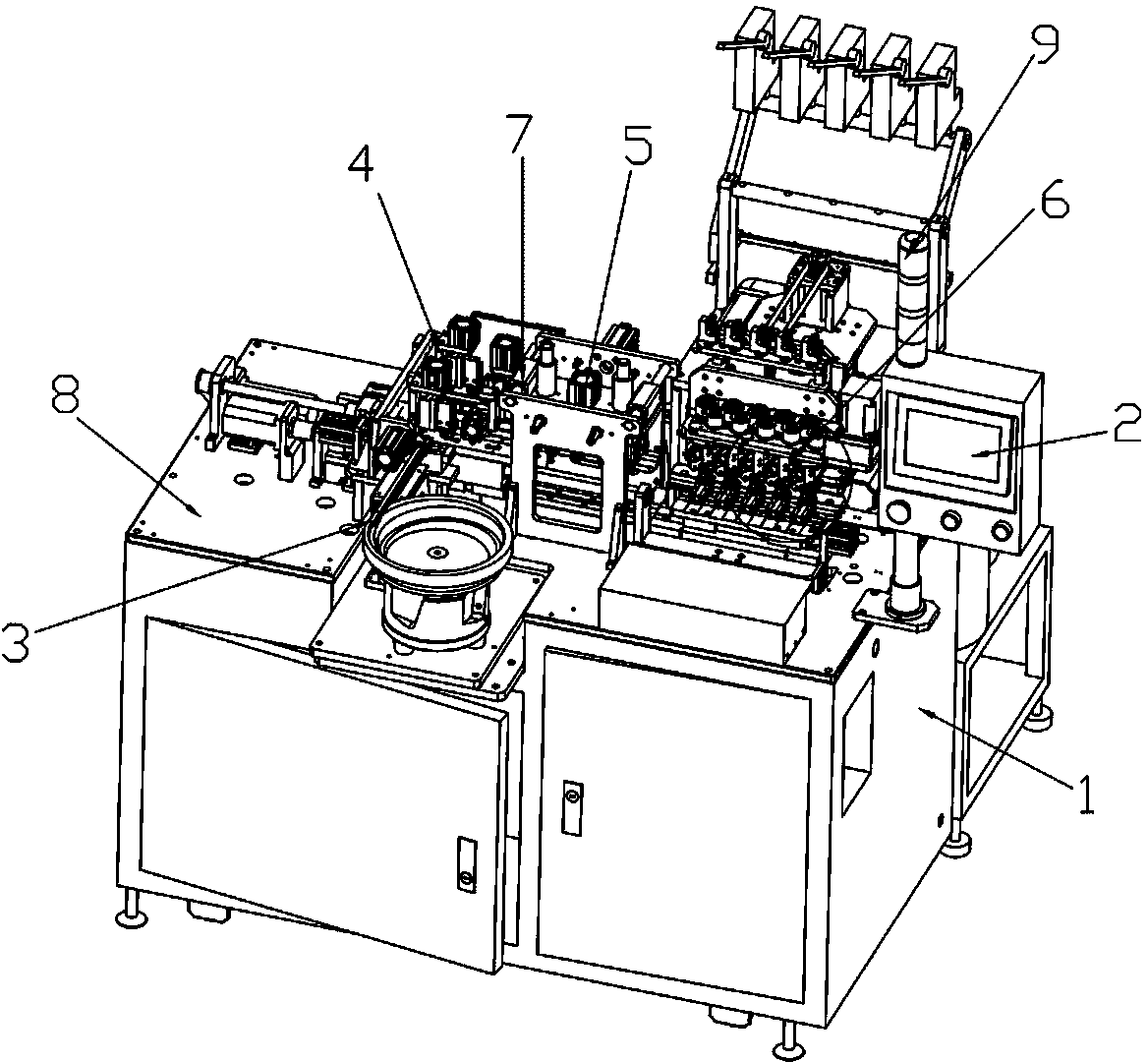

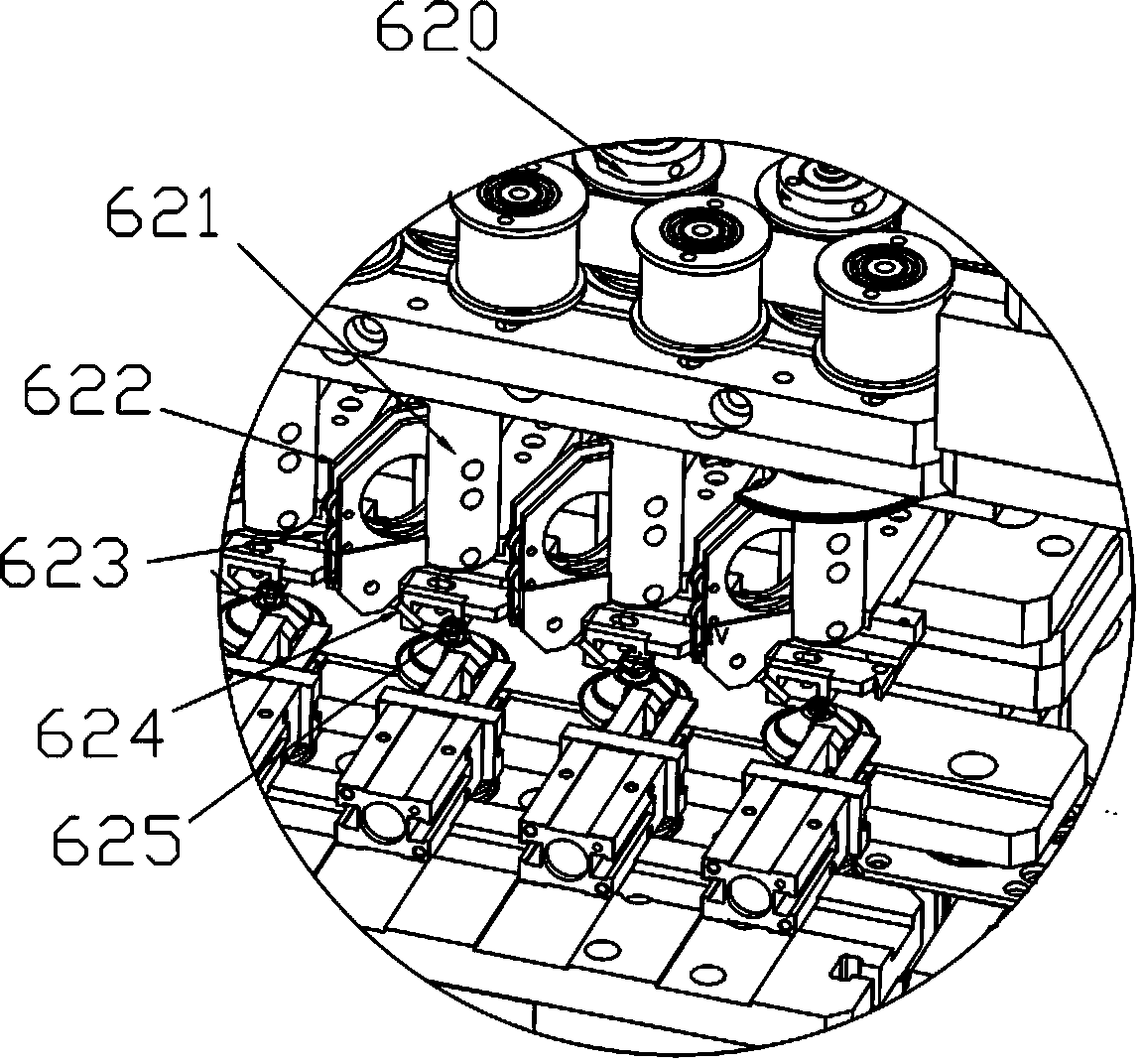

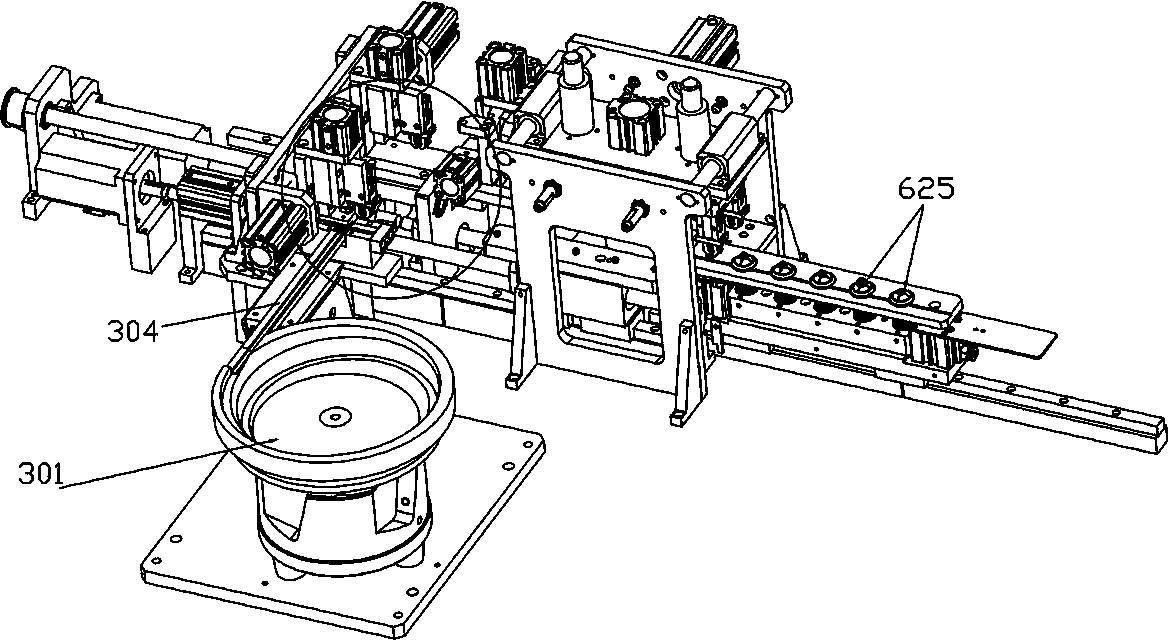

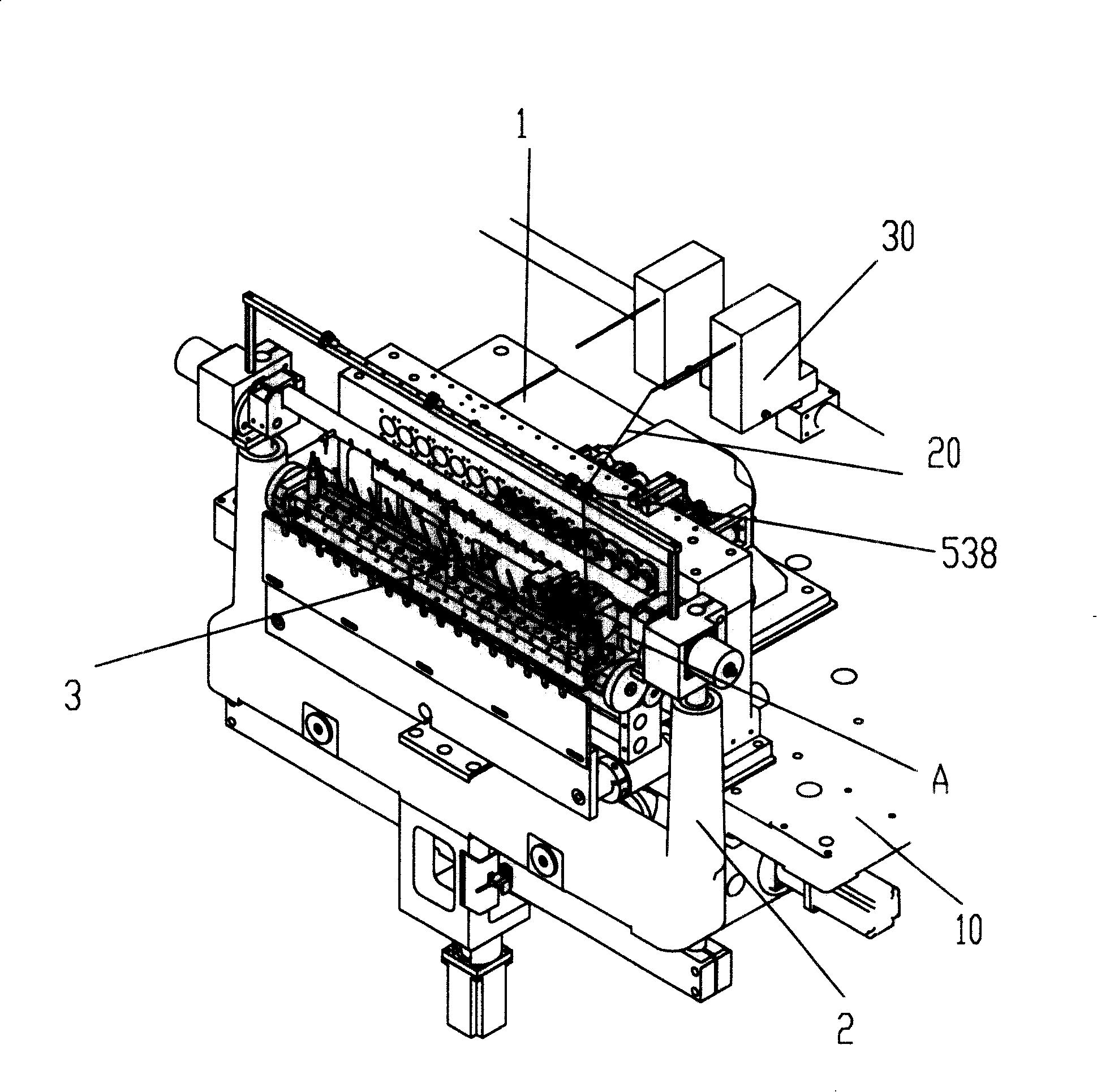

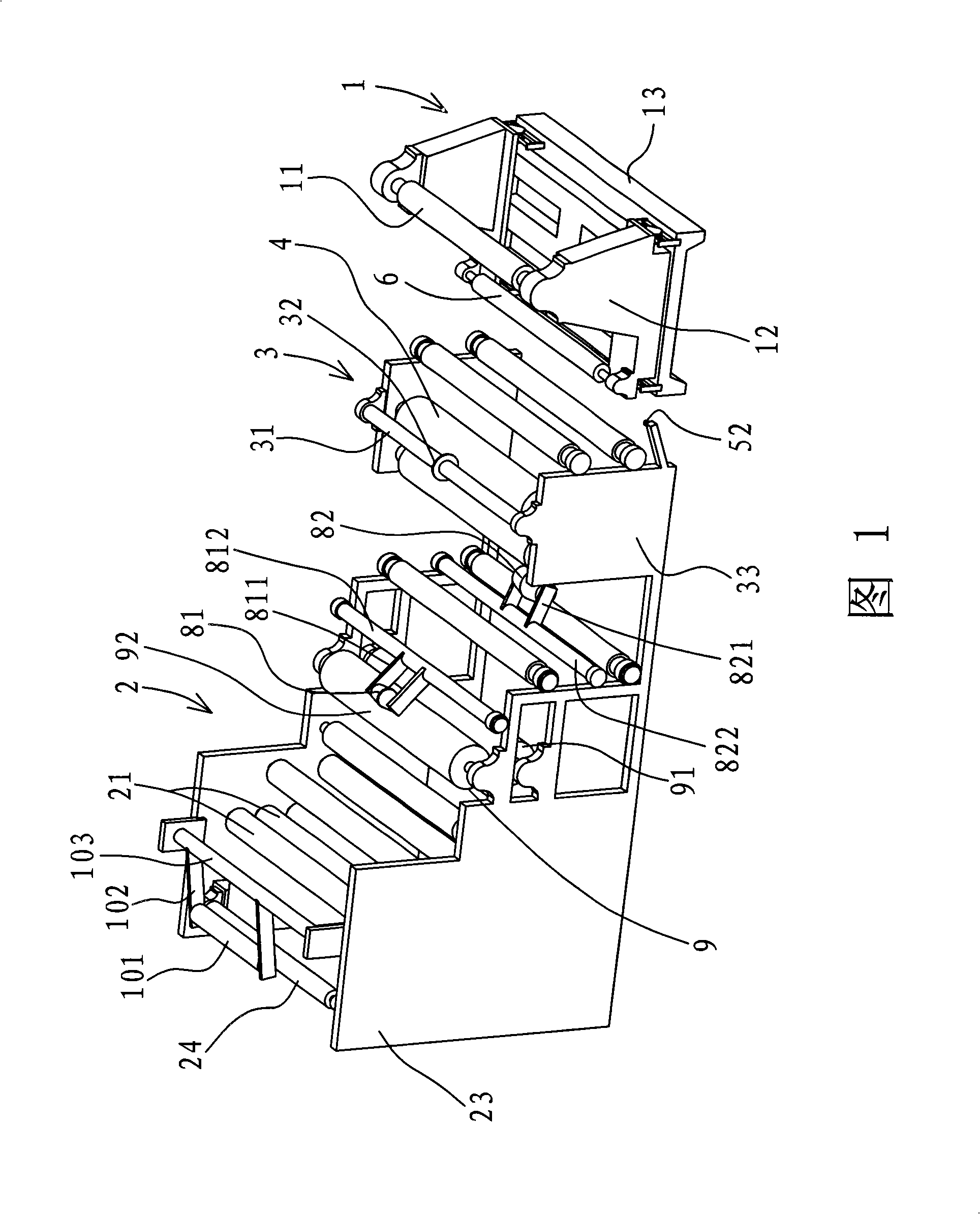

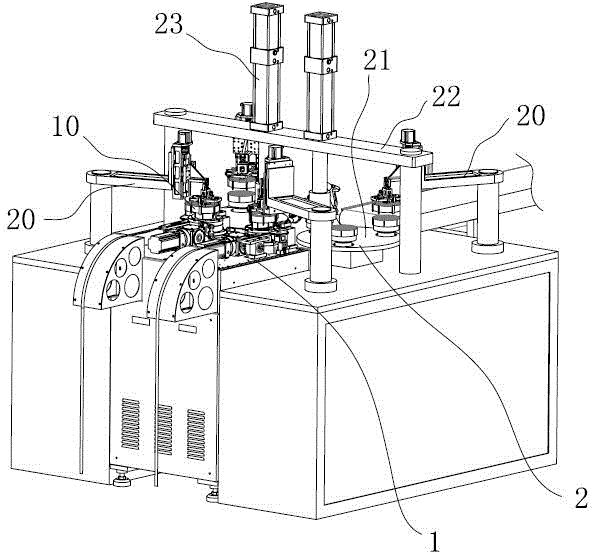

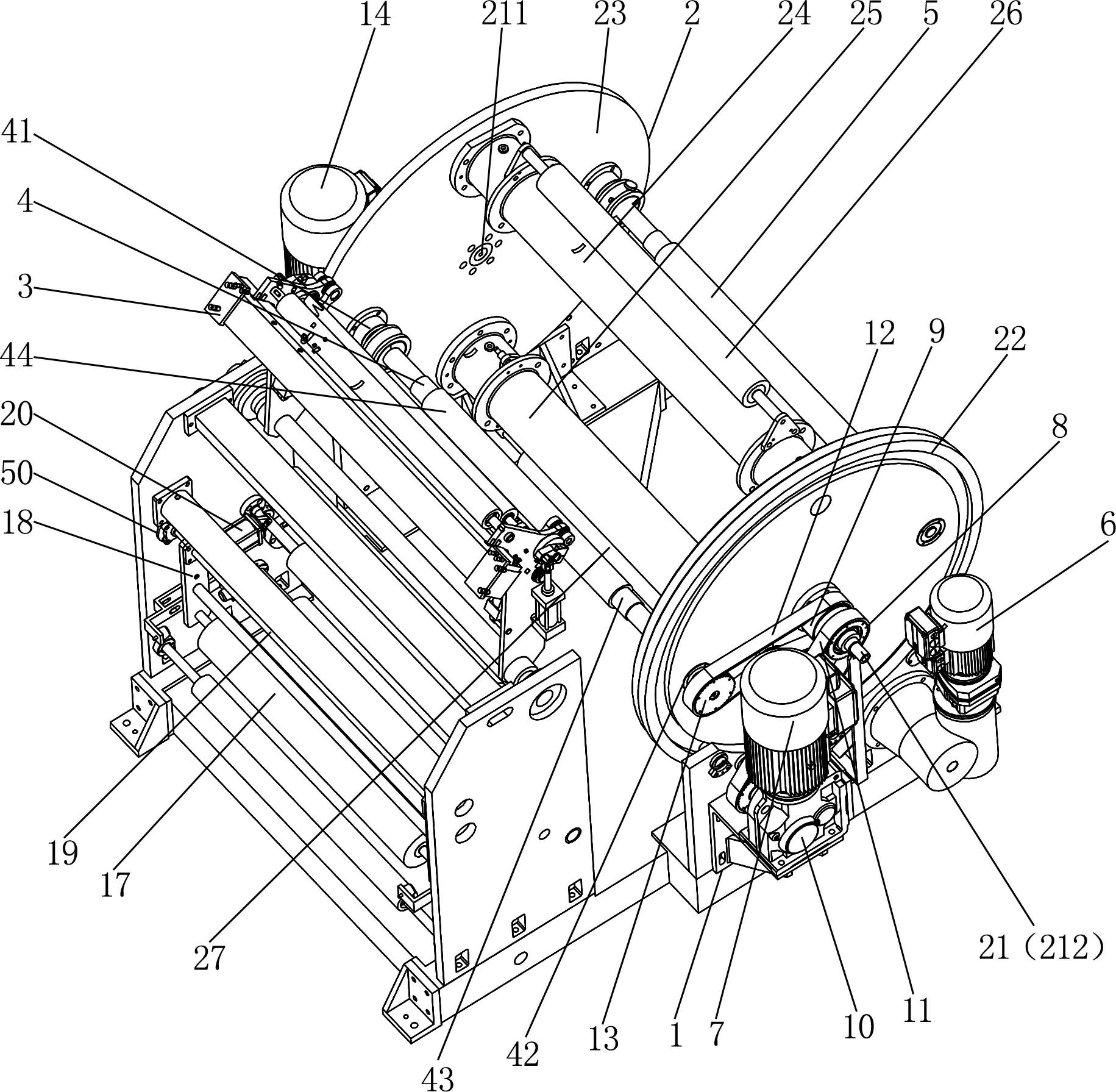

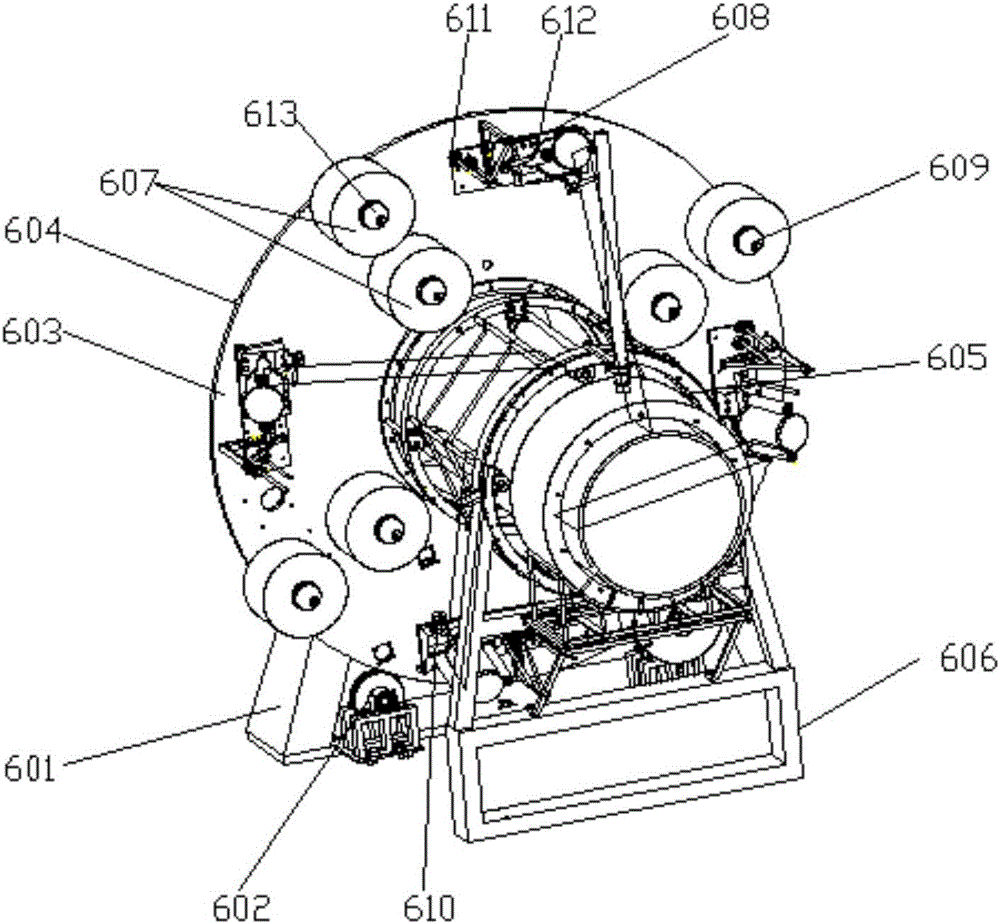

Full-automatic inductance winding machine and winding method thereof

InactiveCN103903852AImprove efficiencyImprove qualityJigging conveyorsCoils manufactureWinding machineCopper wire

The invention discloses a full-automatic inductance winding machine and a winding method of the full-automatic inductance winding machine, and belongs to the field of electronic component machining equipment. The full-automatic inductance winding machine comprises a support, a mechanical feeding mechanism, a mechanical discharging mechanism, a transfer mechanism, a winding mechanism and an operation panel and further comprises a secondary wire pressing mechanism. Compared with a traditional manual winding technology, the full-automatic winding machine has the advantages that efficiency is higher and quality is greatly improved. Compared with an existing automatic winding machine, the full-automatic inductance winding machine has the advantages that one cycle of the full-automatic inductance winding machine lasts for 7 seconds to 8 seconds, five products can be machined in one cycle, and therefore efficiency is not lower than that of a Rite winding machine; meanwhile the structure is simple, operation and maintenance are easy, manufacturing cost is 1 / 3 that of the Rite winding machine, and therefore more cost can be reduced; cut wire residues are shorter, 1 / 10 of copper wires are reduced compared with products with the same yield, it is estimated that ten thousand yuan of the copper wires can be reduced every year, the wire residues are firstly cut and then pressed, and therefore the treatment effect of the wire residues is better.

Owner:DONGGUAN KE RUI AUTOMATION TECH

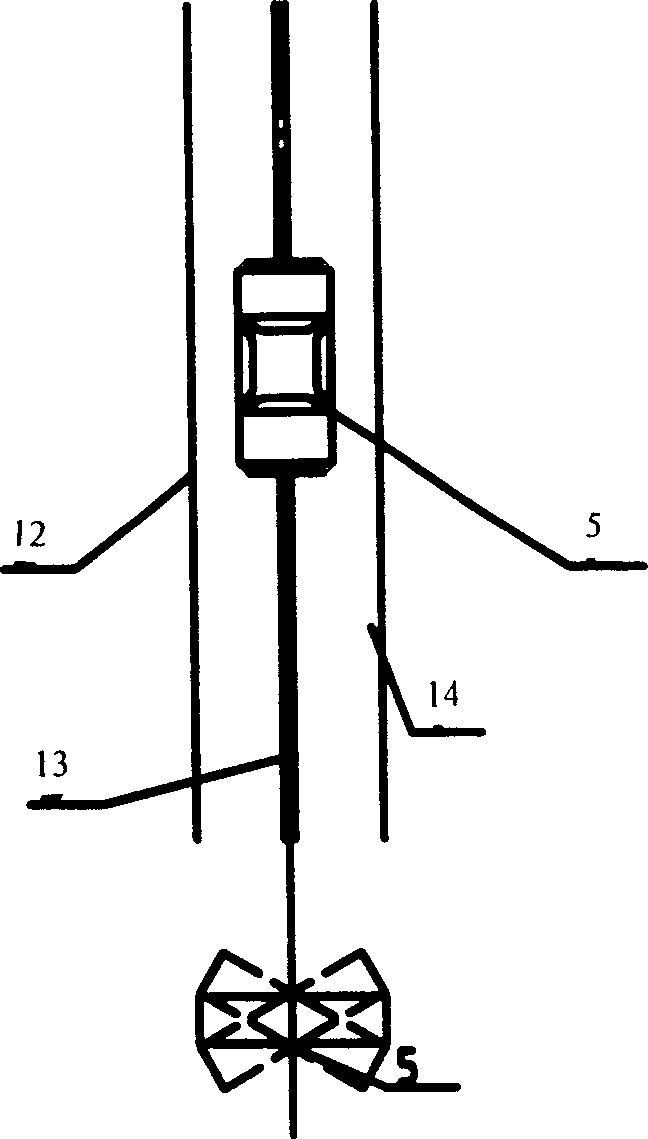

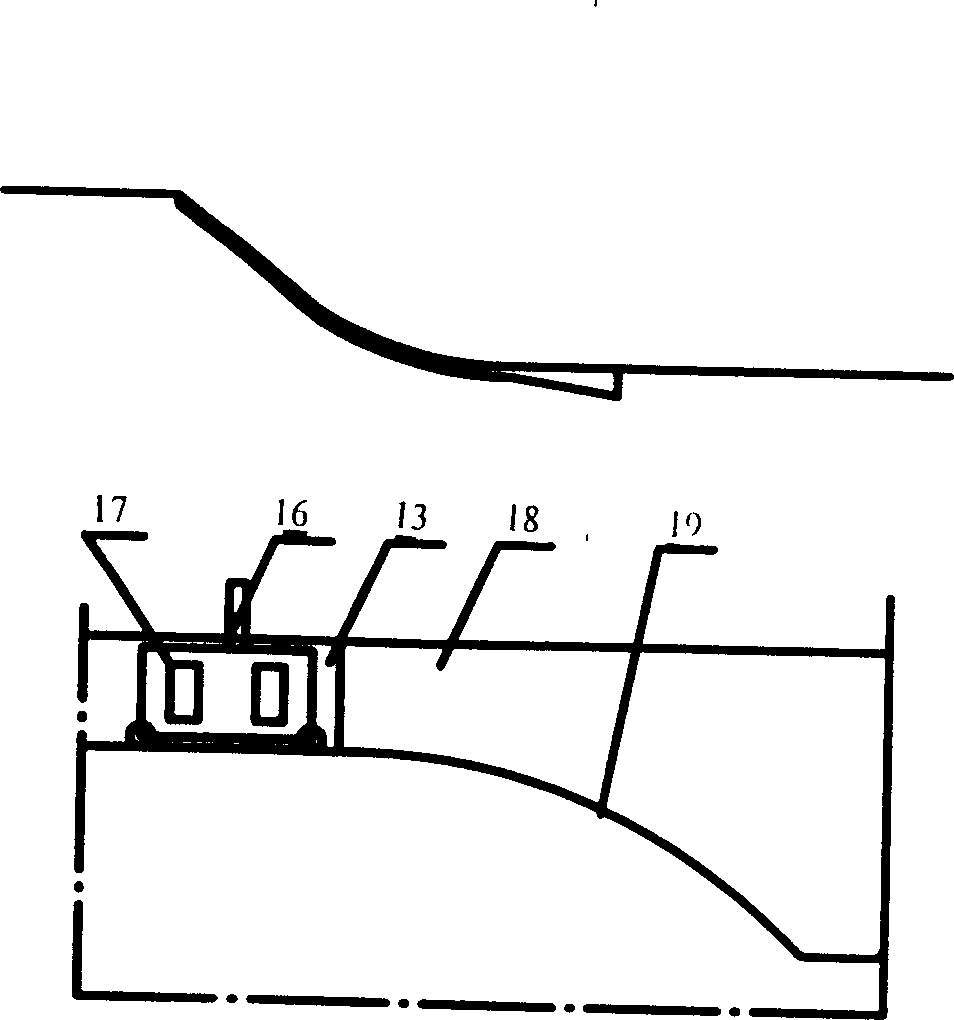

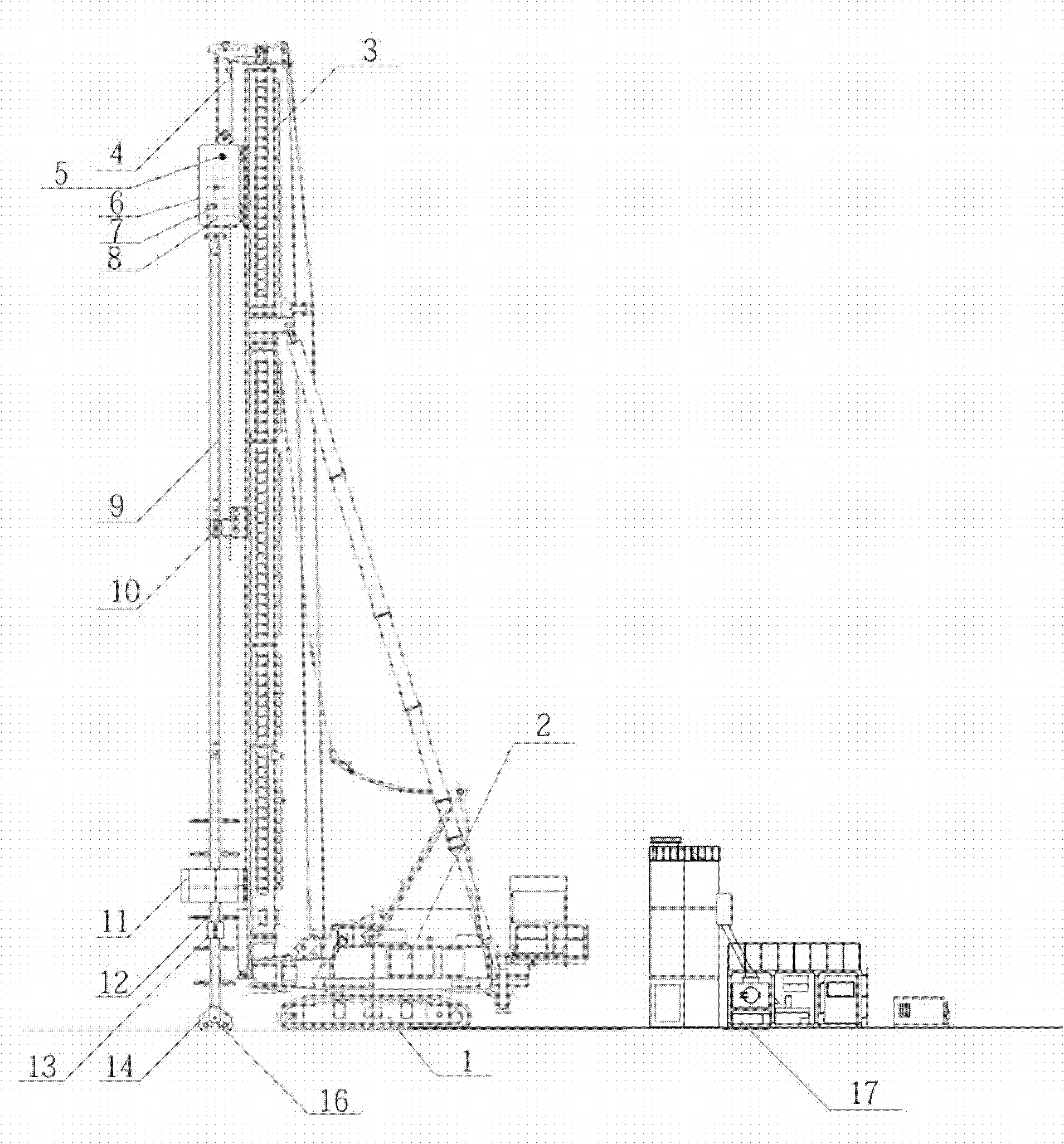

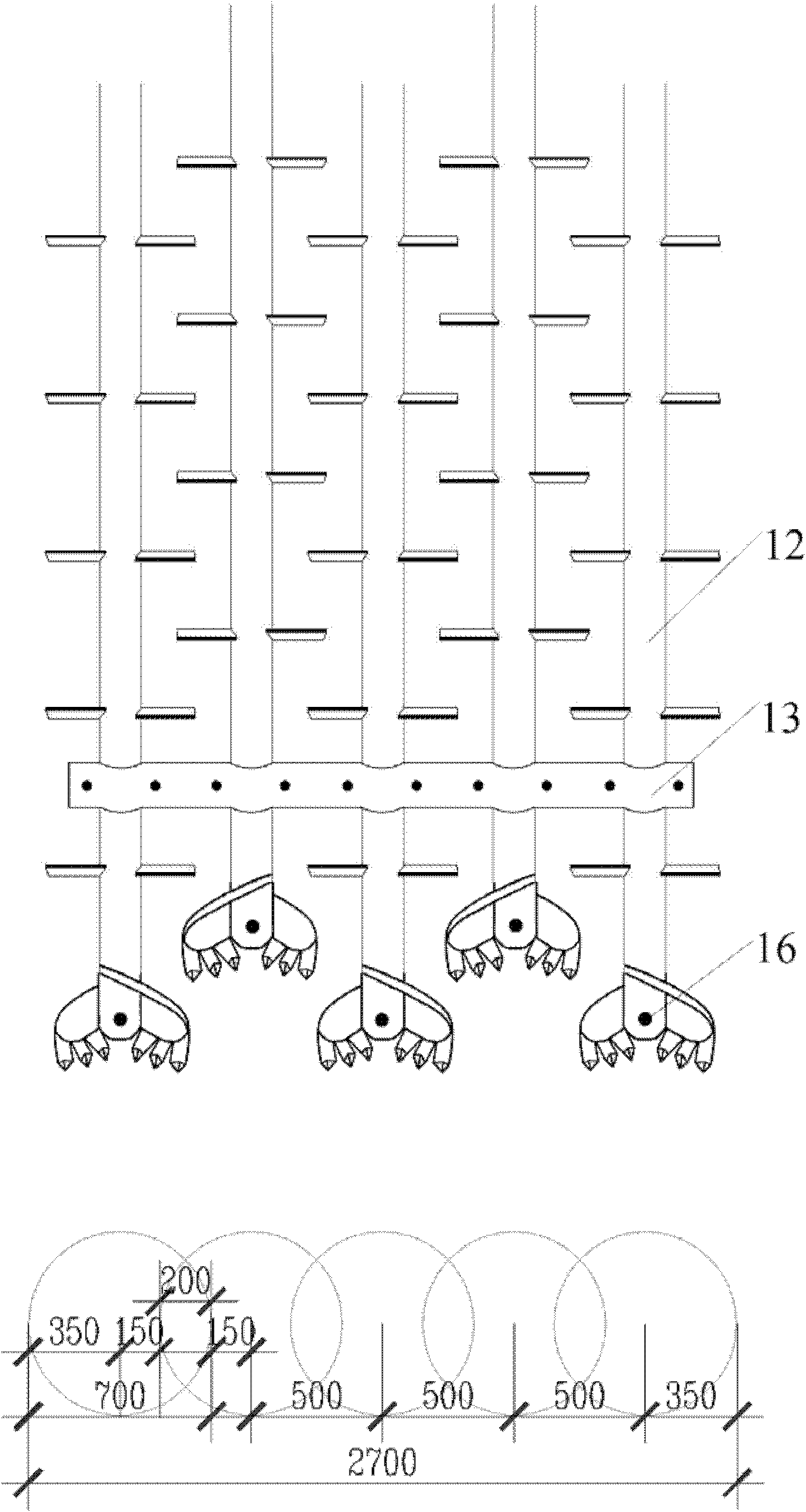

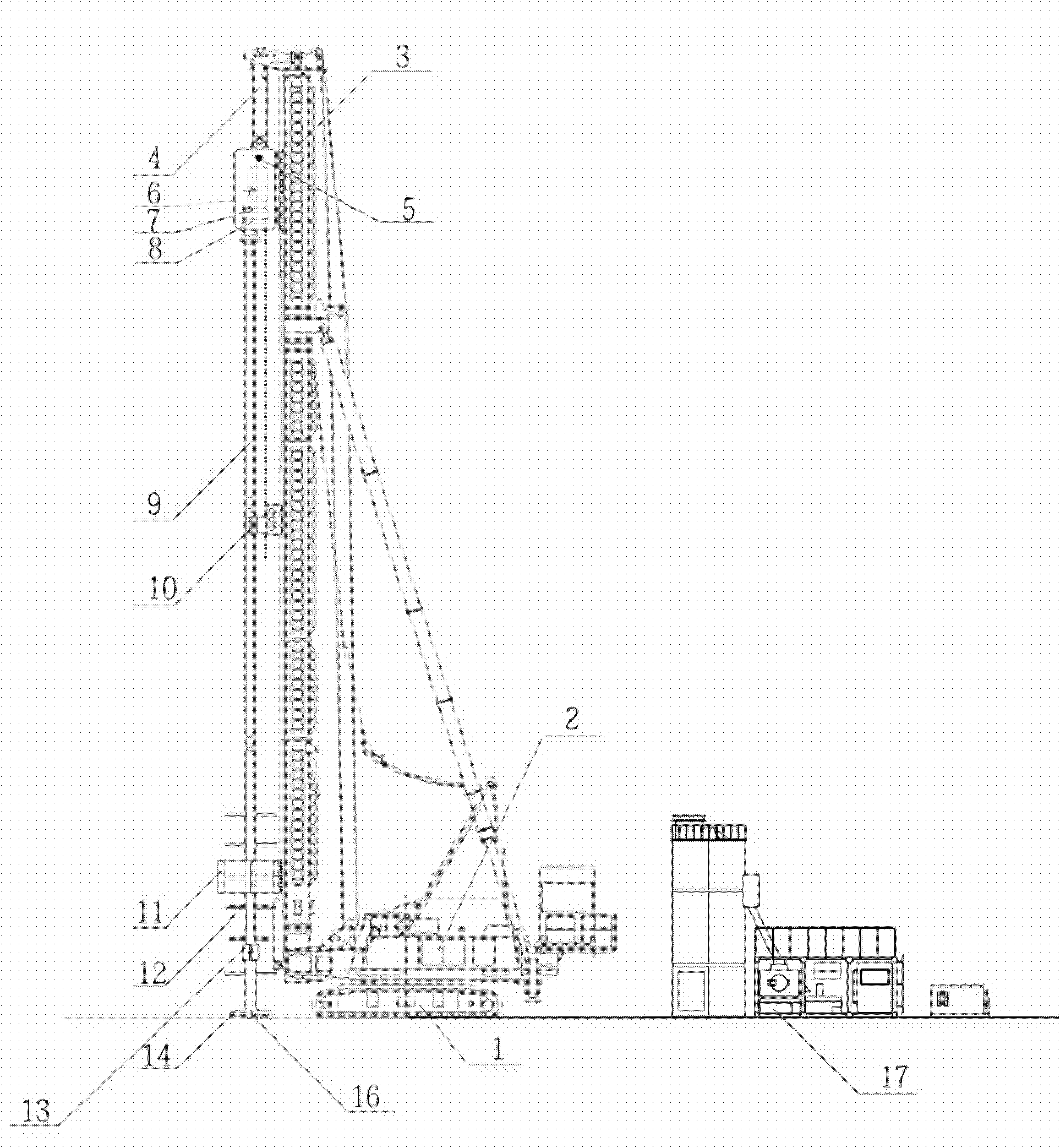

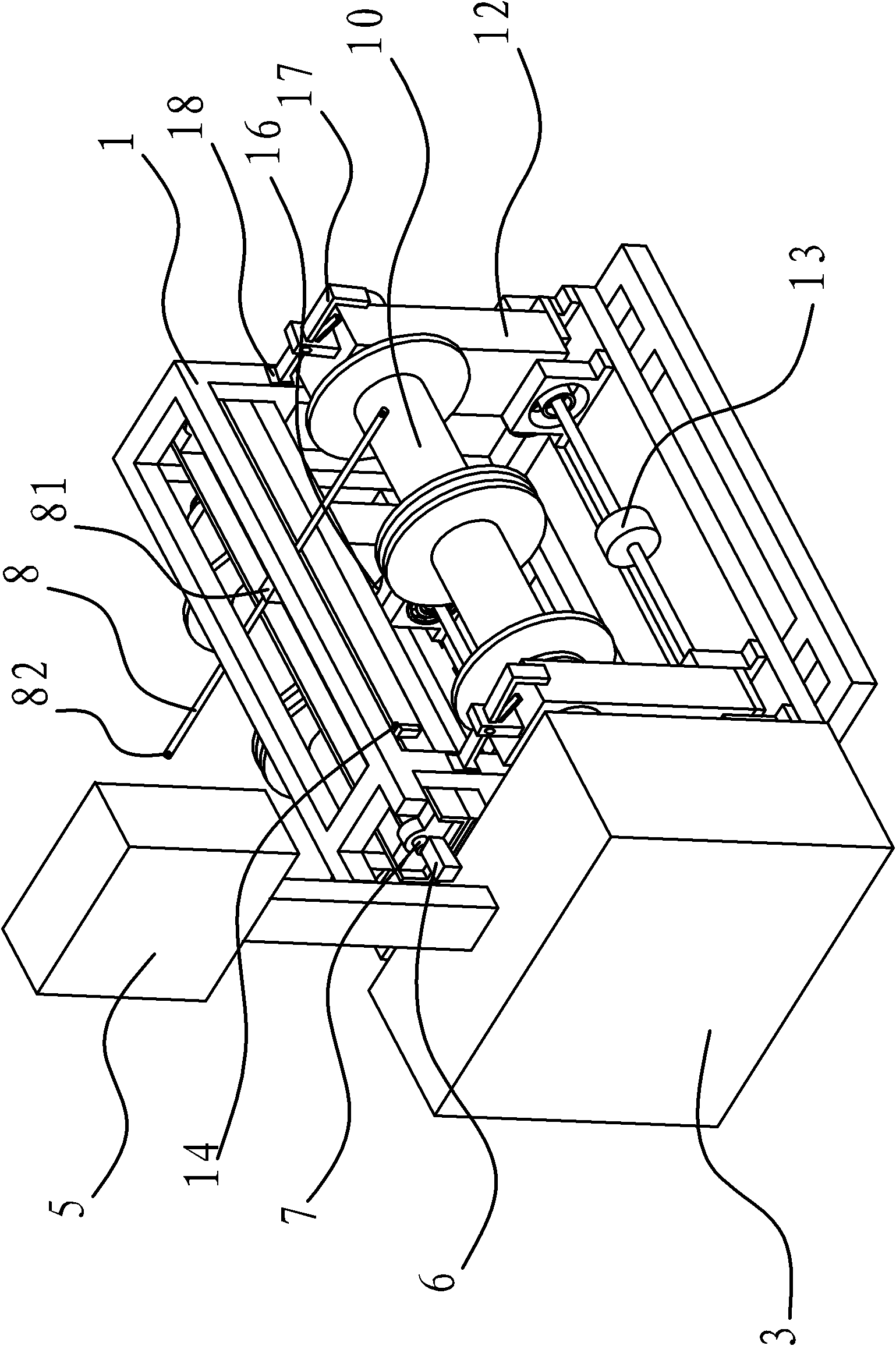

Five-axis cement-soil mixing pile device and construction method

The invention relates to a five-axis cement-soil mixing pile device and a construction method. The device comprises a walking-type and crawler-type host machine, a winding machine, a guide rod, a steel wire rope, a slurry inlet, a power head, a speed change box, a speed reducer, drill stems, a middle support frame, a lower support frame, drill stems with wings, hoops, a multifunctional drill head, a slurry spraying opening and a background cement slurry mixing system, wherein the winding machine and the guide rod are fixed on the host machine; the power head is connected with a pulley on the top of the guide rod through the steel wire rope; the steel wire rope drives the power head to rise and fall in a vertical direction; the power head is connected with five drill stems sequentially through the speed change box and the speed reducer; the middle support frame is arranged on the middle parts of the five drill stems, and the lower support frame is arranged on the lower parts of the five drill stems; the drill stems with wings are connected to the lower ends of the drill stems; the hoops are arranged on the drill stems with the wings; the lower ends of the drill stems with the wings are connected with the multifunctional drill head; and the slurry spraying opening is formed in the multifunctional drill head. Compared with the prior art, the five-axis cement-soil mixing pile device has the advantages of guaranteeing the safety and the quality, reducing the cost, shortening the work period and the like along with no noise, no vibration and high efficiency.

Owner:SHANGHAI CHENGDI CONSTR

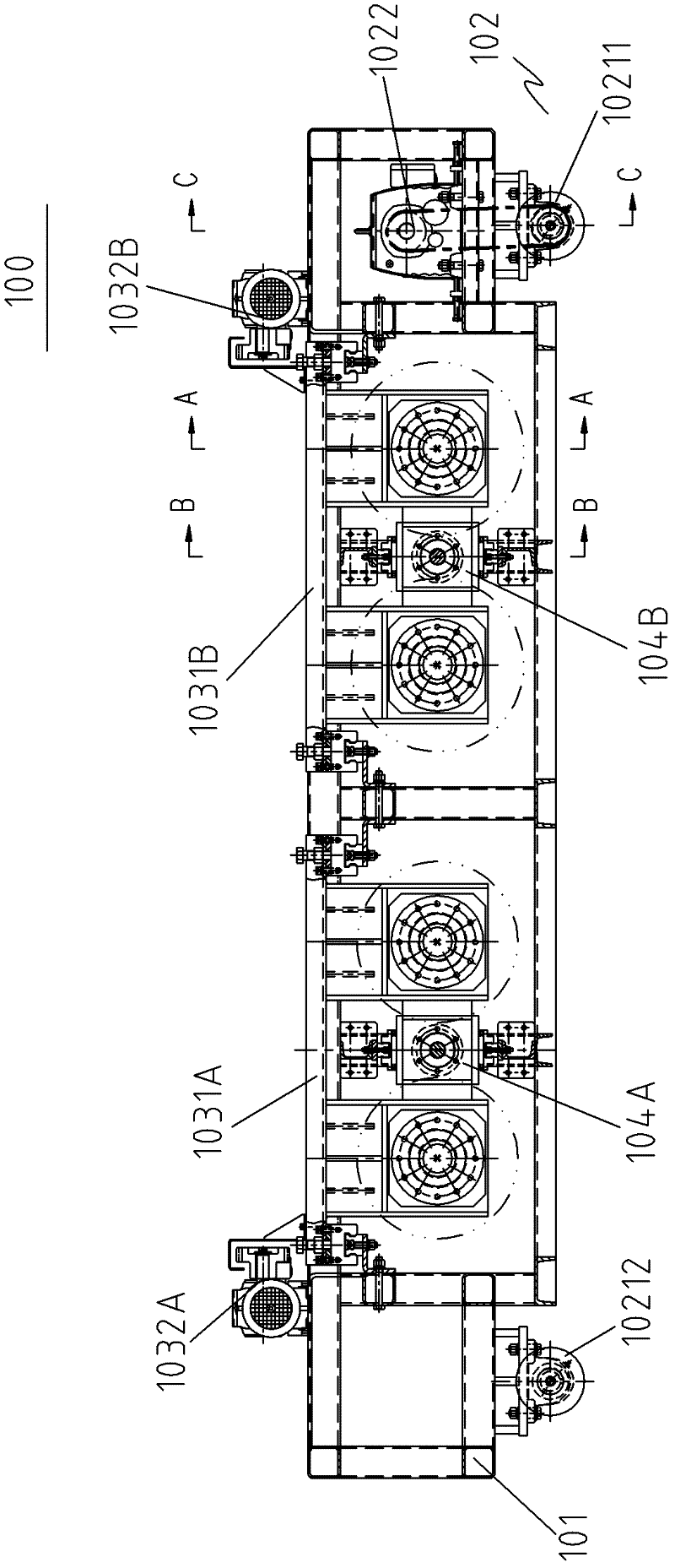

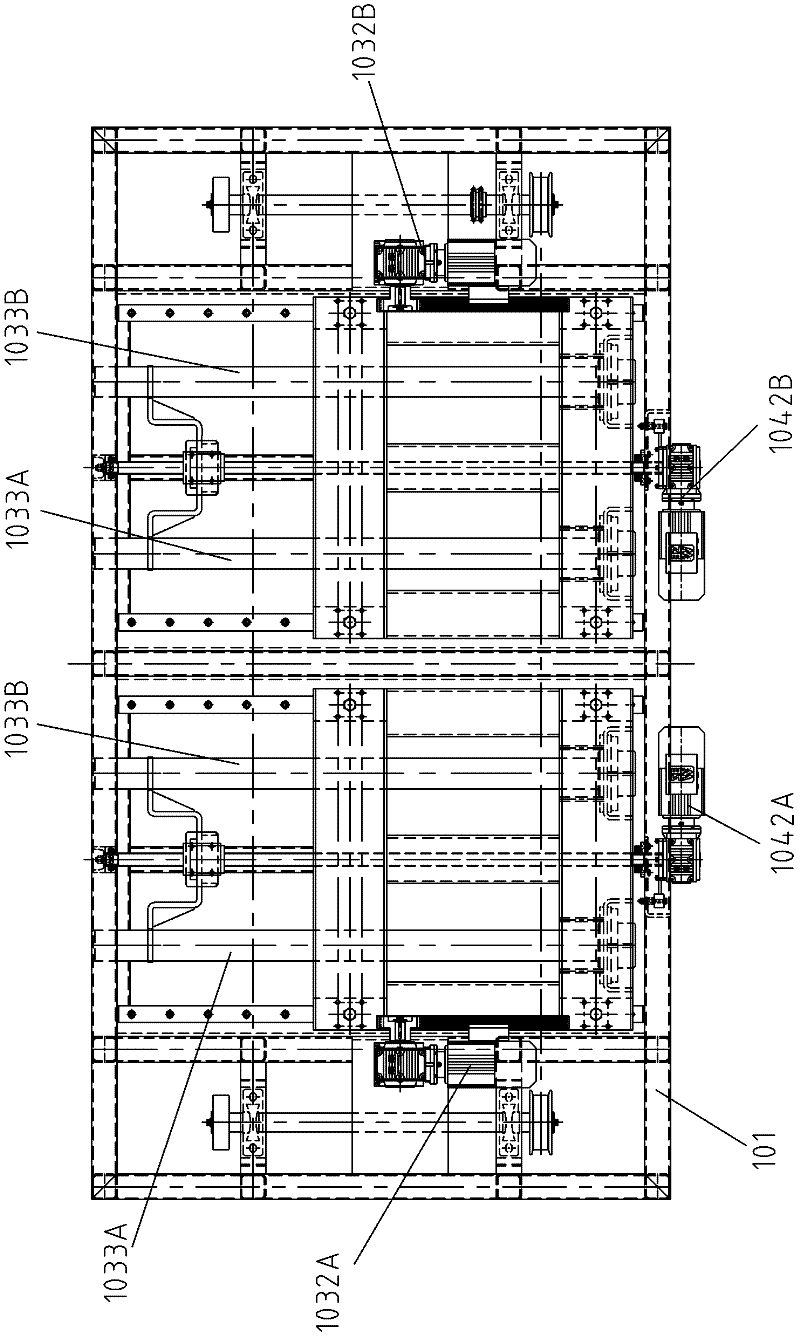

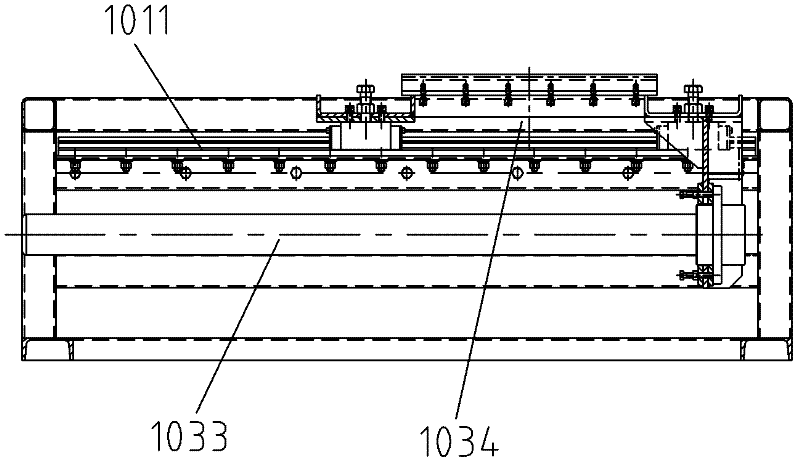

Fully automatic wire winding machine

InactiveCN101879998AGuaranteed uptimeWith alarm functionFilament handlingWinding machineHuman–machine interface

The invention provides a fully automatic wire winding machine, which belongs to the technical field of wire winding machines and solves the problems that the current conventional wire winding machine has low working efficiency and cannot achieve full automation. The fully automatic wire winding machine is connected with a hauling machine; the hauling machine is connected with a wire outlet machine. The fully automatic wire winding machine comprises a base, a detection device, a PLC control-based control cabinet and a man-machine interface arranged on the base, wherein both the detection device and the man-machine interface are connected with the control cabinet; the base is provided with a wire feeding and arranging mechanism, a wire winding mechanism and a wire fetching mechanism; and the wire feeding and arranging mechanism, the wire winding mechanism and the wire fetching mechanism are controlled by the control cabinet to wind a wire on the wire winding mechanism from the wire feeding and arranging mechanism and fetch the wound wire out from the wire winding machine. The fully automatic wire winding machine has the advantages of fully automatic operation, high working efficiency, wire saving and the like.

Owner:台州威旗塑胶机械科技有限公司

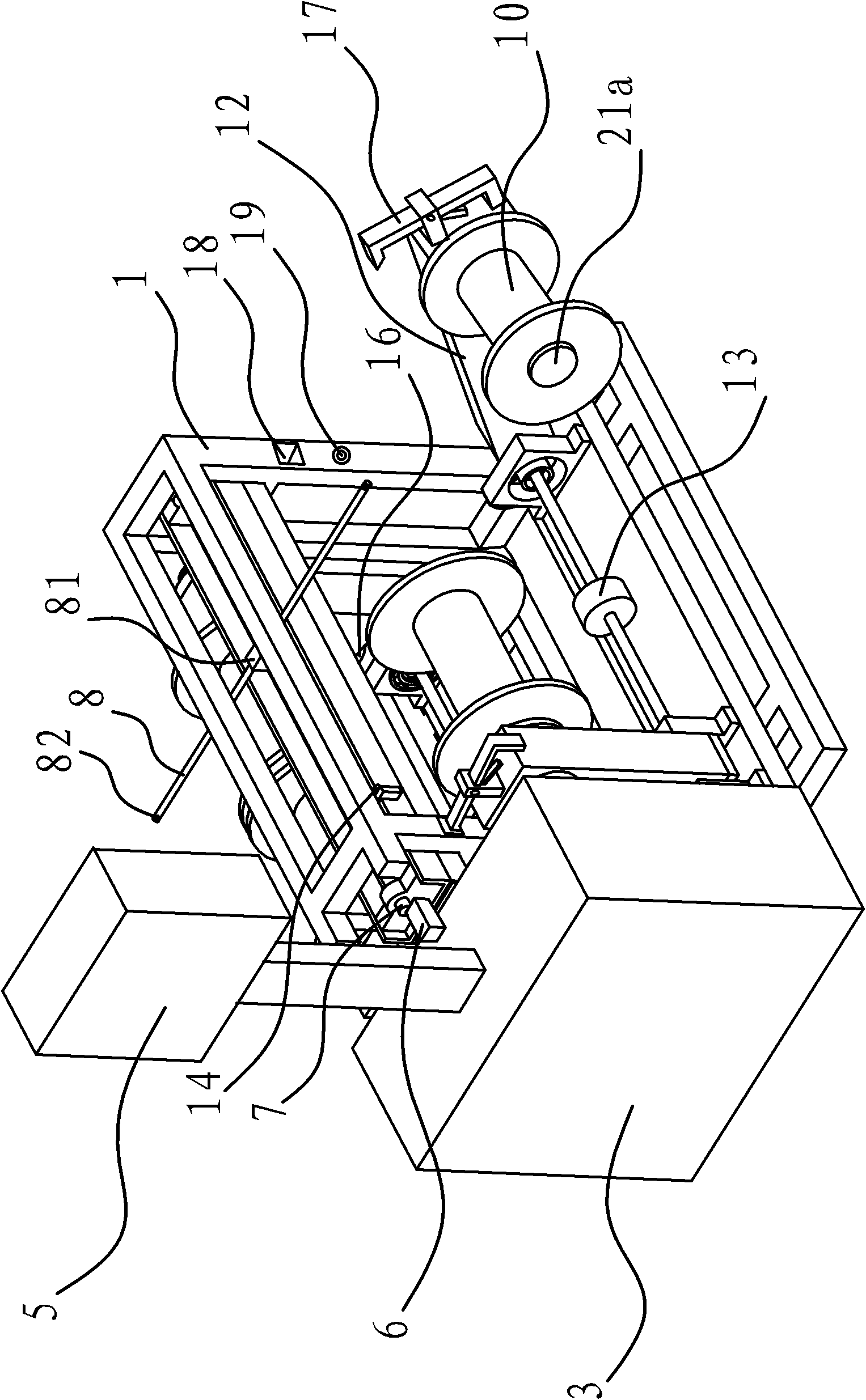

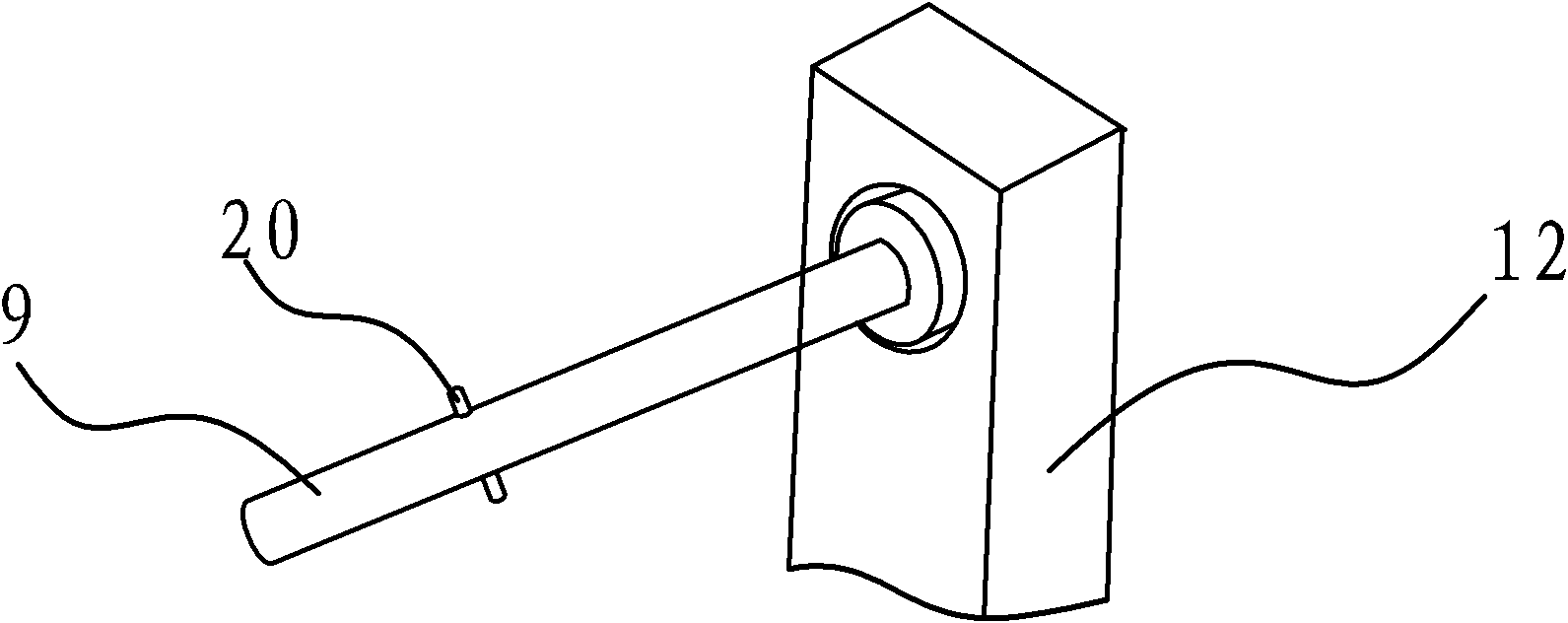

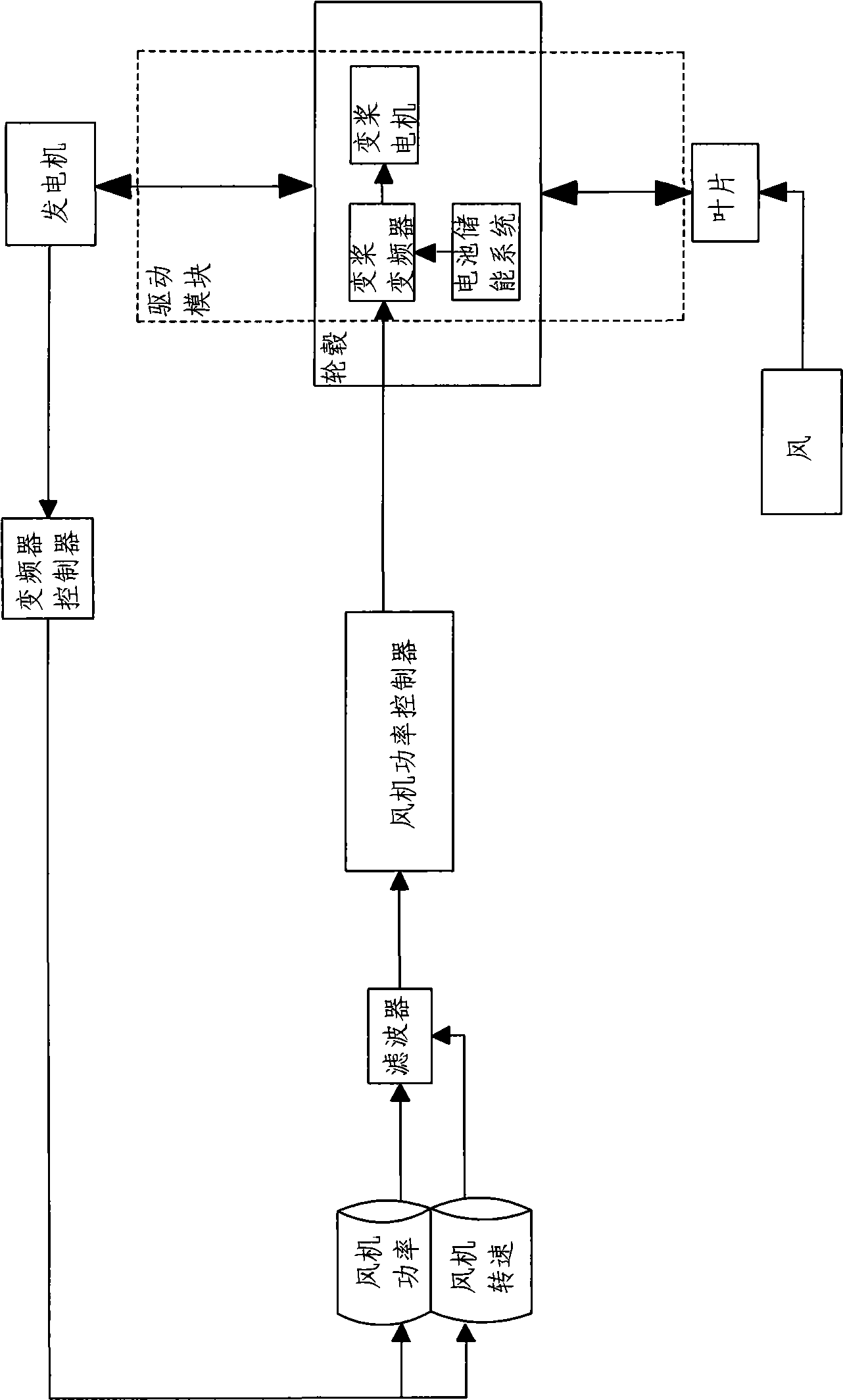

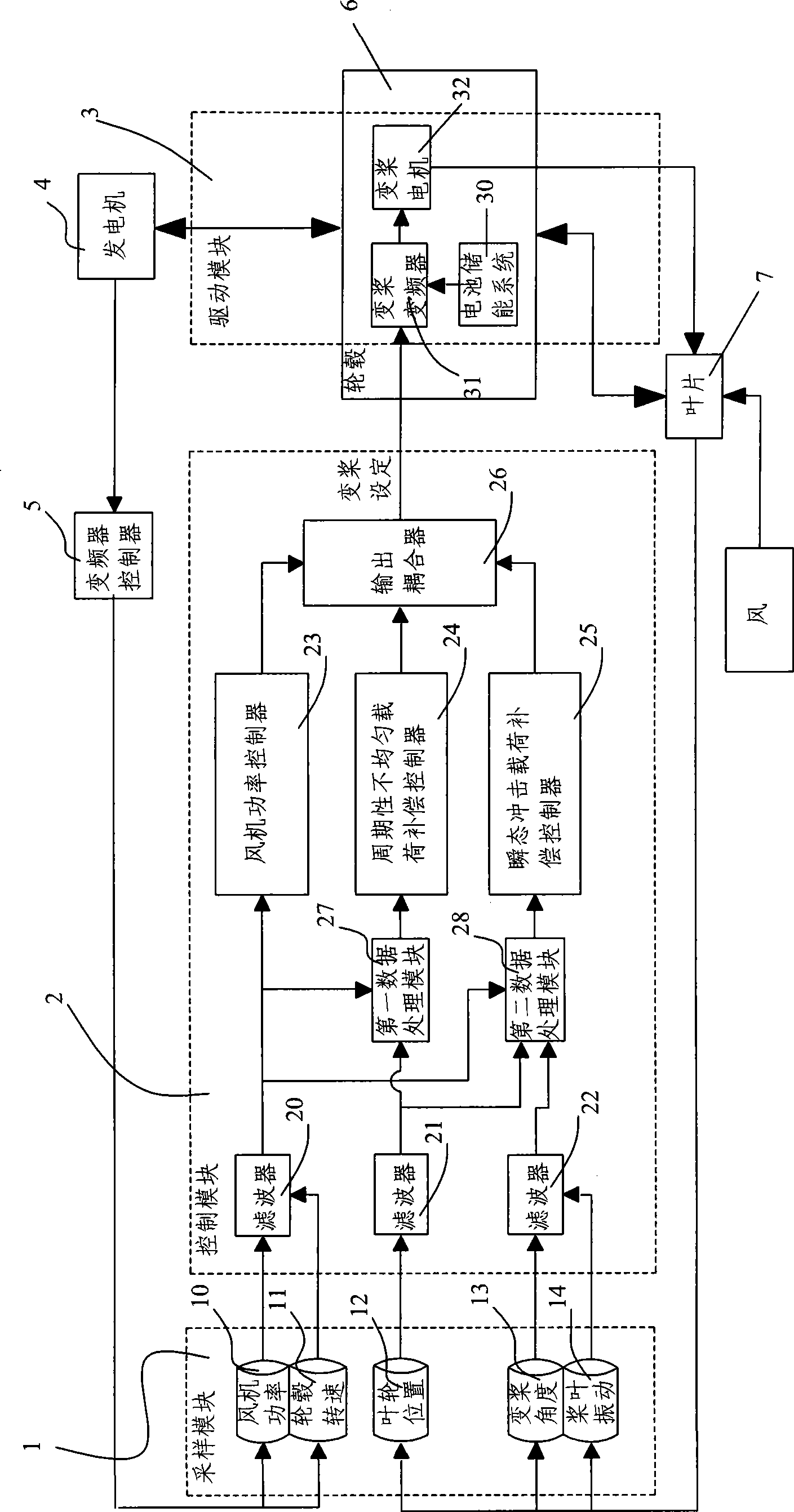

Independent variable oar control system and control method for wind generator set

ActiveCN101476541AIncreased fatigue loadLow mechanical requirementsWind motor controlMachines/enginesWind drivenReduction drive

The invention relates to an independent feathering control system and a control method for a wind driven generating set, wherein the control system comprises a sampling module, a control module and a driving module. A feathering motor in the driving module is connected with the blades of the wind driven generating set through a speed reducer. The sampling module is used to acquire the signals such as the wind driven generating set power, the boss rotating speed, the impeller position, the feathering angle, the paddle vibration, and the like, and to respectively send the acquired signals to the control module. The control module comprises a wind machine power controller for processing the wind driven generating set power signal and the boss rotating speed signal, a periodic unbalanced load compensation controller for processing the impeller position signal, the wind machine power signal and the boss rotating speed signal, a transient state impact load compensation controller for processing the feathering angle signal, the paddle vibration signal, the impeller position signal, the wind machine power signal and the boss rotating speed signal, and an output coupler for processing the signals outputted from the three controllers and comprehensively outputting the signals to the driving module.

Owner:SINOVEL WIND GRP

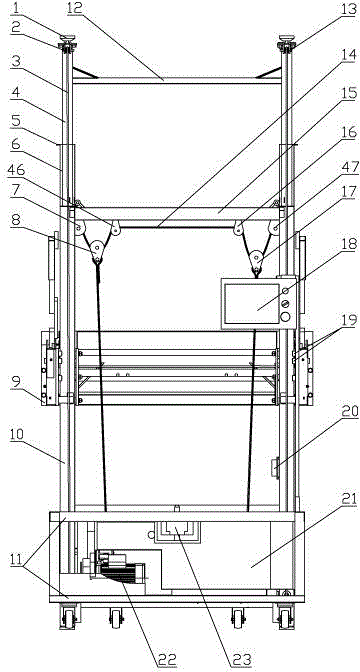

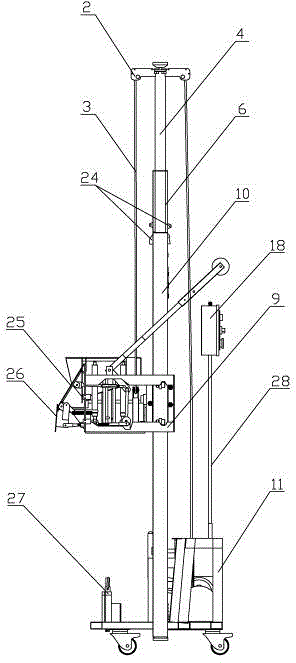

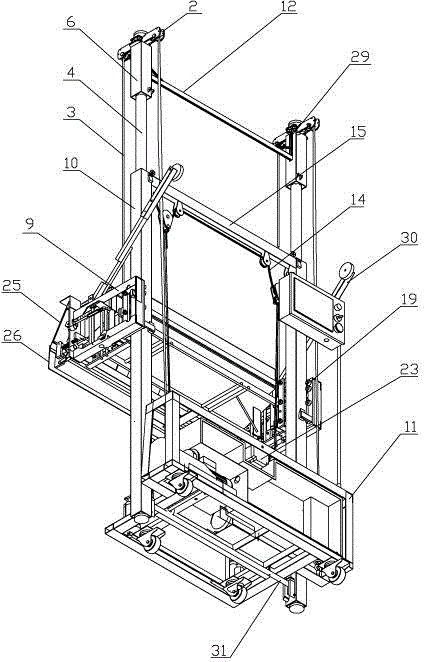

Numerical-control intelligent wall painting machine

ActiveCN105201182AHigh precisionEasy to operateBuilding constructionsWinding machineNumerical control

The invention discloses a numerical-control intelligent wall painting machine. The numerical-control intelligent wall painting machine comprises a movable base, a vertical frame rod stretching device erected on the two sides of the base, a plastering device arranged on the vertical frame rod stretching device, an integrated control device arranged on the base and a power device arranged on the base. The plastering device comprises a plastering plate, a plaster hopper, a plaster hopper frame and a plaster hopper frame lifting device used for lifting the plaster hopper frame. The power device comprises a winding machine A and a winding machine B which are installed on the base. A touch screen controller is further arranged on the base through a supporting rod. The touch screen controller is in communication with the integrated control device. An angle adjusting device capable of automatically and intelligently adjusting the slant angle of stretchable vertical frame rods is arranged between the vertical frame rod stretching device and the base. By means of the numerical-control intelligent wall painting machine, many defects of an existing wall painting machine are overcome, the numerical-control intelligent wall painting machine is wide in application range, easy to operate, good in plastering quality, high in plastering efficiency and convenient to transfer, man-machine safety is guaranteed, time, labor and work are saved, and good economy popularizing value is achieved.

Owner:湖北超顺智能科技有限公司

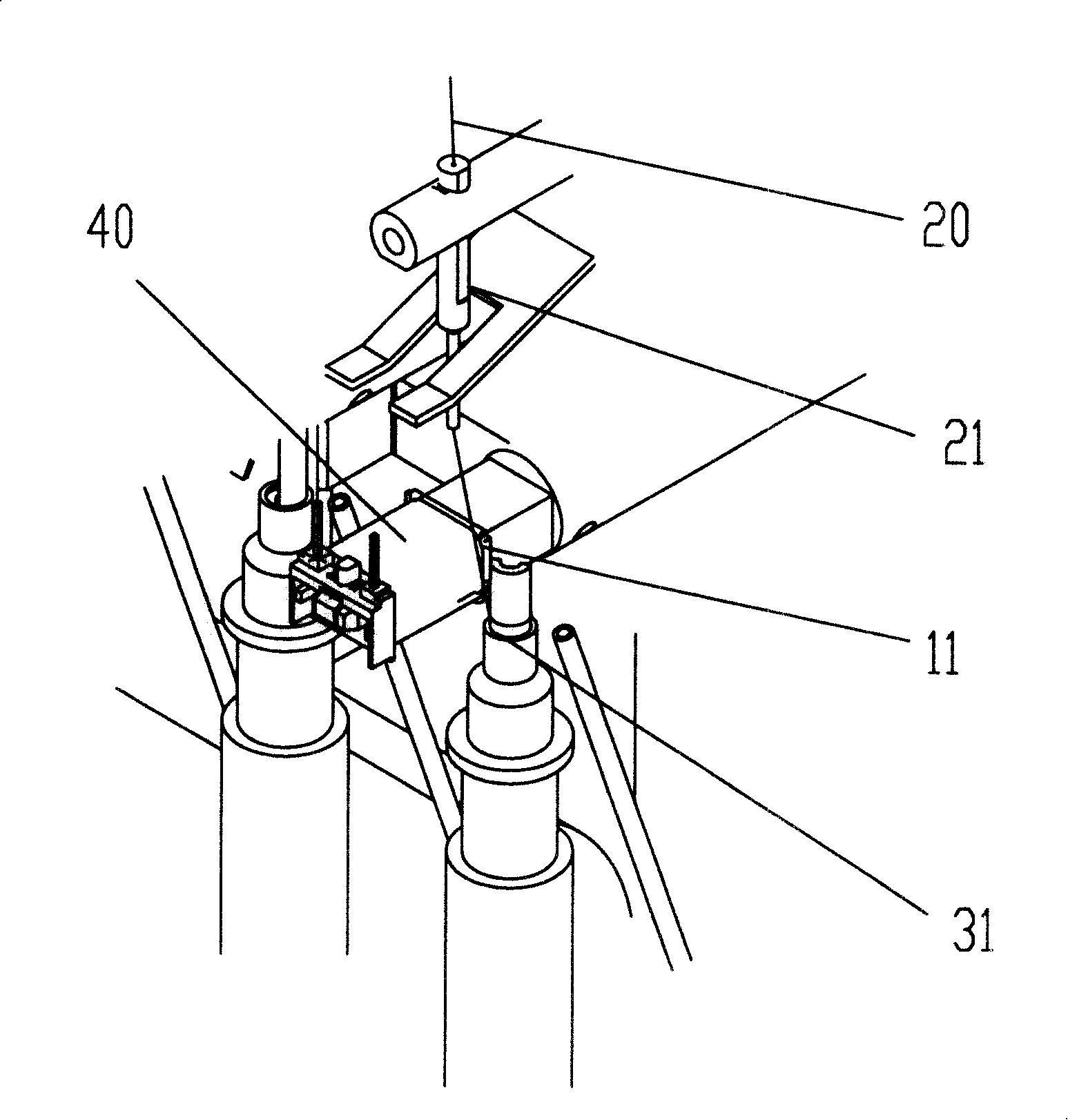

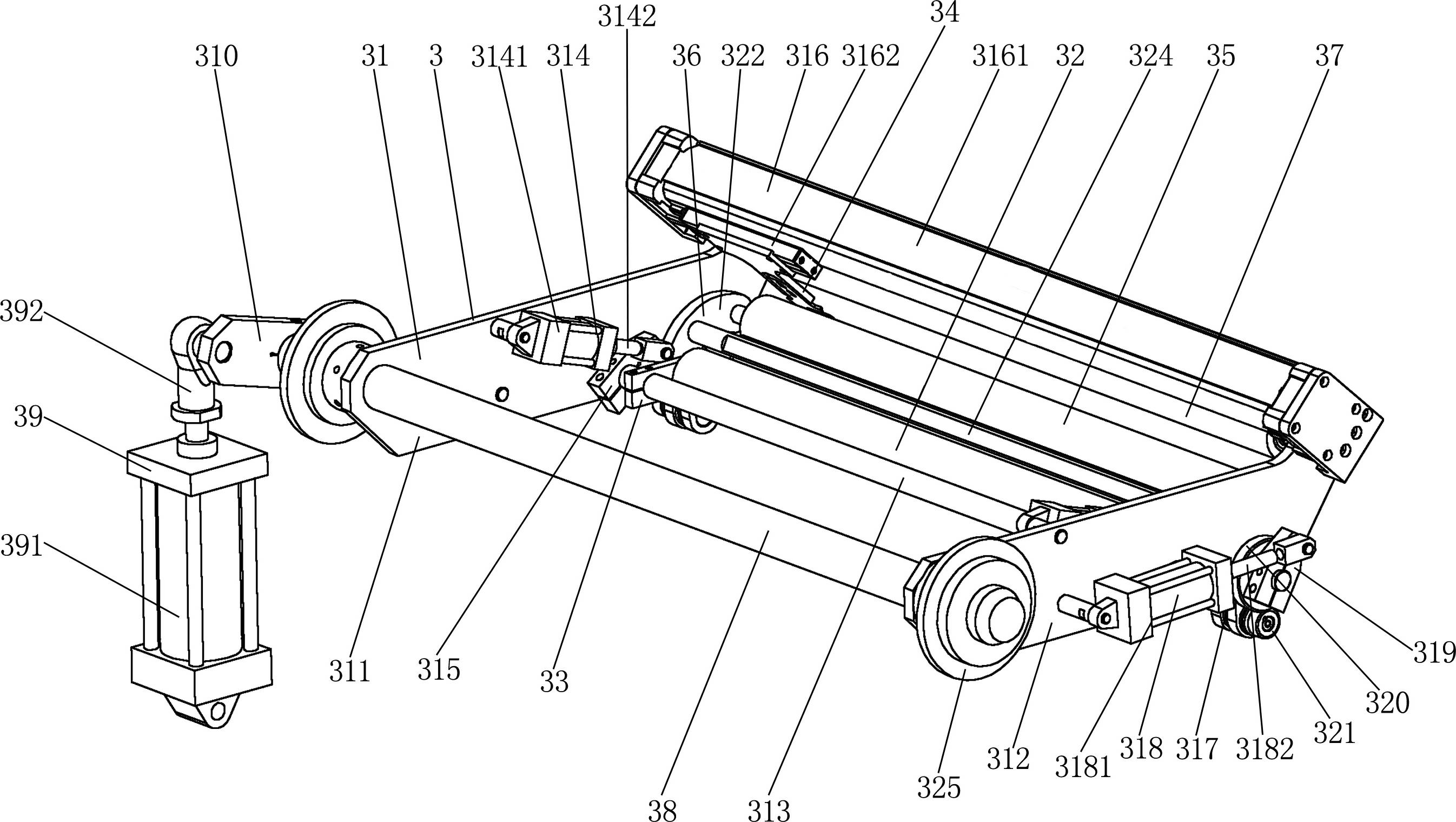

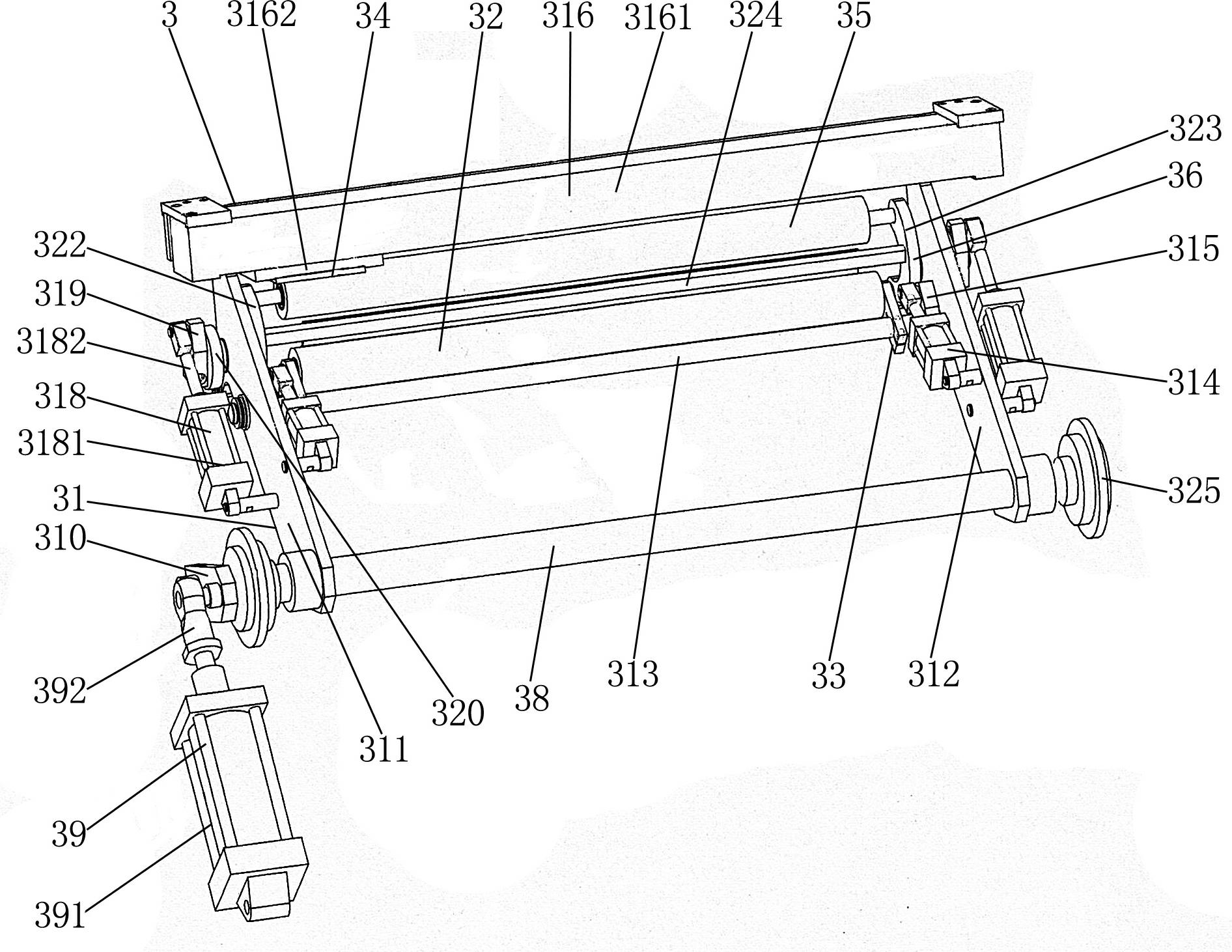

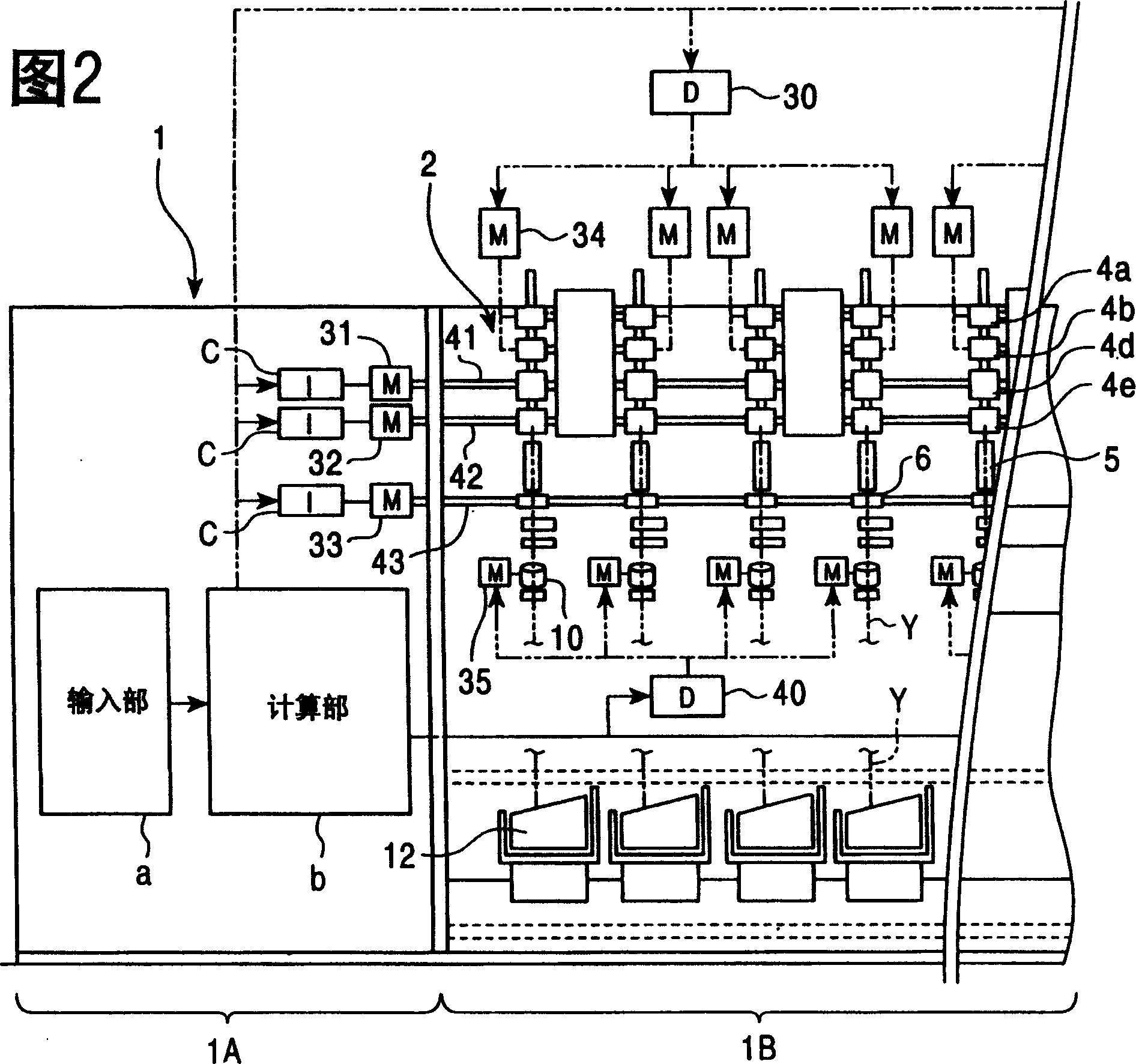

Multiheaded full-automatic wire winder

ActiveCN101211691AImprove motion control response timePrecise positioningCoils manufactureWinding machineElectrical control

The invention discloses a bull full-automatic winding machine, which comprises a main shaft winding mechanism driving a coil frame so as to realize the winding, an automatic line arrangement mechanism for X, Y and Z three axles which can move freely along the transverse, longitudinal and vertical directions so as to realize the winding of the coil frame, a line clamping and cutting mechanism used for realizing clamping the end of the enameled wire at the initiation of the winding and cutting off the outgoing lines of the pins after the pins of the coil frame are wound and an electrical control mechanism used for realizing the control of the main shaft winding mechanism, the automatic line arrangement mechanism for X, Y and Z three axles and the line clamping and cutting mechanism. The invention has the advantages of reasonable structure, high automation degree, extended installation of automatic material loading, material allocating, twisting, flake drip and material unloading systems so as to realize the automation in the entire process, tidy line arrangement, accurate and reliable number of winding rounds, high control accuracy, convenient operation and adjustment, etc.

Owner:XIAMEN HONGFA IND ROBOT CO LTD

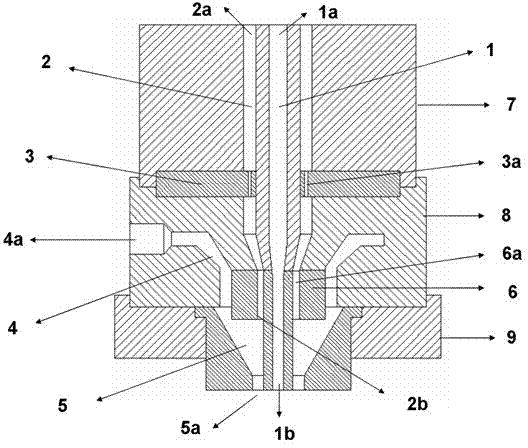

A kind of preparation method of long fiber reinforced hollow fiber membrane

ActiveCN102266726AContact priorityPrevent overflowMembranesSemi-permeable membranesWinding machineHollow fibre membrane

The invention discloses a method for preparing a long fiber reinforced hollow fibrous membrane. The method can be implemented in two ways: (1) adopting a spinning nozzle having a long fiber channel; introducing a long fiber into the long fiber channel; guiding the long fiber into a membrane casting solution and fiber compounding area via a fiber positioning plate; co-extruding the compounded long fiber and membrane casting solution; and forming a membrane under the action of core solution and external coagulating bath or cooling bath, and (2) adopting a spinning nozzle for co-extruding the long fiber and the membrane casting solution; guiding the long fiber out of a liquid material jar; guiding the long fiber to pass by a membrane casting solution pipeline and introducing the long fiber into the spinning nozzle from a membrane casting solution inlet of the spinning nozzle; co-extruding the long fiber and membrane casting solution after positioning the long fiber through the fiber positioning plate; forming the membrane under the action of core solution and external coagulating bath; and finally winding the membrane through a guide wheel and a winding machine. The long fiber reinforced compound membrane prepared by using the method has the advantages that the mechanical strength of the hollow fibrous membrane is increased by 3-5 times according to the quantity and variety of the long fiber in the hollow fibrous membrane, and the water flux, the rejection coefficient and the hydrophilicity are all obviously improved.

Owner:ZHEJIANG UNIV

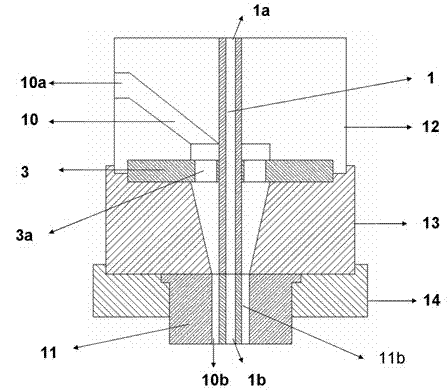

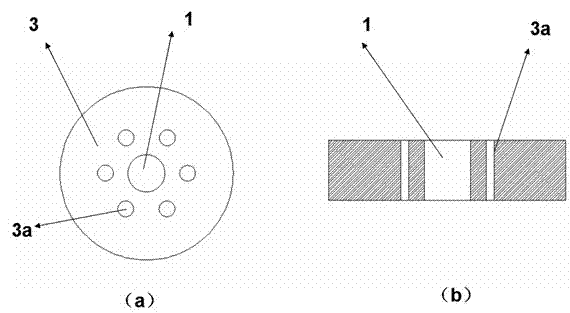

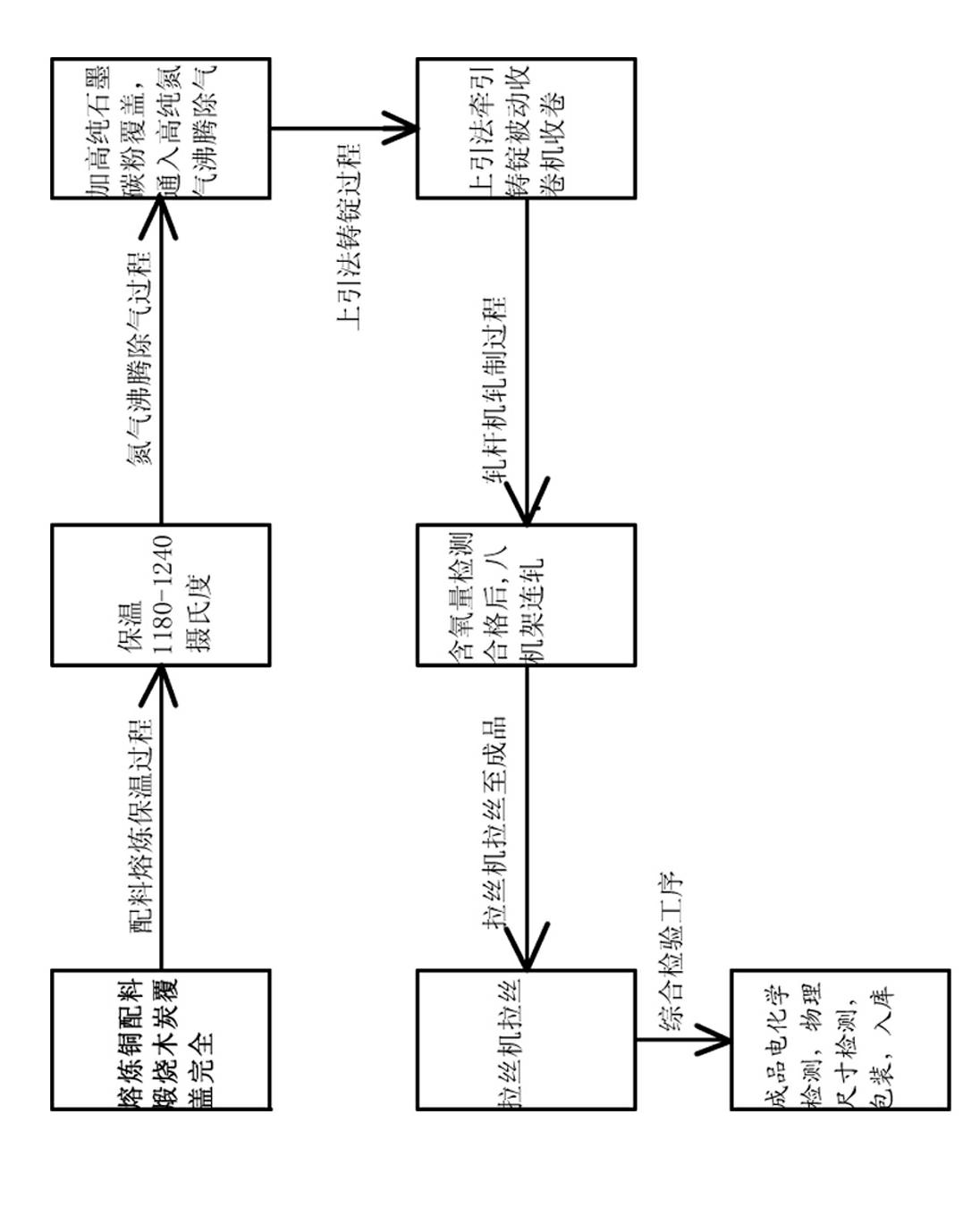

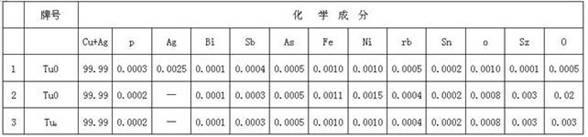

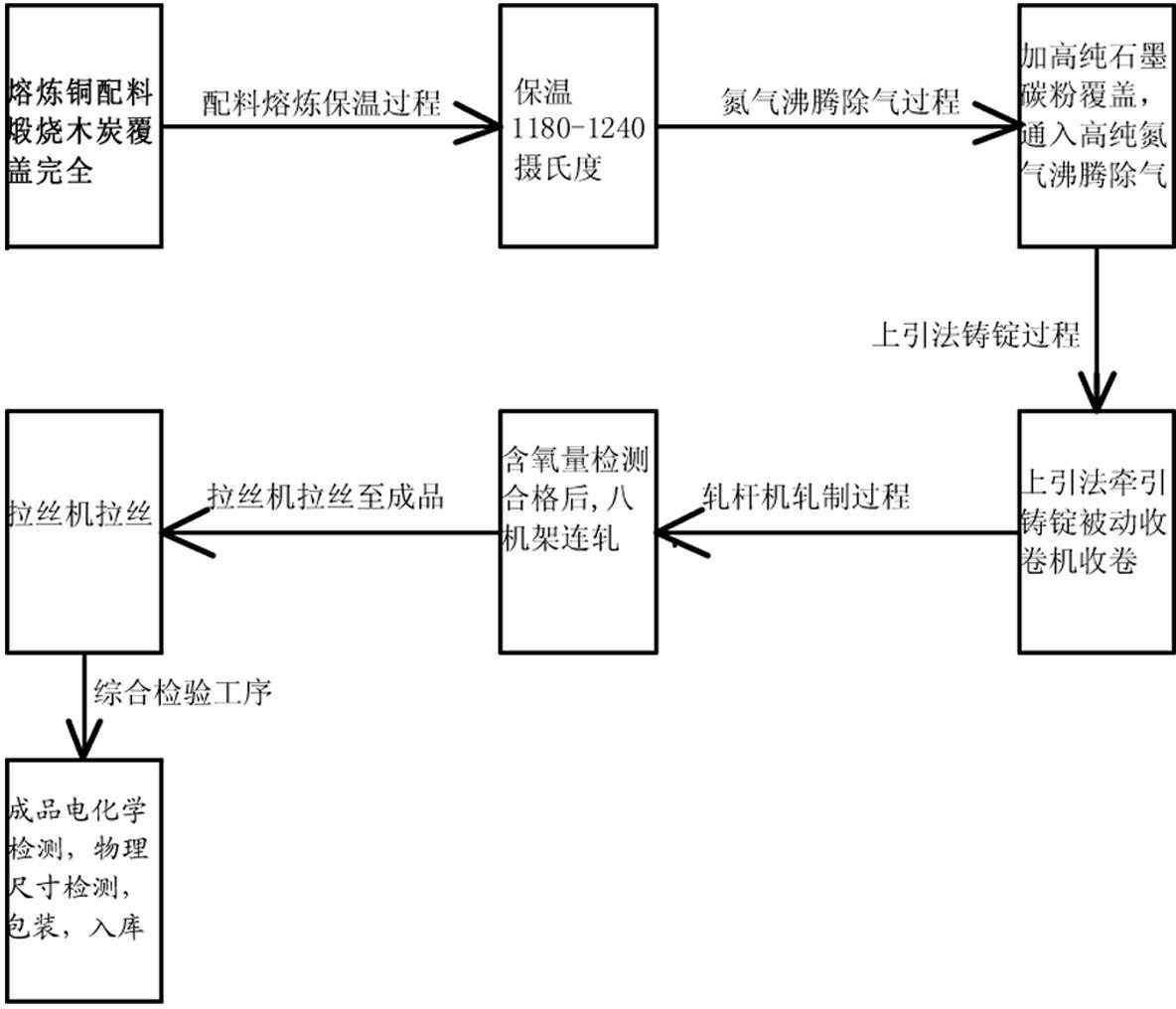

Upcast method for producing high-purity bright copper rod

ActiveCN102168180ALight weightFull reduction reactionProcess efficiency improvementGraphite carbonWinding machine

The invention relates to an upcast method for producing a high-purity bright copper rod. The method comprises the following steps of: drying smelting copper raw materials needed by smelting, mixing, adding the mixture into a smelting furnace, and covering firing charcoal with the thickness of between 100 and 150mm on starting molten copper until red copper is entirely molten, wherein molten copper constantly flows toward a heat preservation furnace under the action of fluid force; boiling the high-temperature molten copper and degassing before ingot guiding, adding prepared high-purity graphite carbon powder onto the liquid level of the molten red copper in the heat preservation furnace, and aerating high-purity nitrogen at the position which is 50 to 100mm lower than the liquid level of the heat preservation furnace; covering the firing charcoal after boiling and degassing, covering a furnace cover, performing draw casting operation, drawing a draw casting machine for draw casting bythe upcast method, cooling in a graphite crystallizer by the upcast method to obtain a qualified high-purity oxygen-free copper rod blank, and winding on a drawn cast ingot passive winding machine; and performing multi-pass rolling and fine-drawing on the high-purity oxygen-free high-brightness copper rod blank by an eight-rack rod cold rolling mill, and drawing the blank until the copper rod is obtained by a wire drawing machine, namely obtaining a finished product after the copper rod passes the inspection.

Owner:ZHONGTIAN ALLOY TECH

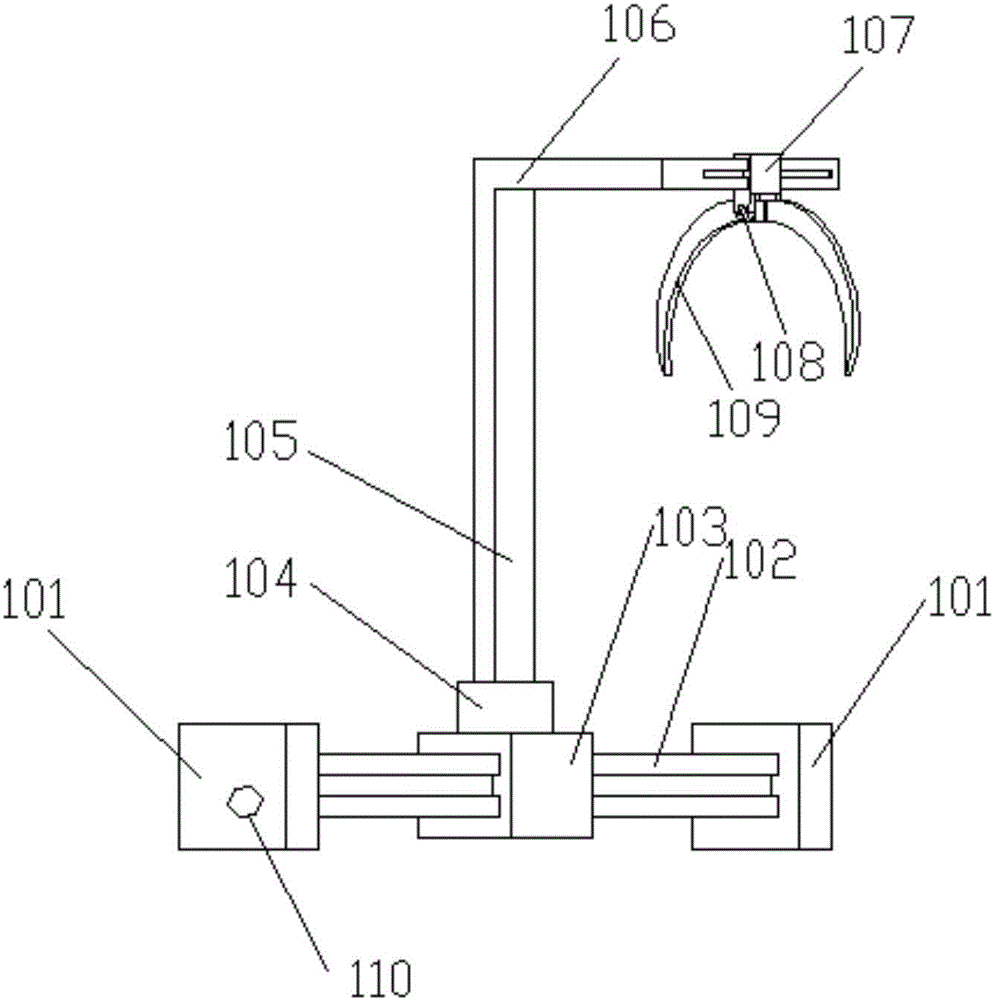

Spooling transport vehicle and automatic spindle conveying system and method

The invention discloses a spooling transport vehicle, an automatic spindle conveying system and an automatic spindle conveying method, belonging to the technical field of chemical fiber production. The automatic spindle conveying system is arranged between a winding machine and a special yarn vehicle, is used for taking down formed spindle from the winding machine and hanging the formed spindle on the special yarn vehicle, and comprises a temporary storage rotary table, a manipulator, the spooling transport vehicle and a control module, wherein the temporary storage rotary table is used for temporarily storing the formed spindle and corresponds to the manipulator, the manipulator is used for hanging the spindle stored on the temporary storage rotary table on the special yarn vehicle, the spooling transport vehicle runs between the winding machine and the temporary storage rotary table, and the control module is in communication connection with the temporary storage rotary table, the manipulator, the spooling transport vehicle and the winding machine respectively. With the arrangement of the spooling transport vehicle, a large amount of labor is replaced, the labor intensity of workers is greatly reduced, the management cost is reduced, and the probability of polluting and damaging the spindle is reduced.

Owner:RIAMB (BEIJING) TECH DEV CO LTD

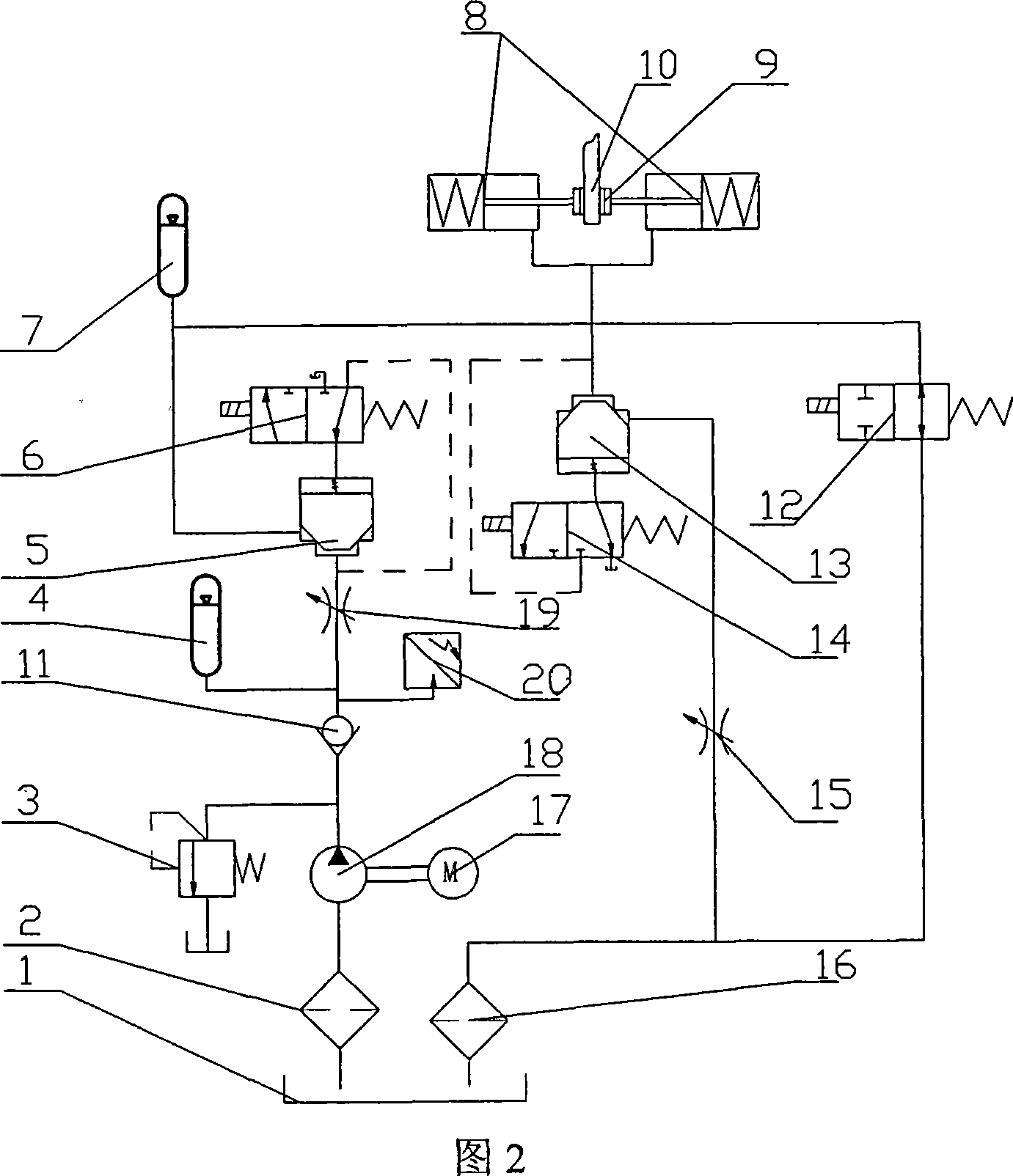

Large and middle wind turbine digital intelligent hydraulic brake system

InactiveCN101033733AWork reliablySimple structureWind motor controlAxially engaging brakesTime ratioFuel tank

The invention discloses a digital, intelligent and hydraulic brake system of large and medium wind machine. The output end of the oil supply system links uniflow valve. Its output end joints to the first accumulator, pressure relay and input end of first plug-in valve through the first throttle valve. The output end of first plug-in valve links the second accumulator. Equip hydraulic cylinders with brake blocks on sucker-rod cavity end, two of which are taken as one group and are located relatively. The sucker-rod cavities of the hydraulic cylinders connect with the output ends of the first and second plug-in valve and the third linking switch valve through the bus. The output end of the second plug-in valve meets oil tank through second throttle valve. Two high-speed switch valves are taken as pilot stage together with two plug-in valves to form digital electro-hydraulic proportional valve. Brake blocks are equipped on both sides of brake chuck of the wind machine to change the open-close time ratio of high-speed switch valves and adjusts hydraulic braking force of the brake chuck. When meeting the working condition of unit braking, adjust the duty ratio of high-speed switch valves in unit time depending on wind speed and main shaft speed to realize intelligent control on braking force.

Owner:ZHEJIANG UNIV

Splitting winding machine for base paper

ActiveCN101301969ACut evenlyOffset is automatically eliminatedMetal working apparatusArticle deliveryWinding machineEngineering

The invention relates to the decorative winding device technical field, in particular to a base paper cutting winding machine which comprises an unwinding device and a winding device. A cutting mechanism comprising a cutting roller and a cutting knife is arranged between the unwinding device and the winding device, the two ends of the cutting roller are movably arranged on a cutting bracket, and the cutting knife is coaxially arranged on the cutting roller. A driving roller is arranged right under the cutting roller, the two ends of the driving roller are movably arranged on the cutting bracket, and the cutting roller is respectively connected with the two ends of the driving roller by driving pairs. Two groups of guiding roller sets are arranged on the winding device, and the guiding roller sets are arranged on a winding frame. A first winding roller and a second winding roller are respectively arranged on the upper part and the lower part of the winding frame, and the first and the second winding rollers are respectively connected with a first driving mechanism and a second driving mechanism. By utilizing the cutting winding machine, cutting and winding works can be completed by one time, furthermore, the cutting is equal and the winding is neat, thus conserving manpower and cost.

Owner:东莞市华富立装饰建材有限公司

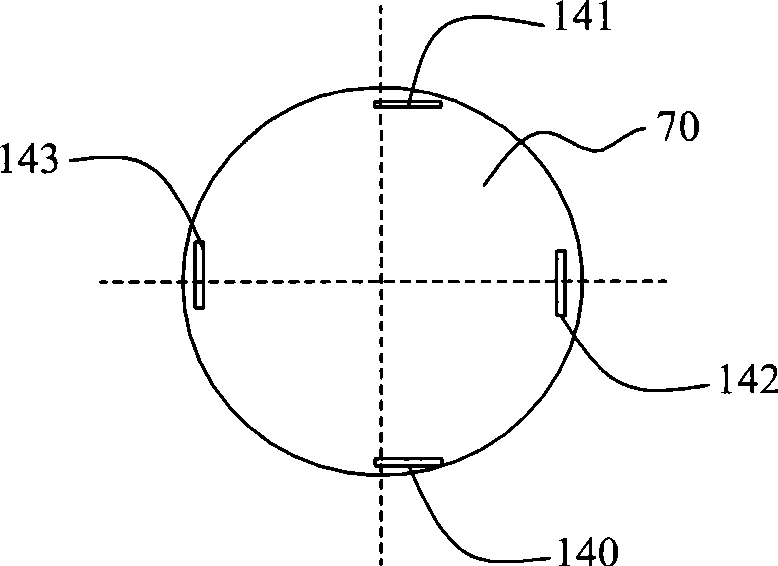

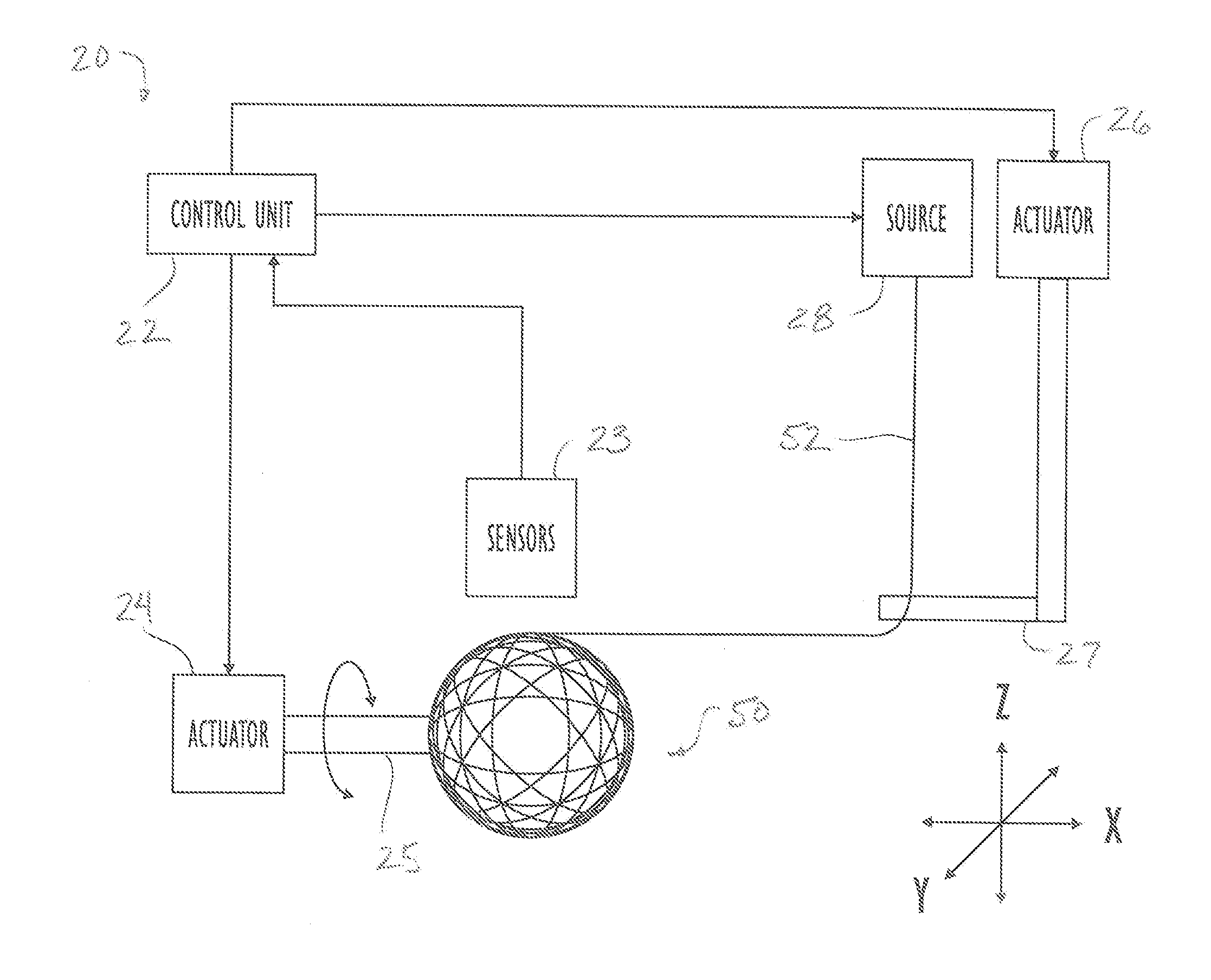

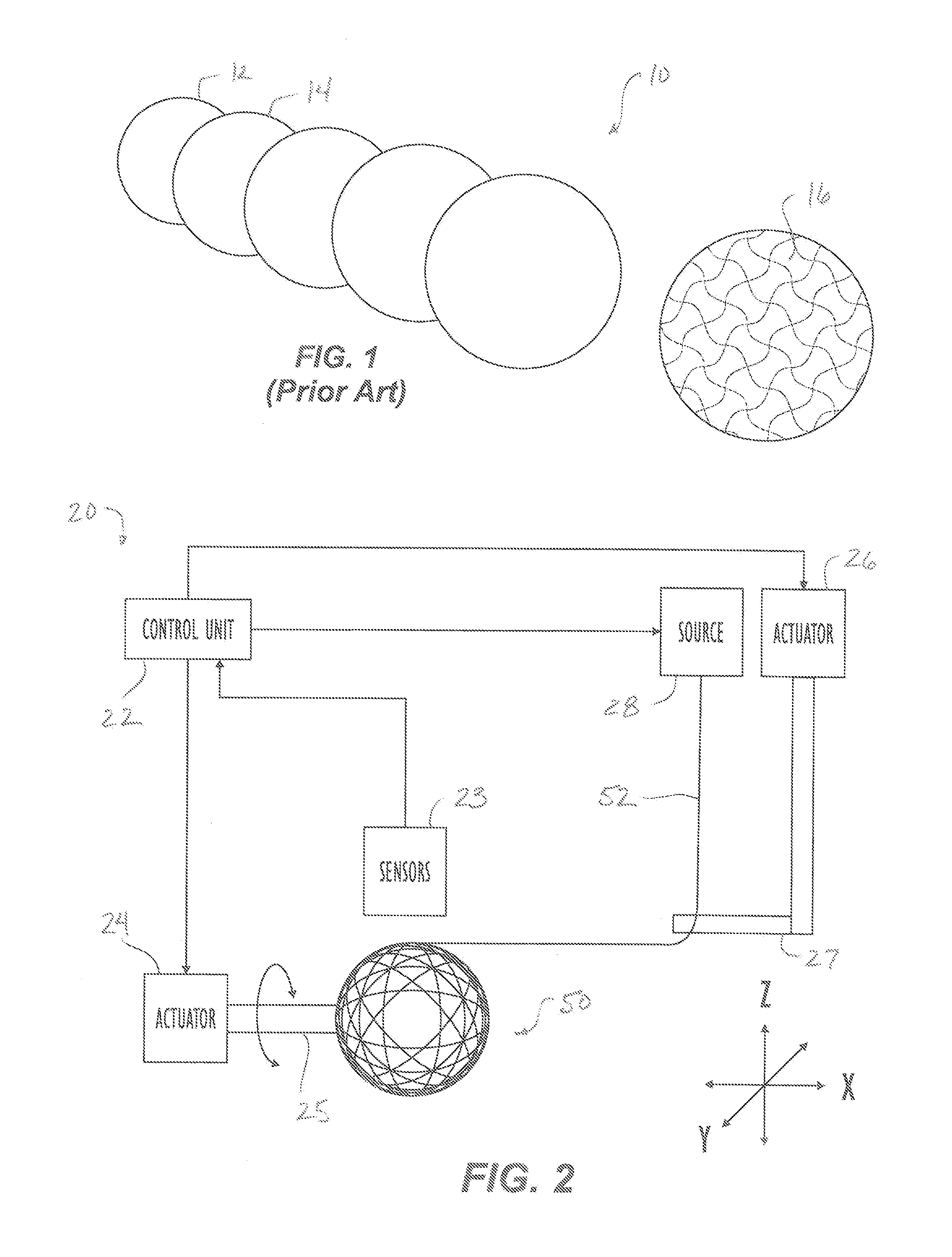

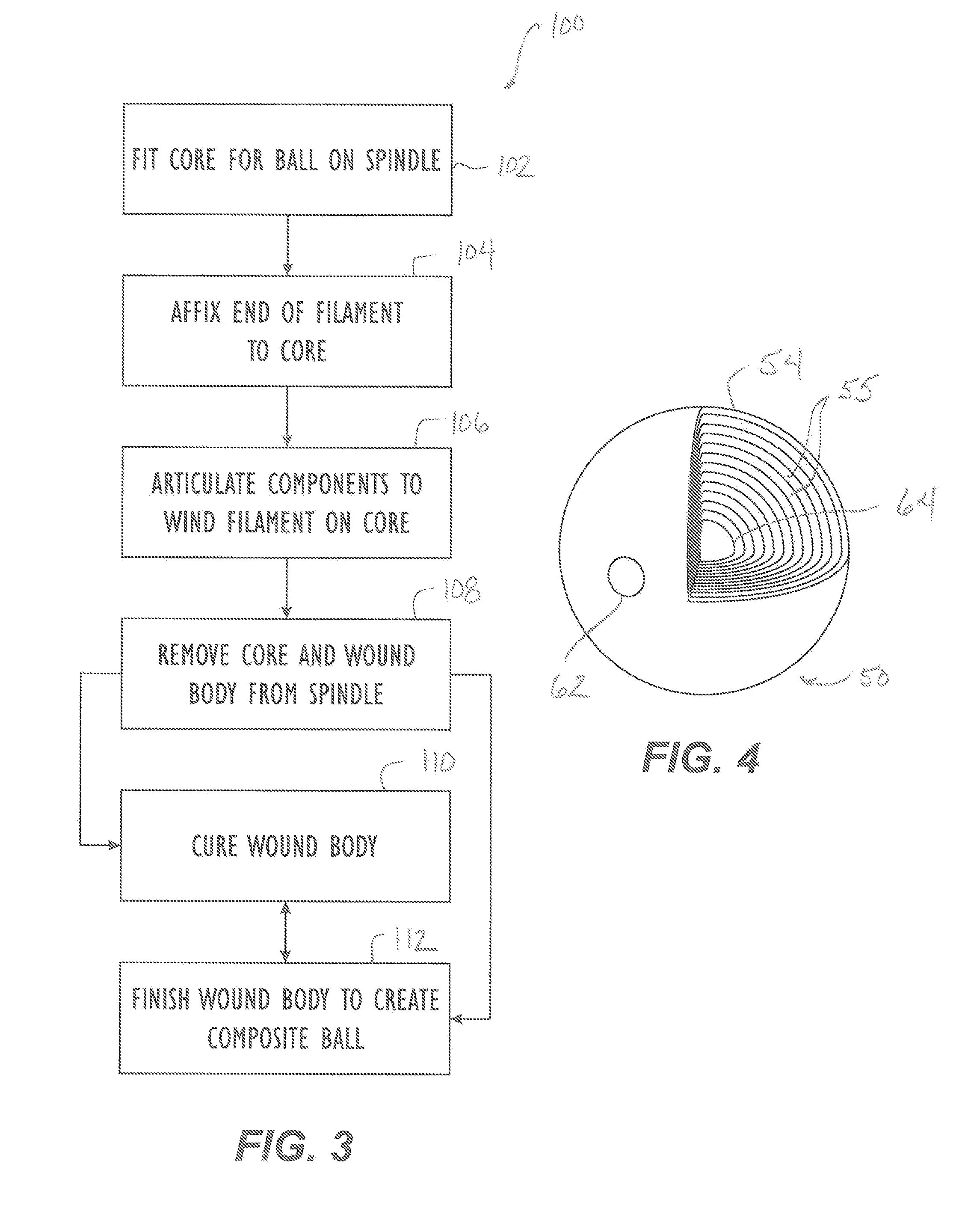

Filament Wound Composite Ball

InactiveUS20140120346A1Increased shear strengthHigh-temperature ratingPaper/cardboard wound articlesDomestic articlesWinding machineFilling materials

A composite ball is formed with wound filament in a winding machine by winding the filament on a core, which can be permanent and form part of the finished ball. Alternatively, the core can be temporary. When winding is completed, the wound body is removed from the winding machine, an exterior of the wound body is finished, and the wound body is cured. When the core is permanent, at least a portion of the core is removed from the winding machine along with the wound body so any excess of the permanent core can be removed. The temporary core, however, is removed from the wound body, and the void is filled with filler material.

Owner:WEATHERFORD TECH HLDG LLC

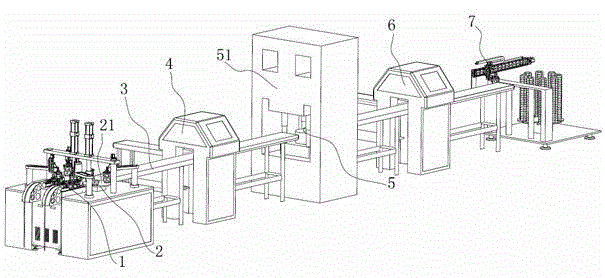

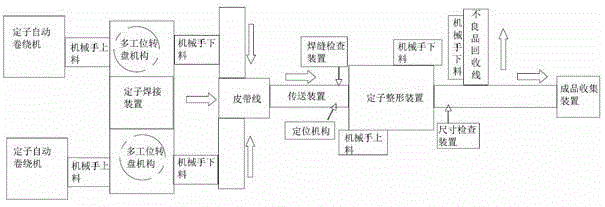

Automatic stator core production line

ActiveCN104810992ARealize intelligent productionIncrease productivityOther manufacturing equipments/toolsManufacturing stator/rotor bodiesWinding machineProduction line

The invention discloses an automatic stator core production line. The automatic stator core production line comprises an automatic stator winding machine, a stator welding device, a conveying device, a weld joint detecting device, a stator reshaping device, a size detecting device and a finished product collecting device, mechanical arm systems are arranged among the devices, and working instructions among the devices are achieved via an instruction system. The automatic stator core production line has the advantages that in the full process, mechanical arms are adopted, automatic pipeline operation is achieved, unqualified stator cores generated in working procedures during production can be removed automatically, intelligent production is achieved, production efficiency is improved, and production cost is reduced.

Owner:CHANGYING XINZHI TECH CO LTD

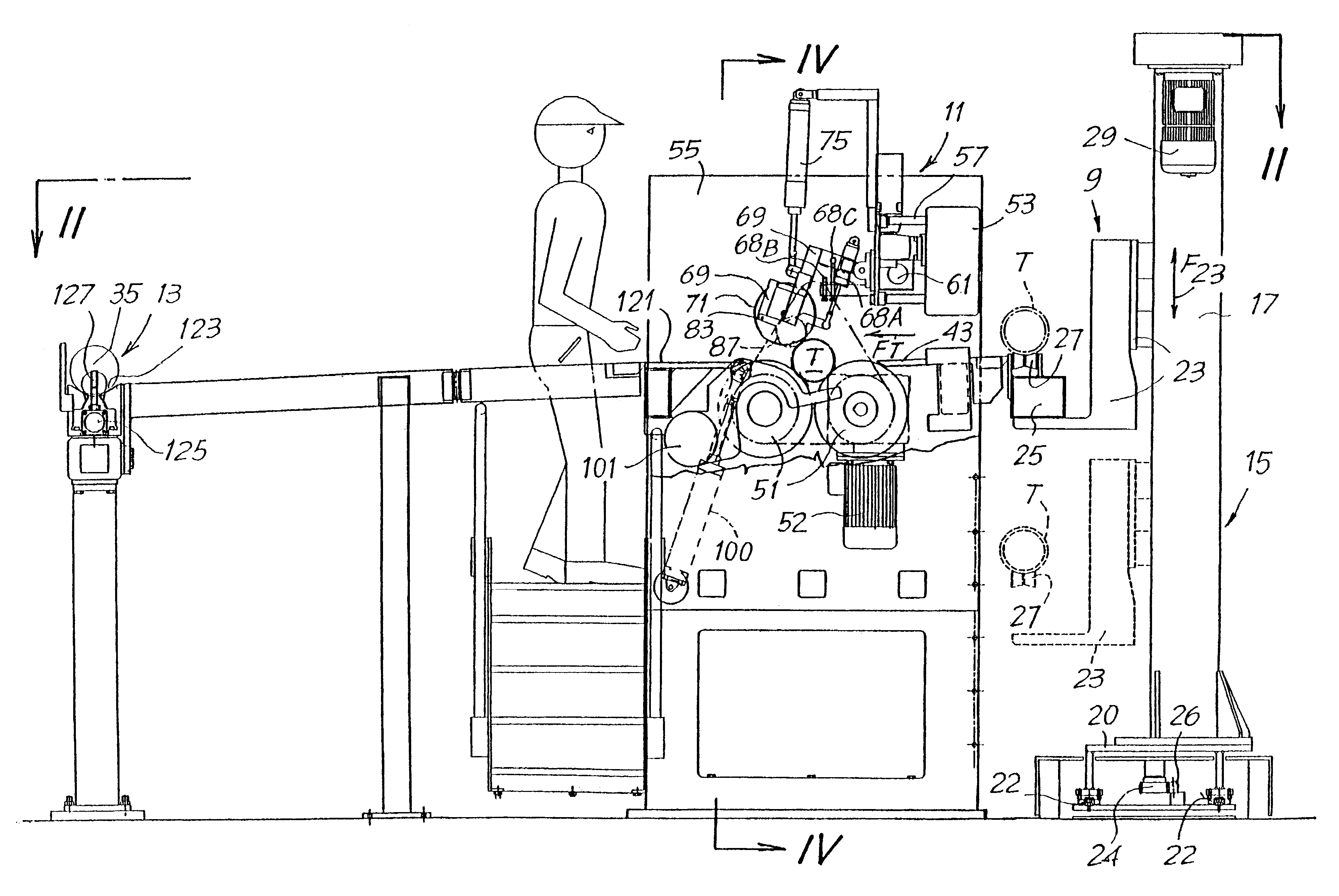

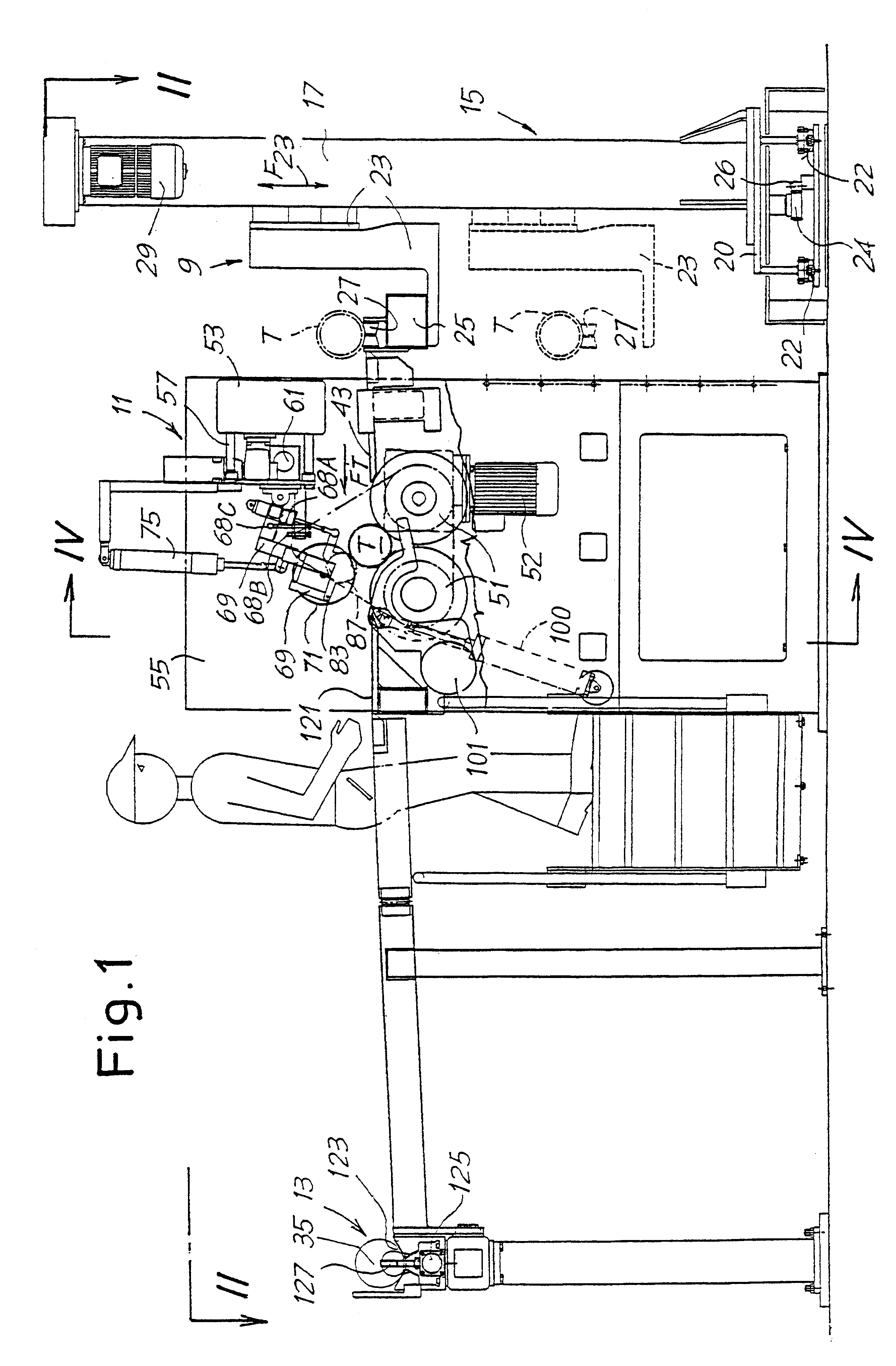

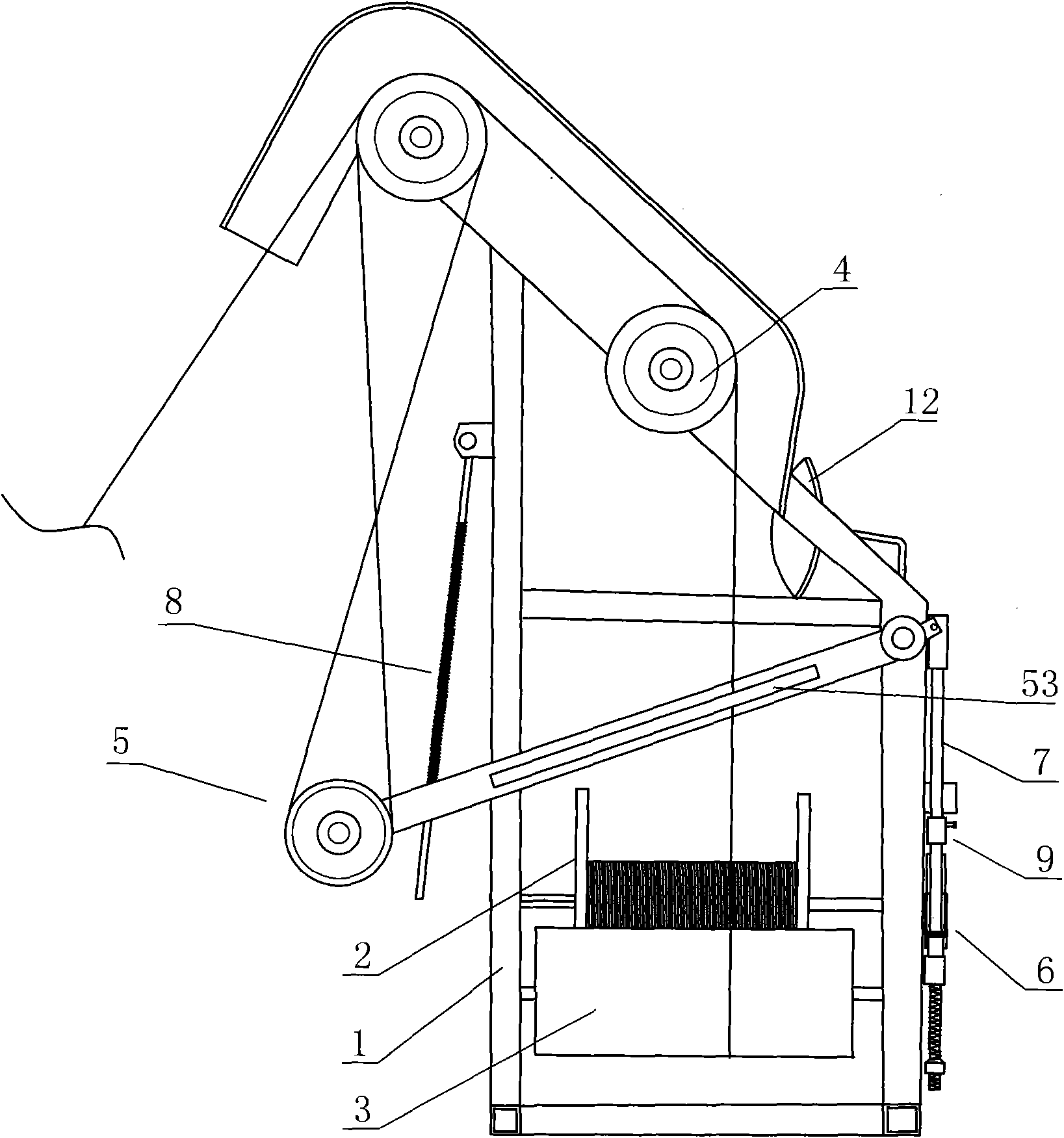

Apparatus and method for preparing winding mandrels and cores for rewinding machines

A description is given of a device for preparing winding mandrels for winding machines or the like, comprising, in combination: an extraction station (9) with an extractor mechanism for extracting a mandrel from one or more rolls of web material and for inserting the extracted mandrel into a tube (T); a cutting station (11) with cutting means (71) for cutting the tube (T) fitted on the mandrel into a set of tubular cores aligned on said mandrel; an insertion station (13) with insertion members (127) for inserting the mandrel with the tubular cores into a winding machine or the like.

Owner:A CELLI NONWOVENS

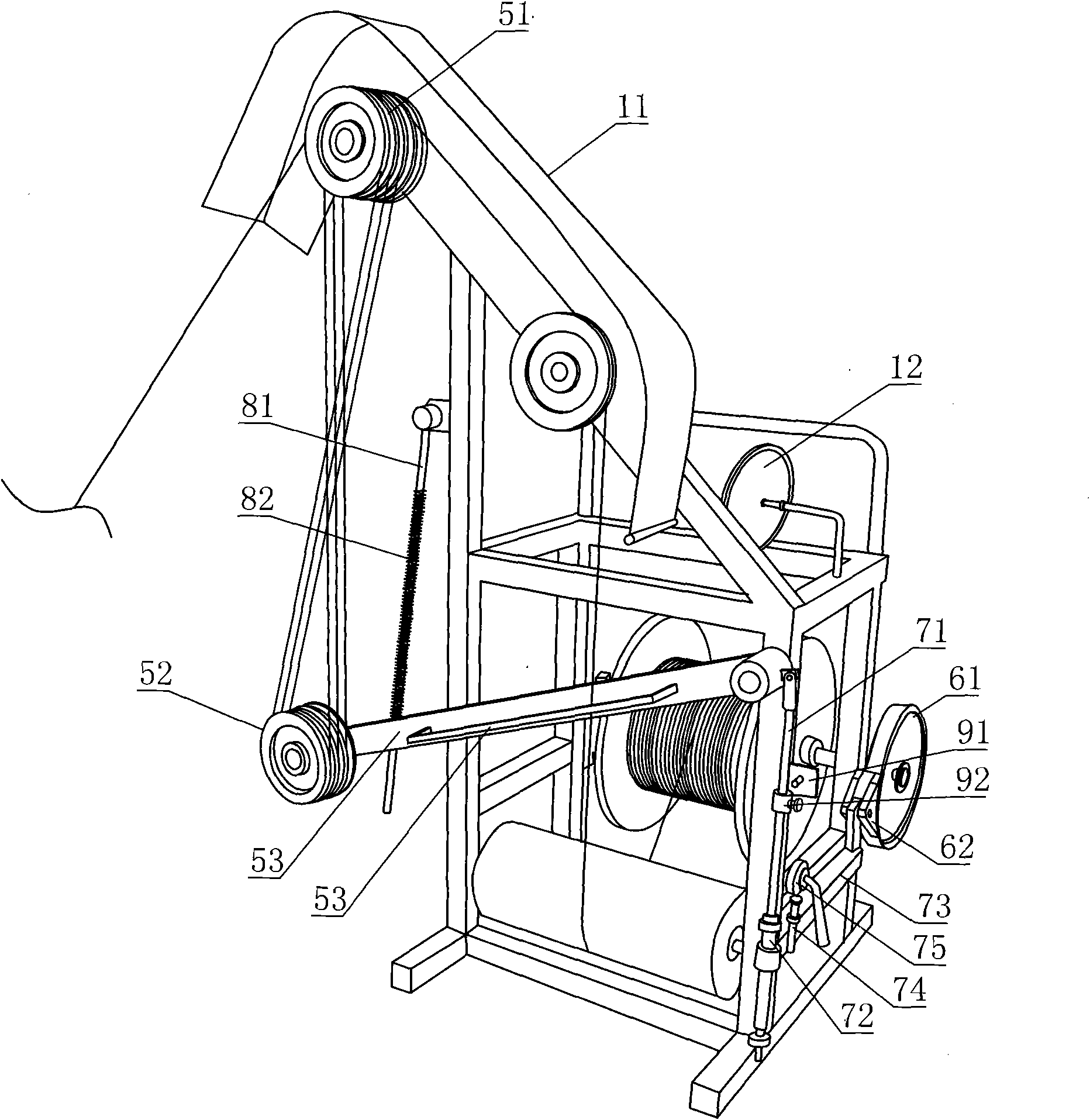

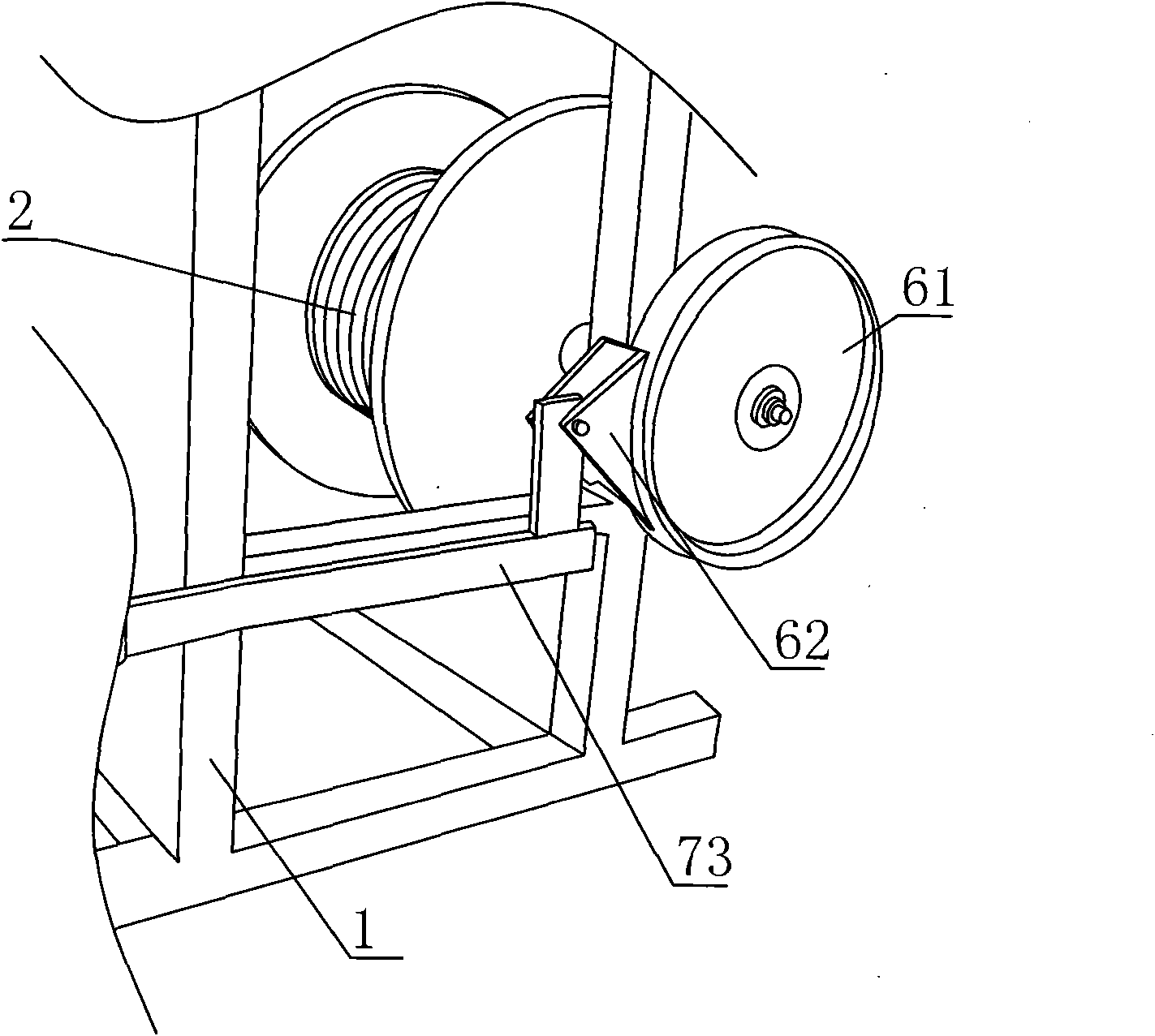

Cable conveyance tension adjustment method and device implementing same

InactiveCN101780905AEnsure personal safetyEasy to monitor working statusFilament handlingWinding machineCable transport

The invention discloses a cable conveyance tension adjustment method. In the method, a frame and a wire coil arranged on the frame are used. The method comprises the following steps: 1, preparing a cable guide roller; 2, preparing a cable guide wheel; 3, preparing a tension control device; 4, preparing a damping device; and 5, preparing an adjustment device so as to adjust the amplitude of swing of the tension control device and set corresponding damping force output by the damping device according to the amplitude of swing. The method provided by the invention has the advantages of quickly and uniformly conveying cables wound in the wire coil to a winding machine with constant tension. A device provided by the invention has a simple structure and high tension control and adjustment accuracy, automatically and continuously detects and adjusts the tension of the cables in the whole production process, keeps the tension constant all the time to actually realize cable transport with the constant tension, is convenient to operate, can automatically convey the cables wound in the wire coil to the winding machine with the constant tension only by starting the winding machine, and improves the production efficiency.

Owner:LINOYA ELECTRONIC TECHNOLOGY CO LTD +1

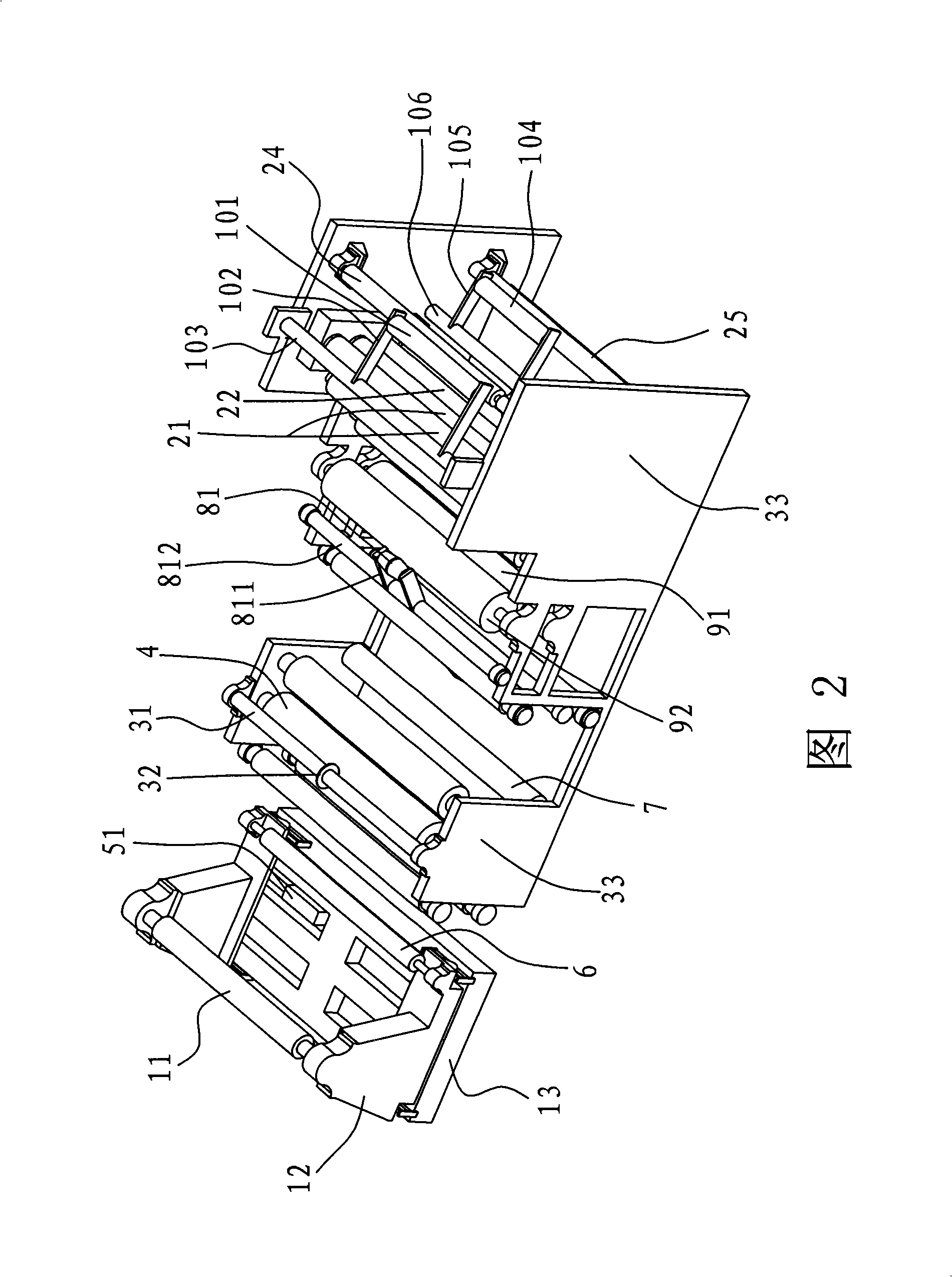

Central winding machine

ActiveCN102658987ARealize automatic roll changeFast roll changeWebs handlingWinding machineConductor Coil

The invention provides a central winding machine. The central winding machine comprises a machine frame and an overturning frame, wherein the overturning frame can be installed on a machine frame in a rotating manner, and a first winding shaft and a second winding shaft are installed on the overturning frame. The central winding machine is characterized by further comprising a material receiving mechanism, wherein the material receiving mechanism comprises a material receiving frame, a press roll, a press roll frame, a cutting tool, a cutting tool translating mechanism, a chip roller and a chip roller frame, wherein the material receiving frame can be installed on the machine frame in a rotating manner, a material receiving frame oscillation control mechanism is arranged on the machine frame, the press roll frame is installed on the material receiving frame in a rotating manner, the press roll is installed on the press roll frame, a press roll oscillation control mechanism is arranged on the material receiving frame, the cutting tool translating mechanism is arranged on the material receiving frame, the cutting tool is connected to a power output end of the cutting tool translating mechanism, the chip roller frame is installed on the material receiving frame in a rotating manner, the chip roller is installed on the chip roller frame, and a chip roller oscillation control mechanism is arranged on the material receiving frame. According to the invention, as the material receiving mechanism is arranged, materials can be cut off and received automatically, automatic roll replacement and high roll replacing speed can be realized, and production efficiency can be increased.

Owner:SHANTOU DACHENG ENVIRONMENTAL PROTECTION PRECISION MACHINE TECH CO LTD

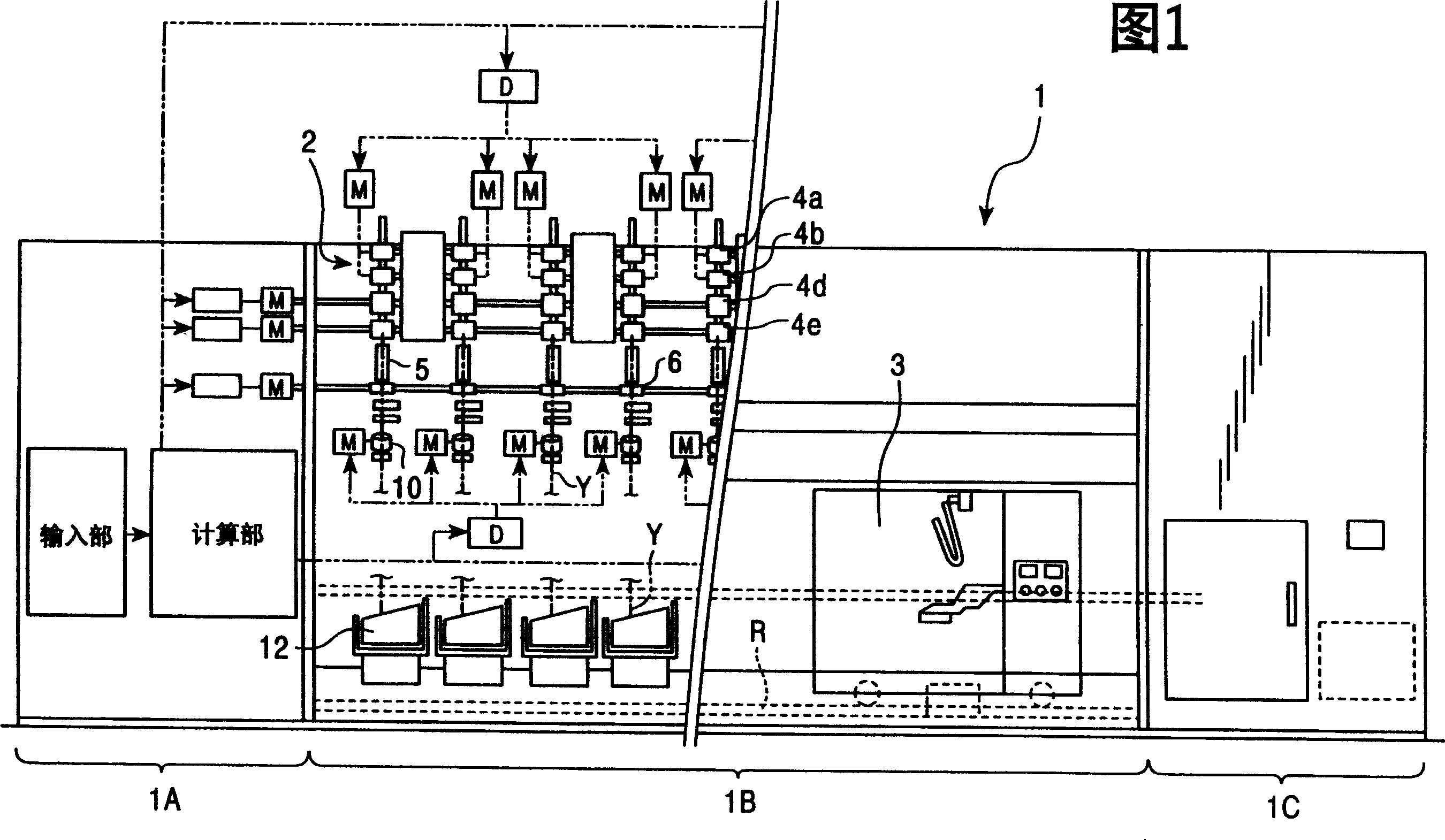

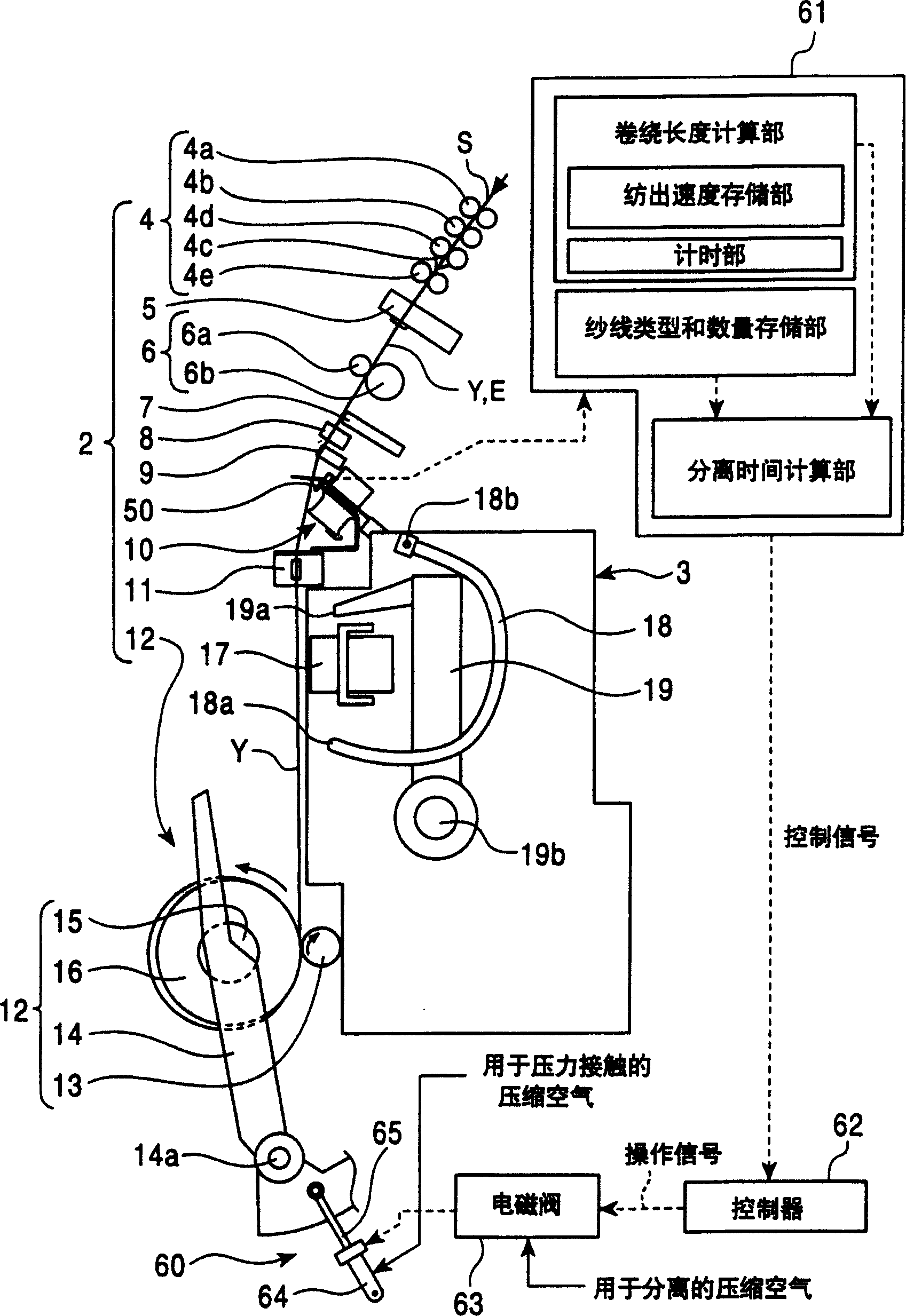

Yarn winding machine

The present invention prevents the amount of slack from decreasing below a predetermined value when a yarn slack eliminating device is used to control a winding tension during a yarn winding process executed by a spinning machine. A winding device 12 winds a yarn spun by a spinning device 5, into a package 16, while a yarn slack eliminating device 10 is eliminating the slack of the yarn. During this process, when it is detected that the amount of slack in the yarn slack eliminating device 10 decreases below a predetermined value, the package 16 is separated from a rotating drum 13 to reduce a winding speed to increase the amount of slack. At this time, the time for which the package 16 remains separated is controlled in accordance with the winding diameter of the package 16 to adjust the aspect of reduction of the winding speed. When the amount of slack is increased, the time for which the reduction of the winding speed is continued and the amount of speed reduction are adjusted taking the winding diameter of the package into account. Therefore, the optimum speed reduction aspect can be set in accordance with a variation in the inertia moment of the package.

Owner:MURATA MASCH LTD

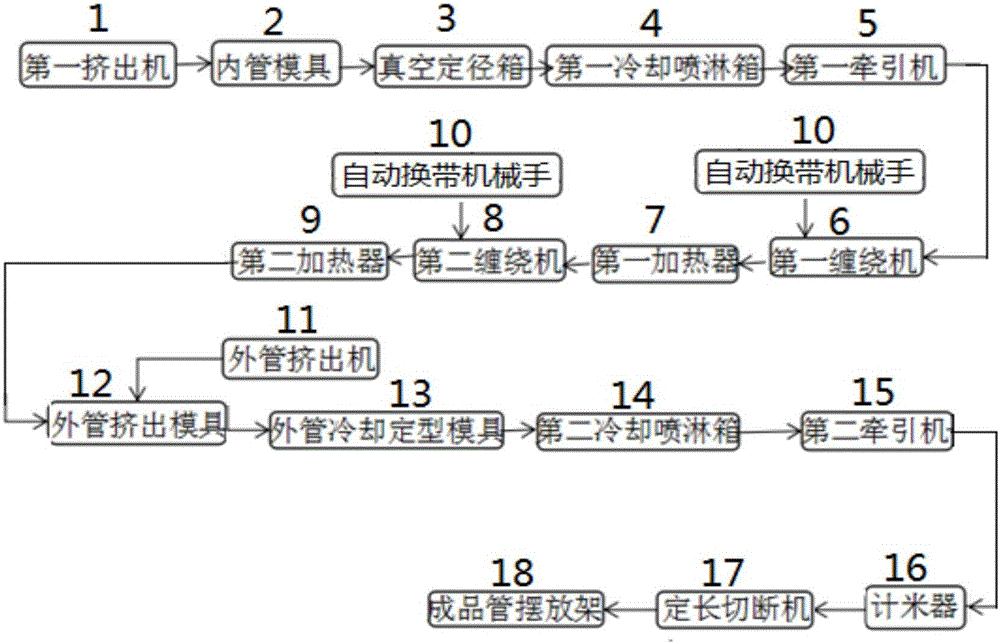

Continuous production device and method for glass fiber reinforced belt polyethylene composite pipe

ActiveCN106182841AEliminate vacuum sizing processAvoid stratificationCoatingsRigid pipesGlass fiberWinding machine

The invention belongs to the technical field of plastic pipes, and particularly relates to a continuous production device and method for a glass fiber reinforced belt polyethylene composite pipe. A main structure of the production device comprises a first extruder, an inner pipe die, a vacuum sizing box, a first cooling spraying box, a first tractor, a first winding machine, a first heater, a second winding machine, a second heater, an automatic belt replacing mechanical arm, an outer pipe extruder, an outer pipe extrusion die, an outer pipe cooling sizing die, a second cooling spraying box, a second tractor, a meter counter, a fixed-length cut-off machine and a finished pipe containing frame. The technology process of the production method comprises total four steps of inner pipe extrusion forming, continuous composite belt winding, outer pipe extrusion wrapping and cutting warehousing, and continuous online production of the glass fiber reinforced belt polyethylene composite pipe is achieved. According to the production device for the glass fiber reinforced belt polyethylene composite pipe, the using environment is friendly, the production method principle is scientific and reasonable, the produced and prepared glass fiber reinforced belt polyethylene composite pipe is high in compression strength and small in pipe thickness, the production cost is low, and energy saving and environment friendliness are achieved.

Owner:王庆昭

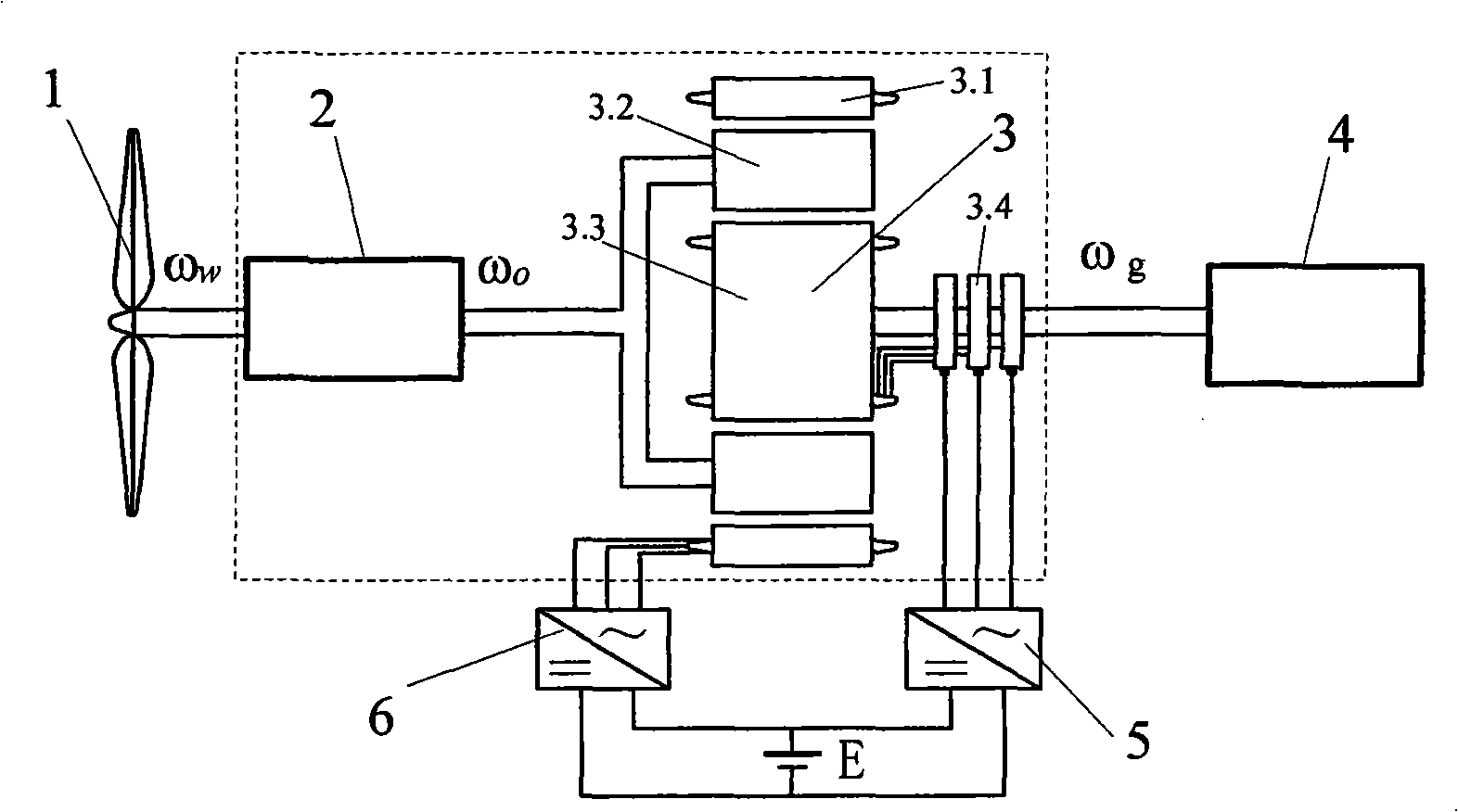

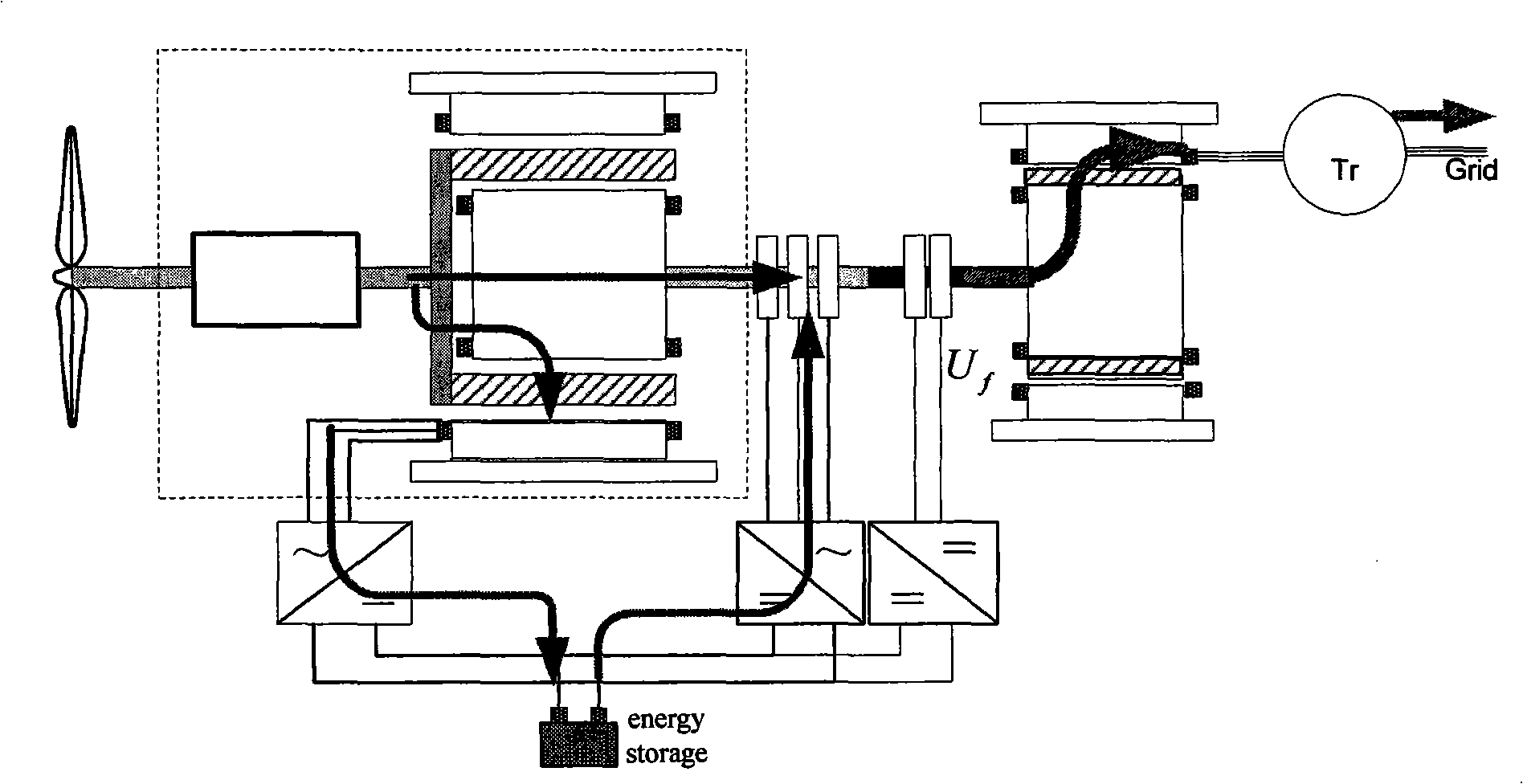

Electro-mechanical mixed stepless speed-changing wind power generation plant

InactiveCN101272084AIncrease working pointImprove utilization efficiencyDynamo-electric gearsWind motor combinationsConstant frequencyEngineering

An electromechanical infinite variable speed wind generating device is capable of realizing the real variable speed constant frequency operation, remarkably improving the reliability and the operation efficiency of a system as well as the operating factor of the wind energy, remarkably promoting the working point and the operating efficiency of an electrical variable transmission as well as the efficiency of the whole system. The device includes a wind machine (1), a mechanical speed increaser(2), an electrical transmission (3), a generator (4), a first power inverter (5), a second power inverter (6) and a third power inverter (7). If a DC power consists of an energy storage unit (storage battery, capacitor, etc), partial power can be stored in a form of electricity, or the energy in the energy storage can be released into an output shaft. When the power of the wind machine is larger than that of the generator, the redundant energy can be converted into electricity and stored; on the contrary, when the power of the wind machine is smaller than that of the generator, the energy in the energy storage unit can be released to complement the insufficiency of the inputted power.

Owner:SOUTHEAST UNIV

Full-automatic winding machine for winding plastic pipe

InactiveCN101301971AImprove work efficiencyGood automation effectFilament handlingWinding machineElectric machinery

The invention relates to a full-automatic winding machine used for winding plastic tubes, aiming at simplifying the complicated structure of the winding machine and comprising a main-machine base, a rotary big arm arranged on the main-machine base, a tube-distributing mechanism and a tension control mechanism, wherein, two winding disks are symmetrically arranged on the rotary big arm, and after improvement, two winding-disk driving motors are symmetrically arranged on the rotary big arm and respectively connected with the two winding disks in a transmission way. The invention adopts the design of configuring driving sources respectively for the two winding disks to overcome the defects of complicated winding disk supporting and jointing devices, etc. existing by sharing one driving source, and the improvement reduces parts and reduces the manufacturing accuracy of the parts so as to simplify action program and distinctly enhance the reliability of equipment. The full-automatic winding machine of the invention improves the automation capability of plastic hose winding, enhances winding efficiency and is suitable for the automatic manufacturing line of various plastic hoses.

Owner:武志生

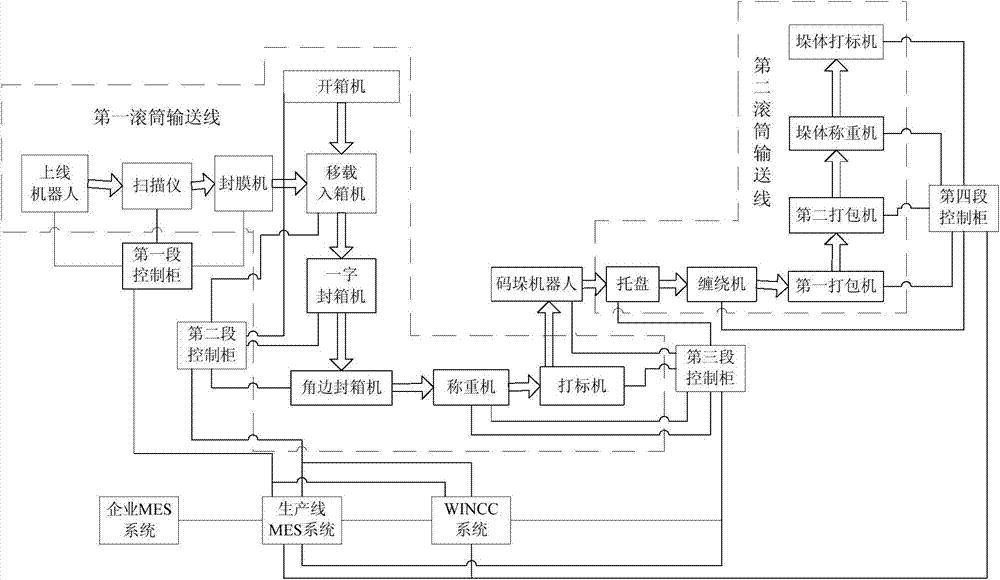

Intelligent flexible packaging production line for box type products

ActiveCN103935568ADynamic adjustment of process parametersWith intelligent line change functionPackaging automatic controlPackaging machinesWinding machineProduction line

The invention discloses an intelligent flexible packaging production line for box type products. The intelligent flexible packaging production line comprises a first roller conveying line, a second roller conveying line, a production line MES system, a WINCC system, a robot palletizer and four control cabinets. A scanner, a film sealing machine, a transferring boxing machine, a linear box sealing machine and a corner and edge box sealing machine are sequentially arranged between the feeding segment and the discharging segment of the first roller conveying line. A box body is arranged between the film sealing machine and the transferring boxing machine. A tray, a winding machine and a first packaging machine are sequentially arranged between the feeding segment and the discharging segment of the second roller conveying line. The robot palletizer is arranged between the feeding segment of the first roller conveying line and the discharging segment of the second roller conveying line. According to the intelligent flexible packaging production line for the box type products, the intelligent flexible packaging production line is compatible with the box type products with different appearances, procedures of feeding, film sealing, vacuum pumping, box opening, box entering, box sealing, weighing, packaging, stacking, marking, discharging and the like can be intelligently finished in a full-automatic mode. The intelligent flexible packaging production line for box type products is wide in application and suitable for packaging of many products in the communication industry.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com