Patents

Literature

731 results about "Slant angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

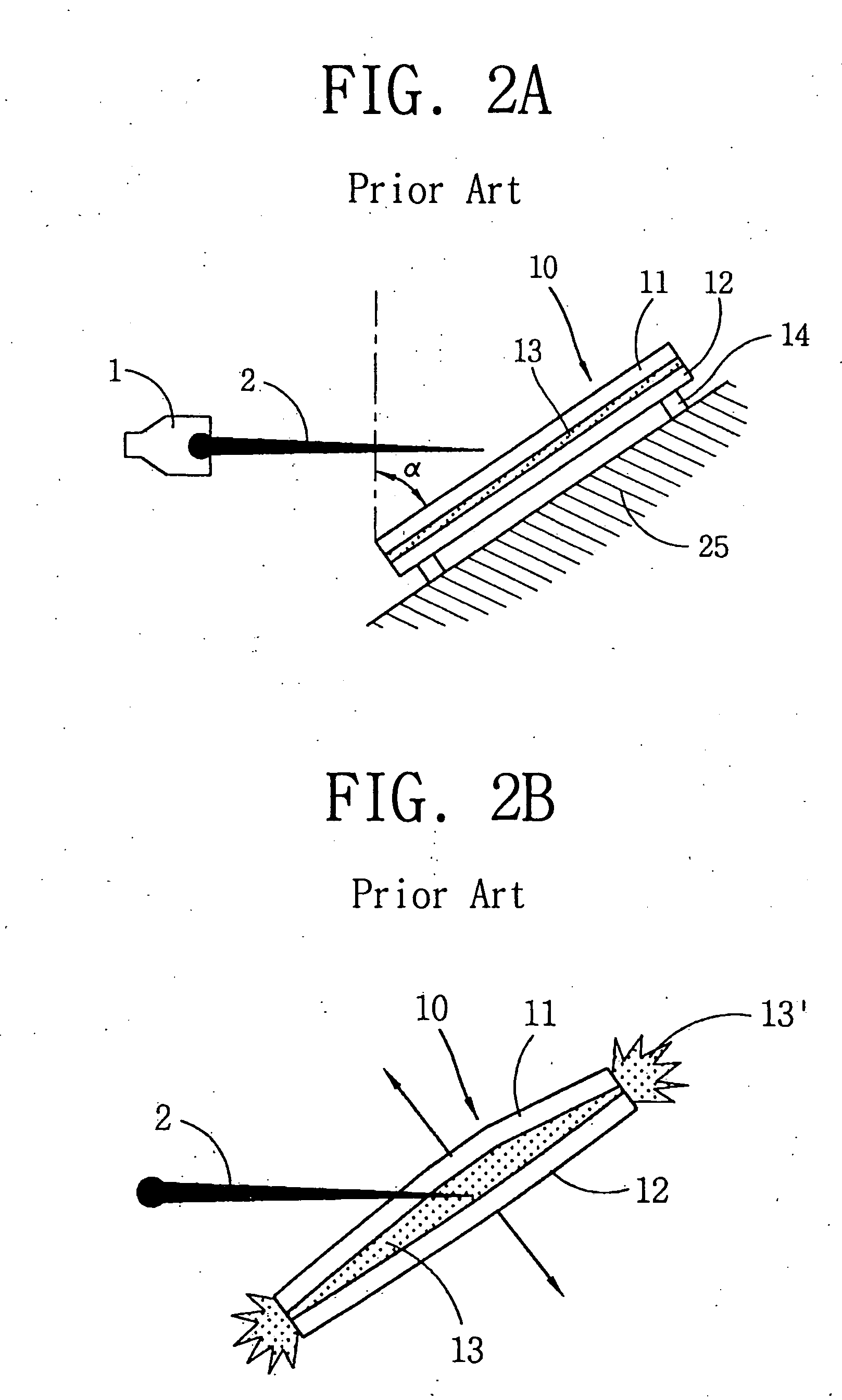

To address this issue, a new angle named “slant angle” is introduced. The slant angle of a pick is determined by its tilt angle and the inclination angle of the rock surface. The calculation of the slant angle is presented.

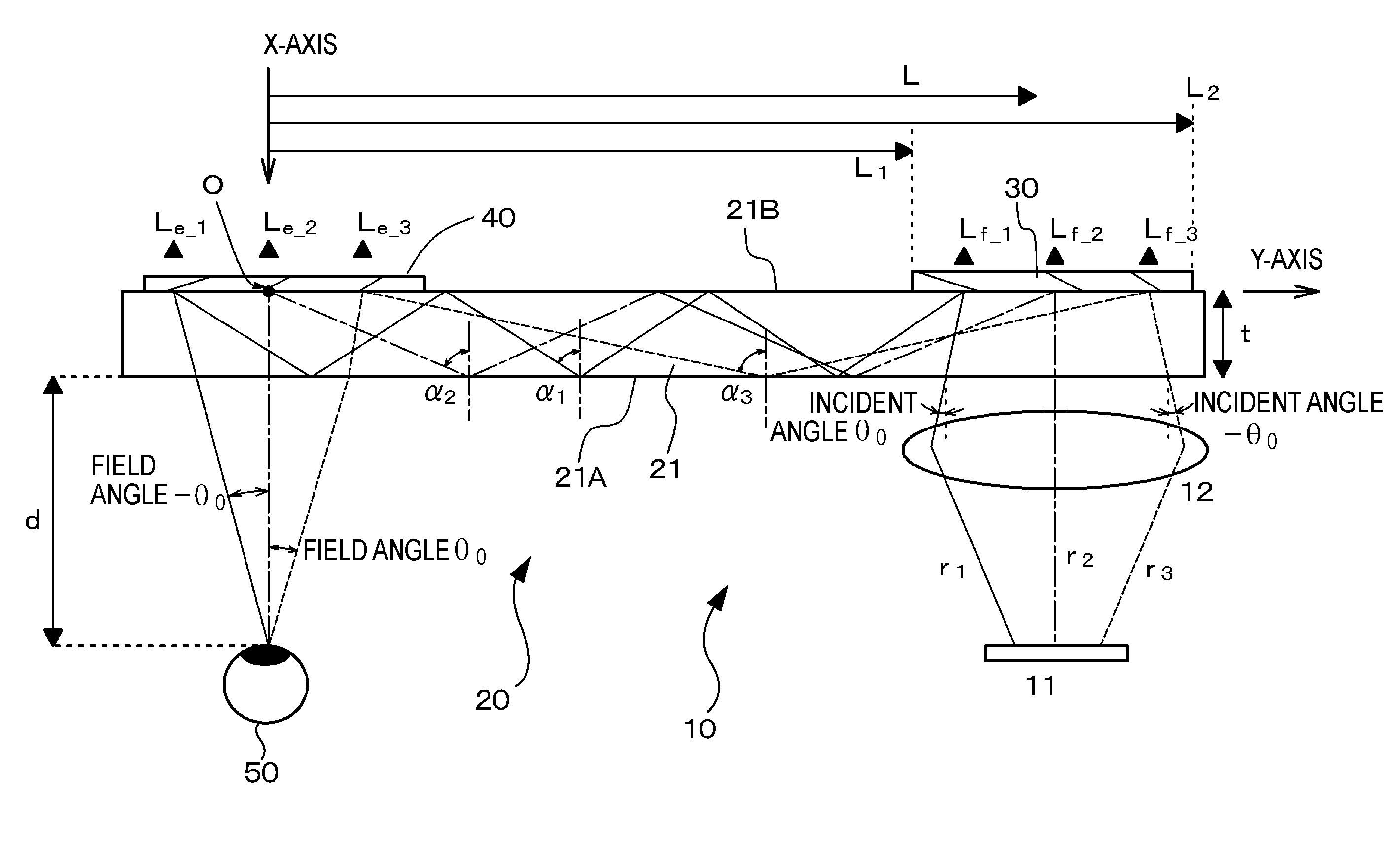

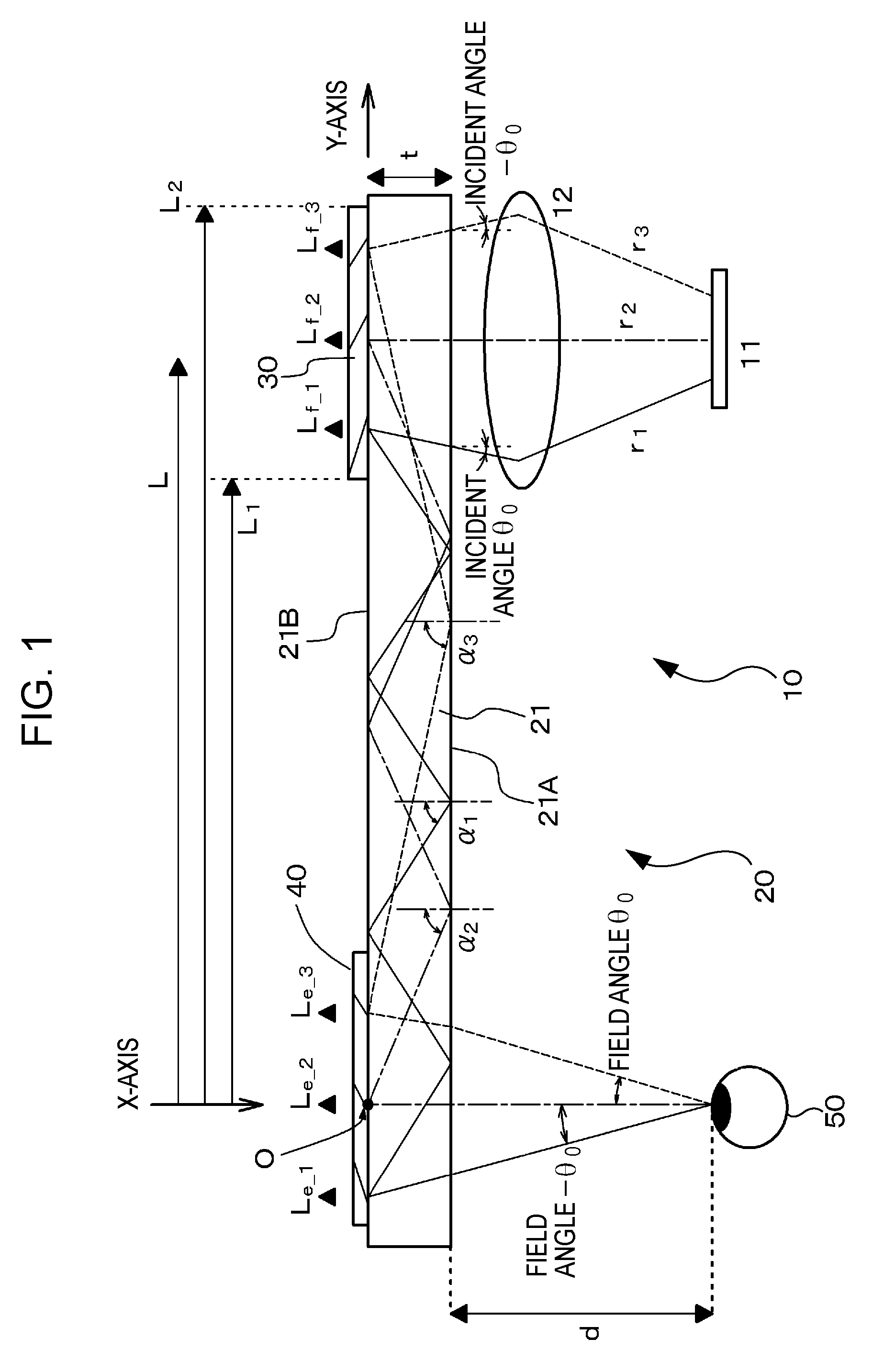

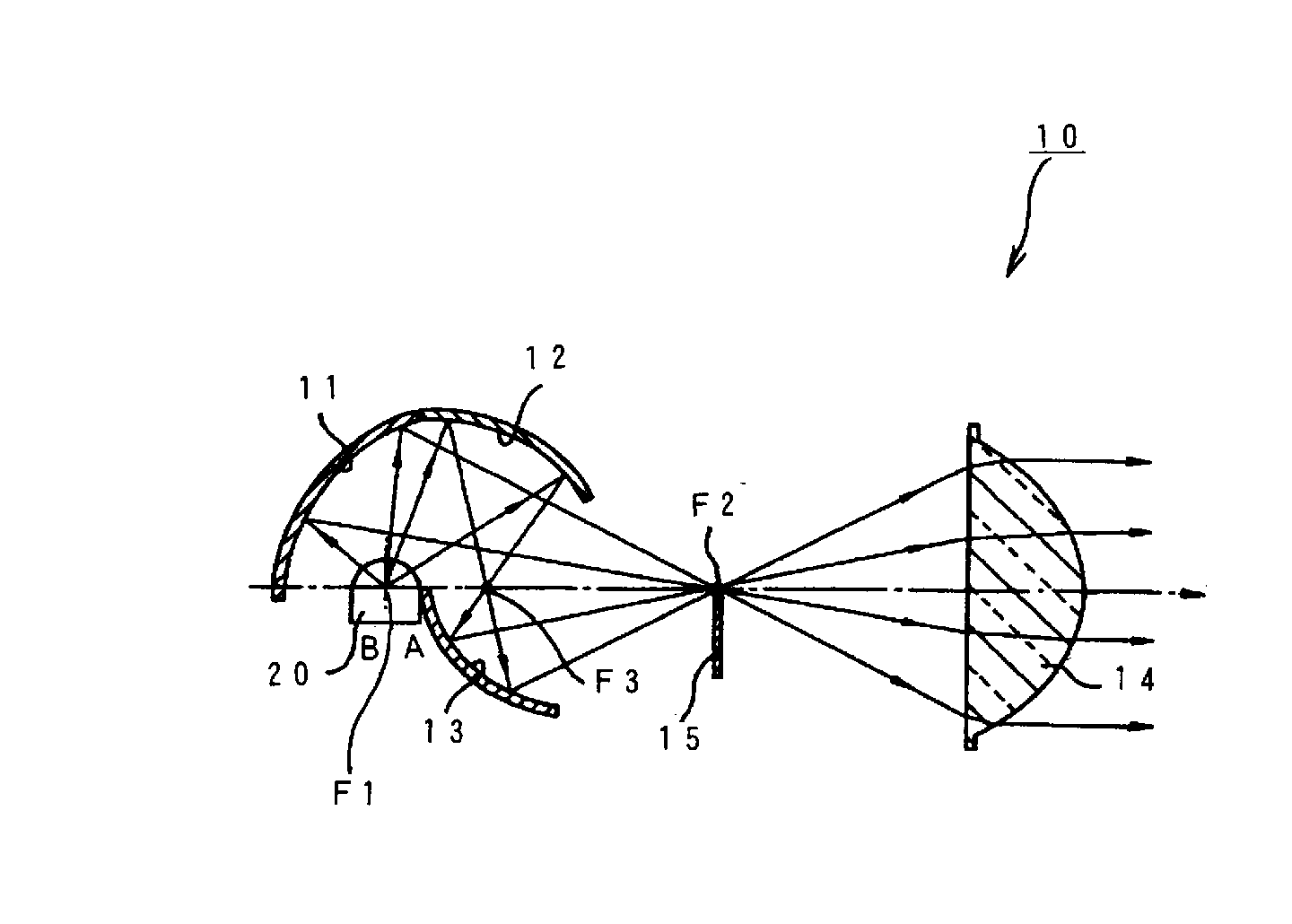

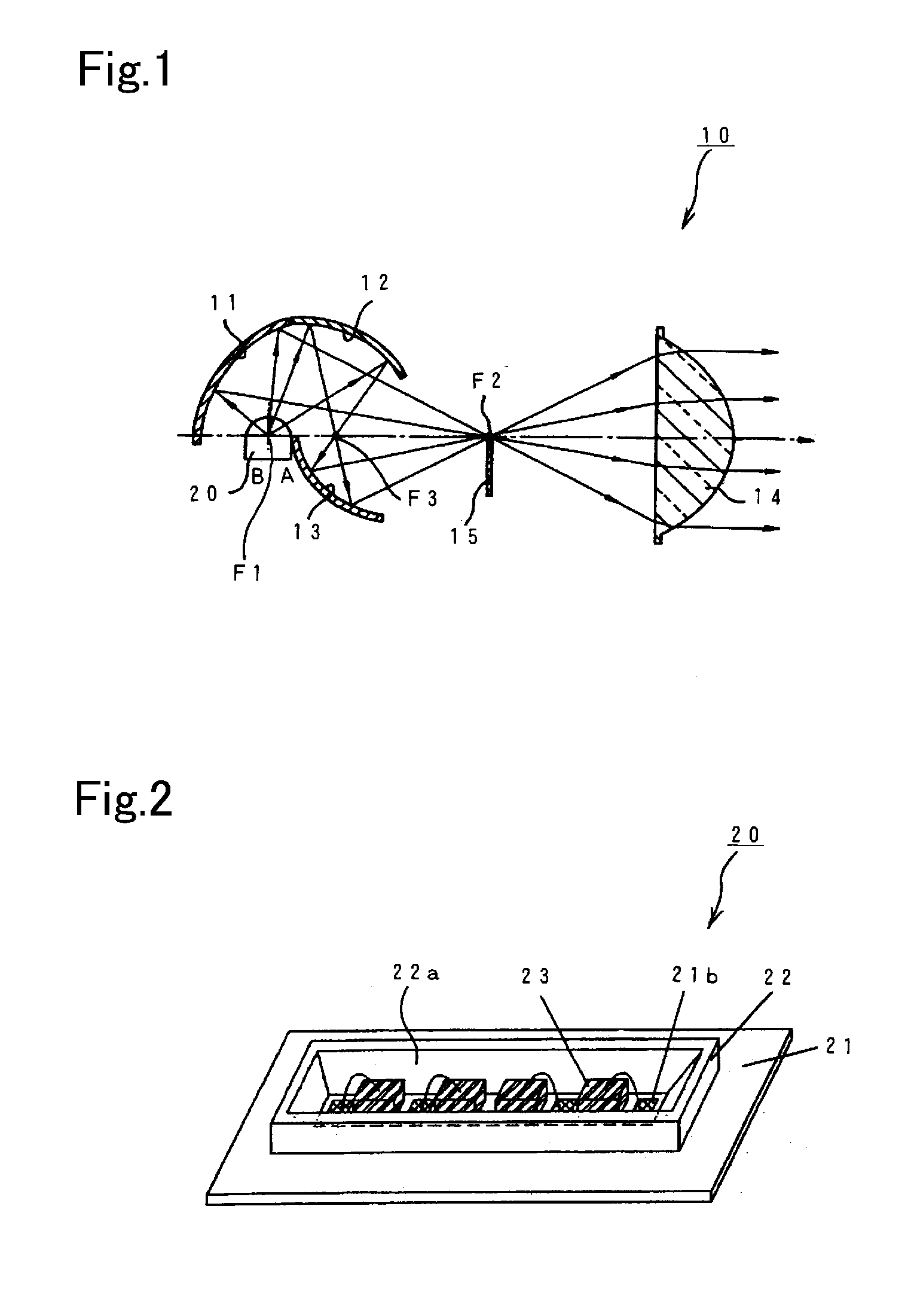

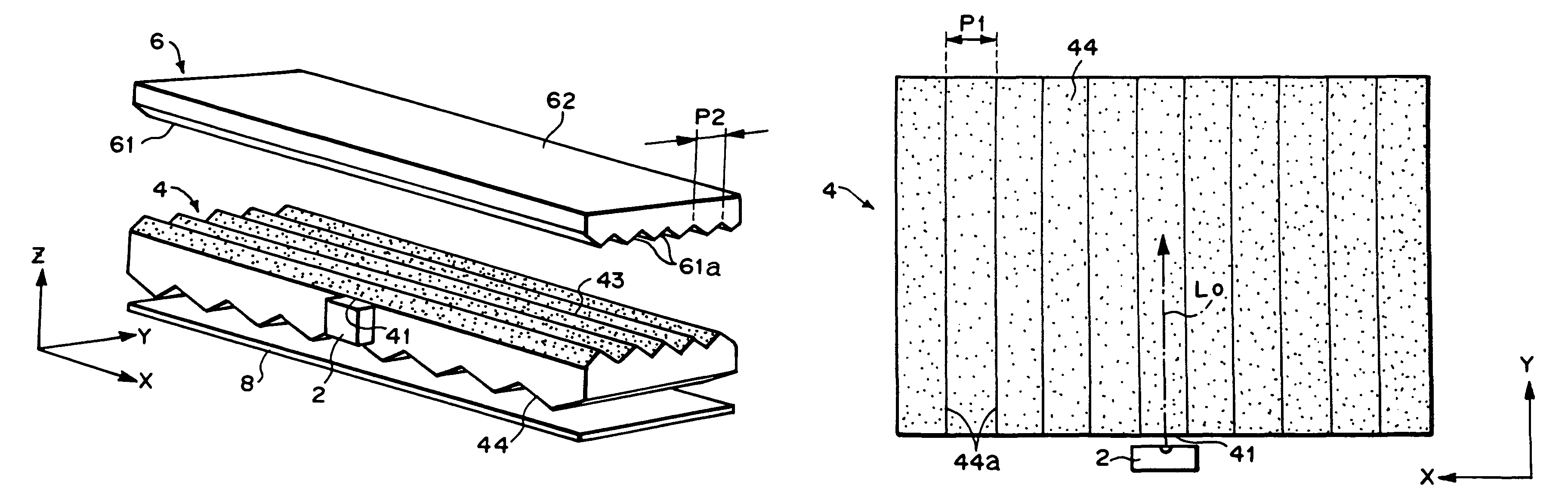

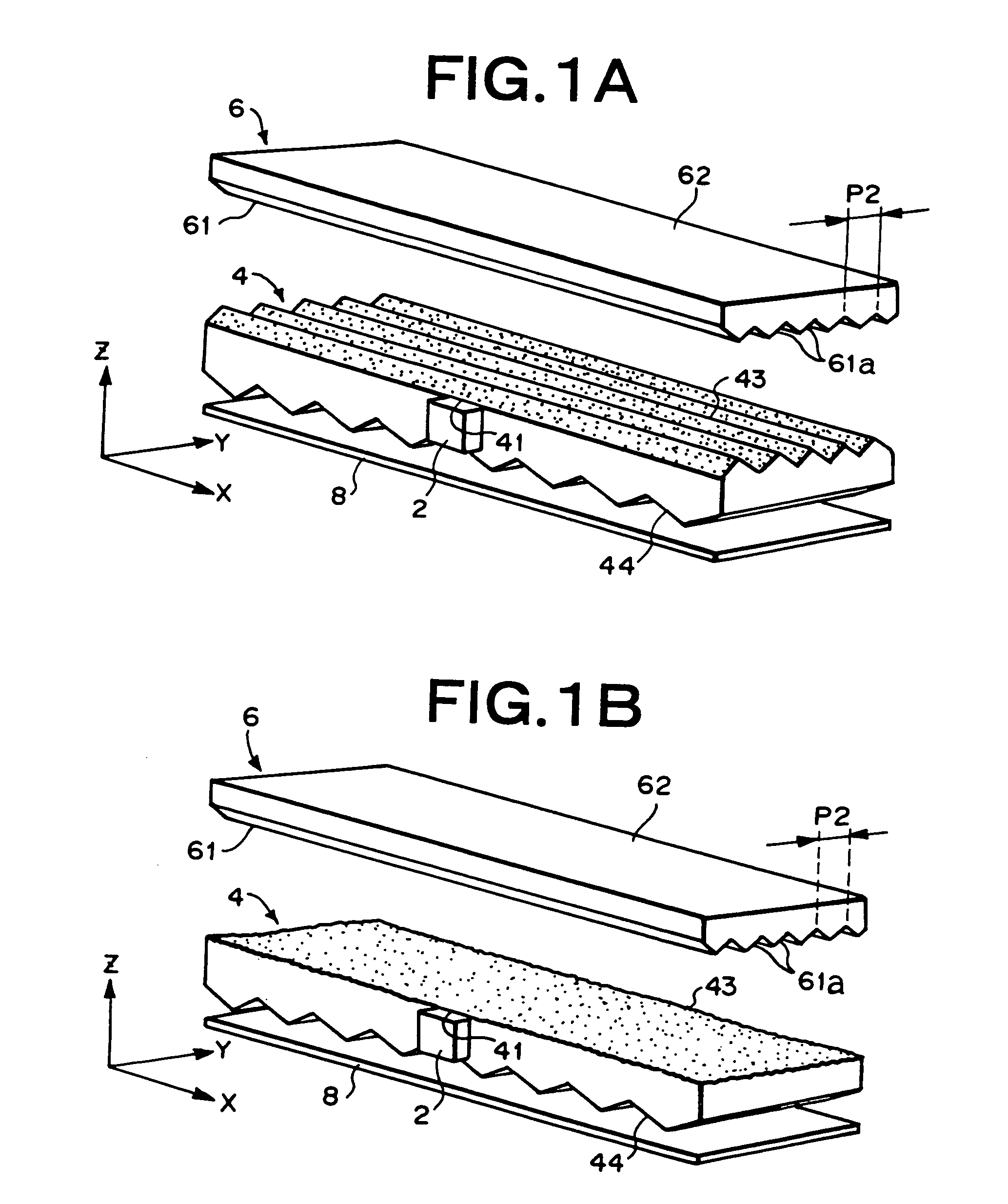

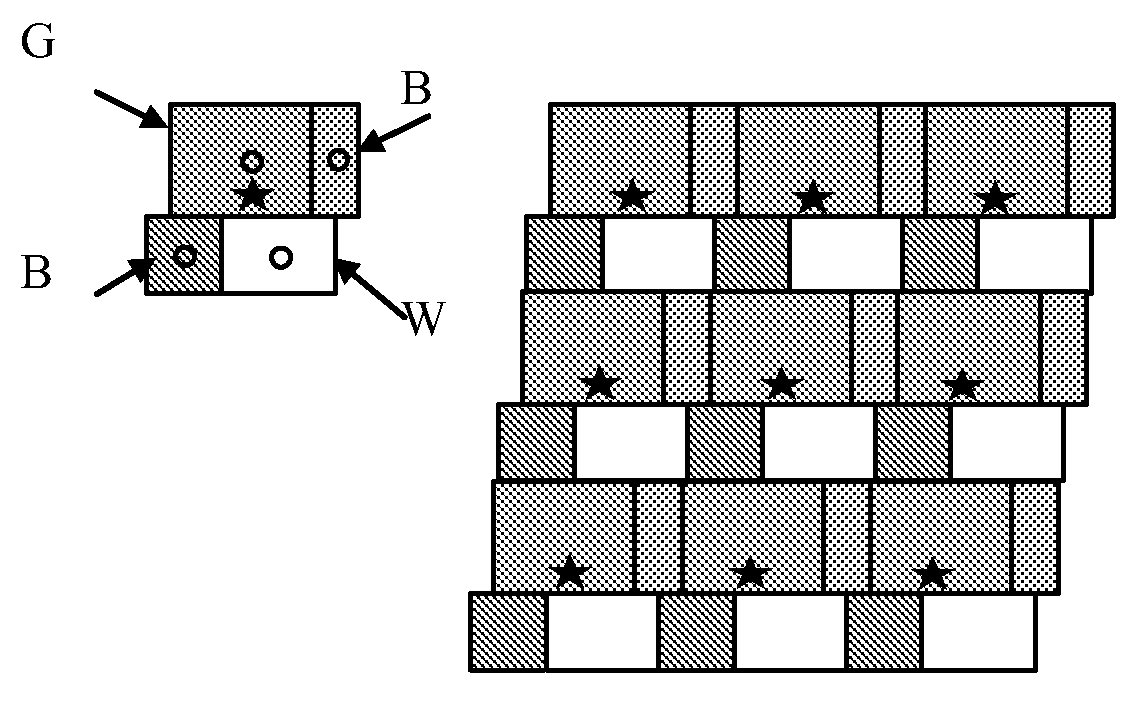

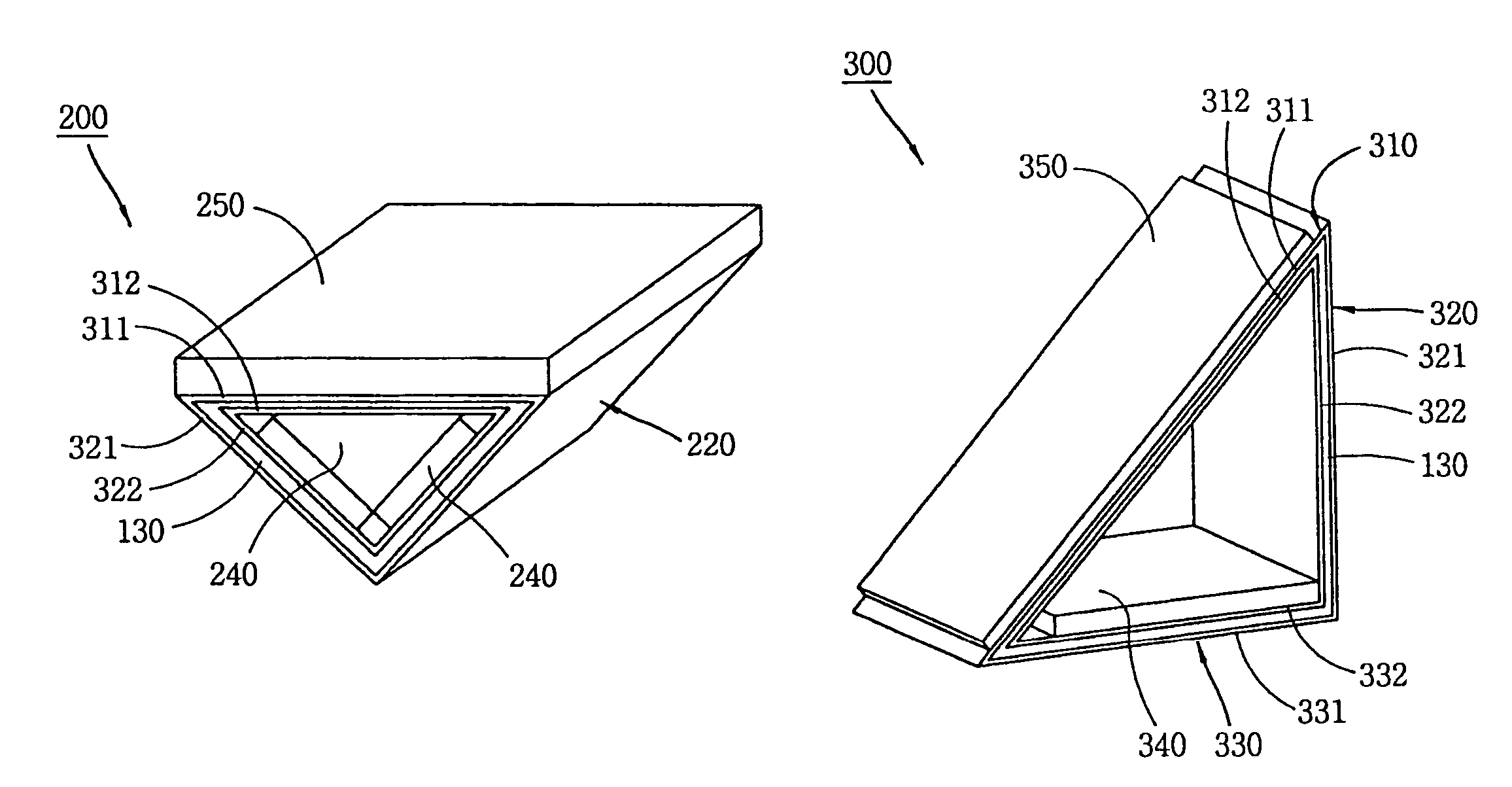

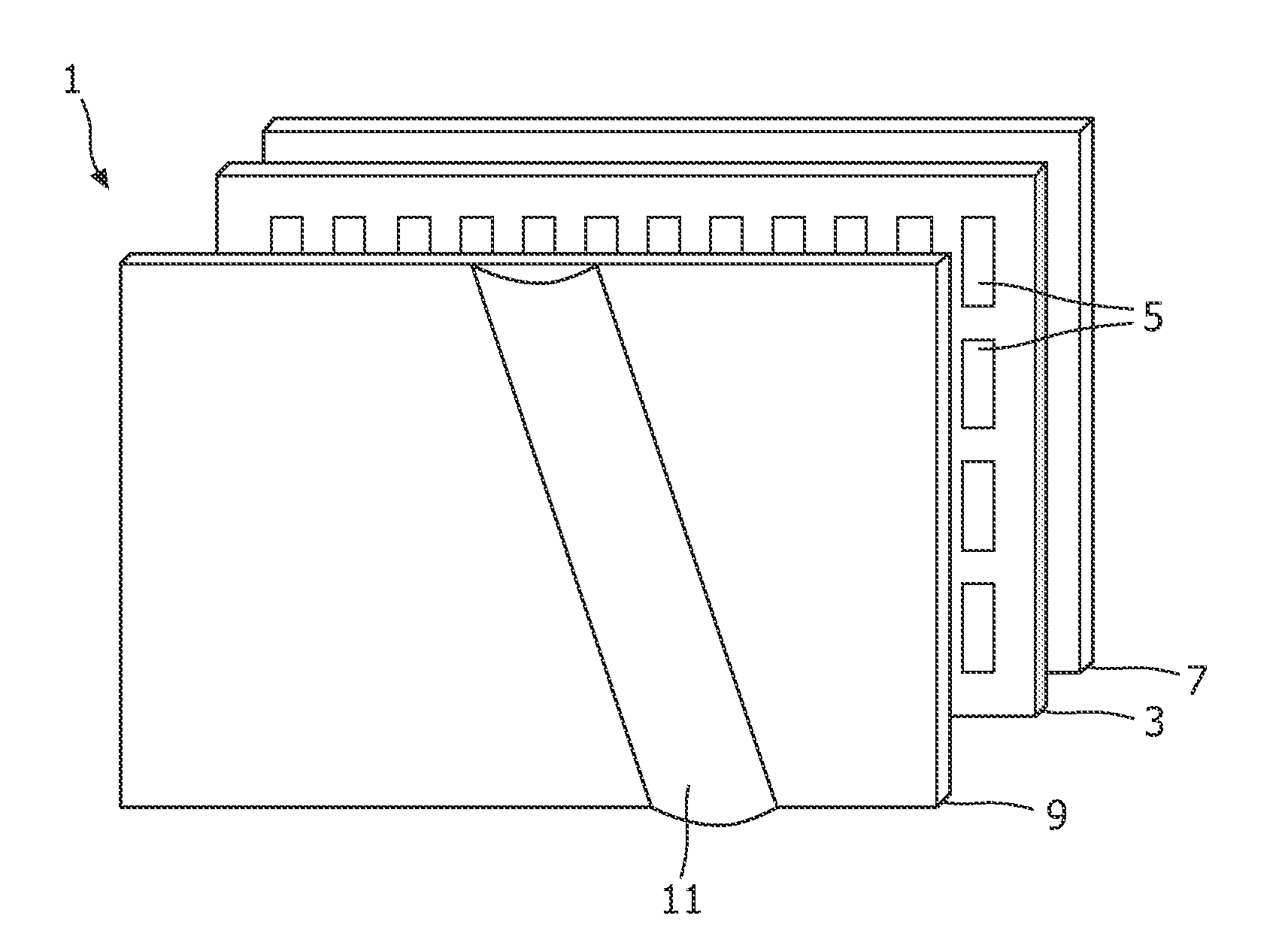

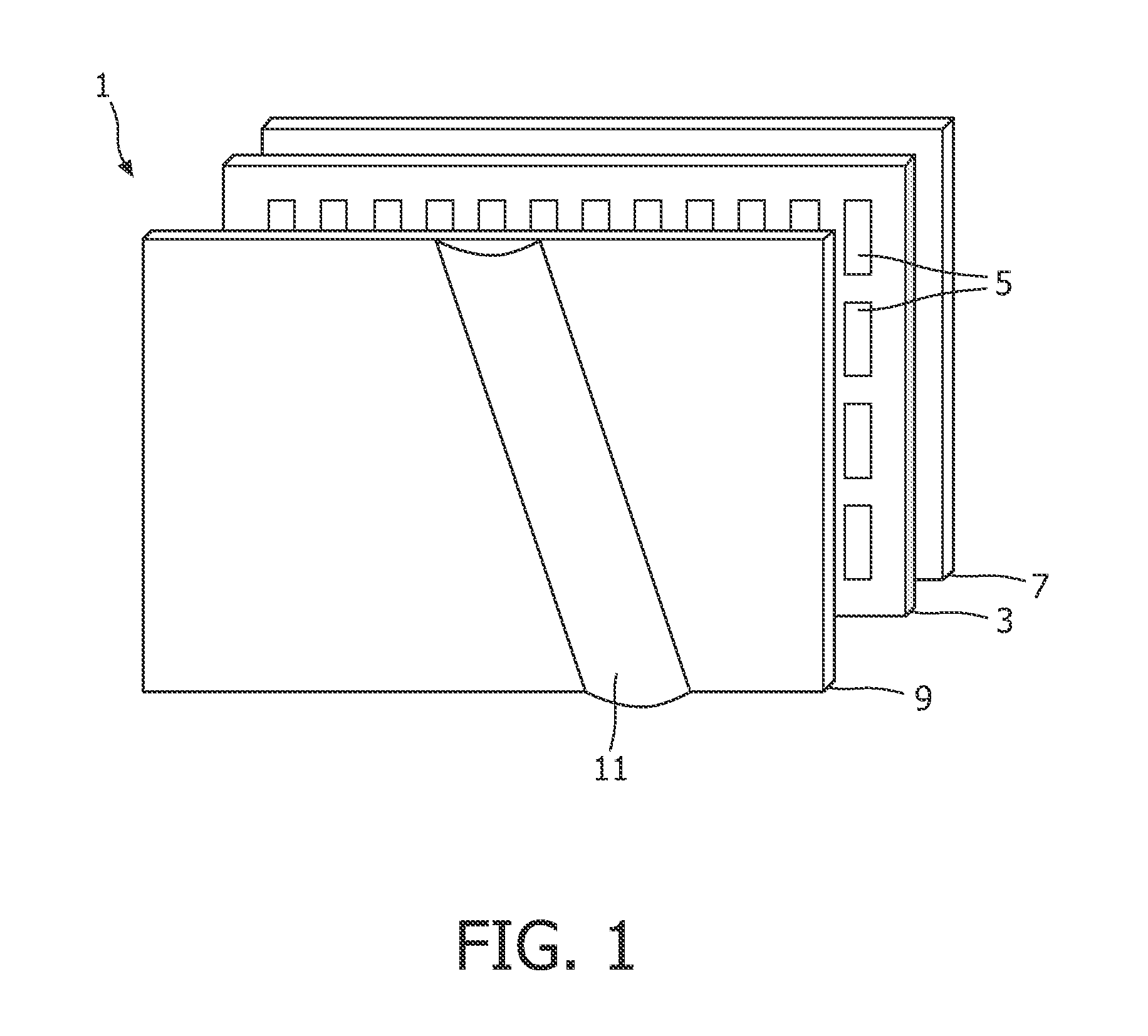

Optical device and image display apparatus

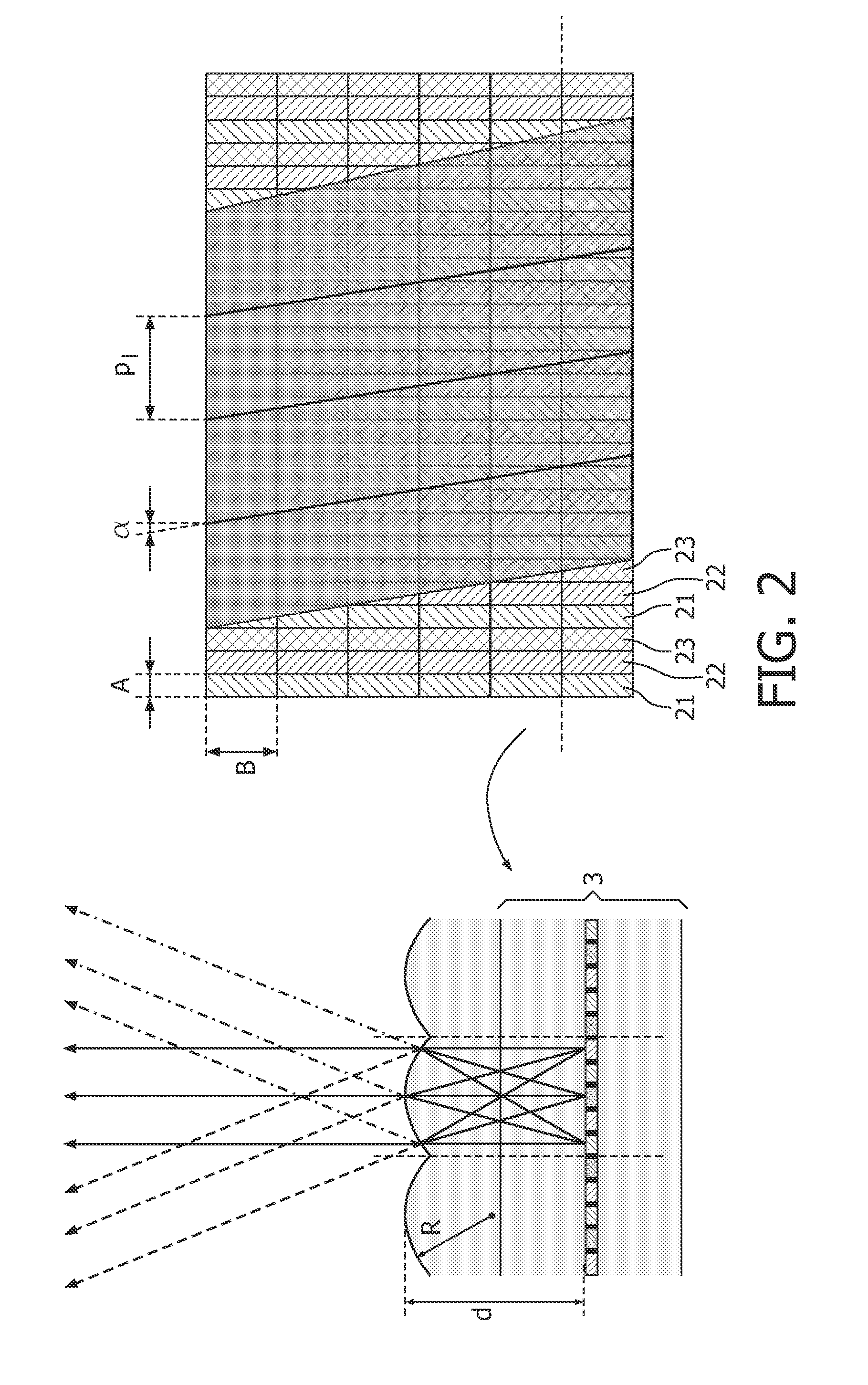

InactiveUS20070070504A1Increase rangeReduce thicknessDiffraction gratingsOptical light guidesLight guideSlant angle

An optical device includes a light guide plate, and first and second reflective volume hologram diffraction grating members. The first member has interference fringes extending from therewithin towards surfaces thereof and arranged at an equal pitch. Each interference fringe and each surface of the first member form an inclination angle therebetween. The first member has the following conditions. (a) In an outer region positioned farther away from the second member than a minimum inclination angle region having a minimum inclination angle, the inclination angles of the interference fringes increase with increasing distance from the minimum inclination angle region. (b) In an inner region positioned closer to the second member than the minimum inclination angle region, the inclination angles of the interference fringes include a maximum inclination angle in an inner area disposed adjacent to the minimum inclination angle region and decrease with increasing distance from the minimum inclination angle region.

Owner:SONY CORP

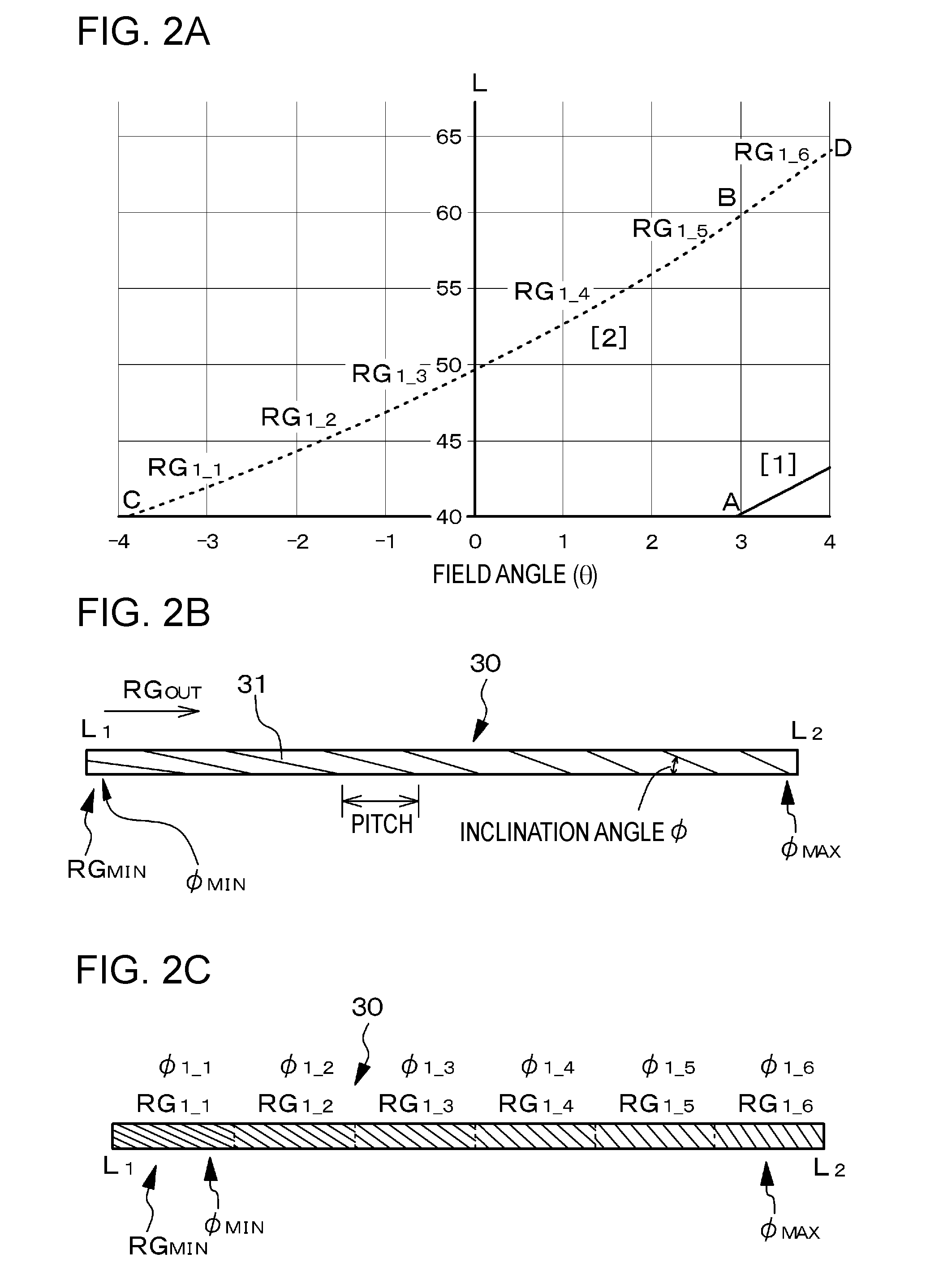

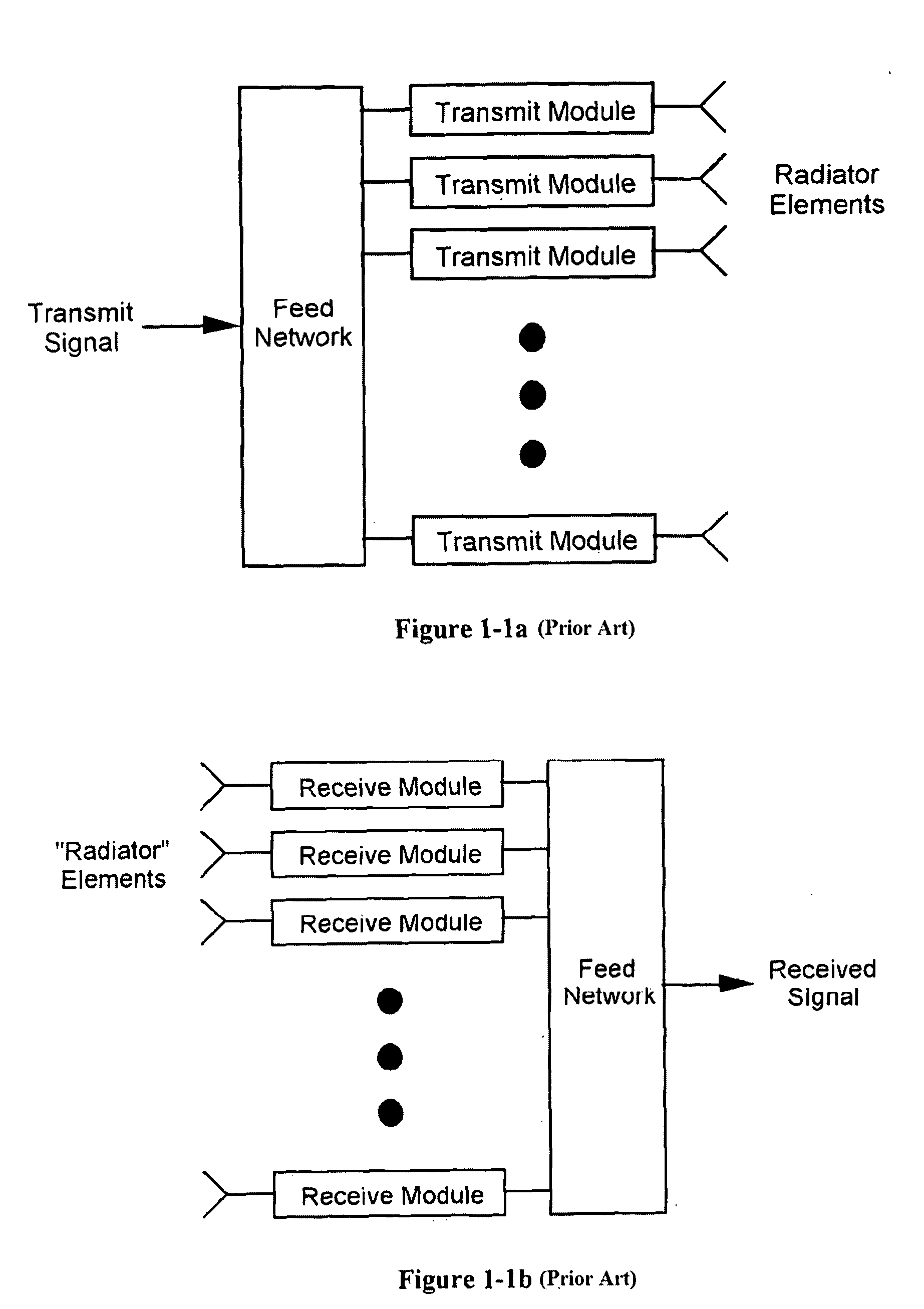

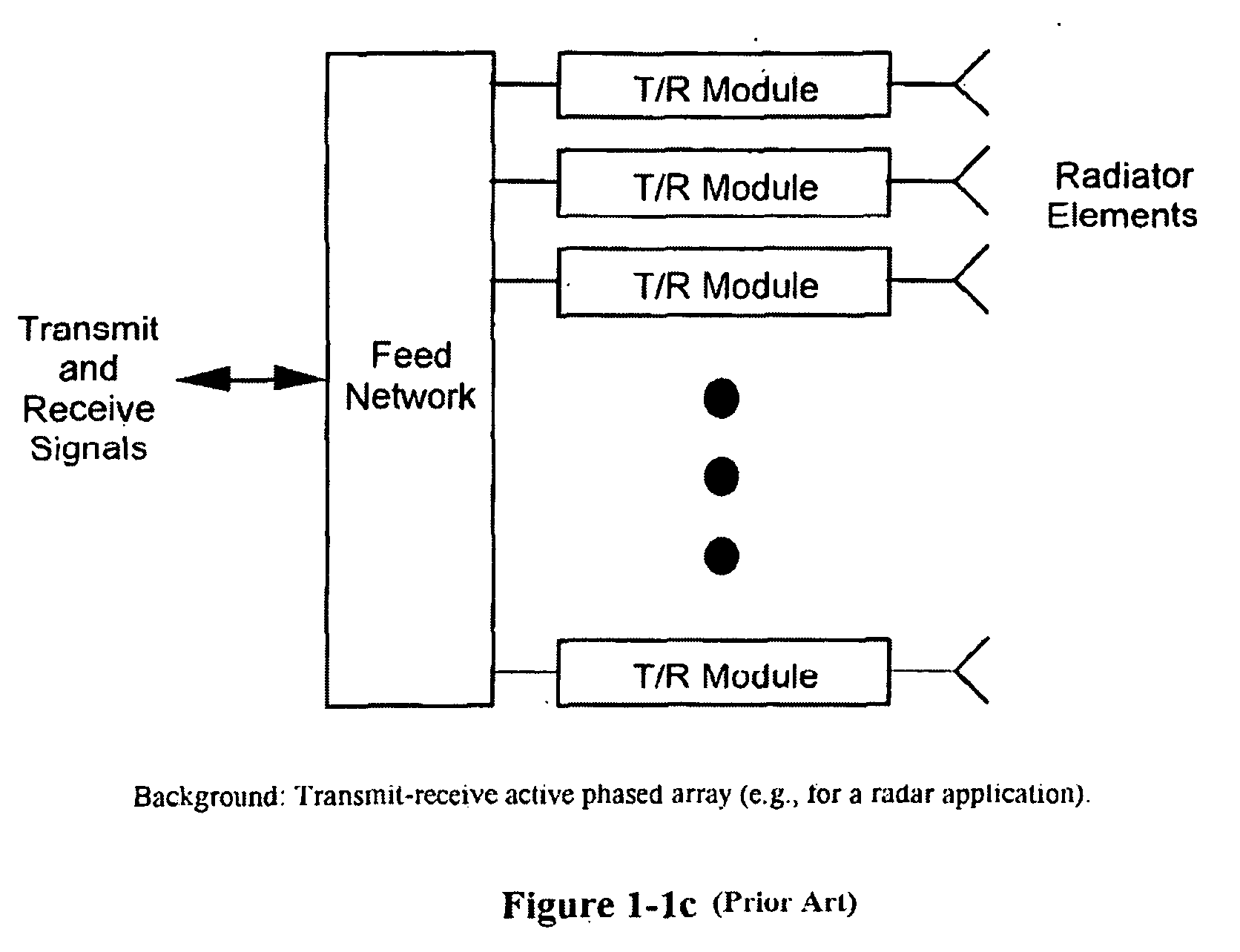

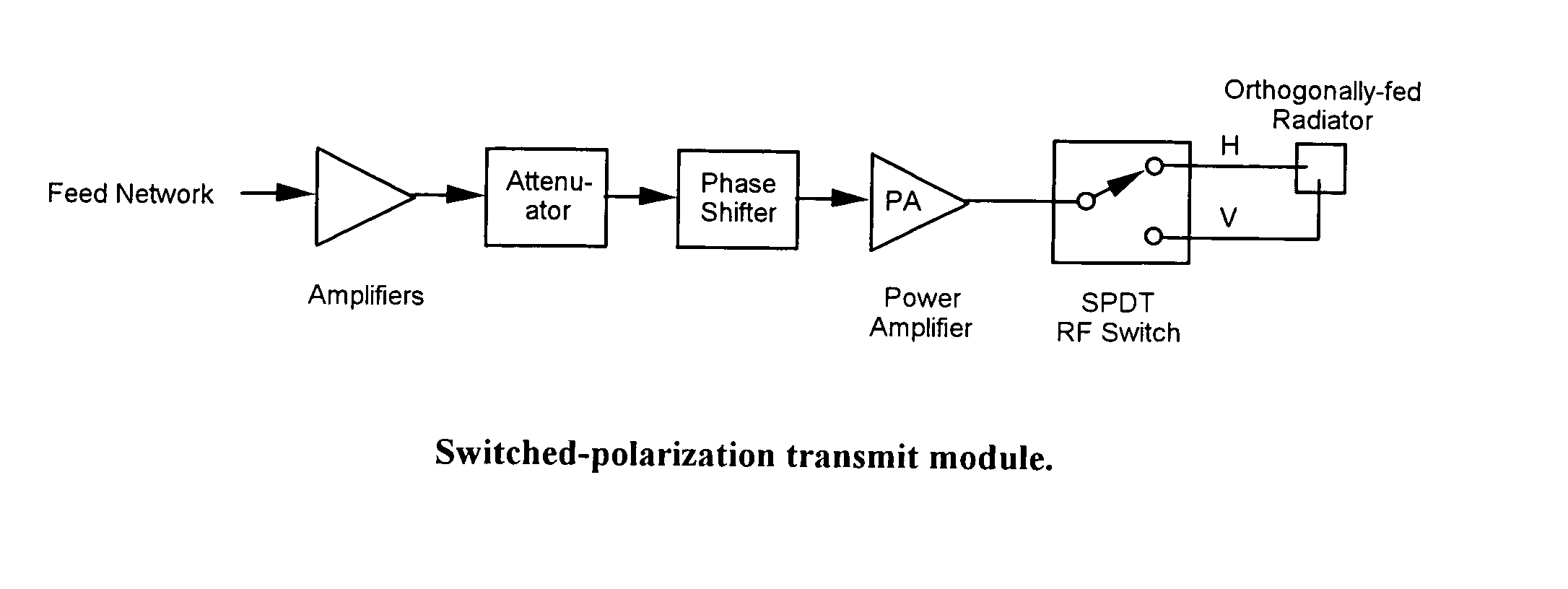

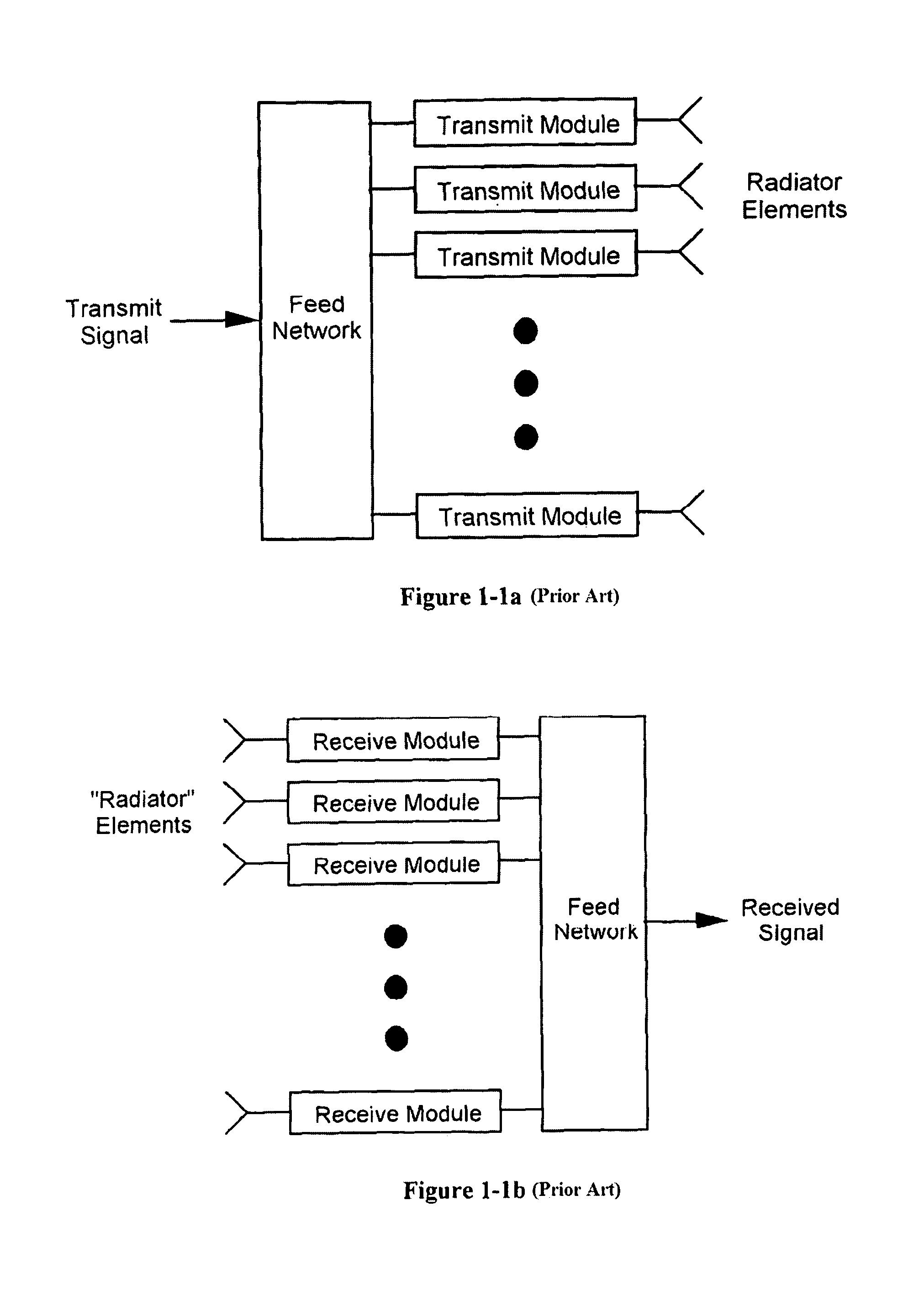

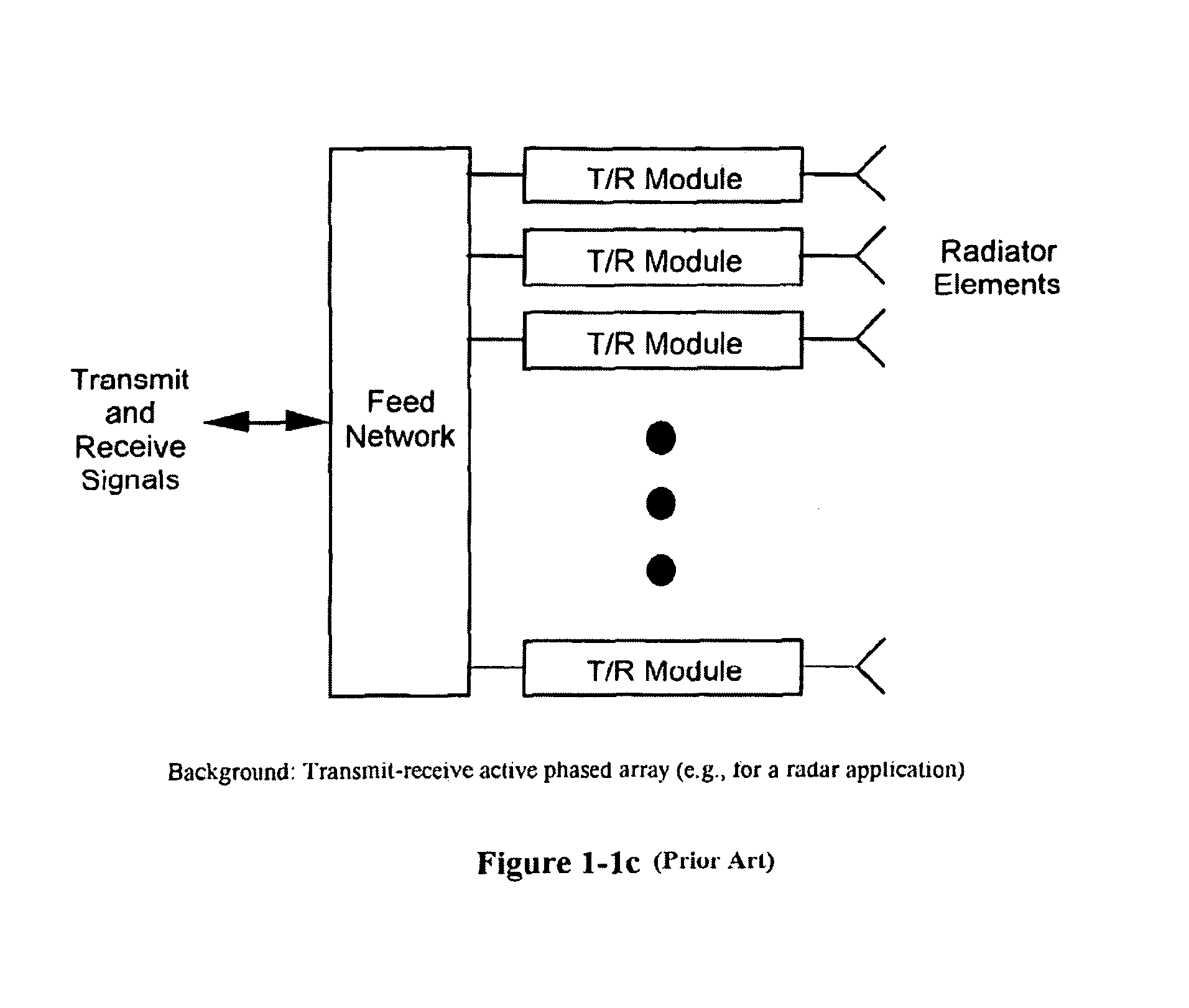

Device and method for polarization control for a phased array antenna

A method of configuring a phased array antenna having a plurality of radiators, each said radiator elements capable of radiating or receiving signals in one of two orthogonal polarizations determined to achieve a pseudo-random mix of horizontally and vertically polarized radiators. Upon switching of each of the radiator elements to a calculated one of said two polarizations, a desired slant angle for the antenna is achieved.

Owner:L 3 COMM TITAN CORP

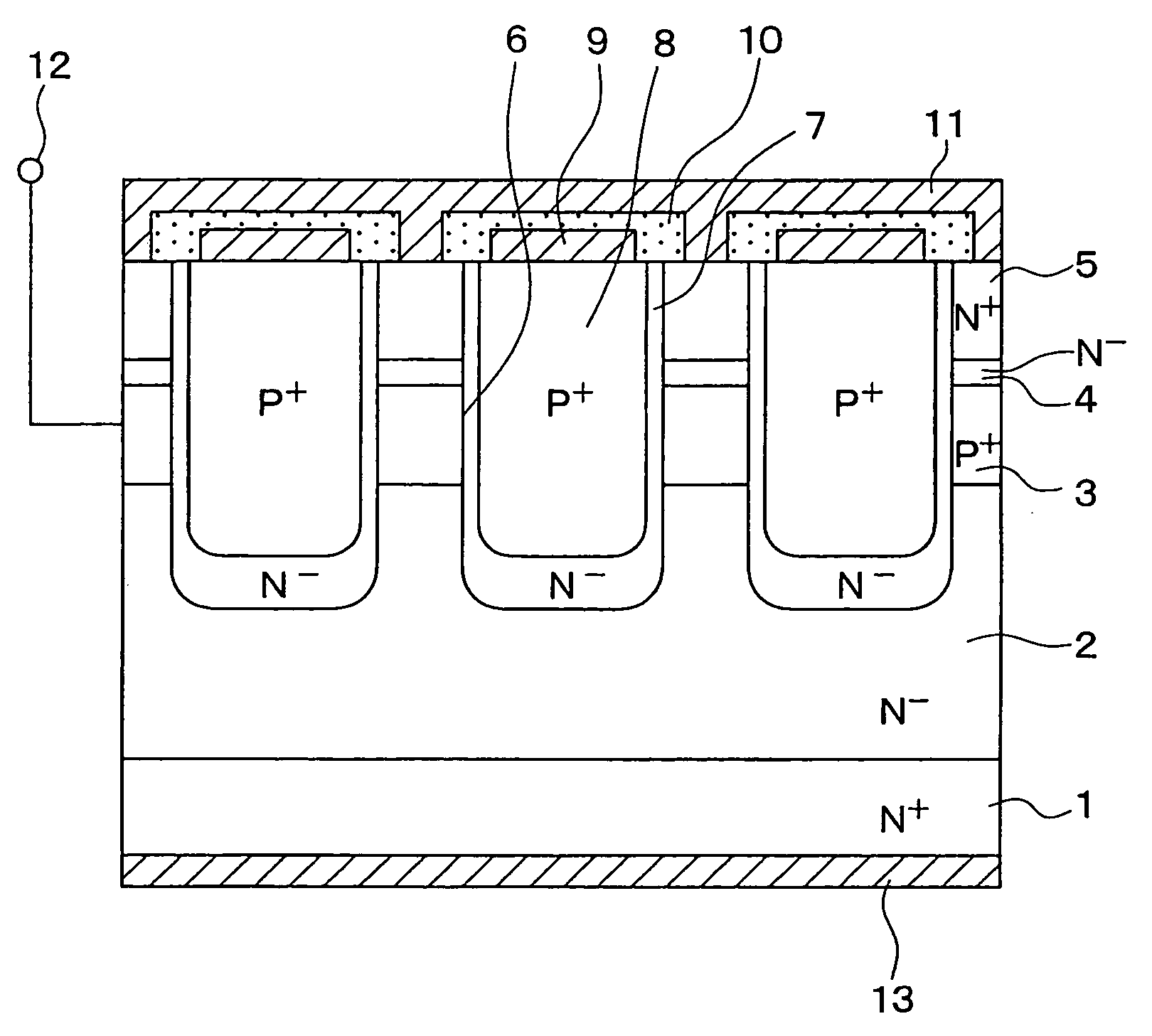

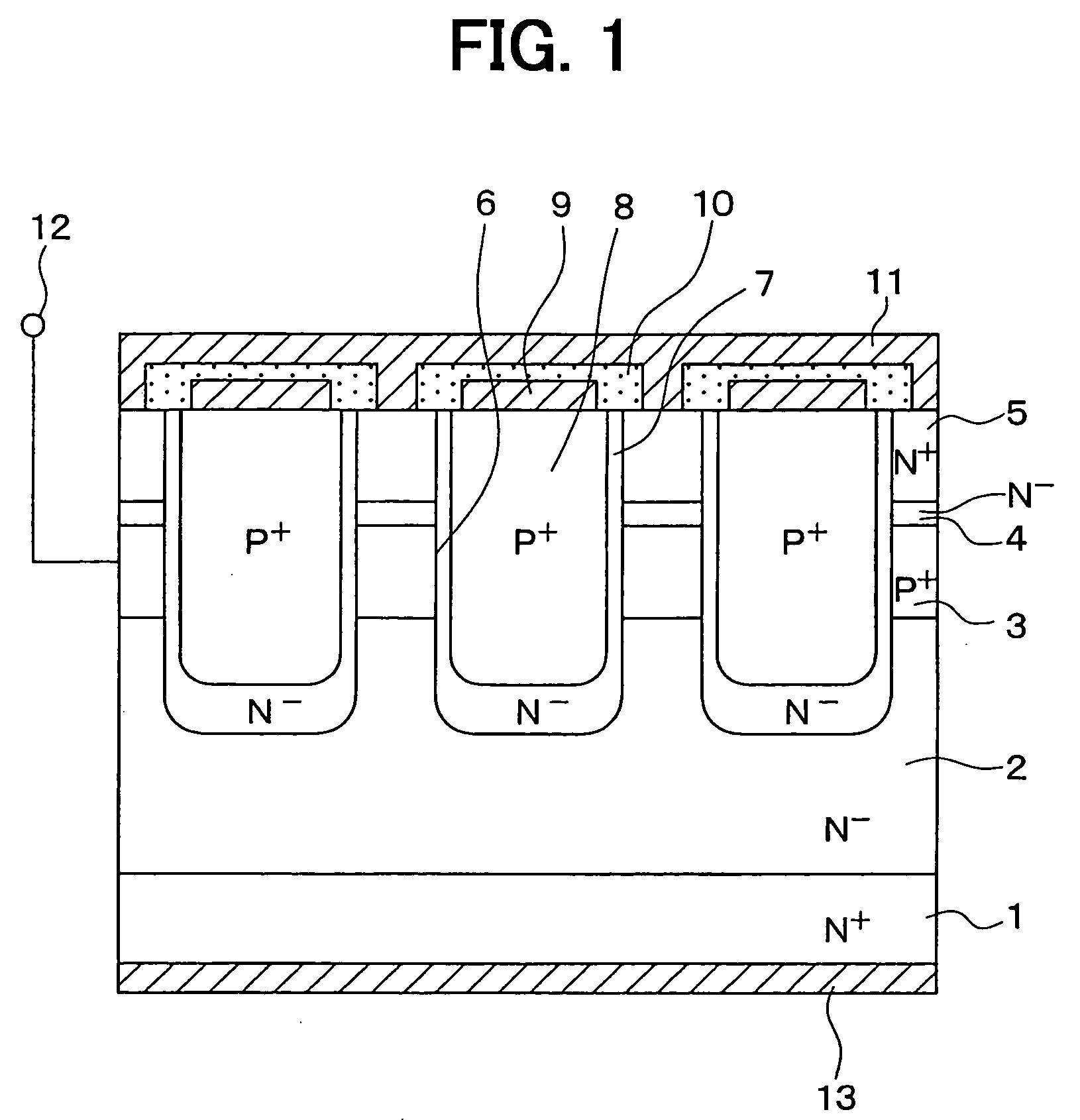

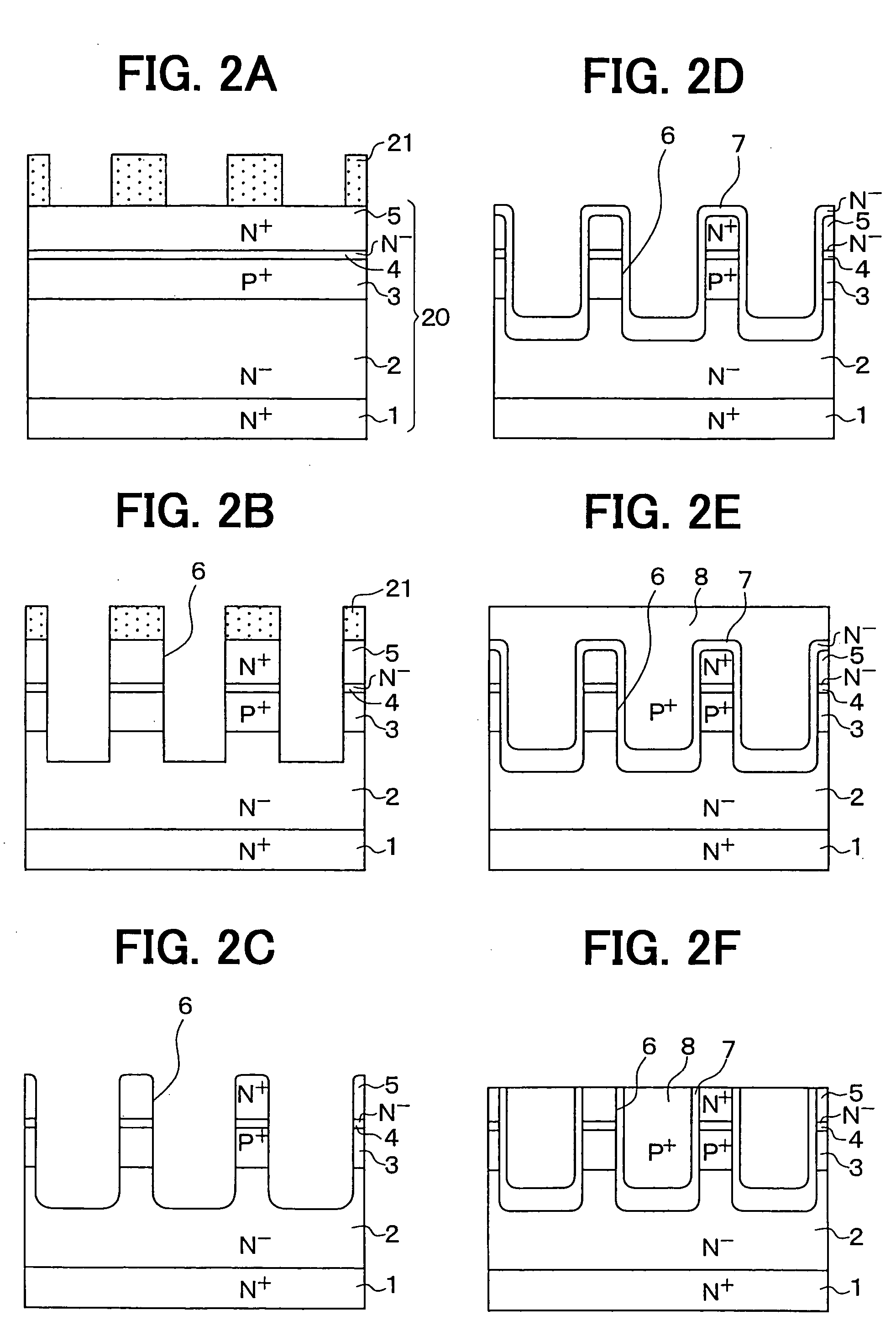

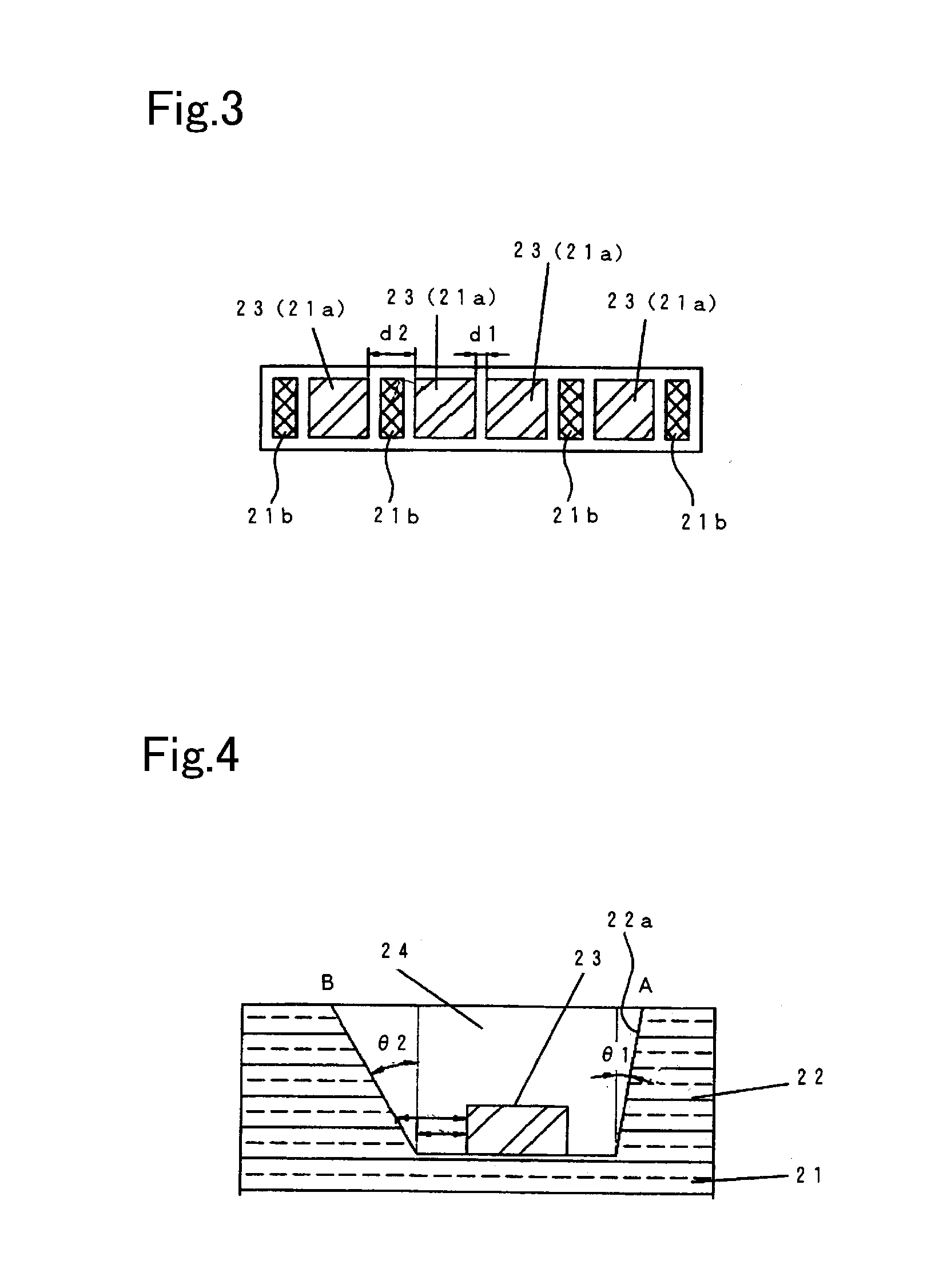

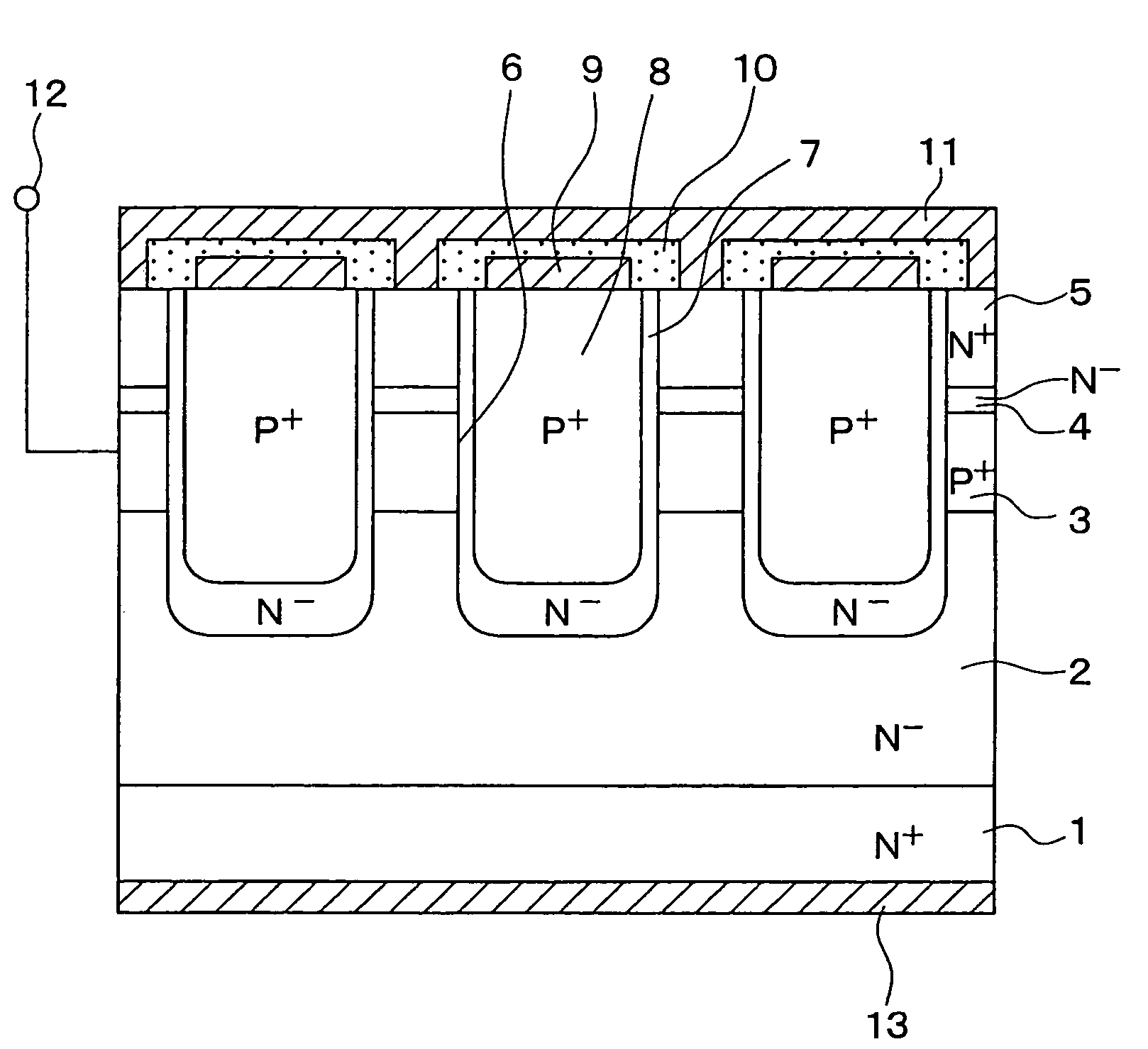

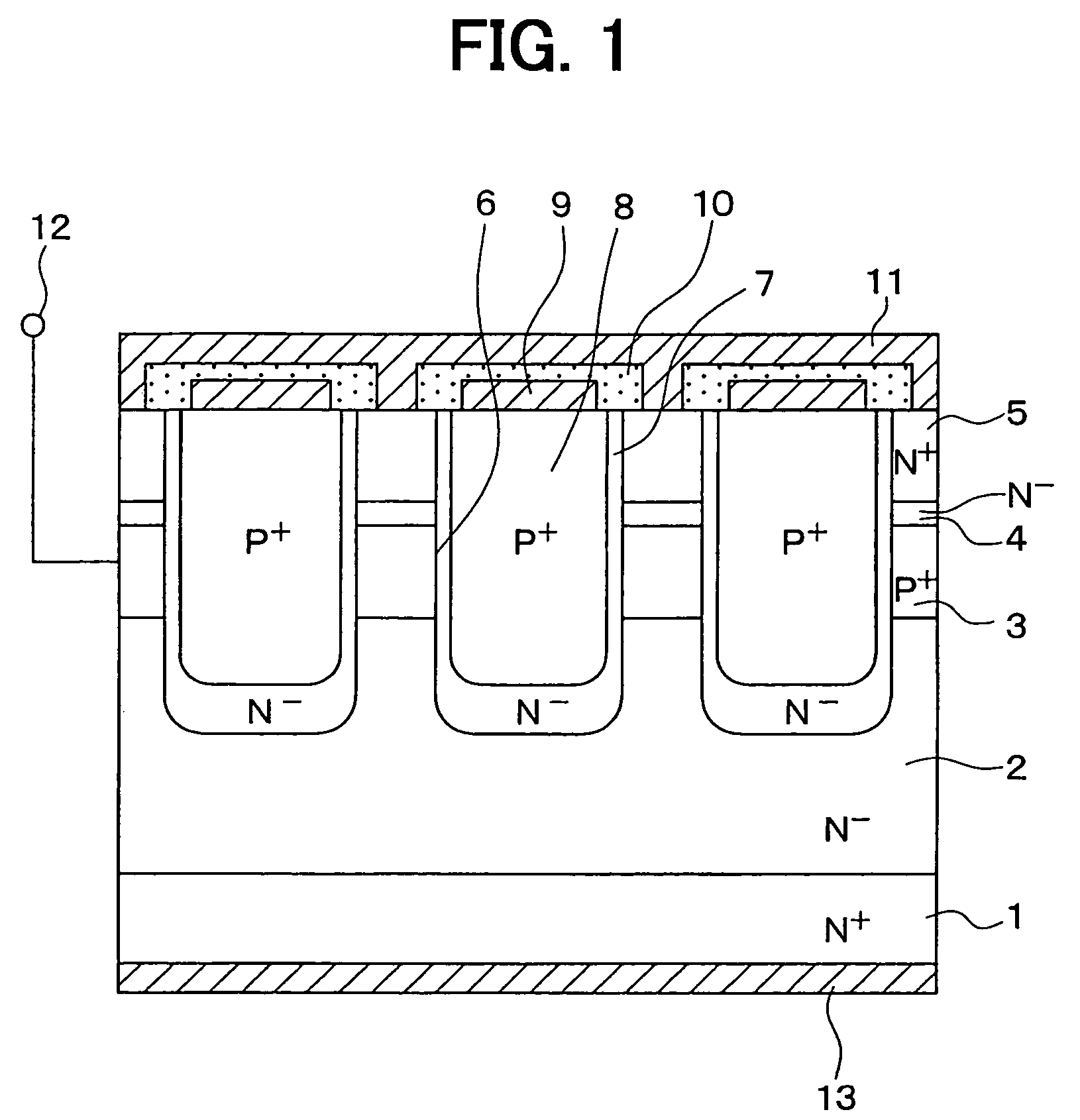

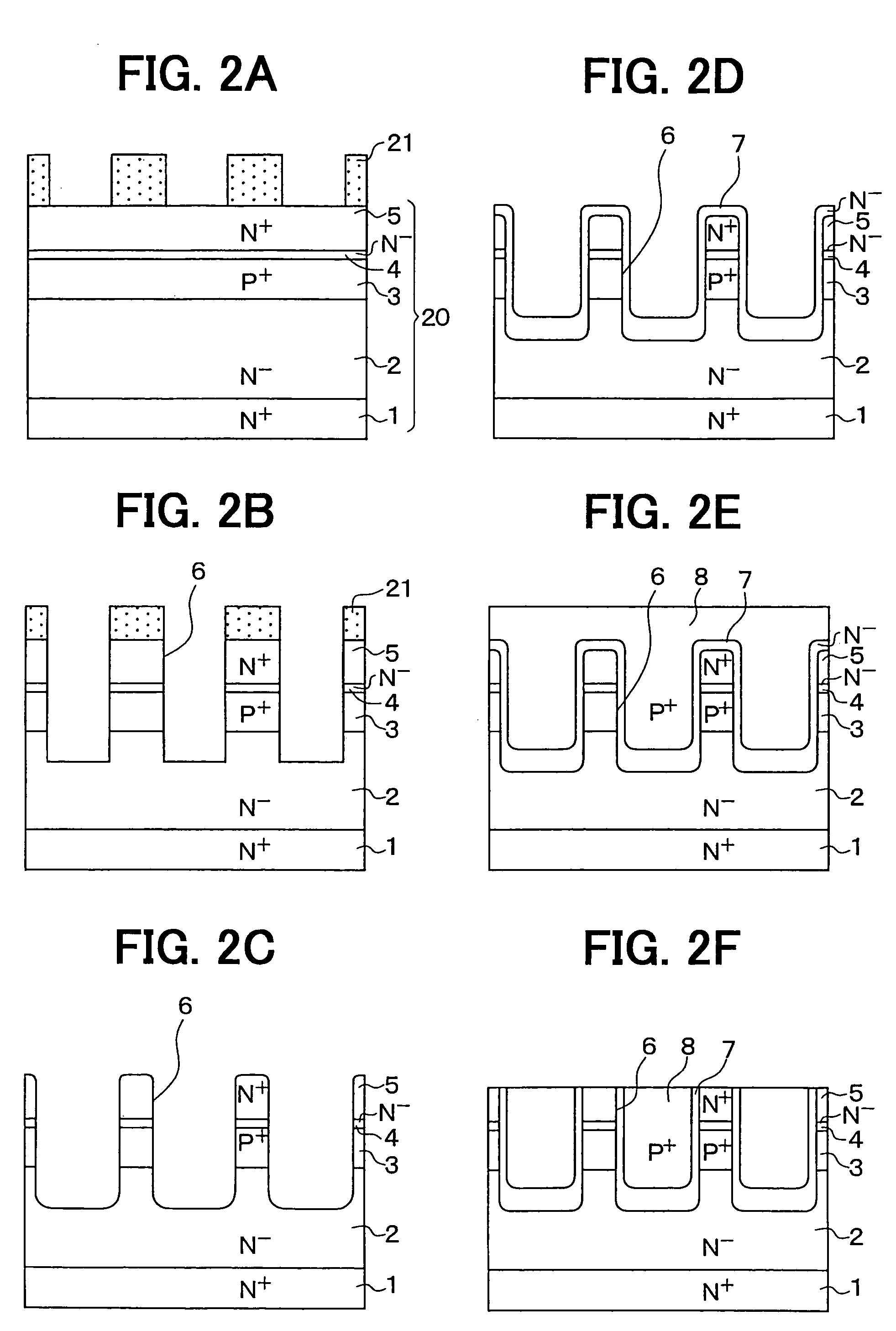

Method for manufacturing semiconductor device having trench in silicon carbide semiconductor substrate

ActiveUS20050233539A1Uniform shapeGood on-off performanceSemiconductor/solid-state device manufacturingFrom condensed vaporsSlant angleHydrogen atmosphere

A method for manufacturing a silicon carbide semiconductor device includes the steps of: forming a trench mask on an upper surface of a semiconductor substrate; forming the trench such that the trench having an aspect ratio equal to or larger than 2 and having a trench slanting angle equal to or larger than 80 degrees is formed; and removing a damage portion in such a manner that the damage portion disposed on an inner surface of the trench formed in the semiconductor substrate in the step of forming the trench is etched and removed in hydrogen atmosphere under decompression pressure at a temperature equal to or higher than 1600° C.

Owner:DENSO CORP

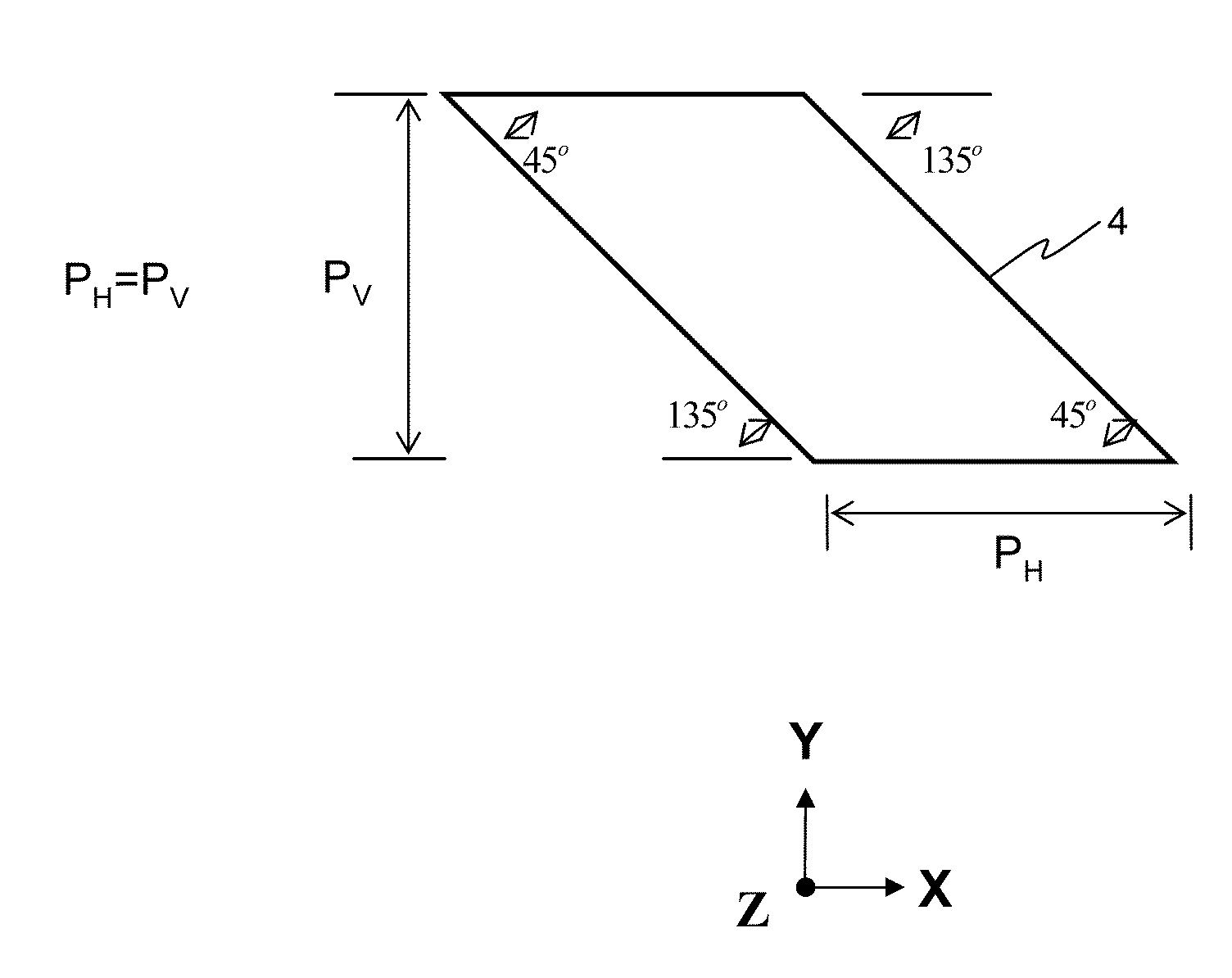

Dual-directional 3D image displaying method

The present invention relates to a dual-directional 3D image displaying method, being used in a case when a flat-panel display screen and a view separation device are used for dual-directional 3D image displaying, which comprises the steps of: using a display screen having a sub-pixel arrangement of 45-degree slant angle to display a multi-view 3D combined image; and using a view separation device featured by a 45-degree slant angle to perform a view separation operation upon the multi-view 3D combined image. Thereby, an object of dual-directional displaying of 3D images can be achieved using only one view separation device, without being bothered by conventional problems, such as cross-talk and color distortion.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

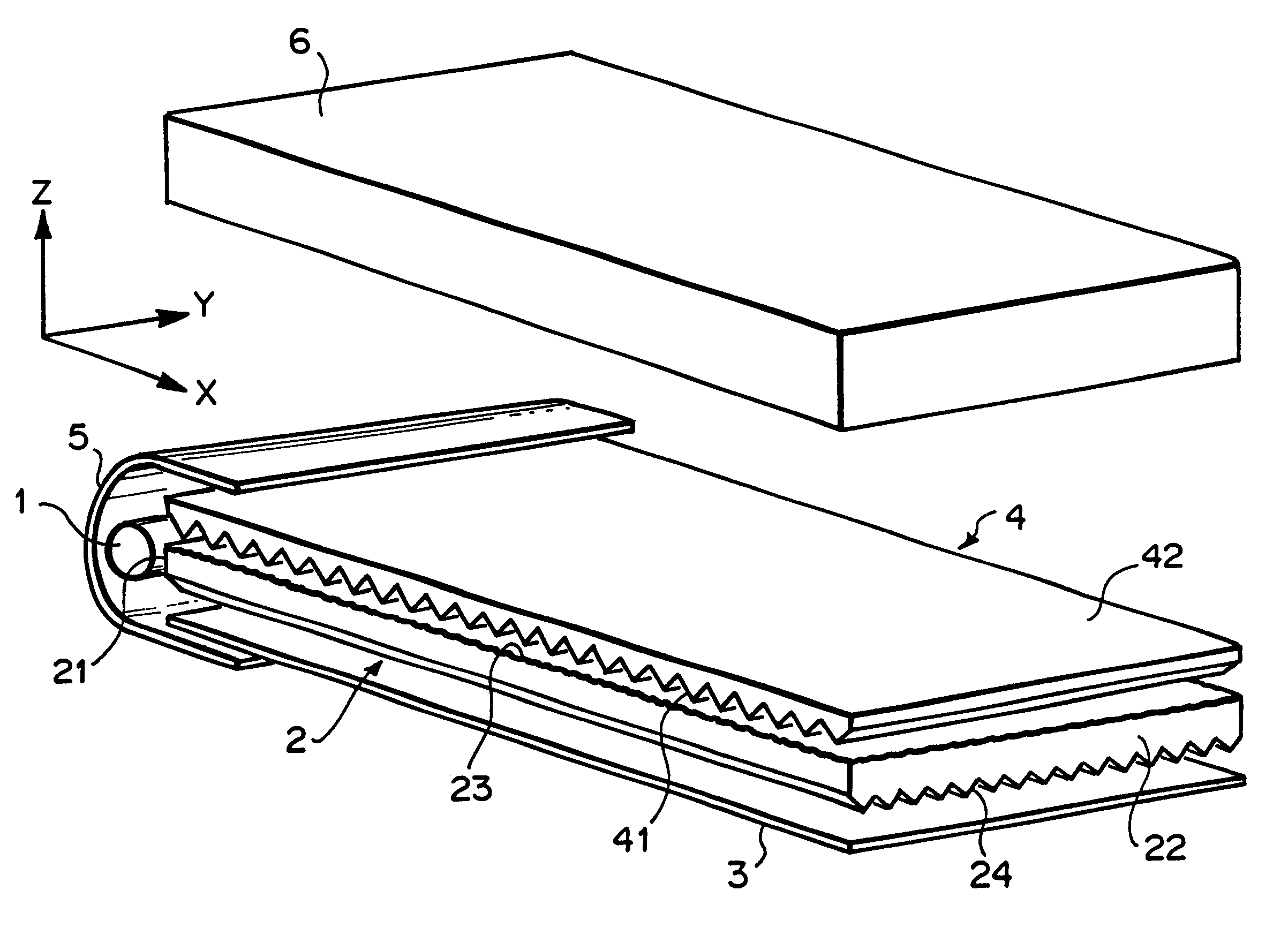

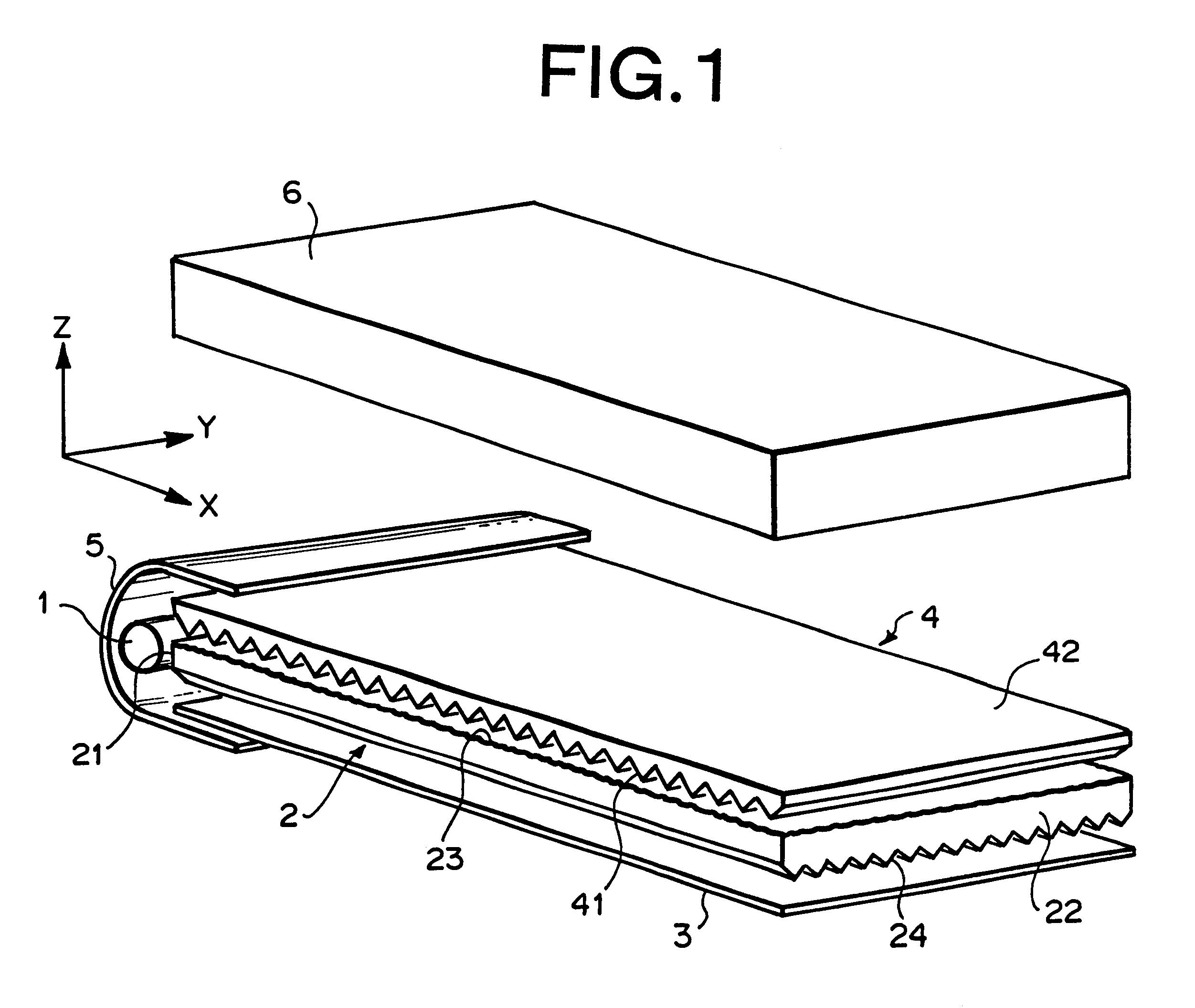

Planar light source device and liquid crystal display apparatus

InactiveUS6502947B2Measurement apparatus componentsMachines/enginesLiquid-crystal displayLight guide

Owner:MITSUBISHI RAYON CO LTD

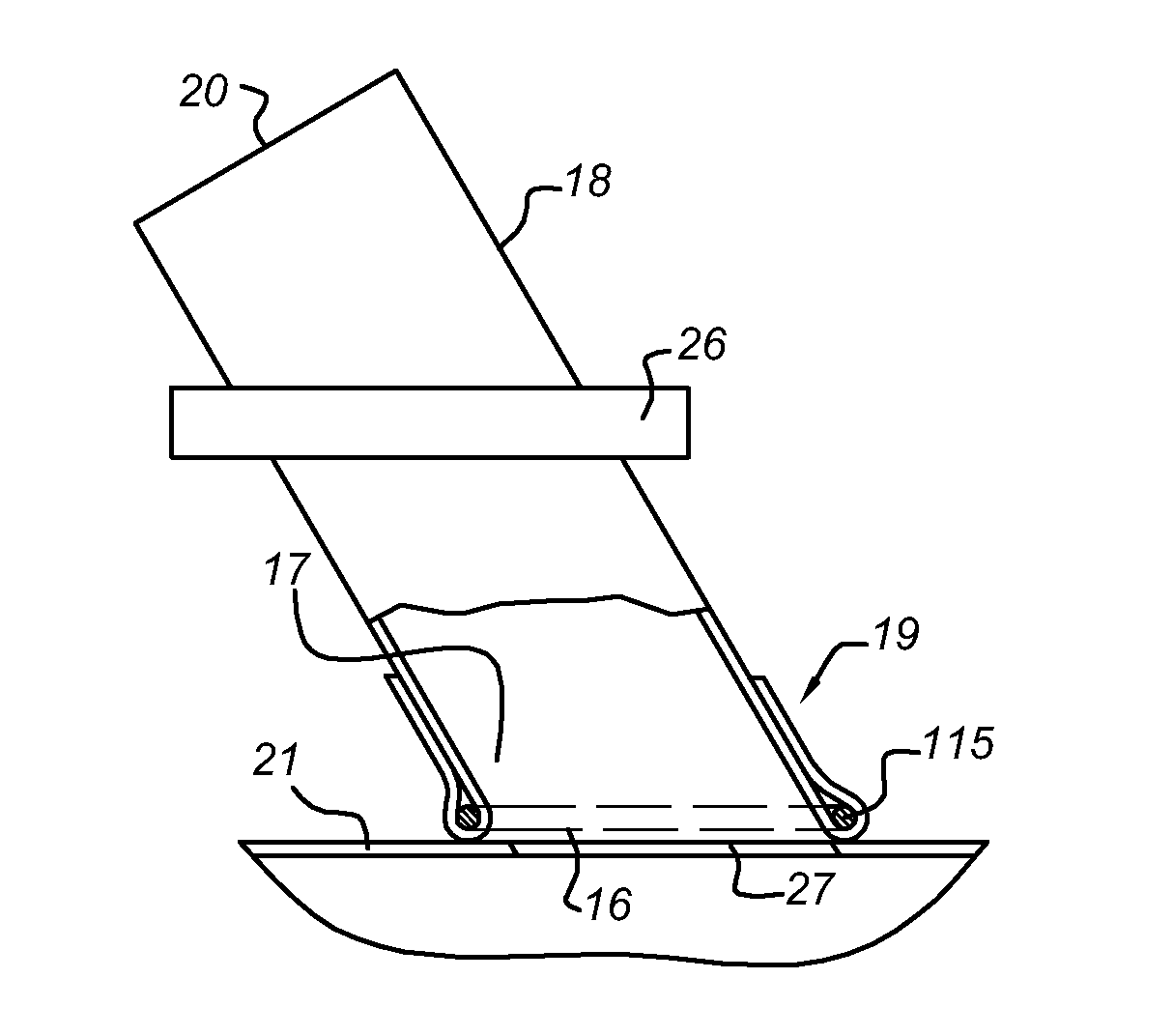

Laser catheter for bypass surgery and assembly comprising said catheter

ActiveUS20100331793A1Obstruct passageAvoid leaningCatheterSurgical instrument detailsSlant angleLight beam

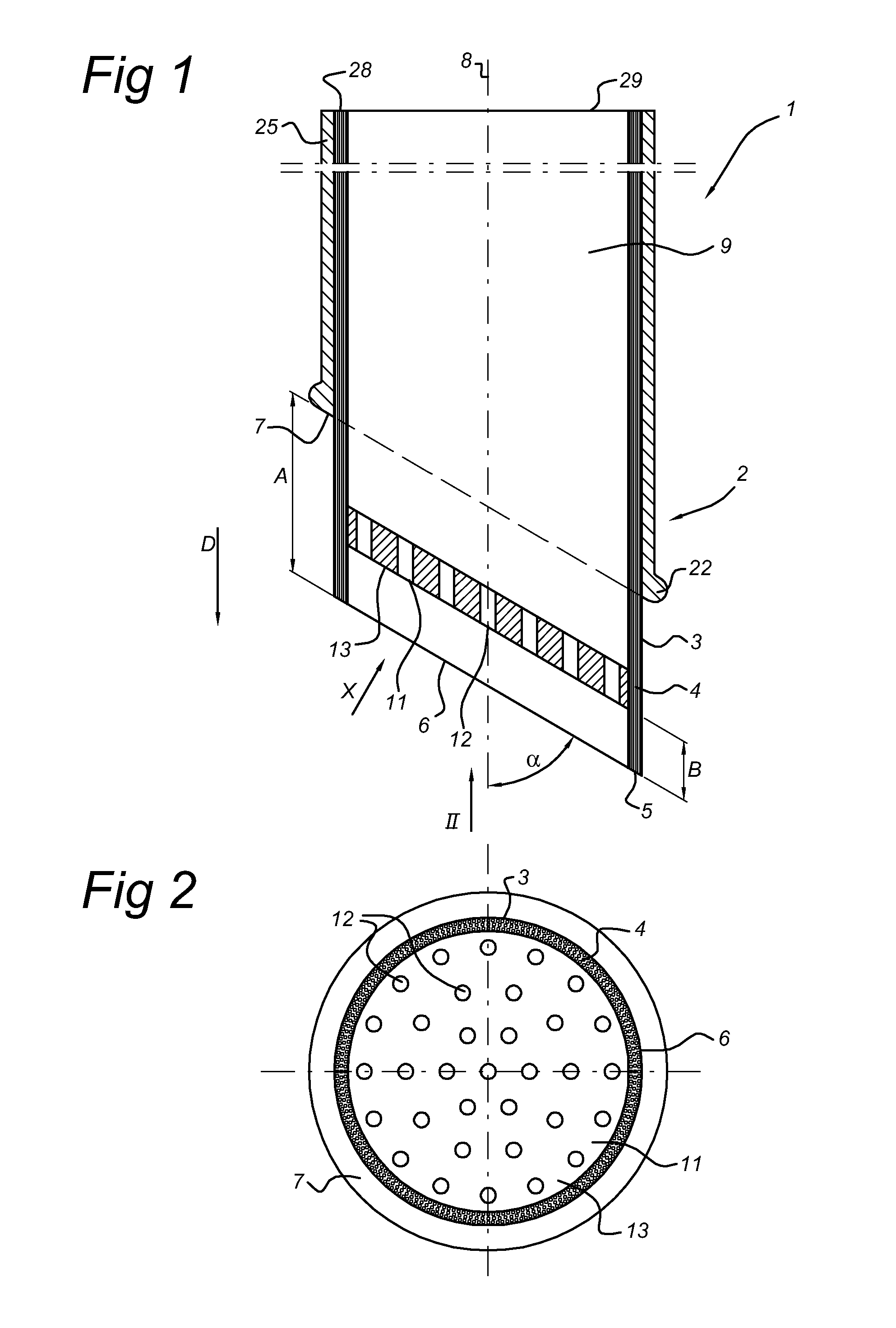

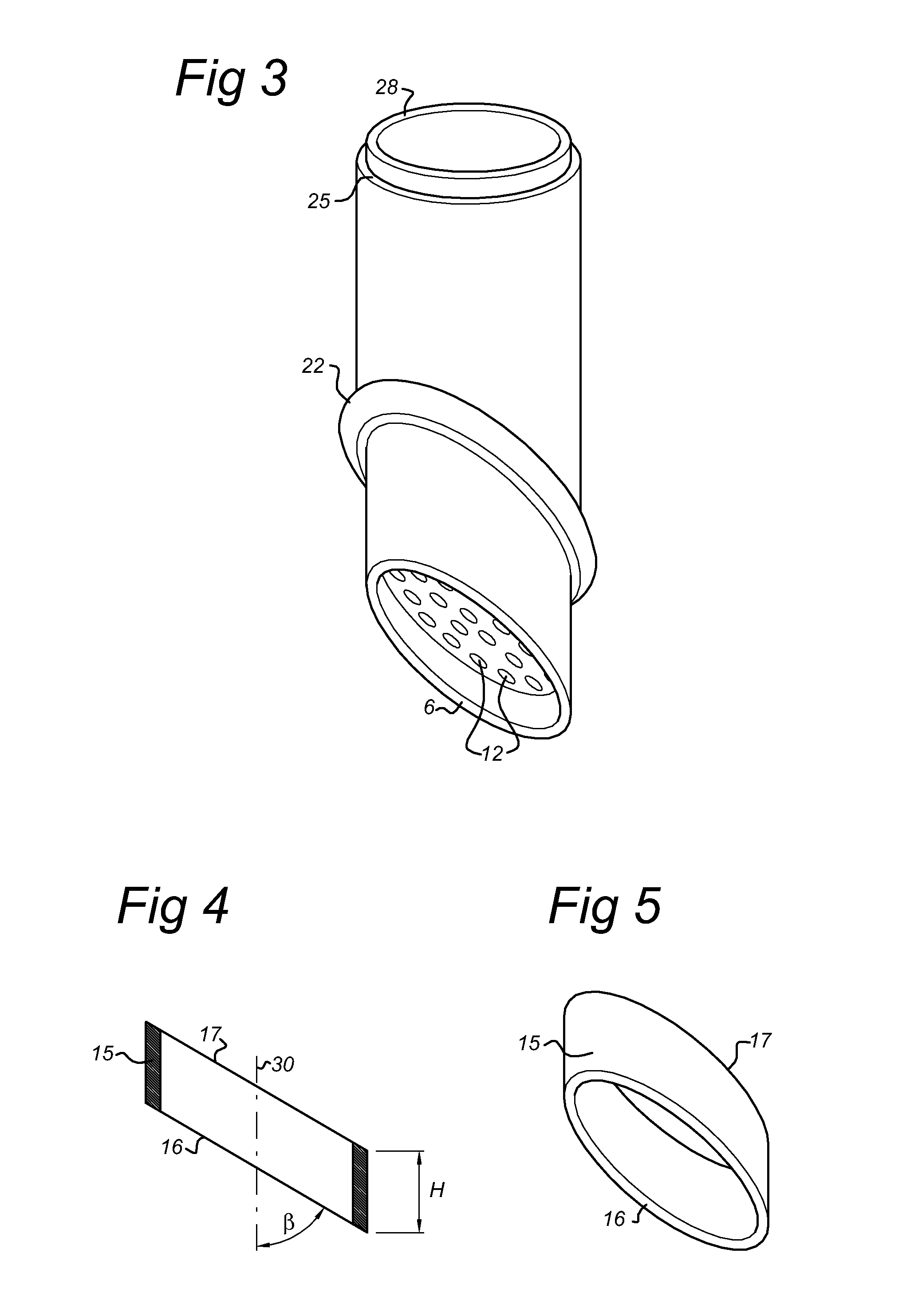

The invention is directed to a laser catheter (1) for bypass surgery, wherein the distal part (2) of the catheter (1) is provided with: a tubular arrangement (3) of optical fibres (4) having distal ends (5) defining a ring-shaped light emergence surface (6) for emitting a tubular bundle of light beams in the distal direction (D) of the catheter (1); and a stop surface (7) extending around the tubular arrangement (3) of optical fibres (4) and facing in the distal direction (D), the stop surface (7) being arranged at a distance (A) proximally from the light emergence surface (6). The light emergence surface (6) slants at a slanting angle (α) in the range of [20°, 60°] with respect to the longitudinal axis (8) of the catheter (1). The invention further relates to an assembly comprising such a catheter.

Owner:AMT MEDICAL

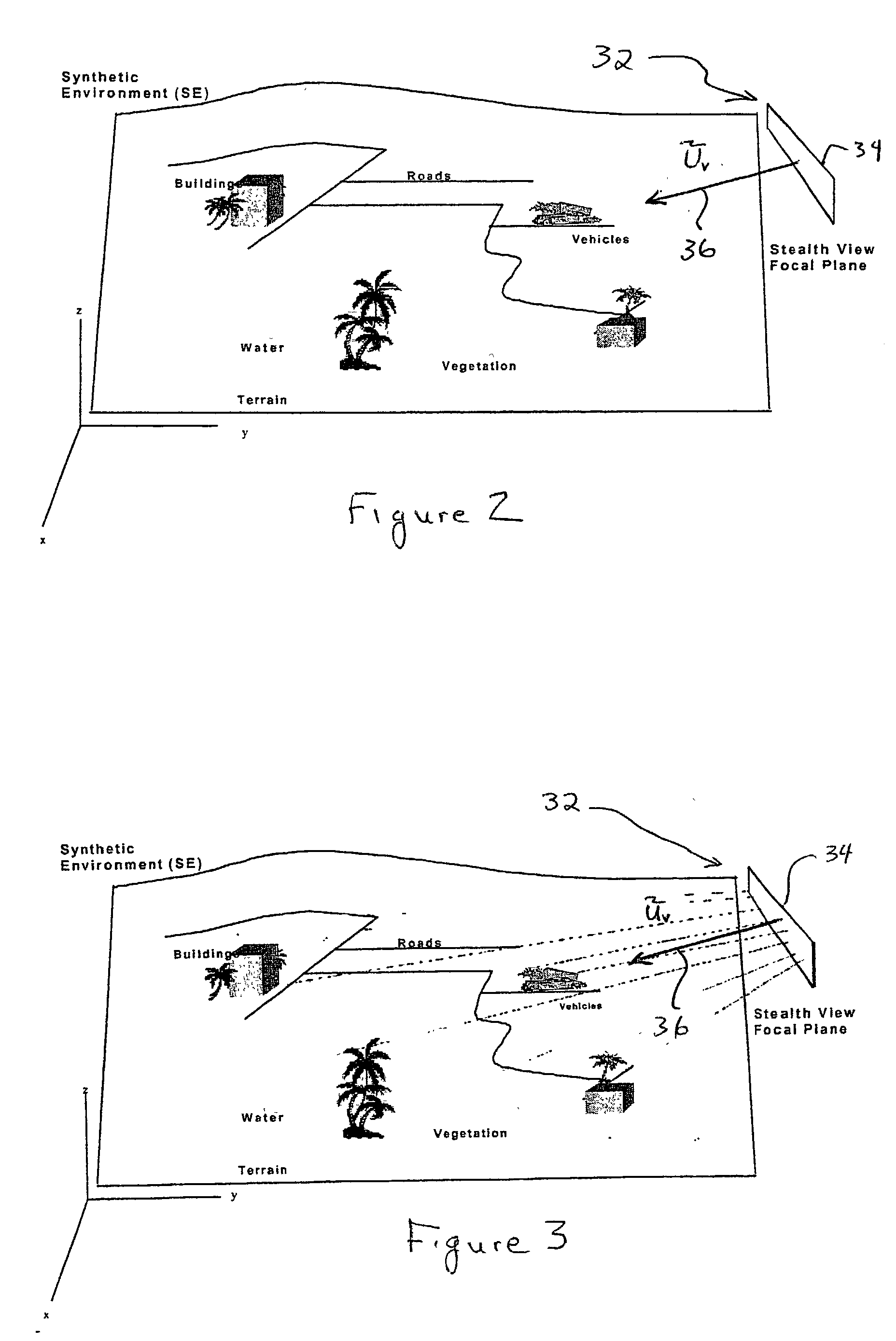

Method and apparatus for determining the geographic location of a target

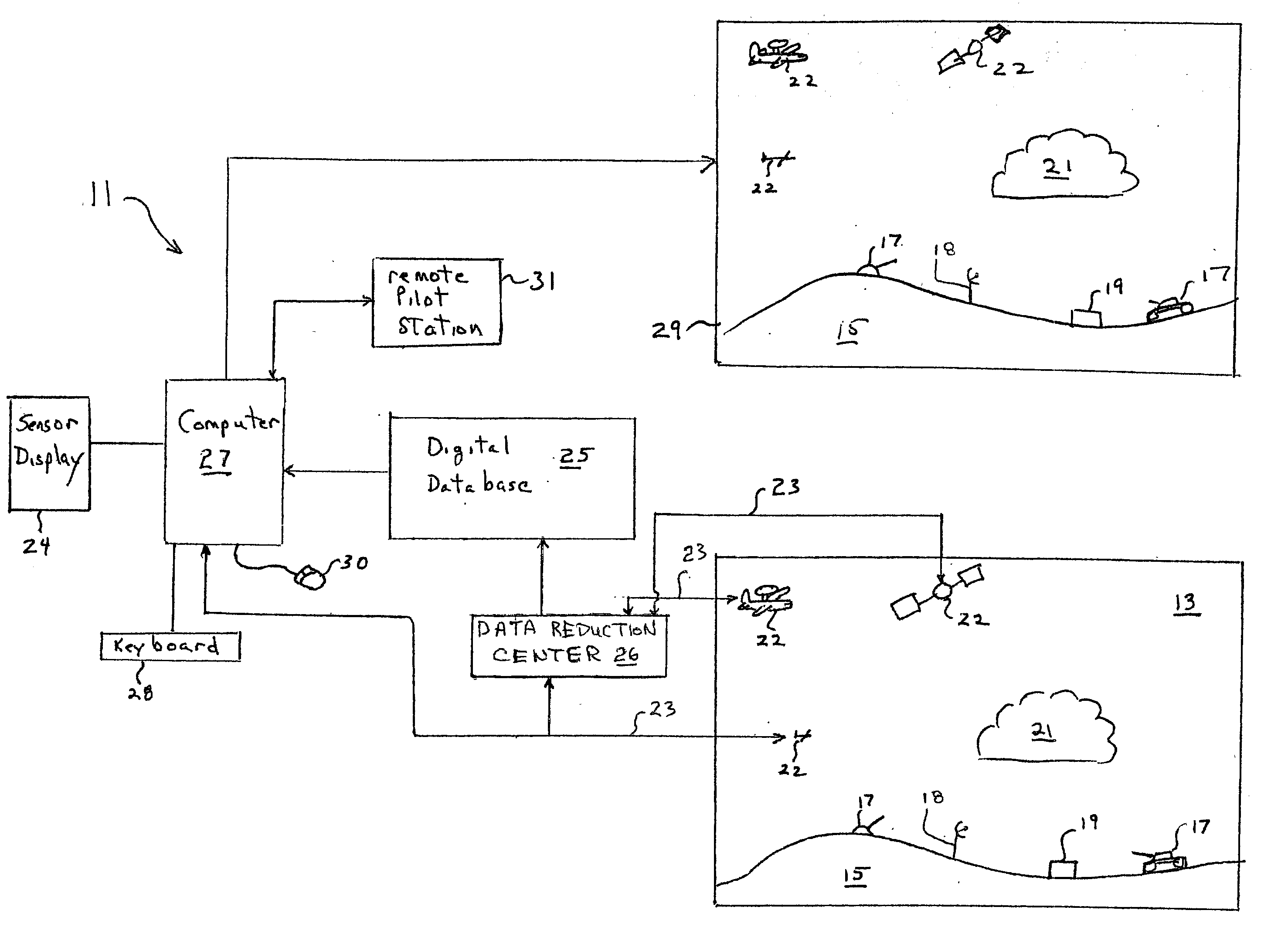

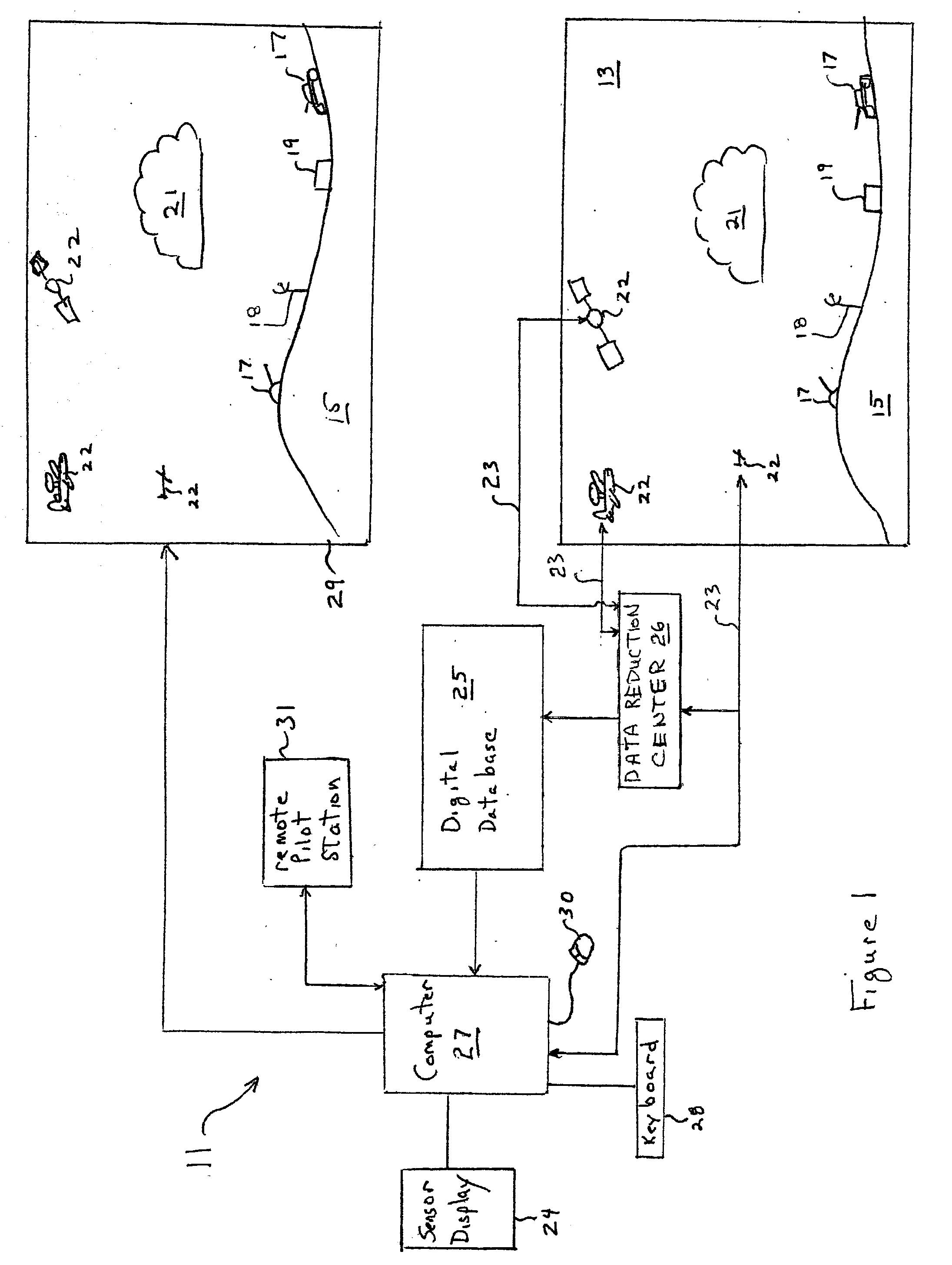

This invention generally relates to a method and apparatus for locating a target depicted in a real-world image that has a slant angle and vantage point location that are only approximately known using a virtual or synthetic environment representative of the real-world terrain where the target is generally located; and more particularly, to such a method and apparatus wherein a set of views of the virtual environment is compared with the real-world image of the target location for matching the simulated view that most closely corresponds to the real-world view in order to correlate the real-world image of the target with the selected simulated view in order to correctly locate the target in the virtual environment and thereby determine the exact location of the target in the real-world

Owner:LOCKHEED MARTIN CORP

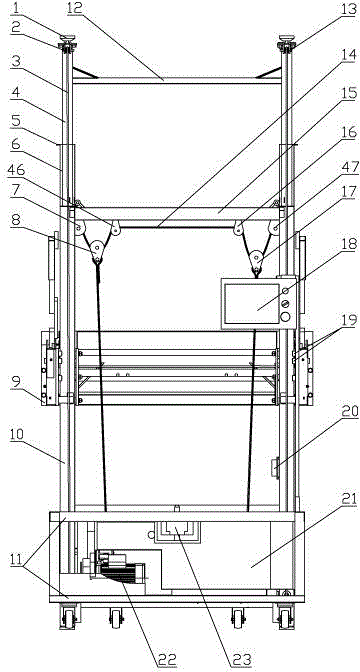

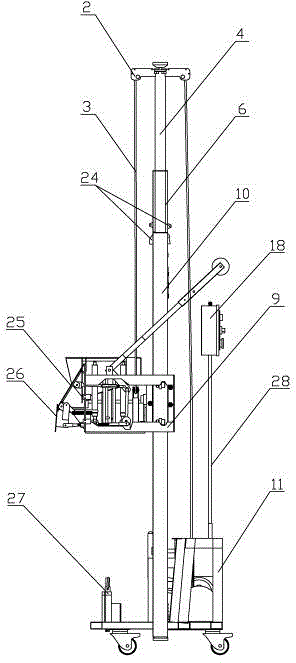

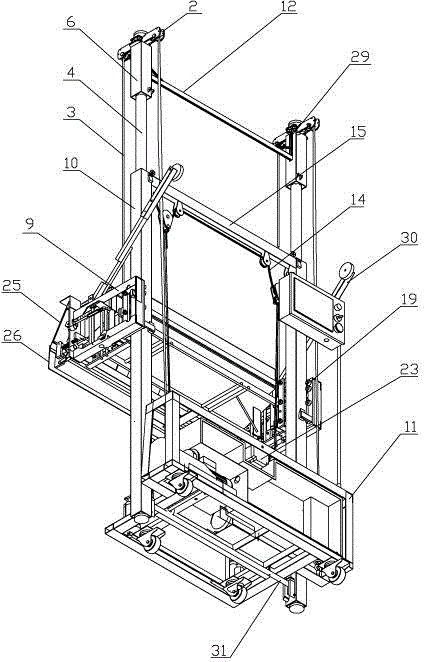

Numerical-control intelligent wall painting machine

ActiveCN105201182AHigh precisionEasy to operateBuilding constructionsWinding machineNumerical control

The invention discloses a numerical-control intelligent wall painting machine. The numerical-control intelligent wall painting machine comprises a movable base, a vertical frame rod stretching device erected on the two sides of the base, a plastering device arranged on the vertical frame rod stretching device, an integrated control device arranged on the base and a power device arranged on the base. The plastering device comprises a plastering plate, a plaster hopper, a plaster hopper frame and a plaster hopper frame lifting device used for lifting the plaster hopper frame. The power device comprises a winding machine A and a winding machine B which are installed on the base. A touch screen controller is further arranged on the base through a supporting rod. The touch screen controller is in communication with the integrated control device. An angle adjusting device capable of automatically and intelligently adjusting the slant angle of stretchable vertical frame rods is arranged between the vertical frame rod stretching device and the base. By means of the numerical-control intelligent wall painting machine, many defects of an existing wall painting machine are overcome, the numerical-control intelligent wall painting machine is wide in application range, easy to operate, good in plastering quality, high in plastering efficiency and convenient to transfer, man-machine safety is guaranteed, time, labor and work are saved, and good economy popularizing value is achieved.

Owner:湖北超顺智能科技有限公司

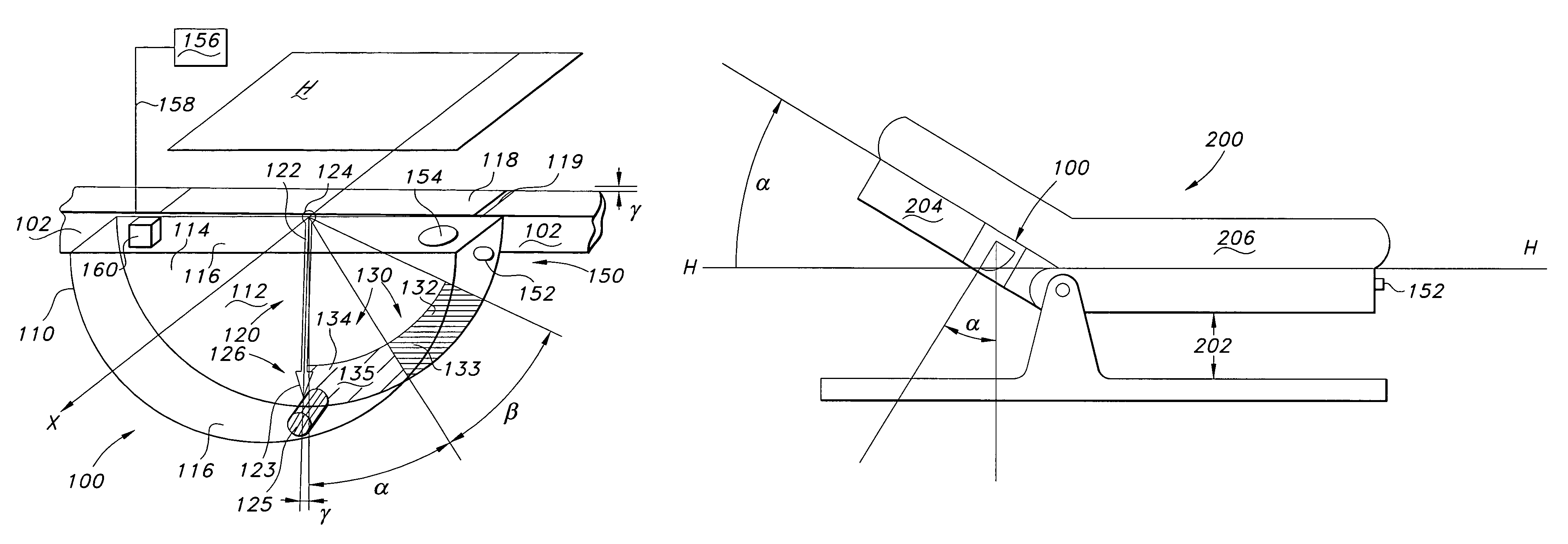

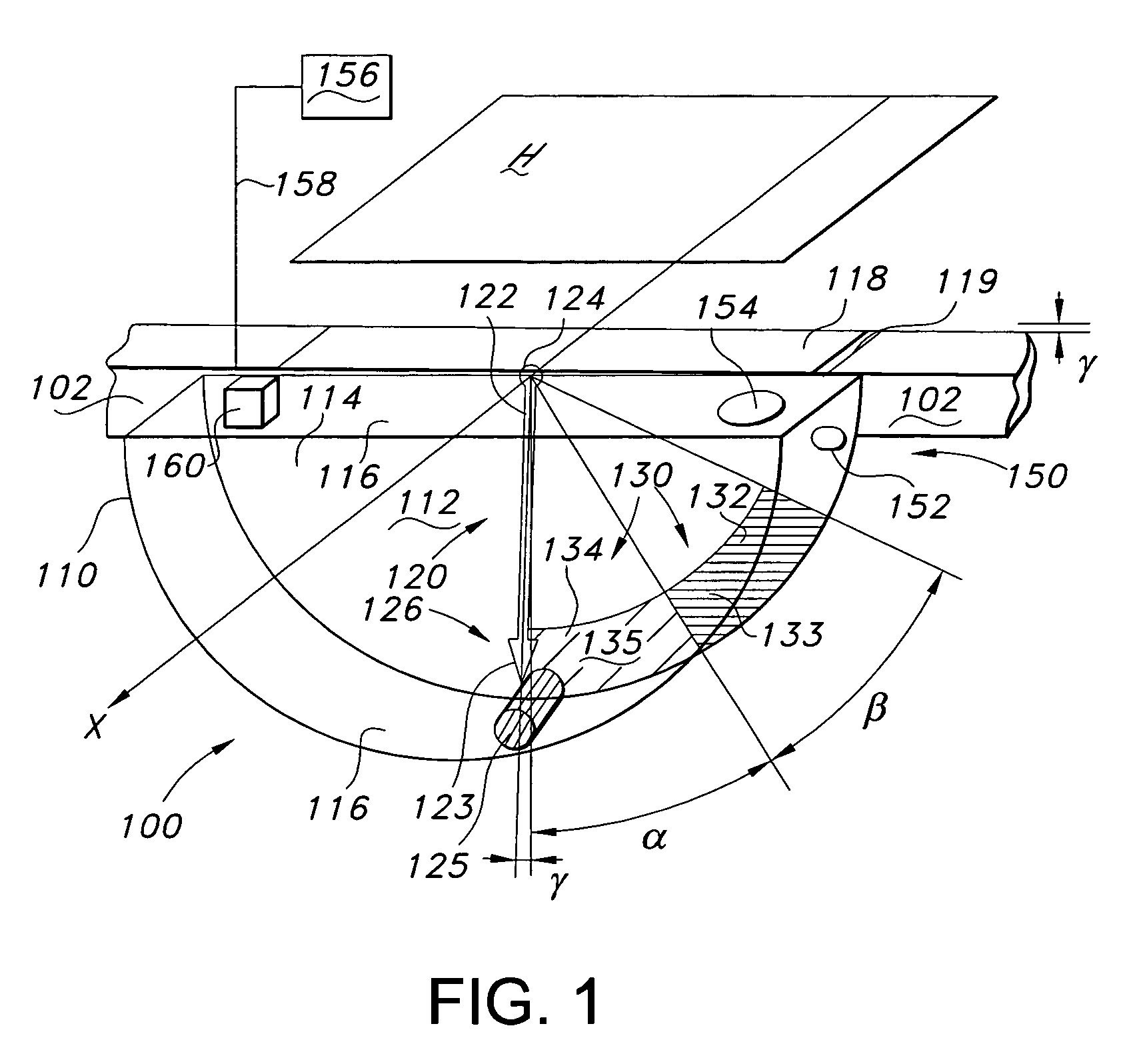

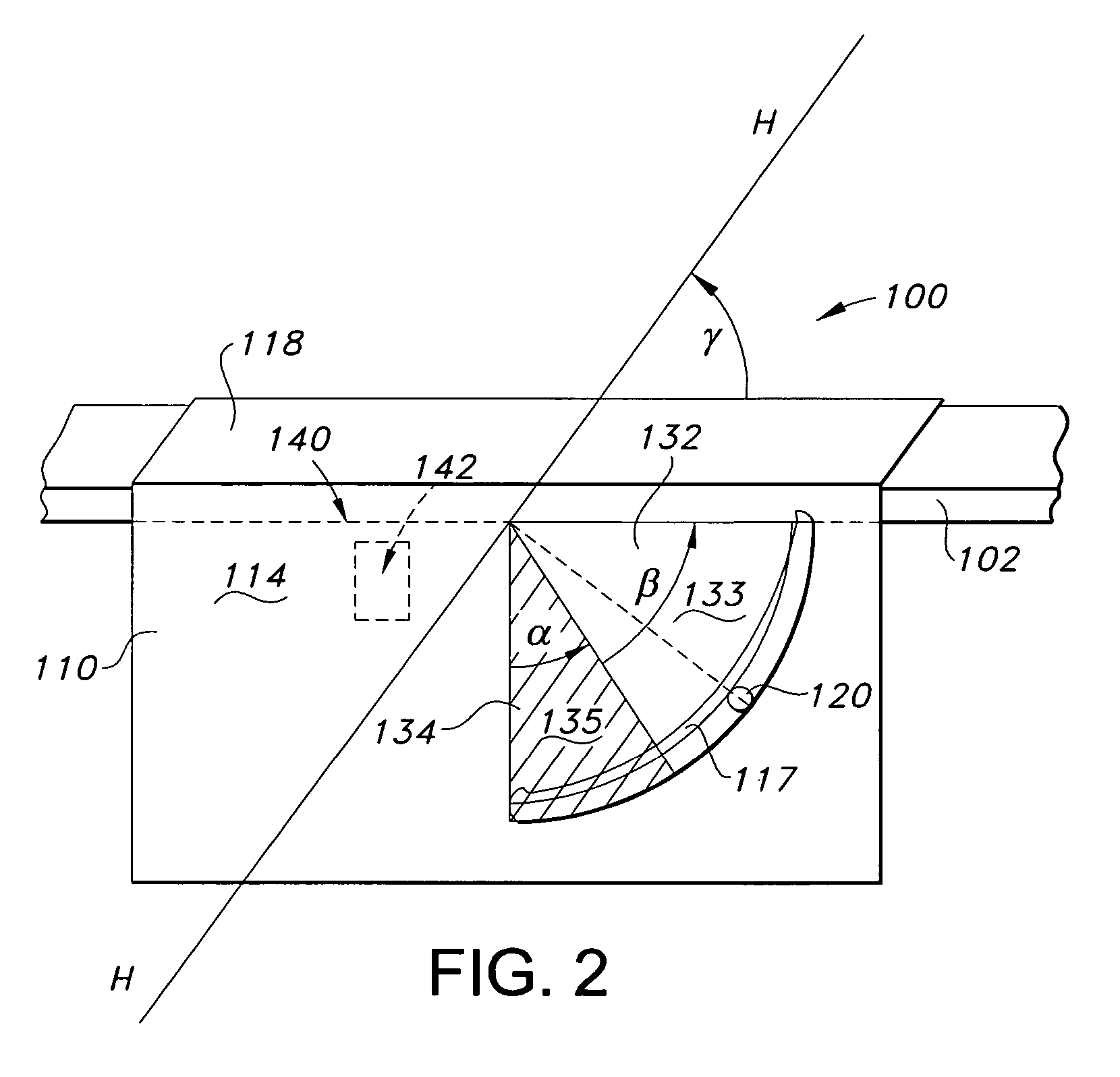

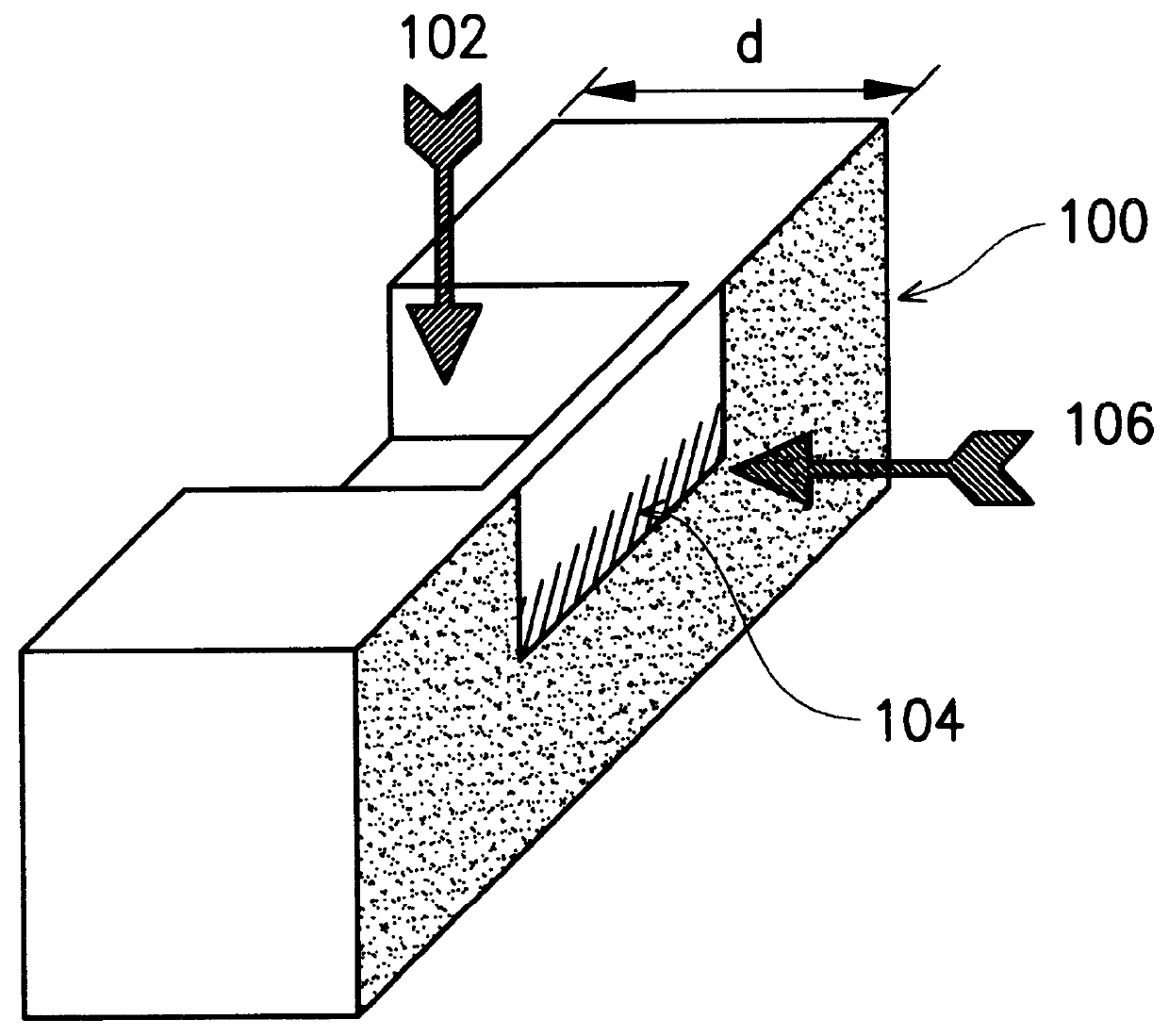

Angle indicator

An angle indicator is provided for measuring an angle of inclination of a structure with respect to a plane, such as a horizontal or vertical plane. The angle indicator includes a housing adapted and configured to be mounted to the structure, an indicator movably disposed in the housing having an angular range of motion about an axis intersecting the plane, and indicia provided on the housing for indicating proper angulation of the structure with respect to the plane. The indicia can be defined at least in part by a first arcuate segment, wherein the indicia and the indicator are configured to be in visual alignment to an observer when the angle of inclination of the structure with respect to the plane achieves a predetermined angle. In accordance with a preferred embodiment of the invention, the predetermined angle can be about thirty degrees.

Owner:THE GENERAL HOSPITAL CORP +1

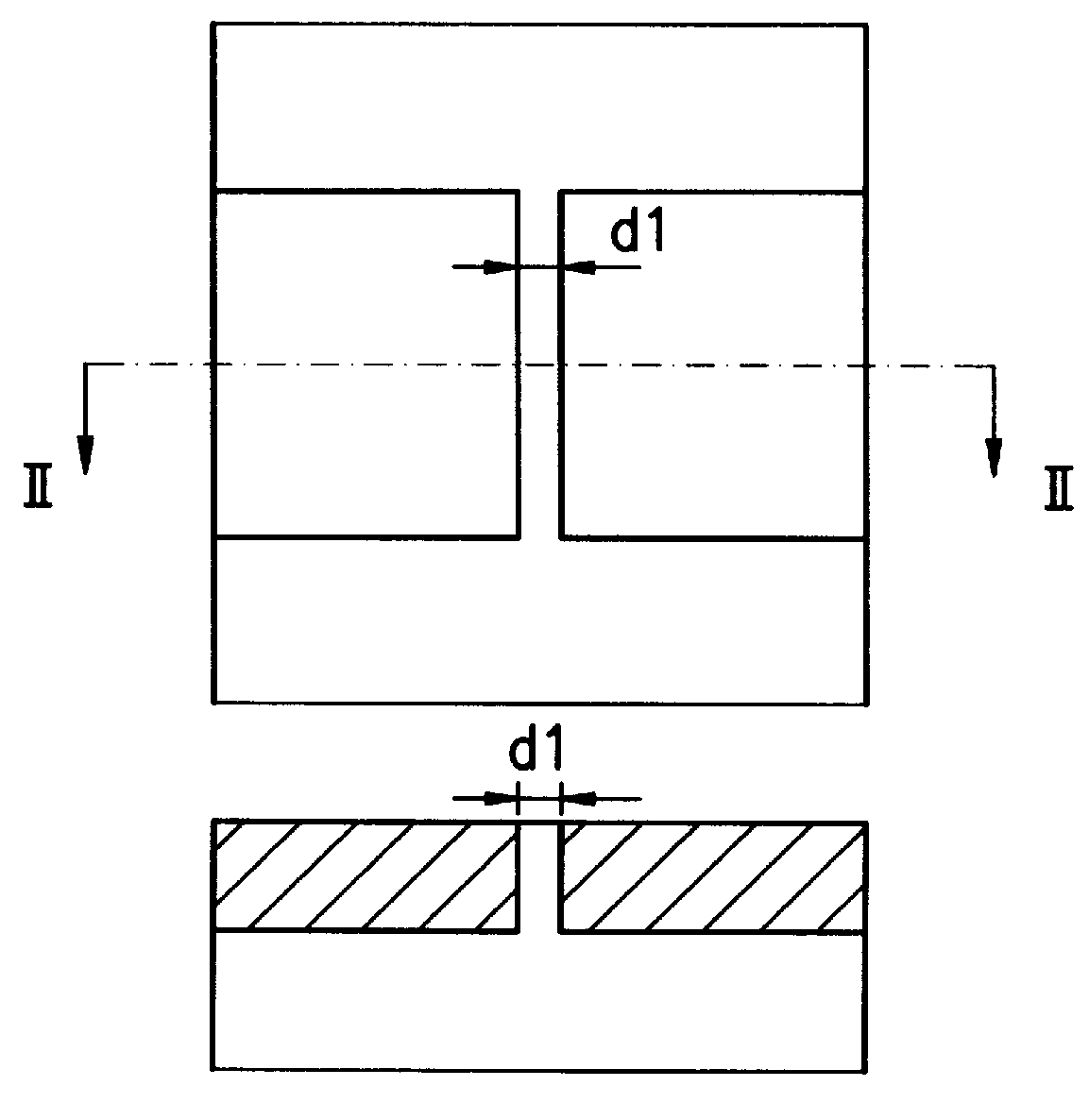

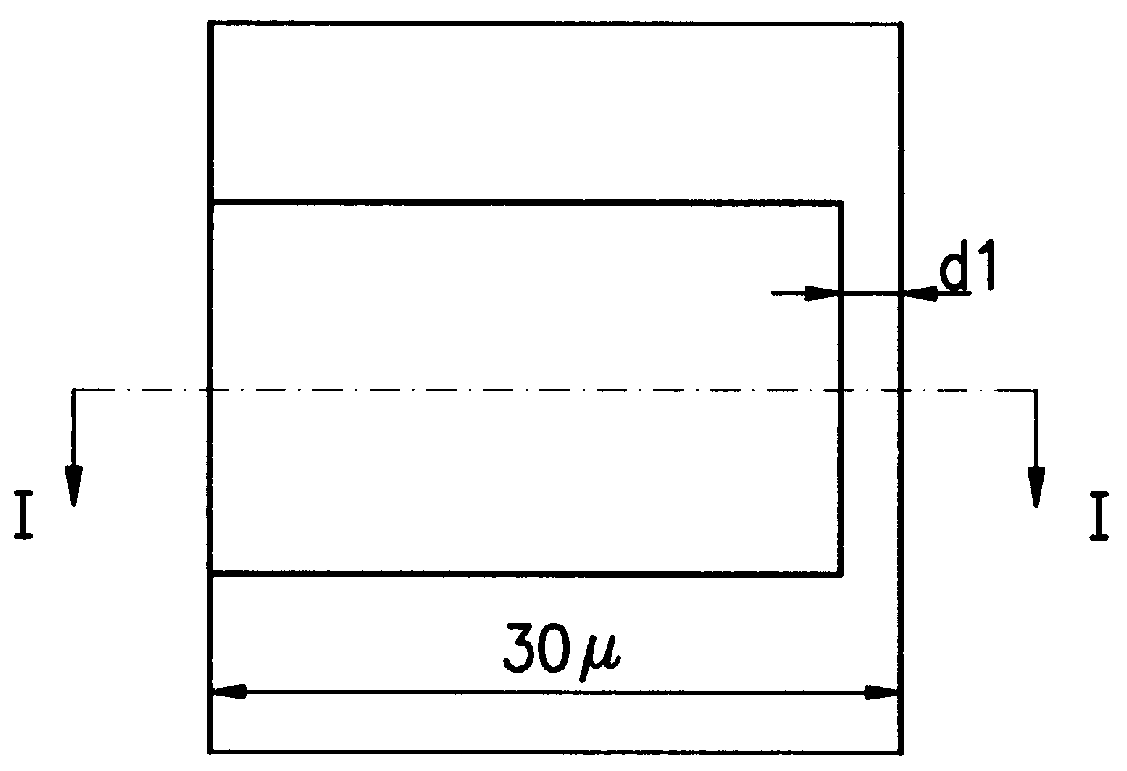

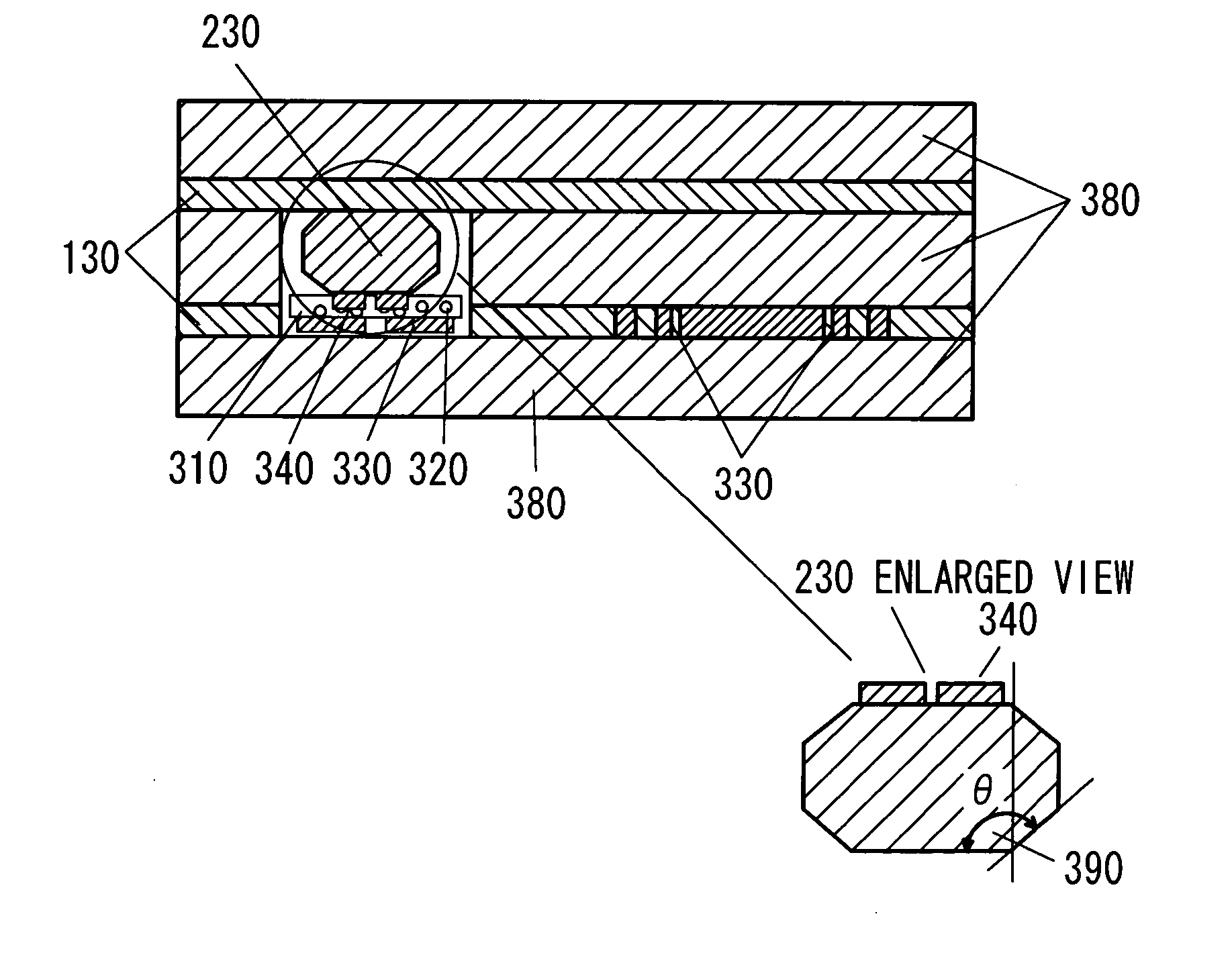

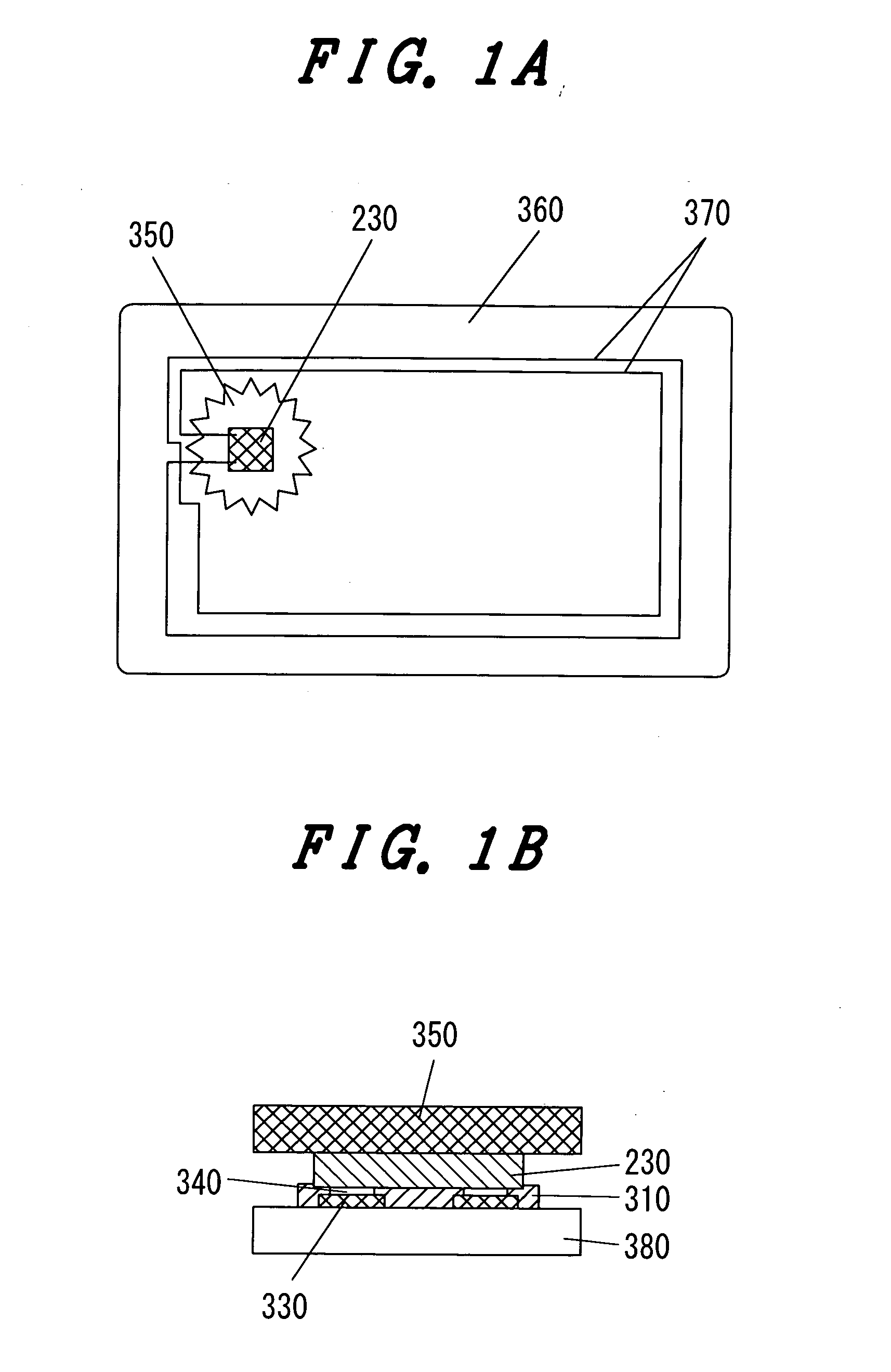

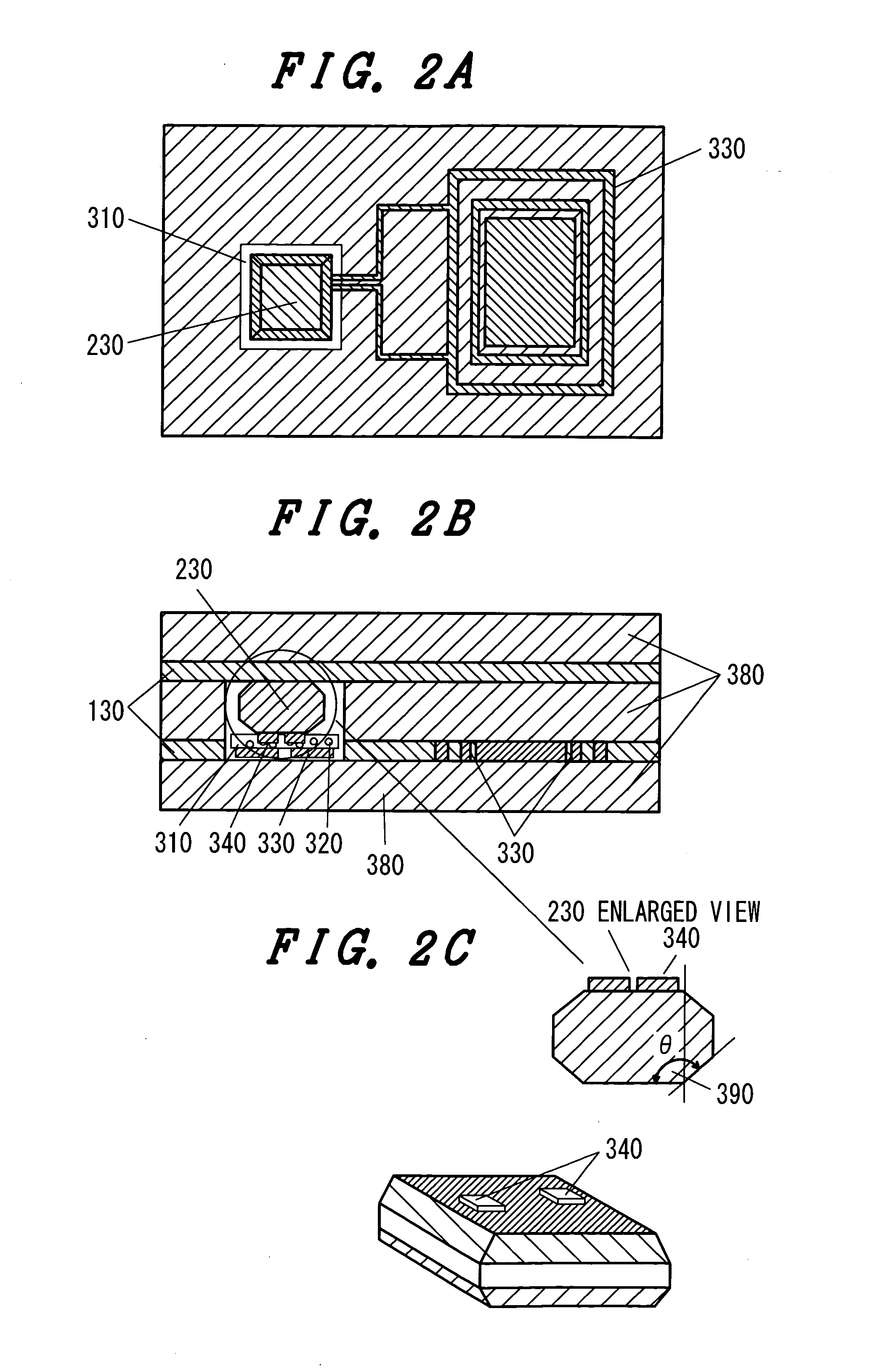

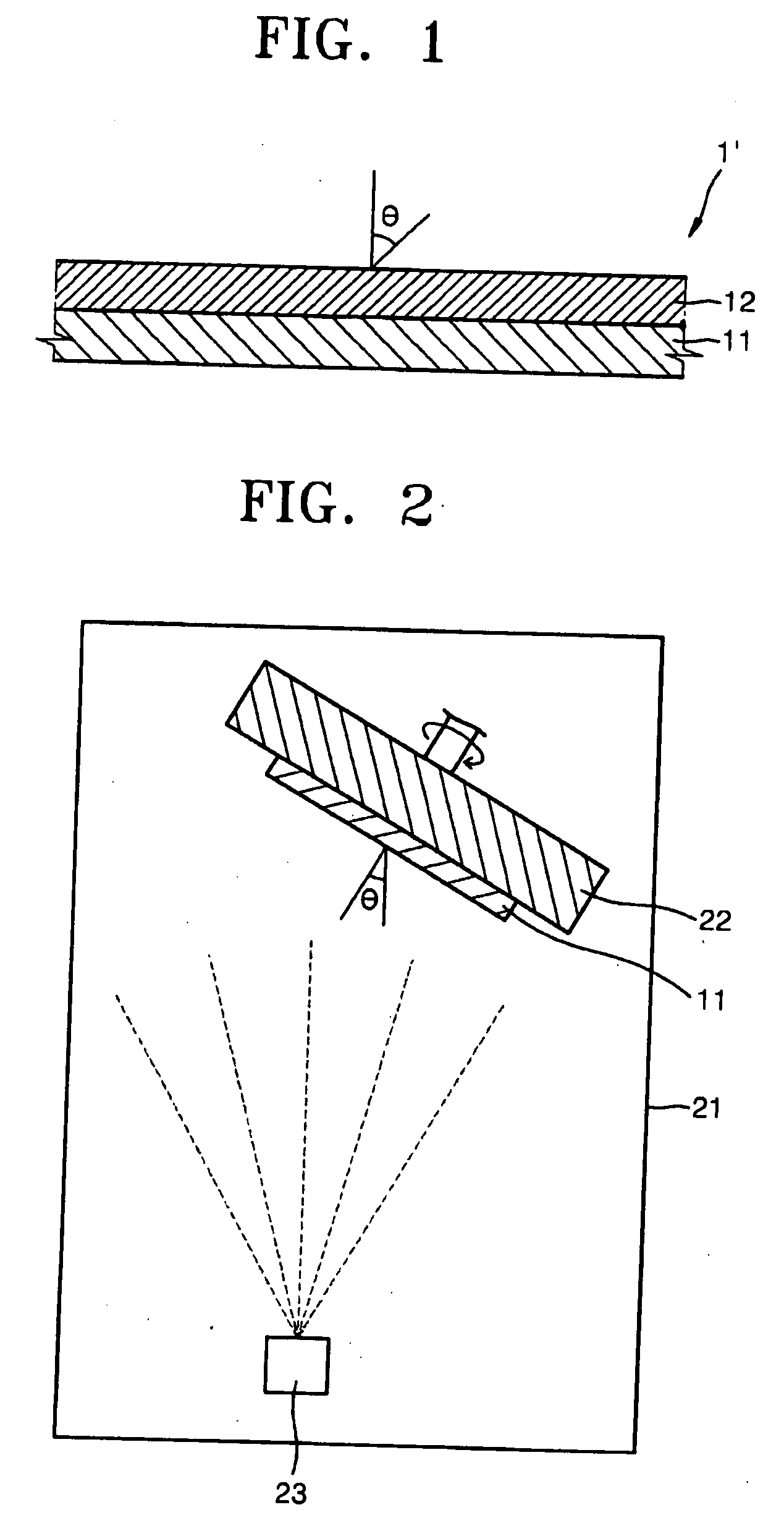

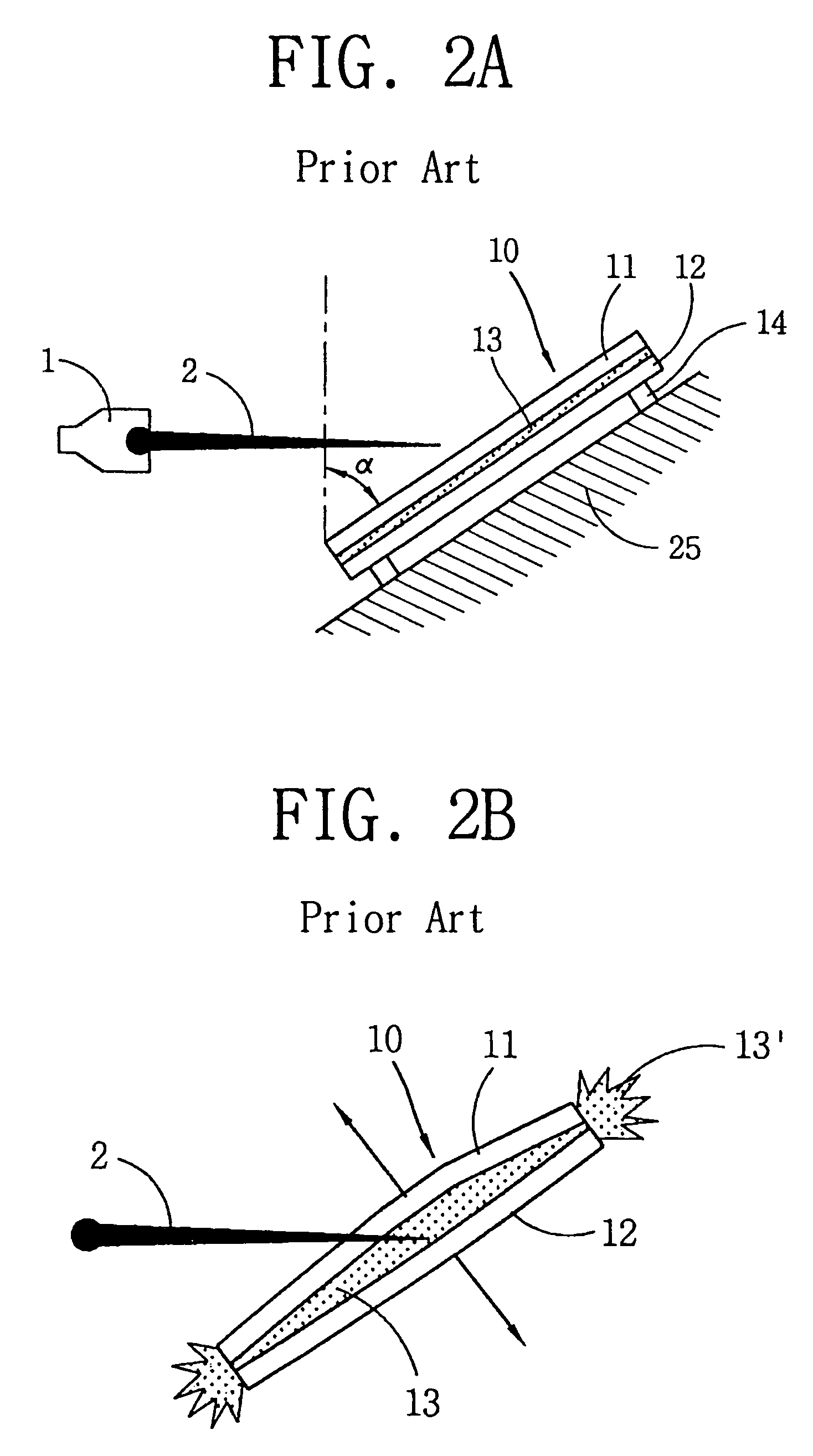

Method for milling a transmission electron microscope test slice

InactiveUS6080991AMaterial analysis using wave/particle radiationElectric discharge tubesSlant angleElectron microscope

A focused ion beam (FIB) is used to mill a test slice to form an observable wall for a transmission electron microscope (TEM). A slanting angle theta of the observable wall surface is automatically formed. The method for milling the test slice includes the following steps: The first step is to measure the slanting angle theta . The next step is to tilt the test slice with the slanting angle theta in both a counterclockwise direction and a clockwise direction and to perform FIB milling so that the TEM observable wall has a uniform thickness. Furthermore, during the FIB milling, an aperture in the TEM observable wall serves as a milling stop signal.

Owner:UNITED MICROELECTRONICS CORP

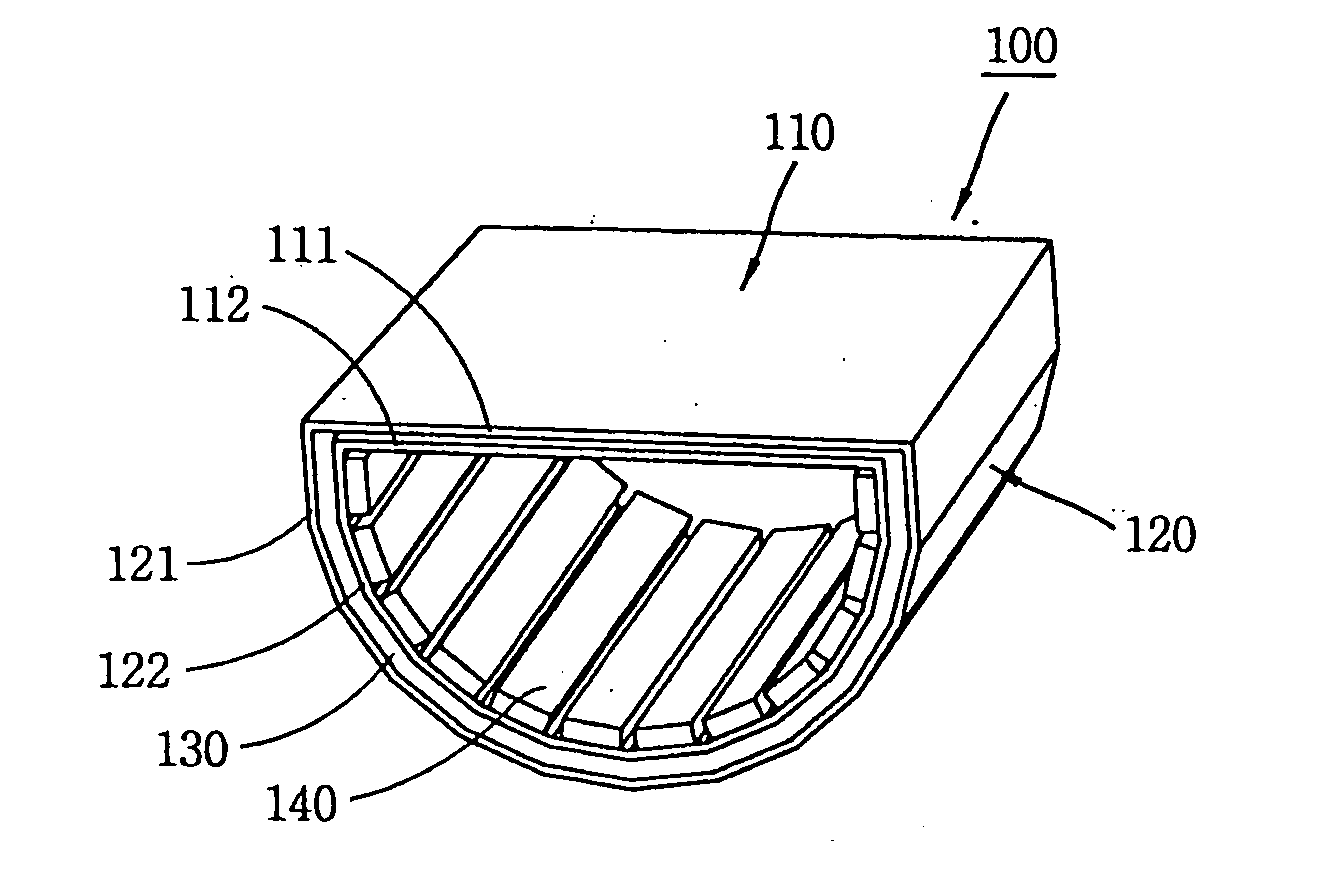

Light Source and Vehicle Lamp

ActiveUS20070285939A1Favorable light distribution patternNon-electric lightingVehicle headlampsSlant angleMiniaturization

The disclosed subject matter includes light sources that have a high luminous flux and a favorable bright distribution, and includes vehicle lamps that have both a favorable light distribution pattern and a capability of being miniaturized by using the LED light sources. The light source can include a base board, a reflector having a cavity with a slender rectangular opening, a plurality of semiconductor light emitting chips located in a line in the cavity, and an encapsulating resin in the cavity. At least one chip among the plurality of semiconductor light emitting chips can be located on a central bottom portion of the cavity. The cavity can have one slant angle in a direction of a short side that is smaller than another slant angle. The vehicle lamp can include the light source, a shield plate, an optical lens, and reflectors that are selected according to a kind and / or design of a vehicle lamp.

Owner:STANLEY ELECTRIC CO LTD

Device and method for polarization control for a phased array antenna

Owner:L 3 COMM TITAN CORP

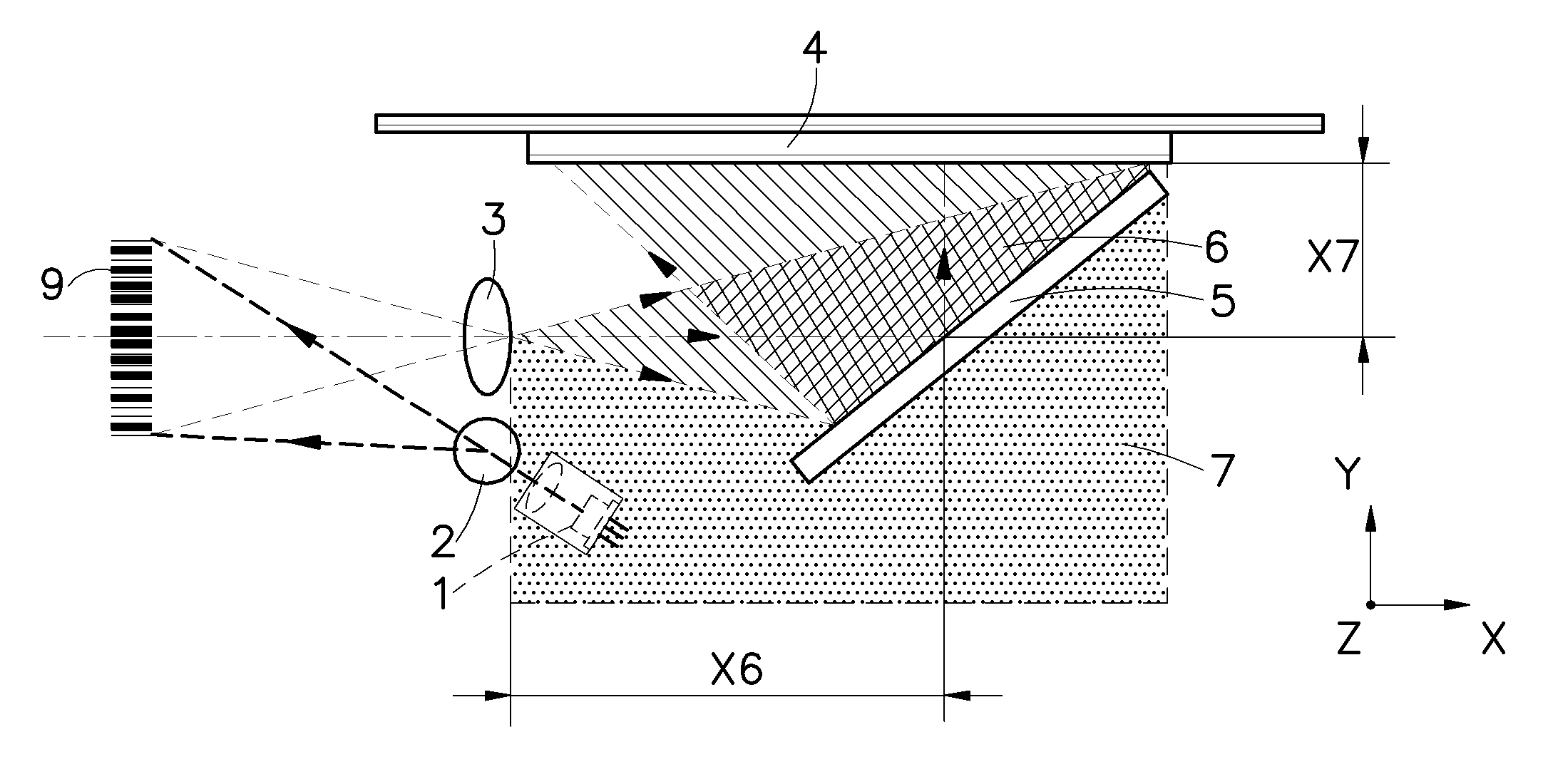

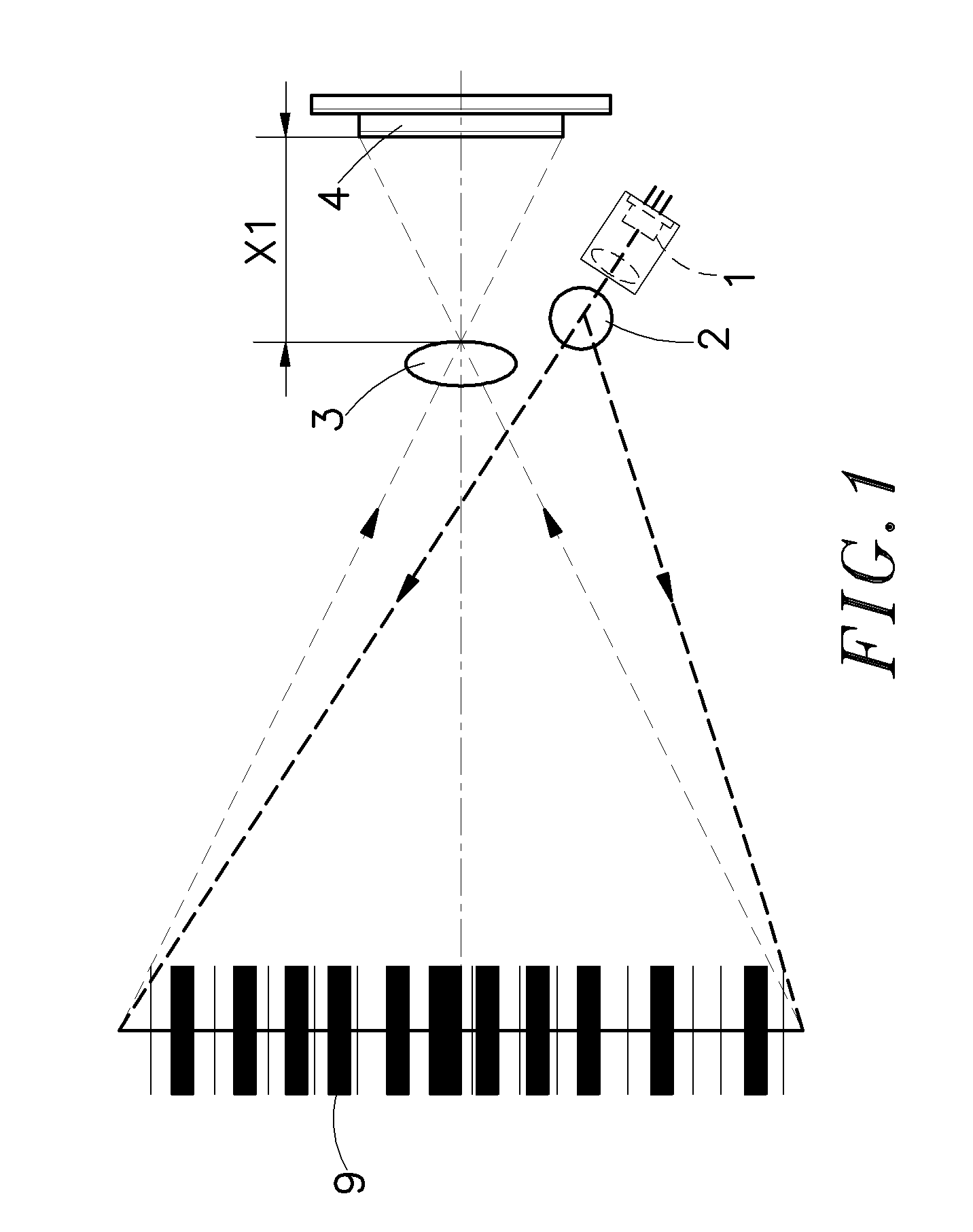

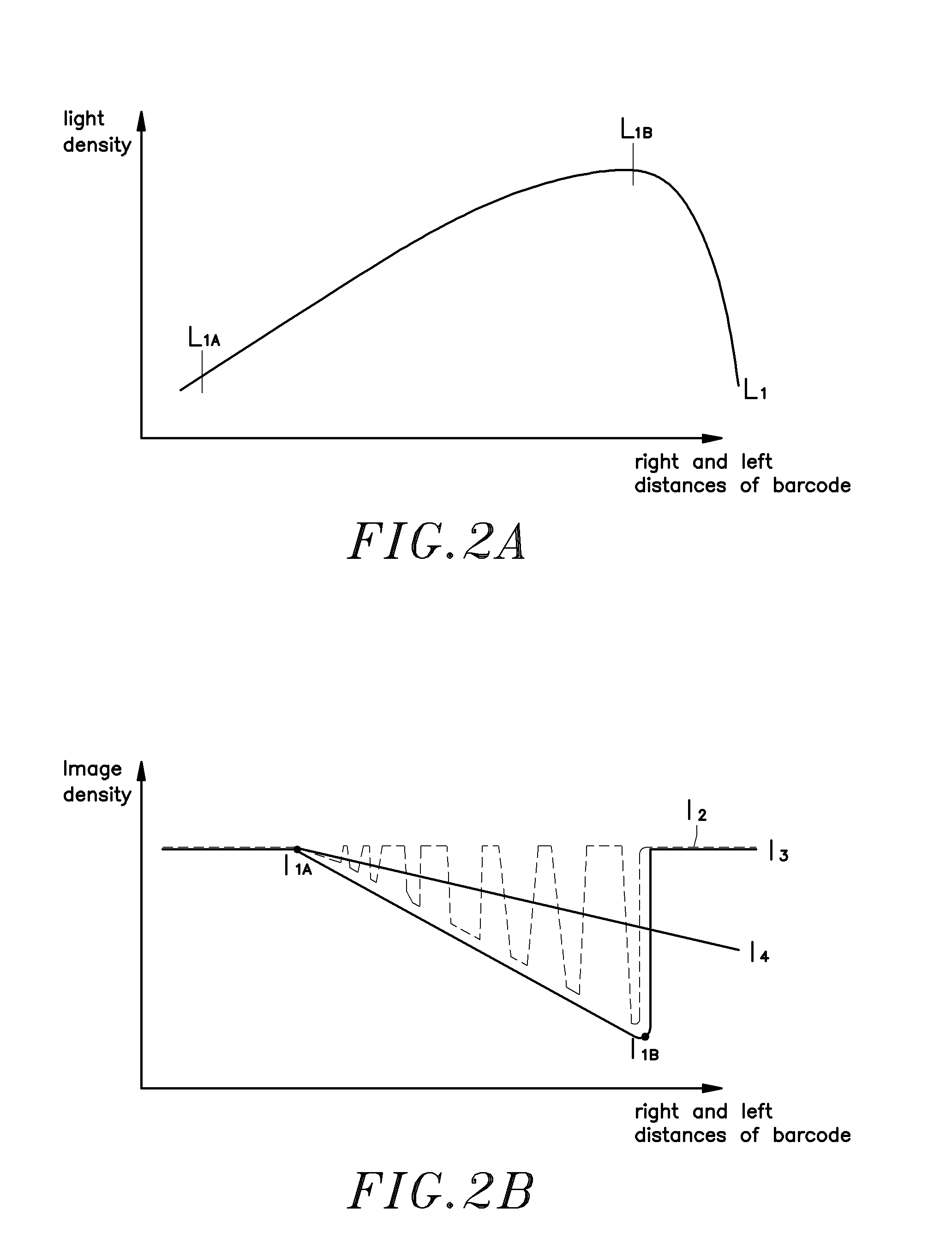

Optical system for barcode scanner

InactiveUS20070205287A1Visual representatino by photographic printingSensing by electromagnetic radiationSensor arraySlant angle

An optical system used in a barcode scanner is disclosed to include a light source for emitting a dot-shaped light beam in a slanting angle, a standing cylindrical lens for expanding the dot-shaped light beam produced by the light source as a line-shaped light beam onto a barcode of a product in a slanting angle, which line-shaped light beam showing a light intensity distribution curve that is asymmetric between the left side and the right side, a linear sensor array, and a focusing lens for focusing a reflective image of the barcode onto the linear sensor array. A reflector means can be provided for overlapping the light path to reduce the size of the barcode scanner. Further, a shaking means may be used to cause reciprocation of the light beam in direction perpendicular to the light path of the light source, thereby eliminating image noises due to existence of black holes.

Owner:RIOTEC

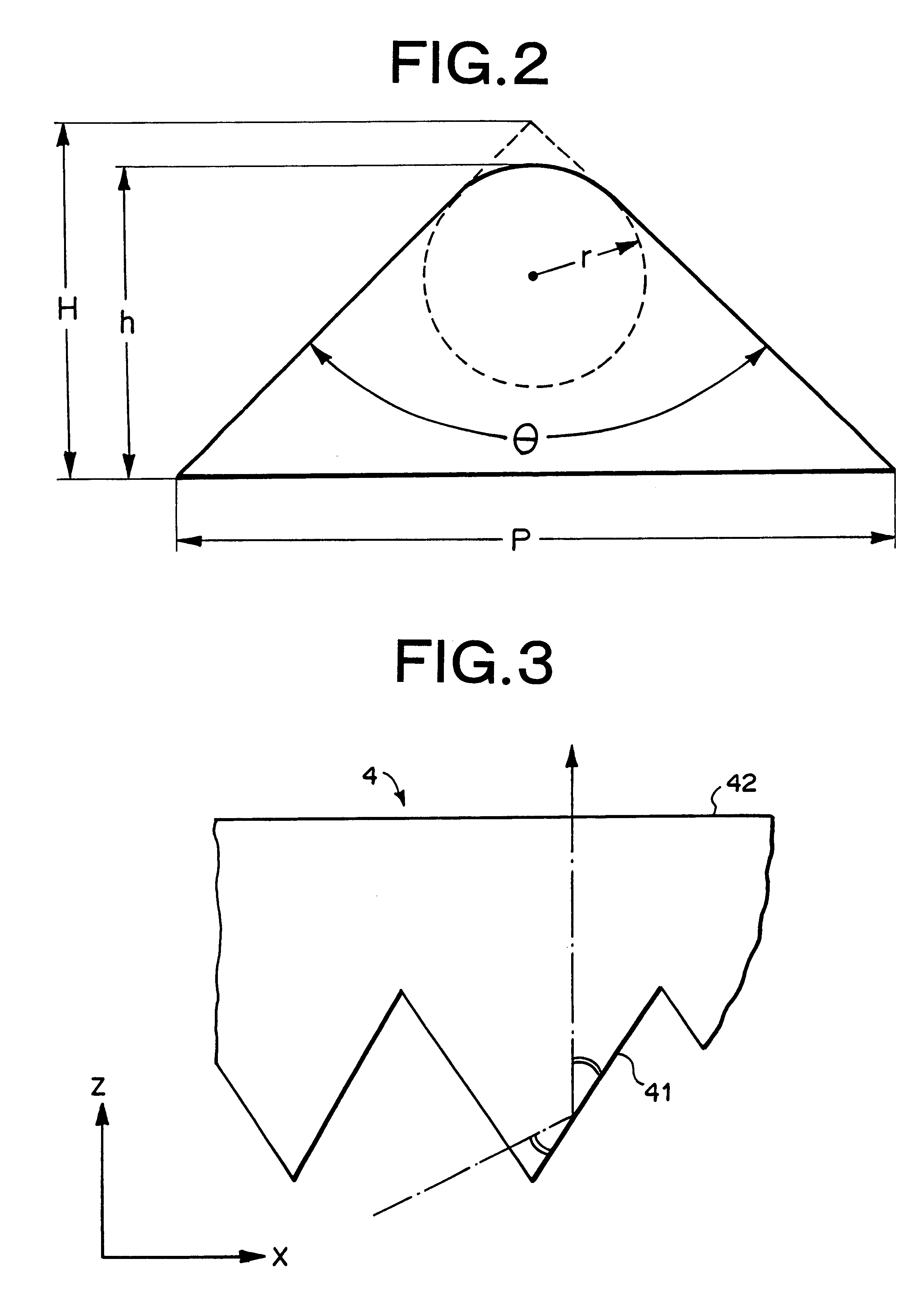

Area light source and lightguide used therefore

InactiveUS7736045B2Lowering of in distributionLowering of luminance in luminanceMechanical apparatusLight guides for lighting systemsRough surfaceLight guide

A plate-shaped light guide for a planar light source device that guides a light emitted from a primary light source includes a light incident end face, a light emitting face and a back surface on the opposite to the light emitting face, wherein a plurality of first elongated lenses having an average slant angle of 0.5 to 60° are continuously or intermittently formed on one of the light emitting face and the back surface, and at least a portion of a surface of each first elongated lens, or at least a portion of the other one of the light emitting face and the back surface, or at least the portion of the surface of each first elongated lens and at least the portion of the other one of the light emitting face and the back surface includes a rough surface having an average slant angle of 0.1 to 8°.

Owner:MITSUBISHI CHEM CORP

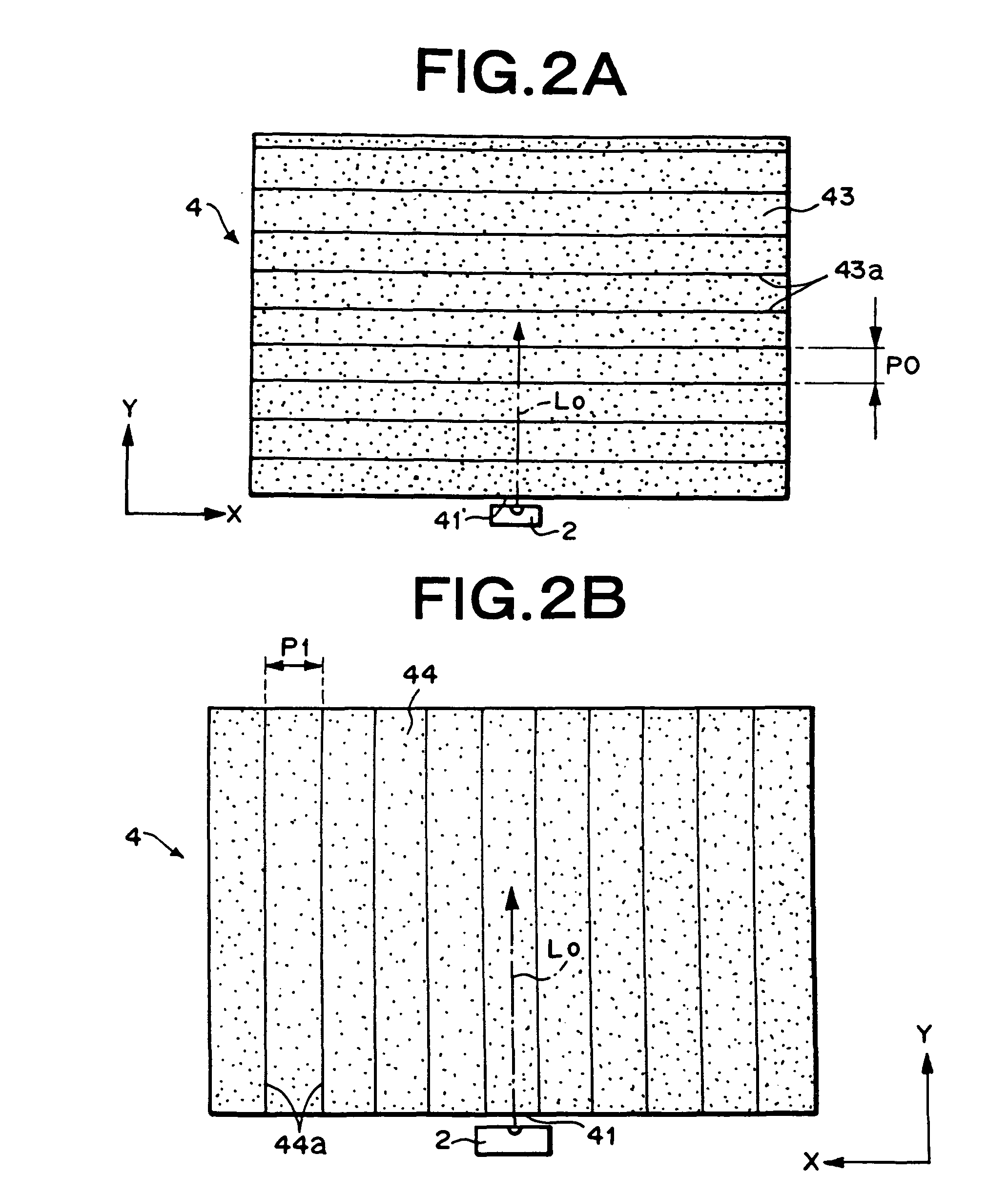

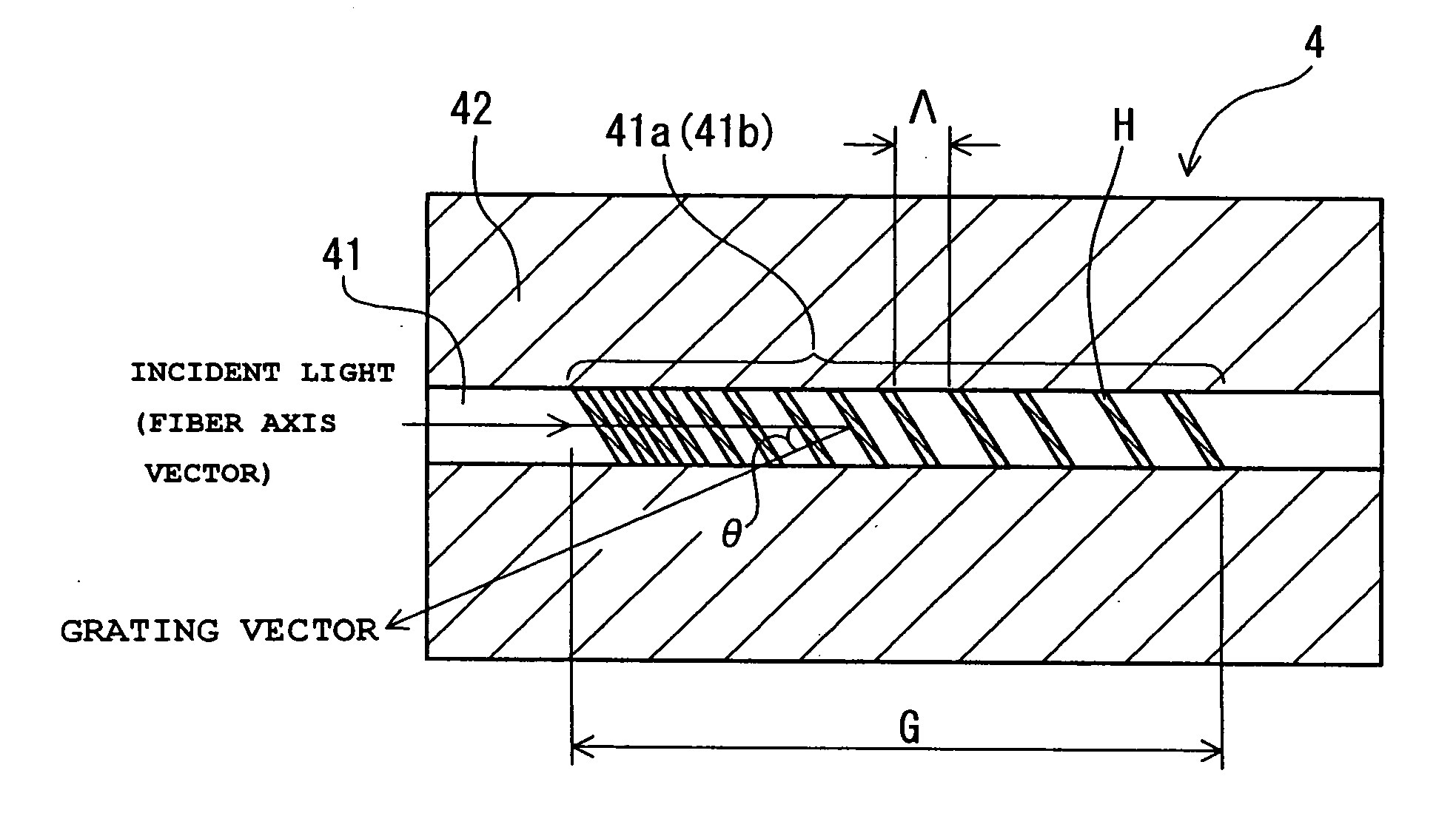

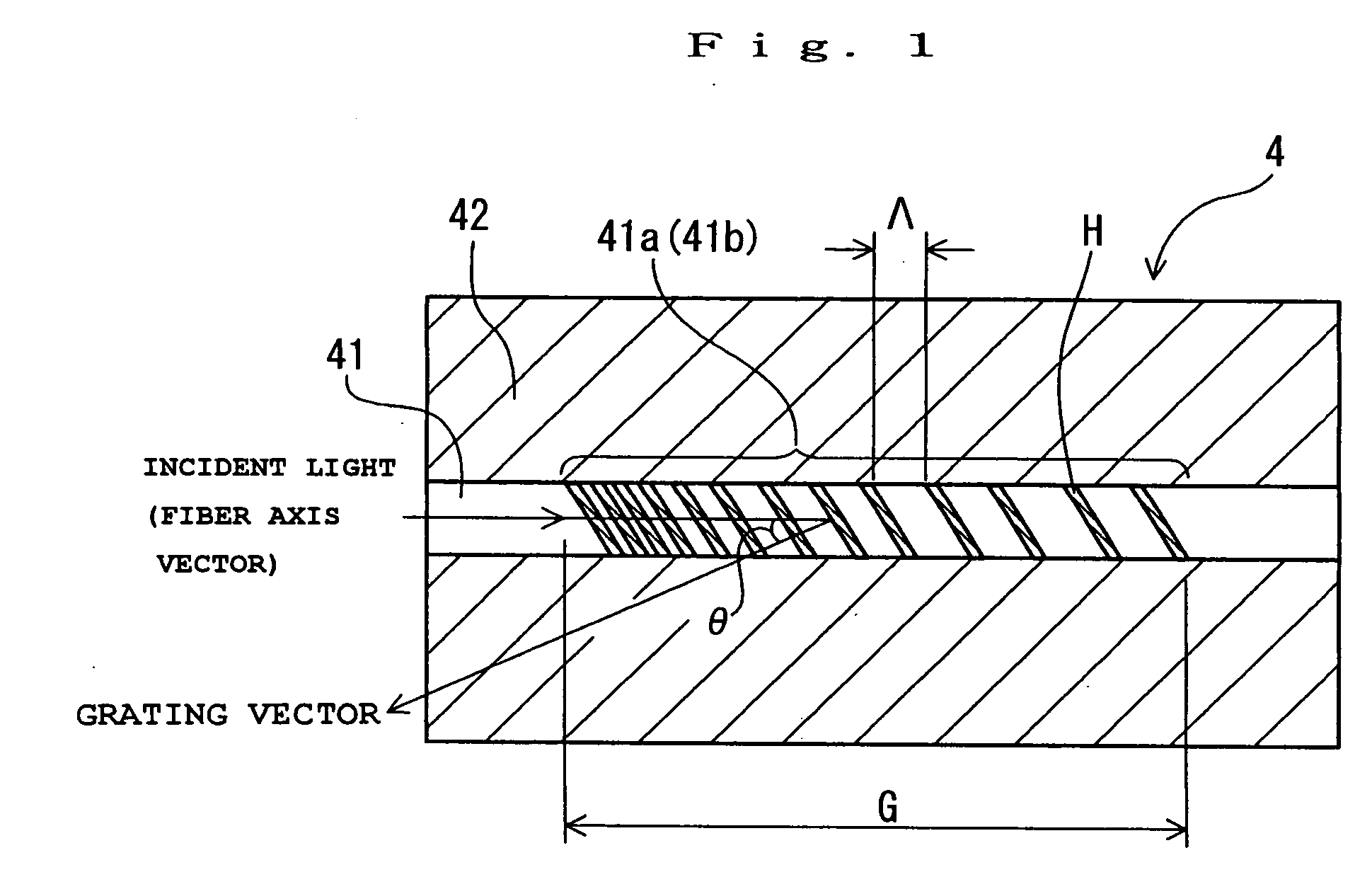

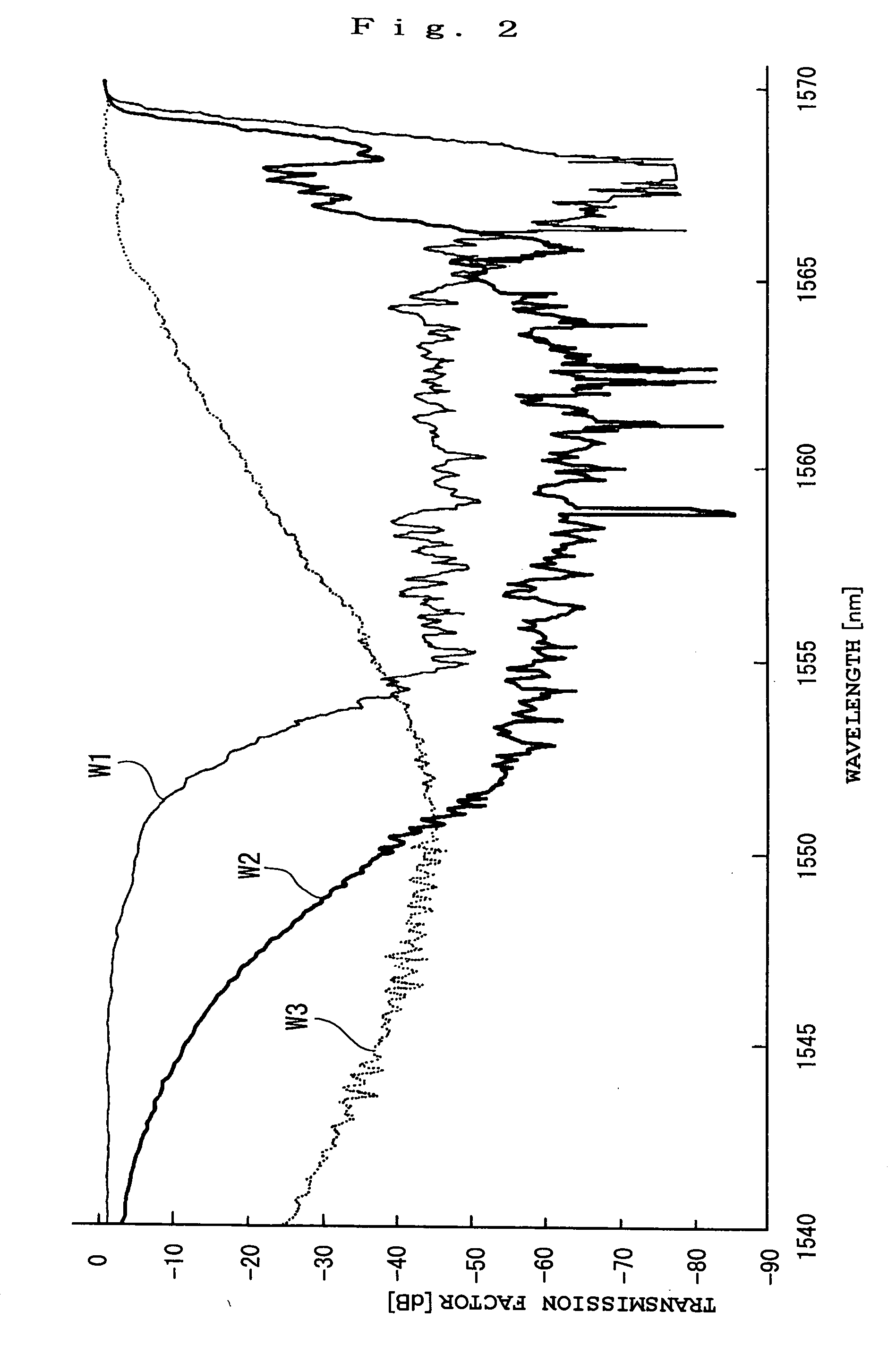

Pseudo slant fiber bragg grating, multiple series fiber bragg grating, optical fiber type coupler and optical connector

InactiveUS20060067616A1Improve featuresEnhanced couplingCoupling light guidesOptical multiplexRelative refractive indexSlant angle

An optical fiber 4 having a clad diameter of 125 μm is made by adding Ge to a core 41 having a core diameter of 8 μm and a relative refractive index difference of 0.3 %, and two refractive index grating portions 41a and 41b having a slant angle of 2° are formed in series in the optical fiber 4 by a phase mask method using KrF excimer laser (λ=248 nm). The central period (2Λ) of the phase mask of a chirped grating is 1,140 nm, the chip rate (C) of the period is 1.2 nm / mm, the length (G) of the first and second index grating portions 41a and 41b is 8 mm, the effective refractive index of the first and second index grating portions 41a and 41b is 1.447, the refractive index modulation is 3×10−3, and the gap between the first and second index grating portions 41a and 41b is 1 mm.

Owner:SHOWA ELECTRIC WIRE & CABLE CO LTD

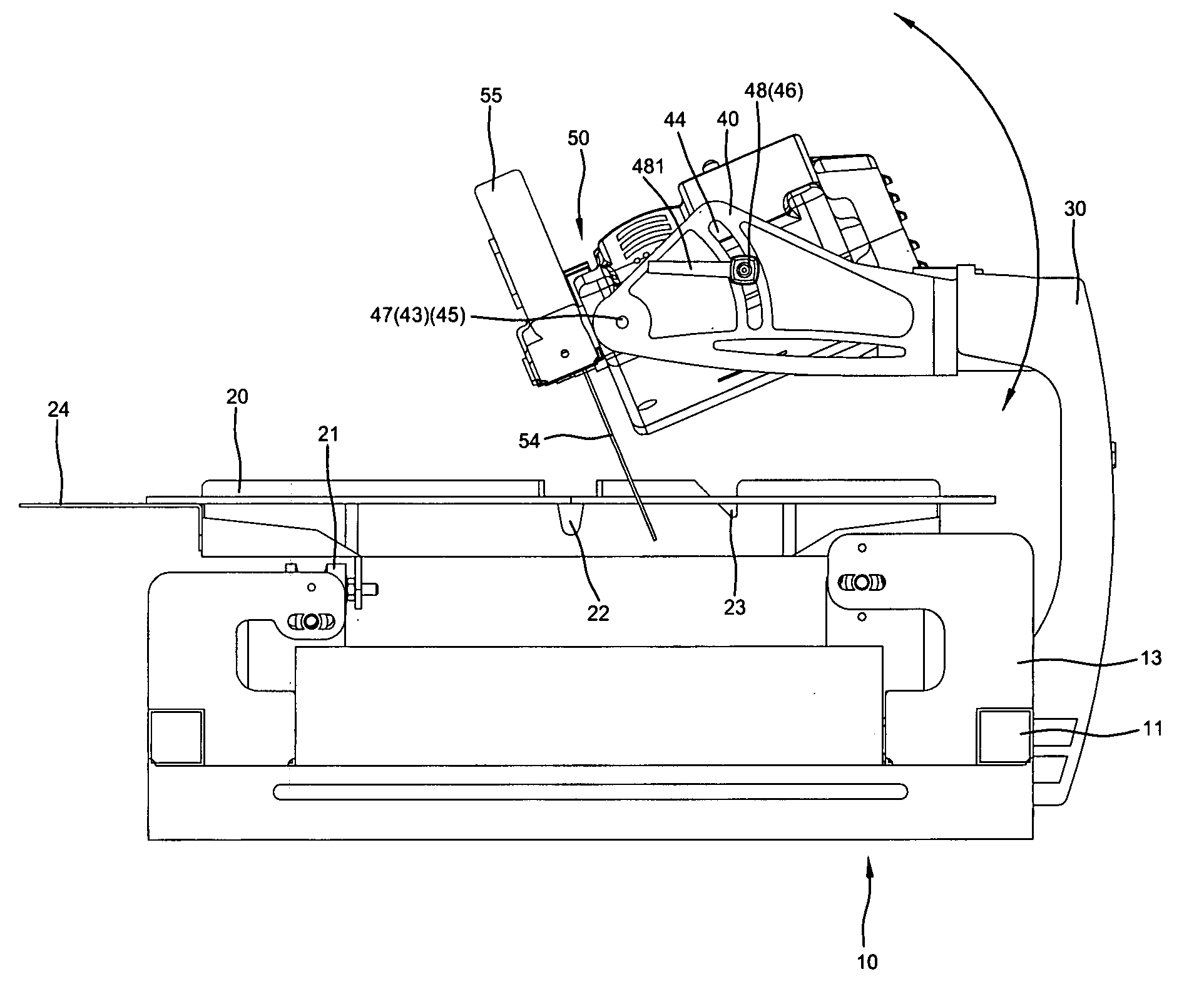

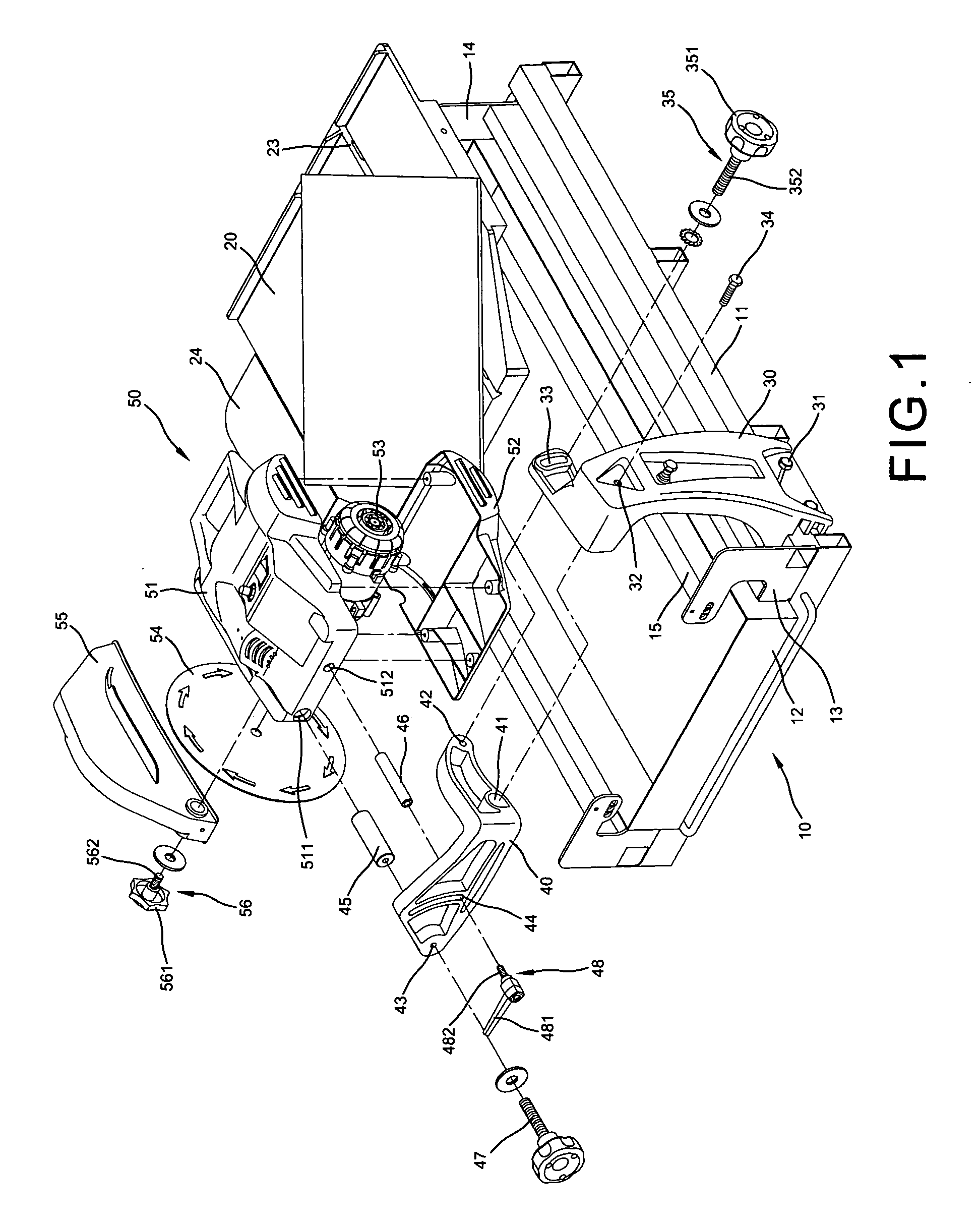

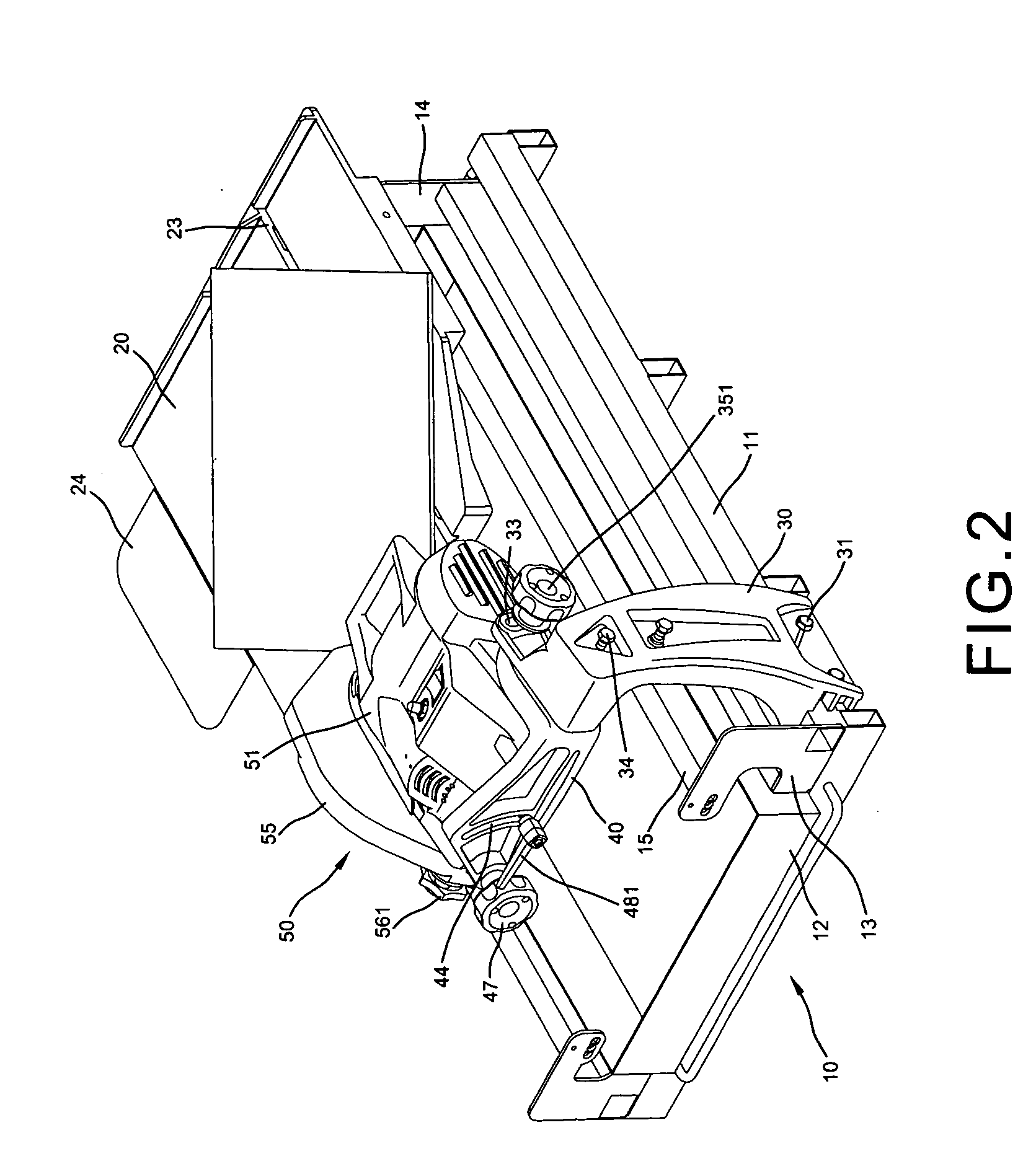

Blade angle adjustment device for a stone cutter

InactiveUS6932075B1Easy to adjustEasy to operatePortable power driven sawsMetal working apparatusSTONE CUTTERSlant angle

A blade angle adjustment device for a stone cutter includes a framed base having a working table slidably disposed on the base including a vertical cutting groove and a slant cutting groove in upper surface, a tool plate and a support arm respectively secured to a lateral side thereof, a L-shaped link having pair of screw holes in a longitudinal portion engaged with a screw hole and oblong hole on the top of the support arm and secured by a screw and a first swivel lock, a screw hole and an arcuate slot in a transverse portion respectively engaged with the front ends of a large and a small internally threaded large and small connection rods and secured by a second swivel lock and a handled screw, a motor protected by an upper housing and a lower housing which is connected to the rear end of the connection rods and a guarded circular blade connected to an axis of the motor so that slides the first swivel lock in the oblong hole to define the elevational angle for the cutting mechanism and slides the small connection rod to define the slant angle for the blade up to 45 degree.

Owner:TSAO WEN HAI

Semiconductor device and method for fabricating the same

InactiveUS20050062135A1High mechanical strengthImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSlant angleDevice material

A semiconductor device and manufacturing method are provided in which chippings are reduced even if they occur during dicing. At least edge portions of a chip and another surface are chamfered to have a slant surface having a chamfering slant angle θ, respectively, where 90°<θ<180°. Preferably, the chamfering slant angle θ is 100° to 135° or, alternatively, all of the chamfering slant angles of four sides of the chip are about 135°.

Owner:HITACHI LTD

Method for manufacturing semiconductor device having trench in silicon carbide semiconductor substrate

ActiveUS7241694B2High crystallinitySemiconductor/solid-state device manufacturingFrom condensed vaporsSlant angleHydrogen atmosphere

A method for manufacturing a silicon carbide semiconductor device includes the steps of: forming a trench mask on an upper surface of a semiconductor substrate; forming the trench such that the trench having an aspect ratio equal to or larger than 2 and having a trench slanting angle equal to or larger than 80 degrees is formed; and removing a damage portion in such a manner that the damage portion disposed on an inner surface of the trench formed in the semiconductor substrate in the step of forming the trench is etched and removed in hydrogen atmosphere under decompression pressure at a temperature equal to or higher than 1600° C.

Owner:DENSO CORP

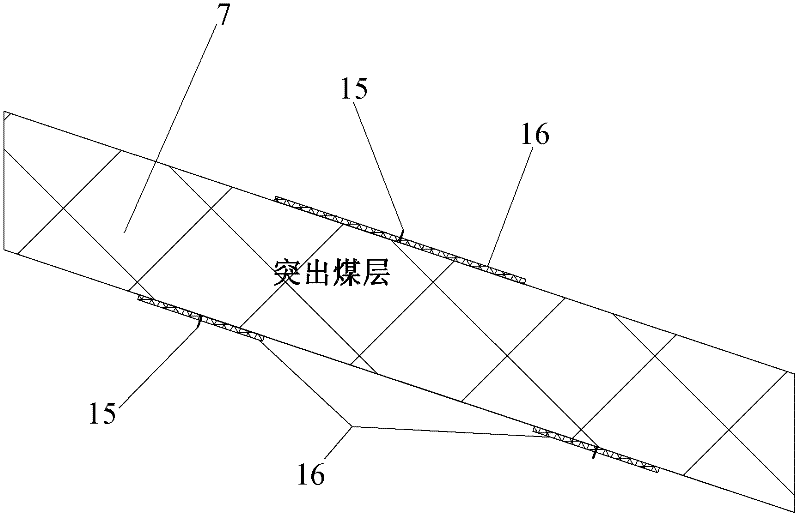

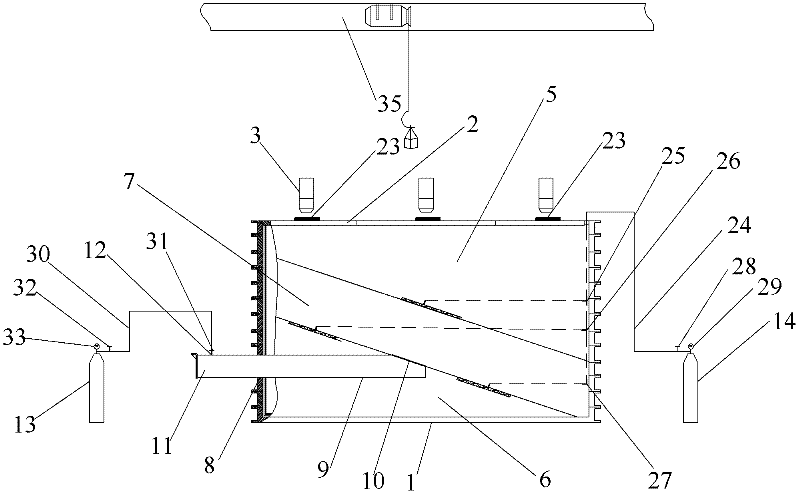

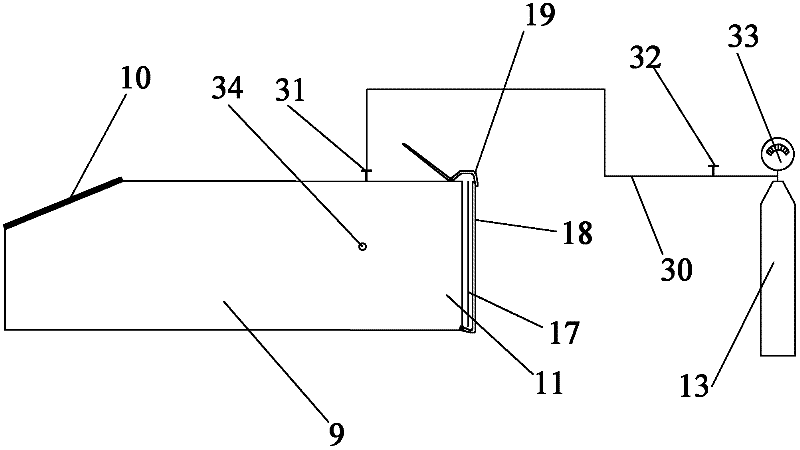

Simulation test system of coal-gas outburst during rock cross-cut coal uncovering

The invention discloses a simulation test system of coal-gas outburst during rock cross-cut coal uncovering, comprising a box provided with an opening at the top thereof, wherein the opening is equipped with a loading steel plate; a top plate and a bottom plate are paved in a closed cavity; a coal layer is paved between the top plate and the bottom plate; a slant angle is formed between the coal layer and the horizontal plane; an outburst simulation roadway is stretched in the bottom plate till being intersected with the coal layer; a notch attached to the coal layer is arranged at the intersection of the outburst simulation roadway; a diaphragm is arranged at the notch; an outburst opening and a gas balance opening are arranged at a part of outburst simulation roadway, which is exposed out of the box; the outburst opening is provided with a quick-opening seal structure; the gas balance opening is communicated with an air pressure tank; surface inflatable structures are respectively arranged on the contact surface of the coal layer and the top plate as well as the contact surface of the coal layer and the bottom plate; and the surface inflatable structures are communicated with a gas pressure tank. According to the invention, a mechanical release-diaphragm rupture method is adopted to ensure that the whole-process simulation of the coal-gas outburst during the rock cross-cut coal uncovering is realized.

Owner:SHANDONG UNIV OF SCI & TECH

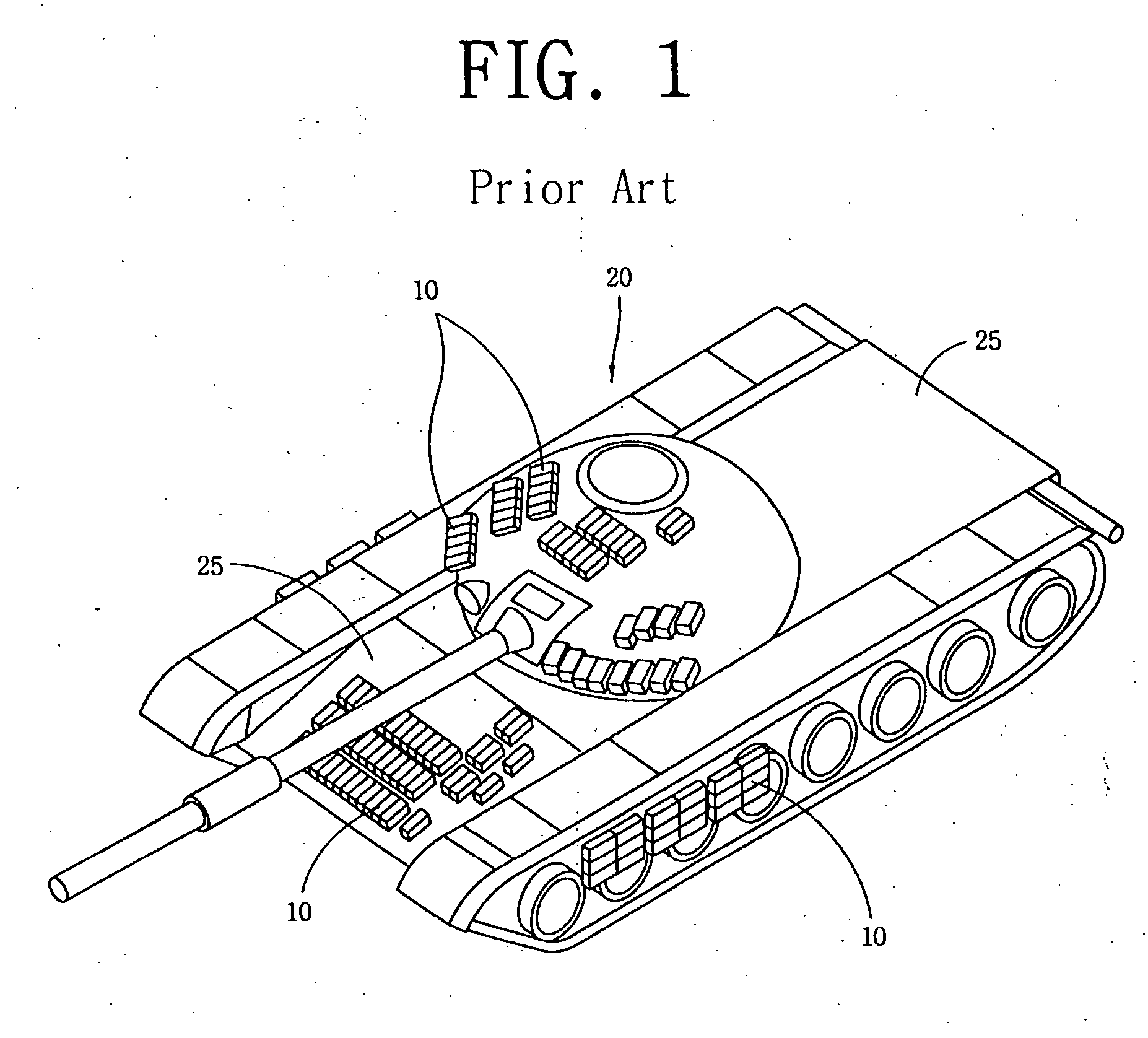

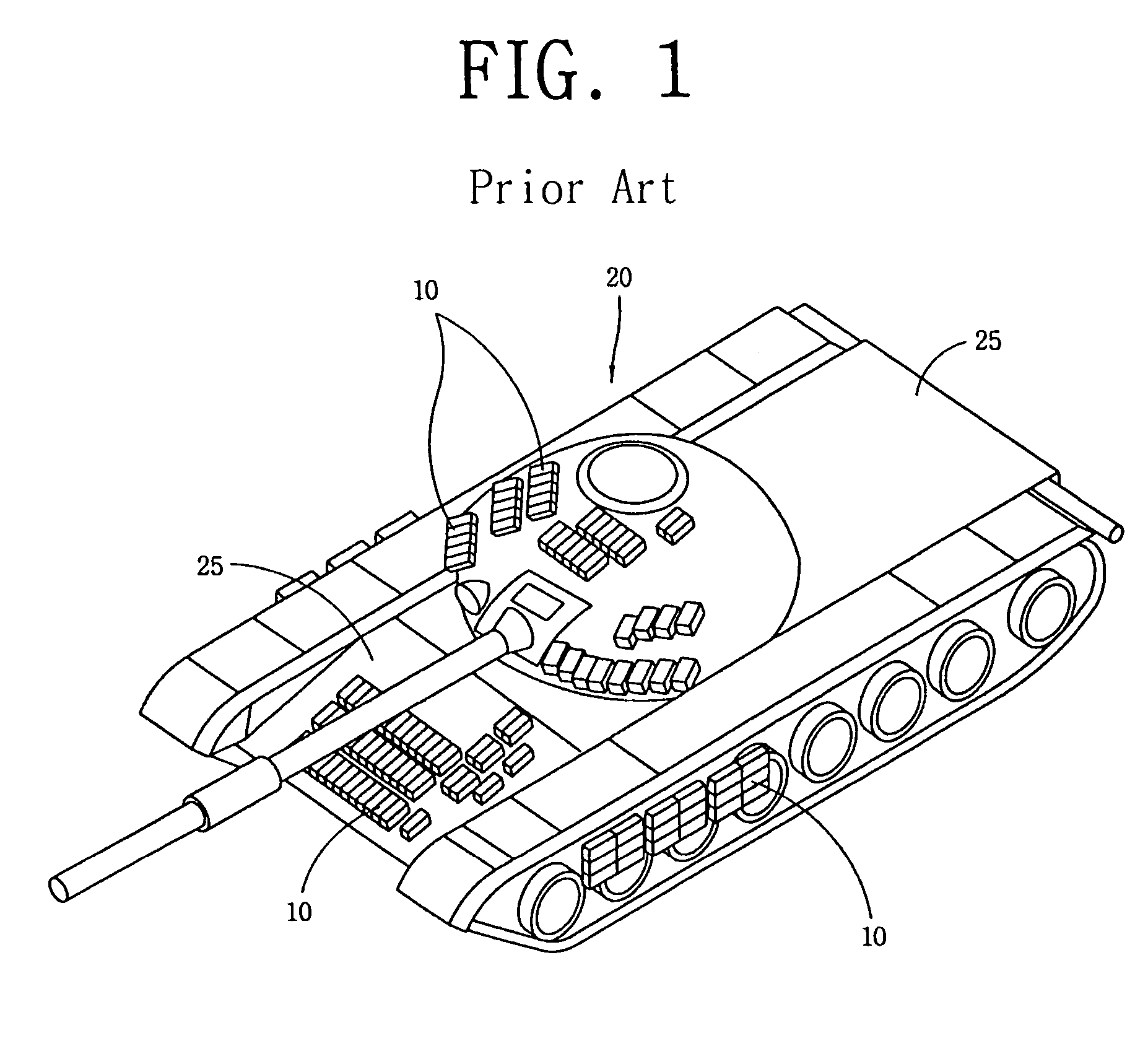

Explosive reactive armor with momentum transfer mechanism

ActiveUS20060086243A1Enhanced interactionImprove protectionDefence devicesArmoured vehiclesDetonationSlant angle

Disclosed is an explosive reactive armor with a momentum transfer mechanism by developing a new protection mechanism in which a momentum transfer mechanism by detonation of a reactive material is integrated with a thickness increase mechanism. In this explosive reactive armor with the momentum transfer mechanism, a flying element always travels with a vertical angle or a slant angle with respect to an ongoing direction of the threat such that a momentum of the flying element is transferred to the threat effectively. As a result of this, shear force is induced over an entire length of the threat and thus the threat can be destroyed. Therefore, a protection effect can always be achieved regardless of an impact angle of the threat. Also, a protection capability can be achieved even in case of a vertical impact which is the most vulnerable case for the existing explosive reactive armor.

Owner:AGENCY FOR DEFENSE DEV

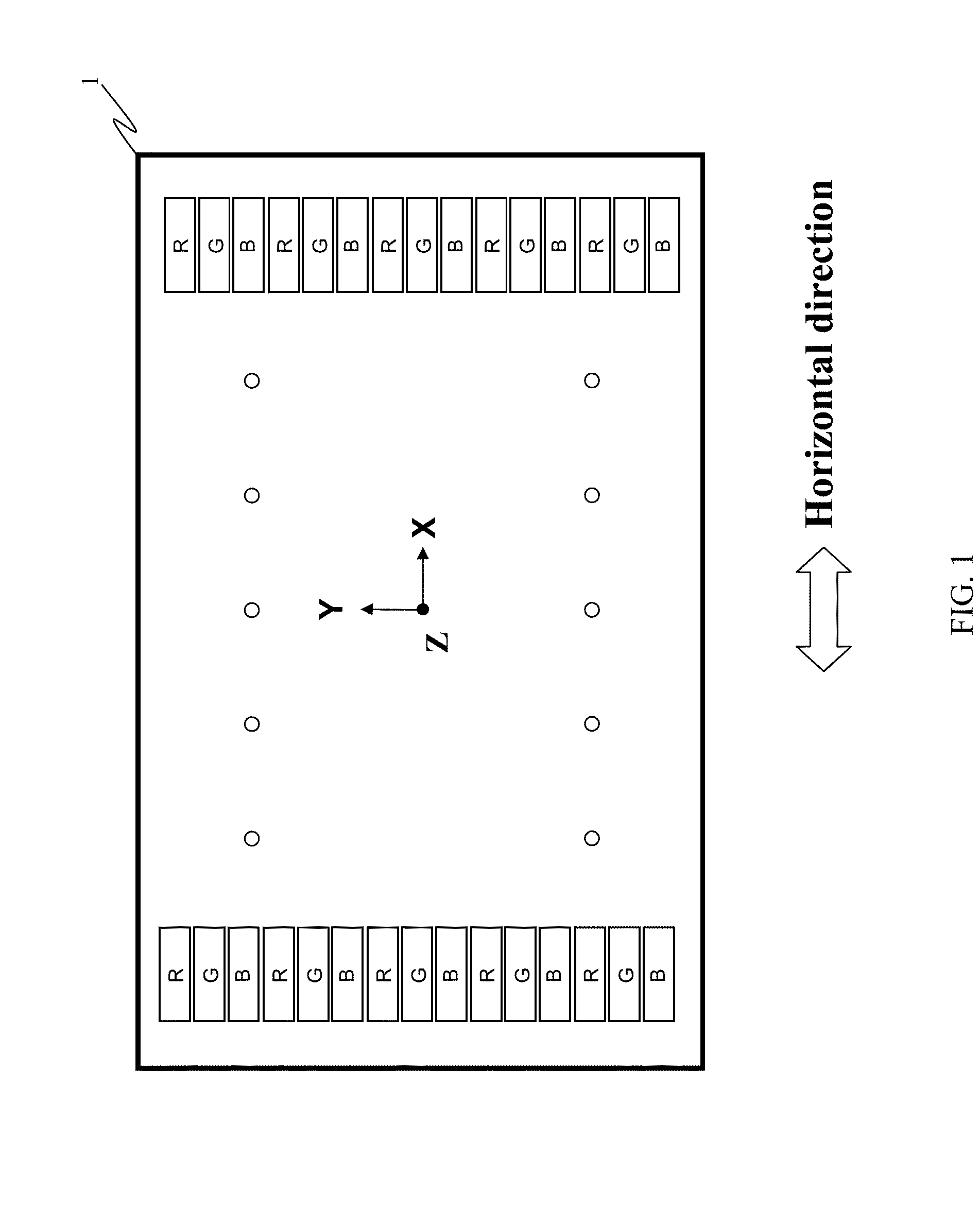

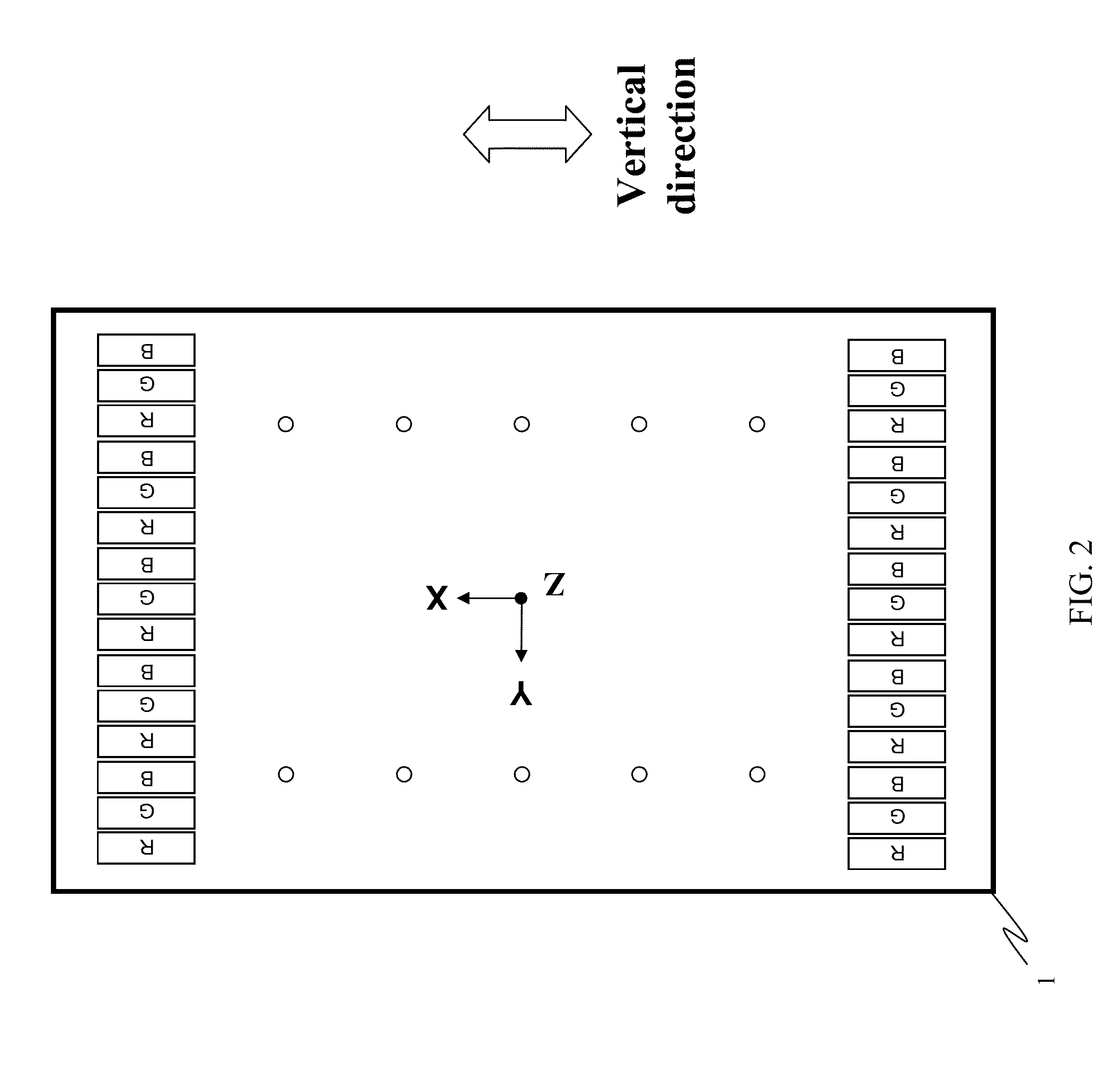

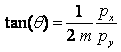

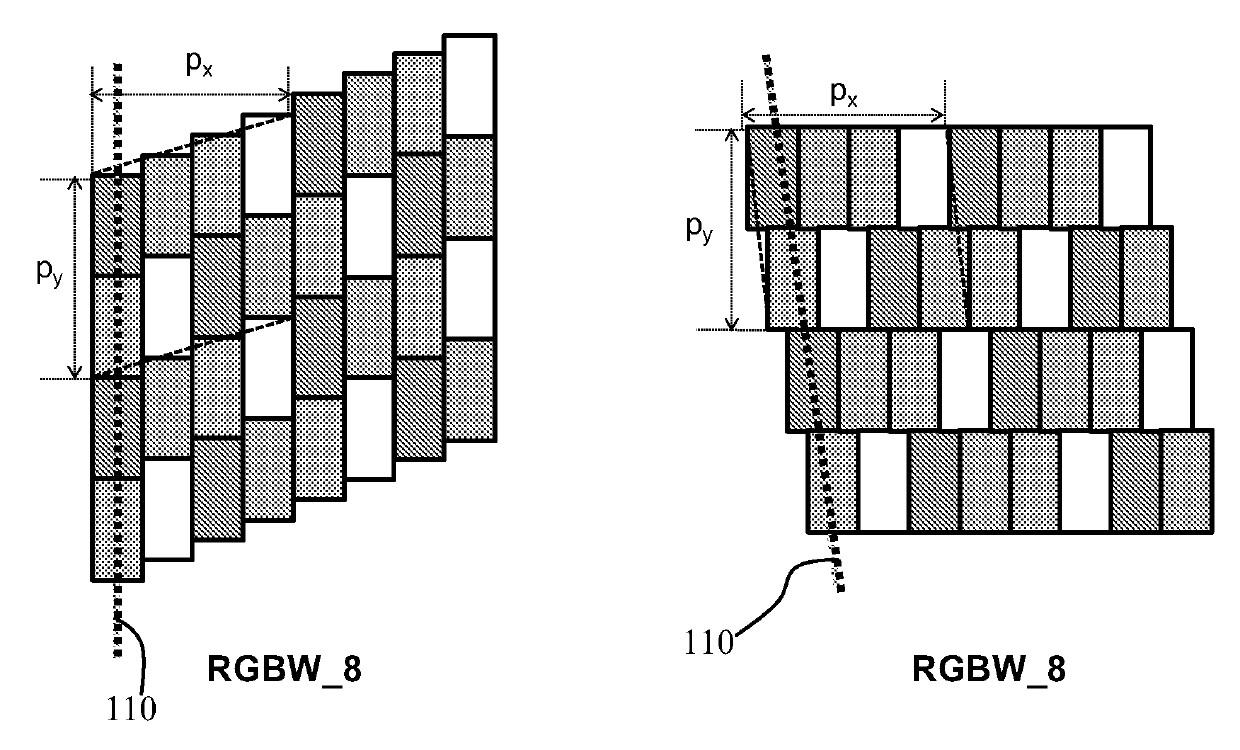

Autostereoscopic display device

The invention provides a autostereoscopic display device with a particular design of lenticular lens array (lens pitch and slant angle) to optimize the quality of the views provided to the user, when a multi-primary pixel layout is used, with at least four sub-pixels of at least three different colors. The slant angle and lens pitch is related to the pixel pitch (in the row and column directions) as well as the number of different color sub-pixels.

Owner:KONINKLJIJKE PHILIPS NV

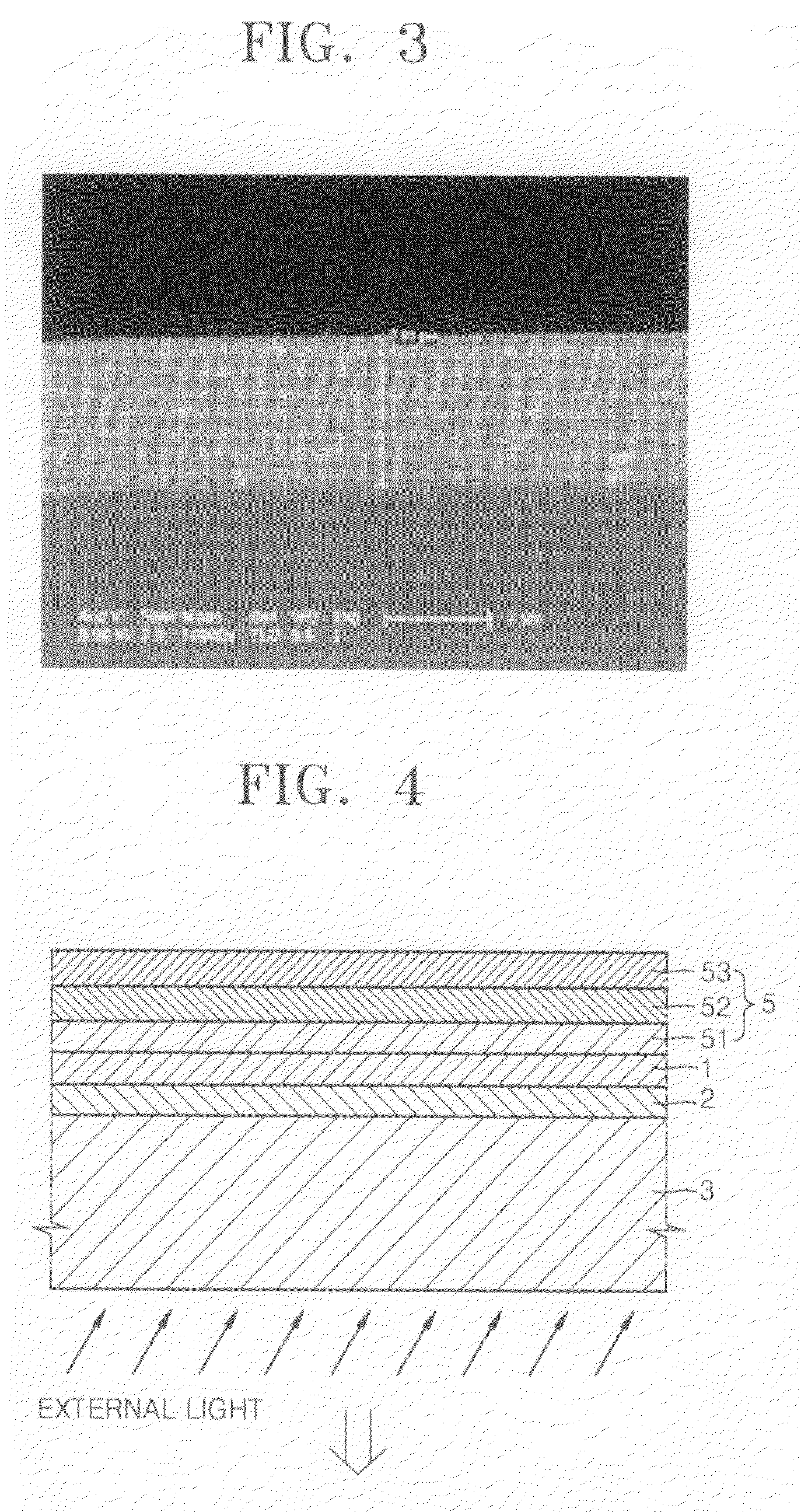

Retardation layer and organic light-emitting device including the same

InactiveUS20080157655A1Increase contrastIncrease brightnessDischarge tube luminescnet screensElectroluminescent light sourcesSlant angleOrganic light emitting device

A wideband retardation layer (or film) that can perform circular polarizing so that the retardation layer can be formed with an organic light-emitting device to be relatively thin and have a relatively high contrast with no reduction in brightness, and an organic light-emitting device including the retardation layer. The retardation film includes a base and a retardation layer including an alkali oxide layer grown to be inclined on a surface of the base, wherein the alkali oxide layer is disposed by slant-angle depositing alkali oxide on the surface of the base.

Owner:SAMSUNG DISPLAY CO LTD

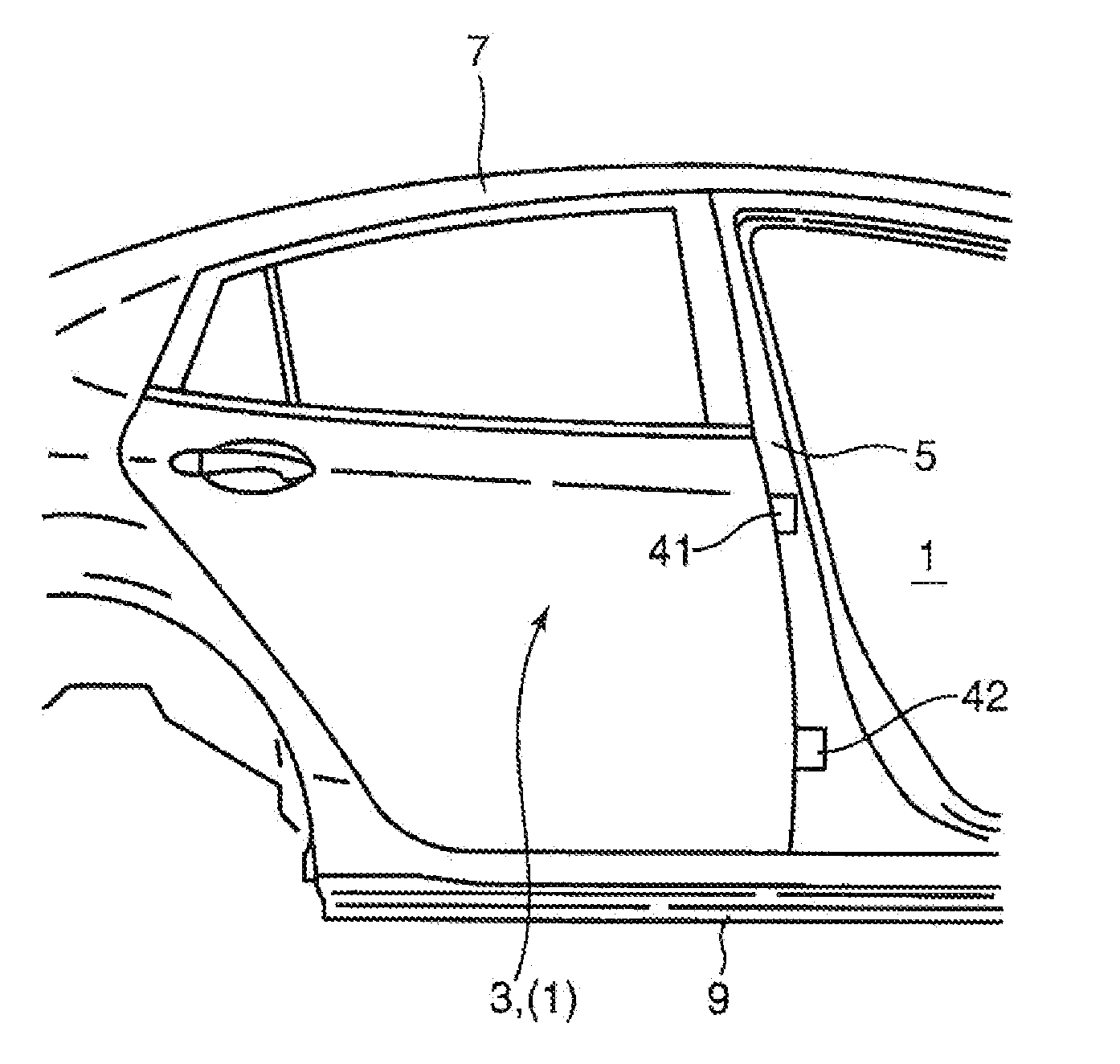

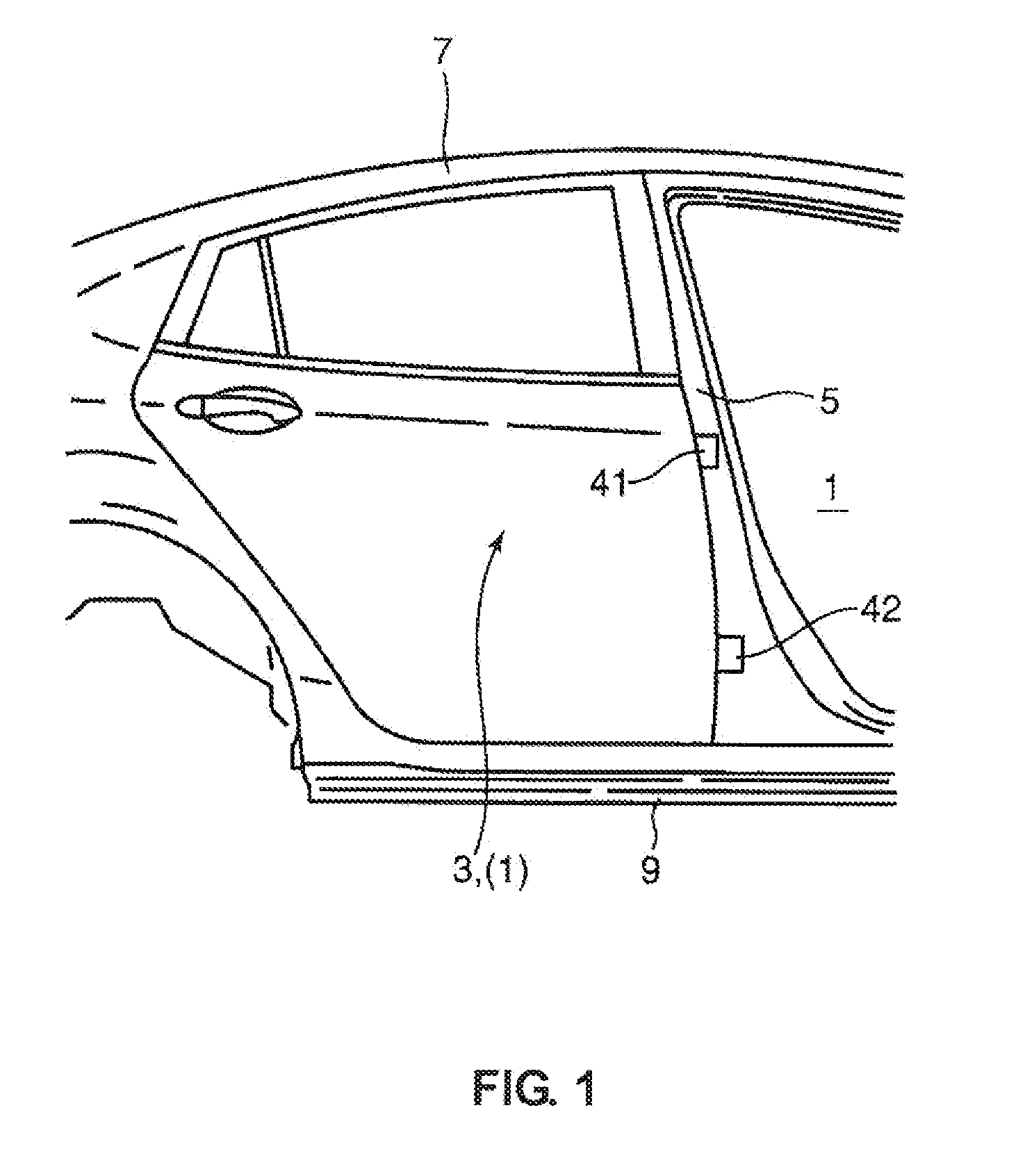

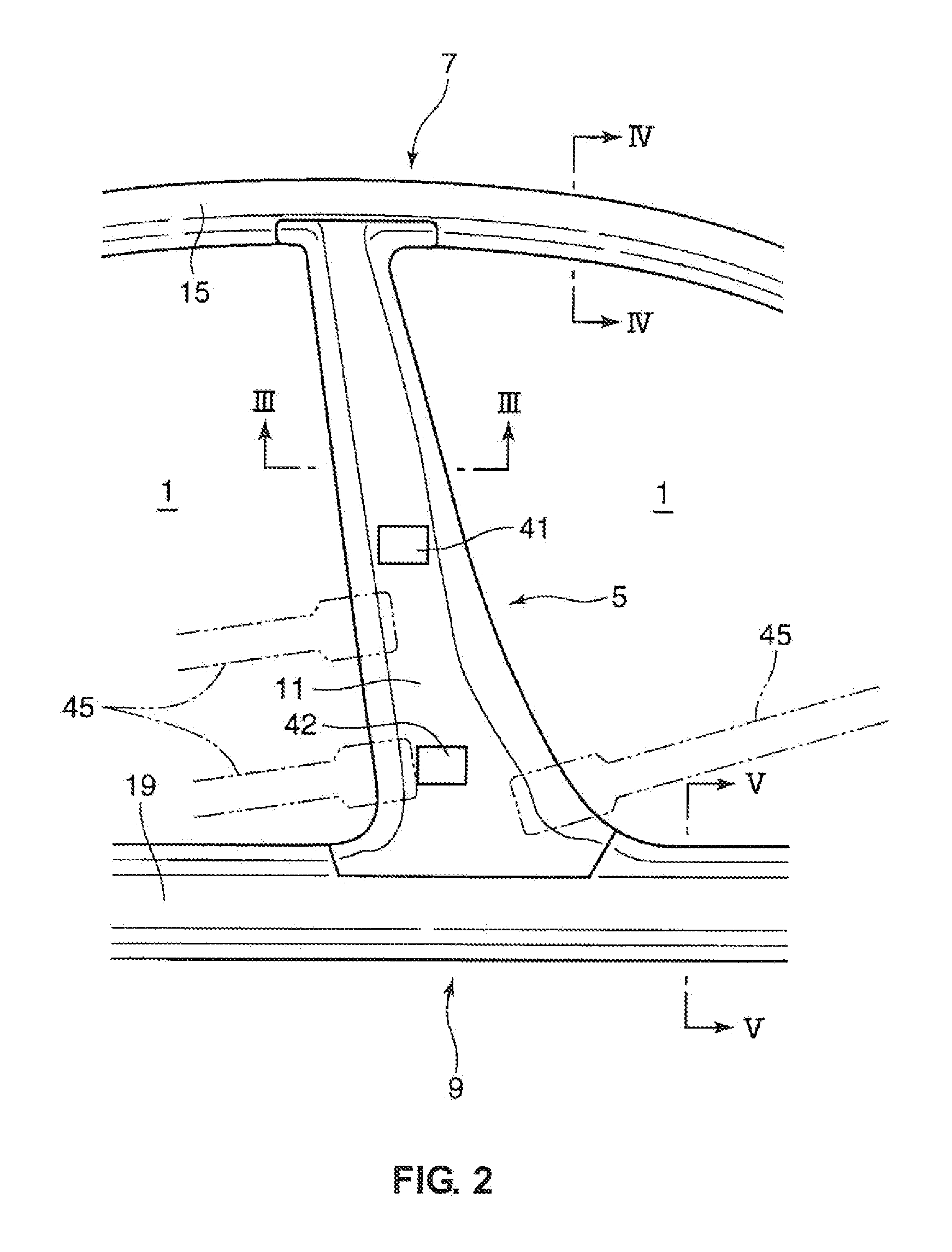

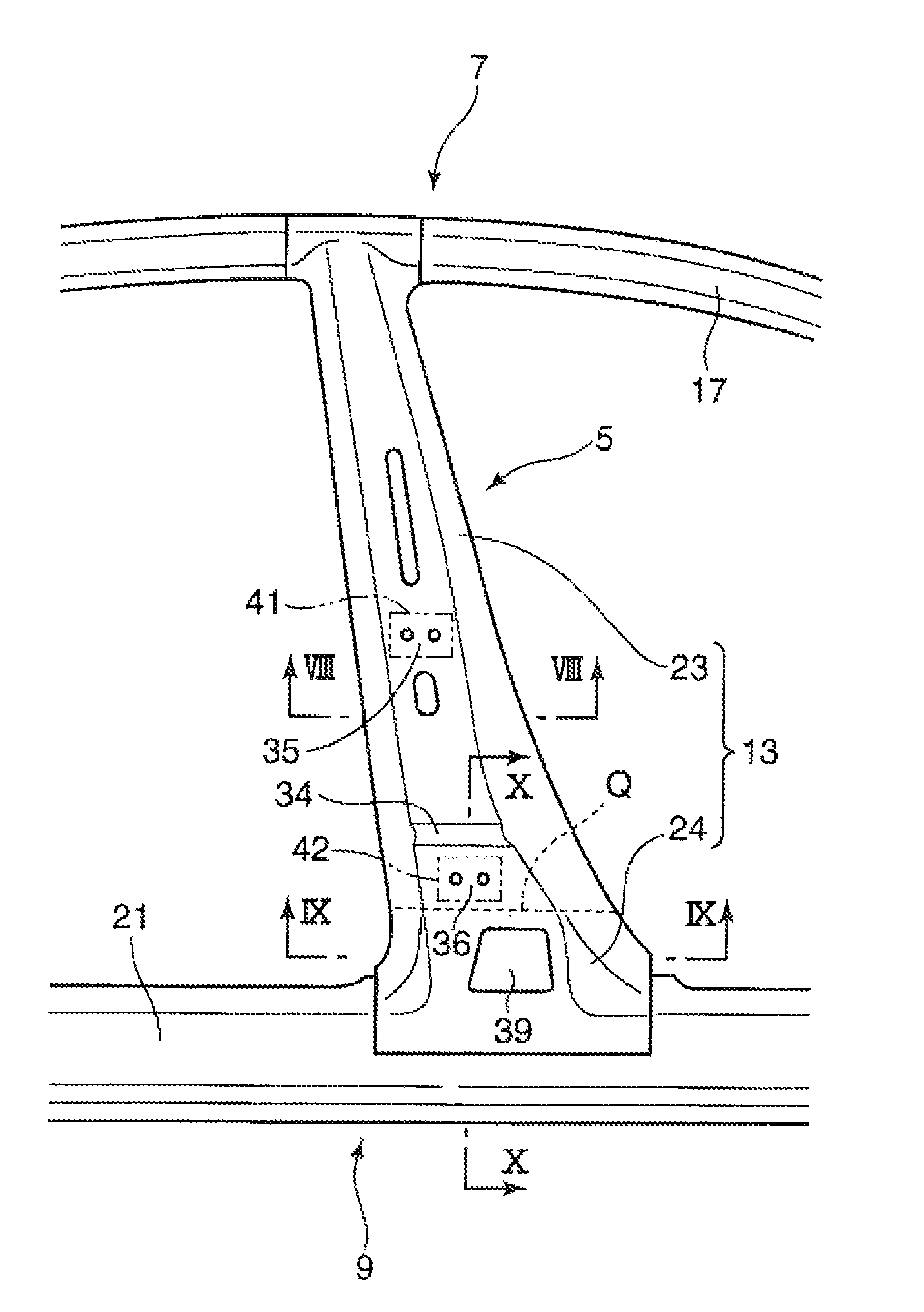

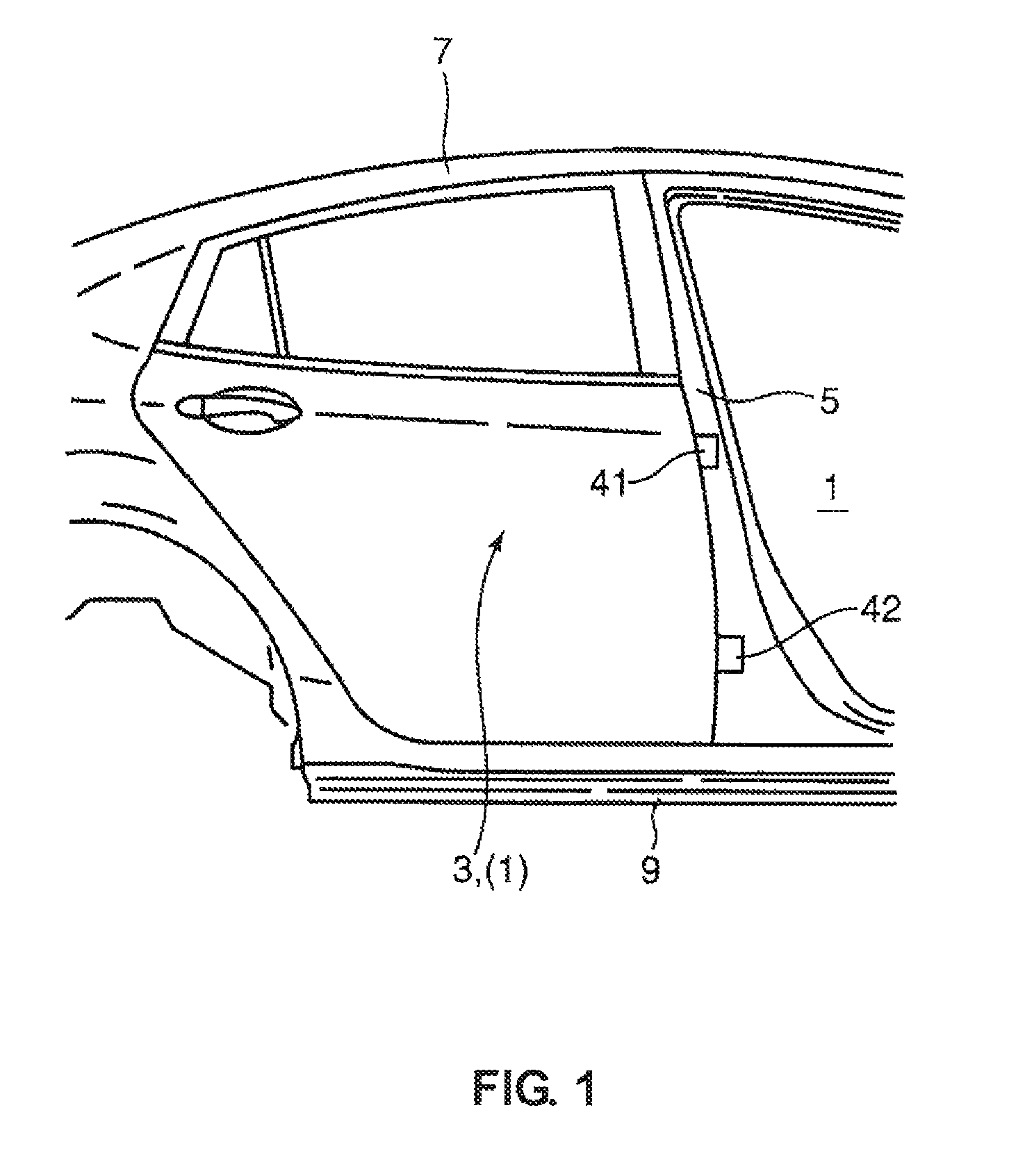

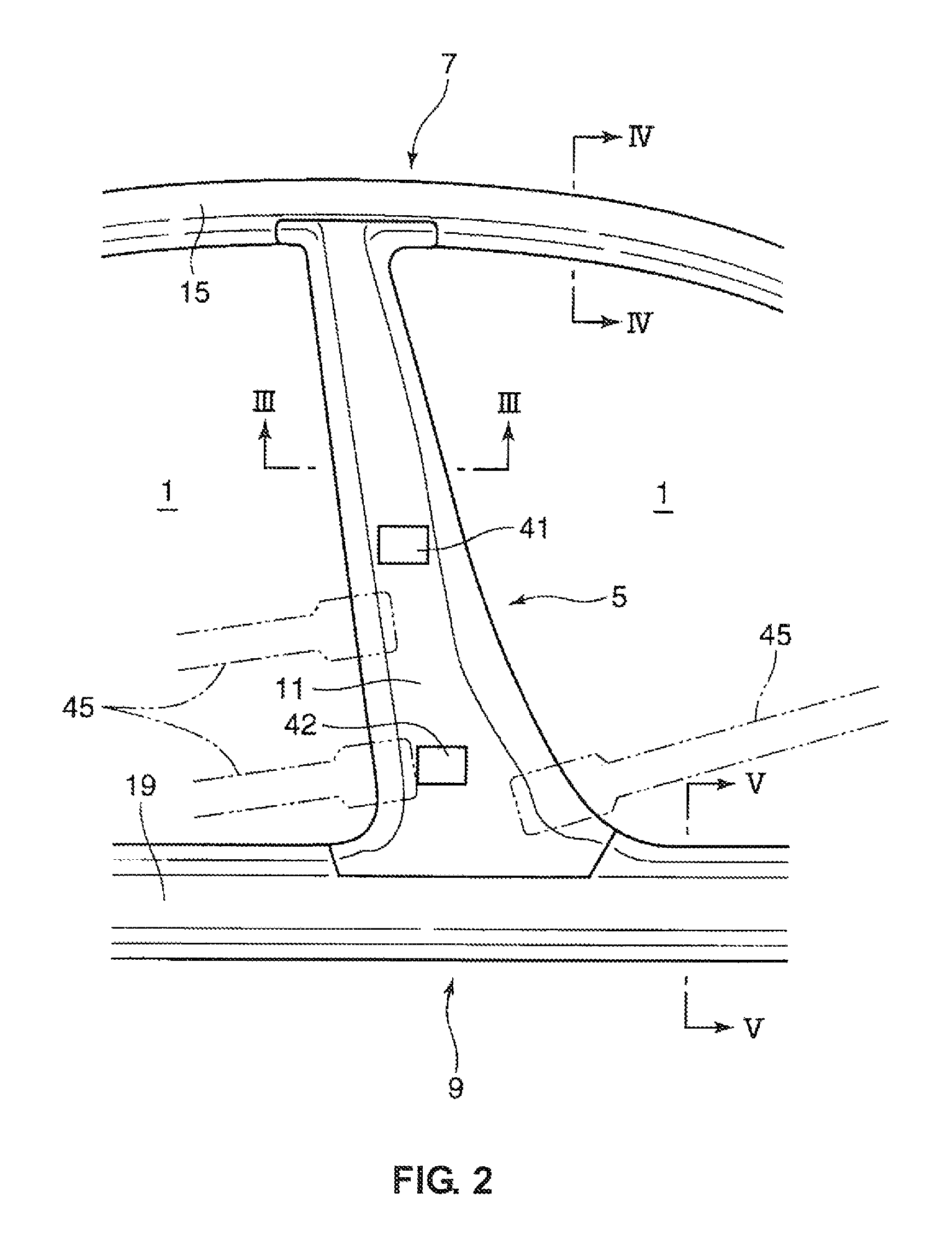

Side vehicle-body structure of vehicle

A pillar reinforcement of a center pillar comprises an upper part and a lower part with a boundary line of these parts being positioned below the middle level of the pillar reinforcement. The upper and lower parts respectively include side wall portions which extend along a vehicle side face and pairs of vertical wall portions which extend inwardly from front and rear end portions of the side wall portions. The pair of vertical wall portions of the lower part is slant relative to the vehicle width direction so that the distance between the vertical wall portions becomes wider toward the inward direction, and a slant angle of the pair of vertical wall portions of the lower part is greater than that of the vertical portions of the upper part.

Owner:MAZDA MOTOR CORP

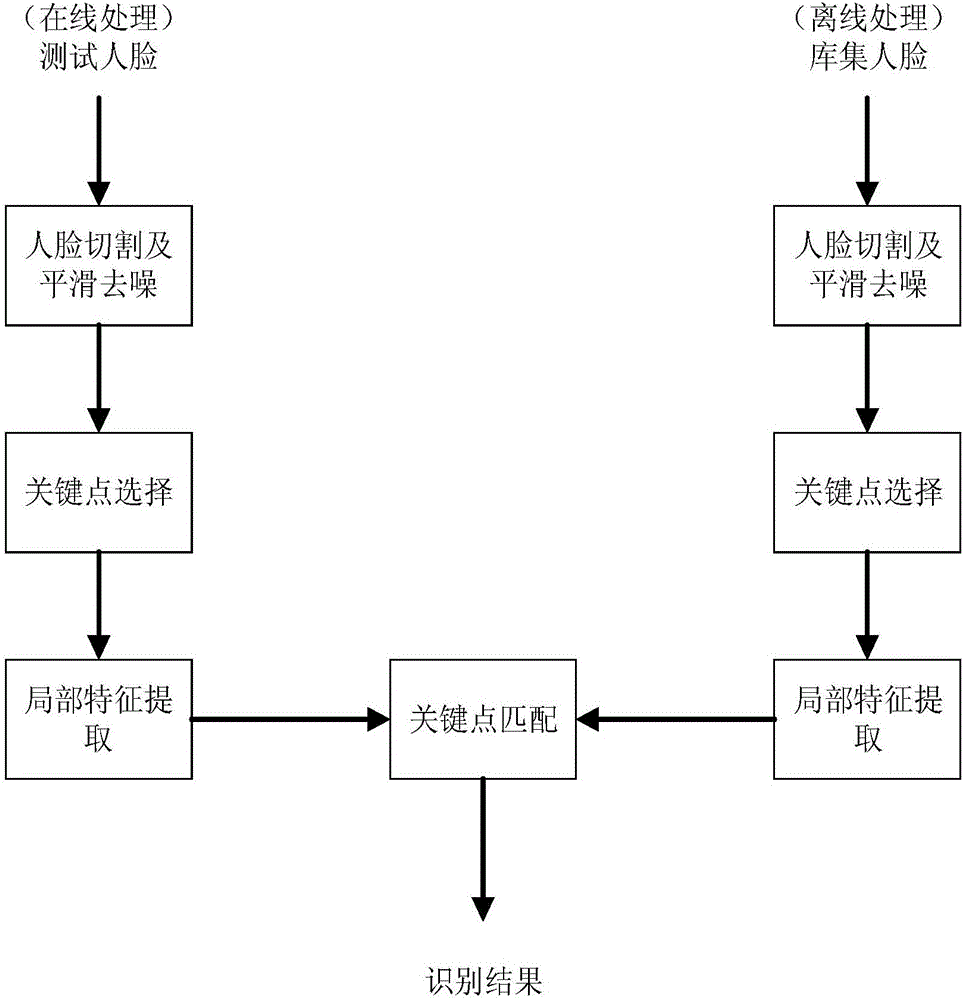

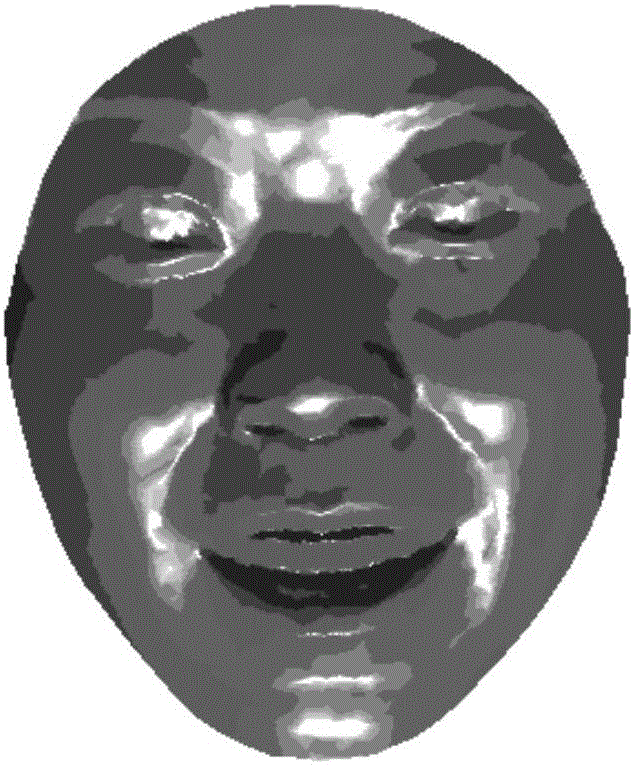

Key point and local characteristic-based three-dimensional human face identification method

InactiveCN106096503ARepresentativeRotation invariantThree-dimensional object recognitionCrucial pointSlant angle

The invention discloses a key point and local characteristic-based three-dimensional human face identification method. The method comprises the steps of preprocessing a three-dimensional human face model by human face region cutting, smoothing processing and pose normalization, and arranging all human faces in a pose coordinate system; detecting key points according to valuable contour lines and an average curvature; constructing a spatial structure of local characteristics in the form of a DAISY descriptor; adopting a shape index histogram, a slant angle histogram and a directional angle histogram as the local characteristics; and performing key point matching, and measuring the similarity of curved surfaces of two human faces by using the number of successfully matched key points. The method is relatively good in identification performance and has the robustness for expression change to a certain extent.

Owner:SOUTHEAST UNIV

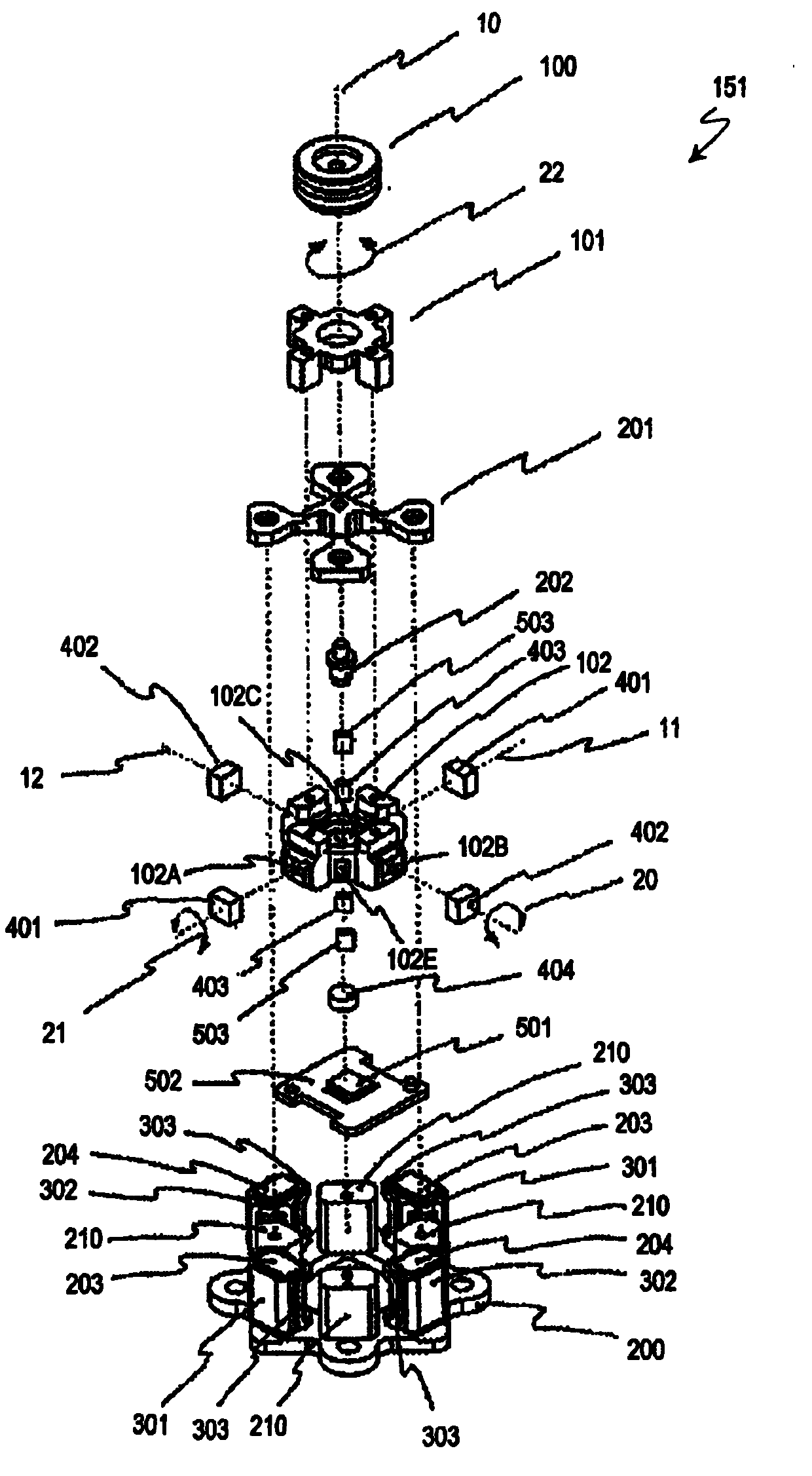

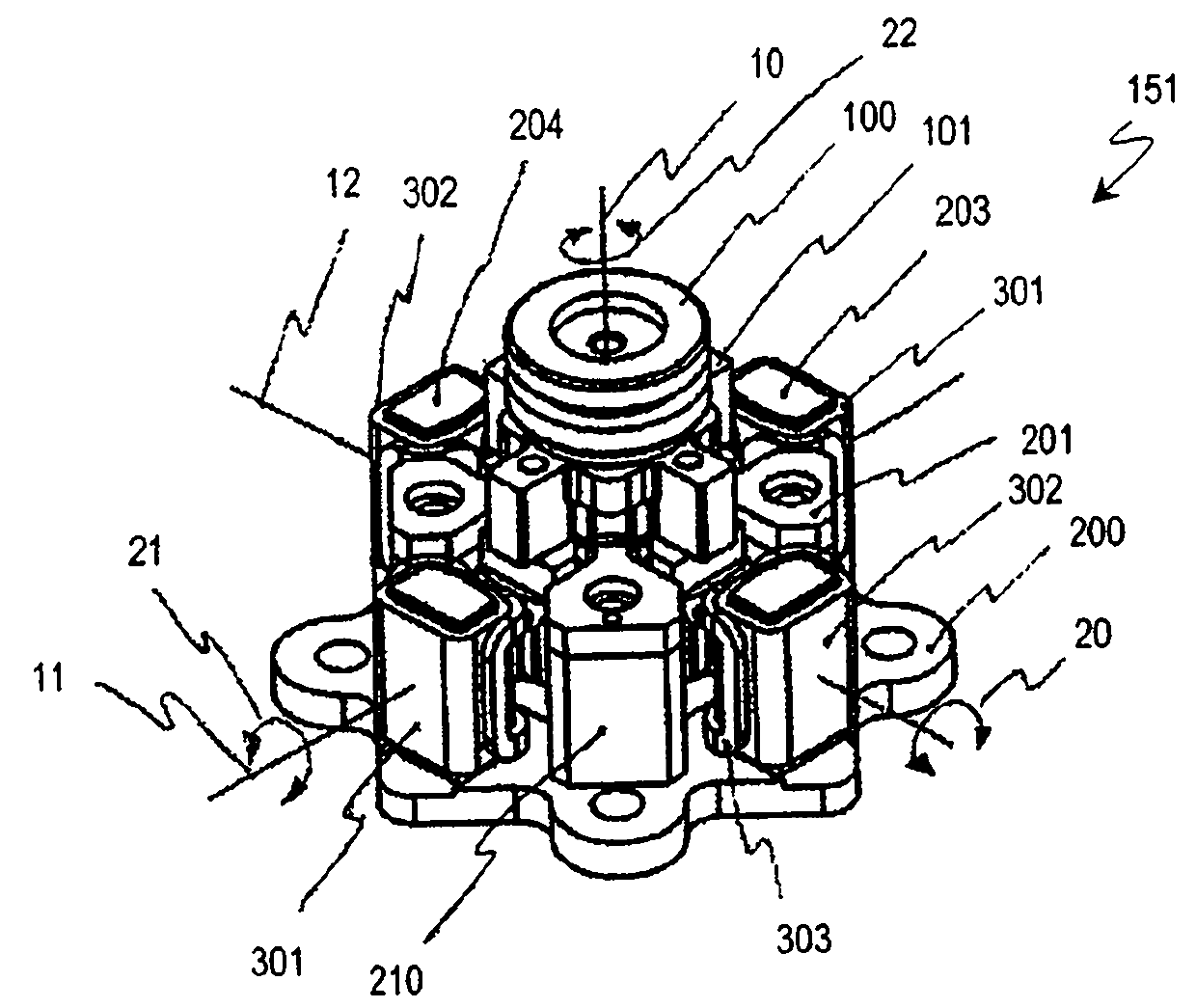

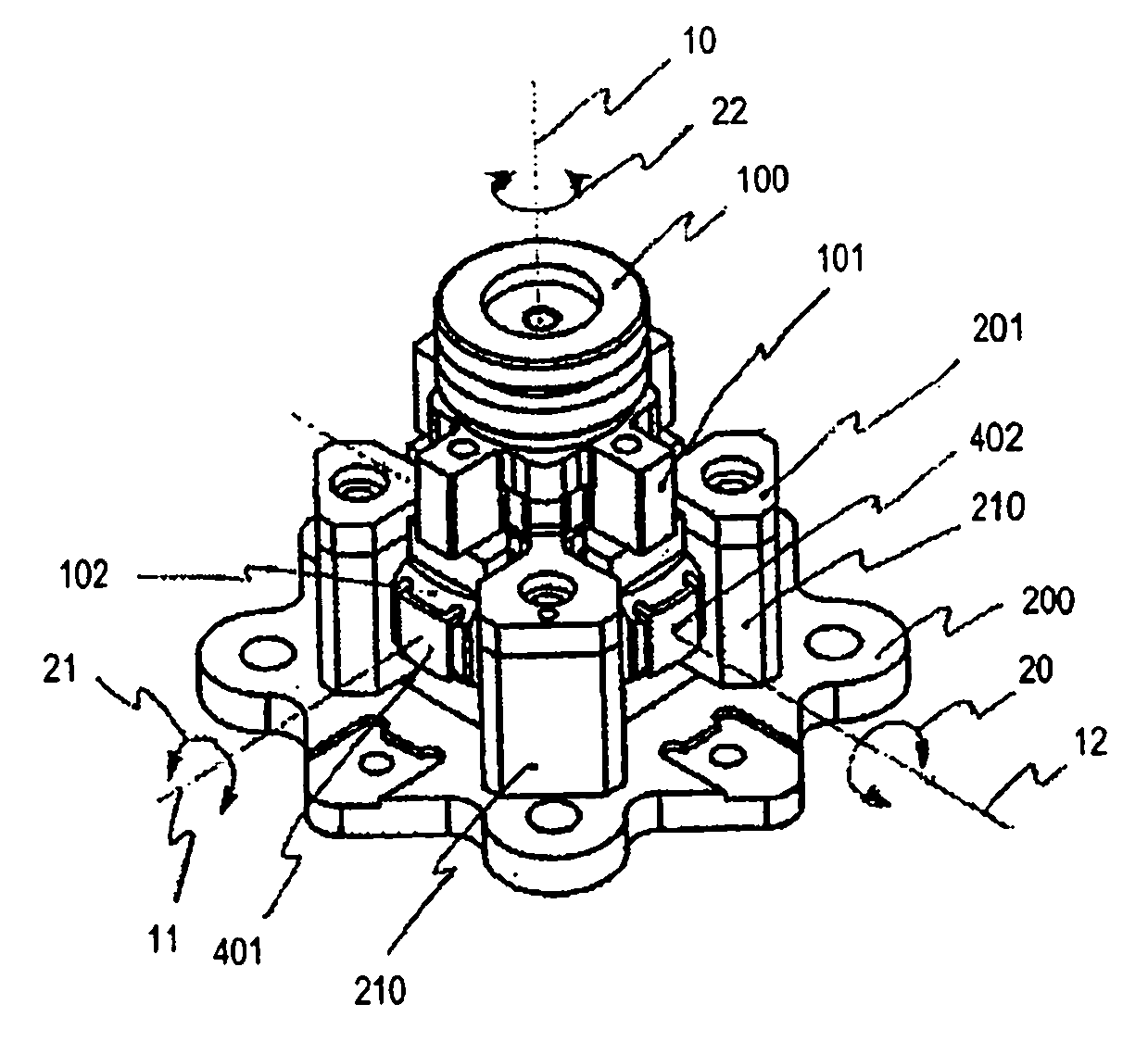

Camera driver

ActiveCN101772730AFree rotationWon't fall offProjector focusing arrangementCamera focusing arrangementFree rotationOptical axis

The camera driver is provided with a camera part that comprises an image pickup element, a lens that forms an object image on the image pickup surface of the image pickup element and a lens barrel that holds the lens; a fixed unit, at least a portion of which is made of a magnetic substance and which comprises a protruding part provided with a shape that is at least a portion of a spherical surface; a movable unit that comprises a first movable part comprising an attraction magnet that generates a magnetic attraction force on the magnetic substance and a contact surface with a conical shape into which the protruding part fits as a result of the magnetic attraction force, and which rotates freely with respect to the center of the sphere of the spherical surface of the protruding part, and a second movable part, which is equipped with the camera part and fixed to the first movable part, and which comprises a fall-off prevention regulating surface provided with a prescribed intervening gap that allows free rotation with respect to the fixed unit when the first movable part rotates; a detector that detects the slant angle of the camera part with respect to the fixed unit and the rotation angle of the camera part around the optical axis of the lens; a first driving part that slants the camera part with respect to the fixed unit; and a second driving part that rotates the camera part with respect to the fixed unit around the center of the optical axis.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

Explosive reactive armor with momentum transfer mechanism

ActiveUS7540229B2Enhanced interactionImprove protectionDefence devicesArmoured vehiclesDetonationSlant angle

Disclosed is an explosive reactive armor with a momentum transfer mechanism by developing a new protection mechanism in which a momentum transfer mechanism by detonation of a reactive material is integrated with a thickness increase mechanism. In this explosive reactive armor with the momentum transfer mechanism, a flying element always travels with a vertical angle or a slant angle with respect to an ongoing direction of the threat such that a momentum of the flying element is transferred to the threat effectively. As a result of this, shear force is induced over an entire length of the threat and thus the threat can be destroyed. Therefore, a protection effect can always be achieved regardless of an impact angle of the threat. Also, a protection capability can be achieved even in case of a vertical impact which is the most vulnerable case for the existing explosive reactive armor.

Owner:AGENCY FOR DEFENSE DEV

Autostereoscopic image output device

ActiveUS20110001803A1Good view-distributionGood image pixel structureSteroscopic systemsAutostereogram3d image

An autostereoscopic image output device comprises an image panel having an array of image pixels (5) defining an image, the image pixels being arranged in rows and columns. An array of parallel lenticular elements (11) is positioned over the image panel, the lenticular elements having optical focal axes that are slanted at an angle (φ) to the image pixel columns. The image output device is operable in first and second modes, with the image panel and lenticular element array rotated by 90 degrees between the modes, thereby providing a landscape mode of operation and a portrait mode of operation, the slant angle φ in the landscape mode satisfies: 1≧tan φ≧1 / 2. This enables a 3D image device to be used in both the landscape and the portrait mode, while maintaining a good view-distribution and image pixel structure.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

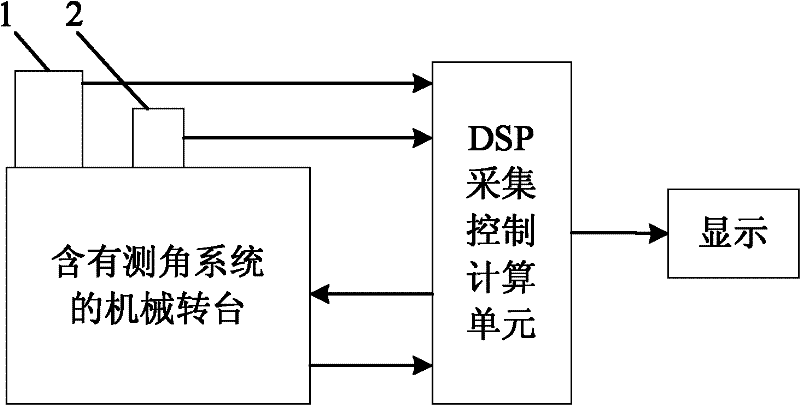

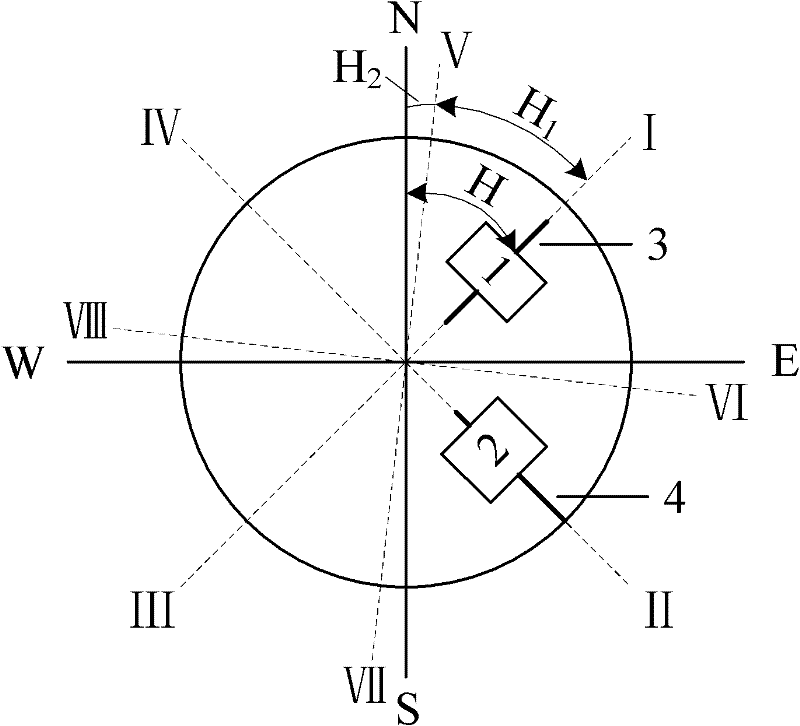

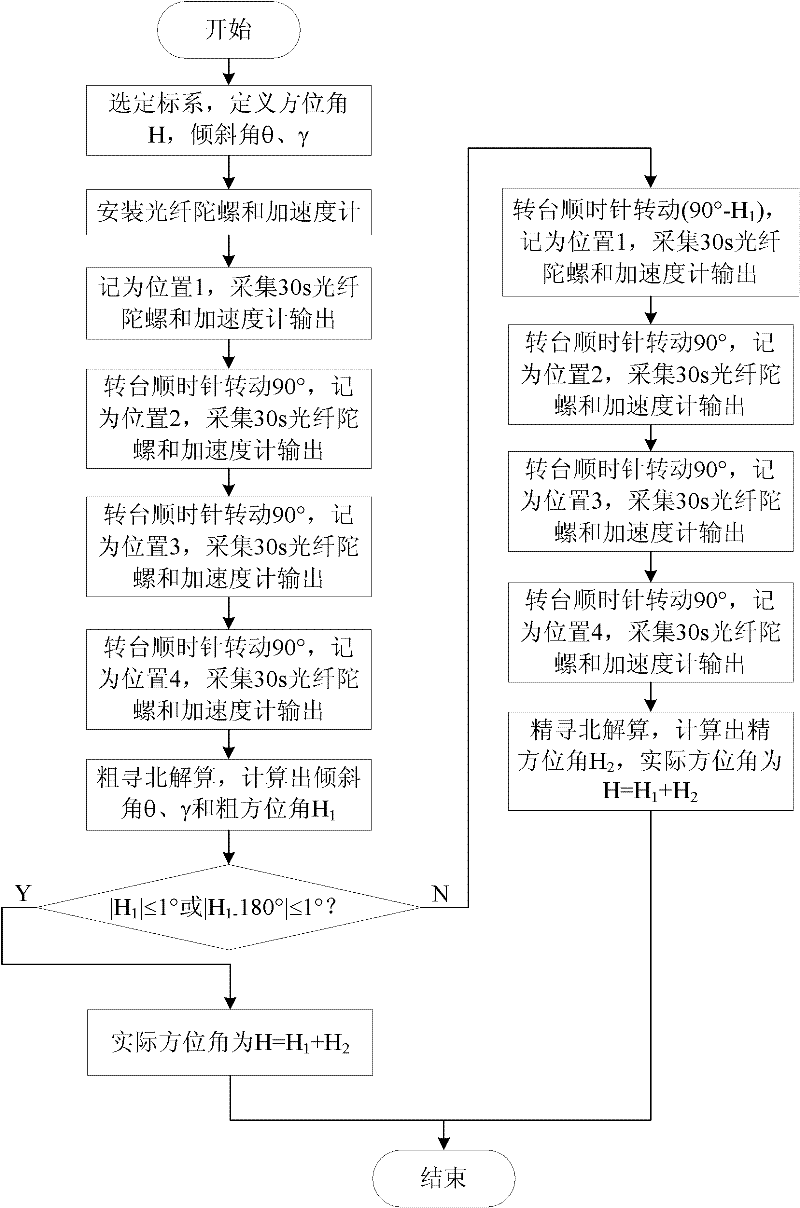

North-finding method based on orientation effect error compensation

InactiveCN102207386ARealize online compensationReal-time calculation of tilt angleNavigational calculation instrumentsSagnac effect gyrometersFiberAccelerometer

A north-finding method based on orientation effect error compensation. A fiber optic gyro and an accelerometer are first arranged on a rotary table containing an angle measuring system, and then the rotary table is arranged on a carrier. The method comprises the following steps: 1) defining a geographic coordinate system, a carrier coordinate, an azimuth H, and slant angles of theta and gamma; 2) arranging the fiber optic gyro and the accelerometer on the carrier; 3) recording a current position as a position 1, successively turning the rotary table clockwise by 90DEG, recording a position 2, a position 3, and a position 4, acquiring 30s output values of the fiber optic gyro and the accelerometer on the four positions and calculating mean values, and then calculating a current pitching angle theta, a current roll angle gamma and a current coarse azimuth H1; 4) if H satisfies a relation that |H1|<=1 DEG or |H1-180 DEG|<= 1 DEG, H1 being an actual azimuth; otherwise, controlling the rotary table to turn by (90 DEG-H1) clockwise, repeating step 3), calculating a current accurate azimuth H2, and using (H1+H2) as an actual azimuth for north-finding.

Owner:SOUTHEAST UNIV

Side vehicle-body structure of vehicle

A pillar reinforcement of a center pillar comprises an upper part and a lower part with a boundary line of these parts being positioned below the middle level of the pillar reinforcement. The upper and lower parts respectively include side wall portions which extend along a vehicle side face and pairs of vertical wall portions which extend inwardly from front and rear end portions of the side wall portions. The pair of vertical wall portions of the lower part is slant relative to the vehicle width direction so that the distance between the vertical wall portions becomes wider toward the inward direction, and a slant angle of the pair of vertical wall portions of the lower part is greater than that of the vertical portions of the upper part.

Owner:MAZDA MOTOR CORP

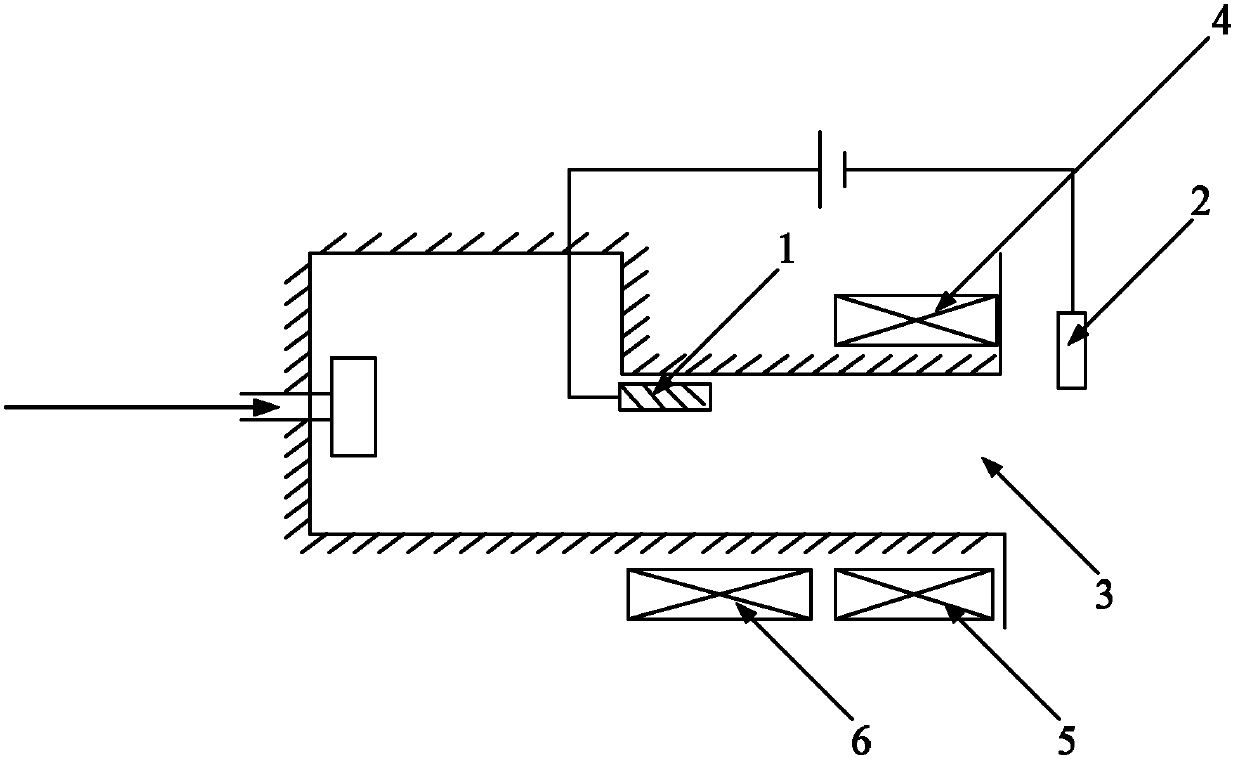

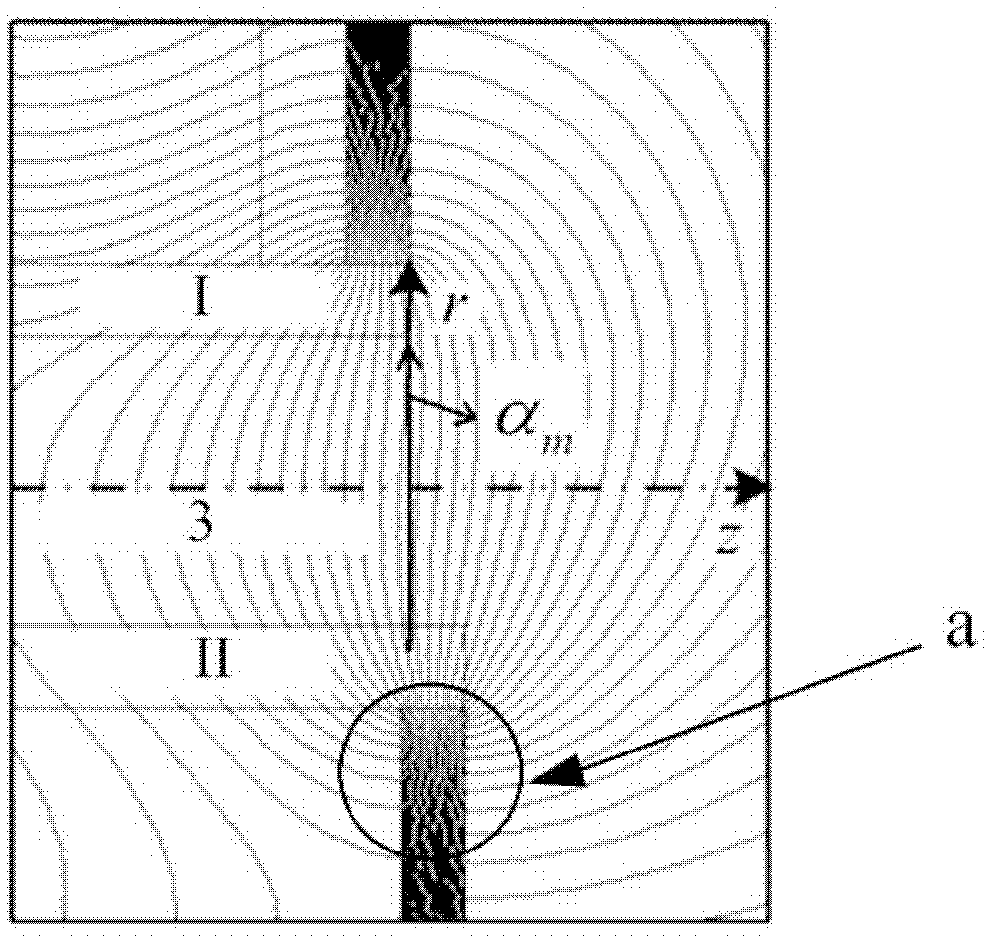

Hall thrustor based on magnetic focusing

InactiveCN102493936AExtend your lifeReduce erosionMachines/enginesUsing plasmaHigh energySlant angle

A Hall thrustor based on magnetic focusing relates to a Hall thrustor and aims to resolve the problem that in an existing Hall thrustor, as high-energy ions sputter and force out wall surface materials, a ceramic wall surface of a channel is punctured, so that performances of the existing Hall thrustor are greatly changed, and finally the thrustor is failure. An anode is arranged in the middle of a discharge channel, and a cathode is arranged at an outlet of the discharge channel; an outer coil and an inner coil are symmetrically arranged on two sides of the outlet of the discharge channel, and respectively generate axial magnetic induction strength and radial magnetic induction strength; a slant angle of each magnetic line of force of magnetic field configurations generated by the outer coil and the inner coil is am, and two magnetic field configurations are generated by means of changing exciting current intensity of the outer coil 4 and the inner coil 5; if the magnetic lines of force are coincident to a radial direction, the am equals to 0 degrees; and if the magnetic lines of force are inclined to the direction of the anode 1, the am is smaller than 0 degree. A method of reducing erosion of a wall surface of the channel and prolonging the service life of the thrustor is realized by means of affecting sputtering parameters including ion flux, energy, incident angles and the like of a forced-out wall surface.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com